Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

543 results about "Surge tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surge tank is a water storage device used as pressure neutralizer in hydropower water conveyance system to resists excess pressure rise and pressure drop conditions. A surge tank (or surge drum or surge pool) is a standpipe or storage reservoir at the downstream end of a closed aqueduct, feeder, dam, barrage pipe to absorb sudden rises of pressure, as well as to quickly provide extra water during a brief drop in pressure.

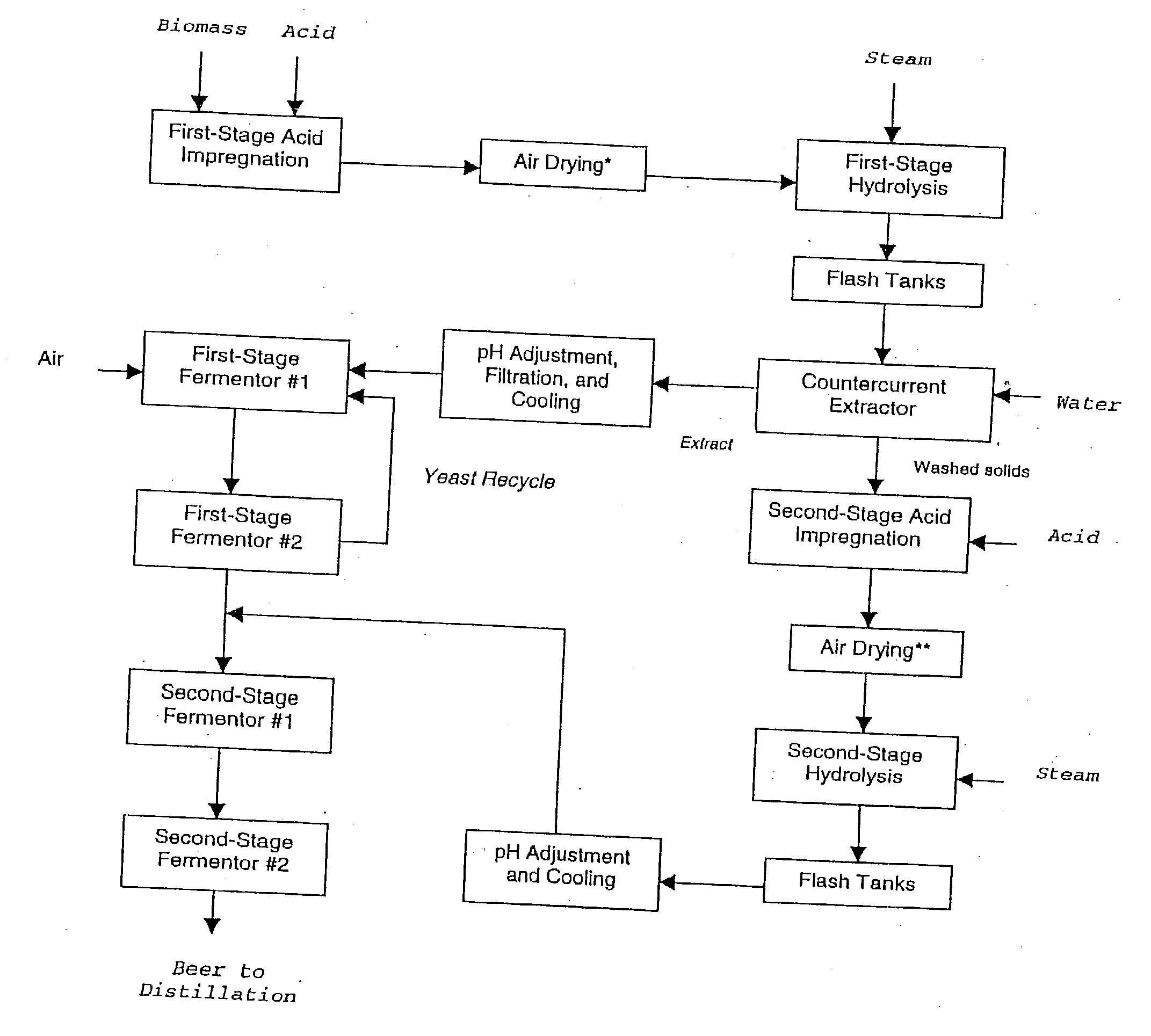

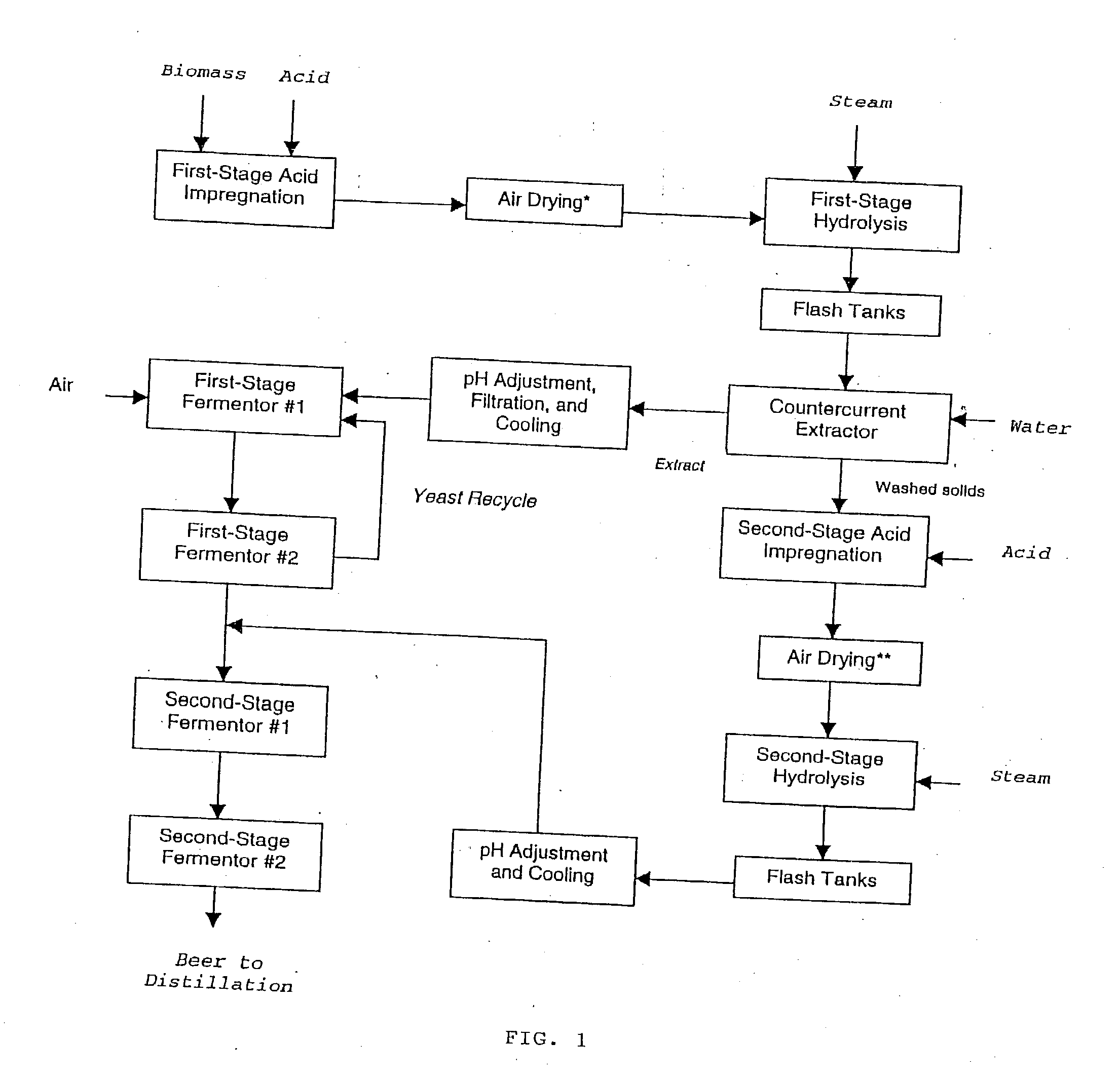

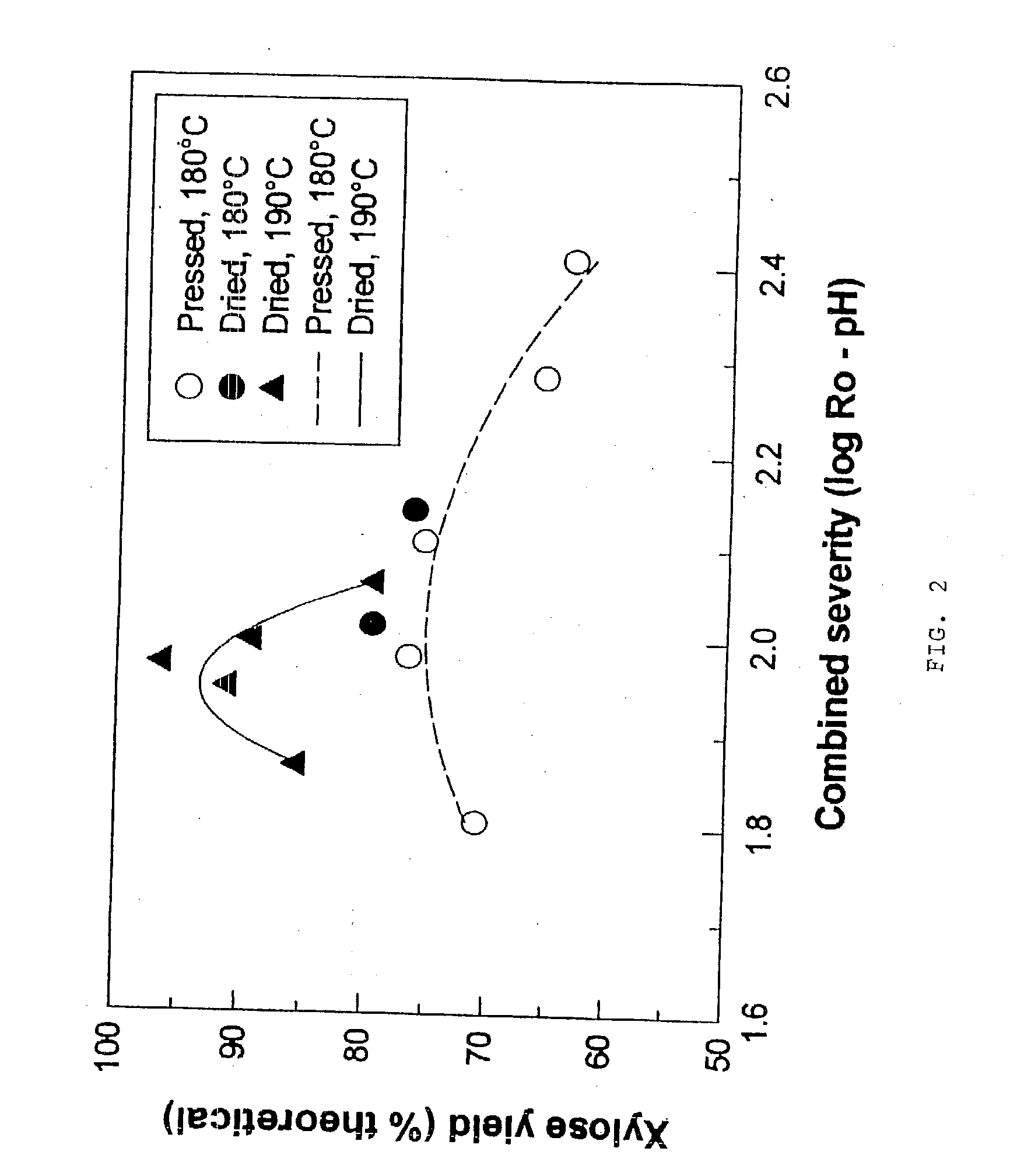

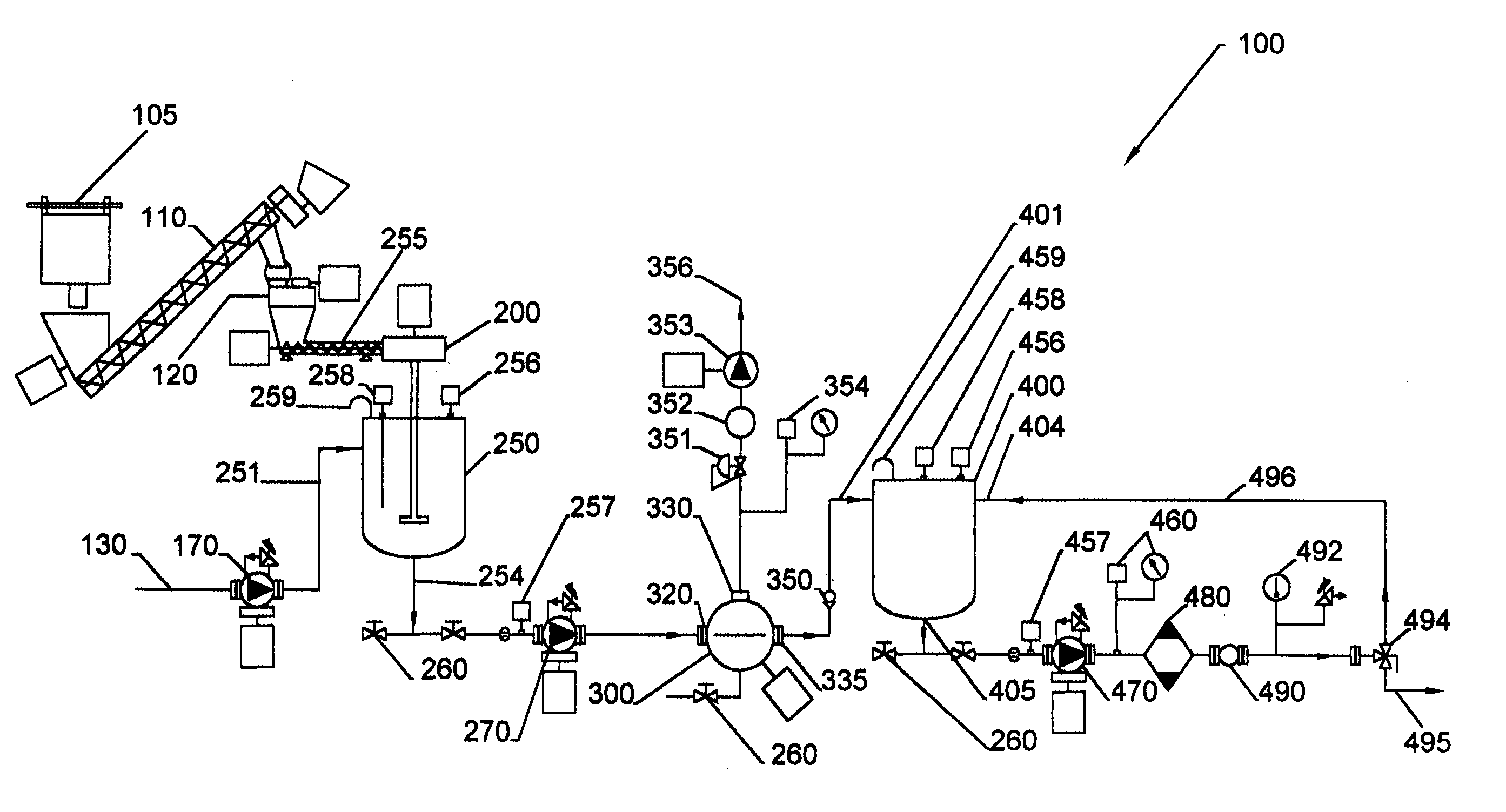

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

Method of collecting carbon dioxide contained in fumes

The fumes flowing in through line 1 are contacted in column C1 with a solvent, at low vapour pressure, absorbing the carbon dioxide. The solvent laden with carbon dioxide is regenerated by distillation in column C2. In order to improve the regeneration operation, a gas is injected through line 11 into column C2 so that this gas carries along the carbon dioxide contained in the solvent. The carbon dioxide-rich gaseous effluent obtained at the top of column C2 can be liquefied by compression and cooling, then stored in surge tank R, which allows its transportation and possibly underground sequestration.

Owner:INST FR DU PETROLE

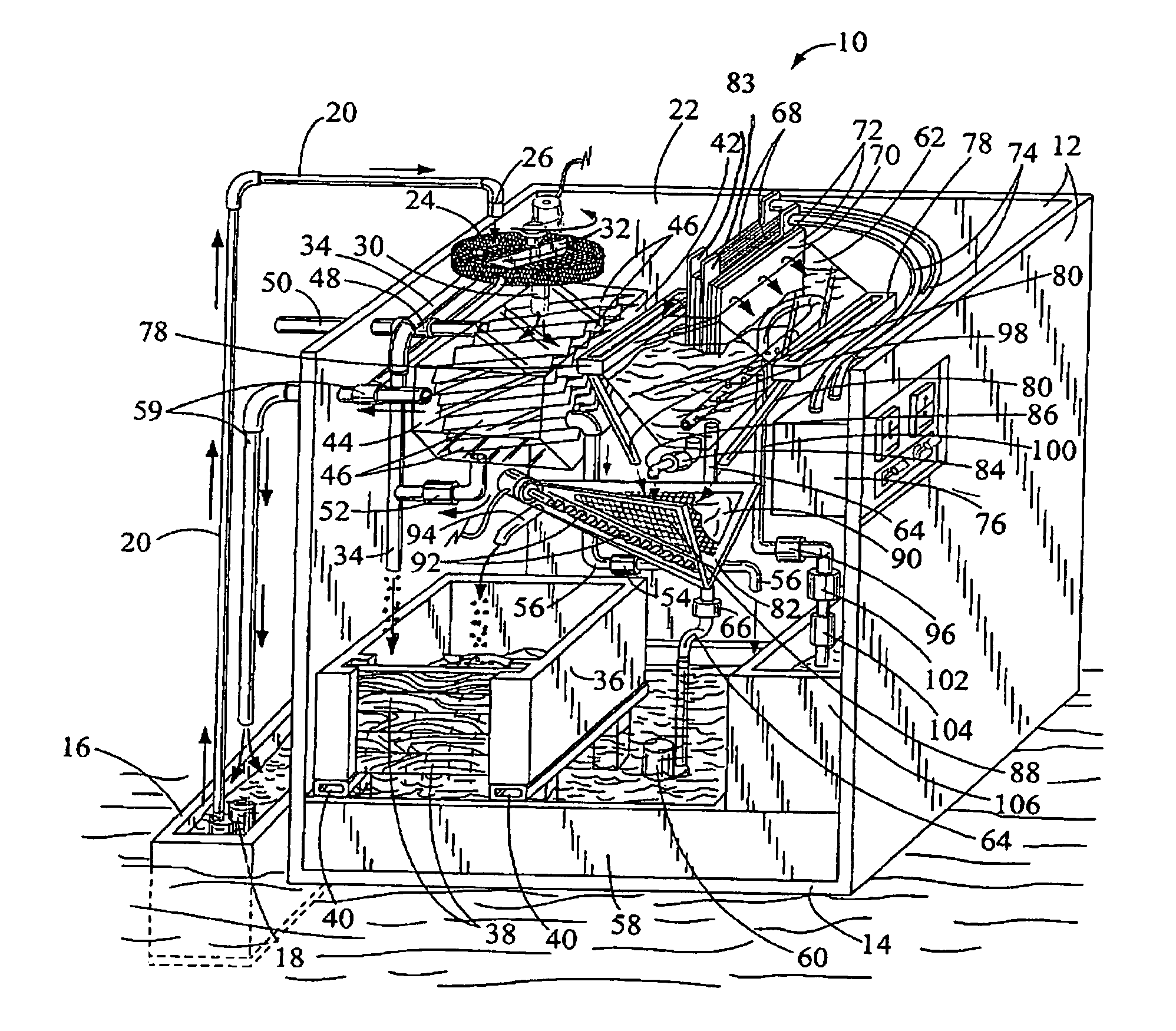

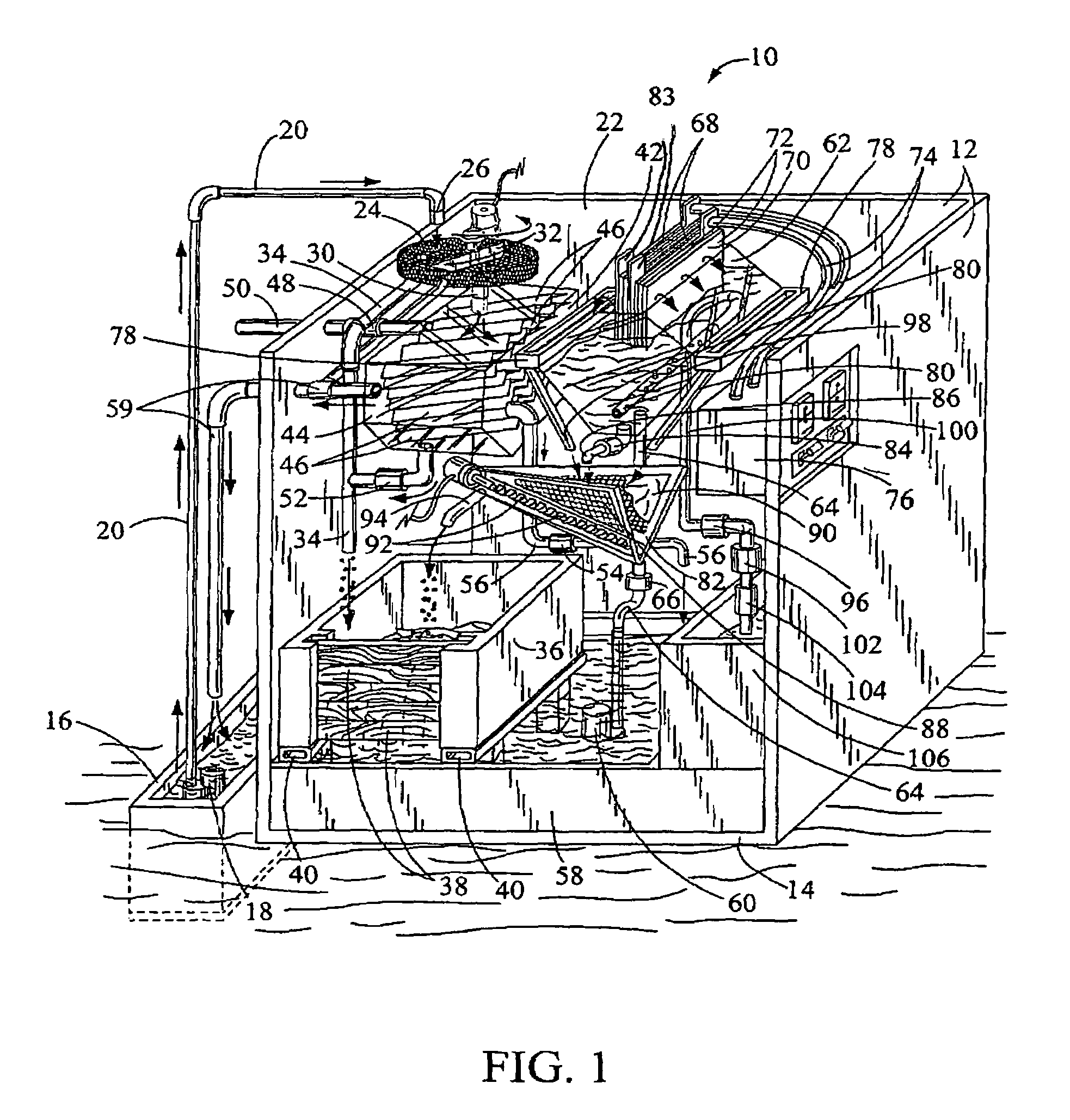

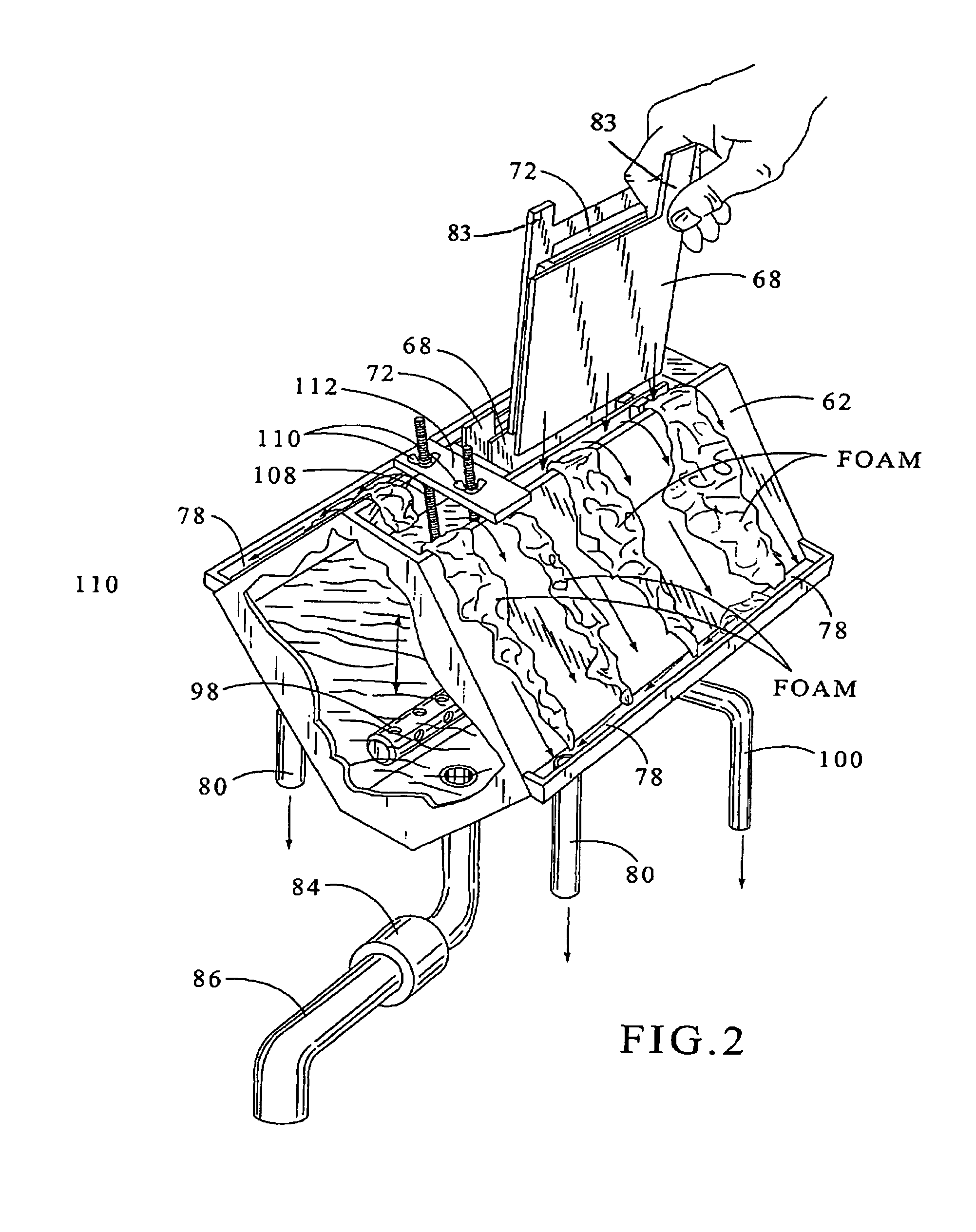

Electrocoagulation waste water batch tank treatment system

InactiveUS7258800B1Lower levels of contaminationEasy to replaceTreatment involving filtrationLiquid displacementSurge tankWater treatment system

A waste water treatment system and process for treating waste water received in a batch tank. The waste water is discharged in a headwork screen for removing large solids in the water. The solids are into a sludge drying bin. The screened water is transferred into a top of an influent surge tank with an oil / water separator. The oil / water separator includes a plurality of coalescing plates for separating free oil from the waste water. Heavy solids in the surge tank are drained into the sludge drying bin. The waste water is now dropped into a containment pan. From the containment pan, the waste water is pumped into a water treatment tank. The water treatment tank includes two or more electrodes mounted in the top thereof. The electrodes are separated using insulating support spacers for providing proper electrode spacing and insulation between the electrodes. The electrodes are used for providing current to the waste water and separating the contaminates in the water by electrocoagulation. The treated water in the water treatment tank is discharged after a completion of a period of settling or dwell time into a clean water tank.

