Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Save a lot of cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

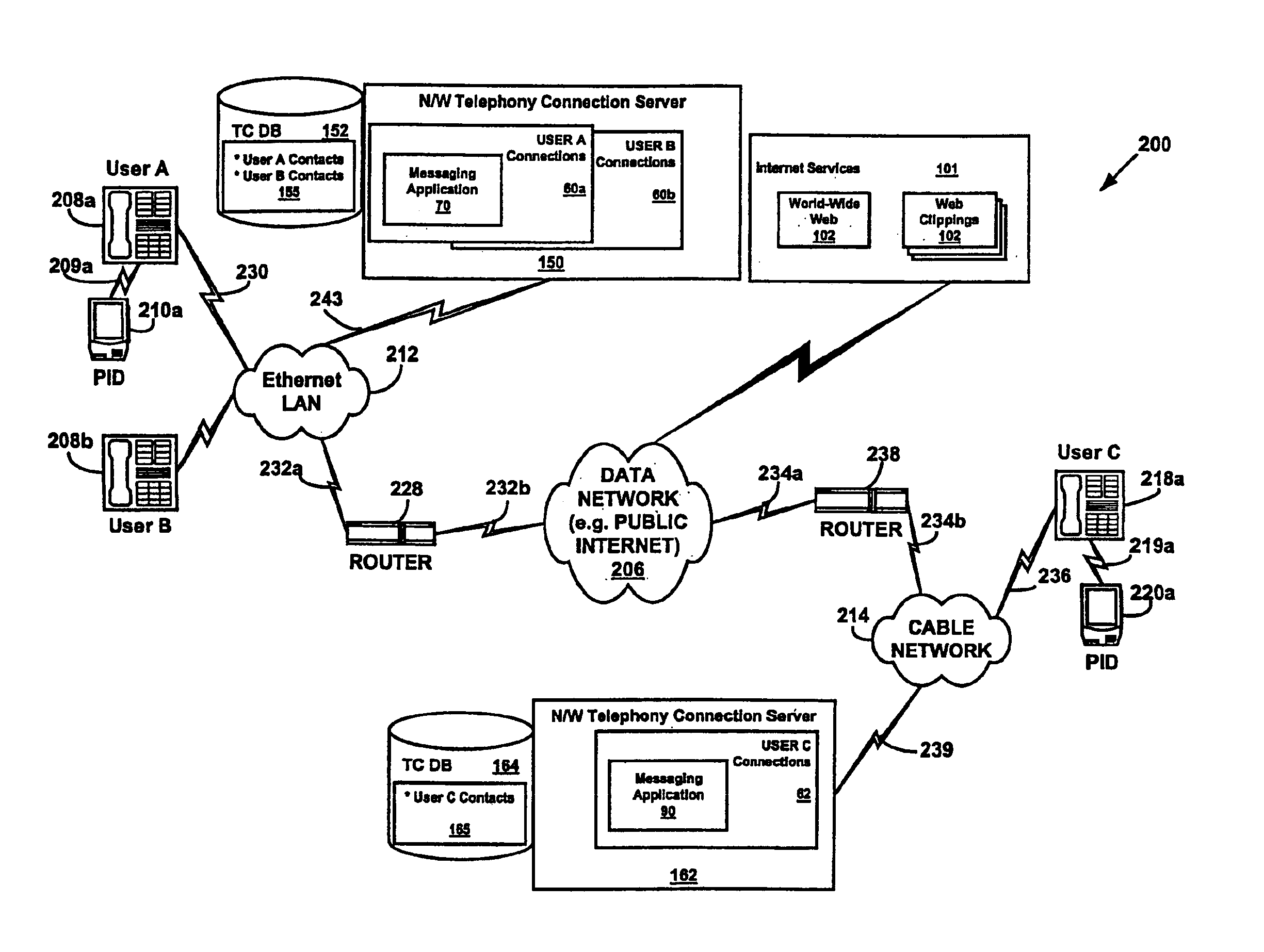

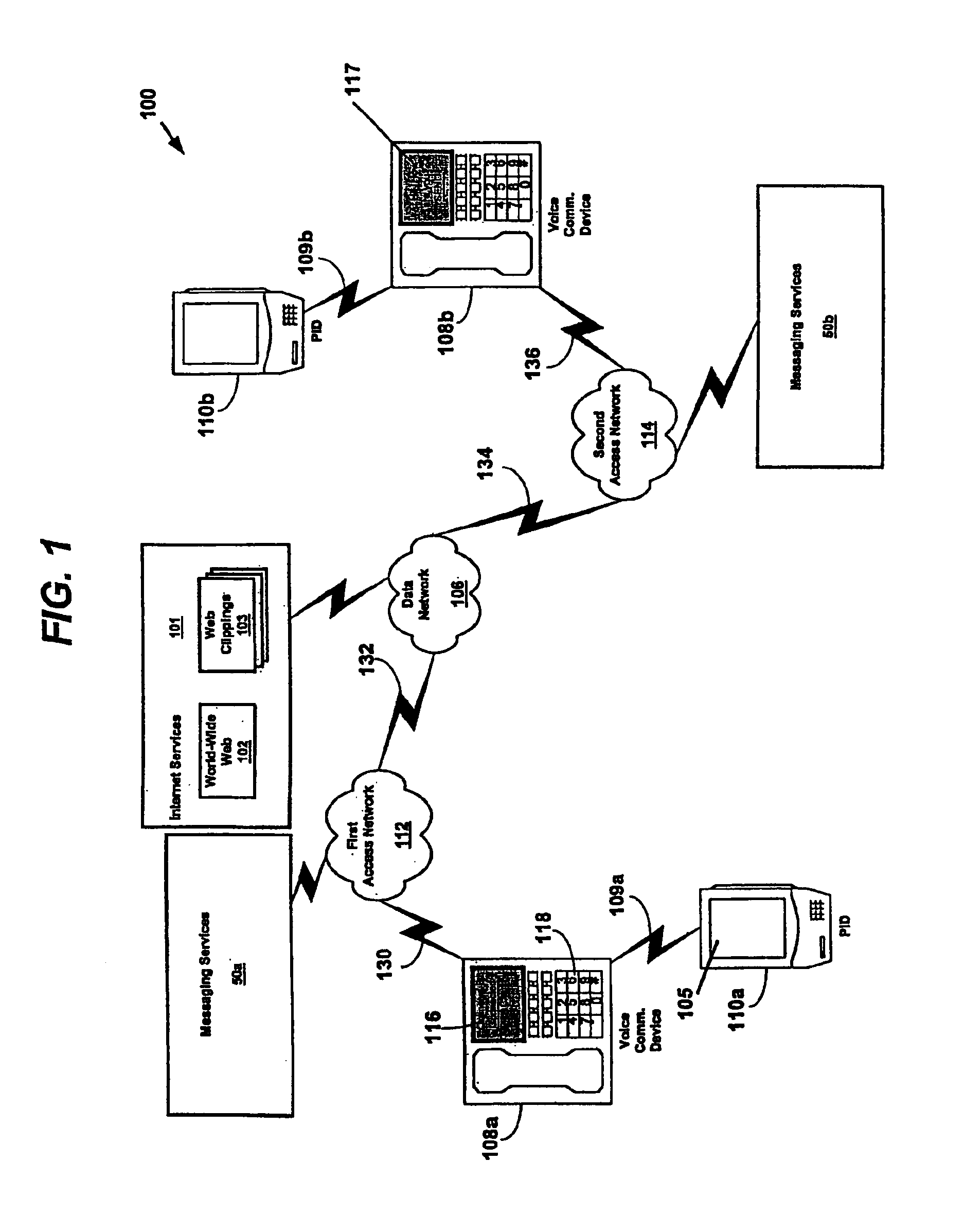

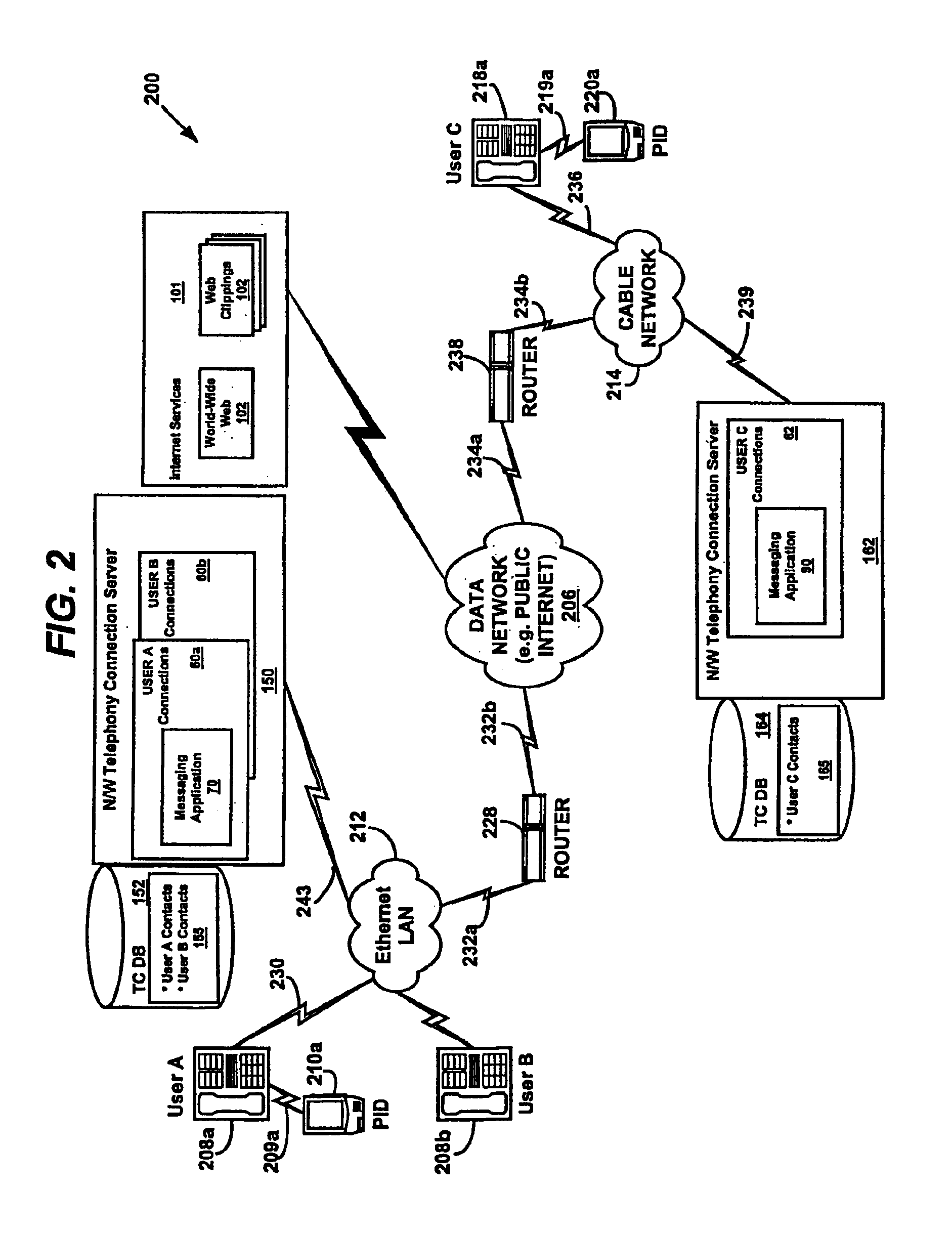

System and method for performing messaging services using a data communications channel in a data network telephone system

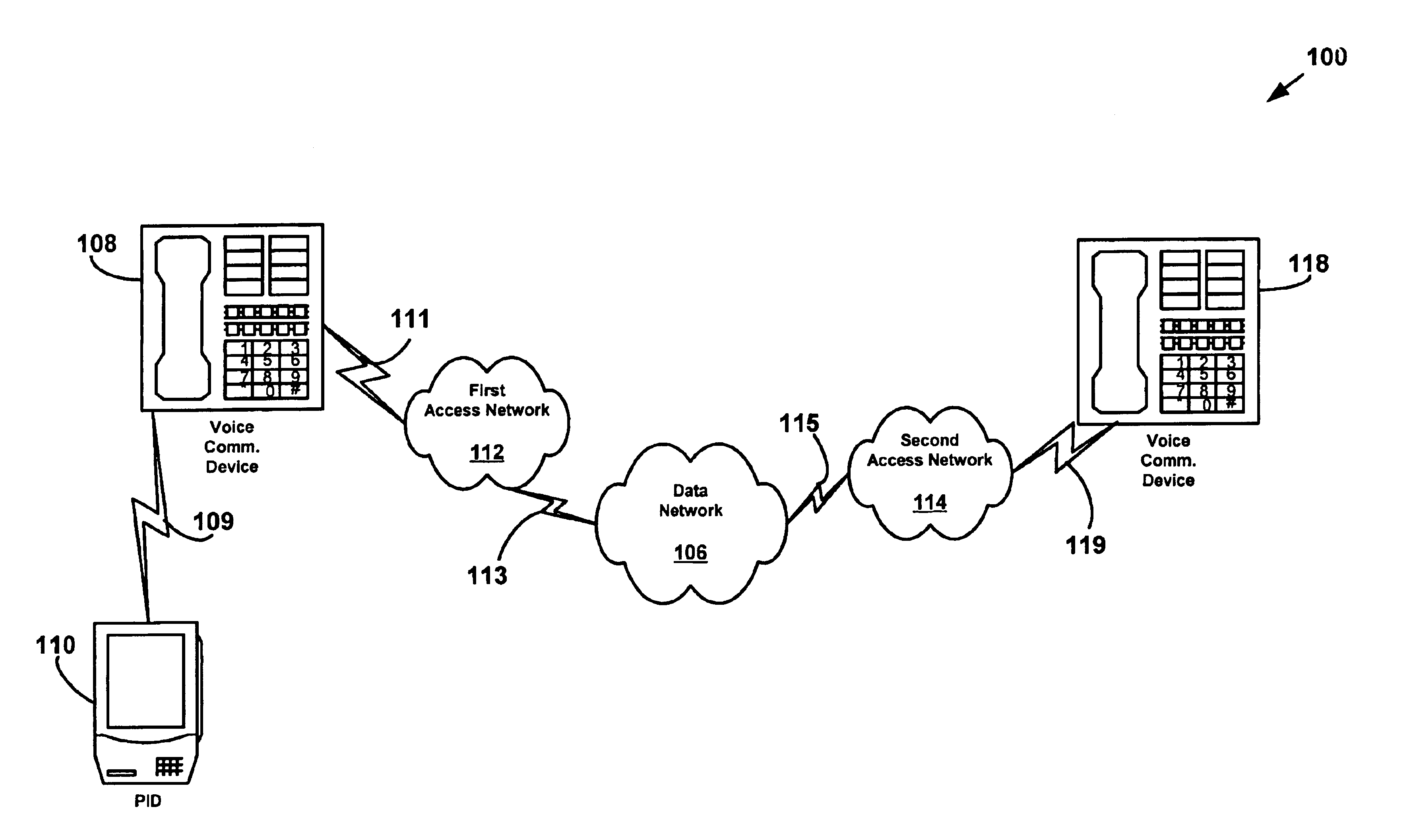

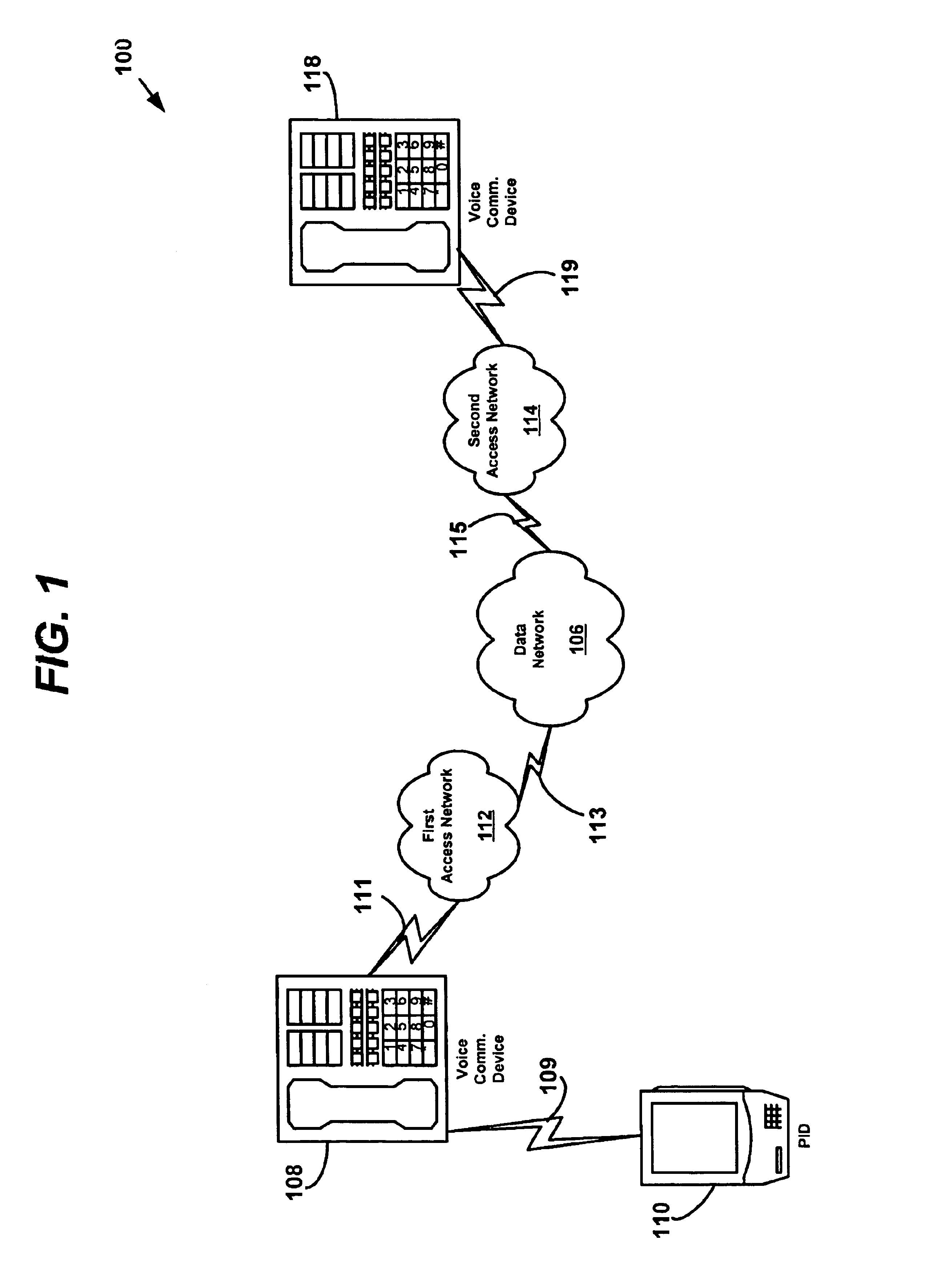

InactiveUS6870830B1Save a lot of costLow costMultiplex system selection arrangementsSpecial service for subscribersProgram managementMessage passing

A system and method for performing messaging between telephones in a data network telephone system. The message communications may be managed by a messaging application connected to the data network. The messaging application detects when a telephone is connected to another telephone and sends a messaging input screen to the first telephone. The messaging application may determine the availability of other users for messaging and may control messages communicated between the first telephone and the other users. The messages may be text or voice messages.

Owner:VALTRUS INNOVATIONS LTD

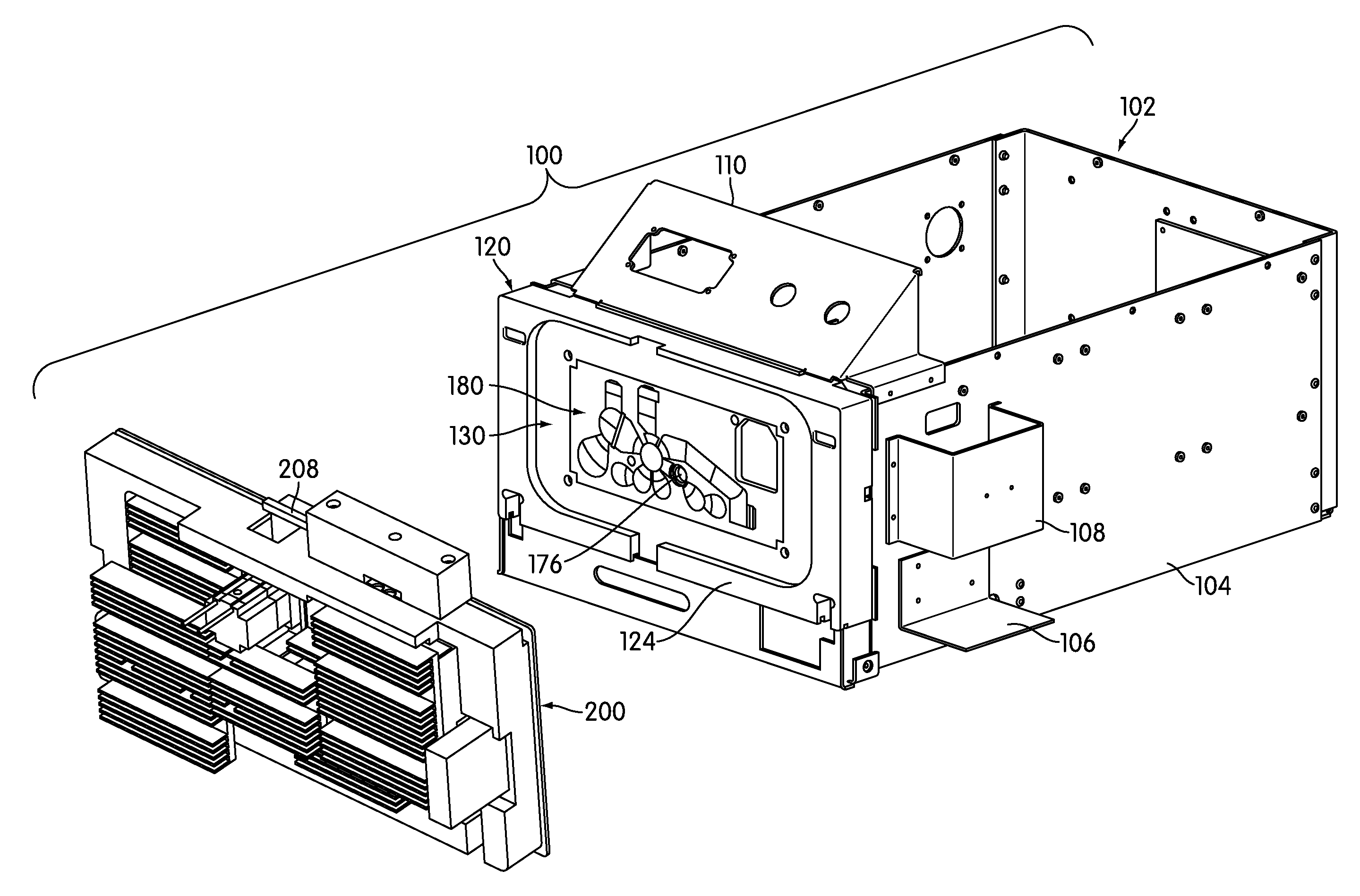

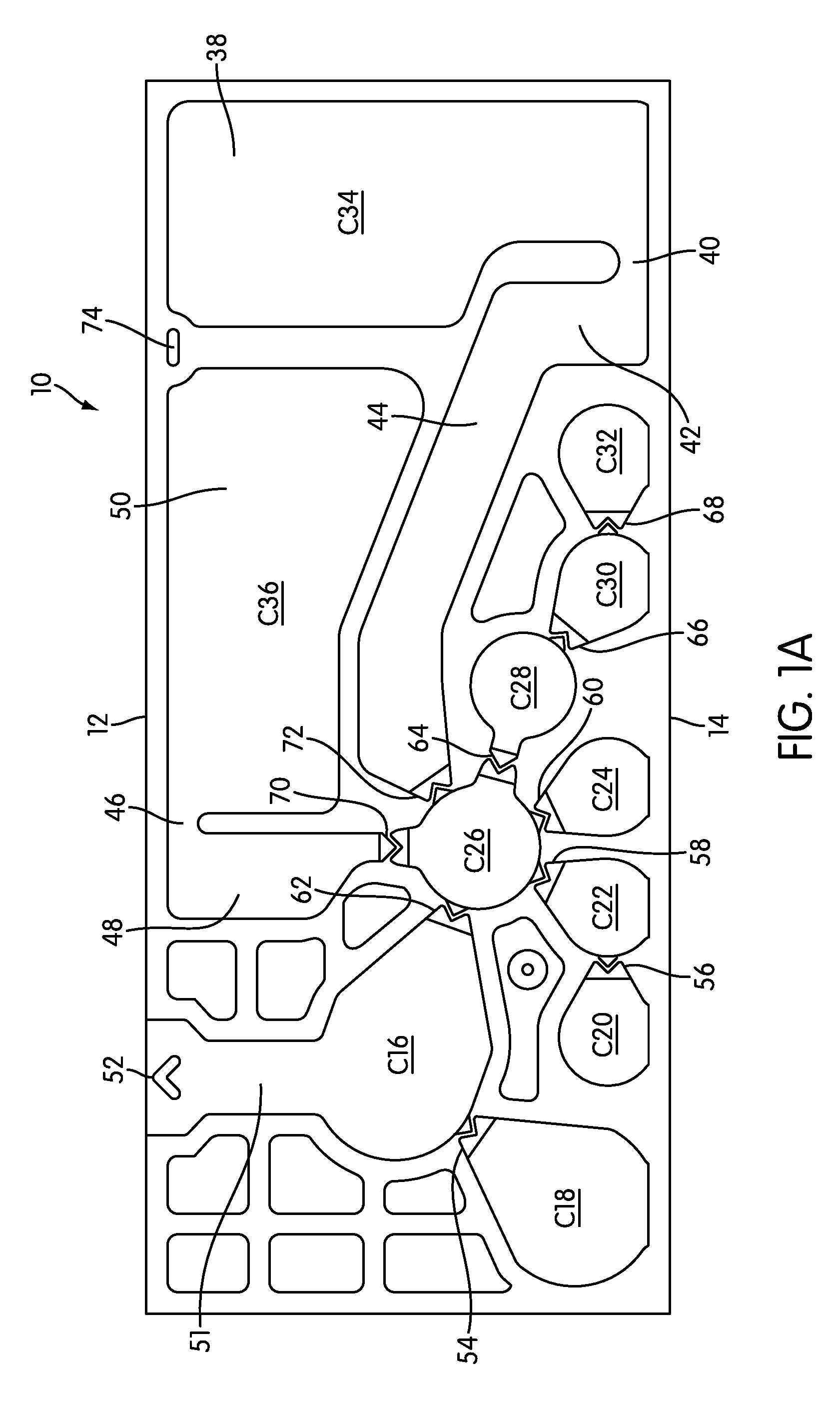

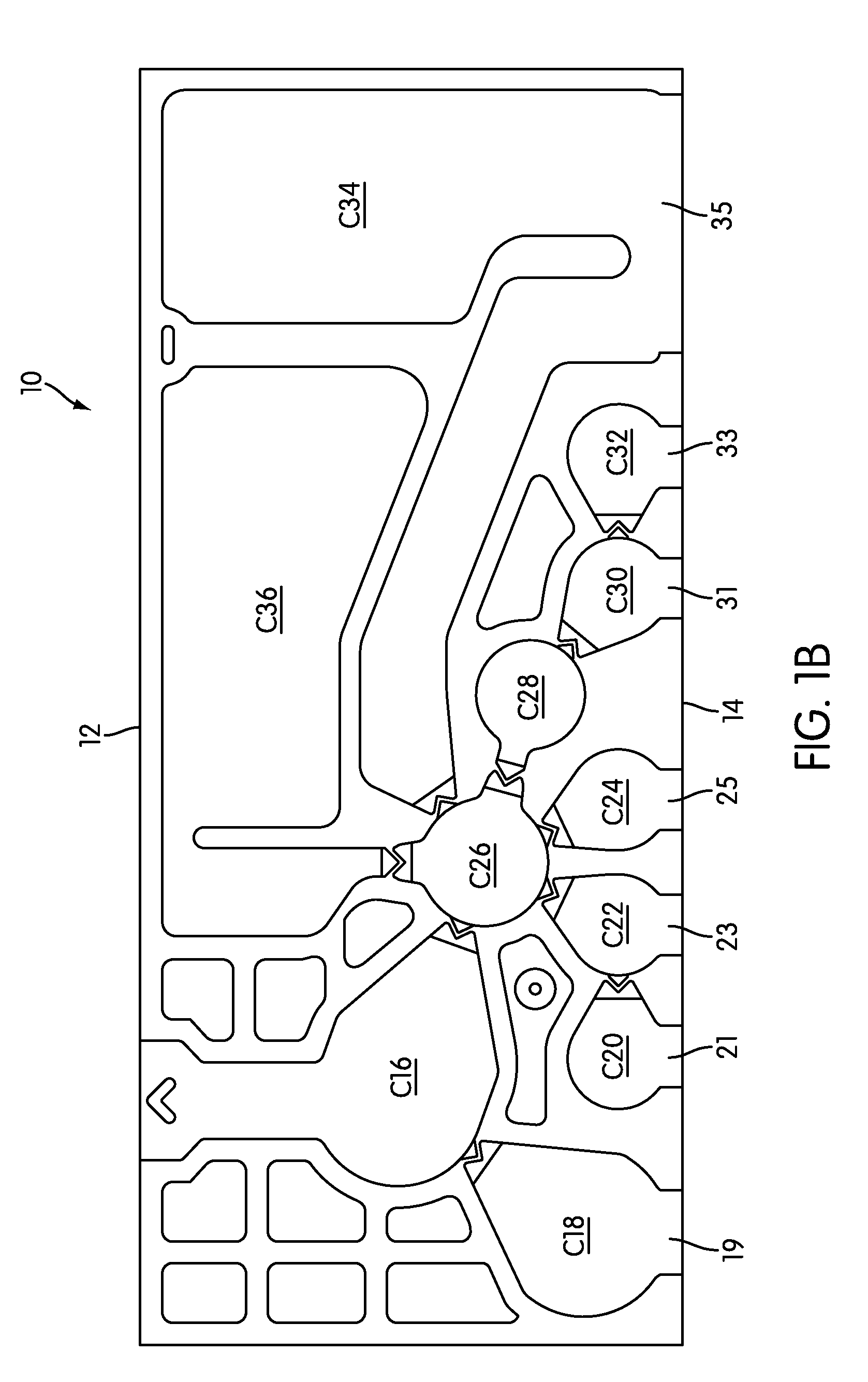

Multi-Channel Optical Measurement Instrument

ActiveUS20090021728A1Save a lot of costMinimize opportunityShaking/oscillating/vibrating mixersHeating or cooling apparatusAmount of substanceOptical measurements

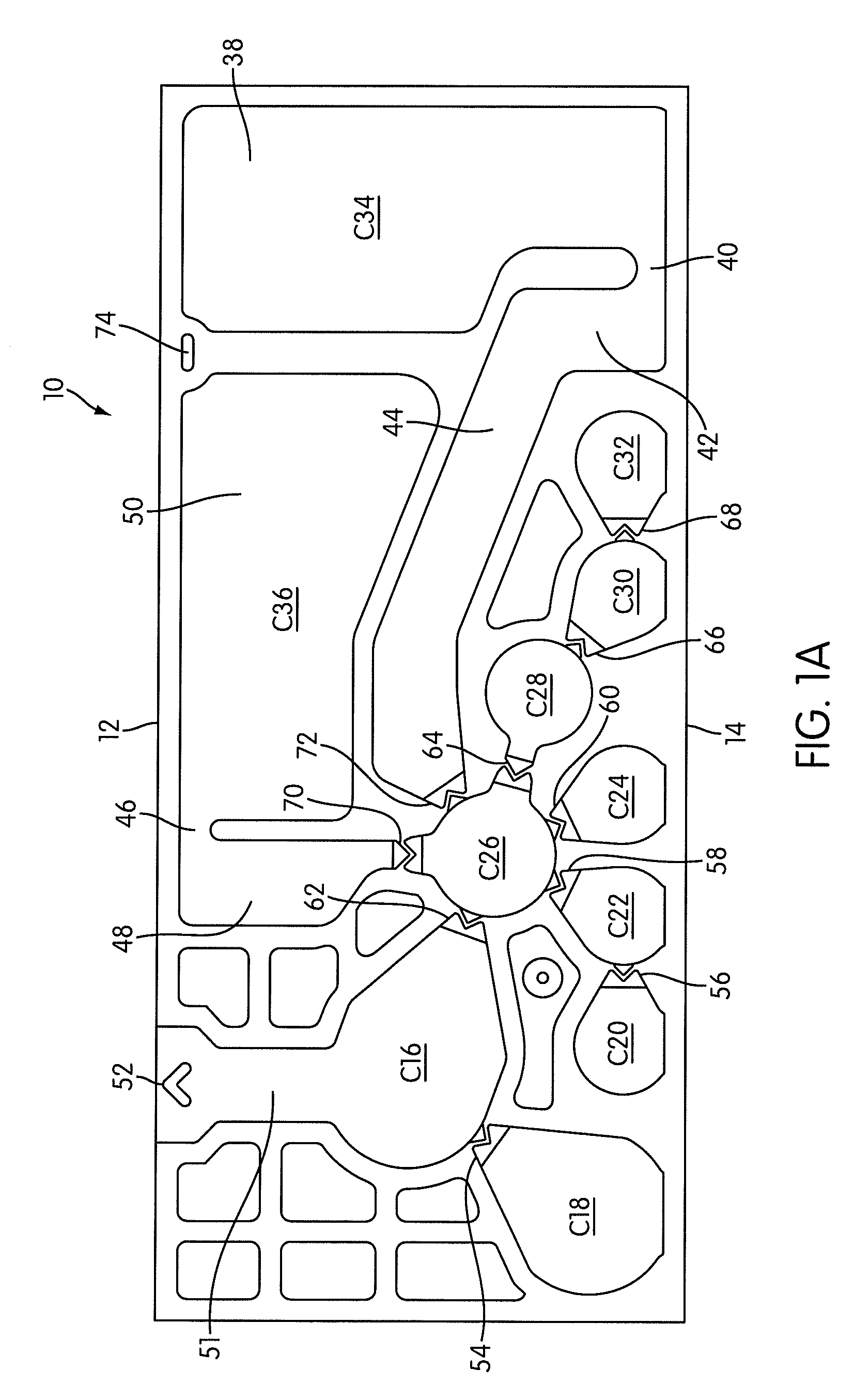

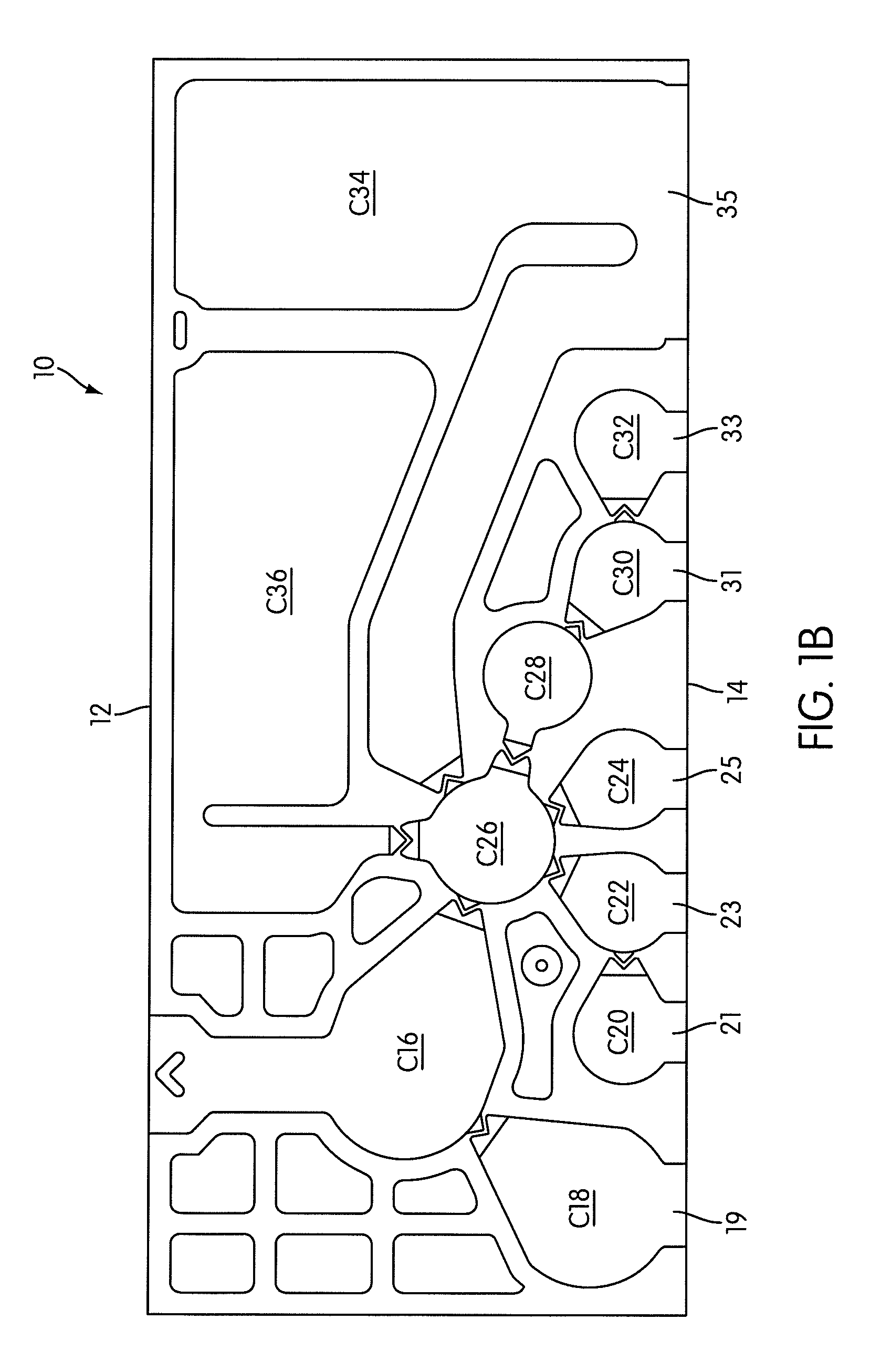

A receptacle having a plurality of interconnected chambers arranged to permit multiple process steps or processes to be performed independently or simultaneously. The receptacles are manufactured to separate liquid from dried reagents and to maintain the stability of the dried reagents. An immiscible liquid, such as an oil, is included to control loading of process materials, facilitate mixing and reconstitution of dried reagents, limit evaporation, control heating of reaction materials, concentrate solid support materials to prevent clogging of fluid connections, provide minimum volumes for fluid transfers, and to prevent process materials from sticking to chamber surfaces. The receptacles can be adapted for use in systems having a processing instrument that includes an actuator system for selectively moving fluid substances between chambers and a detector. The actuator system can be arranged to concentrate an analyte present in a sample. The detector can be used to detect an optical signal emitted by the contents of the receptacle.

