Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1945 results about "Wash water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

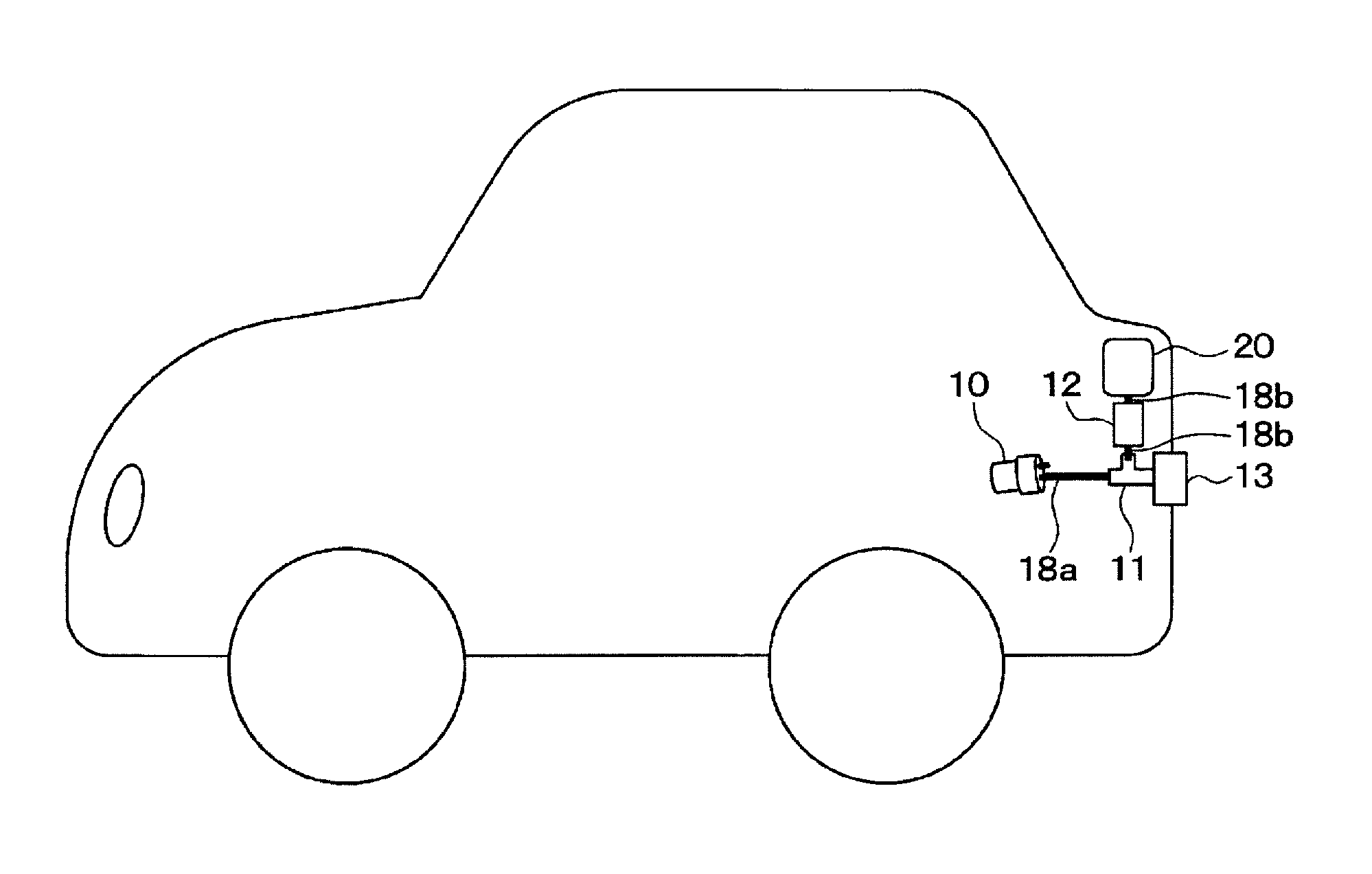

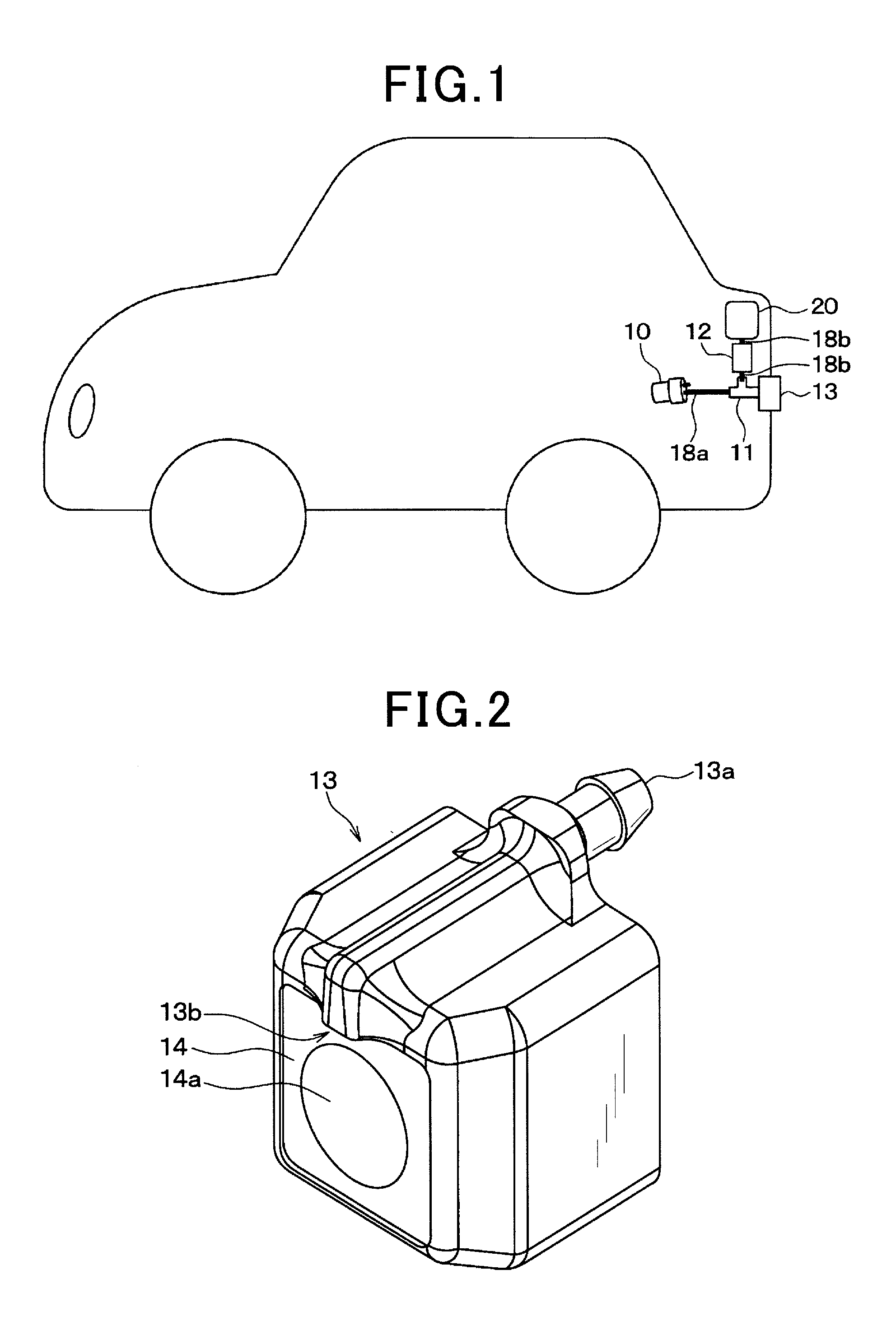

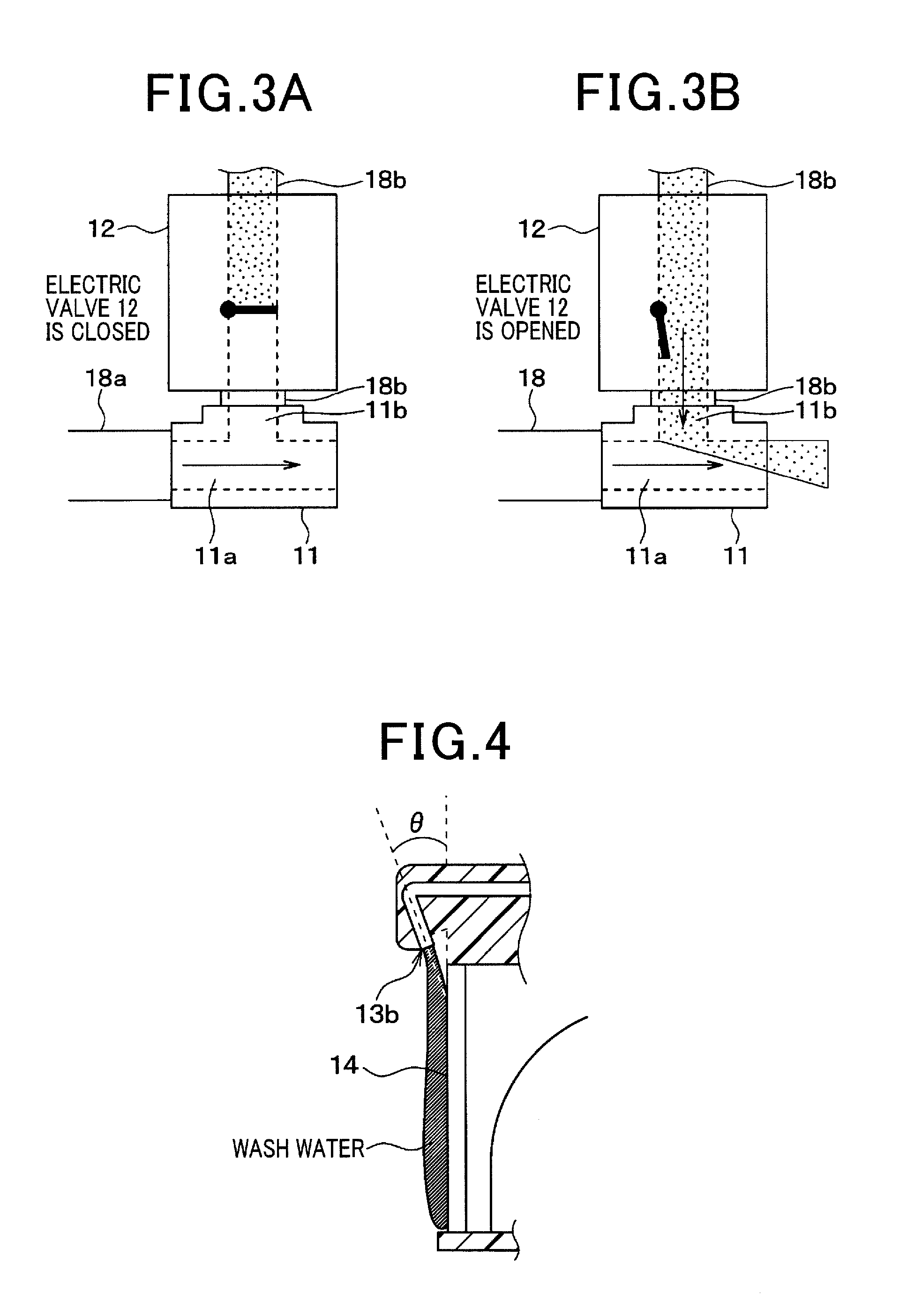

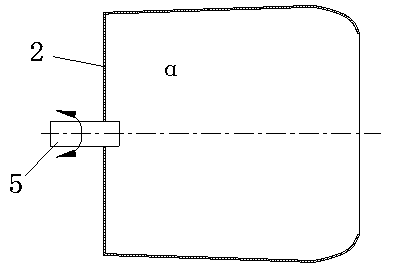

Camera washing device for camera lens

ActiveUS20130092758A1Reduce water consumptionShorten the time periodSpray nozzlesVehicle cleaningCamera lensWash water

A camera washing device has an air pump, a wash water tank storing wash water, an injection nozzle with an injection part, a junction joint having a high-pressure air passage and a wash water passage, and an electromagnetic valve. The air pump generates and supplies high-pressure air to the high-pressure air passage. When the control part instructs the electromagnetic valve to be switched to an open state, the wash water and the high-pressure air are mixed in the junction joint to generate water particles. The generated water particles are supplied to the injection nozzle. When the electromagnetic valve is switched to the open state after injecting the high-pressure air only to a lens of a rear camera, the injection part injects the water particles to the lens of the camera.

Owner:DENSO CORP

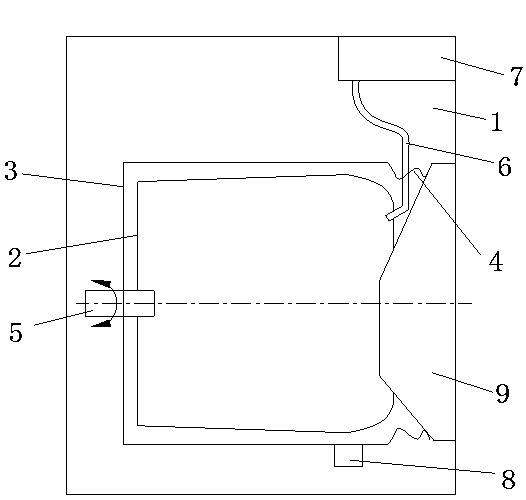

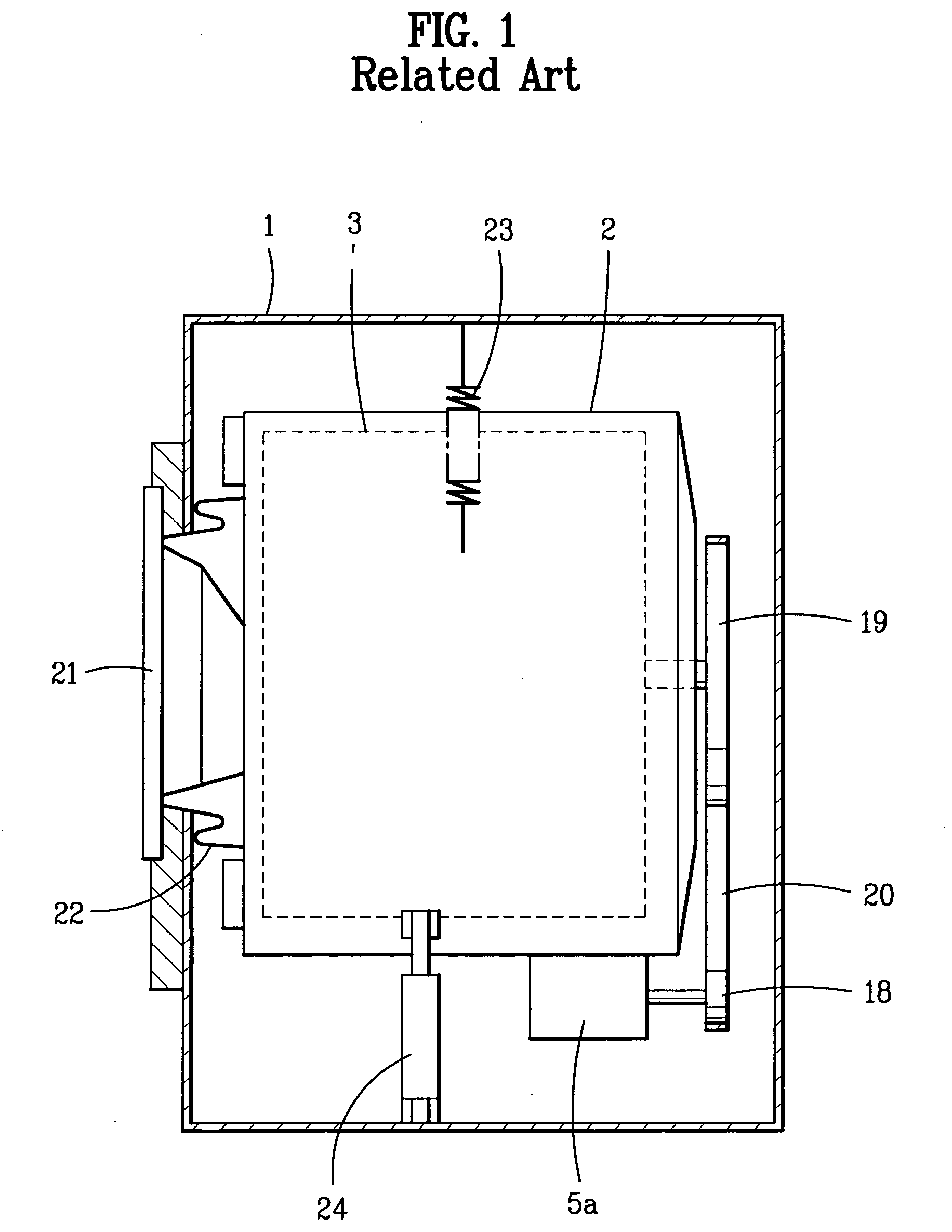

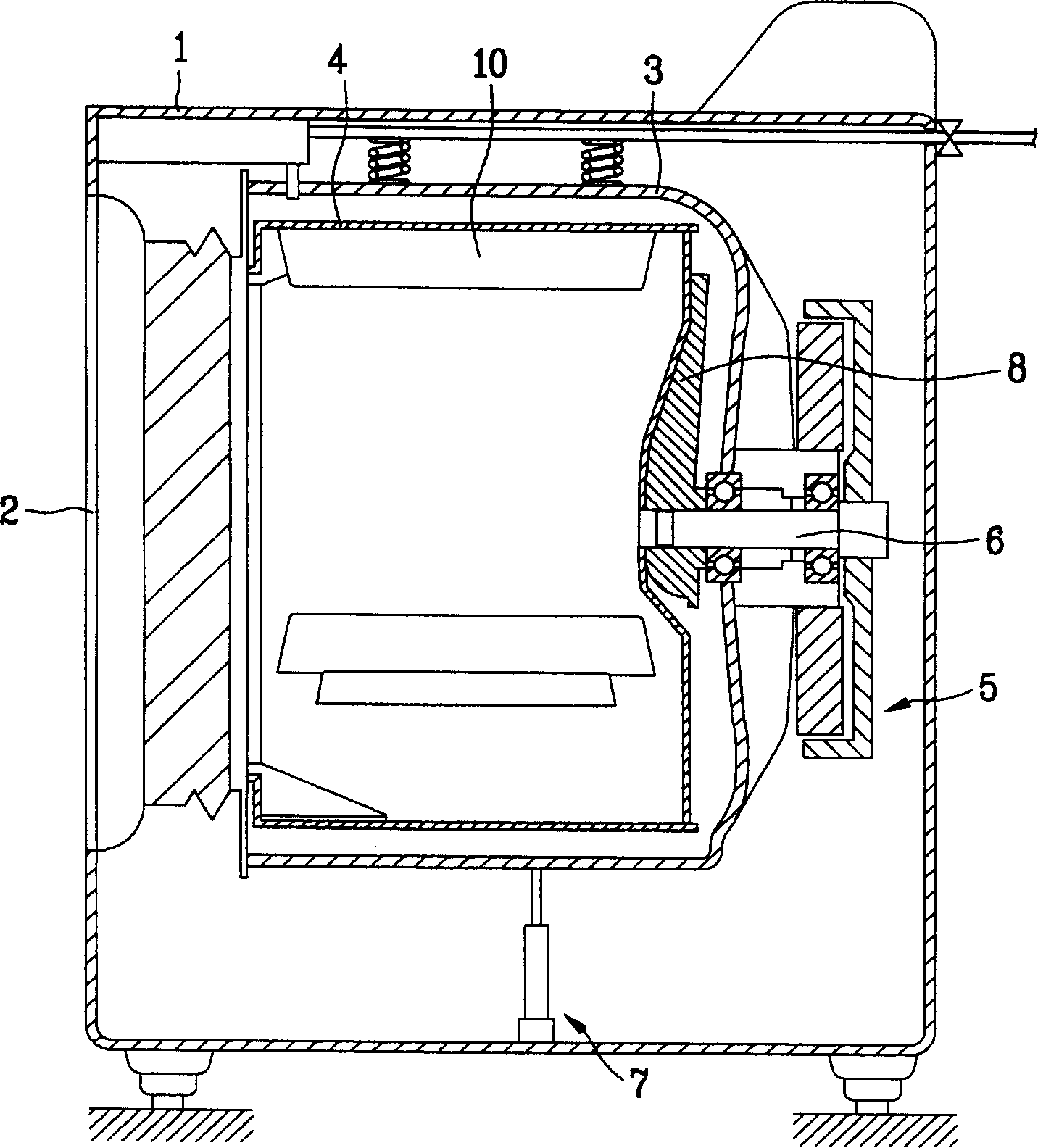

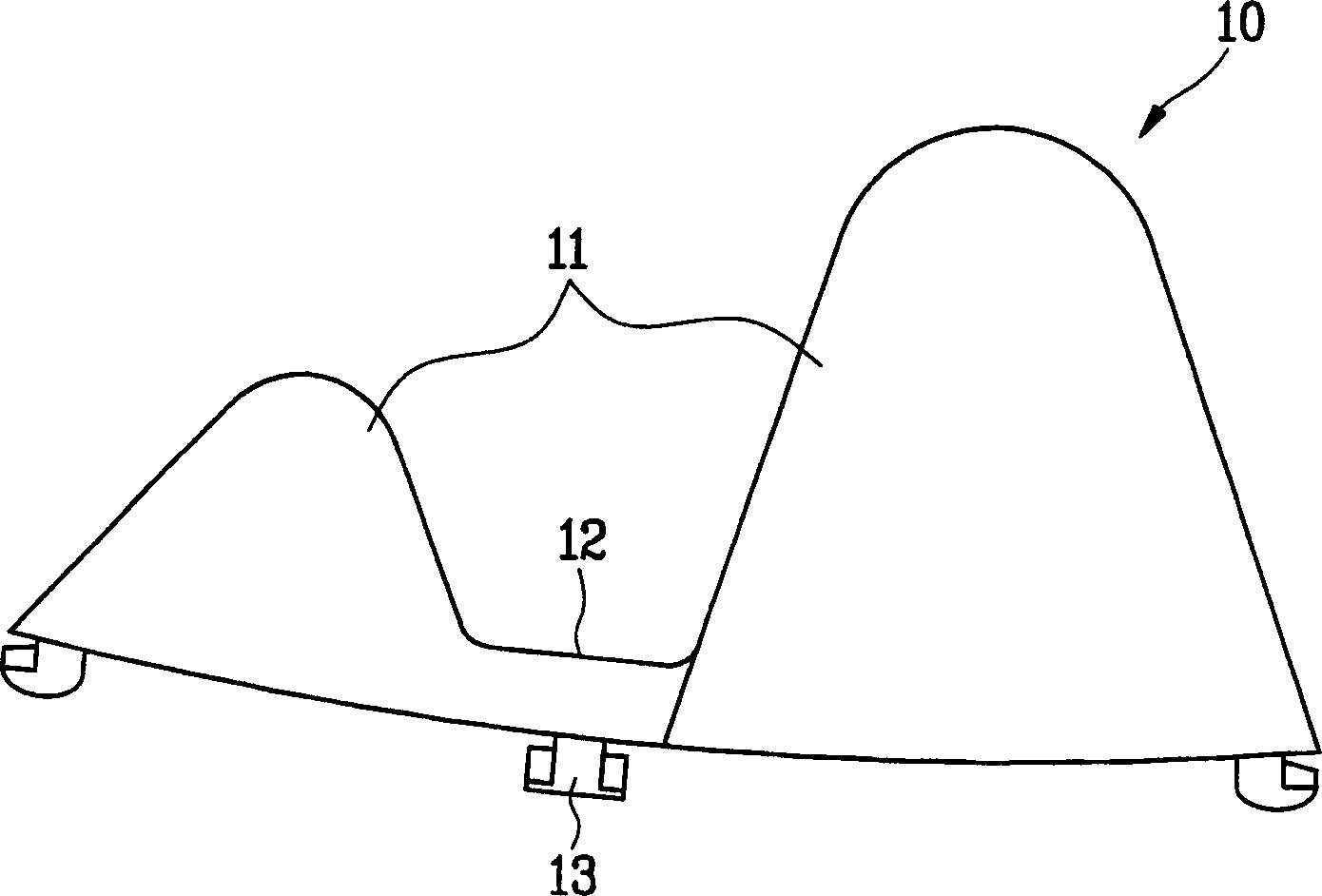

Roller washing machine

ActiveCN104005201AAvoid waterReduce washing water consumptionOther washing machinesWashing machine with receptaclesWater dischargeWash water

The invention relates to a roller washing machine. The roller washing machine comprises a box body, wherein an inner barrel and an outer barrel are arranged in the box body, a door seal is arranged between the outer barrel and the box body, the inner barrel is connected with a driving device, the inner barrel is a hole-free inner barrel and is a conical barrel of which the diameter at the bottom is small and the diameter at the opening is large, the opening of the inner barrel is contracted inwards in an arc shape, a water inlet guide pipe is arranged on the door seal, one end of the water inlet guide pipe is connected with a wash water rapid heating device, the other end of the water inlet guide pipe penetrates through the door seal and extends into the inner barrel, and a water discharging opening and a water pressure detection device are arranged on the outer barrel. According to the technical scheme, the inner barrel is the hole-free inner barrel, water enters the inner barrel through the water inlet guide pipe arranged on the door seal and is discharged through the shape of the inner barrel in the water discharging process, so that water is prevented from being accumulated between the inner barrel and the outer barrel, and the amount of washing water is largely saved.

