Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2015results about How to "Adjustable thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

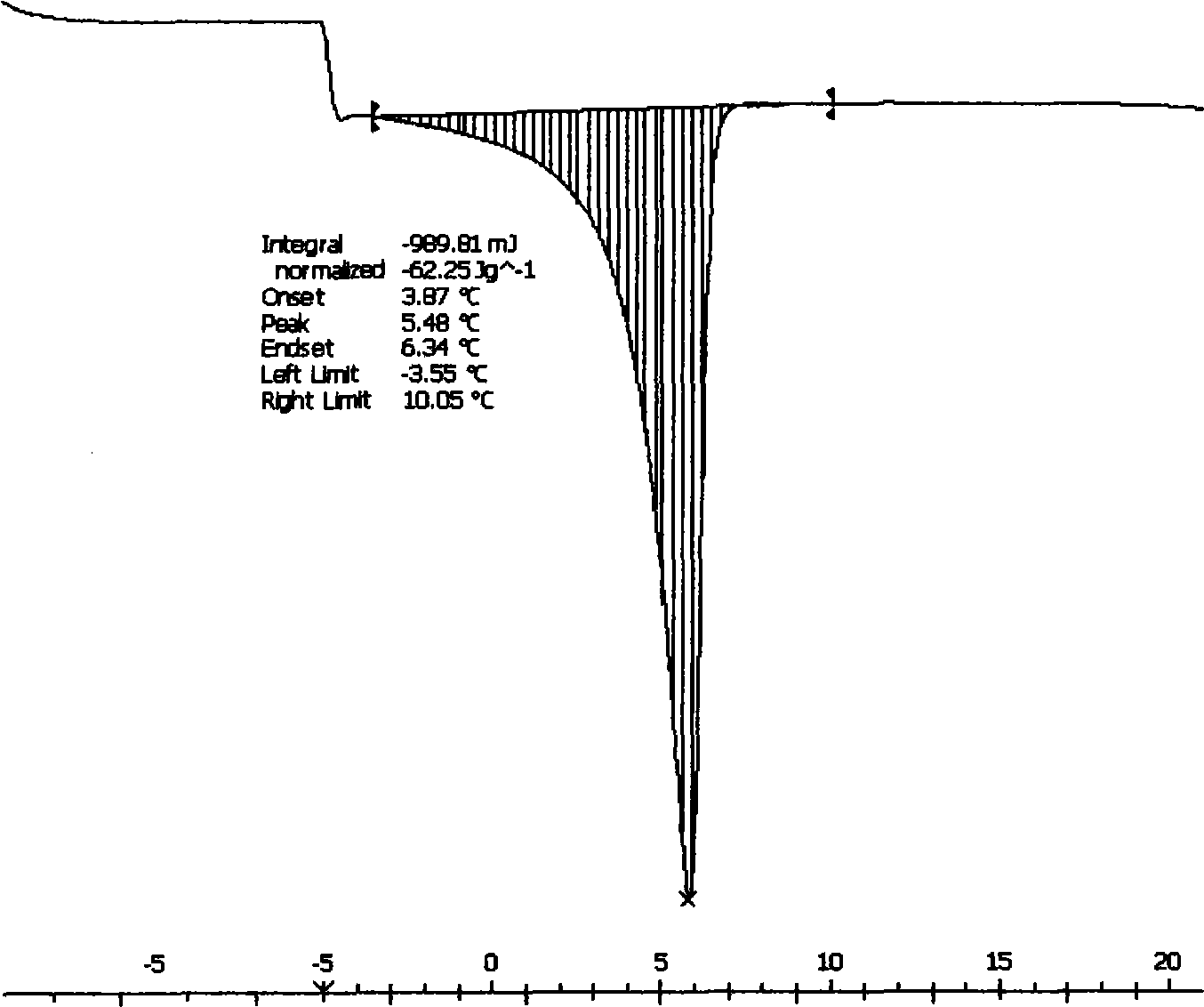

Microcapsule of organic phase change energy storage material and preparation method thereof

ActiveCN101555401AHas infrared reflective propertiesHas infrared absorption propertiesEnergy storageHeat-exchange elementsChemistryIn situ polymerization

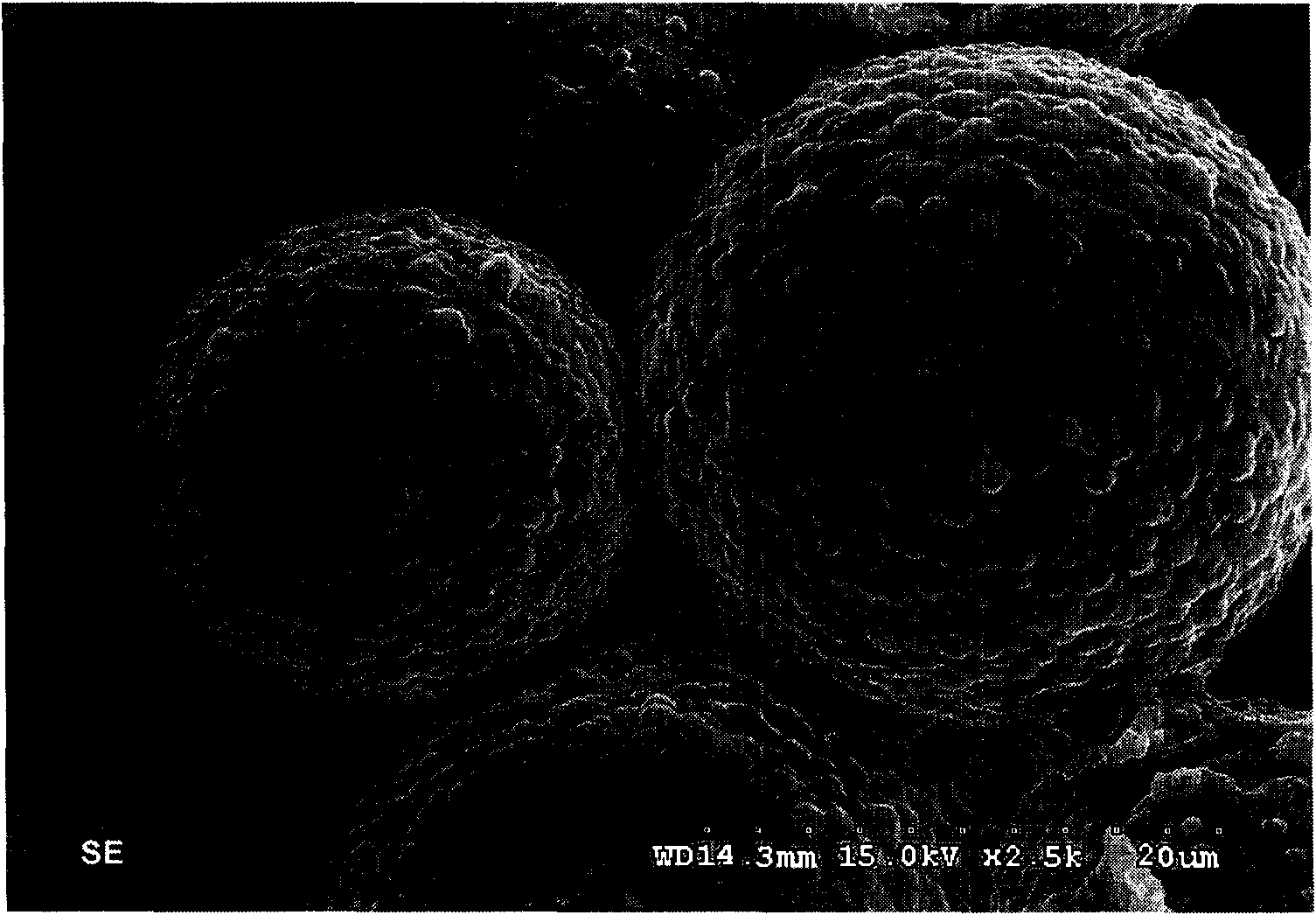

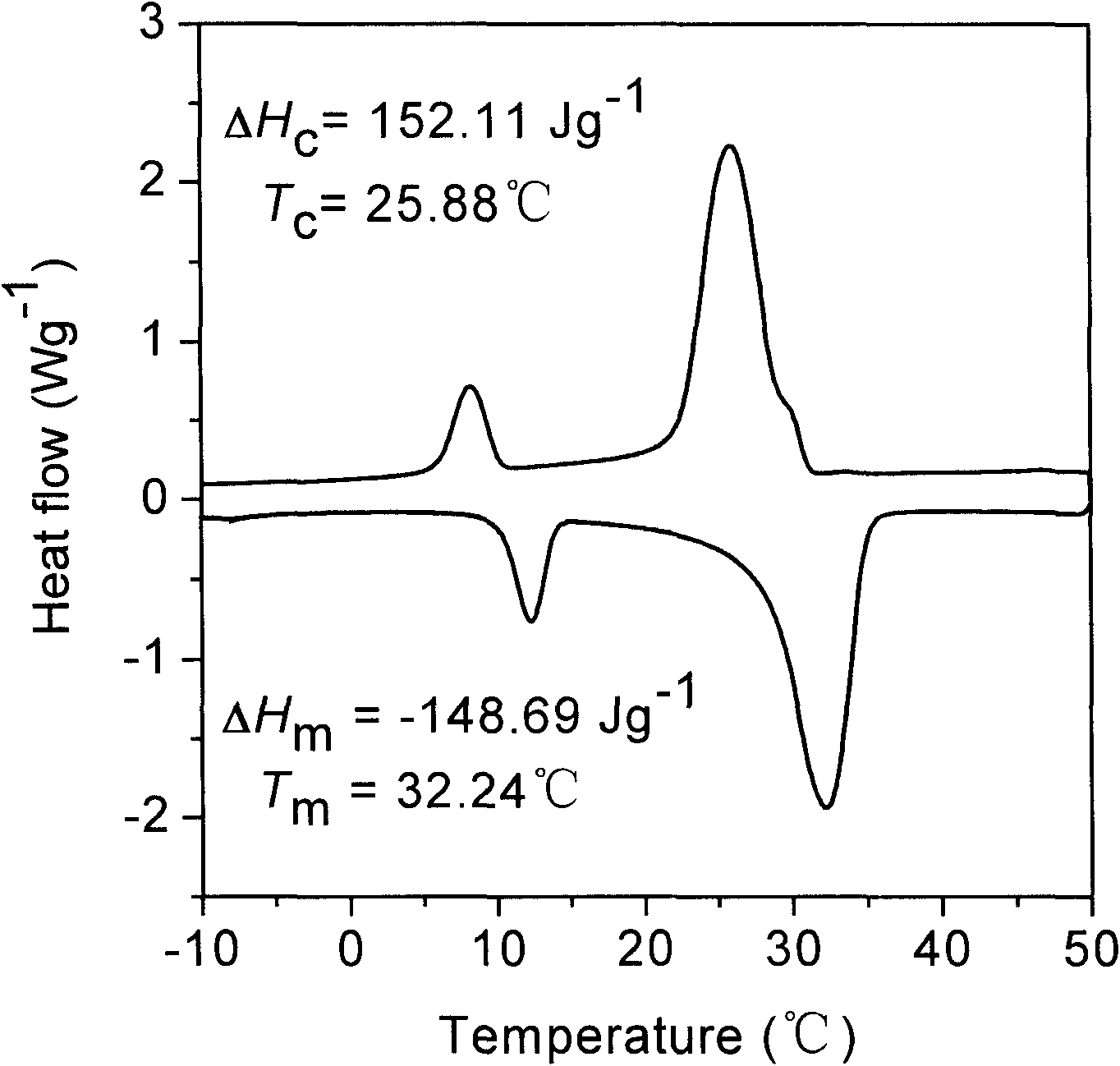

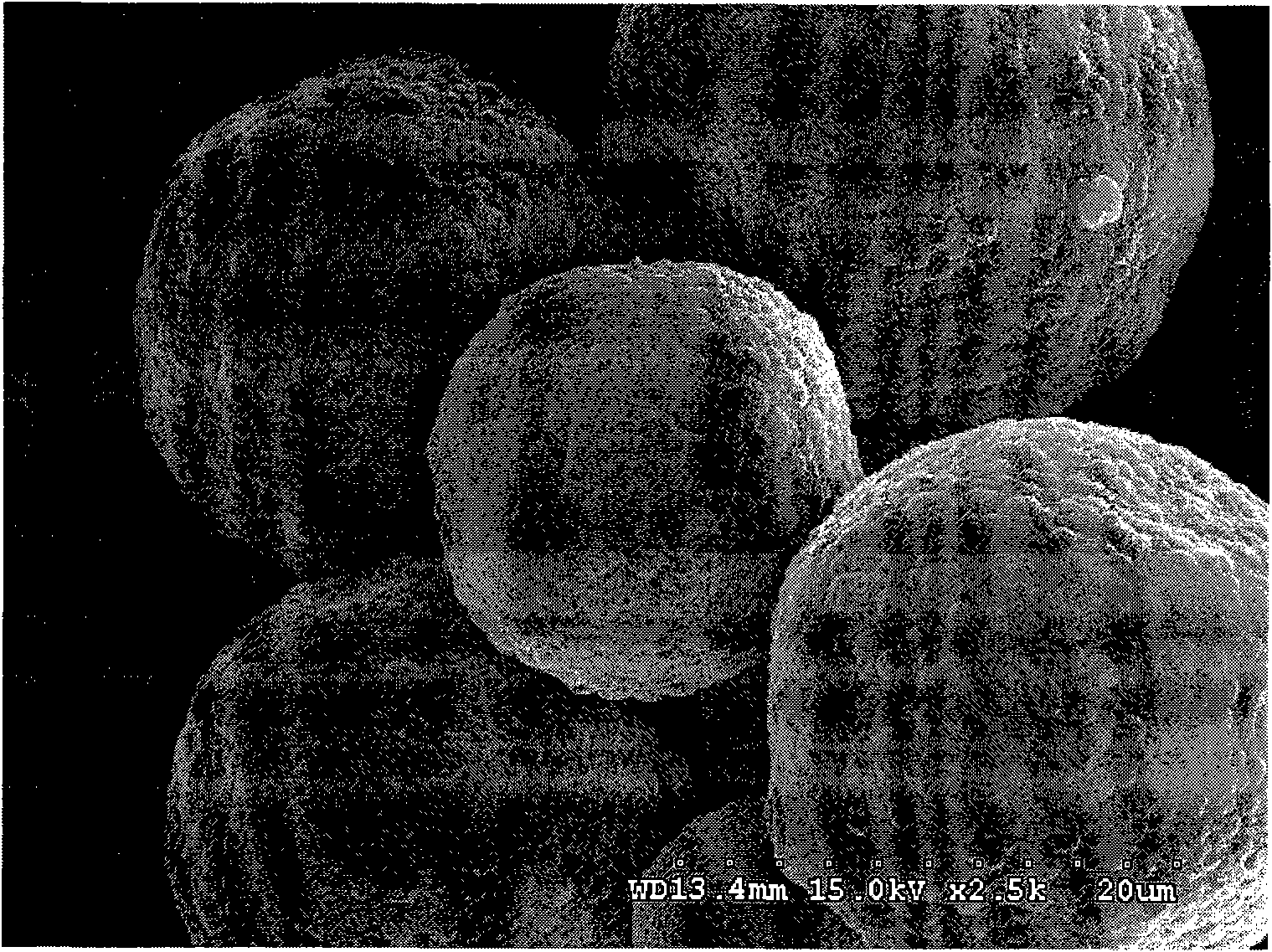

The invention discloses a microcapsule of an organic phase change energy storage material and a preparation method thereof. The microcapsule of an organic phase change energy storage material comprises a core and a nucleocapsid, wherein the material of the core comprises the organic phase change energy storage material; the nucleocapsid at least comprises an inner layer and an outer layer, the inner layer is packaged by any one of an in situ polymerization method, an interface polymerization method, a reaction phase separating method, a double agglomeration method and a sol-gal process, and the outer layer is packaged by any one of an in situ polymerization method, a reaction phase separating method, a sol-gal process and a double agglomeration method. The microcapsule has adjustable size, nucleocapsid composition and shell thickness, favorable flexibility, mechanical strength, penetrability resistance and dispersibility and can be widely applied to the fields of energy sources, materials, aero-space, textile, electric power, medical apparatus, architecture, and the like, such as solar utilization, industrial afterheat and waste heat recovery, architecture energy storage, dress with constant temperature, air conditioners for cool and heat accumulation, constant temperature of electric appliances, and the like.

Owner:BEIJING NEW BUILDING MATERIAL

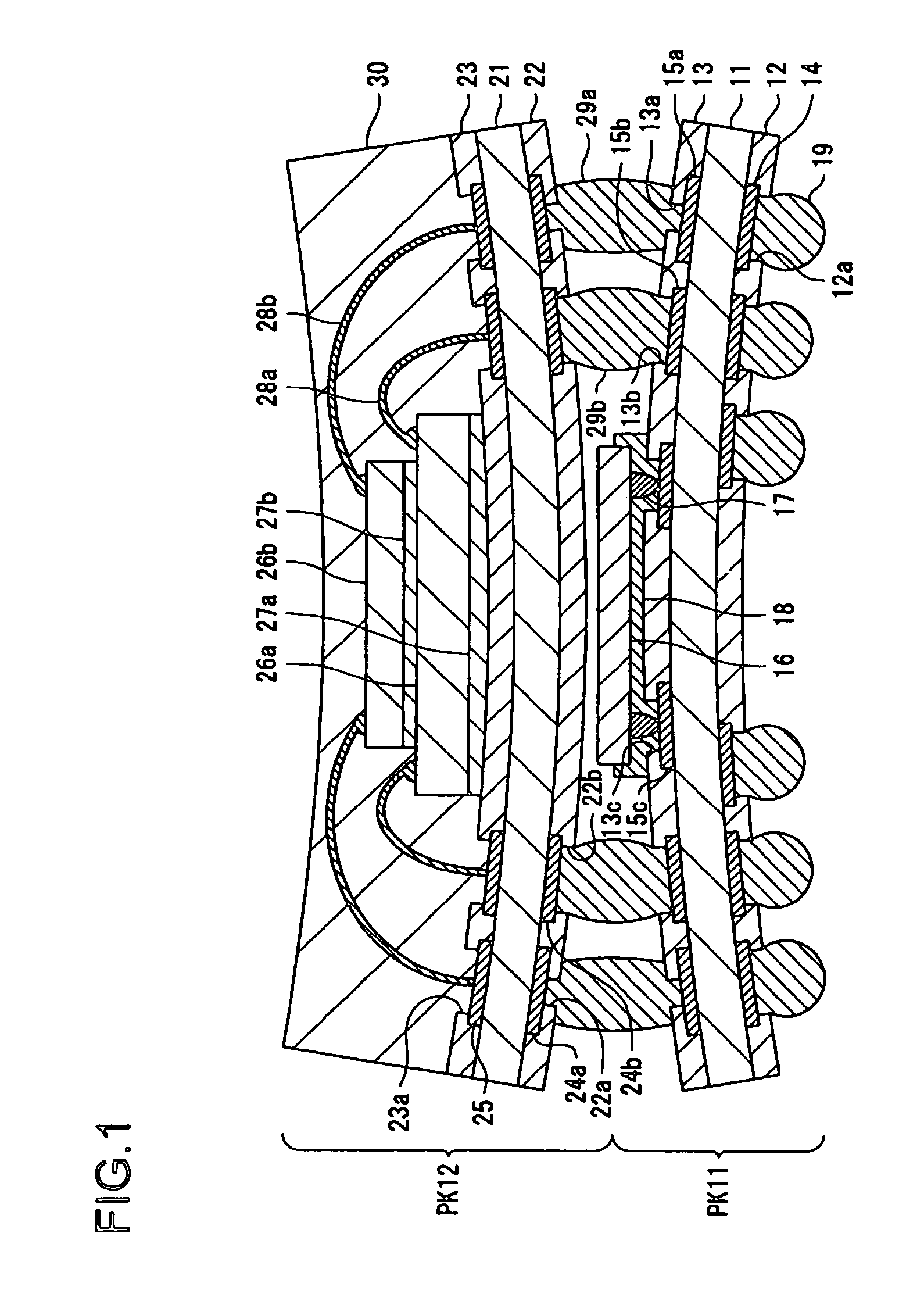

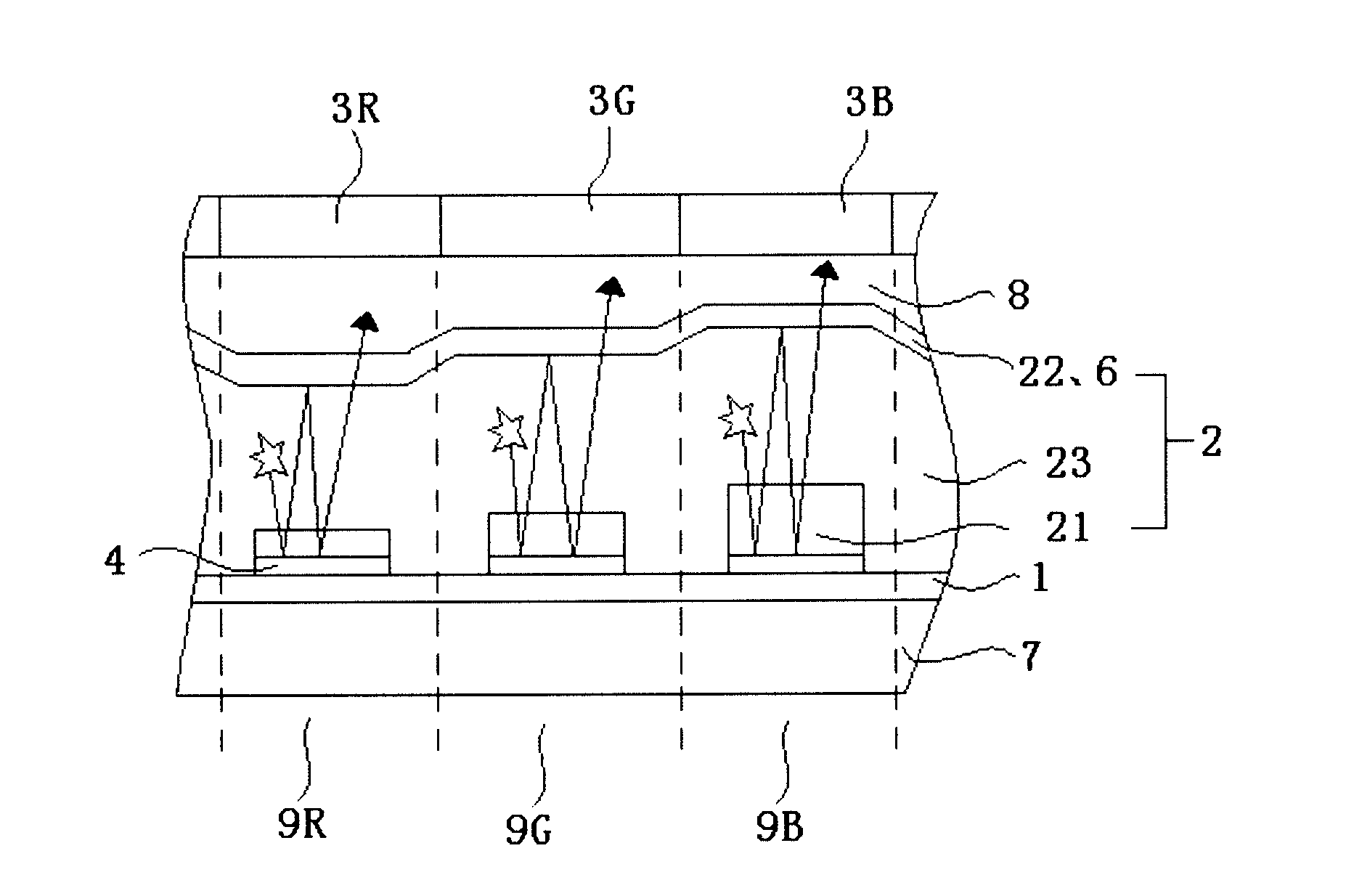

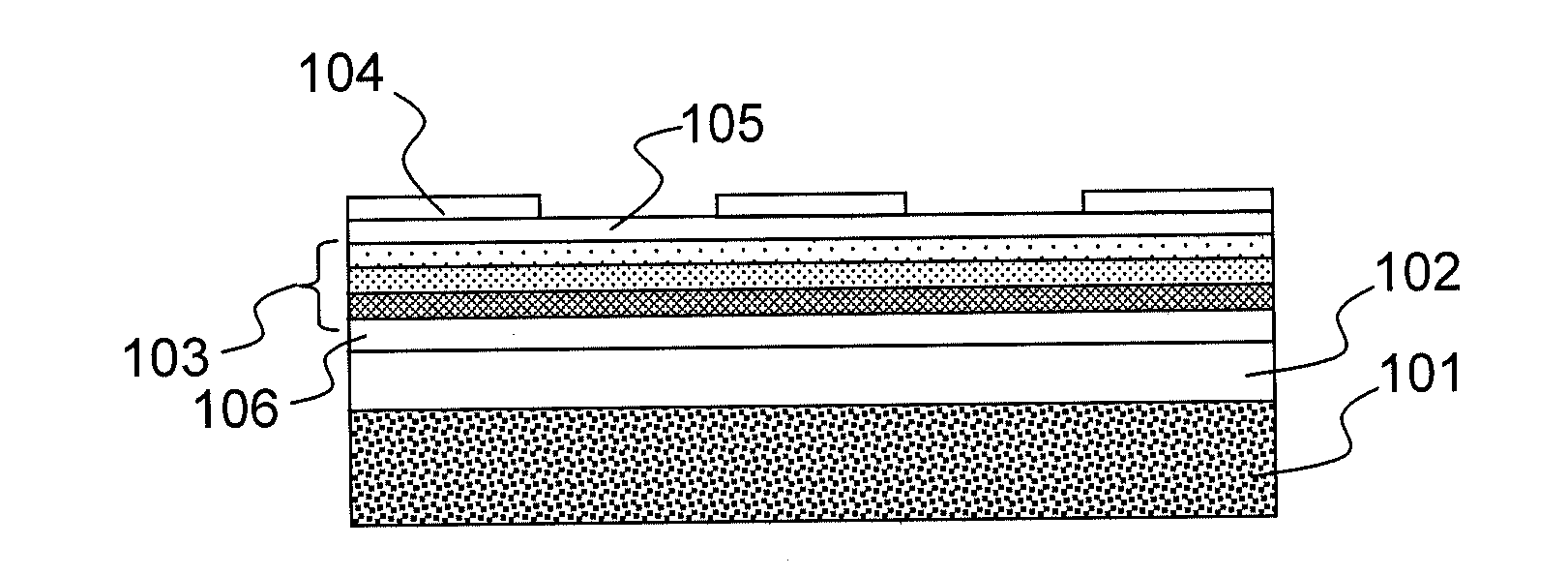

Light emitting diode

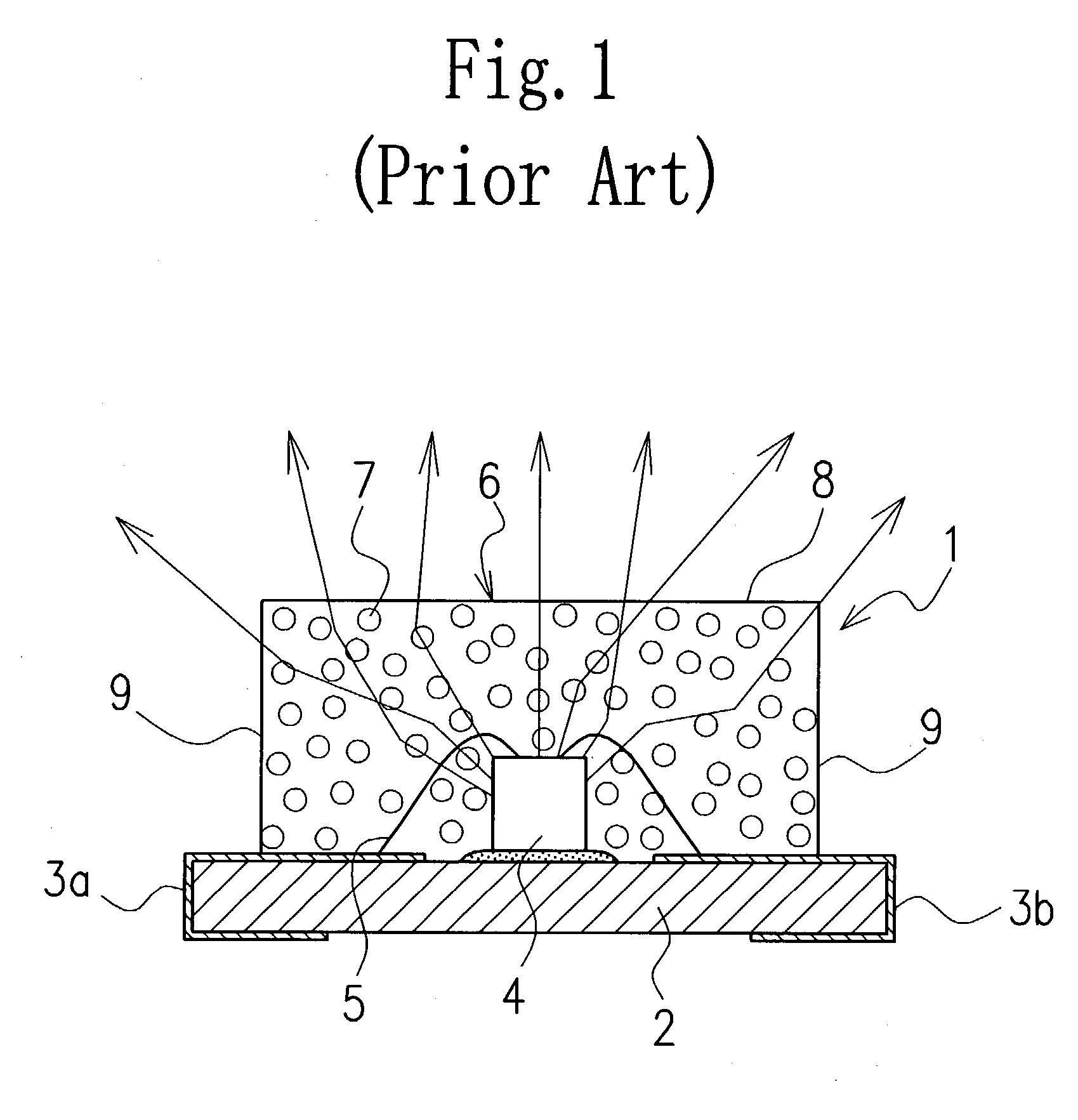

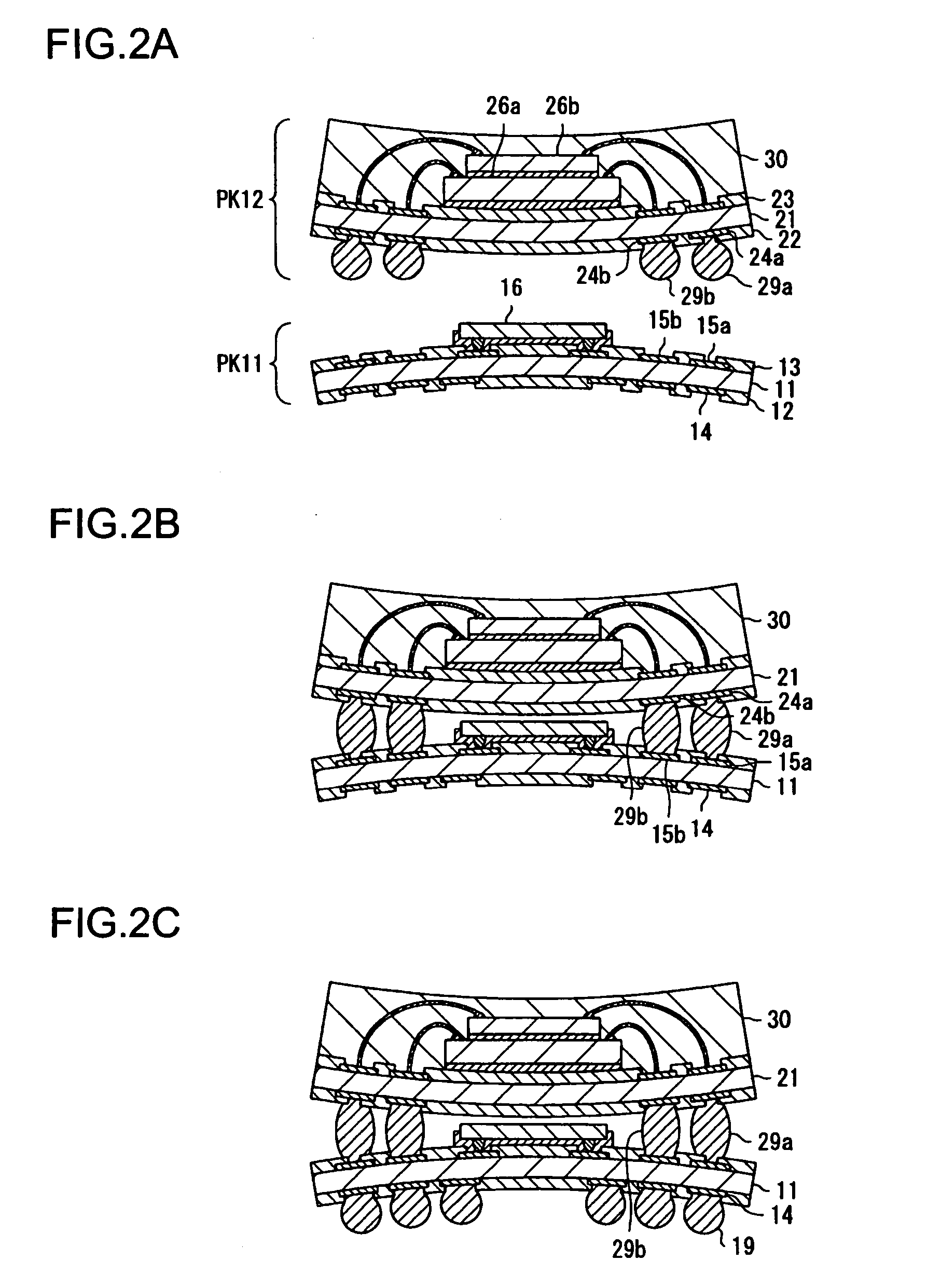

InactiveUS20030189217A1Improve reflectivityTransmissivity decreaseSolid-state devicesSemiconductor devicesSealantLight-emitting diode

