Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1034 results about "Knurling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material.

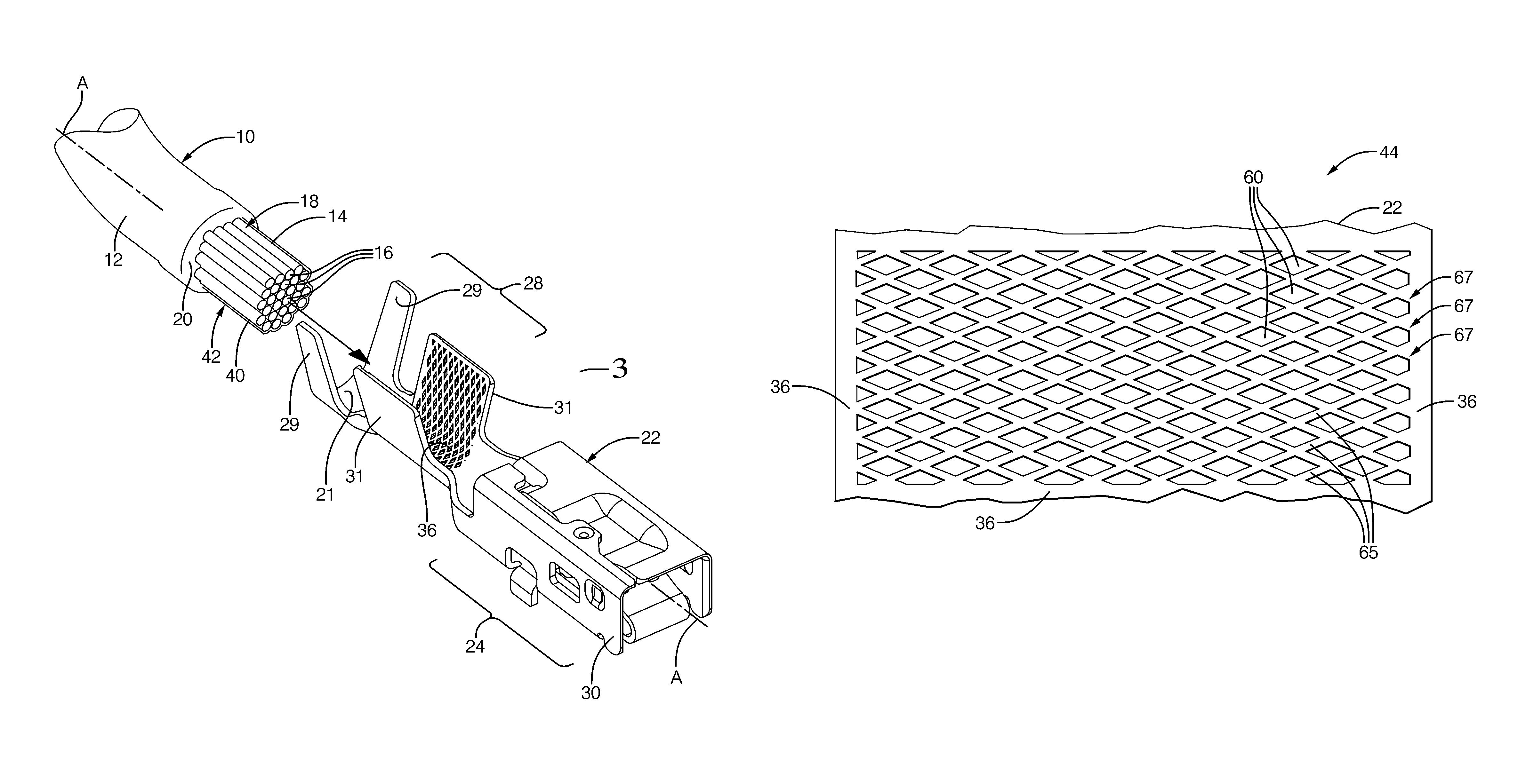

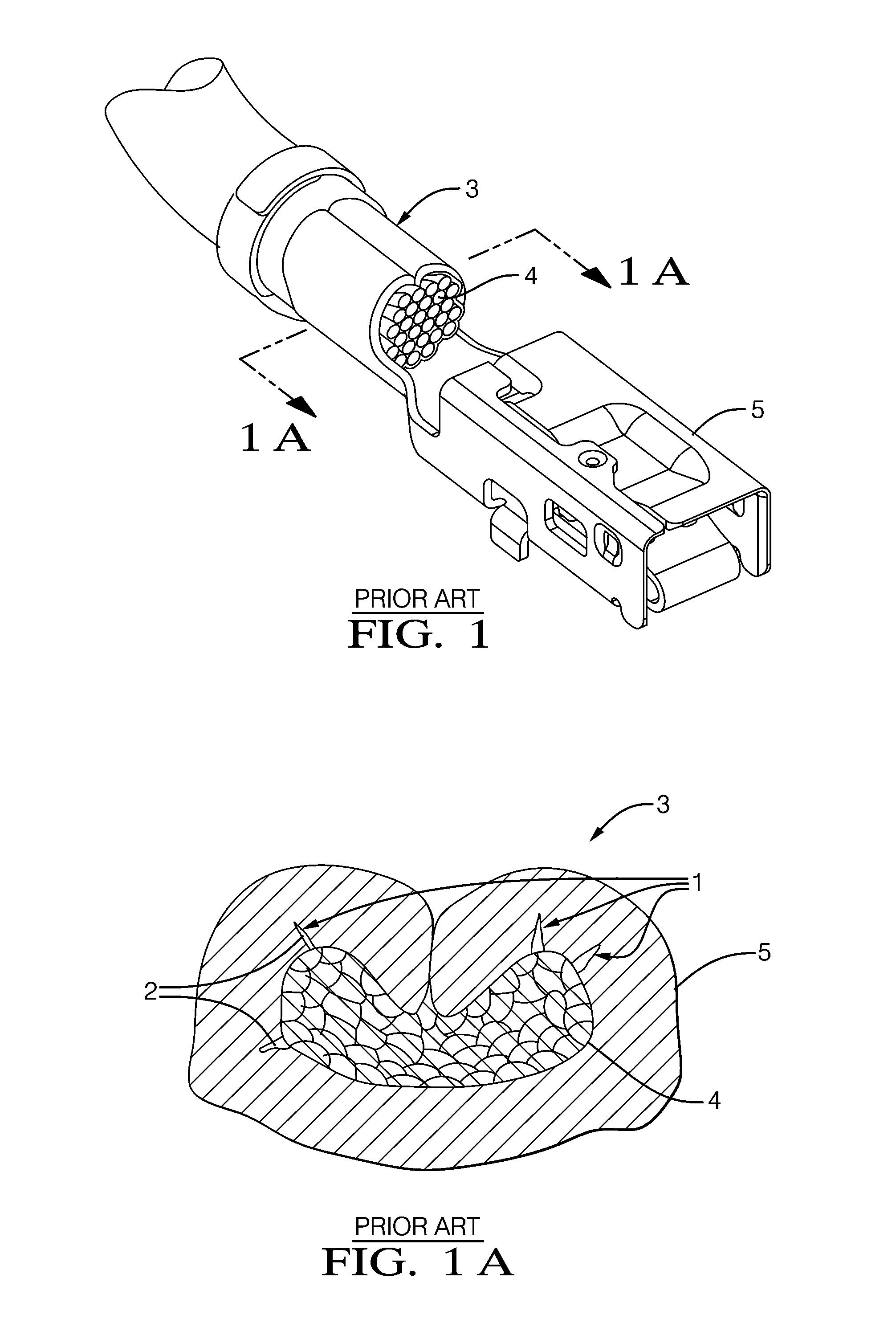

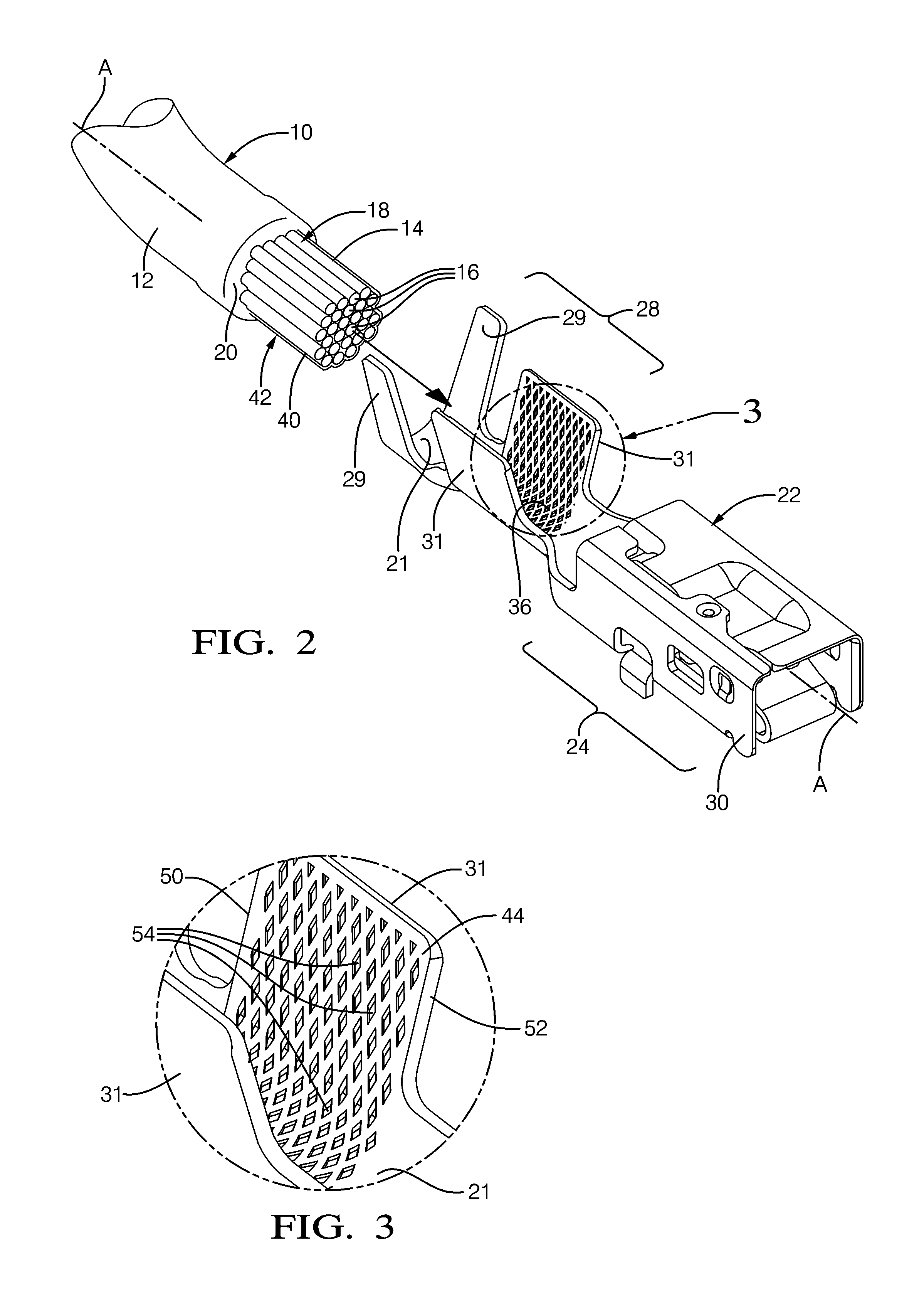

Electrical contact having knurl pattern with recessed rhombic elements that each have an axial minor distance

An electrical contact includes a knurl pattern disposed along at least a portion of an interior surface of the electrical contact. The portion receives a lead of a wire cable along a longitudinal axis and is attached thereto to form a crimp connection. The knurl pattern includes a plurality of recessed elements and each recessed element has a rhombus shape that includes inner corners. An orientation of a first pair of opposing, generally axial inner corners define an axial minor distance therebetween and an orientation of a second pair of opposing, inner corners define a major distance therebetween. The axial minor distance is less than the major distance. The recessed elements of the knurl pattern are especially suitable for engagement with an aluminum wire cable to form the crimp connection. A wire assembly that includes the crimp connection is associated with a cable harness disposed in a motorized vehicle.

Owner:APTIV TECH LTD

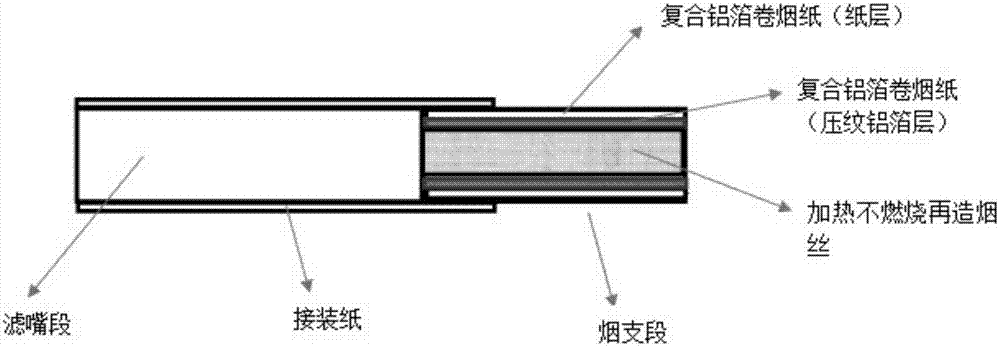

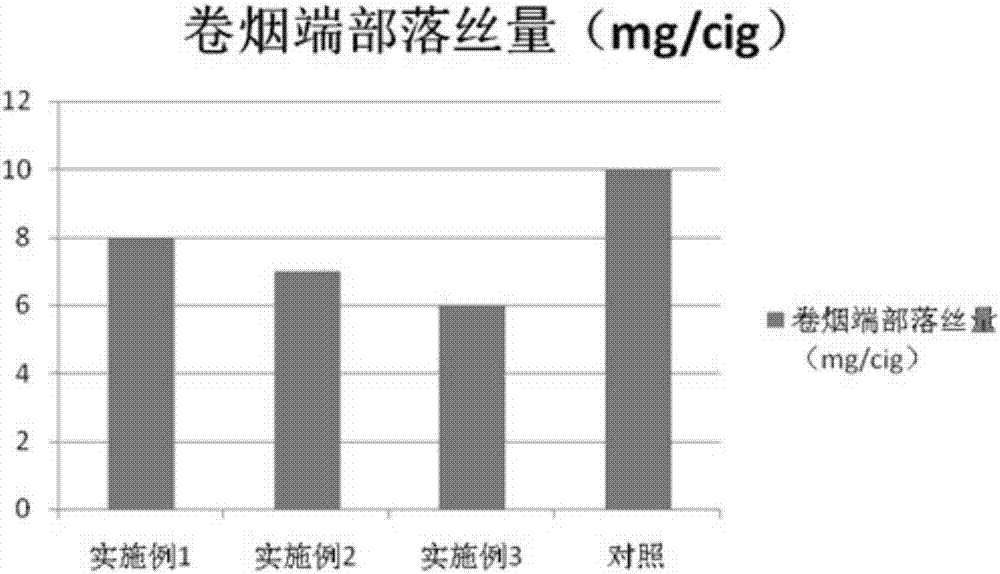

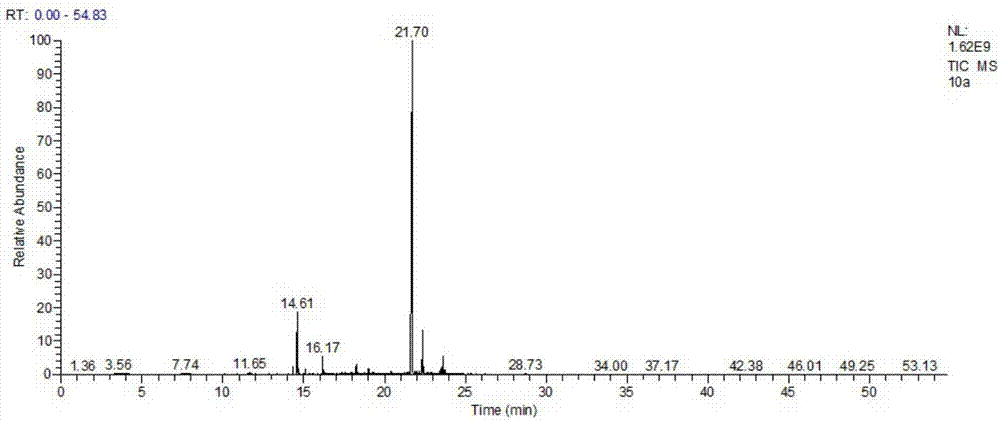

Method for preparing heating but incombustible cigarettes and application thereof

ActiveCN107981405AIncrease frictionLow costTobacco preparationCigarette manufactureKnurlingEngineering

The invention discloses a method for preparing heating but incombustible cigarettes and application thereof. The method and the application have the advantages that novel knurling rolling technologiesare adopted, accordingly, heating but incombustible reconstituted tobaccos with certain thicknesses have uneven surfaces, the surface areas can be enlarged, atomization effects can be enhanced, and surface frictional force can be enlarged; embossed composite aluminum-foil cigarette paper is adopted, accordingly, friction between the reconstituted tobaccos and aluminum-foil pattern surfaces of thecomposite aluminum-foil cigarette paper which is a cigarette making and plug assembling material can be greatly enhanced when the reconstituted tobaccos and the composite aluminum-foil cigarette paper are loaded in a cigarette making and plug assembling machine and cigarette making and plug assembling are powered on in later periods, the heating but incombustible cigarettes are easy to process, equipment shutdown frequencies can be reduced, the heating but incombustible cigarettes can be continuously produced, the production efficiency can be improved, and the material cost and the productioncost can be reduced; low-temperature cigarettes have short cut tobacco sections, accordingly, friction can be improved, the method is beneficial to reducing cut tobacco dropping, and the shortcomingsof low frictional force between smooth surfaces of existing heating but incombustible reconstituted tobaccos and non-embossed aluminum-foil paper which is a wrapping material, severe slipping, frequent equipment shutdown due to incapability of driving cigarette paper, influence on production efficiency, low frictional force due to short cut tobacco sections of existing low-temperature cigarettes,vulnerability to dropping of low-temperature cut tobaccos of the existing low-temperature cigarettes and the like can be overcome.

Owner:HUBEI CHINA TOBACCO IND

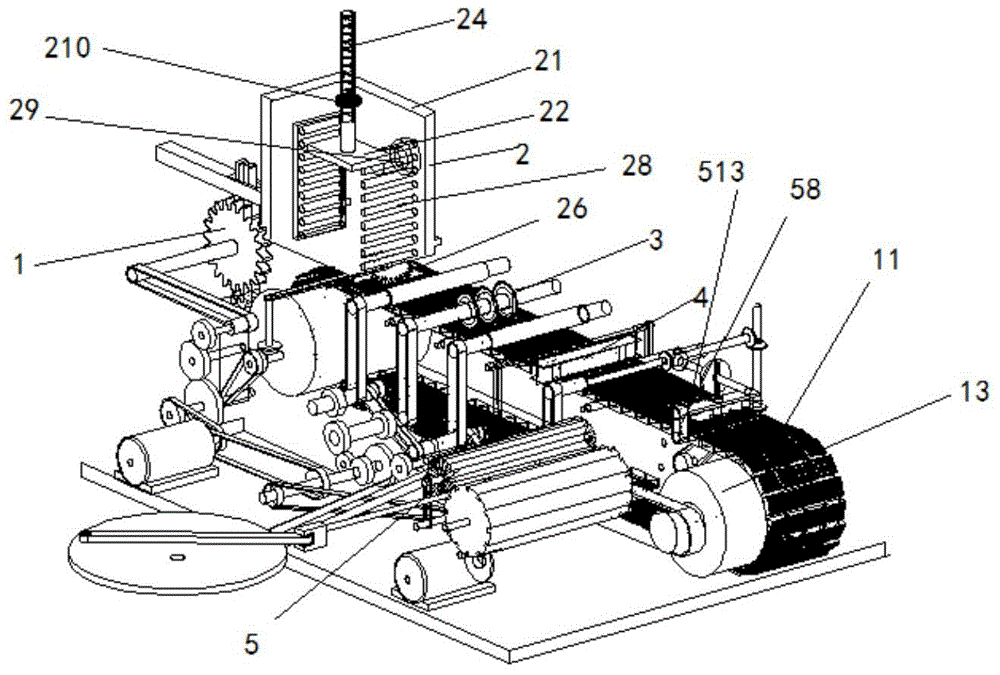

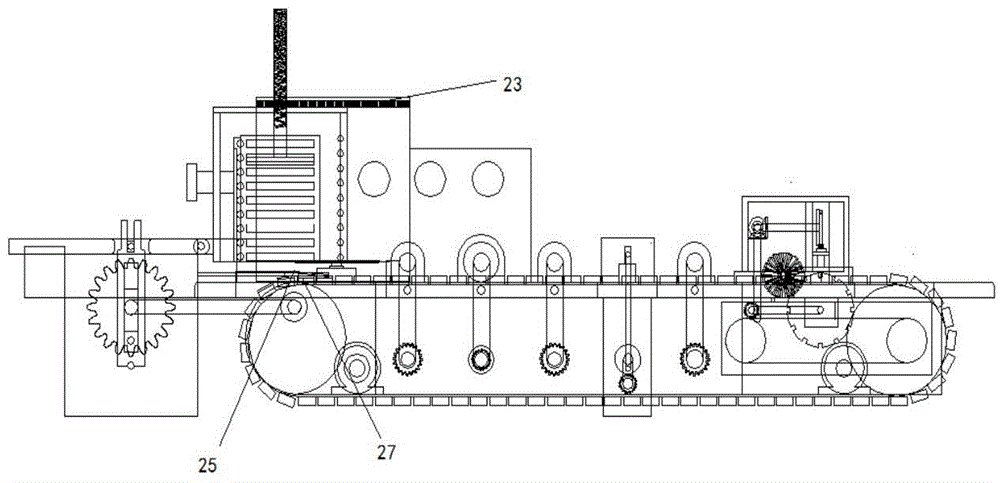

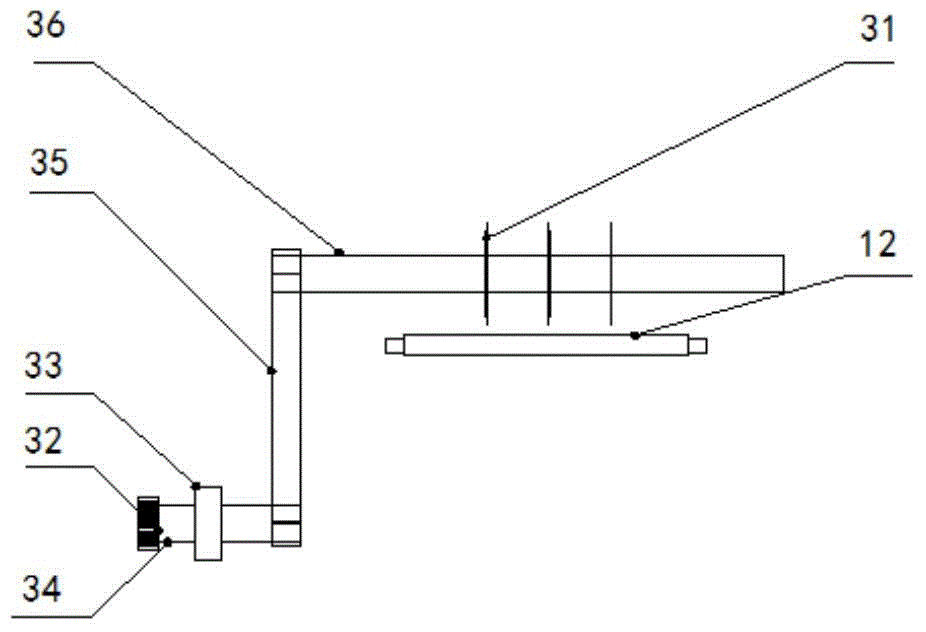

Automatic stringer

InactiveCN104920572AReduce in quantityControl running speedMeat/sausage hanging-upPutting meat on skewersPunchingKnurling

The invention relates to an automatic stringer which comprises a power transmission device, an automatic meat slicing device with a propelling automatic meat locking box, a knurling tool meat cutting device, a shearing and feeding device and an automatic prod punching device, wherein the device integrates slicing, slitting, bar-cutting and prod-stringing, so that the production efficiency is improved, automation and multi-functionalization can be further realized, the automatic stringer is multipurpose, and the consumption of manpower and material resources as well as financial resources is greatly reduced. The automatic stringer not only can string meat, but also can string various foods such as balls and the like. Moreover, meat in different thicknesses and different sizes can be stringed. The mechanical degree and the production efficiency are improved, and the automatic stringer is easy to operate and maintain, low in cost, small in size and high in degree of automation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

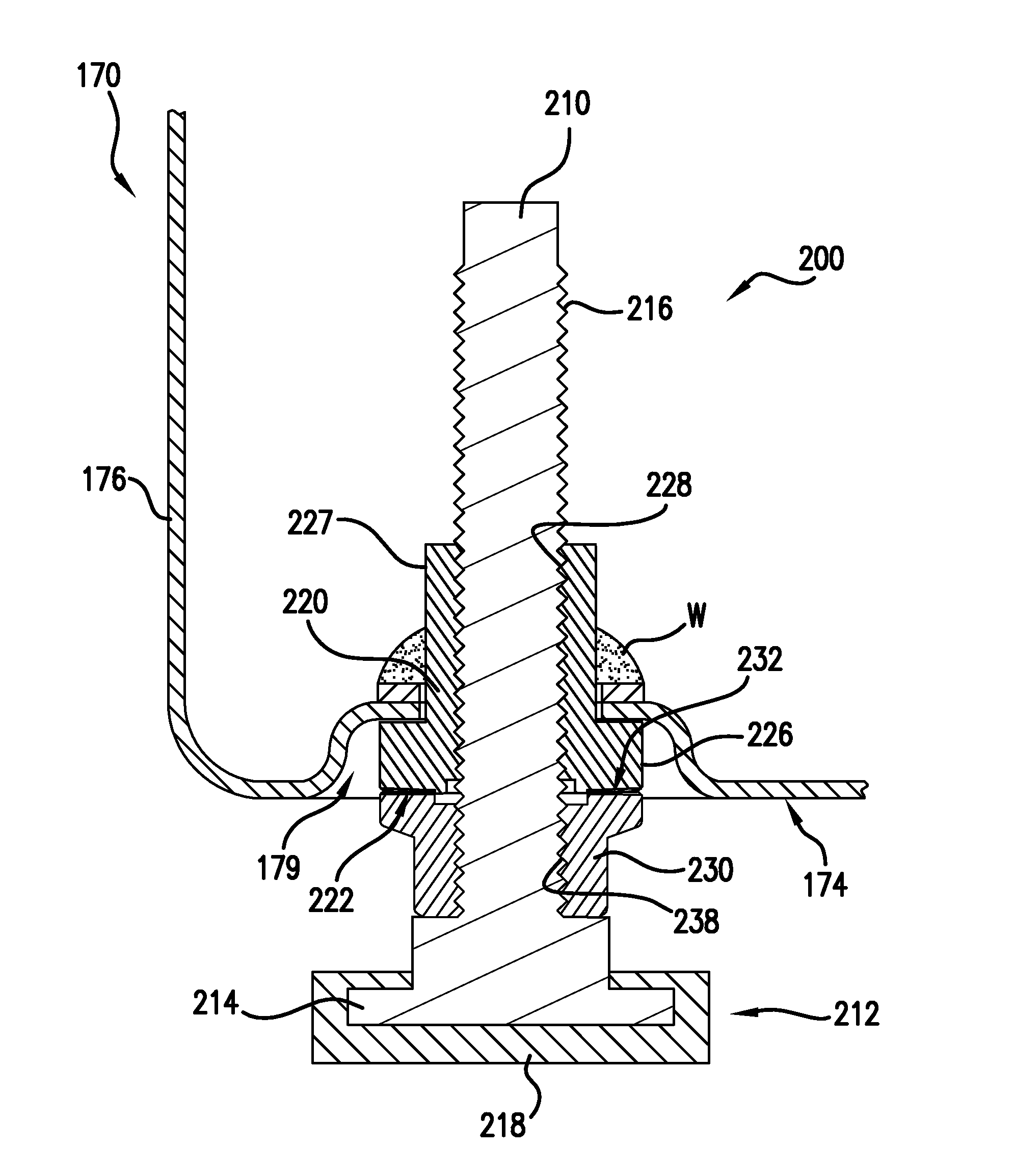

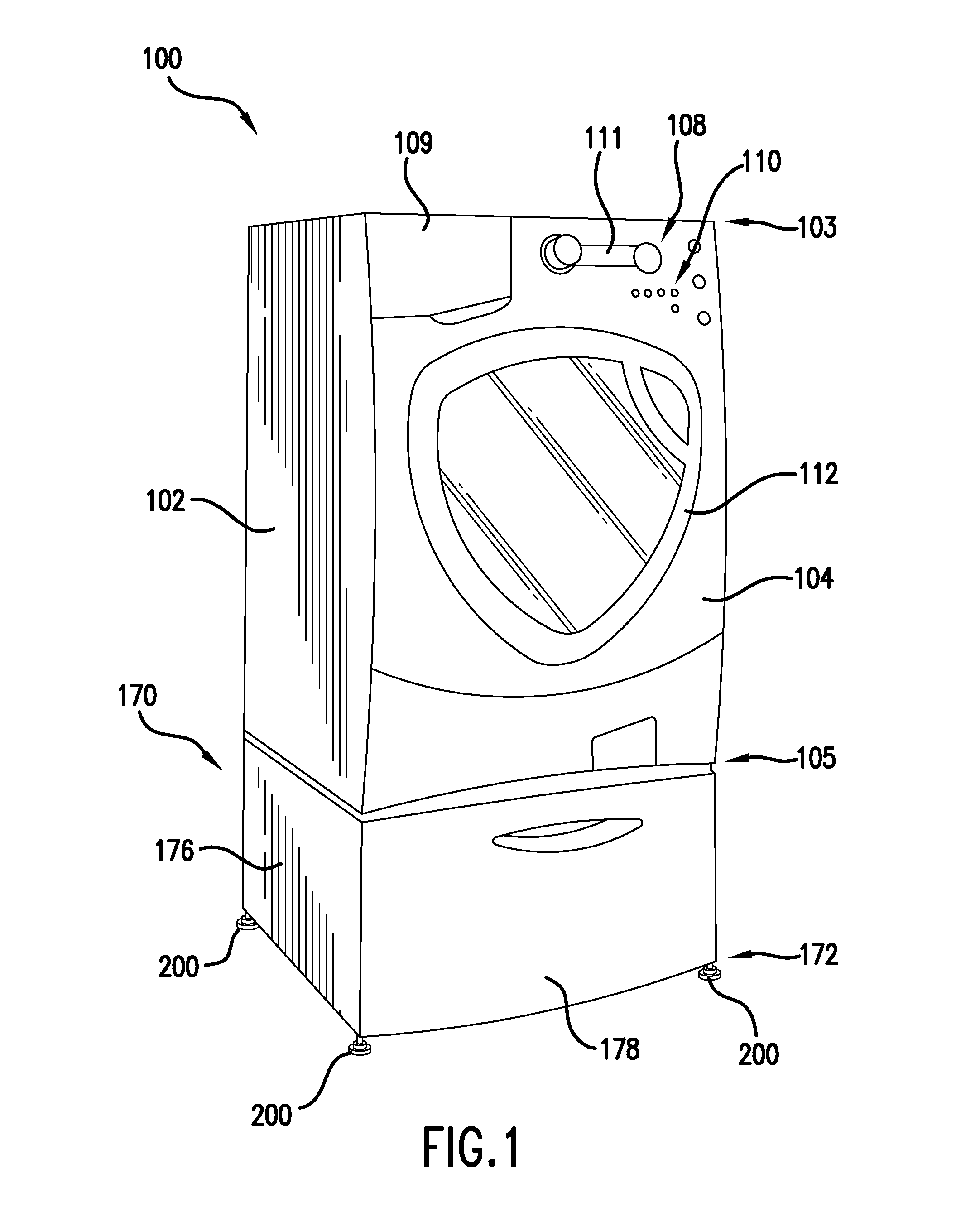

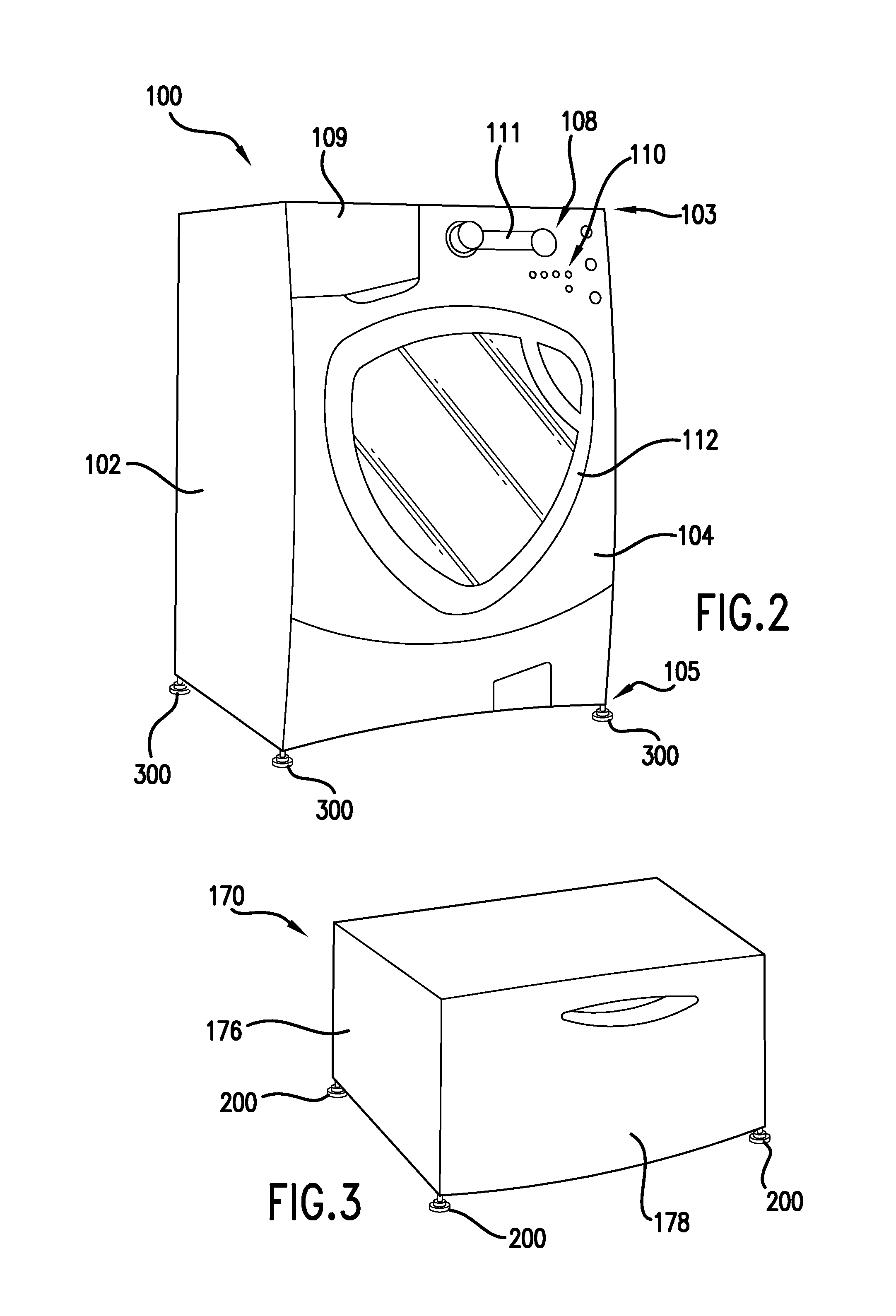

Leveling assembly for an appliance

A leveling assembly for an appliance is provided. The leveling assembly includes a clench nut mounted to the appliance and a jam nut. The clench nut and the jam nut each have a knurled surface. A leveling leg is threaded through the clench nut and the jam nut such that the knurled surfaces of the clench nut and jam nut are facing. The knurled surfaces of the clench nut and jam nut can engage one another to lock the leveling leg in position by impeding rotation of the leveling leg.

