Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235results about How to "Overcome mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical/ionic/physical compounding cross linking hydrogel and preparation method thereof

The invention relates to chemical / ionic / physical compounding cross linking hydrogel and a preparation method thereof. The hydrogel is polymerized in a way that olefin monomer M1, a chemical cross-linking agent M2, multivalent ion biomacromolecule M3, an ionic cross-linking agent M4 and a physical cross-linking agent M5 are dissolved in water. The method comprises the following steps: preparing chemical / physical cross linked gel prepolymerization liquid, preparing chemical / ionic / physical cross linked gel prepolymerization liquid and preparing and purifying chemical / ionic / physical compounding cross linked gel. According to the invention, the characteristics and properties of the chemical cross-linking agent, the physical cross-linking agent and the ionic cross-linking agents are taken into consideration comprehensively, the compounding cross linking of molecular chains is realized; the prepared hydrogel is optically transparent and has higher mechanical ductility and rebound elasticity; the mechanic, optical and thermal performances and other performances can be regulated conveniently by controlling technology parameters and conditions; and the prepared hydrogel can be used in the fields such as tissue engineering, food industry, agricultural irrigation, daily chemical engineering, oil production, dye adsorption and biological medicine.

Owner:TIANJIN POLYTECHNIC UNIV

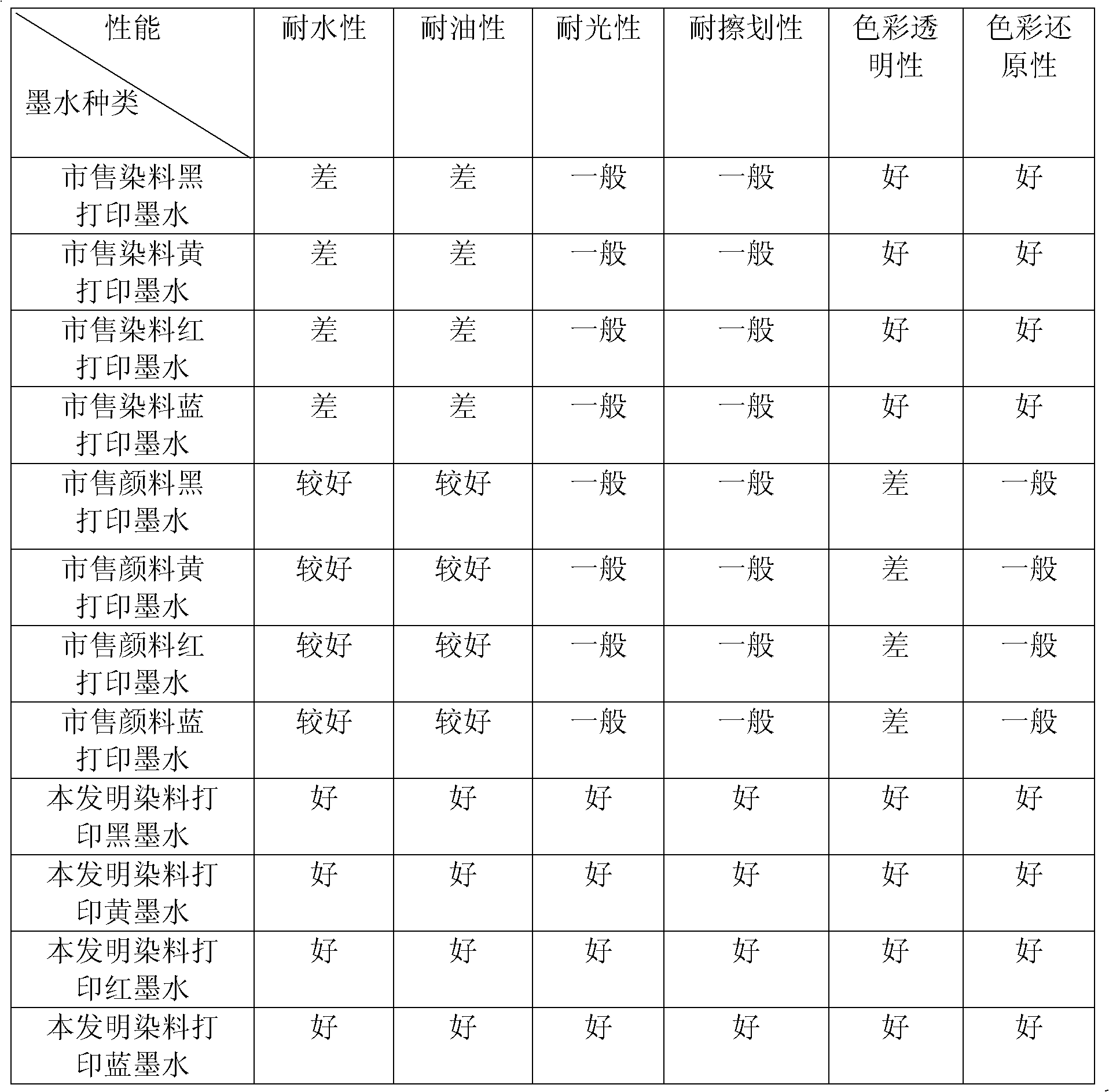

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

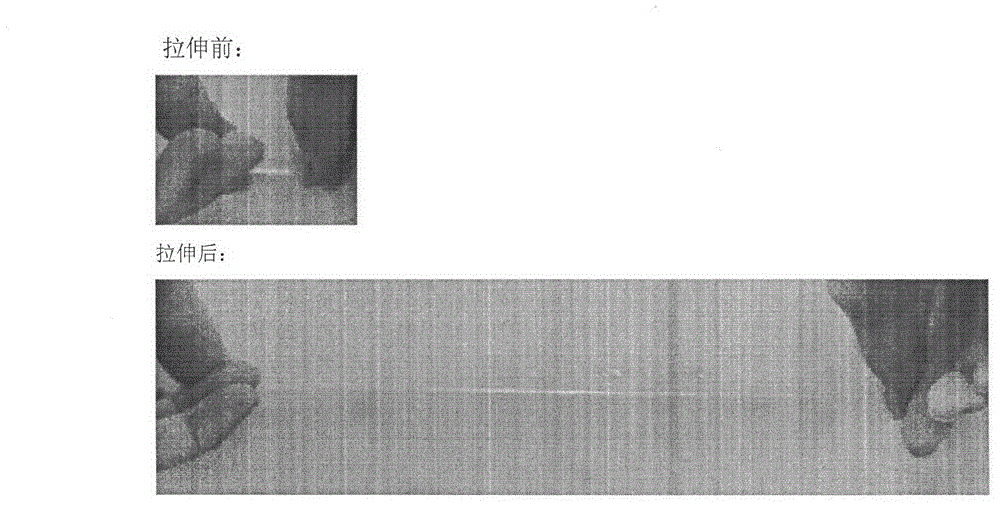

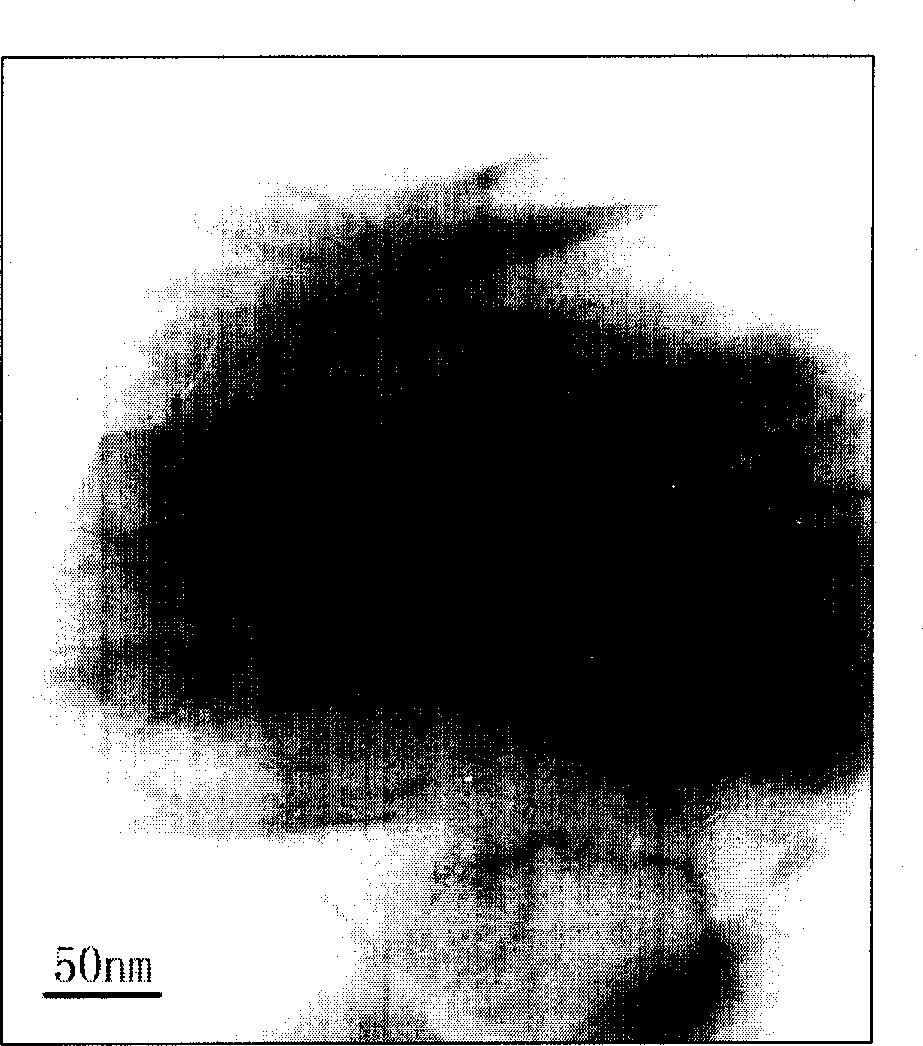

Process for preparing organic modified clay and styrene butadiene rubber nano composite material

The process of preparing nanometer composite material of organically modified clay and styrene butadiene rubber includes the first mixing organic modifier aqua and water clay suspension, the subsequent mixing with styrene butadiene latex, demulsifying and flocculating, drying, pugging and final vulcanizing to obtain the composite material. The organic modifier is alkyl ammonium salt and has the weight ratio to the clay of 0.1-0.5. The composite material has large rubber molecule entering the clay lamella to form obvious intercalation, nanometer scale dispersing of clay lamella in rubber base to result in excellent strengthening effect, and obviously raised mechanical performance, especially stretching strength, of the vulcanized rubber.

