Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3539results about "Ornamental structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

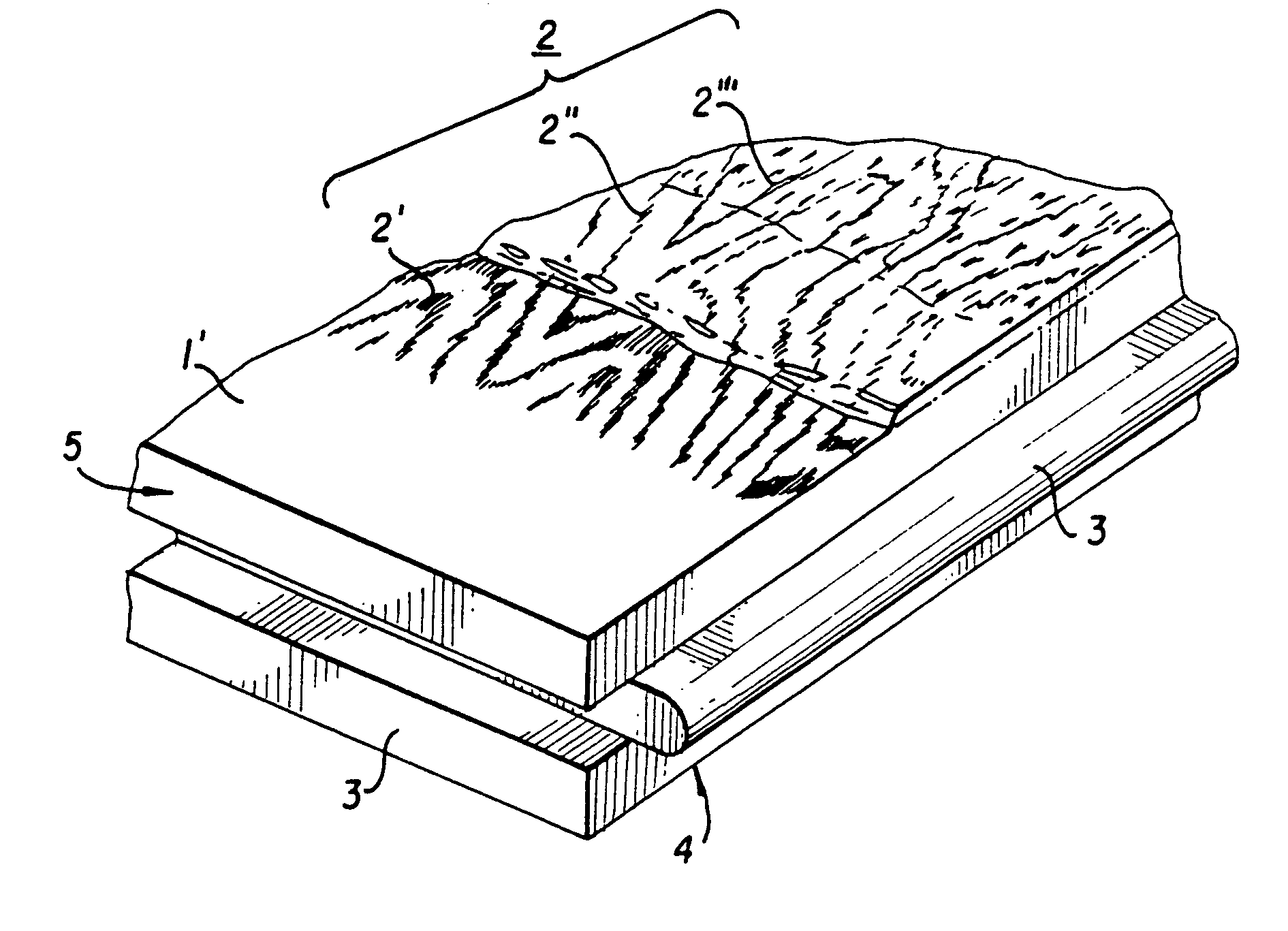

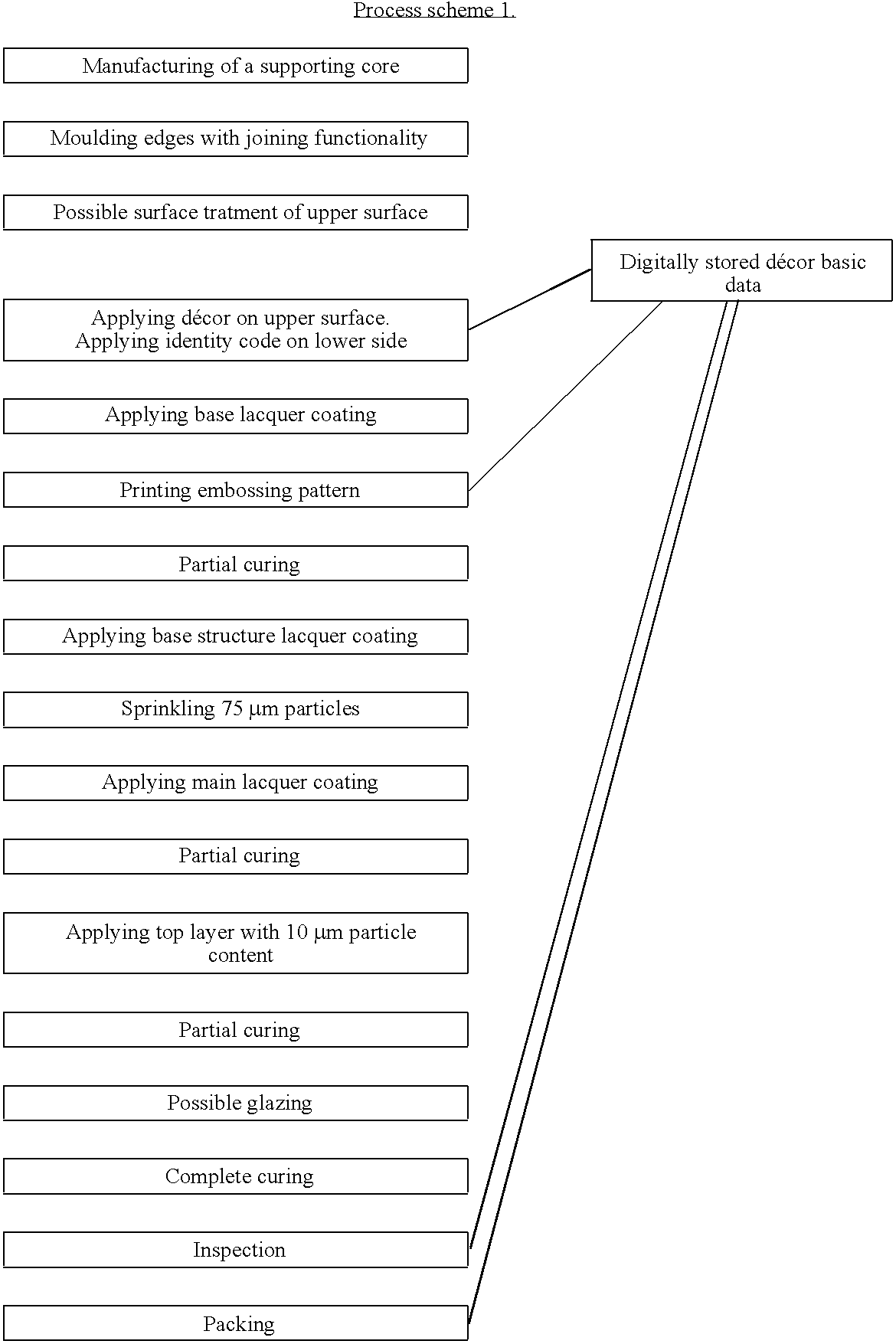

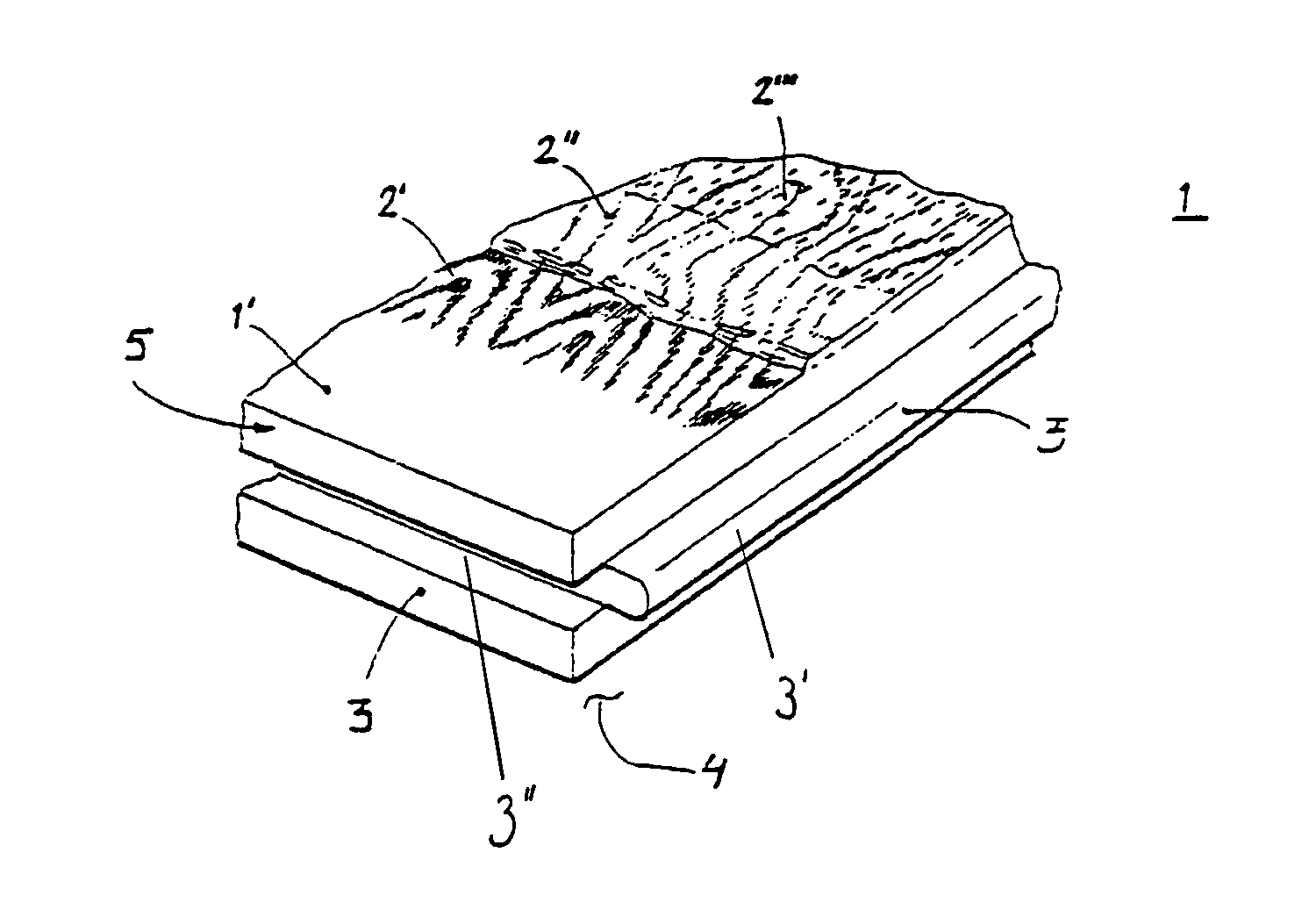

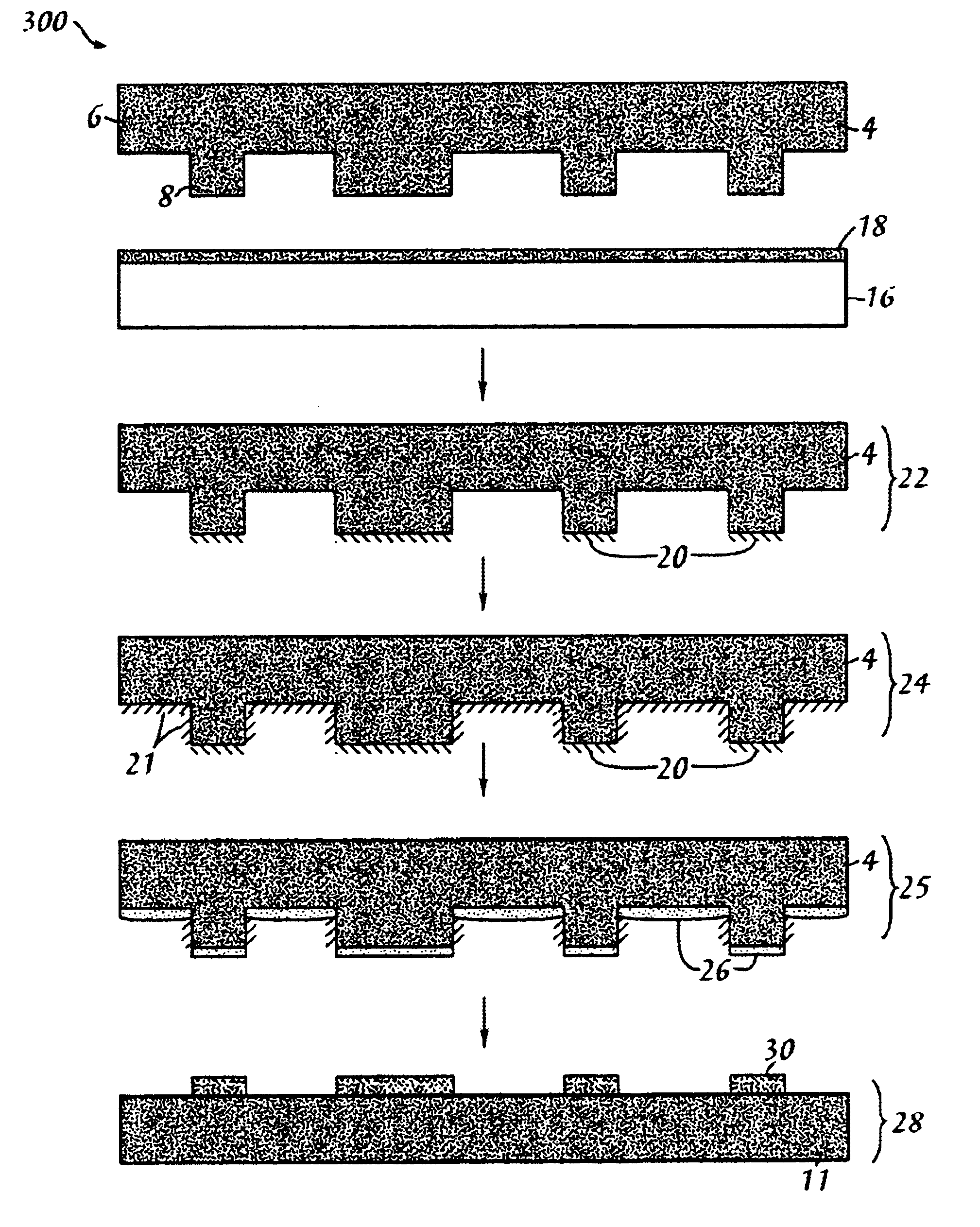

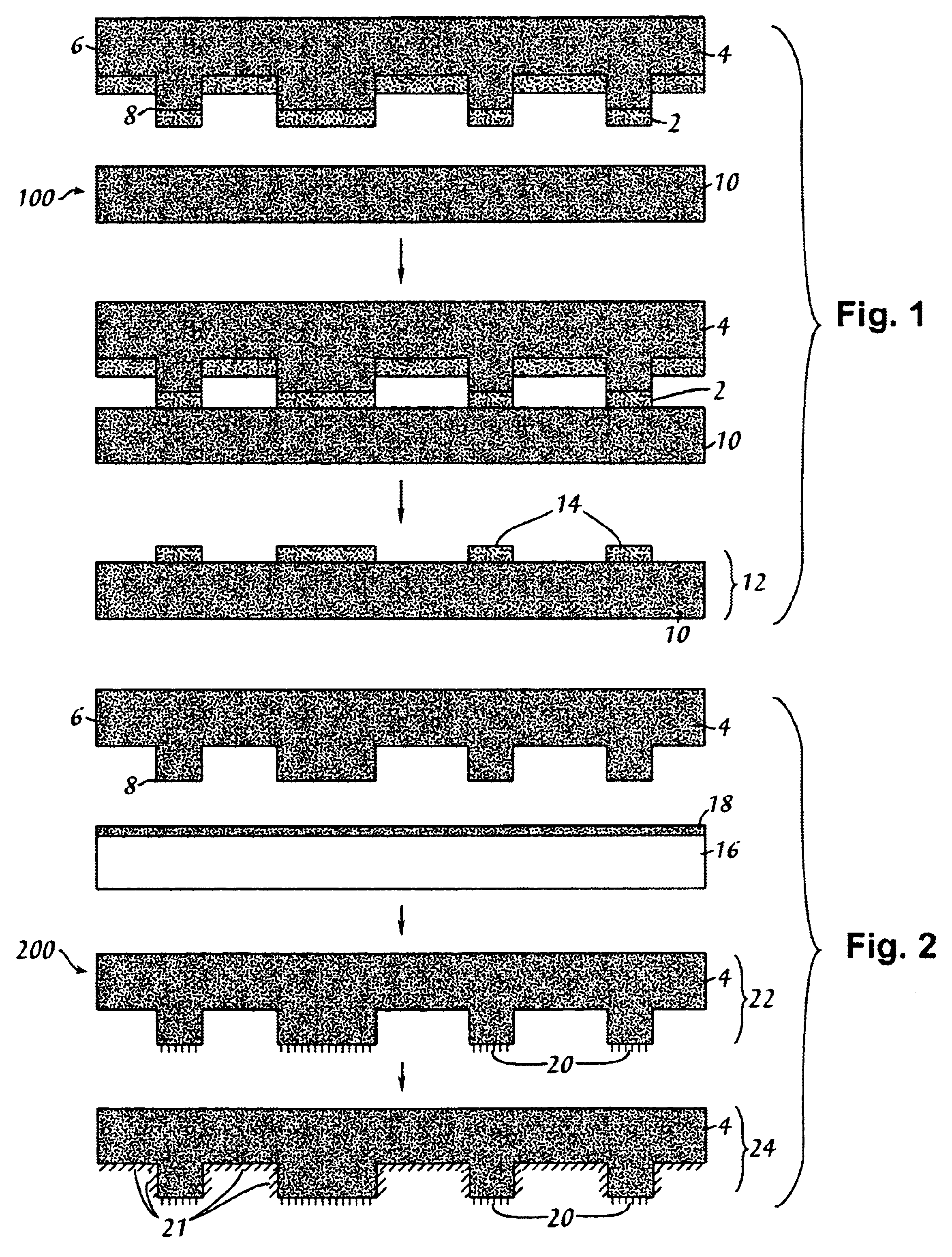

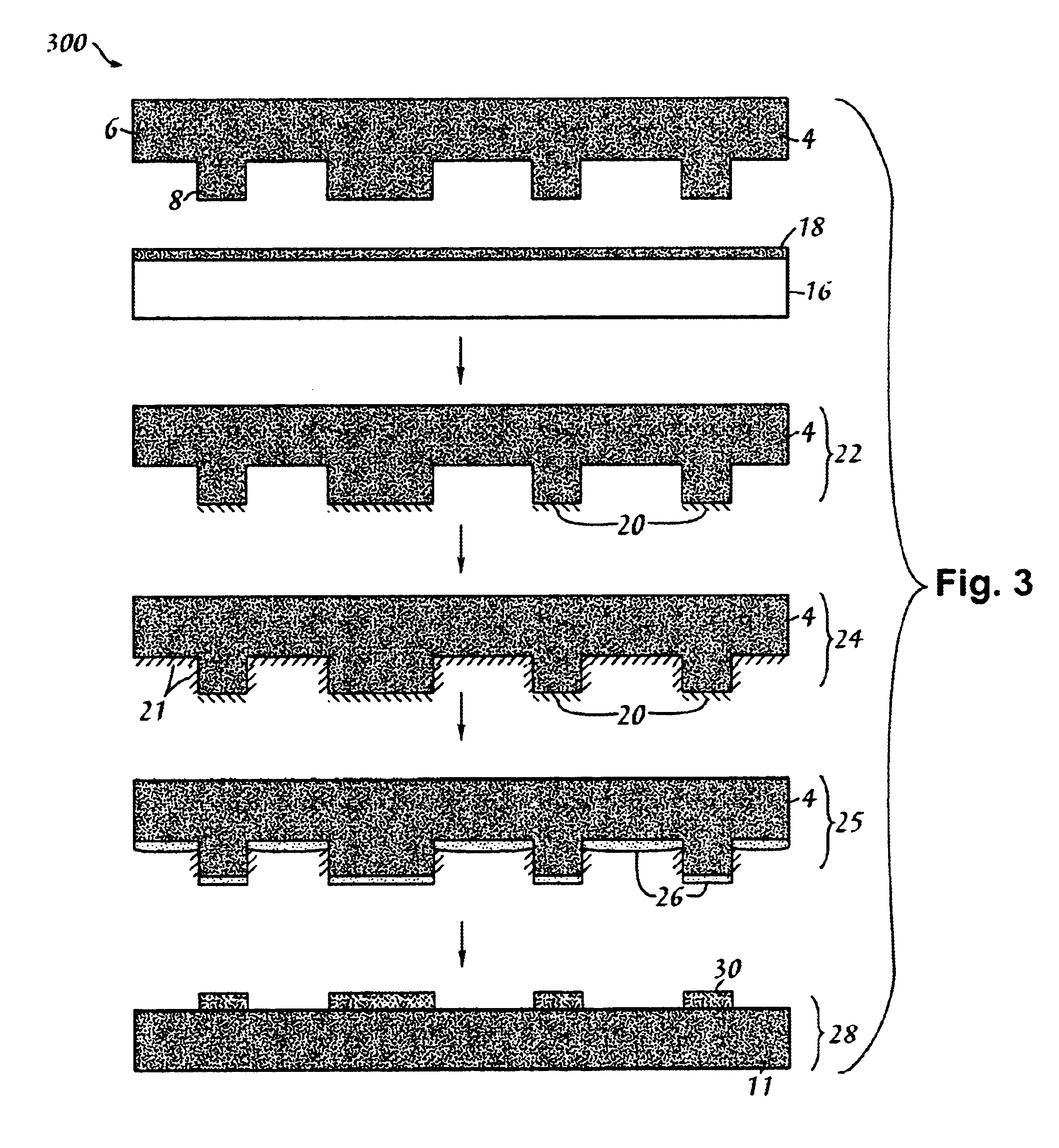

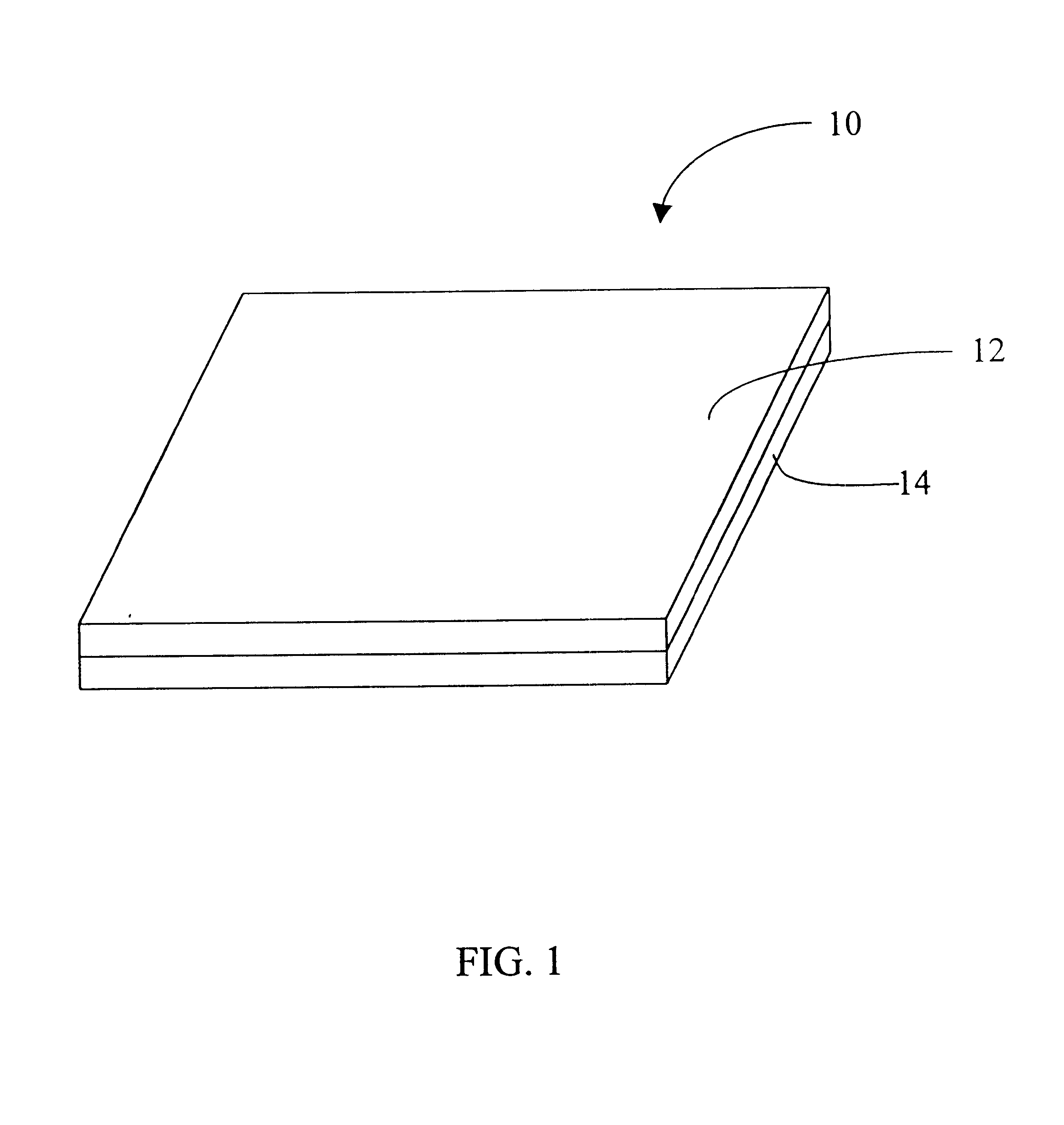

Process for the manufacturing of surface elements with a structured upper surface

InactiveUS6991830B1High resolutionRearrange décorCovering/liningsOrnamental structuresLacquerEngineering

A process for the manufacturing of a decorative surface element, which element comprises a base layer and a decorative upper surface. A wetting repellent lacquer is printed in a predetermined pattern on the decorative upper surface. The wetting repellent lacquer covers only parts of the decorative upper surface. A wear layer of a UV or electron beam curing lacquer is then applied on top of the decorative upper surface which UV or electron beam curing lacquer is repelled from the parts of the surface being covered by the wetting repellent lacquer whereby a surface structure is achieved.

