Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Vibrant and saturated colors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

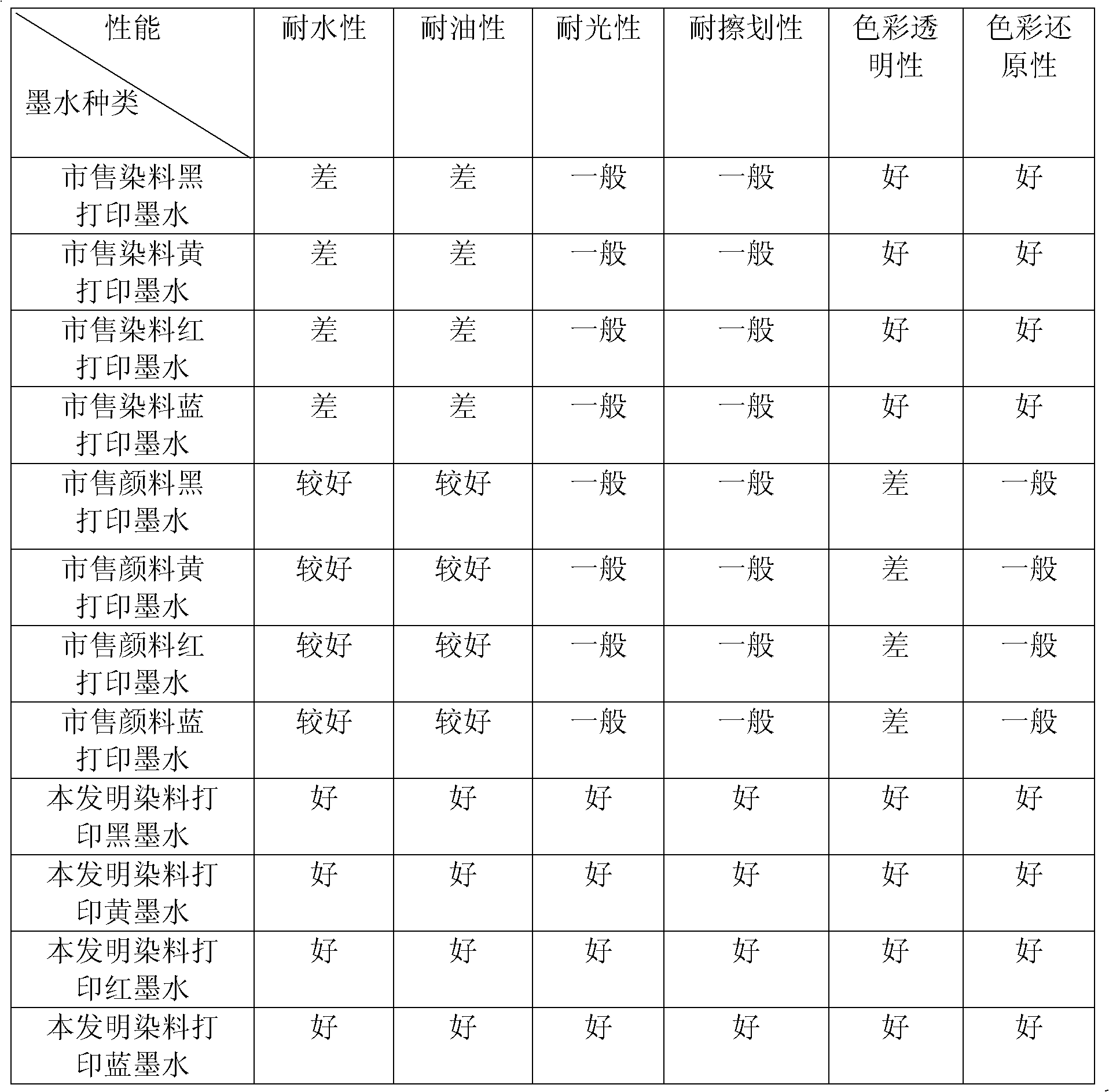

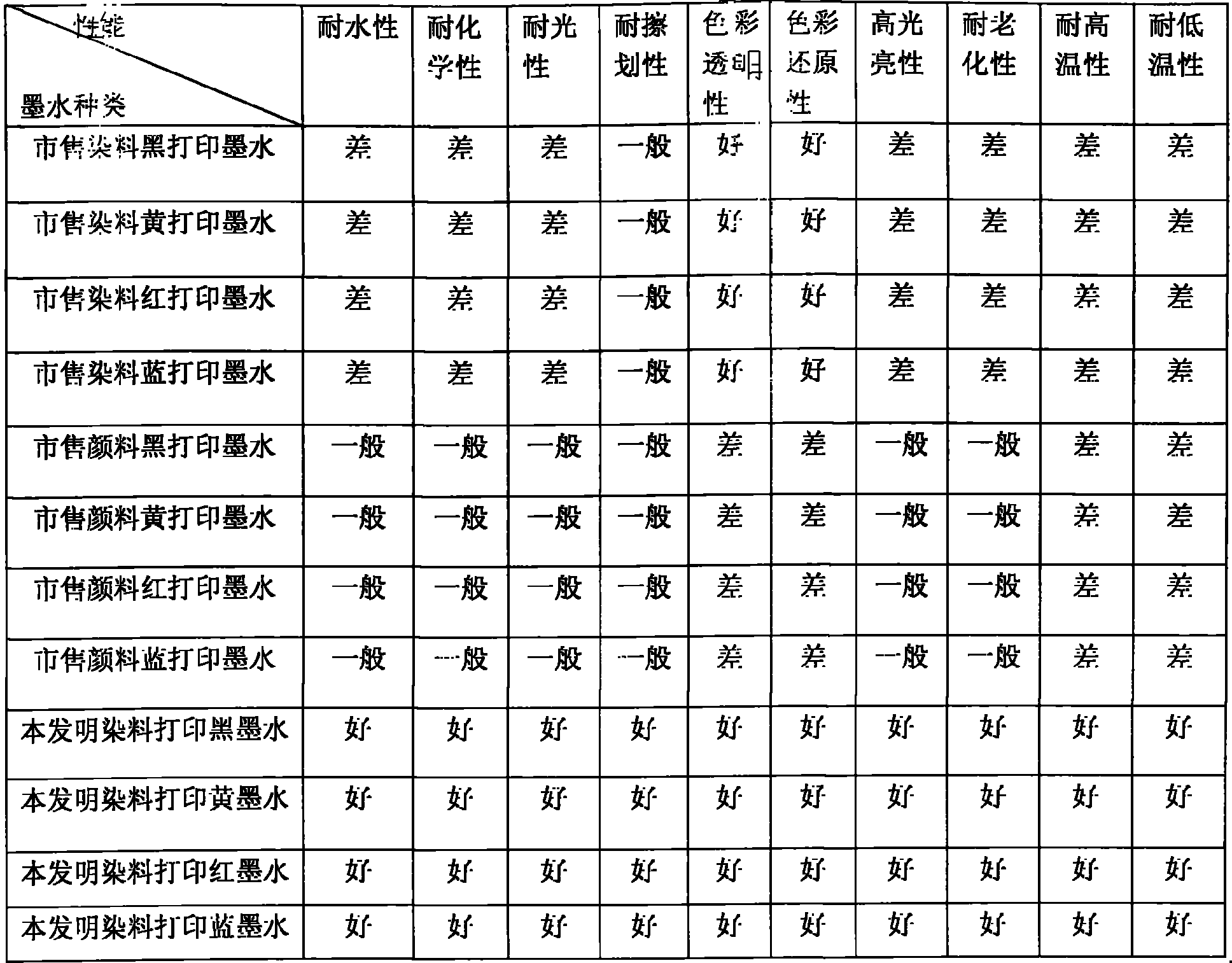

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

Modified polyurethane resin emulsion dye ink and application thereof

ActiveCN101914324AHigh color reproductionRaw materials are abundant and completeFibre treatmentInksTextile printerUltraviolet

The invention discloses a modified polyurethane resin emulsion dye ink and an application thereof. The modified polyurethane resin emulsion dye ink comprises the following components based on weight ratio: 0.1-12% of solvent dye and / or water-soluble dye, 13.5-49.8% of polyurethane resin solid content, 0.01-1% of ultraviolet absorber and the balance of solvent, wherein various additives can be added in the dye ink. The dye ink disclosed in the invention can be used in the fields such as jet ink, cipher paint ink, textile printing ink, aqueous printing ink, fountain pen word ink, rolling maker ink, coating, leather finishing agent, surface finishing and the like, and has the advantages of good storage stability, excellent water resistance, chemical resistance and light resistance, favorable mechanical performance, high brightness, high and low temperature resistance, ageing resistance, good color reproducivity and transparency, easily-obtained raw materials, simple manufacture, easy detection, low cost and wide market application prospect.