Owner:BEIJING UNIV OF CHEM TECH

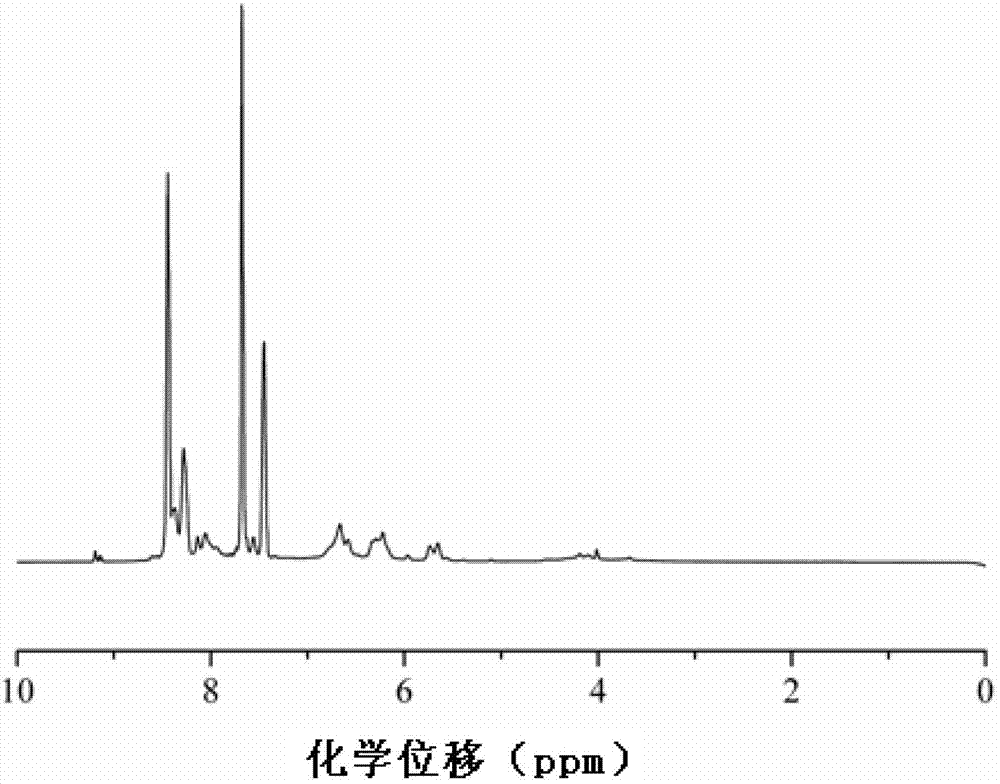

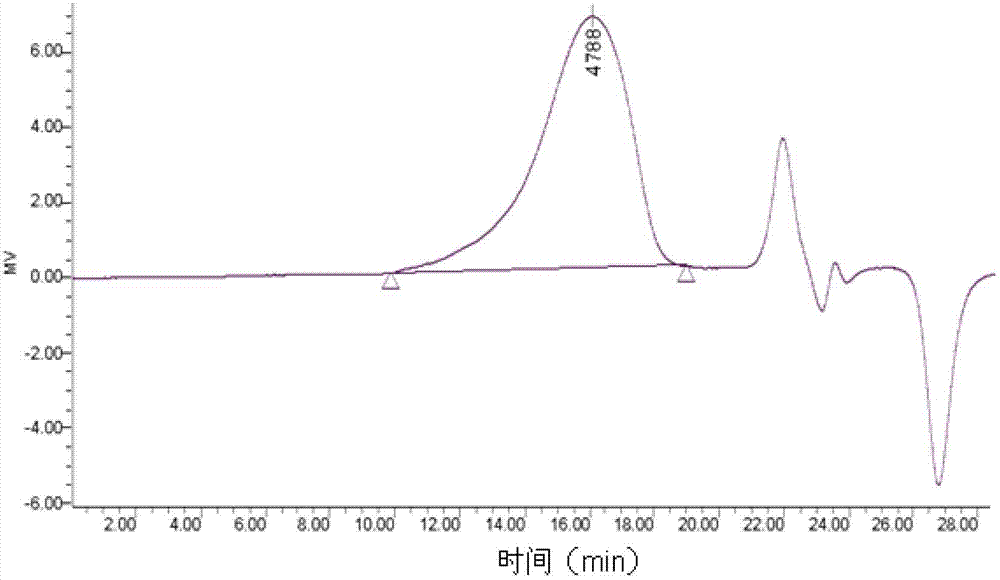

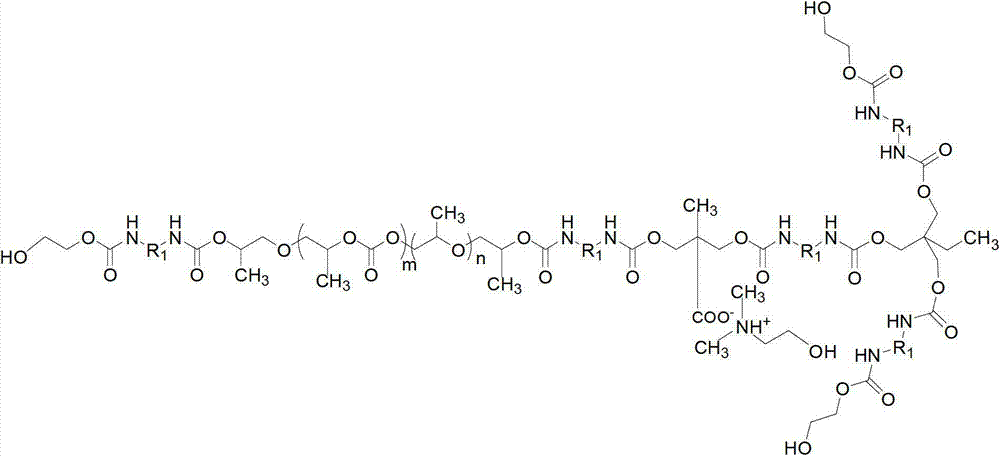

Waterborne polyurethane adhesive and preparation method thereof

ActiveCN103045150AOvercome water resistanceOvercome mechanical propertiesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention provides a waterborne polyurethane adhesive which comprises polyurethane with a structure of a formula (I). The invention also provides a method for preparing the waterborne polyurethane adhesive. The polyurethane provided by the invention is prepared by reacting poly (carbonate ester-ether) with a structure of a formula (II) with trimethylolpropane, diisocyanate, dyhydroxy methyl acrylic acid, ethylene glycol and dimethyl ethanolamine. The poly (carbonate ester-ether) dihydric alcohol has a polyester structure and a polyether structure, the defects that the polyester is poor in water resistance and the polyether is poor in mechanical performance are overcome, a prepared polyurethane main chain is provided with a polyester unit and a polyether unit through a copolymerization reaction, and the adhesion performance is improved.

Owner:吉林天泽二氧化碳科技有限公司

Collagen base freezing gel suitable for biological medical material and preparation thereof

ActiveCN101234216APromote degradationGood tissue compatibilitySurgeryAbsorbent padsCross-linkPorosity

The invention provides a collagen matrix freezing gel used for biomedical materials and a preparation method thereof. The collagen matrix freezing gel is the collagen extracted from skins or tendons of healthy domestic animals using the enzyme method with the molecular weight of 280 to 320kDa and a well maintained triple helical structure; the collagen reacts for 1 to 7 days in the condition of low temperature of 0 to minus 50 DEG C in a die after through cross linked and modified reaction with hydroformylation polysaccharide, then extrudes the die and is defrosted, thus forming the collagen matrix freezing gel. The preparation of the collagen matrix freezing gel of the invention in particular relates to the extraction of the collagen, the preparation of the hydroformylation polysaccharide and the synthesis of hydroformylation polysaccharide-collagen matrix freezing gel. The hydroformylation polysaccharide-collagen matrix freezing gel prepared by the invention improves the mechanical property, thermal stability and anti-enzyme degradation, etc., of pure collagen gels, and the freezing gel has the advantages of porosity, plasticity, hydrophilic property and non-toxicity, and can be used as biomedical materials such as bio-scaffold, cell cultivation, drug controlled release and biological dressings.

Owner:北京益而康生物工程有限公司

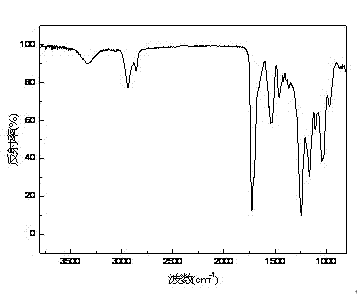

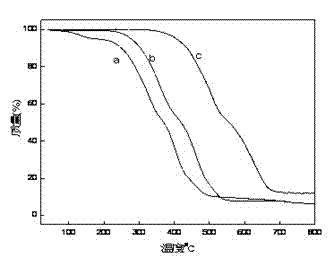

Flame-retardant heat-resistance polyurethane resin and preparation method of aqueous emulsion of polyurethane resin

ActiveCN103242504AOvercome mechanical propertiesImprove heat resistancePolyureas/polyurethane adhesivesInksPolyesterPolymer science

The invention belongs to the field of high molecular materials and in particular relates to flame-retardant heat-resistance polyurethane resin. The resin structure contains a residue structure obtained after reaction of heterocyclic polyol A, flame-retardant polyol and polyisocyanate, and the resin is obtained by adding heterocyclic polyol B as a crosslinking agent at the post phase of polyurethane synthesis. The flame-retardant heat-resistance polyurethane resin and an aqueous emulsion thereof are prepared by carrying out a reaction on heterocyclic polyol, polyester or polyester polyol, flame-retardant polyol, polyisocyanate and the like. As the heterocyclic structure is introduced in a polyurethane molecule chain, except for the characteristics of the common polyurethane paint coating, the flame-retardant heat-resistant polyurethane resin further has excellent heat resistance, corrosion resistance and high mechanical strength and mechanism performance and is high-grade flame-retardant polyurethane aqueous resin. The defects of the existing polyurethane coating in terms of heat resistance and mechanical property are overcome; and the prepared flame-retardant heat-resistance polyurethane resin has the advantages of intrinsic flame retardance, high heat resistance, large hardness, excellent mechanical property and high cost performance, is convenient to use and can be dried at low temperature.

Owner:DALIAN UNIV OF TECH

High-molecular-weight furyl aromatic polyamide, preparation method and application thereof

ActiveCN110256668AImprove mechanical propertiesImprove thermal stabilityWet spinning methodsMonocomponent polyamides artificial filamentFuranDiaminodiphenyl ether

Owner:UNIV OF SCI & TECH OF CHINA

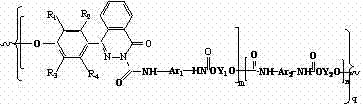

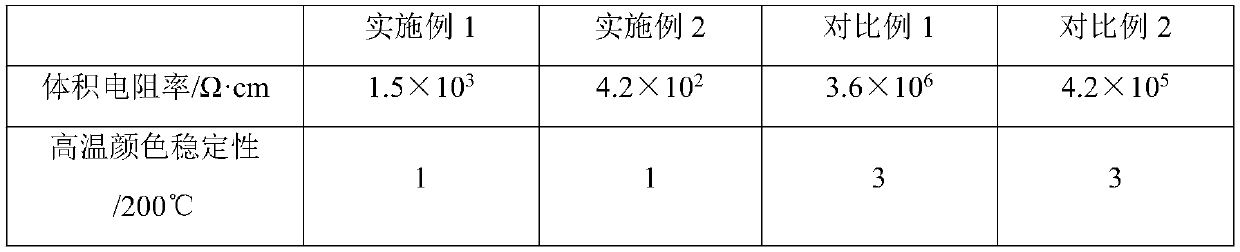

High-conductivity polyetheretherketone composite material and preparation method thereof

The invention provides a high-conductivity polyetheretherketone composite material and a preparation method thereof, and belongs to the field of conductive polymer materials. The high-conductivity polyetheretherketone composite material comprises, by weight, the following raw materials: 80-100 parts of PEEK, 10-20 parts of a reinforced fiber, 10-15 parts of grafted modified carbon nanotube, 3-8 parts of a wear-resistant agent, 2-5 parts of a coupling agent, 0.5-1 part of an antioxidant and 1-2 parts of a lubricant. According to the material, PEEK is used as a base material, and the reinforcingfiber, the carbon nanotube, the wear-resistant agent and the like are added, so that the prepared composite material not only has excellent mechanical properties, high temperature resistance and wearresistance, but also is chemically grafted and modified from the carbon nanotube, so that the composite material has high electrical conductivity and high-temperature appearance color stability.

Owner:苏州聚泰新材料有限公司

Carbon fiber reinforced nylon 6 resin composite material and preparation method thereof

The invention relates to a carbon fiber reinforced nylon 6 resin composite material with excellent heat conducting performance and a preparation method thereof. The composite material consists of the following materials in parts by weight: 100 parts of nylon 6 resin, 20-80 parts of carbon fiber, 10-20 parts of inorganic filling material, 0.5-5 parts of coupling agent, 0.2-1 part of antioxidant and 0-3 parts of lubricating agent. The preparation method comprises the following steps: weighing each component raw material in proportion; mixing each component raw material except for the carbon fiber at a high speed; adding an obtained mixed material into a double-screw extruder hopper, adding the carbon fiber from a fiber charging opening of the extruder, and then extruding and pelletizing. Compared with the prior art, the composite material provided by the invention is high in rigidity and good in heat conducting performance, is suitable for production and processing of thin-walled and light-weight automobile parts and electronic / electrical products; meanwhile, the composite material is low in raw material cost and simple in manufacturing process, and is suitable for industrial continuous production.

