Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1756results about "Glucose production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

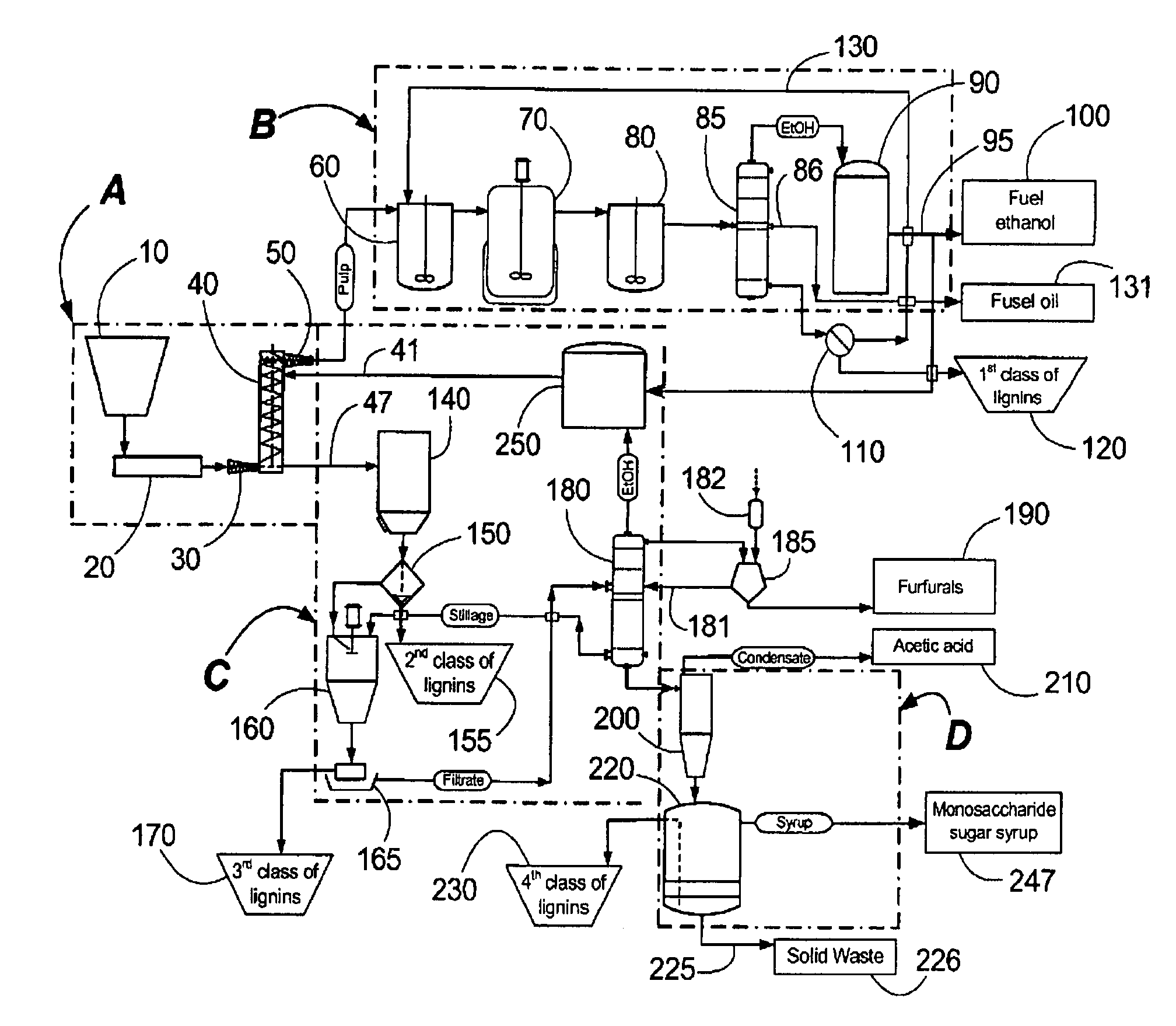

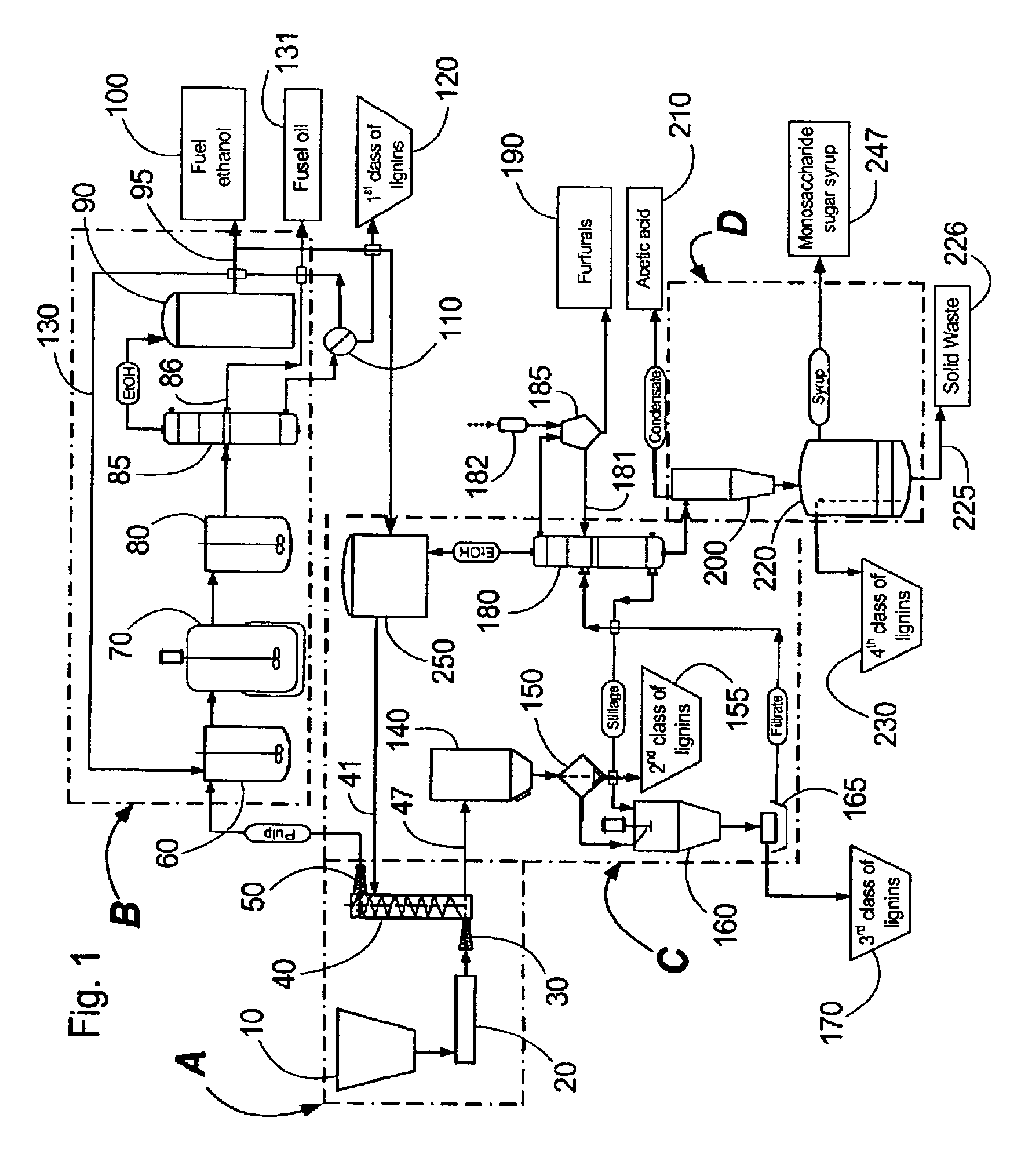

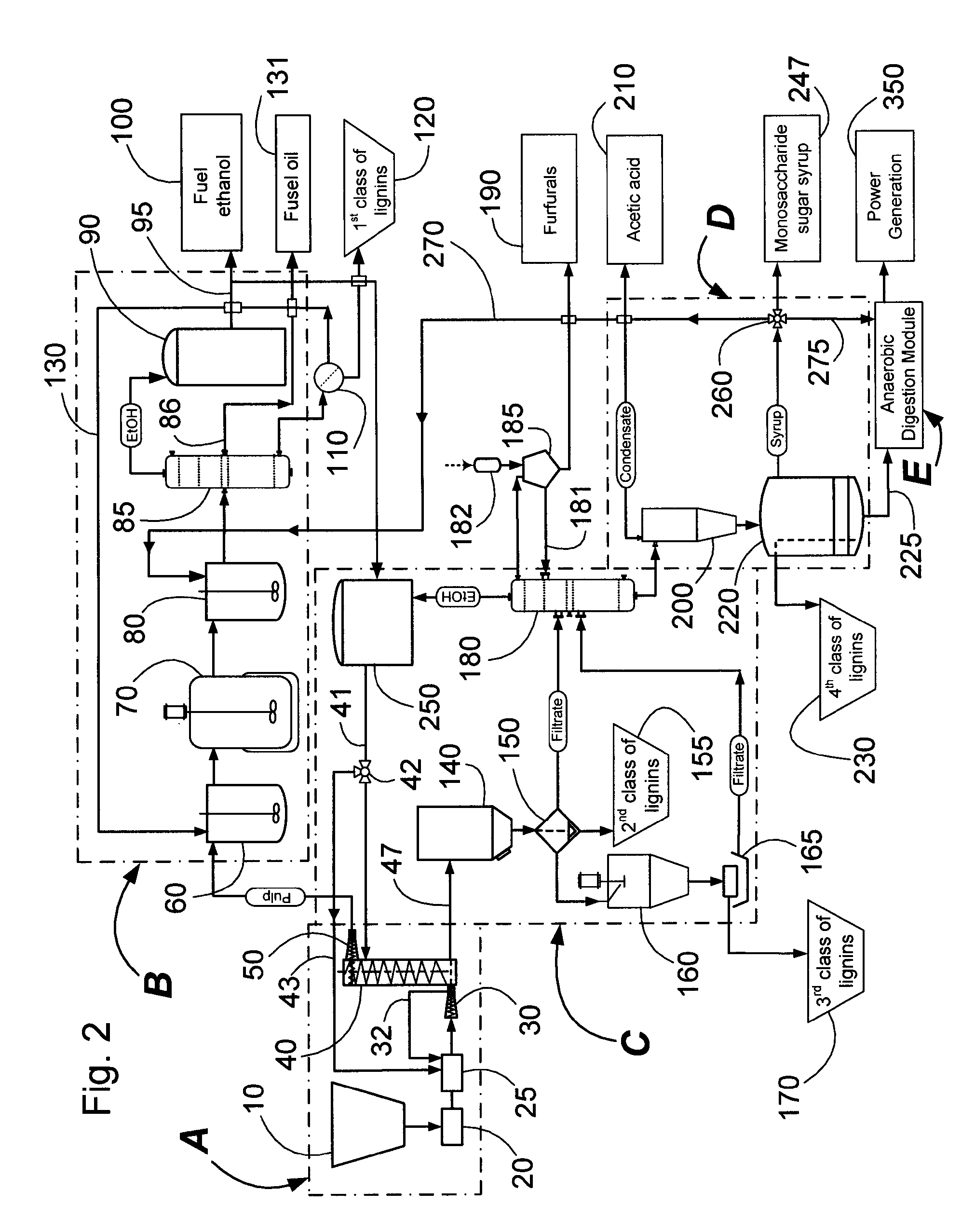

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

Inorganic salt recovery during processing of lignocellulosic feedstocks

InactiveUS20080102502A1Reduce inhibitionOvercome disadvantagesBiofuelsFermentationInorganic saltsCellulose

A method for recovering inorganic salt during processing of a lignocellulosic feedstock is provided. The method comprises pretreating the lignocellulosic feedstock by adding an acid or a base to the feedstock to produce a pretreated lignocellulosic feedstock. A soluble base or acid is then added to the pretreated lignocellulosic feedstock to adjust the pH and produce a neutralized feedstock. The neutralized feedstock is then hydrolyzed to produce an hydrolyzed feedstock and a sugar stream. Inorganic salt is recovered from a wash stream obtained from the pretreated lignocellulosic feedstock, a stream obtained from the neutralized feedstock, a stream obtained from the sugar stream, or a combination of these streams. The inorganic salt may be concentrated, clarified, recovered and purified by crystallization, electrodialysis, drying, or agglomeration and granulation, and then used as desired, for example, as a fertilizer.

Owner:IOGEN ENERGY CORP

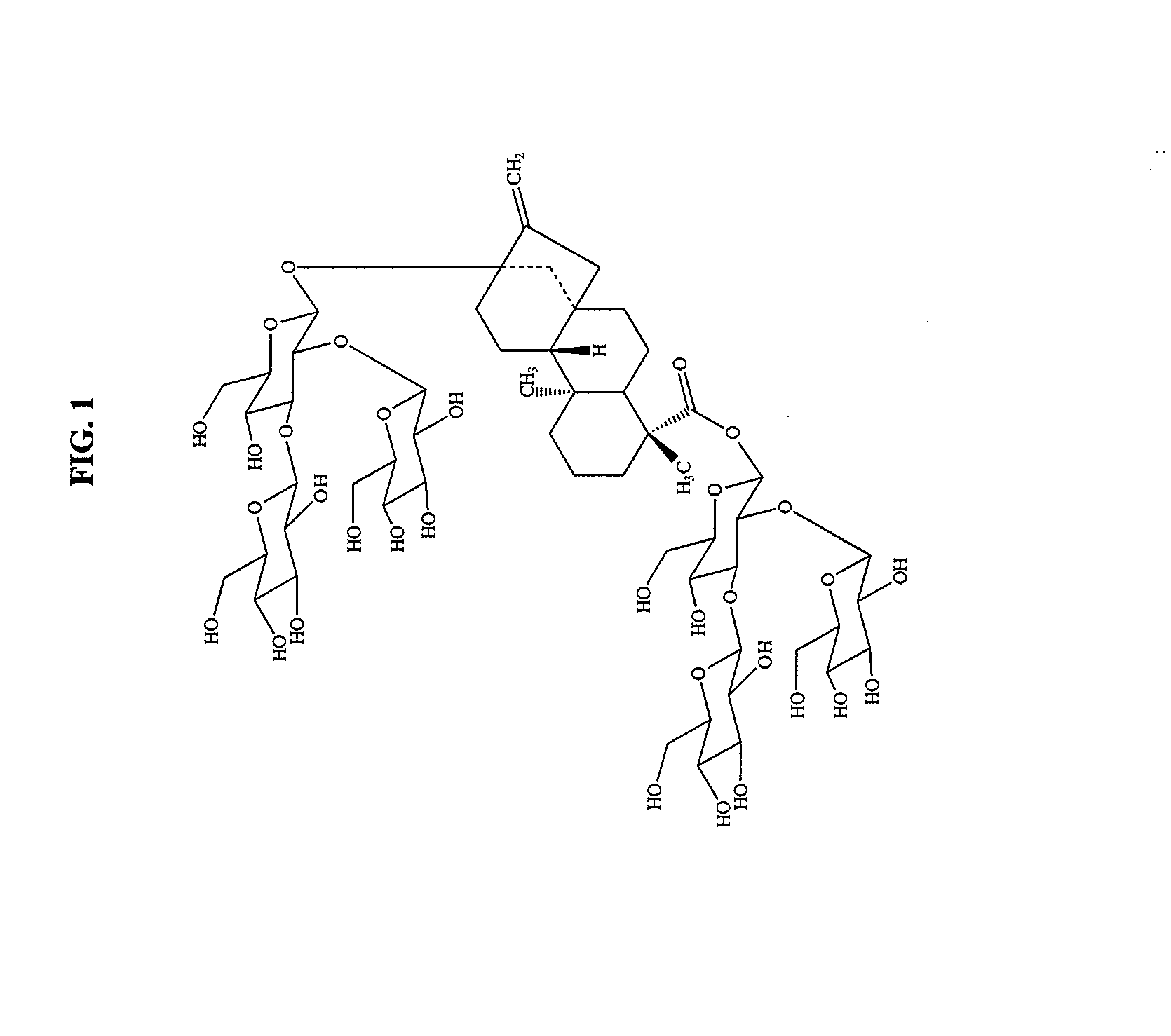

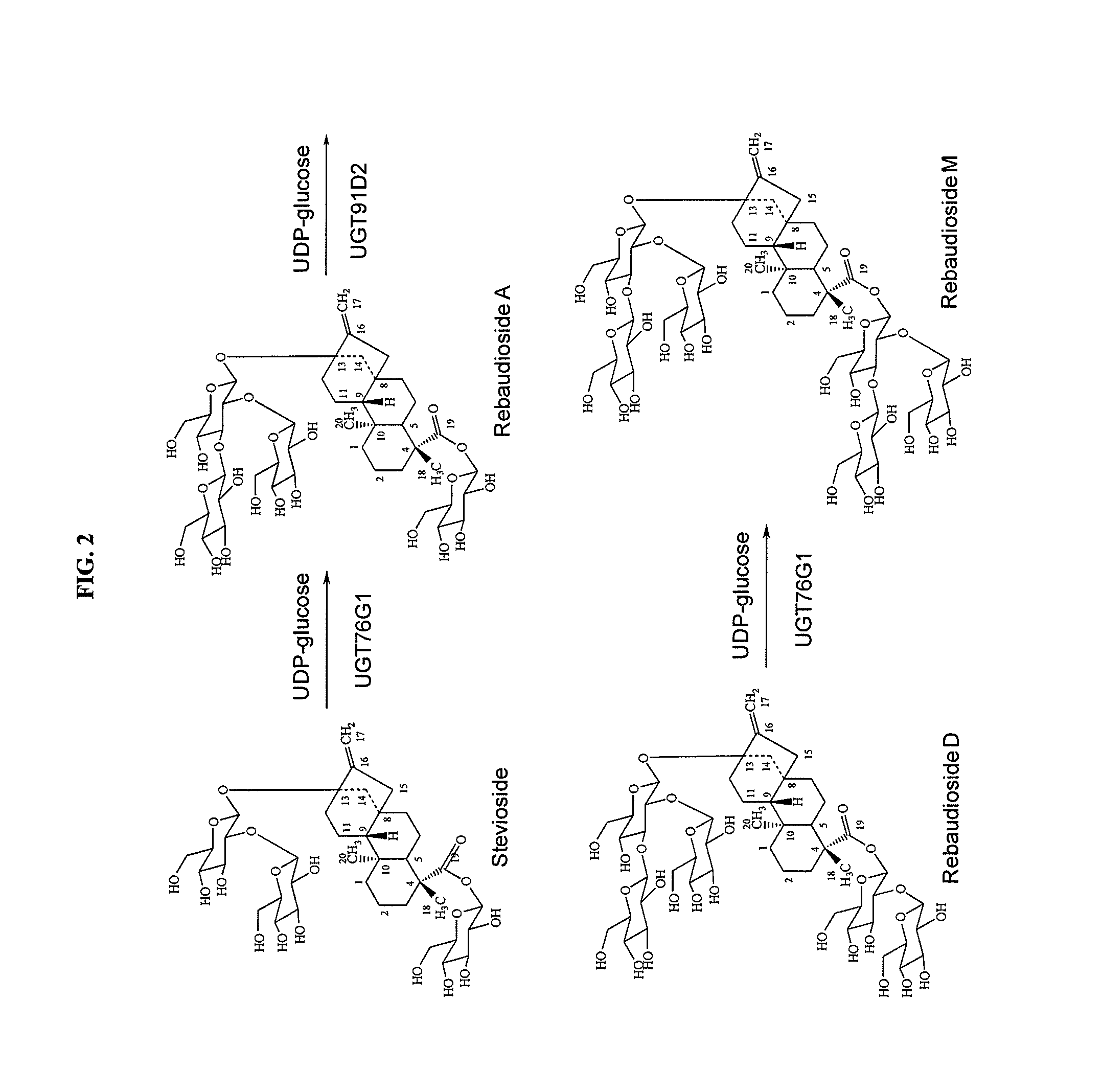

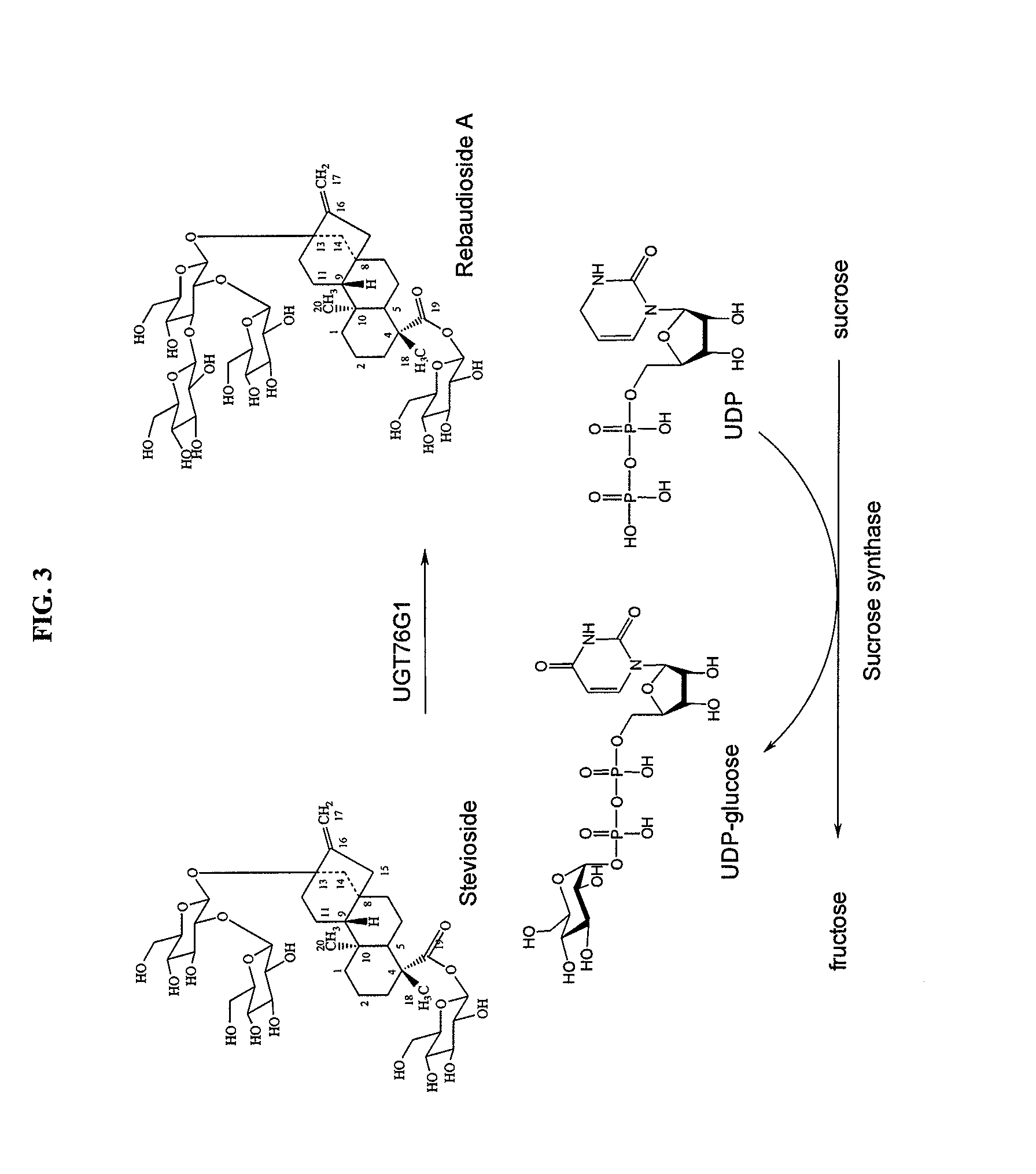

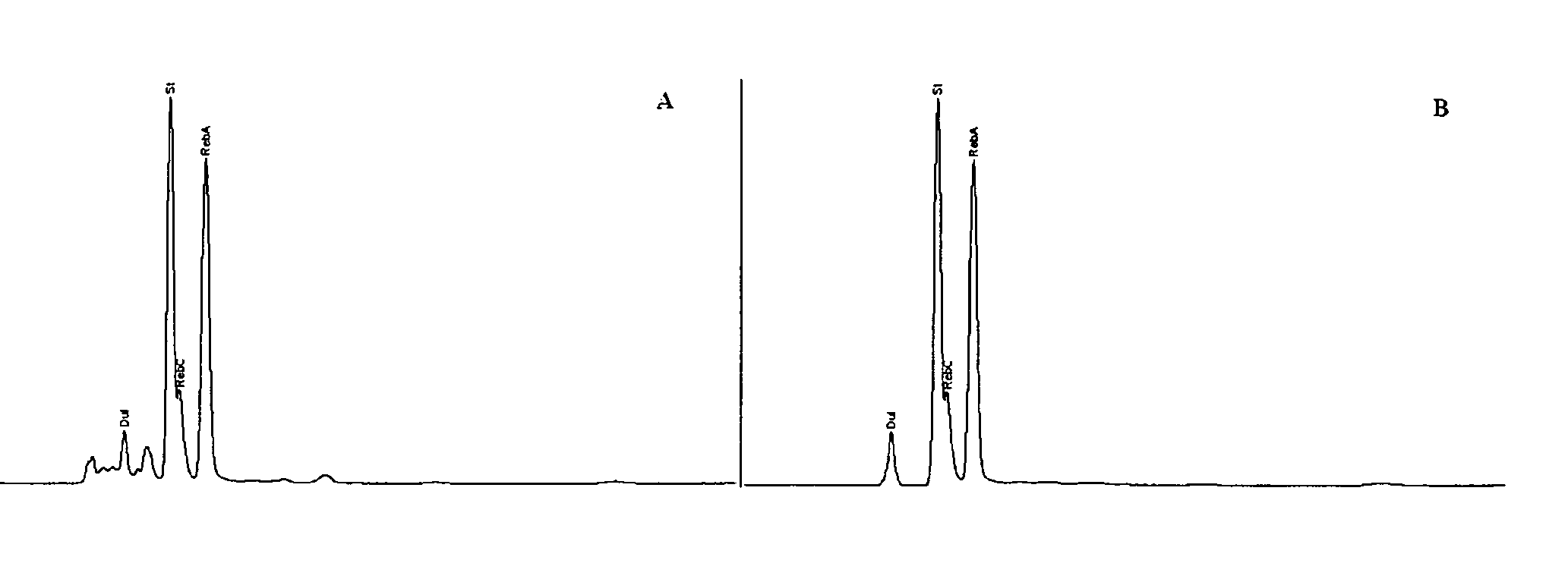

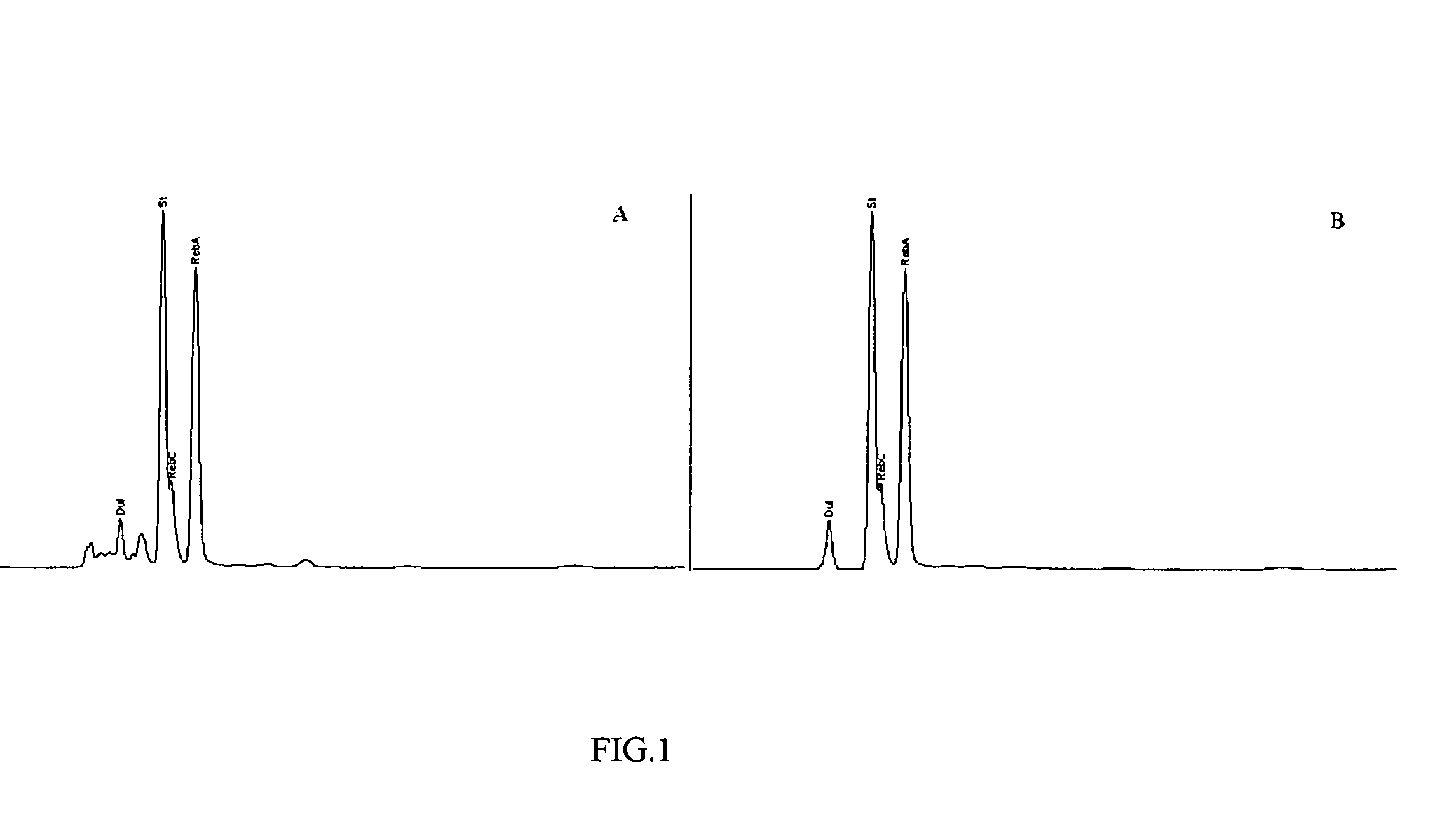

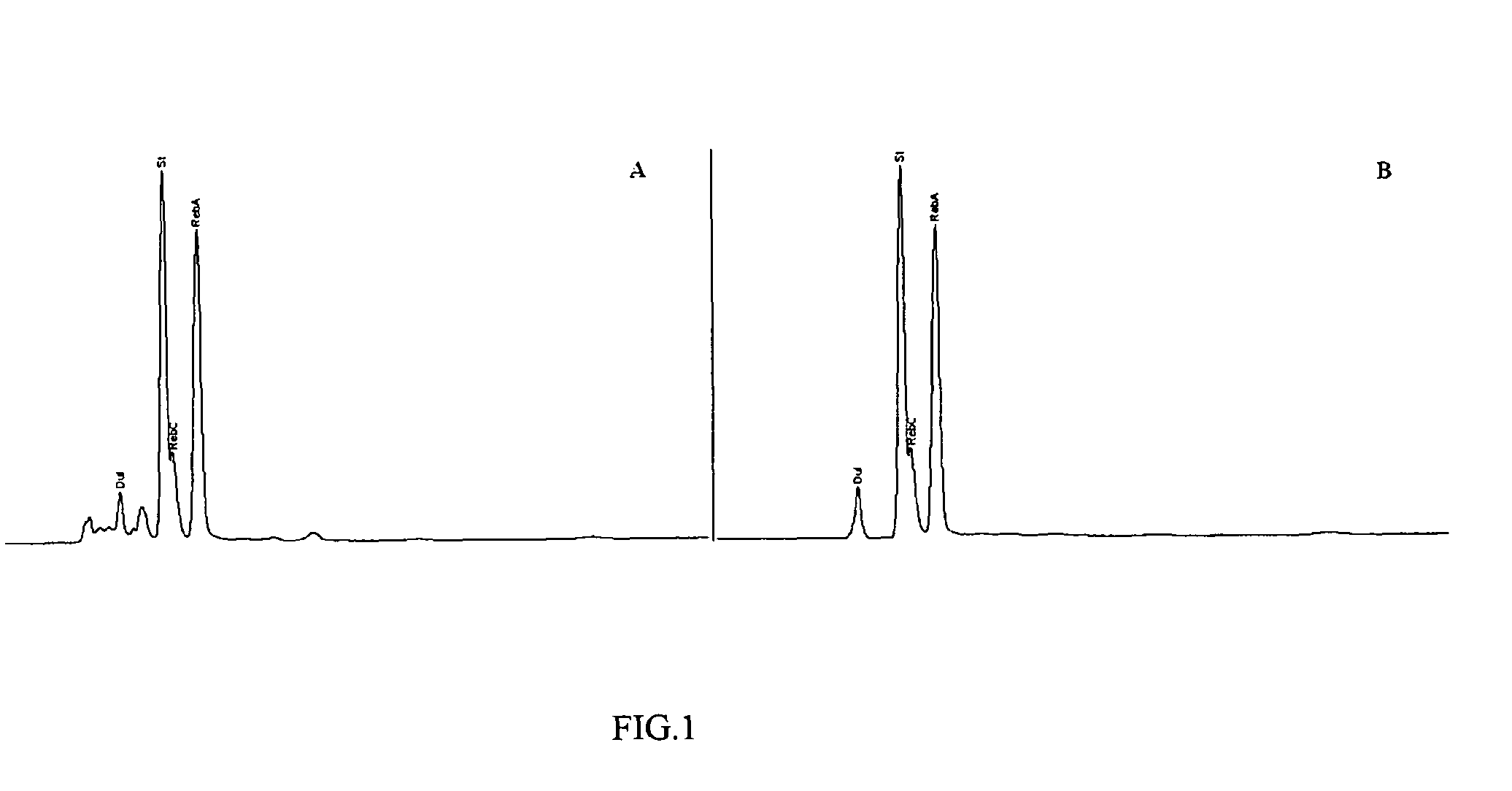

High-purity steviol glycosides

Methods of preparing highly purified steviol glycosides, particularly rebaudiosides A, D and M are described. The methods include utilizing recombinant microorganisms for converting various staring compositions to target steviol glycosides. In addition, novel steviol glycosides reb D2 and reb M2 are disclosed, as are methods of preparing the same. The highly purified rebaudiosides are useful as non-caloric sweetener in edible and chewable compositions such as any beverages, confectioneries, bakery products, cookies, and chewing gums.