Owner:GEN PROBE INC

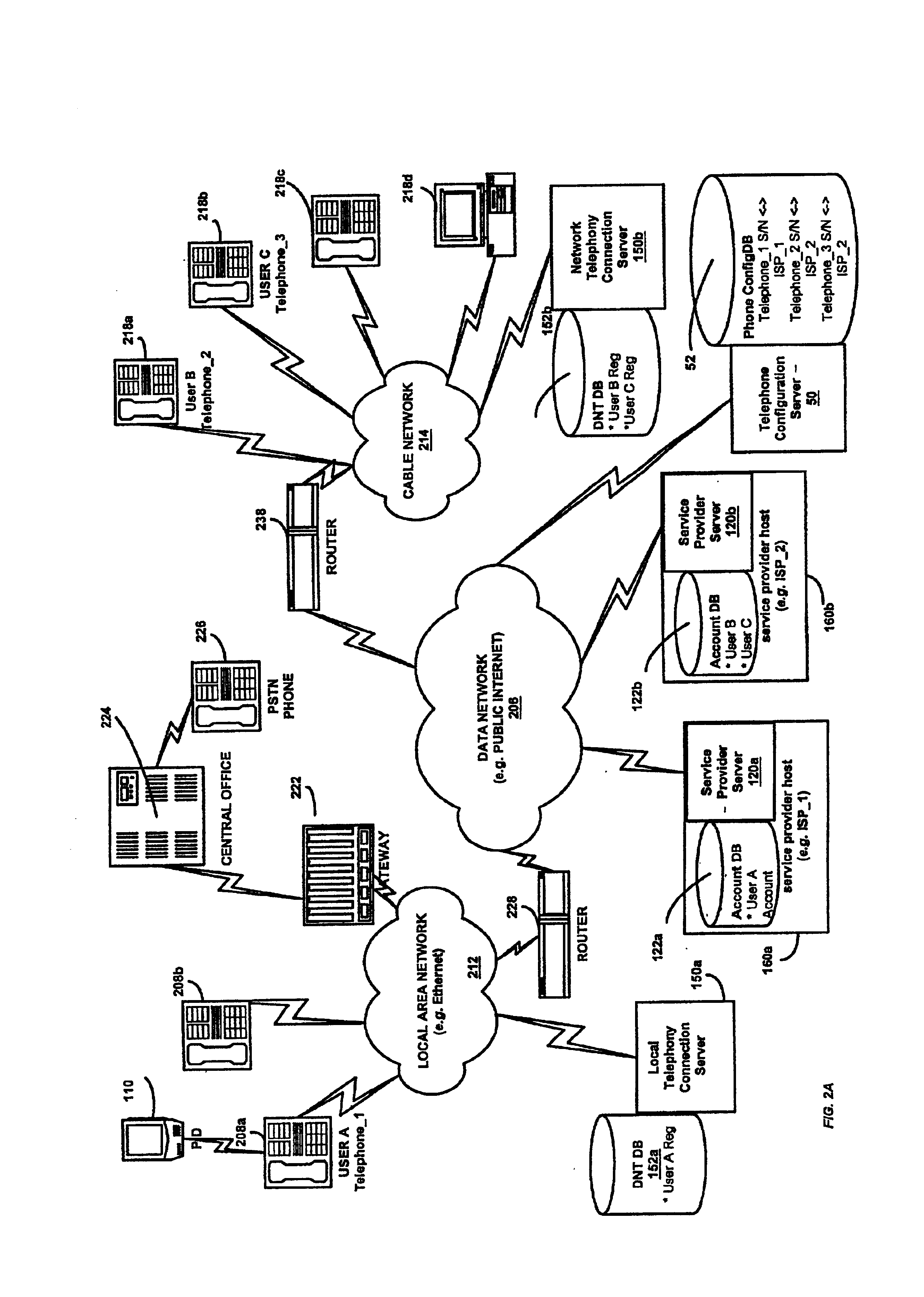

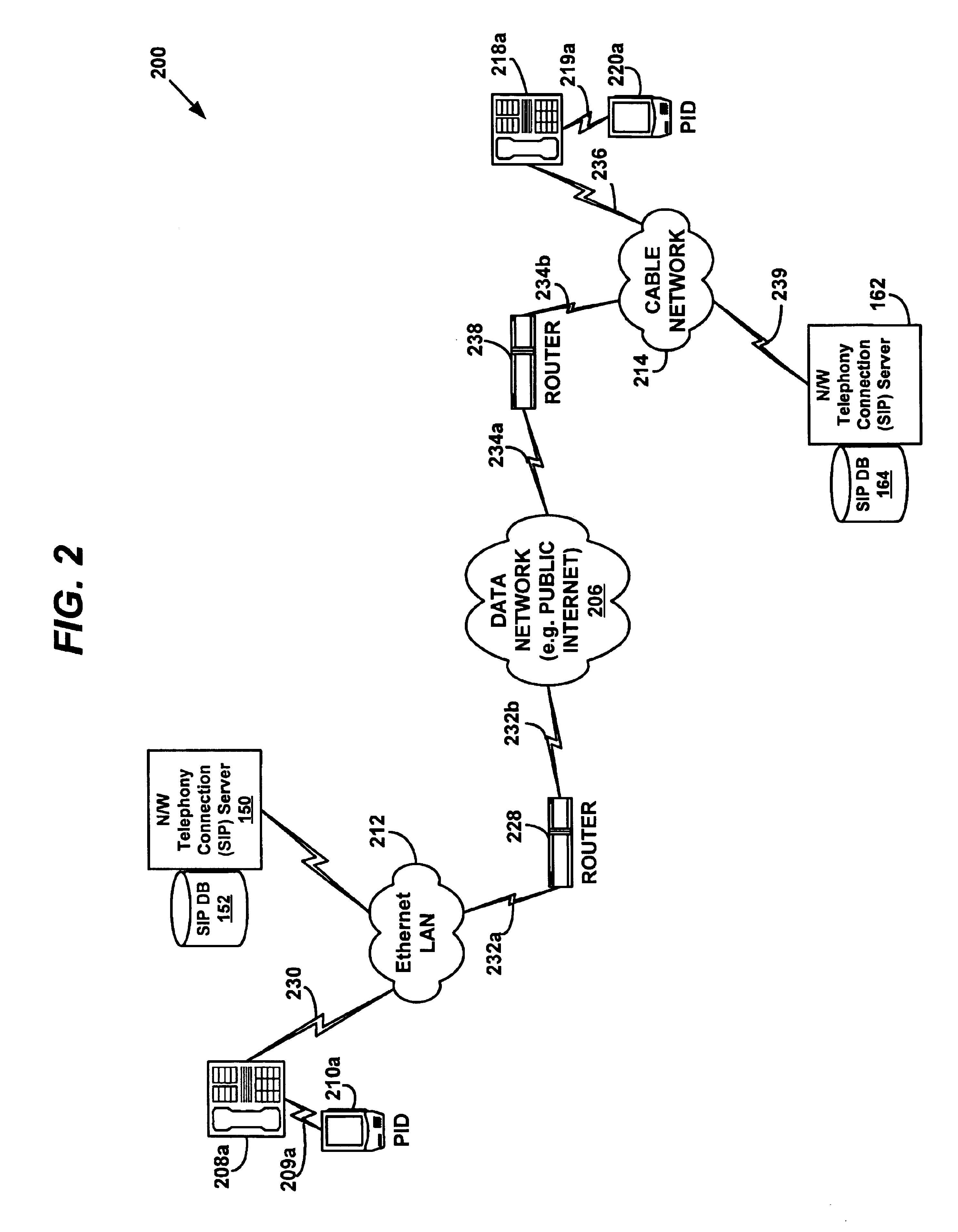

System and method for providing service provider configurations for telephones using a central server in a data network telephony system

InactiveUS6856616B1Simplify the manufacturing processSave a lot of costMultiplex system selection arrangementsData switching by path configurationService provisionSerial code

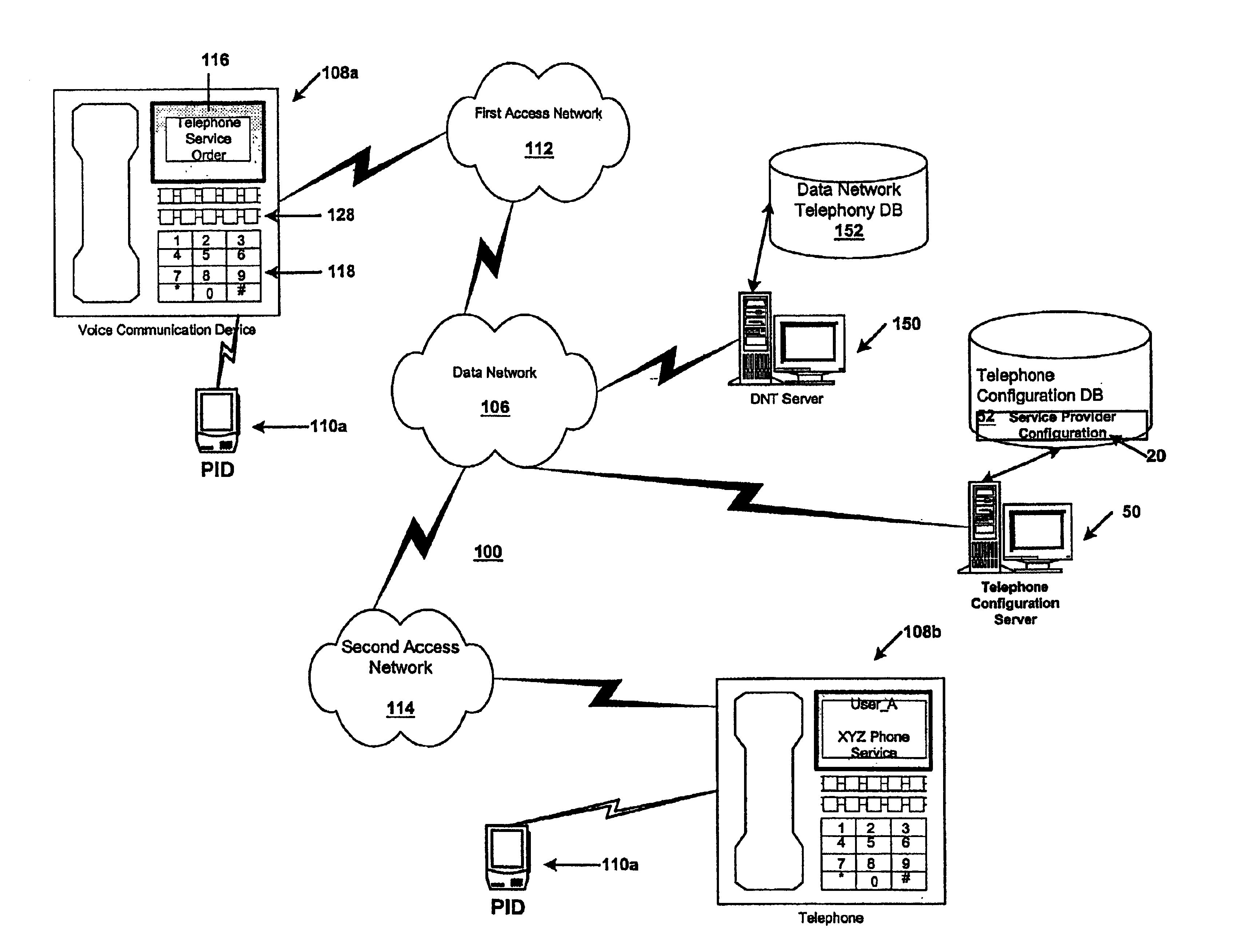

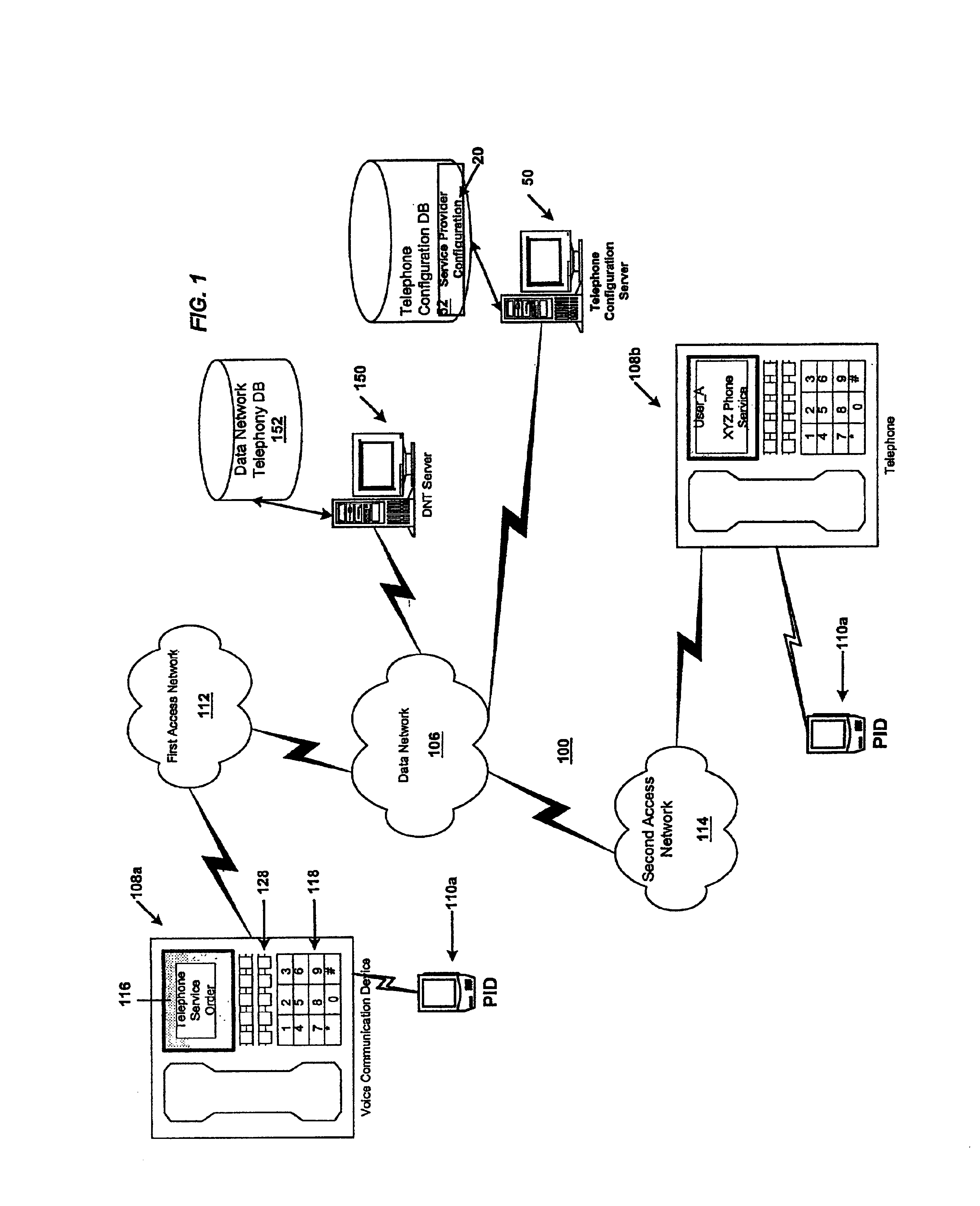

A system and method for providing service provider configured telephone service to a user of a data network telephone. The user connects a data network telephone to the data network. The data network telephone may establish a connection to a telephone configuration server. The data network telephone may communicate a part number, such as a serial number, to the telephone configurations server. The telephone configuration server retrieves a service provider configuration, such as a service provider proxy address to send to the data network telephone. The data network telephone may use the service provider proxy address to register and provision the data network telephone for service.

Owner:UNILOC 2017 LLC

System and method for enabling encryption/authentication of a telephony network

InactiveUS6857072B1Secure transmissionSave a lot of costGraded-service arrangementsSecuring communicationTelephone networkInformation device

A system and method for enabling encryption and / or authentication services on a telephony network. A portable information device, such as a personal digital assistant is used to exchange encryption and / or authentication data with a second portable information device. The portable information devices may be linked to the telephony network to enable encryption and / or authentication services using the encryption and / or authentication data exchanged by the portable information devices.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

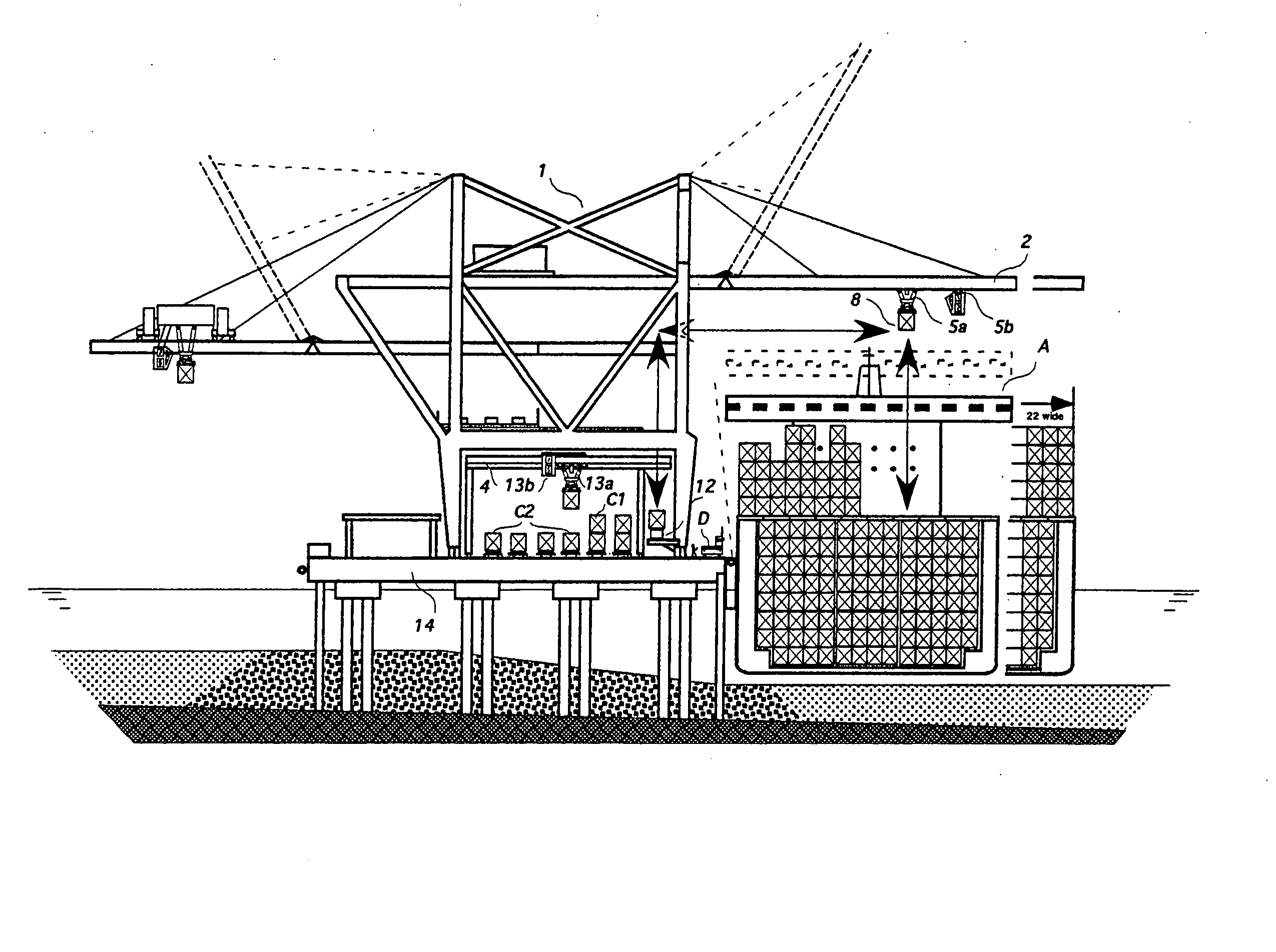

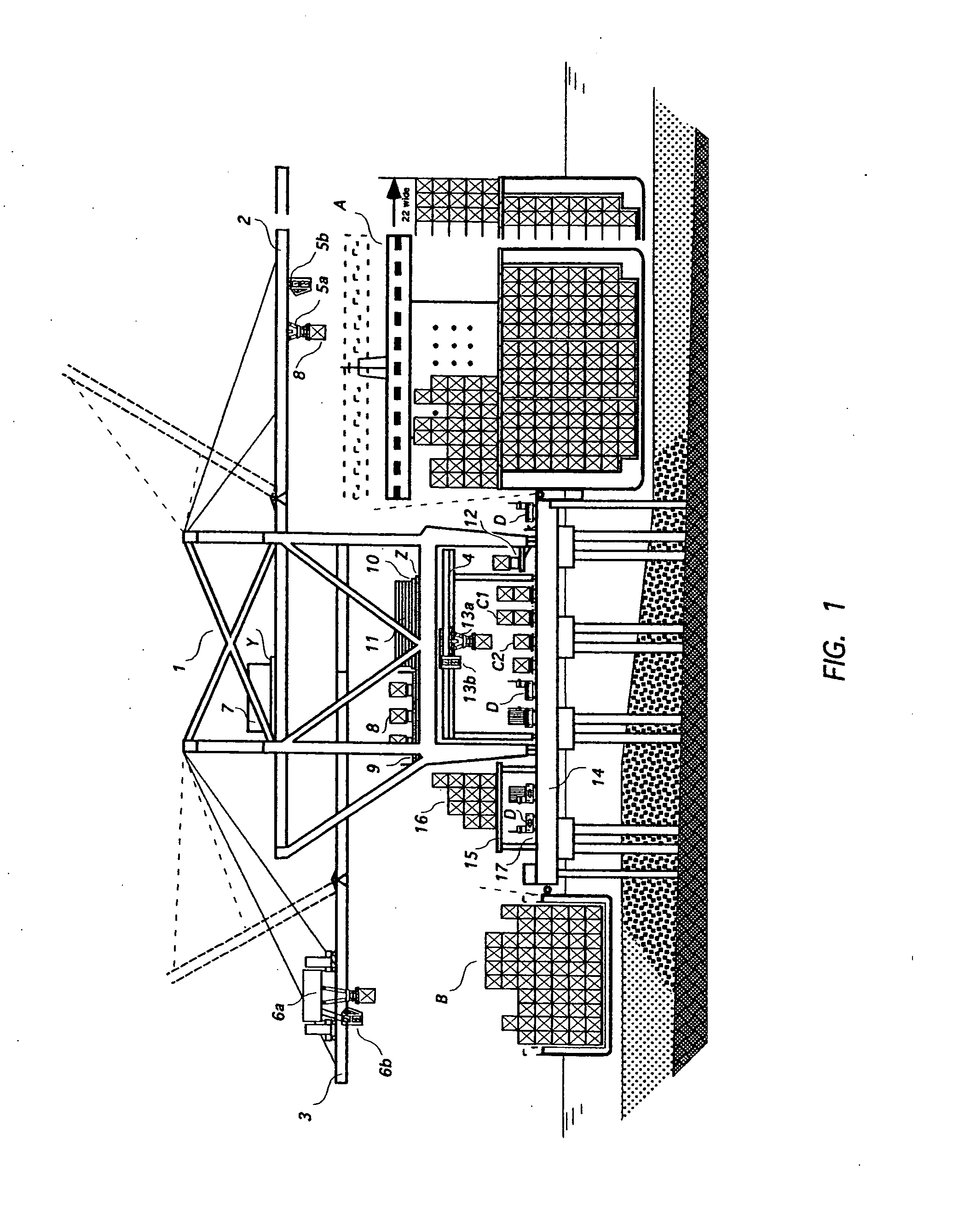

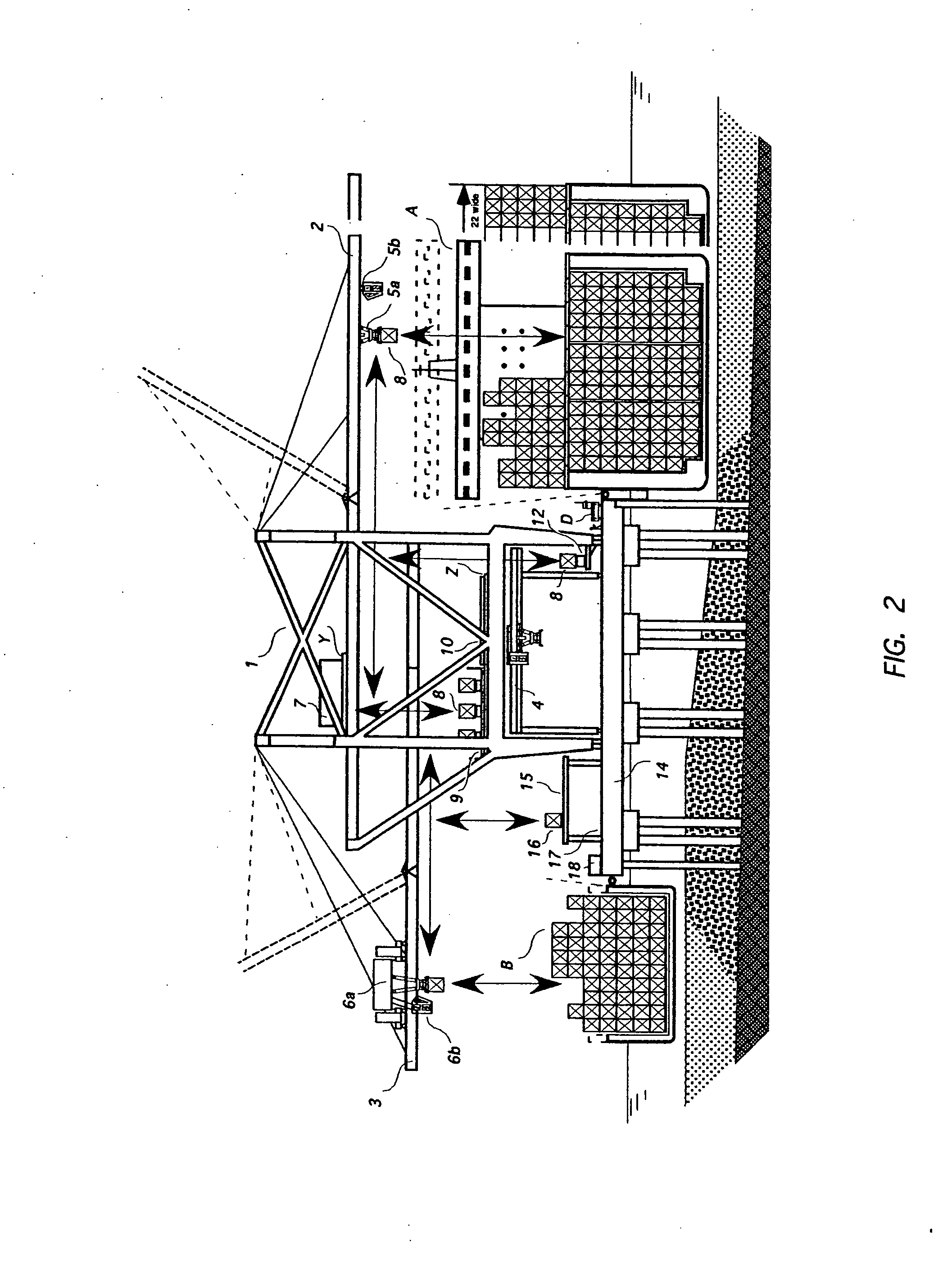

Container crane apparatus and method for container security screening during direct transshipment between transportation modes

InactiveUS20080219804A1Save a lot of costCargo handling apparatusBase supporting structuresContainer craneGround vehicles

A crane apparatus installed on a pier, wharf, bulkhead wharf or other foundation directly transships containers from a vessel moored alongside the foundation to another transportation mode without ground placement of the containers. The crane apparatus includes a parent crane displaceable along the foundation for unloading containers from the vessel and placing them on a first platform of the parent crane, and a sibling crane displaceable along the foundation independently of displacement of the parent crane for loading containers from the first platform directly onto over-the-ground vehicles or onto another vessel moored alongside the foundation. The parent crane has a first trolley-hoist-spreader movable along an outreach boom for unloading containers from the vessel and placing them on either the first platform or a second platform of the parent crane, and a second trolley-hoist-spreader movable along a backreach boom for loading containers from the second platform onto another vessel or onto over-the-ground vehicles. A container security scanning system may be provided on the second platform for scanning the containers while on the second platform to determine whether one or more preselected chemical, biological, explosive or nuclear materials are present in the containers.