Owner:SHANGHAI JIAO TONG UNIV

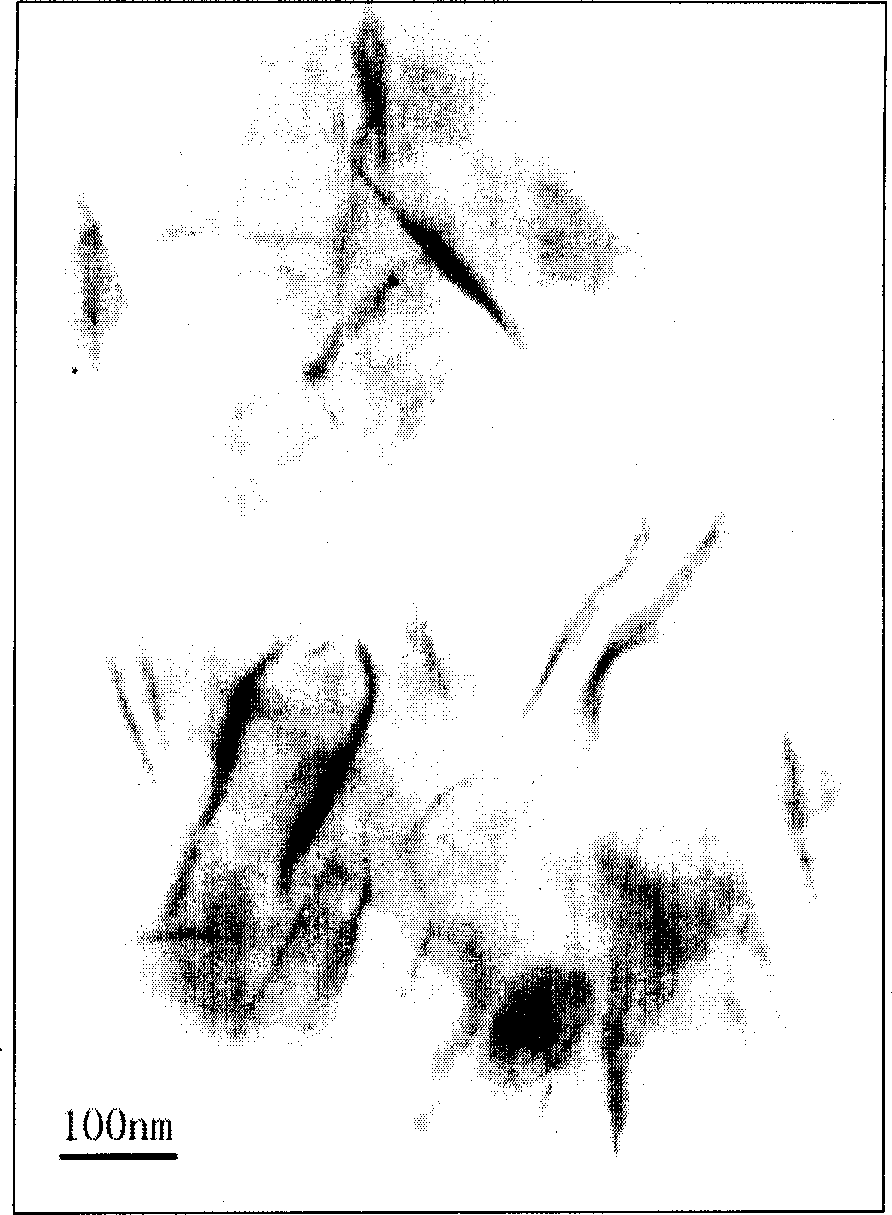

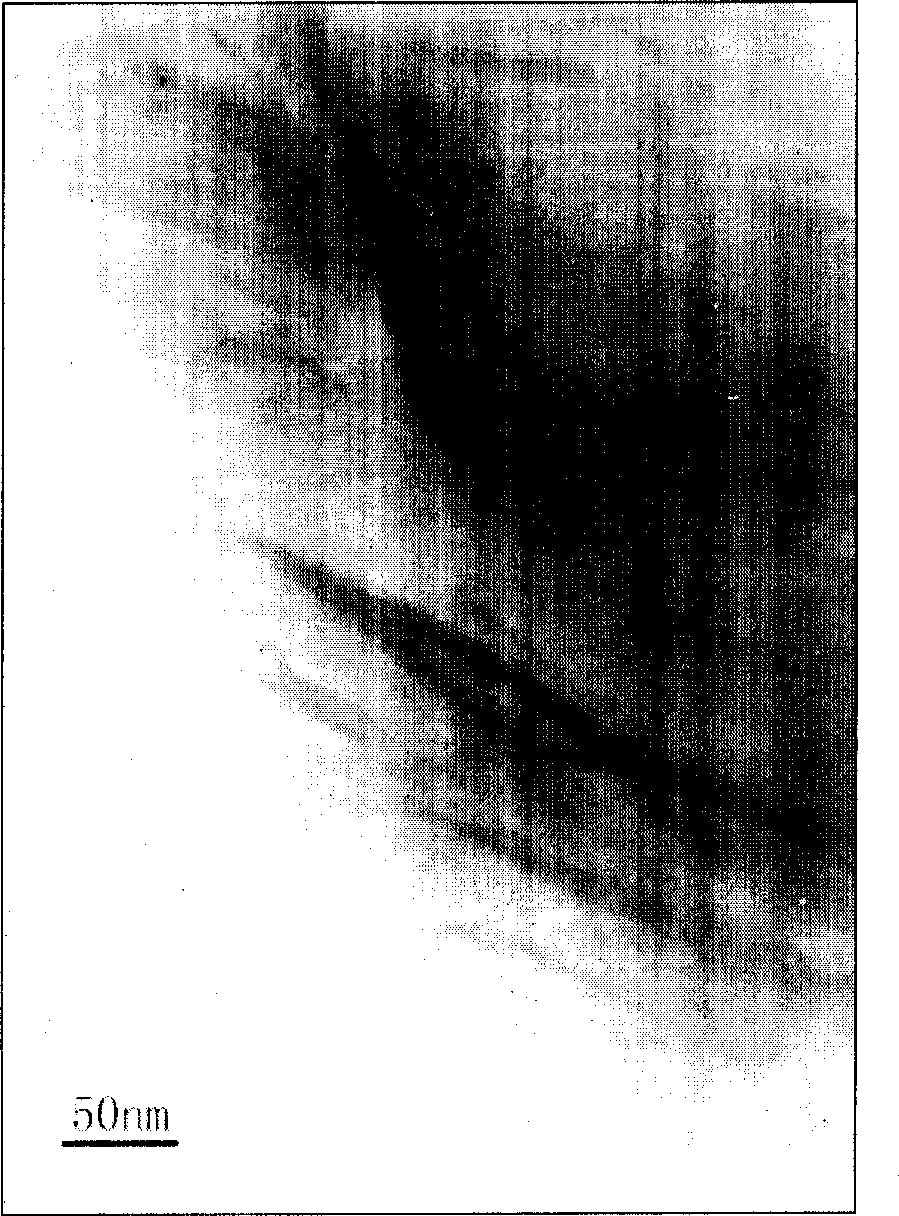

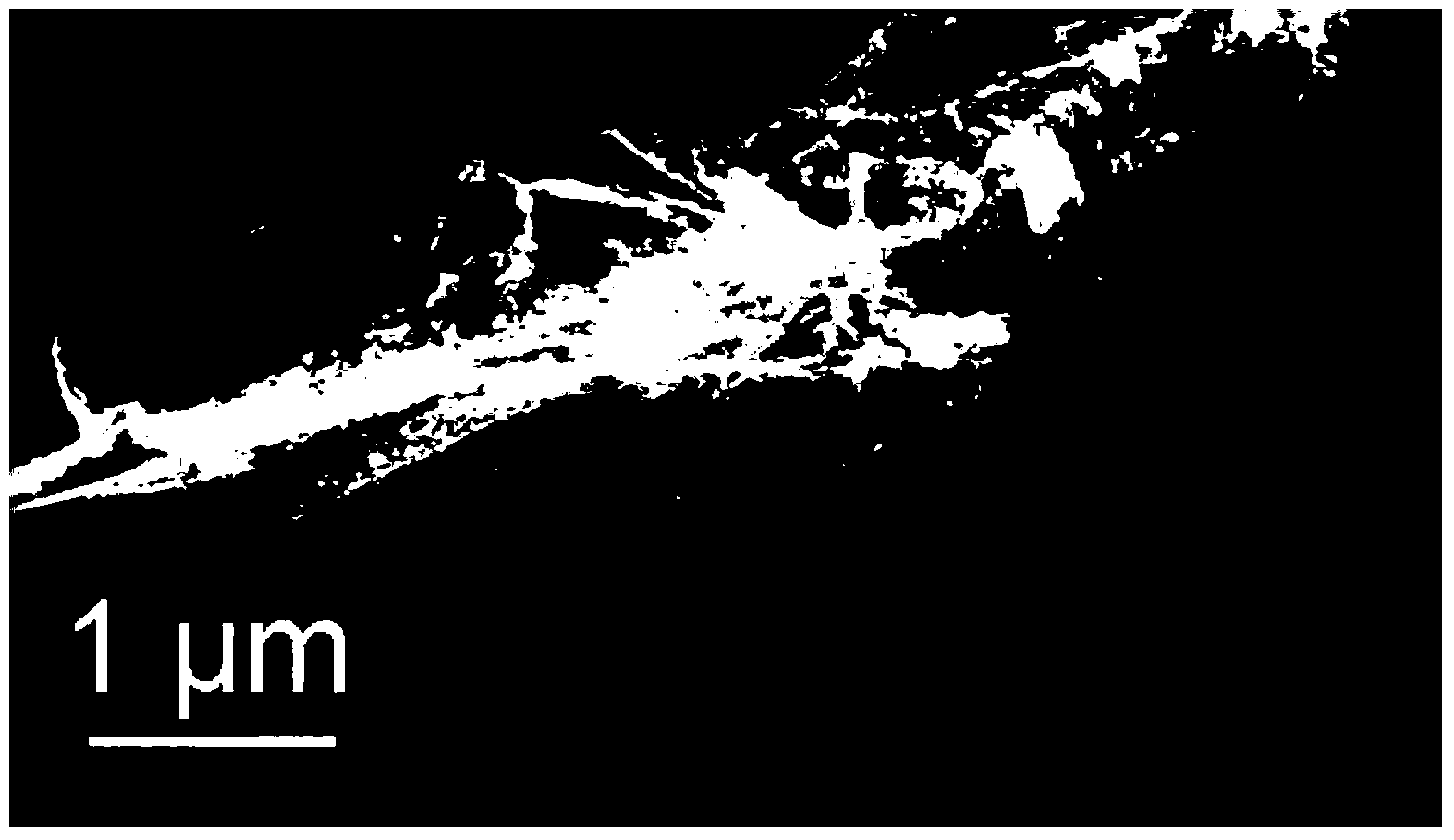

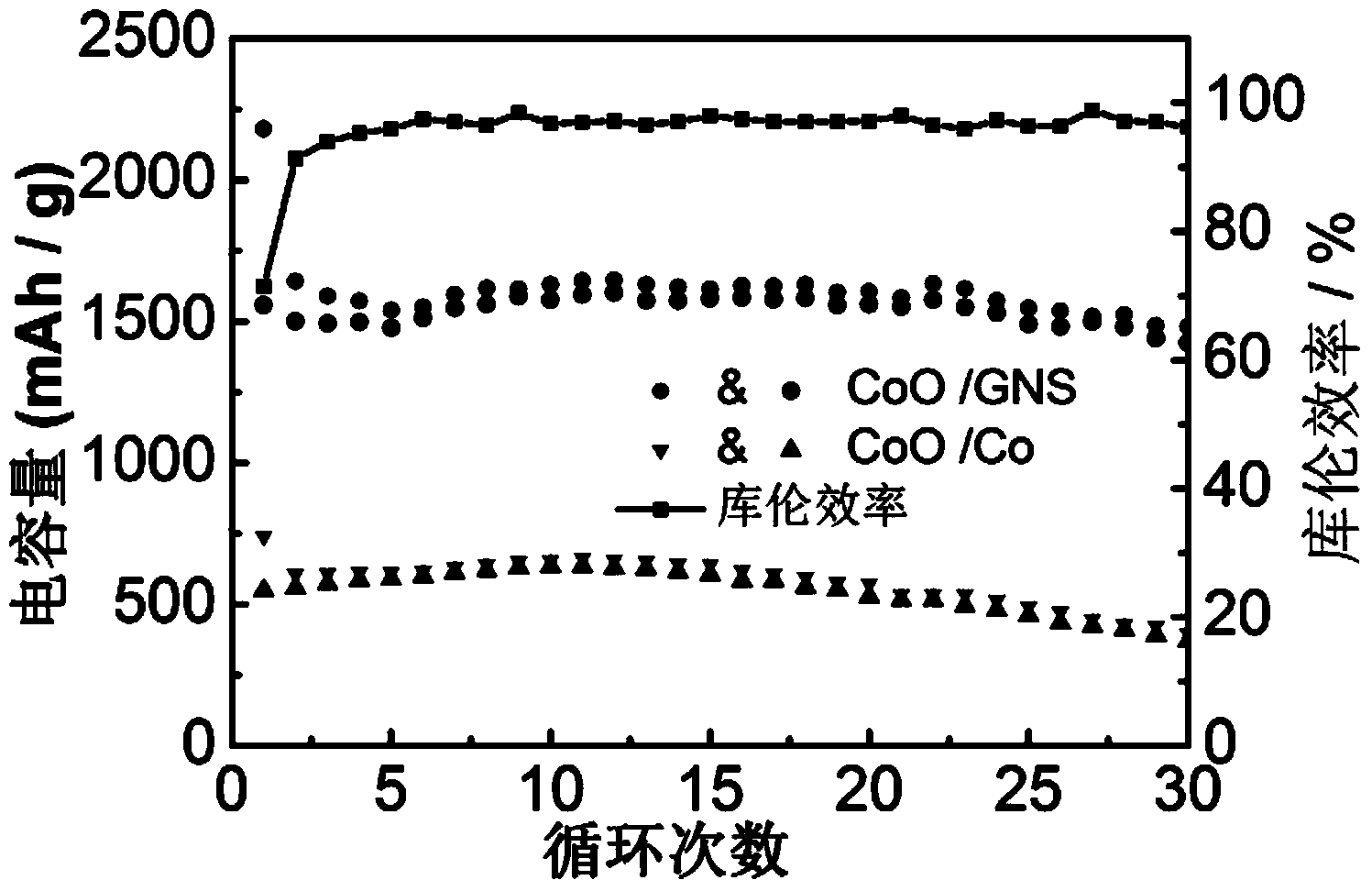

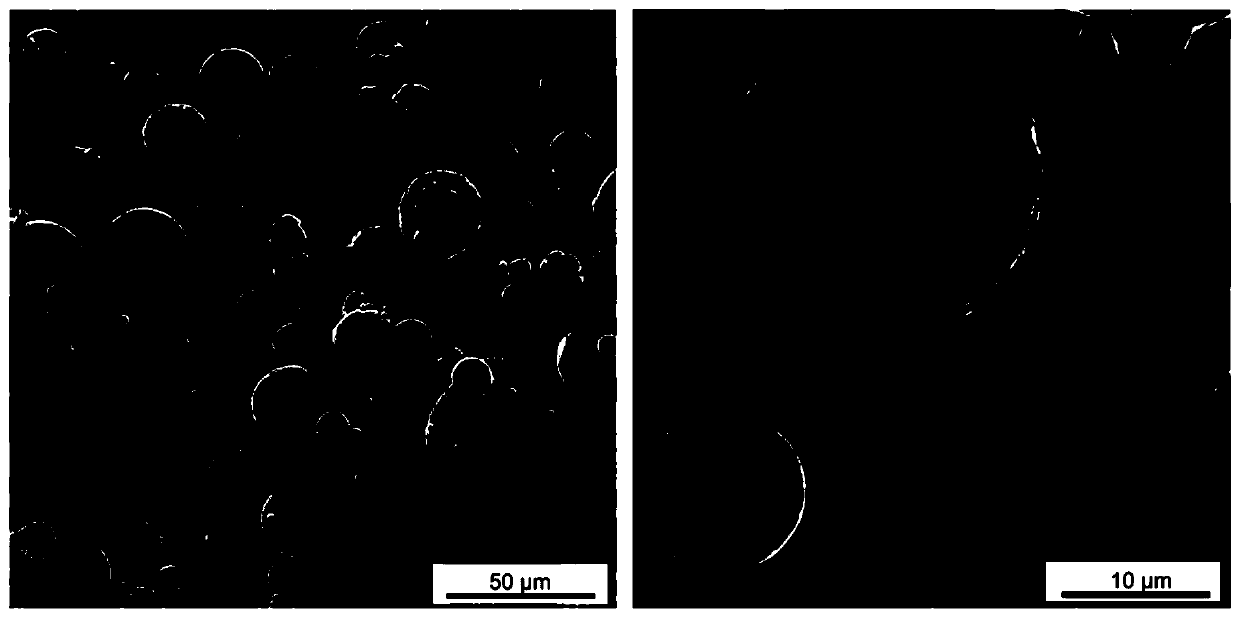

Nano crystalline CoO-graphene composite material as well as preparation and application thereof

