Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1471 results about "Depolymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Depolymerization (or depolymerisation) is the process of converting a polymer into a monomer or a mixture of monomers. This process is driven by an increase in entropy.

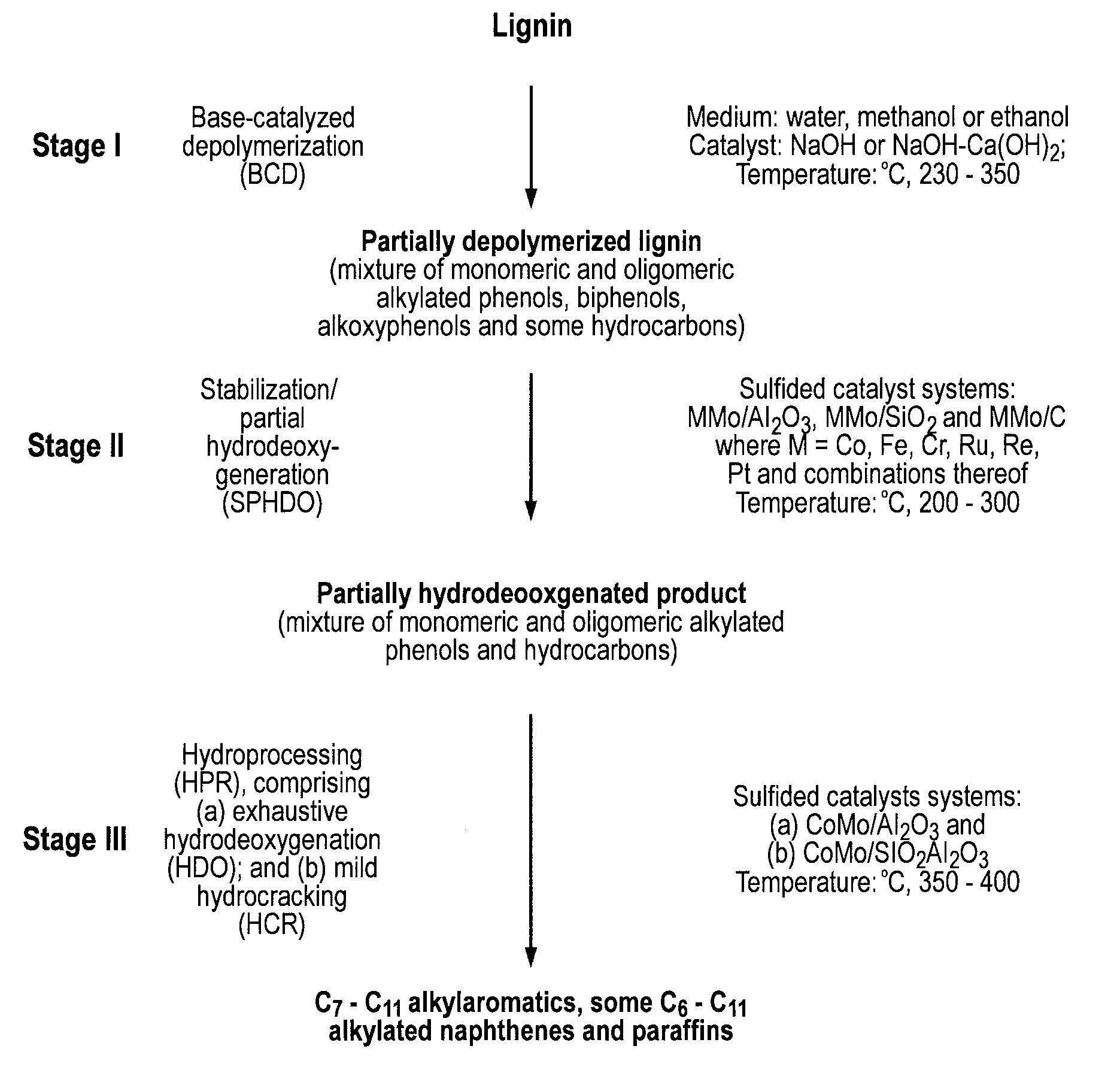

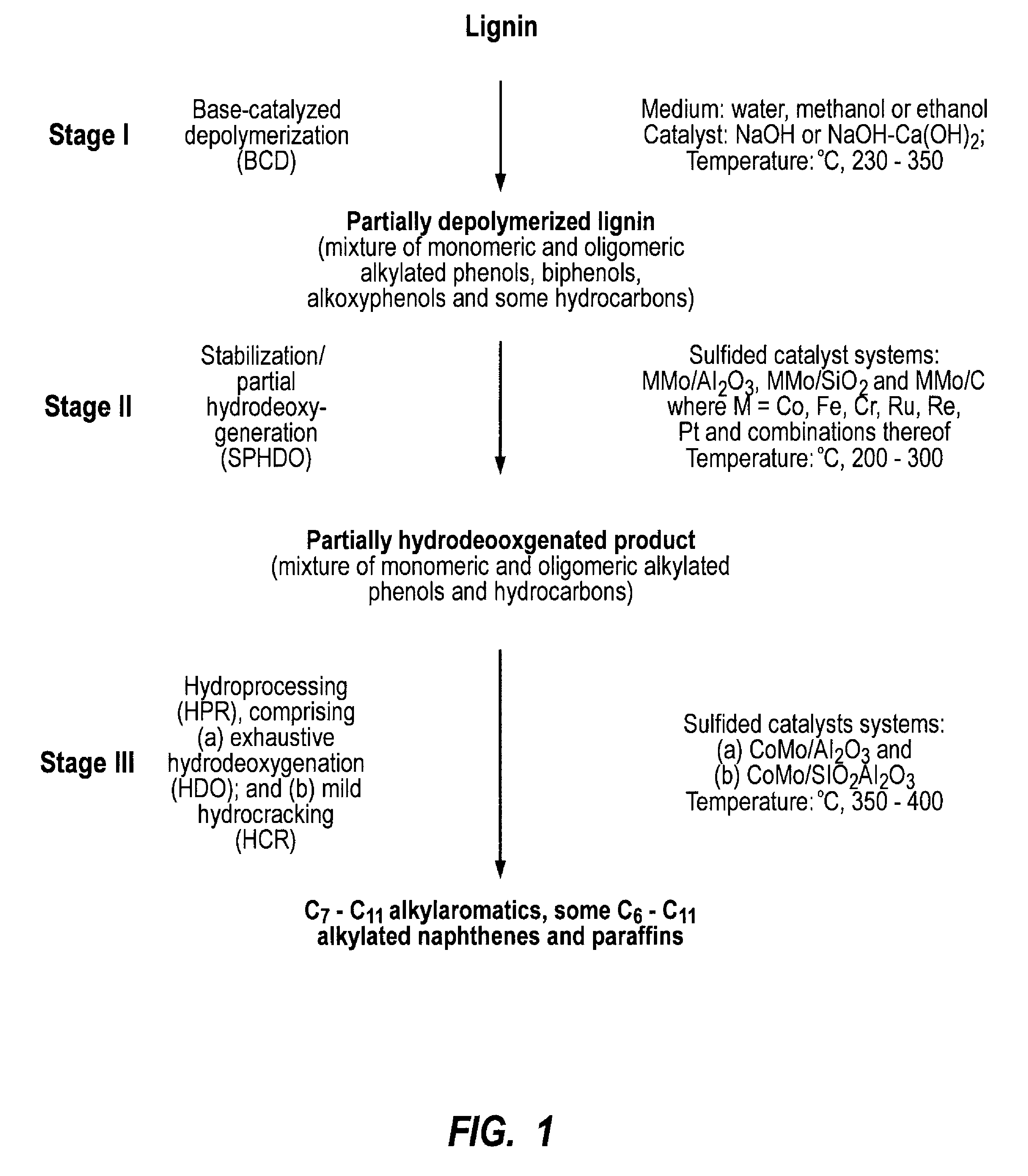

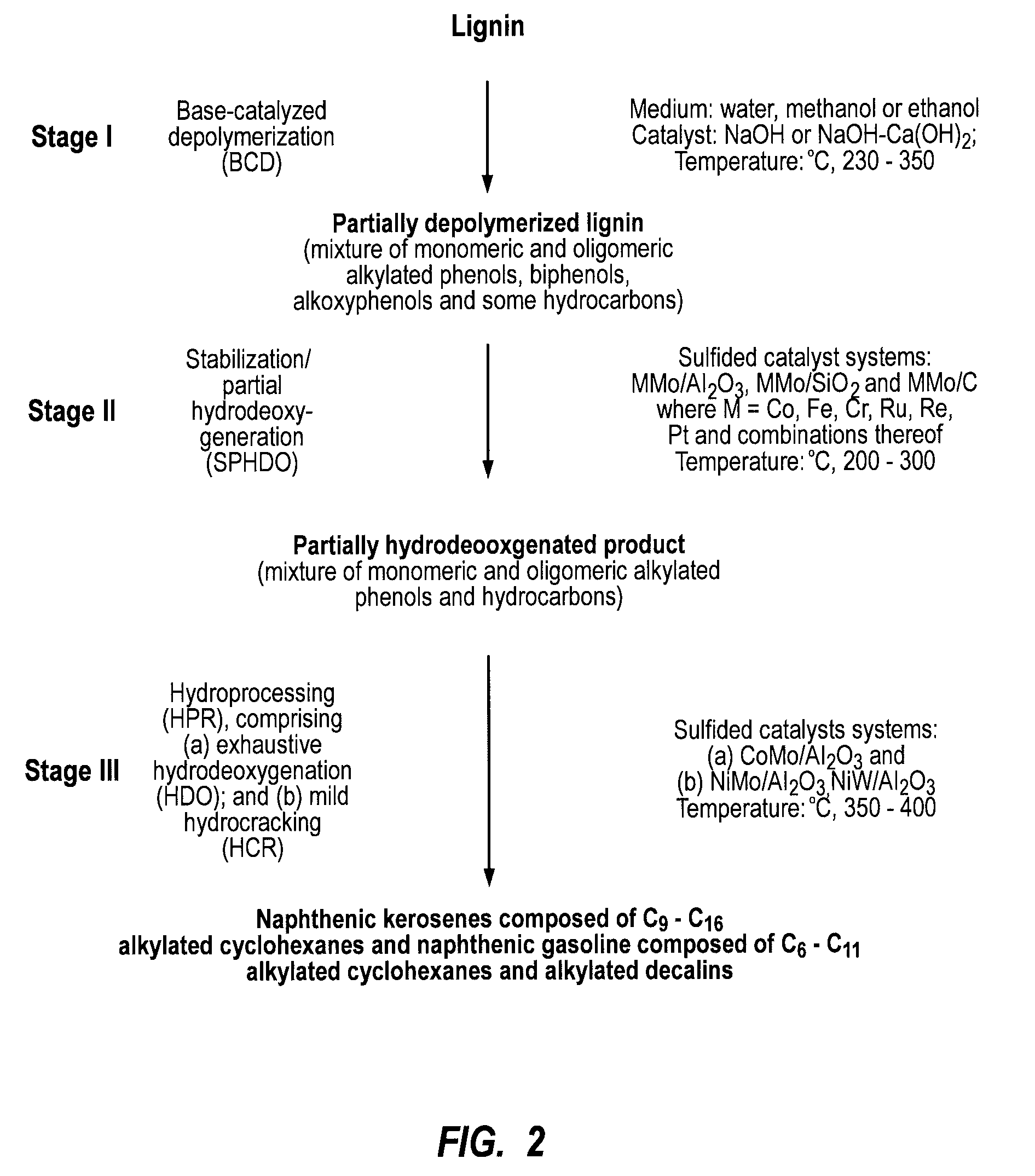

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

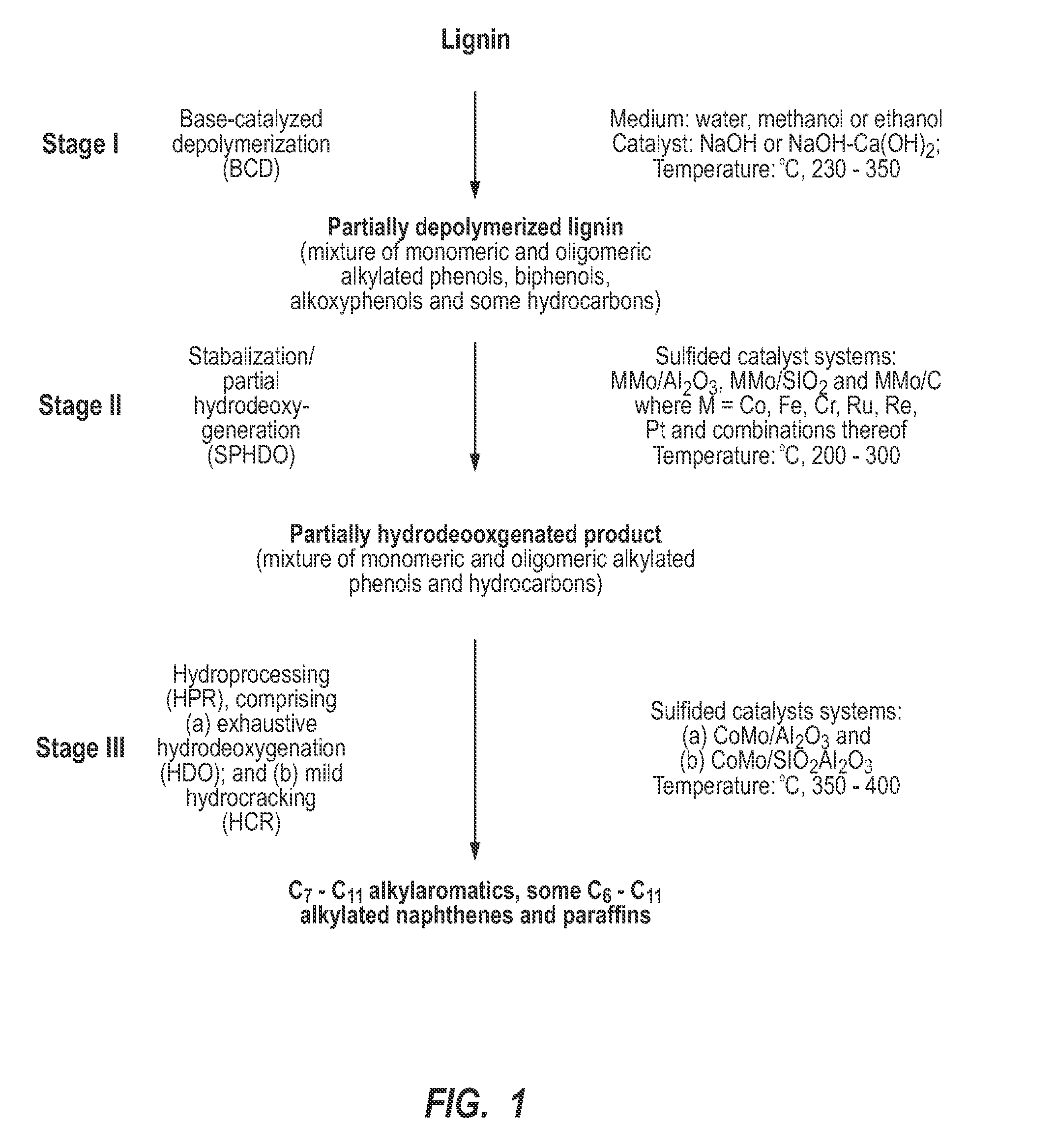

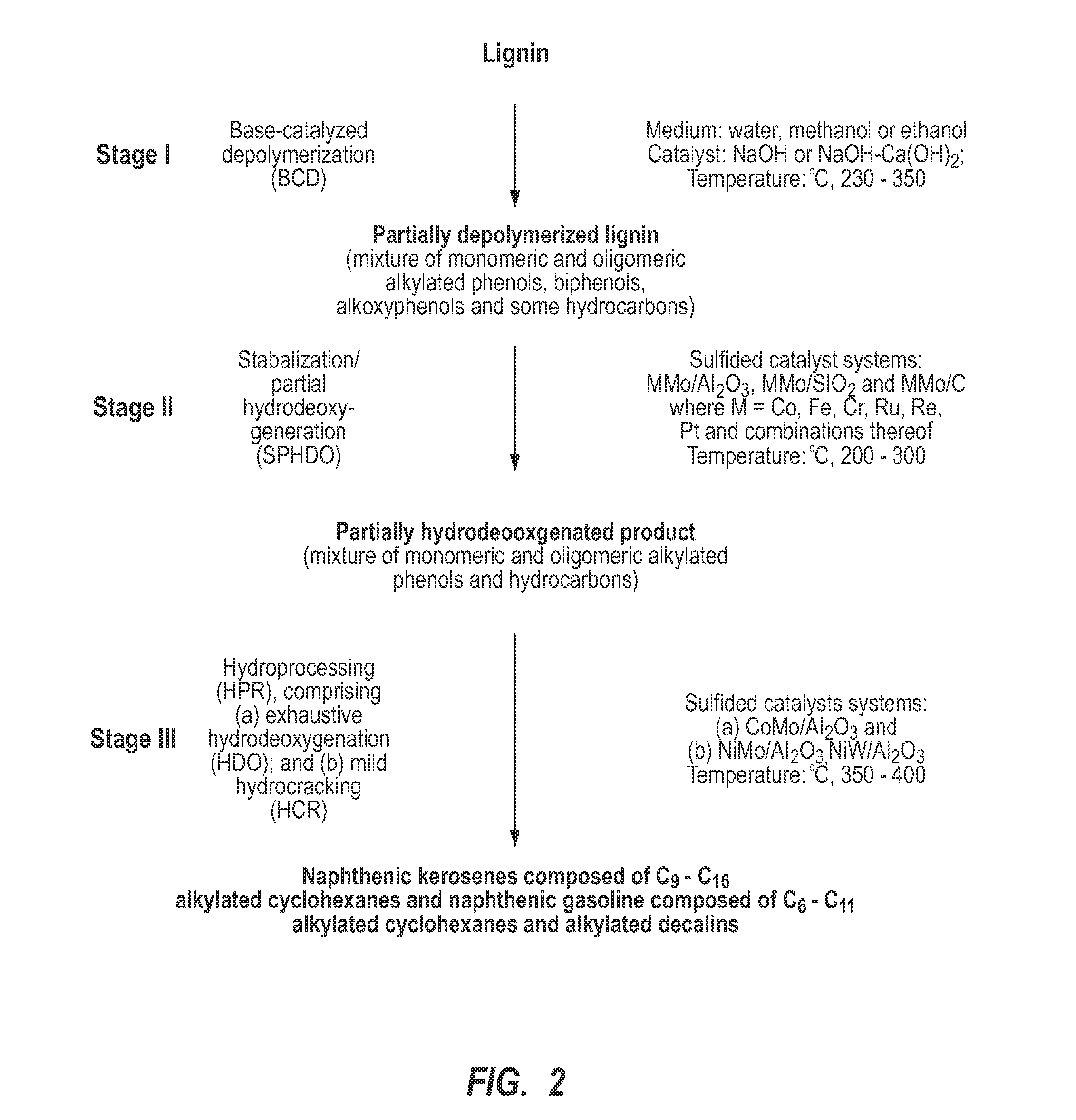

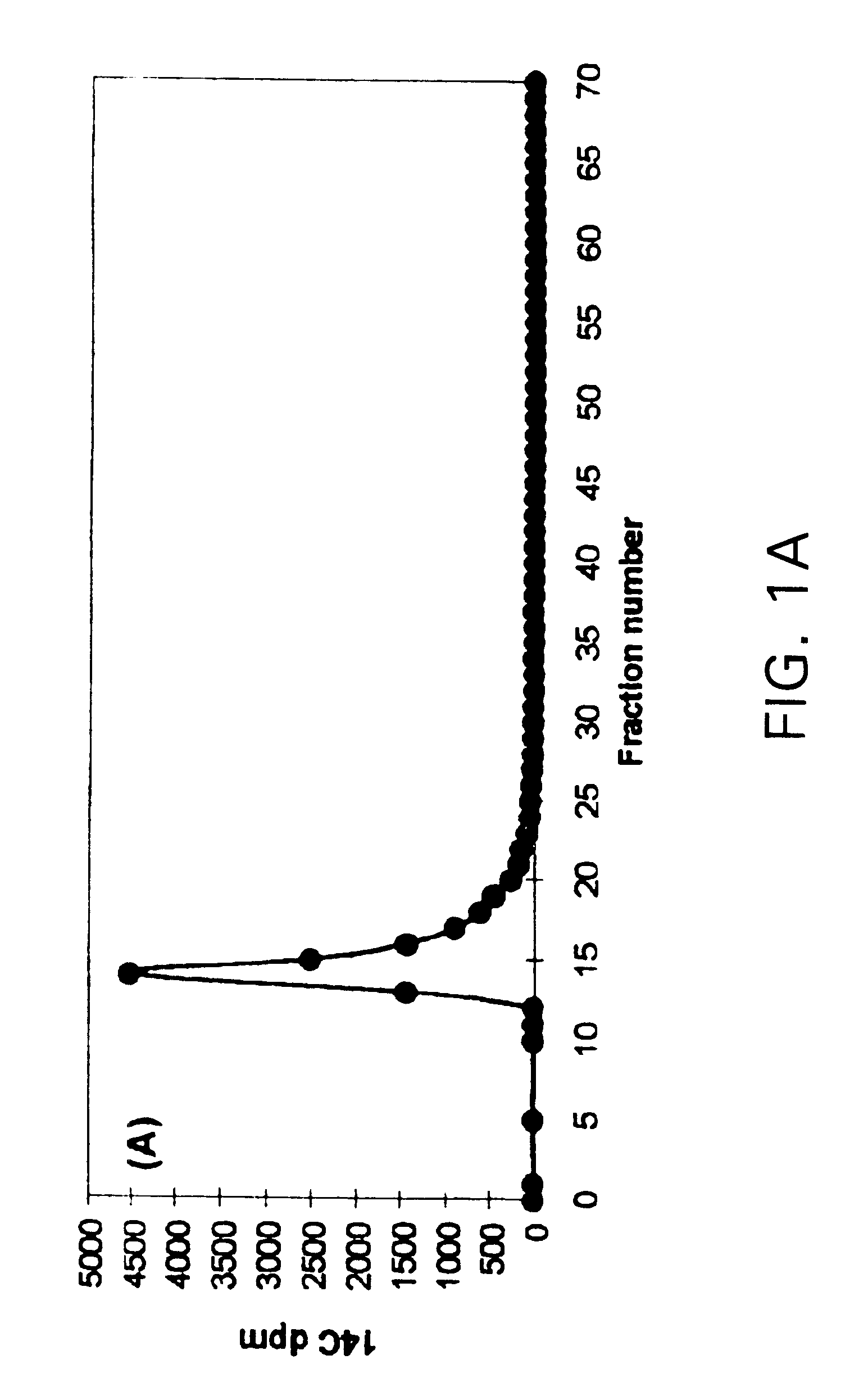

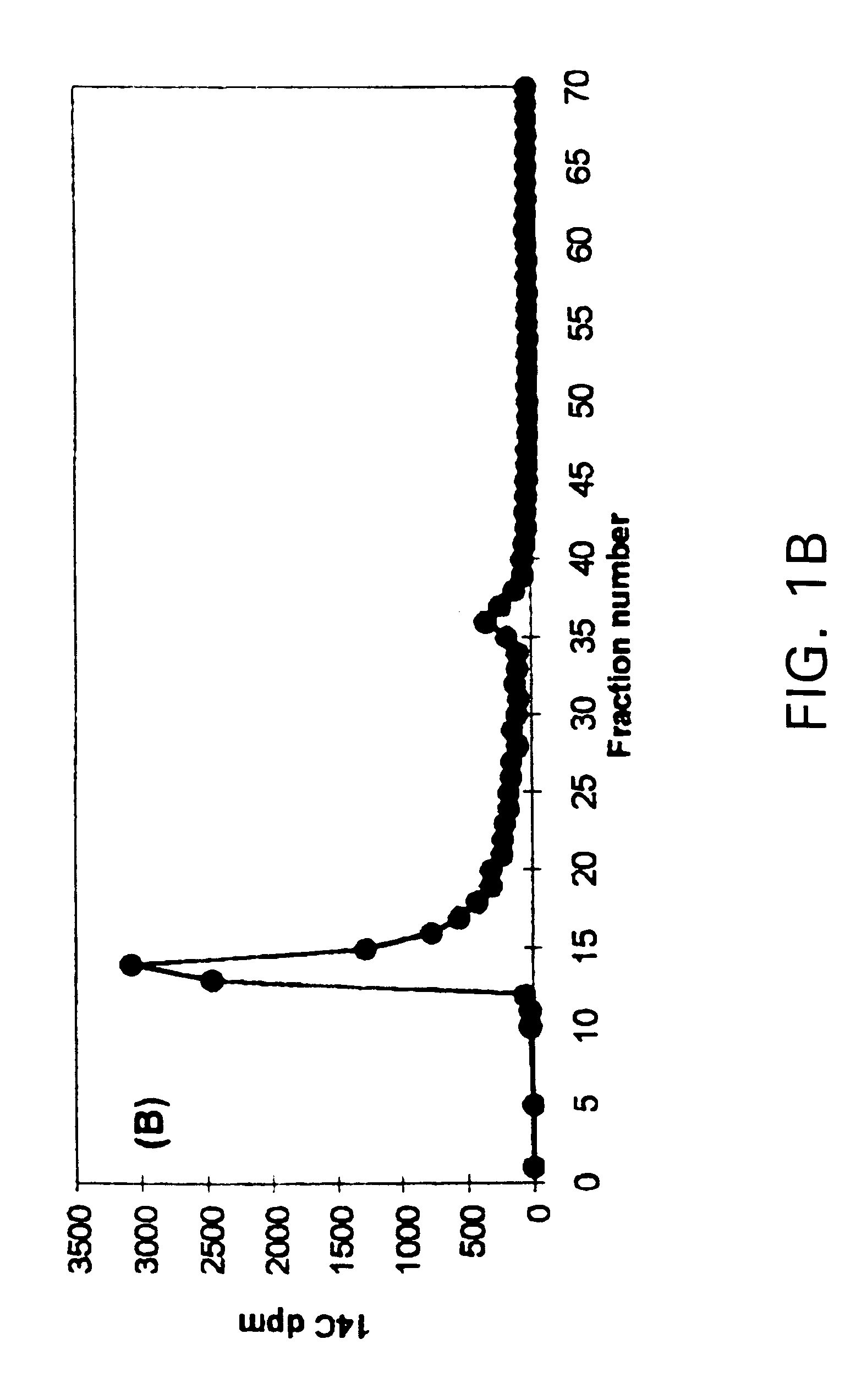

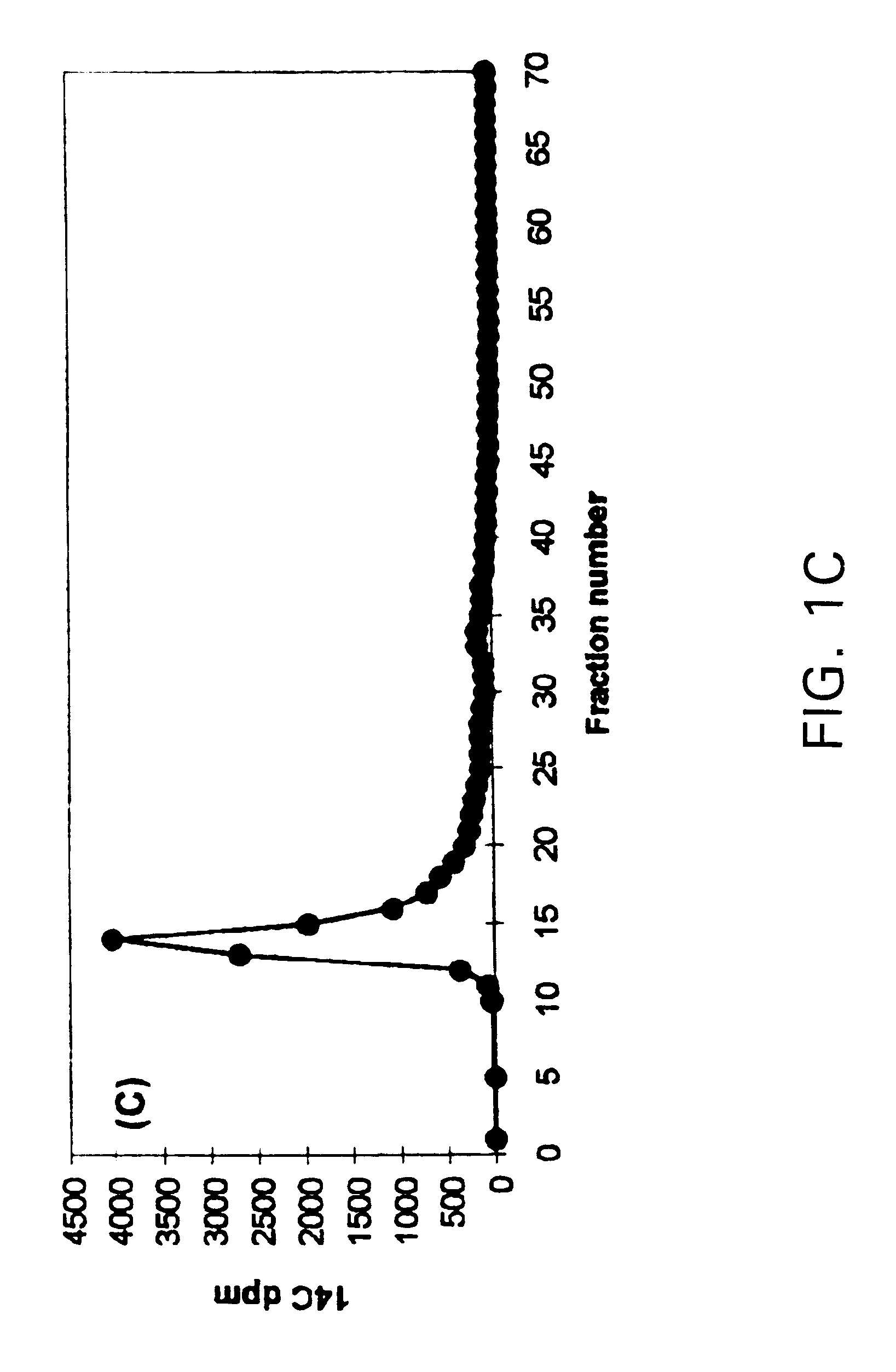

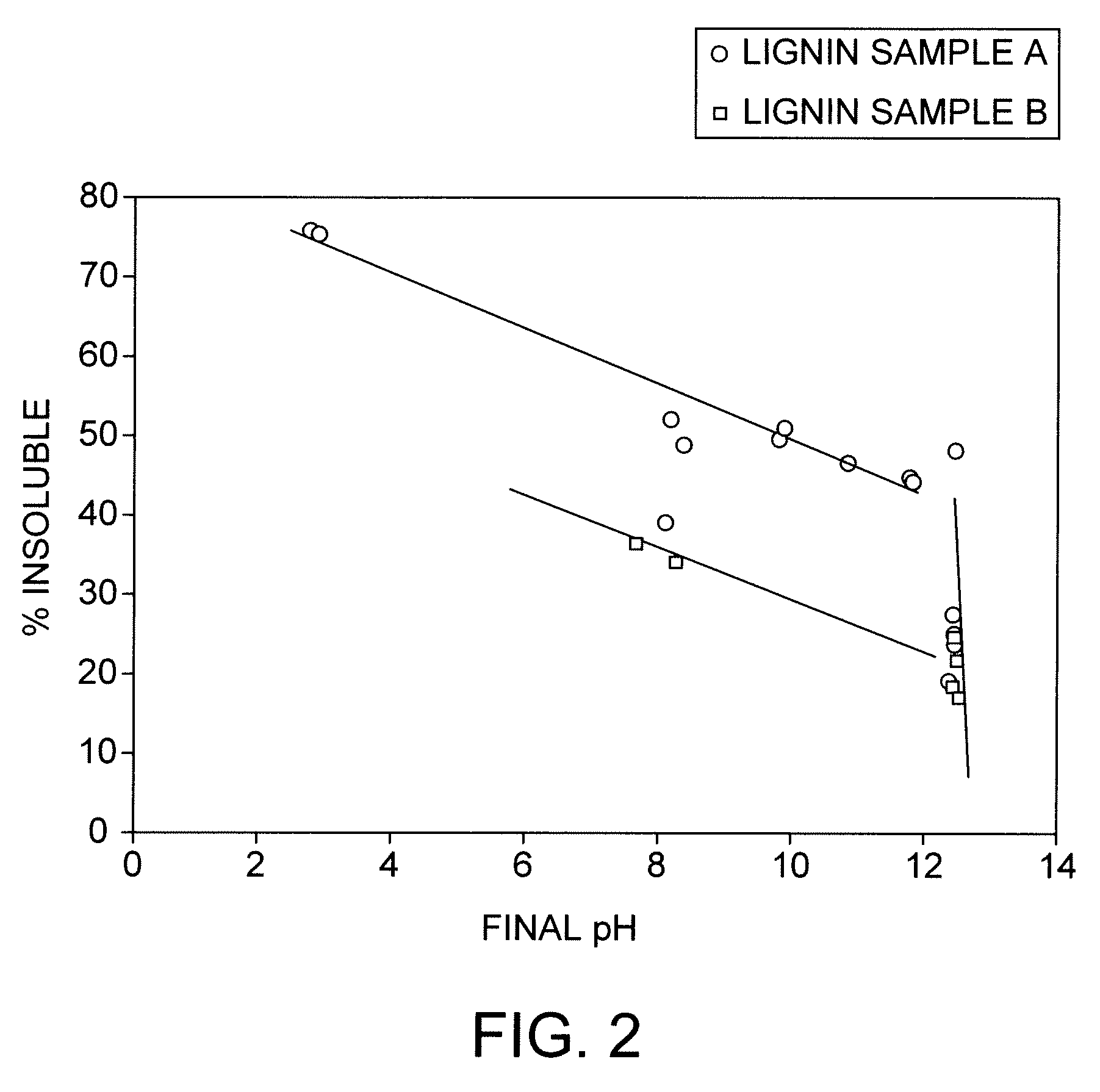

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

Pyrophosphorolysis and incorporation of nucleotide method for nucleic acid detection

InactiveUS7090975B2Useful in detectionSugar derivativesMicrobiological testing/measurementDepolymerizationNucleic acid detection

Processes are disclosed using the depolymerization of a nucleic acid hybrid and incorporation of a suitable nucleotide to qualitatively and quantitatively analyze for the presence of predetermined nucleic acid target sequences. Applications of those processes include the detection of single nucleotide polymorphisms, identification of single base changes, genotyping, medical marker diagnostics, mirosequencing, and.

Owner:PROMEGA

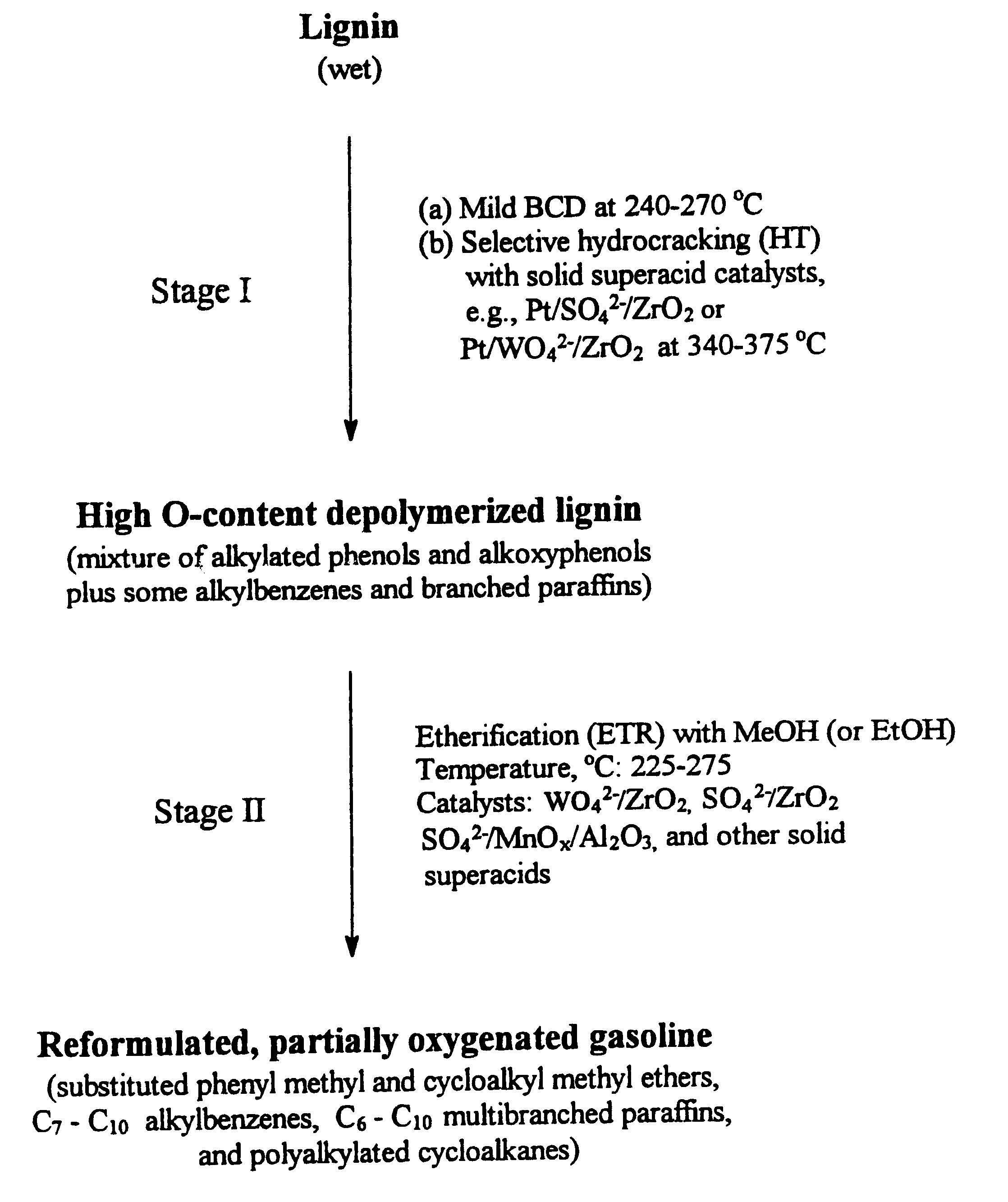

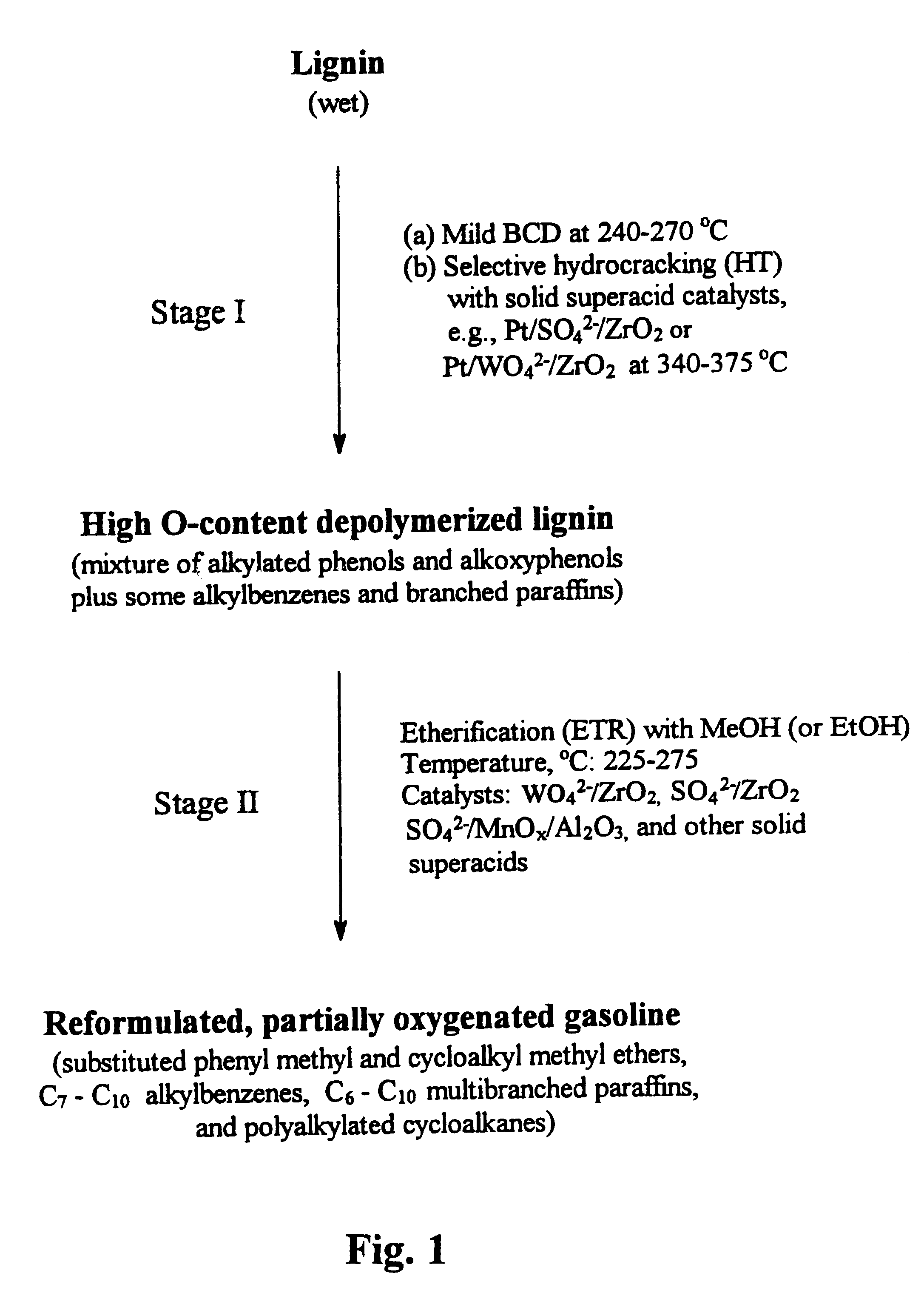