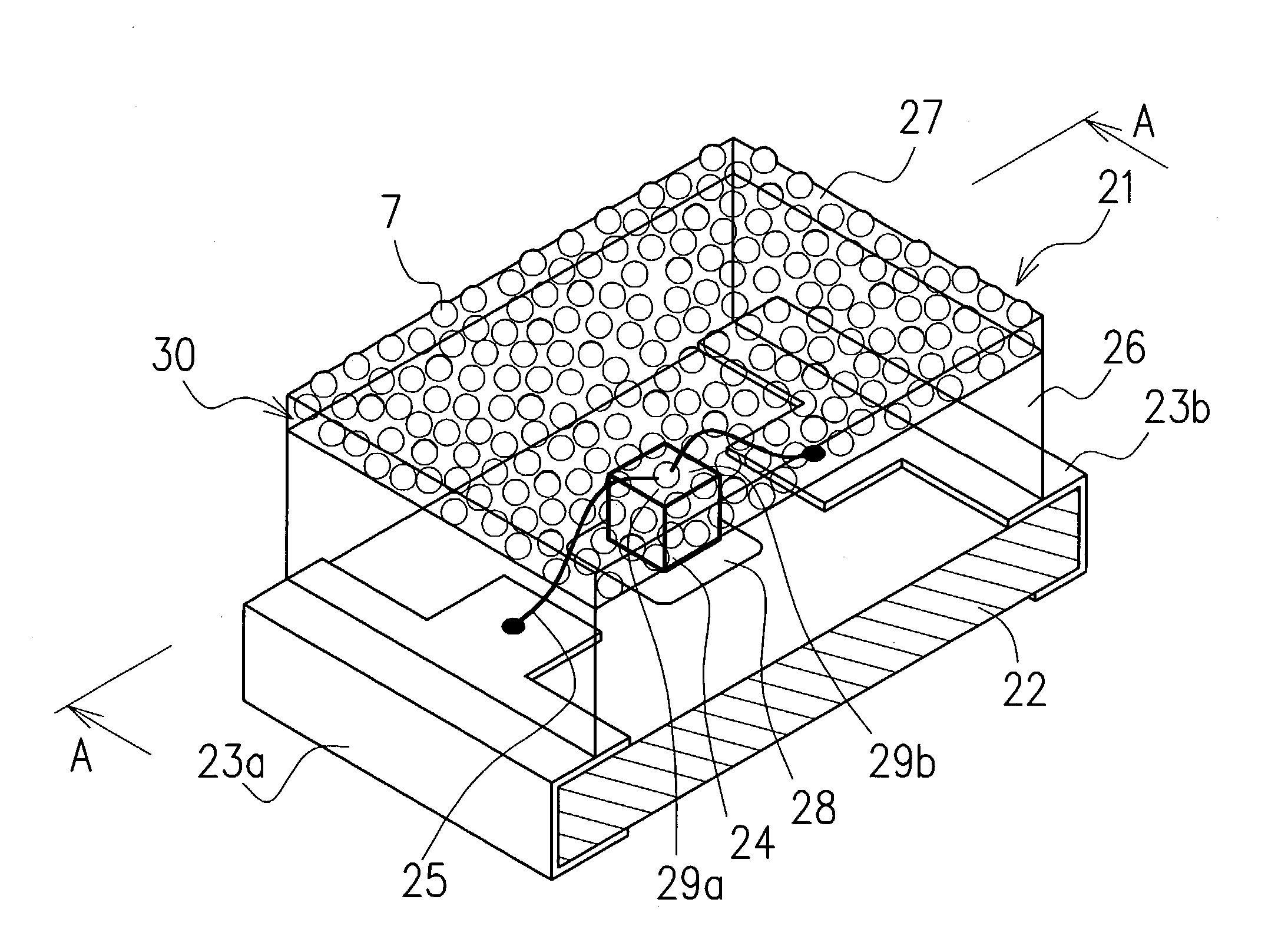

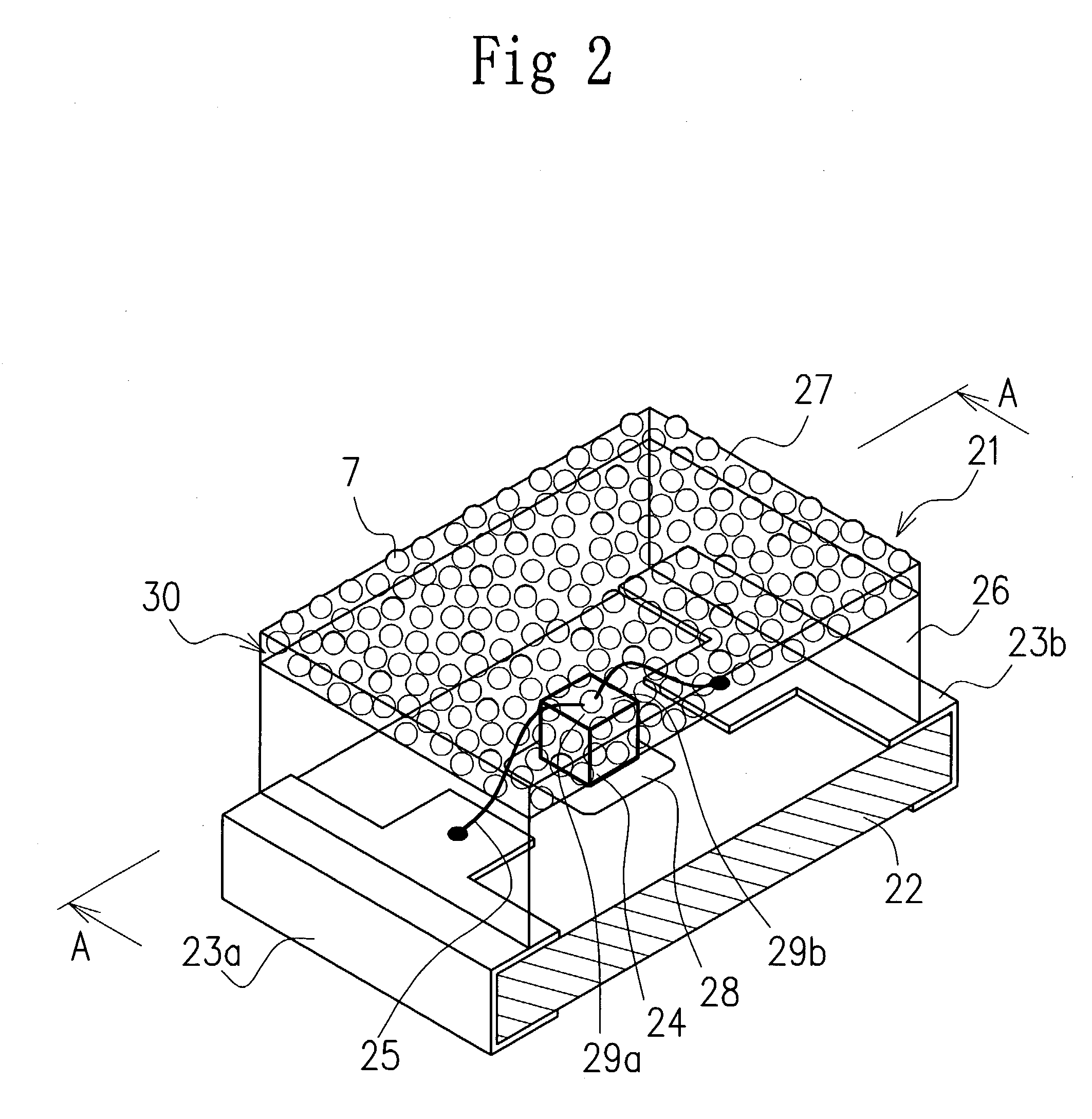

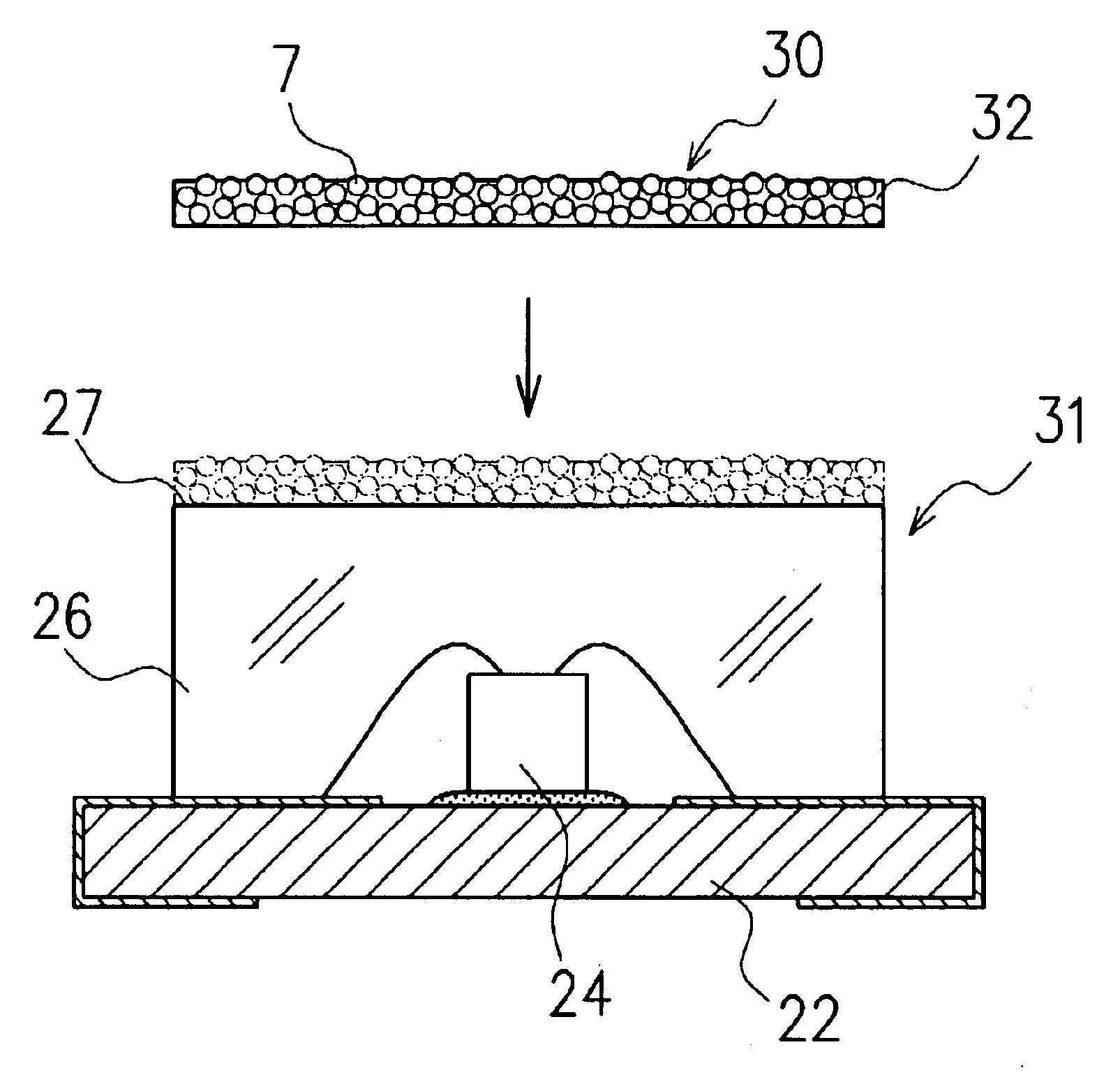

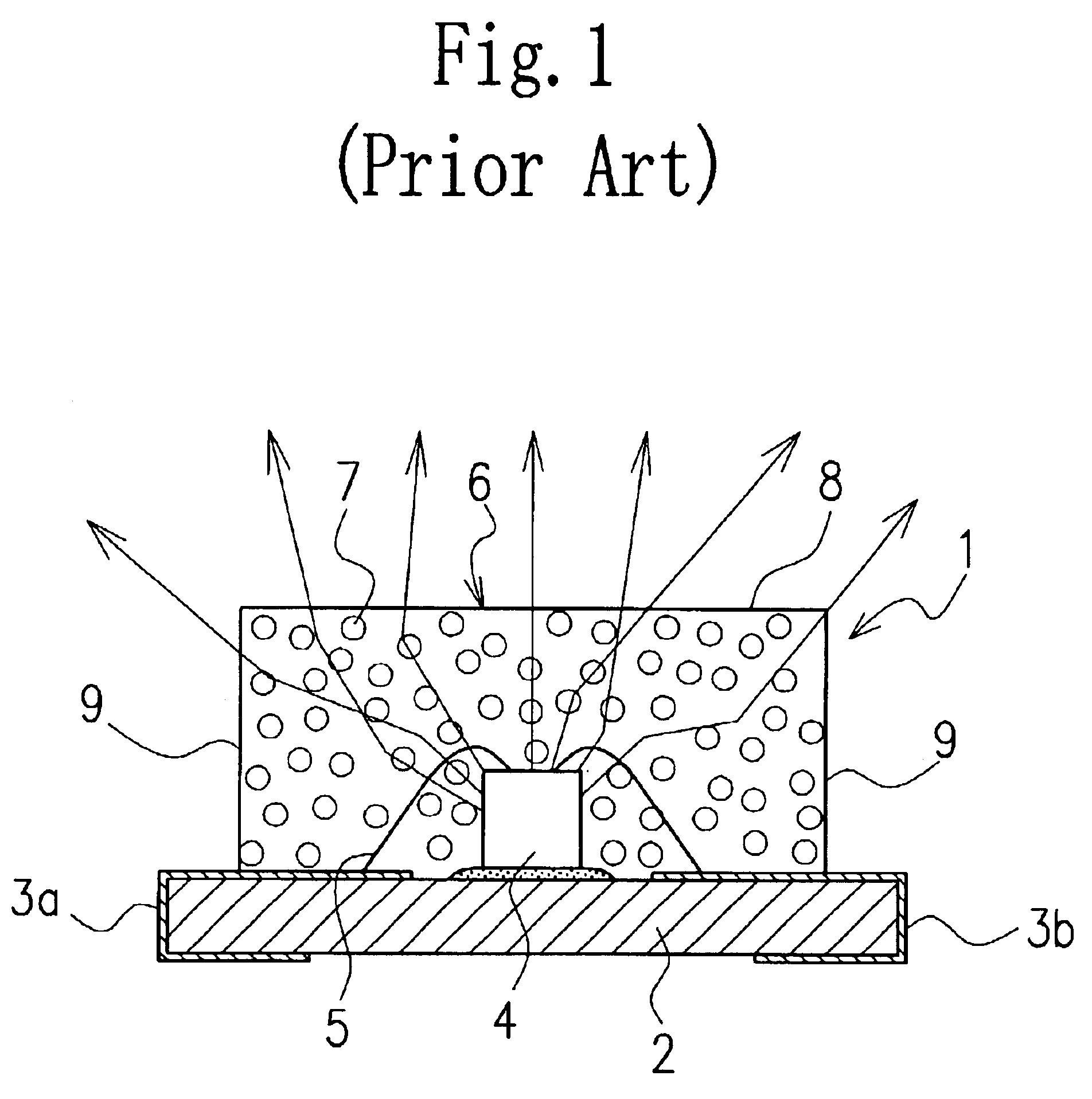

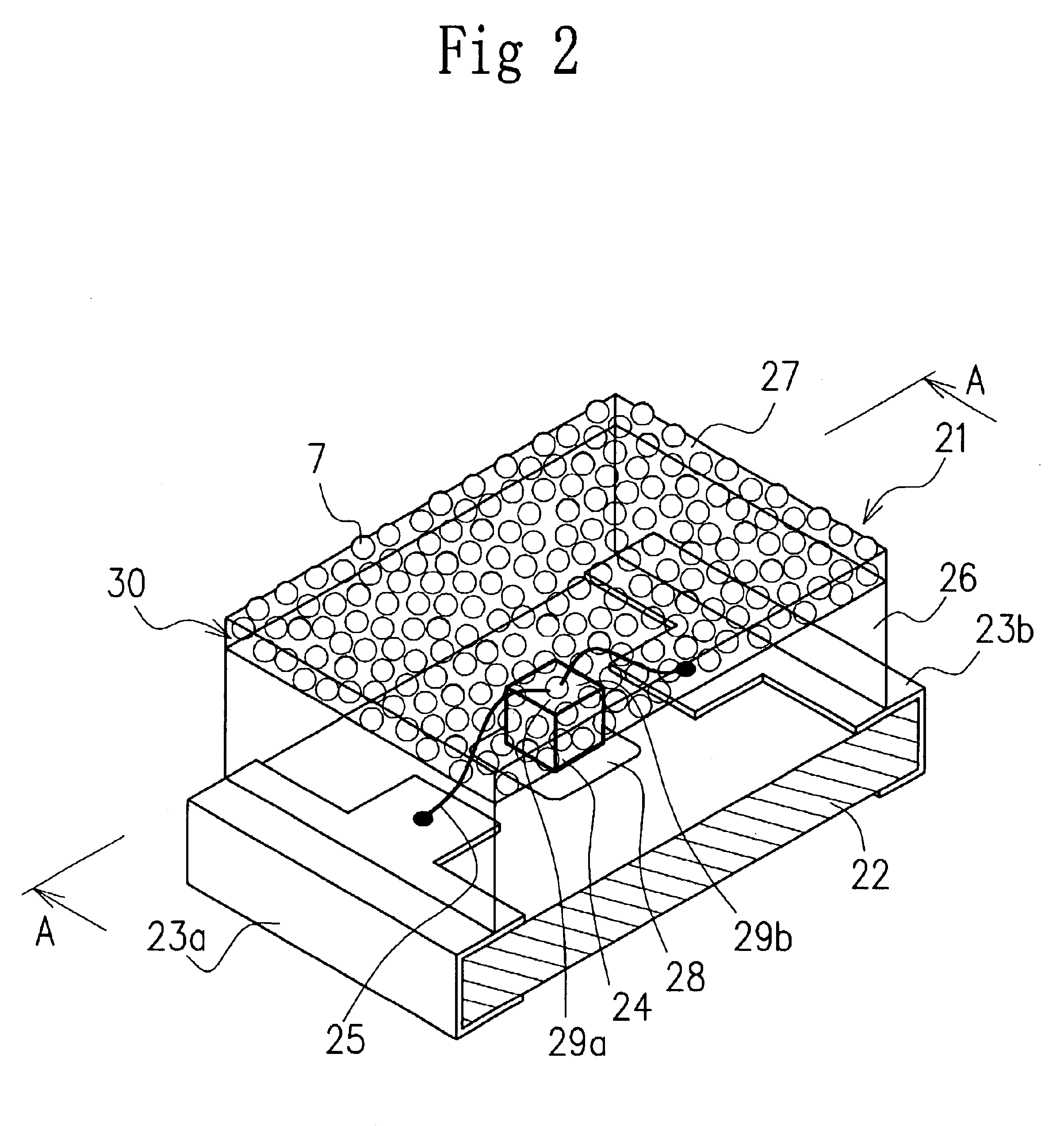

A light emitting diode is disclosed which can enhance the scattering of light produced by a light emitting element to improve a brightness not only at an upper surface but also at side surfaces of a resin sealant covering the light emitting element, thereby providing a high brightness level in a wider range of angle. This light emitting diode comprises a substrate 22, a pair of electrodes 23a, 23b provided on the substrate, a light emitting element 24 mounted on the substrate and electrically connected to the electrodes, a sealant 26 provided on the substrate to seal the electrodes 23a, 23b and the light emitting element 24; and a light scattering layer 30 formed on an outermost layer of a light projecting surface 27 of the sealant 26.

