Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155 results about "Wool fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wool Fiber. Wool fiber is the natural hair grown on sheep and is composed of protein substance called as keratin. Wool is composed of carbon, hydrogen, nitrogen and this is the only animal fiber, which contains sulfur in addition.

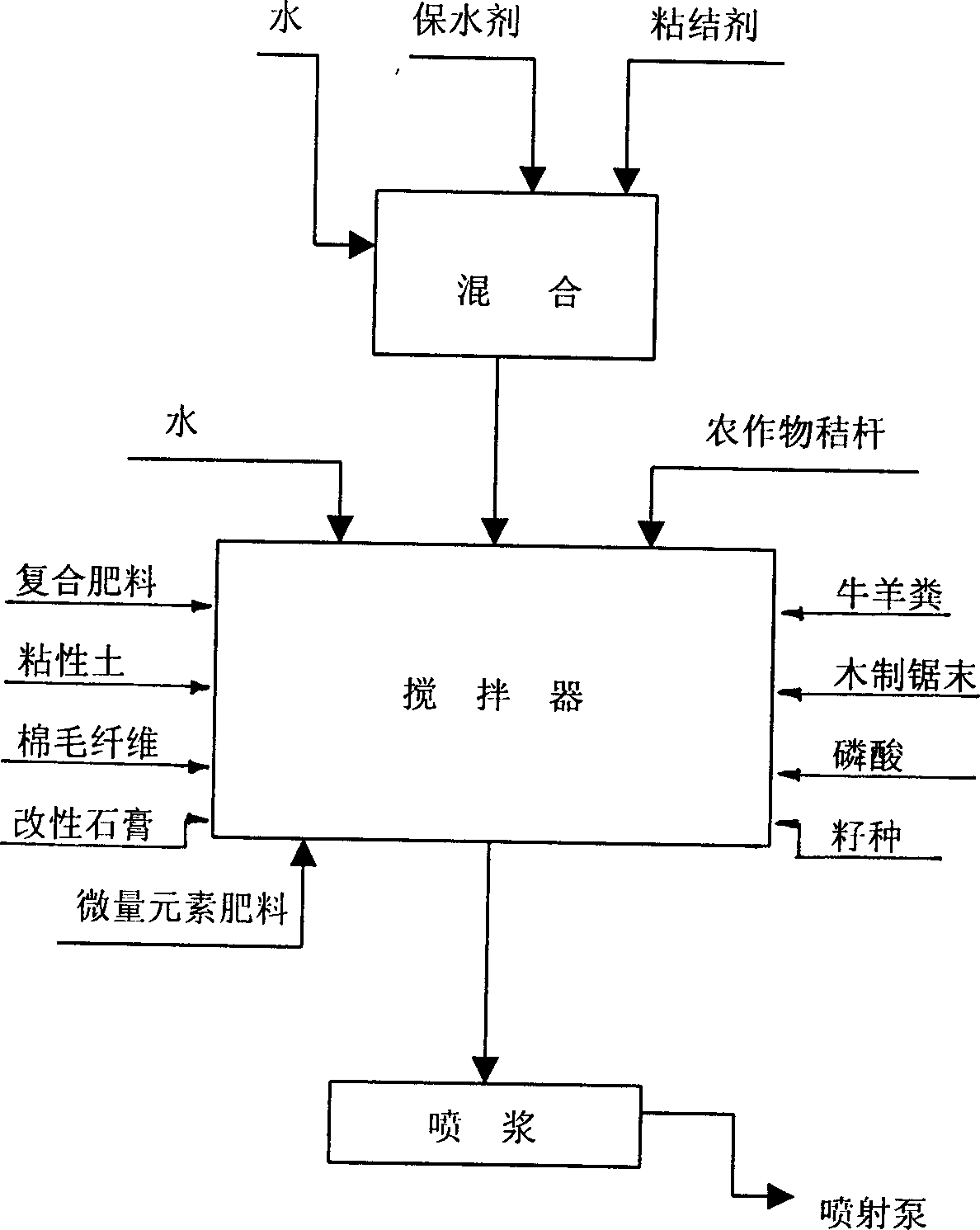

Gunite and method for fixing sand through forming covering by gunite

InactiveCN1466869AWill not polluteFast greeningCultivating equipmentsSoilless cultivationAdhesivePhosphoric acid

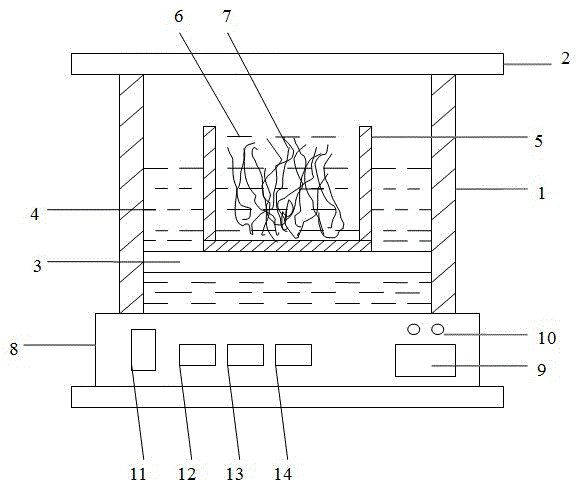

A method for fixating sand while growing plants by spraying slurry to form a cover layer on the surface of desert or ground includes such steps as proportionally preparing slurry from water, strew or stalk or industrial fibrous dregs, adhesive loess or laterite, water-preserving agent, adhesive, cotton or wool fibres, composite fertilizer, trace element fertilizer, modified gypsum, ox(or sheep) dung, saw dust, phosphoric acid and plant seeds, and spraying it onto surface of desert or ground. Its advantages are high effect and low cost.

Owner:格尔木昆成农业科技开发有限公司

Wool fibre fabric sweat shirt (pants) with functions of powerful antibiosis, cancer prevention and life prolonging by utilizing nano silver, selenium and germanium

InactiveCN101703319AReduce permeationAnti-electromagnetic wave shieldingMonocomponent protein artificial filamentHeavy metal active ingredientsSe elementHuman immunodeficiency virus (HIV)

The invention provides a wool fibre fabric sweat shirt (pants) with functions of powerful antibiosis, cancer prevention and life prolonging by utilizing nano silver, selenium and germanium, belonging to the technical field of healthy wool textile fibre fabrics clothes production. In the real life of people, various germs, viruses and fungi are contacted unavoidably, in particular, various bird flu and HIV discovered currently seriously threaten the health of human beings. Nano silver can kill 650 types of pathogens; far-infrared rays are almost absorbed by the skin of human body completely to lead the surface temperature of the skin to rise; heat energy impels the blood vessel to expand, improves blood circulation and microcirculation; the electromagnetic wave is colorless, tasteless and formless, can easily cause pollution to human body and is a potential killer. The anions in the air are vitamins and longevity elements in the air and are beneficial to human body; selenium and germanium are important elements to prevent and resist cancer; and the mixture of bee series can comprehensively supplement a plurality of nutrient active components required by human body. After nano treatment, the efficacy of anti-aging traditional Chinese medicine can be improved to 100 times.