Owner:PURECIRCLE SDN BHD

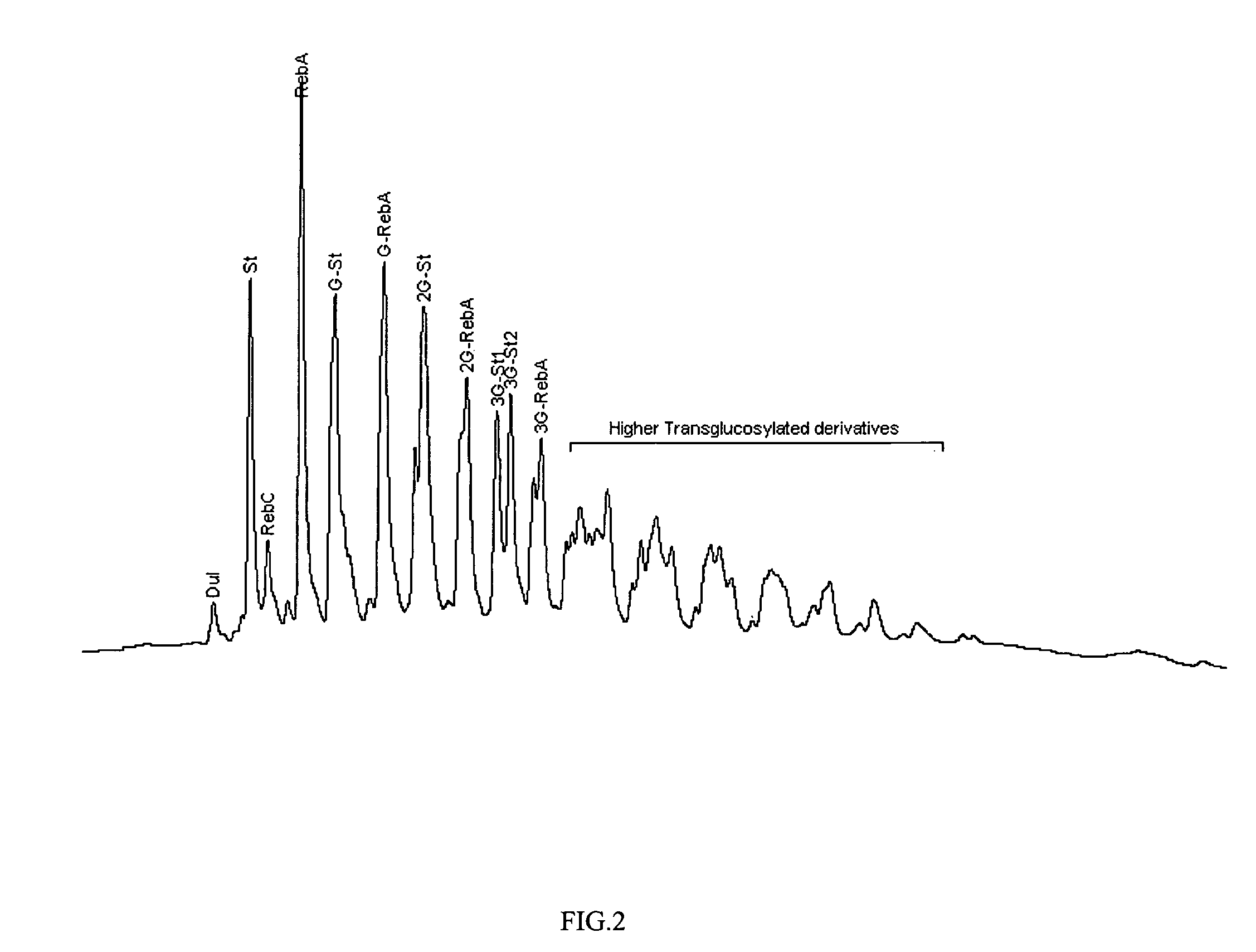

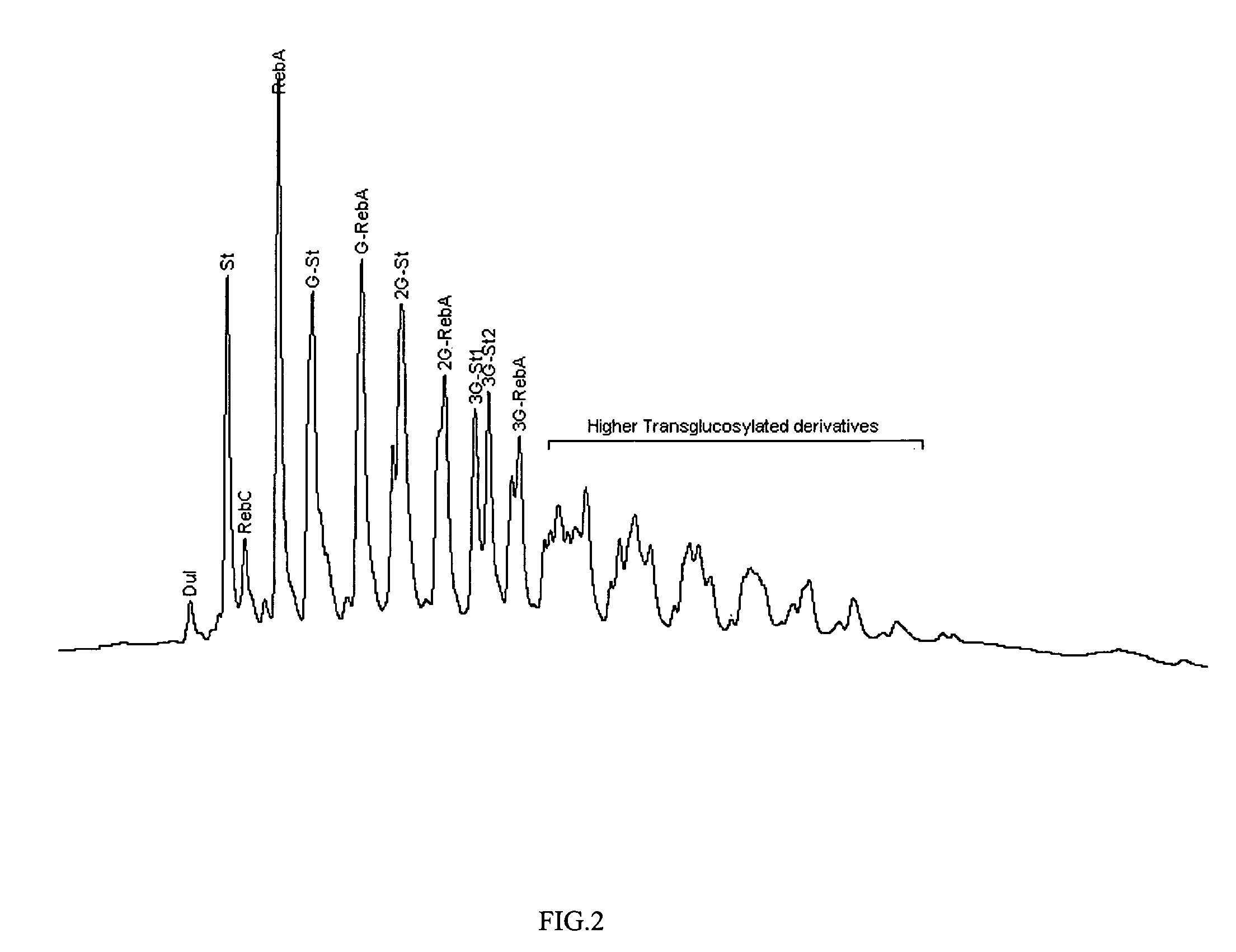

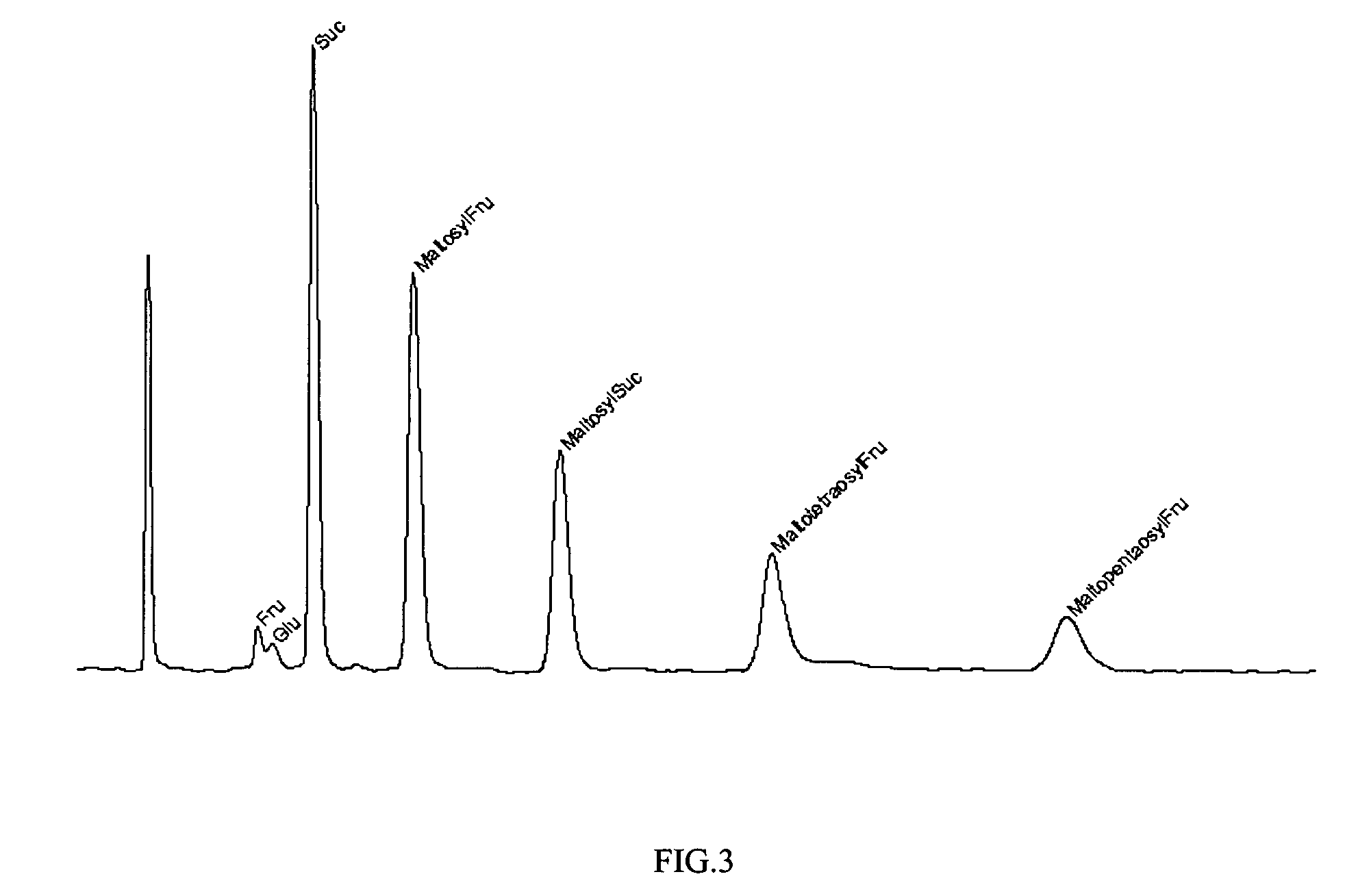

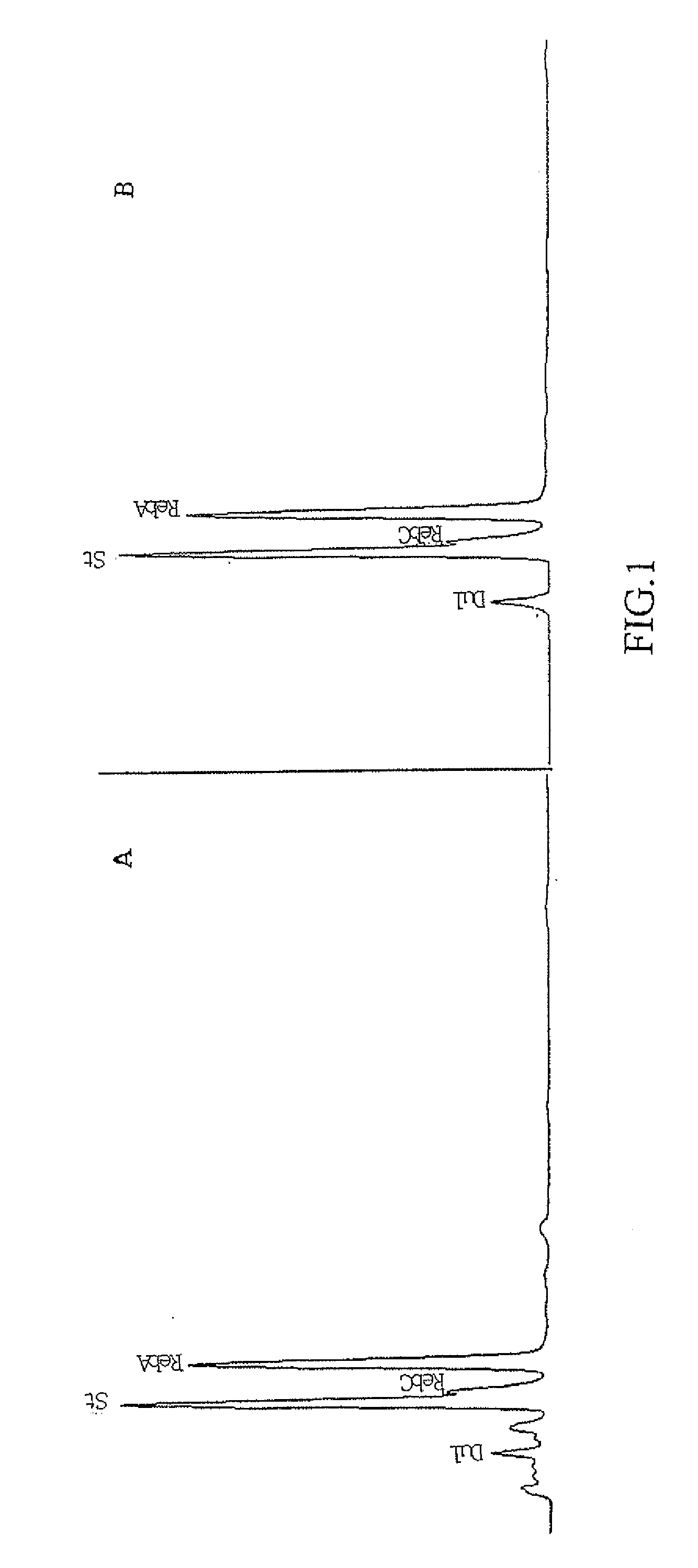

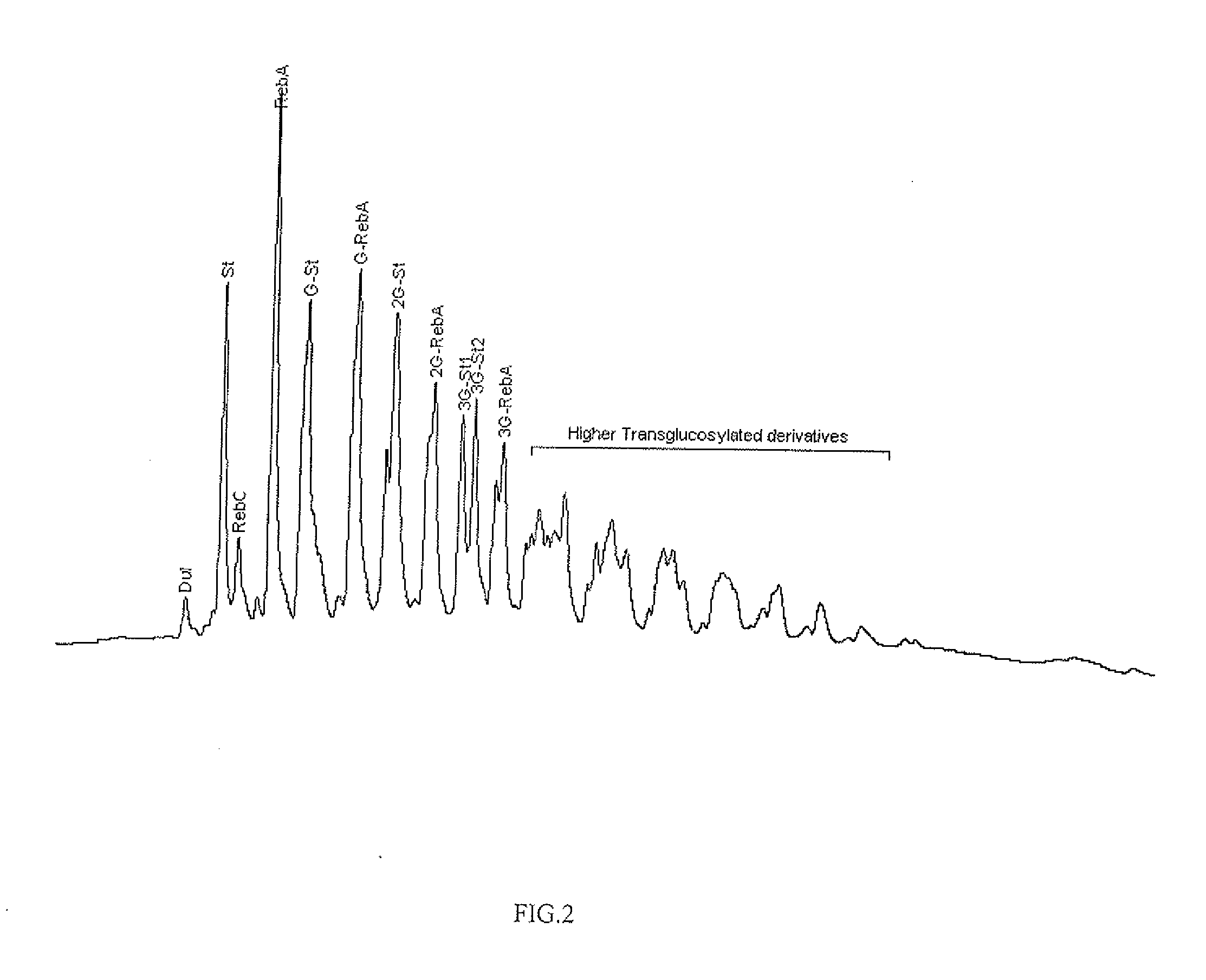

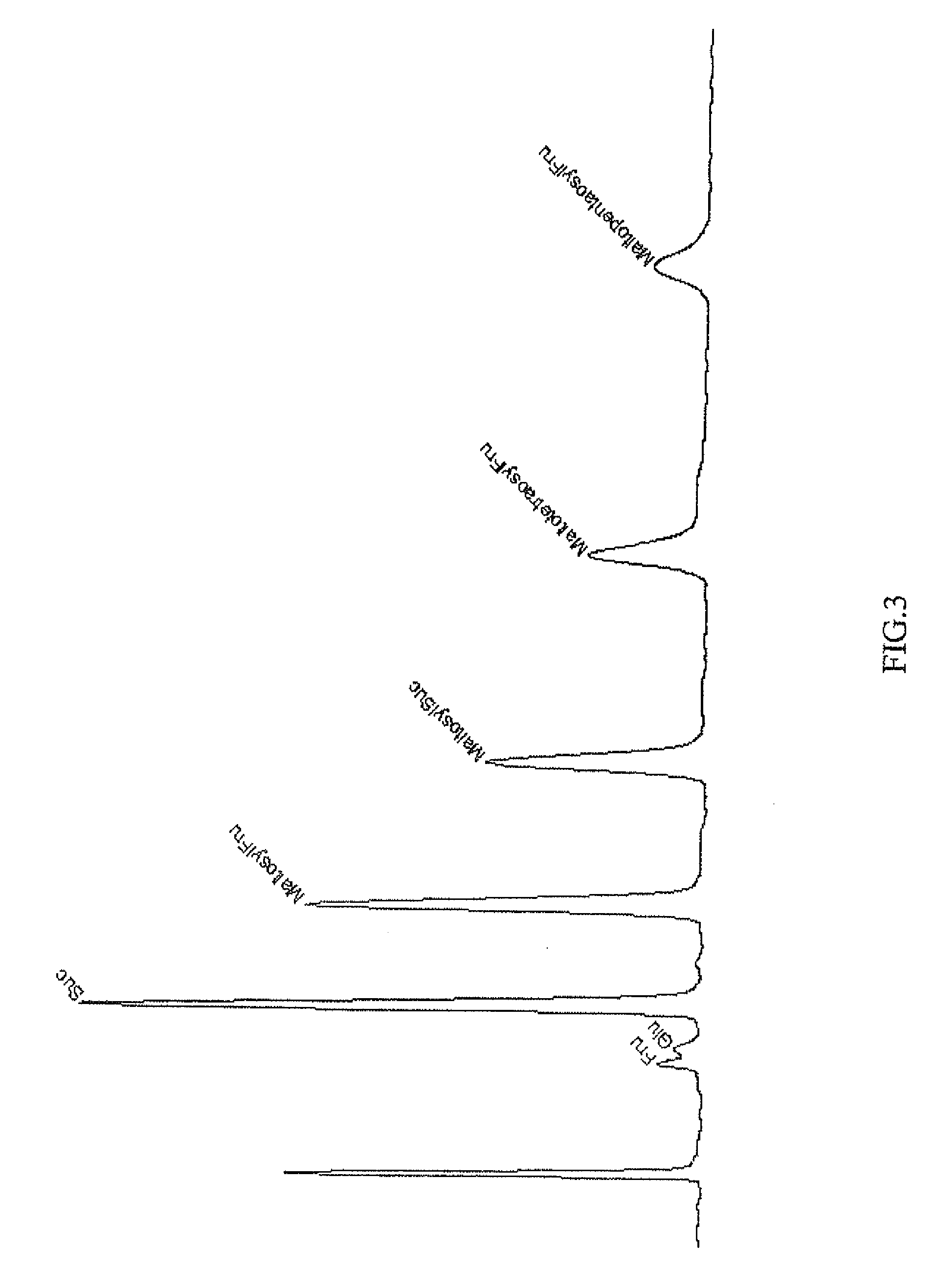

Sweetner and use

Sweeteners on the basis of a simultaneously transglucosylated sweet glycoside mixture of Stevia rebaudiana Bertoni are prepared. The transglycosylation was developed in the presence of starch under the action of cyclodextrin glucanotransferase. The remaining maltodextrins are transferred to the fructose-terminated oligosaccharides. The sweeteners are purified to not less than 98% content of sweet glycosides and derivatives. The preparations are almost non-caloric, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, cosmetics and milk products.

Owner:PURECIRCLE SDN BHD

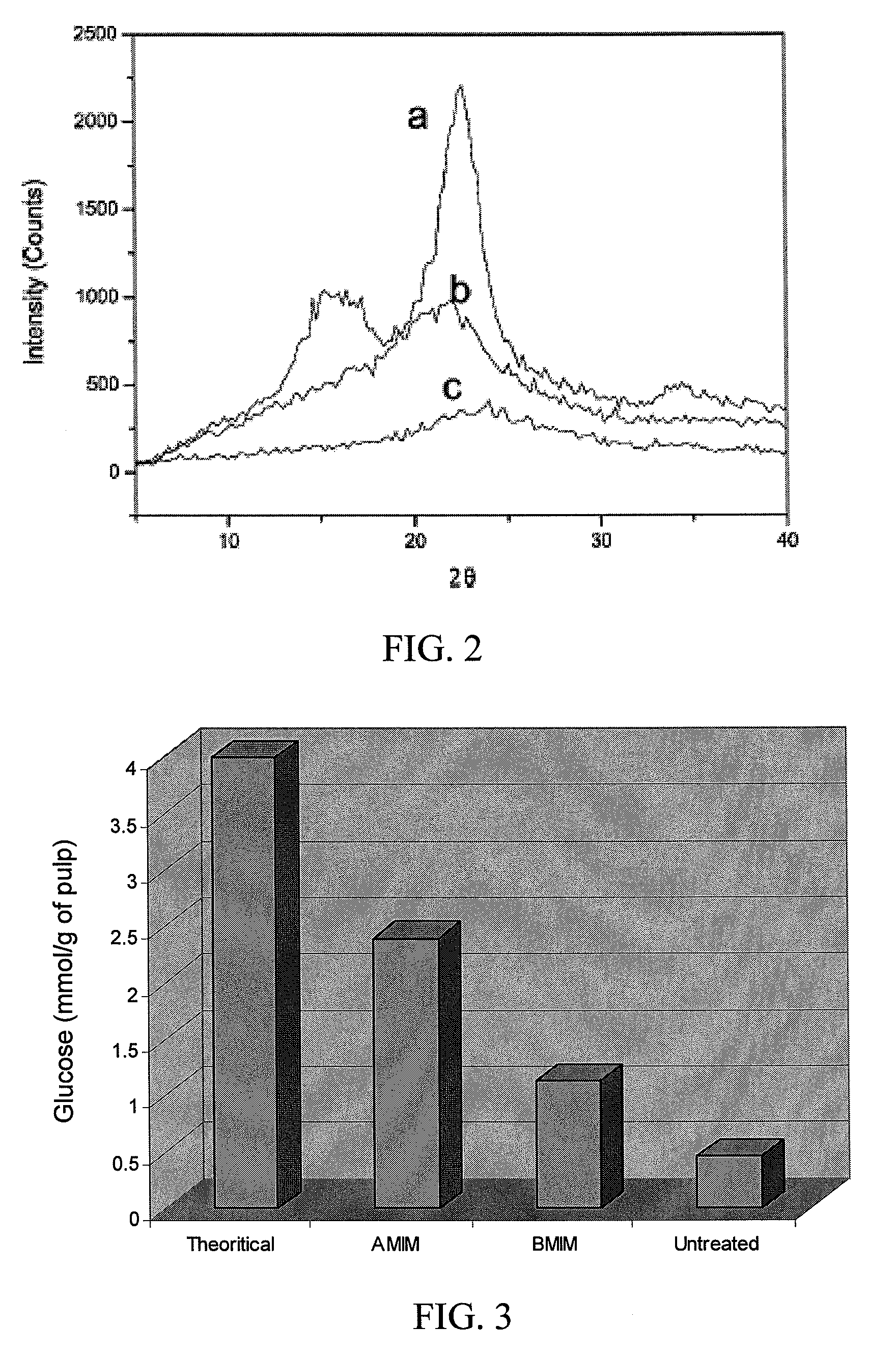

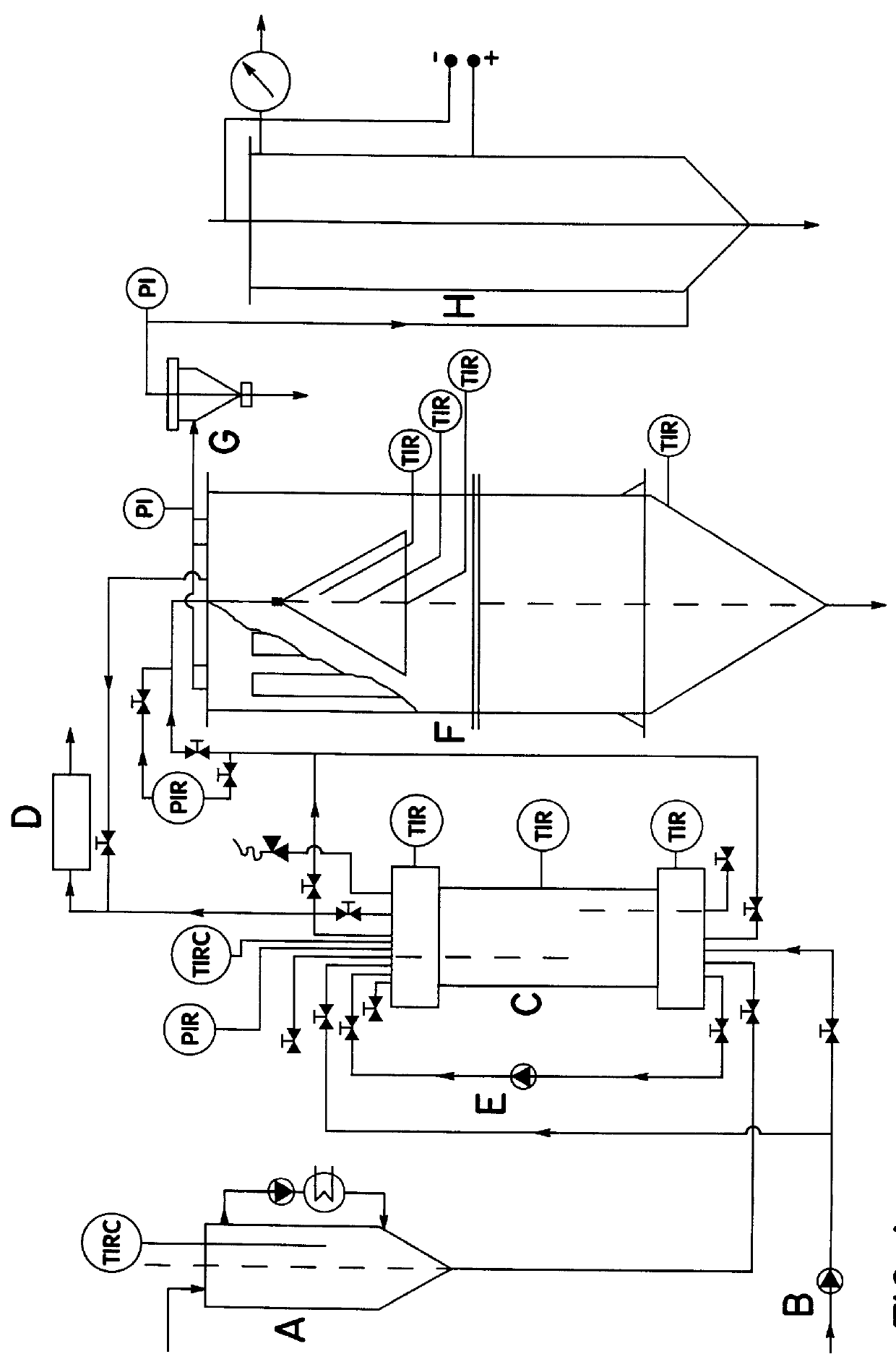

Use of lignocellulosics solvated in ionic liquids for production of biofuels

InactiveUS20080190013A1Guaranteed economic efficiencyReduced availabilityCellulosic pulp after-treatmentSugar productsBiofuelEvaporation

The present invention provides a method for converting lignocellulosic material into biofuel. In particular embodiments, the method comprises pre-treating lignocellulosic material by dissolving the material in ionic liquids. The pretreated lignocellulosic material can be isolated, such as by precipitation with a regenerating solvent (e.g., water), and be used directly in the formation of biofuel, including undergoing hydrolysis to form sugar and fermentation to form fuel, such as bioethanol. The ionic liquid can be recycled for further use, such as by evaporation of the water introduced during precipitation, and the recycling provides a route to a hemicellulose rich fraction and an ionic liquid of consistent quality and wood dissolution characteristics. The recovered hemicelluloses are of significant utilization potential toward commodity and specialty applications.