Owner:CHATTEY NIGEL

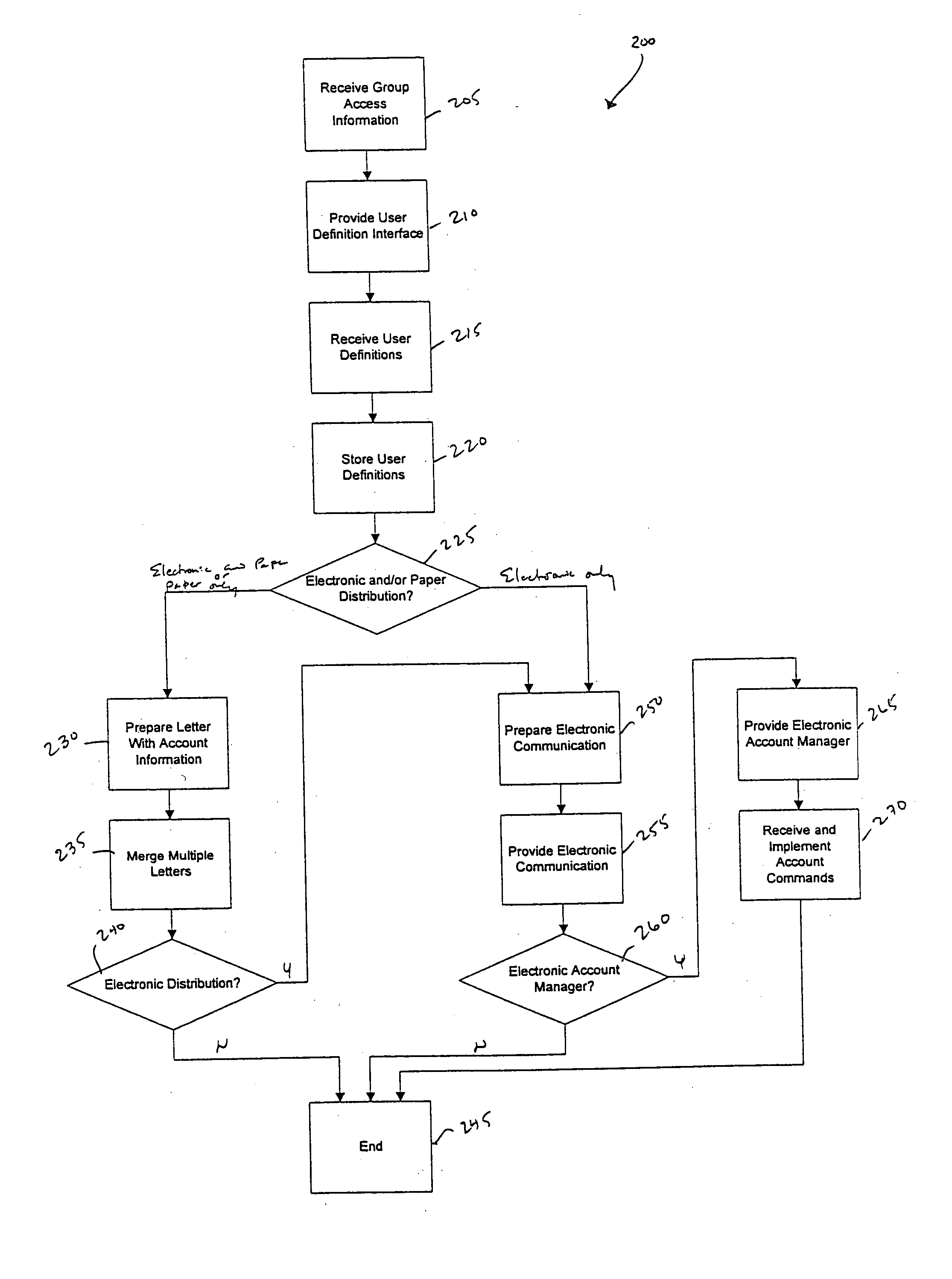

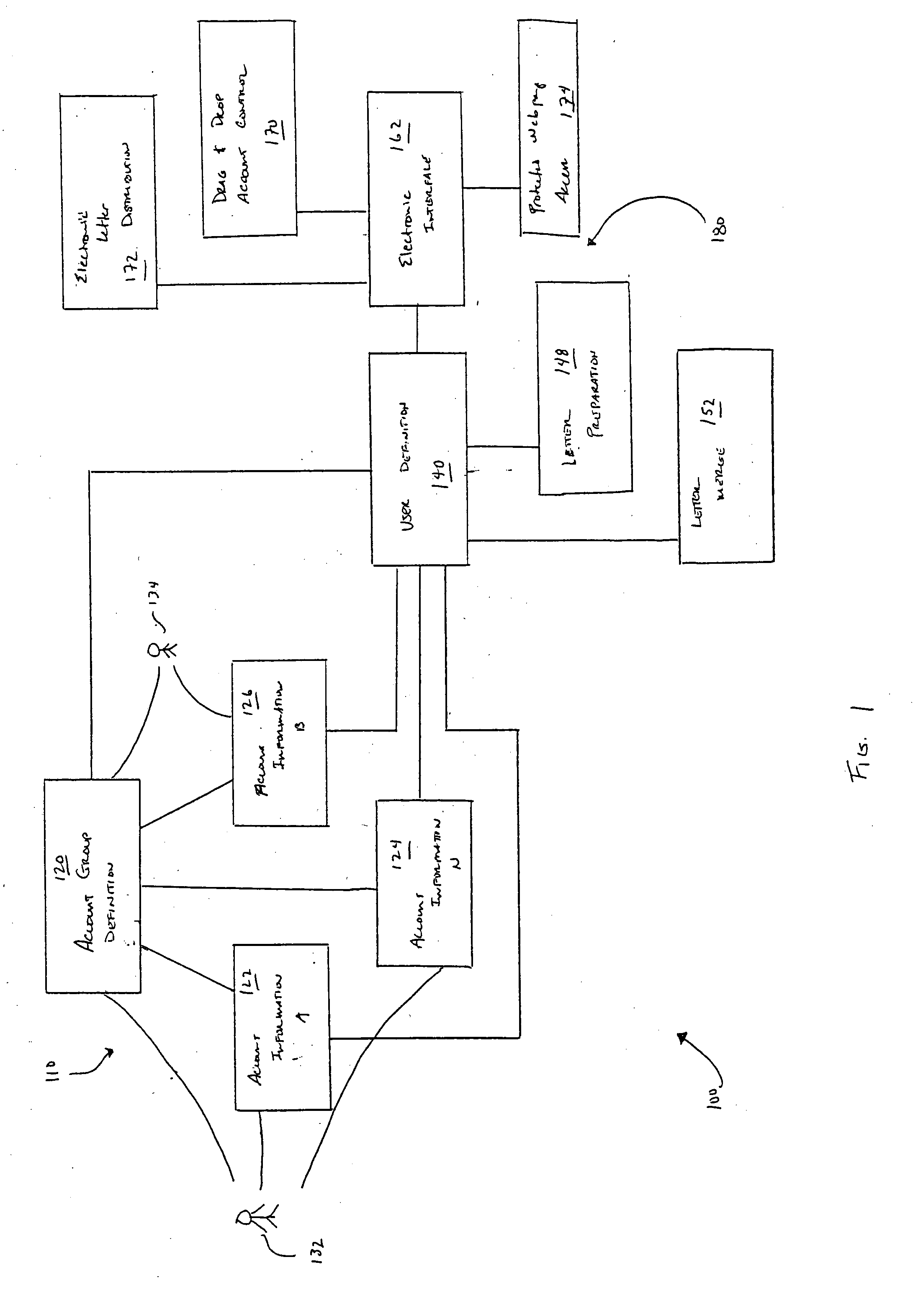

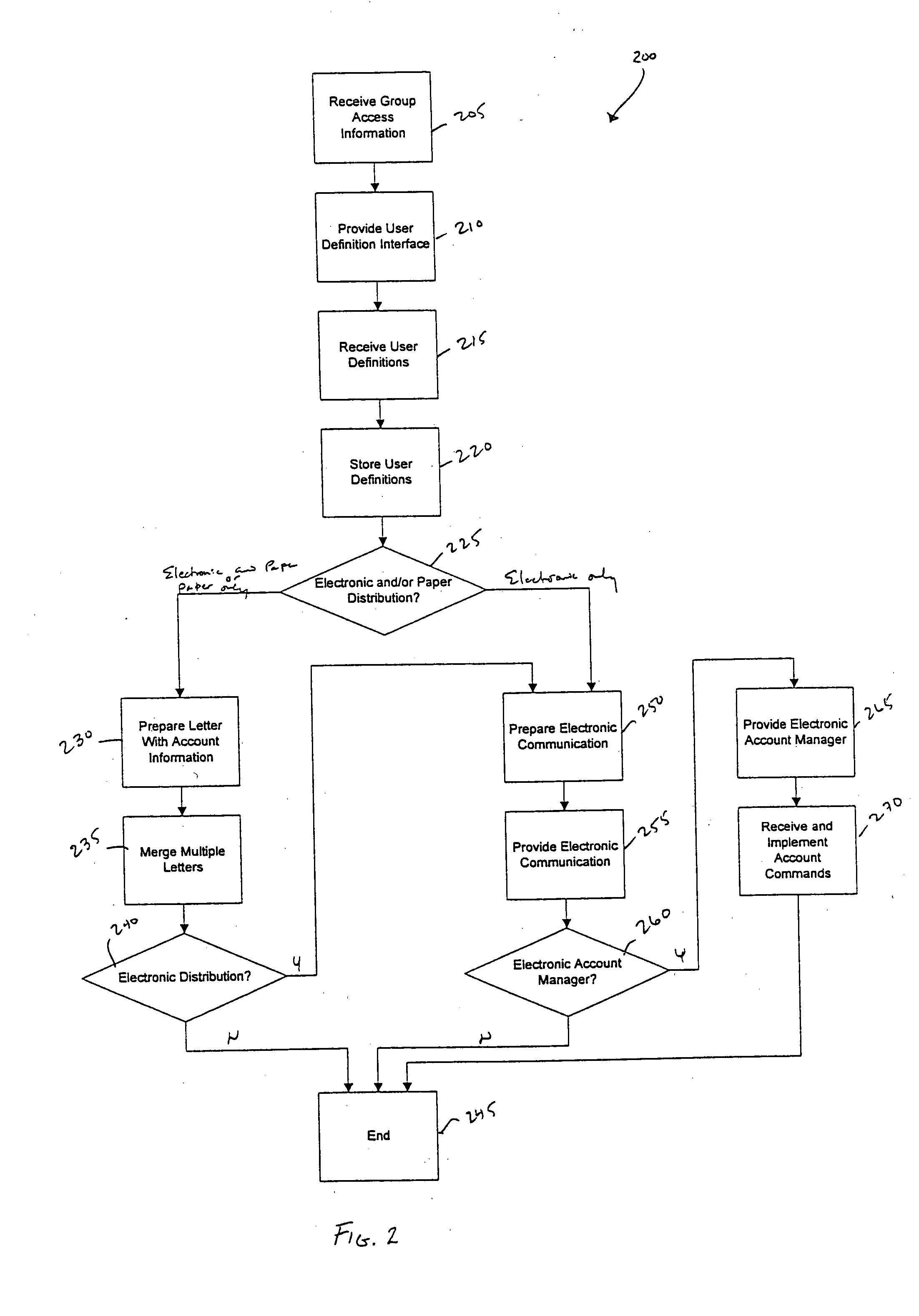

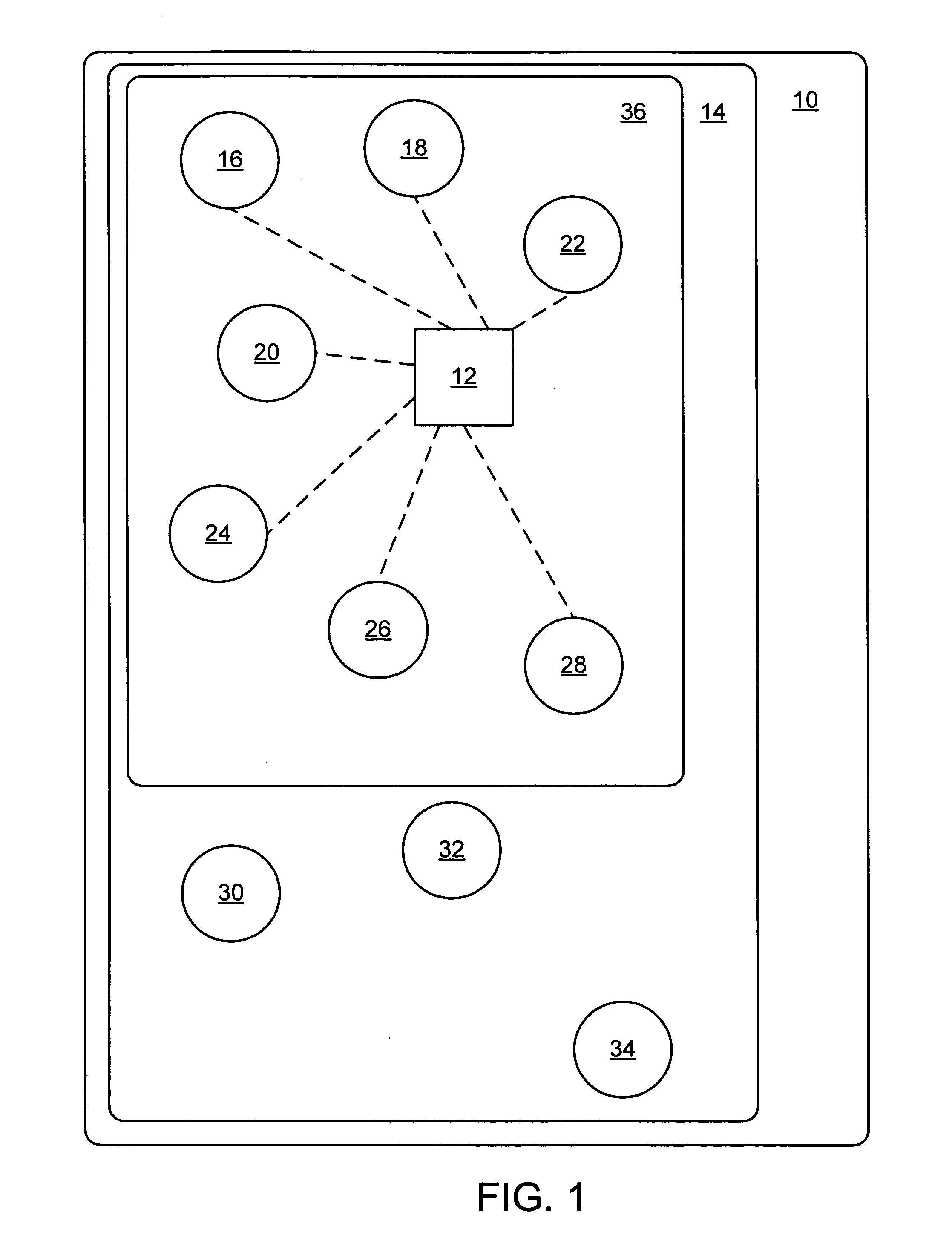

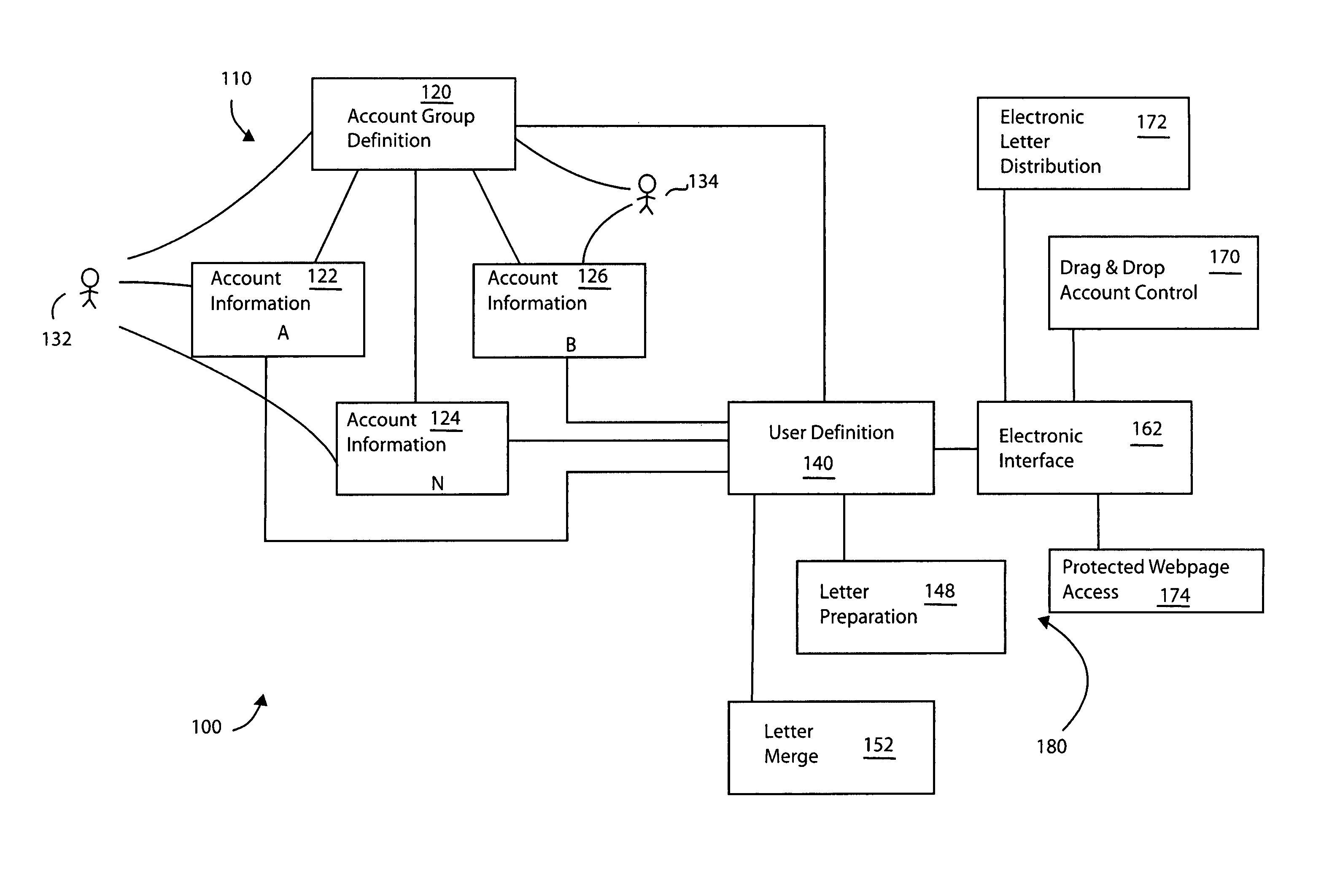

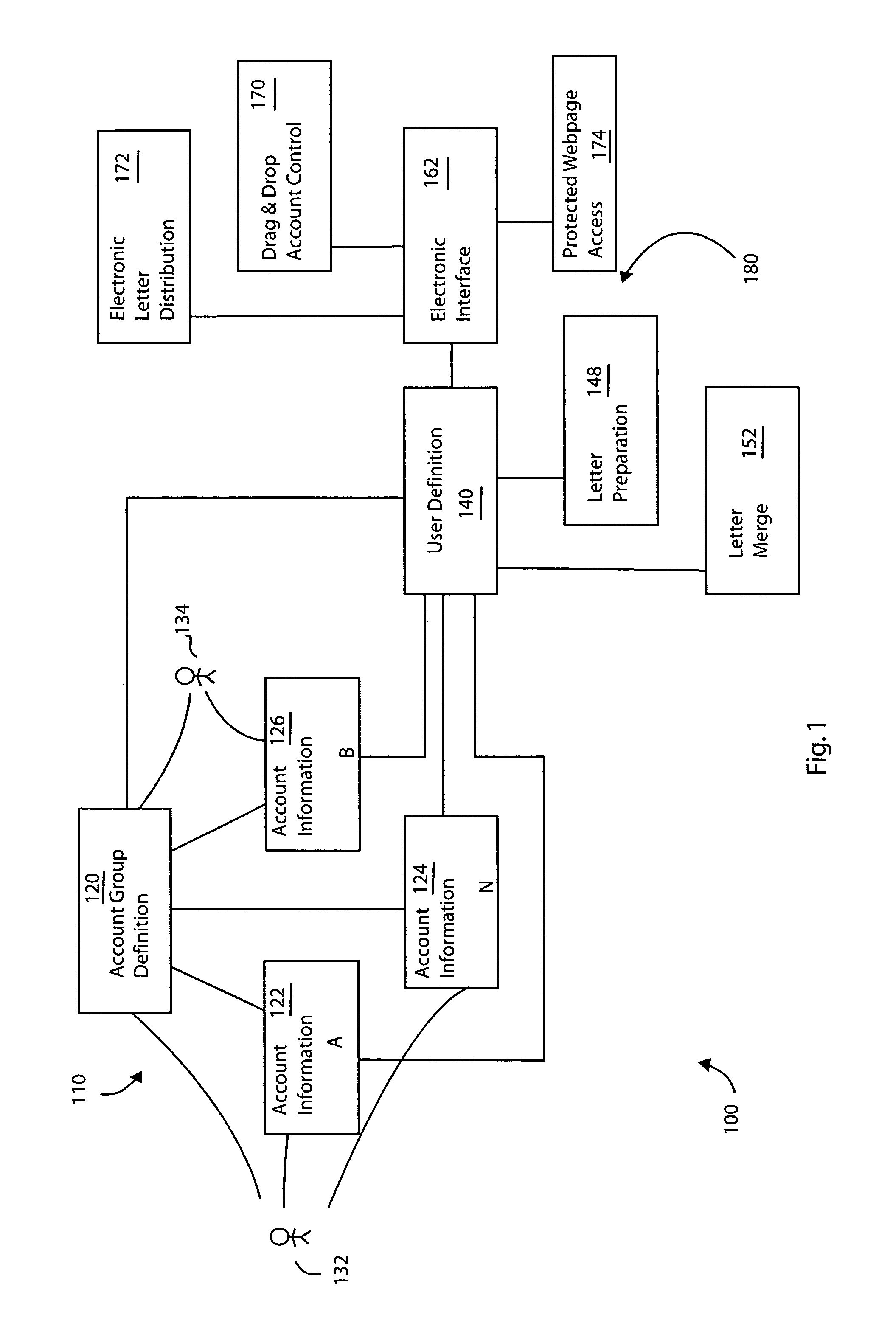

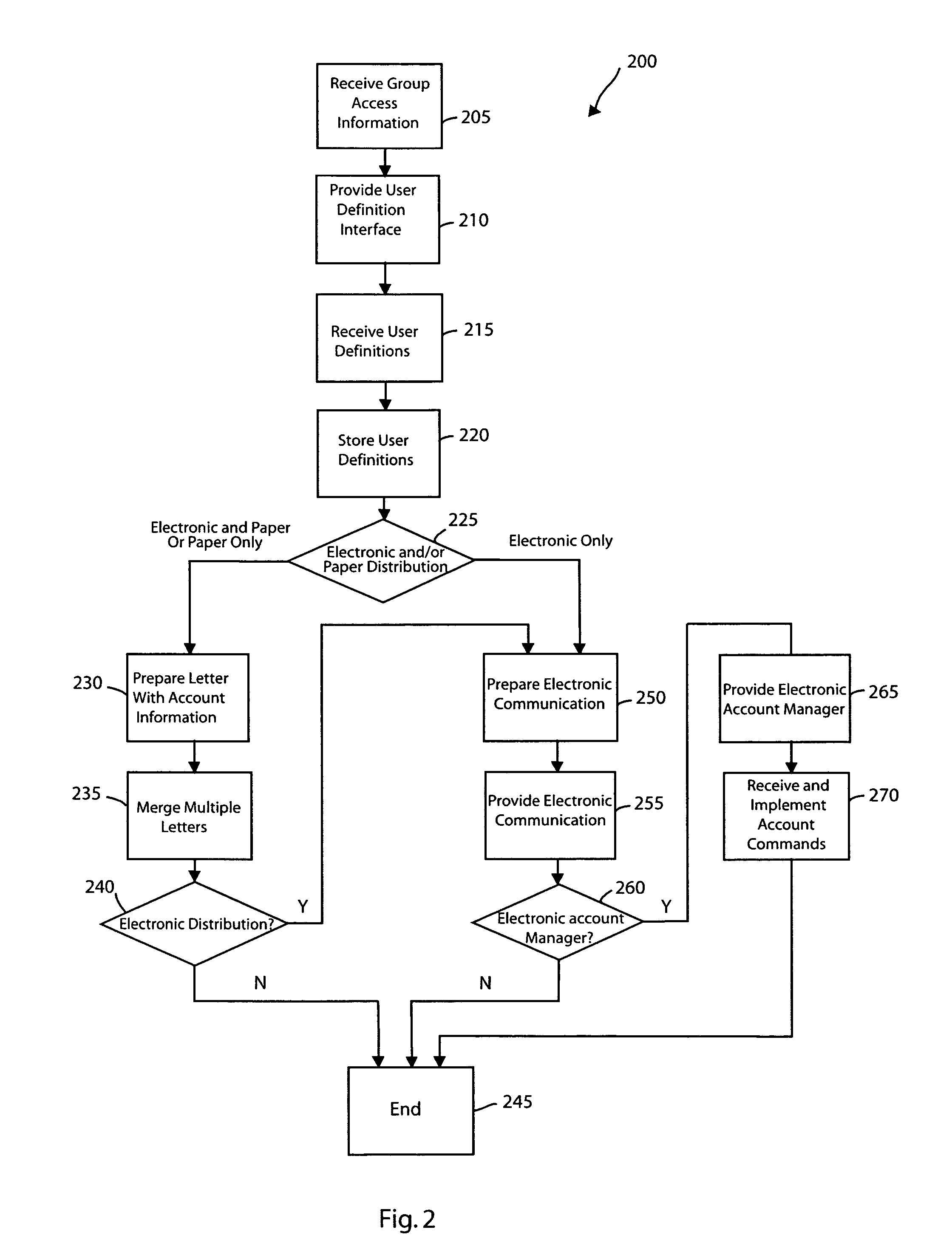

Systems and methods for participant controlled communications regarding financial accounts

ActiveUS20050080691A1Save a lot of costAvoid communicationComplete banking machinesFinanceControl communicationsDirect communication

Owner:FIRST DATA

Systems and methods for detecting a signal and applying thermal energy to a signal transmission element

ActiveUS20100196908A1Save a lot of costMinimize opportunityOptical radiation measurementBioreactor/fermenter combinationsThermal energyEngineering

A signal detection system configured for detecting a signal emitted by the contents of a reaction receptacle is also configured to apply thermal energy to a portion of the reaction receptacle to affect a reaction occurring within the reaction receptacle. More particularly, a system for detecting electromagnetic radiation emitted by the contents of a reaction receptacle includes a transmission element configured for transmitting electromagnetic radiation from the contents of the receptacle, a thermal element associated with the transmission element and configured to apply thermal energy to at least a portion of the receptacle, and a detector configured to receive electromagnetic radiation from the transmission element and to generate a signal corresponding to a characteristic of the electromagnetic radiation received by the detector.

Owner:GEN PROBE INC

Lamp base improvement of a street lamp

InactiveUS20090323343A1Save a lot of costLighting support devicesPoint-like light sourceEngineeringProjection direction

An illumination device of a lamp base improvement of a street lamp to change the projection direction is disclosed. A lamp base formed a plurality of brackets inside. Bottoms of the brackets are longitudinally set to be slanted. Lighting modules corresponding to the brackets are disposed along the bottoms. A transparent mask is combined to the lamp base to cover those lighting modules. Whereby, it can provide an LED street lamp which can change the projection direction.