Owner:成钢

Light ventilated thermal fabric and preparation method thereof

The invention discloses light ventilated thermal fabric and a preparation method thereof. The light ventilated thermal fabric is prepared by the following raw materials in parts by weight: 35-65 parts of wool fiber, 12-35 parts of modal fiber, 25-45 parts of cotton fiber, 2-15 parts of polyester short fiber, 2-15 parts of viscose fiber, 2-15 parts of spandex fiber, 8-30 parts of tencel fiber, 8-25 parts of silk fiber, 2-15 parts of chinlon fiber and 15-35 parts of polyester fiber. The preparation method comprises the following steps: twisting the wool fiber, the modal fiber, the cotton fiber and the polyester short fiber into weft yarns; twisting the viscose fiber, the spandex fiber, the tencel fiber, the natural silk fiber, the chinlon fiber and the polyester fiber into warp yarns; obtaining the light ventilated thermal fabric after warping and weaving processes.

Owner:湖南寐家居科技有限公司

Energy-saving insulating brick

InactiveCN101172831AExcellent heat absorption and heat preservation effectImprove insulation effectSolid waste managementBrickPortland cement

The invention relates to an energy saving heat preserving brick which solves the technical problems that the prior construction wall has cockamamie energy saving and heat preserving measure constructions, long construction period and high cost. The invention comprises the steps as follows: mixing and stirring the raw materials, extruding for shaping and maintaining. The weight ratio of the raw materials is that: 230 to 320 parts of portland cement, 35 to 20 parts of swelling perlite, 430 to 610 parts of general sand, 70 to 15 parts of cinder, 6 to 3 parts of straw, 4 to 2 parts of plant ash, 1.6 to 2 parts of felted wool fibre, and 97 to 135 parts of water. The invention has good energy saving and heat preserving capacities and good compression resisting intensity.

Owner:江苏康顺鼎上节能保温科技股份有限公司

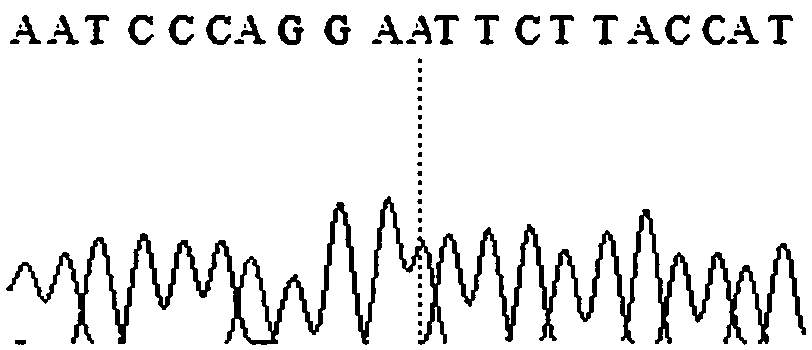

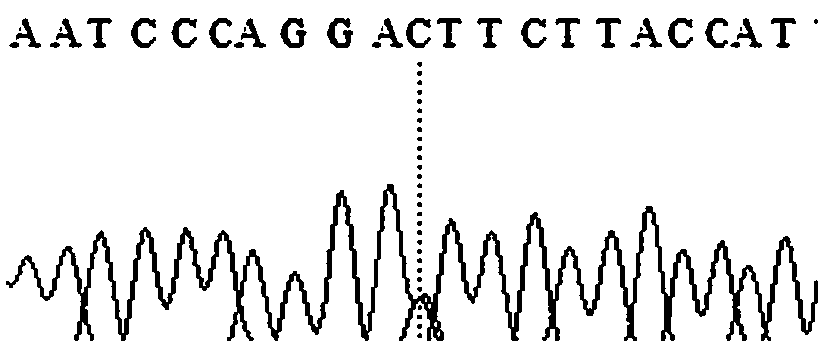

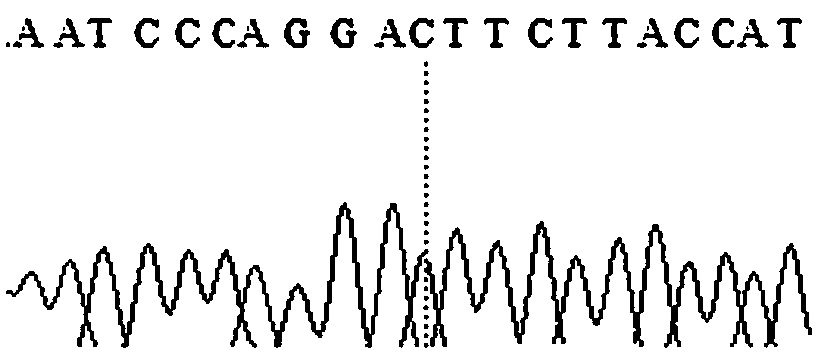

Molecular marker related with diameter character of sheep wool fibers as well as specific primer and application thereof

ActiveCN107604078AHigh precisionSpeed up the breeding processMicrobiological testing/measurementDNA/RNA fragmentationAnimal scienceFiber diameter

The invention relates to the technical field of animal molecular markers, in particular to a molecular marker related with a diameter character of sheep wool fibers as well as a specific primer and application thereof in selection of diameter character of Chinese Merino sheep wool fibers. The molecular marker related with the diameter character of the sheep wool fibers is located at the No.30 exonof the No.21 chromosome of FAT3 gene. The molecular marker has the advantages that the function of using rs425144268 SNP site as the molecular marker of the diameter of the sheep wool fibers is disclosed for the first time, and the function of applying the rs425144268 SNP site to the selection of the diameter character of the Chinese Merino sheep wool fibers is disclosed for the first time; whenthe excellent diameter character of the wool fibers is identified by the molecular marker related with the diameter character of the sheep wool fibers, the operation is simple, and the sheep with smaller fiber diameter can be screened in an assisting way; because the detection level of the molecular marker is started, the accuracy of variety selection is improved, and the detection efficiency is improved.

Owner:新疆畜牧科学院畜牧研究所 +1

Method for dyeing wool fibres by using acidic mordant dye

InactiveCN102206923AReduce the content of free chromium ionsReduce total chromium ion contentDyeing processWastewaterWool fibre

The invention discloses a method for dyeing wool fibres by using acidic mordant dye, comprising the following steps of: firstly, dyeing wool fibres with dye; secondly, mordanting the dyed wool fibres; and finally, soaping the mordanted wool fibres to finish the dyeing operation. In the method for dyeing wool fibres by using the acidic mordant dye, disclosed by the invention, the traditional dyeing technique is not changed, but an assistant is added on the basis of the traditional technique, no influence is caused to all kinds of dyeing indexes and convenience is provided for use in factories.Deducted from the principle of the new method, the new method can be used for remarkably reducing the content of free chromium ions on the wool fibres and dramatically reducing the content of the total chromium irons in the residual dyeing solution. A new dyeing method is provided for the safe use of the acidic mordant dye and is used for avoiding damage to health and reducing the damage of the chromium ions in the discharge of the waste dyeing water to the environment.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Preparation method of special antibacterial wool fiber for wool hat

