Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1817 results about "Industrial water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

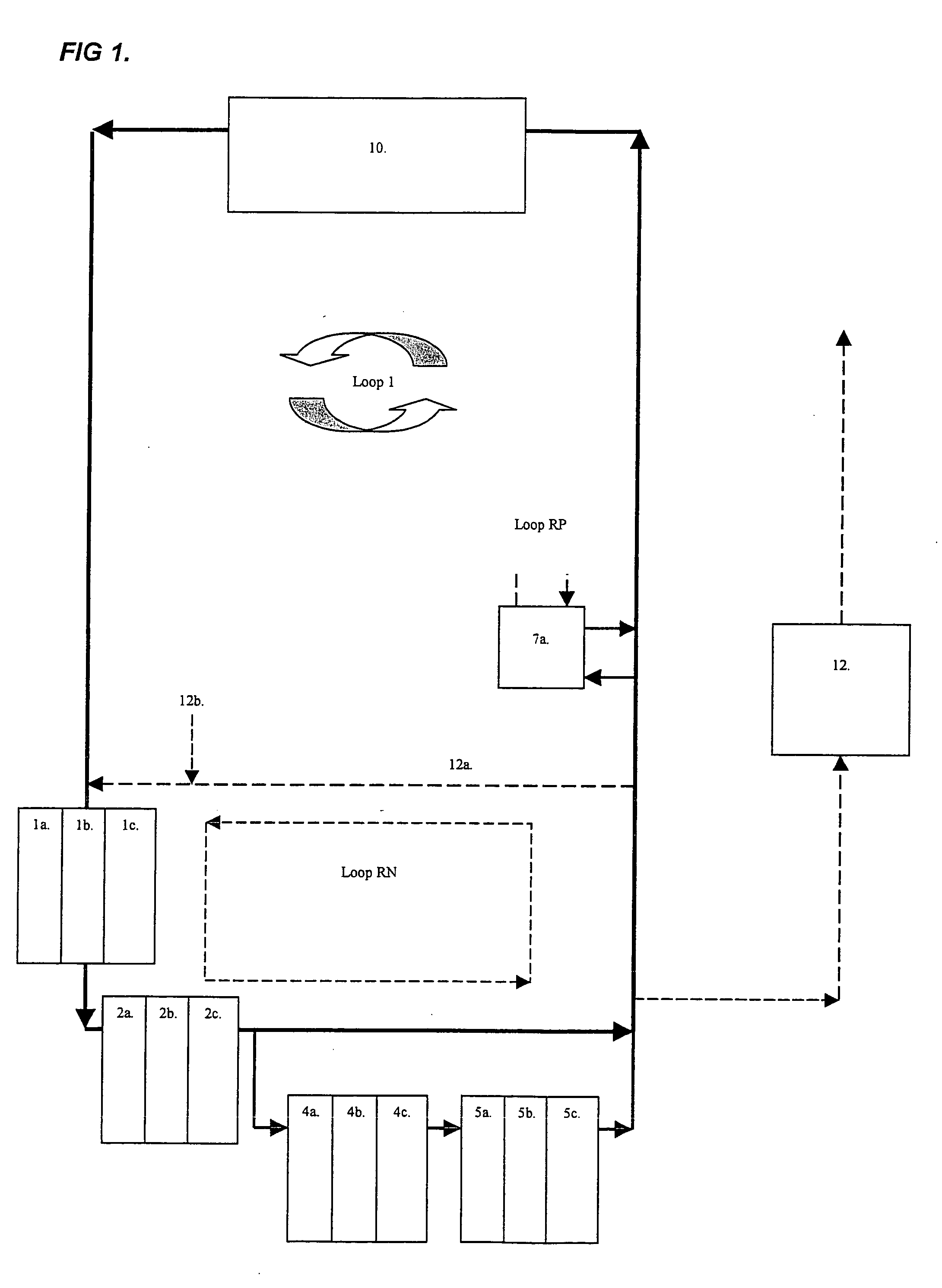

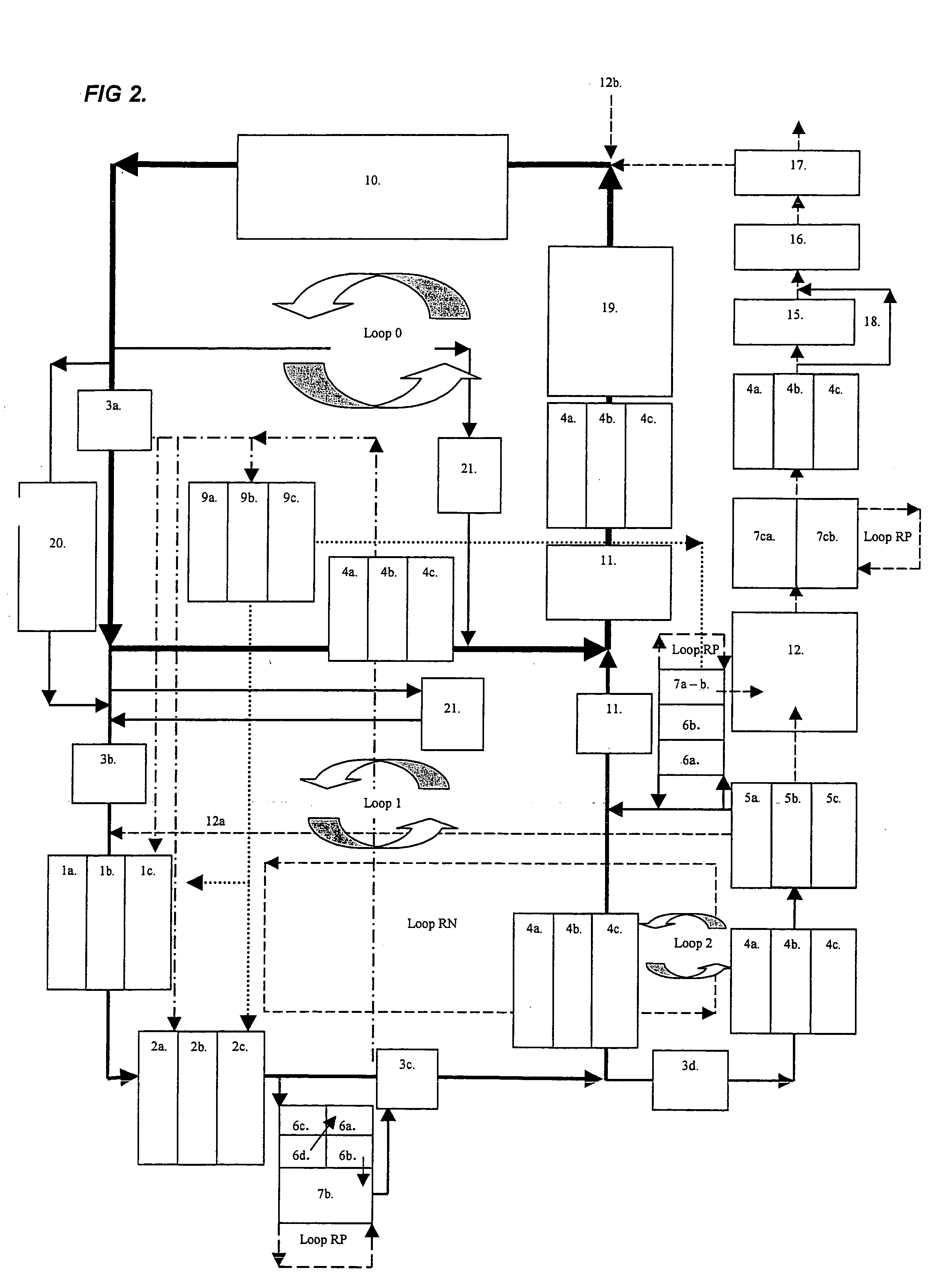

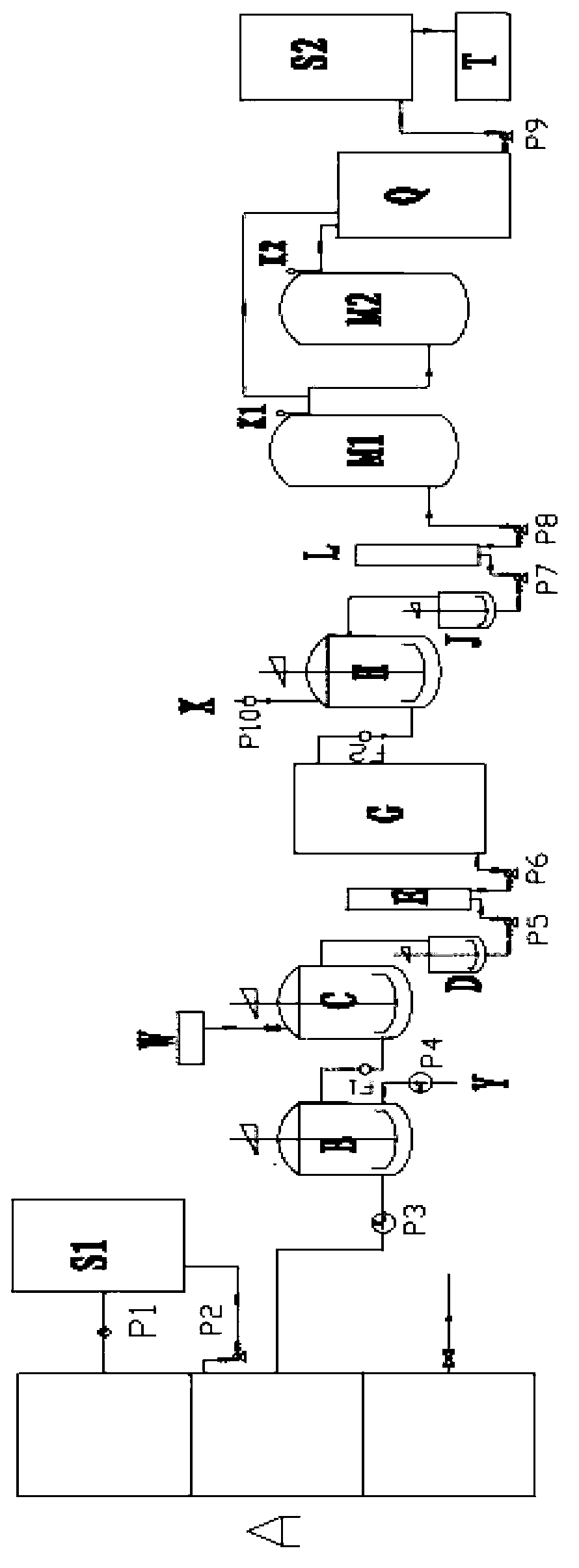

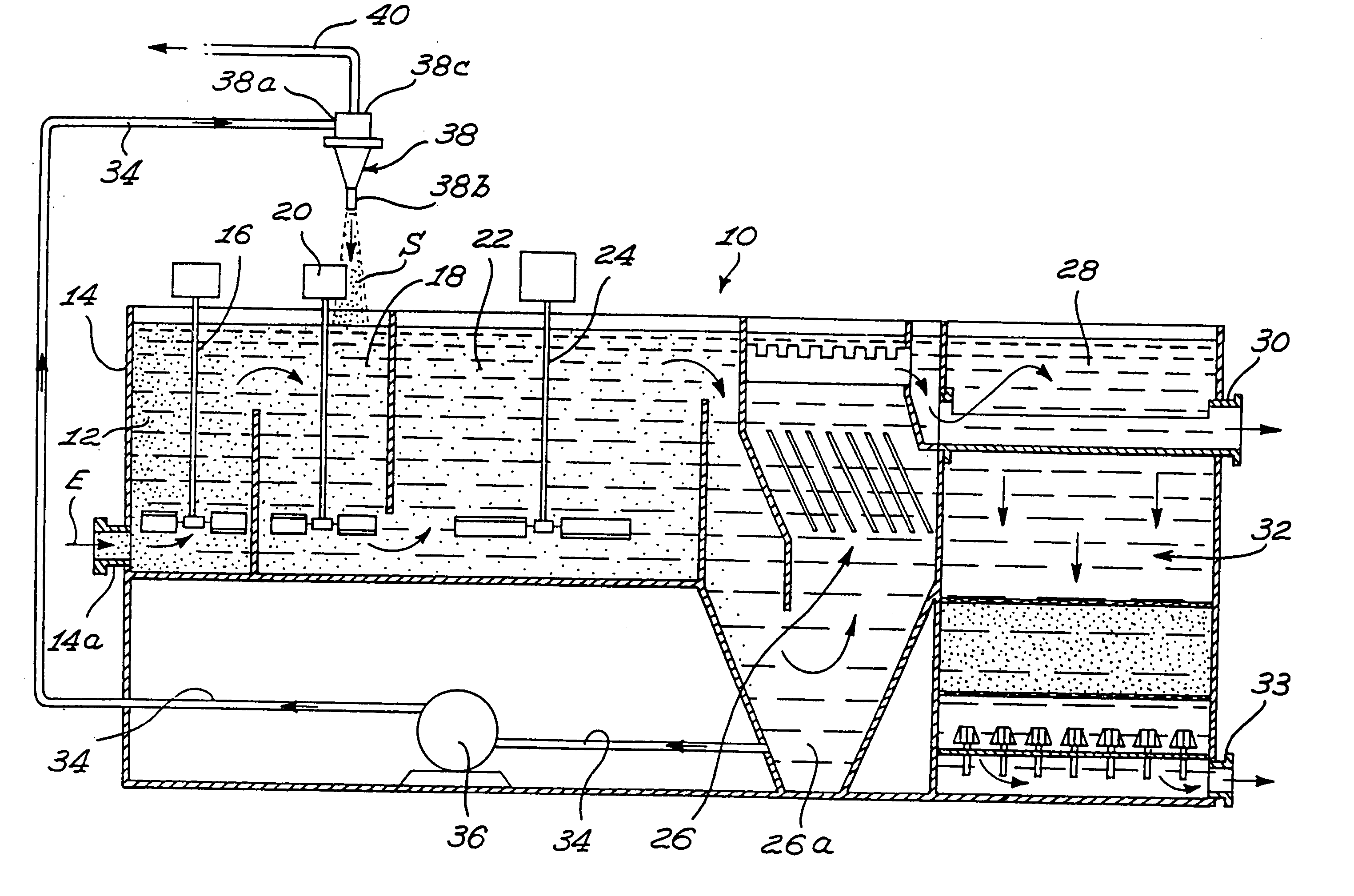

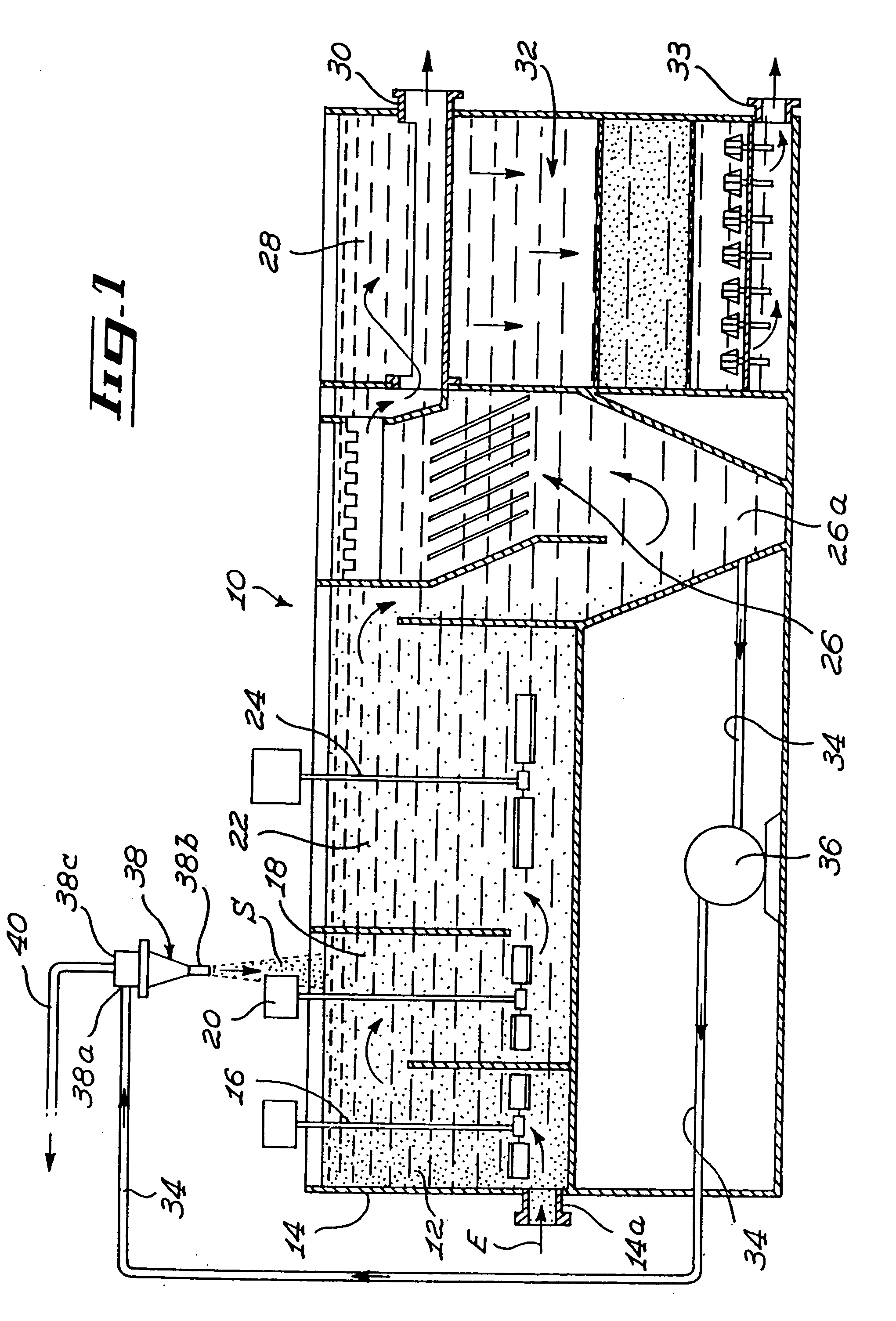

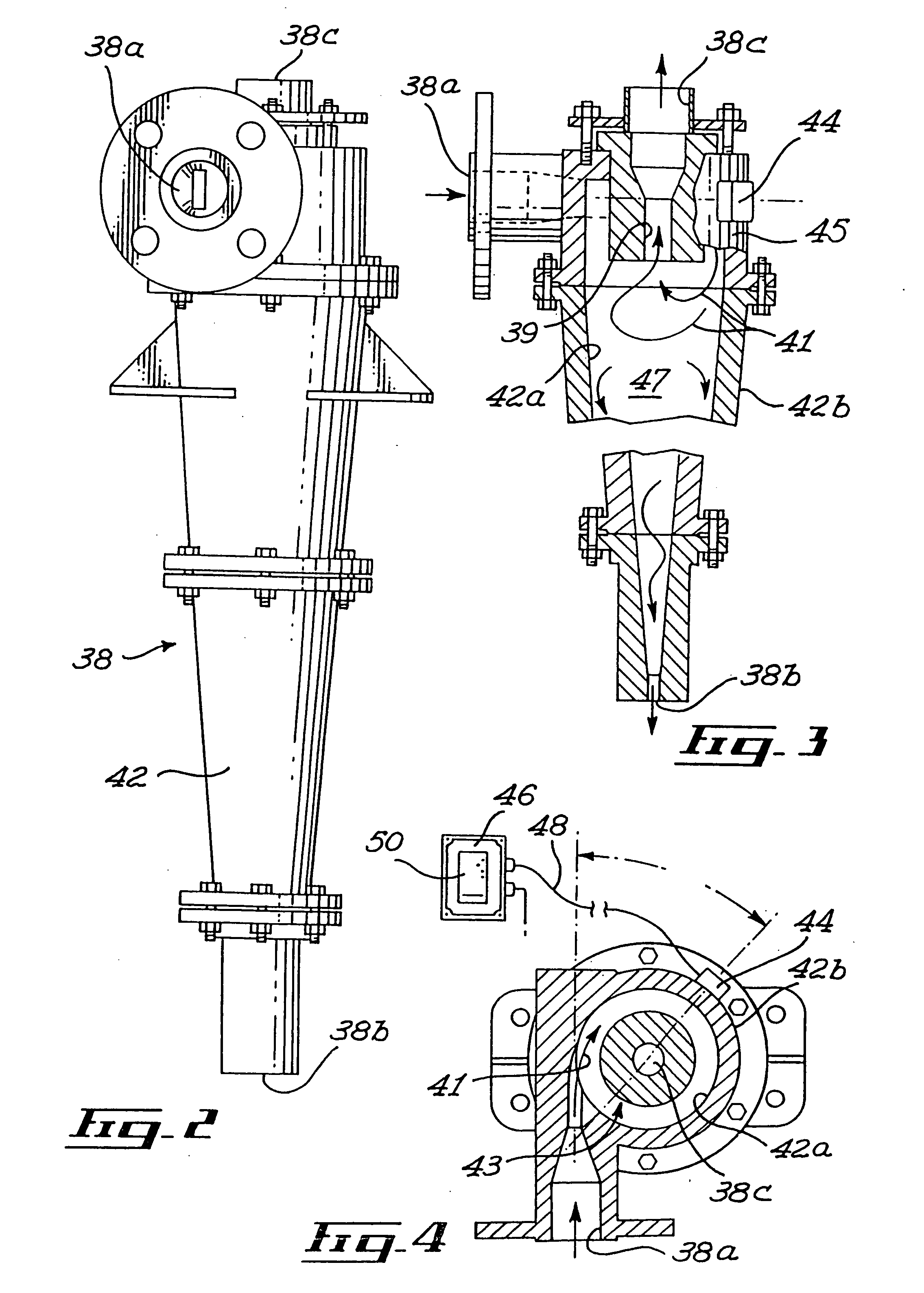

Integrated closed loop system for industrial water purification

InactiveUS7001519B2Improve purification efficiencyTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

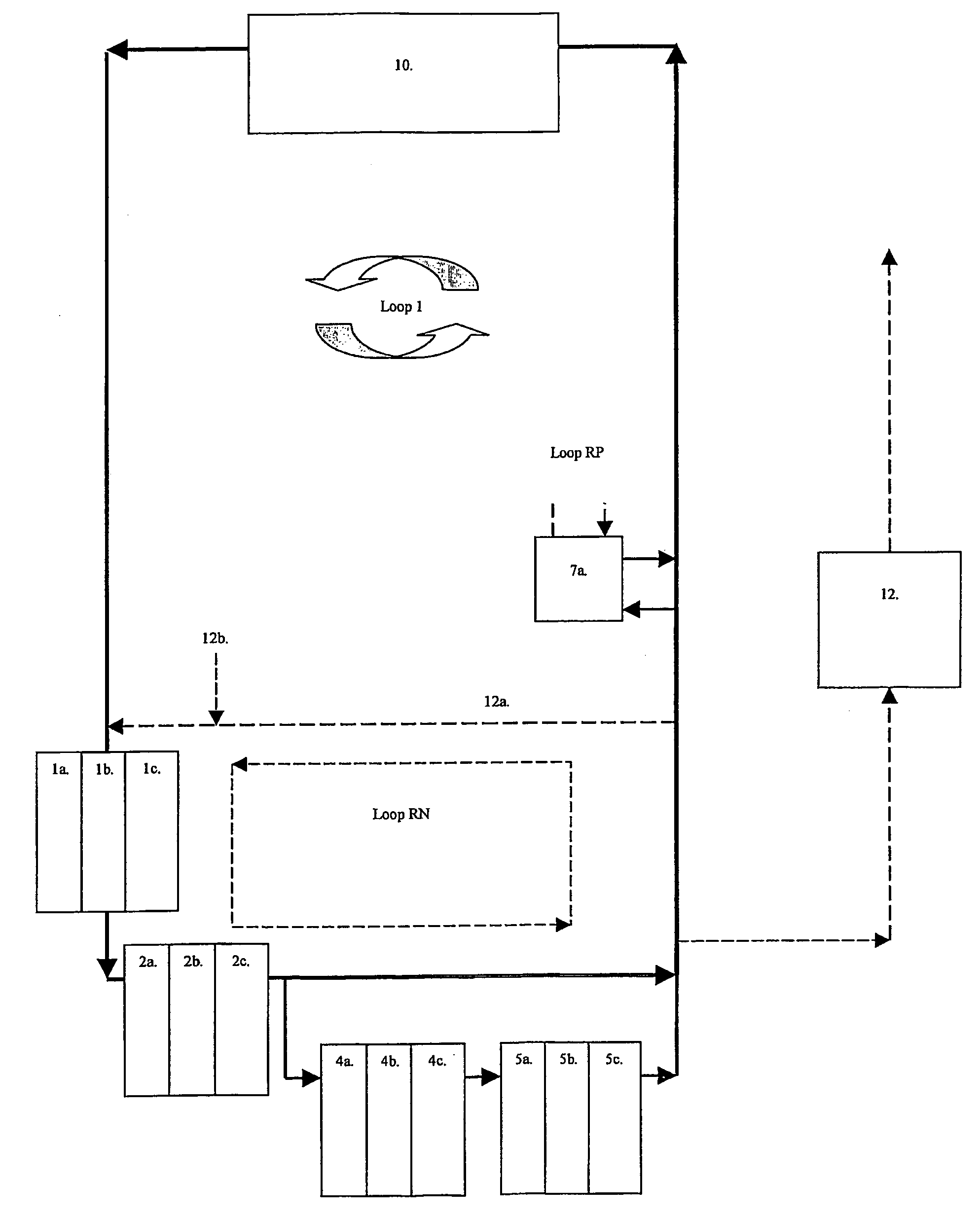

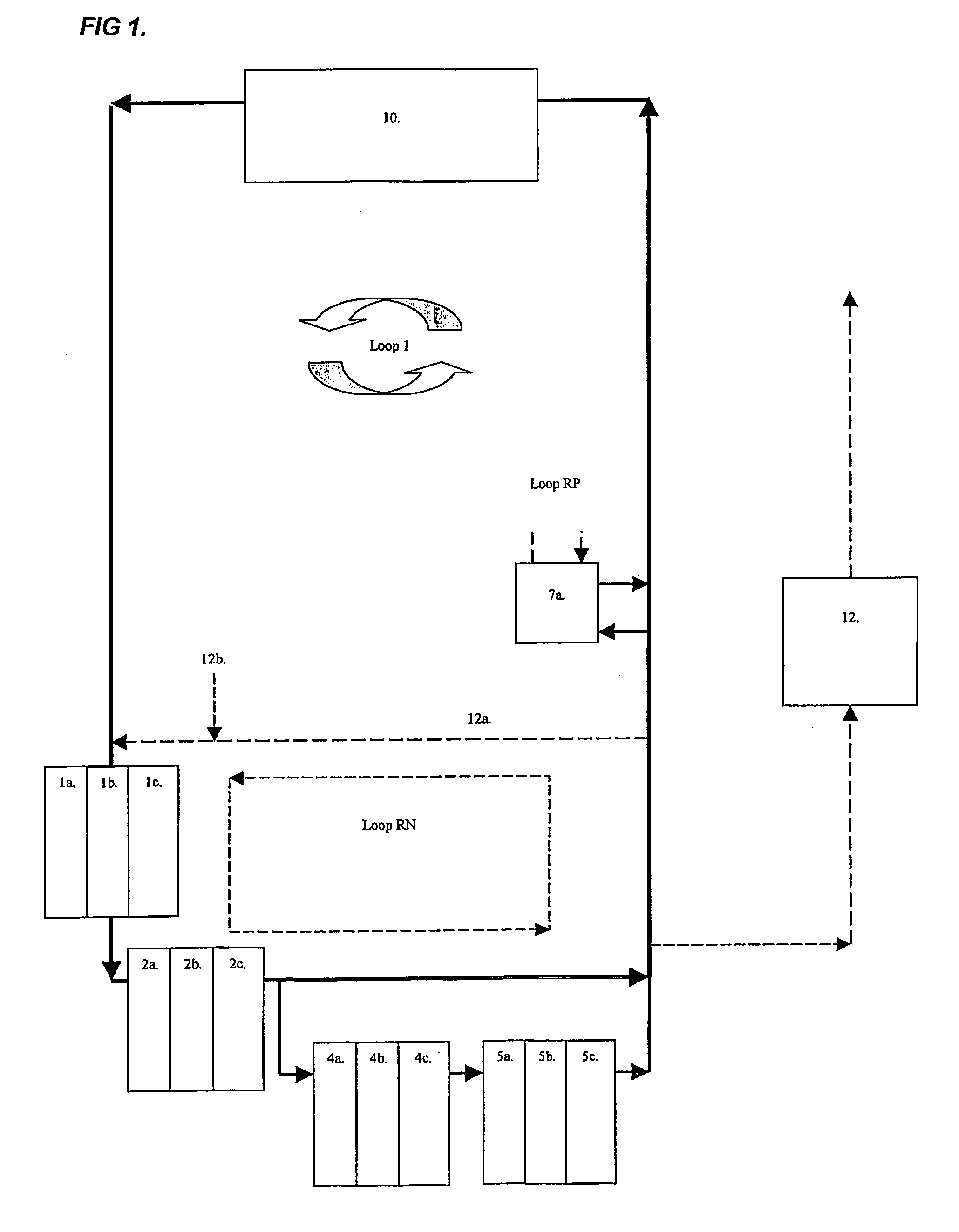

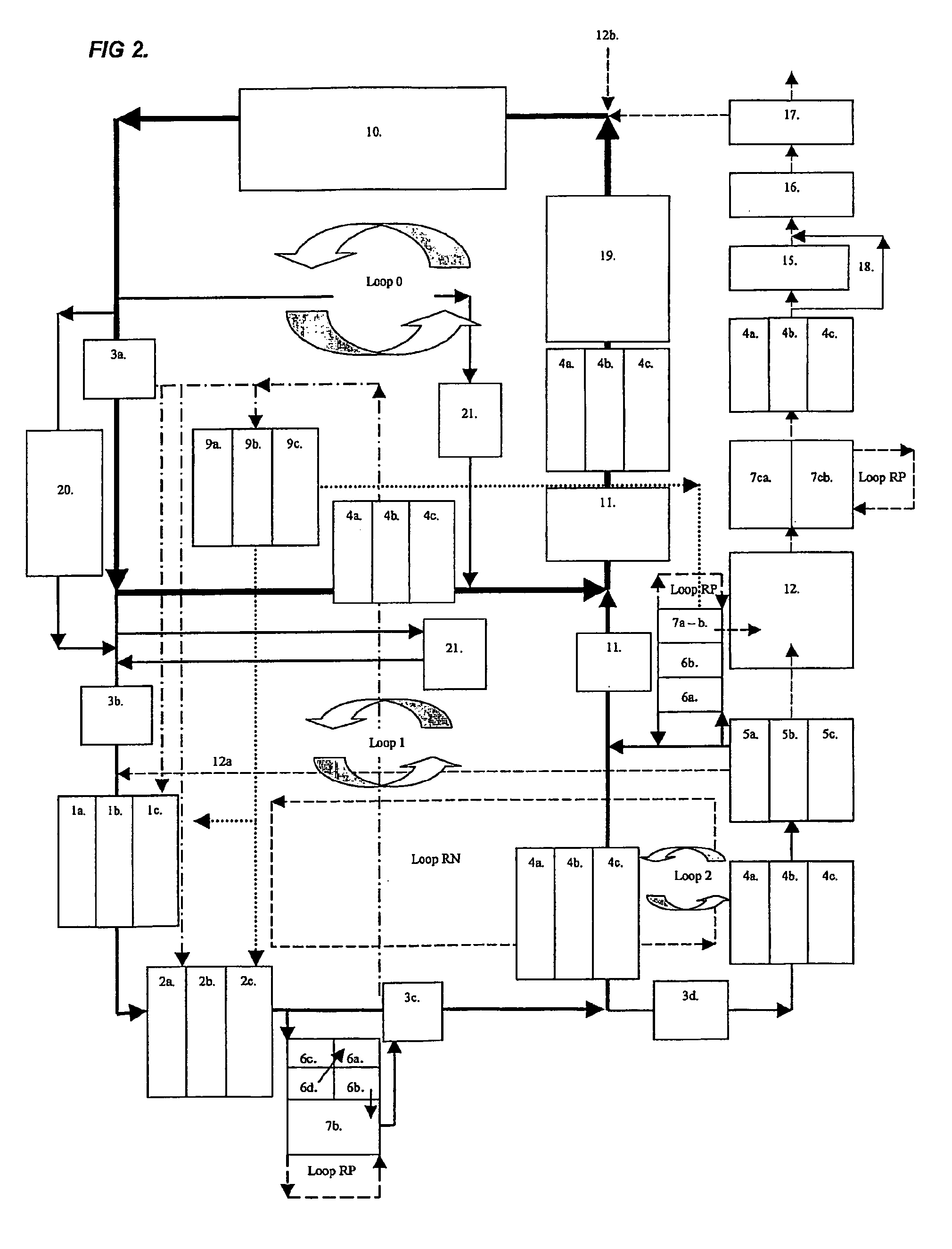

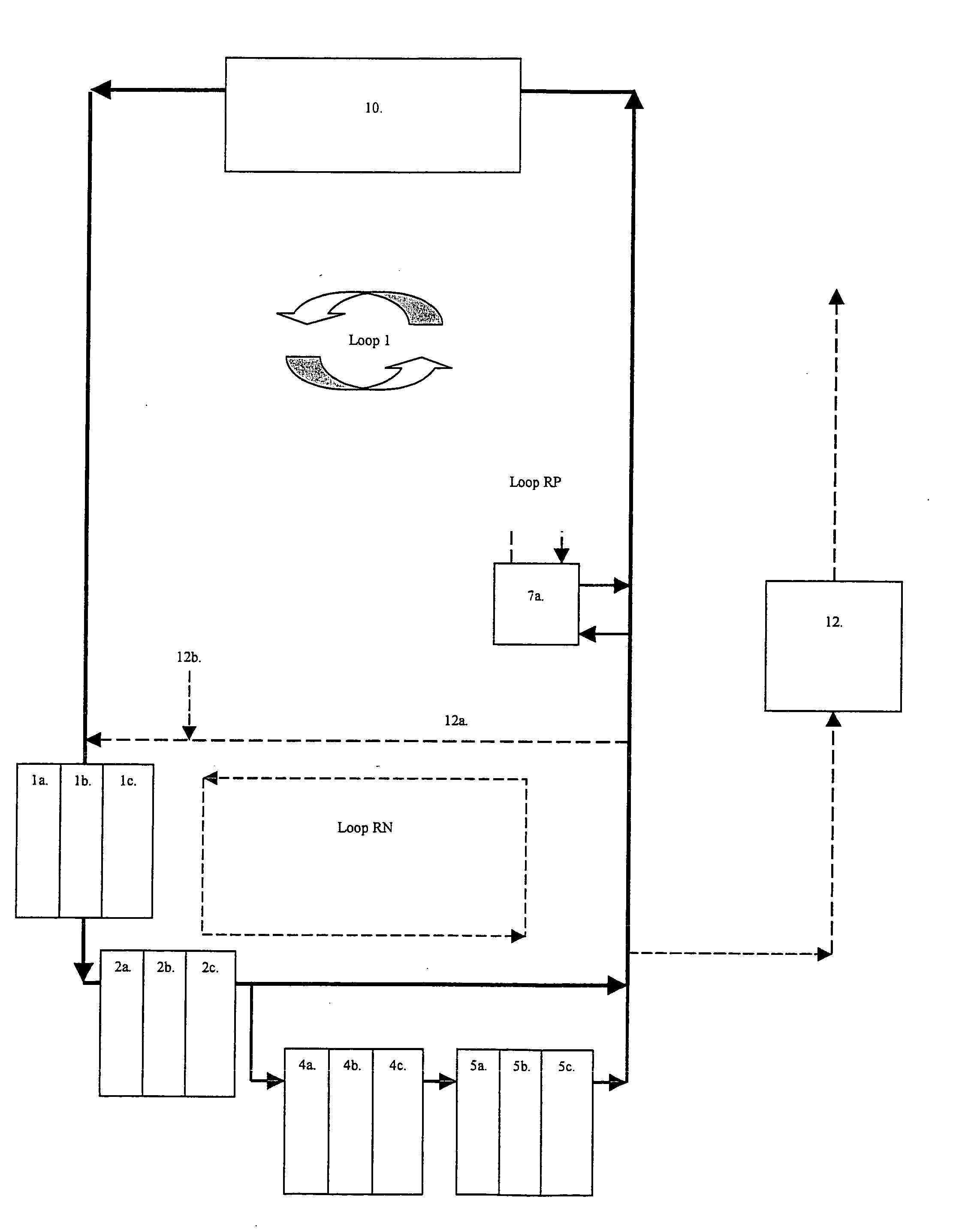

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

Integrated closed loop system for industrial water purification

InactiveUS20050061737A1Small surface areaIncreasing biofilm thicknessTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS6840251B2Reduce Microbial ContaminationReduce removalDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

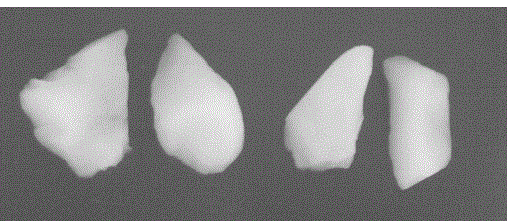

Soluble salt ceramic tile and production method thereof

The invention discloses a soluble salt ceramic tile and a production method thereof. The method comprises the following steps: (1) preparing ceramic tile powder for later use by a conventional method; (2) preparing a water-soluble soluble salt ink for the soluble salt ceramic tile; (3) preparing surface paste of the soluble salt ceramic tile; (4) preparing a ceramic tile green compact; (5) drying; (6) applying the surface paste; (7) carrying out ink-jet printing; (8) drying and firing; (9) edging; and (10) sorting, packaging and warehousing. The invention solves the following problems in the soluble salt ceramic tile production process in the prior art: the pattern obtained by the soluble salt technique does not have bright and abundant colors; in the subsequent polishing process, the consumption of the grinding material, energy sources and industrial water is high, and abundant polishing waste is generated, thereby influencing and polluting the environment; and the soluble salt ceramic tile has high requirements for the green compact raw materials, thereby causing increase of production cost and great waste of resources. The production method disclosed by the invention is more environment-friendly and economic, and has more abundant decorative effects.

