Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2377results about "Sucessive textile treatments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of antibacterial nanofiber membrane

ActiveCN105200663AImprove antibacterial propertiesOvercome mechanical propertiesSolvent-treatmentSucessive textile treatmentsFiberCross-link

The invention provides a preparation method of an antibacterial nanofiber membrane. The method comprises the procedures of preparation of a nanofiber membrane, preparation of germicide solutions and modification of the nanofiber membrane by the germicide solutions. The method is characterized in that the antibacterial nanofiber membrane is prepared by soaking the nanofiber membrane in the germicide solutions of different concentrations; the nanofiber membrane is formed by being subjected to a polymerization reaction in an organic monomer or a solution of the organic monomer and an inorganic germicide, or is formed by being directly soaked in a polymer solution or a germicide solution of a polymer and an inorganic mixed solution. The preparation method comprises the following steps: step (1), preparing the germicide solutions; step (2), preparing a polymer electrostatic spinning solution and preparing the nanofiber membrane; step (3), modifying the nanofiber membrane by the germicide solutions; an obtained hierarchical-pore nanofiber cross-linked-structure thin film of a core-shell structure is an antibacterial nanofiber membrane finished product.

Owner:上海展恒环保科技有限公司

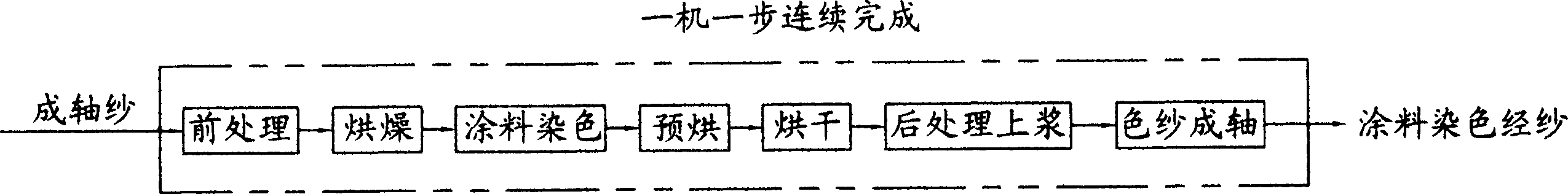

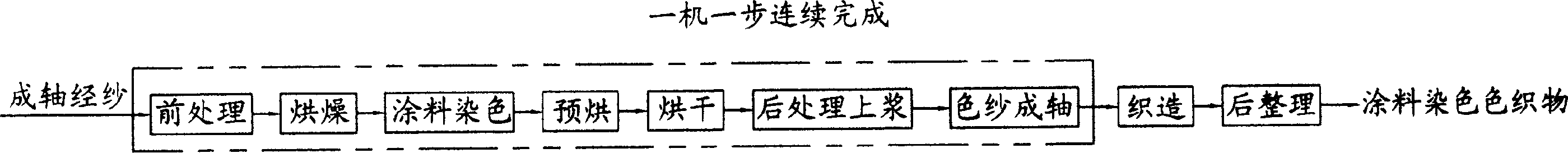

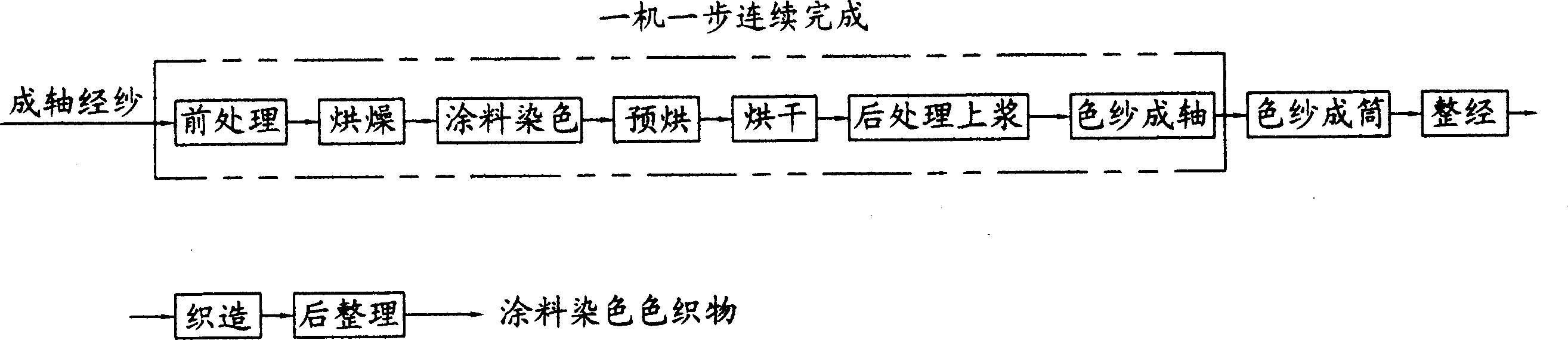

Pigment dyed colored cloth production method

InactiveCN1884659AQuality improvementGood processing depthSucessive textile treatmentsSingeingSewageEnergy consumption

The invention discloses a manufacturing method of paint dyeing weaver with oxford textile, chambray and denim, which comprises the following steps: predisposing warp; drying; dyeing; predrying; drying; after-treating; shafting warp; weaving; dressing; finishing one step by one machine continually. The invention satisfies large batch and scale manufacturing request, which is fit for producing original paint dyeing and other pain dyeing weaver product.

Owner:常州市森容纺织品有限公司

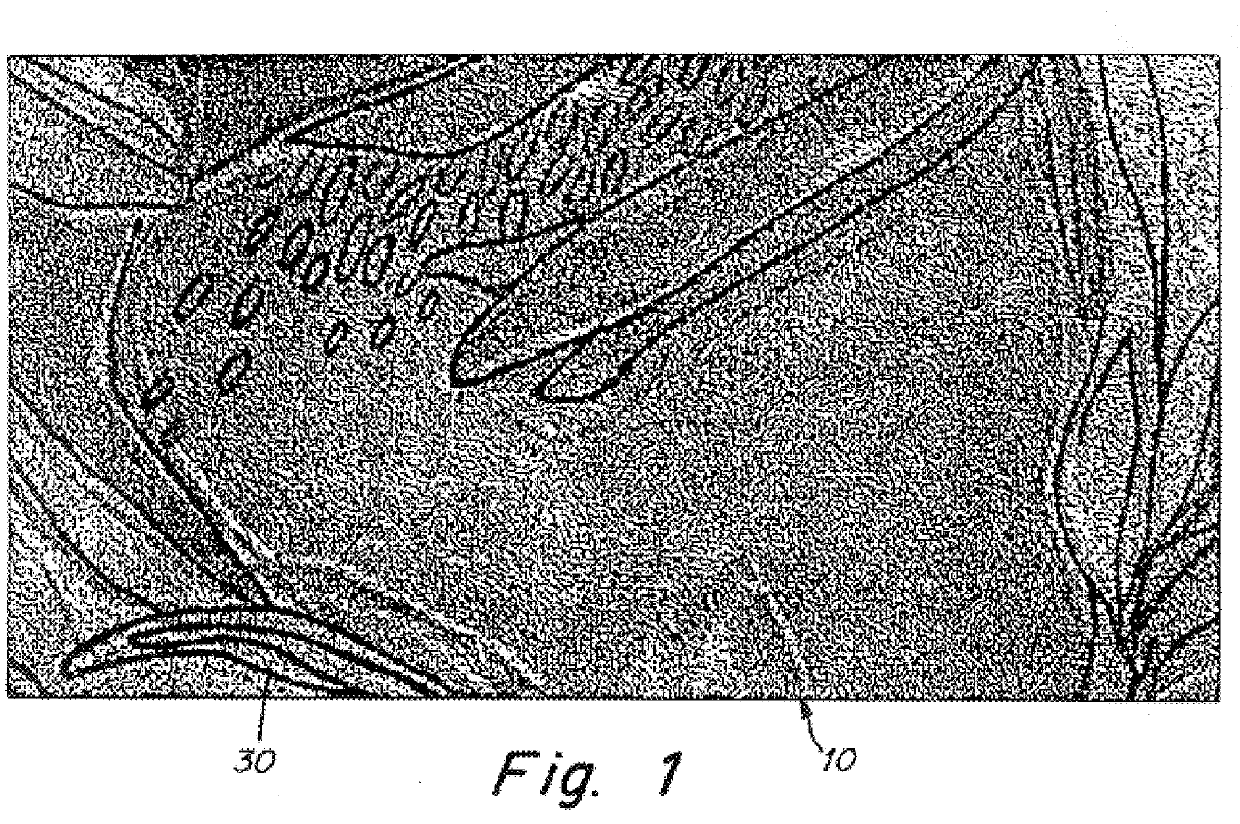

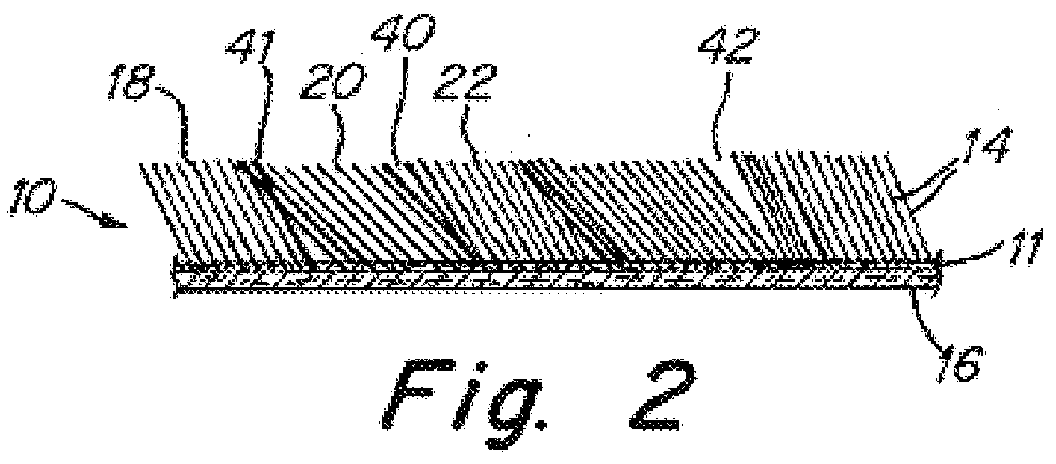

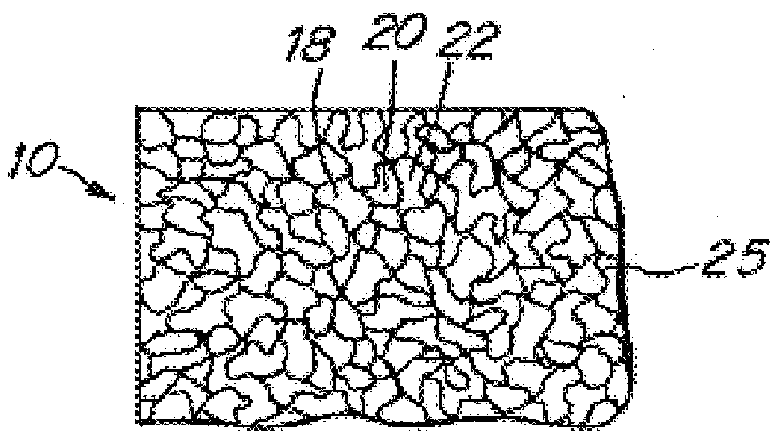

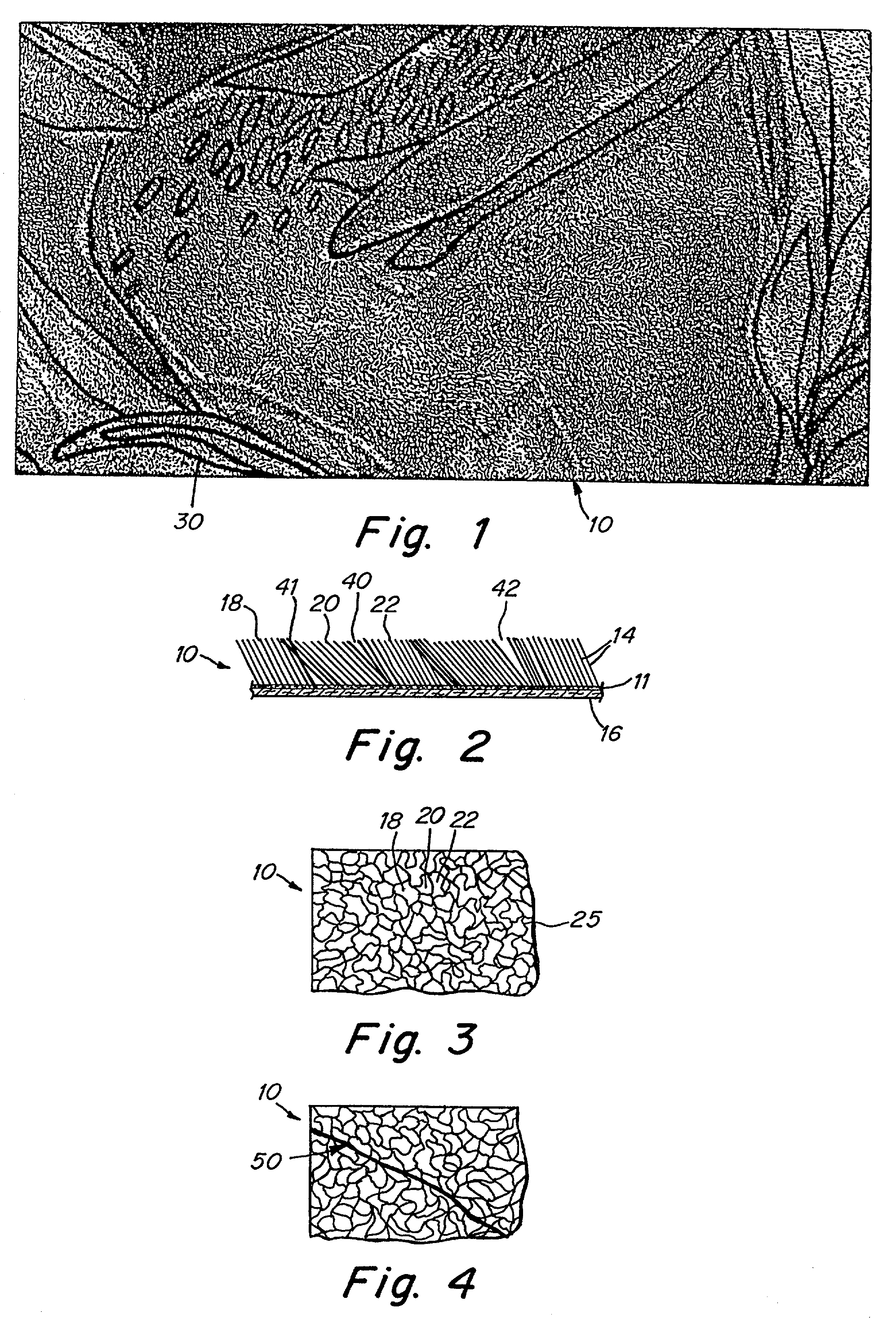

Printed flocked pile fabric and method for making same

InactiveUS6247215B1Soft handMore volumeLiquid surface applicatorsSucessive textile treatmentsFiberEngineering

Methods of forming a printed multicolor synthetic pile fabric having a substrate and pile formed of fibers arranged in random groups extending essentially unifomn-y across the entire width and along the entire length of the fabric are disclosed. The methods can be utilized to form fabrics wherein each of the above-mentioned groups comprises a random number of fibers extending at angles and in directions that randomly vary from the angles and directions of the fibers in adjacent groups. The methods can involve washing griege goods for selected times and at selected temperatures so as to randomly re-orient the fibers forming the flocked surface of the fabric. In preferred embodiments, the fabrics are printed after fiber re-orientation.