Owner:CITIZEN ELECTRONICS CO LTD

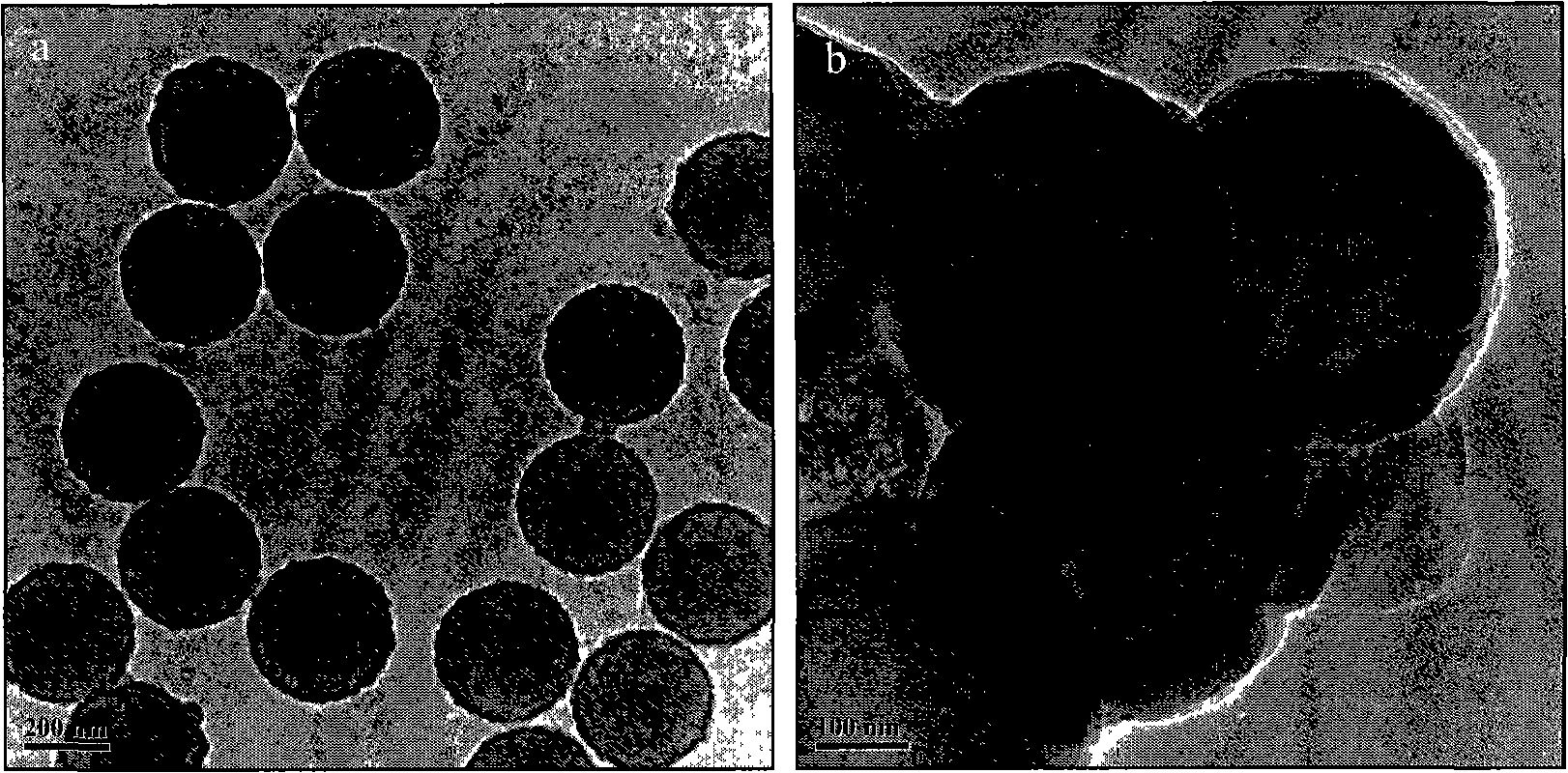

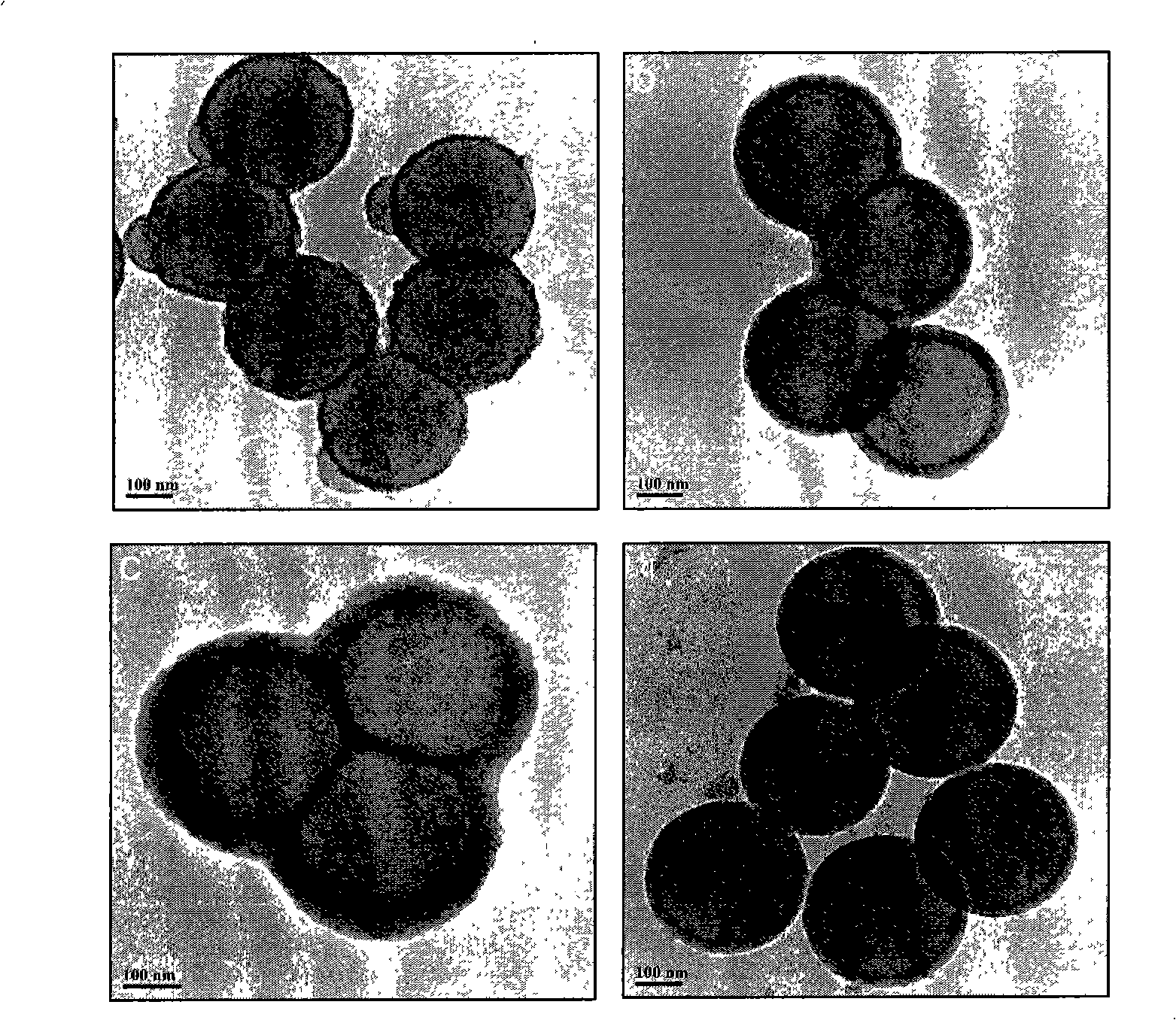

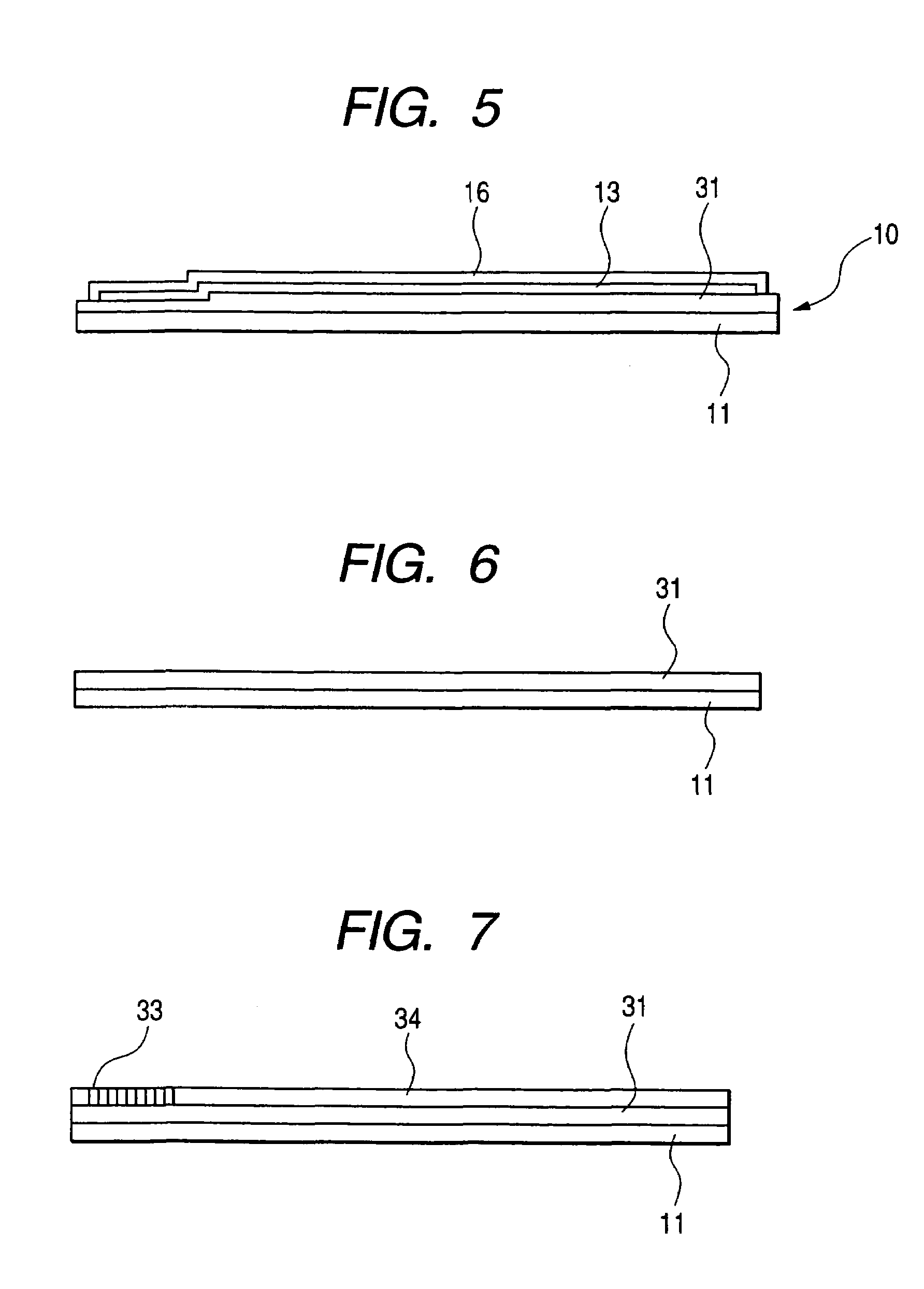

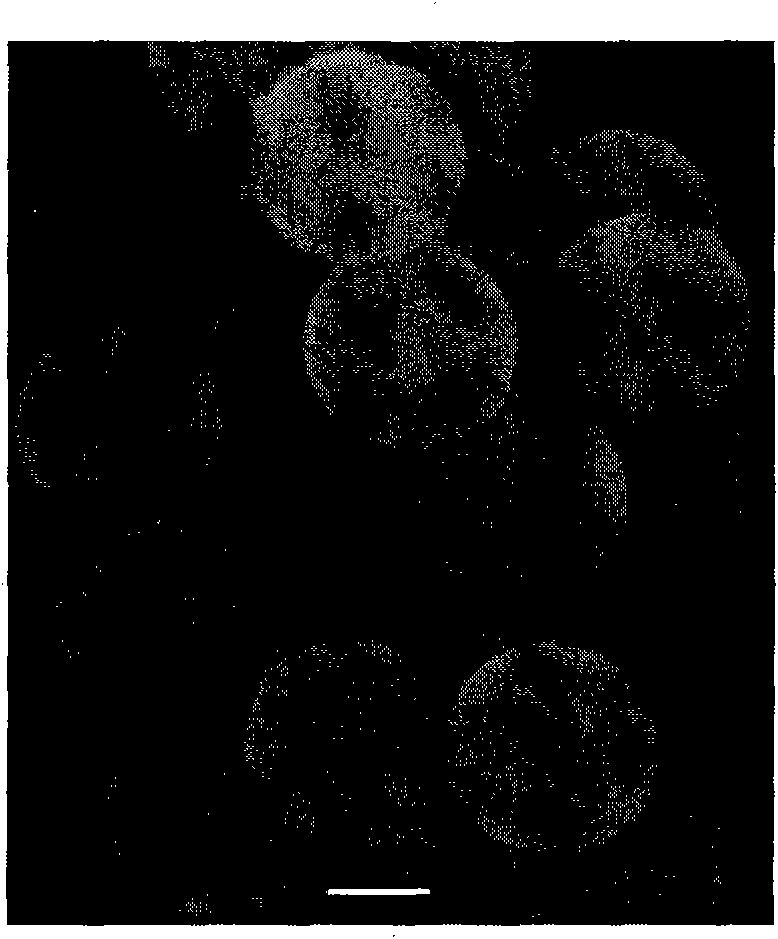

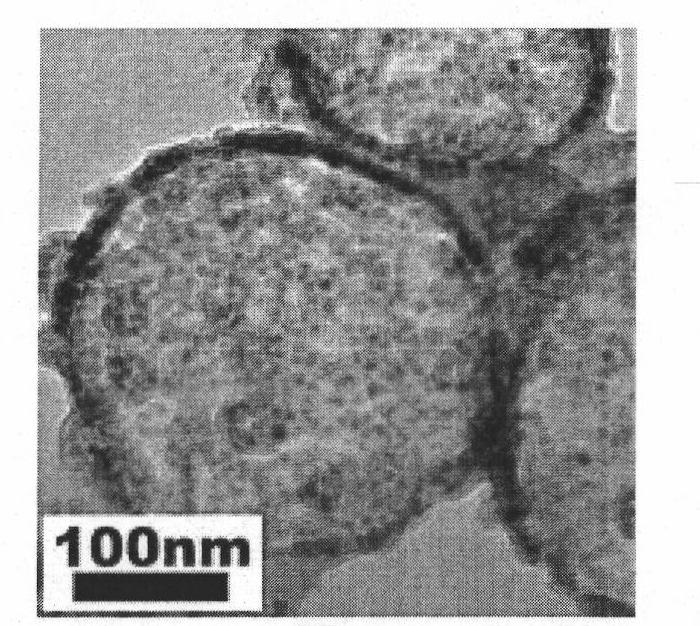

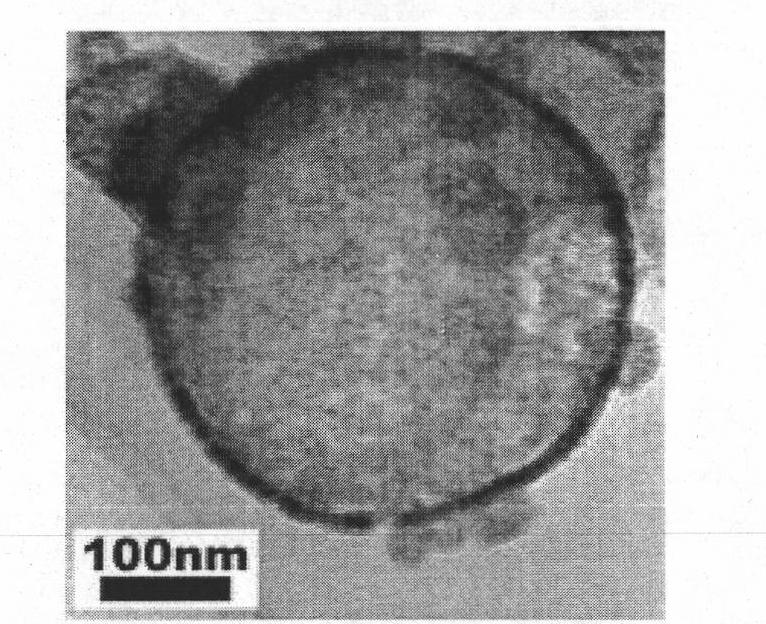

Sol-gel method for preparing earth silicon/titanic oxide hollow microballoon

InactiveCN101274246AFlexible production processRaw materials are cheap and easy to getMicroballoon preparationMicrocapsule preparationPolystyrene microsphereSol-gel

The invention provides a method for preparing an SiO2 / TiO2 hollow microsphere by a sol-gel method. The method is mainly characterized in that cation polystyrene microsphere (PS) is used as a formwork; ethyl silicate and butyl titanate are respectively used as raw material and diluted ammonia is taken as regulator of pH value; a multi-layer organic-inorganic hybrid composite microsphere is obtained by the sol-gel reaction under the temperature of 70-80 DEG C. Formwork particle of the obtained deposition is removed by a calcining process to obtain the SiO2 / TiO2 hollow microsphere. By changing the consistency of reactant, content of surfactant and calcining temperature, the SiO2 / TiO2 hollow microsphere with different spherical shell thickness, density and grain size can be obtained. The hollow microsphere prepared by the method has high photo-catalytic activity, overcomes the shortage that existing preparation method of hollow microsphere can only prepare single shell layer microsphere; the multi-layer hollow microsphere can be prepared, the technique is simple, the cost is low and the preparation method of the invention is suitable for industrialized production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

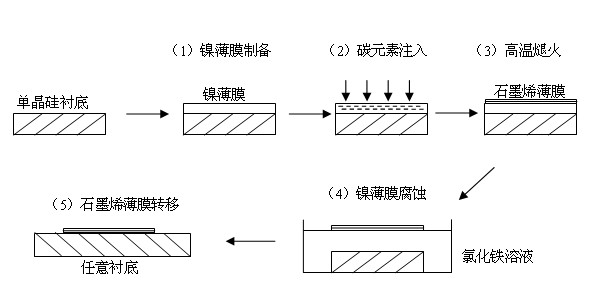

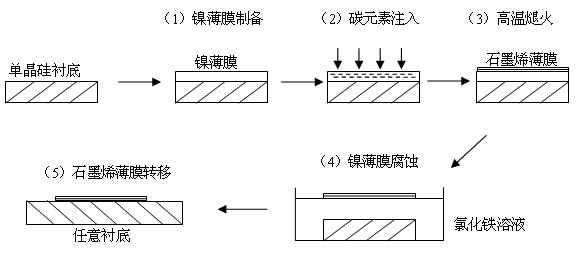

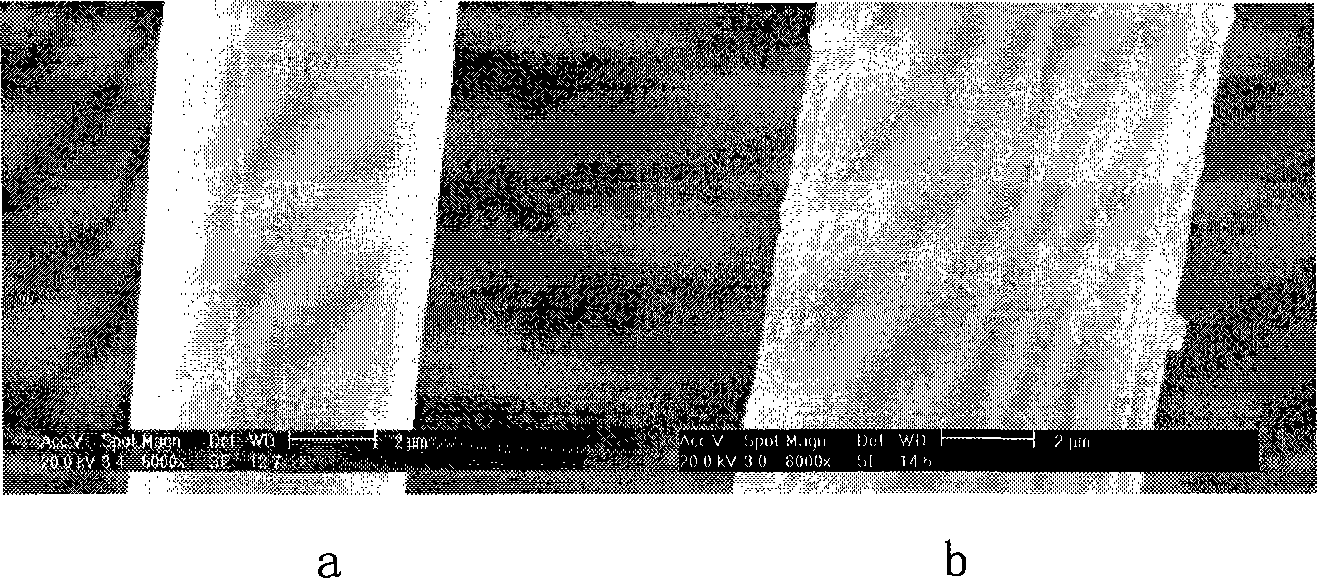

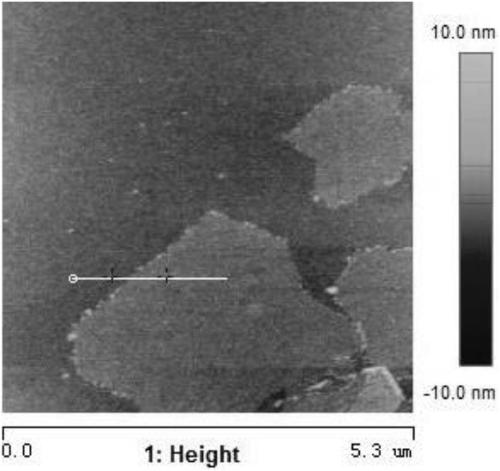

Method for preparing large-scale two-dimensional nanomaterial graphite

The invention relates to a method for preparing a large-scale two-dimensional nanomaterial graphite, comprising the following steps of: plating a nickel film with the thickness of 100-300nm on the surface of monocrystal silicon, and then injecting carbon element into the nickel film by adopting an ion implantation mode; annealing for 15min-1h at a high temperature between 600 DEG C and 1,000 DEG C and a vacuum degree of from (10-5)Pa to 1Pa, and cooling to room temperature so that carbon atoms are separated out from the nickel film and recombined. Therefore, a layer of graphite film (the film thickness depends on various experiment parameters, such as carbon injection content, and the like) can be formed on the surface of the nickel film. When a sample is put into a FeCl3 solution, the nickel film can be corroded, and the graphite film can be separated out and floats on the surface of the liquid; and at the moment, the graphite film can be transferred away from the liquid with any substrate. Therefore, the large-scale graphite film with the size of several centimeters can be prepared.

Owner:SOUTHEAST UNIV

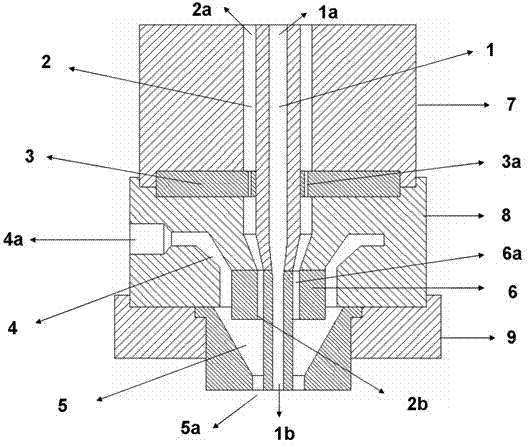

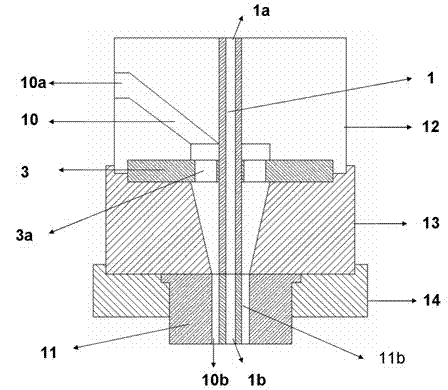

A kind of preparation method of long fiber reinforced hollow fiber membrane

ActiveCN102266726AContact priorityPrevent overflowMembranesSemi-permeable membranesWinding machineHollow fibre membrane

The invention discloses a method for preparing a long fiber reinforced hollow fibrous membrane. The method can be implemented in two ways: (1) adopting a spinning nozzle having a long fiber channel; introducing a long fiber into the long fiber channel; guiding the long fiber into a membrane casting solution and fiber compounding area via a fiber positioning plate; co-extruding the compounded long fiber and membrane casting solution; and forming a membrane under the action of core solution and external coagulating bath or cooling bath, and (2) adopting a spinning nozzle for co-extruding the long fiber and the membrane casting solution; guiding the long fiber out of a liquid material jar; guiding the long fiber to pass by a membrane casting solution pipeline and introducing the long fiber into the spinning nozzle from a membrane casting solution inlet of the spinning nozzle; co-extruding the long fiber and membrane casting solution after positioning the long fiber through the fiber positioning plate; forming the membrane under the action of core solution and external coagulating bath; and finally winding the membrane through a guide wheel and a winding machine. The long fiber reinforced compound membrane prepared by using the method has the advantages that the mechanical strength of the hollow fibrous membrane is increased by 3-5 times according to the quantity and variety of the long fiber in the hollow fibrous membrane, and the water flux, the rejection coefficient and the hydrophilicity are all obviously improved.

