Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

166 results about "Desalter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A desalter is a process unit in an oil refinery that removes salt from the crude oil. The salt is dissolved in the water in the crude oil, not in the crude oil itself. The desalting is usually the first process in crude oil refining.

Desalting adjunct chemistry

InactiveUS6120678AImproves separation of waterReduce decreaseDewatering/demulsification with chemical meansLiquid separation by electricityChemical treatmentMeth-

Improved performance in the phase separation of aqueous brines from hydrocarbons within an electrostatic desalter operation is obtained by the addition to the crude oil emulsions entering the desalter of an effective asphaltene dispersing amount of an alkyl phenol-formaldehyde liquid resin polymer, optionally in the presence of a lipophilic / hydrophilic vinylic polymer. The preferred resin is a nonyl phenol-formaldehyde resin having a molecular weight of from 1,000-20,000, and the preferred vinylic polymer is a copolymer of lauryl (meth)acrylate and hydroxyethyl (meth)acrylate. Best results from the electrostatic desalter are obtained when also using a demulsifier chemical treatment along with the asphaltene dispersing treatments. Desalter efficiency is increased and desalter brine effluent quality is greatly increased.

Owner:ECOLAB USA INC +1

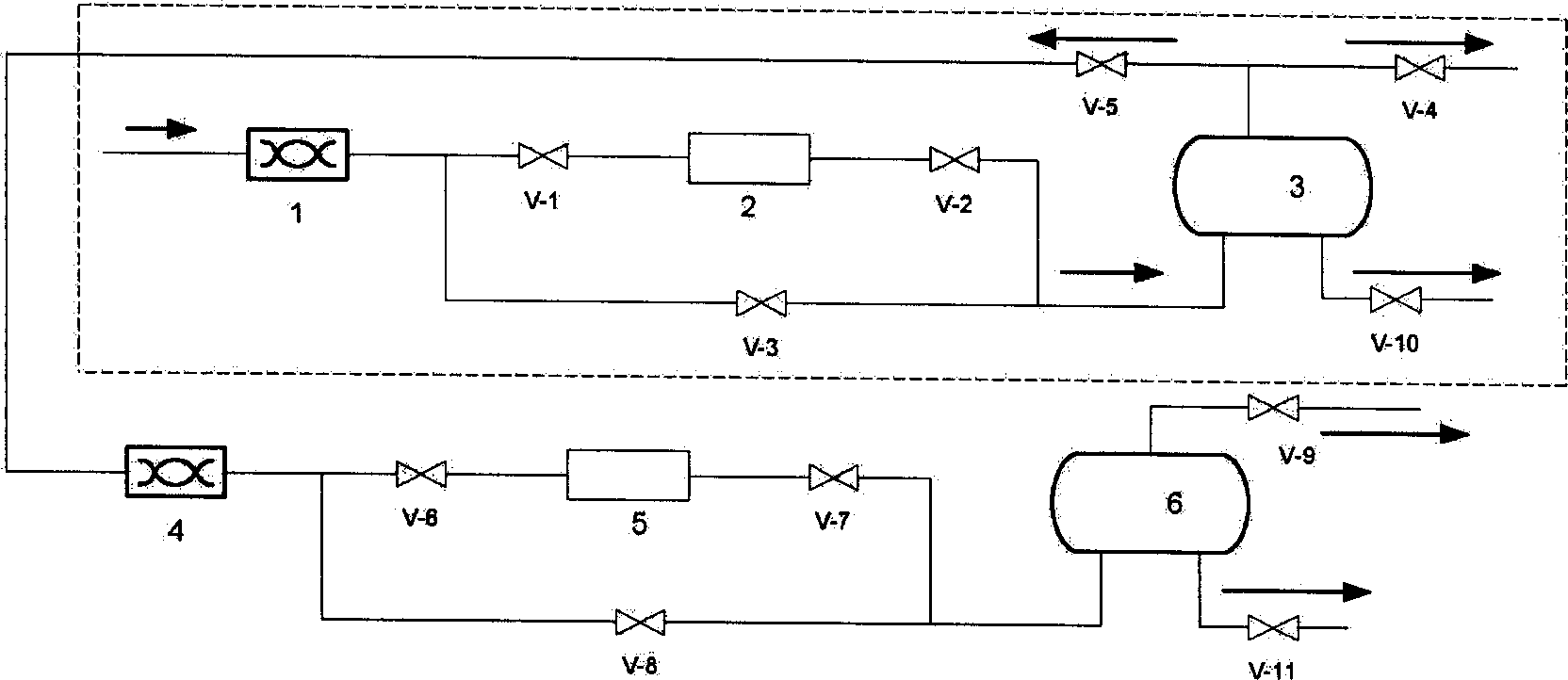

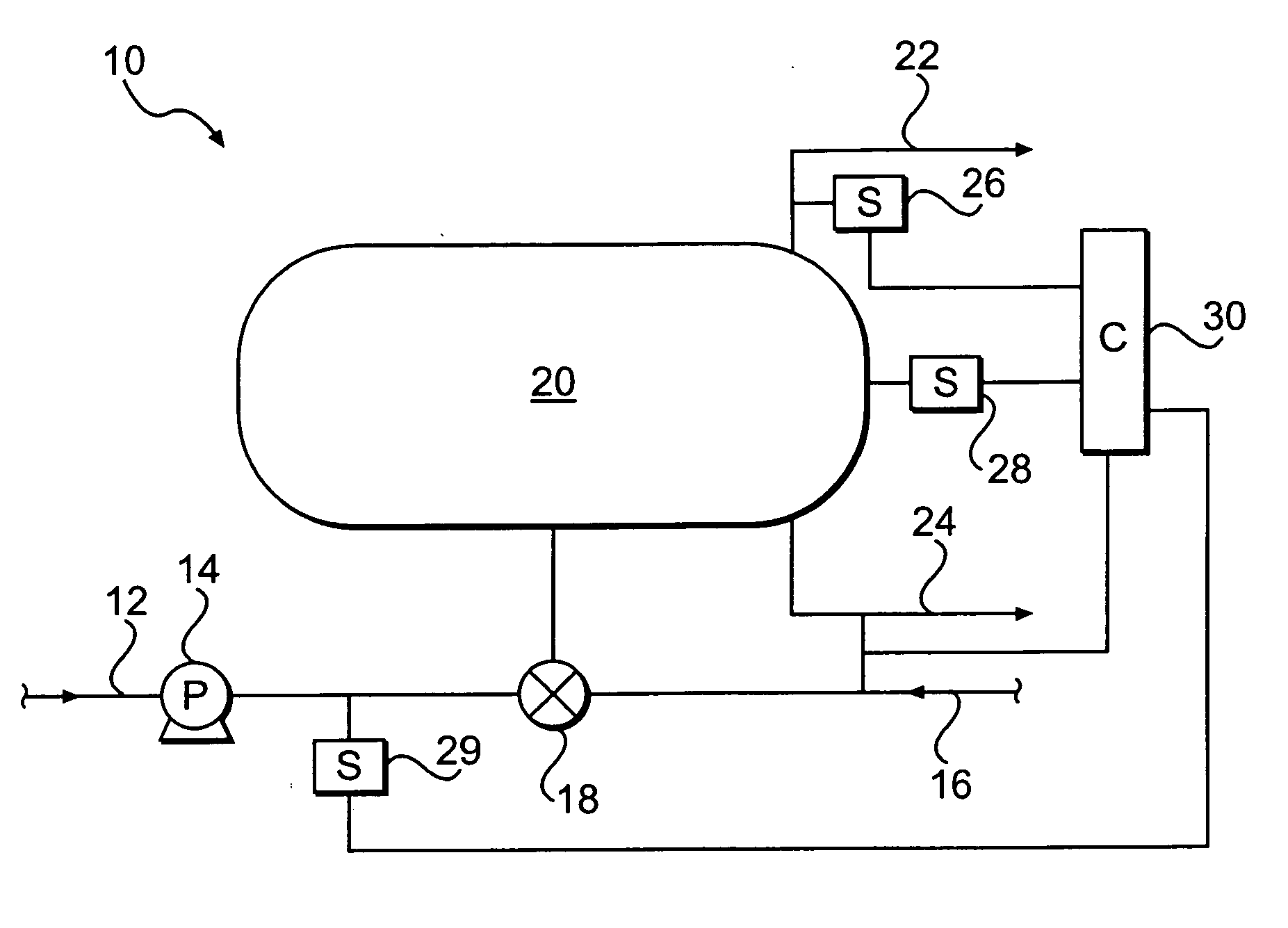

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS20130026082A1Low viscosityLiquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

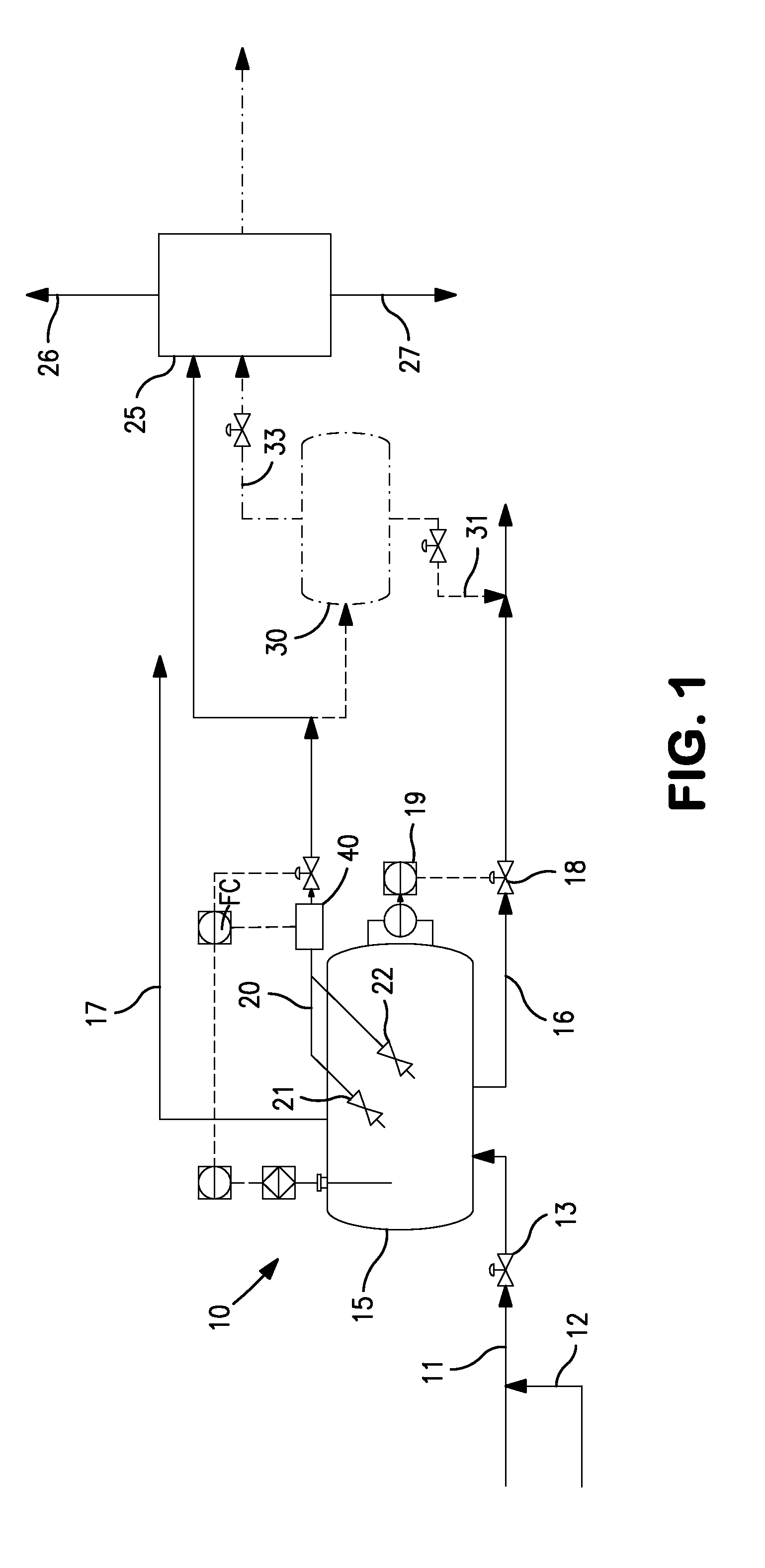

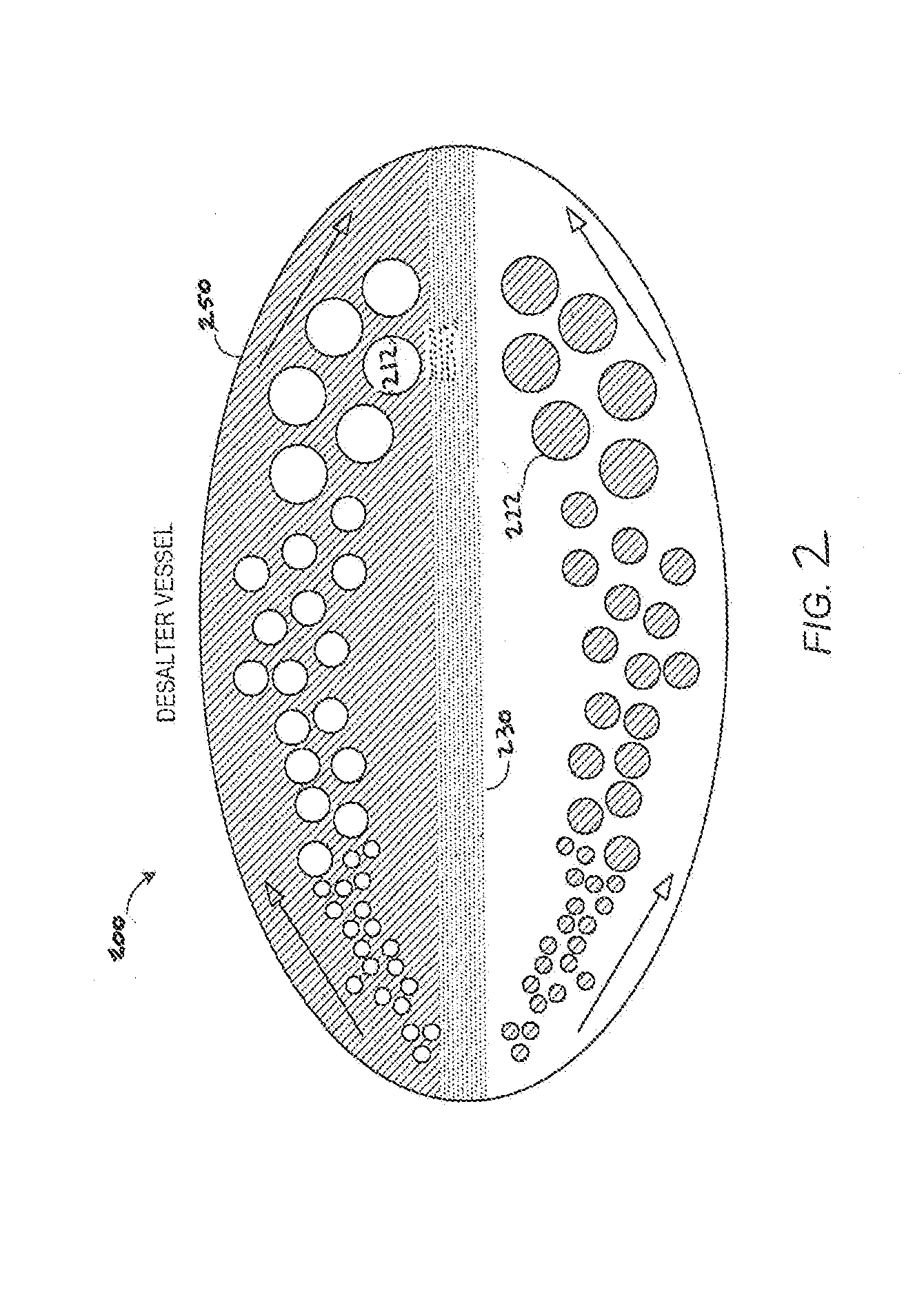

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

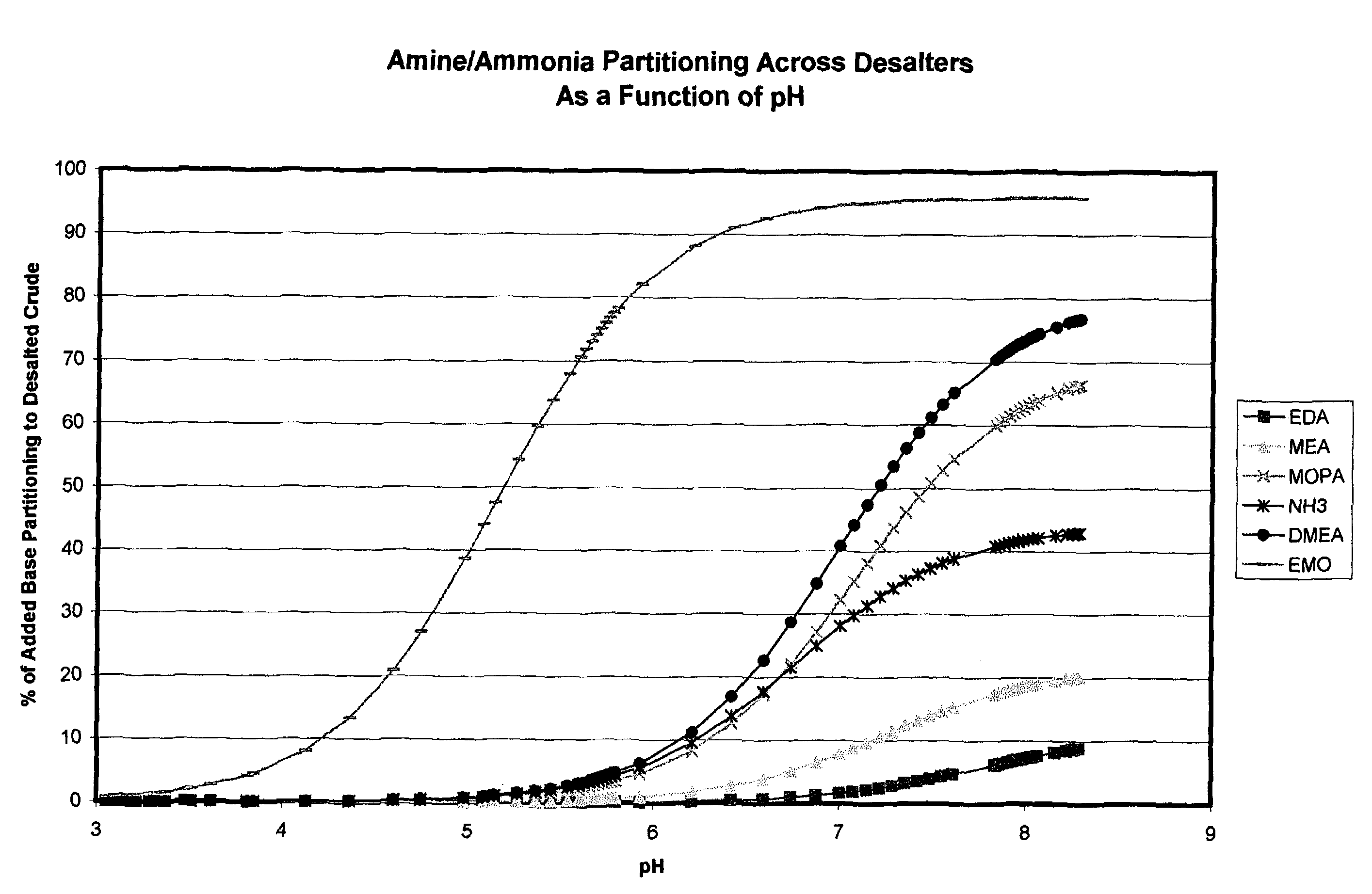

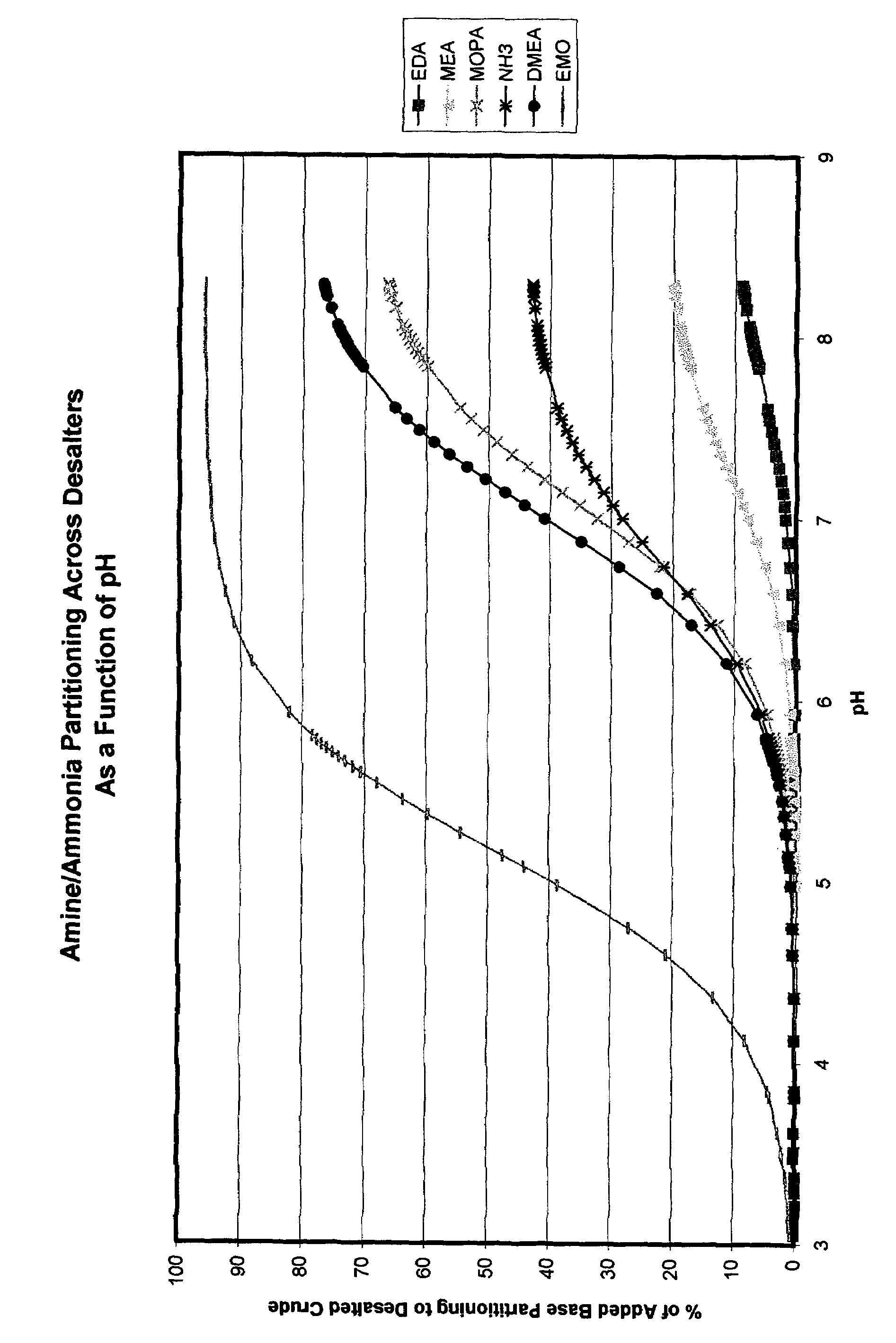

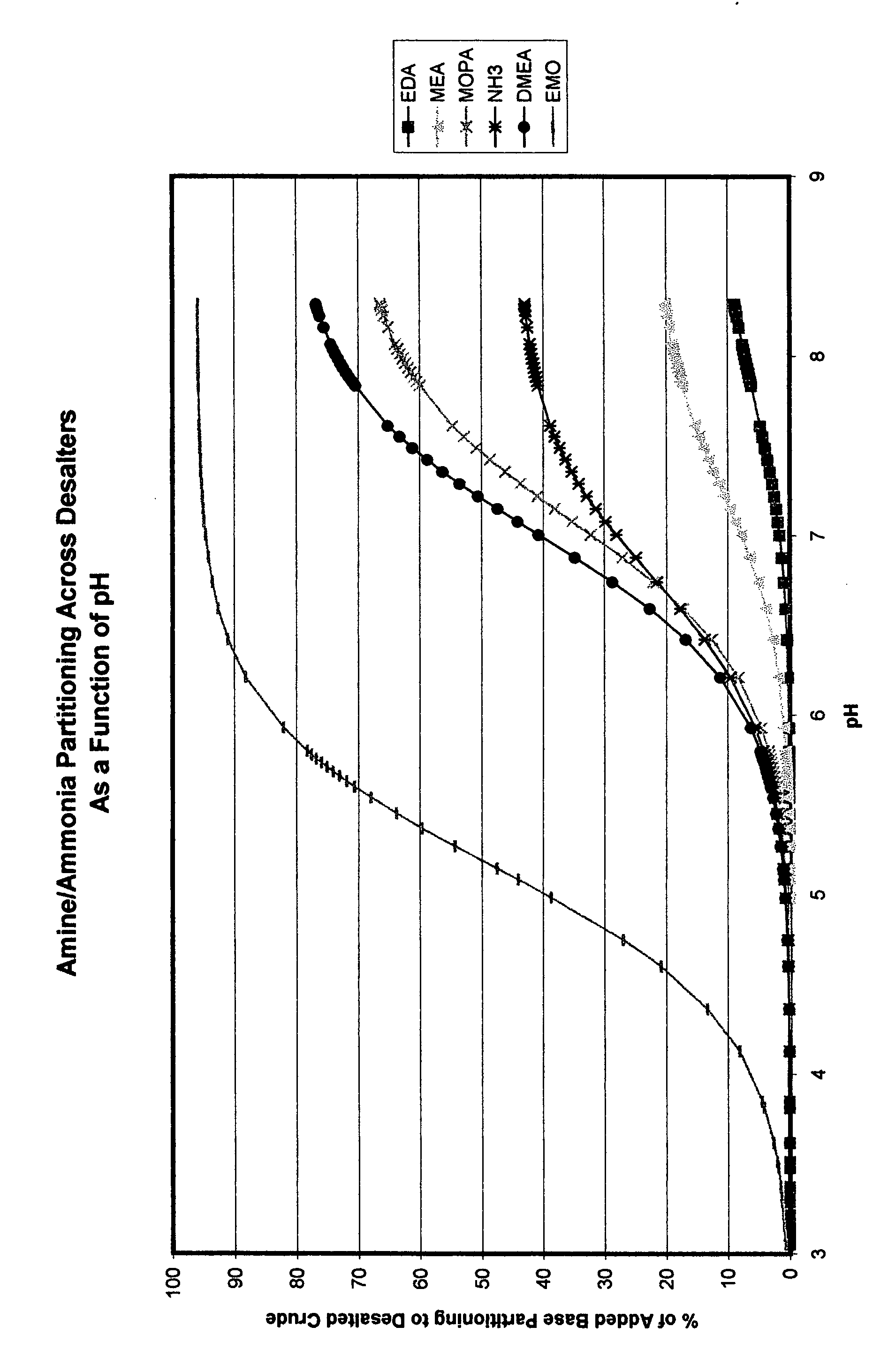

Additives to enhance metal and amine removal in refinery desalting processes

ActiveUS7497943B2Dewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansWash waterChloroacetic acids

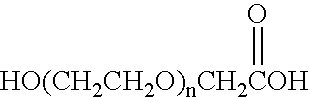

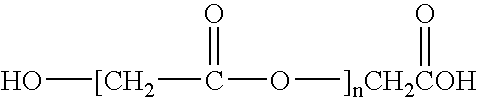

It has been discovered that metals and / or amines can be removed or transferred from a hydrocarbon phase to a water phase in an emulsion breaking process by using a composition that contains water-soluble hydroxyacids. Suitable water-soluble hydroxyacids include, but are not necessarily limited to glycolic acid, gluconic acid, C2-C4 alpha-hydroxy acids, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof. The composition may also include at least one mineral acid to reduce the pH of the desalter wash water. A solvent may be optionally included in the composition. The invention permits transfer of metals and / or amines into the aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil emulsions, and in removing calcium and other metals therefrom.