Owner:UNILIN NORDIC AB

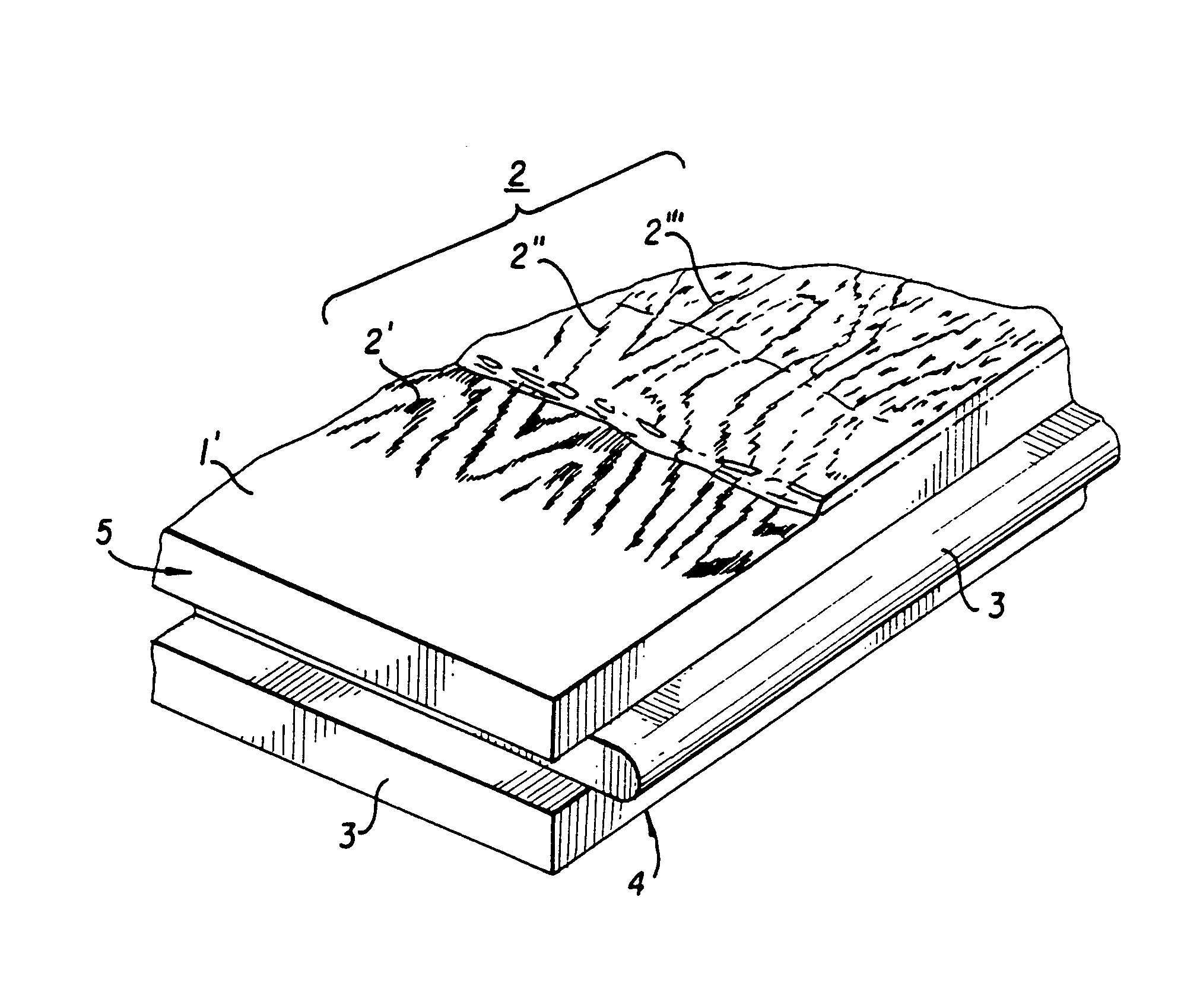

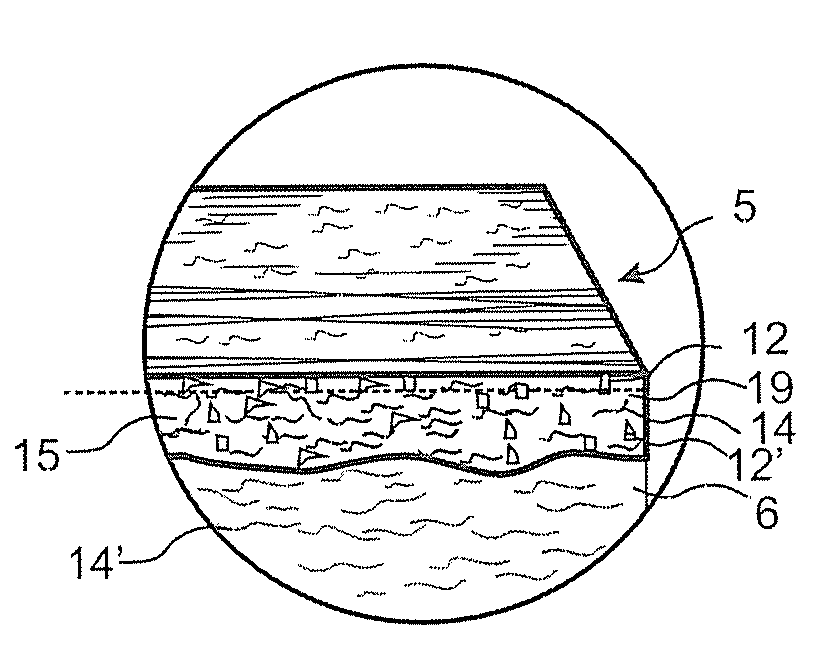

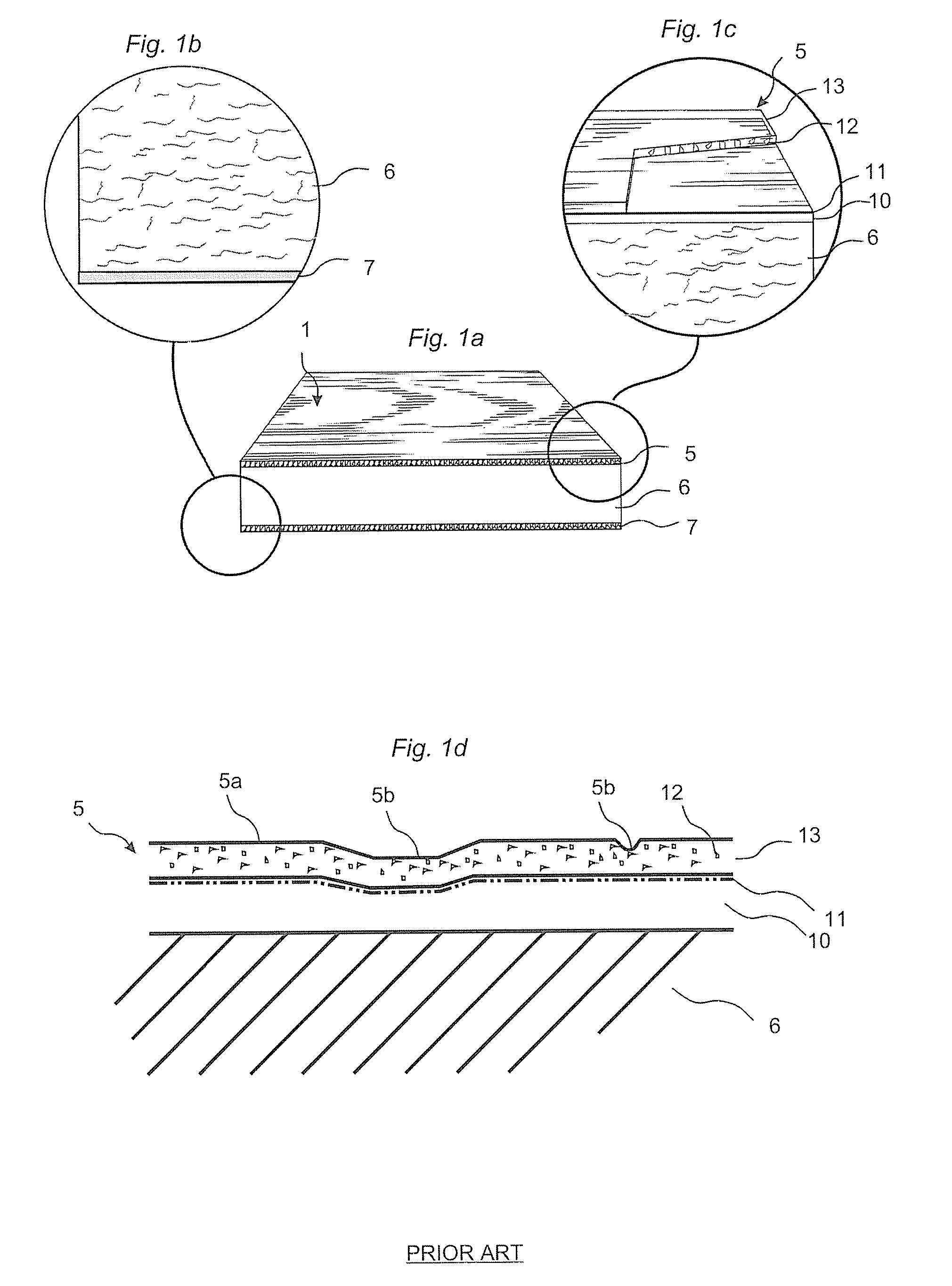

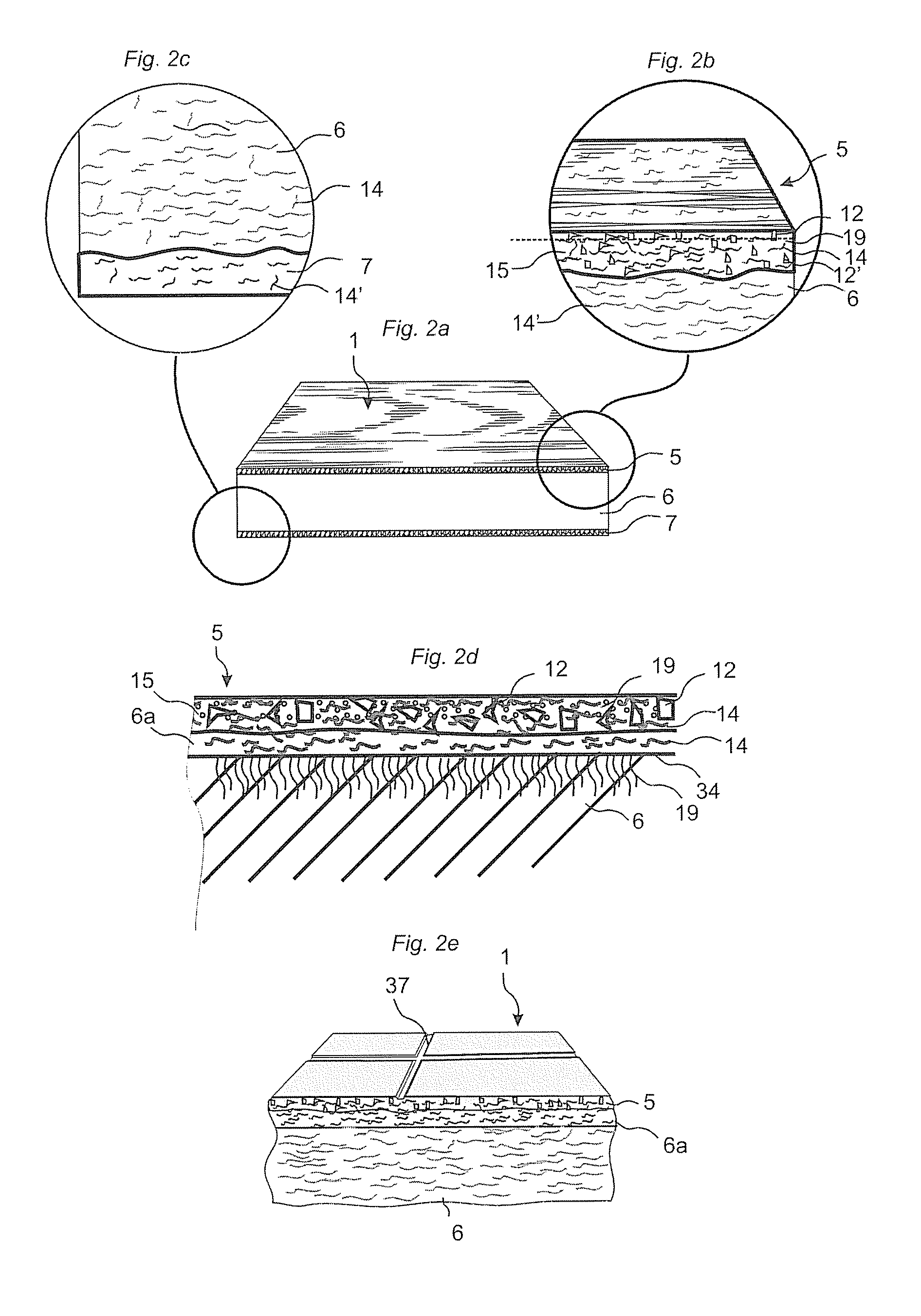

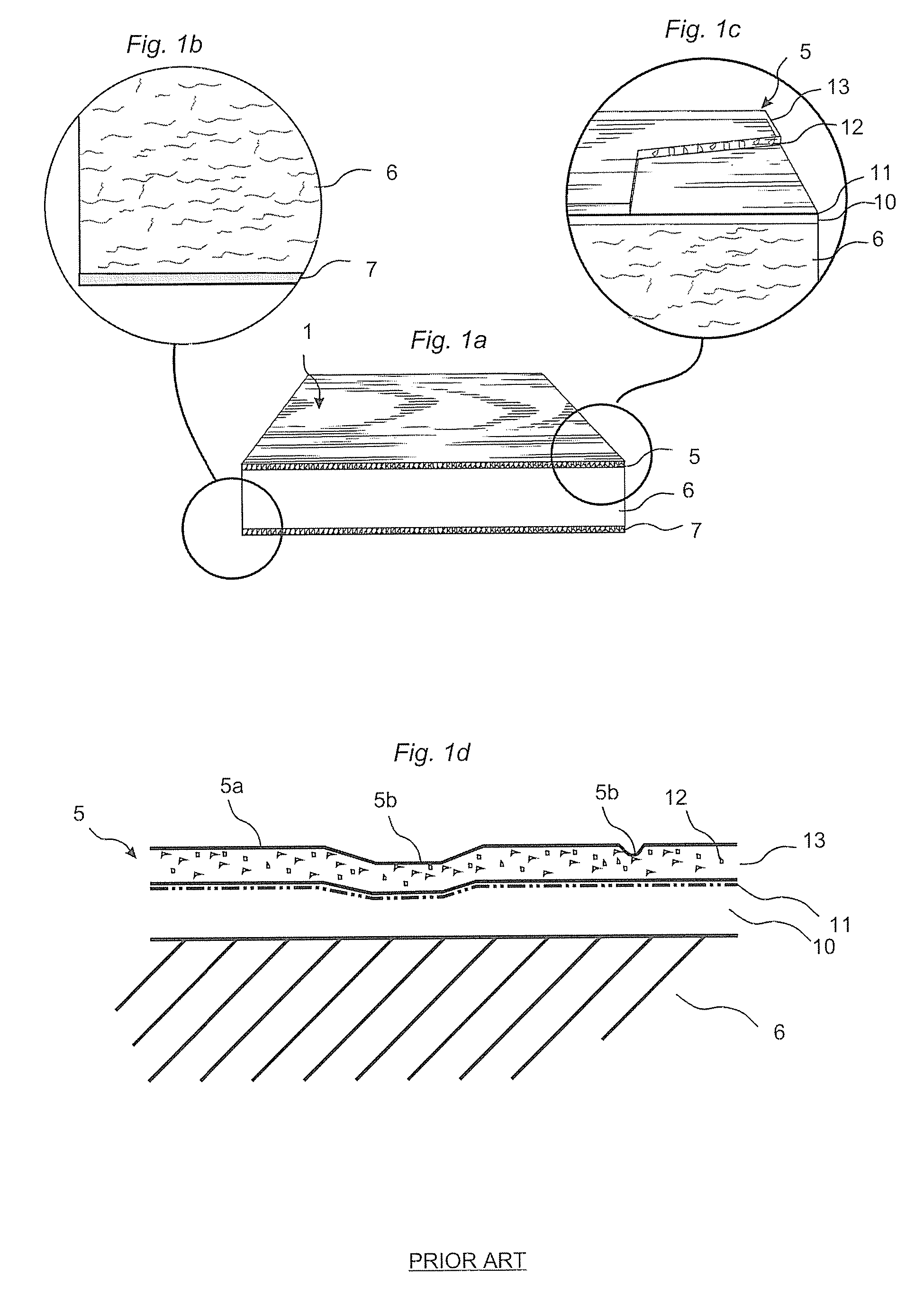

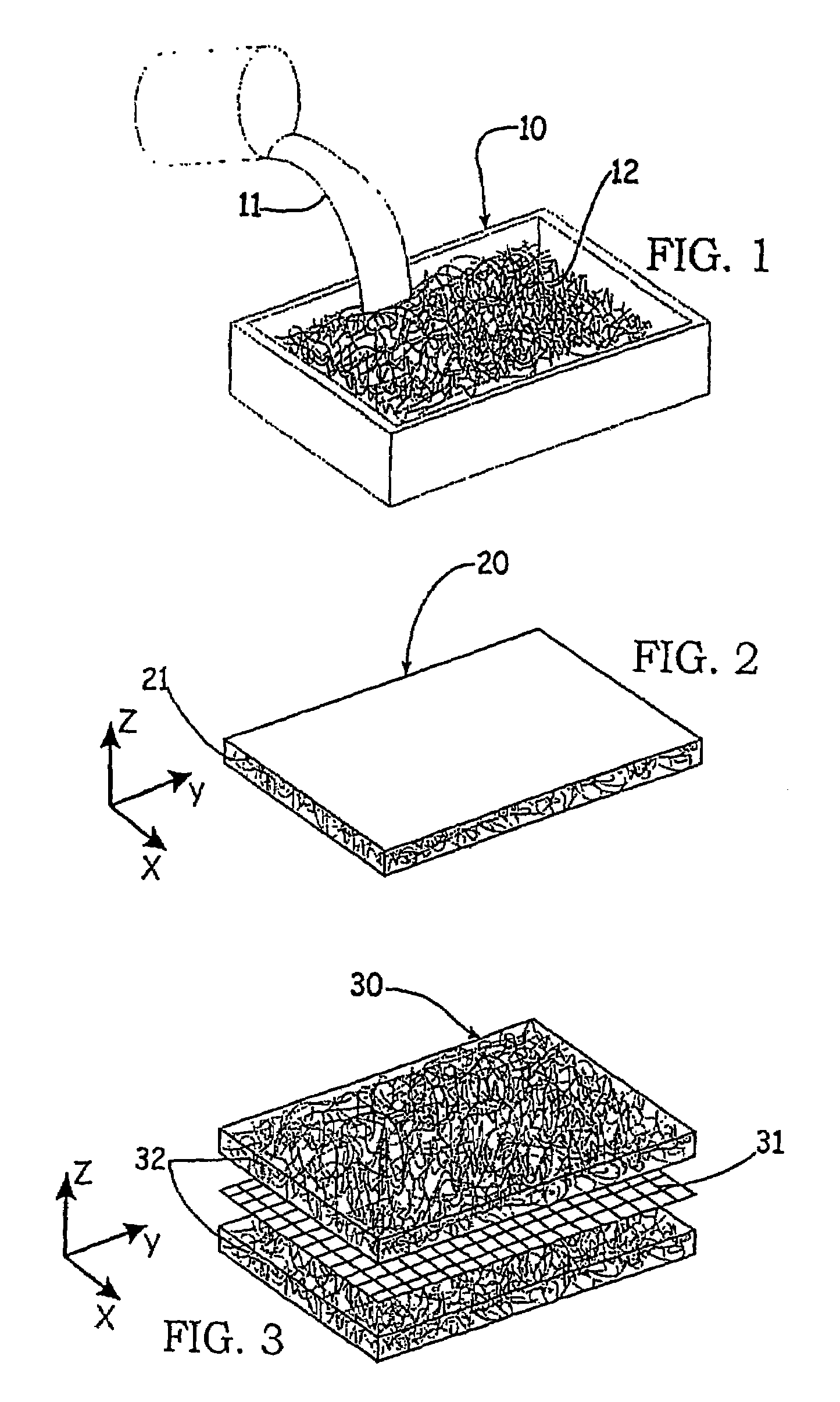

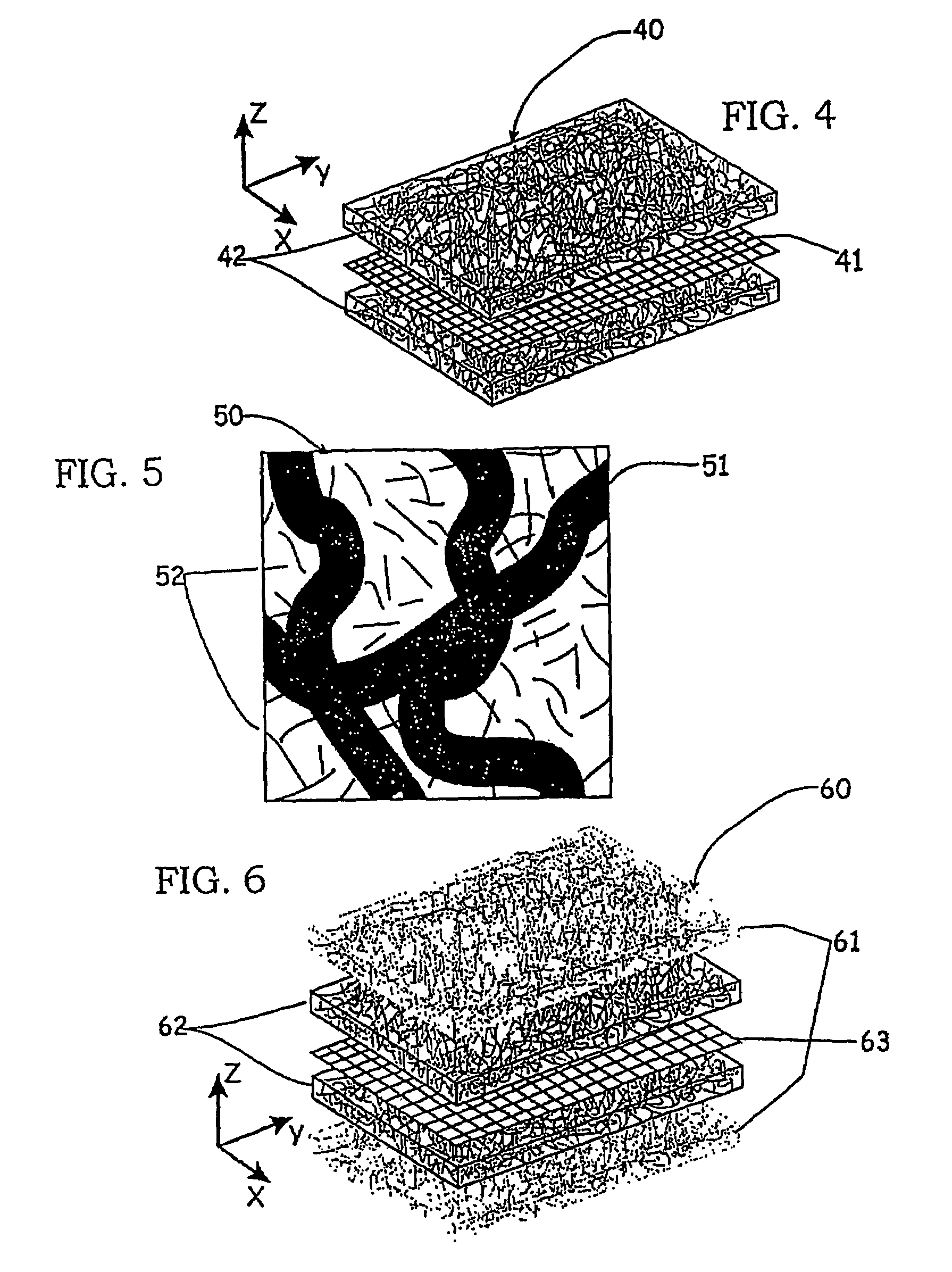

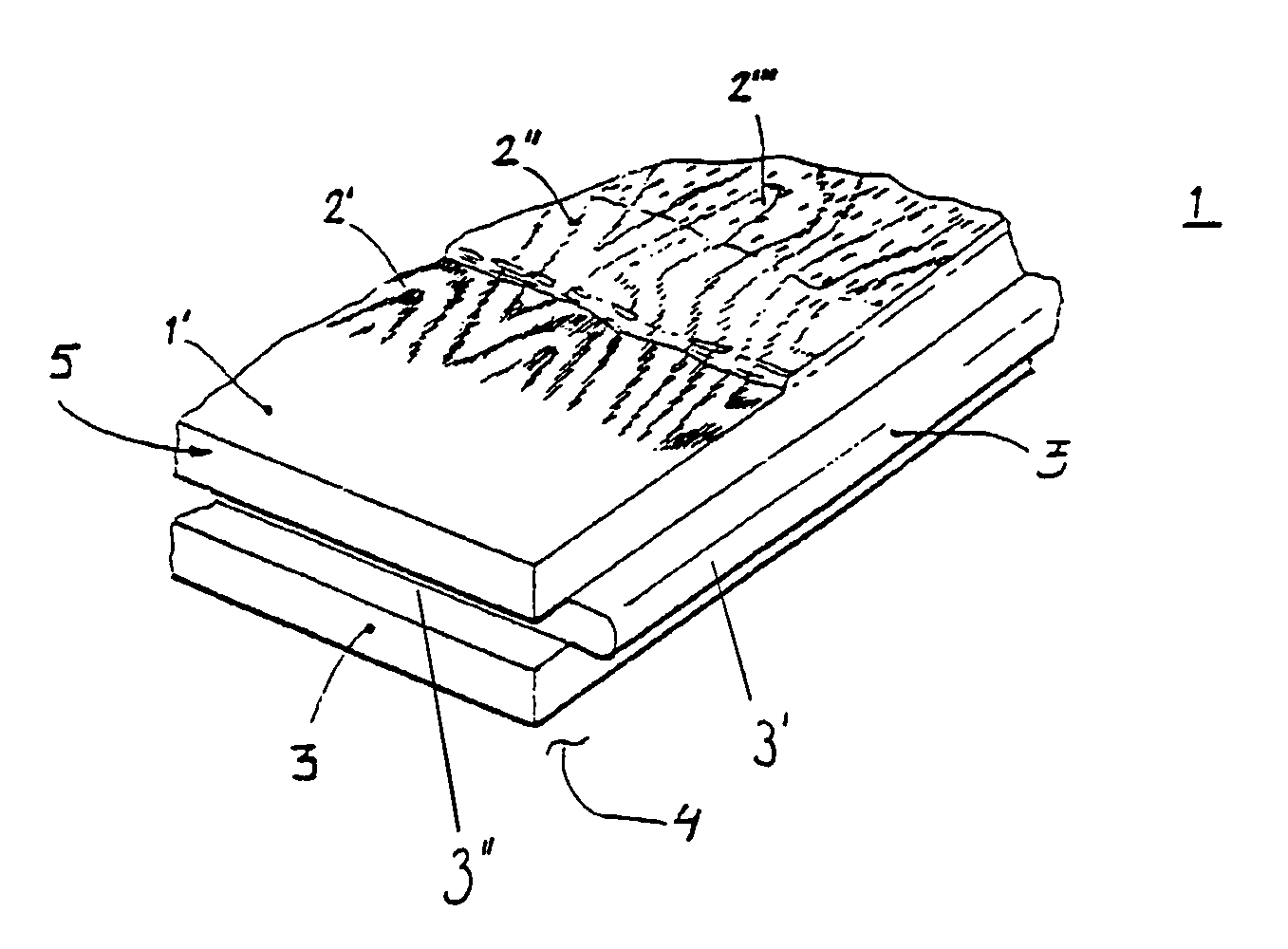

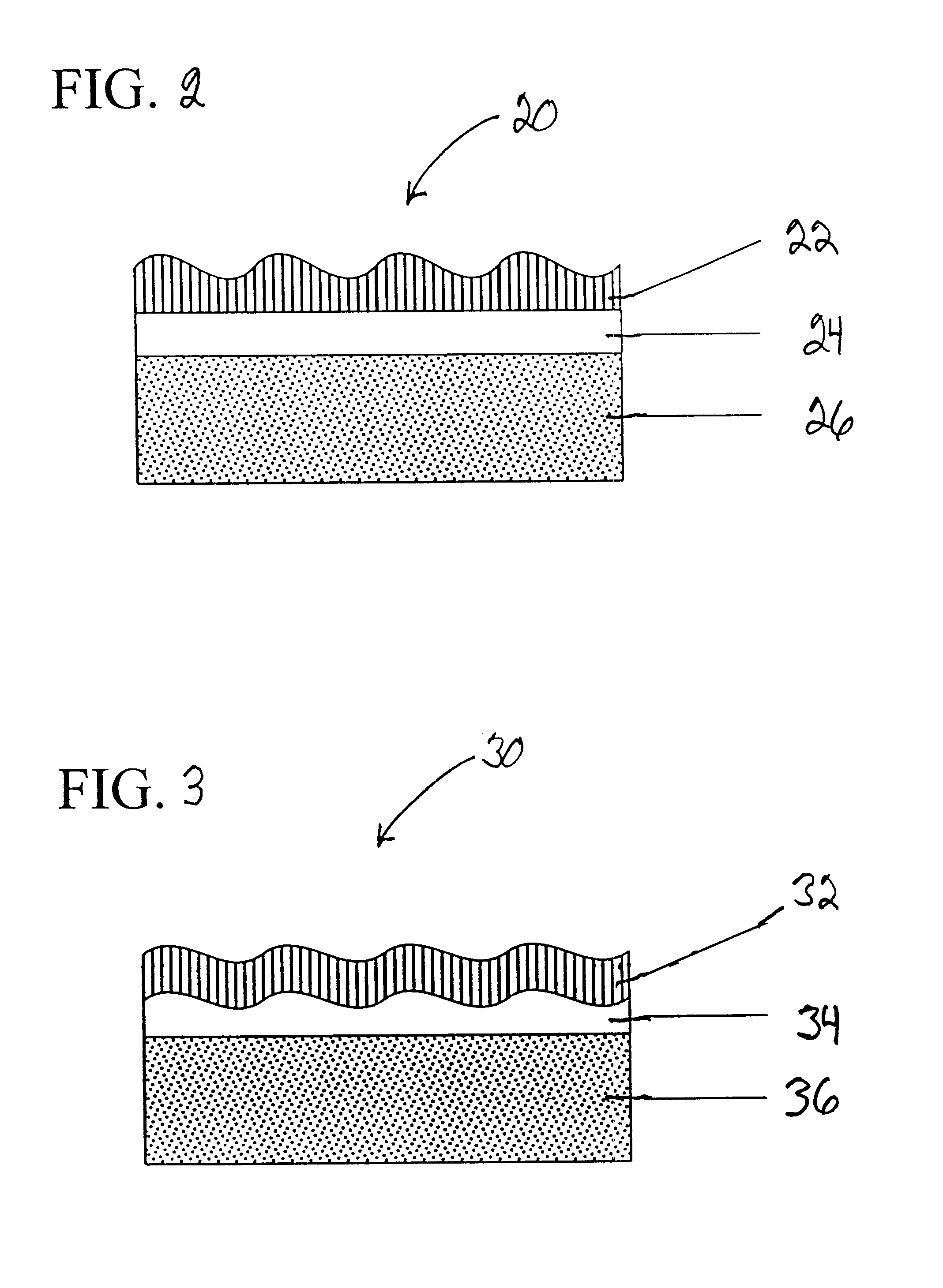

Wood fibre based panels with a thin surface layer

ActiveUS20100092731A1Large market shareImprove impact resistanceLiquid surface applicatorsCovering/liningsSurface layerWood fibre

Building panels with a thin and embossed surface layer and a sub layer between a surface layer and a core.

Owner:VÄLINGE INNOVATION AB

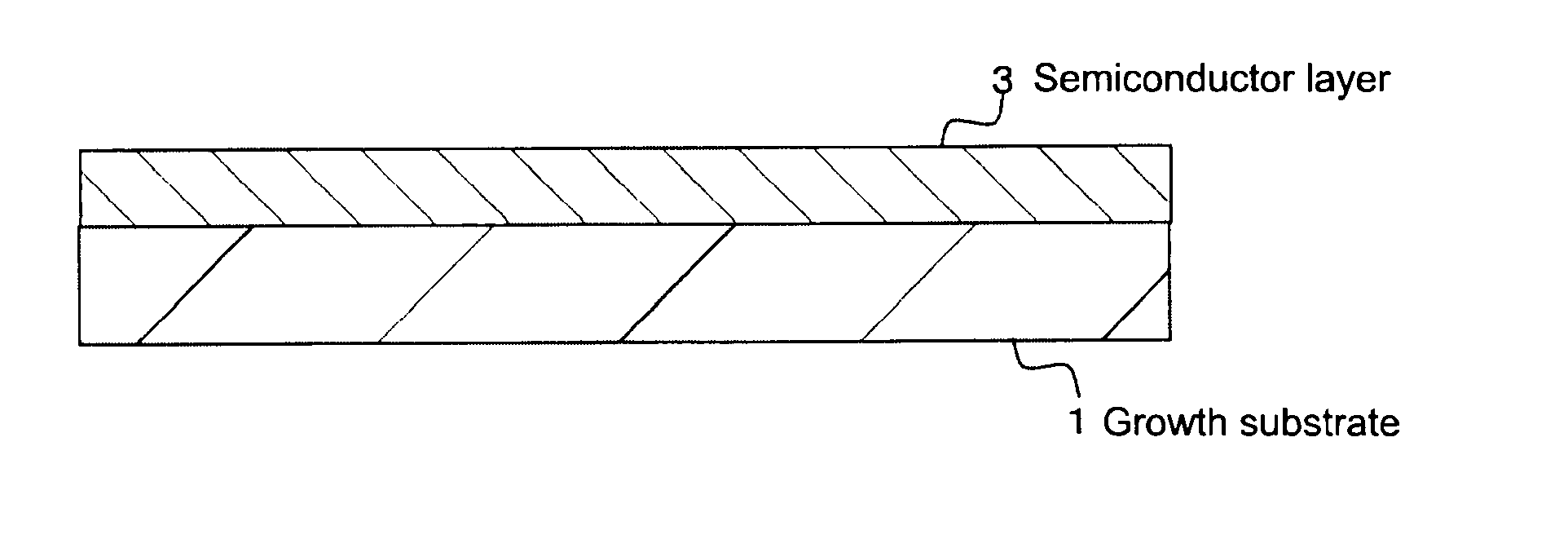

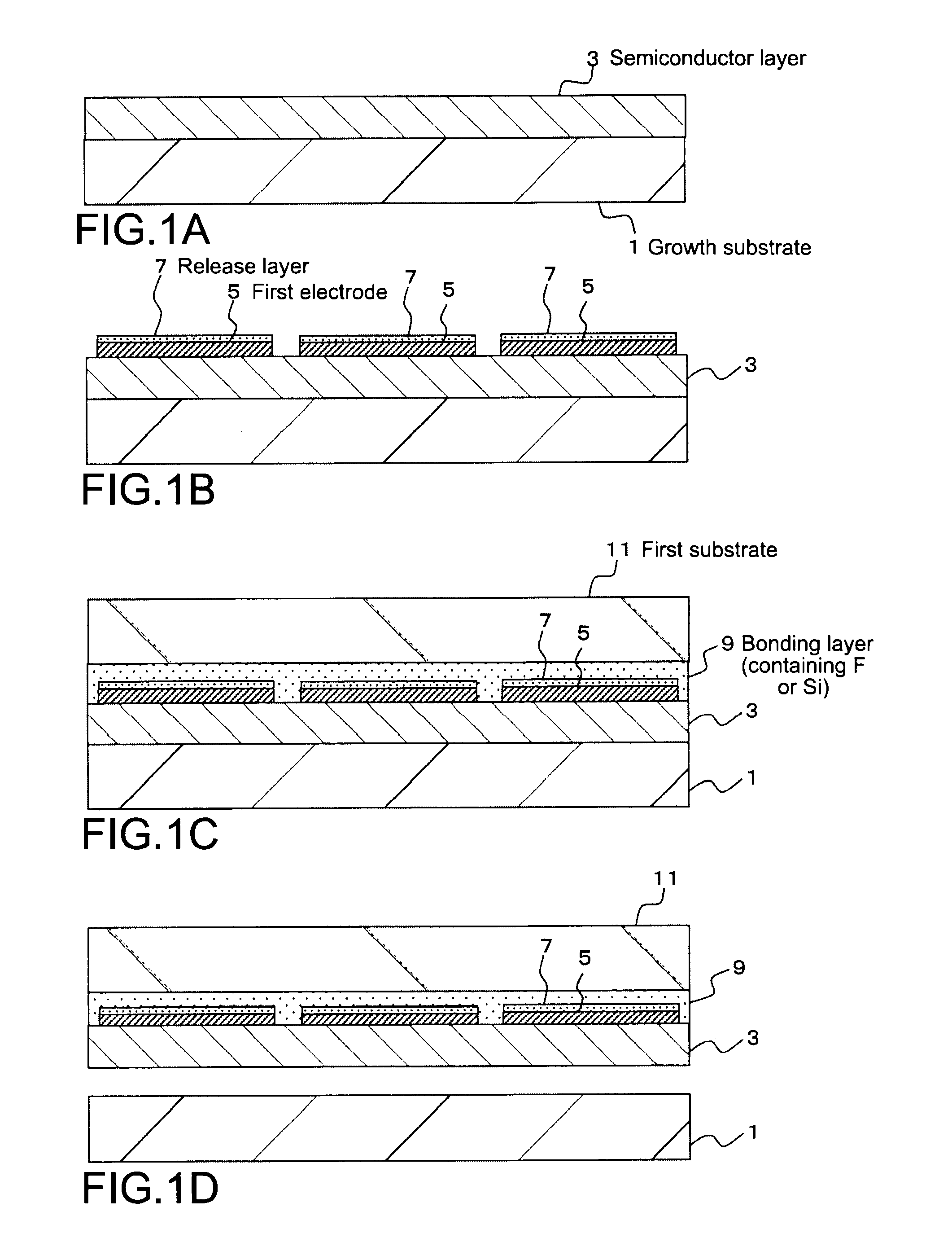

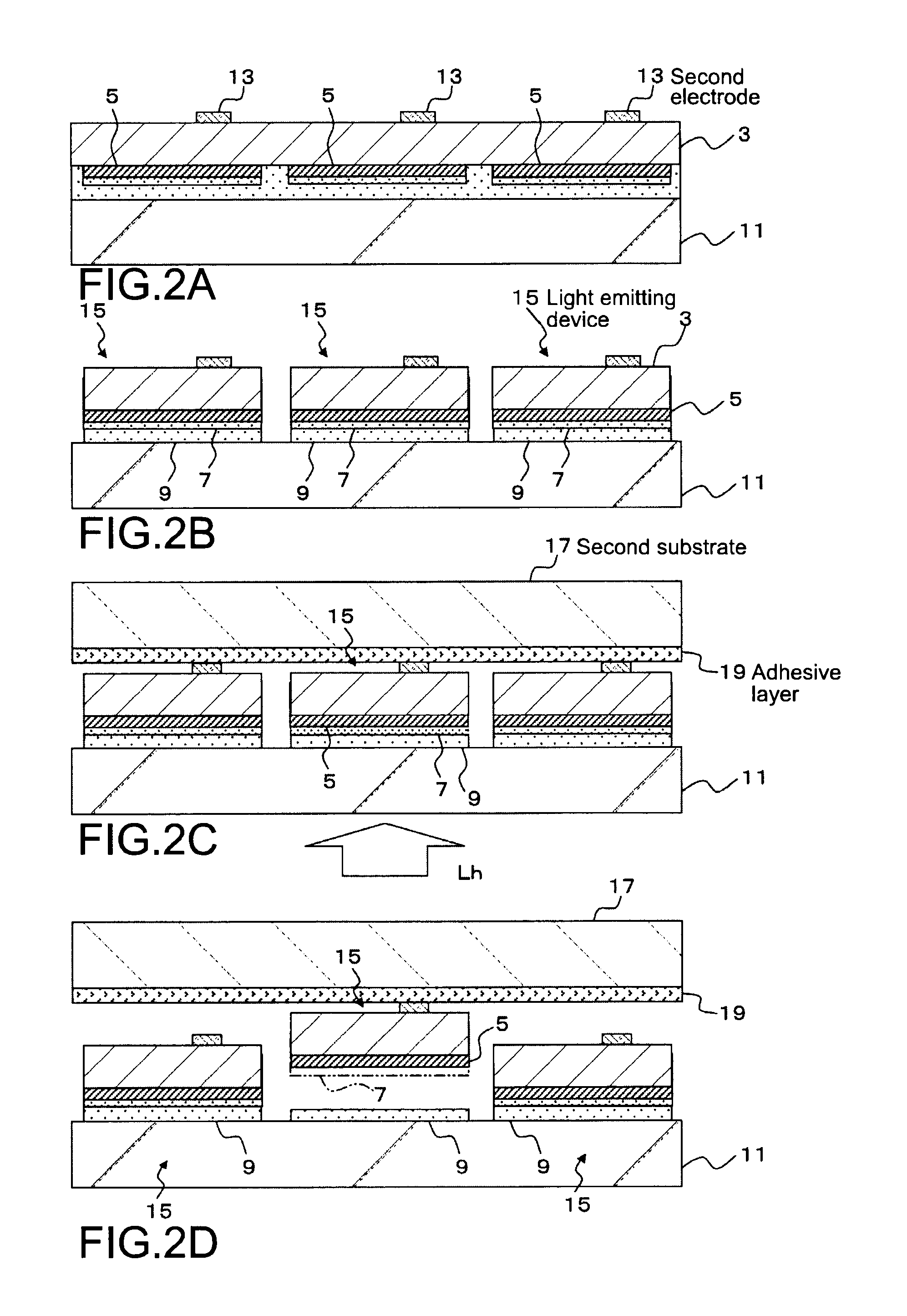

Method of transferring a device and method of manufacturing a display apparatus

InactiveUS20100186883A1Easily ablatedSufficient bonding propertyOrnamental structuresSolid-state devicesLight irradiationOptoelectronics

A method of transferring a device includes: arranging a release layer and a device in the stated lamination order on a first substrate having light transmitting property via a bonding layer having light transmitting property; arranging an adhesive layer formed on a second substrate so that the adhesive layer is opposed to a surface of the first substrate on which the device is arranged; and ablating the release layer by performing light irradiation on the release layer from the first substrate side and transferring the device onto the second substrate with the bonding layer being left on the first substrate.