InactiveCN107974828ASoft touchFeel smoothPhysical treatmentBiochemical fibre treatmentThioureaUltraviolet lights

The invention discloses a preparation method of a special antibacterial wool fiber for a wool hat. The preparation method comprises the steps of dipping the wool fiber in acetone, airing after washing, adding into a mixed aqueous solution of sodium cyanate and hydrogen peroxide, airing after dipping, and irradiating through an ultraviolet light to obtain a pretreated wool fiber; adding thiourea, urea and butyl titanate into absolute ethyl alcohol for mixing, adjusting a pH value, adding deionized water for stirring until a Tyndall effect occurs, standing for ageing, drying, grinding, and calcining to obtain modified nanometer titania; adding chitosan into an acetic acid aqueous solution, adjusting a pH value, adding the modified nanometer titania, adjusting a system pH value, adding glutaraldehyde after temperature rising, standing for reacting, centrifuging, washing, and drying to obtain modified chitosan; adding the modified chitosan, a plant extract, beta-cyclodextrin and a silane coupling agent KH-550 into the deionized water, and stirring to obtain an antibacterial solution; adding the pretreated wool fiber into the antibacterial solution for padding processing, and baking after drying.

Owner:安徽中福毛纺制帽有限公司

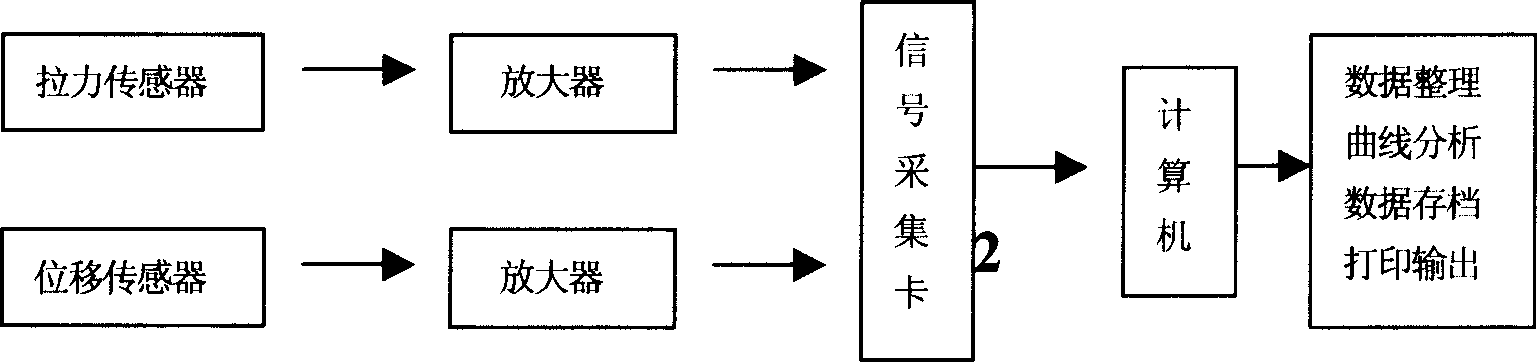

Flame-retardant treatment method for wool fibers

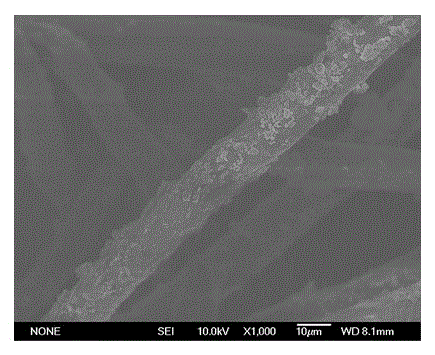

InactiveCN102720053AShort processGood flame retardant and washing resistancePhysical treatmentAnimal fibresPolymer scienceTriethoxysilane

The invention relates to a flame-retardant treatment method for wool fibers. The flame-retardant treatment method includes aiming at flammability of the wool fibers, microwave irradiating the wool fibers in the microwave reactor, impregnating the postirradiation wool fibers into carbon-ball suspension made of deionized water, gamma-mercaptopropyl triethoxysilane and nitric acid modified carbon balls serving as a flame retardant, and performing flame-retardant treatment in a supersonic disperser. The flame-retardant treatment method is short in process procedure and accurate and real in data, the wool fibers are flame-retardant and fine in resistance to washing, the limit oxygen index of the wool fibers after being washed for 30 times is 34%, and the flame retardancy of the wool fibers can be improved by 36%. Besides, the flame-retardant treatment method for the wool fibers is high in efficiency.

Owner:TAIYUAN UNIV OF TECH

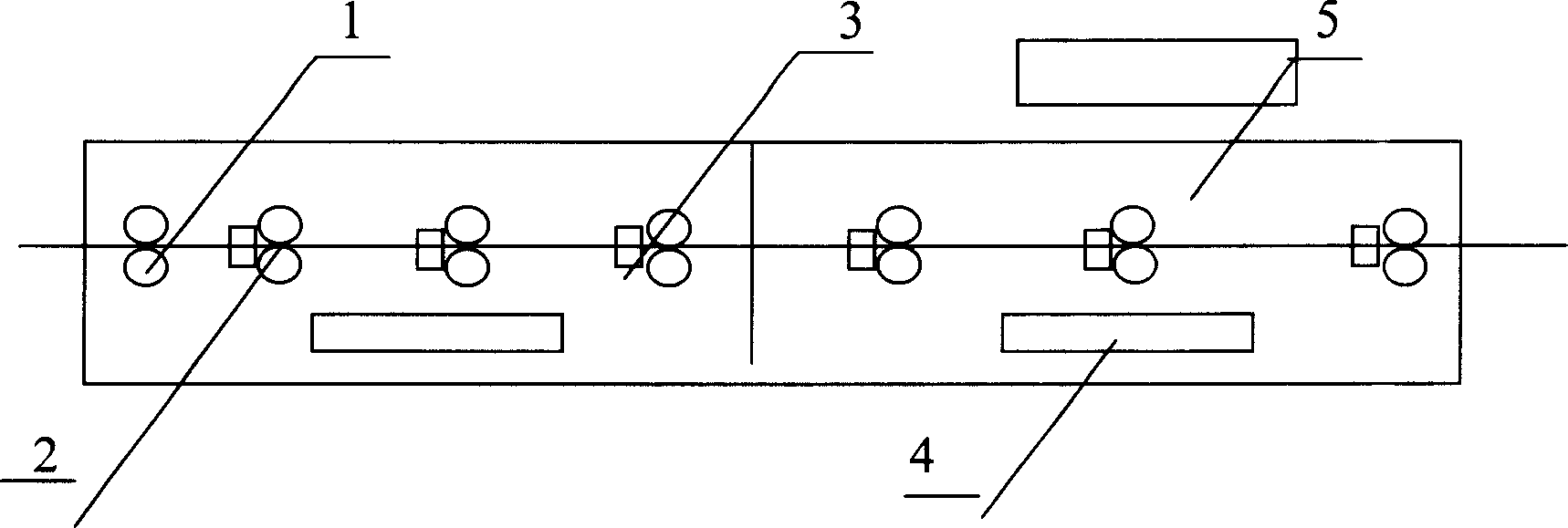

Method for drawing and modifying wool fibre

InactiveCN1916263ALiquid/gas/vapor textile treatmentMechanical treatmentPolymer scienceNatural fiber