Owner:MICROFIBERS

One-bath process continuous production process for treating cotton and its blended fabric before dyeing and printing

InactiveCN1515735AAchieving low alkali dischargeEmission reductionSucessive textile treatmentsBiochemical fibre treatmentWastewaterPulp and paper industry

The present invention relates to a pretreatment one-bath continuous production process before printing and dyeing cotton and blended fabric in dyeing and finishing production of textile industry. Three steps of desizing, refining and bleaching can be combined into one steop to implement, it utilizes biological enzyme and chelate dispersant WS to form the high-effective green pretreatment agent, adds hydroperoxide to prepare treatment liquor. The fabric can be undergone the processes of pad-steaming or pad-thermodepositing treatment on the continuous steaming long carriage, water-washing and drying or undergone the processes of dip dyeing on overflow dyeing machine or dip dyeing machine, water-washing and drying.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

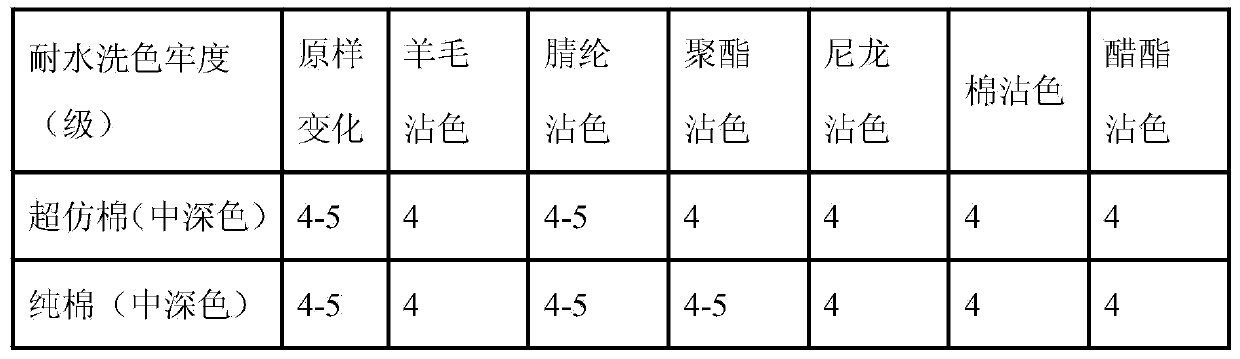

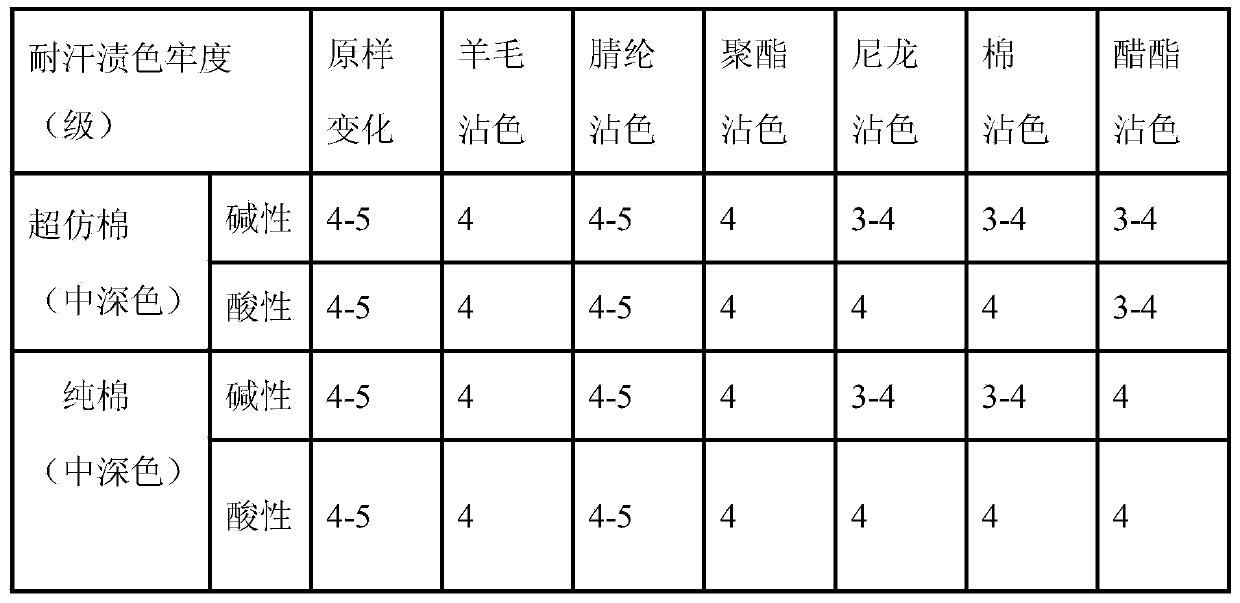

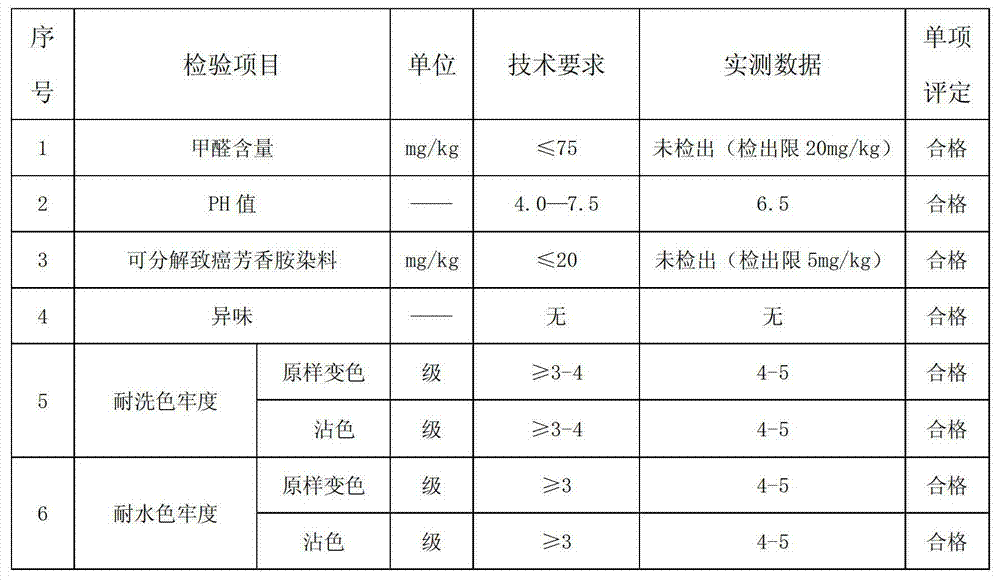

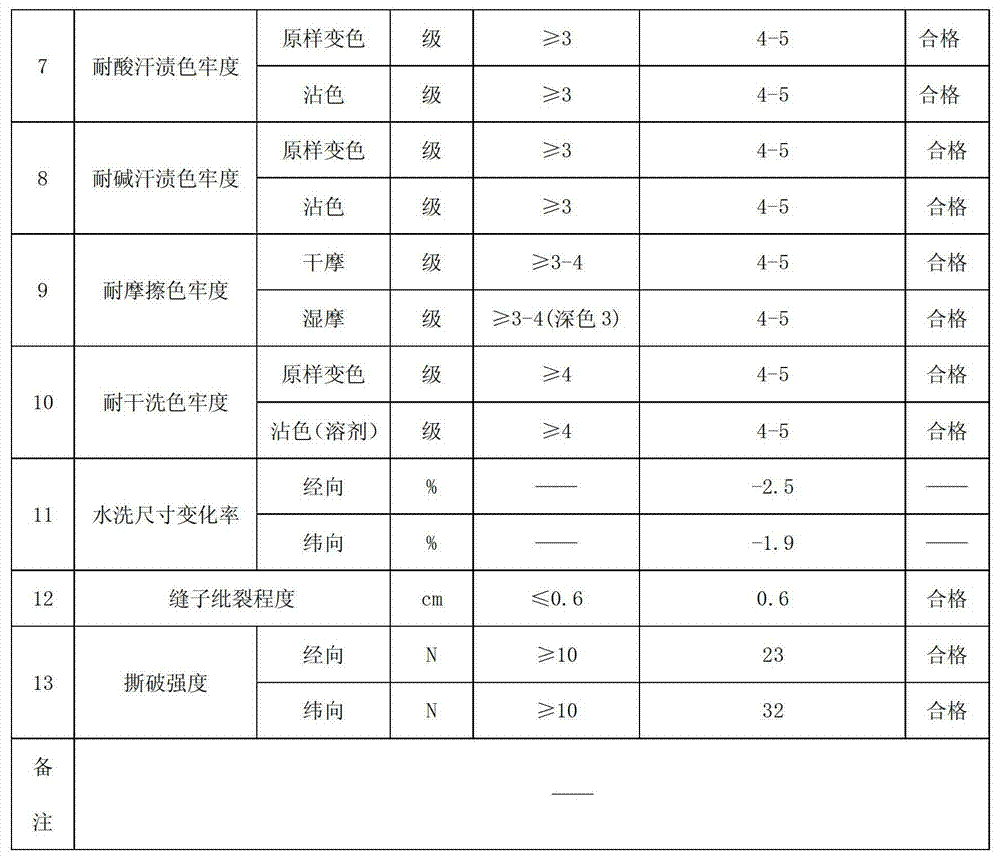

Preparation method of high-imitation cotton printed fabric

InactiveCN103741417AReduce tensionFully swollenSucessive textile treatmentsWoven fabricsPolyesterYarn

The invention discloses a preparation method of a high-imitation cotton printed fabric. The preparation method comprises the following steps: (1) weaving cloth; (2) sizing and oiling; (3) desizing and refining; (4) reducing alkaline amount; (5) shaping; (6) sanding; (7) printing; (8) post-shaping and drying; and (9) absorbing moisture, sweating and finishing. According to the preparation method, superfine denier fiber is used for weaving; warps and wefts adopt high-fischer yarns; compared with normal polyester cotton fabric, the high-imitation cotton printed fabric s better in moisture absorption and air permeability, and smoother in hand feeling; according the preparation method, raw material selection and structure design are used; and the processes of loosing and desizing, shaping, sanding, padding, absorbing moisture, sweating and finishing are used for preparing the high-imitation cotton printed fabric; the preparation method is simple and practical in process and strong in adaptability; the overall process has the characteristics of obviously saving energy and water; test of performances of colour fastness, strength and anti-static property proves that the high-imitation cotton printed fabric completely achieves the effect of the cotton.

Owner:浙江弘晨印染科技股份有限公司

Preparation method of regenerated cotton

InactiveCN104593910AReduce pollutionReduce defective rateMechanical cleaningPressure cleaningYarnFiber

The invention discloses a preparation method of regenerated cotton. The method comprises the following steps: a, sorting: firstly performing vibratory screening treatment on leftover, scrap, waste silk and yarn ends to obtain various cotton textile scraps; b, pretreating: performing alkaline cleaning, primary washing, hydrogen peroxide bleaching and secondary washing treatment on the obtained various cotton textile scraps respectively to obtain a pure white fabric stock with moisture content of being smaller than 1 percent; c, reprocessing: cutting the pure white fabric stock into fabrics with a physical character of being smaller than 1,200 mm, then reducing the fabrics into wool cotton, next loosening the wool cotton, and finally fluffing the wool cotton to form the regenerated cotton; d, packing: collecting fibers with length of 26-28 mm in the regenerated cotton, and packing the collected fibers to obtain the qualified regenerated cotton. According to the method, the waste textiles such as the leftover, the cloth scrap, the waste silk and the yarn ends are recovered and recycled.

Owner:YIBIN WEILUO TEXTILE

Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

ActiveCN103952845AImprove hydrophilicityGood wicking and moisture-wicking functionSucessive textile treatmentsWeft knittingYarnPolyester

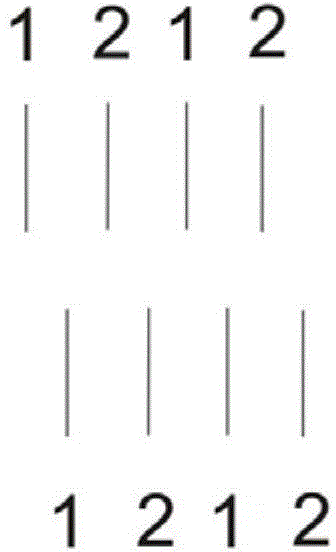

The invention discloses a moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and a preparation method thereof. The fabric is formed by weaving first yarns, second yarns, third yarns and fourth yarns, wherein the first yarns are regenerated cellulose fiber type blended yarns formed by blending linen, wool or cashmere, one or more types of cotton fibers and regenerated cellulose fibers, or regenerated cellulose multi-filaments, or regenerated cellulose staple fiber yarns; the second yarns are modified polyester fiber yarns with non-circular cross sections; the third yarns are cotton fiber type blended yarns formed by blending one or two of polyester staple fiber yarns or polyacrylonitrile fibers and cotton fibers, or all cotton yarns; the fourth yarns are polyurethane fiber yarns. The moisture absorption and heat-generating value of the fabric exceeds national standards, the moisture absorption and quick-drying performance is excellent, and the thermal insulation rate meets national standards; the fabric also has comfortable elasticity and soft and smooth hand feeling of one surface next to the skin. Meanwhile, the preparation method is simple in process, and convenient to operate.

Owner:武汉爱帝针纺实业有限公司

High-temperature high-pressure swelling dyeing method

InactiveCN101191306ASolving Dyeing PuzzlesIncrease profitSucessive textile treatmentsDyeing processPolymer scienceCrystallinity

The invention relates to a high temperature high pressure bulking dyeing method which comprises dyeing and after treatment. By adoption of the dyeing method of the invention, fibers or textile fabrics like aramid fibers, polysulfonamide fibers, polyphenylene sulfides, polybenzimidazole, poly-p-phenylene benzobisoxazole fibers, phenol formaldehyde resins, fibrilia and so on which have high crystallinity and high orientation degree or high glass transformation temperature can be dyed, and fibers after dyeing have the advantages of evenness, bright colors, high dyefastness, improvement of light fastness and little impact on physical properties.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