Owner:PYROSWIFT HOLDING CO LIMITED

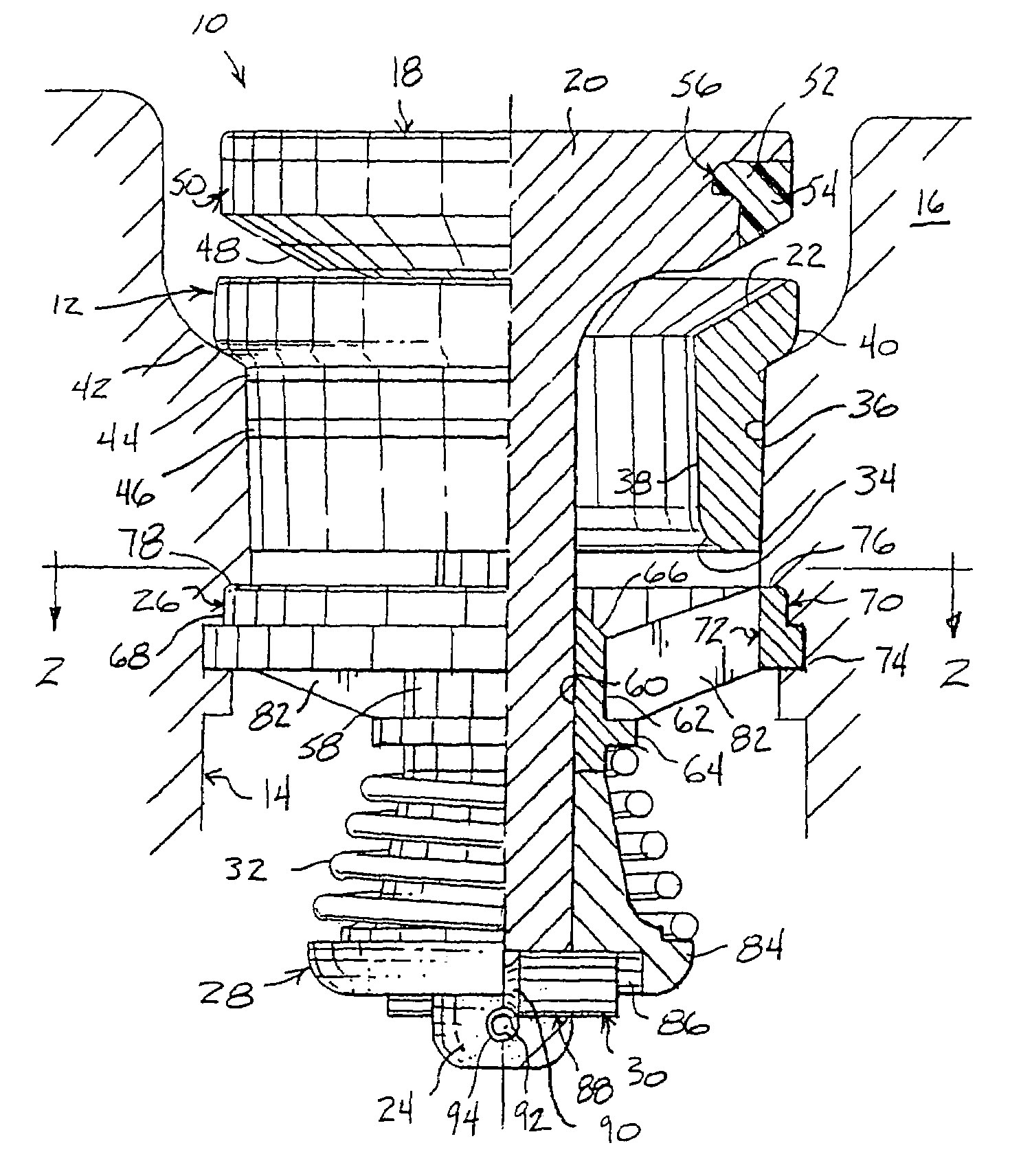

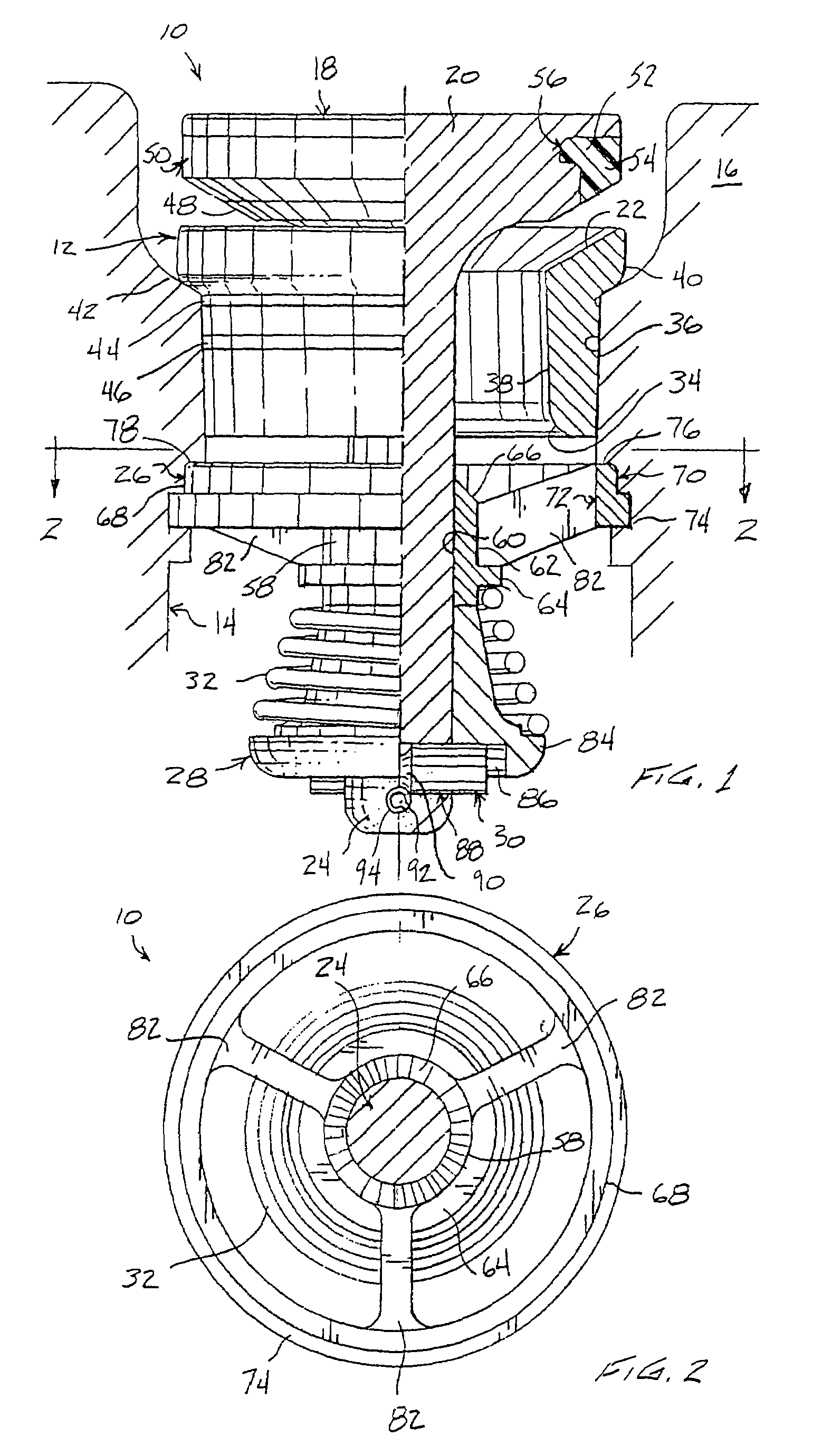

Suction valve

Owner:GARDNER DENVER INC

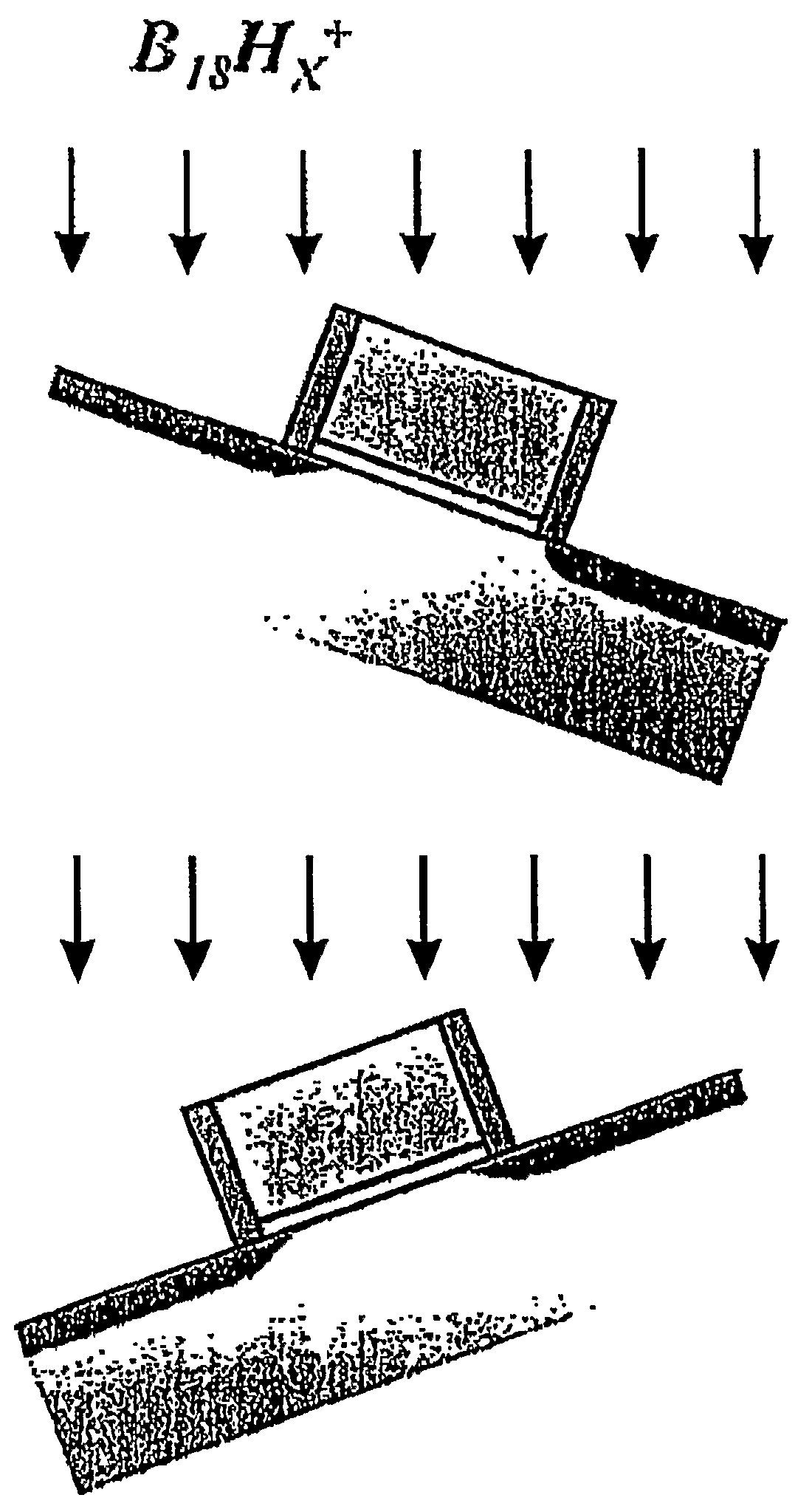

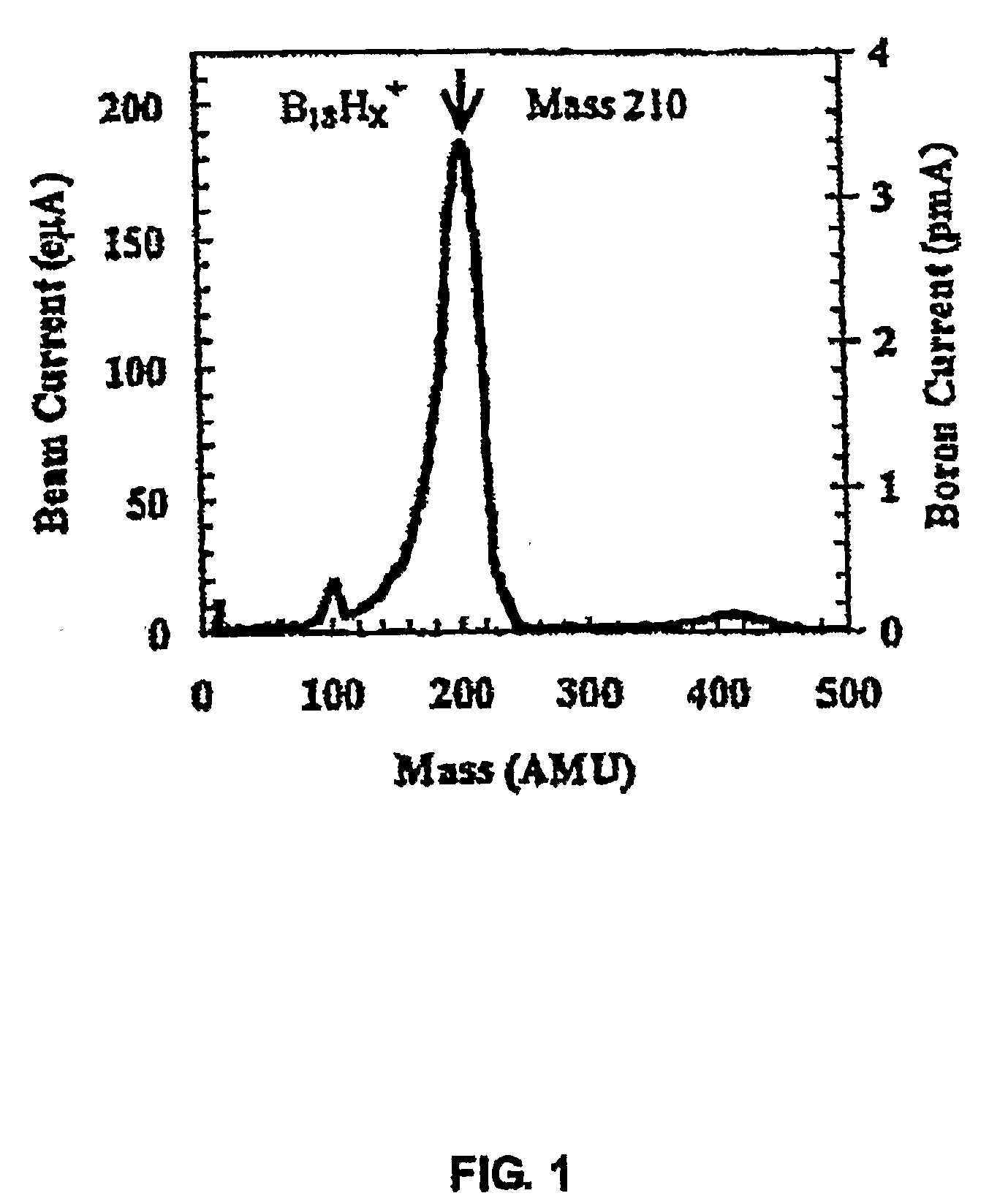

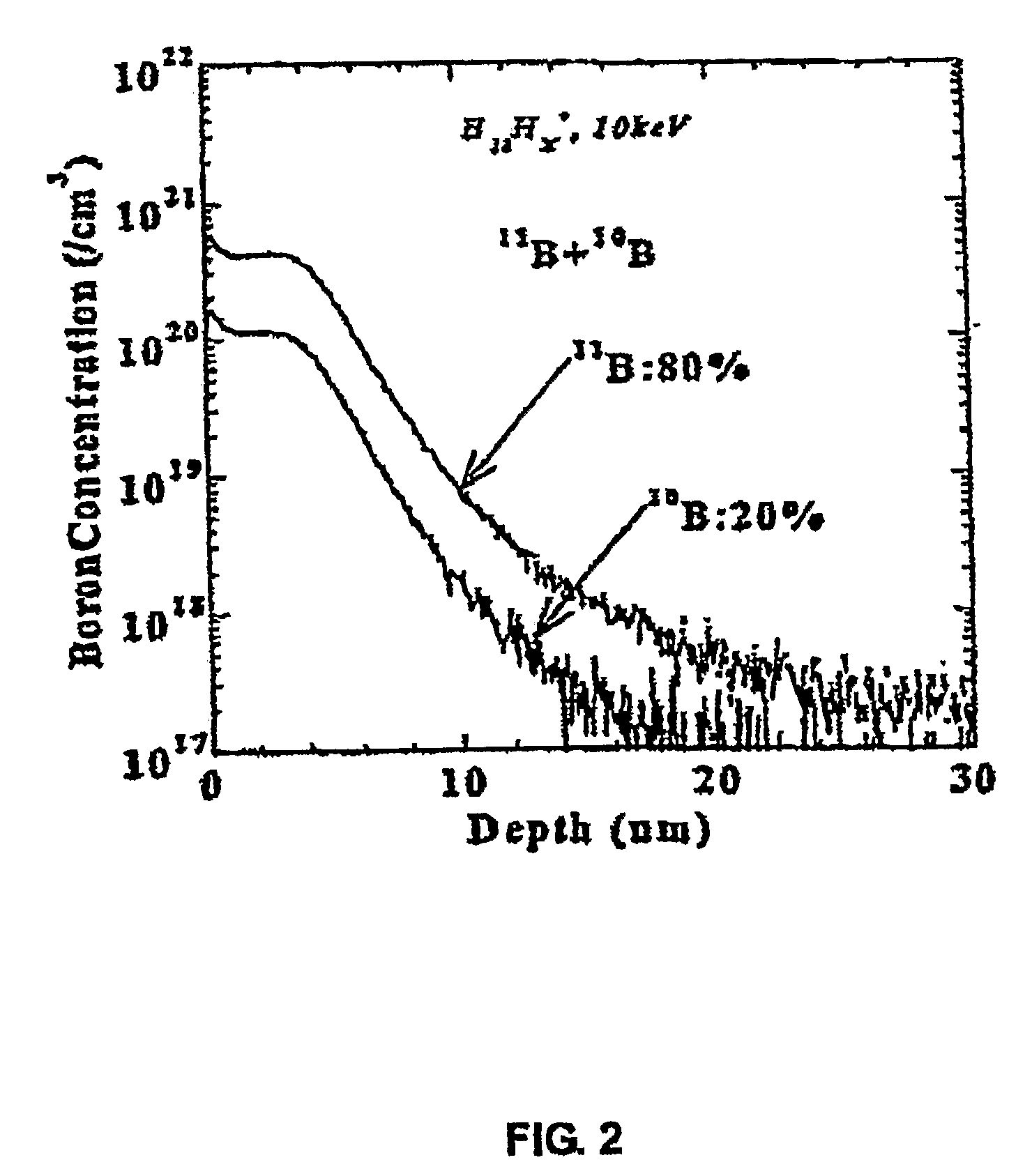

Method Of Manufacturing Semiconductor

InactiveUS20080242066A1Save a lot of costImprove performanceTransistorSemiconductor/solid-state device manufacturingOctadecaboraneBiomedical engineering

A method of producing ultra shallow junctions ( 104 ) for PMOS transistors, which eliminates the need for pre-amorphization implants, is disclosed. The method utilizes dopant species, such as cluster ions, e.g., octadecaborane, B18H22. In accordance with the present invention, the pre-amorphizing step may be eliminated, greatly reducing cost per processed wafer. An appropriate process sequence has been suggested to take advantage of cluster ion implantation for PMOS manufacturing. In addition, the novel use of tilted implants for the source / drain extension and for pocket implants has been described.

Owner:SEMEQUIP +1

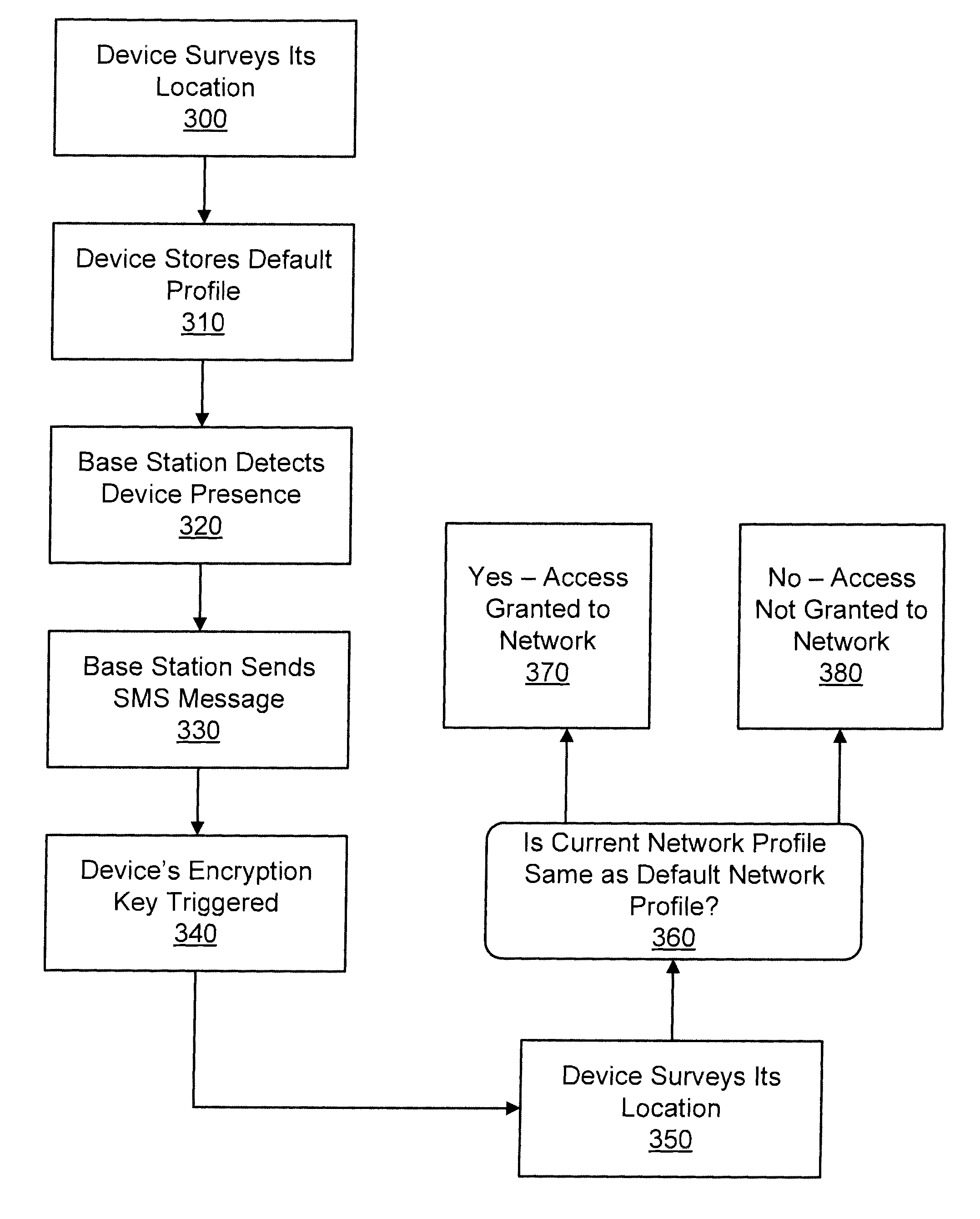

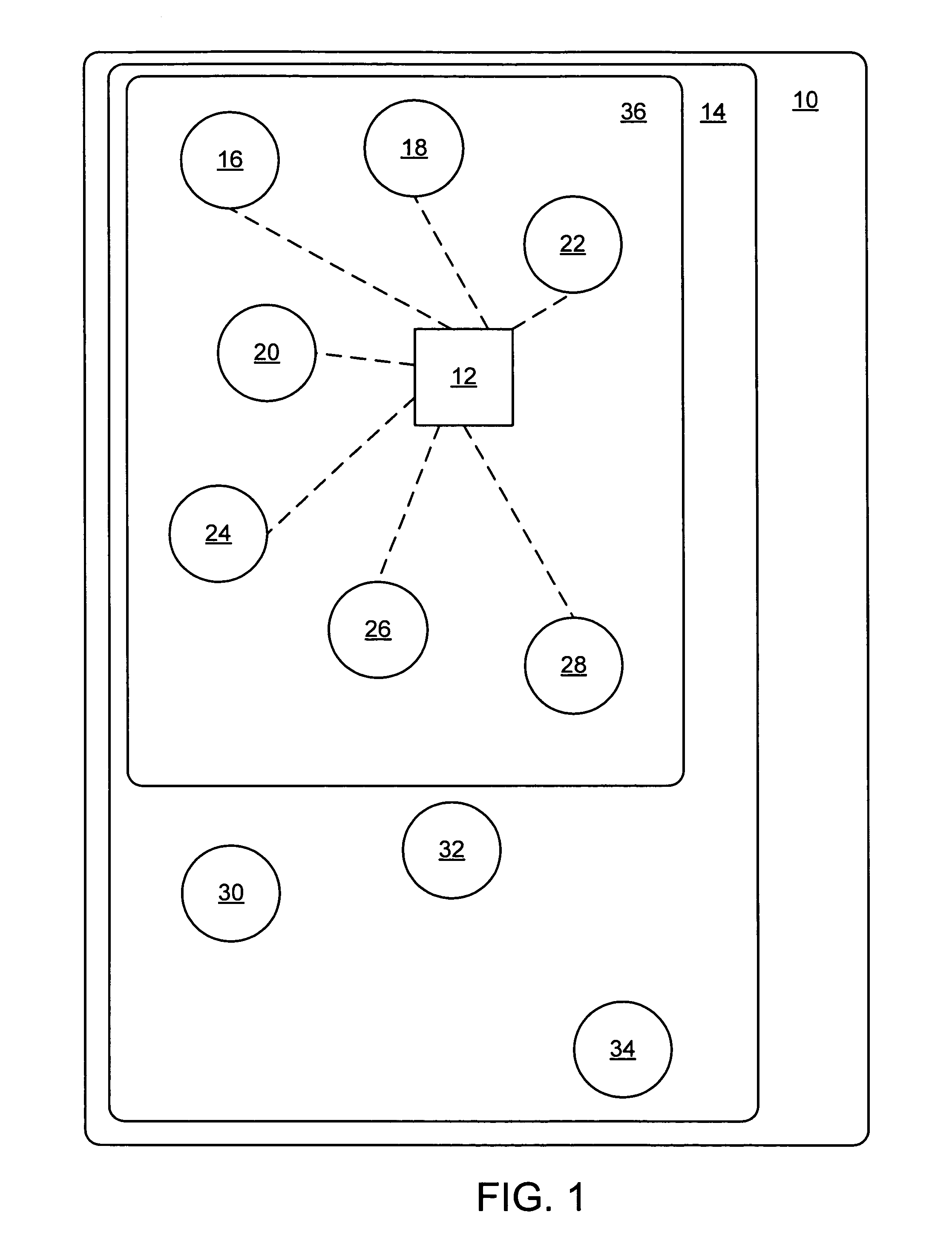

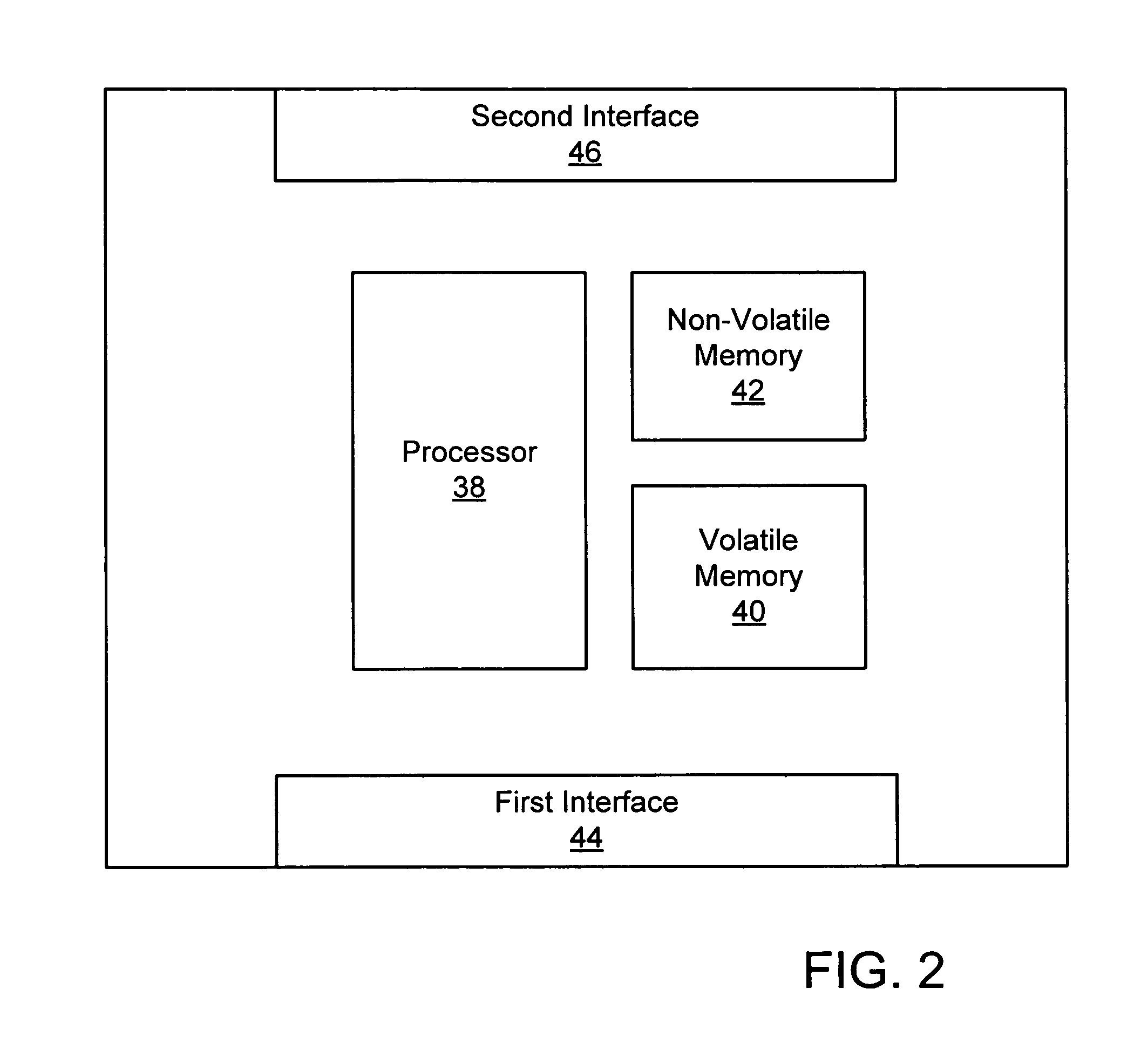

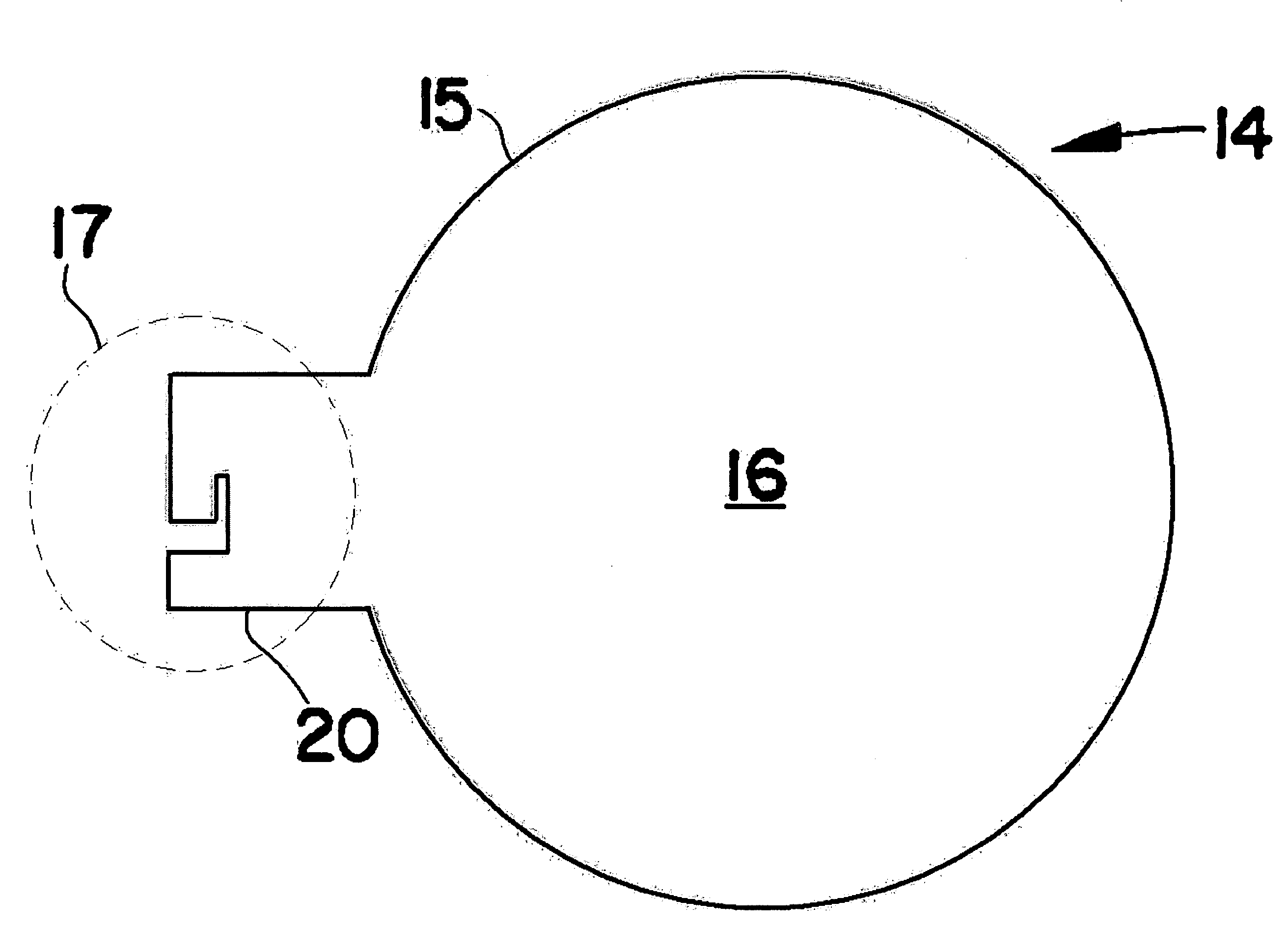

System and method for provisioning a wireless device to only be able to access network services within a specific location

InactiveUS20060143438A1Save a lot of costImprove distributionNetwork traffic/resource managementUnauthorised/fraudulent call preventionAccess networkNetwork service

A system and method for provisioning wireless devices such that they are only capable of accessing network services when in a specified location. A device surveys the current location of the device for existing base stations and stores a corresponding network environment profile. After the profile is stored, network services will only be provided to the device if the current network profile matches the stored profile.