Owner:SONY CORP

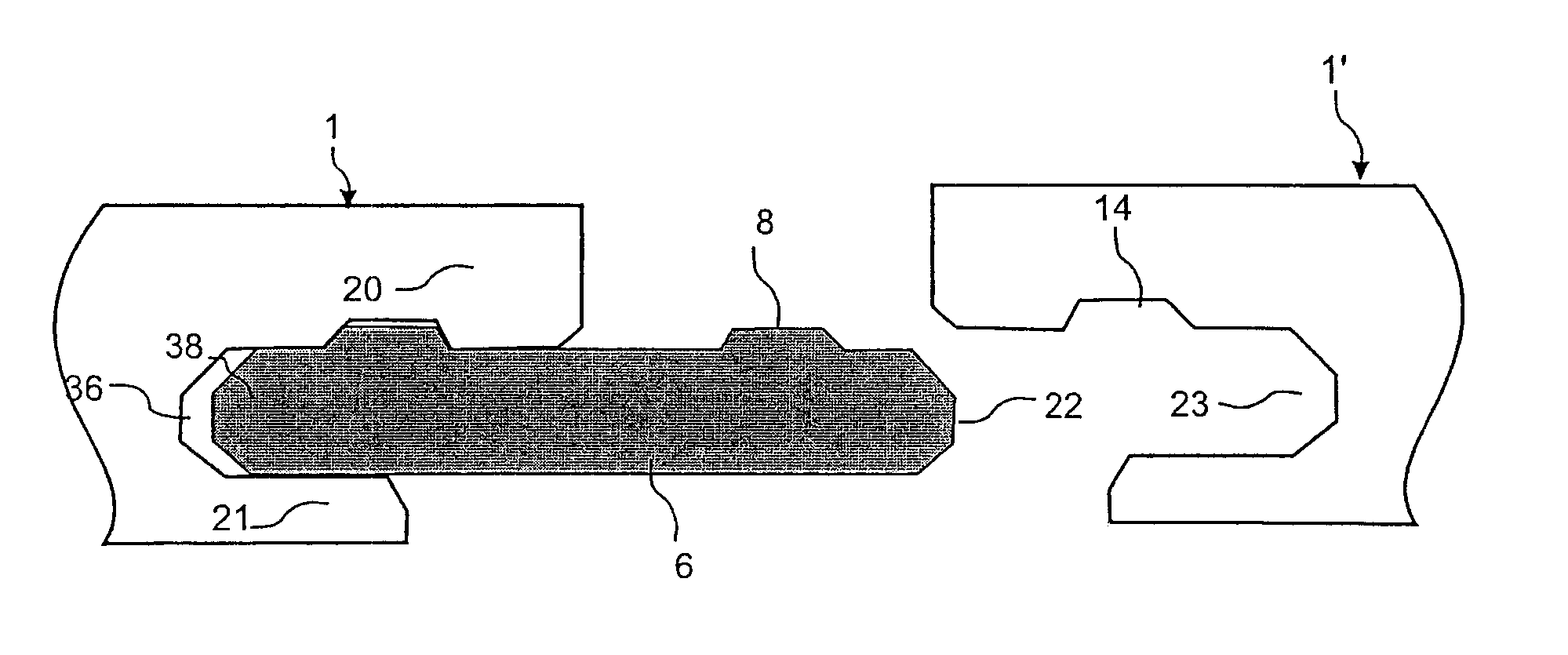

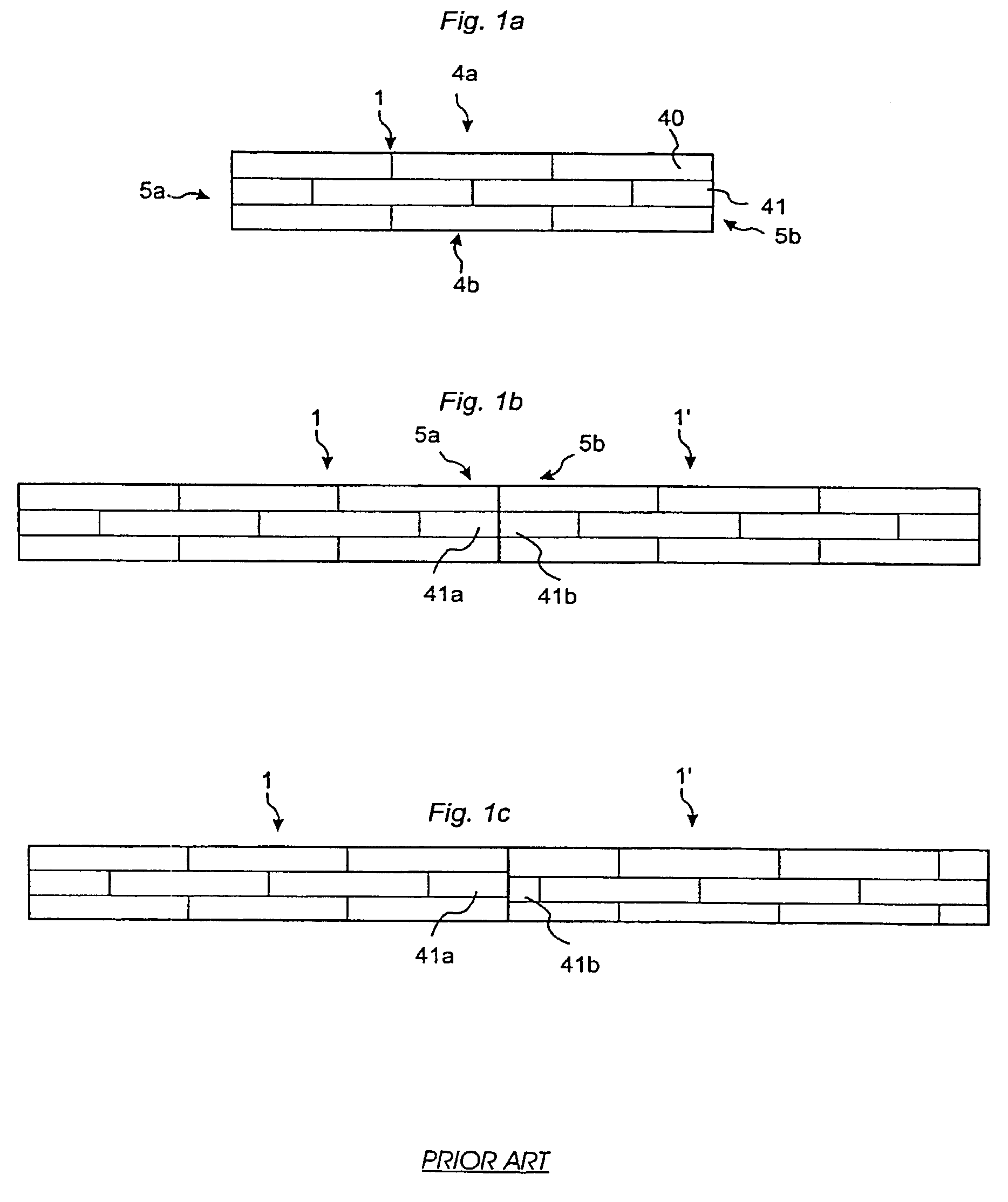

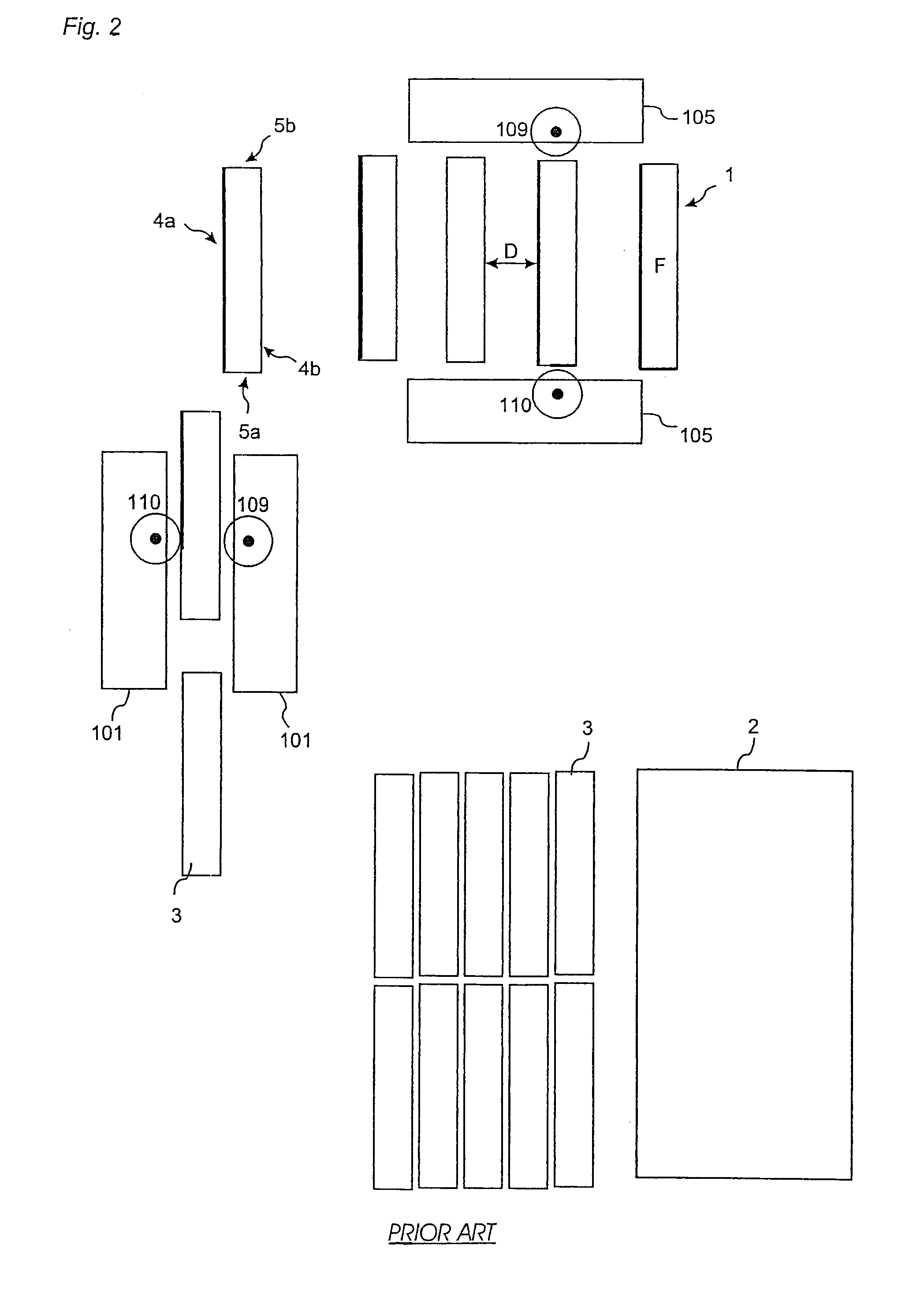

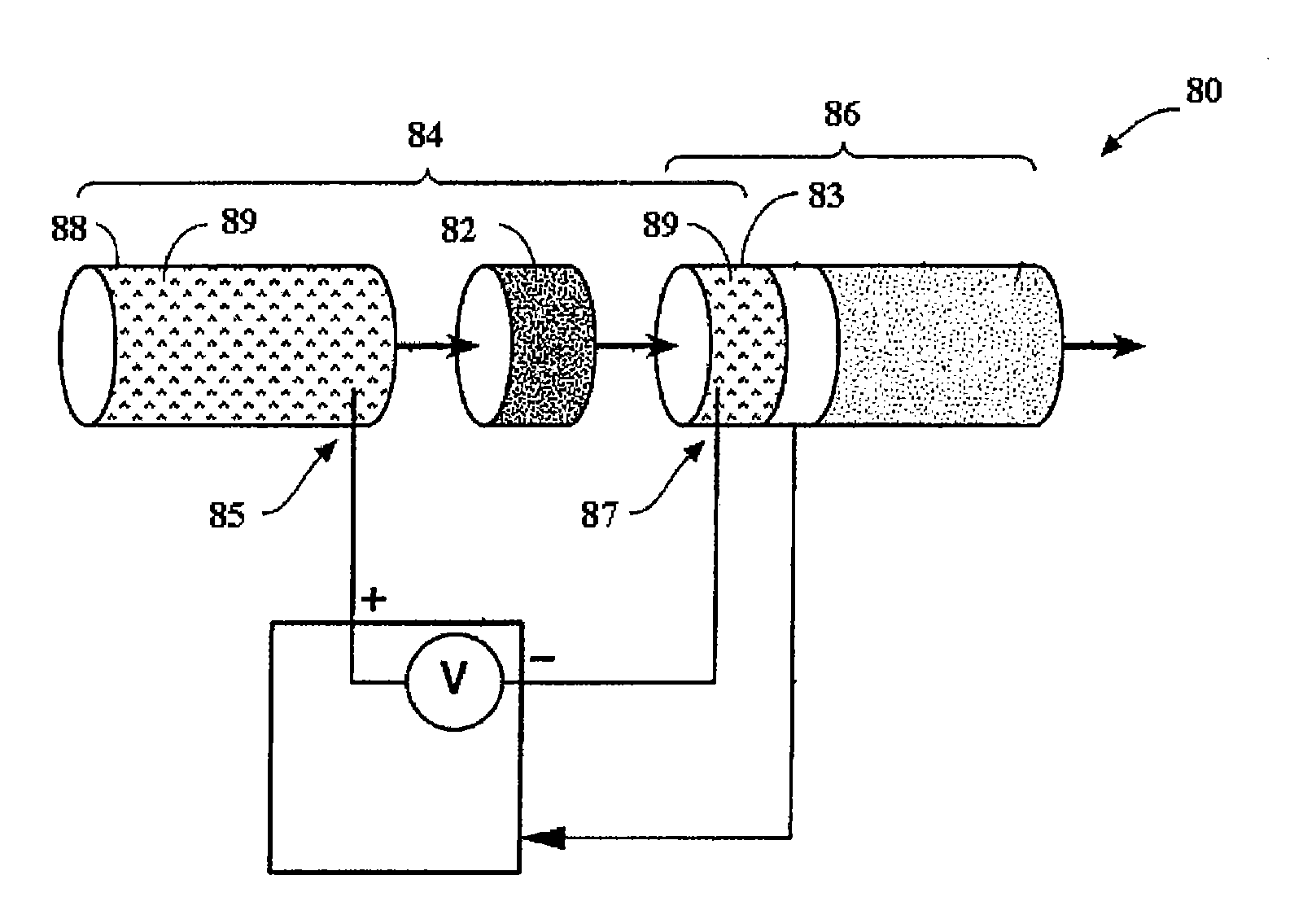

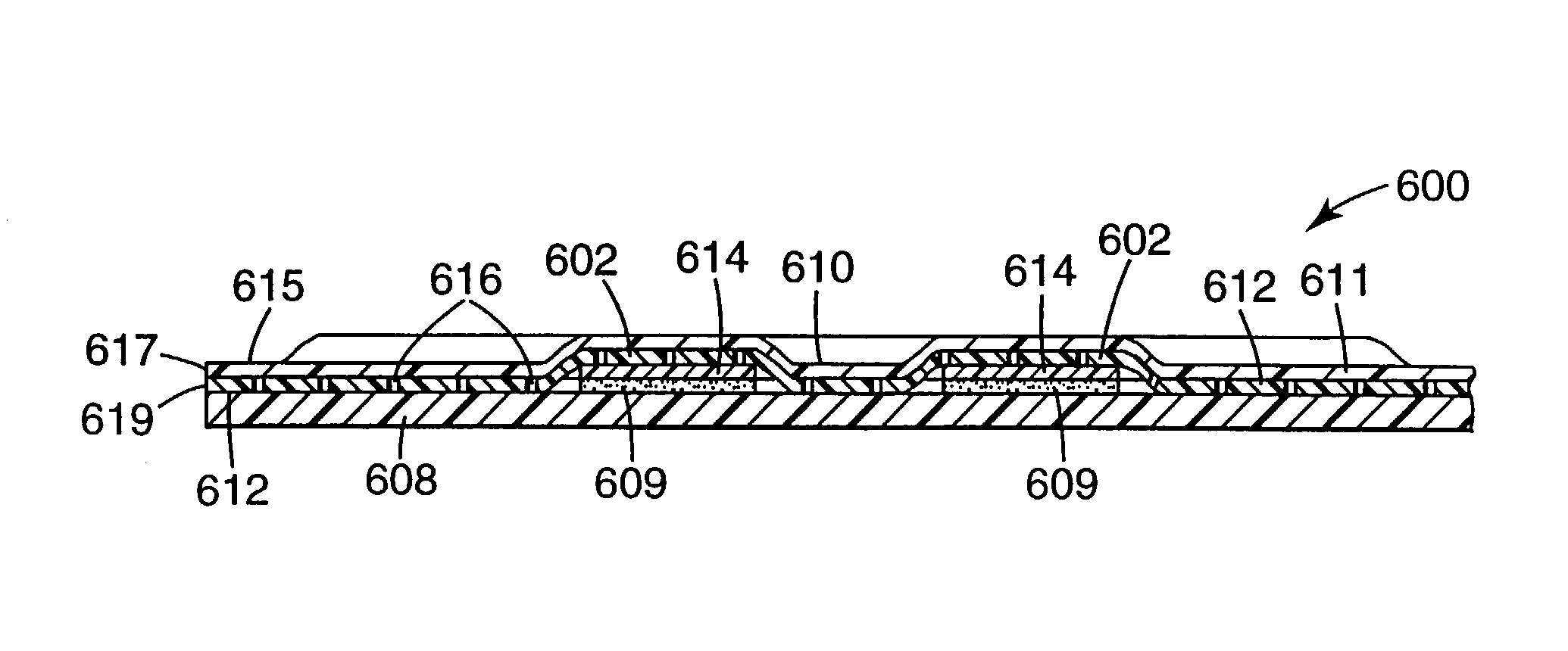

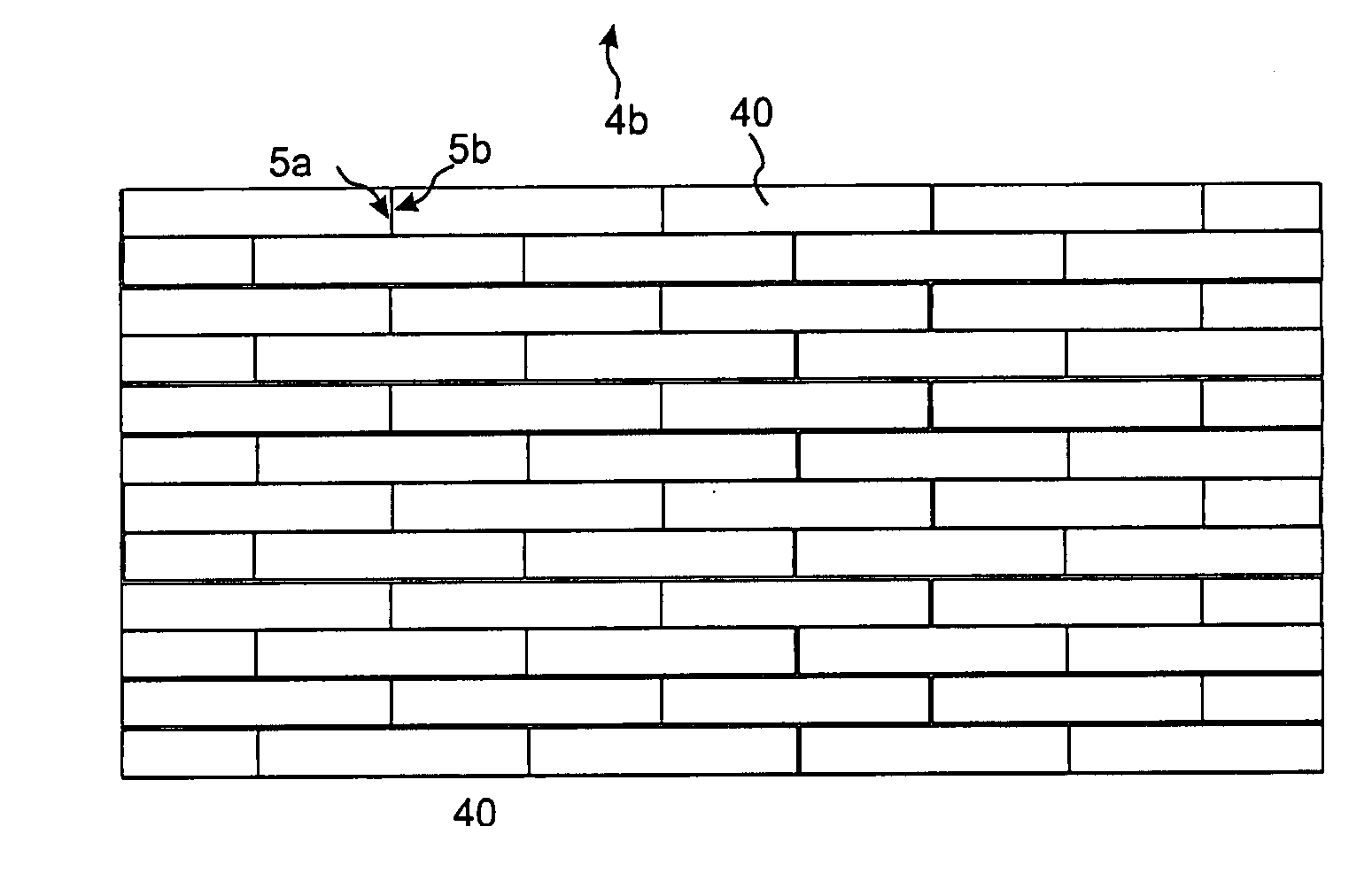

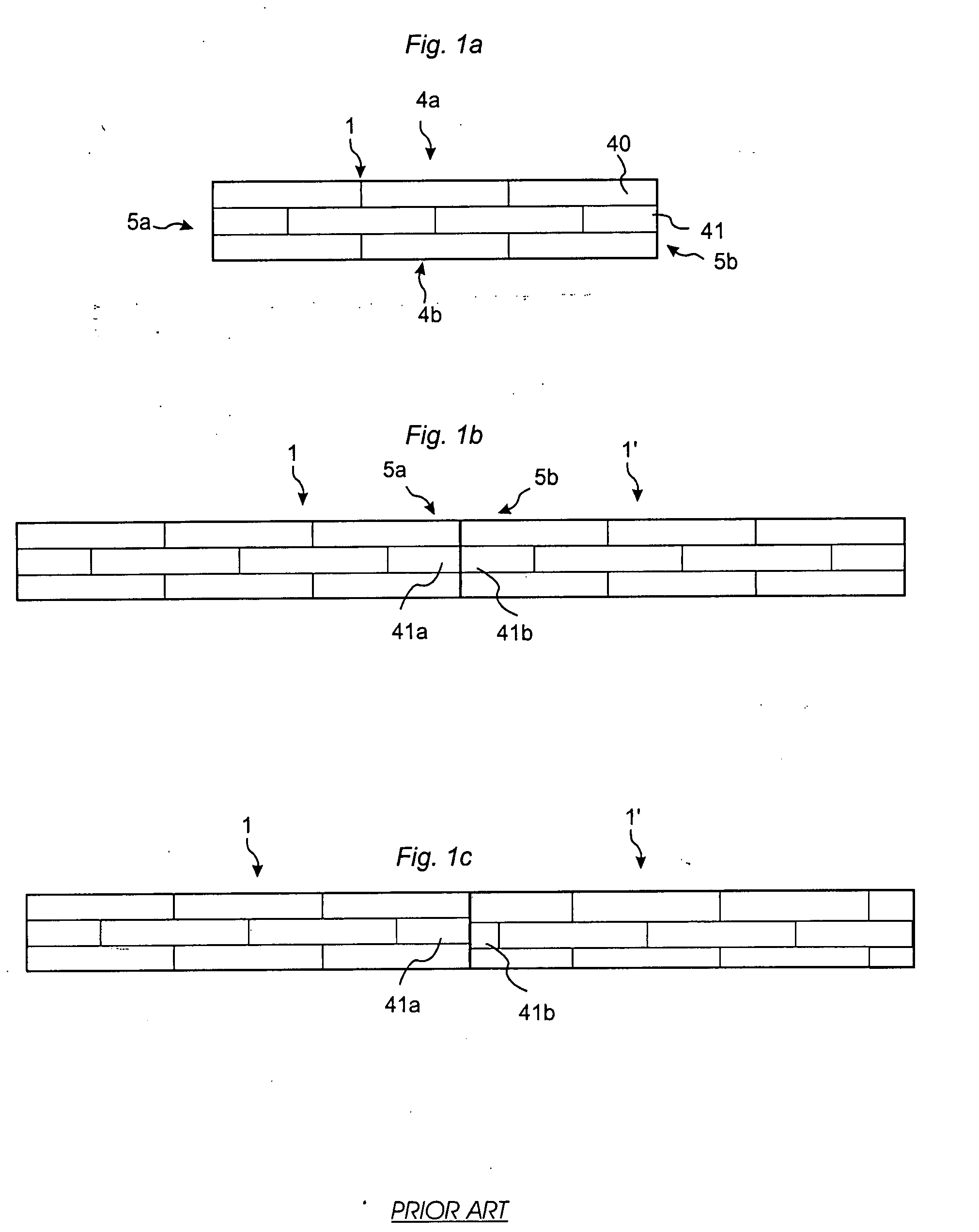

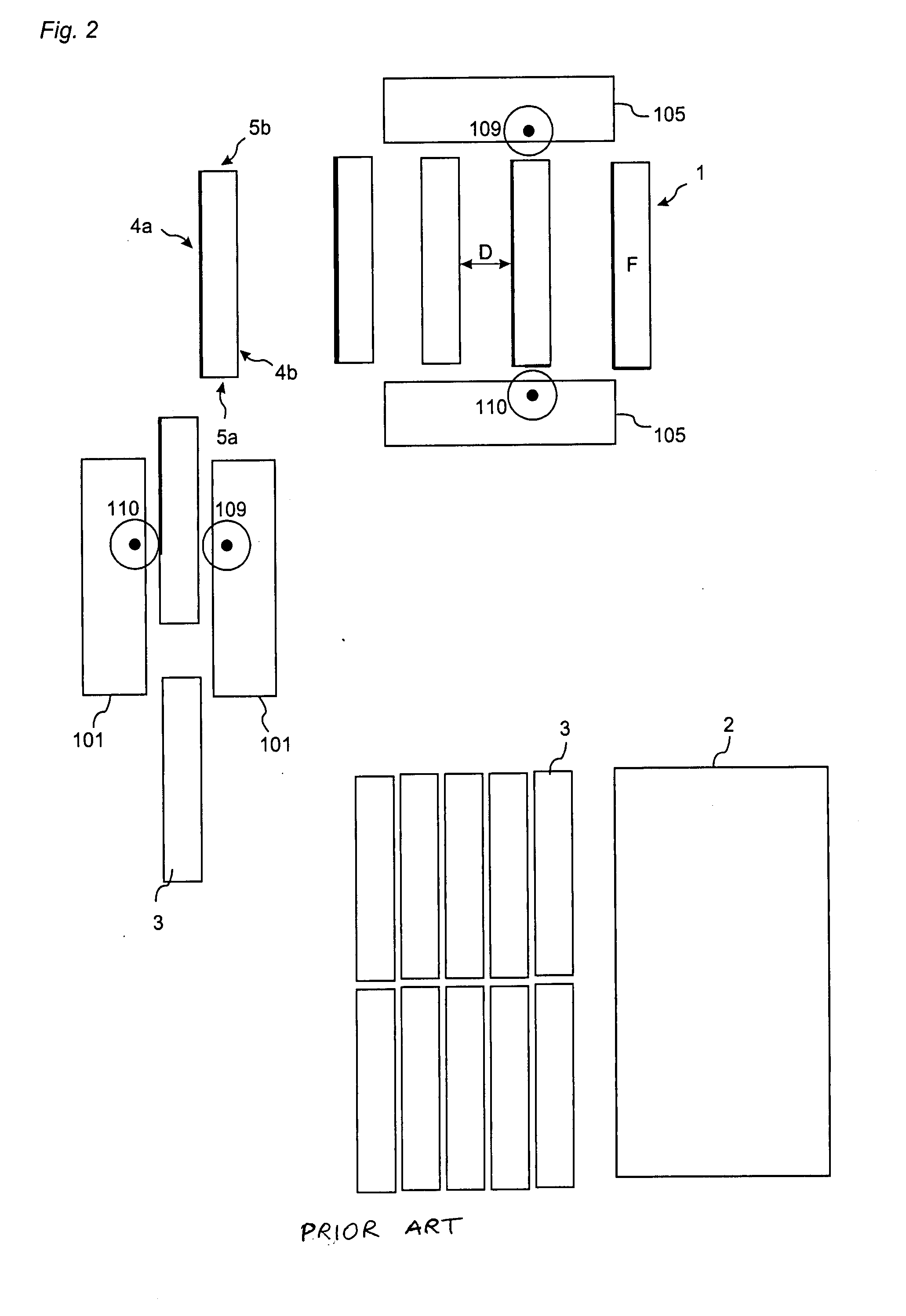

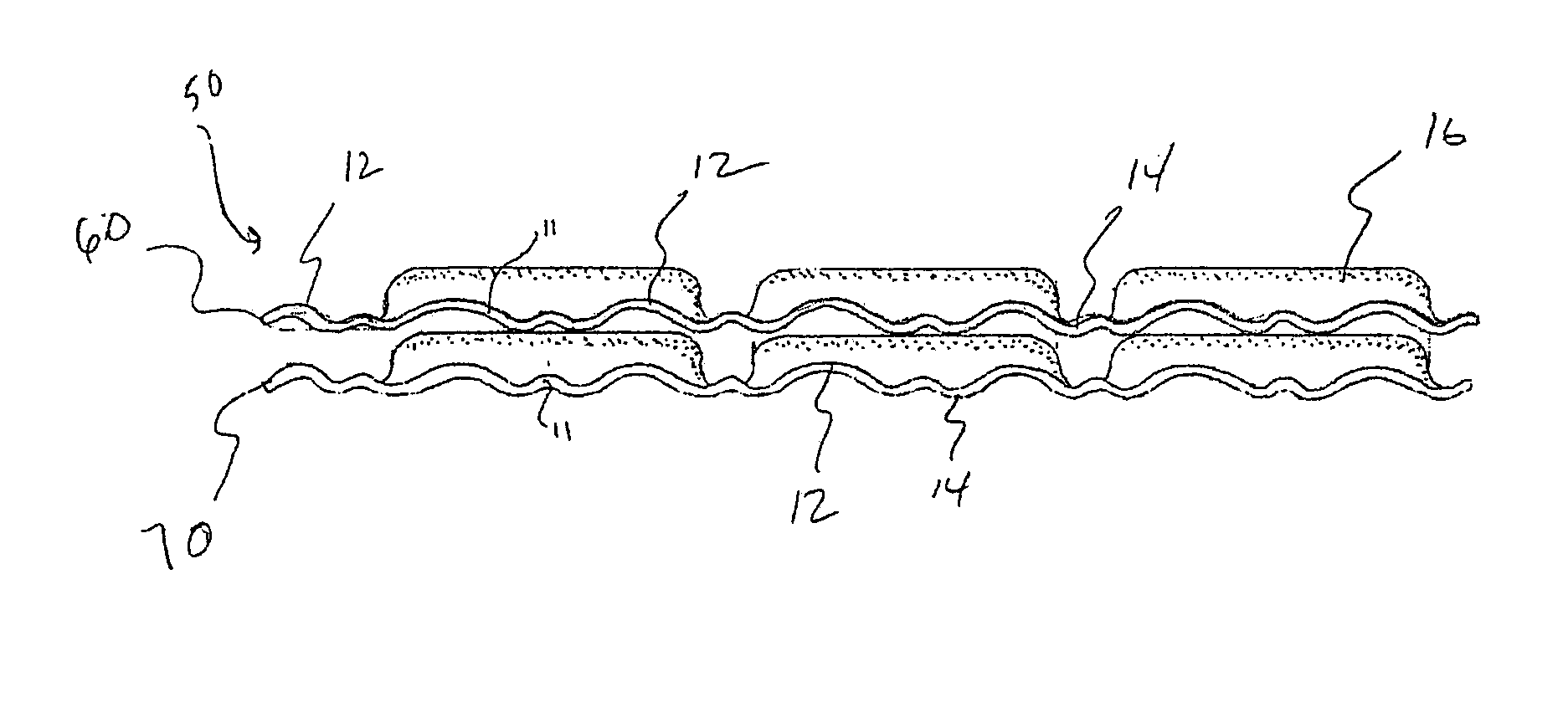

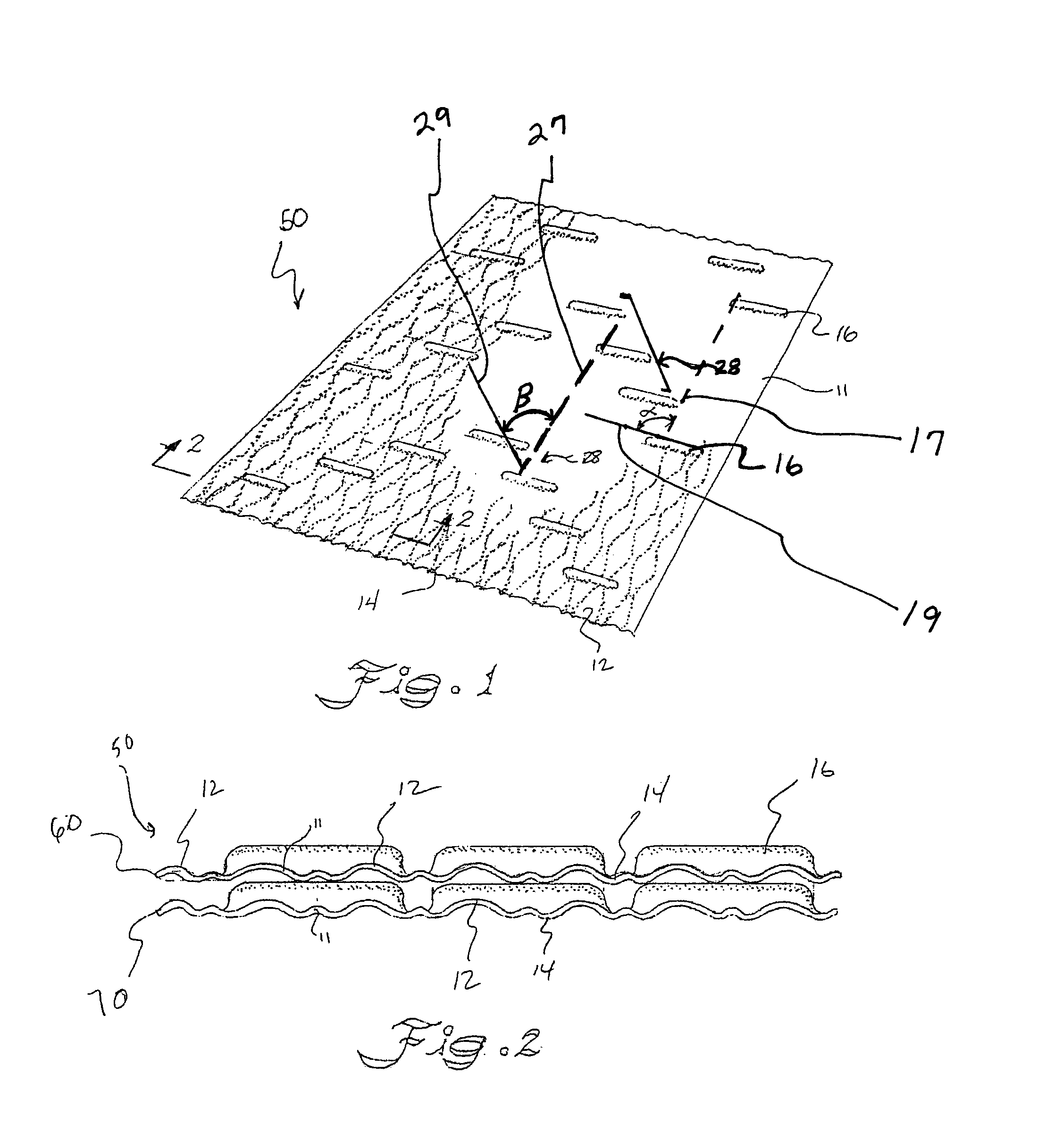

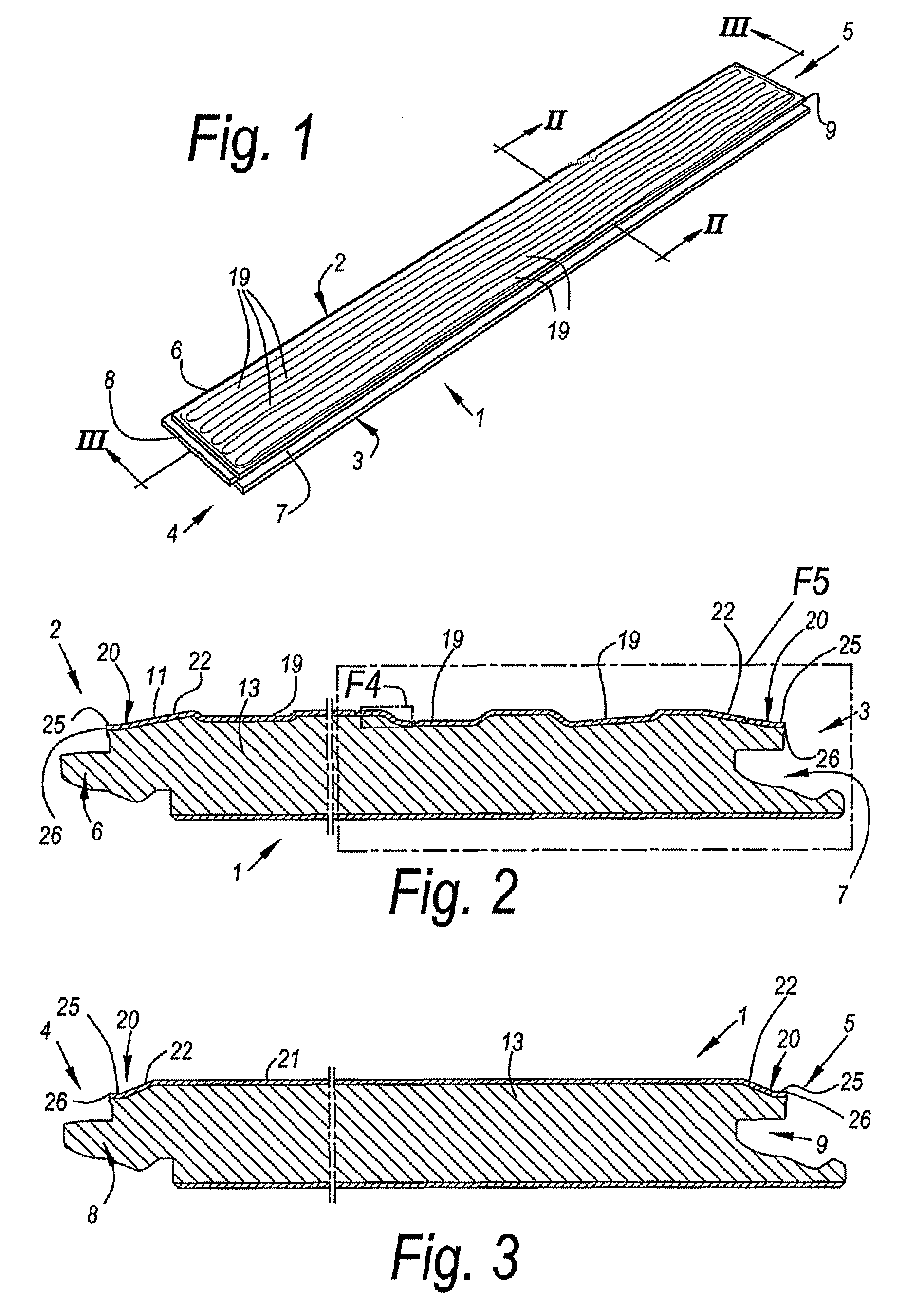

Floorboards, flooring systems and method for manufacturing and installation thereof

InactiveUS20080005998A1Easy to handleSmall floorboardWallsOrnamental structuresSurface layerEngineering

Floorboards with a format corresponding to a traditional parquet block for laying of mechanically joined floating flooring. Rectangular floorboards include a surface layer and a core with two long sides and two short sides, for making a floating flooring, which floorboards are mechanically lockable and which along their four sides have pairs of opposing connectors for locking similar, adjoining floorboards to each other both vertically and horizontally wherein the long sides have a length not exceeding 80 cm and the short sides have a width not exceeding 10 cm.