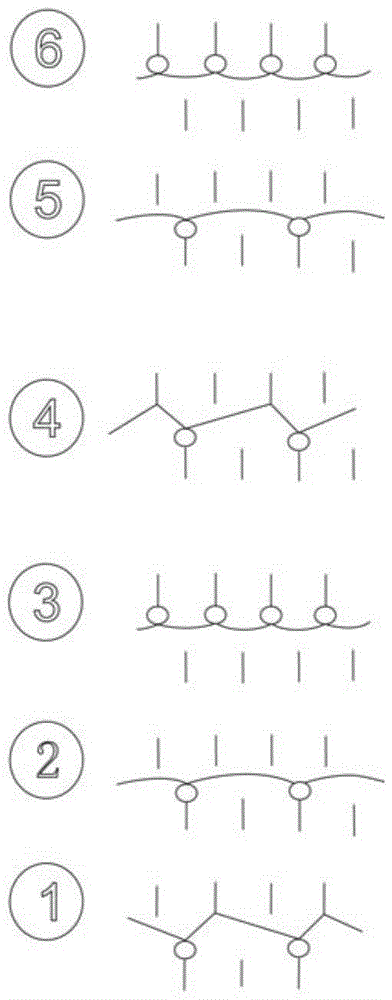

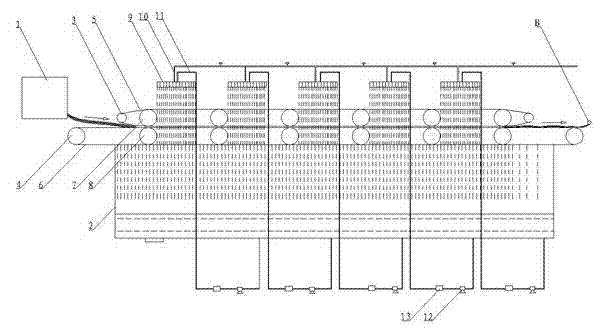

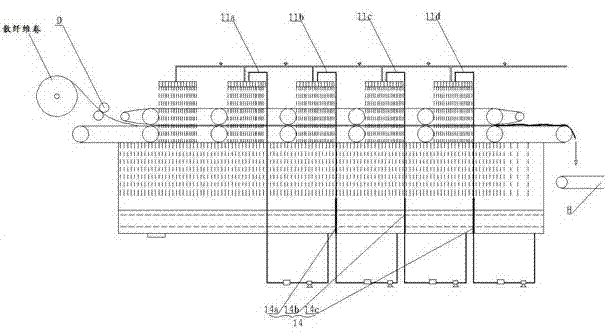

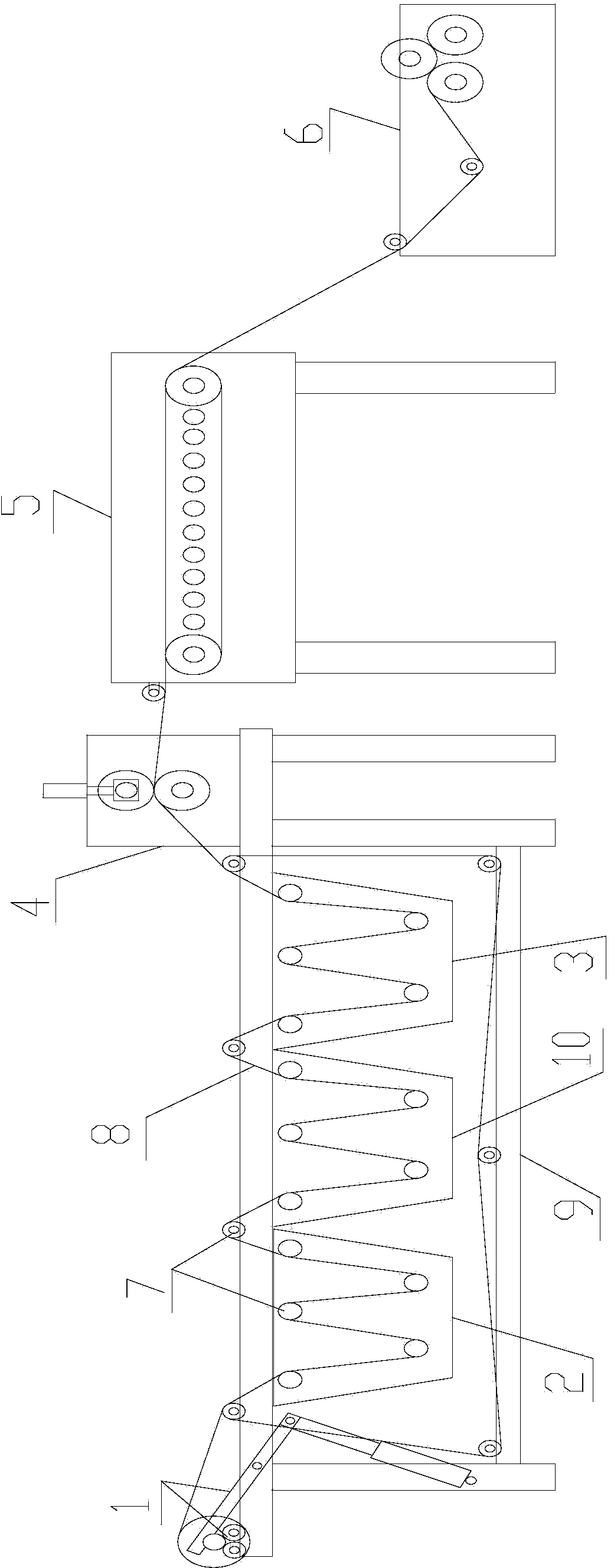

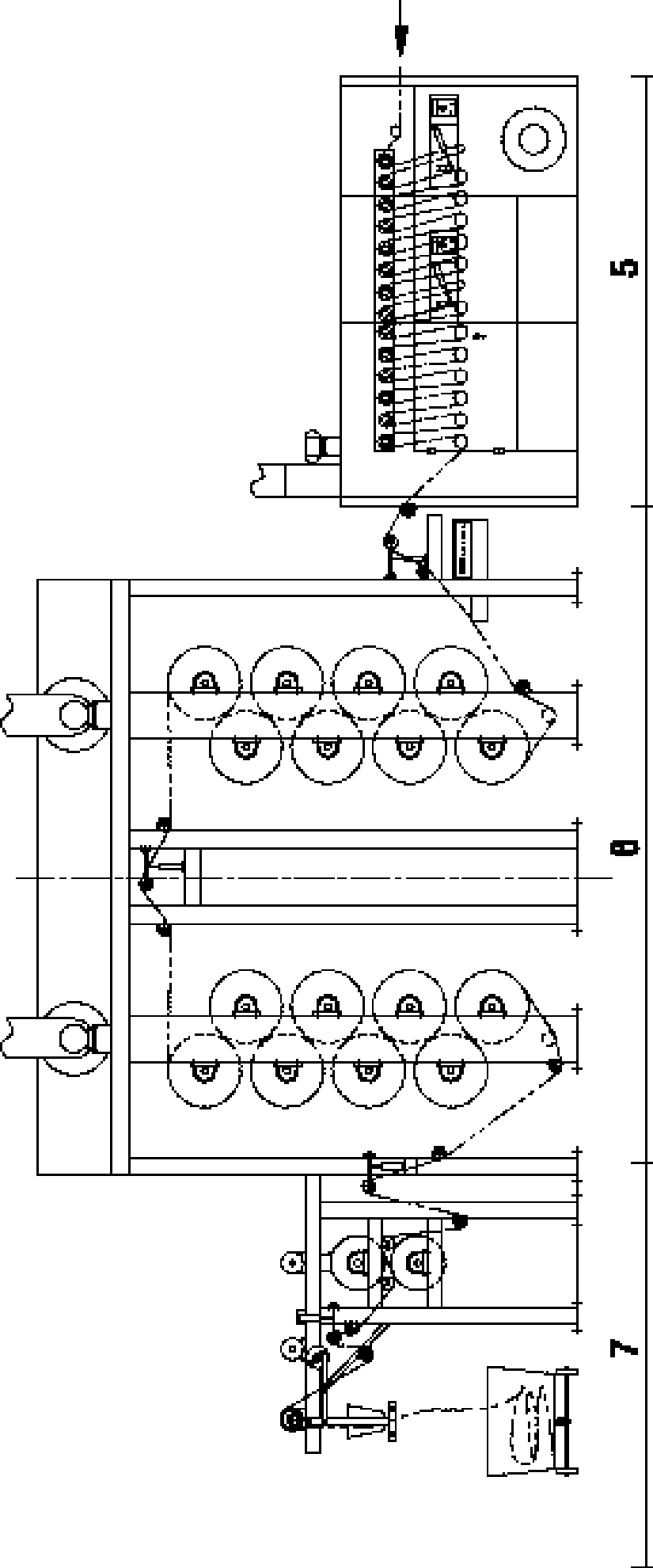

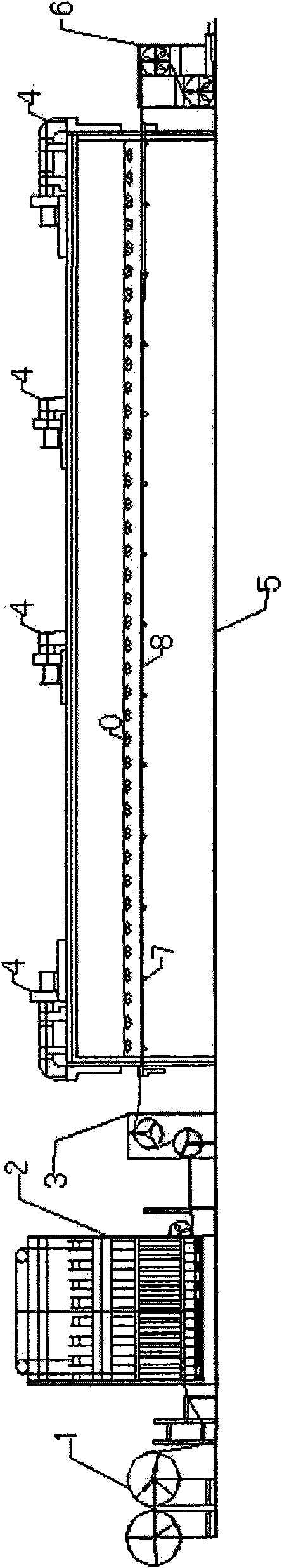

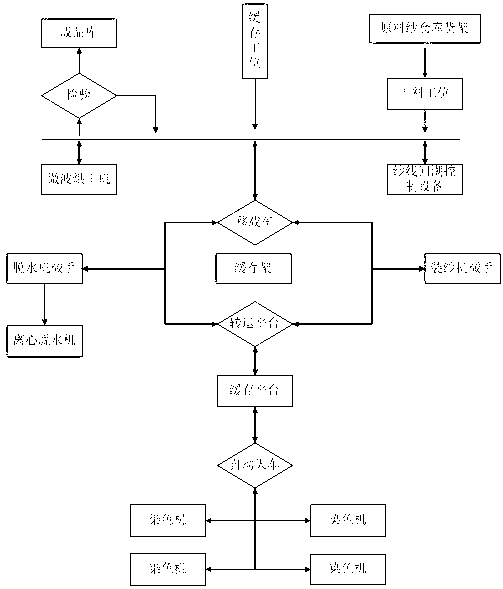

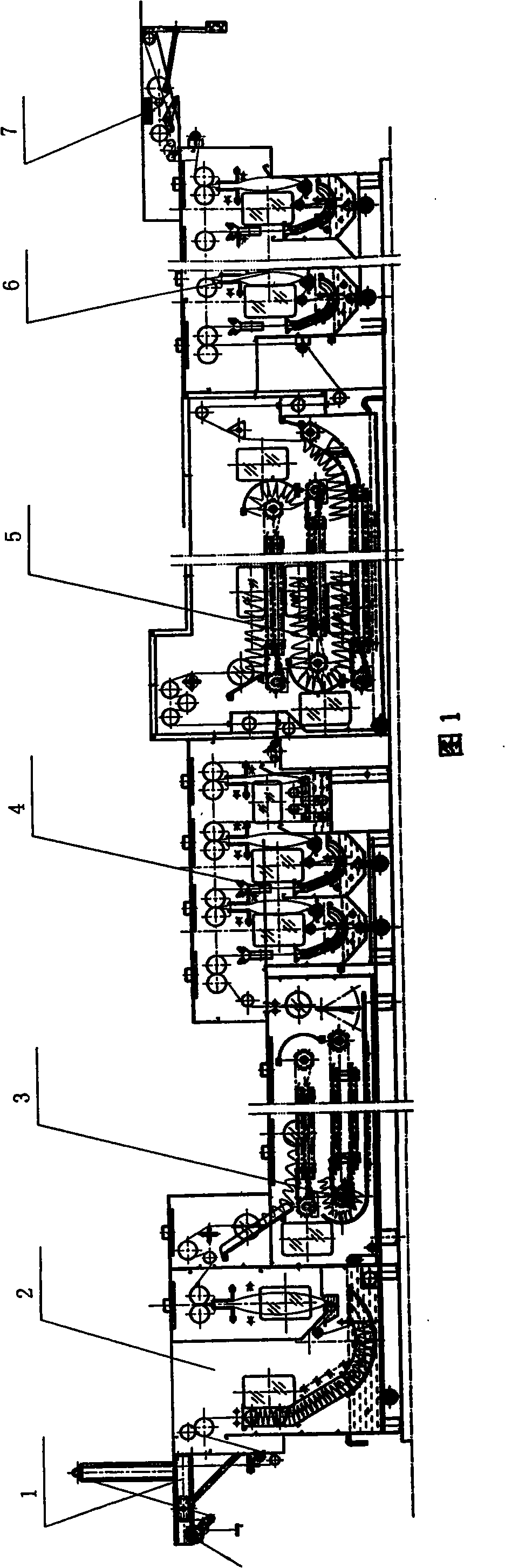

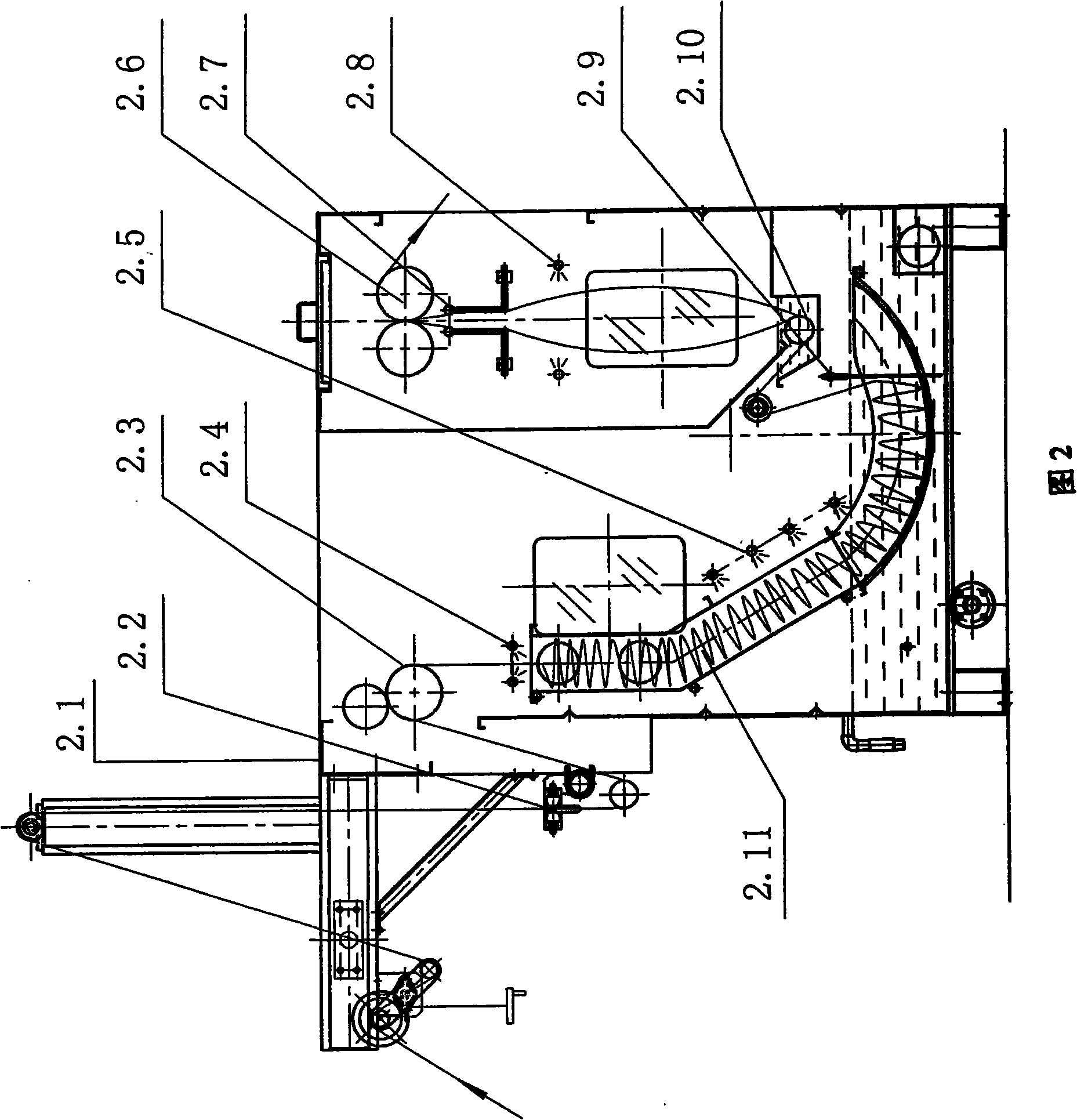

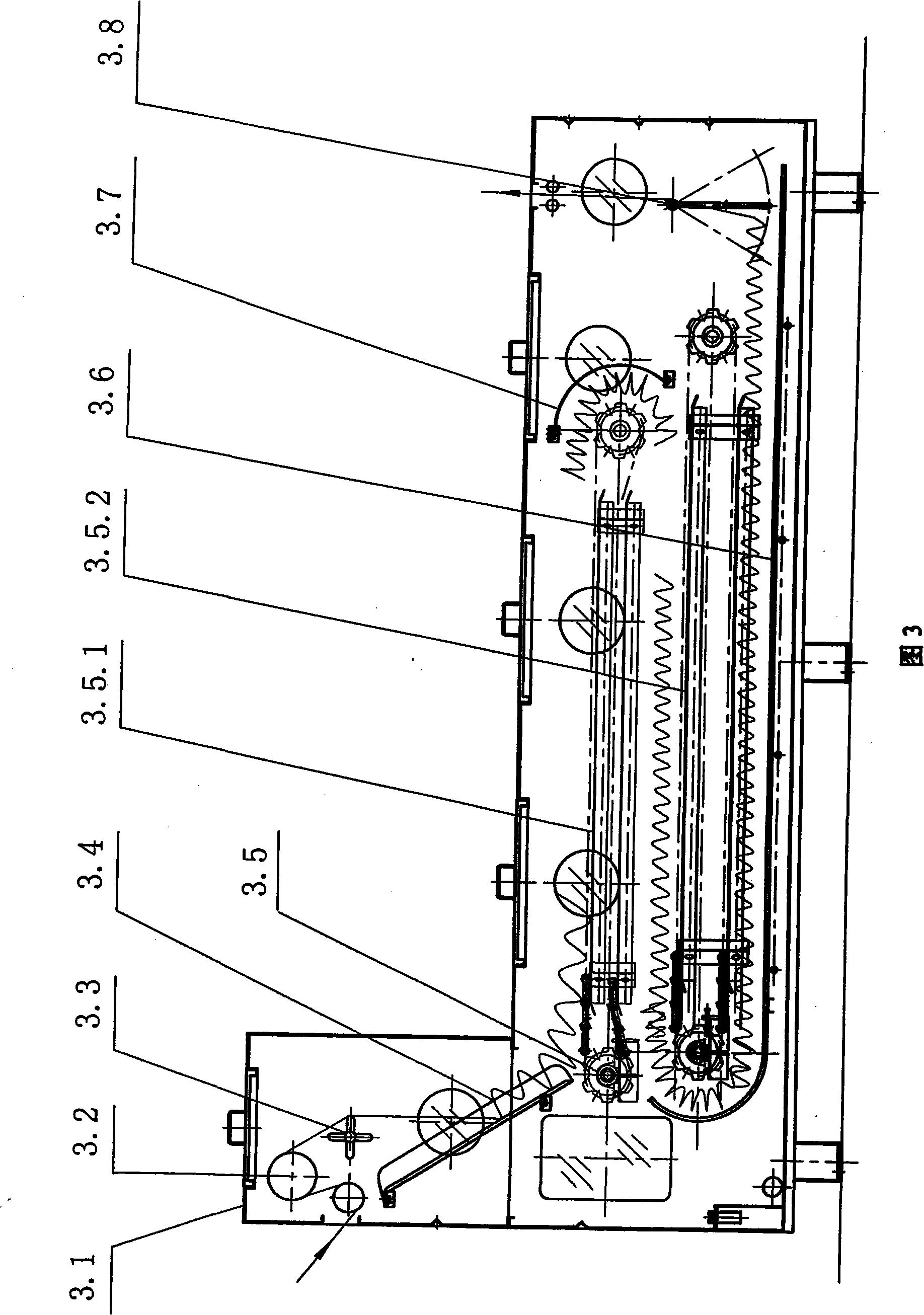

Continuous type colored loose fiber machining device

ActiveCN103774368ASolve uneven dyeingResolution cycleSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberEngineering

The invention relates to a continuous type colored loose fiber machining device, and belongs to the technical field of loose fiber dyeing. The continuous type colored loose fiber machining device comprises a spray-rolling type drying machine, a coiling roller, a cold-batch fixation device, cotton conveying rollers, a spray-rolling type washing machine, a conveyor belt and a squeezing device in sequence. Loose fibers are subjected to spraying dyeing by being horizontally clamped by a transmission component of the spray-rolling type drying machine, the coiling roller is arranged on the rear portion of a lower guide belt of the spray-rolling type drying machine and coils the dyed loose fibers to be loose fiber coils, the loose fiber coils are transferred to the cold-batch fixation device for cold-batch fixation, the loose fiber coils are conveyed to the spray-rolling type washing machine through the cotton conveying rollers, spray washing is carried out on the cotton conveying rollers when the cotton conveying rollers are conveyed by being horizontally clamped through the transmission component of the spray-rolling type washing machine, the washed loose fibers fall down on the conveyor belt behind the spray-rolling type washing machine under the gravity of the loose fibers themselves, and the loose fibers are conveyed to the squeezing device for dewatering. The continuous type colored loose fiber machining device can continuously produce colored loose fibers, and greatly lower processing cost.

Owner:绍兴国周针织科技有限公司

Antifouling, water-proof and non-ironing post finishing method for woven plus material

ActiveCN101122082AEasy to decontaminateImprove waterproof performanceSucessive textile treatmentsSingeingEngineeringStain

A stain proof, water proof and non-iron post-management method for textile fabrics relates to a post-management technology for textile fabrics, in particular to a stain proof, water proof and non-iron post-management processing technology. The method includes singeing, desizing, mercerizing, first setting, batching, neutralizing and water washing, second setting, baking and shrinking. The one-stop textile special post-management processing technology of ''Moist-cure+ stain easily removable+ refreshing+ three proofs'' can provide the cotton fabrics surface material with stain easily removable, refreshing, water proof, oil proof, stain proof and iron free functions at the same time, which greatly improves the service performance of the surface material, and better meets the demand of the consumers.

Owner:JIANGSU LIANFA TEXTILE

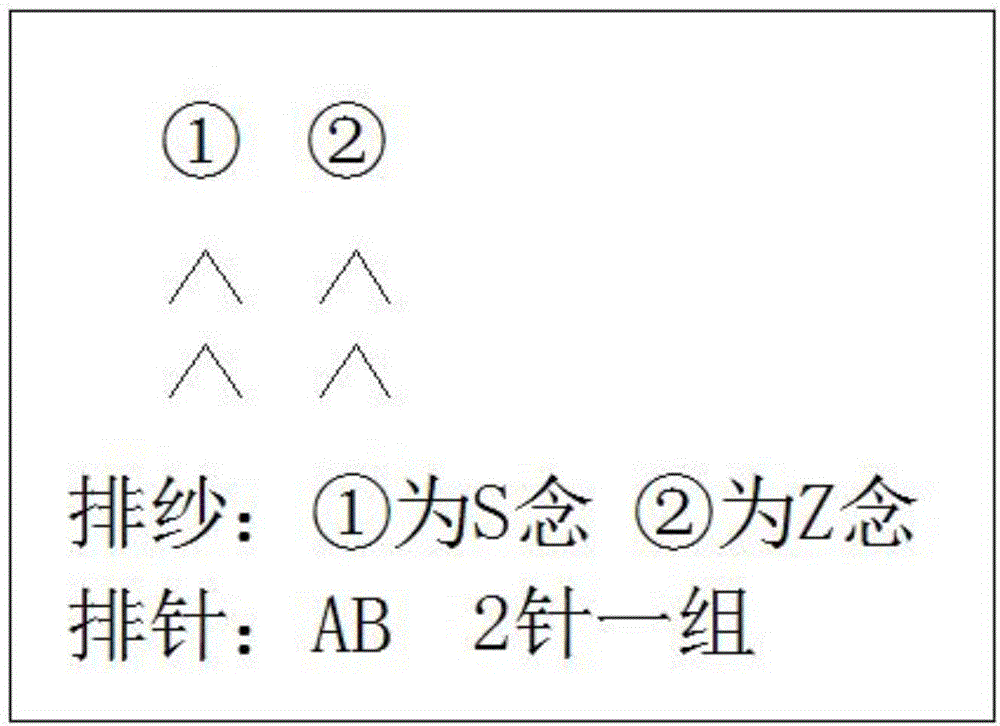