ActiveCN104393283AAvoid pollutionThe preparation process is simple and cheapMaterial nanotechnologyCell electrodesCapacitanceSingle layer graphene

The invention discloses a graphene composite material, in particular a CoO and graphene composite material. The invention also relates to a preparation method of the graphene composite material and application of the graphene composite material in a lithium-ion battery. The preparation method comprises the steps of performing low-temperature recrystallization on cobalt acetate tetrahydrate, compositing the recrystallized cobalt acetate tetrahydrate and graphene oxide to obtain a precursor, and performing low-temperature annealing on the precursor under a high vacuum environment to obtain two-dimensional nano crystalline CoO-graphene composite material, wherein single-layer graphene with the thickness of 1-50 micrometers is taken as a carrier frame, and CoO nanocrystals with the average particle diameter of 2-20 nm are uniformly embedded in the upper and lower surfaces of the single-layer graphene. The prepared nano crystalline CoO-graphene composite material can be used as the negative electrode of a lithium-ion battery to effectively improve the capacitance of the lithium-ion battery; the preparation method is simple, the preparation period is short, the preparation efficiency is high, no toxic effect exists, the environment pollution is avoided, and the potential safety hazard is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

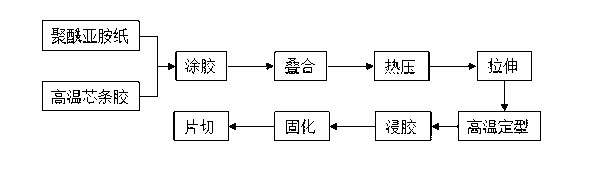

Preparation method of polyimide paper honeycomb core

ActiveCN103264530AExtended service lifeImprove heat resistancePaper/cardboard articlesSynthetic cellulose/non-cellulose material pulp/paperHeat resistanceHoneycomb

The invention relates to a preparation method of a polyimide paper honeycomb core. The method includes the following steps: (1) raw material paper is glued, laminated and hot-pressed, and a honeycomb stacked block is manufactured; (2) the honeycomb stacked block is molded at high temperature after being pulled, and a white honeycomb block is manufactured; (3) gum dipping is carried on the white honeycomb block, and the white honeycomb block is solidified; (4) a honeycomb after the gum dipping and solidification is sliced. The method is characterized in that the raw material paper is polyimide paper. Due to the fact that the polyimide paper is made of polyimide fibers, good characteristics of the polyimide fibers are inherited. Therefore, the prepared polyimide paper honeycomb core has better heat-resistant performance, dielectric performance, smoke and fire toxicity and mechanical performance compared with an aramid fiber paper honeycomb core in the prior art, the water absorption rate is low, the application field is widened, and service life of the honeycomb is prolonged in special environments. Production equipment of the aramid fiber paper honeycomb core in the prior art can be used, novel instruments and devices do not need to be added, process procedures are basically unchanged, operation is convenient, and equipment cost is not increased.

Owner:ARAMICORE COMPOSITE

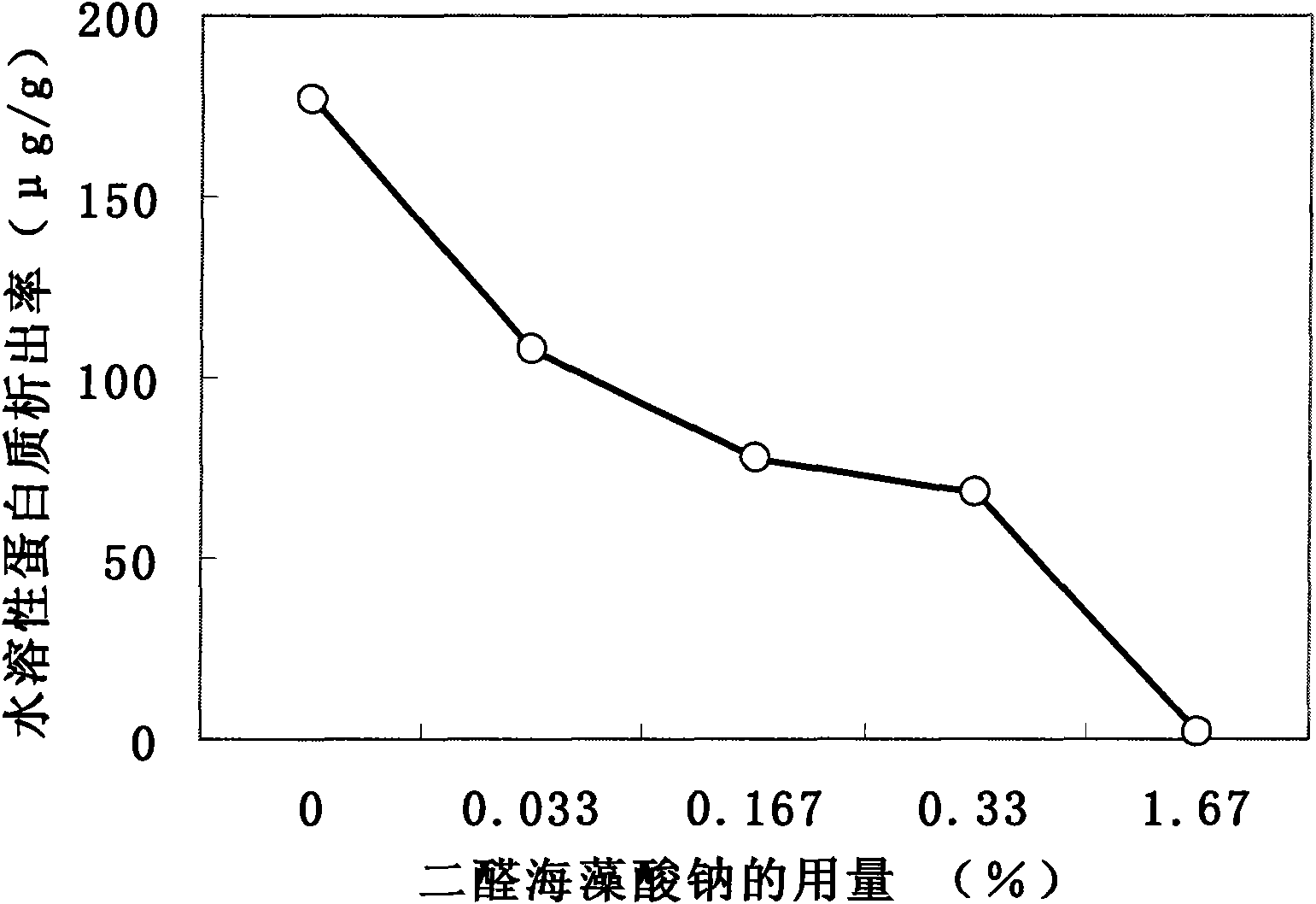

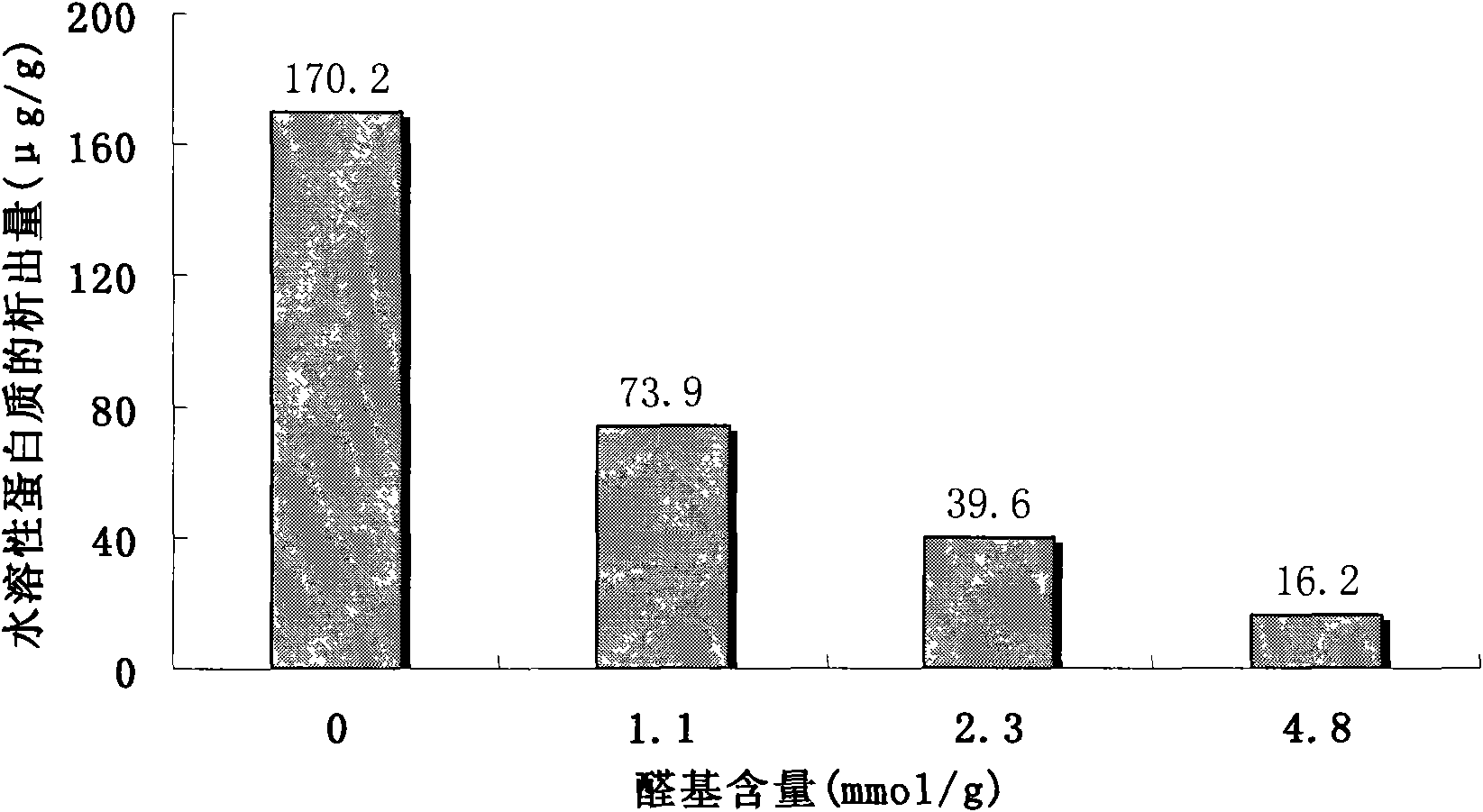

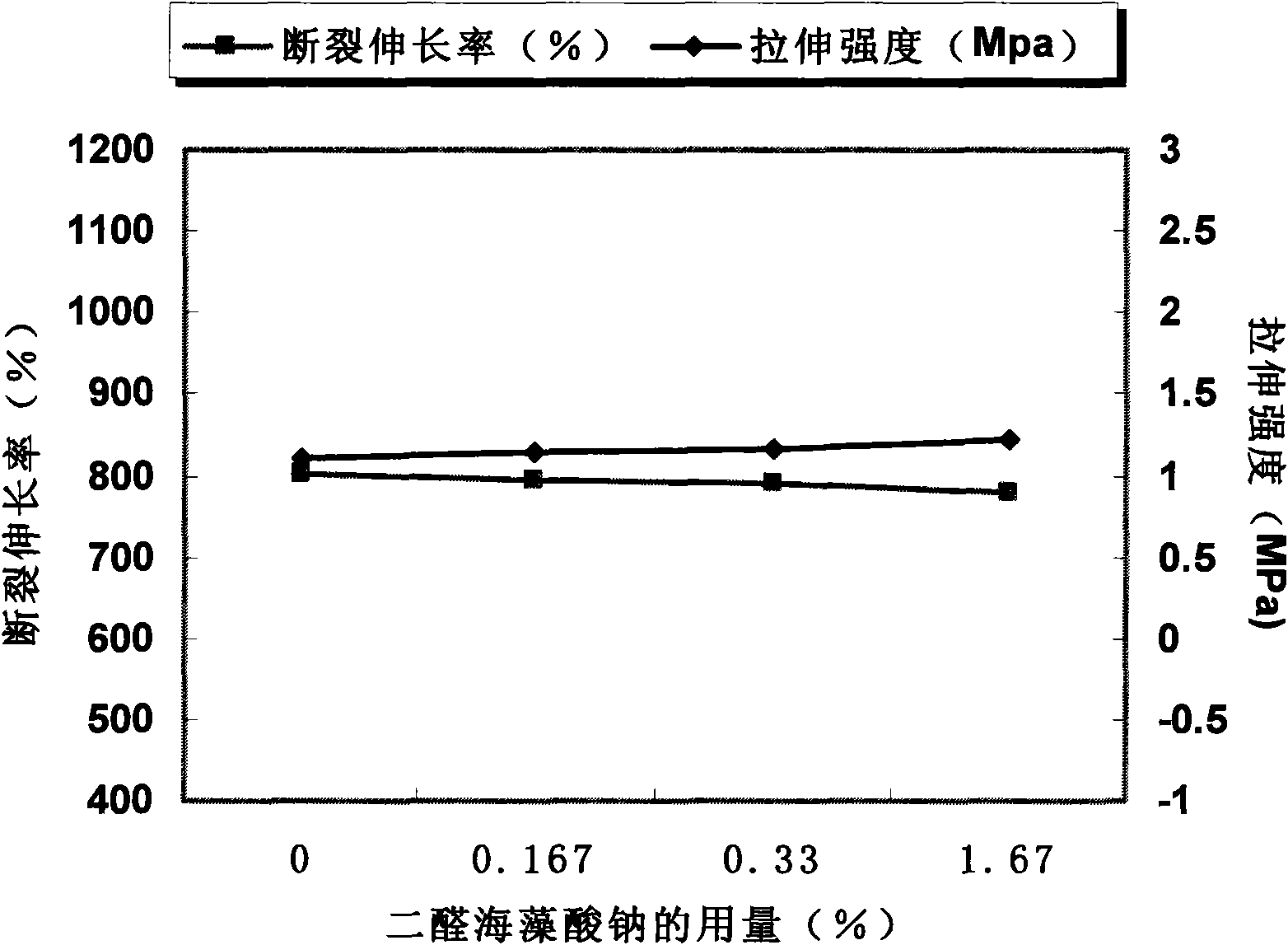

Natural rubber latex protein fixation method

InactiveCN101613422AAddress allergiesGood biocompatibilityCarrier-bound/immobilised peptidesInterpenetrating polymer networkWater soluble

The invention discloses a natural rubber latex protein fixation method aiming to solve the problem of protein allergy of natural latex products; in the method, dialdehyde polysaccharide ammonia water solution is added in natural latex and then films can be prepared by standing and drying; wherein, the dialdehyde polysaccharide is prepared by oxidizing natural polysaccharide with sodium periodate. The invention uses the aldehyde group of the oxidized polysaccharide to process a crosslinked action with proteins and increases the molecular weight of the proteins to enable the proteins to lose water-solubility; in addition, the invention uses the structure characteristic that interpenetrating polymer networks can be formed by using polysaccharide and latex and fixes proteins which lose water-solubility firmly in the latex film. The method provided by the invention overcomes the defects that the latex stability and the mechanical properties of the obtained rubber products are poor in the traditional methods such as enzymic degradation method, avoids the environmental problems caused by chlorination treatment and has low production cost, thus having a wide application prospect in rubber industry.