Owner:H2O TECH

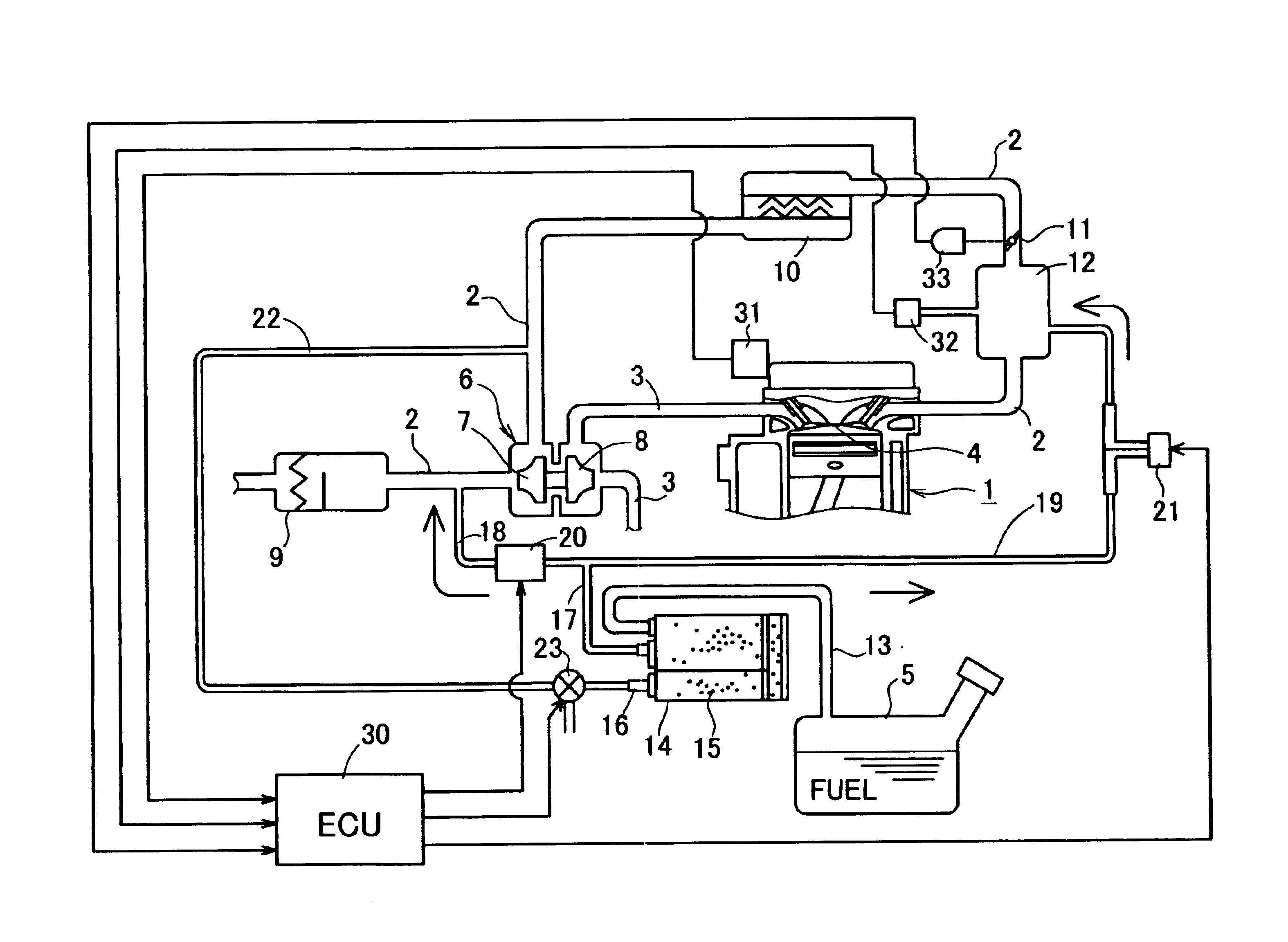

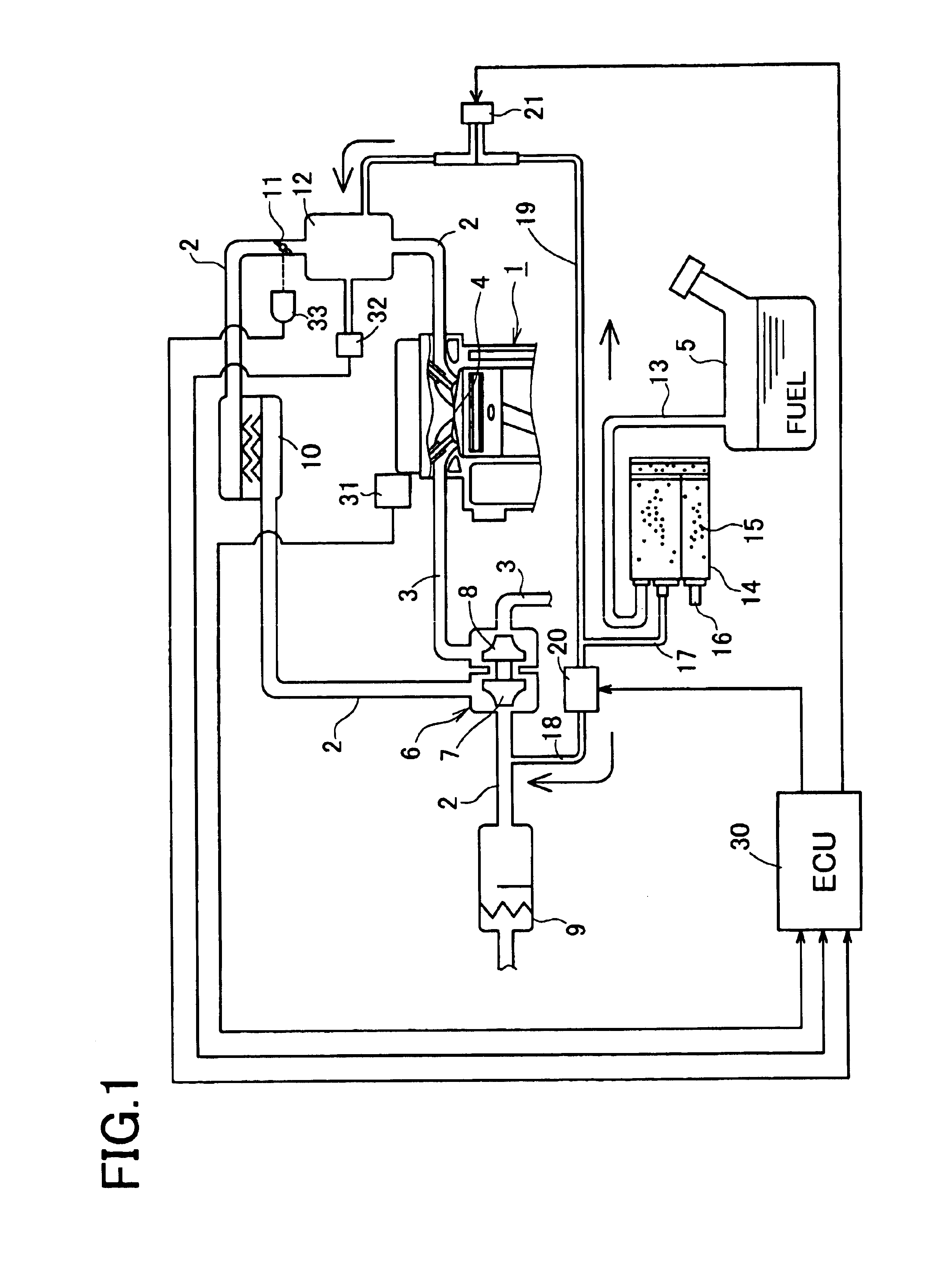

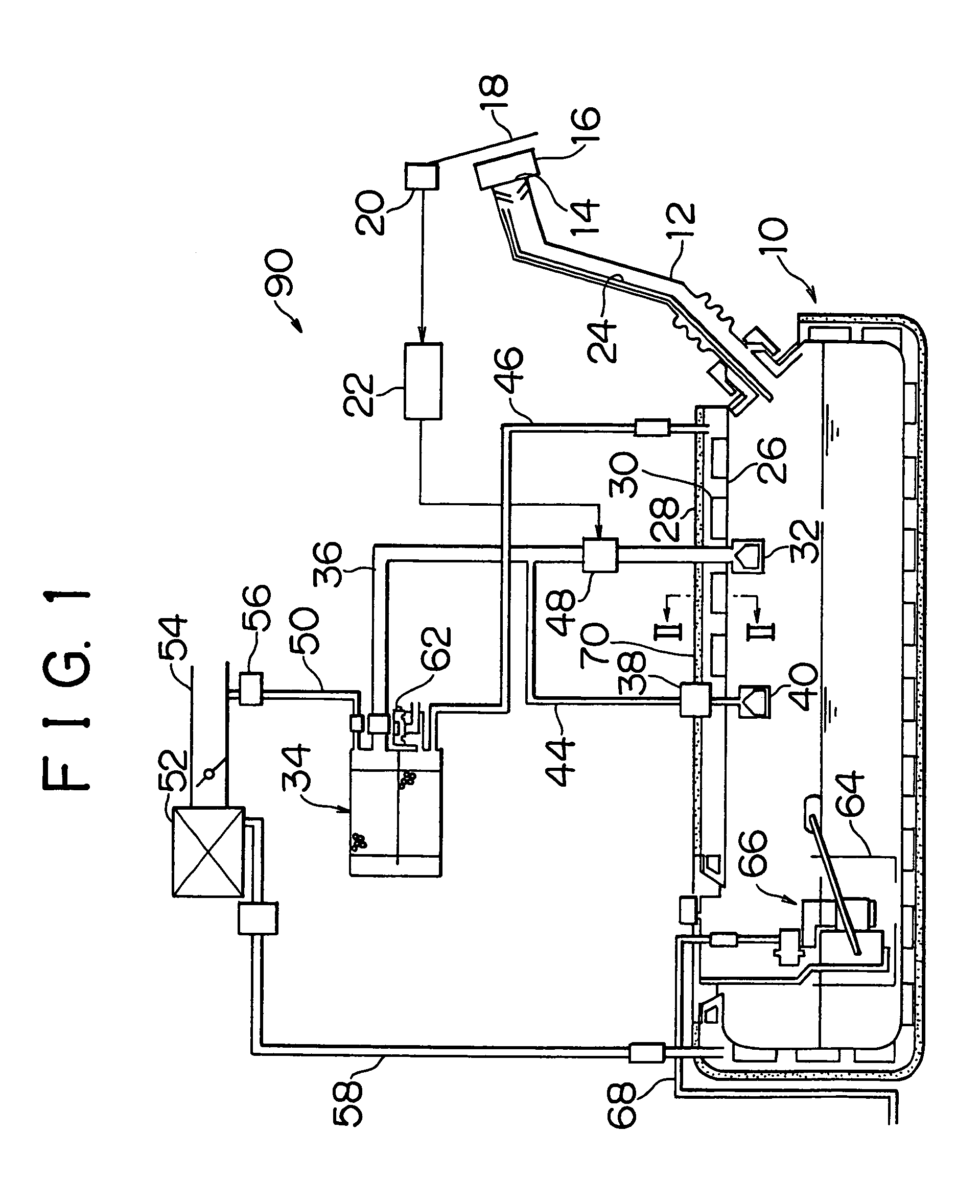

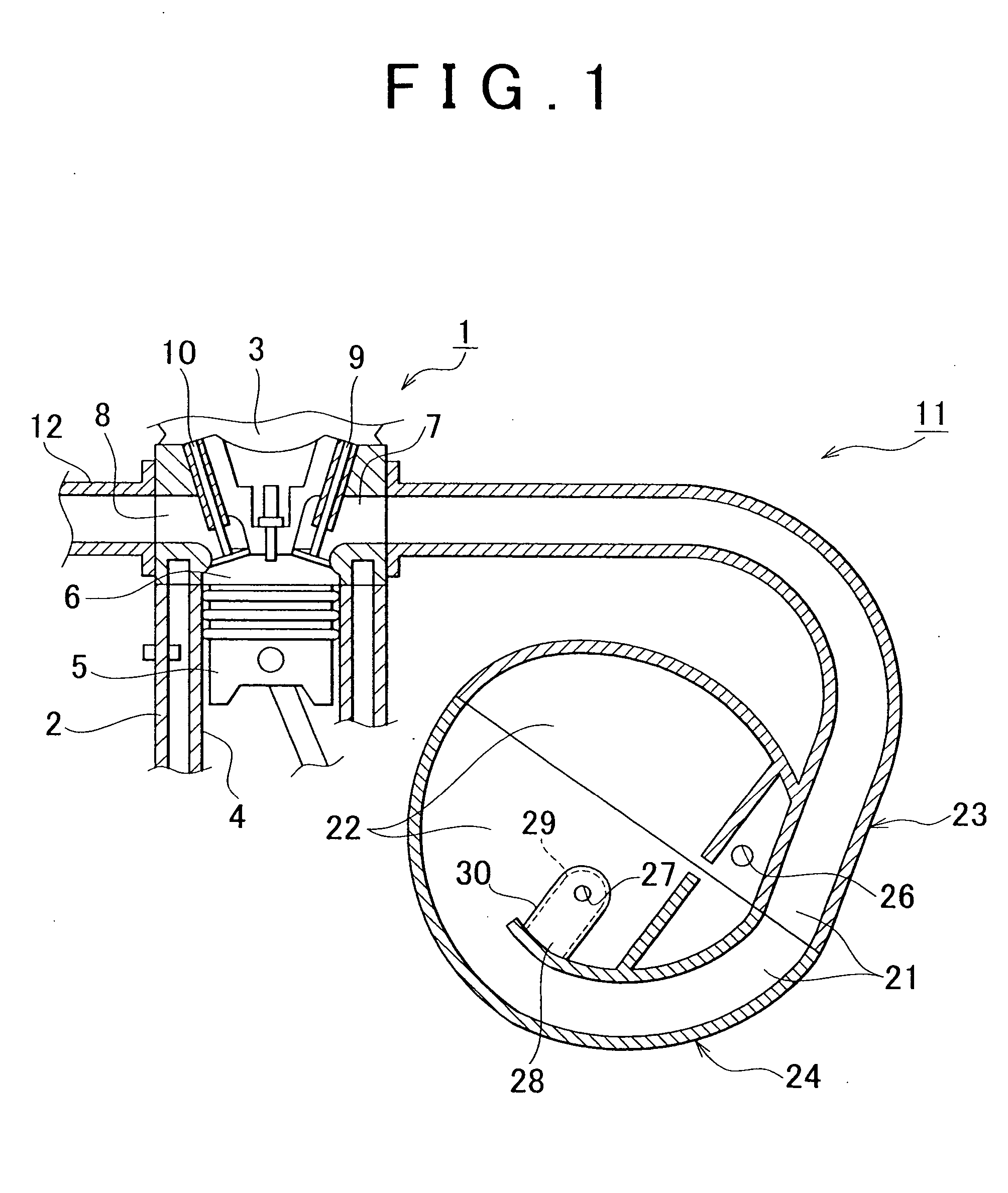

Evaporated fuel processing apparatuses for engines with supercharger

In an engine with a supercharger, there is provided an evaporated fuel processing apparatus for collecting vapor generated in a fuel tank into a canister and purging the collected vapor into an intake passage. The supercharger includes a compressor. The evaporated fuel processing apparatus comprises a purge passage through which the vapor is purged from the canister into the intake passage upstream of the compressor, a second purge passage through which the vapor is purged from the canister into a surge tank, two electromagnetic valves which are operated to open and close the two purge passage, various sensors which detect an operating condition of the engine, and an electronic control unit (ECU) which controls the electromagnetic valves respectively on the basis of values detected by the sensors.

Owner:AISAN IND CO LTD

Fuel tank system

InactiveUS6957542B1Improve cooling effectEasy to cleanInternal combustion piston enginesNon-fuel substance addition to fuelSurge tankBuffer tank

A fuel tank body has a double-layer structure composed of an inner tank shell and an outer tank shell, so that an inter-tank-shell space is formed therebetween. Because heat of fuel in the fuel tank body is discharged into the inter-tank-shell space, the temperature of fuel in the fuel tank body is prevented from rising. If the pressure in a canister becomes negative due to a negative pressure in an intake system of an engine, more specifically, a negative pressure in a surge tank leading to an air cleaner, high-temperature air in the inter-tank-shell space between the inner tank shell and the outer tank shell flows into the canister. On the other hand, low-temperature air flows from the air cleaner into the inter-tank-shell space which has become negative in pressure.

Owner:TOYOTA JIDOSHA KK +1

Packer packing multi-layer hydropower abrasive perforating and fracturing integrated technique

InactiveCN101270639AGuaranteed Design DisplacementEffective transformationFluid removalAbrasive blastingSurge tank

An integrative method for a packer to pack off a multi-layer hydraulic sand-spraying perforation and pressure fracture is used in the multi-layer perforation and the pressure fracture of a well of well completion of a petroleum casing. A pipe column comprises an oil pipe, a safety joint, a hydraulic ejector, a K34 or a Y34 packer, a uniflow valve, a sieve vessel and an end cap, wherein, the lower layer of a hydraulic ejector position requires perforation depth. With the completion of perforation, the hydraulic sand-spraying fractures the lower layer by actively circulating the lower layer of the hydraulic sand-spraying perforation. When the hydraulic sand-spraying pressure fracture for the lower layer is completed, a reverse circulation surge tank is processed and the pipe column is leveled up and dragged to the upper layer of perforation pressure fracture to continue to fracture the upper layer by hydraulic sand-spraying perforation. After completion, the pipe column is lifted to be put into the well-completion pipe column to discharge liquid and finish production. The perforation is not required by each layer because only an oil pipe needs to be dragged to finish the multiple fracturing of multiple layers of the well. The integrative method integrating the perforation, the fracture and the packing-off together is new stimulation treatment technology. In addition, the fracture is reliable, construction is easy and convenient and period is short.

Owner:PETROCHINA CO LTD

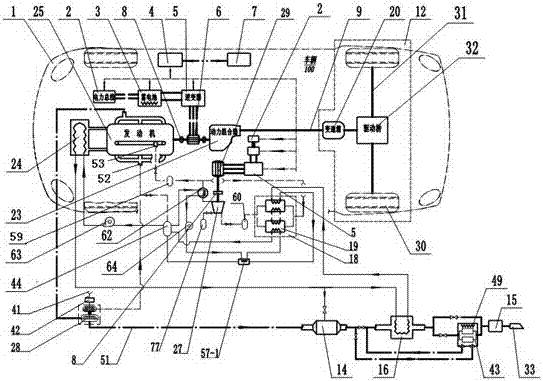

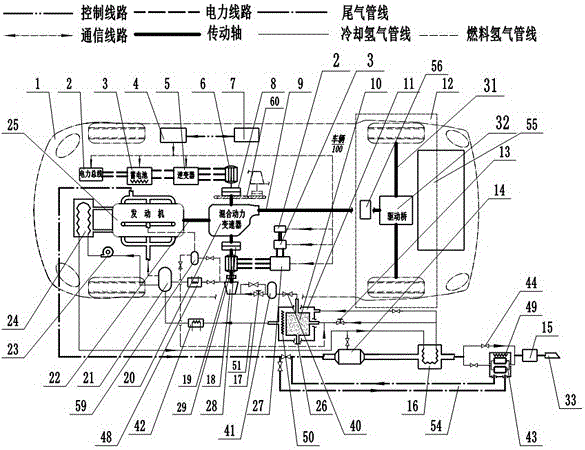

Efficient hydrogen energy vehicle power system for purifying ambient air

ActiveCN106915235AReduce consumptionIncrease motivationHybrid vehiclesInternal combustion piston enginesPower combinerEngineering

The invention relates to an efficient hydrogen energy vehicle power system with an ambient air purifying function. The efficient hydrogen energy vehicle power system comprises a drive system, a gas turbine, a high pressure hydrogen storage tank, a hydrogen compression unit, a hydrogen gas surge tank, an inverter, an electric-power generator, an expander, a storage battery and an exhaust gas treating and discharging system. The high pressure hydrogen storage tank is connected to an inlet of the expander, one path of an outlet of the expander is connected to a hydrogen inlet through a cold capacity recovery device and the hydrogen gas surge tank, and the other path is connected to the inlet of the expander through a hydrogen compression unit and an intermediate tank. A power combiner is connected with the gas turbine and / or the electric-power generator, according to the technical scheme, the gas turbine is replaced with a hydrogen fuel engine, and the power combiner is connected with the drive system through a drive shaft. According to the efficient hydrogen energy vehicle power system with the ambient air purifying function, the gas turbine is combined with the electric-power generator, so that work efficiency of the hydrogen energy vehicle power system is improved. By recycling of exhaust gas heat, air pollution is reduced, and the natural environment can be protected easily.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