Owner:GUANGDONG BANGGU CHEM TECH

Composite special water-based ink for plastic inner printing

The invention discloses a composite special water-based ink for plastic inner printing, comprising the following components by weight ratio: 55-65 parts of water-based acrylic emulsion with a Tg (triglyceride) value being minus 40-25 DEG C, 25-35 parts of water-based color paste, and 3-4 parts of water-based assistant, wherein the water-based assistant comprises 0.2-0.5 part of water-based wetting agent, 0.5-0.8 part of water-based dispersing agents with a medium pH value, 0.5-0.8 part of water-based leveling agent, 0.5-2 part of water-based quick drying agent, and 0.5-1 part of water-based adhesion promoter. The ink has neither residual solvent nor pollution to food packaging, and is healthy, green and safe. A printing product of the ink has the characteristics of high gloss, friction resistance, anti-reverse adherence, high adhesion, high temperature resistance, an excellent leveling property, a saturated and brilliant color, wonderful color expression and the like.

Owner:福建格林春天新材料股份有限公司

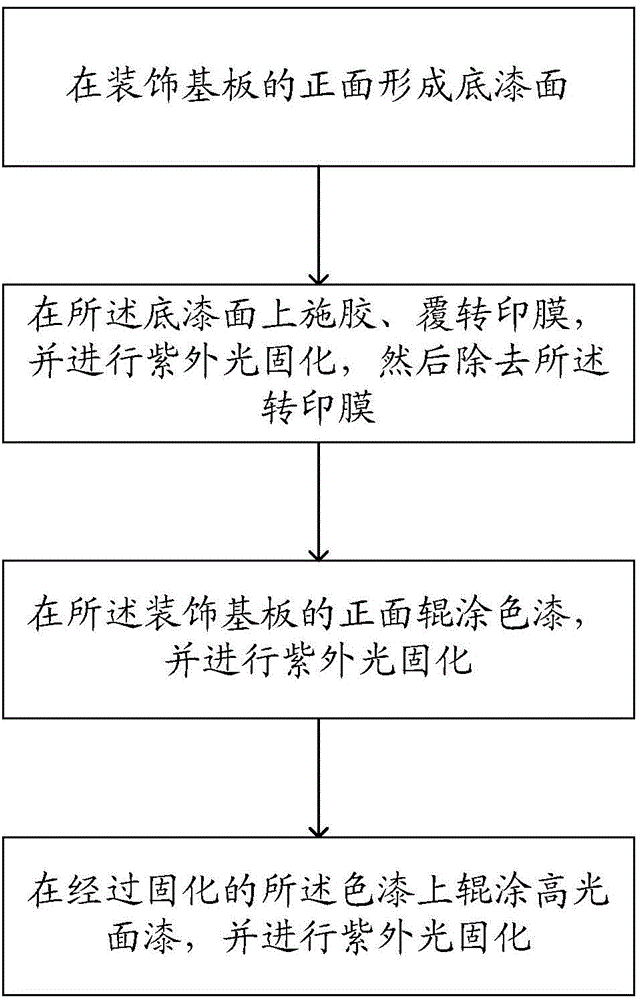

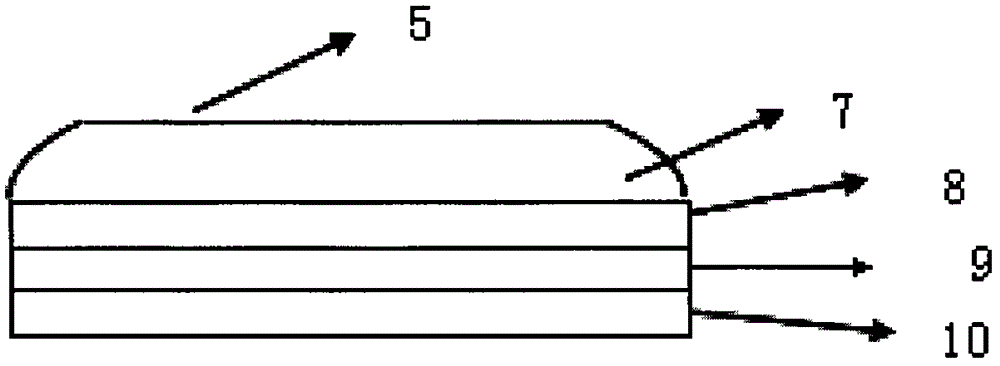

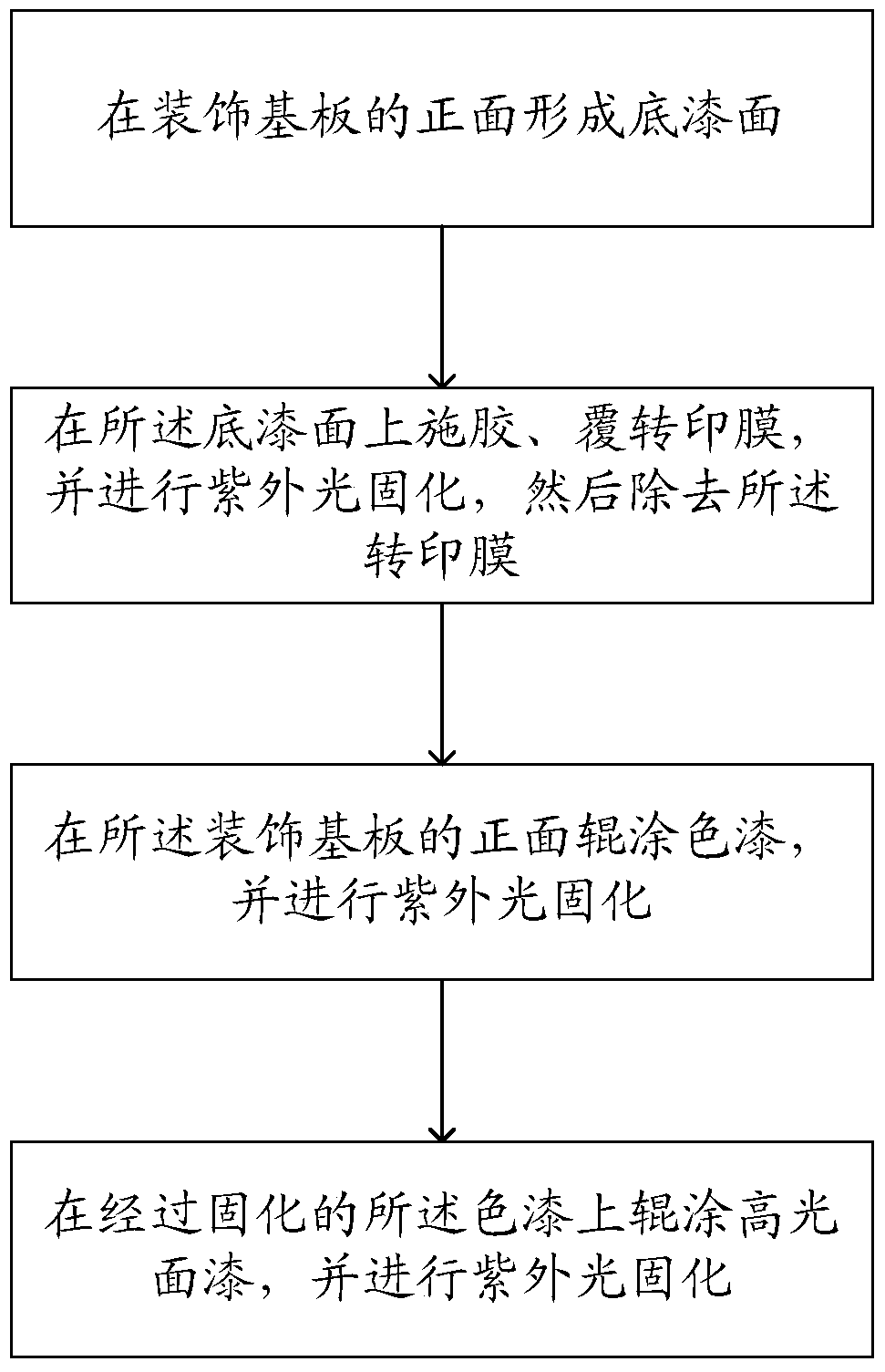

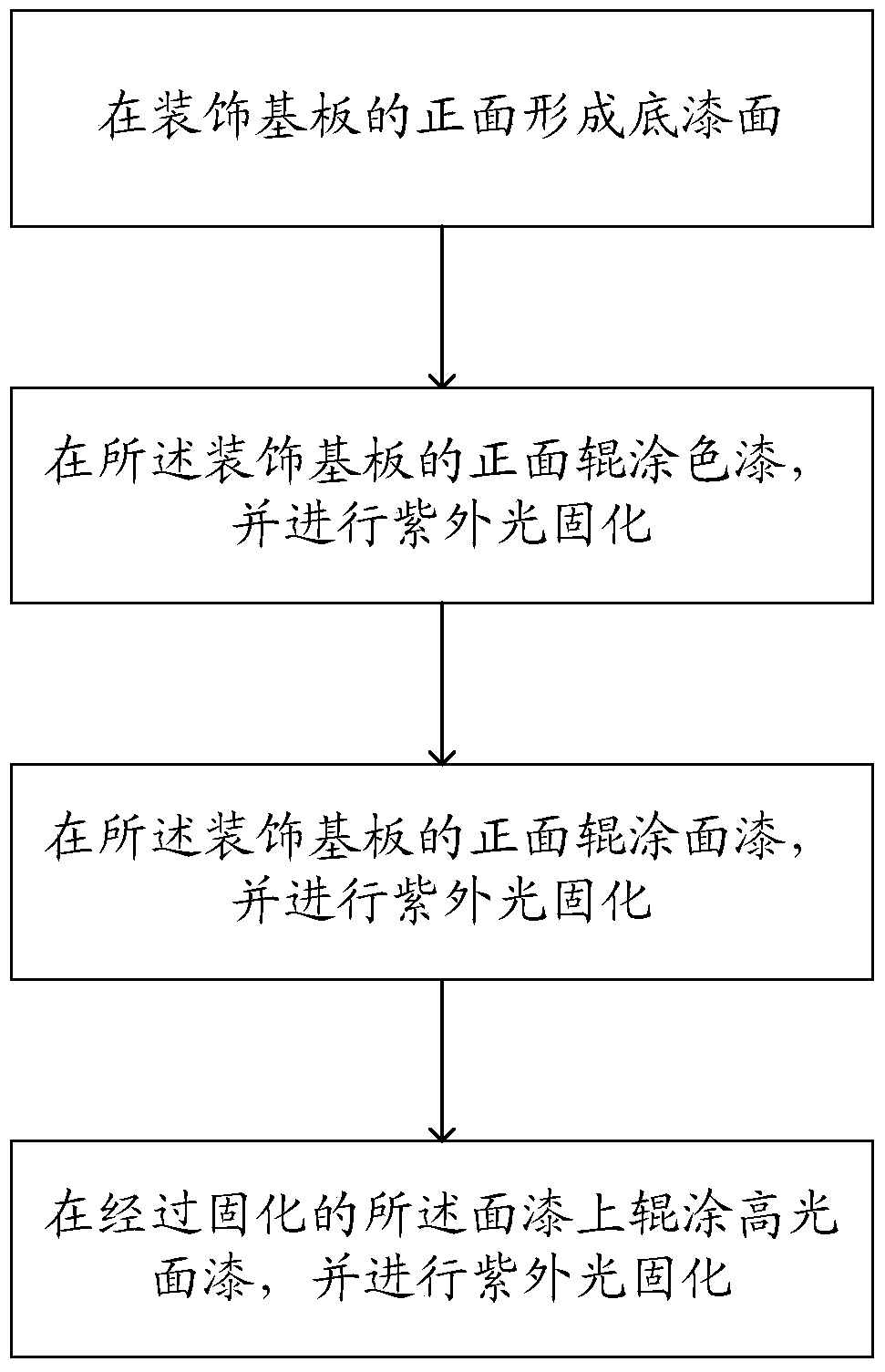

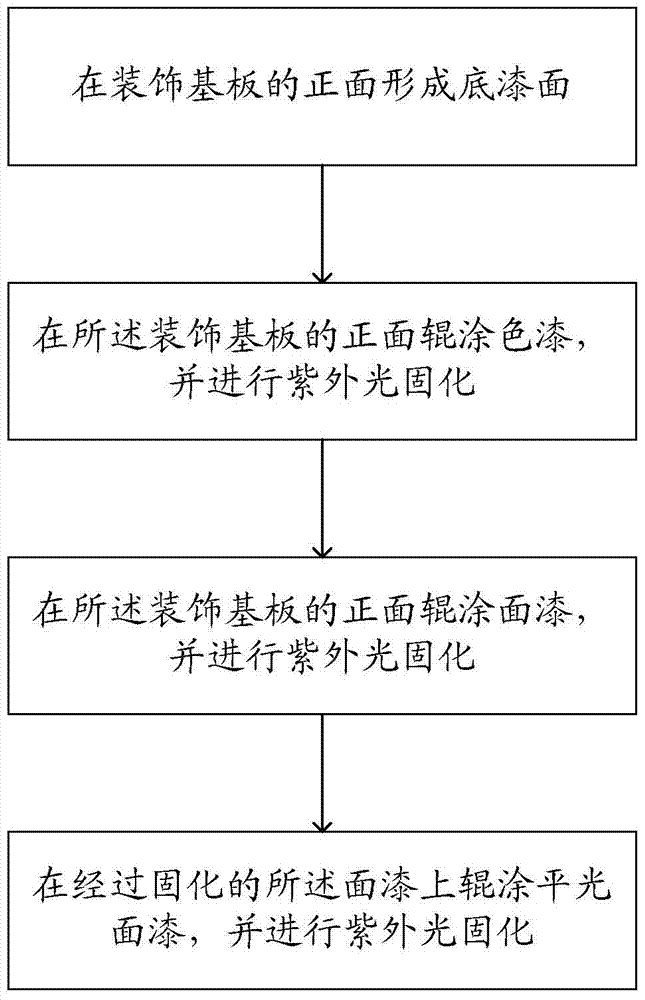

Ultraviolet curing transfer-printing high-gloss decoration plate and manufacturing method thereof