Owner:SUN YAT SEN UNIV

Preparation process of nano concave soil base inorganic flame-retarded agent

InactiveCN100999669AMake the most of synergiesImprove flame retardant performanceFireproof paintsZinc borateBoric acid

The present invention is the preparation process of composite inorganic flame retardant with nanometer attapulgite clay core and coating of Mg, Al, Sb, etc. The preparation process of the composite inorganic flame retardant includes the following steps: compounding water suspension of nanometer attapulgite clay with solid content of 10-200g / L; heating to 40-100 deg.c and coating the nanometer attapulgite clay with inorganic material Al2O3 hydrate, MgO hydrate, antimony oxide hydrate, ZnO hydrate and / or zinc borate via stirring; letting stand for the coated nanometer attapulgite clay to deposit; solid-liquid separation; filtering, washing, drying at 80-150 deg.c and crushing to obtain the composite inorganic flame retardant. The composite inorganic flame retardant of nanometer attapulgite clay has both flame retarding and excellent reinforcing effects.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

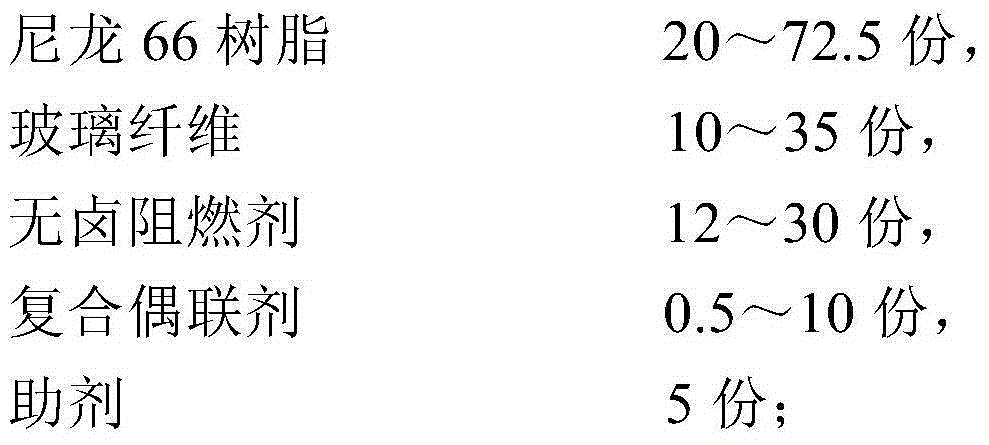

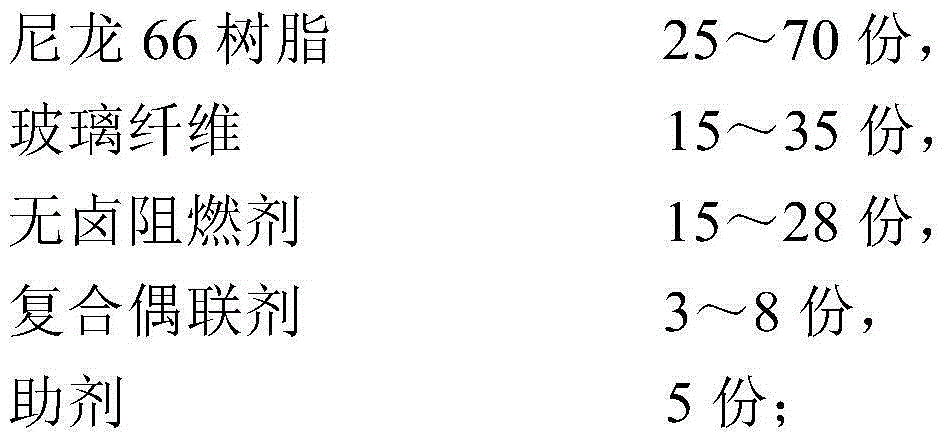

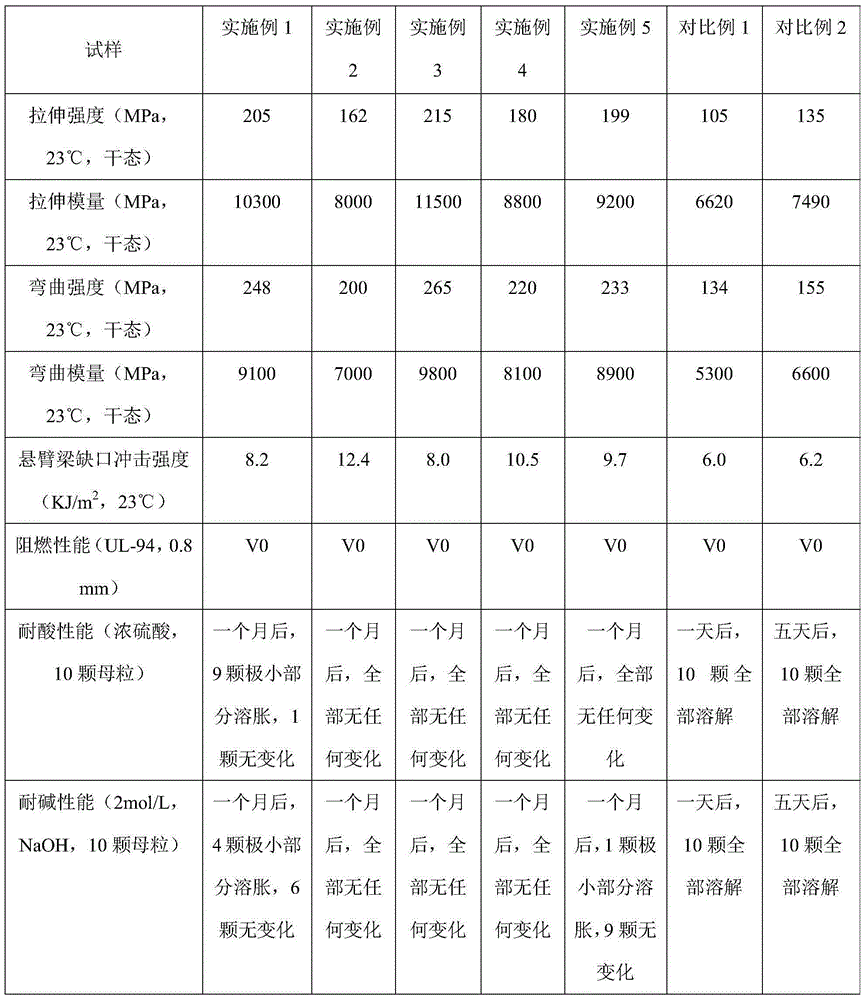

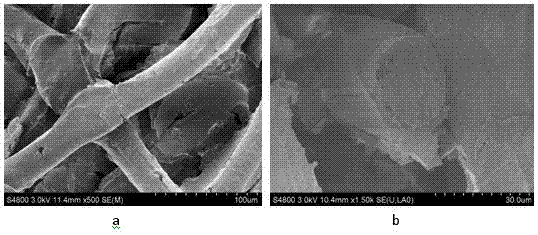

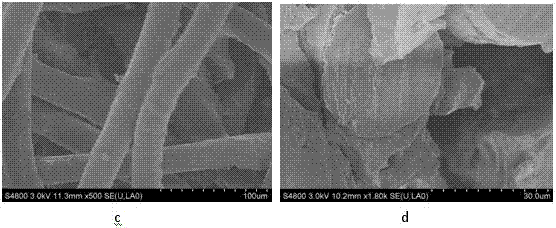

Halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance and preparation method of PA66 composite material

InactiveCN105062050AGood acid and alkali resistanceStrong acid and alkali resistanceEpoxyGlass fiber

The invention discloses a halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance. The PA66 composite material comprises raw materials in parts by weight as follows: 20-72.5 parts of PA66 resin, 10-35 parts of glass fiber, 12-30 parts of a halogen-free flame retardant, 0.5-10 parts of a composite coupling agent and 5 parts of an auxiliary, wherein the composite coupling agent is selected from a mixture formed by mixing gamma-aminopropyl triethoxysilane with gamma-epoxy propoxy propyl trimethoxysilane or epoxy resin in the weight ratio being 1: (1-50). The composite material has higher acid and alkali resistance, good processing fluidity as well as excellent mechanical properties, heat resistance and flame retardation, the problem of insufficient acid and alkali resistance of PA products in the prior art is particularly solved, the acid and alkali resistance is improved remarkably, and the composite material has broad market prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Preparation method and application of modified polypropylene non-woven fabric

InactiveCN102965929AOvercome mechanical propertiesOvercoming pollutionFibre treatmentWater/sewage treatment by sorptionDesorptionSolvent

The invention discloses a modified polypropylene non-woven fabric, its preparation method and application. The preparation method comprises: impregnating a polypropylene non-woven fabric in a grafting solution containing a graft monomer, a crosslinking agent, a non-ionic surfactant and a photosensitizer, and initiating graft polymerization under ultraviolet irradiation, thus obtaining the modified polypropylene non-woven fabric, which can be widely used in adsorption separation treatments of dye wastewater, heavy metal ion wastewater, inorganic anion acid radical-containing chemical wastewater and the like as a filtering material. The modified polypropylene non-woven fabric provided by the invention has the characteristics of high mechanical strength, large water flux, and great saturated adsorption capacity. Meanwhile, after being subjected to a regeneration treatment in a cationic surfactant-containing ethanol solvent desorption solution, the adsorbed filtering material can be recycled.

Owner:SUZHOU UNIV

High-strength coarse-grain-ring-free aluminum alloy bar for automotive control arm and preparation method of aluminum alloy bar

The invention discloses a high-strength coarse-grain-ring-free aluminum alloy bar for an automotive control arm. The high-strength coarse-grain-ring-free aluminum alloy bar for the automotive control arm comprises the following components: 0.9-1.2% of Si, 0.3% of Fe, 0.15-0.2% of Cu, 0.4-0.6% of Mn, 0.7% of Mg, 0.17-0.25% of Cr, 0.15% of Zn, 0.02-0.04% of Zr and the balance of Al. By fusing, drossing, alloy preparing, refining, standing, casting, homogenizing and extruding, the finished bar is obtained finally. When the high-strength coarse-grain-ring-free aluminum alloy bar for the automotive control arm is in an extruded state, coarse grain rings do not exist, after forging and T6 heat treatment, the grain size in the center of a forge piece reaches level-one grain (inspection is carried out according to the standard of GB / T 3246.2, and the average area of the grain is smaller than or equal to 0.026 mm<2>), a coarse grain ring on the outer ring of the force piece is smaller than 2 mm, after forging and heat treatment, grains cannot be expanded easily, the mechanical property of a material can be as follows: the tensile strength is greater than or equal to 385 Mpa, the specified non-proportional extension strength is greater than or equal to 365 Mpa, and the elongation A is greater than or equal to 11%. Requirements on strength of a high-end automotive aluminum alloy steering control arm material are met.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

Lead-free environmentally friendly soldering flux and preparation method thereof

InactiveCN101972906AReduce manufacturing costIncrease productivityWelding/cutting media/materialsSoldering mediaSolventRosin

The invention relates to a lead-free environmentally friendly soldering flux and a preparation method thereof. The method comprises the following steps of: mixing synthetic organic acid, an activating agent and a mixed alcohol solvent at normal temperature according to a component formula; pouring an obtained mixture into a stainless steel container, and then adding modified rosin particles; stirring materials in the container until the rosins are all dissolved, and then stopping stirring; and standing still, filtering and hermetically packaging to obtain a soldering flux product. The lead-free environmentally friendly soldering flux is a no-clean soldering flux with low solid content, less rosin and no halide, has the characteristics of quick dry, bright and firm welding spot, uniform spreading, full structure, no corrosivity, excellent solderability, good soldering wetting, stable property, and the like, conforms to the property requirements of various electrical appliances and is suitable for soldering computers and peripheral equipment or high-precision multilayer board electronic assemblies. When in use, the soldering flux product has the advantages of low smoke, no pollution to working environment, no influence on the human health, no pollution to tracks and clamps of a tinning furnace, higher insulating impedance, good environment friendly performance and stronger market competitiveness.