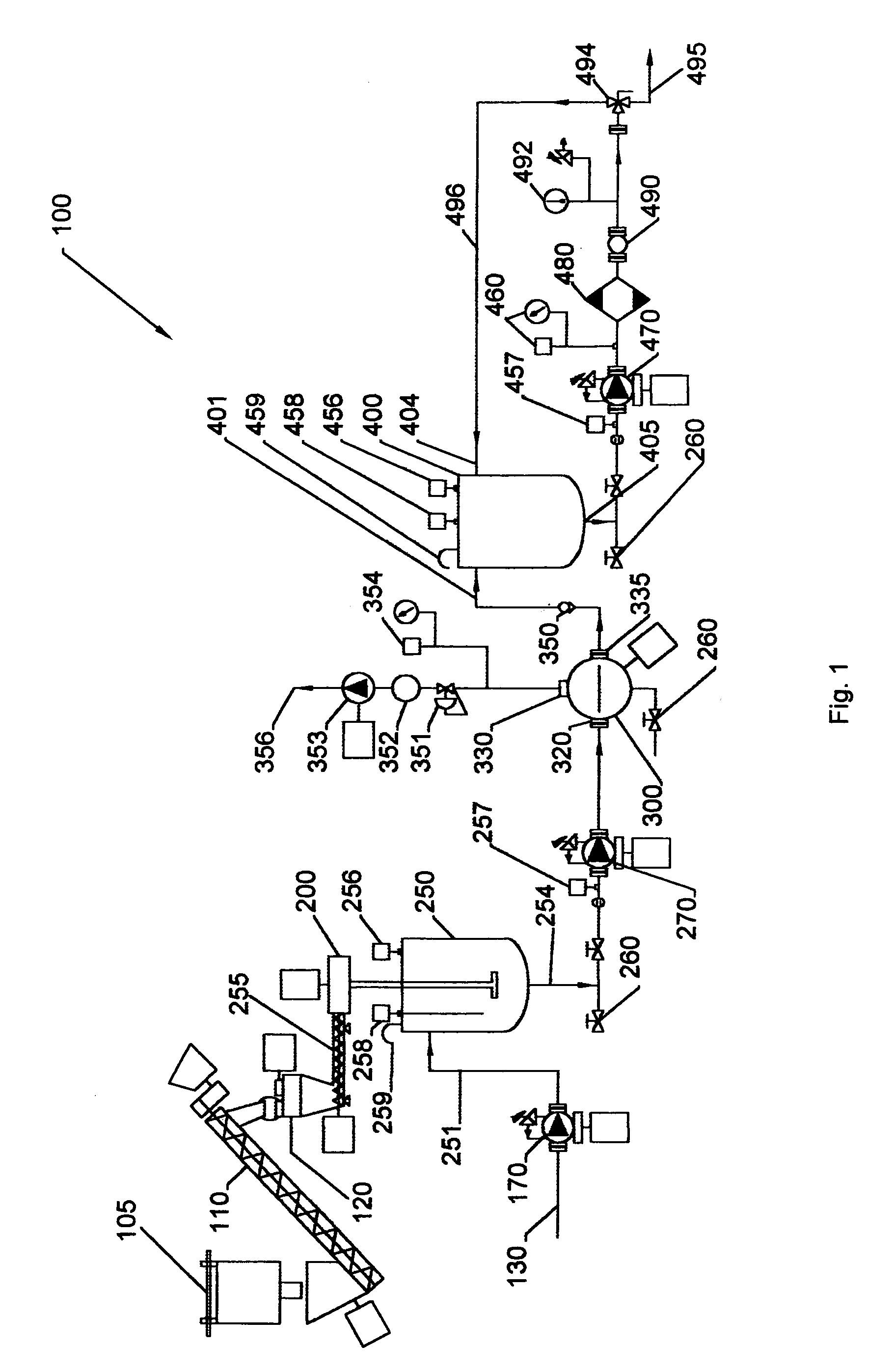

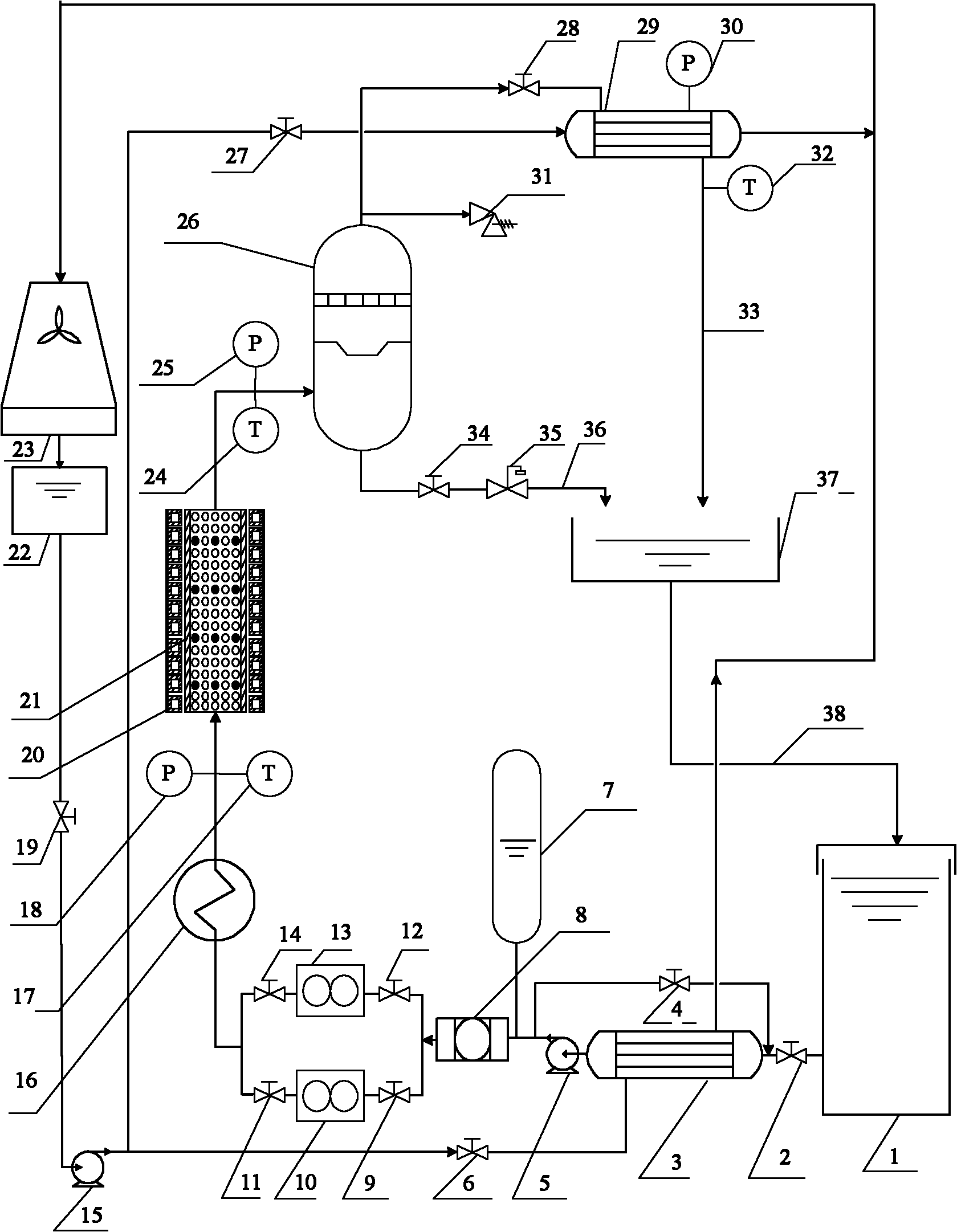

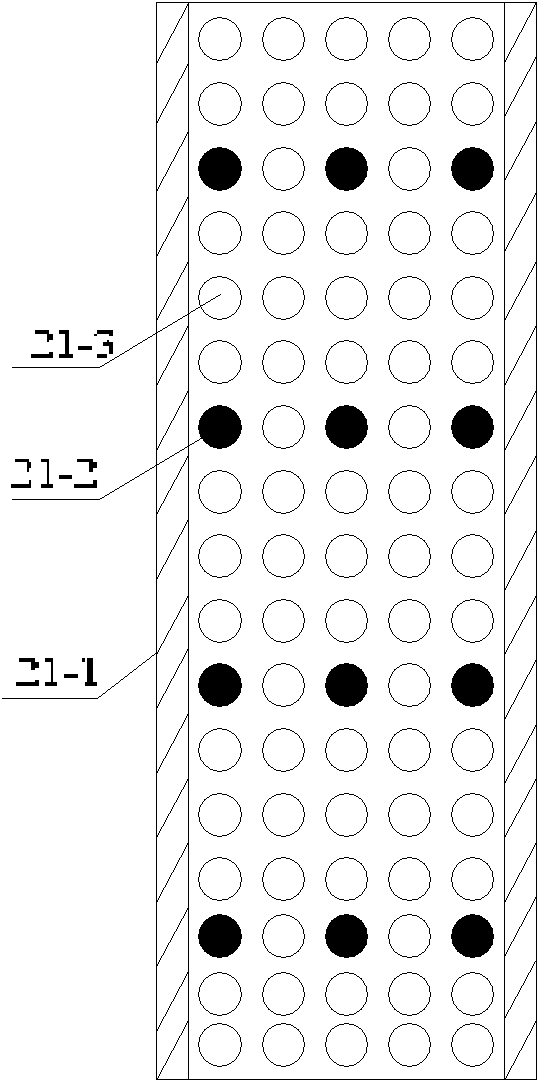

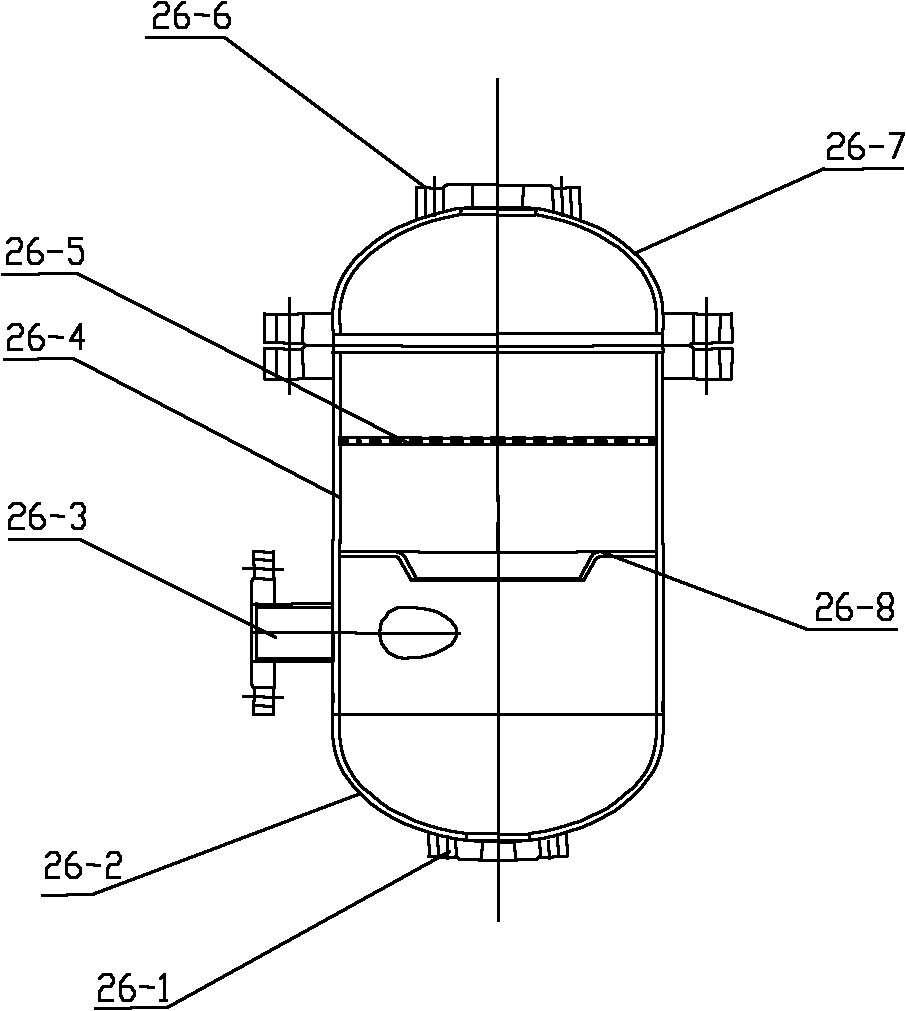

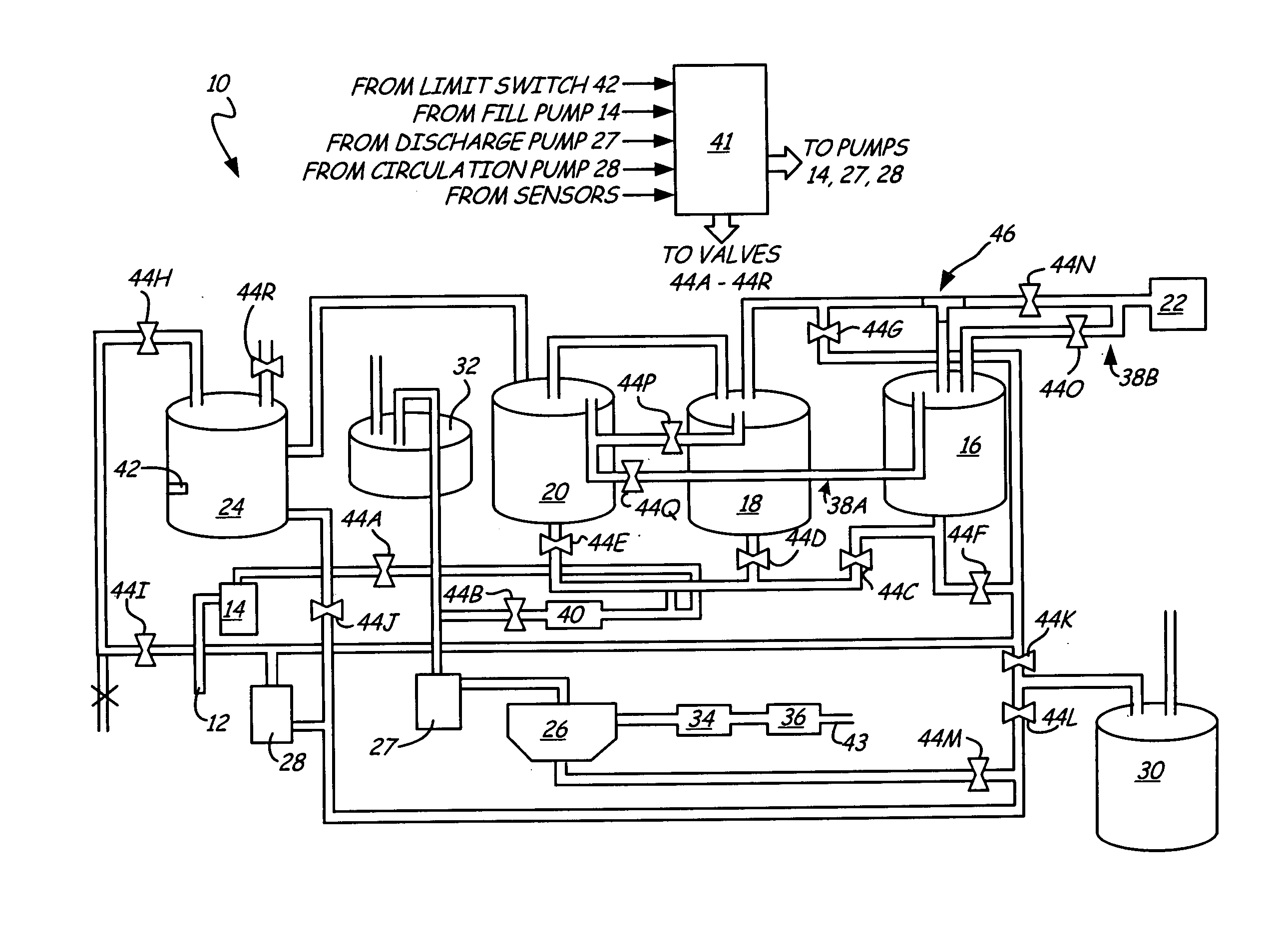

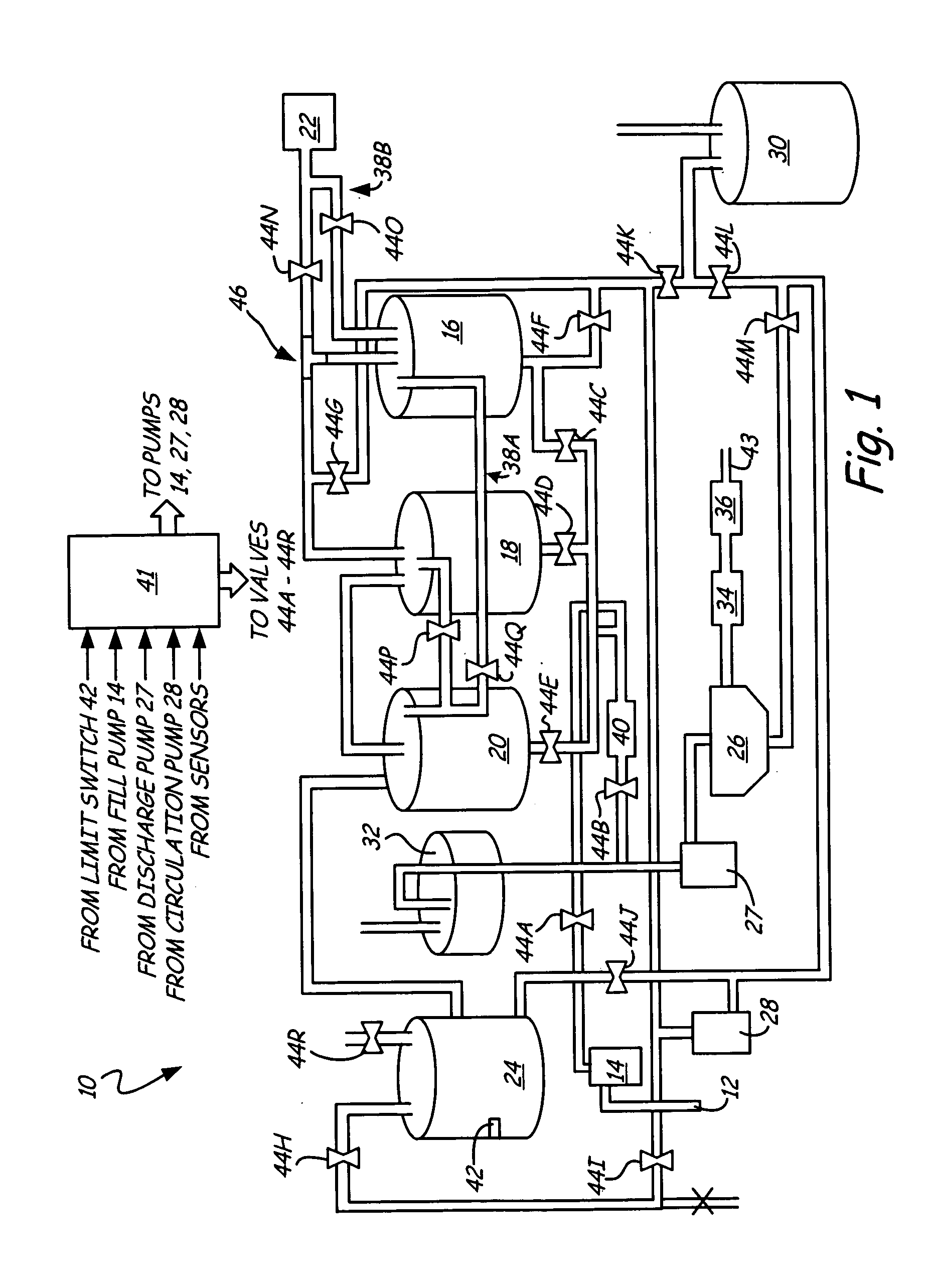

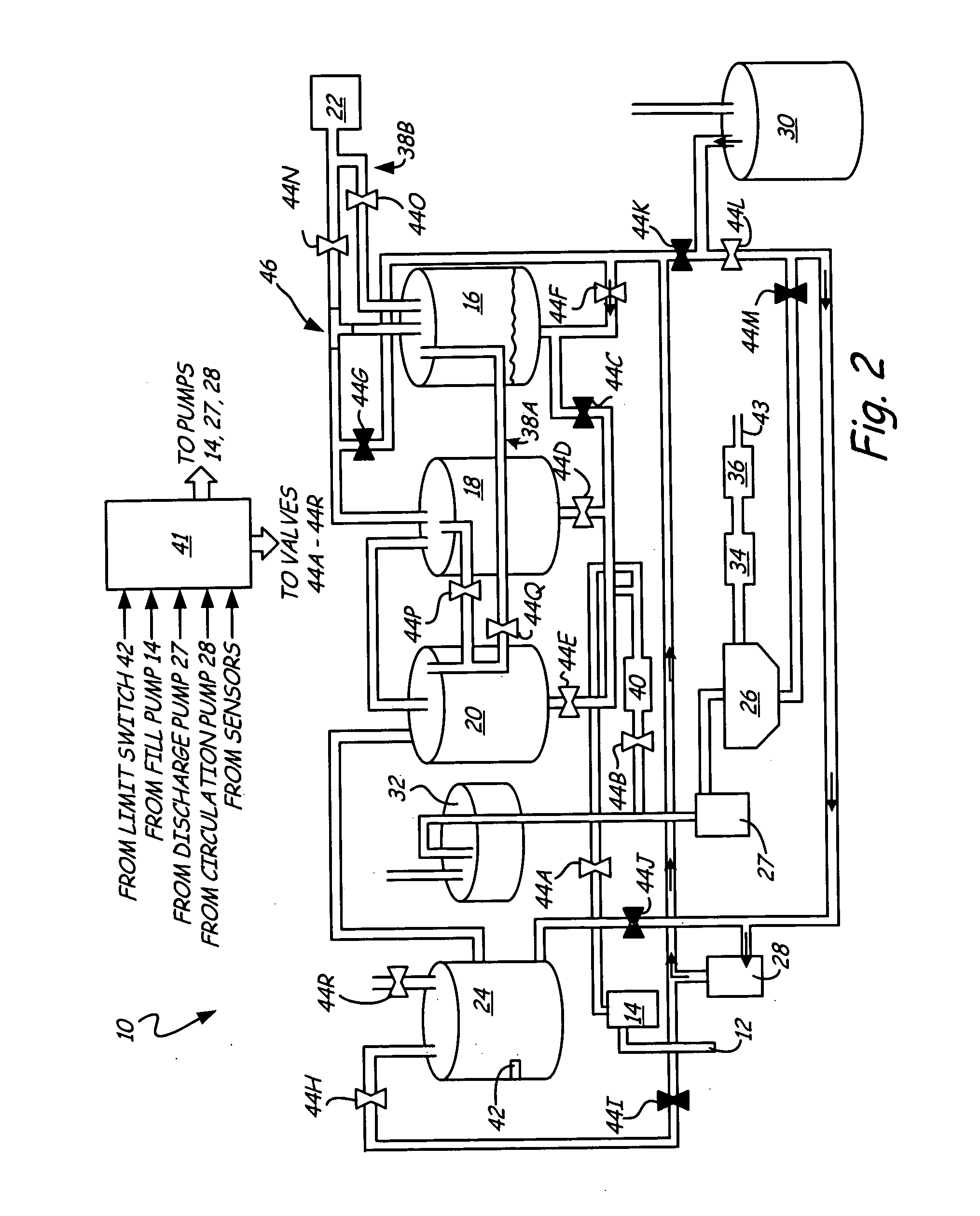

Control system and method for continuous mixing of slurry with removal of entrained bubbles

InactiveUS6994464B2Easy to controlControlling ratio of multiple fluid flowsRotary stirring mixersSurge tankControl system

The present invention comprises a control system and method for the continuous mixing of slurry while removing entrained bubbles. The control system for continuous mixing of slurry with removal of entrained bubbles comprises a power and fluid rate control, wherein the powder and fluid rate control is coupled to a mixer through a powder feeder and a liquid pump. A fluid level control is coupled to the mixer and a surge tank, and a flow rate is coupled to the surge tank. The present invention also comprises a method for controlling the continuous mixing of slurry while removing entrained bubbles comprising providing a powder and fluid rate control, wherein the powder feeder and fluid rate control is coupled to a mixer through a powder feeder and a liquid pump. A fluid level coniol is coupled to the mixer and a surge tank and flow rate control is coupled to the surge tank.

Owner:MOBIUS TECH

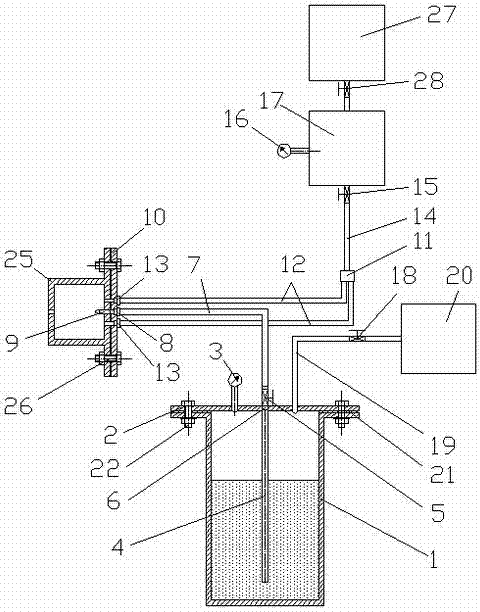

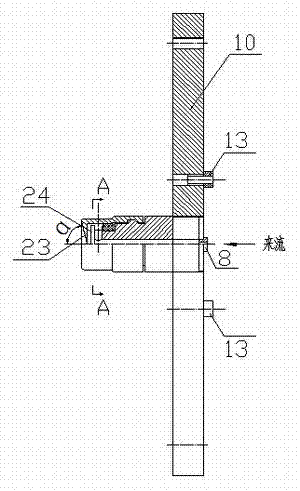

Forced-convection heat transfer experimental device for strong inner heat source containing porous medium passage

The invention provides a forced-convention heat transfer experimental device for a strong inner heat source containing porous medium passage. The device mainly comprises a water storage tank, a cooler, a surge tank, a filter, a preheater, a pebble bed experimental section, a vapor-water separator, a condensing cooler, a water return tank, a cooling water tank and a cooling tower which are connected through pipelines, wherein an electromagnetic inductor is arranged outside the pebble bed experimental section; a circulating water pump is arranged between the cooler and the filter; a cooling water pump is arranged among the cooling water tank, the condensing cooler and the cooler; valves or measuring instruments are arranged on related positions of the pipelines; and the measuring instrumentis connected with a data collection system. By adopting proper technology and reasonable design, the device realize simultaneous heating on all metal balls in the porous medium passage to ensure thatthe passage becomes a strong inner heat source containing porous medium passage, so that the heating condition of the pebble bed water-cooled reactor passage can be truly simulated.

Owner:HARBIN ENG UNIV

Fuel injection device of cylinder injection type internal combustion engine and fuel injection method thereof

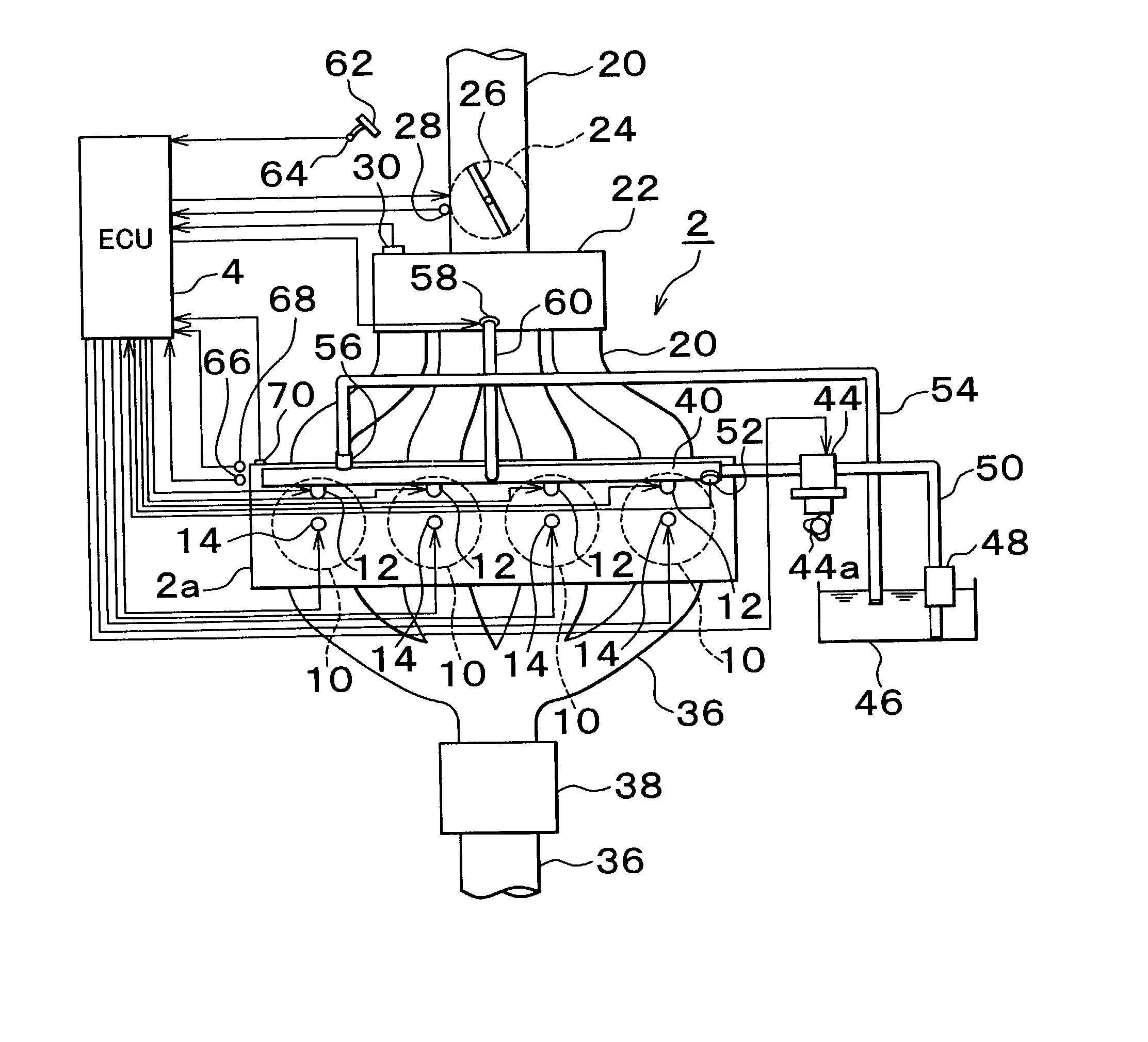

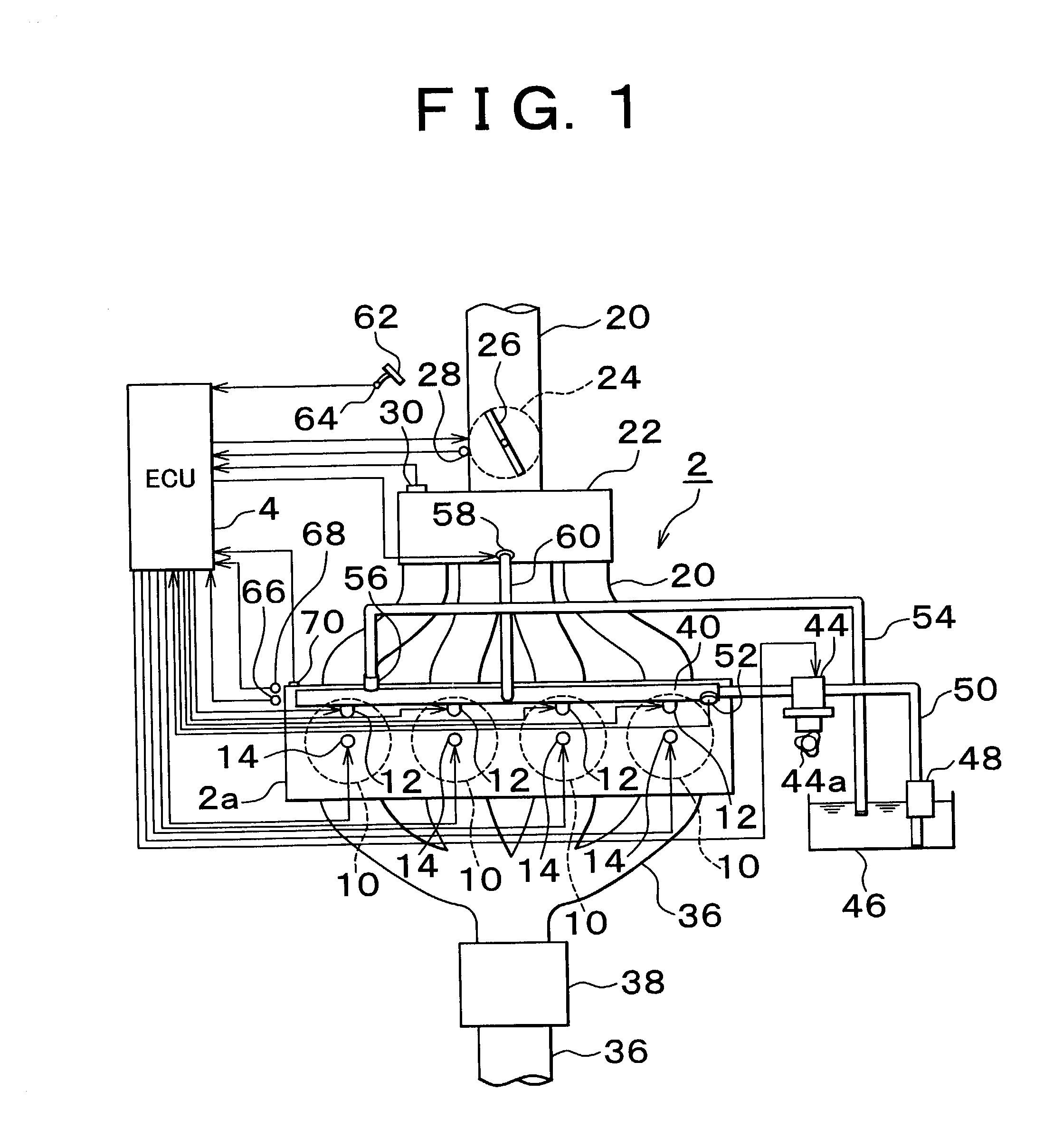

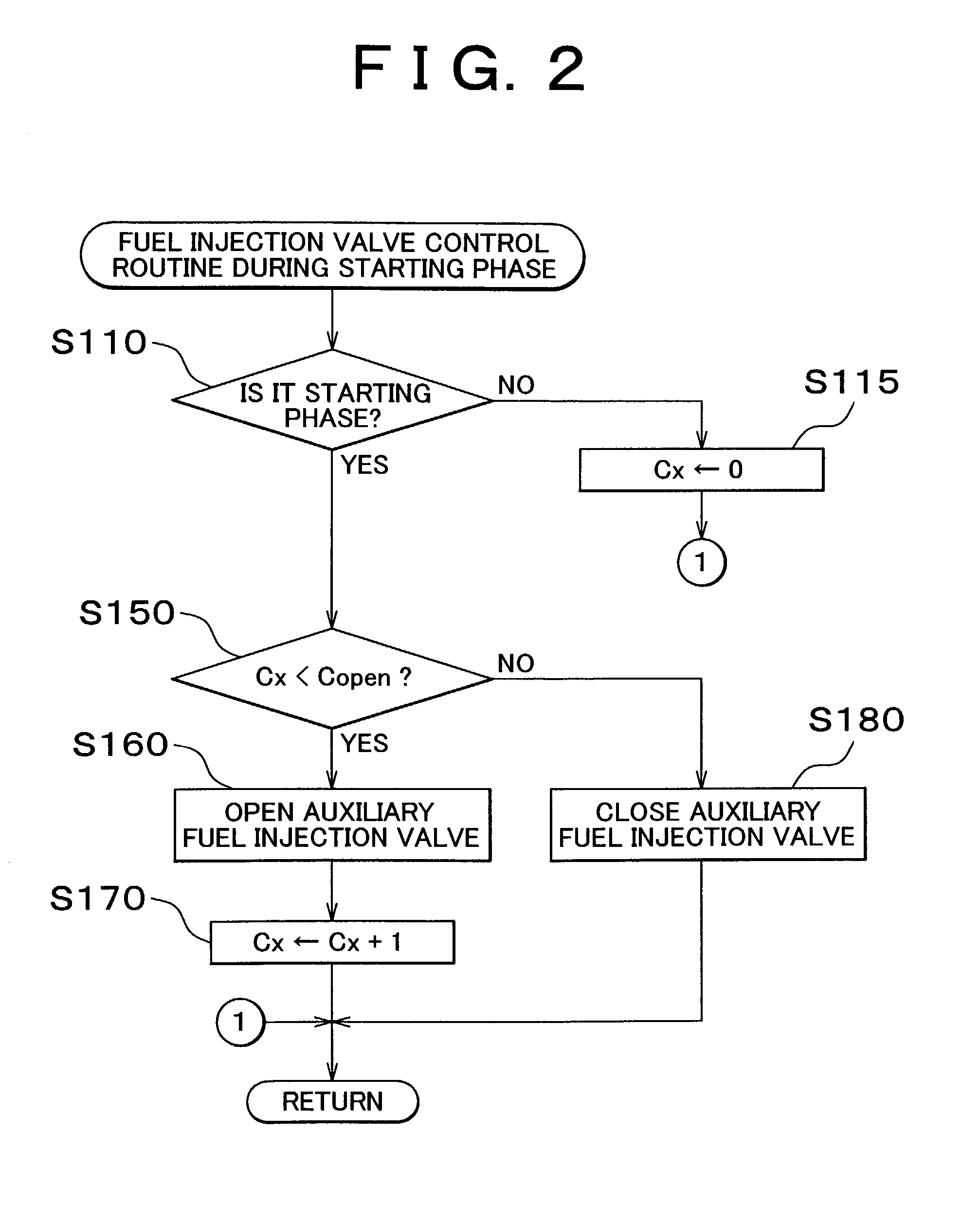

InactiveUS20030041838A1Electrical controlInternal combustion piston enginesSurge tankCombustion chamber

A fuel injection device and method includes a main injection valve that injects a high-pressure fuel supplied to a delivery pipe into each combustion chamber of an engine, and an auxiliary fuel injection valve supplied with the high-pressure fuel from the delivery pipe. The auxiliary fuel injection valve is capable of injecting the high-pressure fuel in sucked air flowing in a surge tank when the engine is started under cold conditions. In addition, a fuel pressure can rapidly be increased in a starting phase since vapor in the delivery pipe can be discharged by temporarily opening the auxiliary fuel injection valve.