Owner:GENERAL ELECTRIC CO

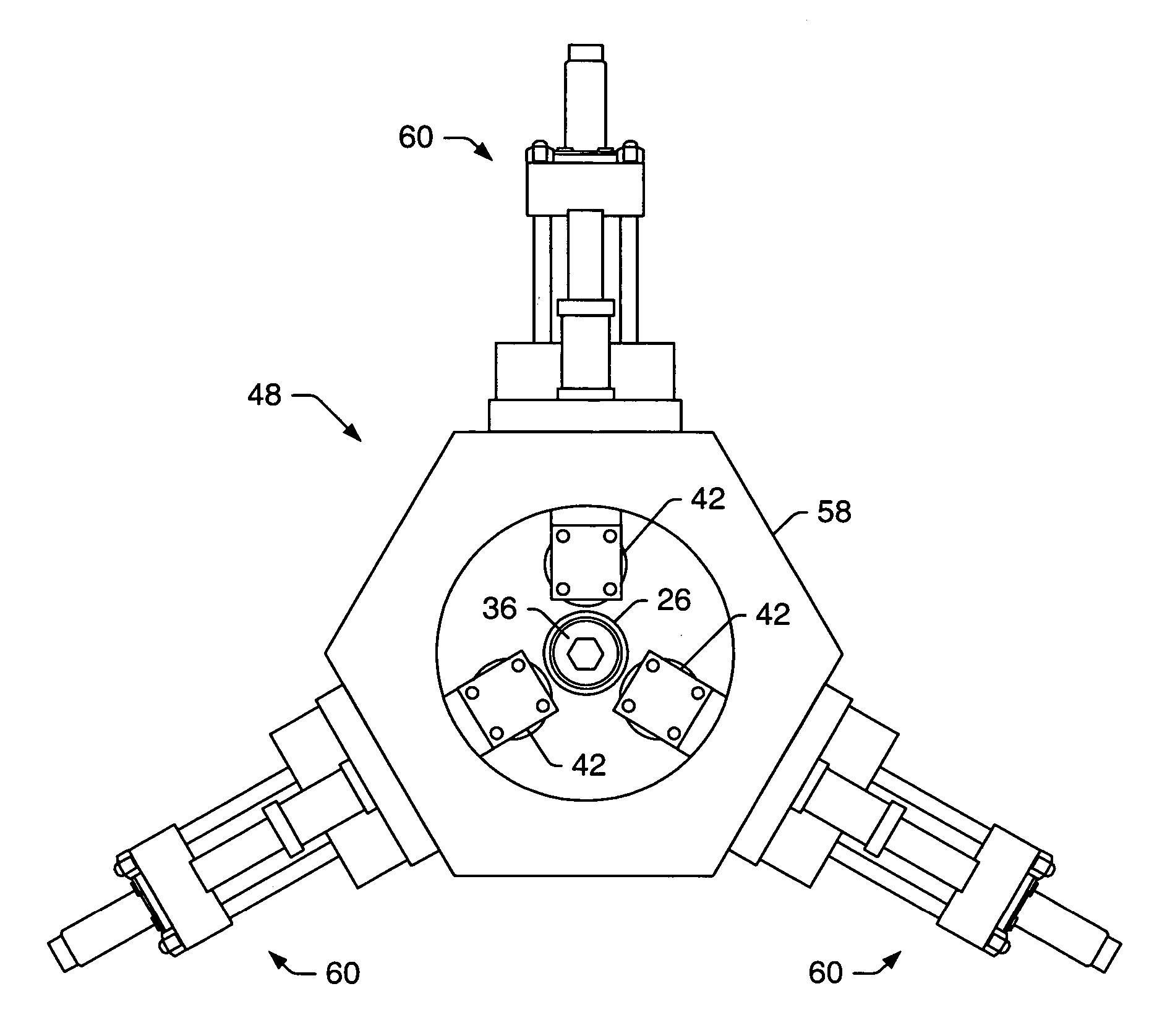

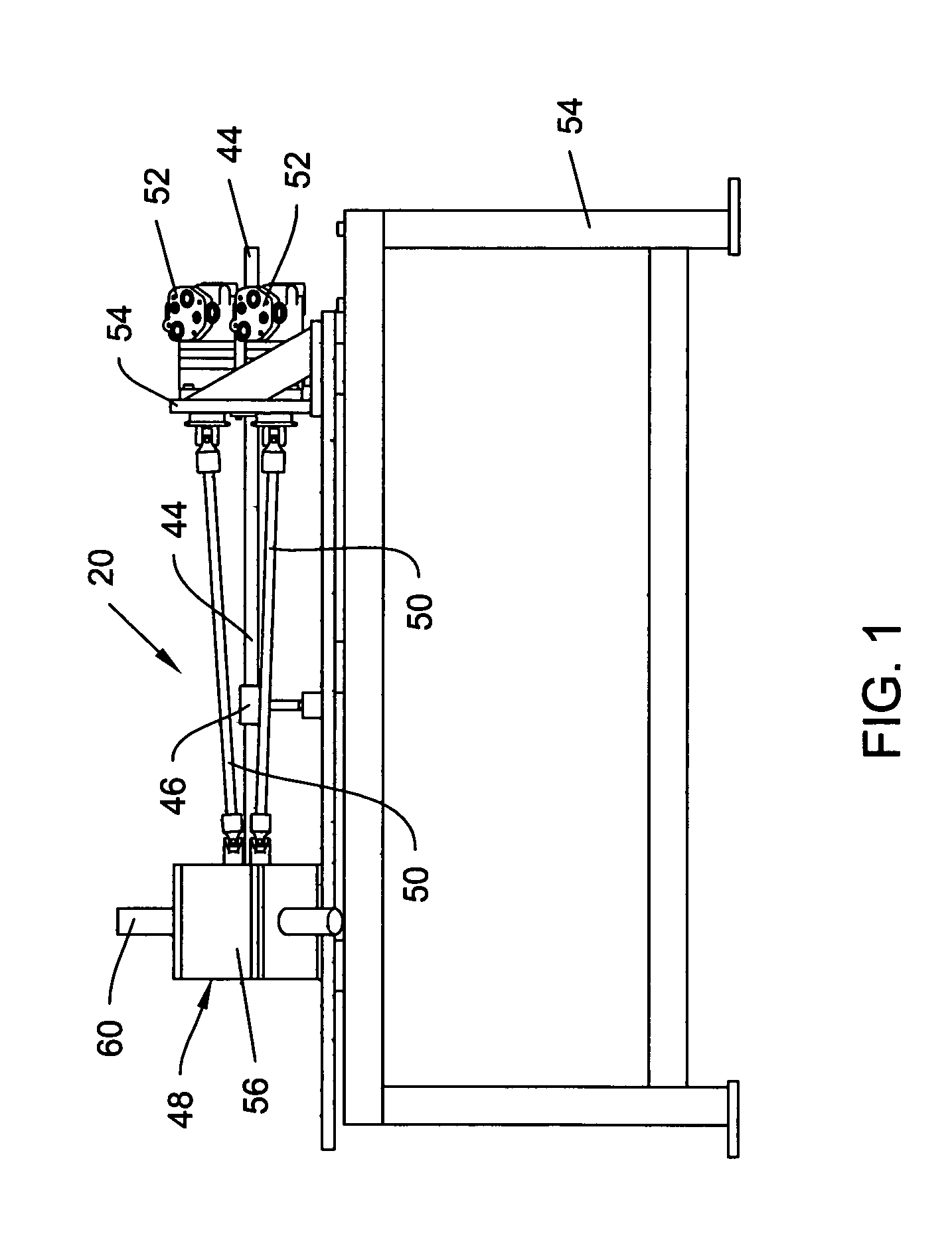

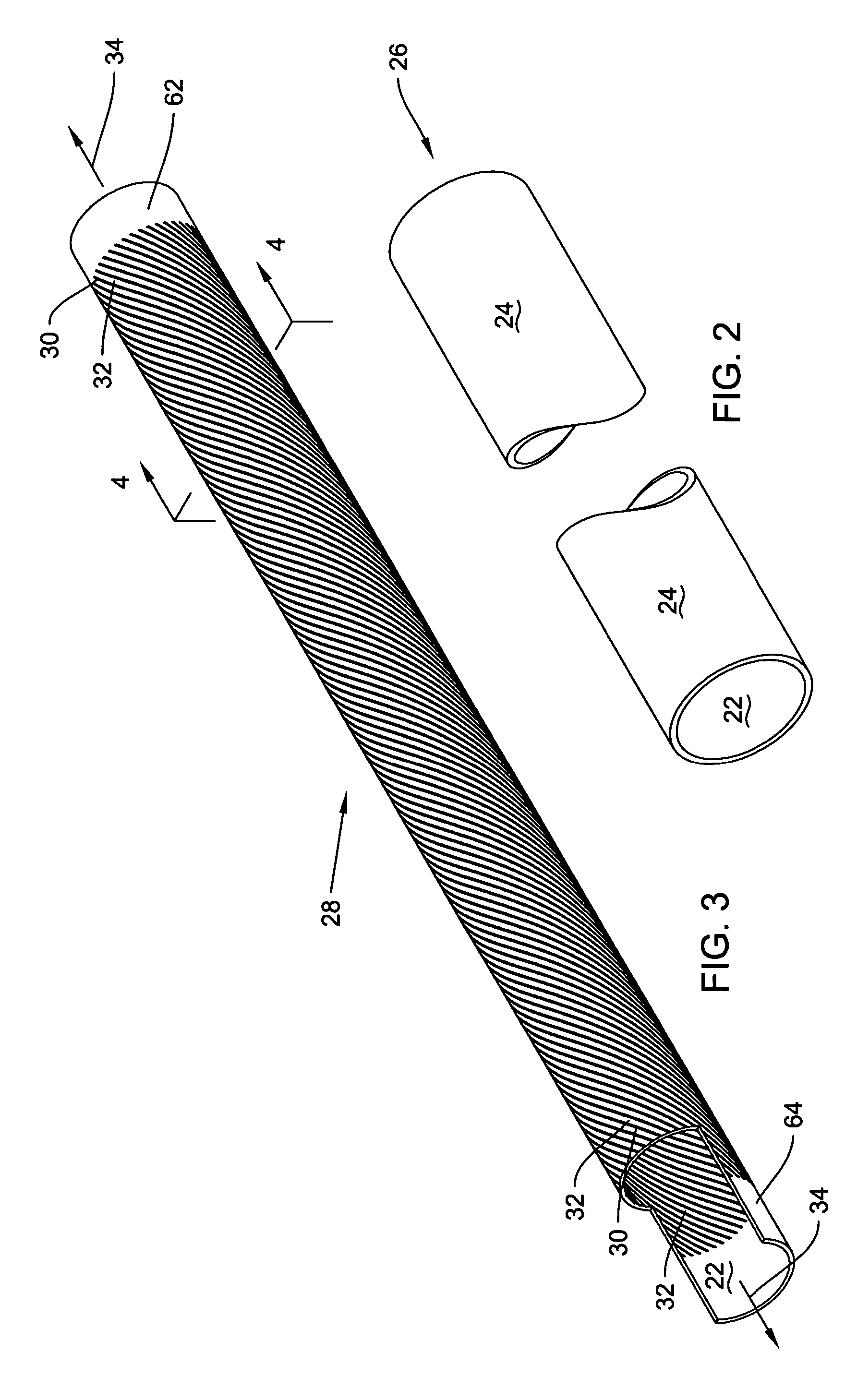

Apparatus and methods for forming internally and externally textured tubing

InactiveUS6968719B2Reduce the overall diameterGood adhesionMetal rolling arrangementsKnurlingBiomedical engineering

A machine may produce a tube having textured internal and external surfaces in a single operation. Inner and outer knurling tools may form the textured surfaces. The texturing of the internal and external surfaces may be helical patterns of ribs and grooves. The height of the ribs formed in the internal and external surfaces may be less than about 35 mils. The angles of the patterns relative to a longitudinal axis of the tube may be less than about 45°. The angle of the helical pattern allows textured tubes to be used as heat exchanger elements wherein flow is directed substantially coaxial to the longitudinal axes of the tubes. The helical pattern formed in the external surface may be oriented in a right hand or left hand helical orientation. Similarly, the helical pattern formed in the internal surface may be oriented in a right hand or left hand orientation.

Owner:PACKLESS METAL HOSE

Glue spreader

ActiveCN101862723AGuarantee paste qualityReduce the amount of glueLiquid surface applicatorsCoatingsKnurlingPulp and paper industry

The invention relates to a glue spreader, which comprises a rack. The two ends of a conveying support roller are arranged on the rack. A glue spreading roller is arranged above the conveying support roller. The conveying support roller and the glue spreading roller are respectively connected with a driving mechanism. The invention is characterized in that the two ends of the glue spreading roller are arranged on a lifting mechanism which is arranged on the rack, the surface of the glue spreading roller is provided with hatching knurling, one side of the glue spreading roller is provided with a measurement scraper which is connected with a measurement adjusting mechanism and the measurement adjusting mechanism is arranged on the lifting mechanism. The surface of the glue spreading roller is provided with the hatching knurling. Proper glue volume can be controlled and glue can be spread on the surface of base material evenly. When the surface course pasting quality is ensured, the glue usage amount and the manufacture cost are reduced.