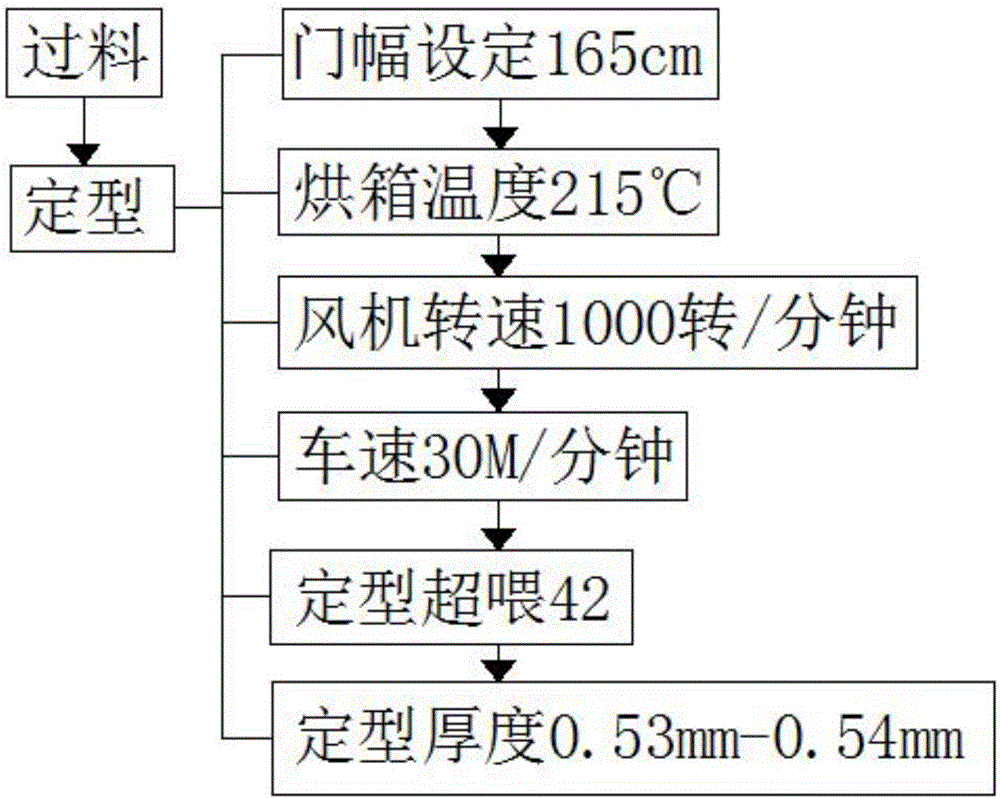

Automotive interior trim skin single face cloth

InactiveCN106048870AMeet the pullMeet tearSucessive textile treatmentsWeft knittingAfter treatmentGram

The invention relates to the technical field of automotive lining technologies, and particularly relates to an automotive interior trim skin single face cloth. The technique includes: a first step, gray fabric weaving; a second step, pretreatment (performing washing in a dyeing vat); and a third step, after-treatment (shaping). The beneficial effects of the invention are that needle arrangement and after-treatment shaping of the conventional knitting technology is changed, the skin base cloth can meet the demands of tension, tearing, and dead load tensile strength, and is decreased in gram weight and thickness; and the use cost is reduced.

Owner:信德汽车内饰材料江苏有限公司

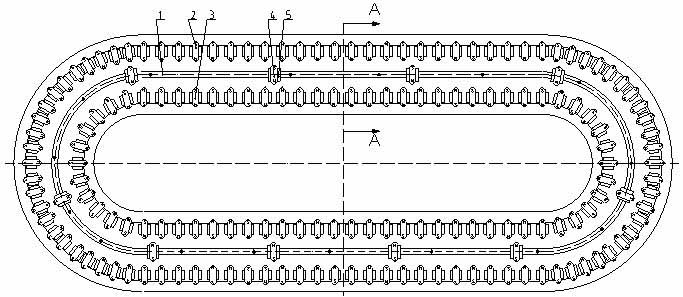

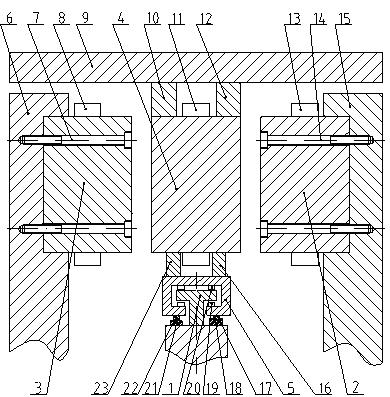

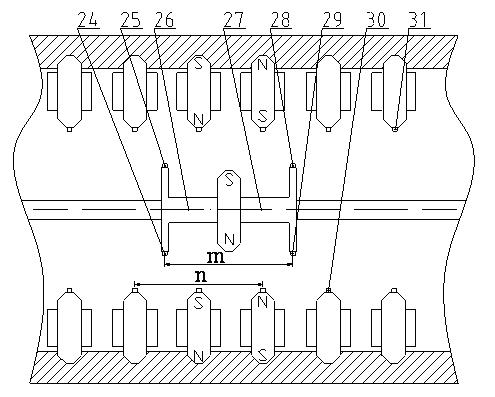

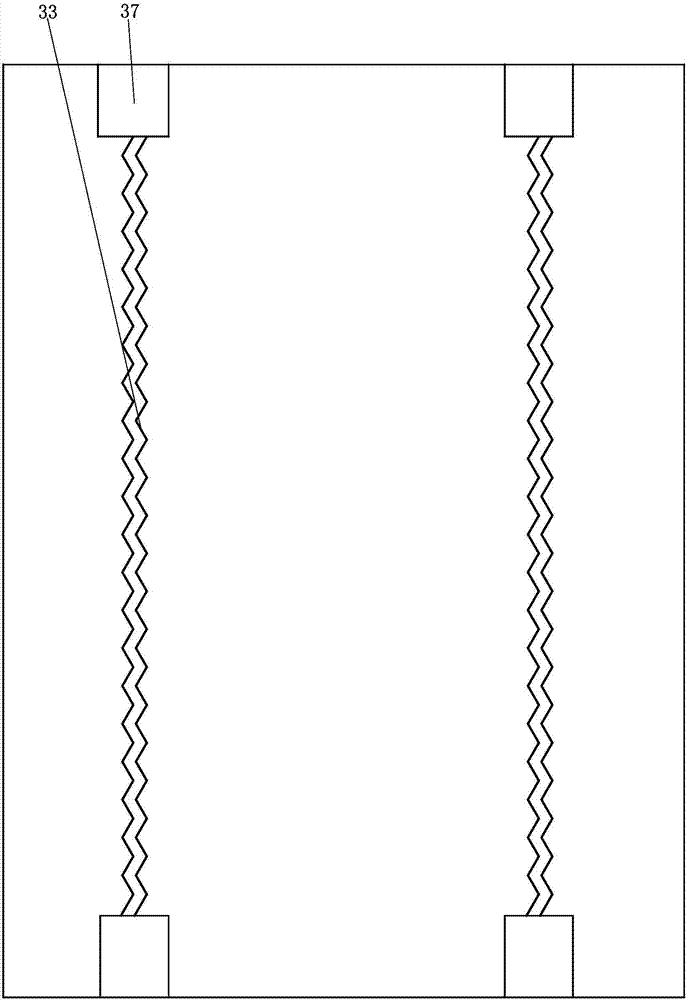

Low-energy-consumption no-motor-drive type transmission device used for stenter

ActiveCN102505394ARealize motorless driveRealize automatic guidanceSucessive textile treatmentsTextile treatment machine partsMotor driveElectric machine

The invention discloses a low-energy-consumption no-motor-drive type transmission device used for a stenter, which comprises brackets; electrostatic magnets are evenly mounted on the brackets; guide rail supports are mounted at the centers of the two brackets; a maglev guide rail pair is mounted on the guide rail supports; a lower bearing block is installed on the maglev guide rail pair; a movable electromagnet is installed on the lower bearing block; an upper bearing block is installed on the movable electromagnet; a workbench is installed on the upper bearing block; and coils are wound on all the electrostatic magnets and the movable electromagnet. According to the invention, no motor drive and automatic guiding of the movable guide rails are realized, the energy consumption during the transmission operation is greatly reduced, the friction in the transmission process is eliminated and the precision in the working process is improved.

Owner:苏州盛泽科技创业园发展有限公司

Light and thin roving high-count flat-coated tweed and production process

The invention discloses a light and thin roving high-count flat-coated tweed which is a twill-weave fabric, and warps and wefts of the flat-coated tweed are high-count coarse yarns of 25 / 1 metric count. The production process of the light and thin roving high-count flat-coated tweed comprises the steps of preparing fibrous materials, spinning, weaving and finishing. According to the production process, the concepts of roving and fining operation are adopted, and the coarse yarns of 25 / 1 metric count are used to be woven into the light and thin roving high-count flat-coated tweed, the light and thin roving high-count flat-coated tweed has good fiber cohesion and antistatic property, and roving high-count wool yarn strips have the advantages of uniformity, large intensity, lightness and smoothness of the fabric, fullness and smoothness of hand feelings and have skinny feelings.