Owner:WHIRLPOOL CHINA

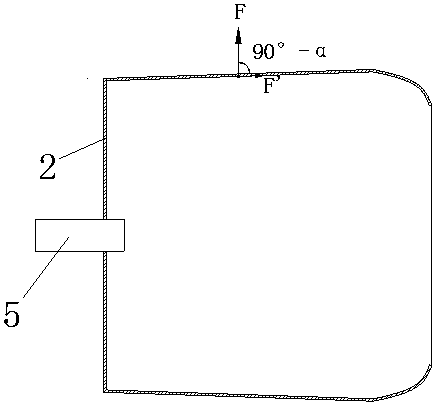

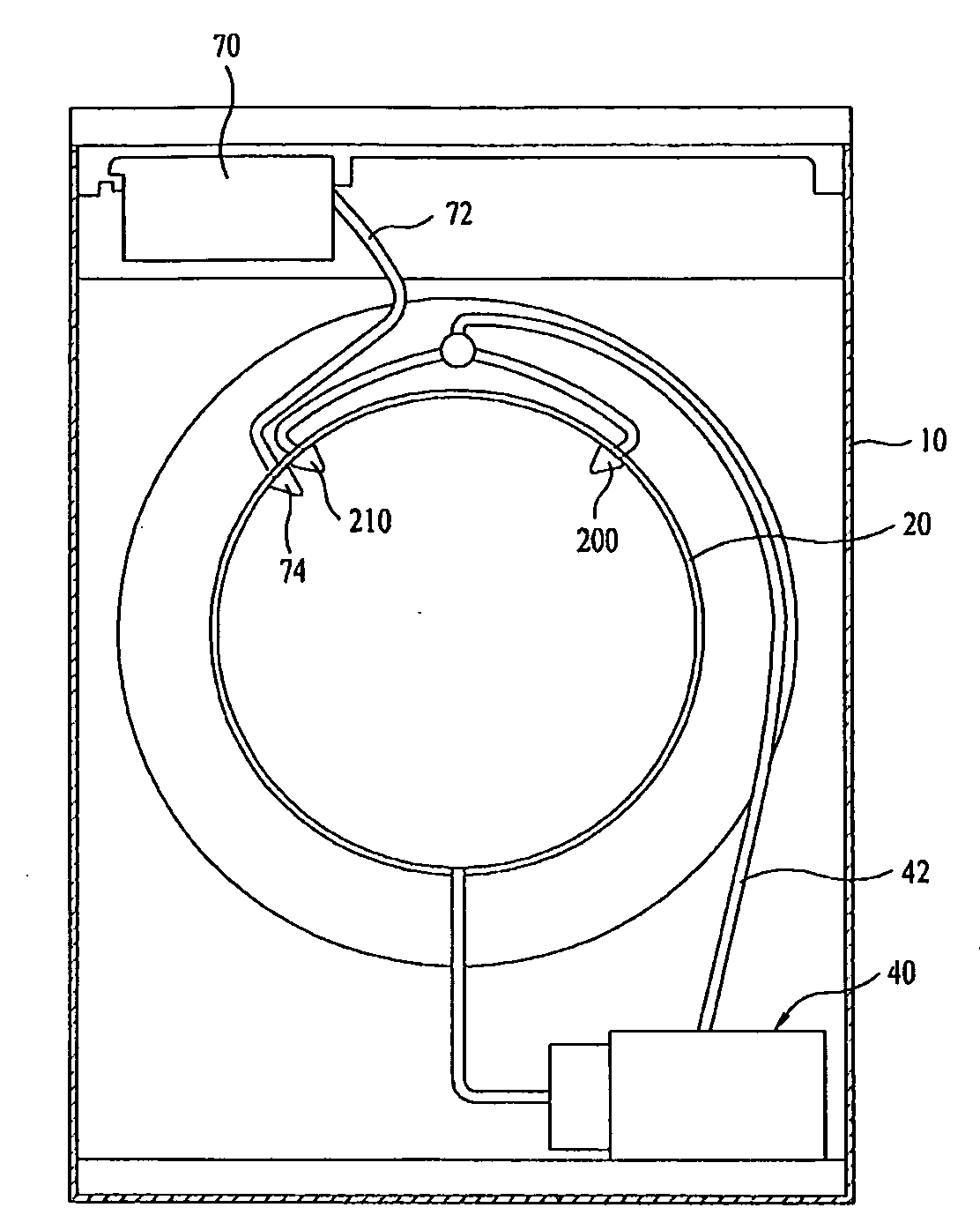

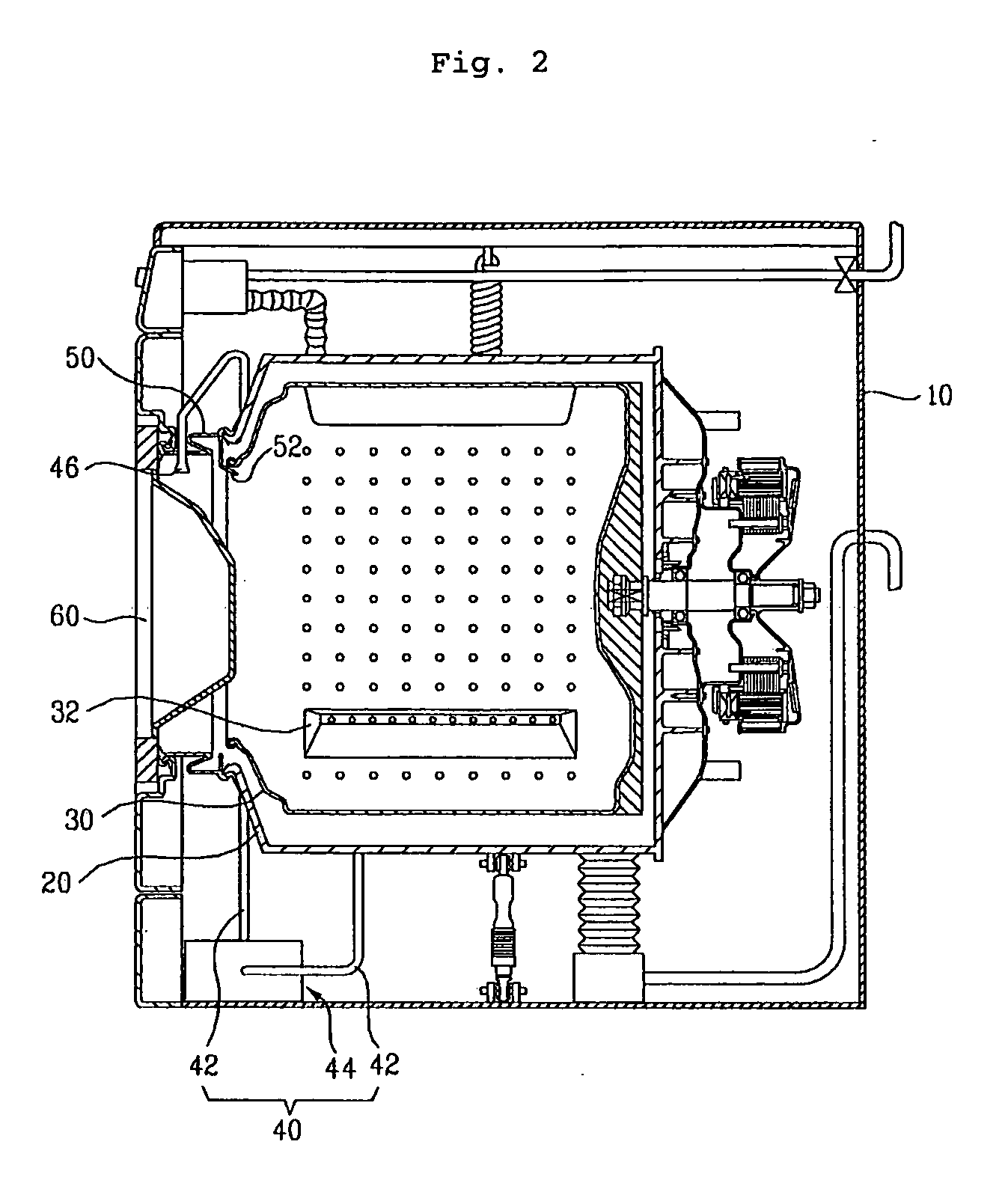

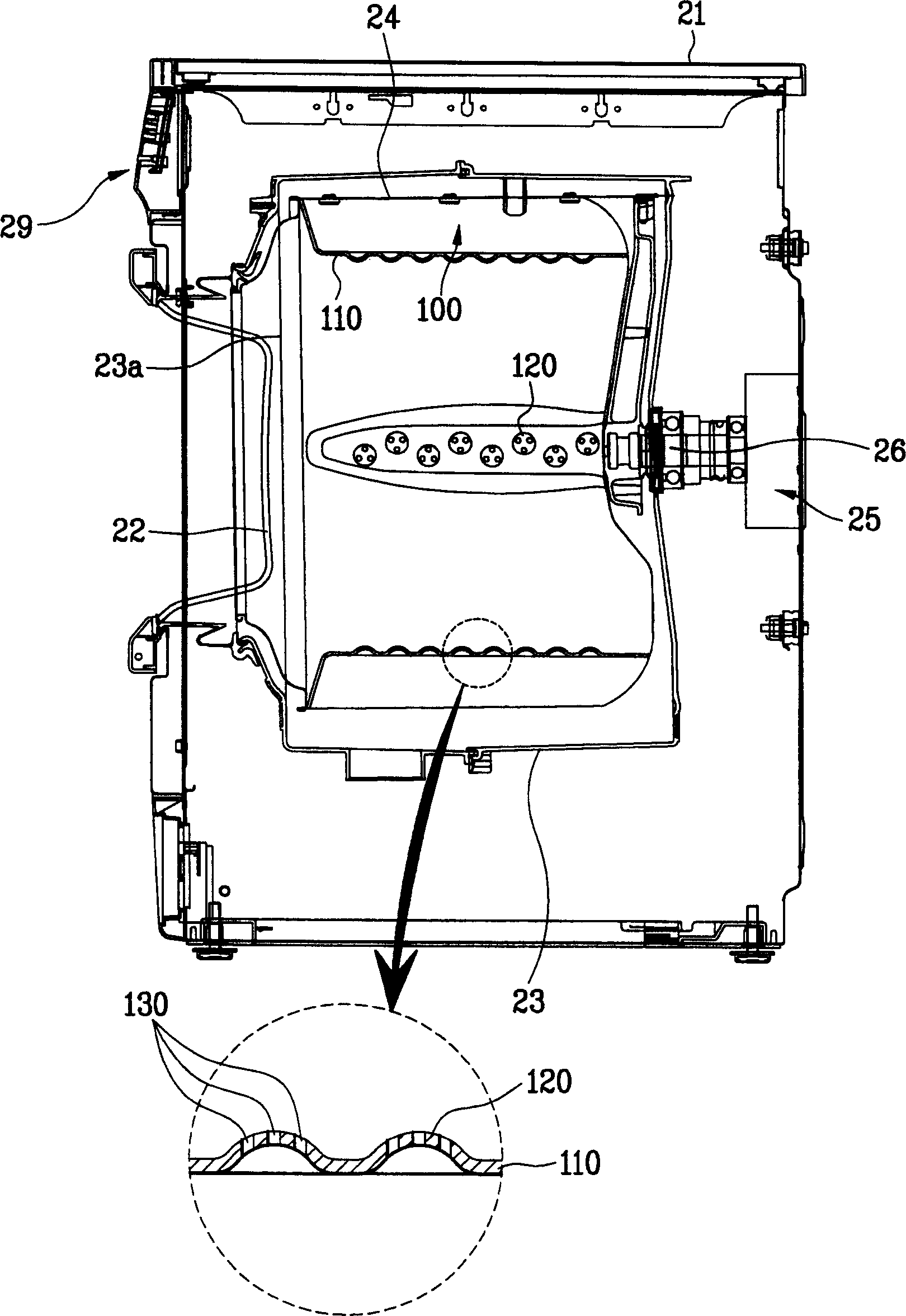

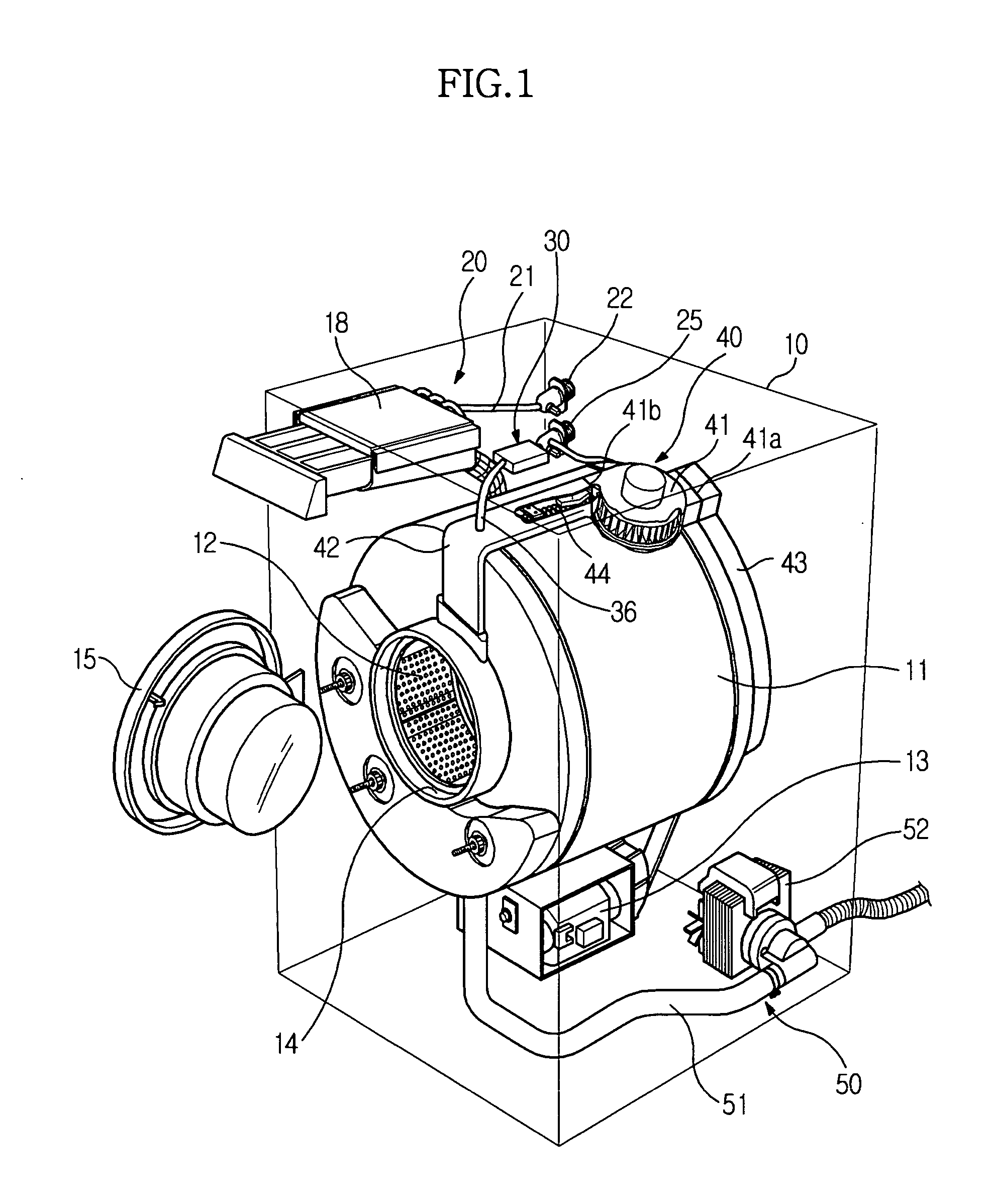

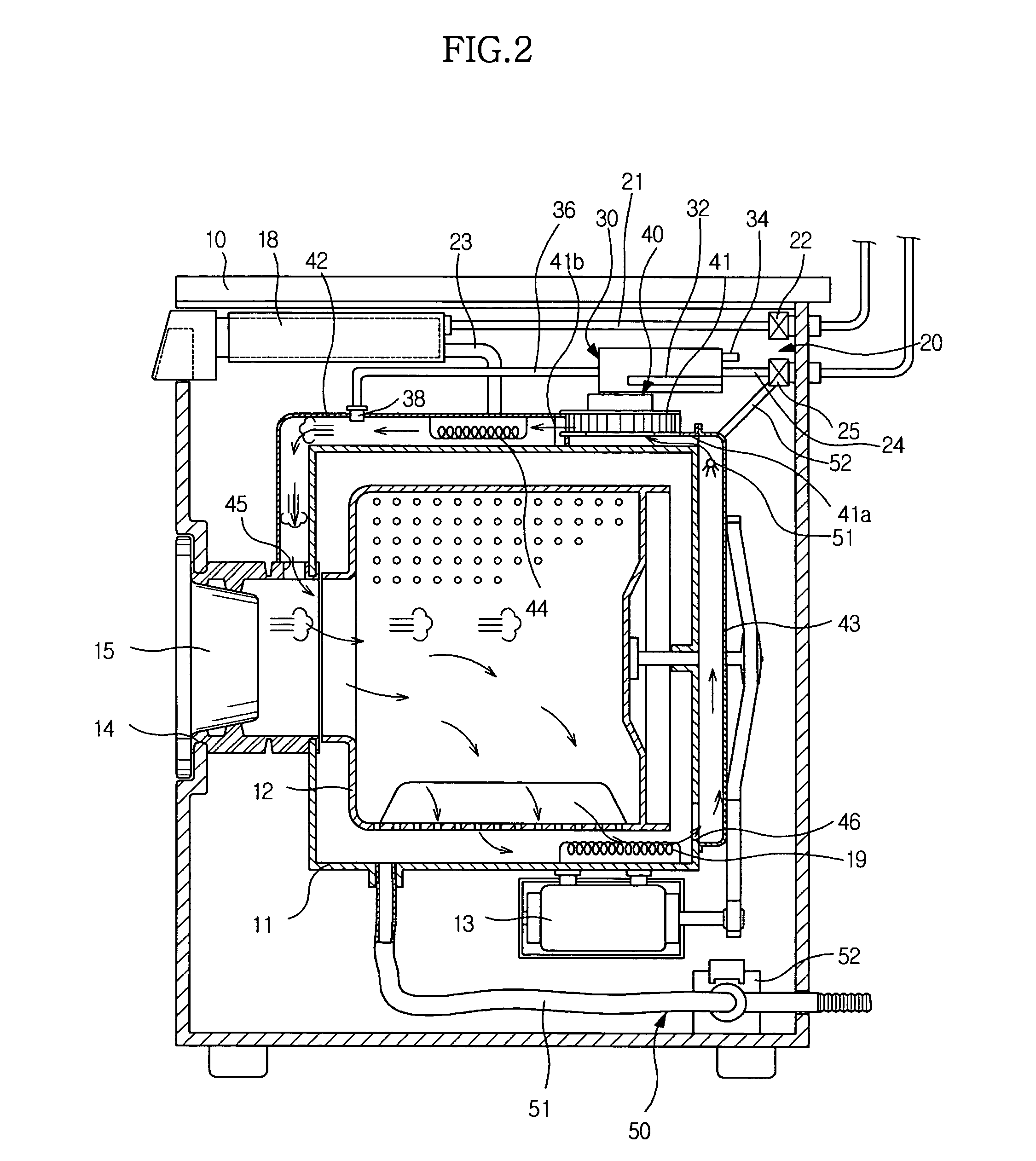

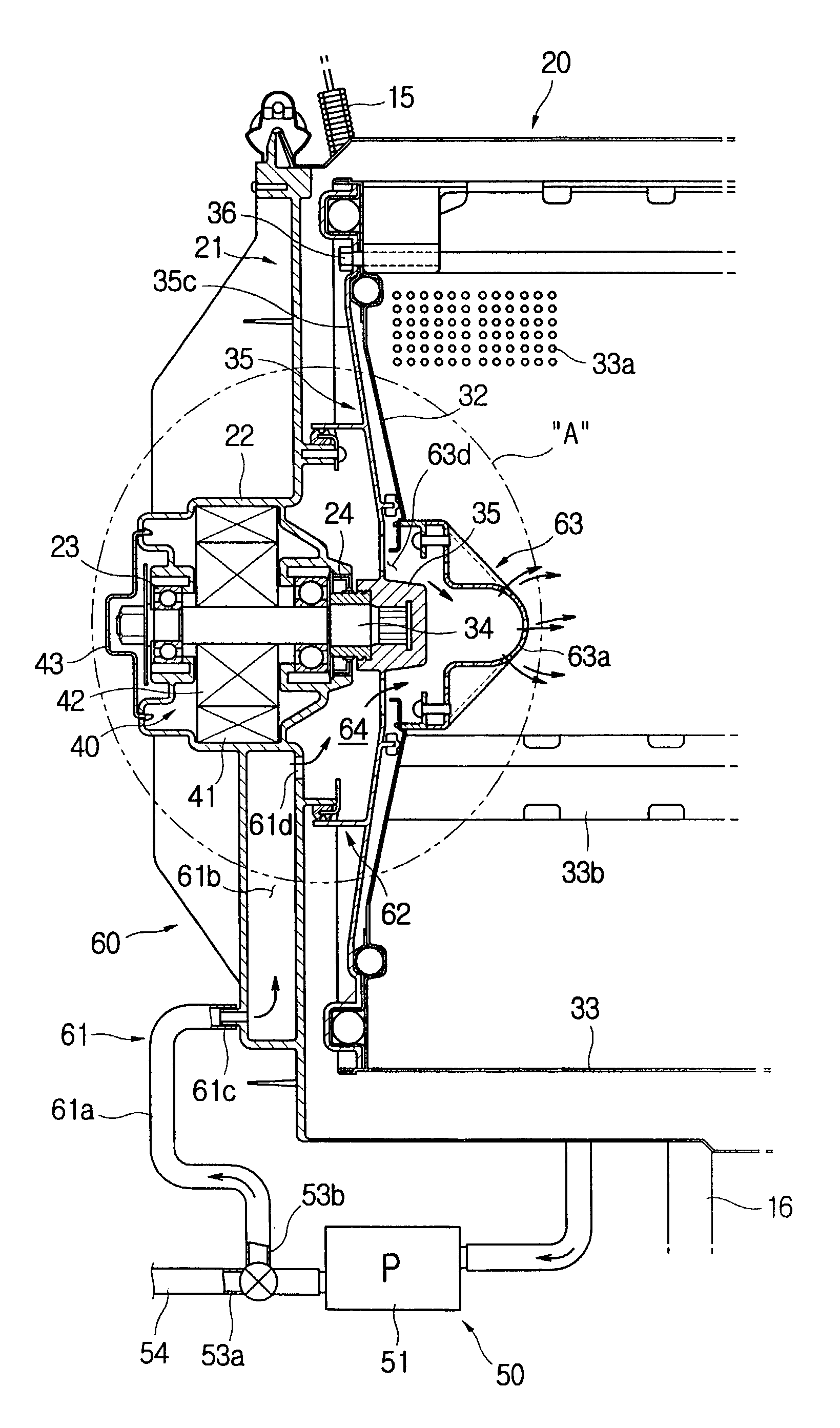

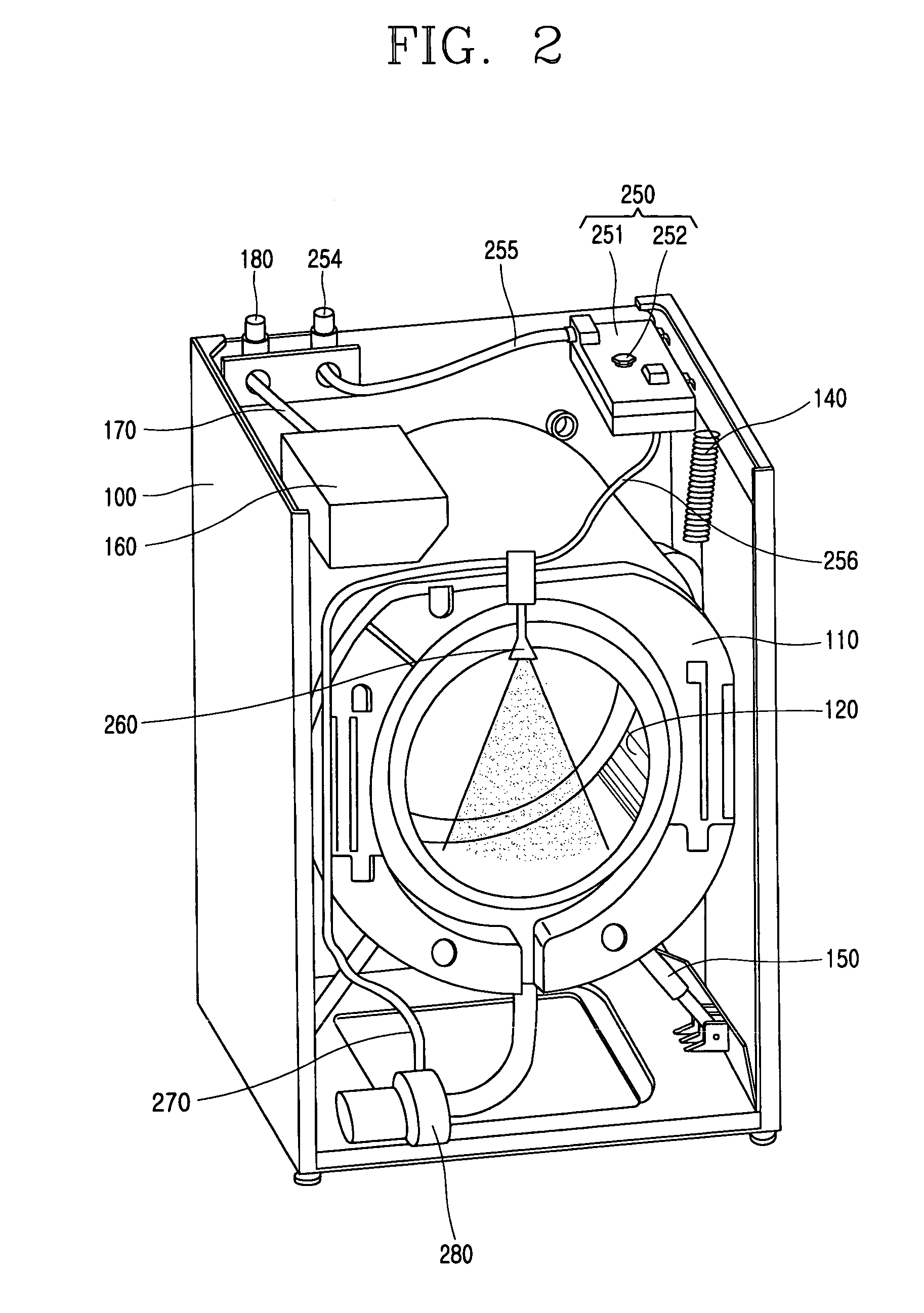

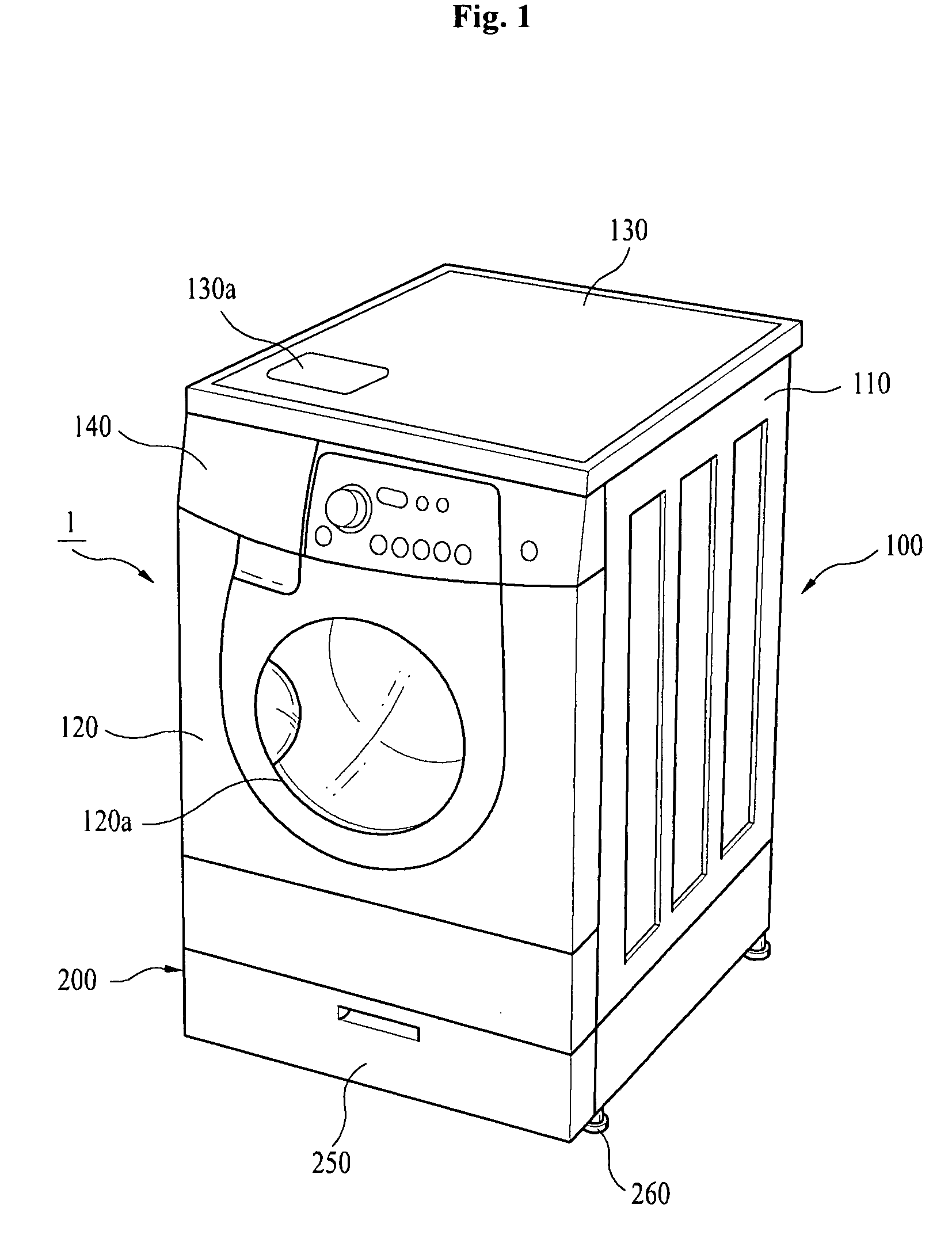

Washing machine

InactiveUS20090249840A1Improve rinsing efficiencyImprove washing efficiencyTextile treatment machine partsOther washing machinesWash waterEngineering

A washing machine includes a cabinet constituting the external appearance of the washing machine, a tub mounted in the cabinet for receiving wash water, a drum rotatably mounted in the tub for receiving laundry to be washed, a circulation unit for circulating wash water in the inner lower part of the tub through the upper part of the tub, and at least one circulation nozzle for spraying the wash water, supplied by the circulation unit, inwardly of the drum along a rotation axis of the drum in a longitudinal direction of the drum. According to the present invention, it is possible to improve washing or rinsing efficiency of the washing machine.

Owner:LG ELECTRONICS INC

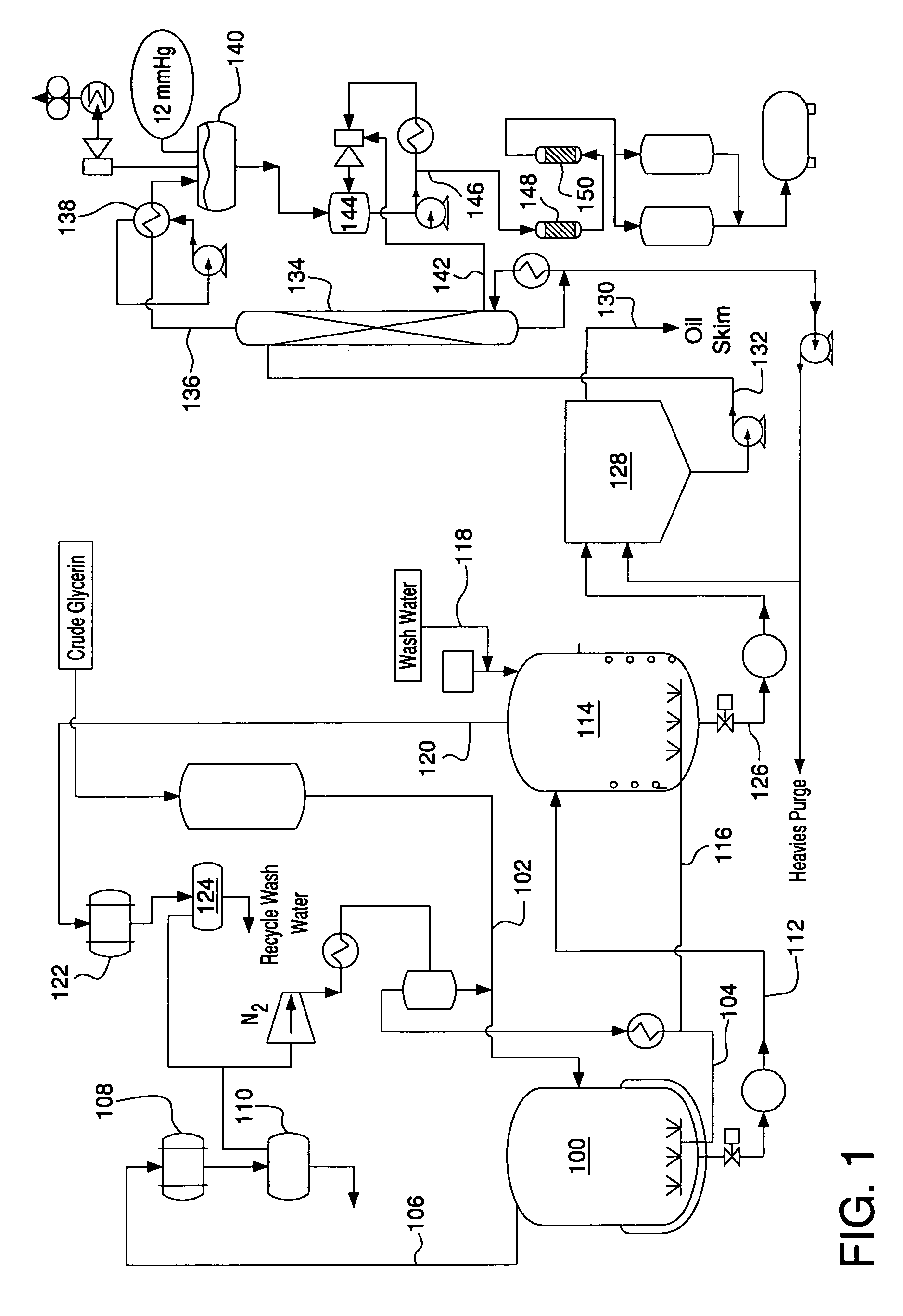

Purification of glycerin

InactiveUS7126032B1Low costEfficient recyclingOrganic compound preparationOxygen compounds purification/separationAlcoholWash water

A process for purifying glycerin recovered as a byproduct of biodiesel production comprises heating a glycerin effluent stream containing a low molecular weight alcohol, water and fatty acid esters of the low molecular weight alcohol to cause transesterification of the fatty acid esters to glycerides and additional low molecular weight alcohol. The reaction mixture is sparged with nitrogen to help remove water and low molecular weight alcohol, which drives the transesterification reaction towards glyceride formation. A wash water stream may also be added to the recovered glycerin stream from biodiesel production. Either before or following the transesterification reaction, an oil layer can be separated from the recovered glycerin stream by reducing the pH of the stream to below 7. Following separation of the oil layer and transesterification the glycerin stream is flash distilled to separate glycerin from water, salts, and glycerides.

Owner:SUNOCO INC (R&M)

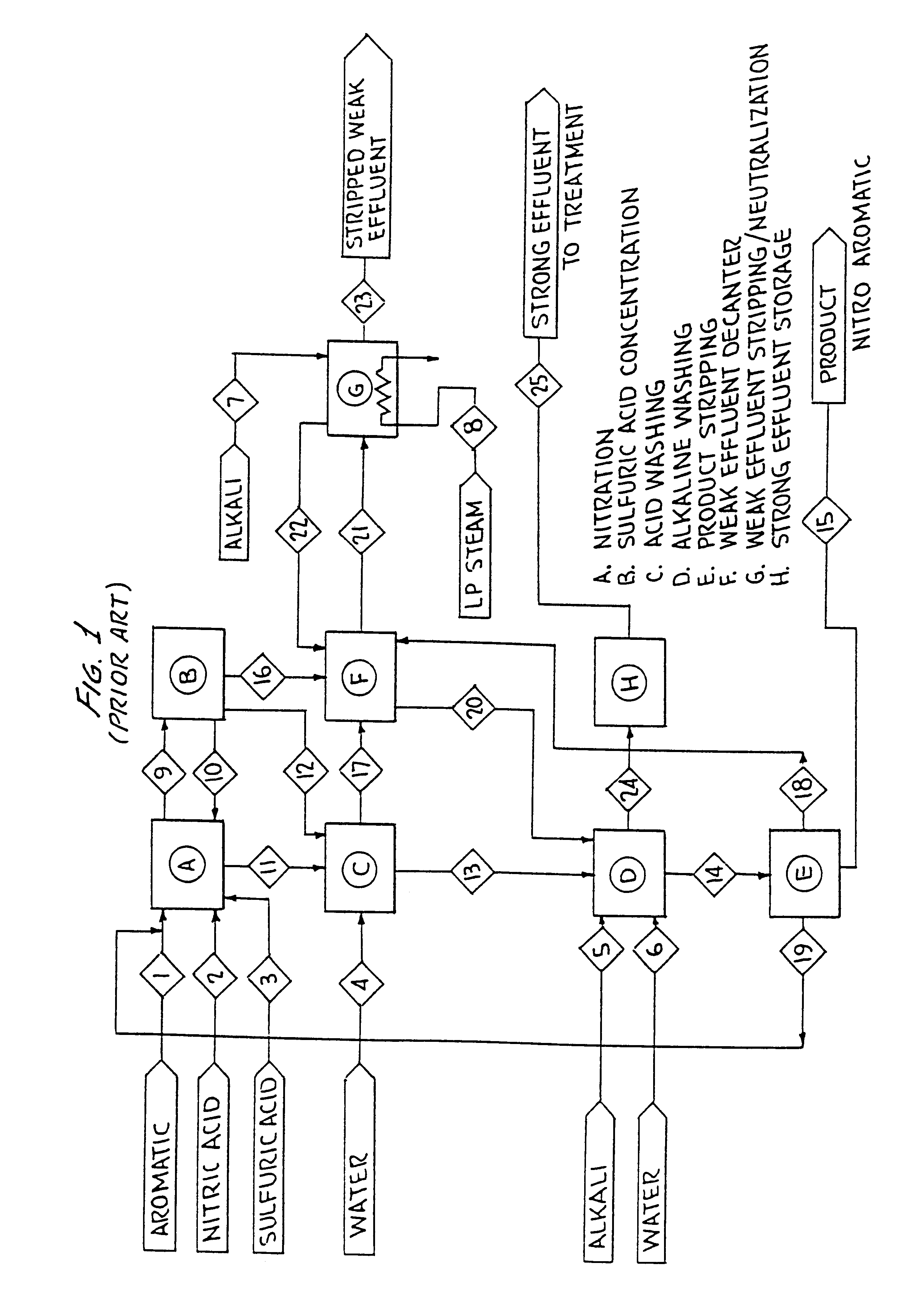

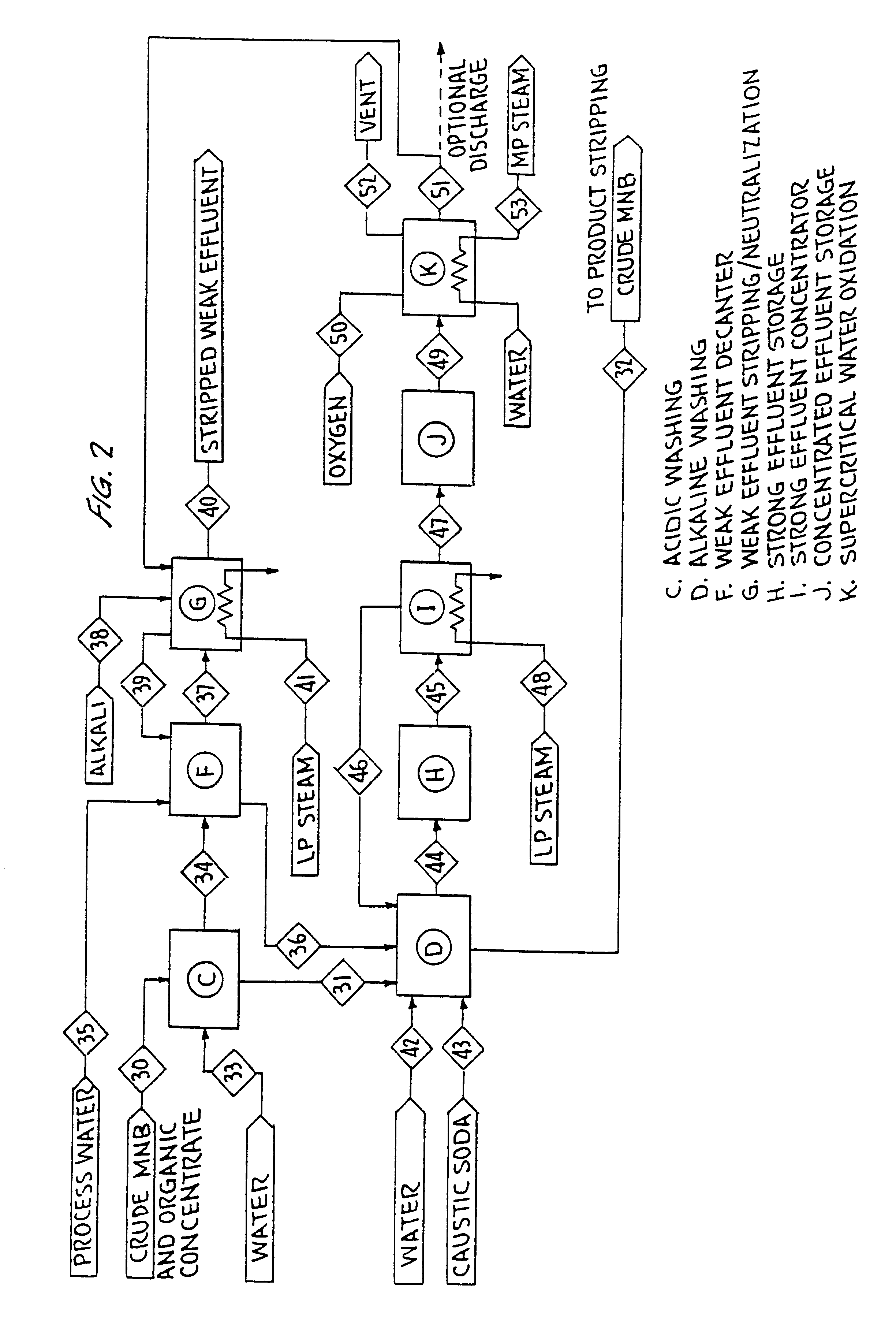

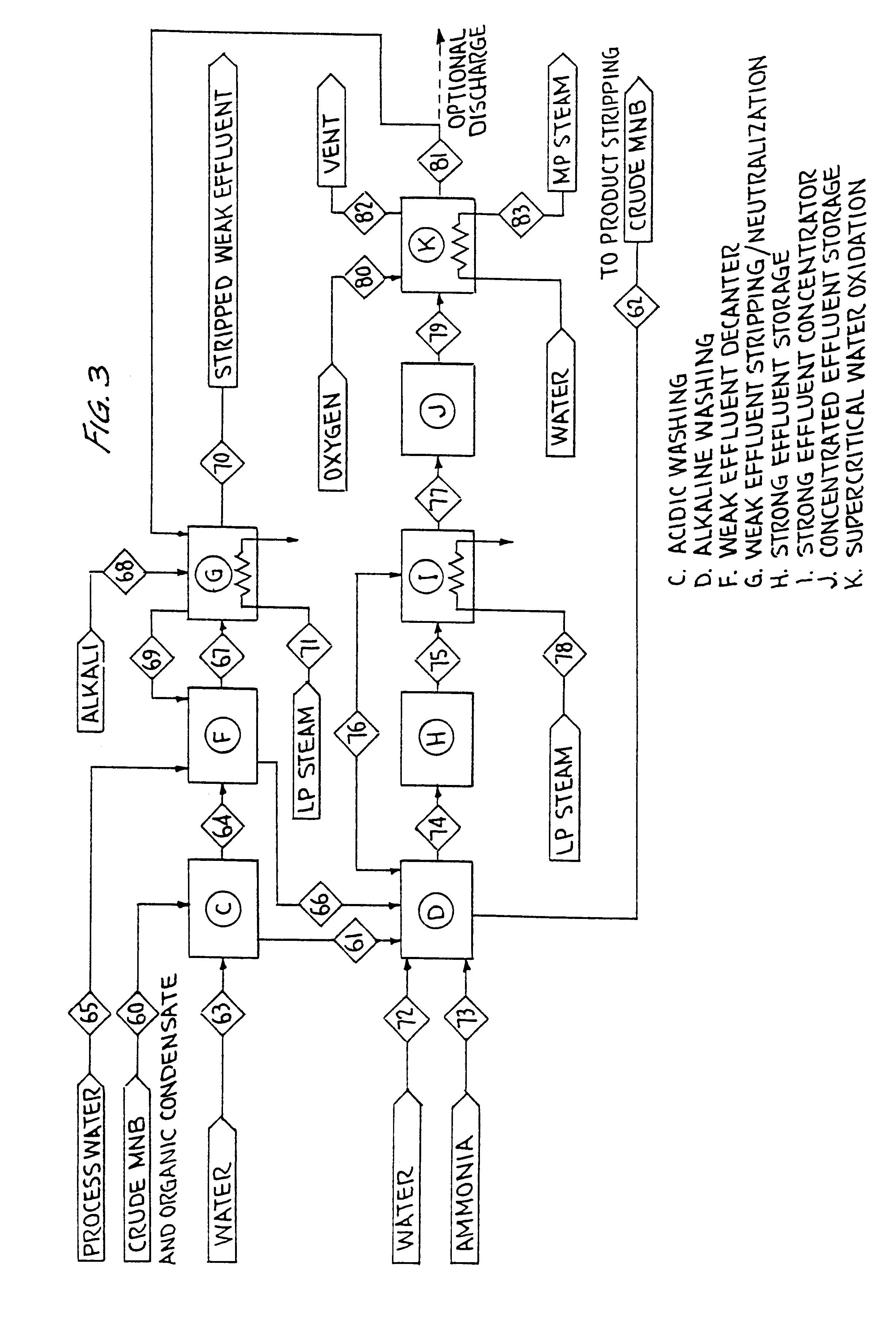

Integrated effluent treatment process for nitroaromatic manufacture

InactiveUS6288289B1Highly destructiveReduce consumptionOrganic chemistrySludge treatment by oxidationWash waterSupercritical water oxidation

An integrated process for treating alkaline wash water effluent from nitroaromatic manufacture, principally containing nitro-hydroxy-aromatic compounds is described. The integrated process concentrates the alkaline wash water to recover chemicals and water prior to treating the concentrate through supercritical water oxidation. The supercritical water oxidation step consists of treating the concentrate in the presence of an oxygen source at conditions, which are supercritical for water to cause a substantial portion of the organic component of the concentrate to oxidize. The product effluent includes a gaseous component and a clean water component, and in the event that insoluble ash is formed, an ash component. The new integrated process results in reduced chemical and water consumption compared to existing processes. In addition, the treated wash water effluent can be recycled to process or directly discharged.