Owner:WUXI SHENGJIN MACHINERY

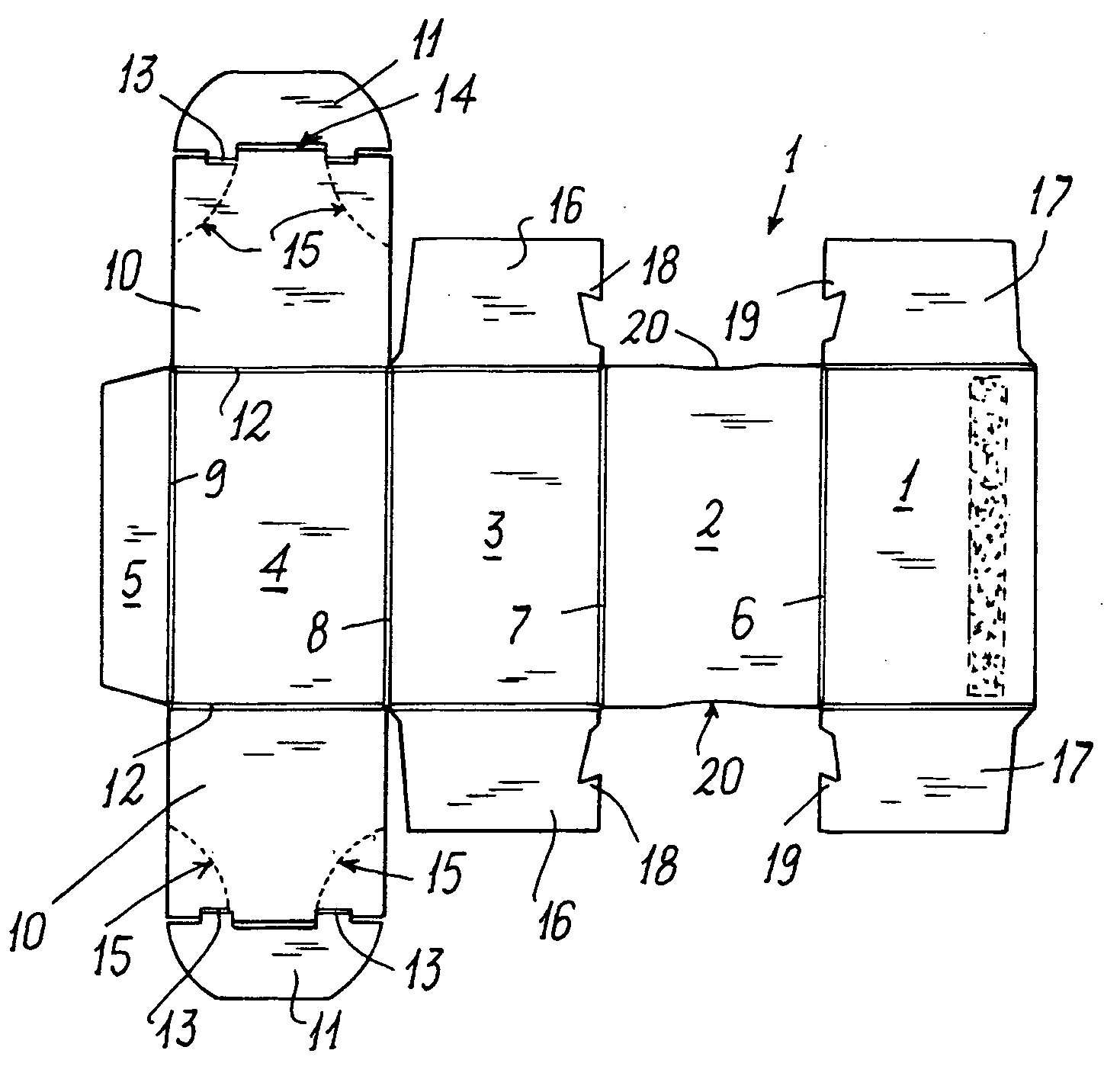

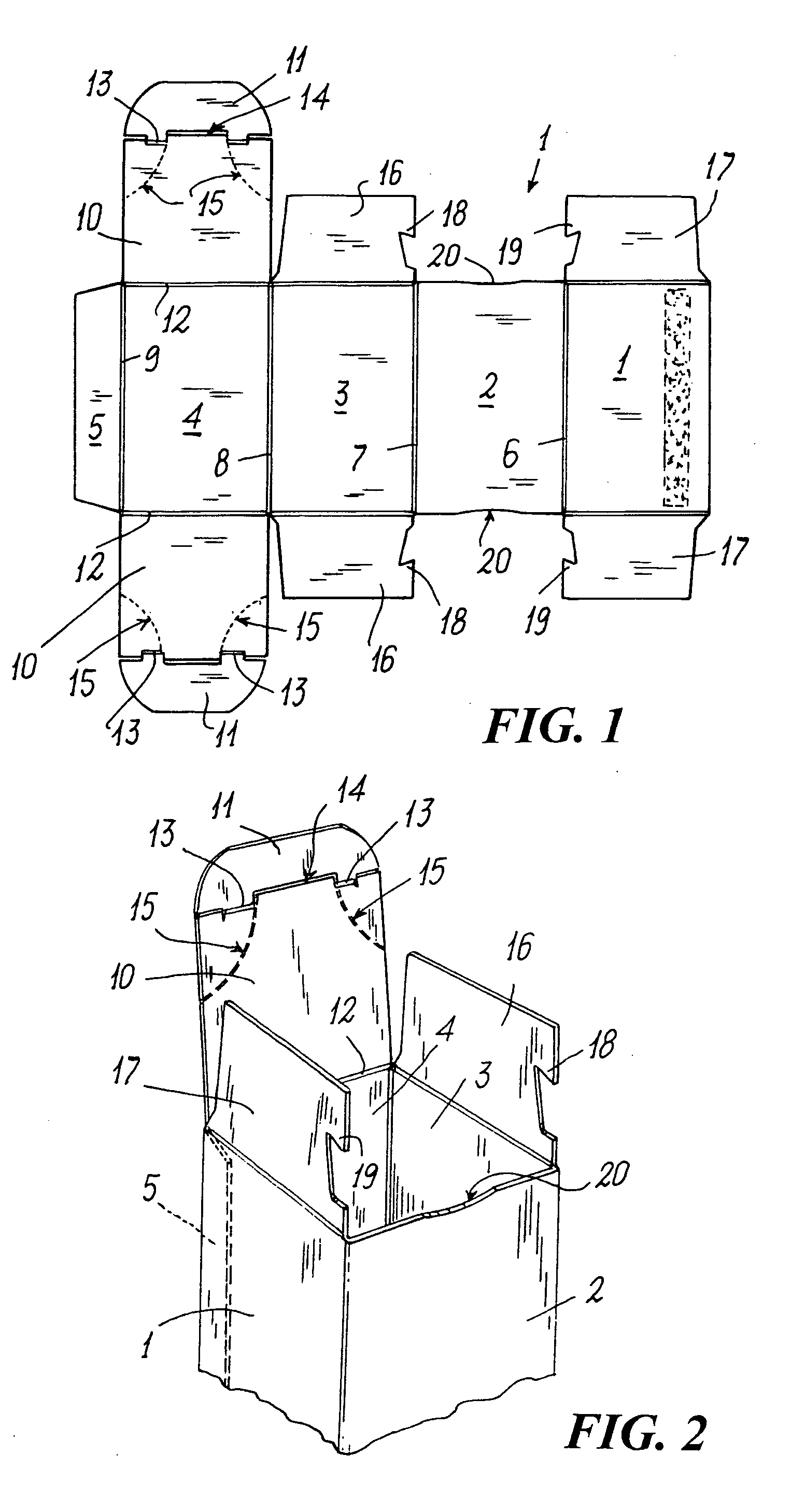

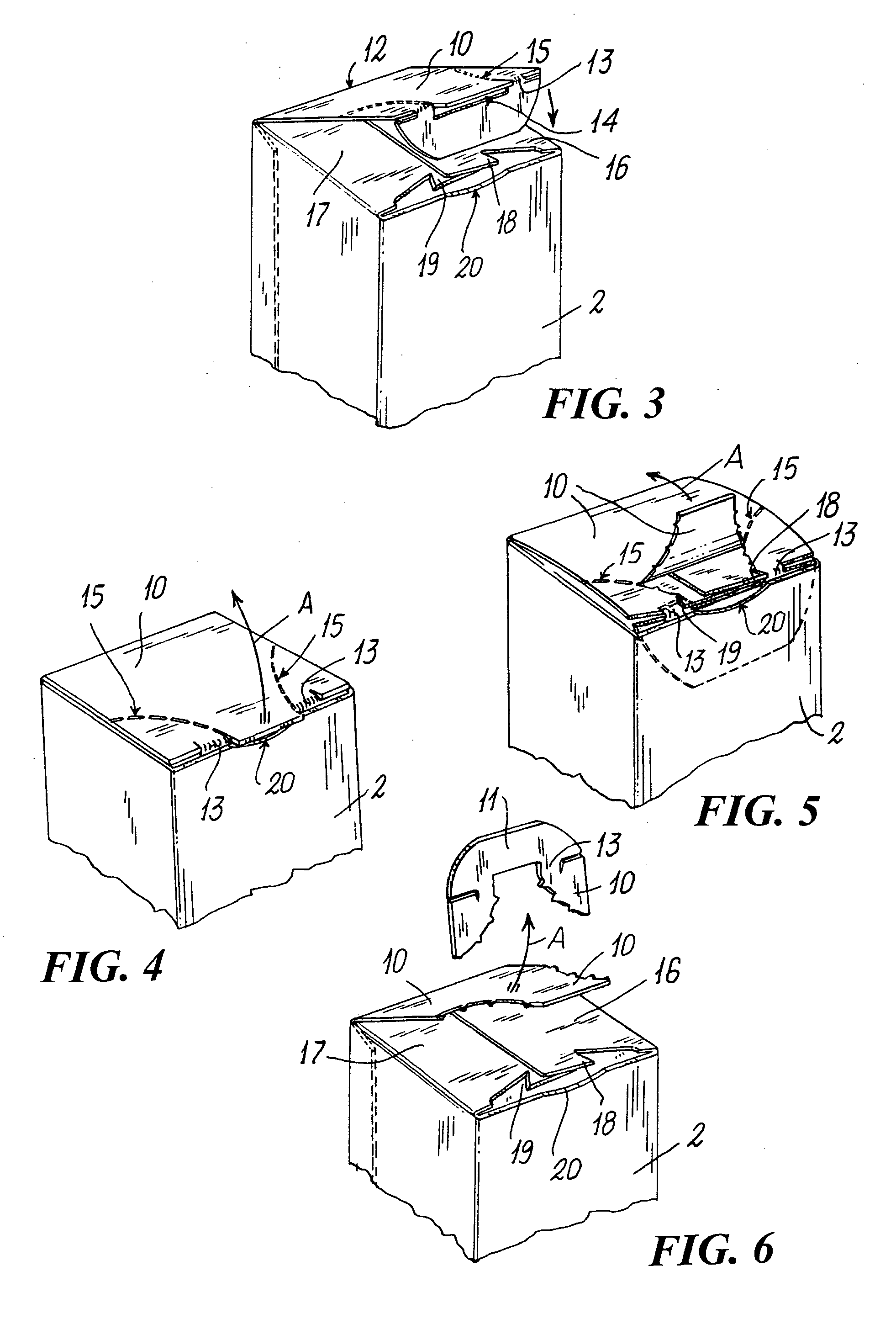

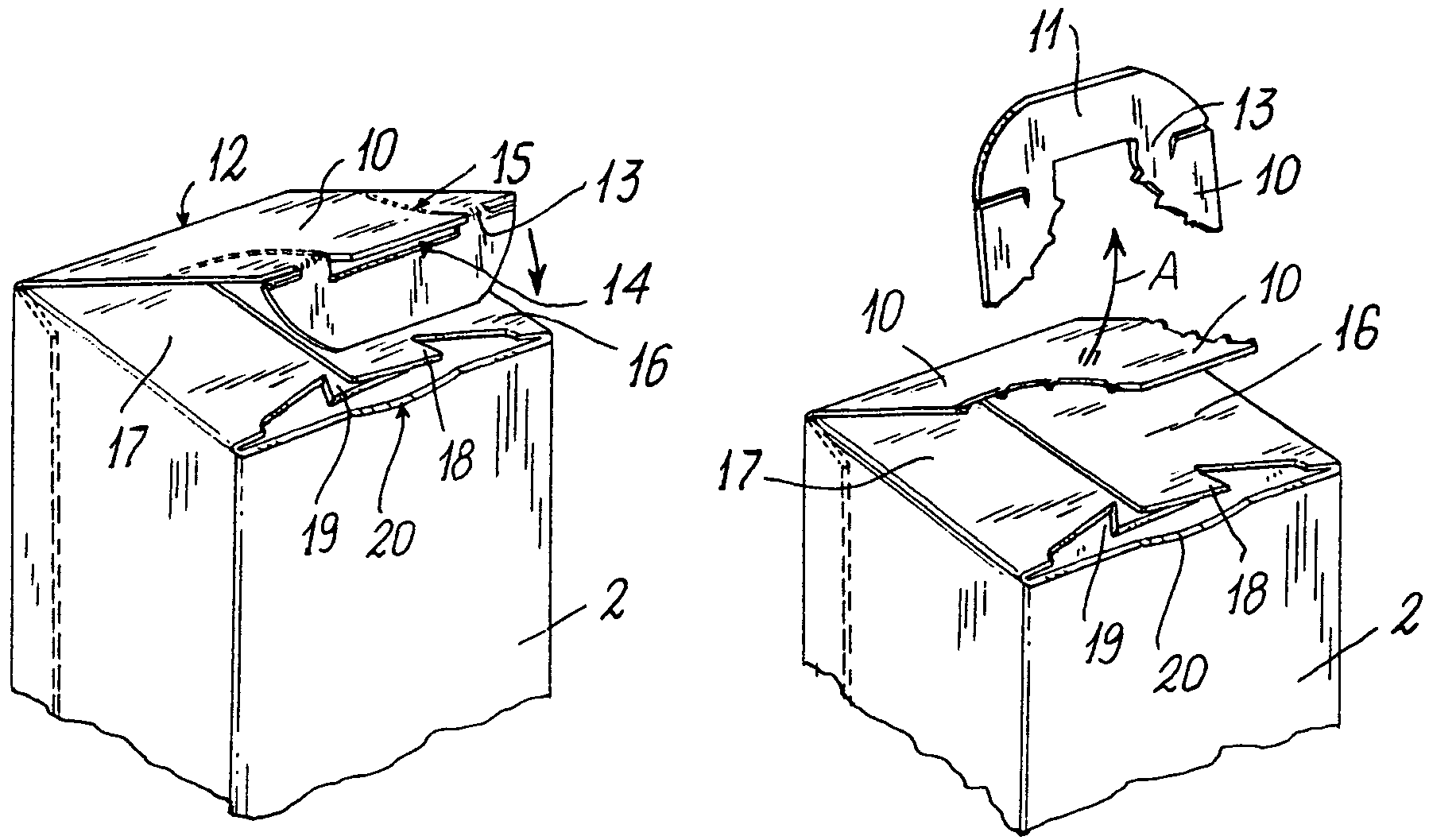

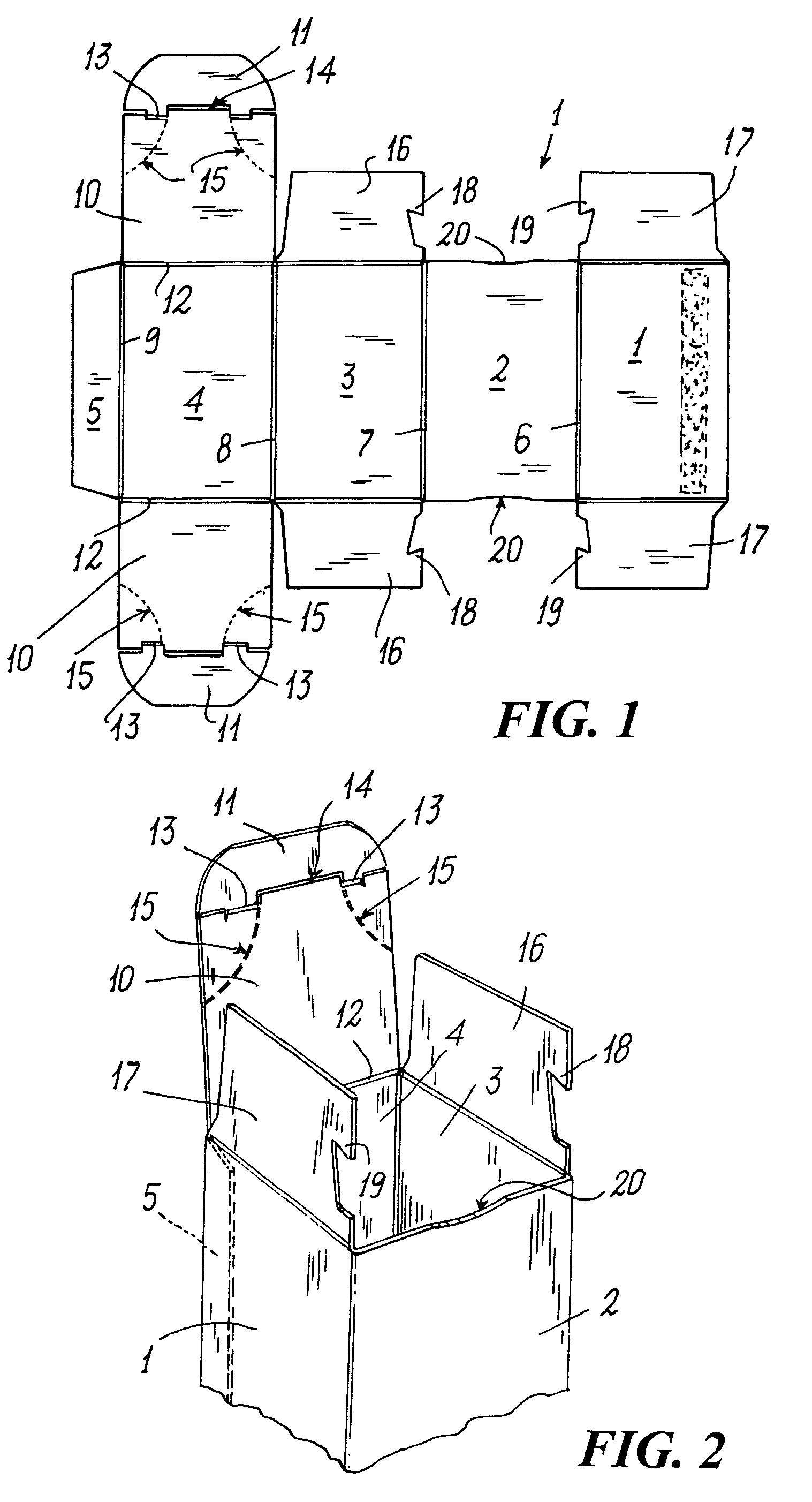

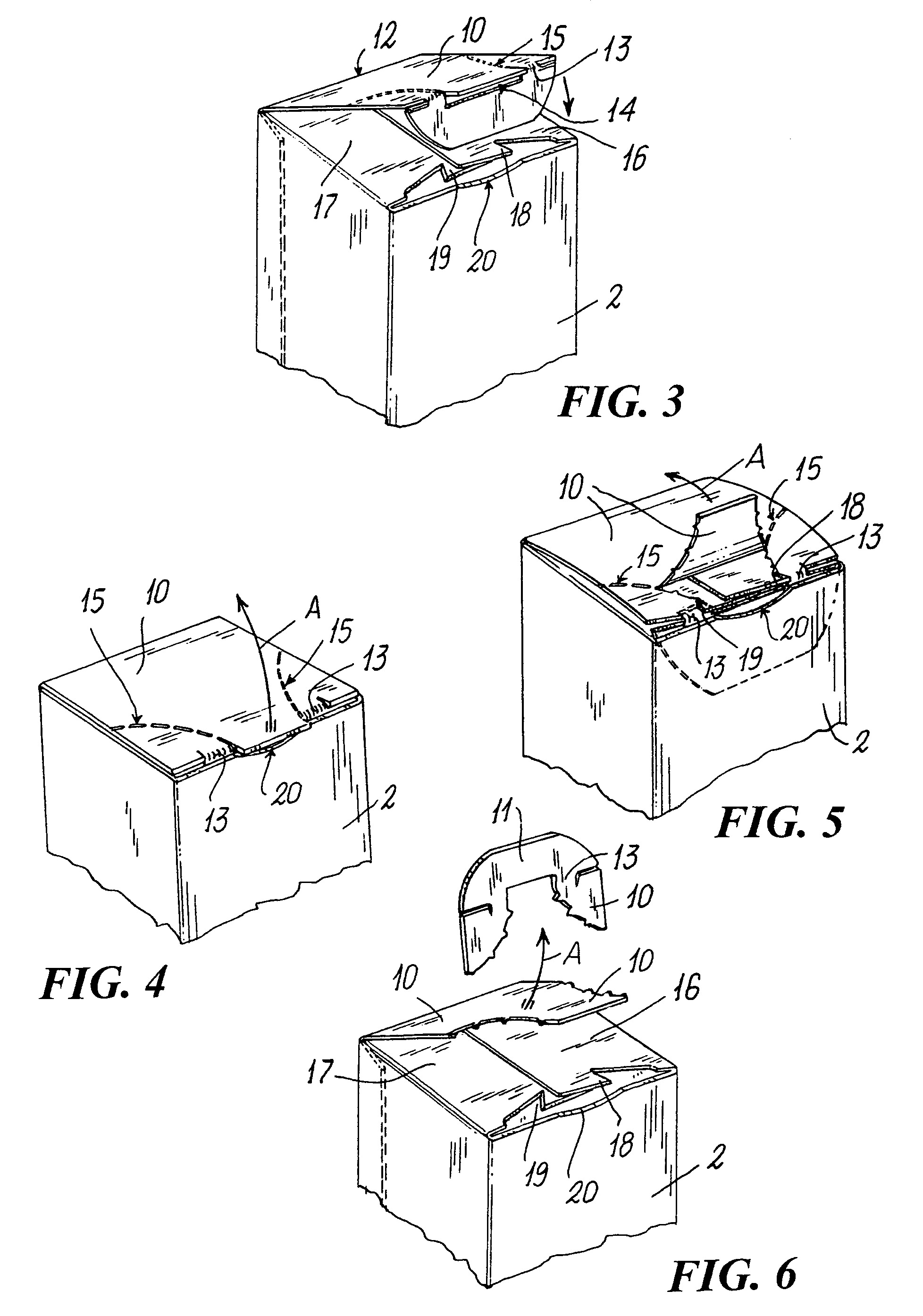

Box with base resistant to opening and having its portions breakable to prevent it from being reclosed after its initial opening

Box with at least one base which is resistant to opening and of which portions become broken off to prevent the base being reclosed after being opened for the first time. The base comprises a panel projecting from the box and a tab projecting from and separated from the panel by a folding line in which there is provided a cut through which hook-shaped teeth extend and hook thereonto, these latter projecting from two opposing lateral flaps positioned below said panel in the box when closed. In this base panel there are provided knurlings which extend from each end of said cut as far as the adjacent lateral edge of the panel, to hence define portions which break away from the base of the box.

Owner:GI BI EFFE

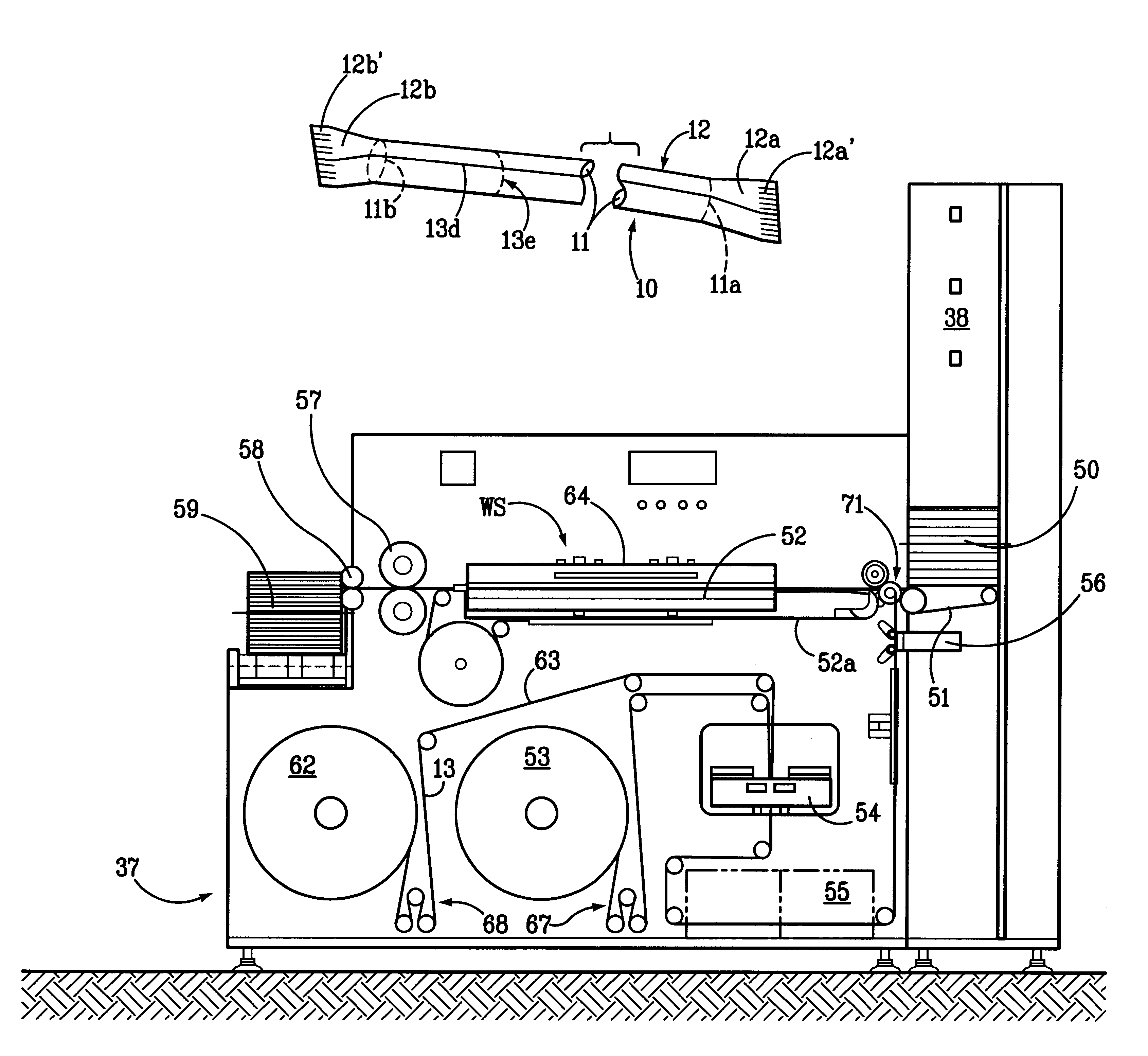

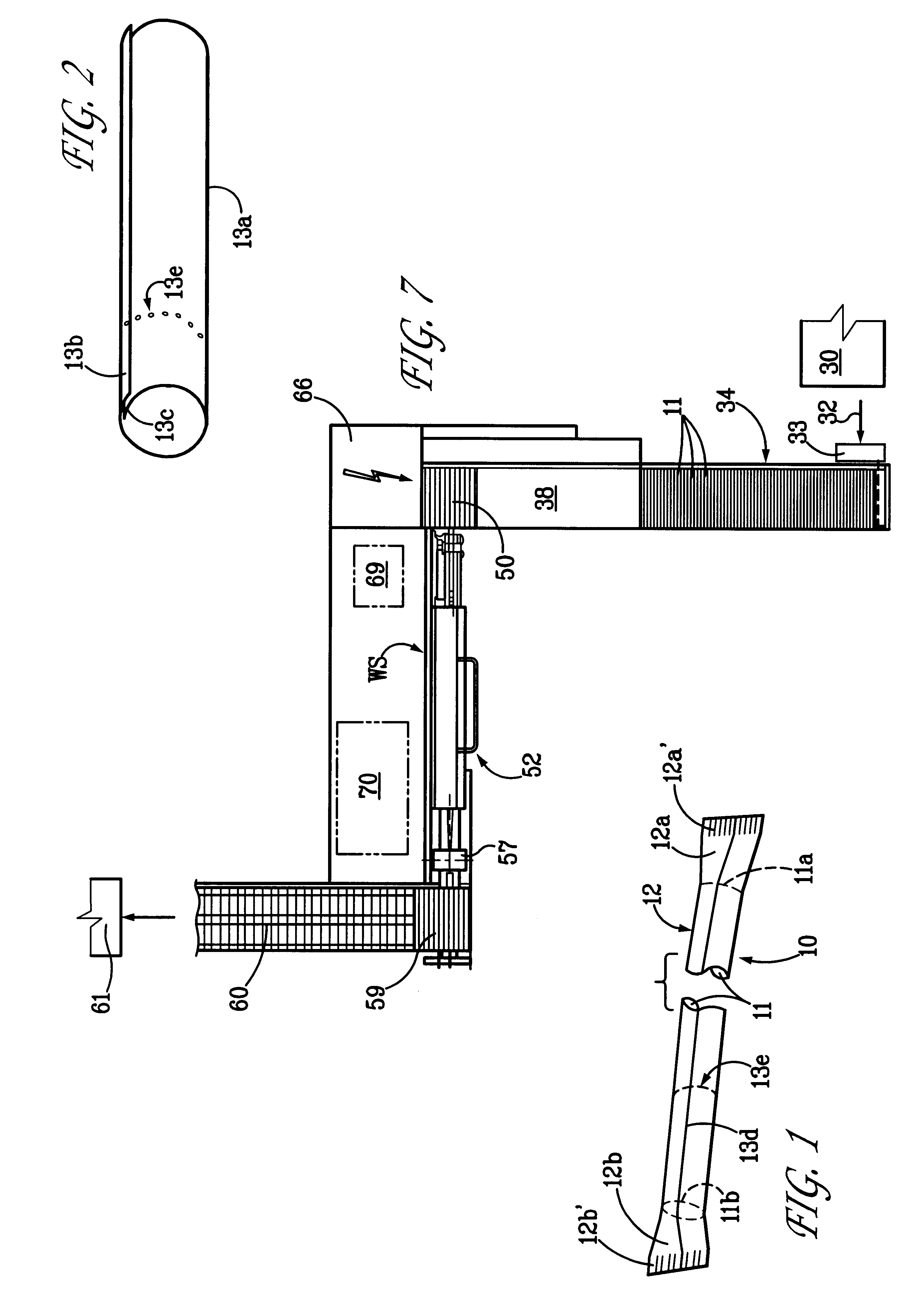

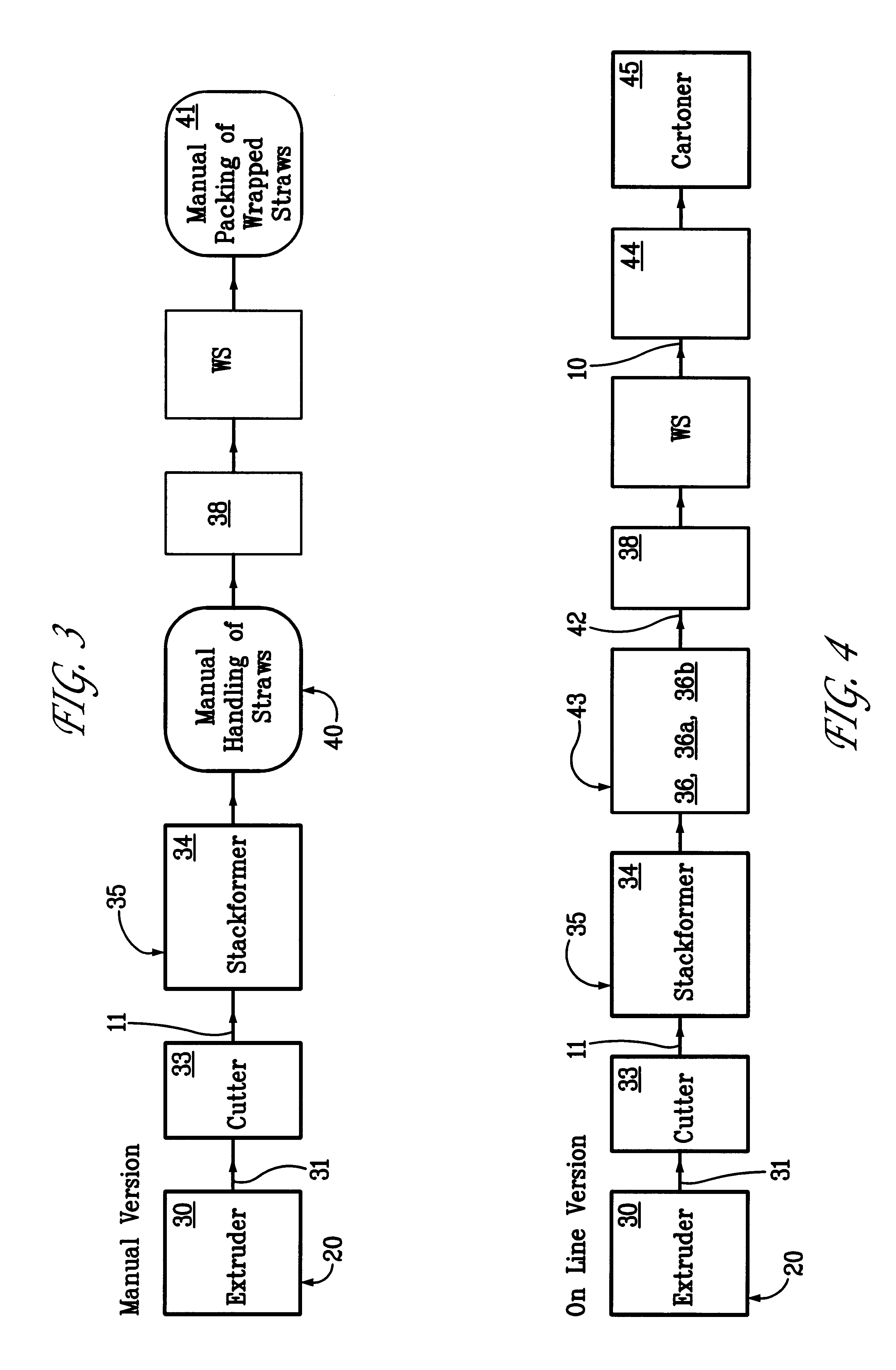

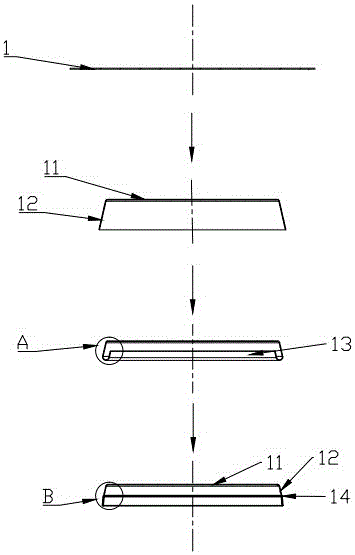

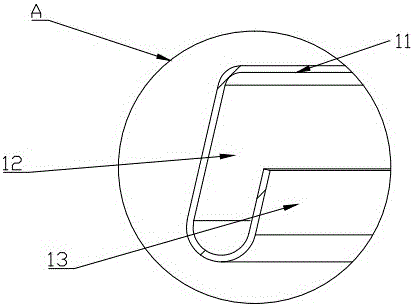

Apparatus for wrapping drinking straws

InactiveUS6212860B1Inexpensive mannerSimplifies removal and extractionPackaging cigaretteWrapper twisting/gatheringKnurlingEngineering

Sipping straws are confined in discrete envelopes while advancing in a single file of spaced-apart straws through a wrapping station. The envelopes are obtained from a continuous strip of wrapping paper which is conveyed to the wrapping station in the direction of advancement of the file of spaced-apart straws and is draped around the straws in such a way that one of its longitudinally extending marginal portions overlies and adheres to the other marginal portion with simultaneous formation of a seam rather than an outwardly extending fin. The thus obtained tubular wrapper is thereupon severed in the gaps between successive spaced-apart straws, and the end portions of the thus obtained discrete envelopes are sealed by knurling, e.g., simultaneously with severing of the tubular wrapper.

Owner:HAUNI RICHMOND

Lockbolt for forming a mechanically secured and sealant sealed connection between components

A lockbolt includes a bolt head, a shank, a locking portion, a predetermined breaking point, and a break-away portion. The locking portion includes a knurled surface having knurling peaks between intersecting knurling grooves that extend in a direction with an axial component, e.g. spiraling helically. A sealant on two workpieces smears onto the knurled surface when the bolt is inserted in a hole therein, but does not need to be removed. A locking collar is swaged onto the locking portion to secure the workpieces between the head and the collar. The sealant is distributed as a thin layer to provide a seal and an adhesive bond between the collar and the knurled surface. Excess sealant is squeezed-out axially, without forming encapsulated pressurized sealant pockets and without hindering the swaged engagement of the locking collar onto the knurling. Then the break-away portion is broken-off at the breaking point.

Owner:AIRBUS OPERATIONS GMBH

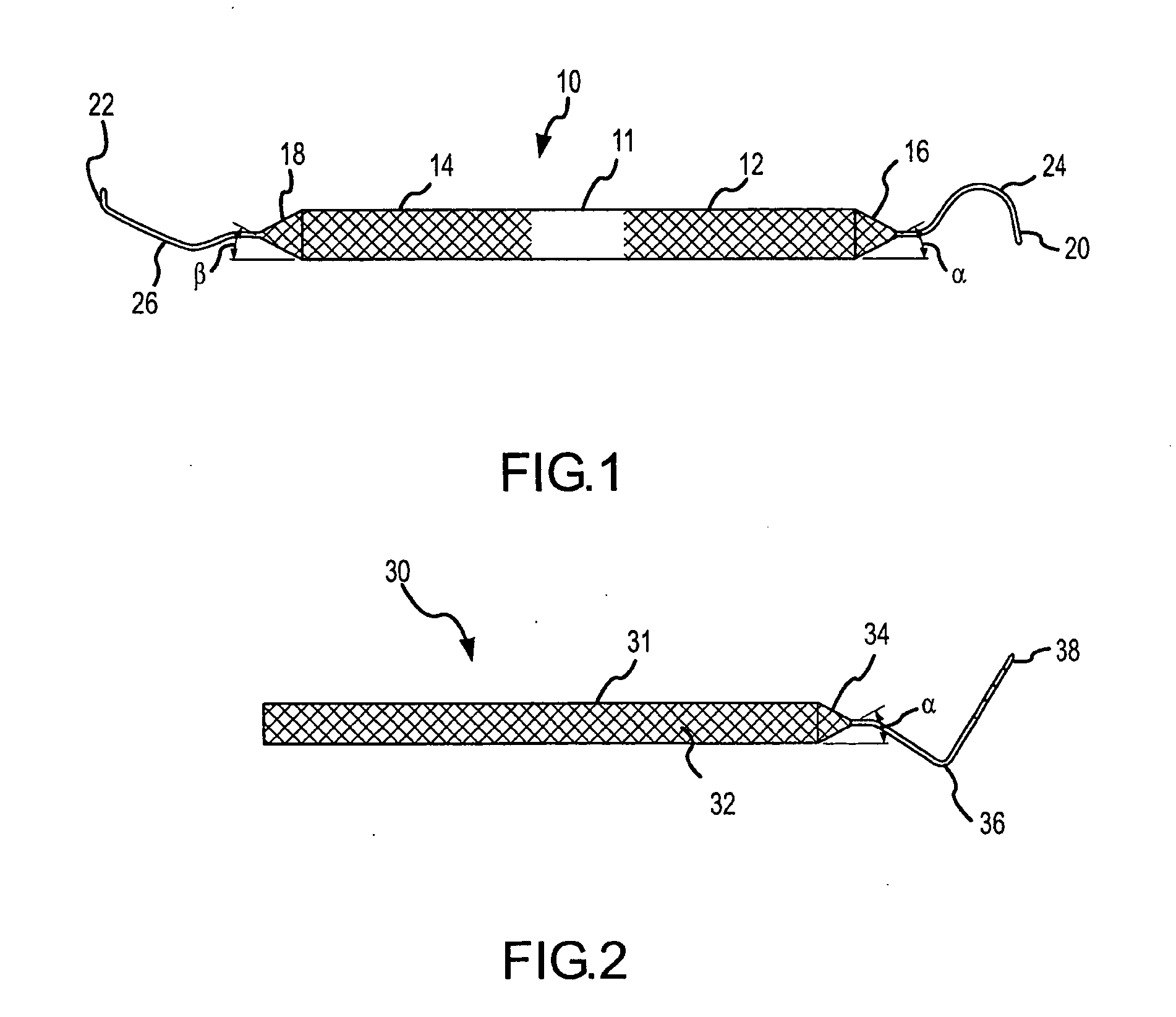

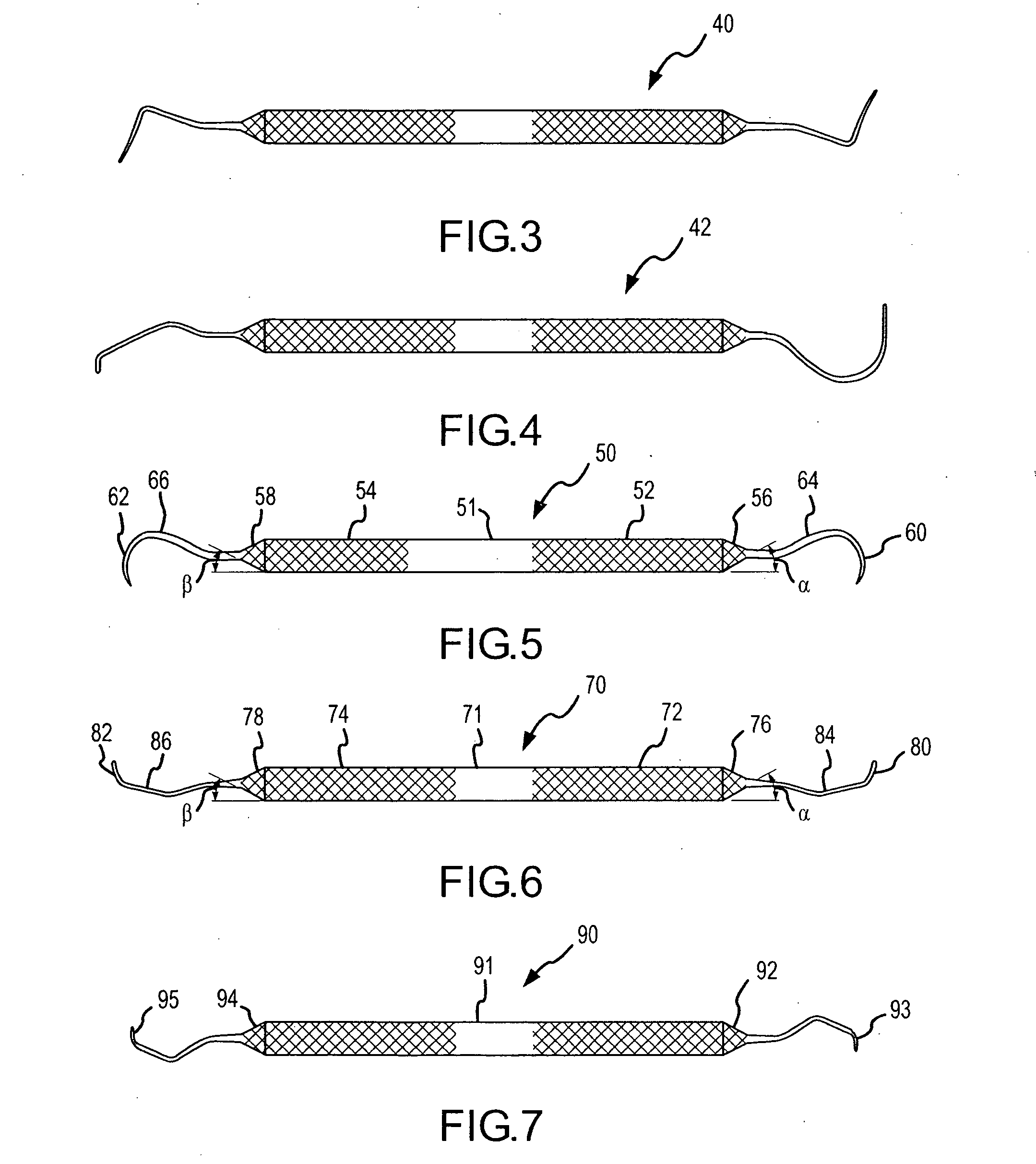

Ergonomic dental instruments for small hands

The invention provides systems and methods for ergonomic dental instruments for dental professionals with small hands. In one embodiment, a dental instrument includes an elongated metal handle having a length in the range of about 3-7 / 16 inches to about 3-15 / 16 inches and a diameter in the range of about 1 / 4 inches to about 3 / 4 inches. A working end may be operably coupled to one or both ends of the handle via a sweated fit. The length and knurling of the elongated metal shaft and terminal shaft facilitate optimum performance for the user.

Owner:CHAPIN HILL INSTR

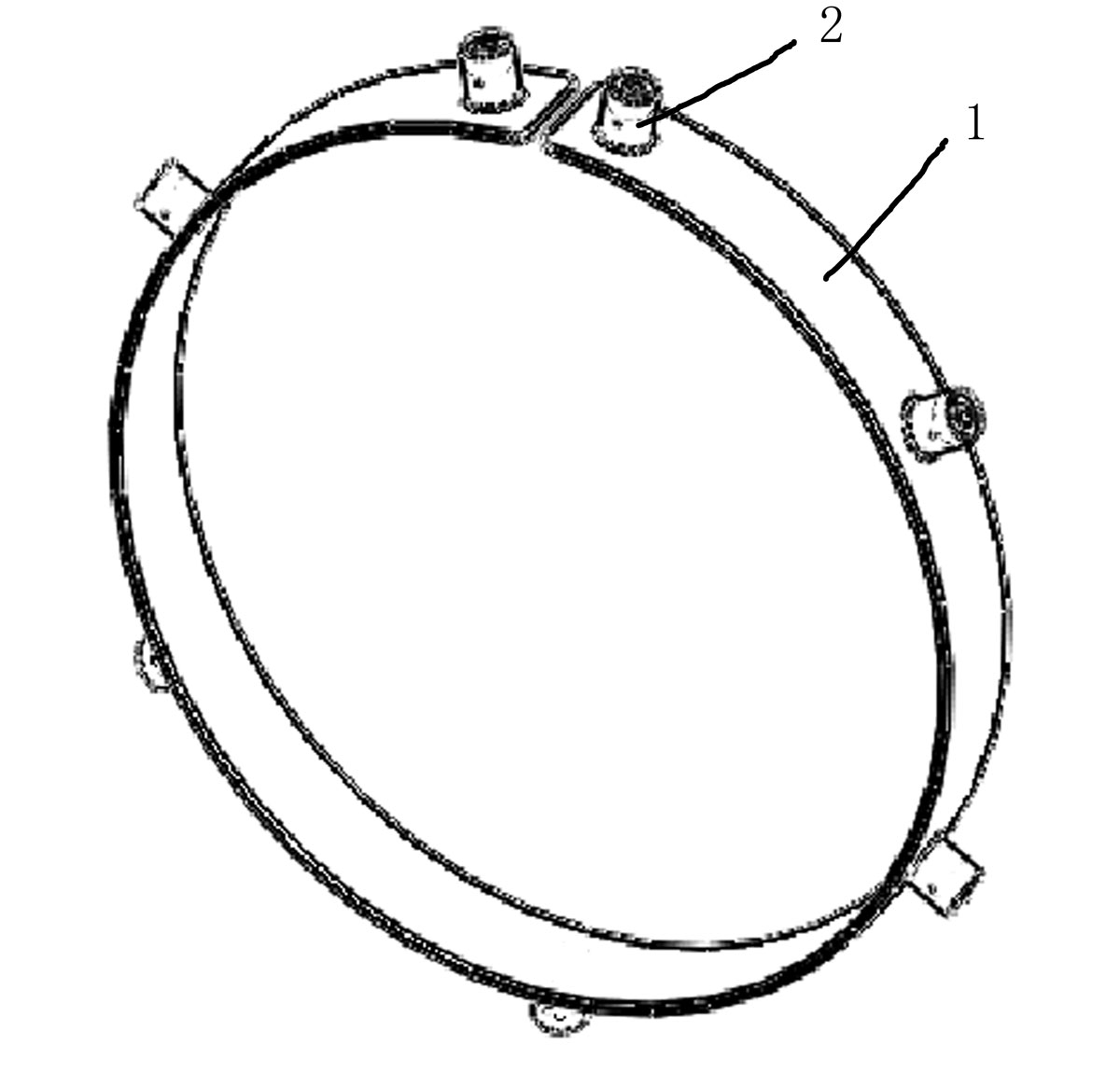

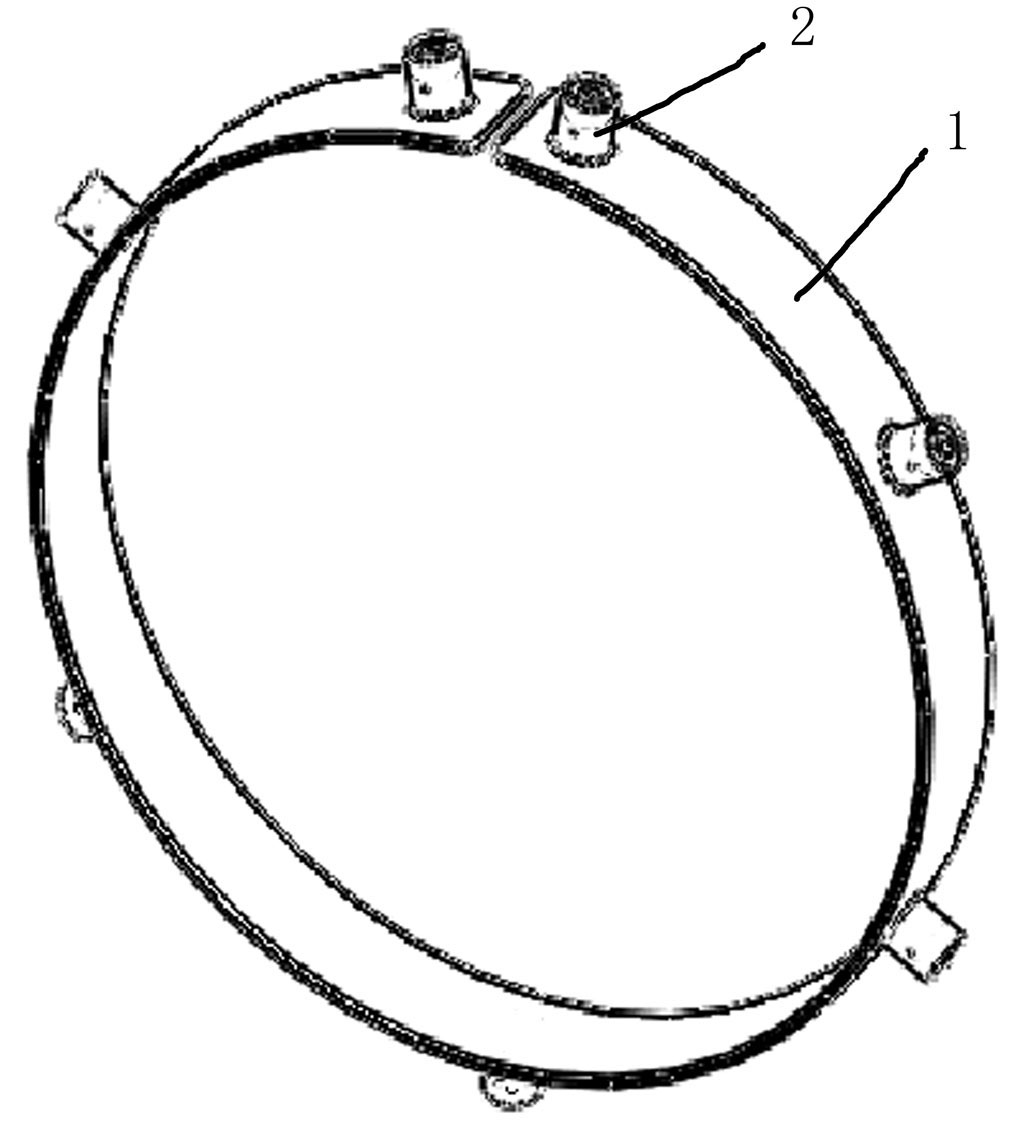

Preparation process of sputtering tantalum ring

The invention relates to a preparation process of a sputtering tantalum ring, comprising the following steps of: firstly preparing a tantalum strip for the ring, welding both ends of the circularly rolled tantalum strip, carrying out thermal treatment and profiling, knurling the inner surface and the outer surface of the tantalum strip, cutting off welded junctions, and carrying out end knurling; then processing a welding notch on the surface of the ring, carrying out acid washing, welding a boss on the welding notch on the surface of the ring, and then carrying out acid washing again; and blasting sand in the specified zone, and finally cleaning by utilizing ultrasonic waves. Each performance index of the sputtering tantalum ring prepared in the preparation process meets the use requirement of a semi-conductor industry, and the preparation process has the advantages of simplicity, low processing difficulty and high processing efficiency.