Owner:VÄLINGE INNOVATION AB

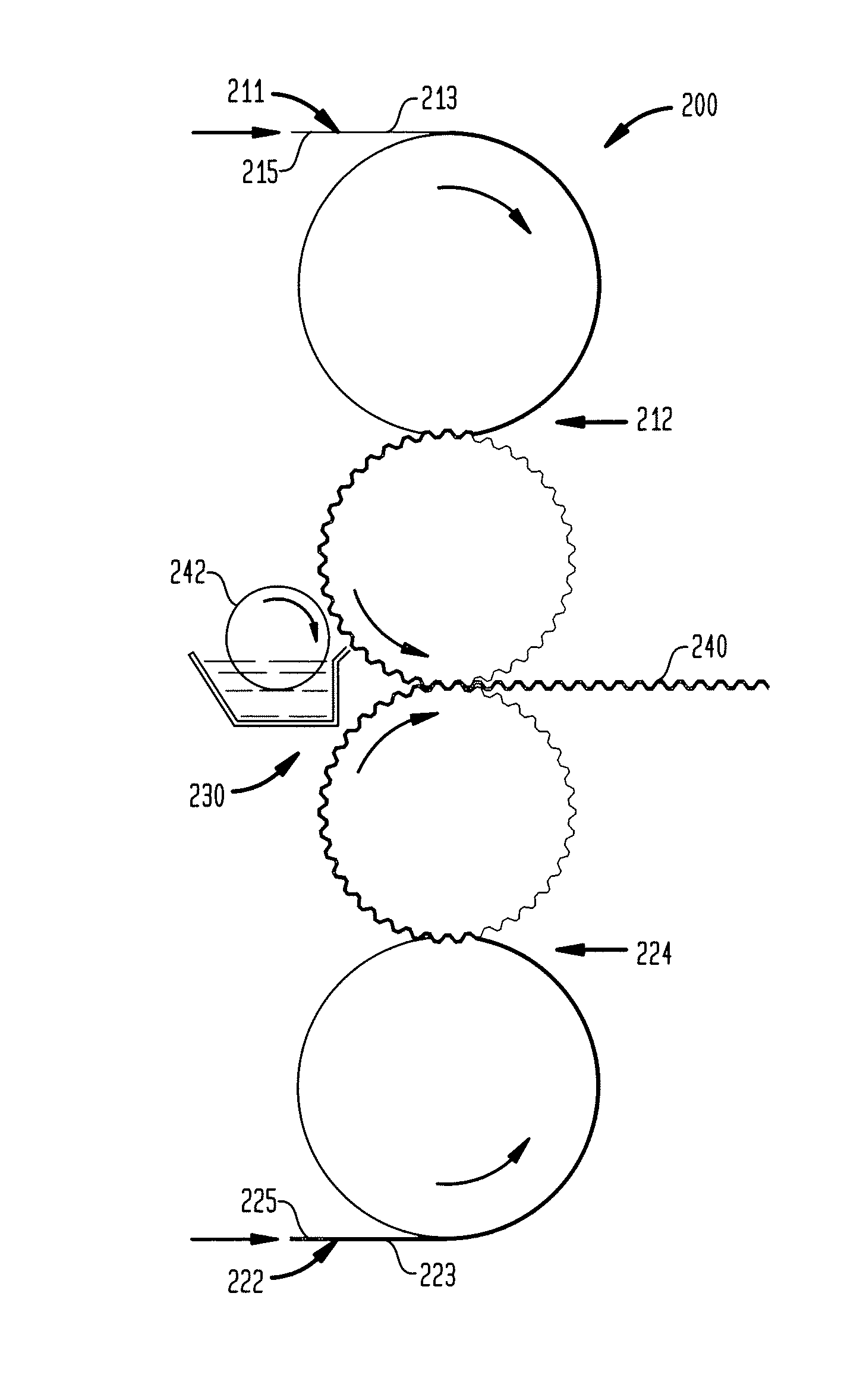

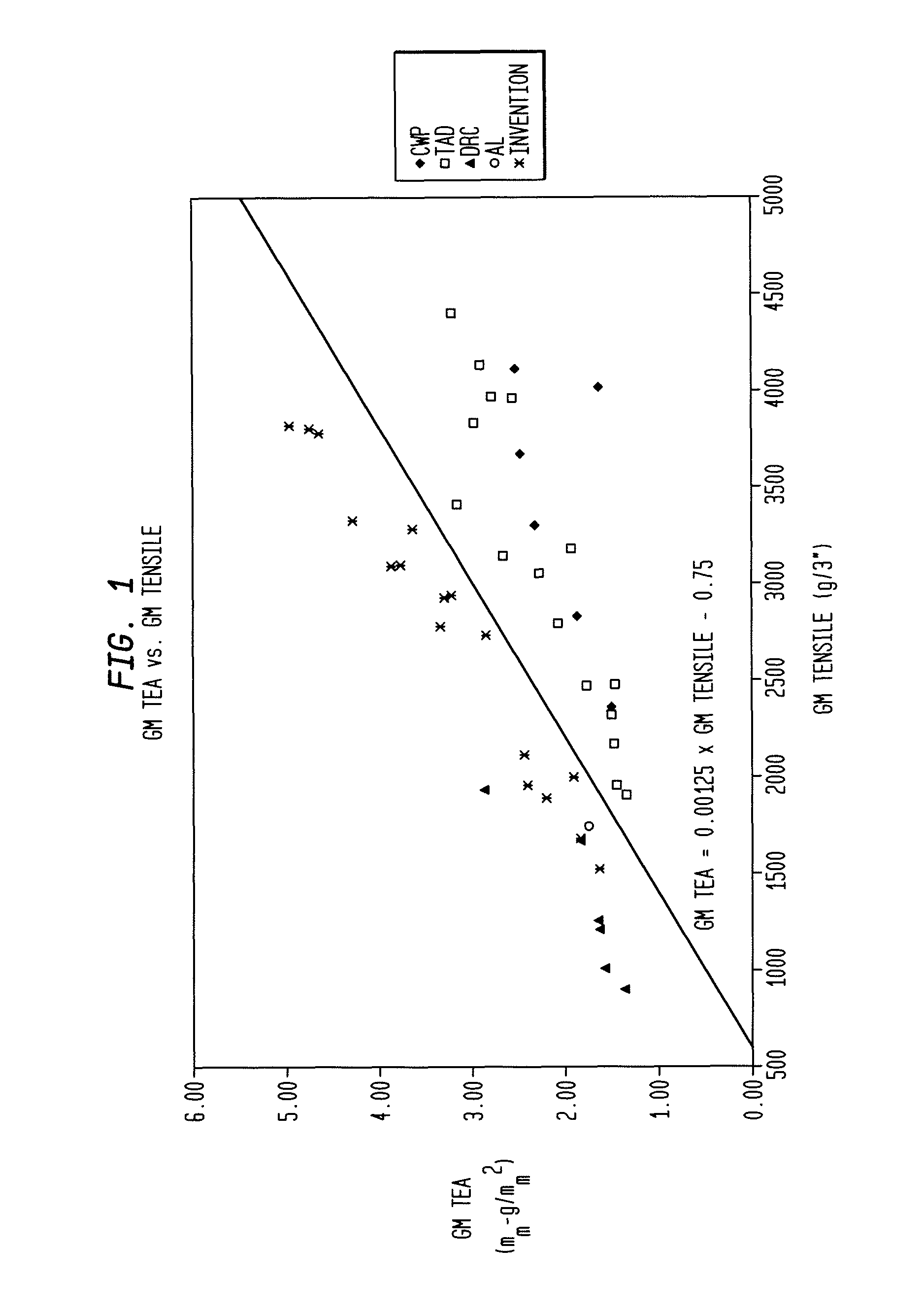

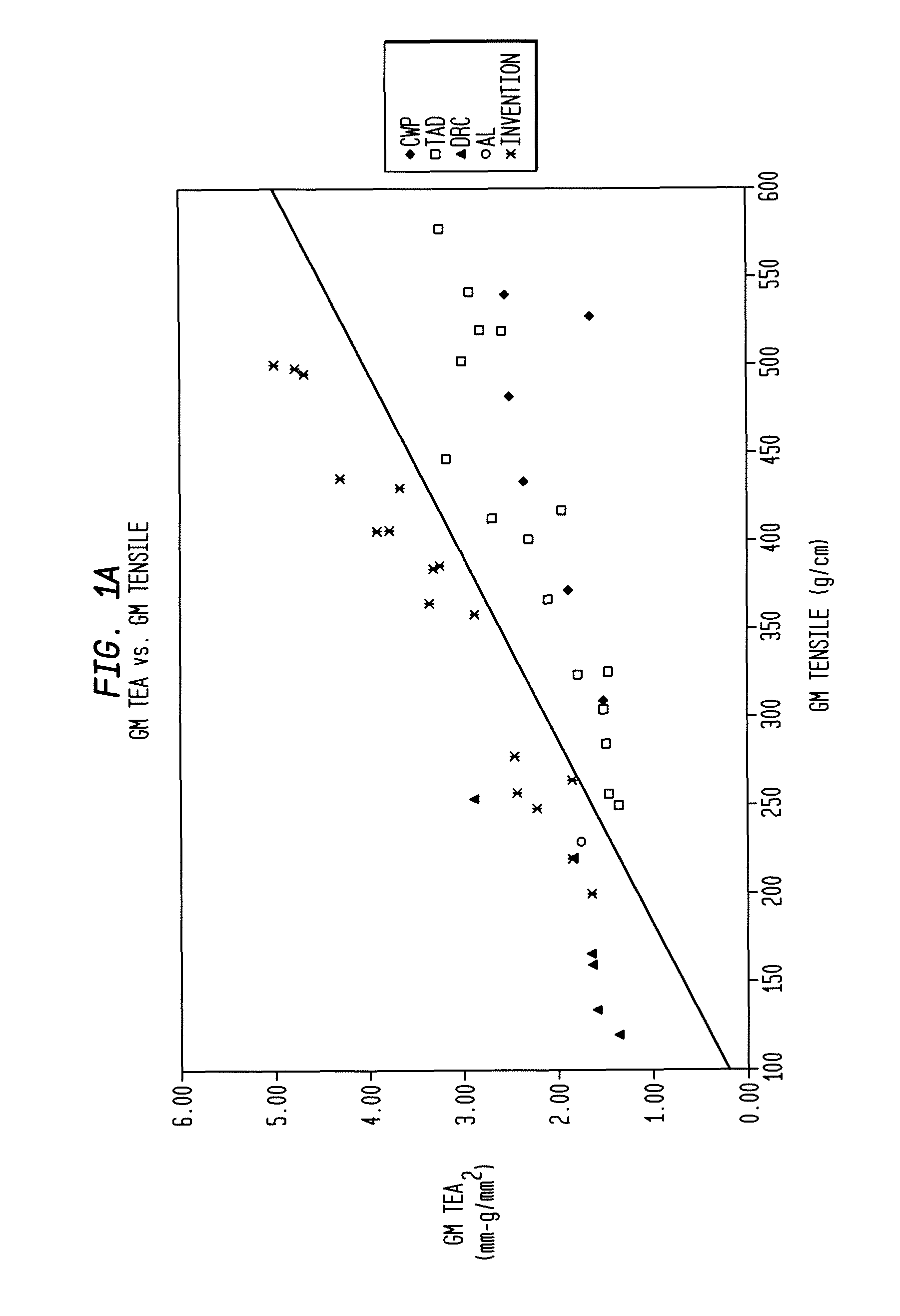

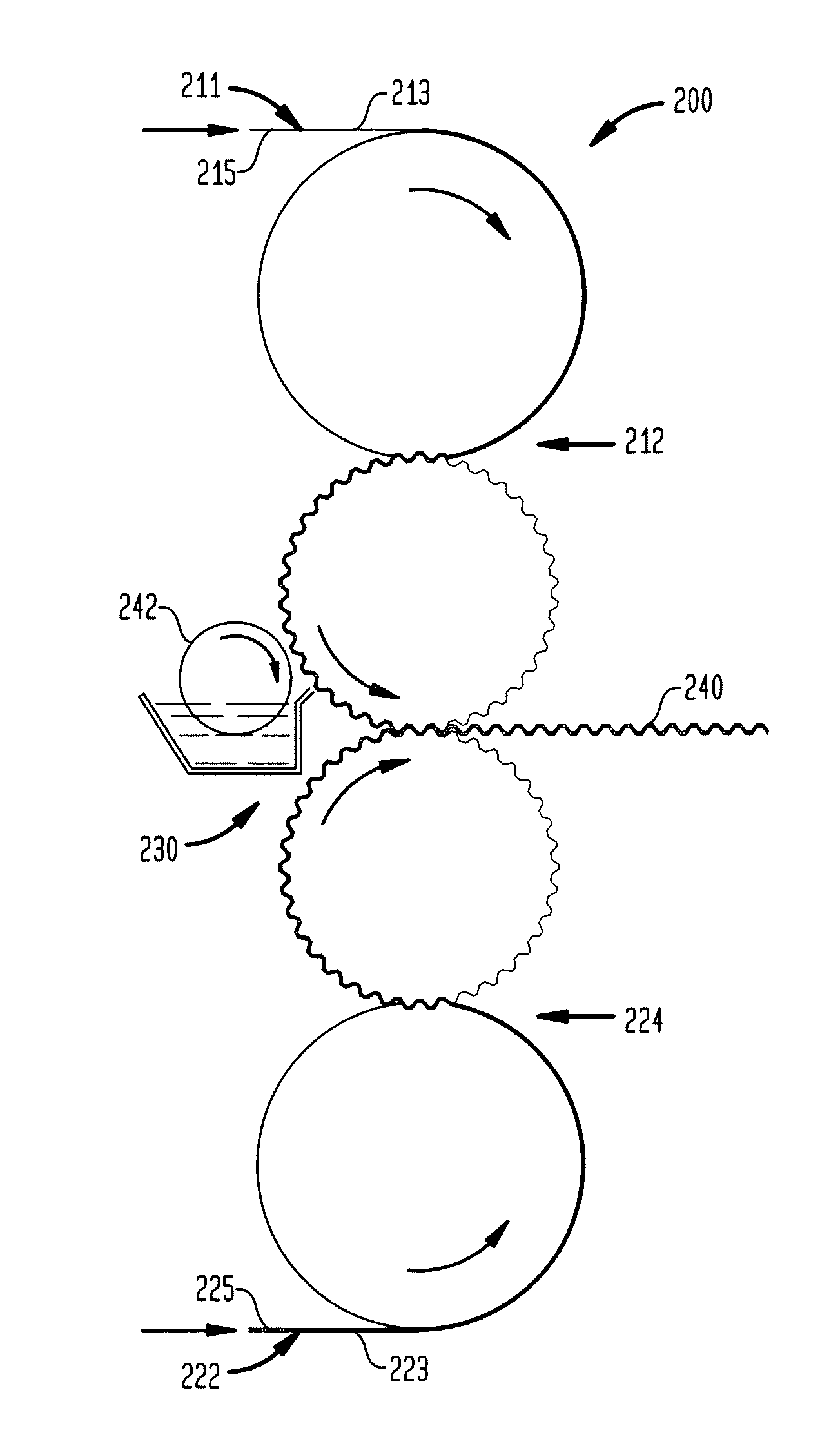

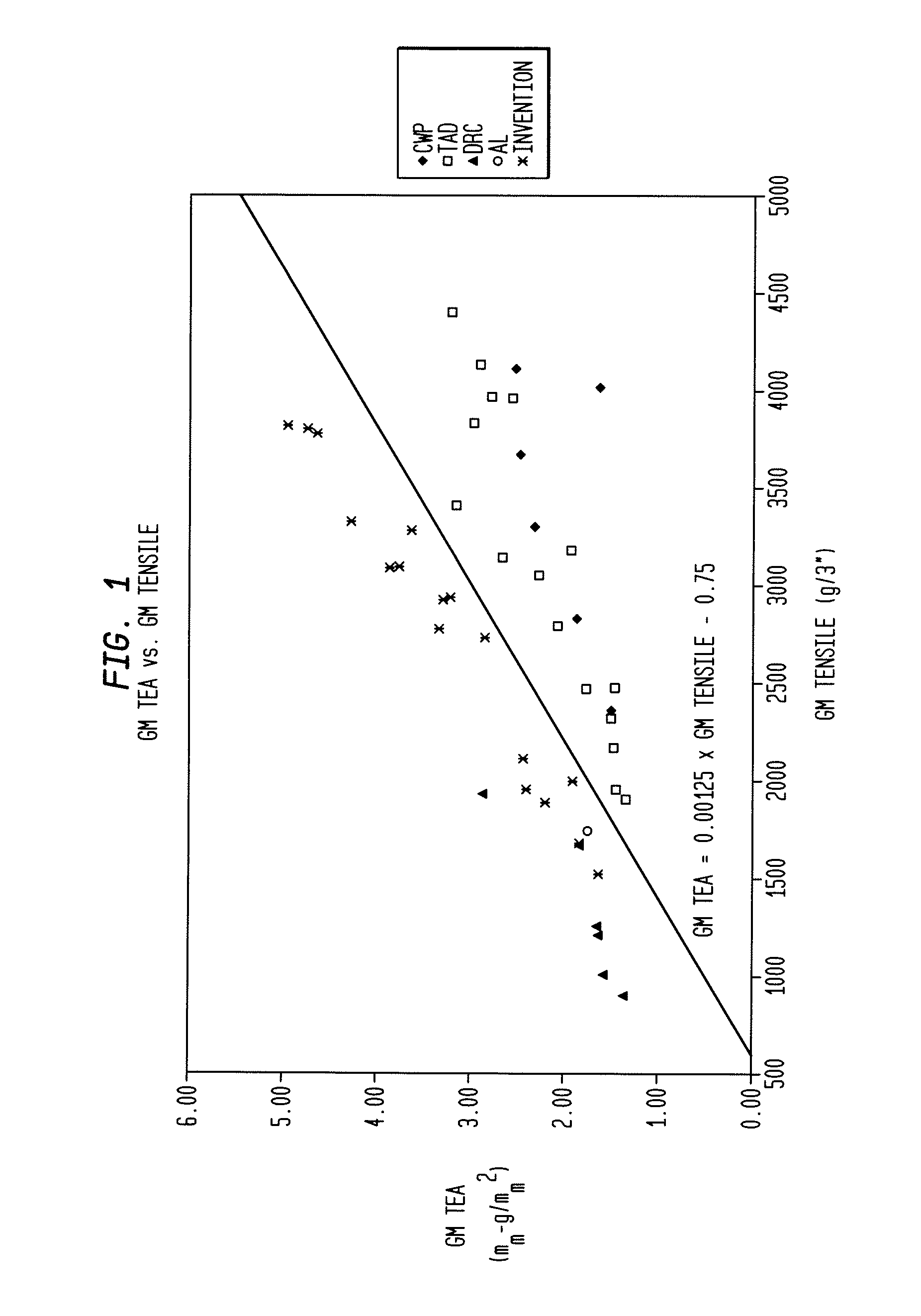

Multi-ply paper towel with creped plies

ActiveUS8409404B2Improve toughnessHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaper towel

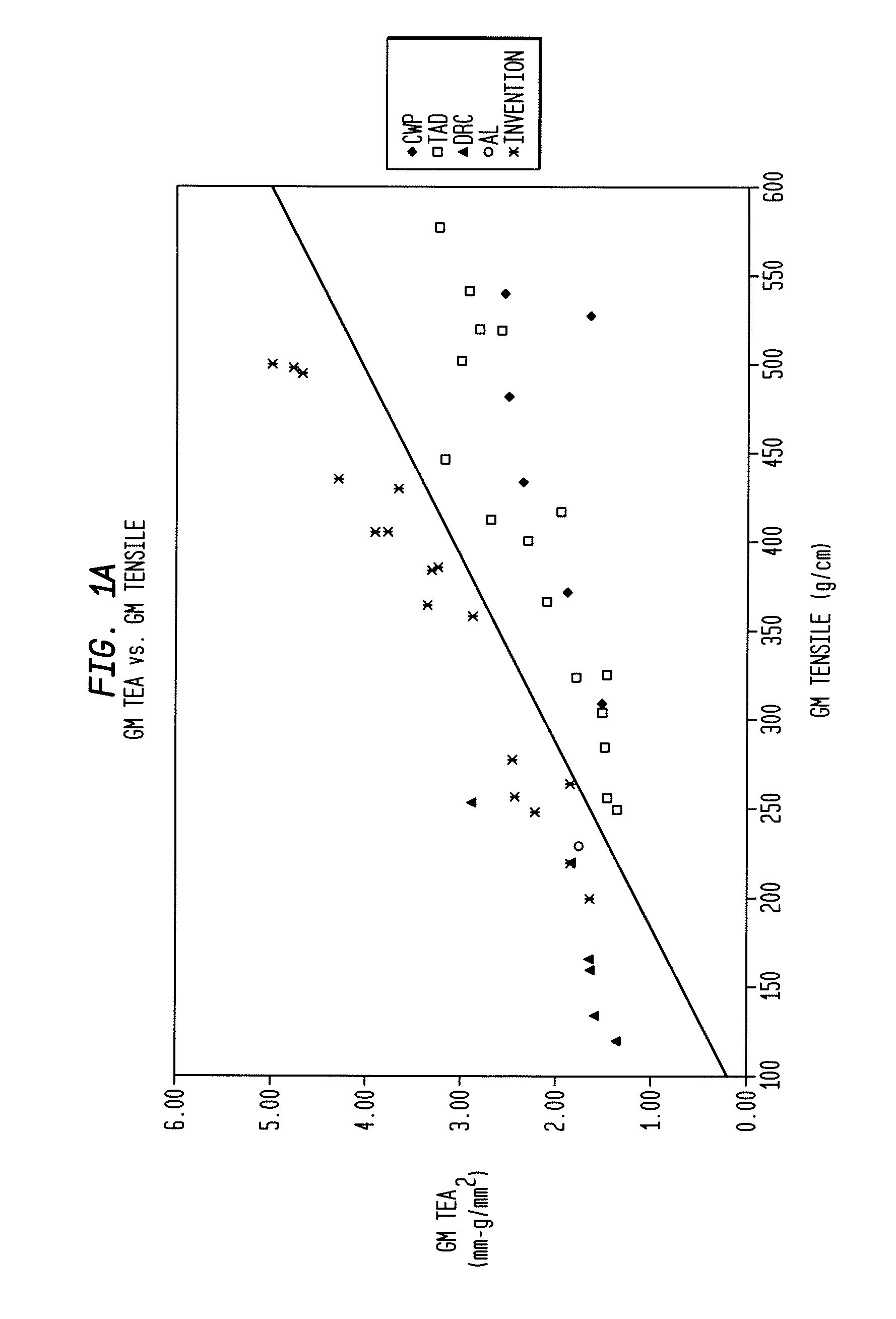

A multi-ply absorbent towel made from papermaking fiber comprising at least a first ply and a second ply bonded together, the towel having a basis weight of greater than 30 lbs per 3000 ft2 ream (48.8 gsm) and less than 50 lbs per 3000 ft2 ream (81.4 gsm), wherein the plies are selected and adhered together such that the towel typically exhibits (i) a GM TEA, mm-g / mm2 of greater than [0.00125 (GM Tensile, g / 3″)−0.75] and (ii) a GM Tensile Modulus, g / in / %, less than [0.0083 (GM Tensile Strength, g / 3″)+15.4] {(i) a GM TEA, mm g / mm2, of greater than [0.00952 (GM Tensile, g / cm)−0.75] and (ii) a GM Tensile Modulus, g / cm / %, less than [0.0249 (GM Tensile Strength, g / cm)+6.06}.

Owner:GPCP IP HLDG LLC

Electrically conductive compositions and method of manufacture thereof

A method for manufacturing a conductive composition comprises blending a polymer precursor with a single wall carbon nanotube composition; and polymerizing the polymer precursor to form an organic polymer. The method may be advantageously used for manufacturing automotive components, computer components, and other components where electrical conductivity properties are desirable.

Owner:SABIC INNOVATIVE PLASTICS IP BV

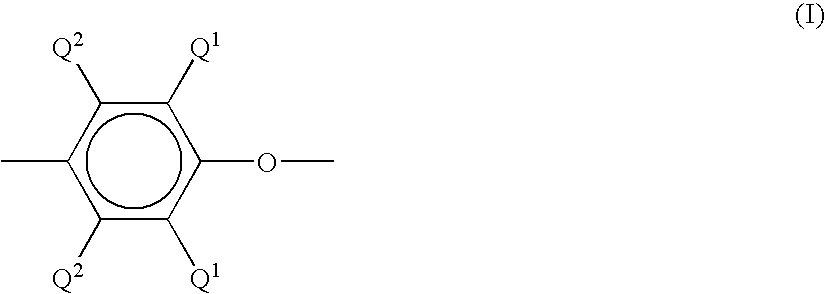

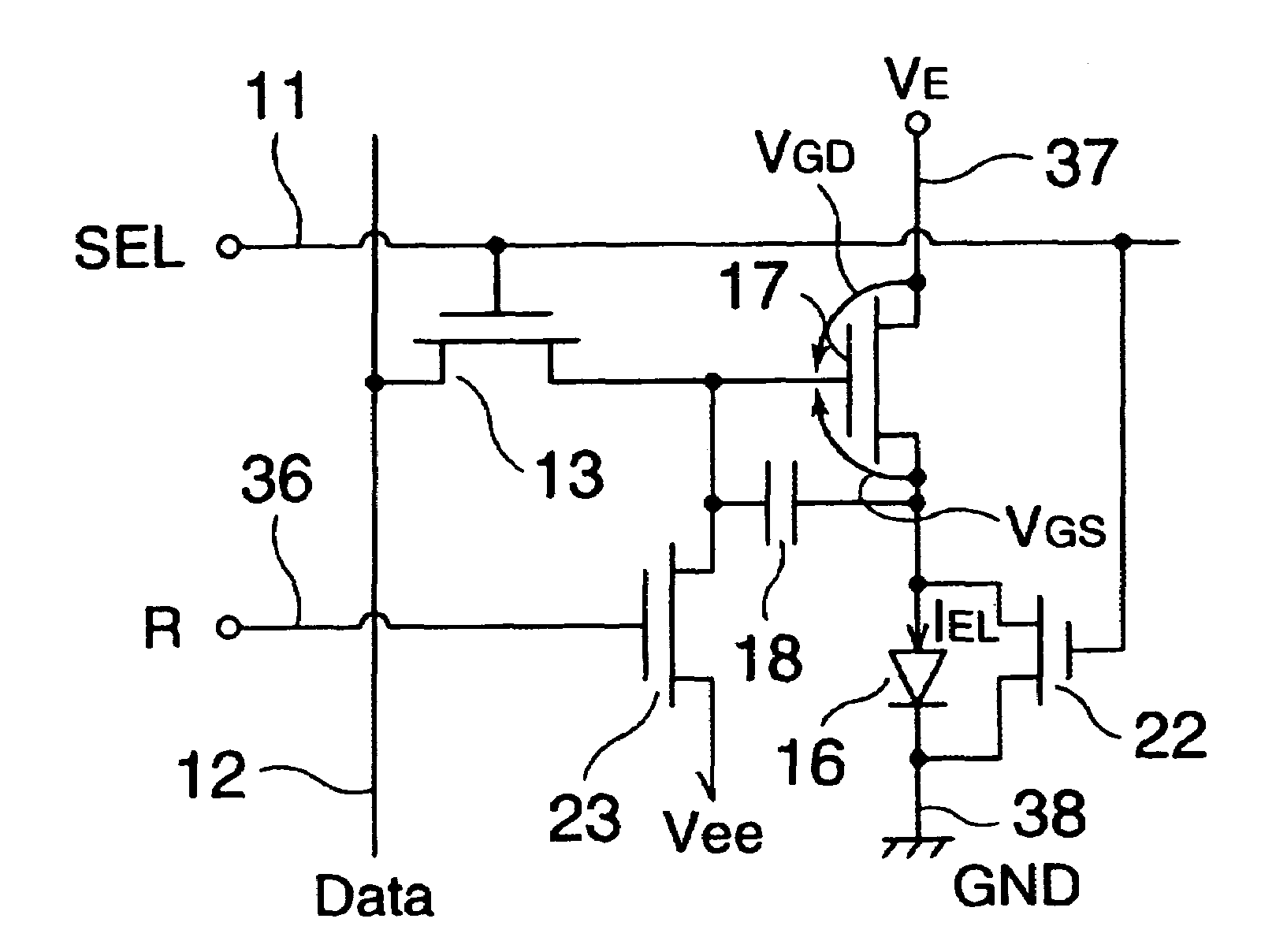

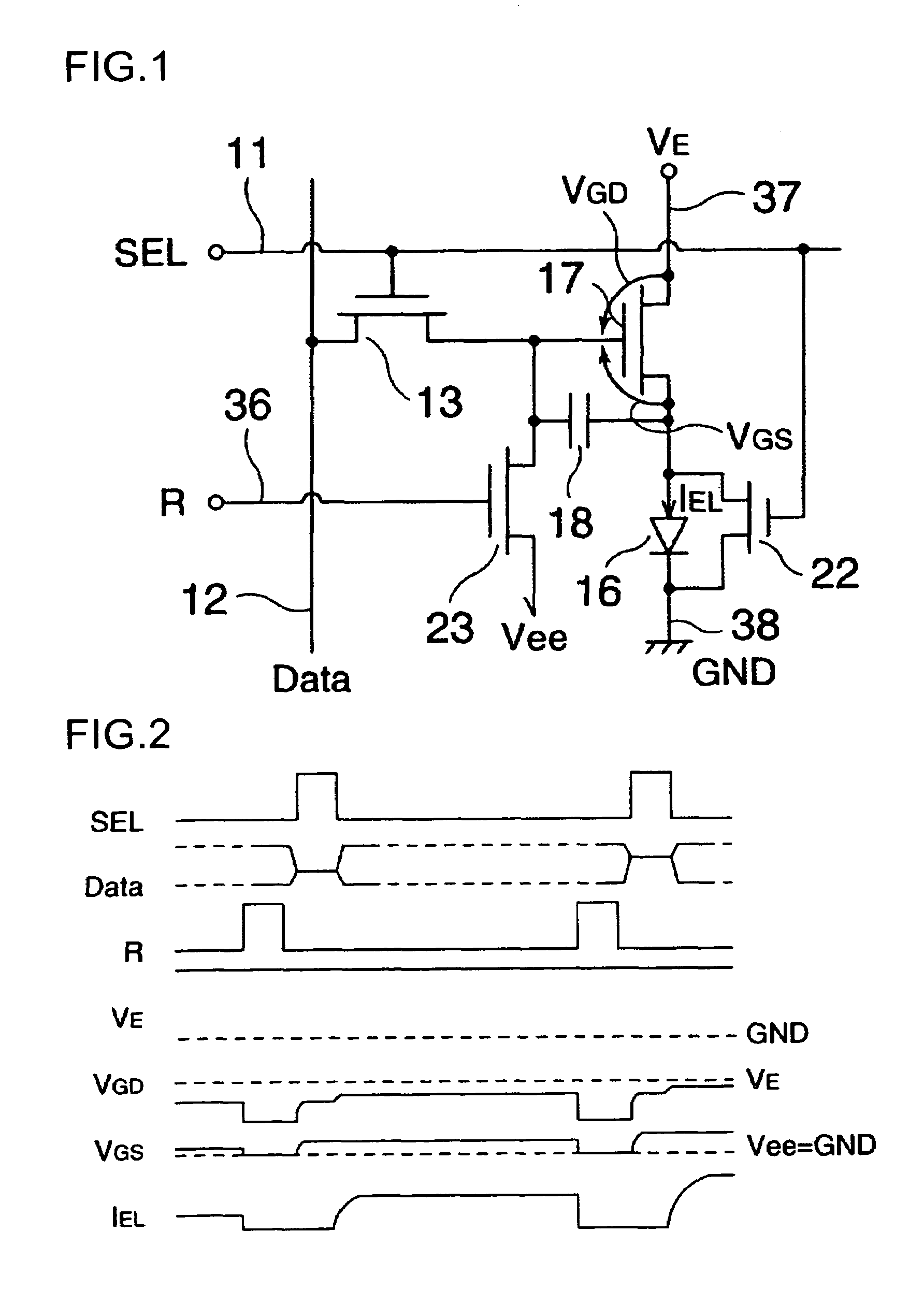

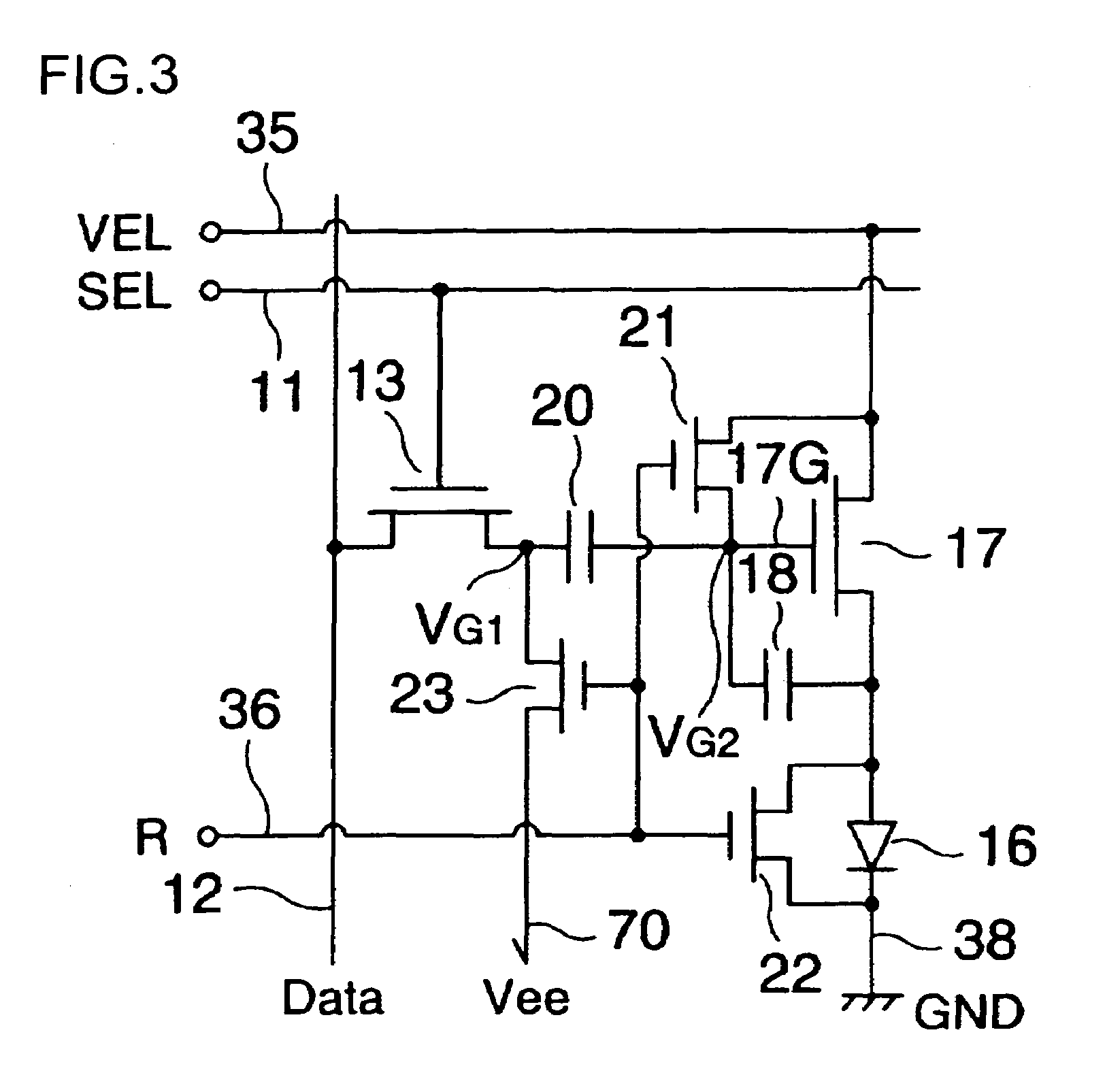

Electro-optical device and driving device thereof

ActiveUS7274345B2Improve display qualityMore accuracyDecorative surface effectsElectroluminescent light sourcesDriving currentDriven element