Process for conversion of lignin to reformulated, partially oxygenated gasoline

InactiveUS6172272B1Short reaction timeMaintain good propertiesOrganic compound preparationHydrocarbon from oxygen organic compoundsDepolymerizationMethyl group

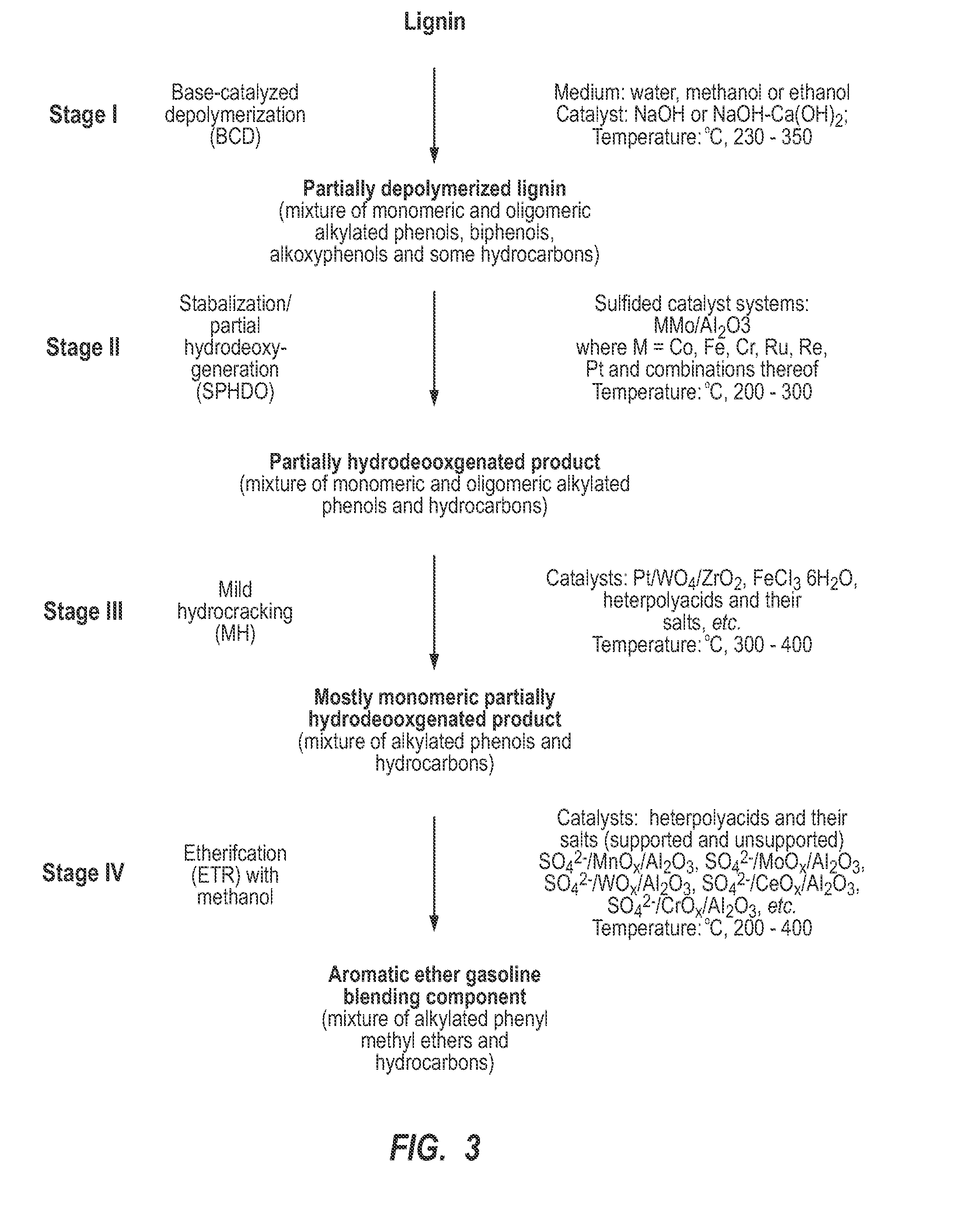

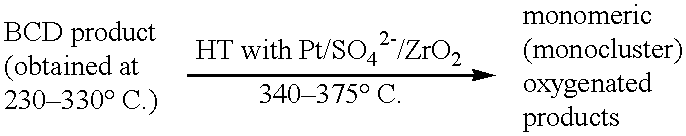

A high-yield process for converting lignin into reformulated, partially oxygenated gasoline compositions of high quality is provided. The process is a two-stage catalytic reaction process that produces a reformulated, partially oxygenated gasoline product with a controlled amount of aromatics. In the first stage of the process, a lignin feed material is subjected to a base-catalyzed depolymerization reaction, followed by a selective hydrocracking reaction which utilizes a superacid catalyst to produce a high oxygen-content depolymerized lignin product mainly composed of alkylated phenols, alkylated alkoxyphenols, and alkylbenzenes. In the second stage of the process, the depolymerized lignin product is subjected to an exhaustive etherification reaction, optionally followed by a partial ring hydrogenation reaction, to produce a reformulated, partially oxygenated / etherified gasoline product, which includes a mixture of substituted phenyl / methyl ethers, cycloalkyl methyl ethers, C7-C10 alkylbenzenes, C6-C10 branched and multibranched paraffins, and alkylated and polyalkylated cycloalkanes.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