Owner:BAKER HUGHES INC

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

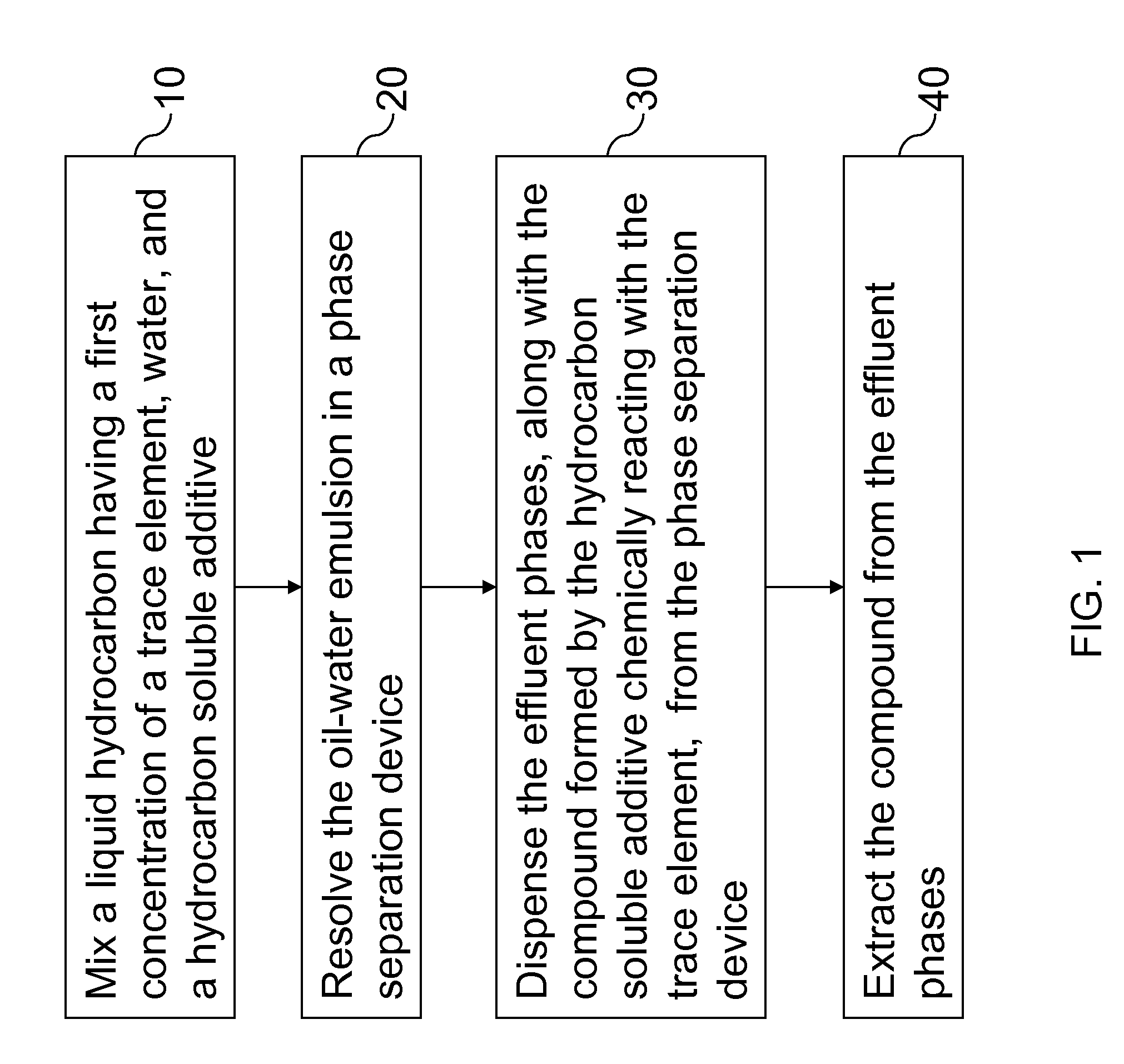

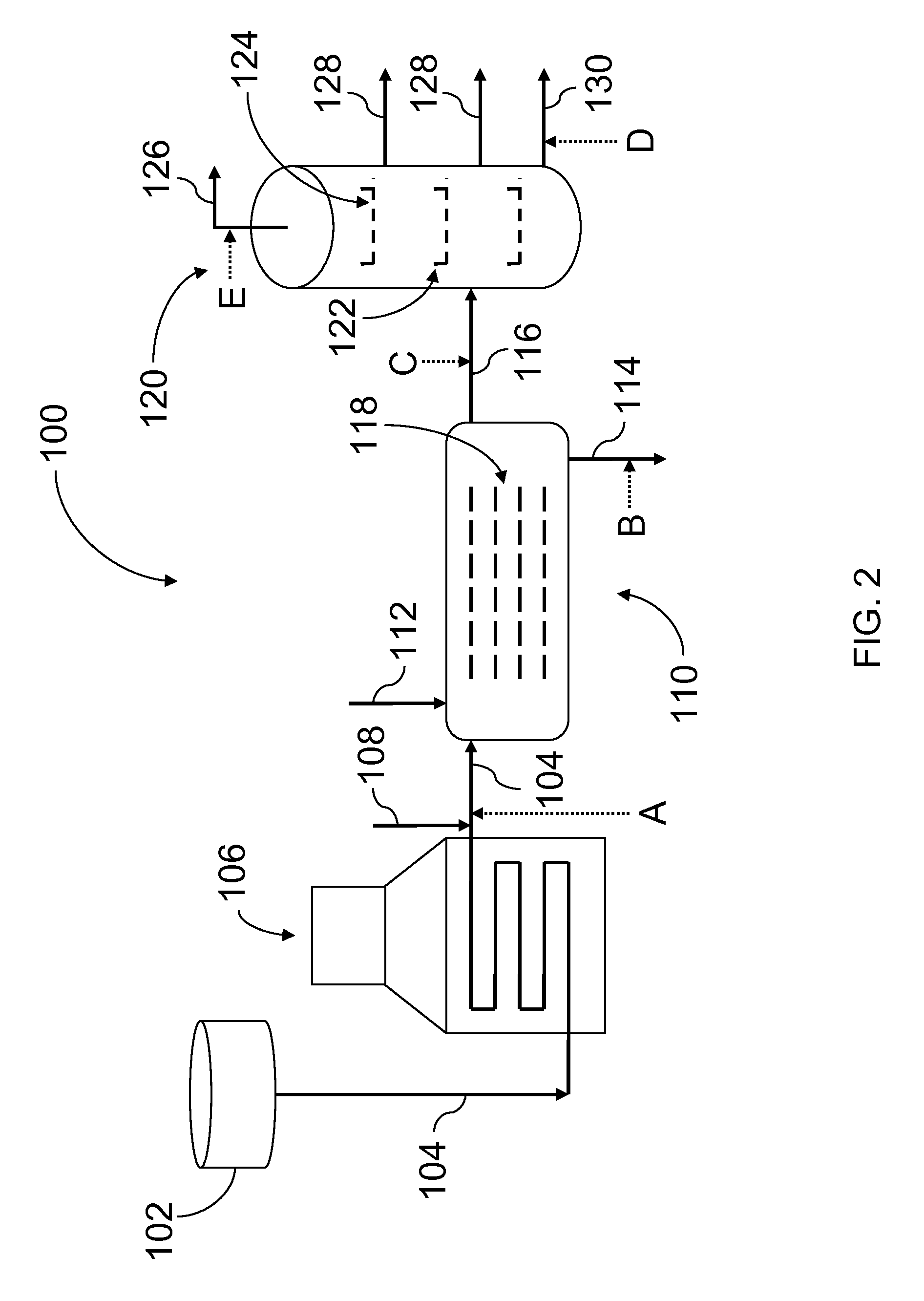

System and method for separating a trace element from a liquid hydrocarbon feed

InactiveUS20100000910A1Easy to removeEasy to separateTransportation and packagingRefining by water treatmentChemical reactionTrace element

The present invention is generally directed to removing a trace element from a liquid hydrocarbon feed. The liquid hydrocarbon feed, containing the trace element, is mixed with the water along with a hydrocarbon-soluble additive. While being mixed, a compound, which in some cases is preferably insoluble, is formed by the hydrocarbon-soluble additive chemically reacting with the trace element. A phase separation device, such as a desalter or an oil-water separator, receives the oil-water emulsion containing the compound and resolves the mixture to produce the compound, effluent brine, and effluent liquid hydrocarbon with a reduced concentration of the trace element as compared to the liquid hydrocarbon feed. In some embodiments, the present invention is directed to removing elemental mercury from a liquid hydrocarbon feed. A hydrocarbon-soluble sulfur-containing additive, typically an organic polysulfide, is mixed with the liquid hydrocarbon feed and water. The hydrocarbon-soluble, sulfur-containing additive reacts with the mercury, rapidly forming an agglomeration of mercuric sulfide which is then dispensed with the effluent brine or the effluent liquid hydrocarbon.

Owner:CHEVROU USA INC

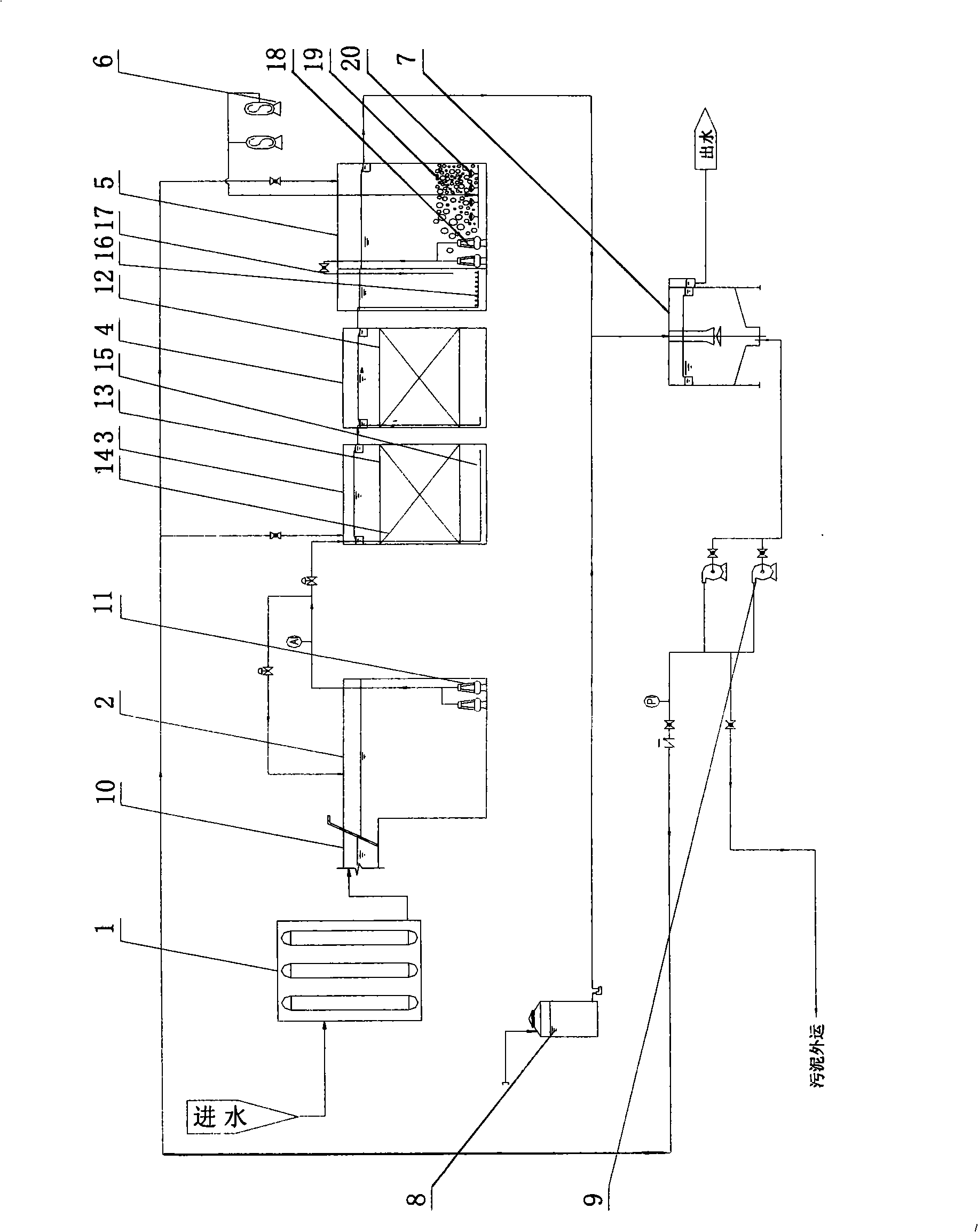

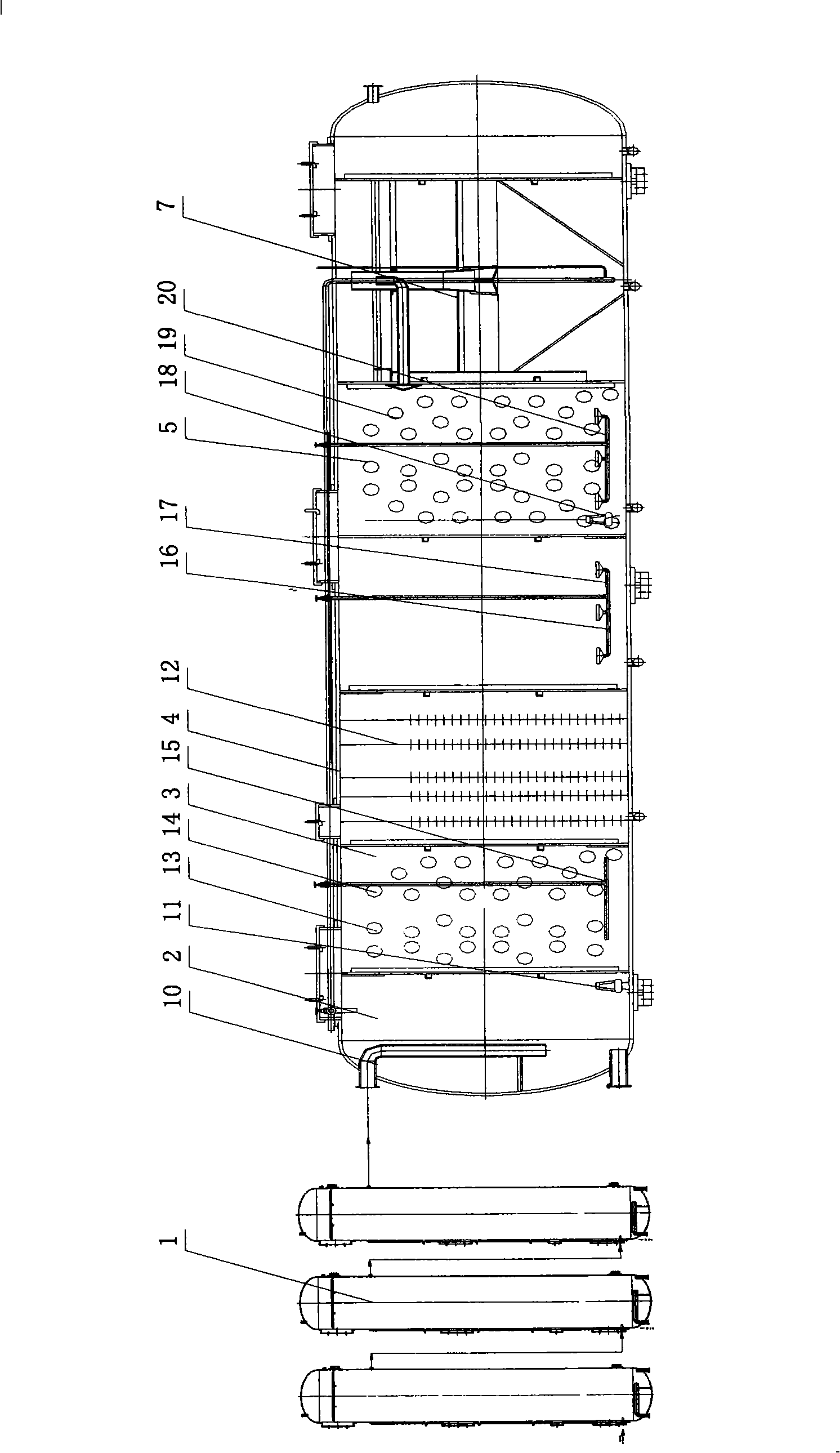

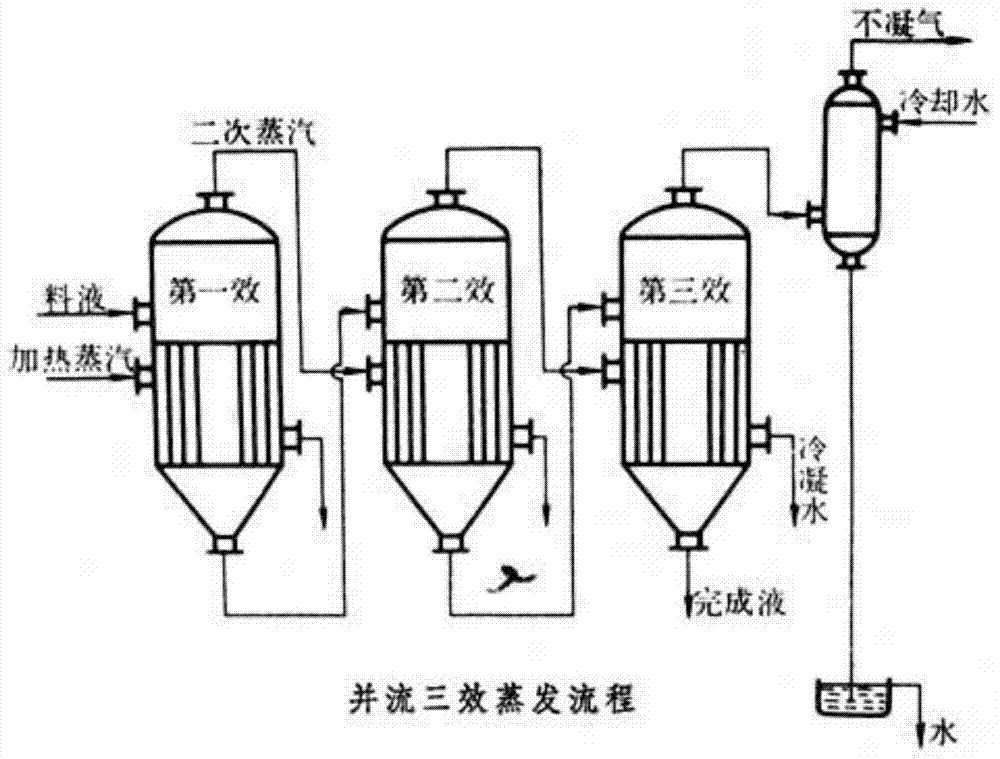

Method for processing high-toxicity high-concentration highly salt-containing organic waste water with biochemistry combination process of catalytic oxidation

InactiveCN101314510AGood effectIn line with environmental protection development ideasWater contaminantsWater/sewage treatment by electrochemical methodsComing outHigh concentration

The invention belongs to the water treatment technical field, in particular to a method for treating high-toxicity high-concentration high-salinity organic wastewater by a process of combining catalysis, oxidation and biochemistry. The method comprises the following specific steps that: wastewater enters a triple-effect distillation desalter; a pressure of the distillation desalter is controlled between 9 and 11 KG; a temperature of the distillation desalter is controlled between 85 and 95 DEG C; a water body is pretreated by a grating well and an adjusting tank and enters a micro electrolytic oxidation and oxidation tank by a lifting pump; the treated water automatically flows into a hydrolysis acidification tank, and the dwell time of water power is between 12 and 15 hours; the addition amount of combined type fillers is 50 to 70 percent of a usable capacity of the hydrolysis acidification tank; the treated water coming out from the hydrolysis acidification tank enters an oxygen compatible tank of an A / O tank; simultaneously, activated sludge is pumped into the oxygen compatible tank, and the dwell time of water power is between 5 and 8 hours; effluent water enters an aerobic tank by a circulating pipeline; the dwell time of water power in the aerobic tank is between 10 and 15 hours; the addition amount of suspended fillers is 30 to 40 percent of a volume of the aerobic tank; water treated by the A / O tank flows into a secondary sedimentation tank; the effluent water is discharged; and the residual sludge is discharged. The method applies the triple-effect distillation technology to the wastewater treatment technology and is organically combined with the subsequent catalysis oxidation technology and the biotreatment technology, thereby providing a brand-new development idea for the wastewater treatment of the type.