The invention provides an electro-optical device having circuits for driving electro-optical elements, such as organic EL elements, and a driving device, which can employ driving elements having low driving ability, such as α-TFTs. By providing a charge storage capacitor between the source electrode and the gate electrode of a driving transistor which is between power sources, the electro-optical device can allow the driving transistor to control a driving current, even when an electro-optical element is connected to the source side of the driving transistor. In addition, driving data can be stored in the charge storage capacitor by applying a predetermined voltage to the source electrode of the driving transistor.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

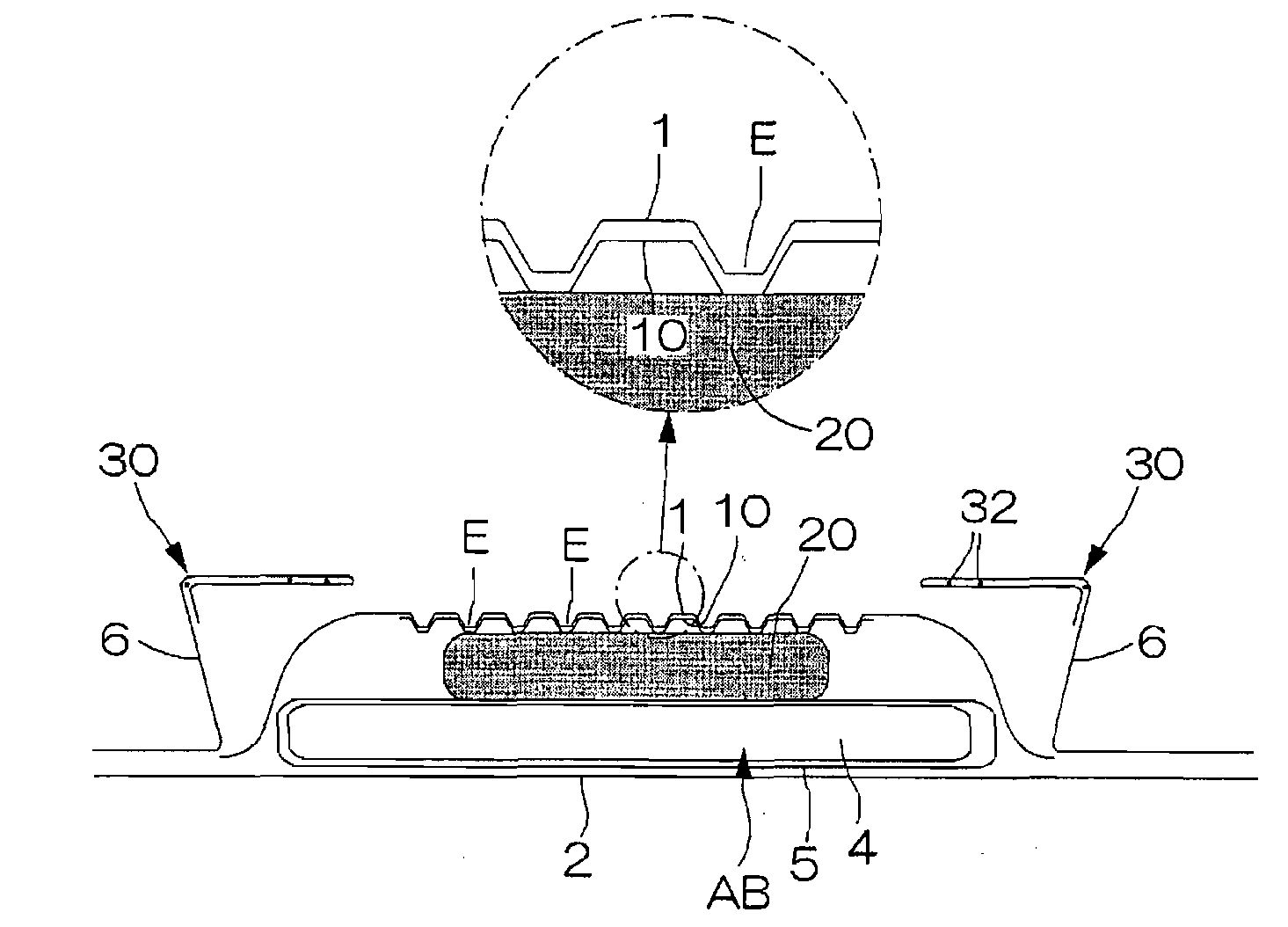

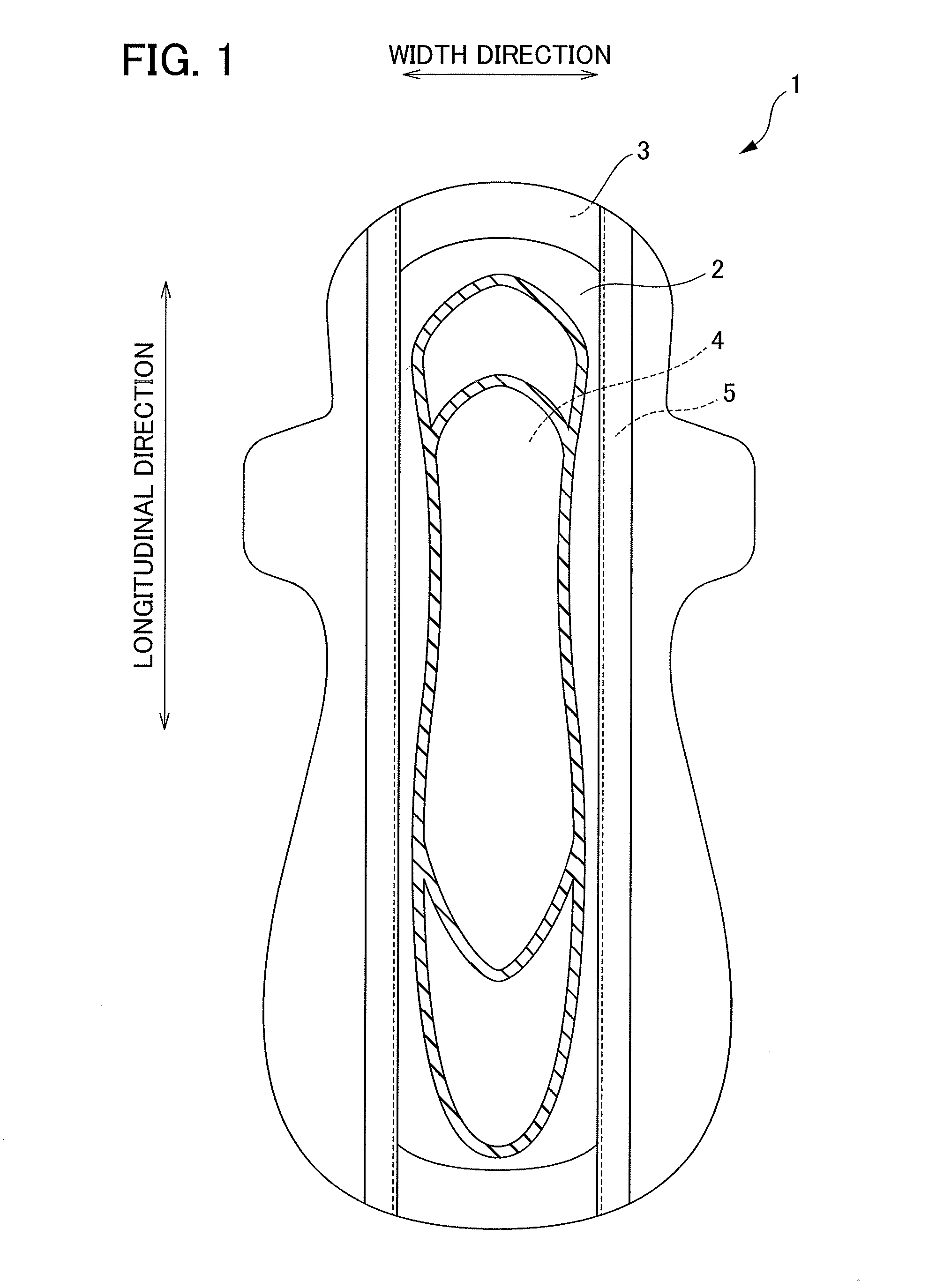

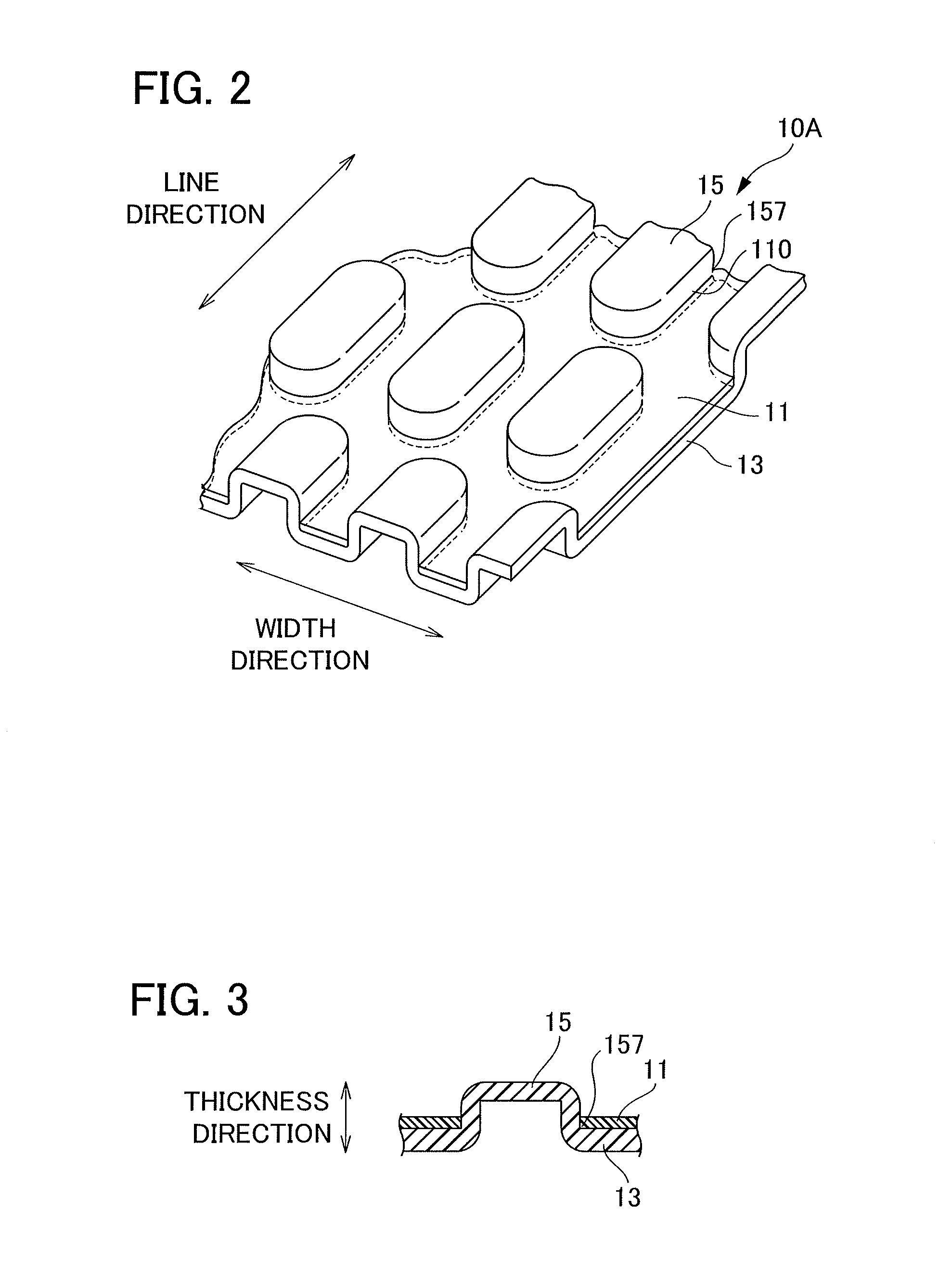

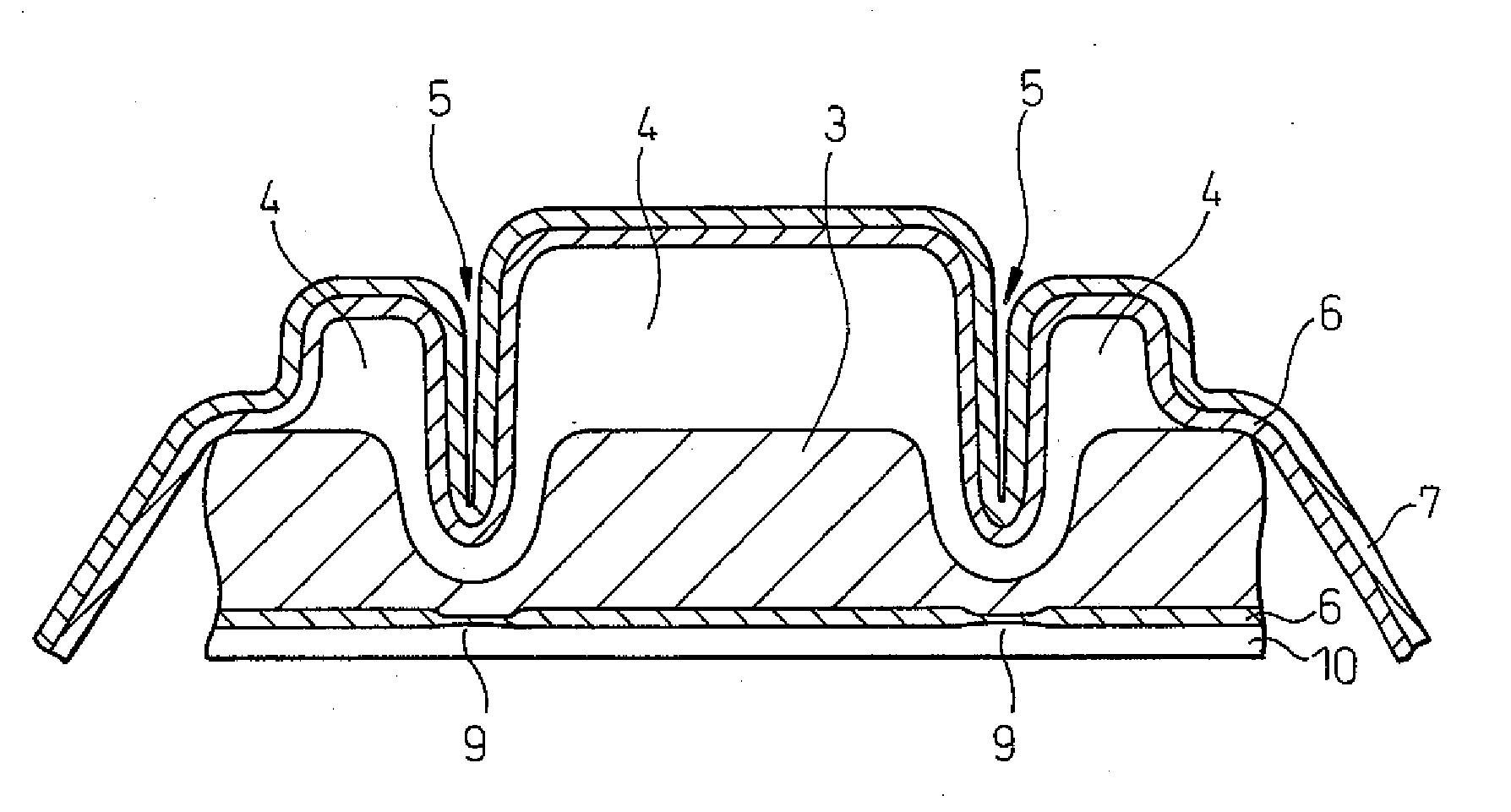

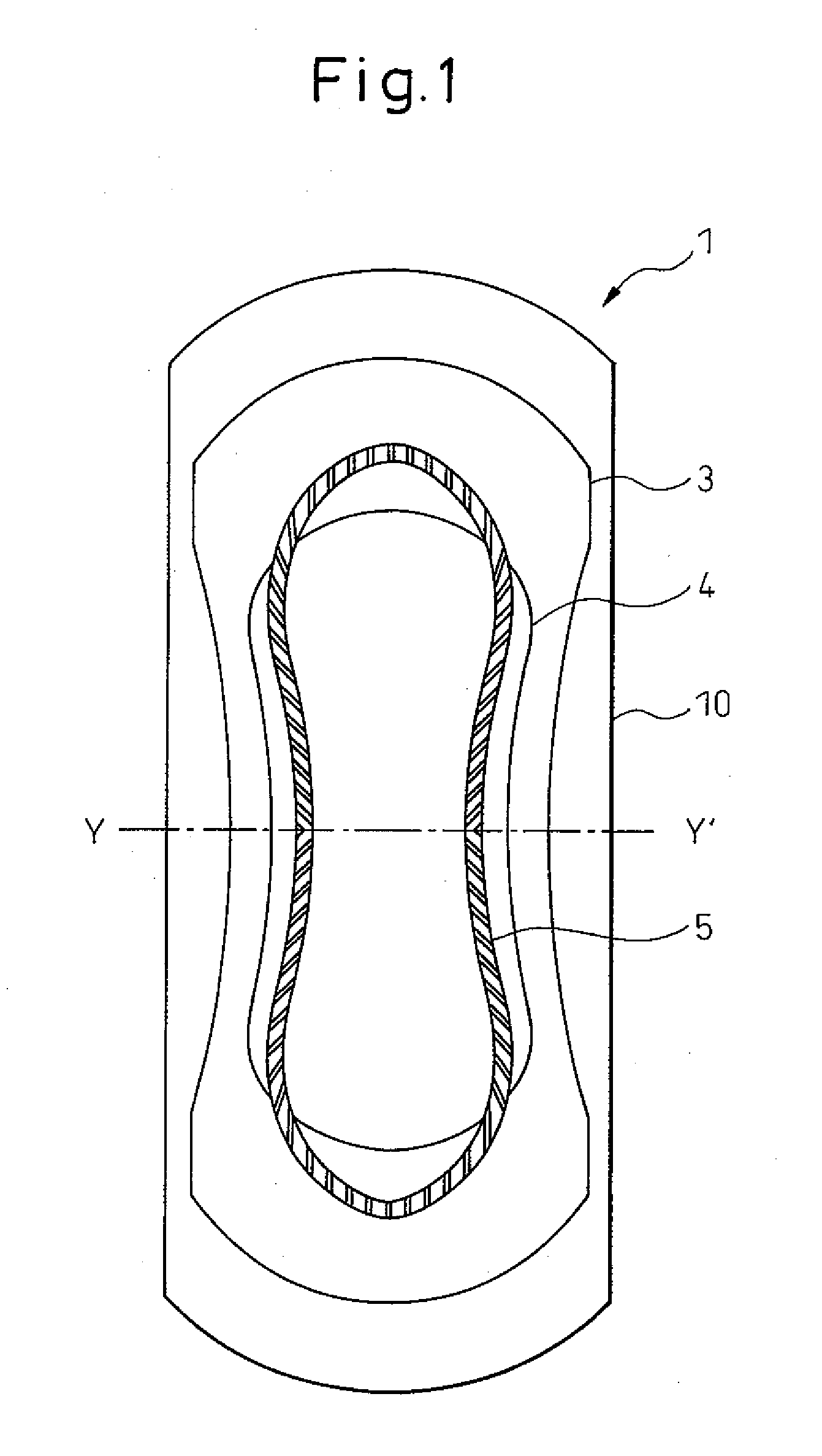

Body Fluid Absorbent Article and Producing Method Thereof

ActiveUS20090247977A1Poor feelReduce contact areaOrnamental structuresSpecial ornamental structuresFiberBody fluid

[Subject] To provide a body fluid absorbent article including a second sheet, which fulfills its own function, while the “sticking”, which would have been caused by the conventional second sheet, is prevented on the account of embossing.[Means for Solving Problem] A body fluid absorbent article having a face sheet 1, a body fluid permeable member 20 including an assembly of fibers in tows, a body fluid retainable absorbent element AB in this order, and a face-side second sheet 10, which is interposed between the above face sheet 1 and the above body fluid permeable member 20 with such a positional relation that the above face-side second sheet 10 is at least partly superposed on the above body fluid permeable member 20; and embossing is carried out integrally on the above face sheet 1 and the above face-side second sheet 10 while embossing is not carried out on the above body fluid permeable member 20.

Owner:DAIO PAPER CORP

Multi-Ply Paper Towel

ActiveUS20100224338A1Improve toughnessHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberMedicine

A multi-ply absorbent towel made from papermaking fiber comprising at least a first ply and a second ply bonded together, the towel having a basis weight of greater than 30 lbs per 3000 ft2 ream (48.8 gsm) and less than 50 lbs per 3000 ft2 ream (81.4 gsm), wherein the plies are selected and adhered together such that the towel typically exhibits (i) a GM TEA, mm-g / mm2 of greater than [0.00125 (GM Tensile, g / 3″)−0.75] and (ii) a GM Tensile Modulus, g / in / %, less than [0.0083 (GM Tensile Strength, g / 3″)+15.4] {(i) a GM TEA, mm g / mm2, of greater than [0.00952 (GM Tensile, g / cm)−0.75] and (ii) a GM Tensile Modulus, g / cm / %, less than [0.0249 (GM Tensile Strength, g / cm)+6.06}.

Owner:GPCP IP HLDG LLC

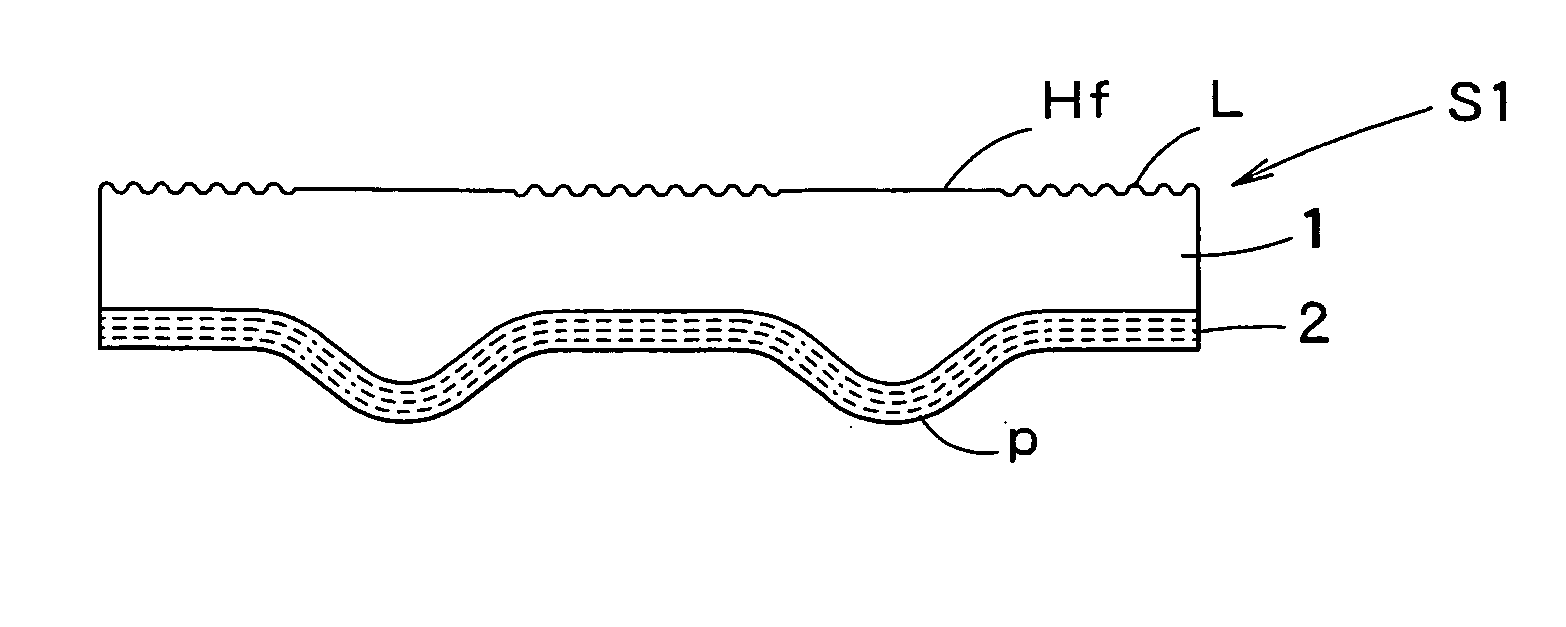

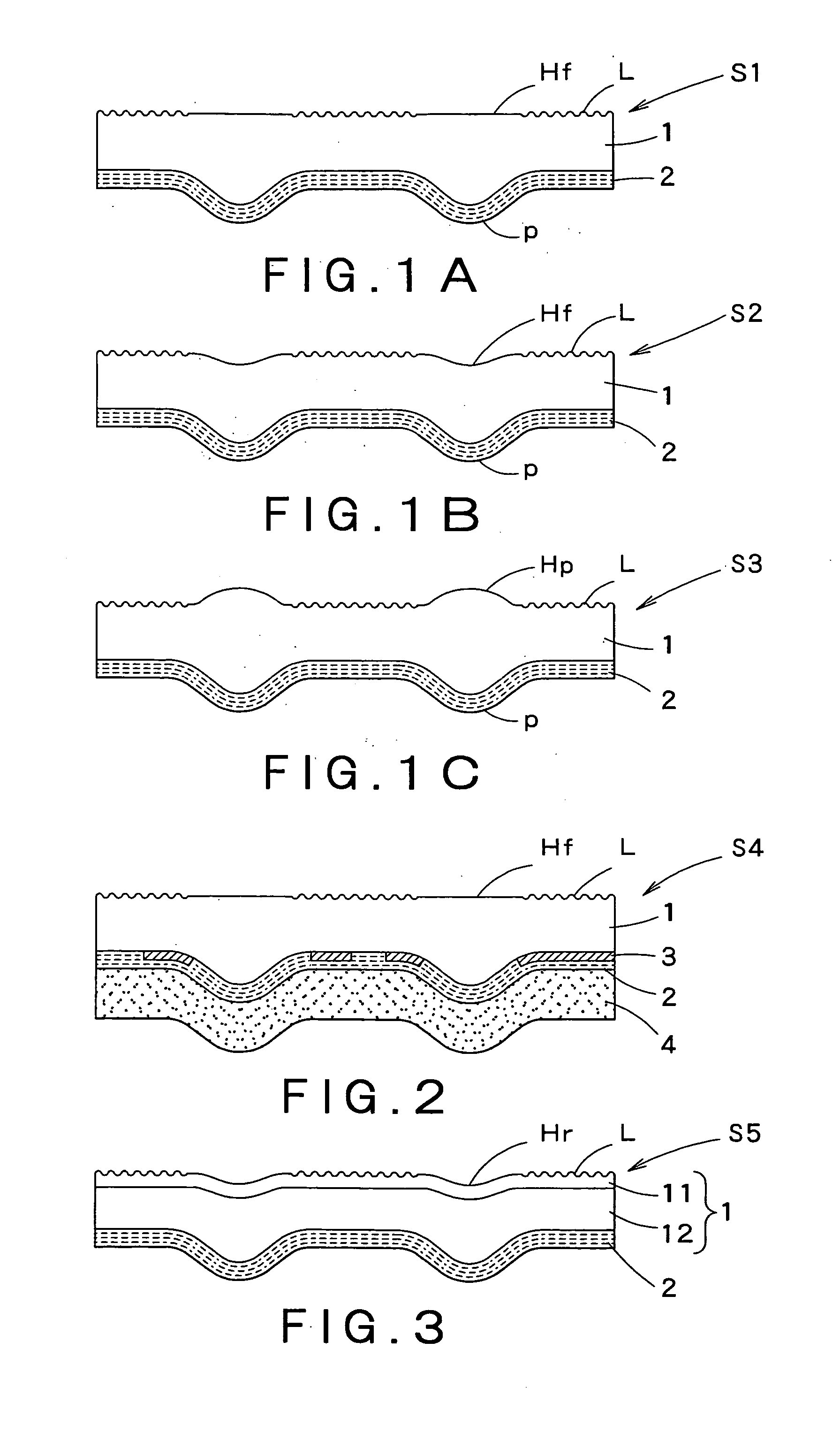

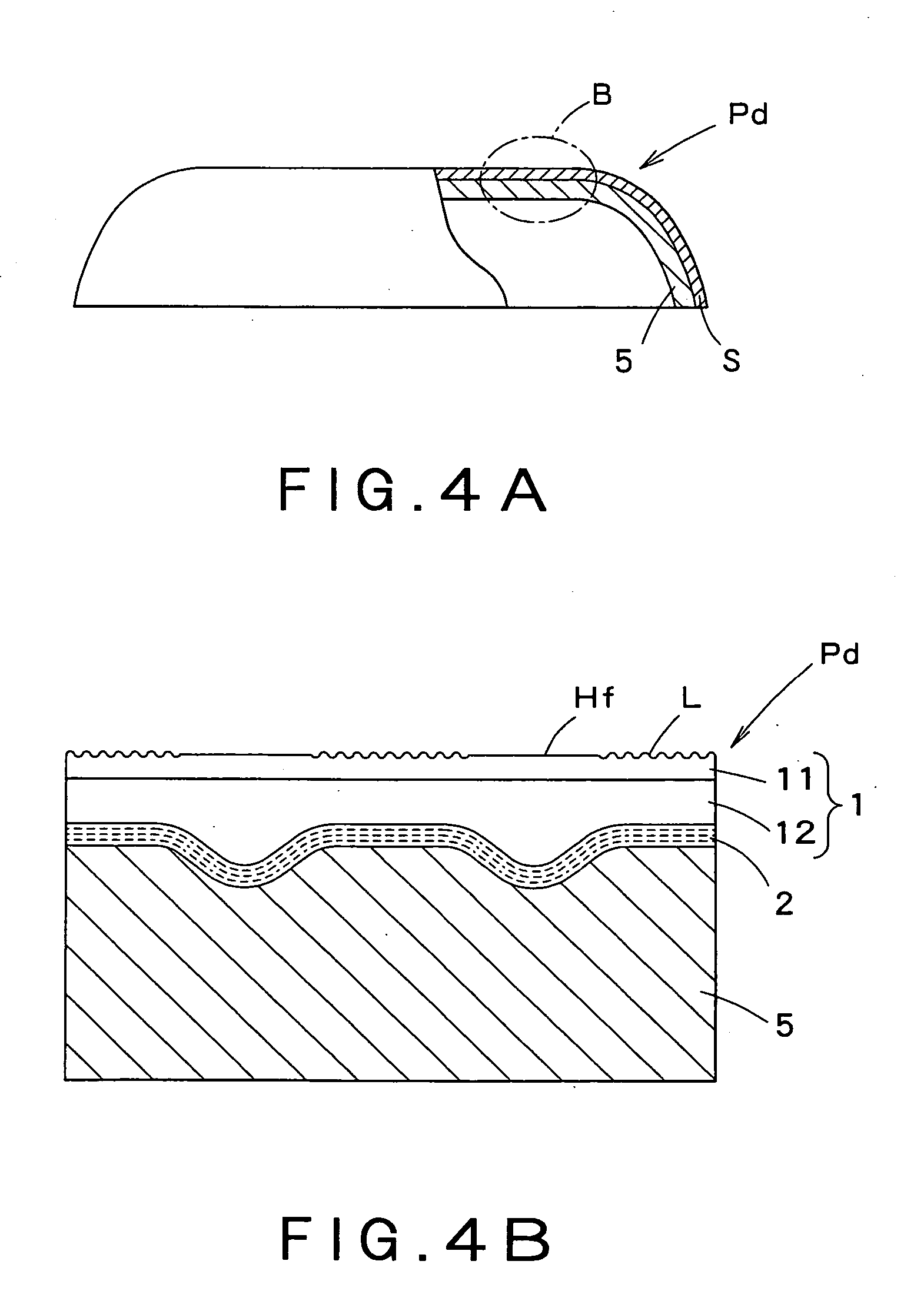

Decorating sheet, decorating molded article and in-mold decorating injection molding

ActiveUS20070026197A1Easy to manufactureOrnamental structuresSpecial ornamental structuresShell moldingEngineering

A decorating sheet comprises a transparent resin substrate sheet 1 and a glossy layer 2 laminated to the back surface of the transparent resin substrate sheet 1, and the front surface of the transparent resin substrate sheet 1 is divided into high-gloss portions H and low-gloss portions L. The transparent resin substrate sheet 1 is thick at the high-gloss portions and thin at the low-gloss portions, and, owing to these portions, the decorating sheet can provide a pattern that is visually sensed as if it were a three-dimensional pattern. This transparent resin substrate sheet 1 is composed of two layers, a crystalline resin layer 11 and a non-crystalline resin layer 12. A decorated molded product Pd can be obtained by laminating this decorating sheet to a resin molded product 5.

