Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8756results about "Construction material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

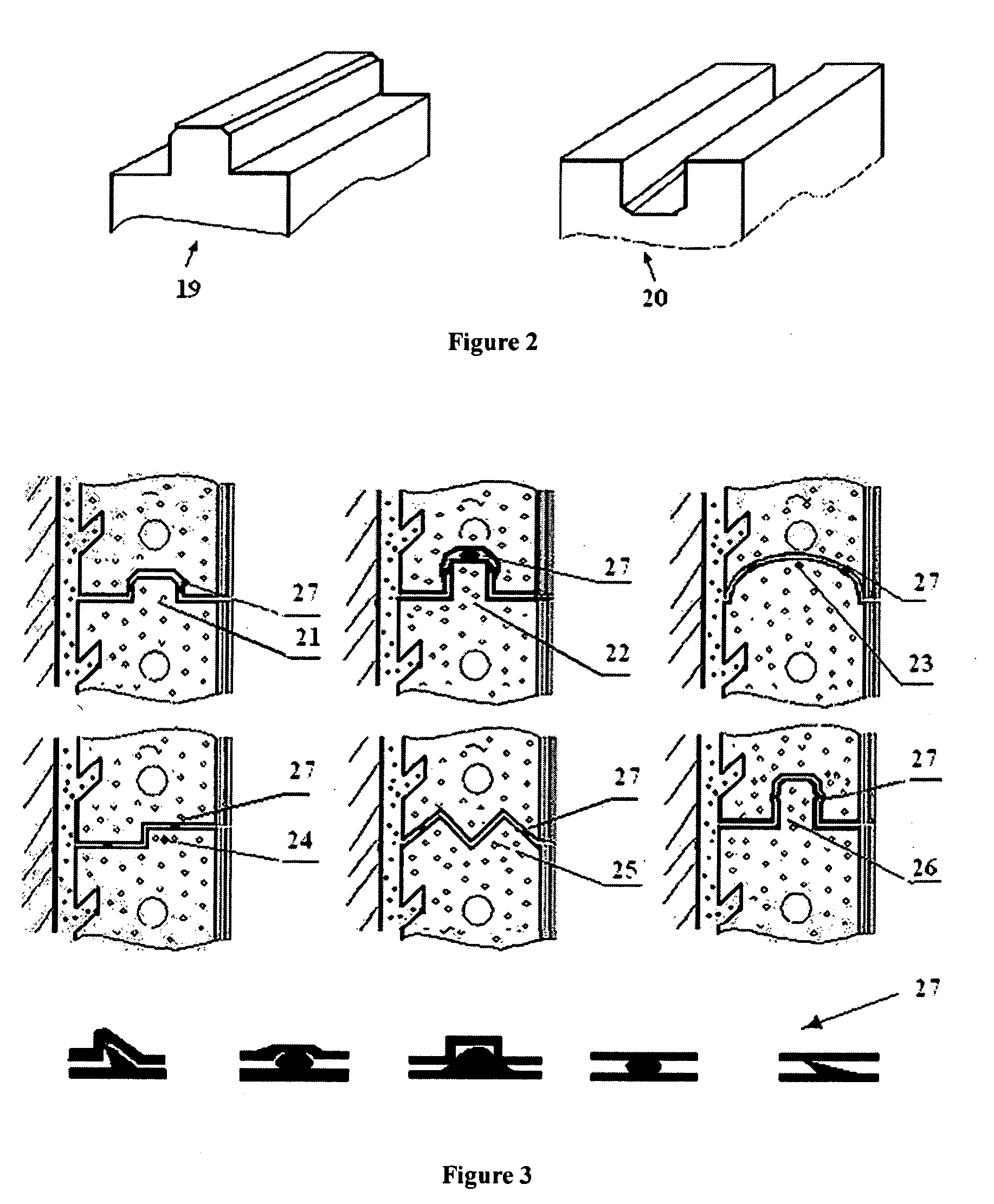

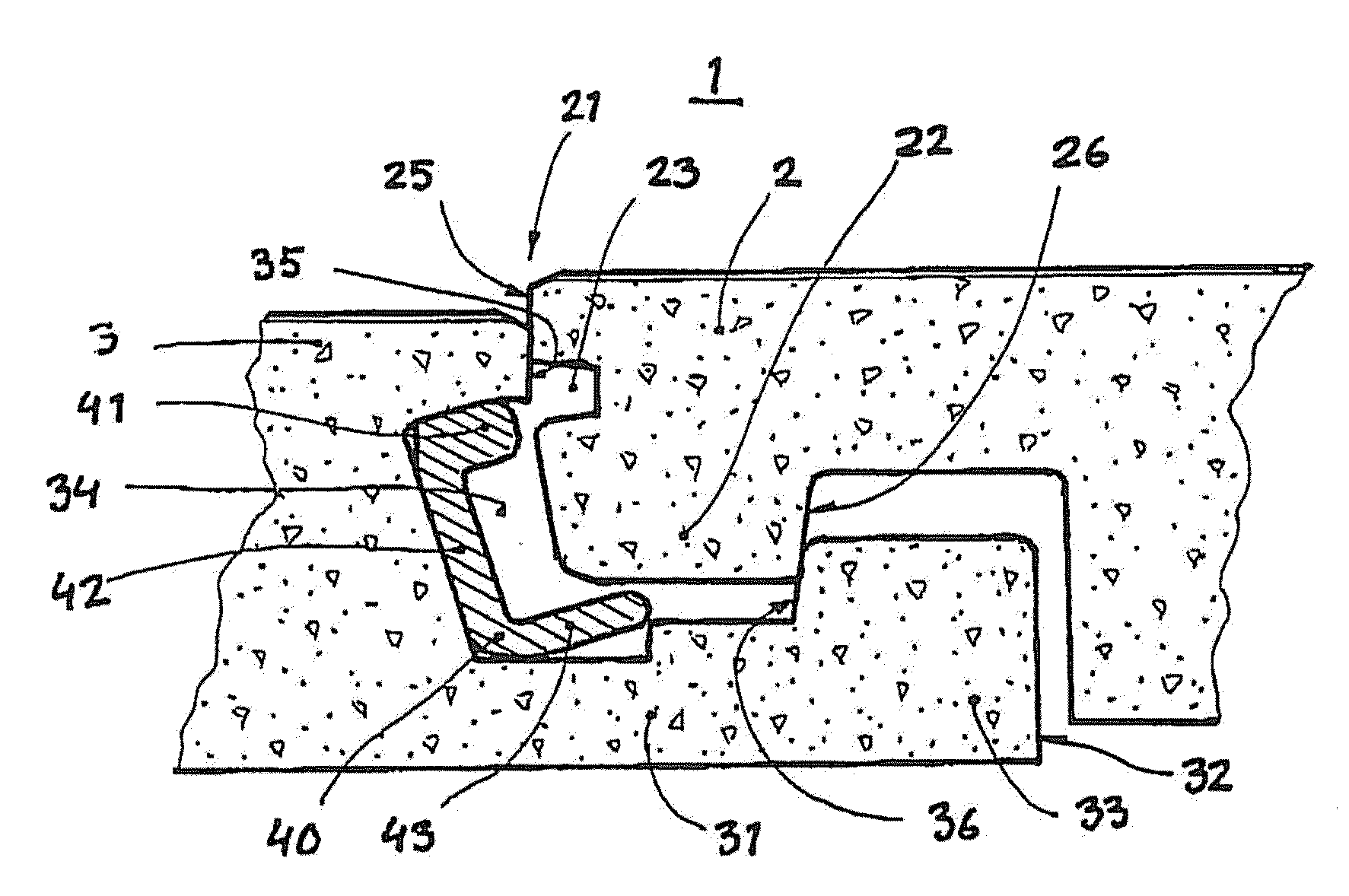

Joint for panels

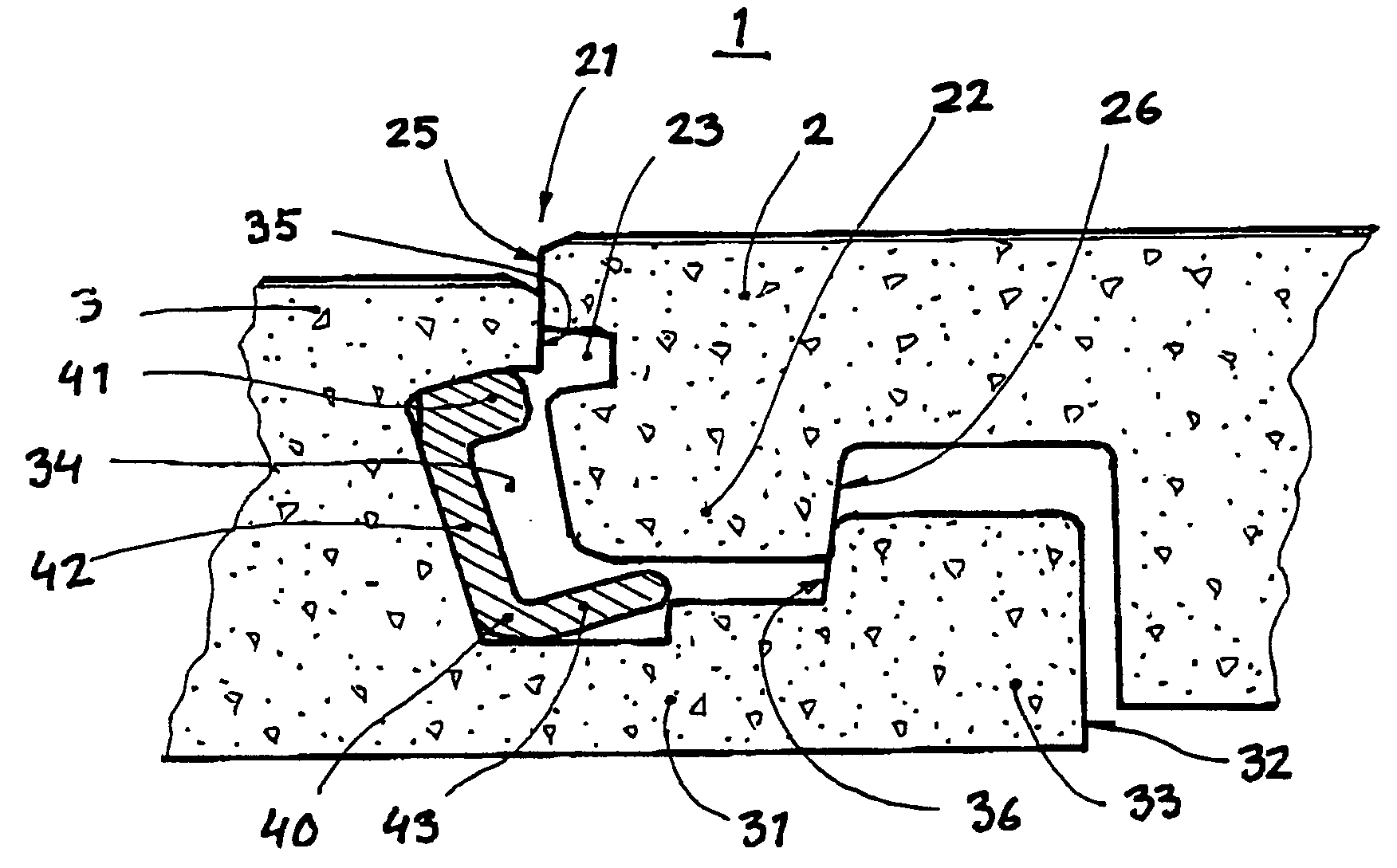

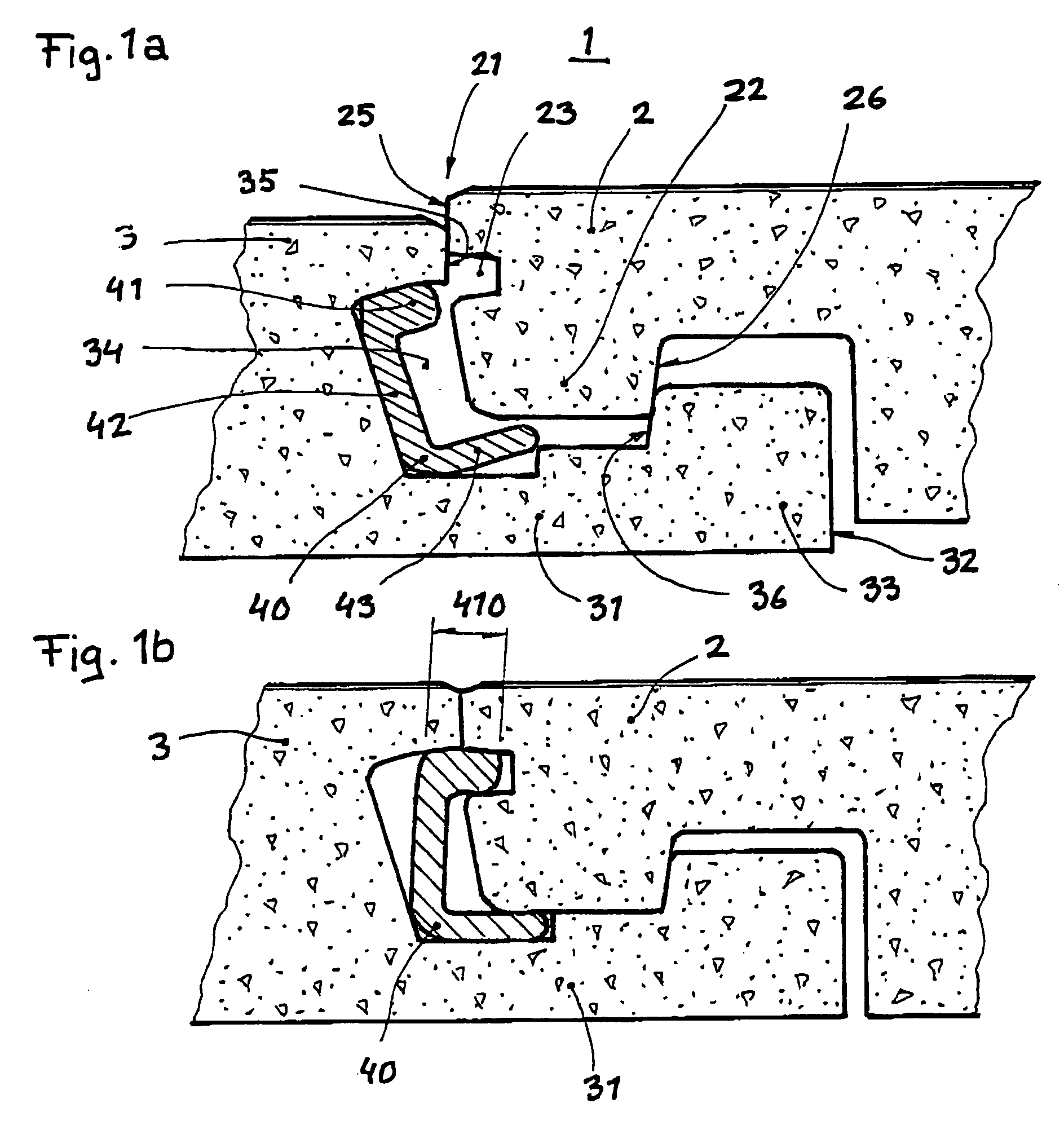

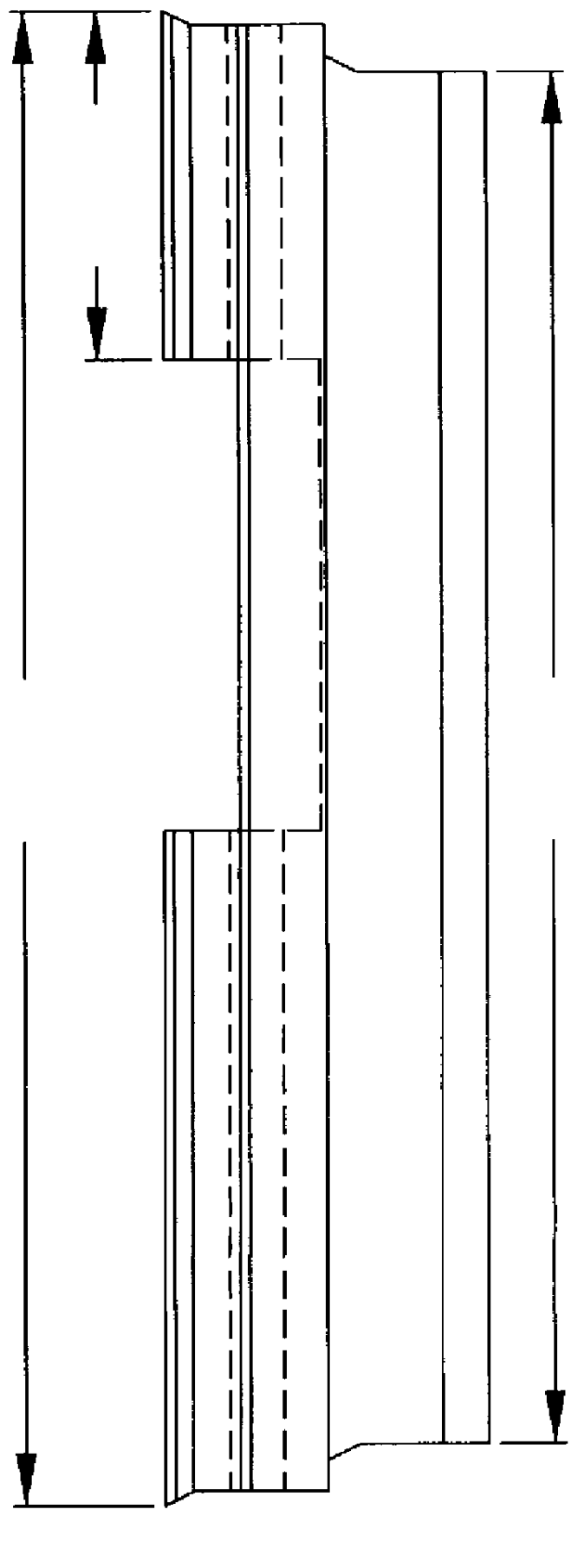

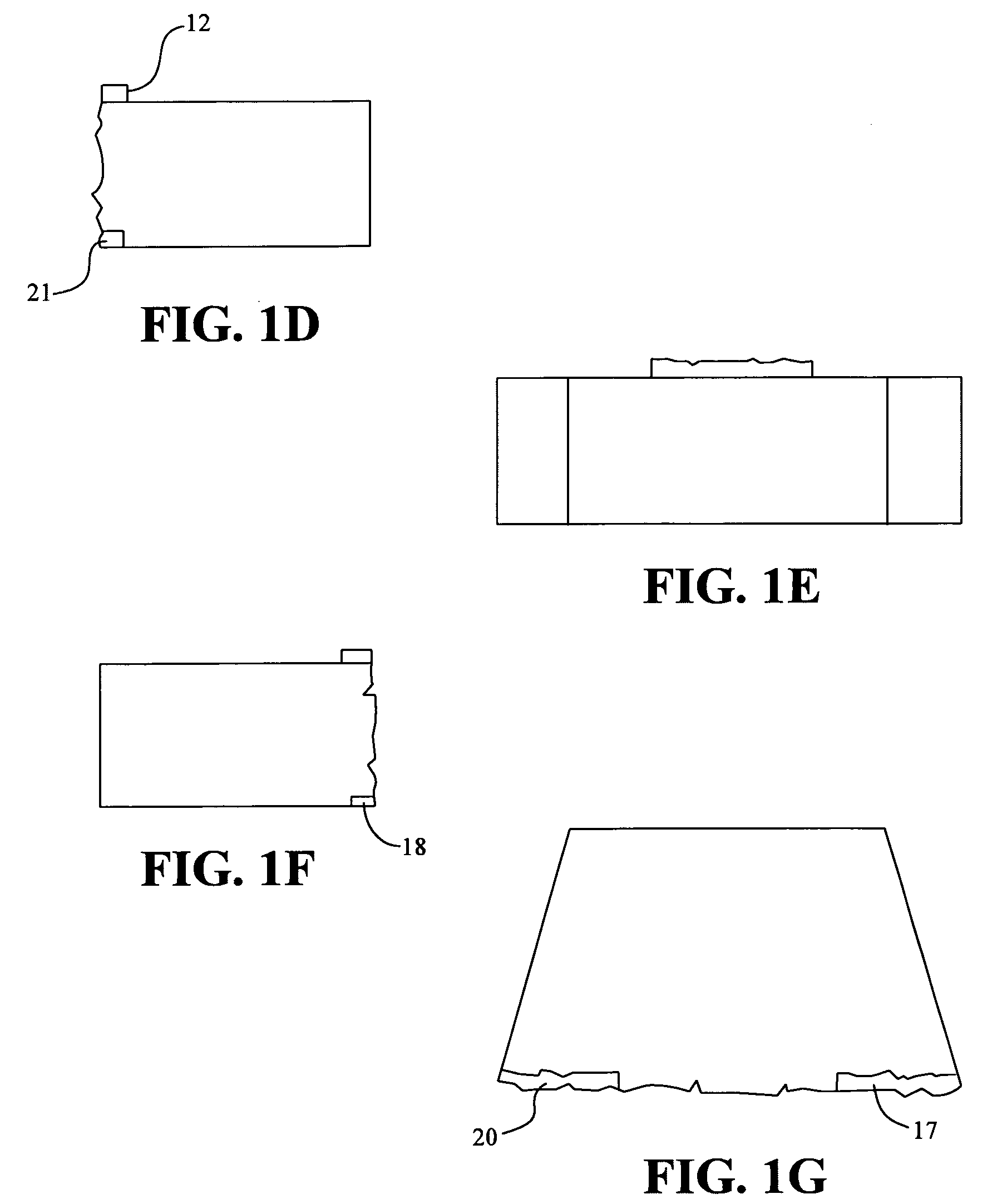

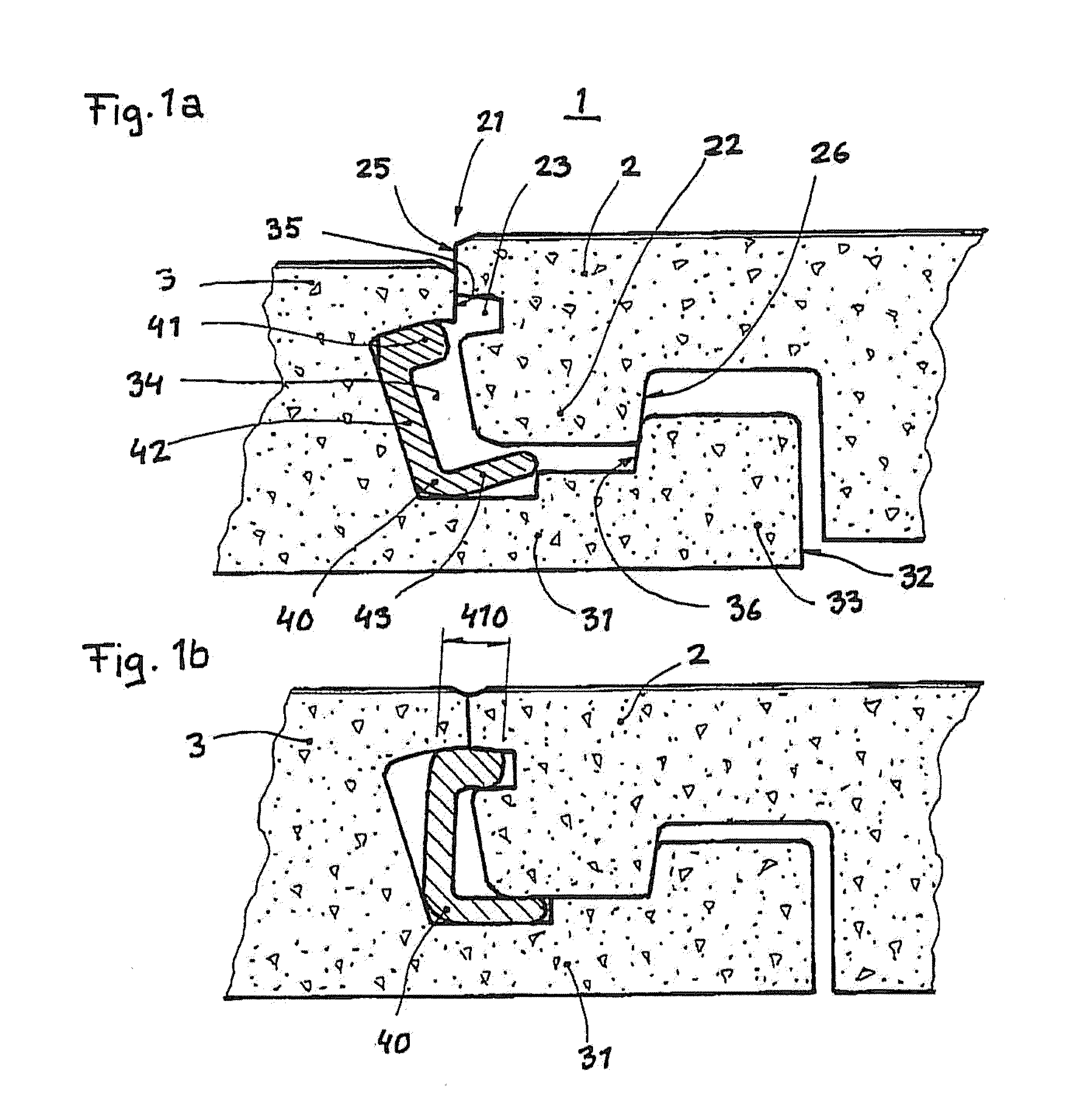

A joint (1) having a first edge (2) and a second edge (3), the first edge (2) being provided with a distal edge (21) and a downwards protruding heel (22) The distal edge (21) is further provided with an upper joint edge (25) beneath which a groove (23) is arranged. The second edge (3) is provided with lower cheek (31) having a distal end (32) at which an upwards protruding lower cheek heel (33) is arranged. The second edge (3) is further provided with an upper joining edge (35) beneath which an undercut (34) is arranged. A moveable locking element (40) is arranged in the space created by the undercut (34). The moveable locking element (40) have a locking tongue (41), a locking tongue leg (42) and a manoeuvring leg (43).

Owner:PERGO

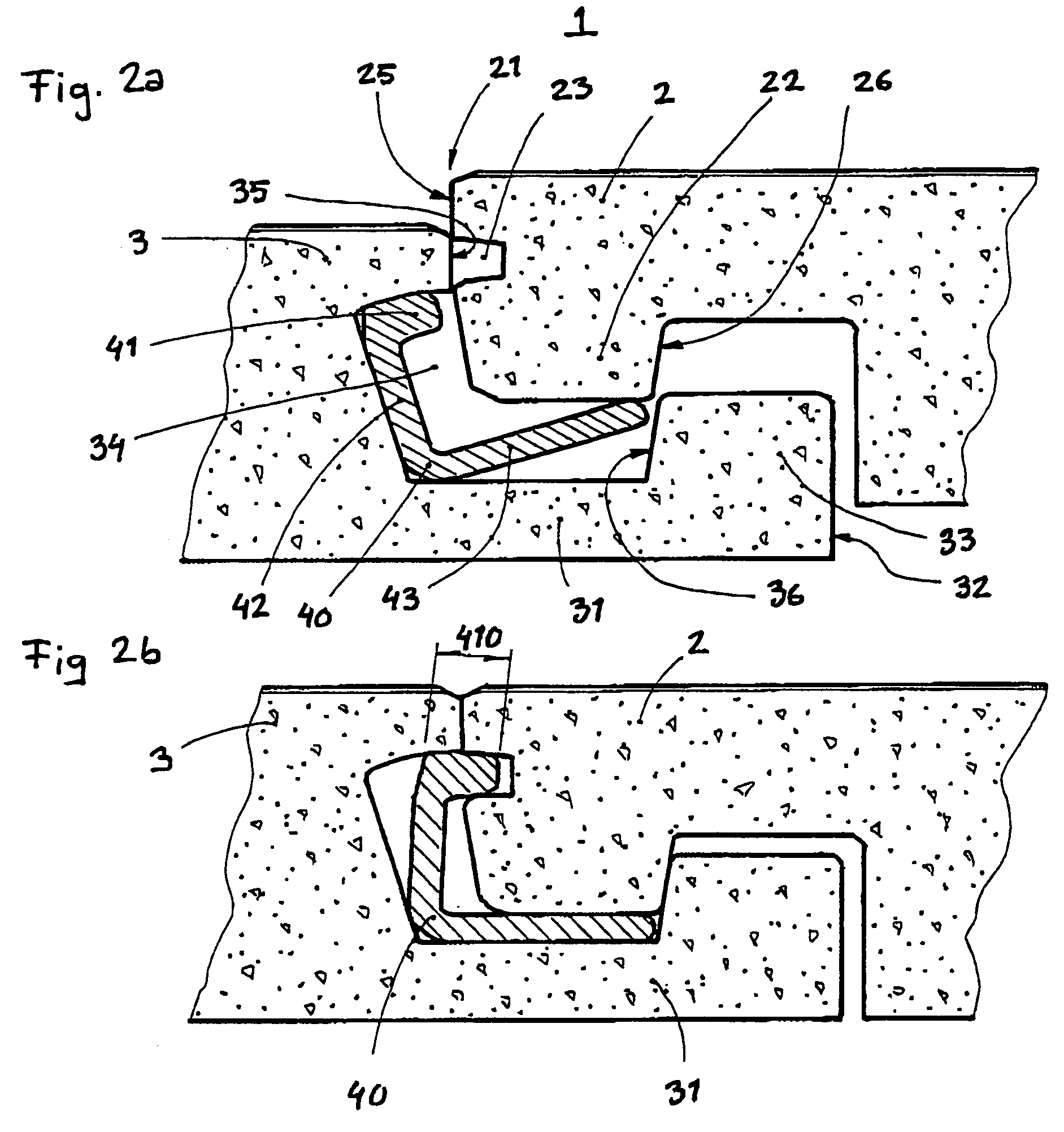

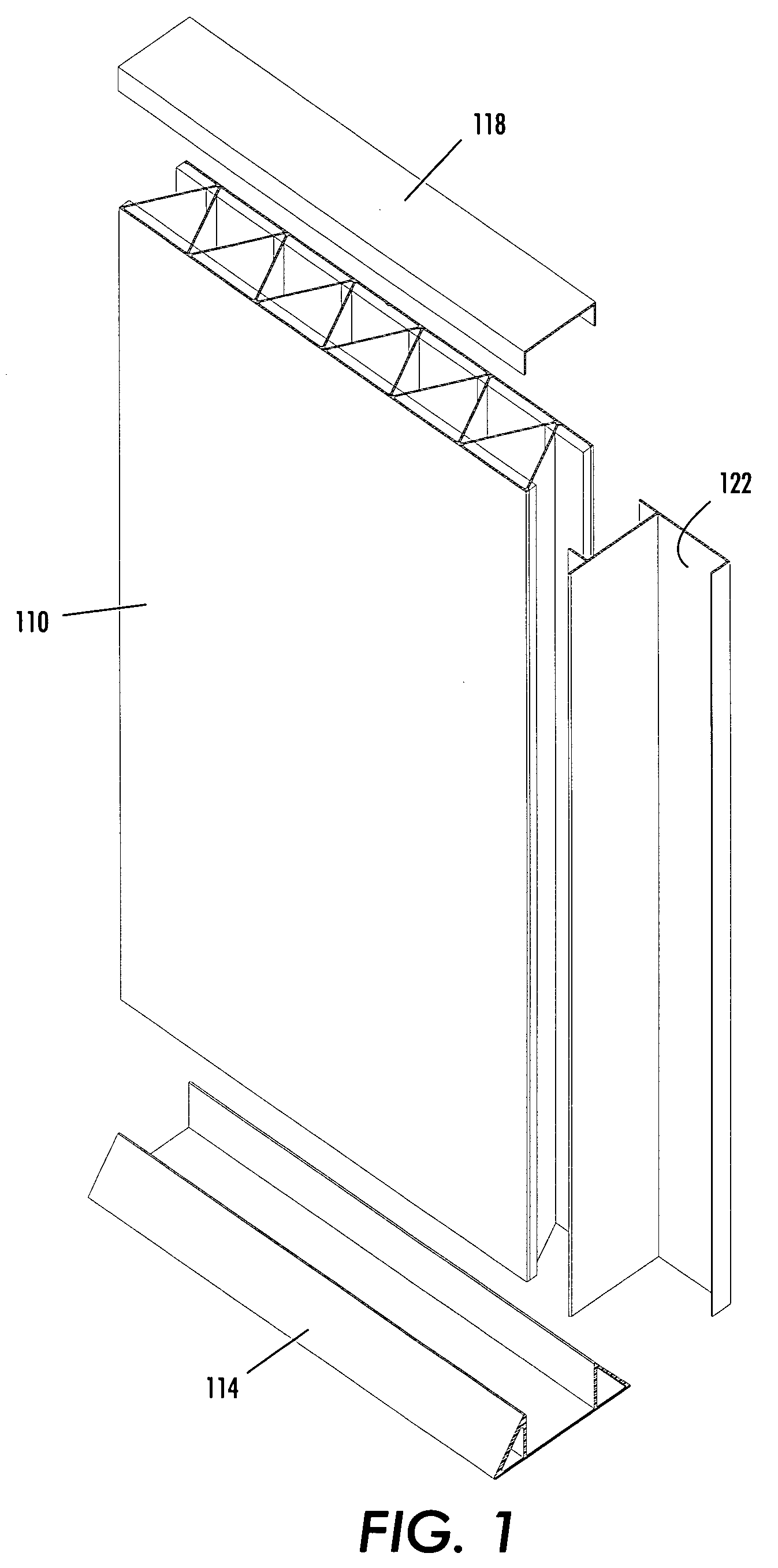

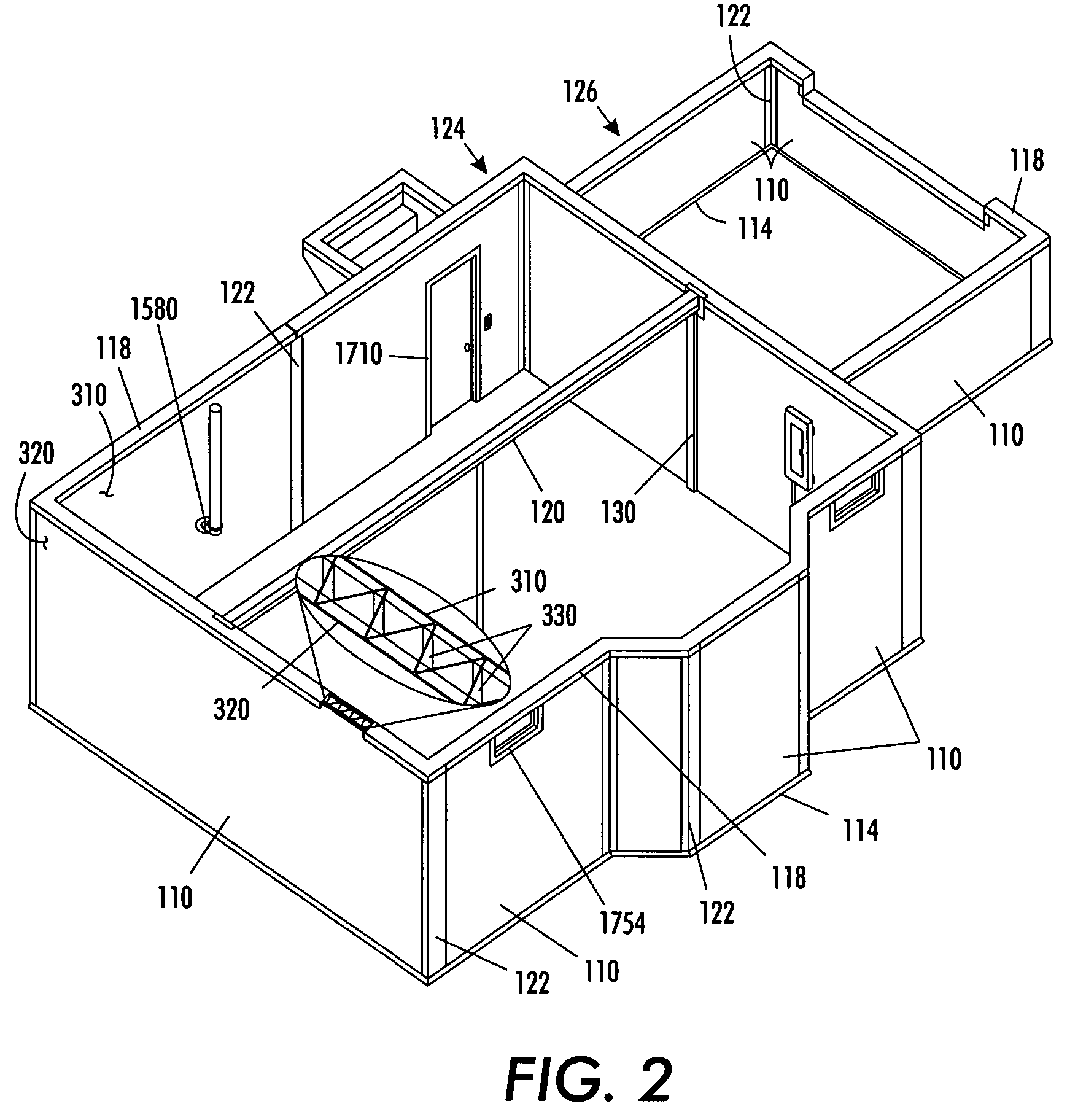

System for modular building construction

InactiveUS20080134589A1Facilitating selective interconnectionGood choiceConstruction materialLighting and heating apparatusEnvironmental systemsModular unit

