Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

836results about How to "Clear texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood antiquing agent and application thereof

InactiveCN103817758AFast penetrationSimple processWood treatment detailsWood impregnation detailsFiberMaterials science

The invention provides a wood antiquing agent, which is prepared by mixing the following raw materials in percentage by mass: 1 to 10 percent of K2CO3, 0.1 to 1 percent of KMnO4 and the balance of water. The wood antiquing agent can rapidly permeate in wood fibers to give an ancient feeling after the surface of wood is brushed, spray-coated or impregnated with the wood antiquing agent, so that the added value of a product is increased; a process is simple, and the wood antiquing agent is low in cost, and can be widely applied to the manufacturing and repair of ancient furniture, ancient wooden crafts and ancient building door and window components.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Ultra fine soft wool yern and its production method

The present invention provides a superfine flexible wool yarn. It is characterized by that in the described yarn 60%-95% of superfine wool and 5%-40% of acrylic fiber, its single twist is 460-1200 twist / m, yarn number is 26-68 metric counts, the wool fibre length in the described yarn is 35mm-68mm, the wool fibre fineness is 22.6-15.5mic, and the acrylic fiber length is 35mm-68mm. Said invention also provides its production method and concrete steps.

Owner:顾民强 +3

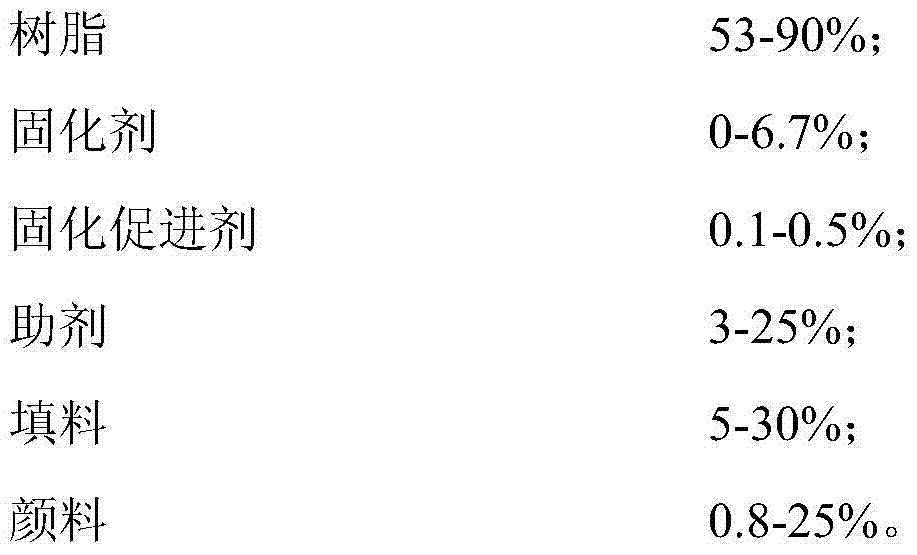

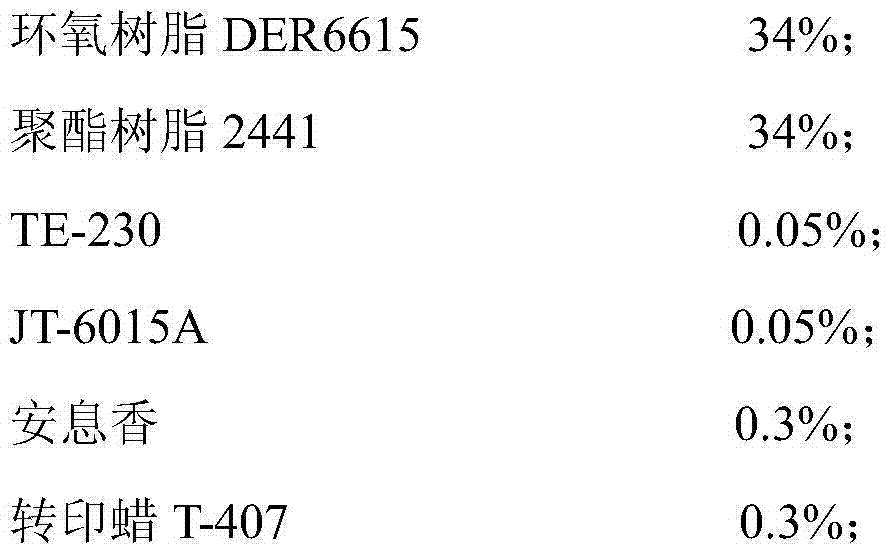

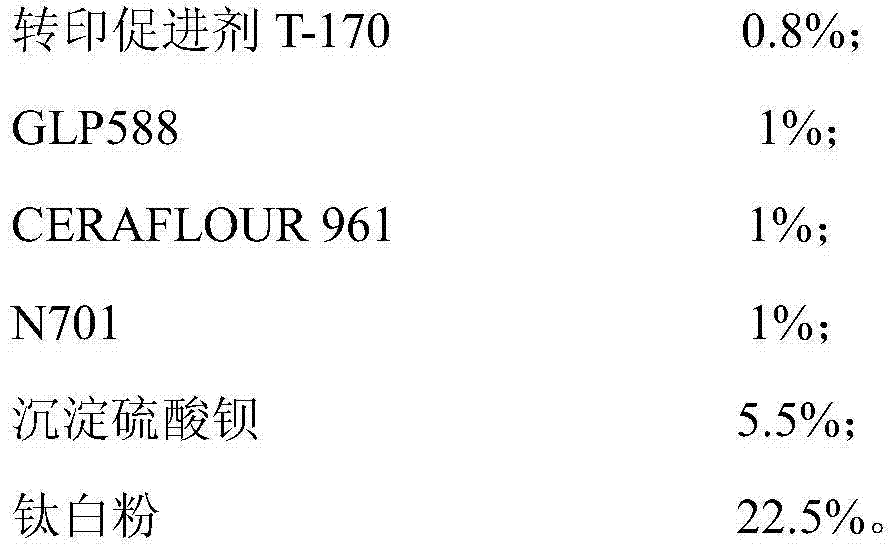

Powder coating for MDF transfer printing and application method of powder coating

PendingCN104497808AImprove texture clarityEasy to tear offDuplicating/marking methodsPowdery paintsWeather resistanceWear resistance

The invention relates to powder coating and particularly relates to powder coating for MDF transfer printing and an application method of the powder coating. The powder coating is prepared from the following raw materials in percentage by weight: 53-90% of resin, 0-6.7% of a curing agent, 0.1-0.5% of a curing accelerant, 3-25% of auxiliaries, 5-30% of filler and 0.8-25% of pigment. After the powder coating is used for transfer printing, the texture is clear, the penetration is deep, the third dimension is strong, the transfer printing paper can be easily uncovered, the thermal transfer printing product is durable in use, and the patterns are not dropped, cracked or faded; moreover, the thermal transfer printing only achieves a surface decoration effect without changing the characteristics of the original glossiness, the wear resistance, the weather resistance, the acid and alkali resistance, and the like of the product. The invention also provides an application method of the powder coating.

Owner:山东朗法博粉末涂装科技有限公司

Full polish ceramic product and preparation method thereof

The invention relates to a full polish ceramic product and a preparation method thereof. The full polish ceramic product comprises a ceramic green body and a full polish layer outside the ceramic green body, wherein the full polish layer mainly comprises powder which comprises following components by weight percent: 42-62% of albite, 2-7% of potash feldspar, 0-4% of dolomite, 4-8% of calcite, 0-2% of barium carbonate, 6-8% of aluminum oxide, 3-5% of fired talc, 2-4.6% of zinc oxide, 3-9% of quartz powder, 0.5-2.5% of soochow kaolin, 1-6% of calcined kaolin, 5-10% of aedelforsite, 0.1-3.0% of spodumene, and 0.1-2.8% of borocalcite. The full polish slurry is prepared by burdening and ball milling once. As the full polish slurry contains less wearproof materials like aluminum oxide, the ball milling time is short, and the production efficiency is higher; due to the addition of little amount of spodumene and borocalcite, the abrasion performance and hardness of the fired full polish ceramic product can be improved.

Owner:JIANGSU BAIFU TECH CO LTD +1

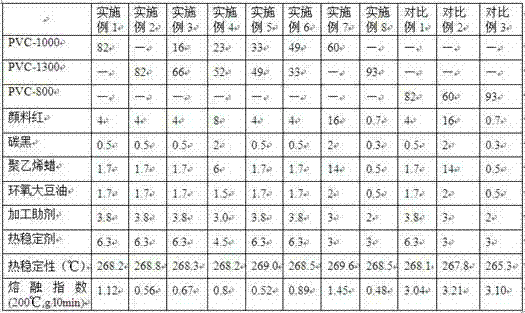

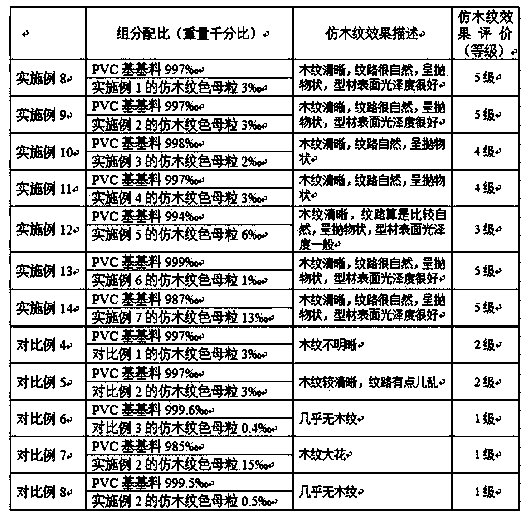

Wood-grain-like color master batch, and preparation method and application thereof

The invention discloses a wood-grain-like color master batch which comprises the following components in percentage by weight: 60-93% of PVC (polyvinyl chloride) resin, 1-18% of pigment, 0.5-14% of dispersant and 3-15% of other assistant. The preparation method comprises the following steps: a) proportionally mixing the components in a high-speed mixer; and b) carrying out melt blending extrusion on the mixture with a single screw extruder at the screw bolt speed of 14-27RPM at the melting temperature of 120-170 DEG C, uniformly dispersing the pigment in the carrier resin through the shearing and compounding of the screw bolt, naturally cooling, granulating, and airing to obtain the wood-grain-like color master batch. The wood-grain-like color master batch has the advantages of low toner consumption, favorable temperature tolerance and excellent dispersibility; when being used for preparing a wood-grain-like wood-plastic composite material, the wood-grain-like color master batch is easy to operate and control and has favorable compatibility with the PVC-based base material; the wood-grain-like wood-plastic composite material has highly simulated wood appearance, natural and clear grains, bright surface color and favorable wood-grain-like effect, and thus, is an ideal wood-like wood-plastic product.