Owner:NINGXIA ORIENT TANTALUM IND +1

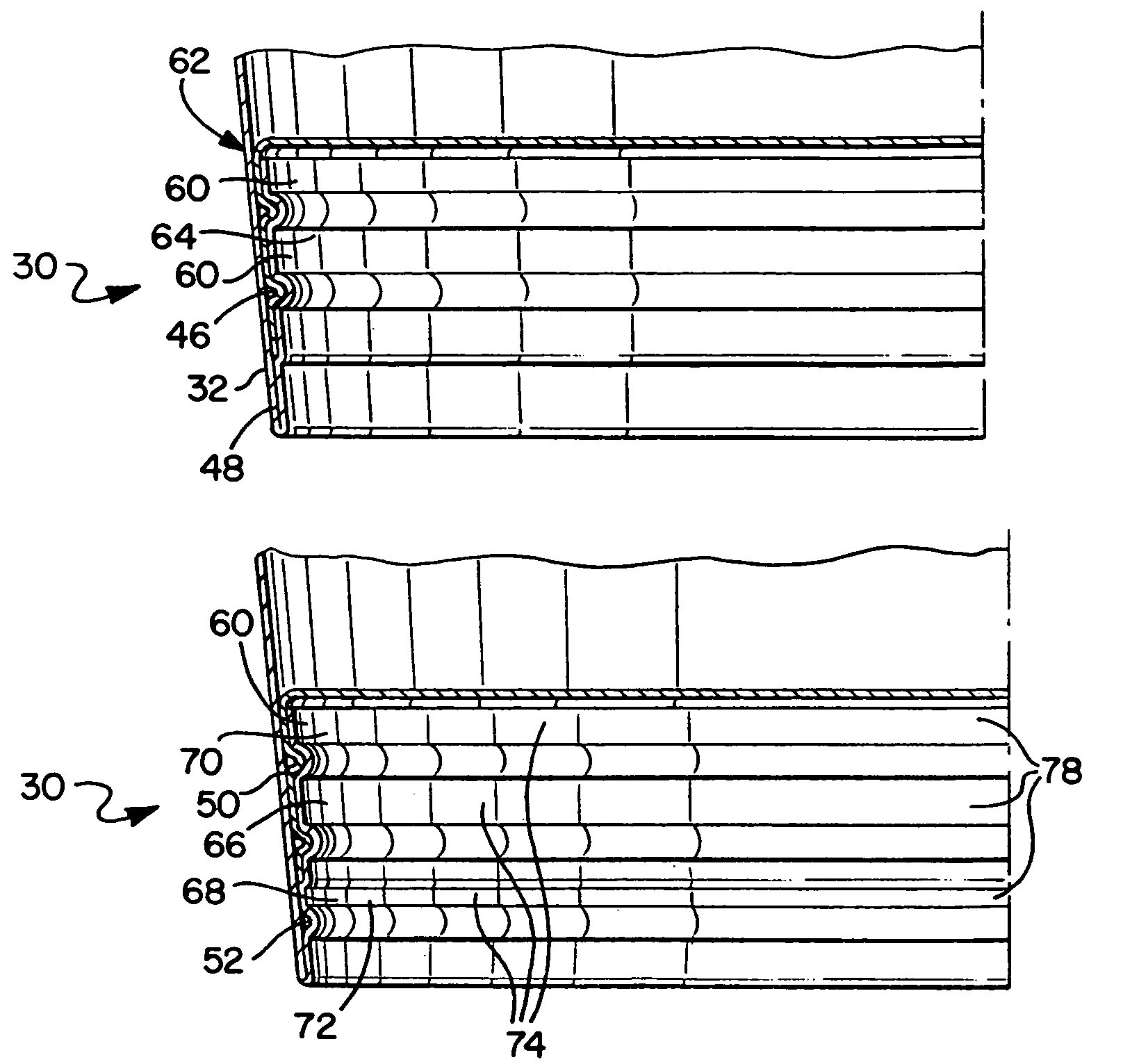

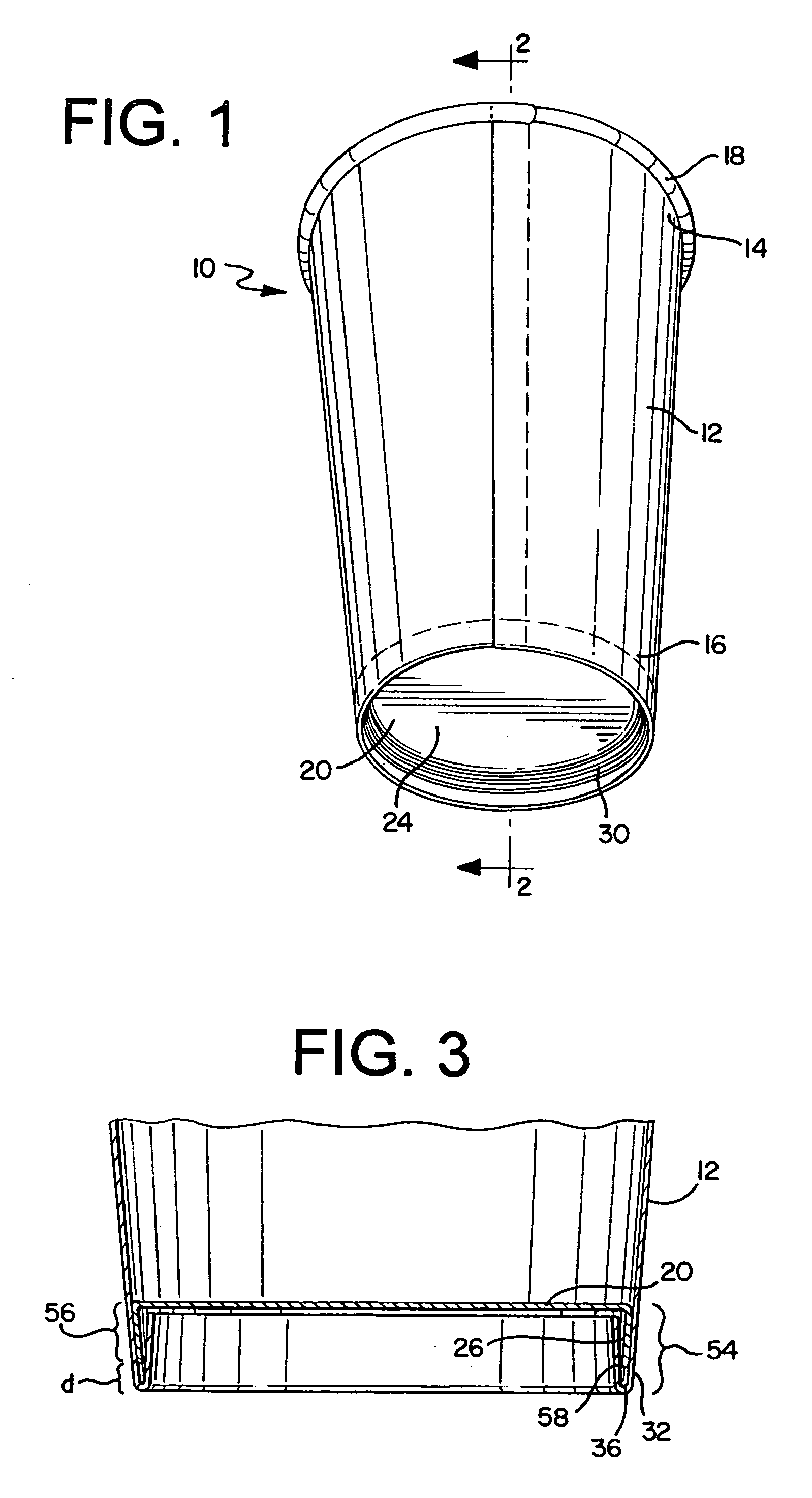

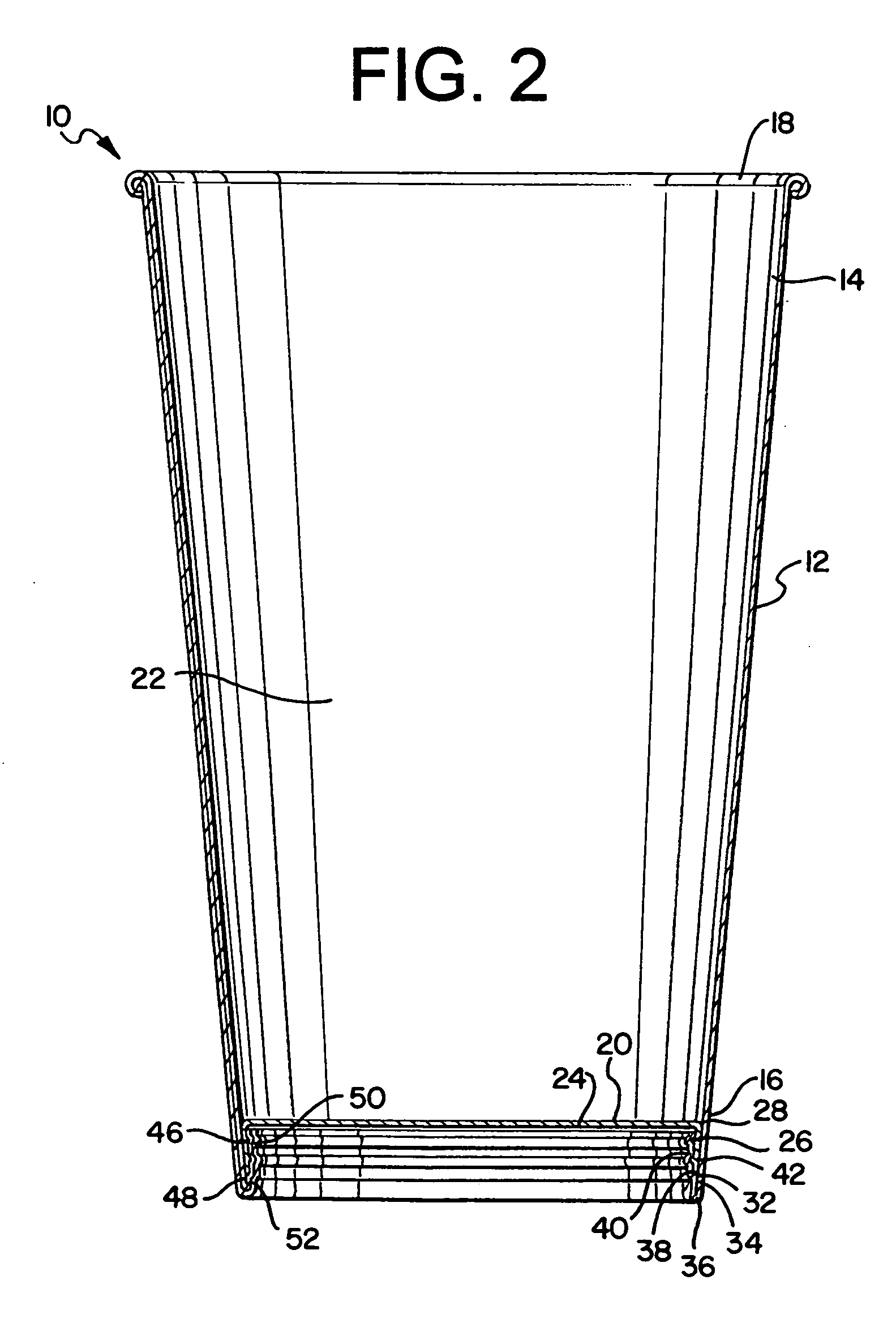

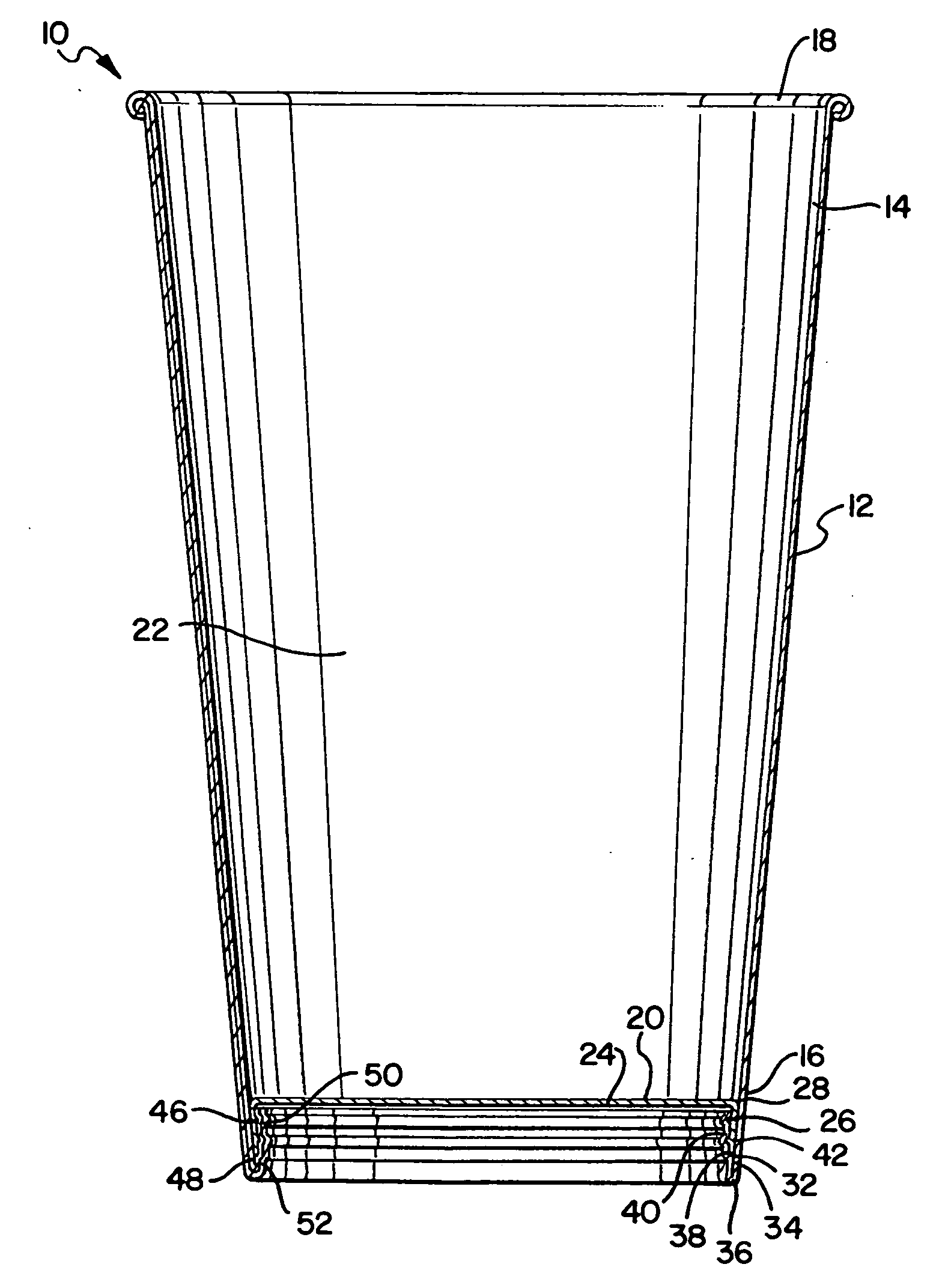

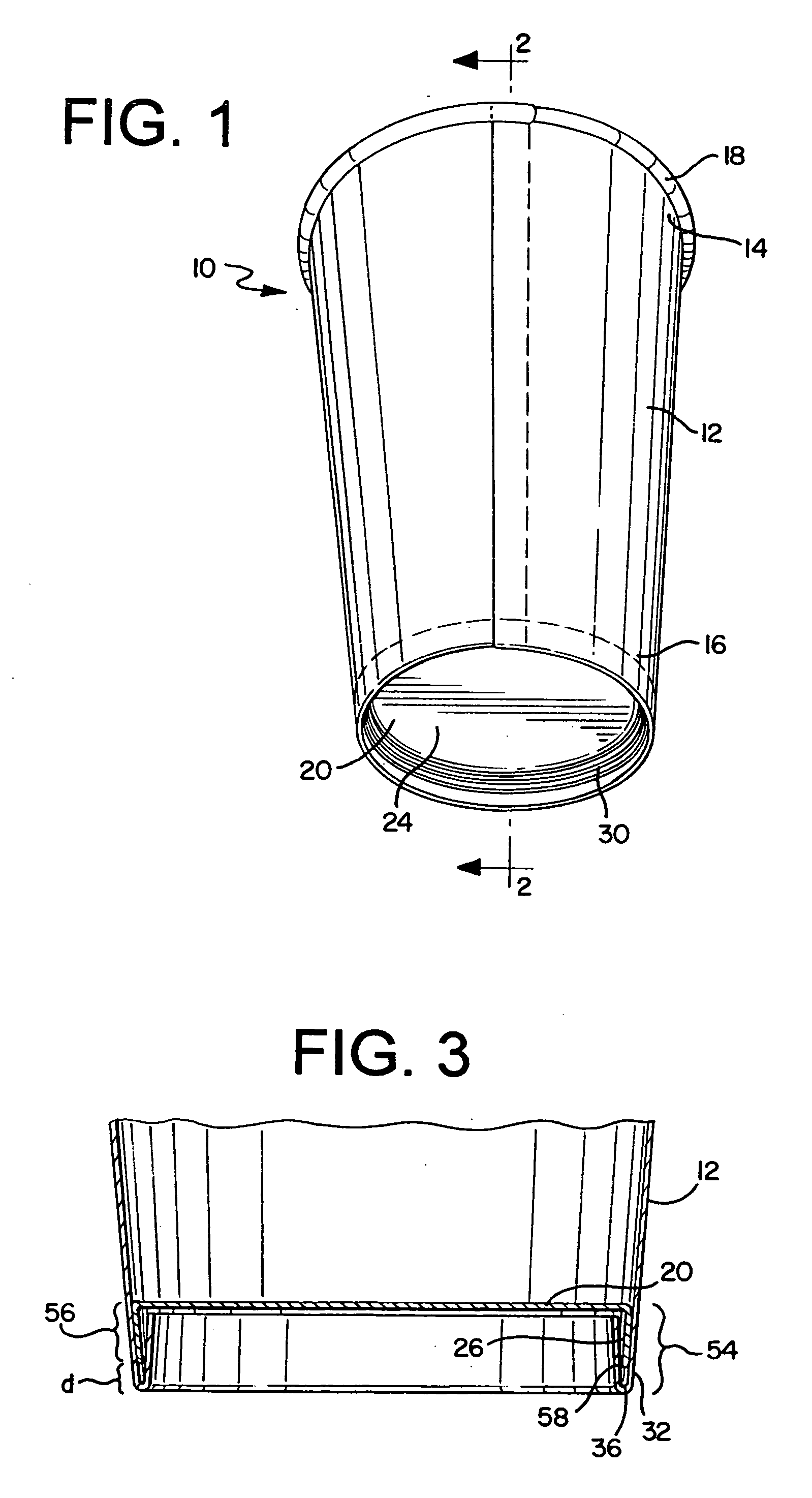

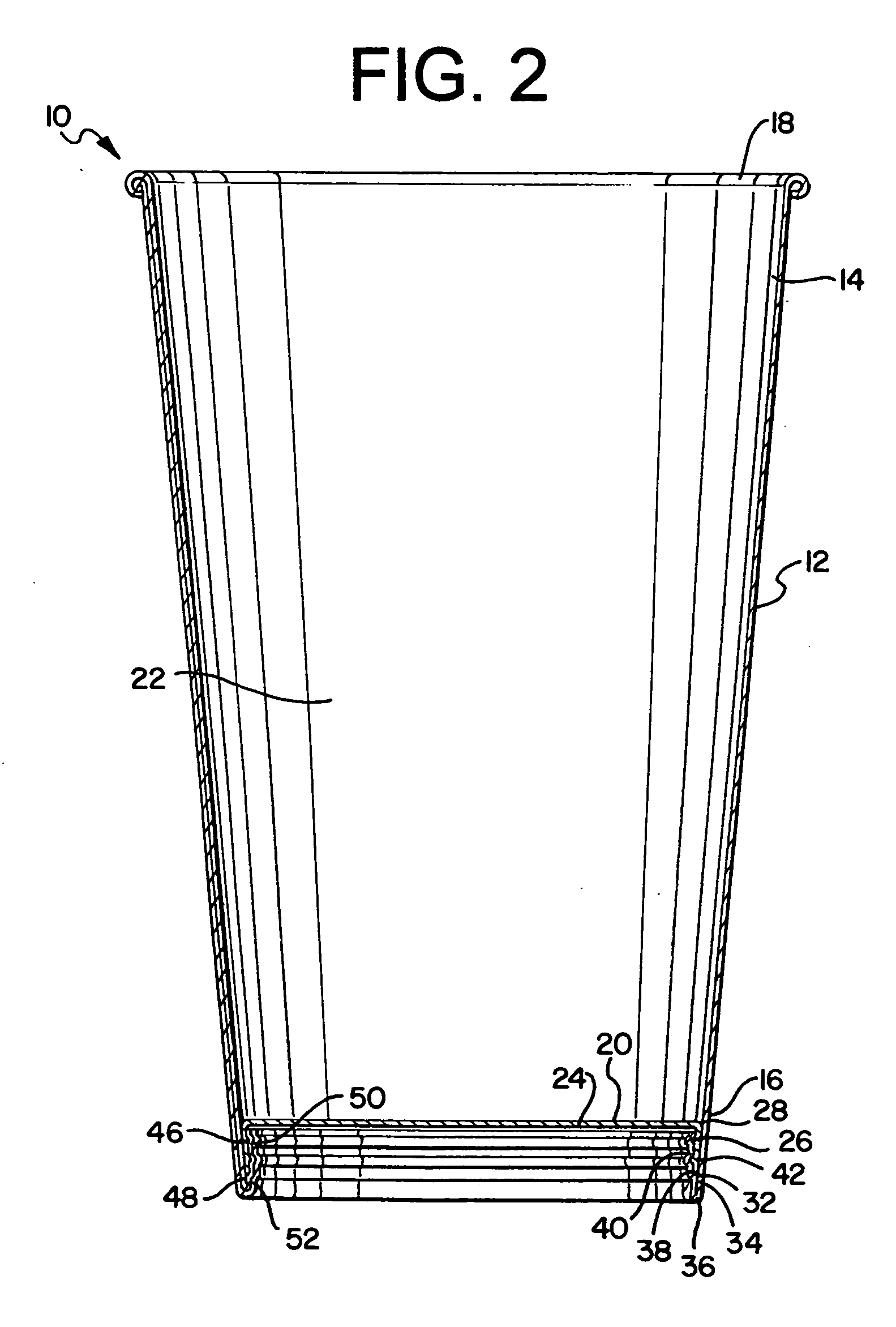

Bottom seal for container

The present invention generally provides a bottom seal for a container. The container has a side wall having an upper end and a lower end. A bottom wall closes the lower end of the side wall. The bottom wall has a base and a skirt projecting from an outer periphery of the base. A bottom seal made of a portion of the lower end of the side wall being folded generally radially inward and back on itself forms a first seal region and an adjacent second seal region. The first seal region includes the skirt and the lower end of the side wall. The second seal region does not include the skirt. One or more concentric ring seals, knurling patterns, or both are formed in at least one of the first and second seal regions of the bottom seal.