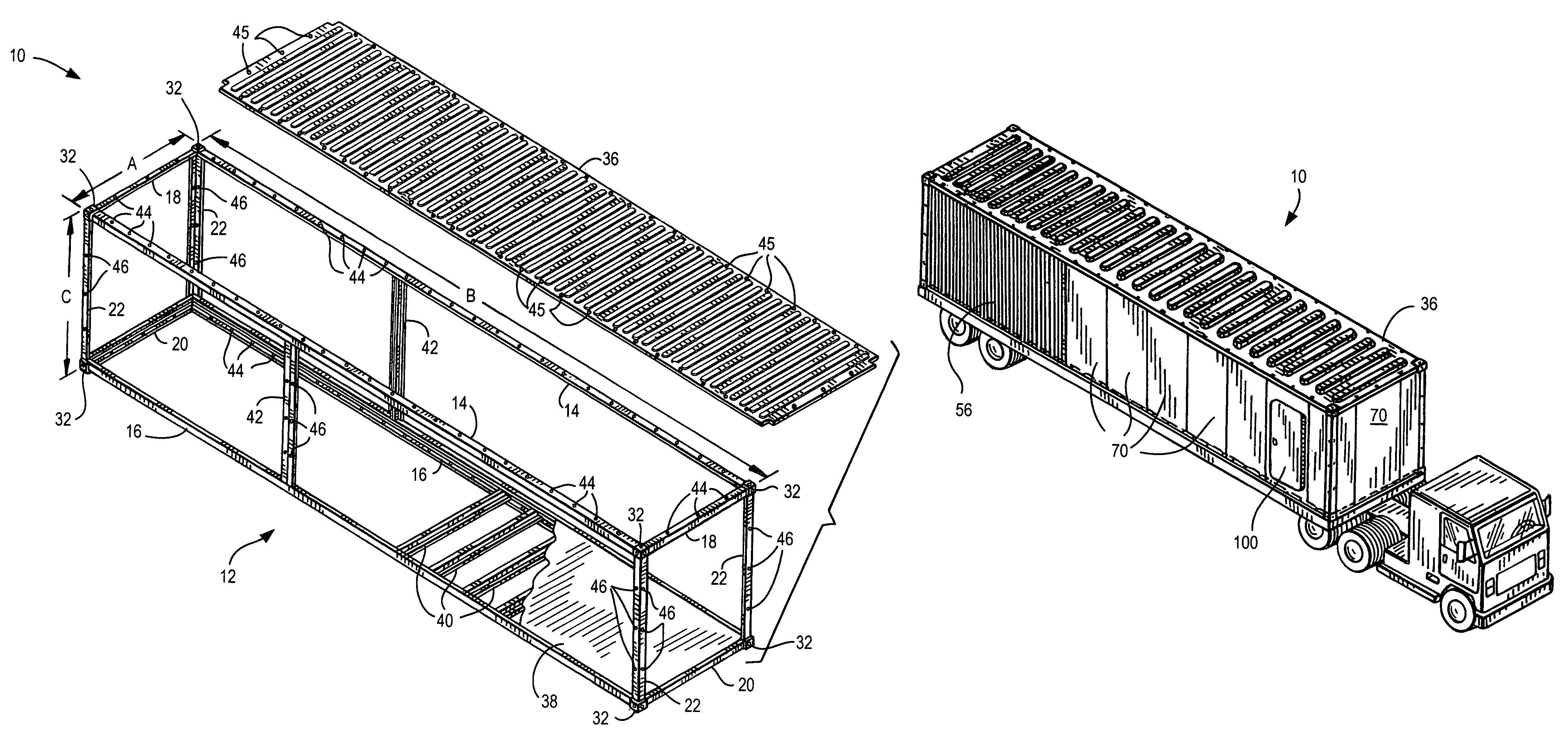

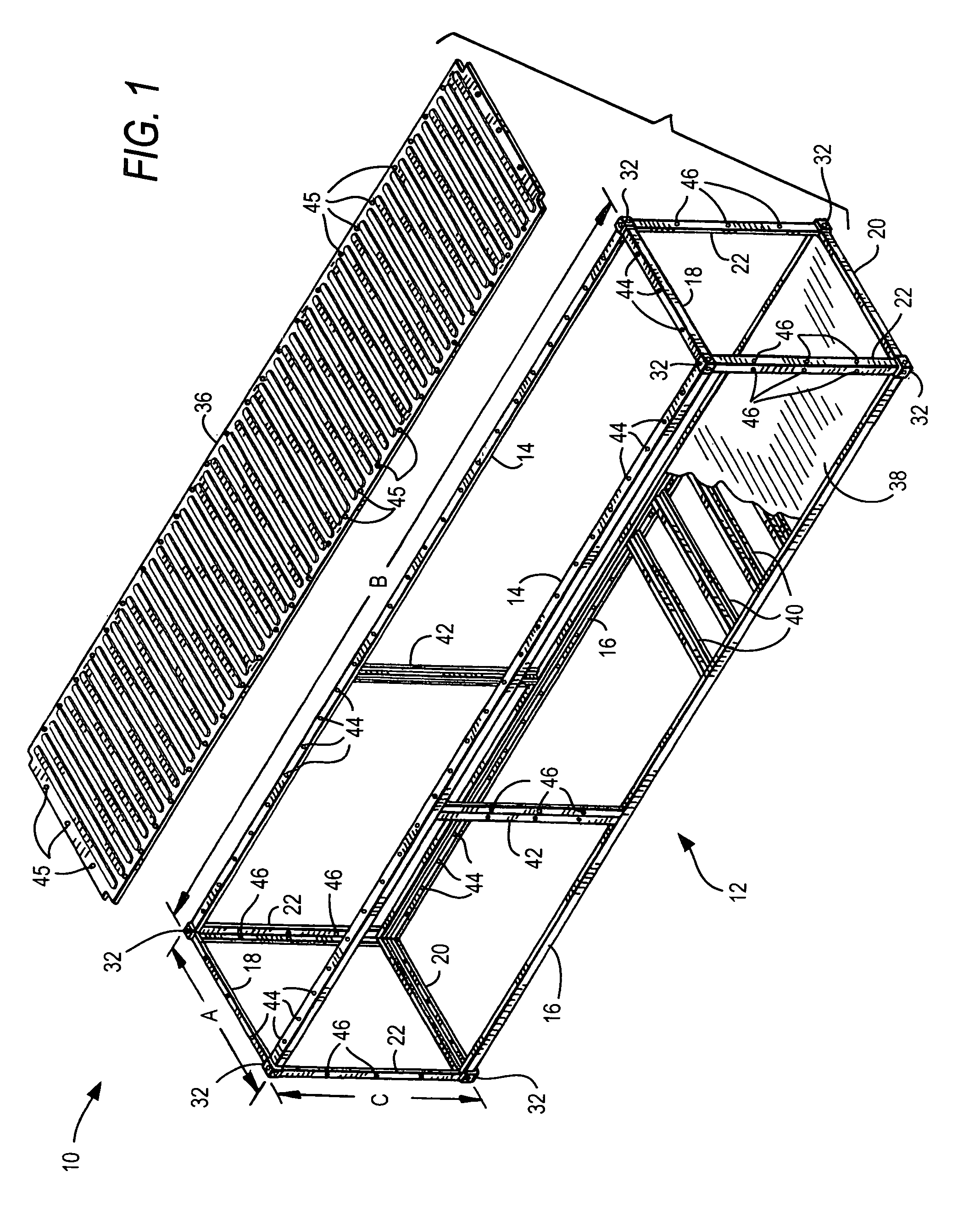

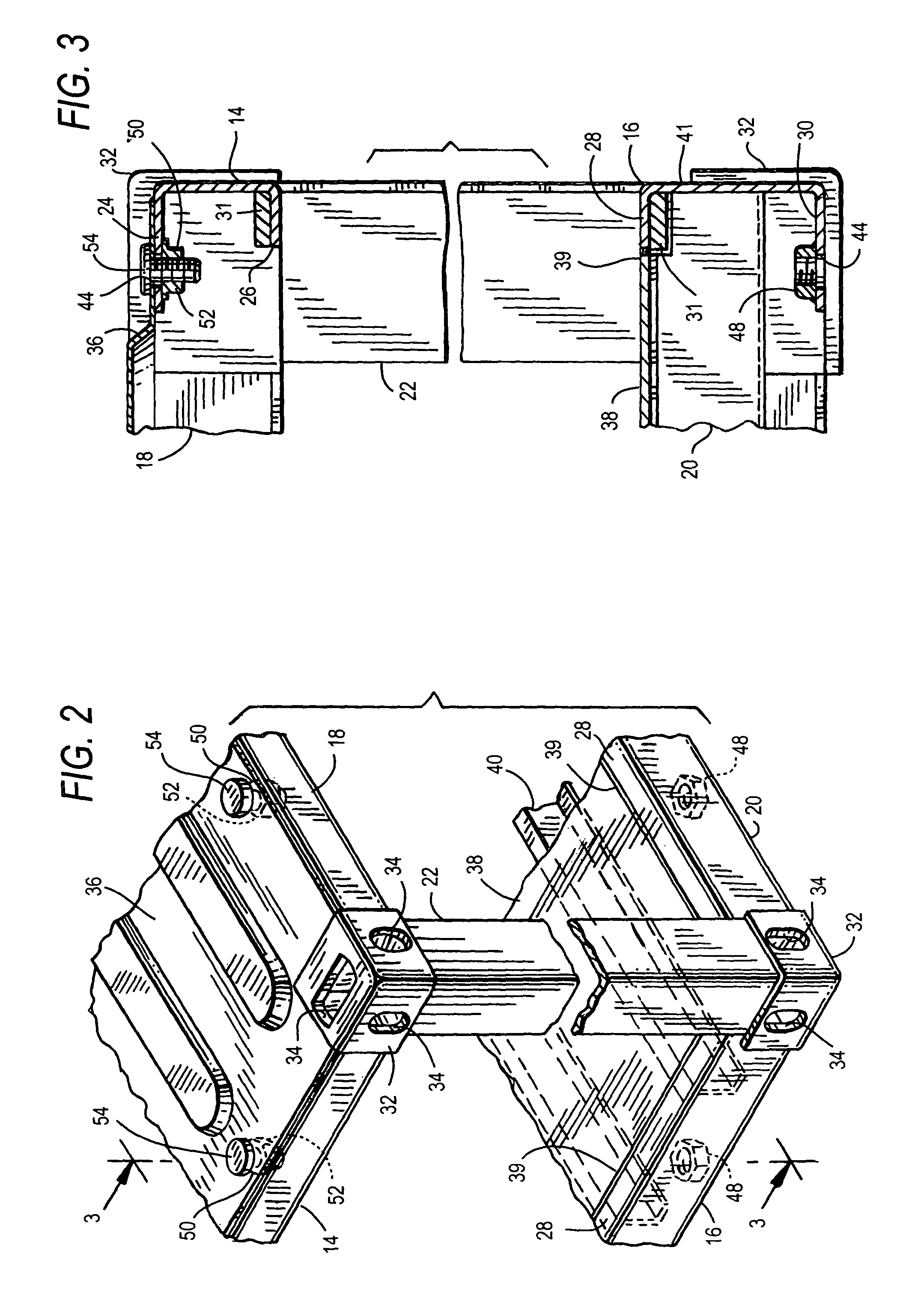

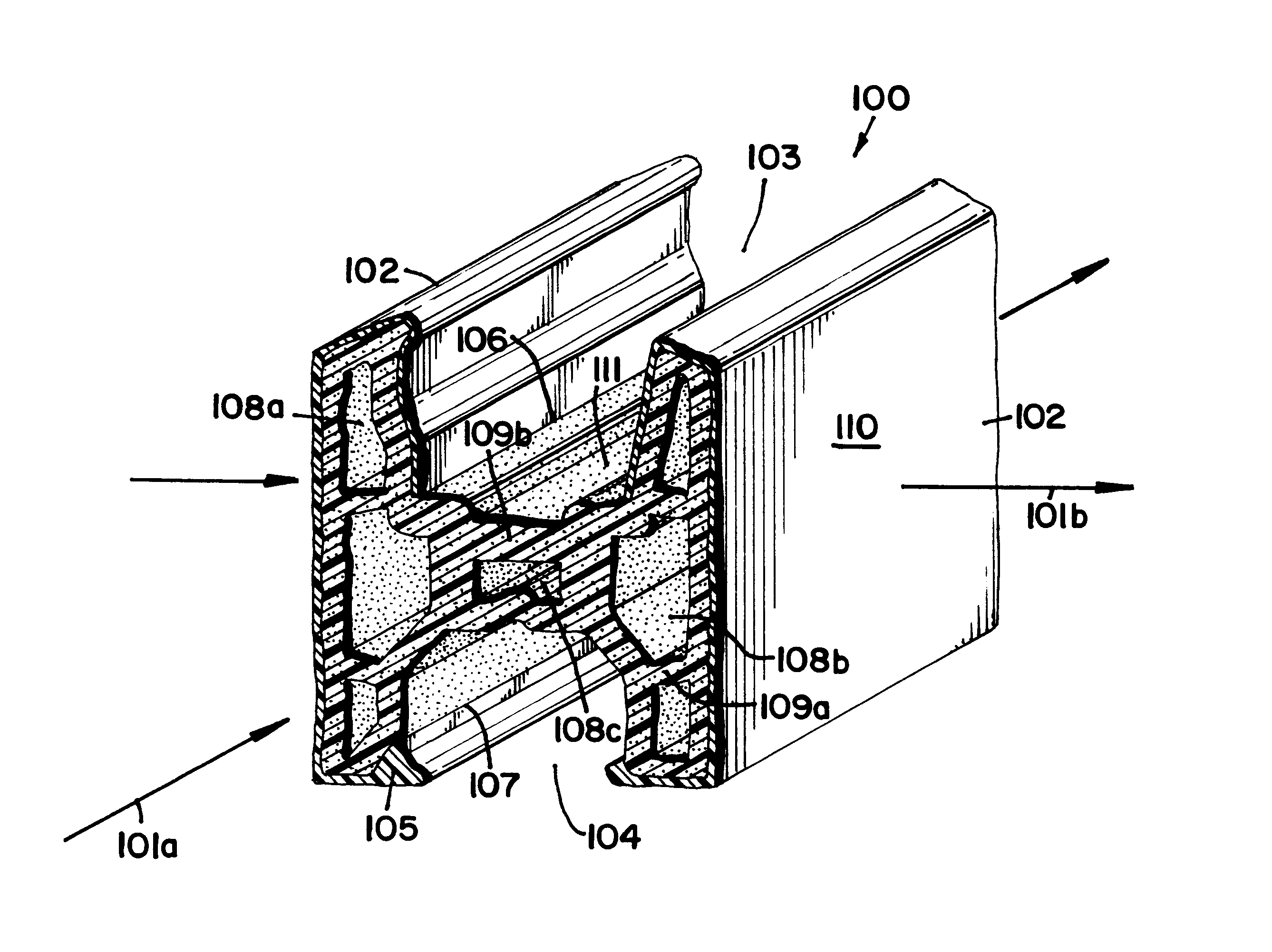

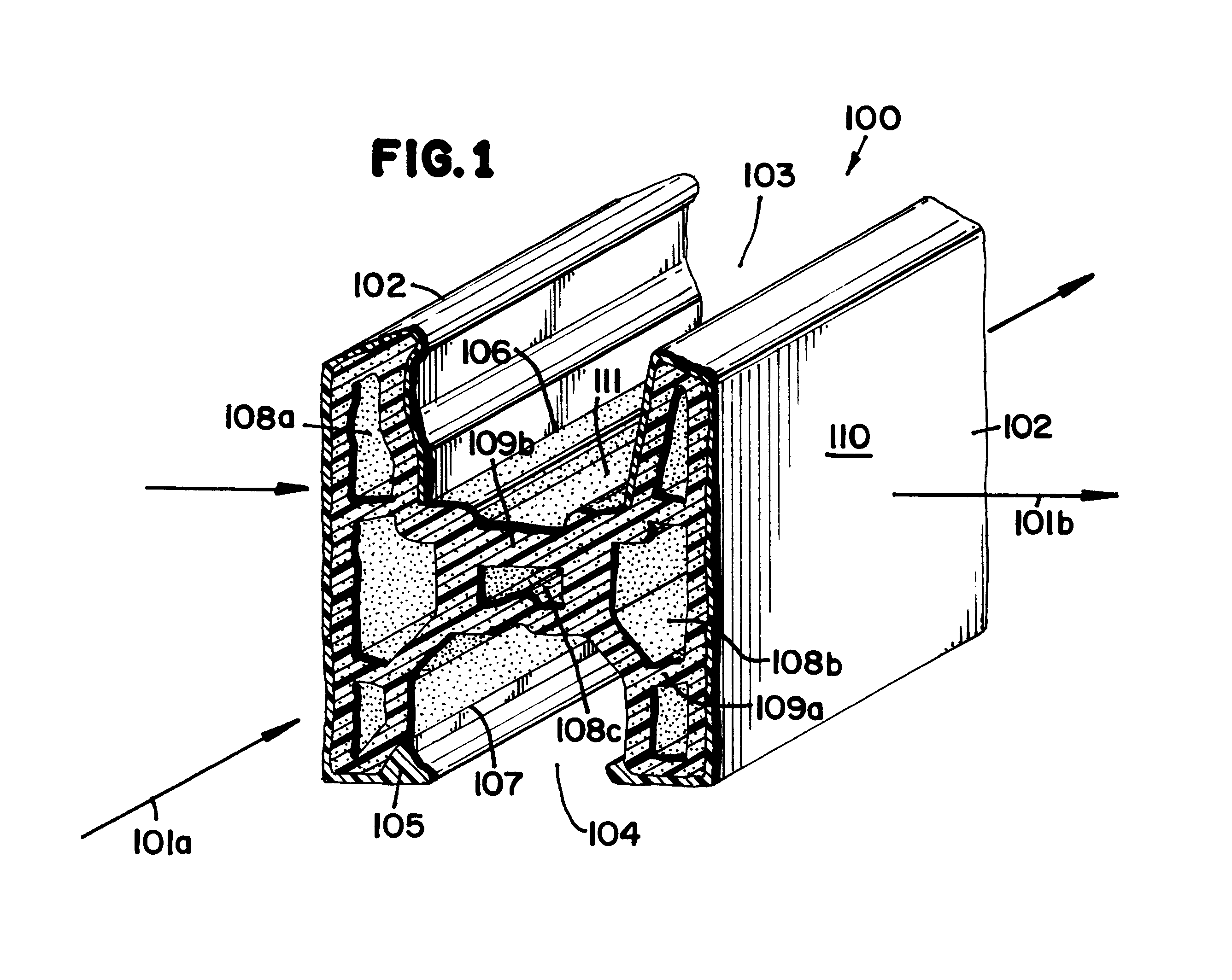

Construction systems for erecting building structures comprise a plurality of prefabricated interconnectable modular building units, each unit not meeting at least one of the ISO certification criteria for transport of cargo but each unit comprising a frame shaped as a rectangular parallelopiped and comprised of framing members and a plurality of nodes, each node situated at a corner of said frame for selective interconnection with other units, the nodes and the exterior dimensions of the frame conforming to ISO shipping standards such that each unit is transportable using the ISO intermodal transportation system, and such that when the units are aggregated horizontally and vertically and adjacent units are interconnected, a building structure comprising at least one habitable space is formed. The modular units are assembled in a factory remote from the job site, and are there constructed to a semi-finished state, including installation of one or more of interior fit-out systems and finishes, exterior envelope systems, plumbing systems, electrical systems, environmental systems, and fire protection systems, following which the semi-finished modular units are transported from the factory to the job site, where they are craned into place and secured to form the structure being erected, a plurality of adjacent pairs of semi-finished modular units also being “stitched” together, and the semi-finished modular units are thereafter constructed to a finished state.

Owner:GLOBAL BUILDING MODULES

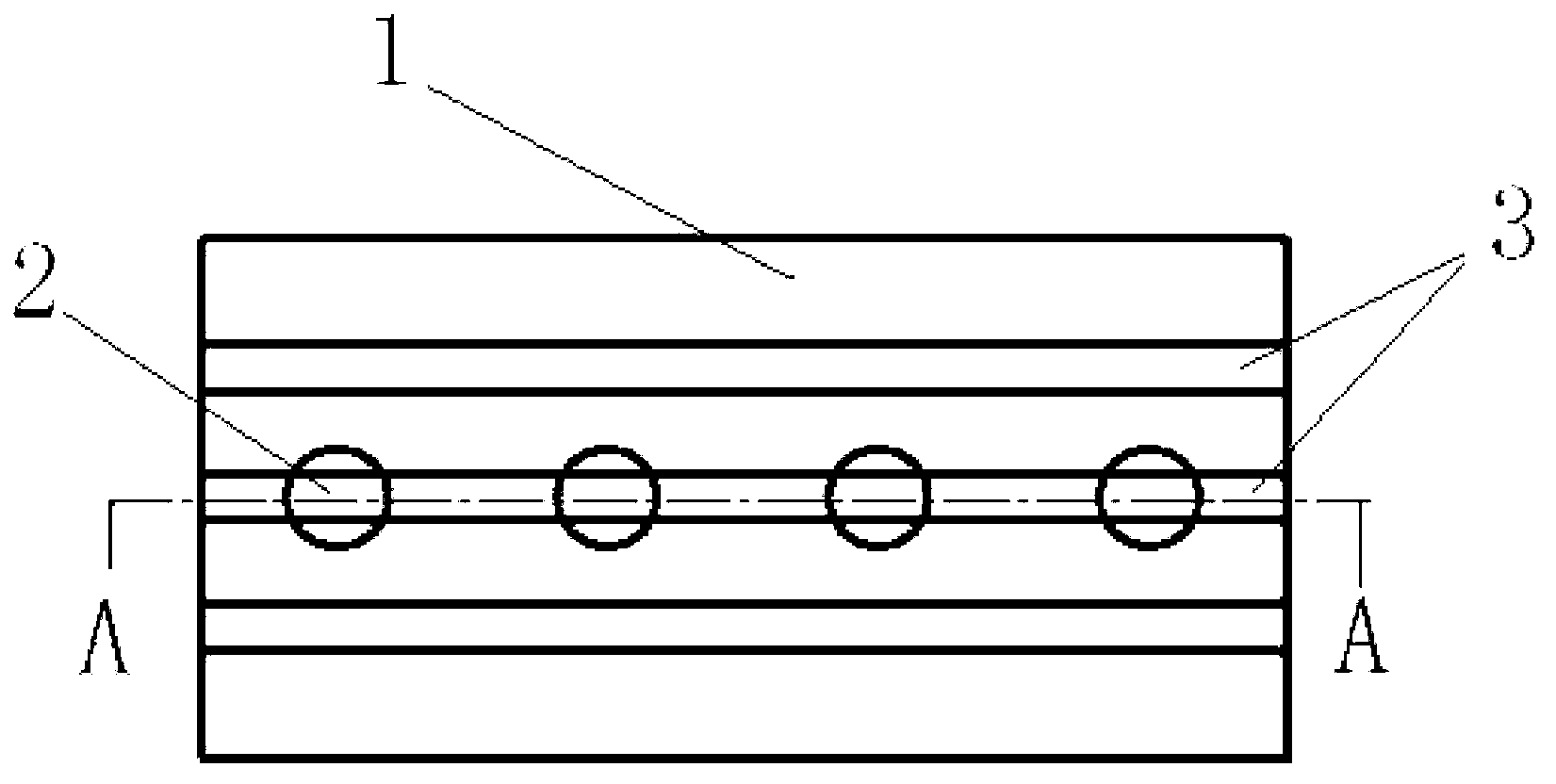

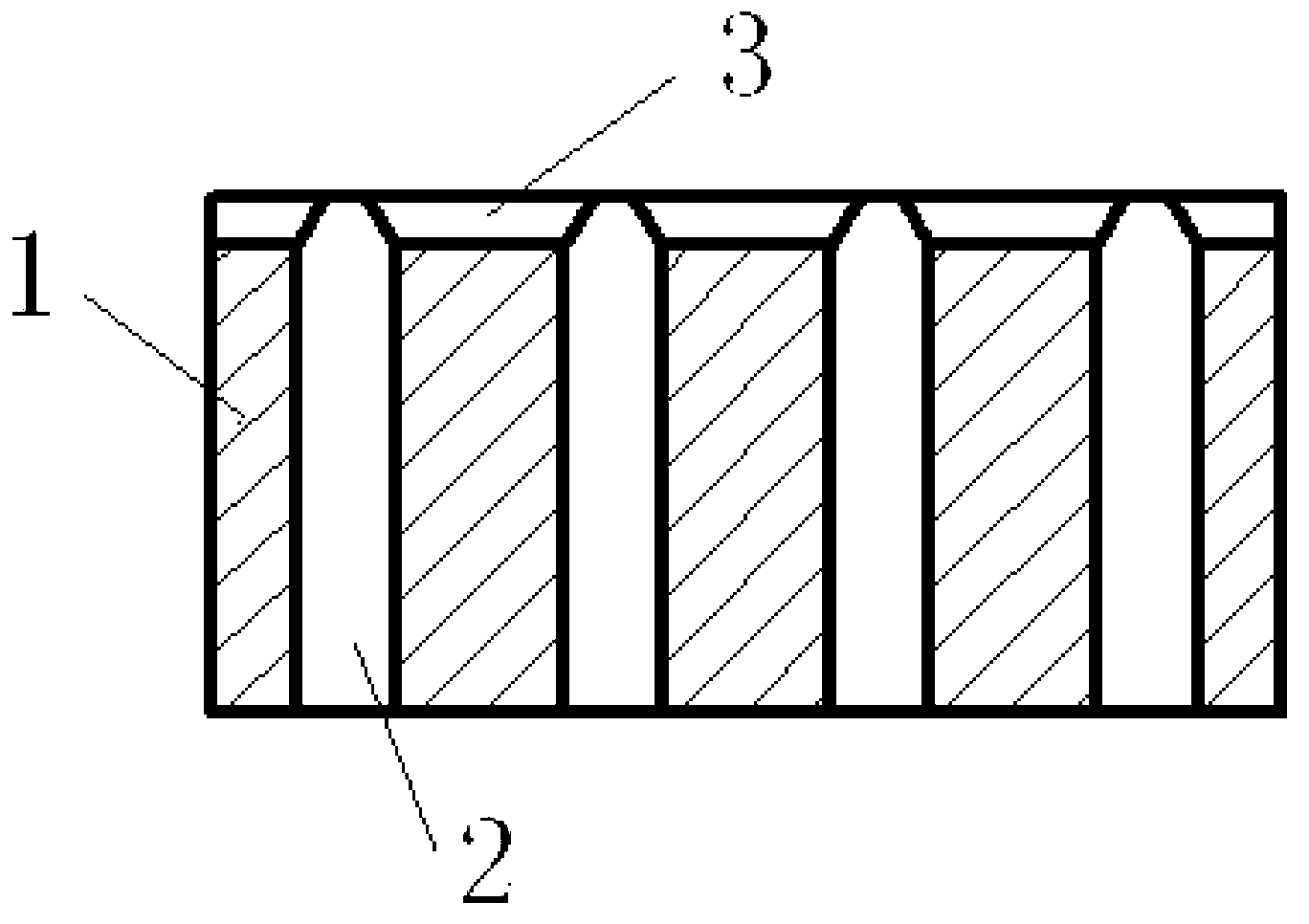

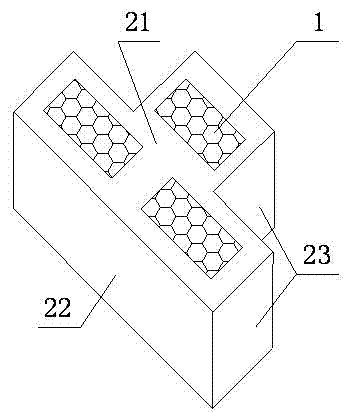

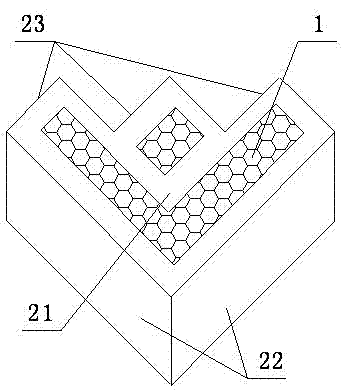

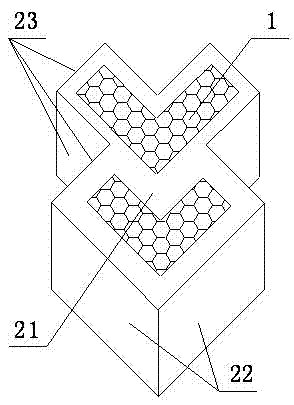

Self-heat-preservation building block and self-heat-preservation wall body consisting of self-heat-preservation building blocks

ActiveCN103243857AMeet heat preservation and energy saving requirementsPlay a role in heat preservationConstruction materialWallsWhole bodySlurry

The invention relates to the field of building materials, and in particular relates to a self-heat-preservation building block and a self-heat-preservation wall body consisting of self-heat-preservation building blocks, which aim to solve the technical problem that conventional building wall body materials cannot have the functions of bearing, heat preservation and fire prevention simultaneously. According to the technical scheme, the self-heat-preservation building block comprises a building block body which is made of foamed cement; transverse through slots are formed in the upper surface of the building block; vertical through holes are formed in the building block; one or several of concrete slurry, cement mortar, plaster and heat preservation plaster is / are filled into the transverse through slots to form core columns; concrete slurry or cement mortar is filled into the vertical through holes to form core columns; and the core columns and the building block body are combined to form a whole body. The self-heat-preservation wall body consists of the self-heat-preservation building blocks. The self-heat-preservation building block and the self-heat-preservation wall body have functions of heat preservation and fire prevention as well as bearing.

Owner:丹东市兄弟建材有限公司

Self-insulation wall with high energy conservation property

The invention discloses a self-insulation wall with a high energy conservation property, and belongs to the field of building wall materials. The self-insulation wall with the high energy conservation property is mainly characterized in that building blocks of a self-insulation wall body are shaped like a T, building blocks of a self-insulation right-angle wall corner are in a flower shape and a scissor shape, building blocks of a self-insulation T-shaped wall corner are provided with either a T-shaped top with a handle or a T-shaped bottom with a handle, when the wall body is built, one of every two horizontally adjacent self-insulation wall bricks is placed in a T shape, the other one is placed in a reverse T shape, when the right-angle wall corner is built, the flower-shaped and scissor-shaped building blocks of the self-insulation right-angle wall corner are alternatively placed, and when the T-shaped wall corner is built, the building blocks, provided with either the T-shaped top with the handle or the T-shaped bottom with the handle, of the self-insulation T-shaped wall corner are alternatively placed. The self-insulation wall with the high energy conservation property has the advantage of improving the energy conservation property.

Owner:SHANDONG UNIV OF SCI & TECH

Floor Covering With Interlocking Design

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:VÄLINGE INNOVATION AB

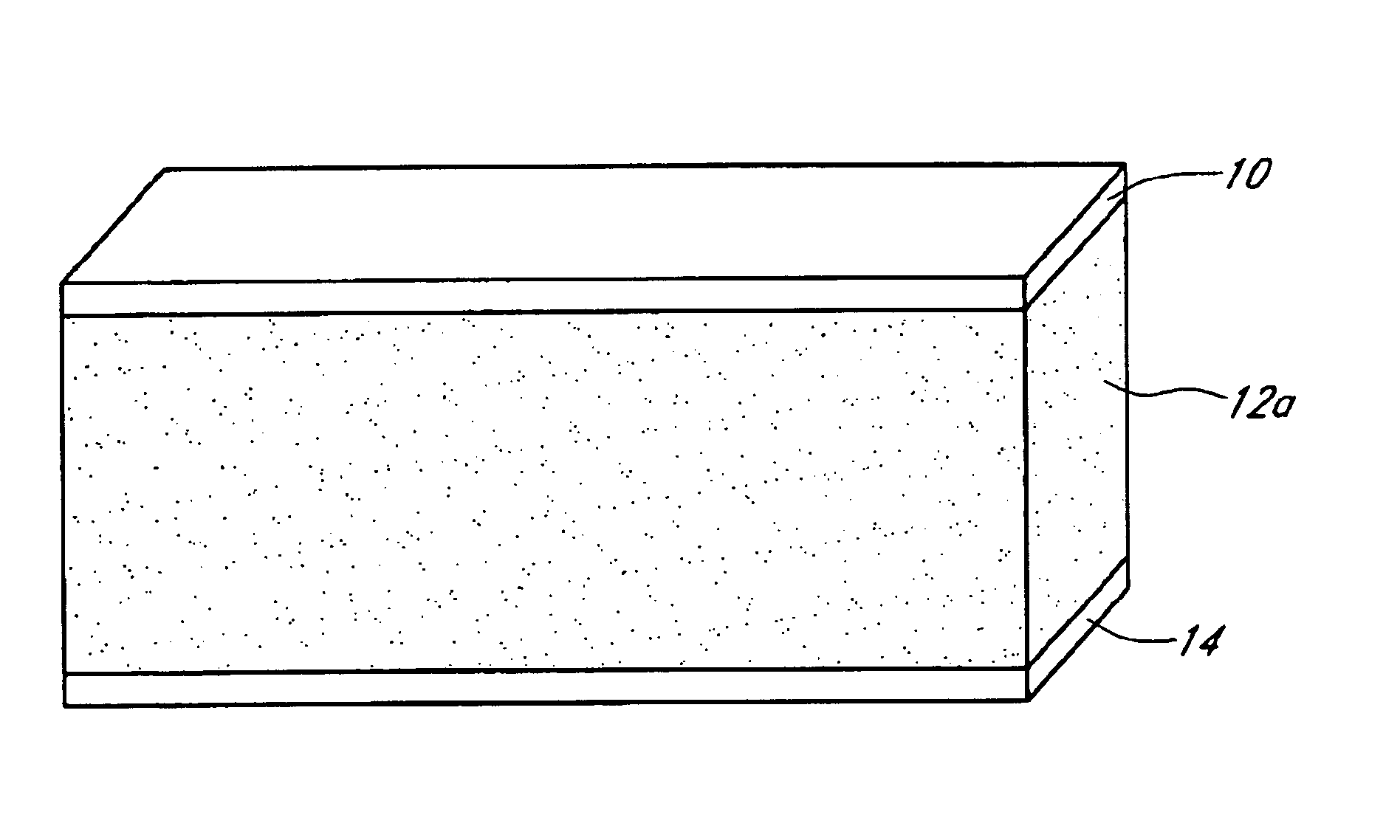

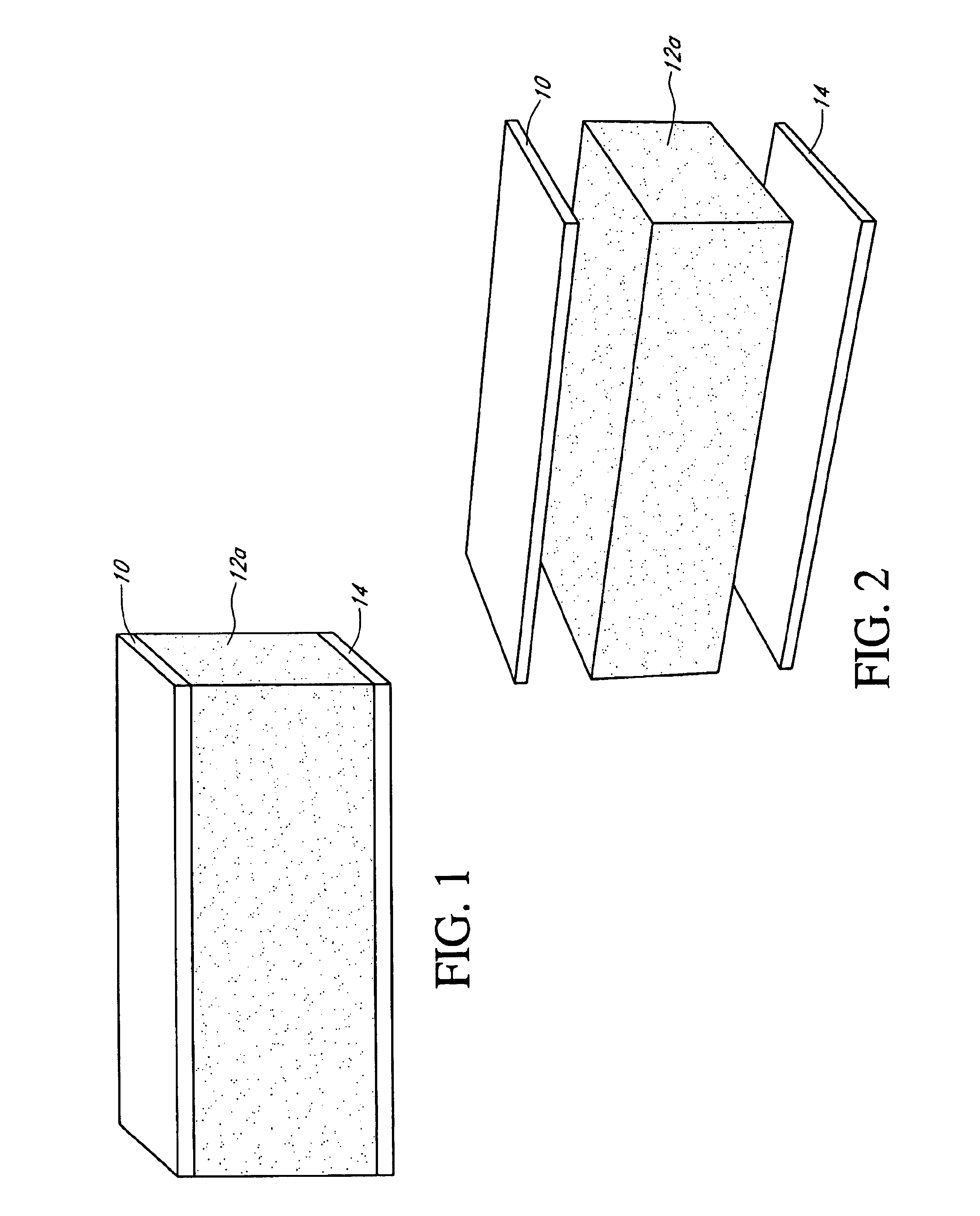

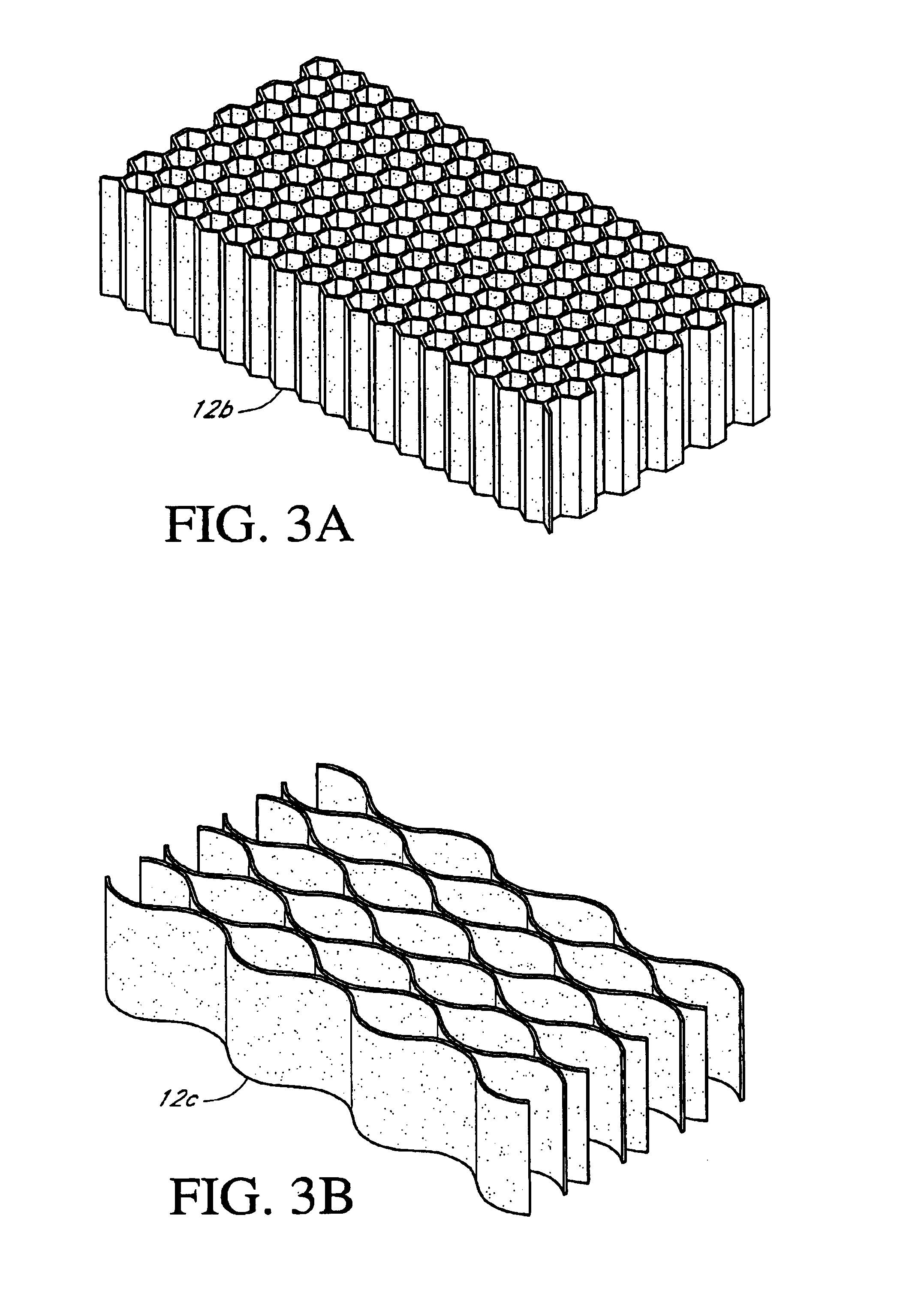

Composite building material

InactiveUS6941720B2Reduce noise transmissionLow acoustic transmissionConstruction materialSolid waste managementArchitectural engineeringPlastic property

This invention generally pertains to a composite building material comprising a lightweight core with a thin fiber cement facing on one side of the core and a second facing material on the other side. The fiber cement facing that is used on at least one of the faces of the building material is 3 / 16″ or less, more preferably ⅛″ or less. The green fiber cement facing is preferably formed by a slurry-dewatering process to form a sheet that is in a plastic, uncured, state prior to manufacture of the composite. The composite building material is assembled in an uncured state and then cured.