Owner:DAI NIPPON PRINTING CO LTD

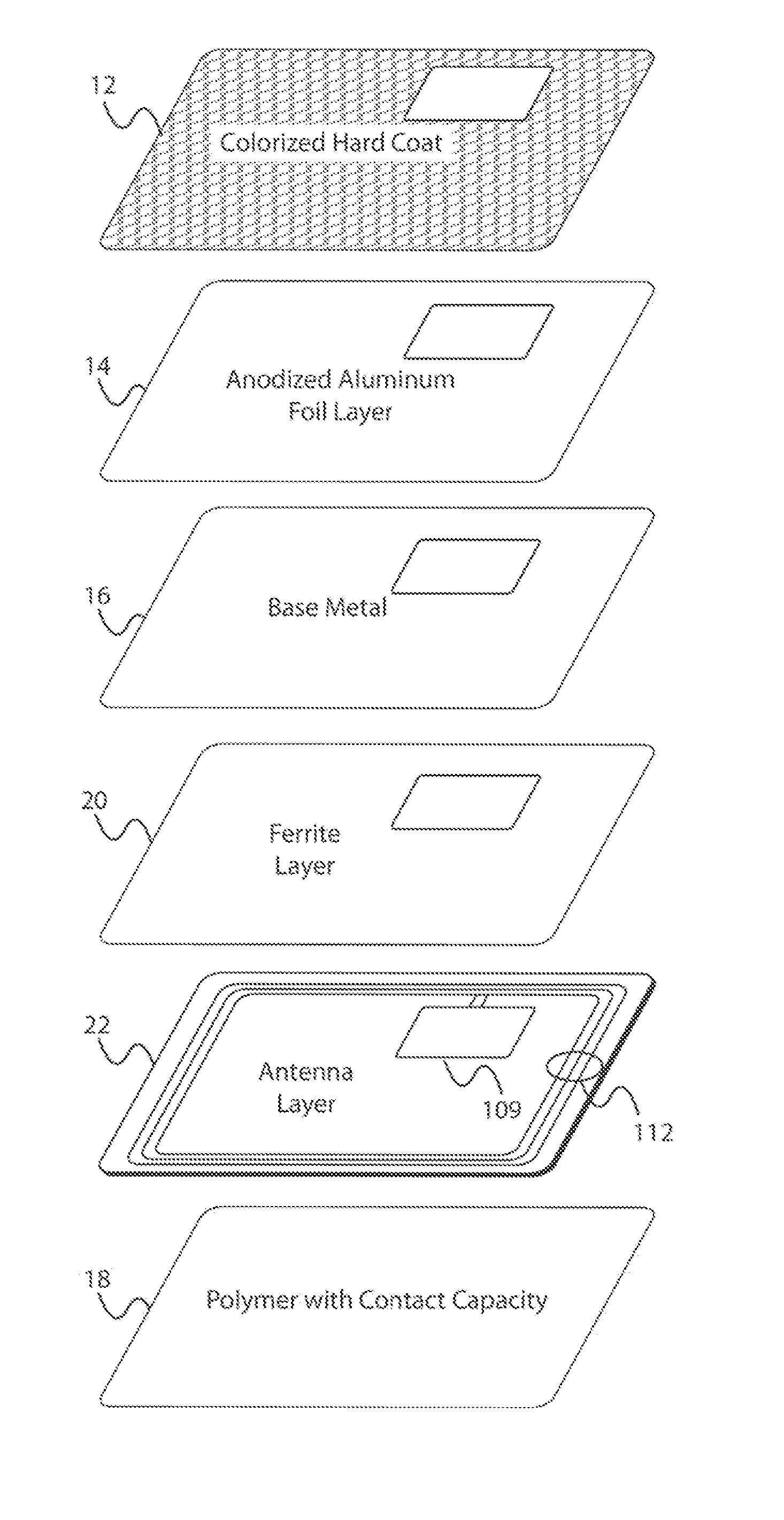

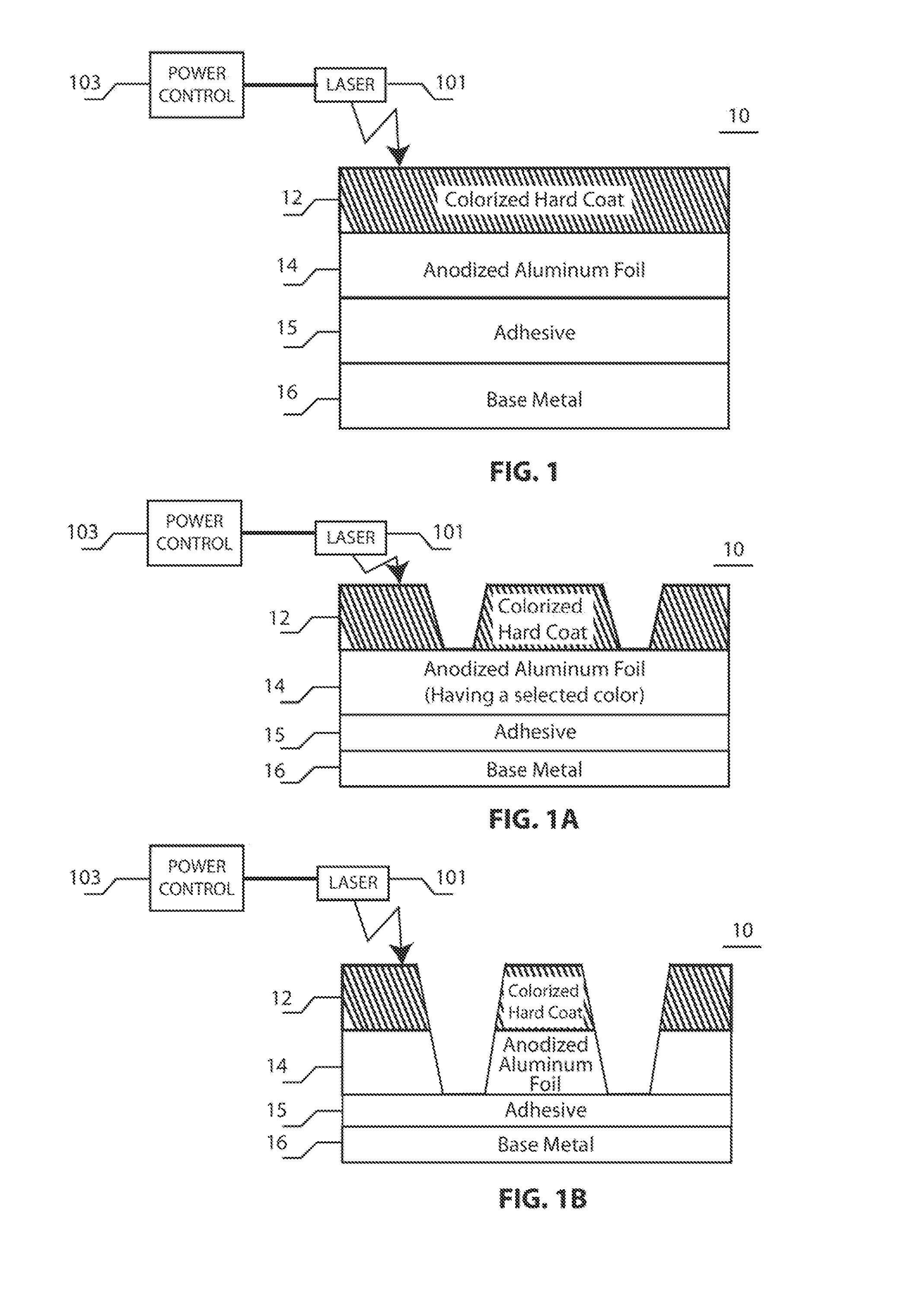

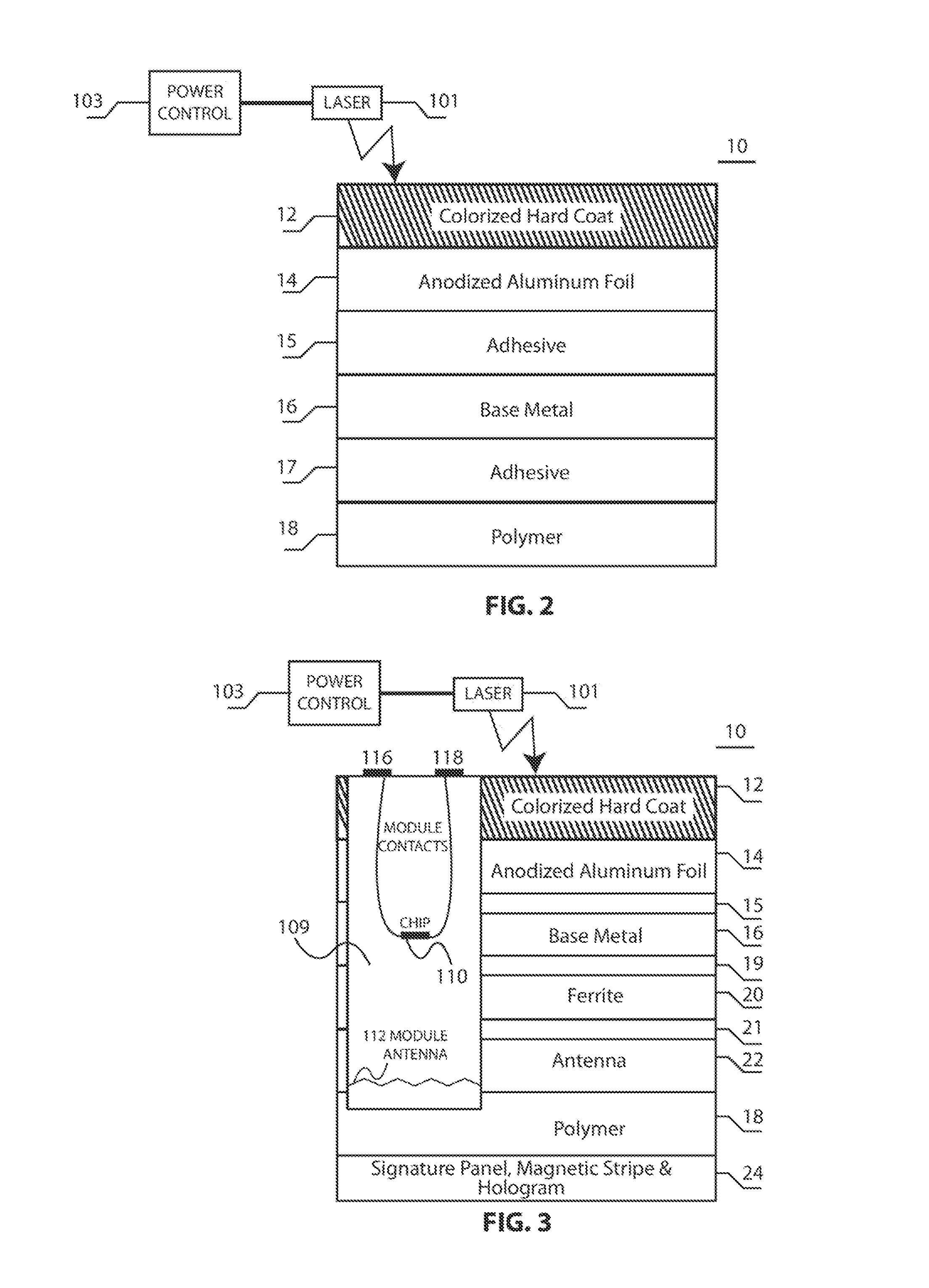

Transaction and id cards having selected texture and coloring

ActiveUS20150339564A1More costAvoid less flexibilityAnodisationWave amplification devicesEpoxyFinancial transaction

Cards made in accordance with the invention include a specially treated thin decorative layer attached to a thick core layer of metal or ceramic material, where the thin decorative layer is designed to provide selected color(s) and / or selected texture(s) to a surface of the metal cards. Decorative layers for use in practicing the invention include: (a) an anodized metal layer; or (b) a layer of material derived from plant or animal matter (e.g., wood, leather); or (c) an assortment of aggregate binder material (e.g., cement, mortar, epoxies) mixed with laser reactive materials (e.g., finely divided carbon); or (d) a ceramic layer; and (e) a layer of crystal fabric material. The cards may be dual interface smart cards which can be read in a contactless manner and / or via contacts.

Owner:COMPOSECURE LLC

Wood fibre based panels with a thin surface layer

ActiveUS8419877B2Larger market shareImprove impact resistanceLiquid surface applicatorsCovering/liningsSurface layerWood fibre

Building panels with a thin and embossed surface layer and a sub layer between a surface layer and a core.

Owner:VÄLINGE INNOVATION AB

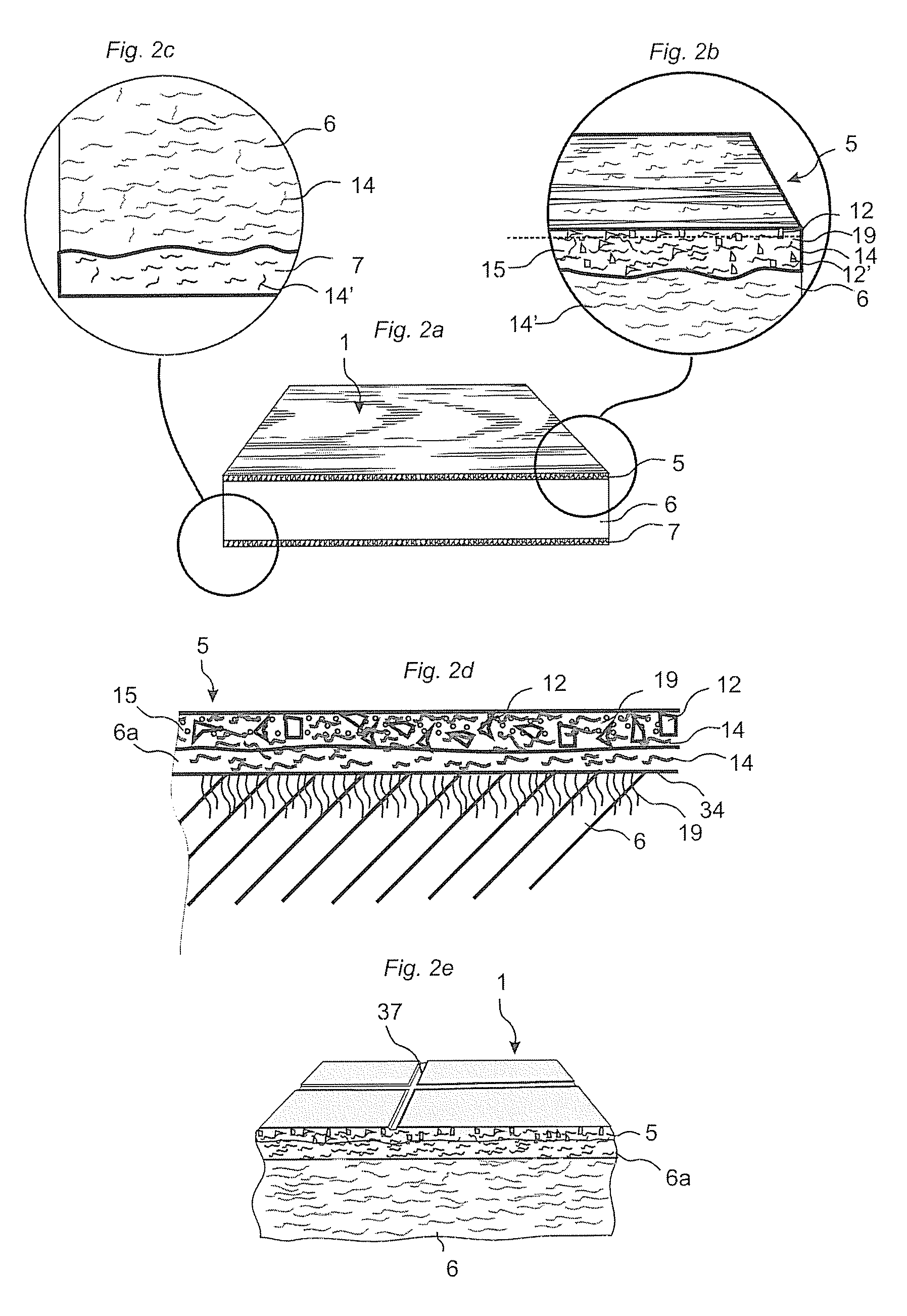

Method for manufacturing an electrokinetic infusion pump

InactiveUS20080149599A1Improve adhesionLamination ancillary operationsDecorative surface effectsPorous flowPorous membrane

A method for producing a porous flow-through element for use in an electrokinetic infusion pump is provided and generally includes providing a porous membrane that is entirely porous along both its length and width, treating the membrane by selectively inactivating portions of the membrane in a desired pattern to define active regions that allow fluid flow therethrough and inactive regions that do not, and laminating the treated membrane. Various techniques can be used to treat the membrane including, for example, applying a heated embossing die to the membrane, contacting selected portions of the membrane with laser energy, applying a pore-penetrating chemical to the membrane, and cutting and removing selected portions of the membrane. The resulting treated membrane can be laminated between opposed films having one or more perforations therethrough with each perforation being aligned with an active region to define a fluid flow pathway therebetween.

Owner:LIFESCAN INC

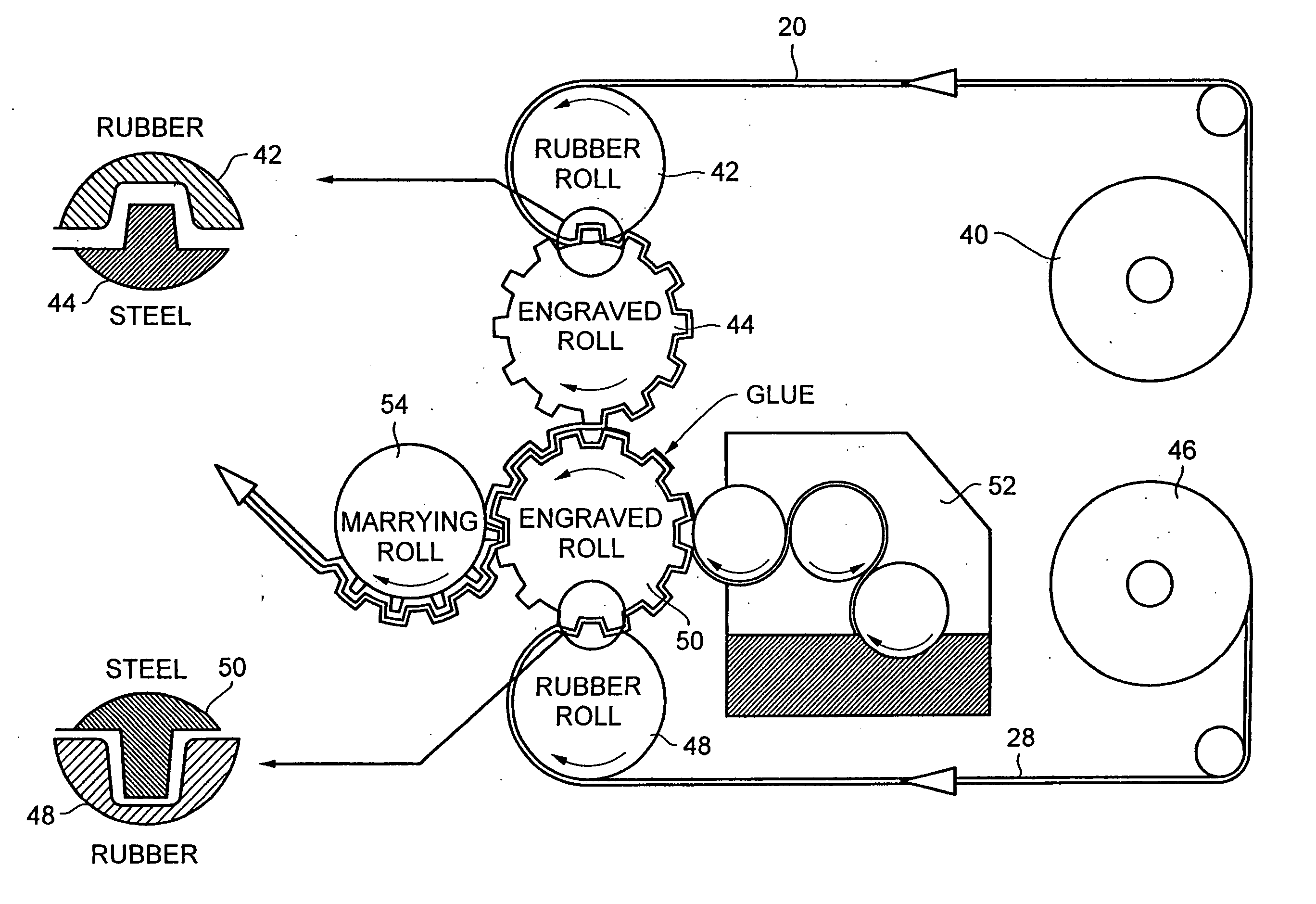

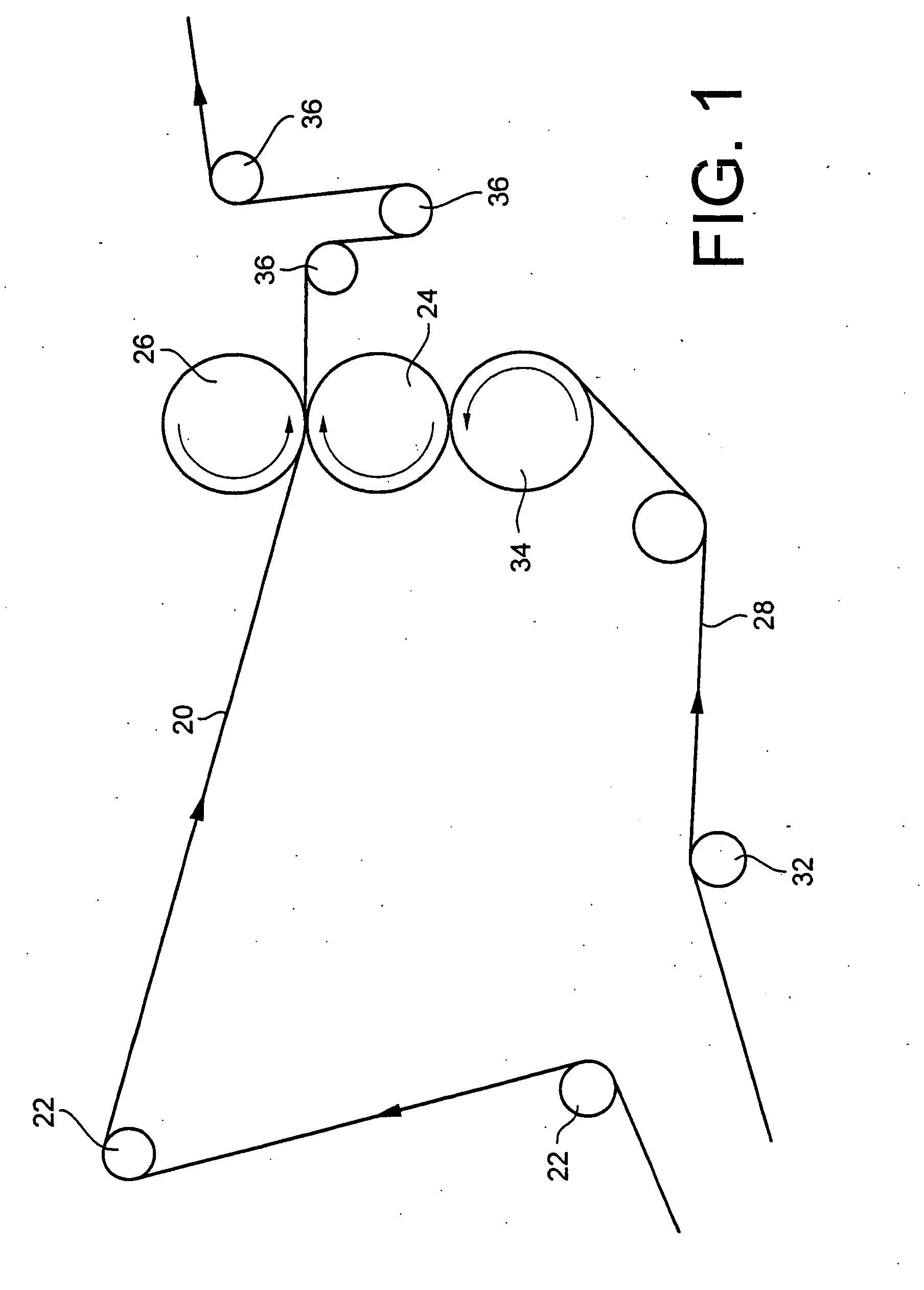

Multi-ply absorbent paper product having impressed pattern

A multi-ply tissue includes a first cellulosic embossed ply having an emboss pattern applied over a portion of its surface and a second cellulosic embossed ply of tissue. The first ply is contact laminated to the second ply so that the primary adhesion between the plies of tissue is the result of contact between cellulosic fibers. The first and second plies contact one another in contact-areas, with the contact areas between the first and second plies defining compliant voids. The contact areas between the first ply and the second ply are elongated and / or rounded contact areas. A method of forming a multi-ply tissue involves conveying a base sheet through a nip between an impression roll and a pattern roll to produce an embossed base sheet having a back side possessing projections, applying adhesive to the back side of the embossed base sheet at spaced apart locations, and applying a flat backing sheet to the back side of the embossed base sheet so that the backing sheet adheres to the back side of the embossed base sheet at said spaced apart locations. A method of producing an embossed tissue involves successively conveying a base sheet through a nip between a first impression roll and a pattern roll, and conveying the base sheet through another nip between the pattern roll and a second impression roll, wherein the second impression roll is made of rubber having a lower hardness than the rubber from which the first impression roll is made.