Owner:NORAM INT

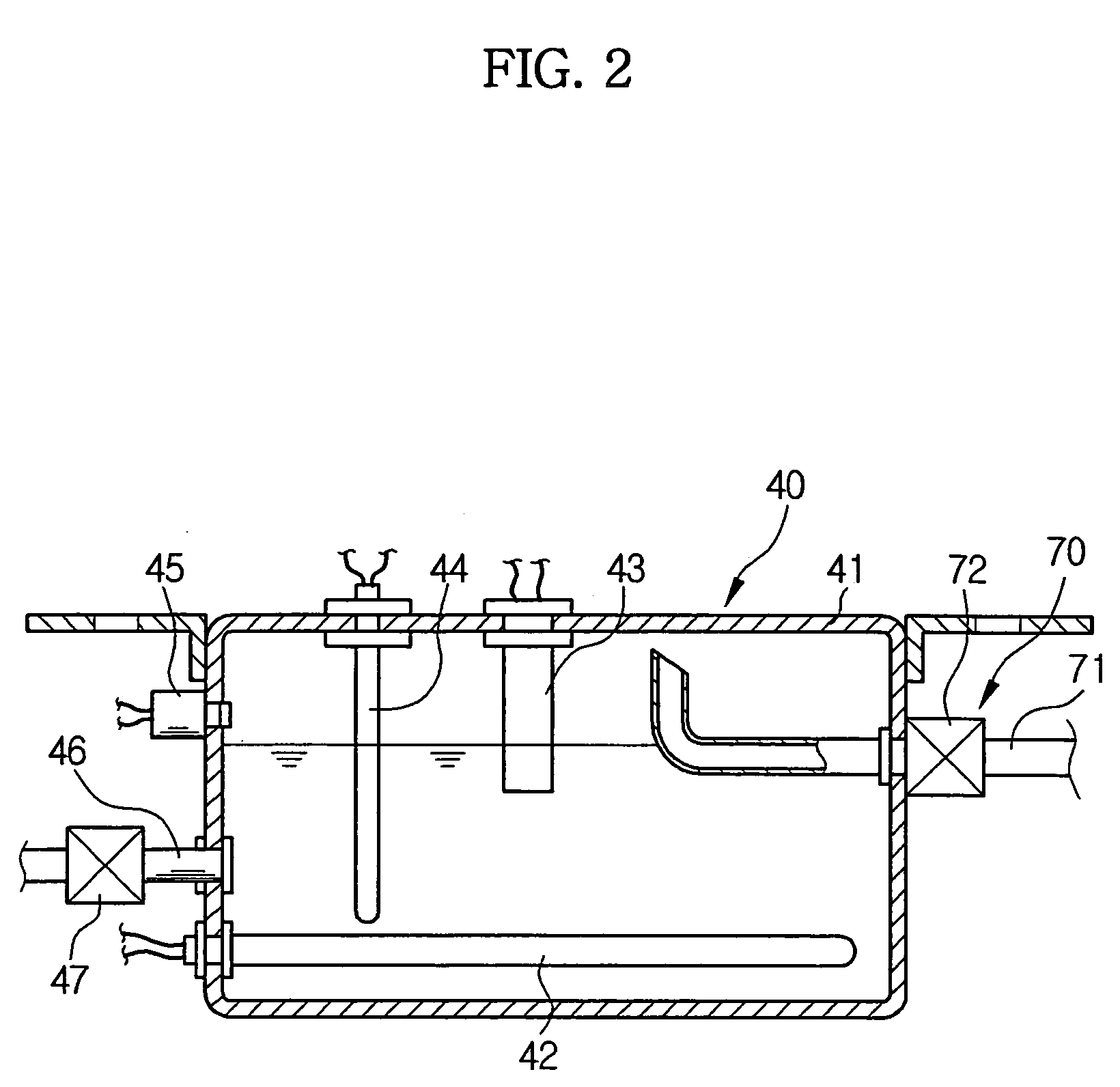

Washing machine having drying function and method for controlling the same

InactiveUS20050223504A1Easy to washIncreased rinse capacityOther washing machinesControl devices for washing apparatusWash waterEngineering

A washing machine having a drying function and a method for controlling the same. The washing machine includes a tub for containing wash water; a drum rotatably placed in the tub for containing laundry, and provided with through holes for circulating the wash water or air therethrough; a drying device provided with a circulation fan and a heater for drying the laundry in the drum; and a pumping device for pumping the wash water in the tub so that the wash water in the tub is circulated into the drum or heated by the air passing through the drying device, and is then circulated into the drum. The washing machine performs washing of laundry without any additional heater for heating the wash water, thereby having low production costs and a simple structure of the tub.

Owner:LG ELECTRONICS INC

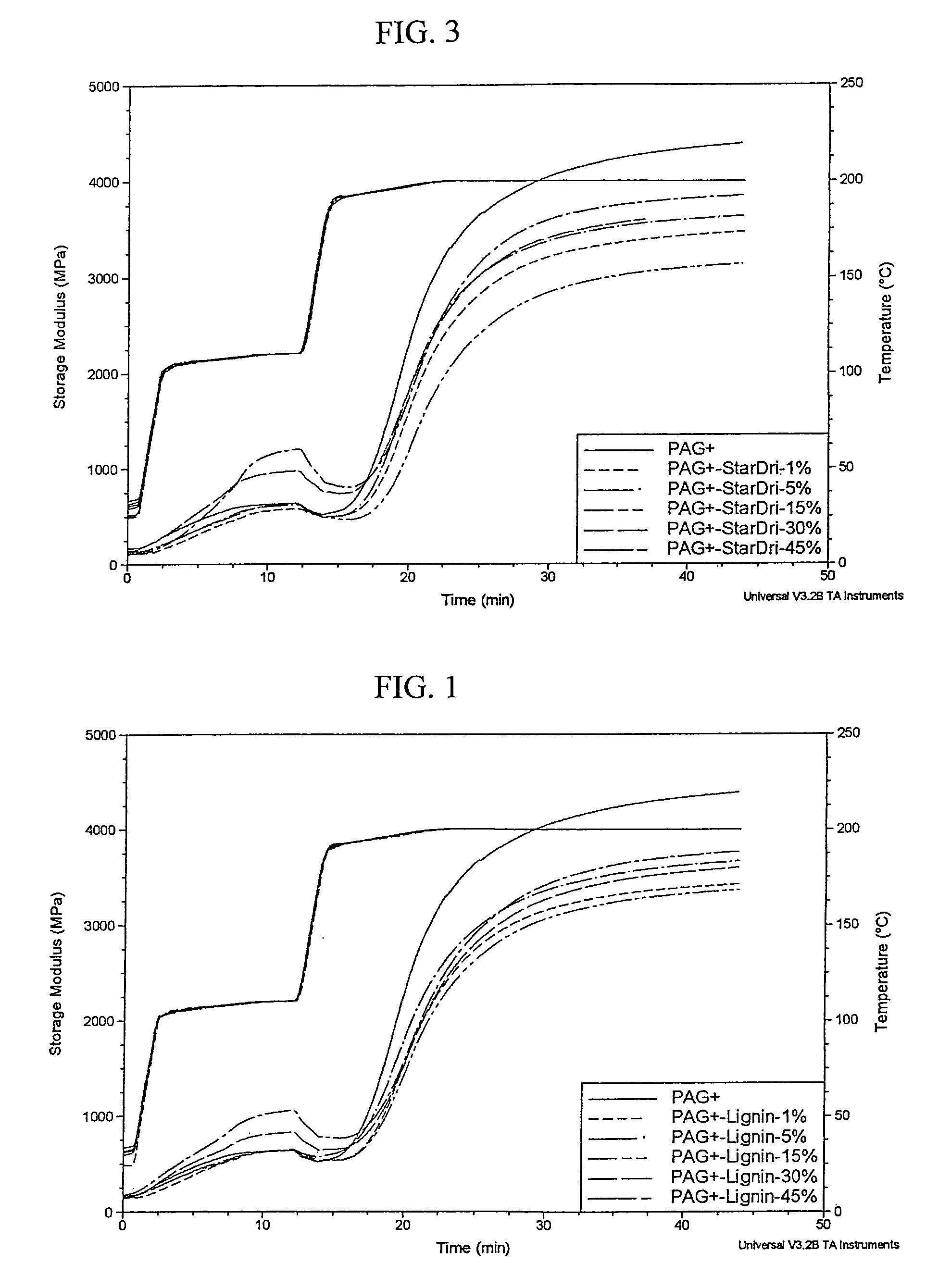

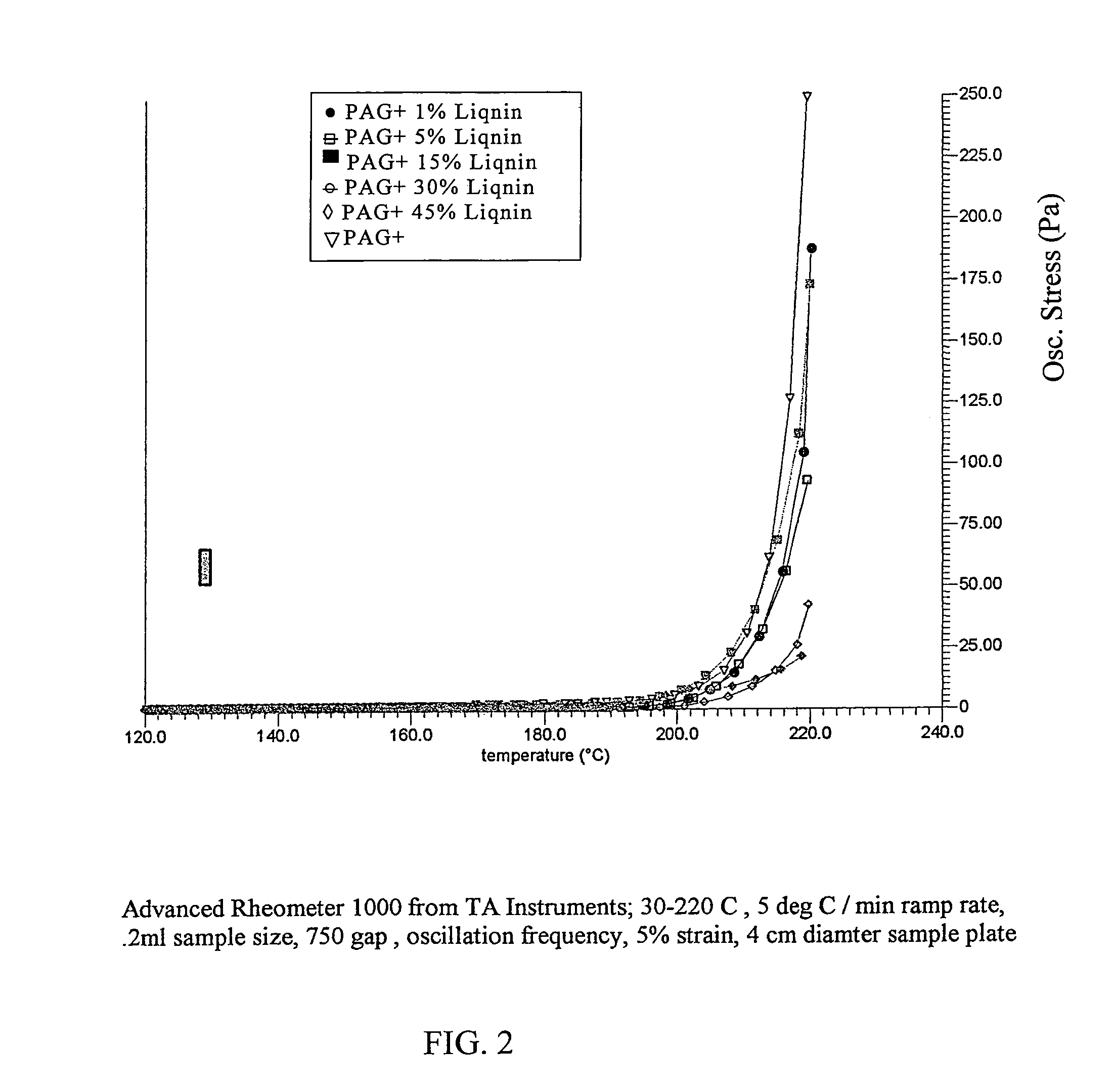

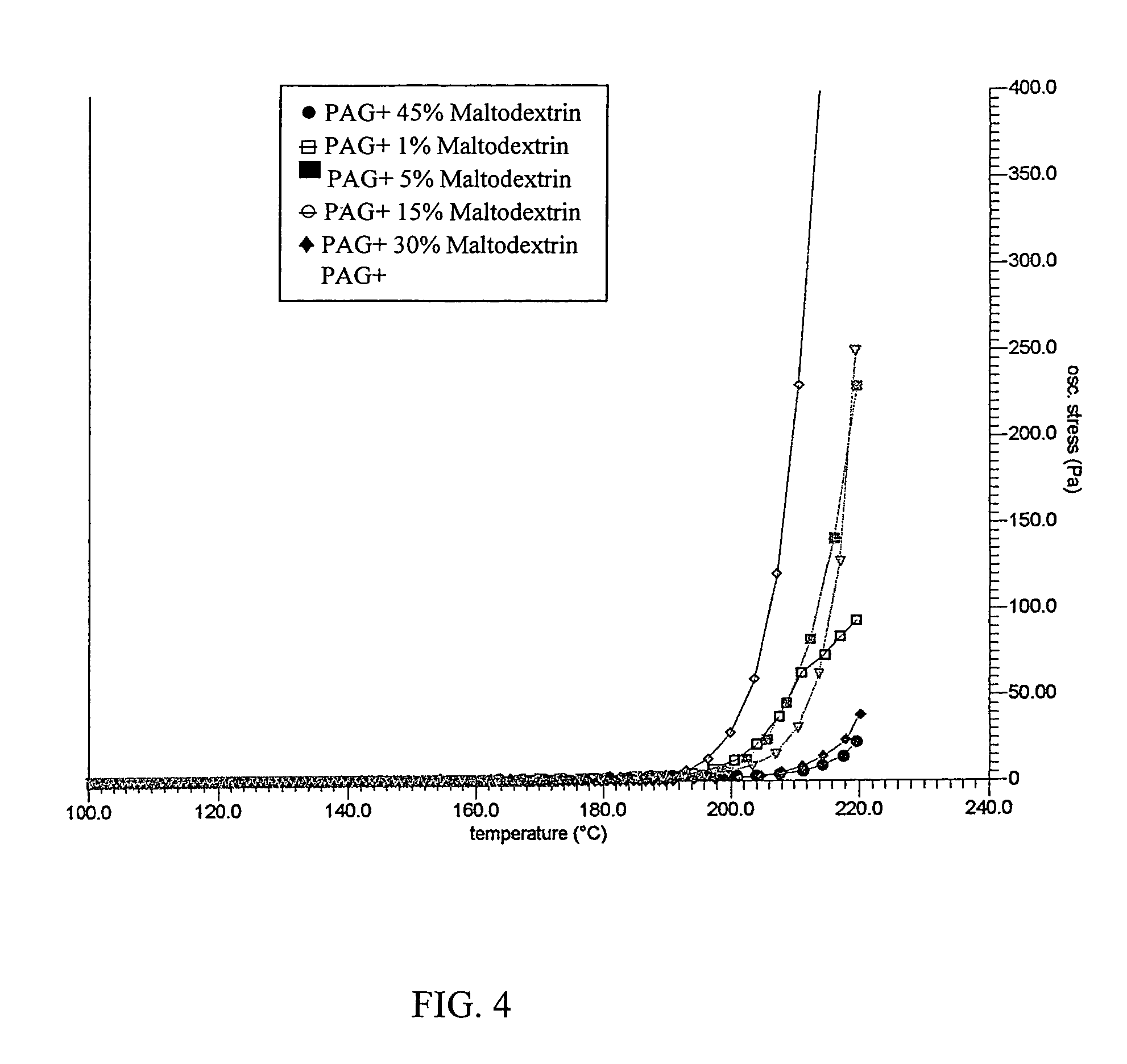

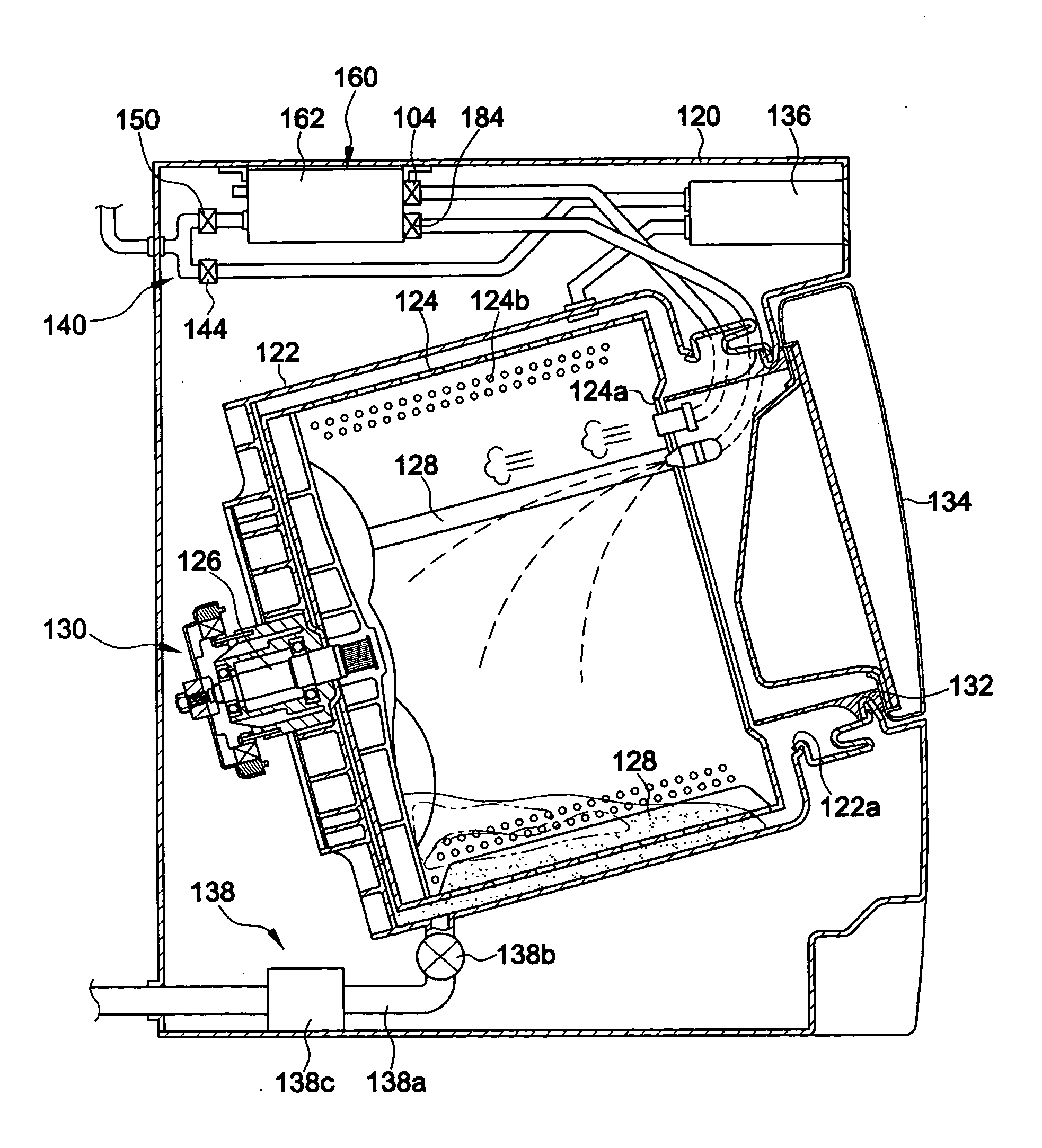

Extended binder compositions

The present invention provides a variety of extended polyacrylic acid based binder compositions comprising a low molecular weight polyacrylic acid (typically hypophosphite or sulfite terminated), a crosslinking agent (such as triethanolamine or glycerol) and one or more water soluble materials, such as lignin, low molecular weight starch and soybean protein. The extended binder composition of the present invention provides a lower cost binder composition without degrading the performance and may be selected to alter one or more characteristics of the basic binder composition such binder wetting, emulsion compatibility, dust suppression and wash water flow properties.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