Owner:KINGFA SCI & TECH CO LTD +2

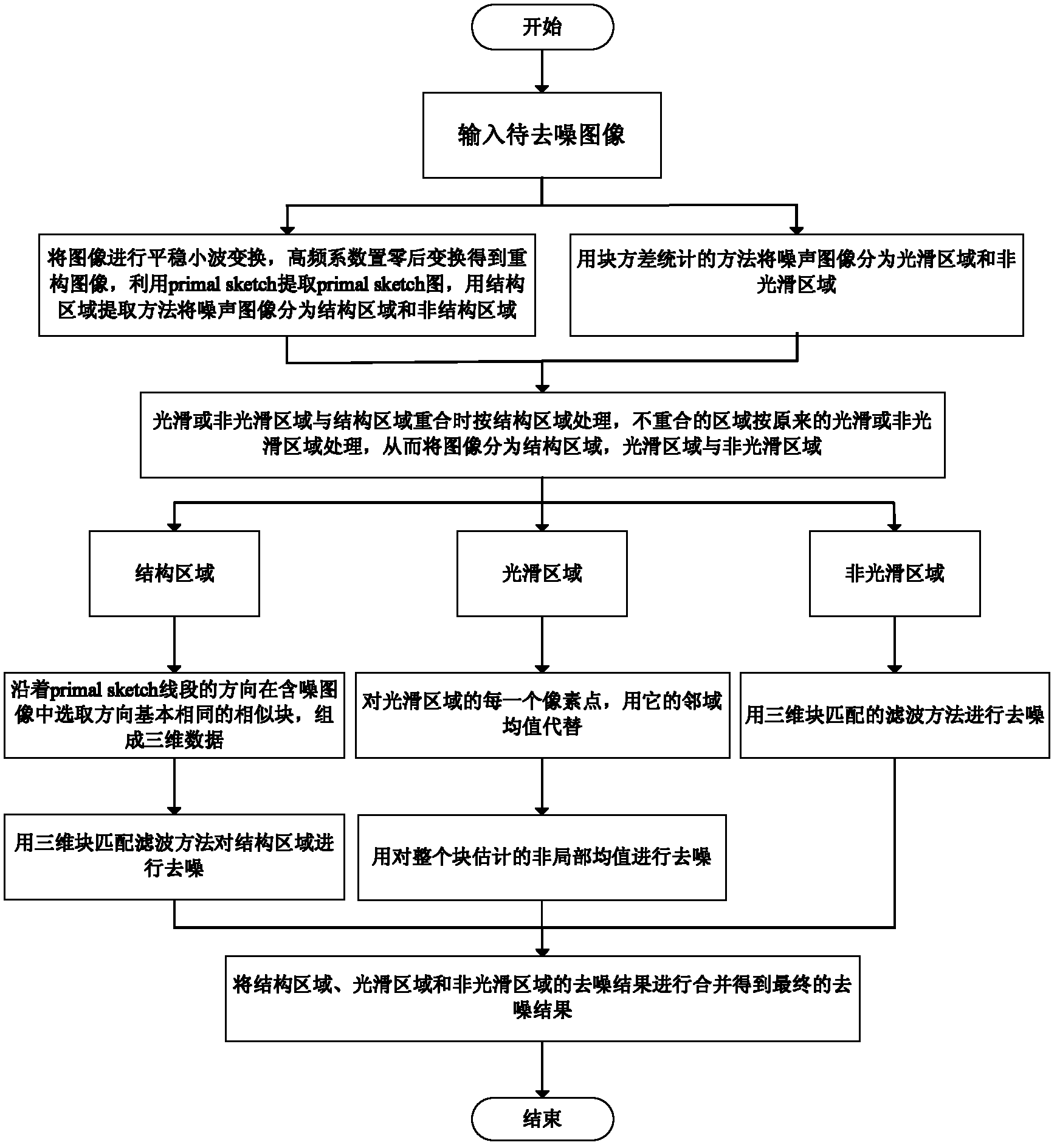

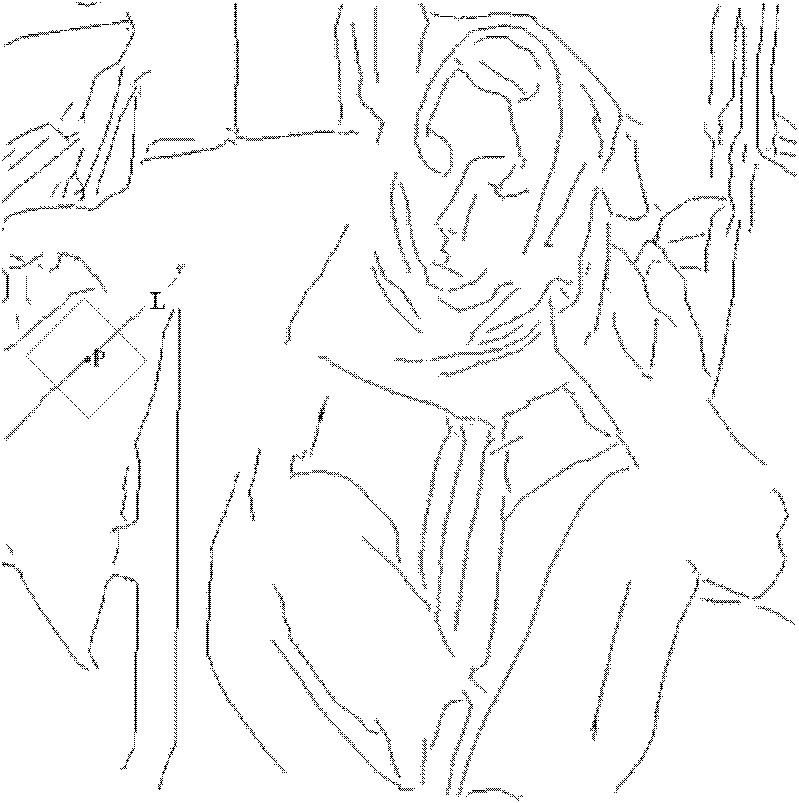

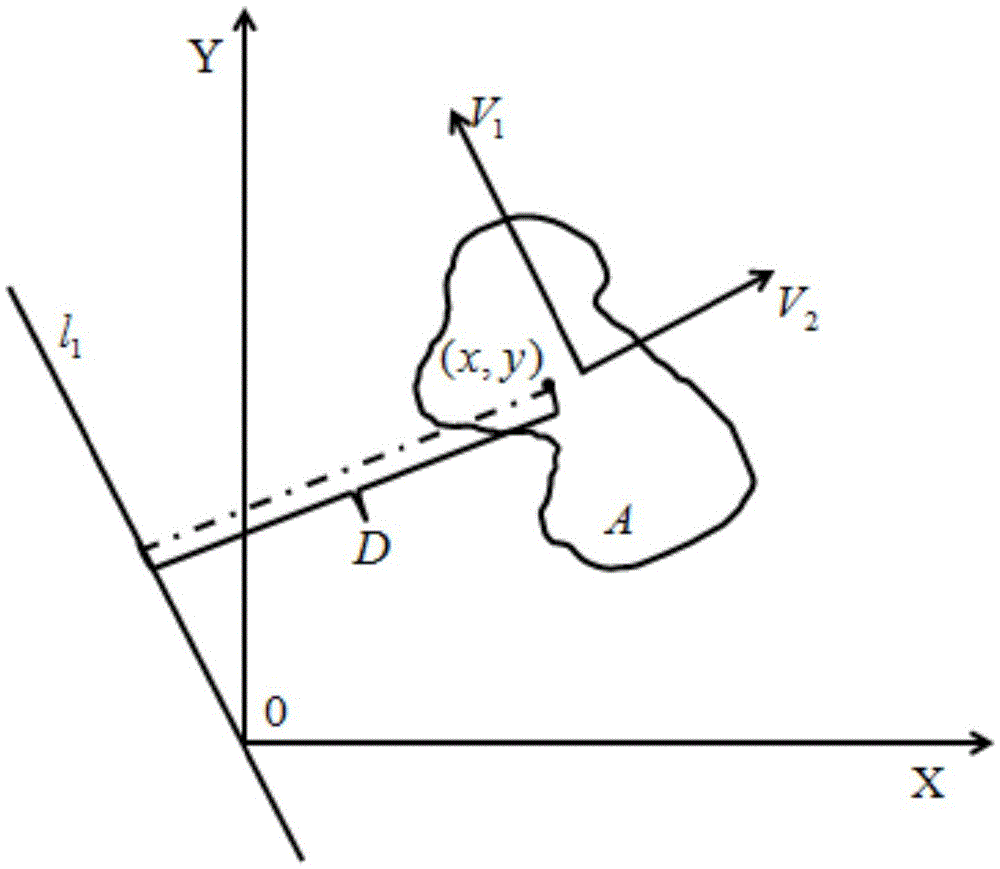

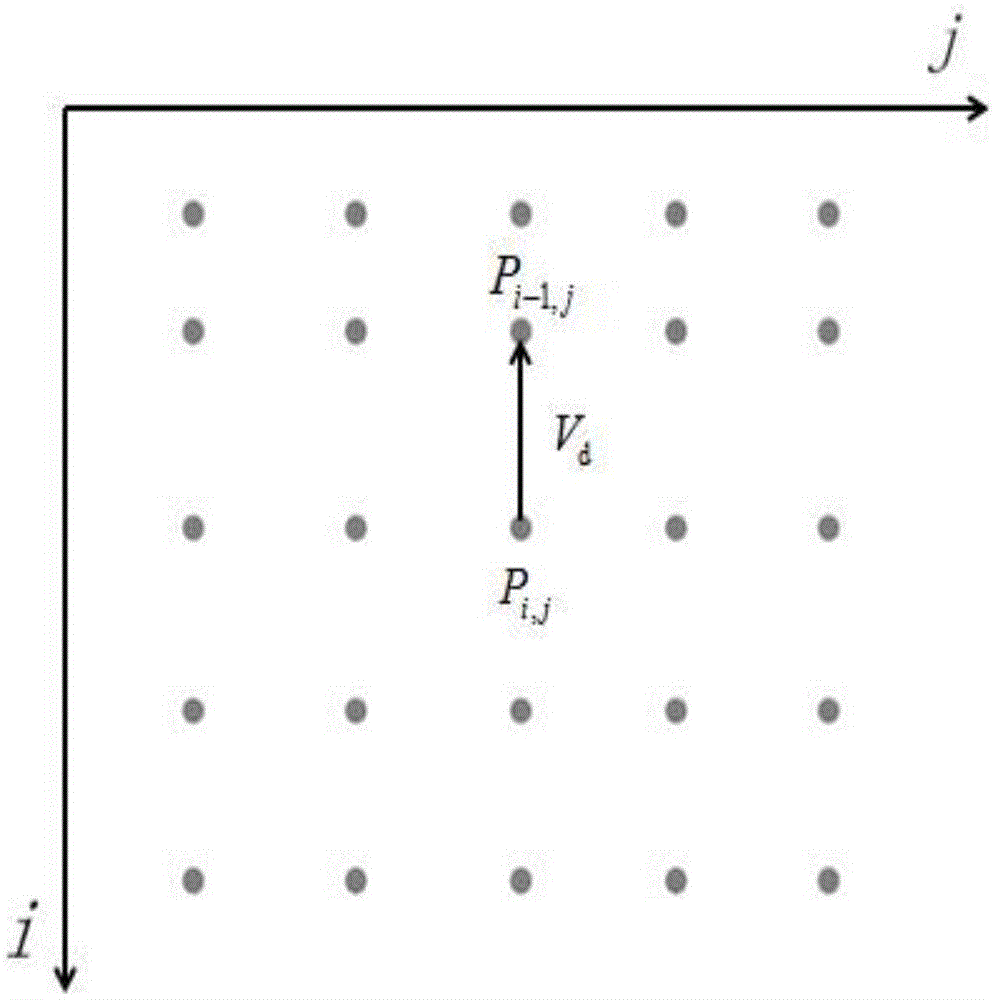

Natural image denoising method based on regional division

ActiveCN102663702AGood removal effectImprove smoothnessImage enhancementDenoising algorithmBlock match

The invention discloses a natural image denoising method based on the regional division, which mainly solves the problem that patches exist in an image after an image is donoised through the existing three-dimensional block matching denoising algorithm. The method comprises the following steps: firstly, performing two-dimensional stationary wavelet transform on an input image to be denoised, and performing inverse transform on a high frequency coefficient subjected to zero setting, so as to obtain a reconstructed image; secondly, exacting the structural information of the reconstructed image, so as to obtain an image structure sketch; thirdly, dividing the noisy original image into a structure region, a smooth region and a non-smooth region through statistic features of an image block and the image structure sketch; fourthly, performing denoising on the smooth region with an improved non-local mean method, performing denoising on the non-smooth region with a BM3D (Block matching 3D) method, and performing denoising on the structure region with a directional feature-based BM3D method; and fifthly, combining estimated results of the structure region, the smooth region and the non-smooth region, so as to obtain the final denoised image. The method can be used for preprocessing natural images.

Owner:XIDIAN UNIV

Environment protective polyurethanes hammer paint

ActiveCN101353550AGood solvent resistanceGood acid and alkali resistancePolyurea/polyurethane coatingsOleoresinDimethyl siloxane

The invention discloses an environmental-protection polyurethane hammer paint which is applied to wood surface decoration and protection and consists of a component A, a component B and a component C; when in use, the component A, the component B and the component C can be evenly mixed by the weight ratio that component A: component B: component C is equal to 1: 0.4 to 0.6: 0.5 to 0.6; wherein, the component A consists of: short oil alkyd resin, 40 to 60 parts; long oleoresin, 2 to 5 parts; dispersing agent, 0.2 to 0.5 part; anti-sedimentation agent, 0.4 to 0.9 part; propylene glycol ether acetate 3 to 6 part; divalent ester 1 to 3 parts; pigment, 0 to 30 parts; defoamers, 0.2 to 0.5 part; leveling agent, 0.2 to 0.7 part; non-floating-type aluminum paste, 1 to 5 parts; n-butyl acetate 5 to 15 parts, polydimethylsiloxane, 0.1 to 0.5 part; the component B consists of the following materials by weight ratio: HDI trimer poly isocyanate: HDI-TDI trimer: n-butyl acetate is equal to 2 to 4: 3 to 5: 1 to 4; the component C consists of the following materials by weight ratio: n-butyl acetate: propylene glycol methyl ether acetate is equal to 7 to 9: 1 to 3. The invention has the advantagesof: 1. good paint film solvent resistance and acid and alkaline resistance, bright color, clear texture, and good hammer effective; 2. high paint film hardness and wide application range, not only being applicable to wood surface, but also being applicable to metal surface decoration and protection; and 3. triphenyl-free, low VOC, and high solid content, and meeting the requirements on environmental protection.