Owner:SHANGHAI CHEMAREA WATER TECH

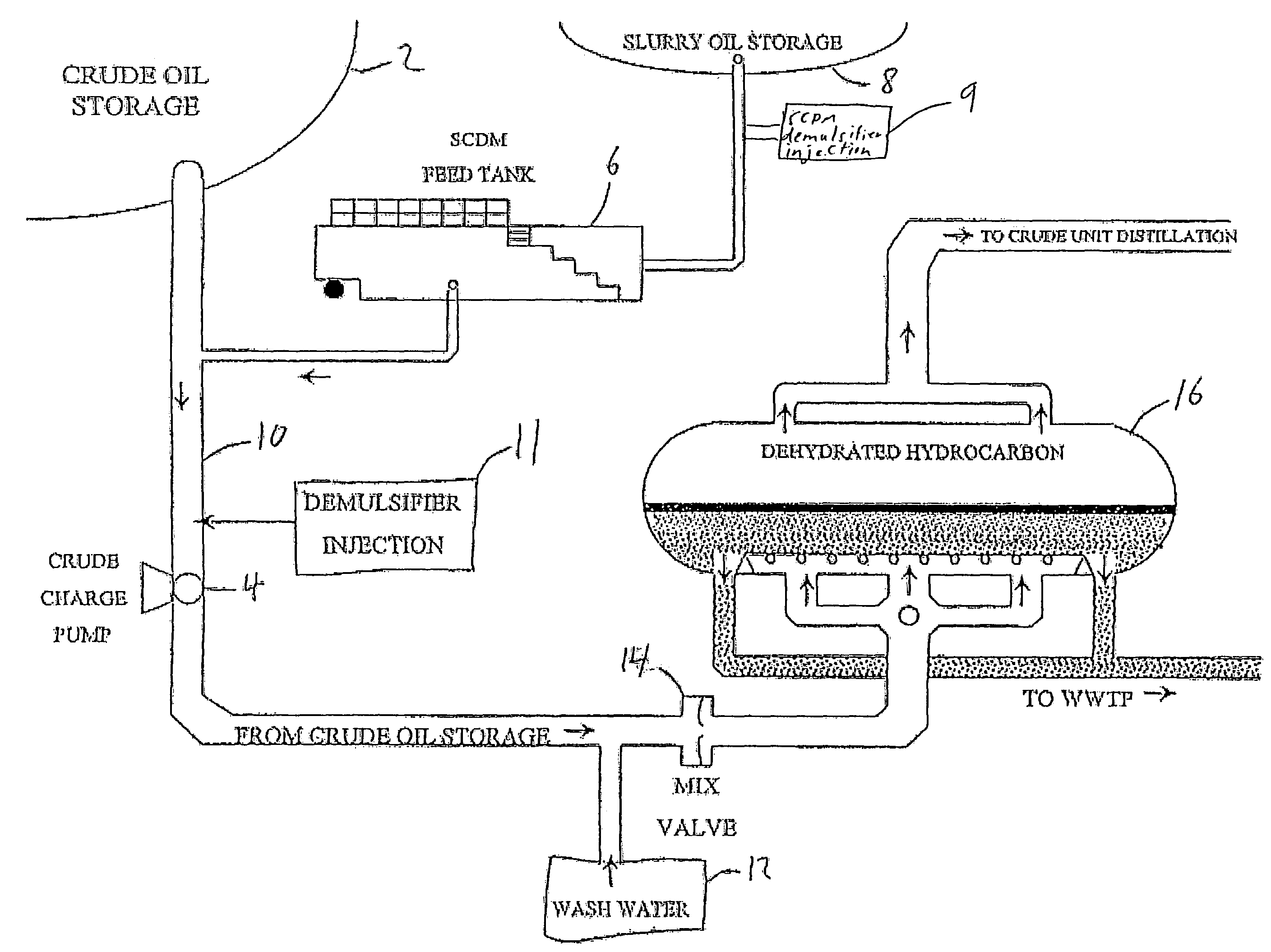

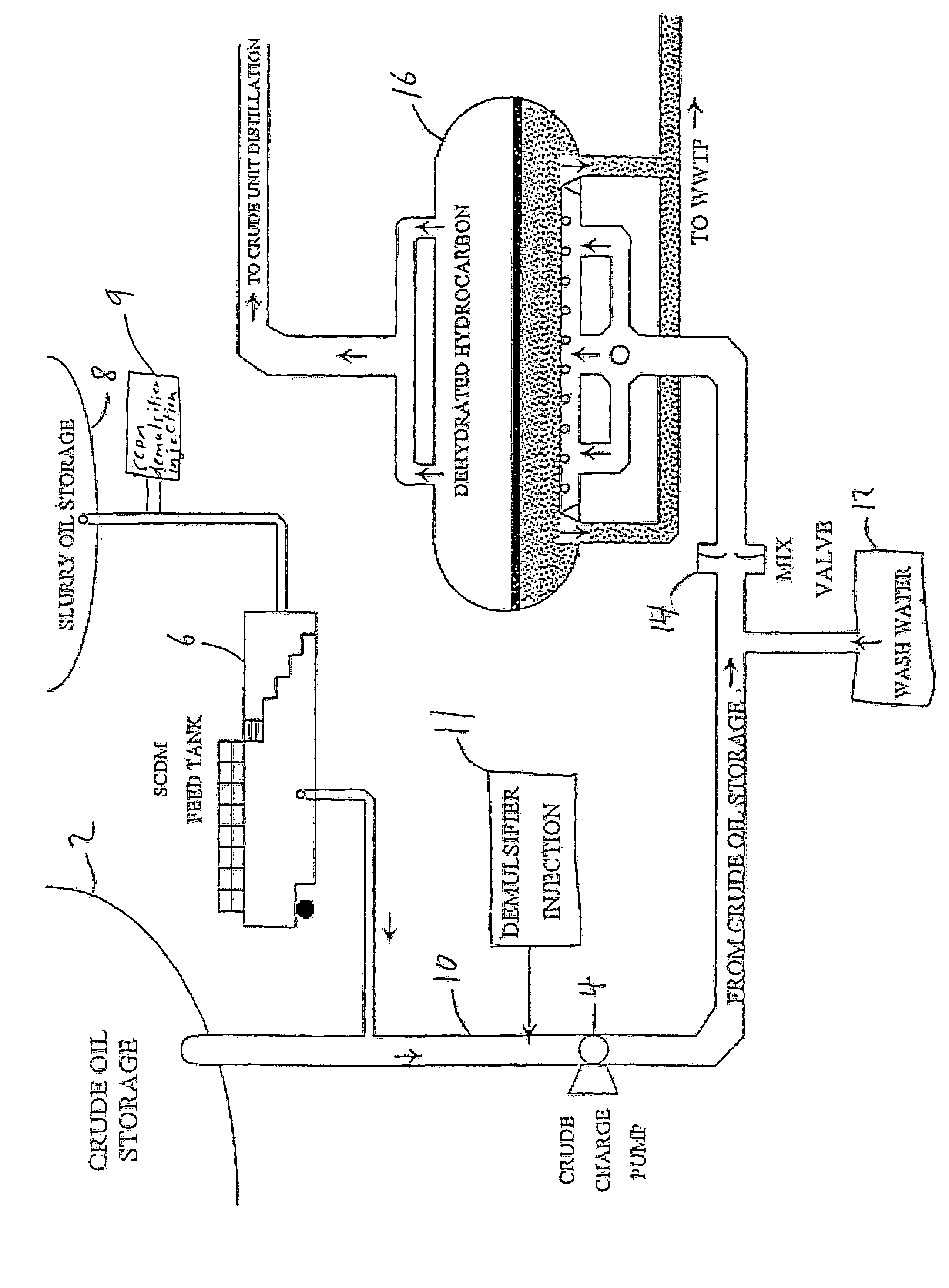

FCC-CFD cat' fine desalting: a method and system for separating hydrocarbons and extracting catalyst fines from a slurry oil/catalyst fines/diluent mixture

InactiveUS7244364B1Detrimental consequenceDifferential sedimentationWater/sewage treatment by flocculation/precipitationDiluentSlurry

The present invention comprises a method for separating hydrocarbons from catalyst fines in a slurry oil / catalyst fines / diluent mixture (SCDM) comprising the steps of removing SCDM from a slurry oil storage tank and combining the SCDM with crude oil entering a desalter in order to separate the slurry oil from the catalyst fines, whereby the desalter causes the hydrocarbon content of the SCDM to exit the desalter with dehydrated hydrocarbon from the crude oil while catalyst fines exit the desalter with basic sediment and water removed from the crude oil.