The invention provides an ultraviolet curing transfer-printing high-gloss decoration plate and a manufacturing method thereof. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing sizing and transfer film-printing of the primer surface, performing ultraviolet curing, and removing the transfer-printing film; (3) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; and (4) performing roller painting of high-gloss finishing paints on the cured colored paints and performing ultraviolet curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:中关村人居环境工程与材料研究院

Glass protector for anti-glare liquid crystal display glass

InactiveCN106273914AReduce distractionsIncrease viewing angleSynthetic resin layered productsGlass/slag layered productsPolyesterLiquid-crystal display

The invention discloses a glass protector for anti-glare liquid crystal display glass. The glass protector comprises an organic silicon pressure-sensitive glue layer, an optical polyester film layer, an acrylic acid adhesive layer, an 2.5D / 3D tempered glass layer and an AF anti-fingerprint layer sequentially arranged on the surface of a liquid crystal display, wherein a layer of AG anti-glare layer prepared by a spraying technology is arranged between the 2.5D / 3D tempered glass layer and the AF anti-fingerprint layer. In the invention, the surface of the protector is subjected to AG anti-glare treatment, the reflected light is scattered, the interference of ambient light can be reduced, the visual angle and brightness of the displayed image are improved, the light reflection of the screen is reduced, the image is clearer, the color is brighter and more saturated, and thus the display effect is remarkably improved.