Owner:ZHEJIANG UNIV

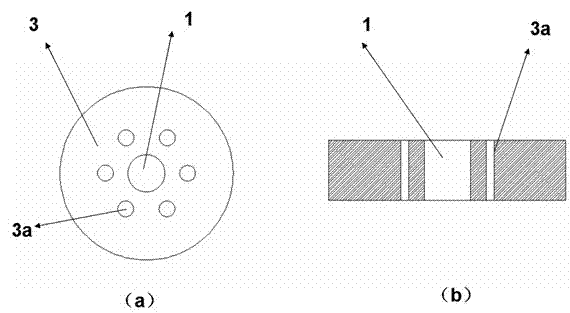

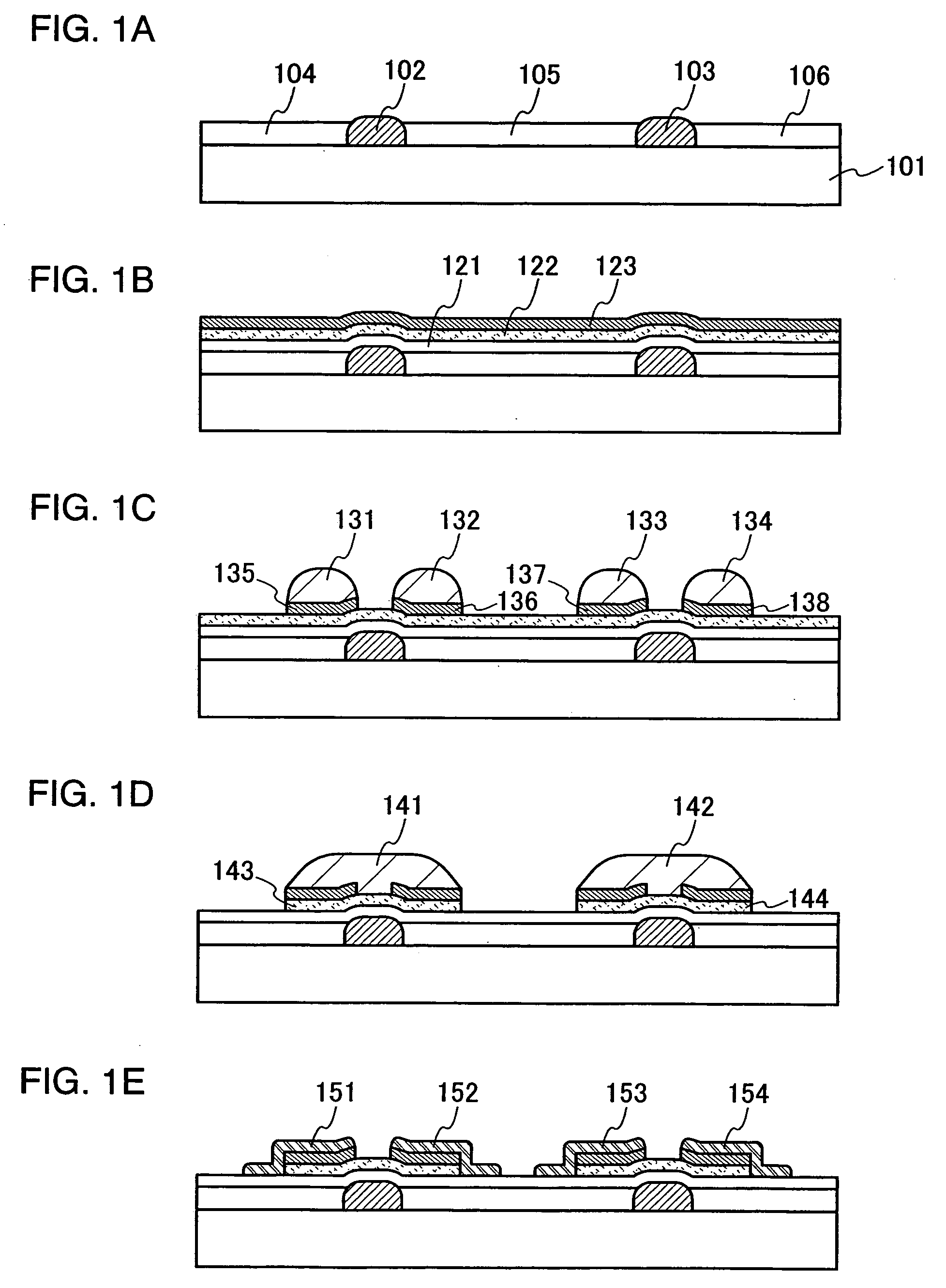

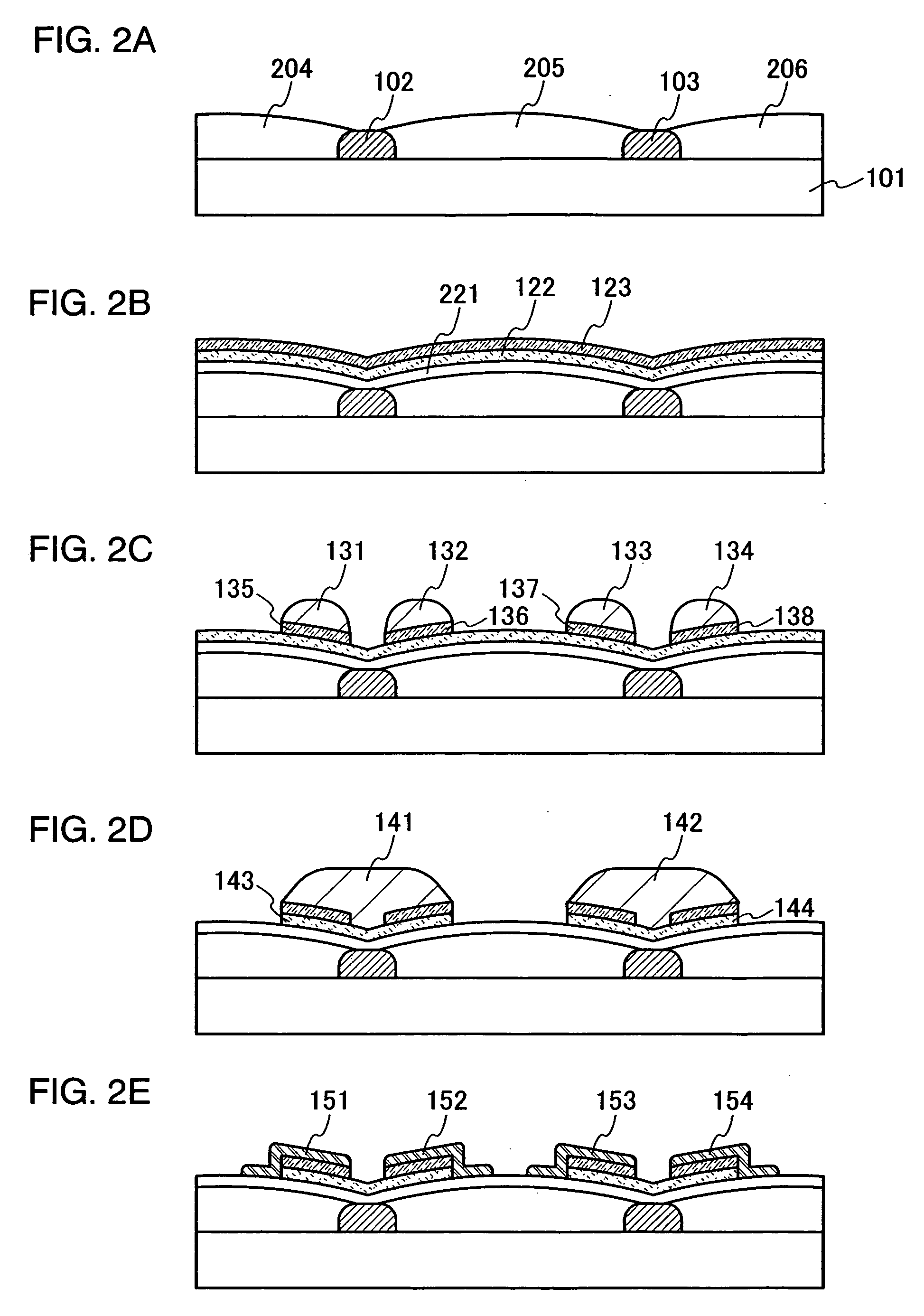

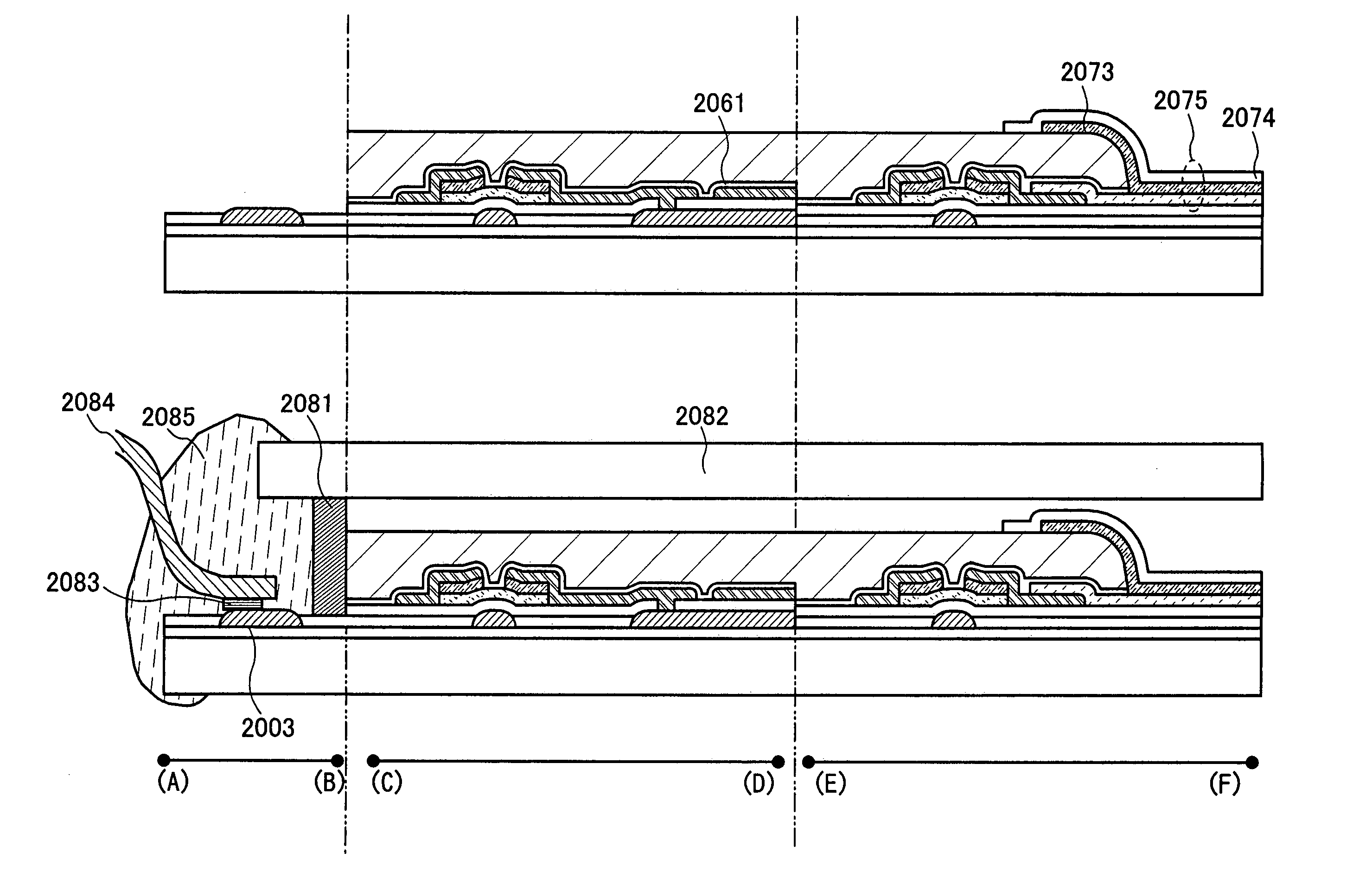

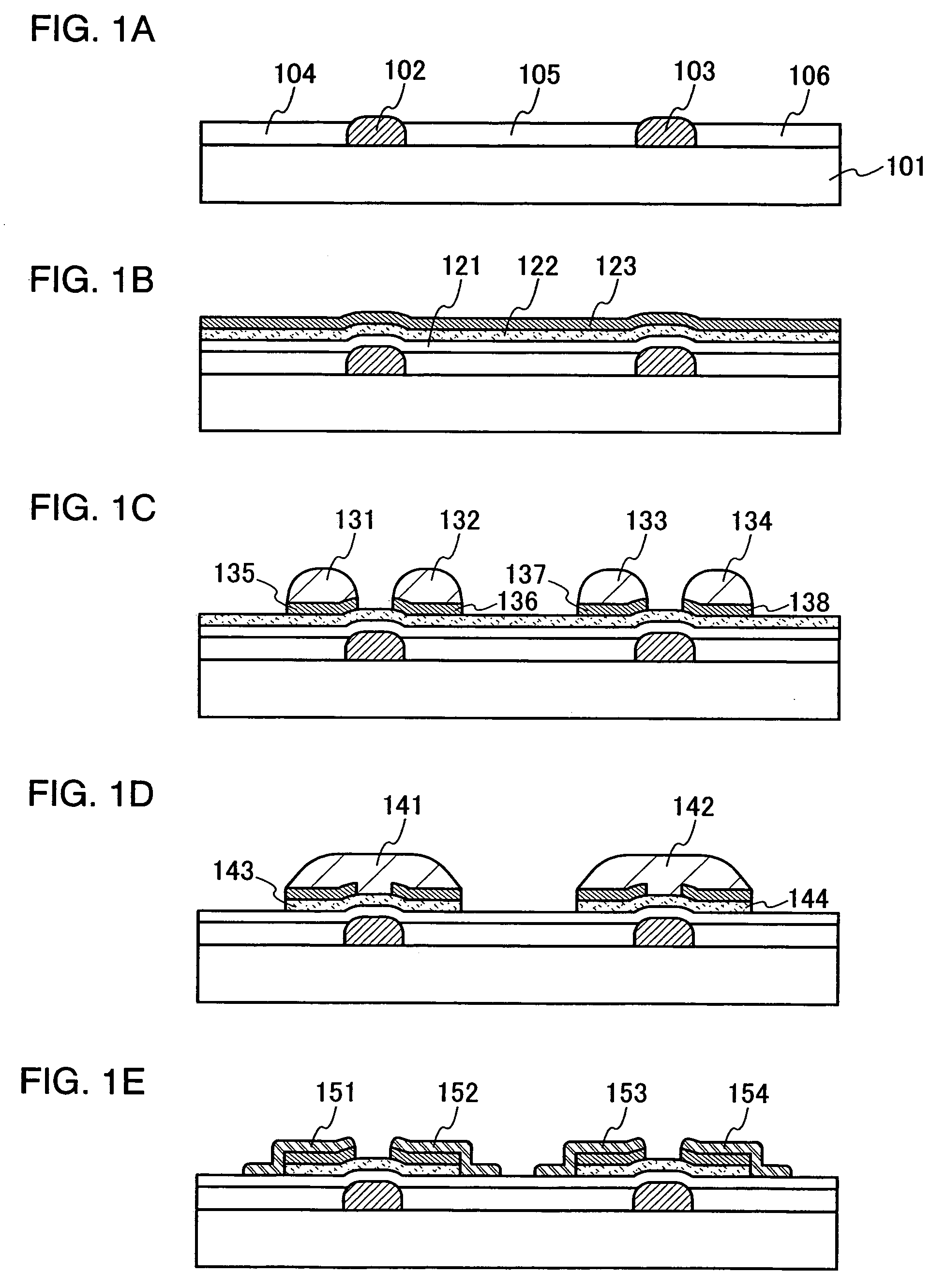

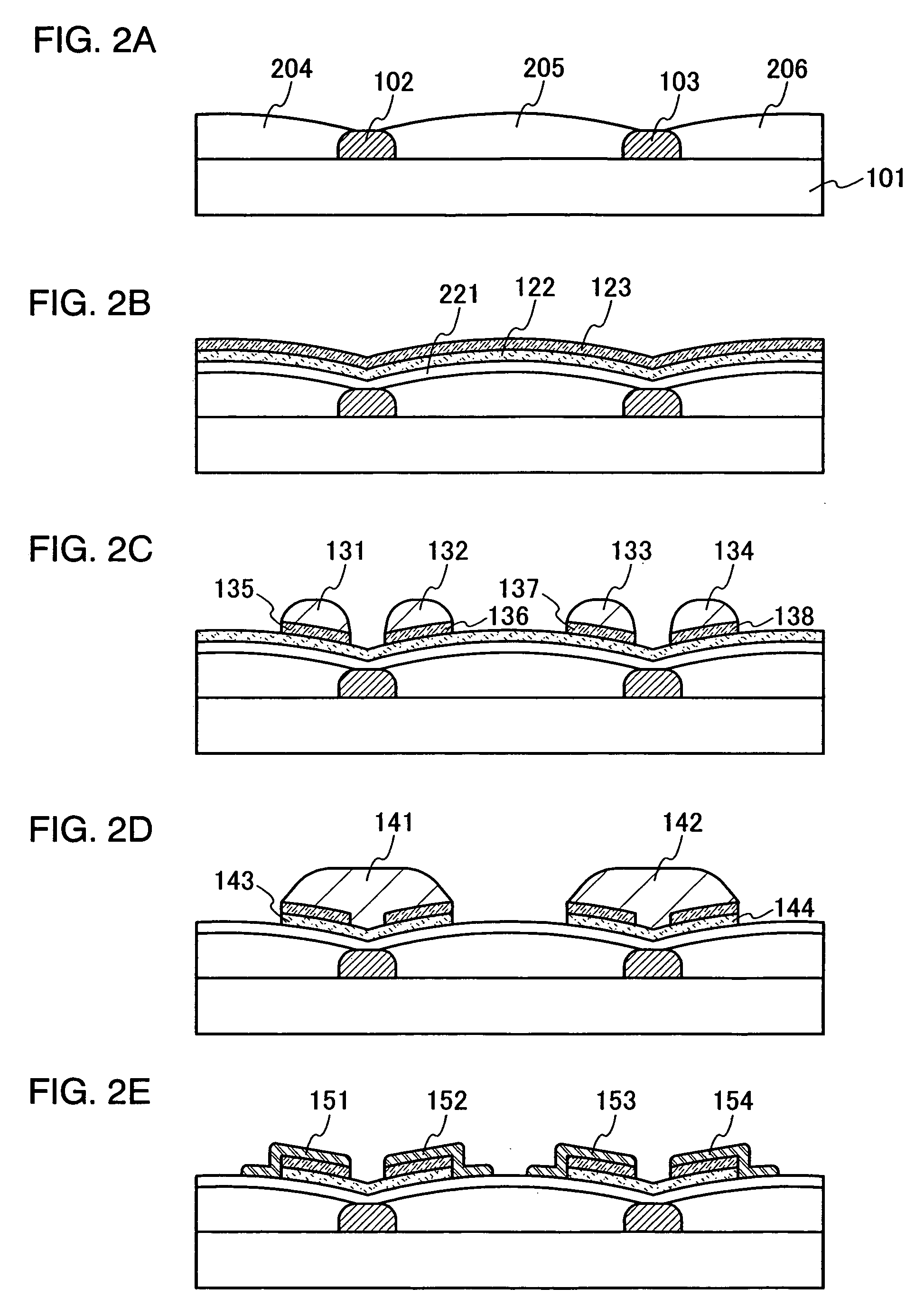

Semiconductor device, method for manufacturing the same, liquid crystal television and EL television

InactiveUS20050214983A1Improve usabilityReduce violationsTransistorSolid-state devicesDevice materialEngineering

A method for manufacturing a semiconductor device by a small number of processes and by a means with high usability of materials to have high-definition and a gate insulating with a high step coverage property is disclosed. According to the present invention, a method for manufacturing a semiconductor device comprises the steps of forming a plurality of first conductive layers over a substrate; forming a first insulating layer to fill the gaps of the plurality of the first conductive layers; forming a second insulating layer over the first insulating layer and the plurality of the first conductive layers; and forming a semiconductor region and a second conductive layer over the second insulating layer.

Owner:SEMICON ENERGY LAB CO LTD

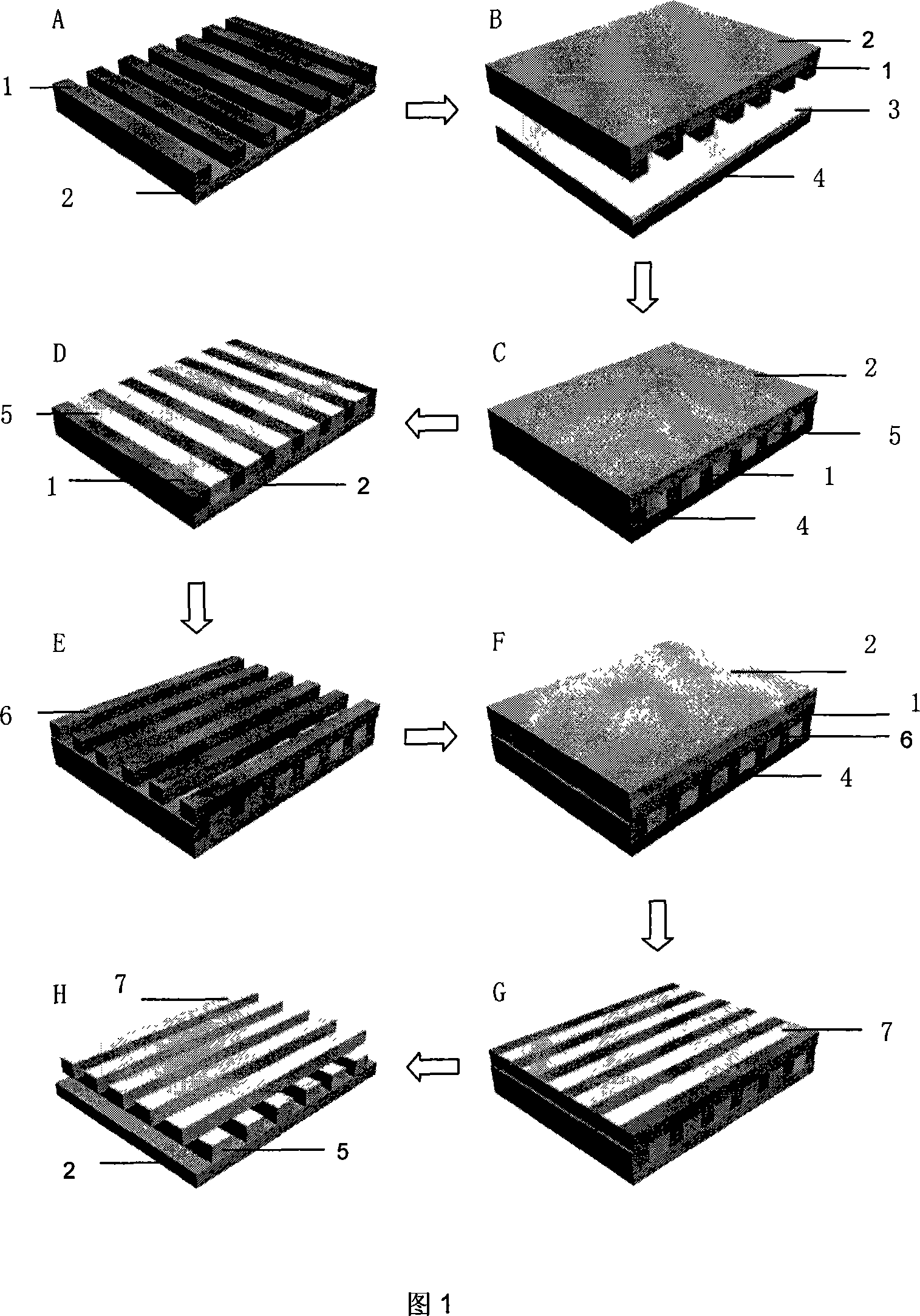

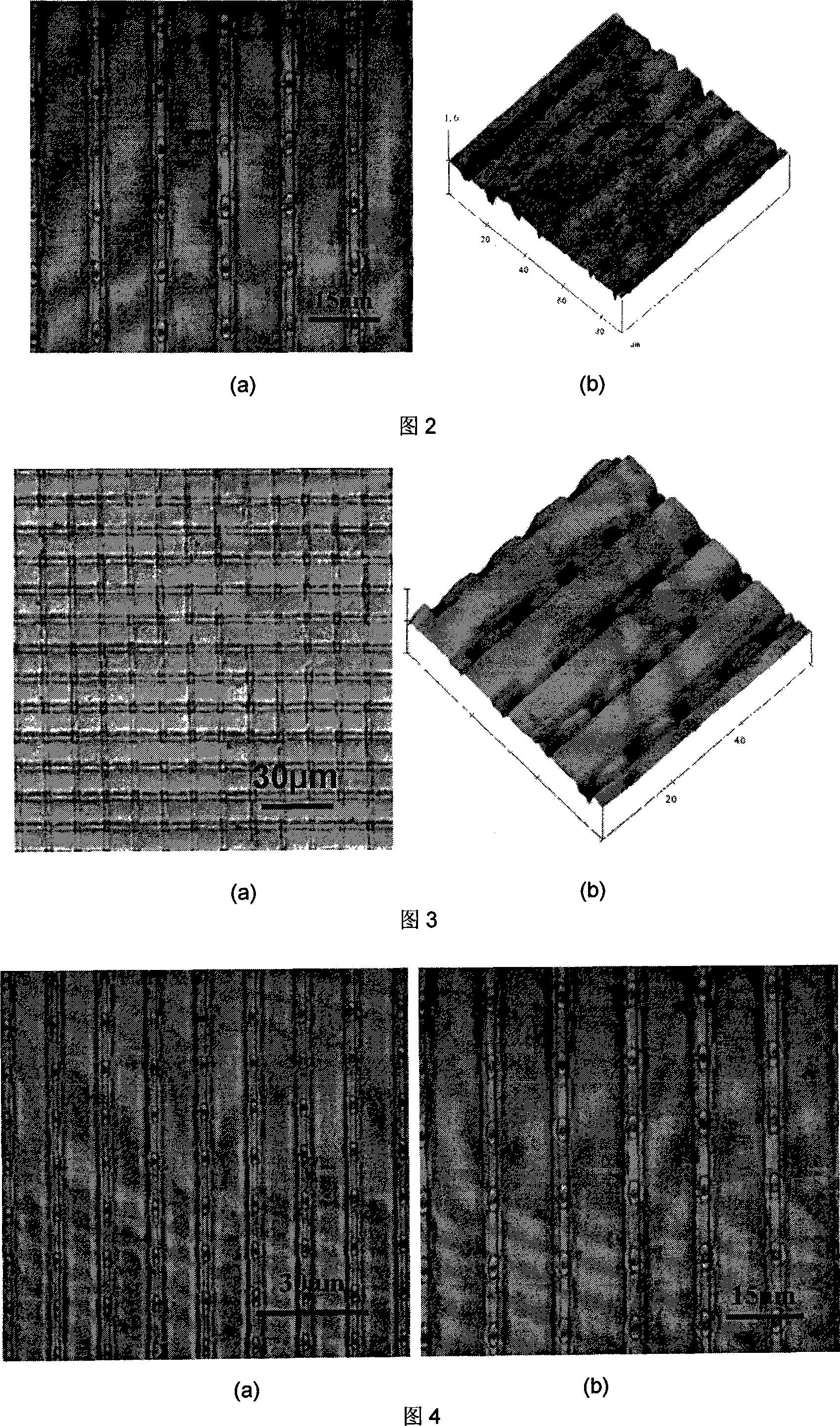

Method for constituting 3-D structure

InactiveCN101024482AShape adjustableAdjustable thicknessDecorative surface effectsPhotomechanical apparatusPhotonic crystalPolymer science

The invention relates to a method to construct 3D microstructure. It includes the following steps: using photoengraving method to construct 2D microstructure surface, extruding polymer performed polymer or ultraviolet glue precursor into the slot on 2D microstructure surface and taking heat or light polymerization to gain target material; constructing polymer or ultraviolet exposal glue array structure, washing sacrificed material at one time to gain the 3D microstructure. The invention has potential application value in the fields of shape, size, thickness, material, photon crystal, catalyst carrier, etc.

Owner:JILIN UNIV

Semiconductor device, method for manufacturing the same, liquid crystal television and EL television

InactiveUS7223641B2Improve usabilityReduce violationsTransistorSolid-state devicesHigh availabilityEngineering

Owner:SEMICON ENERGY LAB CO LTD

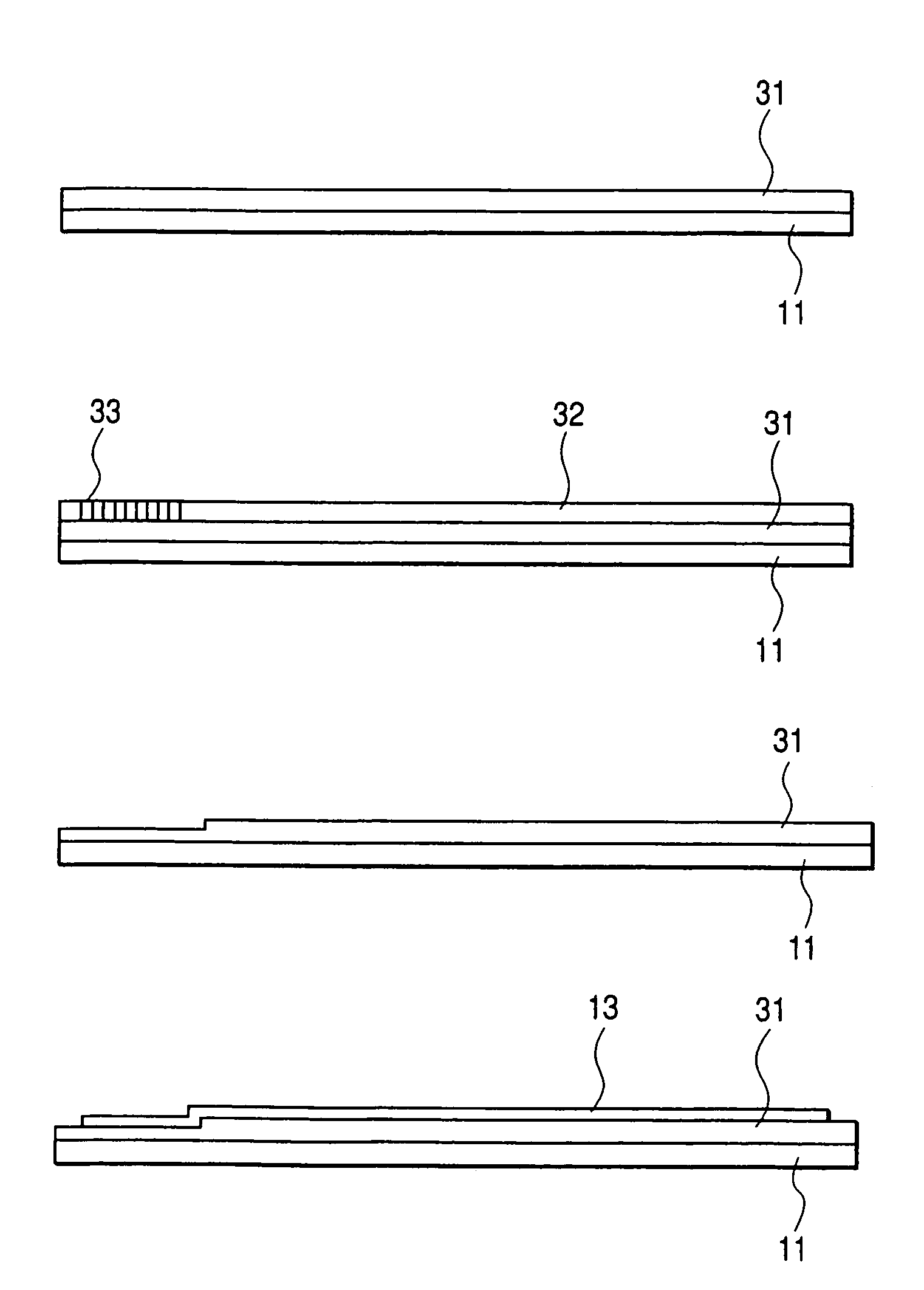

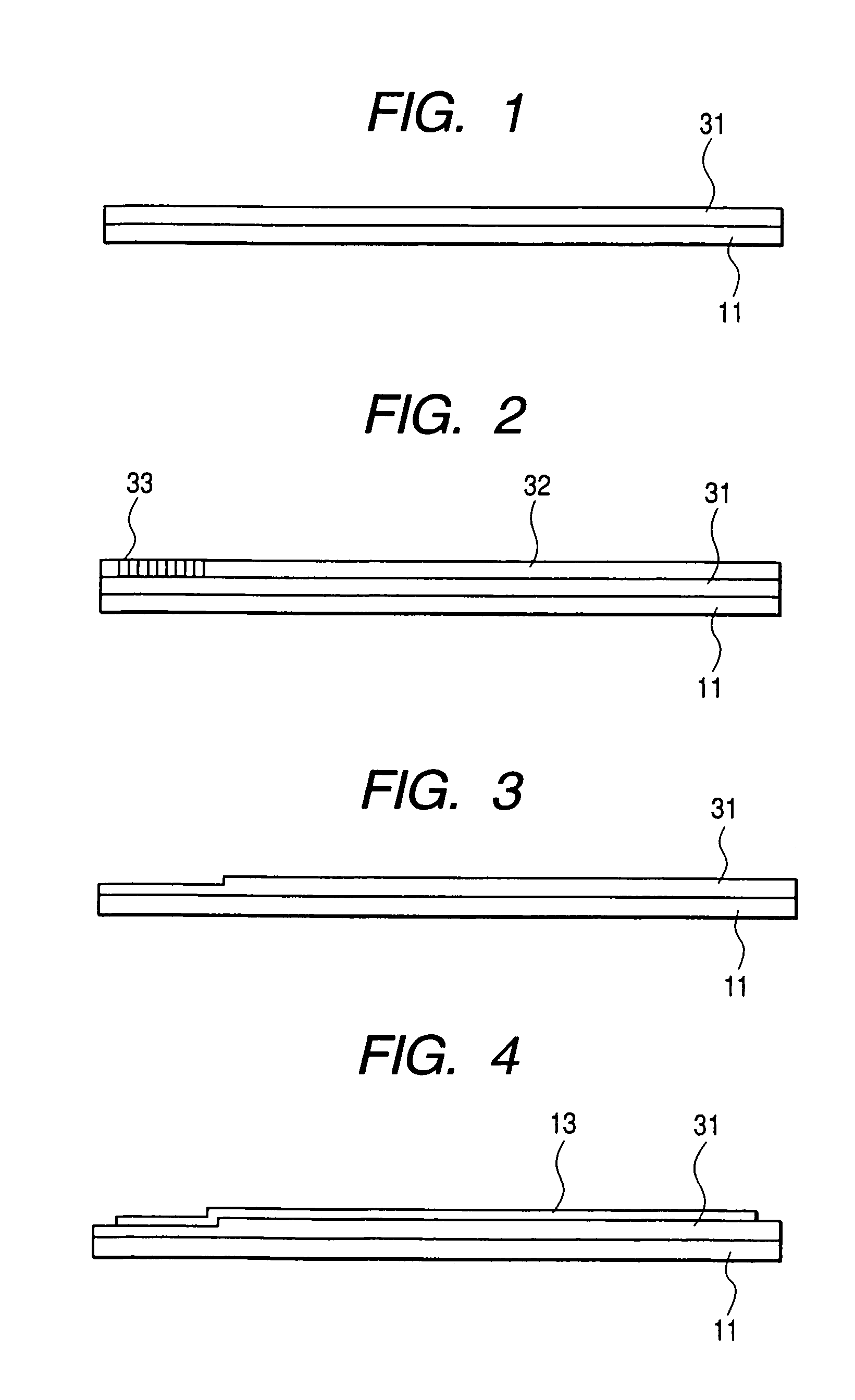

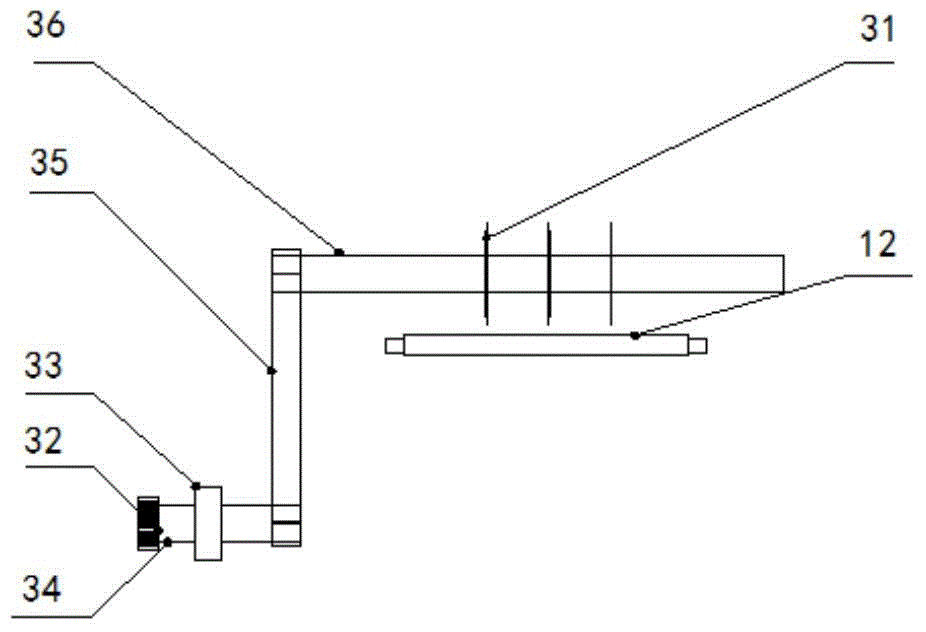

Manufacturing method for magnetic head suspension

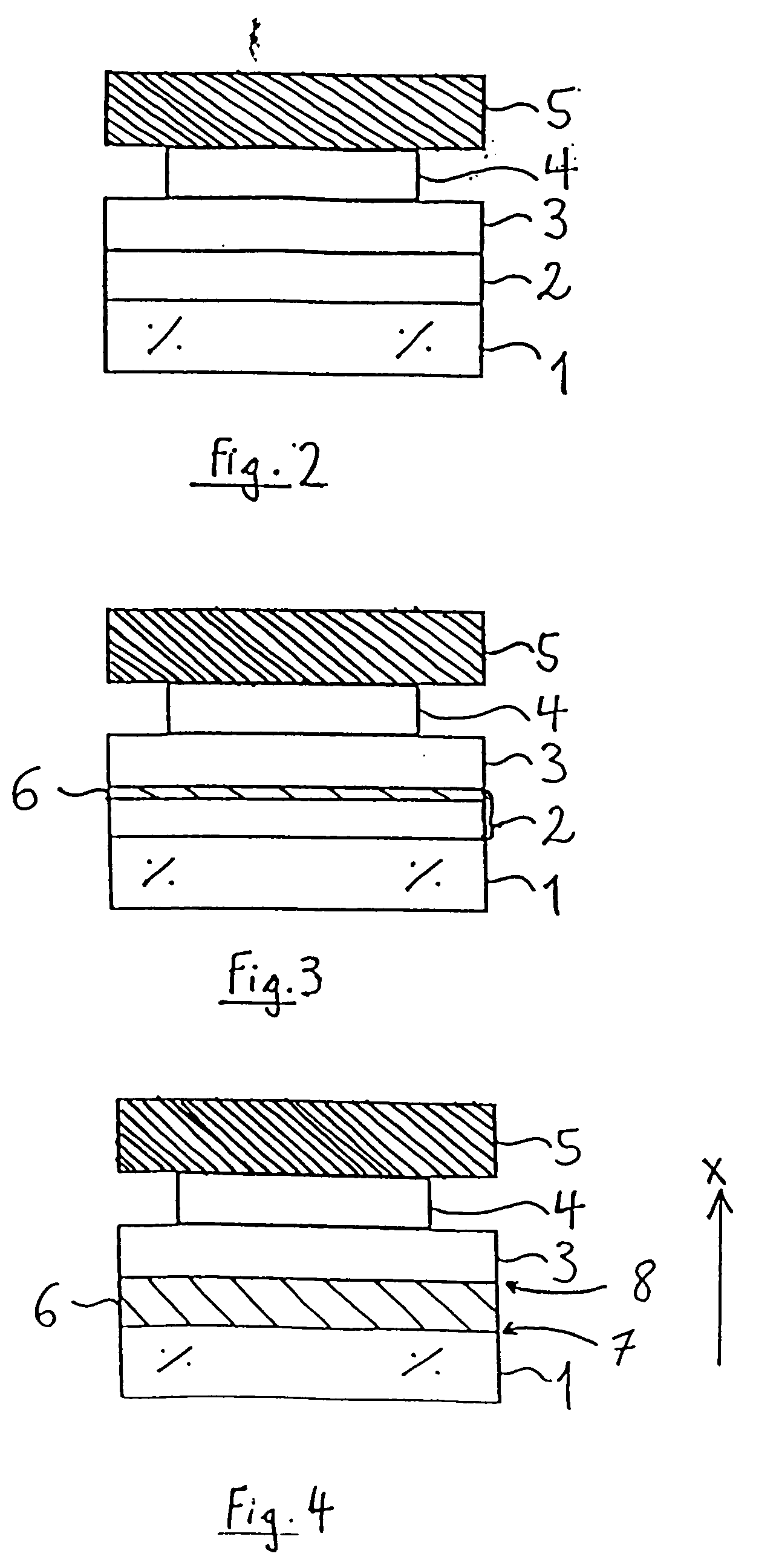

ActiveUS7144687B2Increasing number of processLow costPhoto-taking processesSemiconductor/solid-state device manufacturingTransmittanceEngineering

A step of forming an insulating resin layer 31 includes a process of forming the insulating resin layer 31 made of a photo-sensitive resin on a load beam or a flexure 11 and an exposing and developing process in which a photo-mask 32 having different light transmittance between a part corresponding to a part near a slider mounting part 22 and other parts is applied to the insulating resin layer 31, exposed and developed so that the thickness of the insulating resin layer 31 of the part near the slider mounting part 22 is smaller than the thickness of the insulating resin layer 31 of other parts.