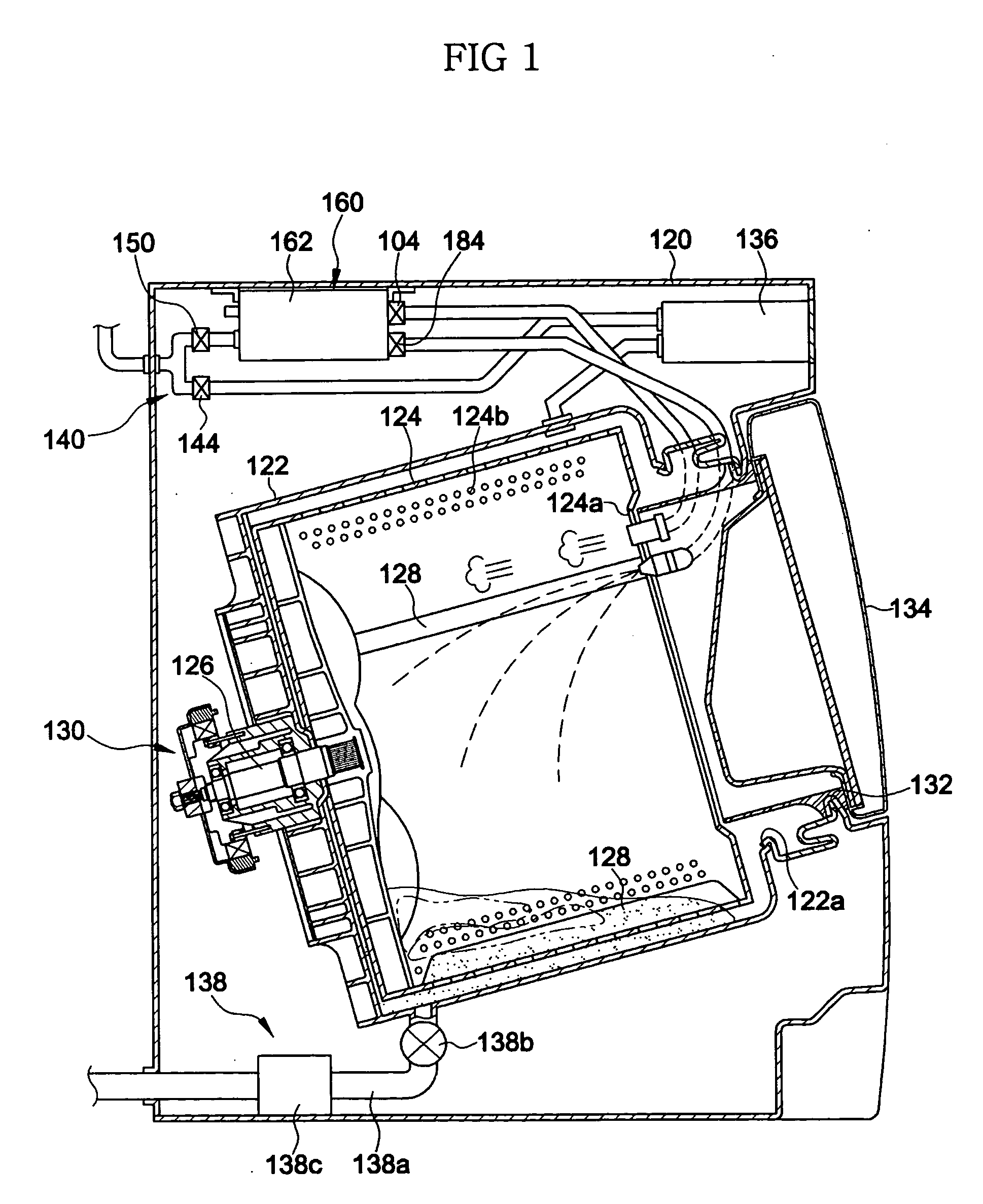

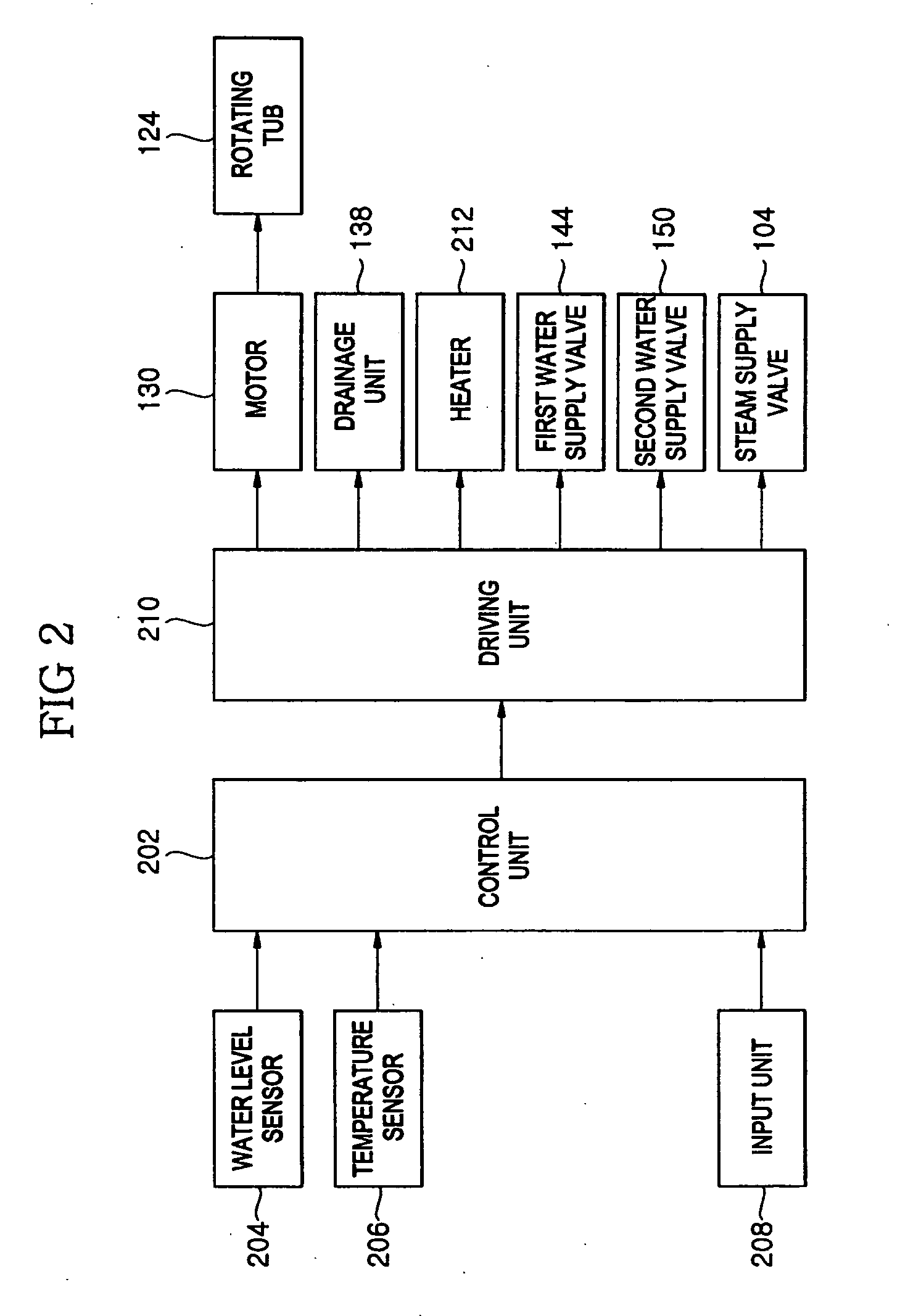

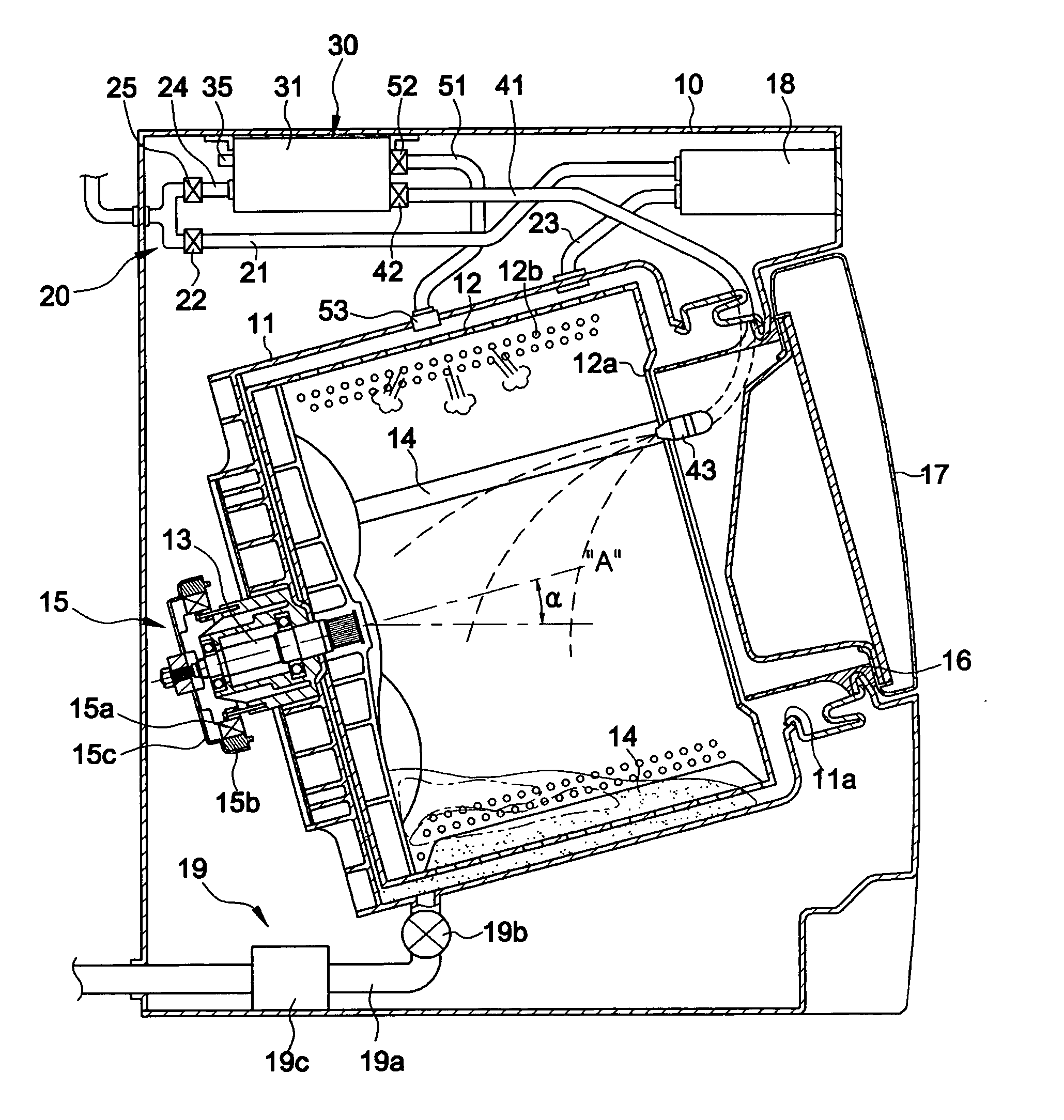

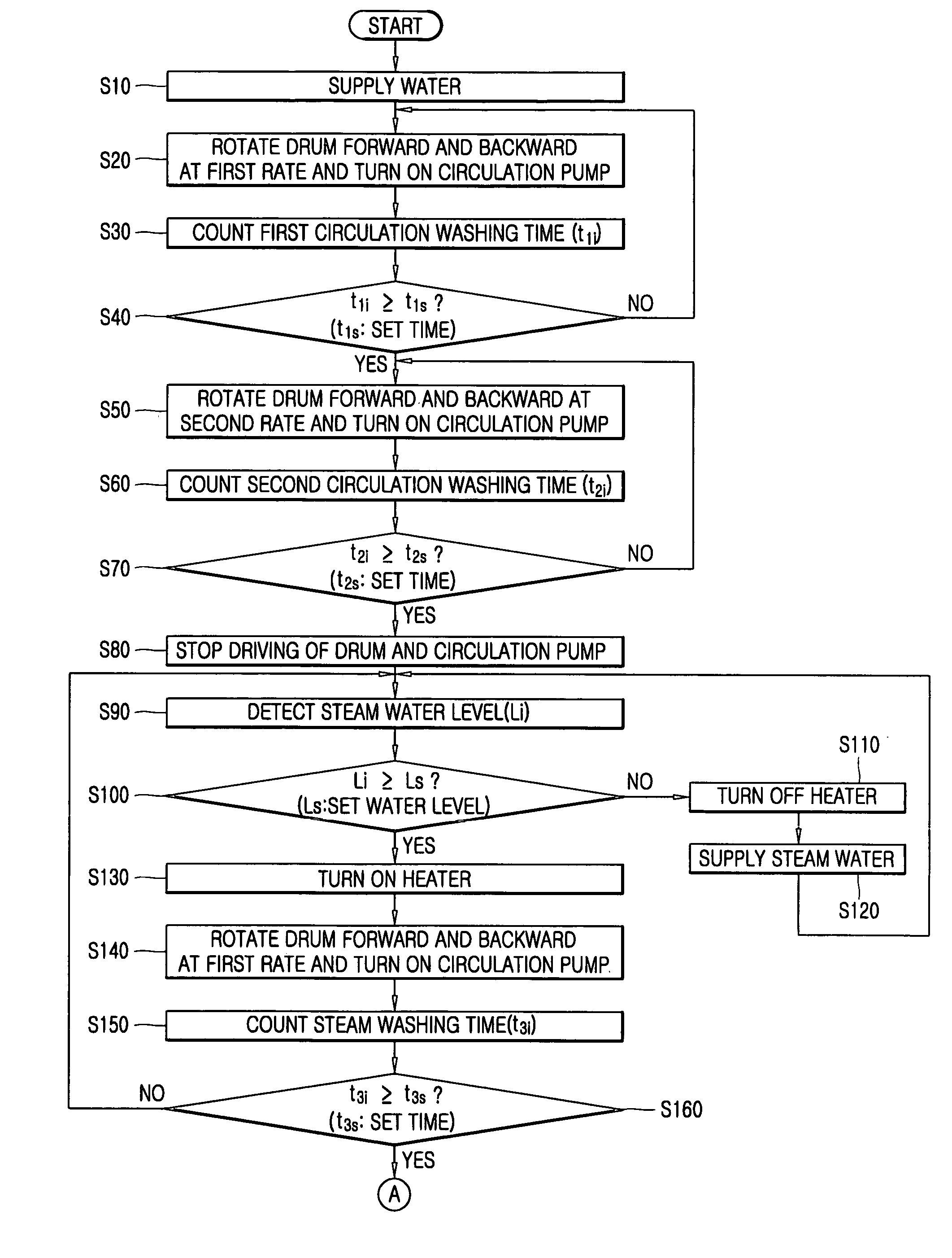

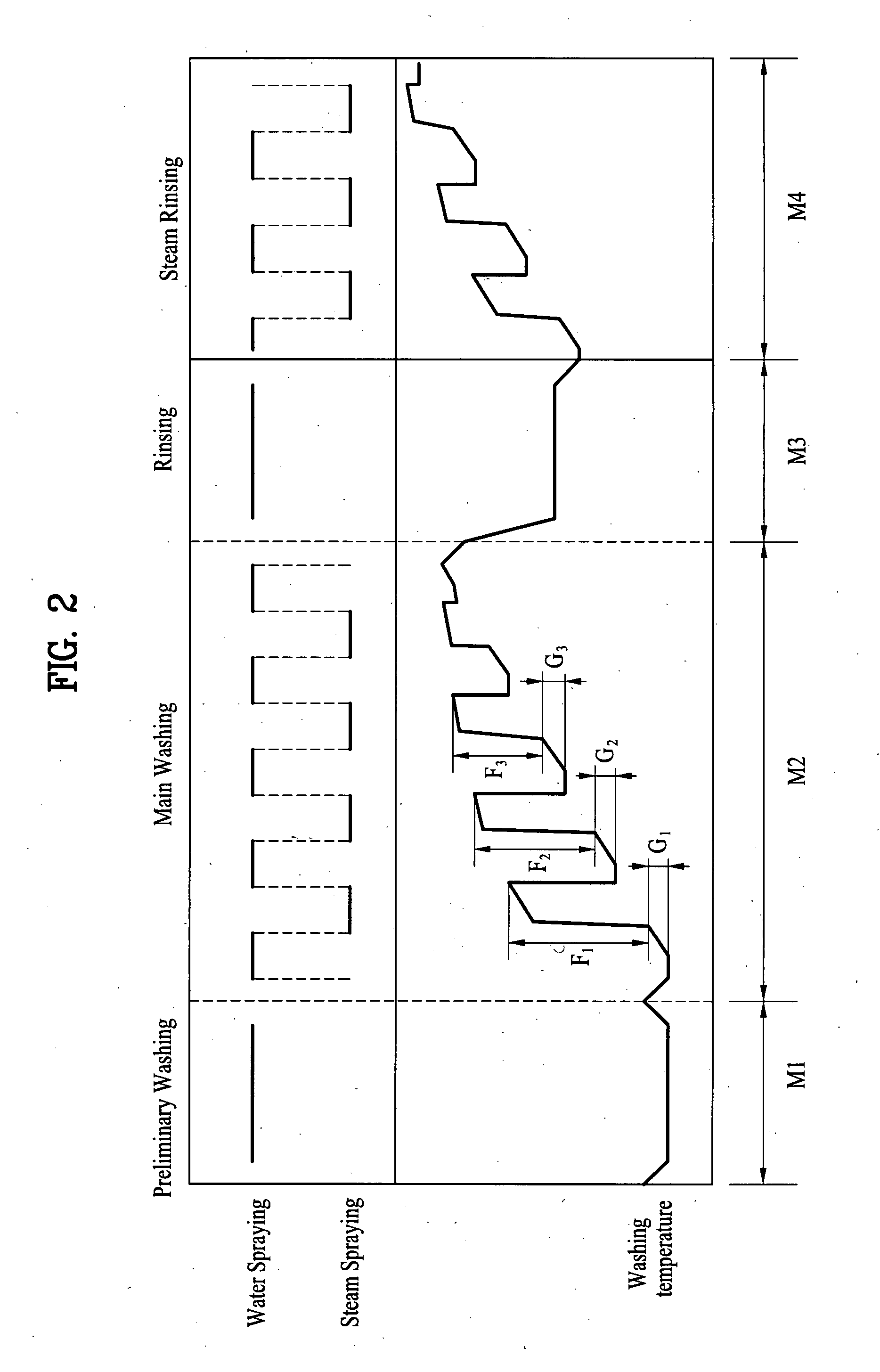

Washing machine and control method thereof

InactiveUS20050132503A1Grow fastShorten washing timeOther washing machinesControl devices for washing apparatusWash waterEngineering

A drum type washing machine in which wash water and laundry contained in a rotating tub are heated by steam supplied into the rotating tub, so as to rapidly increase the temperature of the wash water and laundry, thereby being capable of reducing the total wash time while reducing the amount of wash water to be used, and reducing the consumption of energy caused by heating of the wash water. The washing machine includes a steam generating unit for heating water supplied thereto, thereby generating steam, and a control unit for rotating the rotating tub at a high speed to cause the laundry contained in the rotating tub to be in constant contact with an inner peripheral surface of the rotating tub without falling down, by virtue of a centrifugal force generated during the rotation of the rotating tub, the control unit supplying the steam from the steam generating unit into the rotating tub during the high-speed rotation of the rotating tub, to increase the internal temperature of the rotating tub and the temperature of the laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