Owner:惠州市神头磁电有限公司

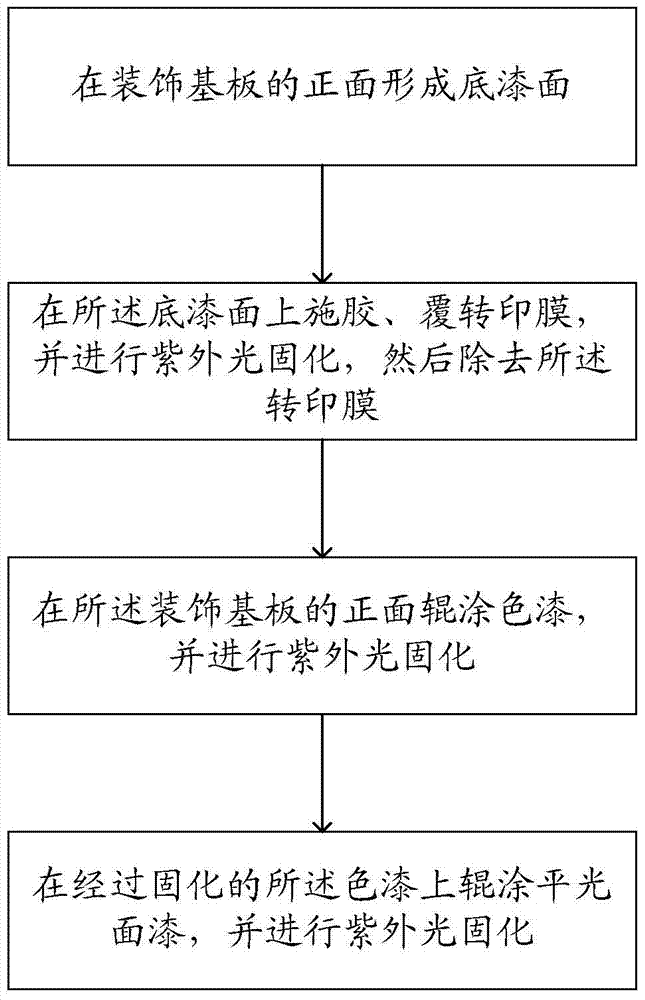

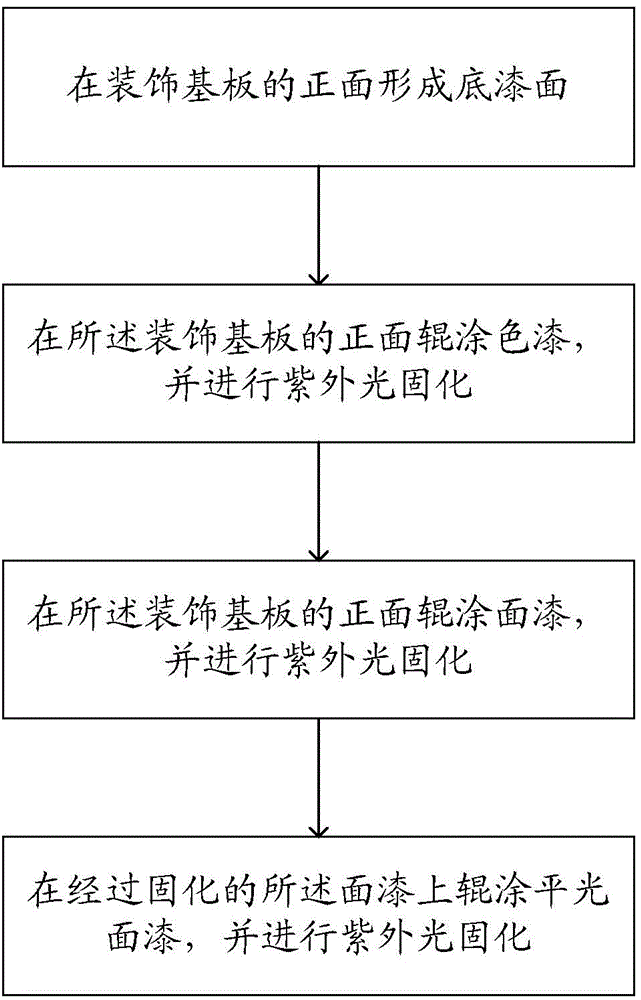

Ultraviolet curing transfer-printing matte decoration plate and manufacturing method thereof

The invention provides an ultraviolet curing transfer-printing matte decoration plate and a manufacturing method thereof. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing sizing and transfer film-printing of the primer surface, performing ultraviolet curing, and removing the transfer-printing film; (3) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; and (4) performing roller painting of matte finishing paints on the cured colored paints and performing ultraviolet curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:中关村人居环境工程与材料研究院

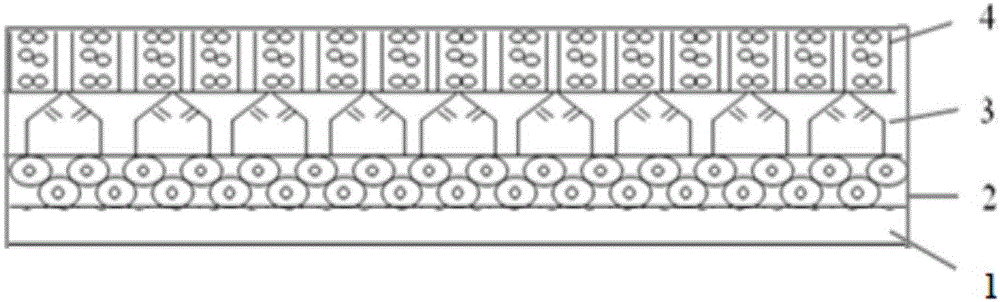

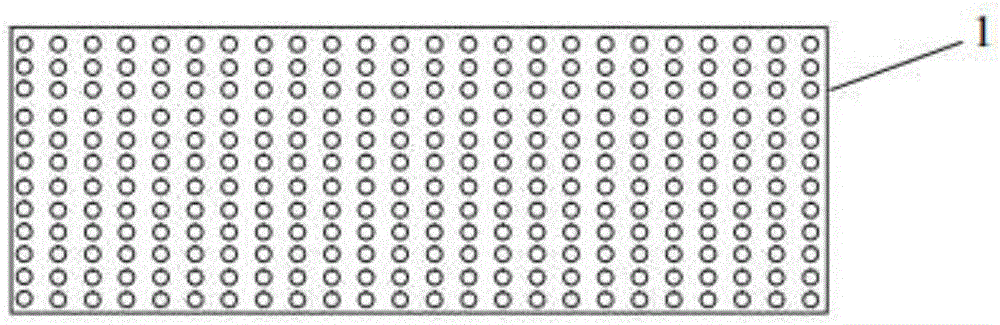

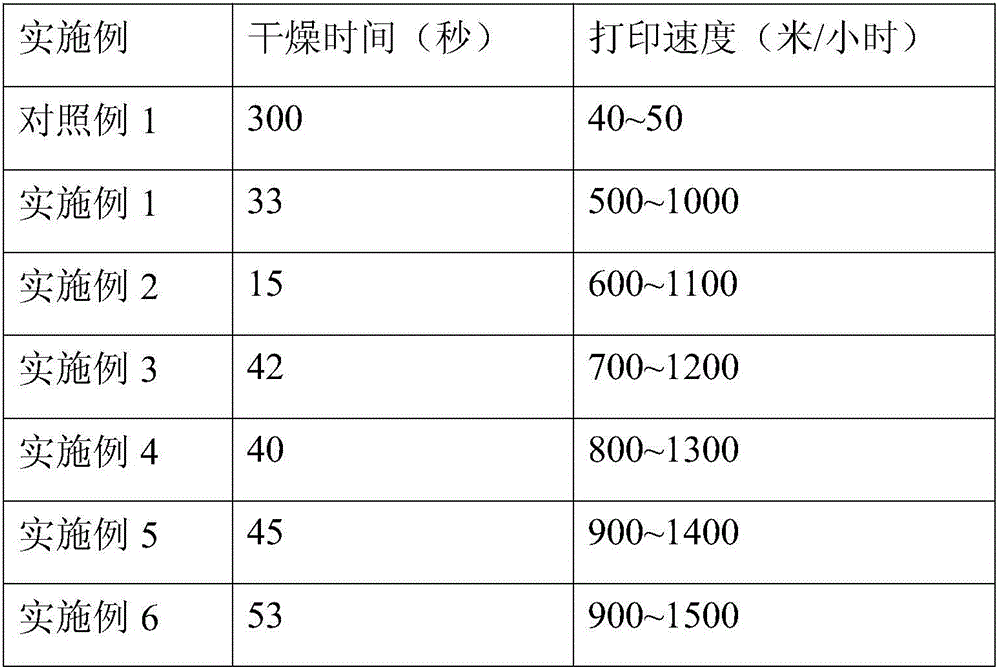

Instant dry type sublimation transfer digital PP paper

ActiveCN106379068AImprove toughnessDoes not affect strengthDuplicating/marking methodsCoatingsCelluloseDigital paper

The invention relates to the technical field of sublimation transfer printing and discloses instant dry type sublimation transfer digital paper. The instant dry type sublimation transfer digital paper comprises perforated PP paper, a water absorbing and permeable layer, a porous layer and a surface channel layer which are sequentially arranged from bottom to top; the porous layer is made of interpenetrating network resin formed by crosslinking of cellulose or sodium carboxymethylcellulose or starch and modified cationic polyacrylamide, or formed by crosslinking of polyacrylamide or cellulose or sodium carboxymethylcellulose and modified cationic starch; on one hand, the interpenetrating network resin can swell to 'catch' a dye for quick ink absorption, and on the other hand, components of the resin are adjusted and the network density is controlled to improve the water permeability, so that water molecules can quickly enter the water absorbing and permeable layer; and the perforated PP paper has excellent flexibility and mechanical strength and is stable in size in the printing process, so that the problem of shrinkage, caused by weather, of the conventional paper base material is solved. The instant dry type sublimation transfer digital PP paper has the characteristics of being instant in drying, quick in ink absorption, good in size stability and low in cost, and can meet the requirements for quick printing and efficient manufacturing at present.