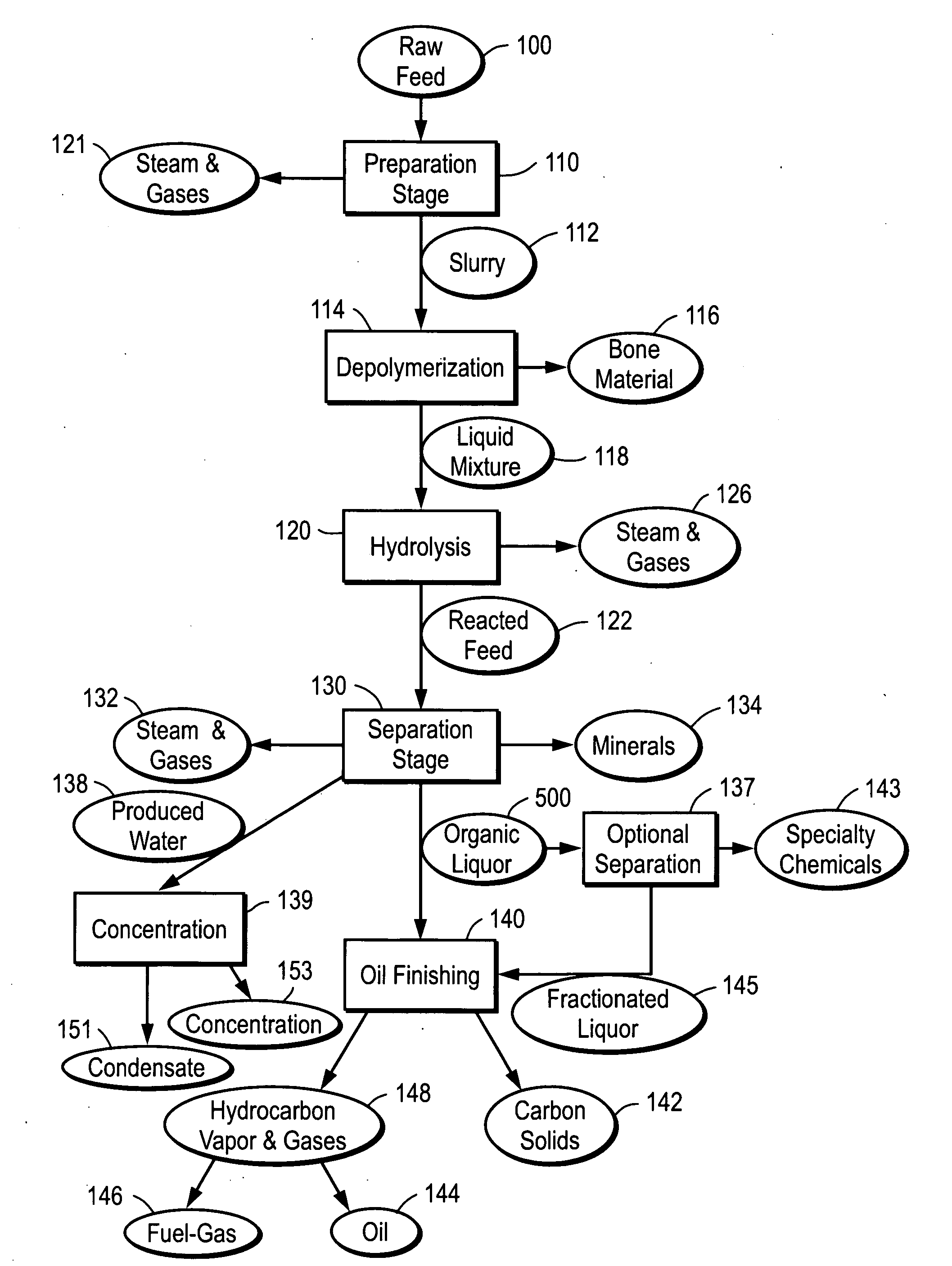

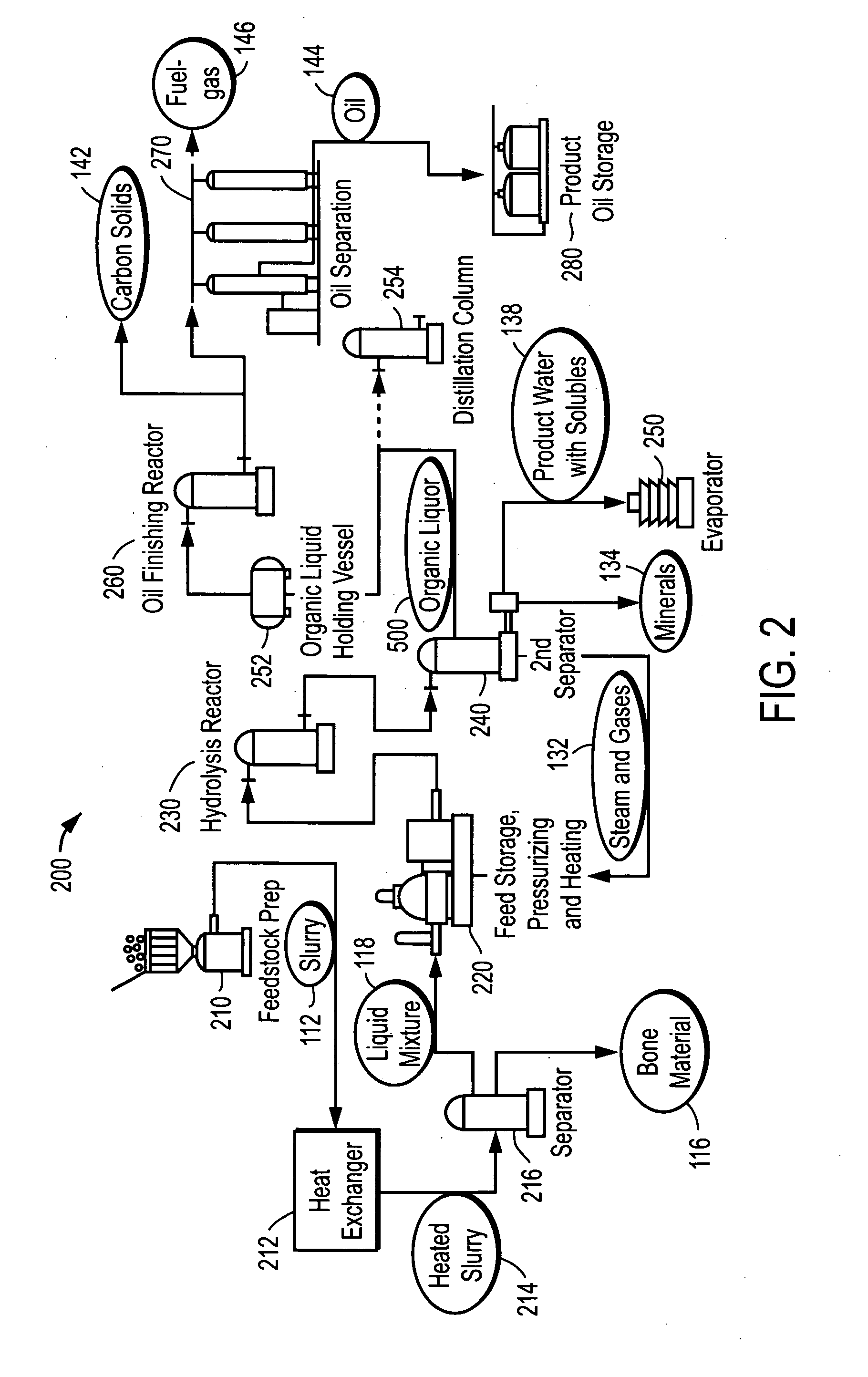

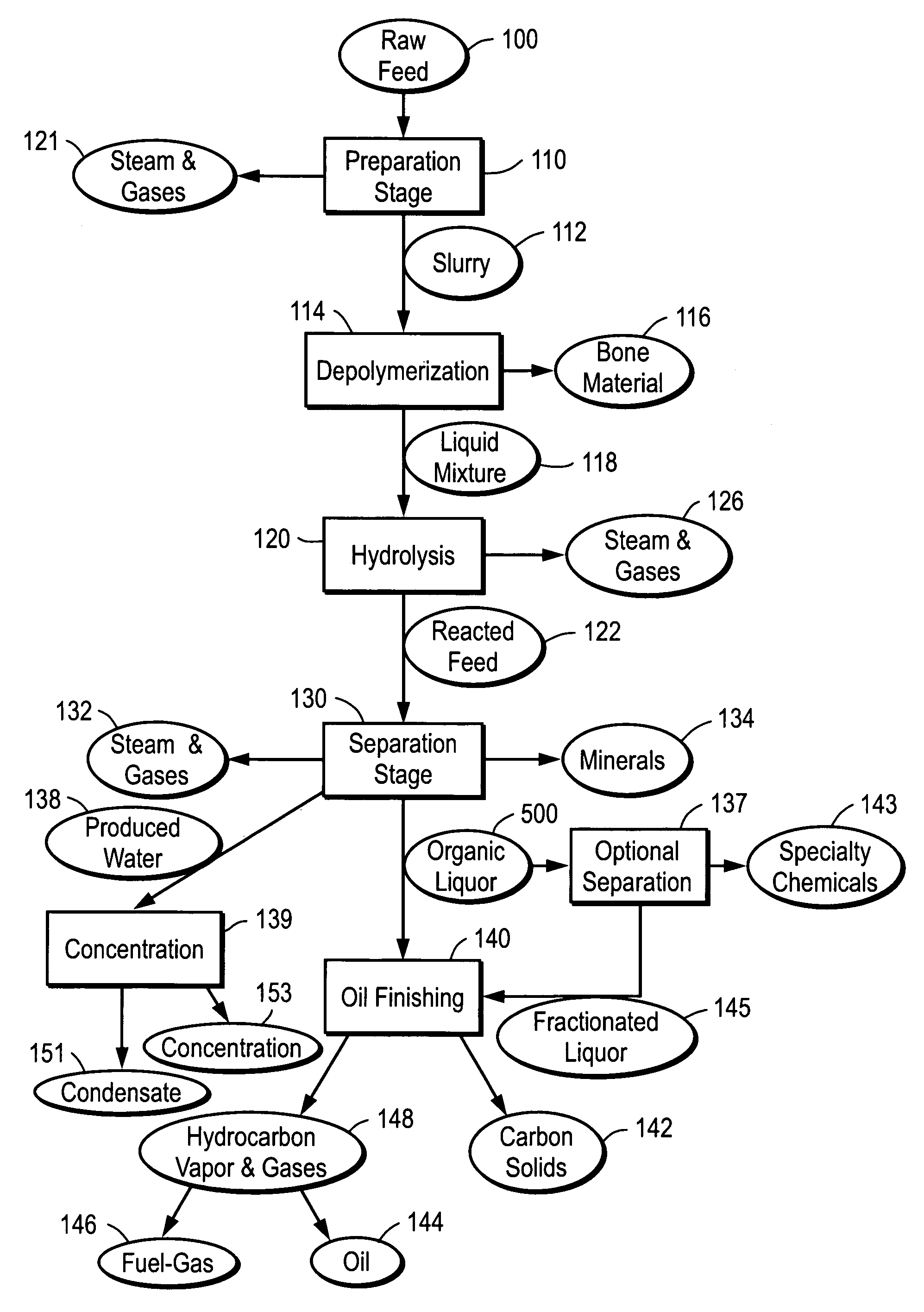

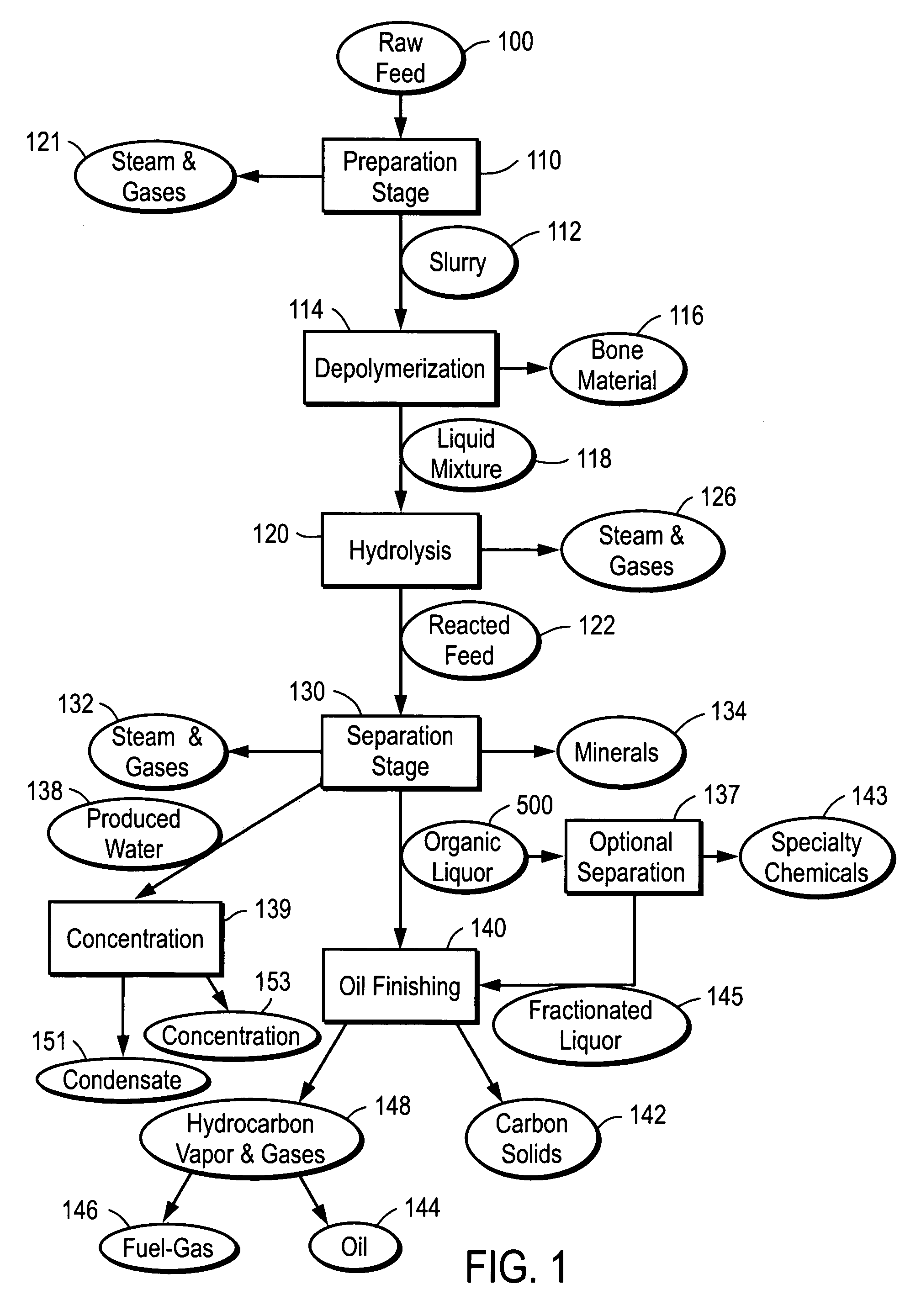

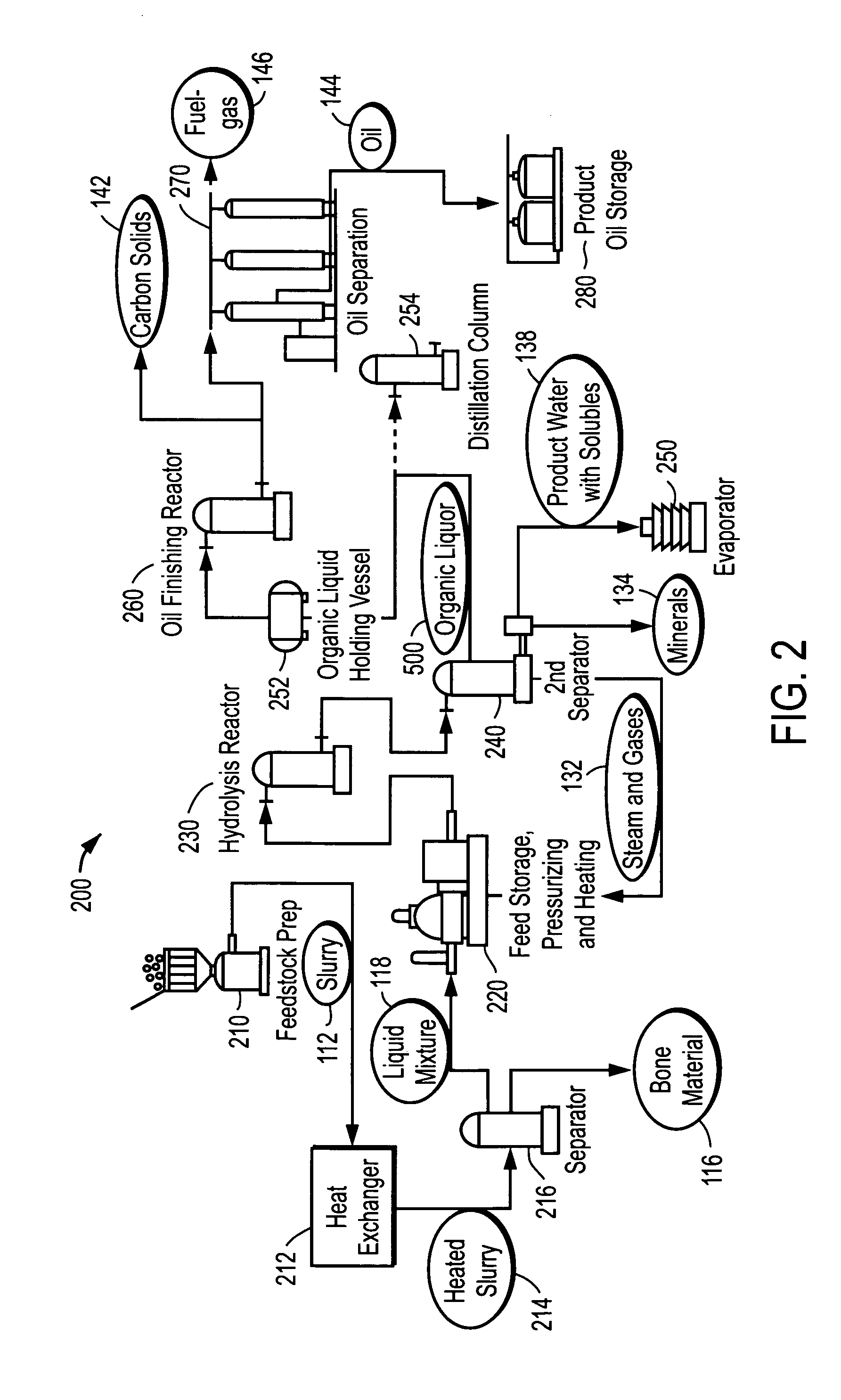

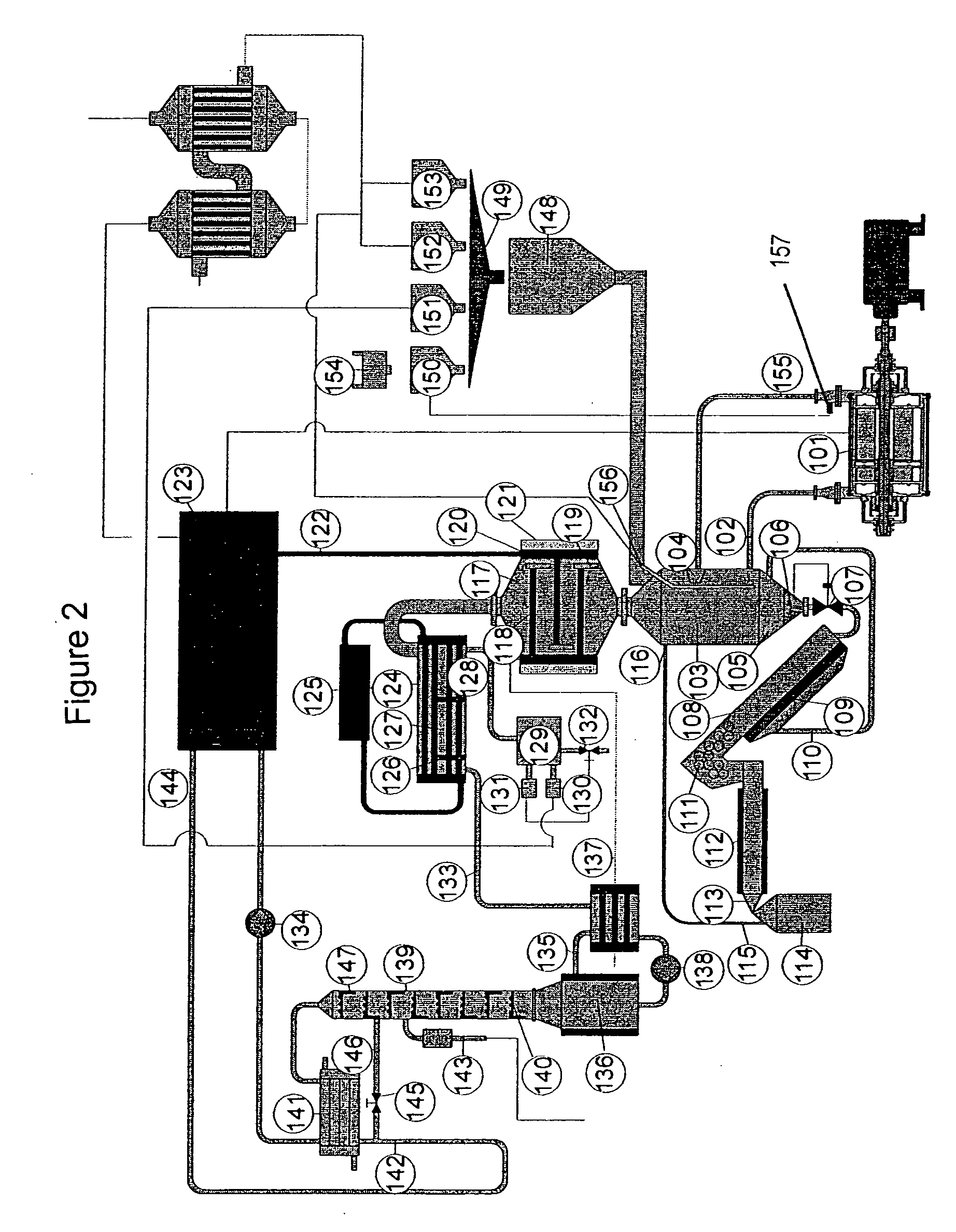

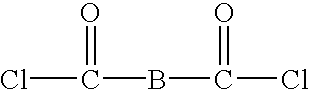

Depolymerization process of conversion of organic and non-organic waste materials into useful products

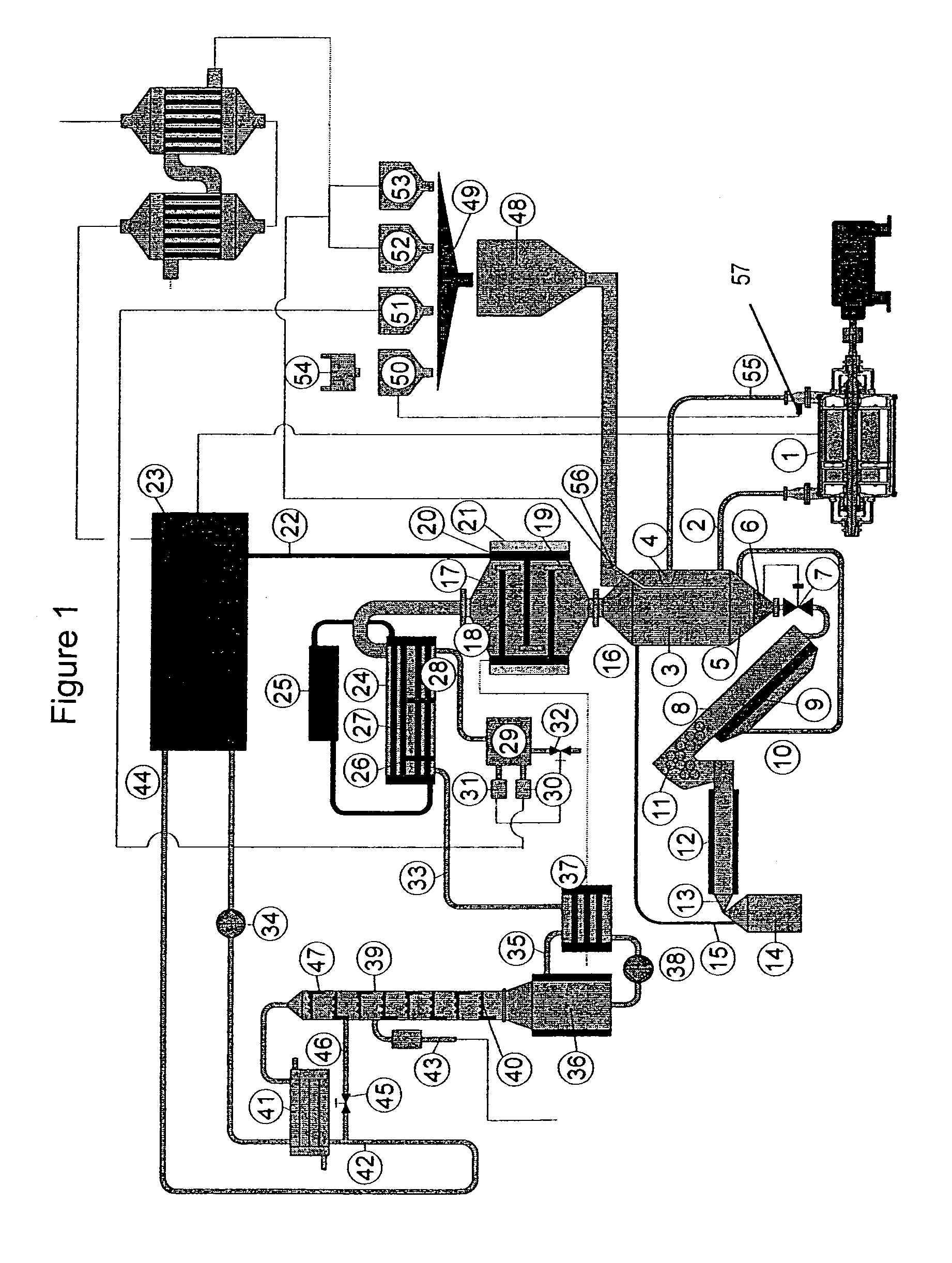

ActiveUS20070098625A1Improve energy efficiencyAcceptable costWaste based fuelLiquid hydrocarbon mixture productionDepolymerizationCost effectiveness

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

Phosphate film-coated powder and preparation method thereof

InactiveCN101045828AUniform particlesParticle size distribution andNon-macromolecular adhesive additivesOther chemical processesDepolymerizationDouble decker

This invention relates to a method of preparing envelope powder. The shattering, depolymerization and coating processed at same time, and solid phase acid-base reaction participate the method. This envelope powder possess double-decker or three-layer structure, inner core is composed by oxide or hydrate or inorganic oxysalt, crust composed by inorganic oxysalt, envelope by aluminum phosphate or boron phosphate. This low cost powder be able to used as fortifier, power stuff, colorant and so on, applied to plastic, rubber, ceramics, dope, binder and paper, set foundation for popularization of ultramicro and nanometer powder.