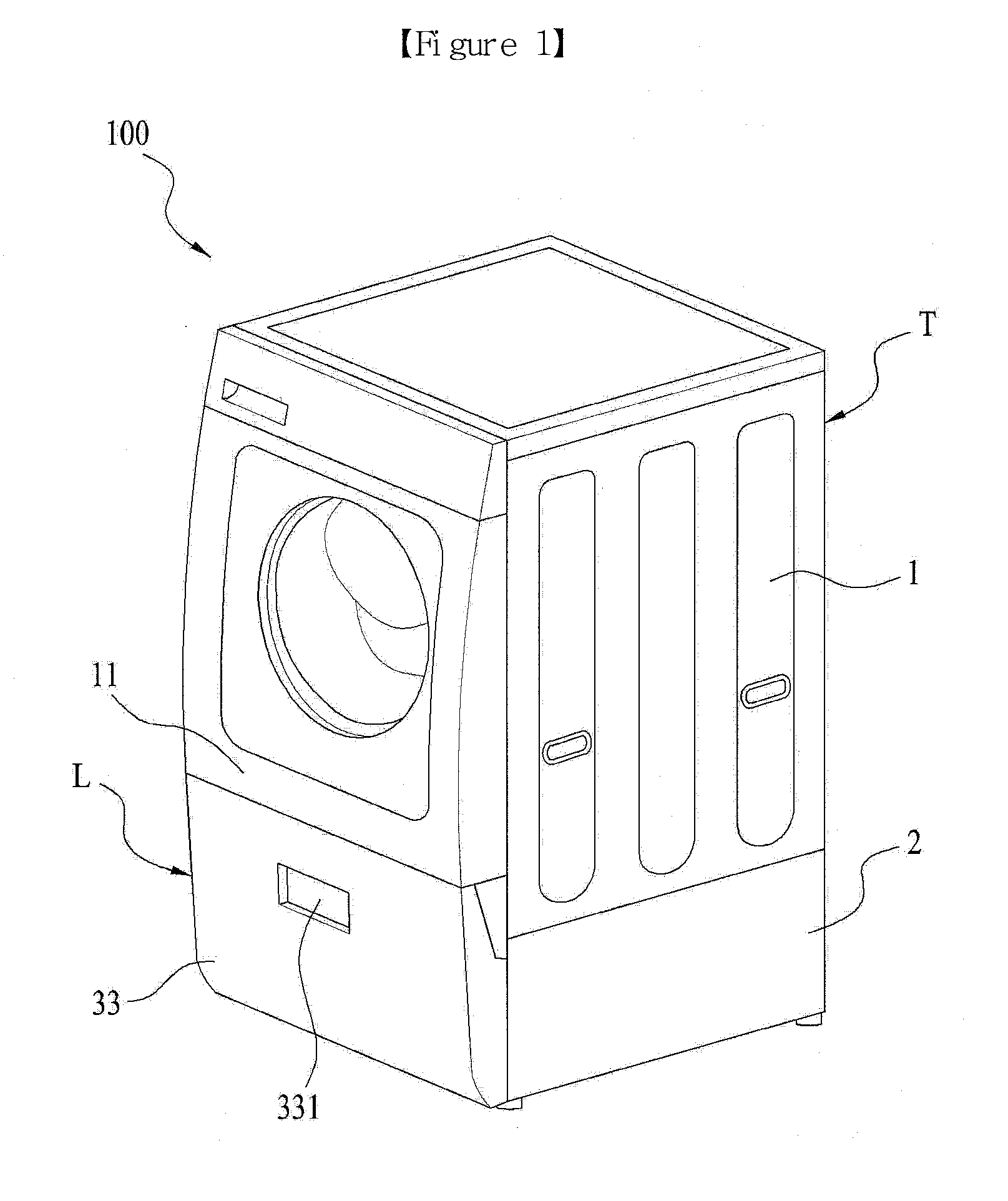

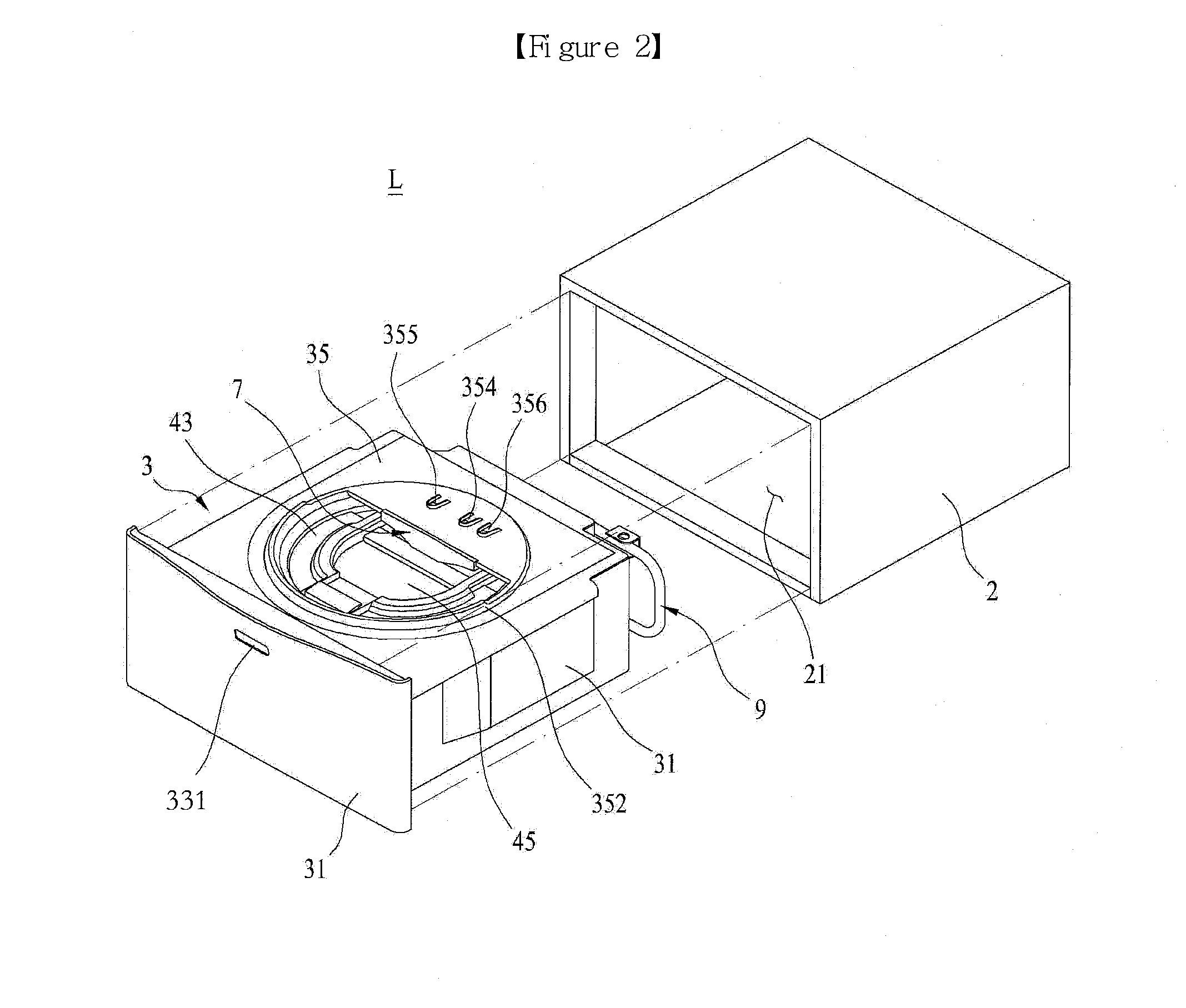

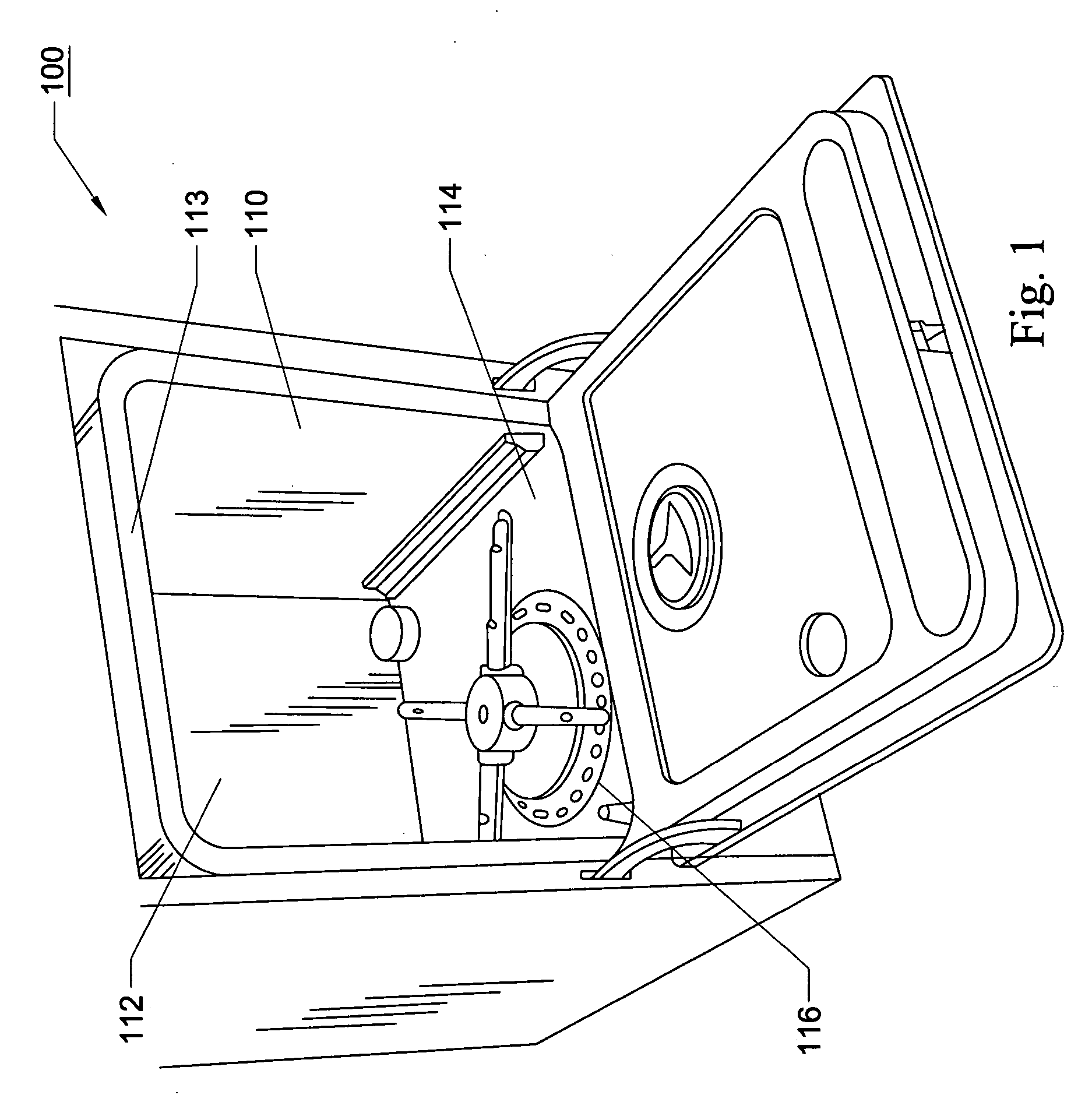

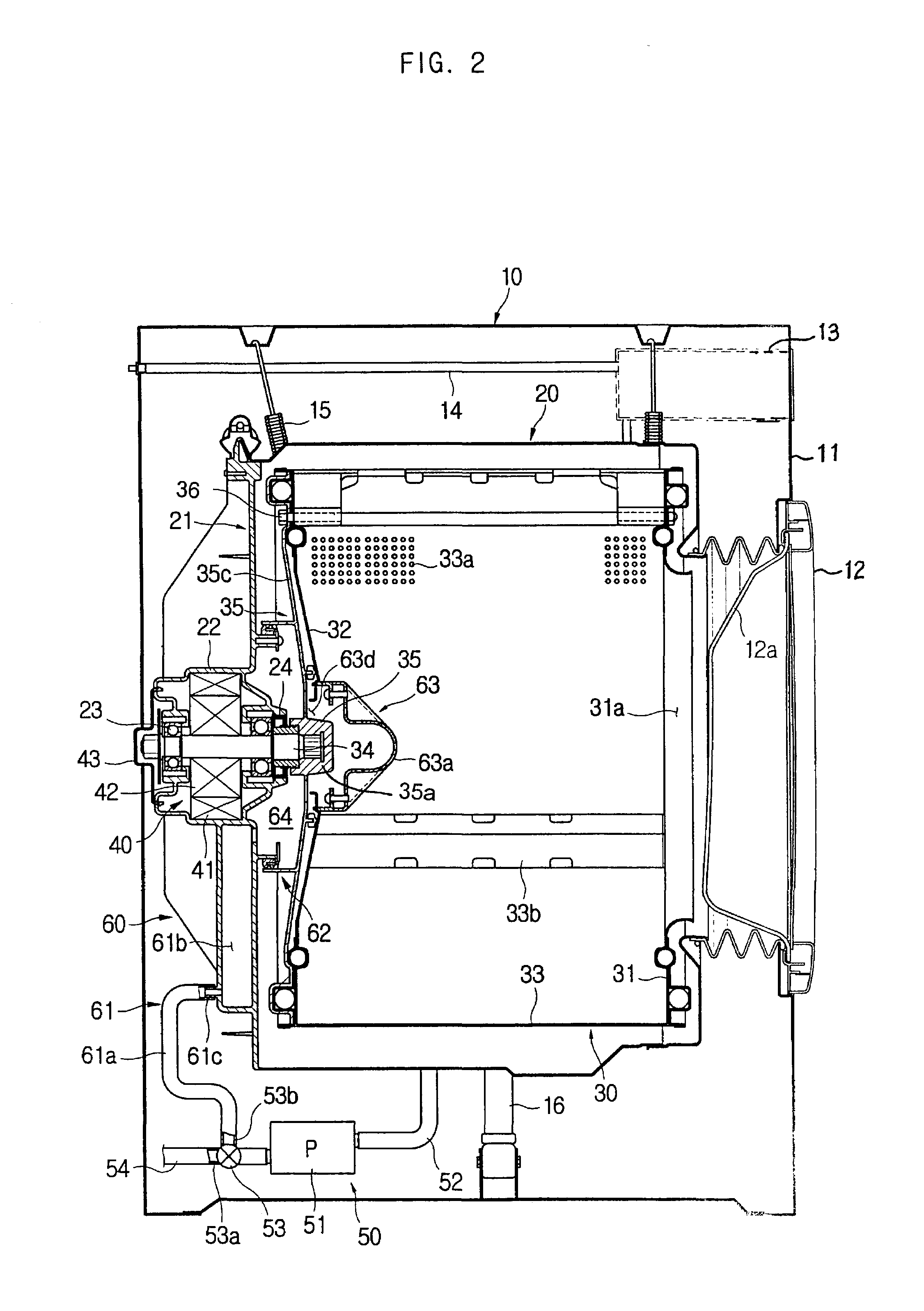

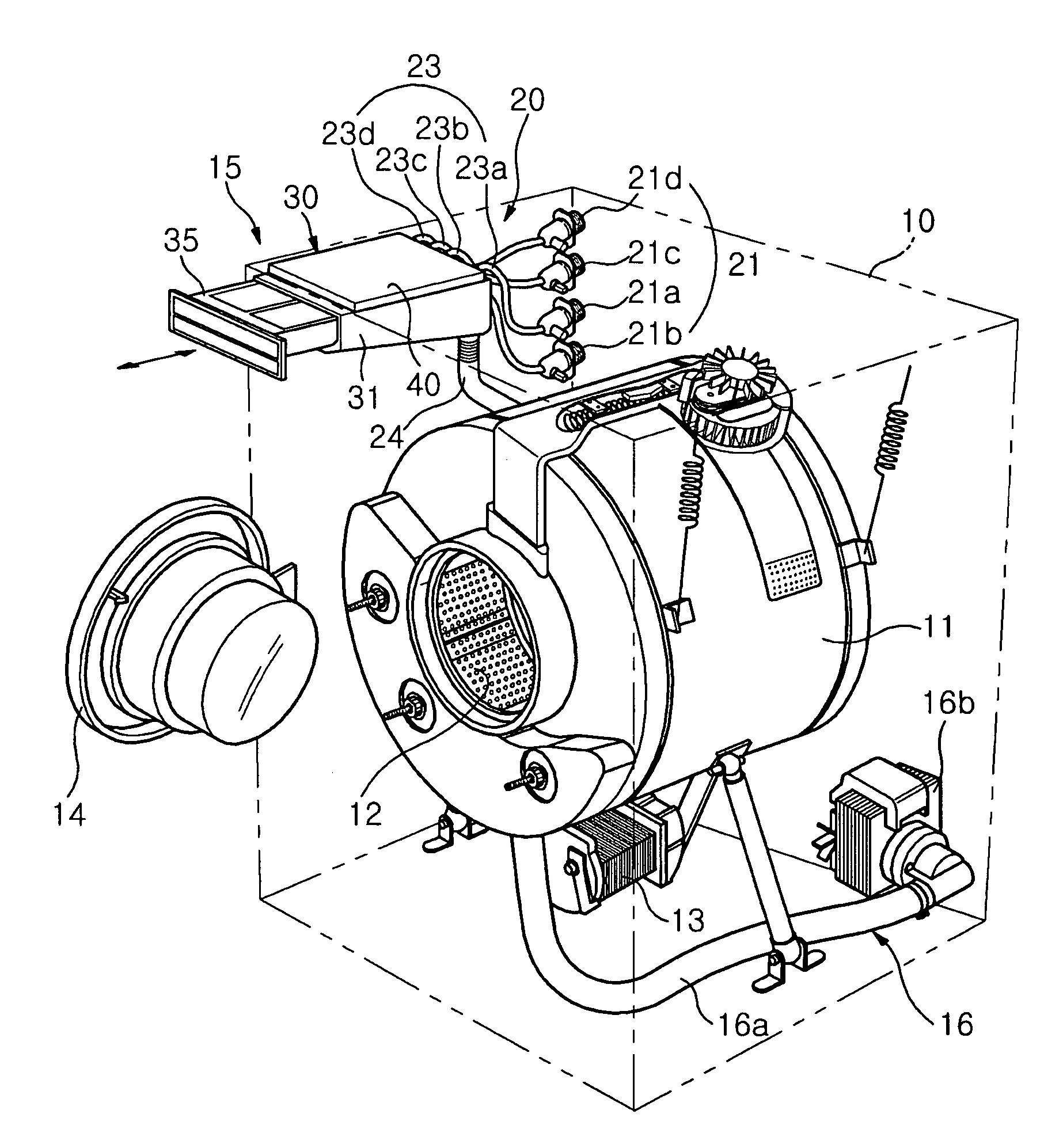

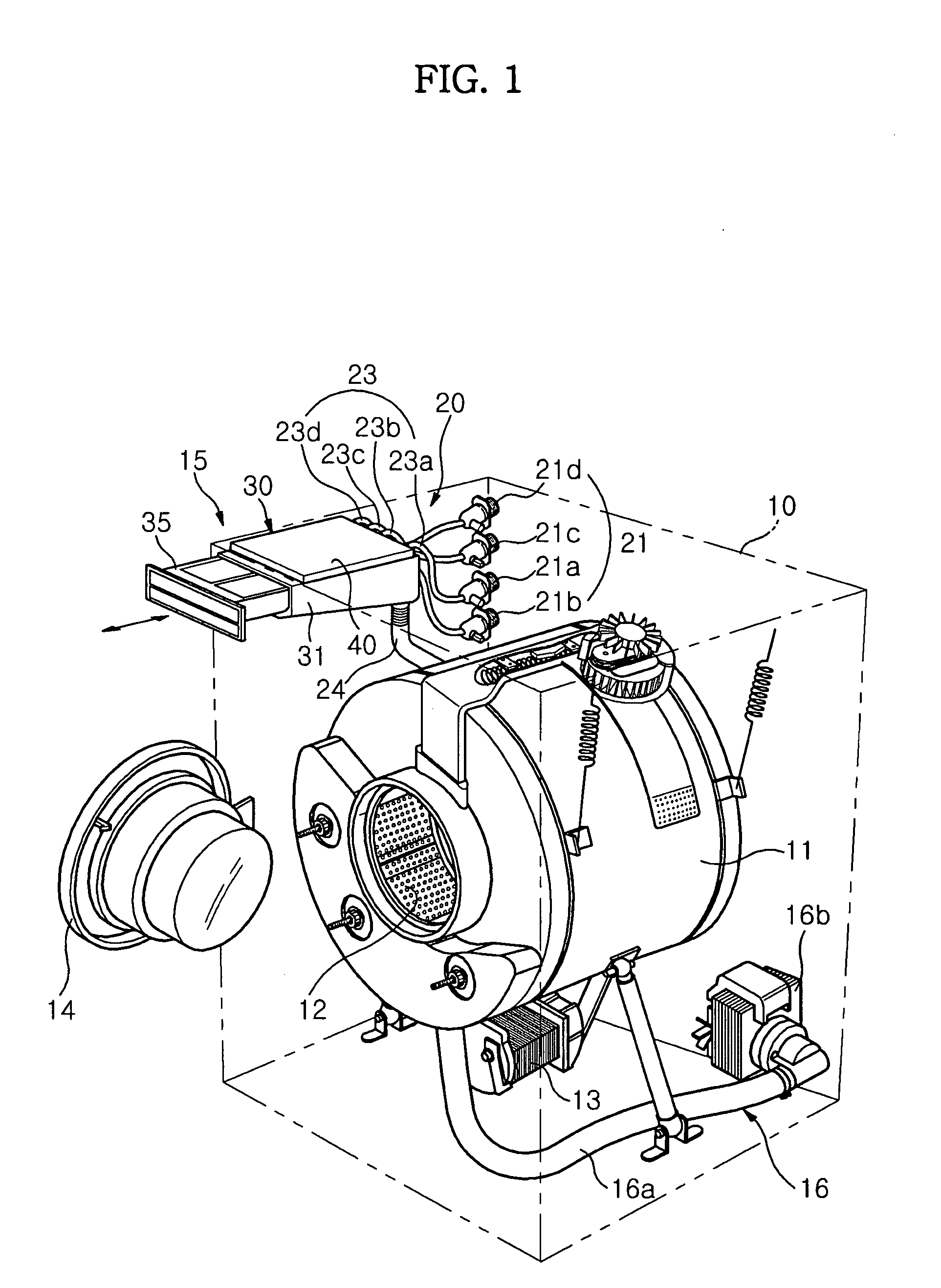

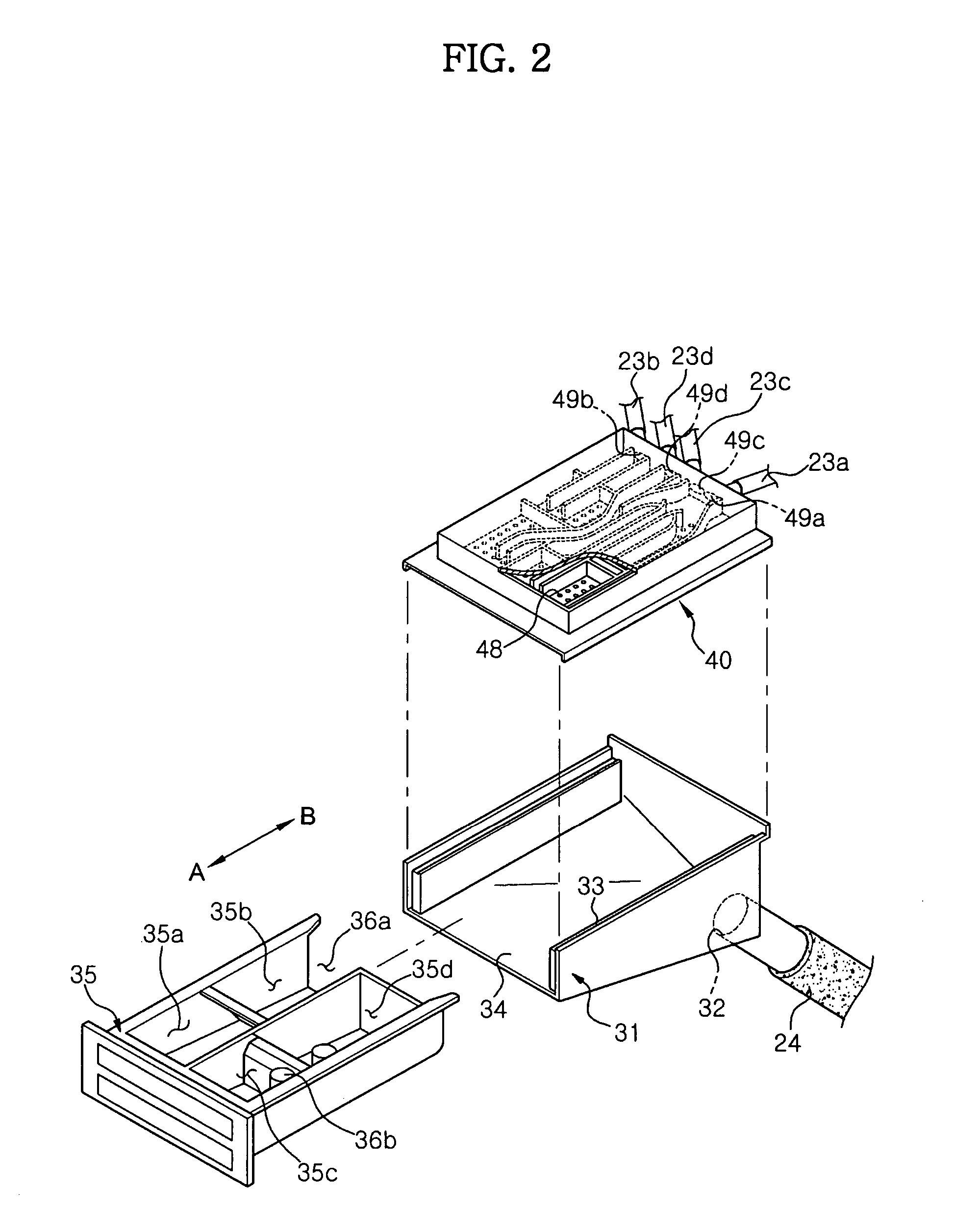

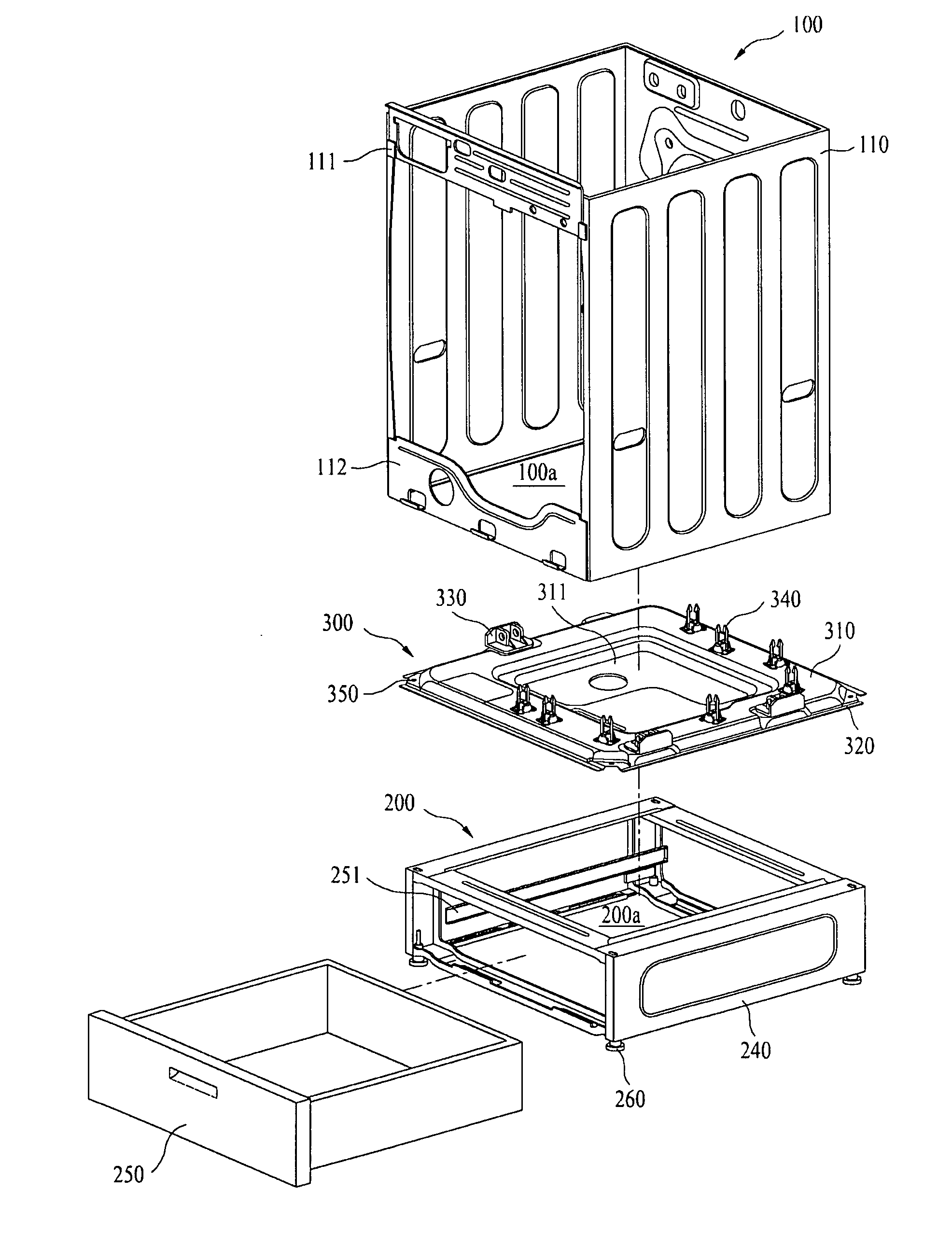

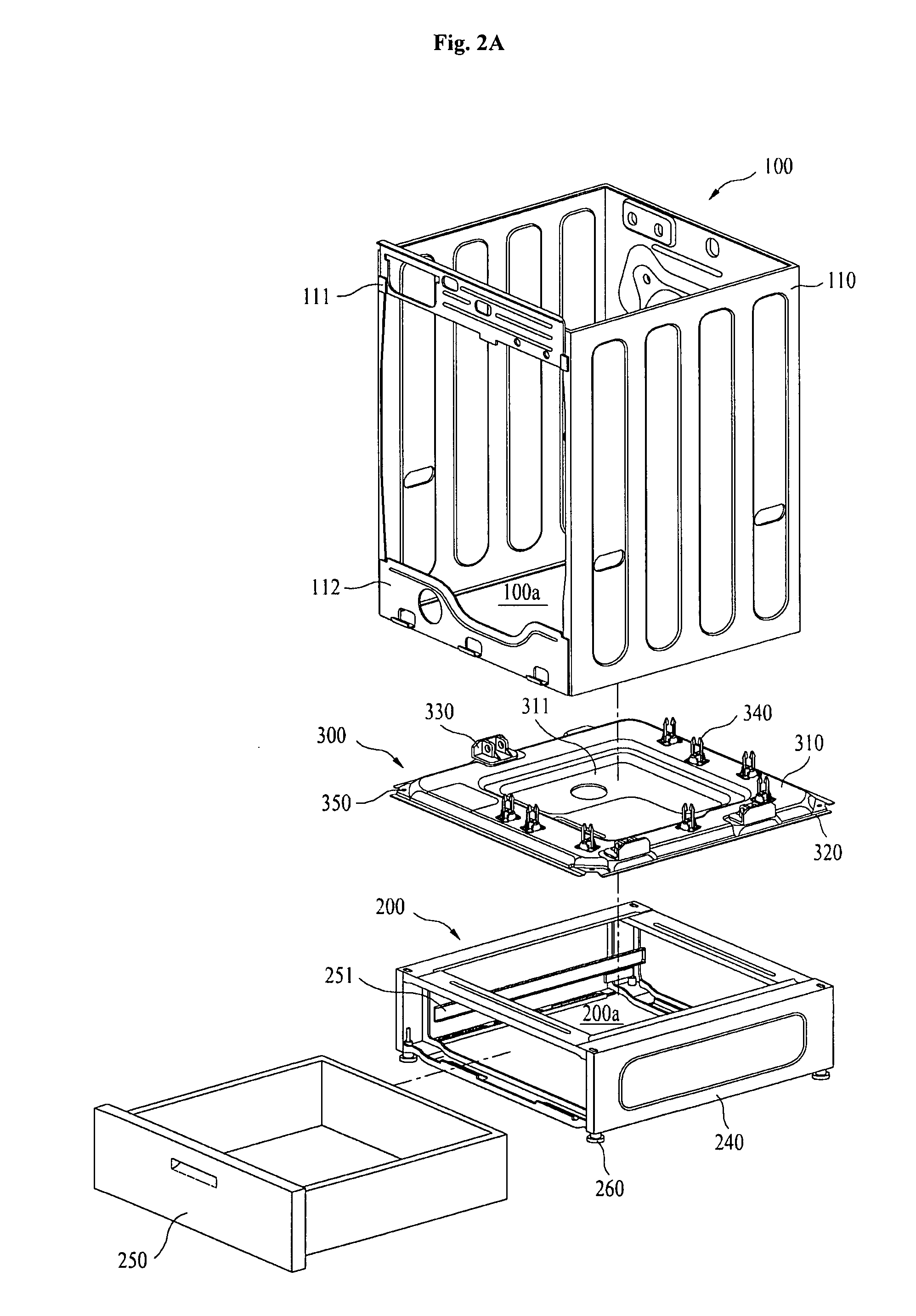

Laundry treating apparatus

A laundry treating apparatus may include a cabinet detachably provided on a first treating apparatus exhibiting a laundry treating apparatus and forming an external appearance of the laundry treating apparatus. A drawer may be provided to be withdrawn from the cabinet and an input hole may be formed thereon. A tub provided within the drawer body may store wash water. A detergent supply unit may be provided to be withdrawn from the drawer body toward a center of the input hole and provide a space for storing detergent. A water supply unit may supply wash water to the detergent supply unit to supply the detergent stored in the detergent supply unit to the tub body.

Owner:LG ELECTRONICS INC

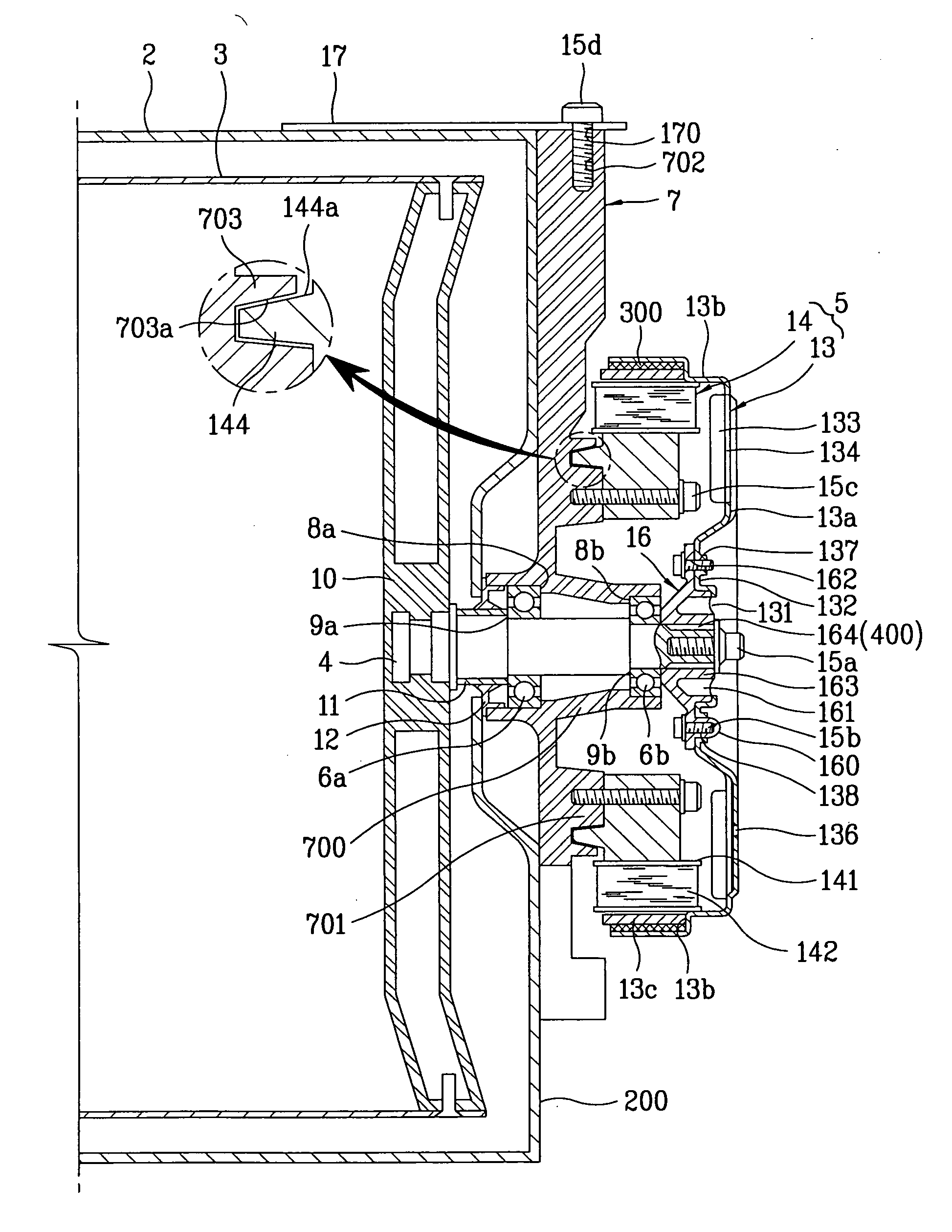

Washing machine

InactiveUS20070125135A1Avoid serious failuresGeneration of noise wellOther washing machinesWashing machine with receptaclesWash waterEngineering

A washing machine, more particularly, an improvement in the structure of a drive unit included in a drum type washing machine is disclosed. The washing machine includes a tub for receiving wash water therein, a drum rotatably disposed in the tub and adapted to wash laundry received therein, a shaft penetrated through the tub to thereby be connected to the drum, the shaft being adapted to transmit a drive force of a motor to the drum, a stator coupled fixedly to a rear wall portion of the tub, and a rotor including at least one magnet, a back yoke defining a magnetic path, and a rotor frame rotatably disposed at the outside of the stator, the rotor frame being connected to the shaft so as to transmit a rotating force of the rotor to the shaft. The rotor frame includes a side wall portion and a rear wall portion, and is made of an aluminum material.

Owner:LG ELECTRONICS INC

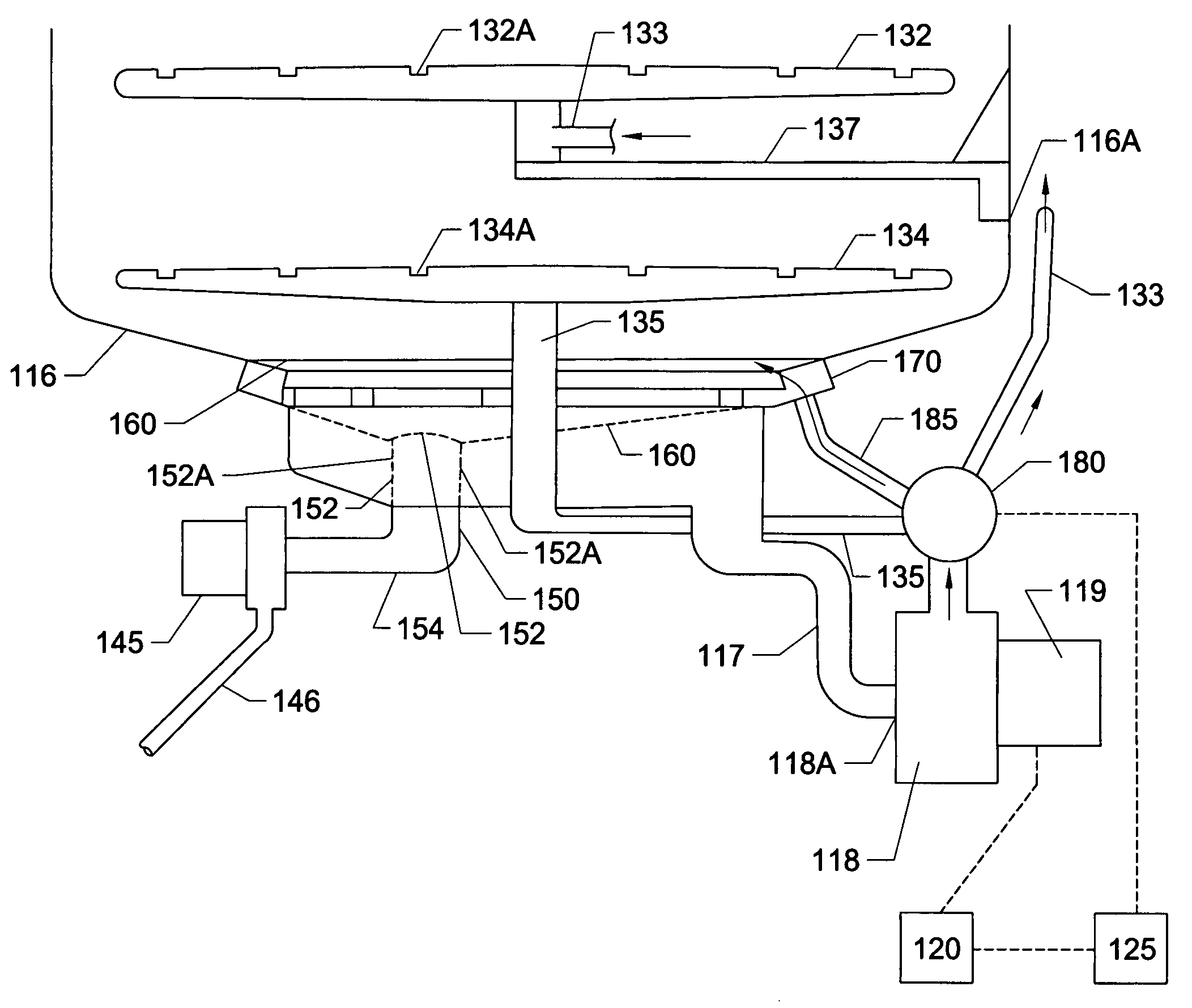

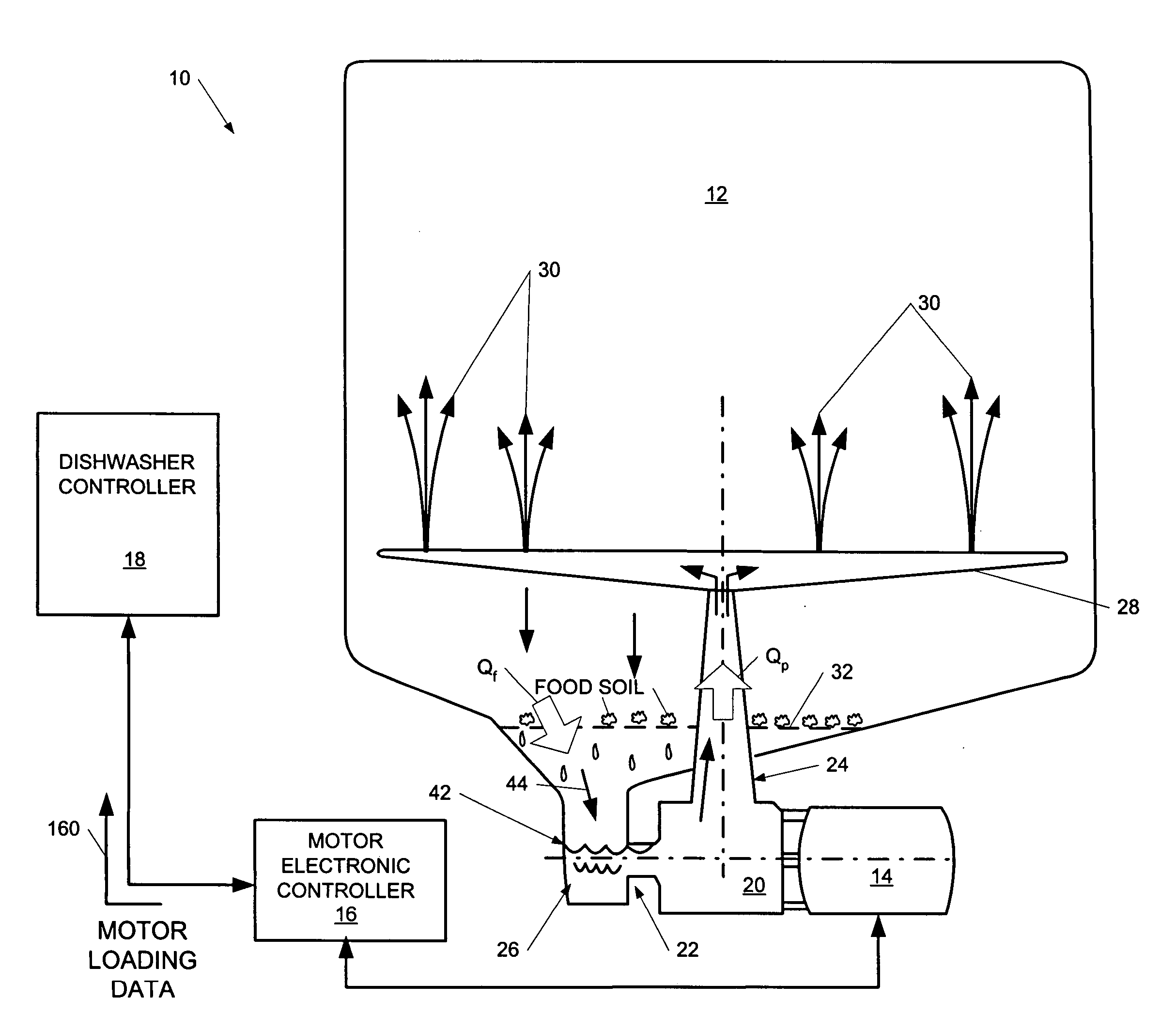

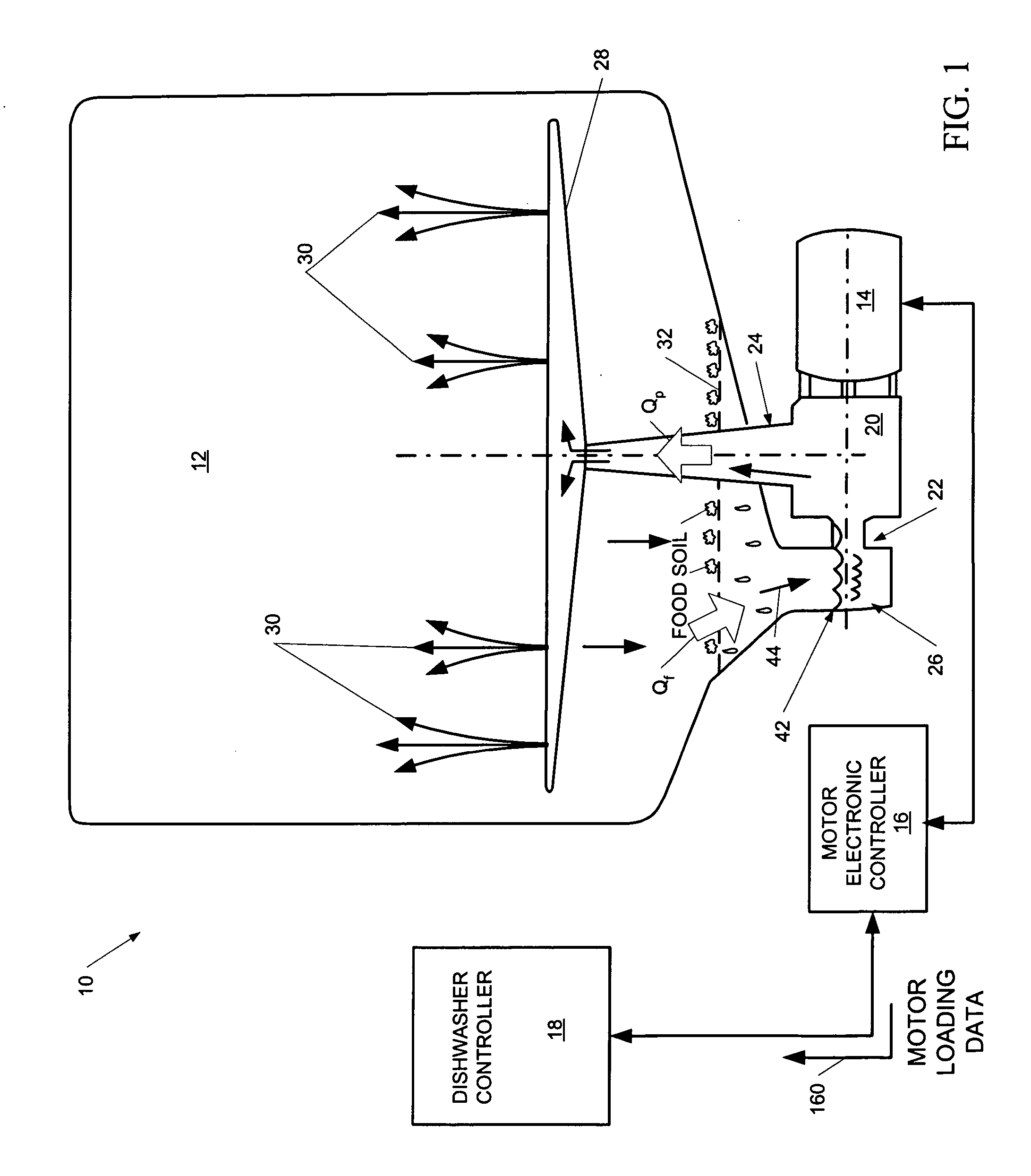

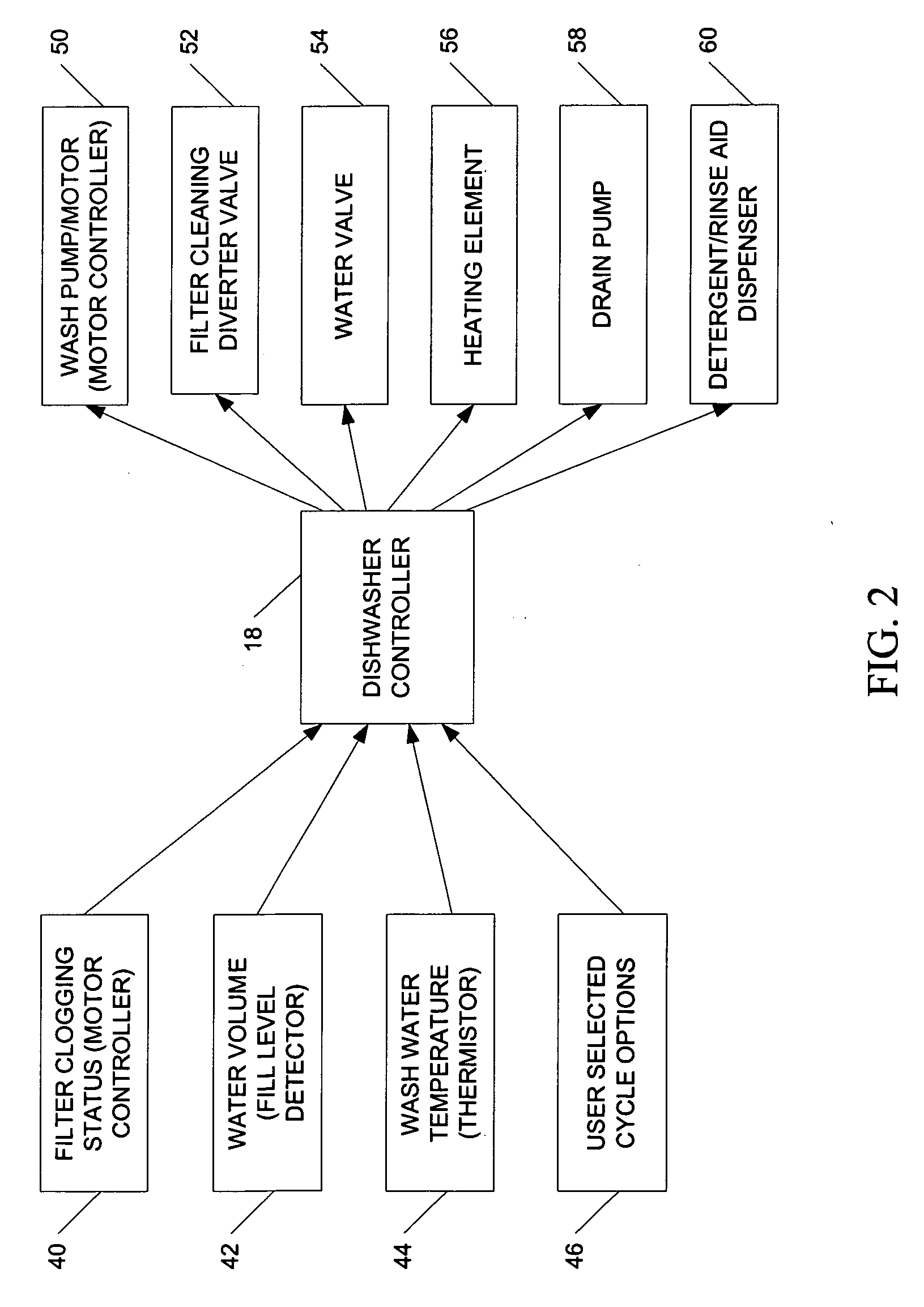

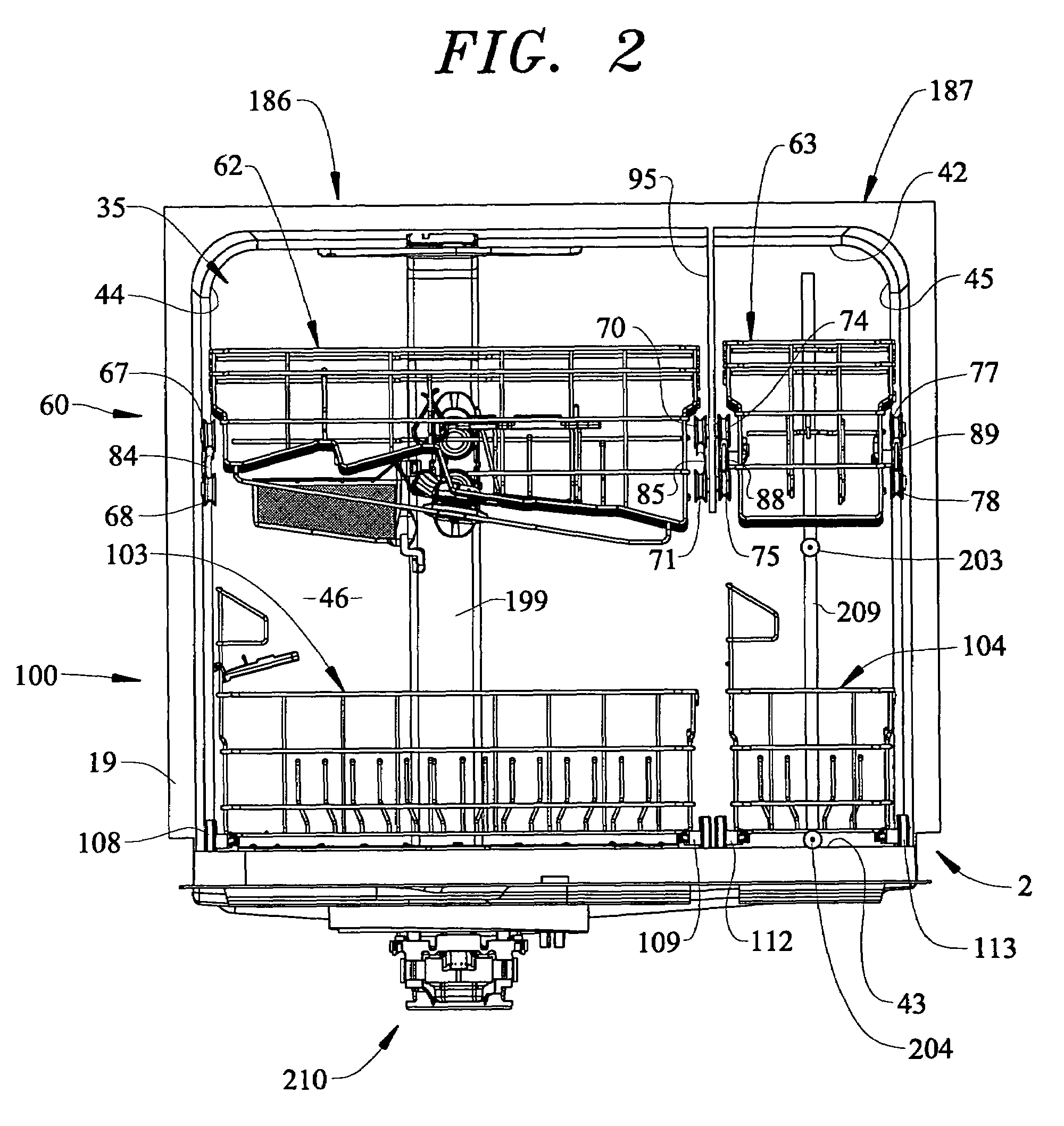

Primary filter cleaning system for a dishwasher

InactiveUS20060237049A1Easy to moveHollow article cleaningElectrostatic cleaningWash waterSpray nozzle

A dishwasher incorporates a primary filter cleaning system for removing food debris from circulated wash water. The dishwasher having a sump formed in the bottom and a wash pump having an inlet in communication with the sump. A collection chamber is formed through the bottom of the sump and a filter is situated over the top of the sump. The filter has an opening for depositing debris in the collection chamber. A stationary manifold is situated about the upper periphery of the sump and is aligned with the discharge of the pump. The manifold has multiple spaced spray nozzles, with each of the nozzles being aligned for spray contact with the filter. When water is pumped from the sump to the manifold, the water is sprayed across the filter to remove any food debris on the filter. The debris is then swept into the collection chamber.