Owner:杭州华大海天科技股份有限公司

Ultraviolet curing transfer-printing flat decoration plate and manufacturing method thereof

The invention provides an ultraviolet curing transfer-printing flat decoration plate and a manufacturing method thereof. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing sizing and transfer film-printing of the primer surface, performing ultraviolet curing, and removing the transfer-printing film; (3) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; and (4) performing roller painting of flat finishing paints on the cured colored paints and performing ultraviolet curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:北京天工人居科技有限公司

Petal cloth with real flower touch and preparation method of petal cloth and artificial flowers

InactiveCN111455678ATactile realEasy to dyeArtificial flowers and garlandsTextiles and paperAziridineCross linker

The invention discloses petal cloth with real flower touch. The petal cloth comprises ordinary cloth. An intumescent coating with real flower touch covers one side or both sides of the ordinary cloth.The intumescent coating is composed of 40%-50% of styrene-butadiene rubber latex (50% of solid content), 15%-20% of talcum powder (800 meshes), 20%-25% of vegetable starch, 1% of calcium stearate, 3%of sodium lauryl sulfonate, 2% of alkylolamides, 0.5% of a polyfunctional aziridine cross-linking agent and 5%-15% of water. The invention further discloses a preparation method of the petal cloth with the real flower touch and a preparation method of artificial flowers with the real flower touch. According to the method, the technical problem that the tactile sensation of the artificial flowersis quite different from that of real flowers is solved. The cloth has the advantages of a smooth and delicate surface, a porous plant structure in the middle, real tactile sensation of the petal clothas the real flowers, easy dyeing, saturated and bright colors, and easy modeling, and the high-end market demand is met.

Owner:东莞东业工艺制品有限公司

Modified polyurethane resin emulsion dye ink and application thereof

ActiveCN101914324BHigh color reproductionRaw materials are abundant and completeFibre treatmentInksTextile printerUltraviolet

The invention discloses a modified polyurethane resin emulsion dye ink and an application thereof. The modified polyurethane resin emulsion dye ink comprises the following components based on weight ratio: 0.1-12% of solvent dye and / or water-soluble dye, 13.5-49.8% of polyurethane resin solid content, 0.01-1% of ultraviolet absorber and the balance of solvent, wherein various additives can be added in the dye ink. The dye ink disclosed in the invention can be used in the fields such as jet ink, cipher paint ink, textile printing ink, aqueous printing ink, fountain pen word ink, rolling maker ink, coating, leather finishing agent, surface finishing and the like, and has the advantages of good storage stability, excellent water resistance, chemical resistance and light resistance, favorable mechanical performance, high brightness, high and low temperature resistance, ageing resistance, good color reducibility and transparency, easily-obtained raw materials, simple manufacture, easy detection, low cost and wide market application prospect.

Owner:GUANGDONG BANGGU CHEM TECH

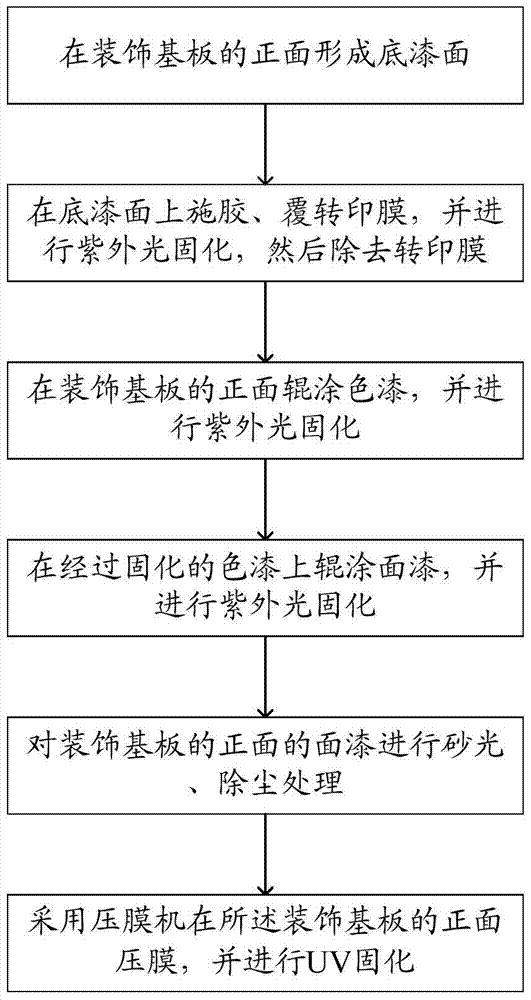

Ultraviolet curing color 3D decoration plate and manufacturing method thereof

ActiveCN104989062AHigh hardnessImprove wiping effectCovering/liningsLamination ancillary operations3d patterningUV curing

The invention provides a manufacturing method of an ultraviolet curing color 3D decoration plate. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; (3) performing roller painting of finishing paints on the cured colored paints and performing ultraviolet curing; (4) performing roller painting of high-gloss finishing paints on the front surface of the decoration substrate and performing ultraviolet curing; (5) performing sanding and dedusting processing of the finishing paints on the front surface of the decoration substrate; and (6) performing film pressing of the surface of the finishing paints by employing a laminator to form 3D patterns and performing UV curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:中关村人居环境工程与材料研究院