Owner:SOLO CUP OPERATING CORP

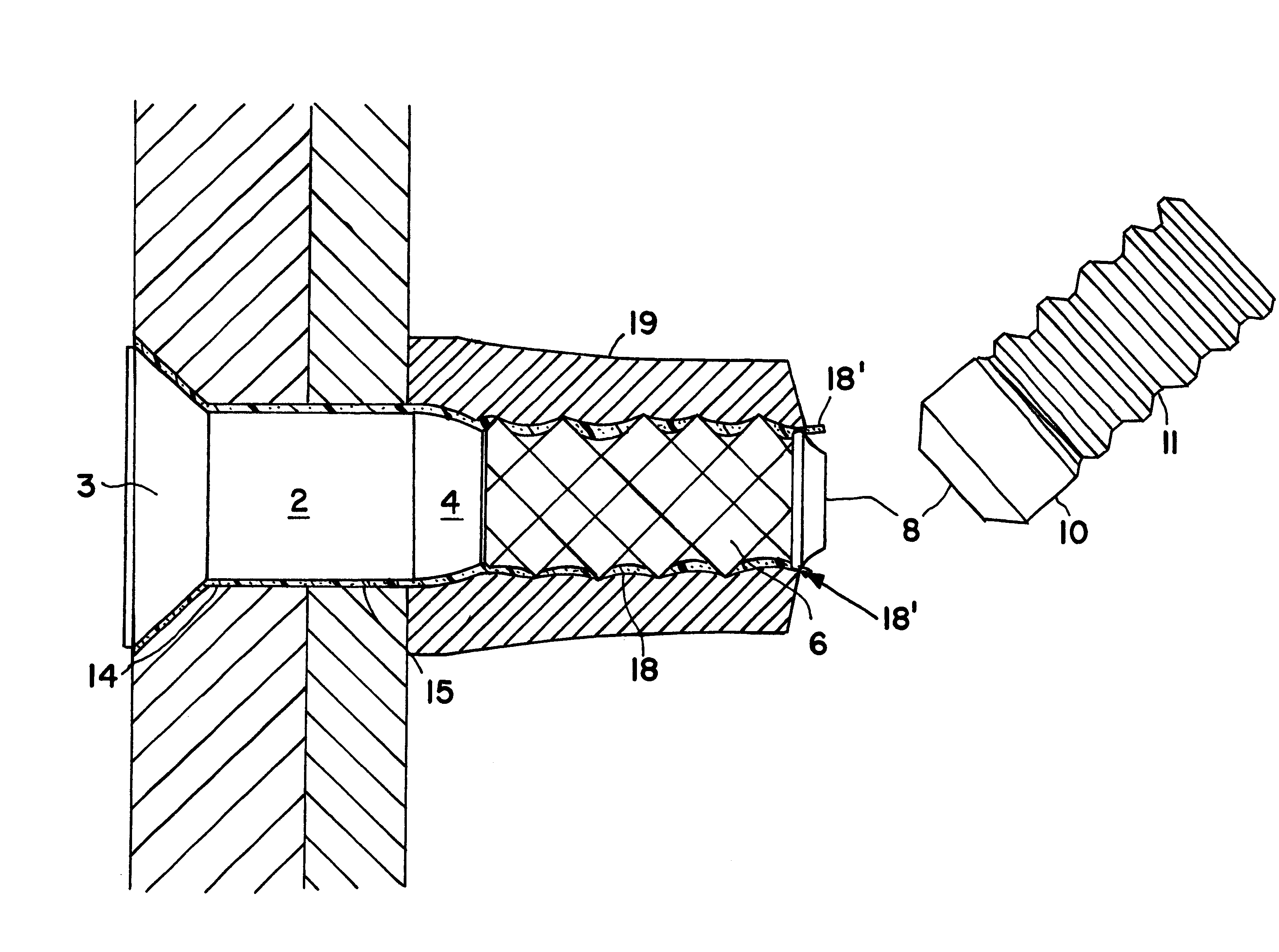

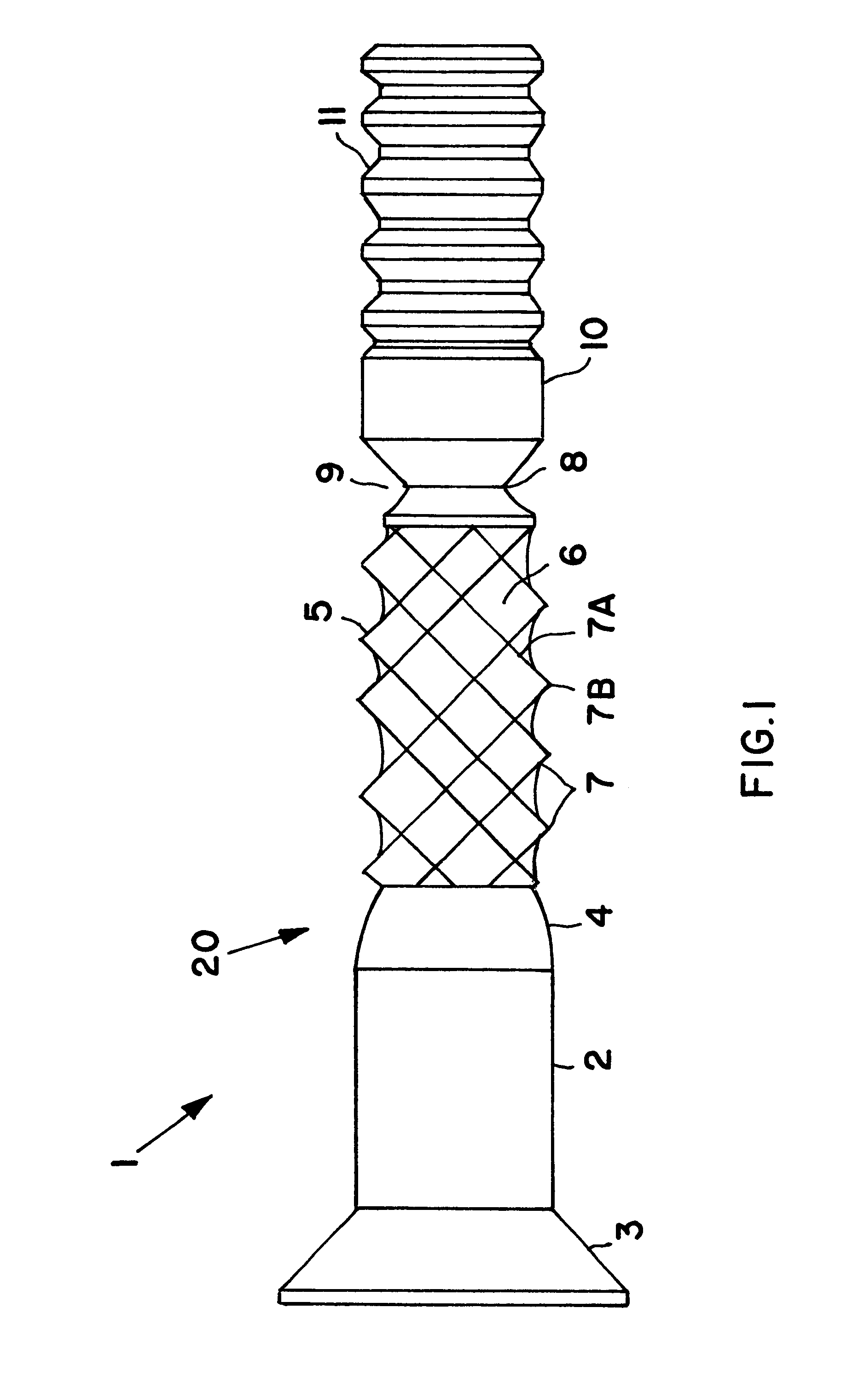

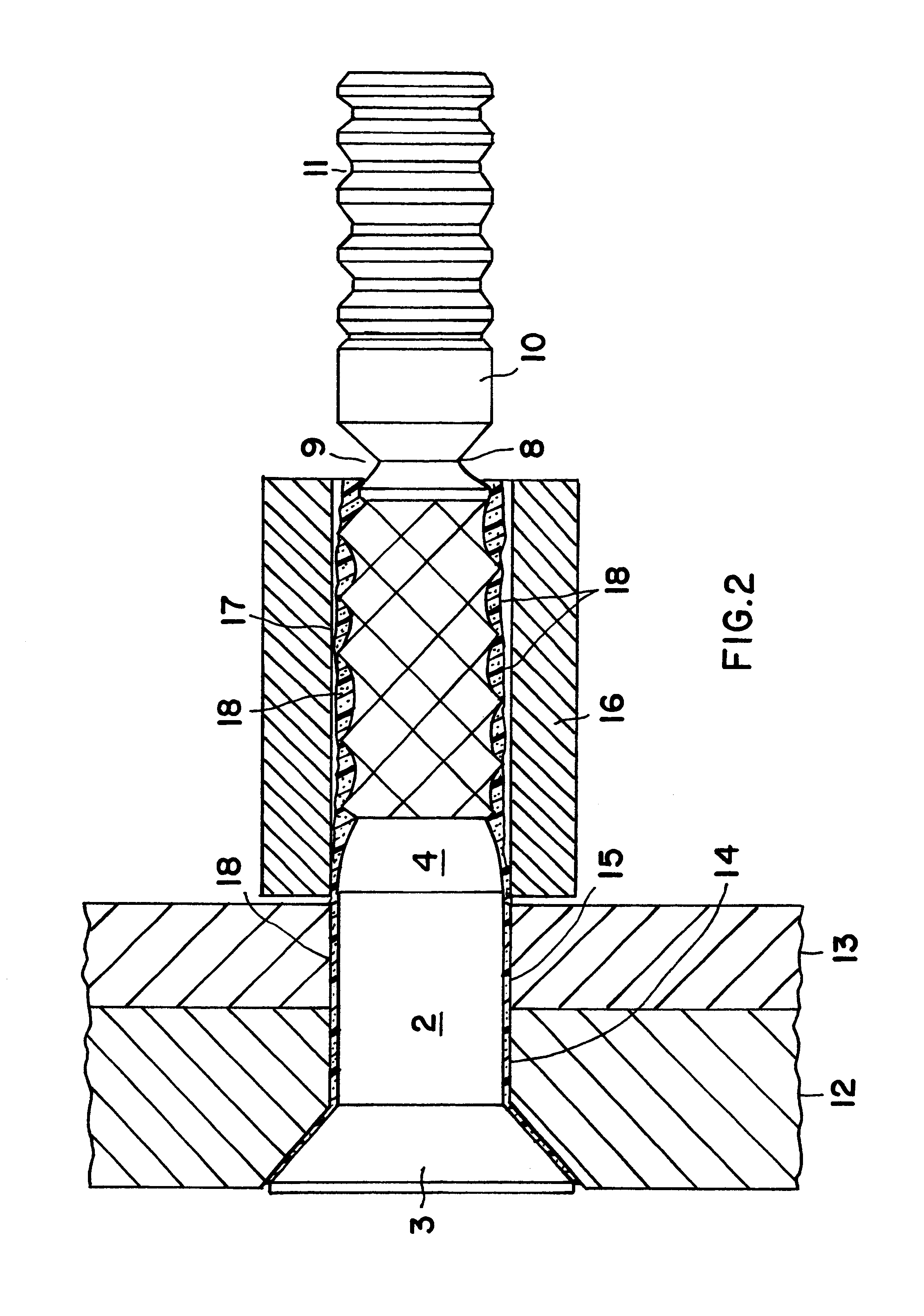

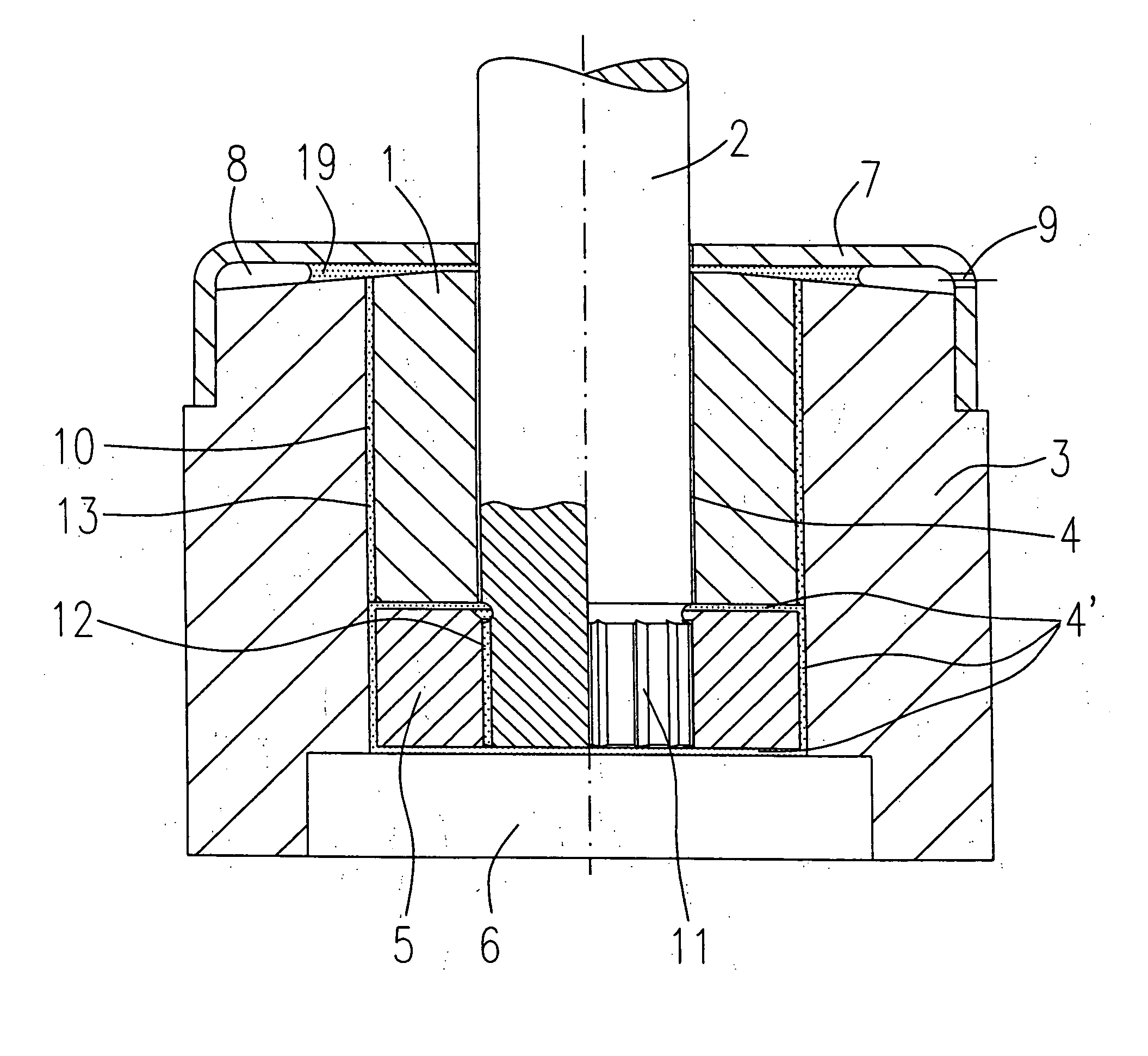

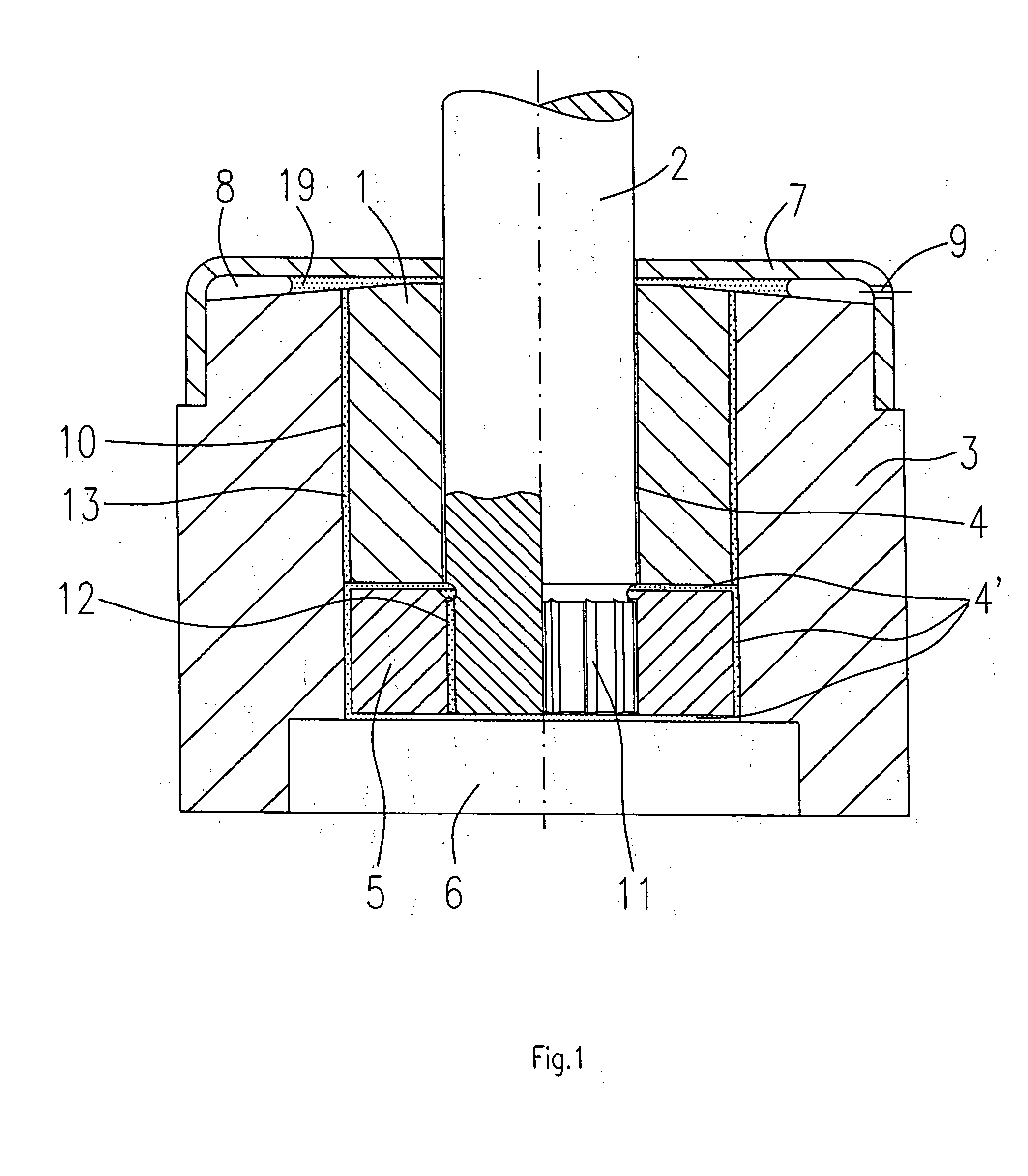

Hydrodynamic bearing system

InactiveUS20050084189A1Guarantee effective circulationAvoid problemsShaftsRecord information storageHard disc driveKnurling

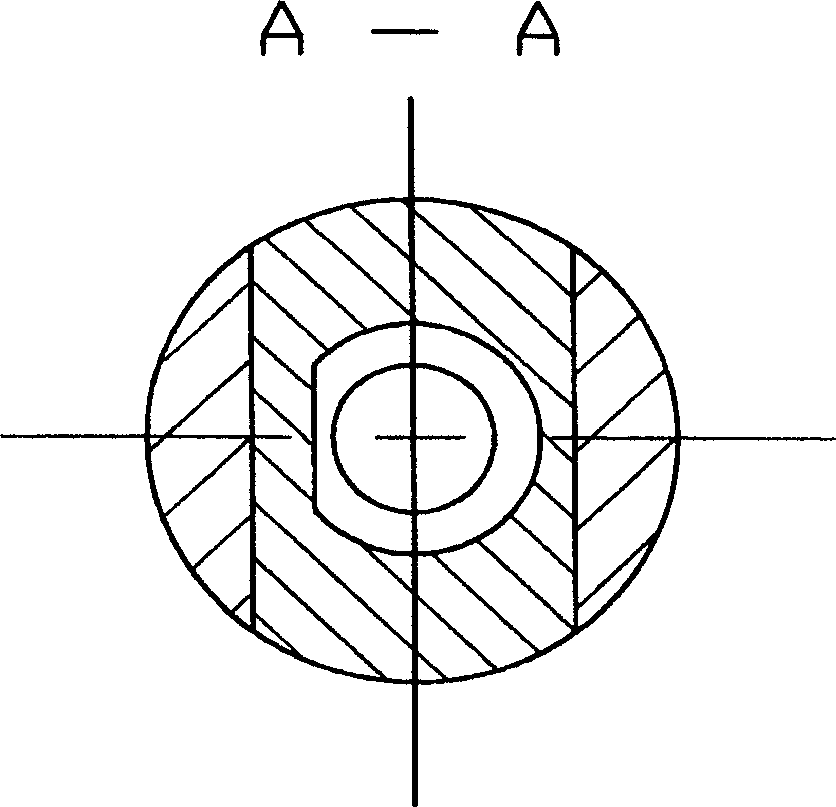

The invention relates to a hydrodynamic bearing system particularly for use as a rotary bearing in a spindle motor for a hard disk drive, comprising a shaft, a thrust plate firmly connected to the shaft by means of a pressfit connection and a bearing sleeve closed at least at one end by a cover plate, the bearing sleeve enclosing the shaft and the thrust plate with a slight radial or axial spacing forming a concentric bearing gap filled with a lubricant. In the hydrodynamic bearing system according to the invention, it is provided that the outer circumference of the shaft, in the area of connection with the thrust plate, has a surface interrupted by regular depressions, preferably formed by knurling, in order to decrease the contact surface proportion of the fit surface. As an alternative, the inner circumference of the thrust plate can also be knurled in the area of connection with the shaft.

Owner:MINEBEA CO LTD

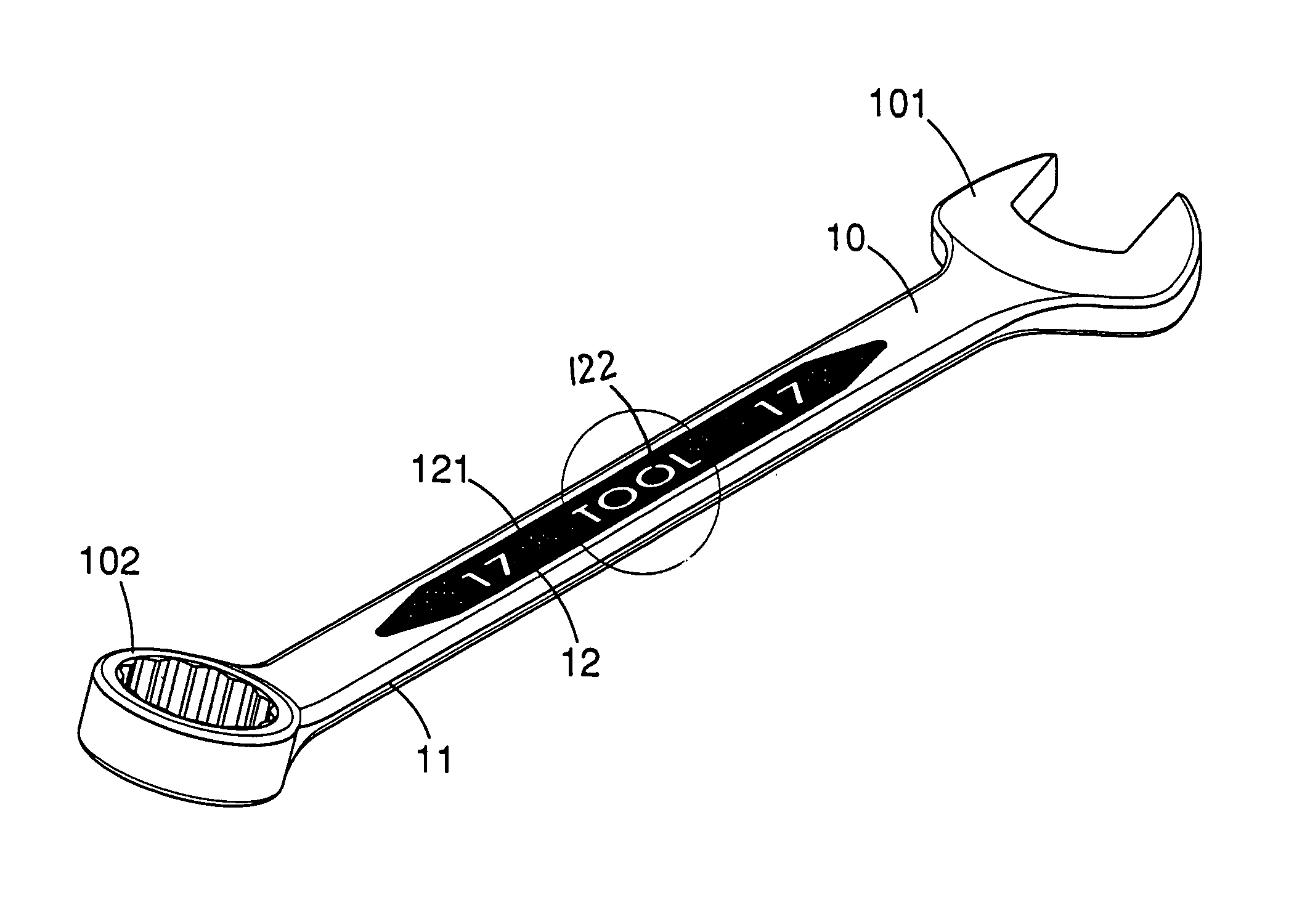

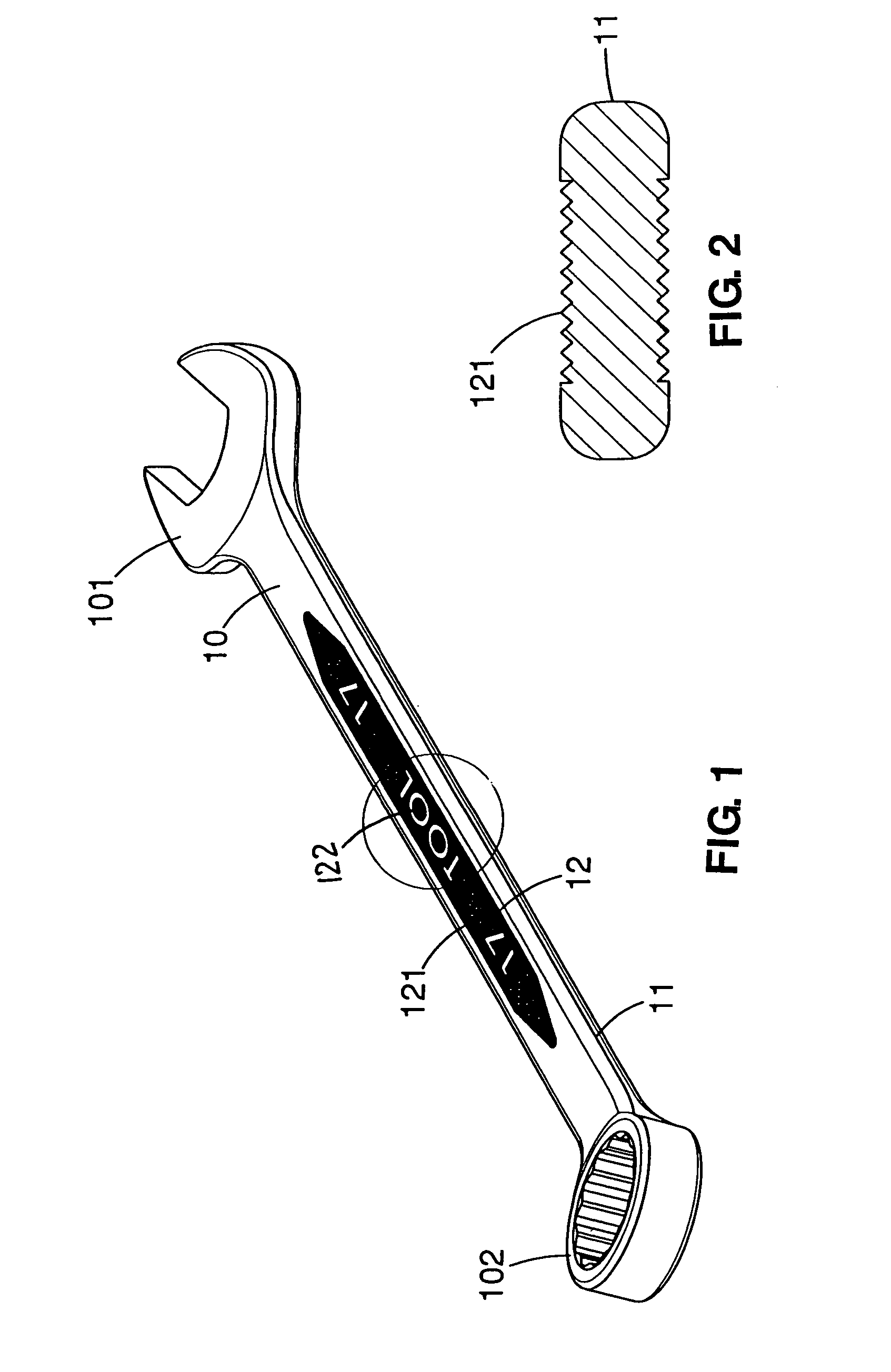

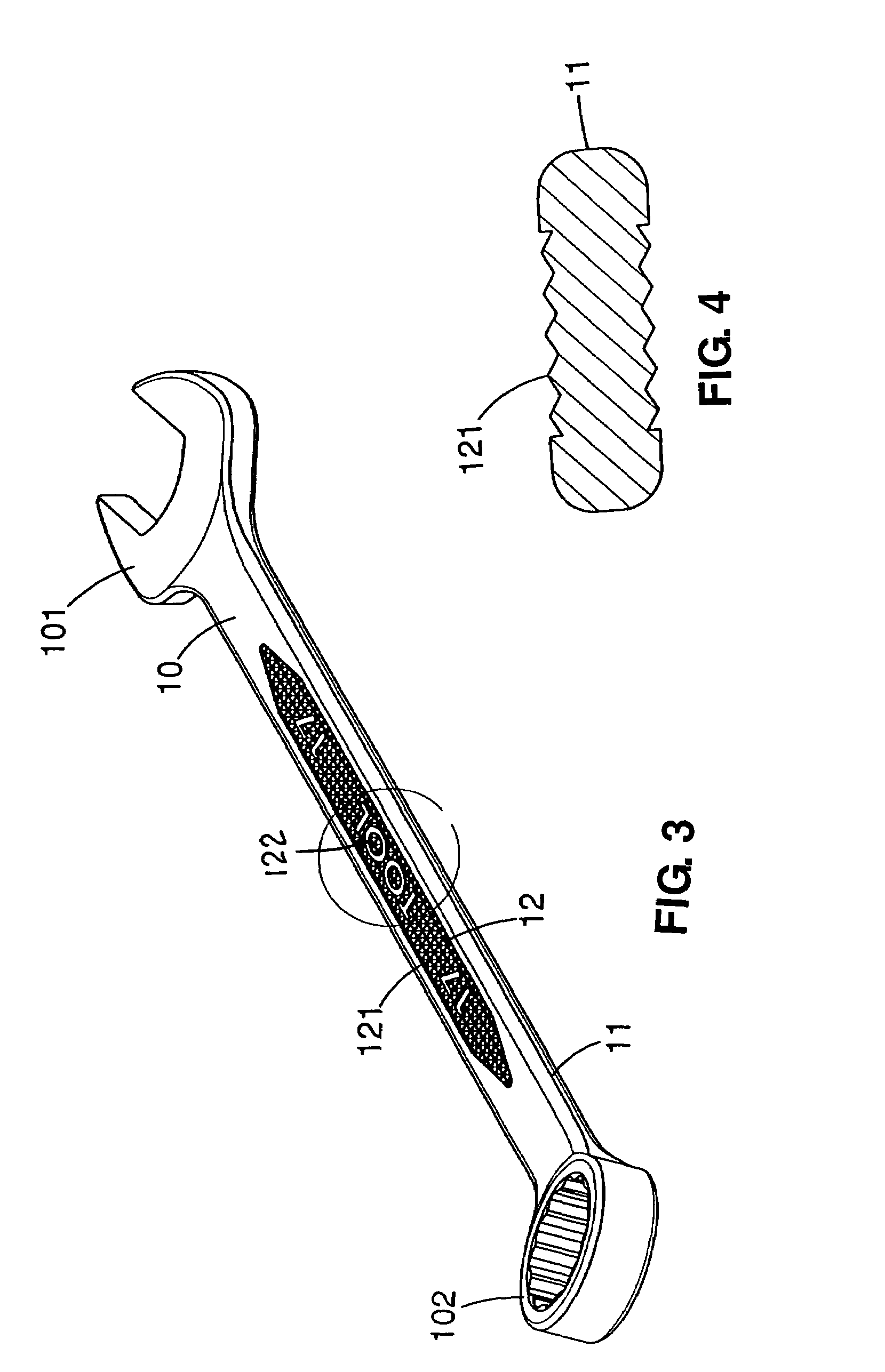

Wrench with outstanding grip

The present invention relates to a wrench of hand tool comprising a grip wherein at least one end of the grip is a driving head, and there is a sunken area on the surface of the grip. The sunken area is filled with many convexities and intensive knurl is implemented and embossed mark is established, the embossed mark being surrounded with the intensive knurl is visually outstanding so that the marks are outstanding of visual identification meanwhile the purpose of comfort and firmness in grip is achieved.

Owner:CHANG CHIOU MAI +1

Production method of negative oxygen ion multifunctional automotive trim leather

ActiveCN107312895AIncrease the fragranceFeel goodTanning treatmentPre-tanning chemical treatmentLiquid ratioKnurling

The invention relates to a production method of a negative oxygen ion multifunctional automotive trim leather. The production method comprises fleshing, liming, deliming, softening, pickling, tanning, retanning, neutralization, dyeing, fat liquoring, drying, softening, bottom coating, middle coating, knurling and top coating; in the pickling and tanning steps, salt is added for pickling, and aldehyde is added for tanning; the pickling by adding the salt is as follows: the leather is washed by softening water; the liquid ratio is 50%; by 100 mass parts of the leather, 50 parts of water are added; the temperature is controlled at 20+-2 DEG C; 7 parts of sodium chloride are added for reaction by 15 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; 0.35 part of 5 wt% of dilute sulfuric acid is added for reaction by 30 minutes; sulfuric acid is added again by the same mode for reaction by 90 minutes; after dilute sulfuric acid is added, the pH value is controlled within 2.8+-0.1; and the reaction is performed by 60 minutes. The production method has the functions of constant release of negative oxygen ions, sterilization and bacteria resistance, achieves the effect of efficiently absorbing, decomposing and degrading such harmful gas as formaldehyde, and achieves softness and excellent shaping property.

Owner:HAINING SENDE LEATHER

Method of manufacturing liner for semiconductor processing chamber, liner and chamber including the liner