The present invention relates to a wool fibre modification method, belonging to the field of natural fibre technology. Said method includes the following steps: preimpregnation treatment of wool fibre, twisting and drawing, heating and moistening, first setting, rinsing, secondary setting and drying so as to obtain high-count fine wool.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Low-temperature dyeing technology for wool fabric

The invention discloses a low-temperature dyeing technology for wool fabric. The technology comprises a mixed dye solution preparation step, a dyeing step, a fixation step, a post-treatment step and the like. By one-bath dyeing, an ionic liquid with a dissolution effect on wool keratins is added to a mixed dye solution; the keratins of wool fibers are partially dissolved at the initial dyeing stage; rapid penetration of dye molecules is accelerated by strong permeability and strong diffusivity of rare-earth ions after heating; and the rare-earth ions with positive charges and negative static electricity of the wool fibers are attracted by each other, can penetrate into the wool fibers, and can coordinate with groups, of exposed lysine residual bonds treated by the ionic liquid and the like, for determining the whiteness of the wool in the wool fibers, so that relatively small yellowing in the colors of the wool before and after being dyed is ensured.

Owner:赤峰圣伦绒毛制品有限公司

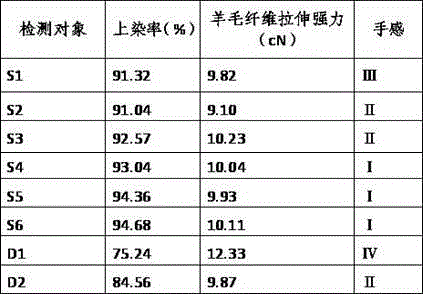

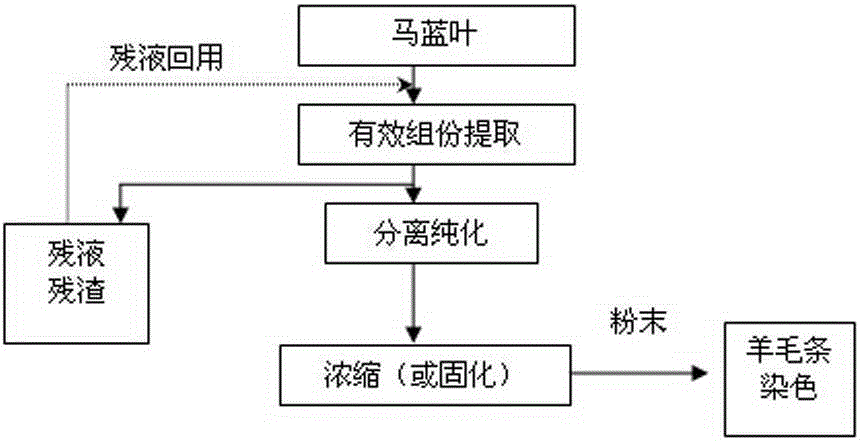

Technological method for dyeing wool tops through plant indigo dye

The invention discloses an extraction technology of extracting plant indigo from baphicacanthus cusia bremek leaves and a dyeing technology of top dyeing of wool fiber tops through the plant indigo. The technology comprises the steps that collected baphicacanthus cusia bremek leaves are cleaned thoroughly, impurities are removed, after natural airing or drying at low temperature is conducted, the baphicacanthus cusia bremek leaves are smashed in a pulverizer, and baphicacanthus cusia bremek leaf plant powder dregs are obtained; a mixed solution of ethyl alcohol and water is poured into the baphicacanthus cusia bremek leaf plant powder dregs, and a plant indigo extracting solution is obtained through ultrasonic treatment; high-speed centrifugation is conducted on the extracting solution, vacuum concentration and drying are conducted after the impurities are removed, and plant indigo powder is obtained; the plant indigo powder is dissolved in soft water, caustic soda and sodium hydrosulfite are sequentially added, the mixture is stirred evenly and added into a top dyeing dye vat, and wool tops to be dyed are completely immersed; the temperature rises to start dyeing, and after heat preservation is conducted for a certain period, the wool tops are taken out of dye liquor to be dewatered; the wool tops are moved into an air blower rapidly, and oxidation is conducted on the wool tops through air which flows at a high speed till the wool tops turn blue from yellow green; the wool tops are put back into the dye vat, soaping is conducted, washing is conducted through clear water after soaping, drying is conducted, and the the wool tops dyed through the plant indigo are obtained.

Owner:JIANGSU DANMAO TEXTILE

Continuous processing technology for non-shrink treatment of chlorine-free wool top and wool product

ActiveCN105986484AQuick contactAct quicklySucessive textile treatmentsSolvent-treatmentWater chlorinationPulp and paper industry

Owner:天津市诺奥科技发展股份有限公司

Anti-wrinkle treatment process of wool and linen yarns

InactiveCN104695203AStrong water absorptionGood sweat absorptionVegetal fibresAnimal fibresPolymer scienceEthylic acid

The invention discloses an anti-wrinkle treatment process of wool and linen yarns. The anti-wrinkle treatment process comprises the following specific steps that 1, selected warp and weft yarns include, by mass, 32-38 parts of wool fiber, 24-34 parts of linen fiber, 9-11 parts of viscose, 7-13 parts of cotton fiber, 6-10 parts of chitosan fiber and the balance corn fiber, and the wool and linen yarns are dipped in a hydrogen peroxide solution to be treated; 2, the wool and linen yarns are dipped in a potassium permanganate solution to be treated; 3, the wool and linen yarns are treated in a solution comprising 0.3% of acetic acid and 0.2% of chitosan; 4, the wool and linen yarns are dipped in an organosilicon quaternary ammonium salt solution to be treated. The anti-wrinkle treatment process is easy to operate, low in treatment cost, good in anti-wrinkle effect, free of corrosion damage, and safe and environmentally friendly in the treatment process.