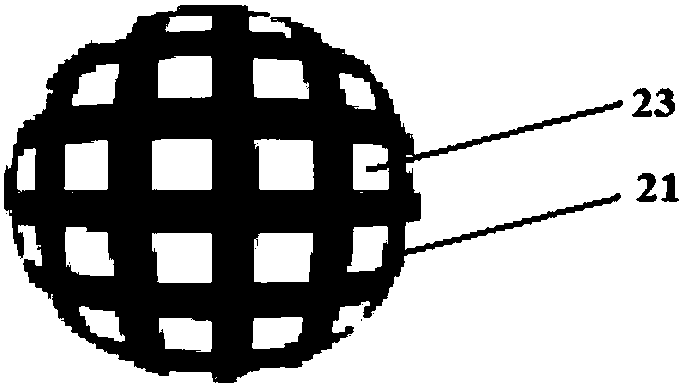

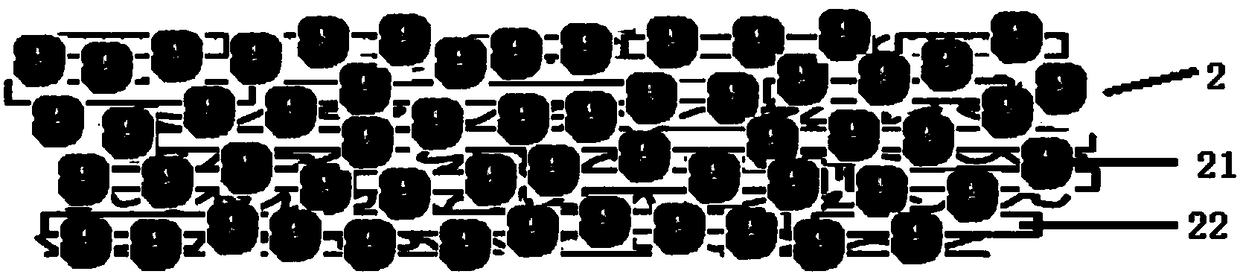

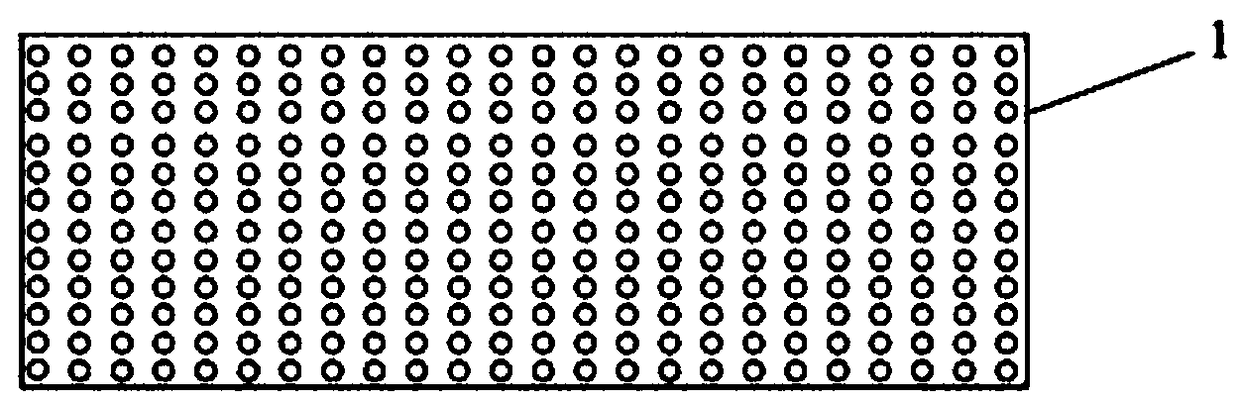

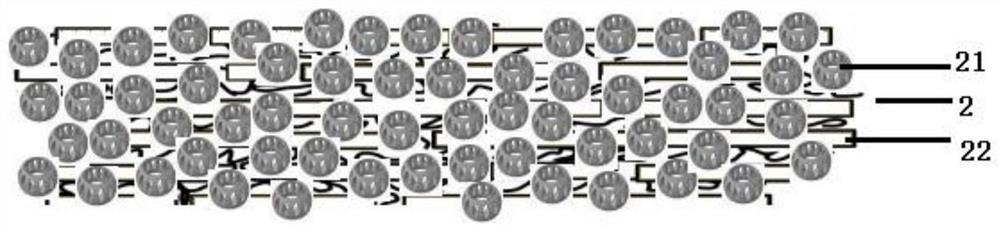

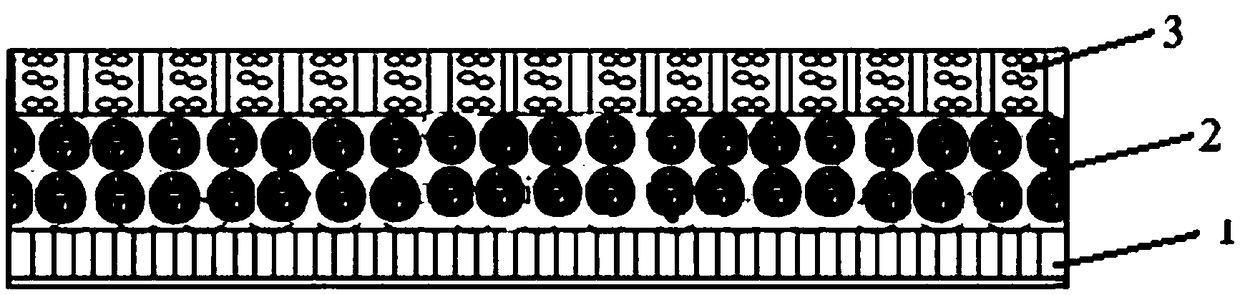

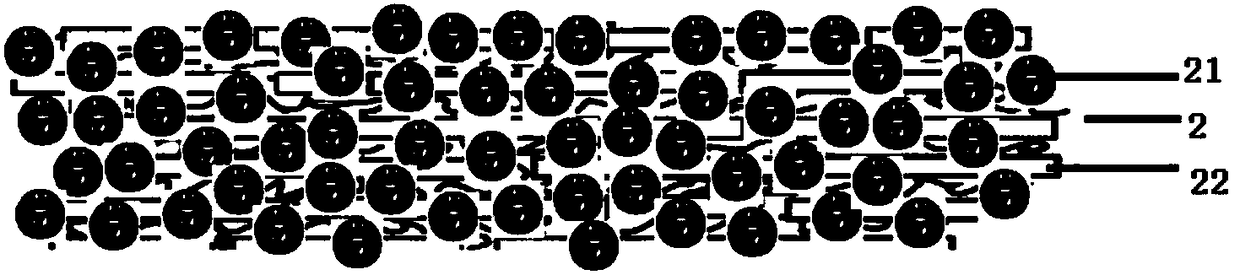

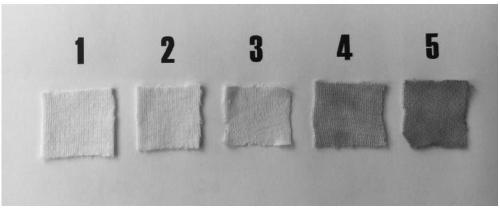

Spherical composite film digital paper for thermal sublimation transfer printing

ActiveCN108360298AVolatile fastFast dryingCoatings with pigmentsSpecial paperComposite filmNetwork density

The invention relates to a spherical composite film digital paper for thermal sublimation transfer printing, belonging to the technical field of thermal sublimation transfer printing. The spherical composite film digital paper comprises, from bottom to top, a substrate paper (1), a spherical composite film (2) and a surface channel layer (3), wherein the spherical composite film (2) is an interpenetrating network spherical composite film composed of hydrophilic network resin and a porous inorganic substance, or cyclodextrin, or a composition of the porous inorganic substance and cyclodextrin,and the hydrophilic network resin is interpenetrating network resin formed by separate crosslinking of cationic polyacrylamide with an acrylic resin composition and carboxymethylcellulose sodium; andthe spherical composite film (2) will expand and wrap up a dye and realizes multilevel separation of dye molecules and water molecules, and the network density of the spherical composite film is adjusted to improve water permeability. The spherical composite film (2) is directly connected with the substrate paper (1), so rapid drying of ink can be achieved. The coating of the spherical composite film digital paper in the invention is of a two-layer structure; and the spherical composite film digital paper is simple in production process, capable of drying immediately after printing, fast in ink absorption and good in transfer printing effect, and meets the requirements of rapid printing and efficient production.

Owner:杭州华大海天科技股份有限公司

A UV-cured transfer high-gloss decorative plate and its manufacturing method

ActiveCN104989045BHigh hardnessImprove wiping effectCovering/liningsUltraviolet lightsPolymer chemistry

The invention provides an ultraviolet light curing transfer high-gloss decorative plate and a manufacturing method thereof. The manufacturing method includes: (1) forming a primer surface on the front surface of the decorative substrate; (2) sizing the primer surface, covering the transfer film, and performing ultraviolet curing, and then removing the transfer film; (3) The front surface of the substrate is coated with color paint and cured by ultraviolet light; (4) a high-gloss finish paint is rolled on the cured color paint and cured by ultraviolet light. The decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:中关村人居环境工程与材料研究院

Topological composite film heat sublimation transfer printing digital paper

ActiveCN108342927AIncrease ink absorptionShorten drying timeCoatings with pigmentsDuplicating/marking methodsNetwork densityGas separation

The invention belongs to the technical field of heat sublimation transfer printing, and discloses a topological composite film heat sublimation transfer printing digital paper. The topological composite film heat sublimation transfer printing digital paper comprises a base material paper layer (1), a topological composite film layer (2), and a surface channel layer (3) successively from bottom totop; the topological composite film layer (2) is composed of a topological network resin and a porous compound; the topological network resin is an interpenetrating network resin formed via crosslinking of a composition of isophorone diisocyanate and triphenylmethane-4,4',4''-triisocyanate with a composition of carboxymethylcellulose sodium and acrylic resin; the topological composite film layer (2) is capable of expanding to intercept dyes, and realizing multi-layer separation of dye molecules and water molecules, and at the same time, the network intensity of the topological composite film layer (2) is adopted to improve separation performance; the topological composite film layer (2) is directly connected with the base material paper layer (1) so as to realize rapid drying of ink. The topological composite film heat sublimation transfer printing digital paper is of a double-layer structure; the production technology is simple; printing instant drying, rapid ink absorption, and transfer printing effects are excellent, and rapid printing and high efficiency manufacturing requirements are satisfied.

Owner:杭州华大海天科技股份有限公司

A kind of UV-cured color matte decorative board and its manufacturing method

ActiveCN104989047BHigh hardnessImprove wiping effectCovering/liningsUltraviolet lightsPolymer chemistry

The invention provides a method for manufacturing an ultraviolet light-cured colored matte decorative board, comprising: (1) forming a primer surface on the front side of the decorative substrate; light curing; (3) roll coating a top coat on the front surface of the decorative substrate, and carry out ultraviolet light curing; (4) roll coating a matte finish paint on the cured color paint, and carry out ultraviolet light curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:北京天工人居科技有限公司

A kind of all-aqueous plastic flexographic printing ink and preparation method thereof

The invention provides full water-based plastic flexible printing ink. The full water-based plastic flexible printing ink is prepared by the following raw materials by weight: 35-70 parts of printing ink connection materials, 25-50 parts of color paste, 1-10 parts of a flatting agent, 1-10 parts of a defoamer, 1-8 parts of wax emulsion, and 5-20 parts of deionized water. The color paste is prepared by mixing the following raw materials by weight: 20-55 parts of printing ink resin, 20-50 parts of organic pigments, 1-8 parts of a wetting dispersant, 1-6 parts of the defoamer, and 20-40 parts of the deionized water. The full water-based printing ink has abroad application range, and has environment-friendly feature compared with the normal water-based printing ink, and is capable of greatly reducing the pollutant residue and volatility gases on the surface of a printed matter, and realizing the zero release of VOC in the printing ink products. The full water-based printing ink has the characteristics of good adhesive force, rub resistance, scratch resistance, weather resistance, water resistance, chemical resistance, resistance and so on, and the high-speed flexible printing is more than 150 m / min.