Owner:HANGZHOU NABEL CERAMIC

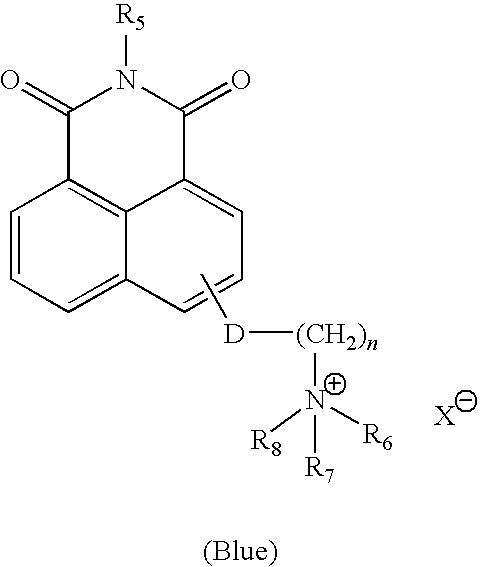

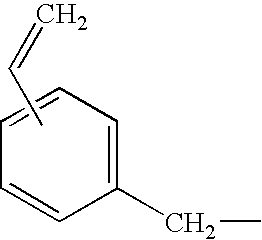

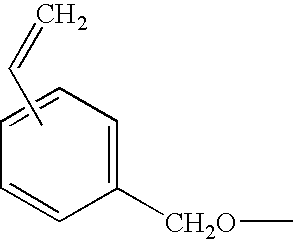

Fluorescent monomers and tagged treatment polymers containing same for use in industrial water systems

Owner:ECOLAB USA INC

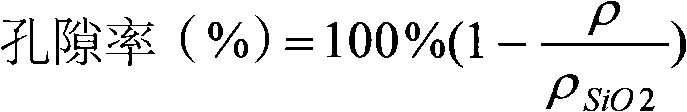

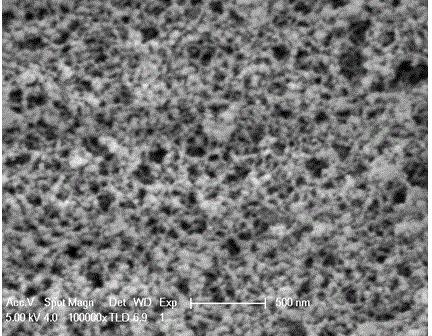

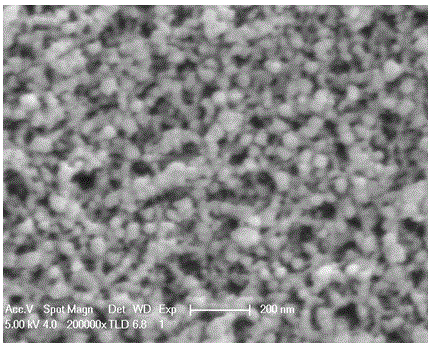

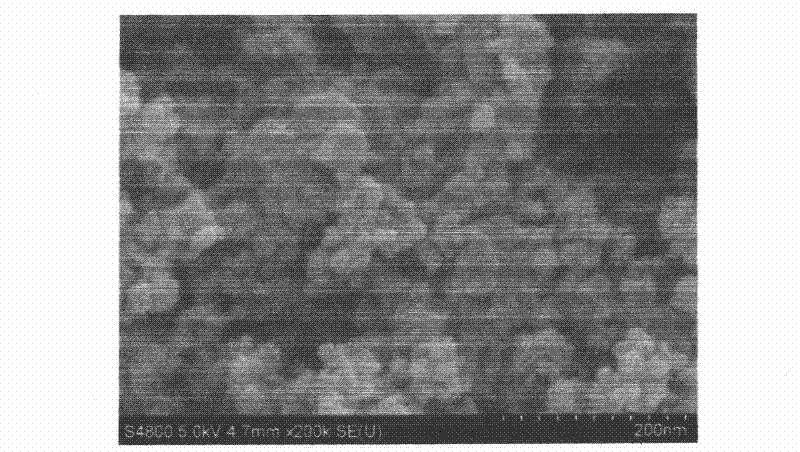

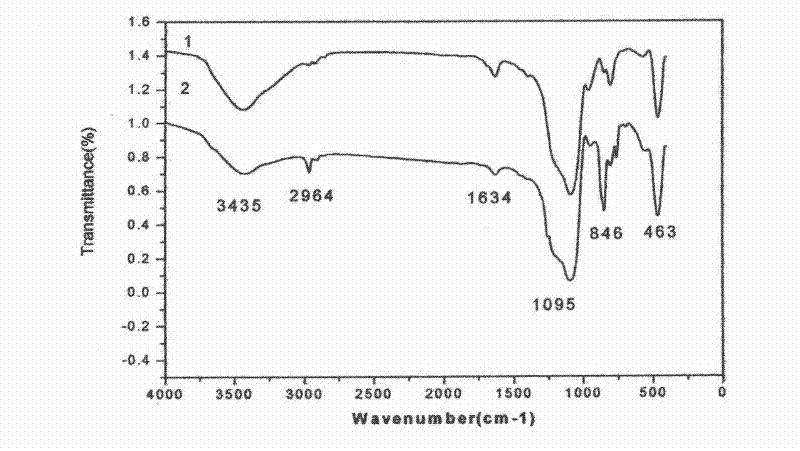

TiO2-SiO2 compound aerogel and its preparation method

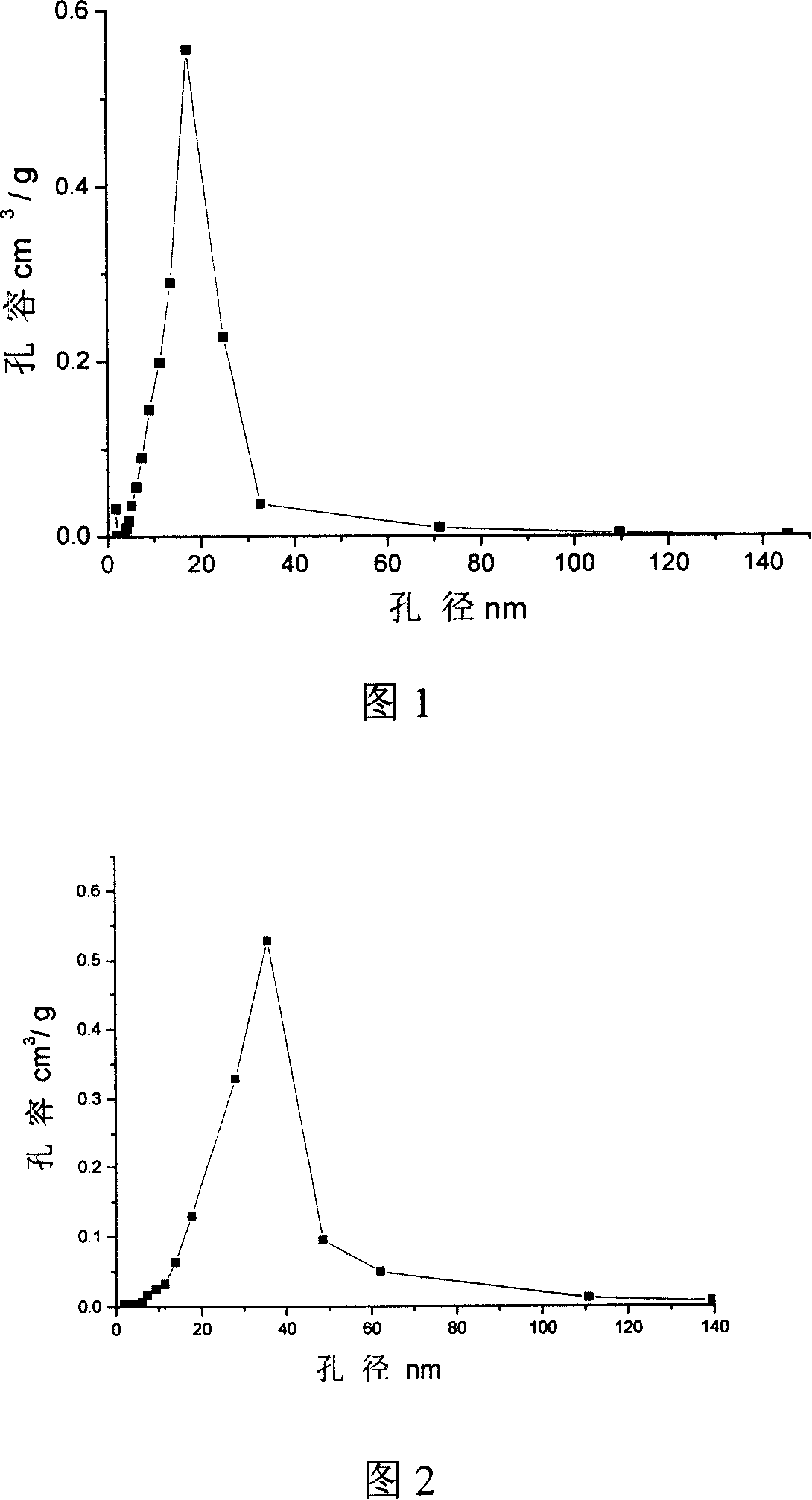

InactiveCN101288835AImprove adsorption capacityPromote degradationColloidal chemistry detailsPorosityAlcohol

The invention provides a TiO2-SiO2 composite aerogel and a preparation method of the TiO2-SiO2 composite aerogel. The Ti / Si molar ratio of the TiO2-SiO2 composite aerogel is ranging from 1:10 to 10:1, the density thereof is 0.1-0.35 g / cm<3>, the porosity thereof is 84-94%, the aperture thereof is 5.0-20.0nm, the pore volume thereof is 1.0-5.0cm<3> / g and the specific surface thereof is 500-1200m<2> / g. The preparation method mainly comprises the steps that modifier consisting of alcohols, silanes and alkanes reagent is used for carrying out the modification and solvent replacing disposal. The TiO2-SiO2 composite aerogel of the invention has the advantages of low density, large specific surface, high pore volume and high porosity; the porosity can achieve 84-94%; the preparation method of the TiO2-SiO2 composite aerogel adopted by the invention adopts cheap and easily gained raw material TiCl4 and industrial water glass and can reduce the production cost; furthermore, the normal-pressure dry-process is convenient and feasible, and suitable for large-scale industrialization production and application.