Owner:SUZHOU CHENHENG WEAVING

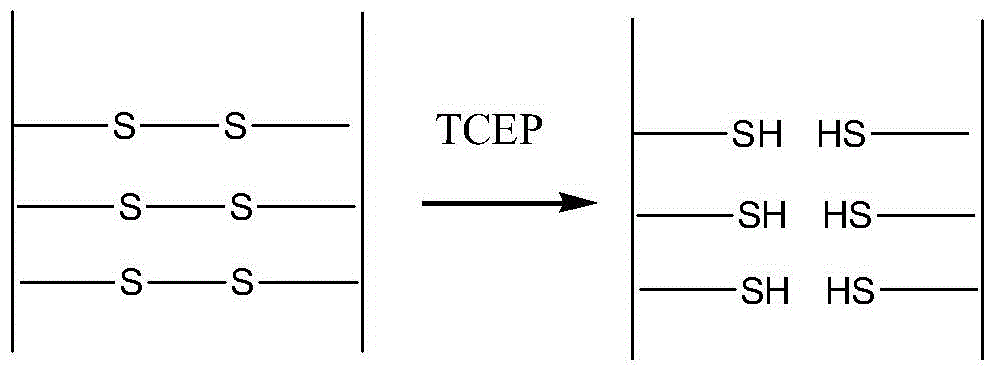

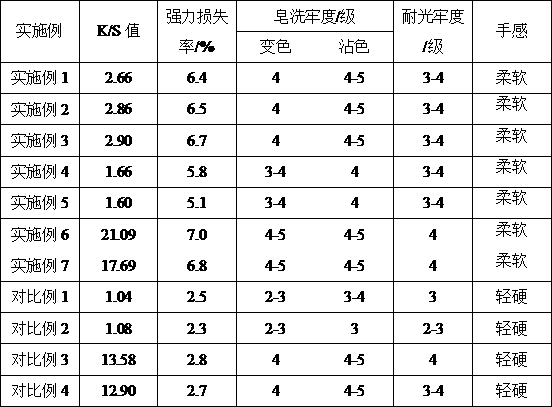

Method for preparing antistatic anti-felting wool fabric with good dyeing property

InactiveCN104404763AGood drapabilityGood warmth retentionAnimal fibresEnvironmental resistanceChemical reaction

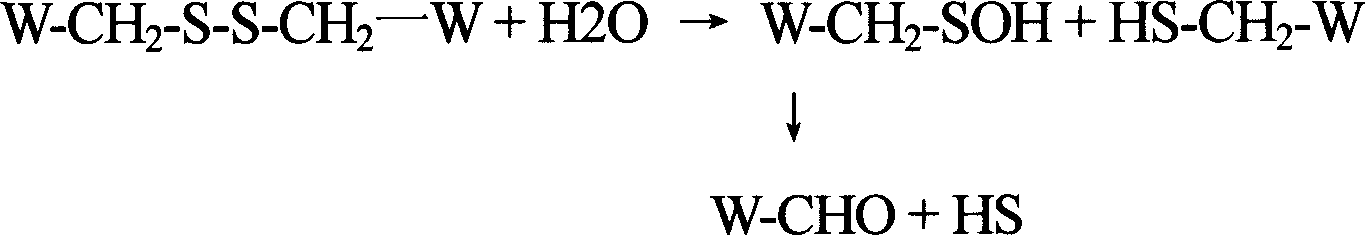

The invention relates to a method for preparing an antistatic anti-felting wool fabric with good dyeing property. The method comprise the following steps: pre-treating wool fabric with tris(2-carboxyethyl) phosphine (TCEP) to break disulfide bonds in wool fabric keratin to form sulphydryl with higher activity, and then grafting molecular chains containing acrylate in the presence of triethylamine through the thiol-ene click chemical reaction to obtain the wool fabric. The method disclosed by the invention not only has remarkable effect but also is safe and environment-friendly, has no harm to human bodies and environments, and is simple and effective as the groups of the wool are directly used as the active groups.

Owner:DONGHUA UNIV

High-efficiency short-process dyeing process

The invention relates to a high-efficiency short-process dyeing process. The dyeing process includes: (1), pretreating; (2), presetting blank cloth; (3), performing reductive cleaning; (4), designing a dyeing auxiliary formulation; (5), dyeing; (6), performing afterfinish wet rapid-steaming. A two-bath method is adopted and includes: dyeing wool fiber: disposing blended fabric in a dyeing container, adding a dyeing auxiliary obtained in the step (4) and dye into the dyeing container at normal temperature to obtain dyed wool fiber; dyeing polylactic acid fiber: disposing a bucket with the blended fabric into the dyeing container, adding the dyeing auxiliary obtained in the step (4), and glacial acetic acid and a dye fixing agent to obtain dyed polylactic acid fiber. The high-efficiency short-process dyeing process has the advantages of being effective in water saving and pollution reducing and high in color fastness.

Owner:JINHUA ZHICHAN MAOYUAN INFORMATION TECH CO LTD

Homochromatic dyeing process of wool/acrylic fiber blended fabric

The invention provides a homochromatic dyeing process of wool / acrylic fiber blended fabric, which comprises the following steps: A)washing fabric; B)dyeing: compositing 1-2%owf leveling agent, a reactive dye and a dispersion-type cationic dye to form a mixed dye, wherein the bath ratio is 1: 10, adjusting the pH value by acetic acid to 4.5-5; bathing at the temperature of 70 DEG C while dyeing, then heating to the temperature of 85 DEG C with rate of 1 DEG C / min, insulating for 10 minutes, heating to 95 DEG C with rate of 0.5 DEG C / min, insulating for 20 minutes, heating to 100 DEG C with rate of 0.5 DEG C / min, insulating for 20 minutes; C) slowly cooling; D)fixing color, washing the dyed fabric by water with temperature of 50 DEG C, adding 10%owf fixing agent, immersing for 30-50 minutes under normal temperature; and E)drying. The homochromatic dyeing process has the advantage of good homochromatic dyeing effect of the blended fabric, aberration delta E of acrylic fiber and wool fiber is less than 3, and the staining fastness and fading fastness of the dyed fabric can reach more than grade 4.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

Preparation method for and application of naturally antibiotic and antistatic yarn

InactiveCN102733023AImprove antistatic performanceImprove antibacterial propertiesBlanketBed linenYarnWool fibre

The invention discloses a preparation method for naturally antibiotic and antistatic yarn. The yarn is processed by blending technology by hemp fiber, woolen fiber and viscose fiber as raw materials and is characterized in that the blending ratio of the hemp fiber, the woolen fiber and the viscose fiber is 20%-40%, 30%-50% and 20%-40%. The method uses the hemp fiber, the woolen fiber and the viscose fiber as main materials and blends the main materials into yarn. The hemp fiber has the characteristics of natural antibiosis and good antistatic property, so a carpet made from the fabric fabricated by the yarns has good antibiotic and antistatic performance for a long time.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Production method of polylactic-acid-fiber-containing spun wool fabric

InactiveCN103898765AEasy to blendGood water absorption and heat preservation performanceCarbon fibresBiochemical fibre treatmentYarnPolymer science

The invention discloses a production method of a polylactic-acid-fiber-containing spun wool fabric. The fabric is spun from wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and polylactic acid fibers. The production method comprises the following steps: respectively carrying out anti-pilling treatment, enzyme treatment and softening treatment on the wool fibers and cashmere fibers; spinning the wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and polylactic acid fibers in a weight ratio of (55-75):(12-18):(18-28):(12-15):(5-8) into a fabric; and finally, carrying out after-treatment on the fabric by using a water-soluble polyurethane wool anti-shrinking agent. The method can greatly reduce the damage of the wool fiber product and reduce pilling; and the fabric has the advantages of softer feeling, greatly lower felting shrinkage and better quality.