Owner:JAMES HARDIE TECH LTD

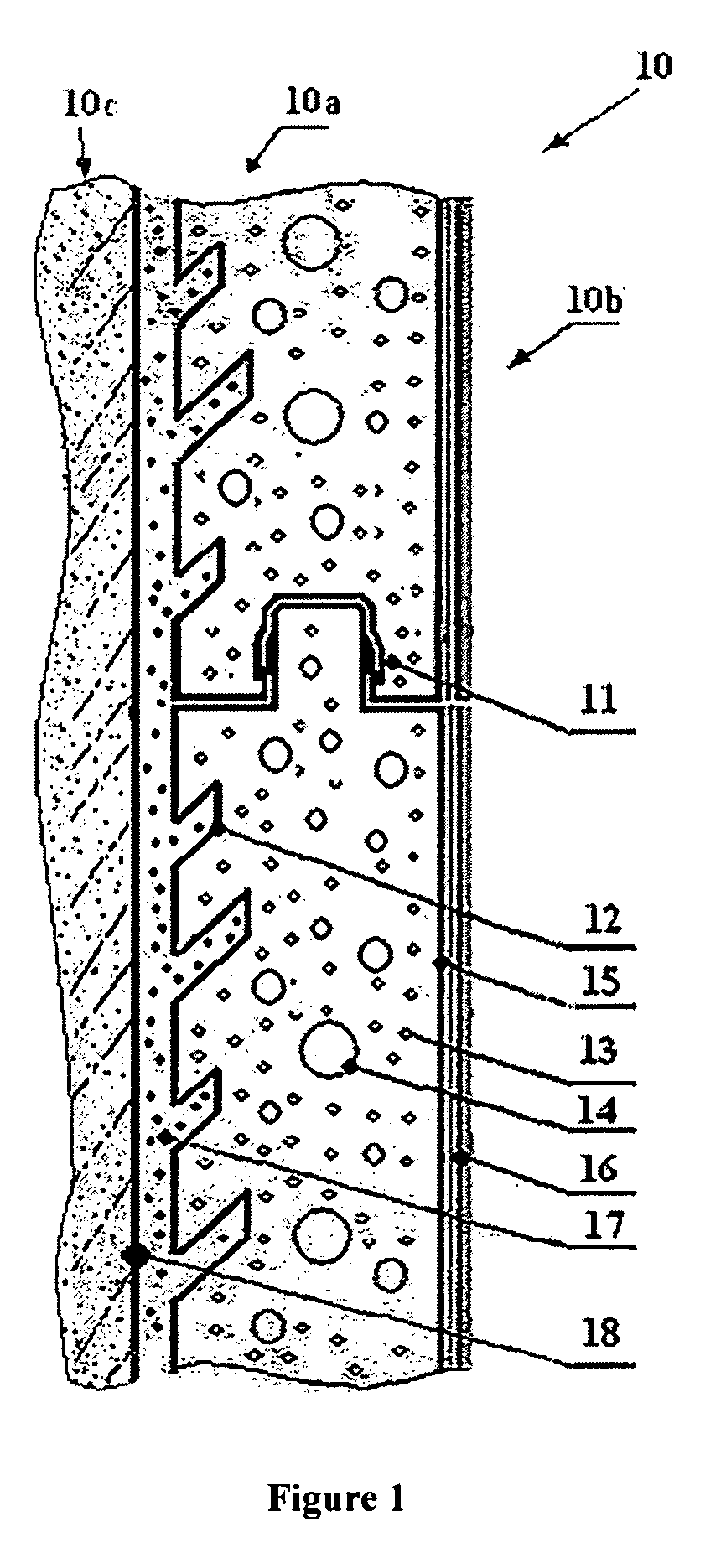

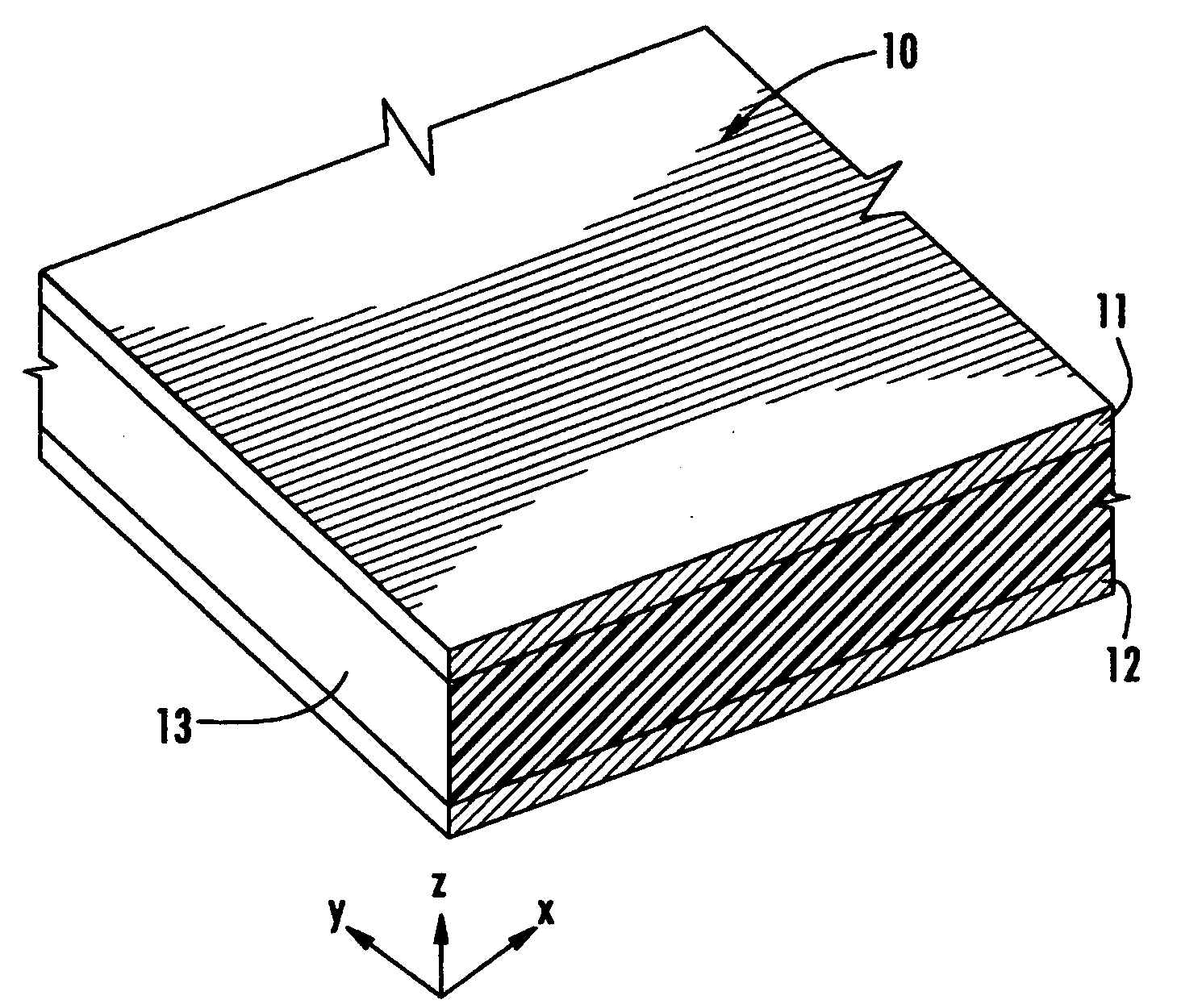

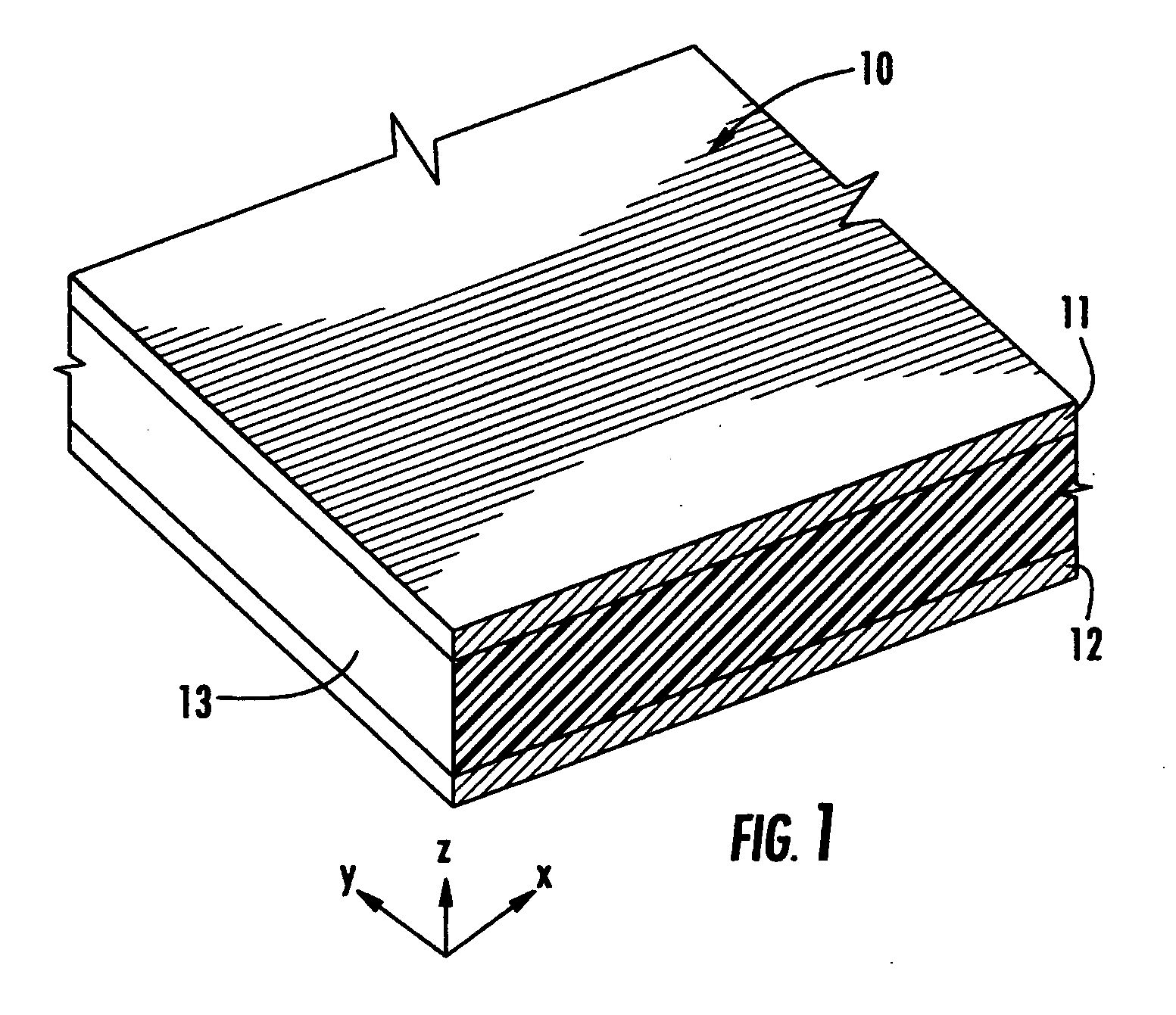

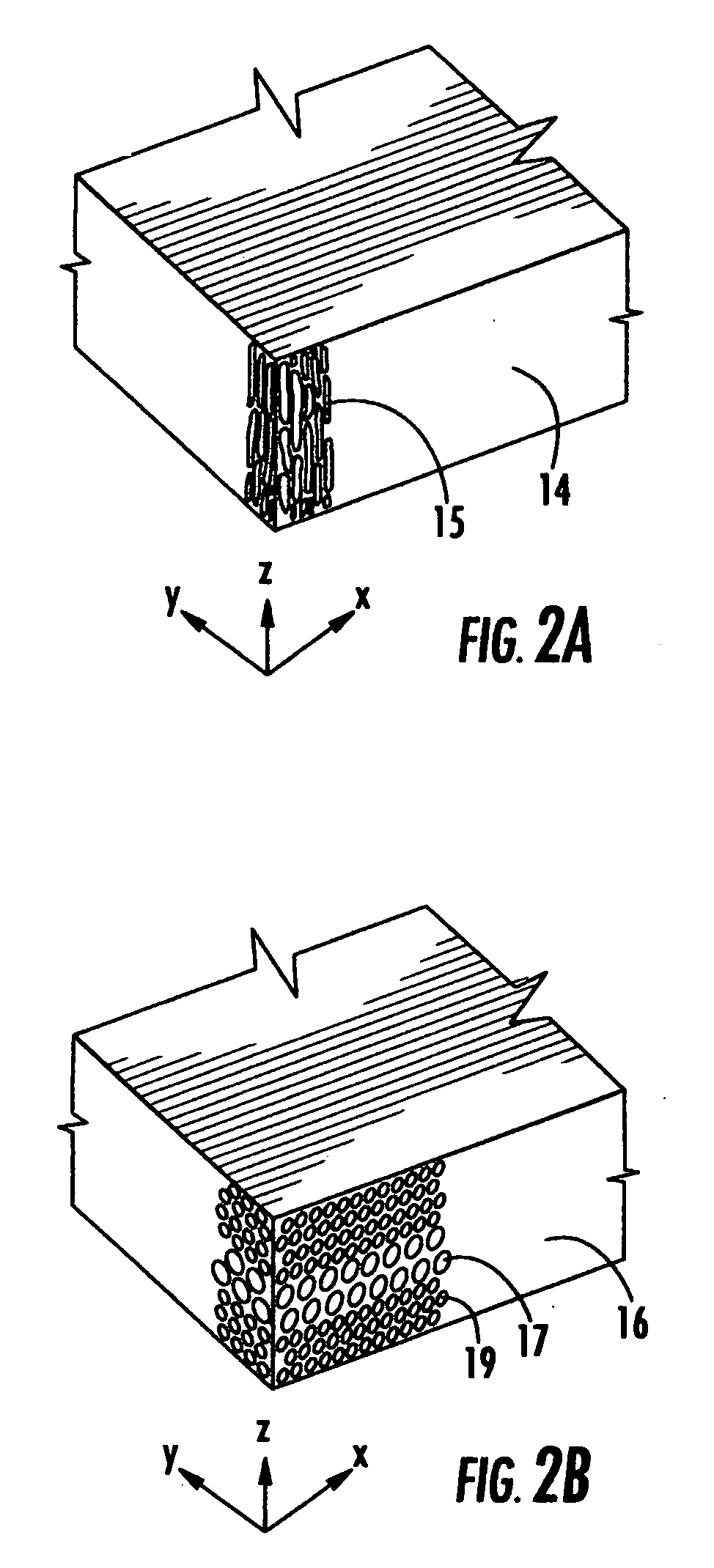

Composite roofing members having improved dimensional stability and related methods

InactiveUS6044604AGood baseRoof covering using slabs/sheetsConstruction materialGlass fiberPolymer science

A composite recovery board (10) containing a foam core (11) of polyisocyanurate, polyurethane materials or mixtures thereof; a facer (15), applied to one major surface (13) of the foam core, where the facer includes polymer materials, reinforced polymer materials, cellulosic materials, paper, aluminum foil or trilaminates thereof, wherein the reinforced polymer material and the cellulosic material are reinforced with glass strands, glass fibers, or mixtures thereof; and, gypsum board (14), applied to the opposite major surface (12) of the foam core. A method of reroofing a roof by applying composite recovery boards of the present invention to a roof deck; and, applying a weather protective layer over the recovery boards. A continuous method of making a composite recovery board by feeding gypsum board (14) into a laminator assembly (21); depositing a foamable polymer liquid (36) onto the gypsum board; feeding a facer material (15) into the laminator assembly above the foamable polymer liquid; allowing the polymer liquid to rise between the gypsum board and facer material forming polymer foam of a pre-determined thickness; curing the polymer foam under heat (44) to create the composite board; and cutting the composite board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

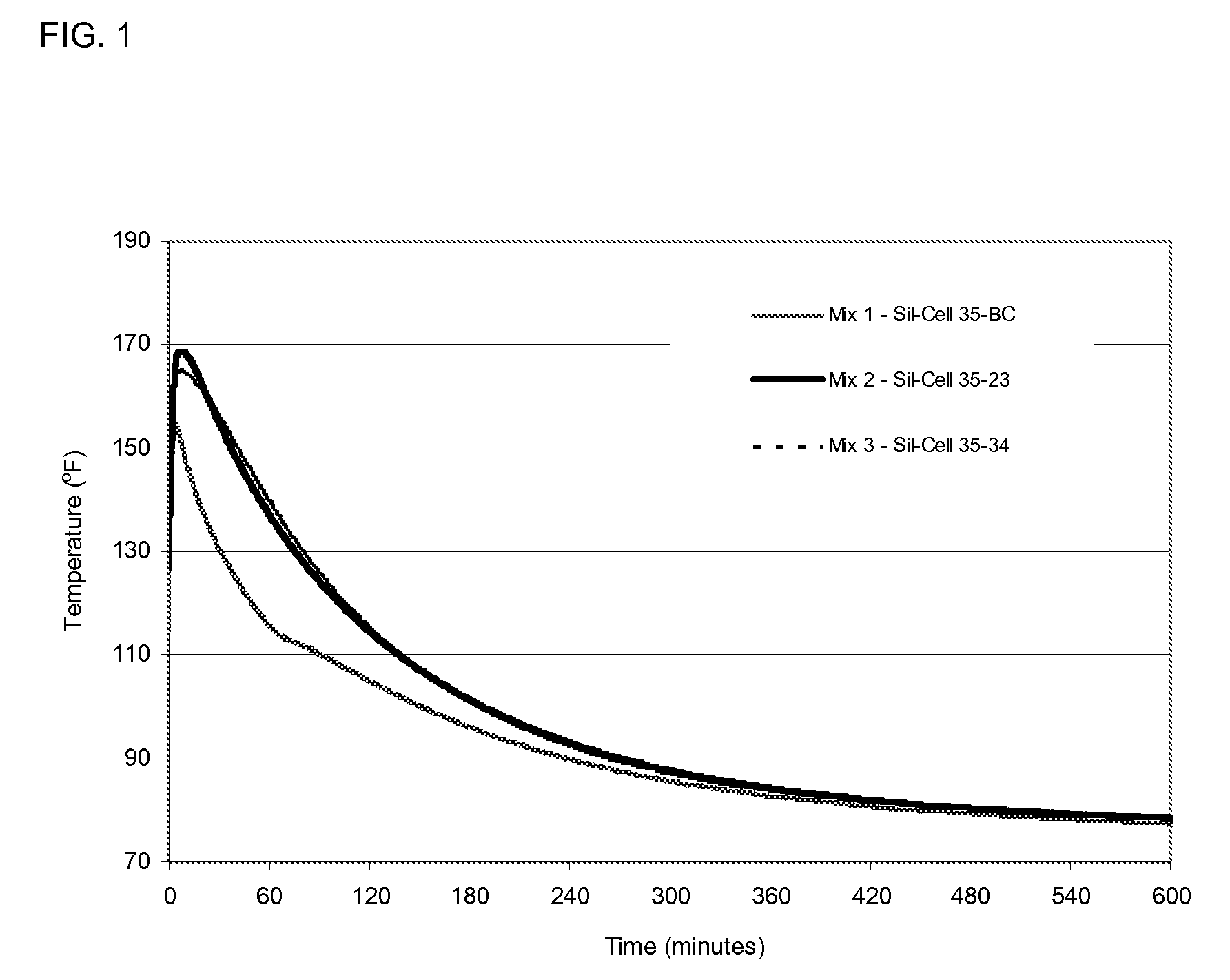

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

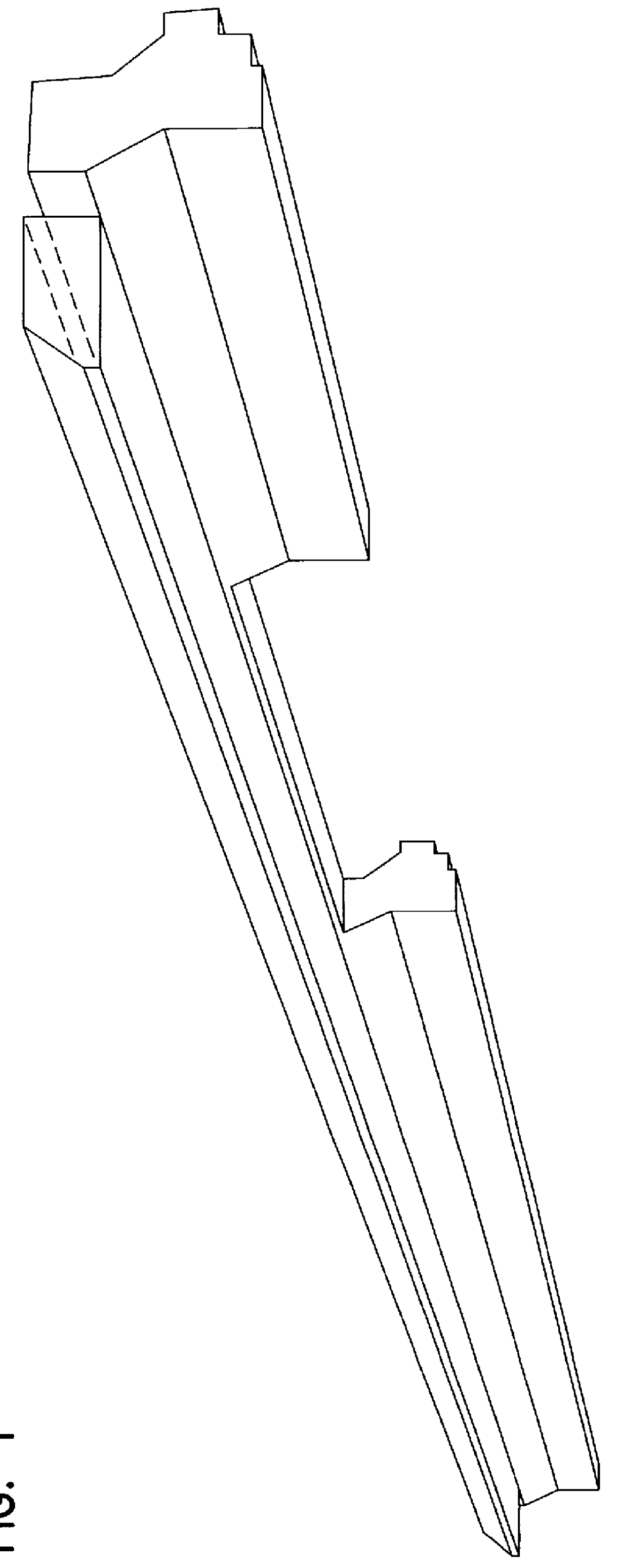

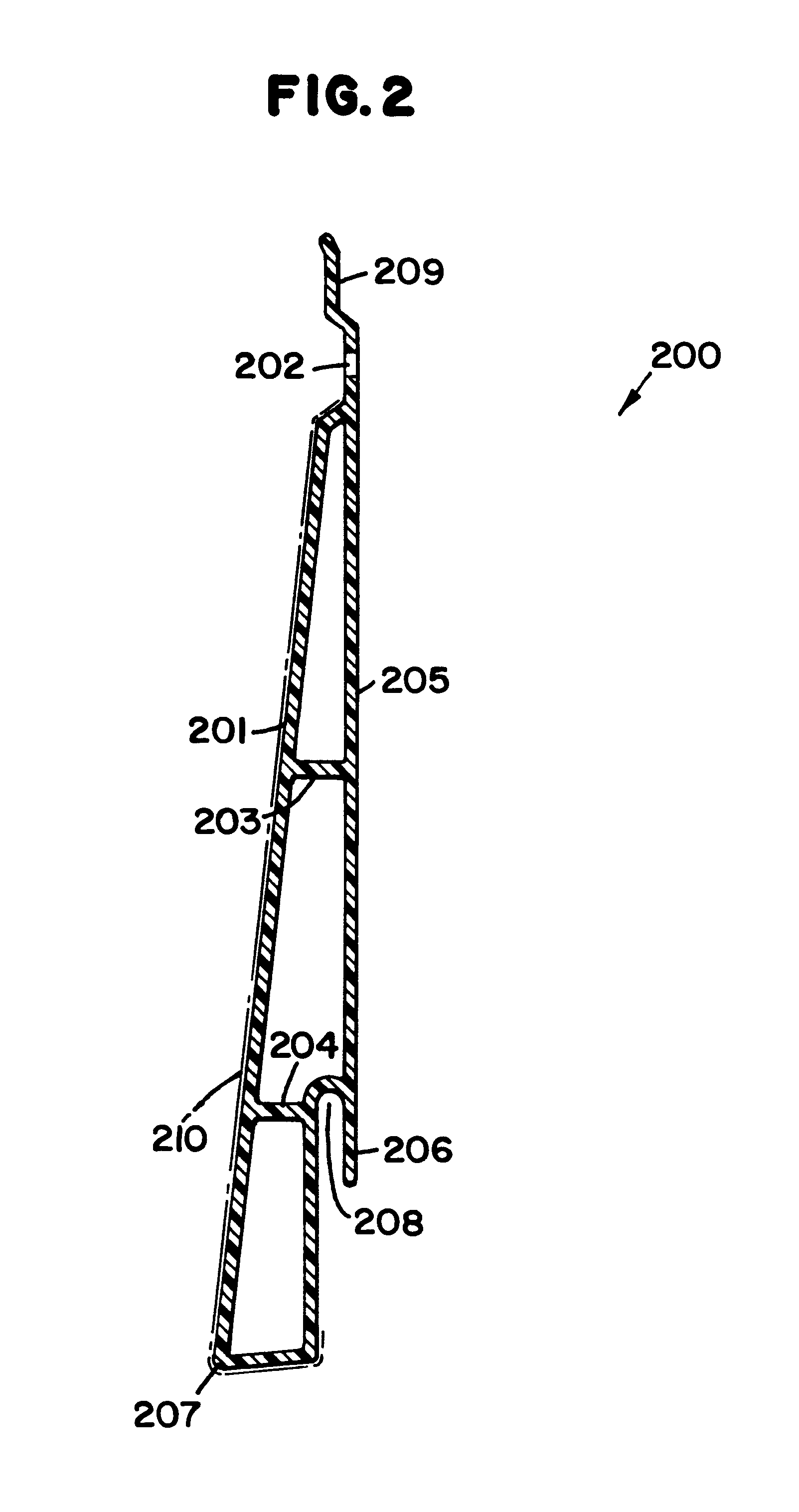

Foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6054207AHigh compressive strengthImproved fastener retentionConstruction materialLoad-supporting elementsComposite constructionThermoplastic

Advanced structural components comprising a foamed thermoplastic that can be used in virtually any application where wooden components have a use. Such structural components can comprise sized lumber, shaped trim, posts, beams or shaped structural members. An advanced profile composite structural component comprising an exterior capping layer with an interior comprising a foamed thermoplastic can be used in the assembly of fenestration units adapted to residential and commercial structures. Preferably the profile structural component can be used in a window or door assembly. The profile member is adapted for ease of construction of the fenestration units, can be easily installed in a rough opening to framing members, and can be trimmed and adjusted on site. The profile is structurally strong, thermally stable, shrink resistant and will accept and retain the insertion of fasteners such as staples, nails and screws permanently with substantial retention and little or no damage to the units. The profile structural components possess strength that permits the manufacture of a structurally sound fenestration unit from two or more foamed profile members or other conventional members.

Owner:ANDERSEN CORPORATION

Retaining wall block with face connection

Single and multiple retaining wall blocks and block systems are disclosed. The blocks are provided with a face connection system which includes at least one front lip extending from a top surface of the block and a bottom channel formed into a front face and bottom surface of the block. The front lips have a length which is less than the width of the blocks.