Owner:NOVATEL WIRELESS

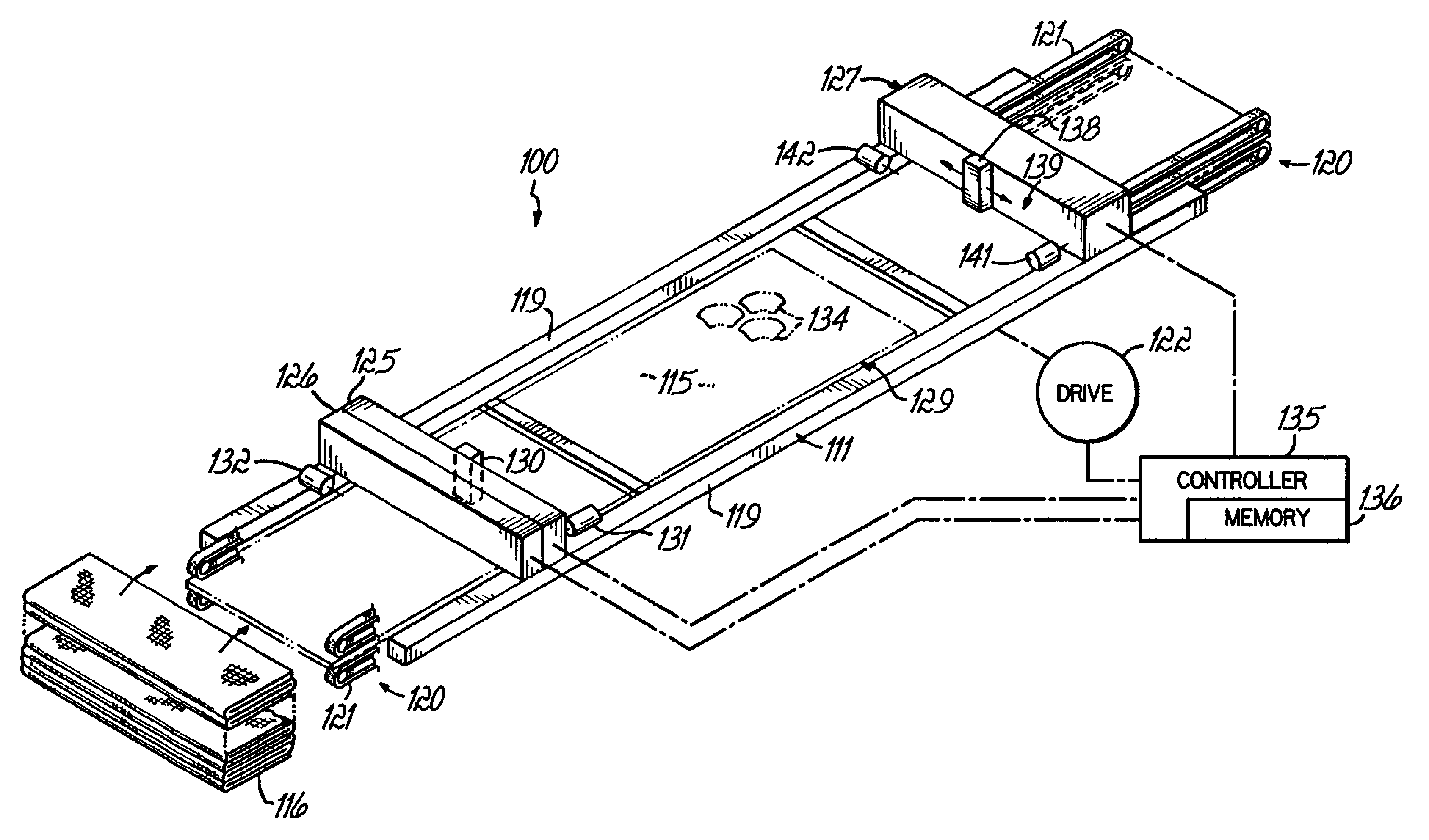

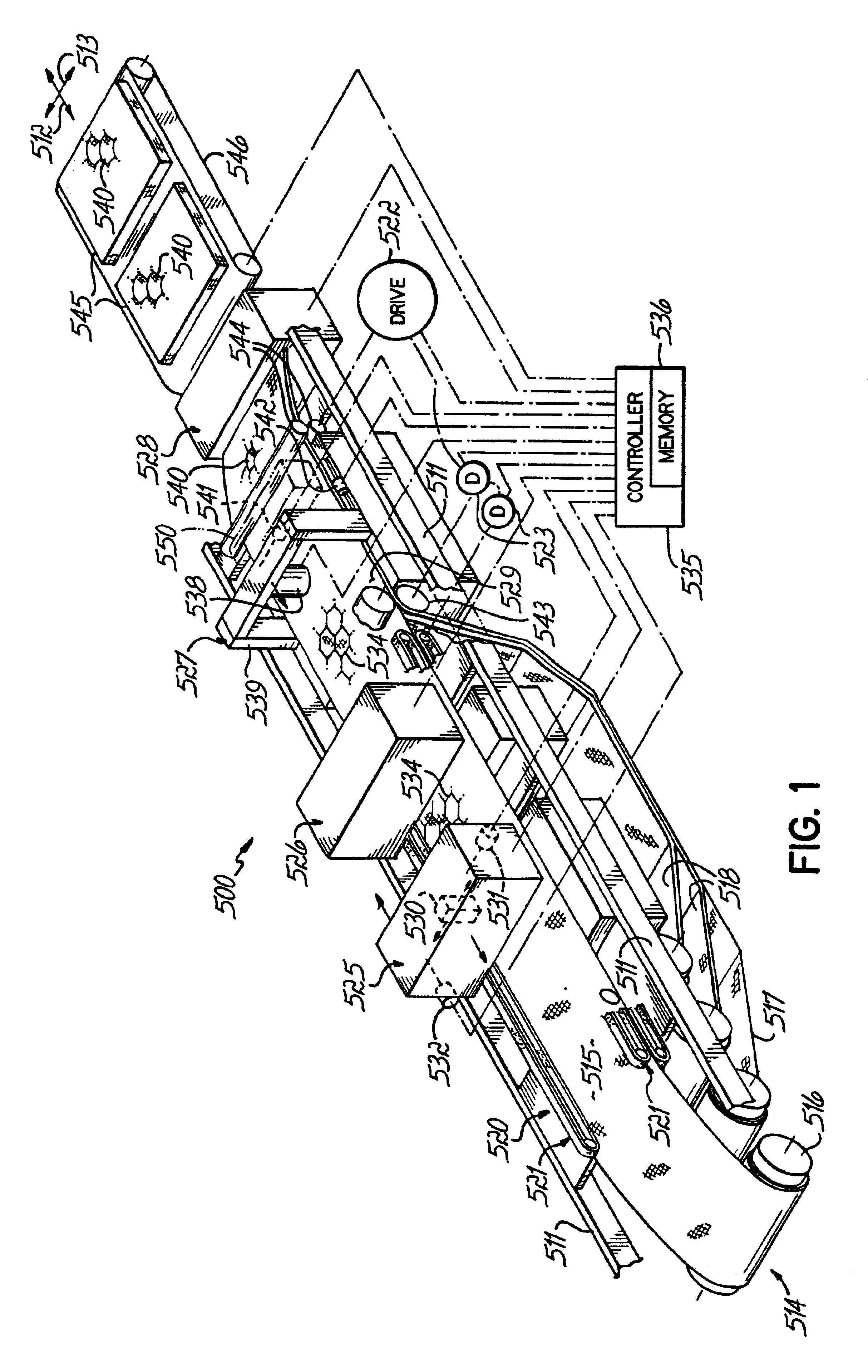

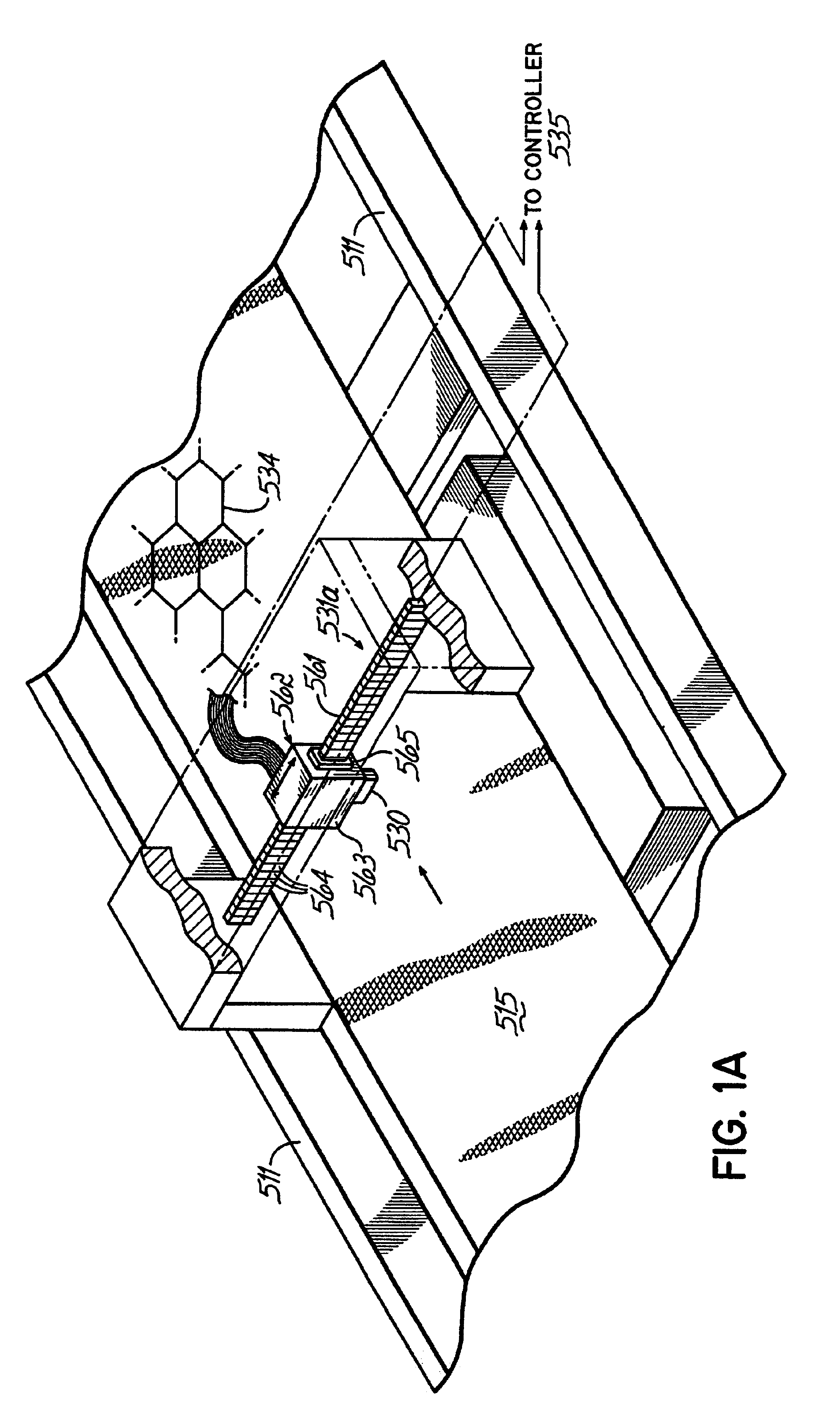

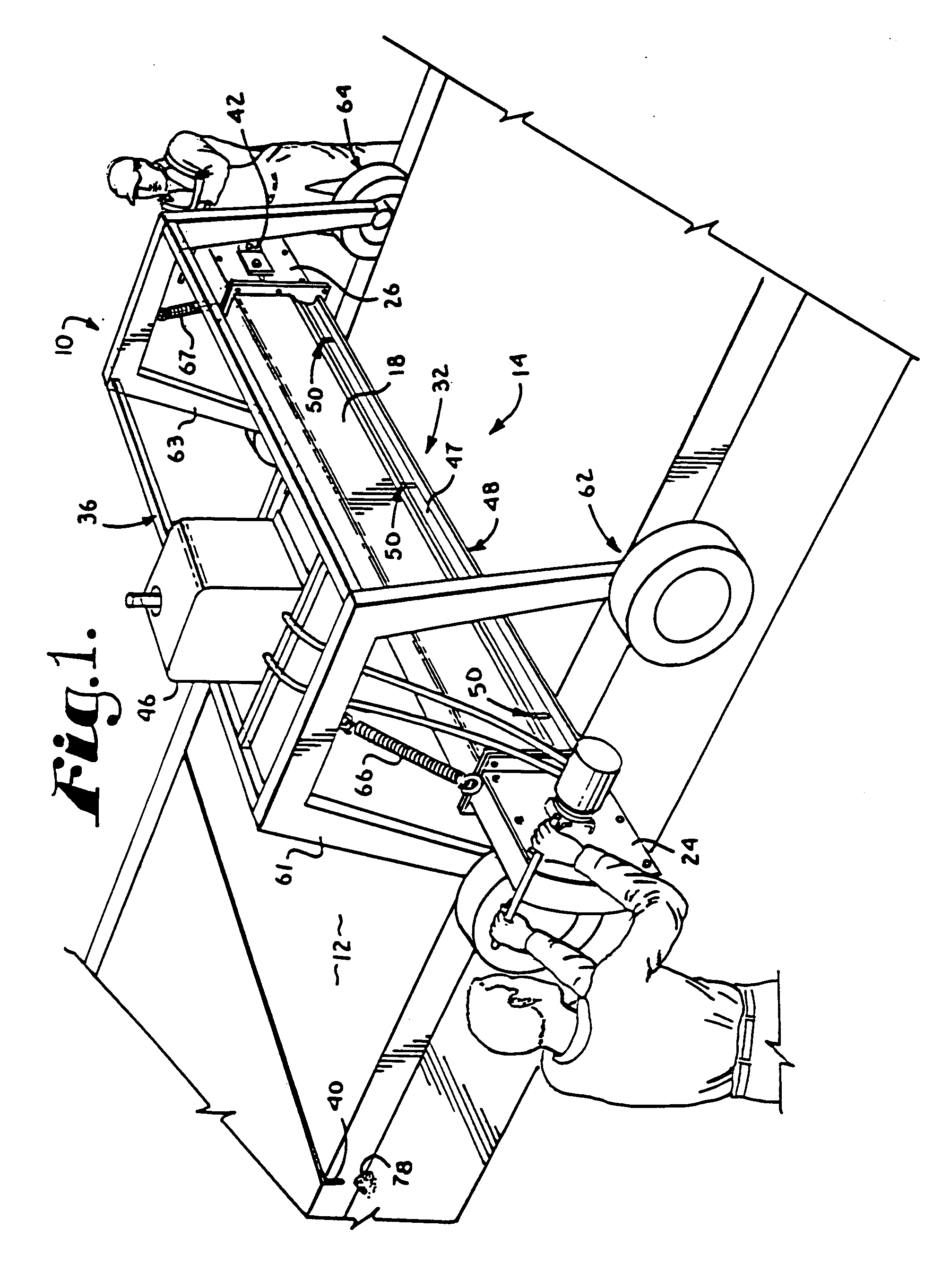

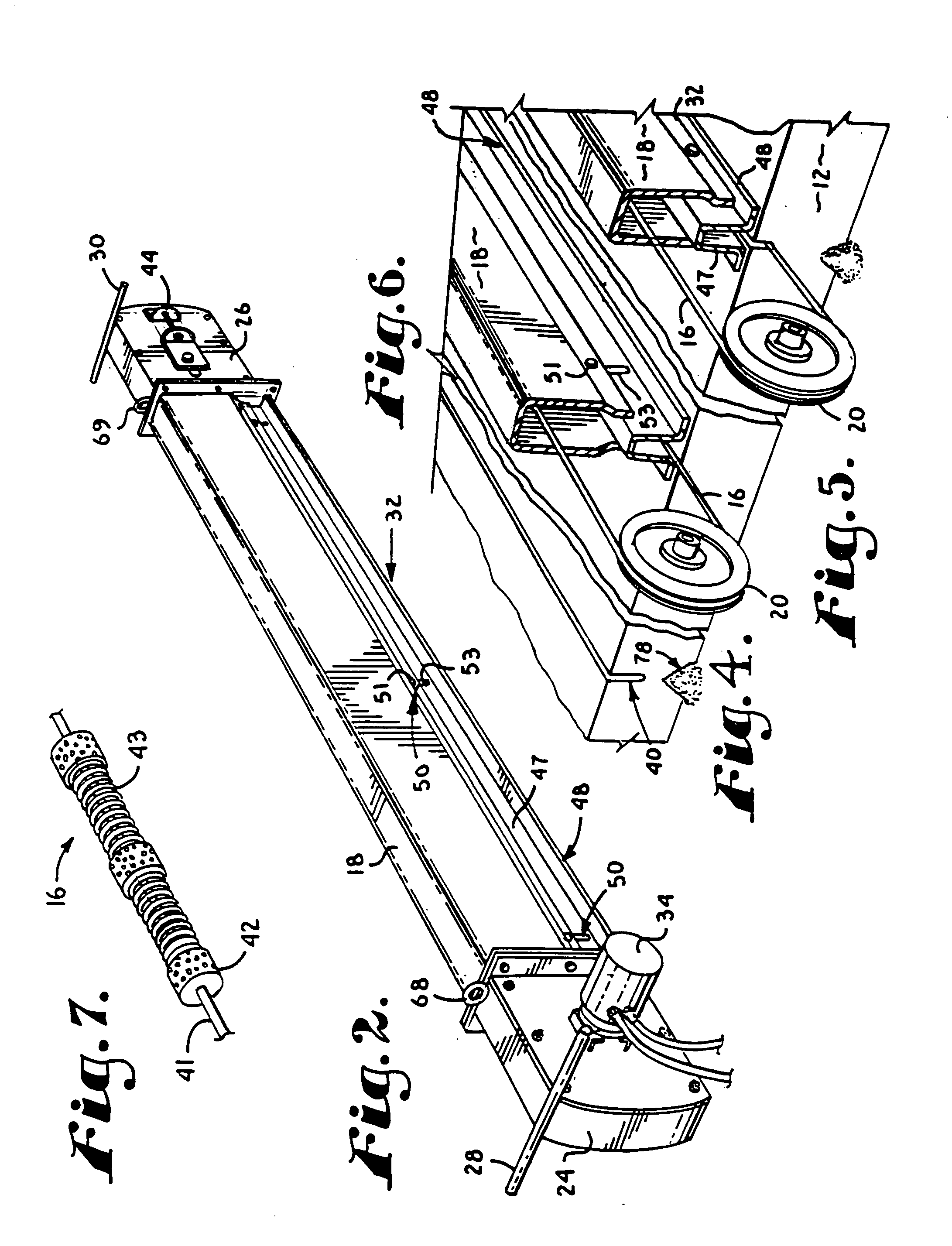

Printing and quilting method and apparatus

InactiveUS6848846B2Efficiently and economicallySave a lot of costRecording apparatusOrnamental textile articlesData fileEngineering

A quilting machine (10, 100, 200, 300, 400, 500, 600) is provided with a printing station (20, 125, 225, 325, 425, 525, 611, 626, 631) and a quilting station (44, 127, 227, 327, 427, 527, 627, 632). The printing station is located either in line and preferably upstream of the quilting station, with a conveyor (520) extending through each of the stations to convey a web of quilting material through the machine, or is off of the quilting line such that the material with a pre-applied pattern thereon is transferred, preferably in web form, to the line of the second station for the application of a pattern in registration with the first applied pattern. At the quilting station, registration longitudinal and transverse registration is measured and skewing or rotation of the material is determined. Opposite transverse sides of the material are differently adjusted to orient and register the material. A master batch controller (90, 135, 235, 335, 435, 535) assures that the proper combinations of printed and quilted patterns are combined to allow small quantities of different quilted products to be produced automatically along a material web. Ticking is preprinted with a plurality of different patterns, organized and communicated by the computer so that a print head can scan the material and print different patterns of different panels (32) across the width of a web. Identifying data (40) for matching the panels of a mattress product can be provided in data files printed on the fabric. Cutting and slitting of the panels from each other and the quilting and combining of the panels for assembly of a mattress product can be carried out manually or automatically using the data.

Owner:L & P PROPERTY MANAGEMENT CO

System and method for provisioning a wireless device to only be able to access network services within a specific location

InactiveUS8064884B2Save a lot of costImprove distributionNetwork traffic/resource managementUnauthorised/fraudulent call preventionAccess networkNetwork service

A system and method for provisioning wireless devices such that they are only capable of accessing network services when in a specified location. A device surveys the current location of the device for existing base stations and stores a corresponding network environment profile. After the profile is stored, network services will only be provided to the device if the current network profile matches the stored profile.

Owner:NOVATEL WIRELESS

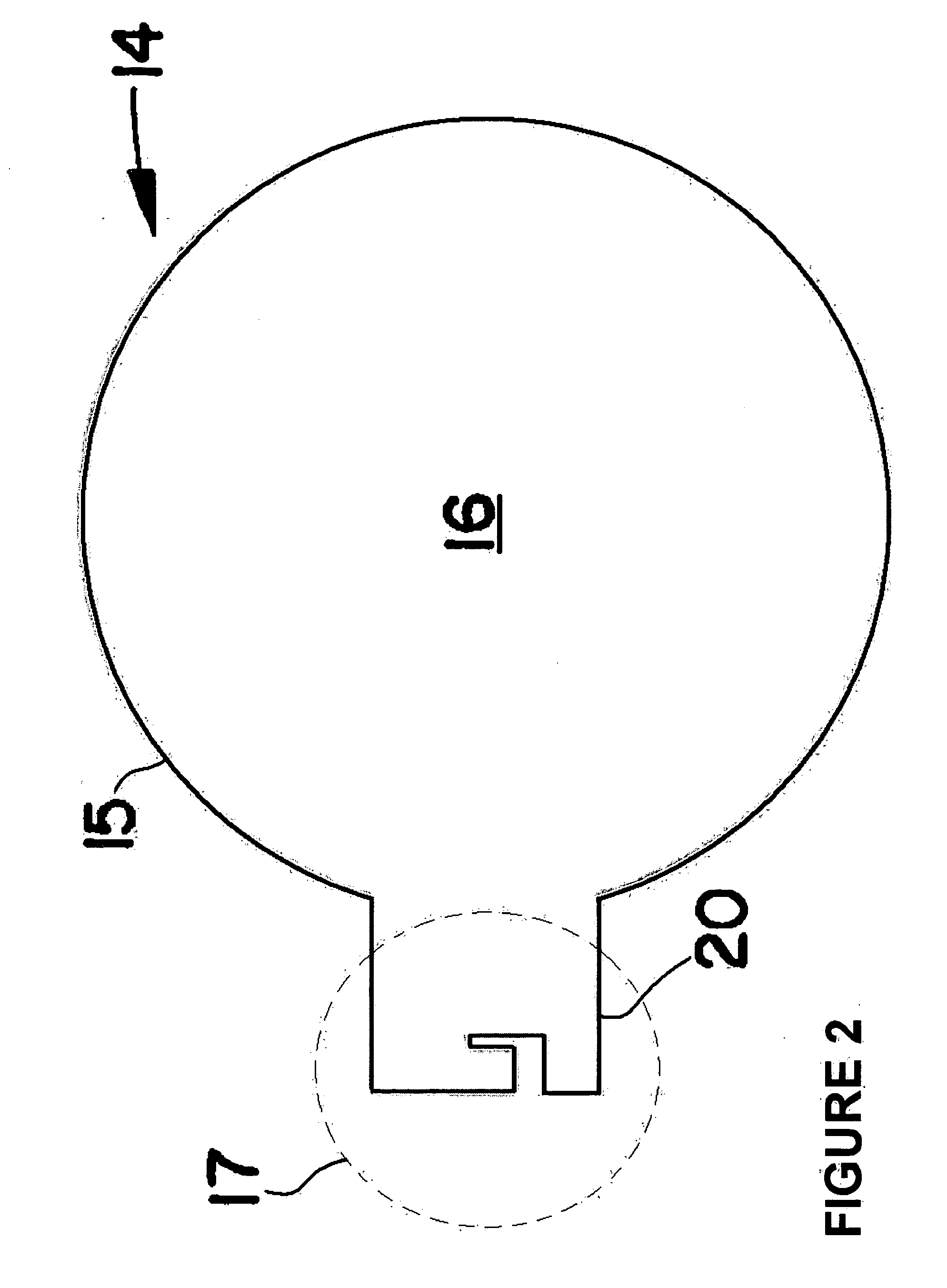

Planar sign geometry

InactiveUS20100083544A1Optimize geometryEasy to disassembleStampsShow cardsEngineeringStructural engineering

A planar sign (16) is retained by a sign holder (1) suitable for mounting on a shelf (18). The sign holder includes a prong (8) that fits within an orifice (11) so that the sign is gripped between panel 7 and the half 12, thereby securing the sign to the shelf 18. The sign includes a tab (20) that is formed with a series of edges (23, 25, 27, 29) that define a circuitous pathway leading to a radius (34) that prevents the further advance of the prong (8). By aligning the circuitous pathway of the sign (16) with the prong (8) and advancing the sign so as to guide the prong through the pathway, the sign may be inserted into the holder (1) even if the holder has been folded and the prong secured while previously used to hold a sign.

Owner:SHIRLEY DAVID H +1

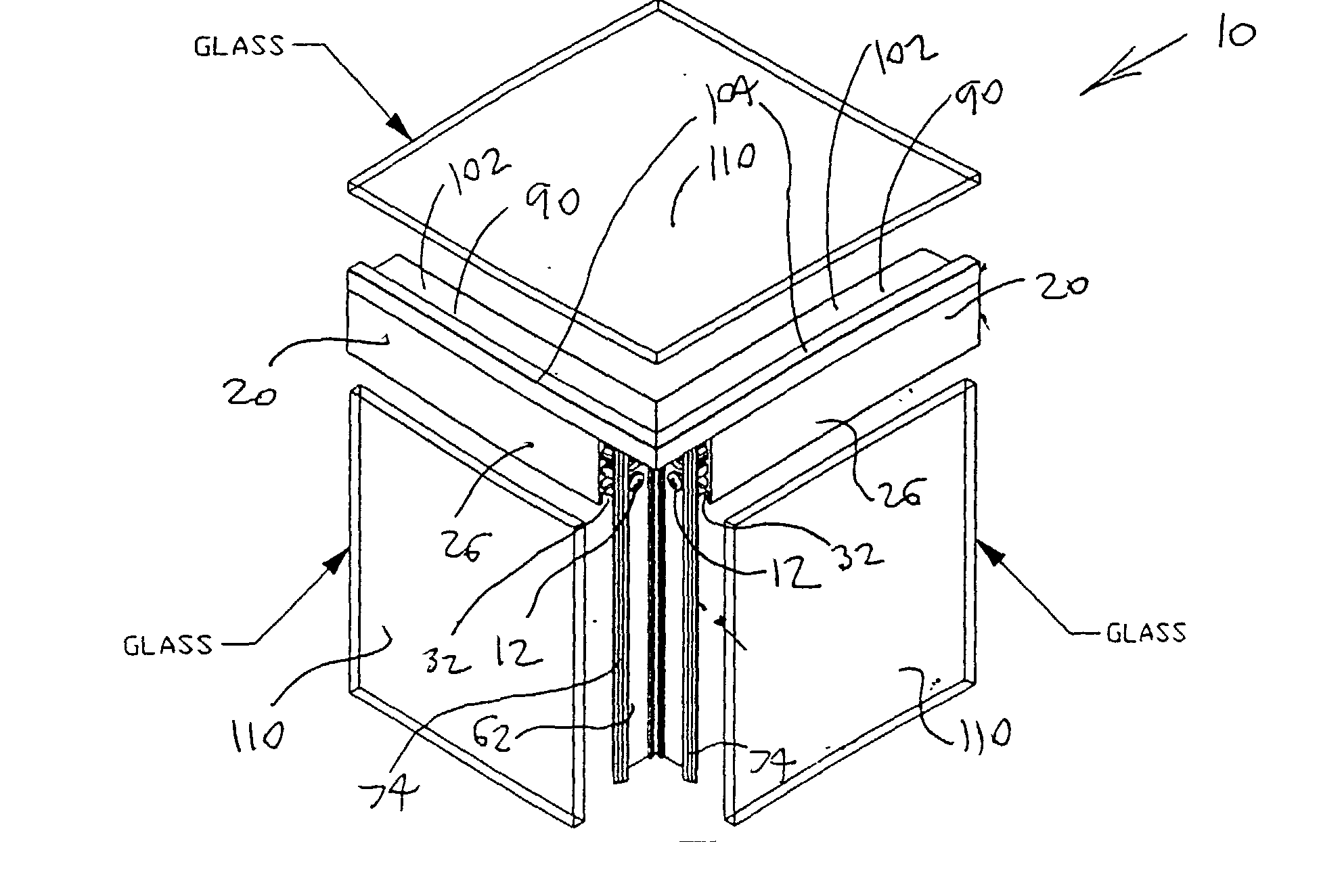

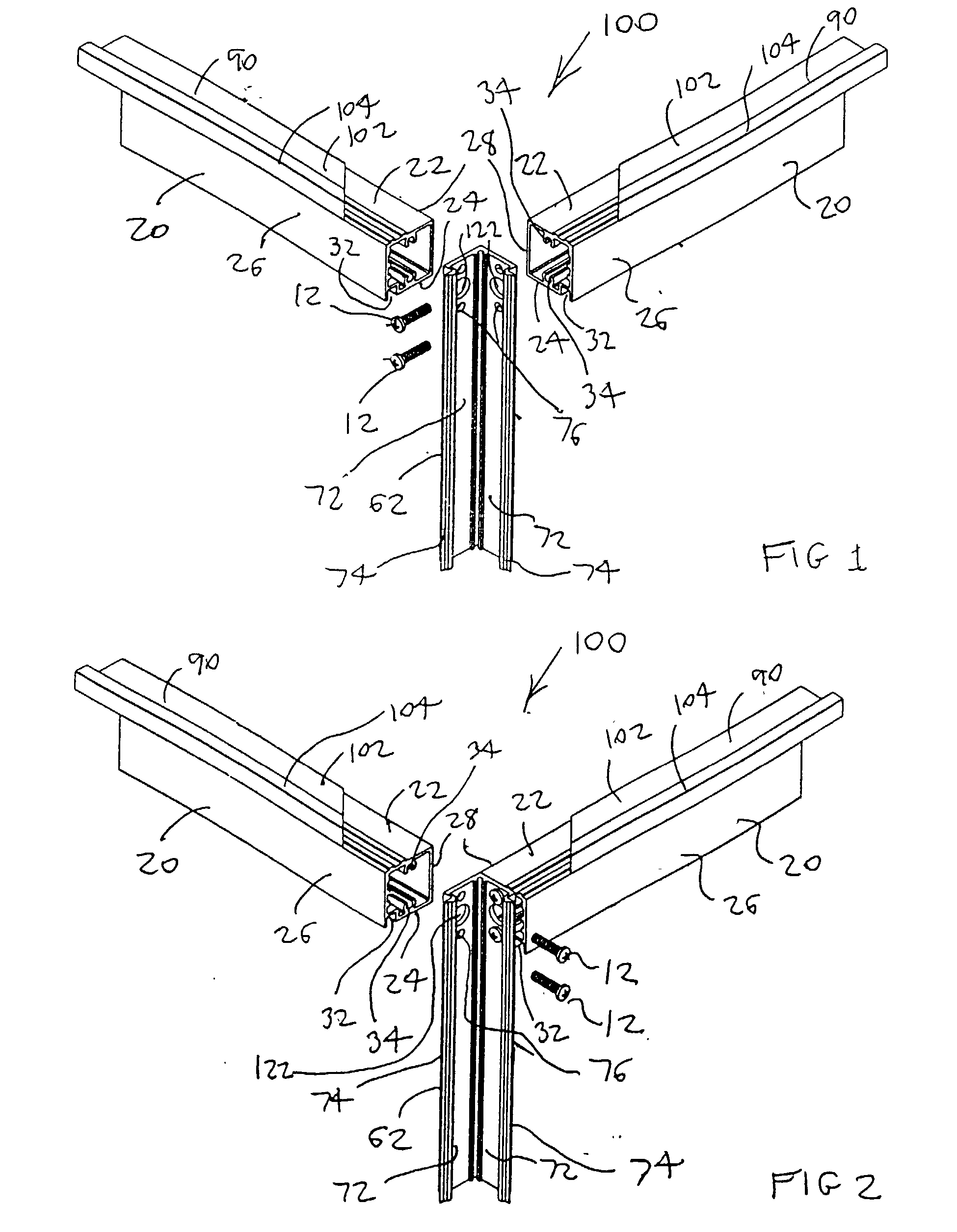

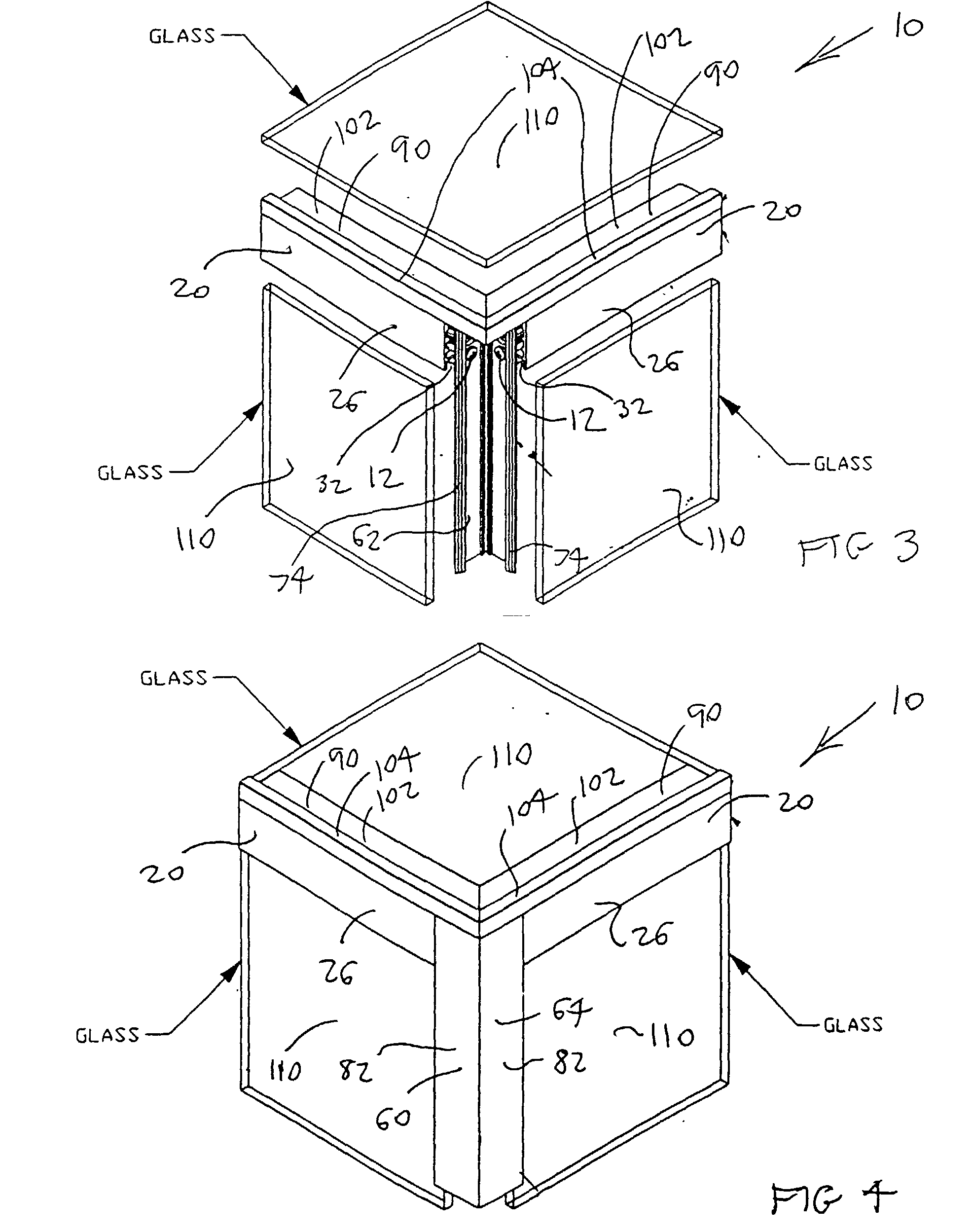

Display case assembly system

InactiveUS20040075371A1Progress efficientlyReduce manufacturing costShow cabinetsFurniture partsEngineeringFastener

A display case assembly system includes several closed frame tubes, each closed frame tube including two closed frame tube longitudinal ends, at least one closed frame tube longitudinal end including a fastener receiving structure; several laterally breakable frame tubes, each breakable frame tube including a breakable frame tube mounting section having a fastener port; at least one fastener fitted through the fastener port in one of the mounting section and into one of the fastener receiving structures in one of the closed frame tube longitudinal ends, so that at least one breakable frame tube is fastened to one closed frame tube longitudinal end; a breakable frame tube cover section with snap engagement structures for snap engagement with the mounting section to form a composite tube concealing the at least one fastener; and a panel mounted and extending between the closed frame tube and the breakable frame tube.