Owner:汤丽娟

Preparation method for improving dyeing depth of natural dye and reactive dye of wool

The invention discloses a preparation method for improving dyeing depth of natural dye and reactive dye of wool. The preparation method comprises the following steps: (1) performing pre-treatment on the wool, namely, soaking wool fibres in a pre-treatment liquid which is compounded by sodium citrate, sodium ethoxide and a penetrating agent, and treating for 20 to 40 minutes at 30 to 50 DEG C; (2)performing acid neutralizing and water washing, namely, neutralizing the pre-treated wool fibres with a suitable amount of acid and washing the neutralized wool fibres with water; and (3) dyeing, namely, dyeing the wool fibres by adopting the natural dye and a reactive dye for wool. According to the preparation method, after the wool fibres are treated at low temperature through a diluted pre-treatment liquid, the wool fibres are dyed through the natural dye or the reactive dye for the wool. A dyed wool product with soft hand feeling, deep colour and excellent colour fastness can be prepared;the method is simple and feasible and is low in implementation cost, and has low damage to wool strength; and energy resources are saved by low-temperature dyeing.

Owner:常州喜莱维纺织科技有限公司

Bamboo fiber-contained non-woven fabrics containing rose essential oil capable of continuously releasing negative oxygen ion and preparation method thereof

InactiveCN106087250AEasy to useIncrease the function of absorbing odorConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyethylene glycolOxygen ions

The invention discloses a bamboo fiber-contained non-woven fabrics containing rose essential oil capable of continuously releasing negative oxygen ion and a preparation method thereof, and is characterized in that the bamboo fiber-contained non-woven fabrics comprises, by amounts by weight, the following raw materials: 4-9 parts of rose essential oil, 3-7 parts of bamboo fiber powder, 2-5 parts of wool fibre, 4-8 parts of nanometer tourmalinite powder, 4-9 parts of PAMAM solution, 5-10 parts of polylactic acid, 1-3 parts of mulberry silk, 1-2 parts of polyethylene glycol 200, 3-5 parts of active carbon, 4-8 parts of mint essence, 10-15 parts of sodium periodate solution, 50-70 parts of isotactic polypropylene, 3-6 parts of diatomite, 1-2 parts of sodium dodecanesulphonate, proper amount of sodium hydroxymethyl cellulose, and proper amount of water. The method comprises the step of adding nanometer tourmalinite powder in the non-woven fabrics to get the effect of releasing negative oxygen ion continuously. The non-woven fabrics has the advantages of calming, easing pain, releasing cough, relieving itching, raising appetite and reducing blood pressure when being used as clothes inner liner; and rose essential oil and pure natural flavoring agent are added. The fabrics is pollution-free.

Owner:安徽泽泓塑业股份有限公司

Fabric containing milk protein fiber, manufacturing technique and textile of fabric containing milk protein fiber

InactiveCN103255536ASoft fabricImprove permeabilityDyeing processWoven fabricsProcess engineeringWool fibre

The invention relates to fabric containing milk protein fiber and a manufacturing technique thereof. The manufacturing technique mainly comprises warp-wise weaving and broad-wise weaving with different raw materials. The fabric containing the milk protein fiber is manufactured through dyeing, sizing, gray fabric test, singeing, relaxation, refining, thermoforming, washing, drying, forming, relaxation, test and curling. The dyeing and sizing technology is adjusted through a dyeing technology which is pretreated and processed through hyperthermic treatment for two times, therefore, a good processing effect is obtained, and damage to the milk protein fiber and wool fiber under various processing technological conditions is reduced effectively. In addition, the fabric containing the milk protein fiber is suitable for being applied to top-grade home textile, top-grade clothing, sports goods and health care goods.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

Wool/crotalaria sp./mulberry silk/cotton/polyester fiber blended fabric and preparation method thereof

The invention relates to a wool / crotalaria sp. / mulberry silk / cotton / polyester fiber blended fabric. The fabric comprises the following material components in percentage by weight: 28% of wool fiber, 35% of crotalaria sp. fiber, 17% of polyester fiber, 18% of cotton fiber and 3% of mulberry silk. The method includes the steps of: 1, top dying process of the cotton fiber and the crotalaria sp. Fiber; 2, dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber; 3, spinning process; 4 weaving process; 5, dying and finishing process; the spinning process includes: mixing and performing primary gilling, secondary gilling, third gilling and fourth gilling on products prepared by the dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber, then being subjected to primary roving, secondary roving and spinning processes together with yarn prepared by the top dying process of the cotton fiber and the crotalaria sp. Fiber, when a double-steel wire hook is adopted in the spinning process. The fabric achieves the purpose of being breathable, antibacterial and health-care, and meanwhile meets the requirements on various technical indexes of spring and summer fabrics.

Owner:江苏华西村纺织服装有限公司

Chlorination and resin method for shrink-resist treatment of knitting wool

InactiveCN1355351AKeep the inherent characteristicsNo effect on color fastnessFibre treatmentColour fastnessInternational standard

A technology for the antishrinking treatment to knitting wool includes chlorination and resin treating steps. Its advantages include high effect (less than 8% for shrinkage of the international standard), high quality of treated knitting wool, no influence to colour fastness of knitting wool, and retaining the inherent feature of wool fibre.

Owner:邓卫生

Novel sound-absorbing blend fiber fabric

InactiveCN104213310AExcellent sound absorption and sound absorption effectWear moisture-absorbing and breathableWeft knittingWarp knittingGlass fiberPalm fiber

The invention discloses a novel sound-absorbing blend fiber fabric. The novel sound-absorbing blend fiber fabric is blended and woven of glass fiber cotton fibers, palm fibers, sea grass fibers and goat wool fibers. The novel sound-absorbing blend fiber fabric comprises the following components in percentage by weight: 16-20 percent of glass fiber cotton fibers, 21-25 percent of palm fibers, 27-31 percent of sea grass fibers and 24-36 percent of goat wool fibers. The fabric is blended and woven of the glass fiber cotton fibers, the palm fibers, the sea grass fibers and the goat wool fibers; the woven fabric has a superior sound absorbing effect, can reduce the volume and the hum and is meanwhile moisture-absorbing, breathable, cool and comfortable to wear.