Owner:中国印刷科学技术研究院有限公司

A kind of ultraviolet curing transfer printing 3D decorative plate and its manufacturing method

ActiveCN104989060BHigh hardnessImprove wiping effectCovering/liningsLamination ancillary operationsUV curingUltraviolet lights

The invention provides an ultraviolet light curing transfer printing 3D decorative plate and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) forming a primer surface on the front side of the decorative substrate; (2) sizing the primer surface, applying a transfer film, and performing ultraviolet curing, and then removing the transfer film (3) roll-coat color paint on the front surface of the decorative substrate, and carry out UV curing; (4) roll-coat topcoat on the cured color paint, and carry out UV curing; Sanding and dedusting the top coat on the front of the decorative substrate; (6) laminating a film on the front of the decorative substrate with a laminating machine, and performing UV curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:中关村人居环境工程与材料研究院

A kind of ultraviolet curing transfer printing flat decorative plate and its manufacturing method

The invention provides an ultraviolet curing transfer printing flat decorative plate and a manufacturing method thereof. The manufacturing method comprises: (1) forming a primer surface on the front surface of a decorative substrate; (2) applying glue on the primer surface, covering a transfer film, and curing with ultraviolet light, and then removing the transfer film; ( 3) Roll-coat color paint on the front surface of the decorative substrate, and perform ultraviolet light curing; (4) Roll-coat smooth topcoat on the cured color paint, and perform ultraviolet light curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated colors, smooth and wear-resistant surface, light weight and low price.

Owner:北京天工人居科技有限公司

A kind of UV curing transfer printing matte decorative board and its manufacturing method

Owner:中关村人居环境工程与材料研究院

A kind of porcelain plate painting production process

ActiveCN105620165BSave fresh industrial waterReduce carbon emissionsOrnamental structuresSpecial ornamental structuresEngineeringManufacturing efficiency

The invention discloses a manufacture process for a porcelain plate painting. The manufacture process comprises the following steps of designing a makeup pattern; cutting porcelain plates and a bottom liner plate; polishing the bottom liner plate and each porcelain plate; cleaning the porcelain plates; drying the porcelain plates; spraying ground glaze on the porcelain plates; drying the ground glaze; analyzing and correcting the pattern with a digital printer; printing the pattern on the porcelain plates with the digital printer; glaze packing is performed on the front surfaces of the porcelain plates; preparing overglaze; spraying the overglaze on the porcelain plates; baking the overglaze; mounting the porcelain plates on the bottom liner plate; and assembling a painting frame and manufacturing a porcelain plate painting product. The porcelain plate painting manufactured in the invention is low-carbon and environment-friendly; the manufacturing efficiency is high; and the painting is attractive and delicate.

Owner:SHENZHEN YIERSHAN CERAMIC CULTURE & ART CO LTD

A kind of ultraviolet light curing color high-gloss decorative board and its manufacturing method

ActiveCN104989059BHigh hardnessImprove wiping effectLamination ancillary operationsCovering/liningsUltraviolet lightsLight cure

The invention provides a method for manufacturing an ultraviolet light-cured colored high-gloss decorative board, comprising: (1) forming a primer surface on the front side of the decorative substrate; curing; (3) roll-coating a top coat on the front surface of the decorative substrate, and performing ultraviolet curing; (4) rolling coating a high-gloss top coat on the cured top paint, and performing ultraviolet curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:中关村人居环境工程与材料研究院

Ultraviolet curing color flat decoration plate and manufacturing method thereof

ActiveCN104989061AHigh hardnessImprove wiping effectCovering/liningsLamination ancillary operationsWear resistantOptoelectronics

The invention provides a manufacturing method of an ultraviolet curing color flat decoration plate. The method includes: (1) forming a primer surface on the front surface of a decoration substrate; (2) performing roller painting of colored paints on the front surface of the decoration substrate and performing ultraviolet curing; (3) performing roller painting of finishing paints on the front surface of the decoration substrate and performing ultraviolet curing; and (4) performing roller painting of flat finishing paints on the cured finishing paints and performing ultraviolet curing. The decoration plate manufactured by the method is advantaged by high-definition emulation, bright and saturated color, smooth and wear-resistant surface, light weight, and low cost.

Owner:中关村人居环境工程与材料研究院

A kind of ultraviolet curing color 3D decorative board and its manufacturing method

ActiveCN104989062BHigh hardnessImprove wiping effectLamination ancillary operationsCovering/linings3d patterningUltraviolet lights

Owner:中关村人居环境工程与材料研究院

Instant dry sublimation transfer printing digital pp paper

ActiveCN106379068BIncrease drying speedShorten drying timeDuplicating/marking methodsCoatingsCelluloseDigital paper

The invention relates to the technical field of sublimation transfer printing and discloses instant dry type sublimation transfer digital paper. The instant dry type sublimation transfer digital paper comprises perforated PP paper, a water absorbing and permeable layer, a porous layer and a surface channel layer which are sequentially arranged from bottom to top; the porous layer is made of interpenetrating network resin formed by crosslinking of cellulose or sodium carboxymethylcellulose or starch and modified cationic polyacrylamide, or formed by crosslinking of polyacrylamide or cellulose or sodium carboxymethylcellulose and modified cationic starch; on one hand, the interpenetrating network resin can swell to 'catch' a dye for quick ink absorption, and on the other hand, components of the resin are adjusted and the network density is controlled to improve the water permeability, so that water molecules can quickly enter the water absorbing and permeable layer; and the perforated PP paper has excellent flexibility and mechanical strength and is stable in size in the printing process, so that the problem of shrinkage, caused by weather, of the conventional paper base material is solved. The instant dry type sublimation transfer digital PP paper has the characteristics of being instant in drying, quick in ink absorption, good in size stability and low in cost, and can meet the requirements for quick printing and efficient manufacturing at present.

Owner:杭州华大海天科技股份有限公司

Cylindrical Composite Film Sublimation Transfer Digital Paper

ActiveCN108360293BFast absorptionEfficient separationCoatings with pigmentsCoatingsCellulosePolymer science

The invention relates to cylindrical composite film digital paper for thermal sublimation transfer printing, belonging to the technical field of thermal sublimation transfer printing. The cylindricalcomposite film digital paper comprises, from bottom to top, a substrate paper (1), a cylindrical composite film (2) and a surface channel layer (3), wherein the cylindrical composite film (2) is composed of a porous inorganic substance and network resin formed by cyclodextrin, and the network resin formed by cyclodextrin is interpenetrating network resin formed by crosslinking of cyclodextrin withcarboxymethylcellulose sodium and cationic polyacrylamide under the action of polyisocyanate; and the cylindrical composite film (2) will expand and wrap up a dye and realizes multilevel separation of dye molecules and water molecules, and the network density of the cylindrical composite film (2) is adjusted to improve separation performance. The cylindrical composite film (2) is directly connected with the substrate paper (1), so rapid drying of ink can be achieved. The coating of the cylindrical composite film digital paper in the invention is of a two-layer structure; and the cylindrical composite film digital paper is simple in production process, capable of drying immediately after printing, fast in ink absorption and good in transfer printing effect, and meets the requirements of rapid printing and efficient production.

Owner:杭州华大海天科技股份有限公司

Cylindrical composite film digital paper for thermal sublimation transfer printing

ActiveCN108360293AFast absorptionEfficient separationCoatings with pigmentsCoatingsComposite filmNetwork density

The invention relates to cylindrical composite film digital paper for thermal sublimation transfer printing, belonging to the technical field of thermal sublimation transfer printing. The cylindricalcomposite film digital paper comprises, from bottom to top, a substrate paper (1), a cylindrical composite film (2) and a surface channel layer (3), wherein the cylindrical composite film (2) is composed of a porous inorganic substance and network resin formed by cyclodextrin, and the network resin formed by cyclodextrin is interpenetrating network resin formed by crosslinking of cyclodextrin withcarboxymethylcellulose sodium and cationic polyacrylamide under the action of polyisocyanate; and the cylindrical composite film (2) will expand and wrap up a dye and realizes multilevel separation of dye molecules and water molecules, and the network density of the cylindrical composite film (2) is adjusted to improve separation performance. The cylindrical composite film (2) is directly connected with the substrate paper (1), so rapid drying of ink can be achieved. The coating of the cylindrical composite film digital paper in the invention is of a two-layer structure; and the cylindrical composite film digital paper is simple in production process, capable of drying immediately after printing, fast in ink absorption and good in transfer printing effect, and meets the requirements of rapid printing and efficient production.