Owner:CONTECH TECH

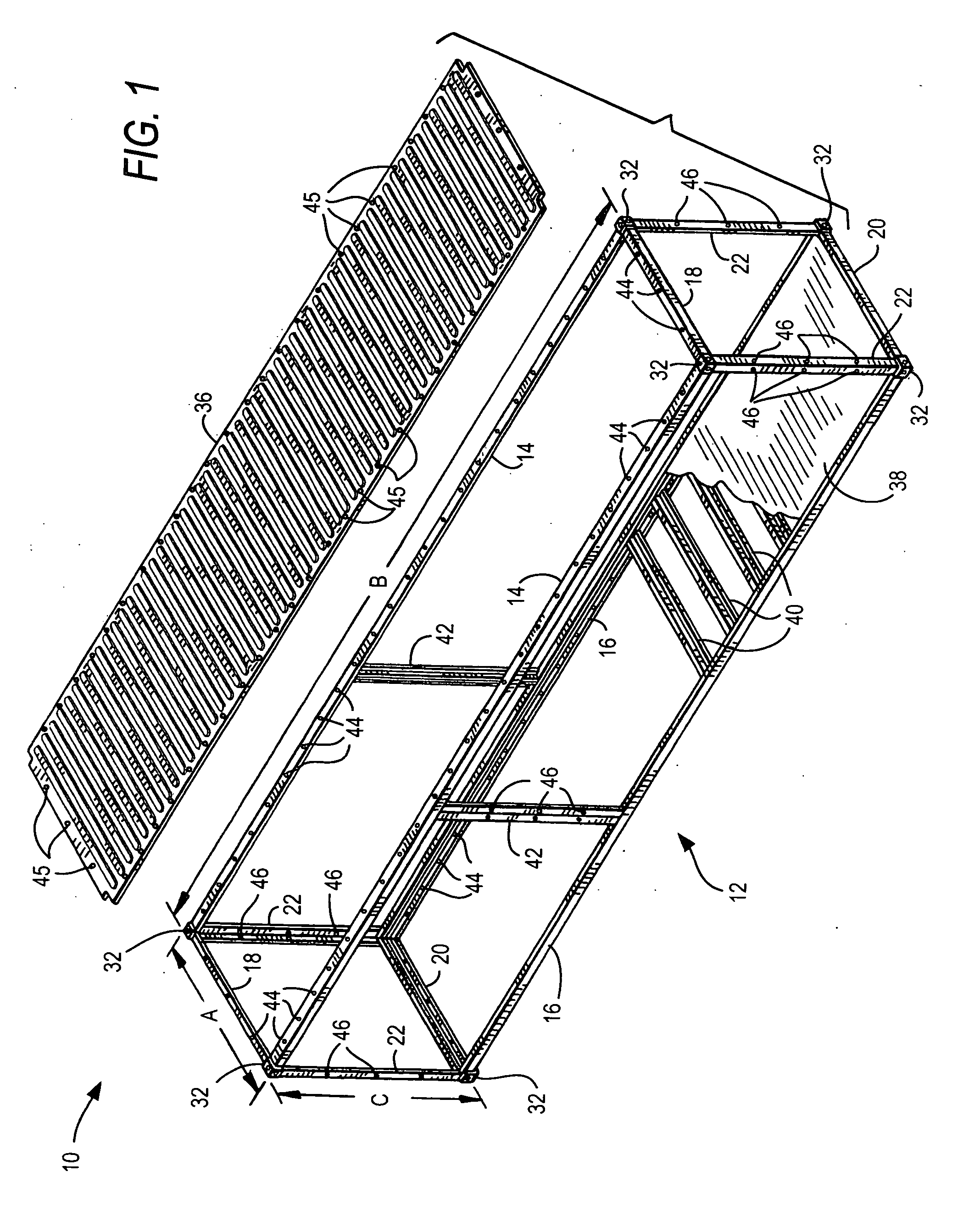

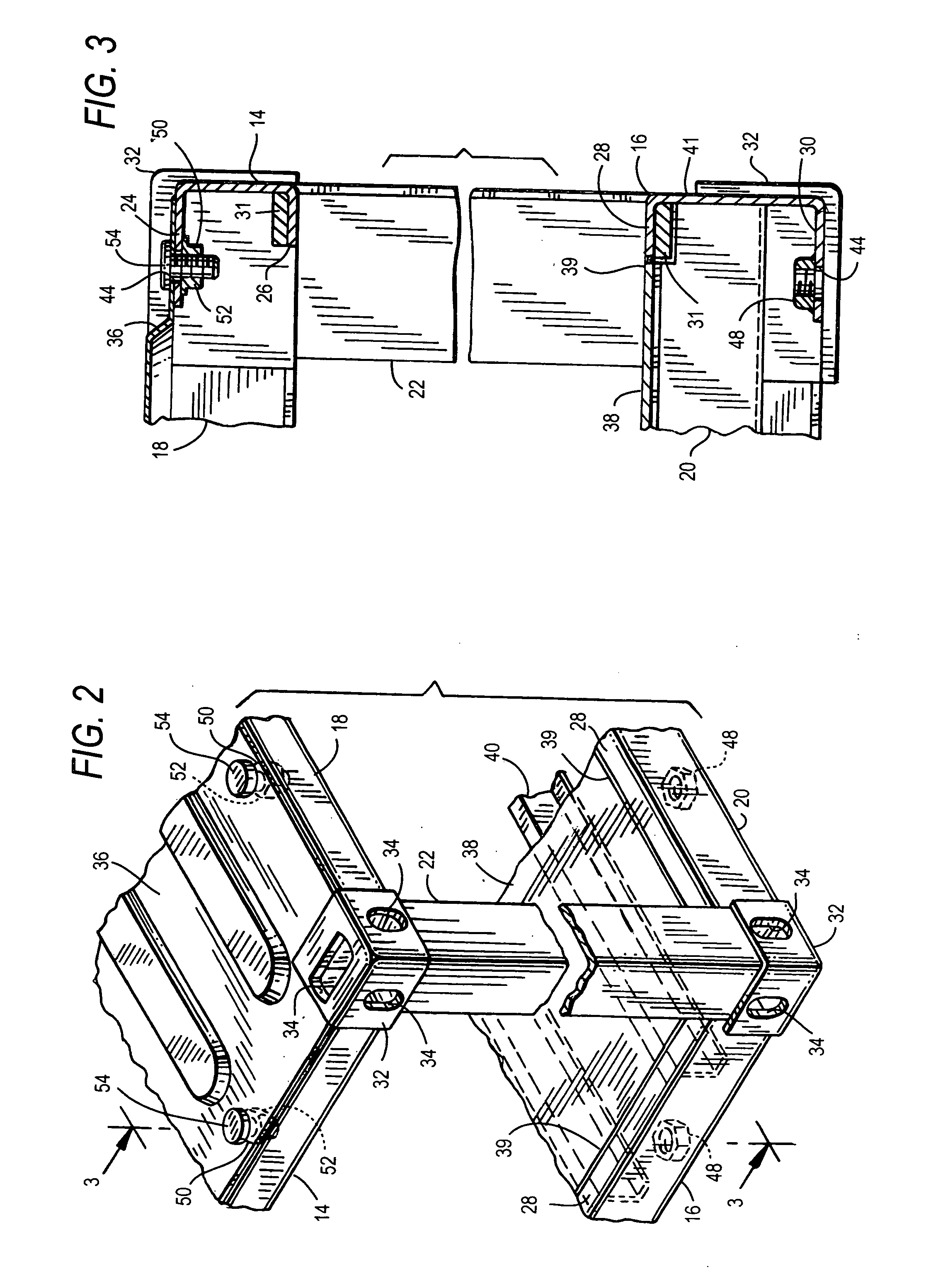

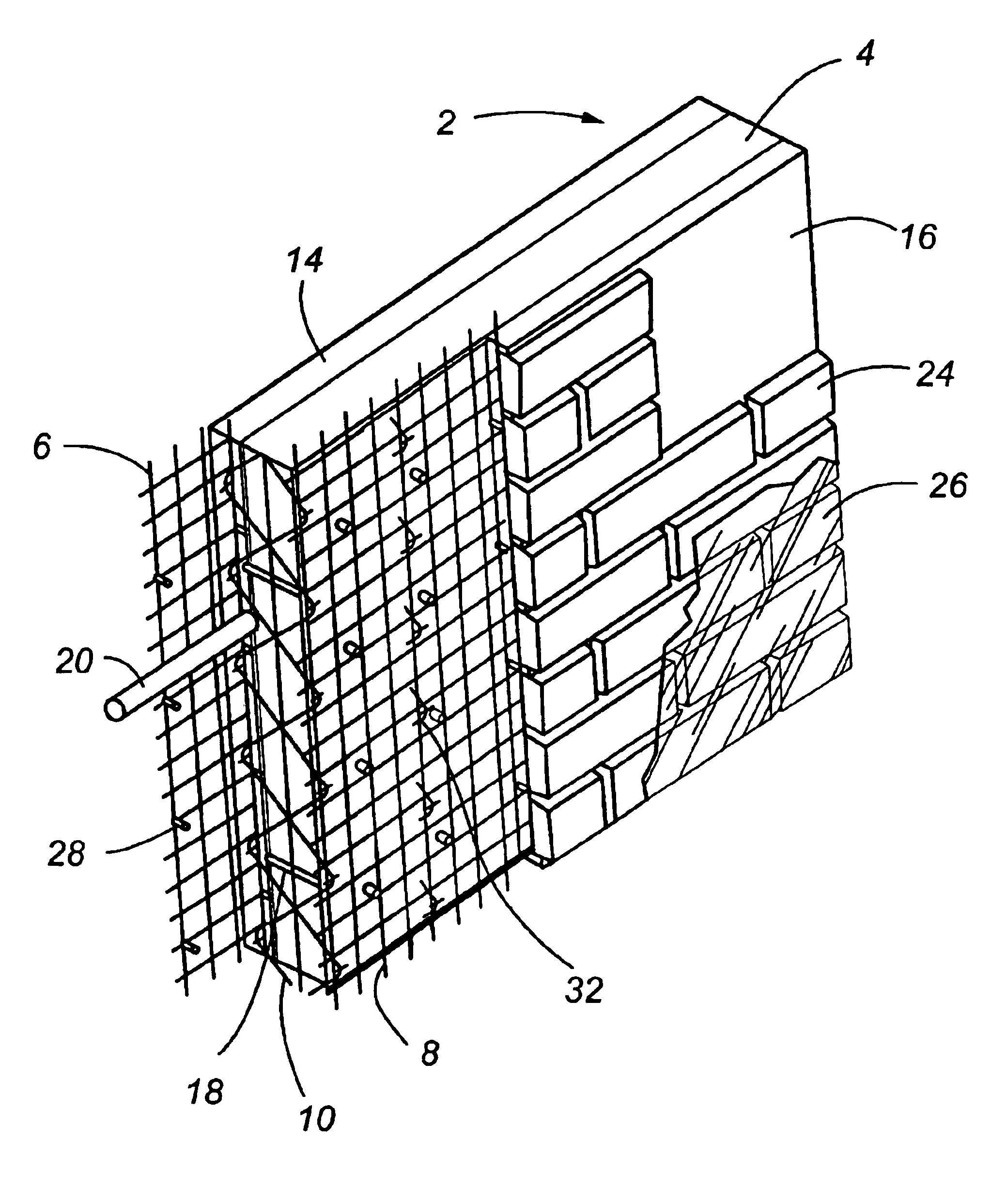

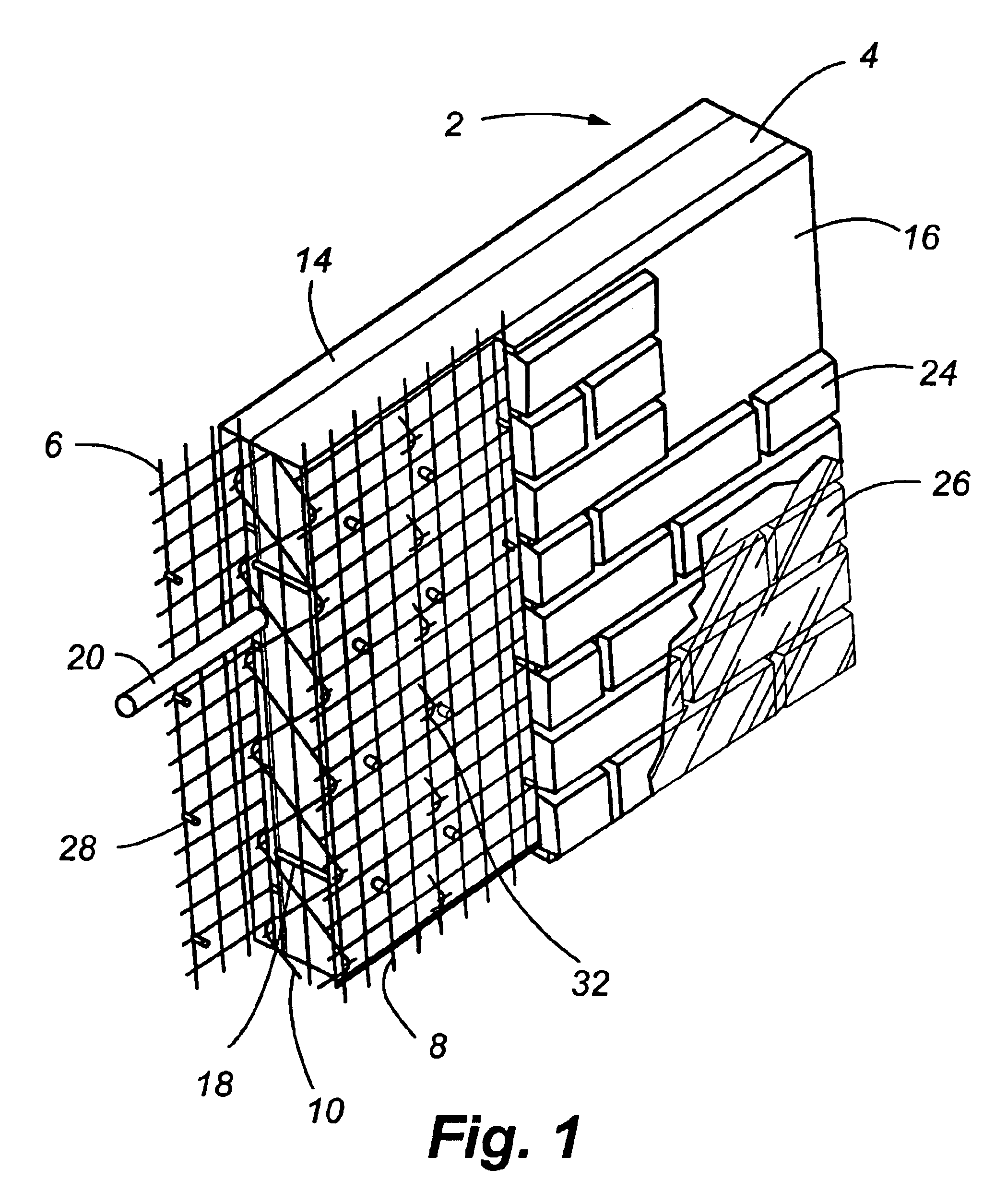

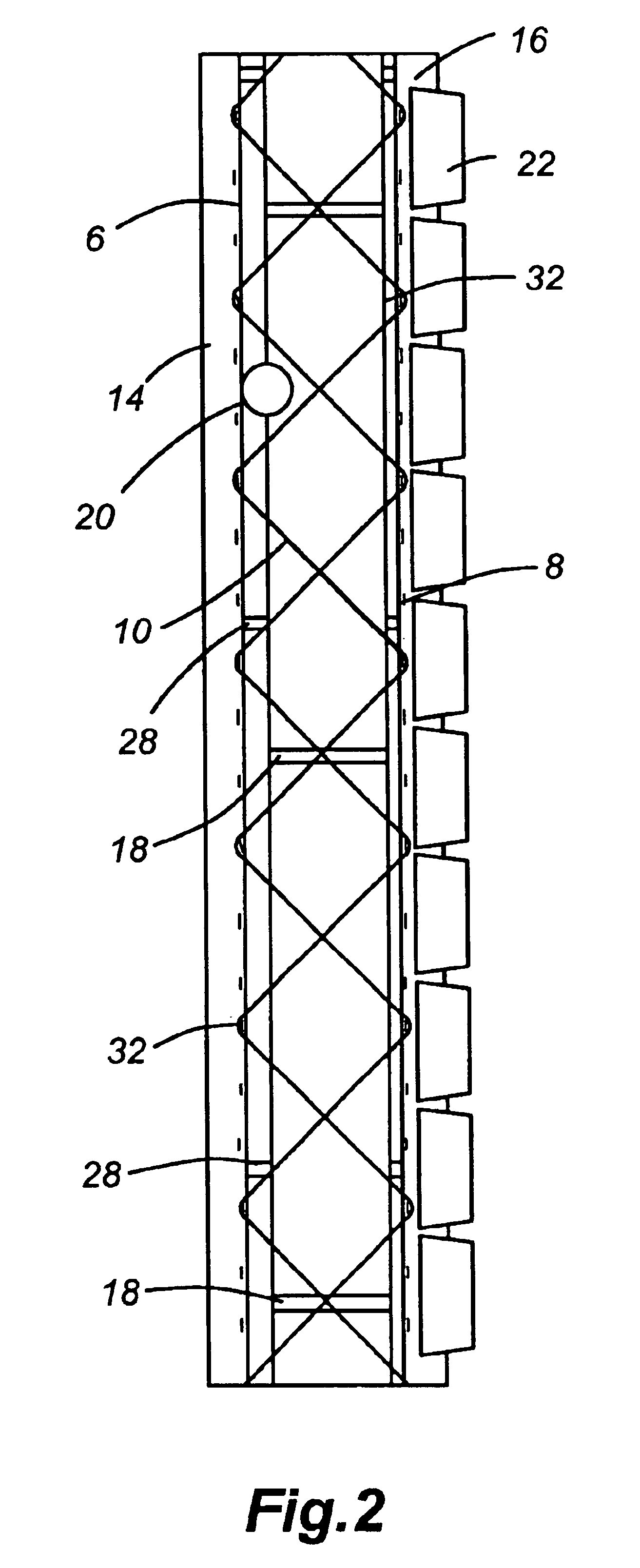

System for modular building construction

InactiveUS7827738B2Good choiceFacilitating selective interconnectionConstruction materialLighting and heating apparatusBuilding unitBuilding construction

Construction systems for erecting building structures comprise a plurality of prefabricated interconnectable modular building units, each unit not meeting at least one of the ISO certification criteria for transport of cargo, but each unit comprising a frame shaped as a rectangular parallelopiped and comprised of framing members and a plurality of nodes, each node situated at a corner of said frame for selective interconnection with other units, the nodes and the exterior dimensions of the frame conforming to ISO shipping standards such that each unit is transportable using the ISO intermodal transportation system, and such that when the units are aggregated horizontally and vertically and adjacent units are interconnected, a building structure comprising at least one habitable space is formed. The modular units are assembled in a factory remote from the job site, and are there constructed to a semi-finished state, including installation of one or more of interior fit-out systems and finishes, exterior envelope systems, plumbing systems, electrical systems, environmental systems, and fire protection systems, following which the semi-finished modular units are transported from the factory to the job site, where they are craned into place and secured to form the structure being erected, a plurality of adjacent pairs of semi-finished modular units also being “stitched” together, and the semi-finished modular units are thereafter constructed to a finished state.

Owner:GLOBAL BUILDING MODULES

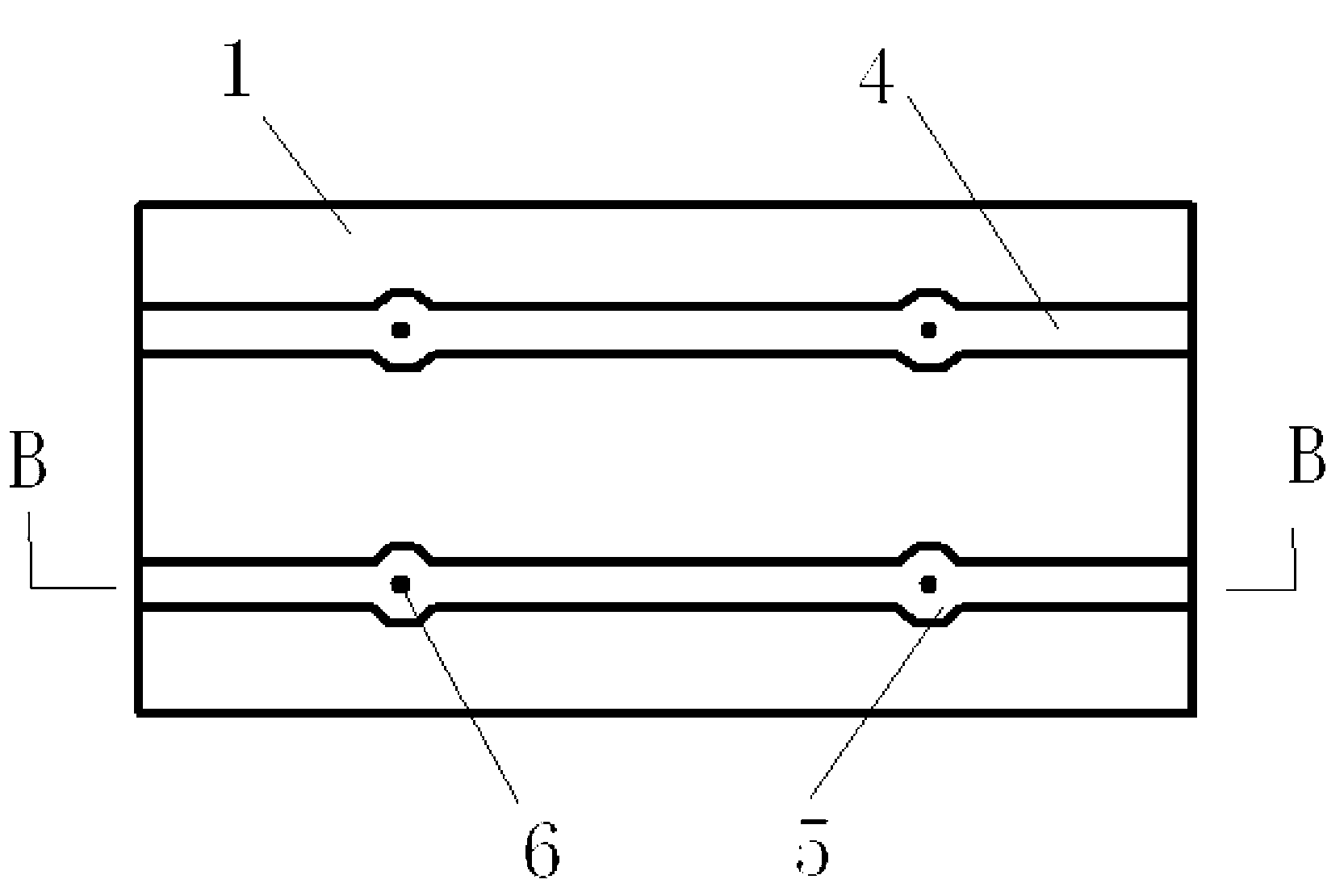

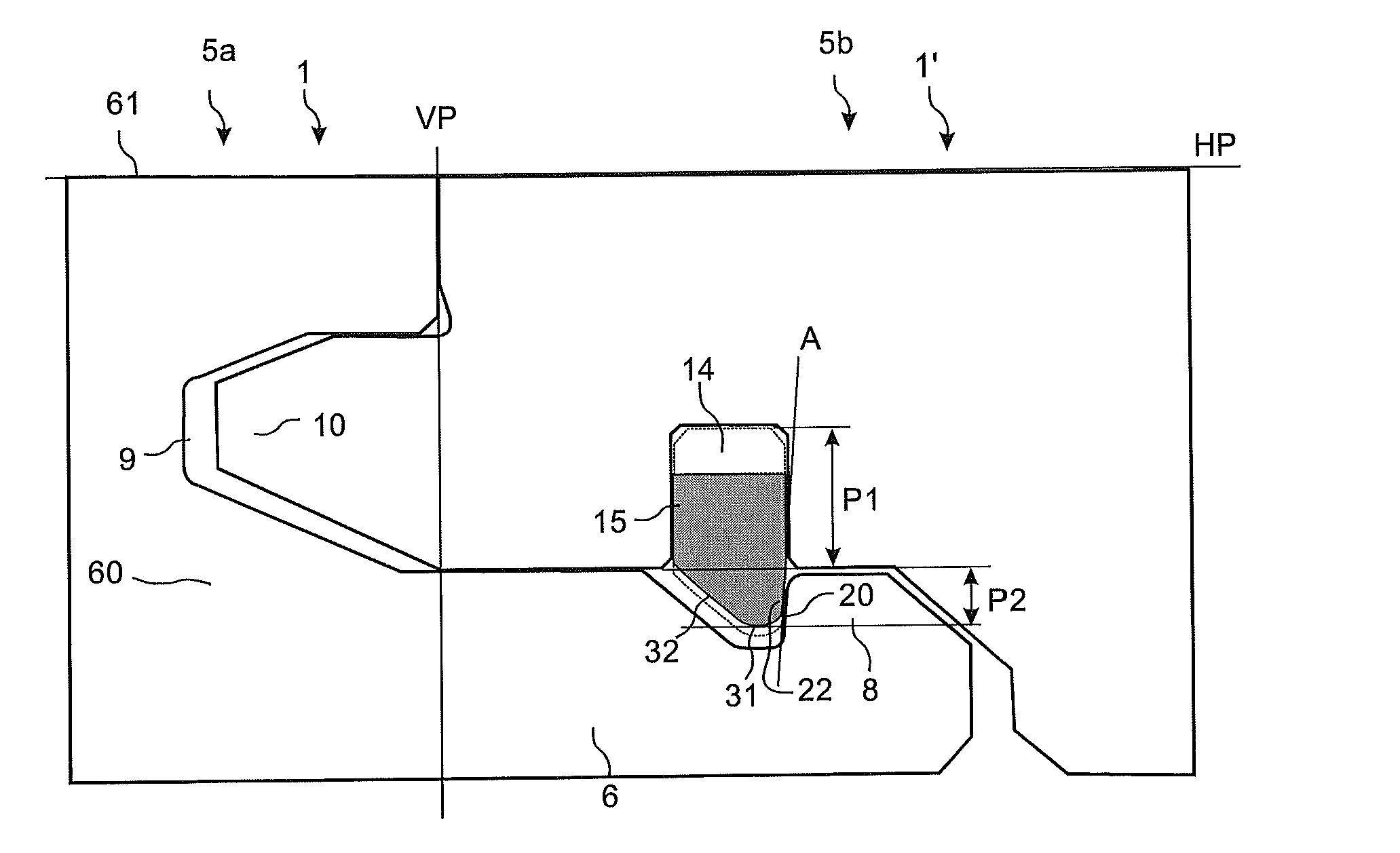

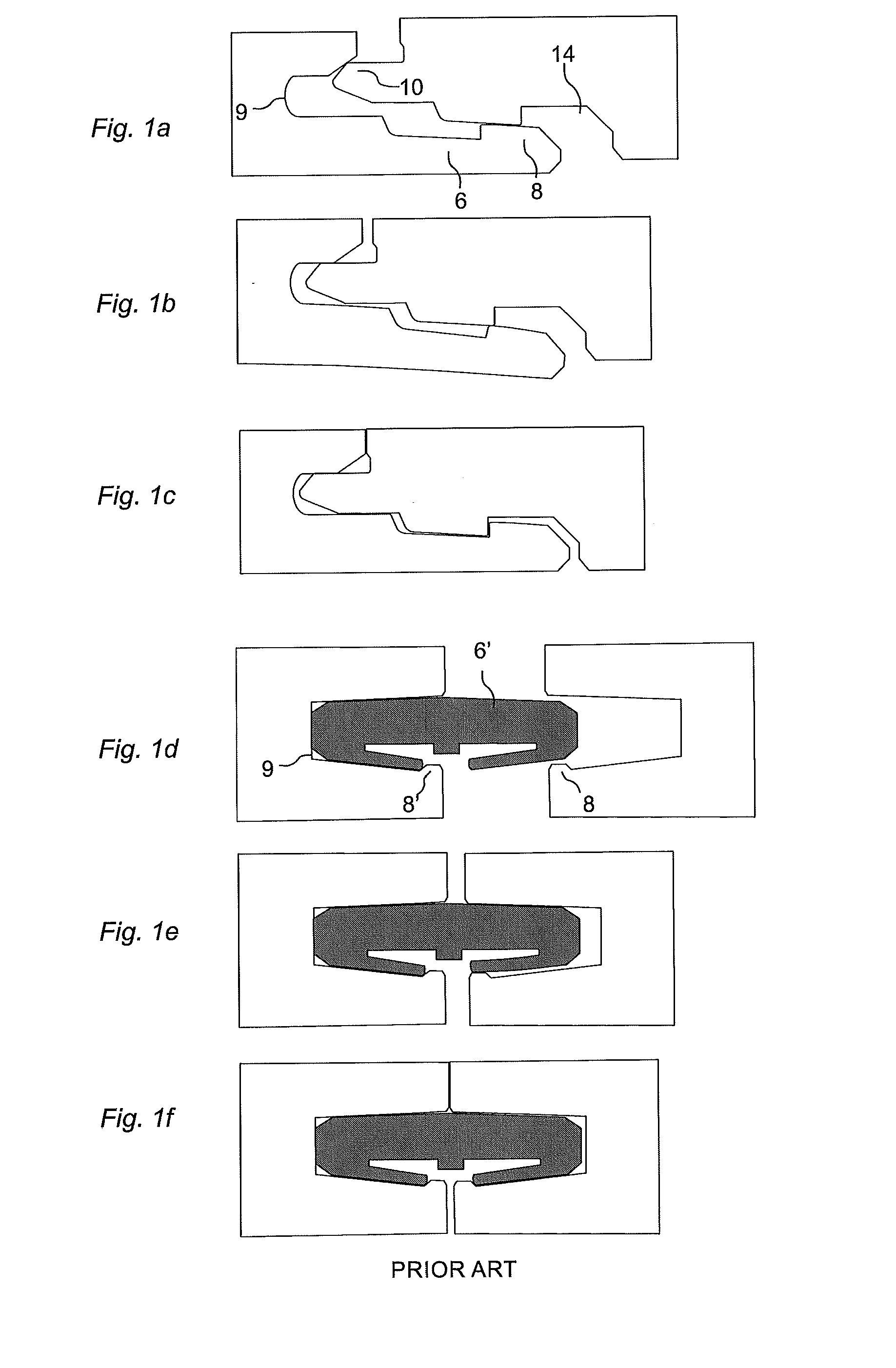

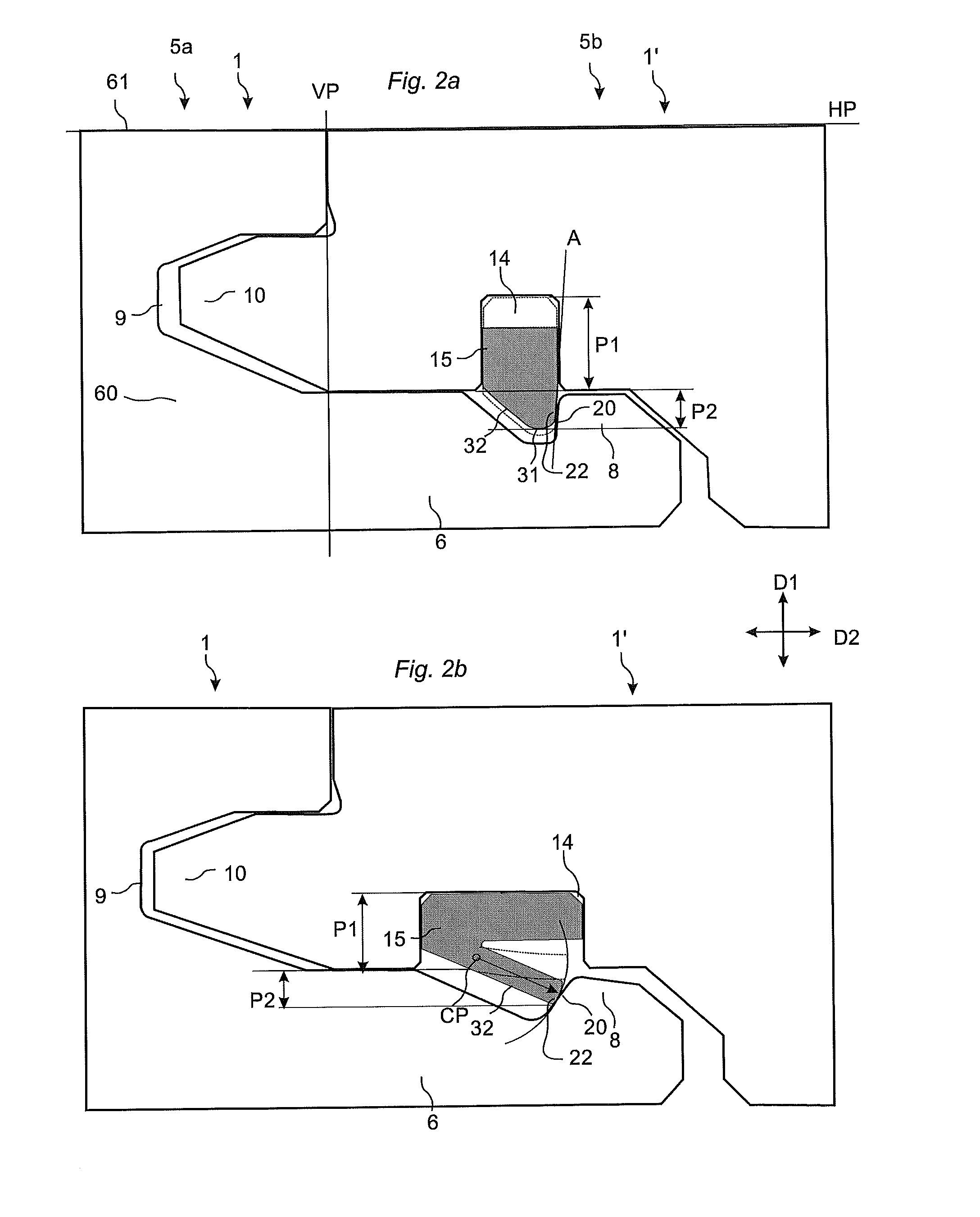

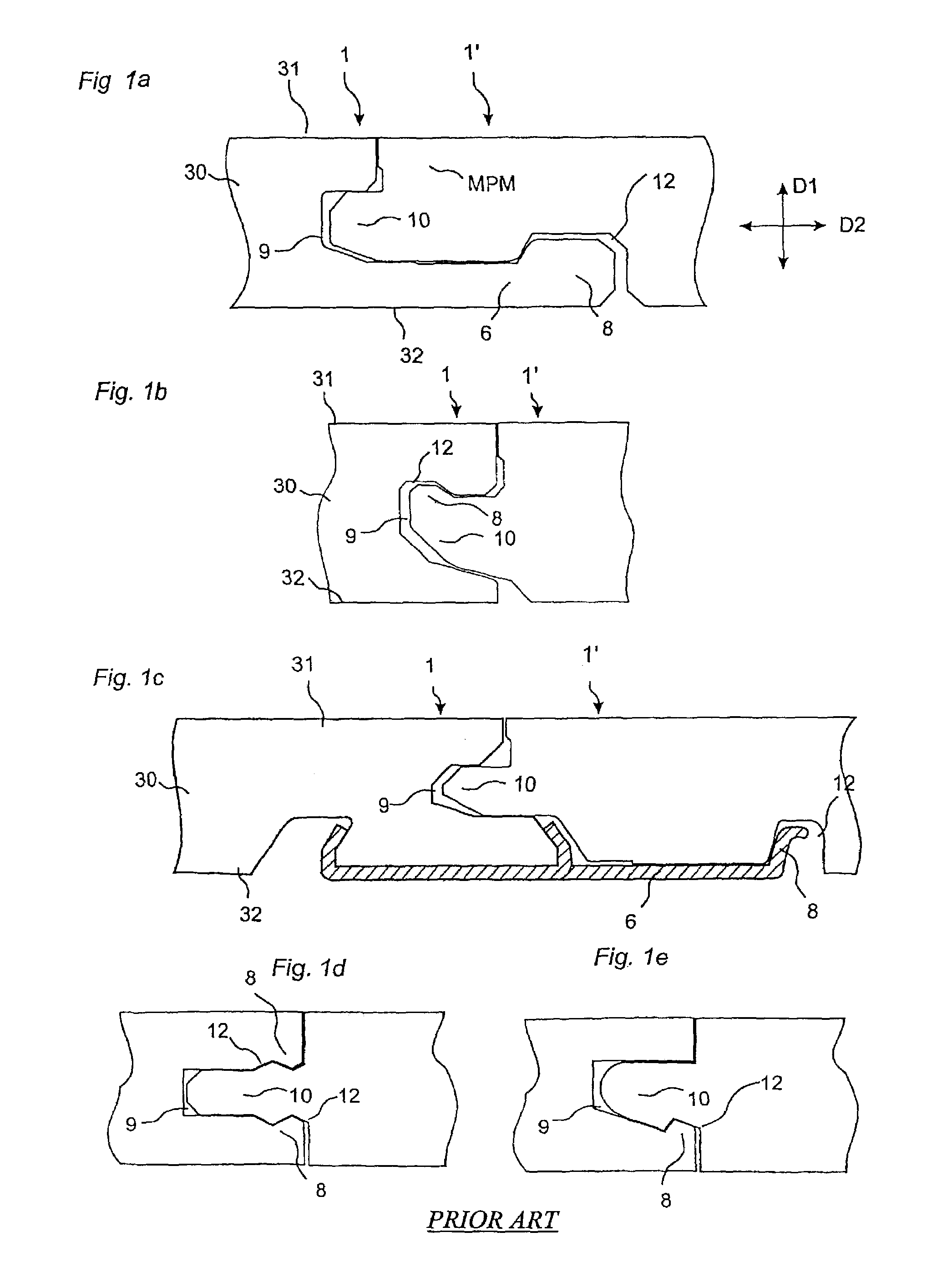

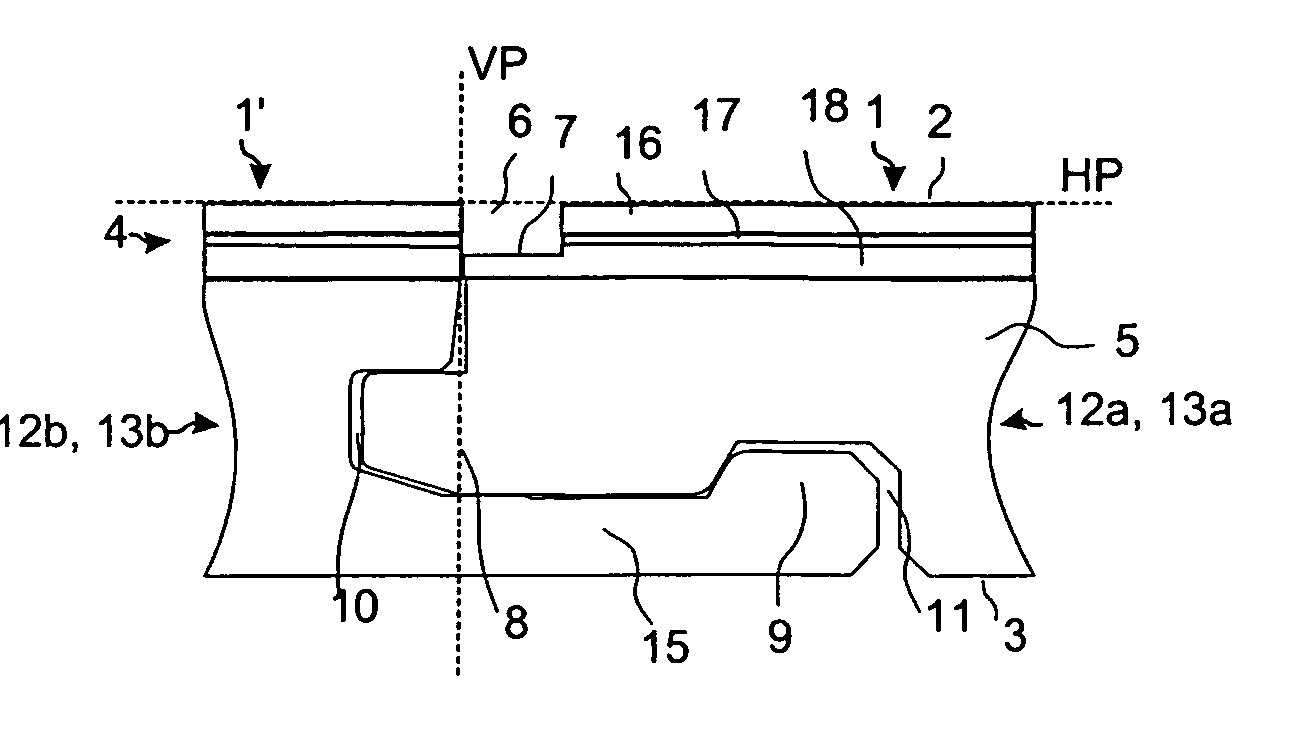

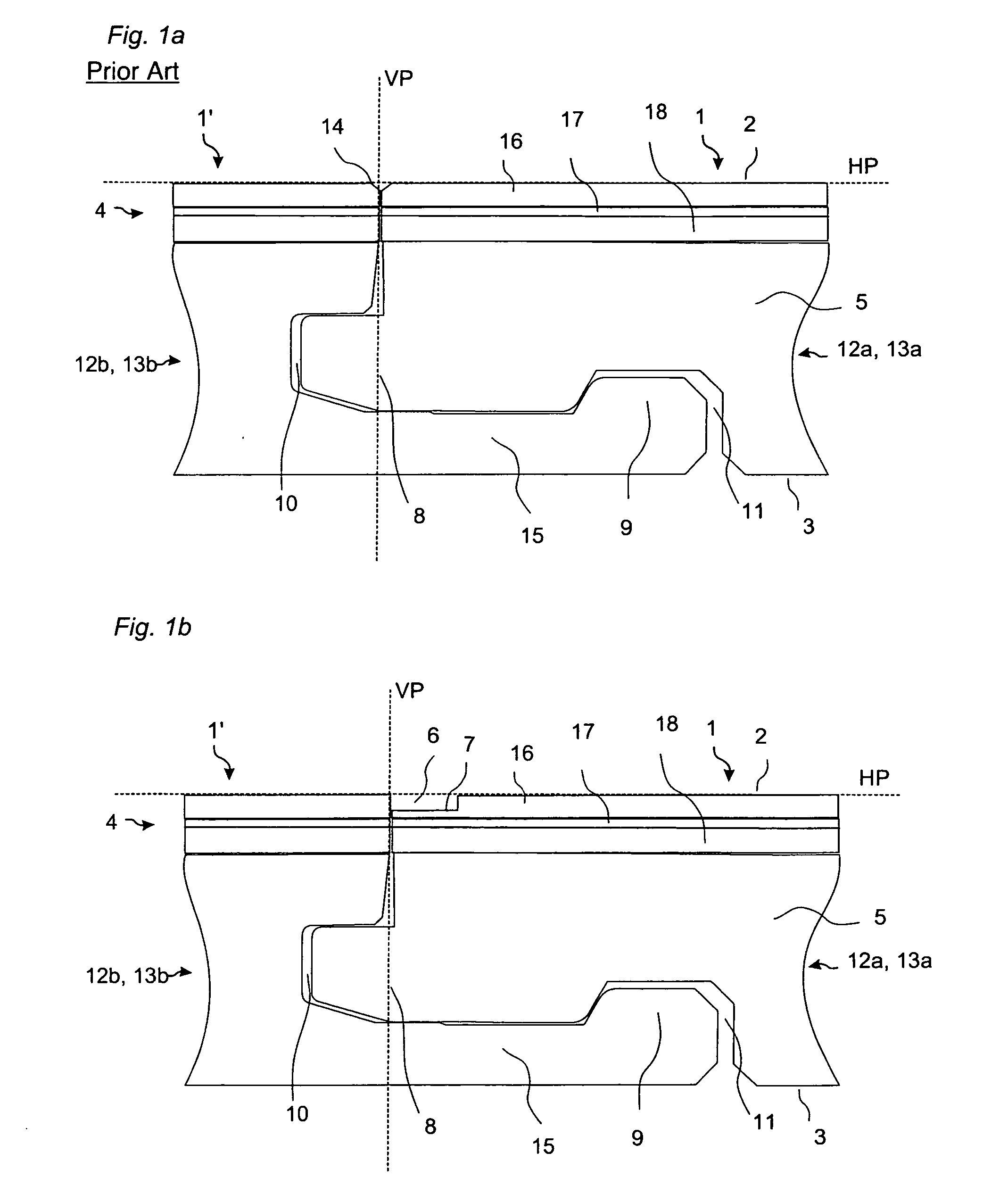

Mechanical locking system for floor panels

ActiveUS20120036804A1Function increaseLower resistanceConstruction materialCovering/liningsMechanical engineering