Owner:TDK CORPARATION

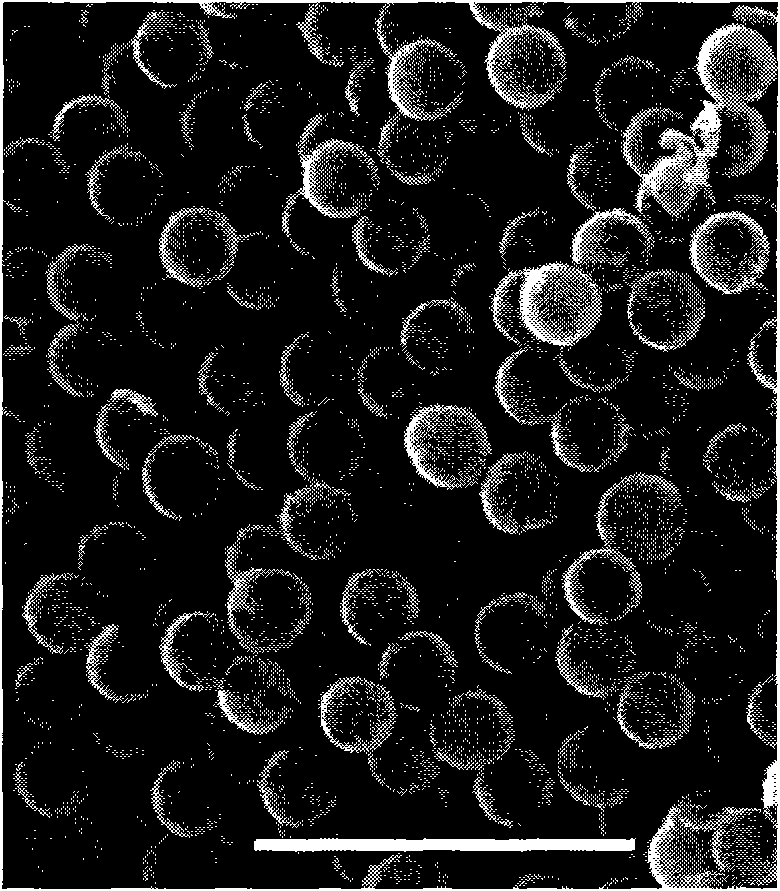

Method for preparing hollow mesoporous lamella spherical silica material

The invention relates to an inorganic porous material synthesis technology field, and concretely relates to a method for preparing hollow mesoporous lamella spherical silica material. In a mixed solvent of alcohol and water, under the catalytic action of ammonia, using a cationic surface active agent of cetyl trimethyl ammonium bromide as a mesoporous template, the inorganic silicon material self-assembles to be mesoporous uniform spheres on the polyphenylacetylene sphere surface, the surface active agent and the polyphenylacetylene sphere are deprived in high temperature environment, the hollow silica spheres with uniform size from micron to millimeter and mesoporous lamella are obtained. The specific surface area of the obtained hollow silica sphere is 800-2000m<2> / g, the bore diameter is 1.8-3.5nm, and the bore volume is 0.5-0.8 ml / g.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

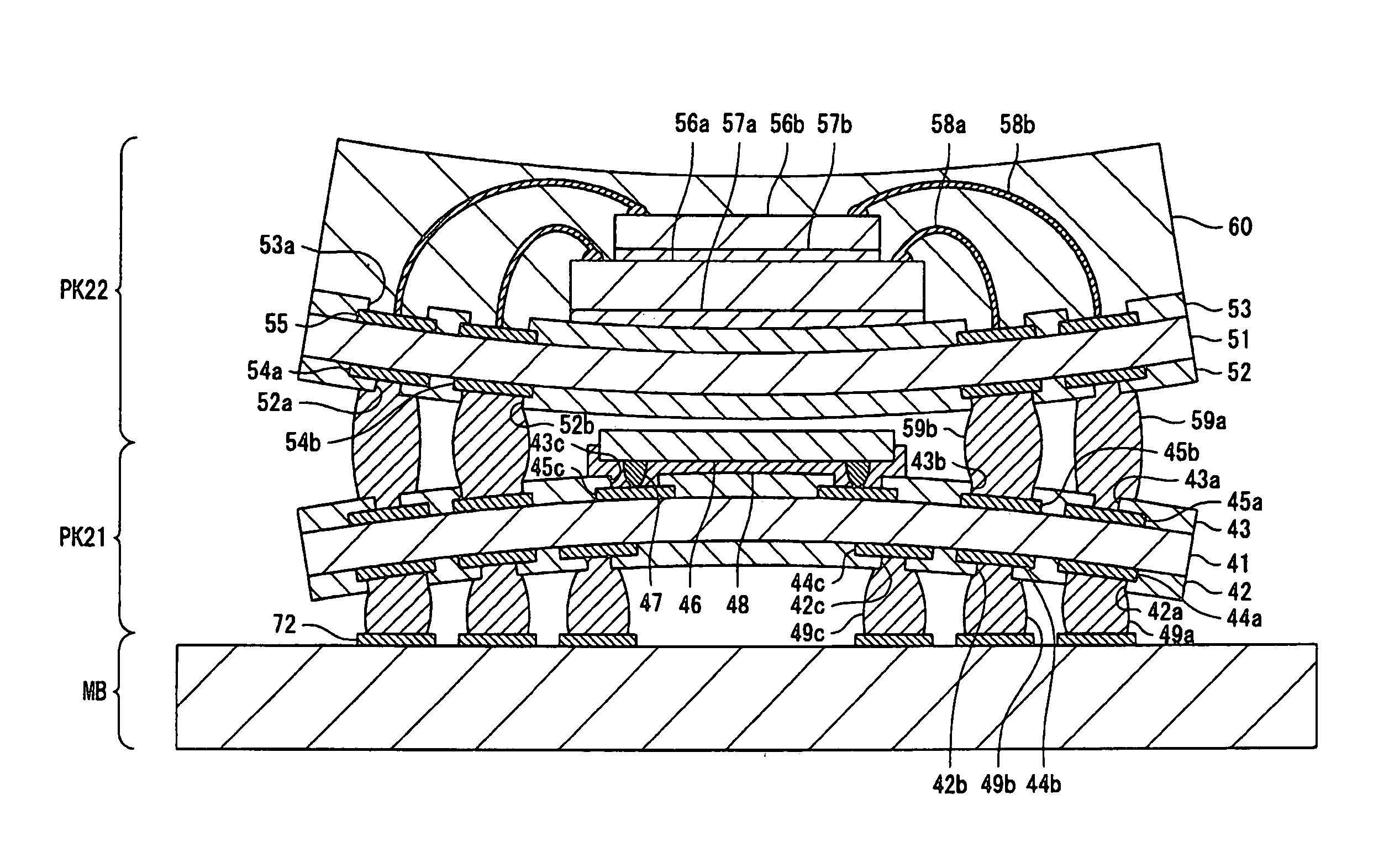

Semiconductor device, semiconductor package, electronic device, electronic apparatus, and manufacturing methods of semiconductor device and electronic device

ActiveUS7091619B2Manufacturing process be complicateConstriction can be suppressedFinal product manufactureSemiconductor/solid-state device detailsEngineeringElectronic equipment

A method is provided to enhance the connection reliability in three-dimensional mounting while considering the warping of packages. Opening diameters of the openings provided corresponding to protruding electrodes, respectively, are set so as to gradually decrease from the central portion toward the outer peripheral portion of a carrier substrate, and the opening diameters of openings provided corresponding to the protruding electrodes, respectively, are set so as to gradually decrease from the central portion toward the outer peripheral portion of another carrier substrate.

Owner:SEIKO EPSON CORP

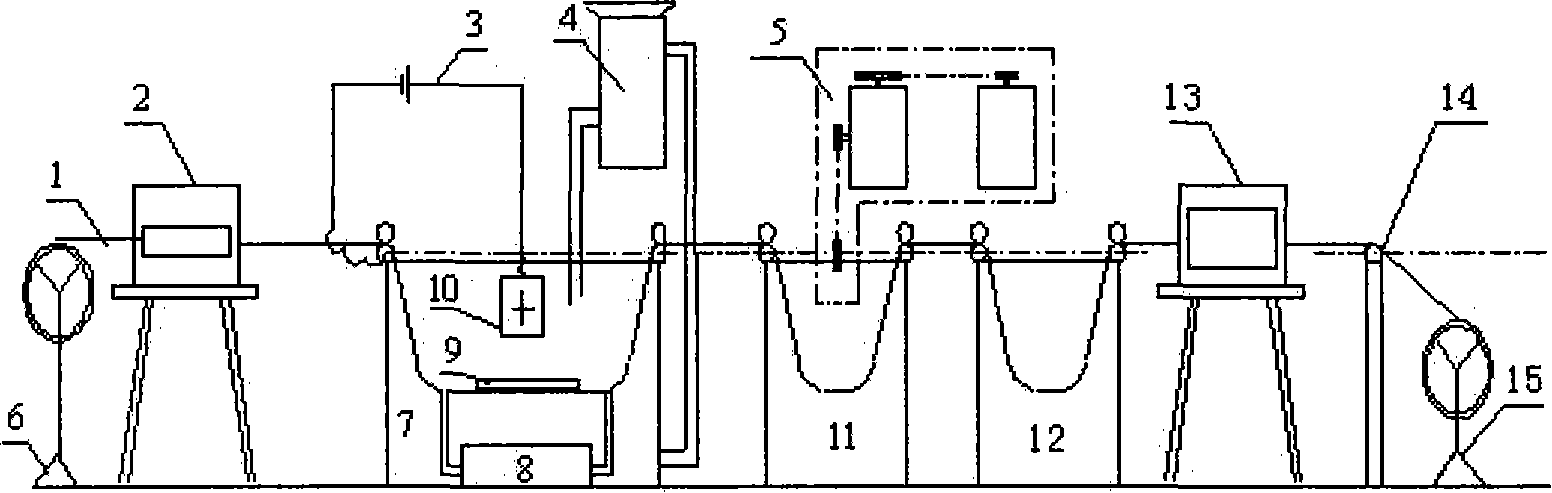

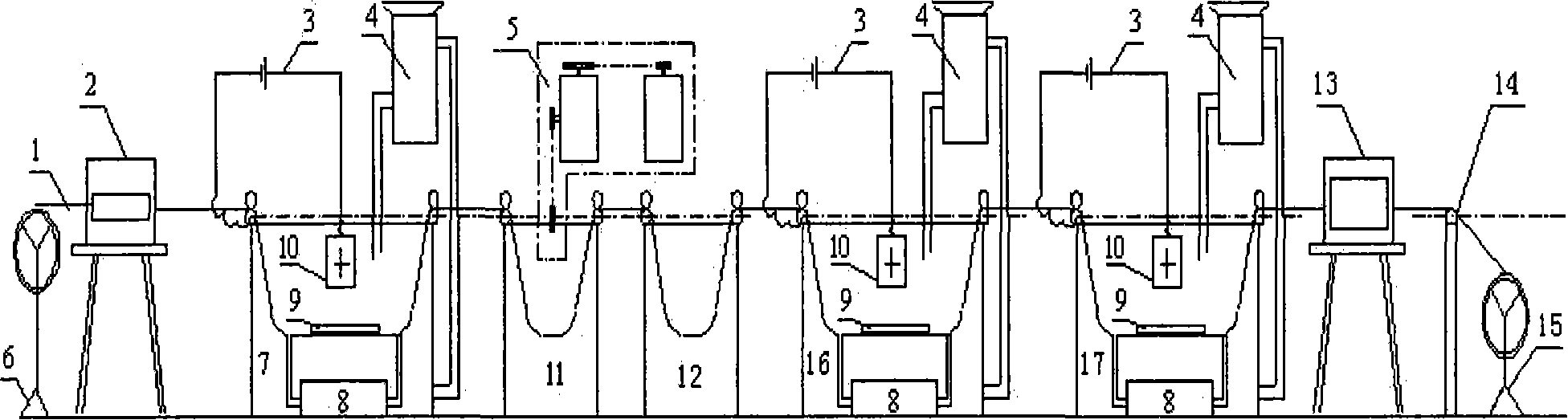

Apparatus and method for continuously composite plating metallic and nano particle on carbon fiber surface

The invention relates to a device and a method for continuous compounding electroplating metal and nanometer granules on carbon fiber surfaces, which mainly comprises a long carbon fiber bundle electrode, an electrode, a direct current source, a neutralizing tank, a filtering pump, a circulating pump, a washing tank, a drive gear, a drying device, a pay-off pulley, a connection layout, an electroplating bath and a take-up pulley. The device and the method are used to the compound plating of carbon fiber surface metal (such as copper or nickel) and nanometer granules (such as carbon nanometer tubes, Fe3O4 and the like), the obtained plating layer is homogeneous and has good continuity, the thickness is adjustable, and a plurality of bundles of carbon fiber can simultaneously be electroplated, and the plating layer is applicable for mass production in industry, the carbon fiber continuous electroplating technology can solve black core (uneven) problem, which enables the surface of each fiber of the fiber bundles to obtain humongous and high quality nanometer compound plating layer.

Owner:TIANJIN UNIV

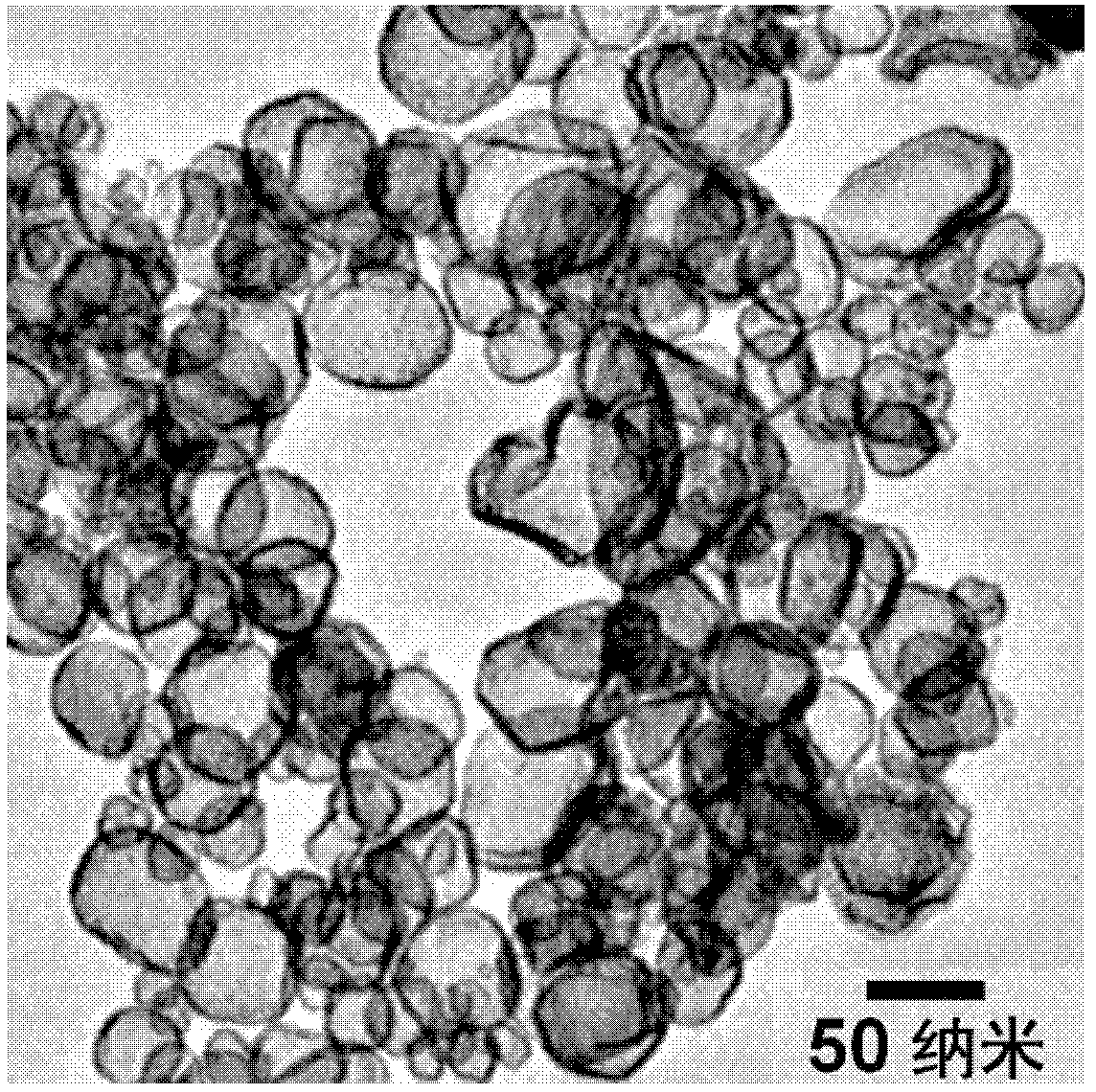

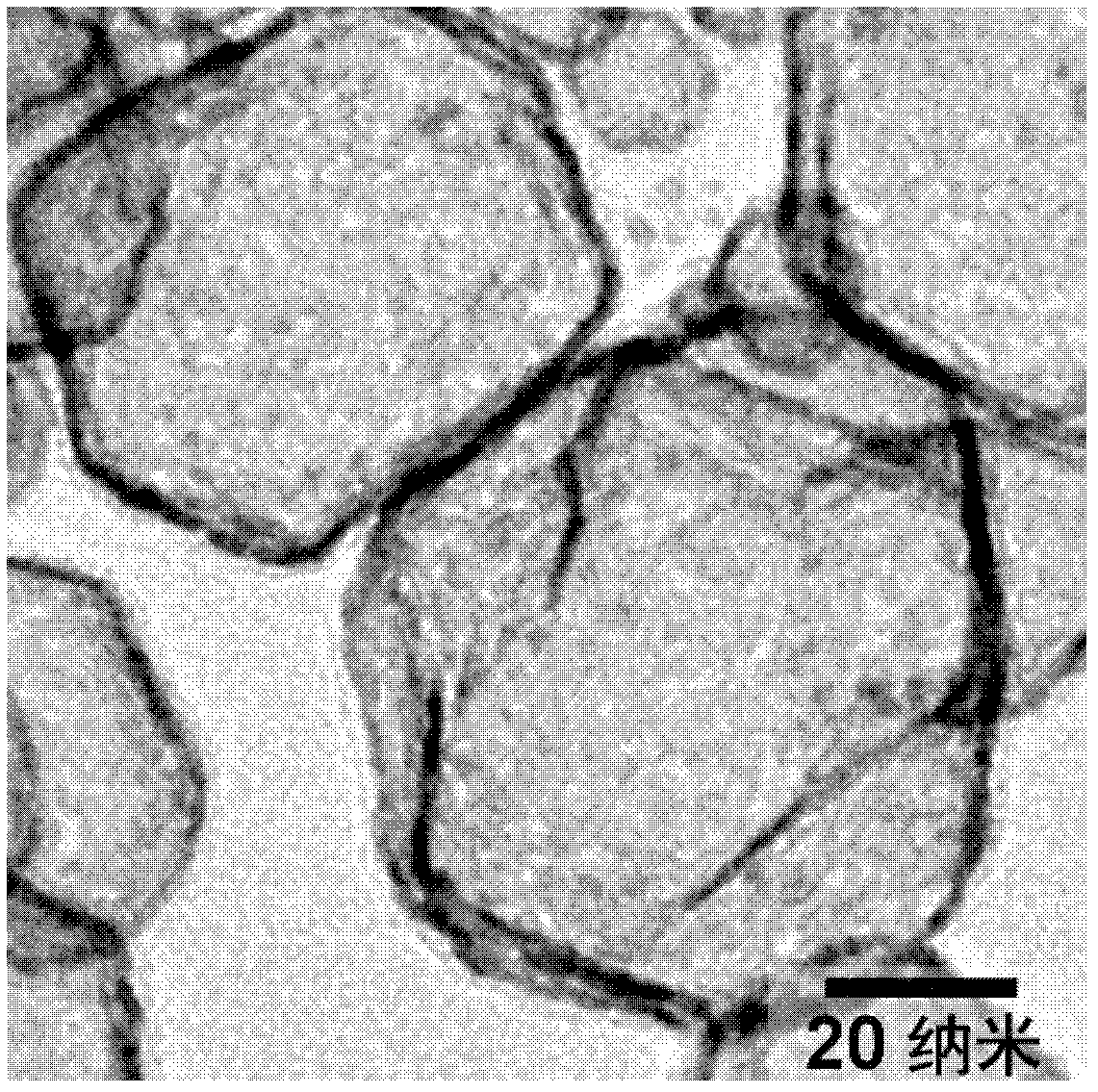

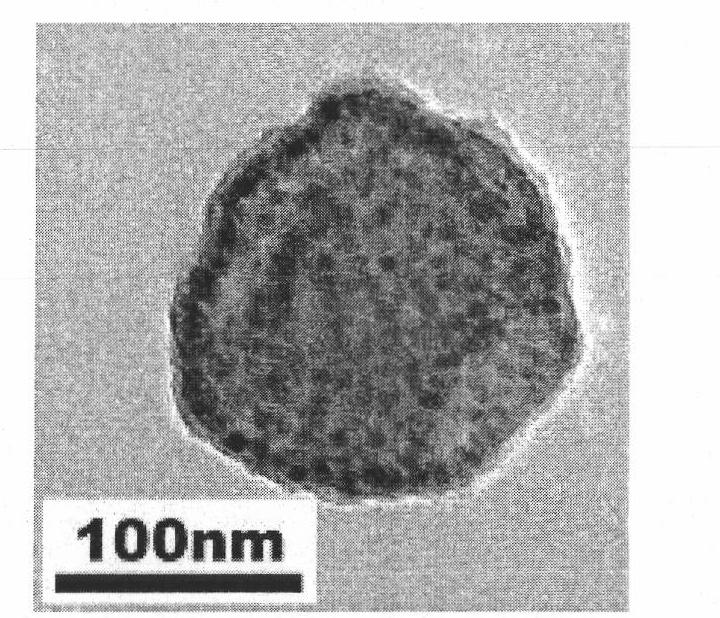

Hollow porous spherical platinum-silver alloy nano-material and preparation method for same

The invention relates to a hollow porous spherical platinum-silver alloy nano-material and a preparation method for the same. The nano-material is of a spherical structure with a porous shell and an internal cavity, the diameter of the spherical structure ranges from 5 nanometers to 500 nanometers, the inner diameter of the cavity ranges from 1 nanometer to 400 nanometers, the thickness of a porewall ranges from 1 nanometer to 50 nanometers, and the pore diameter ranges from 1 nanometer to 20 nanometers. Polyatomic alcohol, inorganic silver salt precursor, inorganic platinum salt precursor and polyvinylpyrrolidone are used as reaction raw materials, inorganic salt containing halogen ions and copper-containing inorganic salt are used as auxiliaries, and the hollow porous spherical platinum-silver alloy nano-material is synthesized by means of reaction. The preparation method is simple in process, convenient in operation, fine in repeatability and low in cost, and the obtained hollow porous spherical platinum-silver alloy nano-material can be used for the fields of chemical and electrochemical catalysis, chemical sensors, biomolecular sensors, information storage, fuel cells, solarcells and the like. Particularly, the hollow porous structure of the nano-material can be effectively applied to slow drug release and target-oriented drug delivery treatment.

Owner:SHANDONG UNIV

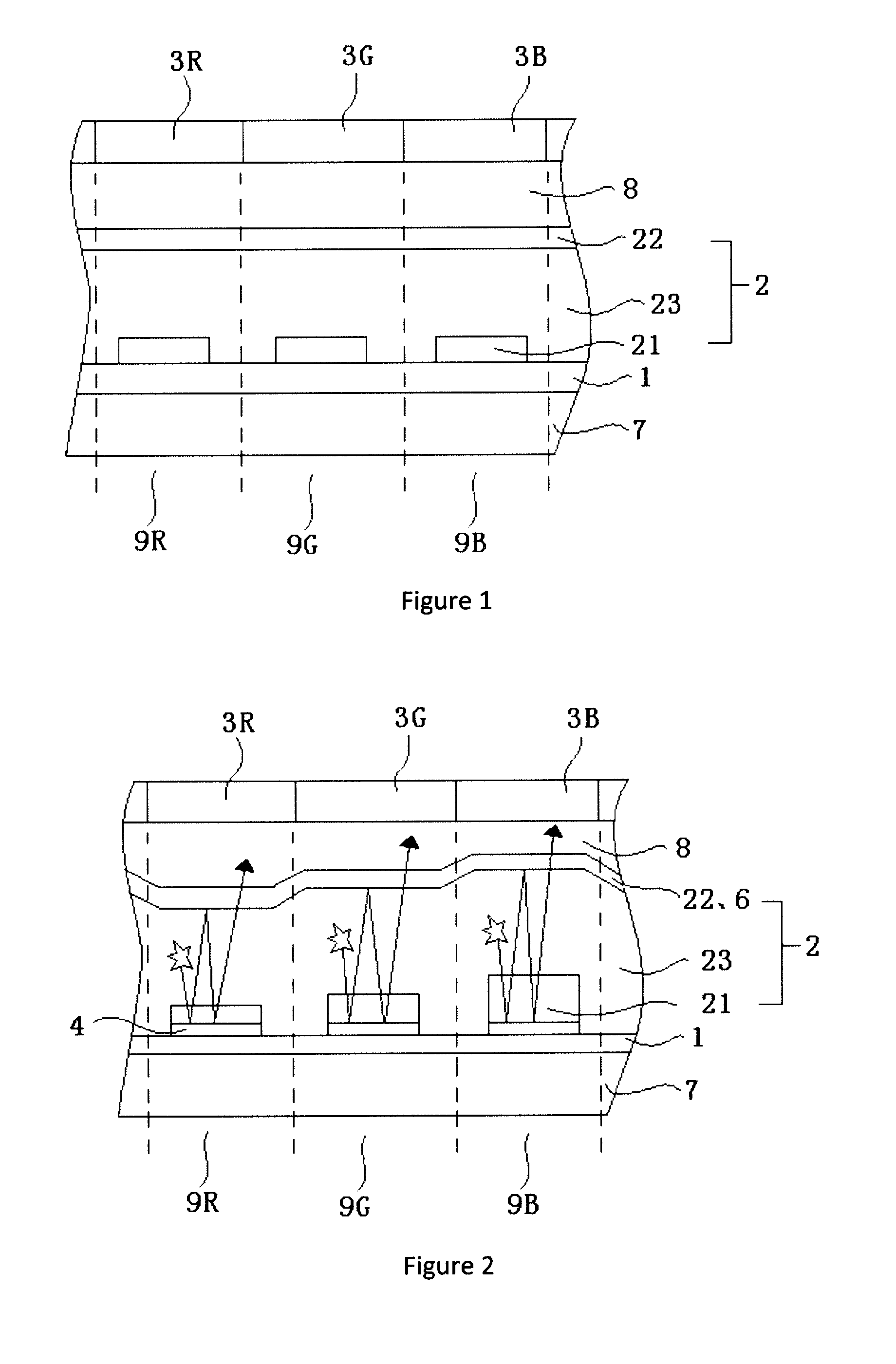

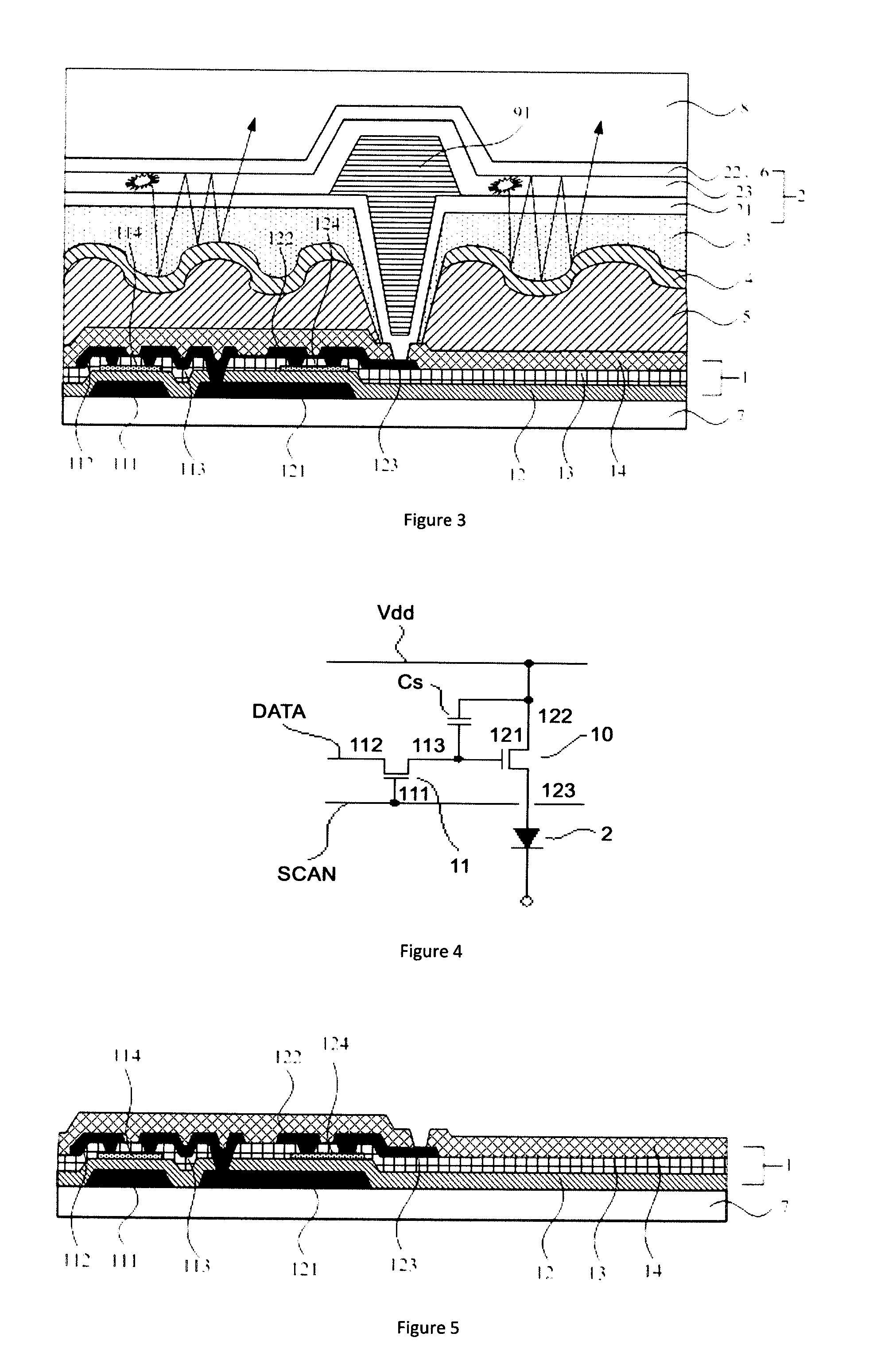

Array substrate, method for fabricating the same, and OLED display device

ActiveUS20140159021A1Simplify the manufacturing processLow costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

This invention provides an array substrate, a method for fabricating the same, and an OLED display device. Each pixel unit of the array substrate comprises: a TFT drive layer; an OLED further away from the substrate than the TFT drive layer and driven by it, the OLED sequentially comprises a first electrode, a light emitting layer, a second electrode, wherein the first electrode is transparent, and the second electrode is a transflective layer, or the second electrode is transparent and has a transflective layer disposed thereon; a reflection layer disposed between the TFT drive layer and the OLED and forming a microcavity structure with the transflective layer, and a reflective surface of the reflection layer has a concave-convex or corrugated structure disposed thereon for causing diffuse reflection of light; and a color filter film disposed between the reflection layer and the OLED and located in the microcavity structure.

