Dye acidic waste water treatment method and device

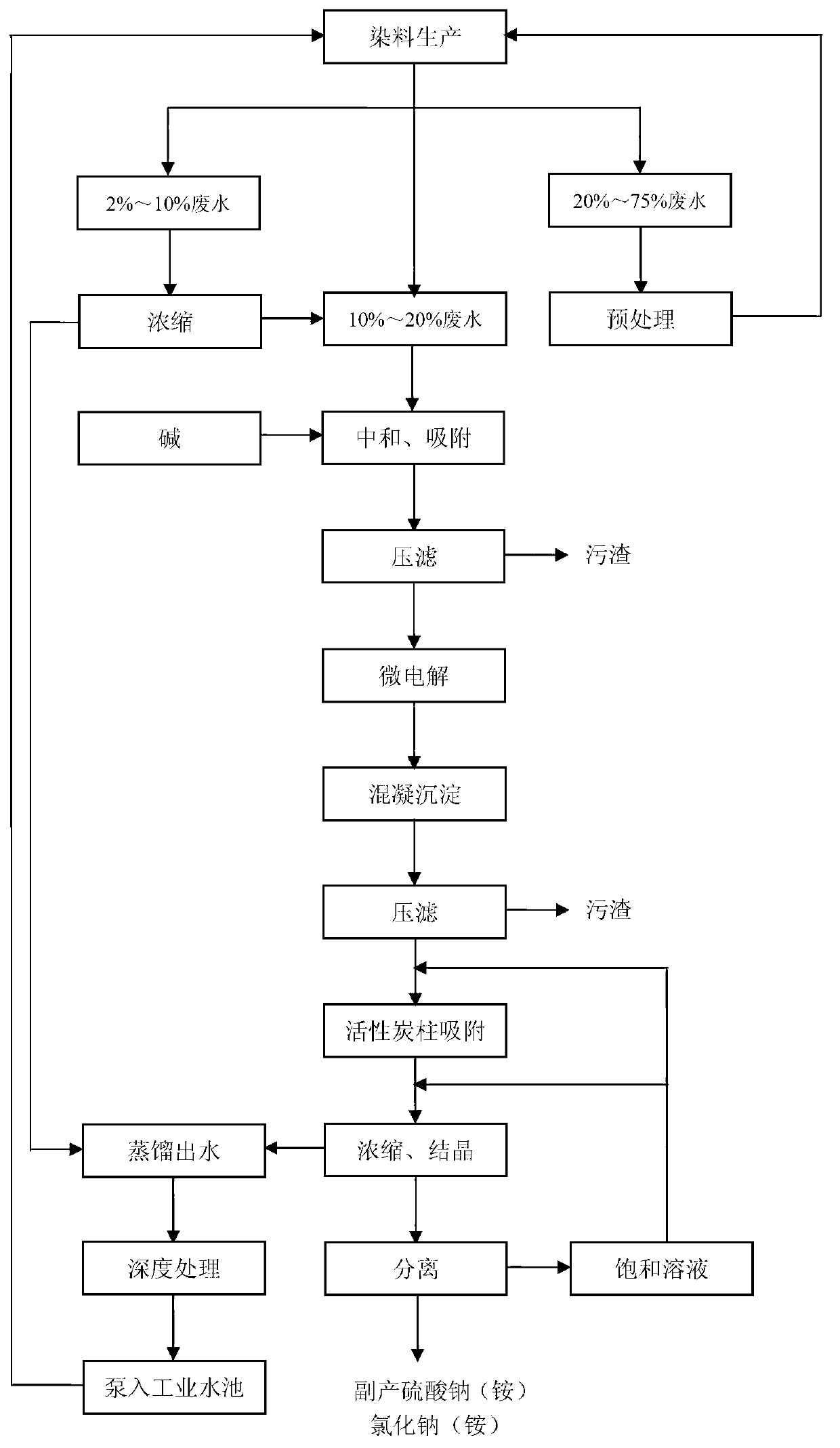

A technology of acid wastewater and treatment method, which is applied in water/sewage treatment, adsorption water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of large amount of oxidant, unsuitable for widespread use, and high treatment cost. The effect of widening the pH range, reducing personnel costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