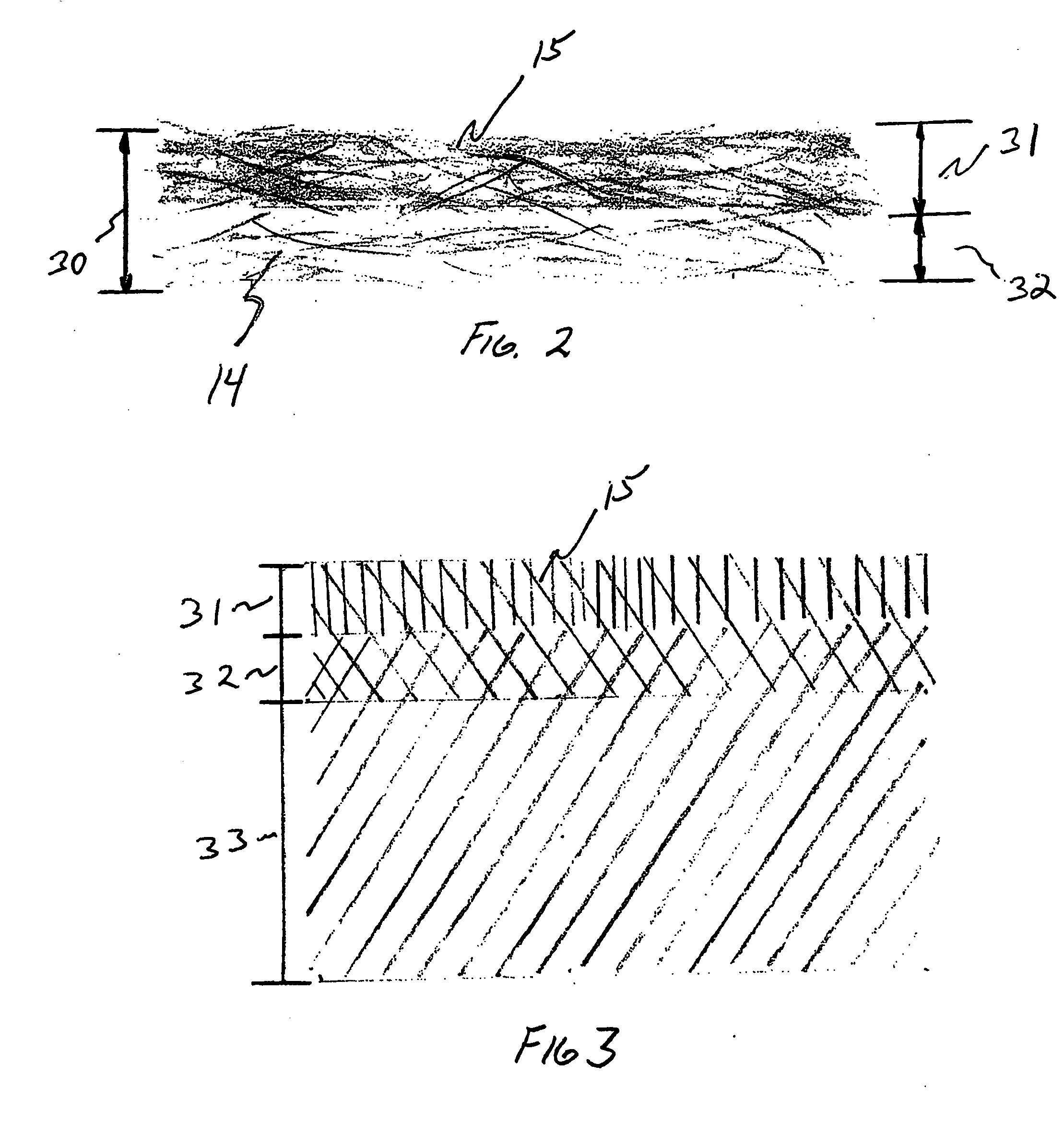

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system consisting of a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

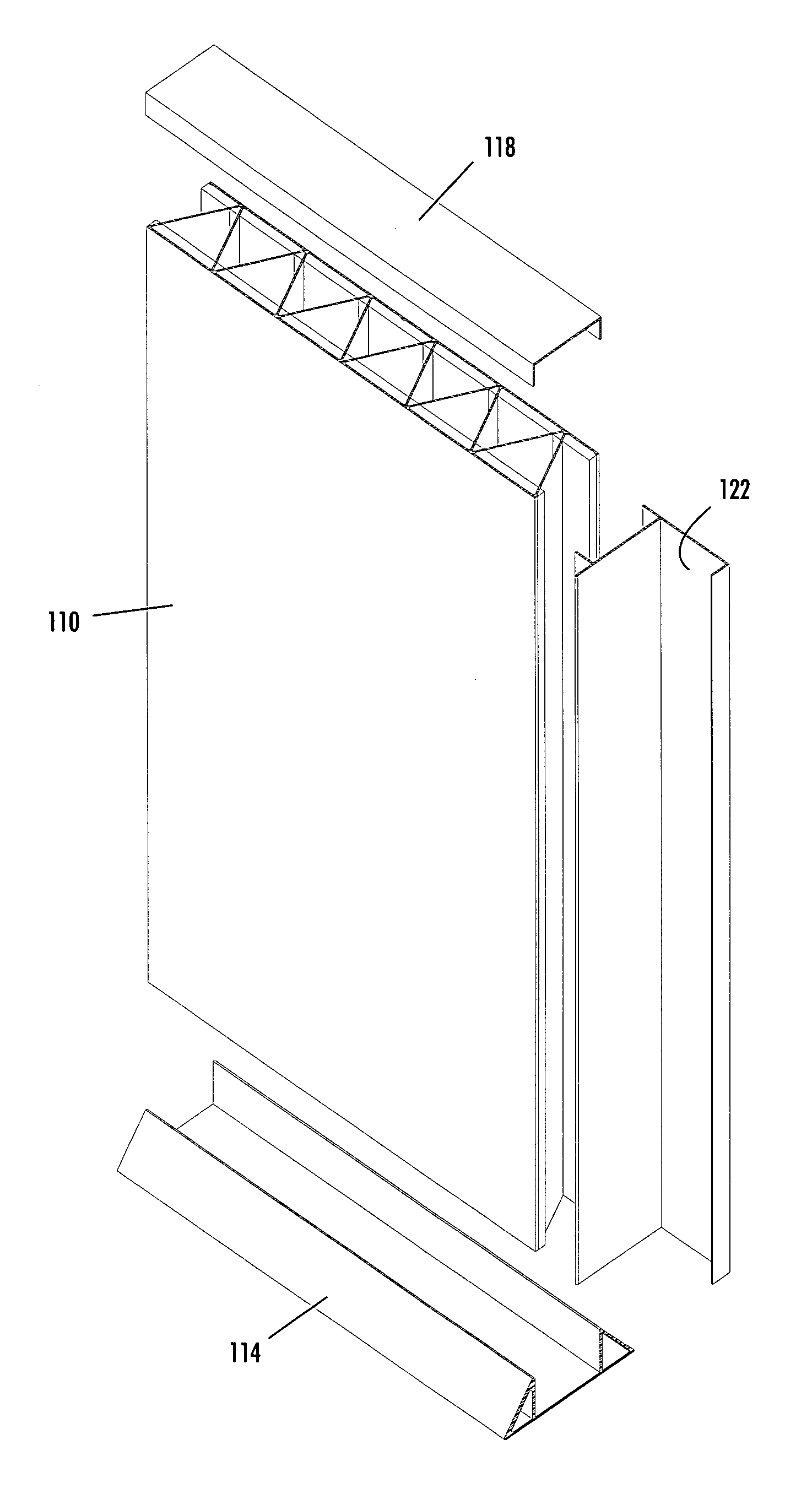

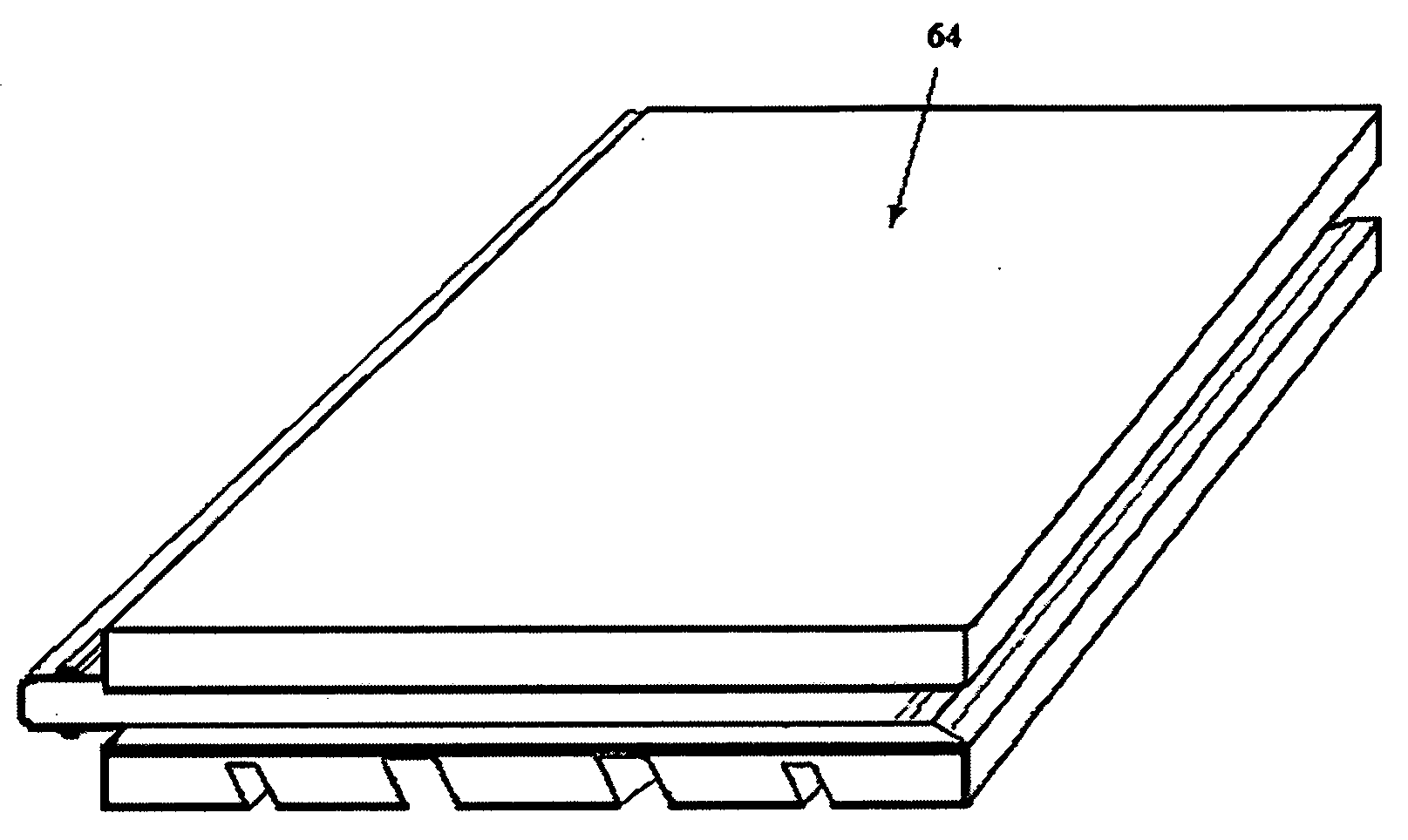

Modular structure for building panels and methods of making and using same

The present invention is a polymeric panel system and method for production and use thereof, enabling the rapid construction of a building foundation wall or other structure and in particular a below-grade foundation. The polymeric foundation system includes polymeric wall panels and other components suitable for withstanding lateral and end compression loads. The walls include two parallel faces separated by a series of webs or ribs, where the webs and faces of the wall panels may be formed of a similar polymer material such as polyvinylchloride (PVC). The wall panels and / or other components may be extruded so as to enable the rapid production of sections of wall panels, where the panels may be cut to length and then affixed to adjacent panels to form a foundation wall. The method of affixing adjacent panels may include welding, gluing or other techniques and may be performed on the job site or in a pre-fabrication facility. Furthermore, the wall panels may be co-extruded with an insulating material inserted in the voids between the parallel faces so as to provide improved thermal performance of the foundation as well.

Owner:DOUGLAS ROBERT B

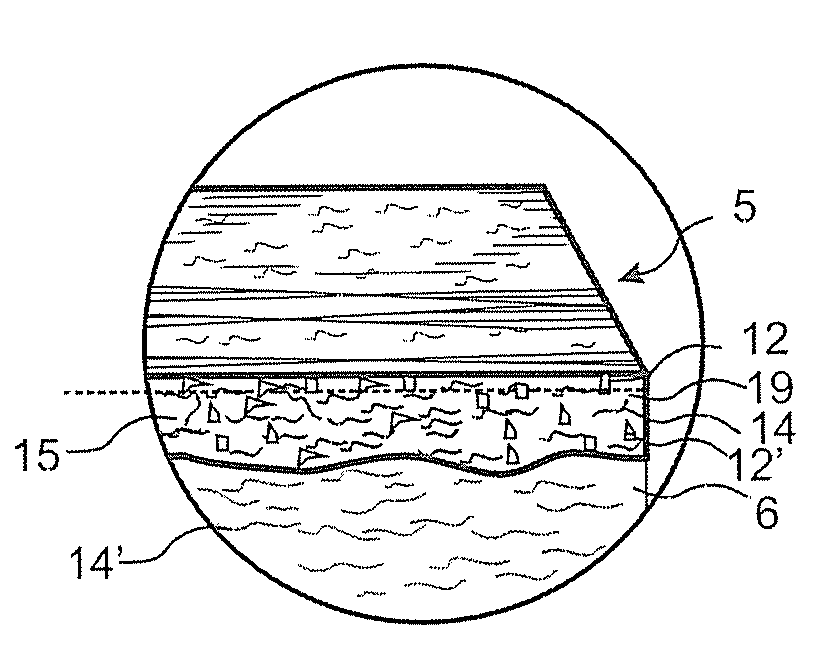

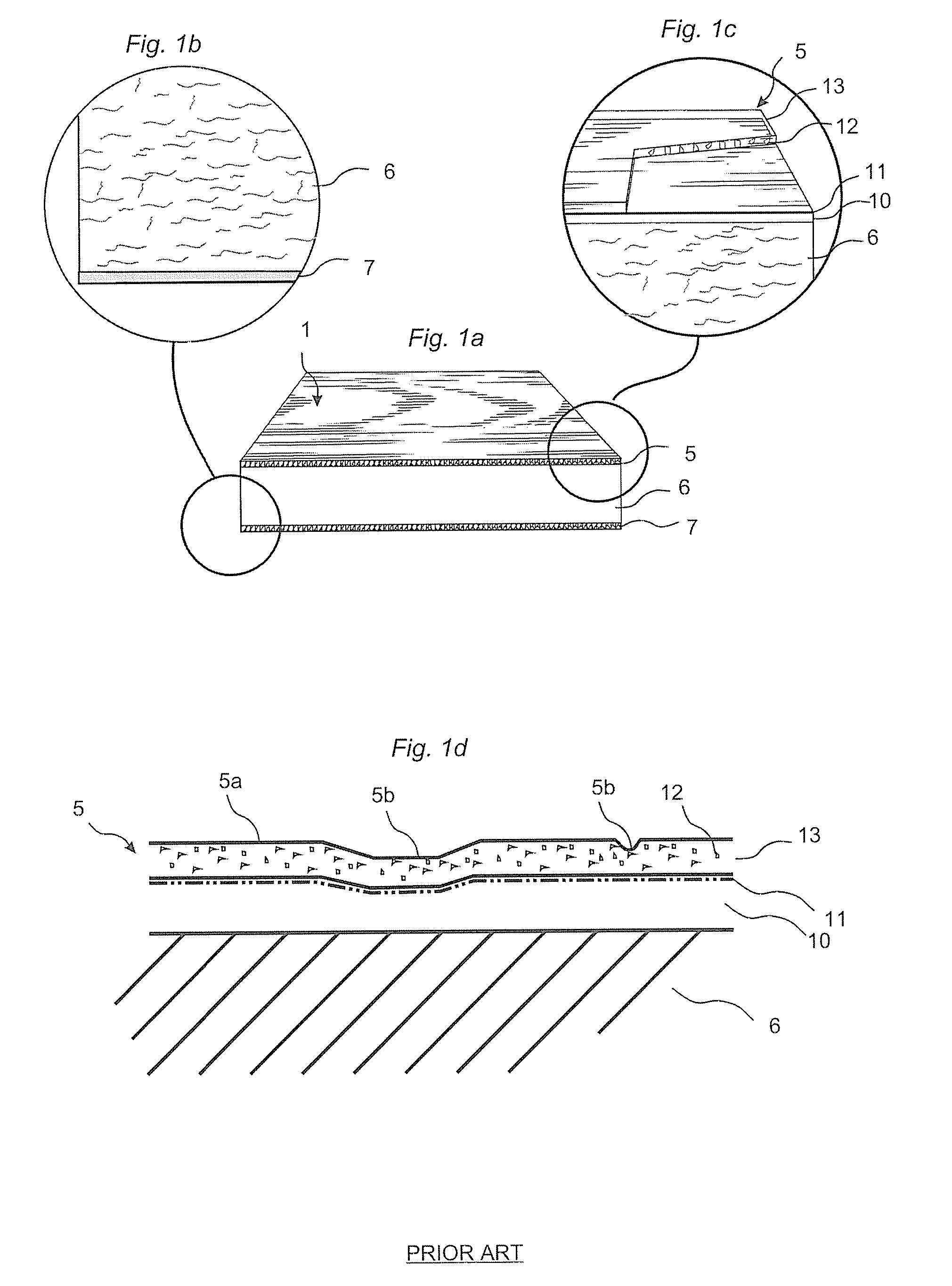

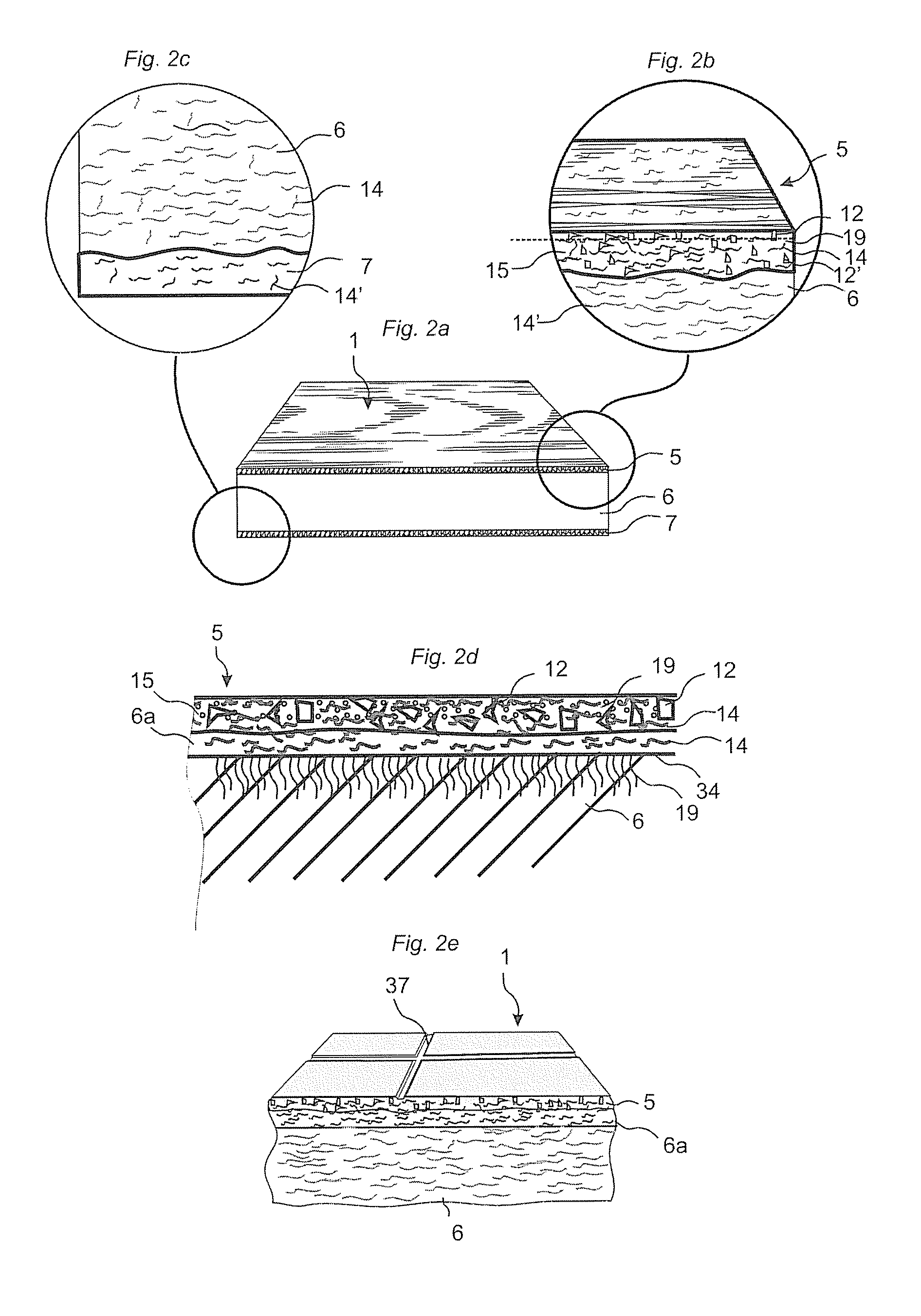

Wood fibre based panels with a thin surface layer

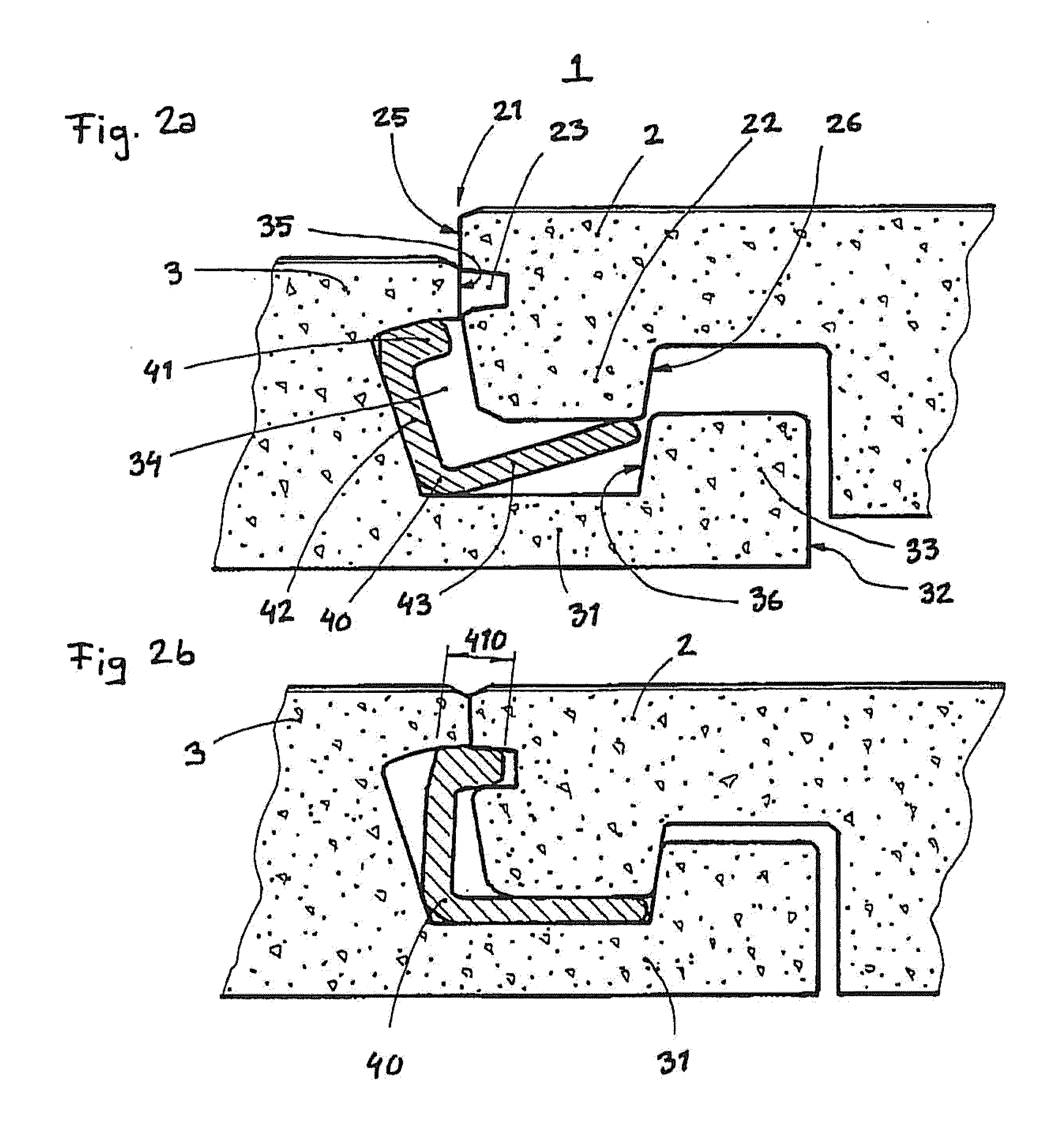

ActiveUS20100092731A1Large market shareImprove impact resistanceLiquid surface applicatorsCovering/liningsSurface layerWood fibre

Building panels with a thin and embossed surface layer and a sub layer between a surface layer and a core.

Owner:VÄLINGE INNOVATION AB

Flooring and method for laying and manufacturing the same

InactiveUS7127860B2The process is simple and fastImprove distributionConstruction materialWallsHerringbone pattern

Owner:VÄLINGE INNOVATION AB

Method for precision bending of a sheet of material and slit sheet therefor

InactiveUS6481259B1Reduce stress concentrationPrecise positioningConstruction materialMetal-working feeding devicesEngineeringSheet material