Owner:NORTH CAROLINA STATE UNIV

Process for the production of particles or powders

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

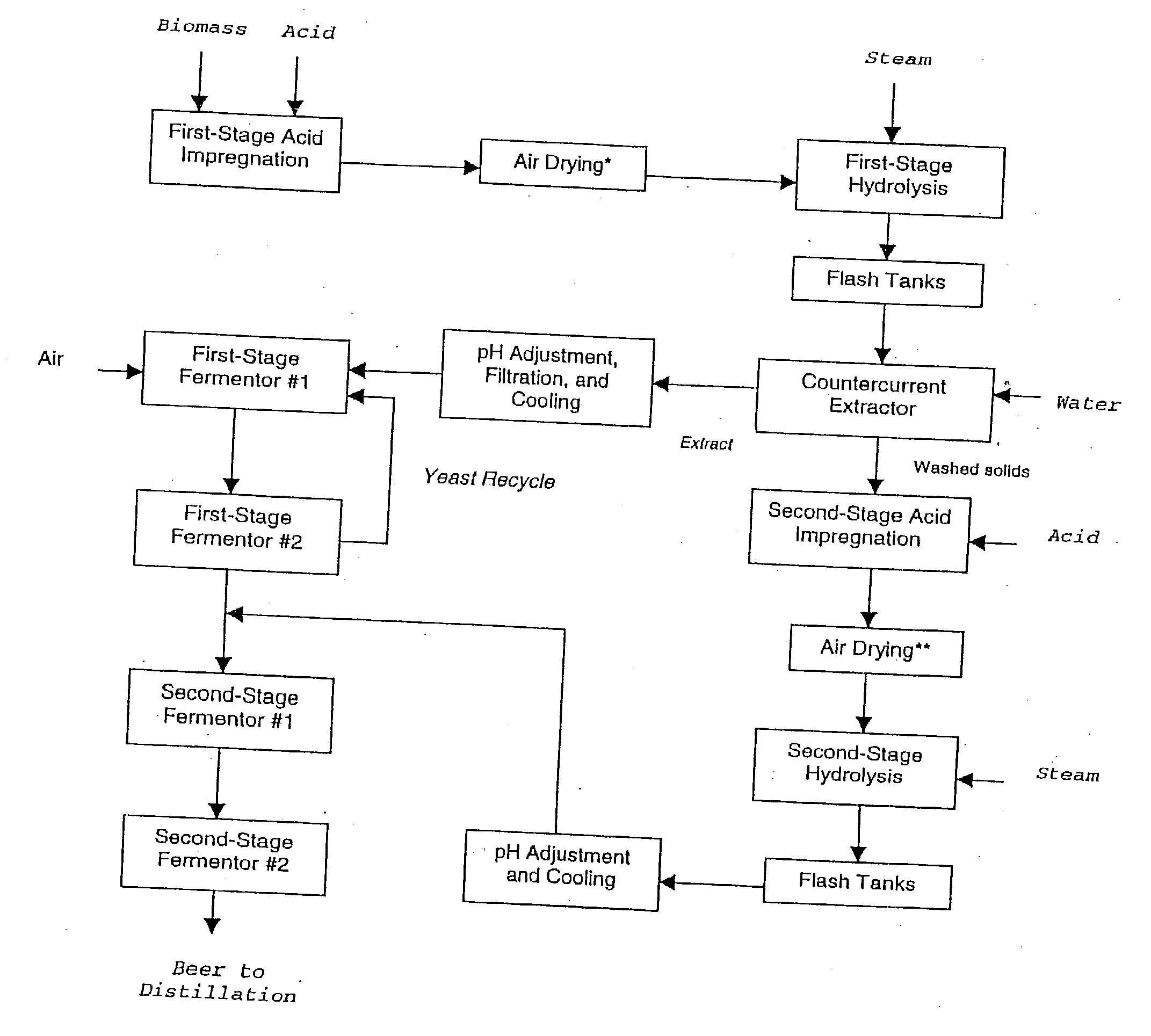

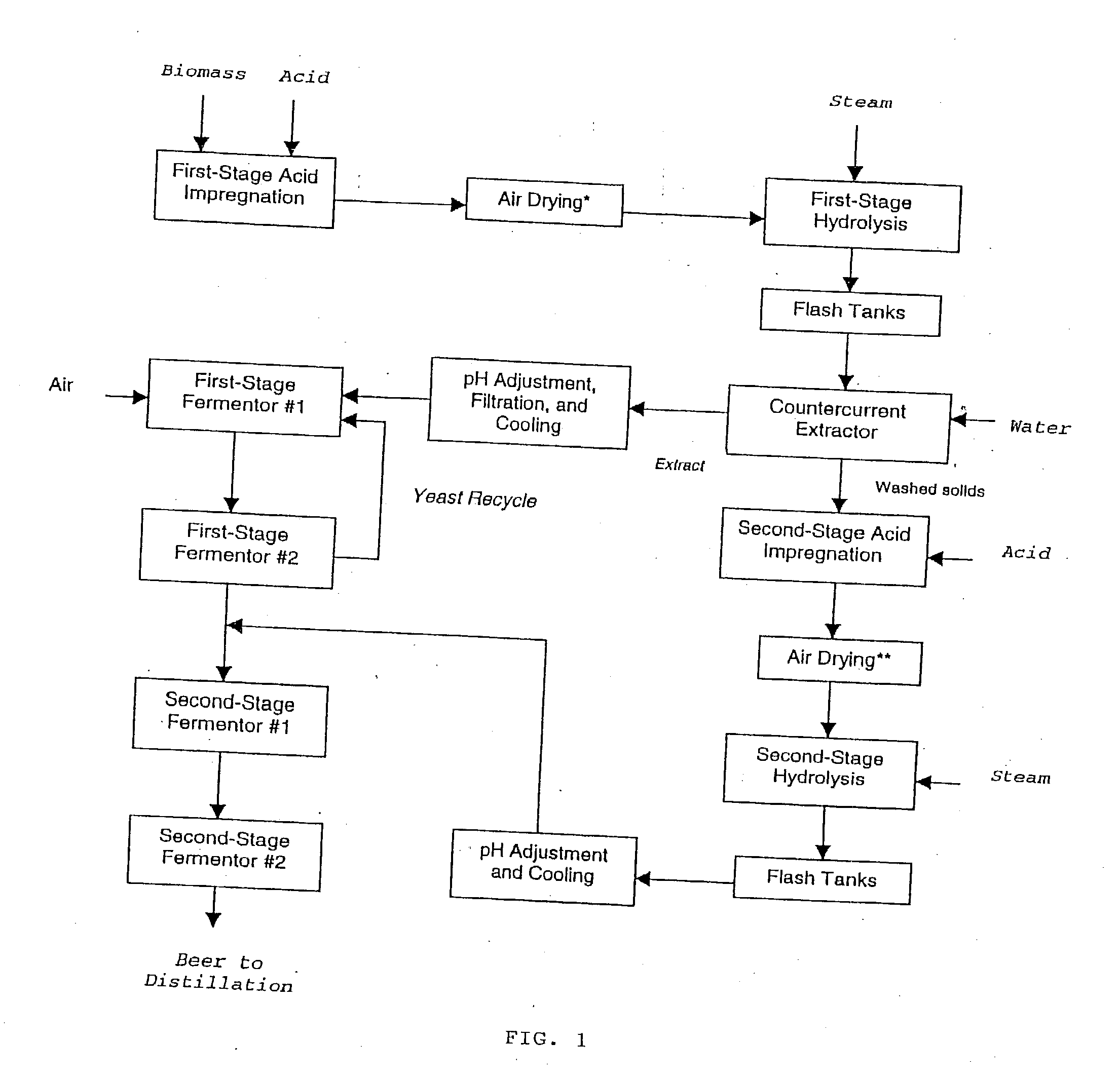

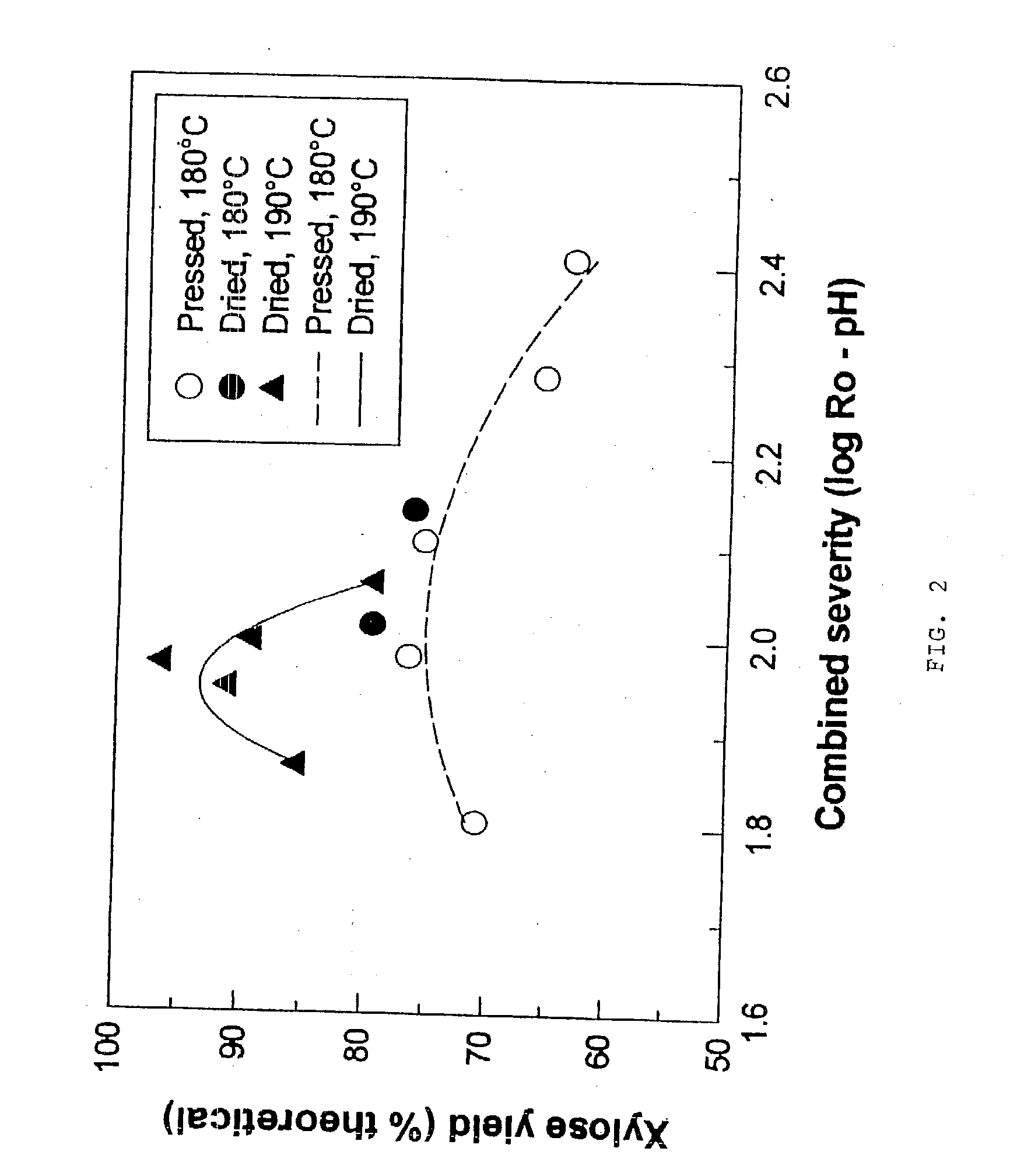

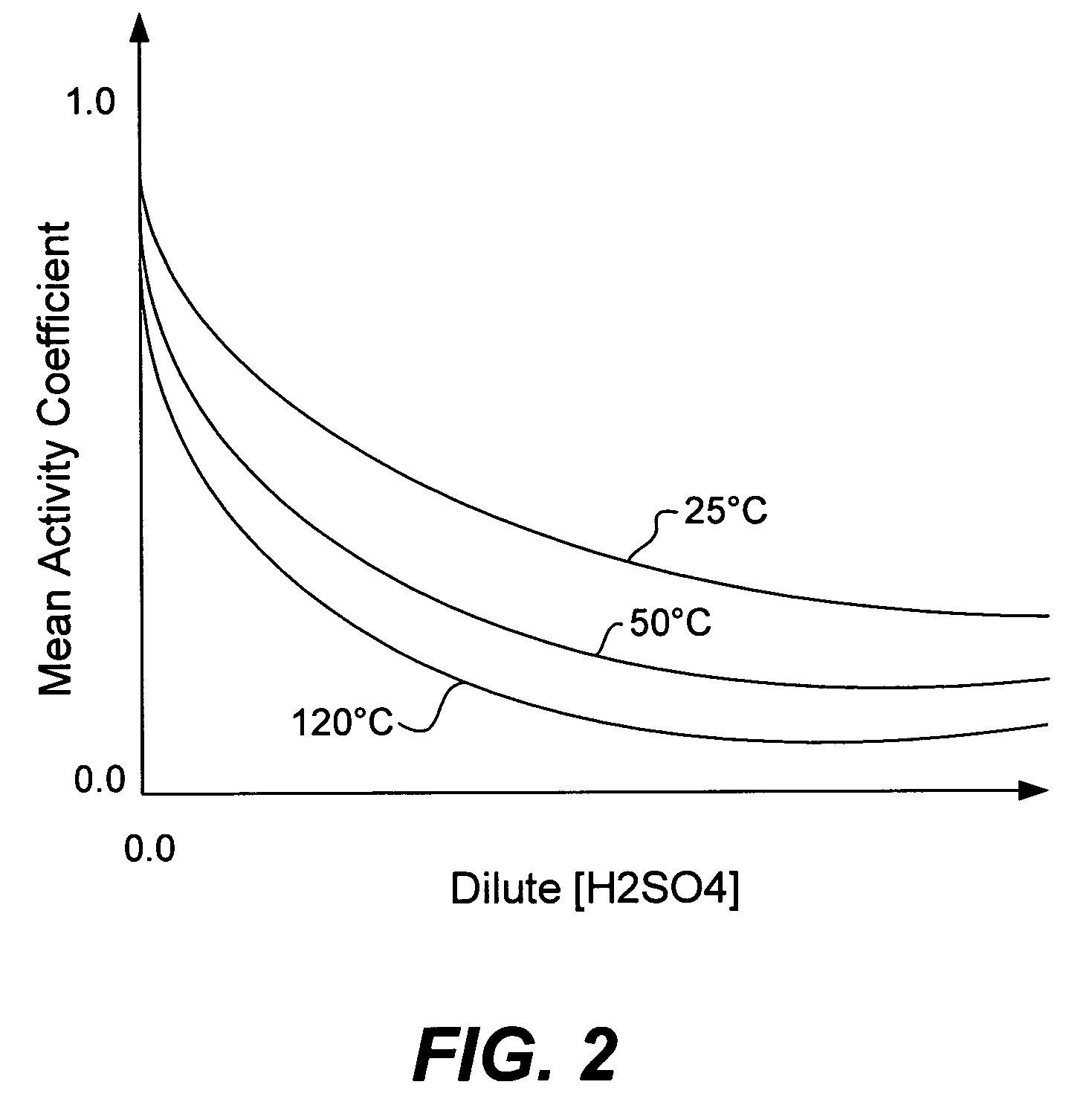

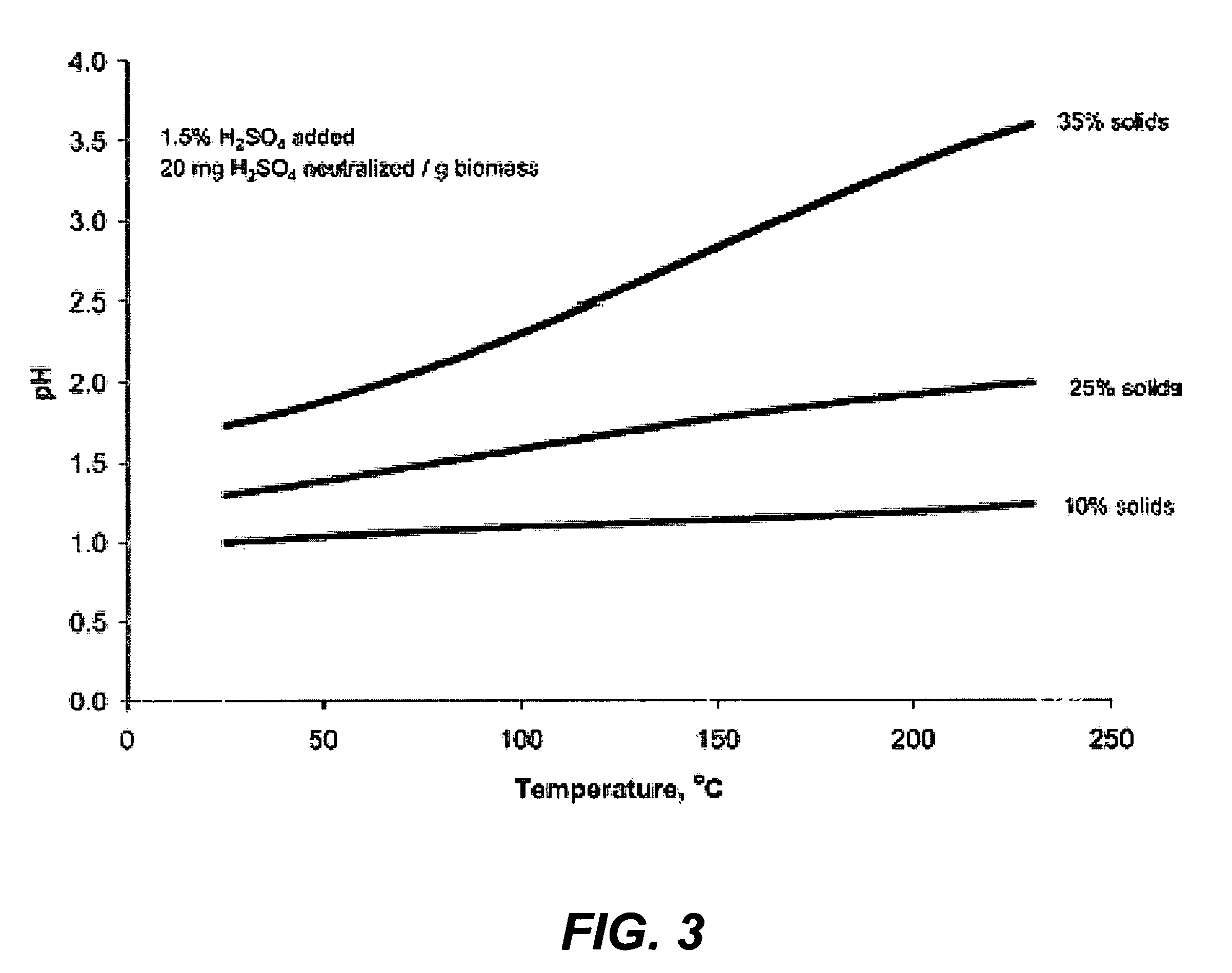

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

Sweetner and use

Sweeteners on the basis of a simultaneously transglucosylated sweet glycoside mixture of Stevia rebaudiana Bertoni are prepared. The transglycosylation was developed in the presence of starch under the action of cyclodextrin glucanotransferase. The remaining maltodextrins are transferred to the fructose-terminated oligosaccharides. The sweeteners are purified to not less than 98% content of sweet glycosides and derivatives. The preparations are almost non-caloric, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, cosmetics and milk products.

Owner:PURECIRCLE SDN BHD

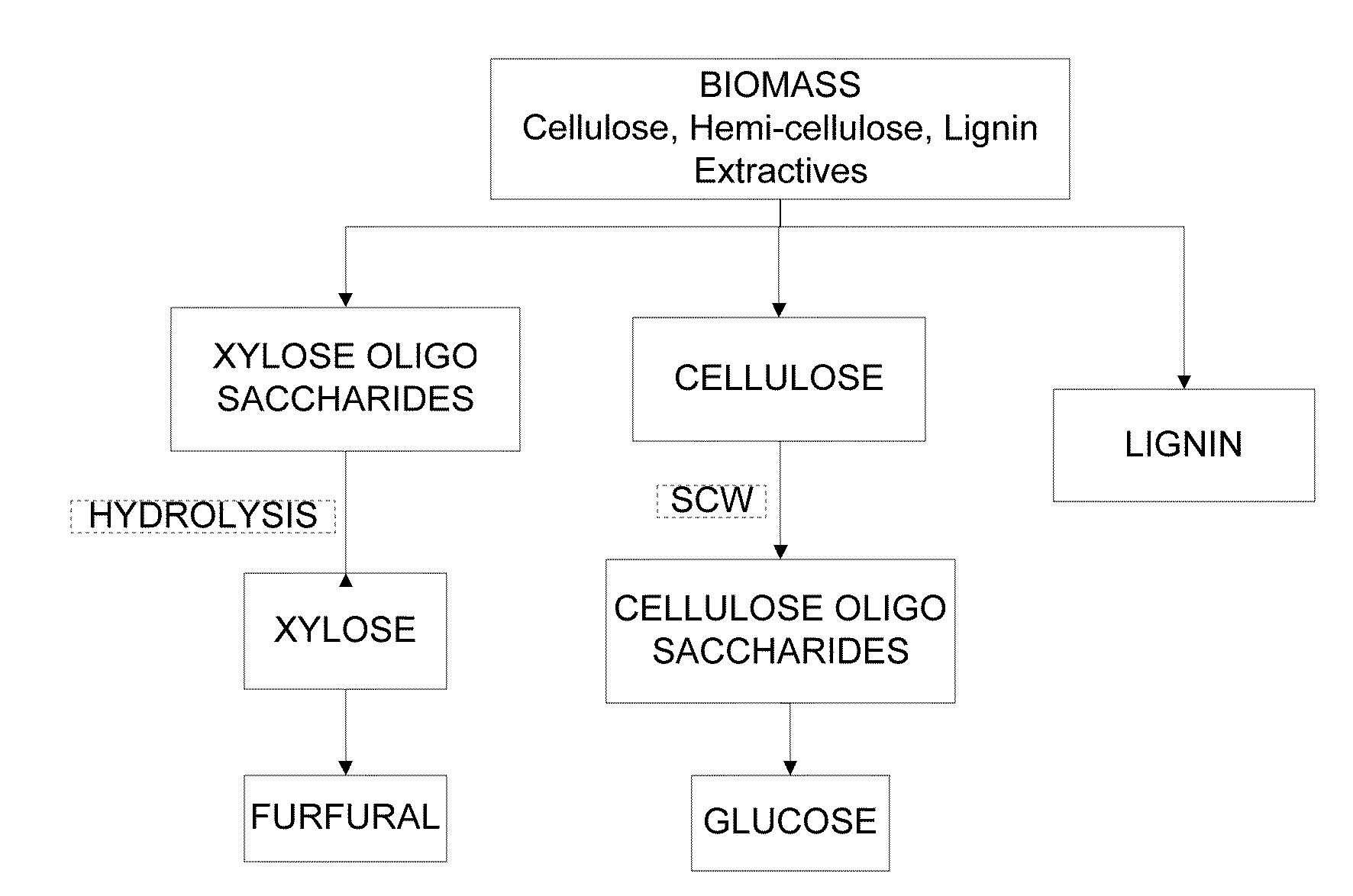

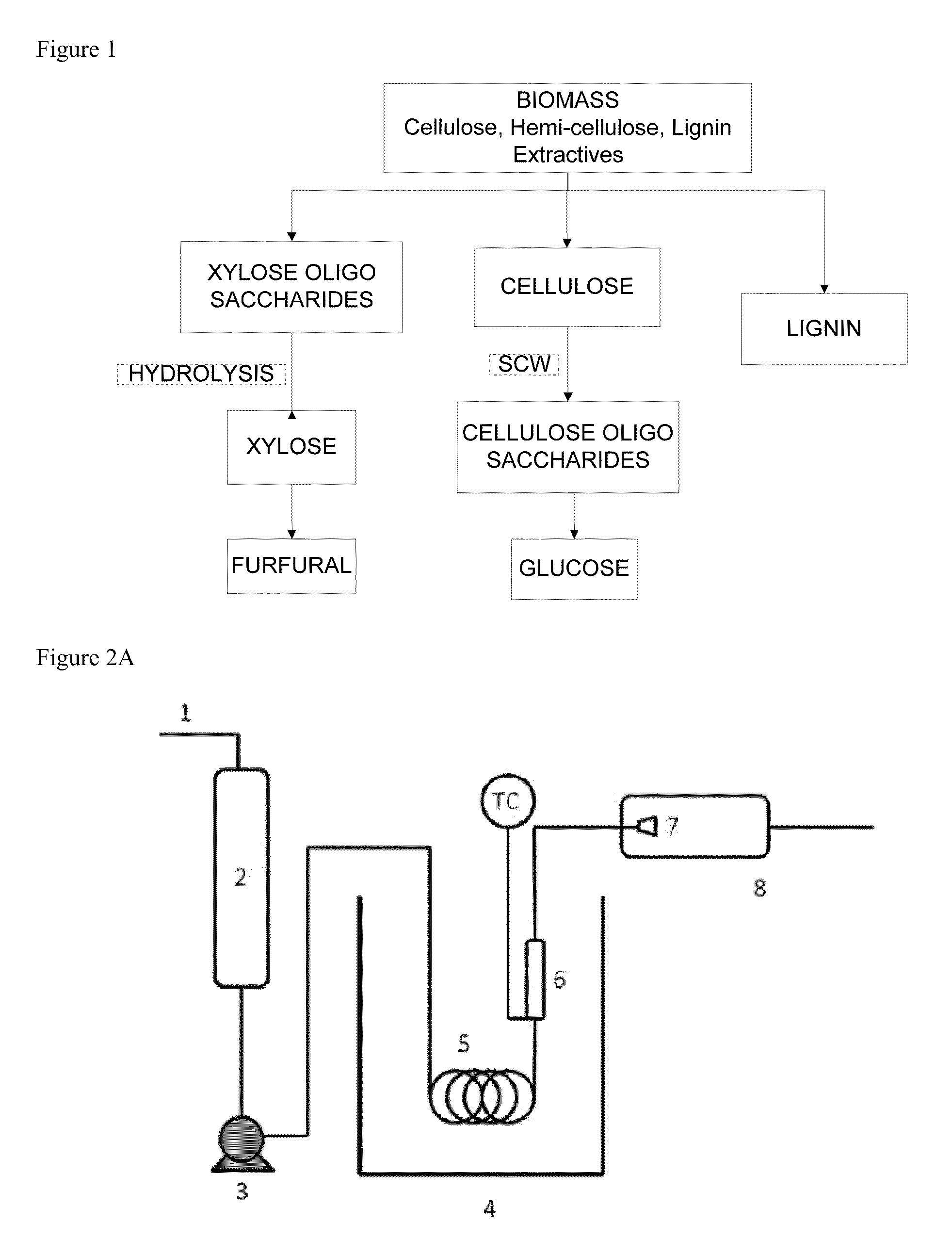

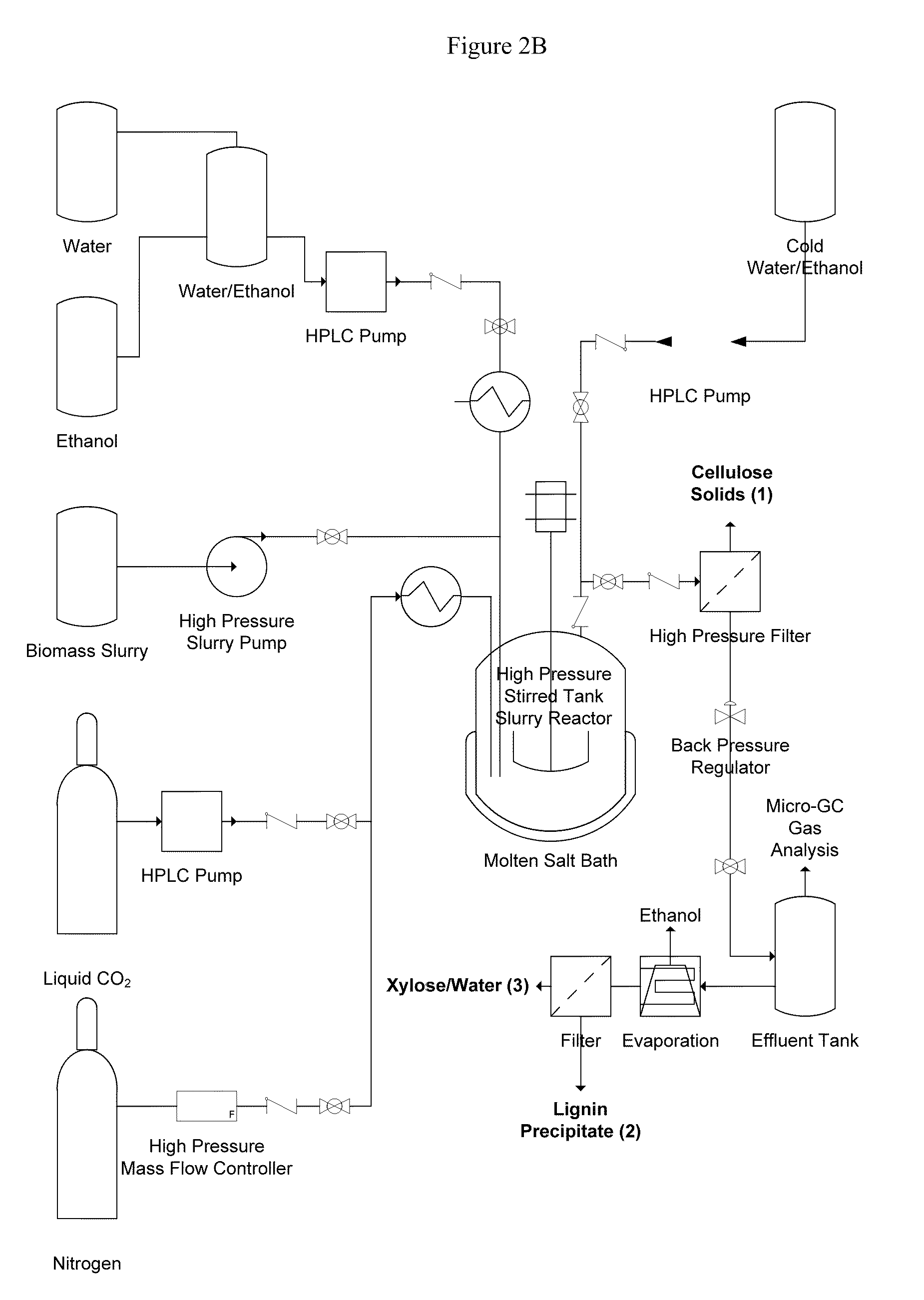

Nano-catalytic-solvo-thermal technology platform bio-refineries

Methods of making glucose and / or furfural from biomass require one or more supercritical fluids that may be used to process biomass, cellulose from the biomass, and / or xylose from the biomass. Examples of supercritical fluids for use in processing biomass include ethanol, water, and carbon dioxide at a temperature and pressure above the critical points for ethanol and carbon dioxide but at a temperature and / or pressure below that of the critical point for water. A supercritical fluid containing carbon dioxide and water may be used to convert cellulose to glucose or convert xylose to furfural. The fluid has a temperature and pressure above the critical point of carbon dioxide, but at least one of the temperature and pressure is below the critical point for water.

Owner:RENMATIX INC

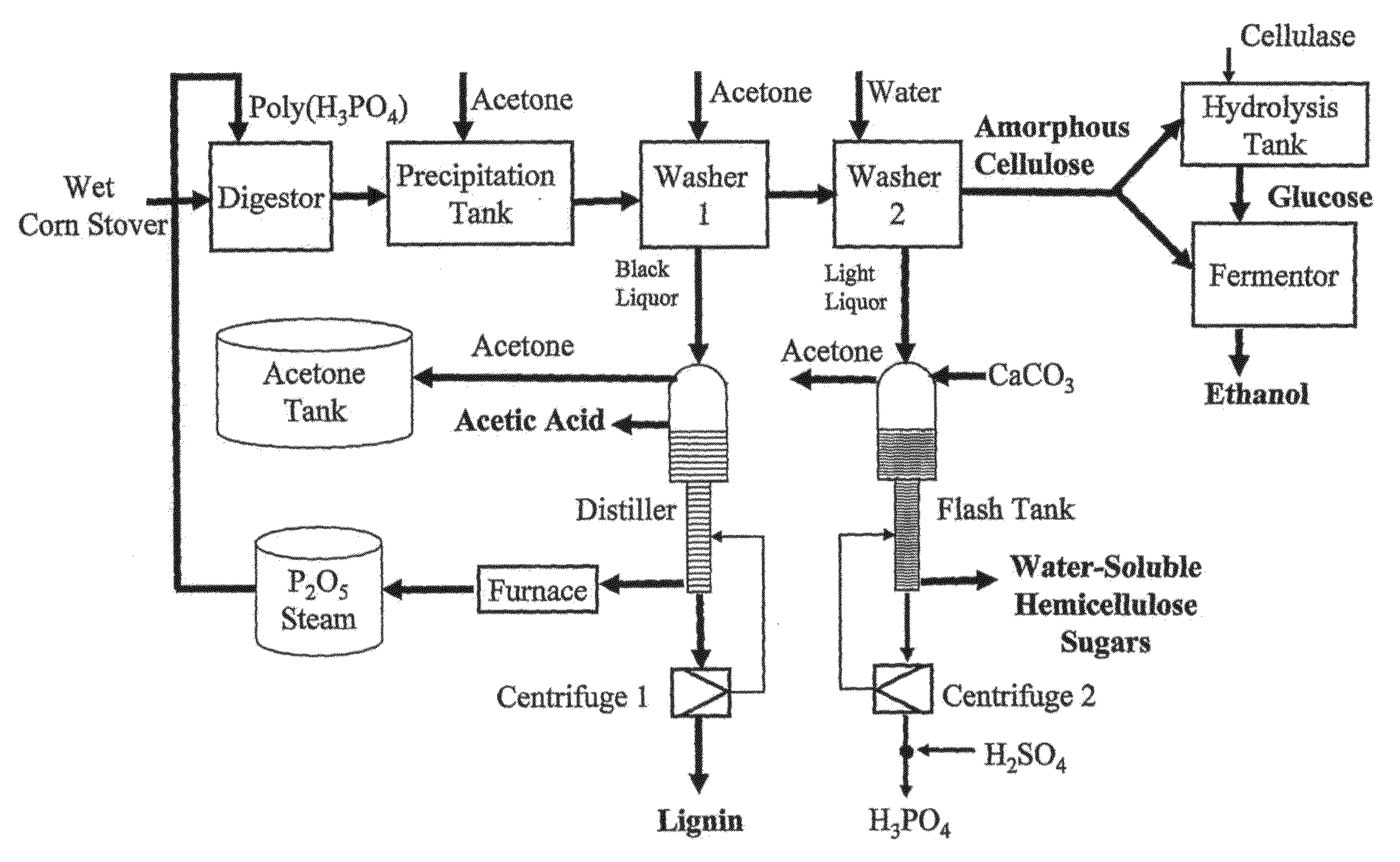

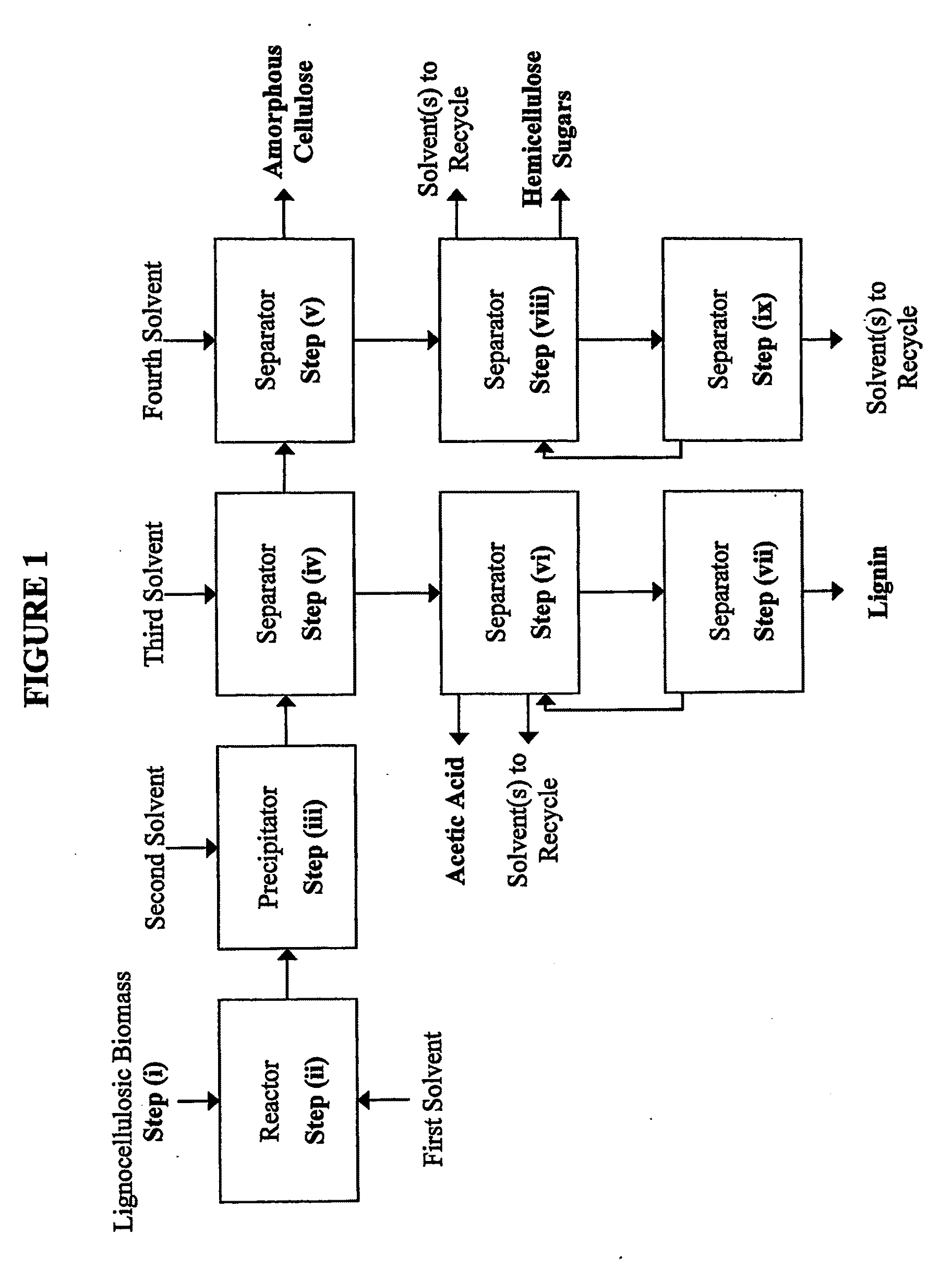

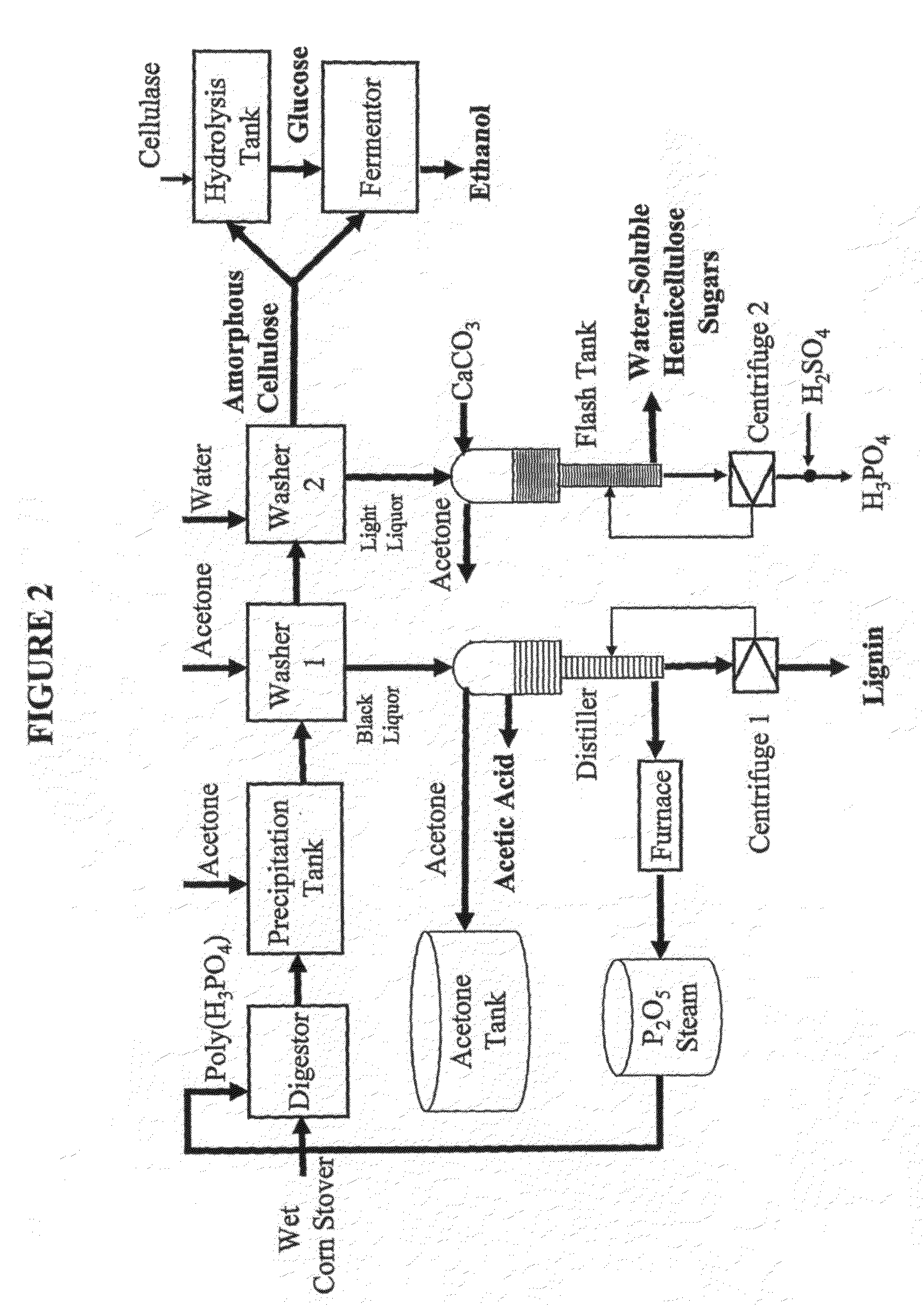

Cellulose-solvent-based lignocellulose fractionation with modest reaction conditions and reagent cycling

InactiveUS20100170504A1Lower cost of capitalReduce operating costsBiofuelsChemical recyclingFractionationProcessing cost

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose sugars, lignin, and acetic acid. The cellulose thus obtained is highly amorphous and can be readily converted into glucose using known methods. Fermentable hemicellulose sugars, low-molecular—weight lignin, and purified acetic acid are also major products of the process and system. The modest process conditions and low solvent / solid ratios of some embodiments of the invention imply relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

Removal of minerals from cellulosic biomass

InactiveUS7503981B2Reduce mineral contentEnhancing cellulosic saccharificationNon-fibrous pulp additionSpecial paperCellulosePre treatment

Disclosed is a method for removing minerals from a cellulosic biomass. For example, the biomass may be prewashed with an acid solution and rinsed with water to remove minerals prior to acid saccharification. The removal of minerals may reduce overall acid requirements, and decrease pretreatment costs.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

Sweetner and use

Sweeteners on the basis of a simultaneously transglucosylated sweet glycoside mixture of Stevia rebaudiana Bertoni are prepared. The transglucosylation was developed in the presence of starch under the action of cyclodextrin glucanotransferase. The remaining maltodextrins are transformed to the fructose-terminated oligosaccharides by the addition of sucrose. The sweeteners are purified to not less than 98% content of sweet glycosides and derivatives. The preparations are almost non-caloric, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, cosmetics and milk products.