Owner:WEBER LARRY J

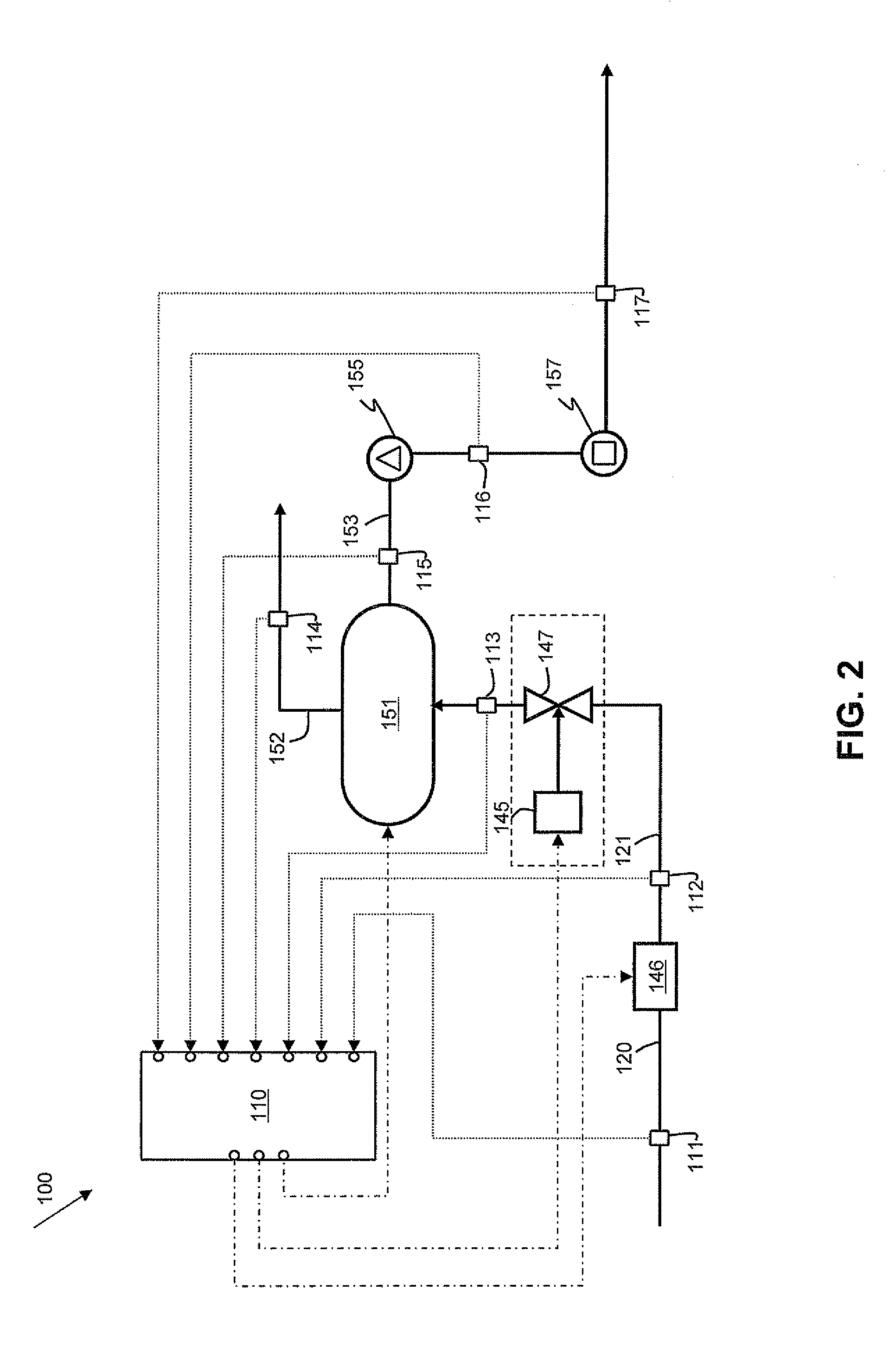

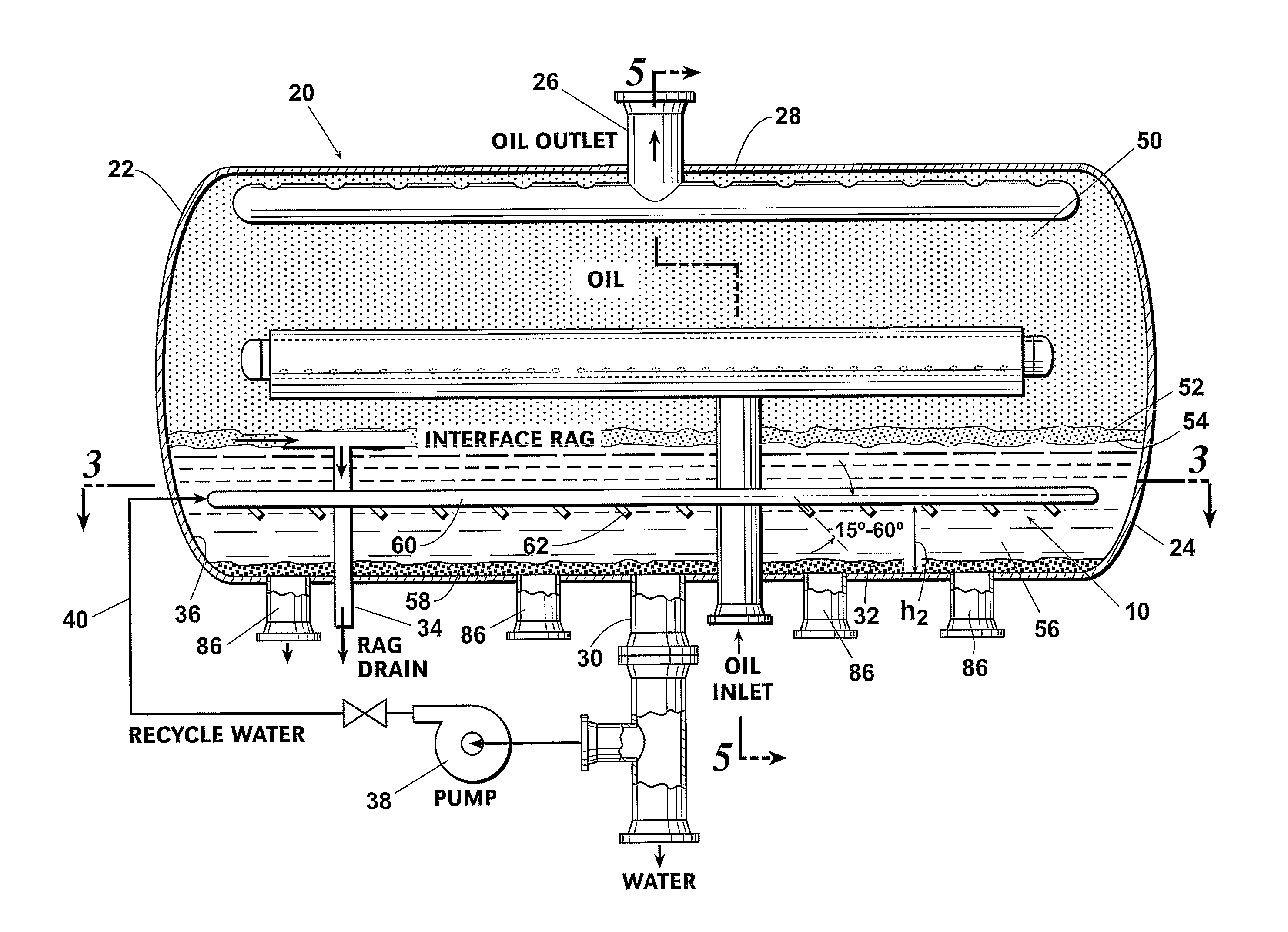

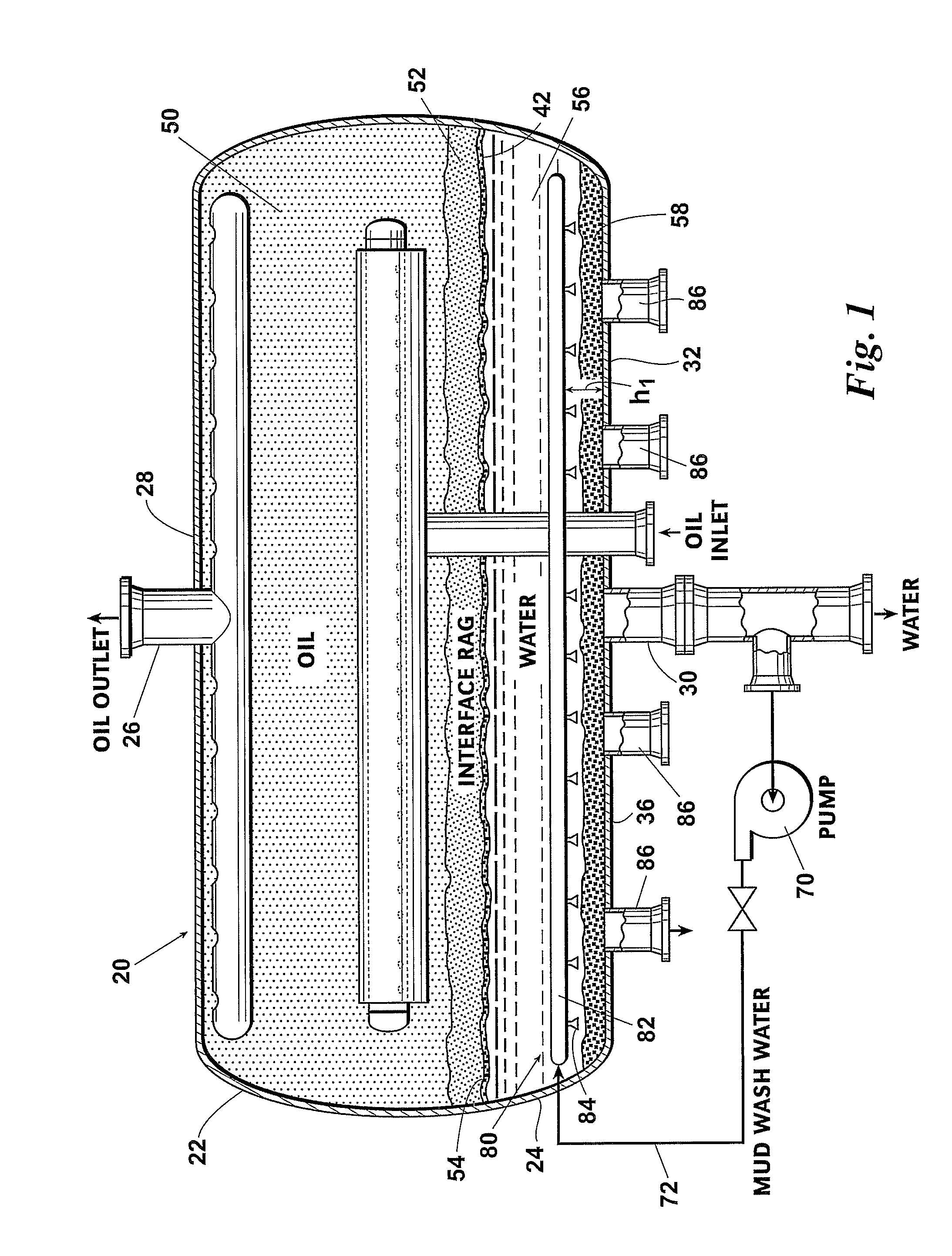

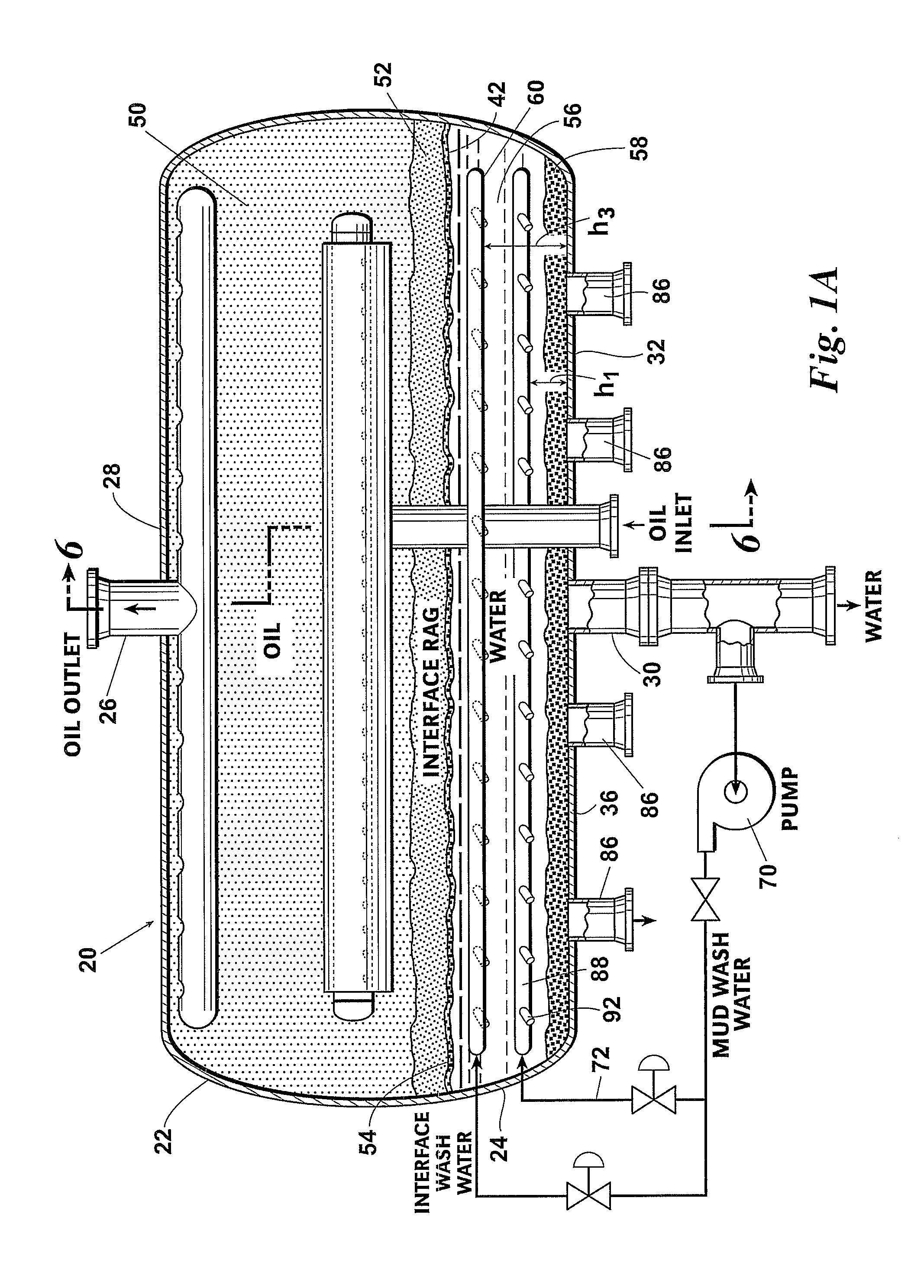

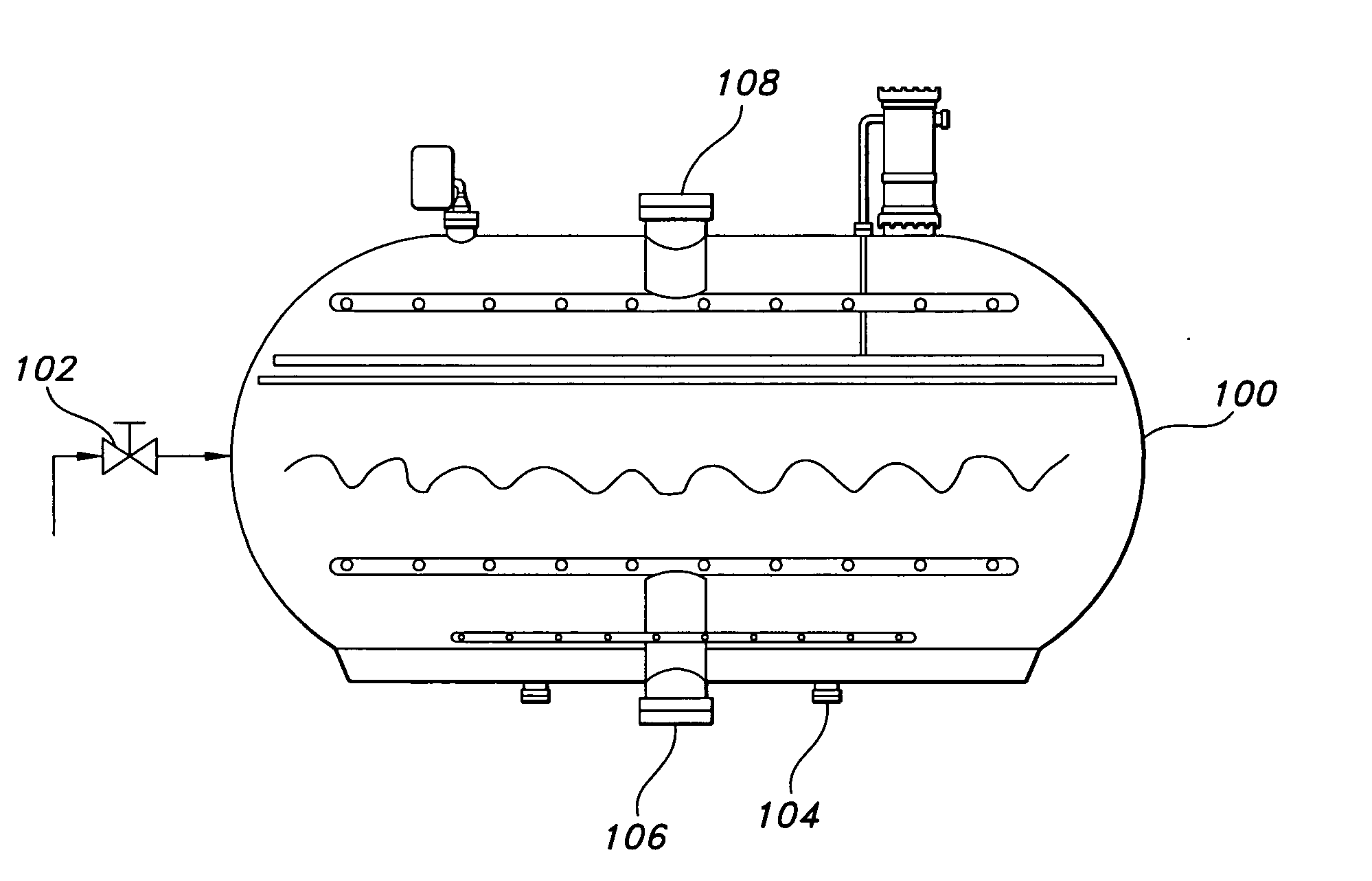

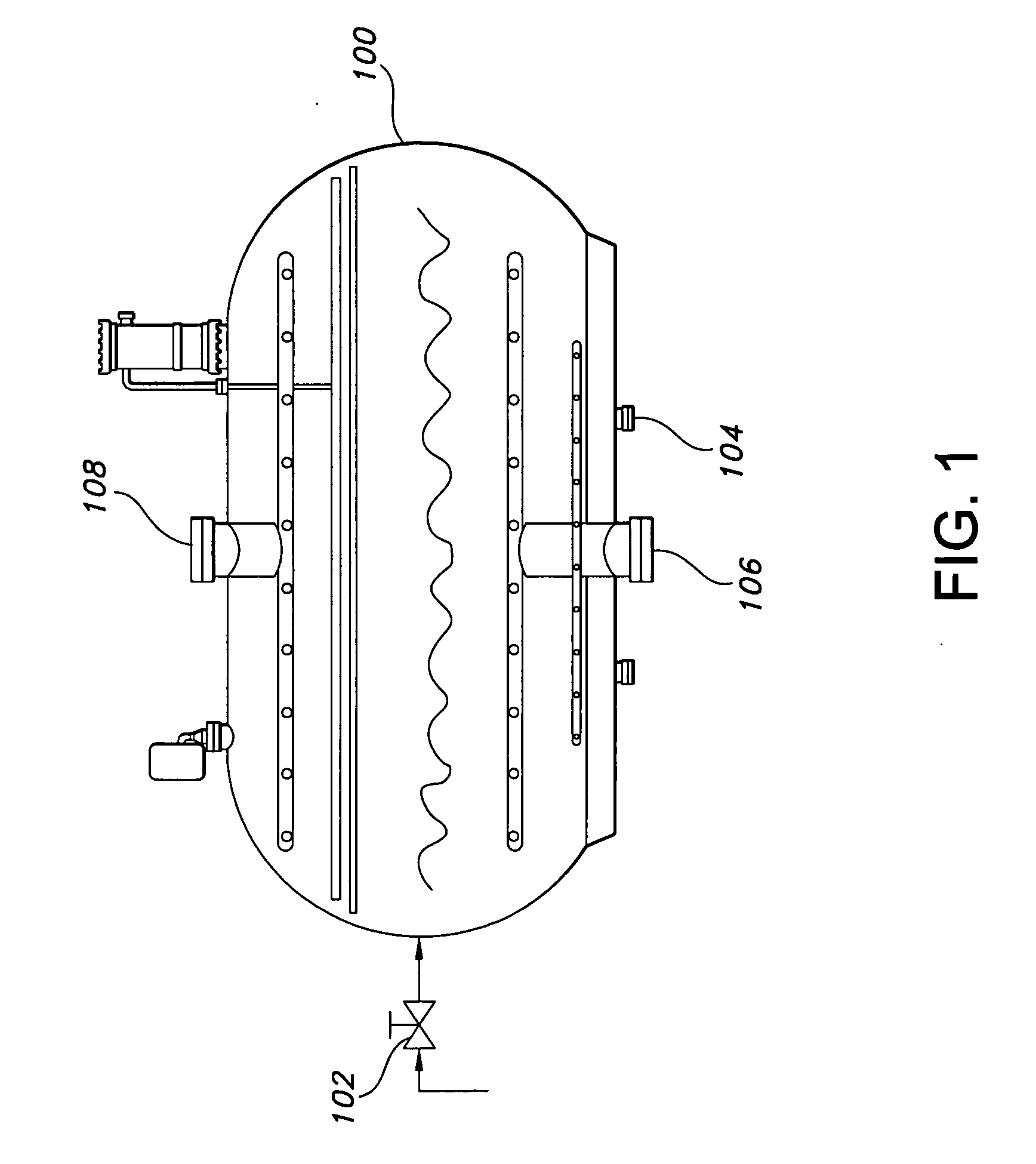

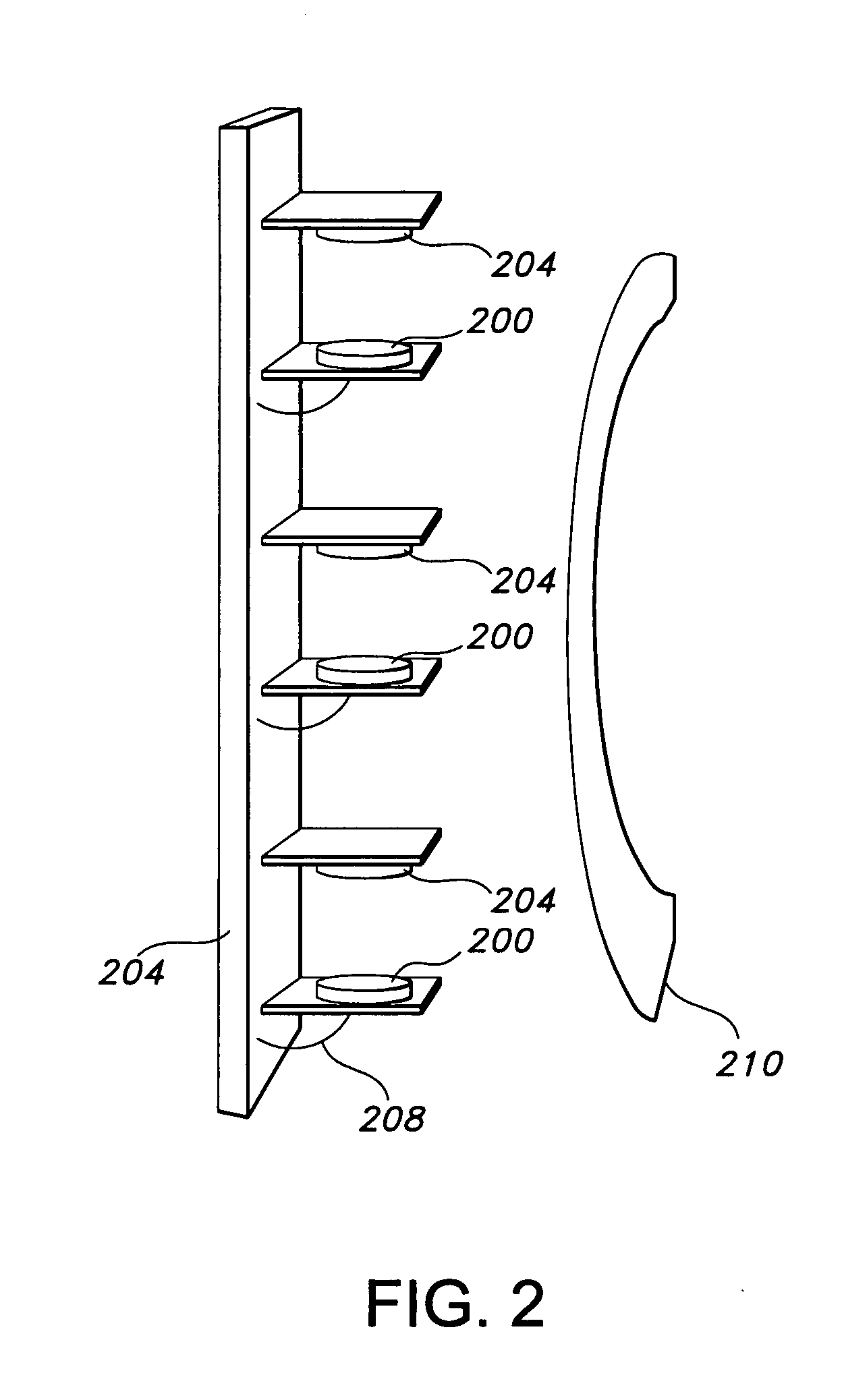

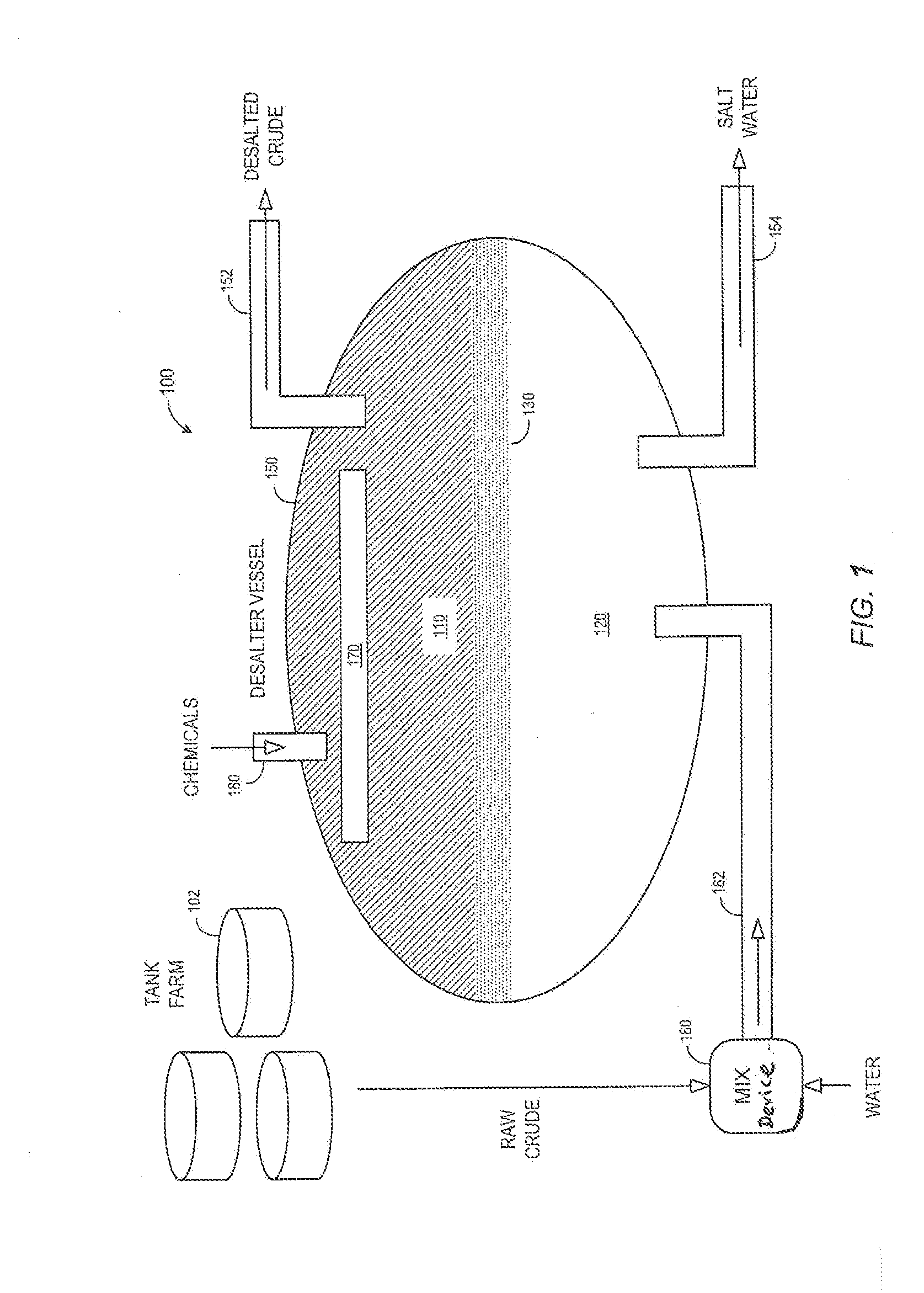

Interface and Mud Control System and Method for Refinery Desalters

ActiveUS20130083620A1Slow and continuous agitationLiquid separation auxillary apparatusDewatering/demulsification with mechanical meansVertical planeEngineering

A method and system for controlling an interface emulsion layer and mud layer within a desalter vessel includes injecting a water flow through a plurality of nozzles arranged about a piping circuit located in the brine water layer. Each nozzle is oriented toward an interior space of the desalter vessel and is arranged oblique to the piping circuit. The water flow through the plurality of nozzles causes a horizontal and vertical rotation of a volume of water that is effective for suspending solids in the water and promoting a collapse of the interface emulsion layer. The water flow through each nozzle, which may be a recycled water flow, is preferably in a range of 1 to 3 fpm and each nozzle is preferably oriented at an angle of about 15° and 60° in a horizontal plane and a downward angle of about 15° and 60° in a vertical plane.

Owner:CAMERSON INT CORP

Raw oil dewatering and desalting process

InactiveCN1772845AReduce irregular movementImprove dehydration (desalination) effectDewatering/demulsification with electric/magnetic meansDemulsifierWave field

The present invention relates to raw oil dewatering and desalting process, and is especially combined stationary ultrasonic wave-electric field process of dewatering and desalting various kinds of oil product. The technological scheme is that stationary ultrasonic wave field and electric field are combined for oil dewatering and desalting aim. That is, raw oil is first added with fresh water and demulsifier and mixed in static mixer or other mixer, then acted with stationary or traveling ultrasonic wave, and finally dewatered and desalted in a conventional electric desalter. The present invention is one improved and reinforced oil product dewatering and desalting process and has raised oil product adapting capacity and low water and salt content of product.

Owner:YANGZI PETROCHEM +1

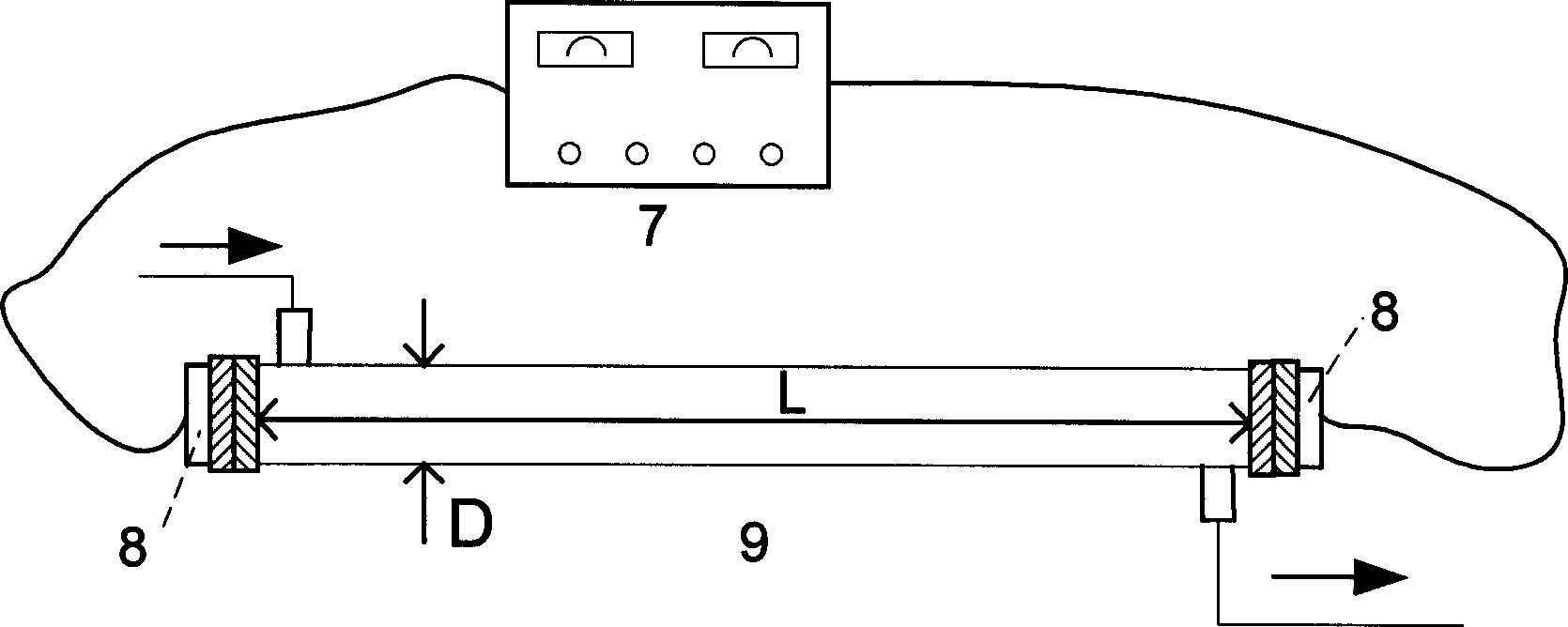

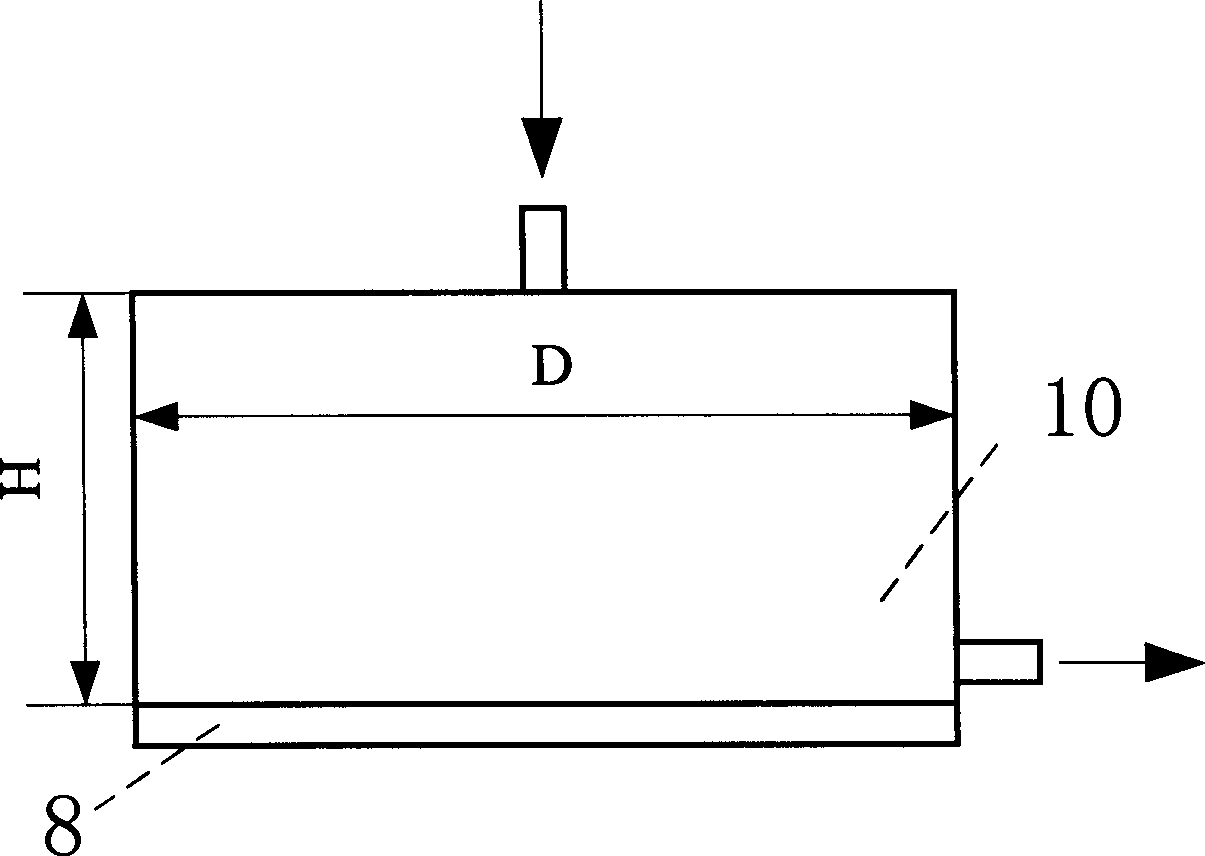

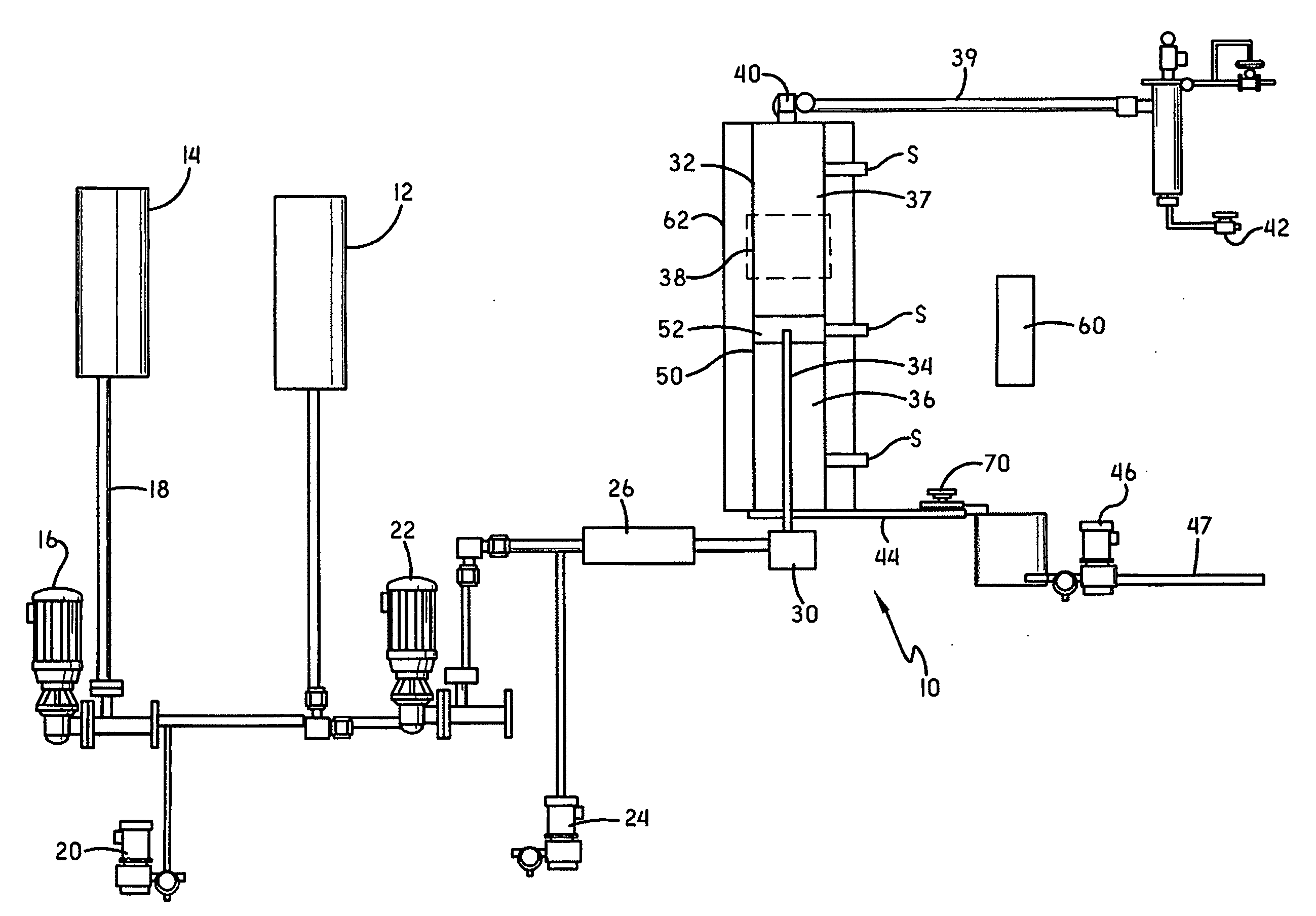

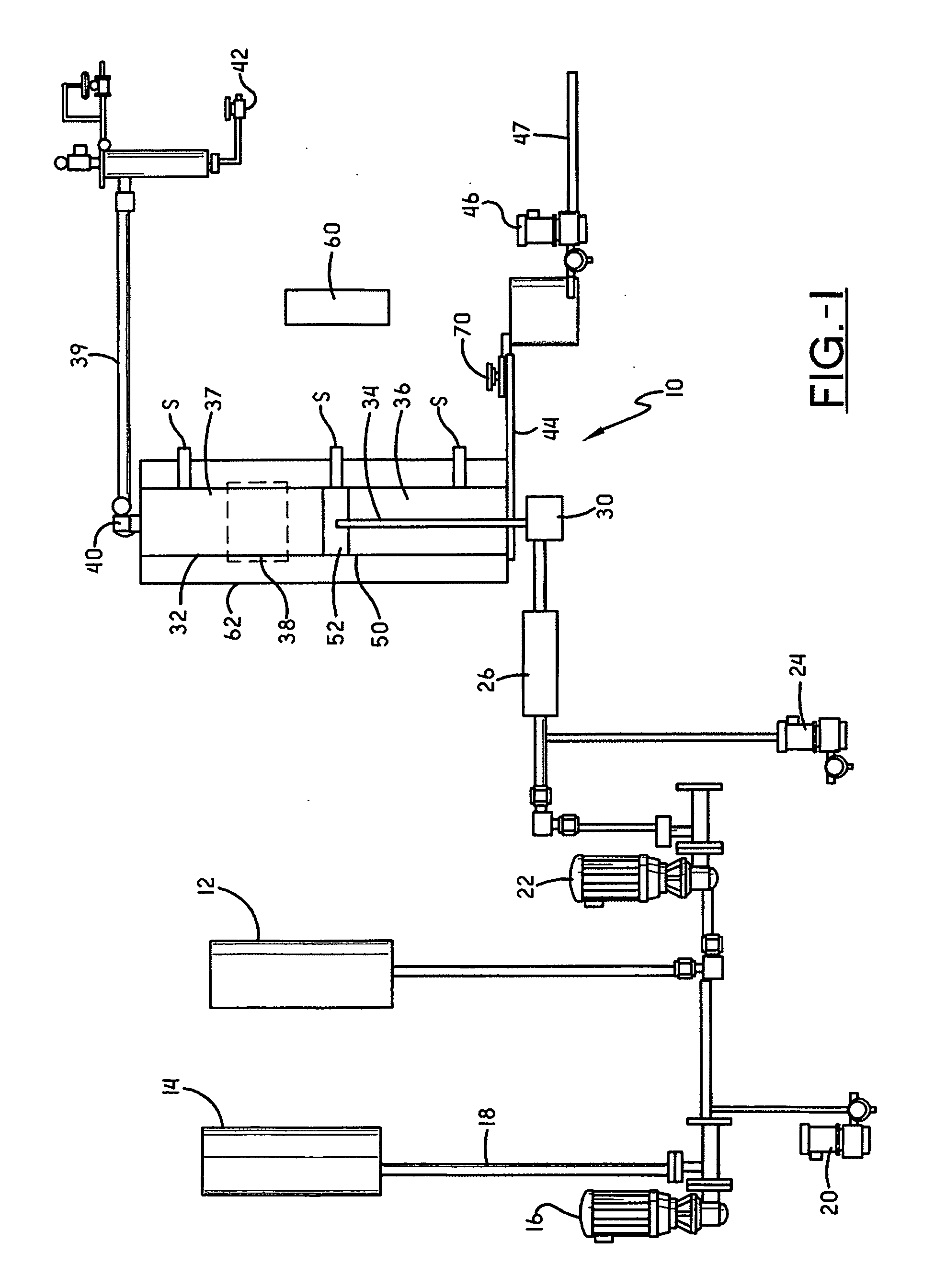

Dynamic desalter simulator

InactiveUS20100015720A1Dewatering/demulsification with chemical meansMixing methodsEmulsionWash water