Owner:TOYOTA JIDOSHA KK

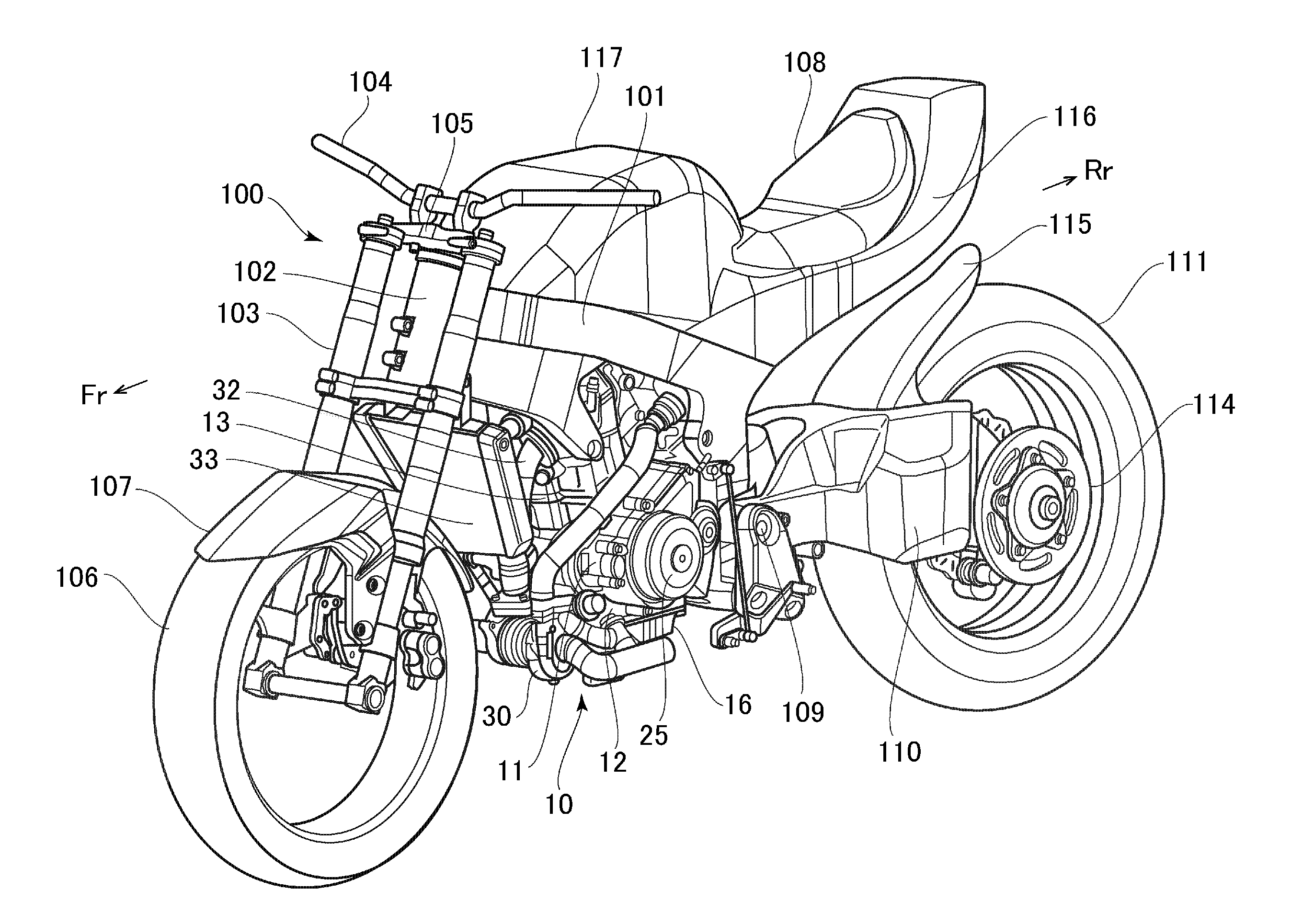

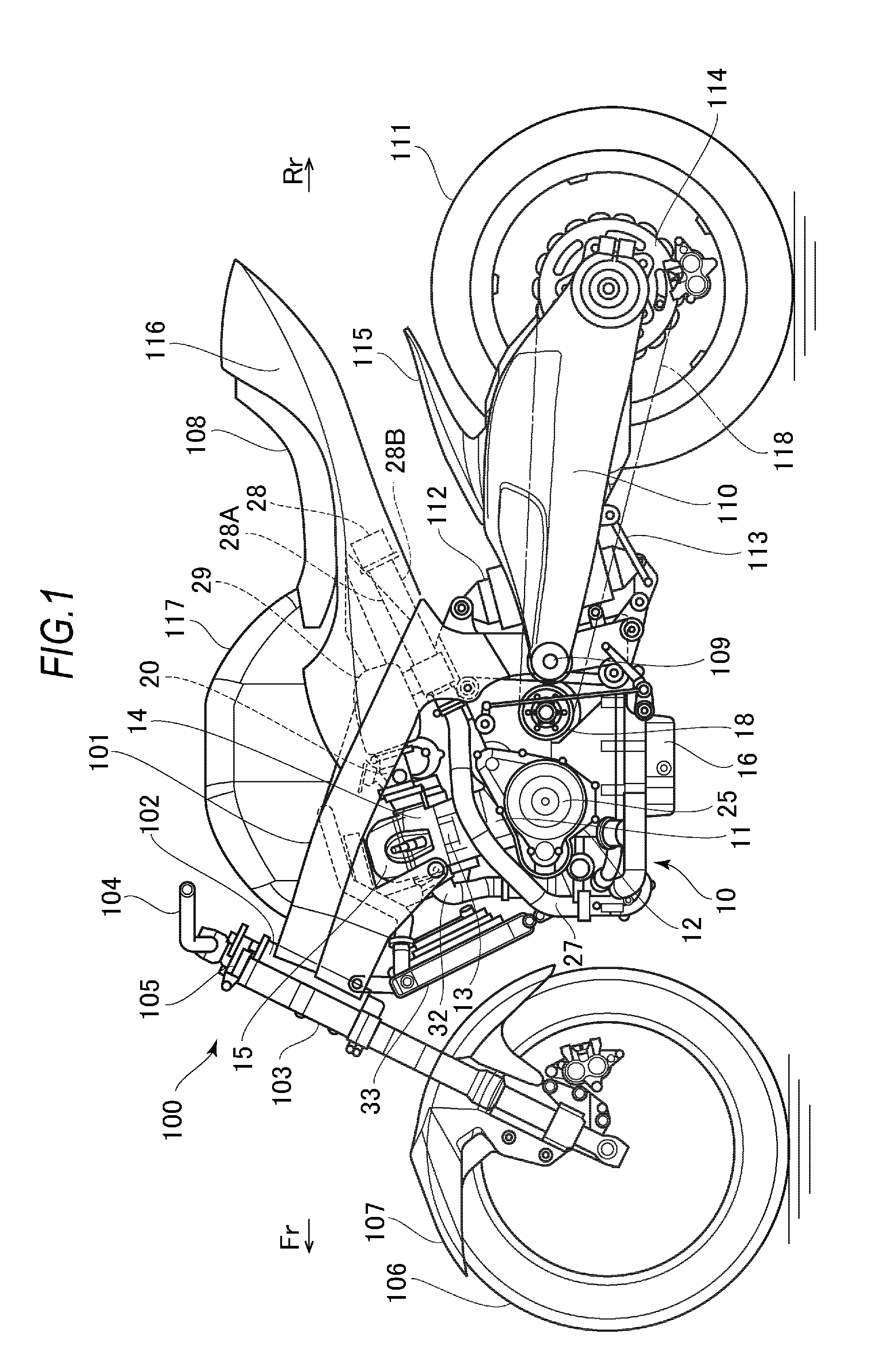

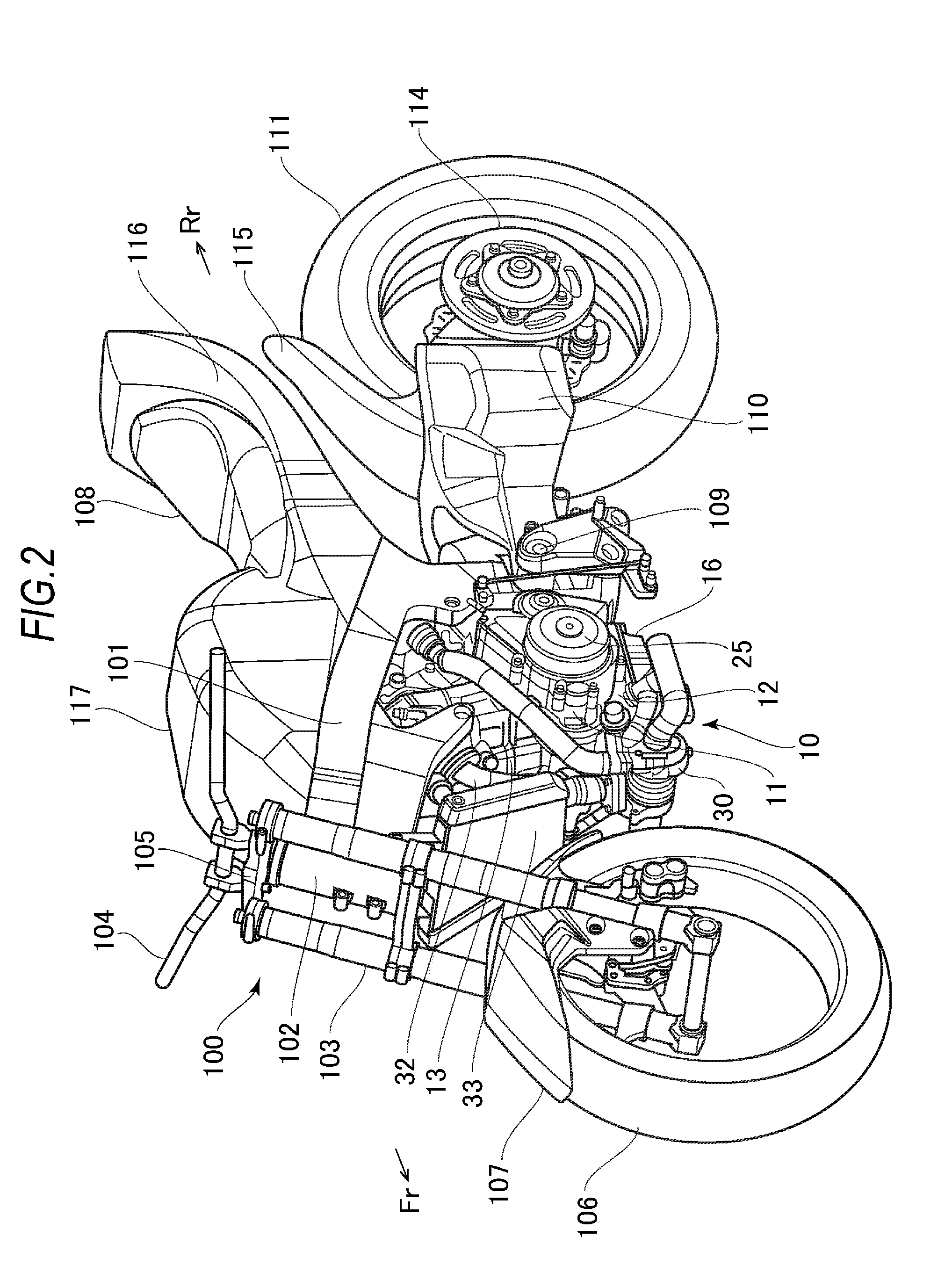

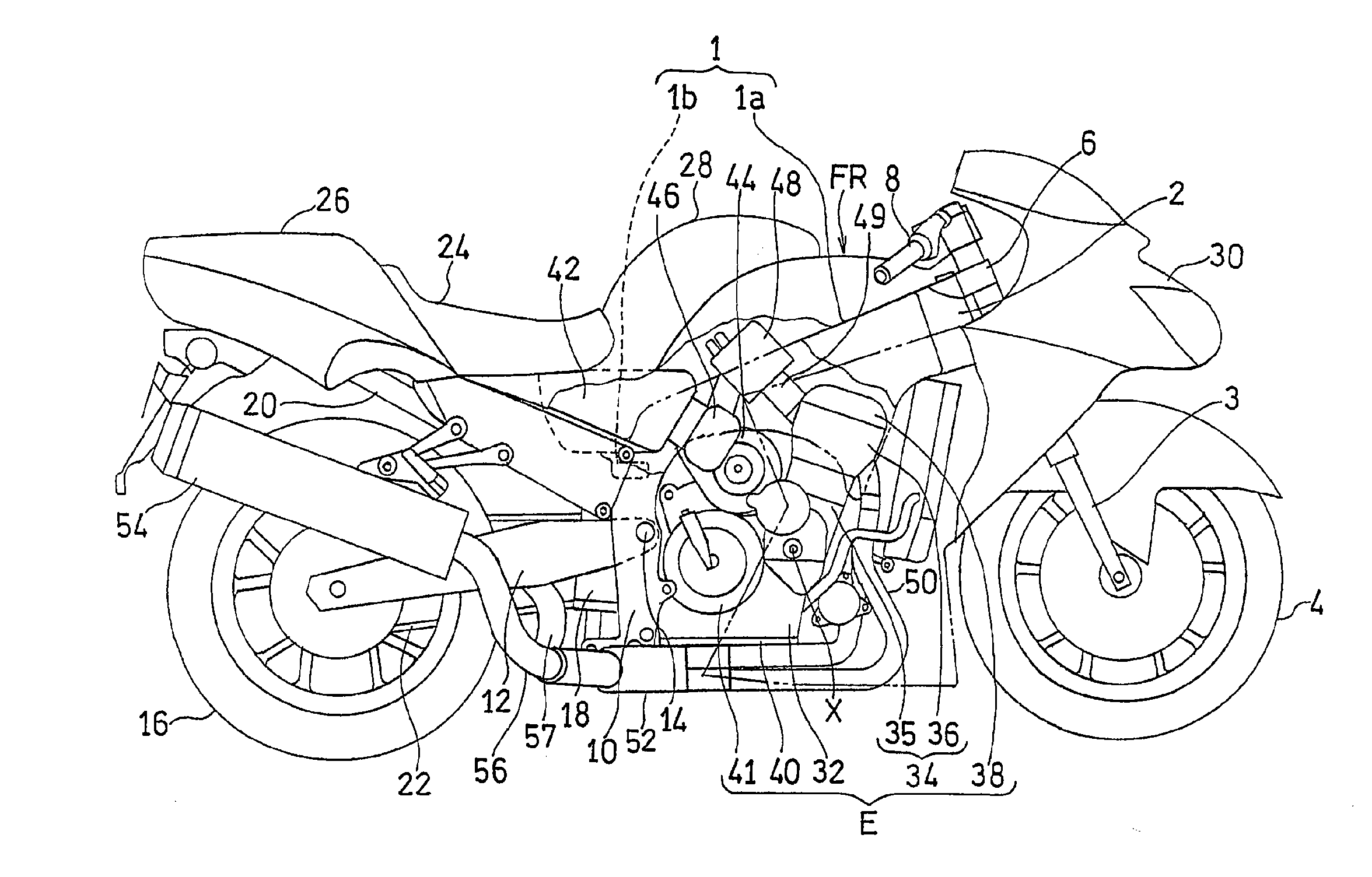

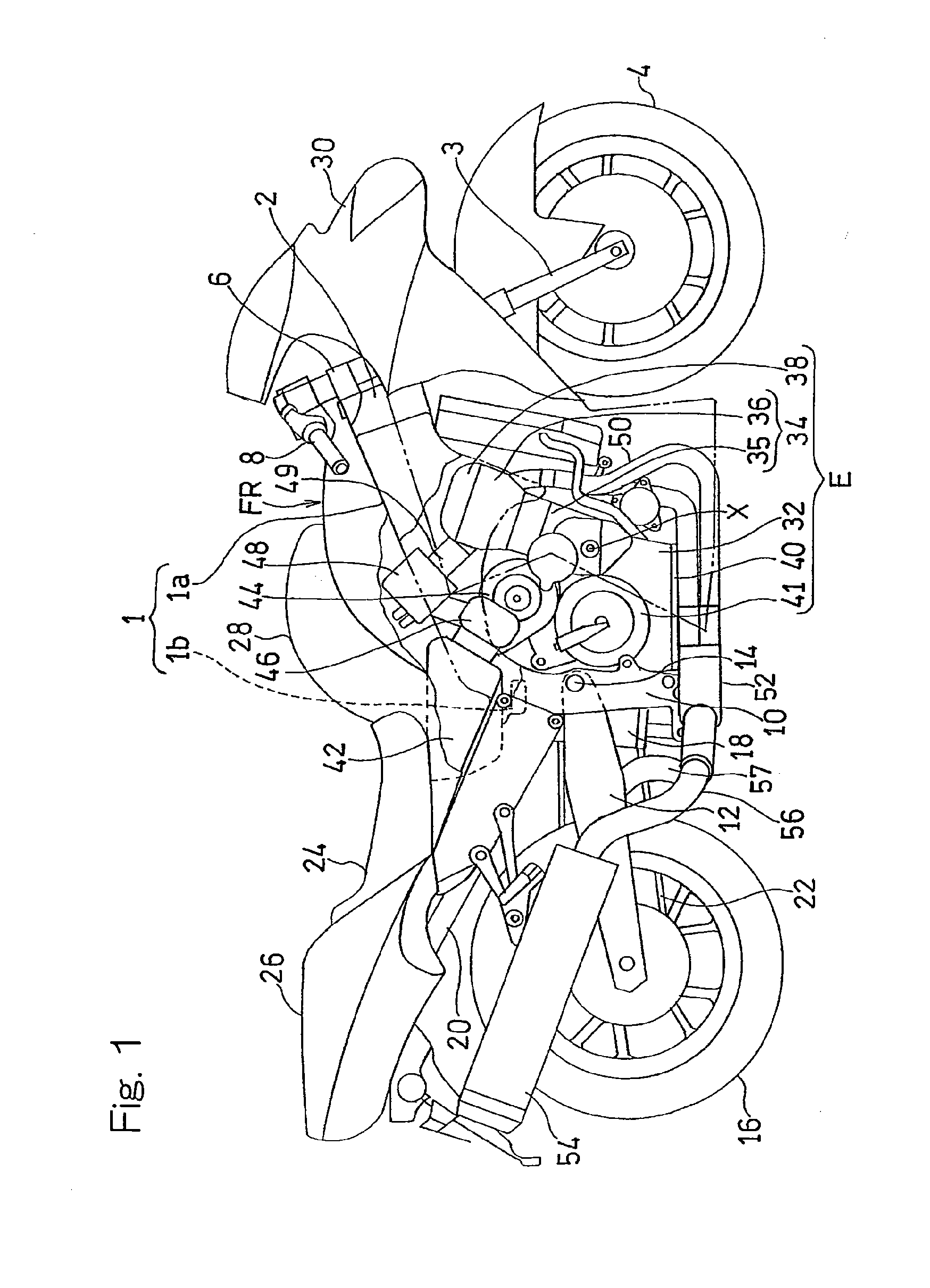

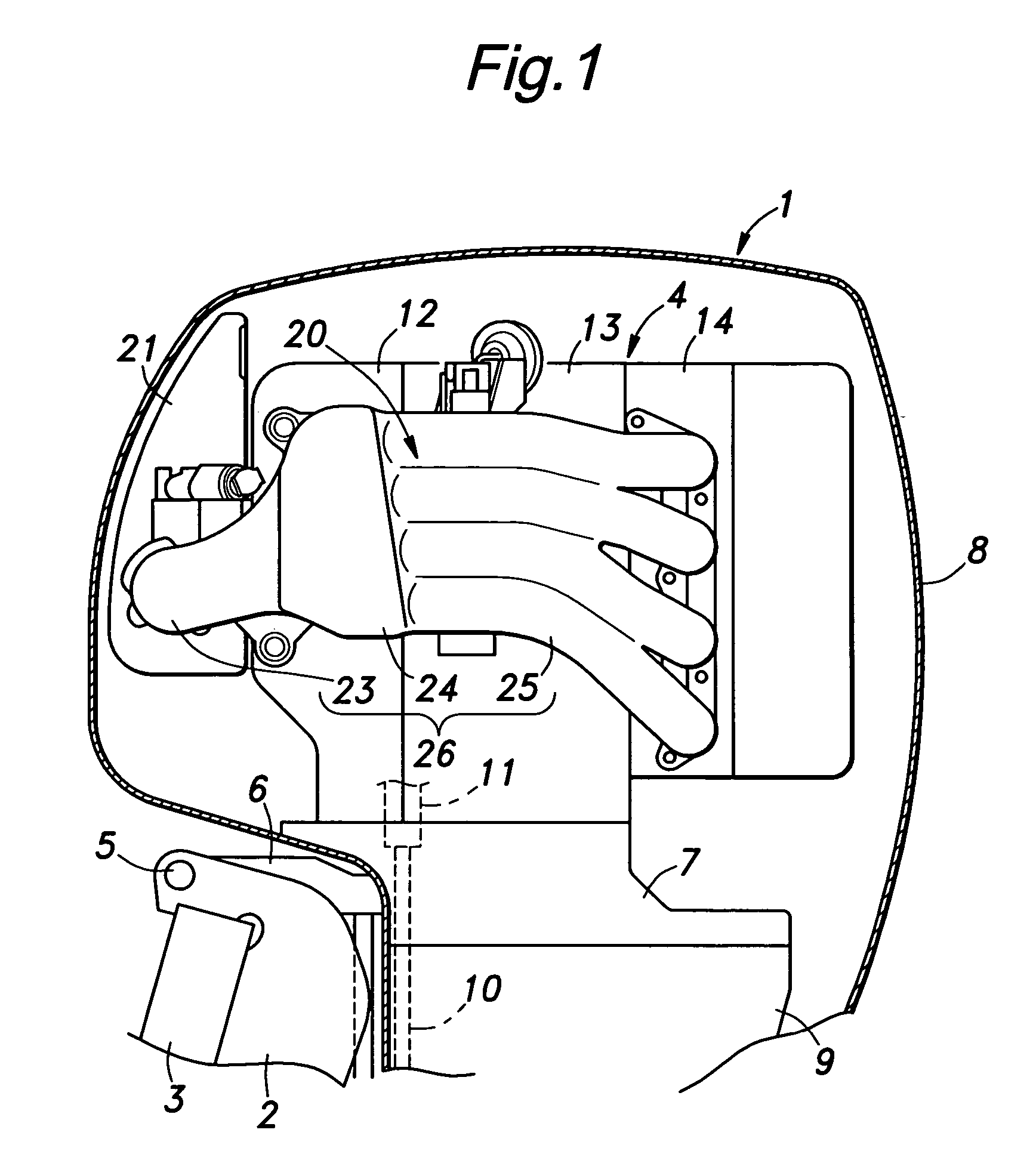

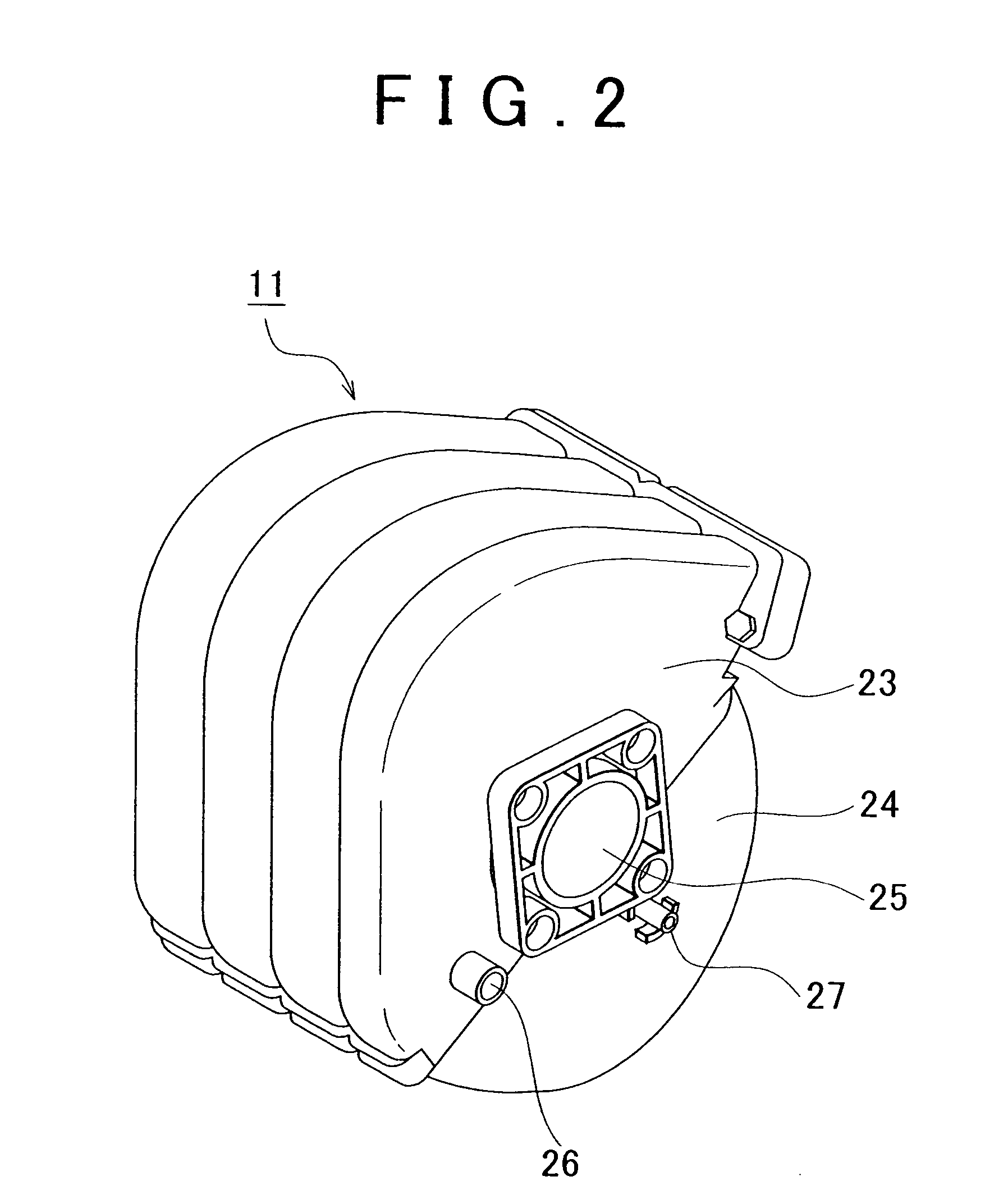

Motorcycle

ActiveUS20150083513A1Effective arrangement structureEffective structureMechanical controlInternal combustion piston enginesSurge tankCylinder head

One or more throttle bodies and a surge tank are disposed behind a cylinder head, and an intercooler is disposed by being adjacent to the surge tank at a position behind the cylinder head and the one or more throttle bodies. A supercharger is provided in front of the intercooler.

Owner:SUZUKI MOTOR CORP

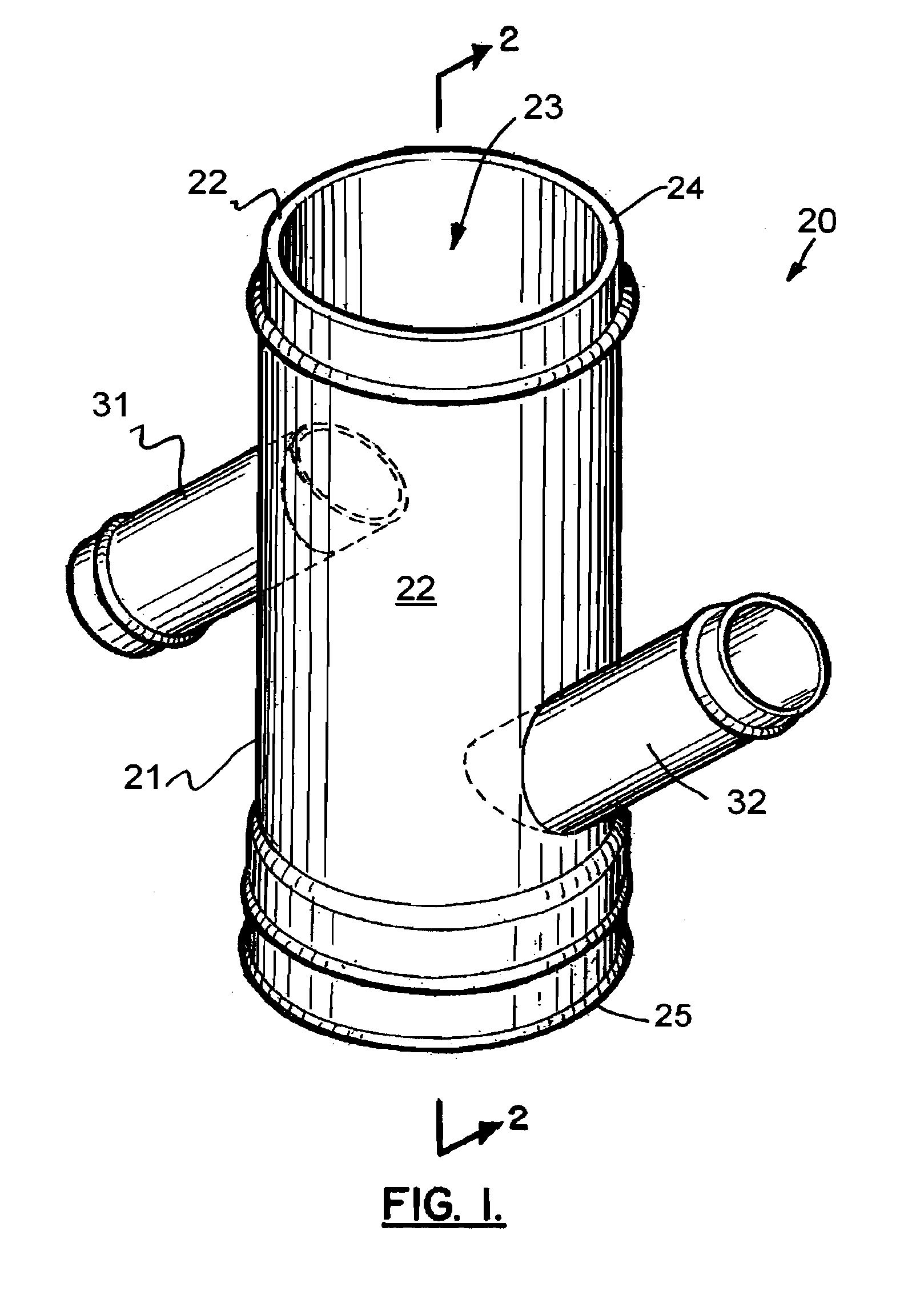

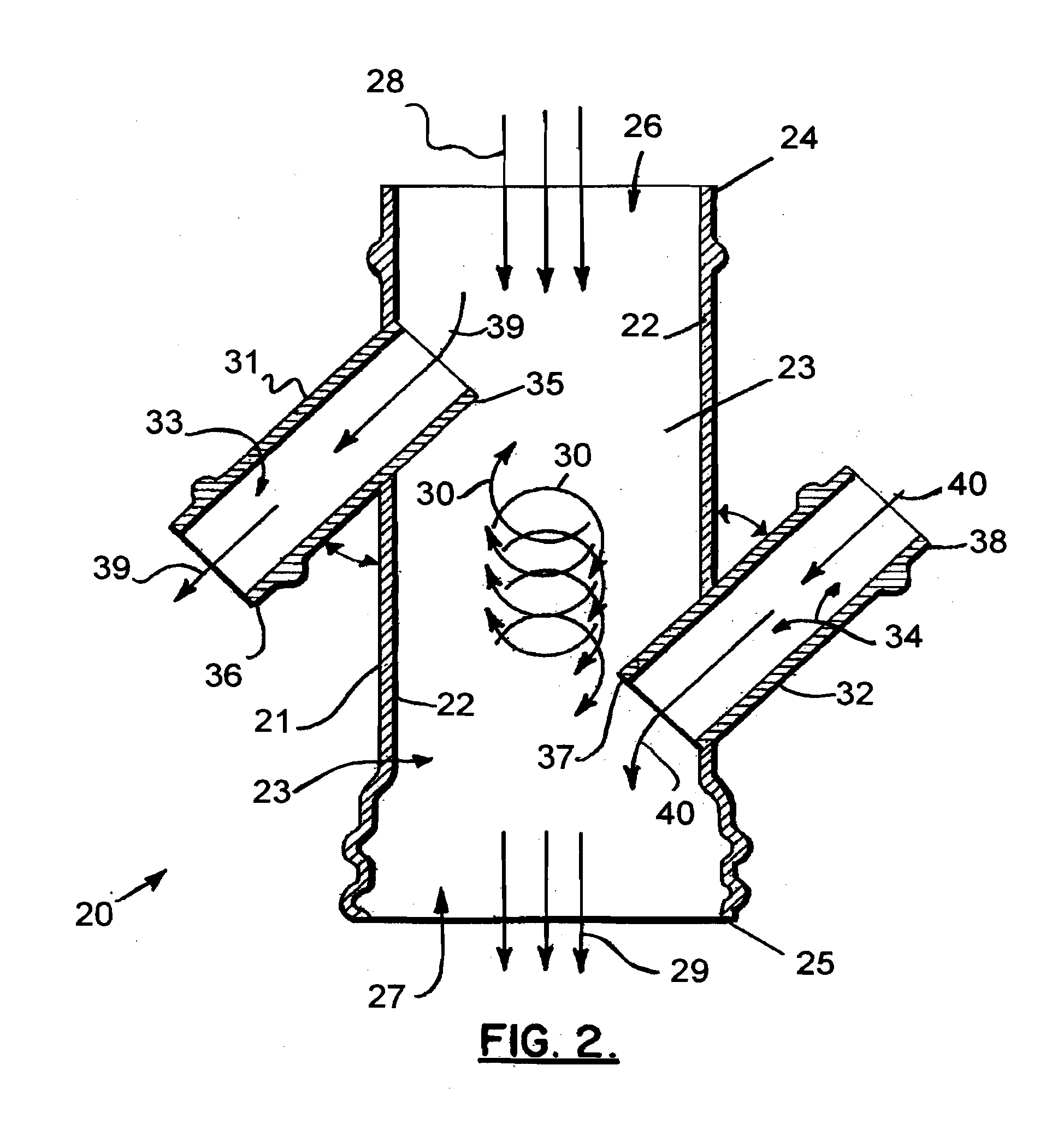

Water heating apparatus for continuous heated water flow and method for use in hydraulic fracturing

ActiveUS8171993B2Increase temperatureHigh temperature riseTemperatue controlInsulationSurge tankWater flow

A method of hydraulic fracturing of an oil producing formation includes the provision of a heating apparatus which is transportable and that has a vessel for containing water. A water stream of cool or cold water is transmitted from a source to a mixer, the cool or cold water stream being at ambient temperature. The mixer has an inlet that receives cool or cold water from the source and an outlet that enables a discharge of a mix of cool or cold water and the hot water. After mixing in the mixer, the water assumes a temperature that is suitable for mixing with chemicals that are used in the fracturing process, such as a temperature of about 40° -120° F.+(4.4 - 48.9° C.+). An outlet discharges a mix of the cool and hot water to surge tanks or to mixing tanks. In the mixing tanks, a proppant and an optional selected chemical or chemicals are added to the water which has been warmed. From the mixing tanks, the water with proppant and optional chemicals is injected into the well for part of the hydraulic fracturing operation.

Owner:HEAT ON THE FLY

Motorcycle with supercharger

ActiveUS20120267182A1Save spaceIncrease capacityCombustion-air/fuel-air treatmentCombustion enginesCombustionSurge tank

A motorcycle includes a combustion engine (E) of a type, in which a cylinder block (34) protrudes upwardly from a crankcase (32), an air cleaner unit (42) for substantially purifying an air, and a supercharger (44) for taking a substantially purified air from the air cleaner unit (42) thereinto and supplying the air towards the combustion engine (E). The supercharger (44) is disposed rearwardly of the cylinder block (34) and the air cleaner unit (42) is disposed rearwardly thereof. Also, a surge tank (48) is disposed rearwardly upwardly of the cylinder block (34) of the combustion engine (E) and above the supercharger (44).

Owner:KAWASAKI MOTORS LTD

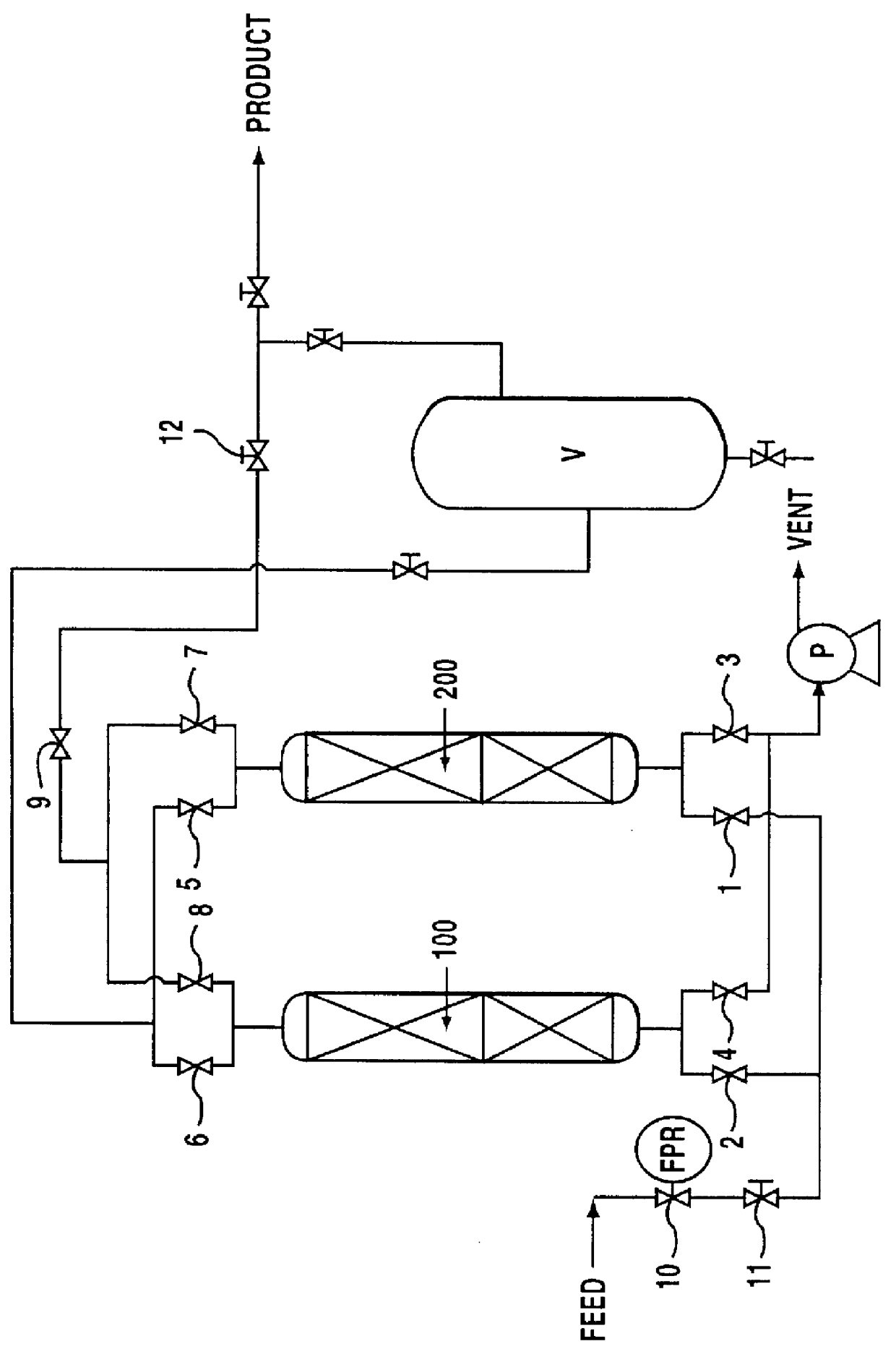

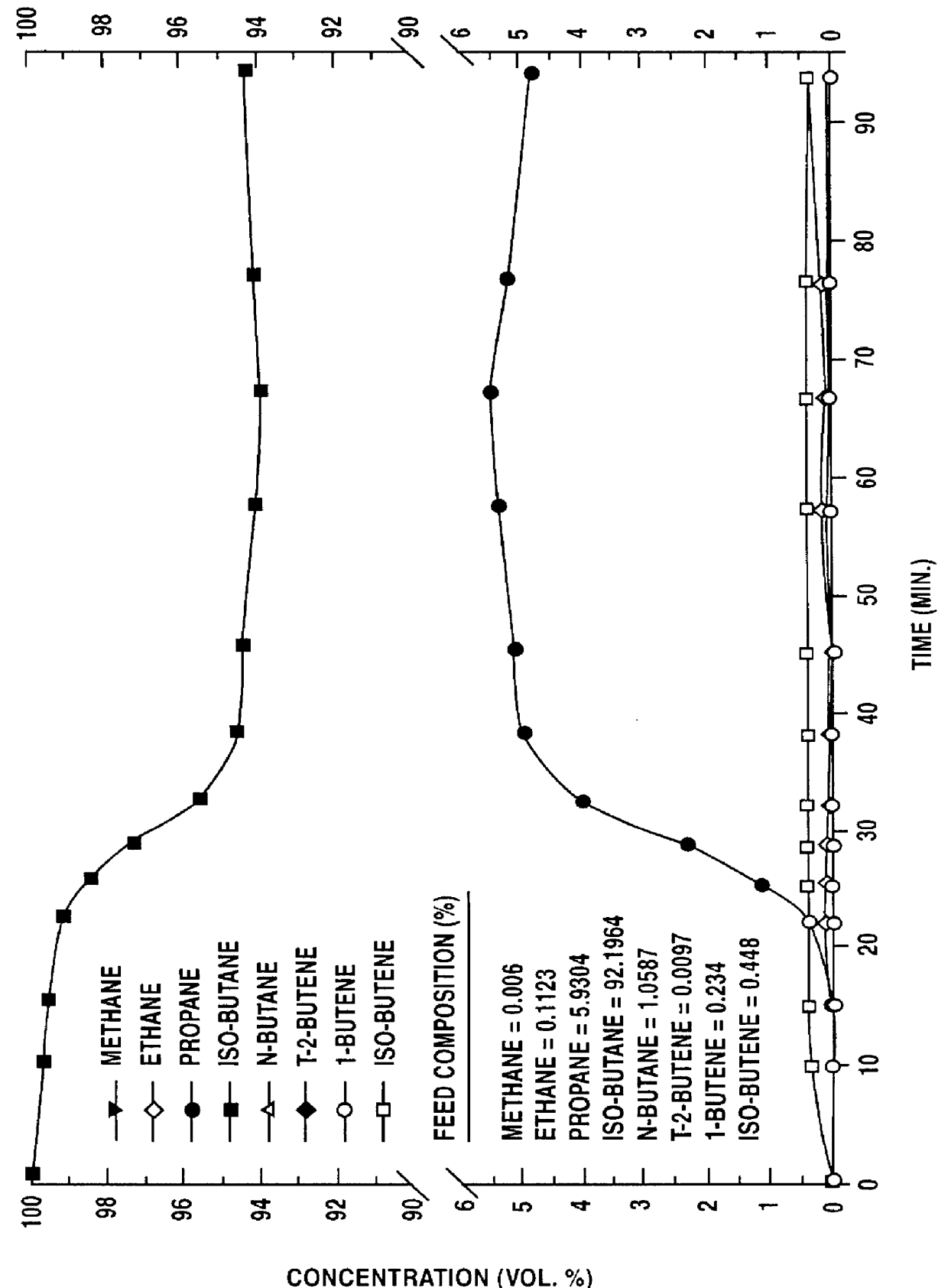

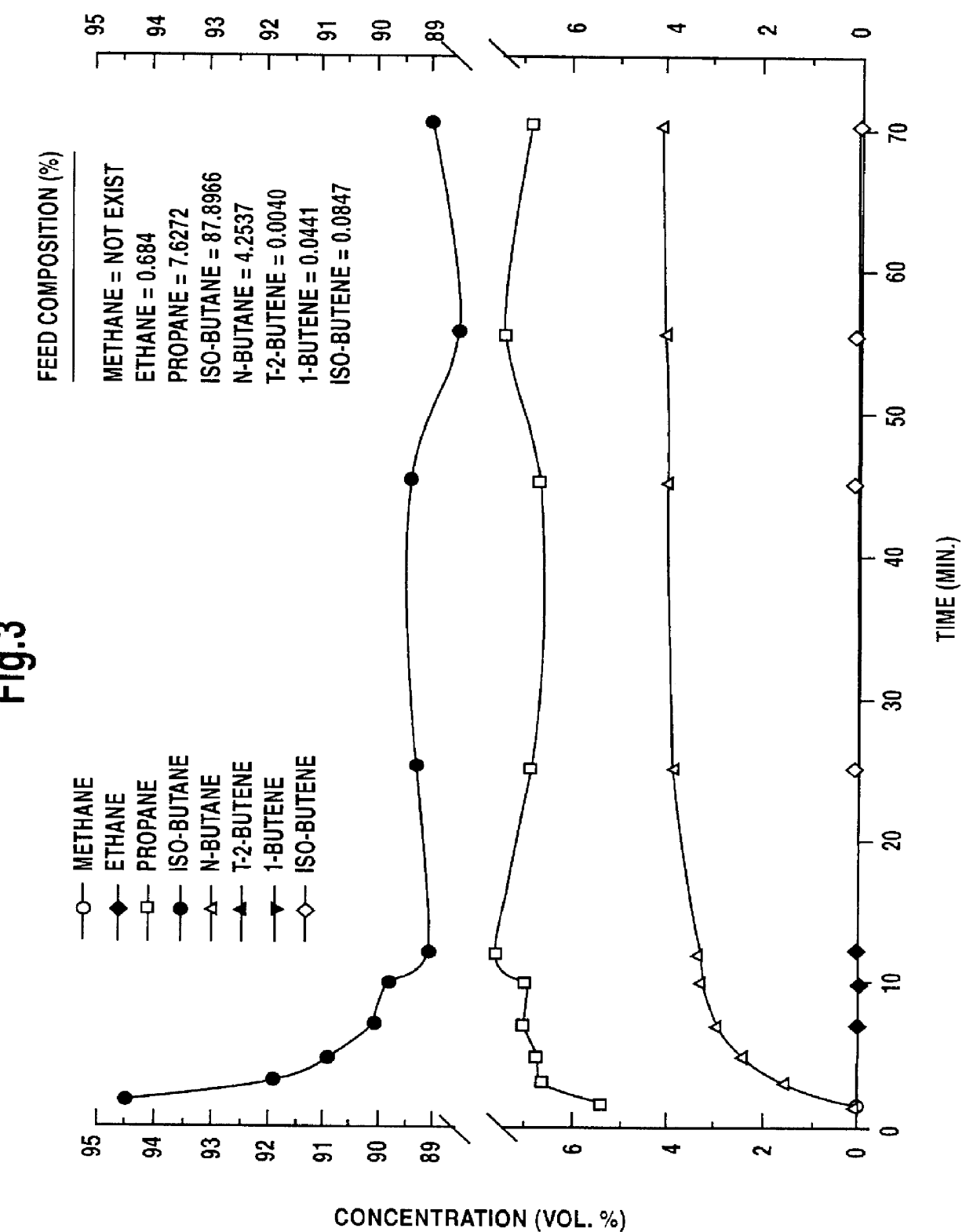

Adsorption separation and purification apparatus and process for high purity isobutane production