Owner:PURECIRCLE SDN BHD

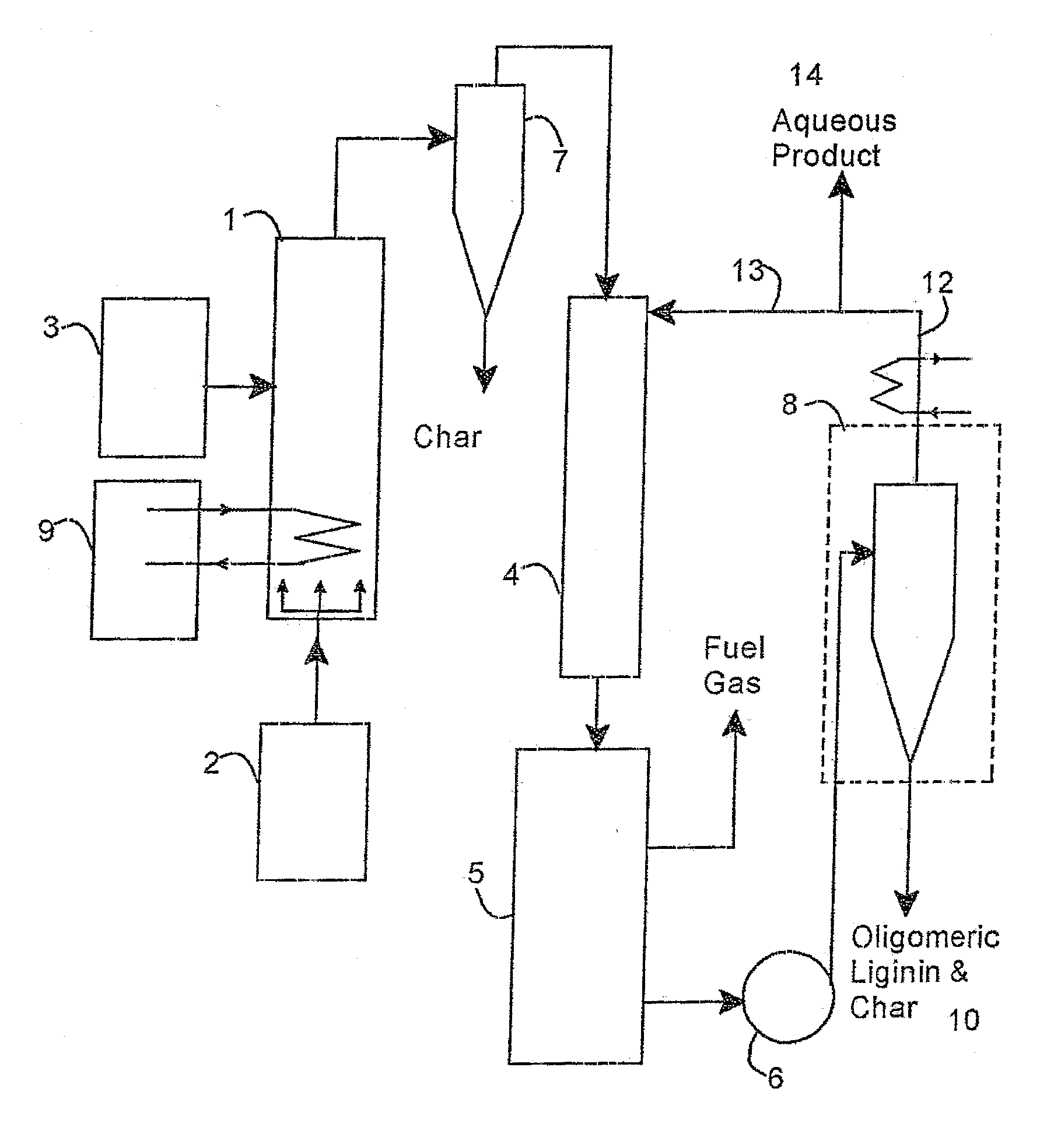

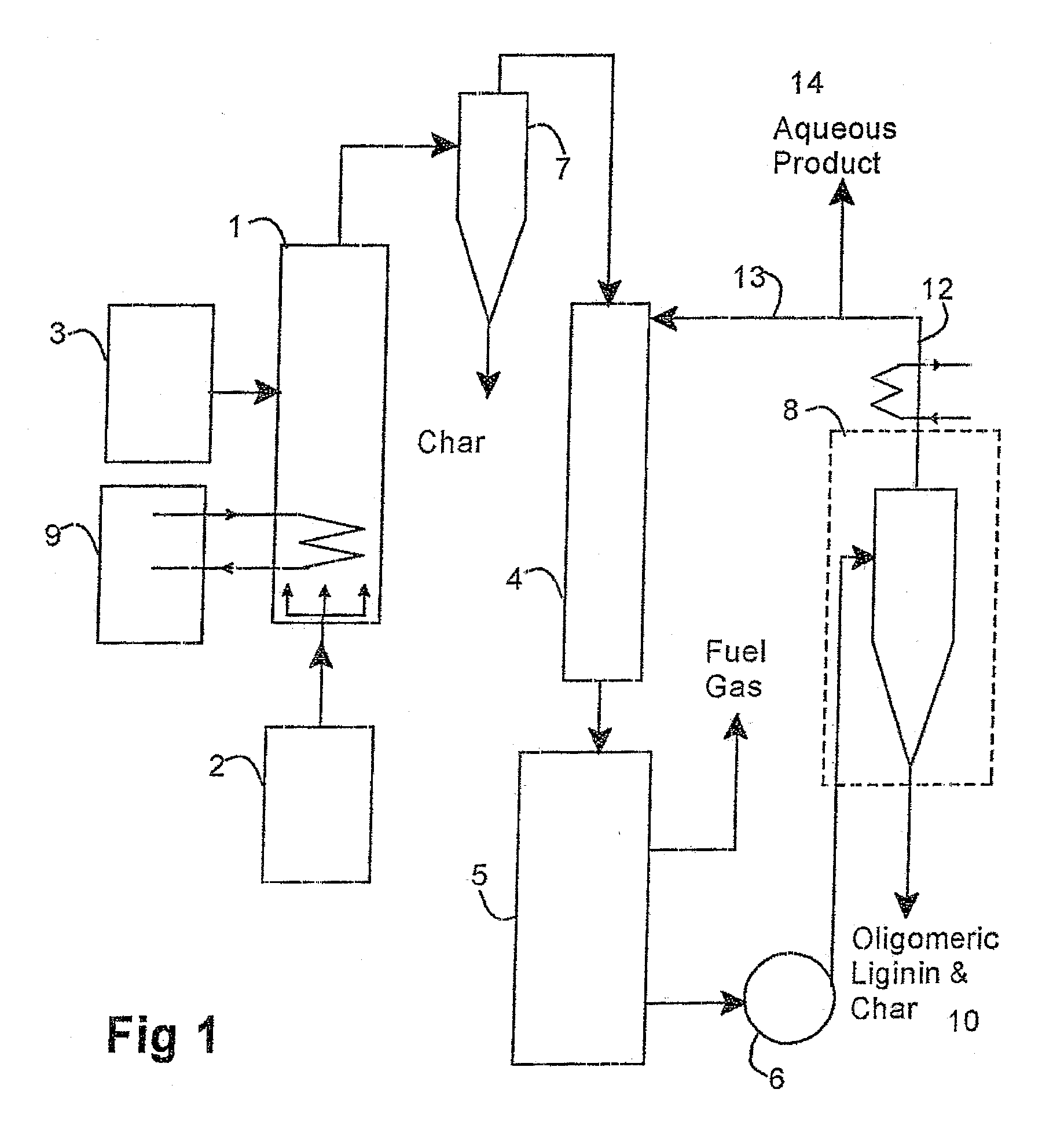

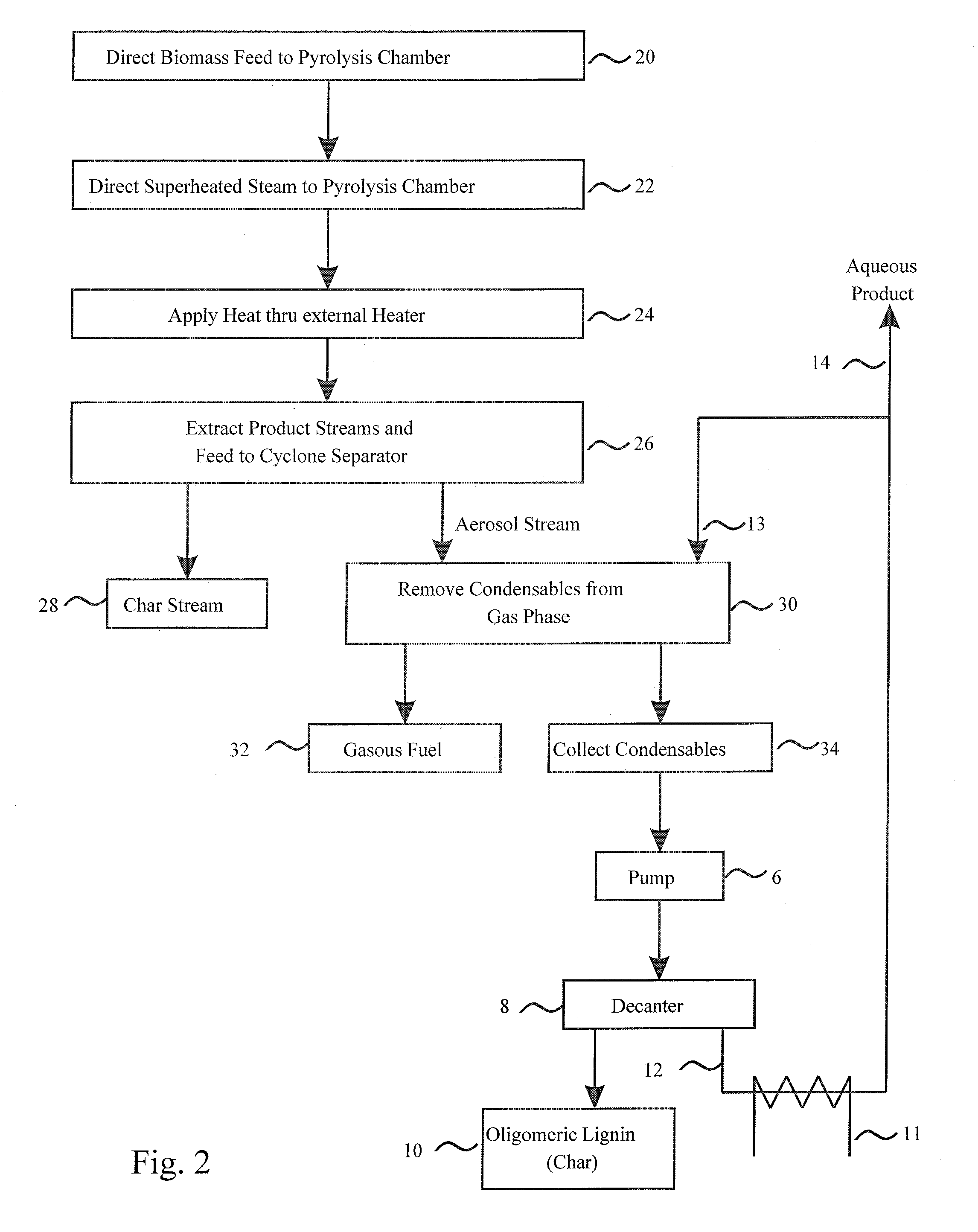

Method of producing hodge carbonyls and oligomeric lignin

ActiveUS20090126433A1Low lignin contentBiofuelsIndirect and direct heating destructive distillationSufficient timeProcess engineering

A method of treating biomass feed by pyrolyzing it in the presence of superheated steam at a selected temperature for a sufficient time to produce at least one product stream.

Owner:KERRY GRP SERVICES INT

Methods for hydrothermal digestion of cellulosic biomass solids in the presence of a slurry catalyst and a digestible filter aid

Digesting cellulosic biomass in the presence of a slurry catalyst may reduce degradation product formation, but catalyst distribution and retention can be problematic. Digestion methods can comprise: providing cellulosic biomass solids and a slurry catalyst capable of activating molecular hydrogen in a digestion unit; providing a digestible filter aid in the digestion unit; distributing the slurry catalyst within the cellulosic biomass solids using fluid flow; retaining at least a portion of the slurry catalyst in a fixed location using the digestible filter aid; heating the cellulosic biomass solids in the presence of the slurry catalyst, a digestion solvent, and molecular hydrogen, thereby forming a liquor phase comprising soluble carbohydrates; and performing a catalytic reduction reaction on the soluble carbohydrates within the digestion unit, thereby at least partially forming a reaction product comprising a triol, a diol, a monohydric alcohol, or any combination thereof in the digestion unit.

Owner:SHELL USA INC

Microvolume crystallization method employing multiple lumens

InactiveUS6872250B2Facilitates the device being rotatedMaterial crystallisationPolycrystalline material growthCrystallizationCrystal

A method for determining crystallization conditions for a material, the method comprising: taking a microfluidic device comprising one or more lumens having microvolume dimensions and a plurality of different crystallization samples within the one or more lumens, the plurality of crystallization samples comprising a material to be crystallized and crystallization conditions that vary among the plurality of crystallization samples; transporting the plurality of different crystallization samples within the lumens; and identifying a precipitate or crystal formed in the one or more lumens.