Owner:BOE TECH GRP CO LTD

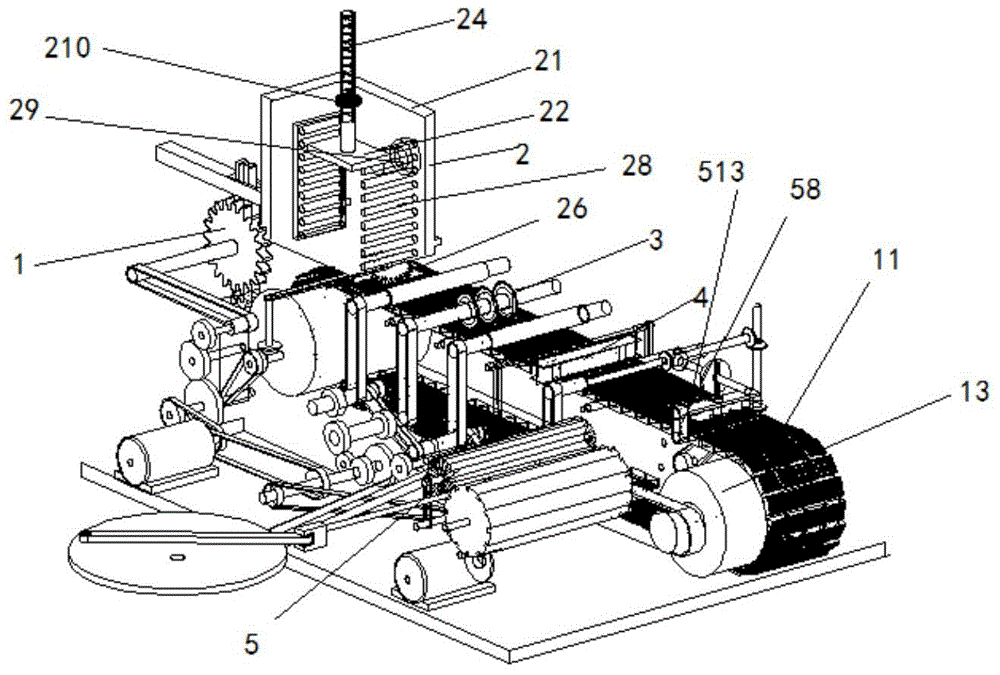

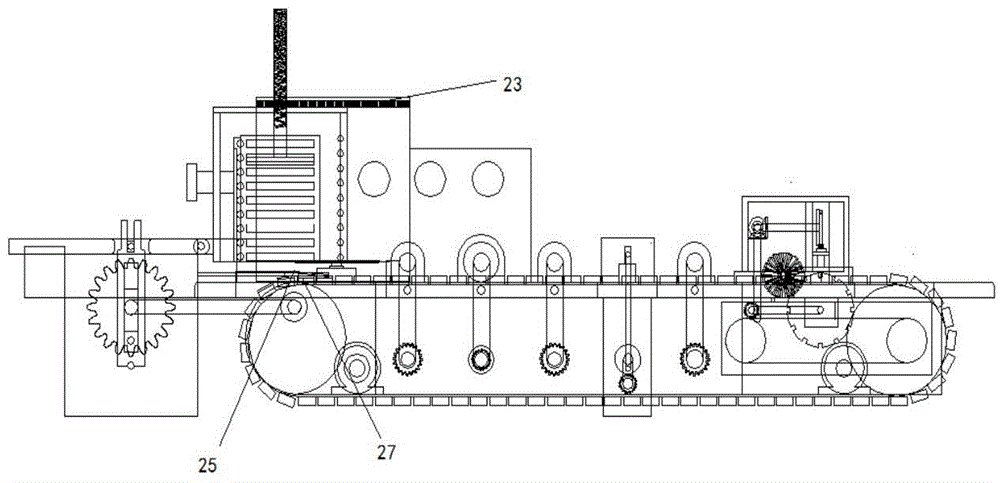

Automatic stringer

InactiveCN104920572AReduce in quantityControl running speedMeat/sausage hanging-upPutting meat on skewersPunchingKnurling

The invention relates to an automatic stringer which comprises a power transmission device, an automatic meat slicing device with a propelling automatic meat locking box, a knurling tool meat cutting device, a shearing and feeding device and an automatic prod punching device, wherein the device integrates slicing, slitting, bar-cutting and prod-stringing, so that the production efficiency is improved, automation and multi-functionalization can be further realized, the automatic stringer is multipurpose, and the consumption of manpower and material resources as well as financial resources is greatly reduced. The automatic stringer not only can string meat, but also can string various foods such as balls and the like. Moreover, meat in different thicknesses and different sizes can be stringed. The mechanical degree and the production efficiency are improved, and the automatic stringer is easy to operate and maintain, low in cost, small in size and high in degree of automation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

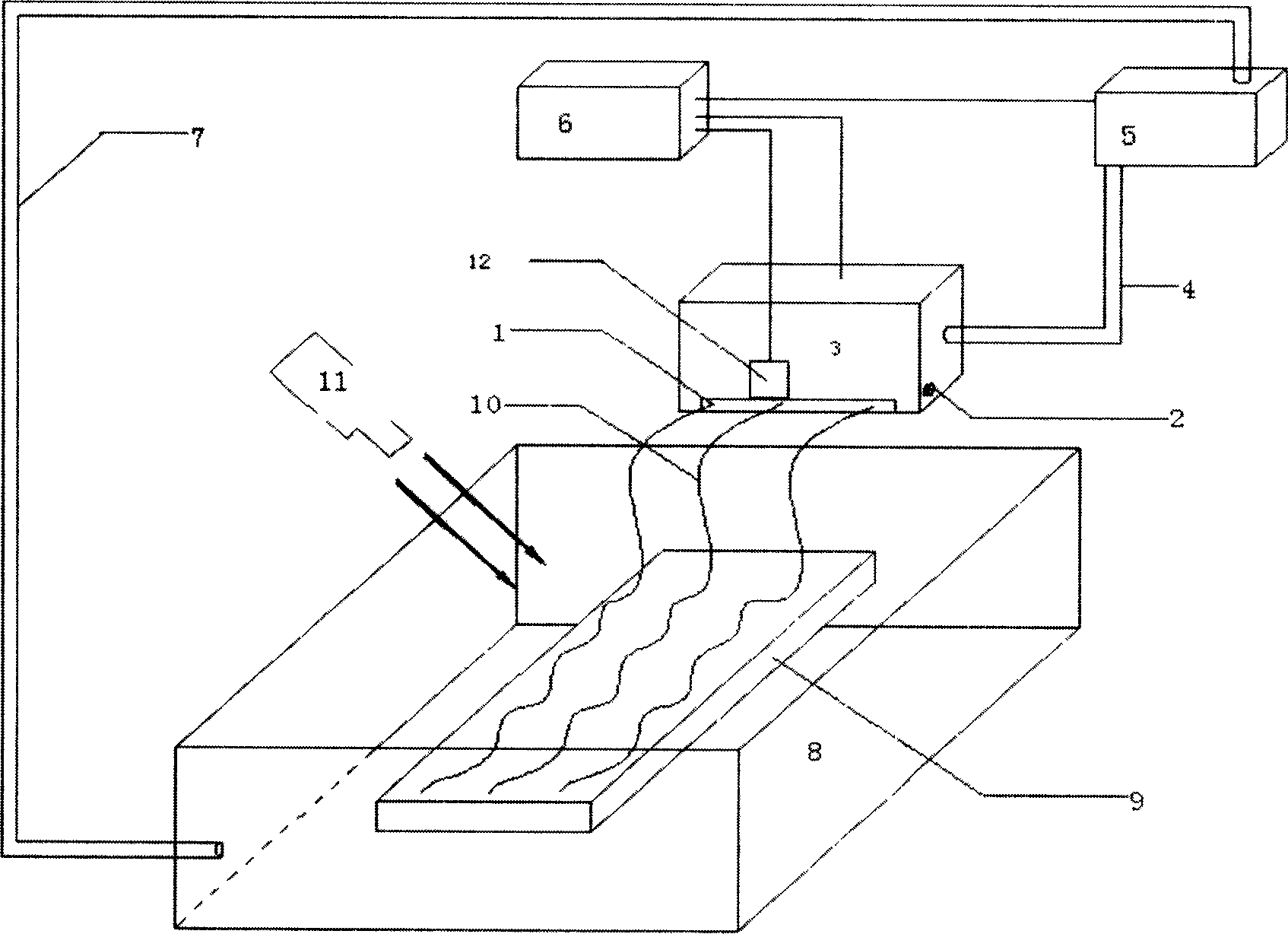

Method and apparatus for supercharging water constraint layer based on laser impact technology

InactiveCN1745955AGuaranteed uniformityReduce splashLaser beam welding apparatusMicrocomputerWater flow

An apparatus based on laser impact technique for pressurizing the water restraining layer is composed of water cleaning unit, water flow controlling box, adjustable tap, following controller of tap, water recovering unit, pressure regulating knob and microcomputer controller. Its method includes such steps as cleaning water, controlling the speed and flow of water stream for preventing turbulent flow and ensuring high thickness uniformity of water layer and pressurizing effect, and recovering water for reuse.

Owner:JIANGSU UNIV

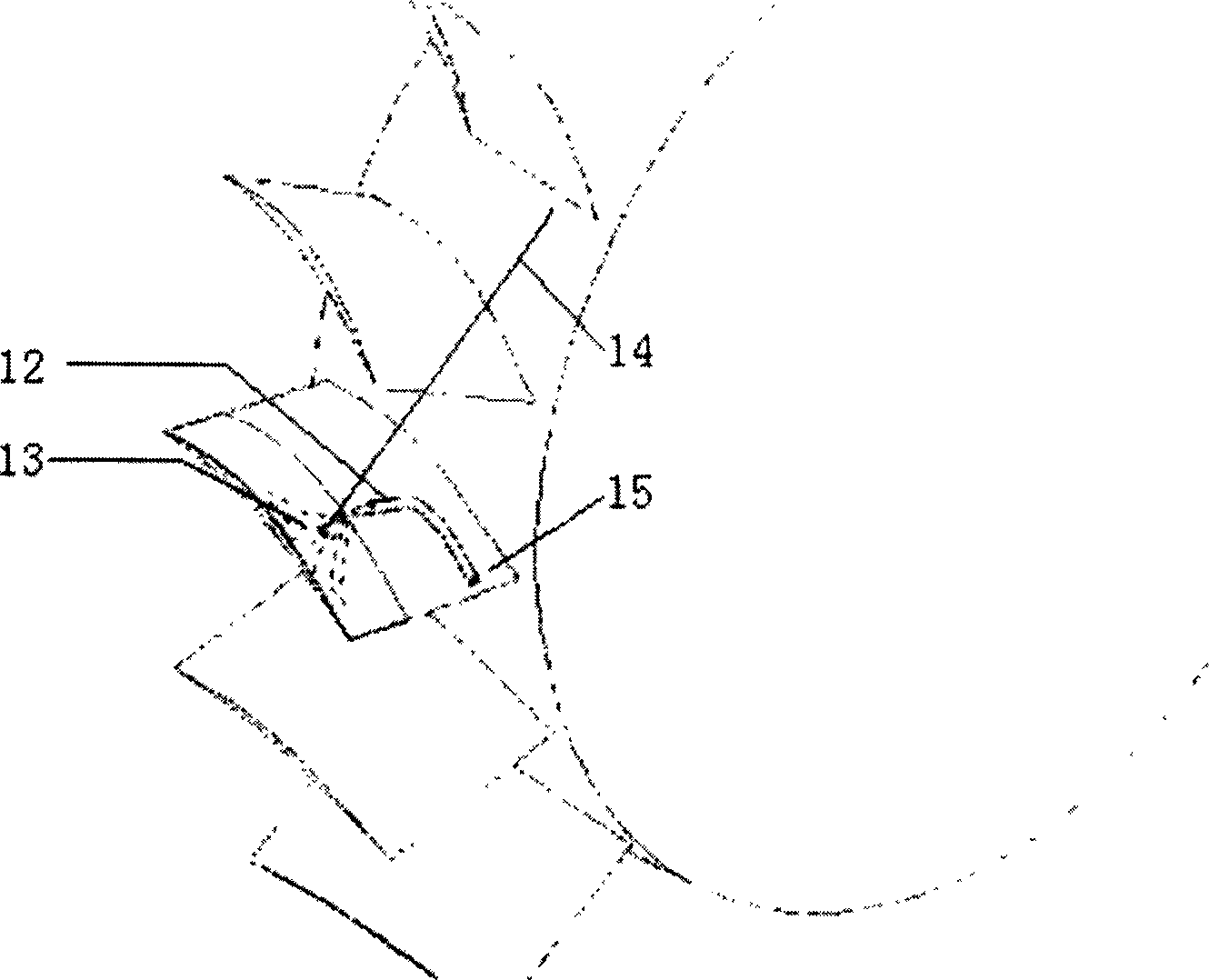

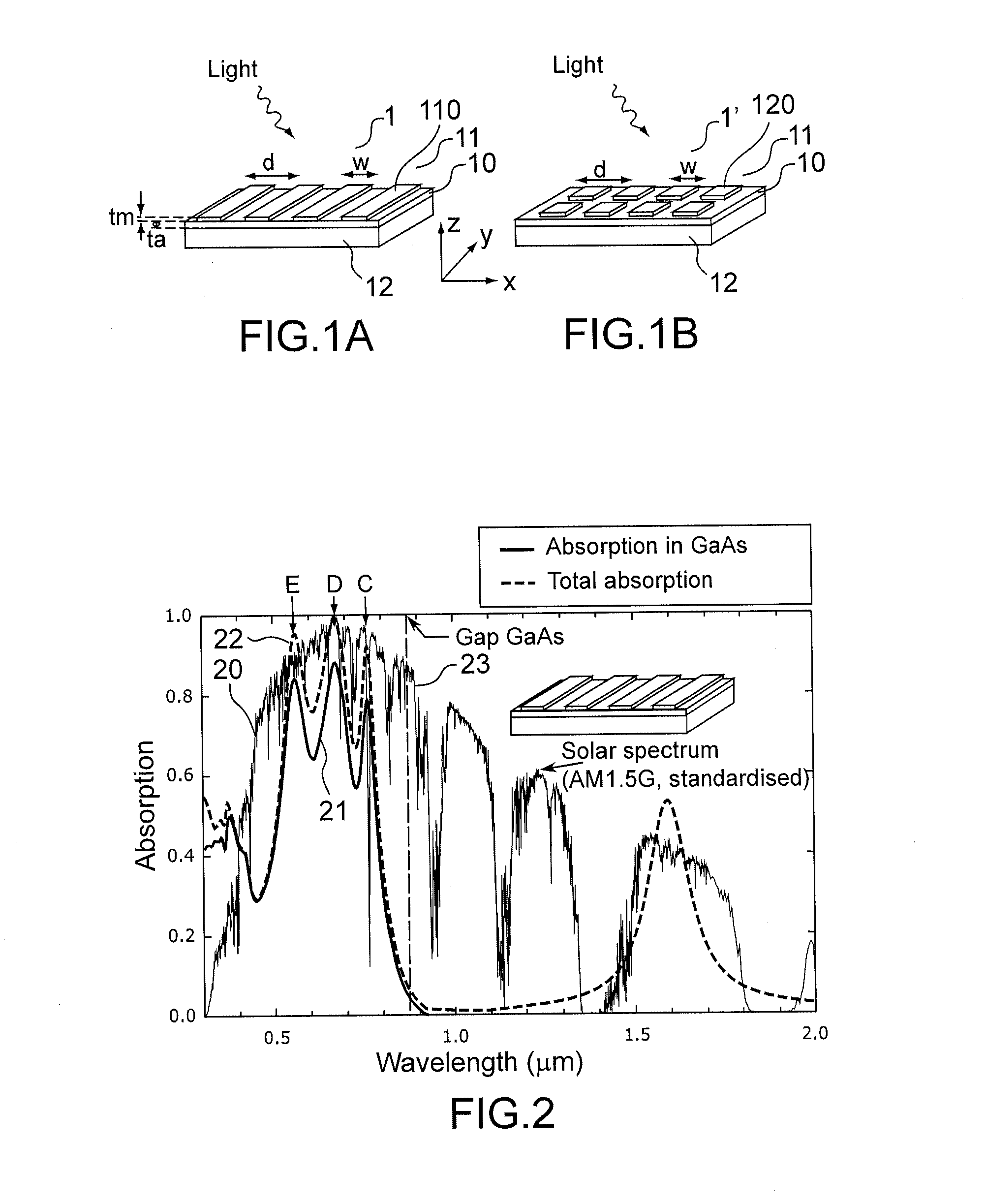

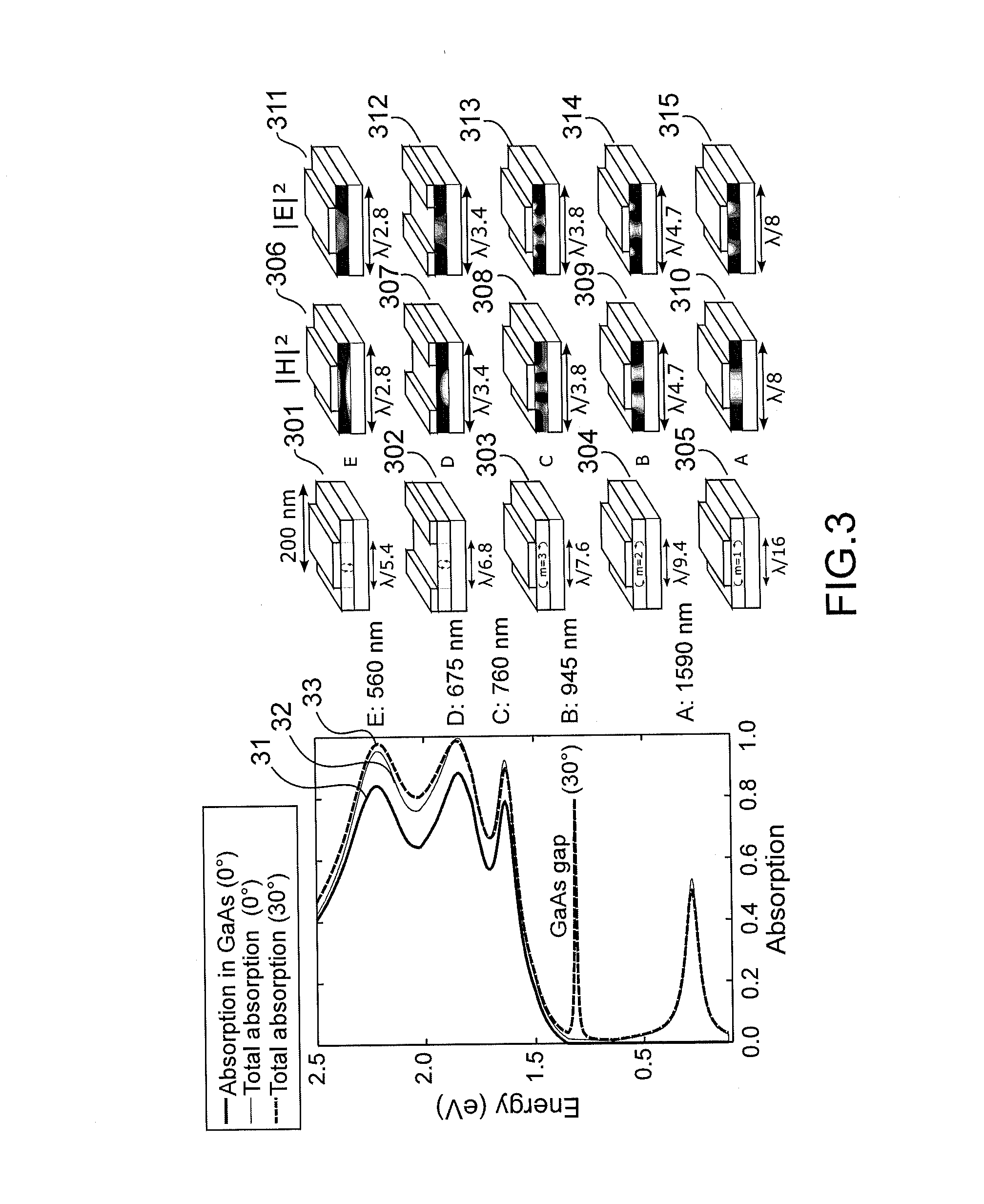

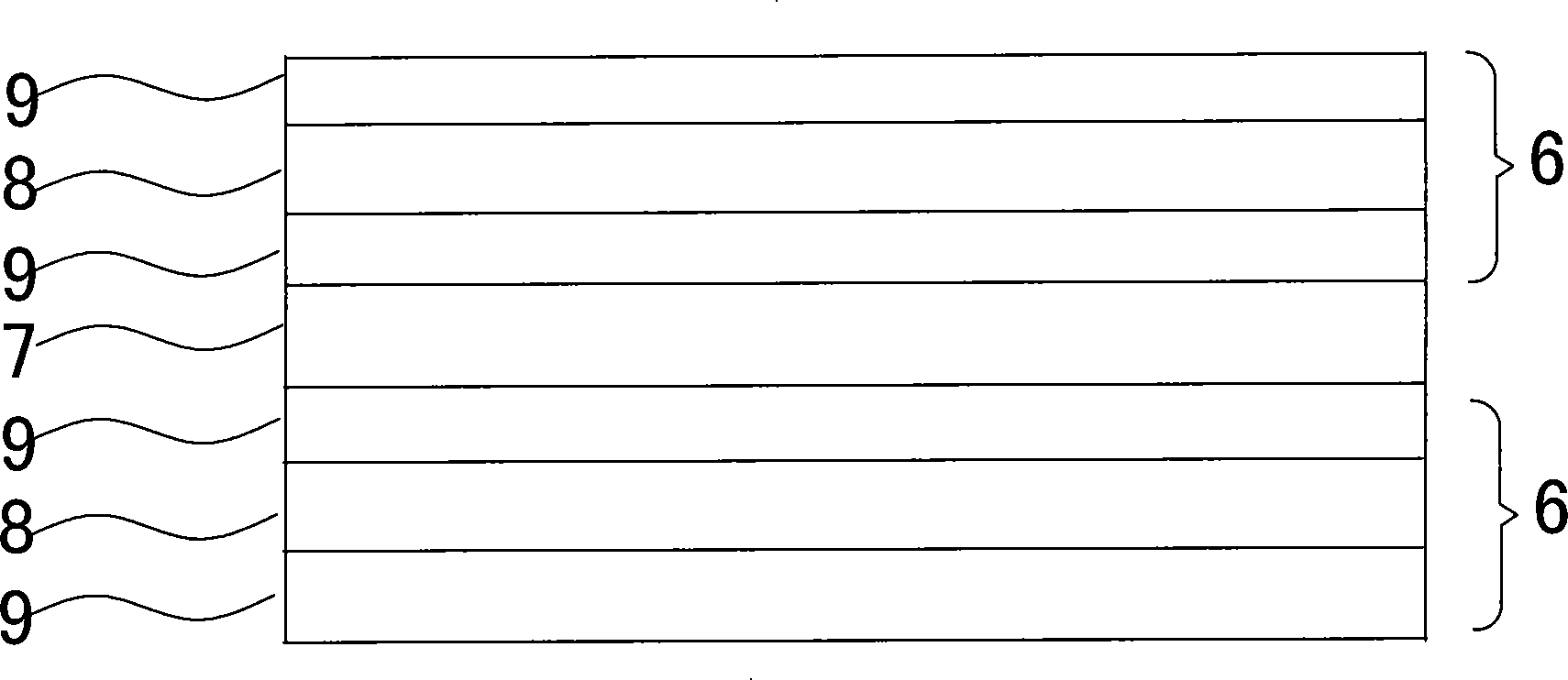

Asymmetric MIM type absorbent nanometric structure and method for producing such a structure

InactiveUS20130092211A1Adjustable thicknessPromote absorptionPV power plantsSemiconductor/solid-state device manufacturingNon symmetricSpectral bands

According to one aspect, the invention relates to an asymmetric MIM type absorbent nanometric structure (1, 1′) intended to receive a wide-band incident light wave the absorption of which is to be optimised within a given spectral band, comprising an absorbent dielectric layer (10) in said spectral band, of subwavelength thickness, arranged between a metal array (11) of subwavelength period and a metal reflector (12). The elements (110, 120) forming the metal array exhibit at least one dimension (w) suitable for forming a plasmonic resonator between the metal array and the metal reflector, under the elements of the array, which plasmonic resonator forms a Fabry-Pérot type longitudinal cavity resonating at a first wavelength of the aimed-for spectral absorption band, and the absorber layer exhibits, between the metal array and the metal reflector, at least one first thickness (ta) suitable for forming at least one first Fabry-Pérot type vertical cavity, resonating at a second wavelength of the aimed-for absorption spectral band.

Owner:CENT NAT DE LA RECHERCHE SCI

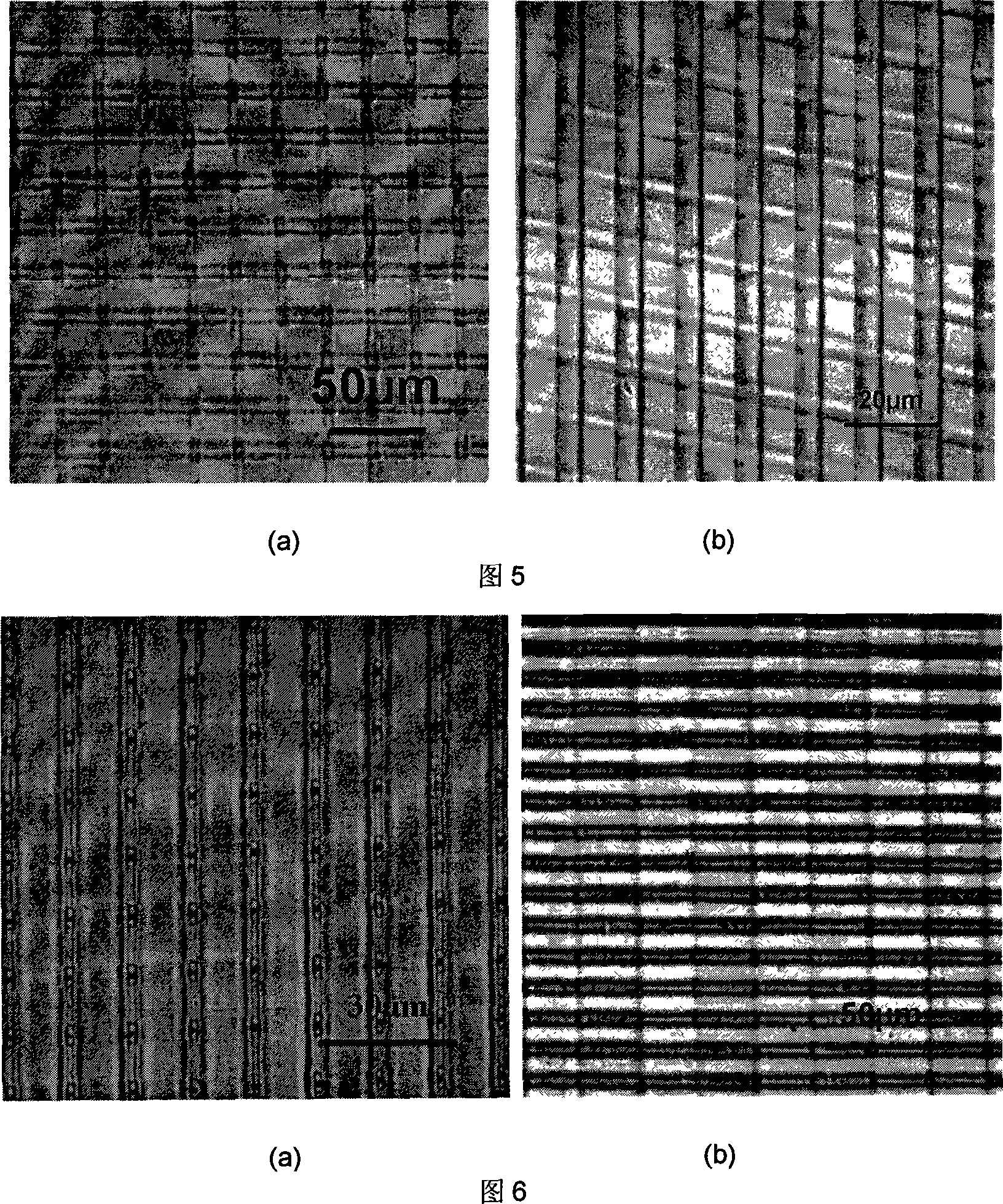

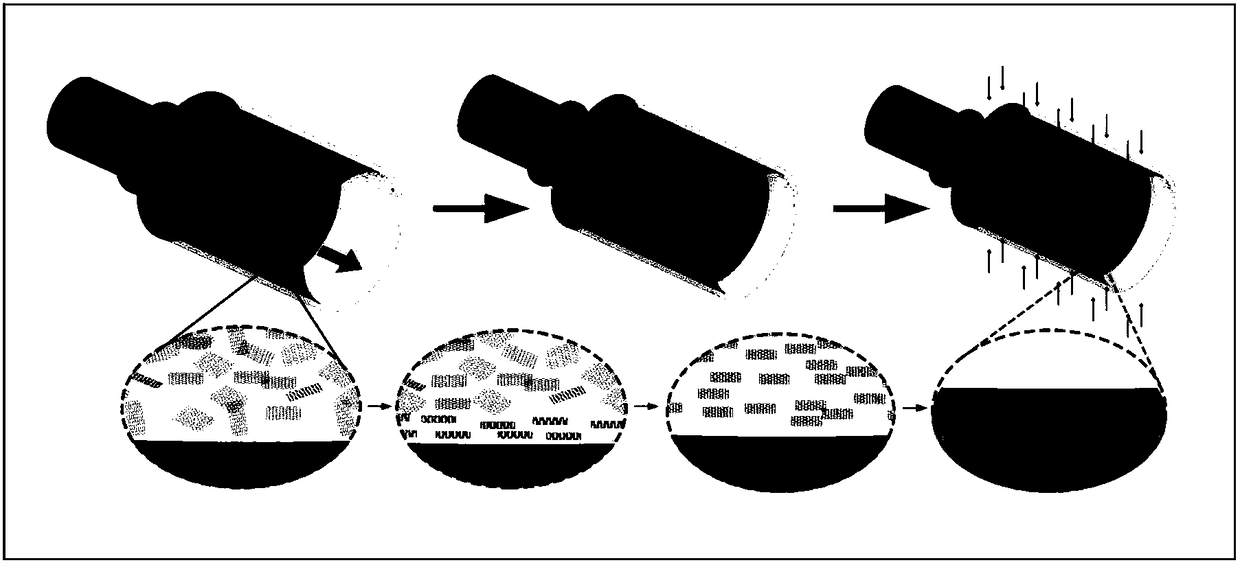

Method for effectively preparing high-orientation and high-compactness two-dimensional material thin film

ActiveCN108568926ASolution coatingUniform coatingFlat articlesCoatingsComposite filmMechanical property

The invention relates to the field of preparation and application of two-dimensional materials, in particular to a method for effectively preparing a high-orientation and high-compactness two-dimensional material thin film. The method comprises the following steps: taking a circular tube with a smooth inner surface as a casting die; pouring a solution which contains a two-dimensional material intothe die when the die rotates in the peripheral direction at high speed; uniformly coating the inner surface of the die with the solution by using centrifugal force; forming shear force which drives the two-dimensional material to be regularly arranged layer by layer in an oriented manner in the peripheral direction in the solution in a centrifugal rotating process; and meanwhile, driving the two-dimensional material to be accumulated at high compactness by the centrifugal force so as to obtain the two-dimensional material thin film with high orientation and high compactness. The method is suitable for preparing various two-dimensional materials such as graphene, and composite thin films and laminated heterostructure thin films of the two-dimensional materials; electric property, heat property, mechanical property and the like of the thin film are greatly improved; and the method is used in the field of high-performance electric conduction / heat-conduction thin films, heat management materials, high-strength thin films, electronic / optoelectronic devices, compact energy storage, gas / ion separating films, proton transmitting films and the like.