Owner:GUANGDONG SANVO CHEM IND TECH

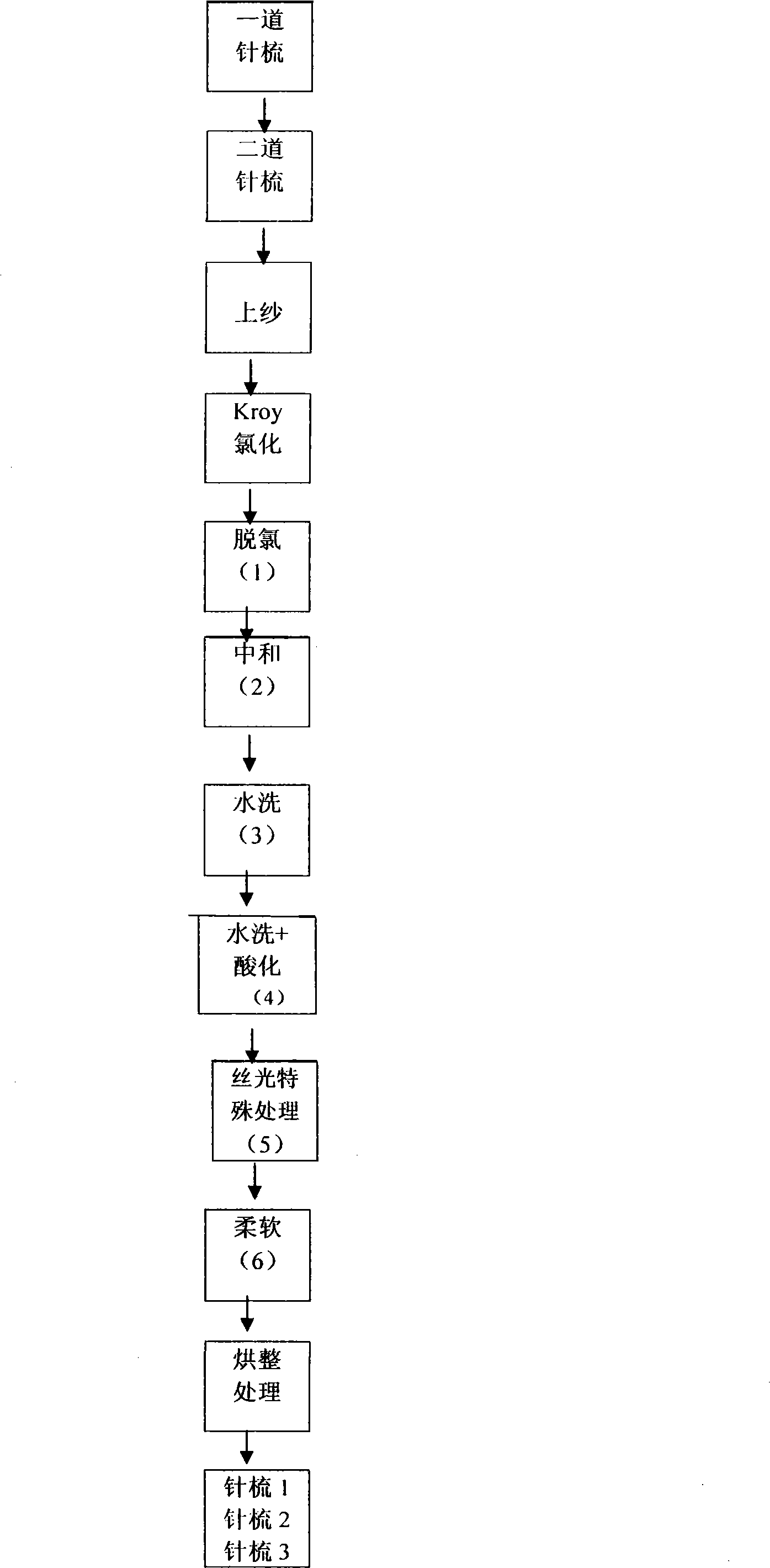

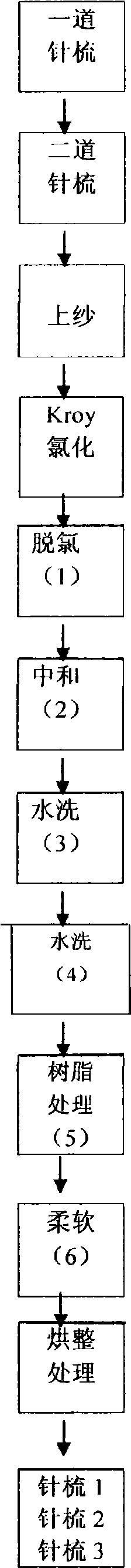

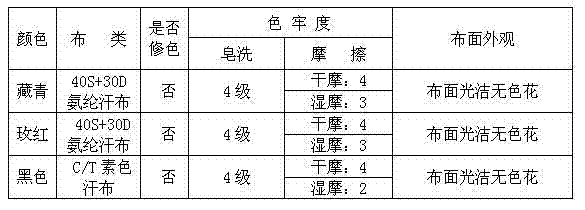

Wool shrinkproof mercerization method

ActiveCN101519838AGorgeous ingredientsRaw materials are simpleMercerising of sliversBiochemical fibre treatmentChlorinated solutionsEngineering

The invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloriThe invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloridization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thedization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequentially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared wntially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared with the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advith the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool prodantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool product and prolongs the service life of the wool product for wearing.uct and prolongs the service life of the wool product for wearing.

Owner:浙江新中和羊毛有限公司

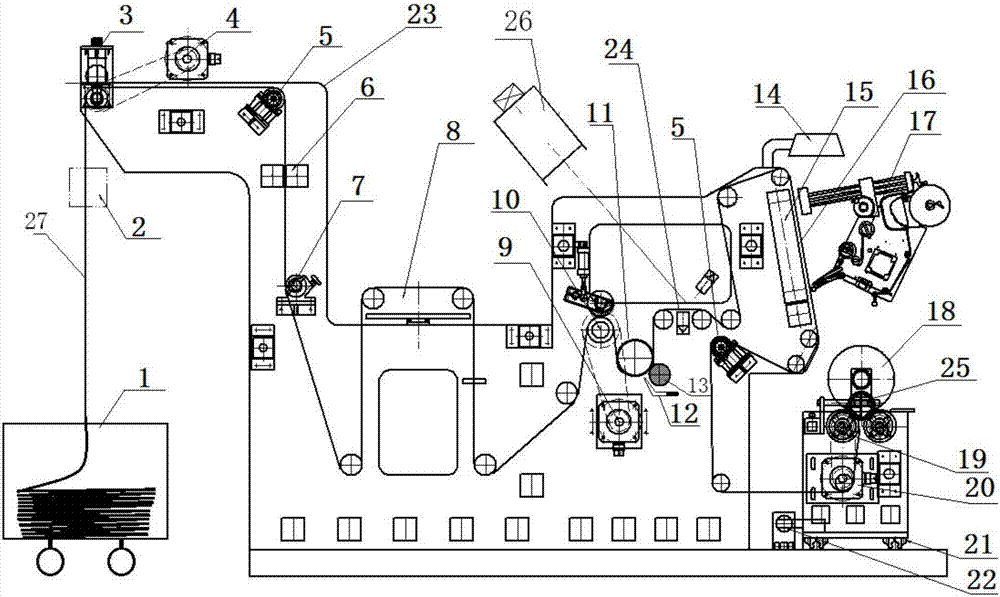

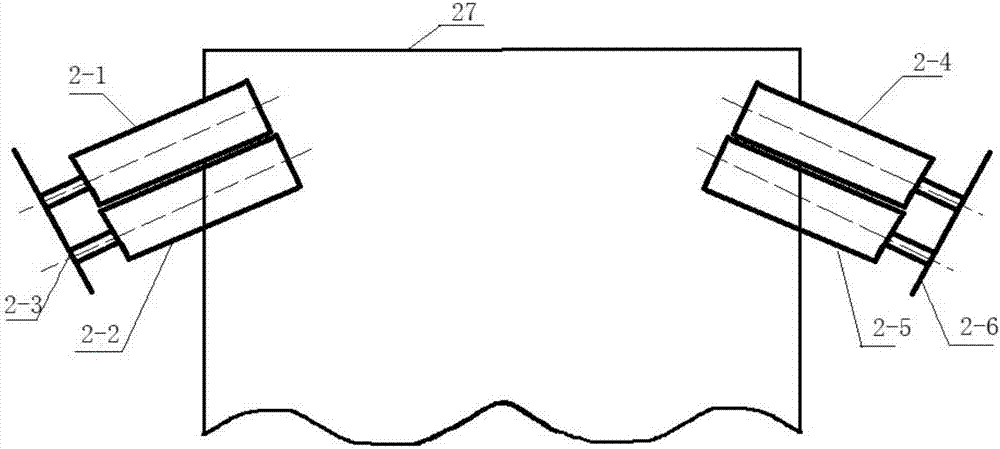

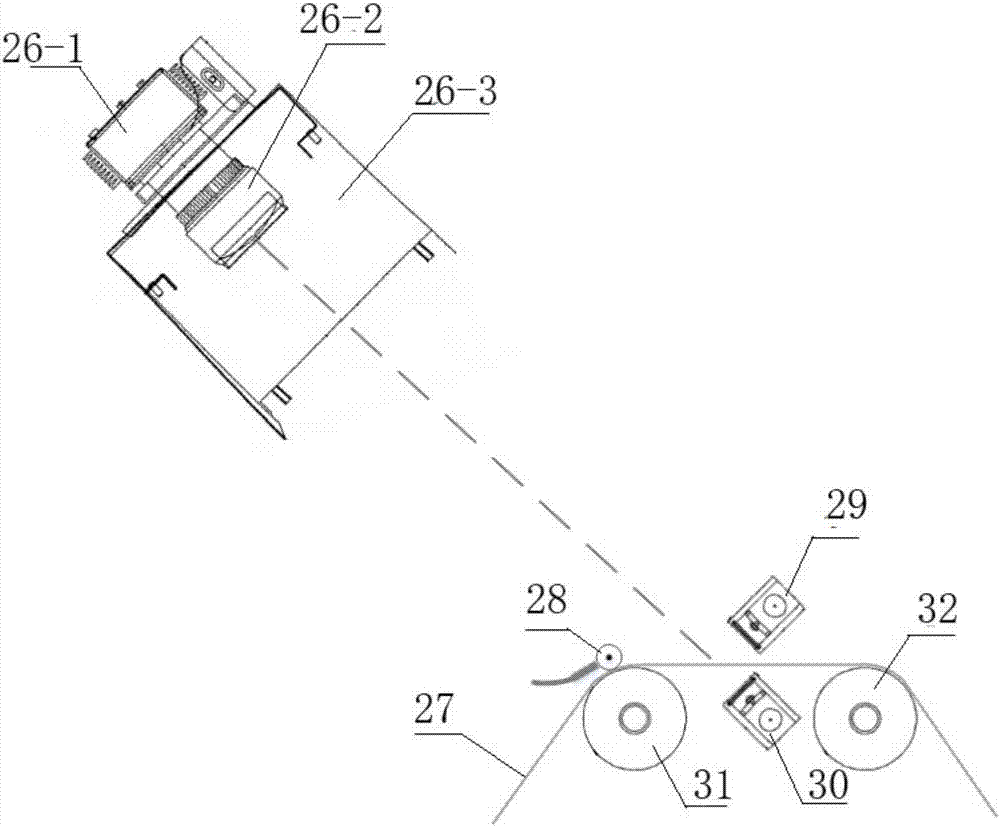

Fabric surface defect detection machine set, and detection method

ActiveCN107044987AThe test result is accurateImprove detection efficiencyOptically investigating flaws/contaminationForeign matterMachine vision

The invention discloses a fabric surface defect detection machine set, and a detection method based on the fabric surface defect detection machine set. The fabric surface defect detection machine set comprises a machine frame, a feeding roller assembly, a foreign matter removing device, a flattening device, a deviation correcting device, a drawing roller assembly, a wrinkle removing device, an industrial camera, a marking machine, and a coiling machine. According to the detection method based on the fabric surface defect detection machine set, before detection, impurity removing, flattening, deviation correcting, and wrinkle removing are adopted so as to conveying flat fabric into a detection zone steadily; the fabric surface defect detection machine set can be used for on-line detection of fabric surface, increasing fabric surface detection efficiency and fabric detection result accuracy.