Owner:TAKEDA SAN DIEGO

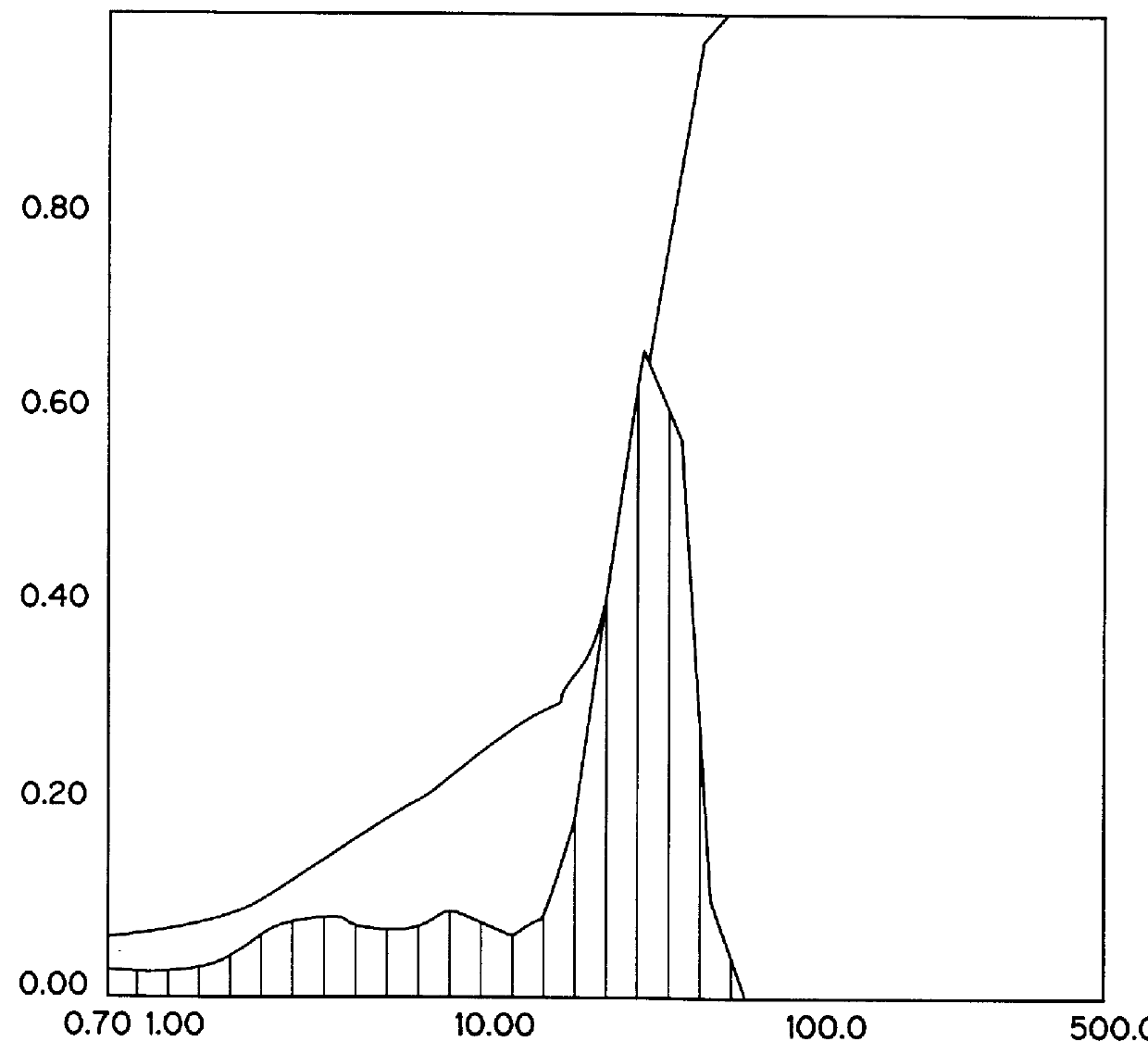

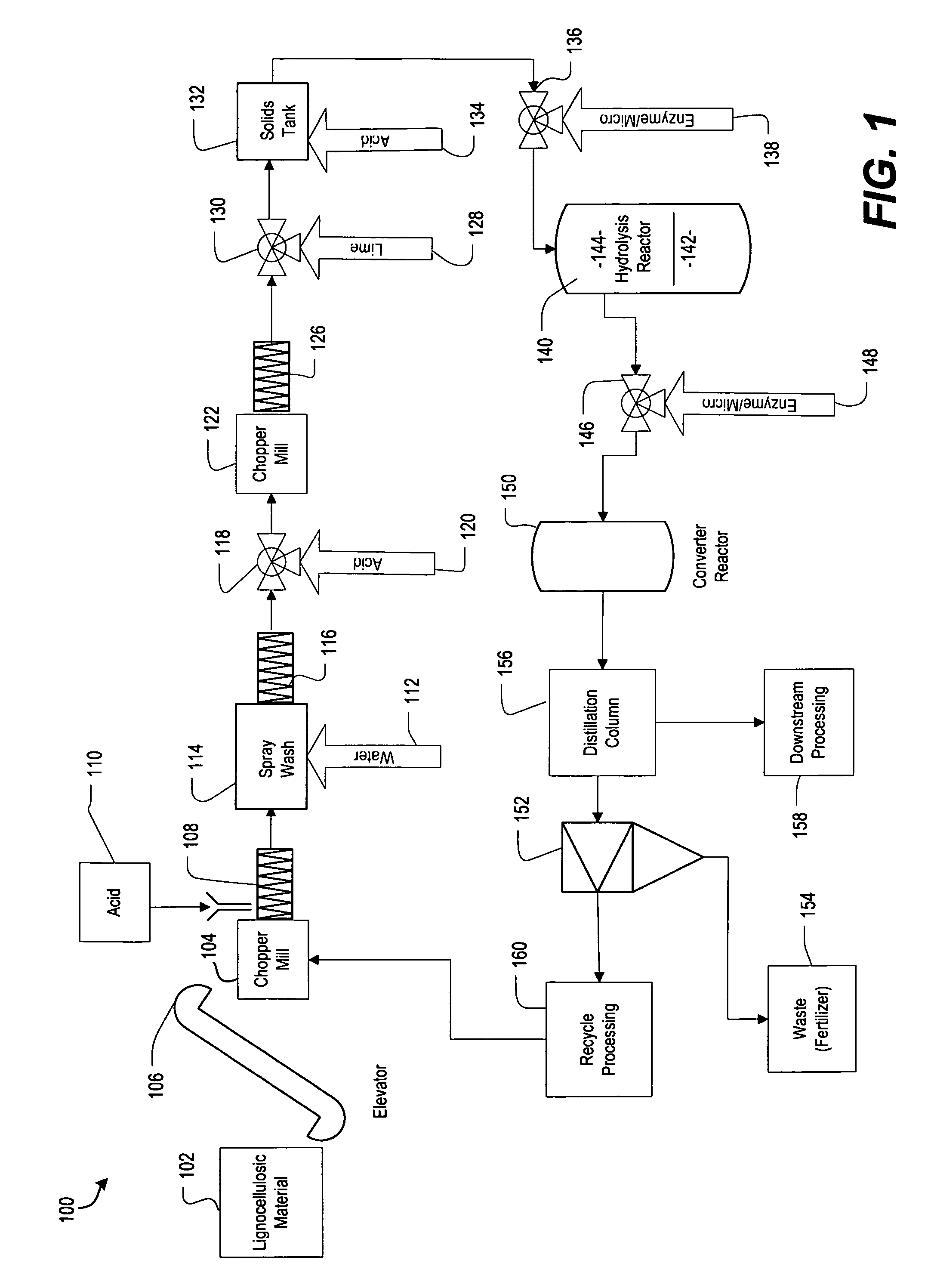

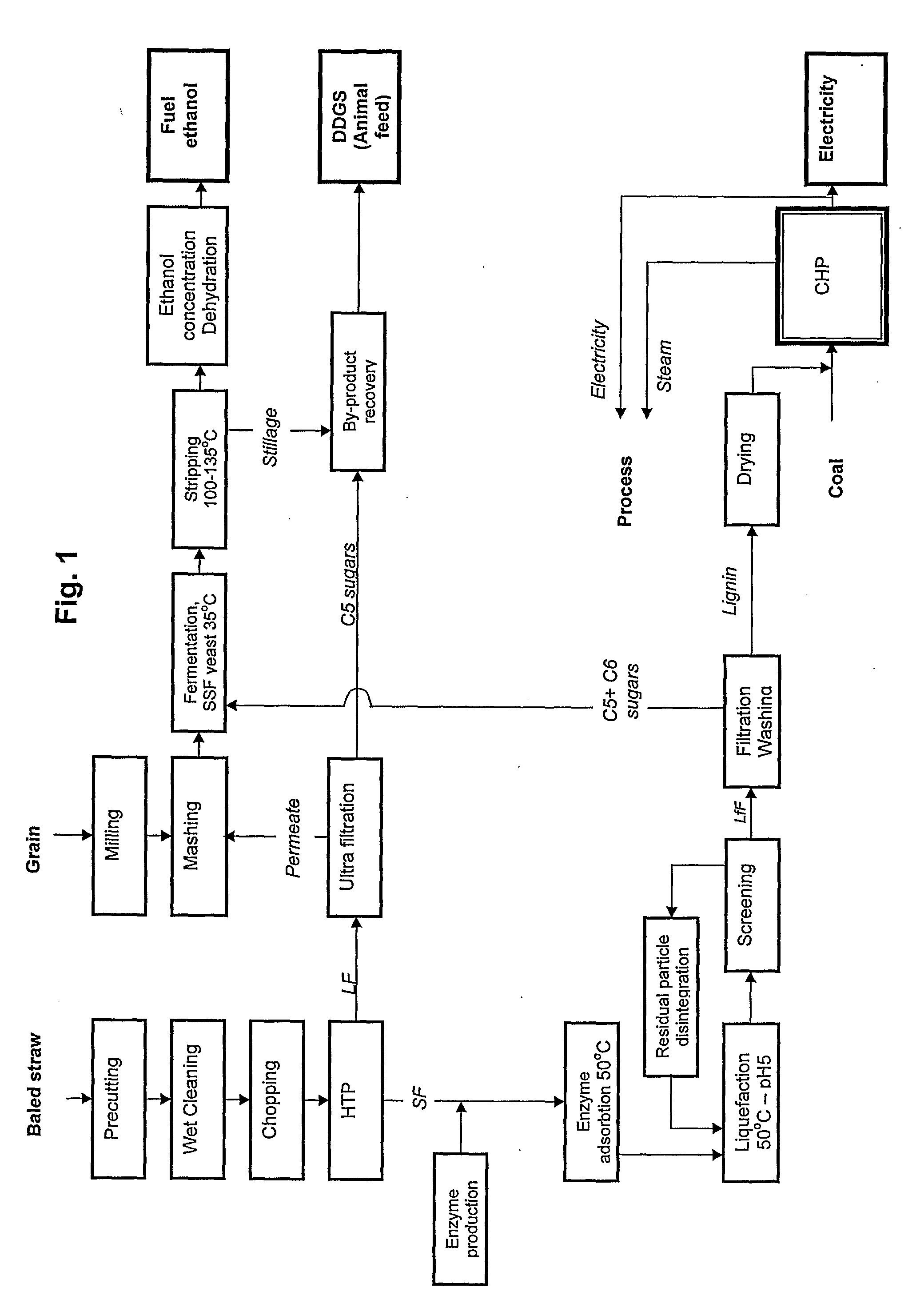

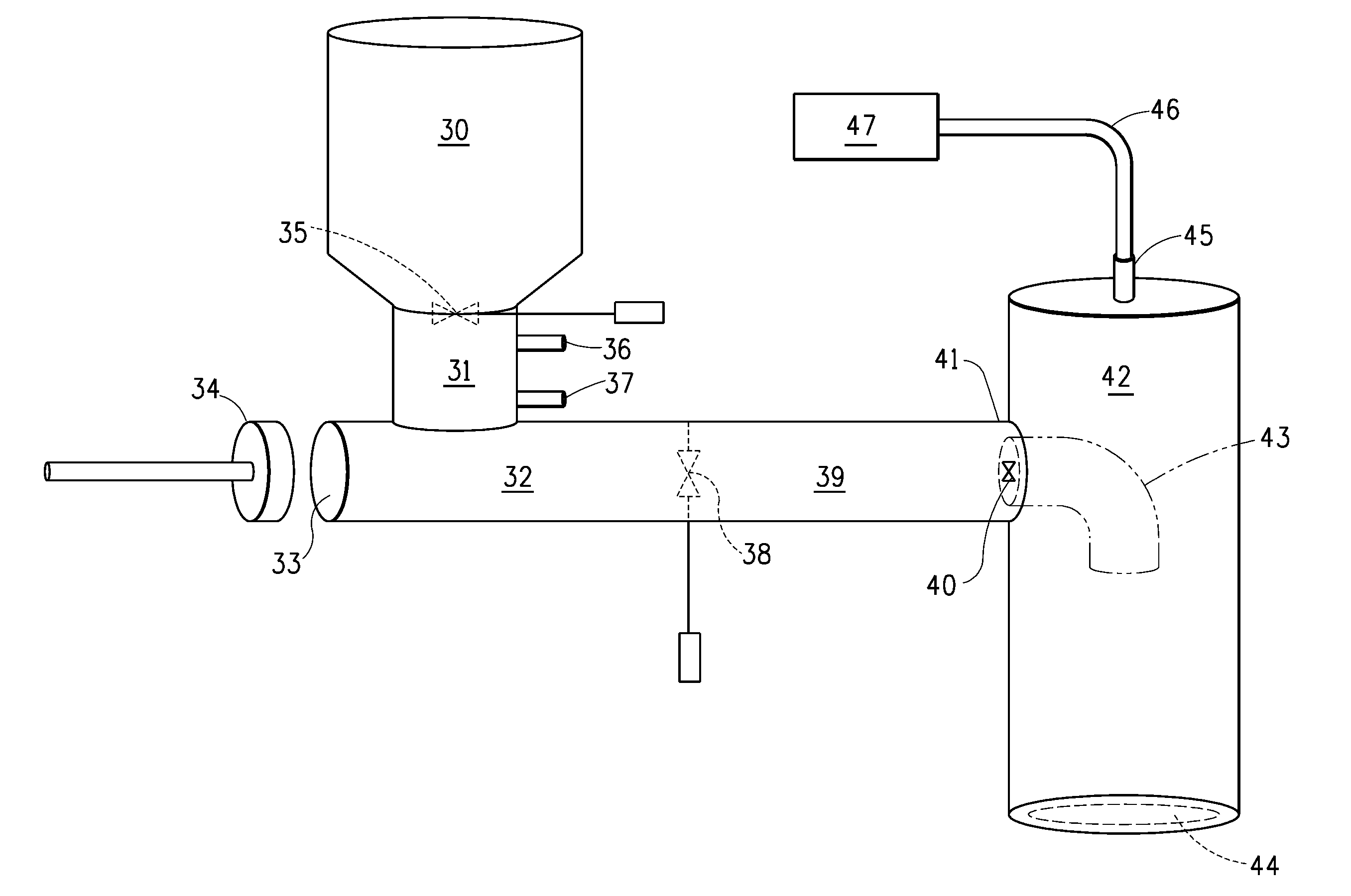

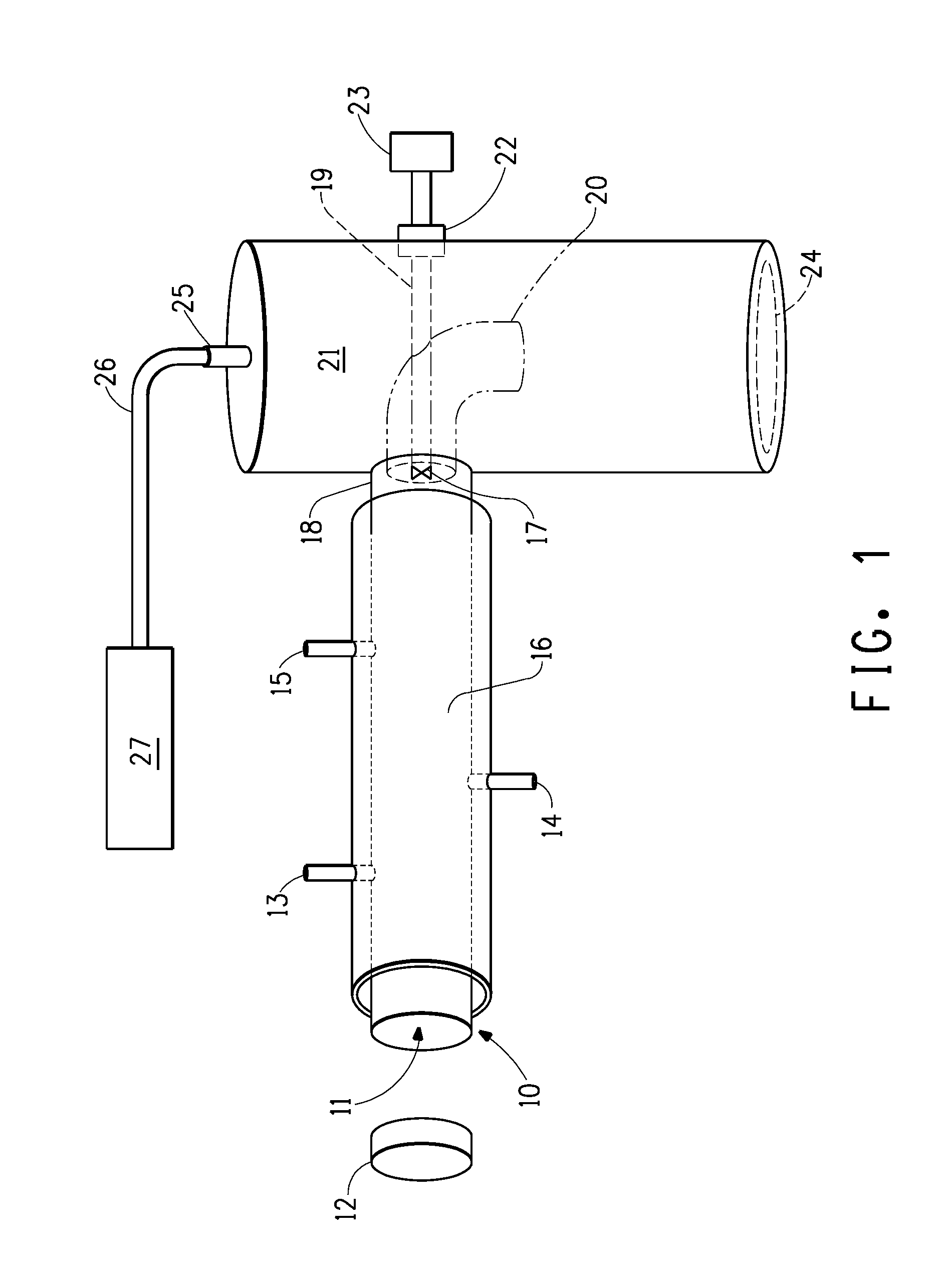

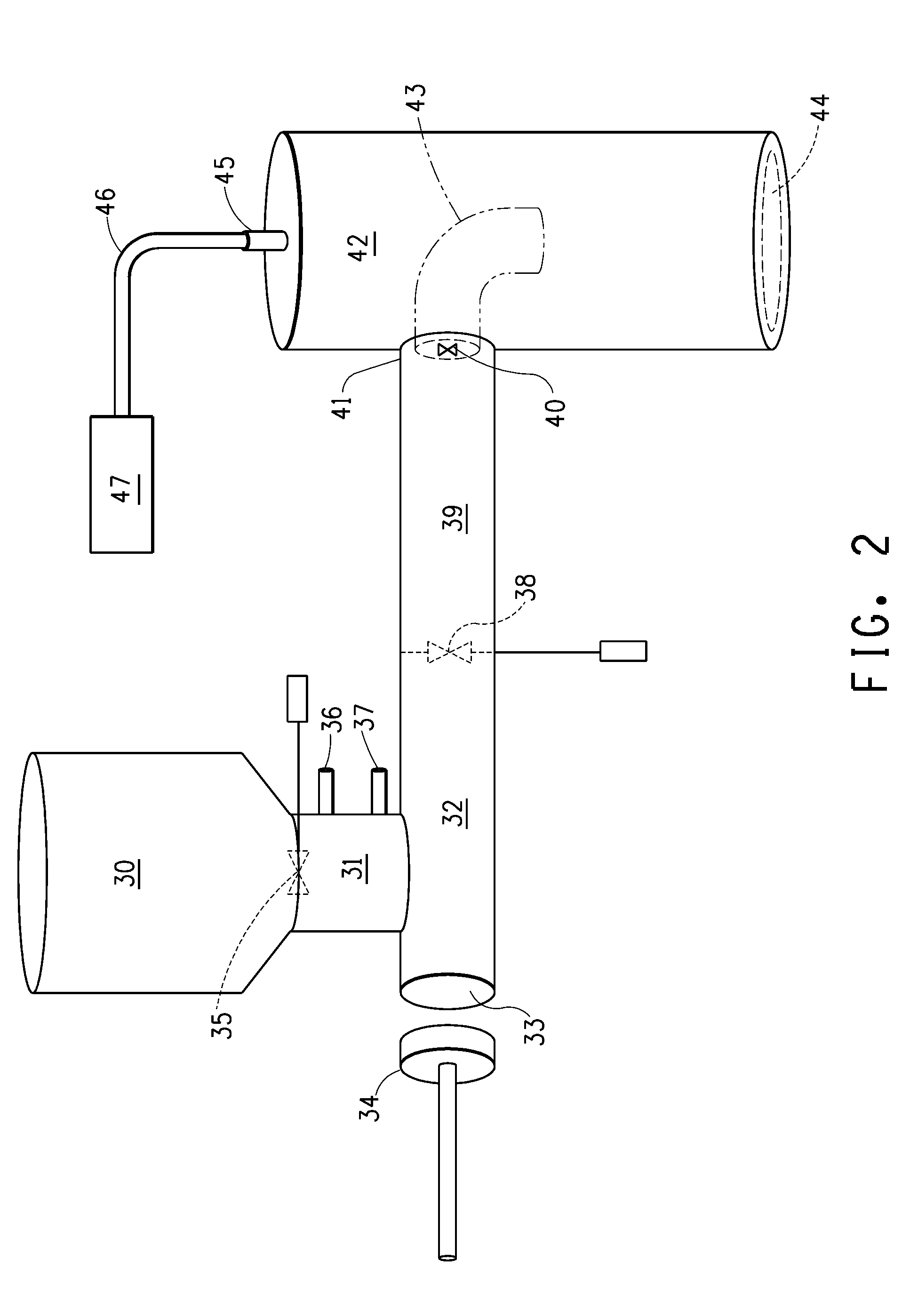

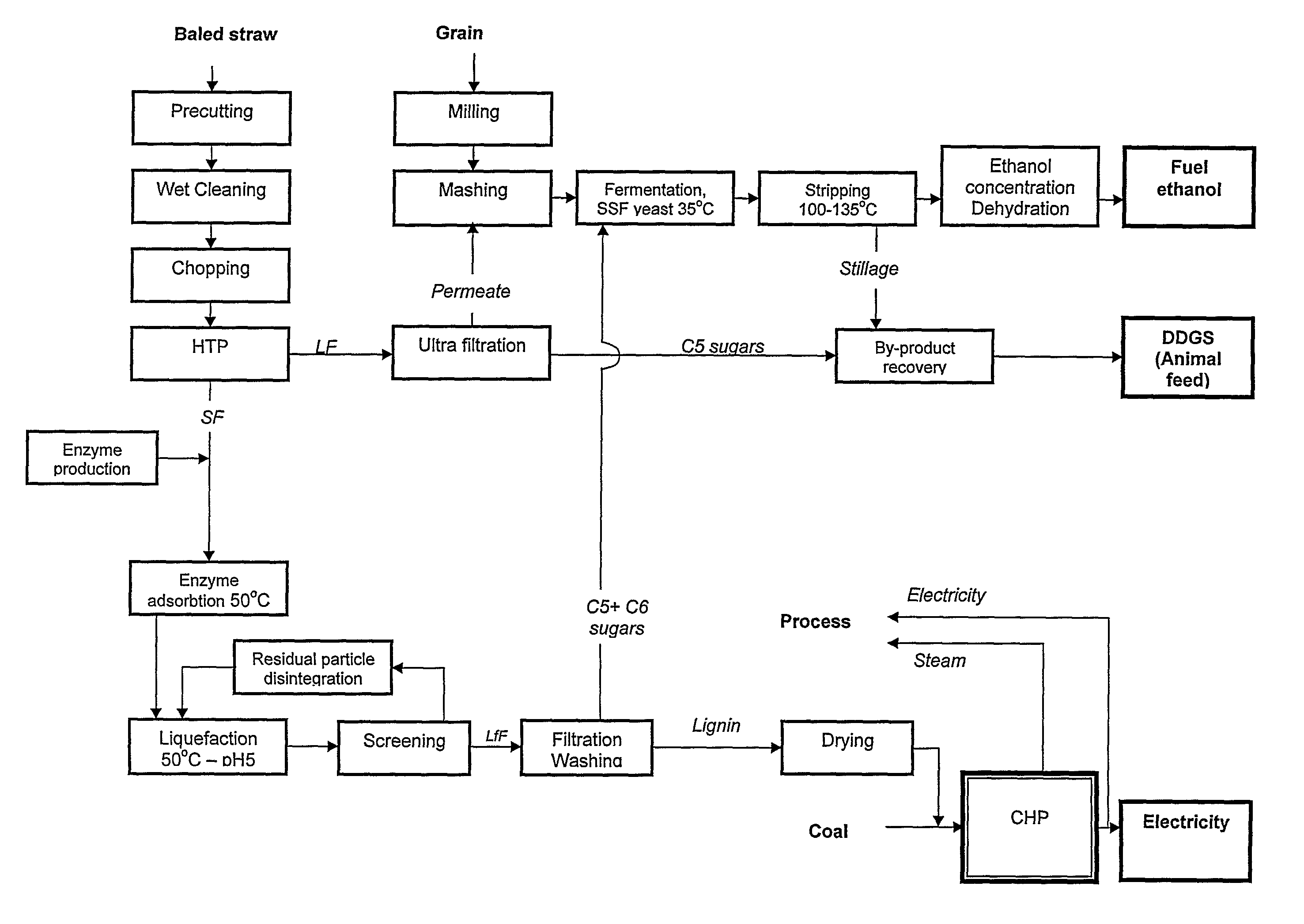

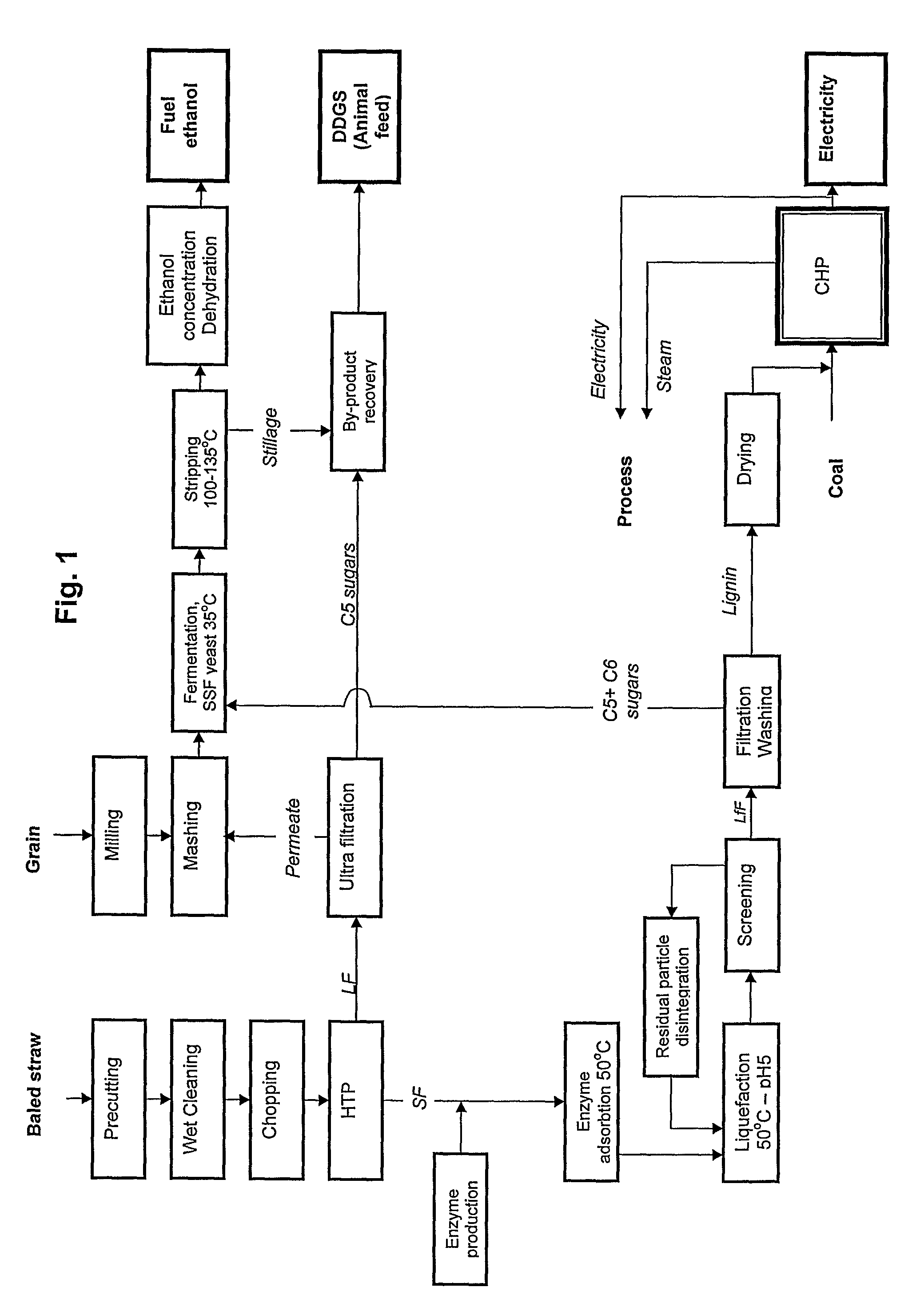

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS20100041119A1Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fibre fraction are produced. The fibre fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurised reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fibre fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fibre fraction.

Owner:INBICON AS

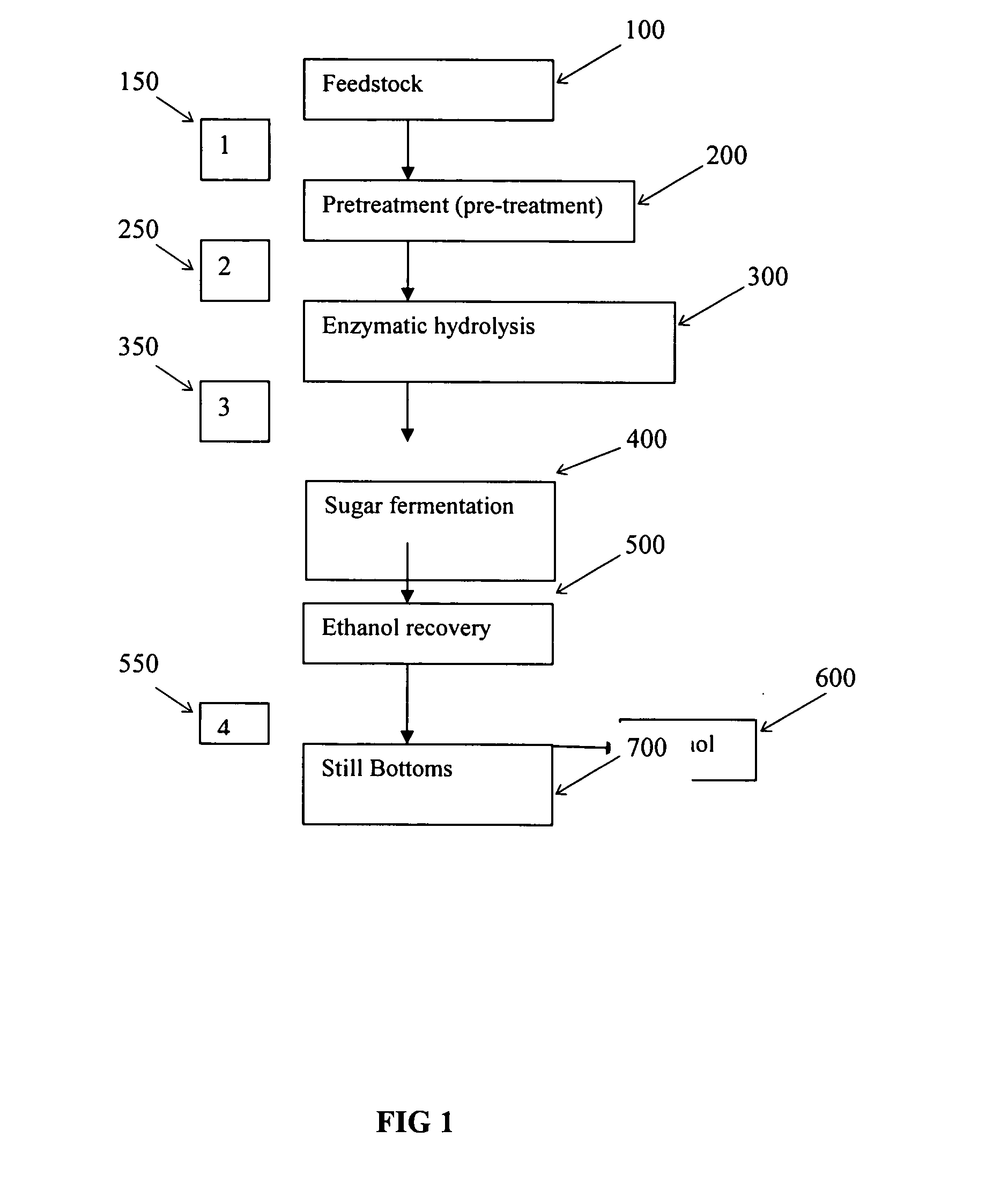

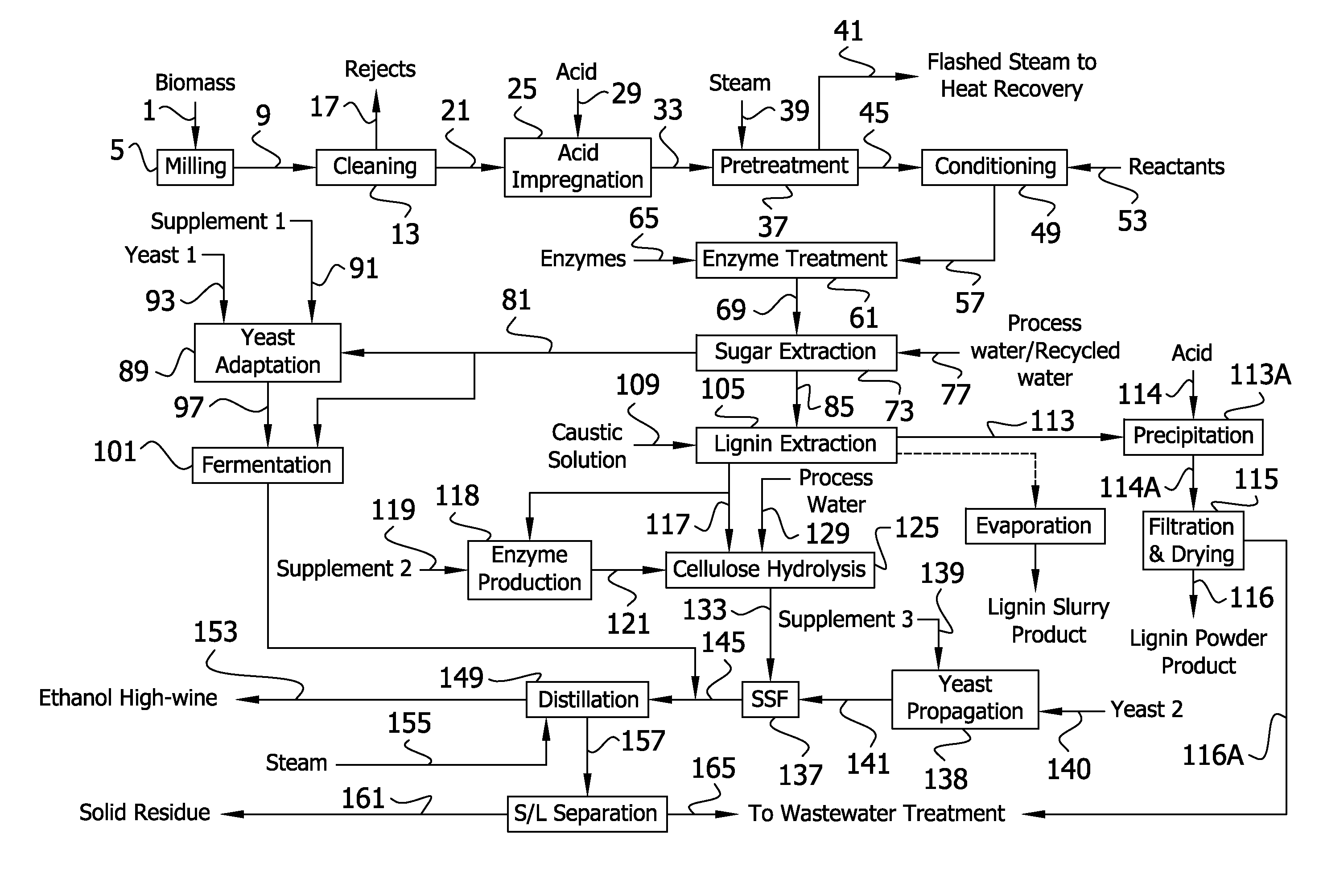

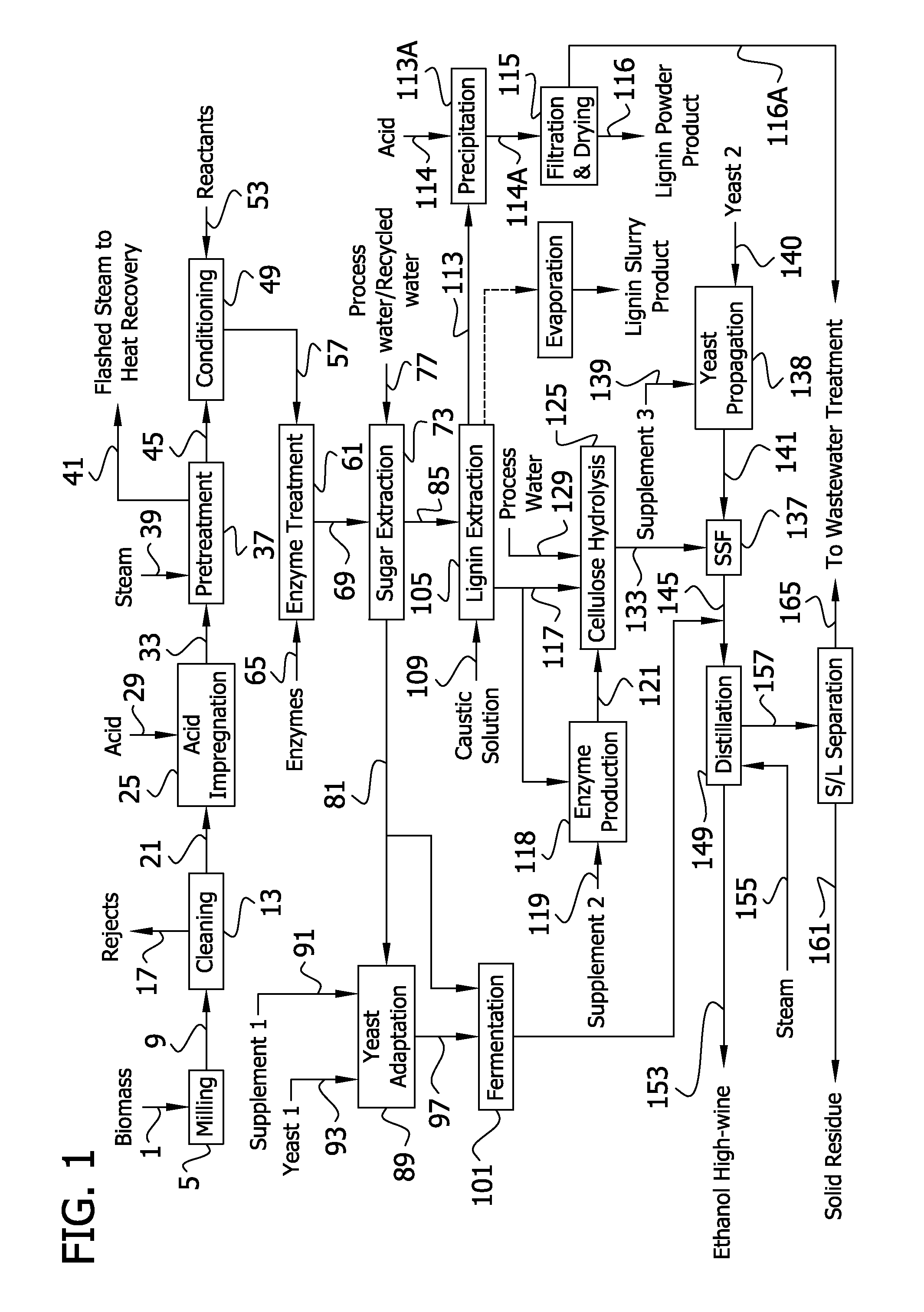

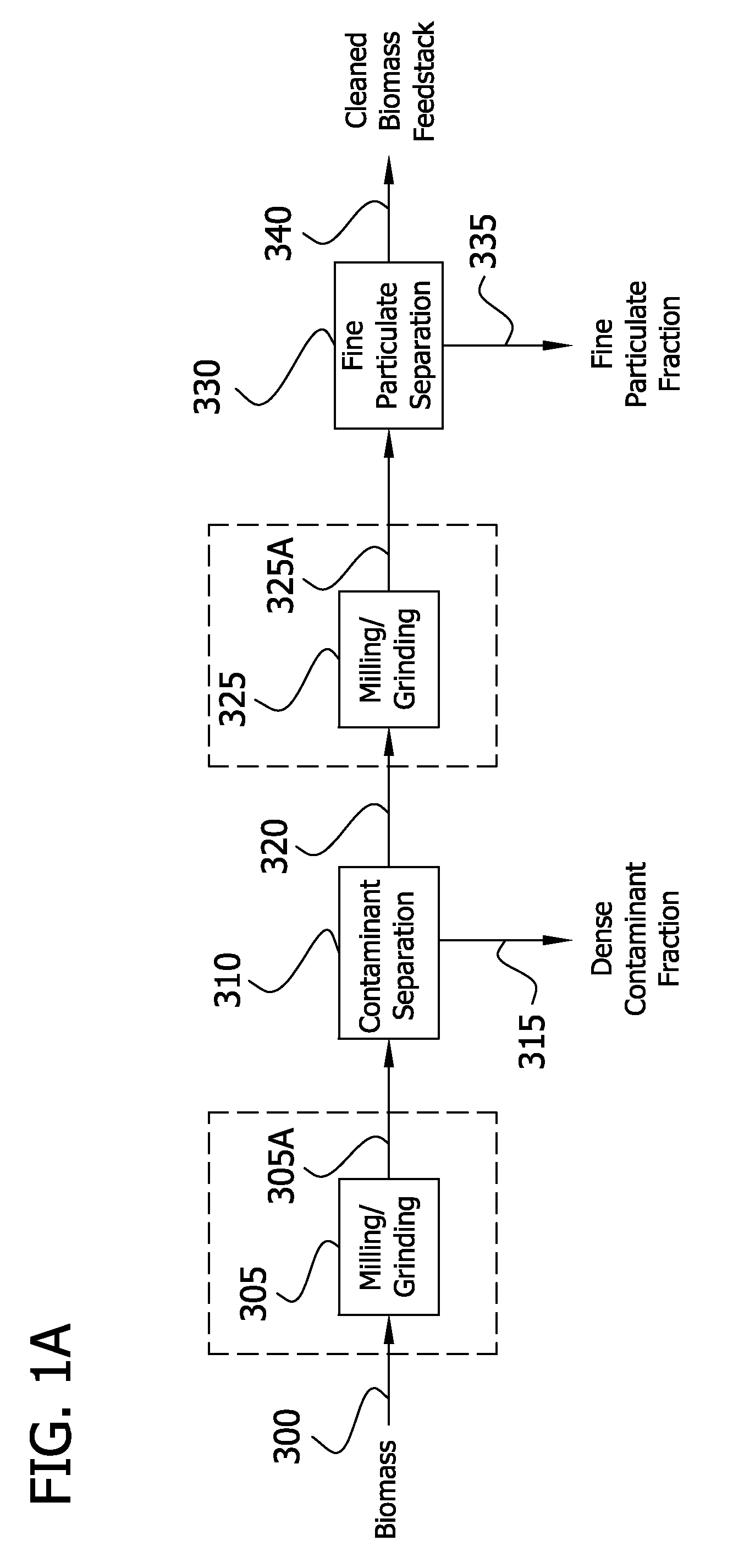

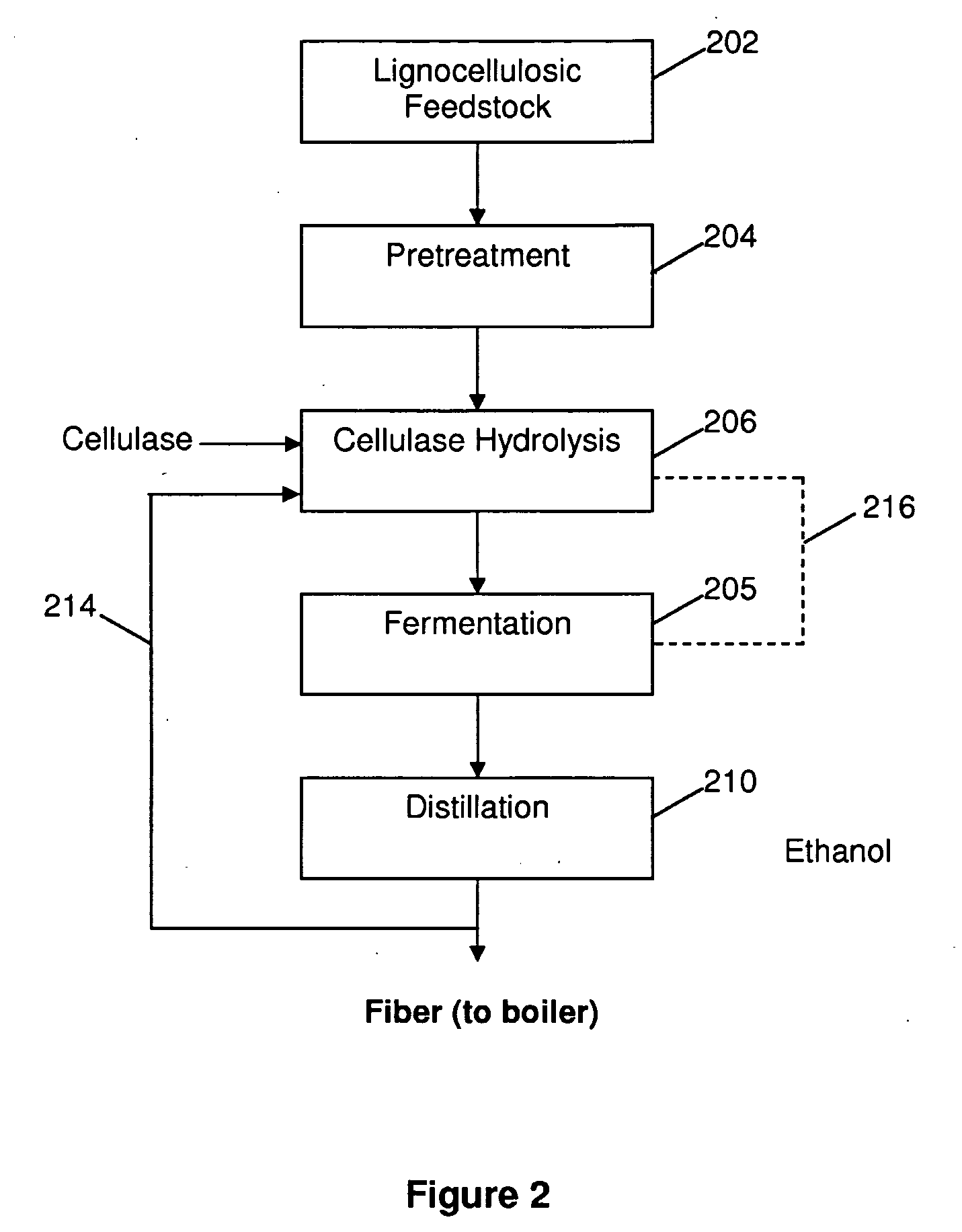

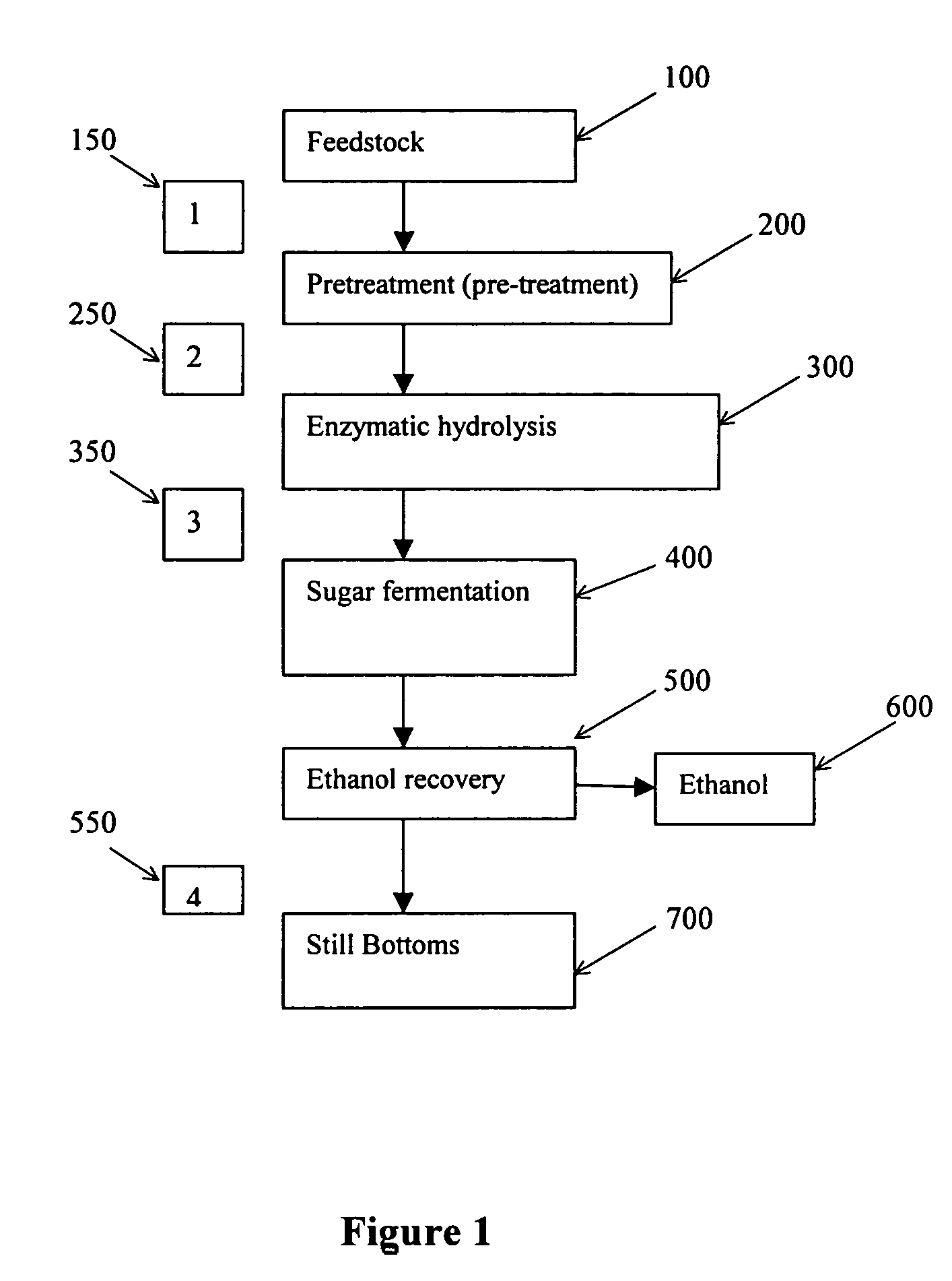

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20120006320A1Increased ethanol productionImproved co-productsFuel supply regulationPretreatment with acid reacting compoundsCelluloseLignocellulosic biomass