A small-scale dynamic simulator for crude oil refinery desalters has a pressurized oil deviblis configured to hold a supply of crude oil and a water deviblis configured to hold a supply of wash water. At least one chemical feed pump selectively adds emulsion breaker chemicals to the desalter simulator and a low shear metering pump is configured to pump crude oil and wash water through the desalter simulator. An emulsion forming device forms a crude oil-wash water emulsion that is then received in a desalter vessel. The desalting vessel is fitted with electric grids which simulate those found in electric desalters. The emulsion is resolved within the desalter vessel with the assistance of the emulsion breaker chemicals so the wash water and crude oil form distinct phases, with substantially desalted crude oil removed from an upper portion of the desalter vessel and substantially oil-free wash water removed from a bottom portion of the desalter vessel. A portion of the desalter vessel is substantially transparent to allow visualization of the demulsification process and at least one light source is positioned adjacent to the desalter vessel to aid in visualization of a rag layer formed in the desalter vessel. A heated jacket surrounds the desalter vessel to maintain the desalter vessel at the desired temperature.

Owner:GENERAL ELECTRIC CO

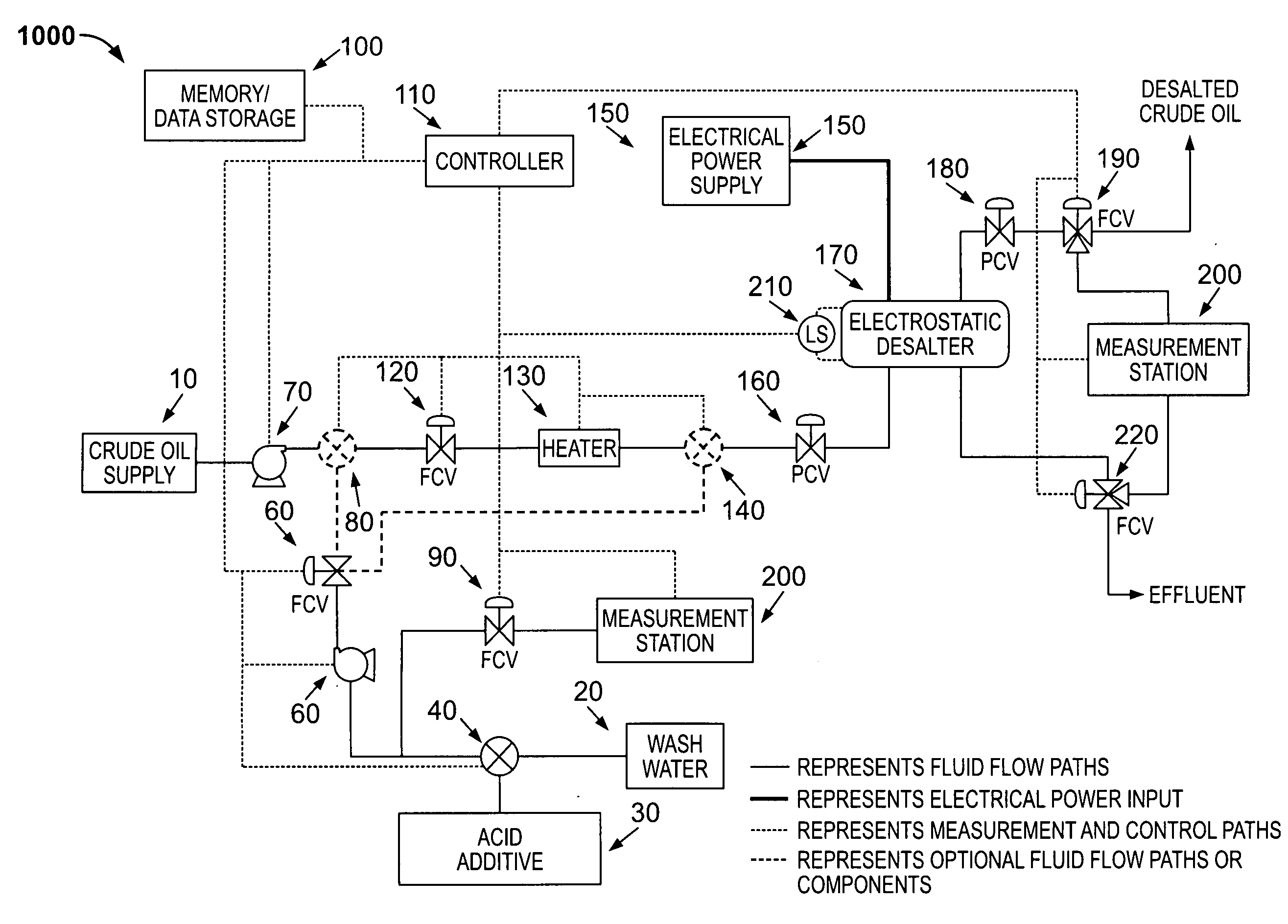

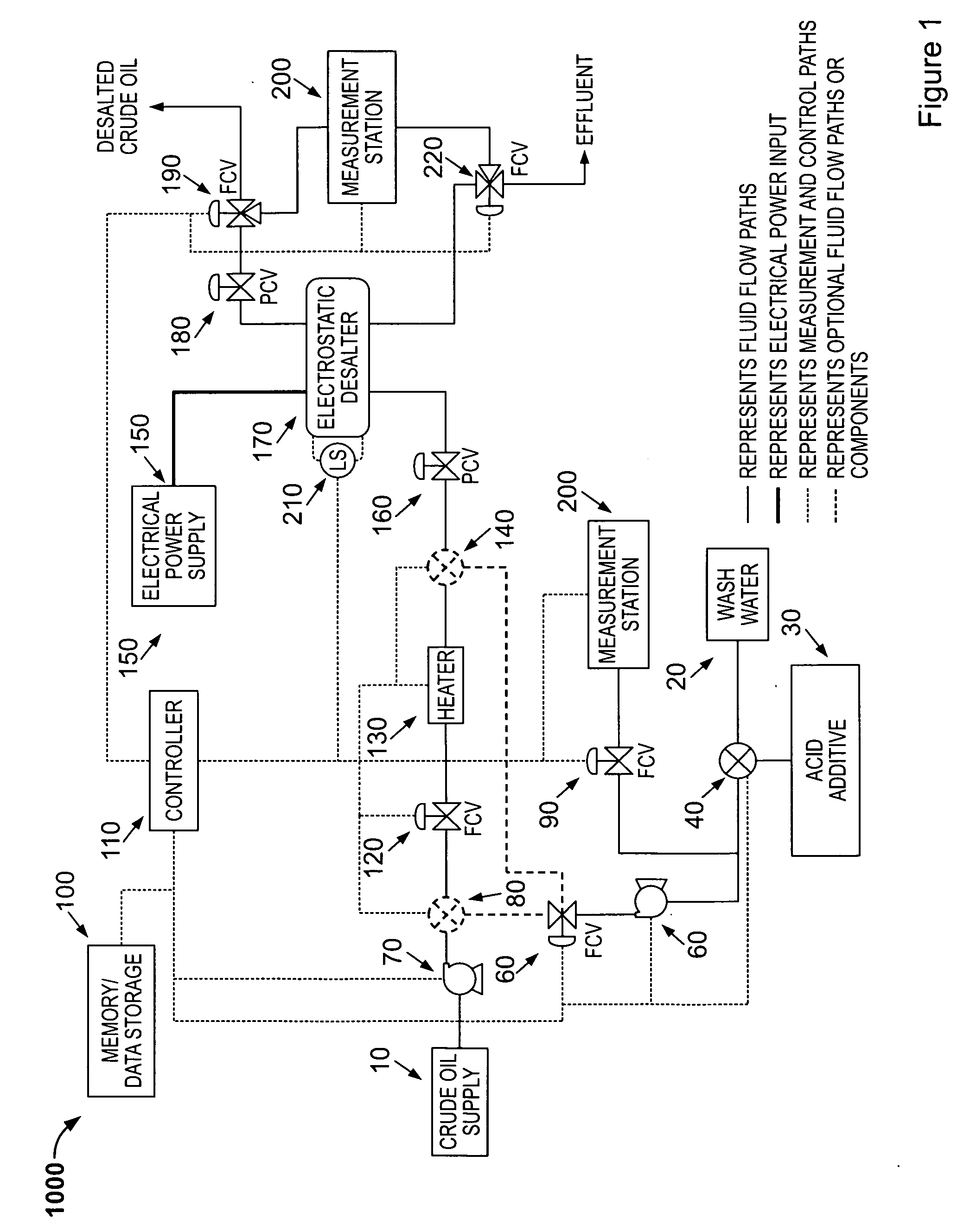

Method and device for electrostatic desalter optimization for enhanced metal and amine removal from crude oil

InactiveUS20110120913A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionChloroacetic acidsAlpha hydroxy acid

A method for removing calcium, iron, other metals, and amines from crude oil in a refinery desalting process includes the steps of: running a plurality of tests to determine at least one statistically significant processing characteristic of the refinery desalting process; adding a wash water to the crude oil; adding the wash water to the crude oil to create an emulsion; adding to the wash water, the crude oil or the emulsion an acid additive consisting of at least one of the following: oxalic acid, citric acid, water-soluble hydroxyacid selected from the group consisting of glycolic acid, gluconic acid, C.sub.2-C.sub.4 alpha-hydroxy acids, malic acid, lactic acid, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof; resolving the emulsion containing the acid additive into a hydrocarbon phase and an aqueous phase; and adjusting a control setting of the processing characteristic as a function of the tests.

Owner:ASSATEAGUE OIL

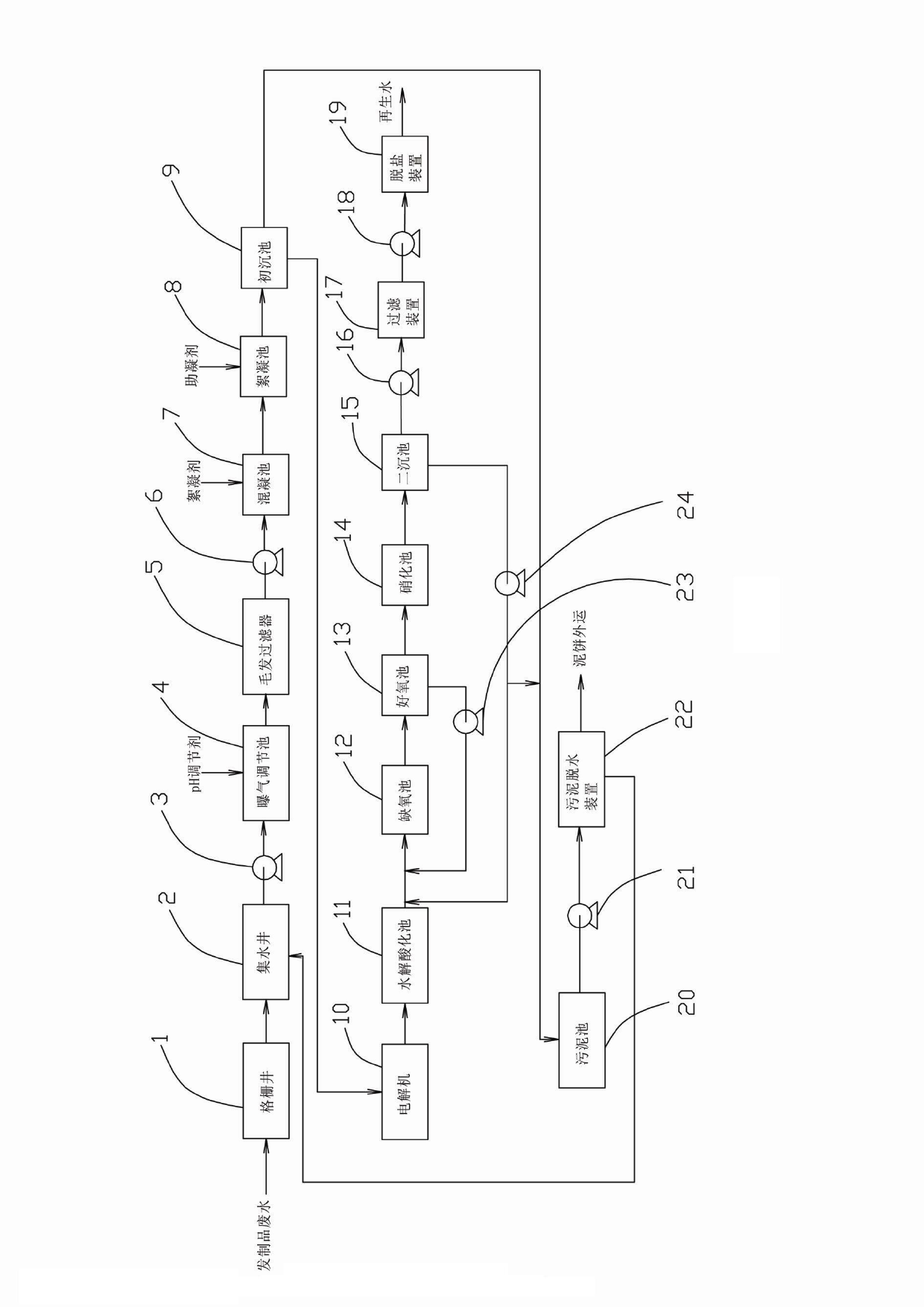

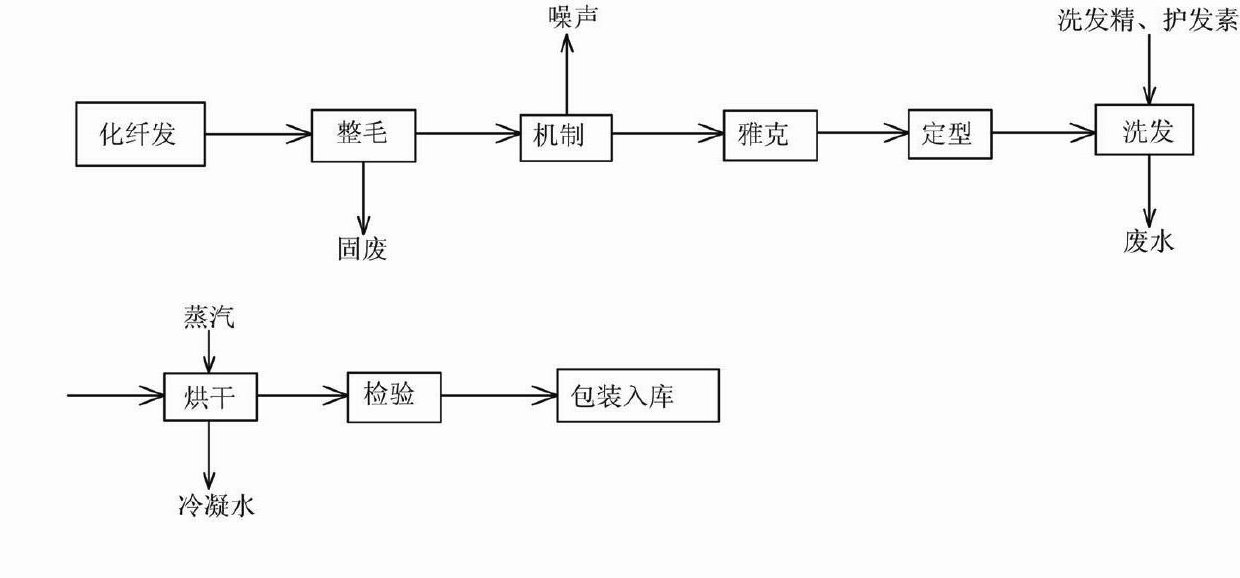

Hairwork waste water cyclic utilization device and treatment method thereof

InactiveCN102344227AImprove biodegradabilityBiochemical conditions are goodTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentDesalterAnaerobic treatment

The invention discloses a hairwork waste water cyclic utilization device and a treatment method thereof, which relate to the regenerating cyclic utilization of waste water. The device is provided with a screen well, a collector well, a water pump, an aeration adjusting tank, a hair filter, a coagulating tank, a flocculation tank, a primary settling tank, an electrolysis machine, a hydrolysis acidification tank, an anoxic tank, an aerobic tank, a nitrification tank, a secondary settling tank, a sludge tank, a sludge dewatering device, a filtering device and a desalter. The waste water can reach an industrial water standard through mutually matching all devices. The treatment method comprises the following steps: flocculating settling, electrolysis, anaerobic treatment, aerobic treatment, settling, filtering and desalting. Through the treatment method, regenerated water can reach the industrial water requirement of industrial production, the discharge of the waste water is reduced, the consumption of a chemical agent is low, the running cost is low, and the use ratio of the waste water is high.

Owner:BOYING XIAMEN SCI & TECH

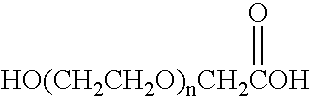

Additives to enhance phosphorus compound removal in refinery desalting processes

ActiveUS20050241997A1Dewatering/demulsification with chemical meansOther chemical processesAlkaneChloroacetic acids

Reactive phosphorus species can be removed or transferred from a hydrocarbon phase to a water phase in an emulsion breaking process by using a composition that contains water-soluble hydroxyacids. Suitable water-soluble hydroxy-acids include, but are not necessarily limited to glycolic acid, gluconic acid, C2-C4 alpha-hydroxy acids, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof. The composition may optionally include a mineral acid to reduce the pH of the desalter wash water. A solvent may be optionally included in the composition. The invention permits transfer of reactive phosphorus species into the aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil emulsions, and in removing calcium and other metals therefrom.

Owner:BAKER HUGHES INC

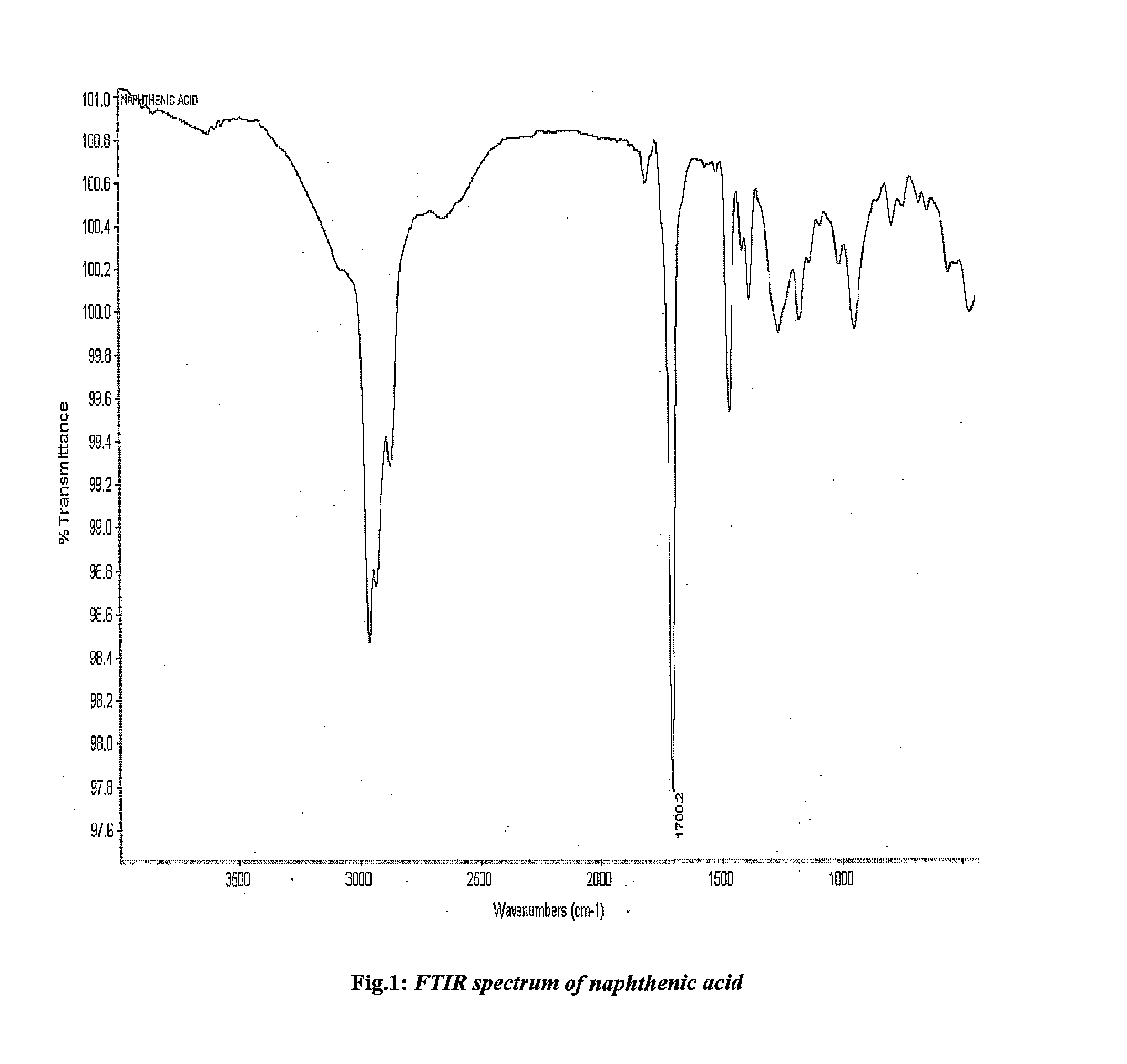

Method of removal of calcium from hydrocarbon feedstock

InactiveUS20100163457A1Treatment with plural serial refining stagesRefining with acid-containing liquidsFumaropimaric acidDesalter