Owner:VIKING RANGE

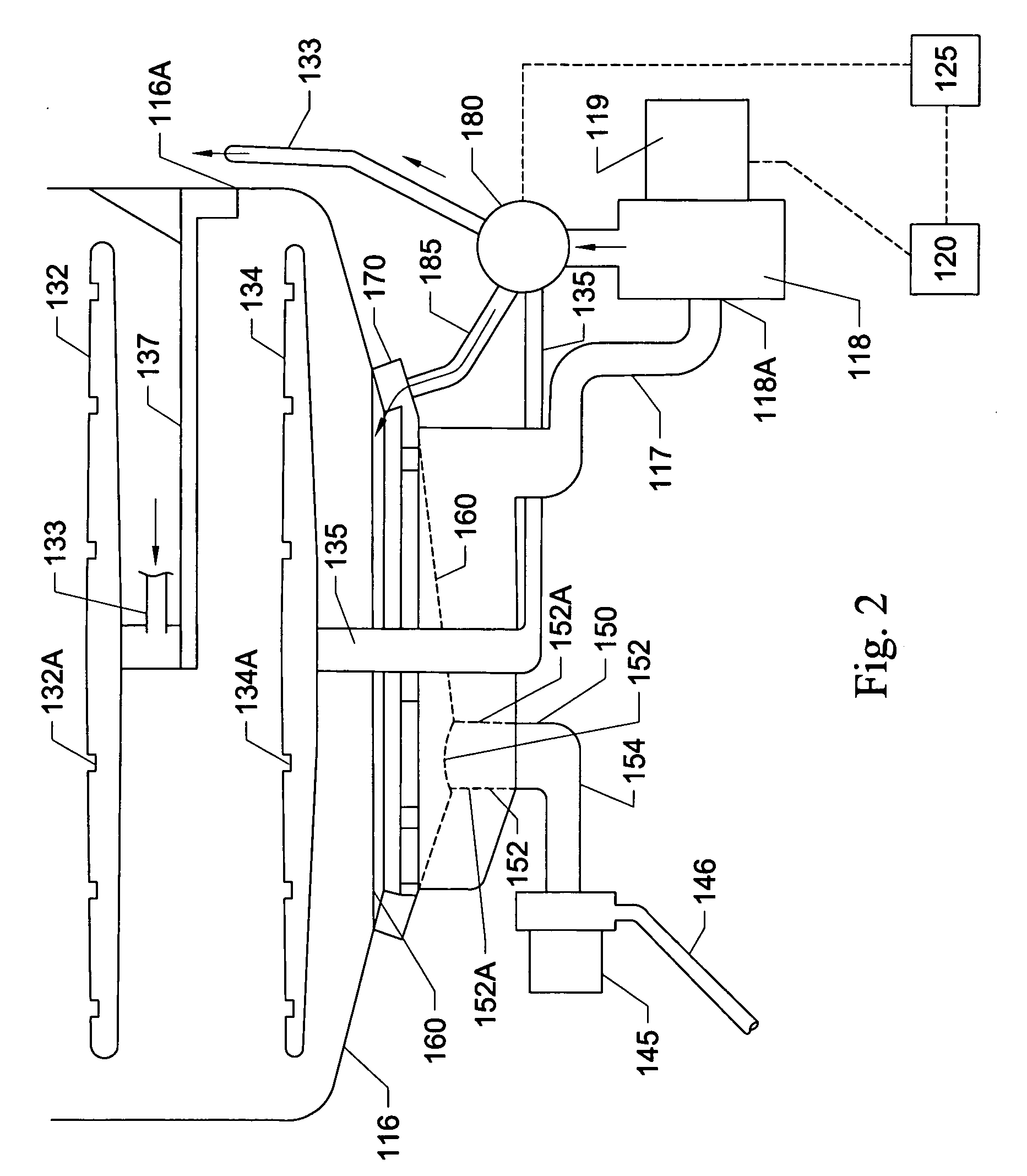

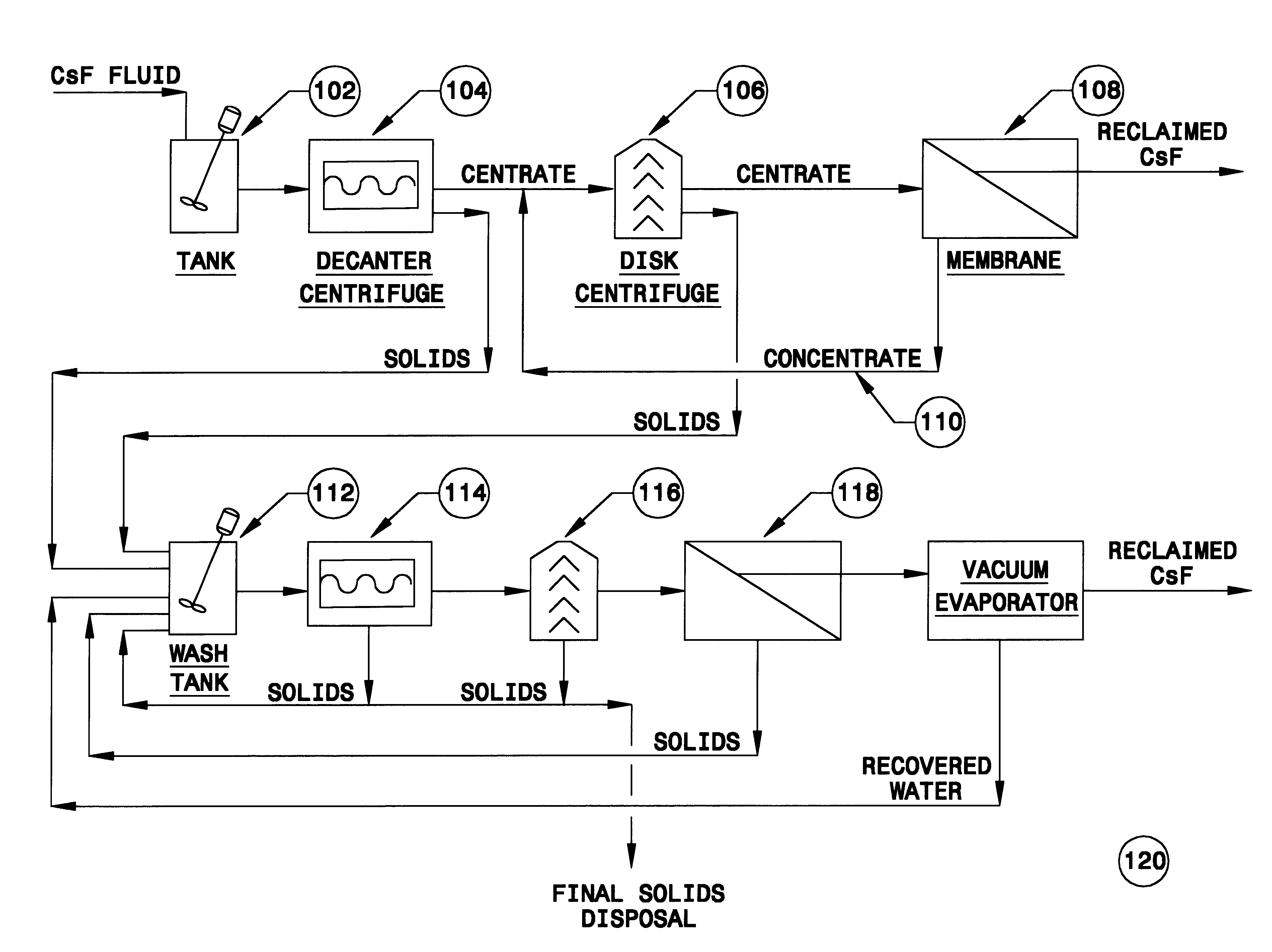

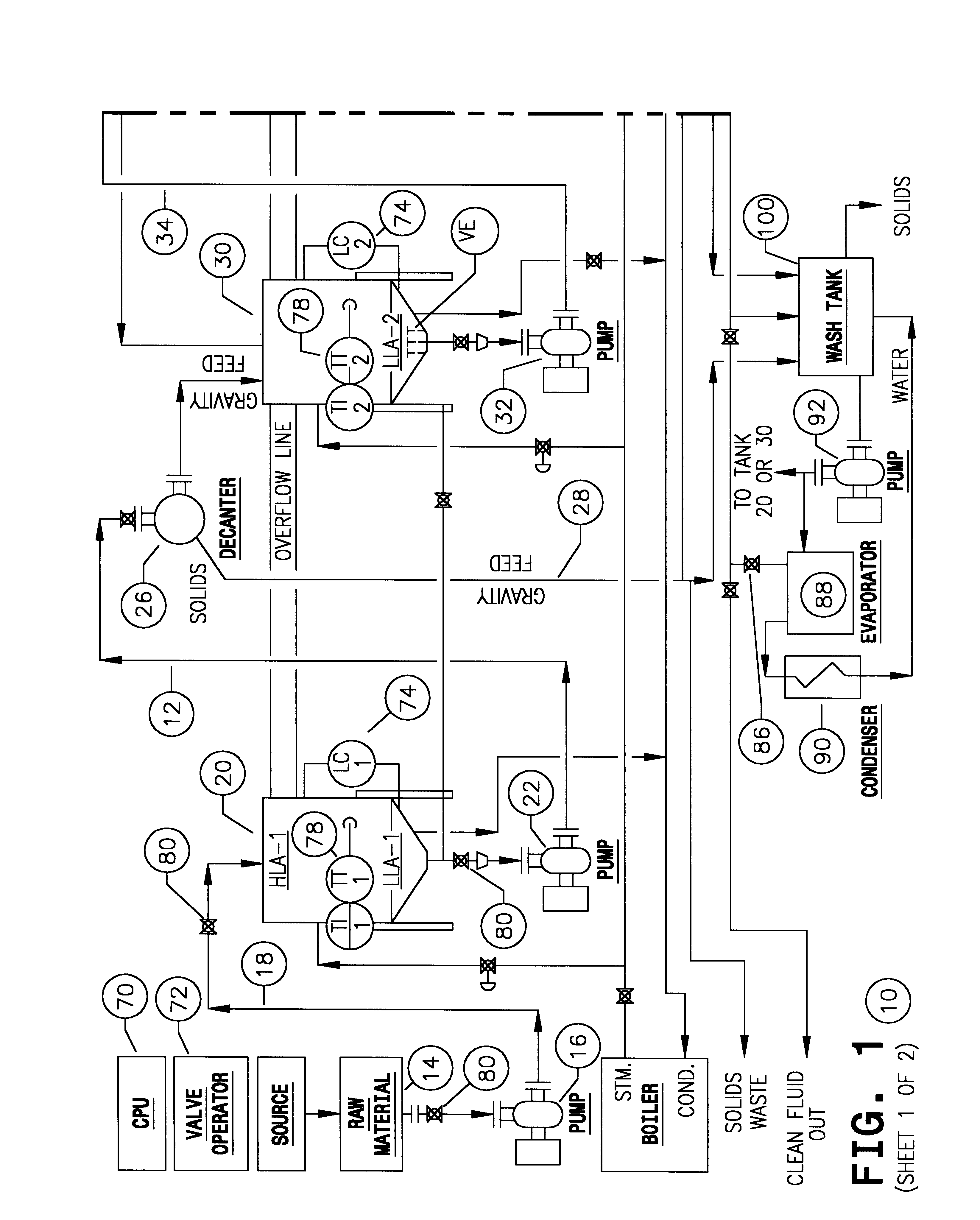

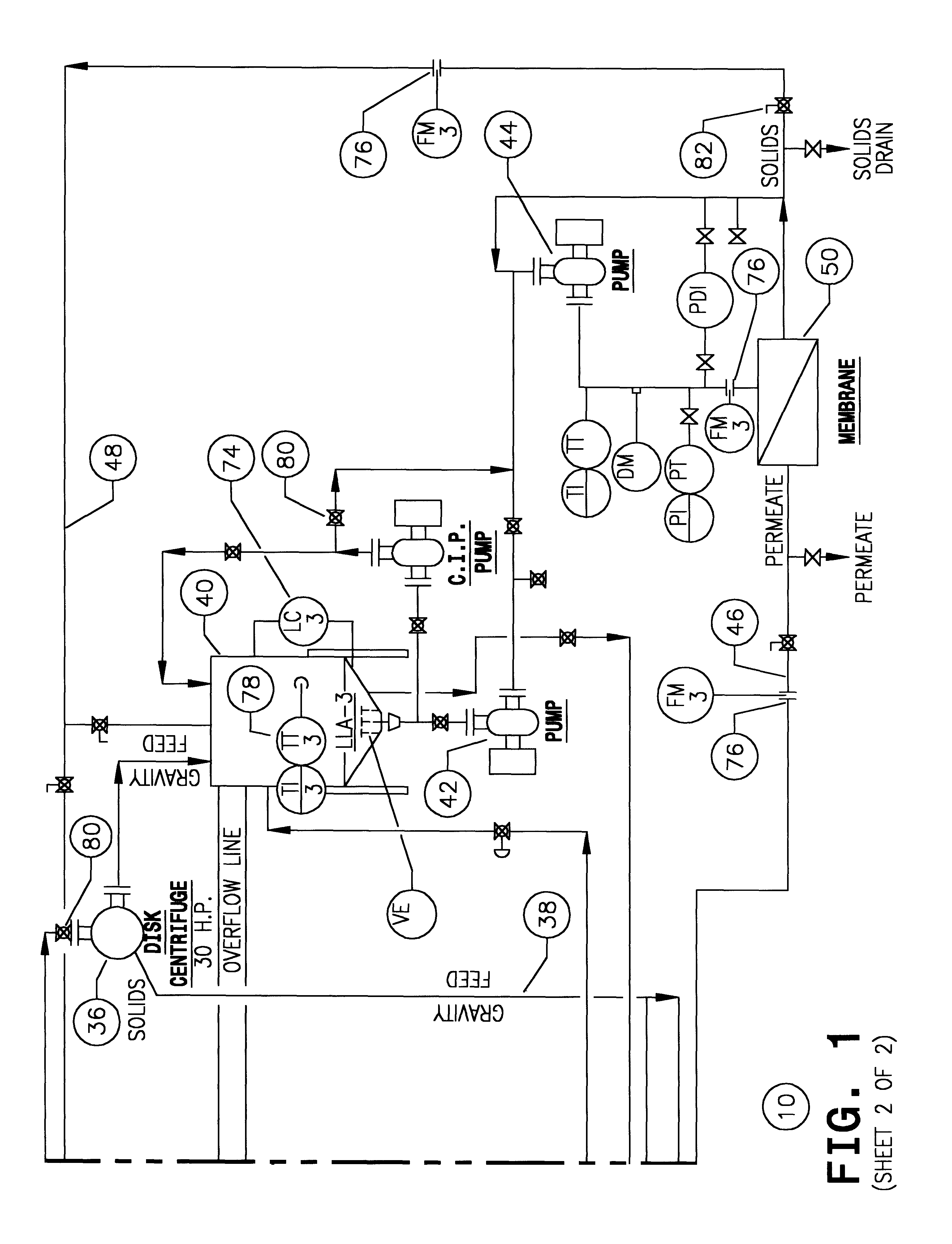

Cesium formate drilling fluid recovery process

InactiveUS6177014B1Liquid separation auxillary apparatusWater/sewage treatment by centrifugal separationFormateWash water

This disclosure sets out a method and apparatus for recovery of cesium formate in water solution after use in a drilling process where trash and other debris accumulate in the drilling fluid. It incorporates a first stage centrifuge, a second stage centrifuge and a membrane separator serially connected, and incorporates a feedback loop. A feedback loop iteratively redirects solids and heavy weight concentrate after processing and recycles it to enhance recovery by enhanced removal of cuttings and trash in the stream. In addition, cuttings and other solids removed from the fluid stream are introduced into a wash tank, mixed with water, and the cuttings are further processed to remove remnants of the cesium formate. These recovered cesium formate remnants are passed through an evaporator to regain the density loss attributable to the dilutive wash water. The cuttings can then be thrown away without throwing away the valuable cesium formate in the drilling solution.

Owner:HUTCHISON HAYS SEPARATORS

Washing machine having deodorizing means and control method thereof

InactiveUS20050262644A1Other washing machinesControl devices for washing apparatusWash waterProcess engineering

A washing machine which deodorizes an object placed in the washing machine using functional water independently of a washing process, and a control method thereof. The washing machine includes a tub to contain wash water therein, a drum rotatably installed in the tub, and deodorizing means which includes a functional water producing unit to produce functional water having a deodorizing effect, a heating tank to receive and to heat the functional water, and a steam supply pipe to supplying steam obtained from the functional water heated by the heating tank, to an object placed in the drum to be deodorized.

Owner:SAMSUNG ELECTRONICS CO LTD

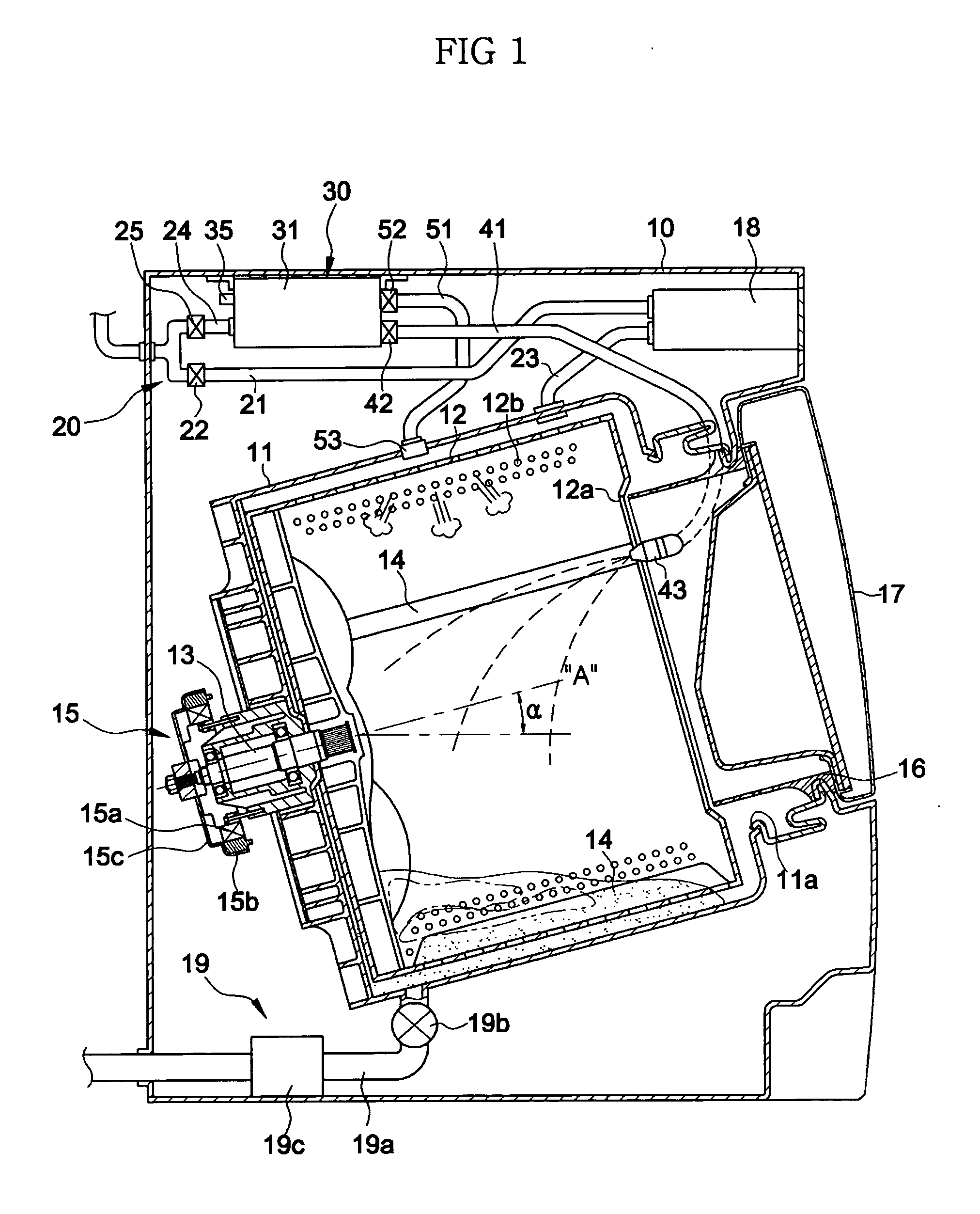

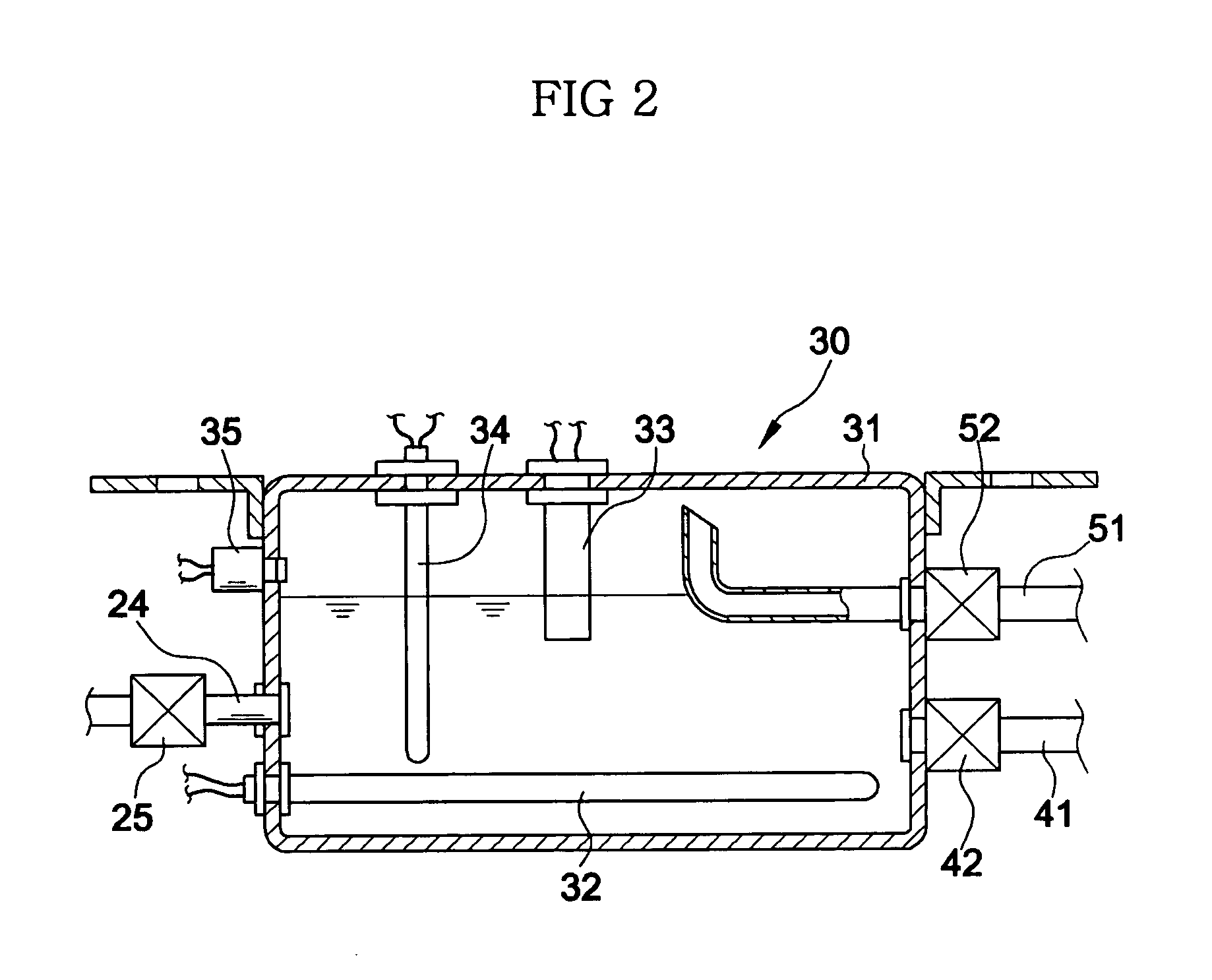

Drum type washing machine and method for use thereof

InactiveUS20050132504A1Increase temperatureShorten washing timeOther washing machinesControl devices for washing apparatusWash waterEngineering

A drum type washing machine, where steam and hot water are supplied to heat wash water, including: a water tub for containing wash water; a rotating drum rotatably mounted in the water tub and having, at a peripheral wall thereof, a plurality of through holes; a heating tank for heating water and generating steam; a water supply unit for supplying water into the water tub and the heating tank; and a steam supply pipe, adapted to guide the steam from the heating tank to the water tub, connected to the water tub In this drum type washing machine, the temperature of wash water can be rapidly increased in accordance with steam and hot water supplied into the water tub. Accordingly, it is possible to reduce the overall wash time while reducing the amount of wash water to be used.

Owner:SAMSUNG ELECTRONICS CO LTD

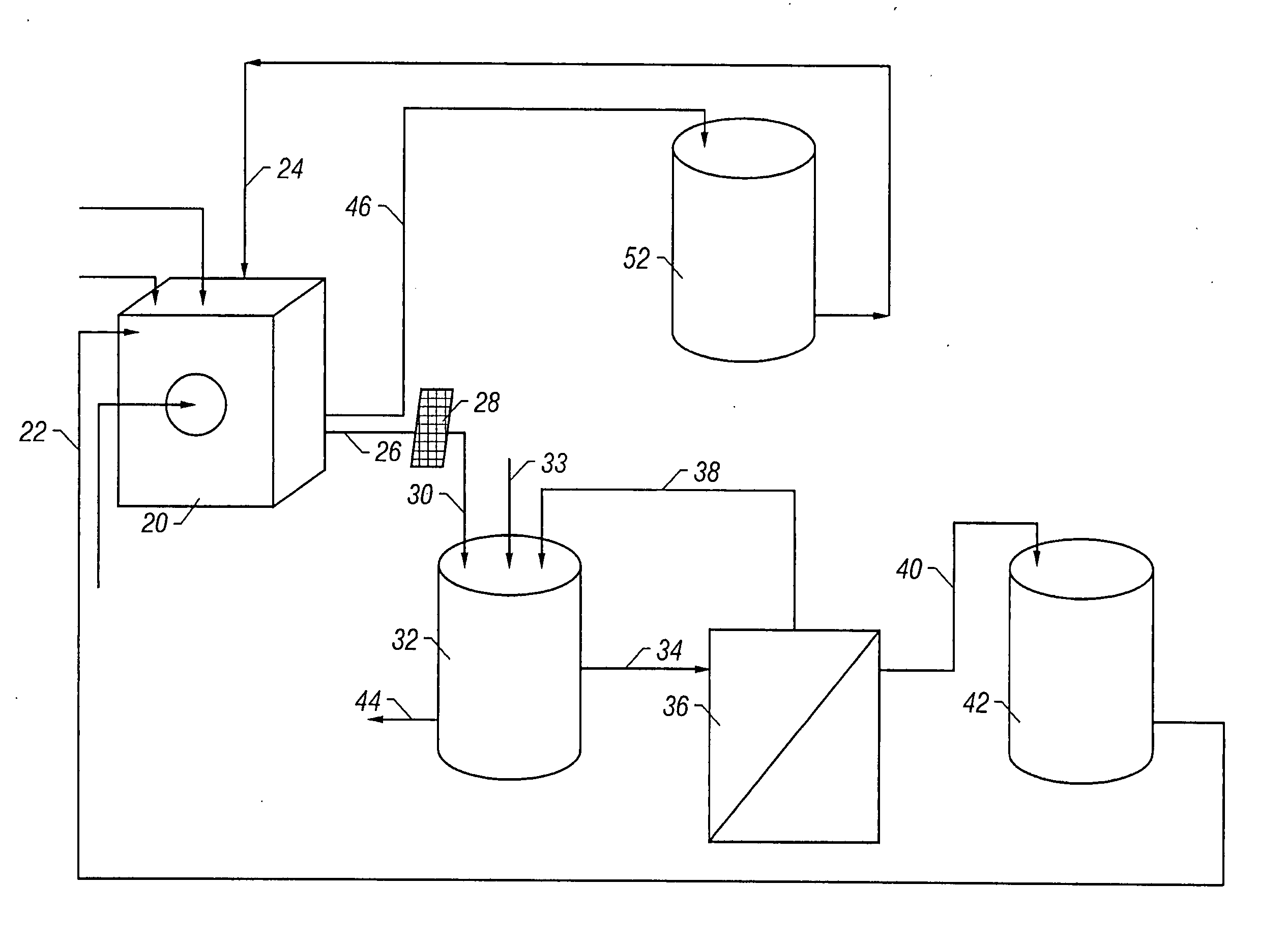

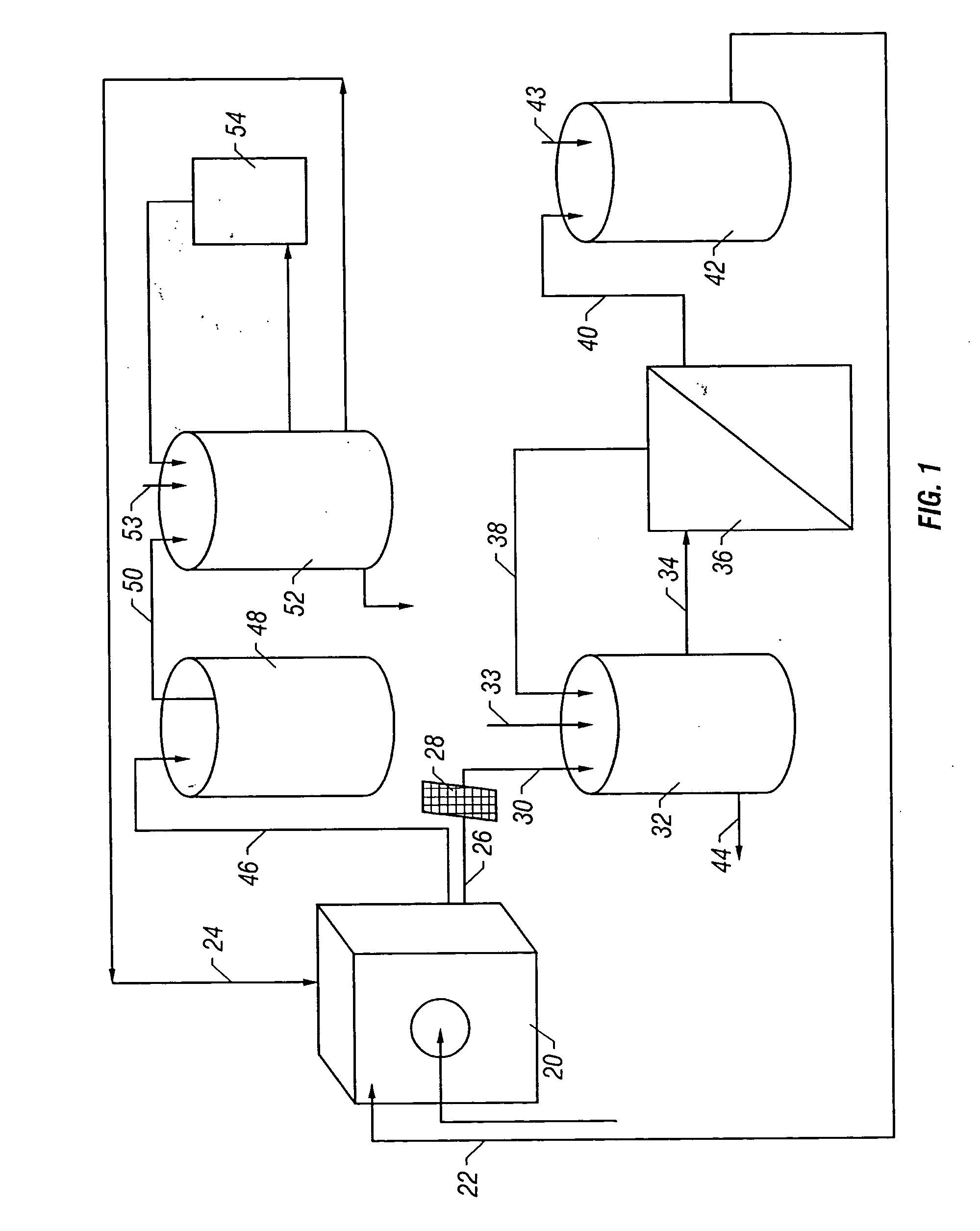

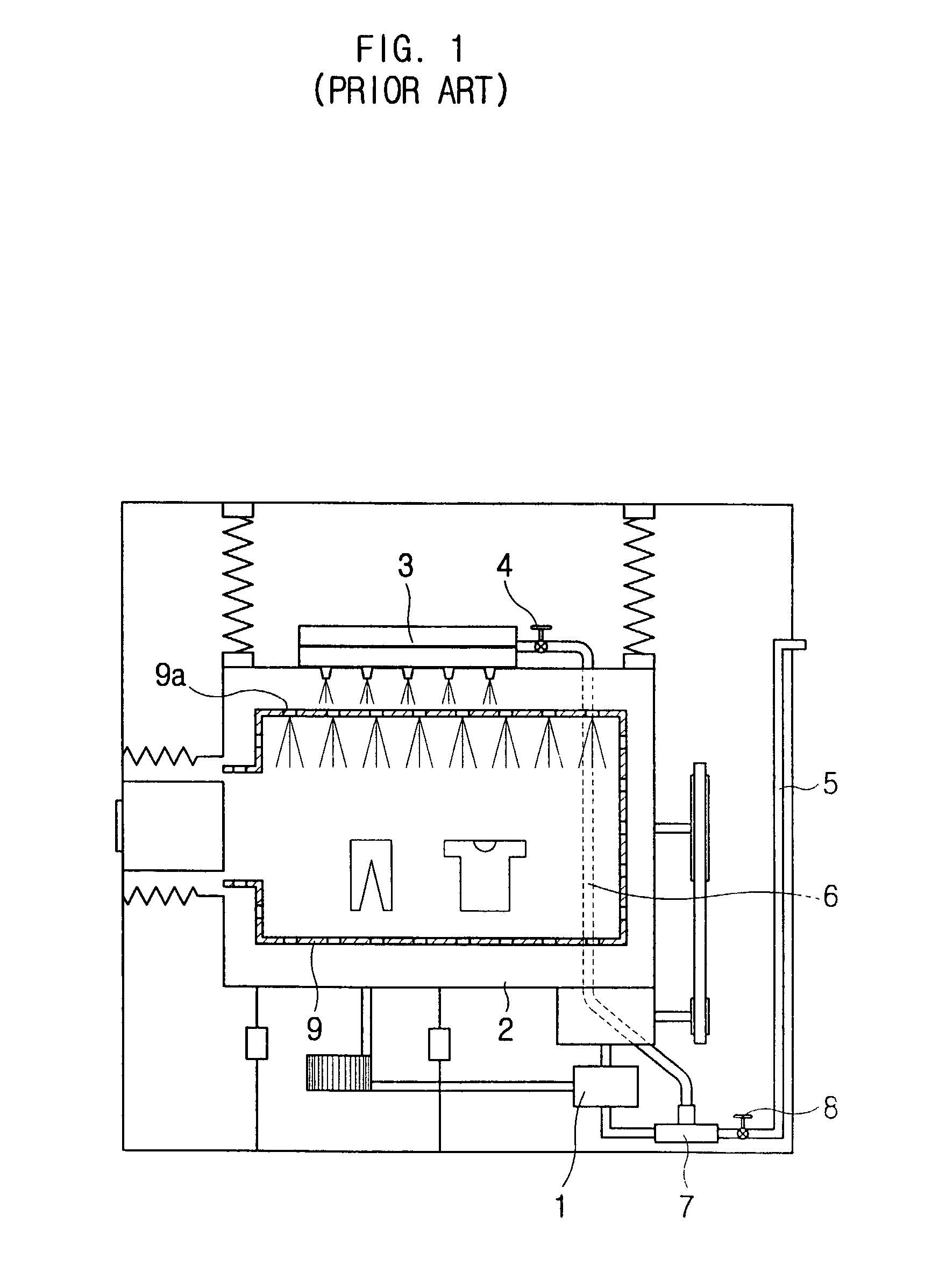

Method for economically viable and environmentally friendly central processing of home laundry

InactiveUS20060123563A1Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesEnvironmental effectWash water

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:RANEY KIRK HERBERT +5

Washing machine

InactiveCN1414163AImprove detergencyEasy to take outOther washing machinesWashing machine with receptaclesFree rotationWash water

Washing machines having improved frictional forces with laundry. Those machines include a cabinet with a door, a tub inside for retaining wash water, and an internal vessel, inside the tub that is coupled with a motor that rotates the internal vessel. A friction member inside the internal vessel rubs against laundry. The frictional member includes a friction enhancer, such as a spherical structure or a freely rotating ball, that enhances laundry friction during washing and reduces adhesion of laundry after a dehydration cycle.