Owner:大连盛德科技发展有限公司

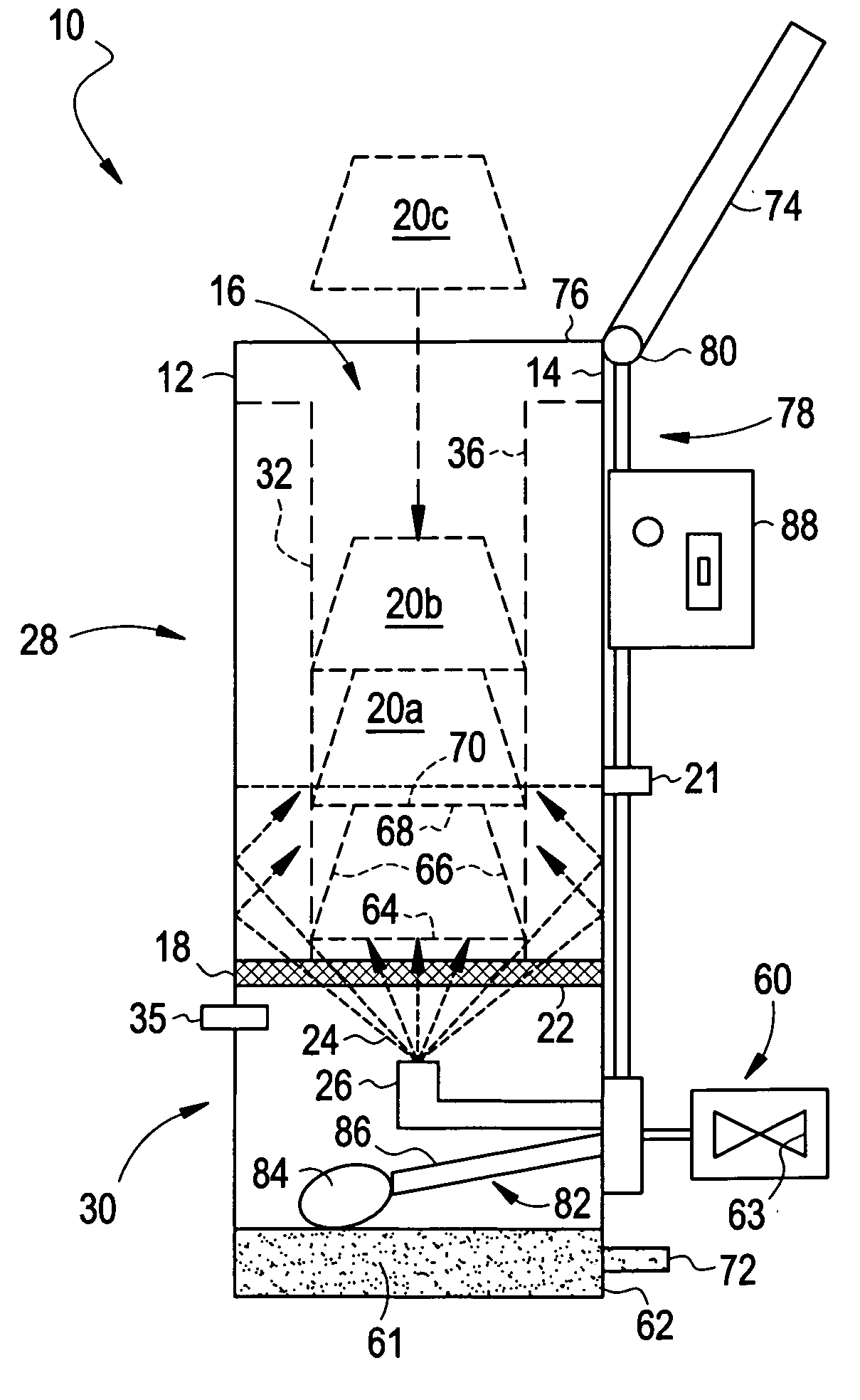

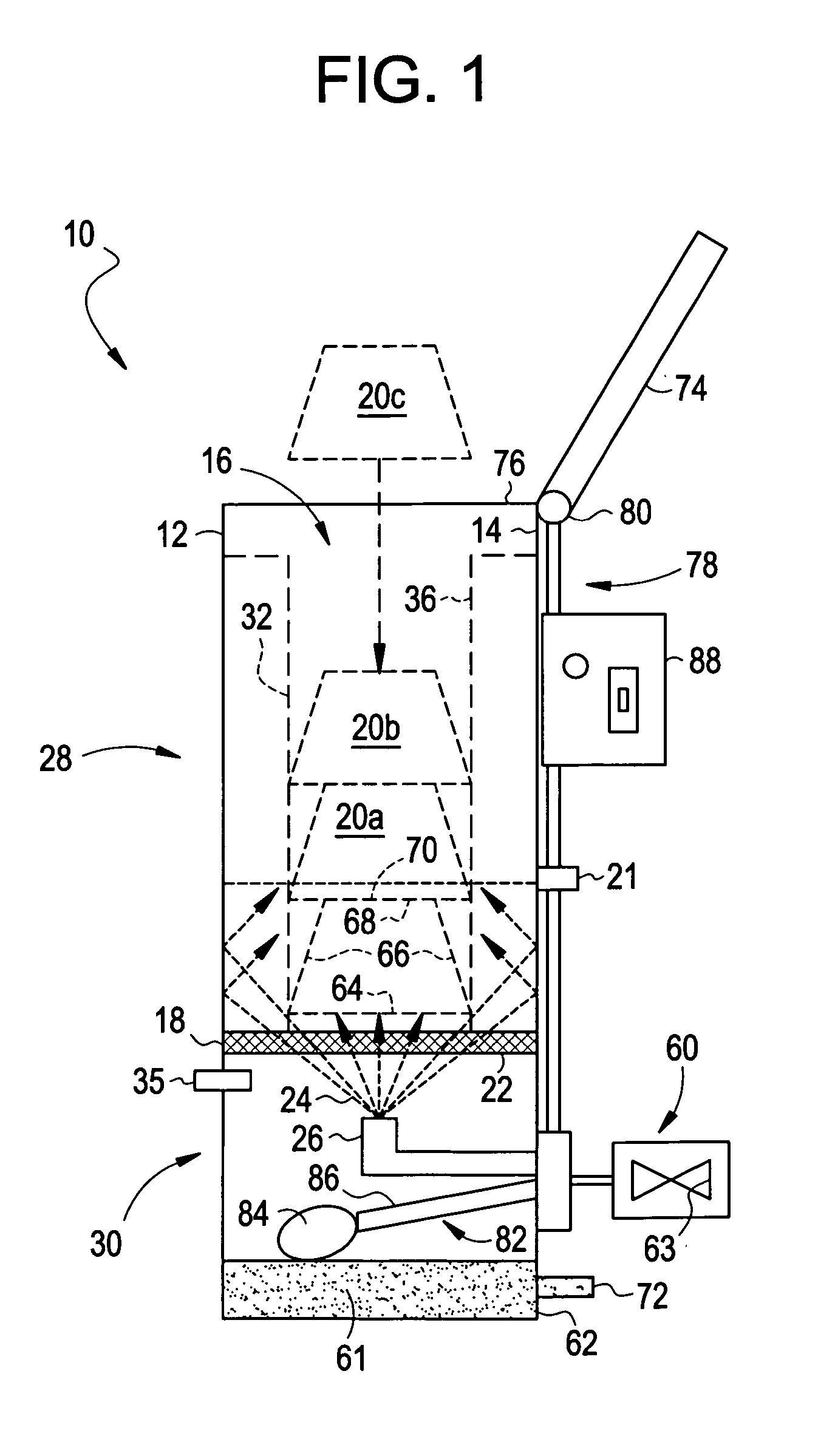

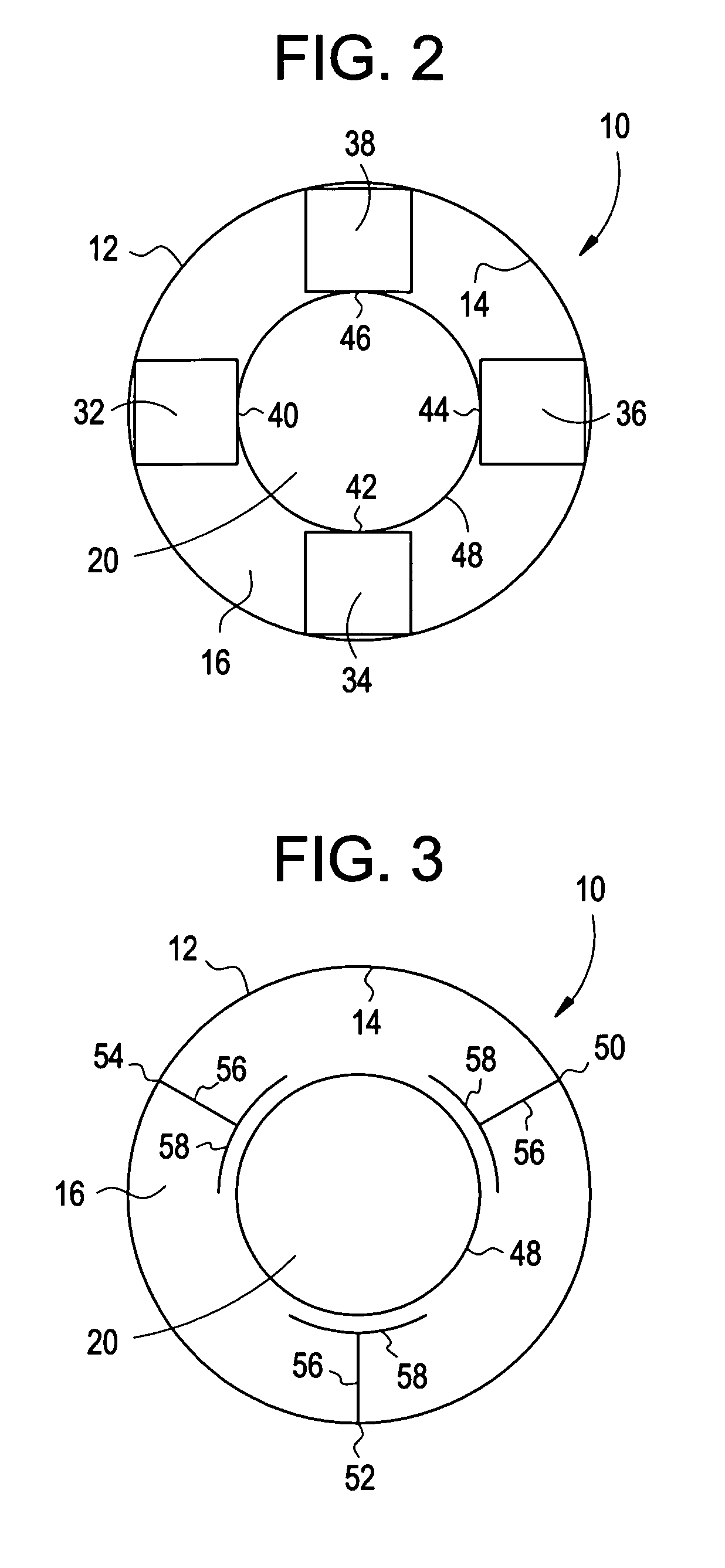

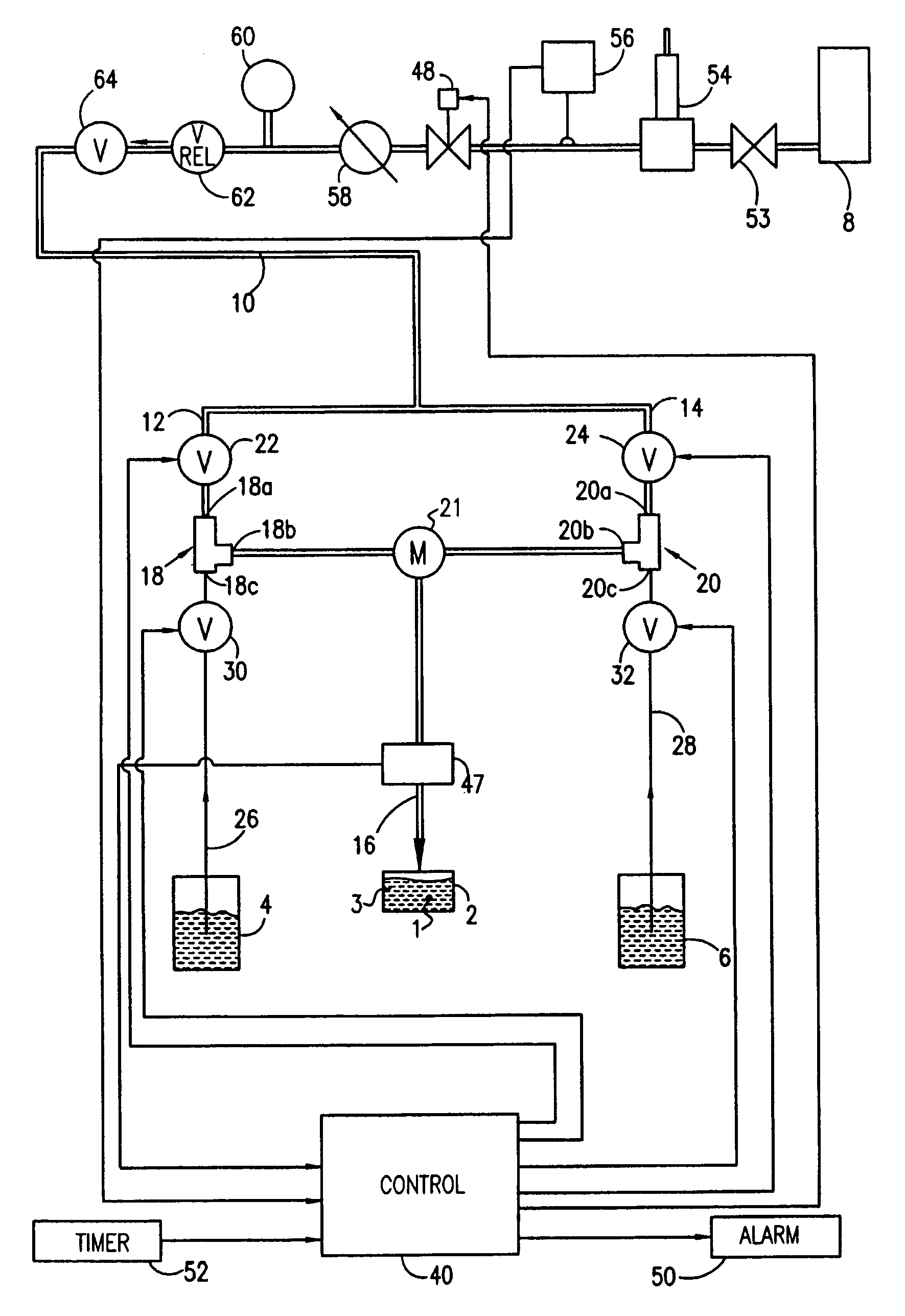

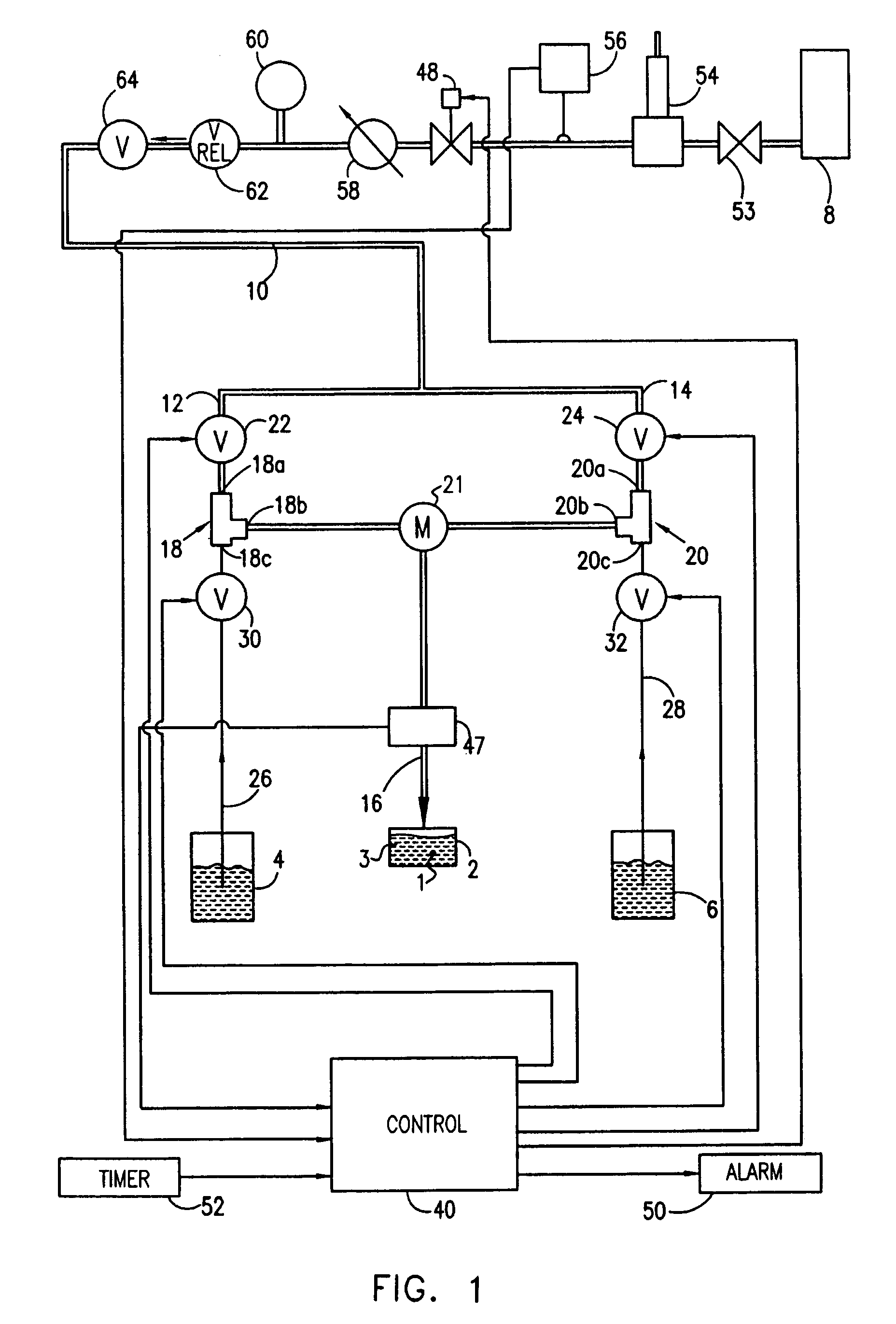

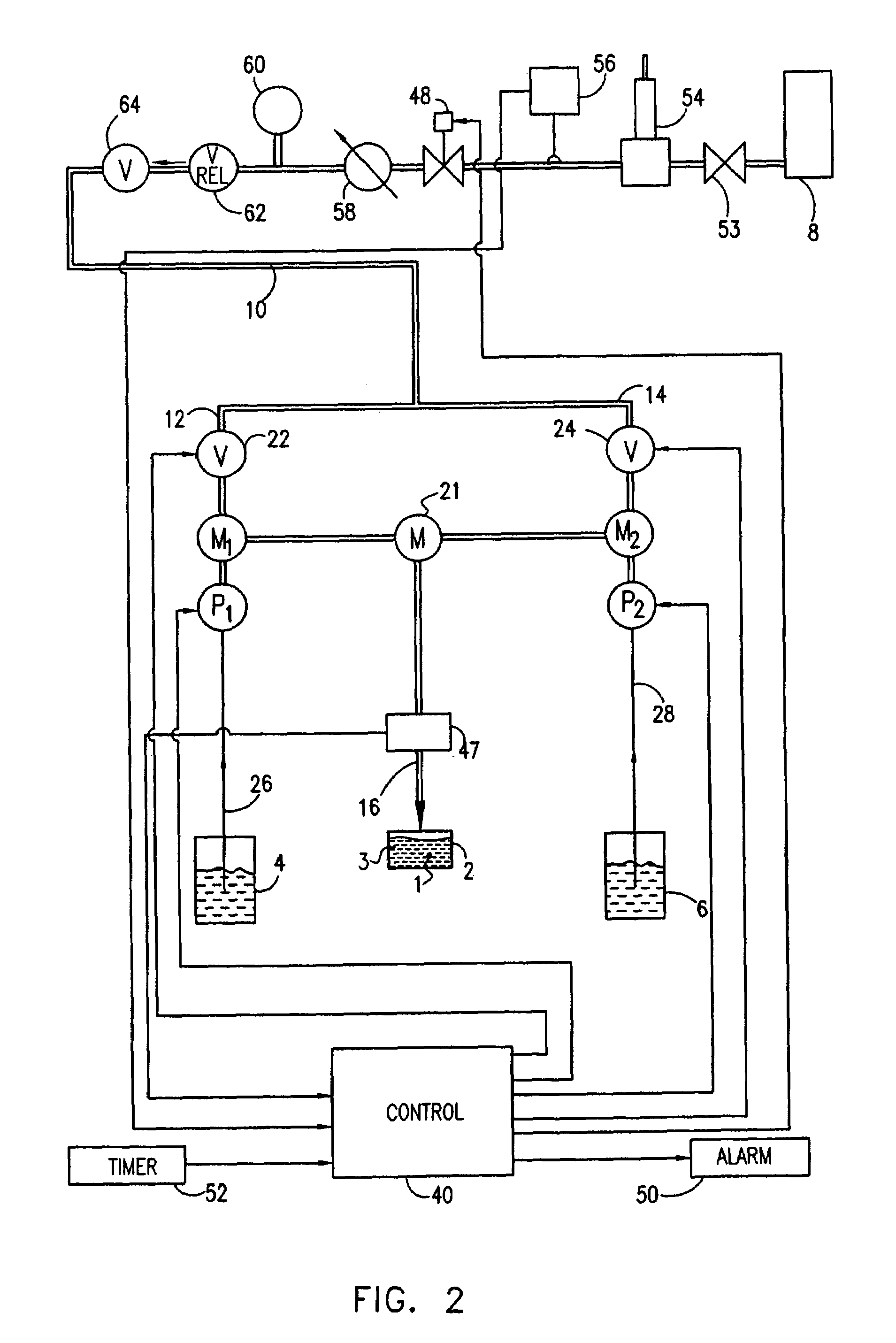

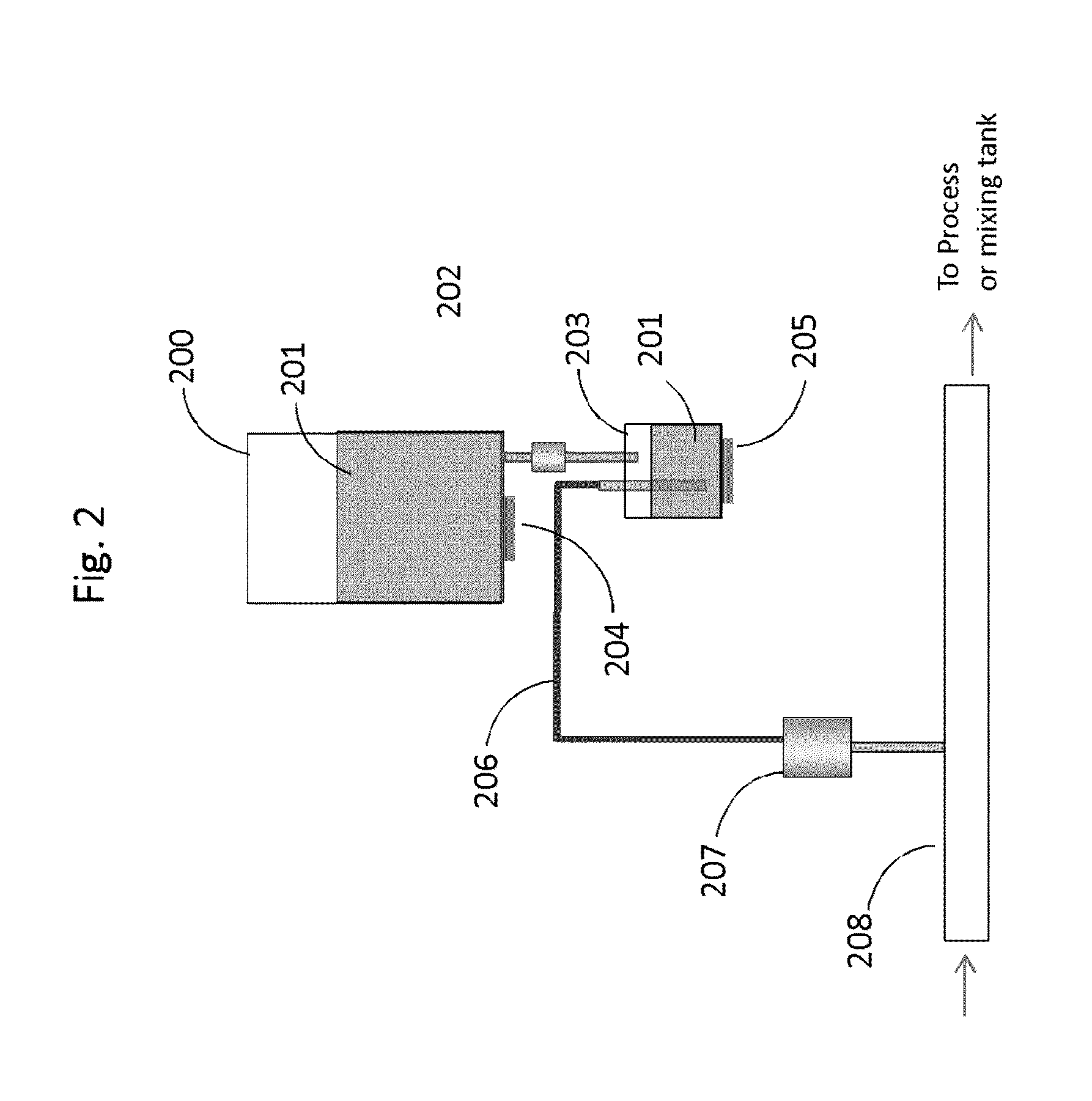

Solid product dissolver and method of use thereof

InactiveUS20050244315A1Easy to transportEasy to assembleWater treatment parameter controlDissolving using flow mixingIndustrial waterWater treatment

The present invention provides a device for producing a water treatment solution from a solid chemical block for distribution into a water system selected from the group comprising an institutional water system and an industrial water system. The device includes a housing to contain the solid chemical block. A fluid, preferably water at ambient temperature, is introduced into the housing to dissolve the block and form a liquid solution that may then be dispensed into either an institutional water system or an industrial water system. A method of dispensing the liquid solution with the device is also provided.

