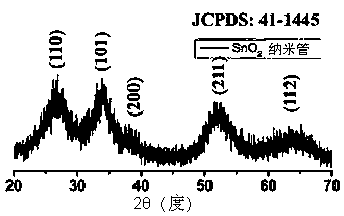

Stannic oxide nanotubes with high electrical properties and preparation method therefor

A technology of tin dioxide and electrical properties, applied in the direction of tin oxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem that the battery cycle performance and battery capacity cannot meet the needs of industrial applications, cannot reach industrial applications, The problem of battery specific capacity attenuation, etc., achieves the effect of superior battery performance, good rate charge-discharge cycle performance, and good product batch performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a tin dioxide hollow tube with high electrical performance, the steps of the method are as follows:

[0034] A) adopting the method for preparing silica hollow tubes (nanotubes) in the early stage;

[0035] a, adopt the method for preparing the sodium chloride crystal of nano-cubic appearance in the early stage, prepare the sodium chloride glycerin solution that concentration is 2.0M, add the sodium chloride glycerin solution of 0.5ml in the 100ml isopropanol solution, at normal temperature ( 25°C) for 5 minutes;

[0036] b. Add a certain amount of tetraethyl orthosilicate (TEOS) 2.0ml, ammonia water (NH4OH) 1.0m and water 5ml into the solution in step a twice, and react at room temperature (25°C) for a total of 8 hours;

[0037] c, add dropwise the deionized water of 10ml in the solution of step b;

[0038] d, centrifuging the solution obtained in step c, washing with ethanol, and then centrifuging again, repeating this s...

Embodiment 1

[0054] 1) Adopt the method of preparing silica hollow tube in the early stage

[0055] a, adopt the method for preparing the sodium chloride crystal of nano-cubic shape in the early stage, prepare the sodium chloride glycerol solution that concentration is 2.0M, add the sodium chloride glycerol solution of 0.5ml in the 100ml isopropanol solution, at normal temperature ( 25°C) for 5 minutes;

[0056] b. Add a certain amount of tetraethyl tetrasilicate (TEOS) 2.0ml, ammonia water (NH4OH) 1.0m and water 5ml into the solution of step a twice, and react at room temperature (25°C) for a total of 8 hours; c , add dropwise the deionized water of 10ml in the solution of step b;

[0057] d, centrifuging the solution obtained in step c, washing with ethanol, and then centrifuging again, repeating this several times;

[0058] e, drying the powder obtained in step d in an oven at a temperature of 100°C and 300°C for 3 hours to obtain silica nanotubes;

[0059] 2) Take a certain mass of ...

Embodiment 2

[0072] 1) Adopt the method of preparing silica hollow tube in the early stage

[0073] a, adopt the method for preparing the sodium chloride crystal of nano-cubic shape in the early stage, prepare the sodium chloride glycerol solution that concentration is 2.0M, add the sodium chloride glycerol solution of 0.5ml in the 100ml isopropanol solution, at normal temperature ( 25°C) for 5 minutes;

[0074] b. Add a certain amount of tetraethyl tetrasilicate (TEOS) 2.0ml, ammonia water (NH4OH) 1.0m and water 5ml into the solution of step a twice, and react at room temperature (25°C) for a total of 8 hours; c , add dropwise the deionized water of 10ml in the solution of step b;

[0075] d, centrifuging the solution obtained in step c, washing with ethanol, and then centrifuging again, repeating this several times;

[0076] e, drying the powder obtained in step d in an oven at a temperature of 100°C and 300°C for 3 hours to obtain silica nanotubes;

[0077] 2) Take a certain mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com