Owner:深圳烯材科技有限公司

Light emitting diode

InactiveUS6774404B2Improve reflectivityTransmissivity decreaseSolid-state devicesSemiconductor devicesSealantLight-emitting diode

A light emitting diode is disclosed which can enhance the scattering of light produced by a light emitting element to improve a brightness not only at an upper surface but also at side surfaces of a resin sealant covering the light emitting element, thereby providing a high brightness level in a wider range of angle.This light emitting diode comprises a substrate 22, a pair of electrodes 23a, 23b provided on the substrate, a light emitting element 24 mounted on the substrate and electrically connected to the electrodes, a sealant 26 provided on the substrate to seal the electrodes 23a, 23b and the light emitting element 24; and a light scattering layer 30 formed on an outermost layer of a light projecting surface 27 of the sealant 26.

Owner:CITIZEN ELECTRONICS CO LTD

Novel shading rubber belt

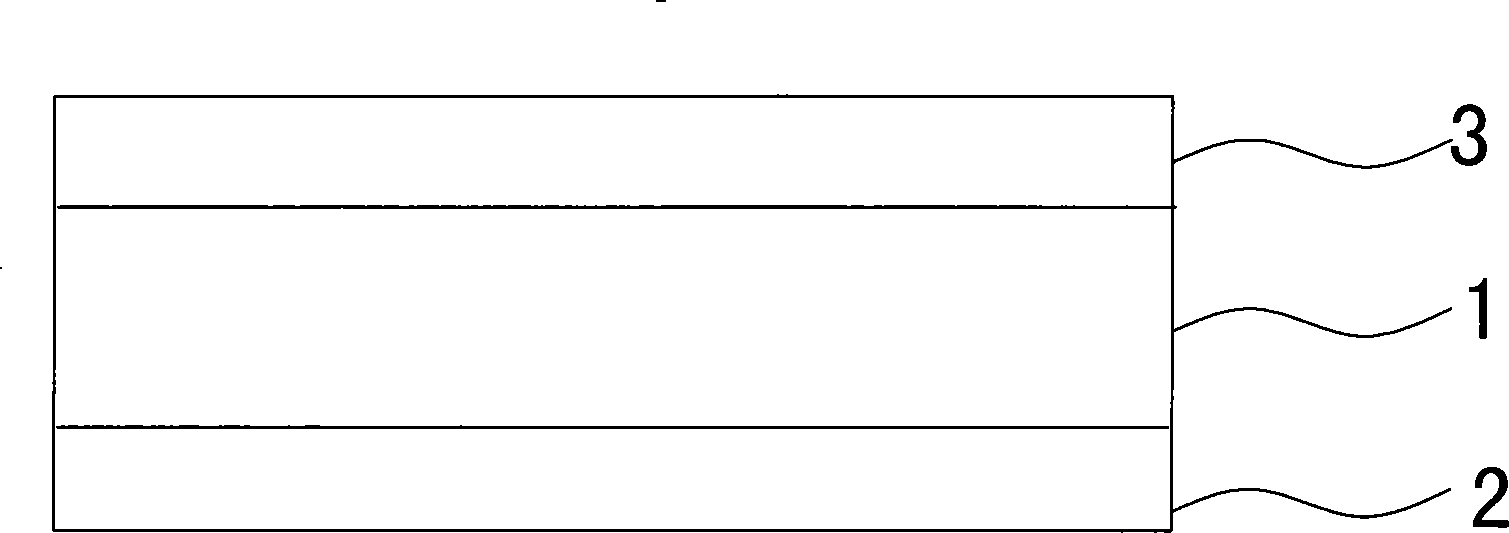

InactiveCN101245226AUniform textureAdjustable thicknessFilm/foil adhesivesNon-linear opticsPolyethylene terephthalateThin layer

The invention relates to a shading belt which comprises a light shielding layer and an adhesive layer, and is characterized in that: the light shielding layer is black polyethylene terephthalate thin layer; the adhesive layer is two sided tape and is composed of a substrate layer and adhesive agent layers at two sides; the adhesive layer is fixedly connected with the surface of the light shielding layer by an adhesive layer on the same surface; the two sided tape is compounded on one side or two sides of the black PET thin layer, thus forming light shielding single side tape or light shielding two sided tape. The thickness of the light shielding tape can be adjusted by choosing PET films with different thicknesses and the two sided tapes with different thicknesses, which avoids the adjustment of the thickness of the light shielding tape by using a large amount of glue, and avoids the glue-spilling phenomenon in die-cutting.

Owner:SUZHOU JINFU TECH

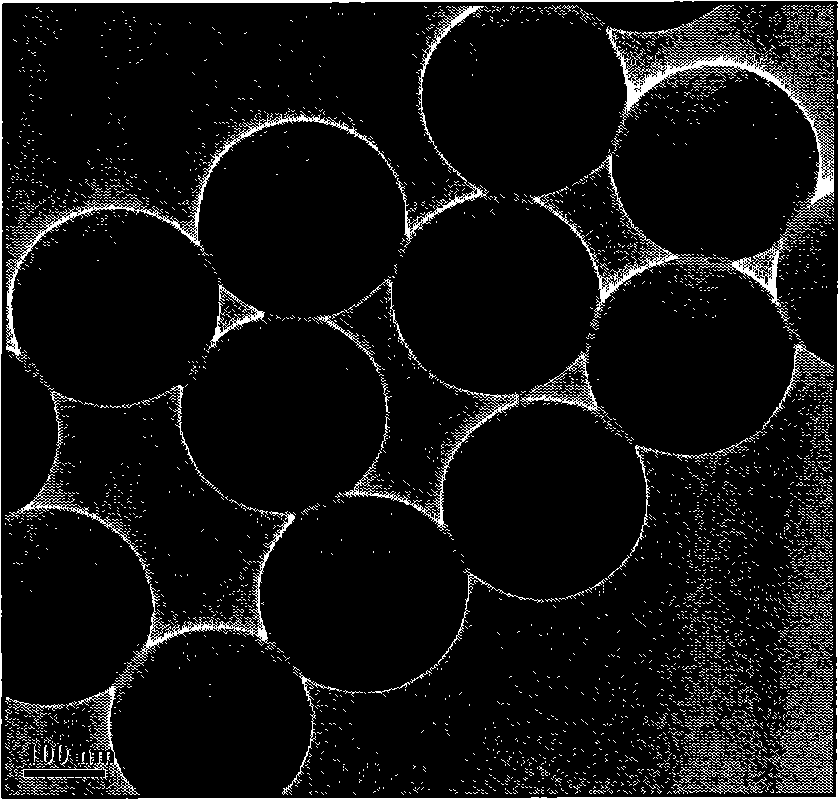

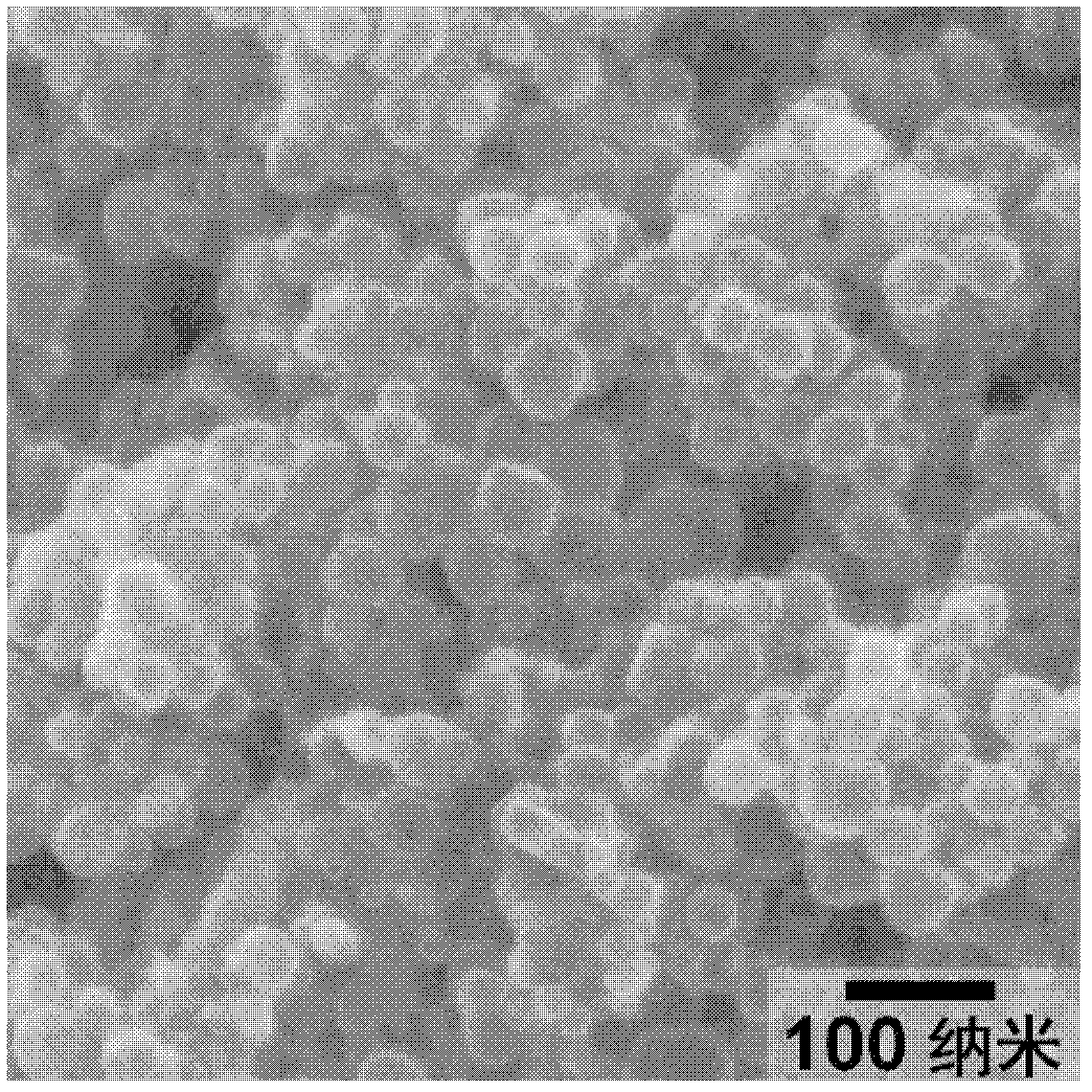

Method for preparing silicon dioxide-coated magnetic microspheres

InactiveCN101783217AThe operation process is simpleHigh magnetic contentSilicaFerroso-ferric oxidesTetraethyl orthosilicateReaction timing

The invention discloses a method for preparing silicon dioxide-coated magnetic microspheres, which belongs to the technical field of nano-magnetic materials. In the method, the characteristic that nanoparticles are easily arranged on a two-phase solution interface is utilized to form oil-in-water emulsion or microemulsion which is stabilized by oil-soluble magnetic nanoparticles and the hydrolysis of tetraethyl orthosilicate is further produced on the surfaces of droplets, so that a silicon dioxide-coated layer is formed. The method has the advantages of no need of using any surfactant, simple reaction operation process and short reaction time; particle diameters of the coated magnetic microspheres are 50 to 400nm; and the magnetic content of the microspheres can be simply controlled at the same time when the particle diameters of the magnetic microspheres are controlled.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

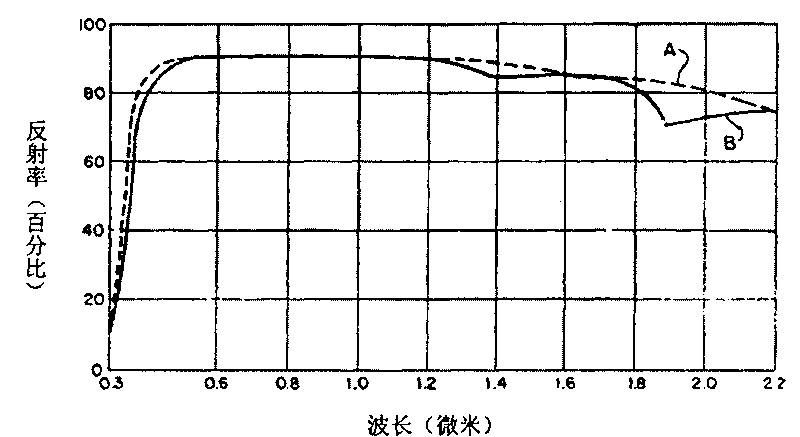

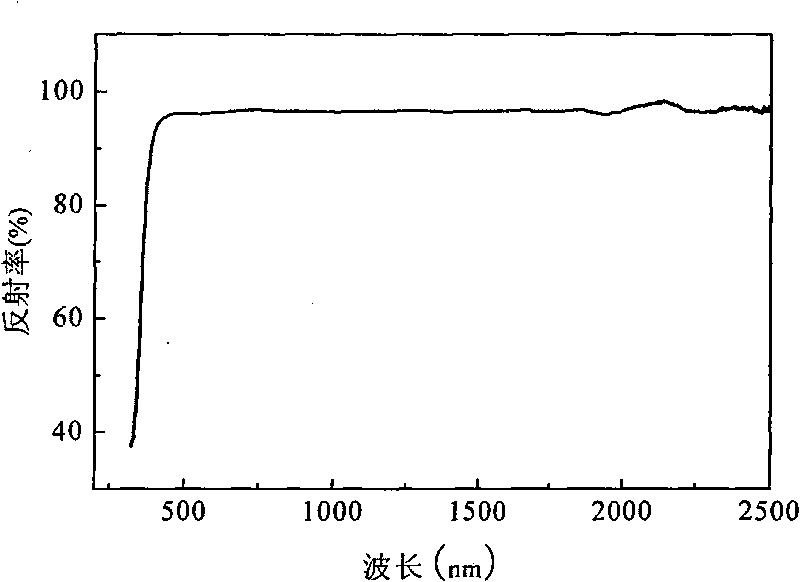

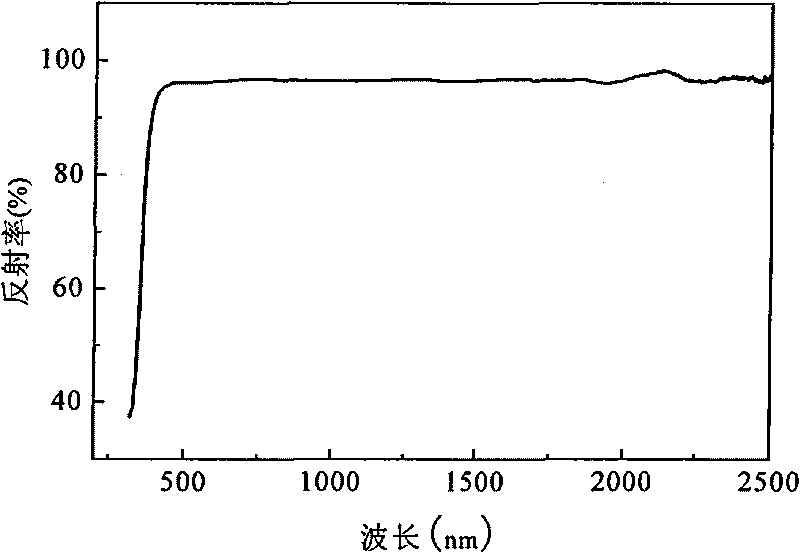

Method for preparing high-temperature resistant anti-infrared thermal radiation energy-saving coating

The invention discloses a method for preparing a high-temperature resistant anti-infrared thermal radiation energy-saving coating. The method comprises the following steps of: adding inorganic crystal whisker or / and fiber materials to sol containing titanium and kalium elements, evenly stirring the mixture to form pulp; and coating the pulp on the surface of heat insulating materials, fireproof materials or thermal insulating materials, and sintering the pulp at the temperature of between 200 and 700 DEG C for 0.5 to 5 hours to form compact coatings with the thickness of 0.1 to 5mm, wherein the content of the inorganic crystal whisker or / and fiber materials in the pulp is 5 to 70 weight percent. In the temperature range of between 400 and 1,200 DEG C, the reflectivity of the compact coating which is prepared by the method in a thickness of 0.1 to 5mm on the infrared thermal radiation with the wave length of 500 to 2,500nm is over 90 percent, and after the coating of the invention undergoes 5 thermal shock stability tests at the temperature of 1,000 DEG C, no crack occurs.

Owner:NANJING TECH UNIV +1

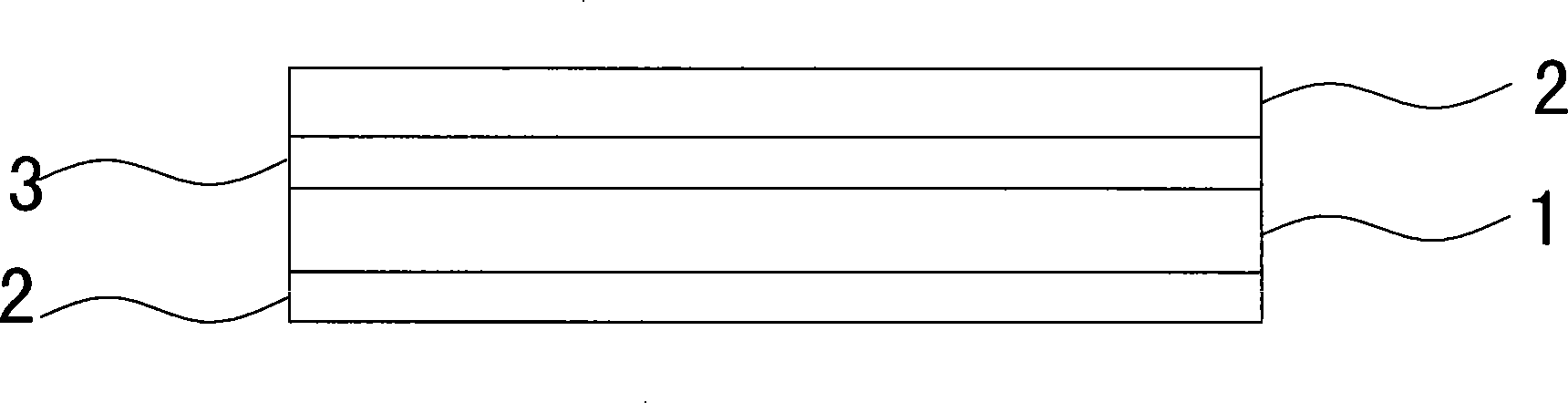

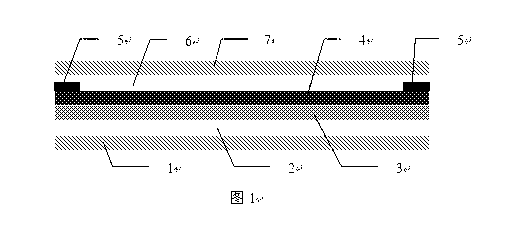

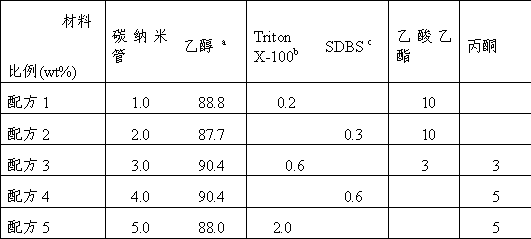

Low-temperature radiation electrothermal film and preparation method thereof

InactiveCN103305051AHigh peel strengthImprove adhesion strengthInksOhmic-resistance heatingPolyesterRadiant heater

The invention discloses a low-temperature radiation electrothermal film and a preparation method thereof. The carbon nanometer conductive ink comprises the following components in mass percent: 1 to 5% of carbon nano tube, 94 to 98% of solvent, and 0.2 to 2% of surface active agent. The preparation method comprises the following steps: manufacturing a hot melt adhesive layer on a polyester film; printing a carbon nanometer conductive ink layer onto the hot melt adhesive layer; printing a generating and heating ink layer on the ink layer; manufacturing an electrode; and then hot-processing and compounding the polyester film through a hot melt adhesive film. The low-temperature electric radiant heater film has the characteristics that the peeling strength is high and the electro thermal power can be flexibly adjusted.

Owner:KMT纳米科技(香港)有限公司

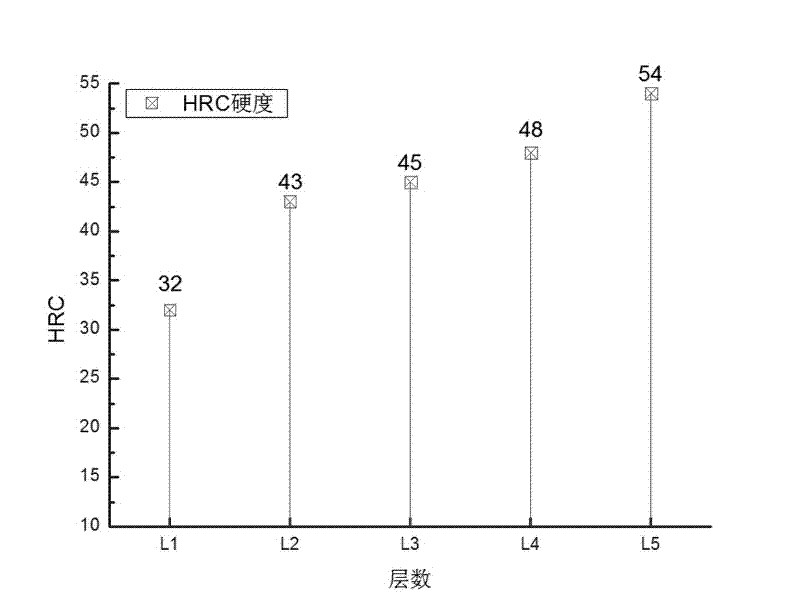

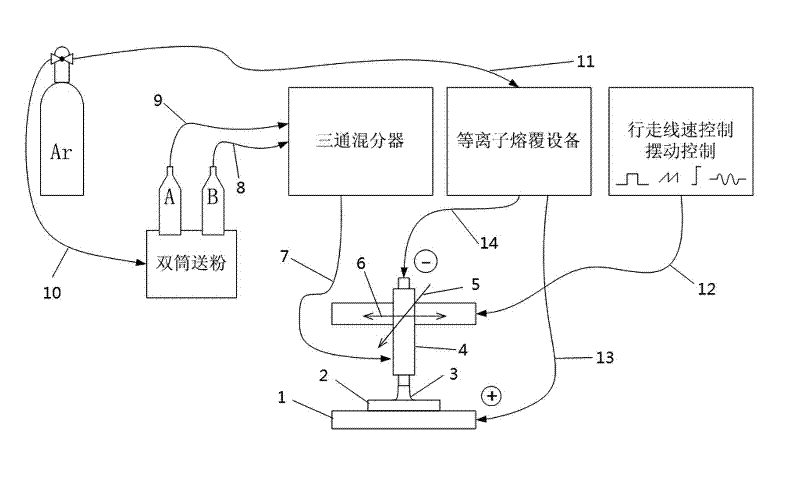

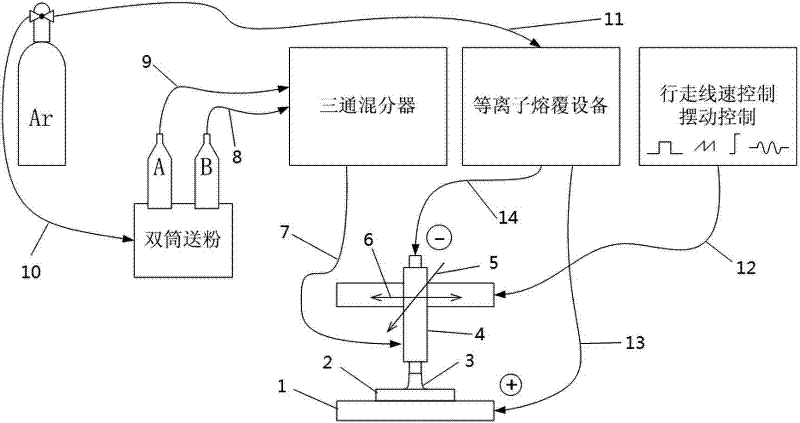

Method for preparing Fe-based WC-Ni gradient coating by using plasma cladding method

InactiveCN102392241AWide selection of materialsFlexible moving processMetallic material coating processesNumerical controlMetal powder

The invention discloses a method for preparing an Fe-based WC-Ni gradient coating by using a plasma cladding method, comprising the steps of: designing the number of layers of the gradient coating and the proportion of ceram A at each layer; supplying the A and metal powder B by a binocular; mixing the powder A and B through a three-way device and then putting the mixture into a coaxial powder feeding cladding gun which is controlled by a numerical control device; controlling the transverse size of the coating by controlling the walking speed, the swinging speed and the swinging amplitude as well as obtaining required coating thickness by controlling the powder feeding amount and the plasma arc power; cleaning the surface after the coating is solidified; and repeating the second to fifth steps to complete the preparation of the coating. In the invention, the used equipment is simple; the investment is low; the length, the width and the thickness of the gradient coating are adjustable; the components in the coating are uniform; the gradient coating can be prepared at local positions of workpieces; and metallurgic combination can be achieved between the coating and matrixes or between coatings with high interface combination strength.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

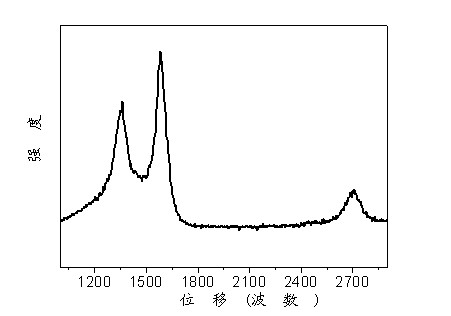

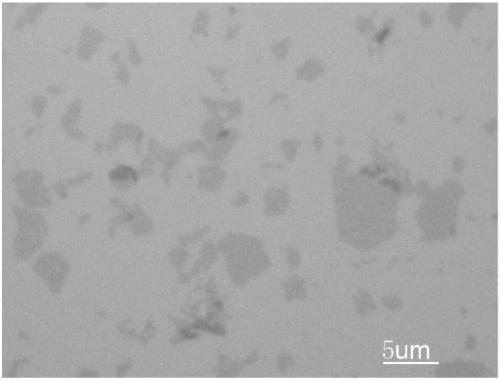

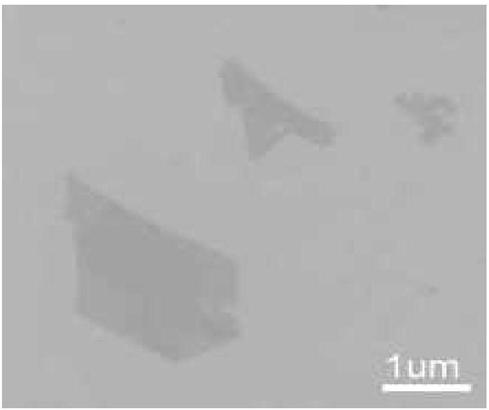

Two-dimensional nanosheet and preparation method and usage thereof

InactiveCN110371932ALower synthesis costSuitable for large-scale industrial productionMaterial nanotechnologyTitanium sulfidesTransmittanceOrganic matter

The invention provides a two-dimensional nanosheet and a preparation method and usage thereof. Through a means of solution stripping, the two-dimensional nanosheet which is large in sheet layer size,high in quality and small in defect number and mainly takes a single layer is prepared. The morphology of the two-dimensional nanosheet is represented through an optical microscope, a scanning electron microscope, a transmission electron microscope and an atomic force microscope. A Raman spectrum is utilized to represent that the two-dimensional nanosheet obtained through solution stripping and atwo-dimensional nanosheet obtained through a chemical vapor deposition method have the equally high crystalline quality. An infrared transmittance spectrum is utilized to represent successful modification of organic matter to the two-dimensional nanosheet. Research results show that the two-dimensional nanosheet synthesized through the preparation method has the advantages of being large in size,high in quality, small in defect number, easy to modify and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