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

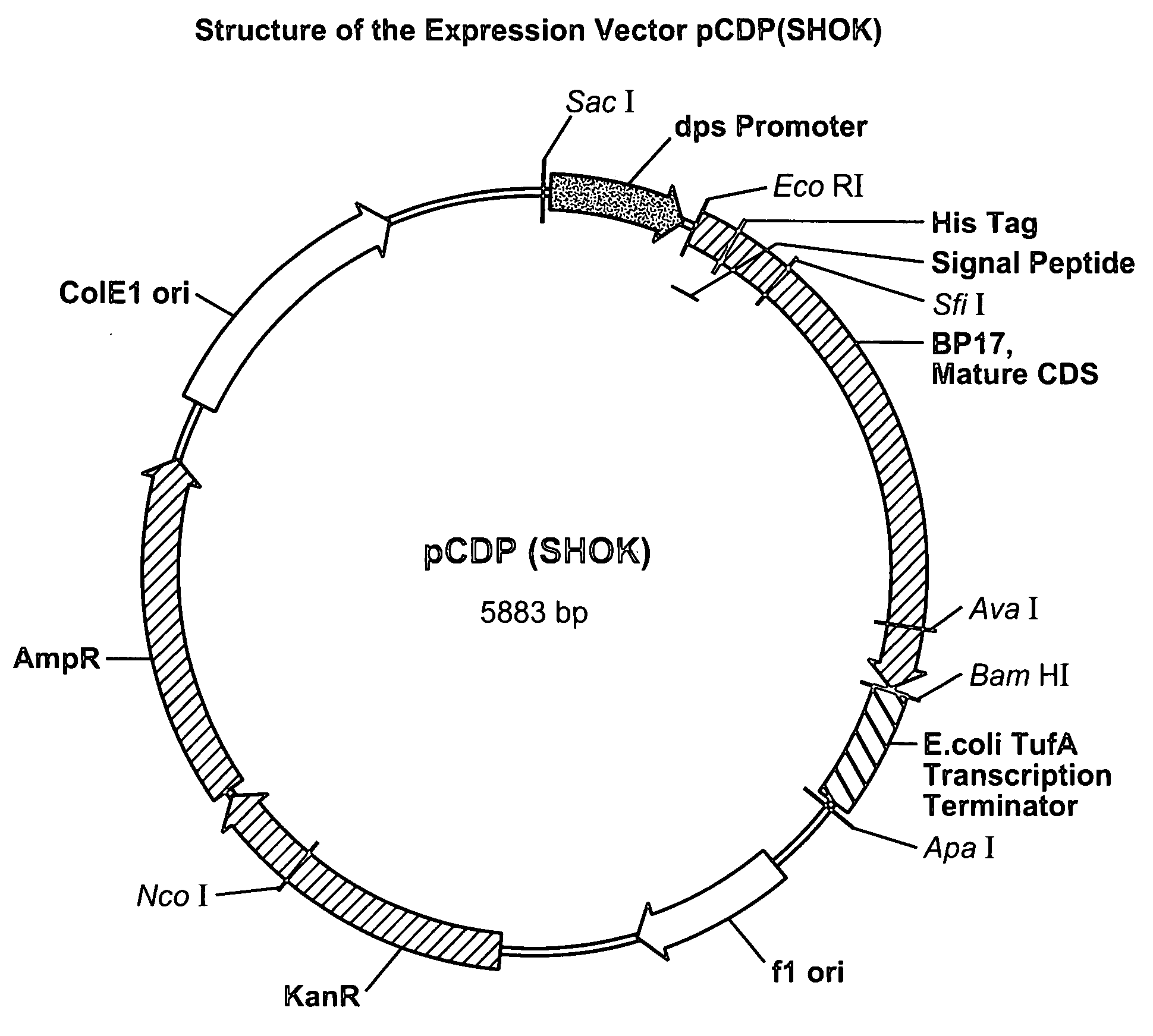

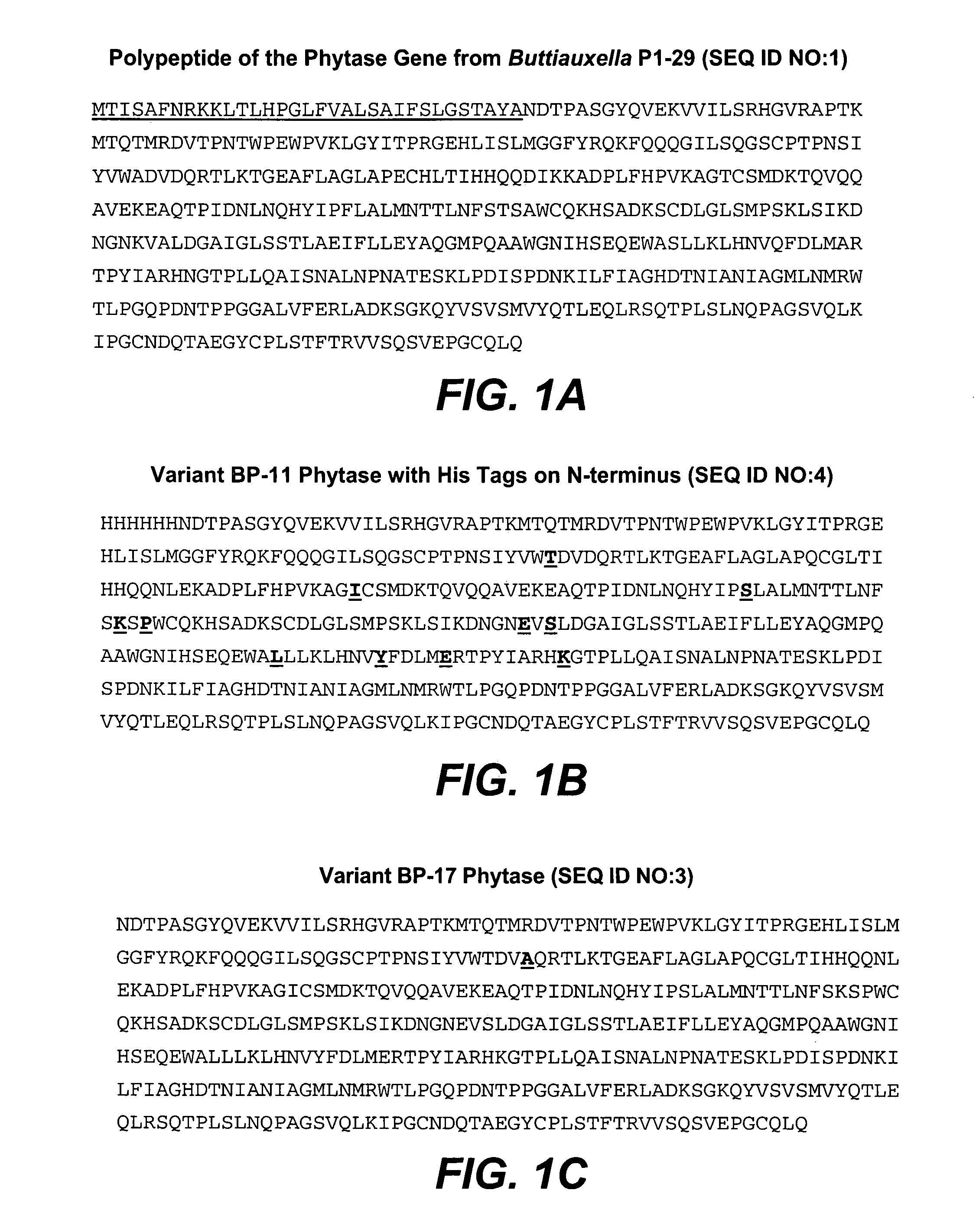

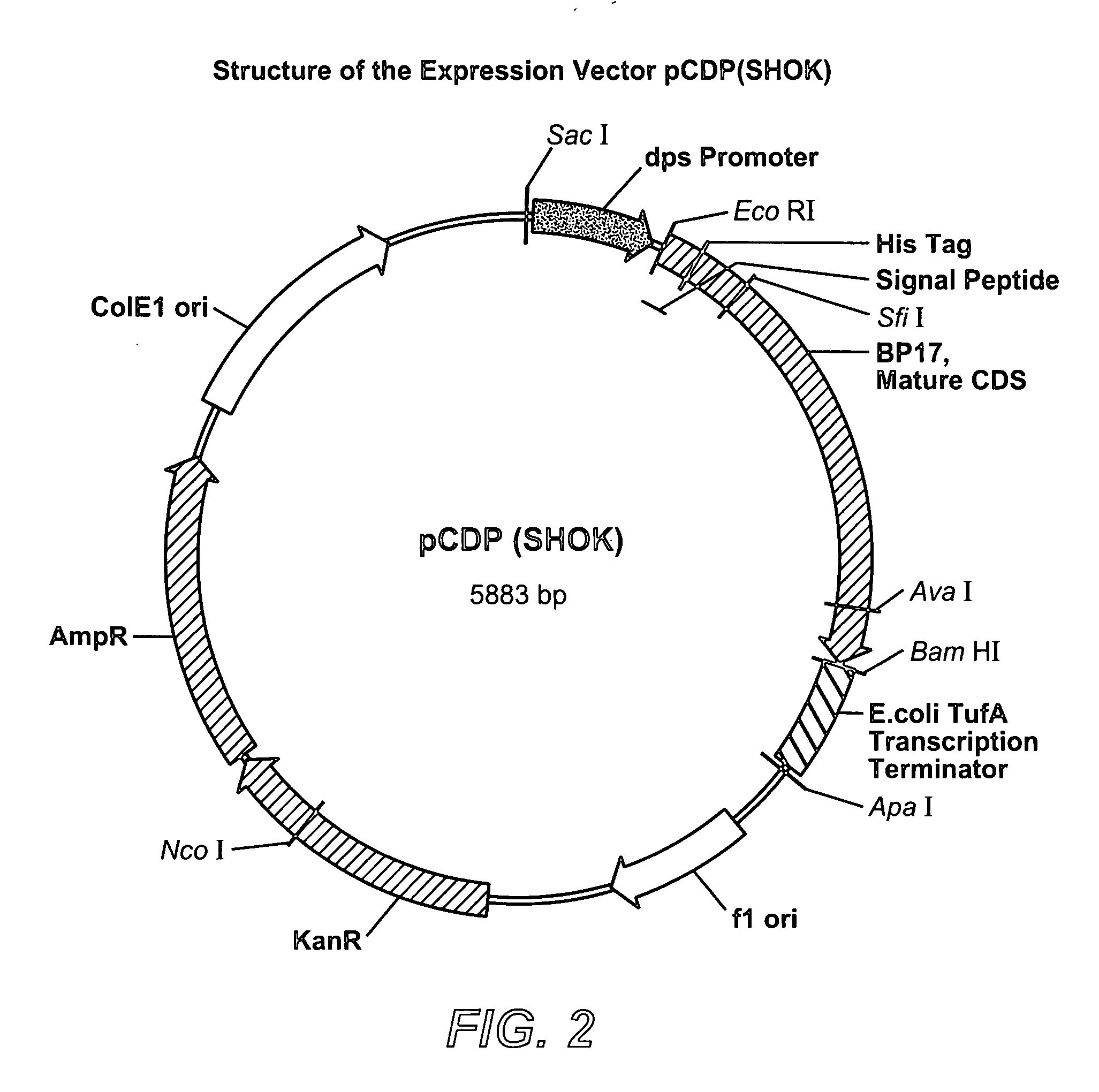

Variant Buttiauxella sp. phytases having altered properties

InactiveUS20080220498A1Improve thermal stabilityImprove featuresSugar derivativesHydrolasesButtiauxella sp.Botany

Owner:DANISCO US INC

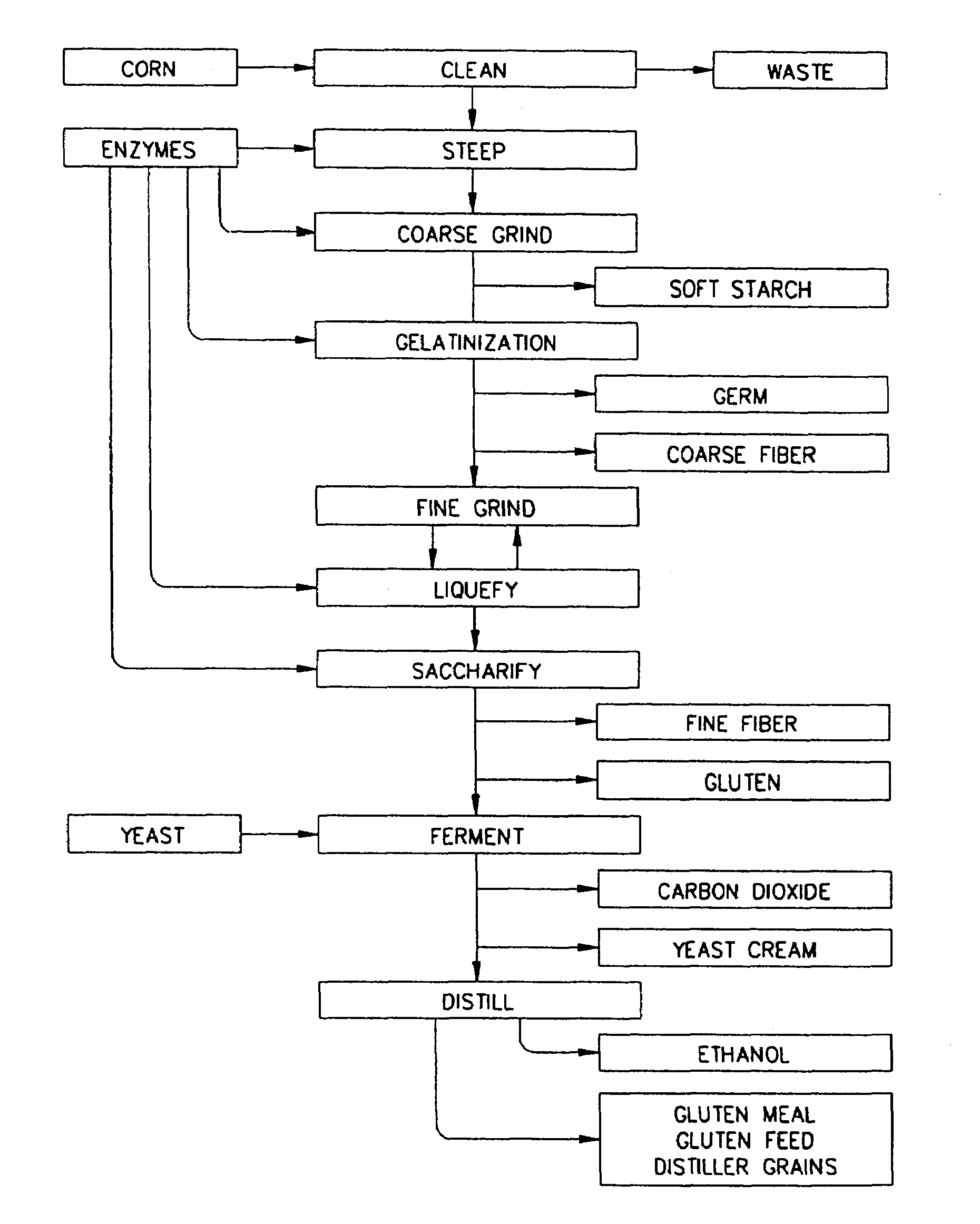

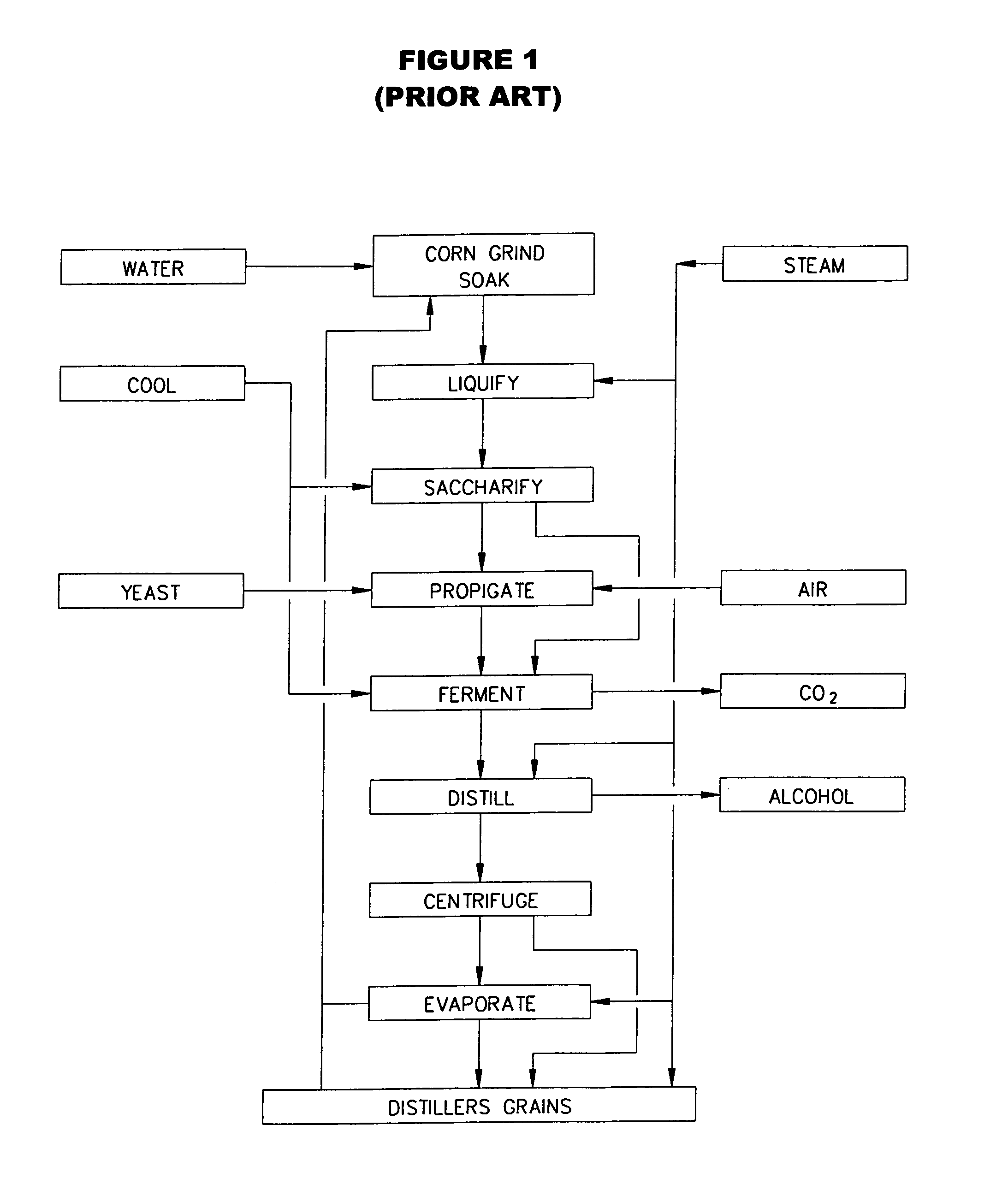

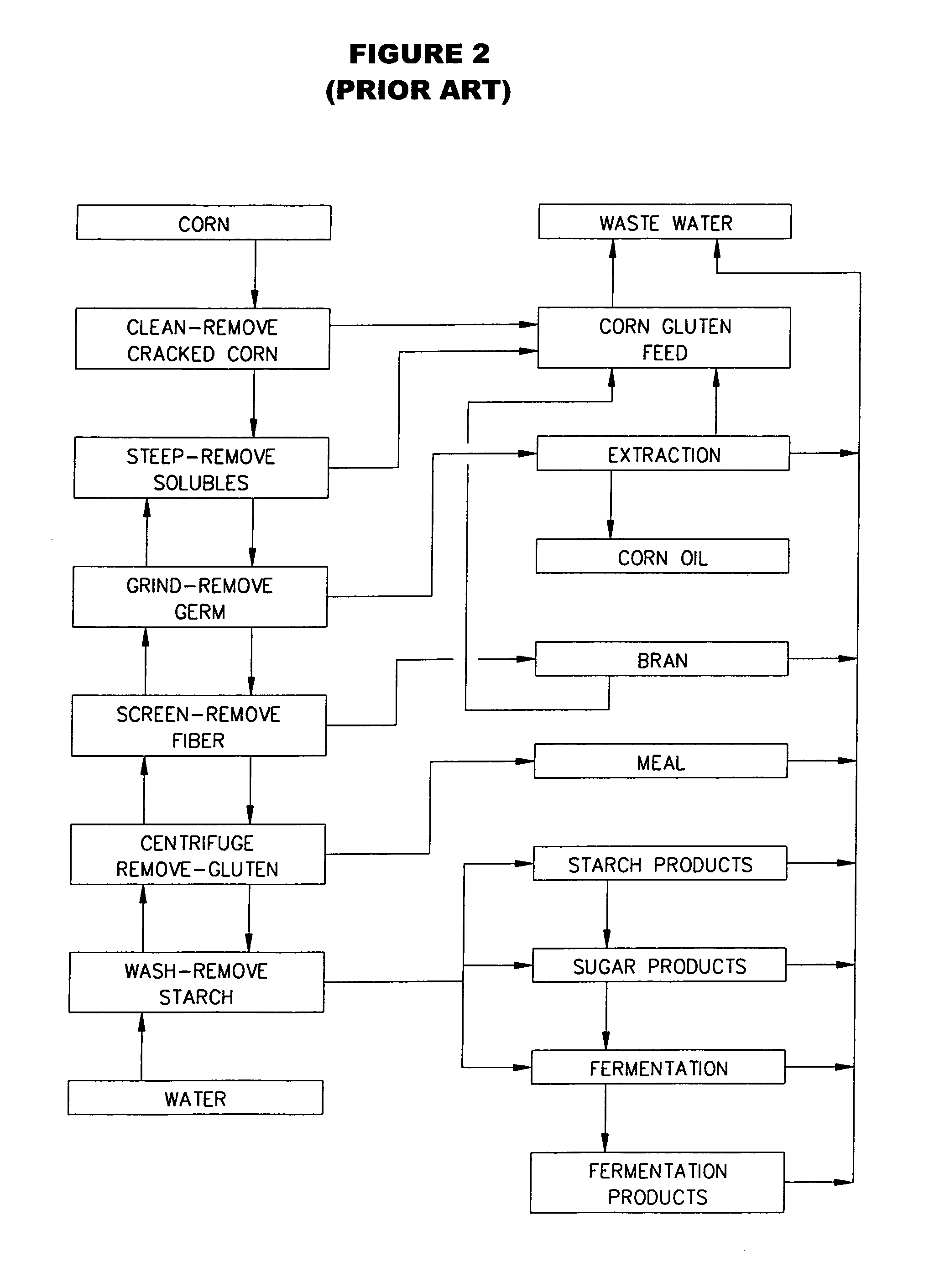

Corn refining process

InactiveUS7452425B1Quickly and efficiently producedAvoid large quantitiesJuice extractionBiofuelsSteepingSlurry

A grain containing starch, such as corn, is refined. The grain is steeped in water at a temperature of about 125 to 160° F., which water is essentially free of sulfurous acid and contains recycled enzymes from downstream processes, in a counter-current steeping reactor for about 10 to 20 hours to produce an aqueous slurry of steeped grain having a moisture content of about 40 to 50 percent. The various components of the grain are then separated and the starch is converted to ethanol.

Owner:LANGHAUSER ASSOC

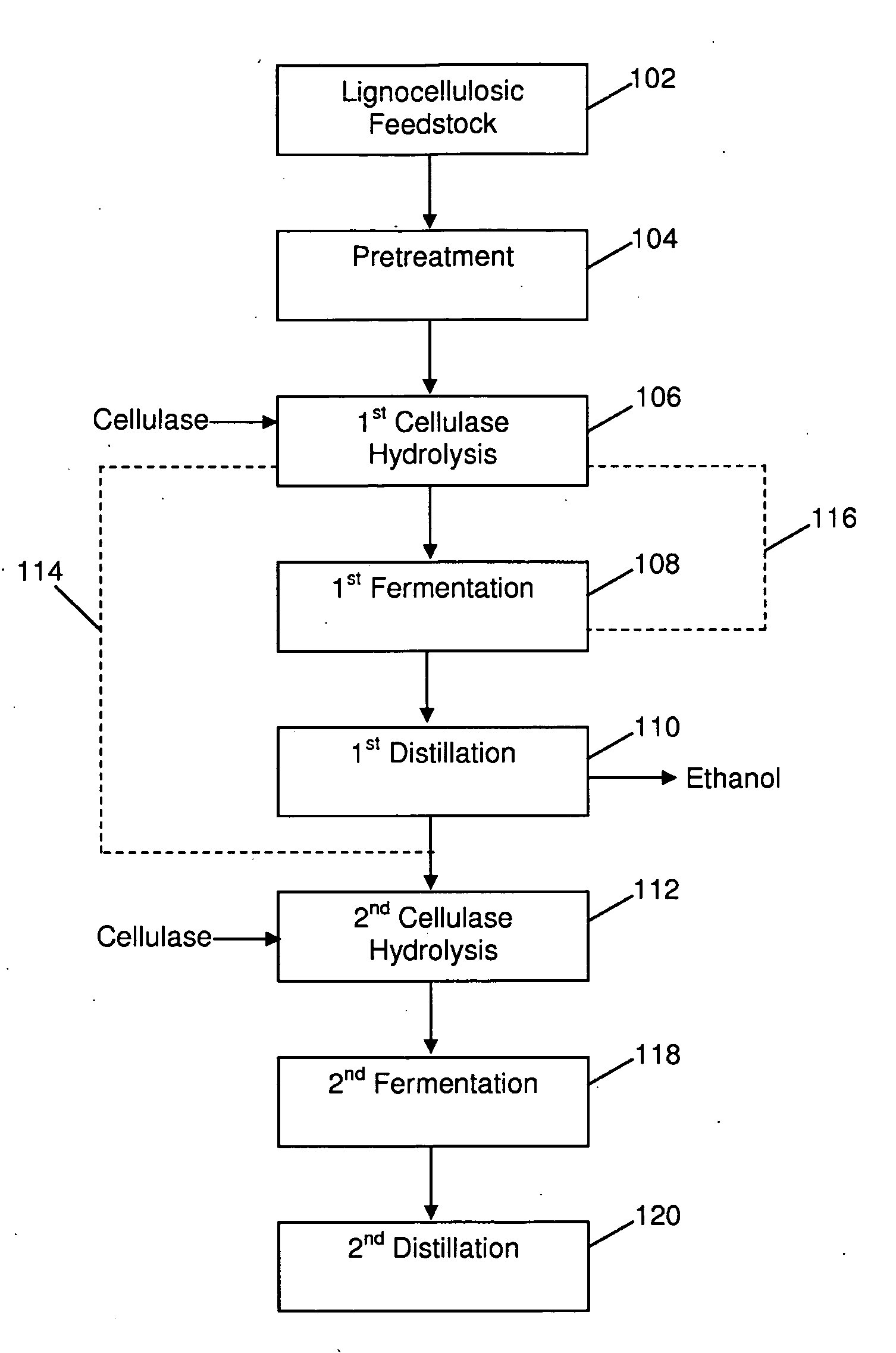

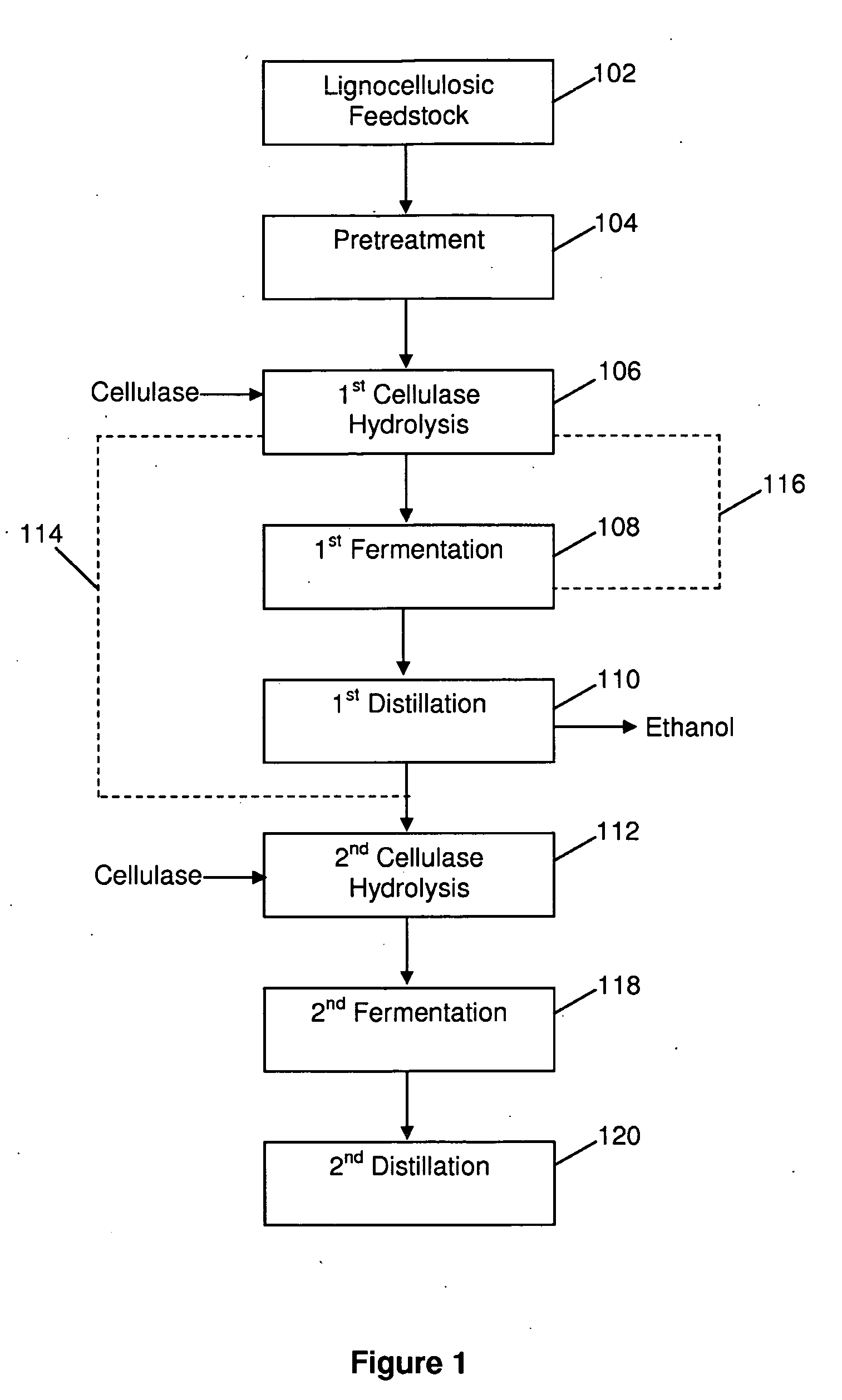

Method for the production of alcohol from a pretreated lignocellulosic feedstock

ActiveUS20090035826A1Increase volumeIncrease productionFermented solutions distillation/rectificationBiofuelsAlcoholSlurry

A process for the production of glucose from a pretreated lignocellulosic feedstock is provided. The method comprises enzymatically hydrolyzing the pretreated lignocellulosic feedstock with cellulase enzymes to produce a hydrolyzate slurry comprising glucose and unhydrolyzed cellulose and fermenting the hydrolyzate slurry in a fermentation reaction to produce a fermentation broth comprising alcohol. A process stream is obtained comprising unhydrolyzed cellulose, which is then subjected to a denaturing step, preferably comprising exposing the unhydrolyzed cellulose to elevated temperatures, thereby producing a heat-treated stream comprising the unhydrolyzed cellulose. The heat-treated stream comprising unhydrolyzed cellulose is then further hydrolyzed with cellulase enzymes to hydrolyze the cellulose to glucose.

Owner:IOGEN ENERGY CORP

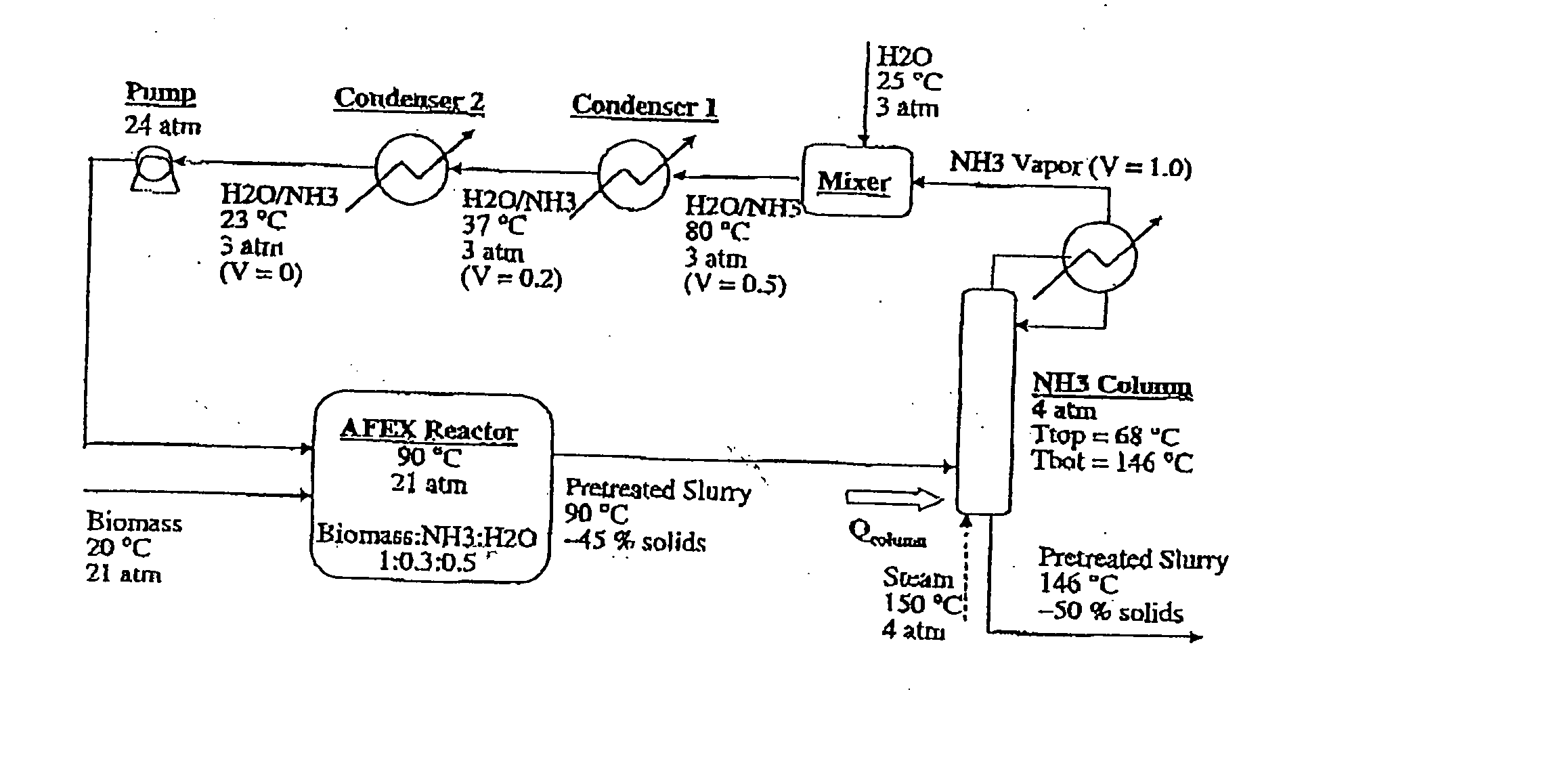

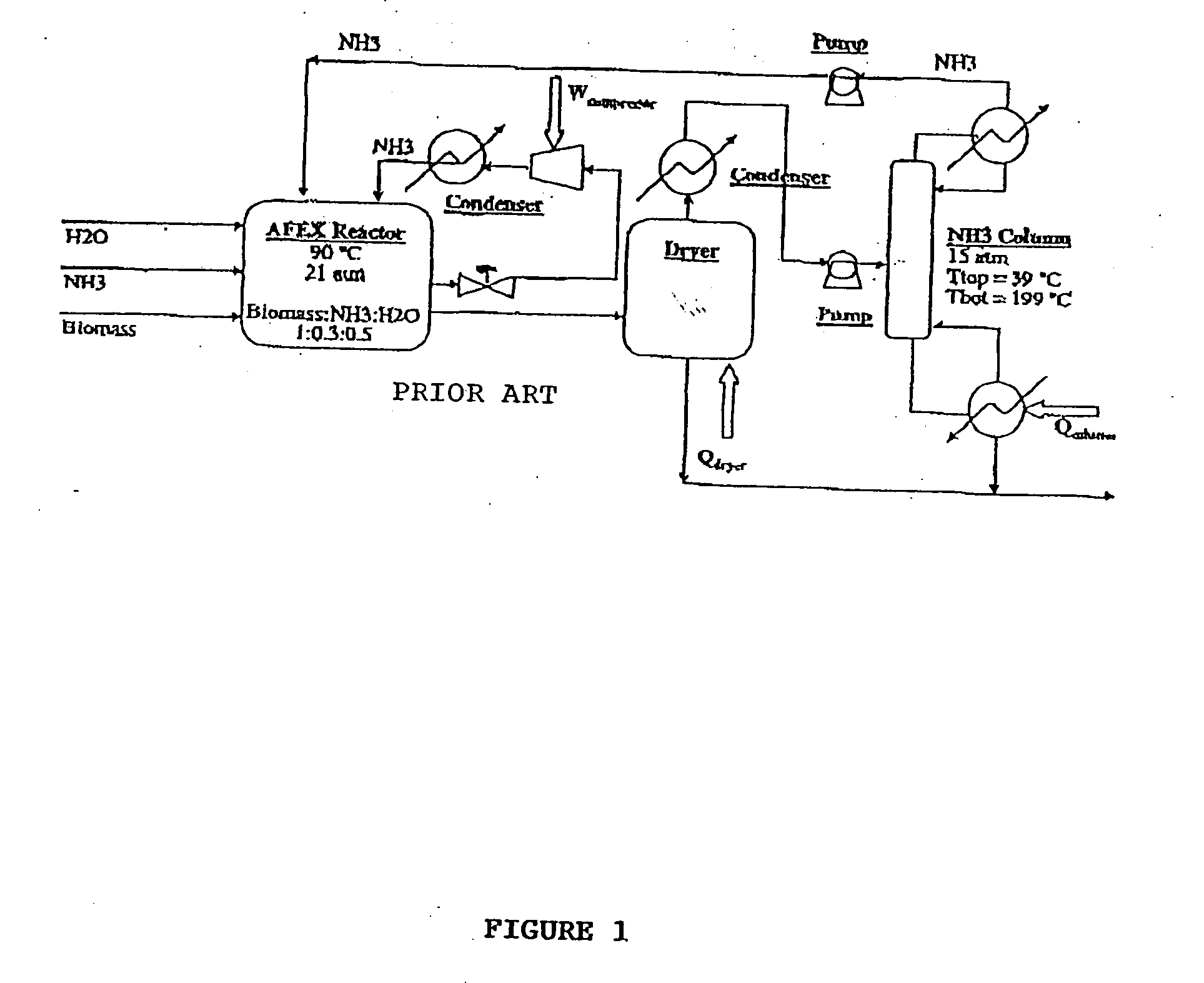

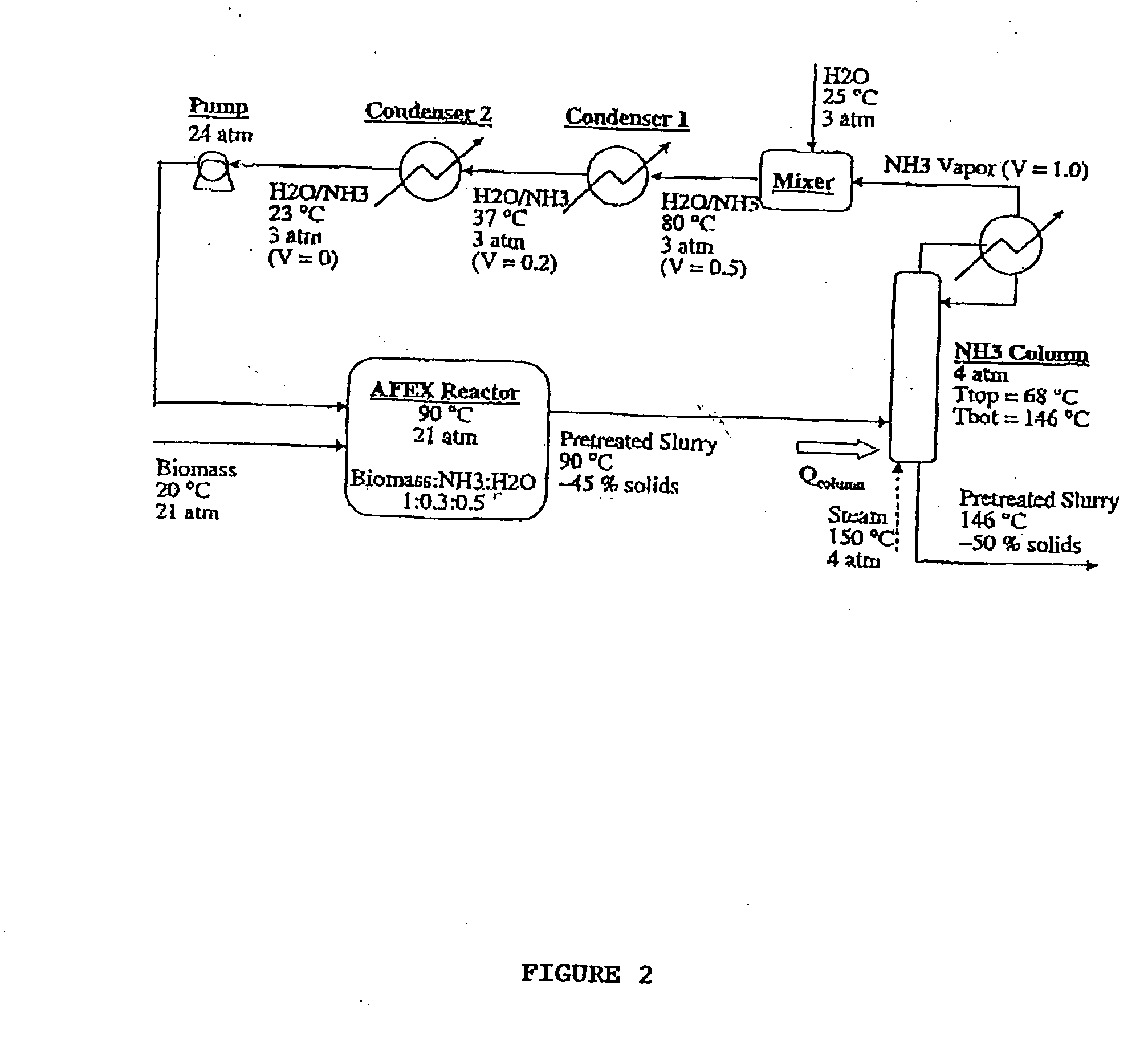

Process for the treatment of lignocellulosic biomass

ActiveUS20080008783A1Lower the volumeIncreasing fractionBiofuelsAnimal feeding stuffCelluloseEnergy source

A process for the treatment of biomass to render structural carbohydrates more accessible and / or digestible using concentrated ammonium hydroxide with or without anhydrous ammonia addition, is described. The process preferably uses steam to strip ammonia from the biomass for recycling. The process yields of monosaccharides from the structural carbohydrates are good, particularly as measured by the enzymatic hydrolysis of the structural carbohydrates. The monosaccharides are used as animal feeds and energy sources for ethanol production.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Biomass Pretreatment

A method is provided for producing an improved pretreated biomass product for use in saccharification followed by fermentation to produce a target chemical that includes removal of saccharification and or fermentation inhibitors from the pretreated biomass product. Specifically, the pretreated biomass product derived from using the present method has fewer inhibitors of saccharification and / or fermentation without a loss in sugar content.