Owner:LG ELECTRONICS INC

Washing machine with steam generating device and method for controlling the same

InactiveUS20060101588A1Improve washing effectReduce energy consumptionOther washing machinesControl devices for washing apparatusWash waterProcess engineering

A washing machine having a drying function, which includes a steam generating device for spraying steam directly onto laundry, and a method for controlling the same. The method for controlling the washing machine, which supplies hot air, heated by a drying heater, to laundry through a drying duct, includes heating supplied wash water to generate steam; spraying the generated steam onto the laundry through the drying duct to perform a washing operation; determining whether or not a drying operation after the washing operation is performed; and performing a dehumidifying operation such that a drying fan is operated to remove moisture remaining in the drying duct when it is determined that the drying operation is not performed, thereby improving washing capacity, reducing an energy consumption rate, and effectively removing the moisture remaining in the drying duct when the drying operation after the washing operation is not performed.

Owner:SAMSUNG ELECTRONICS CO LTD

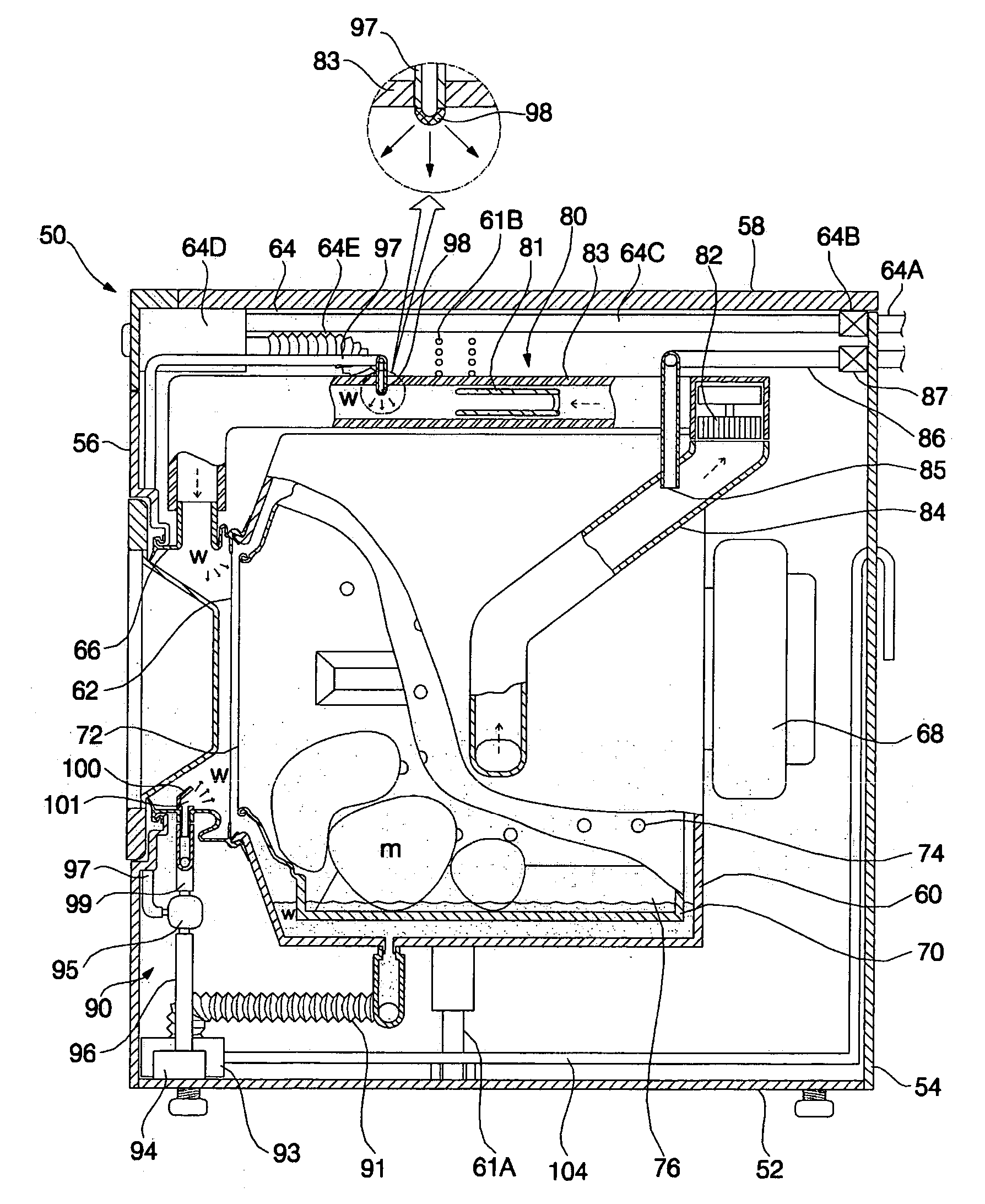

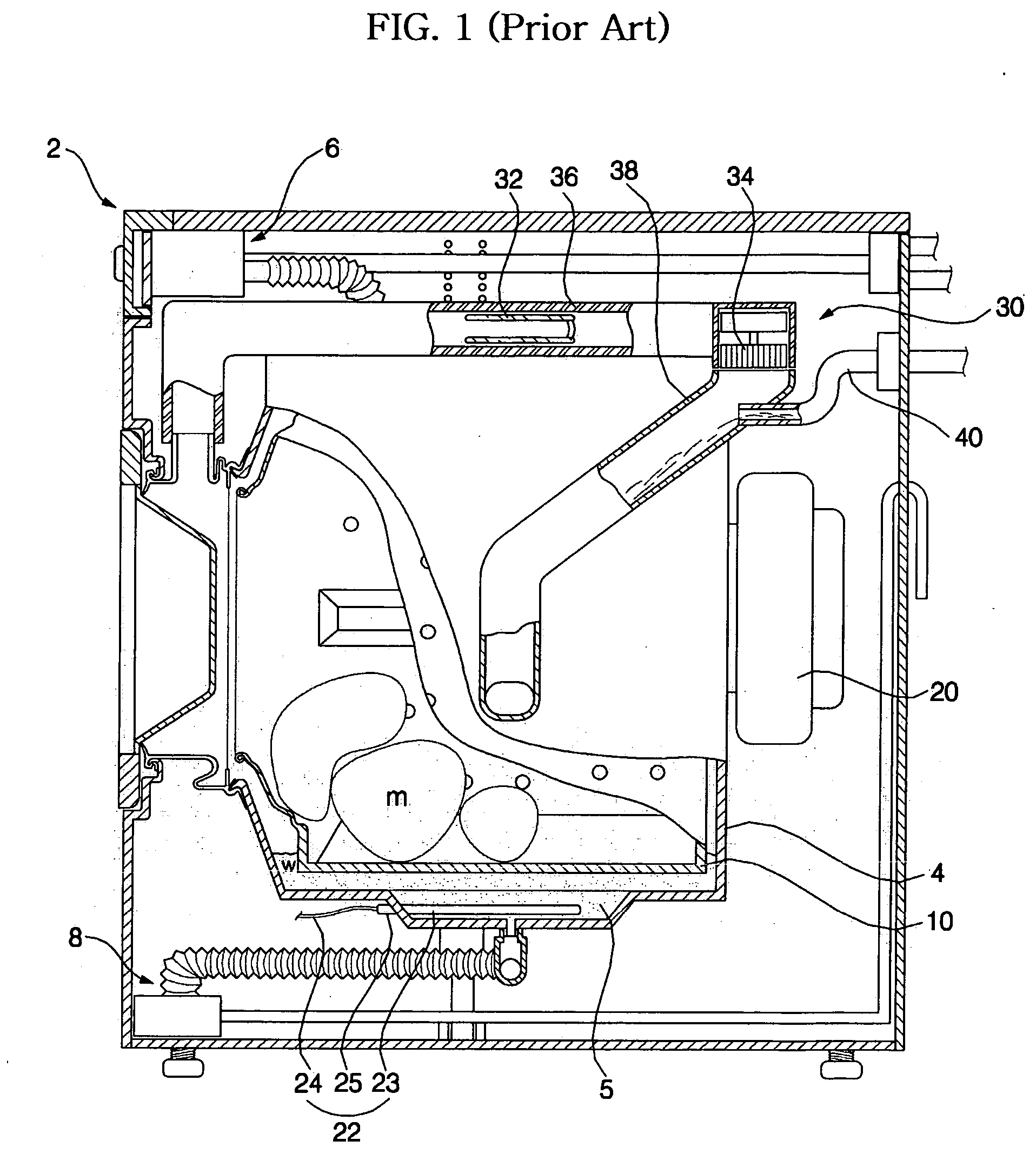

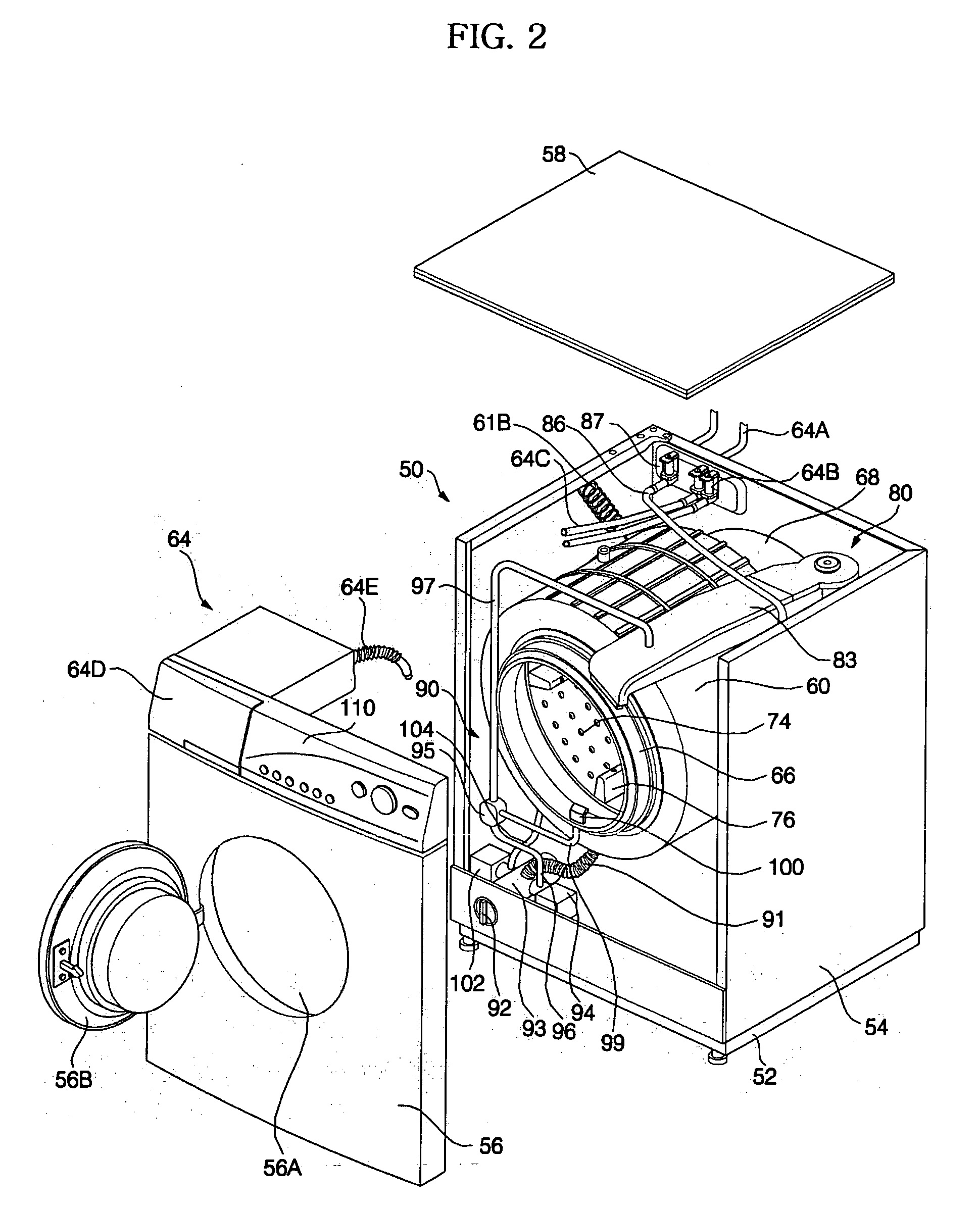

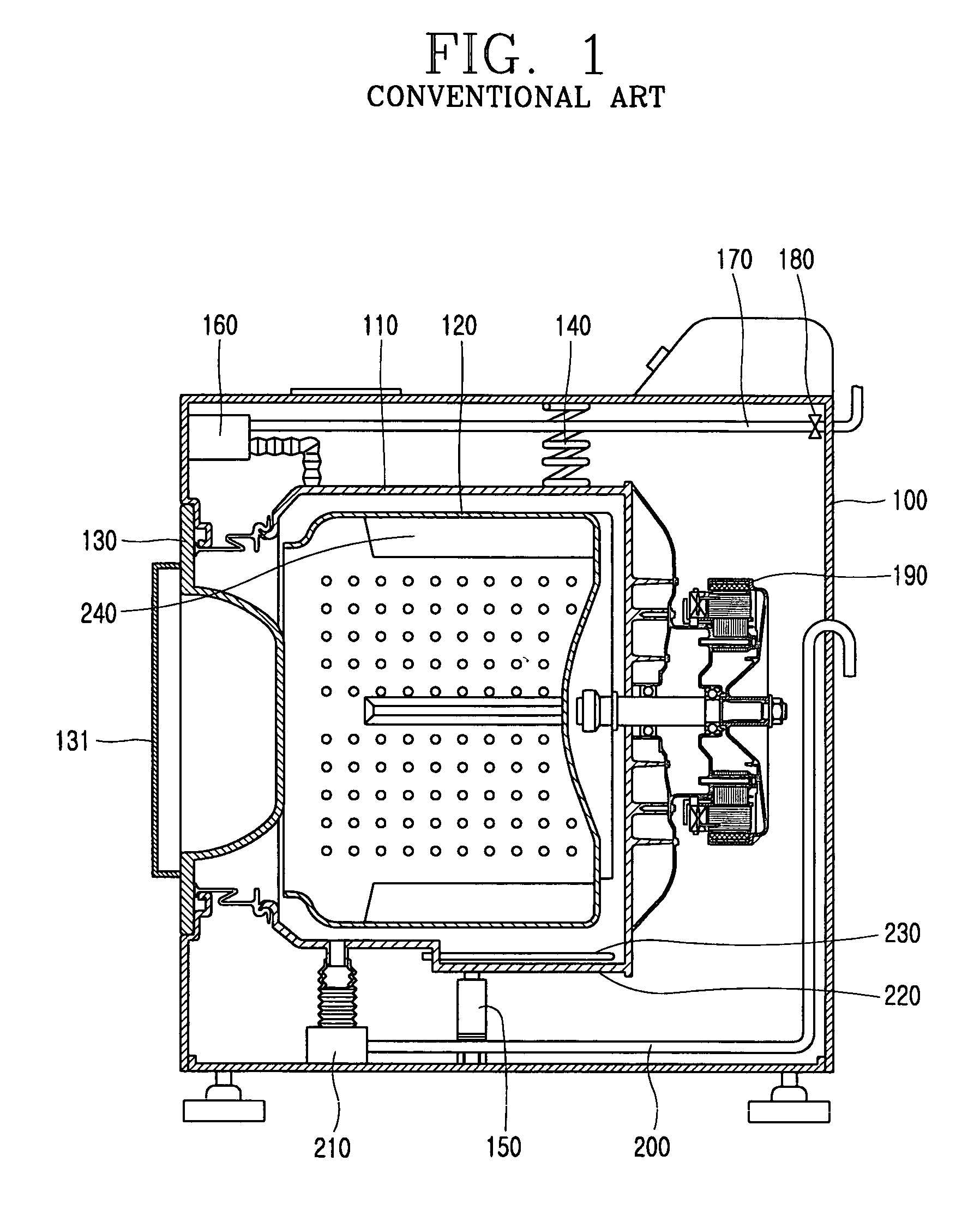

Drum type washing machine

InactiveUS6981395B2Promote water circulationImprove efficiencyTextile treatmentOther washing machinesWash waterWater circulation

A drum type washing machine includes a cabinet, a fixed drum set in the cabinet to contain wash water therein, a rotary drum rotatably set inside the fixed drum, a pump which forcibly pumps out the wash water contained in the fixed drum, and a water circulation device which feeds the wash water pumped by the pump into the rotary drum in a washing operation. The water circulation device includes a storing unit and a spraying unit. The storing unit defines a space which temporarily holds the wash water pumped by the pump, and is provided between rear panels of the fixed drum and the rotary drum. The storing unit guides the wash water to the rear panel of the rotary drum. The spraying unit is provided at the rear panel of the rotary drum, and sprays the wash water contained in the storing unit into the rotary drum.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for reducing corrosion

InactiveUS20060198954A1Limiting amount of downtimeAvoid damageGlass making apparatusLiquid surface applicatorsGlass fiberWash water

A method for reducing corrosion of a wash water system for glass forming lines, by using a corrosion meter, is provided. Also provided is a fiberglass manufacturing process that utilizes the method.

Owner:FRECHEM BART SHANNON +2

Washing machine having detergent supply device

A washing machine having a detergent supply device for mixing detergent, filled in a detergent container, with wash water, and supplying the mixed detergent and wash water into a washing tub. The detergent supply device includes a housing, a detergent container, and water supply chambers. The housing includes a plurality of inlets connected with respective water supply pipes, and an outlet connected with a washing tub. The detergent container is detachably inserted in the housing and includes a plurality of detergent receiving chambers. The water supply chambers include a plurality of flow channels, and one of the flow channel is adapted to supply wash water, supplied from the inlets, into the detergent receiving chambers while adjusting the pressure of the wash water within a predetermined range.

Owner:SAMSUNG ELECTRONICS CO LTD

Process for working up the waste water obtained in the preparation of dinitrotoluene

ActiveUS6936741B2Easy to transportReduce pointsLiquid degasificationOrganic compound preparationWash waterWastewater

The present invention relates to a process for working up or treating aqueous waste waters which are formed during the nitration of toluene to dinitrotoluene with nitrating acid. These aqueous waste waters containing acidic wash water and alkaline wash water from the dinitrotoluene washing step, and distillate from the sulfuric acid concentration step. The process comprises,a) combining the acidic and alkaline waste waters from the washing step and the aqueous distillate from the sulfuric acid concentration step such that the resulting mixture has a pH below 5,b) separating the aqueous and organic phases which are formed by phase separation,c) subjecting the aqueous phase from b) to an extraction step, whereind) the organic components contained in the aqueous phase from c) are extracted with toluene, ande) introducing the toluene phase enriched with the organic components into the toluene nitration.

Owner:COVESTRO DEUTSCHLAND AG

Method of washing laundry in drum washing machine

ActiveUS20060010613A1Reduce the amount requiredOther washing machinesControl devices for washing apparatusWash waterWater level

Disclosed is a method of washing laundry in a drum washing machine by which the amount of wash water used and the amount of power use can be decreased when doing washing in the drum washing machine. The method comprises supplying wash water to a tub up to a first preset water level; and washing laundry in a drum by rotating the drum of the drum washing machine forward and backward simultaneously while drawing the wash water and supplying the drawn wash water to the drum.

Owner:LG ELECTRONICS INC

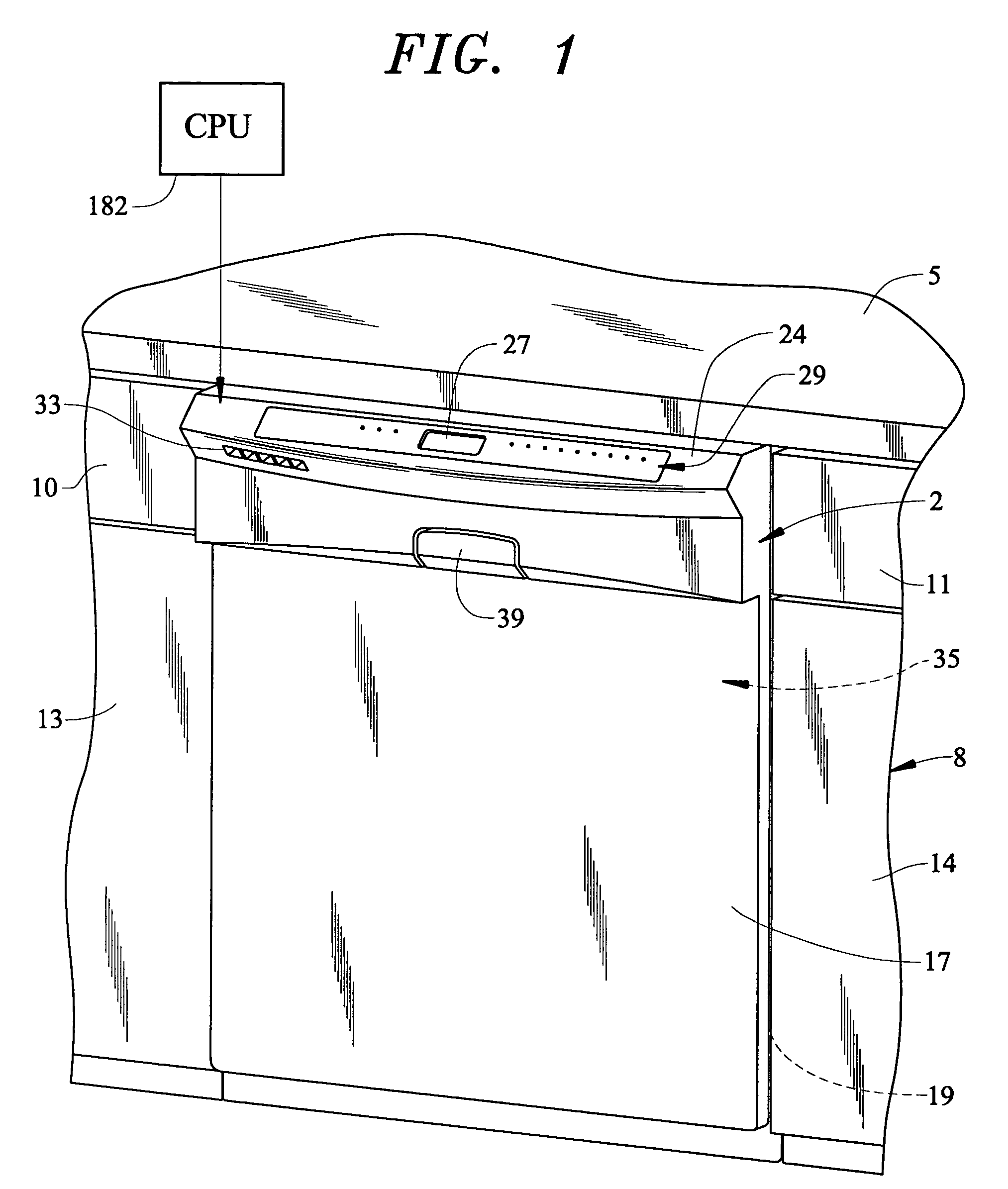

Computer-controlled system for dishwashers

InactiveUS20060237052A1Minimize and (optimize) cycle timeMinimize and (optimize) and water usageAutomatic washing/rinsing machine detectionHollow article cleaningComputer control systemWash water

A method and system for dynamically controlling operation of a dishwasher during a cleaning cycle. The method includes detecting a plurality of conditions in the dishwasher during operation, evaluating the plurality of detected conditions to determine a dynamic control response, and sending a signal representing the dynamic control response to at least one component of the dishwasher. The plurality of detected conditions can include some or all of a rate of change of a wash water temperature, an approximate surface area and thermal mass of a plurality of dishes loaded in the dishwasher, an amount of wash water added to the dishwasher and a status of a full flow filter. The control system includes means for detecting a plurality of conditions in the dishwasher during operation, means for evaluating the plurality of detected conditions to determine a dynamic control response, and means for sending a signal representing the dynamic control response to control at least one component of the dishwasher.

Owner:VIKING RANGE

Washing machine

ActiveUS20090145176A1Improve internal space utilizationImprove space utilizationOther washing machinesTextiles and paperWash waterEngineering

A washing machine is disclosed. A washing machine includes a tub holding wash water, a drum rotatable within the tub to hold laundry, a first cabinet defining a first space to wash laundry together with the tub and the drum, a second cabinet defining a second space for an additional function, the second cabinet formed as one body with the first cabinet, and a single partition provided between the first and second cabinets to partition off the second space from the first space.

Owner:LG ELECTRONICS INC

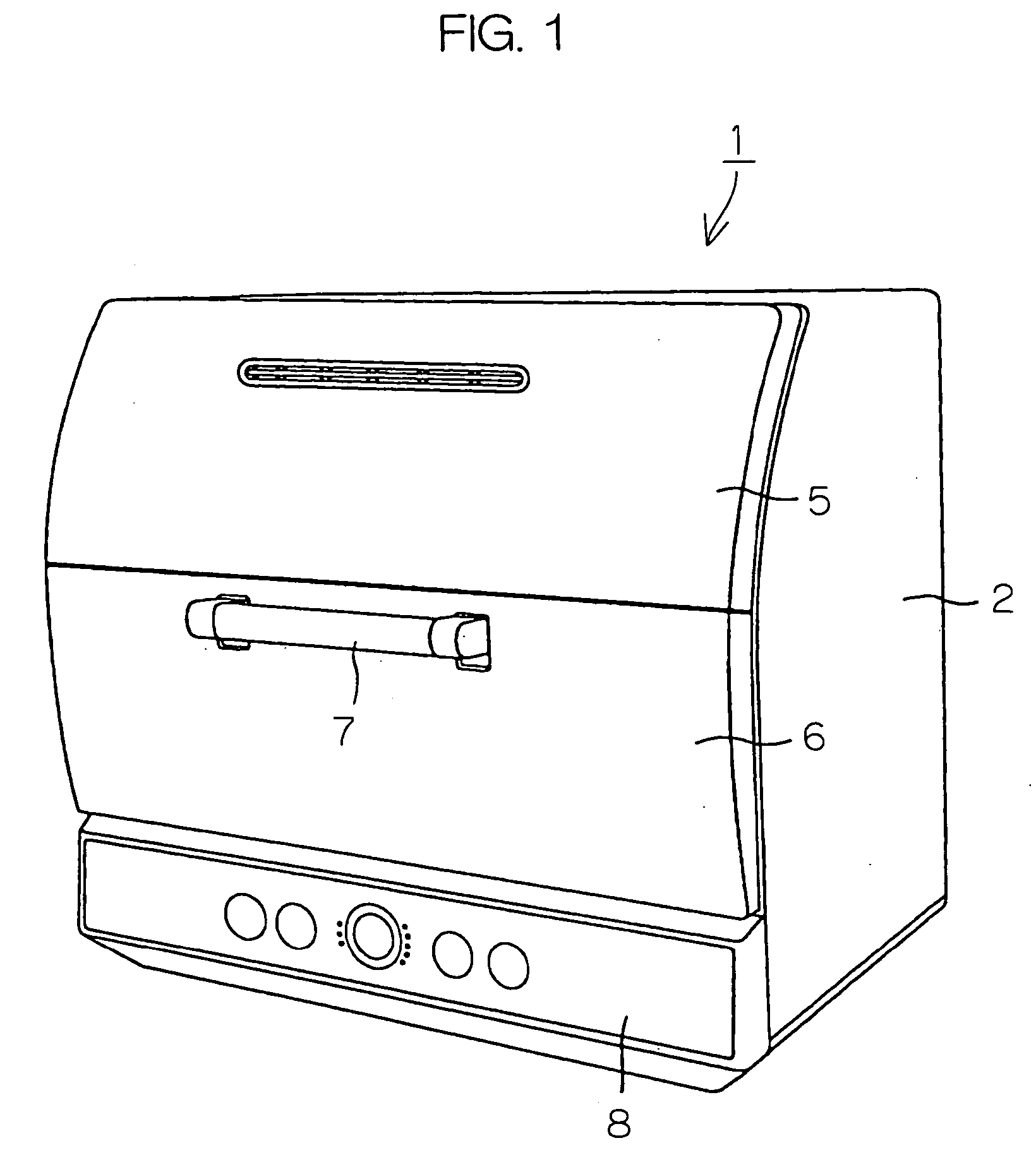

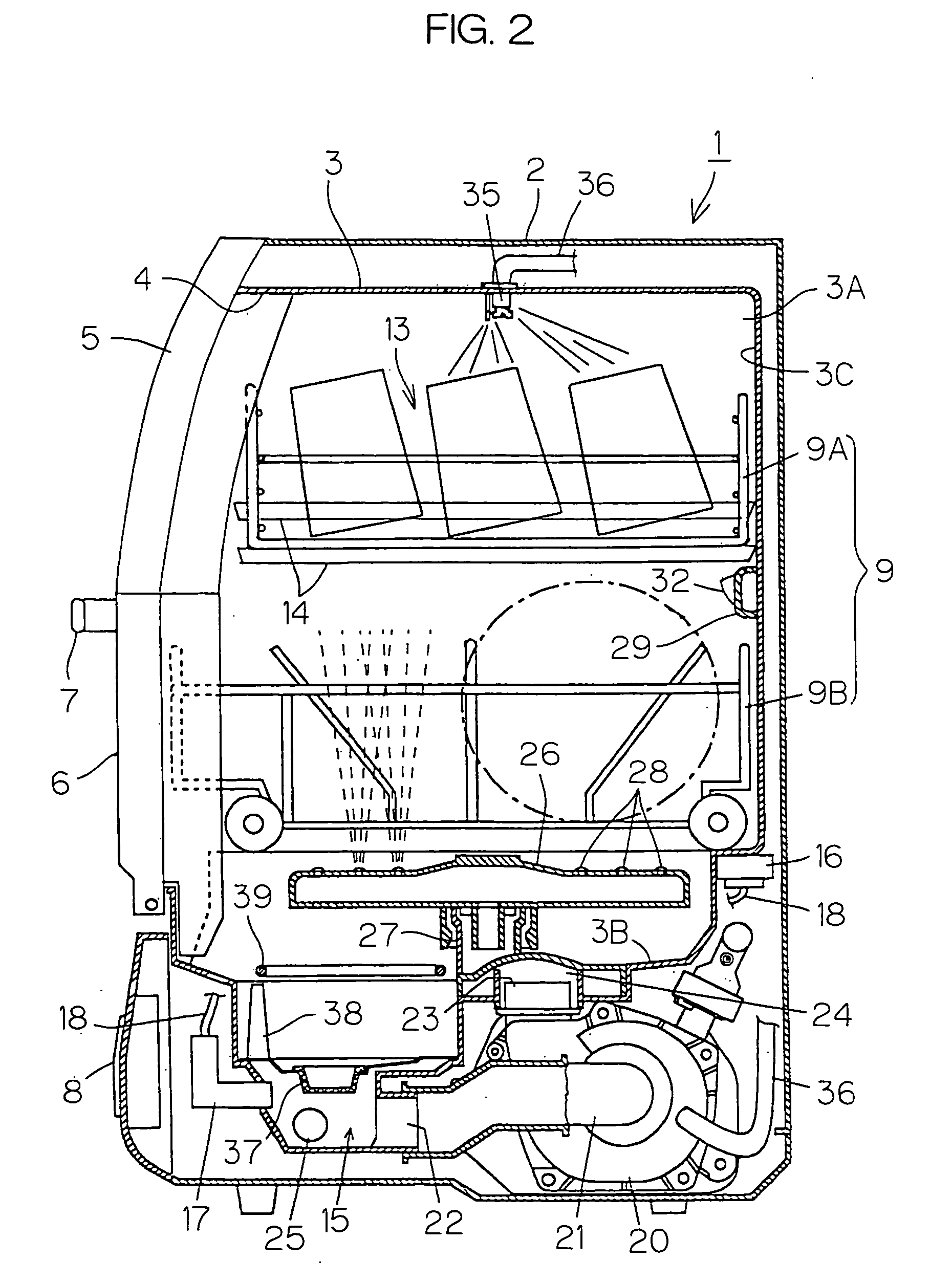

Dish washing machine

InactiveUS20050022847A1Avoid a lotEasy to washTableware washing/rinsing machine detailsWashing processesWash waterHigh heat

A dish washing machine according to the present invention carries out, in a kitchen detergent course, a soaking step for spraying a wash water stored in a containing tank toward dishes and leaving the dishes for a predetermined time precedent to a washing step. In the soaking step, a low temperature soaking is carried out in which the wash water in a washing tank is kept at about 30° C. (temperature appropriate for removing soils containing protein ingredients with a kitchen detergent, especially a neutral detergent), and thereafter a high temperature soaking is carried out in which the wash water in the washing tank is kept at about 50° C. Thereby, the soils containing protein ingredients attached to the dishes can be well removed away with the kitchen detergent.