Owner:张义纲 +1

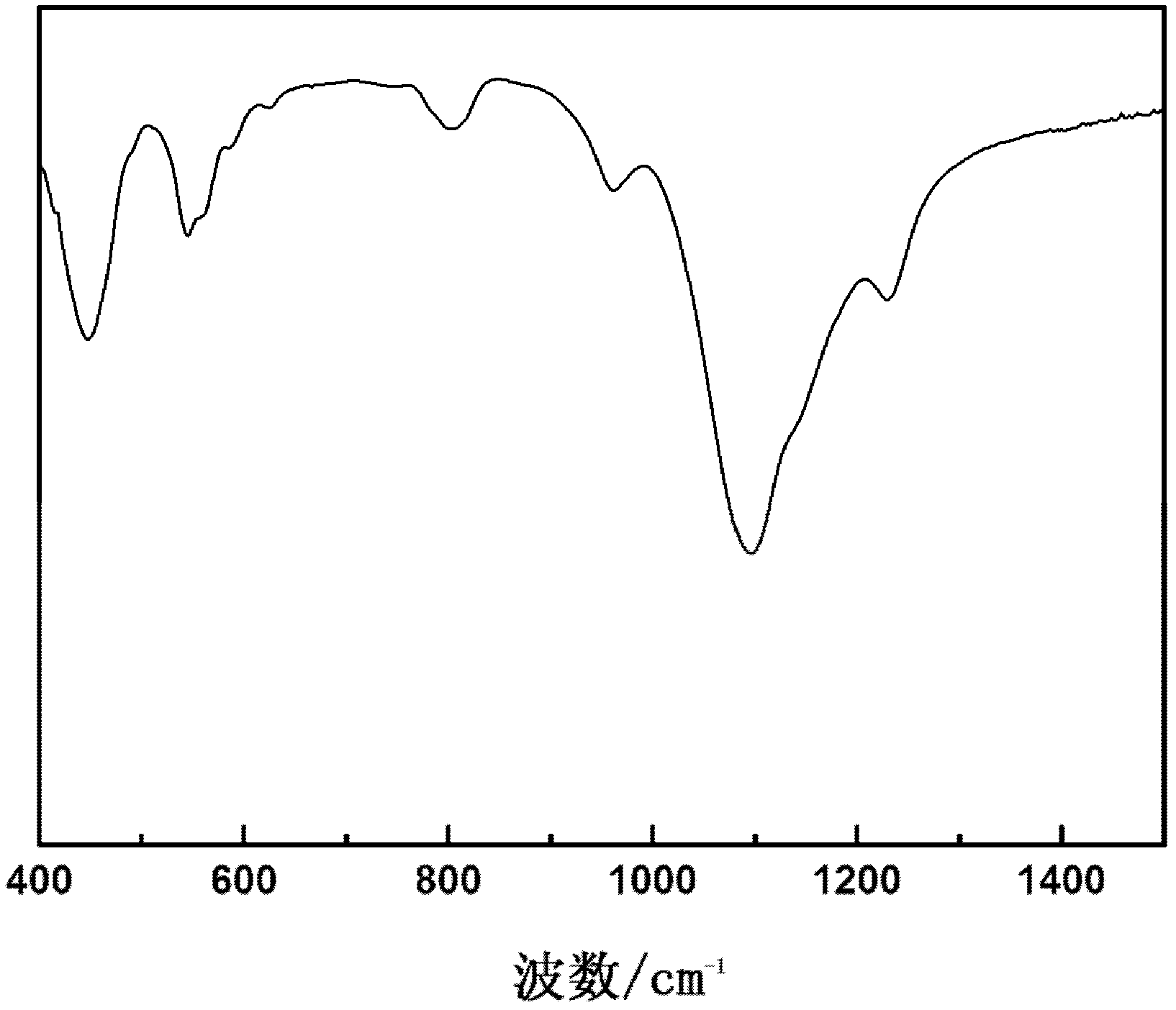

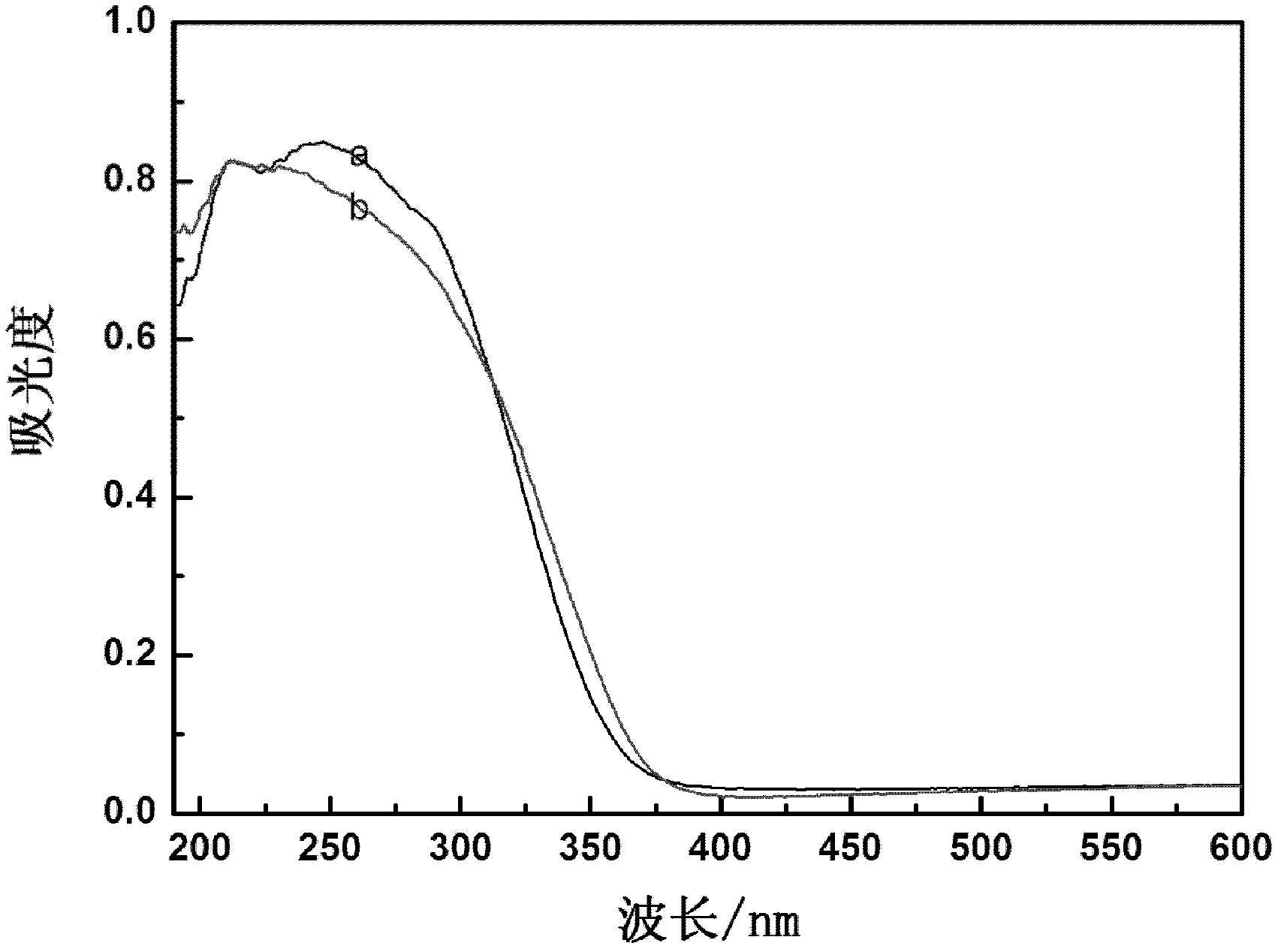

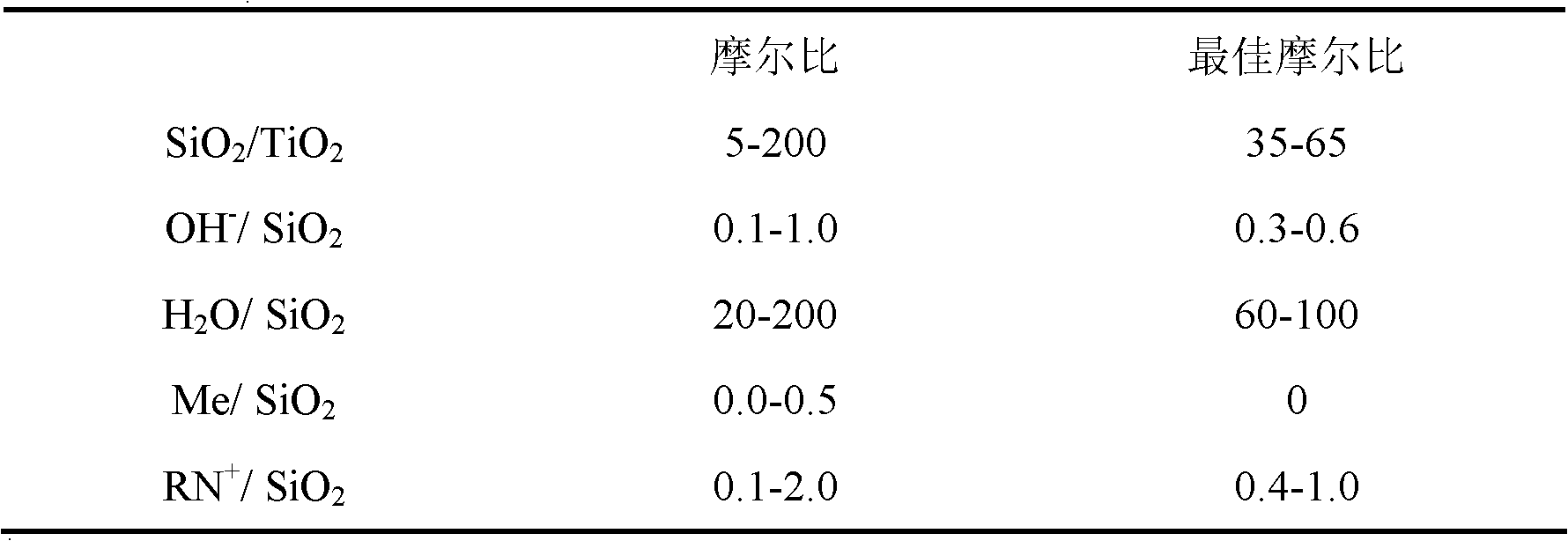

Synthesis method of titanium silicalite TS-1

ActiveCN102320619ASuppress generationLow costCrystalline aluminosilicate zeolitesMolecular sieveDepolymerization

The invention belongs to the field of preparation of molecular sieve material, and discloses a synthesis method of a titanium silicalite TS-1. The method is characterized by comprising the following steps of: preparing a titanium-silicon gel with a silicon source, a titanium source, a template agent, an alkaline mineralizing agent and water according to certain proportion, and introducing right amount of alkali metal salt in the gel preparation process through a direction method or an indirection method; then, executing hydrothermal crystallization at 160-180 DEG C; and obtaining the titanium silicalite TS-1 after filtering, washing, drying and roasting. With the synthesis method provided by the invention, depolymerization of the silicon source can be promoted in the gel preparation process, so that titanium can enter into a skeleton smoothly and generation of amorphous six-coordinate non-skeleton titanium can be restrained. Based on the action of alkaline metal ions and an acid site of the molecular sieve non-skeleton titanium, the acid site of the cheap titanium silicalite TS-1 is removed, and selectivity of propylene epoxide is greatly improved while taking the titanium silicalite TS-1 as the catalyst for the propylene epoxidation.

Owner:DALIAN UNIV OF TECH

Method of depolymerizing polyethylene terephthalate and process for producing polyester resin

InactiveUS20050096482A1Depolymerization of R-PETShort timePlastic recyclingPreparation by transesterificationPolymer sciencePolyethylene terephthalate

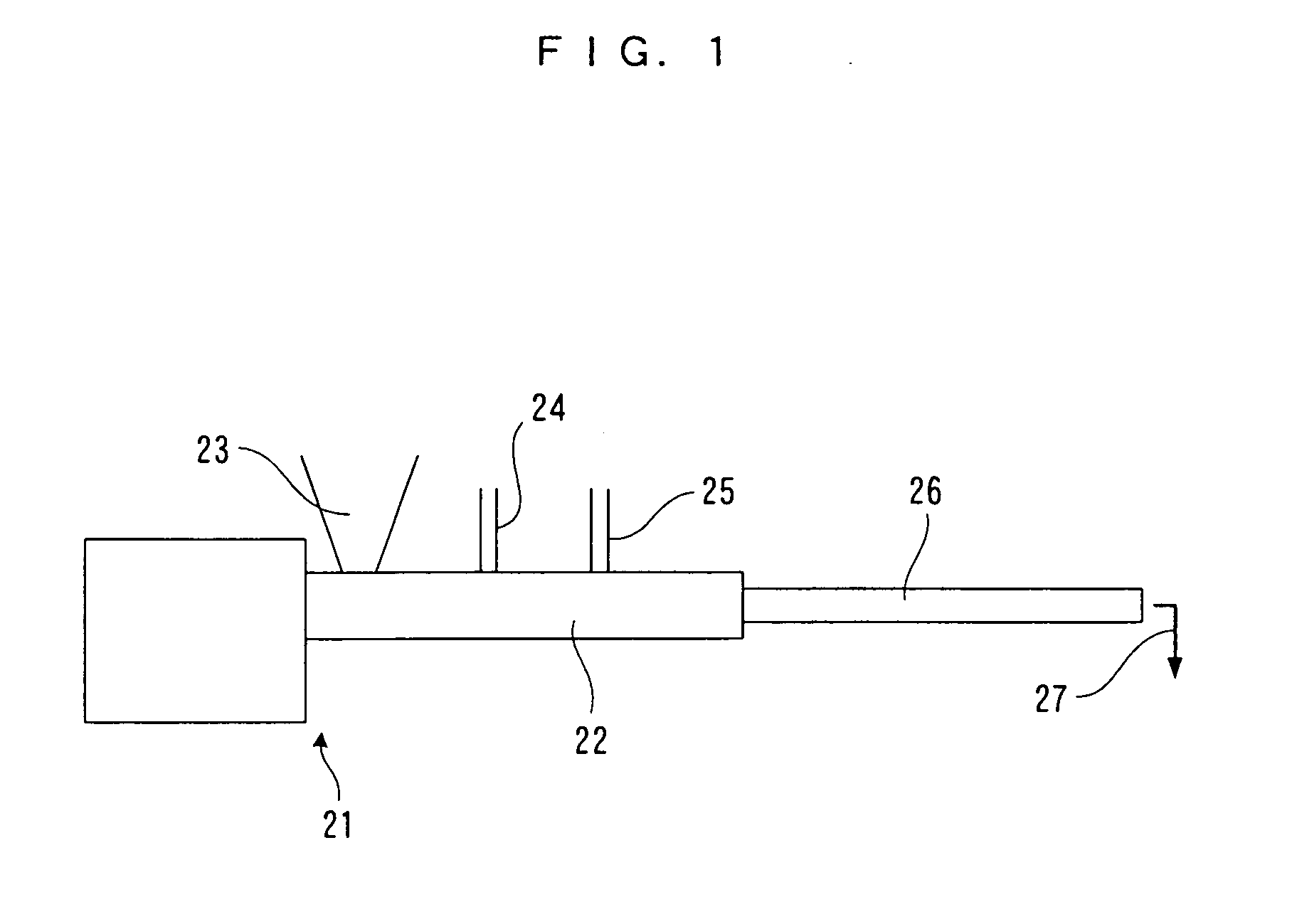

A method of depolymerizing polyethylene terephthalate, and a method of manufacturing a polyester resin. When heating, melting and depolymerizing polyethylene terephthalate to be recycled, the heating, melting and depolymerization reaction of the polyethylene terephthalate to be recycled are carried out all at once using one or a plurality of extruders or using an extruder and a reactor provided at an outlet of the extruder. When manufacturing a polyester resin, the reactants are irradiated with microwaves, thus promoting the heating of the reactants, and promoting the esterification reaction.

Owner:KUBOTA LTD +1

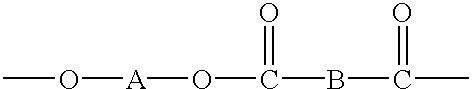

Preparation method of a polyester particle dispersion and polyester particle dispersion prepared by the same

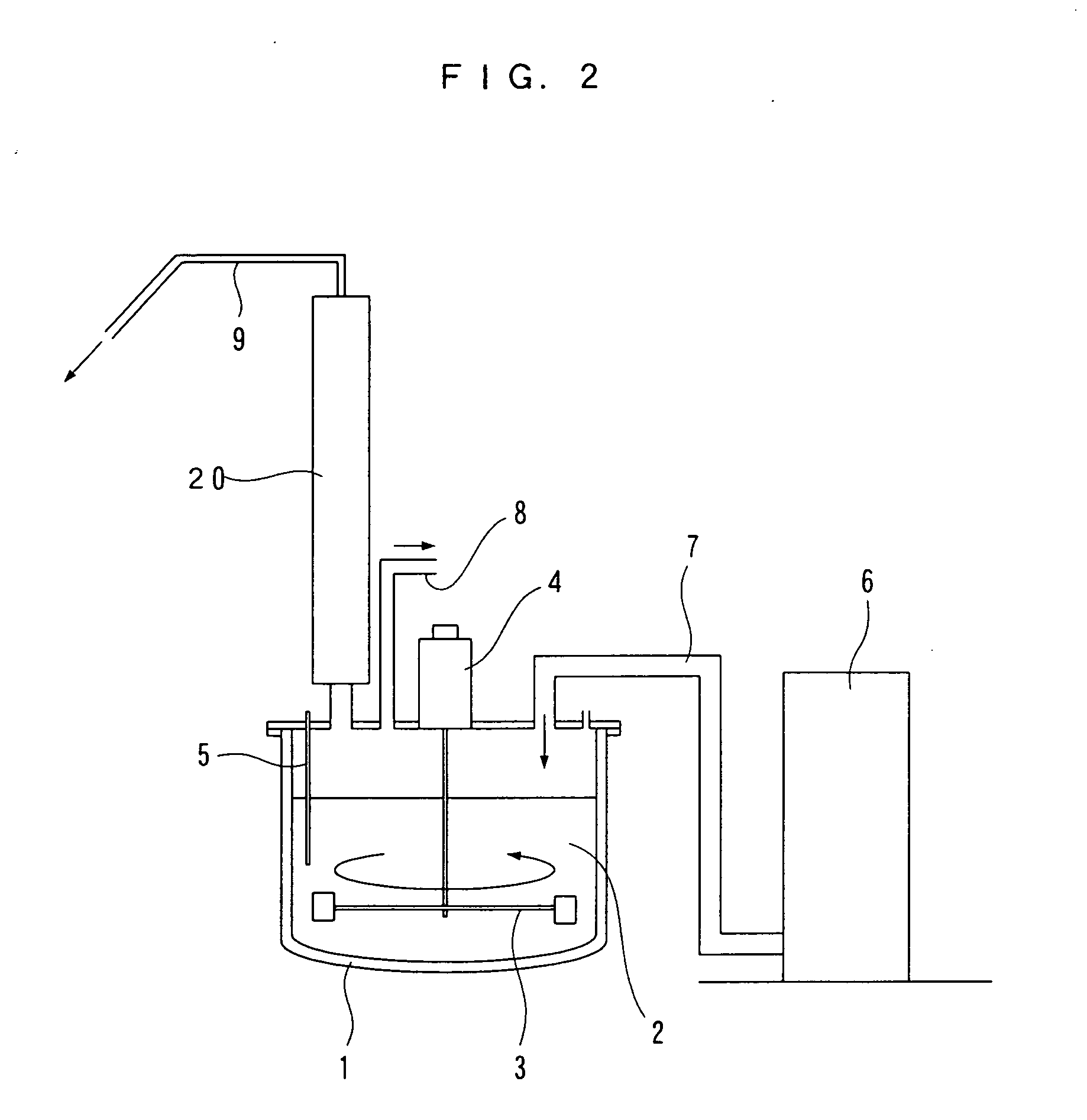

A preparation method of a polyester particle dispersion includes: under predetermined depolymerization conditions, mixing a polyester binder resin, a resin dissolvent and a polycondensation catalyst to depolymerize the polyester resin and form a first reaction mixture; adding a first monomer to the first reaction mixture to form a second reaction mixture; under predetermined polymerization conditions, adding a second monomer to the second reaction mixture to polymerize the depolymerized polyester resin and form a third reaction mixture; adding a neutralizing agent to neutralize the polymerized reaction product of the third reaction mixture; (e) adding a reverse-neutralizing agent to reverse neutralize the neutralized mixture; and adding a mixture of an anionic surfactant and a nonionic surfactant to the reverse-neutralized mixture.