Owner:ECOLAB USA INC

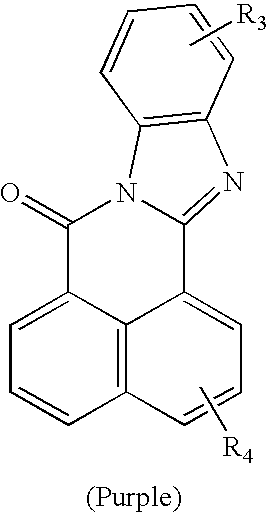

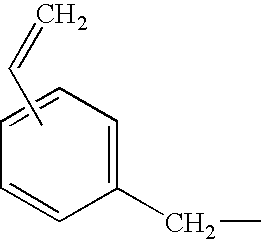

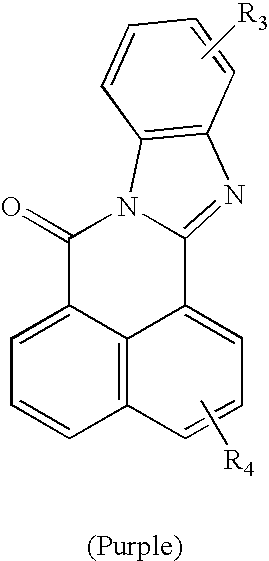

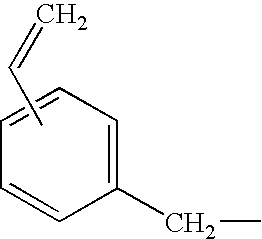

Fluorescent monomers and tagged treatment polymers containing same for use in industrial water systems

Fluorescent monomers are described and claimed which are synthesized by reacting a substituted or non-substituted naphthalic anhydride with an amine and with a moiety containing a polymerizable group. Such monomers are useful for the preparation of tagged treatment polymers. Such tagged treatment polymers are useful as scale inhibitors in industrial water systems.

Owner:ECOLAB USA INC

Method for preparing silicon dioxide aerogel with low density and large specific surface area at ordinary pressure

The invention discloses a method for preparing silicon dioxide aerogel with low density and large specific surface area at ordinary pressure. The method comprises the steps of taking cheap industrial water glass as a precursor and absolute ethyl alcohol as a solvent, performing hydrolysis and polycondensation reaction by the catalysis of acid and alkali respectively to form wet gel, performing water bath drying and aging, performing solvent exchange for many times, and performing graded drying at the ordinary pressure after surface modification to form the silicon dioxide aerogel with the low density. According to the method, the completely modified super hydrophobic silicon dioxide aerogel is obtained by using the least amount of modifier; the cheap industrial water glass is adopted as a silicon source, so that the production cost is greatly lowered; and the energy source is greatly saved for drying at the ordinary pressure in comparison with supercritical drying.

Owner:HEFEI KESIFU SAFETY TECH

Chemical composition for treatment of nitrate and odors from water streams and process wastewater treatment

InactiveUS20020011447A1Efficient processSolid sorbent liquid separationWater softeningSodium BentoniteBisulfide

Owner:MAXICHEM

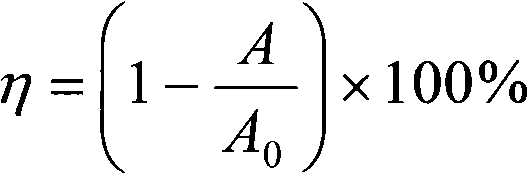

Control of development of biofilms in industrial process water

There is provided a method of inhibiting the development of a biofilm adjacent a surface, the method comprising intermittently applying a biofilm inhibiting substance to a collection of microorganisms having biofilm developing potential. There is also provided a method of inhibiting the development of a biofilm adjacent a surface, the method comprising inhibiting the biofilm developing potential of a collection of microorganisms without completely eradicating said collection of microorganisms. Also provided are a system for inhibiting the development of a biofilm, and a method and system for inhibiting the production of an enzyme by a collection of microorganisms.

Owner:A Y LAB

Water-based weather-proof stain-proof thermal reflective insulation coating and preparation method thereof

InactiveCN104250498ALow costInhibitionAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention discloses a water-based weather-proof stain-proof thermal reflective insulation coating which comprises the following components in percentage by mass: 30%-50% of film forming emulsion, 10%-20% of heat reflection pigment, 6%-15% of hollow microspheres, 5%-10% of fillers, 3%-8% of a water repellent agent, 4%-8% of an assistant and the balance of de-ionized water. By introducing the industrial water repellent agent, the coating is excellent in weather resistance, stain resistance and adhesion on basic materials, and then the reflective insulation property is kept for a long time. The invention further provides a preparation method of the coating; the preparation method comprises the following steps: stirring, uniformly mixing, filtering, and packaging. According to the preparation method, the damage on the hollow microsphere structures can be reduced to the maximum extent, and the coating is guaranteed to be good in heat insulation property; in addition, the coating is low in VOC (volatile organic compound) content and environment-friendly, and the preparation process is simple and easy for large-scale industrialized production.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

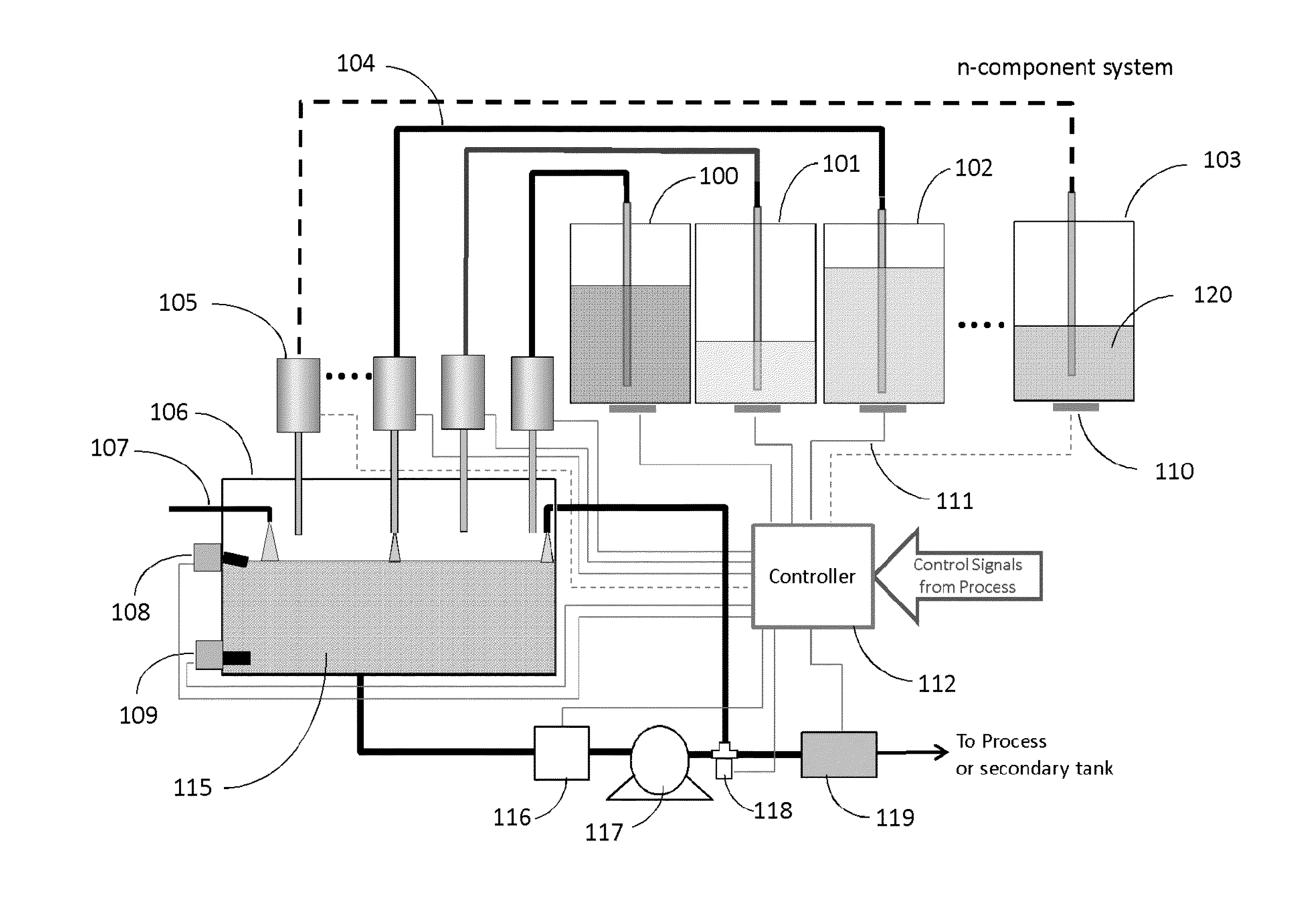

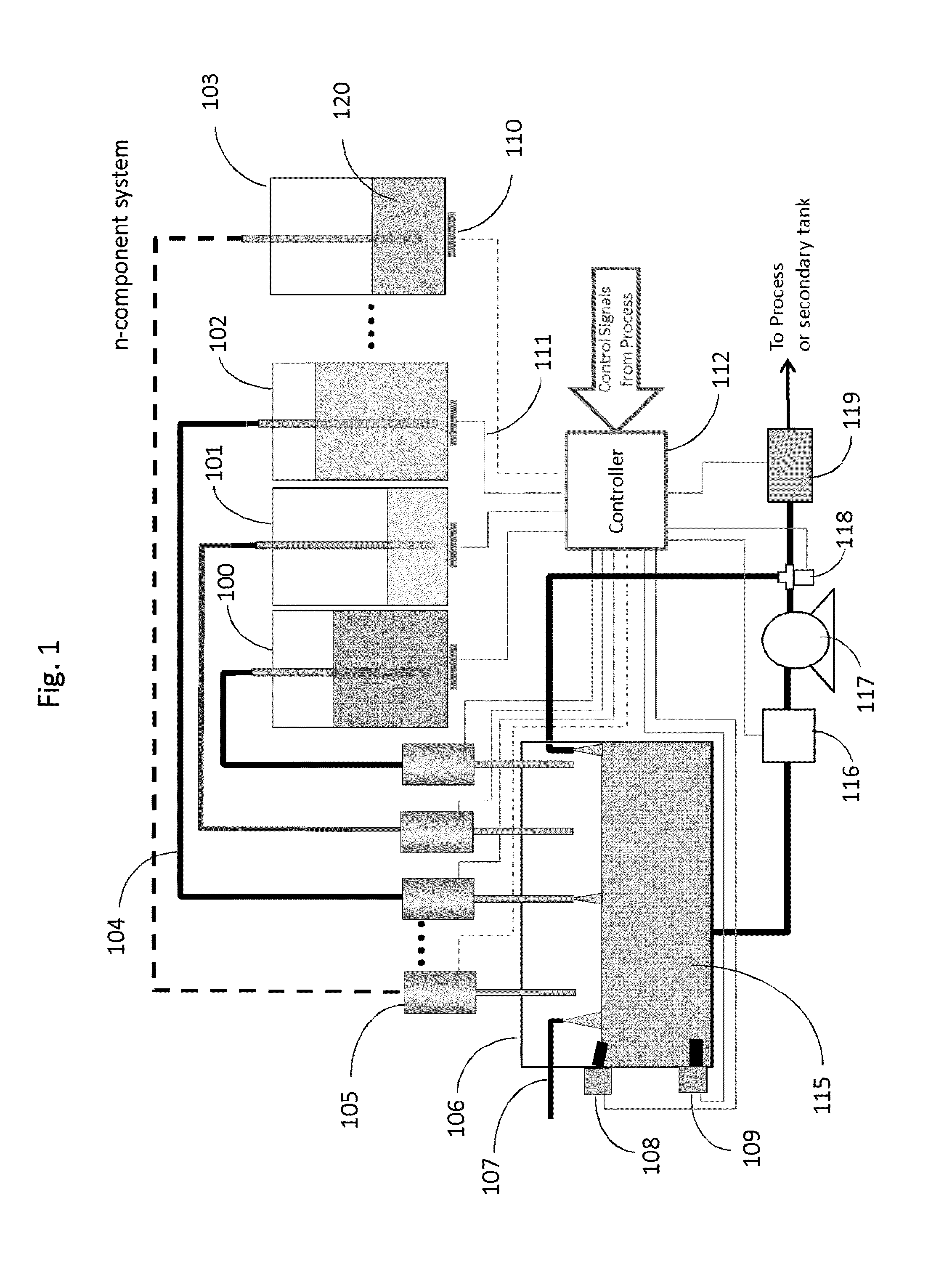

Treatment of industrial water systems

InactiveUS20130233796A1Easy to controlProgramme controlSemi-permeable membranesEnvironmental engineeringBULK ACTIVE INGREDIENT

A method for controlling treatment of an industrial water system is disclosed. The method comprises the steps of providing an apparatus for controlling delivery of at least one treatment chemical, the apparatus comprising at least one sensor and an electronic input / output device carrying out a protocol; measuring a parameter of the industrial water system using the at least one sensor; relaying the measured parameter to the electronic device; adjusting the protocol based on the measured parameter; delivering a concentrated treatment chemical into a stream of the industrial water system according to the adjusted protocol, the concentrated treatment chemical comprising an active ingredient, the active ingredient traced as necessary, the active ingredient having a concentration; repeating the measuring, the adjusting, and the delivering; and optionally repeating the steps for n-number of parameters, n-number of active ingredients, and / or n-number of concentrated treatment chemicals.

Owner:ECOLAB USA INC

Fluorescent monomers and tagged treatment polymers containing same for use in industrial water systems

Fluorescent monomers are described and claimed which are synthesized by reacting a substituted or non-substituted naphthalic anhydride with an amine and with a moiety containing a polymerizable group. Such monomers are useful for the preparation of tagged treatment polymers. Such tagged treatment polymers are useful as scale inhibitors in industrial water systems.

Owner:ECOLAB USA INC

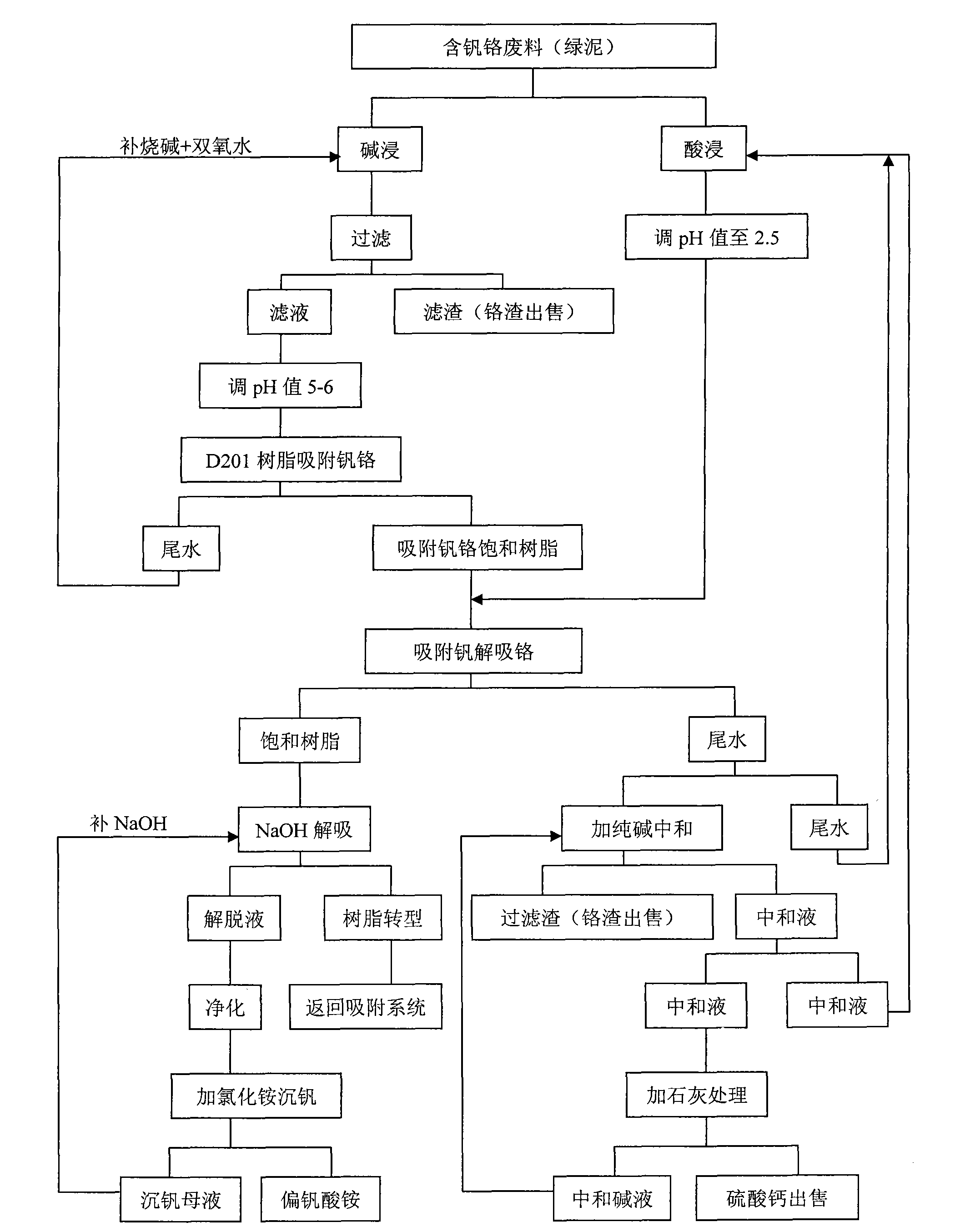

Method for separating and recovering vanadium and chrome from vanadium and chrome-containing waste

InactiveCN101538652ALess investmentMature production processProcess efficiency improvementDesorptionIon exchange

The invention relates to the field of chemical hydrometallurgy, in particular relates to a method for separating and recovering vanadium and chrome from a vanadium and chrome-containing waste. The method comprises the following steps: (1) alkaline leaching; (2) adsorption of alkaline leaching liquid; (3) acid leaching; (4) ion exchange; (5) desorption and devanadation; and (6) vanadium precipitation. The method has the advantages that: (1) the method has lower cost than a primary and secondary compound amine extraction process; (2) the method has short process flow, convenient operation, easy control, easy mastering and mature production process of recovering vanadium and chrome once the vanadium and chrome are separated; (3) the method has low production cost, and excluding sales revenue from chrome residues and calcium sulphate, the cost of fine vanadium is only 50000-60000 yuan / t; (4) the vanadium and the chrome are completely separated by the method; and (5) the method produces no secondary pollution, all the production processes are performed at normal temperature and has no roasting fume, and industrial water is recycled and subject to zero discharge; produced neutralization residues are of high-quality chrome residues and calcium sulphate and can be sold to chemical plants and cement plants as a raw material.