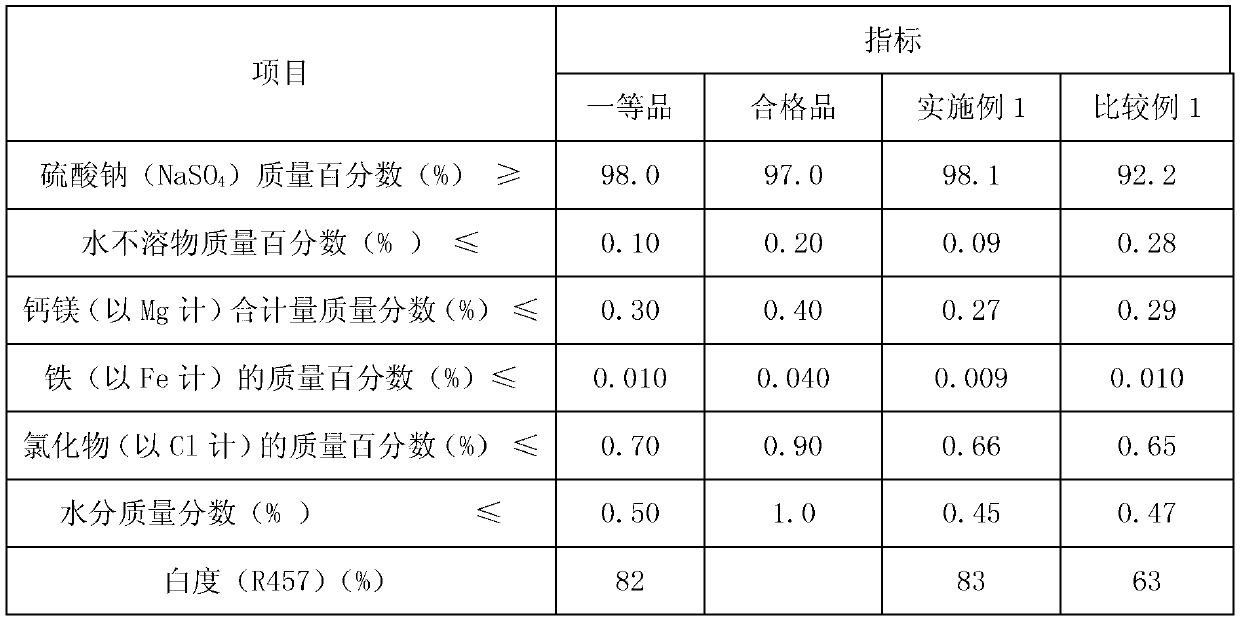

Examples

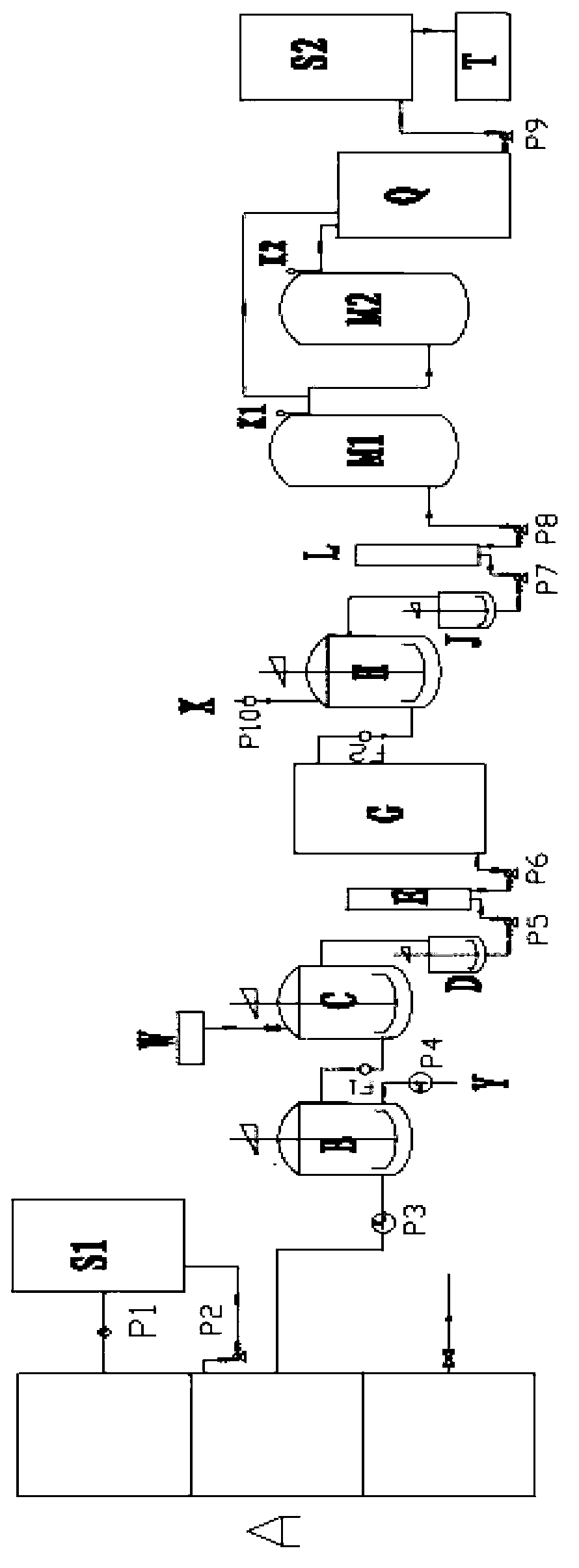

Embodiment 1

[0072] The waste sulfuric acid with a mass percentage of 2% (chroma 256 times, TOC value 1000mg / L) collected by classification is pumped to MVR equipment S1 by pump P1 and concentrated to about 11% sulfuric acid mass percentage. The concentrated waste sulfuric acid is continuously pumped to the neutralization tank B through the metering pump P3, and at the same time, the sodium hydroxide solution is continuously pumped in through the metering pump P4. After the pH value is 8.1 measured by the online pH meter, the neutralization solution passes through the overflow port Continuously flow into the adsorption tank C, and at the same time, the white clay with a mass of 0.3% relative to the influent flow rate is continuously and automatically added by the twisting cage device W for adsorption. The mixed liquid in the pump is filtered by the filter press E, and the filtrate is pumped to the micro electrolytic cell G through the metering pump P6 (wherein the mass ratio of iron is 90%,...

Embodiment 2

[0074] Use the pump P1 to pump the waste hydrochloric acid with a mass percentage of 8% (color 256 times, TOC value 1200mg / L) collected by classification into the MVR equipment S1 to concentrate until the mass percentage of hydrochloric acid is about 11%, and the concentrated waste hydrochloric acid The metering pump P3 is continuously pumped to the neutralization kettle B, and the sodium hydroxide solution is continuously pumped into the metering pump P4 at the