Owner:DANFENG RONGYI ELECTRONICS

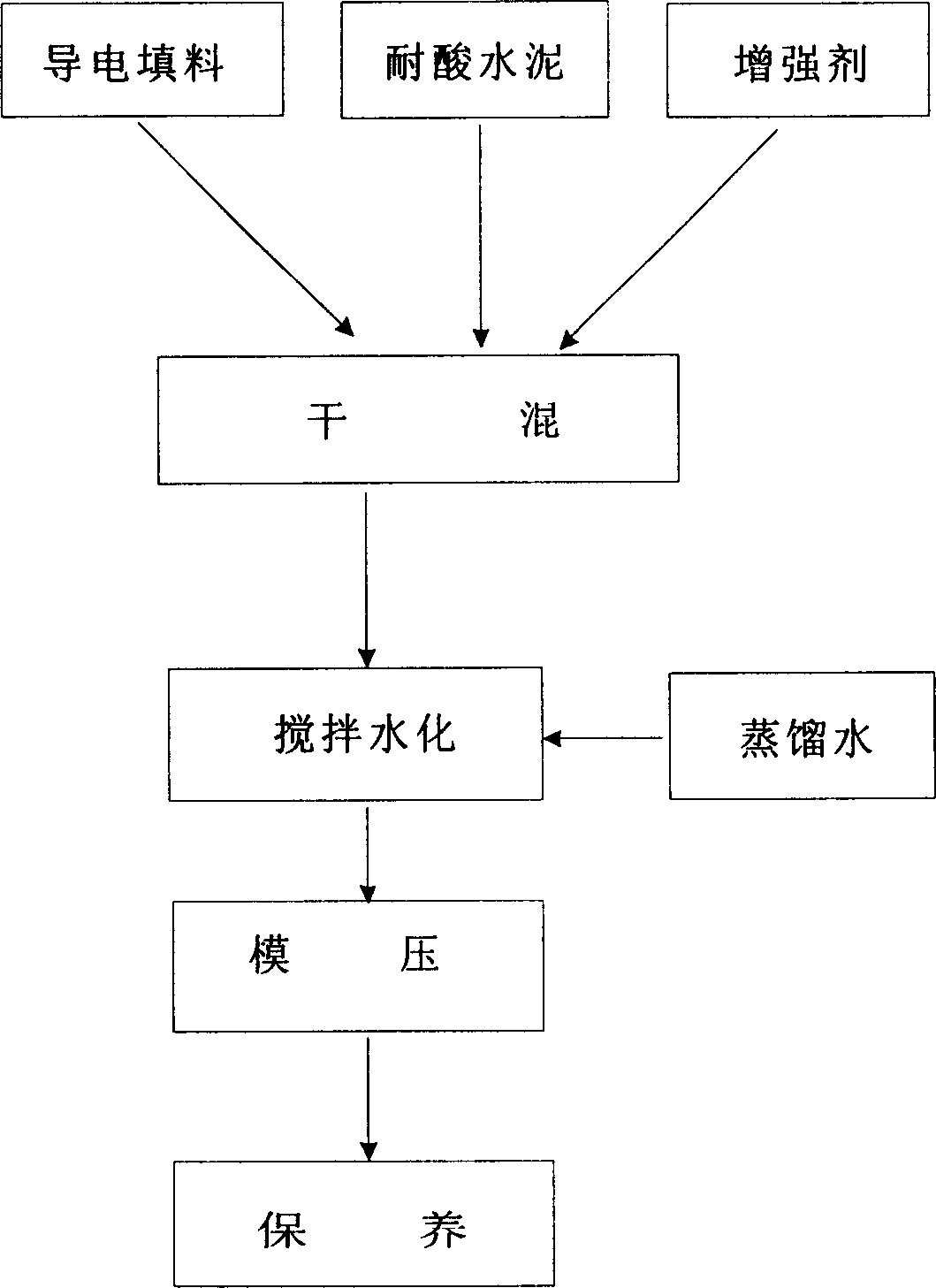

A bipolar plate for fuel cell with proton exchange membrane and preparation method thereof

InactiveCN1595697AOvercome conductivityOvercome mechanical propertiesFinal product manufactureCell electrodesSilicon dioxideMechanical property

The invention relates to a dual-pole plate having function of inner humidification for proton exchange membranes fuel cell and its manufacturing method, which uses Ti3SiC2, graphite powder as conductor filler, acid proof cement as agglomerant and thermoplastic resin polyvinylidene fluoride as reinforcing agent to make dual-pole plate with air flow field and cooled water channel by once one-off combined die pressing. By millimicron and micron sized micro-hole formed in conducting composite material in the hydration course acid proof cement agglomerant, the invention has realized protection to water created in negative electrode plate of fuel battery or cooled water channel and inner humidification to proton exchange membranes; by high conductibility and plasticity of conductor filler Ti3SiC2, it has made the dual-pole plate manufactured by die stamping method has high electric conductivity as well as excellent mechanical property.

Owner:WUHAN UNIV OF TECH

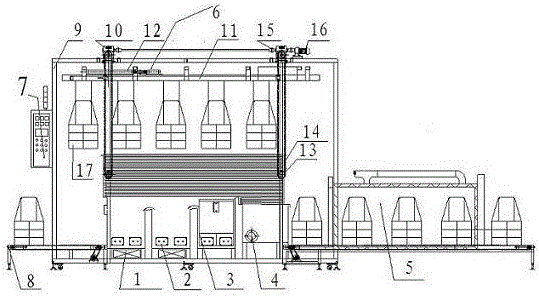

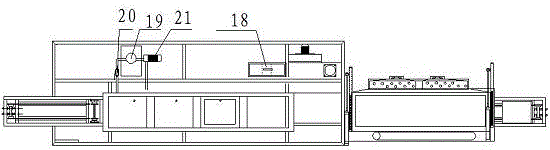

Full-automatic ultrasonic cleaning machine for nickel-based conductor materials

ActiveCN106111618ANot volatileNo wasteDrying gas arrangementsDrying machines with progressive movementsCleansing AgentsContamination

A full-automatic ultrasonic cleaning machine for nickel-based conductor materials is of a closed structure and comprises first ultrasonic rough cleaning tanks, second ultrasonic cleaning tanks, a heat soaking rinse tank, a steam bath wash tank, a hot air internal circulation tunnel type drying box, an automatic portal lifting and travelling mechanism and an electrical control system. According to the full-automatic ultrasonic cleaning machine for the nickel-based conductor materials, automatic all-round cleaning can be conducted, a net bag containing nickel pieces does not need to be rolled over manually, and cleaning can be conducted in place. Besides automatic cleaning, an automatic drying function can also be achieved, original manual airing is omitted, and the nickel pieces are prevented from secondary contamination. Further, an active carbon adsorption device is arranged at an air outlet of the cleaning machine, residual volatile cleaning agents brought out during drying can be effectively adsorbed, and the cleaning agent is prevented from contaminating the air.

Owner:JIANGSU K TECH PRECISION TECH +1

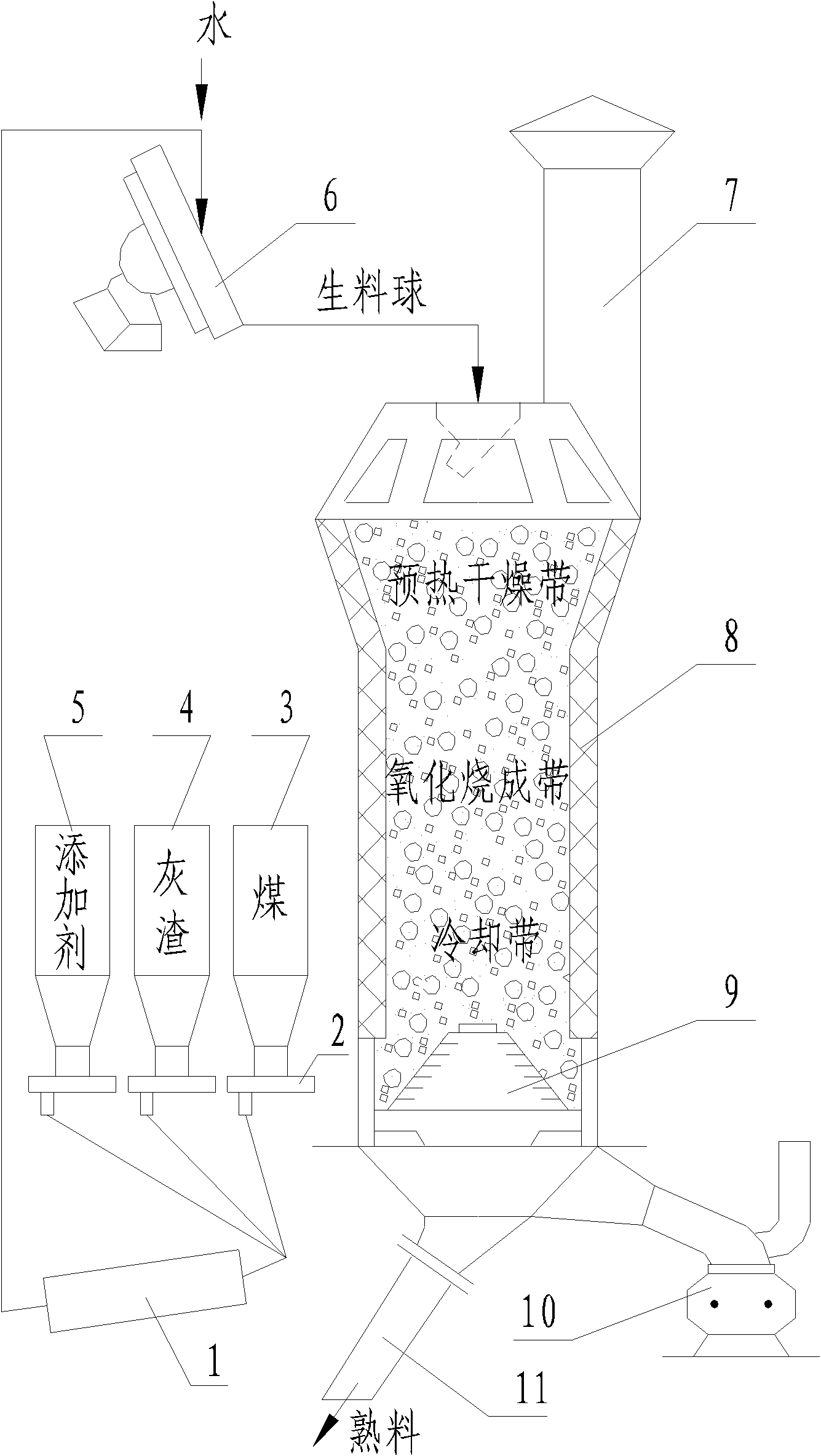

Pelletizing and calcination method for vanadium-containing stone coal ash

The invention relates to a pelletizing and calcination method for vanadium-containing stone coal ash. The equipment adopted by the method includes a moving-bed calcinator, which comprises a vertical furnace body, a chimney, a clinker discharger and a fan. The method includes the following steps that: NaCl, CaF2 and CaCO3 are prepared into complex additive, vanadium-containing stone coal, the complex additive and anthracite or stone coal as fuel needed by calcination are mixed into mixture material, the mixture material is uniformly mixed, fine-ground and pelletized into raw pellets, the raw pellets are fed into the furnace body via a feeder on the top of the furnace body, meanwhile, the fan blows the air into the furnace body via the clinker discharger on the bottom of the furnace body, the raw pellets and the air are calcined and reversely flow under the internal temperature condition of 800 DEG C to 900 DEG C, the calcined material enters the clinker discharger and is discharged out of the furnace body via the clinker discharger, and after cooling, clinker for the leaching of V2O5 is produced; and after calcination, the air is exhausted out via the chimney on the top of the furnace body. The technique and the equipment adopted by the method are relatively simple, the heat utilization rate is high, the product quality is stable, and the production cost is low.