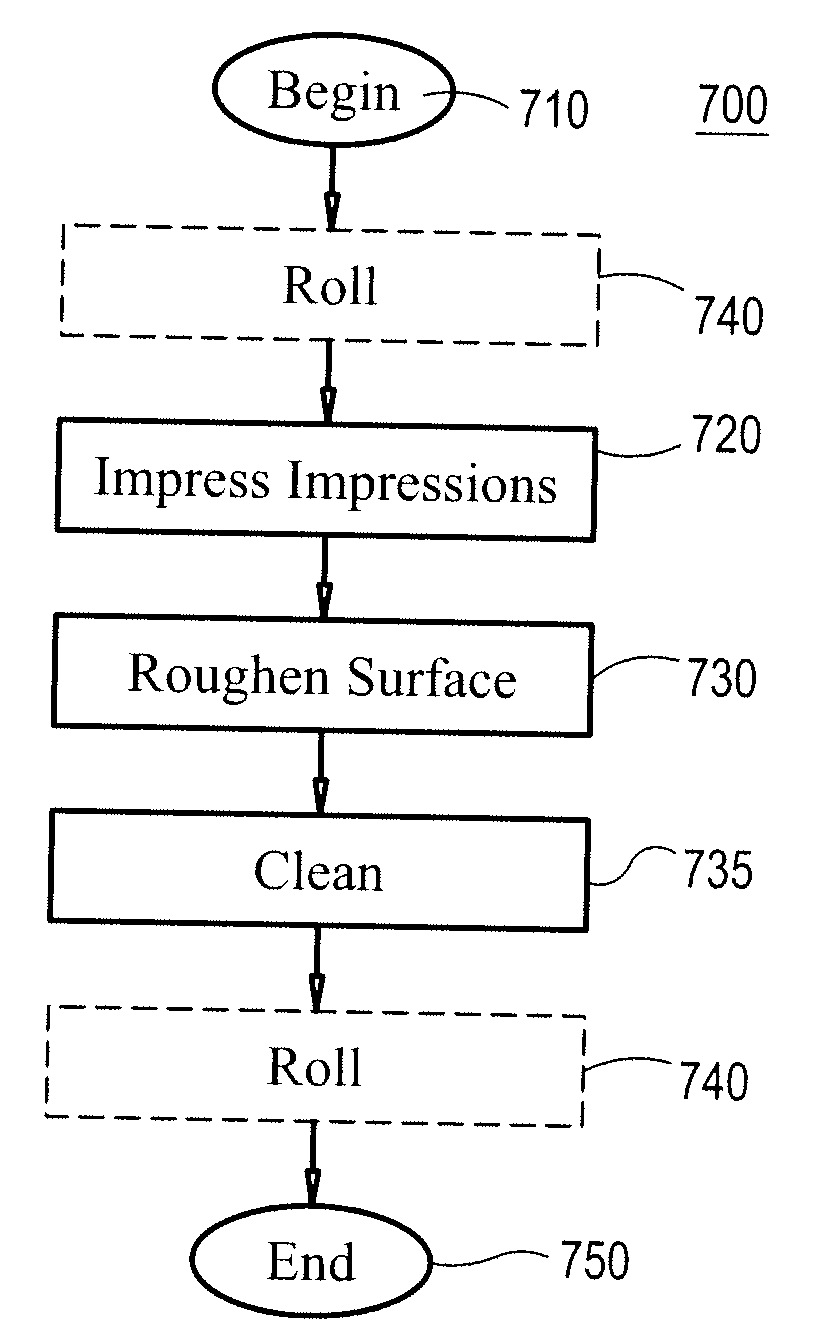

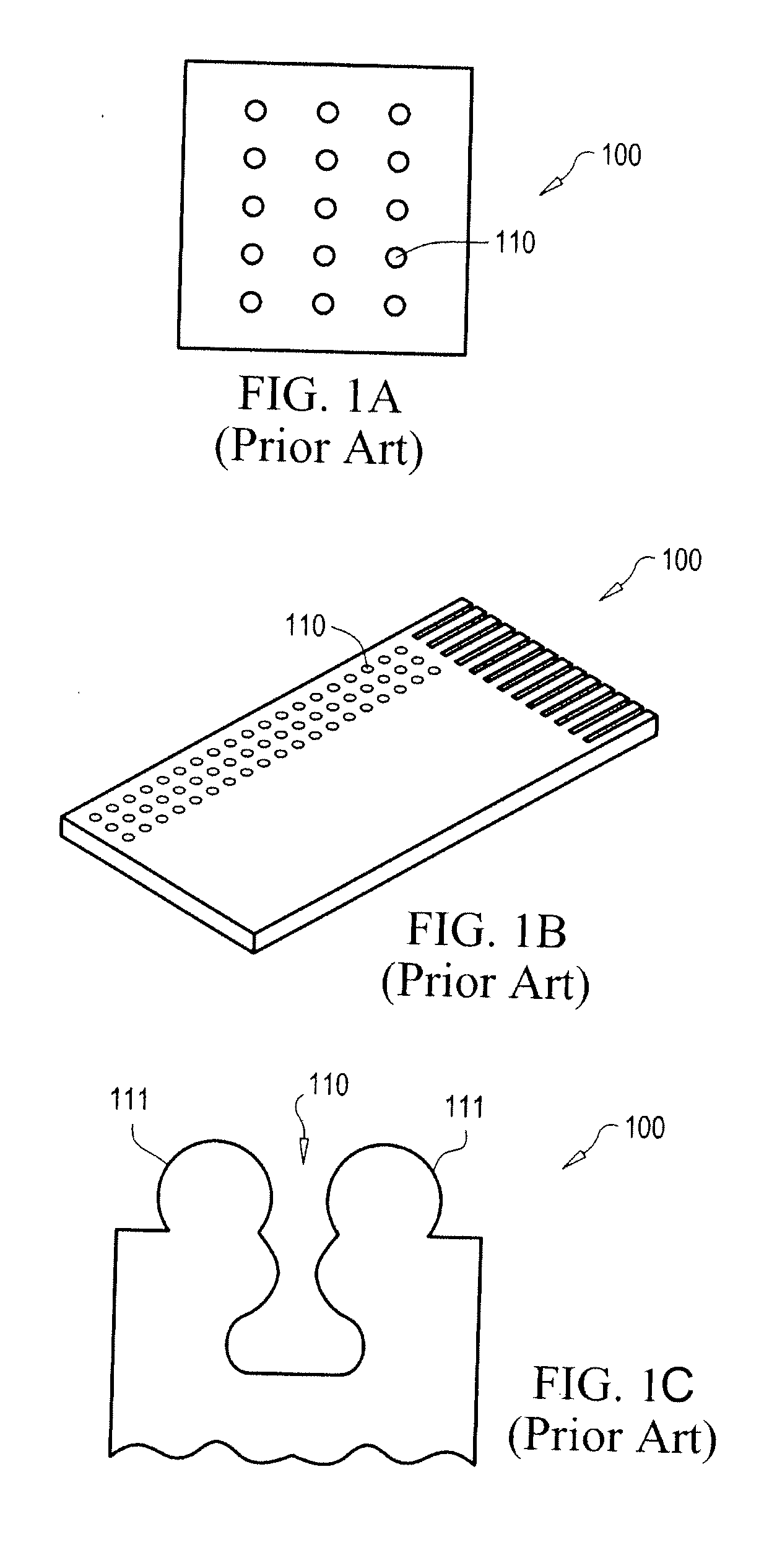

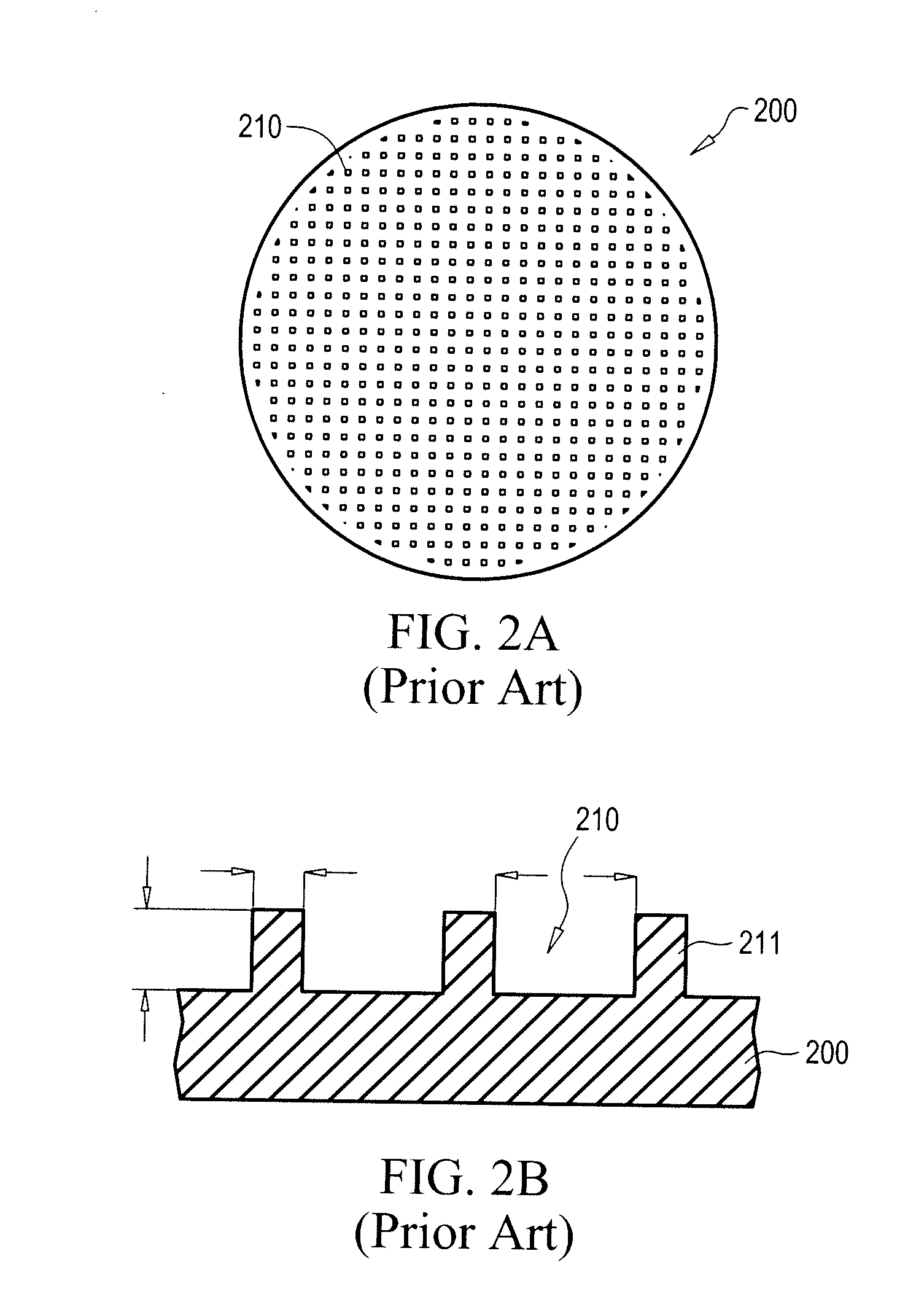

A method for manufacturing a liner for a process chamber, a liner and a process chamber including the liner. A surface of a liner material is impressed with impressions by pressing, punching, dimpling, embossing, drilling, knurling or otherwise mechanically altering the surface without removing material. The impressions include depressions, protuberances, or a combination of depressions and protuberances that are separate or merge together. The impressions may be formed as one group or as two consecutive groups and may have different shapes and arrangement patterns. The surface may be roughened before or after forming the impressions. The roughening may be obtained from particulate blasting, plasma spray, and arc spray. The sheet of material may be aluminum, steel, an alloy or a composite material that is capable of being impressed by pressing or punching. The liner may be disposable or may be cleaned after a certain number of usage cycles.

Owner:B&H ENG

Bottom seal for container

The present invention generally provides a bottom seal for a container. The container has a side wall having an upper end and a lower end. A bottom wall closes the lower end of the side wall. The bottom wall has a base and a skirt projecting from an outer periphery of the base. A bottom seal made of a portion of the lower end of the side wall being folded generally radially inward and back on itself forms a first seal region and an adjacent second seal region. The first seal region includes the skirt and the lower end of the side wall. The second seal region does not include the skirt. One or more concentric ring seals, knurling patterns, or both are formed in at least one of the first and second seal regions of the bottom seal.

Owner:SOLO CUP OPERATING CORP

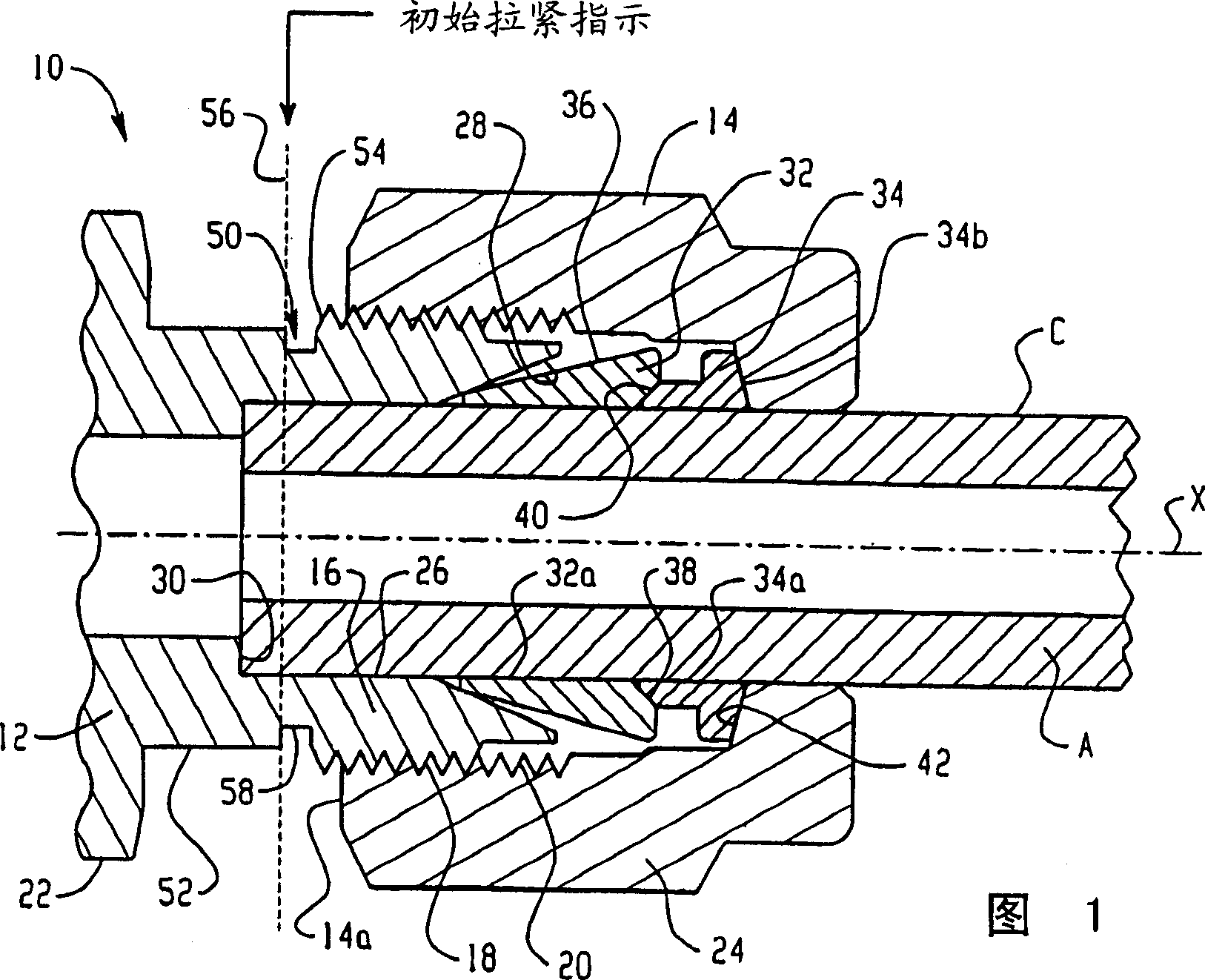

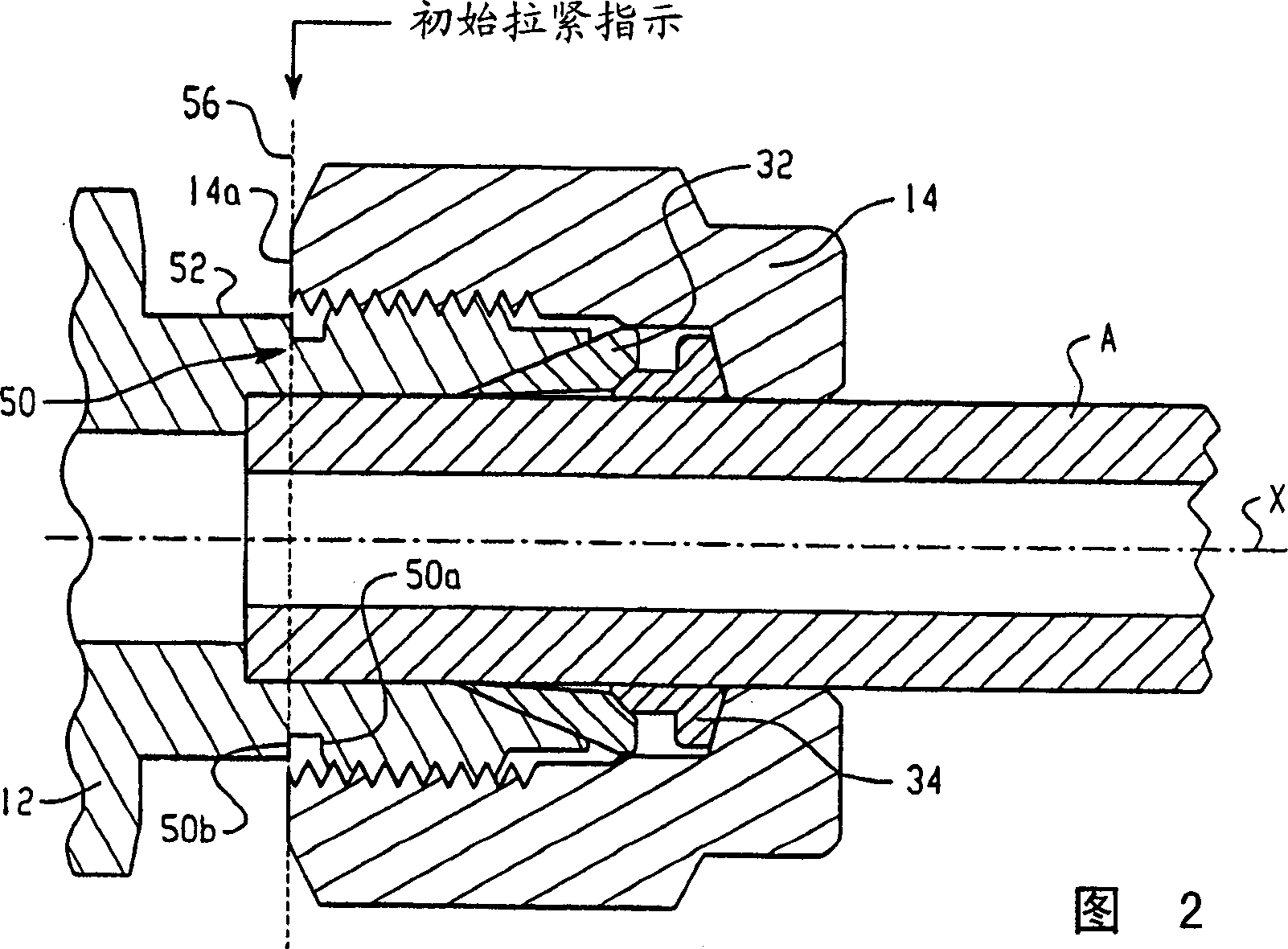

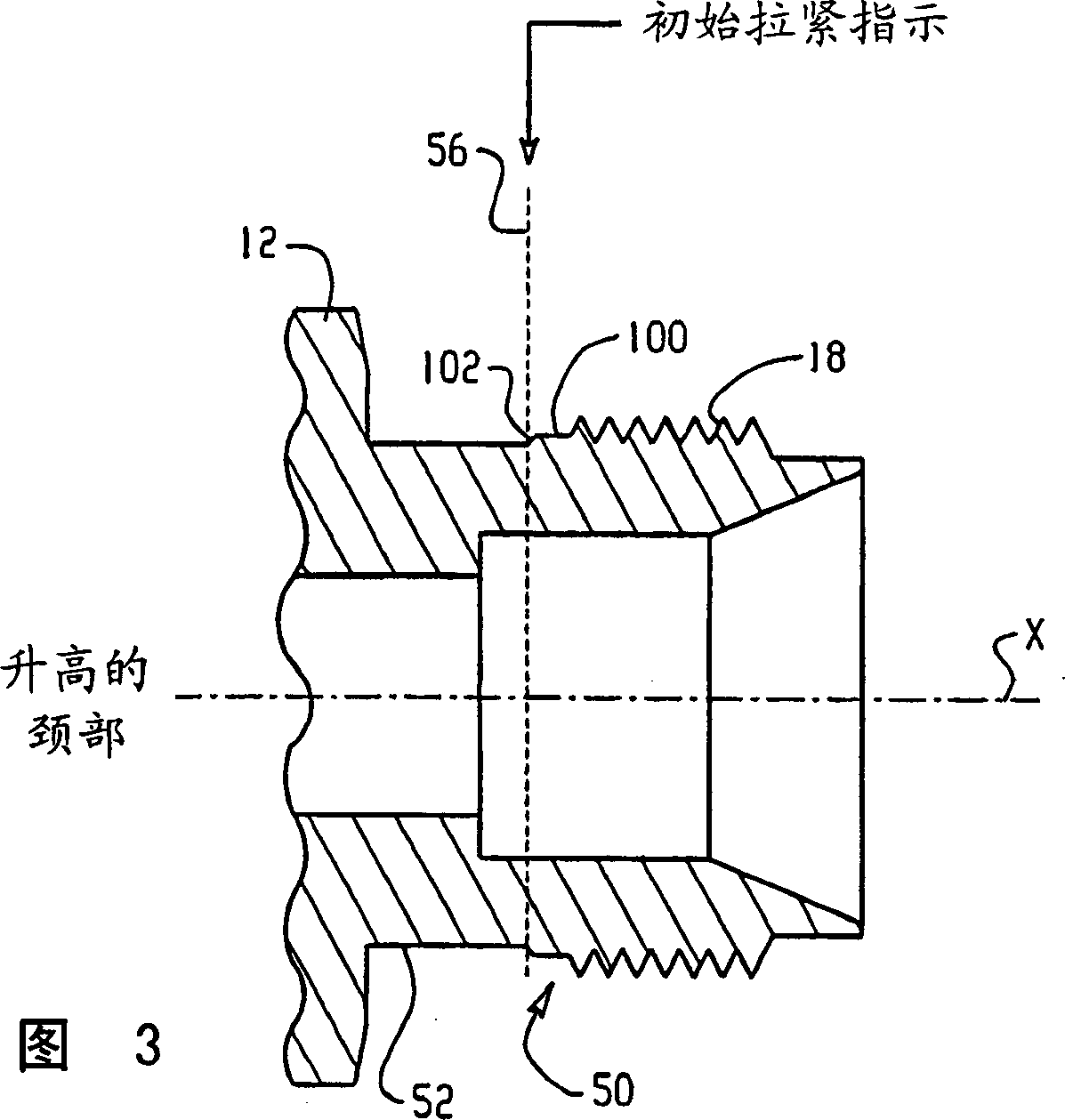

Tube fitting with indicating means

An intrinsic gauging device for a ferrule type tube fitting of the type having a coupling nut, a coupling body and at least one ferrule, includes a precisely formed marking that has a predetermined relationship with the coupling nut when the fitting has been initially pulled-up. The marking may be realized as a precision groove or recess machined into a surface. The groove can be made more easily visually perceptible such as by roughening, knurling or coloring the surface. The groove defines an edge at a precise position that corresponds to a predetermined axial displacement of the nut relative to the body for initial pull-up. The marking may also be formed with a precise dimension such as an axial length to provide a second edge that corresponds to a predetermined axial displacement of the nut relative to the body beyond initial pull-up for fitting assemblies that are remade.

Owner:SWAGELOK CO

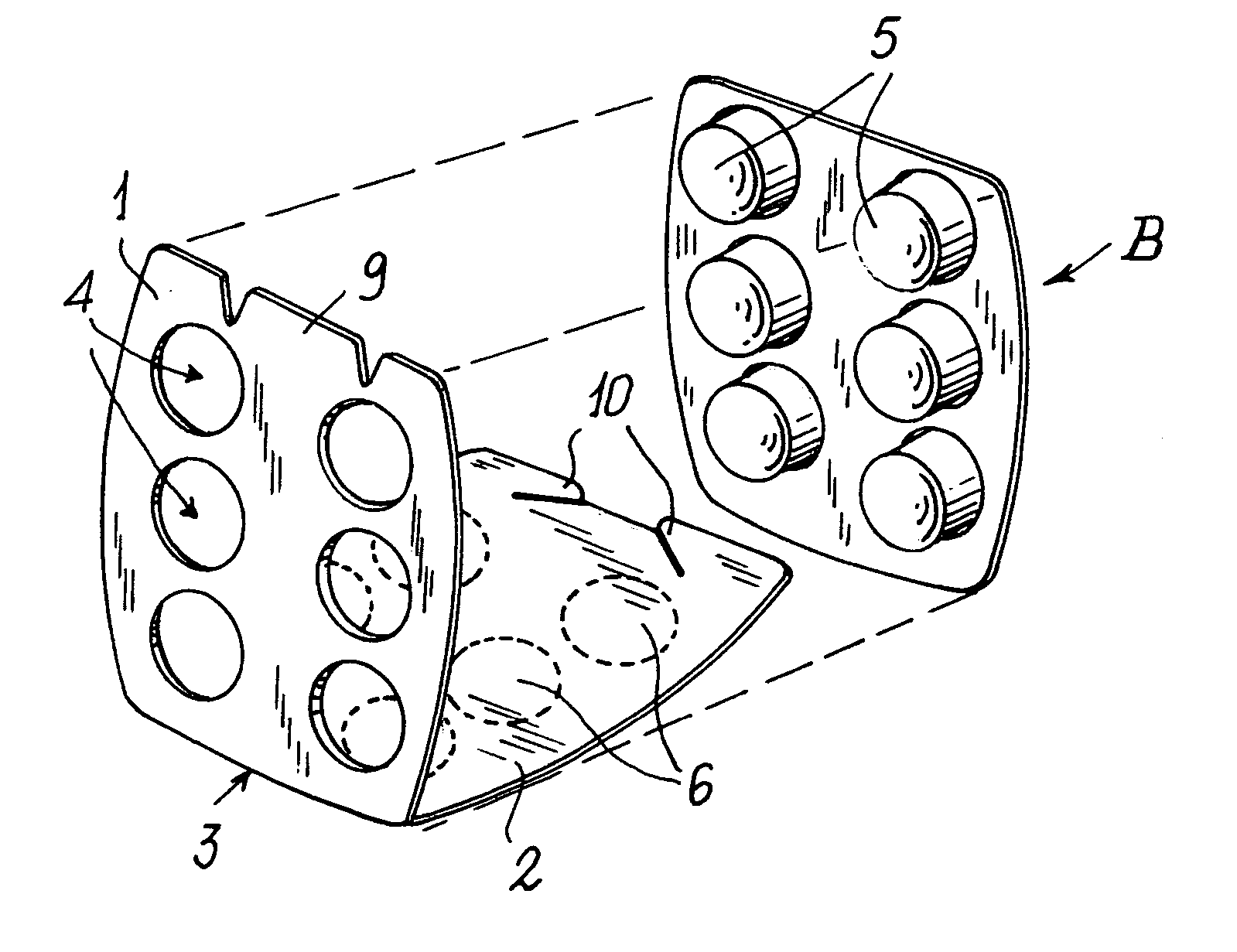

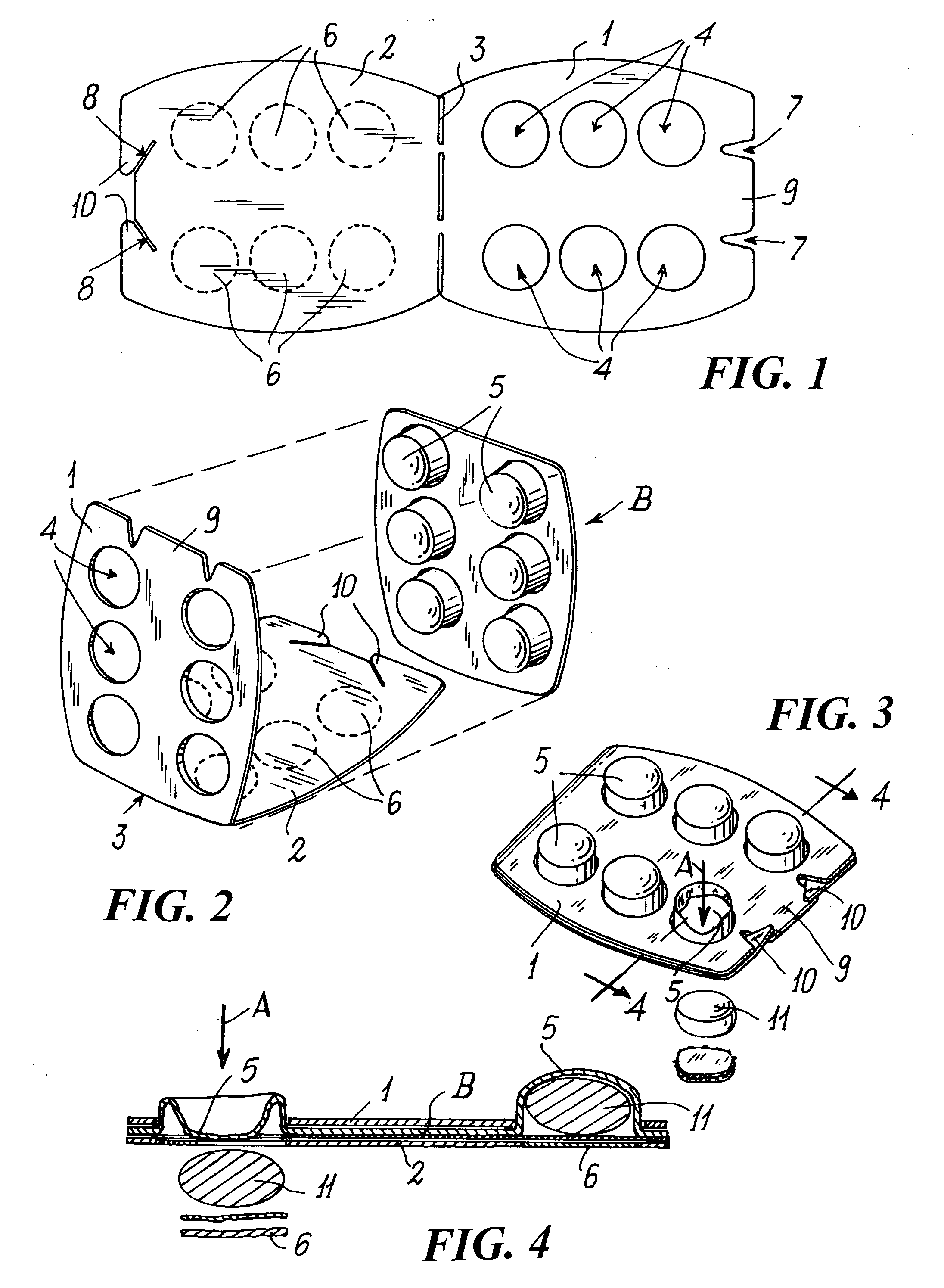

Device for selectively dispensing solid products from a blister strip retained in the device

Device for safeguarding a blister strip and enabling a tablet or the like to be dispensed from a respective housing on the blister strip, which is retained and protected within the device. This latter is formed from a single sheet of cardboard folded about the blister strip, the blisters of which extend through holes provided in a part of the sheet, in the other part of which there being provided breakable knurlings defining removable discs which are aligned with said holes to enable said discs to break with consequent detachment of said discs and expulsion of said tablets when the individual blisters of the blister strip are pressed with the finger of one hand.

Owner:GI BI EFFE

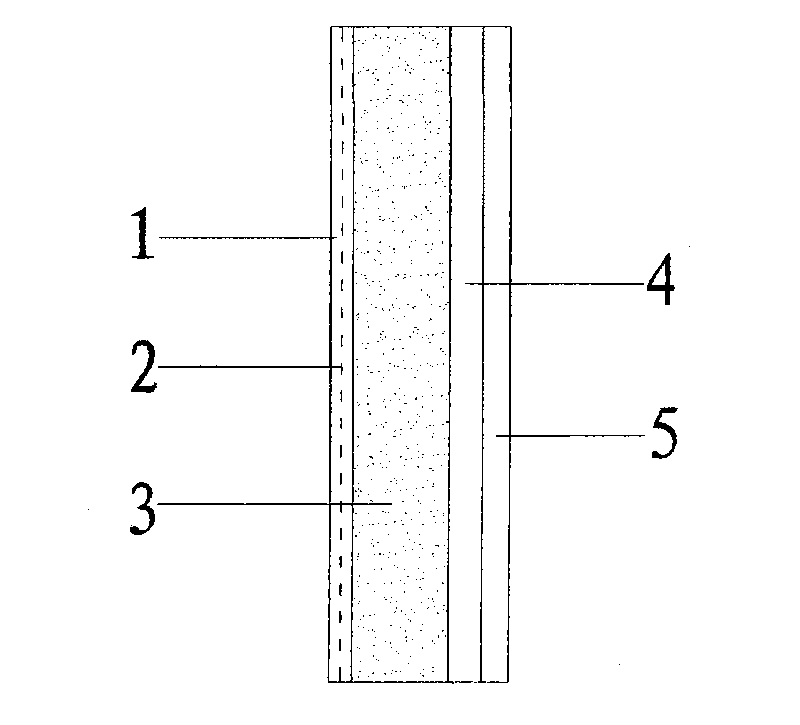

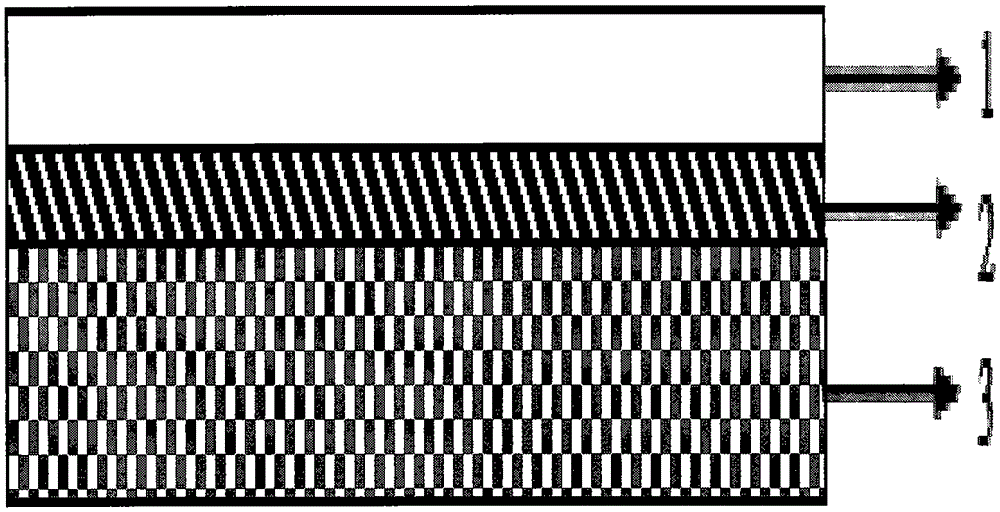

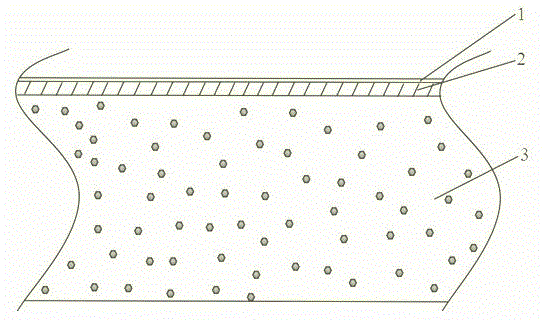

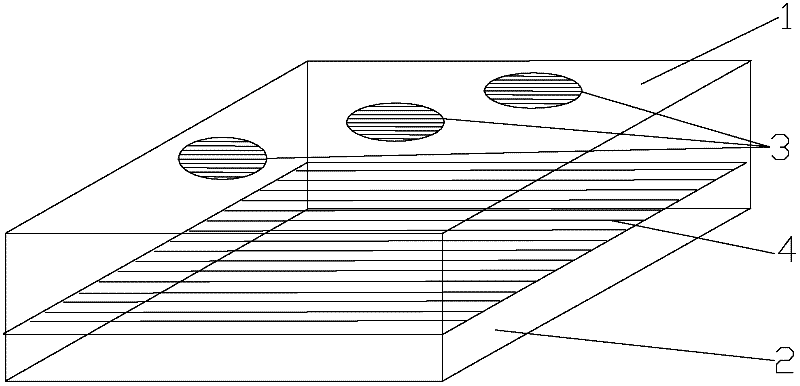

Flexible decorative facing brick and production process thereof

The invention provides a flexible decorative facing brick. By adopting a sheet as a basic-layer matrix body 1, polymer color-sand glue material on the matrix body as a brick body 2 and transparent paint as a brick-surface protection layer 3, the flexible decorative facing brick is produced through the processes of scraping, coating, baking, spraying and cutting. A production process comprises: manufacturing a sheet matrix body in advance for later use; washing, screening and drying natural color sand; weighing 55 to 65 percent of natural color sand and 35 to 45 percent of polymer latex in a weight ratio, putting the two into a kettle for preparing the polymer color-sand glue material, stirring uniformly and producing the polymer color-sand glue material for later use; introducing the sheet matrix body onto a gathering platform of a production line for the flexible decorative facing brick, adding the polymer color-sand glue material, performing scraping-coating, pressing, knurling and block division, sending the obtained product into the production line for dewatering and drying; spraying the transparent paint serving as the brick-surface protection layer; and cutting and packaging the obtained product according to size. The decorative facing brick manufactured by the method has the advantages of good elasticity and flexibility, and the production process is high in manufacturing efficiency and saves energy.