Owner:江苏博虏智能科技有限公司

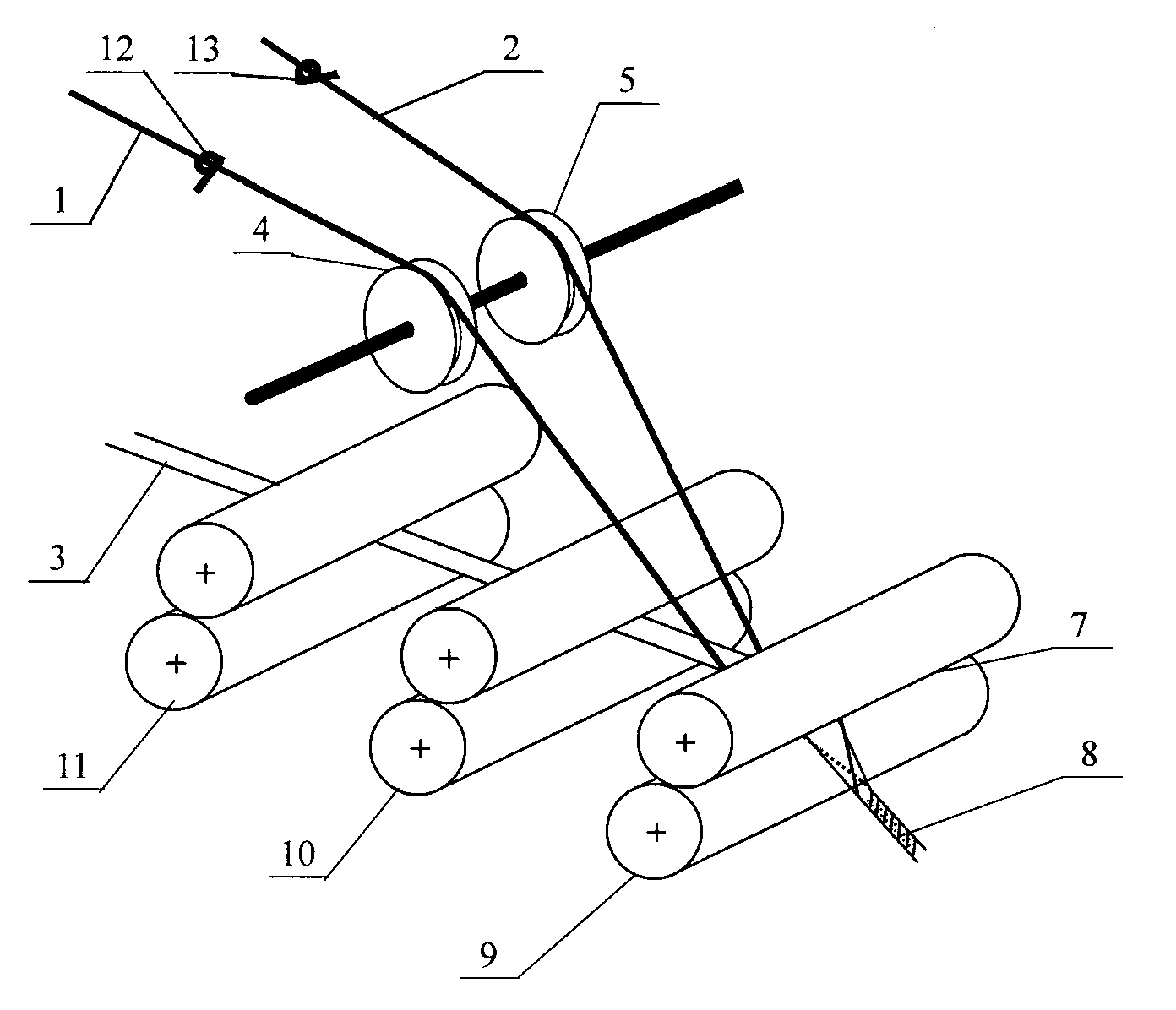

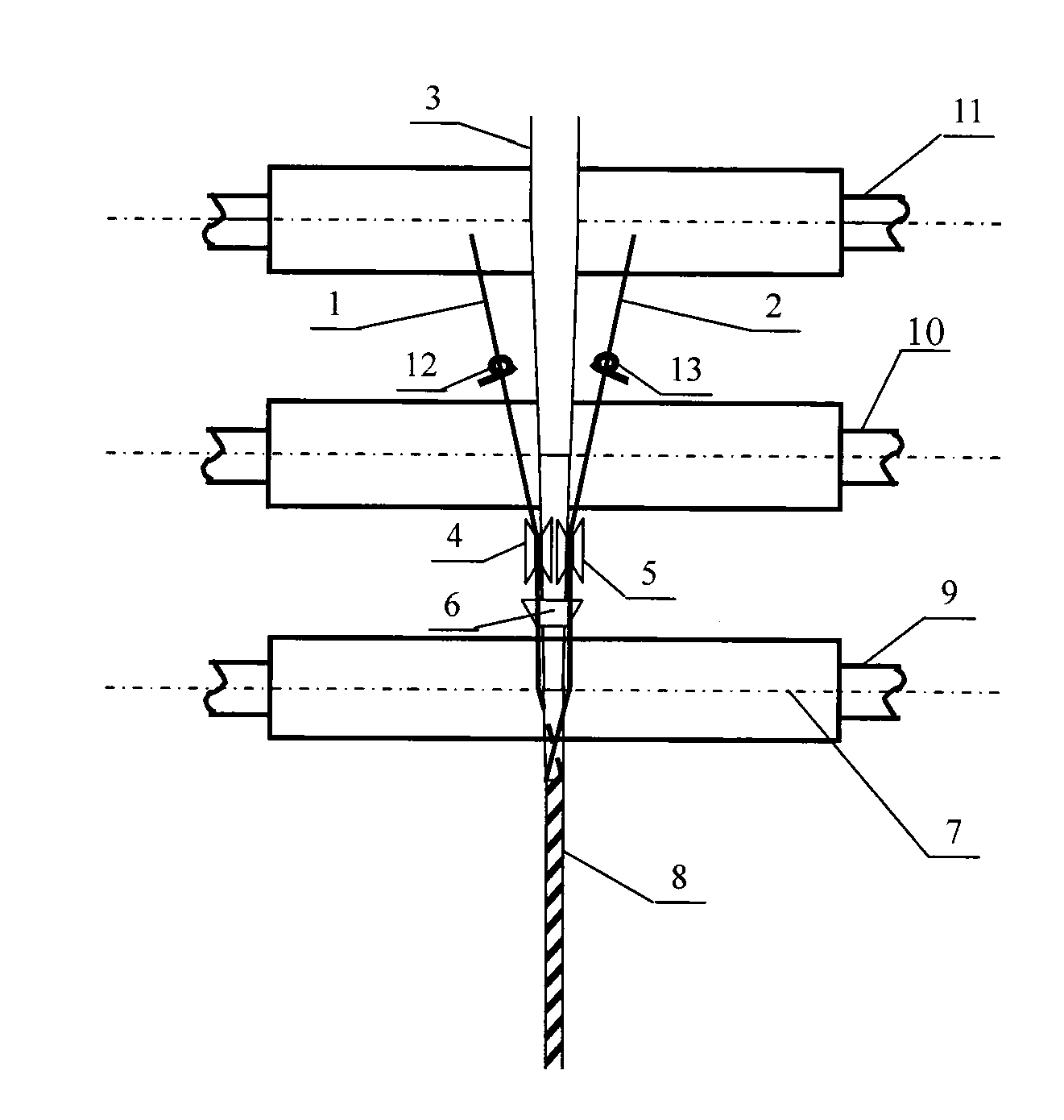

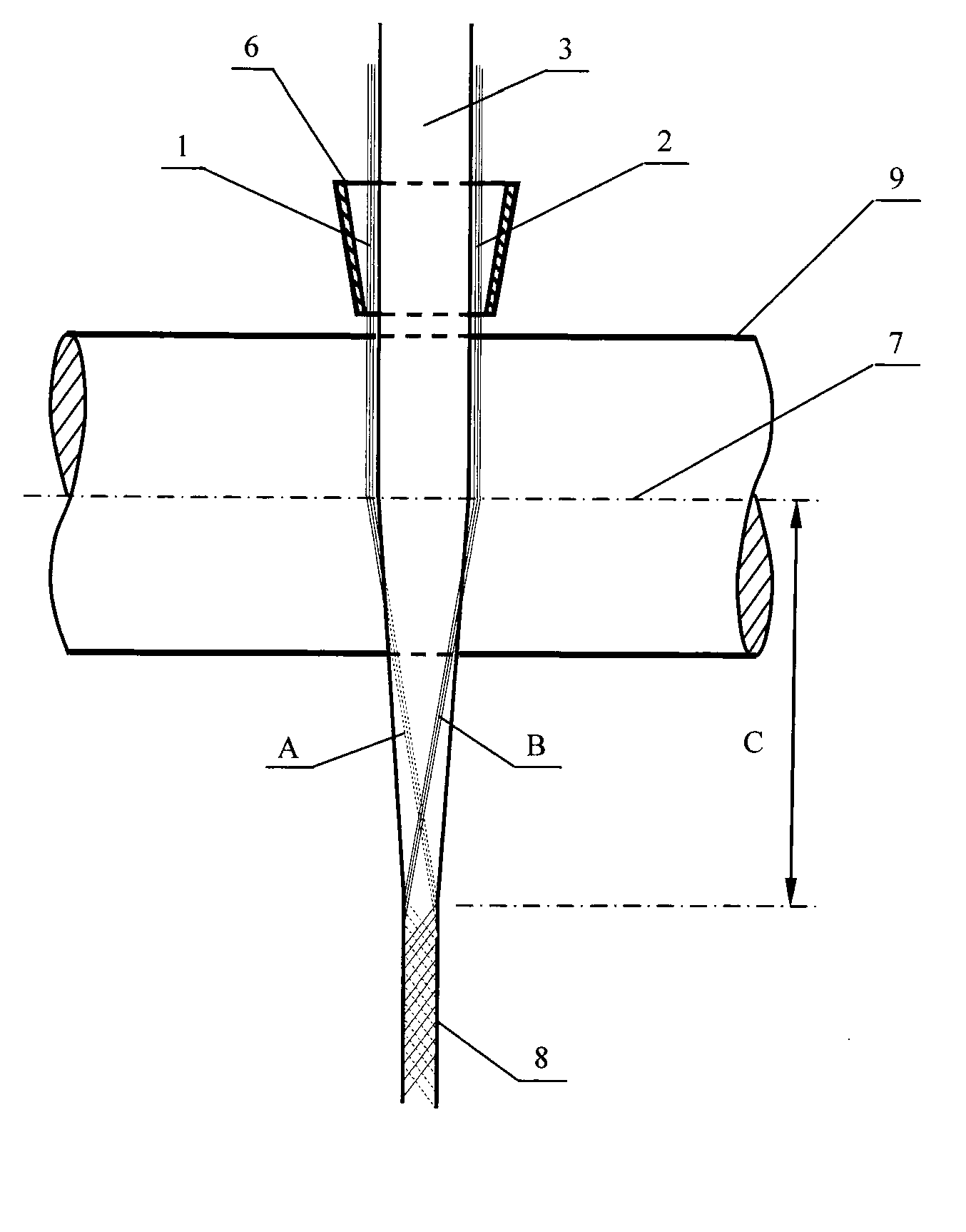

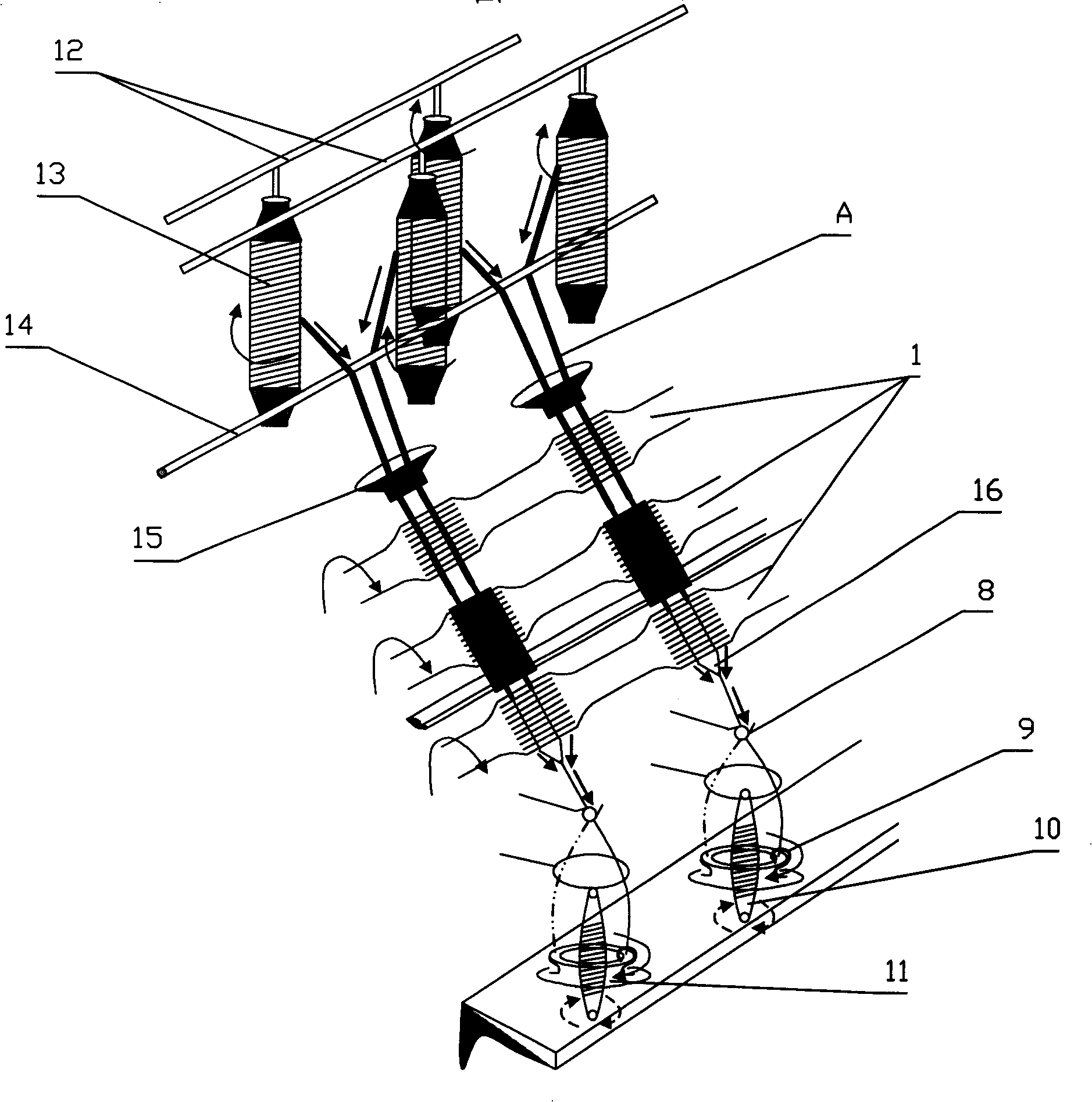

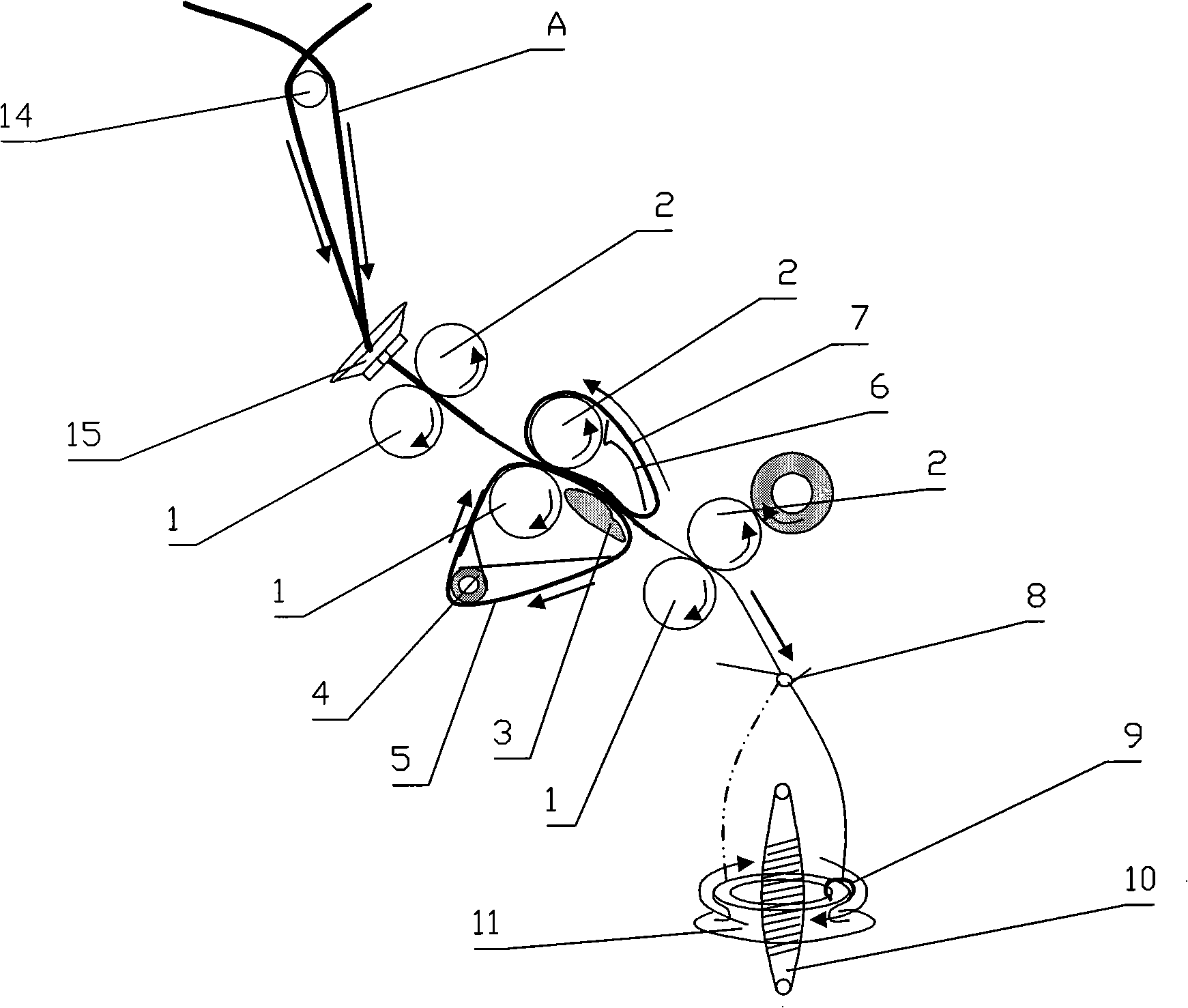

Three-shafting composite spinning method of constant-tension double-filament adjoining and twisting triangular zone and application thereof

The invention relates to a three-shafting composite spinning process of a constant-tension double-filament adjoining and twisting triangular zone and application thereof. The process comprises the steps of adopting a double-tension wheel to enable two beams of filaments to synchronize with the three-shafting in a way of adjoining left and right sides of a short fiber whisker strip via constant tension to be fed into a front roller through a beam concentrator; after outputting from a jaw of the front roller, wrapping the two beams of the filaments on the short fiber whisker strip in the twisting triangular zone to form a smooth composite yarn with the short fiber whisker strip wrapped by the double filaments basically in a no self-twisting manner. The process is simple and practical, can efficiently improve spinning efficiency and high branching of fibers with worse spinnability and reduce flying, scraps and fluffs in the spinning process, and is suitable for composite spinning of high-count smooth yarns and superfine yarns of shorter, weaker and ultra-short fibers.