Owner:ZHEJIANG UNIV

Cartilage preservation solution

InactiveCN102308787AOvercome mechanical propertiesOvercoming chondrocytesDead animal preservationCartilage cellsFiber

The invention relates to a cartilage preservation solution. Each 1000ml of the preservation solution comprises 20-30mmol of potassium dihydrogen phosphate, 80mmol of histidine or 15mmol of a histidine salt, 75-95mmol of lactobionic acid, 50-70mmol of sucrose, 0.8-1.2mmol of allopurinol, 45-55g of low molecular dextran-40, 45-55mmol of NaCl, 25-35mmol of KCl, 3-7mmol magnesium sulfate, 70-90U of penicillin, 2-4mmol of reduced glutathione, 3-7mmol of adenosine, 2-5g of trehalose, and the balance deionized water, and the pH value of the cartilage preservation solution is 7.33-7.53. The cartilagepreservation solution is packaged, sealed and preserved at 0-4DEG C. By adopting the preservation solution to preserve cartilage tissues, the death speed of cartilage cells is slowed, the activity ofcartilage fibers is maintained, the performance of the cartilage tissues is kept, and the antibiotic property is increased, so the preservation solution has a good preservation effect and a long preservation time on the cartilage tissues, and is in favor of clinic cartilage tissue transplant operations.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

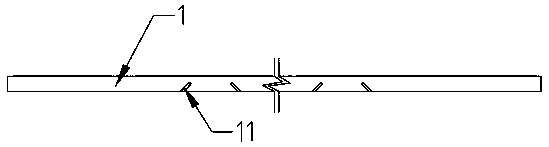

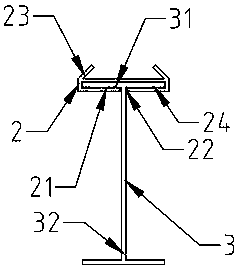

Self-anchored thermal insulation decorative assembly type wallboard and counter-attack preparation process thereof

InactiveCN108086579AAdvantages of anti-hitting preparation processOvercome the weak point of installationConstruction materialLamination ancillary operationsThermal insulationEngineering

The invention discloses a self-anchored thermal insulation decorative assembly type wallboard and a counter-attack preparation process thereof. The thermal insulation decorative assembly type wallboard sequentially comprises a concrete structure layer, a thermal insulation layer and a veneer layer from inside to outside, wherein the veneer layer is formed by hard thin plates, and an inner anchoring part is embedded in the back of each hard thin plate; an outer anchoring part is inserted in each inner anchoring part. The preparation process of the assembly type wallboard comprises the followingsteps: prefabricating each thermal insulation decorative integrated board with the embedded inner anchoring part veneer layer in the back, and fixing a formwork; reversely spreading the thermal insulation decorative integrated boards on a steel formwork platform one by one; installing one outer anchoring part on each inner anchoring part of each thermal insulation decorative integrated board; filling with slab joints; placing prefabricated steel bar grids or cages; pouring concrete and vibrating; maintaining; removing the formwork. The obtained self-anchored thermal insulation decorative assembly type wallboard and the counter-attack preparation process have the advantages of simple manufacturing steps, short construction period, fire safety, energy-saving and thermal insulation, and lowcost of natural granite sheet veneer.

Owner:中建科技成都有限公司 +1

Preparation of wear resistant thermoplastic alkene complex

The invention relates to a method for preparing wear-resistant thermoplastic olefin hydrocarbon compound, which comprises: first, chemical grafting modification is carried out on thermoplastic olefin hydrocarbon polymer in an initiation system by silane coupling agent under the condition that peroxide initiator exists, thus leading the thermoplastic olefin hydrocarbon polymer to take along alkoxy or chloro-silane branched chain; polysiloxane which has super high molecular weight and H+ active group on at least one end is mixed together with the thermoplastic olefin hydrocarbon polymer which is processed by grafting modification in a melt extrusion way, so that hydrogen bond connection is formed between the polysiloxane with super high molecular weight and the polymer silane branched chain to obtain the thermoplastic olefin hydrocarbon compound. The method greatly improves the compatibility between the polysiloxane with super high molecular weight and the thermoplastic olefin hydrocarbon compound, thus the adding quantity of the polysiloxane can be increased by about ten times, and the long-term wearing resistance of the products can be improved. After being rubbed for 10,000 times, the product has the friction depth being about half of the traditional technical product added with wear resistant addition agent, and the static state friction coefficient and the dynamic friction coefficient being 10% more than the traditional blending technical product.

Owner:SHANDONG DAWN POLYMER CO LTD

Bacterial cellulose/chitosan composite gel and preparation thereof, and application of composite gel in body surface wound surface healing

ActiveCN103463124AGood compatibilityWide viscosity rangeAntibacterial agentsOrganic active ingredientsWound surfaceBody surface

The invention relates to a bacterial cellulose / chitosan composite gel and preparation thereof, and application of the composite gel in body surface wound surface healing. The composite gel is composed of a chitosan solution, bacterial cellulose, an antimicrobial agent, a thickener solution and a neutralization agent. The invention also relates to application of the bacterial cellulose / chitosan composite gel in preparing body surface wound surface healing medicines. The preparation method comprises the following steps: uniformly mixing the chitosan solution, thickener solution, bacterial cellulose and antimicrobial agent, adding the neutralization agent to regulate the pH value to 6.0-9.0, and standing for deforming. The composite gel provided by the invention has favorable film-forming action, and performs the functions of isolating the wound surface and protecting the wound; and the bacterial cellulose / chitosan has the advantages of simple preparation process and easy technical control, and is convenient for industrial production.

Owner:江西佑创销售有限公司

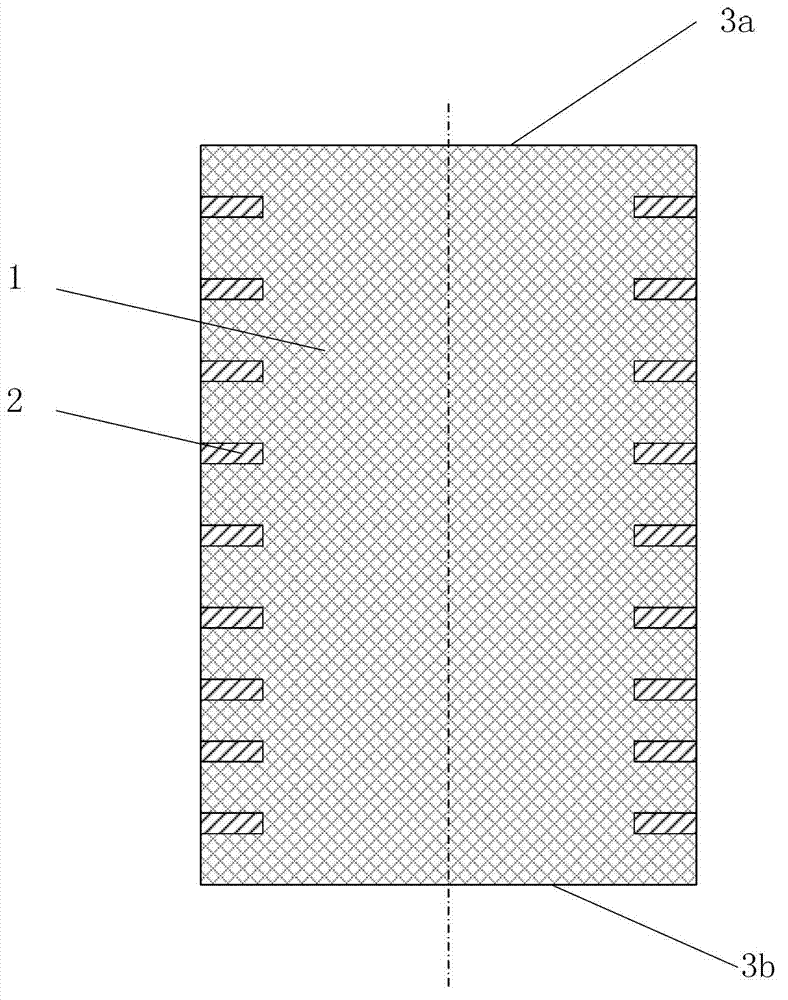

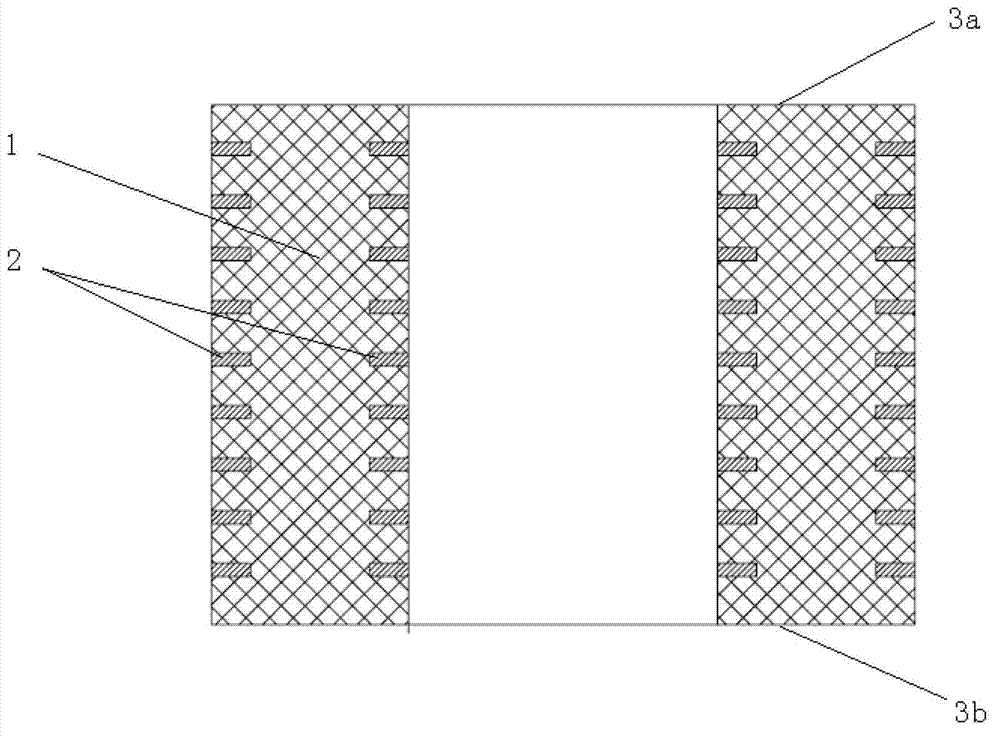

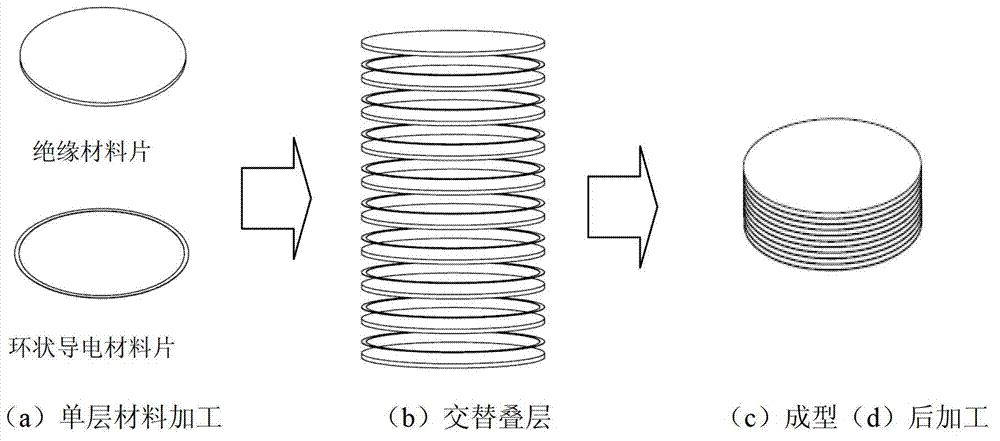

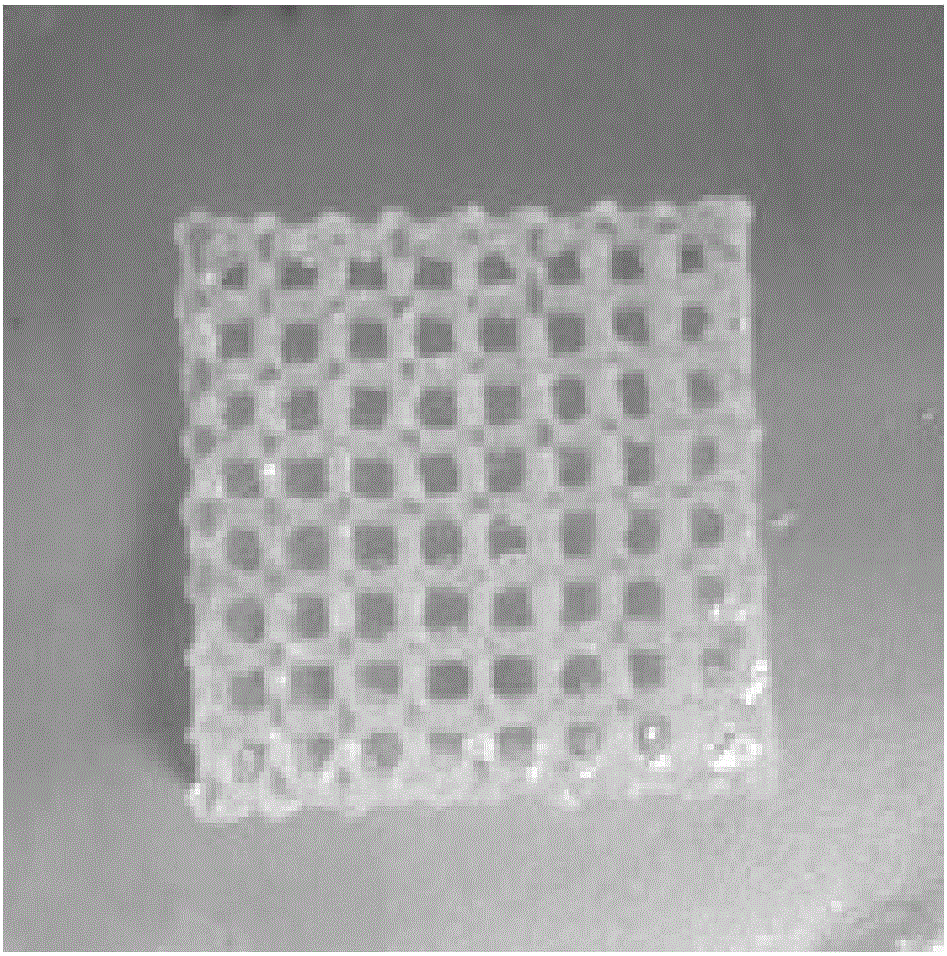

Multi-layer high gradient insulator and manufacturing method thereof

ActiveCN103247395AOvercome mechanical propertiesOvercome difficultySuspension/strain insulatorsSecondary electronsConductive materials

The invention discloses a multi-layer high gradient insulator for a high-voltage pulse power supply and a manufacturing method thereof. The multi-layer high gradient insulator is characterized in that thin conductive layers are regularly embedded in an insulator body made of an insulated material, the side surface of the insulator, which is in a certain depth, is formed by an insulated material layer and a conductive material layer, and the interior of the insulator is formed by a single insulated material. According to the invention, a conductive array is embedded in the side surface of the insulator body, the secondary electron emitting characteristic of the surface of the insulator and the surface load charge accumulation are restrained, the vacuum surface flashover characteristic of the insulator body is improved, the surface impact voltage of the insulator body is improved, the problem that the insulated material layer is not matched with the mechanical and thermal performance of the conductive material layer is solved, and the process difficulty and cost for manufacturing the multi-layer high gradient insulator are remarkably lowered.