Owner:SAMSUNG ELECTRONICS CO LTD

Biodegradable polylactic acids for use in forming fibers

A method for forming a biodegradable polylactic acid suitable for use in fibers is provided. Specifically, a polylactic acid is melt processed at a controlled water content to initiate a hydrolysis reaction. Without intending to be limited by theory, it is believed that the hydroxyl groups present in water are capable of attacking the ester linkage of polylactic acids, thereby leading to chain scission or “depolymerization” of the polylactic acid molecule into one or more shorter ester chains. The shorter chains may include polylactic acids, as well as minor portions of lactic acid monomers or oligomers, and combinations of any of the foregoing. By selectively controlling the hydrolysis conditions (e.g., moisture and polymer concentrations, temperature, shear rate, etc.), a hydrolytically degraded polylactic acid may be achieved that has a molecular weight lower than the starting polymer. Such lower molecular weight polymers have a higher melt flow rate and lower apparent viscosity, which are useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

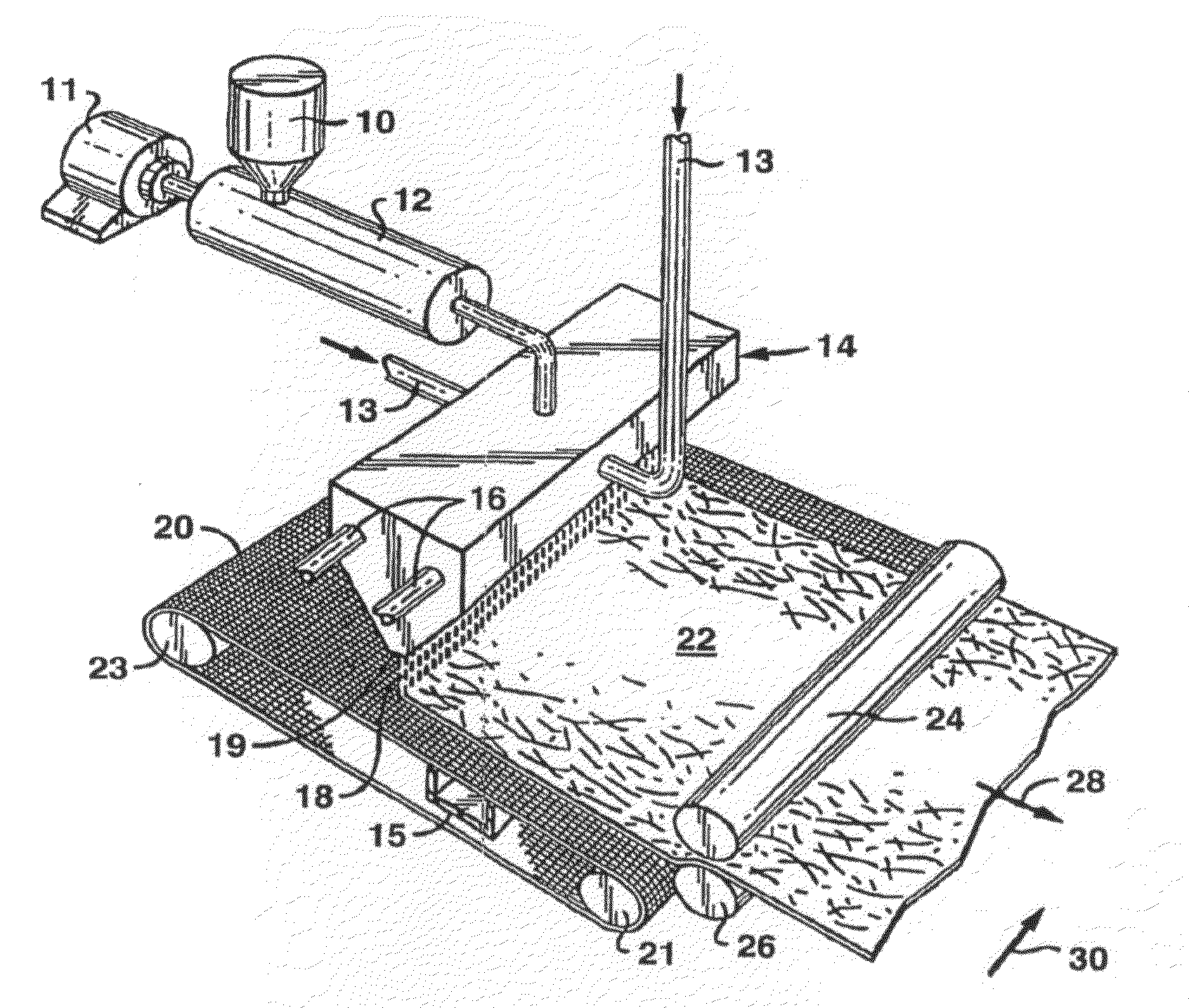

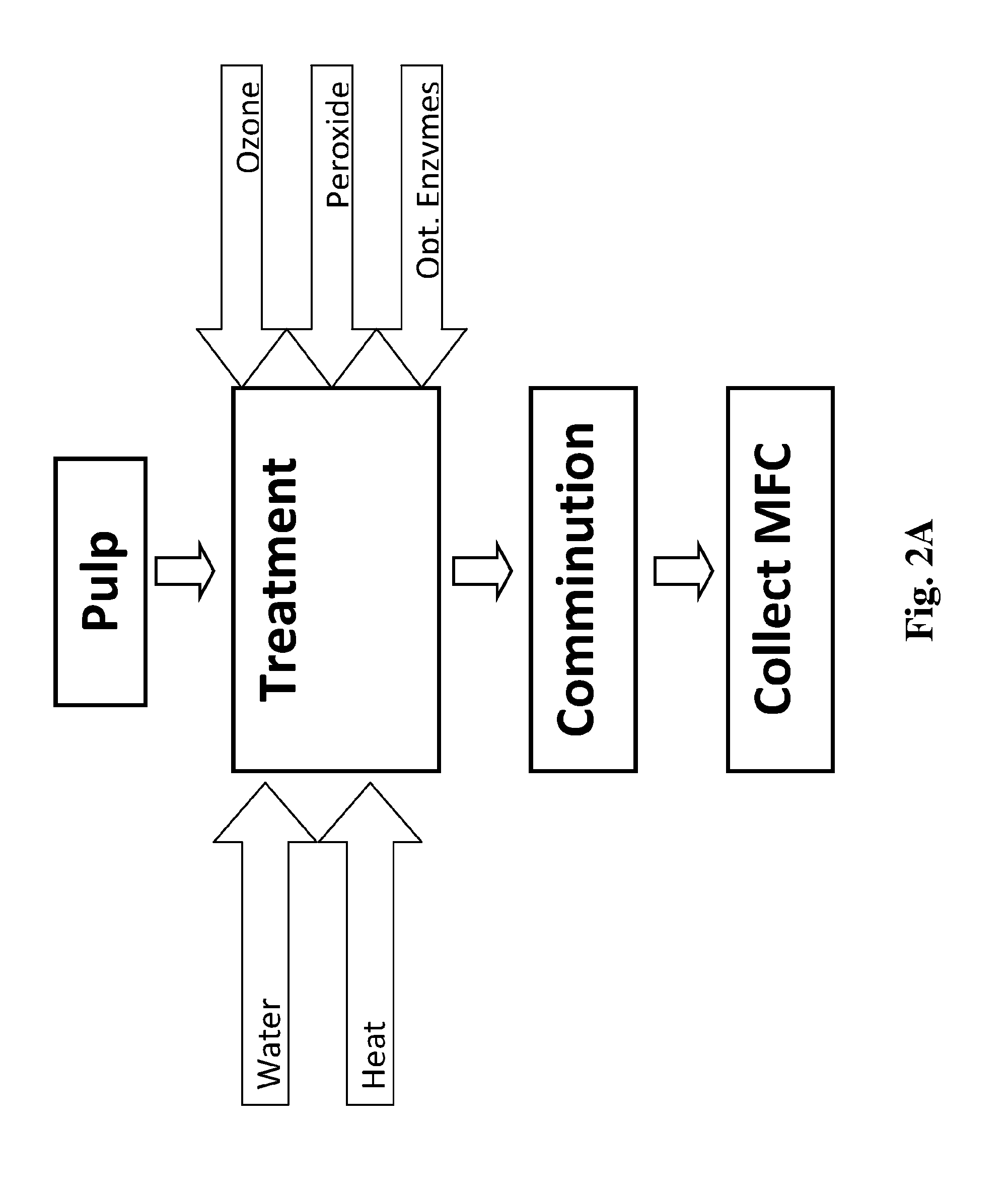

Energy Efficient Process for Preparing Nanocellulose Fibers

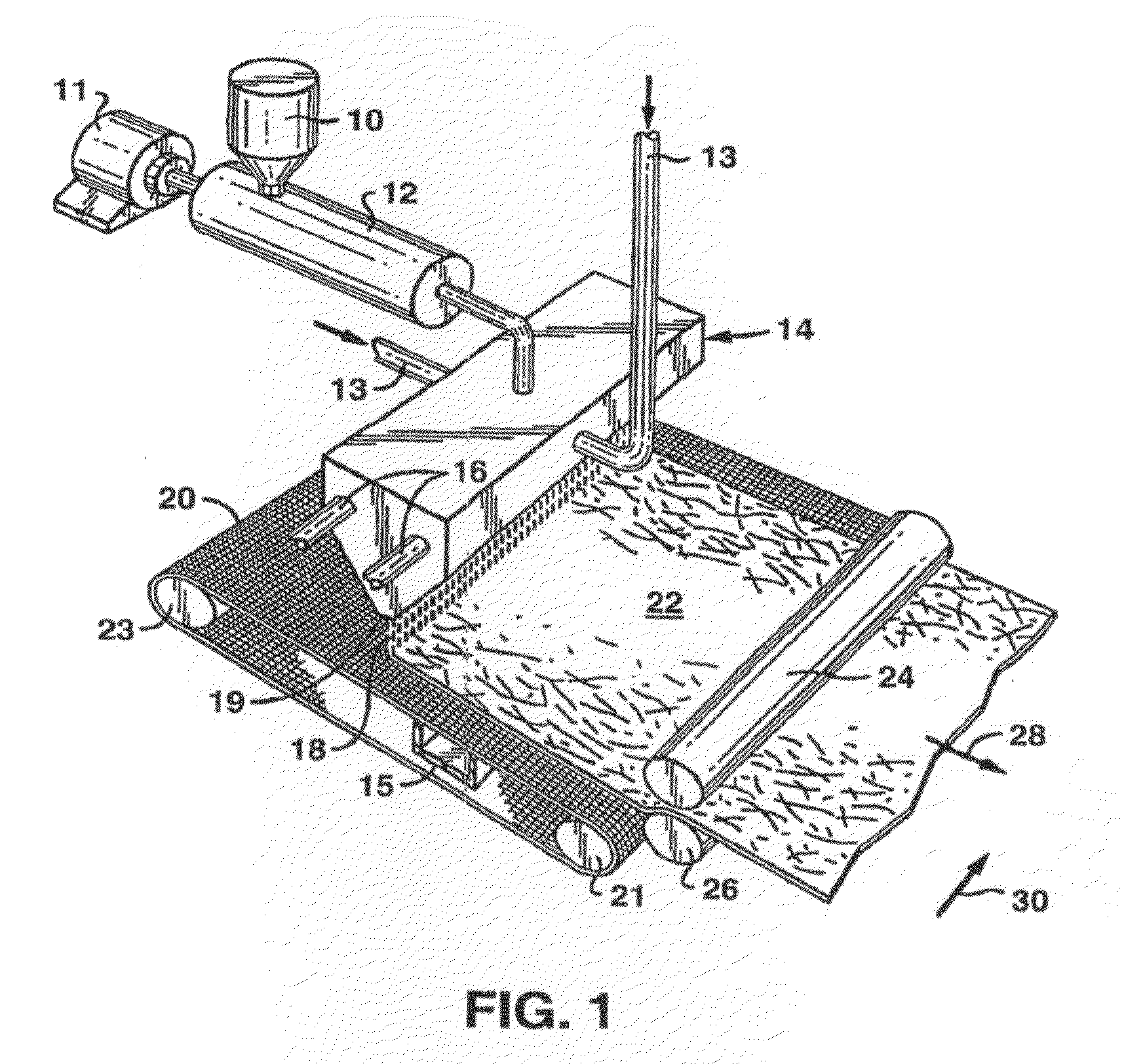

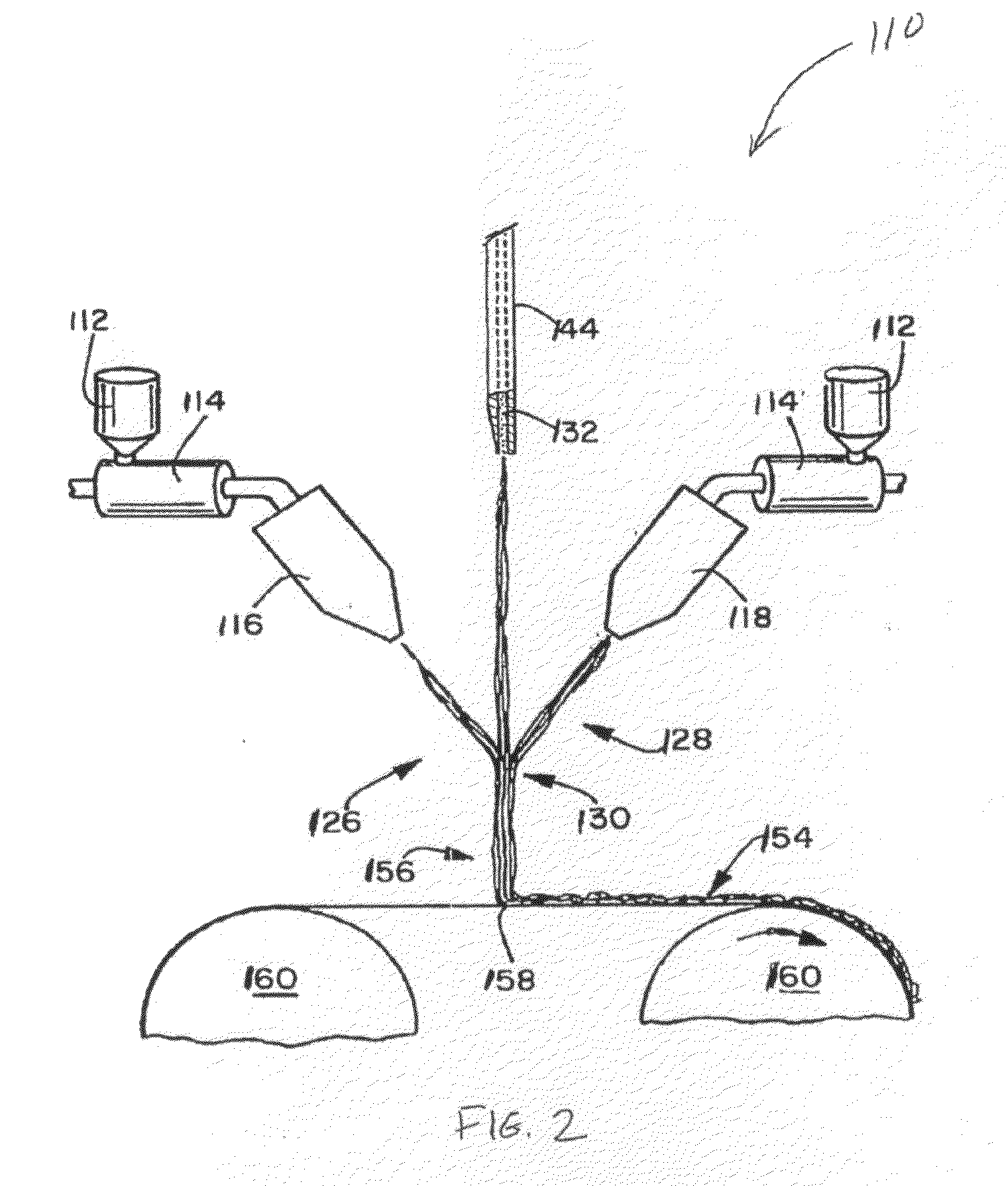

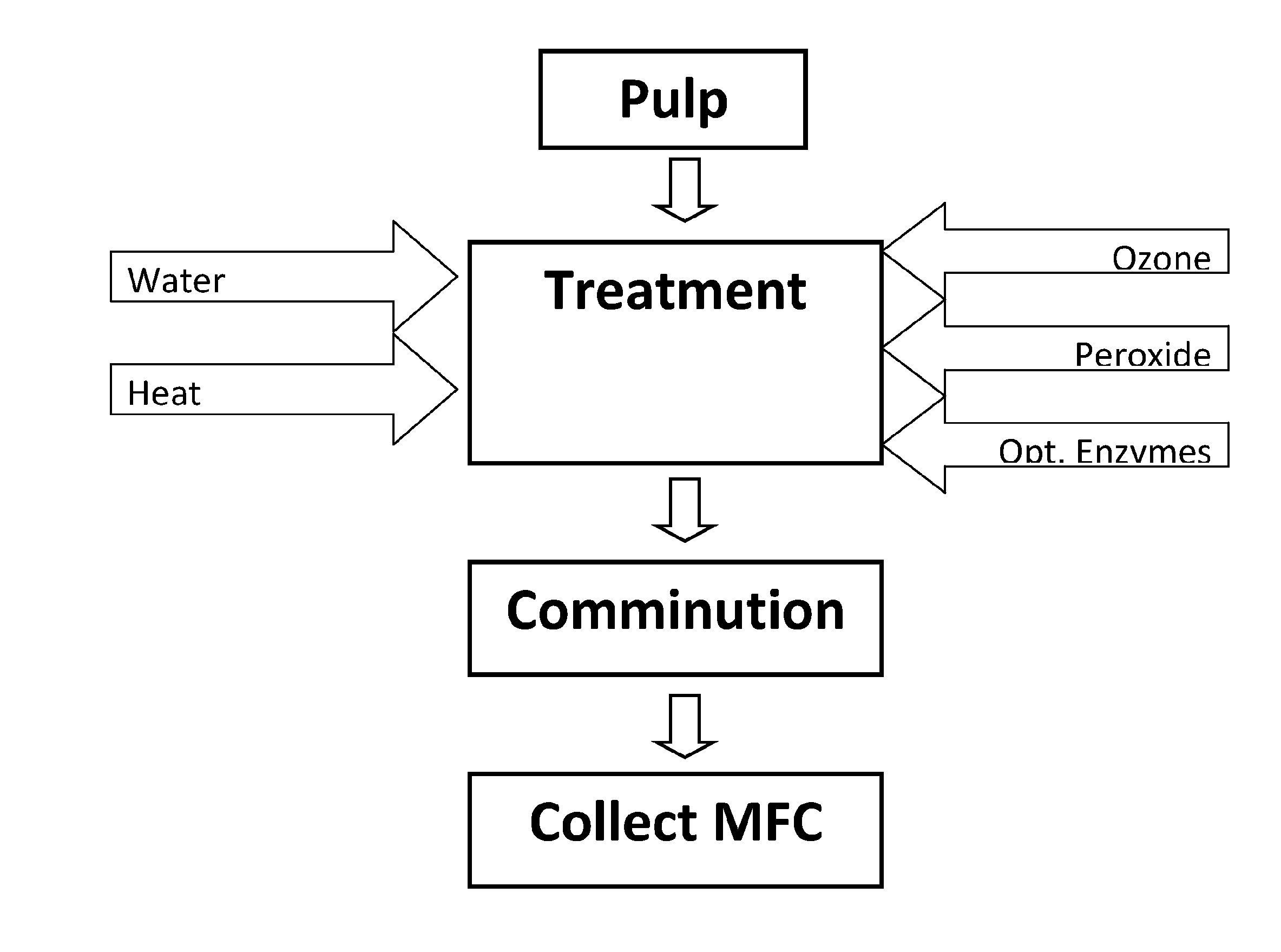

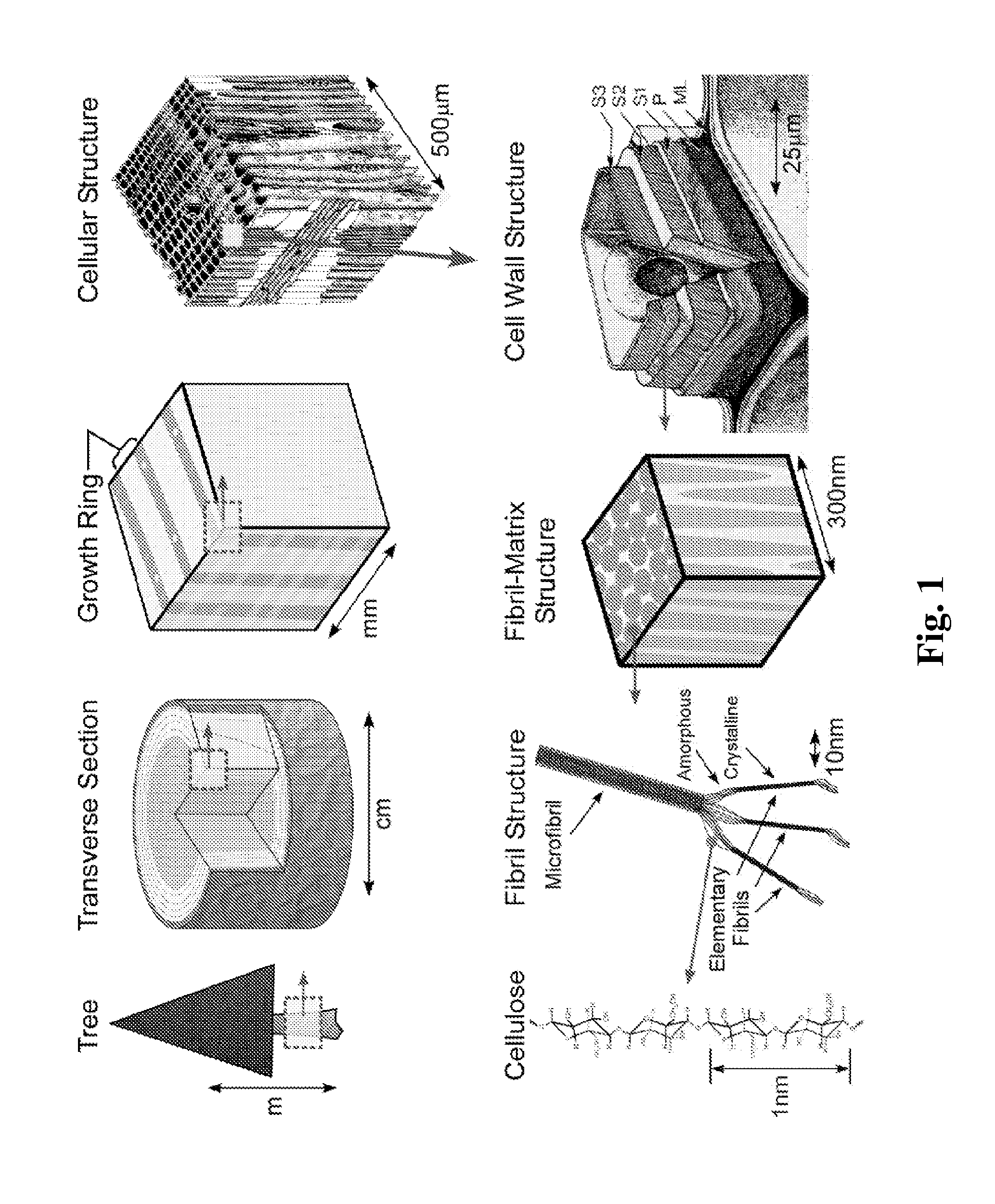

ActiveUS20150167243A1Improve efficiencyWeaken energySpecial paperPaper after-treatmentDepolymerizationNanofiber

A scalable, energy efficient process for preparing cellulose nanofibers is disclosed. The process employs a depolymerizing treatment with one or both of: (a) a relatively high charge of ozone under conditions that promote the formation of free radicals to chemically depolymerize the cellulose fiber cell wall and interfiber bonds; or (b) a cellulase enzyme. Depolymerization may be estimated by pulp viscosity changes. The depolymerizing treatment is followed by or concurrent with mechanical comminution of the treated fibers, the comminution being done in any of several mechanical comminuting devices, the amount of energy savings varying depending on the type of comminuting system and the treatment conditions. Comminution may be carried out to any of several endpoint measures such as fiber length, % fines or slurry viscosity.

Owner:UNIVERSITY OF MAINE

Method for continuously preparing liquid reclaimed rubber by aid of screw extruder

The invention relates to a method for continuously preparing liquid reclaimed rubber by the aid of a screw extruder, which belongs to the field of waste rubber recycling. The method is characterized in that a cross-linked network of pretreated waste rubber powder is crushed to obtain the liquid reclaimed rubber under the combined action of temperature, pressure, shearing and desulfurizer in the screw extruder by means of a physical and chemical linkage method and by the aid of the screw extruder. The method is simple in technical process and has the advantages of high desulfurization and depolymerization degree, energy conservation, environmental protection and continuity. The obtained liquid reclaimed rubber can be used with asphalt or replaces the asphalt for paving, and can be used with pure rubber to manufacture waterproof anticorrosion materials and the like.

Owner:宿迁绿金人橡塑机械有限公司

Depolymerization process of conversion of organic and non-organic waste materials into useful products

ActiveUS7771699B2Efficient processingSmooth connectionWaste based fuelLiquid hydrocarbon mixture productionSpeciality chemicalsDepolymerization

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

Chemical method for lignin depolymerization

InactiveUS6214976B1Improve efficiencyWithout major damage to cellulosePulp bleachingLignin derivativesDepolymerizationAqueous solution

A process for depolymerizing and / or chemically modifying lignin or lignin-like compounds in which a solution of copper and peroxide acts on lignin and / or lignin-like substance at a temperature of less than 100° C., characterized in that the solution is an aqueous solution containing copper or a copper complex, a coordination compound and peroxide and wherein the concentration of the copper or copper complex is between 0.001% and 5%, and wherein the concentration of the coordination compound is lower than 20% and wherein the concentration of peroxide is between 0.01% and 20%.

Owner:ANNIKKI GMBH +1

High-speed chamber mixer for catalytic oil suspensions as a reactor for the depolymerization and polymerization of hydrocarbon-containing residues in the oil circulation to obtain middle distillate

InactiveUS20070131585A1Eliminate disadvantagesQuality improvementThermal non-catalytic crackingCatalytic crackingDepolymerizationDistillation

Production of diesel oil from hydrocarbon-containing residues in an oil circulation with separation of solids and product distillation for the diesel oil product by energy input with a high-speed chamber mixer and the use of fully crystallized catalysts that consist of potassium-, sodium-, calcium-, and magnesium-aluminum silicates, wherein the energy input and conversion occur primarily in the high-speed chamber mixer.