Owner:VIRA INSIGHT

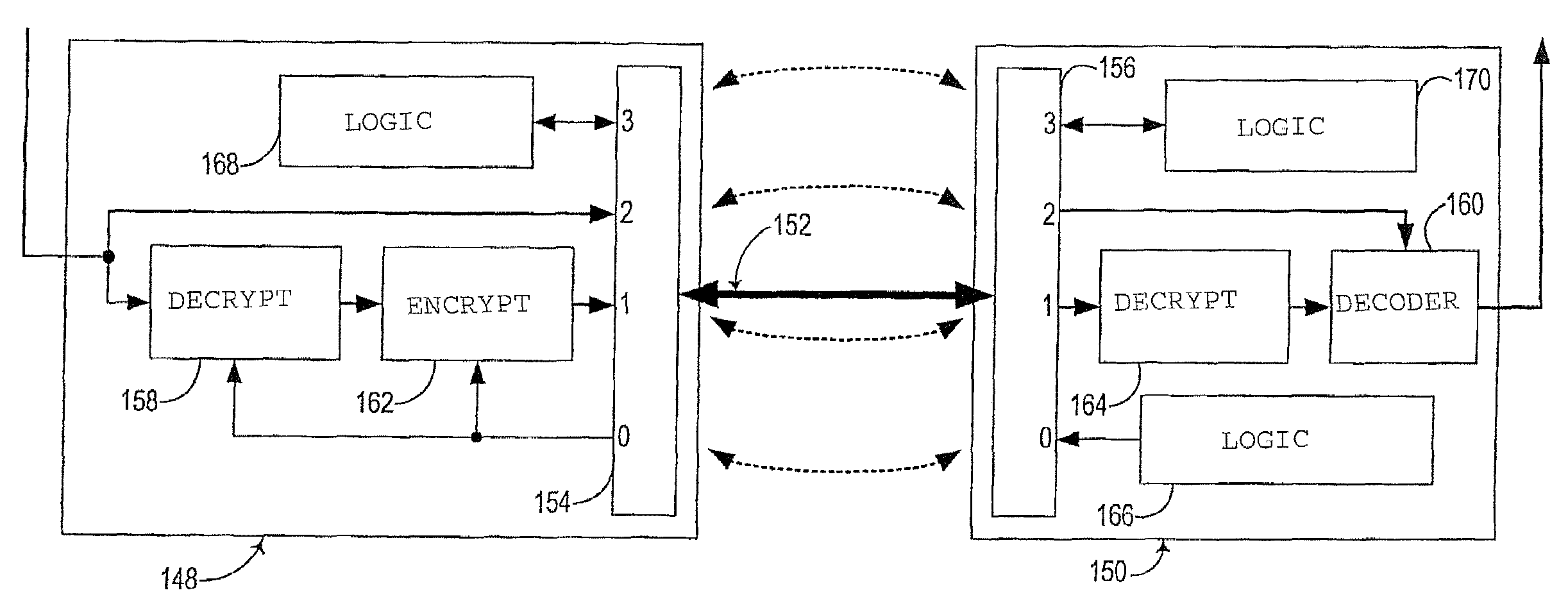

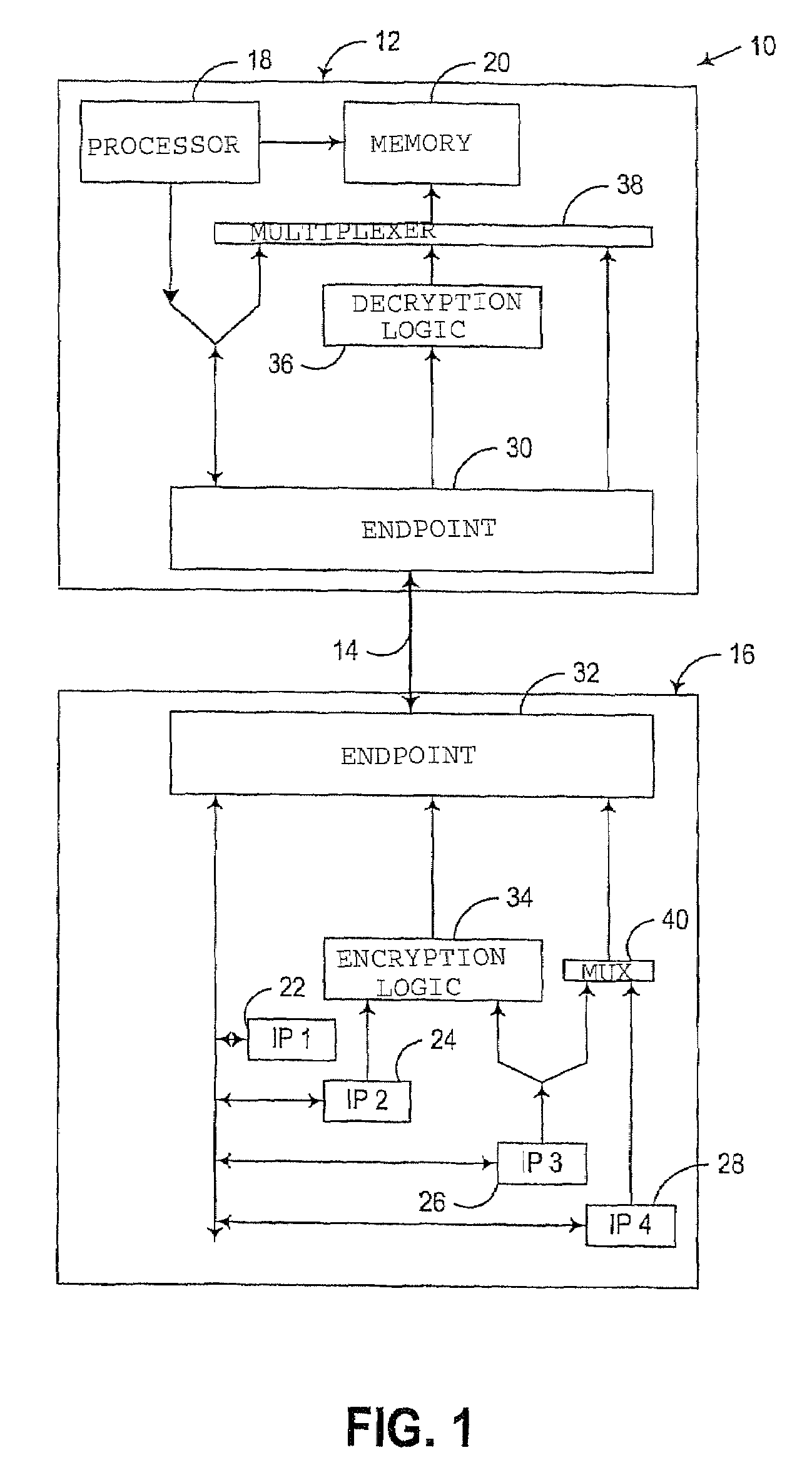

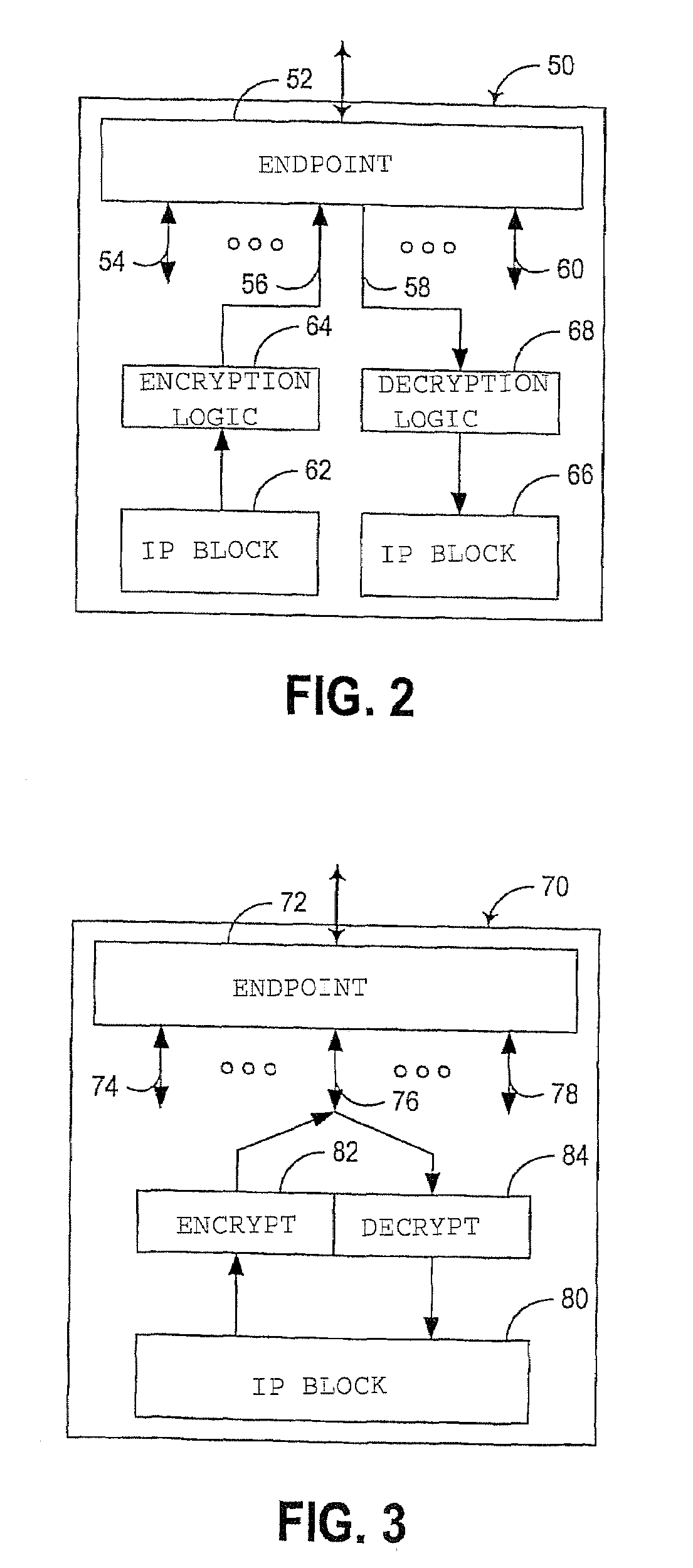

Dedicated encrypted virtual channel in a multi-channel serial communications interface

InactiveUS7673140B2Cost efficientProtection be often compromiseTelevision system detailsEncryption apparatus with shift registers/memoriesCommunication interfaceDigital data

A data processing system, circuit arrangement, and method to communicate data over a multi-channel serial communications interface (14) using a dedicated encrypted virtual channel from among multiple virtual channels supported by the communications interface (14). Encryption for the dedicated encrypted virtual channel is provided by a hardware encryption circuit (34) that is coupled to the interface, such that encryption may be performed at a relatively low level, and with substantial protection from compromise, particularly along chip boundaries. In one particular application, access control may be provided for a digital data stream using a multi-chip access control scheme that relies on one chip (148) to provide access control over a received digital data stream, with another chip (150) utilized to process the digital data stream once authorized to do so. A secure, multi-channel serial communications interface between the multiple chips re-encrypts a digital data stream that has been decrypted on the access control chip (148) using hardware encryption logic (162) disposed on the access control chip (148), communicates the re-encrypted digital data steam over a dedicated encryption virtual channel supported by the multi-channel serial communications interface, and decrypts the re-encrypted digital data steam using hardware decryption logic (164) disposed on the other chip (150).

Owner:ENTROPIC COMM INC

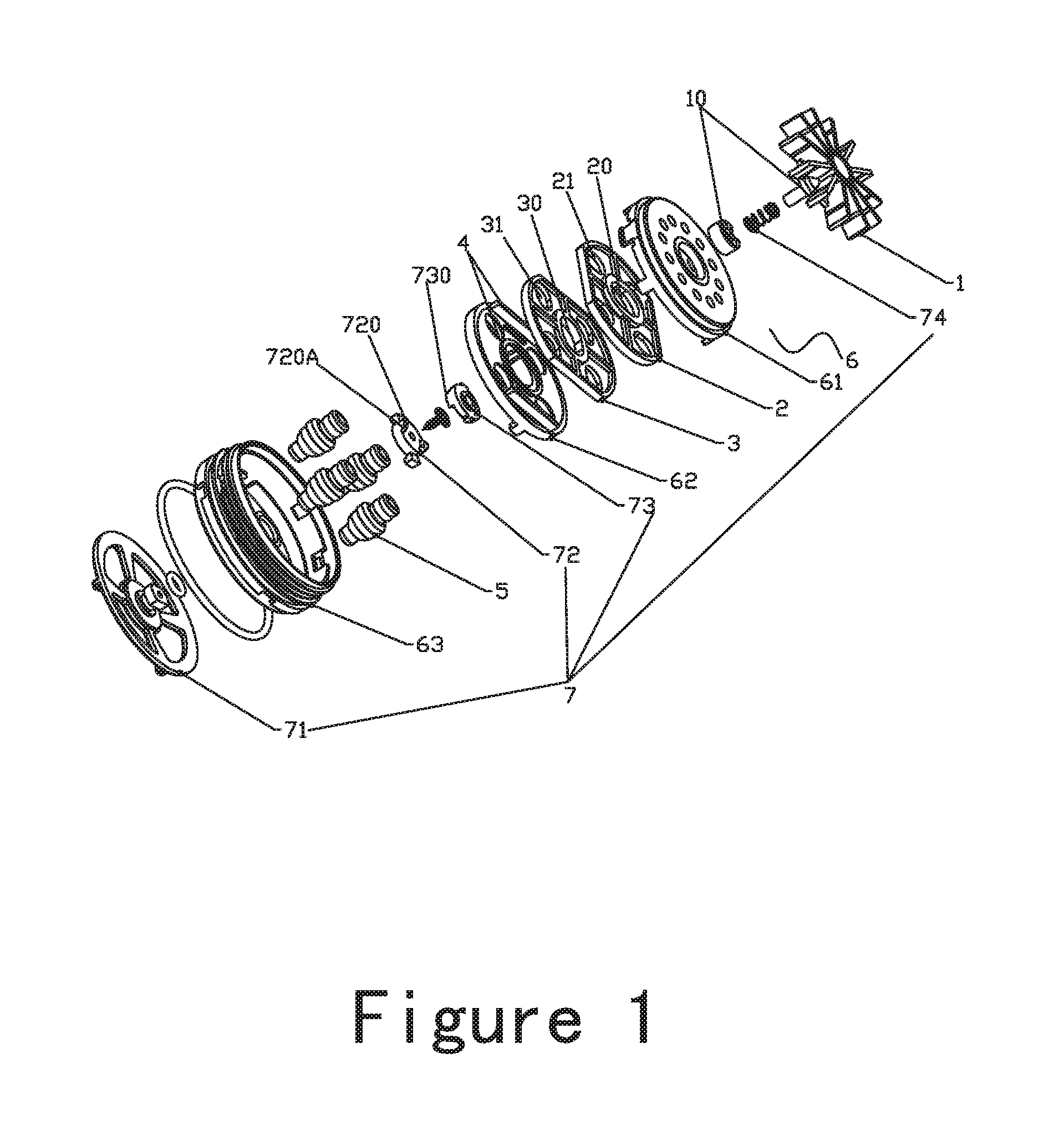

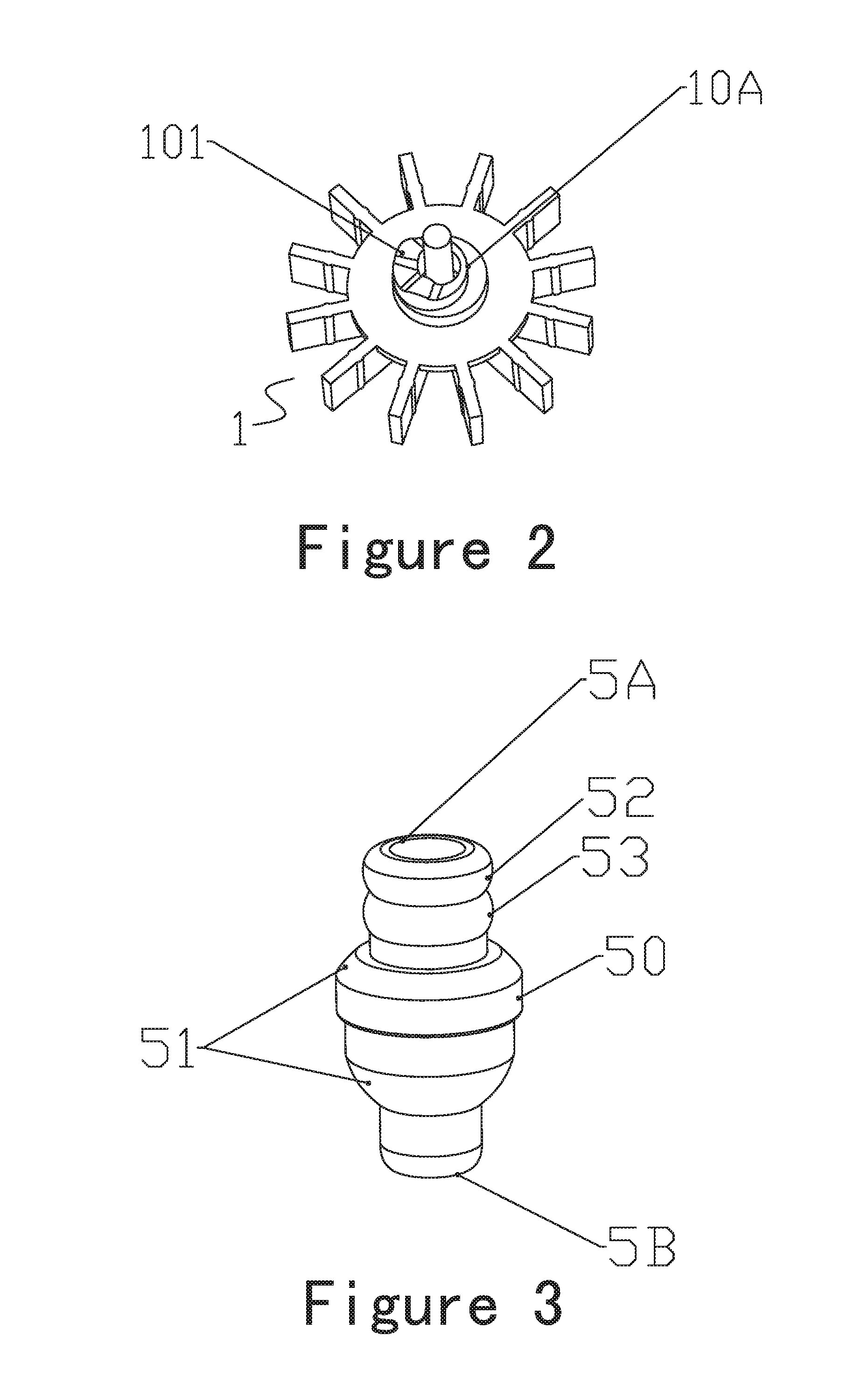

Water outlet device with rotary outlet function and a water outlet device with different water outlet means of function

ActiveUS20160228887A1Simple structureFew or no effectsMovable spraying apparatusSpray nozzlesWater flowEngineering

A water outlet device with rotary outlet function has a fixing part, a driving mechanism, a control mechanism, at least two sliding units and several water outlet nozzles, the water outlet nozzles are movably connected to the fixing part, the sliding unit can slide with respect to the fixing part; the driving mechanism can be driven by the water flow pressure, at least two sliding units are connected with the driving mechanism and driven by the driving mechanism to drive, and at least two sliding units are communicated with the water outlet nozzles in rotary manner around the rotating axis by intersection way. The control mechanism is connected with the driving mechanism and at least two sliding units to control at least one of sliding units to slide, the sliding action of the sliding units connected to the water outlet nozzles cause the water outlet nozzles to move.

Owner:FUJIAN XIHE SANITARY WARE TECH

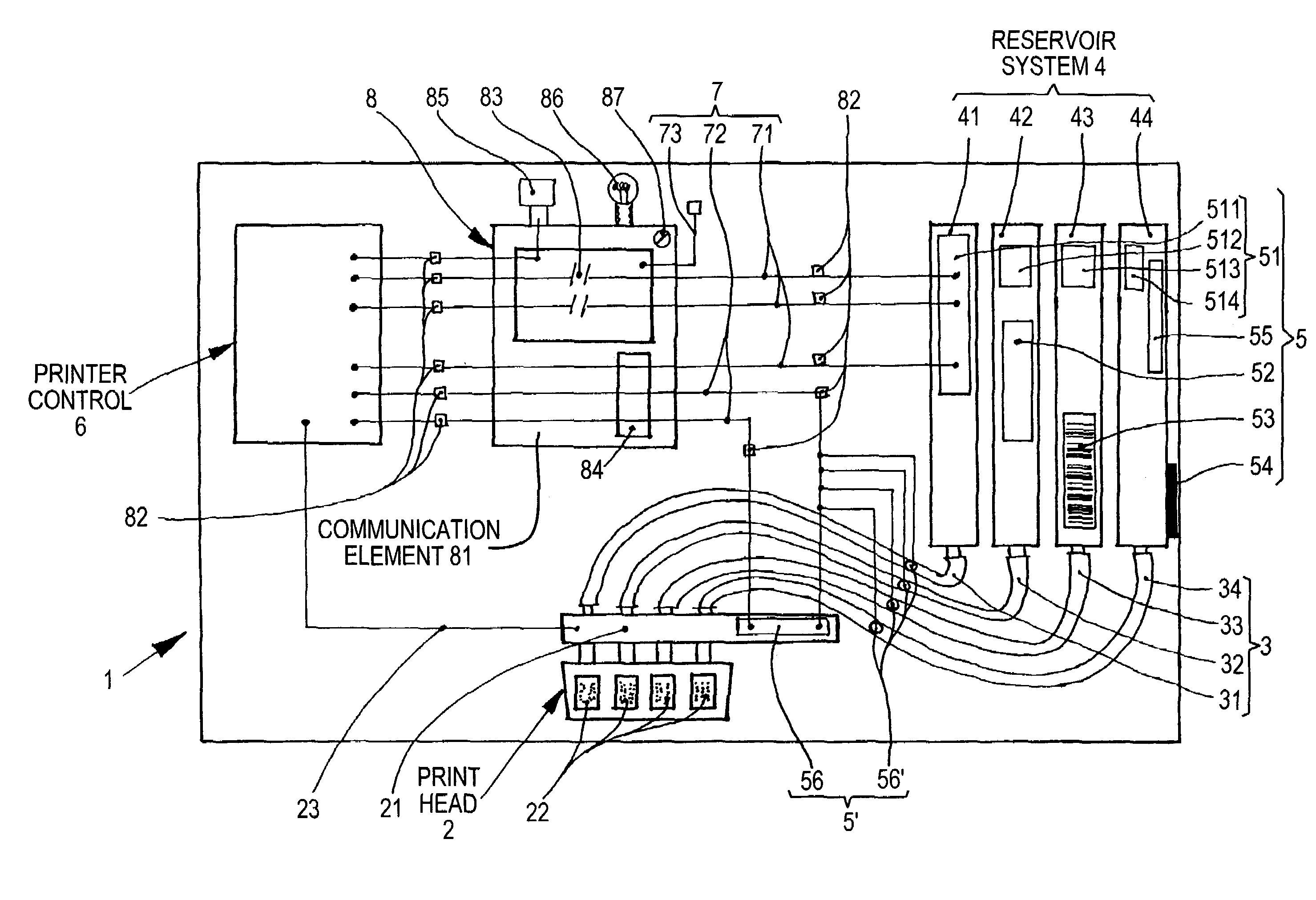

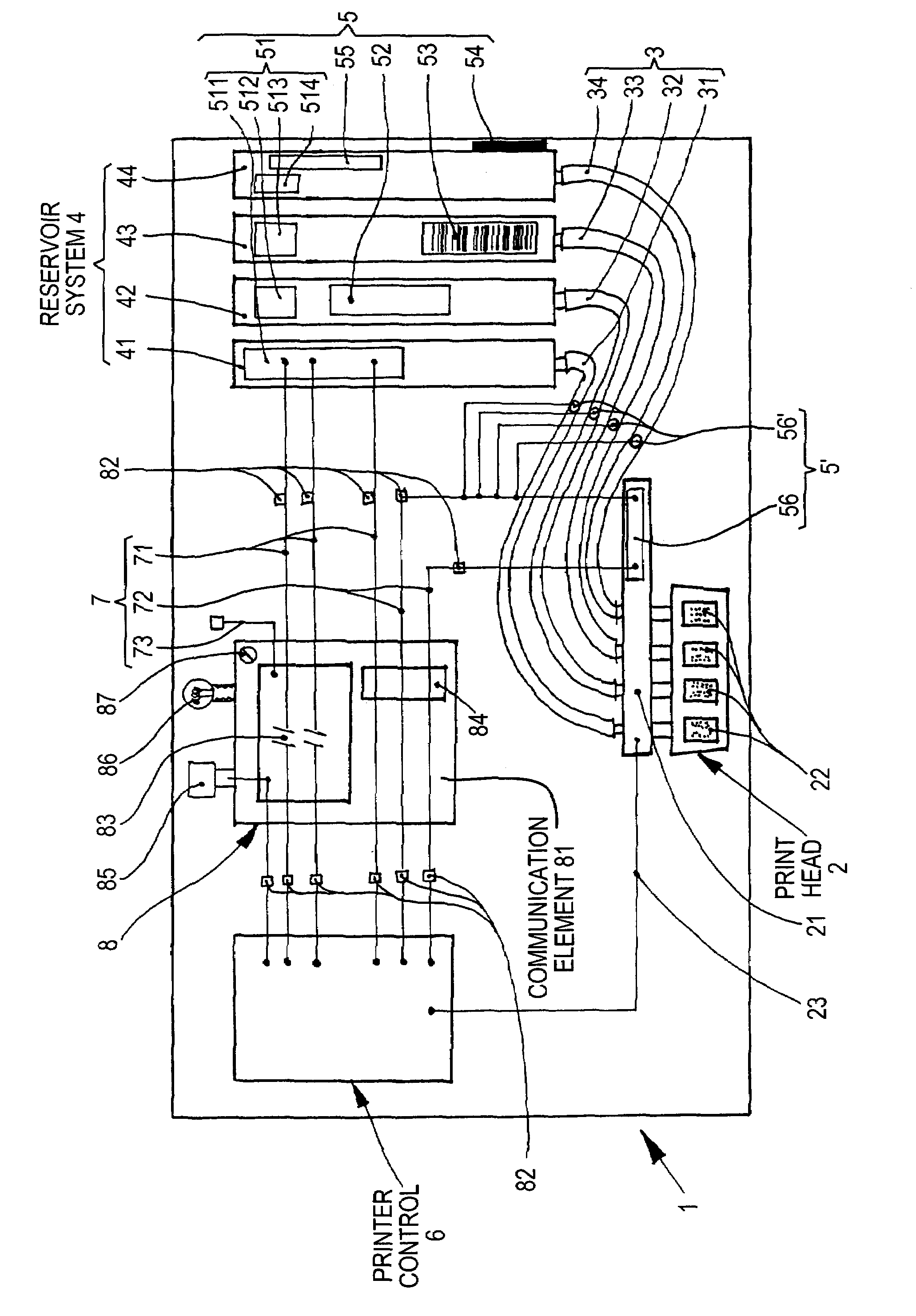

Printer or other automatic printing system with additional control device and control device therefor

InactiveUS7286249B2Simple and easySave a lot of costDigitally marking record carriersDigital computer detailsCommunications systemReservoir system

A printing system has at least one print head, a refillable or exchangeable ink reservoir or reservoir system, an electronic device for printing, a communication system as a control device for transmitting, blocking, and processing different signals, pulses, information, and data. The communication system is connected to the electronic device for printing and the ink reservoir or the reservoir system.

Owner:J S STAEDTLER

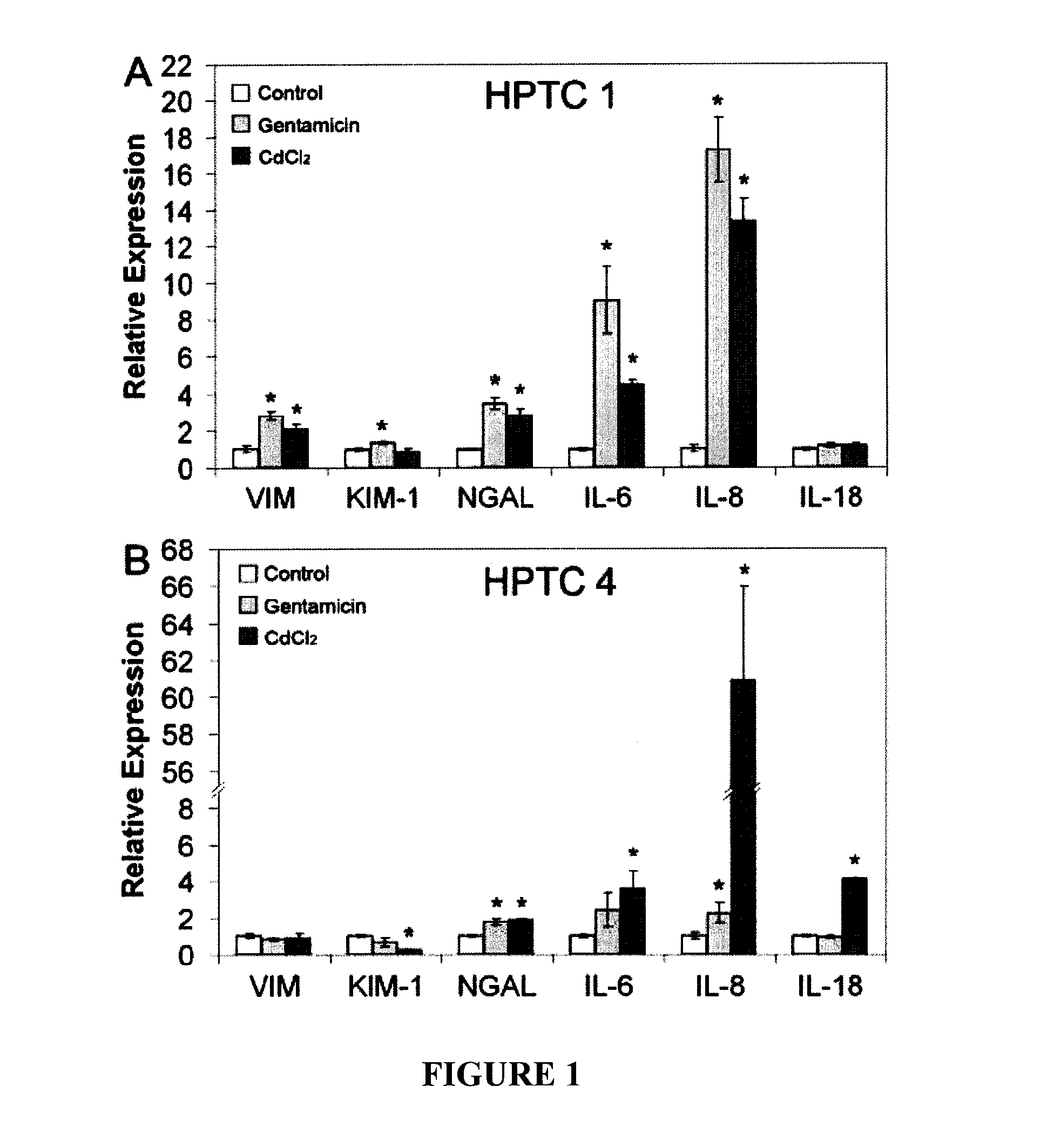

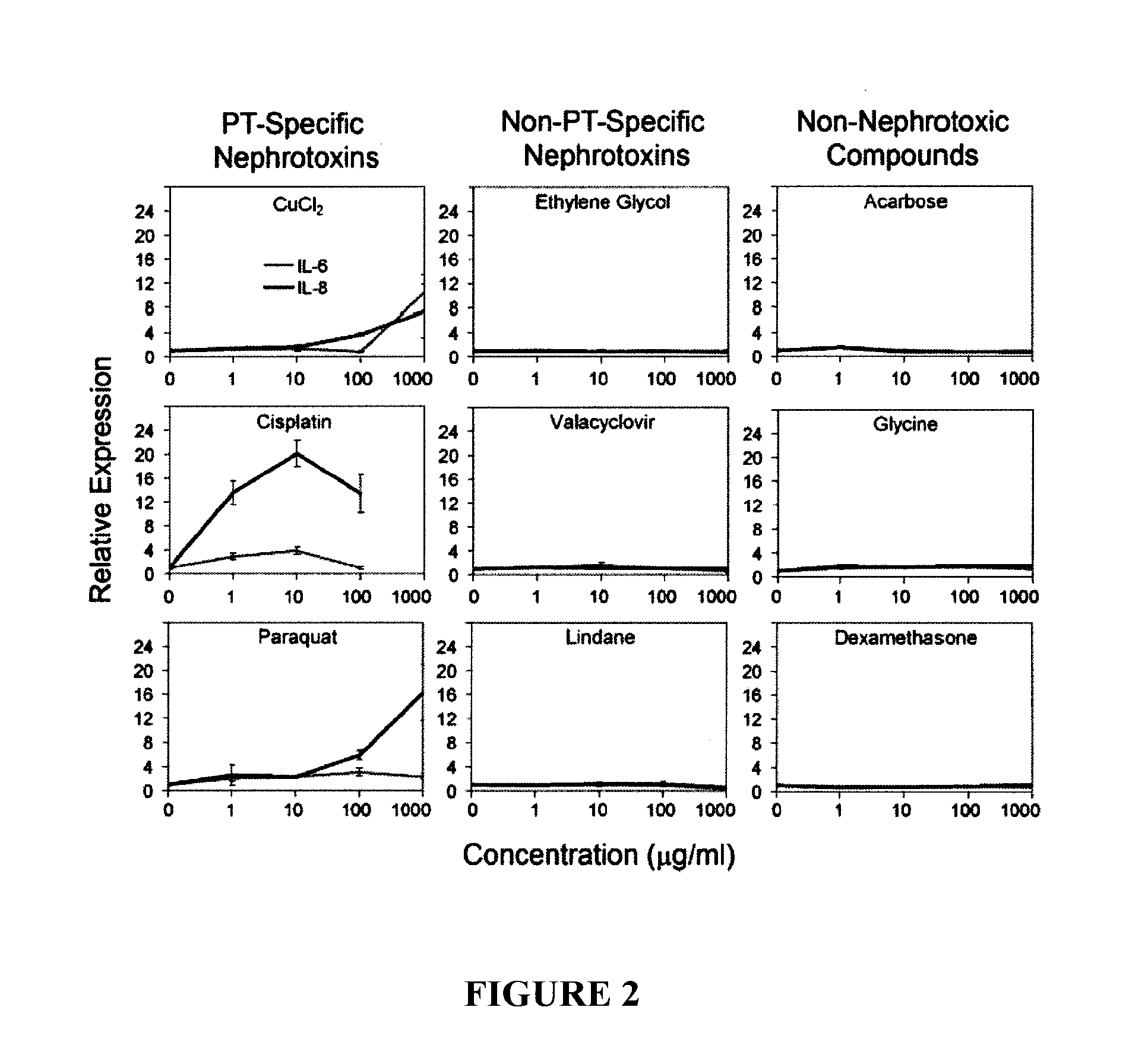

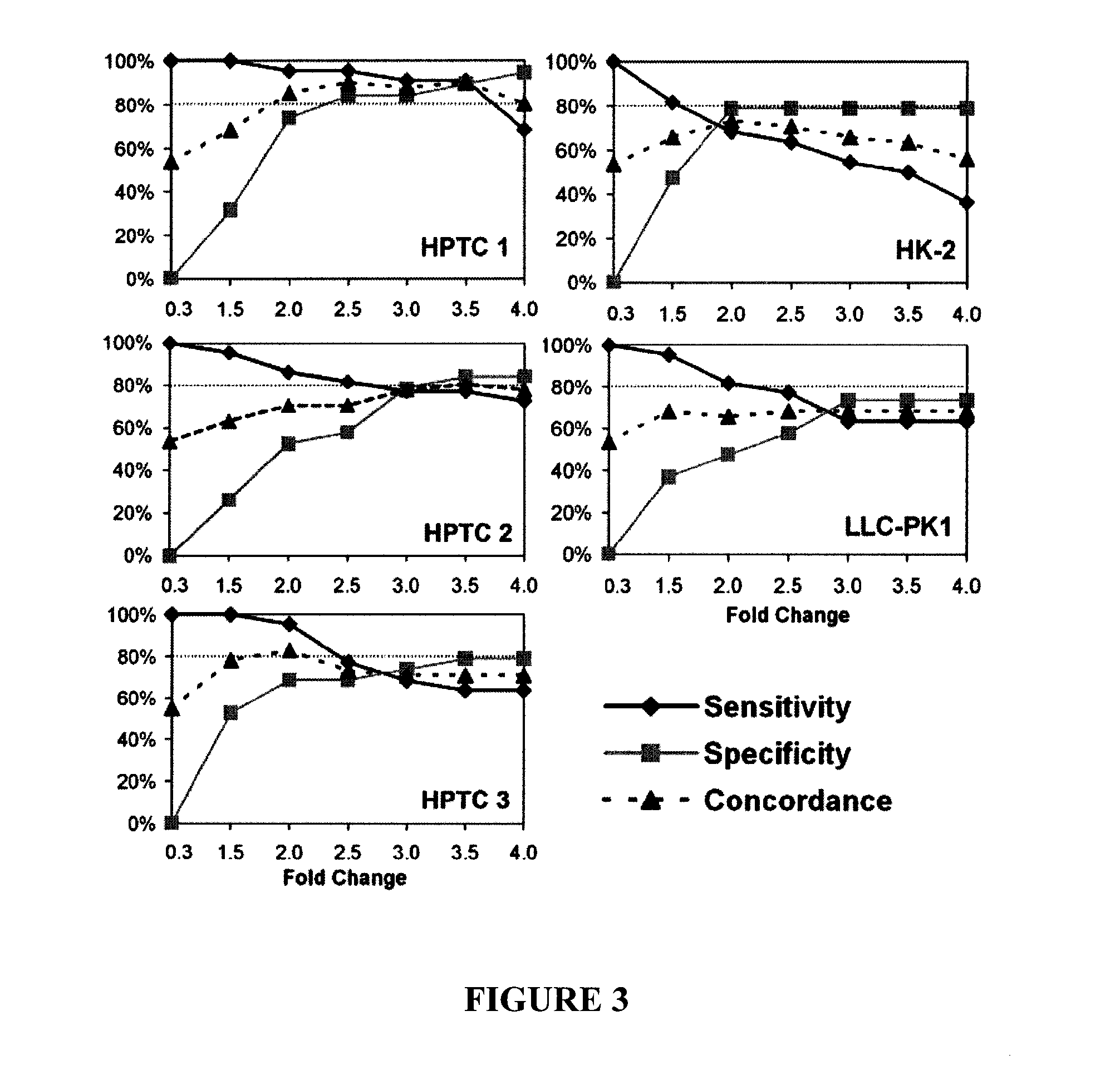

In vitro assay for predicting renal proximal tubular cell toxicity

InactiveUS20150197802A1Save a lot of costEarly detectionMicrobiological testing/measurementLibrary screeningInterleukin 6Interleukin 8

There is provided an in vitro assay for screening a test compound for toxicity in renal proximal tubular cells. The method comprises contacting a test compound with a test population of renal proximal tubular cells; and determining the expression level of an interleukin in the test population, the interleukin being interleukin-6 (IL-6) or interleukin-8 (IL-8), or both. Expression levels of the interleukin in the test population being greater than expression levels in a control population of renal proximal tubular cells not contacted with the test compound is indicative that the test compound is toxic for renal proximal tubular cells.