A high purity isobutane adsorption separation and purification apparatus is provided including a pressure regulator which regulates the pressure of an isobutane-containing gas; the at least one adsorption bed packed with zeolite 5A and carbon molecular sieve arranged downstream of and operatively associated with the pressure regulator; a flow control valve disposed between the pressure regulator and the at least one adsorption bed; a surge tank operatively associated with and for receiving a purified isobutane product from the at least one adsorption bed; a vacuum pump operatively associated with and for removal of impurities from the at least one adsorption bed; and valves disposed between the pressure regulator and the at least one adsorption bed, between the at least one adsorption bed and the surge tank, and between the at least one adsorption bed and the vacuum pump. An adsorptive separation and isobutane purification process is also provided which may be used with the apparatus of the invention.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO +1

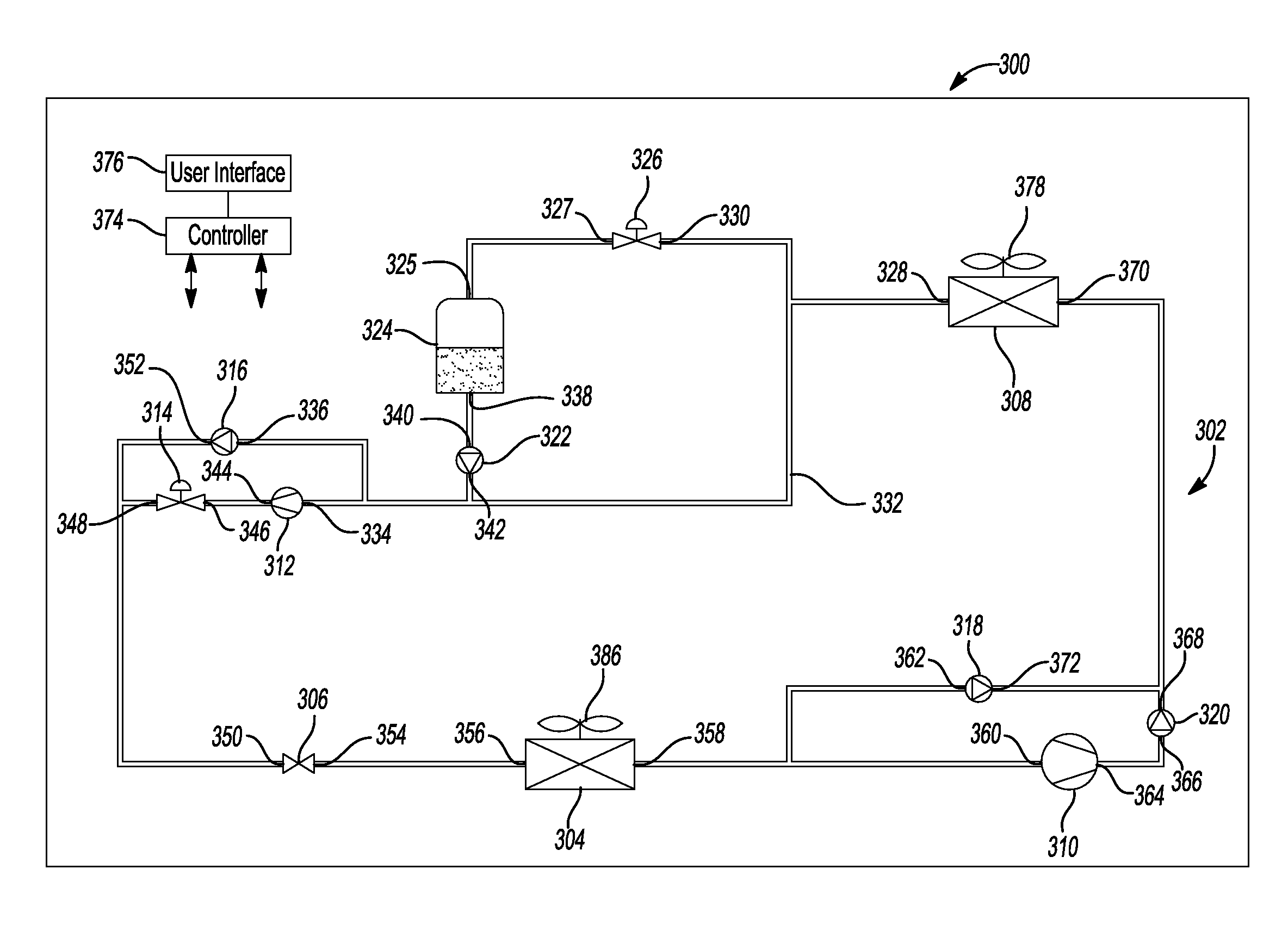

Receiver tank purge in vapor compression cooling system with pumped refrigerant economization

A cooling system includes a cooling circuit having an evaporator, a condenser, a compressor, an expansion device, a liquid pump, and a receiver / surge tank coupled between the condenser and the liquid pump. The cooling system has a direct expansion mode and a pumped refrigerant economizer mode. When the cooling system switches from the direct expansion mode to the pumped refrigerant economizer mode, refrigerant is flushed from the refrigerant / surge tank so that the cooling circuit is overcharged when it begins operating in the pumped refrigerant economizer mode.

Owner:VERTIV CORP

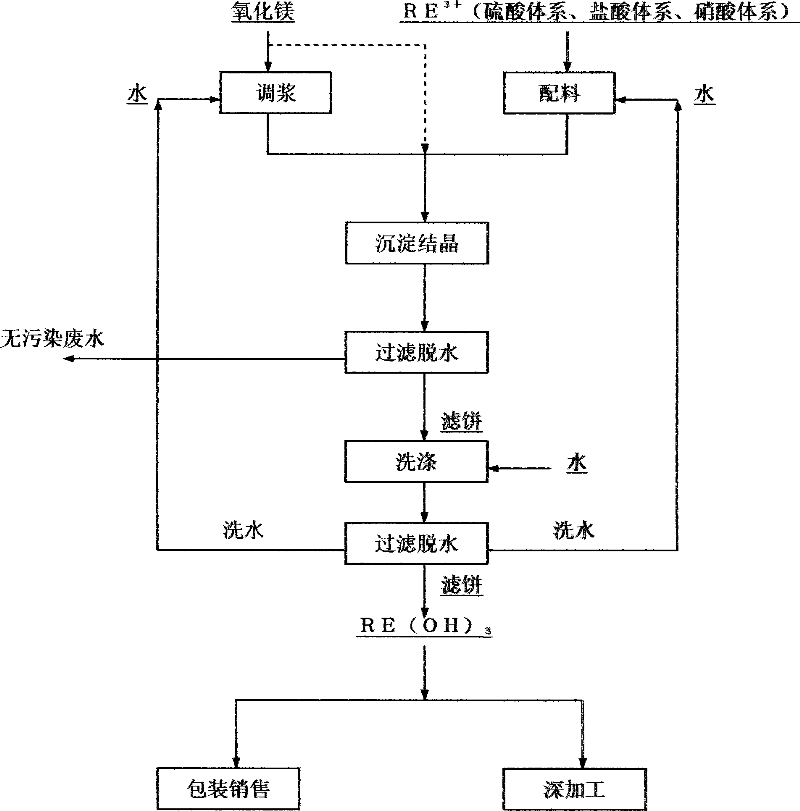

Production process of magnesia used for rear earth solution precipitator

ActiveCN101037219ASolve processing problemsPromote cleaner productionRare earth metal compoundsSurge tankWash water

The present invention belongs to the rare earth preparation field, wherein magnesia serving as precipitator is used for the precipitation process of rare earth solution. The surge tank is filled with water and heated, and magnesia is added into the water to be confected; an amount of water and rare earth feed liquid are confected and injected into dosage bunker to be heated; the confected rare earth feed liquid and magnesia feed liquid are injected into precipitation tank in term of equal equivalent to execute precipitation reaction; the slime after precipitation reaction is pumped into a filter kettle to execute filter dehydration to obtain filter cake which is confected by water and is scrubbed, and then solid rare earth hydrate is obtained after filter dehydration, wherein the wash water can be recovered and reused. The present invention is capable of overcome the disadvantage of the prior art, reducing the cost greatly, overcoming the problem of wastewater treatment, enlarging the application field of precipitator, promoting the clean production of rare earth industry.

Owner:BAOTOU HUAMEI RE PRODS

System and method for treating wastewater

InactiveUS20070045181A1Water treatment parameter controlBiological treatment regulationActivated sludgeSurge tank

A system for treating wastewater comprises a source of activated sludge, a compressor for supplying pressurized air, at least one anaerobic reactor for anaerobically treating wastewater with the activated sludge, at least one aerobic reactor for aerobically treating wastewater with the activated sludge and pressurized air, a pressure control system for regulating pressure in the system, a discharge system for removing byproducts of the system, and a discharge system for removing treated wastewater and activated sludge from an anaerobic and an aerobic reactor, and a surge tank for holding removed wastewater and activated sludge and thereby further treating the wastewater.

Owner:SKYBLUE WATERS USA

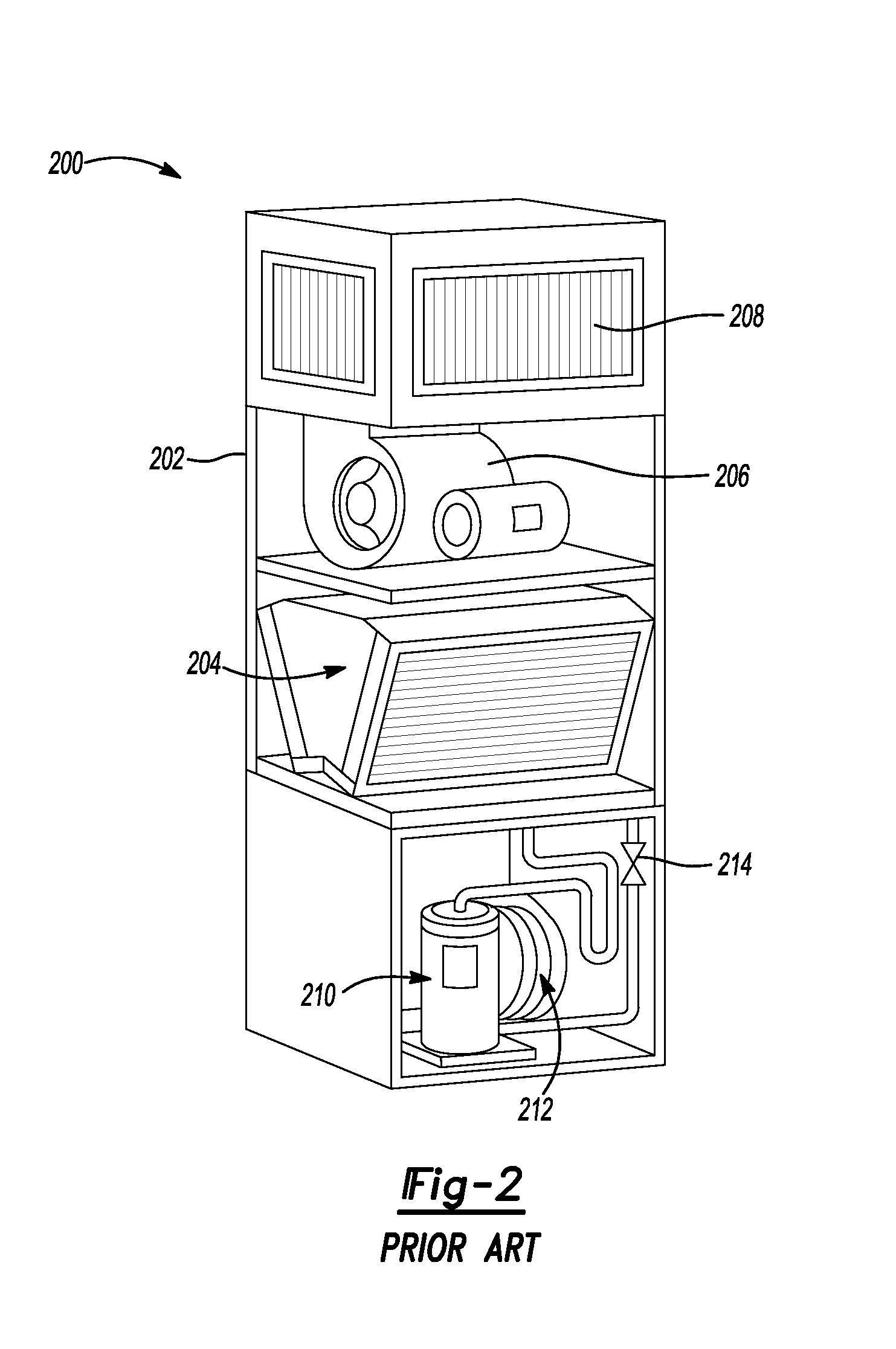

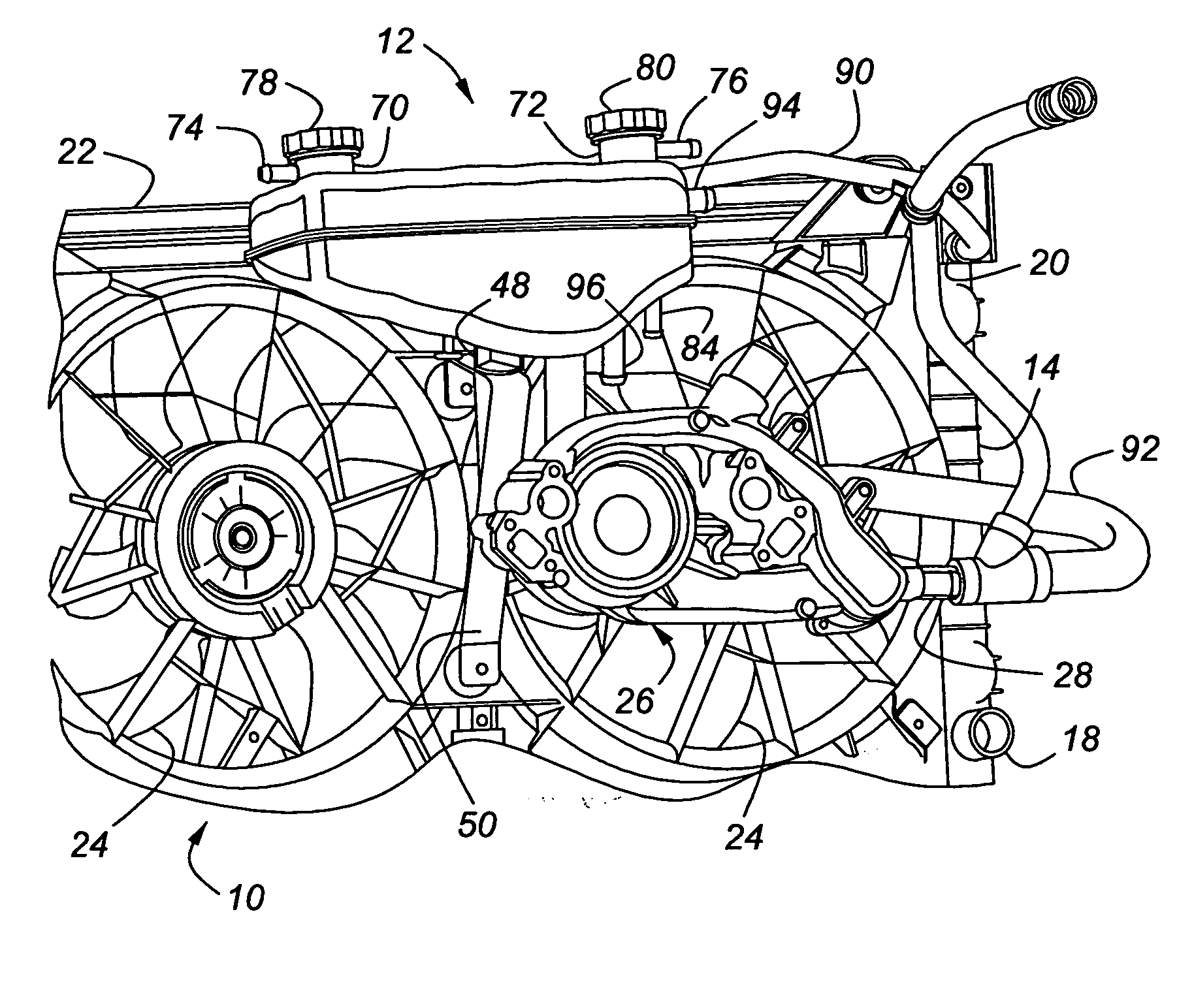

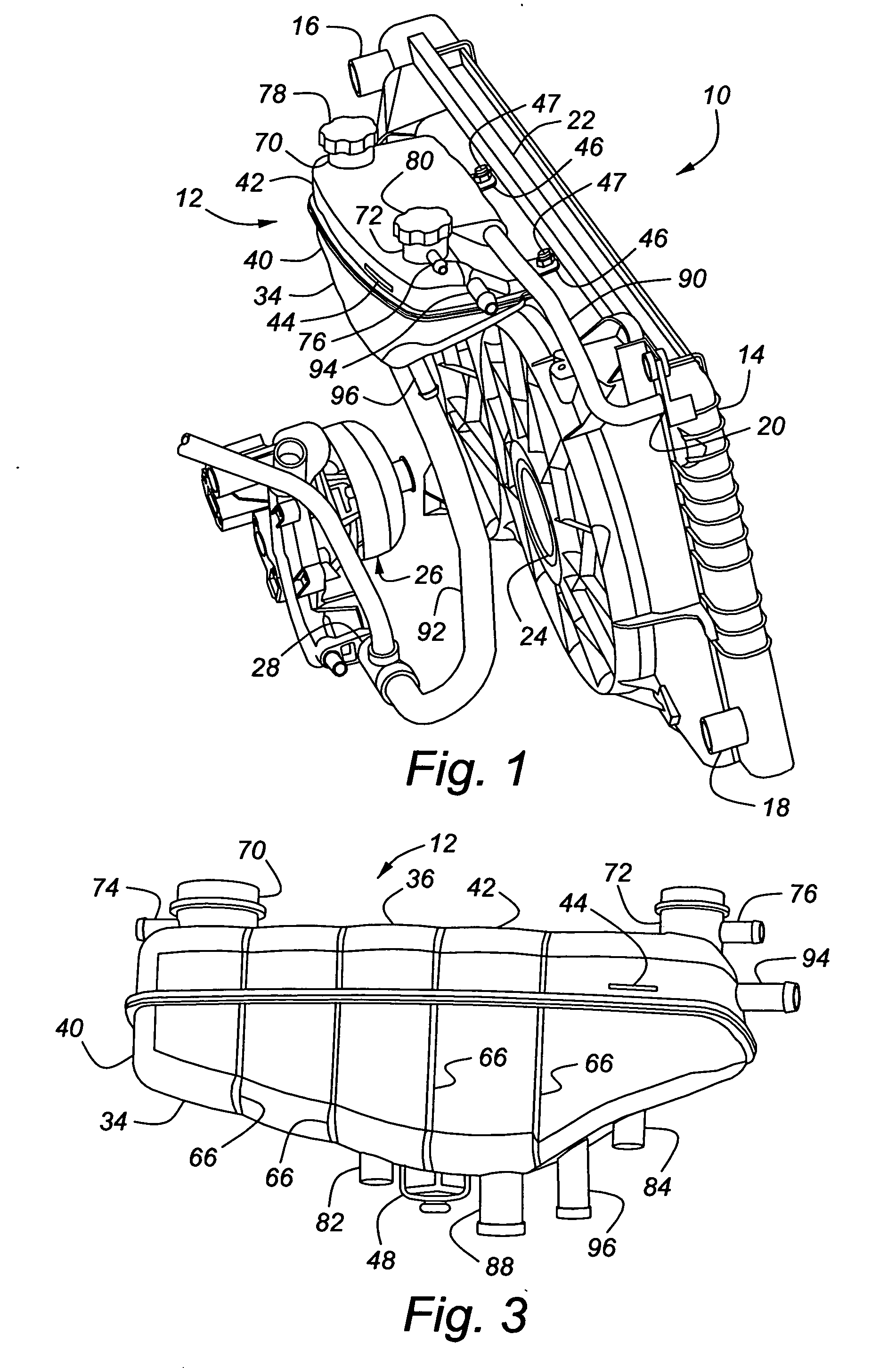

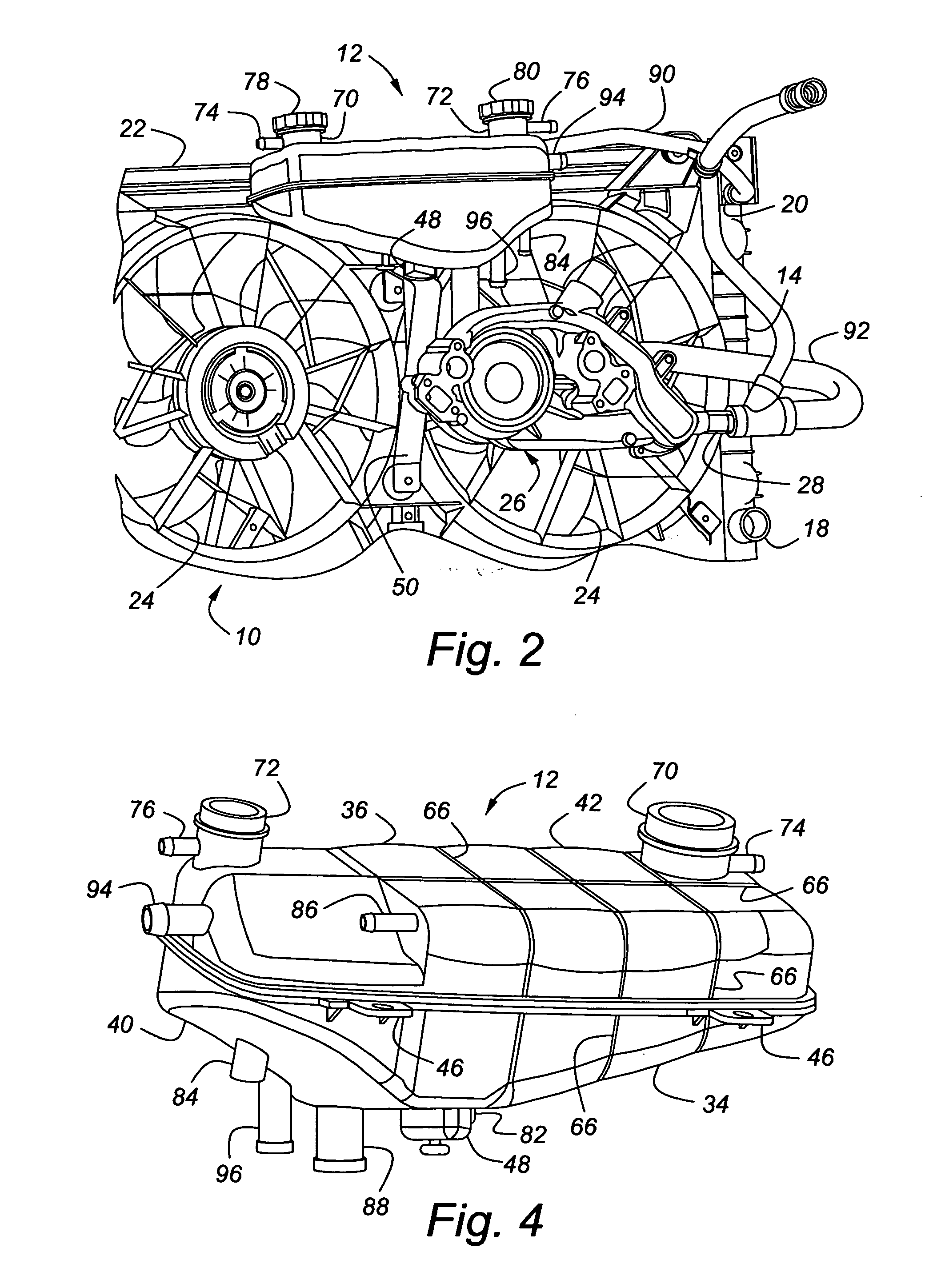

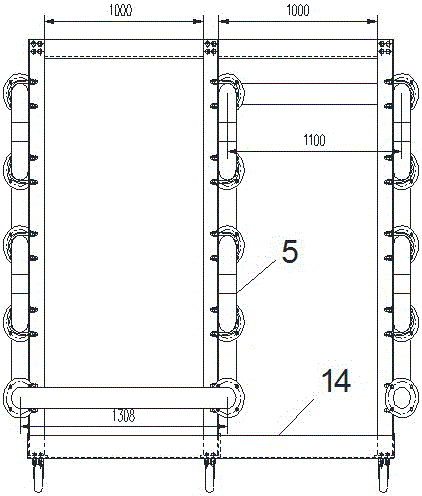

Dual surge tank for vehicle cooling system

InactiveUS20070044938A1Improves vehicle packagingLow costAir-treating devicesVehicle heating/cooling devicesSurge tankElectronics

The invention concerns a dual surge tank for use in a cooling system of a vehicle. The dual surge tank includes a housing having an outer wall defining a container, and a divider, located within the housing, dividing the container into a first chamber adapted to contain a first liquid and a second chamber adapted to contain a second liquid, with the divider sealing the first chamber from the second chamber. The divider may provide heat insulation between the two chambers. The first chamber may contain engine coolant and the second chamber may contain electronics coolant.