Owner:杭州大统纺织有限公司

Printed flocked pile fabric and method for making same

InactiveUS20010008039A1Soft handMore volumeLiquid surface applicatorsSucessive textile treatmentsFiberEngineering

Owner:ALBOOM CARLOS VAN +1

Preparation method for combination electrode for all-vanadium redox flow battery

InactiveCN104241661AImprove electrochemical activityImprove energy efficiencySucessive textile treatmentsCell electrodesCarbon fibersCharge discharge

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method of a bismuth-base catalyst / carbon nanofiber combination electrode for an all-vanadium redox flow battery. Firstly, spinning solution required for an experiment is prepared and then bismuth salt and the spinning solution are uniformly mixed. According to an electrostatic spinning method, a required nanofiber film is prepared and then the nanofiber film is pre-oxidized in the air and is carbonized in an inert atmosphere tube furnace so as to obtain the required bismuth-base electrocatalyst / carbon nanofiber combination electrode. After the obtained electrode material is cleaned and dried, testing of related electrochemical performance representation and charge-discharge properties can be carried out on the electrode material. The carbon fiber diameter, which is prepared according to the preparation method, is in the nano class; compared with a specific surface area of a conventionally used electrode material, the specific surface area of the bismuth-base catalyst / carbon nanofiber combination electrode is greatly increased. Moreover, the carbon nanofibers are compounded with a high-activity bismuth-base electrocatalyst, and thus, electrochemical activity of the electrode can be greatly improved, so that energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

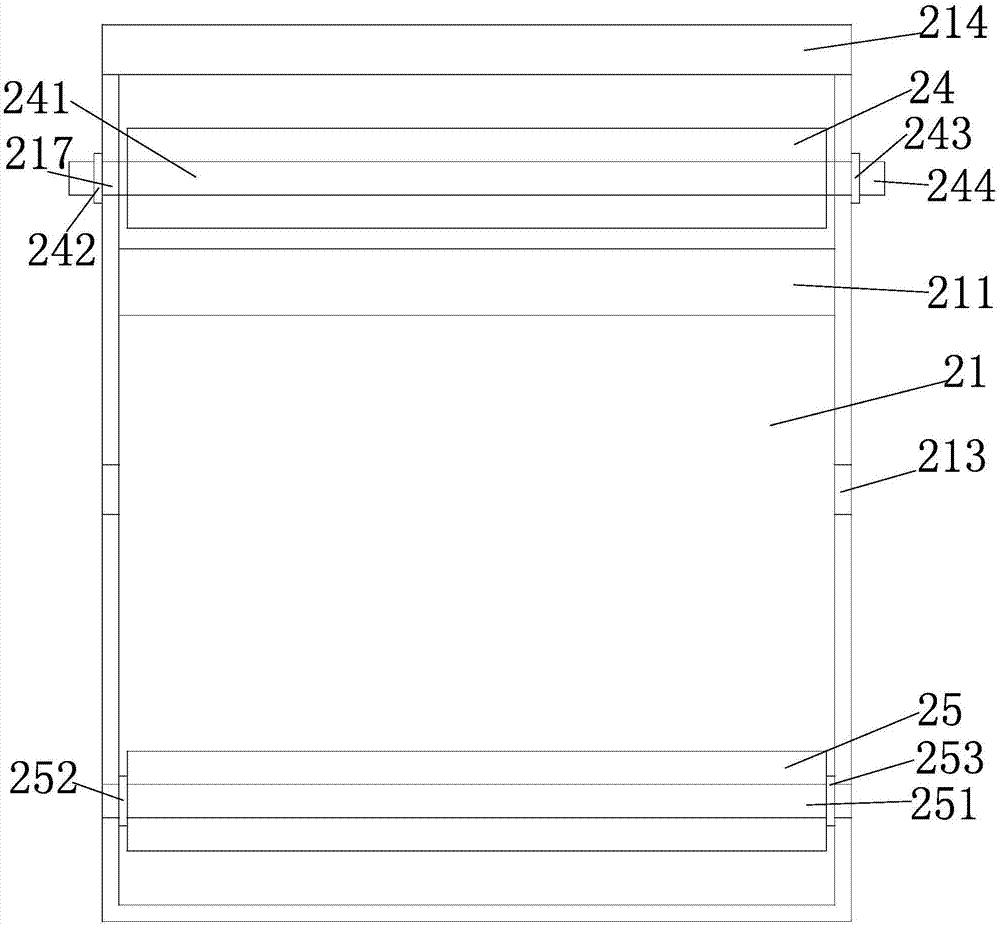

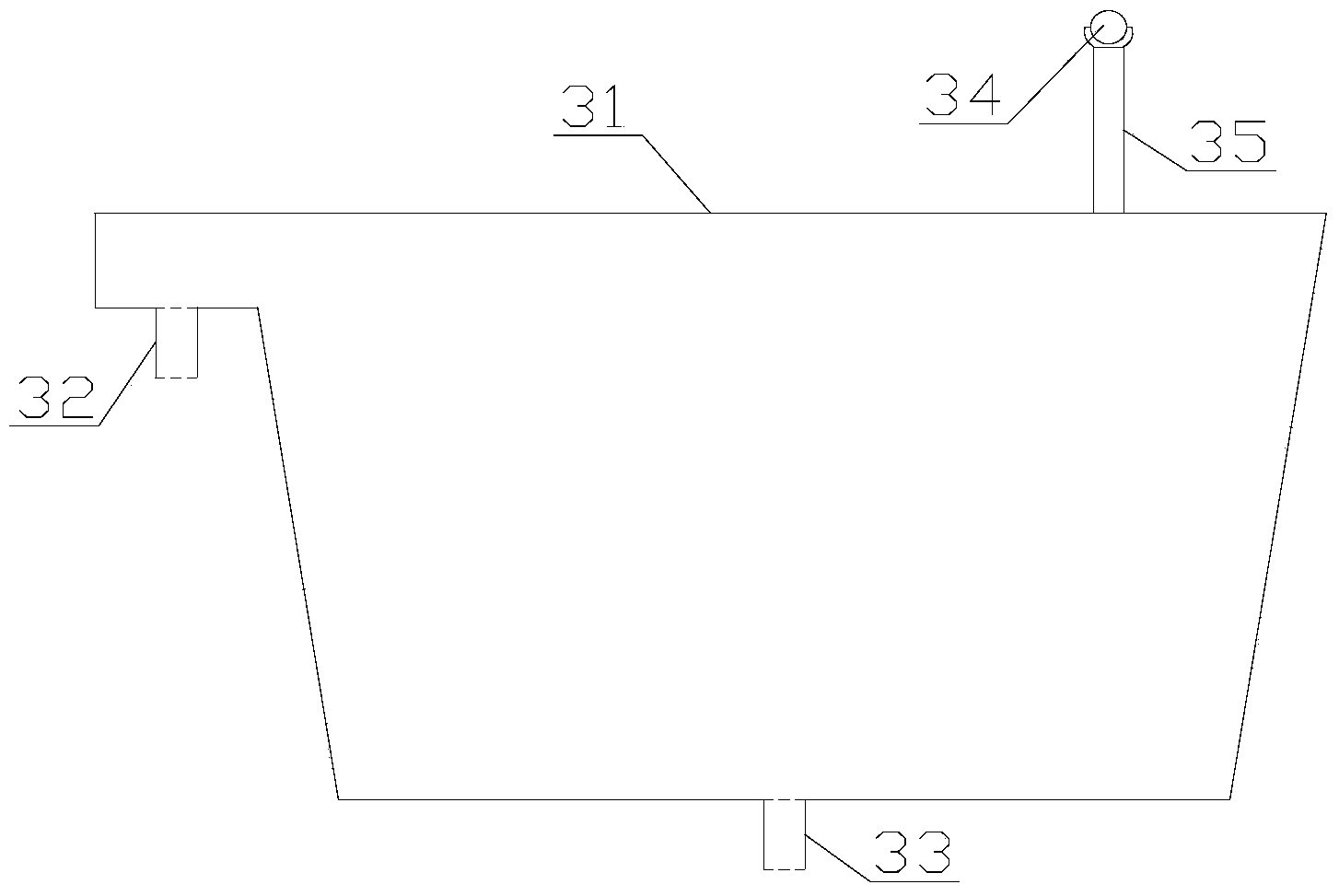

Washing and drying integrated machine for high-end fabric

InactiveCN107090682AWashing to achieveNo wasteSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersTextile technologyWater storage tank

The invention provides a washing and drying integrated machine for high-end fabric, belongs to the technical field of textile and solves the technical problem that the washing and drying effect of an existing washing and drying integrated machine for high-end fabric is not high. The washing and drying integrated machine for the high-end fabric comprises a rack, wherein a washing device for washing the fabric, a drying device for drying the washed fabric, a fabric collecting device for collecting the dried fabric and a wastewater recycling device for recycling wastewater produced during fabric washing are arranged on the rack, the washing device, the drying device and the fabric collecting device are sequentially arranged along the rack, the washing device comprises a washing tank, a water storage tank and a water pump I, multiple upper drums and multiple lower drums are horizontally arranged in the washing tank, multiple overflow ports are formed in the middle of the washing tank, the upper drums are located above the overflow ports, the lower drums are located below the overflow ports, and a nozzle is arranged at the top of the washing tank. The washing and drying effect of the machine is good, and the water resource is saved.

Owner:HAINING MEILI KNITTING CO LTD

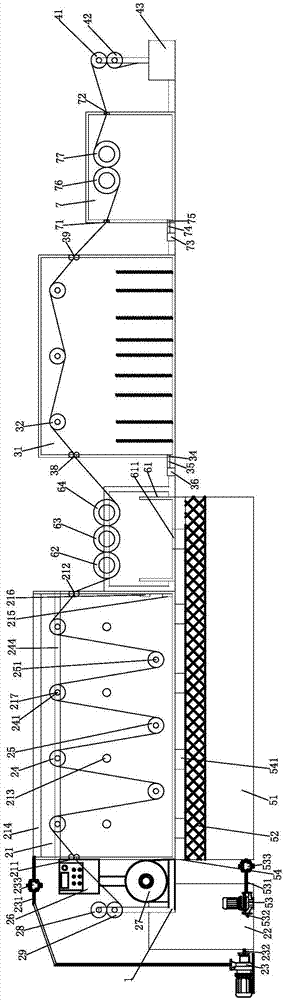

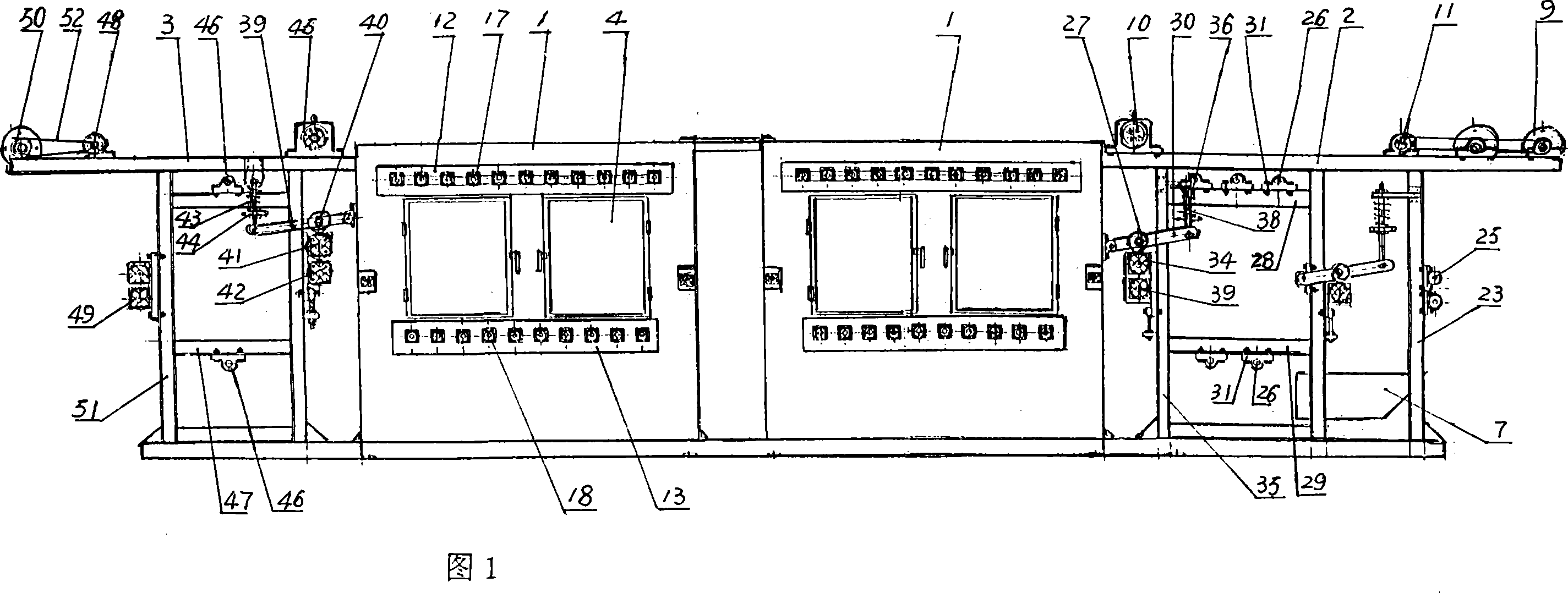

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

Cotton fabric high-efficiency dyeing and finishing process

InactiveCN104988713AImprove hydrophilicityImprove dye uptakeSucessive textile treatmentsLiquid/gas/vapor removalFiberInorganic salts

The invention discloses a cotton fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment; at the same time, before a dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and finally is treated by chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