Owner:烟台同化防水保温工程有限公司

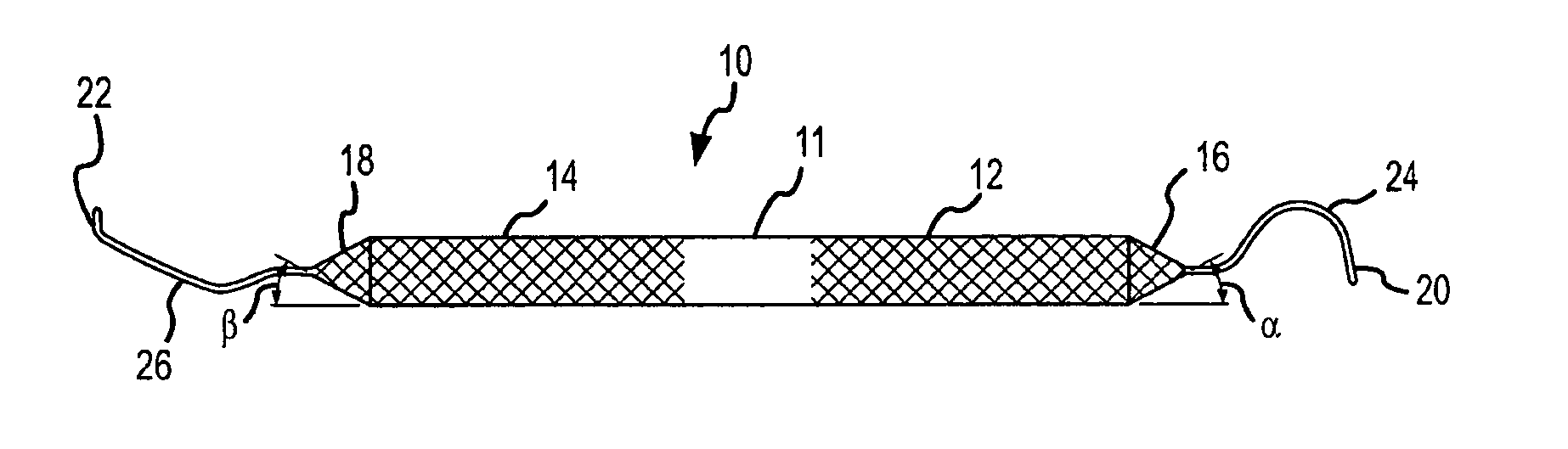

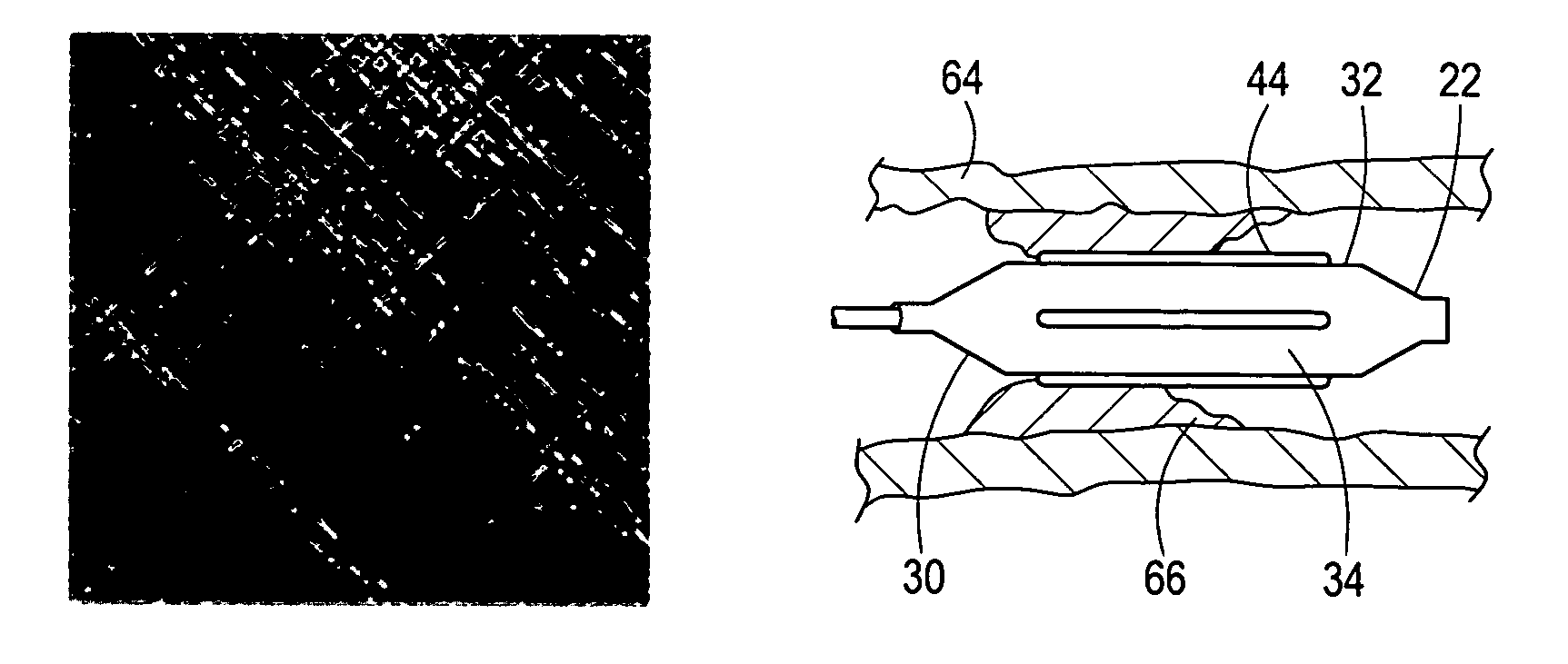

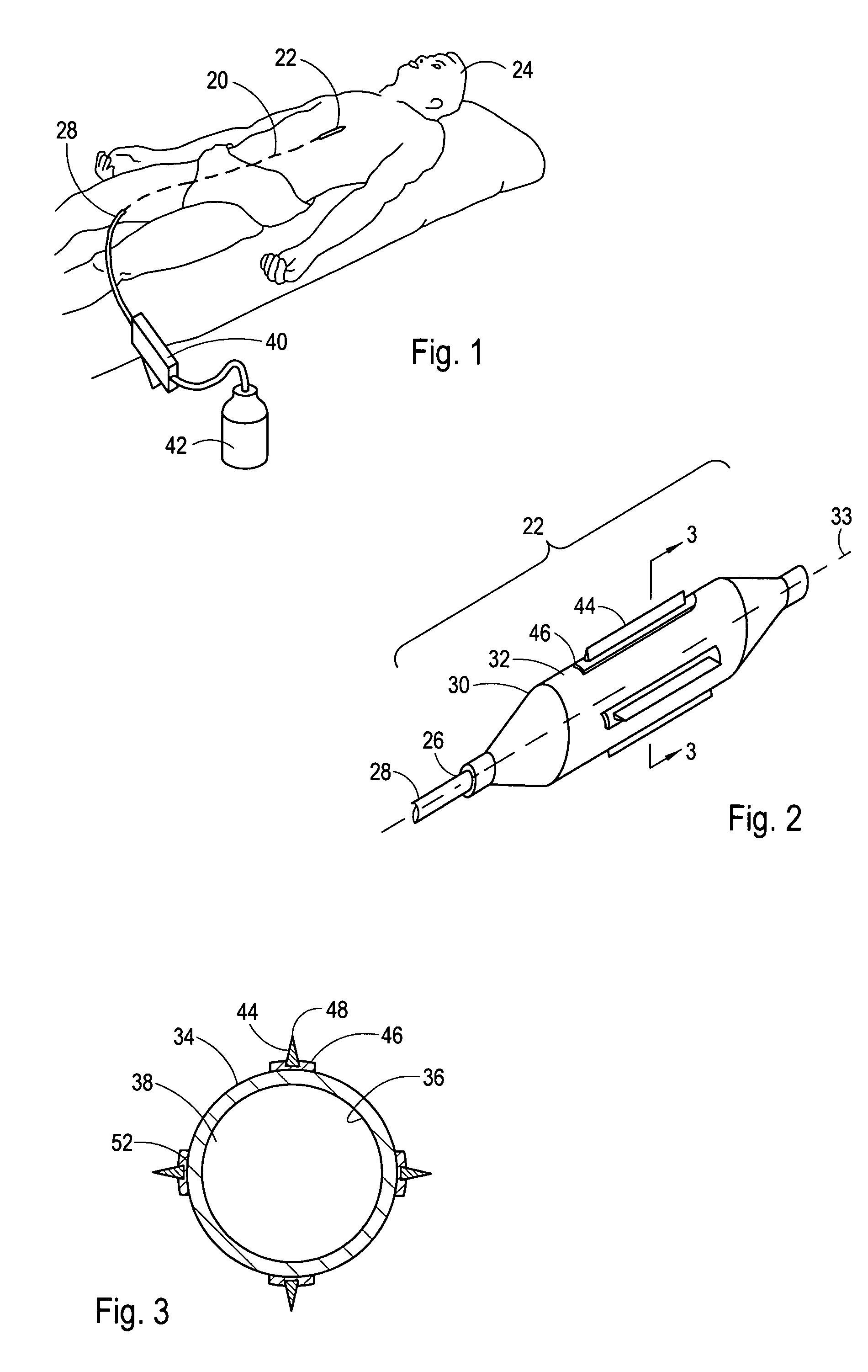

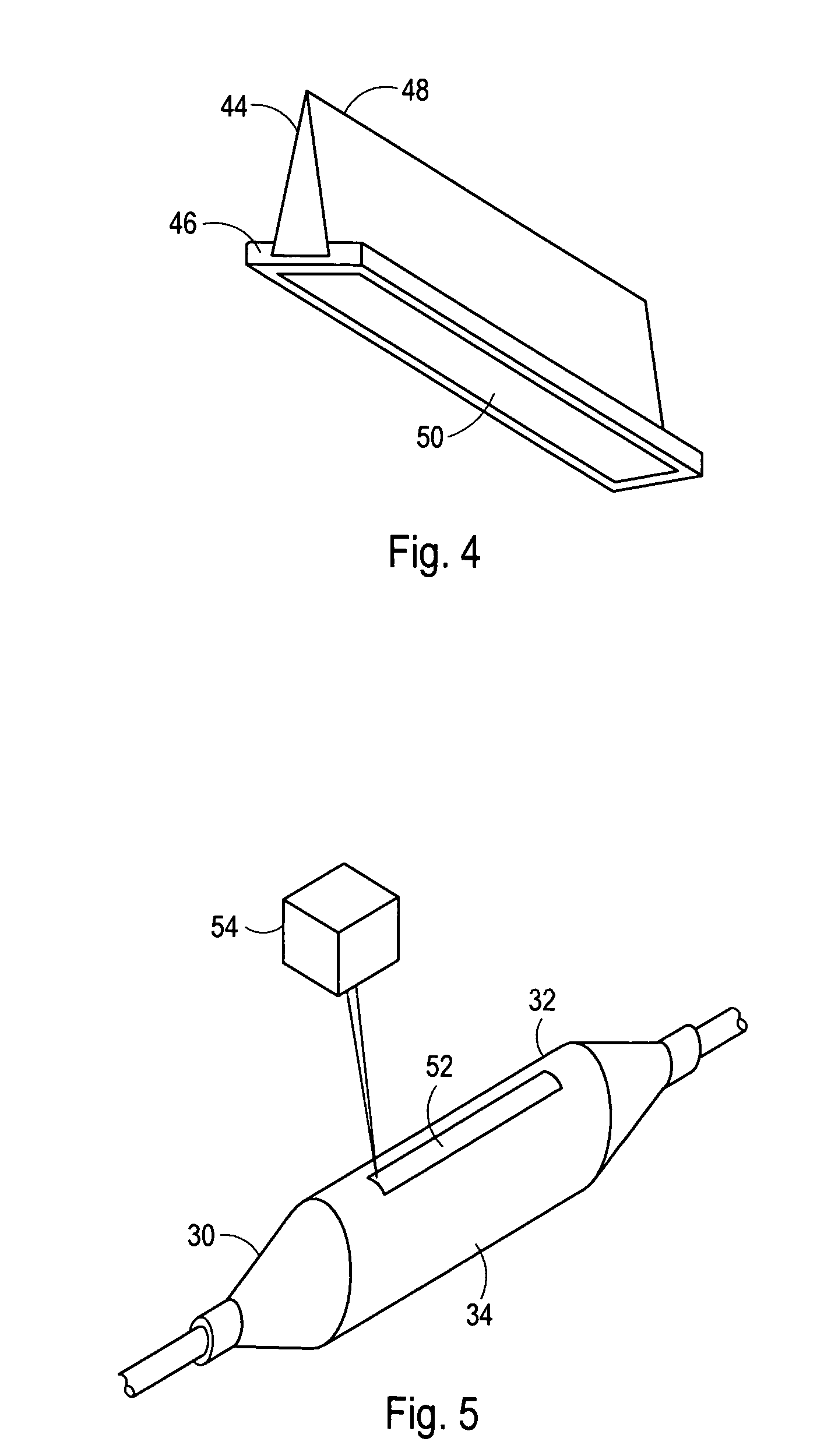

Textured balloons

A cutting balloon for use in PTCA and PTA procedures and methods for manufacturing cutting balloons are disclosed. One or more surfaces of the cutting balloon are formed with a non-smooth surface texture to improve adhesion between cutting blades and the inflatable balloon, to improve traction between the cutting balloon and the arterial wall, or to prevent inadvertent balloon perforation by a cutting blade. Textures, which can include a knurling texture and a nodular texture can be formed on the inflatable balloon surface directly using laser ablation. Alternatively, the texture can be formed on a mold surface used to mold the inflatable balloon from a parison. Mold surfaces can be textured using a laser photolithography process, sandblasting or a high-speed tool such as a diamond saw.

Owner:BOSTON SCI SCIMED INC

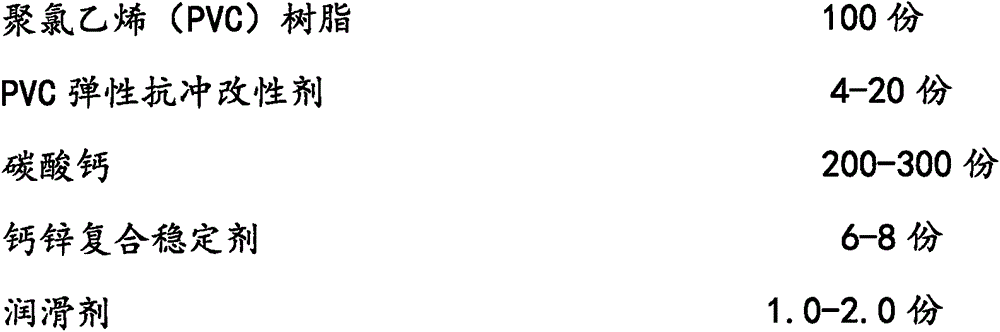

Novel PVC board and manufacturing method thereof

ActiveCN105295256ASimple processReduce production processConstruction materialCovering/liningsKnurlingPolyvinyl chloride

The invention provides a novel PVC (polyvinyl chloride) board and a manufacturing method thereof. The novel PVC board comprises a PVC transparent wearing layer, a PVC simulation pattern film layer and a PVC bottom layer from top to bottom, wherein the PVC bottom layer contains a PVC elastic anti-shock modifier; the PVC bottom layer, the PVC simulation pattern film layer and the PVC transparent wearing layer are together arranged between a first roller and a second roller, a composite layer is formed via rolling depression, and the composite layer is further treated to form the PVC board. By adopting the manufacturing method, production processes are reduced, the production efficiency is improved, the PVC board is firmer, and lines and knurling patterns are clearer and more attractive.

Owner:TAIZHOU HUALI PLASTIC

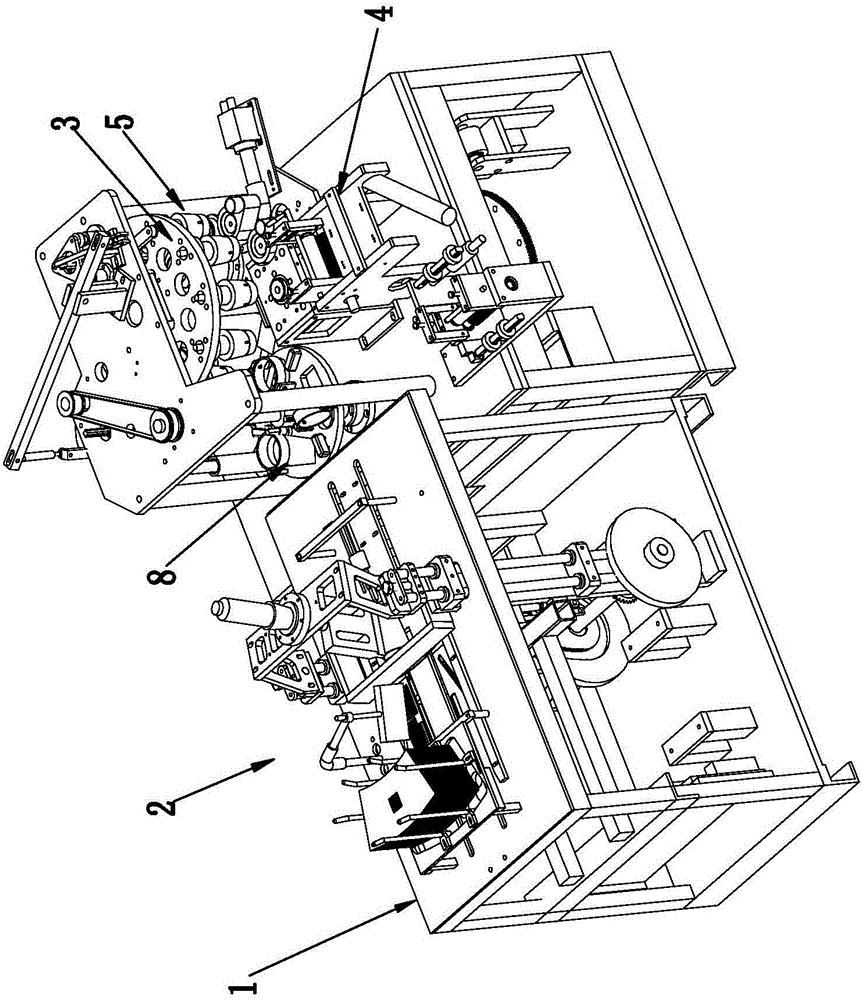

Fully automatic paper cup forming machine

The invention provides a paper cup machining apparatus and specifically provides a fully automatic paper cup forming machine. The fully automatic paper cup forming machine comprises a machine body, a cup body forming mechanism disposed on the machine body, a transfer rotating disc linked to the cup body forming mechanism, a cup bottom conveying mechanism, a cup body and cup bottom combining mechanism, a heating mechanism, a bottom folding mechanism, a knurling mechanism and a crimping assembly, wherein the cup bottom conveying mechanism, the cup body and cup bottom combining mechanism, the heating mechanism, the bottom folding mechanism, the knurling mechanism and the crimping assembly are arranged along the transfer rotating disc successively in order. A cup body steering mechanism is arranged between the cup body forming mechanism and the transfer rotating disc. The cup body steering mechanism comprises an adjusting rotating disc and at least two cup body holding sleeves disposed on the adjusting rotating disc and capable of turning on the adjusting rotating disc. The adjusting rotating disc is driven to rotate by a driving component. The adjusting rotating disc is provided with a turning component driving the cup body holding sleeves to turn. The fully automatic paper cup forming machine increases the machining efficiency, is high in cup body position adjusting speed and is simple in structure.

Owner:RUIAN MINGGUO MACHINERY CO LTD

Ground heating floor made of polymer alloy materials and preparation method thereof

ActiveCN103556796AImprove thermal conductivityHigh thermal conductivityCovering/liningsPolymer alloyHeat resistance

The invention discloses a ground heating floor made of polymer alloy materials and a preparation method thereof. The ground heating floor is structurally characterized in that the ground heating floor is of a three-layer composite structure, and specifically, a bottommost layer, i.e. a base layer, is a PVC (Polyvinyl Chloride)-based polymer alloy composite material layer; a middle layer is a co-extrusion composite decorative layer, and knurling treatment is performed on the surface of the middle layer; a co-extrusion process is adopted to the base layer and the middle layer, so as to form an integral structure once; a topmost layer is a UV (Ultraviolet)-treated transparent antibacterial wear-resisting layer. The preparation method comprises the following steps of (1) mixture and preparation of the base layer; (2) online co-extrusion lamination of the middle layer and the base layer; (3) online knurling treatment of the surface of the middle layer; (4) surface UV antibacterial wear-resisting treatment. The forming preparation process disclosed by the invention has the advantages of simple process and environmental friendliness; the floor has the advantages of high heat conductivity coefficient, high strength, heat resistance, flame retardance and no formaldehyde emission and has an antibacterial wear-resisting effect on the surface; the ground heating floor prepared by using the technique has good ground heating conductivity, dimensional stability, anti-fouling environmental friendliness and use durability.