Owner:AGENCY FOR SCI TECH & RES

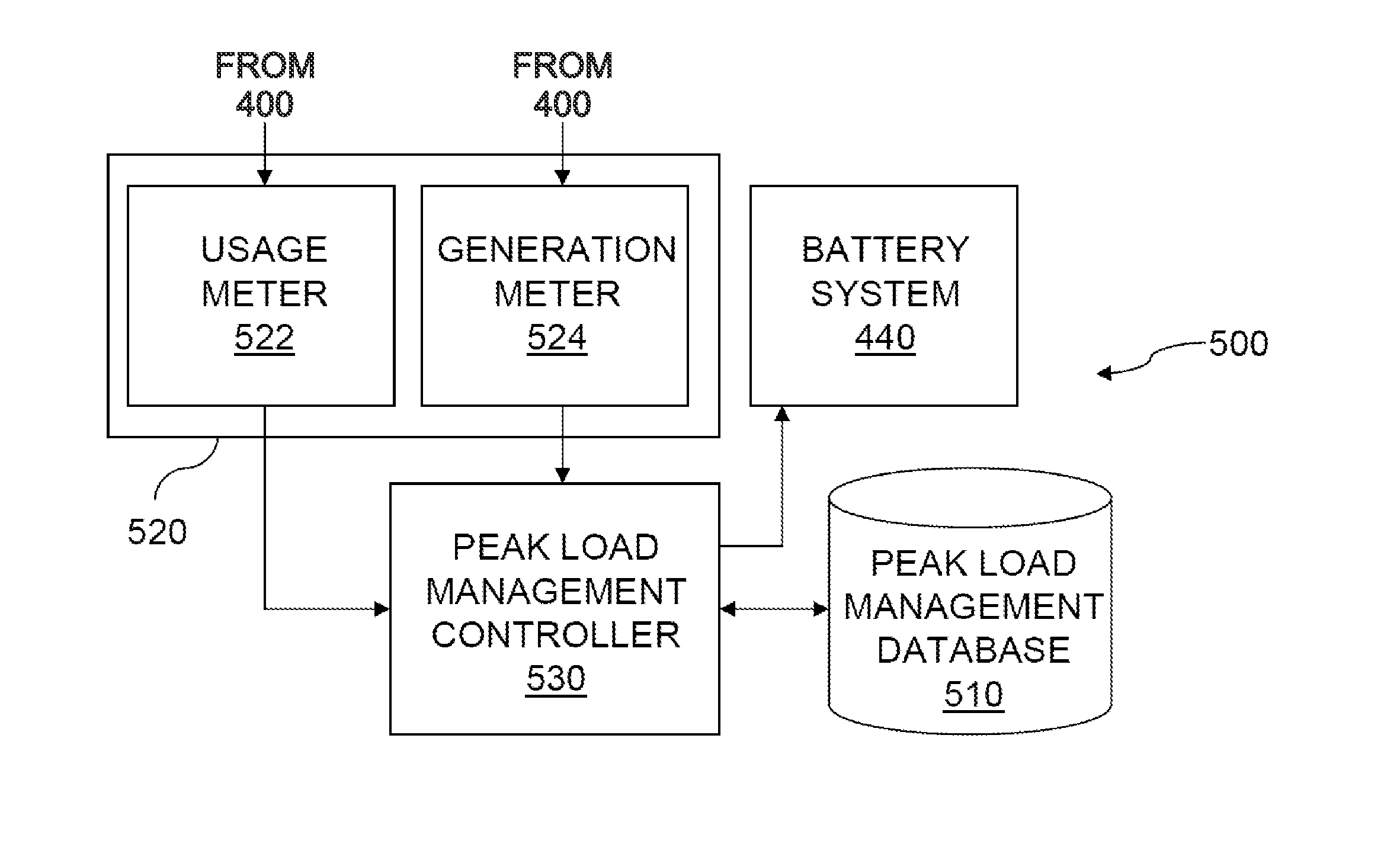

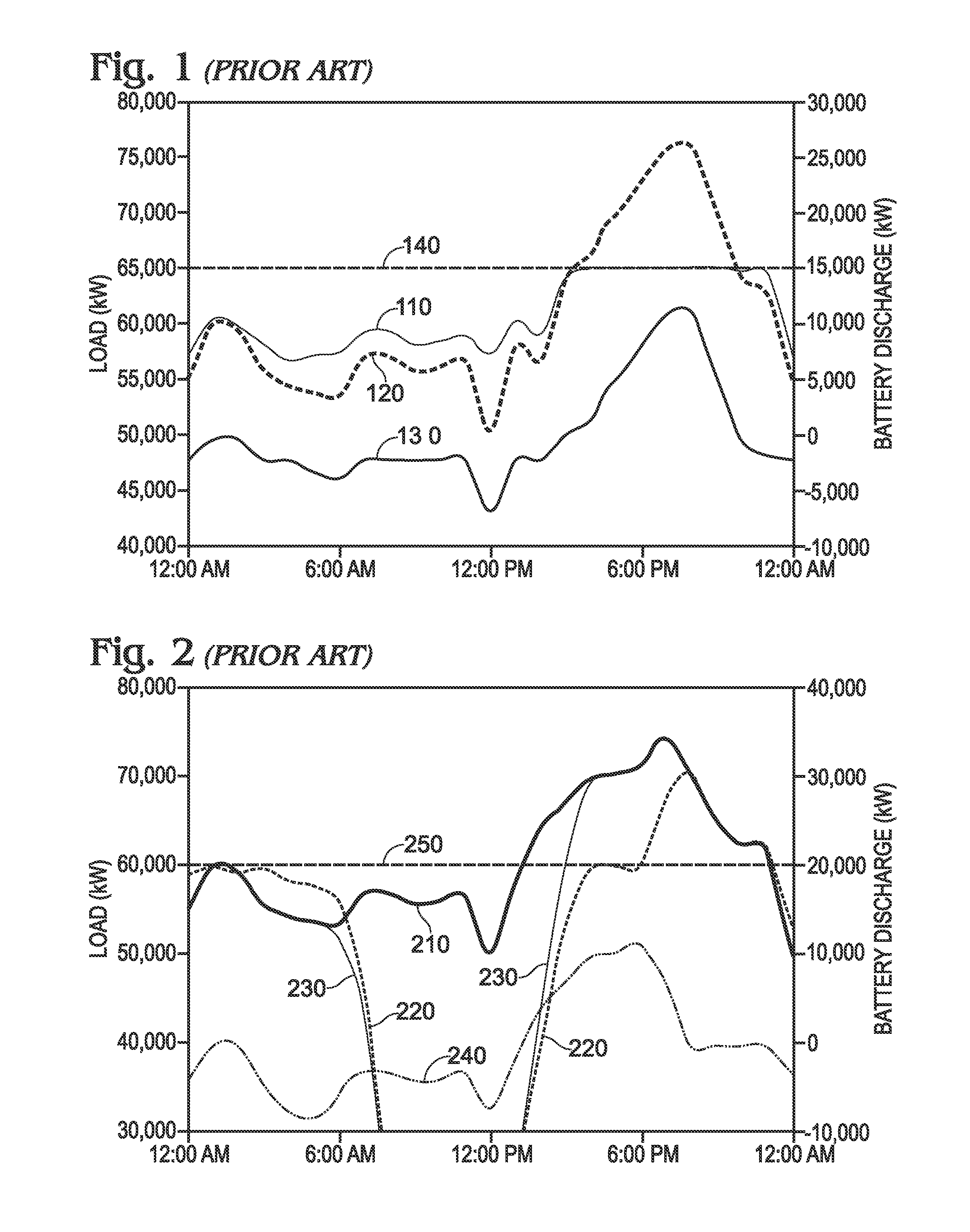

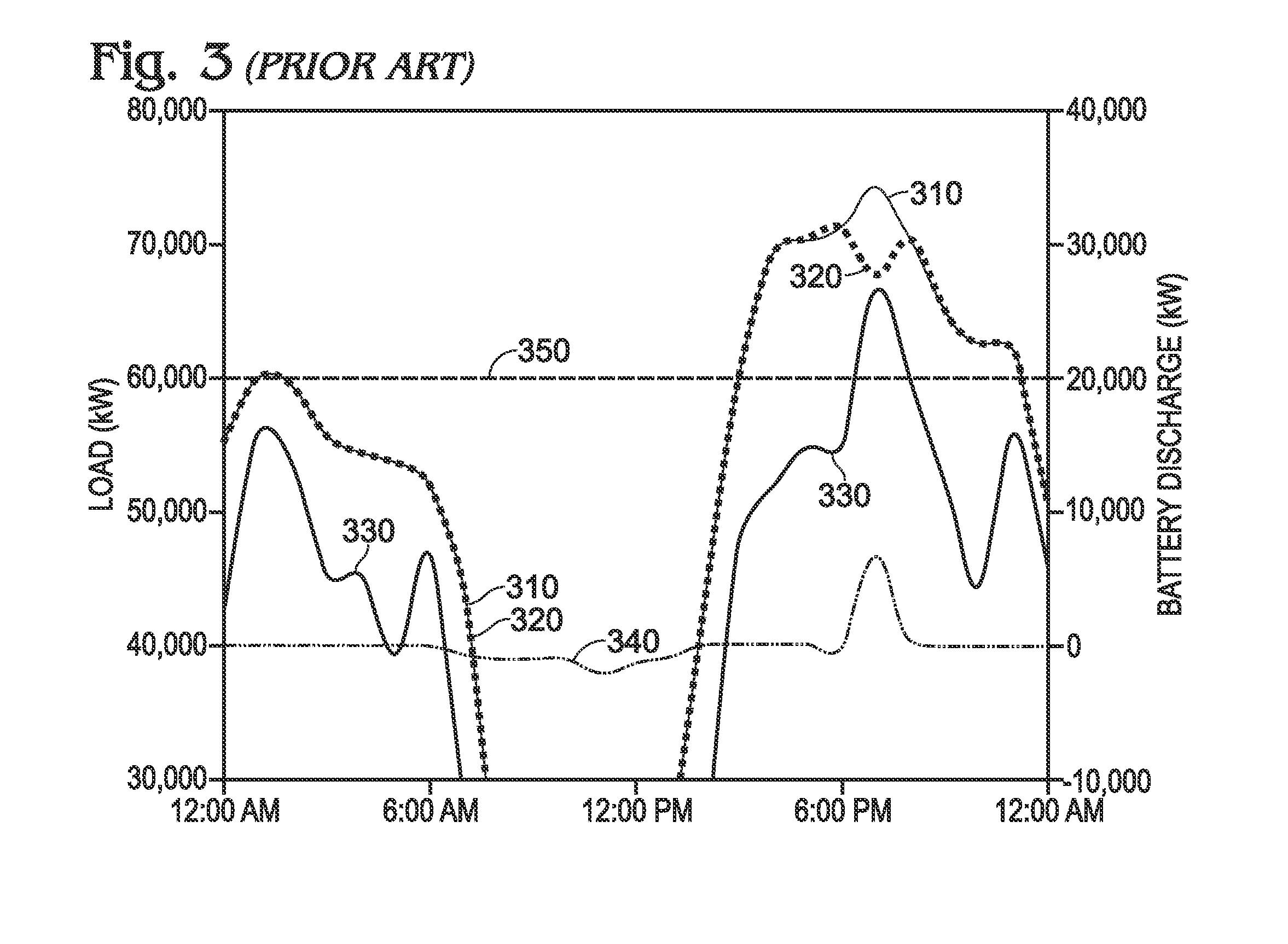

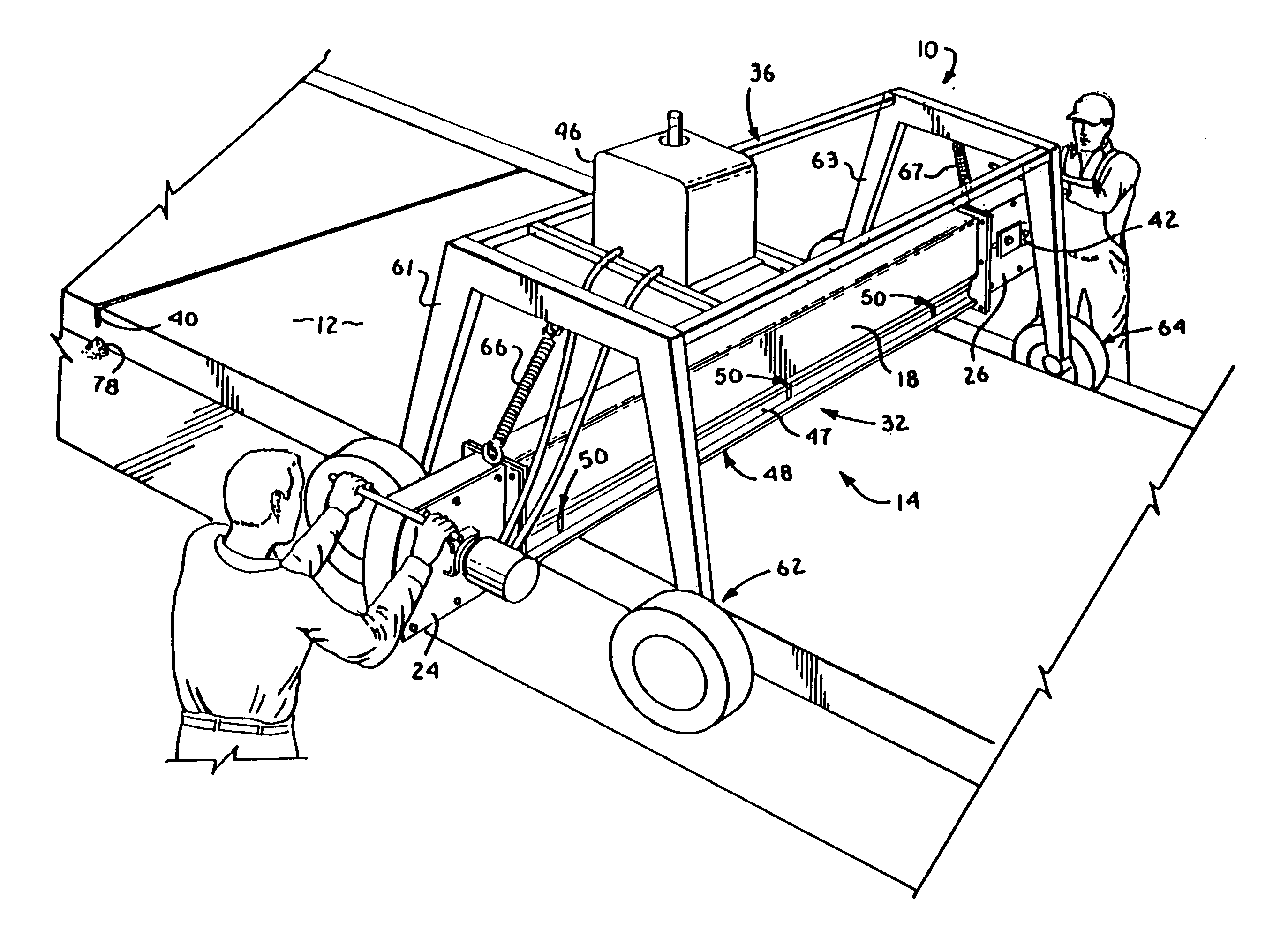

Method and System for Mitigating Impact of Malfunction in Actual Load Determination on Peak Load Management

InactiveUS20130325198A1Reduce the impactSave a lot of costMechanical power/torque controlLevel controlEngineeringPeak load

Method and system for mitigating the impact on peak load management of a malfunction in determining actual load at a site by substituting a predicted load for actual load while the malfunction persists. Using a predicted load as a substitute for actual load during the malfunction period avoids use of a grossly overestimated or underestimated actual load that if used could cause suboptimal use of battery power and decimate cost savings from peak load management.

Owner:NANTENERGY INC

Apparatus for cutting concrete using abrasive cable

InactiveUS20050229915A1Minimizes spallingMinimizes chippingCeramic shaping apparatusStone-like material working toolsClosed loopEngineering

An apparatus for cutting large horizontal slabs of green or uncured concrete, such as roadways, with a single downward motion. The apparatus broadly comprises a cutting head including a cutting element, a drive pulley, an outboard pulley, and a foot structure; a drive motor; and a moveable support carriage. The cutting element is a closed loop of diamond wire entrained about the drive and outboard pulleys, with the drive pulley being driven by the drive motor. The foot structure includes a channel-shaped foot structure having two horizontally-extending flanges that function to minimizes spalling or chipping during cutting. The carriage movably supports the cutting head and the motor on inboard and outboard rolling elements, such as wheels or tracks, that allow for rolling movement over and along the concrete slab. The carriage also allows for lowering and raising the cutting element to engage and disengage the concrete slab during cutting.

Owner:VANGUNDY JEFFERY R

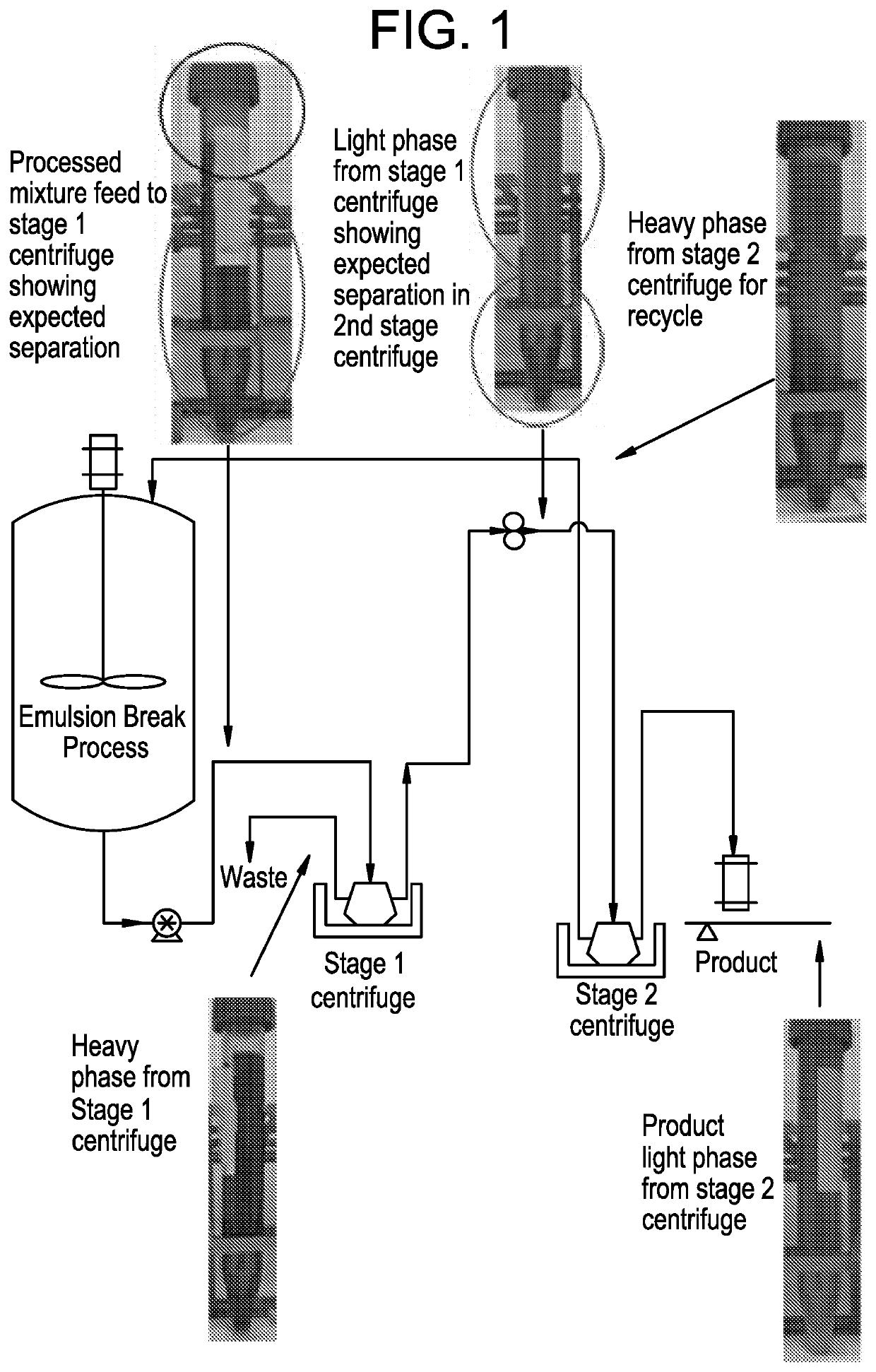

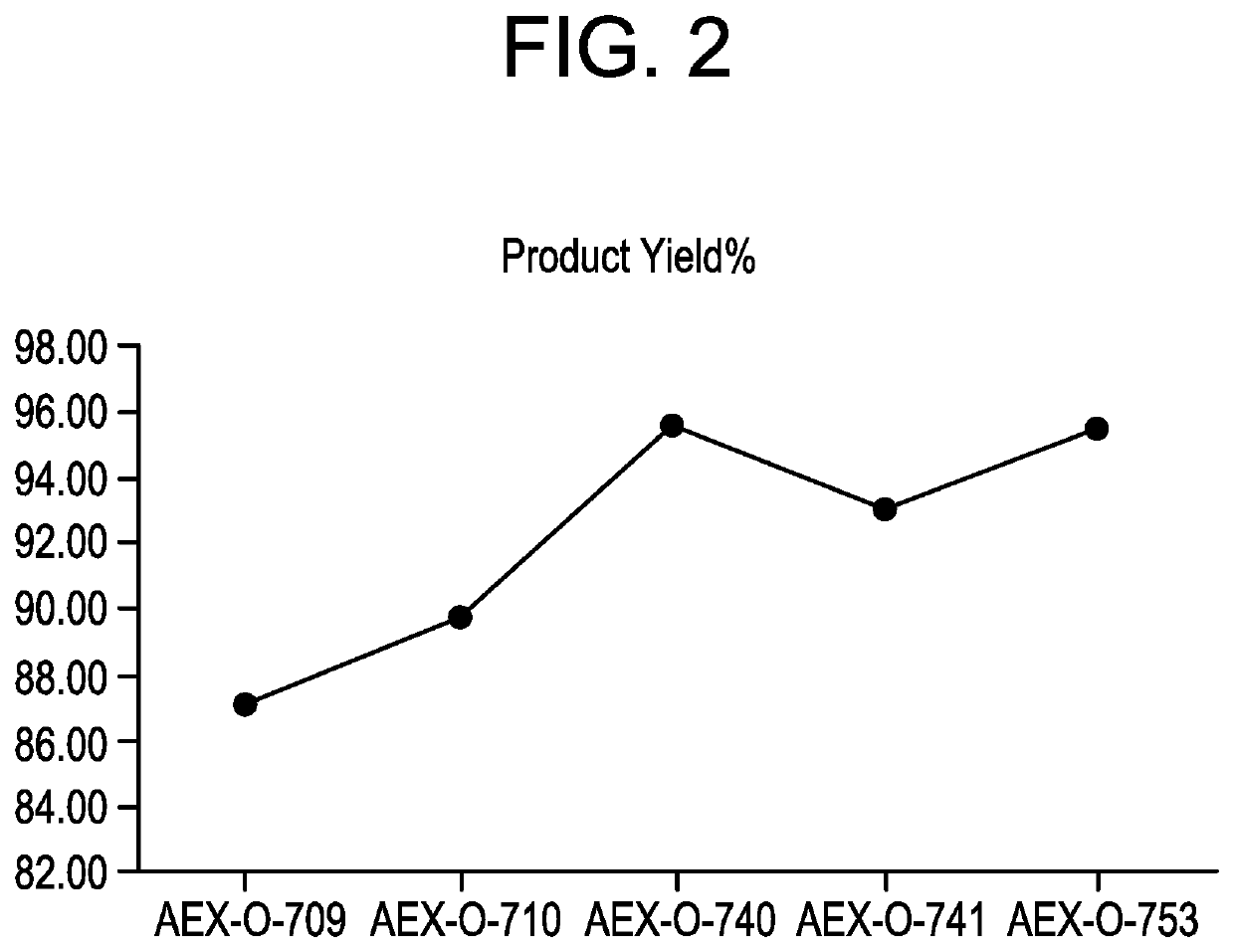

Double centrifugation process for nutritive oil purification

PendingUS20200362373A1Quality improvementLosing on oil yieldCentrifugal force sediment separationFermentationFermentation brothBiotechnology

This invention relates to a method of using a two-step serial centrifugation process in extracting nutritive oil from a fermentation broth, this novel method prevents oil yield losses while preserving product quality.