Owner:DONGHUA UNIV

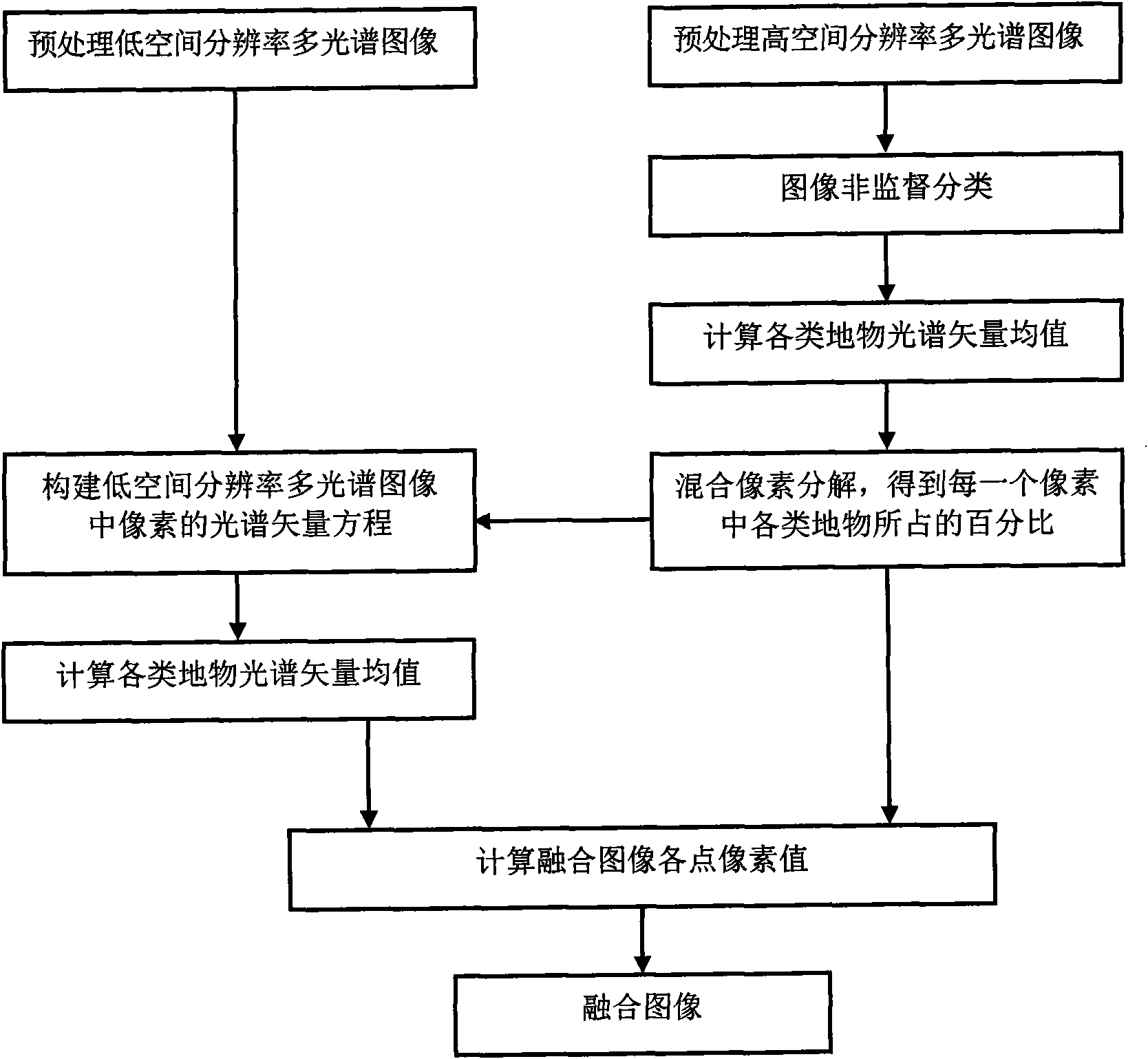

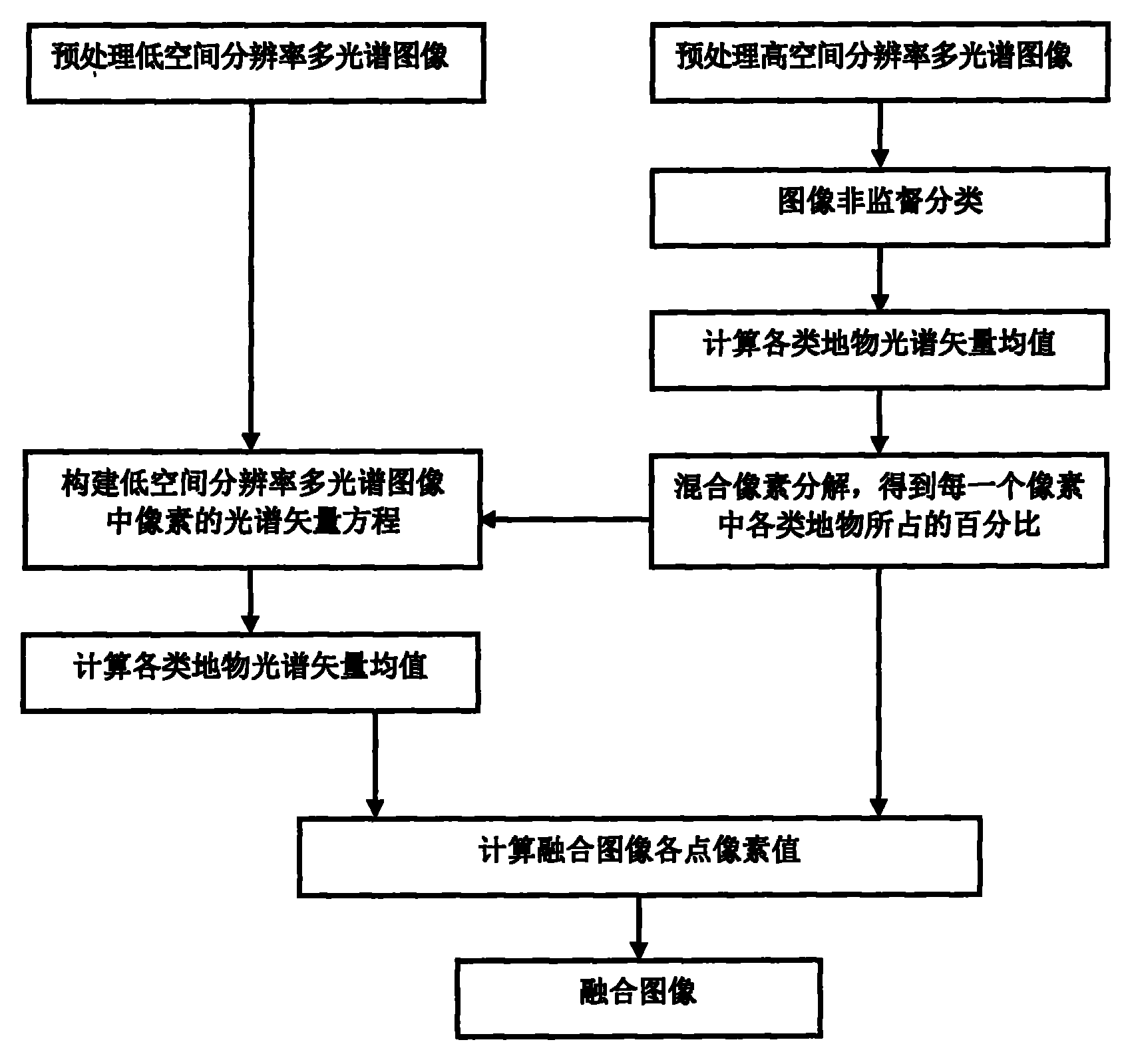

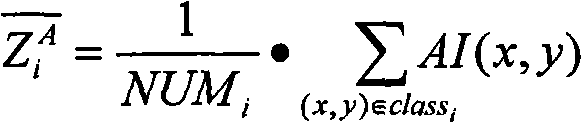

Fusion method of multispectral remote sensing images with different spatial resolutions

The invention belongs to the field of remote sensing image processing, and particularly relates to a fusion method of multispectral remote sensing images with different spatial resolutions. The method comprises the steps of dividing the multispectral image with high spatial resolution into n types of surface features, calculating the spectral vector mean value of all types of the surface features in the multispectral image with high spatial resolution, then conducting mixed pixel decomposition on the multispectral image with high spatial resolution, showing the multispectral image with low spatial resolution by the percent of all types of surface features in each pixel of the multispectral image with high spatial resolution, solving the spectral vector mean value of all types of the surface features in the multispectral image with low spatial resolution, and finally calculating the pixel value of each pixel of a fused image and generating the fused image. The method can fuse the multispectral image with high spatial resolution and the multispectral image with low spatial resolution, and enable the image fused to be sharper.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