Owner:SANYO ELECTRIC CO LTD

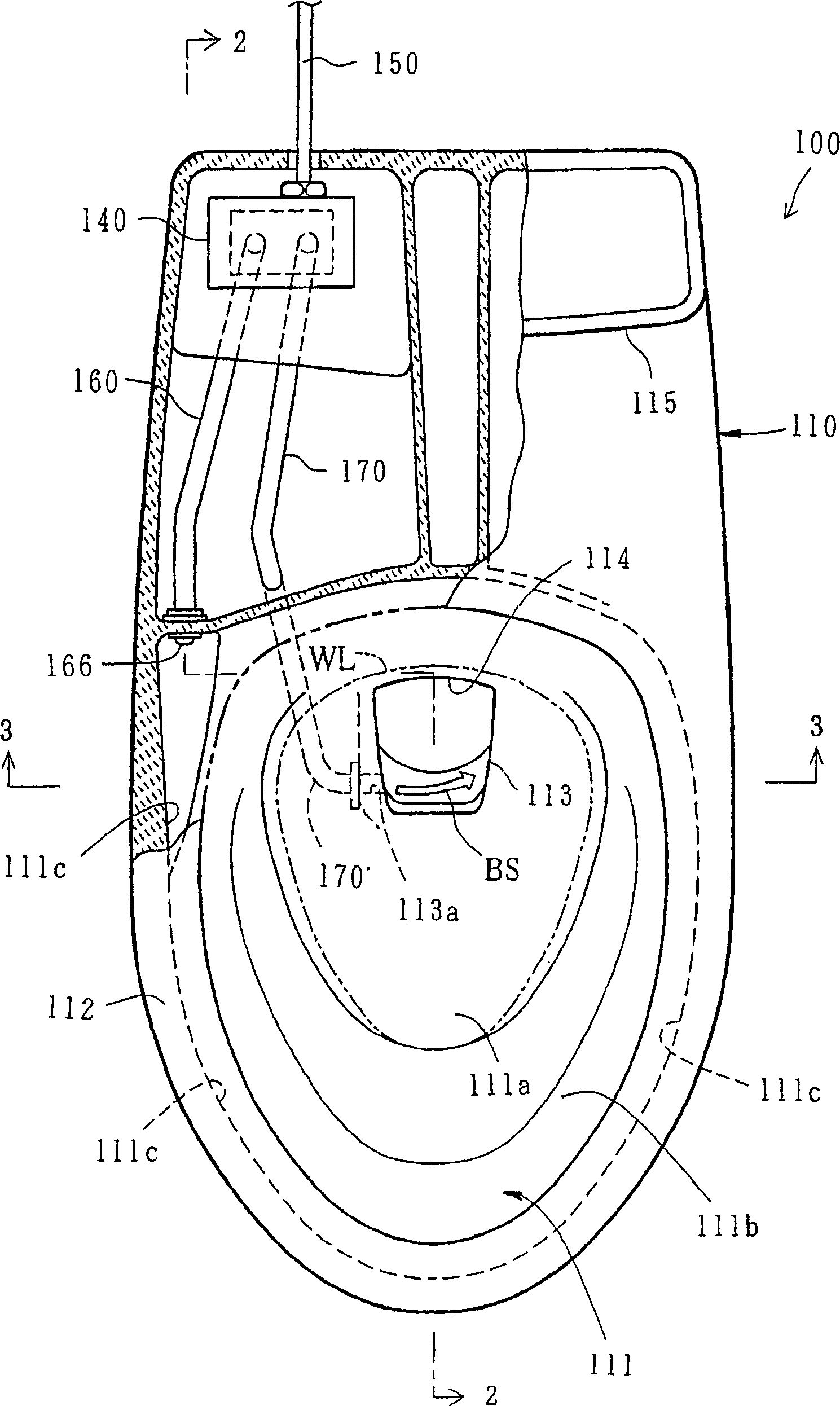

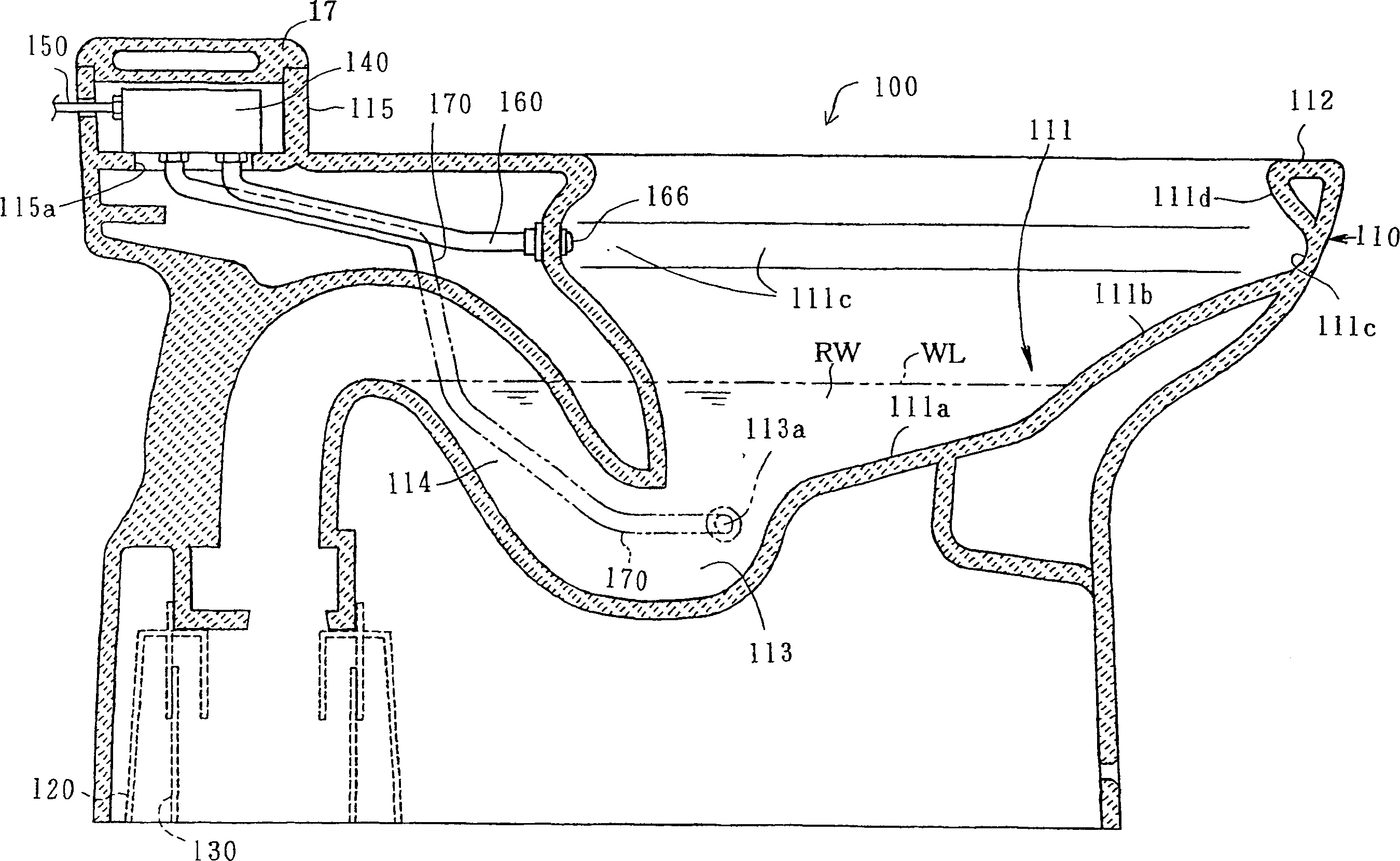

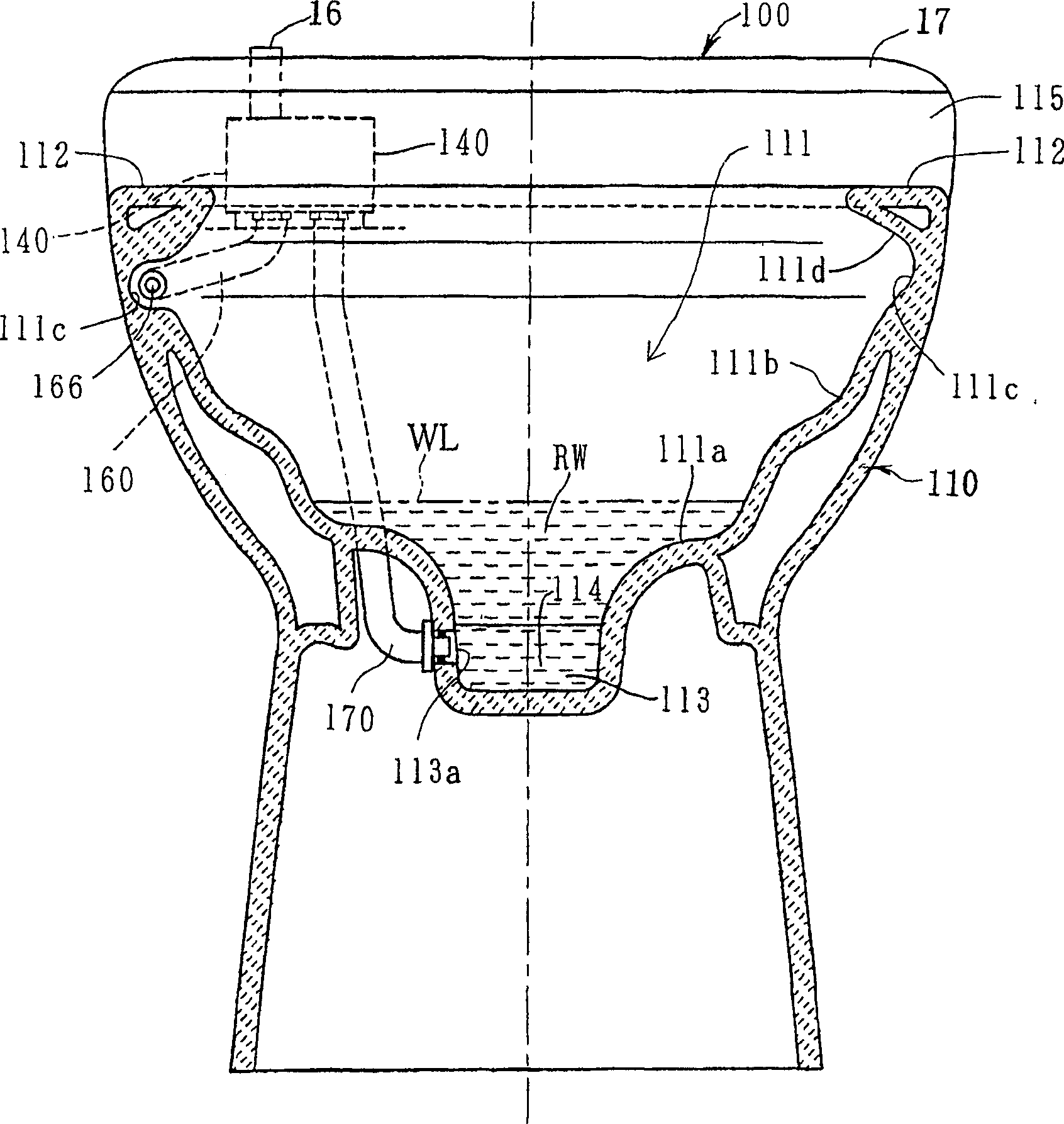

Water closet

A flush toilet comprises a toilet body having a bowl for storing wash water as water seal, first means for supplying the toilet body with pressurized wash water and second means for discharging the wash water substantially horizontally along the upper peripheral portion of the inner surface of the bowl to swirl it along the inner surface of the bowl.

Owner:TOTO LTD

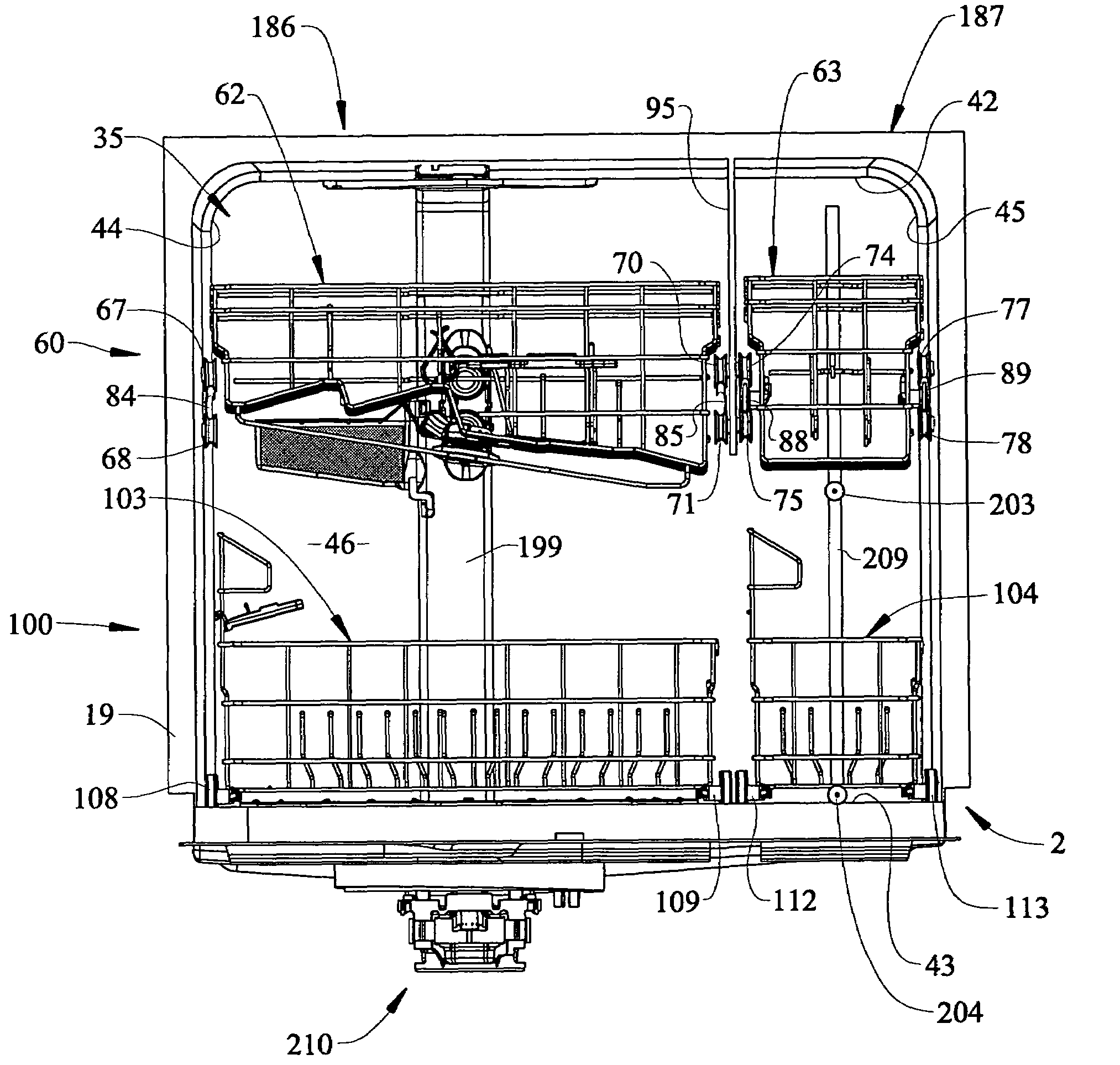

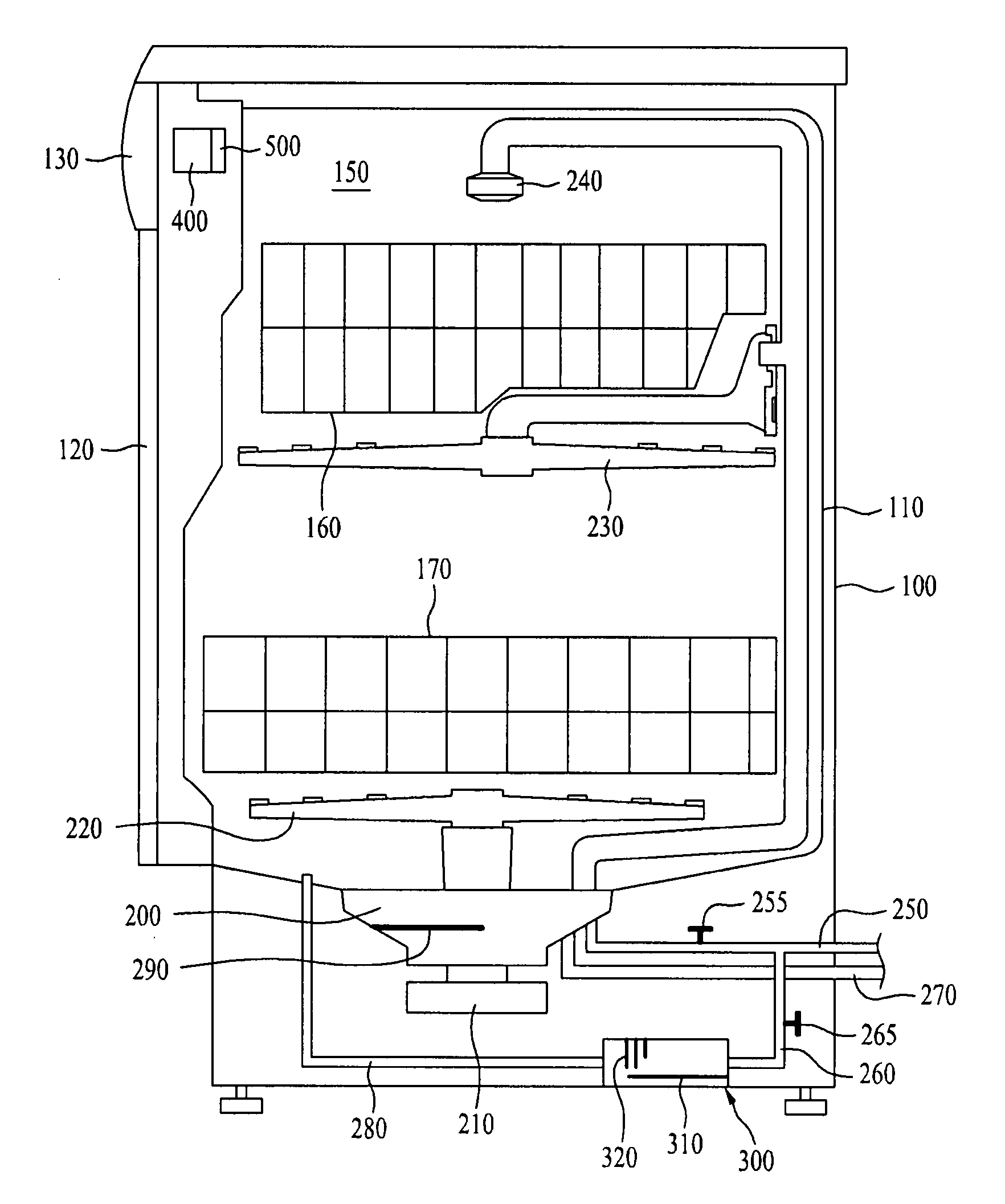

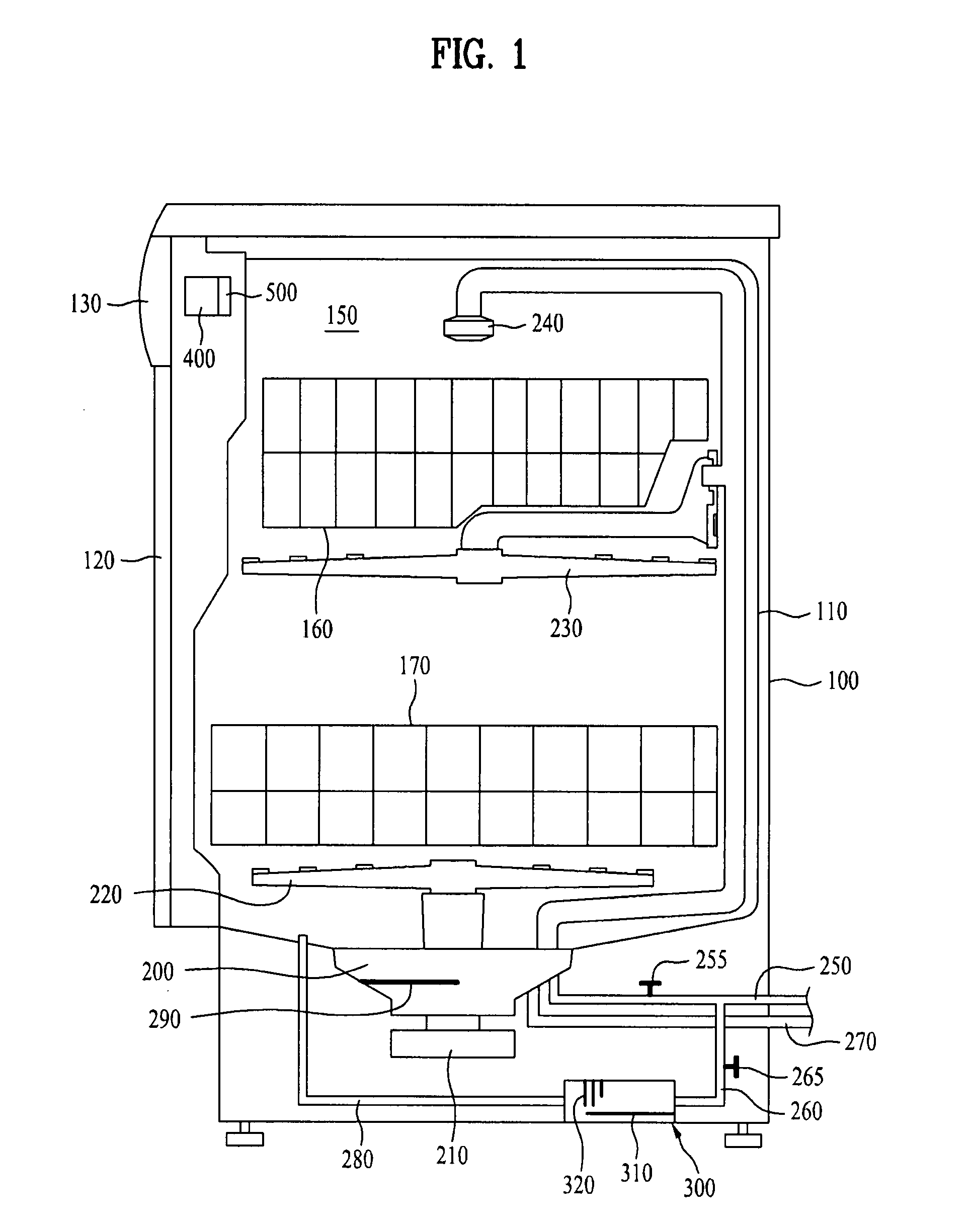

Dishwasher having a side-by-side rack system

InactiveUS7198054B2Tableware washing/rinsing machine detailsHollow article cleaningWash waterEngineering

Owner:MAYTAG

Washing machine

ActiveUS20150184326A1Improved coupling structureSimple structureOther washing machinesWashing machine with receptaclesWash waterEngineering

A washing machine which comprises a fixing unit configured to fix an auxiliary laundry tub located in a rotary tub. The washing machine includes a cabinet, a tub disposed in the cabinet to store wash water, a rotary tub installed in the tub to be rotatable, a balancer coupled to an upper portion of the rotary tub to offset an unbalanced load of the rotary tub, an auxiliary laundry tub disposed in the rotary tub to be removably coupled to the balancer, and a fixing unit installed at the auxiliary laundry tub to be coupled to the balancer and to restrict up and down movement of the auxiliary laundry tub when the rotary tub is operated. Therefore, since the auxiliary laundry tub and the balancer may be stably coupled with each other, the auxiliary laundry tub is prevented from be separated during a washing process.

Owner:SAMSUNG ELECTRONICS CO LTD

Dish washing machine and control method of the same

InactiveUS20080289654A1Safely and efficiently cleanReduce the amount requiredTableware washing/rinsing machine detailsWashing processesWash waterProcess engineering

A dish washing machine and a control method of the same are disclosed. The dish washing machine may include a first heater for heating wash water to wash items in a dishwasher. The dishwasher may also include a second heater for generating steam to be supplied to the dishes. A controller is configured to control the first and second heaters to operate alternately.

Owner:LG ELECTRONICS INC

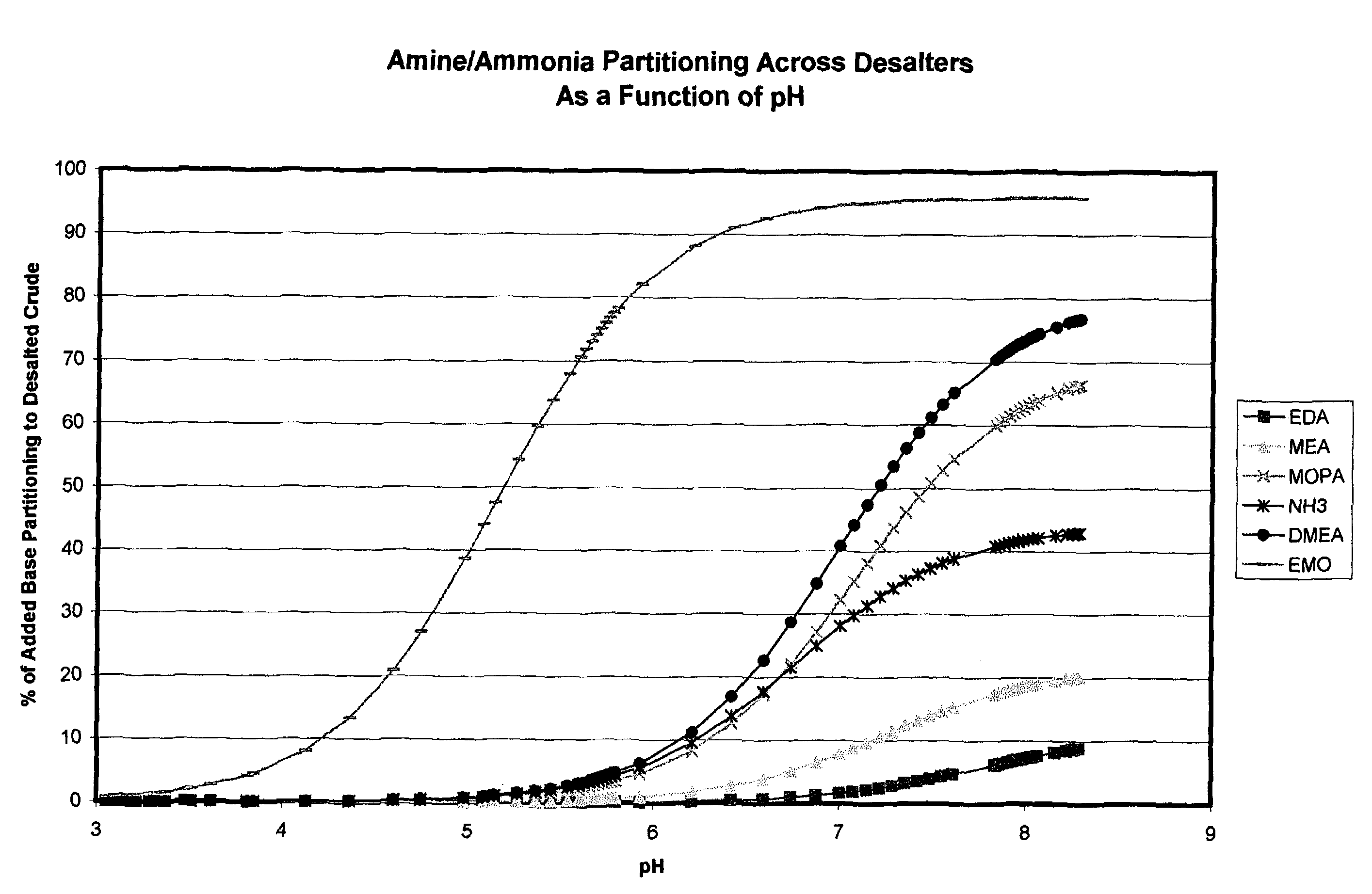

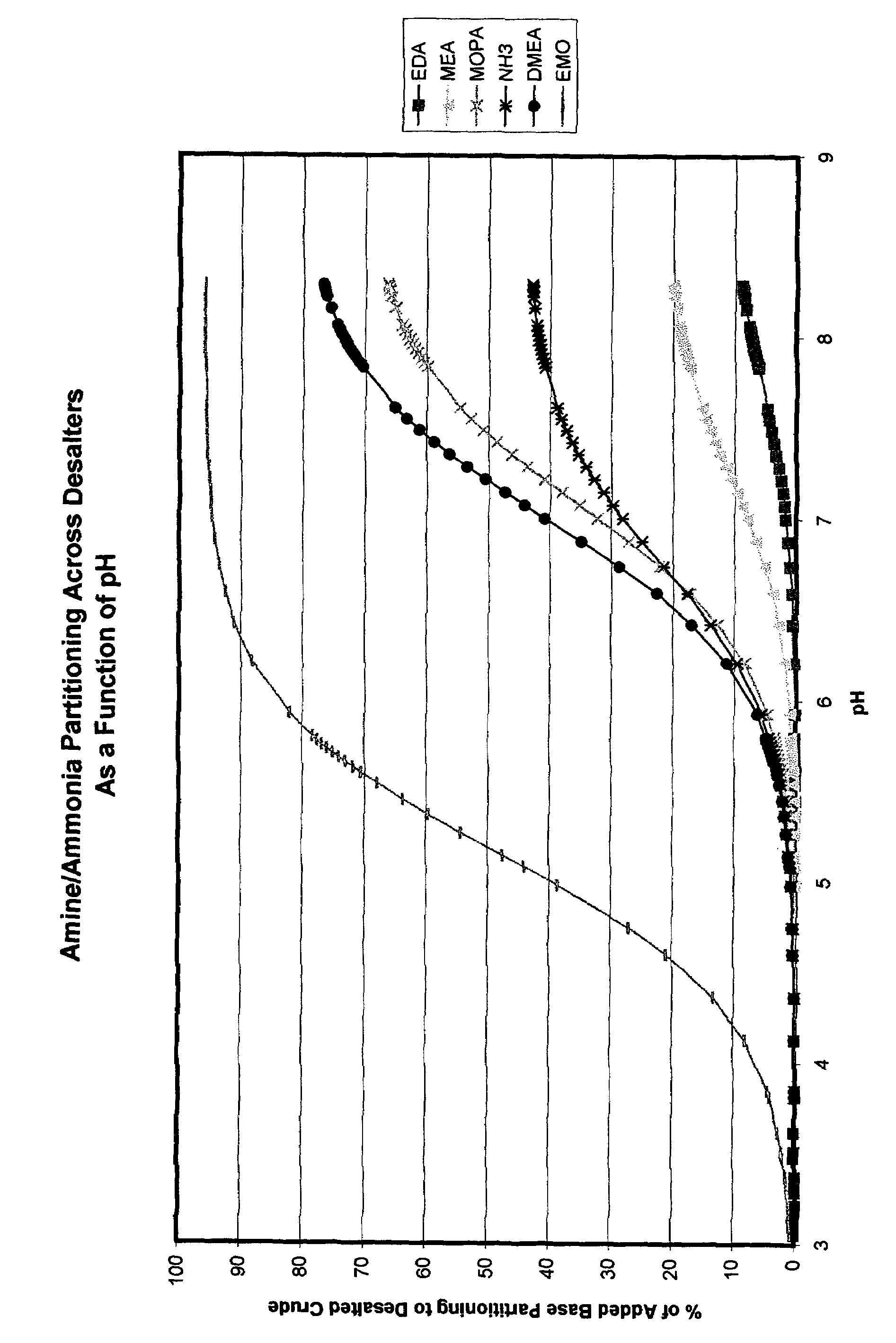

Additives to enhance metal and amine removal in refinery desalting processes

ActiveUS7497943B2Dewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansWash waterChloroacetic acids

It has been discovered that metals and / or amines can be removed or transferred from a hydrocarbon phase to a water phase in an emulsion breaking process by using a composition that contains water-soluble hydroxyacids. Suitable water-soluble hydroxyacids include, but are not necessarily limited to glycolic acid, gluconic acid, C2-C4 alpha-hydroxy acids, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof. The composition may also include at least one mineral acid to reduce the pH of the desalter wash water. A solvent may be optionally included in the composition. The invention permits transfer of metals and / or amines into the aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil emulsions, and in removing calcium and other metals therefrom.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com