Owner:NORTHWEST INST OF NUCLEAR TECH

Carbon fiber reinforced thermoplastic resin composite material and preparation method of carbon fiber reinforced thermoplastic resin composite material

ActiveCN104194286AOvercome mechanical propertiesOvercoming thermal conductivityPolytetramethylene terephthalateCarbon fibers

The invention relates to a carbon fiber reinforced thermoplastic resin composite material and a preparation method of the carbon fiber reinforced thermoplastic resin composite material. The carbon fiber reinforced thermoplastic resin composite material comprises the following raw materials in parts by weight: 100 parts of PBT resin, 20-80 parts of asphalt-based chopped carbon fiber, 10-20 parts of inorganic filler, 0.5-5 parts of a coupling agent, 0.2-1 part of an antioxidant and 0-3 parts of a lubricating agent. Compared with the prior art, the composite material provided by the invention has the advantages of high rigidity, good heat-conducting property, low raw material cost, simple preparation process, is suitable for production and manufacturing of thin-wall and lightweight car parts and electronic / electric products and is suitable for industrial continuous production.

Owner:SHANGHAI JIAO TONG UNIV

Hydrogel material for 3D bioprinting and preparation method and application of hydrogel material

ActiveCN106474560AGood compatibilityImprove structural stabilityAdditive manufacturing apparatusProsthesisHigh cellSolvent

The invention belongs to the technical field of biological materials, and discloses a hydrogel material for 3D bioprinting and a preparation method and application of the hydrogel material. The hydrogel material comprises the following components in percentages by mass: 0.5-10% of gellan gum and / or derivatives, 0.1-20% of PEG and / or derivatives thereof, 0-1% of a crosslinking initiator, 0-15% of biologically active components and the balance of a solvent. The hydrogel material is double-network hydrogel based on the gellan gum and PEG; interpenetrating double-network structures are formed in a physiological environment; and the hydrogel material has good structure and dimensional stability, and has the advantages of quick gum formation under physiological conditions, excellent cell compatibility, small immunological rejection, high cell encapsulation efficiency, controllable mechanical strength, biodegradability and the like. The hydrogel material is applied to 3D bioprinting; the shortcomings of low curing speed, harsh curing conditions, limited mechanical properties, poor cell compatibility and the like are overcome; and the hydrogel material has obvious advantages and good industrialized prospect.

Owner:JINAN UNIVERSITY

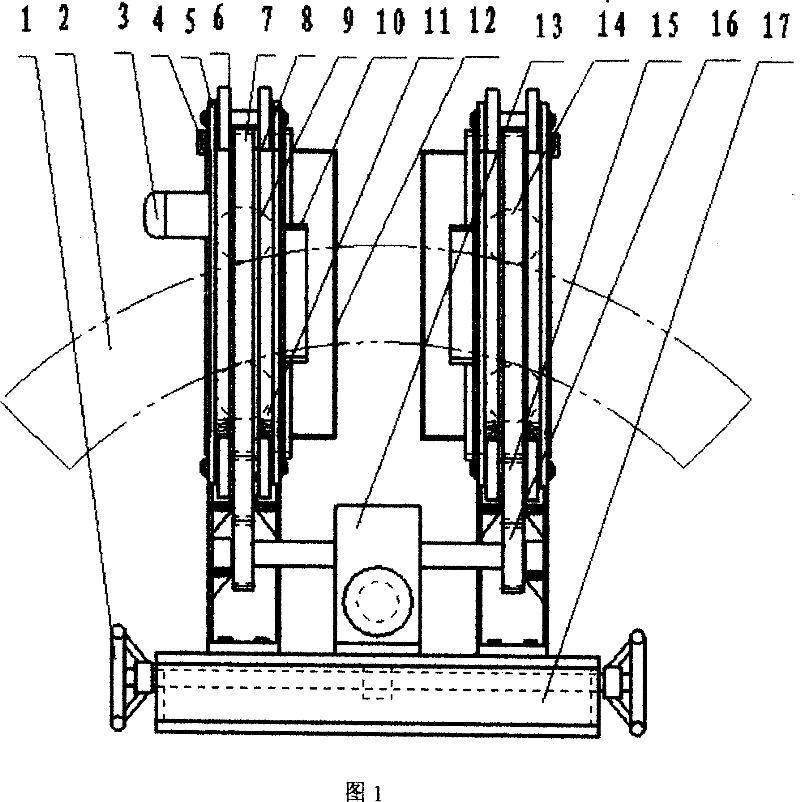

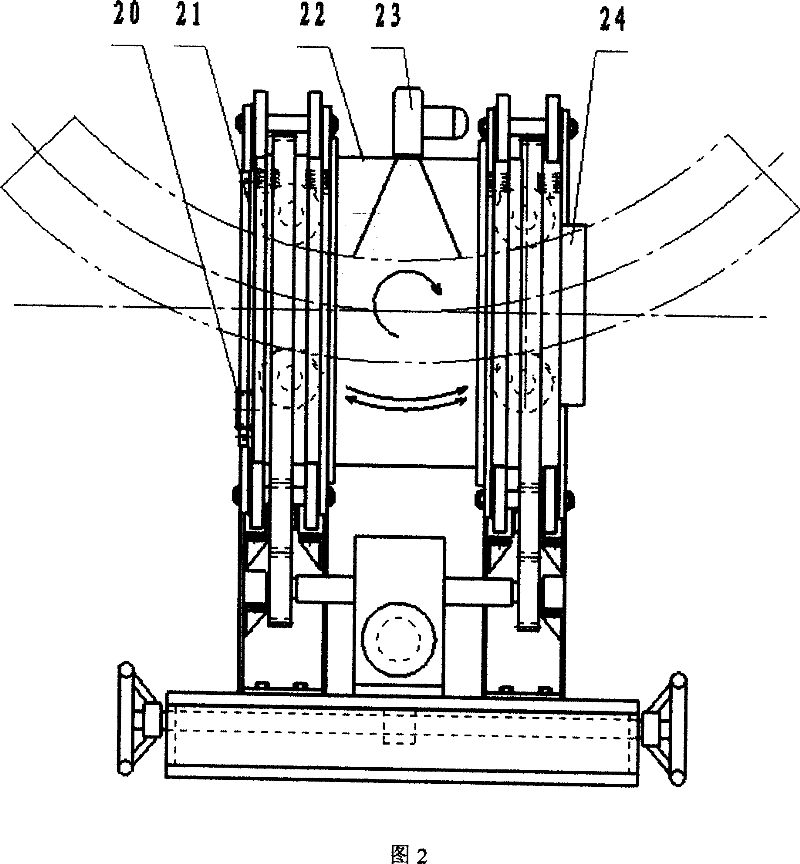

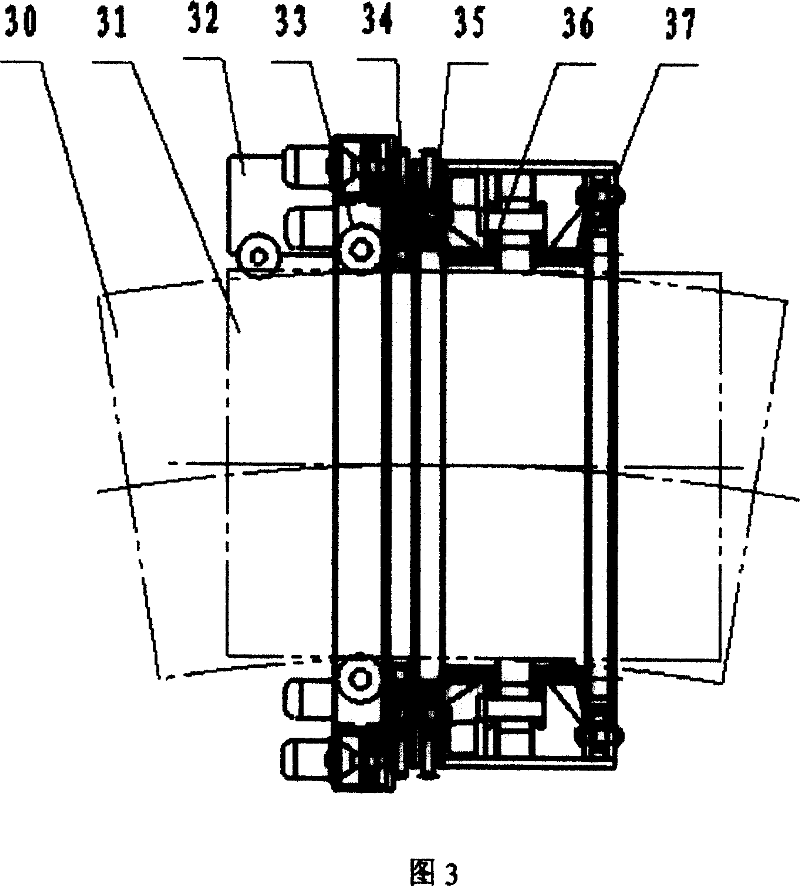

Polyethylene coated steel pipe, online production and equipment thereof

InactiveCN101038048AOvercoming qualityOvercome mechanical propertiesRigid pipesTransformerLow voltage

The invention relates to a polyethylene coated steel pipe and on-line method and apparatus for preparing same. Steel pipe is employed as base material for polyethylene coated steel pipe, and the outer surface of the steel pipe is coated with jointless annular polyethylene gummed tape. Production facilities of the pipe includes steel pipe shot-blast rust cleaning machine comprised of a rotating cylinder bracket, a rotating cylinder, a feeding wheel, a support wheel, a feeding worm wheel speed reducer, a feeding direct current dynamo, a high-frequency induction heating coil, a driving worm wheel speed reducer, a driving AC motor and a electrical control cabinet, and a steel pipe outer anticorrosion coating machine comprised of a induction heating transformer, a walking frame, a swing frame, a rotating frame, a winding device, a supporting frame, a low-voltage electrical casing and a controller. In pipeline installation locale, the steel pipes are welded into pipelines after derusted by the steel pipe shot-blast rust cleaning machine, the steel pipe outer anticorrosion coating machine is nested on the pipeline and carries out helical motion, after high-frequency induction heating on the steel pipe, the spray head injects the epoxy powder on outer surface of the steel pipe, after high-frequency induction heating of the belt-winding cylinder, adhesive tape and polyethylene gummed tape pulled out from the winding device become hot tapes, by helical motion of the steel pipe outer anticorrosion coating machine along pipeline centre-line, the adhesive tape and polyethylene gummed tape are coated on the outer surface of the steel pipes.

Owner:陈炯

High-strength Al-Cr-SC alloy through 3D printing

ActiveCN111001800AReduce anisotropyEasy to manufactureAdditive manufacturing apparatusIncreasing energy efficiencyHigh densityMetal powder

The invention discloses a high-strength Al-Cr-SC alloy through 3D printing. The metal powder for a high-strength aluminum-chromium alloy through 3D printing comprises the following components, by masspercentage, 2.5-10% of Cr, 0.5-2.5% of Mg, 0.1-0.9% of Sc, 0.2-0.7% of Zr, 0.1-0.3% of Si, 0.2-0.45% of Mn, 0.1-0.35% of Fe, 0.1-0.25% of Ti, 0.05-0.5% of AlCl3 powder, 0.05-0.3% of CaCl2 + NaCl andthe balance Al. The preparation method of the metal powder comprises the following steps that Al, Cr, Mg, Sc, Zr, Si, Mn, Fe, Ti pure metal block raw materials are weighed to be heated and melted, atomized for powder making, sieving and heat preservation for drying are conducted, AlCl3, CaCl2 and NaCl powder are added, and milling and mixing are conducted. According to the high-strength Al-Cr-SC alloy through 3D printing, the printed aluminum alloy part has no cracks and has high density, and the mechanical properties, wear resistance, corrosion resistance and high temperature and oxidation resistance are high.

Owner:CENT SOUTH UNIV +1

Polyethylene coating steel pipe and its producing method and production line

InactiveCN101191577AOvercoming qualityOvercome mechanical propertiesLiquid surface applicatorsCorrosion preventionEpoxyAdhesive

The invention relates to a steel pipe painted with polythene and manufacturing method and mobile production line. A drum type rust remover, a drum type threading machine, a drum type spray coater, a drum type winding machine, a drum type cooling fan, a drum type dust removing threading machine, and a drum type spray winding machine are connected in turn to form the mobile production line. At a pipe laying site, a steel pipe in turn enters the drum type rust remover, the drum type threading machine, the drum type spray coater, the drum type winding machine and the drum type cooling fan, and makes helical movement under the support of a feeding wheel and a supporting roller in a rotating drum body. The steel pipe is heated through a high-frequency induction heating method, and rust spots are removed from the external surface of the steel pipe through a mechanical method and the steel pipe is threaded also through a mechanical method, the epoxy powder spray coater is used to spray epoxy powder to the external surface of the steel pipe, the epoxy powder and a composite polythene cold adhesive tape are heated indirectly through the high-frequency induction heating method and the cold adhesive tape is turned into a composite polythene hot adhesive tape, and through a mechanical winding method, the composite polythene adhesive tape is applied onto the epoxy powder layer to produce the steel pipe painted with polythene.

Owner:陈炯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com