Owner:安徽圣源橡塑科技有限公司

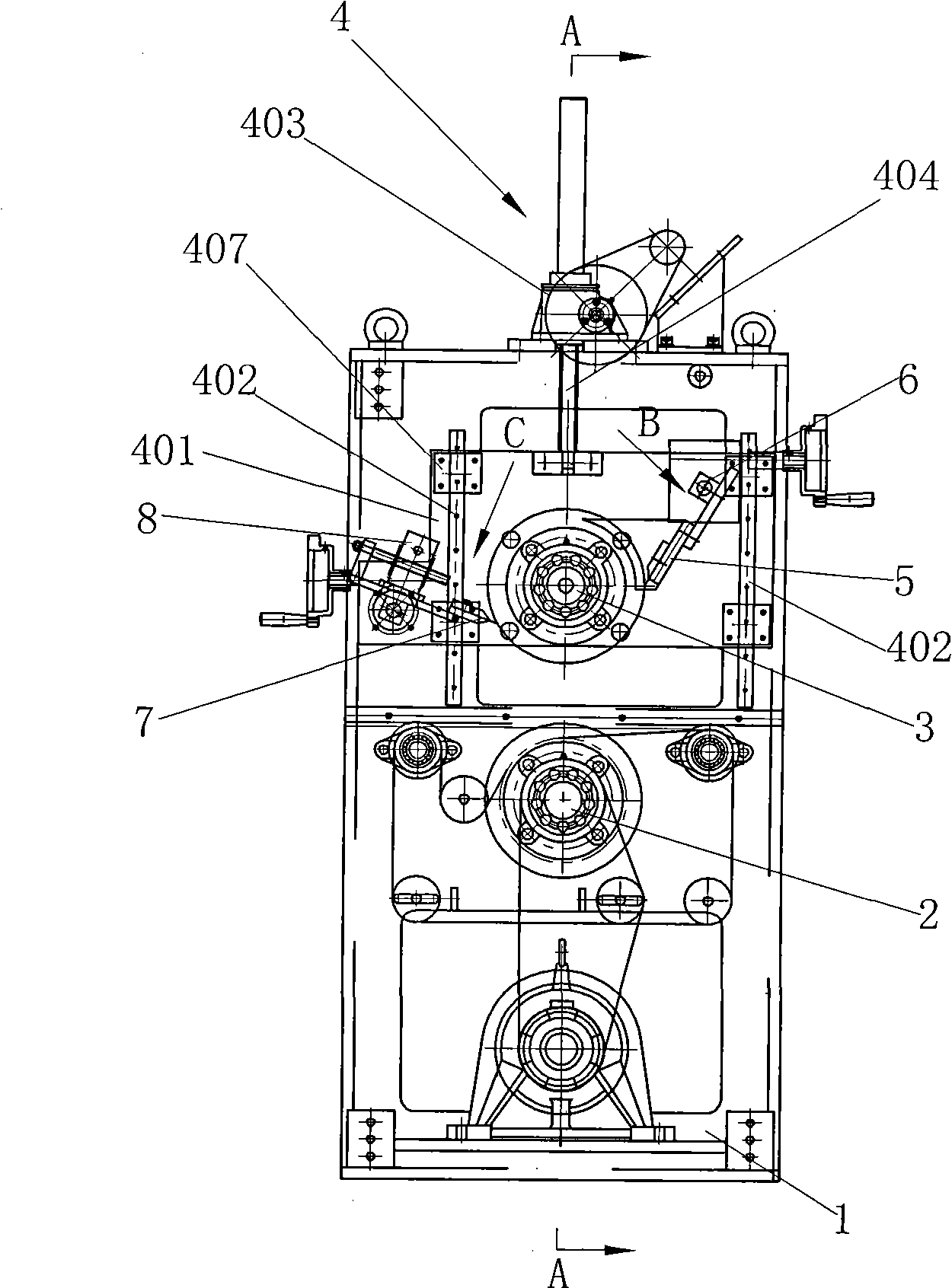

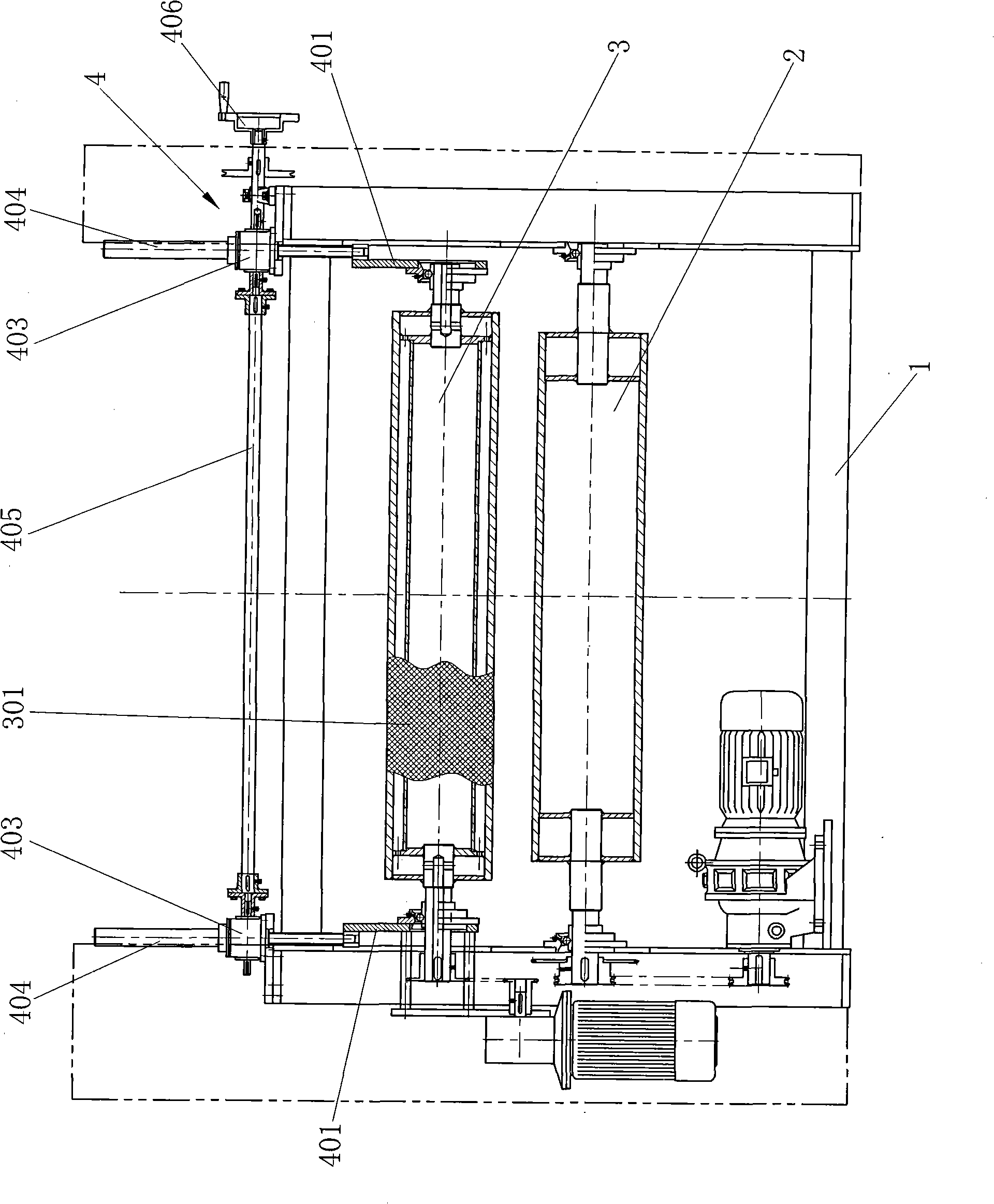

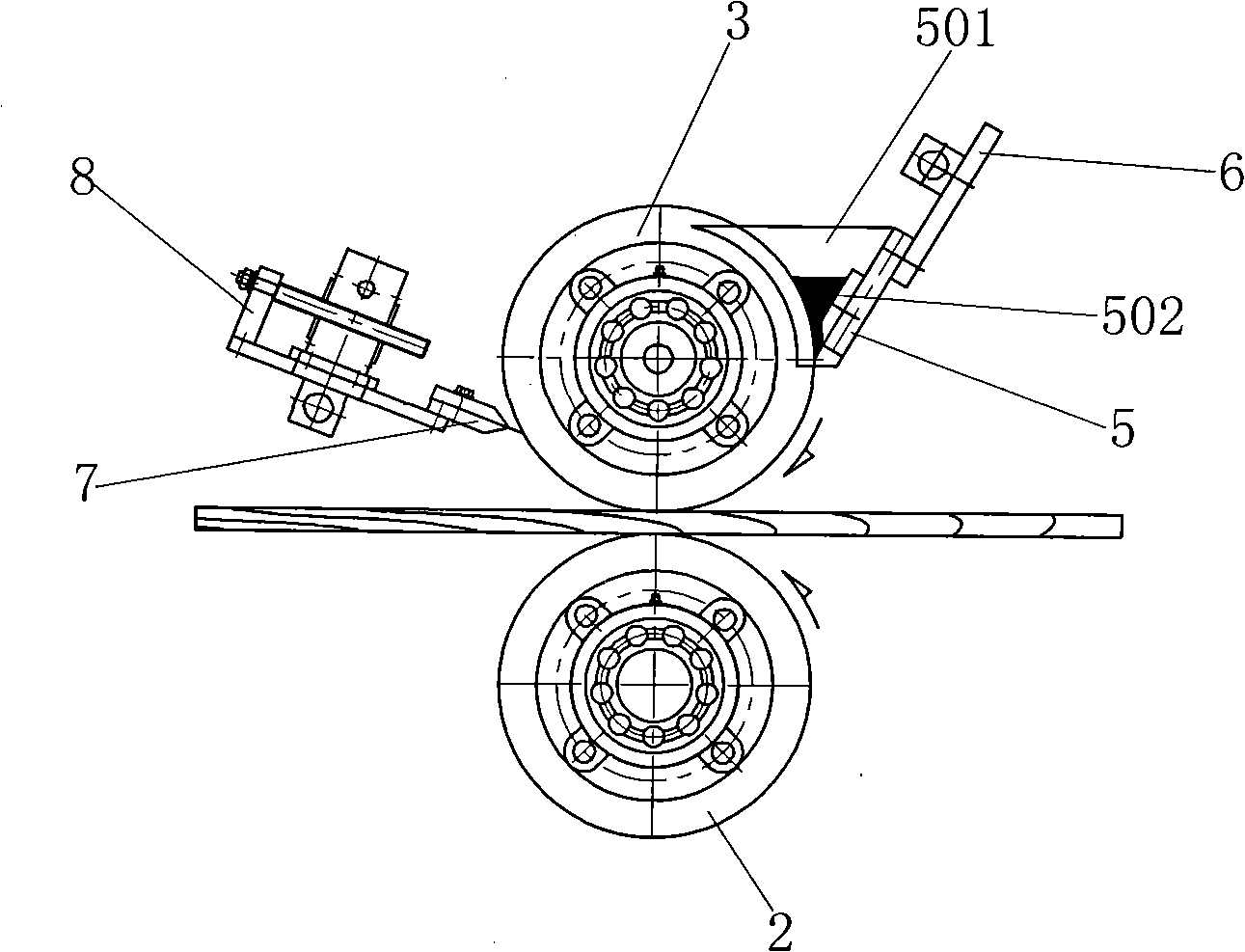

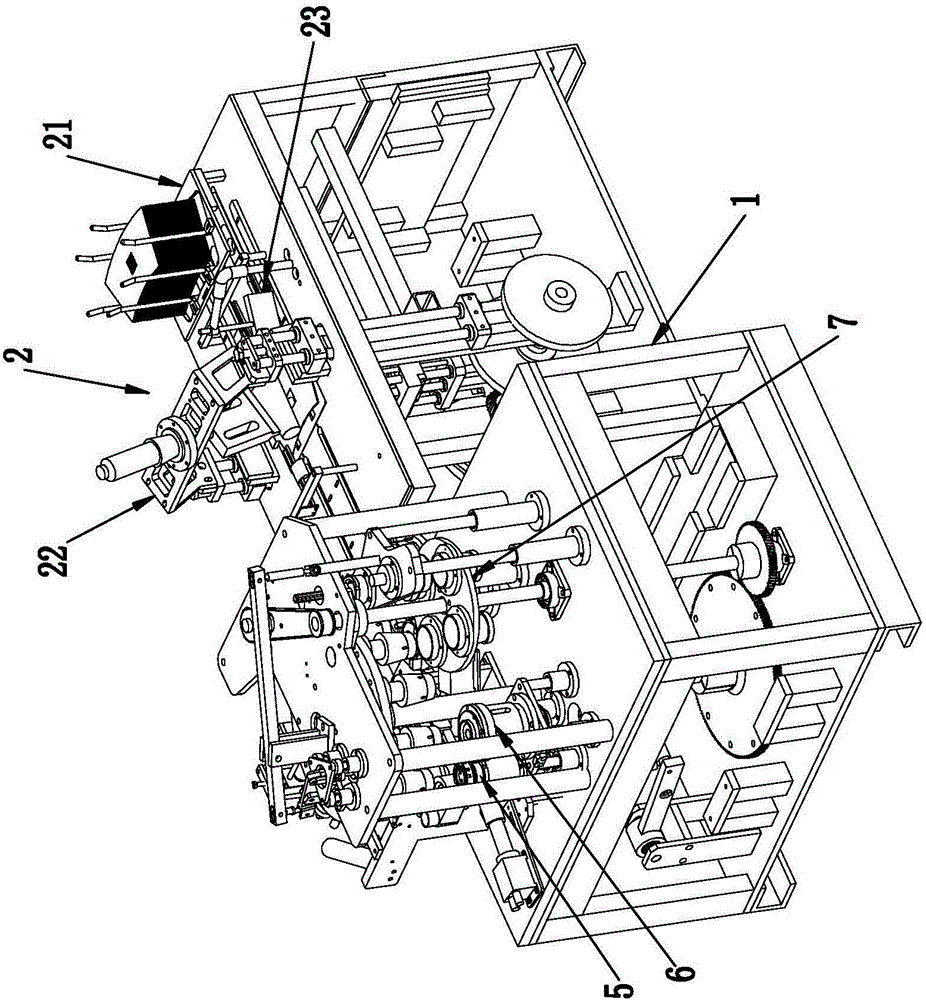

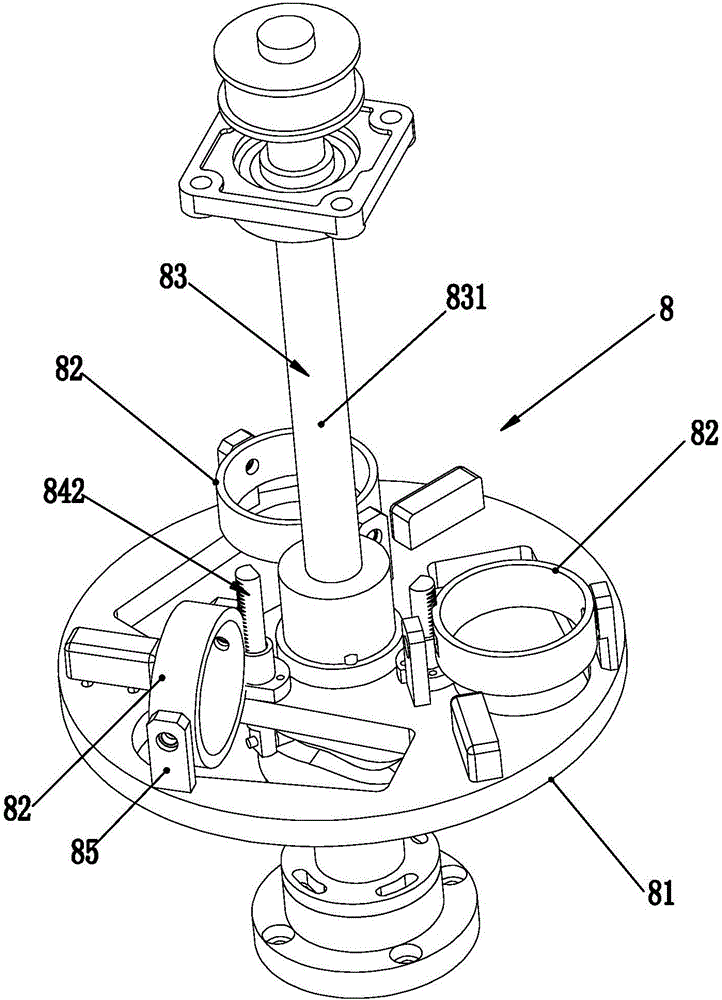

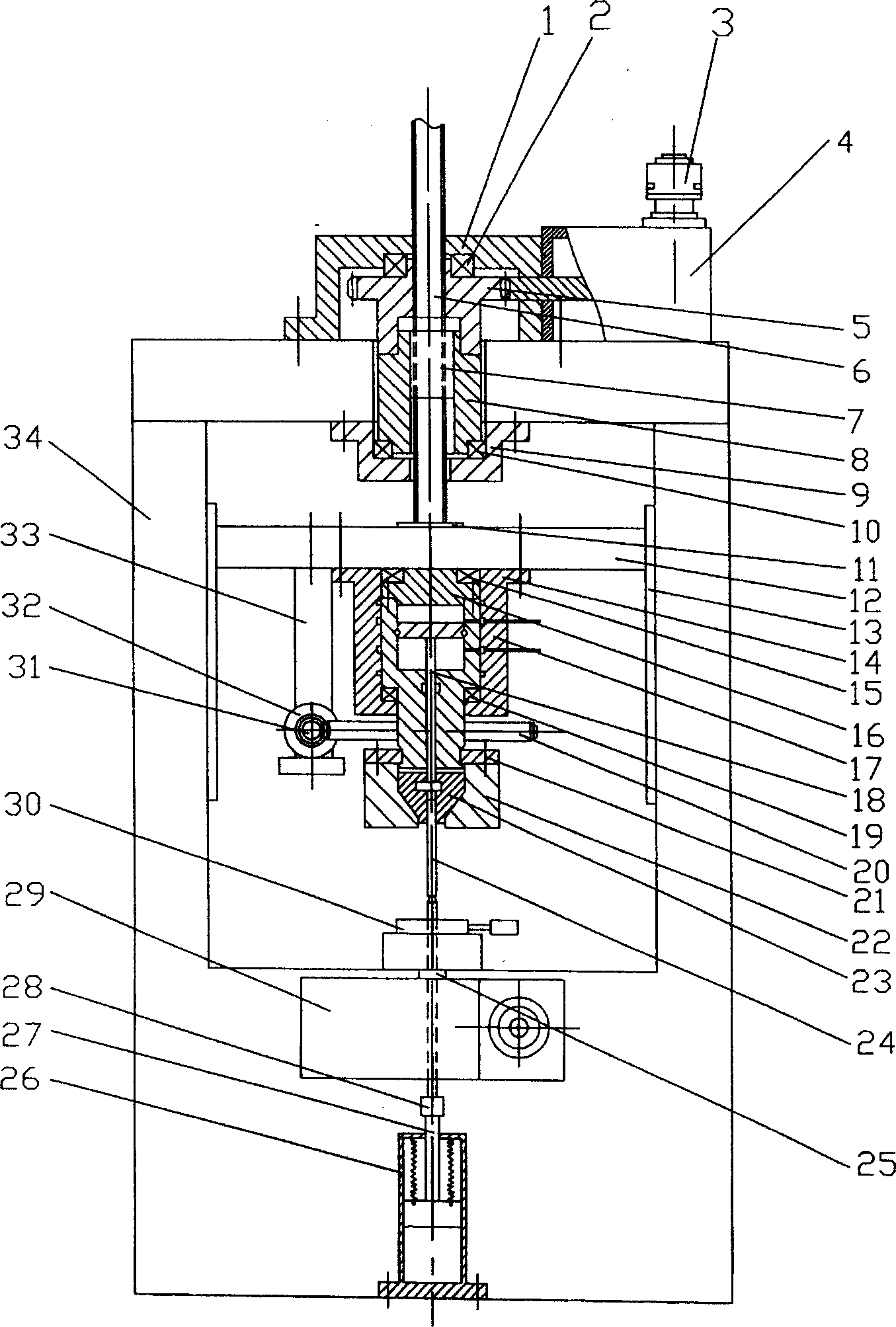

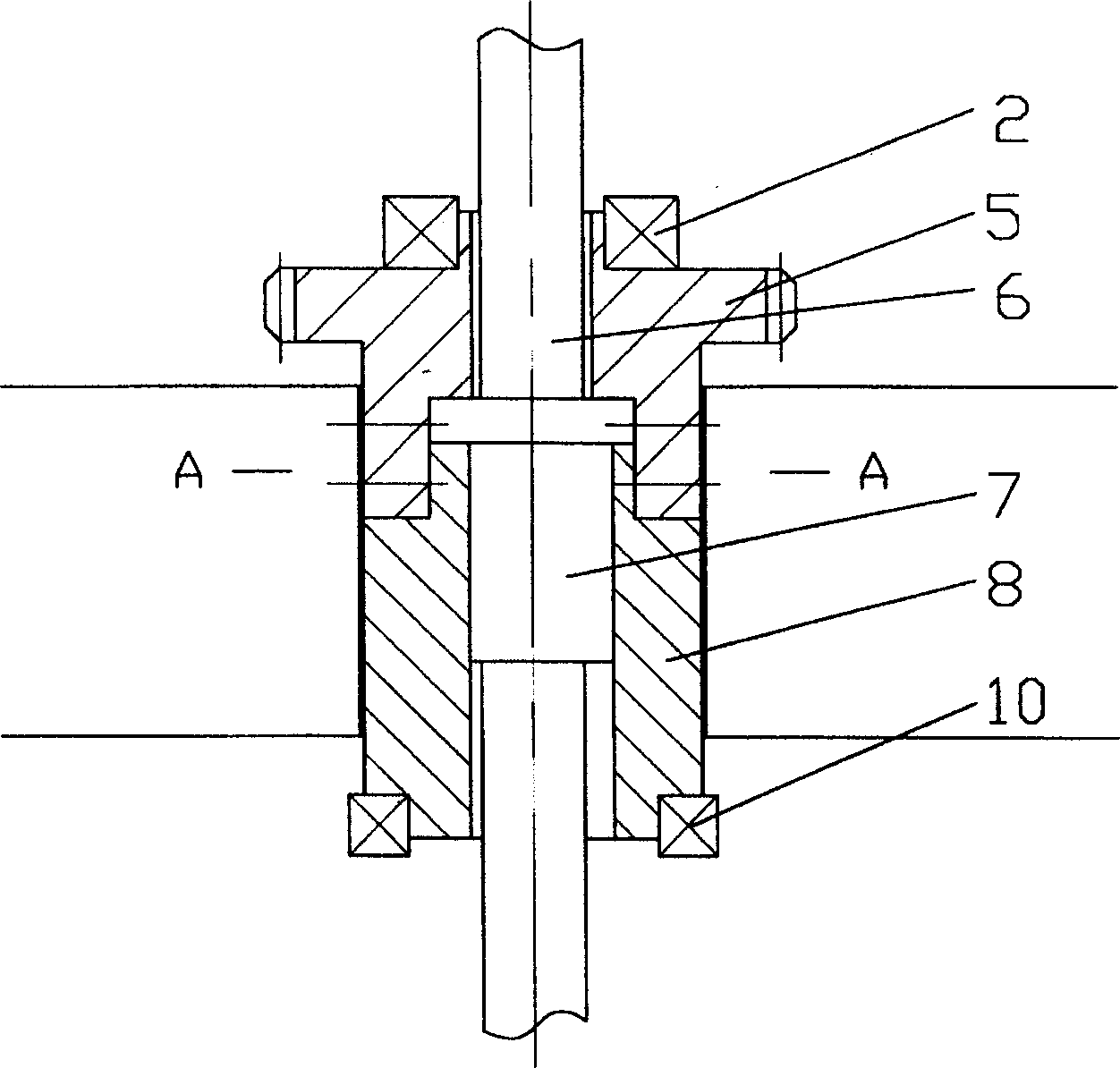

Assembling type axial cam knurling type connection automatic assembling machine

InactiveCN1433870APrecise processingEasy to processAssembly machinesMetal working apparatusGear driveBall screw

The assembled axial cam knurled connection automatic assembling machine relates to an automatic connection equipment of assembled axial cam. The driving mechanism of said equipment is mounted on the top portion of the machine frame, it utilizes motor, gearbox and driving gear connected with nut on the ballscrew to drive ballscrew and make it upward and downward move, said ballscrew is connected with slide block sliding on the leaner guideway, the clamp rotating mechanism includes oil cylinder, oil cylinder outer cover fixed on the slide block and clamping chuck placed in the lower end of oil cylinder, on the cylinder a driving gear driven by motor is fixed, its liftout guide mechanism is a hydraulic oil cylinder fixed on the machine frame base seat, said liftout guide bar is connected with piston, and can be freely rotated.

Owner:JILIN UNIV

Jacquard black-out cloth and production method thereof

InactiveCN102517753AKeep shadingKeep breathableSwivel-woven fabricsLappet-woven fabricsYarnPolyester

The invention discloses jacquard black-out cloth and a production method thereof. The method sequentially includes steps: firstly, selecting raw materials; secondly, preparing before weaving; thirdly, using a loom for weaving; fourthly, post-finishing; fifthly, checking and packaging, and the like. The jacquard black-out cloth is made of warps and wefts by means of jacquard weaving, the warps include face warps and inner warps, the wefts include face wefts and inner wefts which are made of polyester black yarns, the face warps and the face wefts are interwoven into a face layer, the inner warps serve as a middle layer, and the inner wefts serve as an inner layer. The jacquard black-out cloth reserves characteristics of traditional black-out cloth such as light shading, breathability, softness to touch and the like, new characteristics such as diversity in style, layer evidence, richness in color and the like are added through variation of colors and stitches, fabrics produced by the production method have stable patterns and various functions such as light adjusting, privacy protecting, ornamenting, heat insulating, sun blocking, sound insulating, dust filtrating and the like, production process is simple, environment pollution and energy consumption caused by knurling and printing are reduced, production cost is greatly reduced, and popularization and application of the jacquard black-out cloth and the proeduction method are facilitated.

Owner:ZHEJIANG SANZHI TEXTILES

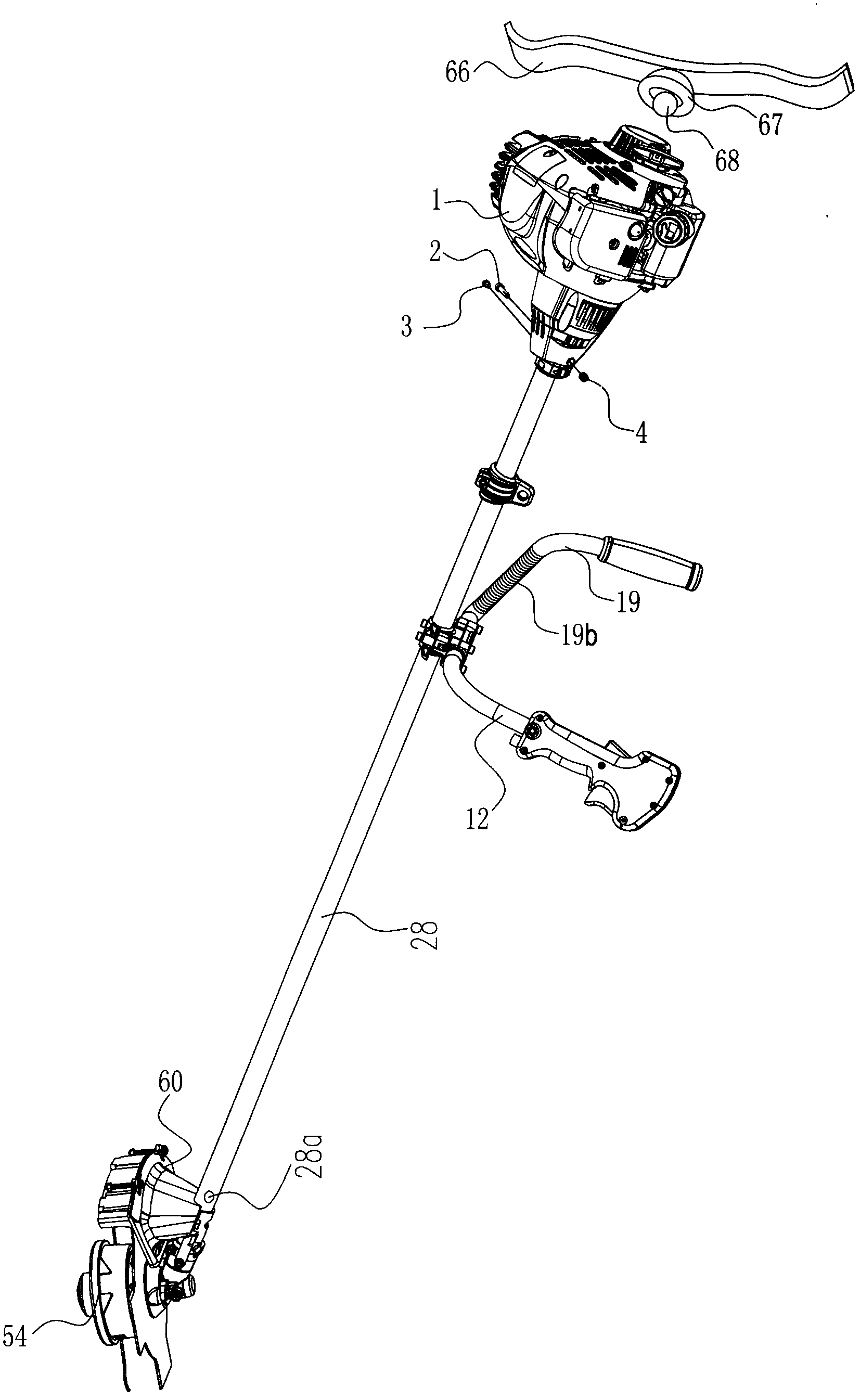

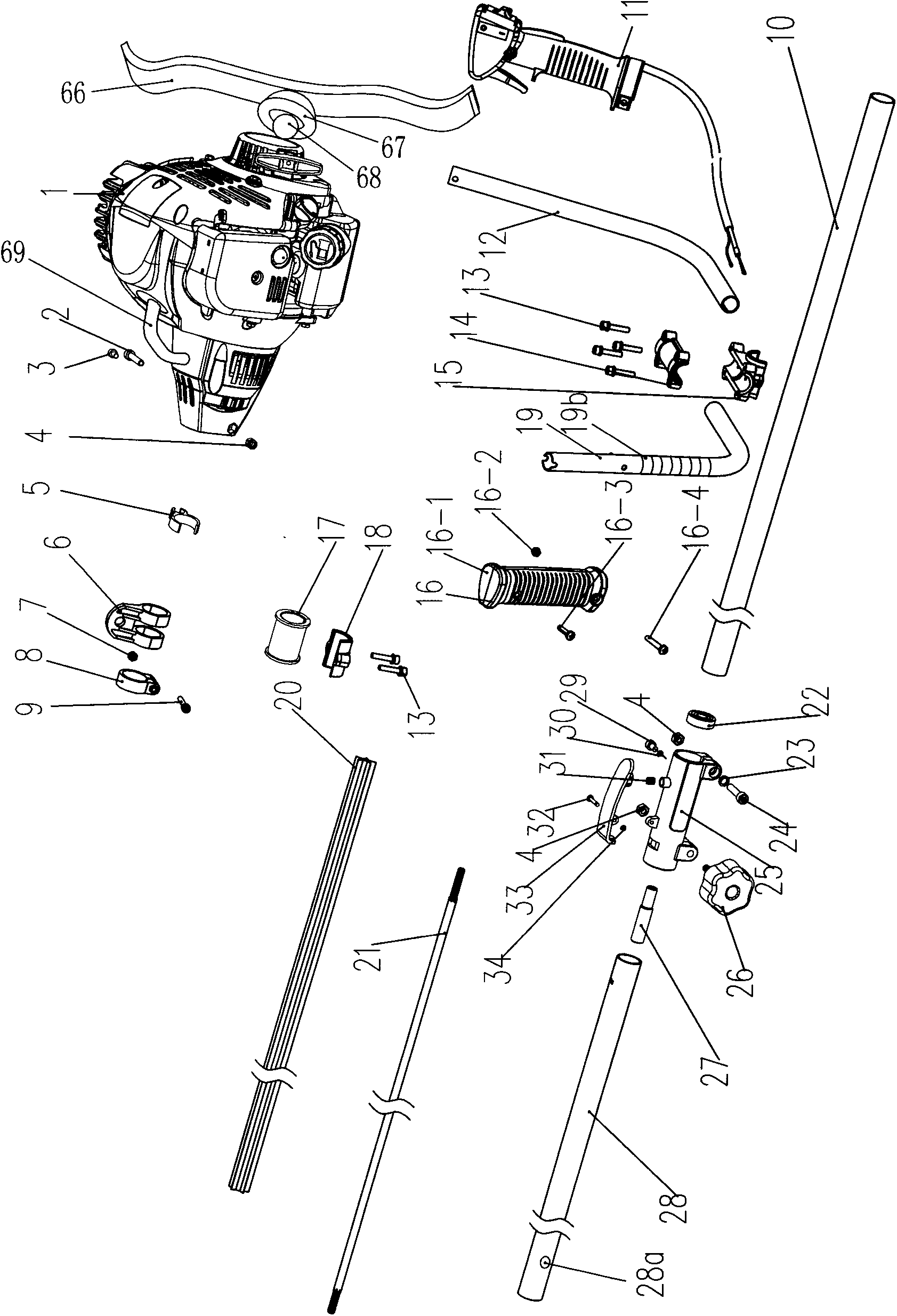

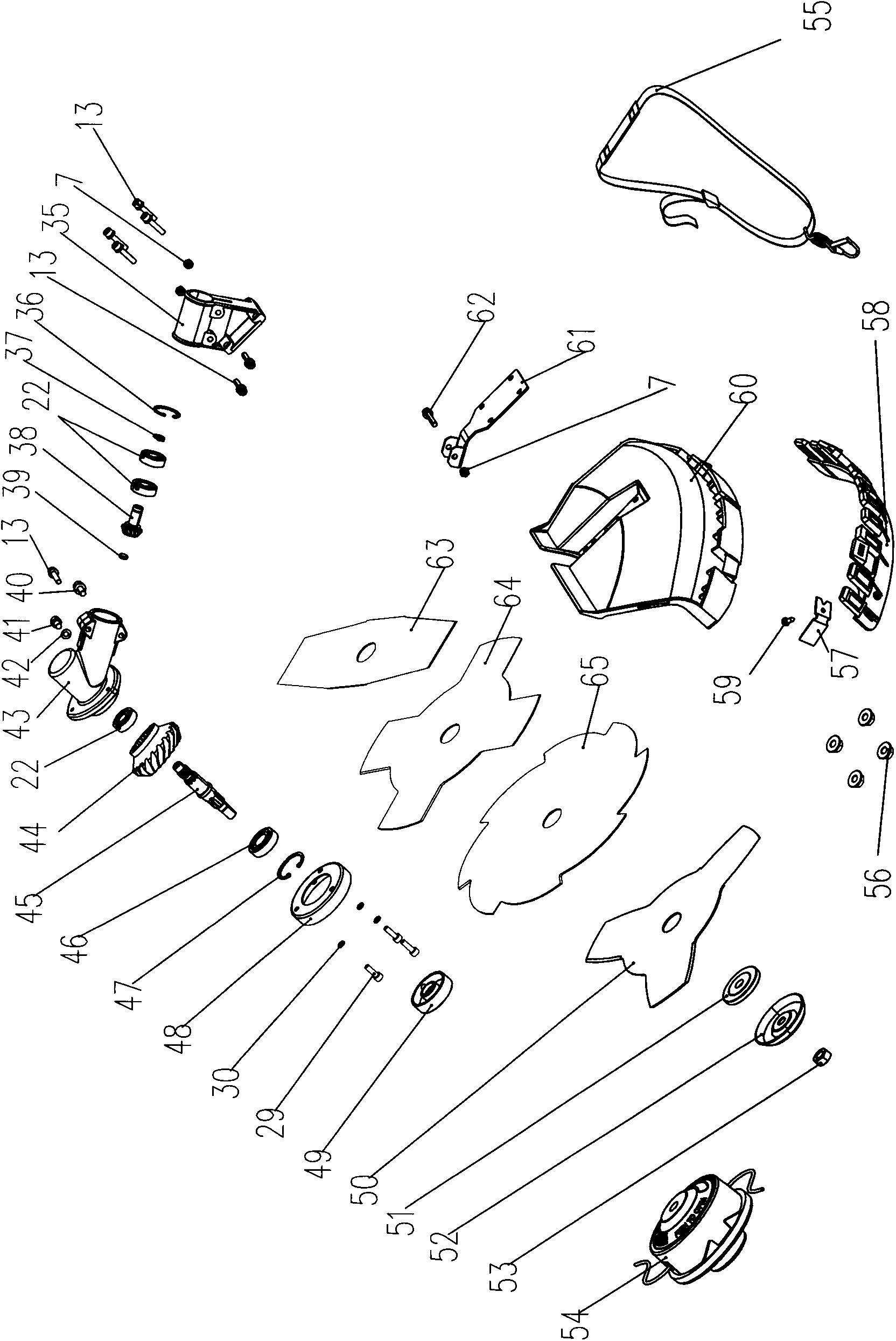

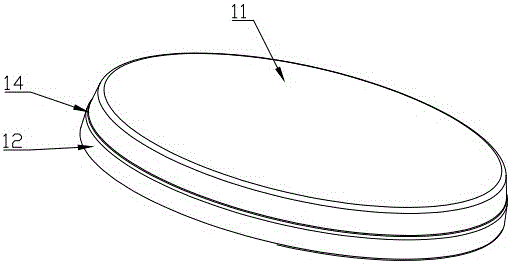

Low-emission gasoline brush cutter with lantern ring cutting function

The invention provides a low-emission gasoline brush cutter with a lantern ring cutting function, which can save energy, reduce emission, improve cutting, enhance a soil moisture conservation effect and beautify patterns of grasslands, and has improved durability and improved quality. A special cutting device of the low-emission gasoline brush cutter is provided with three lantern rings (75) for cutting, each lantern ring is provided with a cutting edge, one lantern ring (75) is concentric to a grass pruning head (54), a pair of symmetric hitches (76) are arranged on the lantern ring (75) and the grass pruning head (54), and the hitches (76) are provided with the other two lantern rings (75) with cutting edges for throwing cutting. The lantern rings (75) with the cutting edges can perform revolution along with a cutting shaft for cutting and also can perform random autorotation for performing sliding cutting, so that the cutting effect is guaranteed, durability is achieved since an autorotation wheel changes the cutting edges, and the conception is ingenious; an air cylinder is additionally provided with a back-flow plate, a piston is additionally provided with a skirt rim, a steel wire rope is adopted for stack cutting and grass pruning, the low-emission gasoline brush cutter with a carburetor realizing gap atomization at the throat is provided with a cutting knife disc with inner saw teeth, and a long grass pressing wheel (74) is arranged for performing grass pressing for preserving soil moisture and is applied to knurling on the ground; the carburetor is provided with a multiple-branch nozzle, realizes gap atomization at the throat and is matched with various measures, and therefore, the quality and the use convenience of the low-emission gasoline brush cutter are promoted.

Owner:NINGBO DAYE GARDEN EQUIP

Paper cup cover and processing technology thereof

ActiveCN106335702ASimple structureEasy to processPaper/cardboard articlesBox making operationsCompression moldingKnurling

A paper cup cover and a processing technology thereof are characterized in that the paper cup cover is of an integrated structure; the processing technology of the paper cup cover comprises the steps of material taking, compression molding, bottom folding and knurling; the structure of the paper cup cover comprises a circular top part and an annular side part surrounding the bottom; a step is formed in the middle section of the annular side part; and the bottom of the annular side part is provided with a flanging which is folded inwards and tightly attached to the inner wall of the annular side part. The paper cup cover and the processing technology thereof have the advantages that the paper cup cover is integrally formed, the structure and the processing technology are simple, and the paper cup cover can be matched with a paper cup better.

Owner:瑞安市贝斯特机械有限公司

Box with a base resistant to opening and having portions thereof breakable to prevent the box from being reclosed after initial opening thereof

Owner:GI BI EFFE

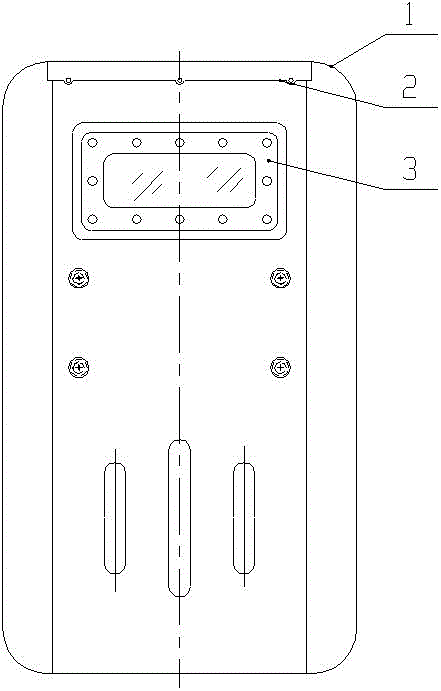

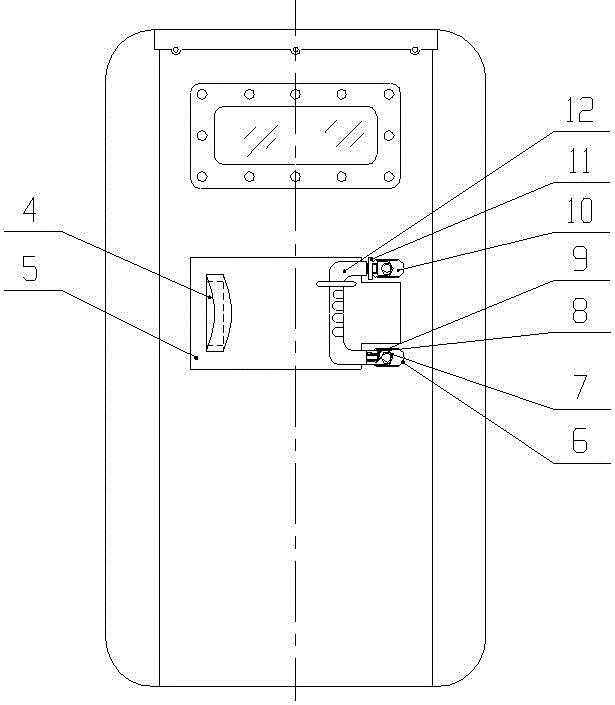

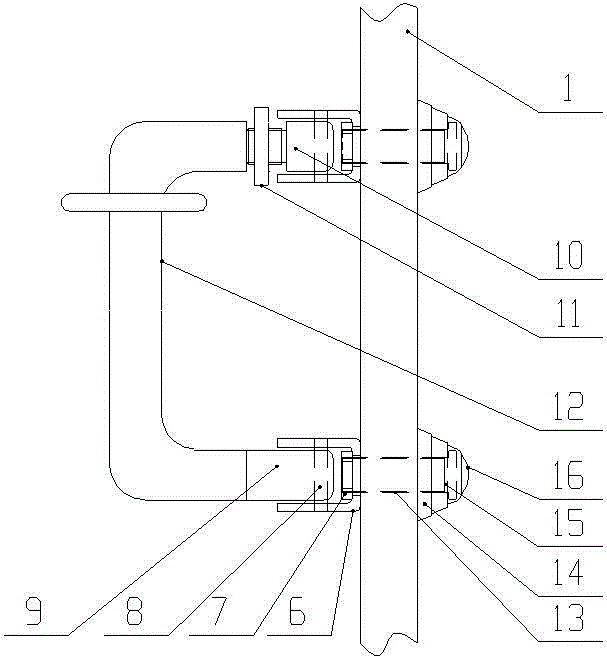

Folding grip shield

The invention discloses a folding grip shield. The middle of the back of the shield is provided with a buffer layer; the buffer layer is adhered to the shield by adhesive; the upper left side of the buffer layer is provided with a longitudinal fixing band; the right side of the buffer layer is provided with two longitudinal fixing brackets; a grip is fixedly connected with the fixing brackets by a rotary long joint, a rotary short joint and a rotary pin; the rotary short joint can rotate in the C-shaped groove of the corresponding fixing bracket around the rotary pin; a junction of the top of the grip and the rotary short joint is provided with a knurling non-return sleeve; the knurling non-return sleeve can rotate to the notch of the C-shaped groove of the corresponding fixing bracket and compress to fix the grip; the bottom of the grip is in threaded connection with the rotary long joint; the rotary long joint can rotate in the C-shaped groove of the corresponding fixing bracket around the rotary pin. The folding grip shield has the advantages of reasonable structure, flexibility in use, storage space saving and transportation cost saving, the wrist position of a user can be protected, and the angle of the grip can be regulated according to the habits of the user.

Owner:JIANGSU WUWEI POLICE EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com