Owner:杨秋良 +1

Process for remediating biofouling in water systems with virulent bacteriophage

InactiveUS8241498B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBiofilmBacteriophage

Owner:DOW GLOBAL TECH LLC

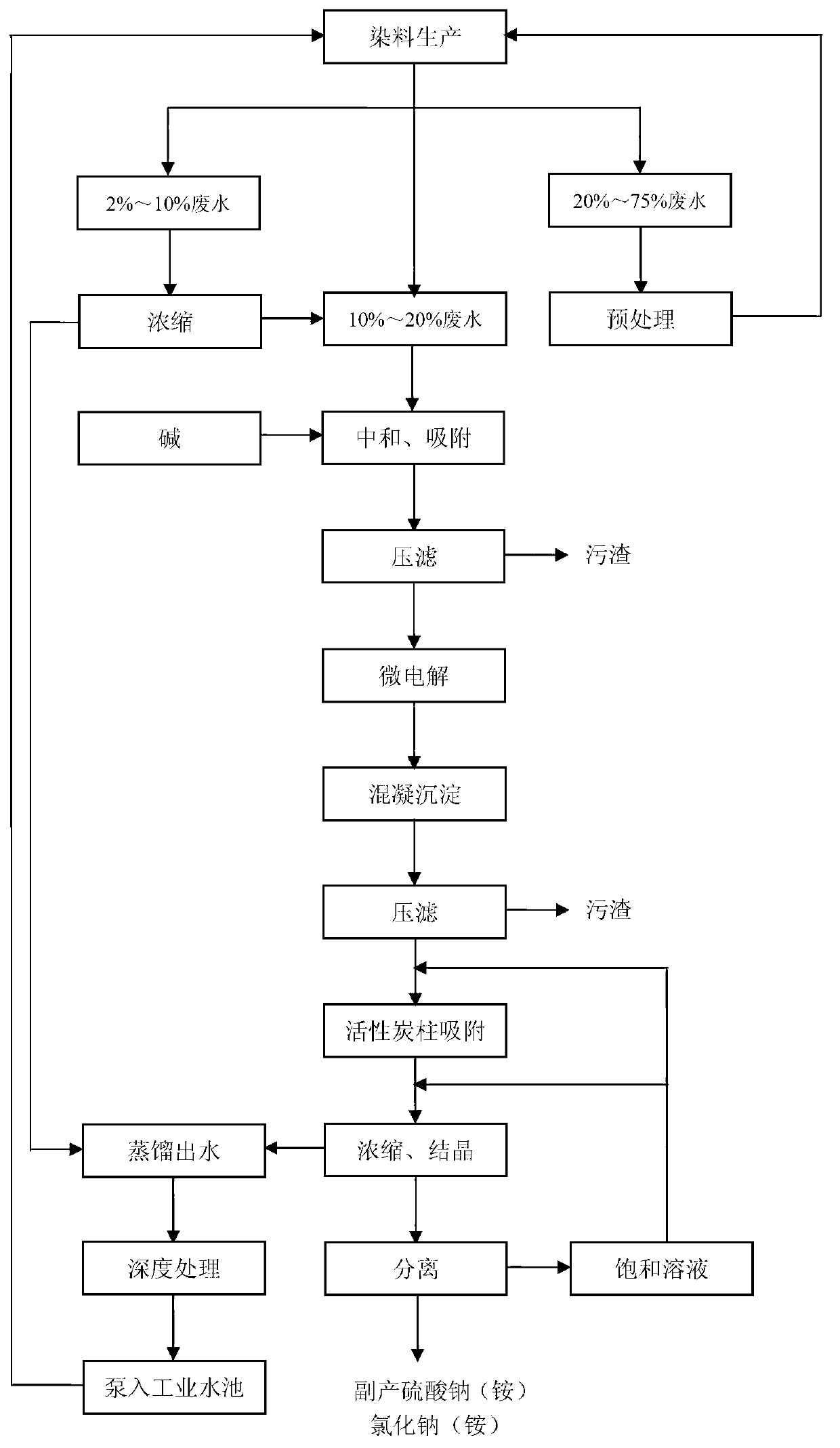

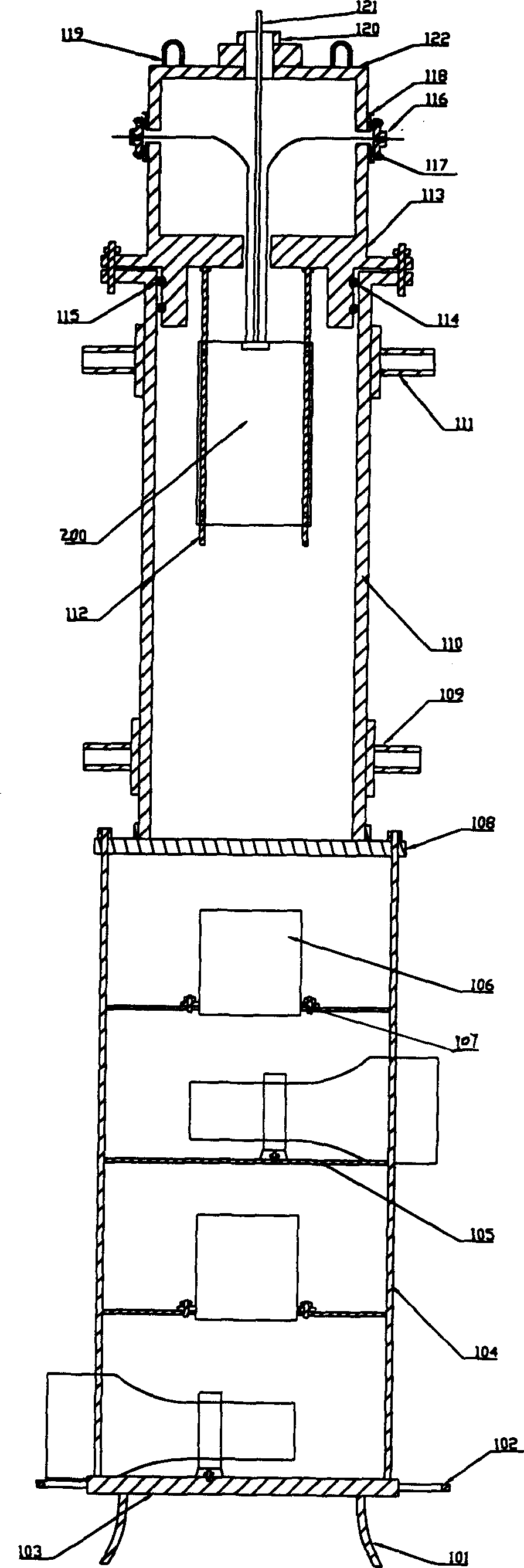

Dye acidic waste water treatment method and device

ActiveCN103130370AWide pH rangeLow costAmmonium sulfatesMultistage water/sewage treatmentAutomatic controlWater discharge

The invention relates to a dye acidic waste water treatment method and device. The method comprises steps as follows: separately collected dye waste acid is subjected to distilling concentration, neutralization, adsorption, micro-electrolysis, coagulative precipitation, activated carbon column adsorption, concentrating crystallization and separation through an automatic control system to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride; and the distilled water is subjected to advanced treatment to reach the industrial reuse water standard, enters an industrial water storage tank, and is circulated to the dye production procedure. The method and device are especially suitable for industries generating abundant waste sulfuric acid and waste hydrochloric acid, such as production of dyes, titanium white and the like. The abundant waste sulfuric acid and waste hydrochloric acid generated in the production process can be utilized to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride, thereby recycling acidic waste water, and changing wastes into valuable substances; and meanwhile, the distilled water can be circulated into industrial production after advanced treatment, thereby reducing the waste water discharge.

Owner:ZHEJIANG DIBANG CHEM

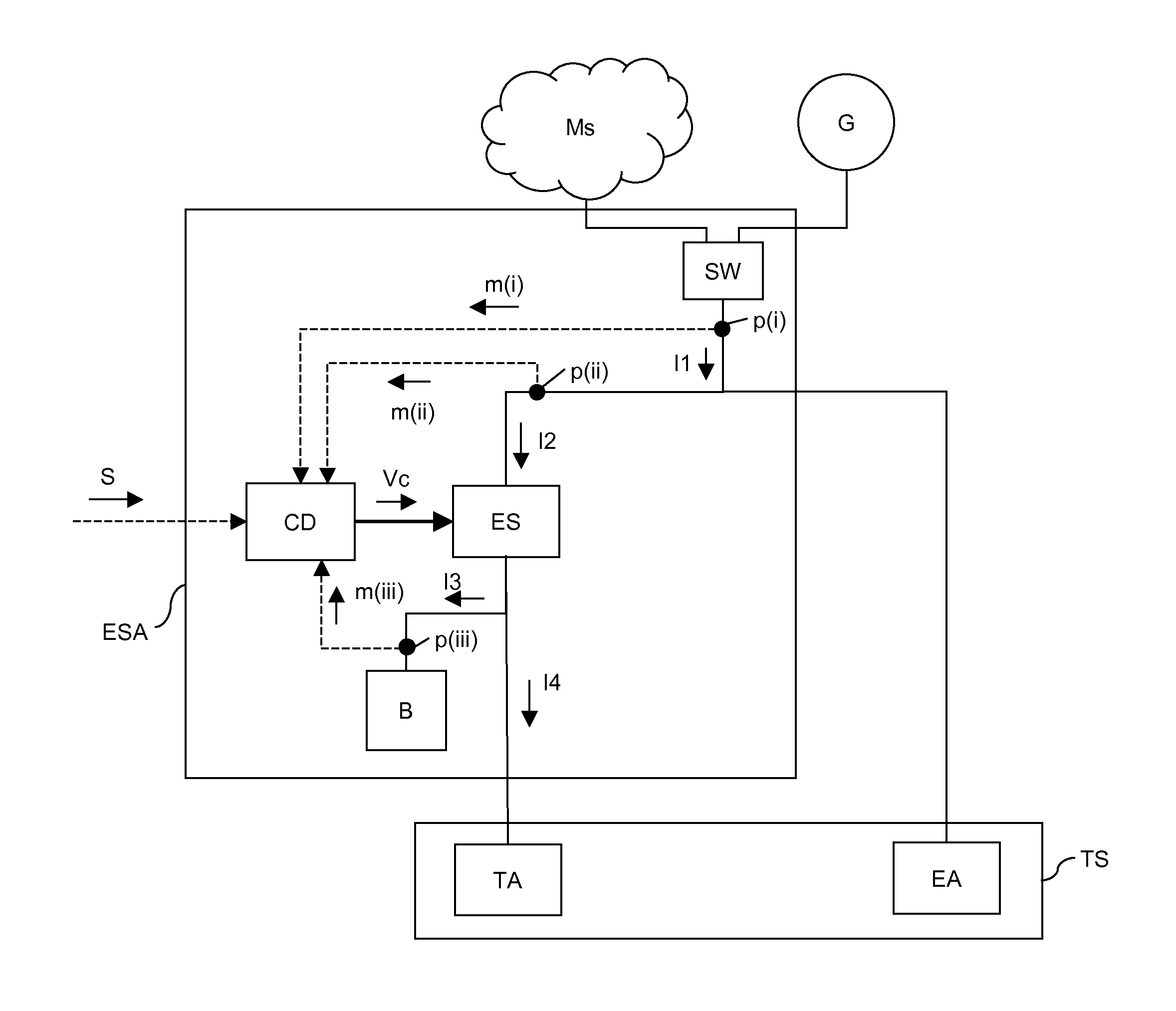

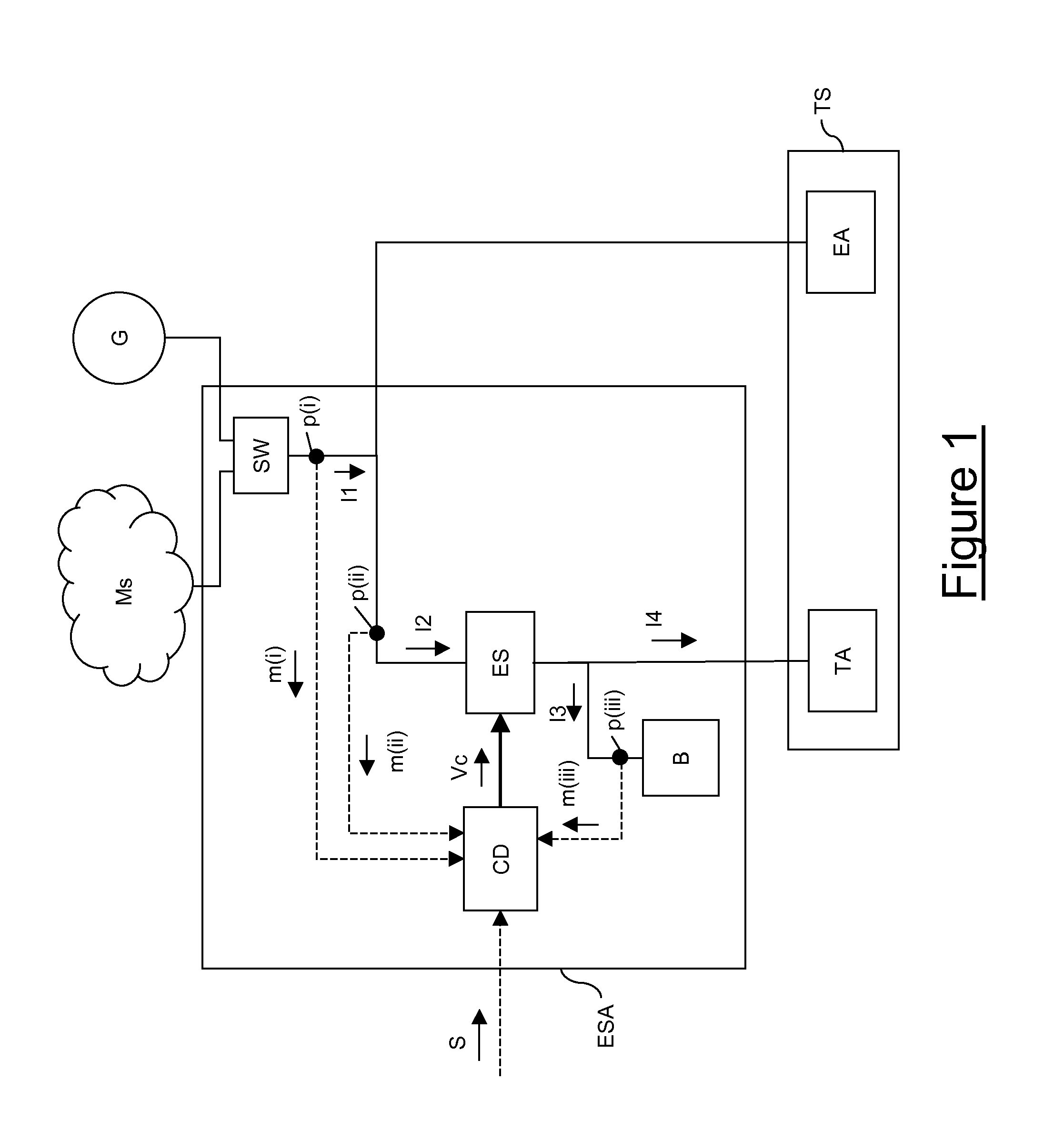

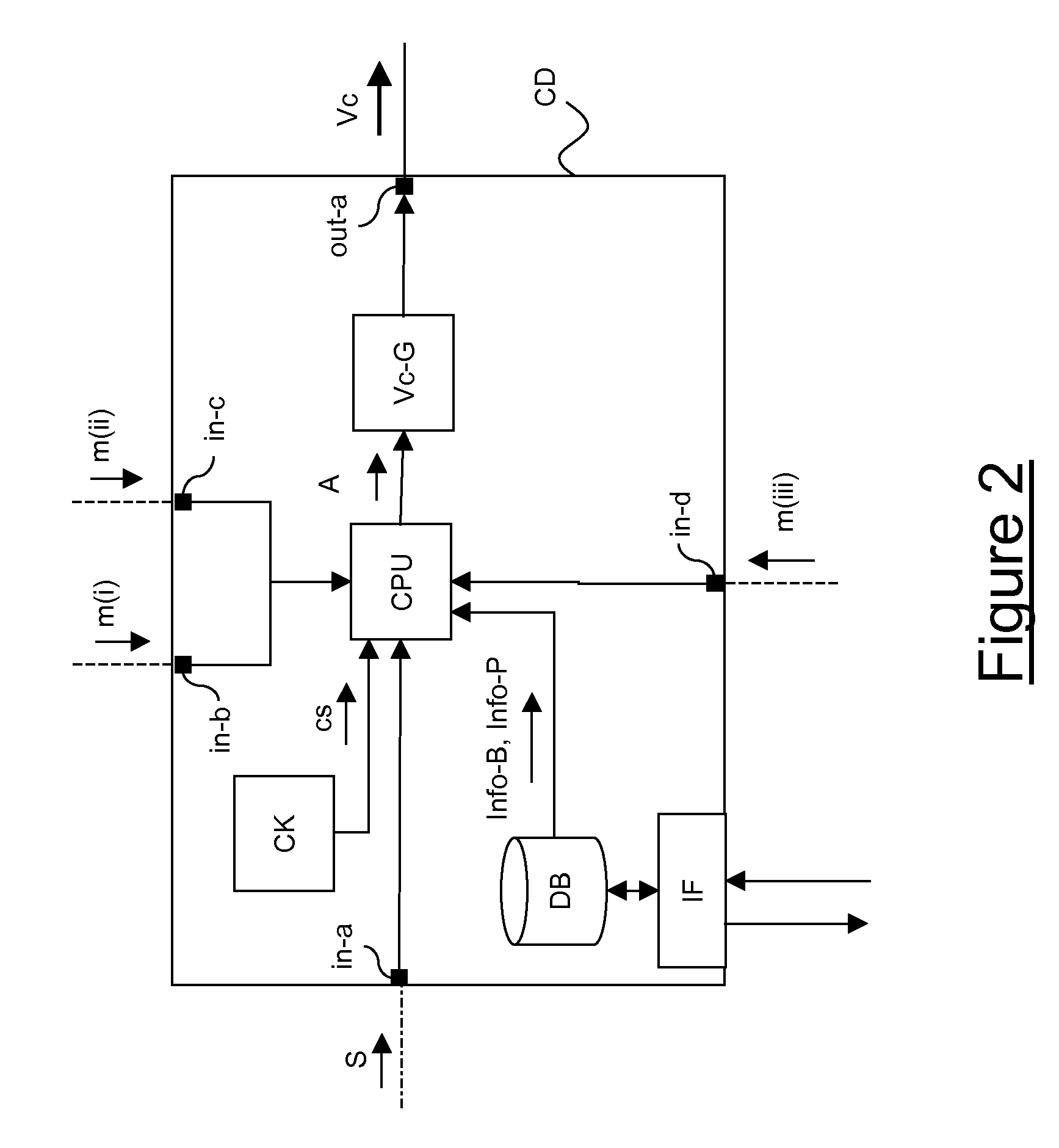

Electricity supply apparatus of an industrial site

ActiveUS20110018502A1Optimising battery usageMinimize risk of damageBatteries circuit arrangementsPower network operation systems integrationElectricityControl signal

An electricity supply apparatus includes a control device configured to calculate an amplitude of a control signal and to generate the control signal; an energy station configured to draw a current from a mains, to provide part of the drawn current to the load, to receive the control signal from the control device, and to vary the drawn current according to the amplitude; and a battery configured to recharge by drawing part of the drawn current and to discharge by supplying the load. The apparatus is characterized in that the control device is further configured to calculate the amplitude of the control signal also according to battery information relating to a recharge and / or a discharge condition of the battery.