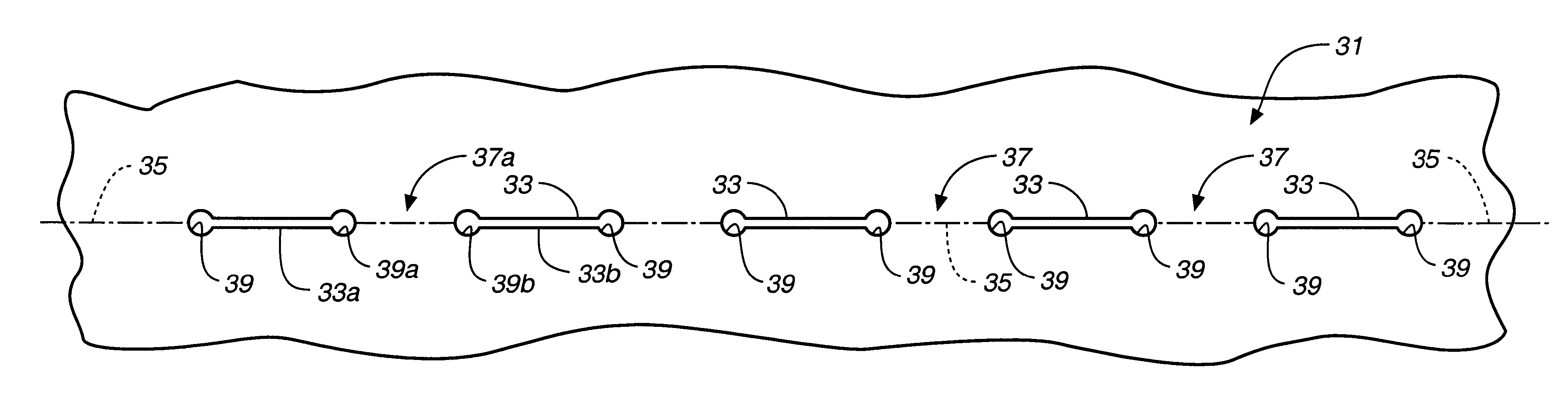

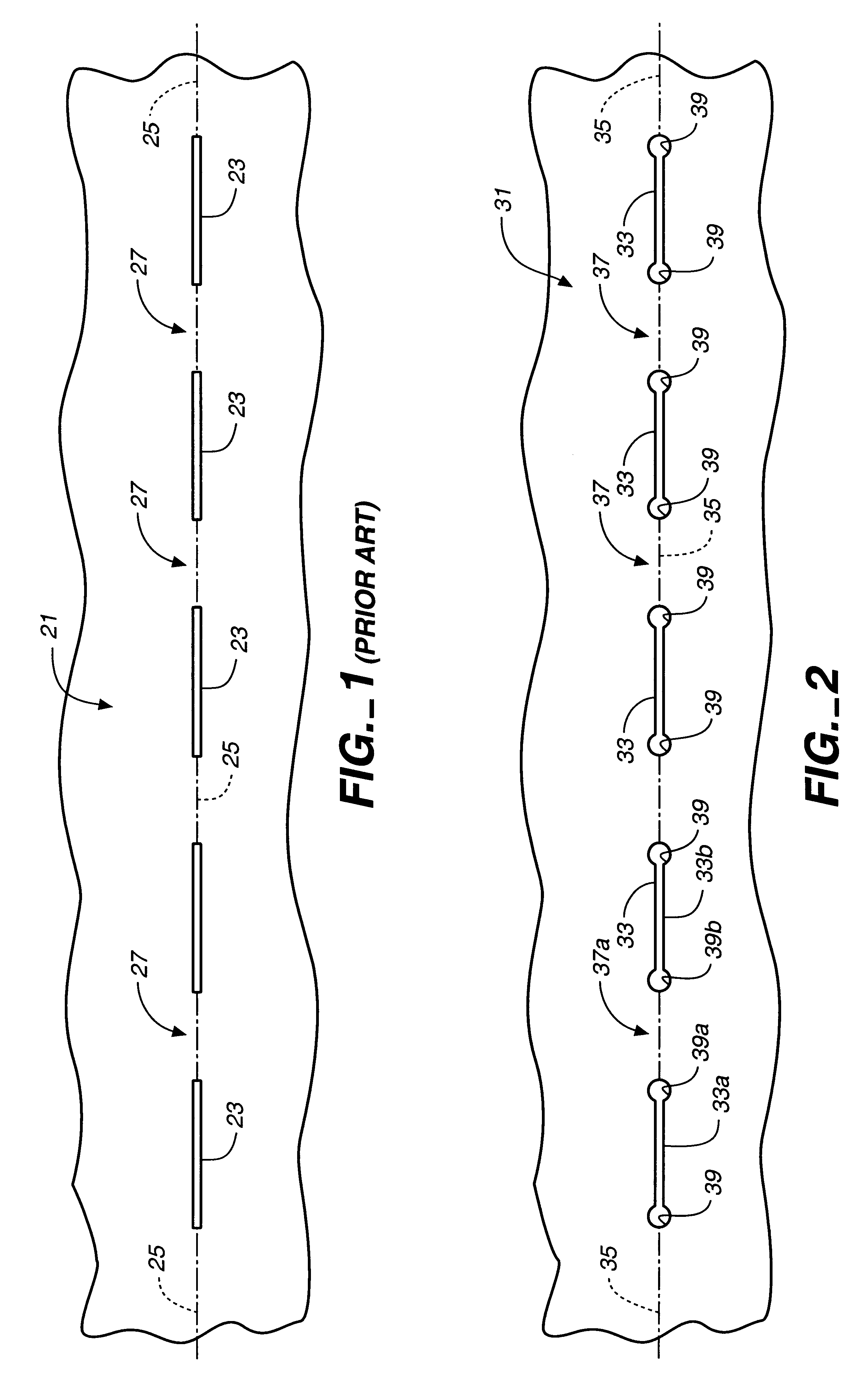

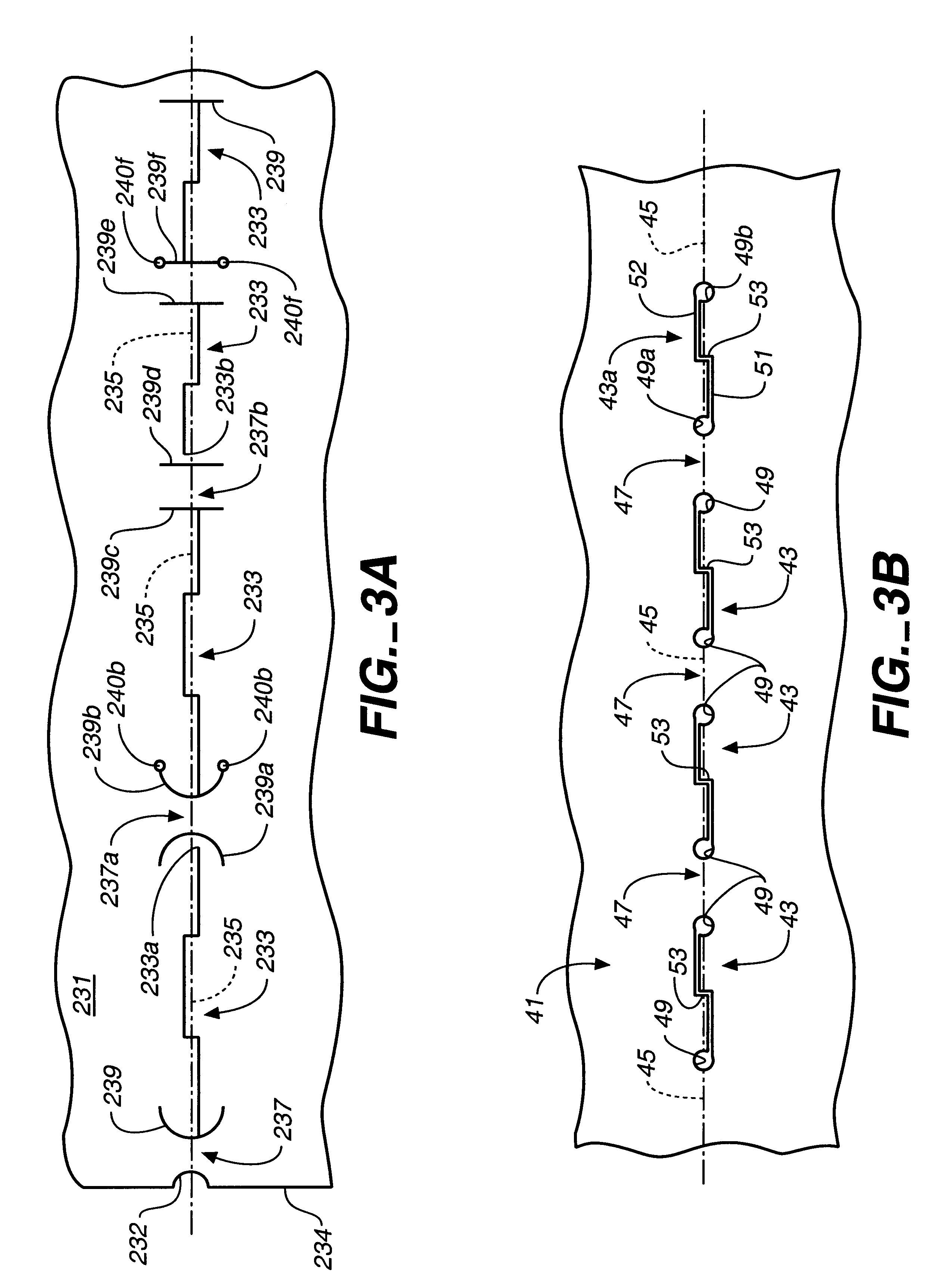

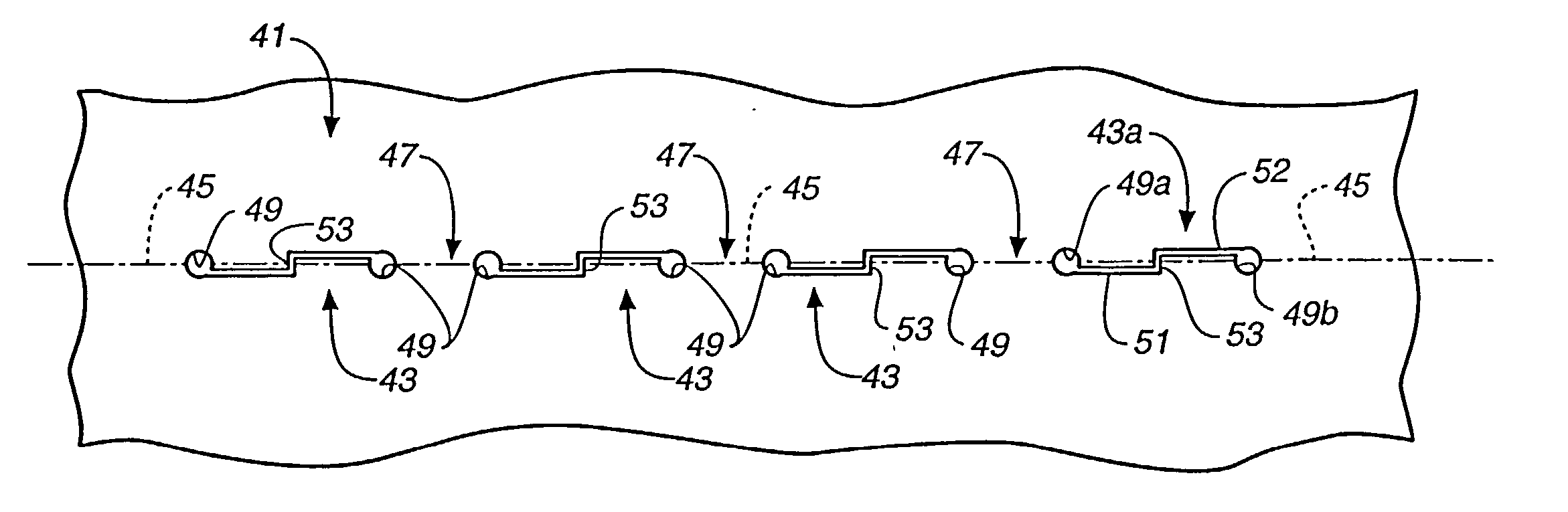

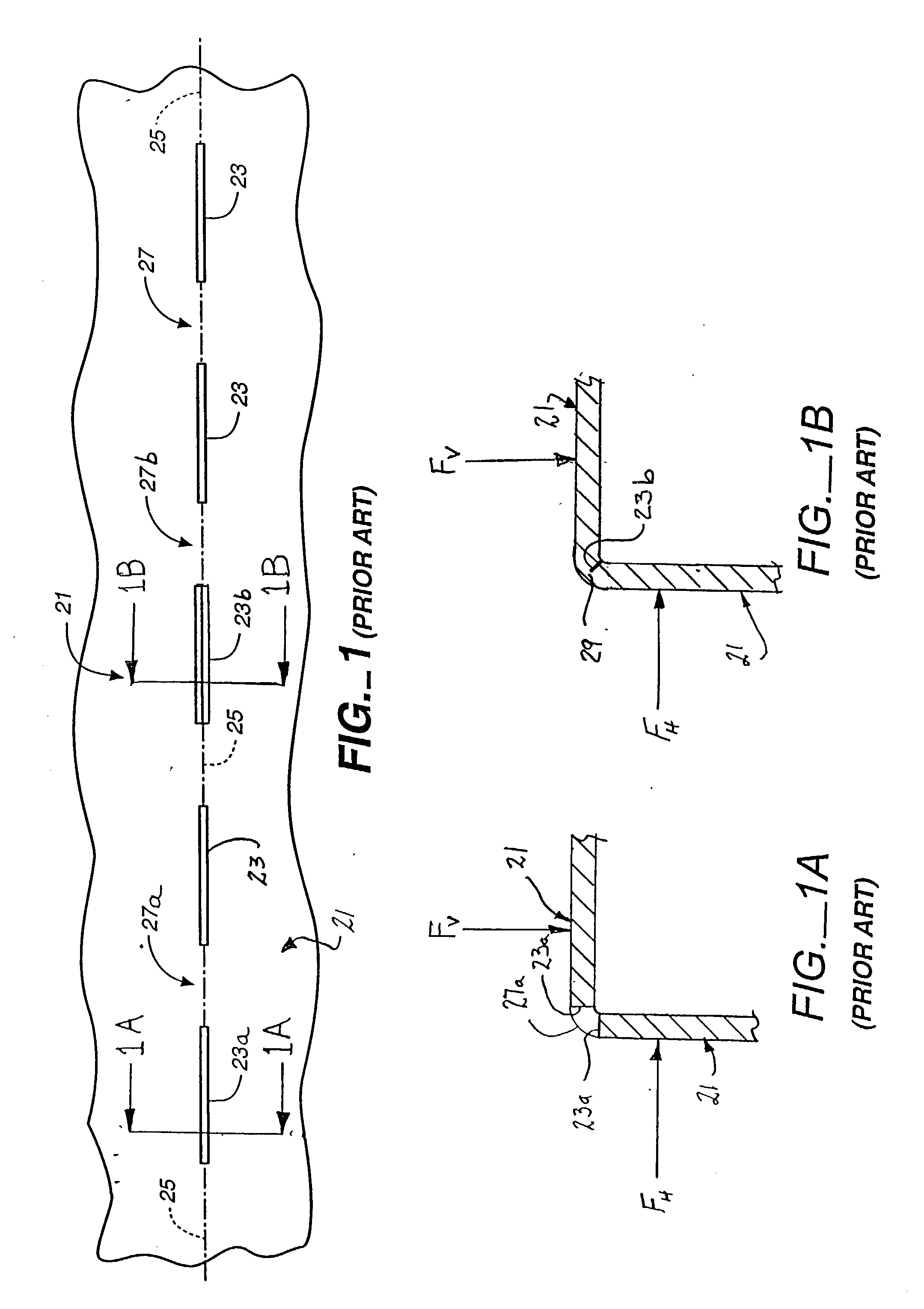

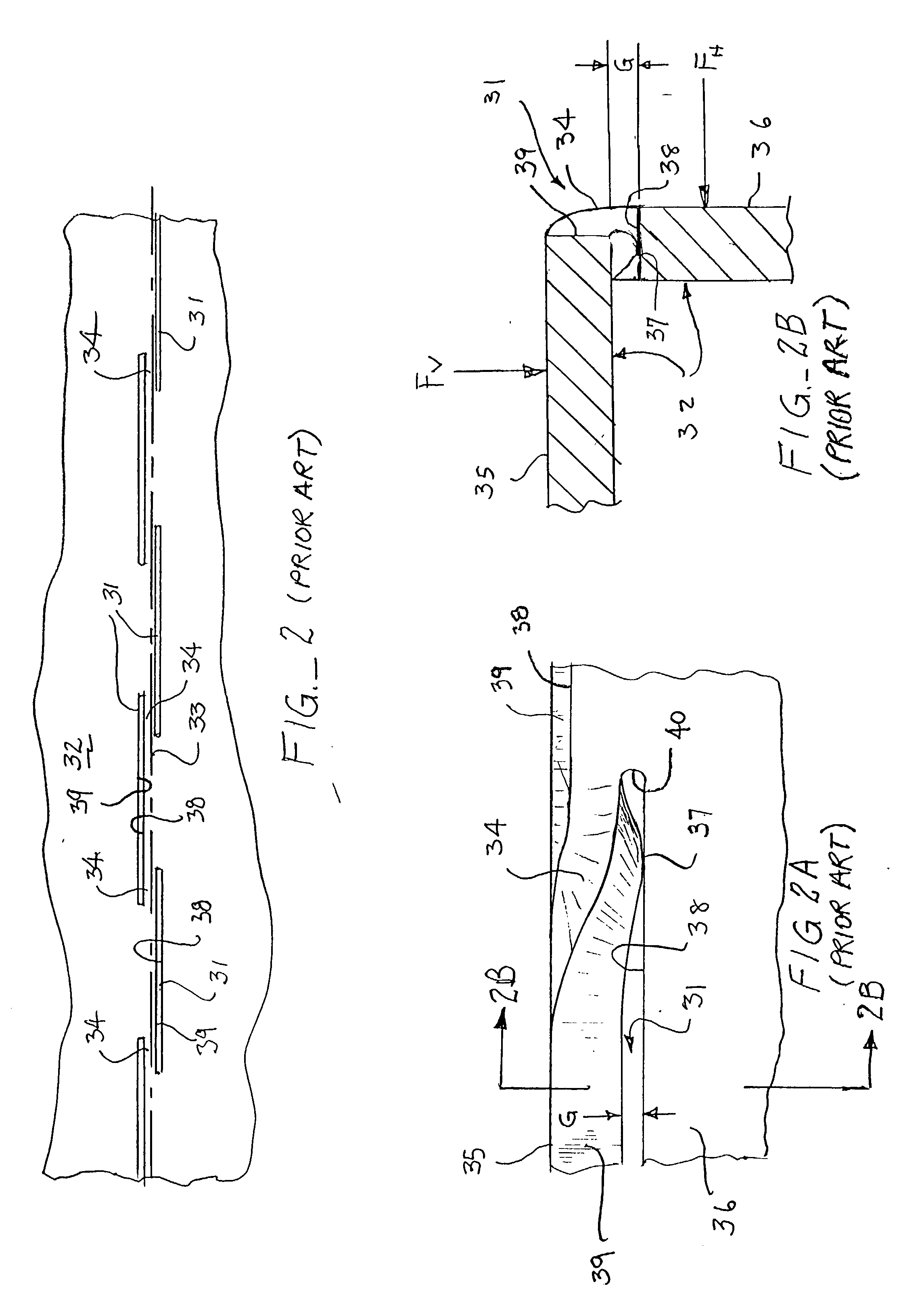

A method for precision bending of a sheet of material (31,41,61,91,231) along a bend line (35,45,62-66,96,235) and the resulting sheet are disclosed. A method includes a step of forming and longitudinally extending slits (33,43,68,92,233) through the sheet of material in axially spaced relation to define bending webs (37,47,71,72,106,237), forming stress reducing structures such as enlarged openings (39,49,69,73) or transversely extending slits (239) at each of adjacent ends of pairs of slits in order to reduce crack propagation across the bending webs. In another aspect, the elongated slits (43,68,92,233) are formed with pairs of longitudinally extending slit segments (51,52;74,76;98,99;127) proximate to and on opposite sides of and substantially parallel to the desired bend line. Longitudinally extending slit segments further are connected by at least one intermediate transversely extending slit segment (53,77,101,128). Sheets of slit material suitable for bending also are disclosed.

Owner:IND ORIGAMI INC CA US

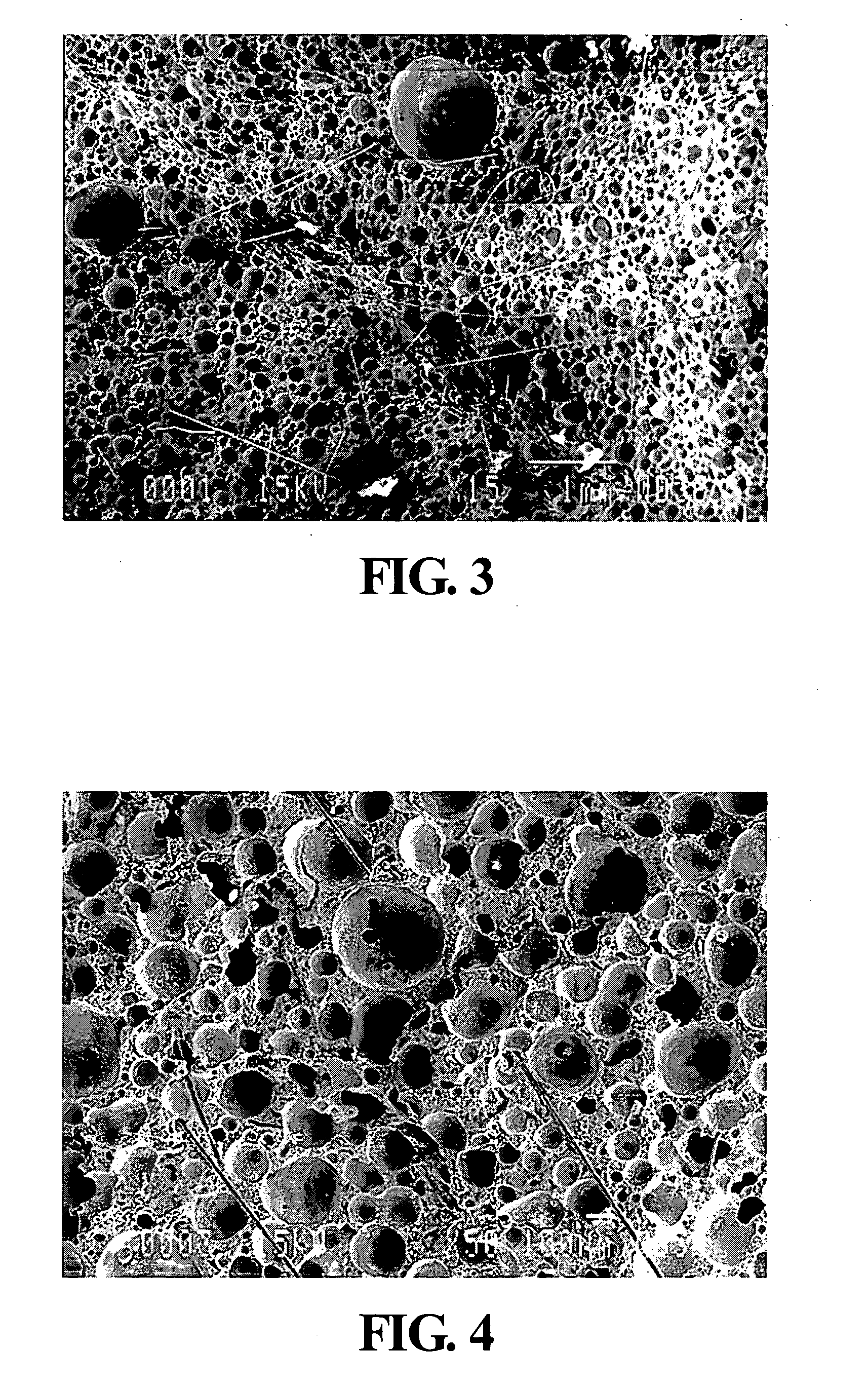

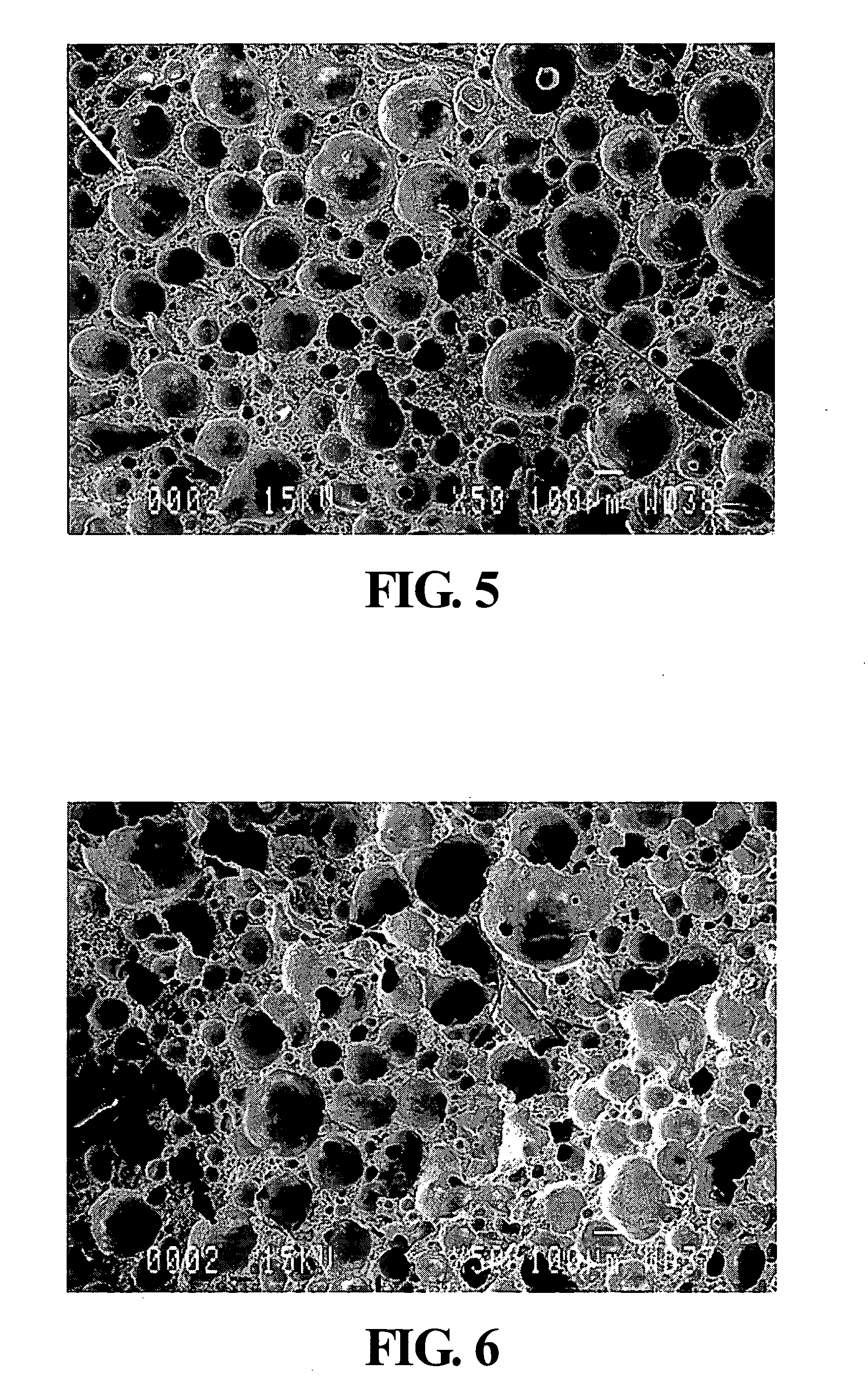

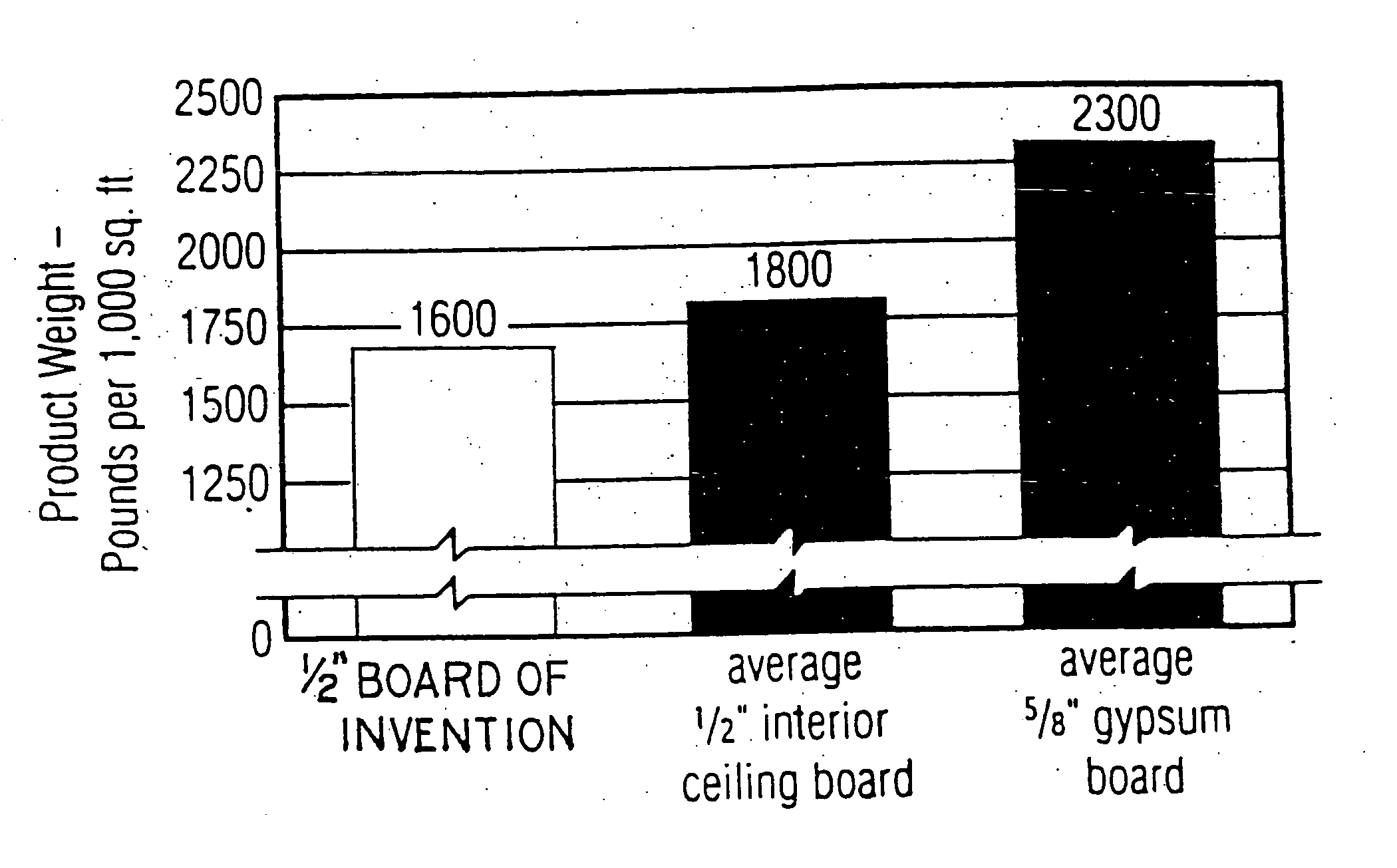

Low dust gypsum wallboard

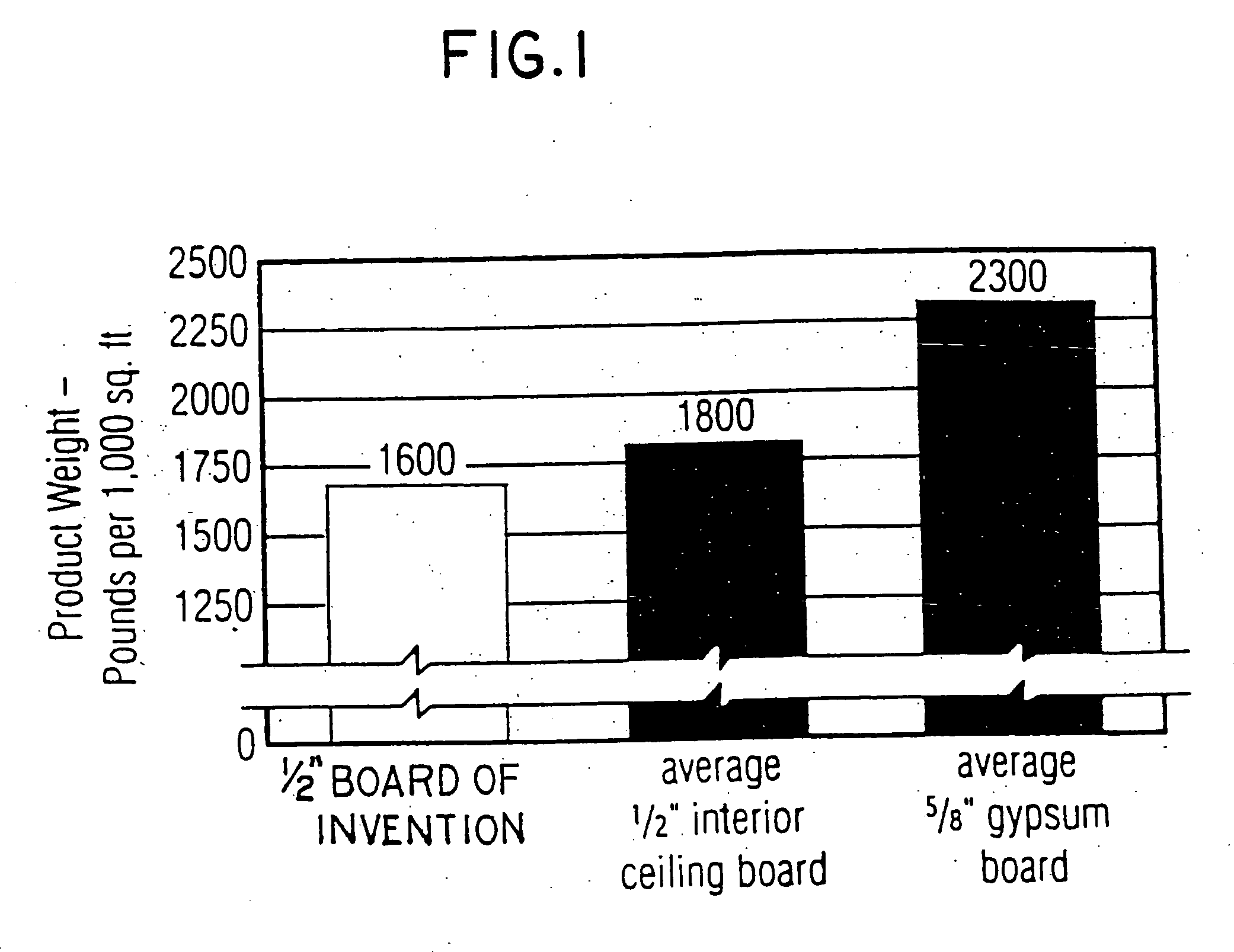

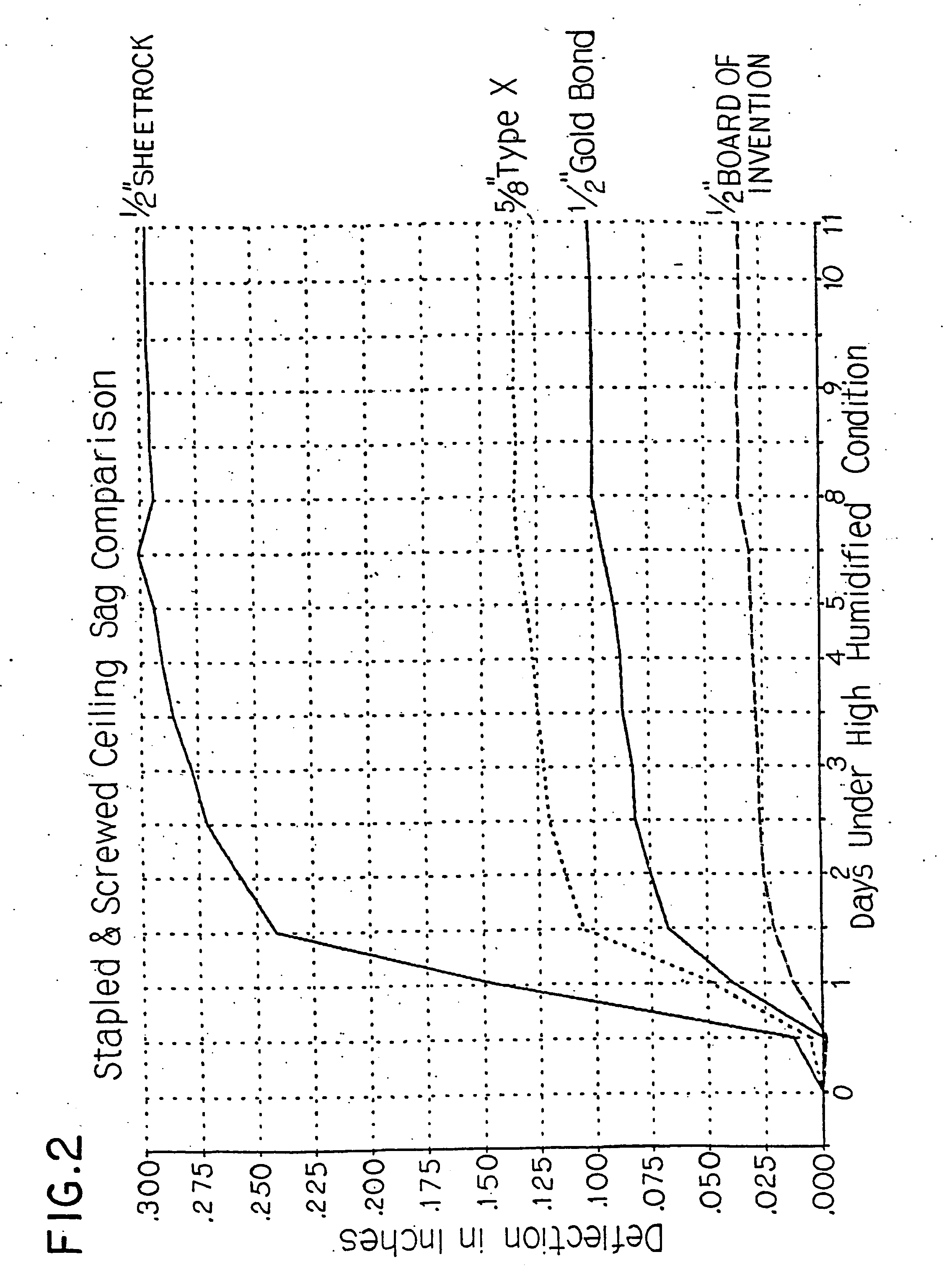

ActiveUS20070048490A1High strengthReduce weightConstruction materialCovering/liningsDust controlSlurry

This invention provides low dust low density gypsum wallboard products having high total core void volumes, corresponding to low densities in the range of about 10 to 30 pcf. The wallboards have a set gypsum core formed between two substantially parallel cover sheets, the set gypsum core preferably having a total void volume from about 80% to about 92%, and made from a slurry including stucco, pregelatinized starch, and a naphthalenesulfonate dispersant. The combination of the pregelatinized starch and the naphthalenesulfonate dispersant also provides a glue-like effect in binding the set gypsum crystals together. The wallboard formulation, along with small air bubble voids (and water voids) provides dust control during cutting, sawing, routing, snapping, nailing or screwing down, or drilling of the gypsum-containing products. This invention also provides a method of making the low dust low density gypsum products including the introduction of soap foam in an amount sufficient to form a total void volume, including air voids, preferably from about 80% to about 92% in the set gypsum core, corresponding to a set gypsum core density from about 10 pcf to about 30 pcf. The wallboards produced by the method generate significantly less dust during working.

Owner:UNITED STATES GYPSUM CO

Substrate and the application

InactiveUS20090308001A1Reducing global warmingImprove energy efficiencyPhotovoltaic supportsSolar heating energyThermal energyThermal insulation

This invention relates to a substrate and the application. In particular, this invention discloses a substrate which has at least one contact structure at least on one side and at least one contact structure at least on one surface of the substrate. The substrate includes a thermal insulation material comprising at least two materials selecting from a thermal energy reflecting material, a homogeneous foam material, a heterogeneous foam material, a skin material, a skeleton structured material, an electromagnetic wave shielding material. The substrate may be used to construct various articles with different features of energy saving, decoration and protection as well as simple installation for various applications.

Owner:WU SHAOBING

Composite panels

A composite panel consisting of outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic. The composite panel can be made by applying external heat and pressure to melt a skin of thermoplastic composite and an initial thickness of a thermoplastic core which has anisotropic properties causing the skin and core to fuse together followed by cooling the fused structure. The composite panel can be made by applying external heat and pressure to melt layers of a thermoplastic adhesive positioned between the outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic, so that the skins are bonded to the core by the melted layers of the thermoplastic adhesive followed by cooling the bonded structure.

Owner:EDWARDS CHRISTOPHER M

Insulative concrete building panel with carbon fiber and steel reinforcement

InactiveUS6898908B2High strengthImprove insulation performanceBuilding roofsConstruction materialFiberCarbon fibers

An insulative, lightweight concrete building panel is provided with one or more fiber or steel reinforcements which are manufactured in a controlled environment and can be easily transported and erected at a building site.

Owner:OLDCASTLE PRECAST

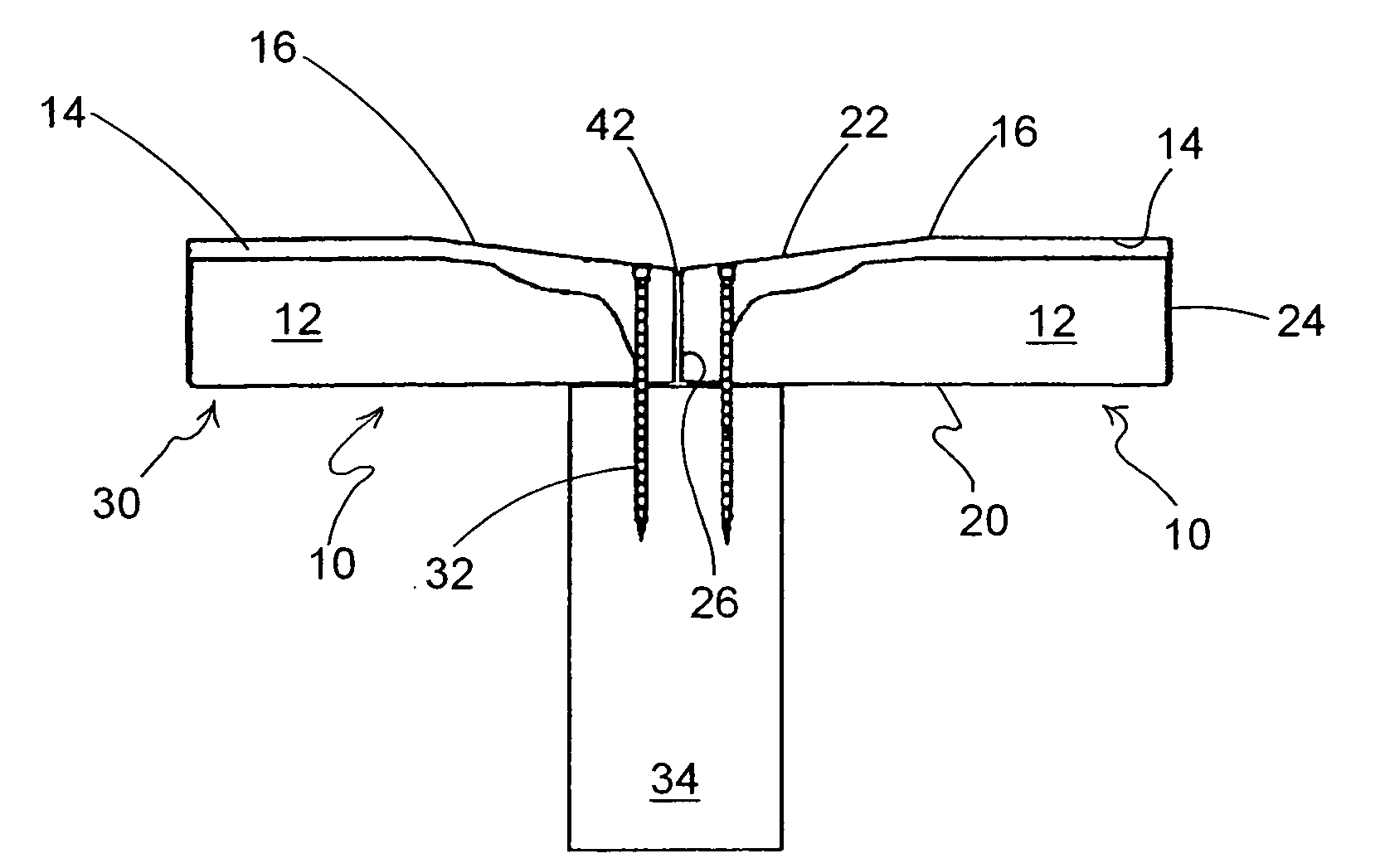

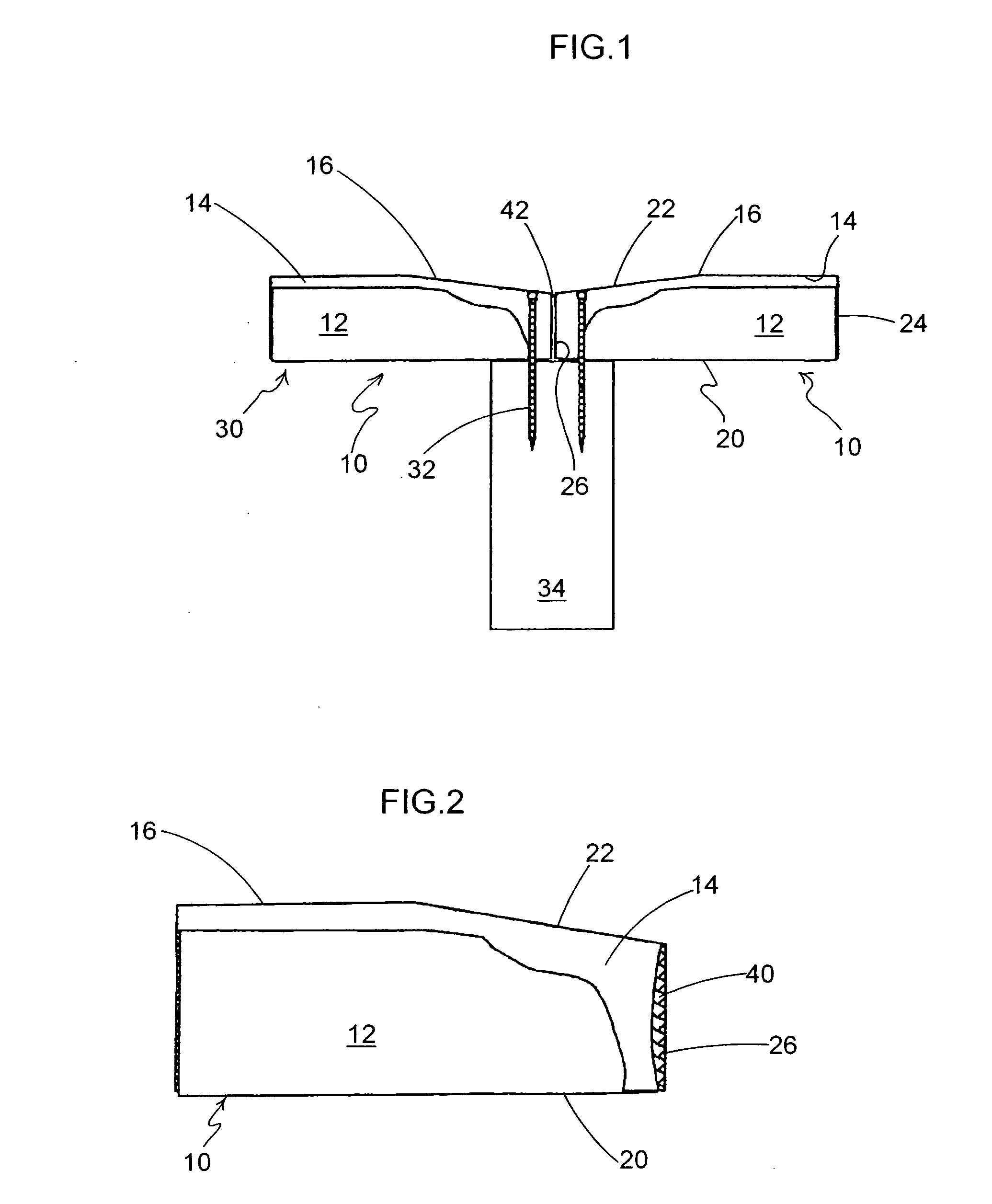

Joint for panels

A joint (1) having a first edge (2) and a second edge (3), the first edge (2) being provided with a distal edge (21) and a downwards protruding heel (22). The distal edge (21) is further provided with an upper joint edge (25) beneath which a groove (23) is arranged. The second edge (3) is provided with lower cheek (31) having a distal end (32) at which an upwards protruding lower cheek heel (33) is arranged. The second edge (3) is further provided with an upper joining edge (35) beneath which an undercut (34) is arranged. A moveable locking element (40) is arranged in the space created by the undercut (34). The moveable locking element (40) have a locking tongue (41), a locking tongue leg (42) and a maneuvering leg (43).