same time. After the pH value is 9.2 measured by the online pH meter, the neutralization solution continuously flows into the adsorption kettle C through the overflow port, and at the same time The bentonite whose mass is 1% relative to the influent flow rate is continuously and automatically added by the twisting cage device W for adsorption. The mixed solution after adsorption flows into the transfer kettle D, and the pump P5 pumps the mixed solution in the transfer kettle D to the pressure. The filter E is filtered, ...

Embodiment 3

[0076] The waste hydrochloric acid collected by classification with a mass percentage of 12% (chromaticity 512 times, TOC value 1500mg / L) is continuously pumped to the neutralization tank B through the metering pump P3, and liquid ammonia is continuously pumped into the neutralization tank B through the metering pump P4 at the same time. After the pH value measured by the pH meter is 8.5, the neutralization solution flows into the adsorption kettle C through the overflow port, and at the same time, the clay with a mass of 5% relative to the influent flow rate is continuously and automatically added by the twisting cage device W for adsorption. The mixed solution flows into the transfer kettle D, and at the same time, the mixed solution in the transfer kettle D is pumped to the filter press E for filtration by the pump P5, and the filtrate is pumped to the micro electrolytic cell G (the mass ratio of iron is 70%, and the mass ratio of copper is 70% by the metering pump P6). ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com