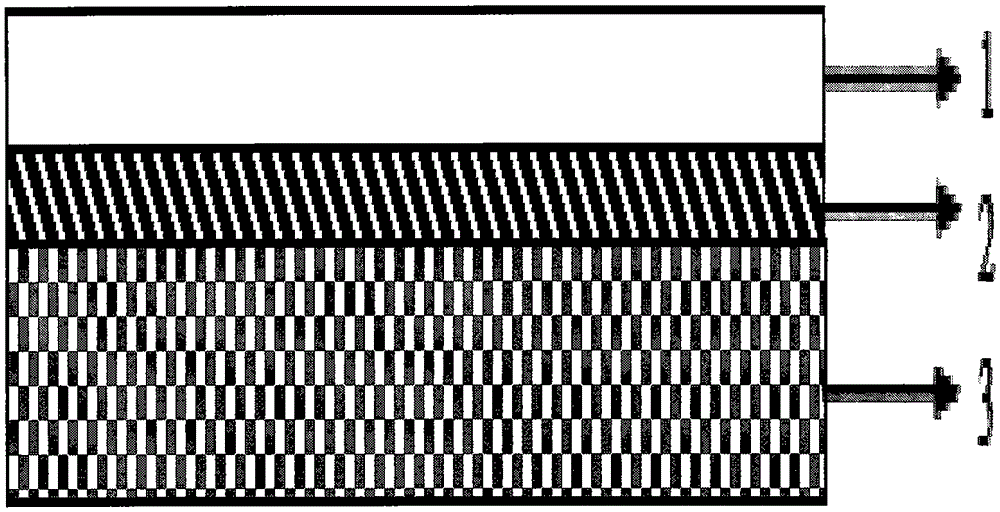

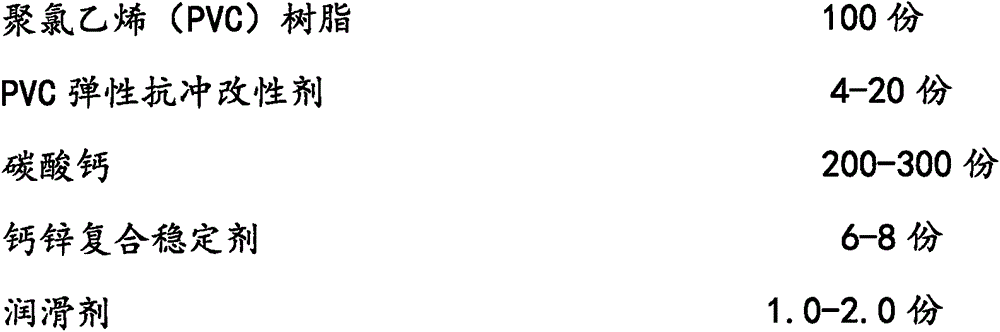

Novel PVC board and manufacturing method thereof

ActiveCN105295256ASimple processReduce production processConstruction materialCovering/liningsKnurlingPolyvinyl chloride

The invention provides a novel PVC (polyvinyl chloride) board and a manufacturing method thereof. The novel PVC board comprises a PVC transparent wearing layer, a PVC simulation pattern film layer and a PVC bottom layer from top to bottom, wherein the PVC bottom layer contains a PVC elastic anti-shock modifier; the PVC bottom layer, the PVC simulation pattern film layer and the PVC transparent wearing layer are together arranged between a first roller and a second roller, a composite layer is formed via rolling depression, and the composite layer is further treated to form the PVC board. By adopting the manufacturing method, production processes are reduced, the production efficiency is improved, the PVC board is firmer, and lines and knurling patterns are clearer and more attractive.

Owner:TAIZHOU HUALI PLASTIC

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804655AReduce energy consumptionTake advantage ofLiquid surface applicatorsWood compressionSolid woodWear resistant

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: forming a solid wood flooring block, sanding the block, removing dust, coloring, coating UV putty coat I, solidifying I, sanding I, coating UV putty coat II, solidifying II, sanding II, coating wear resistant base coat, semi-solidifying I, coating transparent UV base coat, solidifying III, sanding III, coating UV finishing coat, semi-solidifying II, coating formaldehyde-removing UV wear resistant finishing coat, solidifying IV, and forming the finished product. The solid wood flooring produced by the process has the advantages of good colour and lustre, clear texture, high anti-bending static bending strength, good surface abrasion resistance, stable size, small deformation and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

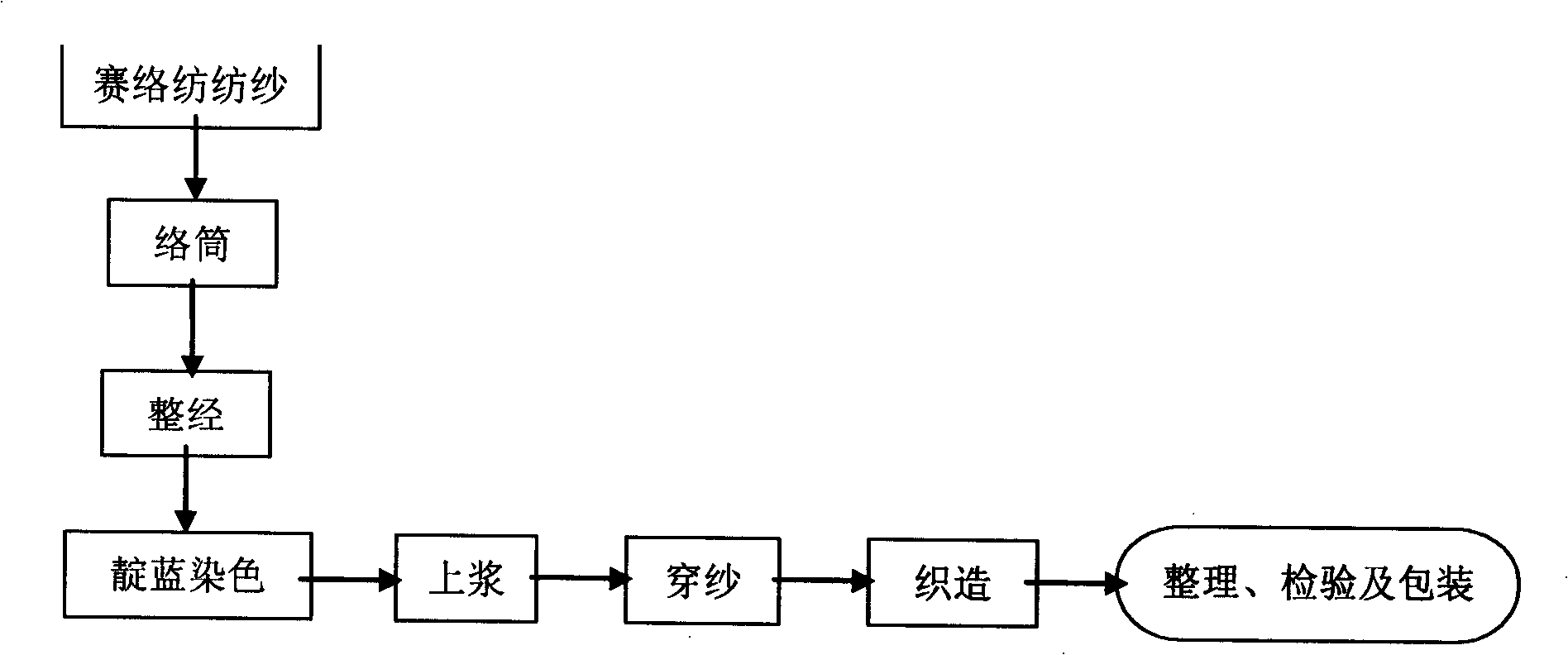

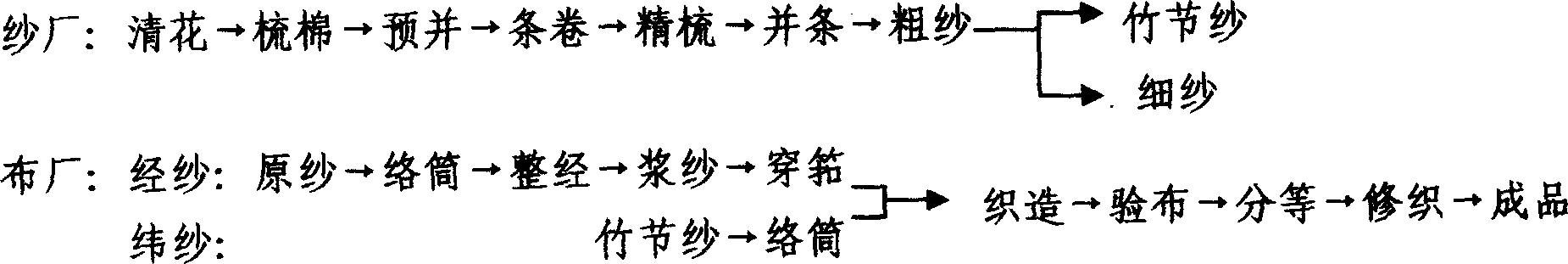

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

Pure cotton striped bunch cloth

A bunchy striped cotton cloth is made through pre-treating warp through winding, beaming, sizing and reeding, pre-treating weft through winding, and weaving to obtain 1 / 1 plain cloth. It features that its warp is JC14.5 tex yarn, its weft is JC18.2tex yarn and bunchy yarn, the warp density is 276 / 10cm, the warp density is 255.5 / 10 cm, and the bunchy yarn has different pitches. Its advantages are clear bunchy nodes, light weight, very thin and soft handle.

Owner:TIANYI TIANJIN TEXTILE GROUP

Thermal sublimation transferring-printing coating pulp and method for carrying out thermal sublimation transferring-printing by using same

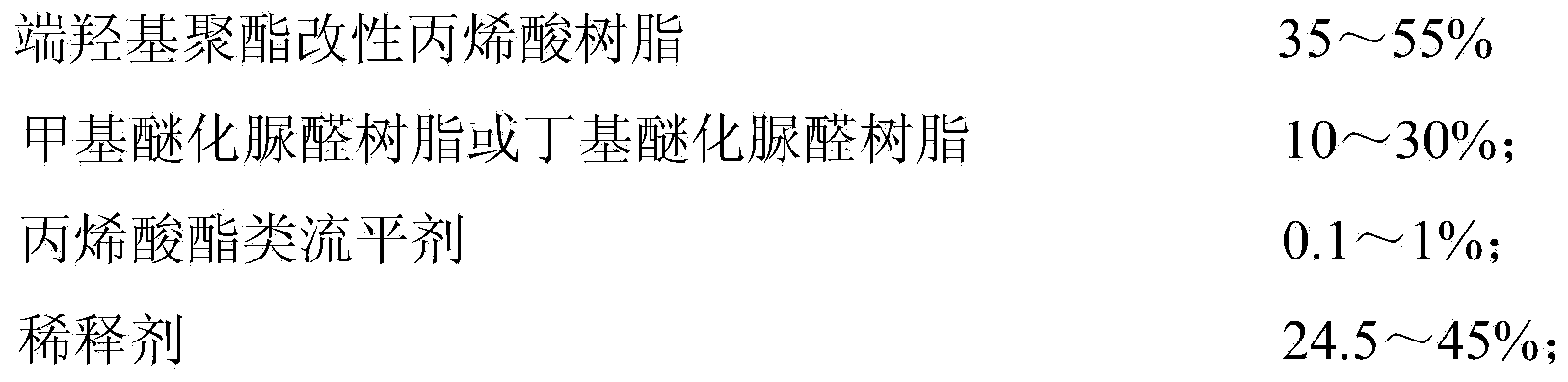

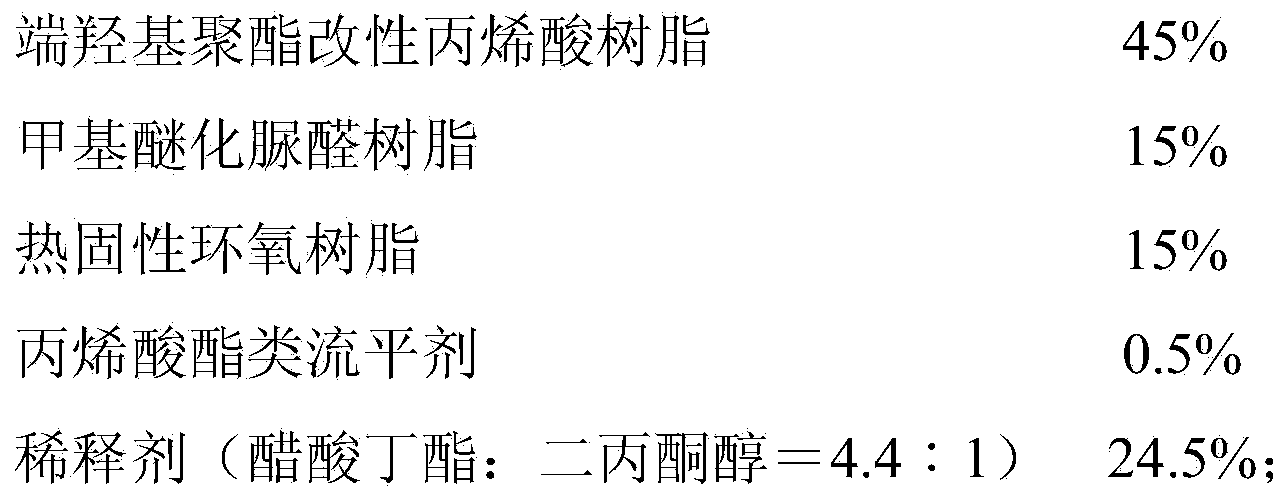

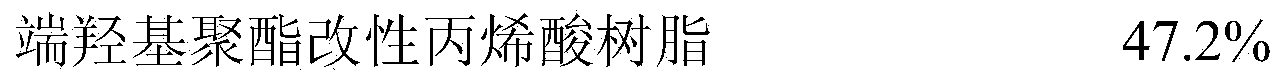

ActiveCN104073103AGood light fastnessExcellent outdoor aging resistanceDuplicating/marking methodsEpoxy resin coatingsCross-linkPolyester

The invention discloses thermal sublimation transferring-printing coating pulp which comprises the following components in percentage by mass: 35-55% of hydroxyl-terminated polyester modified crylic acid resin, 10-30% of methyl etherified urea resin or butyl etherified urea resin, 0.1-1% of acrylic leveling agent and 24.5-45% of diluent, wherein the solid content of the hydroxyl-terminated polyester modified crylic acid resin is 60%+ / -2%, and the acid value is 3-5mgKOH / g; the solid content of methyl etherified urea resin or butyl etherified urea resin is 75%+ / -2%, the acid value is less than 1mgKOH / g; the diluent is a mixture of n-butyl acetate and diacetone alcohol. When the coating pulp is coated on the surface of a printed article and is heated, the hydroxyl-terminated polyester modified crylic acid resin has cross-linking reaction with methyl etherified urea resin or butyl etherified urea resin to form a net-shaped structure, and thus the pattern generated after transferring-printing is clear, full, high in color fastness, long-lasting without fading, and high in glossiness.