Owner:SUSTAINABLE TECH CORP +2

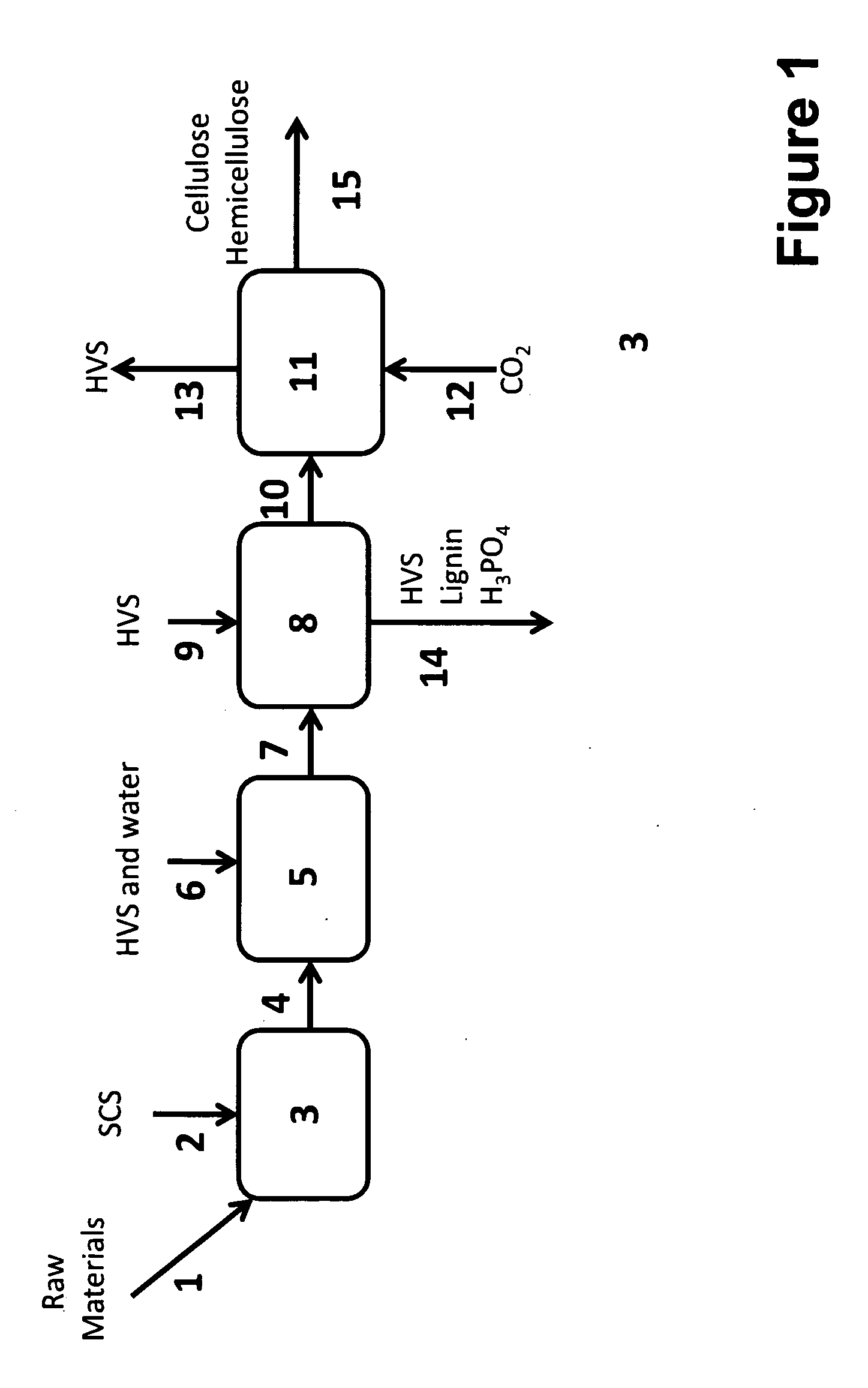

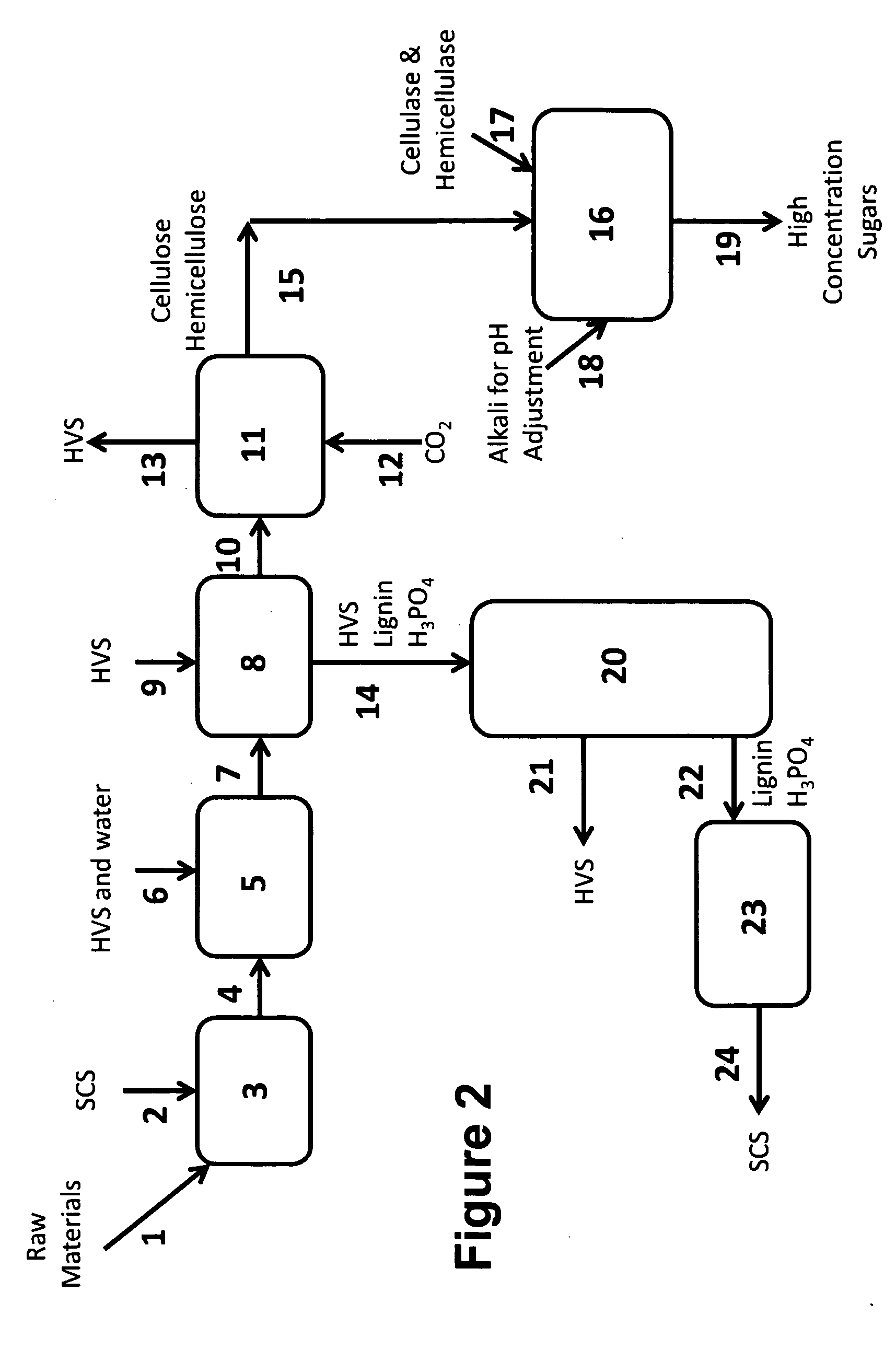

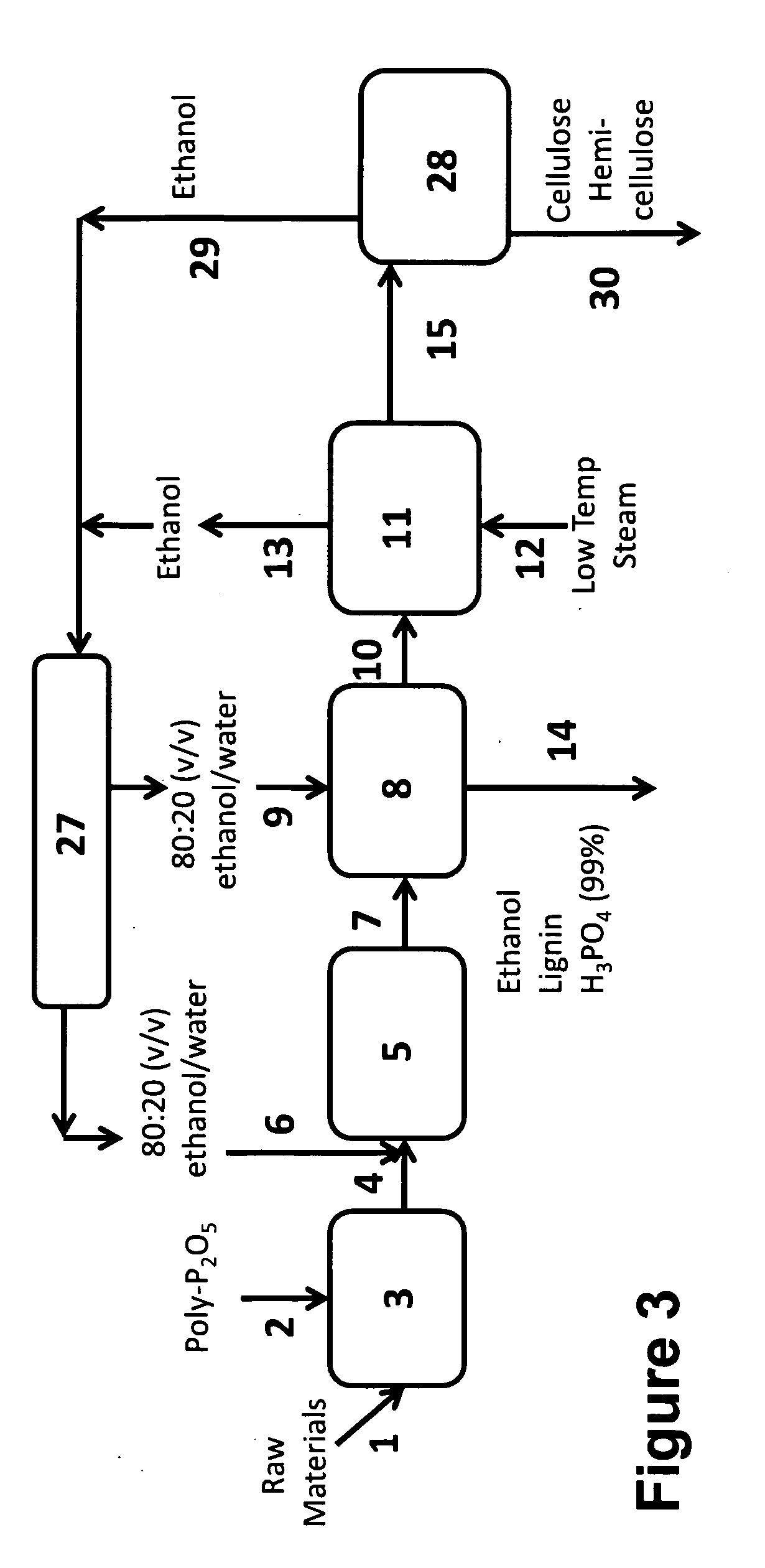

Method and apparatus for lignocellulose pretreatment using a super-cellulose-solvent and highly volatile solvents

InactiveUS20090229599A1Overcome shortcomingReduce solvent usagePressurized chemical processBiofuelsAlcoholGram

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and a system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose, and lignin. The cellulose and hemicellulose thus obtained are highly amorphous and can be readily converted into highly concentrated mixtures of five and six carbon sugars using known methods. Typical yields of sugars exceed 100 grams of sugars per liter of sugar solution. Other products, such as alcohols, can easily be prepared according to methods of the invention. The modest process conditions and low solvent / solid ratios of some embodiments of the invention require relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

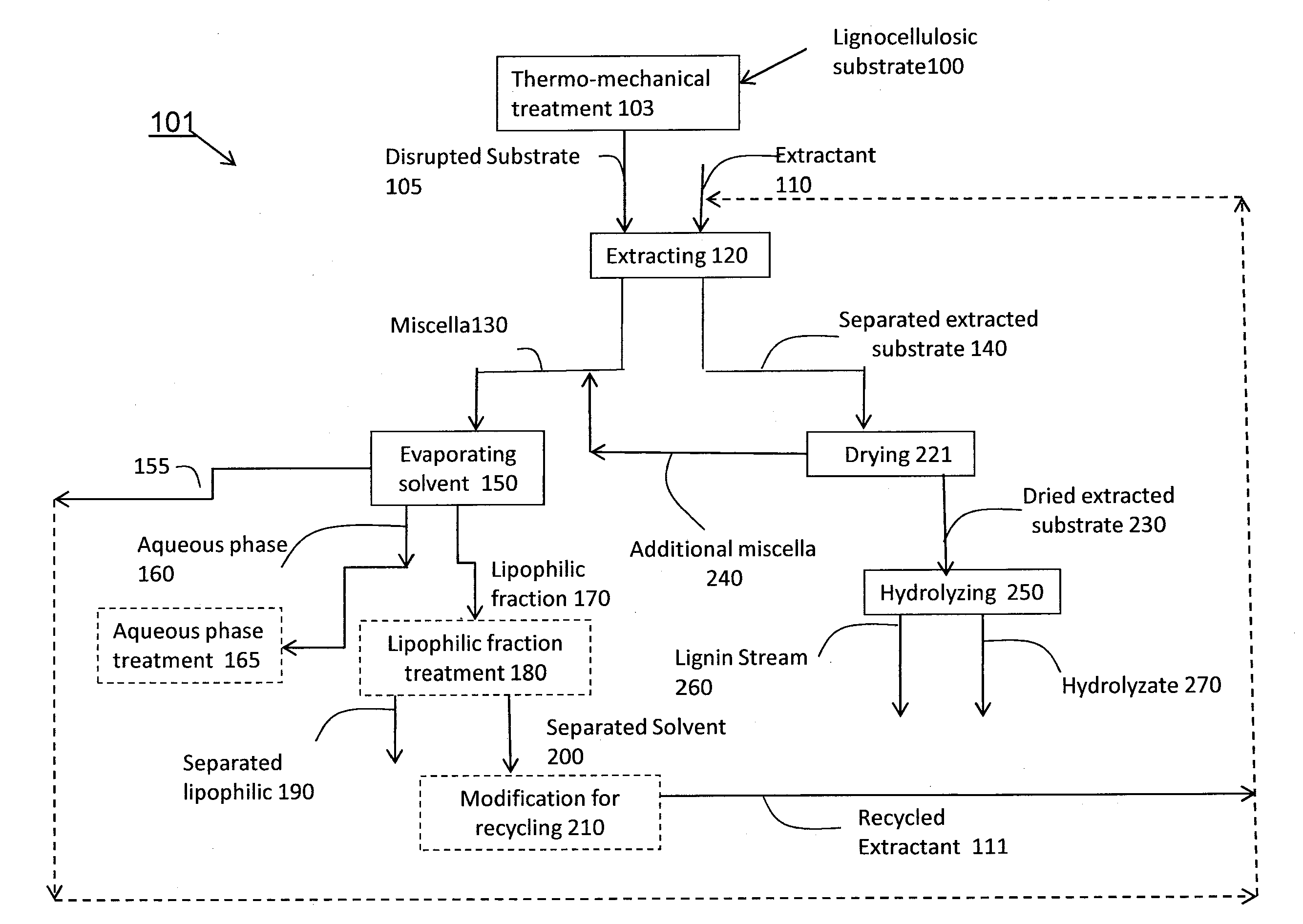

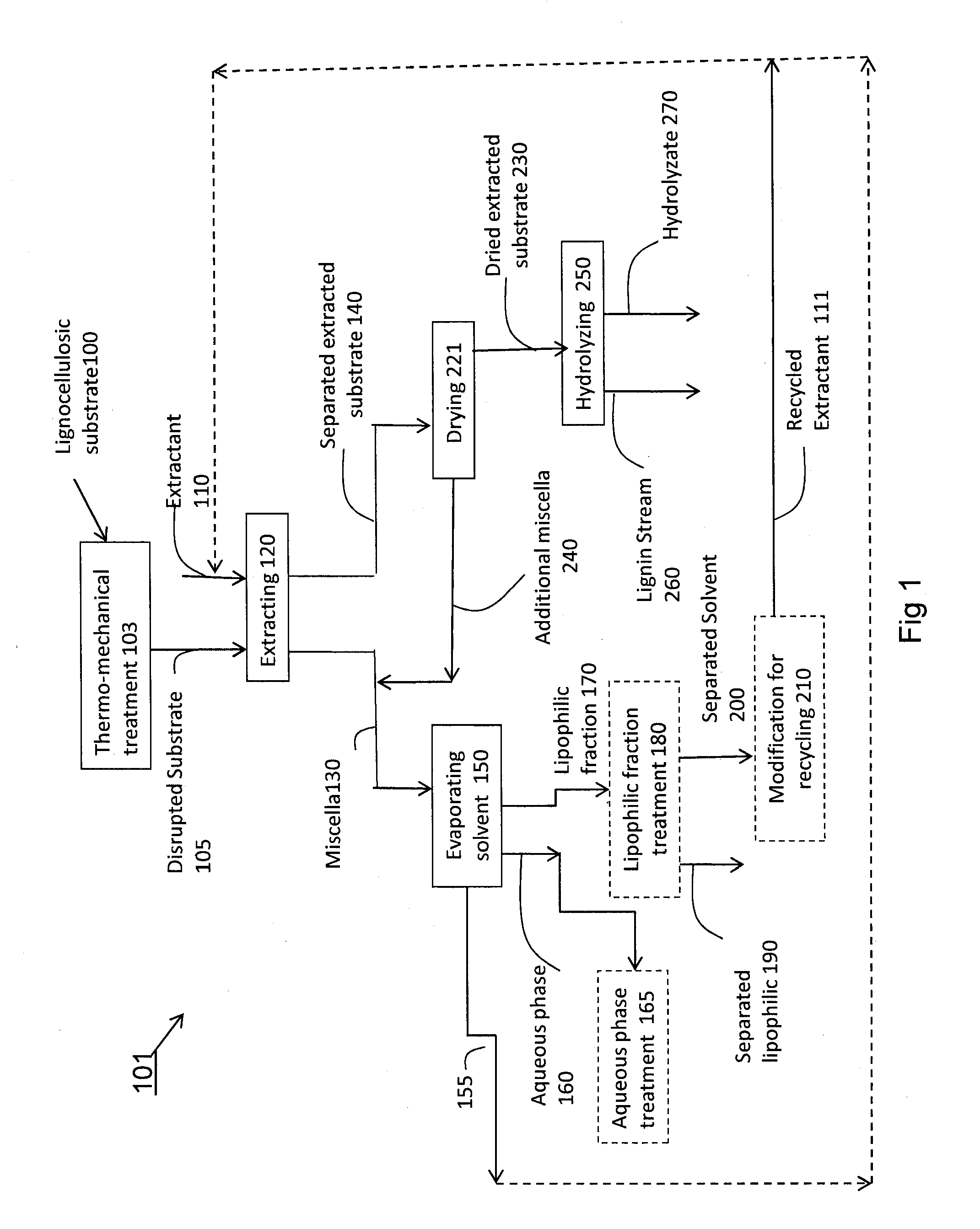

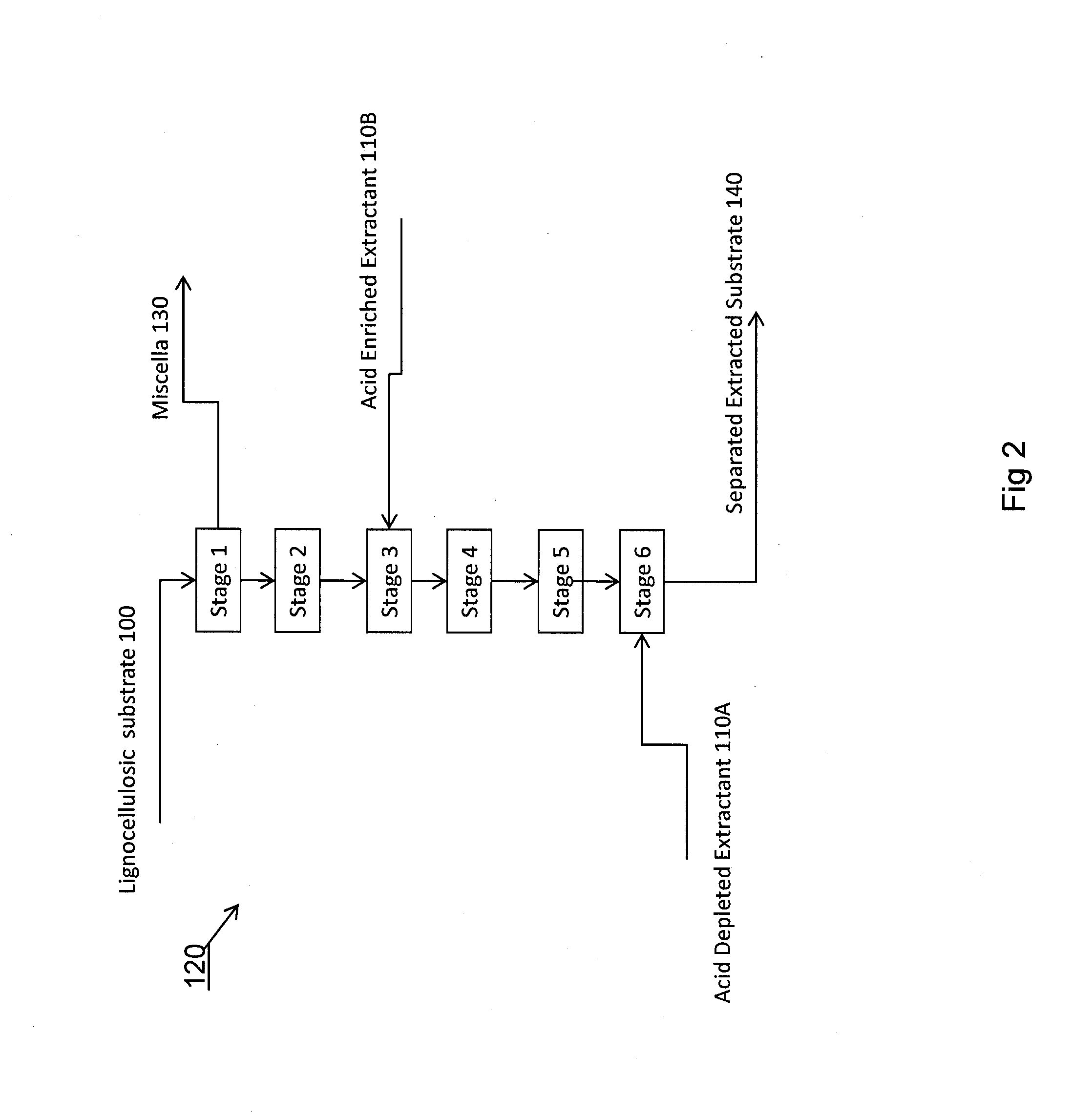

Methods and systems for processing lignocellulosic materials and related compositions

A method comprising: (a) providing a lignocellulosic substrate; (b) contacting said lignocellulosic substrate with an extractant comprising a water-soluble organic solvent to form an extracted substrate and a miscella; (c) removing miscella from said extracted substrate; and (d) hydrolyzing said extracted substrate using a chemically catalyzed process.

Owner:VIRDIA

Method of continuous processing of lignocellulosic feedstock

InactiveUS7754457B2Quantity minimizationEasier to dispense evenlyPretreatment with water/steamSugar derivativesCelluloseChemistry

Owner:IOGEN ENERGY CORP

Method for the production of fermentable sugars and cellulose from lignocellulosic material

ActiveUS8030039B1High yieldIncreased ethanol yieldFats/resins/pitch/waxes removal in pulpPulping with organic compoundsOrganic acidAlcohol

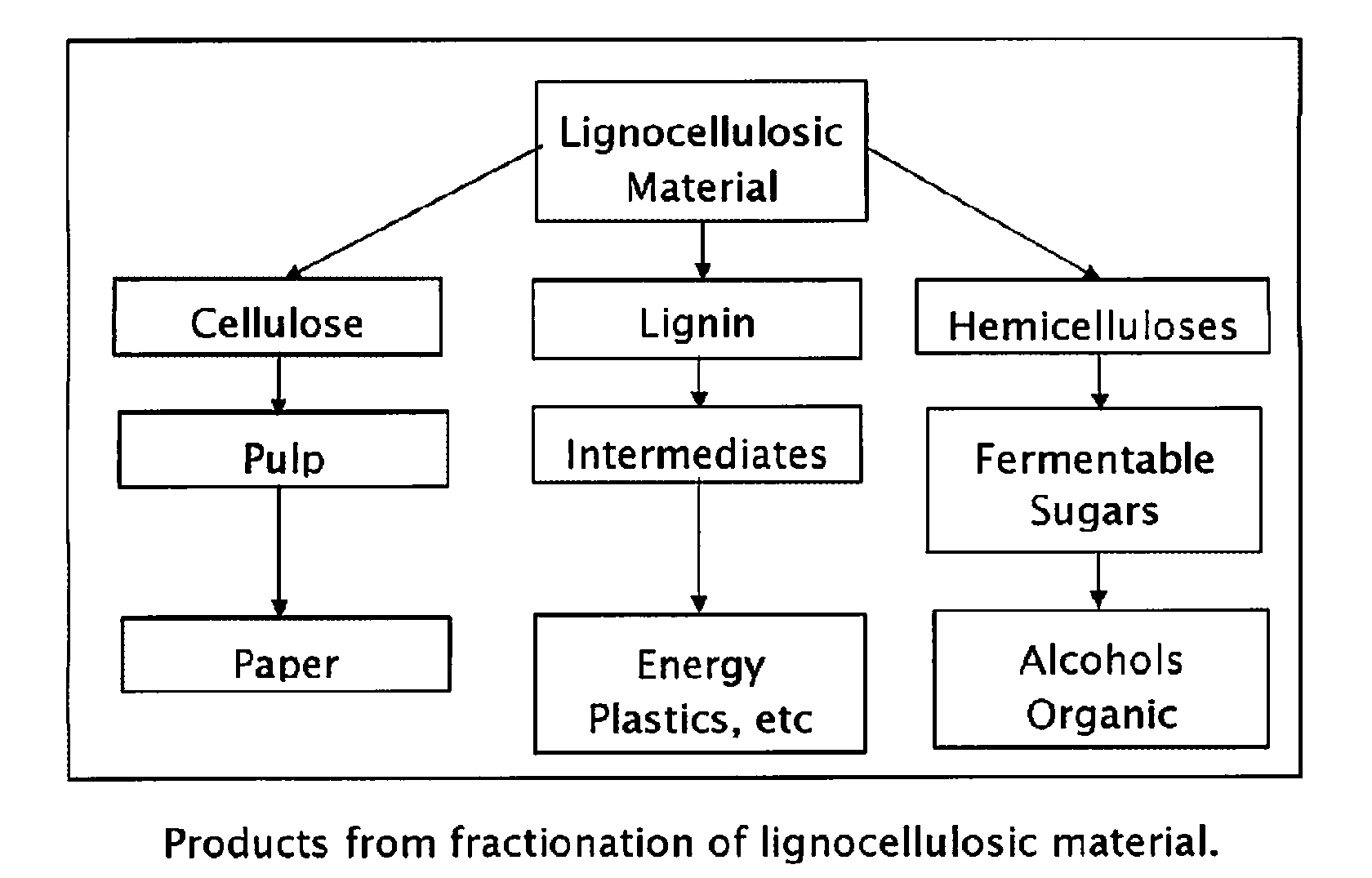

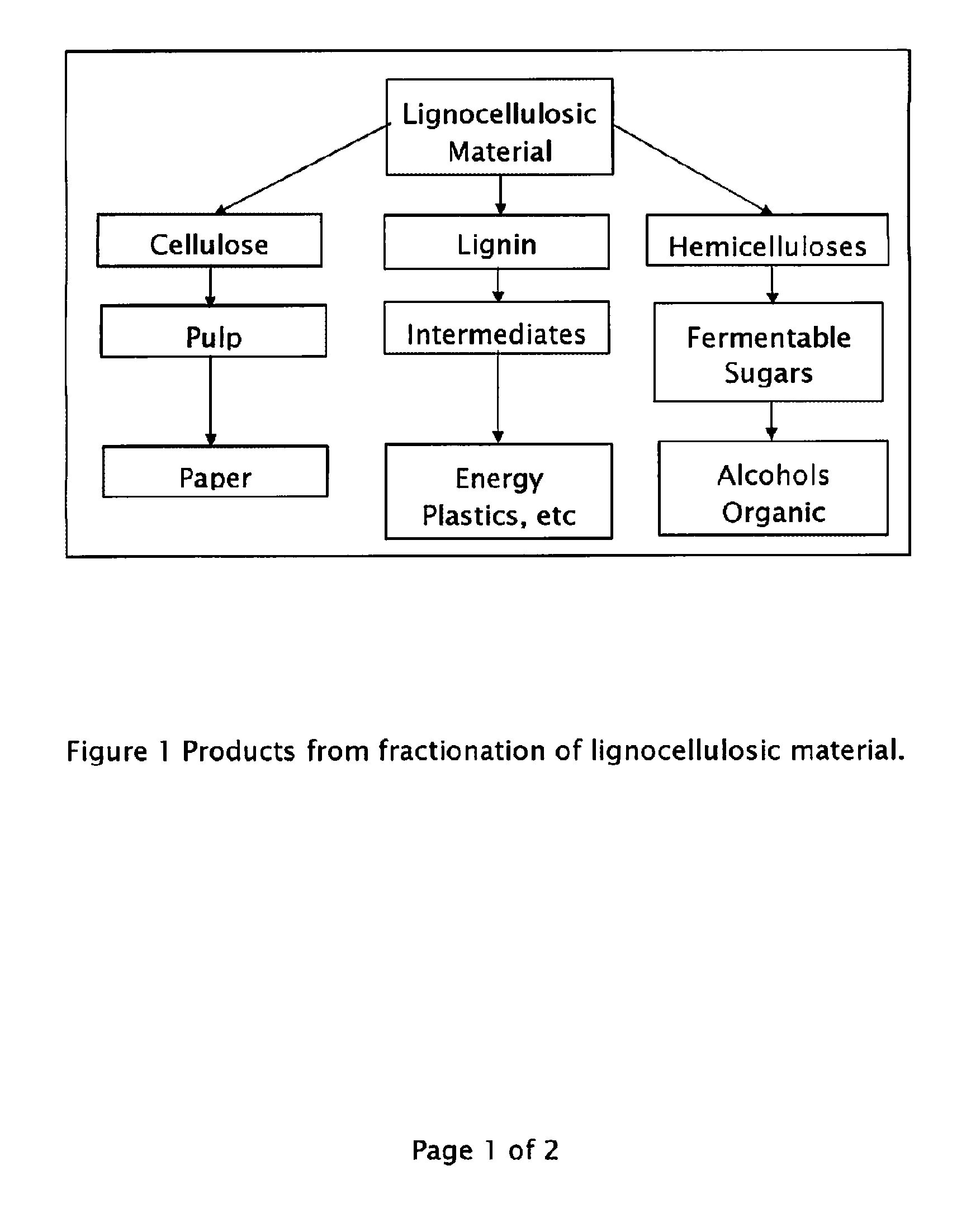

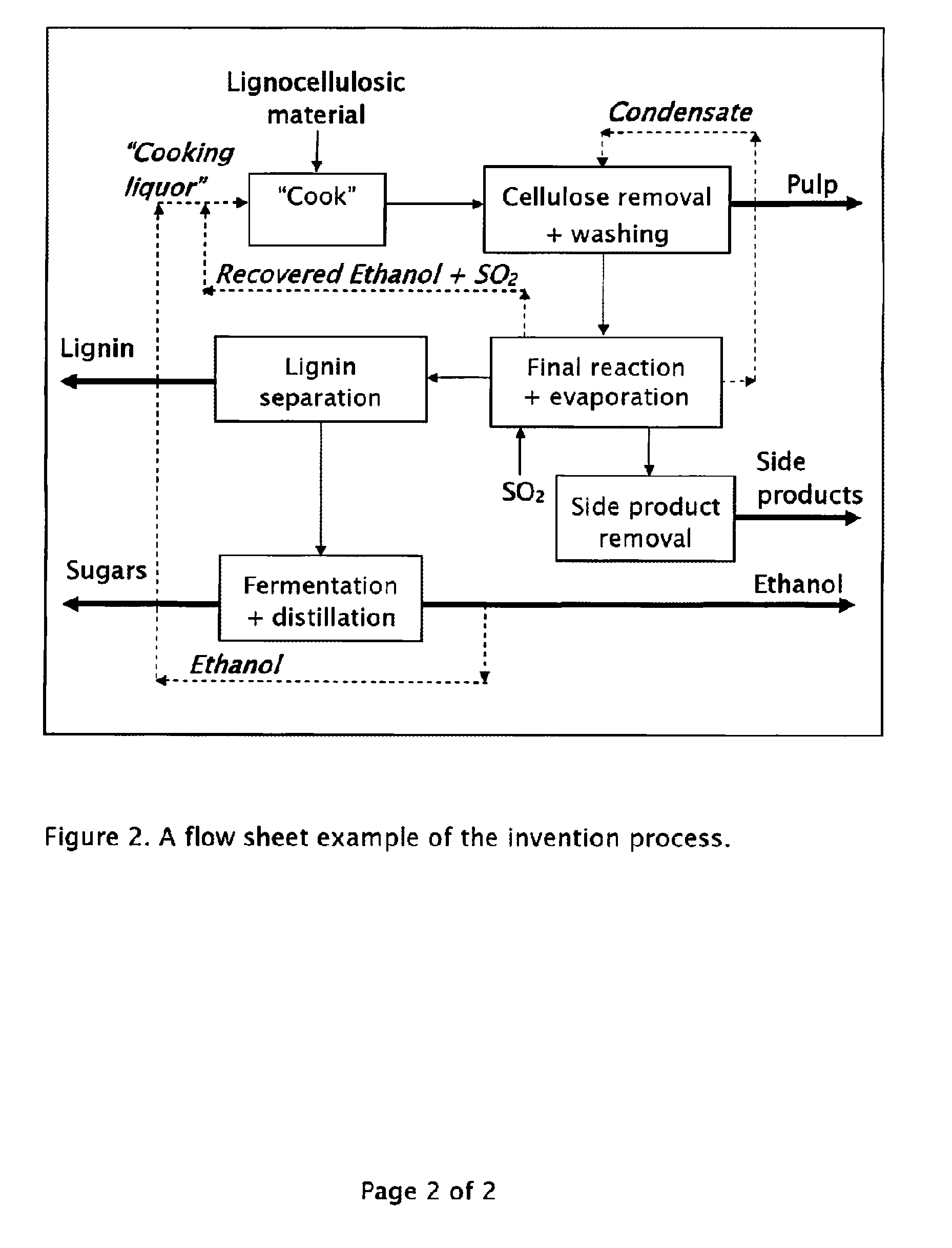

A method for the production of fermentable sugars and high viscosity cellulose from lignocellulosic material in a batch or continuous process is provided. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals can be reused, lignin is separated for the production of process energy, and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

