Continuous processing technology for non-shrink treatment of chlorine-free wool top and wool product

A technology of anti-shrinkage treatment and wool strips, which is applied in the direction of continuous treatment of textile materials, fiber treatment, solvent treatment, etc., to achieve industrialized production, solve pollution, and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

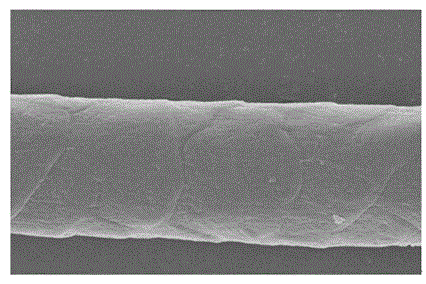

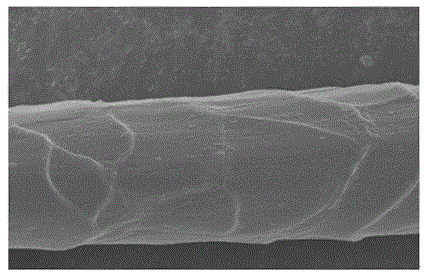

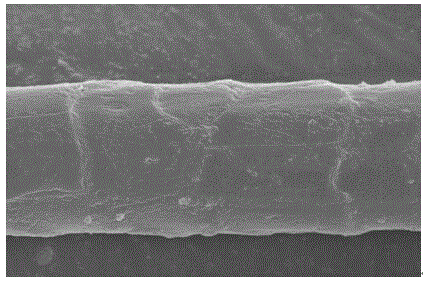

Image

Examples

example 1

[0040] Example 1: processing all-wool wool tops, the specification is 70 pieces. The process includes the following steps:

[0041] The first tank: padding treatment solution. The tank is a suction drum (type) wash tank (general purpose device) with a width of 1 meter, a volume of 360 liters and a circumference of one meter. There is an automatic heating device (general device) in the suction drum tank, and the main components are: High-efficiency catalytic solution of alkaline protease (alkali protease) 3g / L, tris(3-hydroxypropyl)phosphine 3g / L (optional, add non-ionic surfactant JFC 1g / L), pH 9 (as hydrogen phosphate Disodium and sodium dihydrogen phosphate are pH regulators), and the temperature is controlled at 50°C. Spread the wool strips evenly on the top rollers side by side and enter the treatment solution at a constant speed of 8 m / min to completely wet the wool strips to ensure that the surface of each fiber in the wool strips is treated evenly and thoroughly; The...

example 2

[0053] Example 2: processing all-wool wool strips with a specification of 56 pieces. The process includes the following steps:

[0054] The first tank: padding treatment solution. The tank is a suction drum tank with a width of 1 meter, a volume of 360 liters, and a circumference of one meter. There is an automatic heating device in the suction drum tank, and a liquid containing alkaline protease 3g / L, tris(3-hydroxypropyl ) High-efficiency catalytic solution of phosphine 3g / L, pH 10.5, controlled temperature 50°C. Spread the wool tops evenly on the top rollers side by side and enter the treatment solution at a constant speed of 3.8 m / min to completely wet the wool tops to ensure that the surface of each fiber in the wool tops is treated evenly and thoroughly; then pressurize The roller pressurizes the wool sliver to ensure that the liquid removal rate of the wool sliver is 130%; then the wool sliver with enzyme liquid enters the second treatment tank at a speed of 3.8 m / min...

example 3

[0067] Example 3: processing all-wool wool strips, the specification is 90 pieces. The process includes the following steps:

[0068]The first tank: padding treatment solution. The tank is a suction drum tank with a width of 1 meter, a volume of 360 liters and a circumference of one meter. There is an automatic heating device in the suction drum tank, and 3 g / L of alkaline protease, tris(3-carboxypropyl) Phosphine 3g / L, anhydrous calcium chloride 0.3g / L (optional in the range of 0 ~ 2g / L, 0.3g / L in this example), (or add non-ionic surfactant JFC 1g / L) High-efficiency catalytic solution with a pH of 8.5 and a controlled temperature of 50°C. Spread the wool tops evenly on the top rollers side by side and enter the treatment solution at a constant speed of 3.8 m / min to completely wet the wool tops to ensure that the surface of each fiber in the wool tops is treated evenly and thoroughly; then pressurize The roller pressurizes the wool sliver to ensure that the liquid removal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com