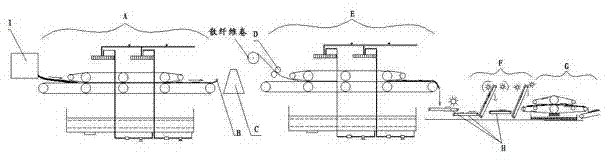

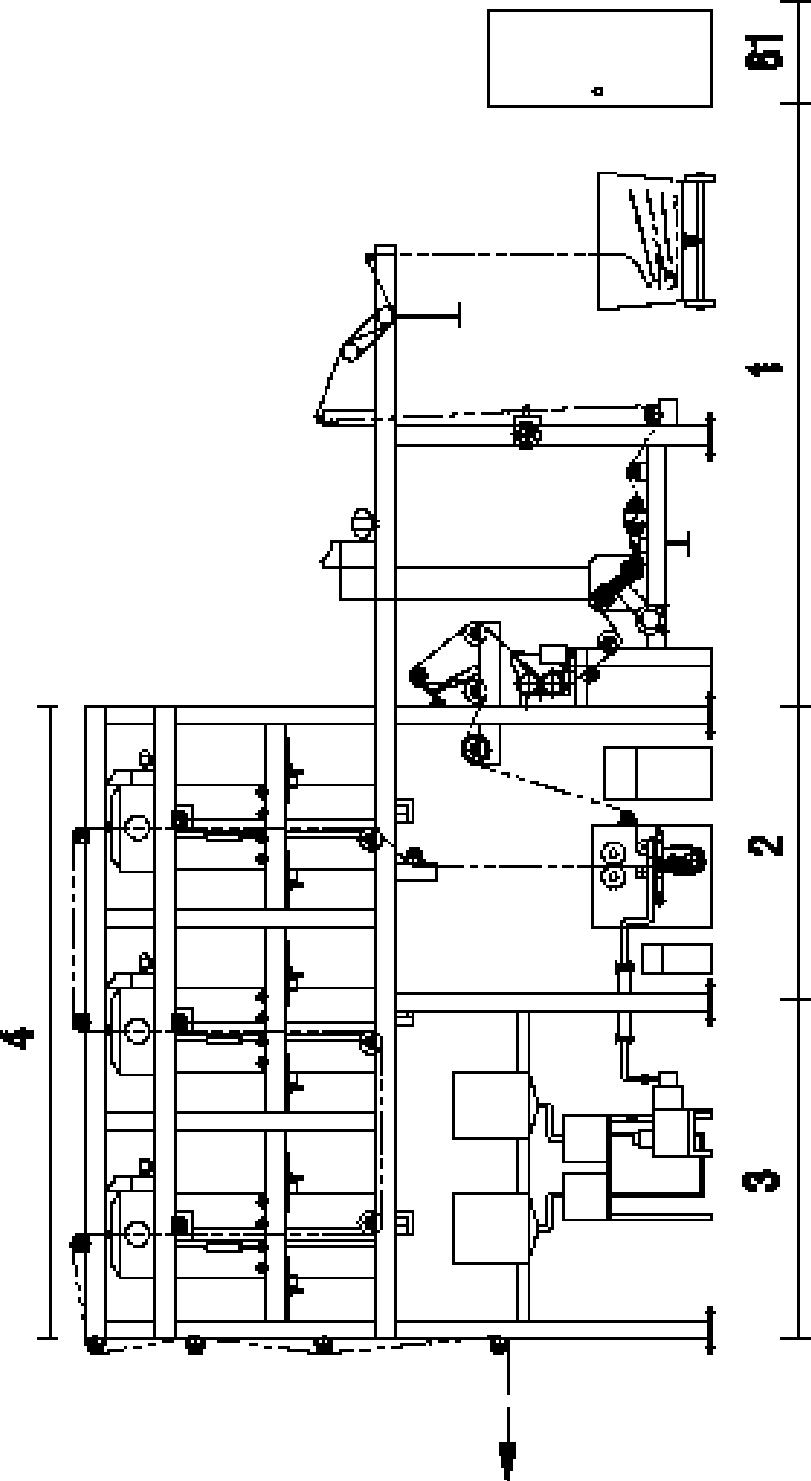

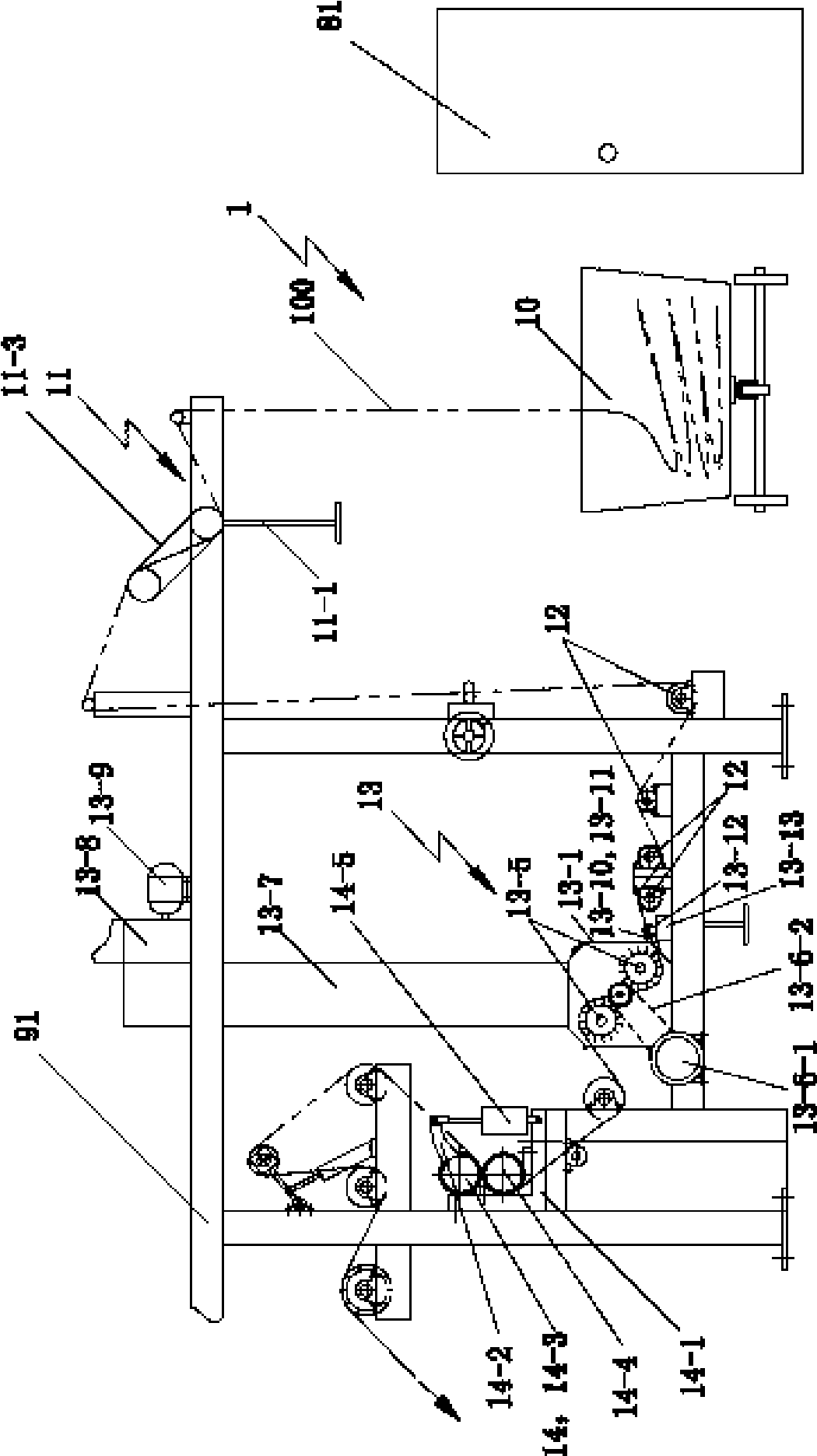

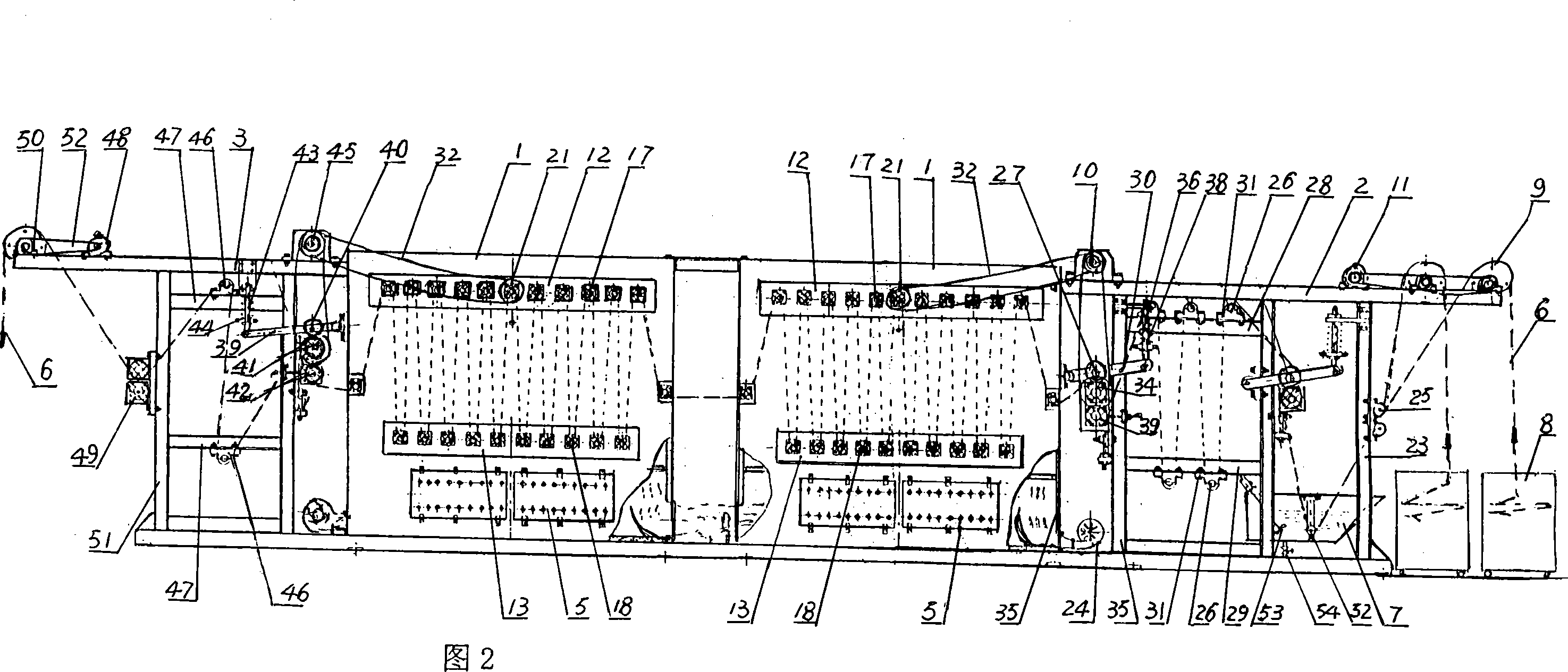

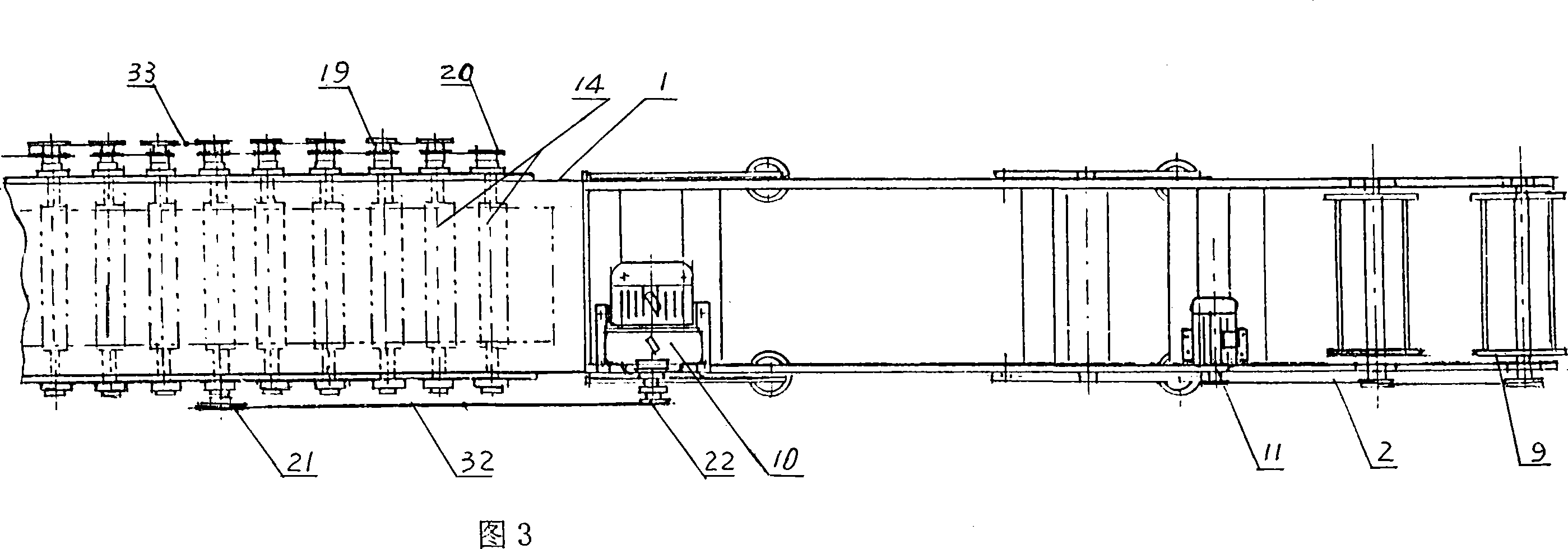

Continuous pigment dyeing pad dyer

InactiveCN101487175AOptimize layoutGuaranteed uptimeSucessive textile treatmentsDrying solid materials with heatEngineeringHot blast

The invention relates to a continuous paint dyeing padding machine. The padding machine comprises a device which brushes hair and collects dusts for the textile, a traction binding vehicle which can obstruct the tensile force of the textile, a padding device, an infrared pre-baking device, a hot-blast pre-baking device, a steam drying device and a fabric outlet disposing device, and all devices are sequentially arranged. All components of the dyeing padding machine are reasonably configured; and when in use, the energy resource is saved, the process is simple and the dyeing effect is good.

Owner:常州市东高染整有限公司

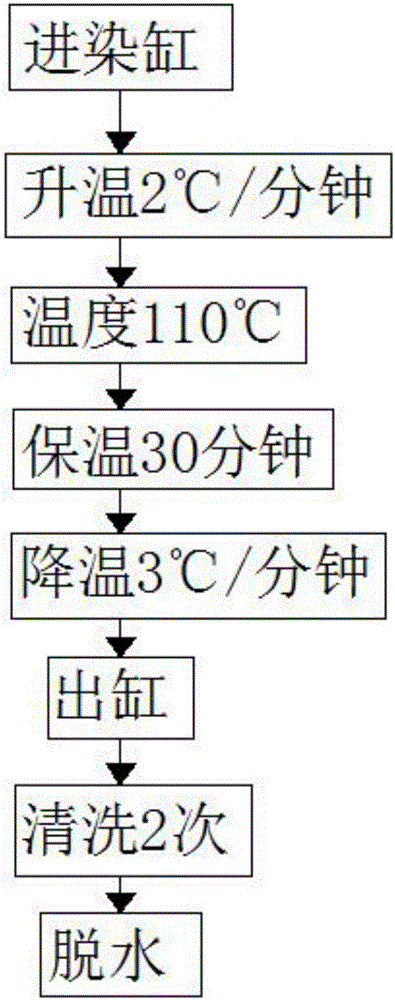

Nano-silver antibacterial shirt fabric and preparation method for same

InactiveCN103205835ABreaking strength without damageElongation at break without damageSucessive textile treatmentsBleaching apparatusFiberAfter treatment

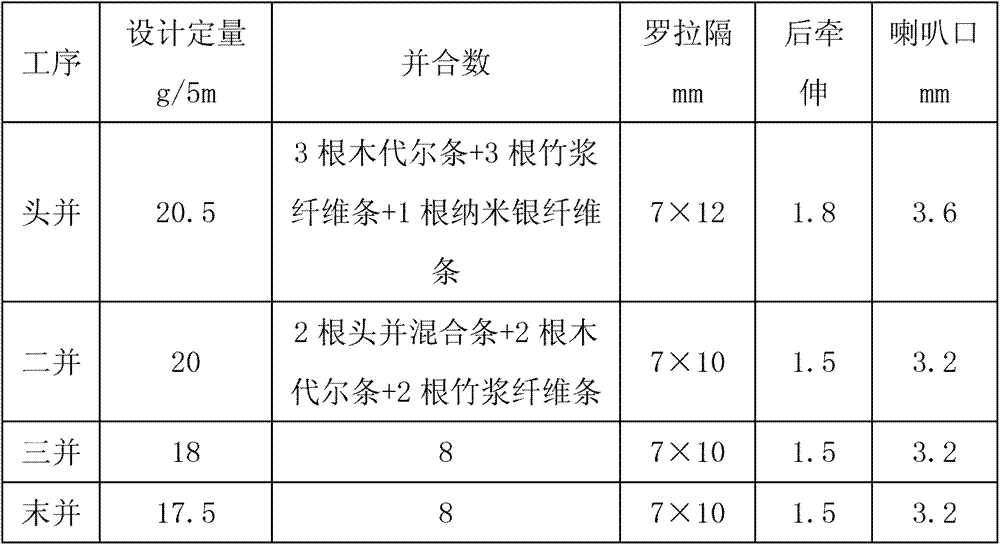

The invention provides a nano-silver antibacterial shirt fabric. Warp of the fabric is compact spinning cotton yarns CF 14.8 tex; weft yarns are blended yarns 14.8 tex of 48%modal fibers / 48%bamboo pulp fibers / 4%nano-silver fibers; and the warp density is 512yarns / 10cm, and the weft density is 512yarns / 10cm. The invention further provides a preparation method for the nano-silver antibacterial shirt fabric. The method comprises the following steps: a, spinning; b, warp and cheese dyeing: cone loosening, caging filling, feeding into a cylinder, pretreatment, dyeing, aftertreatment, dehydration, drying and cone fastening, wherein the pretreatment is performed at a temperature of 120 DEG C for 30min to 60min, the NaOH utilization amount is 1.4g / L to 1.6g / L, the utilization amount of H2O2 in a concentration of 27.5% is in a range of 4.3g / L to 4.7g / L, the bath ratio during dyeing is 1:10, reactive dyes containing two active groups of vinyl sulfone and monochlorotriazine, the utilization amount of the dyes is in a range of 3g / L to 5g / L, the utilization amount of Na2SO4 is in a range of 10g / L to 60g / L, and the utilization amount of Na2CO3 is in a range of 5g / L to 20g / L; c, weaving: warping, sizing, drafting and weaving the fabric, wherein K-5000 size is used during sizing; and d, after treatment.