Owner:GPCP IP HLDG LLC

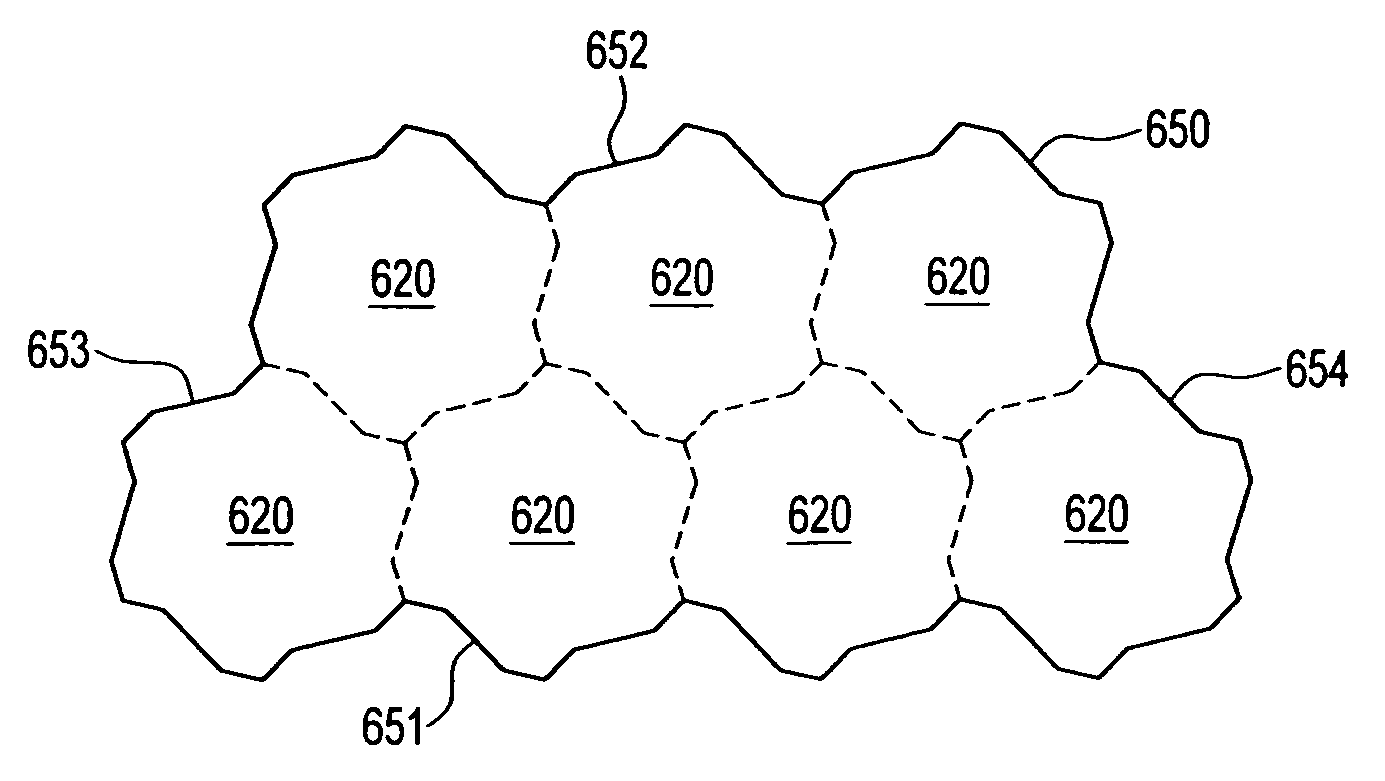

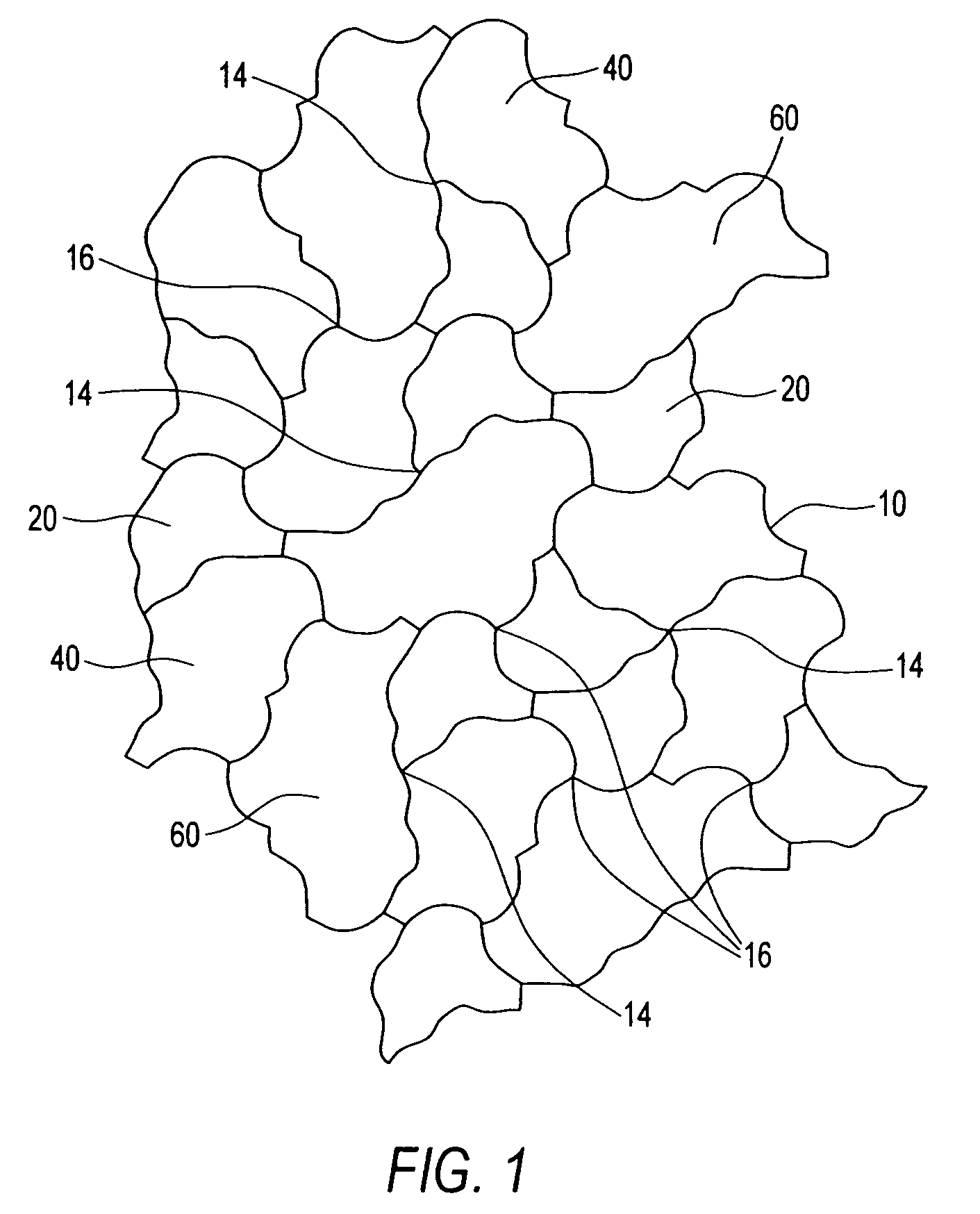

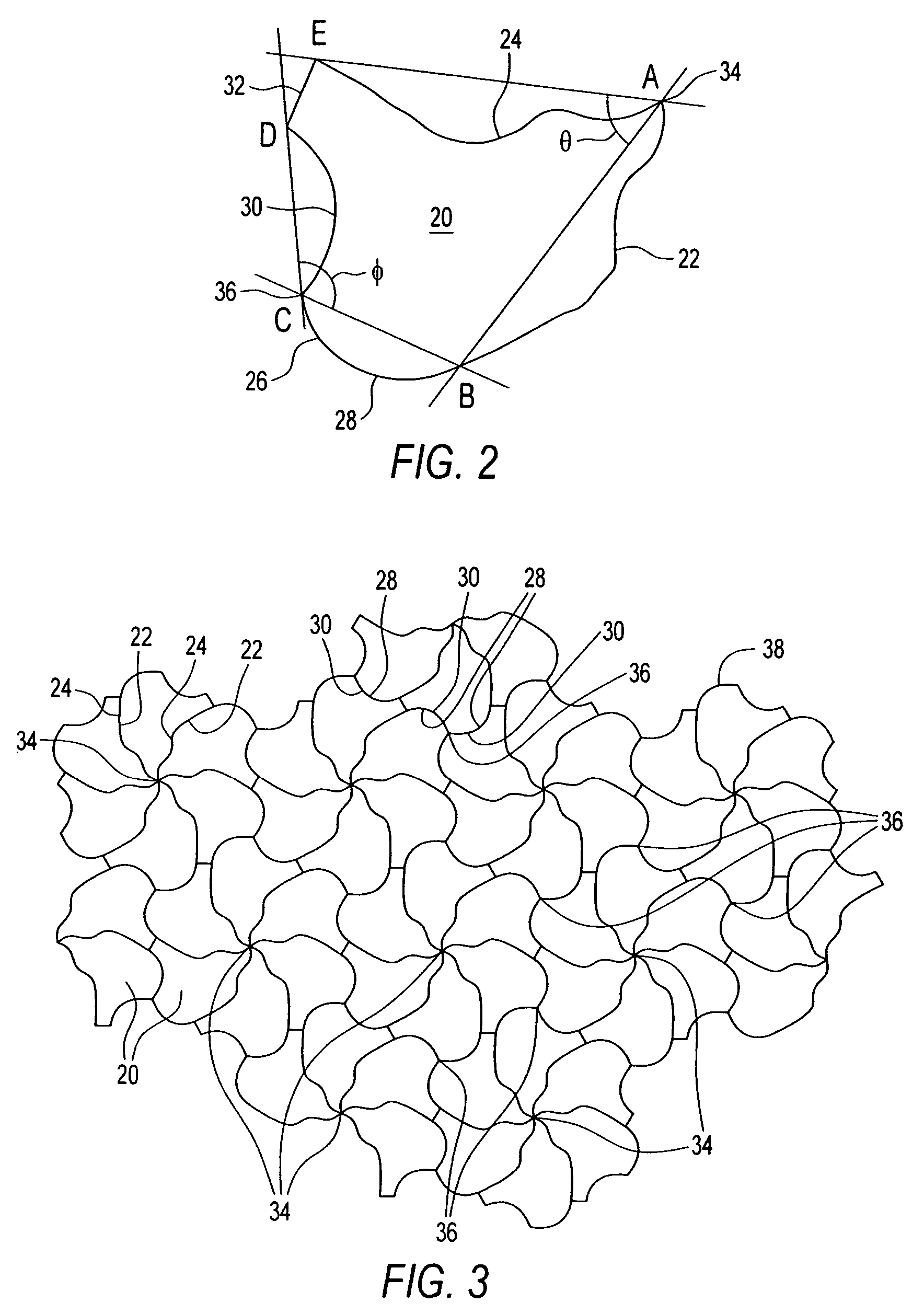

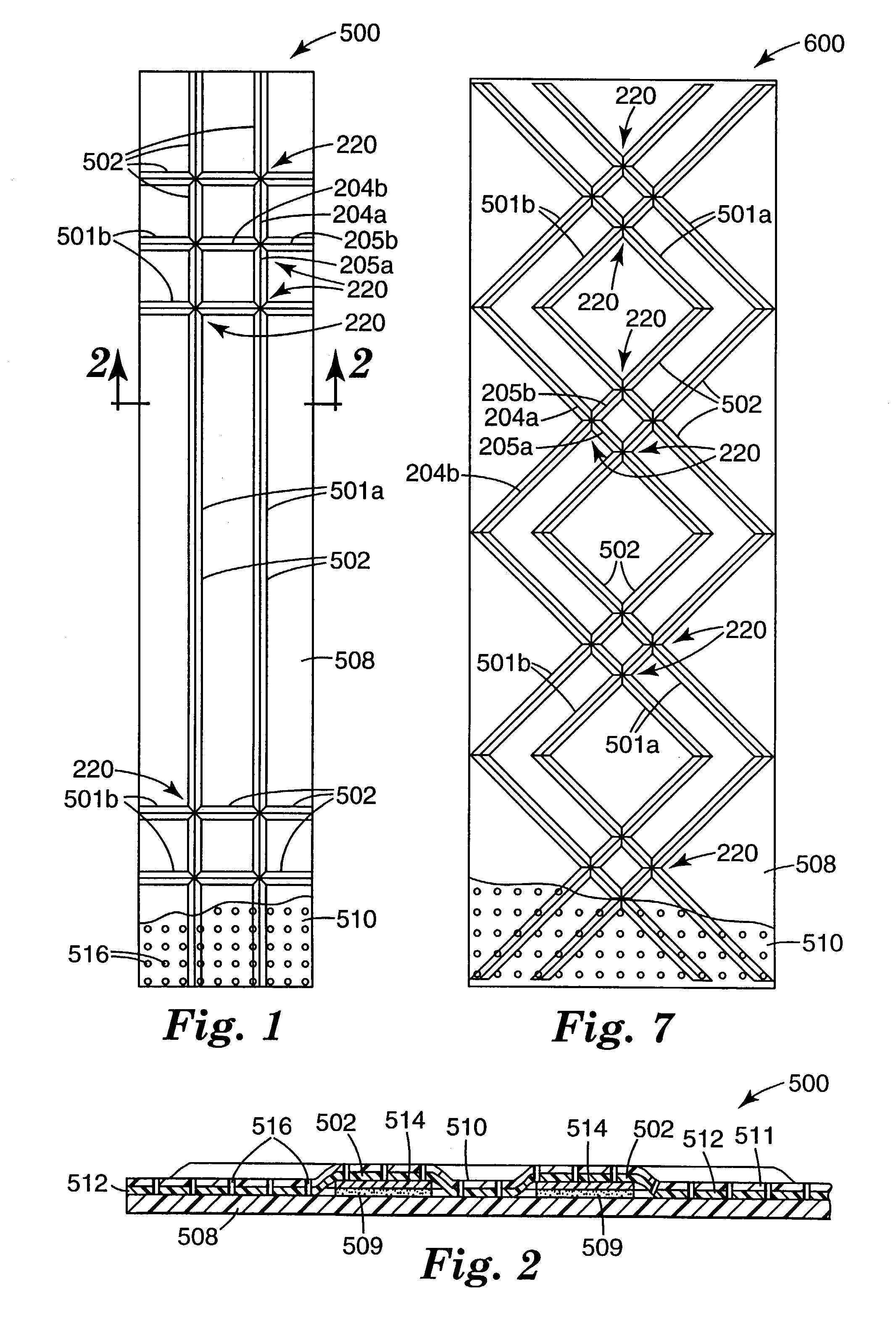

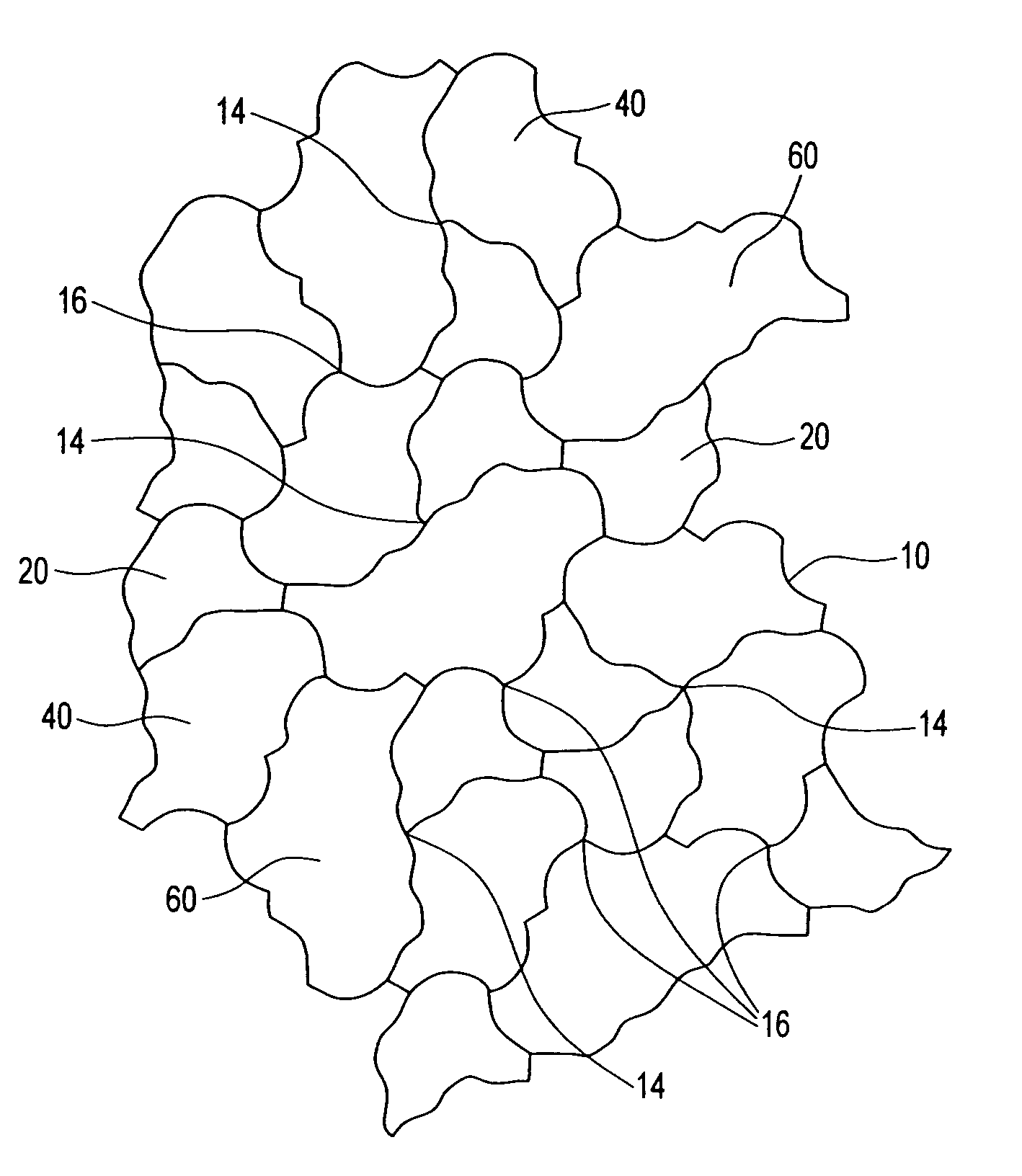

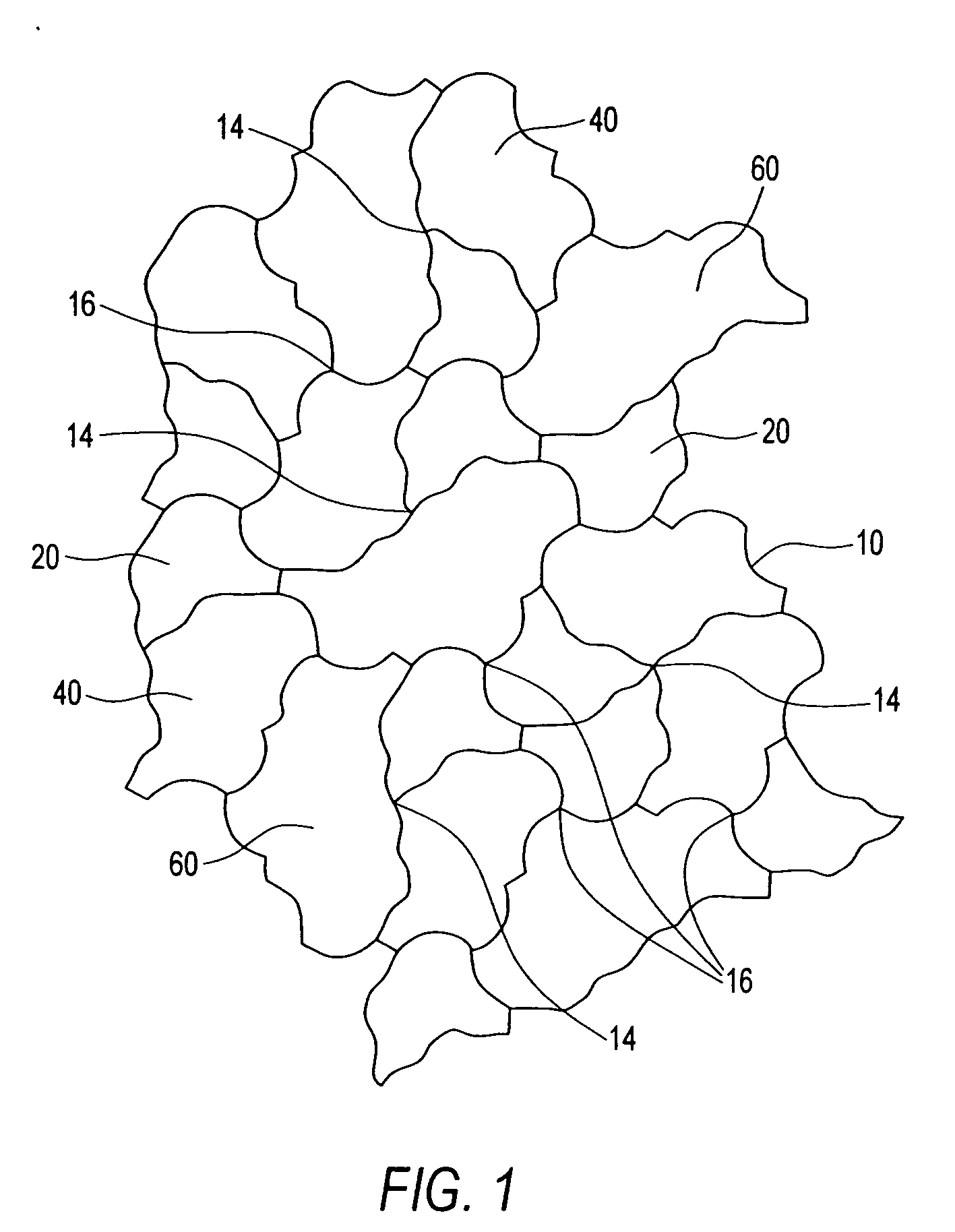

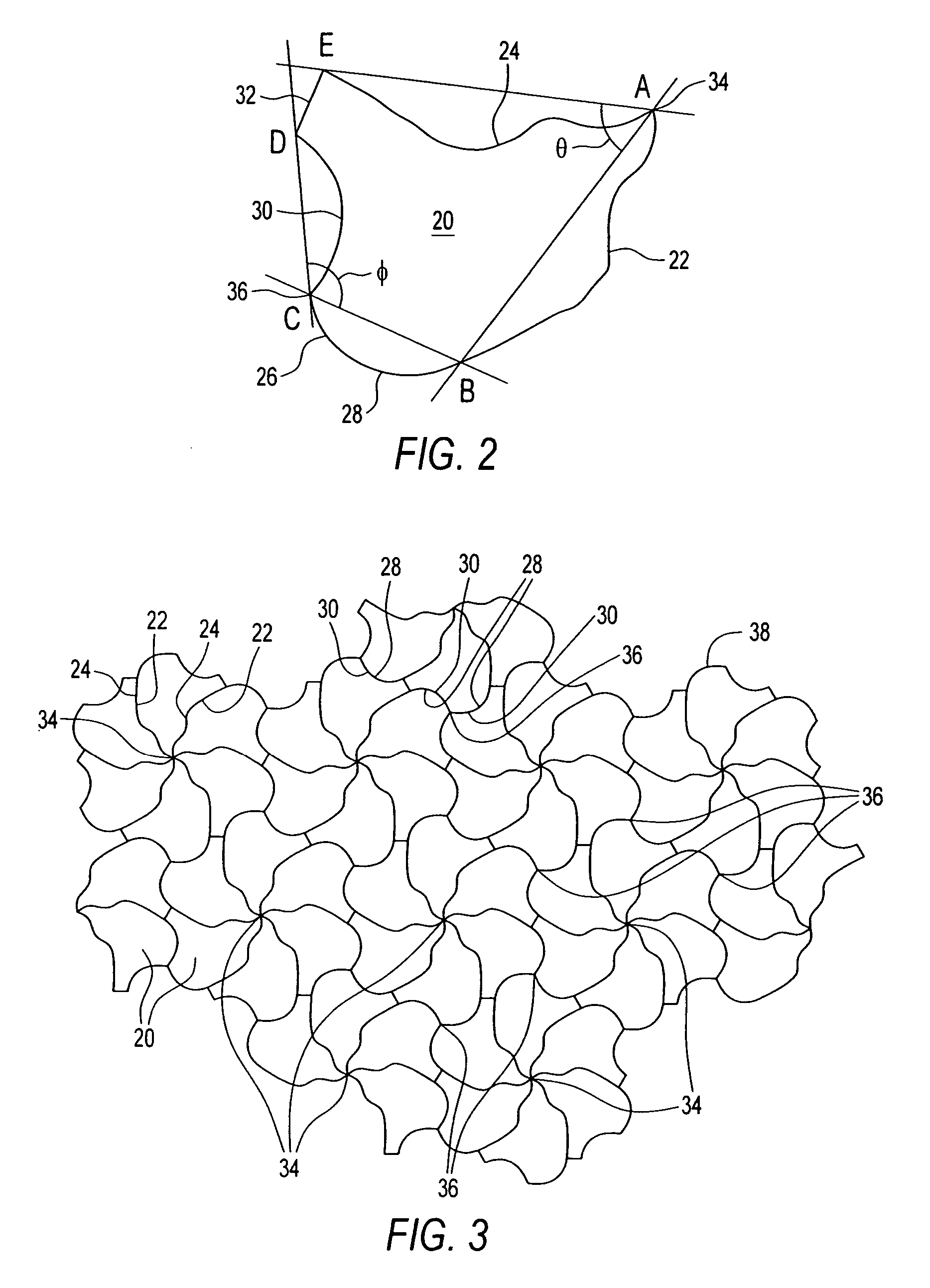

Irregular, tessellated building units

InactiveUS7637688B2Firmly connectedGood lookingOutline designsConstruction materialEngineeringBuilding unit

An irregular, tessellated building unit comprises x primary elements, wherein x is an integer equal to or greater than 1. The primary element is a rotational tessellation having a plural pairs of sides extending in a generally radial direction from plural vertices, respectively. In each pair, the two sides are rotationally spaced by an angle that is divided evenly into 360 degrees. Preferably, all of the sides are irregularly shaped. In one preferred embodiment all six sides are irregularly shaped, images of each other and comprise mid-point rotations. As a result, any side of any unit can mate with any other side of any other unit. Optionally, spacers are provided on the sides of each unit. A wide variety of units may be constructed having different numbers and arrangements of primary elements. As all the units are combinations of primary elements, they readily mate with each other. A surface covering comprises a multiplicity of units assembled to form a continuous surface without overlap between units and without substantial gaps between units. A structure, such as a wall or column can be formed of building units of the invention. Because of the irregular side configurations, and different sizes and shapes of individual units, the resulting surface or structure has a natural, non-repeating pattern appearance. Optionally, minor surface and edges variations are made from unit to unit to further enhance the natural appearance of the surface covering or structure.

Owner:KEYSTONE RETAINING WALL SYST

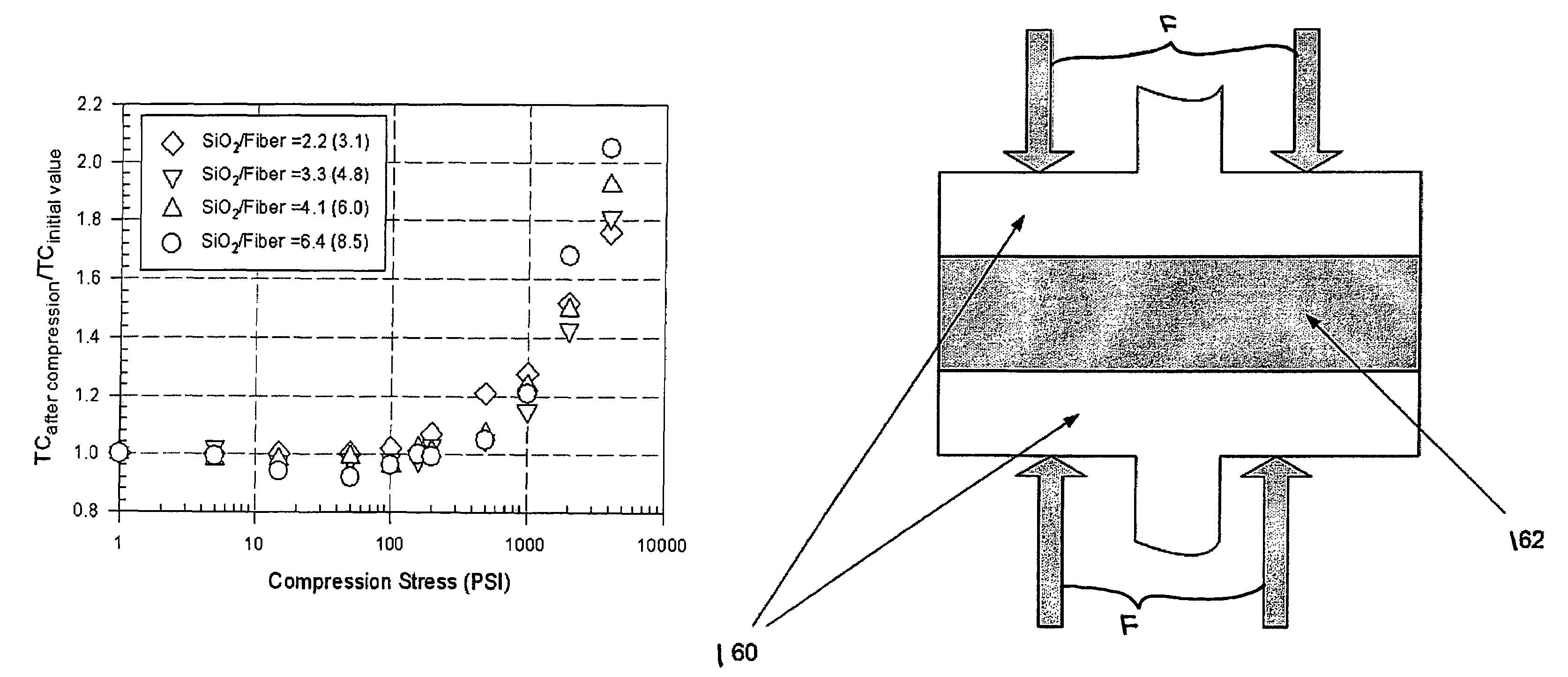

High strength, nanoporous bodies reinforced with fibrous materials

ActiveUS7560062B2High modulusHigh strengthLayered productsOrnamental structuresFlexural strengthHigh intensity

This invention discloses improvements that can be achieved in thermal or mechanical performance of aerogel composites via densification. Densified aerogels and aerogel composites can display higher compressive strength, modulus, flexural strength, and maintains or insubstantially increases the thermal conductivity relative to the pre-densified form. In the special case of fiber reinforced aerogel composites densification via mechanical compression can prove highly beneficial.

Owner:ASPEN AEROGELS INC

Process for achieving décor on surface elements

InactiveUS7003364B1High resolutionRearrange décorCeilingsCovering/liningsComputer terminalEngineering

Owner:UNILIN NORDIC AB

Laminate from which decorative films can be applied to a substrate

InactiveUS6984429B2Precise applicationLamination ancillary operationsDecorative surface effectsEngineeringMechanical engineering

A laminate from which decorative films can be precisely applied to a substrate. The laminate includes a polymeric cover sheet having opposite outer and inner major surfaces. A layer of structured pressure sensitive adhesive is adhered to the inner major surface of the cover sheet. The structured pressure sensitive adhesive has a plurality of spaced passageways extending to at least one edge of the layer of structured pressure sensitive adhesive. A decorative film is adhered to the structured pressure sensitive adhesive. A second layer of pressure sensitive adhesive is adhered to the major surfaces of the decorative film opposite the layer of structured pressure sensitive adhesive. A release liner extends substantially across the second layer of pressure sensitive adhesive and a portion of the structured pressure sensitive adhesive.

Owner:3M INNOVATIVE PROPERTIES CO

Methods of creating patterns on substrates and articles of manufacture resulting therefrom

Methods of creating patterns on substrates are presented, and articles of manufacture resulting therefrom. One method comprises applying a first surface energy modifier to an applicator to form a coating on the applicator; contacting the coating with a receiving member, the receiving member having a topography, the coating only contacting and remaining on at least some protrusions; exposing the first modified receiving member to a second surface energy modifier, thereby forming a second modified receiving member having surface modified recesses; applying a composition comprising a polymeric material to the second modified receiving member, the composition substantially conforming to the topography of the surface modified protrusions and the surface modified recesses; and contacting the composition-coated, surface modified protrusions with a substrate for a time and under conditions sufficient to transfer the polymeric material on protrusions to the substrate. Because the surface energy of the sidewalls is lower than that on the protrusions, polymer dewetting from the sidewalls is promoted, which makes the polymer film discontinuous along the edges of patterns. Therefore, inked polymer patterns from the protrusions of the mold show very smooth edges and smaller dimensions compared to that of the mold.

Owner:AGENCY FOR SCI TECH & RES +1

Irregular, tessellated building units

InactiveUS20070077387A1Strengthen structural connectionsGood lookingOutline designsConstruction materialEngineeringBuilding unit

An irregular, tessellated building unit comprises x primary elements, wherein x is an integer equal to or greater than 1. The primary element is a rotational tessellation having a plural pairs of sides extending in a generally radial direction from plural vertices, respectively. In each pair, the two sides are rotationally spaced by an angle that is divided evenly into 360 degrees. Preferably, all of the sides are irregularly shaped. In one preferred embodiment all six sides are irregularly shaped, images of each other and comprise mid-point rotations. As a result, any side of any unit can mate with any other side of any other unit. Optionally, spacers are provided on the sides of each unit. A wide variety of units may be constructed having different numbers and arrangements of primary elements. As all the units are combinations of primary elements, they readily mate with each other. A surface covering comprises a multiplicity of units assembled to form a continuous surface without overlap between units and without substantial gaps between units. A structure, such as a wall or column can be formed of building units of the invention. Because of the irregular side configurations, and different sizes and shapes of individual units, the resulting surface or structure has a natural, non-repeating pattern appearance. Optionally, minor surface and edges variations are made from unit to unit to further enhance the natural appearance of the surface covering or structure.

Owner:KEYSTONE RETAINING WALL SYST

Floorboards, flooring systems and method for manufacturing and installation thereof

Floorboards with a format corresponding to a traditional parquet block for laying of mechanically joined floating flooring. Rectangular floorboards include a surface layer and a core with two long sides and two short sides, for making a floating flooring, which floorboards are mechanically lockable and which along their four sides have pairs of opposing connectors for locking similar, adjoining floorboards to each other both vertically and horizontally wherein the long sides have a length not exceeding 80 cm and the short sides have a width not exceeding 10 cm.

Owner:VÄLINGE INNOVATION AB

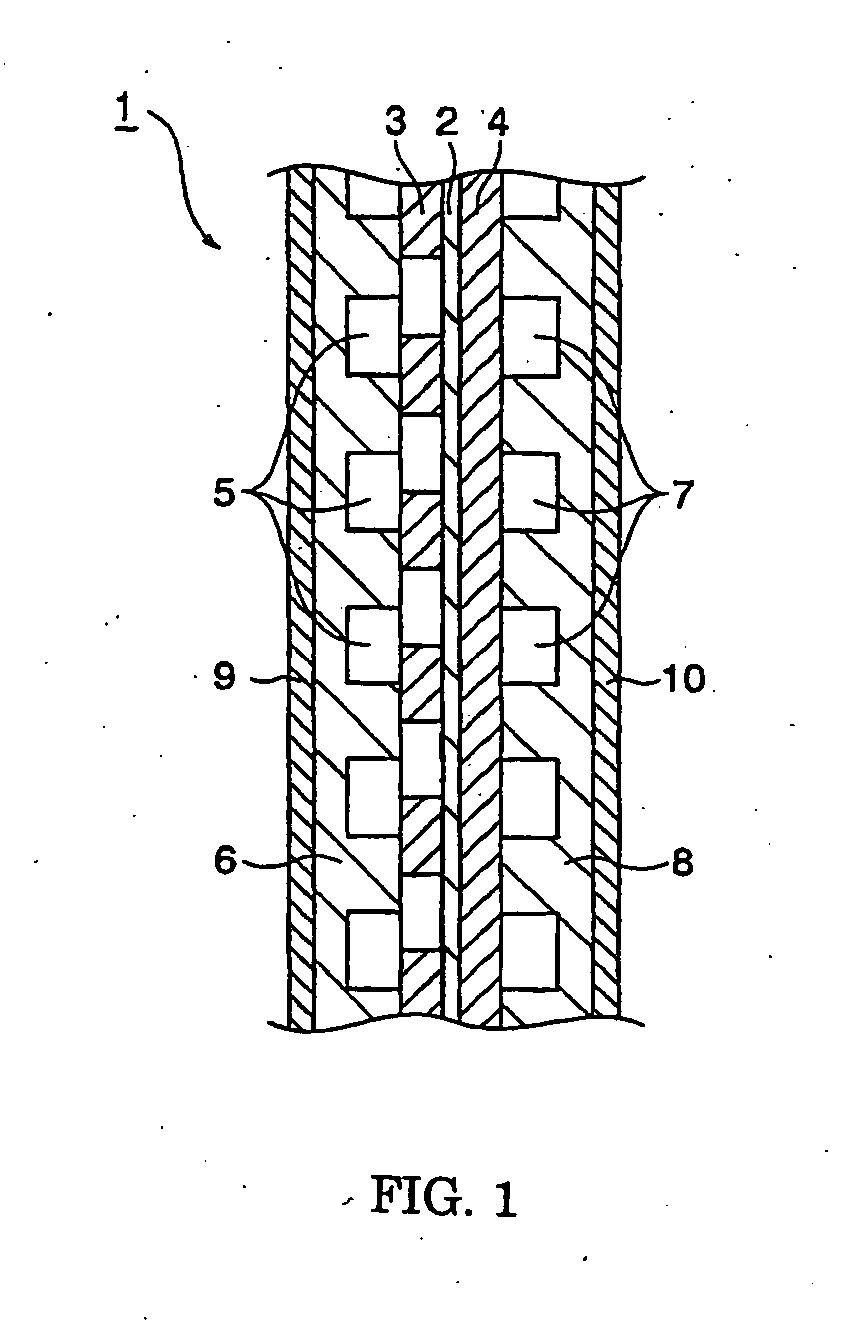

Composite sheet and absorbent article using the composite sheet

It is intended to provide an absorbent article provided with a composite sheet which comprises a film sheet and a fiber mass and is excellent in the ability to draw in a liquid and the ability to prevent the backward flow. Namely, an absorbent article provided with a composite sheet comprising a film sheet having multiple pores formed therein and a fiber mass laminated on one side of the film sheet, wherein the fiber mass has a projected section in which a part of the fiber mass projects through the multiple pores toward the other side of the film sheet.

Owner:UNI CHARM CORP

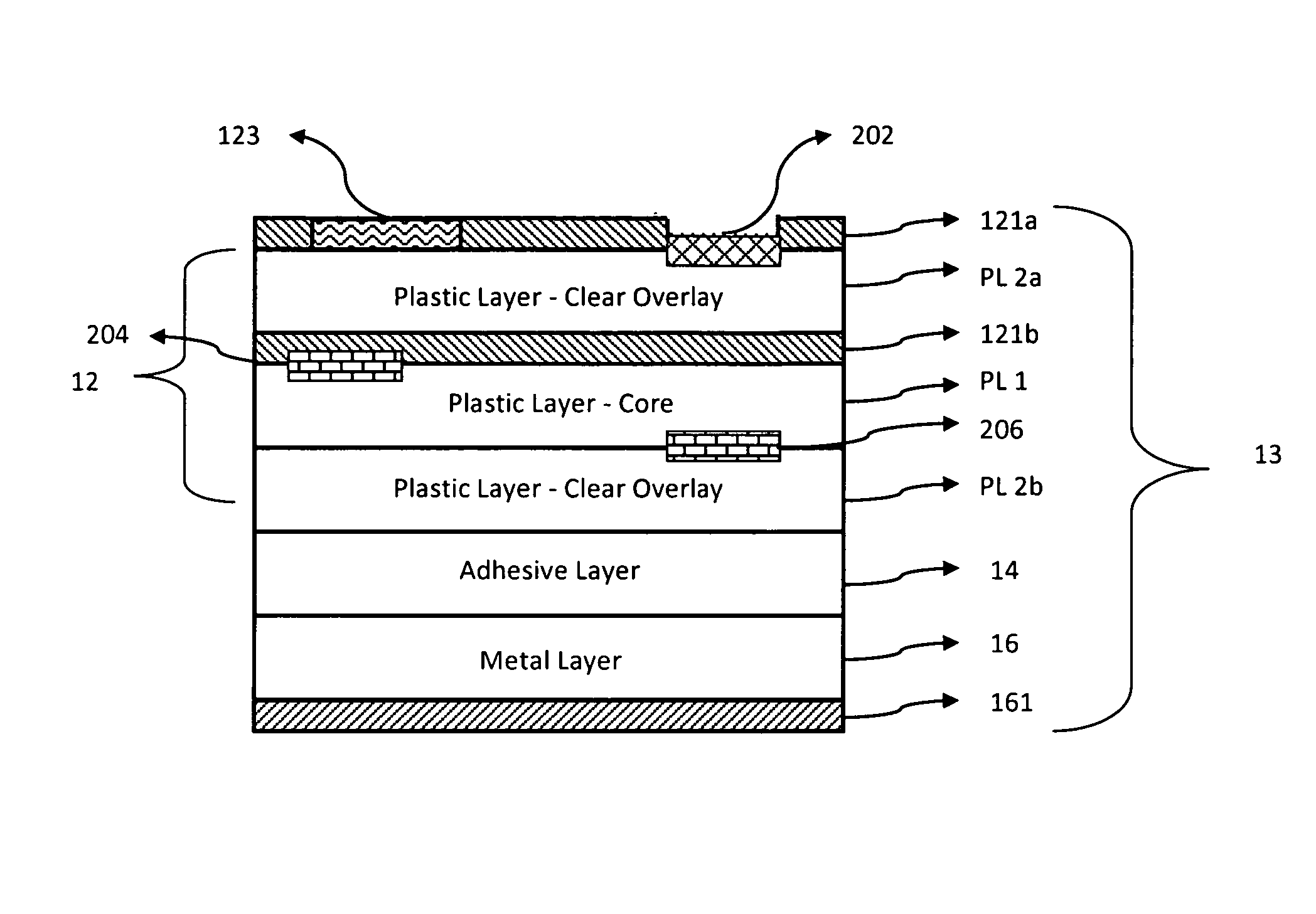

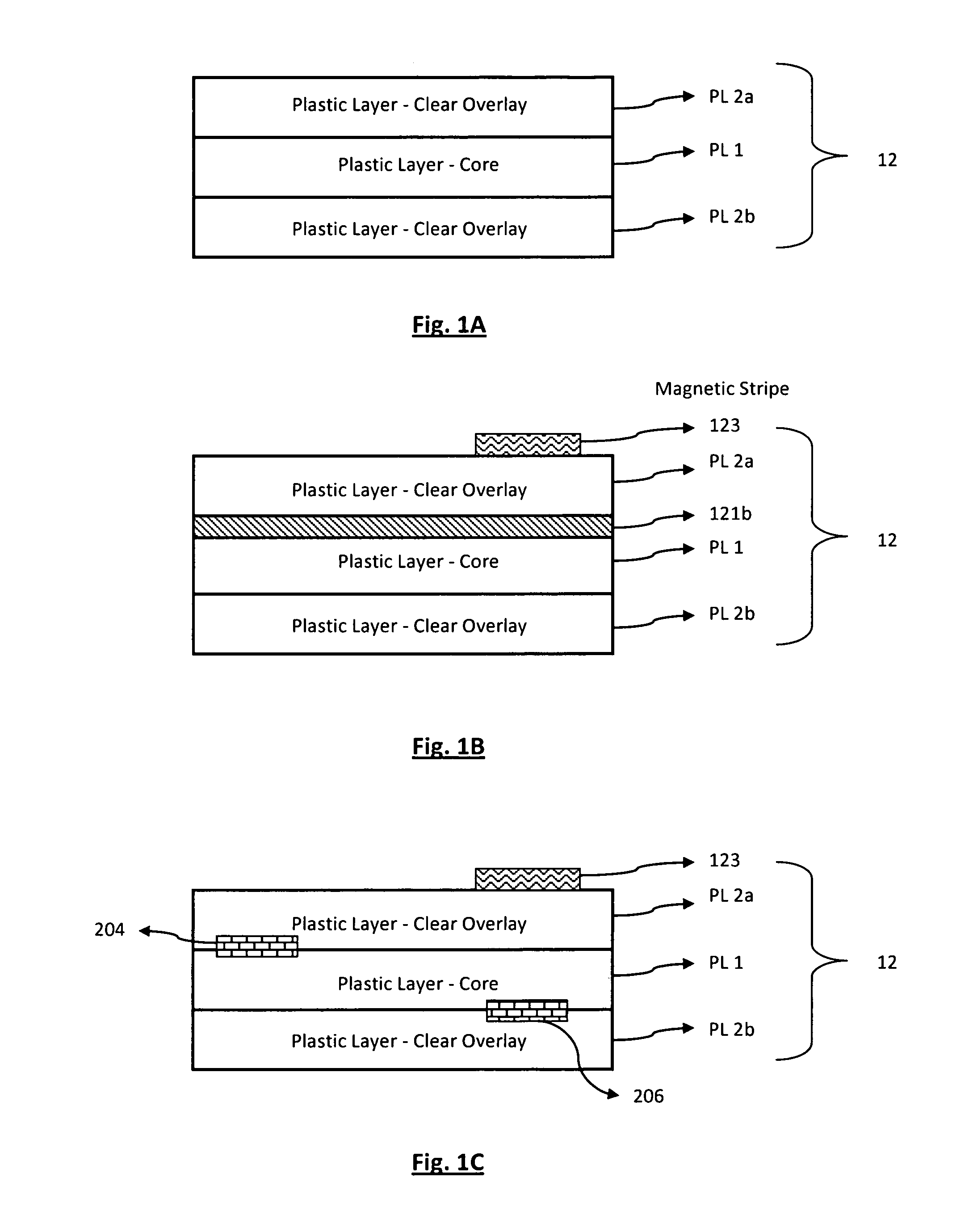

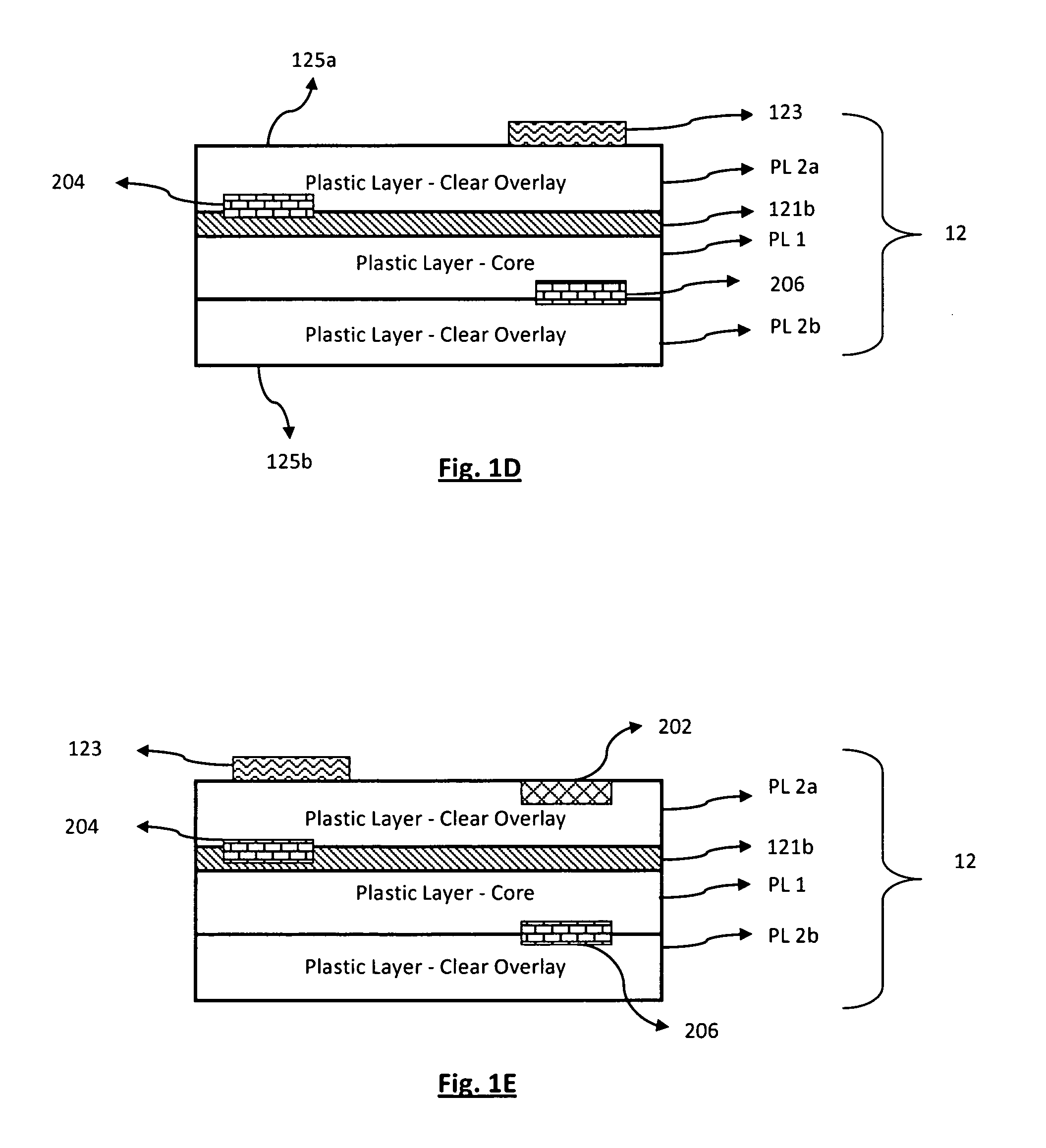

Combination card of metal and plastic

ActiveUS8672232B2Dimensionally stableReduce changesOrnamental structuresSpecial ornamental structuresAdhesiveEngineering

A card formed in accordance with the invention includes a first assembly comprised of multiple plastic layers attached via an adhesive to a metal layer. The multiple plastic layers forming the first assembly are laminated under a first selected temperature and pressure conditions to preshrink the multiple plastic layers, stress relieve the first assembly and render the first assembly dimensionally stable. The laminated first assembly is then attached to a metal layer via an adhesive layer to form a second assembly which is then laminated at a temperature below the first selected temperature to form a card which is not subjected to warpage and delamination.