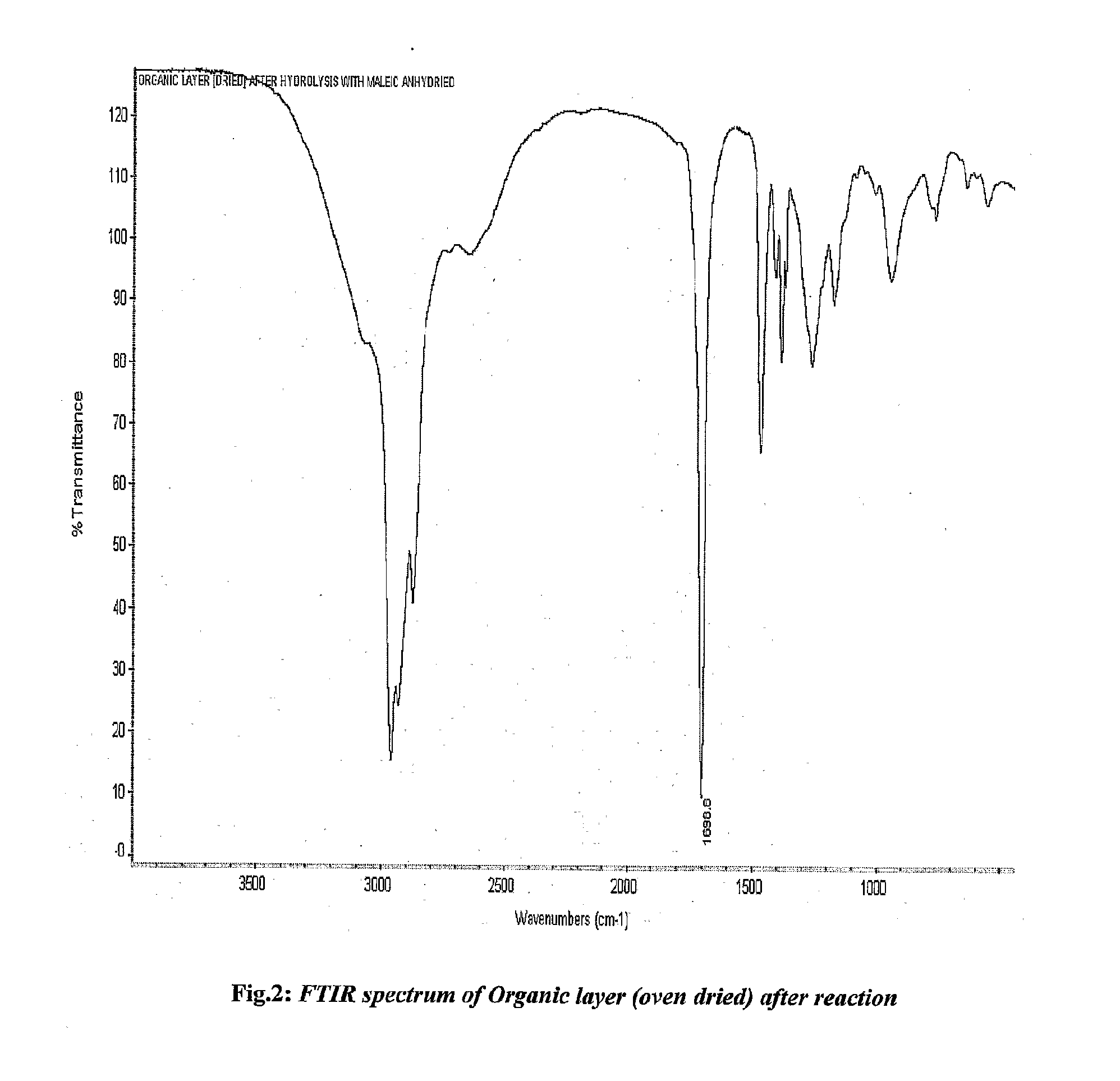

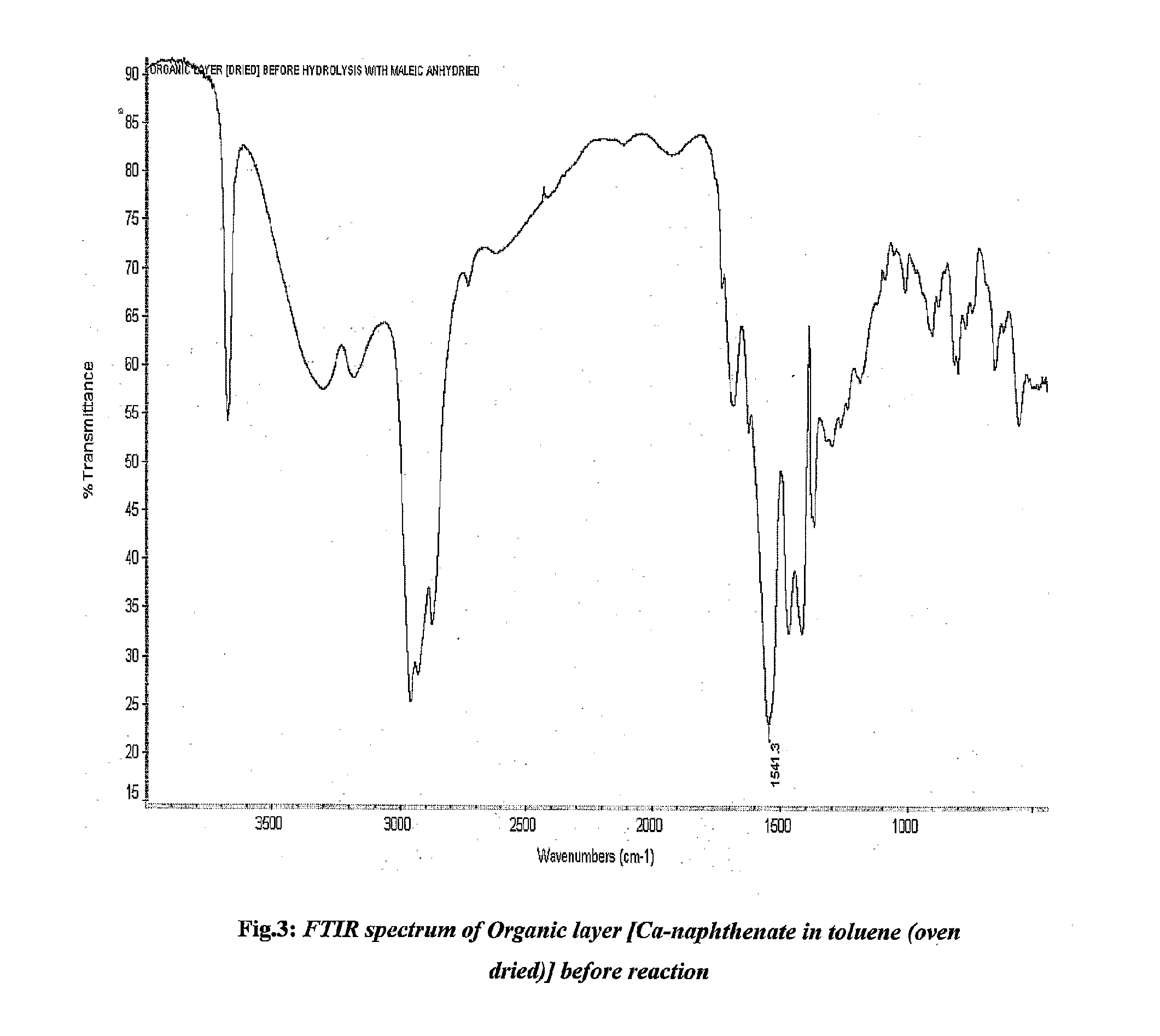

The invention relates to field of processing hydrocarbon feedstock including crude oil, wherein metals such as calcium are removed. In the face of the rising prices of crude oil, refiners are forced to process opportunity crudes such as DOBA, which pose many problems including fouling of equipment due to certain metallic salts, such as calcium napthenate. Calcium, which cannot be removed from crude oil during normal desalting process, poses very serious problems. The invention provides method for removal of calcium, wherein crude oil is mixed, with effective metal removing amount of aqueous extraction solution of an additive comprising a chemical compound selected from a group consisting of metallic acid, maleic anhydride or fumaric acid or salts or derivatives thereof, enabling separation of hydrocarboneous phase and aqueous phase containing metal ions, in crude desalter. Only hydrocarboneous phase devoid of calcium is processed further, thereby preventing fouling of equipment.

Owner:DORF KETAL CHEM (I) PTE LTD

Devices And Processes For Deasphalting And/Or Reducing Metals In A Crude Oil With A Desalter Unit

ActiveUS20100089797A1Easy to processReduce dirtDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDesalterWater soluble

This invention relates to devices and processes for removing asphaltenes and / or metals from crude oil to increase refinery processing of heavy materials. The desalters of this invention reduce and / or remove at least a portion of asphaltenes and / or metals form the crude oil. The separation occurs by mixing water with the crude oil to result in an aqueous phase having water and water soluble salts, an interface phase having asphaltenes and / or metals along with water, and a hydrocarbon phase having desalted, deasphalted and / or reduced metal crude oil.

Owner:BP CORP NORTH AMERICA INC

Separator for desalting petroleum crude oils having rag layer withdrawal

ActiveUS20140251874A1Minimal downtimeDewatering/demulsification with electric/magnetic meansRefining by water treatmentEmulsionAutomatic control

An improved separator for desalting petroleum crude oils which may be operated in a continuous manner under automatic control; the improved desalter is therefore well suited to modern refinery operation with minimal downtime. A portion of the emulsion layer is withdrawn from the desalter through external withdrawal ports according to the thickness and position of the emulsion layer with the selected withdrawal header(s) being controlled by sensors monitoring the position and thickness of the emulsion layer. The withdrawn emulsion layer can be routed as such or with the desalter water effluent to a settling tank or directly to another unit for separation and reprocessing.

Owner:EXXON RES & ENG CO

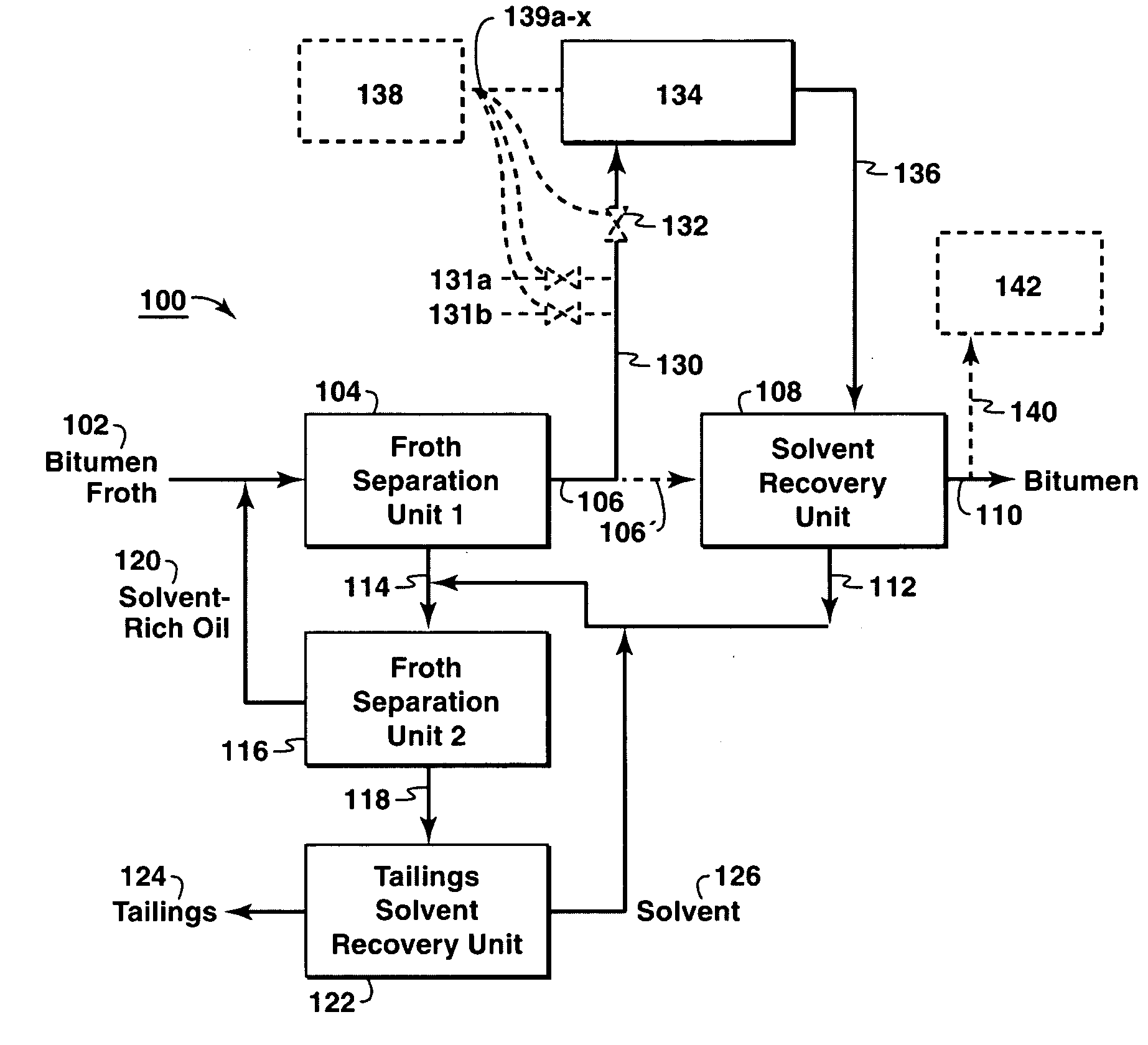

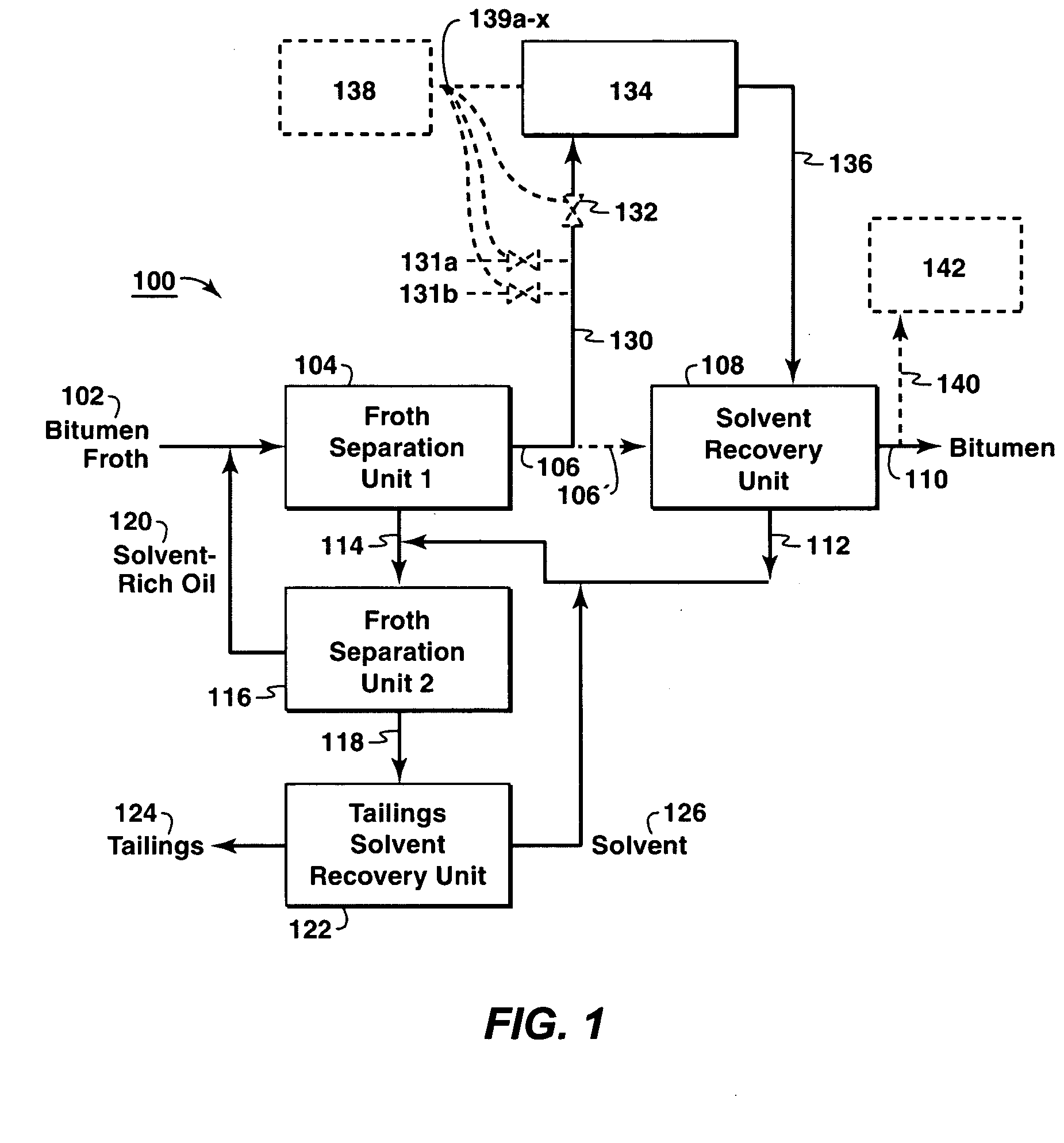

Optimizing Heavy Oil Recovery Processes Using Electrostatic Desalters

InactiveUS20120217187A1Working-up pitch/asphalt/bitumen by selective extractionDewatering/demulsification with electric/magnetic meansFuel oilDesalter

Owner:SHARMA ARUN K +1

Polyethylene heterogeneous ion exchange membrane for electrodialysis desalter of packed bed

InactiveCN1470315AFacilitate cross-linkingIncrease the degree of cross-linkingSemi-permeable membranesGeneral water supply conservationPolymer sciencePolybutylene

The invention discloses polyethylene out-phase ion interchanging film for filled bed electricity oozing salt eliminating device and the manufacturing method. The film comprises: high pressure polyethylene 100, linear high pressure polyethylene 18í½30, chlorine sulphur polyethylene 2í½5, cinnamene-butadiene-cinnamene polymer 3.1í½3.8, polybutylene 15í½30, calcium stearate 5í½8, antioxidant 0.5í½1.5, positive or negative ion interchanging resin power 370í½480. The film combines several kinds of plastic as frame, adds the power into the plastic and rolls them and extracts out the film. Enhances them by terylene cloth, finally, carries on hydraulic pressure and heat pressure.

Owner:上海上化水处理材料有限公司

Making method for charcoal electrode of liquid flow type electroadsorption desalinization device

InactiveCN1544116AImprove conductivityHigh strengthIon-exchange process apparatusIon-exchanger regenerationFiberPorosity

The invention relates to a method of making carbon electrode of fluid electric-absorption desalter. It mainly mixes high specific surface area electrode carbon, nano carbon tube absorption material, carbon fiber, and nano carbon tube conductive material as well as adhesive polytetrafluoroethylene in a certain proportion and in a certain mode to make cold press molding and makes them into a double-faced electrode with a collector interlaid; the carbon electrode has good electric conductivity, small resistance, large electric capacity and low energy consumption; in addition, the modified carbon electrode has larger specific surface area and mesoporous porosity, therefore able to increase the absorption quantity of electrode to salt ions. The carbon electrode is especially applied to the fluid electric-absorption desalter and has higher desalting efficiency.

Owner:上海维安新材料研究中心有限公司 +1

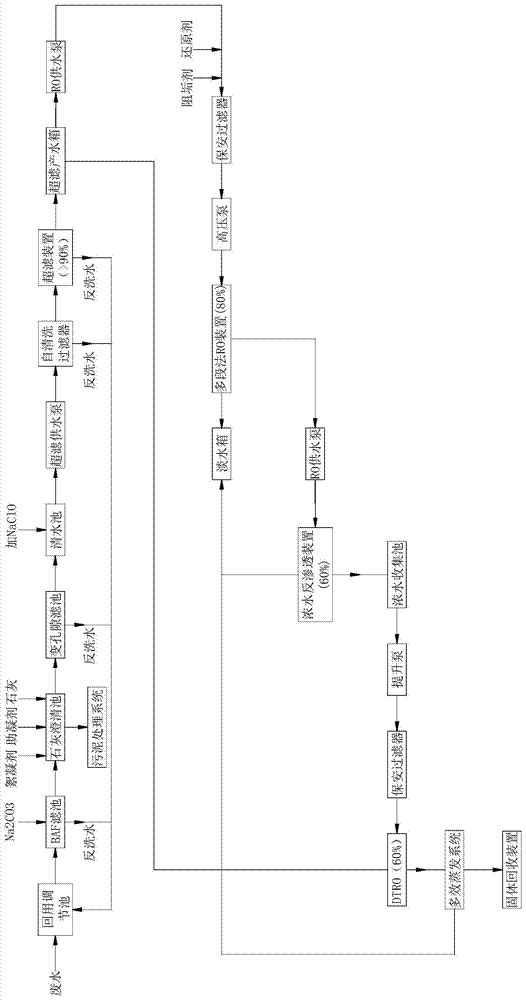

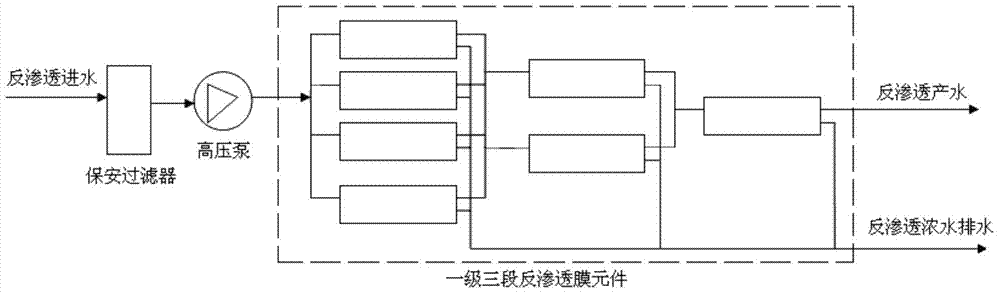

Zero discharge treatment system and method for industrial wastewater with high chemical oxygen demand (COD)

ActiveCN103787552AReduce foulingEasy to handleGeneral water supply conservationMultistage water/sewage treatmentFiltrationEvaporation

The invention discloses a zero discharge treatment system and method for industrial wastewater with a high chemical oxygen demand (COD). The system comprises a reclaimed water regulating reservoir, a biological aerated filter, a lime clarifier, a variable pore filter, an ultra-filtration device, a multi-stage reverse osmosis device, a concentrated water reverse osmosis device, a concentration section desalter, a multi-effect evaporation system and a solid recovery device, which are orderly connected through a pipeline, wherein the biological aerated filter, the variable pore filter and the ultra-filtration device are provided with backwash devices; the backwash devices are connected with the reclaimed water regulating reservoir. By adopting the zero discharge treatment system and method, chemical cleaning times of the ultra-filtration and reverse osmosis devices can be reduced, the service life of membrane elements is ensured, the cost caused by replacing a component is reduced, and zero discharge of the industrial wastewater with high COD is achieved.