Owner:KOCH CHRISTIAN

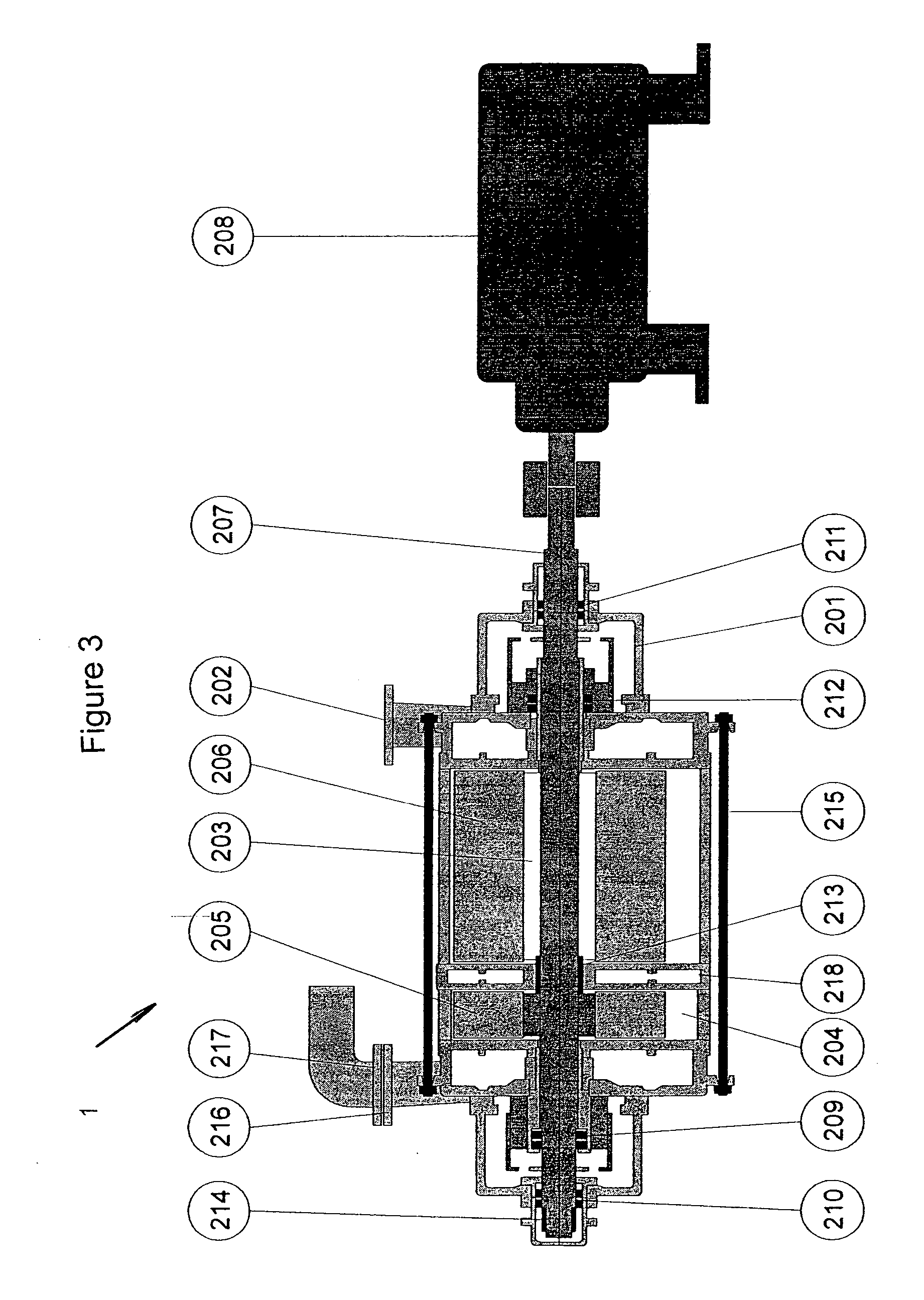

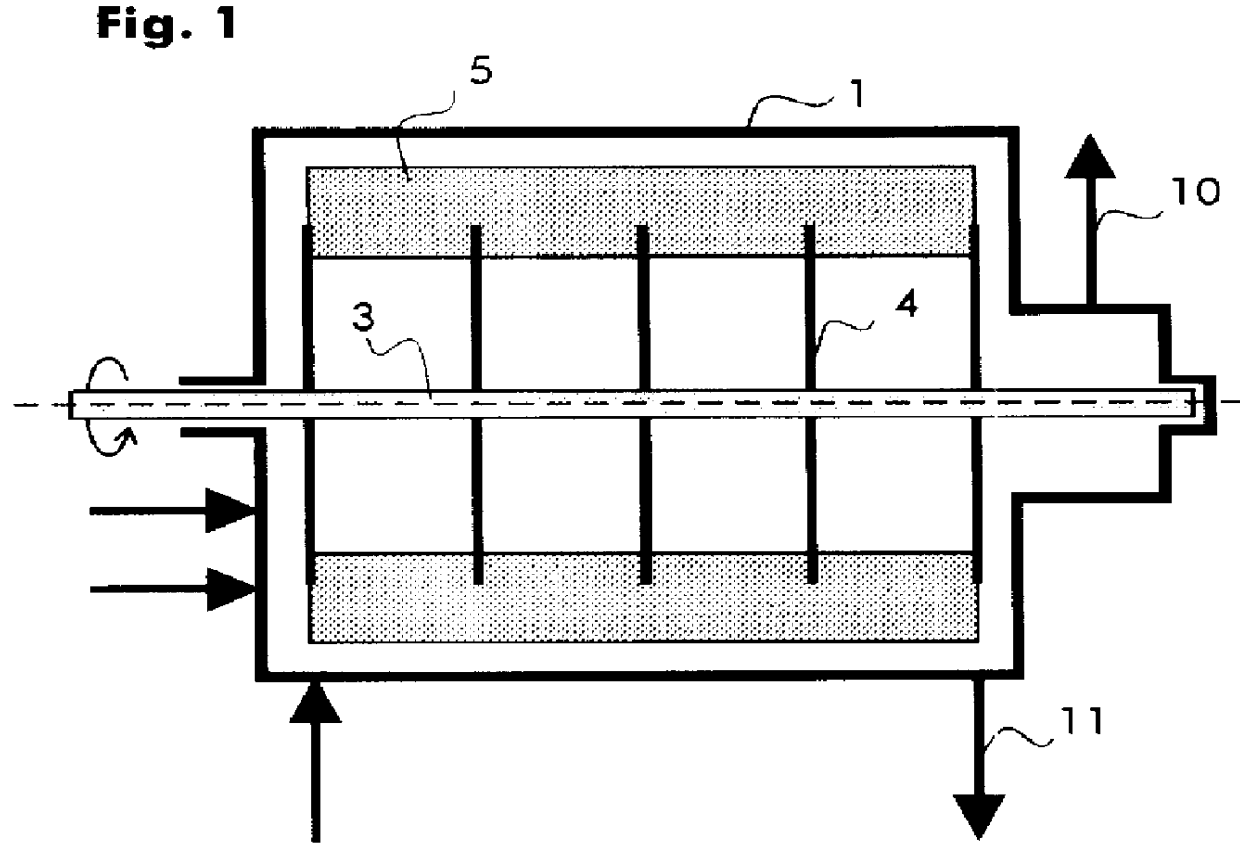

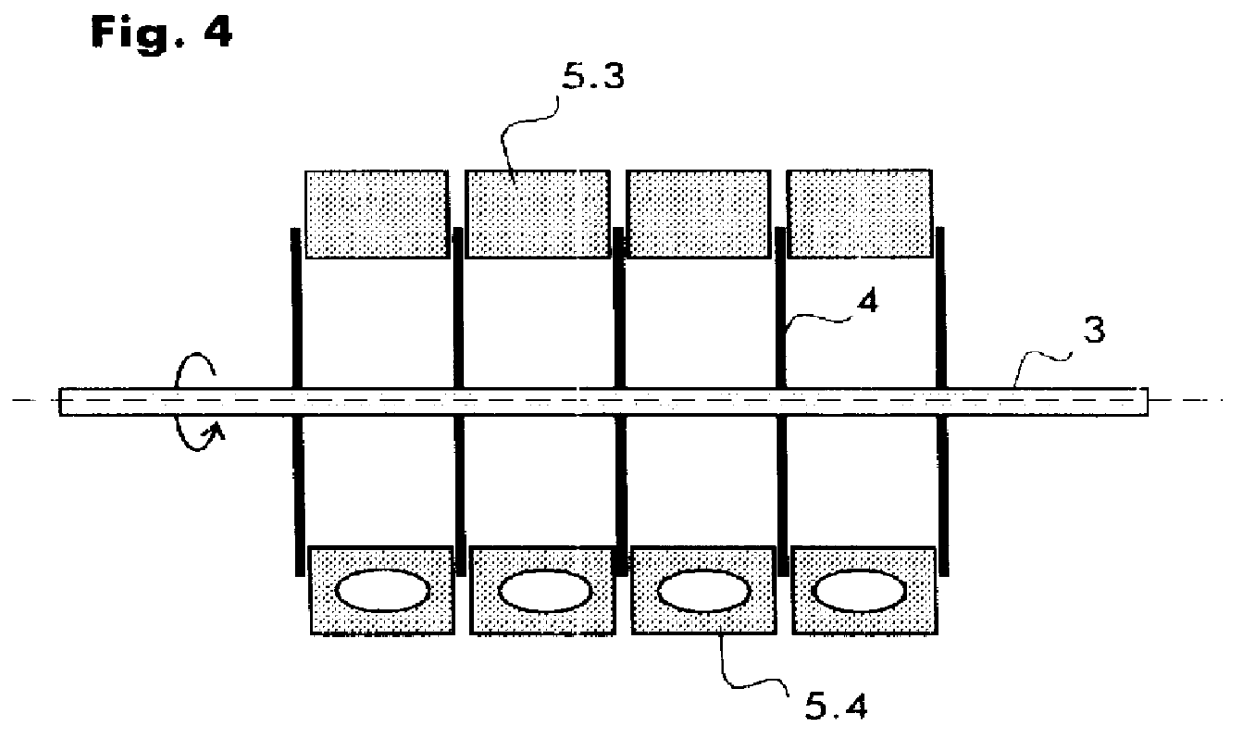

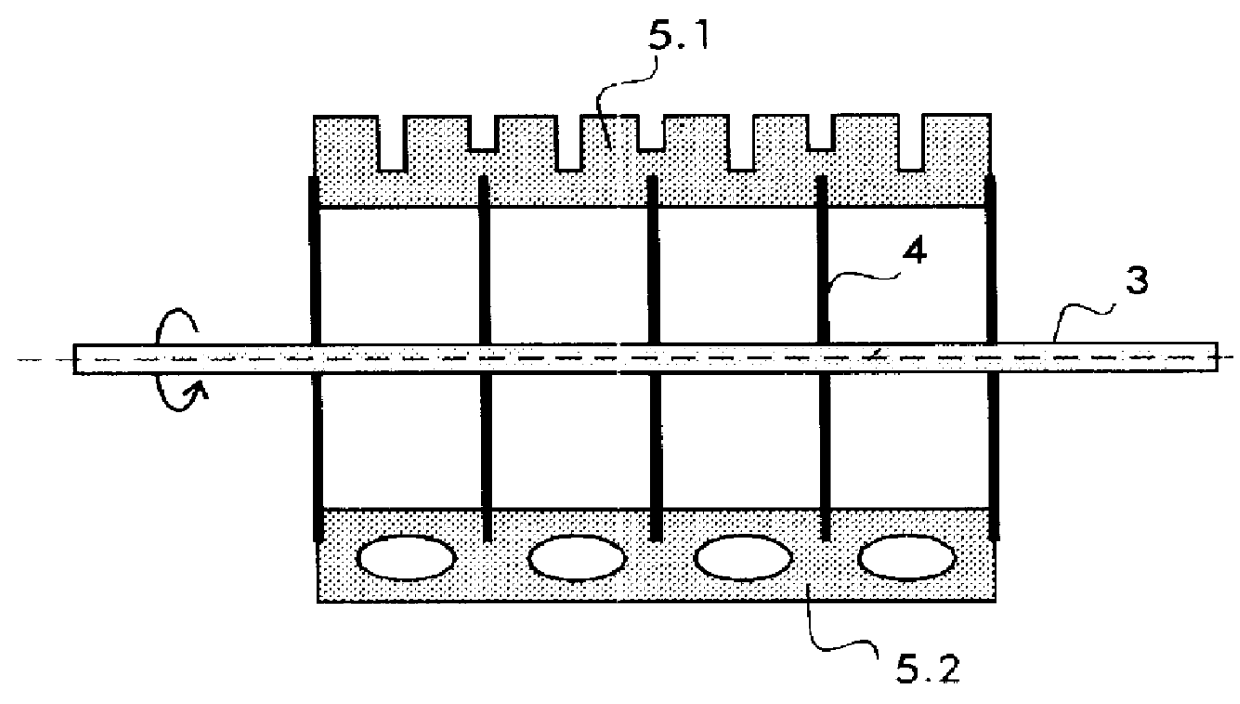

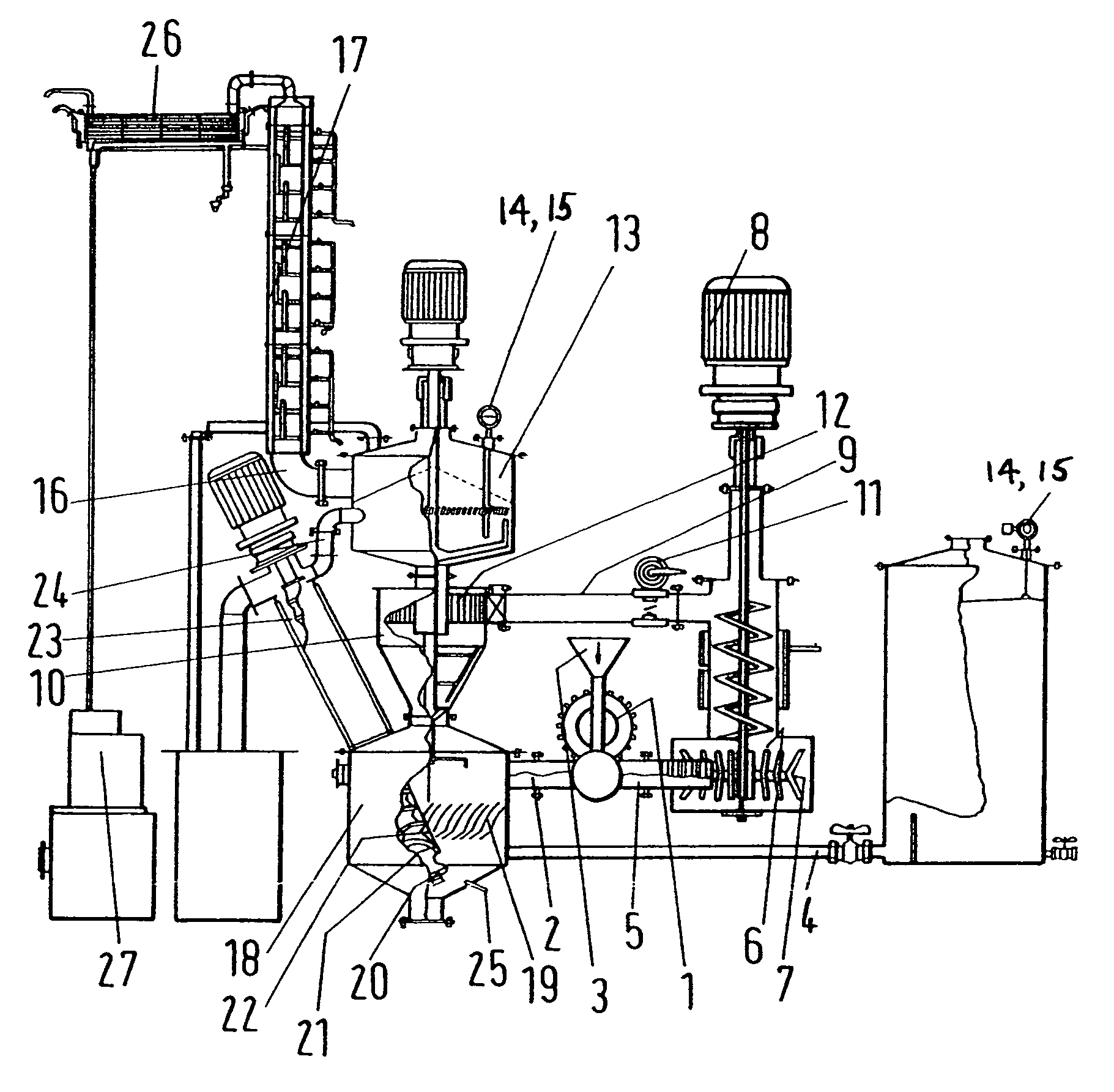

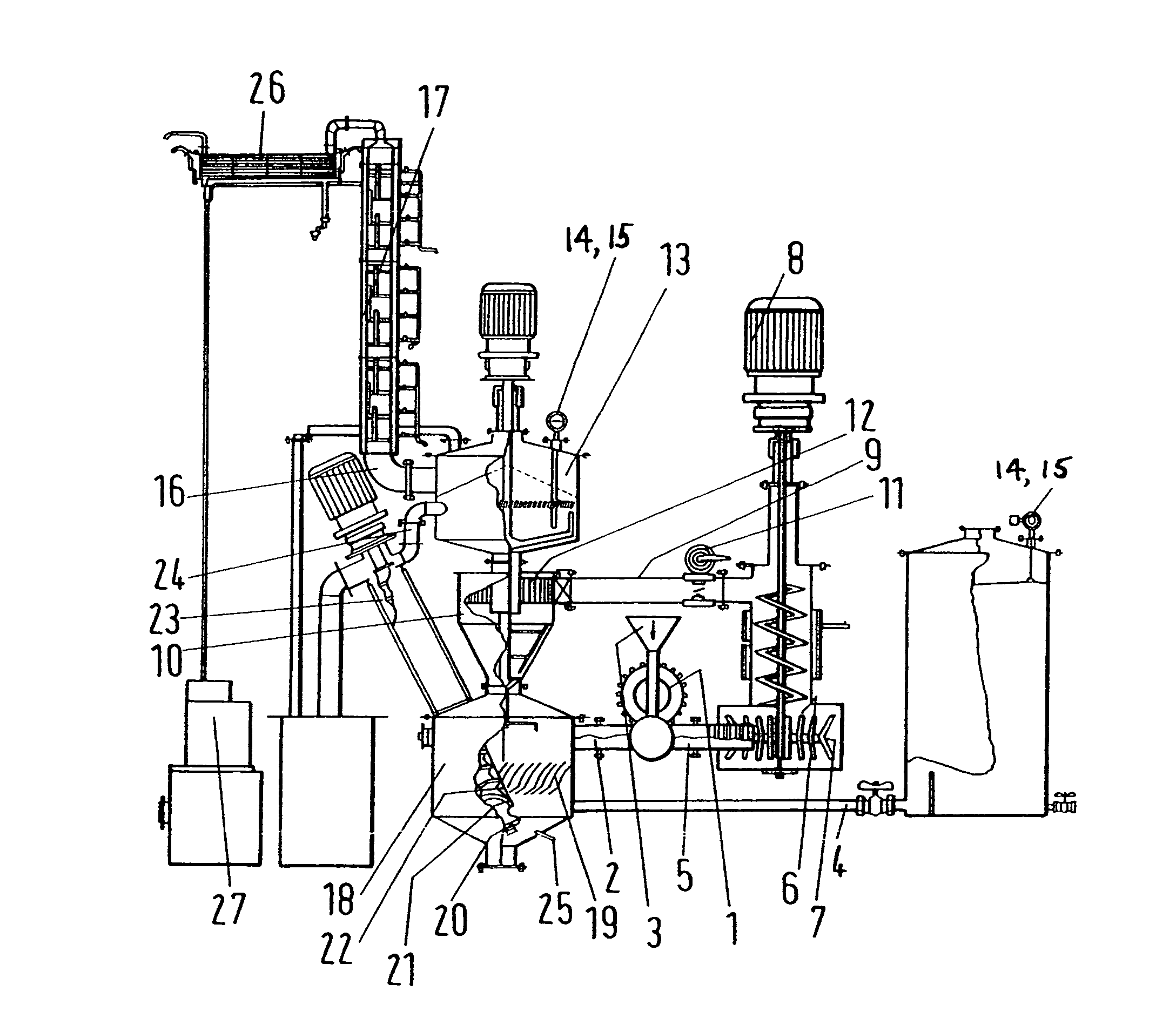

Process for thermal and/or catalytic decomposition and/or depolymerization of low-grade organic substances and device for carrying out the process

InactiveUS6165349AImprove economyEfficient processingCatalytic crackingSolid waste disposalDepolymerizationLower grade

PCT No. PCT / SK97 / 00006 Sec. 371 Date Jun. 1, 1999 Sec. 102(e) Date Jun. 1, 1999 PCT Filed Jul. 4, 1997 PCT Pub. No. WO98 / 39368 PCT Pub. Date Sep. 11, 1998The nature of the process consists in that the low-grade organic substances are subject, at a temperature of 150 DEG C. to 700 DEG C. and at a pressure of 0.1 MPa to 2.5 MPa, to the action of a moving bed of solid particles of a substance which perform whirling motion, whereby the solid particles of a substance constituting the moving bed are set to whirling motion by intensive agitation. The device consists of a reaction chamber (1) with a rotation mechanism (2) which rotation mechanism (2), located rotably in the faces of the reaction chamber (1), consists of a shaft (3) to which vanes (5) are symetrically attached by means of driving discs (4). The vanes (5) may be arranged in 3 to 10 rows, and they may be provided with openings (5.1) or cut-outs (5.2) of various geometrical shapes, and they may be divided into individual segments (5.3). Also the driving discs (4) may be provided with openings (4.1) of various geometrical shapes.

Owner:MADAR IVAN

Aromatic hydrocarbons from depolymerization and deoxygenation of lignin

ActiveUS20130025191A1Speed up the conversion processEconomically beneficialSolid fuelsLiquid carbonaceous fuelsProcess economicsDepolymerization

Processes are disclosed that achieve a high conversion of lignin to aromatic hydrocarbons, and that may be carried out without the addition of a base. Depolymerization and deoxygenation, the desired lignin convention steps to yield aromatic hydrocarbons, are carried by contacting a mixture of lignin and a solvent (e.g., a lignin slurry) with hydrogen in the presence of a catalyst. A preferred solvent is a hydrogen transfer solvent such as a single-ring or fused-ring aromatic compound that beneficially facilitates depolymerization and hinders coke formation. These advantages result in favorable overall process economics for obtaining fuel components and / or chemicals from renewable sources.

Owner:UOP LLC

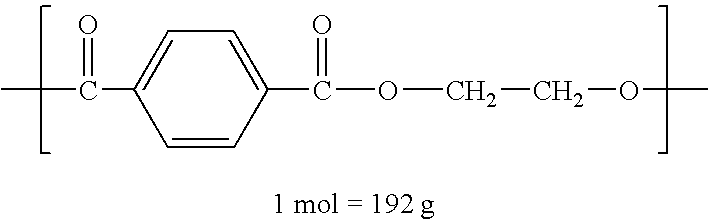

Methods and materials for depolymerizing polyesters

Provided is a method of depolymerizing polyesters from post-consumer products, such as beverage bottles, to produce a high purity reaction product. For the depolymerization reaction, the polyesters are reacted with an alcohol having 2 to 5 carbons and an amine organocatalyst at a temperature of about 150° C. to about 250° C. In one application, the use an organocatalyst with a boiling point significantly lower than the boiling point of the reactant alcohol allows for the ready recycling of the amine organocatalyst. In another application, performing the depolymerization reaction under pressure at a temperature above that of the alcohol allows for accelerated depolymerization rates and the recovery of the organocatalyst with no further heat input. In a further application, glycolytic depolymerization of poly(ethylene terephthalate) (PET) from post-consumer beverage bottles produces a pure reaction product of bis(2-hydroxyethyl)terephthalate (BHET), which may in turn be used to produce high purity beverage bottle grade PET, in a closed loop process with minimal output and waste.