Owner:COMPOSECURE LLC

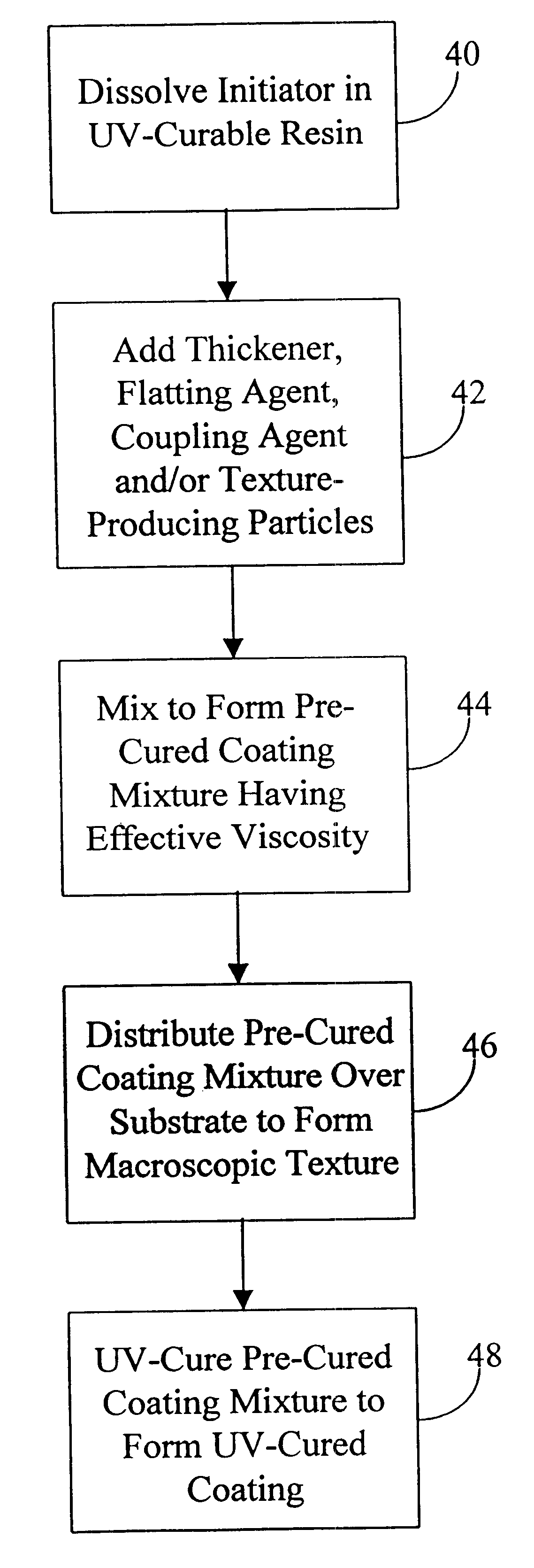

Coating having macroscopic texture and process for making same

InactiveUS6730388B2Increase resistanceHigh transparencyImpression capsOrnamental structuresPolyresinChemistry

In one embodiment the present invention provides a coated substrate comprising a substrate, a radiation-cured coating or a thermally-cured on at least a portion of the substrate, wherein the coating comprises an inherent macroscopic texture. In another embodiment, the present invention provides a pre-cured coating mixture comprising a radiation-curable resin and an initiator, or a thermally-curable resin and thermal initiator, wherein the radiation- or thermally-curable resin and the respective initiator form a pre-cured coating mixture capable of forming a macroscopic texture upon application of the mixture on a substrate. In another embodiment the present invention provides a pre-cured coating mixture comprising a radiation- or thermally-curable resin, an initiator, and texture-producing particles having an effective size to provide a macroscopic texture upon application of the mixture on a substrate. In another embodiment, the present invention provides a coated substrate comprising a substrate and a radiation- or thermally-cured coating on at least a portion of the substrate, wherein the coating comprises an inherent macroscopic texture.In addition, the present invention provides a process for making a coating on a substrate, comprising the steps of distributing a pre-cured coating mixture comprising a radiation-curable resin and an initiator or a thermally-curable resin and thermal initiator over at least a portion of a substrate to form a pre-cured coating having a macroscopic texture, and radiation-curing or thermally curing, respectively, the pre-cured coating to form a radiation-cured or thermally-cured coating having the macroscopic texture.

Owner:LAW DEBENTURE TRUST COMPANY OF NEW YORK

Method for reducing nesting in paper products and paper products formed therefrom

InactiveUS7235156B2Non-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryEngineering

A multi-layered paper product that has bridging regions for inhibiting nesting is provided. For example, the paper product can contain a first and second layer that define ridges and valleys. Bridging regions are formed into at least one of the outer surfaces of the layers. In particular, the bridging regions are positioned at an angle of between about 0° to about 180° relative to the ridges and also have a length sufficient to extend between the peaks of at least two of the ridges. The bridging regions can be formed in a variety of ways, such as with an embossing roll that contains embossing elements. Moreover, the bridging regions can also have a variety of shapes, sizes, orientations, and / or patterns.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Bipolar plate for fuel cell and method for production thereof

InactiveUS20040247978A1Low costSimple structureFinal product manufactureDecorative surface effectsFuel cellsMetal alloy

In a bipolar plate for a fuel cell including a metal substrate and a metallic coating formed on at least part of a surface of the metal substrate, the durability or the resilience is elevated by suitably selecting a material or a shape of the metal substrate and / or the metallic coating. The material of the metal substrate includes one or more of metals or metal alloys selected from a group consisting of iron, nickel, alloys thereof and stainless steel; and the metallic coating includes a combination of conductive platinum-group metal oxides. The metal substrate may be a thermally oxidized substrate, and the metallic coating may be a conductive oxide. Further, the metallic coating may be a metallic porous element or a metallic porous element having a passivity prevention layer on the surface thereof.

Owner:FURUYA KINZOKU KK

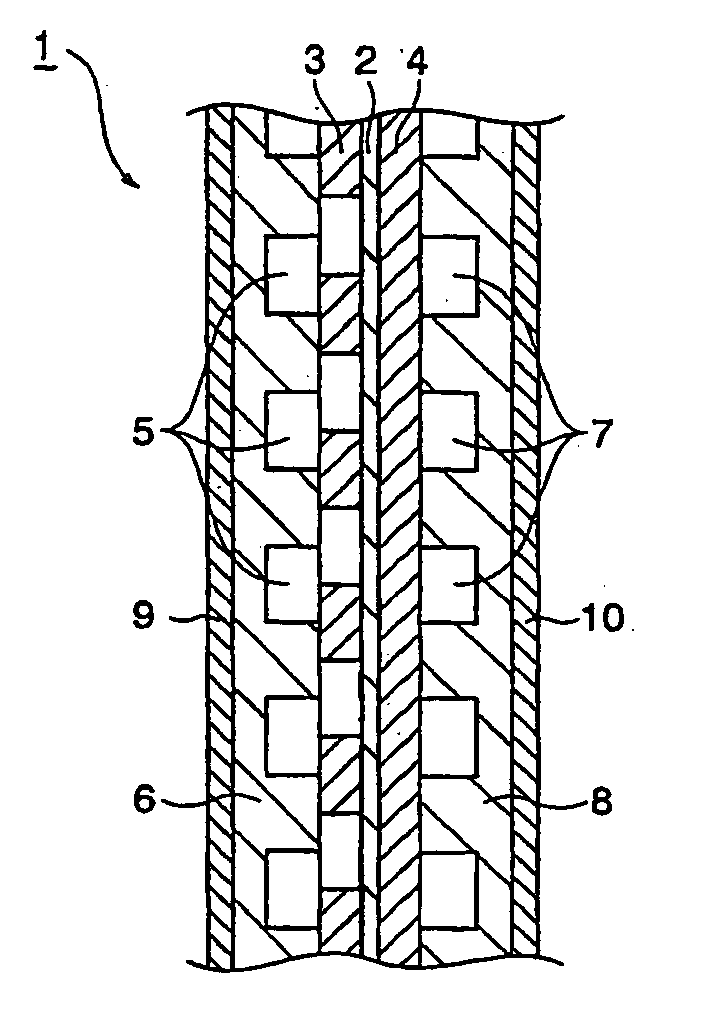

Absorptive article and method of producing the same

InactiveUS20110071486A1Gentle change of rigidityLess discomfortLamination ancillary operationsOrnamental structuresEngineeringEdge region

An absorbent article with high fitting property and high absorptivity, where the end part is less deformed, is provided.An absorbent article comprising at least a liquid-permeable sheet, a liquid-impermeable sheet, and an absorber sandwiched between the liquid-permeable sheet and the liquid-impermeable sheet, wherein the absorber comprises a first absorbing part and a second absorbing part formed nearly on the center part of the first absorbing part and smaller in the area than the first absorbing part, and a compressed groove is continuously provided in nearly closed form to extend from the peripheral edge region in the longitudinal direction of the second absorbing part to the first absorbing part.

Owner:UNI CHARM CORP

Electrically conductive compositions and method of manufacture thereof

A method for manufacturing a conductive composition comprises blending a polymer precursor with a single wall carbon nanotube composition; and polymerizing the polymer precursor to form an organic polymer. The method may be advantageously used for manufacturing automotive components, computer components, and other components where electrical conductivity properties are desirable.

Owner:SABIC INNOVATIVE PLASTICS IP BV

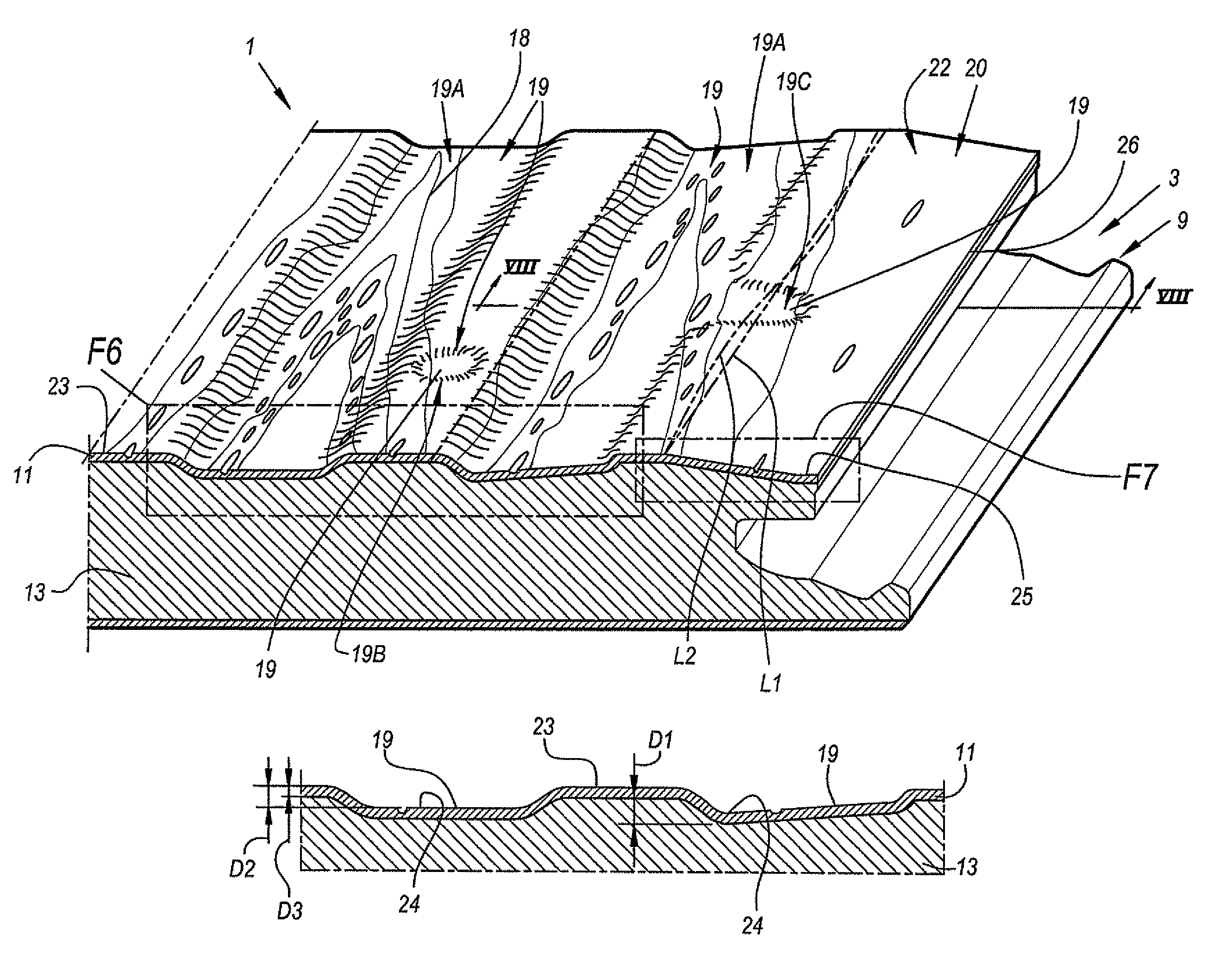

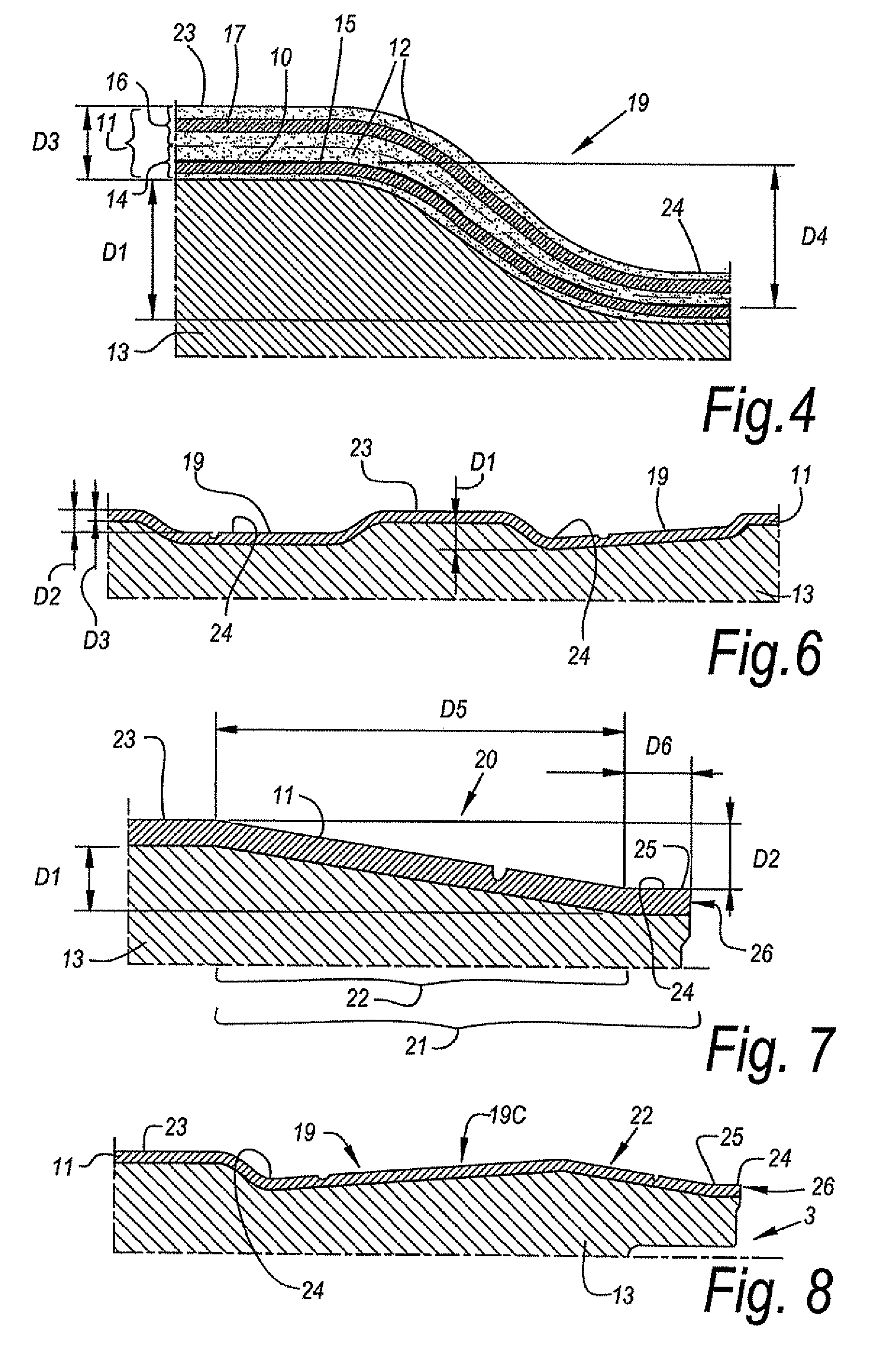

Floor panel, as well as method, device and accessories for manufacturing such floor panel

ActiveUS8272187B2Precise applicationRoof covering using tiles/slatesNatural patternsSynthetic materialsEngineering

Floor panel, more particularly a laminate floor panel, wherein this floor panel comprises a decor, a top layer on the basis of synthetic material, and an underlying substrate (13), whether or not composed of several layers or parts, wherein the floor panel (1), in the surface over which the decor (10) extends, is provided with embossed portions.

Owner:FLOORING IND LTD

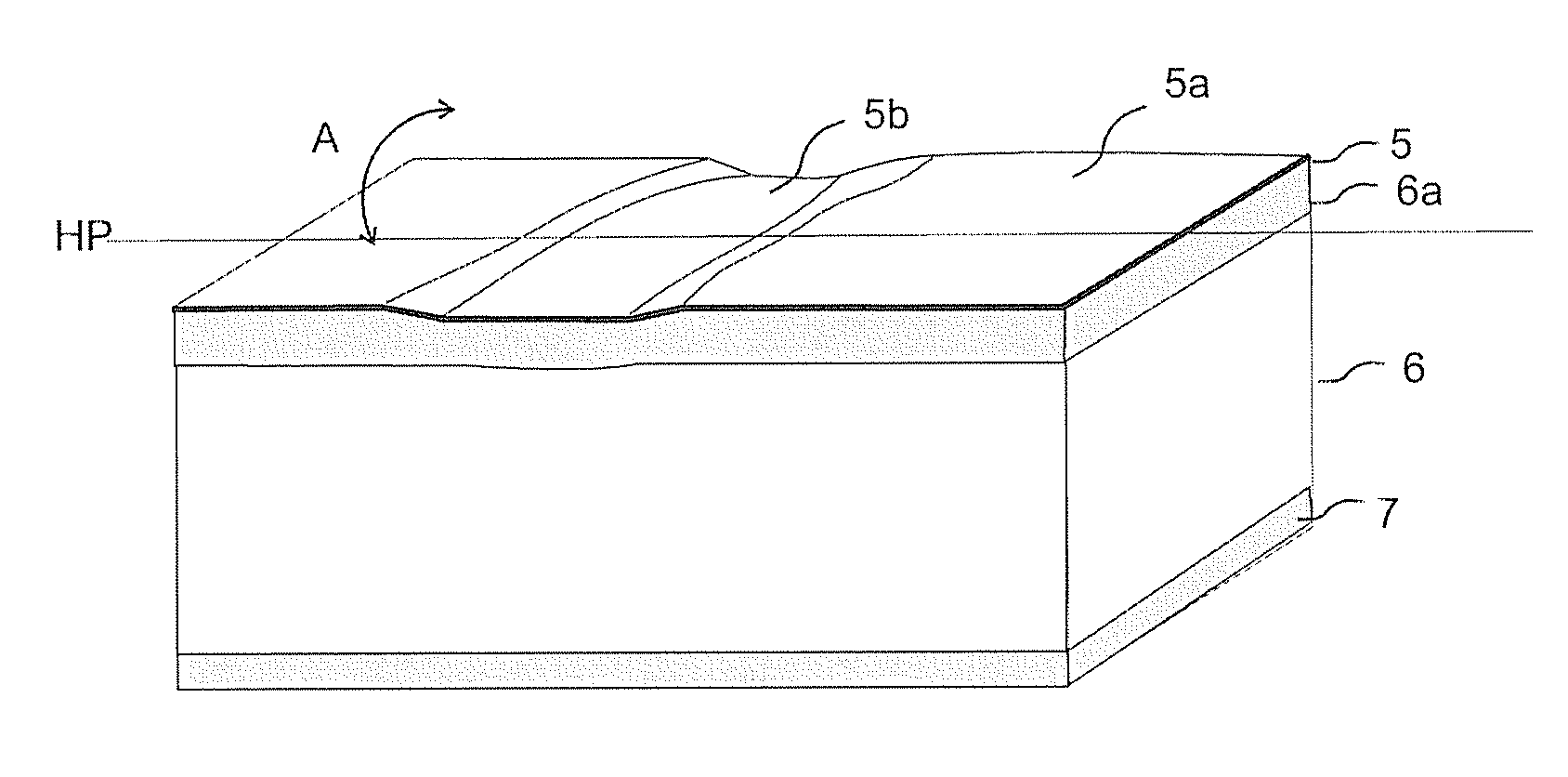

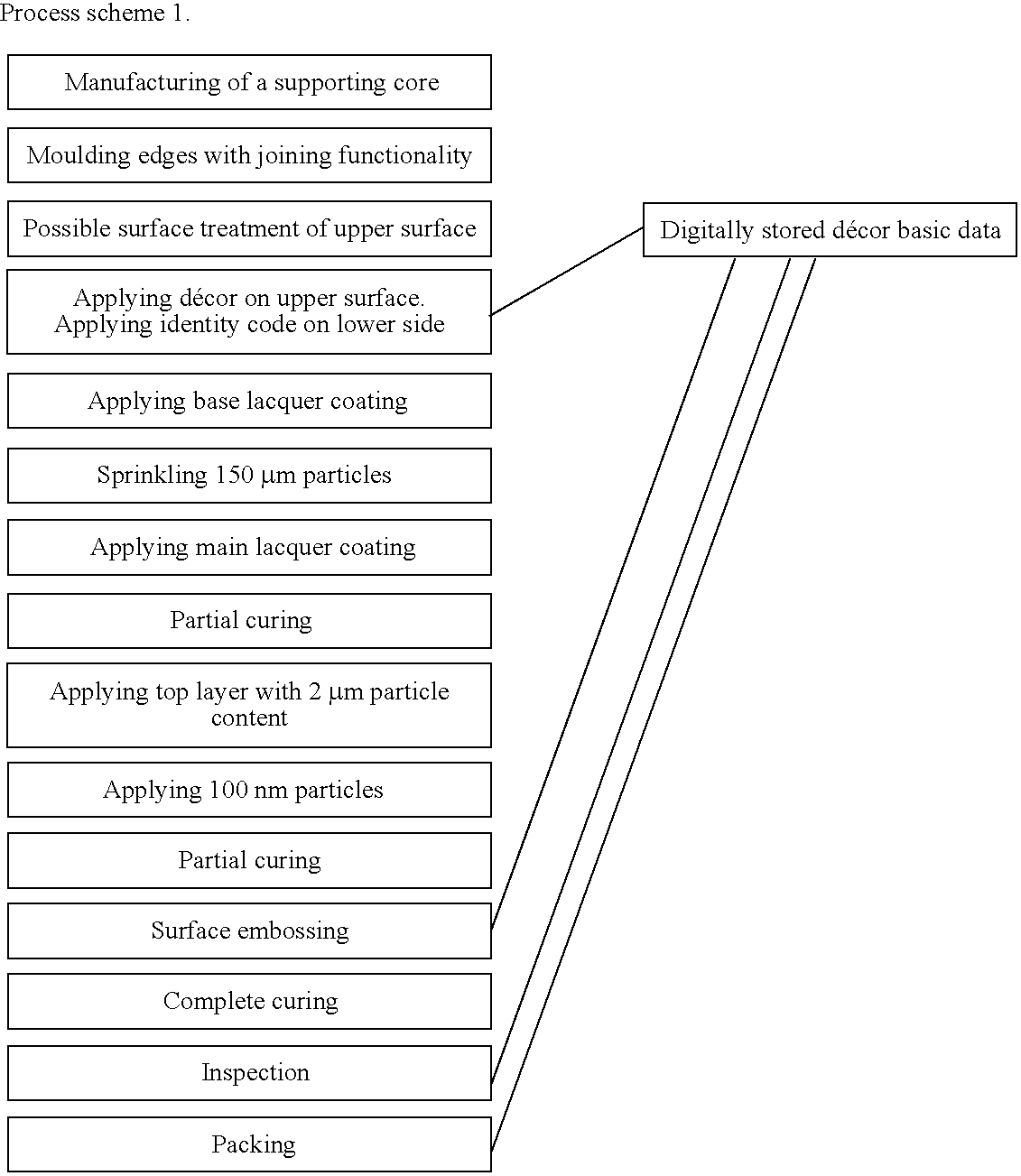

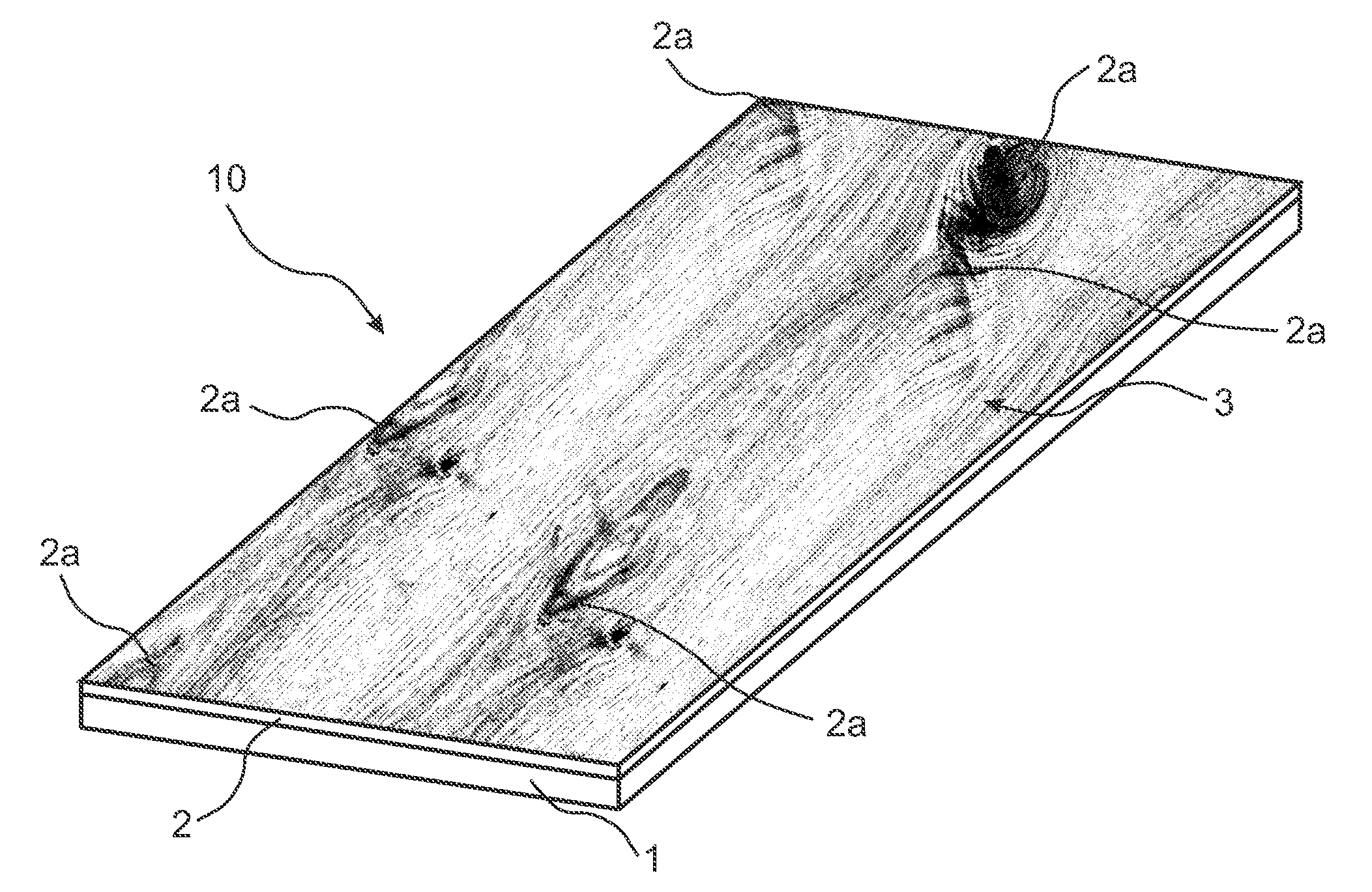

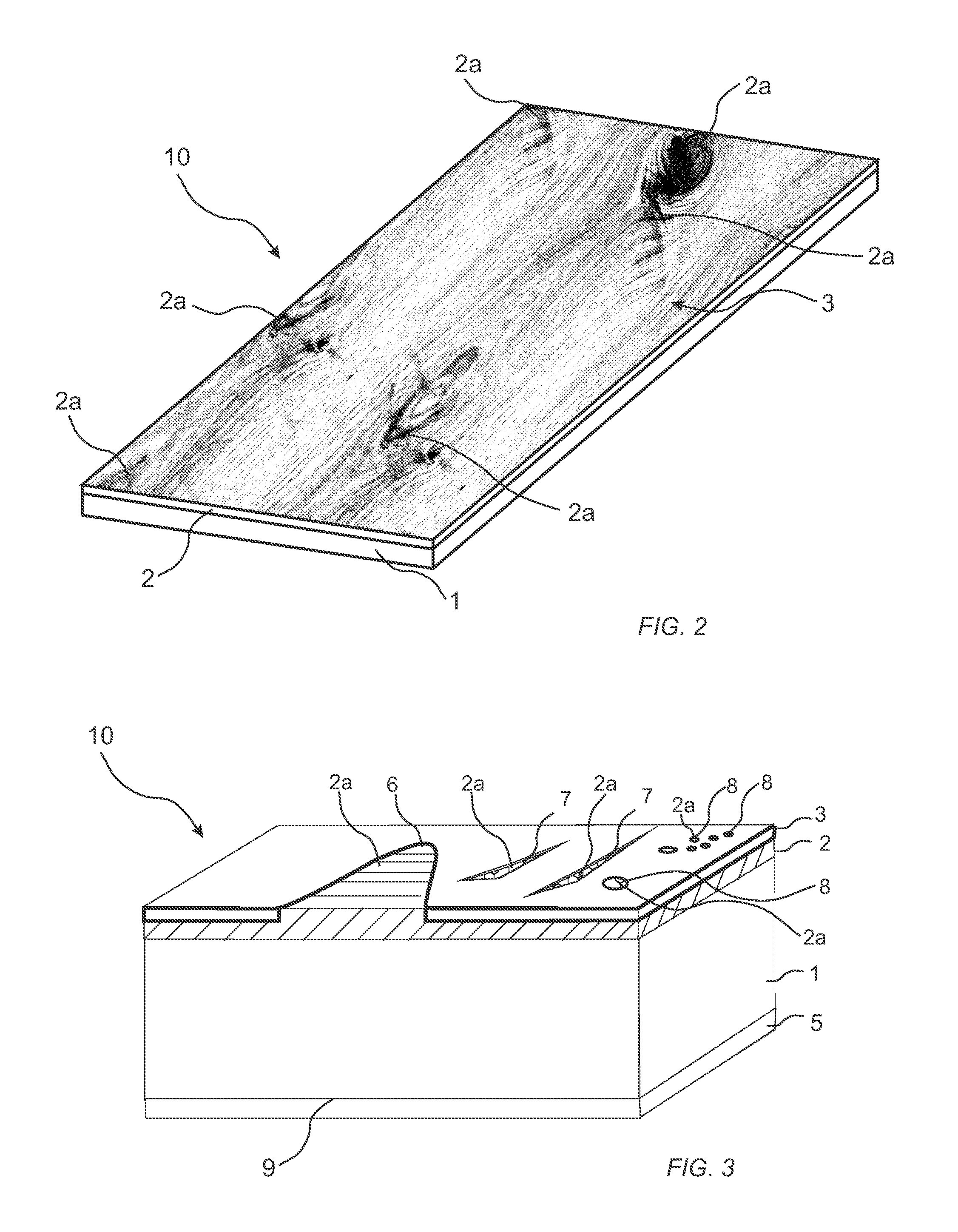

Method of producing a veneered element

ActiveUS20150197943A1Improve wear resistanceDecorative surface effectsOrnamental structuresEngineering

A method of producing a veneered element (10), including providing a substrate (1), applying a sub-layer (2) on a surface of the substrate (1), applying a veneer layer (3) on the sub-layer (2), and applying pressure to the veneer layer (3) and / or the substrate (1), such that at least a portion of the sub-layer (2) permeates through the veneer layer (3). Also, such a veneered element (10).

Owner:VÄLINGE INNOVATION AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com