Owner:东莞隽思印刷有限公司

Ice temperature fresh-keeping method for bred large yellow croaker

InactiveCN101695313AImprove freshnessAdd flavorMeat/fish preservation by freezing/coolingFlavorFresh fish

The invention discloses an ice temperature fresh-keeping method for bred large yellow croaker, which comprises the following steps: pre-treating the large yellow croaker into fillets, penetrating and flavoring the fillets through flavoring prepared by the method at a temperature of 20 + / - 5 DEG C, drying the fillets at the temperature of between 15 and 20 DEG C till the water content of the fillets is 45 to 65 percent, then packing the fillets in vacuum, and refrigerating the fillets in an icebox or a freezer and the like at the ice-temperature preservation temperature of between 1 DEG C below zero and 14 DEG C below zero. After the bred large yellow croaker is pretreated, flavored, dried and packed in vacuum, the freezing point of the fillets in a packing bag can be reduced to 14.6 DEG C below zero, so the ice temperature band of the bred large yellow croaker is broadened, and the large yellow croaker cannot be frozen at the temperature of between 1 DEG C below zero and 14 DEG C below zero. The invention provides the ice temperature fresh-keeping method which can broaden the ice temperature band of the bred large yellow croaker and keep the conditions of freshness, flavor, texture and the like of the fresh fish. The method avoids the freezing phenomenon of the large yellow croaker during refrigerating and fresh keeping in the icebox or the freezer, and keeps the original freshness and flavor of the bred large yellow croaker better.

Owner:NINGBO UNIV

Moisture permeable anti-ultraviolet multifunctional antibiotic facing material and process technique thereof

InactiveCN101109129ASolve the single functionRich patternsOther manufacturing equipments/toolsDyeing processYarnPolyester

The invention discloses an antibiotic shell fabric with multi-functions that can penetrate moisture and resist to ultra-violet rays as well as the processing process for the shell fabric, which pertains to the technical field of compound fabric of synthetic fiber and compound yarn. The warp uses two yarns, wherein, a warp A uses mid-twist S-twist long polyester yarn, while a warp B uses low-twist compound yarn of low-elasticity polyester fiber and high-elasticity polyurethane fiber yarn, the proportion of the warp A to B by weight is 50: 131. The weft uses two yarns, wherein, a weft A uses anti-biotic yarn of low twist, while a weft B uses compound yarn comprising moisture-absorbing and sweat-removing yarn and fine cotton. The two wefts are cross-combined by 1:1, and the proportion of the weft A to B by mass is 1:1. The shell fabric from the invention can reflect or shield ultra-violet rays, convert the energy of ultra-violet rays, dissolve bacteria and contaminants, etc., so as to be antibiotic, absorb moisture, penetrate air and resist ultra-violet rays; in addition, the shell fabric is of rich patterns, clear textures, good elasticity, resistance to winkles and static, etc.

Owner:洪桂焕

Flashing light wool-simulating hemp-simulating surfacing material and process technique thereof

InactiveCN101109125AImprove comfortSpecial glossHeating/cooling textile fabricsDyeing processPolyesterPolymer science

The invention discloses a sparkling fur- / hemp-imitated shell fabric and the processing process for the shell fabric. Wherein, a warp and a weft are woven together, the warp takes blend yarn of bamboo fiber and polyester microfiber as raw materials, the weft uses blended yarn of sparkled and various color from modified polyester and viscose as raw materials. The invention is soft, of good drapability, highly resistant to wear, with good air permeability, resistance to static, good resilience and antibiotic property.

Owner:洪桂焕

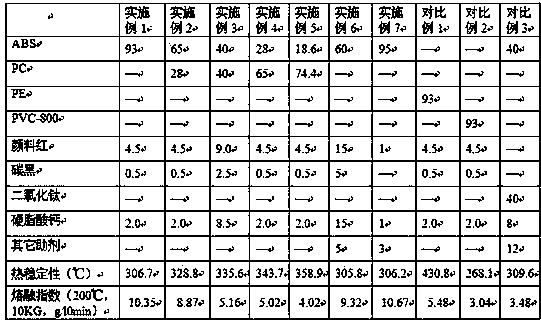

Imitation wood grain color master batch, preparation method, and applications thereof

The invention discloses an imitation wood grain color master batch, which comprises the following components in percentage by weight: 60 to 95% of carrier resin, 1 to 20% of pigment, 1 to 15% of dispersant, and 0 to 5% of other auxiliary agents; wherein the carrier resin is a mixture of PC and ABS, the PC accounts for 0 to 80% of the total weight of the carrier resin, and the ABS accounts for 20 to 100% of the total weight of the carrier resin. The preparation method comprises the following steps: (a) adding the components according to the ratios mentioned above into a high-speed mixer, and evenly mixing the components at the normal temperature and under the normal pressure; (b) melting, mixing and extruding the mixed materials mentioned above in a double-screw extruder, and at the same time subjecting the extruded materials to processes of water cooling, cutting, and wind drying so as to obtain the imitation wood grain color master batch. The imitation wood grain color master batch has the advantages of little color powder usage amount, good temperature toleration ability, and excellent dispersing ability; is easy to operate and control when the color master batch is applied to prepare imitation wood grain composite material of wood and plastic; has a good compatibility with PVC base basic materials and a high imitation wood appearance, thus the formed grains are natural and clear, the surface color is bright and beautiful, and the imitation wood grain effect is good.

Owner:KINGFA SCI & TECH CO LTD +2

Low-melting-point resin material for three-dimensional printer and manufacturing method of low-melting-point resin material

ActiveCN104693637AProne to cloggingLarge specific surface areaAdditive manufacturing apparatusAcrylic resinFumed silica

The invention provides a low-melting-point resin material for a three-dimensional printer. The material comprises the following components in percentage by weight: 30-60% of styrene-acrylic resin, 10-50% of first polyester resin, 0-10% of second polyester resin, 1-15% of additives, 0.5-6% of wax, and 0.1-2% of fumed silica, wherein the glass transition temperature Tg of the styrene-acrylic resin is 55-65 DEG C and the softening point temperature T1 / 2 is 120-130 DEG C; the glass transition temperature Tg of the first polyester resin is 43-48 DEG C and the softening point temperature T1 / 2 is 80-85 DEG C; the glass transition temperature Tg of the second polyester resin is 45-65 DEG C and the softening point temperature T1 / 2 is 80-110 DEG C. By adopting the scheme, the glass transition temperature Tg of the low-melting-point resin material for the three-dimensional printer is 48-65 DEG C and the softening point temperature T1 / 2 is 85-110 DEG C. Therefore, the melting temperature of an FDM three-dimensional printer material is remarkably reduced, and the scald risk of an operator is correspondingly reduced while the energy consumption is reduced.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Polyester resin used for TGIC curing high-toughness thermal transfer printing powder paints, and preparation method thereof

ActiveCN105367765AHigh glass transition temperatureImprove toughnessPowdery paintsPolyester coatingsVitrificationPolyol

The invention relates to a polyester resin used for TGIC curing high-toughness thermal transfer printing powder paints, and a preparation method thereof. The glass-transition temperature of the polyester resin is relatively high, so that prepared powder paint coating possesses high toughness at normal temperature and -15 DEG C. According to the preparation method, the polyester resin is obtained via melt polycondensation of following raw materials: a polyol, a polyacid, an acidolysis agent, an esterification catalyst, an antioxidant, and a curing accelerator. The preparation method comprises following steps: 1) the polyol is delivered into a reaction kettle at a needed ratio, rapid heating esterification is carried out, water is generated, and is removed via distillation; 2) temperature is increased gradually, and an obtained material is maintained to be clear; 3) sample examination is carried out; 4) one half of the antioxidant is added, and negative pressure polycondensation is carried out; and 5) cooling is carried out, one half of the antioxidant and the curing accelerator are added, stirring dispersing is carried out, and an obtained product is cooled, and is collected.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

Two-dimensional imagination expression method of three-dimensional laser-point cloud data

ActiveCN105574905AQuality improvementClear textureReconstruction from projectionPoint cloudScene segmentation

The invention discloses a two-dimensional imagination expression method of three-dimensional laser-point cloud data, and belongs to the field of image technologies. The method is implemented by devices mainly consisting of a mobile robot, a laser scanner and a computer system, wherein the laser scanner and the computer system are both installed on the platform of the mobile robot, and communication is performed between the laser scanner and the computer system by a data line; and the laser scanner is used for collecting the three-dimensional laser-point cloud data information of a scene, and the computer system is used for converting the three-dimensional laser-point cloud data into a two-dimensional gray level image. The method provided by the invention provides a powerful support for scene segmentation and scene understanding based on the laser-point data, and can be applied to large scale data and suitable for multiple scanning modes; and according to the method, the scenery boundary distinction degree and detail quality of the image are improved, and the texture of the image is clearer.

Owner:DALIAN UNIV OF TECH

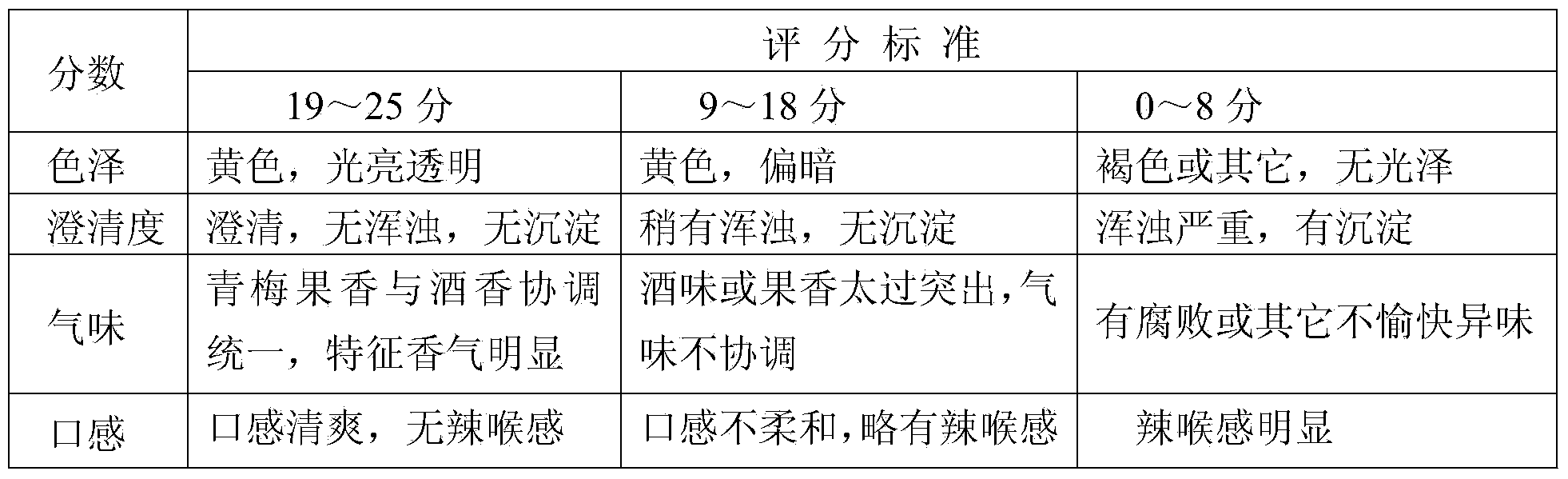

Saccharomyces cerevisiae strain and green plum fruit wine prepared by using saccharomyces cerevisiae strain

ActiveCN103773702ARetain and enrich nutrientsEmbodies and fills with characteristic aromaFungiAlcoholic beverage preparationFlavorMicroorganism

The invention discloses a strain QM5236 special for fermenting green plum fruit wine. The strain is collected in the China General Microbiological Culture Collection Center with the collection number CGMCC No.8485 on November 19, 2013. The green plum fruit wine and a preparation method thereof are further disclosed. The green plum fruit wine is obtained through preparing and treating green plum fruit pulp serving as a raw material by taking the saccharomyces cerevisiae strain QM5236 as a production strain, and performing the processes of primary fermentation, secondary fermentation, aging, filtering, sealing and sterilizing. The saccharomyces cerevisiae strain QM5236 in the technical scheme is suitable for a green plum fruit pulp fermentation system, and the product fruit wine is outstanding in particular flavor and excellent in organoleptic quality.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