Owner:刘喜

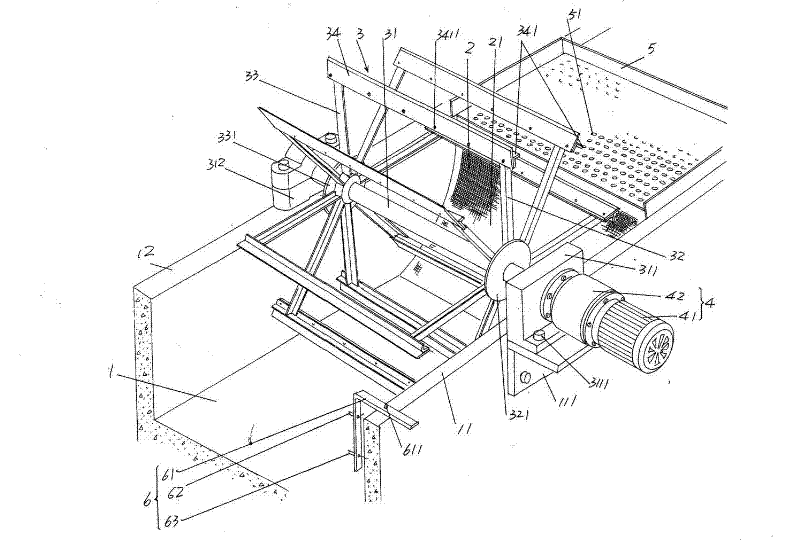

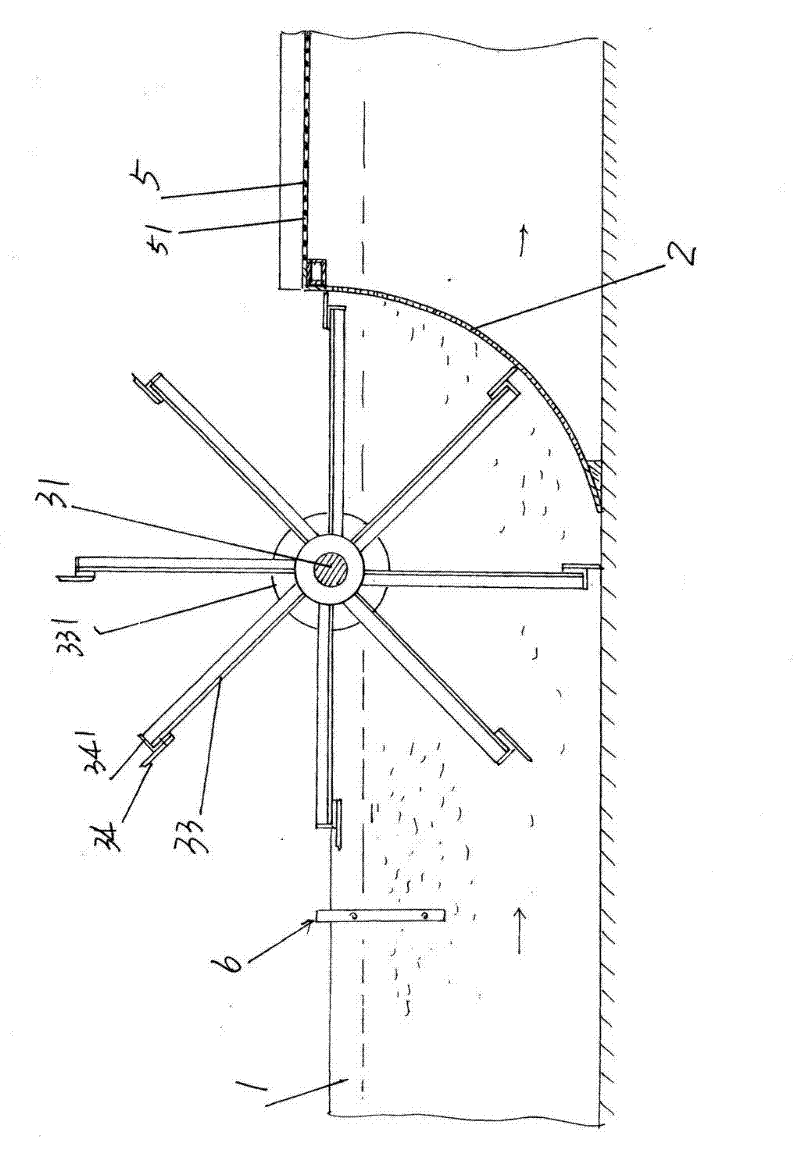

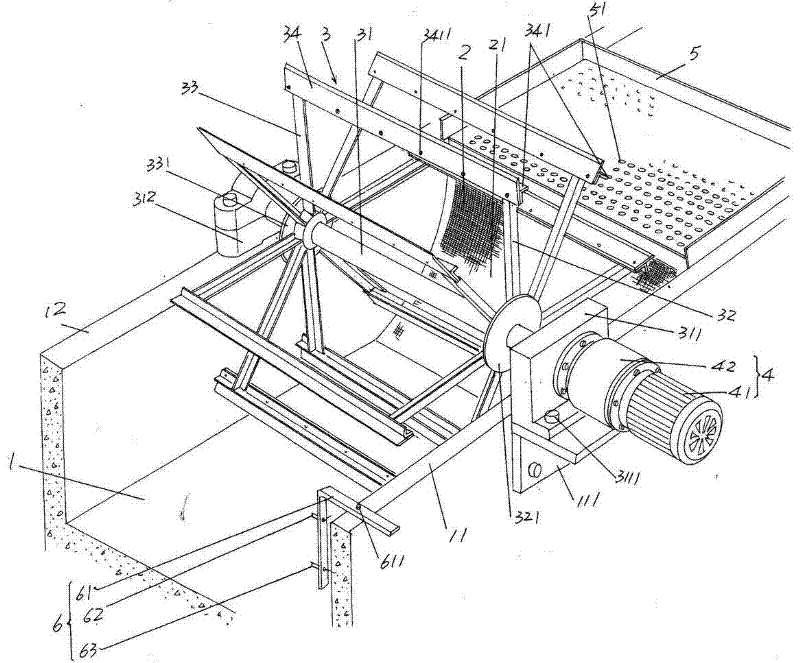

Wool filtering machine for water processing facility

InactiveCN102357320ASimple structureConvenient inspectionMoving filtering element filtersAdhesiveElectrical control

A wool filtering machine for a water processing facility belongs to the technical field of environmental facility. The water processing facility comprises a water collecting and guiding gutter with a first wall body and a second wall body. The wool filtering machine comprises the following components: a web plate arranged on a channel, which waste water passes through, of the water collecting and guiding gutter; a water-sprinkling and wool scraping dolly supported on the water collecting and guiding gutter and corresponding to a side of the web plate; a power transmission mechanism electrically connected with an electric control box, arranged on an outer wall on one side of the water collecting and guiding gutter and drivingly connected with the water-sprinkling and wool scraping dolly; a wool collecting and draining disc used for receiving wool fibres scraped from the web plate by the water-sprinkling and wool scraping dolly and draining off water adhesive to the wool fibres, and arranged on the water collecting and guiding gutter and on the other side of the web plate. The wool filtering machine of the invention has advantages of ideal wool fibre removal efficiency and effect, no special labor required, simple structure and convenient maintenance.