Owner:TELECOM ITALIA SPA

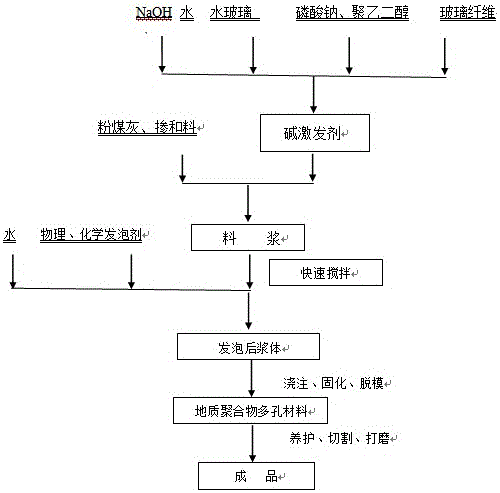

Flyash geopolymer based porous material and preparation process thereof

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

Water curing reverse osmosis membrane chemical cleaning method

InactiveCN101224391AExtended service lifeEasy to cleanReverse osmosisCalcium bicarbonateReverse osmosis

The invention relates to a chemical cleaning method used for a water disposal reverse osmosis membrane, relating to a chemical cleaning method used for cleaning water disposal reverse osmosis membranes in the industrial water disposal process. The invention is characterized in that NaOH solution which contains EDTA is adopted to clean microorganism, organism and silicon dioxide, etc. pollutants on the reverse osmosis membrane; HCI solution is adopted to clean calcium bicarbonate and magnesium bicarbonate filth on the reverse osmosis membrane. By adopting the method of the invention, the reverse osmosis membrane used by captive power plant water disposal can be effectively cleaned in the alumina preparation process. The invention has better cleaning effect, reliable and practiced technique and convenient operation process.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Multifunctional industrial water disposal agent and preparing method thereof

InactiveCN105645611AExtended service lifeImprove heat transfer efficiencyScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processWater qualityHardness

The invention relates to the technical field of industrial recycling cooling water treatment, in particular to a multifunctional industrial water disposal agent with scale inhibition, corrosion inhibition, pre-filming, film repairing, sterilization and algae removing functions and a preparing method thereof. The multifunctional industrial water disposal agent is prepared from scale dissolving agent, scale inhibition agent, dispersing agent, fluidization agent, anticorrosive agent and biocide according to a certain mass percent. A layer of dense protective film can be formed on the surface of a device by the multifunctional industrial water disposal agent, the protective film has a self-repairing function, so that the integrity of the protective film is maintained, and then complicated operation is avoided, the number of required devices is reduced and cost is reduced. The multifunctional industrial water disposal agent can be used in the northern area with three-high water quality (high heavy metal content, high hardness and high pH value) and can also be used in the southern area with low-hardness corrosive water.

Owner:QINGDAO KERUN BIOTECH CO LTD

Low-phosphorus water treatment composition

InactiveCN101746904AReduce phosphorus contentReduce contentScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processCarboxylic saltWater quality

The invention relates to a low-phosphorus water treatment composition, which comprises the following compositions in part by weight: 1 to 3 parts of phosphorus carboxylate, 1 to 30 parts of dirt dispersion agent and 1 to 5 parts of bactericide and algicide. When the concentration multiple is 2 to 6, the corrosion rate and the scale deposition rate of a circulating cooling water system of carbon steel and copper pipelines are all smaller than circulating water quality monitoring and controlling indexes, the industrial water is saved, the environmental pollution is reduced, and the low-phosphorus water treatment composition is widely applied to similar circulating cooling water systems in chemical engineering, petrifaction, steel, electric power and the like, and has great social and economic benefits and promotion value.

Owner:NANJING UNIV OF TECH

Method for preparing low-density high-performance SiO2 aerogel at constant pressure

The invention discloses a method for preparing low-density high-performance SiO2 aerogel at constant pressure, which comprises the following steps of: performing ion exchange to mixed solution of industrial water glass and deionized water with cation exchange resin by using a two-step method of sol-gel so as to remove Na<+>; adjusting a pH value by using HC1 to obtain sol; keeping stand of the sol and adjusting the pH value by using NH2.H2O to obtain wet gel; carrying out fractional aging and solvent exchange; putting the wet gel into aging liquid which is obtained by mixing ethyl orthosilicate and ethanol for aging; putting the aged wet gel into normal hexane for carrying out solvent exchange; performing surface modification; putting the wet gel subjected to the solvent exchange into mixed liquid of trimethylchlorosilane and normal hexane for performing surface modification; and finally, drying the mixture at the constant pressure and putting the wet gel subjected to the surface modification into normal hexane for drying at the constant pressure. The method has the advantages of low preparation process cost, excellent product performance and controlled reaction process.

Owner:陕西得波材料科技有限公司

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS20050150520A1Reduced pHDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

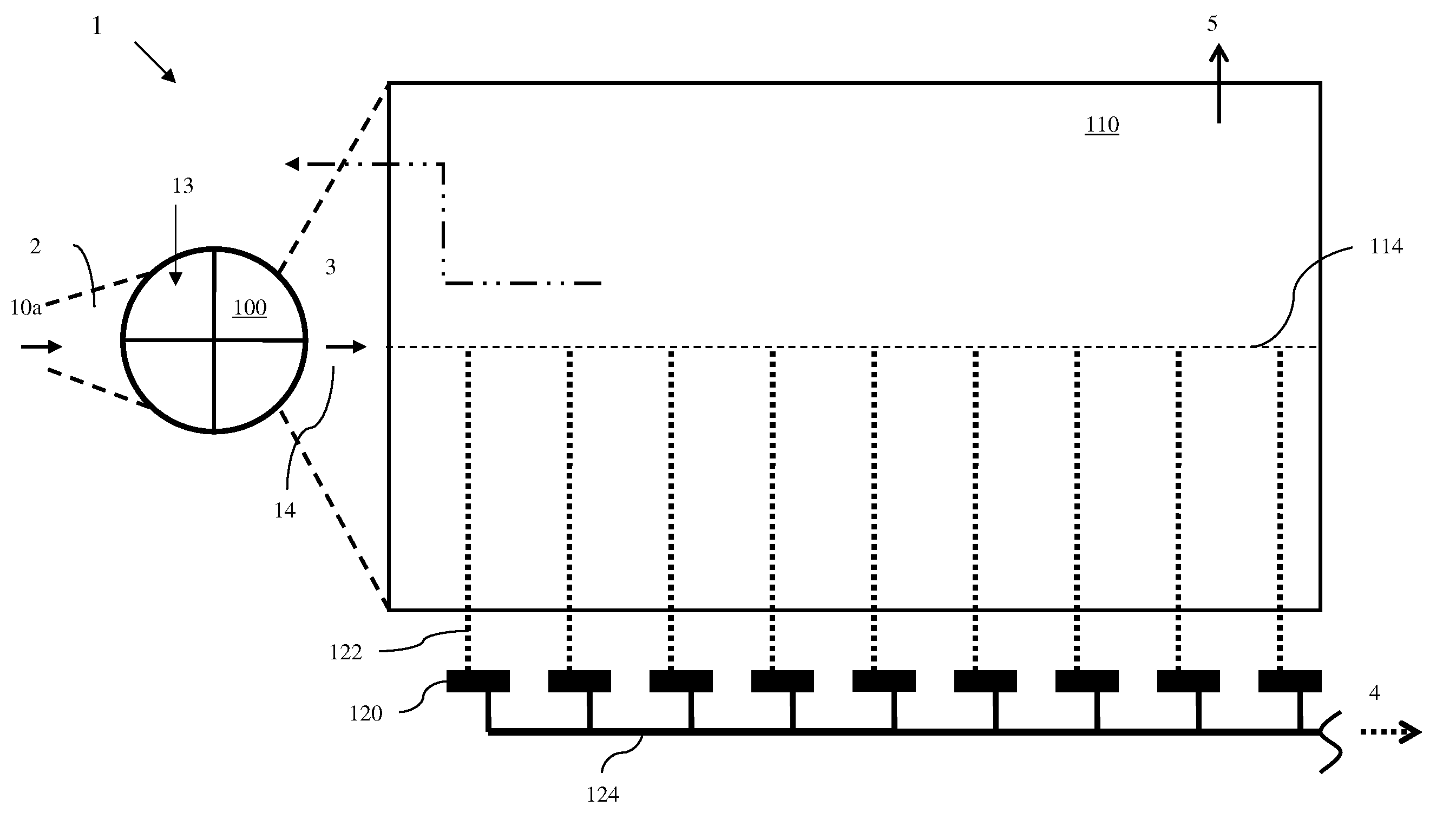

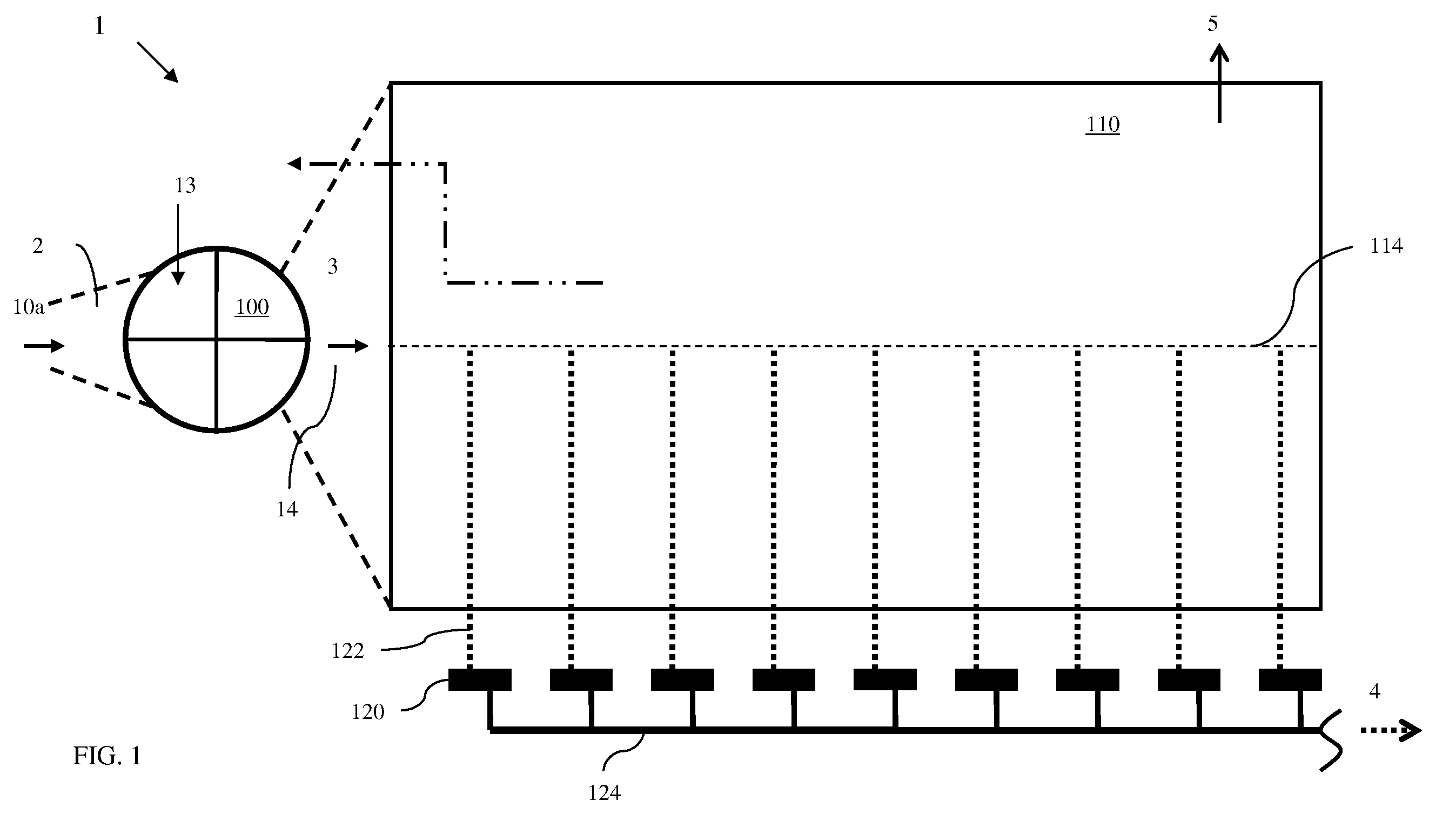

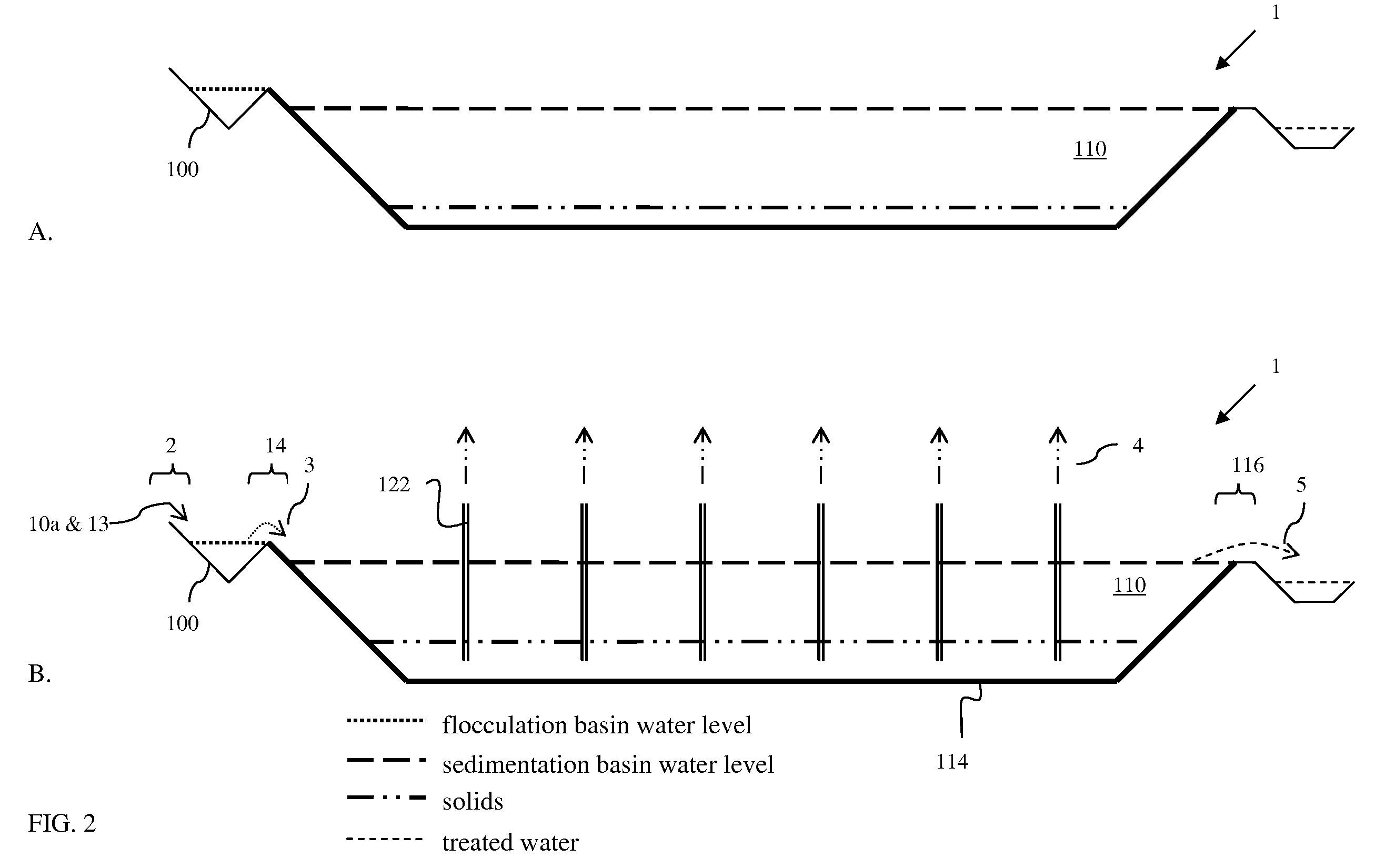

Industrial waste water treatment process

InactiveUS7491333B1Easy to reuseFacilitated releaseSolid sorbent liquid separationWater/sewage treatment by neutralisationClean Water ActIndustrial waste water

A process for the treatment of industrial waste water. The process includes the steps of admixing partially-treated waste water containing precipitated impurities with a flocculating agent in a flocculation basin, directing the admixed waste water to an elongated sedimentation basin, allowing flocculated solids in the waste water to settle to the bottom of the sedimentation basin, removing the settled solids from the bottom of the sedimentation basin and directing the treated water from the sedimentation basin. The process can further include the step of adjusting the pH of the waste water to precipitate impurities in the waste water prior to the addition of the flocculation agent. The elongated sedimentation basin can include a pair of sloped sides to consolidate the settled solids at the bottom of the basin. The settled solids can then be removed by suction. The basins can be formed from the excavation or impoundment of earth in an area adjacent to a waste water-generating facility. Furthermore, the flow of the streams between basins can be controlled by overflow, with flow rates further controlled by recycle of solids and treated water. The treatment of industrial water according to the present processes allows removal of impurities such that the water is suitable for internal re-use in an operating phosphoric acid facility or release. Additionally, the process is able to treat acidic industrial waste water by the removal of impurities as a preliminary treatment stage leading to discharge of the final treated water to natural water bodies in compliance with the Federal Clean Water Act. Moreover, treated water may be processed by reverse osmosis to remove residual impurities. By employing the processes taught herein reverse osmosis becomes possible and practicable in the context of industrial waste water treatment. Treatment of waste water in accordance with the present invention will require less expensive capital equipment for the separation stages and provide a more concentrated solids stream.