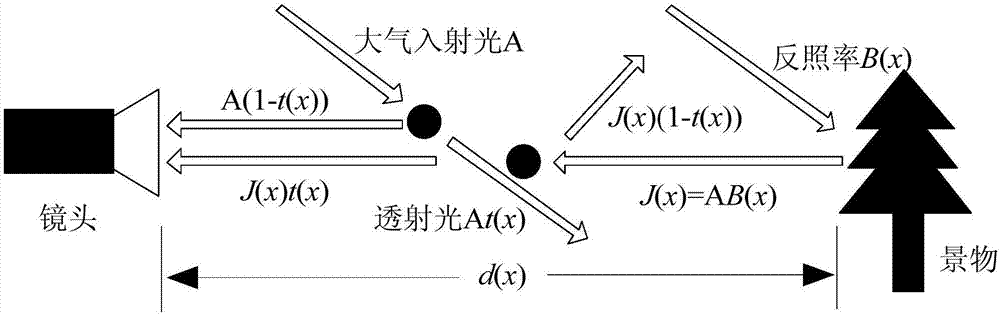

Transformer substation video image sharpening method in accordance with human eye visual characteristics

InactiveCN106940882AAvoid subjective errorClear textureImage enhancementImage analysisHabitSharpening

The present invention discloses a transformer substation video image sharpening method in accordance with human eye visual characteristics, and belongs to the field of image communication, video image processing, intelligent power station and the like. According to the invention, the method comprises the steps of 1) acquiring the video image of a transformer substation; 2) based on the partitioning principle, adaptively acquiring an atmospheric brightness value; 3) according to an atmospheric optical imaging model, establishing an image degradation equation and solving out a rough transmittance and other parameters based on the dark primary color priori knowledge; 4) with the gray-level image of an original image as a bootstrap image, guiding a rough atmospheric light curtain in combination with the bilateral filtering means so as to obtain a new atmospheric light curtain, and further reversely deducing a preliminary restored image; 5) in combination with human eye LMS visual characteristics, enhancing the restored image under an LIPC color logarithmic image processing framework so as to obtain a fog-free clear image more consistent with the habits of human eyes. The method is remarkable in defogging effect, clear in details, natural in color, and wide in application prospect. The method effectively solves the video definition problem of transformer substations in the prior art.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

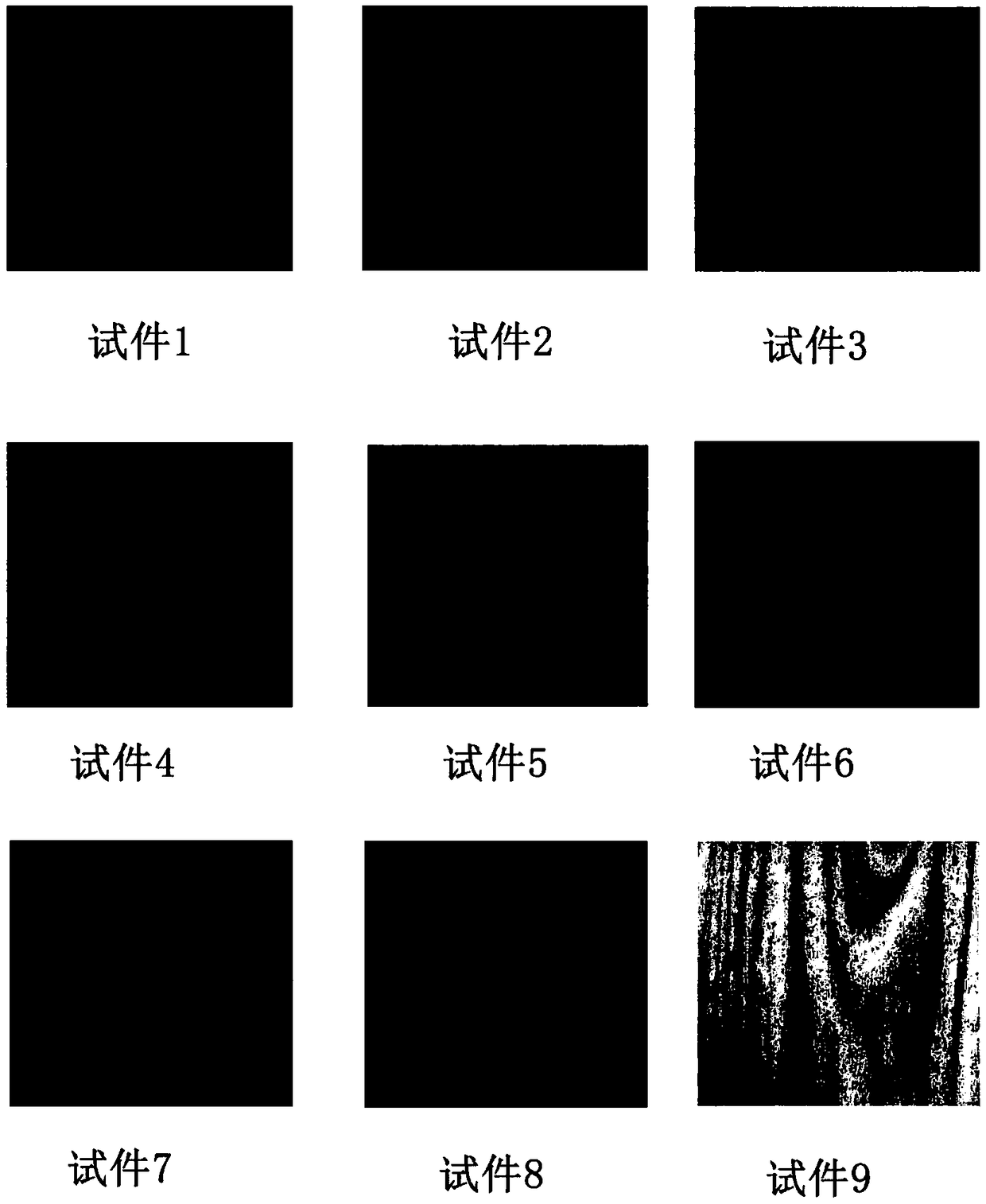

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Deoxidizing and polishing one-bath process dyeing of polyester cotton knitted fabric

The invention discloses deoxidizing and polishing one-bath process dyeing of a polyester cotton knitted fabric and belongs to the technical field of dyeing or printing of textiles. The deoxidizing and polishing one-bath process dyeing of the polyester cotton knitted fabric comprises the following steps of: adjusting temperature to 40-60 DEG C; adjusting a PH value to 5-7; adding 1%-2% of polishing enzyme 988, adding dyes and dyeing assistants after 0-15 minutes, adding sodium sulphate after 30 minutes, adding sodium carbonate after 20 minutes; keeping the temperature for 60 minutes, wherein the polishing enzyme 988 is cellulose bio-enzyme and the addition amount is 1%-2%; the dyeing assistants are scouring and dyeing one-bath agents and are added in two steps with the total addition amount of 1%-2%; the dye bath ratio is 1:5-1:20, and assistant scouring and bleaching, dispersing alkali one-bath dyeing of polyesters and reduction clearing need to be sequentially carried out before the deoxidizing and polishing one-bath process dyeing. By adoption of the technical scheme, the polishing effect which is same to or better than that of separated-bath processing can be achieved; processed cotton fabrics have the advantages of less surface fuzz, clear textures and enhanced anti-pilling level; and dyeing coloured light and depth can not be influenced.

Owner:绍兴市华绅纺织品整理有限公司

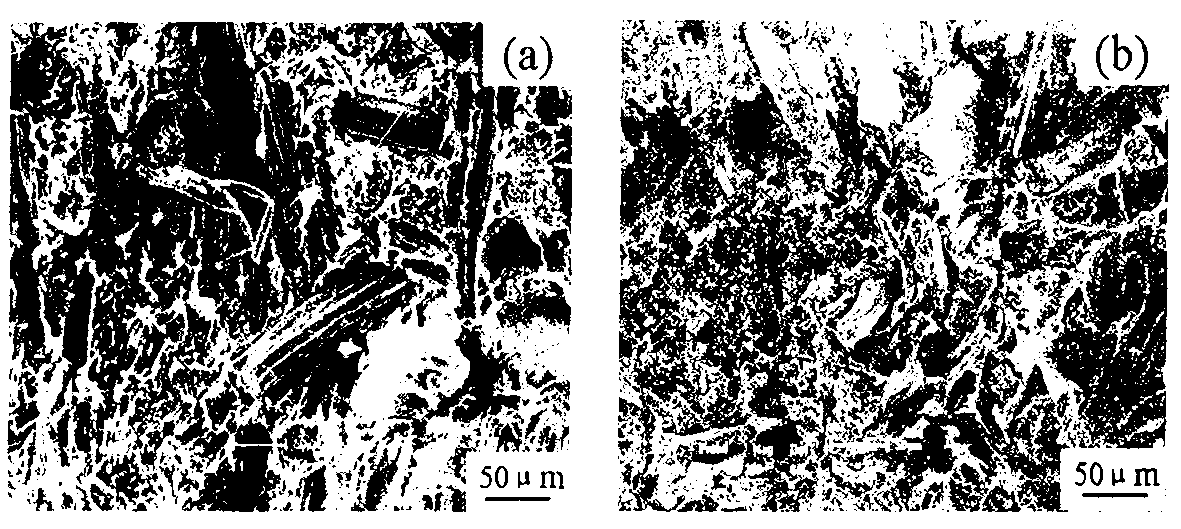

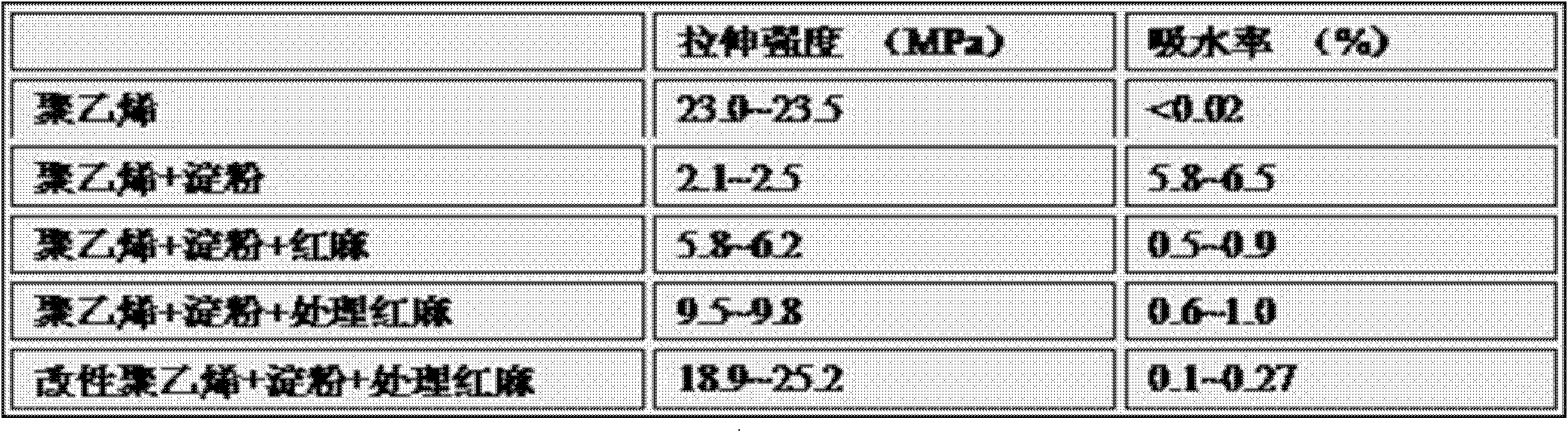

Degradable resin-starch-kenaf extruded plastic master batch

The invention belongs to the field of high polymer materials and in particular relates to a degradable resin-starch-kenaf extruded plastic master batch. The degradable resin-starch-kenaf extruded plastic master batch comprises the following components by volume percent: 30%-60% of polyethylene, 0-50% of starch and 5-40% of kenaf, wherein the polyethylene is composed of low-density polyethylene and maleic anhydride modified polyethylene in the volume ratio of (0.2-5):1. The extruded composite resin (master batch) material with higher tensile strength and good processing performance is prepared by virtue of a molecular design method; the biodegradation rate is 40%-70% in the presence of aerobiont; the using performance and the processing performance of the composite material are similar to those of the polyethylene, so that the material is green and environment-friendly, and therefore, the purposes of protecting the environment, efficiently utilizing the resources and lowering the cost are achieved.

Owner:赵振峰

Production process of cotton-type natural stretch yarn dyed fabric

The invention discloses a production process of a cotton-type natural stretch yarn dyed fabric with good air permeability, and excellent water absorbability and wet permeability. The production process comprises the following steps: cotton yarn bleaching -> dyeing -> warping -> sizing -> weaving -> grey cloth reconditioning -> singeing -> desizing -> mercerizing -> forming -> pre-shrinking. The production process is characterized in that: high alkali concentration of 30-32 baume degrees is adopted in the mercerizing process, and then an alkali-proof high-efficiency penetrating agent is added so as to cause the alkali penetration time to be prolonged to 85-95s; the stacking time before rinsing is 60-95s after alkali shrinkage, the pouring amount of chilled water is increased at rinsing after the alkali shrinkage, and the poured chilled water is drunk up by a vacuum water absorption method; the alkali-proof high-efficiency penetrating agent is isooctanol polyethenoxy ether phosphate, and the structural formula thereof is C8H16O4P-(CH2)2O-n, wherein, n is an integer; and high-elasticity polyurethane-polyurethane is taken as a sizing agent in the forming process. The production process is applicable to the production field of the cotton-type natural stretch yarn dyed fabric.

Owner:张家港市金陵纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com