Owner:GM GLOBAL TECH OPERATIONS LLC

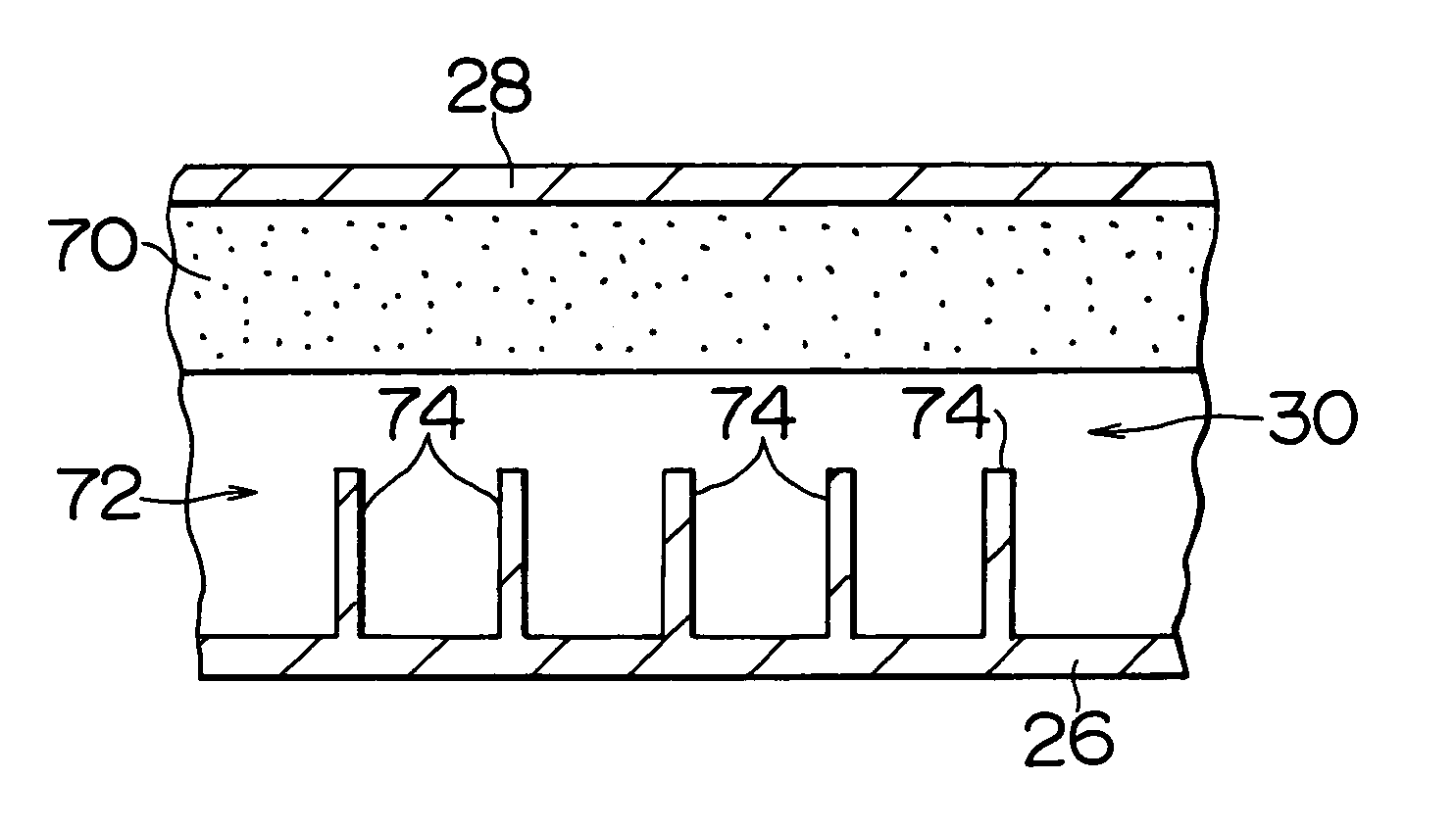

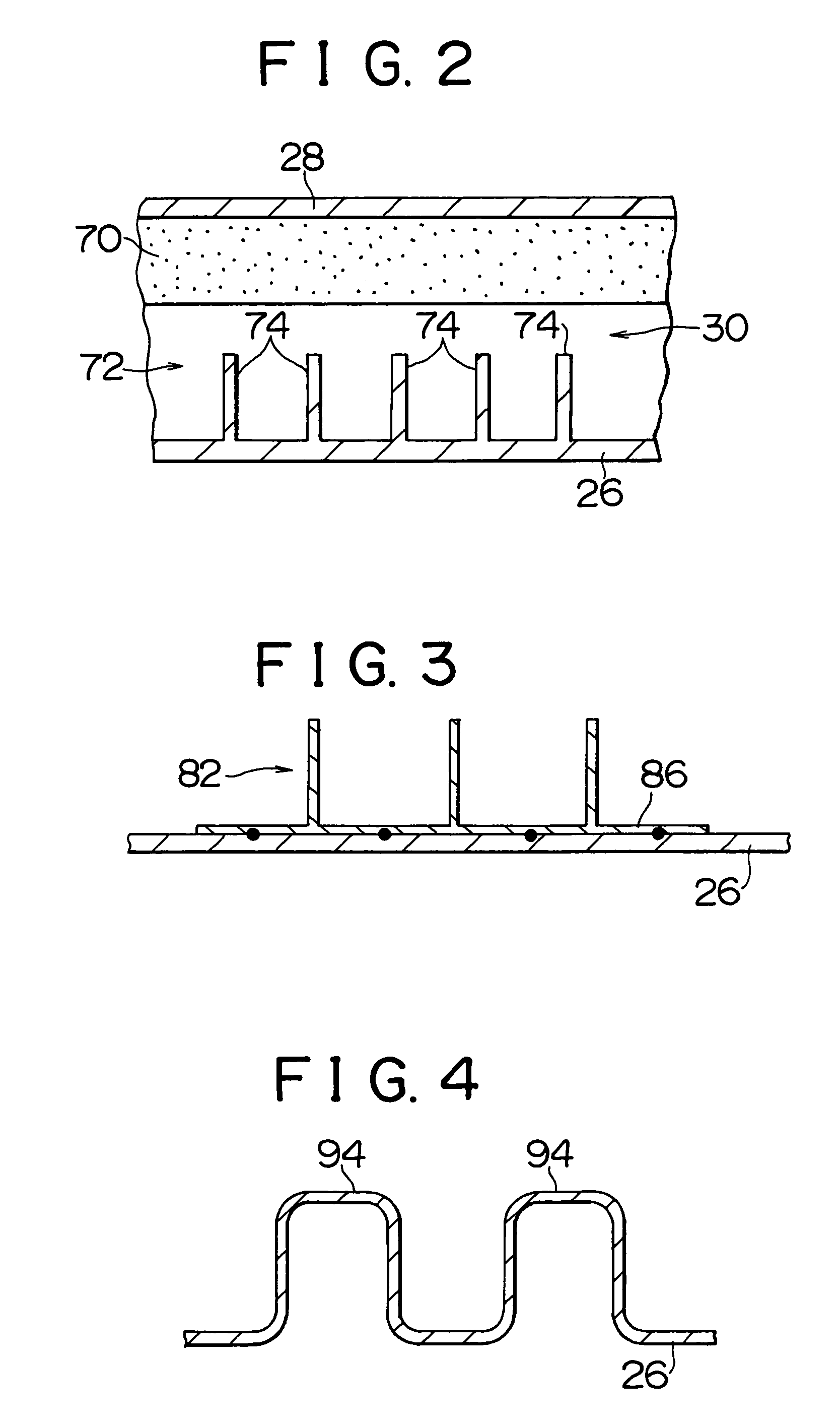

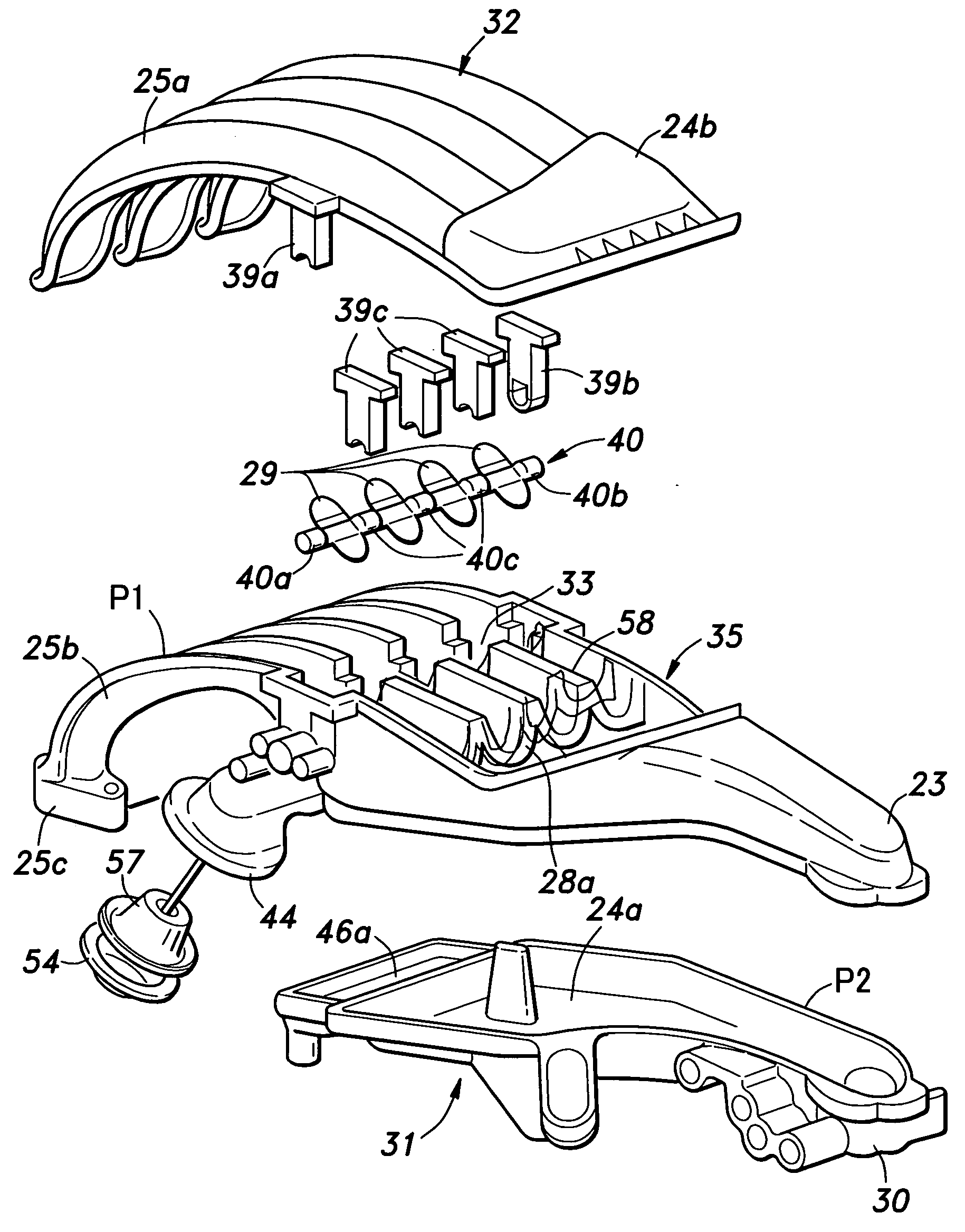

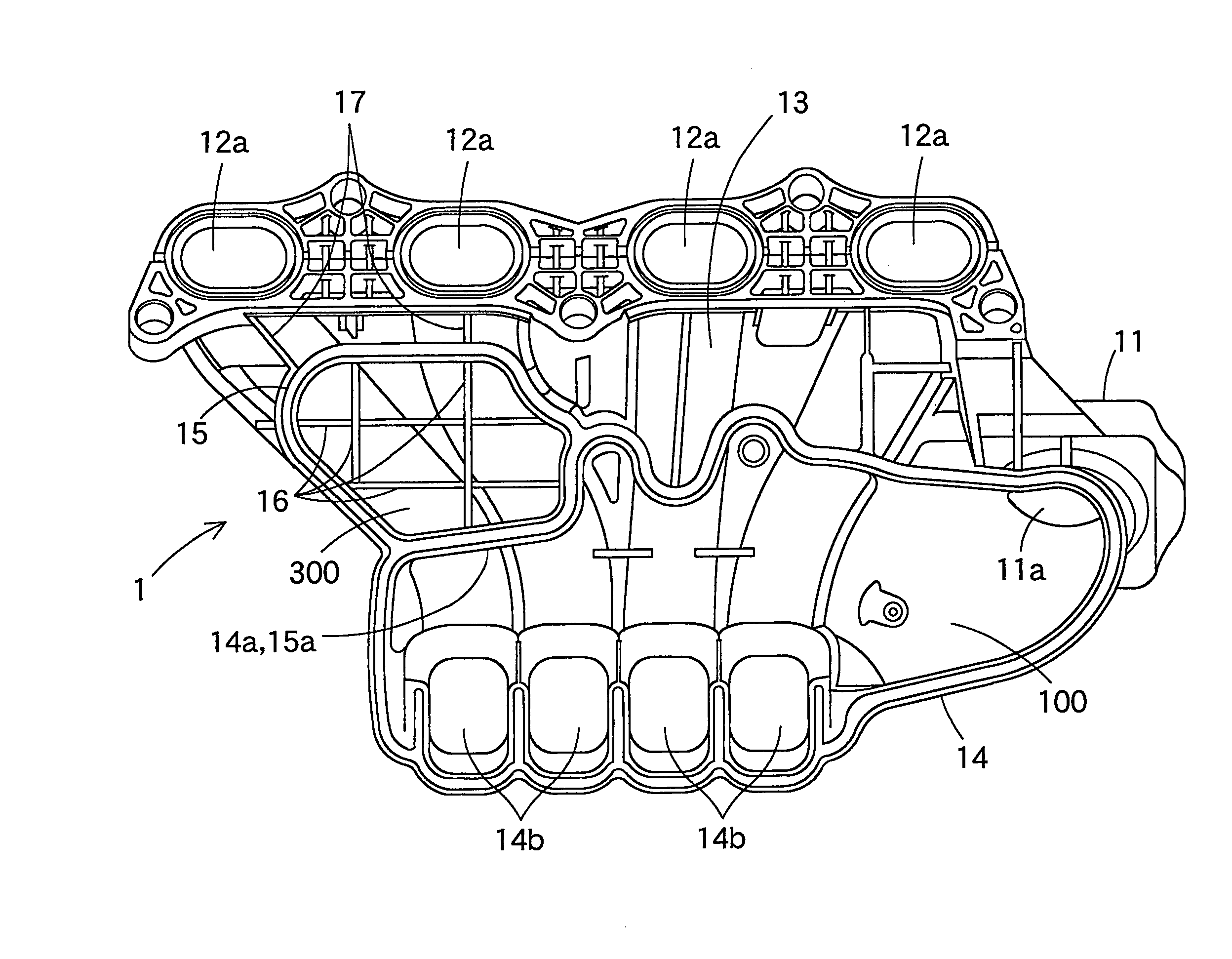

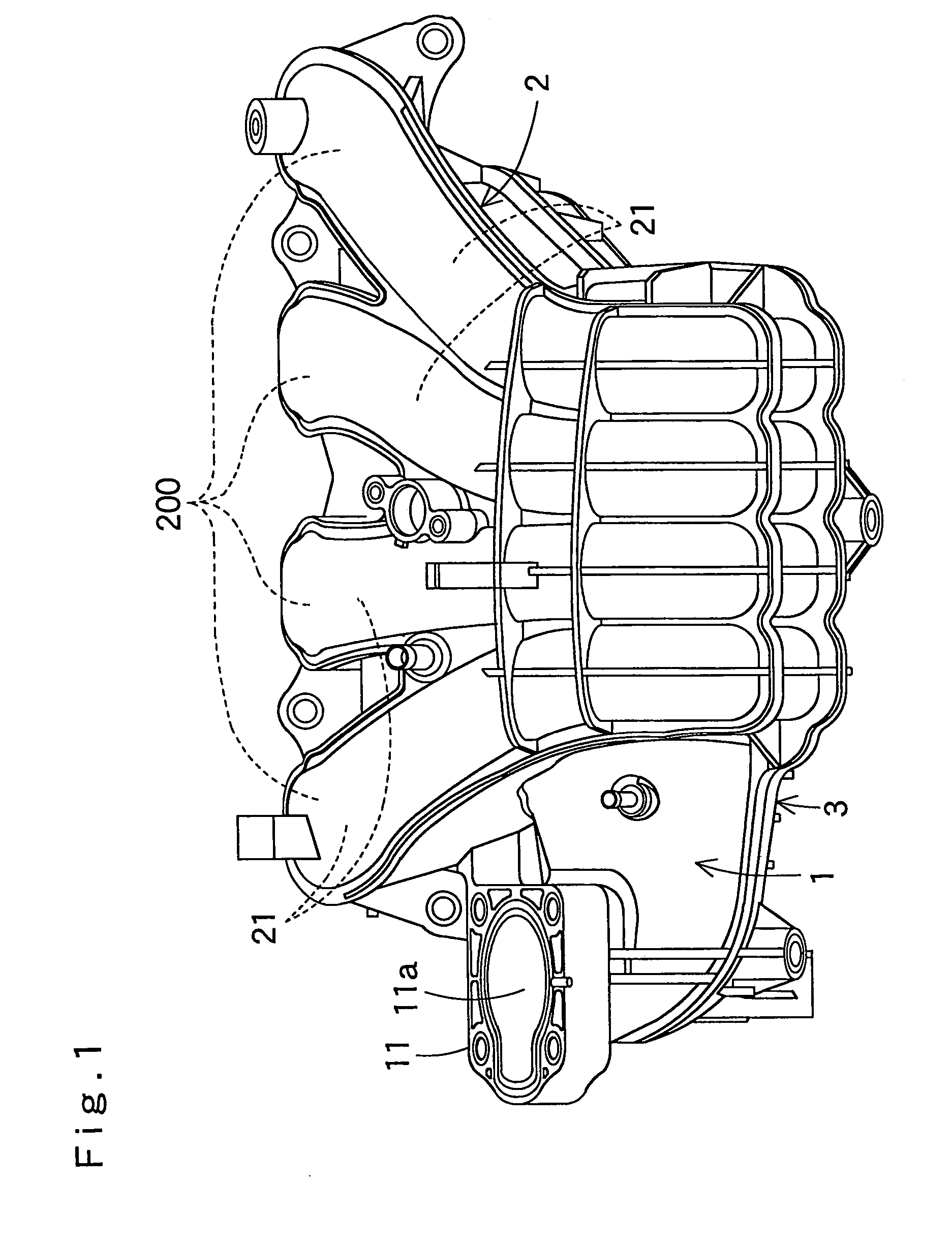

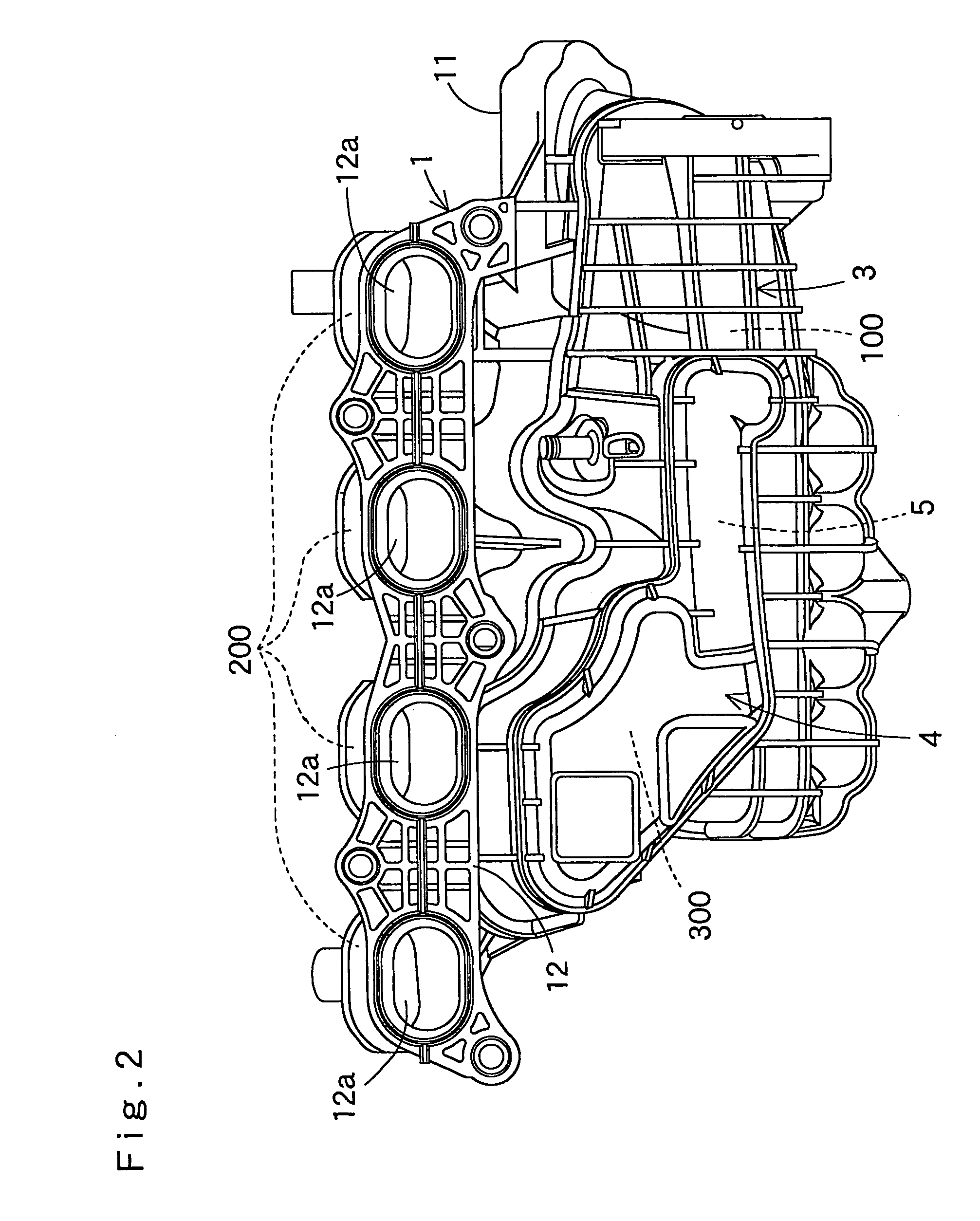

Dual port intake device for an internal combustion engine formed by injection molding

ActiveUS20050016487A1Minimization requirementsEliminate needNon-fuel substance addition to fuelInternal combustion piston enginesSurge tankPlastic materials

In the dual port intake device of the present invention, the intake manifold assembly comprises three blocks each molded from a plastic material by injection molding, the three blocks consisting of a first block defining a half of the surge tank, a second block defining a half of the individual intake pipes and a third block defining a remaining half of the surge tank and a remaining half of the individual intake pipes. Thereby, the intake manifold assembly may be provided with various features for defining a pair of intake pipe sections arranged in a mutually parallel relationship while being made to be suitable for an injection molding process. Because the surge tank are defined by the first and third blocks (optionally with the aid of the second block) while the individual intake pipes are defined by the second and third blocks (optionally with the aid of the first block), the intake manifold assembly essentially consisting of three blocks can internally define essential features required for a dual port intake device without requiring additional component members.

Owner:HONDA MOTOR CO LTD +1

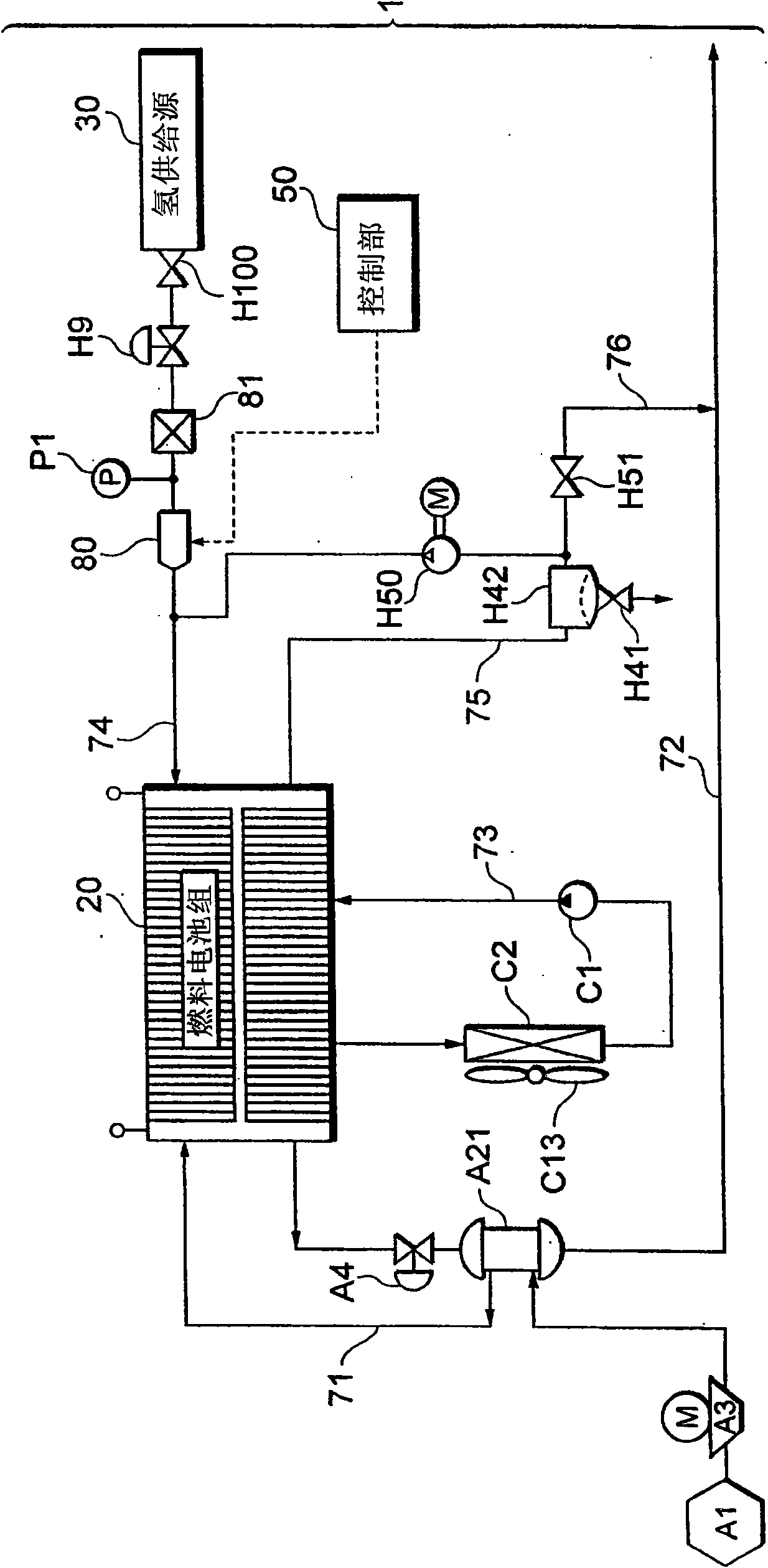

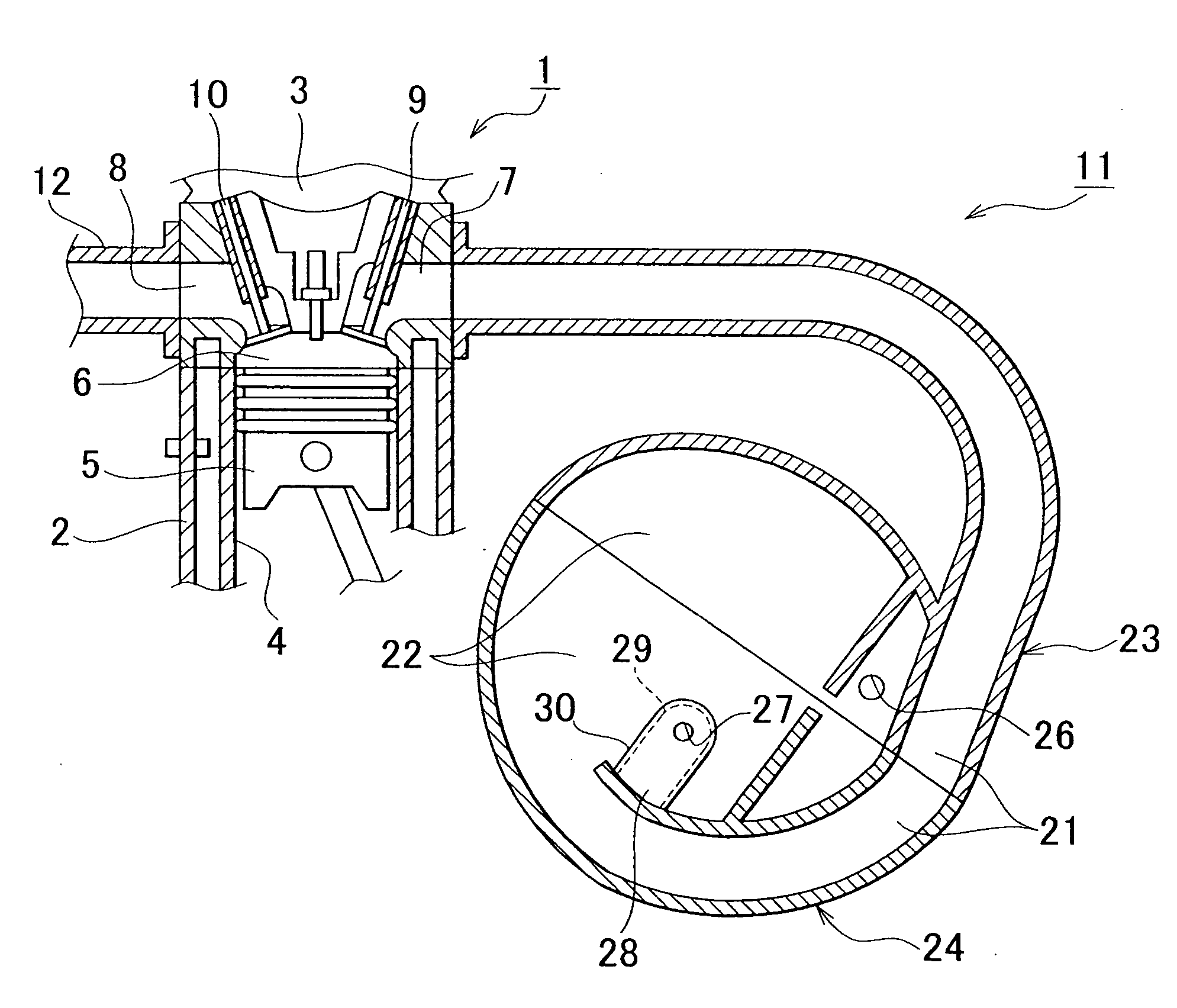

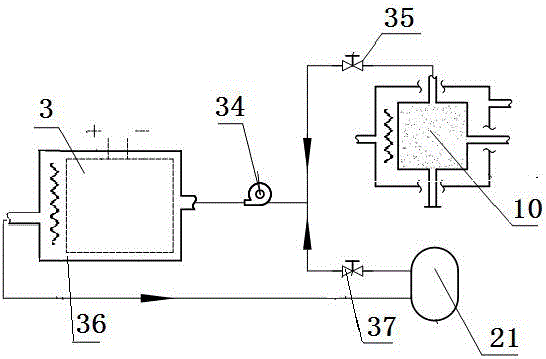

Fuel cell system and fuel cell vehicle

ActiveCN101542805AEasy to controlReduce vibrationFuel cell auxillariesElectric propulsion mountingSurge tankHydrogen supply

A fuel cell system has a hydrogen supply path (74) for supplying hydrogen gas to a fuel cell (20); an injector (80) provided in the hydrogen supply path (74), regulating the pressure of gas on the upstream side of the hydrogen supply path (74), and injecting the pressure-regulated gas to the downstream side of the hydrogen supply path (74); and a surge tank (81) provided at a position on the upstream side of the injector (80) and suppressing variation in the pressure of the gas in the hydrogen supply path (74).

Owner:TOYOTA JIDOSHA KK

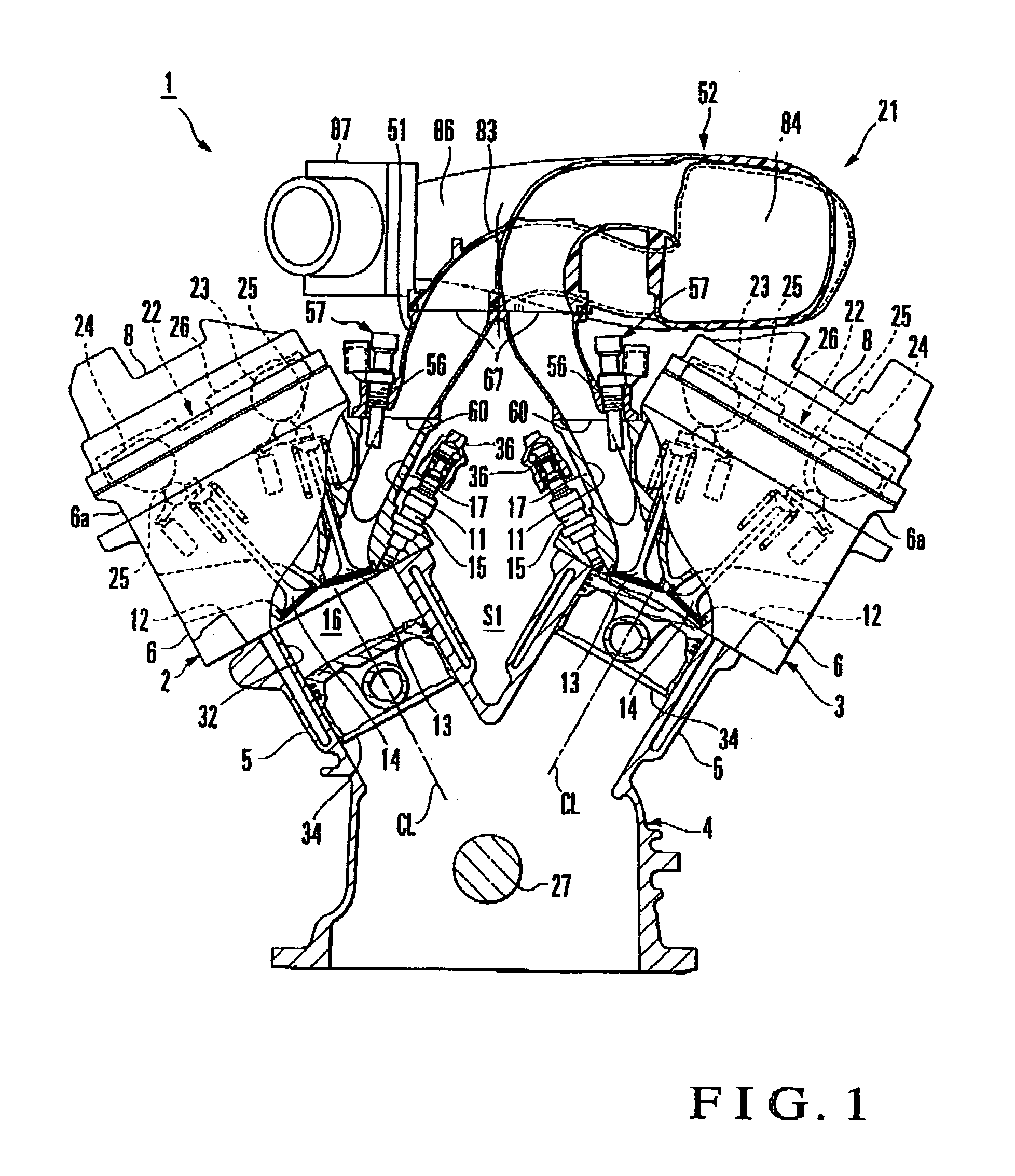

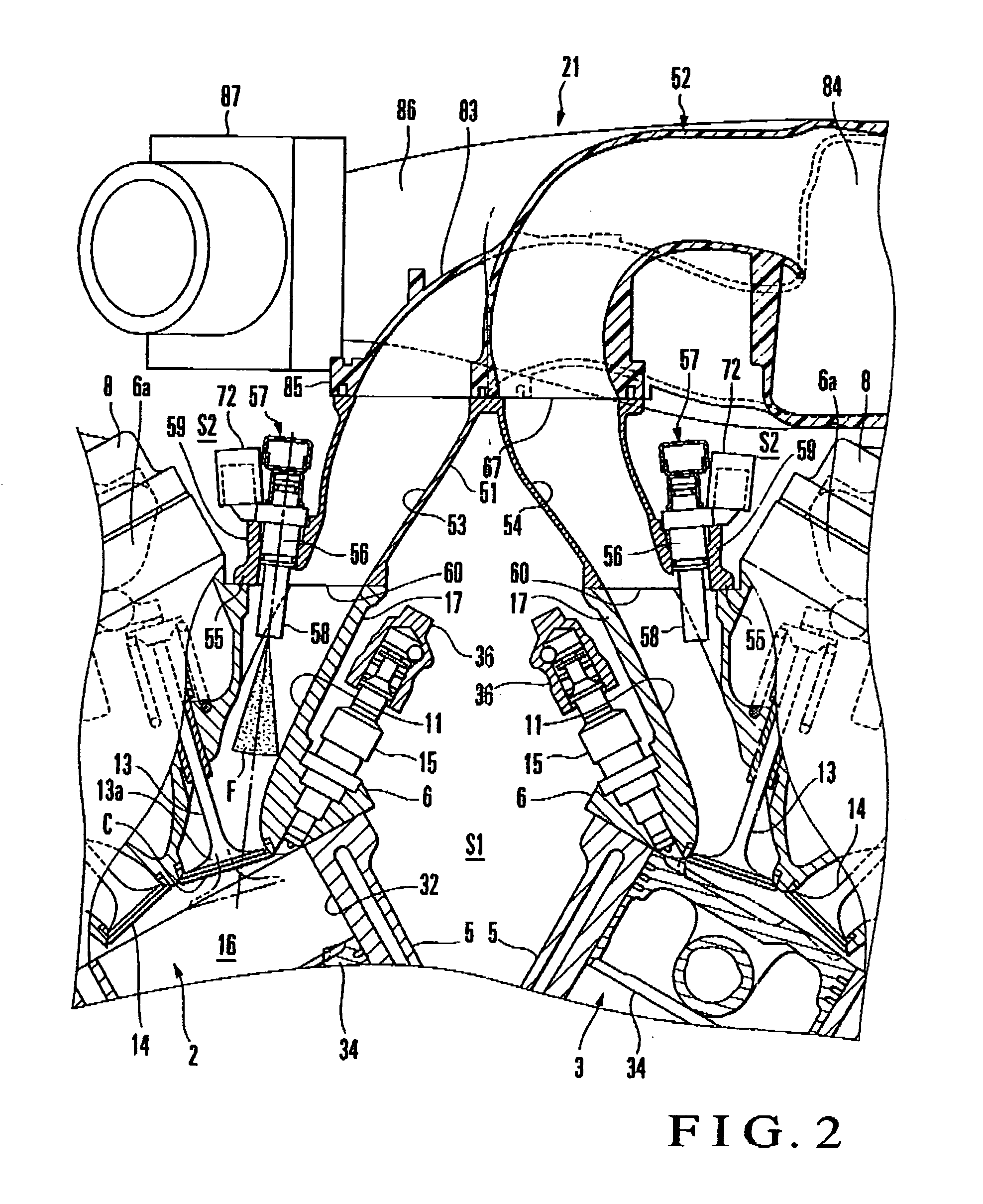

Dual-injector fuel injection engine

ActiveUS20060207527A1Prevents reduction in mounting accuracyEasy maintenanceElectrical controlInternal combustion piston enginesSurge tankCylinder head

A dual-injector fuel injection engine includes a cylinder block, a cylinder head, an intake port, an intake manifold, a surge tank, an in-cylinder injector, an intake pipe injector, and first and second delivery pipes. The in-cylinder injector is positioned below the intake port, when seen from an axial direction of a crank shaft, and attached to the cylinder head. The intake pipe injector and the second delivery pipe are supported above the intake port, when seen from the axial direction of the crank shaft, by the intake manifold to be close to the intake port.