Owner:CLEANWATER TECH

Method for preparing silicon dioxide with large pore volume and large aperture

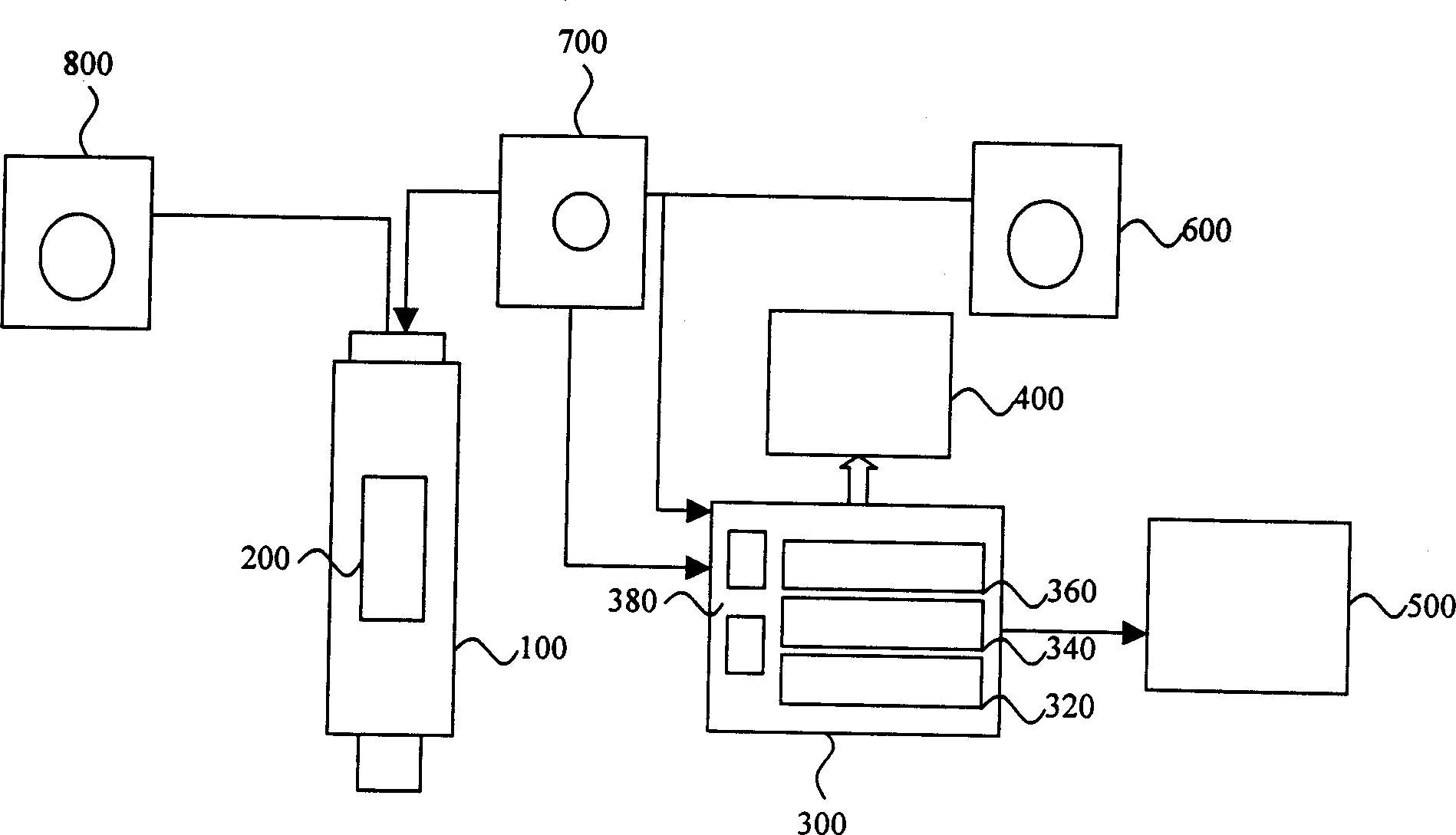

InactiveCN101112991AImprove precipitation effectOrderly distribution of poresSilicaActive agentWater soluble

The invention relates to a preparation method of large pore volume and large pore diameter silica. With industrial water glass as silica source, water soluble polymer and surfactant as hydrophobic agent and hole forming template, by controlling reaction conditions such as temperature, hydrophobic agent, final ph value, etc., the large pore volume silica products are produced; the pore diameter is narrowly distributed, the pore volume is between 2-2.5cm3 / g and the average pore diameter is between 18-35 nm. Especially, the more optimal three-step heating regulation is more beneficial to the stability of hole forming and hole structure and that the distribution of pore diameter reaches between 25-35nm is more proper to be used as flatting agent.

Owner:BEIJING UNIV OF CHEM TECH

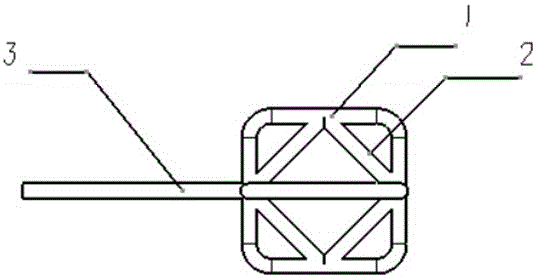

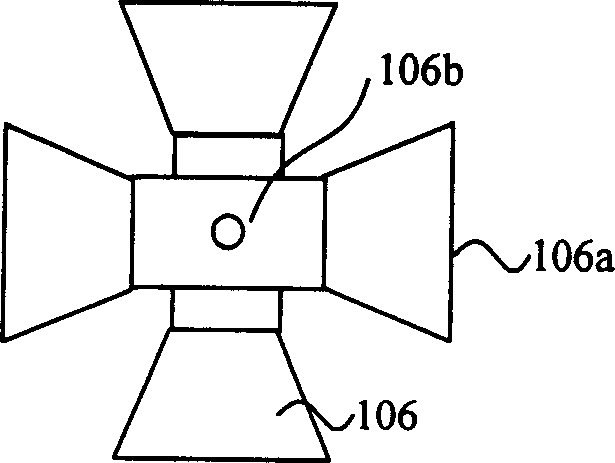

Ultrasonic well logging instrument

InactiveCN1605713AImprove anti-interference abilityStrong transmission abilitySurveySonificationWell logging

The ultrasonic well logging instrument includes well instrument subsystem for sending ultrasonic pulse signal, receiving well wall reflected ultrasonic signal and converting it into electric pulse signal and performing the amplification, filtering and conversion; ground instrument subsystem for providing the well instrument subsystem with proper electric energy, generating sync pulse, receiving the signal from the well instrument subsystem, amplifying and converting the received signal and acquiring correlated data; and computer subsystem connected to the ground instrument subsystem via data lines for comprehensive data acquisition and processing. The present invention is suitable for measurement in small bore well bore with small specific weight slurry, great bore deep well, well bore with great specific weight slurry and well of industrial water.

Owner:SHANDONG UNIV OF SCI & TECH

Acoustic sensor for obstruction in a device circulating vortex-flow fluid

InactiveUS20050173354A1Easy to controlEasy maintenanceWater/sewage treatment by centrifugal separationAnalysing solids using sonic/ultrasonic/infrasonic wavesSludgeOctave

The invention concerns an acoustic sensor (44) for identifying obstruction of a circular grit trap for recycling fine sand in an industrial water clarifying plant. The circular grit trap comprises a cylindrical body having an outer wall and having at one first end a first sand-containing fluid inlet for receiving sludge and fine sand and a first overflow outlet of fluid not containing sand orthogonal to the fluid inlet, to evacuate said sludge, and at a second end a second sand-containing fluid underflow outlet coaxial with the first fluid outlet, to recover said sand. The acoustic sensor is sensitive to the noise radiated by the flow of the sand-containing fluid in the circular grit trap and is applied against the outer wall of the cylindrical body of the circular grit trap, in the plane of the fluid inlet but not coaxially therewith. Said acoustic sensor transmits a warning signal when an abnormal amplitude variation of sound level is measured in the bands of ⅓ octave centered on frequencies of 25 Hz or 200 Hz.

Owner:ODISHA TV

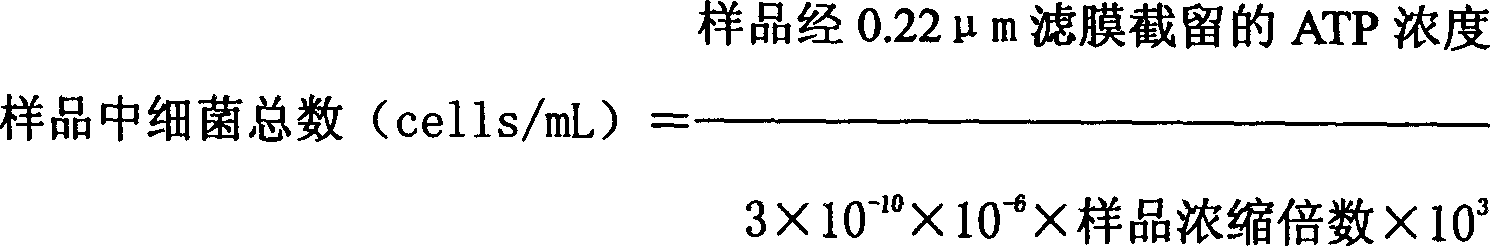

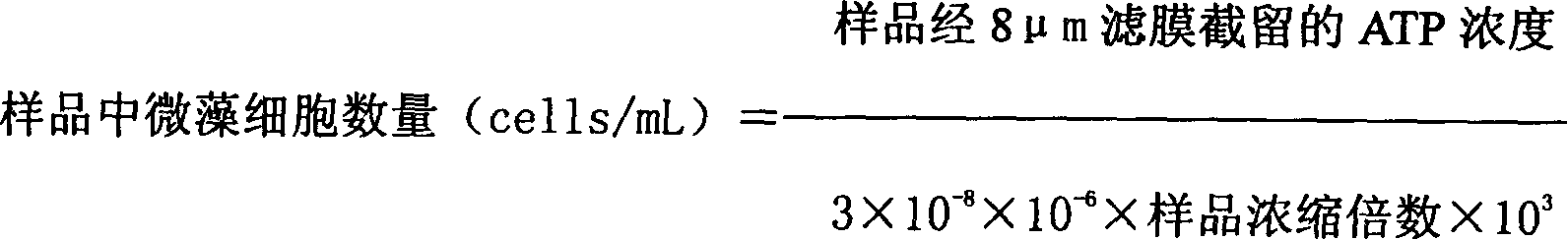

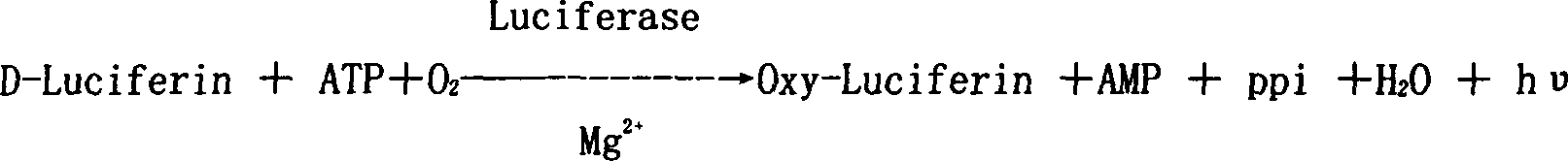

Rapid microbiological detection and reagent for environmental water body

InactiveCN1680805AChemiluminescene/bioluminescencePreparing sample for investigationLinear regressionIndustrial water

A fast detection method of water microbe includes filtering water sample by microhole filtering film with different hole diameter, carrying out ATP luminous detection for used filtering film and for ATP standard solution and new microhole filtering film, calculating linear regression equation of Lg [ATP] = A+ BLg [CPM] based on logarithmic relation of ATP concentration to its luminous pulse counts and calculating out microbe content in water as well as ATP concentration in sample according CPM value of filtering film.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY +1

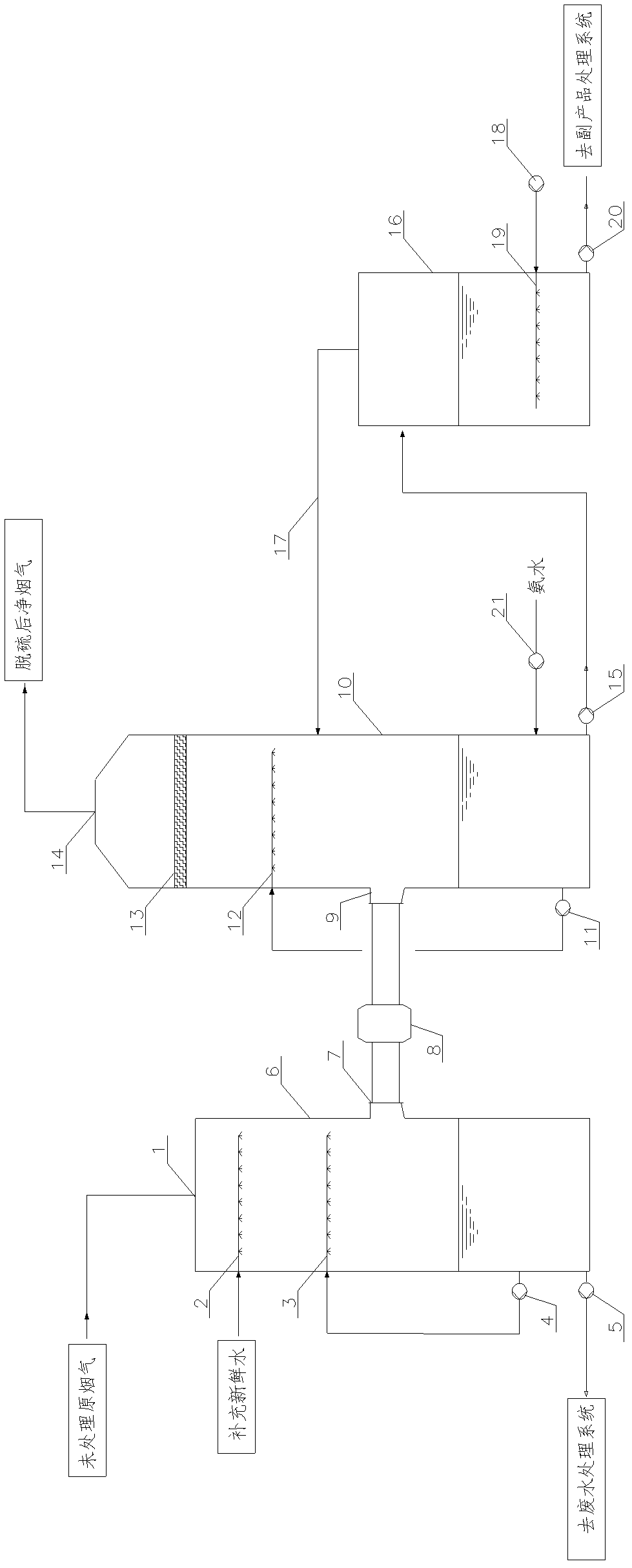

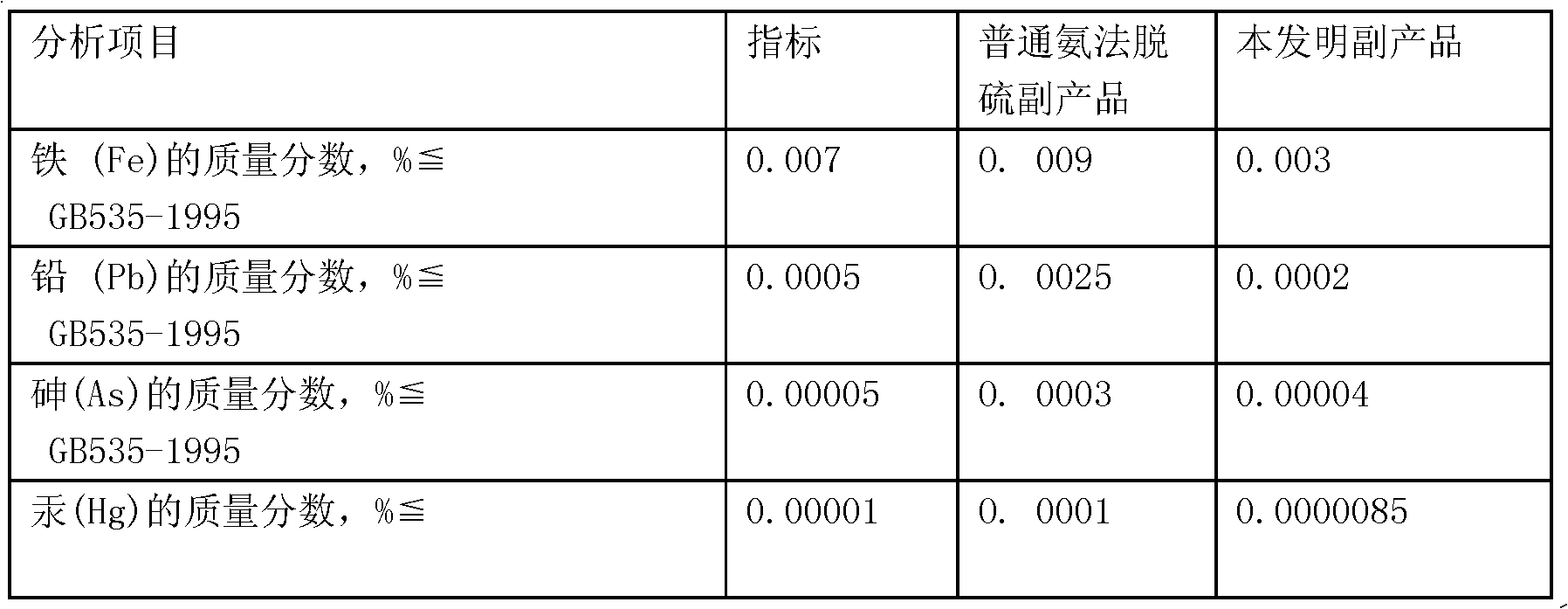

Ammonia desulfurization method for effectively removing chlorine and fluorine ions and heavy metal ions

InactiveCN102423613AAvoid secondary pollutionReduce heavy metal contentCombination devicesPerfluorocarbons/hydrofluorocarbons captureWater dischargeSlurry

The invention relates to an ammonia desulfurization method for effectively removing chlorine and fluorine ions and heavy metal ions. The invention is characterized in that prewashing is carried out before flue gas enters into a desulfurization tower, industrial water and / or circulating water can be used as washing liquid in a prewashing tower, circular spraying and washing are performed, 90-95% Cl<-> and F<-> in flue gas are removed, 70%-80% soluble metal ions Fe<3+>, Hg<2+> and Pb<2+> can be removed, 70%-80% of dust is removed, the washed pollutant is sent to a waste water treatment system through slurry-containing waste water discharged from the bottom of the tower for treating to reach the standard and then discharge. The ammonia desulfurization method of the invention can thoroughly eliminate the problems that severe equipment corrosion is caused by enrichment of Cl<-> and F<-> on the desulphurization system, and heavy metal of the finished product fertilizer exceeds the standard.The desulphurization byproduct ammonium sulfate fertilizer obtained by the method can reach or exceed the quality standard of the national standard superior products.

Owner:赵加勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com