Novel PVC board and manufacturing method thereof

一种PVC板、制造方法的技术,应用在化学仪器和方法、地板覆盖、建筑物构造等方向,达到环保性能优、减少生产工序、纹路和压花清晰的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

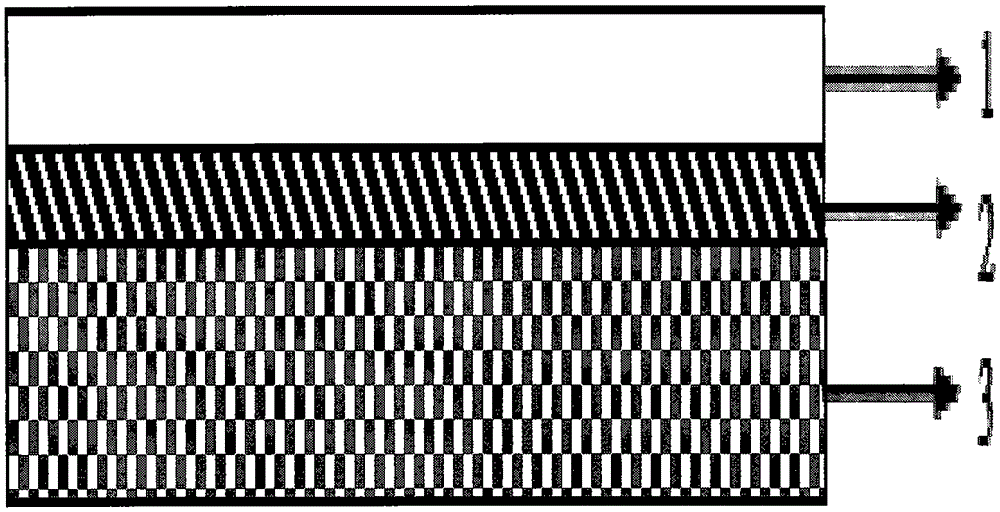

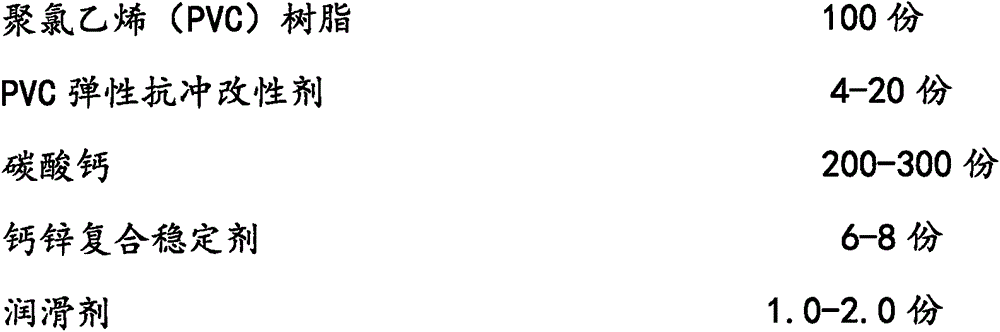

[0033] A new type of PVC board is characterized in that the new type of PVC board is respectively composed of a PVC transparent wear-resistant layer, a PVC simulated pattern film layer and a PVC bottom layer from top to bottom. The PVC bottom layer is a PVC solid layer, and the PVC solid layer uses polyvinyl chloride (PVC) resin, PVC elastic impact modifier, calcium carbonate, calcium-zinc composite stabilizer and lubricant, and the specific components and parts by weight are: polyvinyl chloride 100 parts of ethylene (PVC) resin, 4-20 parts of PVC elastic impact modification, 200-300 parts of calcium carbonate, 6-8 parts of calcium-zinc composite stabilizer, 1.0-2.0 parts of lubricant.

Embodiment 2

[0035] A new type of PVC board is characterized in that the new type of PVC board is respectively composed of a PVC transparent wear-resistant layer, a PVC simulated pattern film layer and a PVC bottom layer from top to bottom. The PVC bottom layer is a PVC micro-foaming layer. The PVC micro-foaming layer uses polyvinyl chloride (PVC) resin, PVC elastic impact modifier, calcium carbonate, calcium-zinc composite stabilizer, foaming agent, foaming regulator and lubricant. agent, the specific components and parts by weight are: 100 parts of polyvinyl chloride (PVC) resin, 4-20 parts of PVC elastic impact modifier, 150-300 parts of calcium carbonate, 6-8 parts of calcium-zinc composite stabilizer, hair Foaming agent 0.2-1.0 parts, foam regulator 4-8 parts, lubricant 1.0-2.0 parts.

Embodiment 3

[0037] The manufacturing method of a kind of new-type PVC plate of embodiment 1, 2 is: put the PVC bottom layer, the PVC emulation pattern film layer and the PVC transparent wear-resistant layer together between the head roller and the second roller, form a composite layer by rolling, and the composite layer It is further processed to form PVC panels. The method for further processing the composite layer includes: placing the composite layer between the second roll and the third roll for further hot rolling. Among them, the head roll is preferably a composite smooth roll, the second roll is preferably an embossed roll, and the third roll is preferably a textured roll. After the composite layer is hot-rolled, the surface of the PVC transparent wear-resistant layer forms a simulated pattern, and the bottom surface of the PVC bottom layer forms a bottom. pattern.

[0038] The method for forming the PVC bottom layer is as follows: according to the raw materials of the PVC bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com