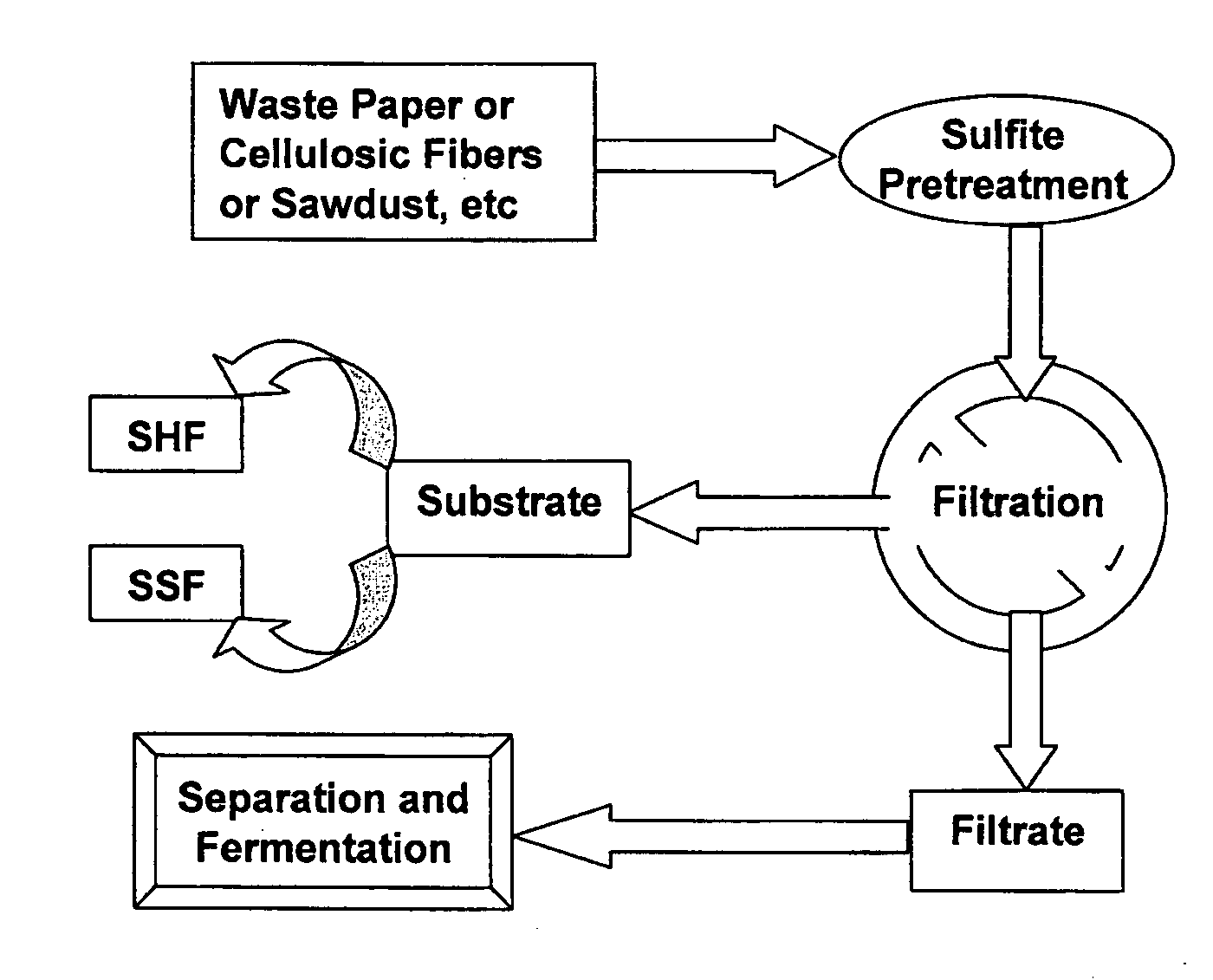

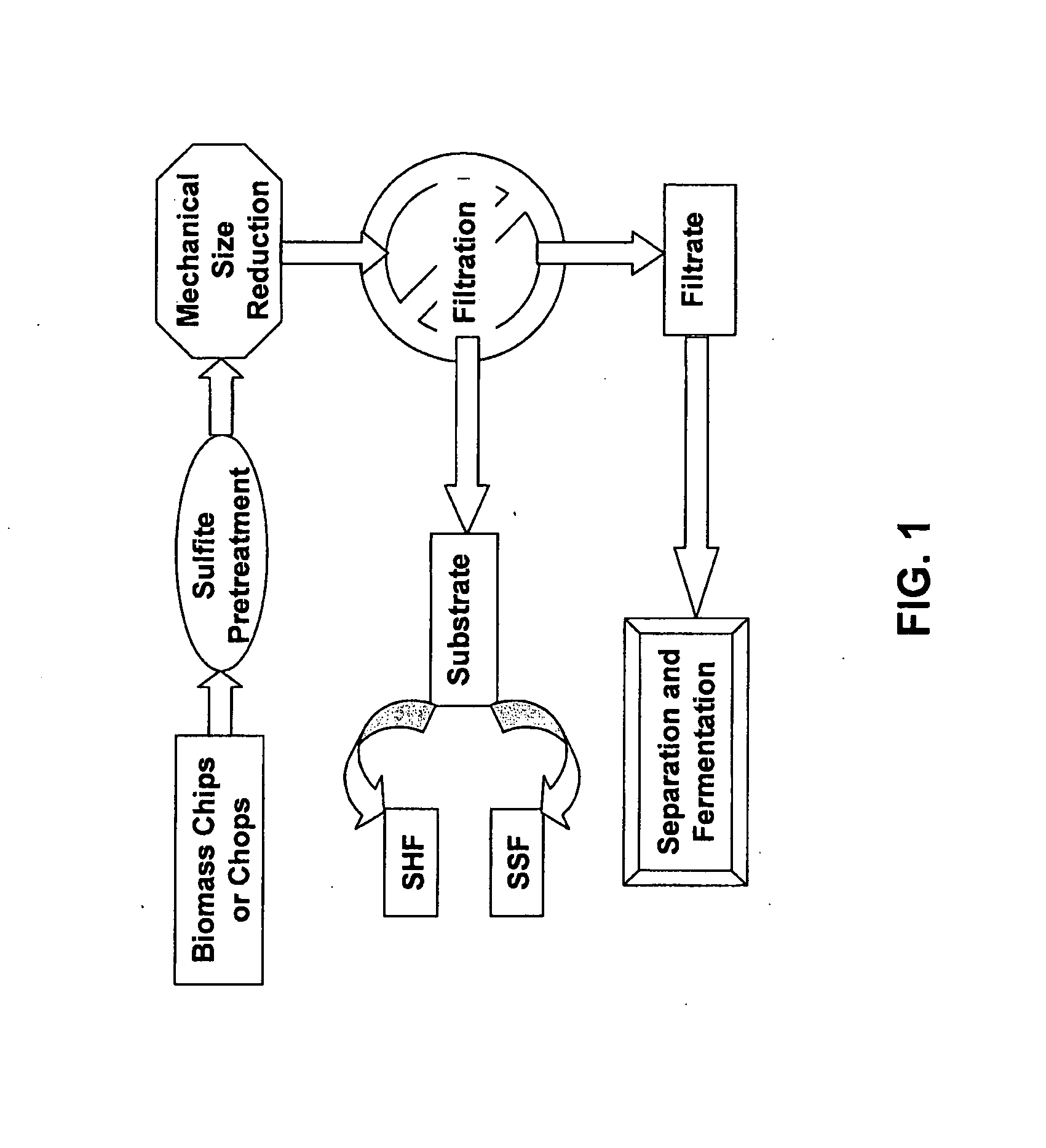

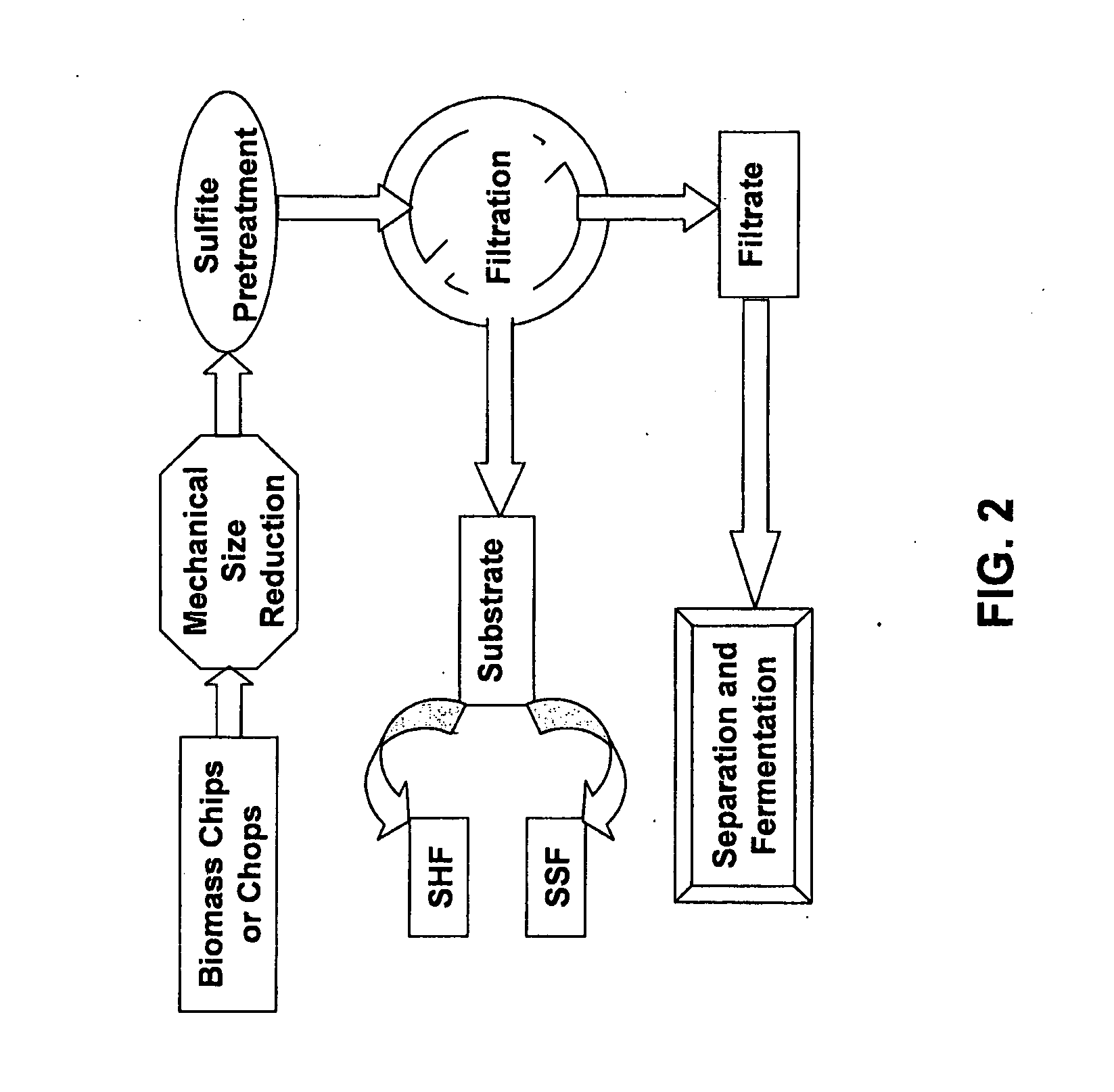

Sulfite Pretreatment For Biorefining Biomass

ActiveUS20090298149A1Save thermal energy consumptionImprove conversion efficiencyBiofuelsPaper recyclingCelluloseSulfite

The present invention relates to a method using sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL). More specifically, it relates to a sulfite-based chemical process for pretreating biomass in solutions to reduce access barriers of enzymes to the lignocellulose, resulting in efficient conversion through enzymatic saccharification.

Owner:US SEC AGRI +1

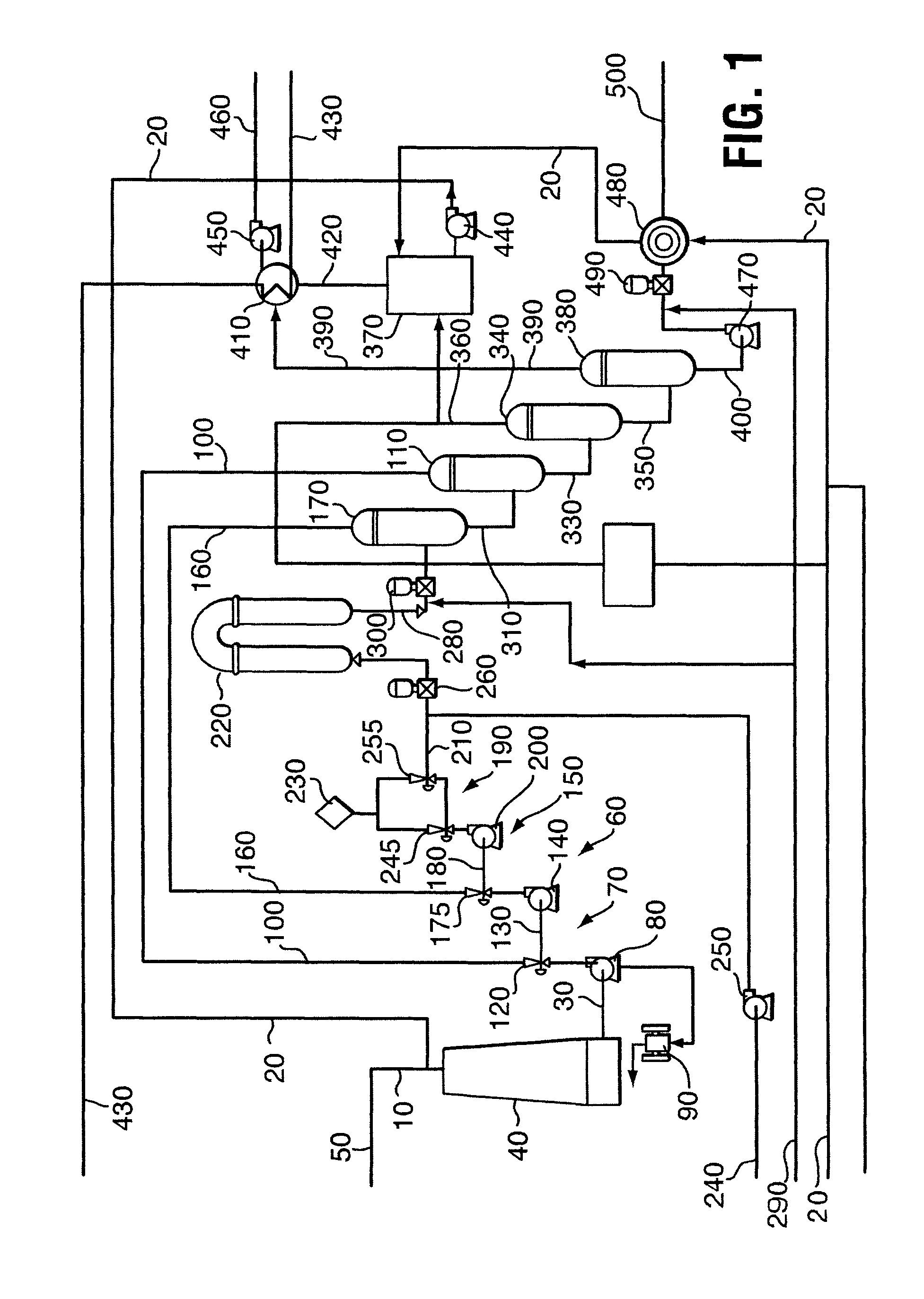

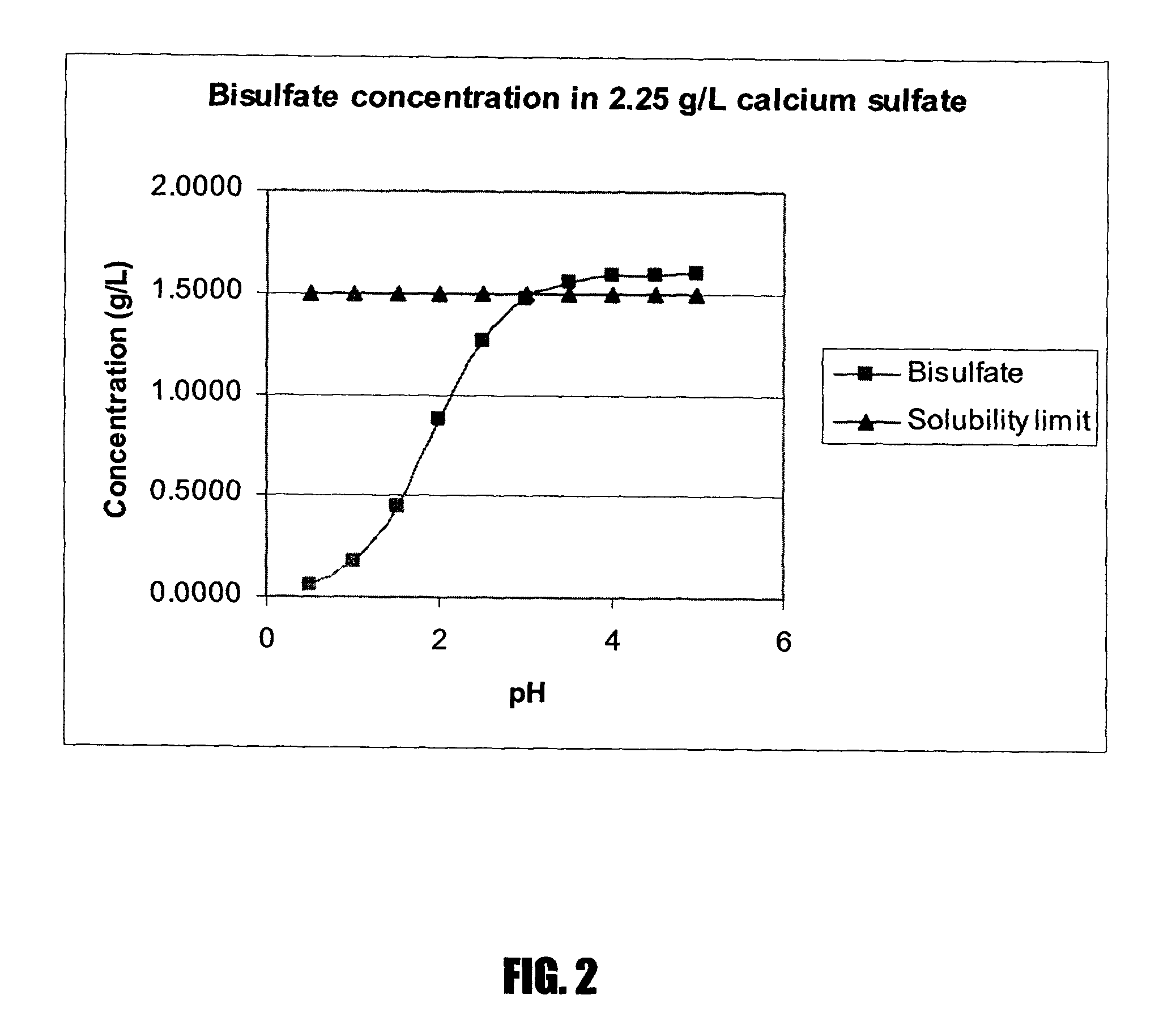

Recovery of inorganic salt during processing of lignocellulosic feedstocks

ActiveUS7585652B2Reduce inhibitionMeet cutting requirementsMagnesium fertilisersIon-exchanger regenerationCelluloseInorganic salts

A method for recovering inorganic salt during processing of a lignocellulosic feedstock is provided. The method comprises pretreating the lignocellulosic feedstock by adding an acid to the feedstock to produce a pretreated lignocellulosic feedstock. A soluble base is then added to the pretreated lignocellulosic feedstock to adjust the pH and produce a neutralized feedstock. The neutralized feedstock is then enzymatically hydrolyzed to produce an enzyme hydrolyzed feedstock and a sugar stream. Inorganic salt is recovered from either a stream obtained from the lignocellulosic feedstock prior to the step of pretreating, a stream obtained from the pretreated lignocellulosic feedstock, a stream obtained from the neutralized feedstock, a stream obtained from the sugar stream, or a combination of these streams. The inorganic salt may be concentrated, clarified, recovered and purified by crystallization, electrodialysis drying, or agglomeration and granulation, and then used as desired, for example as a fertilizer.

Owner:IOGEN ENERGY CORP

Biomass Treatment Method

InactiveUS20090050134A1Small sizeIncrease surface areaPressurized chemical processSugar productsFermentable sugarAmmonia

A method for treating biomass was developed that uses an apparatus which moves a biomass and dilute aqueous ammonia mixture through reaction chambers without compaction. The apparatus moves the biomass using a non-compressing piston. The resulting treated biomass is saccharified to produce fermentable sugars.

Owner:SUSTAINABLE TECH CORP +1

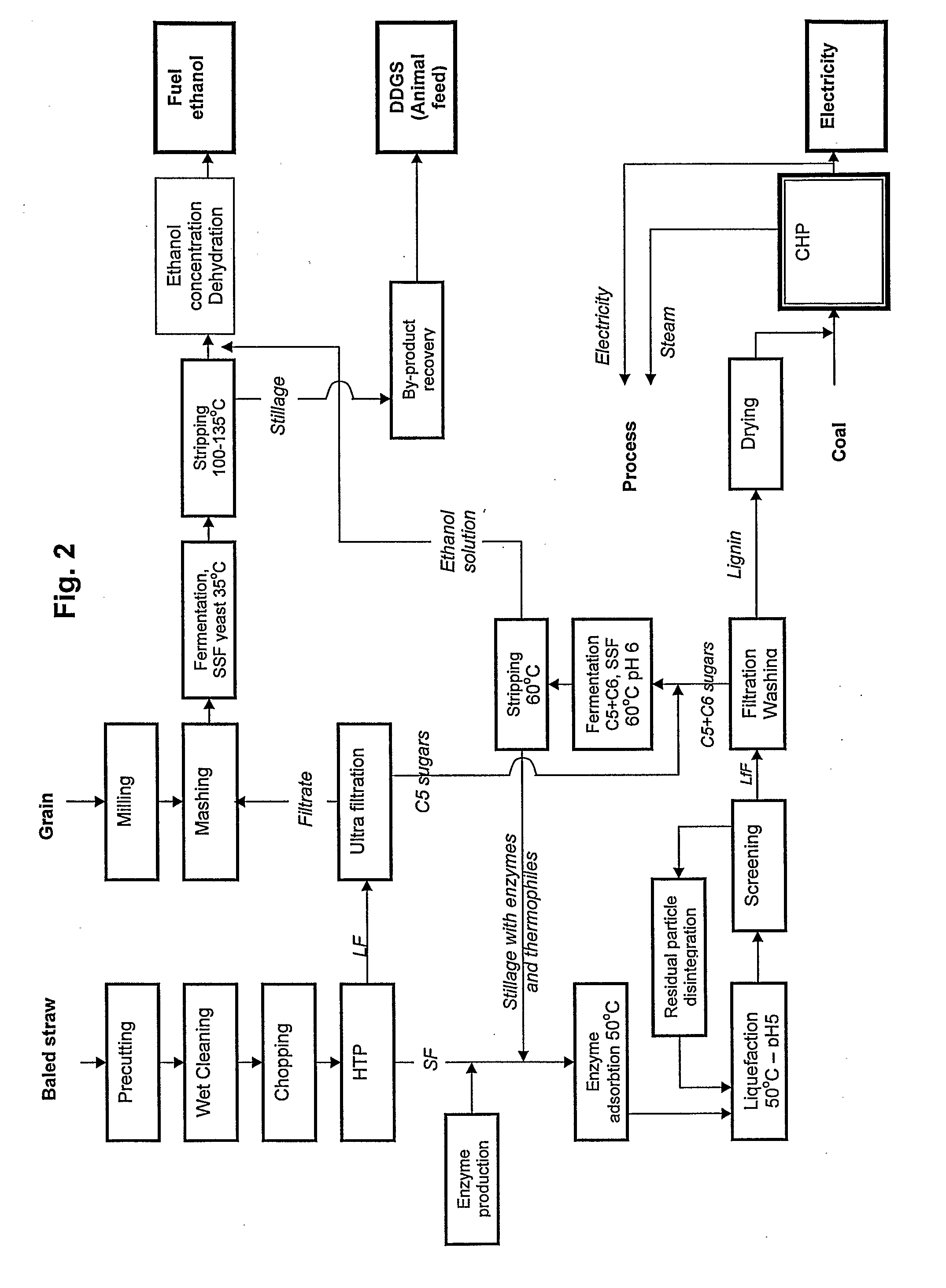

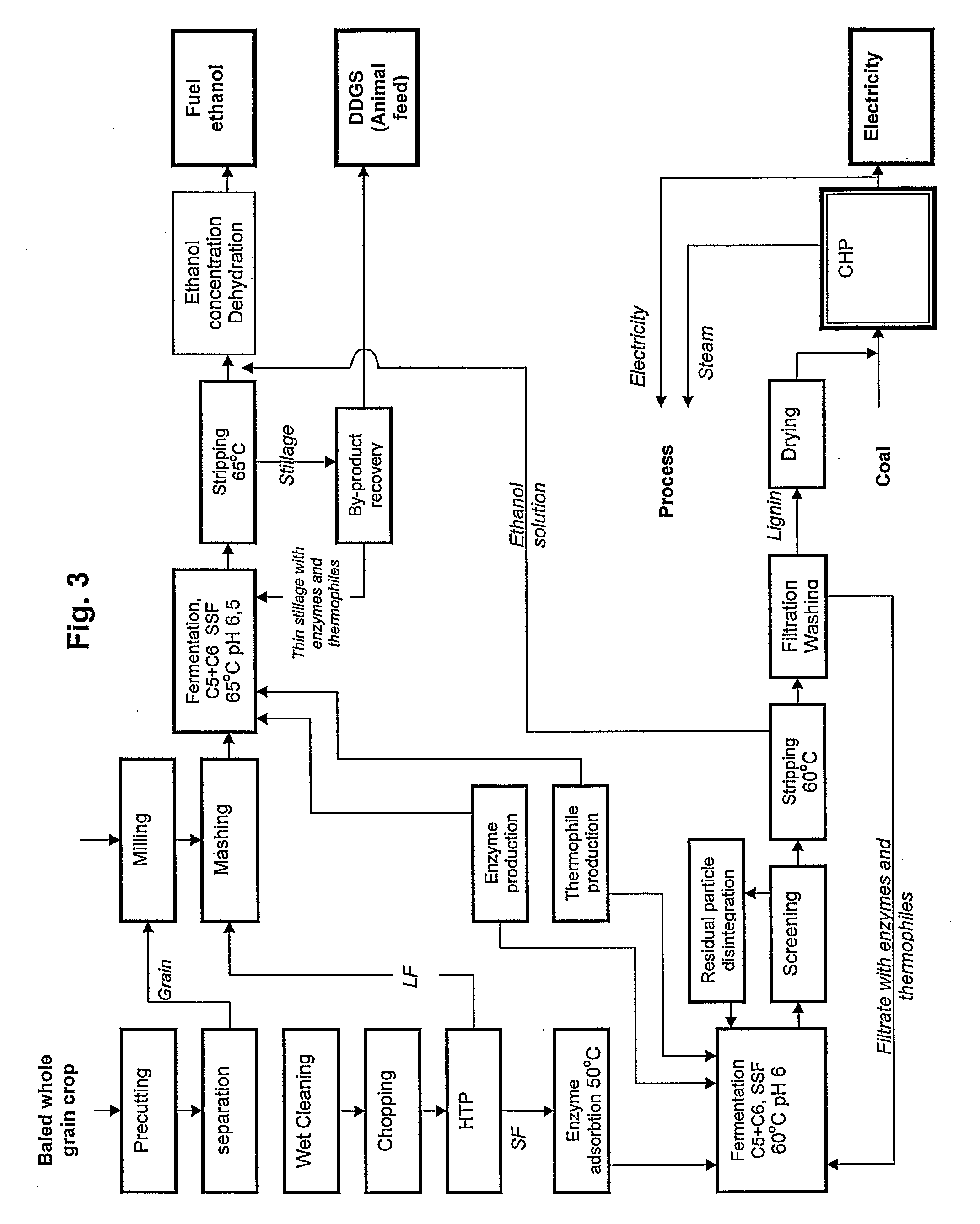

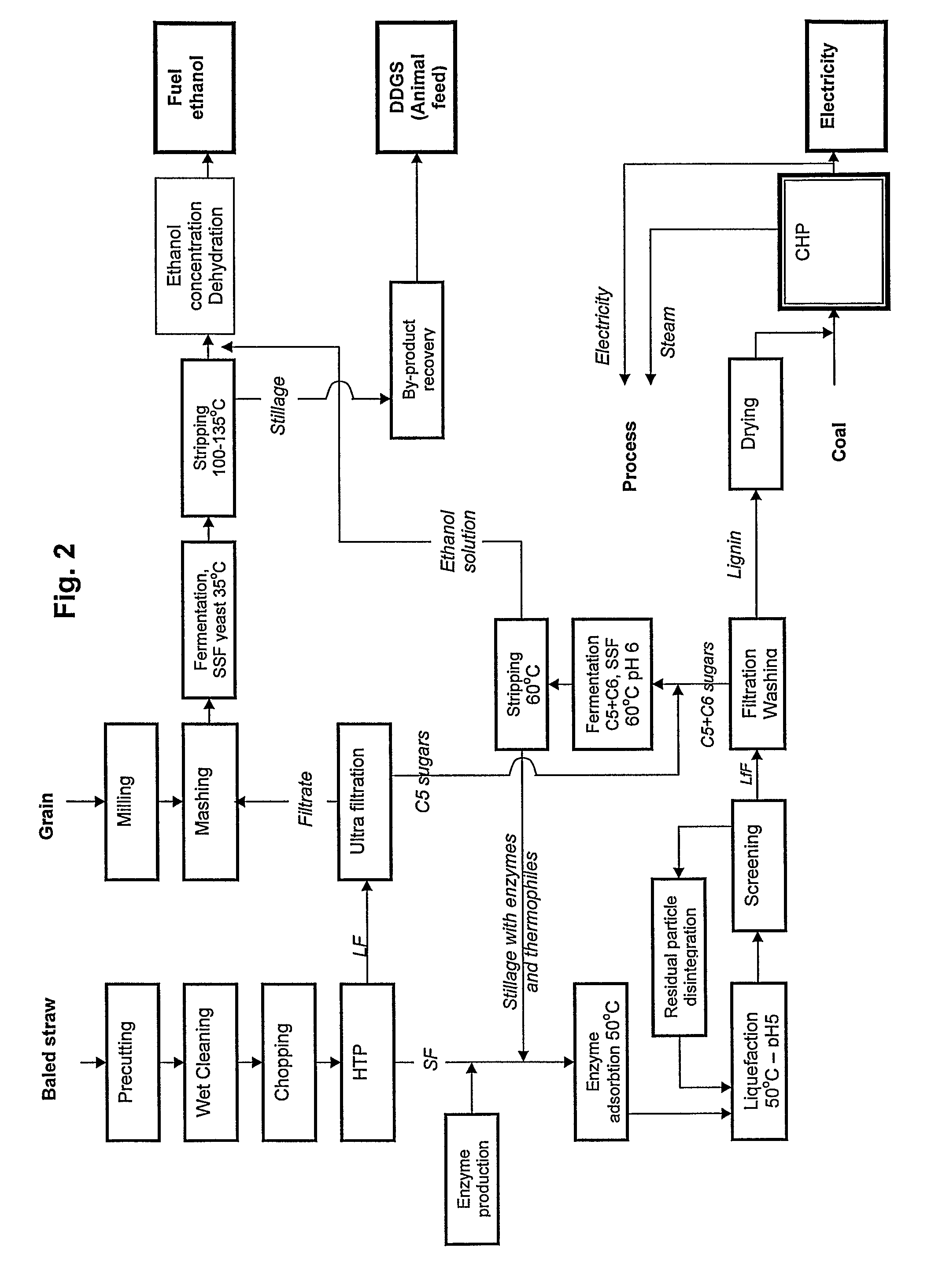

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS8123864B2Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fiber fraction are produced. The fiber fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurized reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fiber fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fiber fraction.

Owner:INBICON AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com