Owner:杭州华大海天科技股份有限公司

Spherical Composite Film Sublimation Transfer Digital Paper

ActiveCN108360298BFast absorptionEfficient separationCoatings with pigmentsSpecial paperCellulosePolymer science

The invention relates to a spherical composite film digital paper for thermal sublimation transfer printing, belonging to the technical field of thermal sublimation transfer printing. The spherical composite film digital paper comprises, from bottom to top, a substrate paper (1), a spherical composite film (2) and a surface channel layer (3), wherein the spherical composite film (2) is an interpenetrating network spherical composite film composed of hydrophilic network resin and a porous inorganic substance, or cyclodextrin, or a composition of the porous inorganic substance and cyclodextrin,and the hydrophilic network resin is interpenetrating network resin formed by separate crosslinking of cationic polyacrylamide with an acrylic resin composition and carboxymethylcellulose sodium; andthe spherical composite film (2) will expand and wrap up a dye and realizes multilevel separation of dye molecules and water molecules, and the network density of the spherical composite film is adjusted to improve water permeability. The spherical composite film (2) is directly connected with the substrate paper (1), so rapid drying of ink can be achieved. The coating of the spherical composite film digital paper in the invention is of a two-layer structure; and the spherical composite film digital paper is simple in production process, capable of drying immediately after printing, fast in ink absorption and good in transfer printing effect, and meets the requirements of rapid printing and efficient production.

Owner:杭州华大海天科技股份有限公司

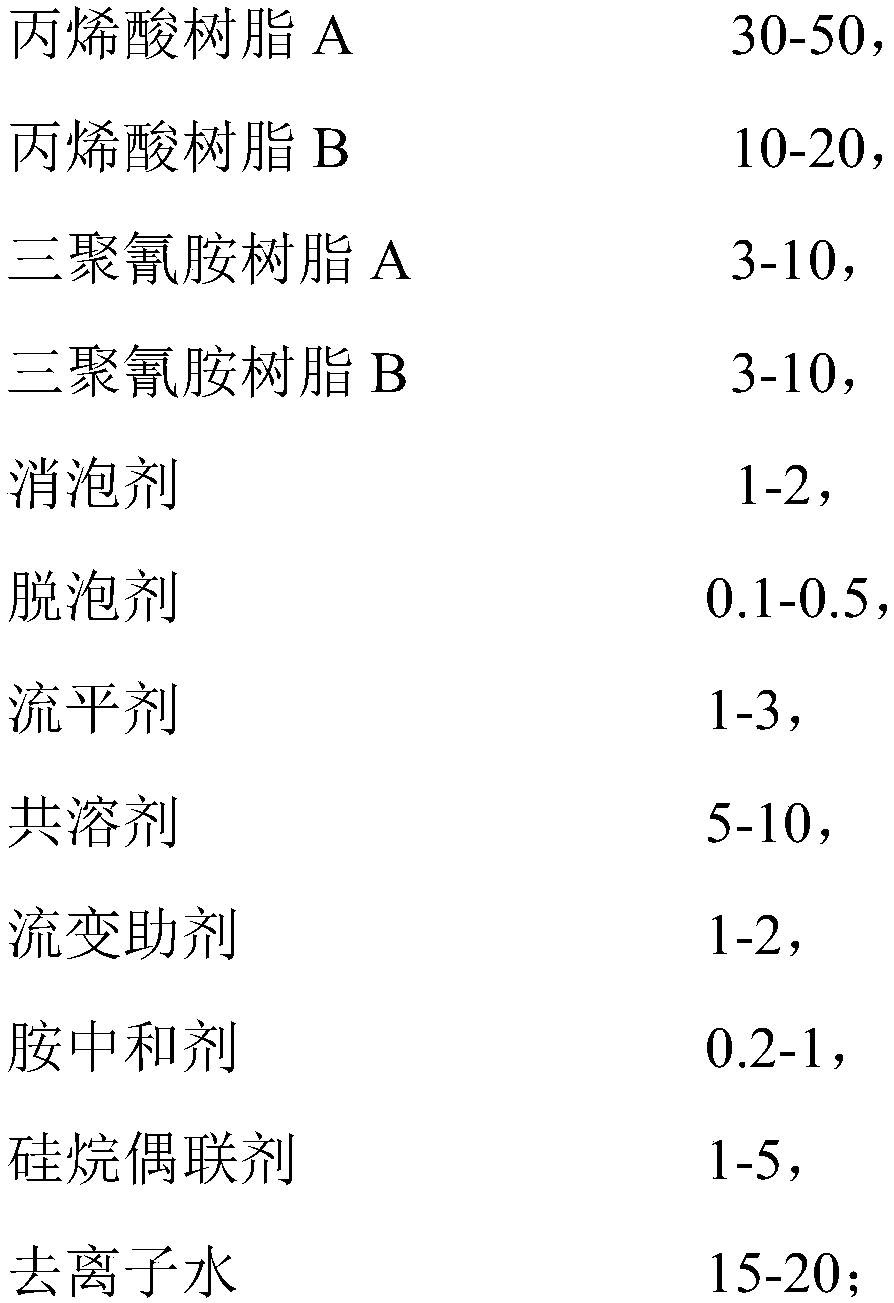

High-gloss waterborne coating for perfume glass bottles

The invention discloses a high-gloss waterborne coating for perfume glass bottles; the high-gloss waterborne coating comprises a component A, a component B, a component C and a component D which are separately packaged, wherein the component A consists of the following components in parts by weight: 30-50 parts of acrylic resin A, 10-20 parts of acrylic resin B, 3-10 parts of melamine resin A, 3-10 parts of melamine resin B, 1-2 parts of an antifoaming agent, 0.1-0.5 part of a defoaming agent, 1-3 parts of a leveling agent, 5-10 parts of a cosolvent, 1-2 parts of a rheological auxiliary agent,0.2-1 part of an amine neutralizer, 1-5 parts of a silane coupling agent, and 15-20 parts of deionized water; the component B is an acid drier with the amount of 1-2 parts by weight; the component Cis deionized water with the amount of 20-30 parts by weight; the component D is dye slurry with the addition amount added according to the needs. The high-gloss waterborne coating can meet the requirements of FDA, and has the characteristics of high gloss, good fullness, excellent adhesive force on glass substrates, water boiling resistance, alcohol scrubbing resistance and abrasion resistance.

Owner:PETER LACKE SHANGHAI

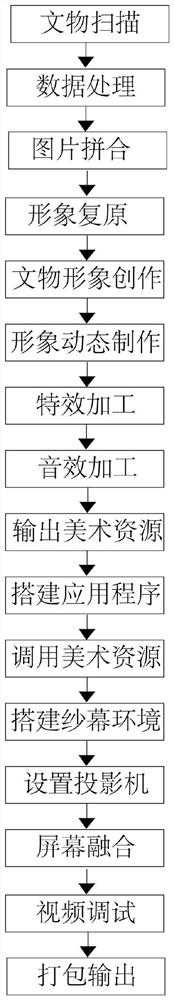

Yarn curtain holographic projection display method for museum exhibition

PendingCN113763246AAdd holographic effectCreate a fully immersive environmentGeometric image transformationFilling planer surface with attributesYarnComputer graphics (images)

The invention relates to a yarn curtain holographic projection display method for museum exhibition, and the method specifically comprises the following steps: S1, scanning a cultural relic, and obtaining a new cultural relic image after processing, restoration and creation; S2, sequentially performing dynamic production, special effect processing and sound processing on the cultural relic image, and then outputting to obtain art resources; and S3, introducing the art resources into the interaction system, and outputting the art resources after completion. Compared with the prior art, the projection screen gets rid of wall limitation, can be arranged in any space of a museum, and can create a full immersion environment and a full immersion type audio and picture experience environment, so that audiences can see objects on the back side through the screen, secondary imaging can be realized by using light transmission, the projection screen has better permeability than a traditional projection screen, and the cultural relic image can suspend in the air.

Owner:FUDAN UNIV

A kind of ultraviolet curing color flat decorative board and its manufacturing method

ActiveCN104989061BHigh hardnessImprove wiping effectCovering/liningsLamination ancillary operationsUltraviolet lightsMaterials science

The invention provides a method for manufacturing an ultraviolet light-cured colored plain decorative board, comprising: (1) forming a primer surface on the front surface of the decorative substrate; curing; (3) roll-coating a finish paint on the front surface of the decorative substrate and performing ultraviolet light curing; (4) rolling-coating a flat top coat on the cured top paint and performing ultraviolet light curing. The manufactured decorative board has the characteristics of high-definition simulation, bright and saturated color, smooth and wear-resistant surface, light weight and low price.

Owner:中关村人居环境工程与材料研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com