Owner:JIANGSU YDTEX GRP LTD

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

Processing technology for super-imitated-cotton/fine-denier damp conduction polyester comfortable mercerized velvet warp knitting fabric

ActiveCN103859664AEasy to takeGood flexibilitySucessive textile treatmentsWarp knittingHeat resistanceEngineering

Owner:ZHEJIANG QINGSONG TEXTILE

Dry method production line of water-based ecological synthetic leather

InactiveCN101942768AIncrease productivityRealize full environmental protectionSucessive textile treatmentsLiquid/gas/vapor removalProduction lineLeather industry

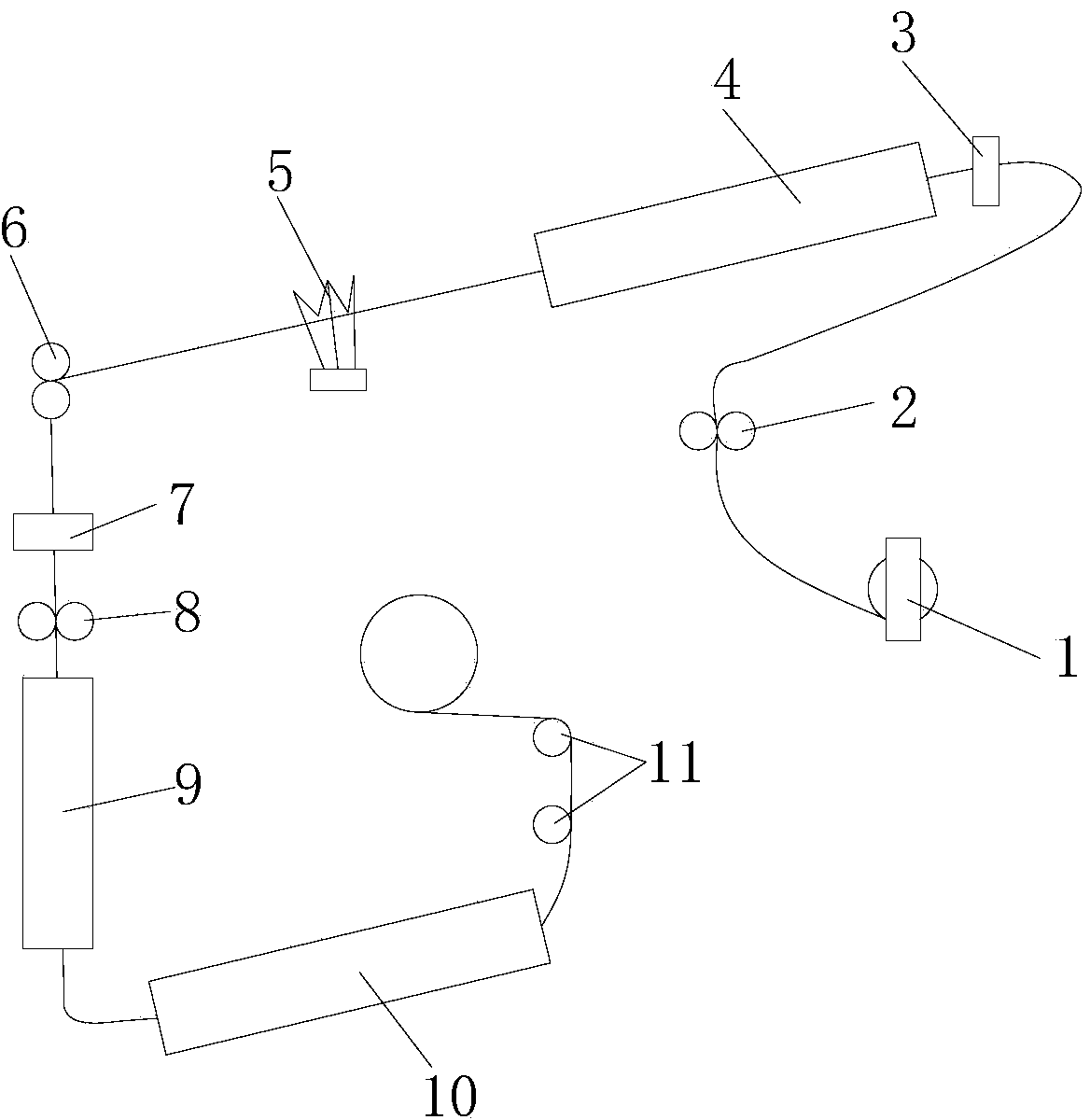

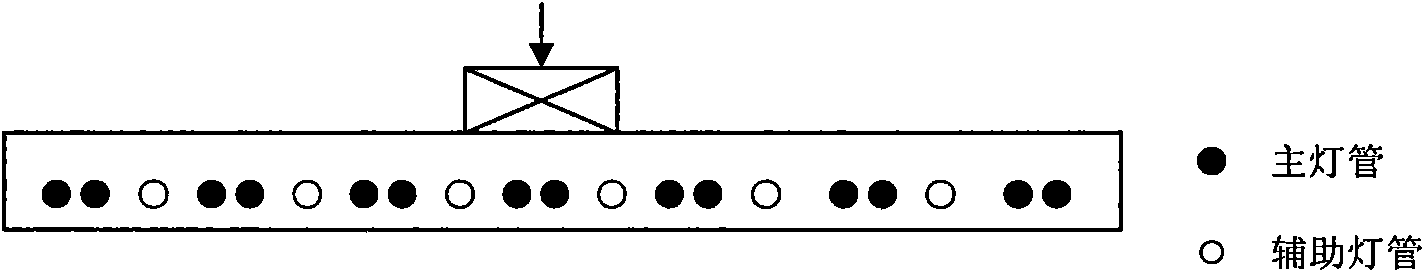

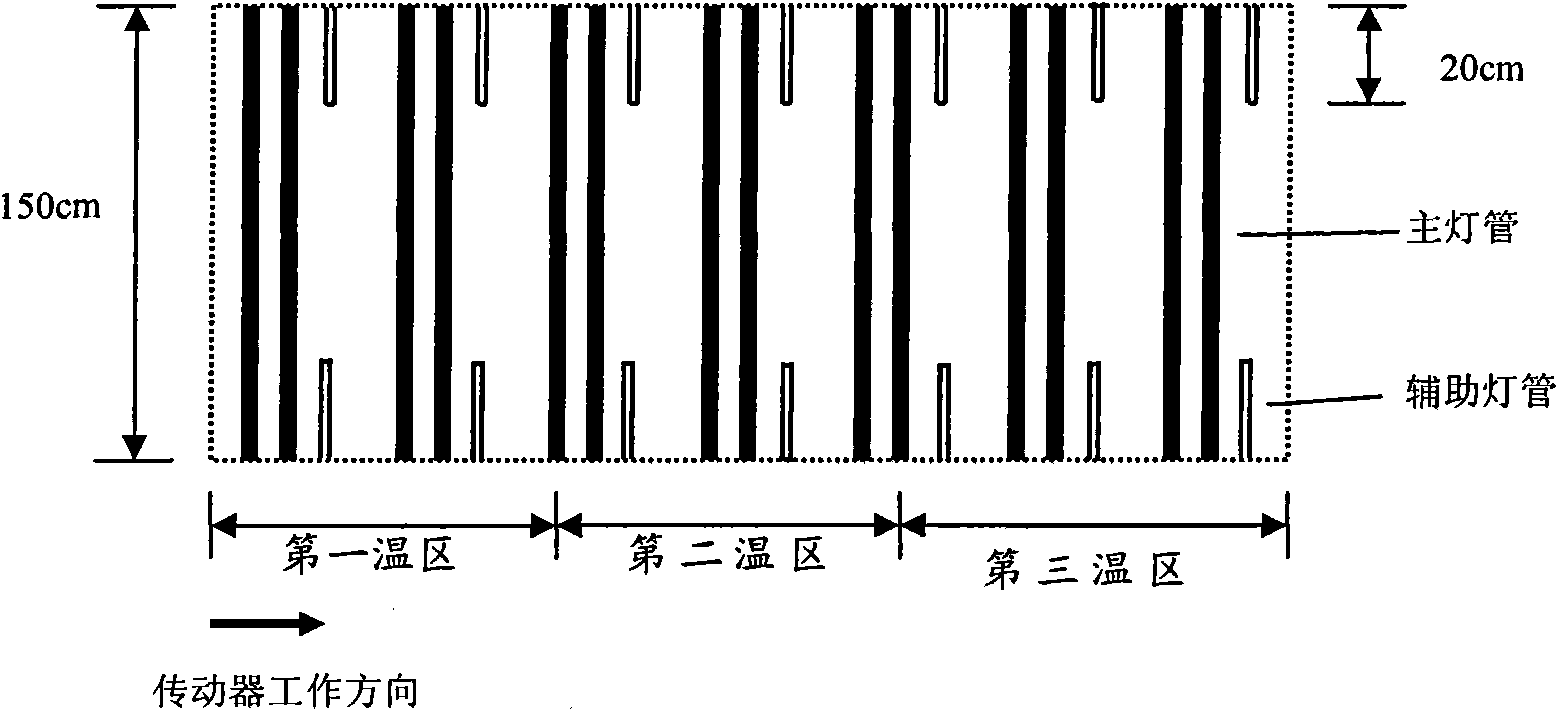

The invention provides a dry method production line of water-based ecological synthetic leather, which comprises a driver, a coating table and an oven, wherein the driver is used for conveying release paper or base clothes; the coating table is used for sizing on the release paper or the base clothes for one time or many times to form a single-layer or multi-layer water-based resin coating; the oven is used for drying the single-layer or multi-layer water-based resin coating; and medium wave infrared drying equipment is arranged in the oven. The production line of the invention has the advantages of safety, energy saving and high production efficiency, has double functions of production lines of the traditional dry method and the traditional wet method for producing leather, realizes the complete environment protection of the synthetic leather industry, and enables the quality of the processed water-based ecological synthetic leather to be more excellent.

Owner:丽水市优耐克水性树脂科技有限公司

Cotton and natural silk napped fabric and method for processing same

The invention relates to a cotton and natural silk napped fabric and a method for processing the same, and belongs to the field of household textiles. The cotton and natural silk napped fabric is made of yarns. 70-90% of staple cotton and 10-30% of natural silk G100 are blended to form the yarns. The cotton and natural silk napped fabric and the method have the advantages that the yarns are starched by starch slurry and are woven on broad-width air-jet looms, and the soft, delicate, skin-friendly and thermal cotton and natural silk napped fabric with fluff not to easily fall off can be formed after dyeing and finishing processes such as a singeing process, a desizing-scouring-bleaching process, a mercerizing process, a carbon brushing process, a printing and washing process and a softening and type approval process are carried out, and is particularly suitable to be used as an autumn and winter bedding article.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

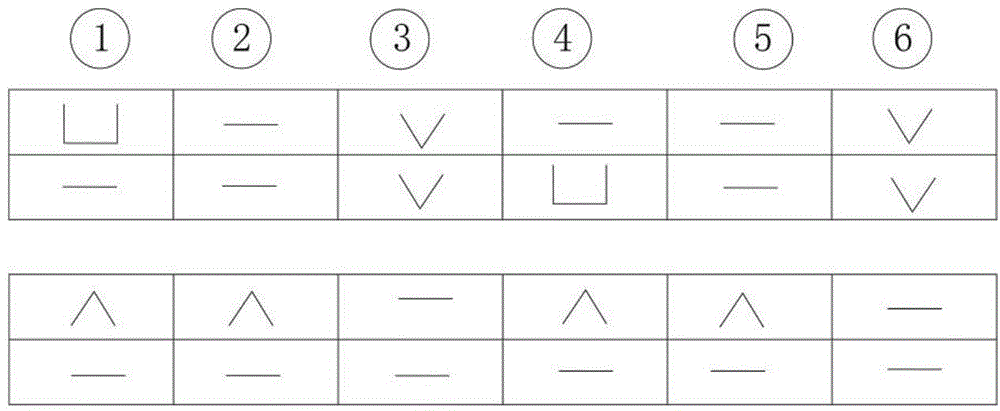

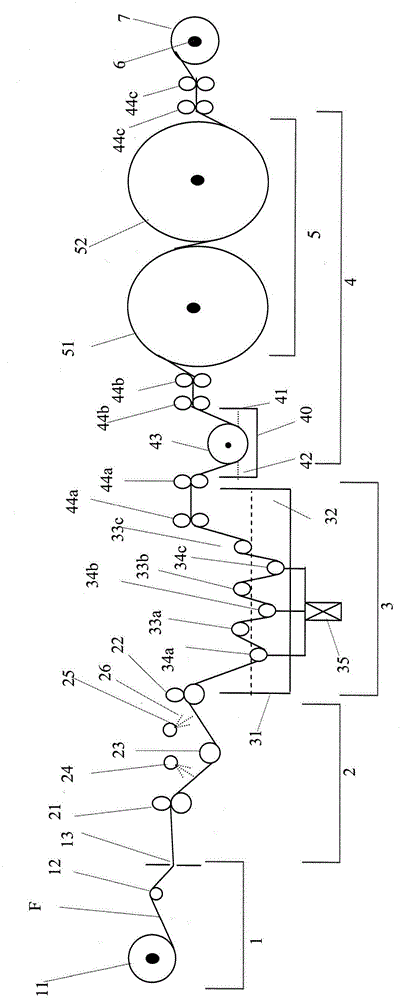

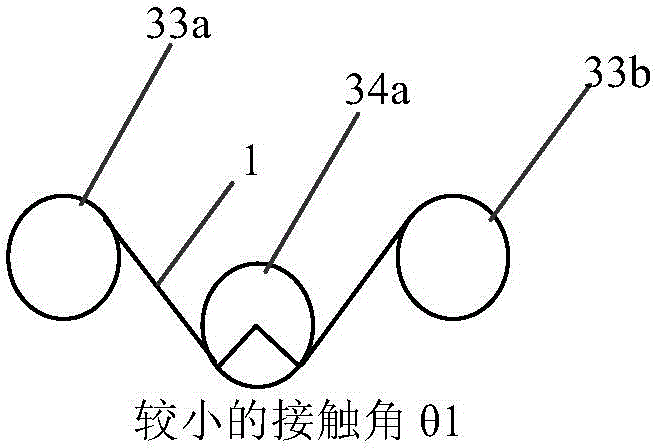

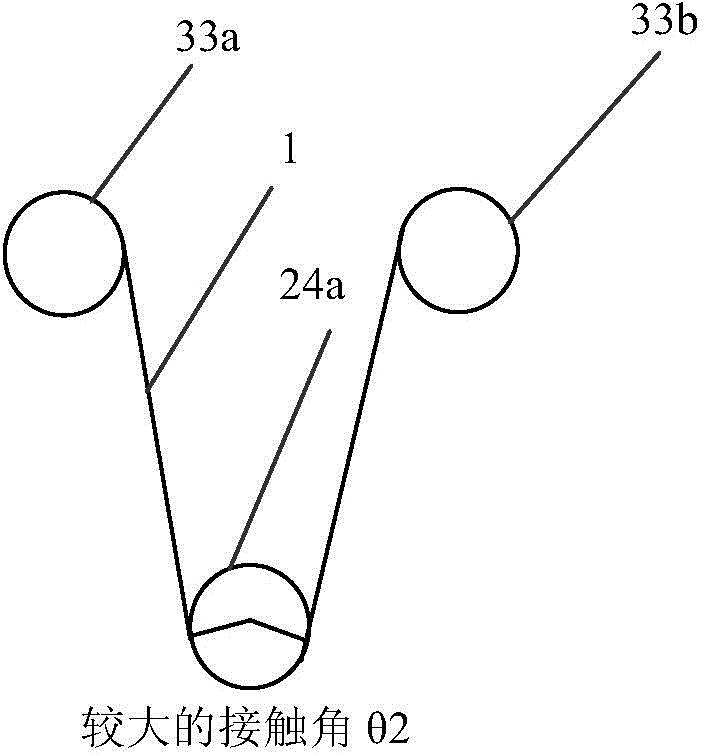

Processing equipment and method for continuous fiber tows

The invention relates to processing equipment and method for continuous fiber tows. The processing equipment comprises a desizing unit, an unfolding and dispersing unit and a sizing unit, wherein the desizing unit uses a fluid washing mode to enable fiber tows to desize, the unfolding and dispersing unit comprises round bars, tension braking rollers and a tension brake which are alternatively arranged, the round bars and the tension braking rollers are used for controlling the contact angles between the fiber tows and the adjacent round bars, the tension brake is connected to each tension braking roller and then used for regulating the tension generated when the tension braking rollers rotate, and the sizing unit is used for conducting re-sizing and drying on the fiber tows. The method for the continuous fiber tows is achieved through the above equipment, the fiber tows after being processed have lowered and uniform fiber distribution density and stable and consistent fiber tow widths, and therefore the fiber tows together with heat plastic plastics can directly be made into heat plastic composite materials or various types of composite material products.