Owner:华电水务工程有限公司 +1

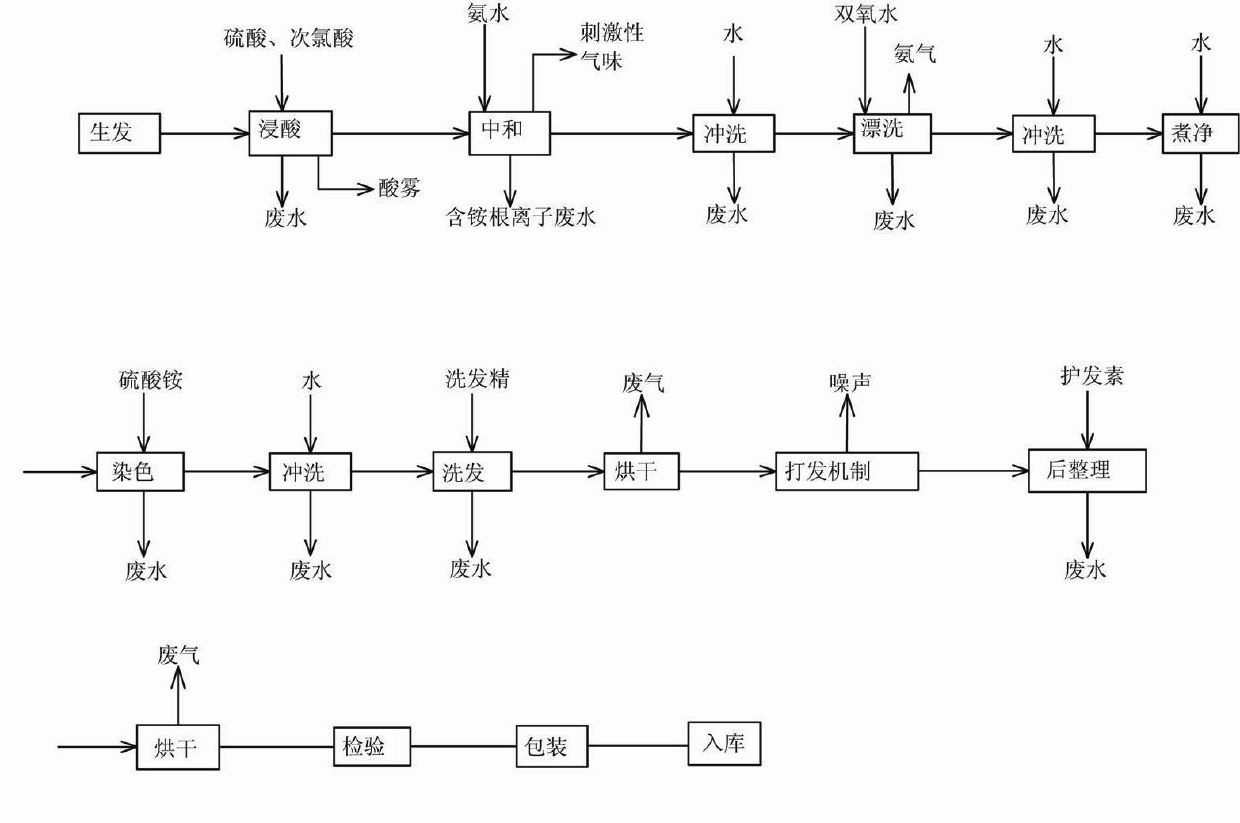

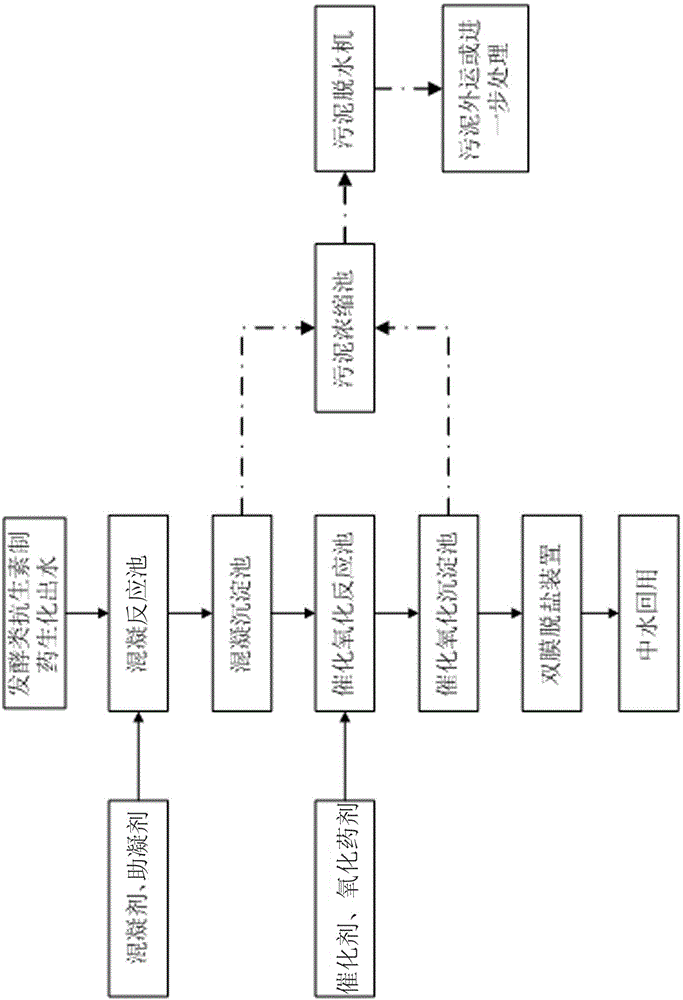

Advanced treatment process for fermentation antibiotic wastewater

InactiveCN106830536AReduce CODReduce COD concentrationSludge treatment by de-watering/drying/thickeningGeneral water supply conservationSludgeReclaimed water

The invention relates to the technical field of wastewater treatment, in particular to an advanced treatment process for fermentation antibiotic wastewater. The advanced treatment process comprises the following steps: the fermentation antibiotic wastewater subjected to biochemical treatment is sent into a coagulation reaction tank, and a coagulant and a coagulant aid are added for a reaction; effluent of the coagulation reaction tank is subjected to precipitation separation treatment in a coagulative precipitation tank, and floc precipitates obtained after precipitation are sent into a sludge thickener; effluent of the coagulative precipitation tank is sent into a catalytic oxidation reaction tank and subjected to a Fenton catalytic oxidation reaction; effluent of the catalytic oxidation reaction tank is sent into a catalytic oxidation precipitation tank for precipitation separation treatment, flocs in the effluent obtained after an oxidation reaction are precipitated in the precipitation tank, and precipitated flocs enter the sludge thickener; effluent of the catalytic oxidation precipitation tank enters a two-membrane process desalter for desalting treatment, and the fermentation antibiotic wastewater treated with the process is high in quality and can meet the requirement for reuse of reclaimed water.

Owner:华夏碧水环保科技股份有限公司

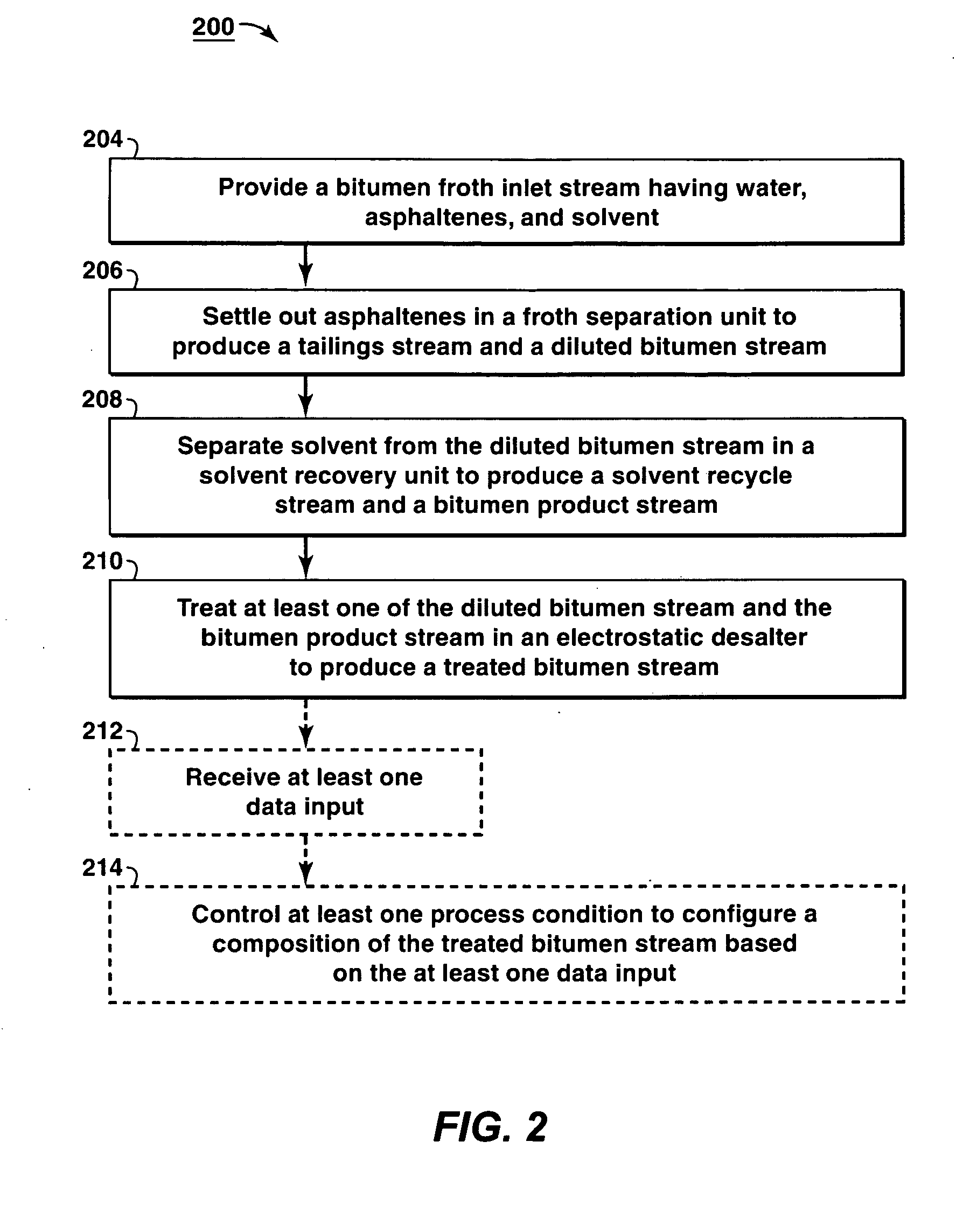

Optimizing Heavy Oil Recovery Processes Using Electrostatic Desalters

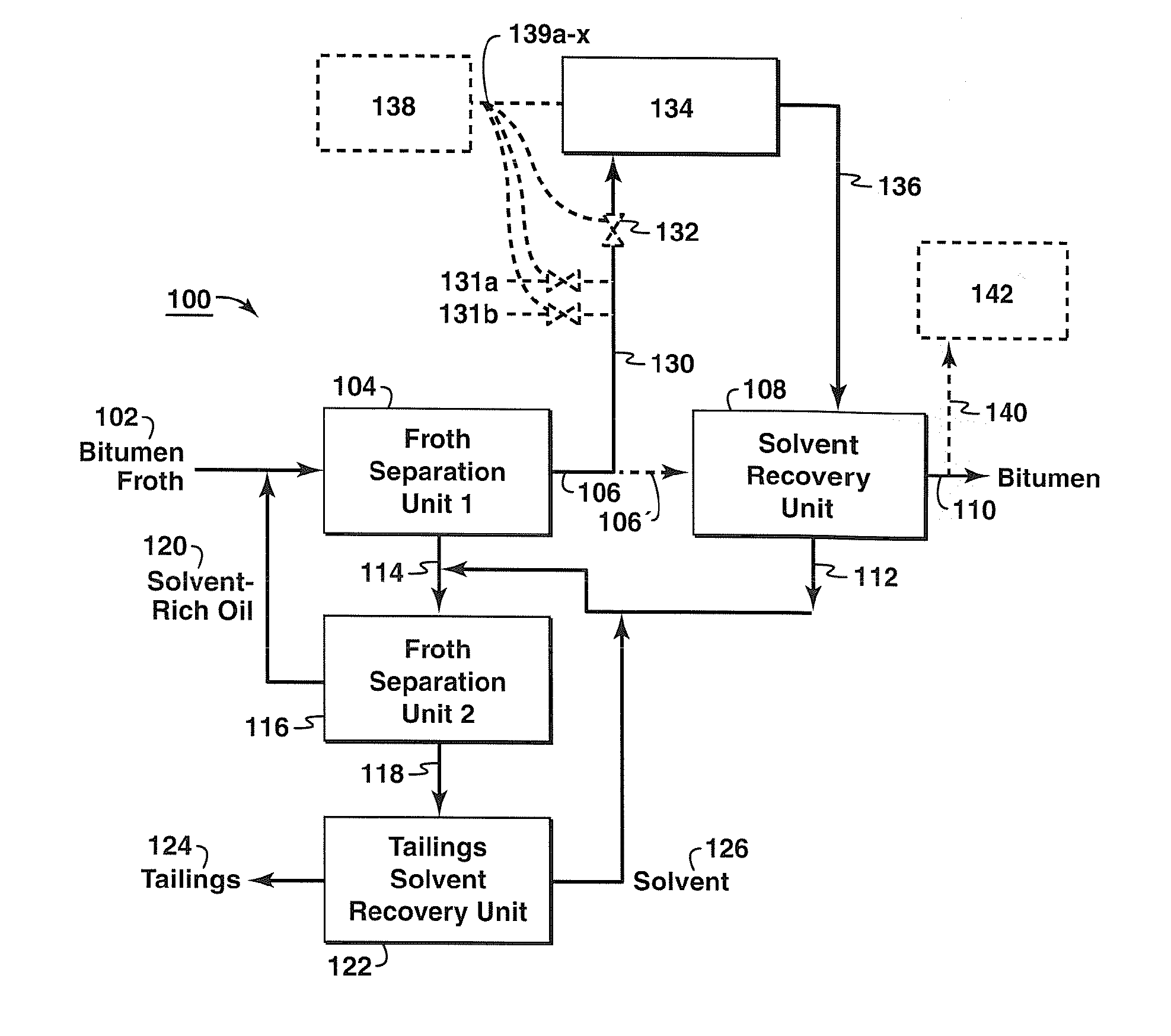

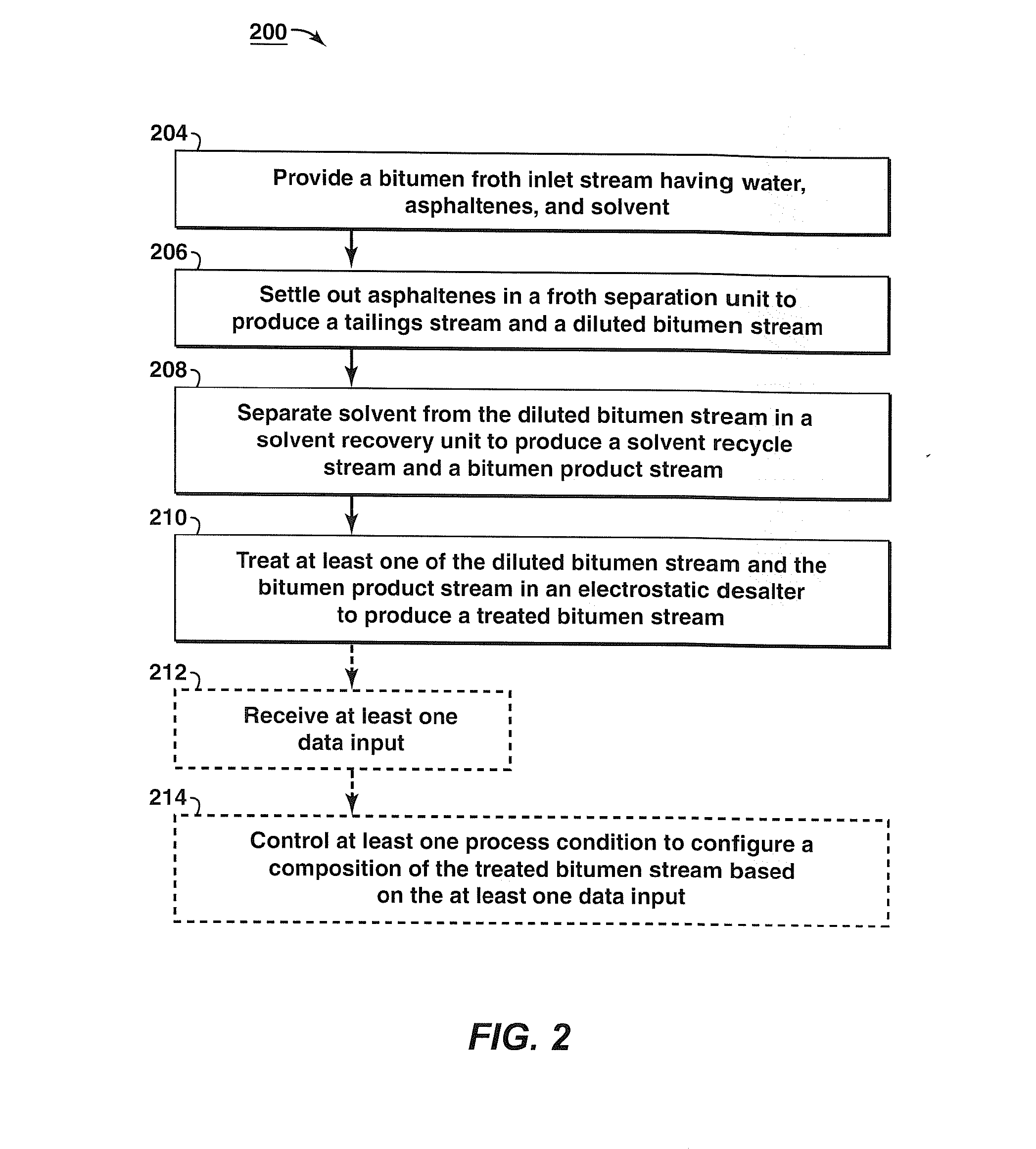

ActiveUS20090321323A1Working-up pitch/asphalt/bitumen by selective extractionSolvent extractionFoam separationDesalter

The invention relates to improved bitumen recovery processes and systems. The process may include providing a bitumen froth feed stream, separating the stream in a froth separation unit to produce a diluted bitumen stream, treating the diluted bitumen stream in an electrostatic desalter to produce a treated bitumen stream, and separating the treated bitumen stream into a solvent recycle stream and a bitumen product stream. The system may include a combined AC / DC desalter with a control unit for optimizing the treatment process to produce a product bitumen stream using less solvent and smaller separators than conventional bitumen froth treatment plants and processes.

Owner:EXXONMOBIL UPSTREAM RES CO

Crude unit desalter emulsion level detector

InactiveUS20060211128A1Material analysis using sonic/ultrasonic/infrasonic wavesRefining by water treatmentEmulsionEngineering

The present invention is directed to a method for determining an emulsion layer within a container comprising, initiating an ultrasonic signal from at least one transmitter through a liquid contained within a tank, receiving the signal at a receiver, measuring the time of flight of the signal, calculating the velocity of the ultrasonic signal, determining the composition of the liquid in the tank; and correlating the composition to an emulsion ratio.

Owner:GENERAL ELECTRIC CO

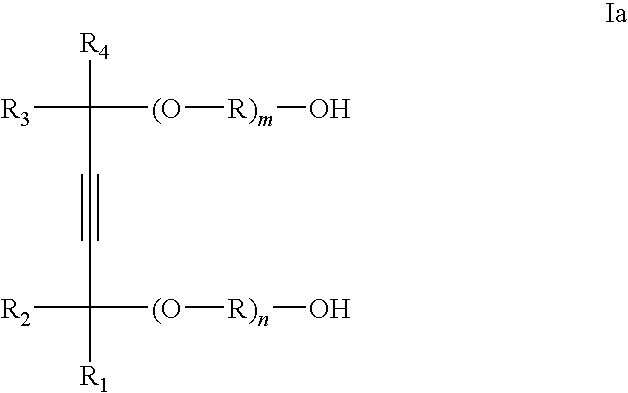

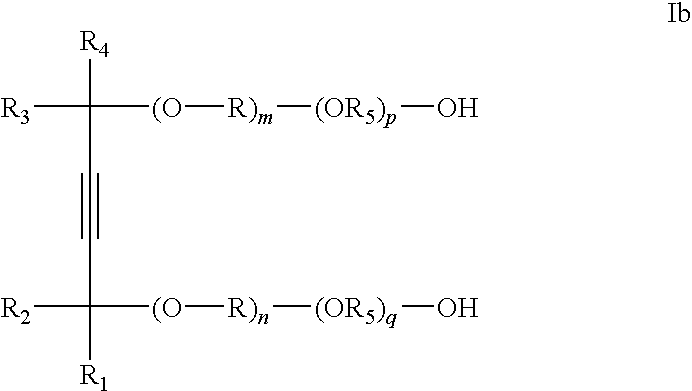

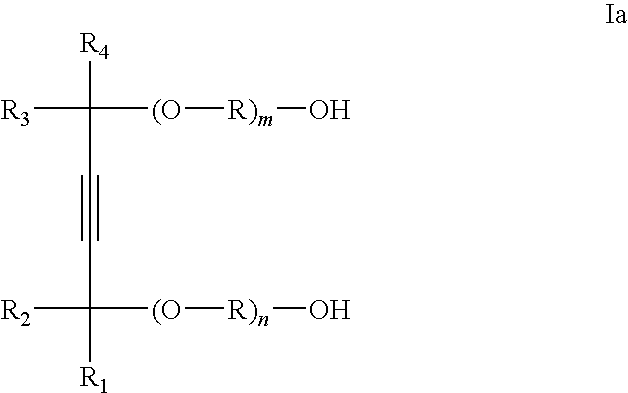

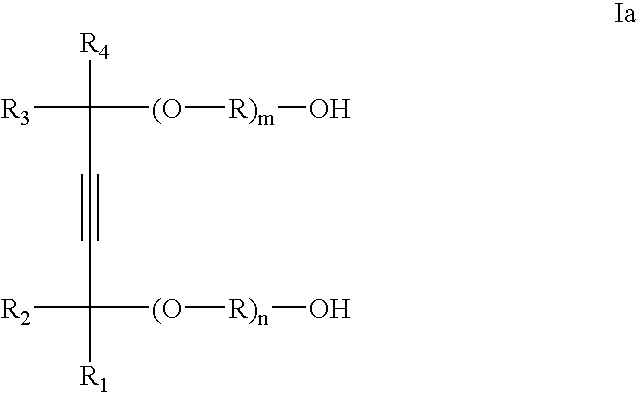

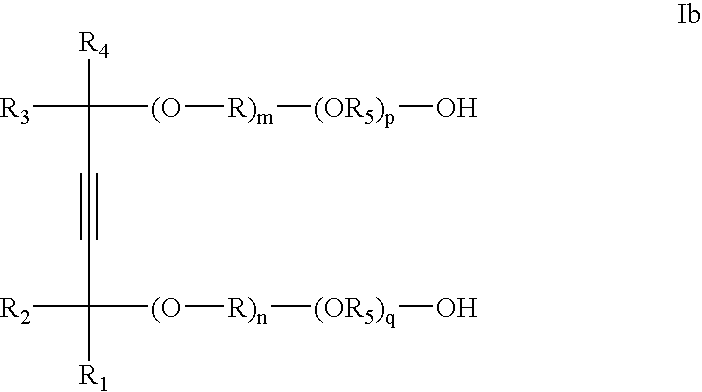

Separatory and emulsion breaking processes

InactiveUS7771588B2Dewatering/demulsification with chemical meansOther chemical processesOil emulsionActive agent

The invention pertains to the use of a class of acetylenic surfactants to resolve or break water and oil emulsions. The surfactants are of particular advantage in resolving crude oil emulsions of the type encountered in desalter and similar apparatus designed to extract brines from the crude as they partition to the aqueous phase in the desalter. Also, the surfactants may be used to separate oil from oil sands and similar oil / solids matrices.