Owner:YAMAHA MOTOR CO LTD +1

Resin intake manifold

InactiveUS7082915B2Easy to operateRemarkable effectMachines/enginesDomestic articlesSurge tankEngine mount

A resin intake manifold is provided with an integrally formed base member. The base member has a U-shaped curved distribution passage lower surface wall portion, an engine mounting flange portion formed in one end of the distribution passage lower surface wall portion, and a surge tank peripheral wall portion formed in another end and a lower surface side of the distribution passage lower surface wall portion. A resonator peripheral wall portion is integrally formed in a dead space in a lower surface side of the distribution passage lower surface wall portion and between the surge tank peripheral wall portion and the engine mounting flange portion. In accordance with the structure in which the wall itself constituting the resonator is formed by the structure member, it is possible to structure the resonator without enlarging a size of the intake manifold and without lowering the strength.

Owner:AISAN IND CO LTD

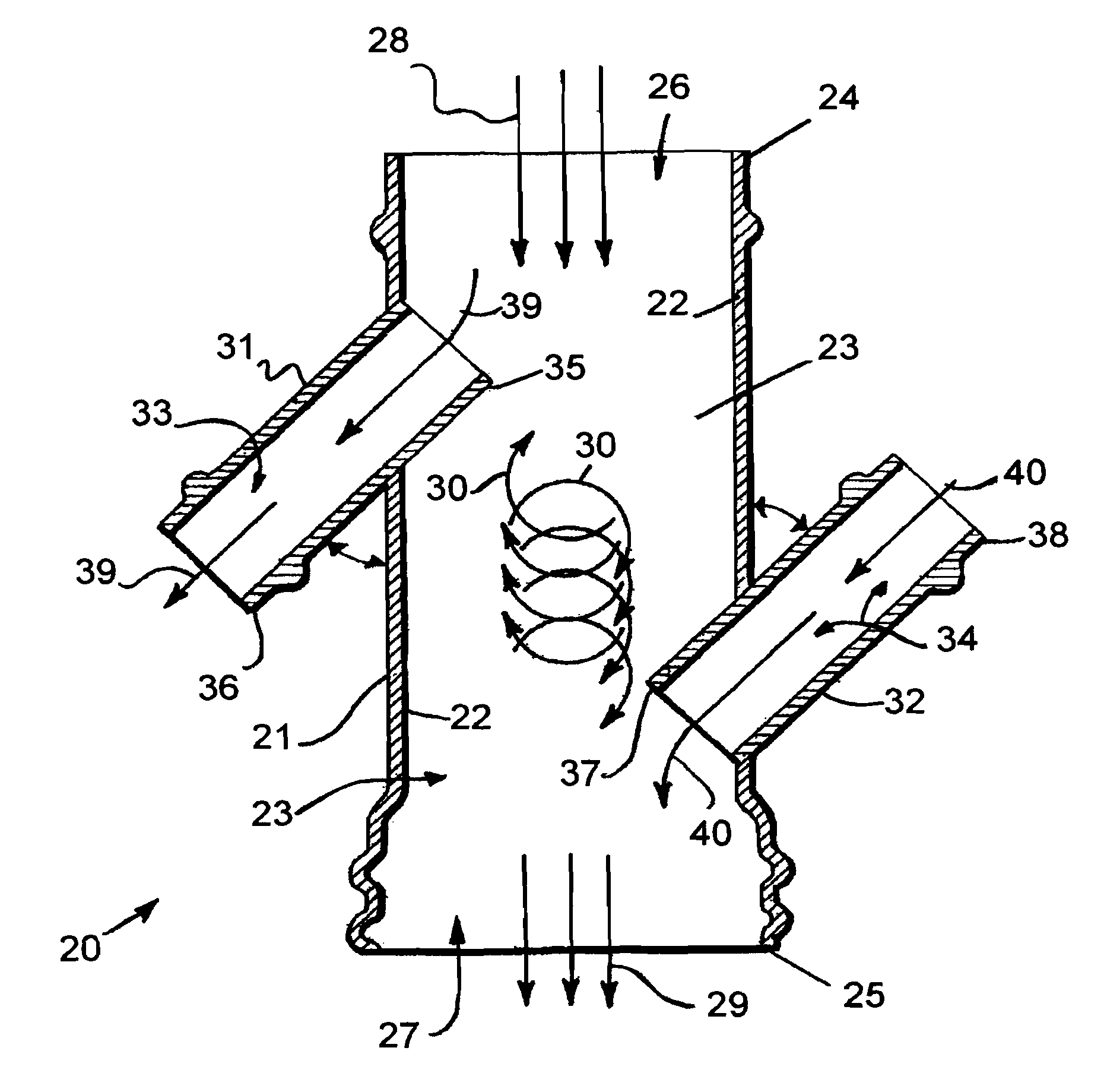

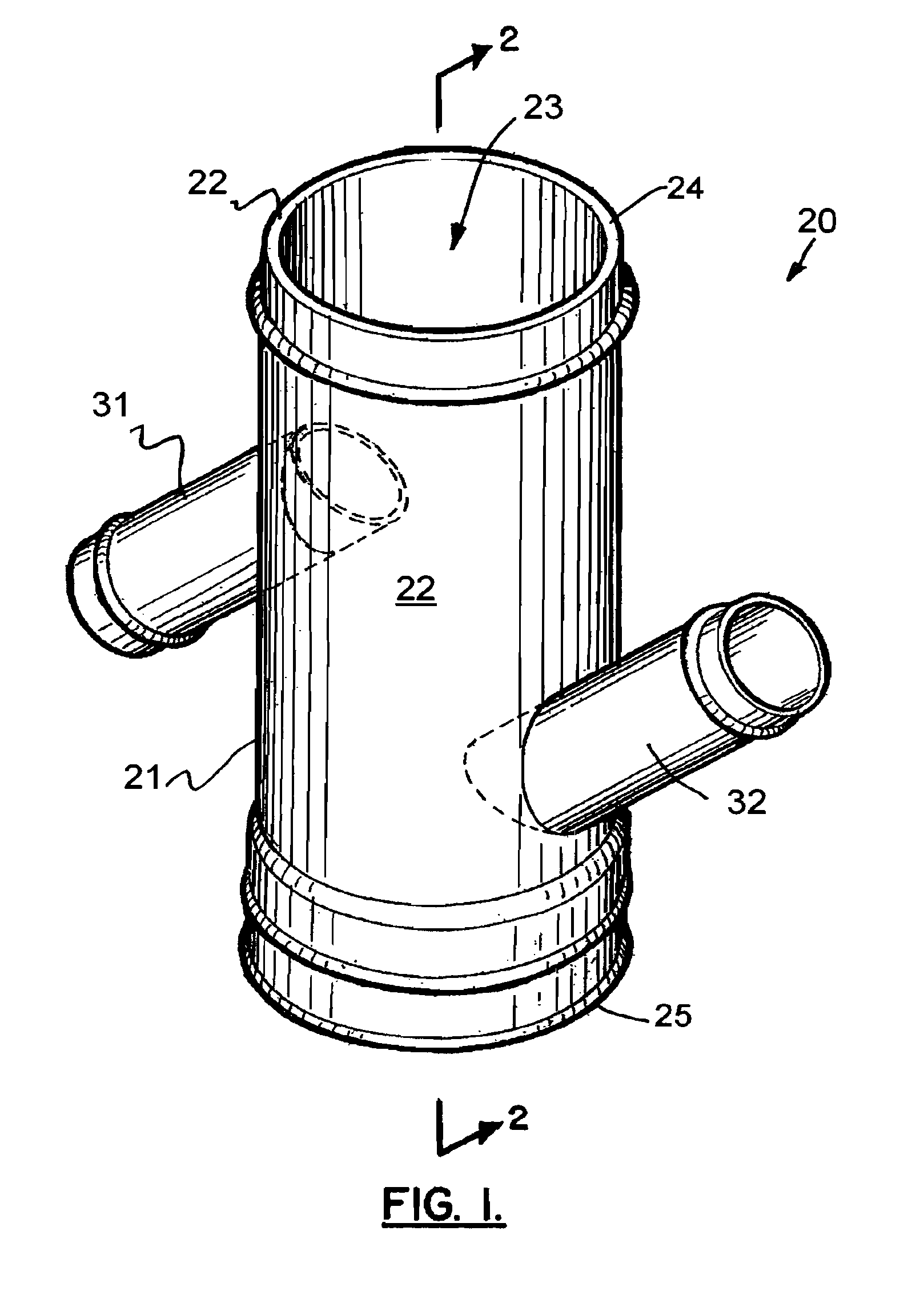

Water heating apparatus for continuous heated water flow and method for use in hydraulic fracturing

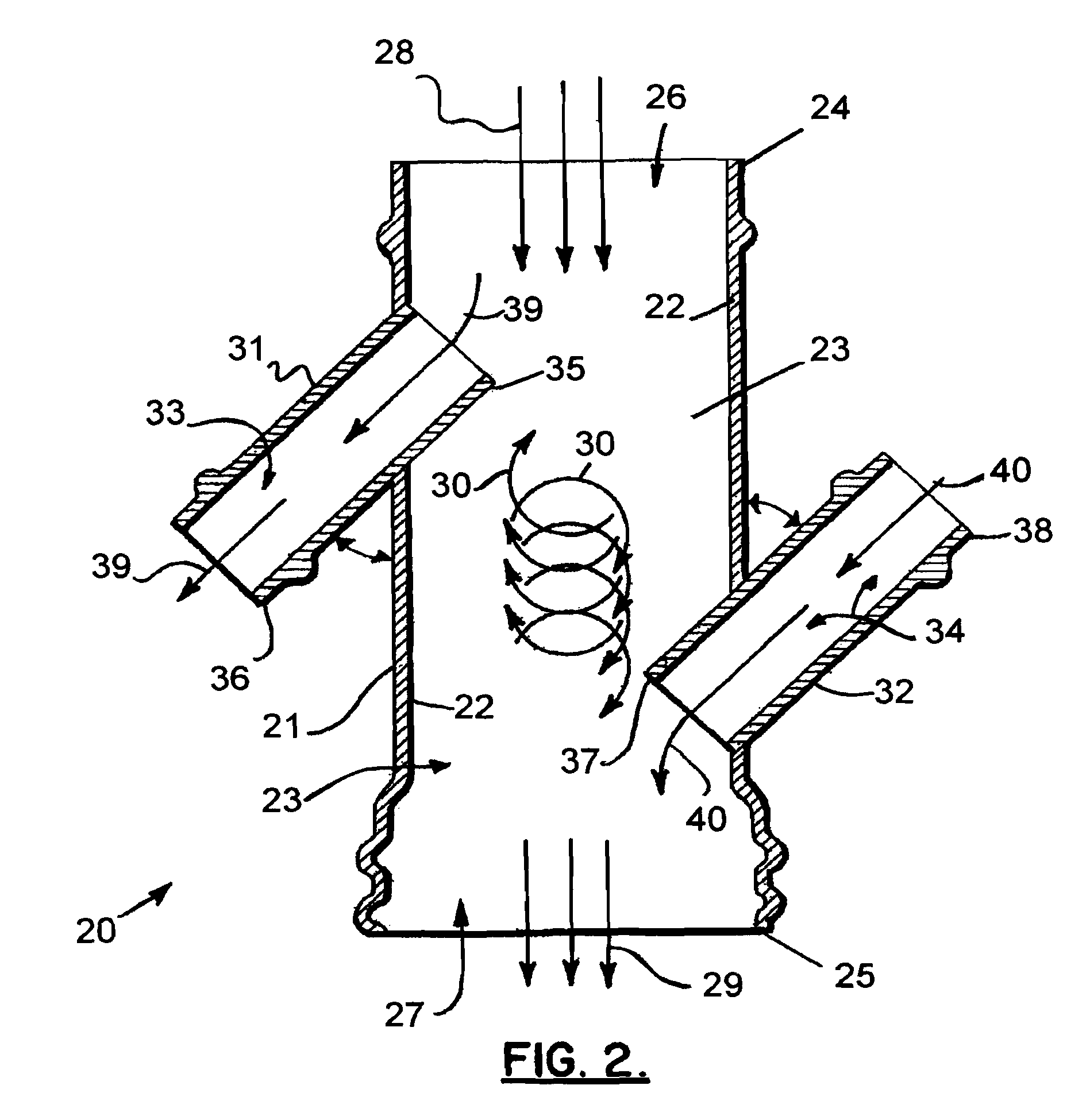

ActiveUS20100294494A1Great mixing actionFacilitate hot water flowTemperatue controlFluid removalSurge tankAcute angle

A method of hydraulic fracturing of an oil producing formation includes the provision of a heating apparatus which is transportable and that has a vessel for containing water. The method contemplates heating the water up to a temperature of about 200° F. (93.3° C.). A water stream of cool or cold water is transmitted from a source to a mixer, the cool water stream being at ambient temperature. The mixer has an inlet that receives cool or cold water from the source and an outlet that enables a discharge of a mix of cool or cold water and the hot water. After mixing in the mixer, the water assumes a temperature that is suitable for mixing with chemicals that are used in the fracturing process, such as a temperature of about 40°-120° F.+ (4.4-48.9° C.+). An outlet discharges a mix of the cool and hot water to surge tanks or to mixing tanks. In the mixing tanks, a proppant and an optional selected chemical or chemicals are added to the water which has been warmed. From the mixing tanks, the water with proppant and optional chemicals is injected into the well for part of the hydraulic fracturing operation. The mixer preferably employs lateral fittings that enable heated water to enter the mixer bore at an acute angle. The mixer can also provide a lateral fitting that exits the mixer bore upstream of the first lateral fitting, the second lateral fitting transmitting water via a conduit such as a hose to the heater.

Owner:HEAT ON THE FLY

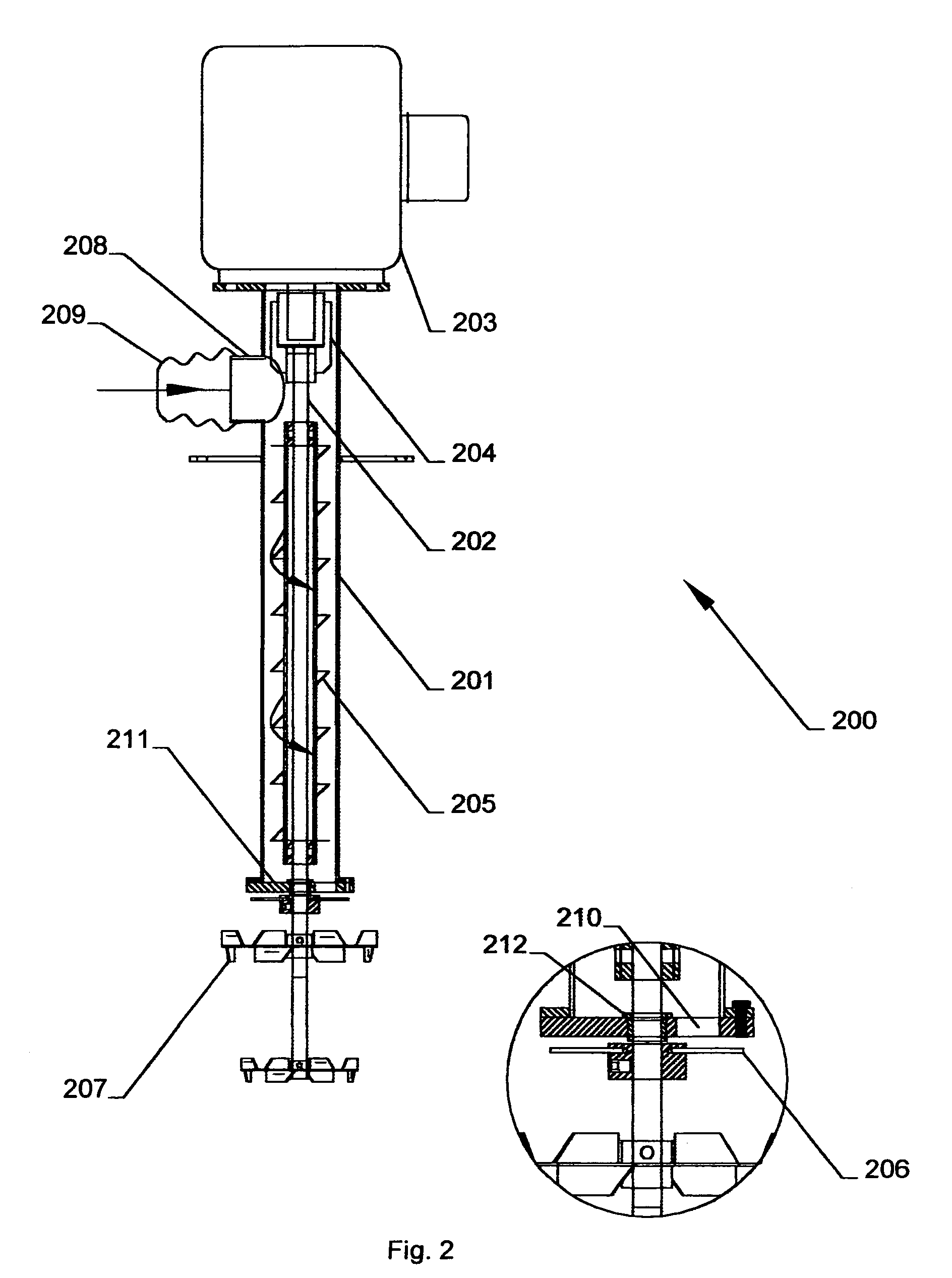

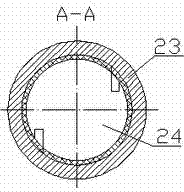

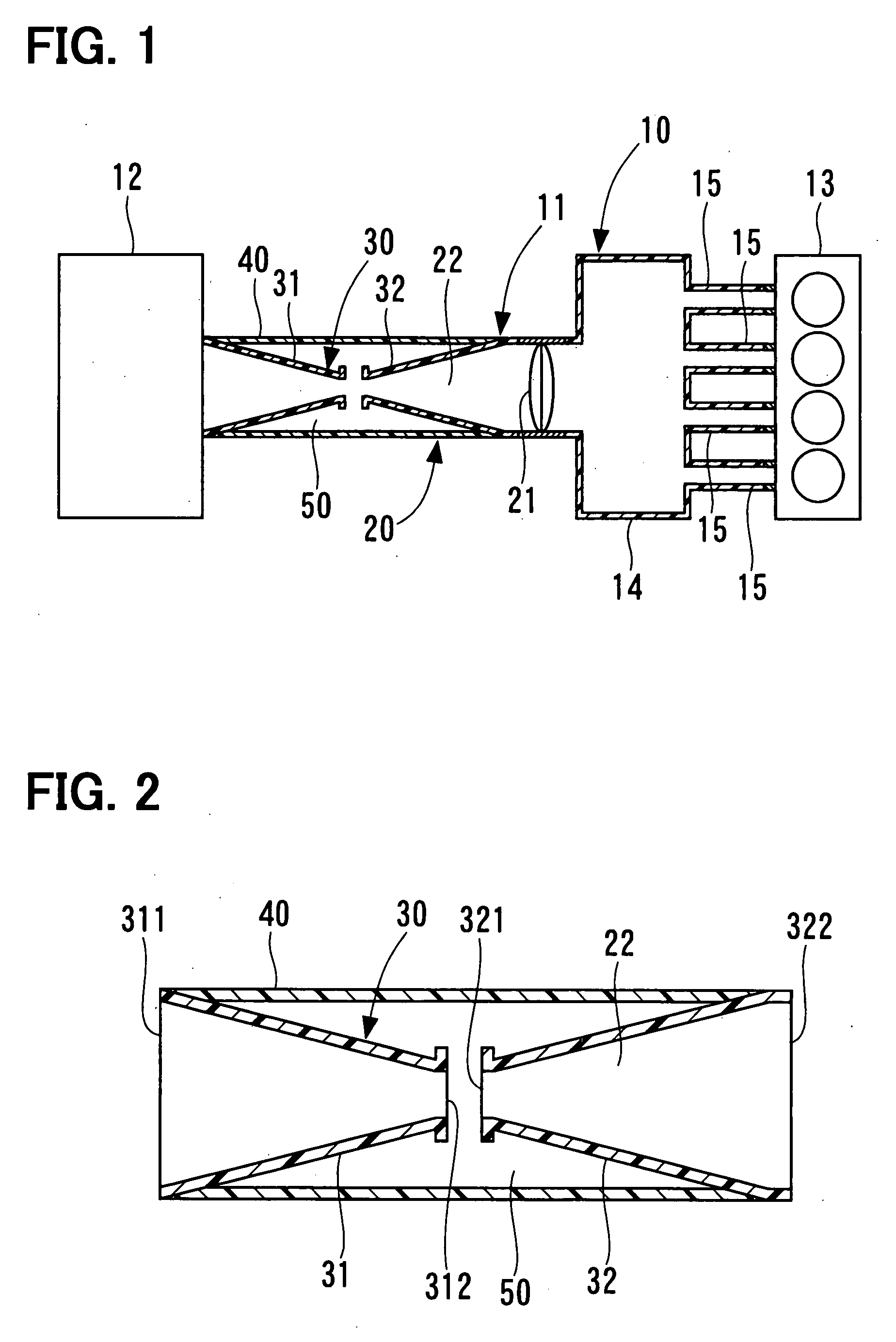

Tracer particle dispensing device and dispensing method for small-size PIV flow field testing experiment

InactiveCN103940573AContinuous and stable productionLow priceAerodynamic testingSurge tankLiquid storage tank

The invention discloses a tracer particle dispensing device and dispensing method for small-size PIV flow field testing experiment and belongs to the technical field of laser particle measurement. The tracer particle dispensing device comprises a liquid storage tank, an air supply source, a surge tank, a pressurized air source and a view cup, the liquid storage tank is sealed by an upper cover board, the pressurized air supply is connected with the liquid storage tank, an inside duct which enters the bottom liquid of the liquid storage tank is connected with the upper cover board, the upper cover board is connected with a swirl nozzle in the view cup through an outside duct, and the surge tank is connected with a pneumatic joint arranged on a flange and connected with the view cup through a branch air inlet pipe. The tracer particle dispensing device is capable of continuously and stably producing tracer particles, the grain diameter is adjustable, the particle quality is high, and the flow field situation can be well reflected; the tracer particle dispensing device is simple in structure, convenient to use, low in raw material cost, and easy to popularize.

Owner:DALIAN UNIV OF TECH

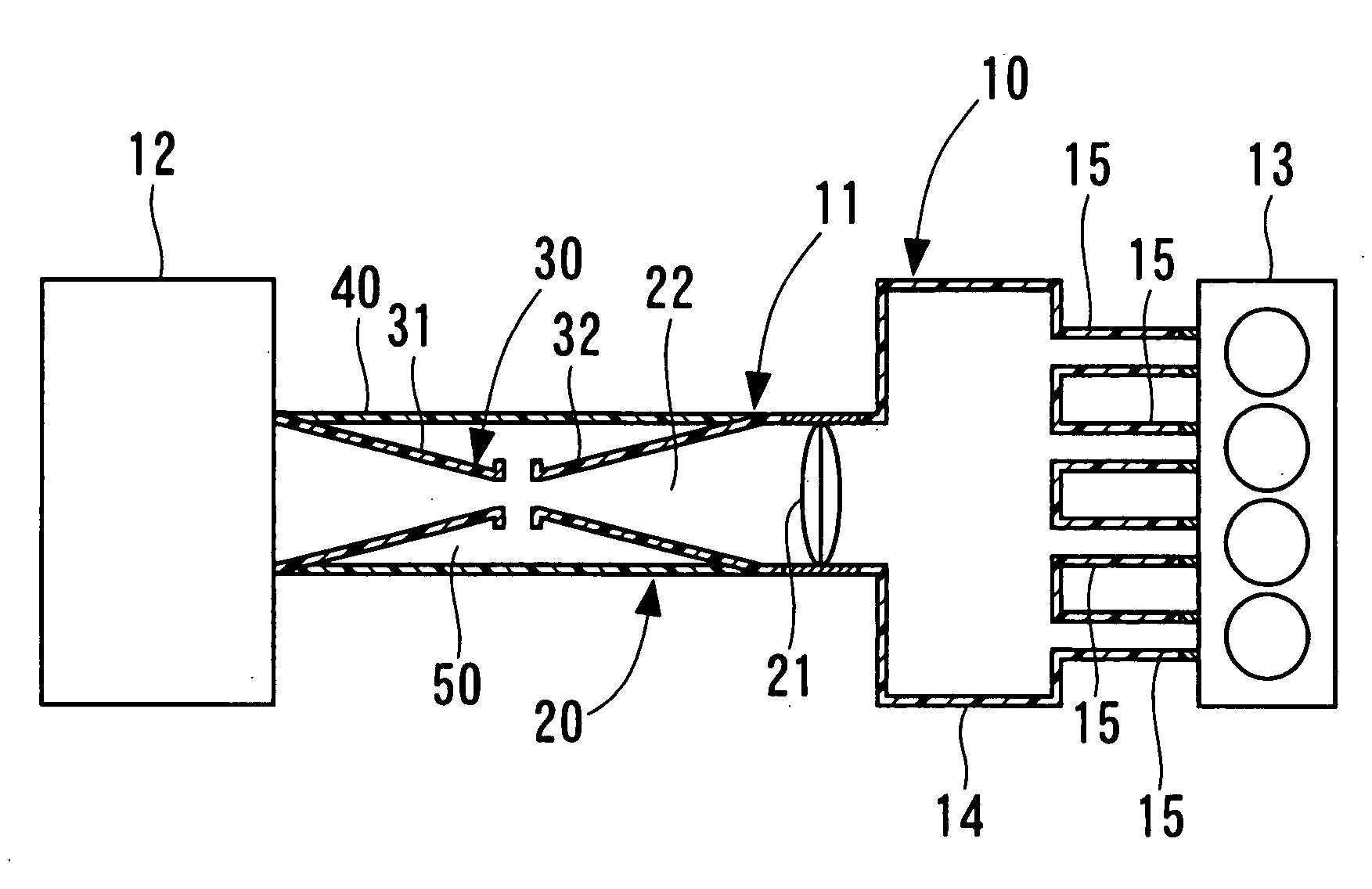

Air-intake apparatus

InactiveUS20080023262A1Reduce air noiseEasy to installMachines/enginesIntake silencers for fuelSurge tankEngineering

An air-intake apparatus includes an inner pipe member and an outer pipe member. The inner pipe member defines an intake passage that connects an inlet and a surge tank. Air is drawn into the inlet. A diameter of the inner pipe member gradually increases when the inner pipe member extends toward a surge tank-side end portion of the inner pipe member. The outer pipe member covers an outer circumferential side of the inner pipe member and defines a resonator between the outer pipe member and the inner pipe member. The resonator communicates with the intake passage.