Owner:FORMOSA TAFFETA CO LTD

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

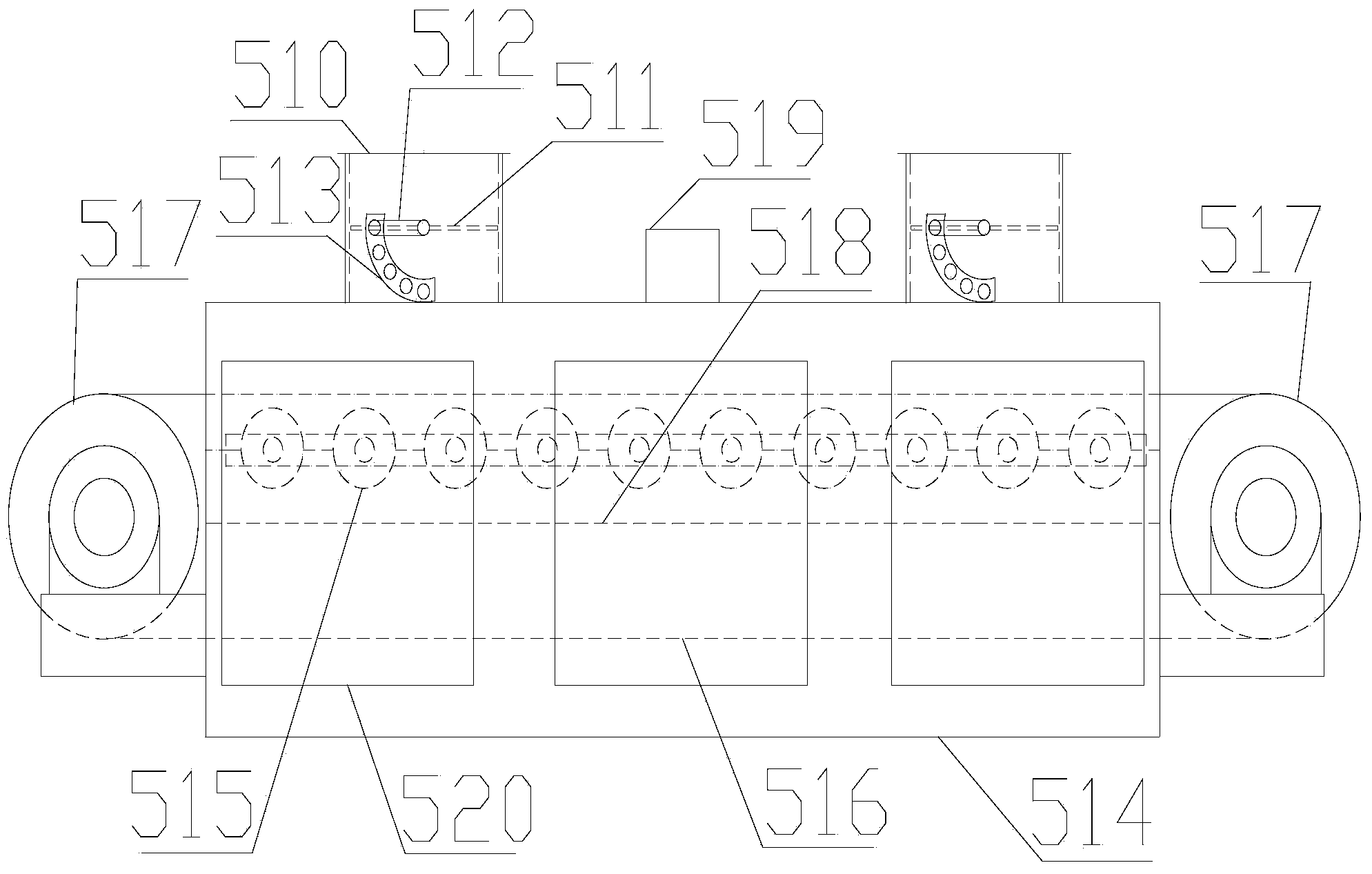

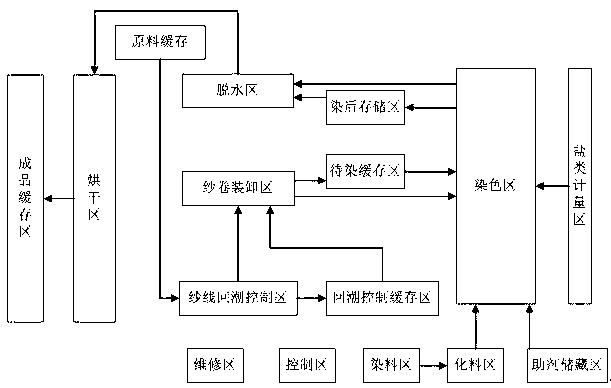

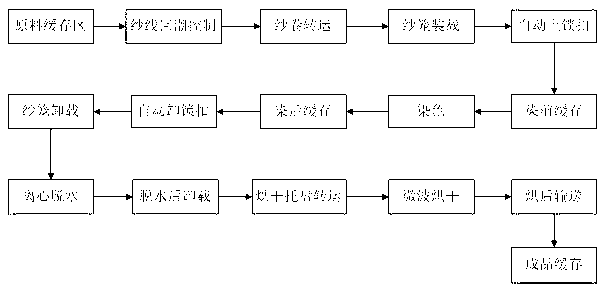

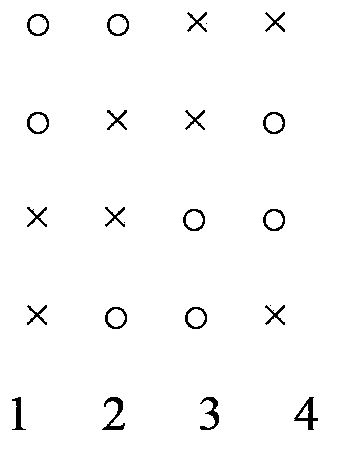

Cheese dyeing method and cheese dyeing production device

ActiveCN103225189AIncrease the level of automationIncrease productivitySucessive textile treatmentsLiquid/gas/vapor treatment of definite length materialsYarnMicrowave

The invention provides a cheese dyeing method and a cheese dyeing production device. The cheese dyeing method comprises the following steps of yarn return control: yarn return control equipment is adopted to carry out return control on a cheese; yarn cage loading: a yarn loading robot is adopted to load the cheese subjected to return control in a yarn cage; yarn cage transferring: an automatic crown block is adopted to transfer the yarn cage to a pre-dyeing cache region, and then is transferred into a vertical dyeing machine from the pre-dyeing cache region; dyeing: the vertical dyeing machine is adopted to dye the cheese subjected to return control; automatic dye weighing; dissolving and dispatching; liquid additive accurate metering and conveying; automatic powder salt additive weighing and conveying; dewatering: the dyed cheese is dewatered; and drying: a microwave drying machine is adopted to dry the dewatered cheese. In the technical scheme, various automatic devices are adopted to improve the automatic dyeing level of the cheese.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Moisturizing skin care warm-keeping knitted fabric and production technology thereof

ActiveCN104047102AHas skin care and moisturizing functionWith warm functionSucessive textile treatmentsWeft knittingTextile technologyPolymer science

The invention relates to the textile technical field, in particular to moisturizing skin care warm-keeping knitted fabric and a production technology thereof. The production technology comprises the following processing steps of a, spinning, b, weaving and c, dyeing and finishing. In the step of spinning, acrylic fibers including arginine and common viscose fibers are spun into siro spinning blended yarns, the proportion of the acrylic fibers in the blended yarns is 50%-80%, the proportion of the viscose is 50%-20%, the yarn count of the yarns is 40-80 S / 1, and the twist coefficient of the yarns is 330-370. In the step of weaving, the siro spinning blended yarns and spandex are interwoven, the linear density of the spandex is 15-40 D, a weft knitting circular weft knitting machine is used for weaving knitted gray cloth, and the tissue is plaiting tissue. In the step of dyeing and finishing, the following processes of pre-shaping, dyeing, soaping, cloth drying, cloth bottom sanding and shaping are included. The produced fabric has the skin care moisturizing function, the moisturizing skin care function cannot be weakened along with repeated washing, and the fabric has the warm-keeping function and is suitable for being worn in autumn and winter in which the air humidity is low.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

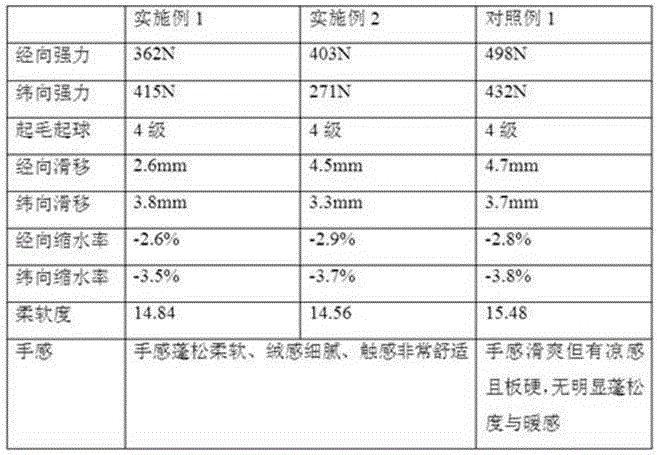

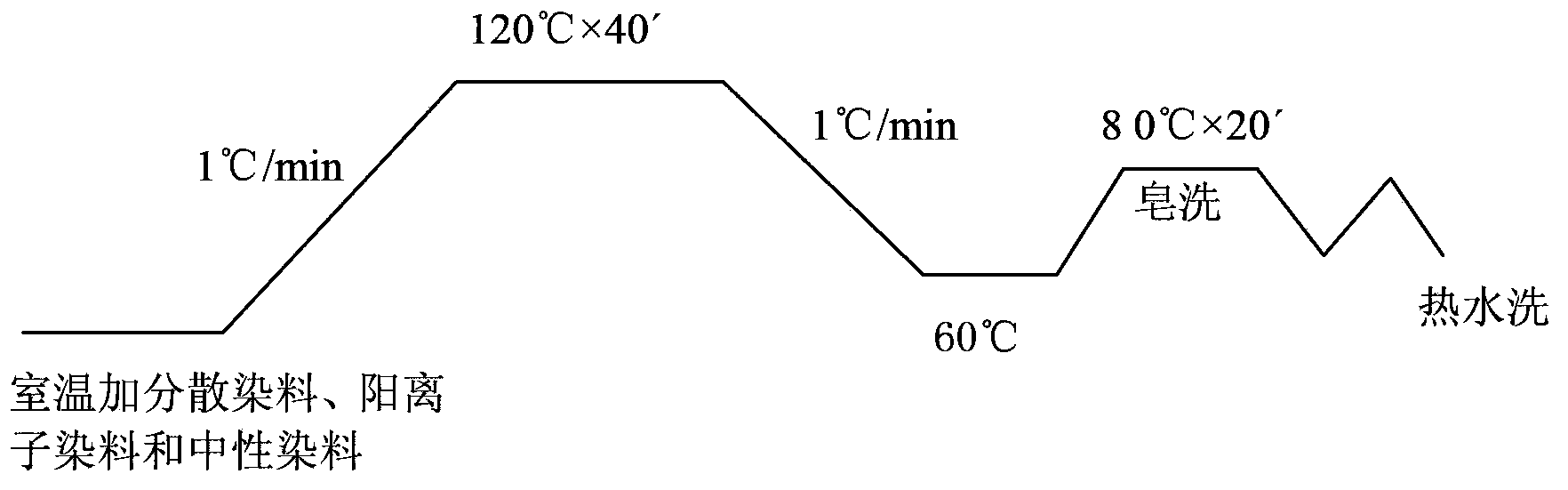

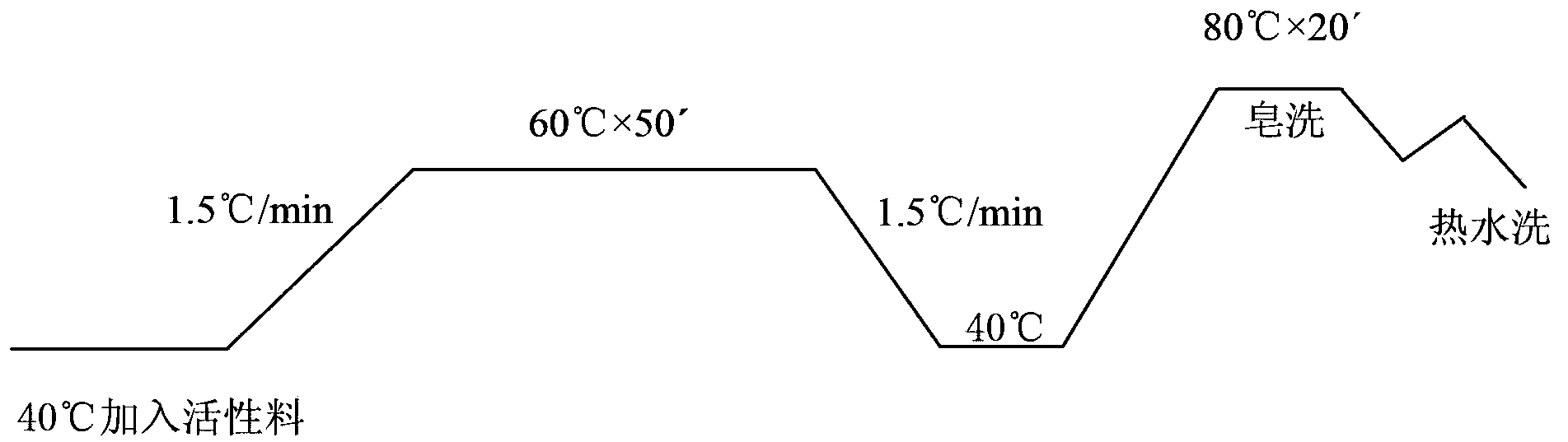

Low-wool-content multi-component chemical fiber blended fabric and preparing method thereof

ActiveCN103835048AImprove perceptionEasy to takeSucessive textile treatmentsWoven fabricsPolyesterPolymer science

The invention provides a low-wool-content multi-component chemical fiber blended fabric and a preparing method of the low-wool-content multi-component chemical fiber blended fabric and belongs to the field of spinning dyeing and finishing. Wool is added to multi-component chemical fibers and the low-wool-content multi-component chemical fiber blended fabric comprises, by weight, 30% to 40% of polyester staple fibers, 20% to 30% of modified polyester fibers, 10% to 20% of mucilage glue, 5% to 15% of Tencel, 8% to 30% of the wool and 0.1% to 0.6% of conductive fibers. The wool content of a traditional product is changed, wool fibers with the content smaller than 30% are blended with the polyester staple fibers, the modified polyester fibers, the mucilage glue, the Tencel and the conductive fibers in the chemical fibers in a combined mode, so that mutual advantage complement of the various fibers is achieved, and multiple colors, the high comfort degree and the easy-maintenance performance of the fabric are achieved with the low wool content. The technology is reasonable, the technical purpose of one bath dyeing of the wool and the multi-component chemical fibers is effectively achieved, and a new path is created for upgrading orientation and the comfort of chemical fiber fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Knitting tubular open width refining rinsing combination machine

InactiveCN101289797AWill not be damaged and fluffedNo creaseSucessive textile treatmentsMechanical engineeringSmelting

Owner:张琦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com