Owner:BL TECH INC

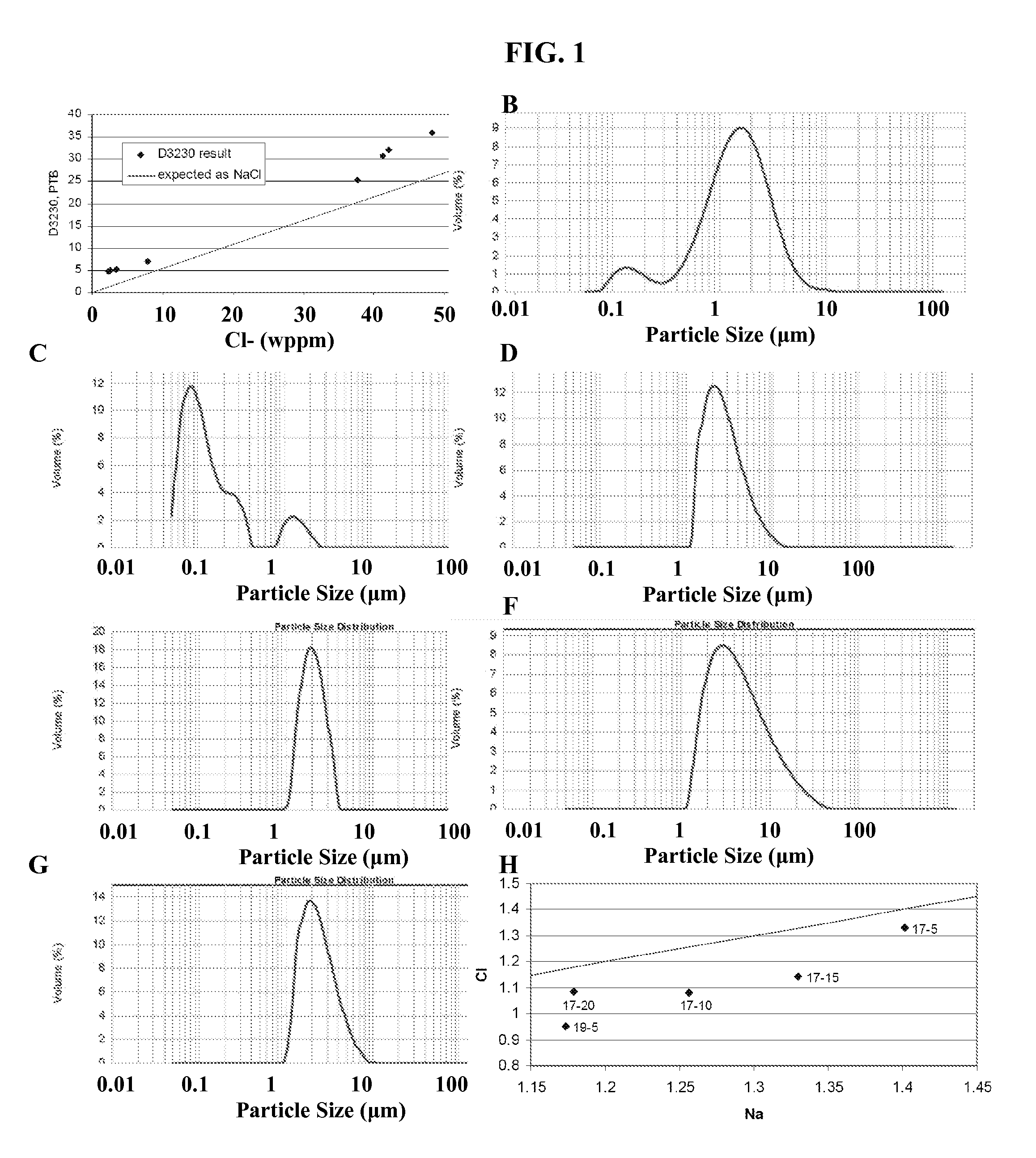

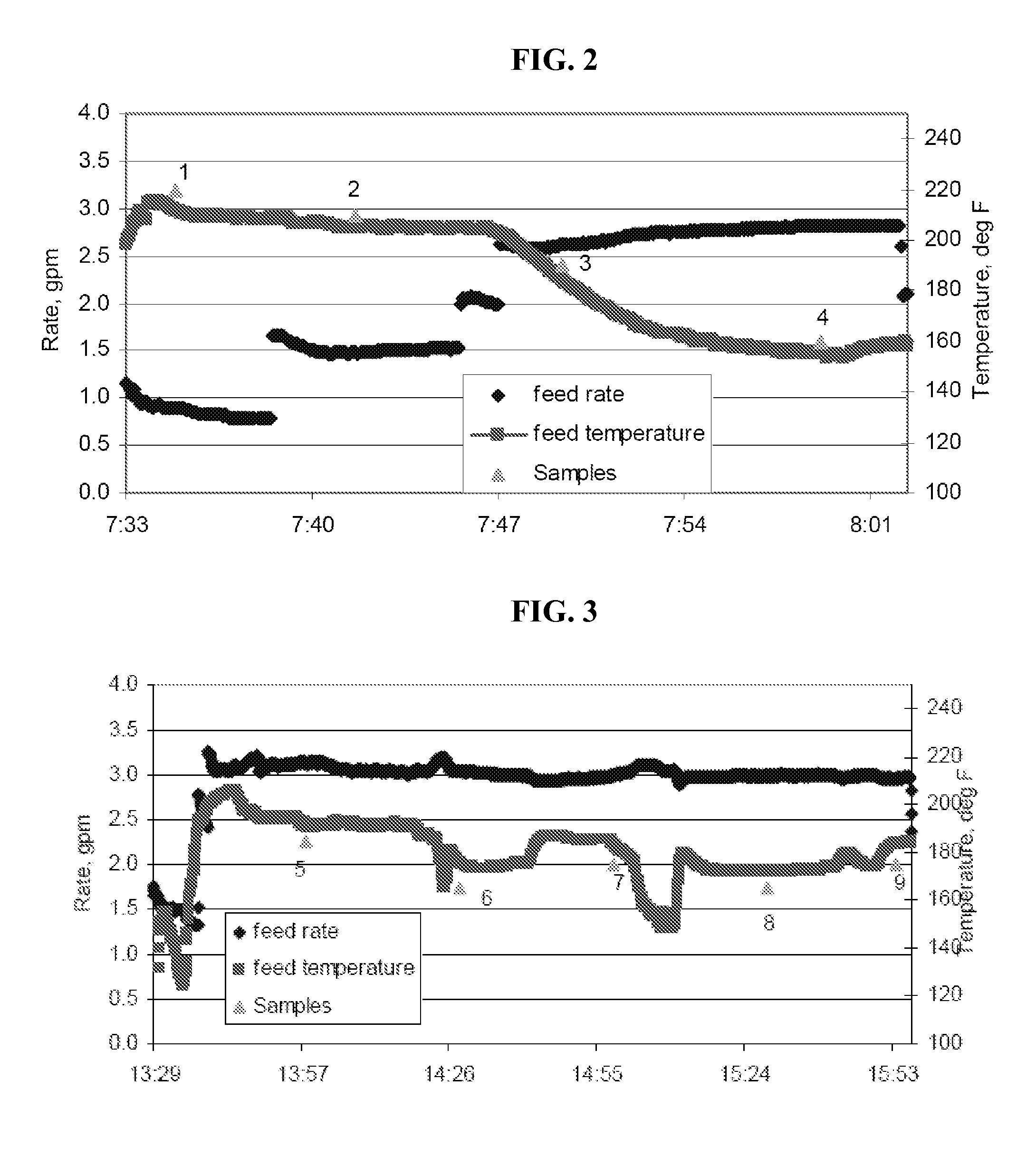

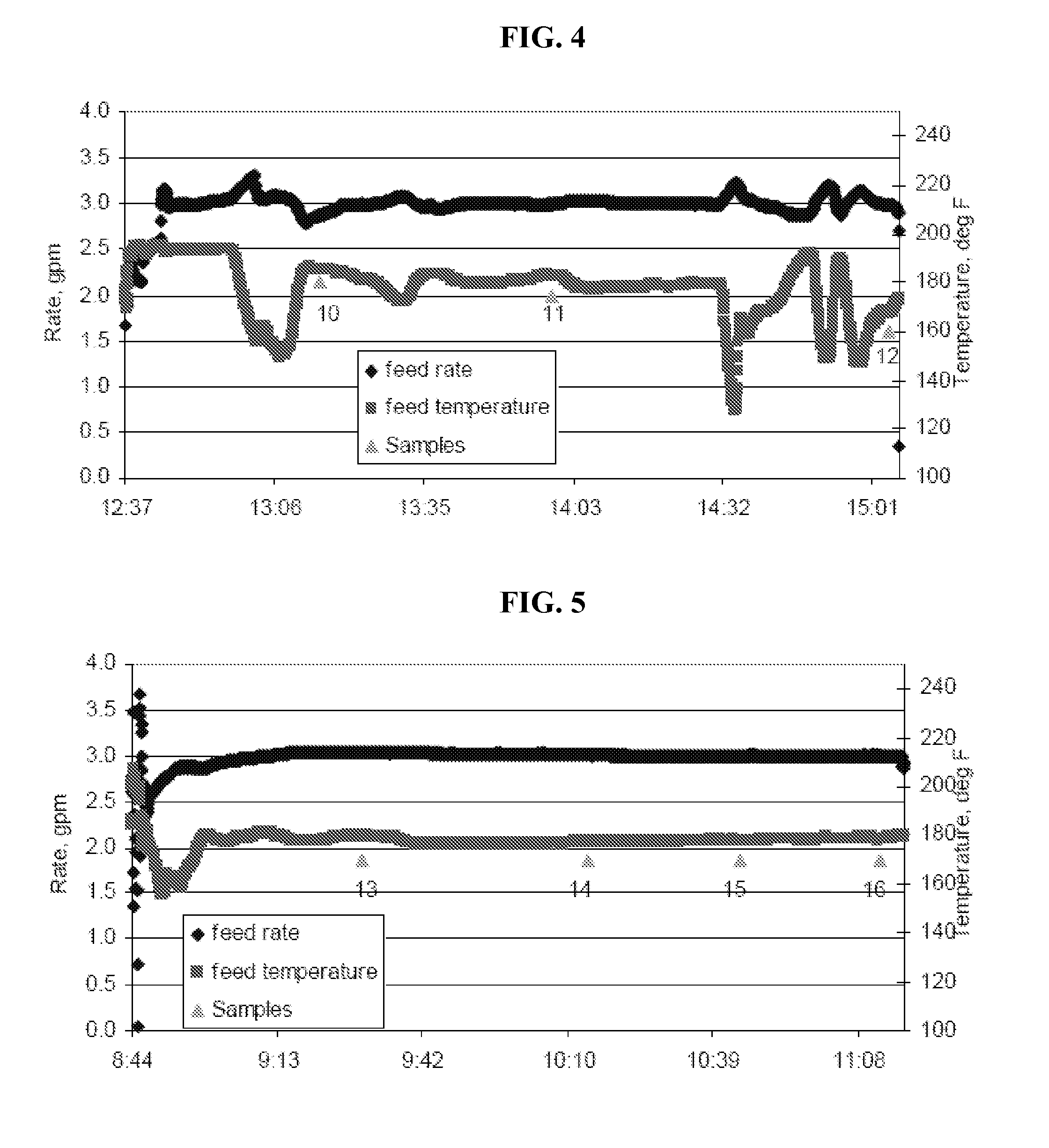

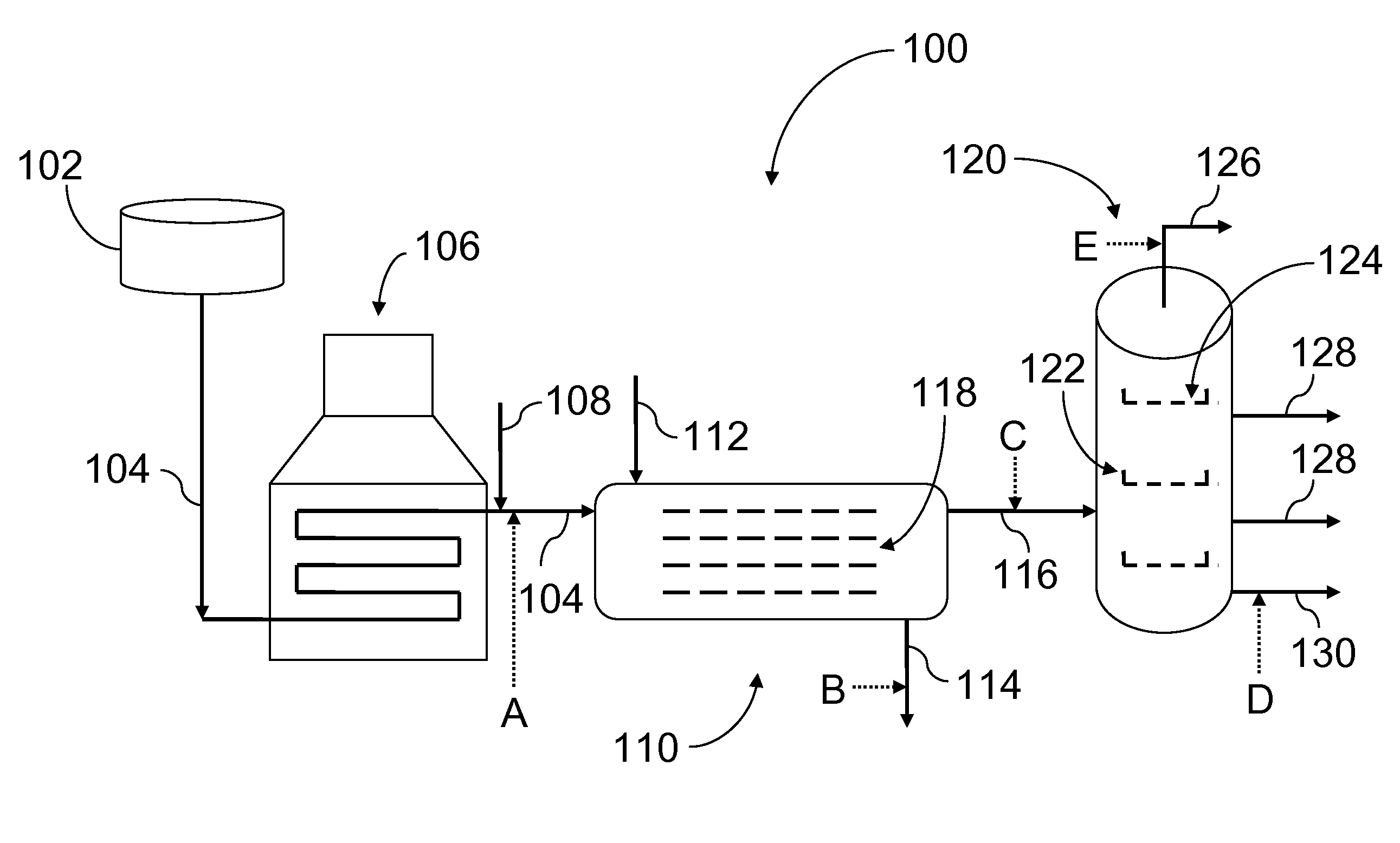

Focused beam reflectance measurement to optimized desalter performance and reduce downstream fouling

InactiveUS20100038286A1Improve performanceLiquid separation by electricityElectrostatic separationEngineeringDesalter

Performance of equipment, such as a desalter, in a refinery is monitored in real-time and on-line to minimize fouling of downstream equipment. Using an instrument to measure particles and droplets in-process allows monitoring of the various operations to optimize performance. Such measurement can also be used during crude oil blending to detect asphaltene precipitates that can cause fouling and can be used for monitoring other fouling streams.

Owner:GREANEY MARK A +3

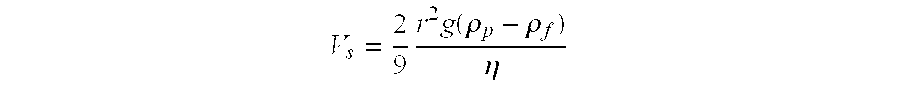

Advisory controls of desalter system

ActiveUS20150361350A1Dewatering/demulsification with chemical meansLiquid separation auxillary apparatusDemulsifierFirst principle

The present invention concerns a method of providing advisory controls for a desalter system. The method allows a user to continuously monitor performance of the desalter system, to continuously monitor position of the emulsion band (or rag layer), to control the emulsion band using demulsifiers, and to recommend to users how to maintain optimal pressure drop at the mixing device of the desalter system. This is achieved by using a first principles based model combined with a sensor to measure the position, quality and size of the emulsion band. The first principles based model takes into account the geometry of the desalter system, physical properties of the crude oil and water, as well as the operating conditions. Thus, the method provides users with sensing of an emulsion layer through direct measurements and also gives recommendations on appropriate corrective actions to be initiated during upsets.

Owner:BL TECH INC

Emulsion breaking process

ActiveUS20070112079A1Dewatering/demulsification with chemical meansOther chemical processesOil emulsionDesalter

The invention pertains to the use of a class of acetylenic surfactants to resolve or break water and oil emulsions. The surfactants are of particular advantage in resolving crude oil emulsions of the type encountered in desalter and similar apparatus designed to extract brines from the crude as they partition to the aqueous phase in the desalter.

Owner:BL TECH INC

Advisory controls of desalter system

InactiveUS20130024026A1Liquid separation auxillary apparatusSampled-variable control systemsDemulsifierProcess engineering

Owner:GENERAL ELECTRIC CO

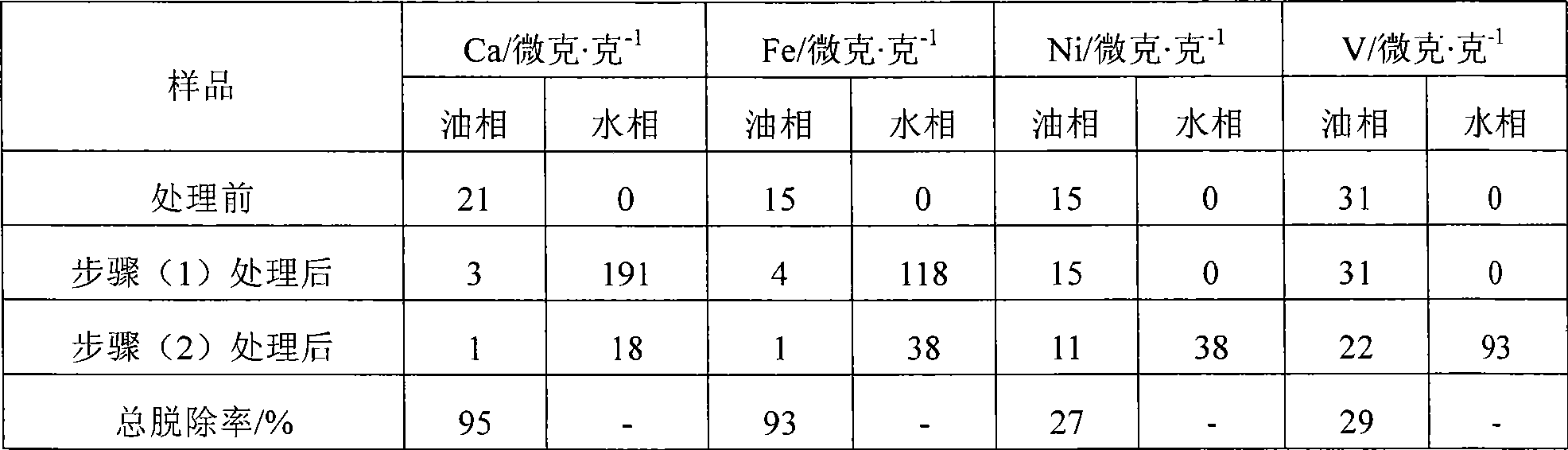

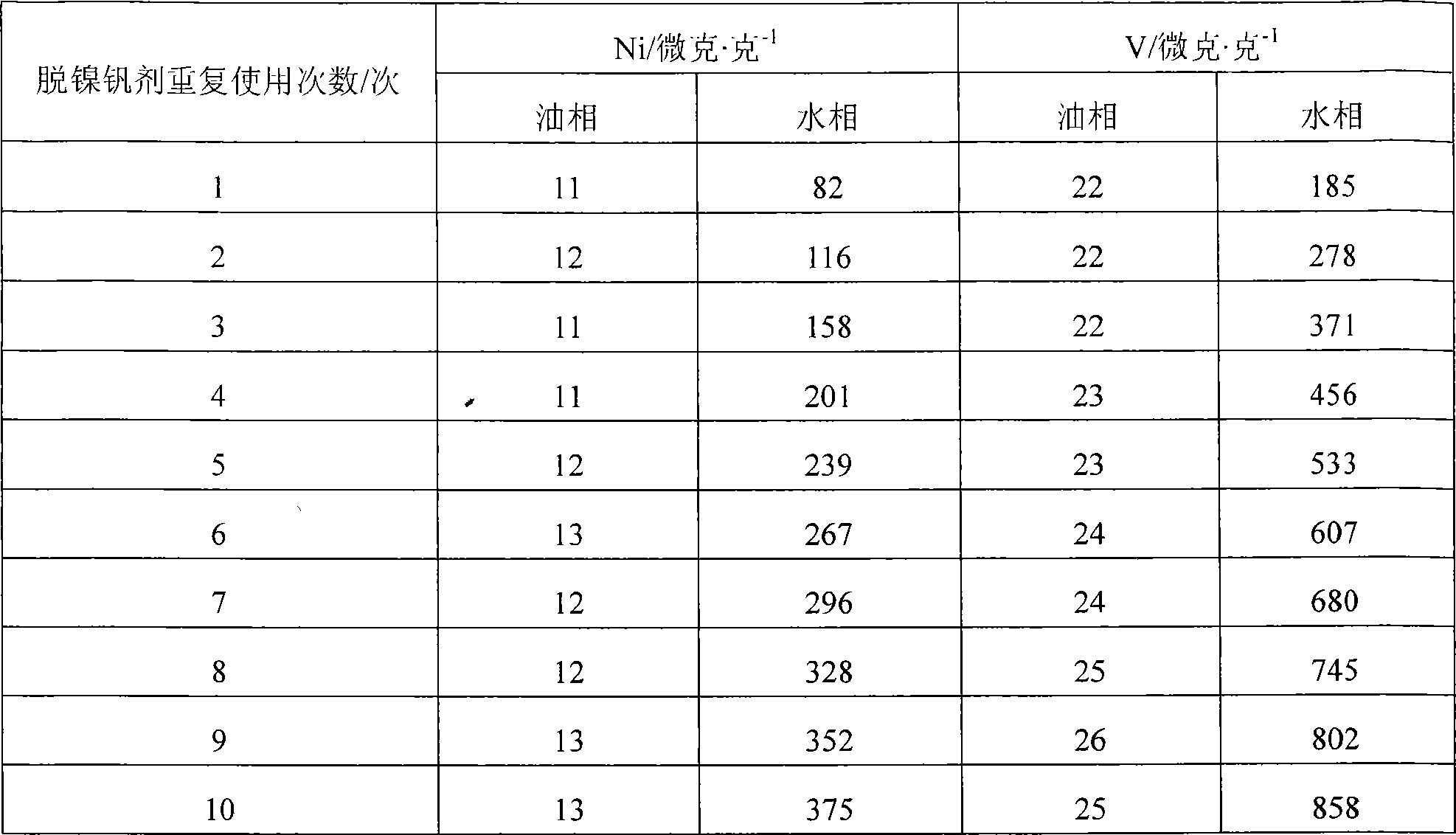

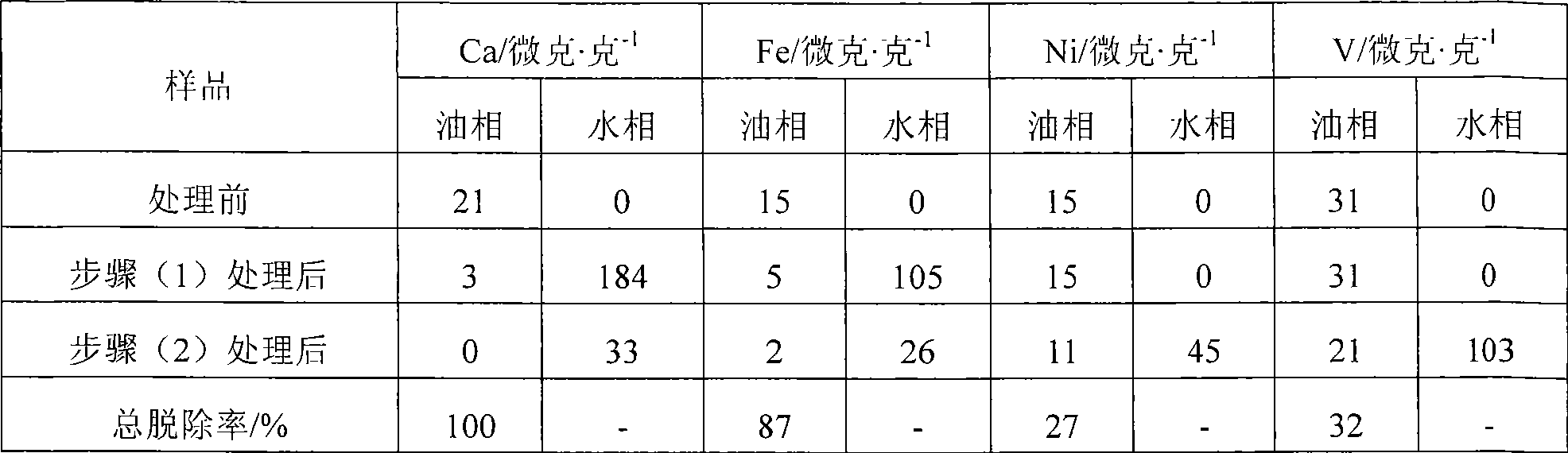

Method for removing nickel and vanadium in hydrocarbon raw material

ActiveCN101469279AReduce consumptionEfficient removalRefining by electric/magnetic meansCyclic processDesalter

The invention relates to a method for removing nickel and vanadium in a hydrocarbon raw material, which comprises the following steps: (1) under the condition of electrostatic desalting, contacting the hydrocarbon raw material with an aqueous solution of a desalter to perform the first stage electrostatic desalting for reducing the total content of the metal in the hydrocarbon raw material to perform oil-water separation, and obtaining the hydrocarbon raw material with reduced metal content; (2) under the condition of the electrostatic desalting, sufficiently mixing the hydrocarbon raw material with reduced metal content obtained in the step (1) and an aqueous solution of a nickel-vanadium removing agent so as to perform the second stage electrostatic desalting, and then performing the oil-water separation so as to obtain an oil phase and a water phase containing the nickel-vanadium removing agent; and (3) using the water phase containing the nickel-vanadium removing agent and separated out in the step (2) as at least part of the aqueous solution of the nickel-vanadium removing agent to be recycled in the next second stage electrostatic desalting, and in the circulating process, controlling the total concentration of the nickel and the vanadium in the circulating water phase containing the nickel-vanadium removing agent and controlling the weight ratio of the total weight of the nickel-vanadium removing agent to the hydrocarbon raw material with reduced metal content. The method greatly reduces the consumption of the nickel-vanadium removing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy-metal-containing flotation wastewater treatment and recycling technique

InactiveCN106045107AReduce dosageEasy to controlWaste water treatment from quariesWater treatment parameter controlSludgePrimary Indicator

The invention belongs to the technical field of flotation mineral separation and clean production, and particularly relates to a heavy-metal-containing flotation wastewater treatment and recycling technique. The technique comprises the following steps: carrying out primary settling, coagulation treatment and flotation on flotation tailings to remove the solid suspended substances, foaming agent and collector, sending into a fluidized adsorber to further remove the residual foaming agent and collector, passing the effluent water through a resin exchange desalter to remove sodium and potassium salts, pumping the primary settling sludge into a filter press, dewarering, discharging into a tailing bin, and sending the filtrate into a regulating tank for continuous treatment. Compared with the prior art, the technique provided by the invention has the advantage of low chemical consumption, and is convenient and accurate for control; and the primary indicators of the wastewater treated by the technique can be respectively controlled within the required ranges in Grade 3 of National Sewage Comprehensive Discharge Standard GB8978-1996, and satisfy the national environmental requirements.

Owner:云南森海清洋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com