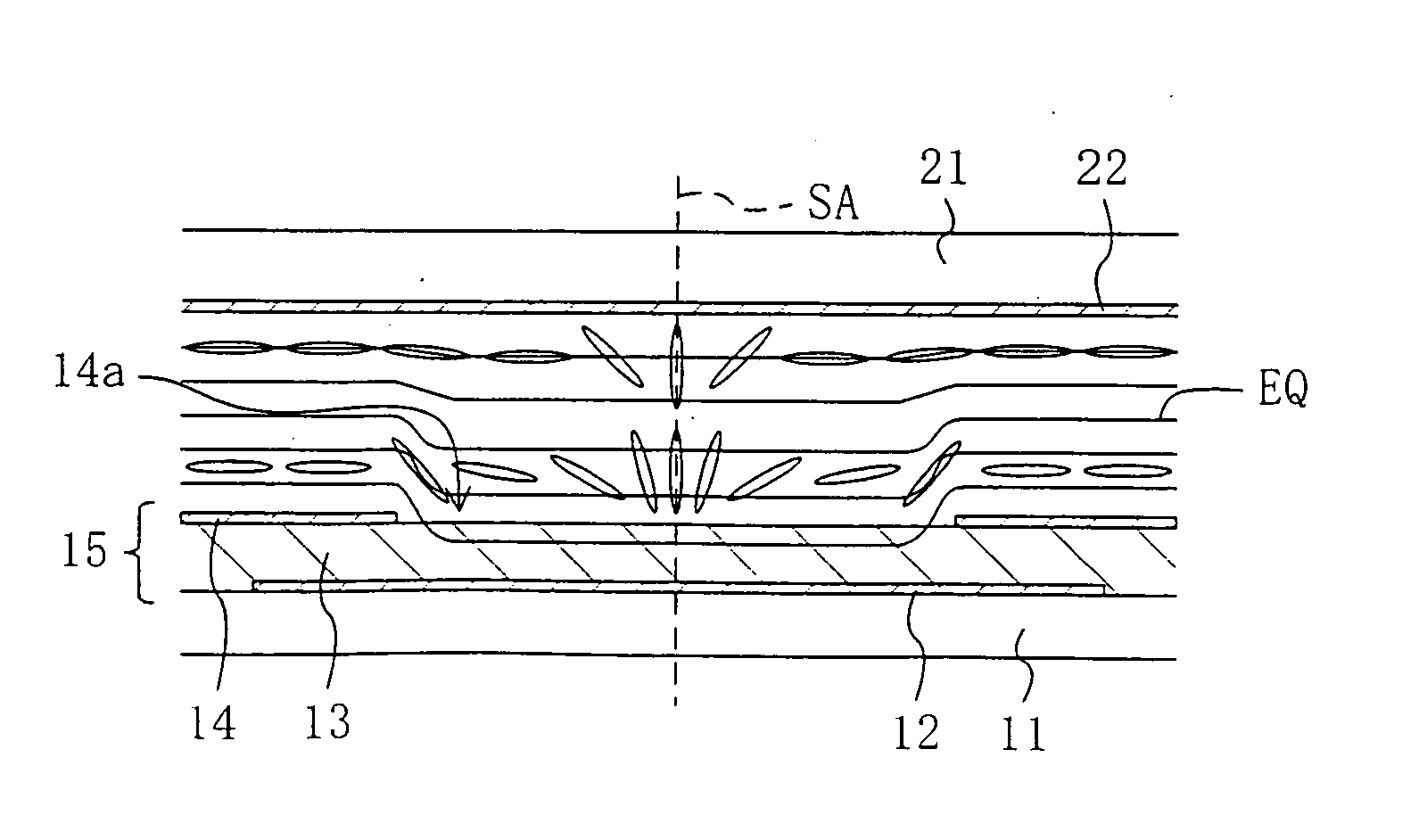

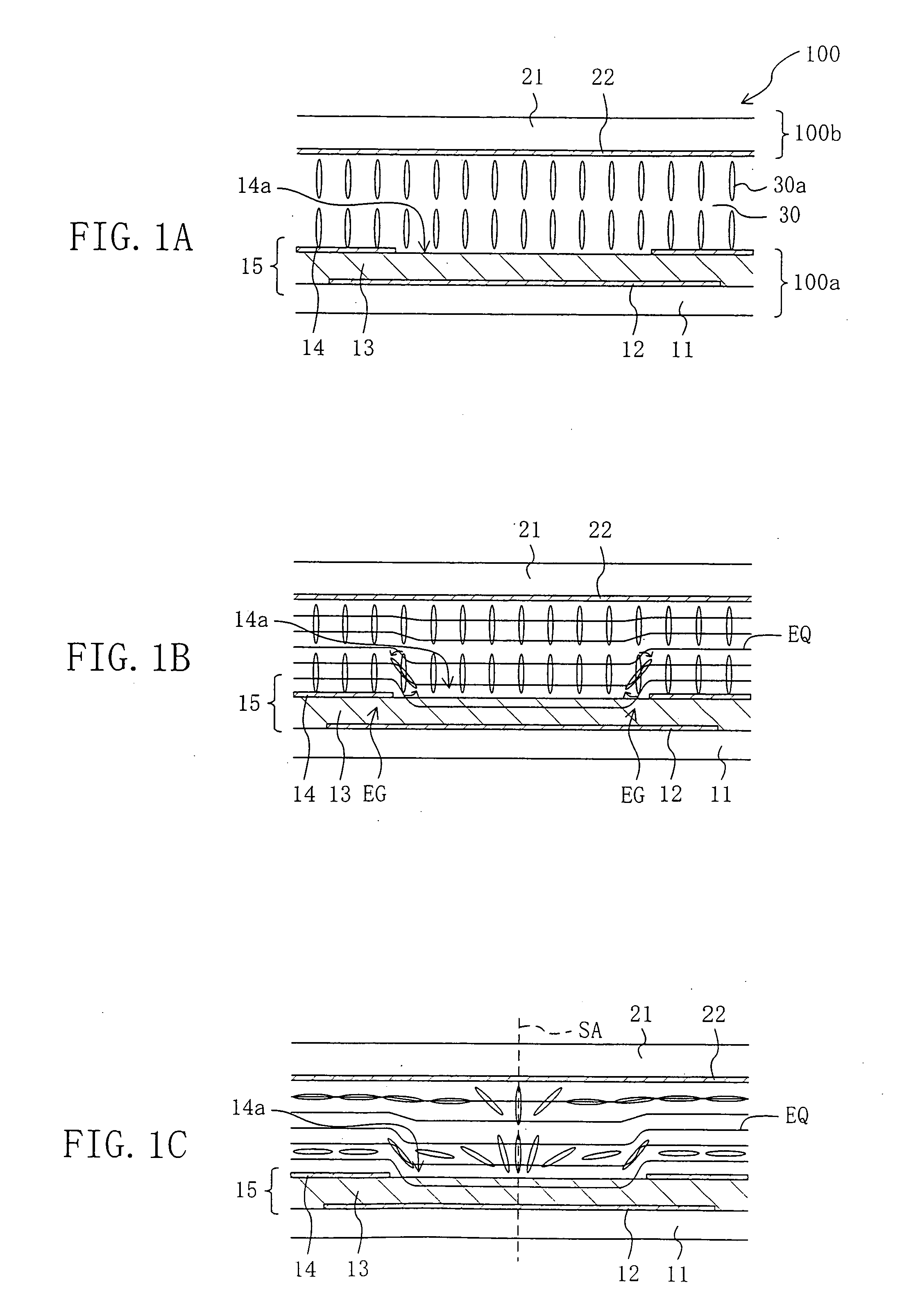

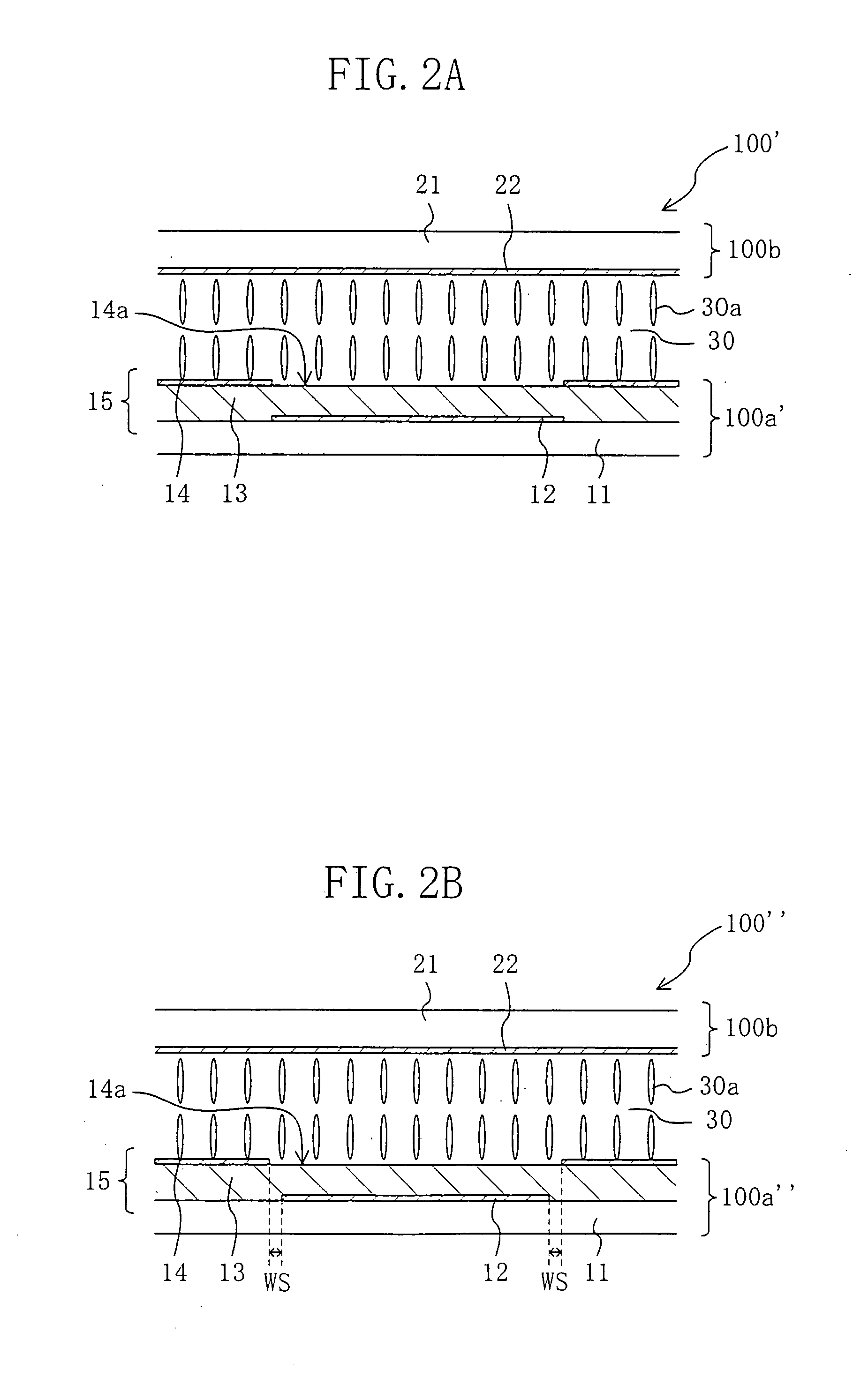

Liquid crystal display device

InactiveUS20050174528A1Improve display qualityAdjustable thicknessNon-linear opticsVertical alignmentDielectric layer

Owner:SHARP KK

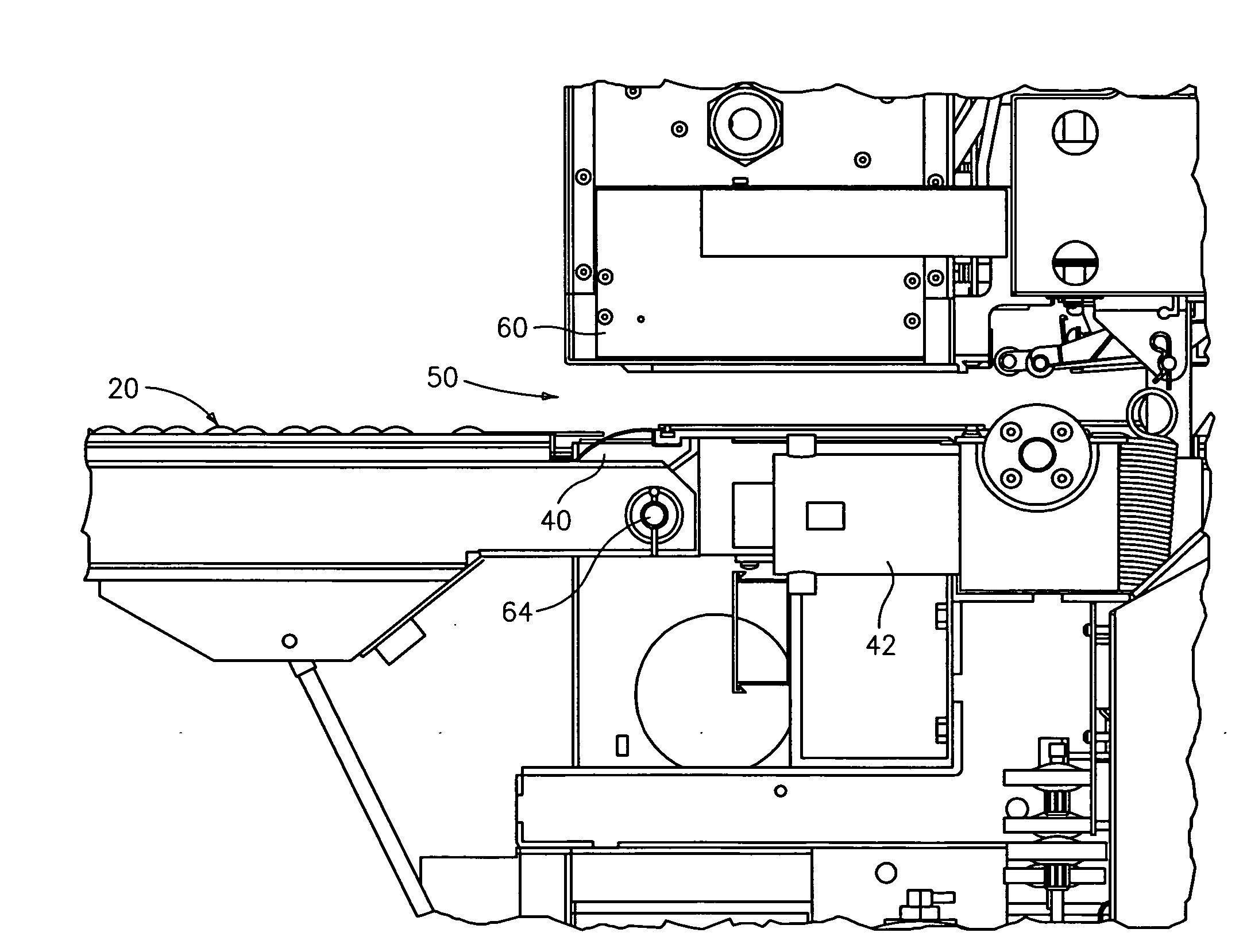

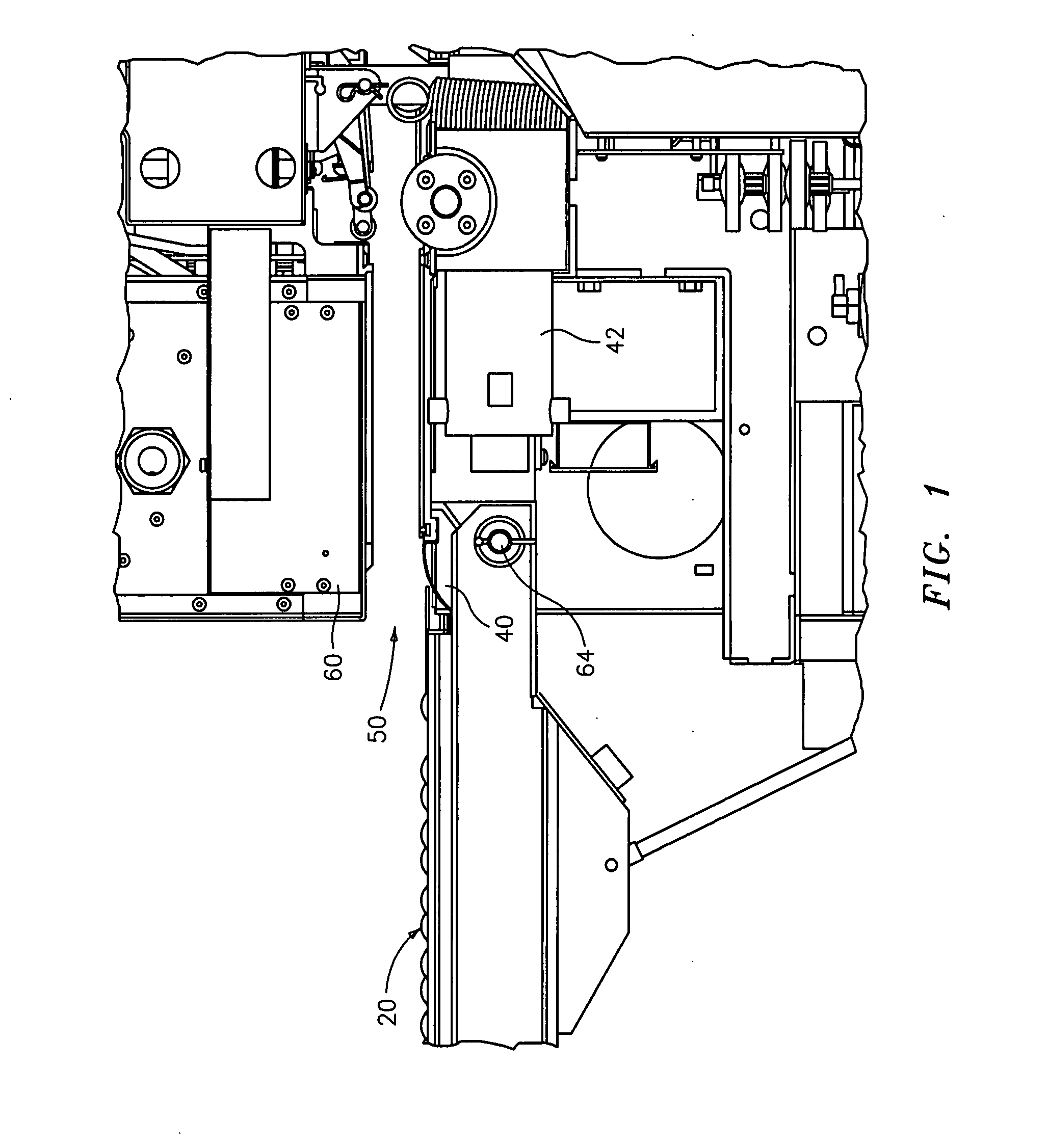

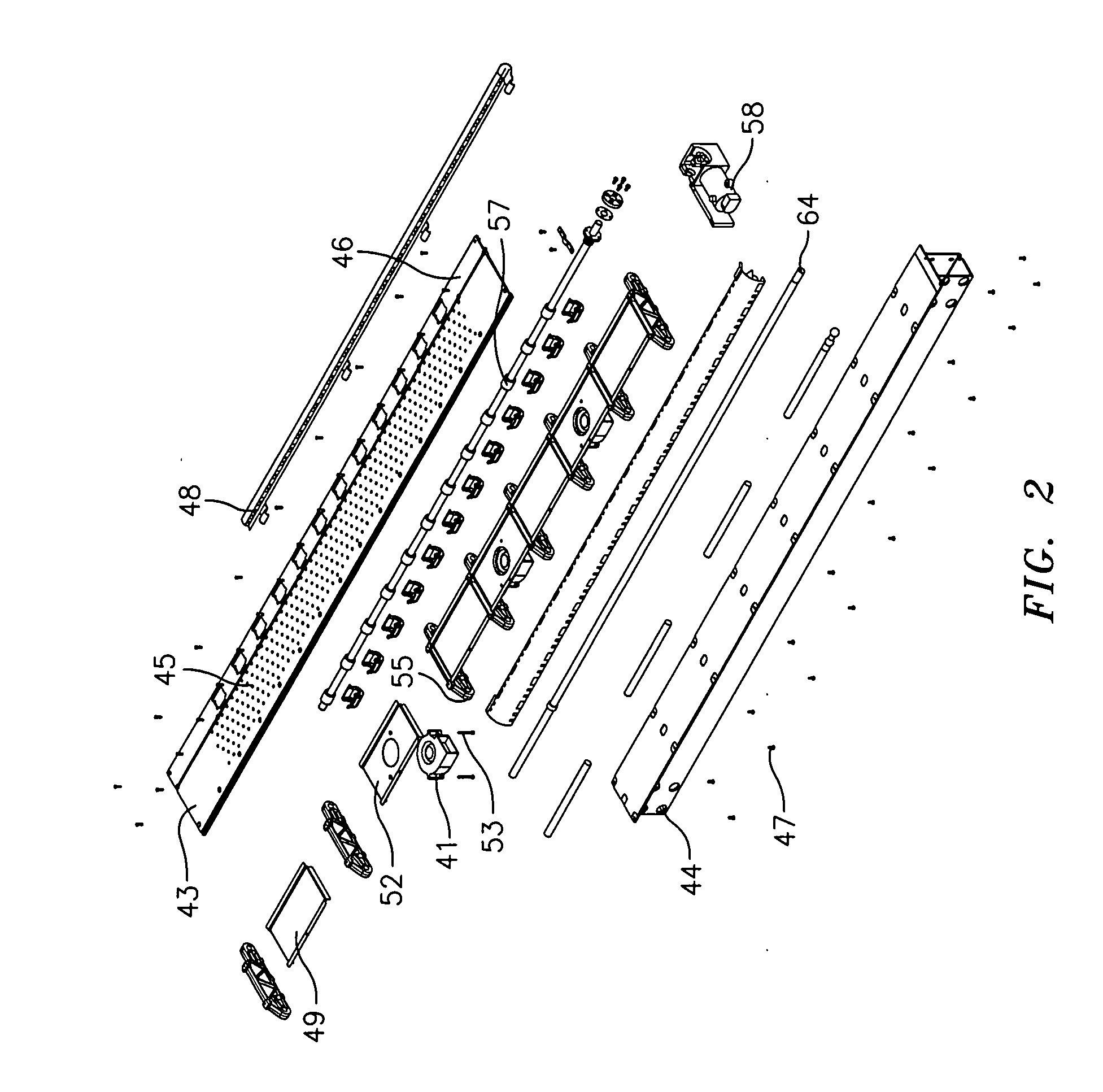

Ink jet printer

ActiveUS20080192075A1Easy to assembleEasy to adjustTypewritersOther printing apparatusPrint mediaMechanical engineering

An improved large-format inkjet printer that is capable of providing more efficient and higher quality printing on a variety of print media, including for example, paper, fabric, corrugated media, and plywood. The improved printer provides improvements to the platen assembly, rail assembly, service station assembly, printhead assembly and vacuum assembly to provide improved printing capability. In addition the printer provides a table assembly that can be integrated into the platen assembly to provide a secure and flush surface for supporting various types of print media.

Owner:HEWLETT PACKARD DEV CO LP

Method of preparing phase-change energy-accumulation material microemulsion

InactiveCN101508887AHigh viscosityLarge apparent specific heat capacityHeat-exchange elementsFreeze thawingSurface-active agents

The invention relates to a method for preparing phase change energy storage material microemulsion, comprising the steps: first, 10 parts by weight of organic phase change energy storage material can be prepared; 1-4 parts by weight of surface active agent, 1-3 parts by weight of cosurfactant, 0.3-1.5 parts by weight of inorganic salt and 10-100 parts by weight of de-ionized water or distilled water are added into the organic phase change energy storage material; after that, the mixed solution is evenly stirred and mixed at a certain temperature and then stands still; finally, the microemulsion is obtained until bubbles are completely removed; wherein, the surface active agent is compound of surface active agent A and surface active agent B, the HLB values of which are respectively 1-10 and 11-20; the weight ratio between the surface active agent A and the surface active agent B is 1:1.5-4.5, and the HLB value is 8-18 after being compounded. The obtained microemulsion is a stable system of thermodynamics, has transparent appearance, and does not have the phenomenon of phase splitting and emulsion breaking caused by a plurality of times of phase transition process due to the actions such as a plurality of times of freeze thawing, centrifugal separation and the like, thereby fundamentally overcoming the defect of poor stability of conventional emulsion and being long in service life.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

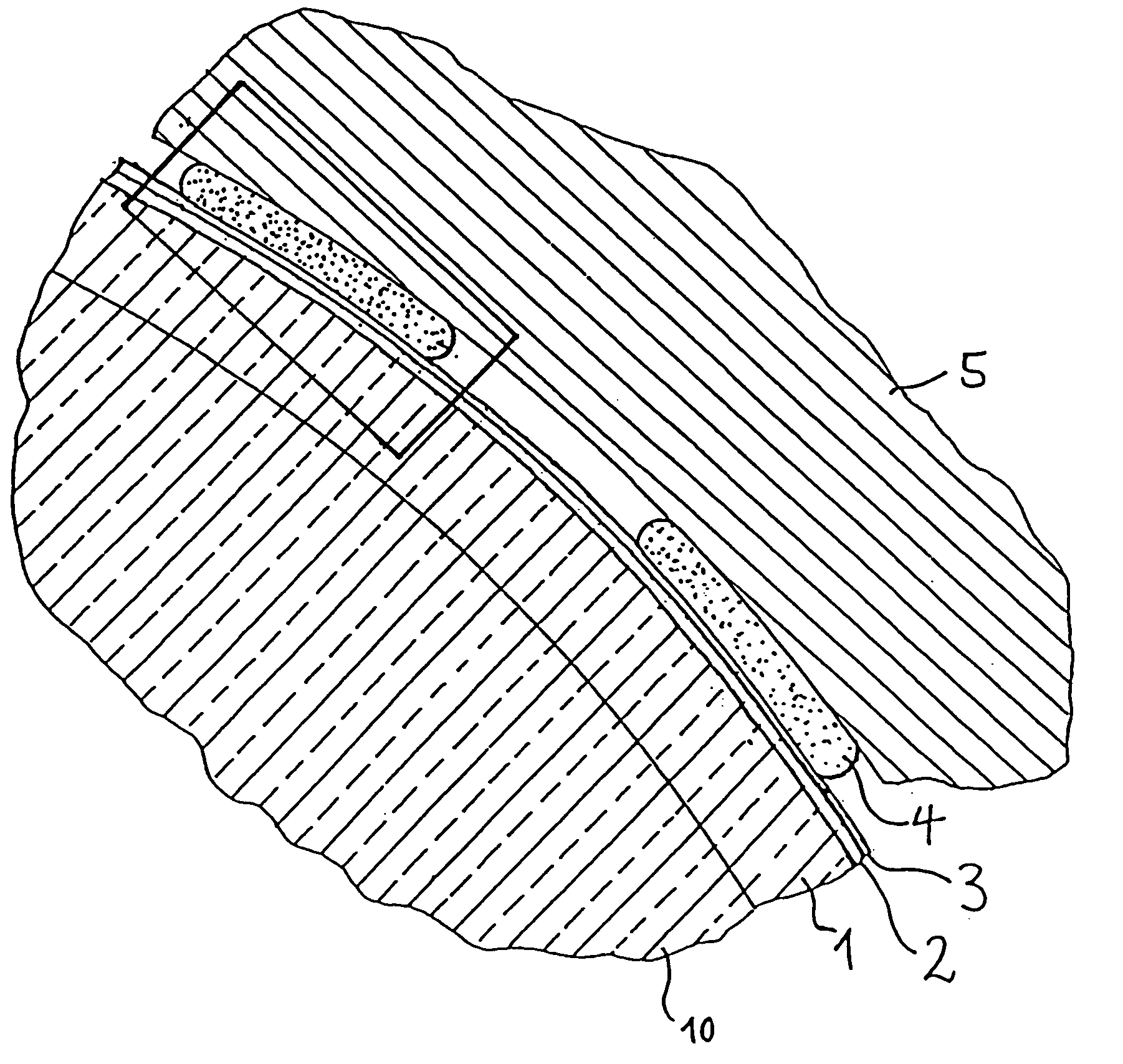

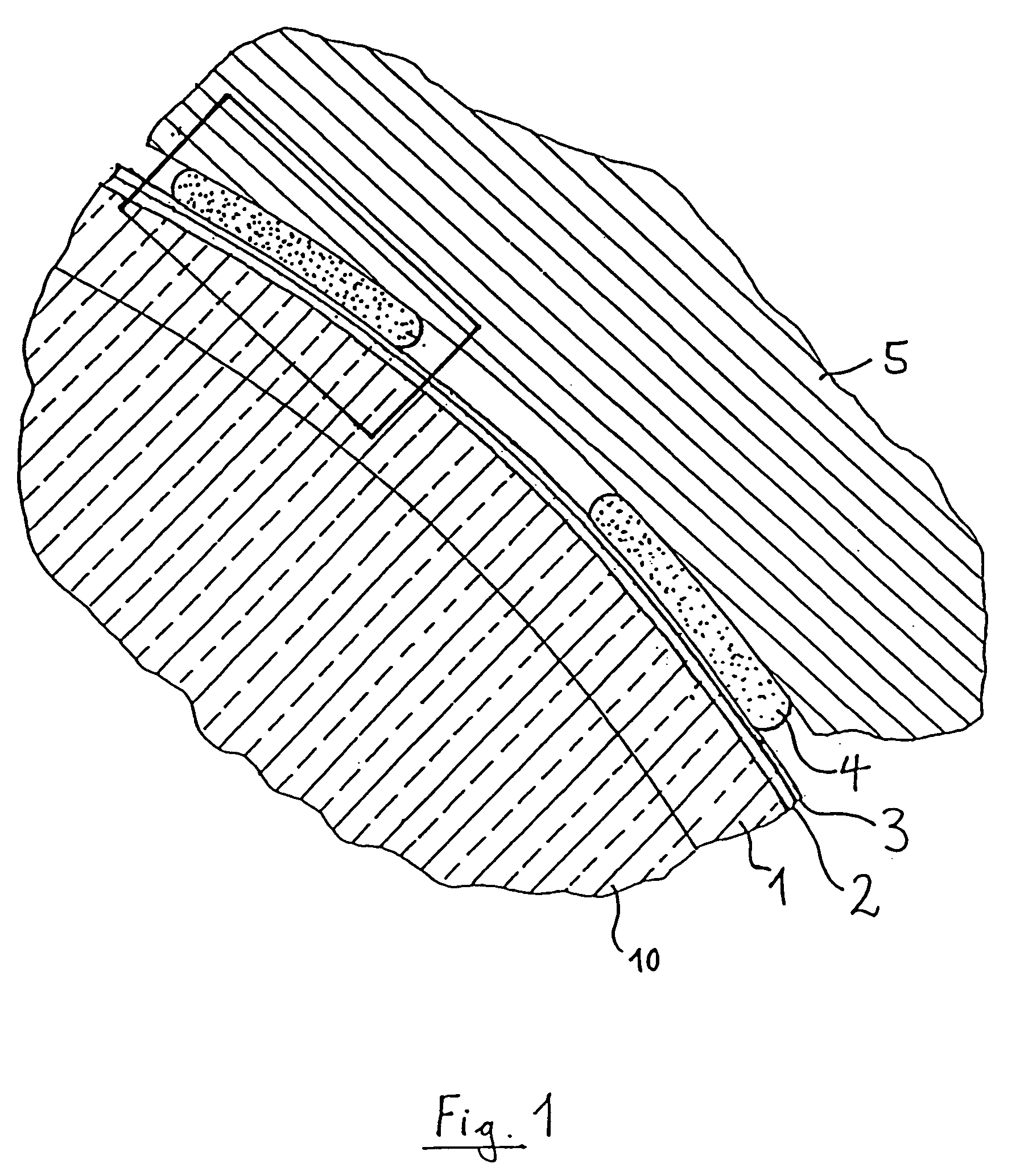

Optical mount with UV adhesive and protective layer

InactiveUS20060033984A1Improve adhesionImprove thermal stabilityPhotomechanical apparatusMountingsOptical mountAdhesive

An assembly includes a holder (5), an optical component (1) transmitting radiation in a first region of ultraviolet (UV) radiation adhered to the holder by an adhesive (4), the adhesive being hardenable by radiation of a second region of ultraviolet radiation, a first layer (3) disposed between the optical component and the adhesive, and a second layer (2) for enhancing adhesion between the optical component and the first layer. The first layer is capable of transmitting radiation of the second region of UV radiation and obstructing to a high degree transmission of UV radiation of the first region by at least one of absorption and reflection. The optical component has a transmitting zone and the first layer is located outside of the transmitting zone. The second layer for enhancing adhesion between the optical component and the first layer is disposed between the first layer and the optical component. The assembly can be used, for example, in an illumination system and / or a projection system of a microlithography projection apparatus.

Owner:CARL ZEISS SMT GMBH

Conductive rubber and application thereof

ActiveCN102176341AGood for dust resistanceEasy to adjustNon-conductive material with dispersed conductive materialContactsOptoelectronicsConductive rubber

The invention relates to a conductive rubber and an application thereof. The conductive rubber is manufactured by the composite of rubber and metal fiber sintered felt in a mould pressing or injection mode; the metal fiber sintered felt is provided with pores which are at least filled with rubber. According to the invention, the metal fiber sintered felt is adopted to replace the traditional metal sponge, metal foam or metal nets to be composited with the rubber, the manufacturing molding is convenient, and the integral conductive performance can be improved; and the conductive rubber can be punched into small round grains, the conductive rubber is used in buttons of a conduction switch of a circuit board as a conductive contact element.

Owner:DONGGUAN MEMTECH ELECTRONICS MEMTECH ELECTRONICS PRO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com