Owner:PERGO

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

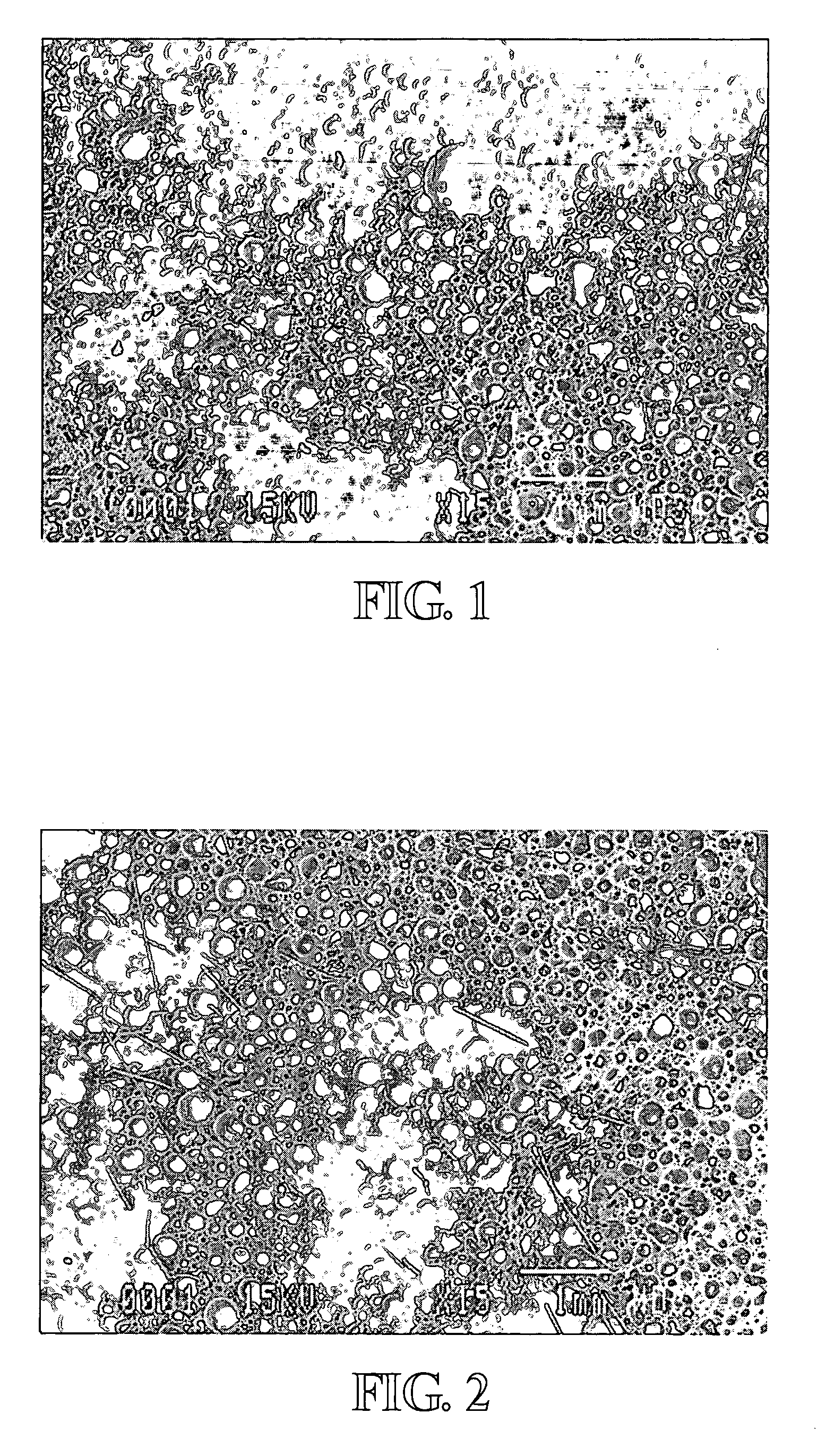

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

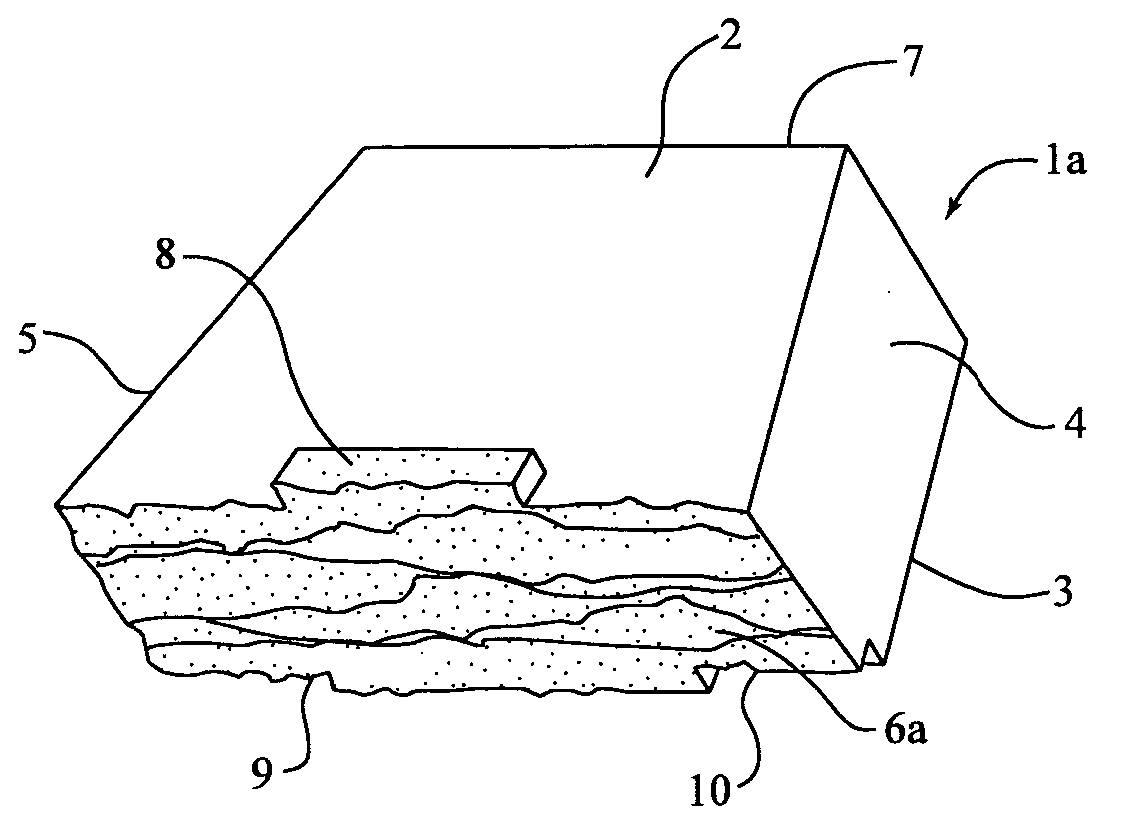

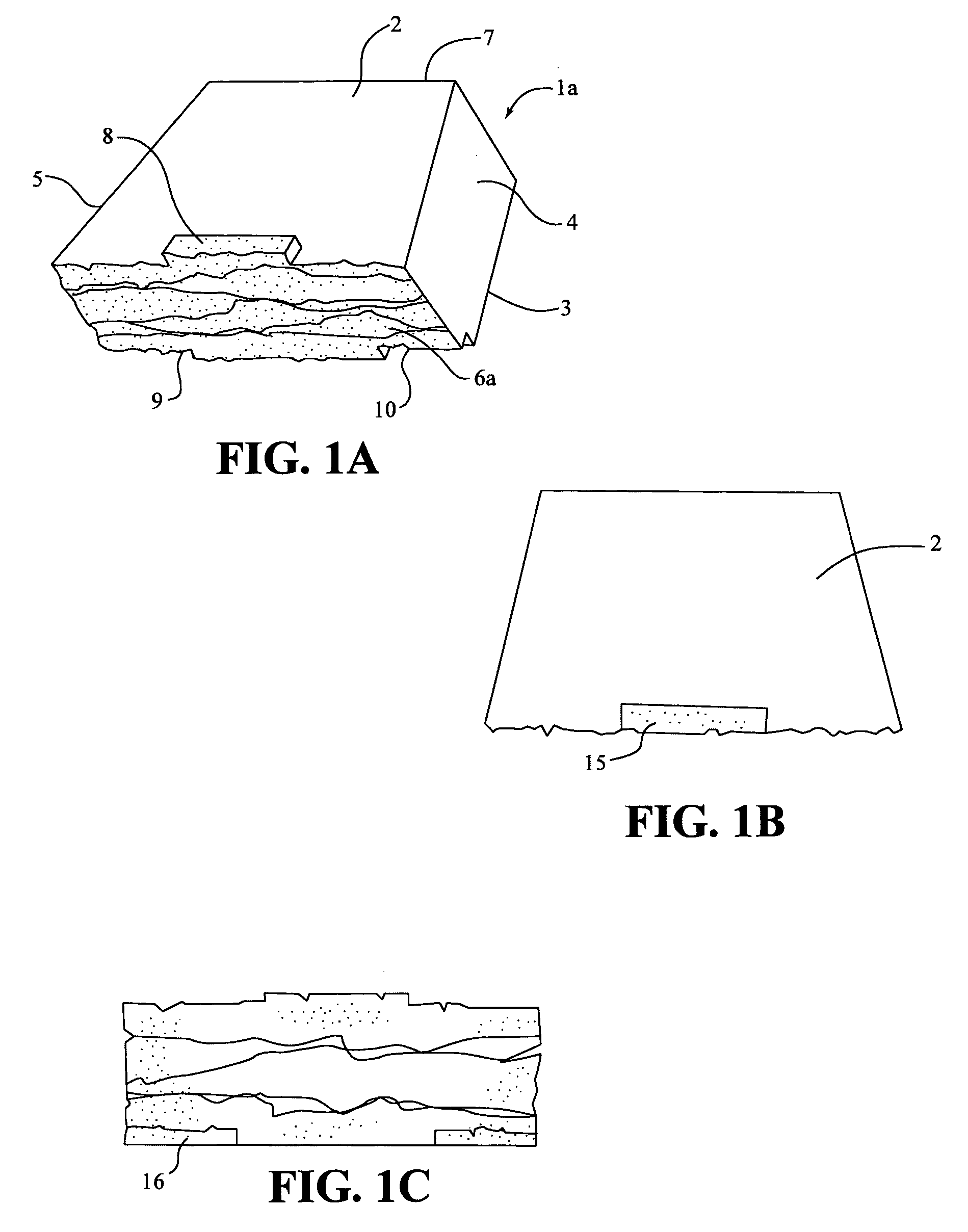

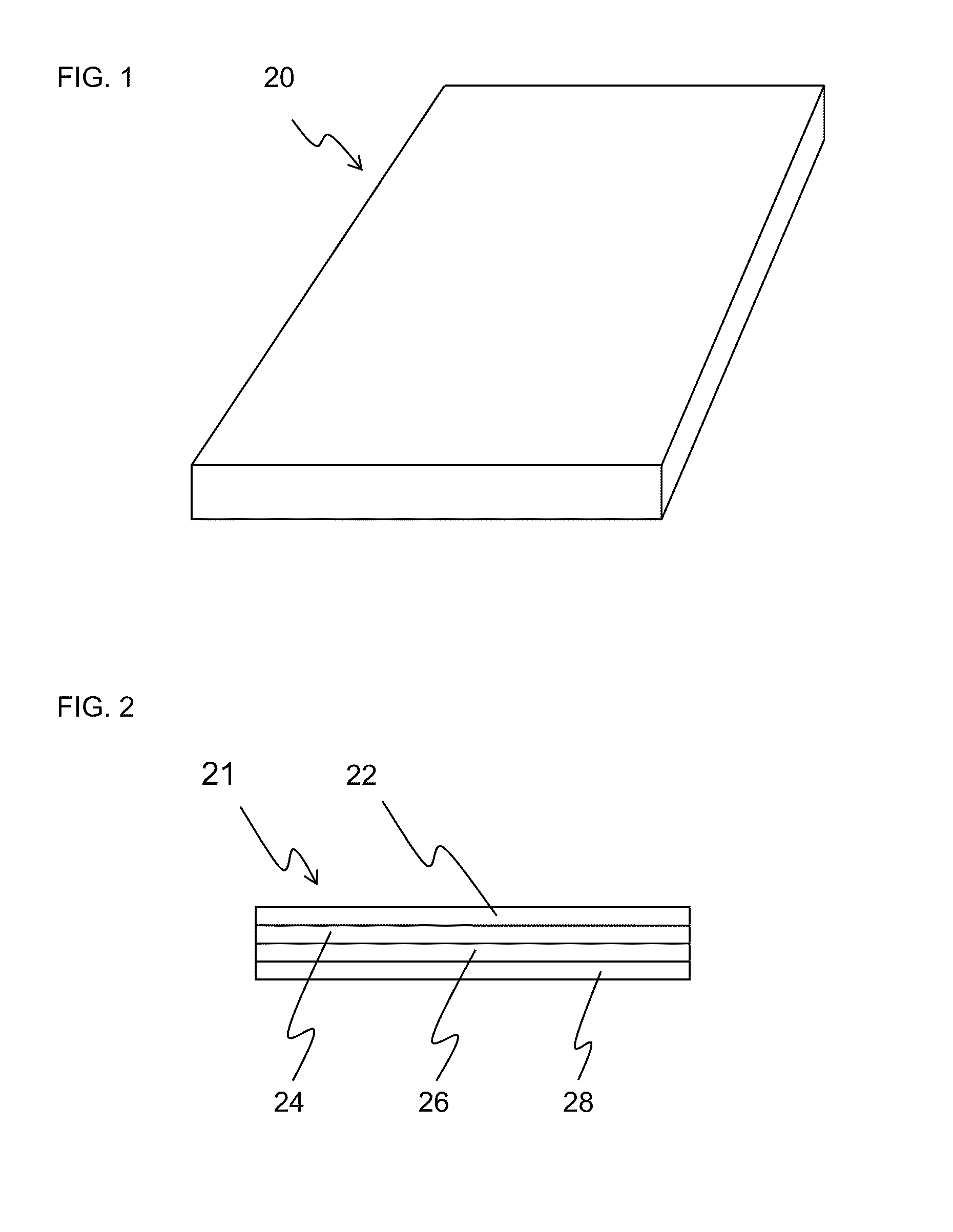

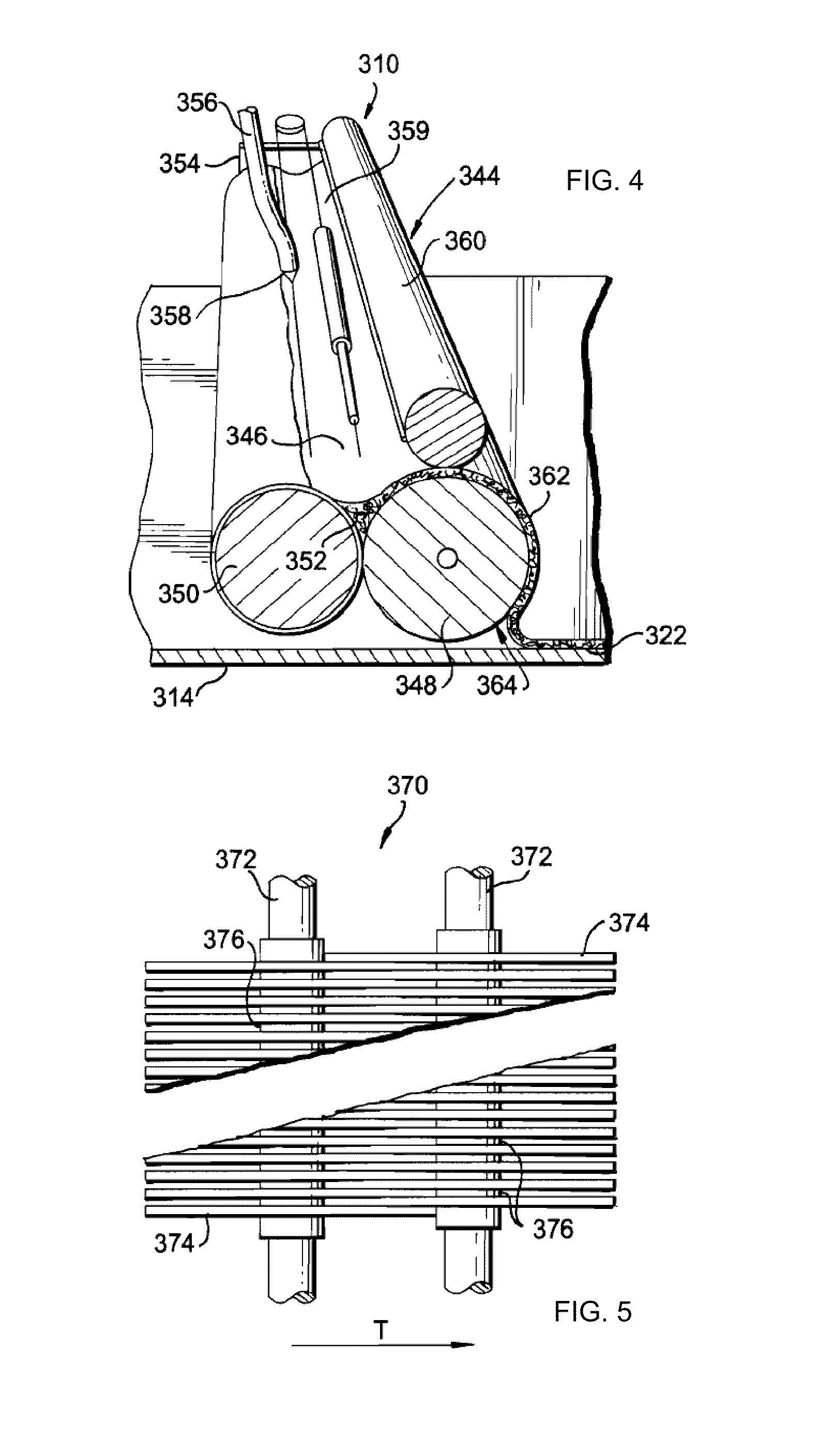

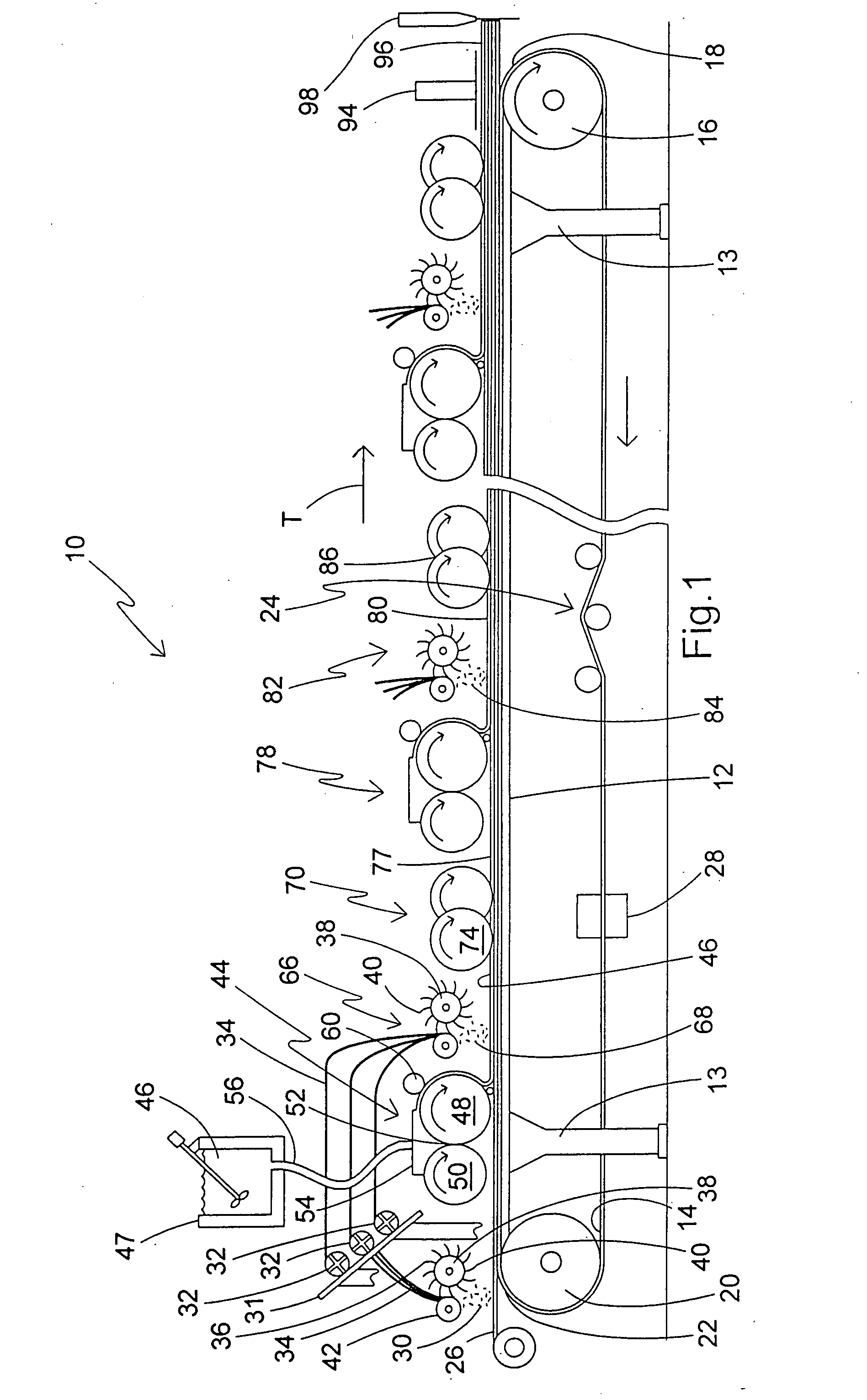

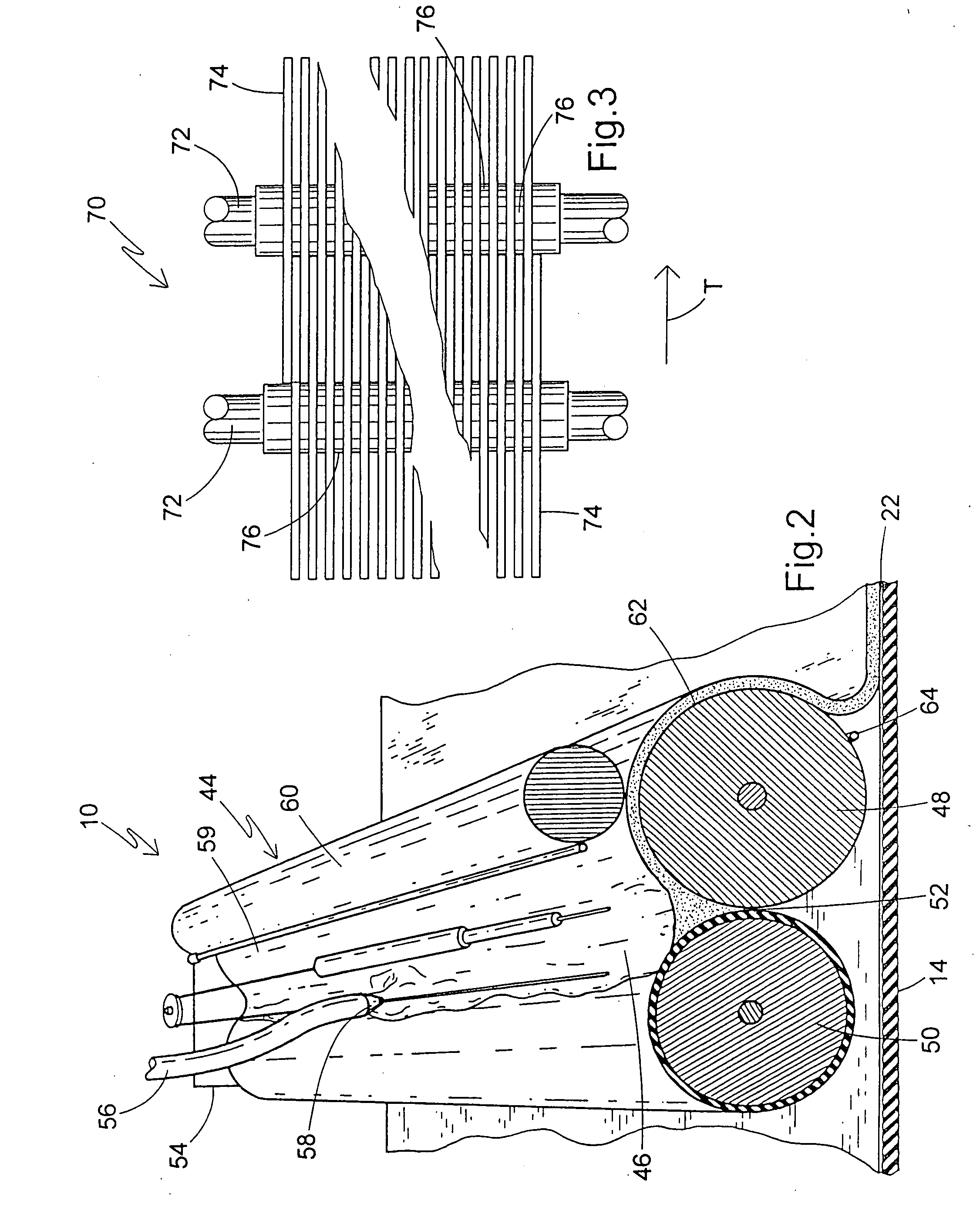

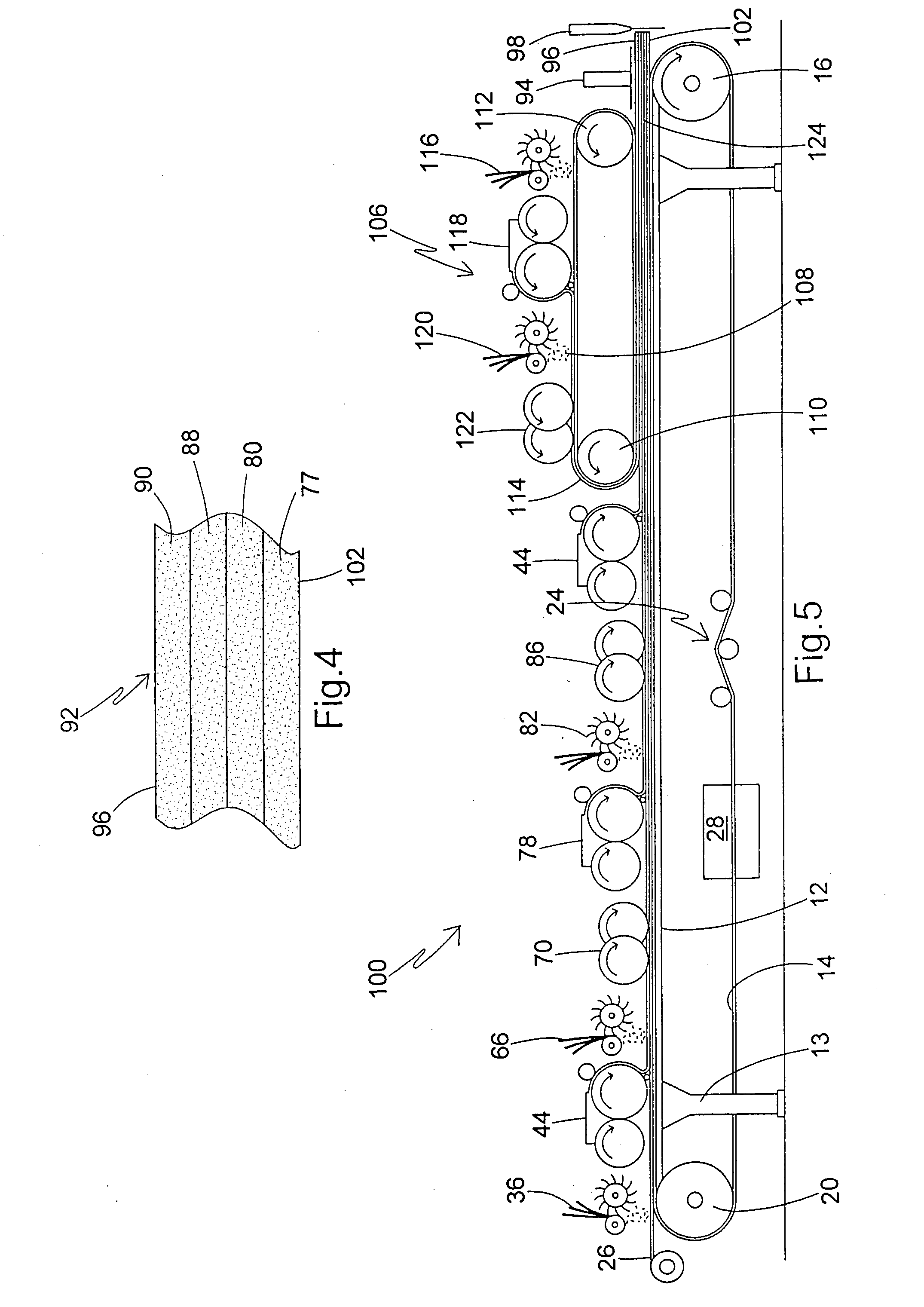

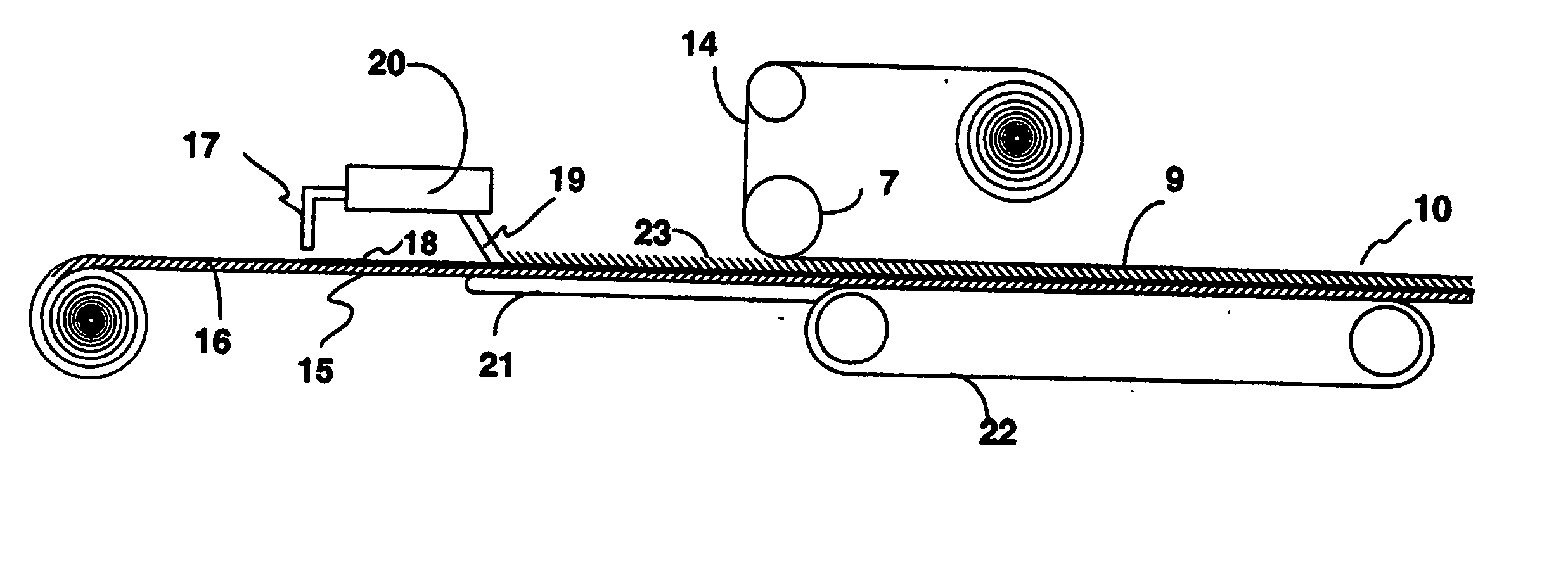

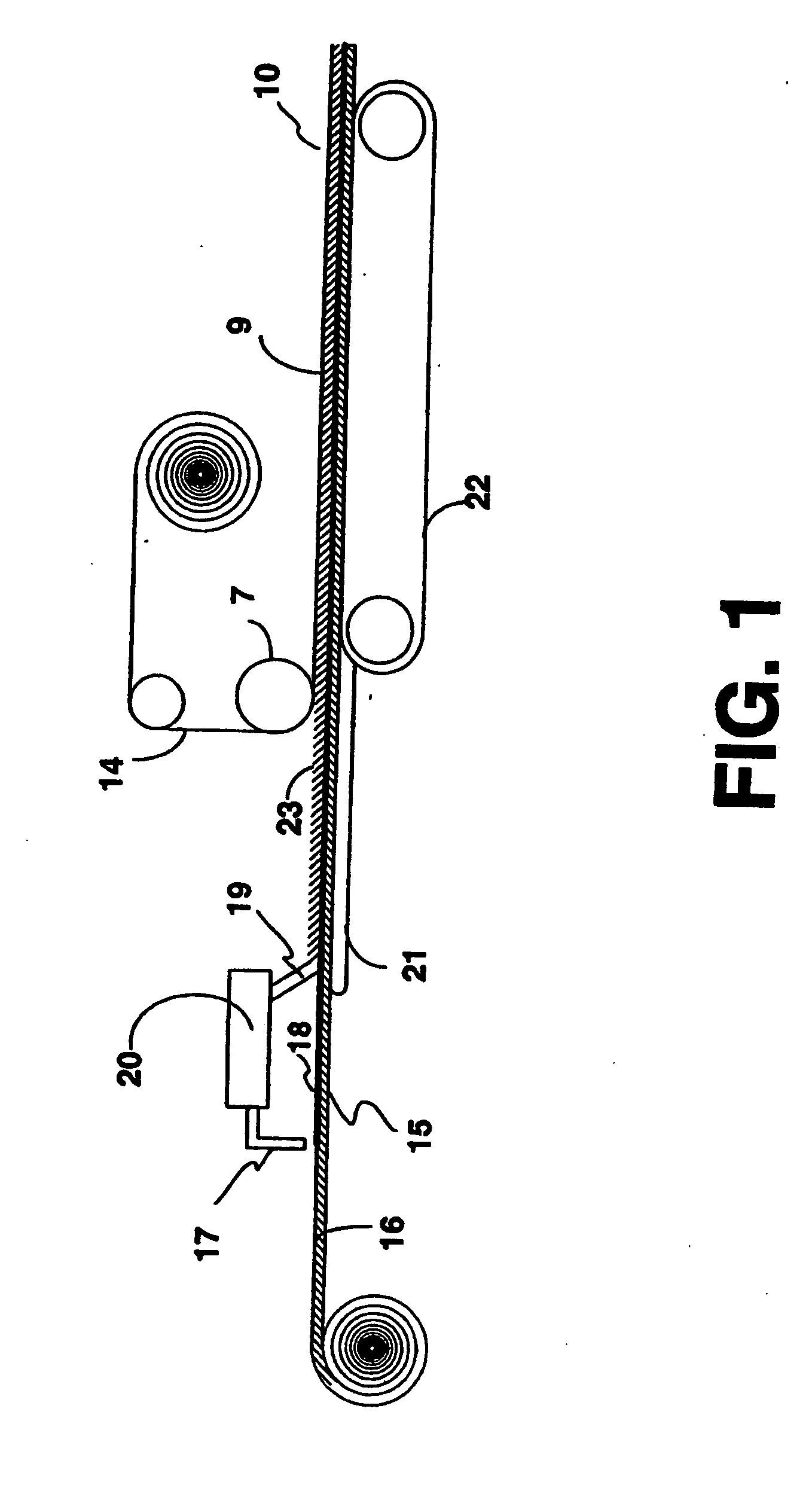

Multi-layer process and apparatus for producing high strength fiber-reinforced structural cementitious panels

ActiveUS20050064164A1Equally distributedStrong panelConstruction materialLaminationCement boardOptoelectronics

A multi-layer process for producing structural cementitious panels, includes, (a.) providing a moving web; (b.) one of depositing a first layer of loose fibers upon the web and (c.) depositing a layer of settable slurry upon the web; (d.) depositing a second layer of loose fibers upon the slurry; (e.) embedding said second layer of fibers into the slurry; and (f.) repeating steps (c.) through (e.) until the desired number of layers of settable fiber-enhanced slurry in the panel is obtained. Also provided are a structural panel produced by the present process, an apparatus suitable for producing structural cementitious panels according to the present process, and a structural cementitious panel having multiple layers, each layer created by depositing a layer of settable slurry upon a moving web, depositing fibers upon the slurry and embedding the fibers into the slurry such that each layer is integrally formed with the adjacent layers.