Owner:IBM CORP

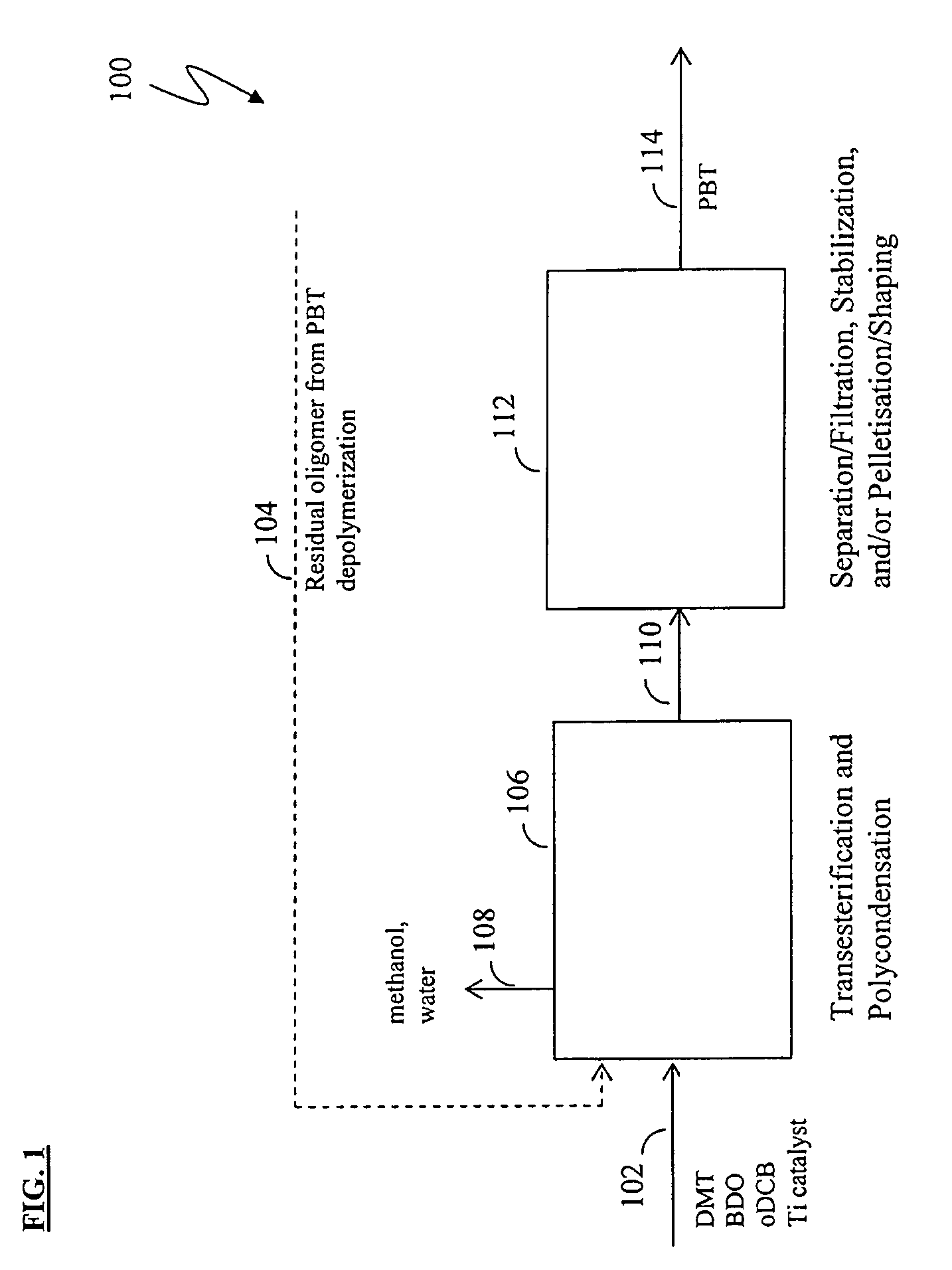

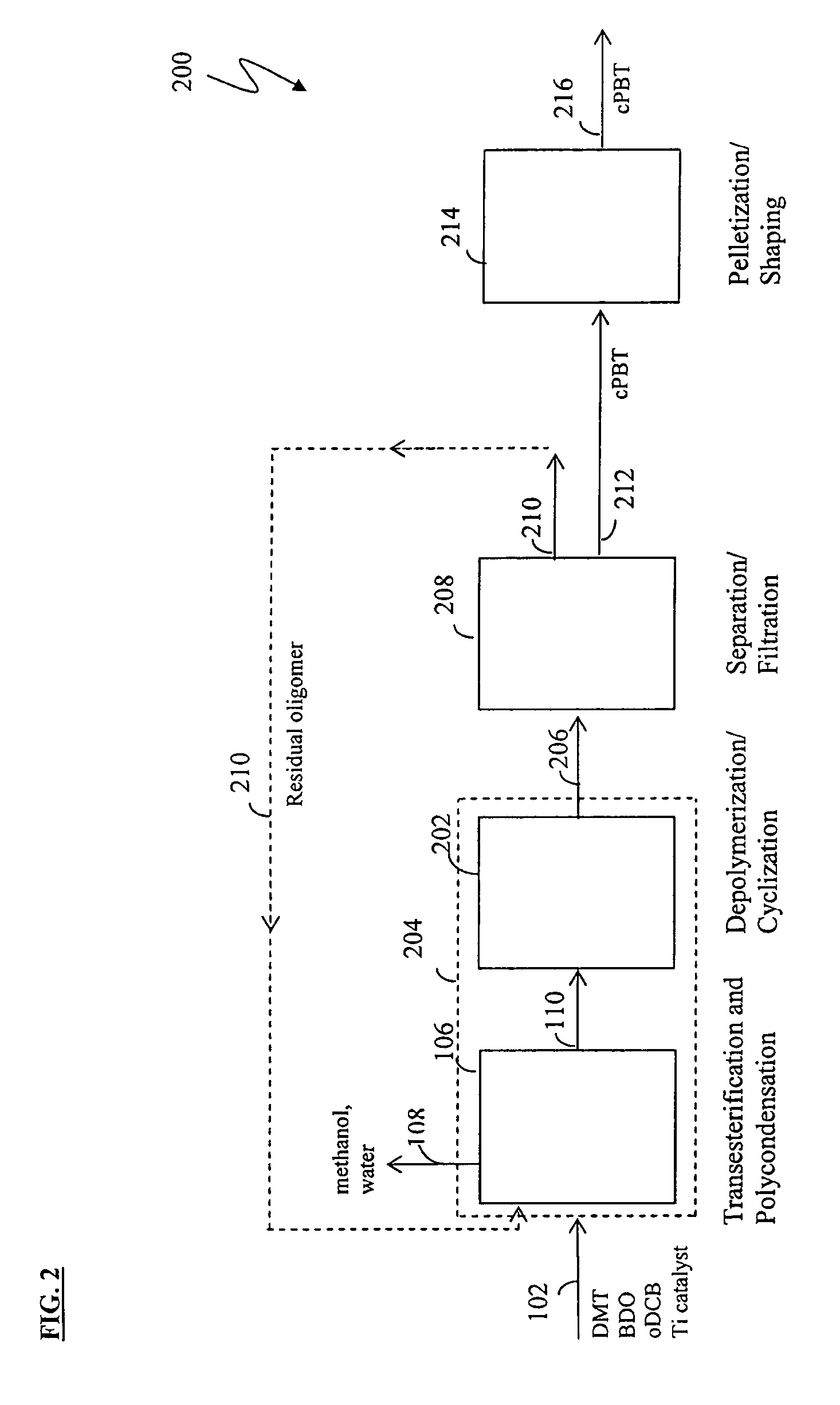

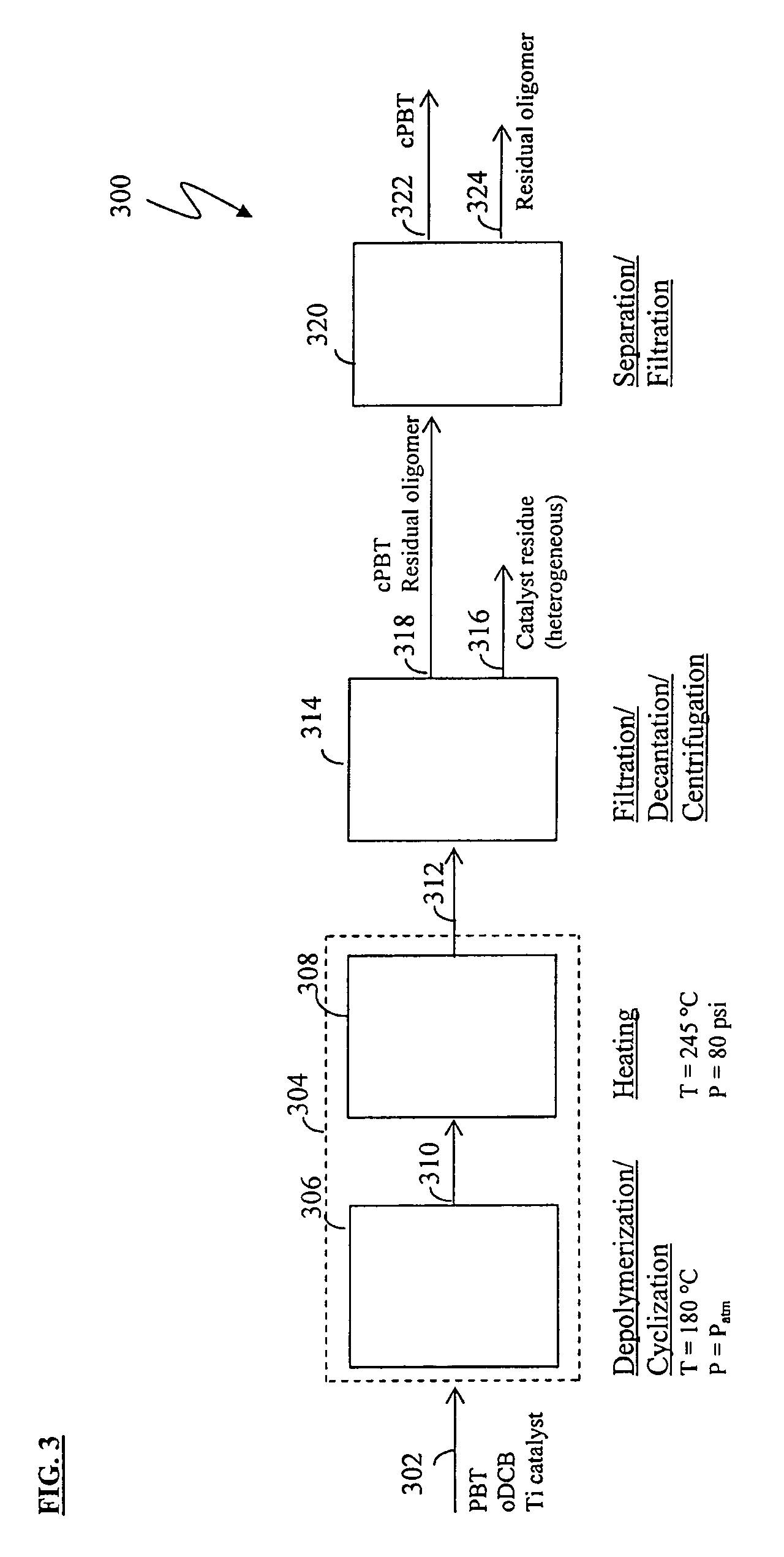

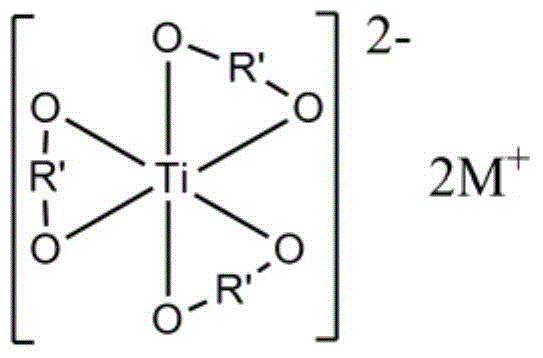

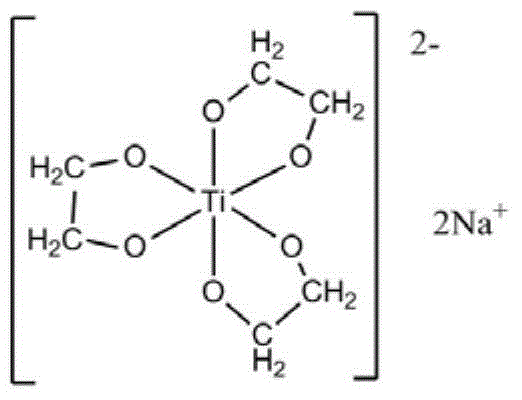

Organo-titanate catalysts for preparing pure macrocyclic oligoesters

InactiveUS6787632B2Organic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPolyesterDepolymerization

Organo-titanate catalysts are prepared that are useful to catalyze depolymerization of a polyester to produce macrocyclic oligoesters substantially free from macrocyclic co-oligoesters.

Owner:CYCLICS CORP

Diesel oil from residues by catalytic depolymerization with energy input from a pump-agitator system

Production of diesel oil from hydrocarbon-containing residues in an oil circuit with solids separation and product distillation for the diesel product with energy input by means of pumps and counterrotating agitators and by the use of fully crystallized catalysts of potassium, sodium, calcium, and magnesium-aluminum silicates, where all surfaces are cleaned continuously by the agitator mechanisms.

Owner:TGE IP LLC

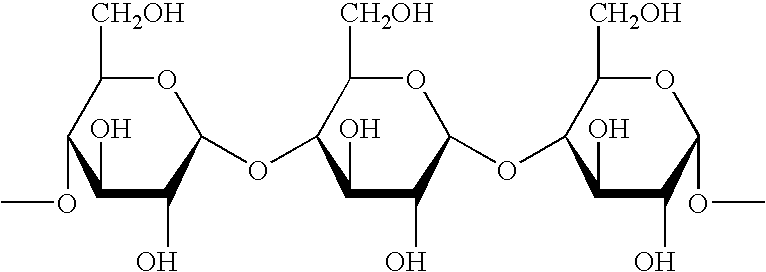

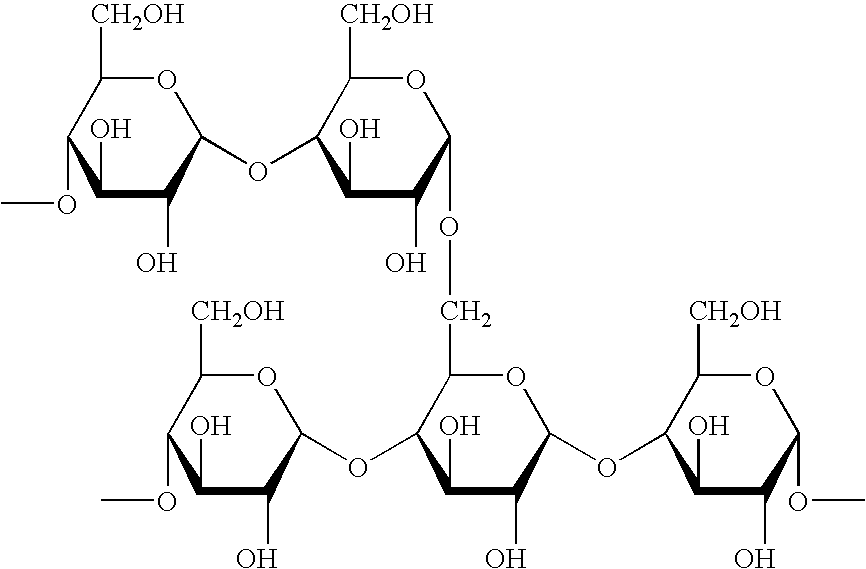

Oligomeric fucosylated glycosaminoglycan and preparation method thereof

ActiveCN101735336ASimple reaction conditionsQuick responseOrganic active ingredientsBlood disorderDepolymerizationGlycan

The invention discloses a method for preparing oligomeric fucosylated glycosaminoglycan which is prepared by depolymerizing fucosylated glycosaminoglycan by a depolymerization method of peroxide catalyzed by a 4th period transition metal ion in an aqueous medium, and the preparation method has mild reaction condition, good reproducibility and stability, high pyrolysis selectivity and uniform and controllable product quality. The polysaccharide molecule number of the obtained oligomeric fucosylated glycosaminoglycan using GalNAc as a reducing end is not less than 80 percent, the weight average molecular weight is about 6, 000-20, 000Da, and the protein disulfide isomerase (PDI) is 1.0-2.0.

Owner:SHENZHEN NEPTUNUS PHARMA RES INST CO LTD

Depolymerization method

InactiveUS20090032015A1Efficiently and economically precipitatedEfficient separationFood preparationGlucose productionTime to effectDepolymerization

The invention relates to a method for depolymerizing starch comprising mixing a starch material with an ionic liquid solvent to dissolve the starch, and then treating the dissolved starch by agitating at a temperature and for a period for time to effect depolymerization of the starch into desired depolymerization products.

Owner:KEMIRA OY

Methods for removing catalyst residue from a depolymerization process stream

InactiveUS7732557B2Minimize presenceIncrease production and recoveryOrganic compound preparationCarboxylic acid esters preparationPolyesterDepolymerization

Owner:LIQUID THERMO PLASTICS

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS7964761B2Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productDepolymerization

Owner:UNIV OF UTAH RES FOUND

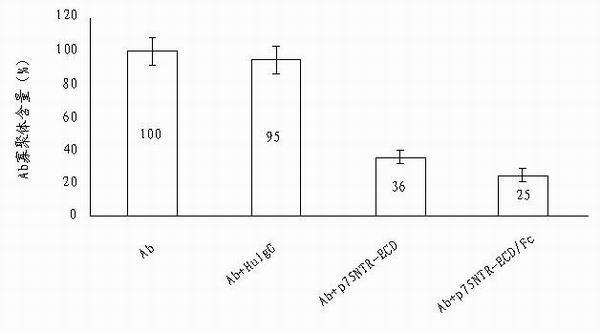

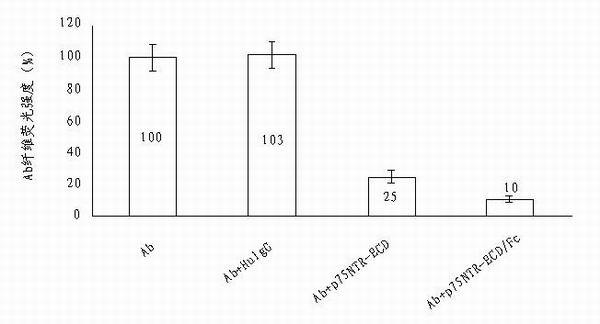

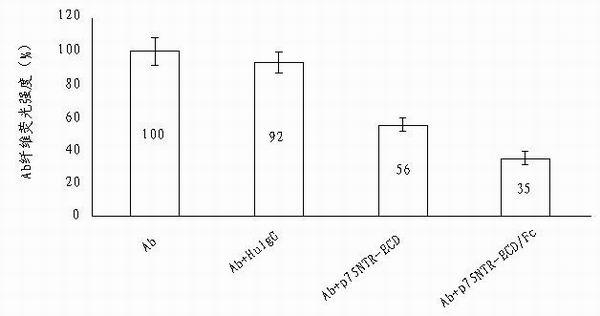

Use of p75neurotrophin receptor-extracellular domain (p75NTR-ECD) in medicine for preventing and treating Alzheimer disease

The invention discloses a medicine for preventing and treating Alzheimer disease. The medicine may comprise p75NTR-ECD of which the nucleotide sequence is represented by the nucleotide sequence SEQ ID No.1 in a sequence table and of which the amino acid sequence is represented by amino acid sequence SEQ ID No.2 in the sequence table. The medicine also may be p75NTR-ECD / Fc of which the nucleotide sequence is represented by the nucleotide sequence SEQ ID No.3 in the sequence table and of which the amino acid sequence is represented by amino acid sequence SEQ ID No.4 in the sequence table. The medicine has the effects of inhibiting Abeta from aggregating into oligomer and fiber, promoting the depolymerization of Abeta fibers, eliminating Abeta in head and resisting Abeta neurotoxicity. The invention provides the new medicine for treating Alzheimer disease, which has a plurality of effects and has a bright clinic application prospect.

Owner:SUZHOU AUZONE BIOLOGICAL TECH CO LTD

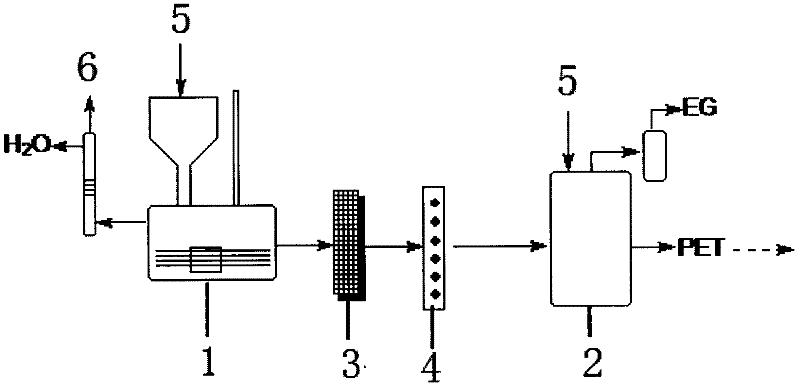

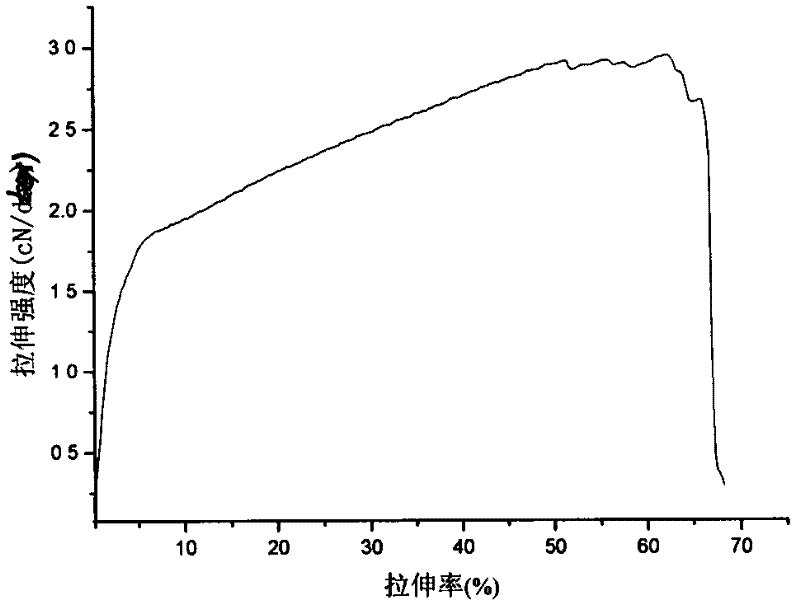

Regenerated terylene filament and preparation method thereof

ActiveCN102505175AAvoid pollutionAvoid exhaustionPlastic recyclingMonocomponent copolyesters artificial filamentPolyesterEnvironmental resistance

The invention provides regenerated terylene filament, which has higher mechanical properties and is prepared by depolymerizing waste polyester with polyol as a solvent. The PET (Polyethyleneglycol Terephthalate) granules are depolymerized in a homogeneous state by optimizing the solvent, pressure, temperature, time, catalyst and parameter conditions as well as controlling the pressure and temperature, so as to improve the depolymerization reaction rate. A composite catalyst is adopted, thus the ratio of the solvent to waste polyester is strictly controlled, the polyol consumption is reduced, the process economy is improved, the generation of diethylene glycol is reduced, and the quality and spinnability of the regenerated polyester are improved. The depolymerization rate of the polyester and the mechanical properties of the regenerated terylene filament are improved by adding a third component, thus the mechanical properties of the prepared regenerated terylene filament achieve the properties of the conventional terylene filament. The preparation method is simple, economical and environmentally friendly and is suitable for industrial production.