Owner:常熟协顺纺织制衣有限公司

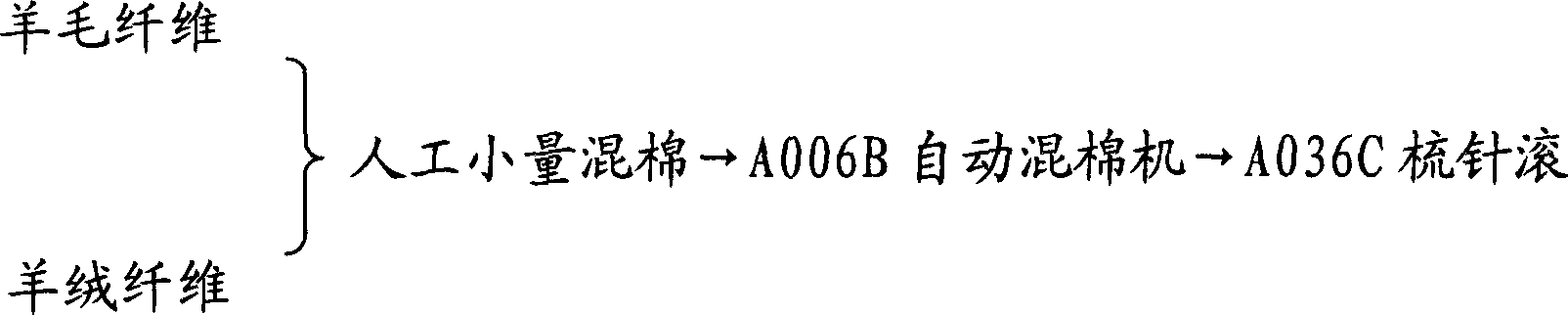

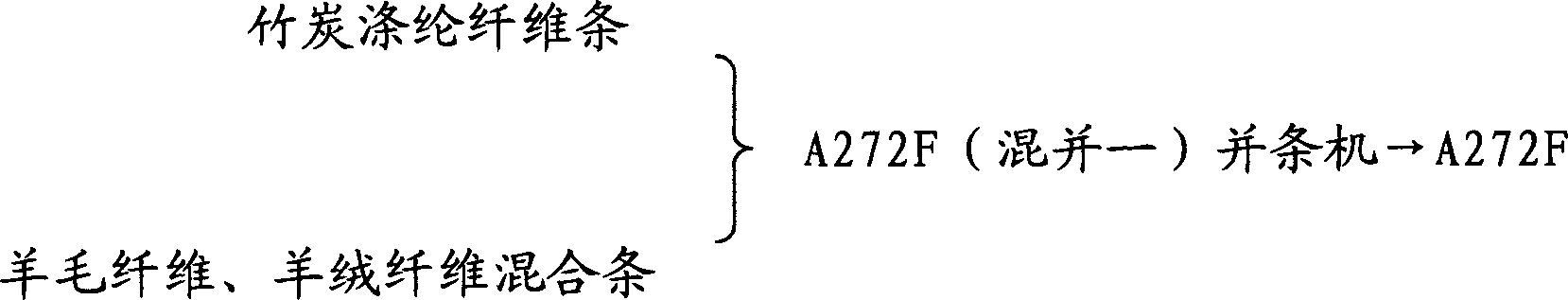

Bamboo carbon dacron fiber, woolen fiber and cashmere fiber blended yarn and producing method thereof

The present invention discloses a bamboo carbon polyester fibre, wool fibre and cashmere fibre blended yarn and its preparation method. It is made up by using 20-40% of bamboo carbon polyester fibre, 50-60% of wool fibre and 10-20% of cashmere fibre through a certain preparation process. The performance indexes of said blended yarn are as follows: single yarn breaking strength is 9.0-18.0 cN / tex, the coefficient of variation CV value of single yarn breaking strength is 8.0-22.0% and the coefficient of variation CV value of yarn evenness is 12.5-24.0%.

Owner:WUXI PAIHO TEXTILES CO LTD

Wool/cattle fluff fiber/mulberry silk/copper ammonia fiber blended fabric and preparation method thereof

InactiveCN104514071AFeel smooth and plumpUniform finenessBleaching apparatusDyeing processCuprammonium rayonPolymer science

The invention relates to a wool / cattle fluff fiber / mulberry silk / copper ammonia fiber blended fabric. The fabric comprises the following material components in percentage by weight: 30% of wool fibers, 24% of cattle fluff fibers, 26% of mulberry silk and 20% of copper ammonia fibers. The preparation method includes the steps of: top dyeing and re-combing, spinning, weaving and dyeing and finishing; the top dying and re-combing process includes, dying separately, dehydrating and backwashing, and mixing the wool fibers, the mulberry silk and the copper ammonia fibers by B412, gilling for three times during the mixing process, adding the mulberry silk for three times, gilling by B303 and B304, and combing by B311, adding the cattle fluff fibers during the gilling process of B305, then gilling by B305 for a second time, and at last combing by B306. The prepared product is gentle in gloss, soft, fine and smooth and good in drapability, has the texture and style of silk fabric, and is low in cost.

Owner:江苏华西村纺织服装有限公司

Technological formula of mulberry silk and wool fiber blended moistening emulsion

The invention discloses a technological formula of a mulberry silk and wool fiber blended moistening emulsion. When mulberry silk and wool fiber blending is conducted by means of a semi-worsted spinning system, moistening pretreatment is conducted on mulberry silk and wool fiber respectively, wherein a pretreatment emulsion of the wool fiber is prepared from, by weight of the wool fiber, 0.3%-0.5% of wool lubricant, 1.0%-1.6% of softening agent, 0.8%-1.2% of electrostatic agent, 0.5%-0.8% of penetrant, 0.3%-0.6% of emulsion and 15%-20% of water, and a pretreatment emulsion of the mulberry silk is prepared from, by weight of the mulberry silk, 0.5%-0.8% of softening agent, 1.5%-1.8% of electrostatic agent, 0.5%-0.8% of penetrant and 18%-22% of water. Treatment is conducted on the two fibers through the two emulsions respectively, the two emulsions can permeate into the interiors of the fibers, the effects of resisting static electricity, softening and increasing cohesive force are achieved, and the spinnability is improved; meanwhile, the technological requirements of spinning can be met, and the phenomena that a carding machine cylinder is wound, and wool is rolled on a drawing frame can be relieved; the technological formula is convenient to operate, low in operation cost and very prone to industrial application.

Owner:TONGXIANG YIDE TEXTILE

Bamboo carbon dacron fiber and woolen fiber scribbled and producing method thereof

The present invention discloses a bamboo carbon polyester fibre and wool fibre blended yarn and its preparation method. Said blended yarn is made up by using 20-40% of bamboo carbon polyester fibre and 60-80% of wool fibre through a certain preparation process. The performance indexes of said blended yarn are as follows: single yarn breaking strength is 9.0-18.0 cN / tex, coefficient of variation CV value of single yarn breaking strength is 8.0-22.0% and the coefficient of variation CV value of yarn evenness is 12.5-24.0%.

Owner:WUXI PAIHO TEXTILES CO LTD

Oxygen bleaching laundry detergent for wool and preparation method thereof

ActiveCN103451043AMild performanceWon't hurtNon-surface-active detergent compositionsSulfite saltLaundry

The invention relates to an oxygen bleaching laundry detergent for wool and a preparation method thereof. The laundry detergent comprises the following components in parts by mass: 10-20 parts of sodium percarbonate, 3-11 parts of sodium perborate, 20-30 parts of sodium sulfite heptahydrate, 1-5 parts of sodium citrate, 1-4 parts of sodium silicate, 1-5 parts of hydrogen peroxide, 0.2-0.5 part of super brightener, 0.3-1 part of water soluble essence, 0.2-1 part of sodium polyacrylate, 1-6 parts of propylene glycol, and 85-130 parts of water. The laundry detergent is mild in performance, can remove various stains such as tea stain, sweat stain, blood stain and coffee stain on woolen products, has strong detersive power, and has no harm to wool fiber.

Owner:威海毛纺织集团有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com