Owner:UNITED STATES GYPSUM CO

Resilient groove

A set of moisture proof floorboards and a flooring of such floorboards with a resilient surface layer provided with a decorative groove and / or a sealing means.

Owner:VÄLINGE INNOVATION AB

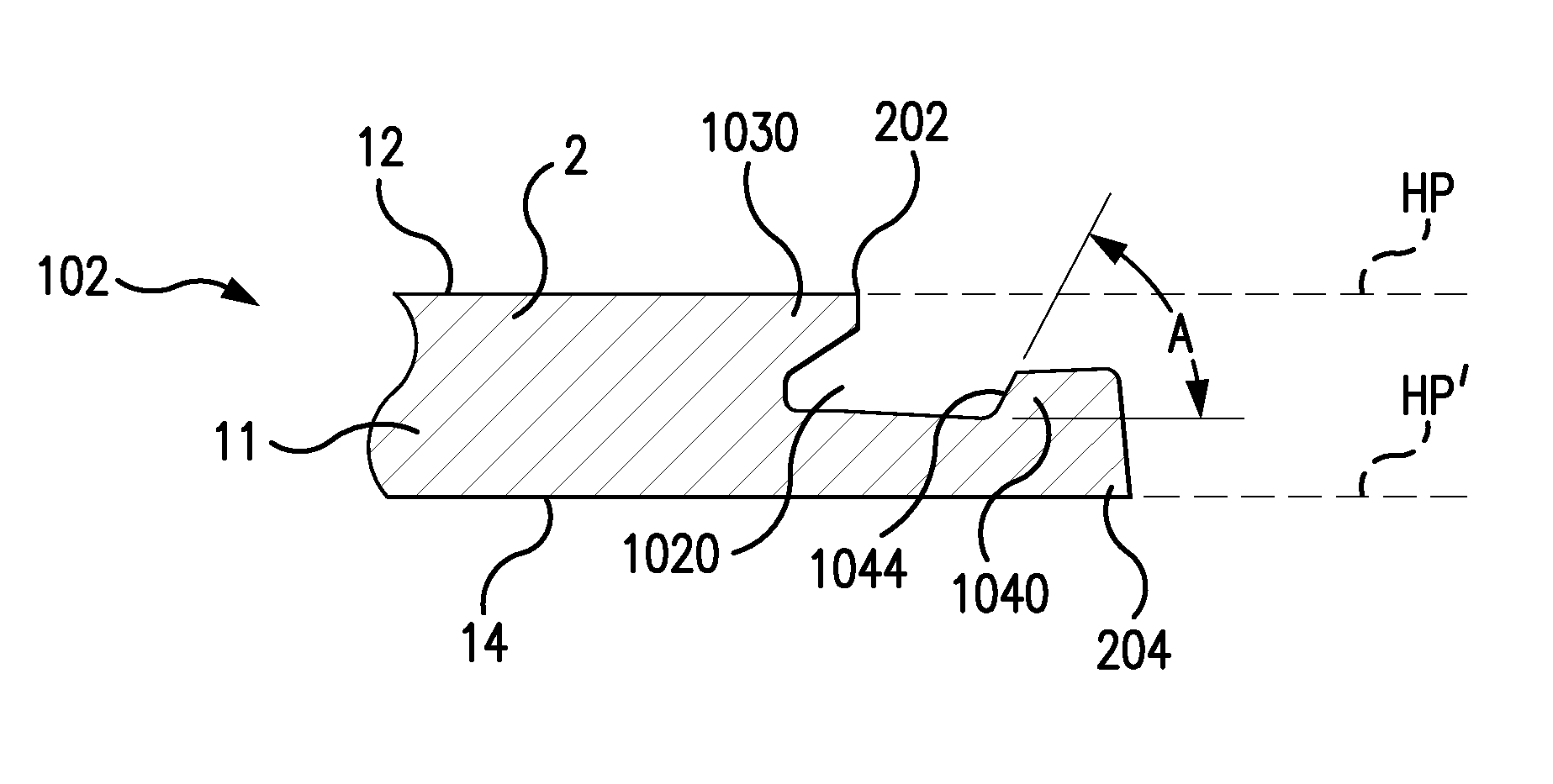

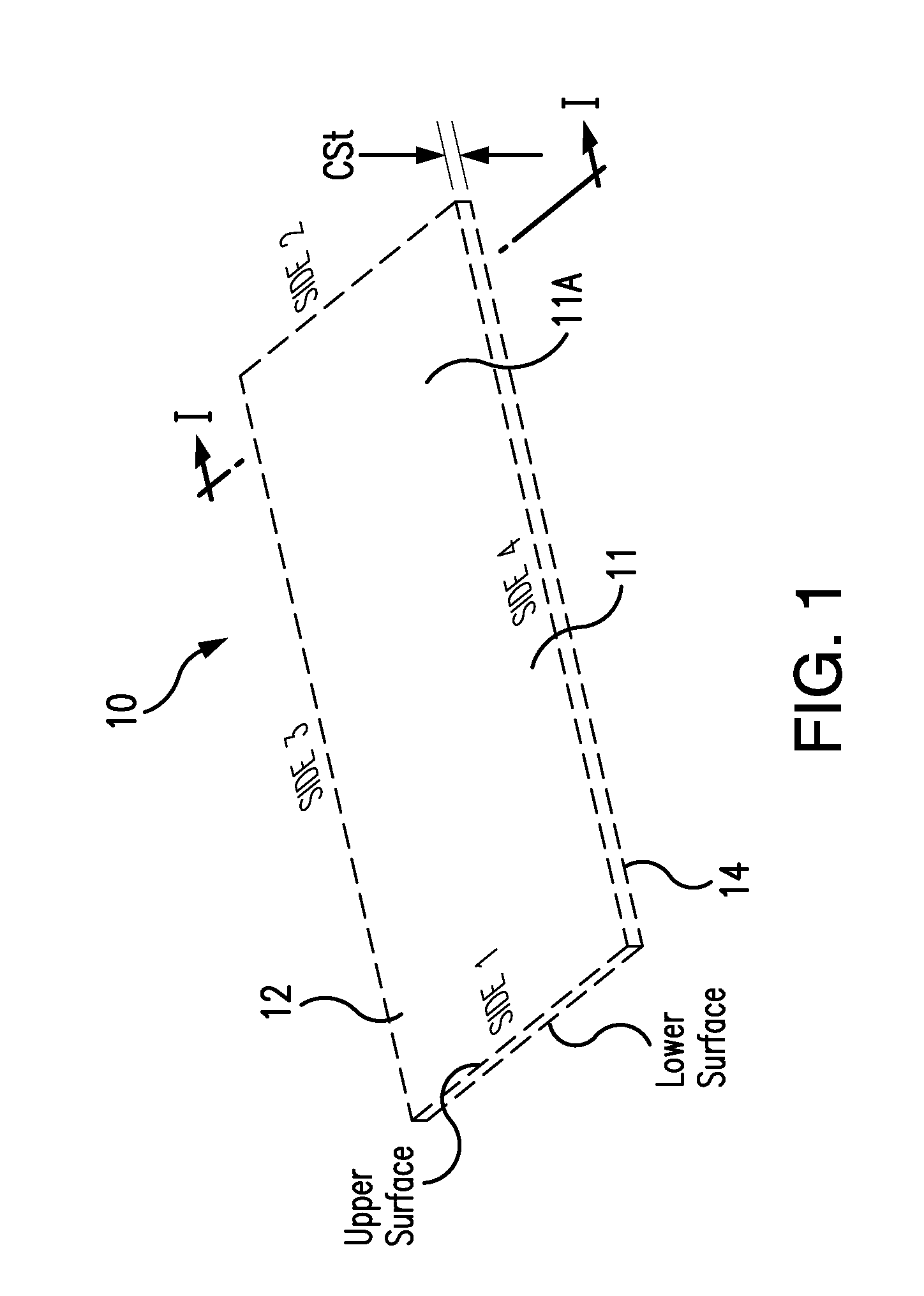

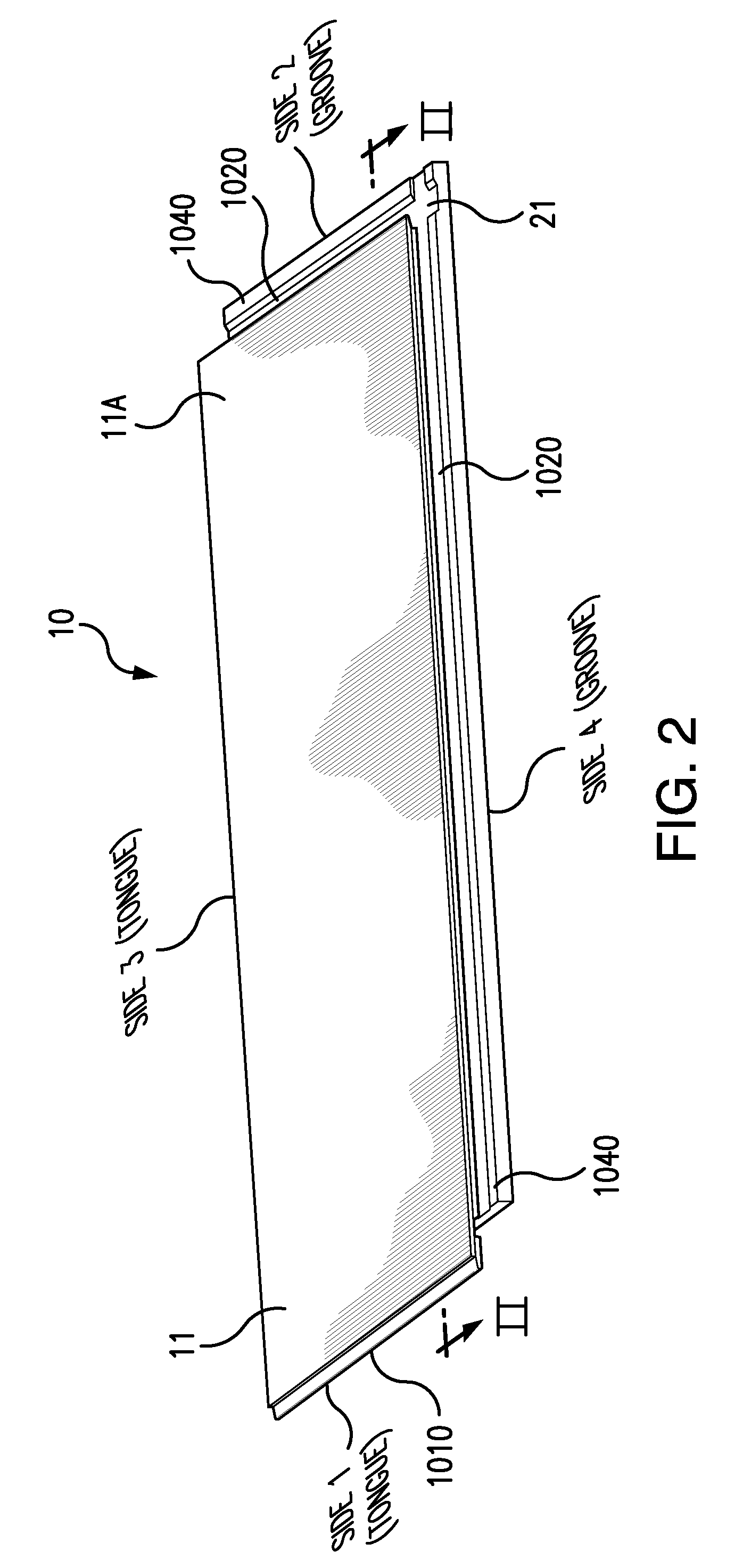

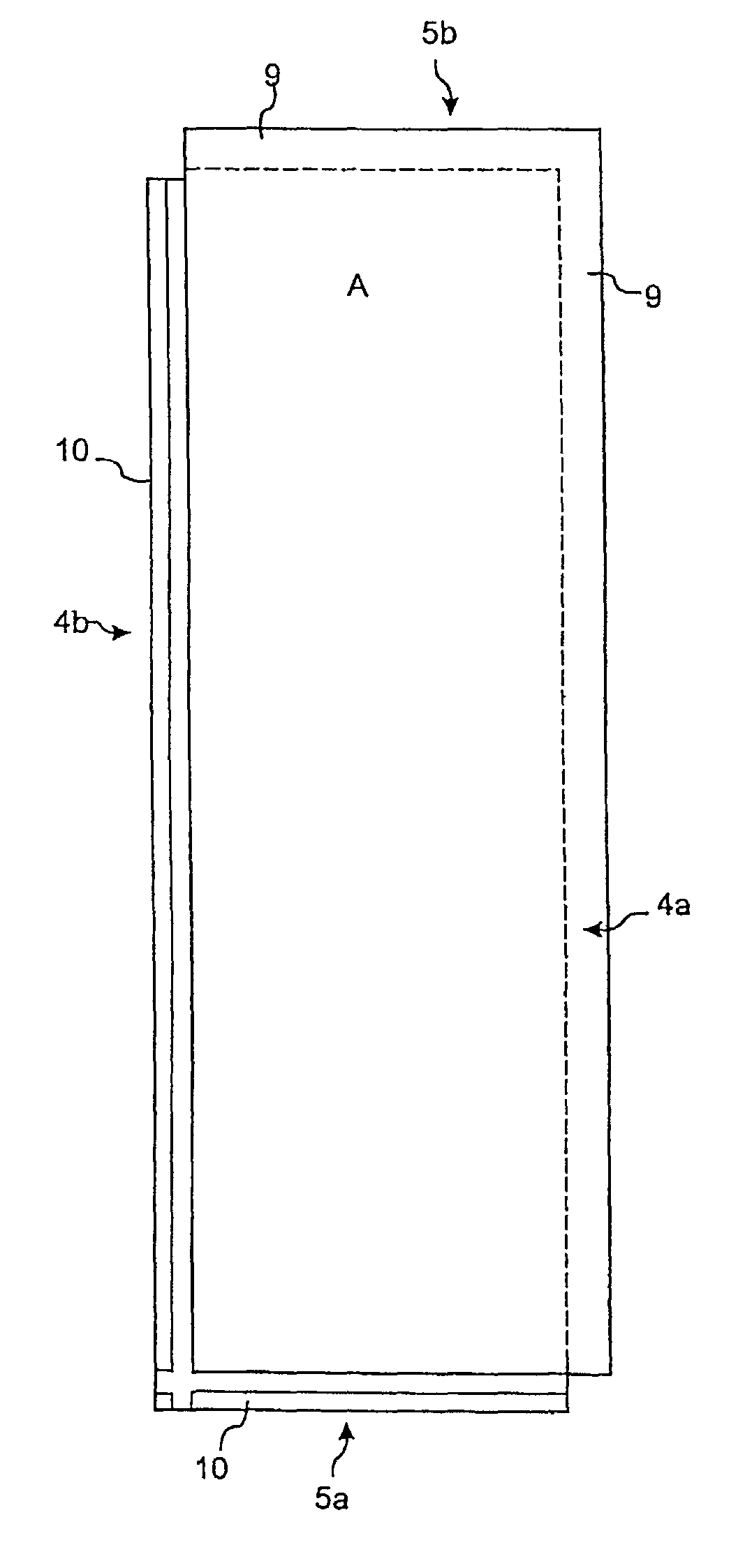

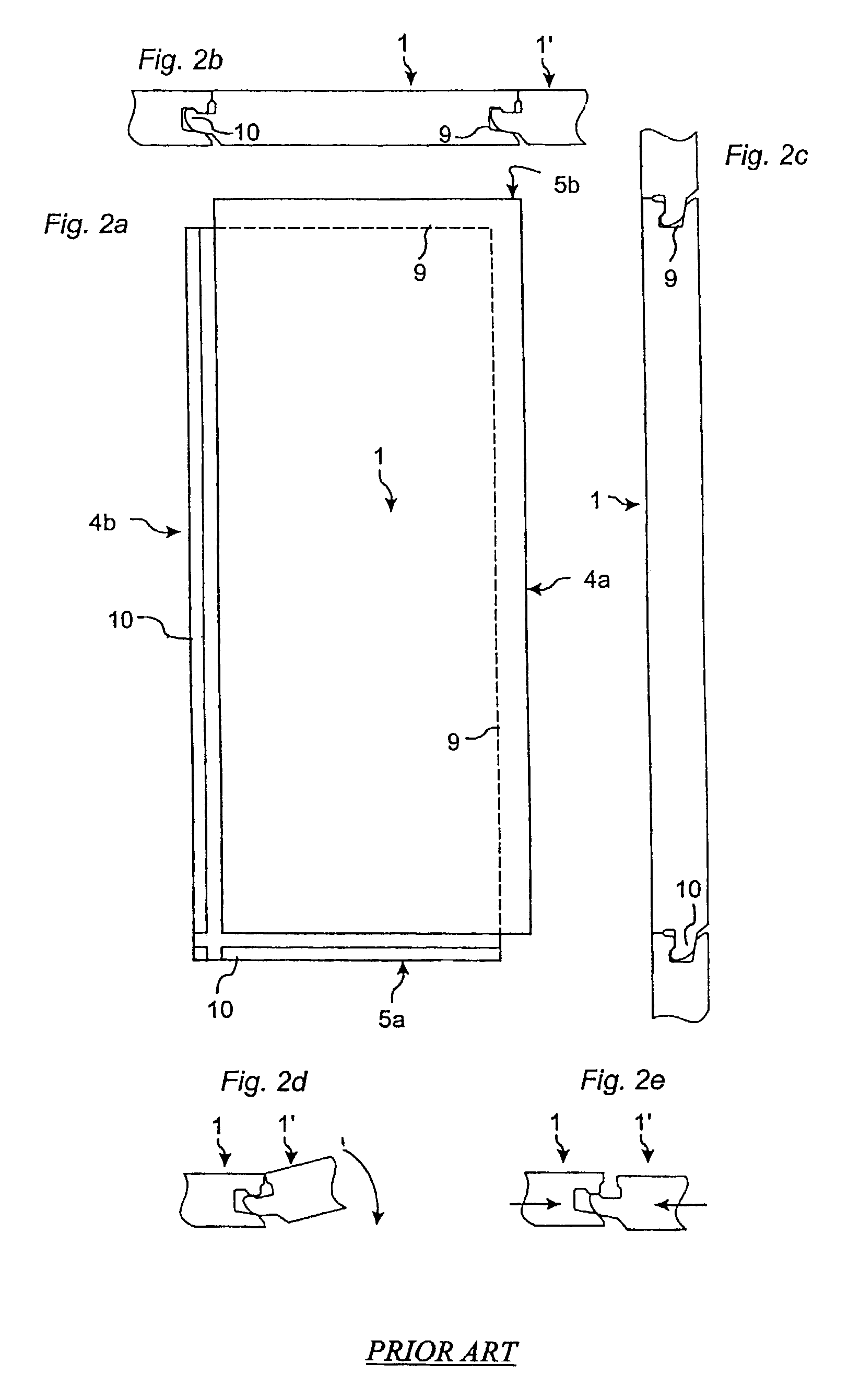

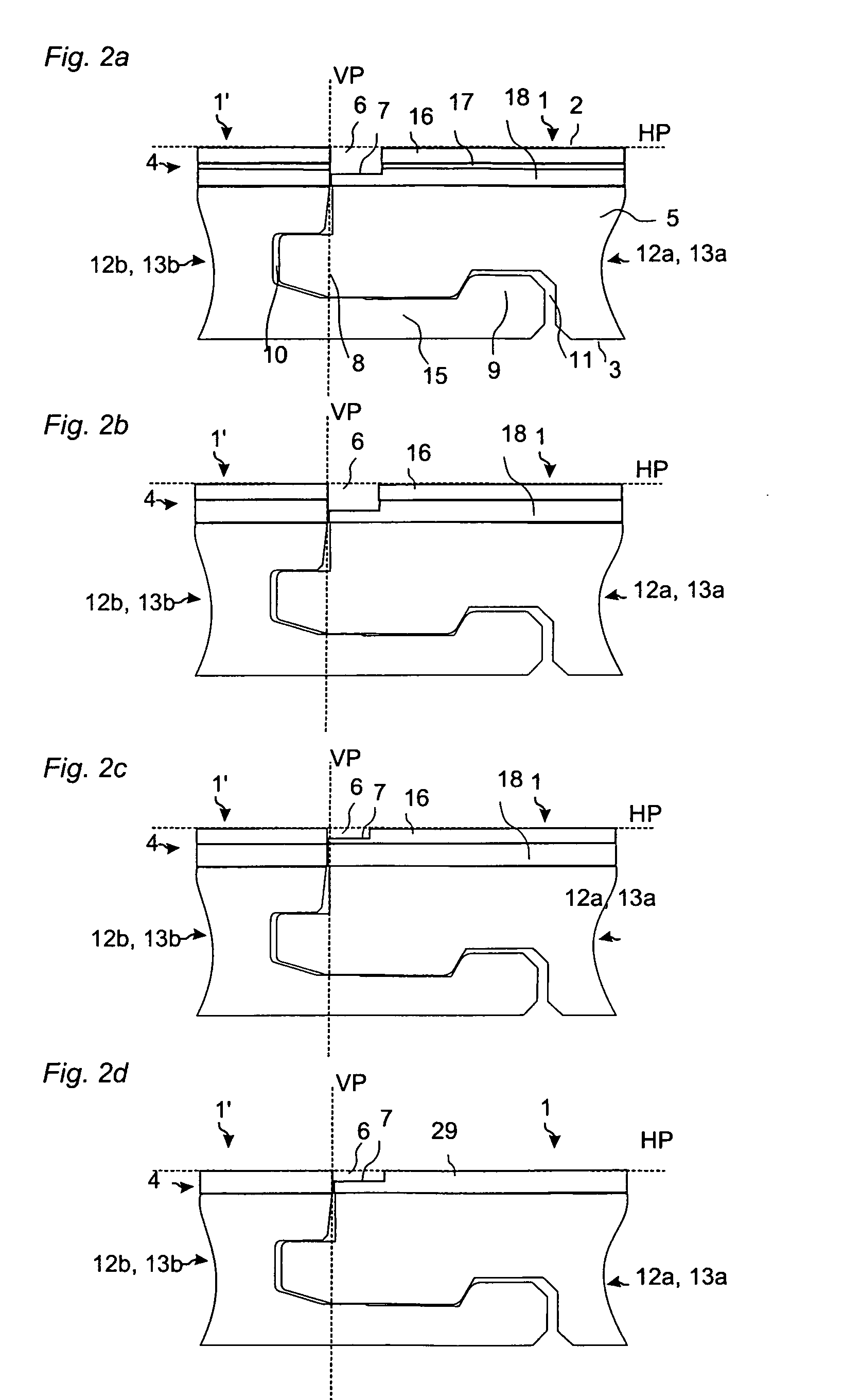

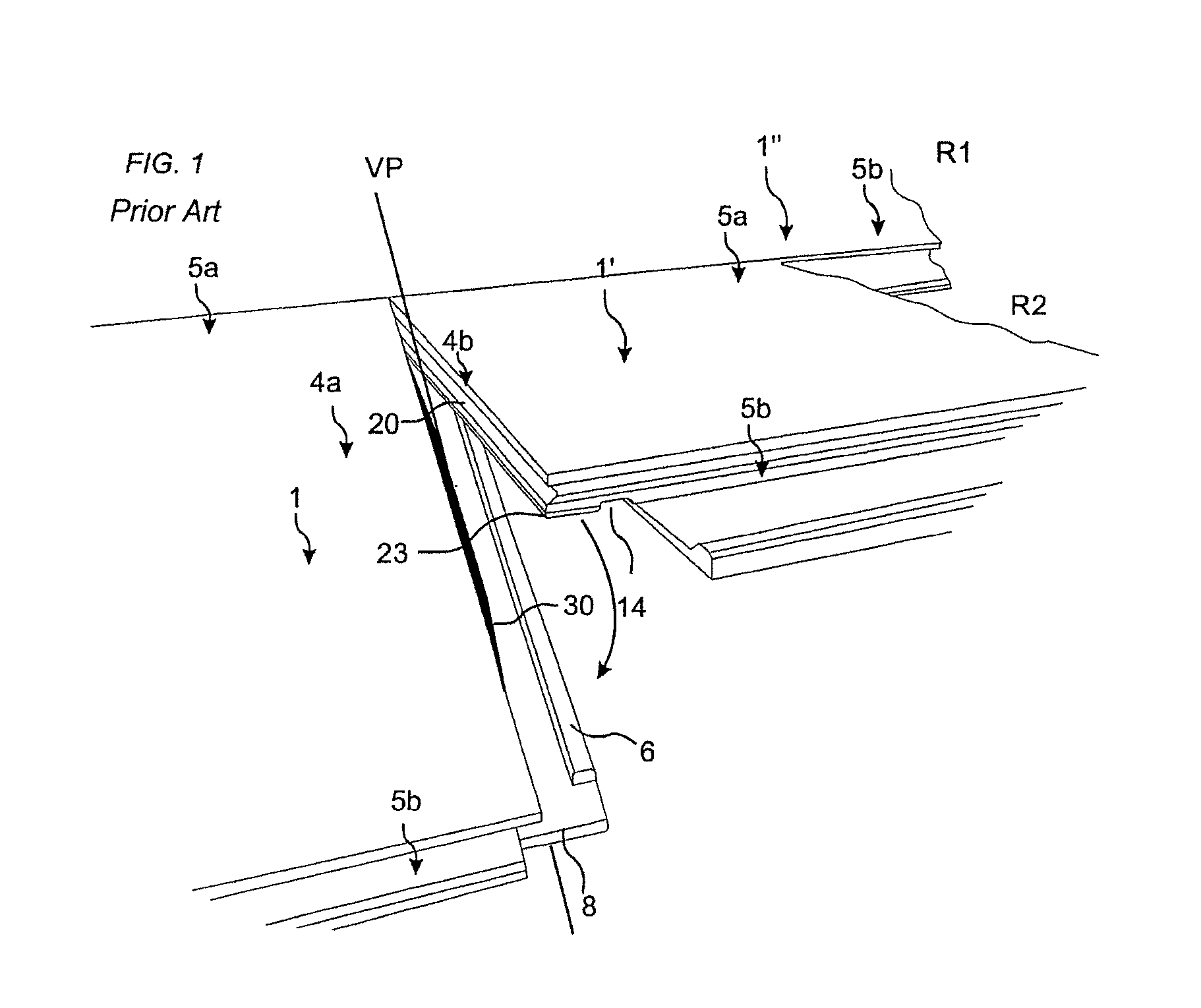

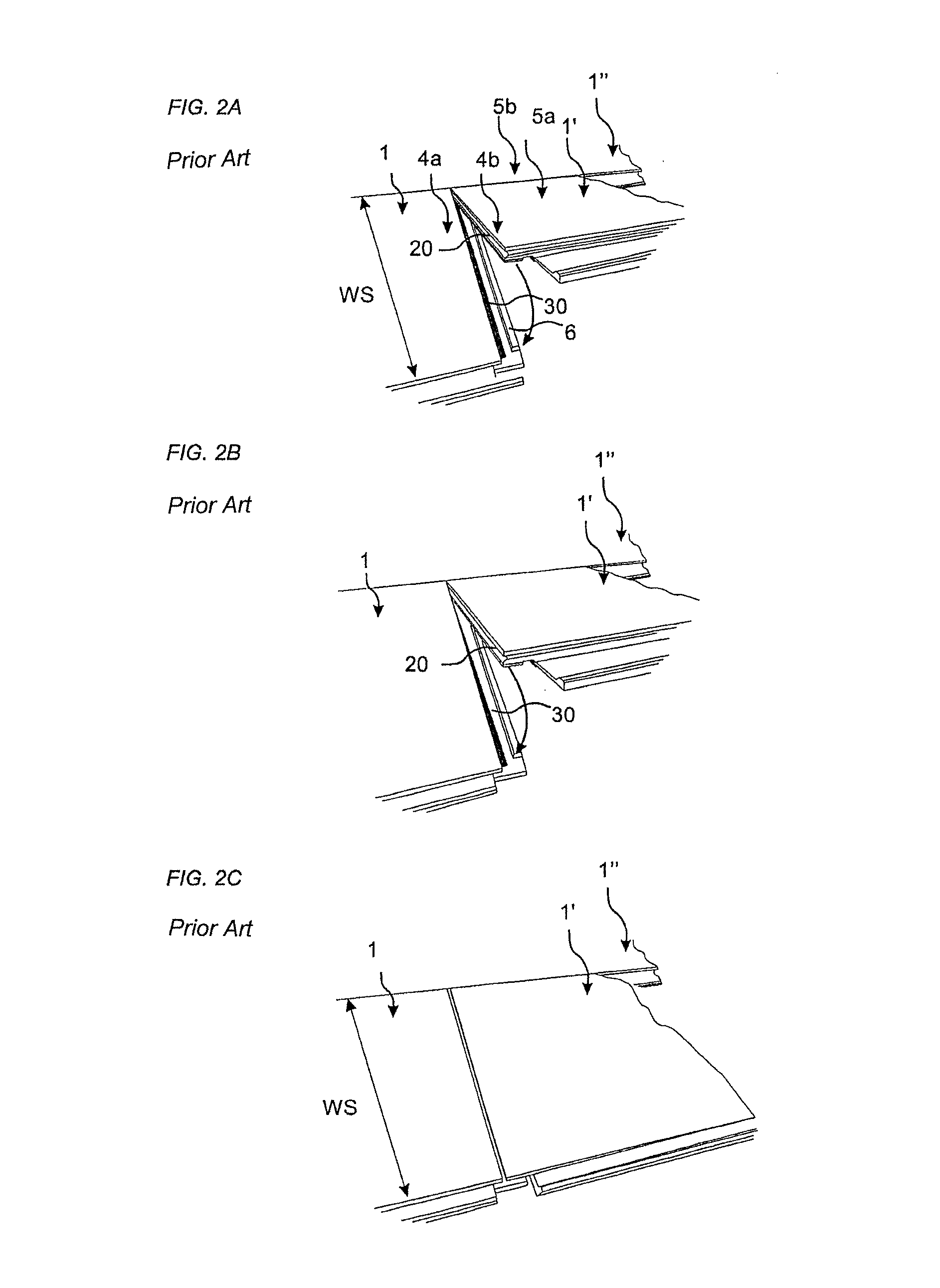

Method for producing a mechanical locking system for building panels

ActiveUS9216541B2Easy to manufactureIncrease elasticityConstruction materialCovering/liningsCivil engineering

Building panels 1, 1′ provided with a mechanical locking system including a tongue 30, at first edge 4a of a first building panel 1, cooperating with a tongue groove 20, at a second edge 4a of an adjacent second building panel 1′, for vertical locking of the building panels and a method for producing such building panels 1, 1′. The method includes the step of forming the tongue of material of the first edge. The insertion groove (40) may have a sidewall (60) at a third edge (5a), which is adjacent the first edge (4a), and may be open at a fourth edge (5b), which is opposite the third edge.

Owner:VÄLINGE INNOVATION AB

Use of pre-coated mat for preparing gypsum board

A gypsum board which comprises a set gypsum core sandwiched between and faced with fibrous mats, wherein a free surface of one of said mats is pre-coated with a combination of a mineral pigment, optionally an inorganic adhesive binder and an organic binder, preferably a hydrophobic, UV resistant polymer latex adhesive binder applied to said surface as an aqueous coating composition, said aqueous coating composition upon drying and setting providing a pre-coated mat satisfying certain morphology requirements.

Owner:GEORGIA PACIFIC GYPSUM LLC

Polyolefin wood fiber composite

InactiveUS6265037B1Improve mechanical propertiesImproved chemicalConstruction materialCovering/liningsPolyolefinEngineering

An improved composite structural member comprising a complex profile structural member, made of a composite comprising a polypropylene polymer and a wood fiber. The material is useful in conventional construction applications. The complex profile, in the form of an extruded thermoplastic composite member can be used in residential and commercial structures as described. Preferably, the structural member is used in the manufacture of the fenestration components such as windows and doors. Such linear members are designed with specifically configured cross-sectional shapes to form structural elements in the fenestration units. Structural elements must possess sufficient strength, thermal stability and weatherability to permit the manufacture of a structurally sound window unit that can be easily installed into a rough opening but can maintain its attractive appearance and structural integrity over the life of the window unit often twenty years or more. The structural member comprises a hollow complex cross-section with at least one structural web or one fastener web formed within the component. The exterior of the extruded component has a visible capstock layer and is shaped and adapted for installation in rough openings. The exterior also contains shape and components capable of supporting the elements of the fenestration unit such as a window, sash or movable door unit. The improved polypropylene structural members have unique advantages and can be assembled in thermoplastic weld processes.

Owner:ANDERSEN CORPORATION

Method for precision bending of sheet of materials, slit sheets fabrication process

InactiveUS20030037586A1Reduce stress concentrationImprove accuracyAdditive manufacturing apparatusConstruction materialSheet materialEngineering

A method for precision bending of a sheet of material (41, 241, 341, 441) along a bend line (45, 245, 345, 445) and the resulting sheet are disclosed. A method includes a step of forming longitudinally extending slits (43, 243, 343, 443) through the sheet of material in axially spaced relation to produce precise bending of the sheet (41, 241, 341, 441) along the bend line (45, 245, 345, 445) with edges (257, 457) engaged and supported on faces (255, 455) of the sheet material on opposite sides of the slits. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line (45, 245, 345, 445). Several slit embodiments (43, 243, 343, 443) suitable for producing edge-to-face engagement support and precise bending are disclosed, as is the use of the slit sheets to enhance various fabrication techniques.

Owner:IND ORIGAMI INC CA US

Gypsum-containing board and tile, and method for producing same

InactiveUS20050019618A1Improve the immunitySave a lot of costLiquid surface applicatorsConstruction materialO-Phosphoric AcidBrick

A method for producing a set gypsum-containing product comprising an interlocking matrix of set gypsum wherein said method comprises applying to said set gypsum one or more enhancing materials selected from the group consisting of phosphoric acid; condensed phosphoric acids, each of which comprises 2 or more phosphoric acid units; and salts or ions of condensed phosphates, each of which comprises 2 or more phosphate units, and monobasic salts or monovalent ions of orthophosphates.

Owner:UNITED STATES GYPSUM CO

Fire-resistant gypsum panel

InactiveUS20080087366A1Improve fire resistanceImprove fire performanceConstruction materialCovering/liningsFire protectionSlurry

A method of continuously forming a multilayer panel includes making a gypsum slurry, then dividing the gypsum slurry into at least a primary gypsum slurry and a secondary gypsum slurry. An additive slurry having water and an intumescent material is created, then added to the secondary gypsum slurry to make an expandable layer slurry that is spread over at least a portion of a facing material. The primary gypsum slurry is distributed over the secondary gypsum slurry over the facing material and the expanding layer slurry to form a core. Optionally, another layer, an edge coating, is applied to the expanding layer for additional fire protection. The edge coating includes a second intumescent material. During a fire, the expanding layer expands to increase the thickness of the fire exposed gypsum panel and the edge coating expands to seal the gap between adjoining gypsum panels.

Owner:UNITED STATES GYPSUM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com