Owner:江苏芮邦科技有限公司

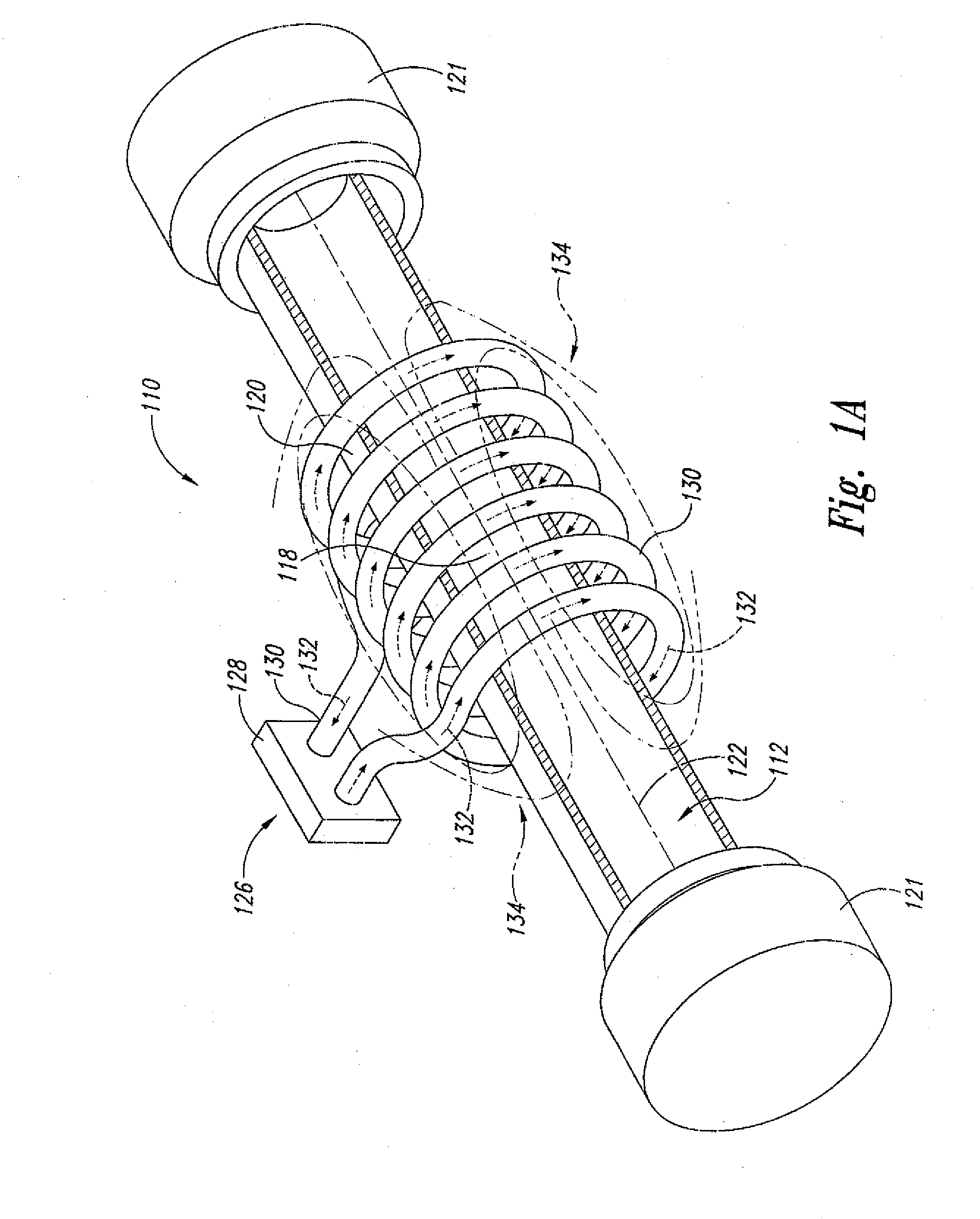

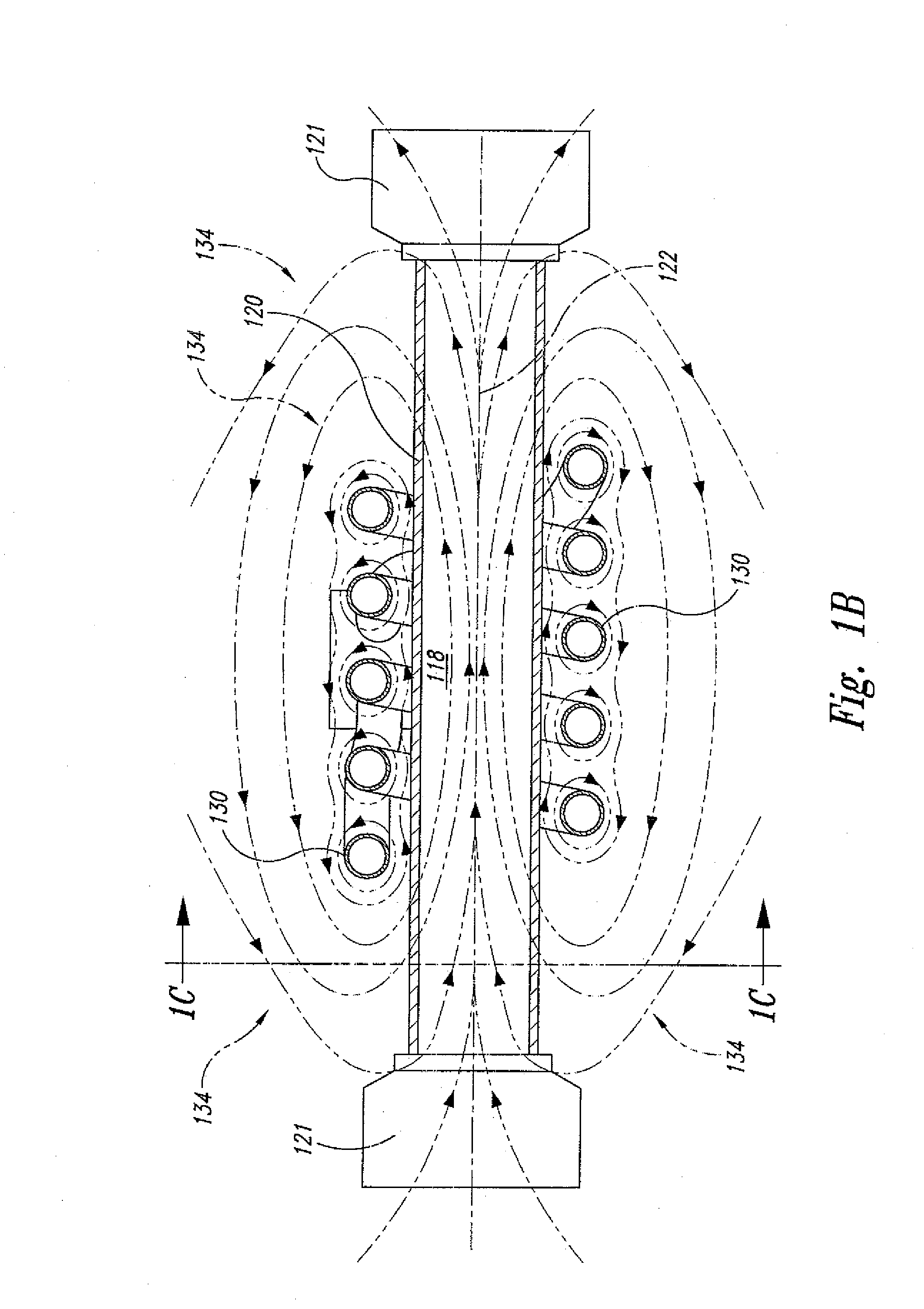

Biomass and waste plastics to neodiesel and valuable chemicals via supercritical water

ActiveUS20100329938A1Enhances the rapid cleavage and depolymerizationSolvent extractionLiquid displacementDepolymerizationChemical reaction

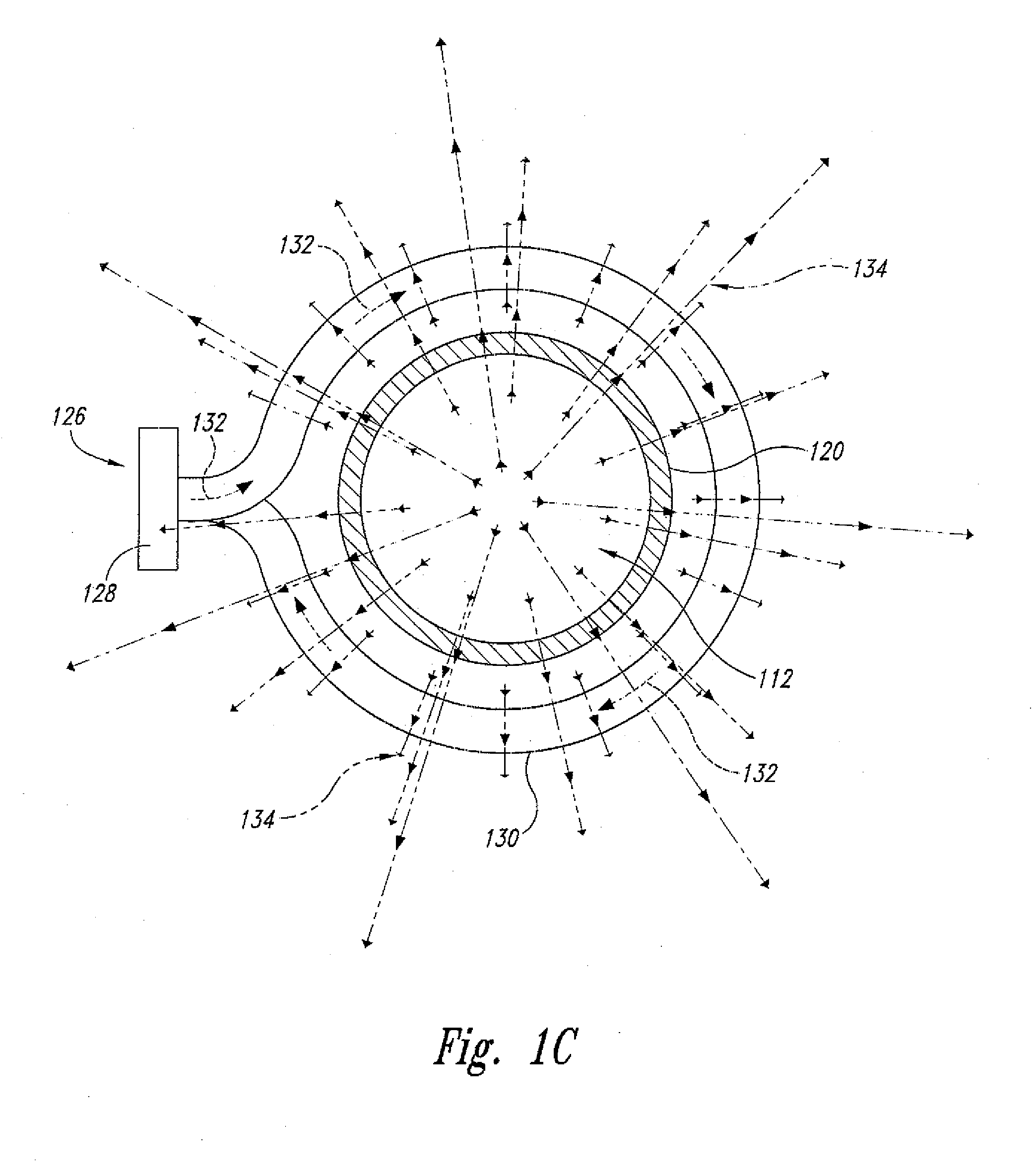

A supercritical fluid polymer depolymerization machine is disclosed herein, which machine is capable of converting a wide range of biomass and / or waste plastic materials into a plurality of reaction products (liquid and gaseous) including fermentable sugars, hydrocarbons, and various aromatic substances that, in turn, are readily convertible into liquid transportation fuel known as “neodiesel.” In one embodiment, a supercritical fluid reaction apparatus for transforming a selected polymeric material flowstream into a plurality of reaction products is disclosed and comprises, in fluidic series: an extruder; a supercritical fluid reaction zone fluidicly connected to the extruder, the supercritical fluid reaction zone being proximate to a circumferentially positioned heater, with the heater being configured to transfer heat to the selected polymeric material flowstream admixed together with water to supercritical conditions to thereby facilitate chemical reaction; and a reaction products separation chamber fluidicly connected to the supercritical fluid reaction zone.

Owner:XTRUDX TECH

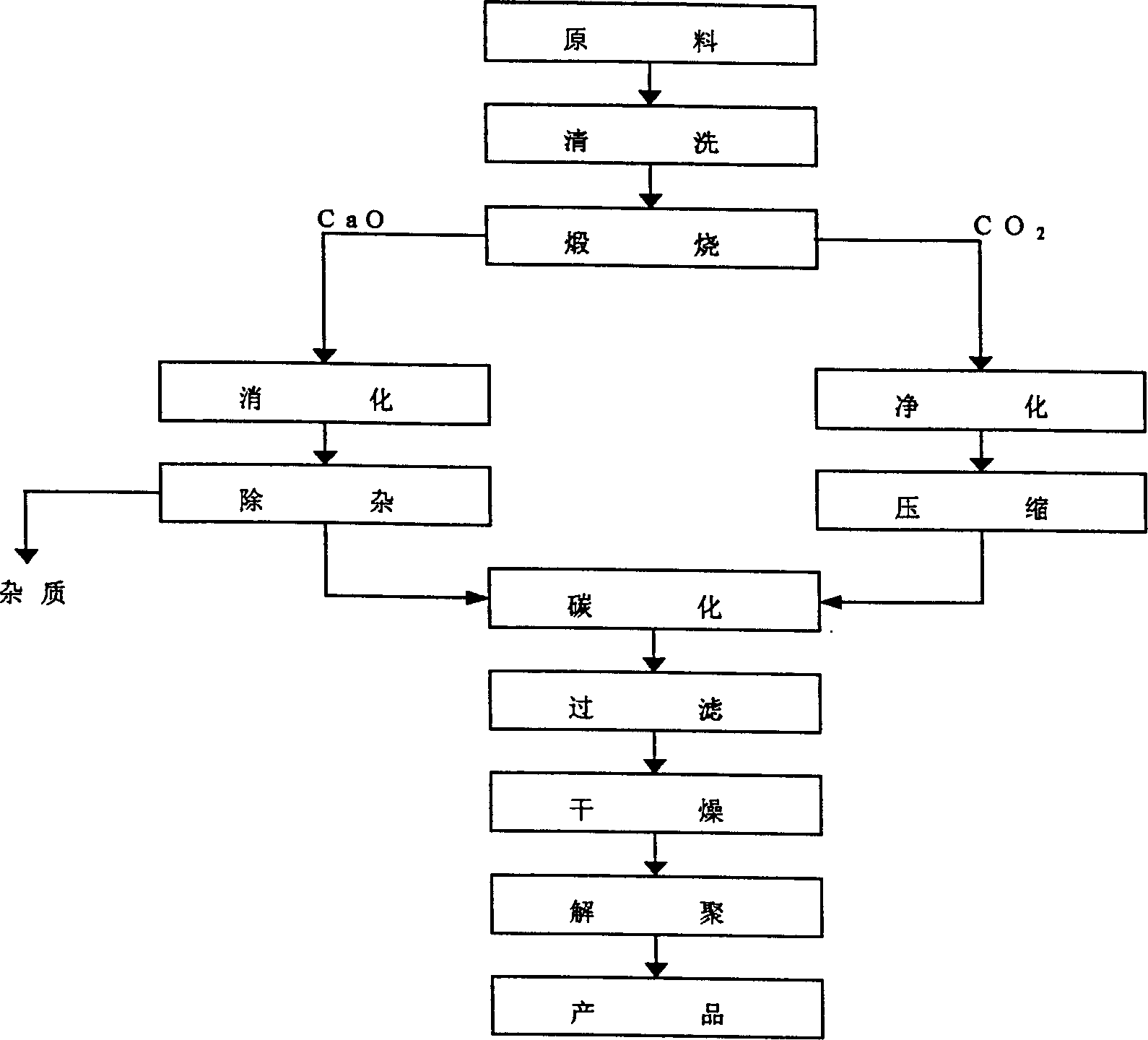

Method for preparing high-white ness nano calcium carbide

InactiveCN1438279AIncrease productivityImprove product qualityInorganic pigment treatmentDepolymerizationFiltration

The invention is a method of preparing high-whiteness degree nano CaCO3. It uses limestone, CaCO3 content>98%, whiteness degree>92% as raw material, washes to calcine into CaO, then adds in the cleaned hot water to get Ca(OH)2, prepares milk of lime by purifying, the concentration 2-10%, uses the cleaned flue gas of CaCO3, calcinations as CO2 source, makes the solution of milk of lime react with CO2 in special synthesis reactor, and adds in crystal-shaped controlling agent to control the time, temperature and stirring speed of the reaction, and after the reaction is finished, makes filtration, drying and depolymerization on the solution. The whole course adopts the technique of controlling whiteness degree.

Owner:NORTHEASTERN UNIV +1

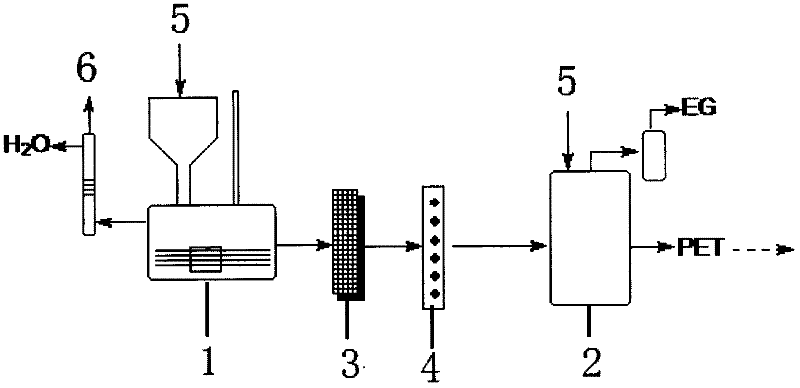

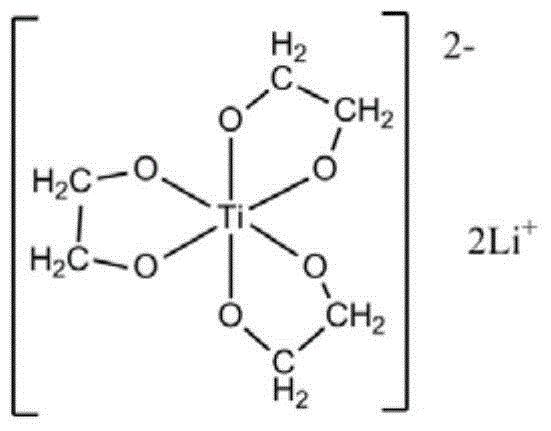

Preparation method of regenerated polyester fibers

ActiveCN104357938AQuality improvementCatalytic recondensation reactionPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsFiberPolyester

The invention discloses a preparation method of regenerated polyester fibers. The preparation method is used in the field of chemical regeneration of waste polyester. According to the method, a glycol titanium alkali metal coordination compound which can be dissolved in ethylene glycol is used as a catalyst for catalyzing ethylene glycol in a waste polyester product for depolymerization and a repolymerization process of depolymerized products; the catalyst is higher in catalysis activity in ethylene glycol depolymerization of polyester and the repolymerization process of the depolymerized products; therefore, in the preparation method of the regenerated polyester fibers, the catalyst is not required to be removed from the depolymerized products in a regenerated polyester fiber preparation process, and can be used for polycondensation, so that the depolymerized product separation and purification cost is greatly reduced, and the quality of regenerated polyester is guaranteed; the color and the intensity of the regenerated polyester fibers can be obviously improved, and continuous closed-loop recycling of the waste polyester product can be realized.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

Method for desulphurization, disaggregation and regeneration of vulcanized rubber

ActiveCN101503525AAvoid secondary environmental pollutionReduce secondary environmental pollutionPlastic recyclingBulk chemical productionDepolymerizationPolymer science

The invention relates to a method for vulcanized rubber regeneration by desulfurization and depolymerization, and belongs to the rubber cyclic regeneration field. The method comprises the following steps: first obtaining supercritical carbon dioxide by adding dry ice in a high pressure reaction kettle in safe and rapid manner, realizing rapid pollution-free permeation of desulfurization reagent into the rubber by the supercritical CO2, then breaking cross bonds of the rubber by cooperation of mechanical shearing, temperature and the desulfurization agent so as to realize desulfurization and regeneration of the rubber. The regenerated rubber has the advantages of safety, rapid performance, low energy consumption, no pollution, and good recycling effect.

Owner:BEIJING UNIV OF CHEM TECH +1

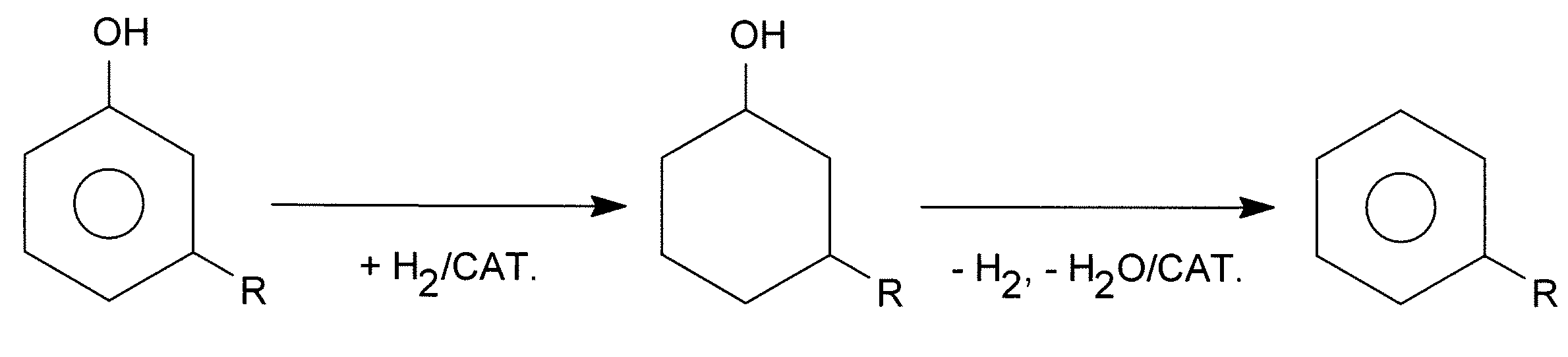

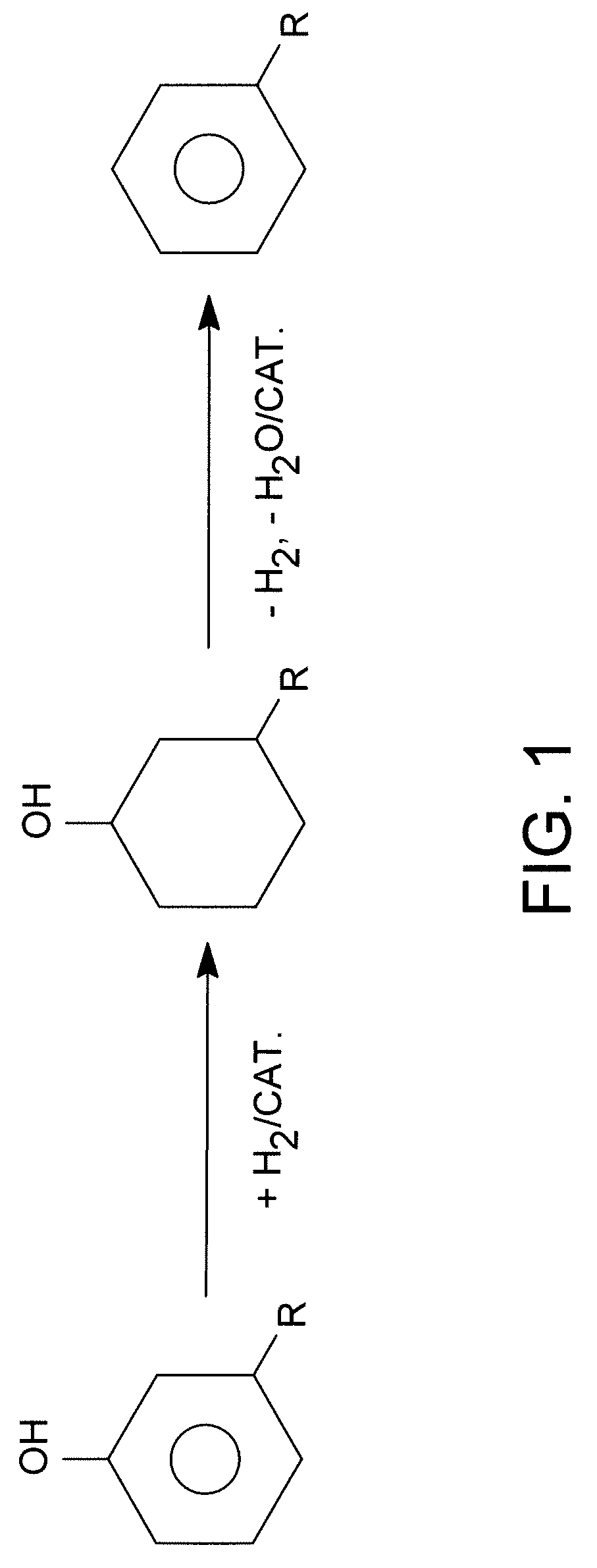

Combination of Hydrogenation and Base Catalyzed Depolymerization for Lignin Conversion

ActiveUS20100137663A1Low oxygenReduce the amount requiredLiquid hydrocarbon mixture productionHydrocarbonsDepolymerizationHydrogen atmosphere

A process for the conversion of lignin to chemical precursors is presented. The process comprises treating the lignin to form less acidic compounds. The process includes reacting lignin with a hydrogenation catalyst under a hydrogen atmosphere to convert acidic oxygenate compounds to less acidic oxygenates or hydrocarbons. The oxygenate compounds are reacted in a dehydrogenation and deoxygenation process to remove the oxygen and to convert the cyclic hydrocarbons back to aromatic compounds.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com