Water-based dye ink and application thereof

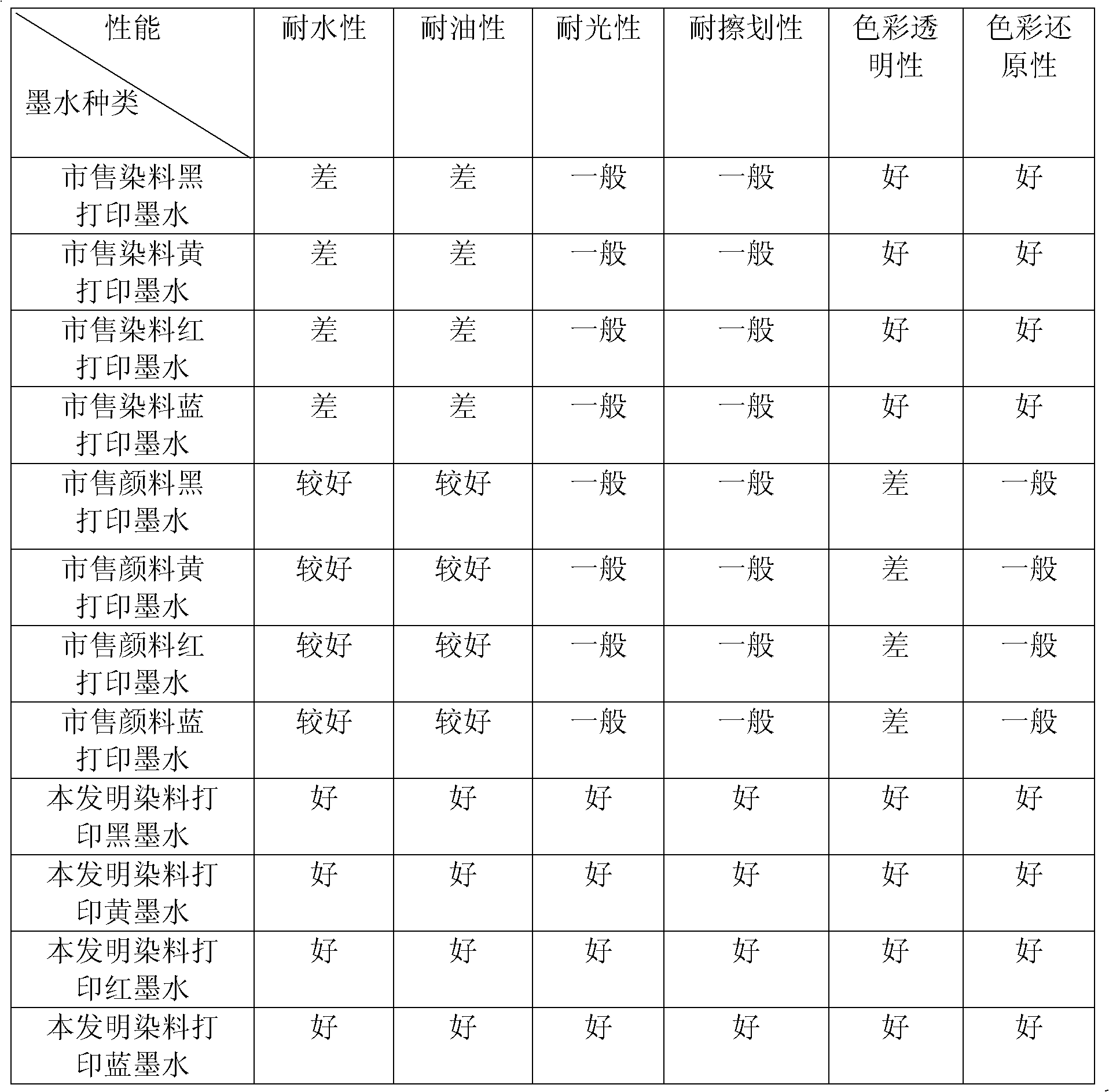

A dye ink, water-soluble dye technology, applied in the application, ink, dyeing method and other directions, can solve the problems of incomplete chromatography, poor transparency, unstable storage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: (embodiment 1——embodiment 4 is inkjet printing ink)

[0061] Component Weight

[0062] Acid Black ATT 0.2%

[0063] Diethylene glycol 15%

[0064] Silicone-Acrylic Emulsion (48% Silicone-Acrylic Solids)

[0065] 80%

[0066] Benzophenone 0.3%

[0067] Benzotriazole 0.2%

[0068] AEO-9 0.5%

[0069] Deionized water balance

Embodiment 2

[0071] Component Weight

[0072] Acid Scarlet GR 4.4%

[0073] Diethylene glycol 15%

[0074] Diethylene glycol monobutyl ether 10%

[0075] Silicone fluorine-acrylic resin emulsion (silicone fluorine-acrylic resin solids content is 42%)

[0076] 62%

[0077] Benzotriazole 0.2%

[0078] Hindered amine 0.3%

[0079] Deionized water balance

Embodiment 3

[0081] Component Weight

[0082] C.I. Direct Blue 199 7%

[0083] Propylene Glycol 15%

[0084] Propylene Glycol Butyl Ether 10%

[0085] Organofluorine-acrylic resin emulsion (organofluorine-acrylic resin solid content is 48%)

[0086] 55%

[0087] Benzophenone 0.3%

[0088] Hindered amine 0.3%

[0089] Deionized water balance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com