Owner:DENSO CORP

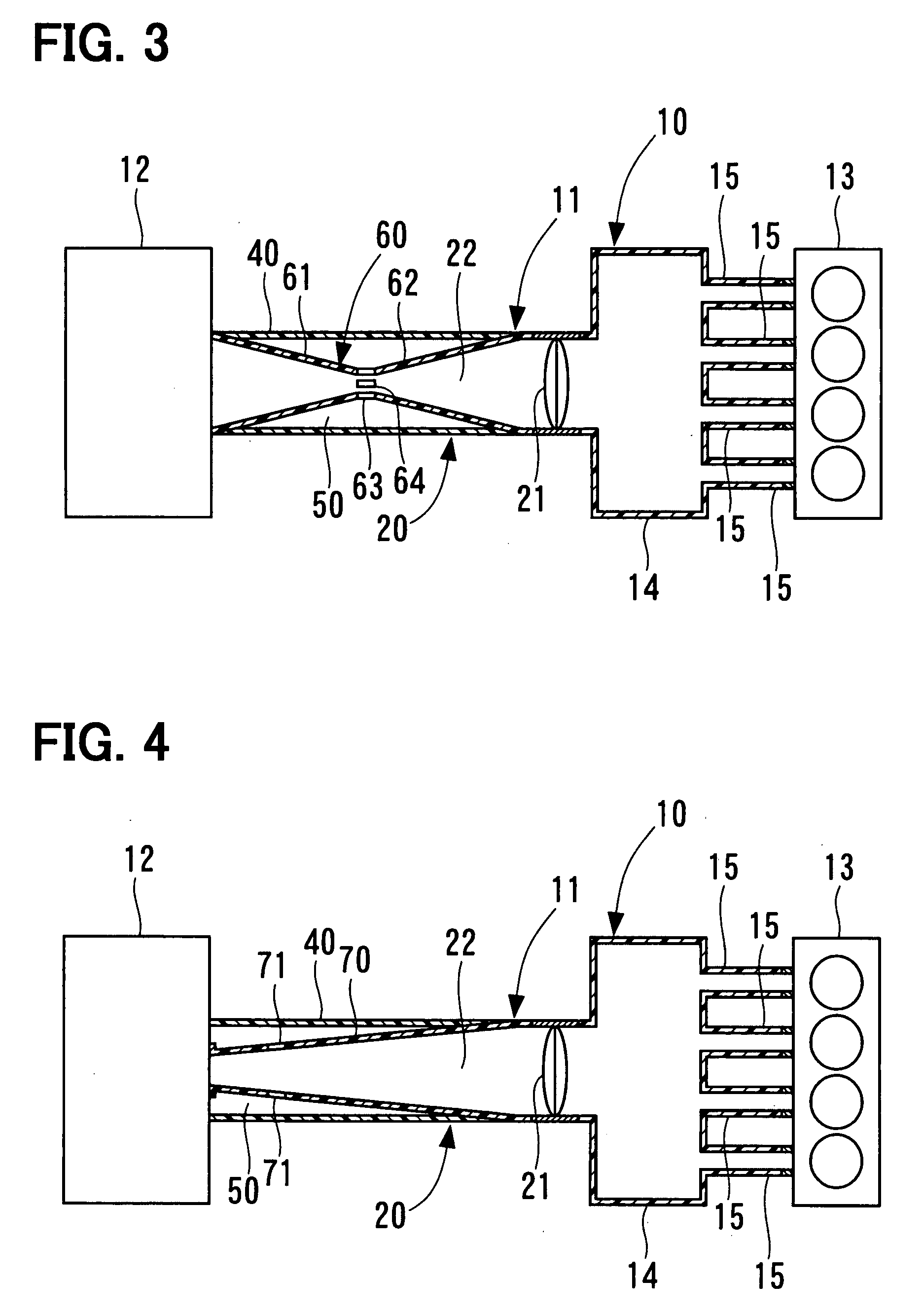

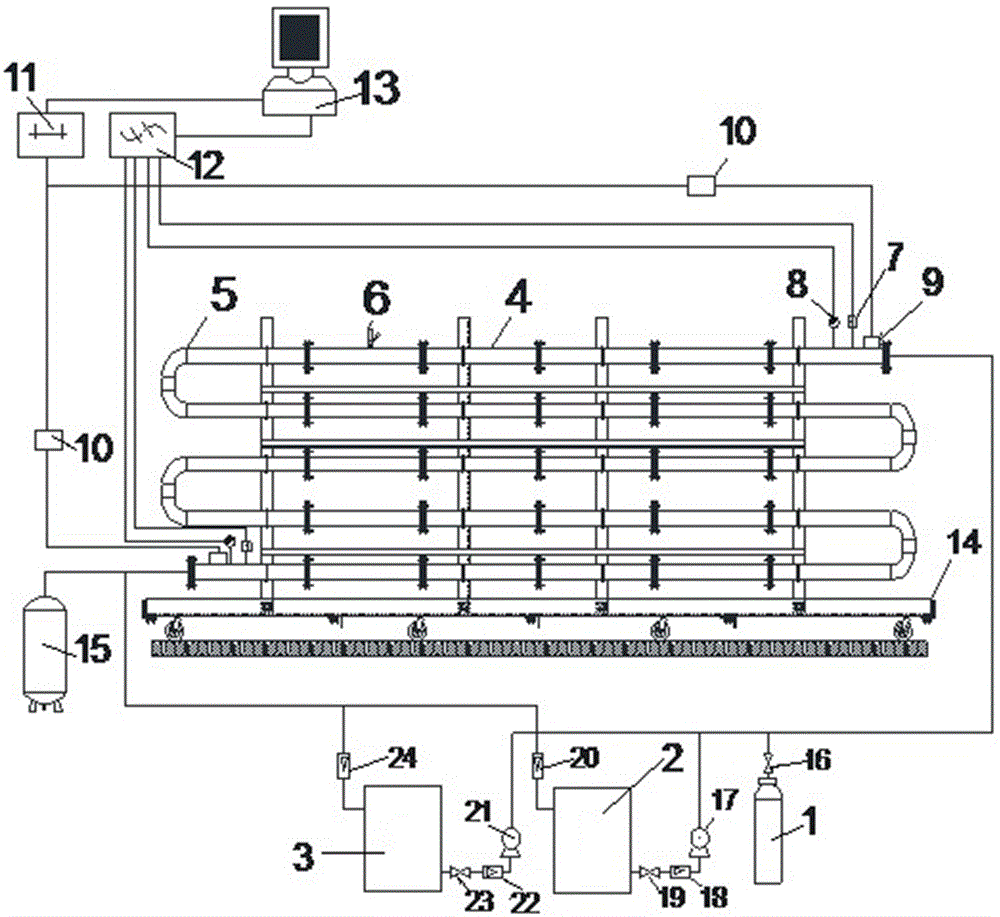

Pipeline leakage detecting and positioning experimental system and detection method thereof

The invention relates to a experimental system for scientific research, in particular to a pipeline leakage detecting and positioning experimental system and a detection method thereof, and the system is used for realizing detection and positioning experiments on leakage of long-distance gas conveying pipelines and long-distance liquid conveying pipelines by virtue of different leakage detection methods. The pipeline leakage detecting and positioning experimental system comprises a conveying pipeline, a medium conveying device, a negative-pressure wave detection device and an acoustic emission detection device; the medium conveying device comprises a conveying pipeline, a medium container, a surge tank, a water pump, an oil pump, a water tank outlet flowmeter, a water tank inlet flowmeter, an oil tank outlet flowmeter, an oil tank inlet flowmeter, a nitrogen cylinder outlet valve, a water tank outlet valve and an oil tank outlet valve; a bent part of the conveying pipeline is of a U-shaped pipeline, and the rest part of the conveying pipeline is a straight pipeline section; the negative-pressure detection device comprises a pressure sensor, an electromagnetic flowmeter, a data acquisition card and a computer; the acoustic emission detection device comprises an acoustic emission sensor, a signal preamplifier, an acoustic emission detection instrument and a computer; the acoustic emission detection instrument is used for processing signals, and transmitting the signals to the computer of the acoustic emission detection instrument so as to analyze the signals.

Owner:NANJING TECH UNIV

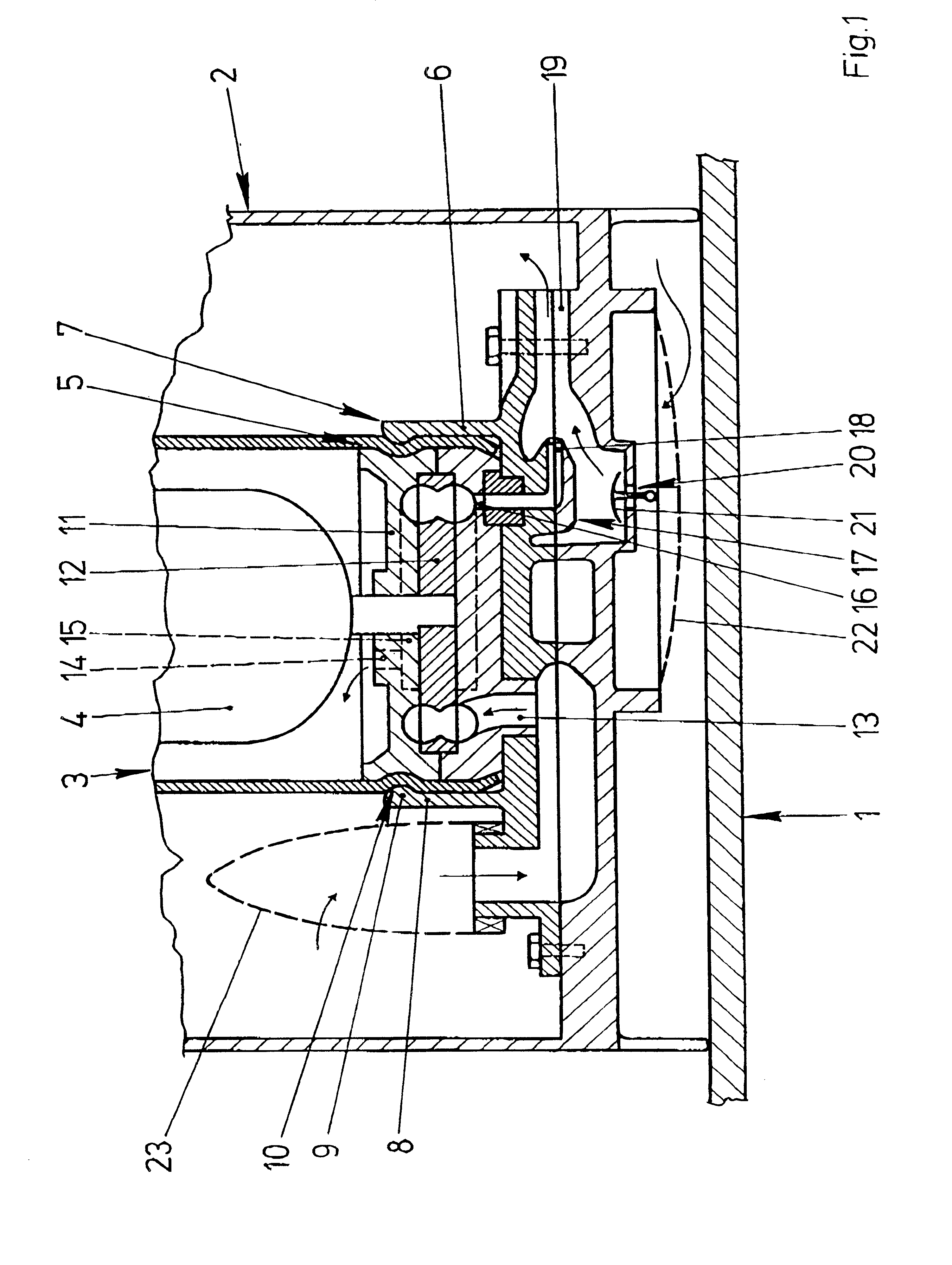

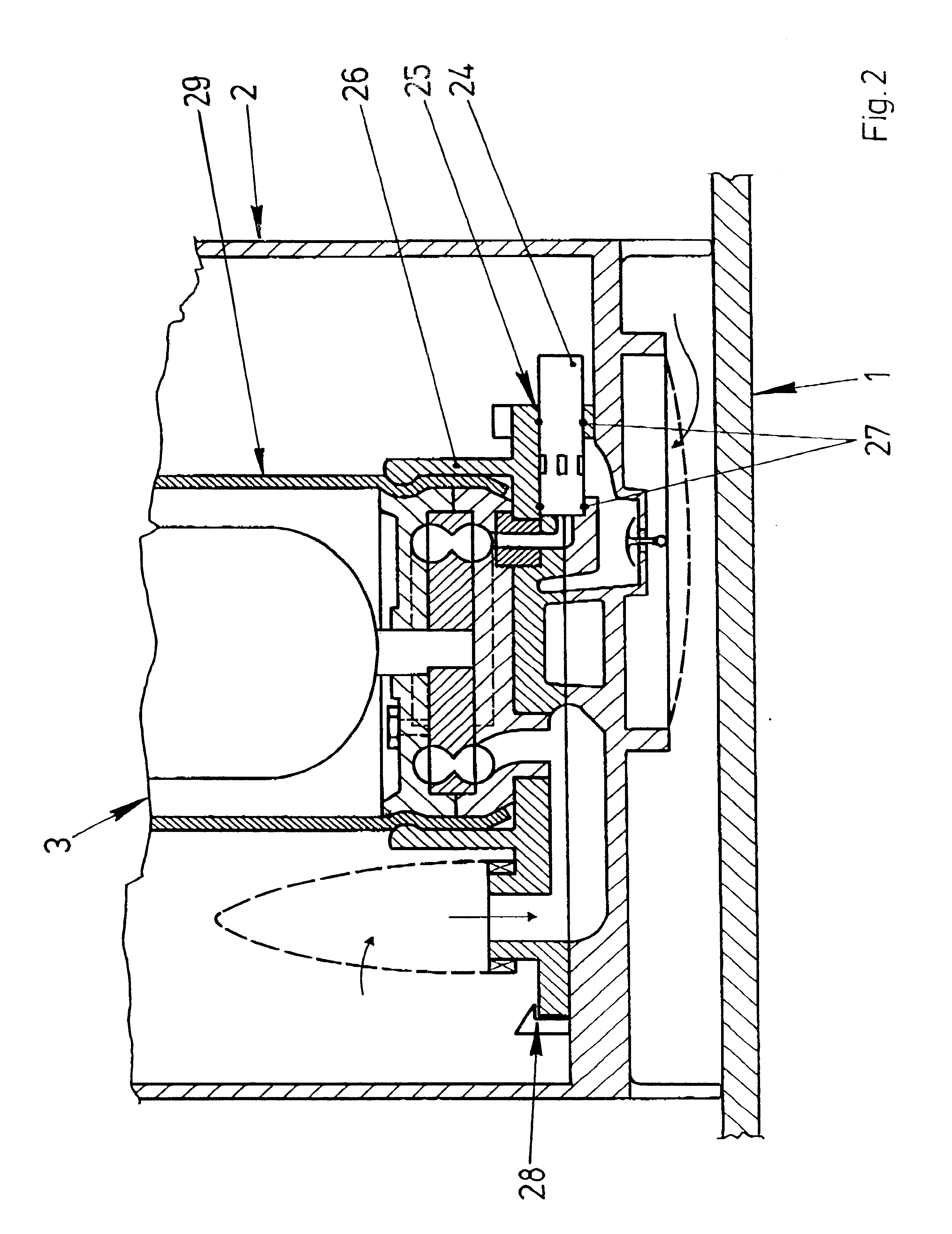

Delivery unit arranged in a surge chamber of a fuel tank of a motor vehicle

InactiveUS6478014B1Easy constructionEasy to make costPiston pumpsLiquid fuel feedersSurge tankFuel tank

A delivery unit arranged in a surge chamber of a fuel tank includes an ejector for filling the surge tank. One half of the ejector is defined by the surge chamber and the other half is defined by a pump holder holding a fuel pump in the surge chamber. The pump holder and the surge chamber are configured as components which are easy to manufacture, thereby allowing the delivery unit to be cost-effectively configured.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Resin intake manifold

InactiveUS20060249115A1Easy to manufacturePrevented from reachingMachines/enginesAir cleaners for fuelSurge tankWater vapor

A raised portion is formed at a predetermined location on an inside surface of a wall portion of an intake manifold. A gas introduction hole for introducing gas containing water vapor is formed in another predetermined location, other than in the raised portion, in the inside surface of the wall portion. An intake air negative pressure outlet hole for releasing intake air negative pressure within the surge tank to the outside is formed in the raised portion. A guide groove which catches moisture that trickles down the inside surface of the wall portion above the raised portion and guides it to a location away from the intake air negative pressure outlet hole, is formed in a region above the intake air negative pressure outlet hole in a rising surface of the raised portion.

Owner:TOYOTA JIDOSHA KK +1

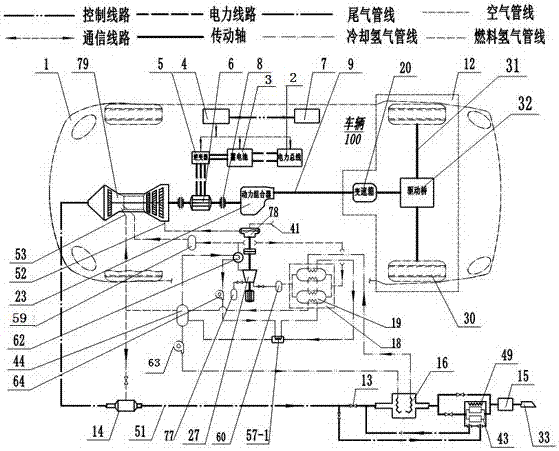

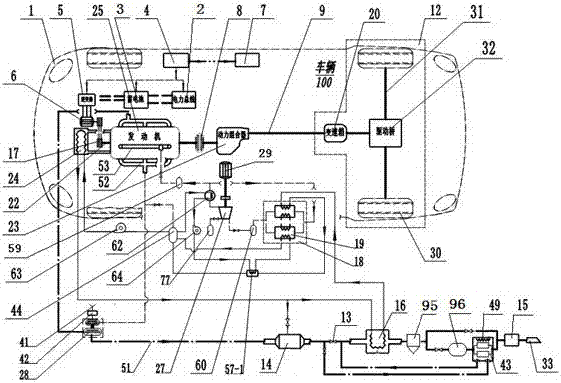

Hybrid power system with waste heat recovery function and environment air purification function and for hydrogen vehicle

ActiveCN106627090AImprove efficiencyFunction increaseHybrid vehiclesAir-treating devicesAtmospheric pollutionRecovery function

The invention relates to a hybrid power system with a waste heat recovery function and an environment air purification function and for a hydrogen vehicle. The hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle comprises a vehicle body, a transmission system, a hydrogen fuel engine, a hybrid power transmission, a metal hydride storage tank, a turbine, a catalyst, a high-pressure surge tank, a hydrogen buffering tank and the like. The metal hydride storage tank is connected to an inlet of the turbine through the high-pressure surge tank. An outlet of the turbine is connected to an inlet of the hydrogen fuel engine through the hydrogen buffering tank or a high-pressure hydrogen buffering tank. An outlet of the hydrogen fuel engine is connected to a discharge outlet through the catalyst, a tail gas heat exchanger, a residual hydrogen absorption unit and a tail gas zero-stage purifier. The hydrogen fuel engine is connected with the hybrid power transmission through a power output shaft. According to the hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle, the hydrogen fuel engine, the turbine and an exhaust gas waste heat recovery and purification system are combined to form the hybrid power system for the automobile, chemical energy of hydrogen is sufficiently used, various kinds of heat energy in the process is recovered, and the working efficiency of the power system is improved; and atmospheric pollution is avoided, the environment air is purified, and protection of the natural environment is facilitated.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

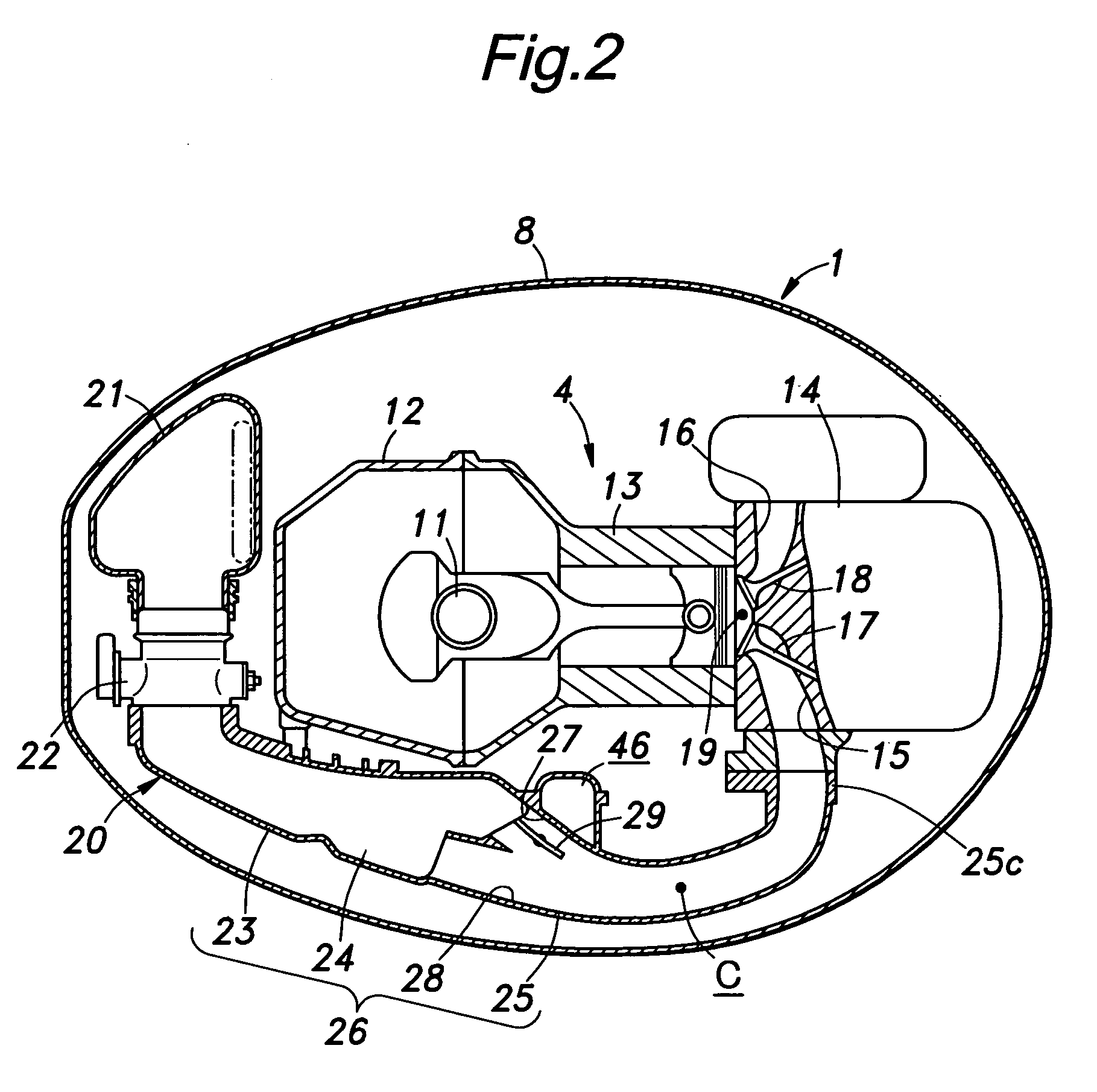

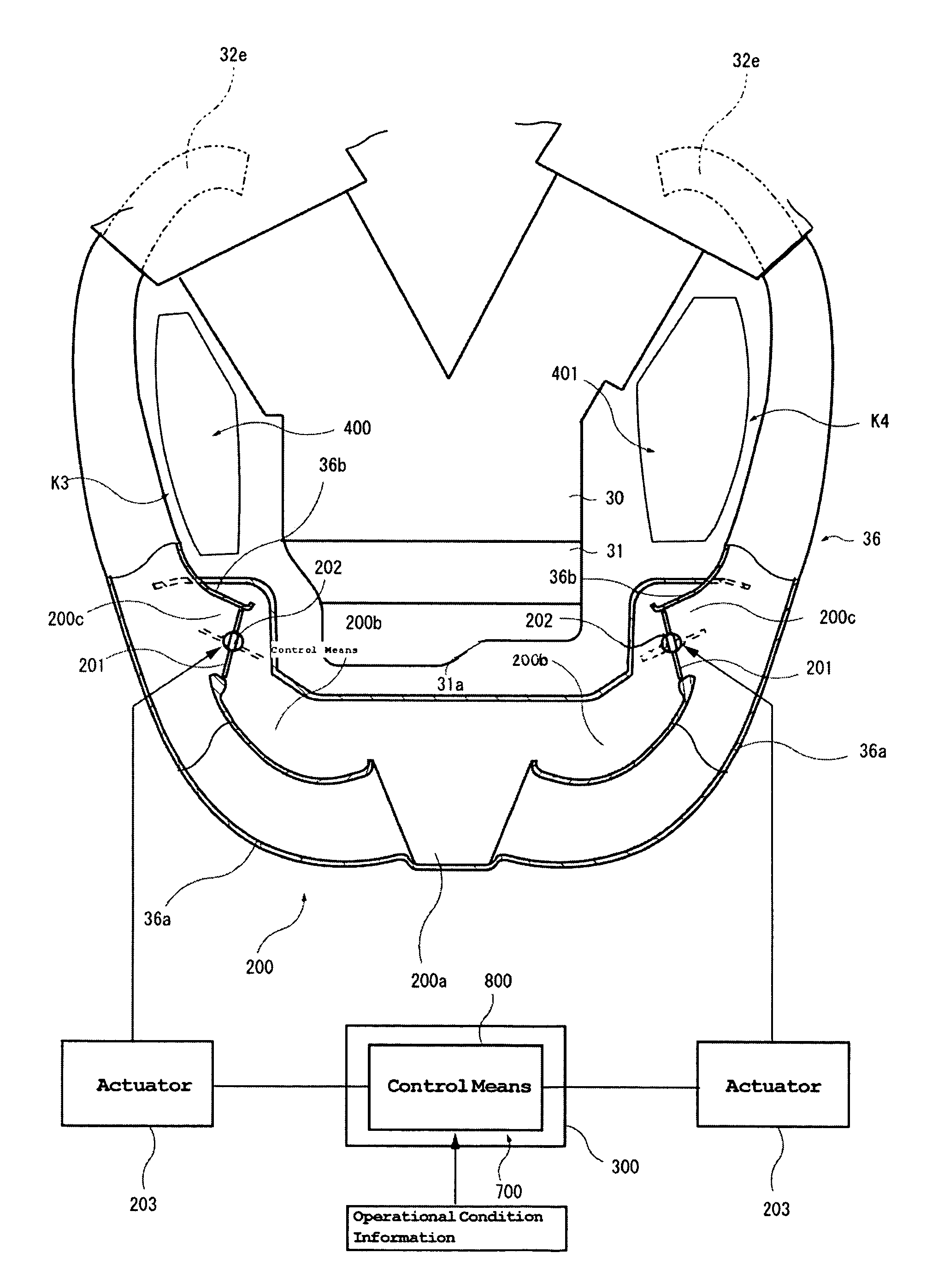

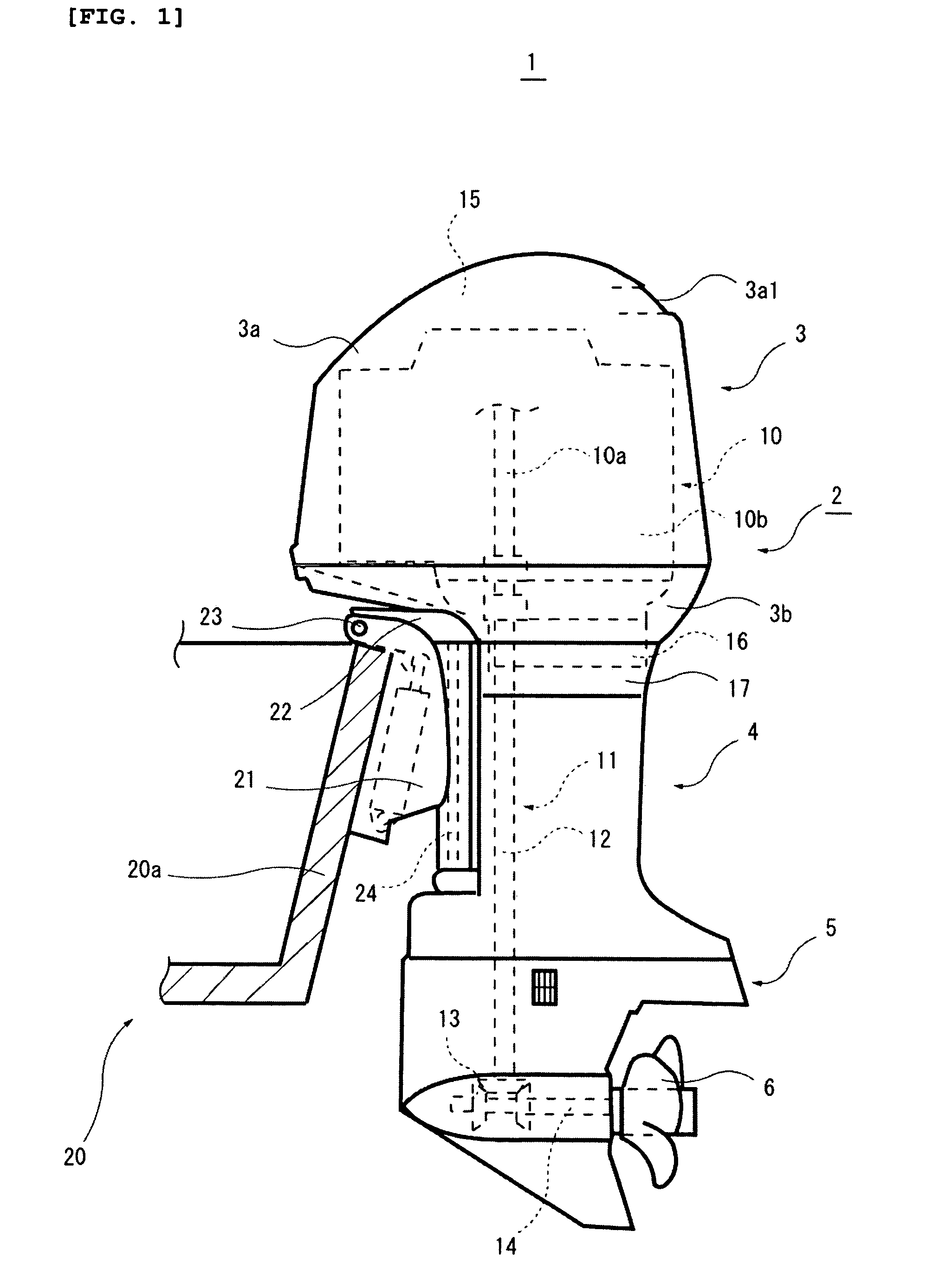

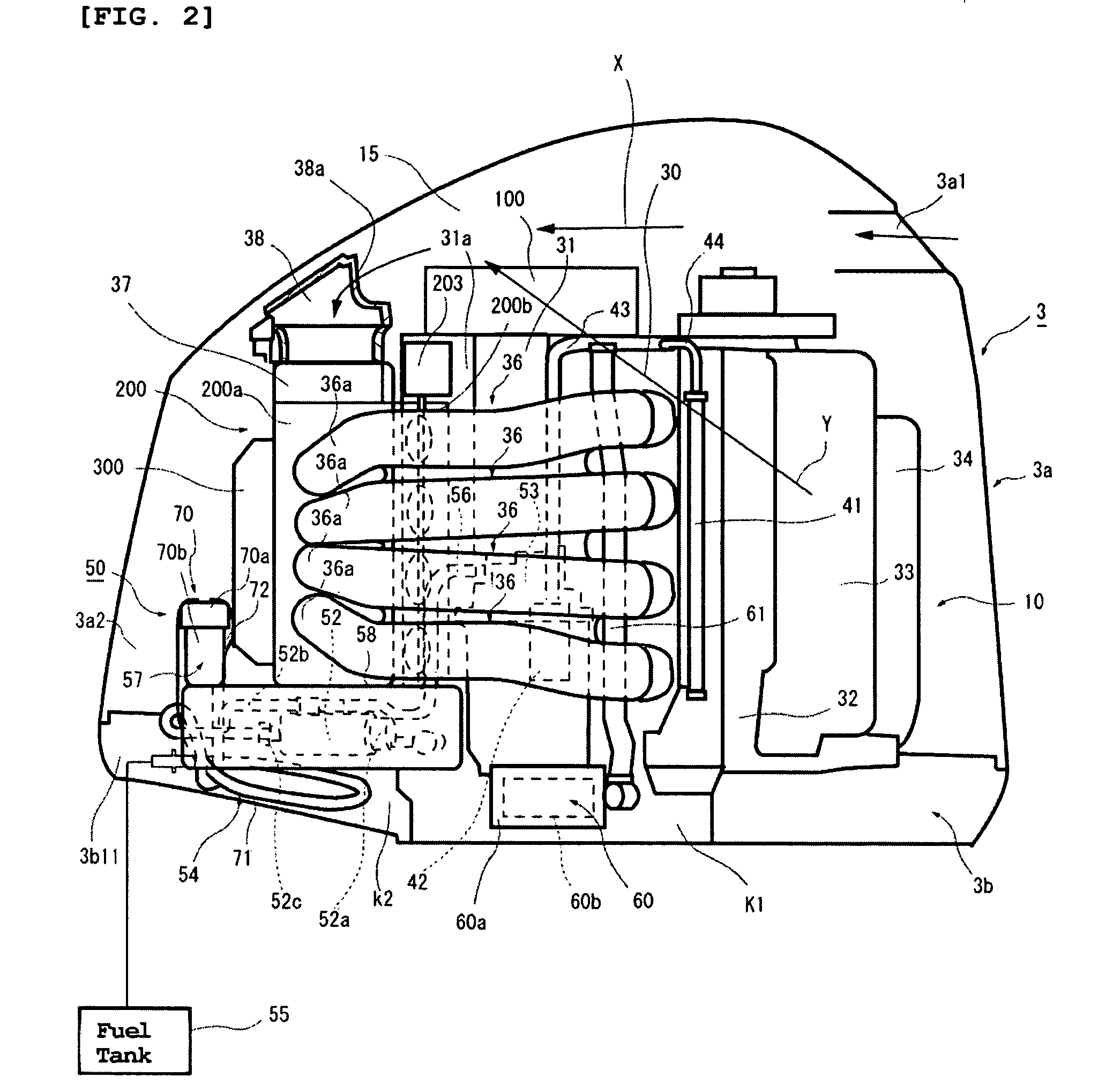

Outboard motor

InactiveUS7441528B2Improve engine performanceSimple structureInternal combustion piston enginesAir intakes for fuelSurge tankEngineering

Owner:YAMAHA MARINE KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com