Owner:EVONIK OPERATIONS GMBH +1

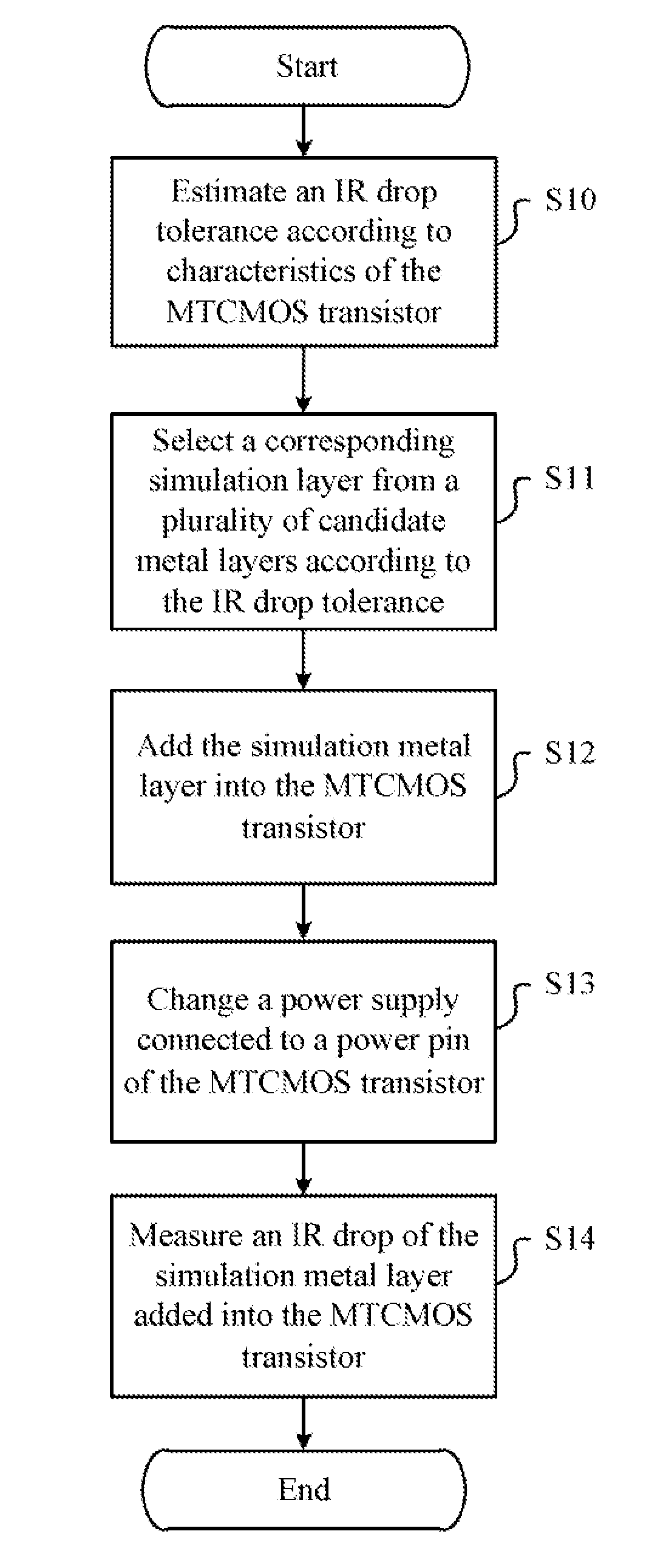

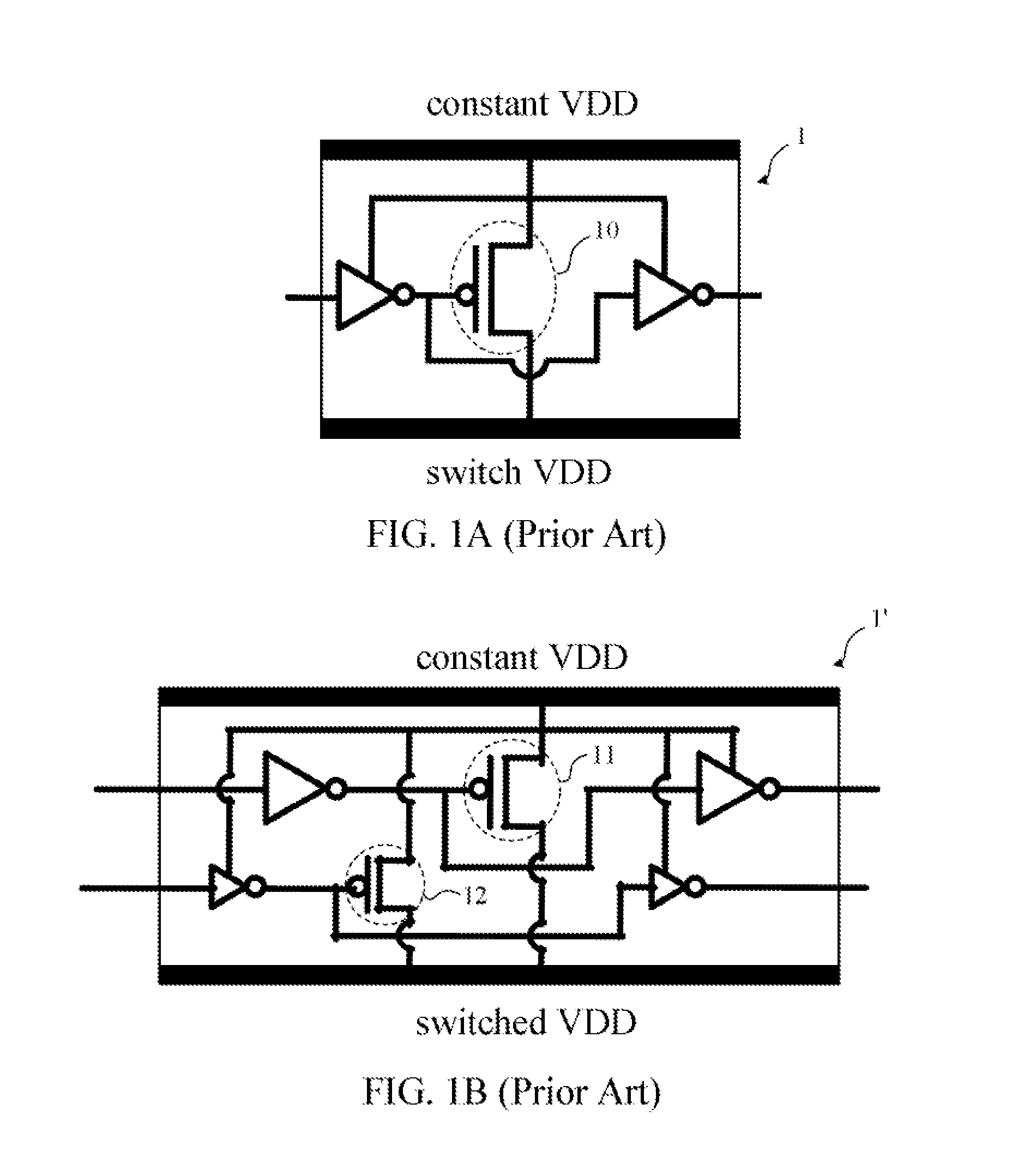

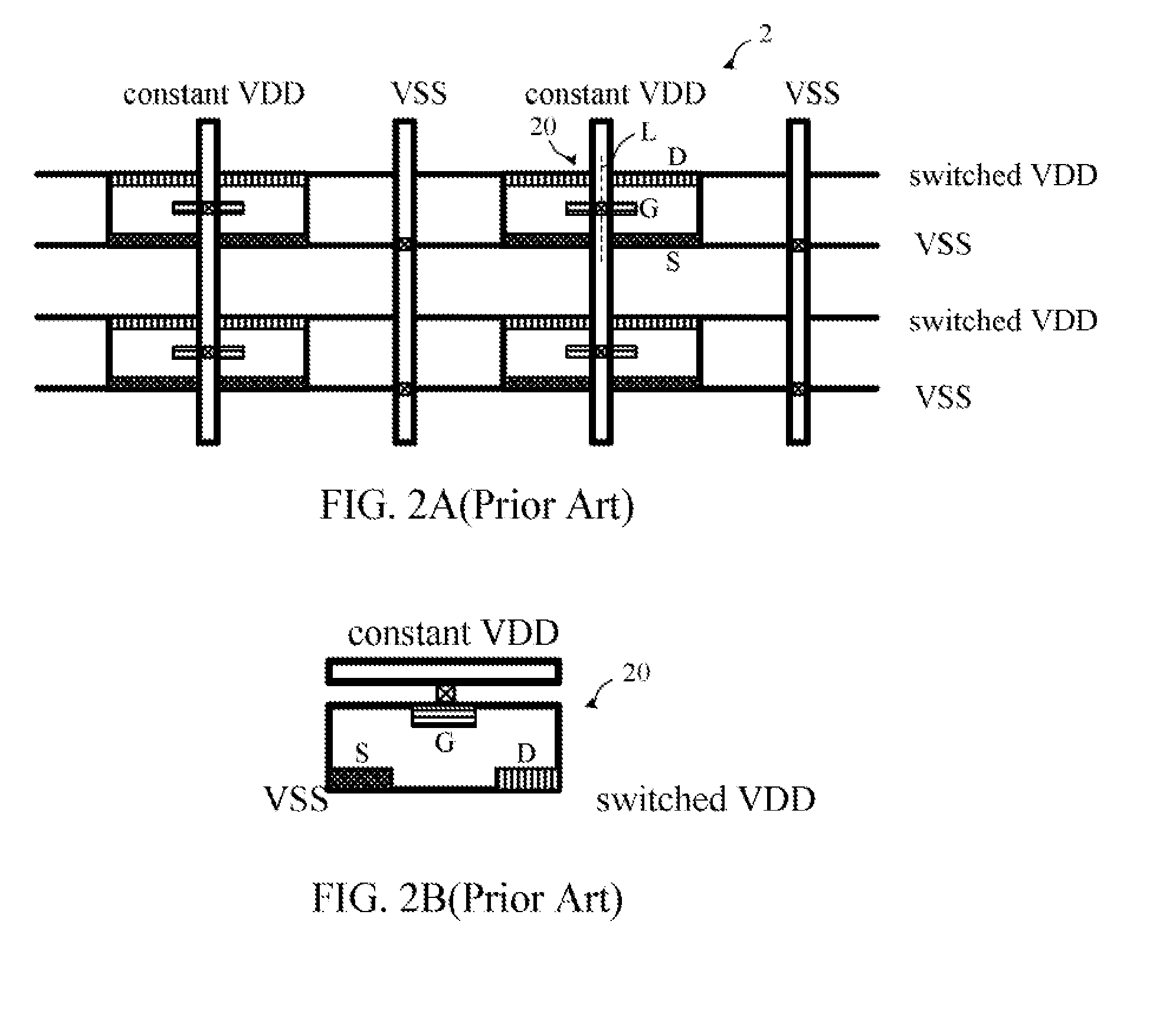

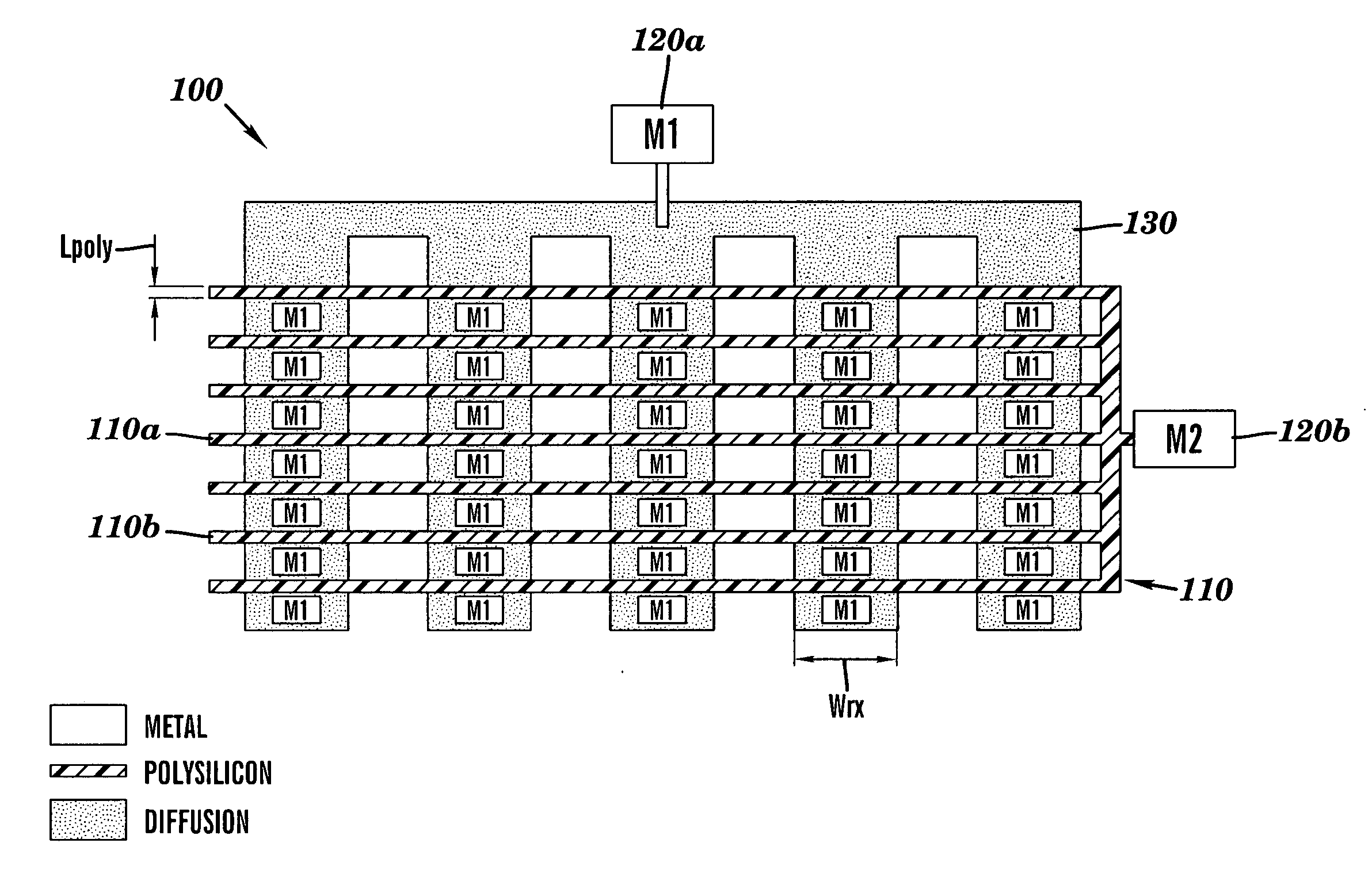

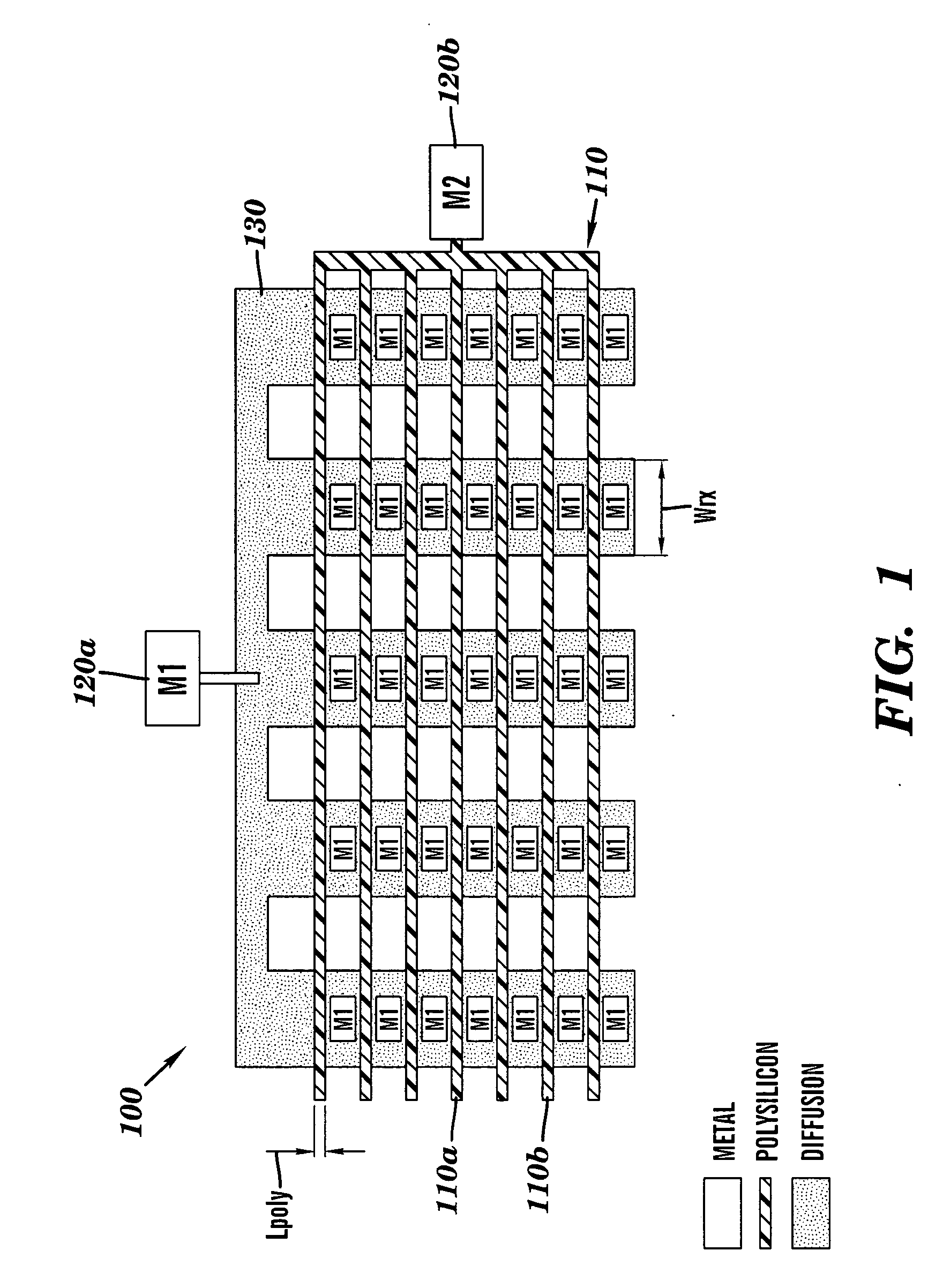

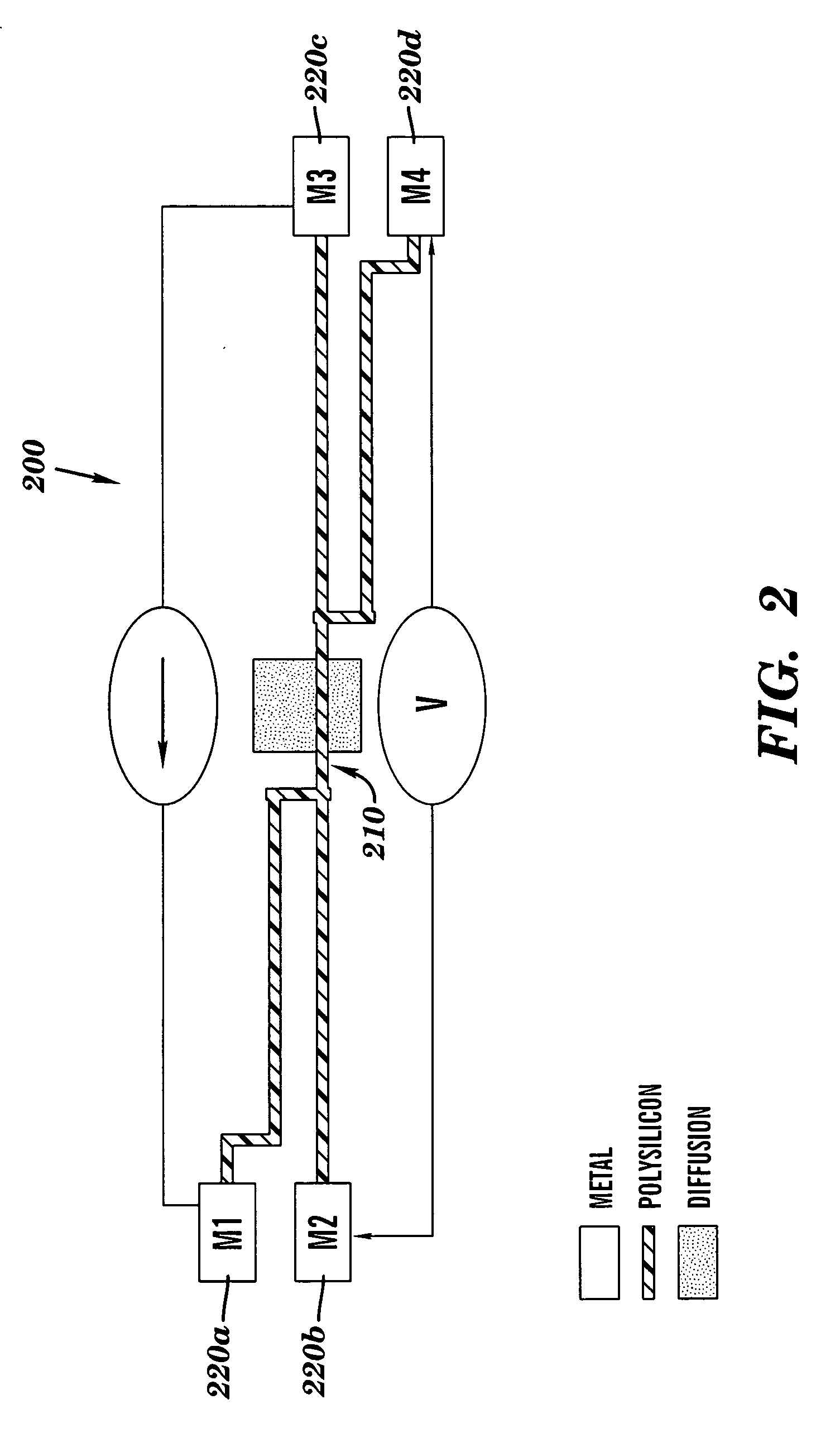

Static IR (voltage) drop Analyzing Apparatus and Associated Method

ActiveUS20110153303A1Accurate measurementSave a lot of costComputer aided designSpecial data processing applicationsVoltage dropComputer module

A static voltage drop analyzing apparatus applied to a Multi-Threshold Complementary Metal-Oxide-Semiconductor (MTCMOS) transistor is provided. The static voltage drop analyzing apparatus includes a calculating module, a processing module, and a measuring module. The calculating module calculates a voltage drop tolerance according to the voltage drop characteristic of the MTCMOS transistor. The processing module selects a simulation metal layer corresponding to the voltage drop tolerance from a plurality of candidate simulation metal layers, and adds the simulation metal layer into the MTCMOS transistor. The measuring module measures the voltage drop of the simulation metal layer added into the MTCMOS transistor. The measured voltage drop of the simulation layer added into the MTCMOS is substantially the static voltage drop of the MTCMOS transistor.

Owner:MEDIATEK INC

Sulodexide production method

ActiveCN104398533ASolve financial and material resourcesSave a lot of costOrganic active ingredientsBlood disorderDermatan sulfateHeparin

The invention discloses a sulodexide production method and belongs to the technical field of bio-pharmaceuticals. The sulodexide production method comprises the following steps: using a heparin byproduct as a raw material, and performing oxidization to obtain an intermediate crude product heparin solution; adding acetate into the intermediate crude product heparin solution, and separating by ultra-filtration to obtain a rapid movement heparin crude product and a dermatan sulfate crude product; then respectively refining a rapid movement heparin crude product and a dermatan sulfate crude product; performing refinement on the rapid movement heparin crude product and the dermatan sulfate crude product; finally mixing and dissolving precipitates obtained by refining, filtering, collecting a filtrate, and carrying out freeze-drying processing to obtain a sulodexide raw material. The method has the advantages that product purity and stability are improved; as the byproduct produced during the production of heparin is used as the raw material, the production cost is reduced, required production equipment is simple, and production conditions are easy to control.

Owner:SHANDONG CHENZHONG BIOPHARM +1

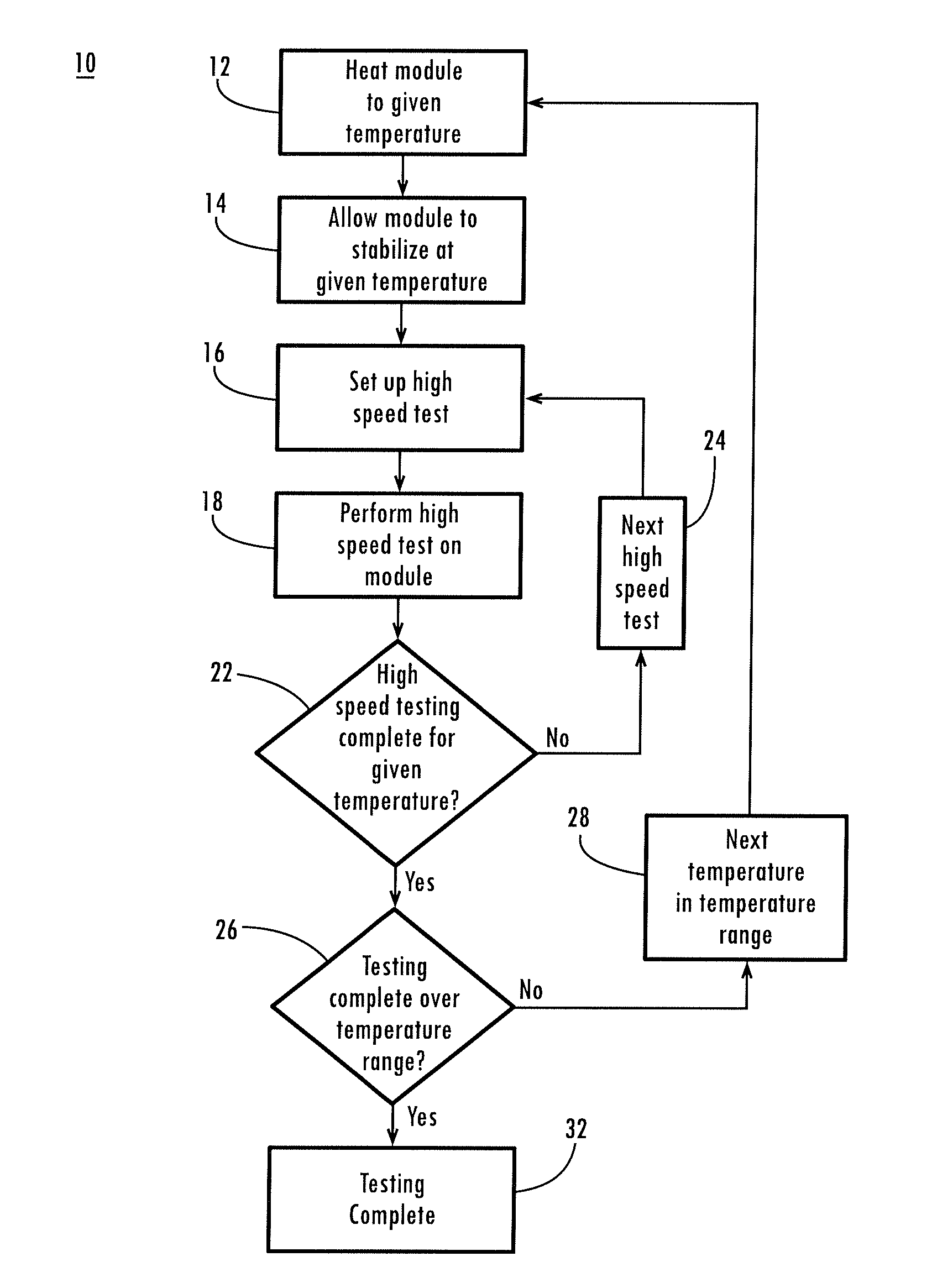

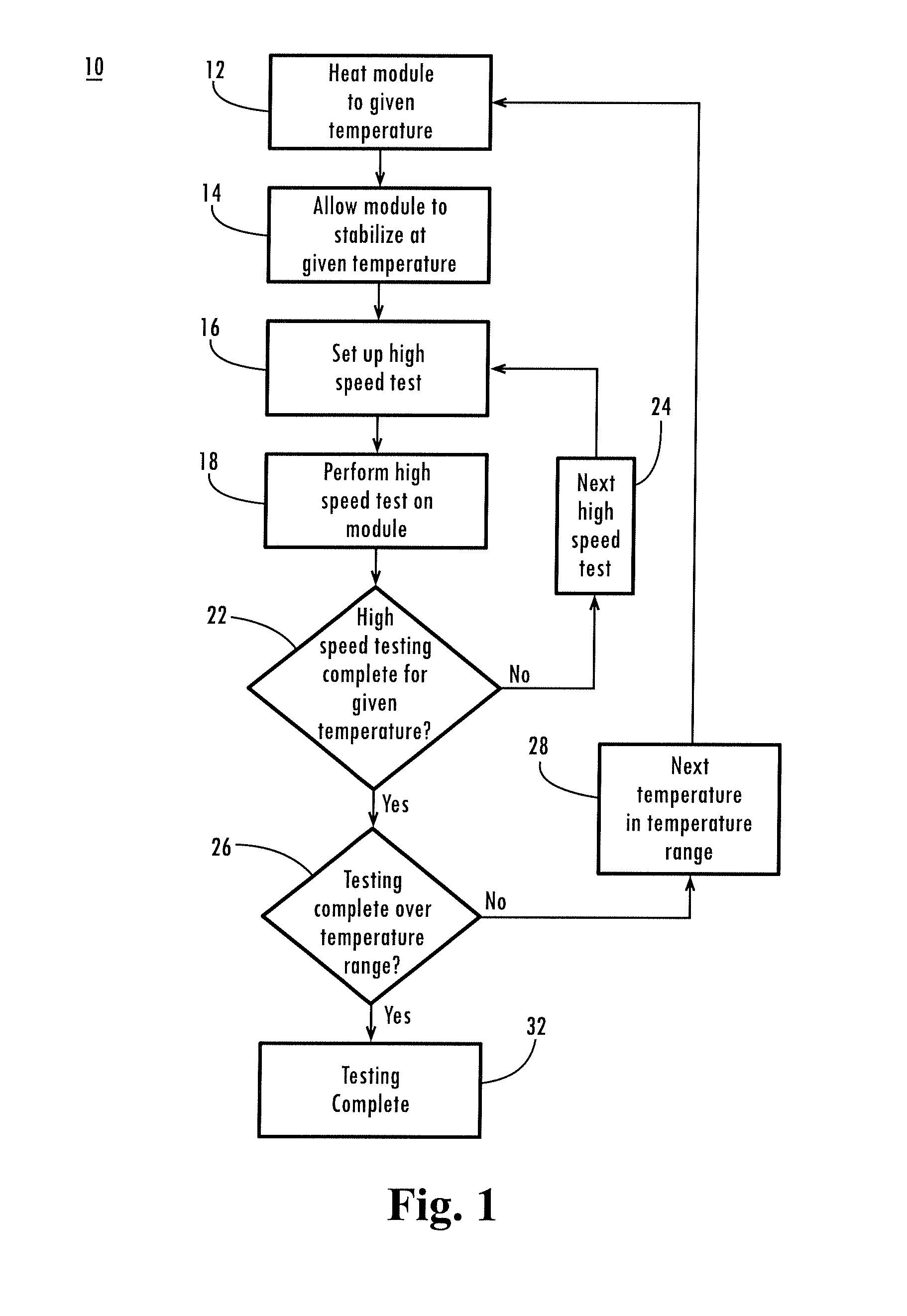

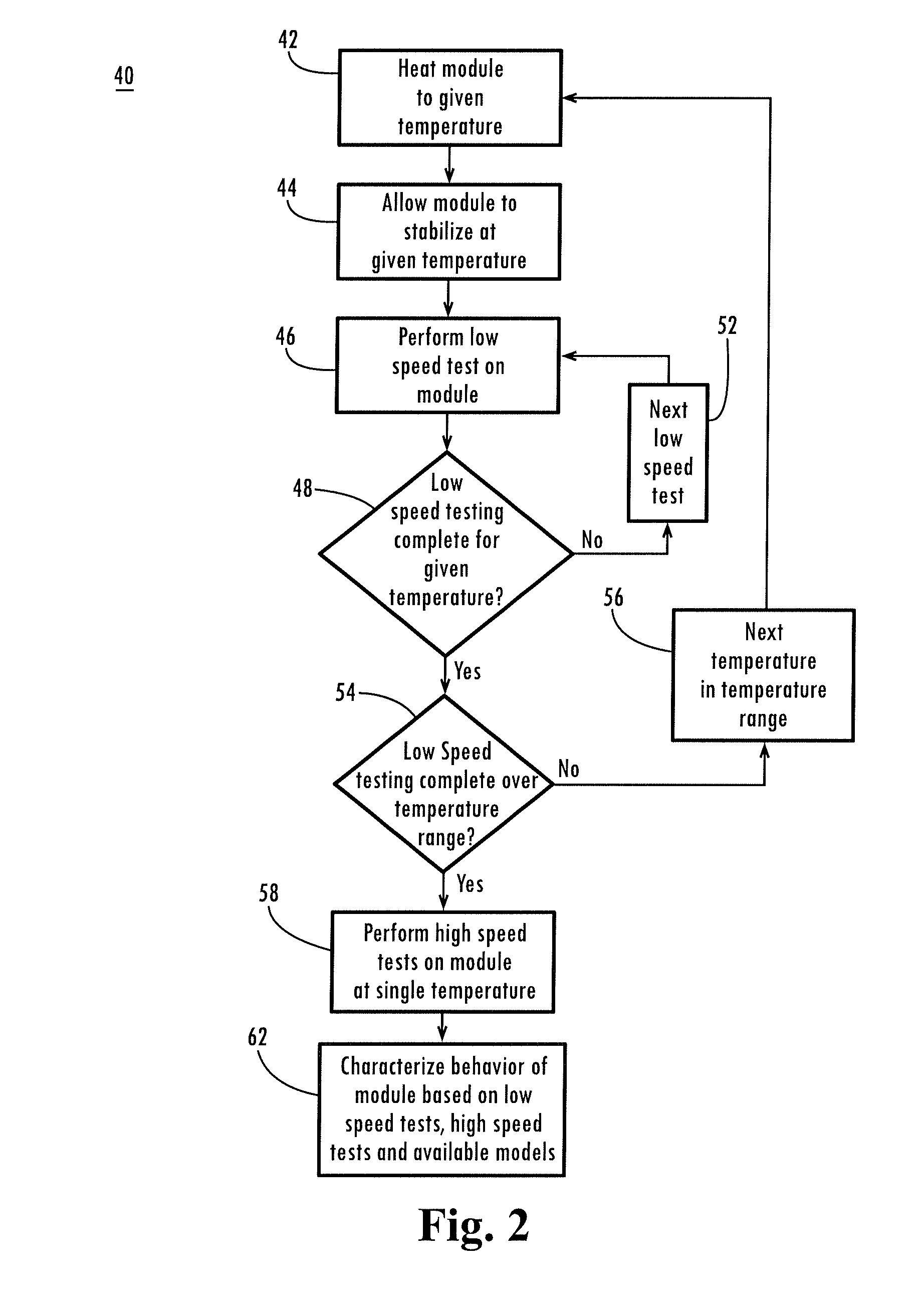

Method for measuring the high speed behavior of fiber optic transceivers

InactiveUS20080145059A1Save a lot of costImprove speed performanceTransmission monitoringTransmission monitoring/testing/fault-measurement systemsFiberLow speed

A method for measuring the high speed behavior of fiber optic transceivers and transceiver modules. The method includes providing a fiber optic transceiver, performing one or more low speed performance tests on the fiber optic transceiver at each of a plurality of temperatures across transceiver operating temperature range, and performing a high speed performance test suite on the fiber optic transceiver at a single temperature within the testing temperature range. Based on the low speed performance tests and the high speed performance test suite at the single temperature, the method can determine, via calculation, approximation or prediction, the high speed behavior of the transceiver over temperature. The basis for determining the high speed behavior of the transceiver also can include the measured or available modeled relationships of high speed performance characteristics of at least a portion of the transceiver to the temperature-dependent parameters measured in the low speed performance tests.

Owner:BROADCOM INT PTE LTD

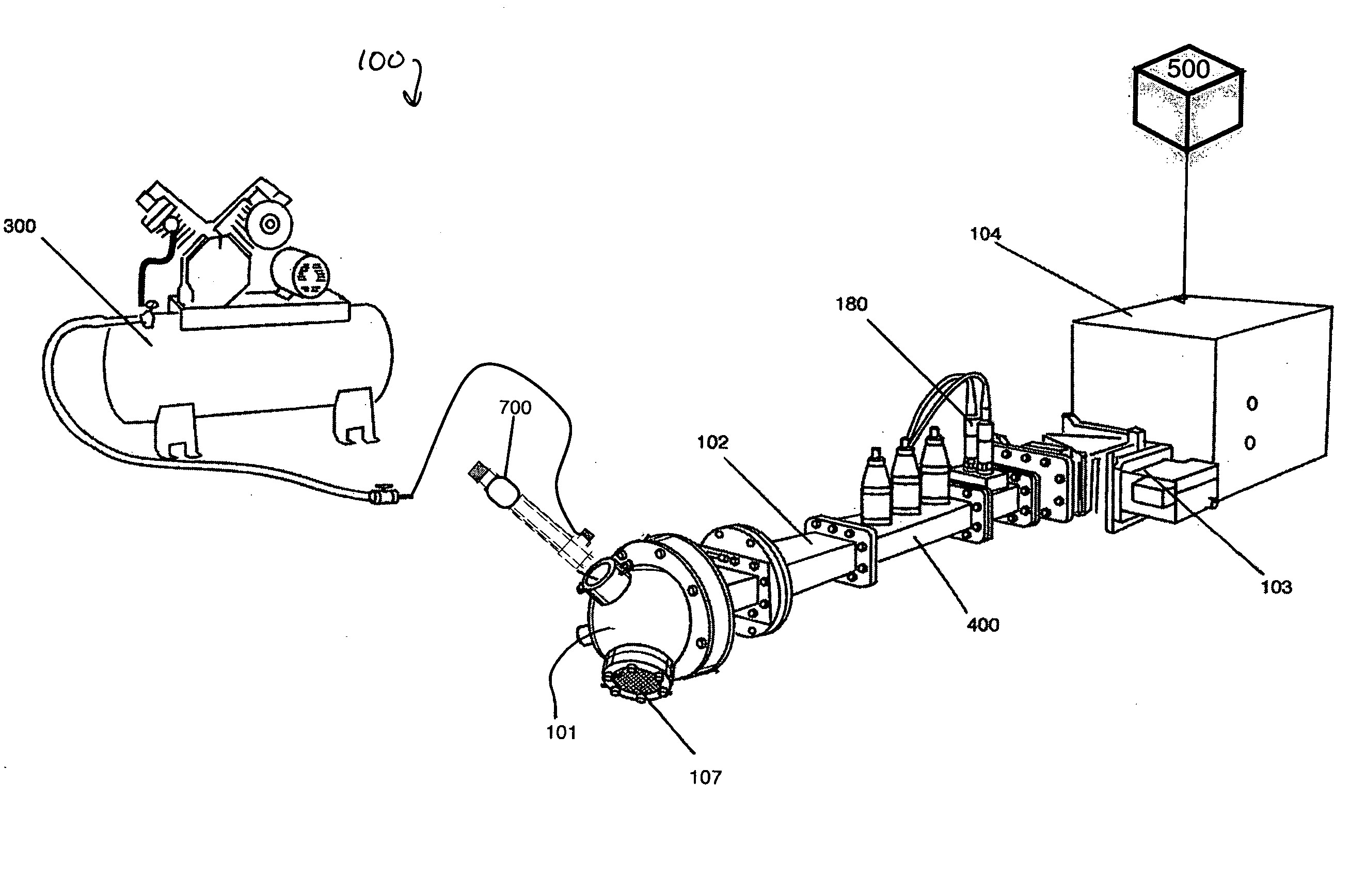

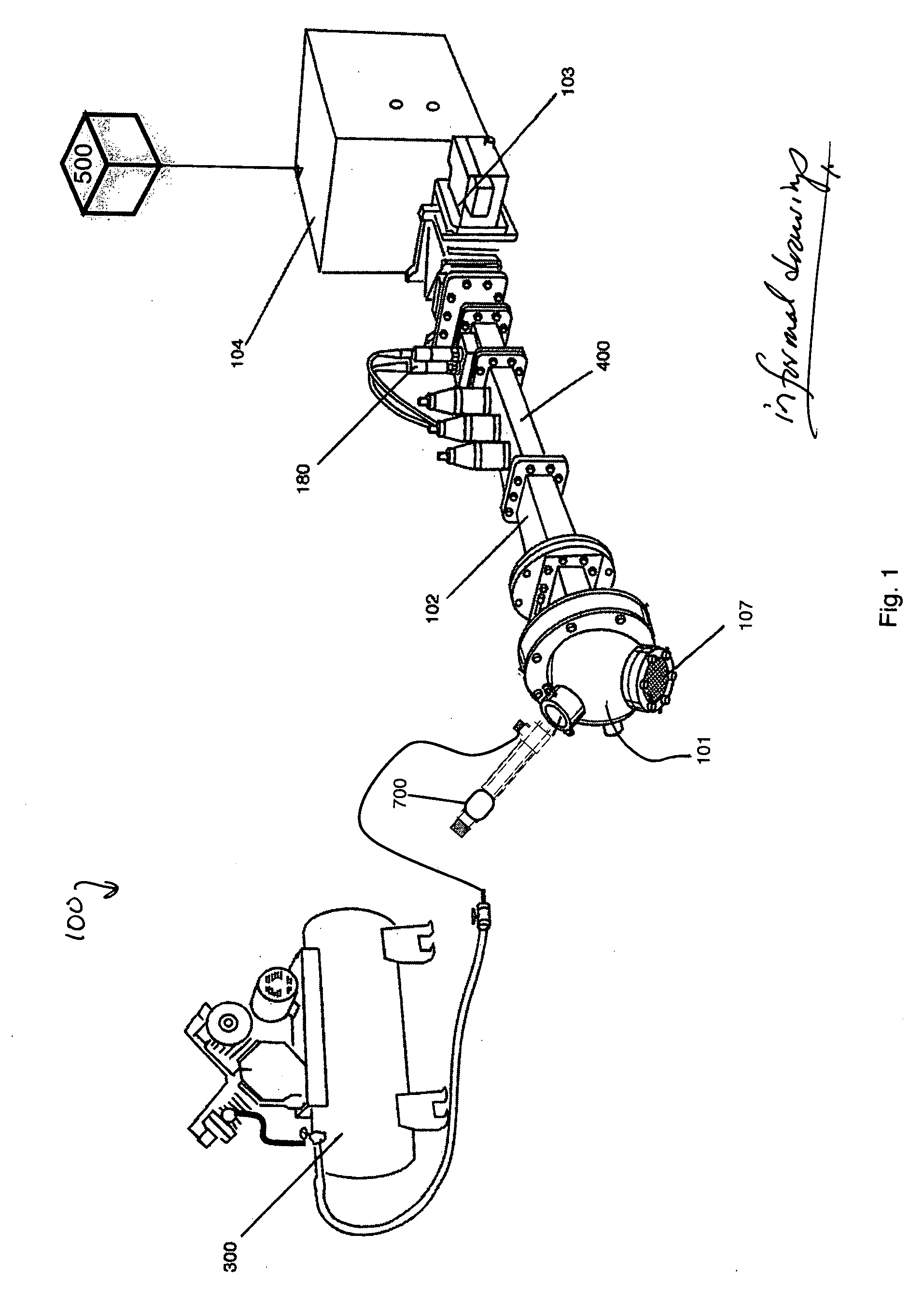

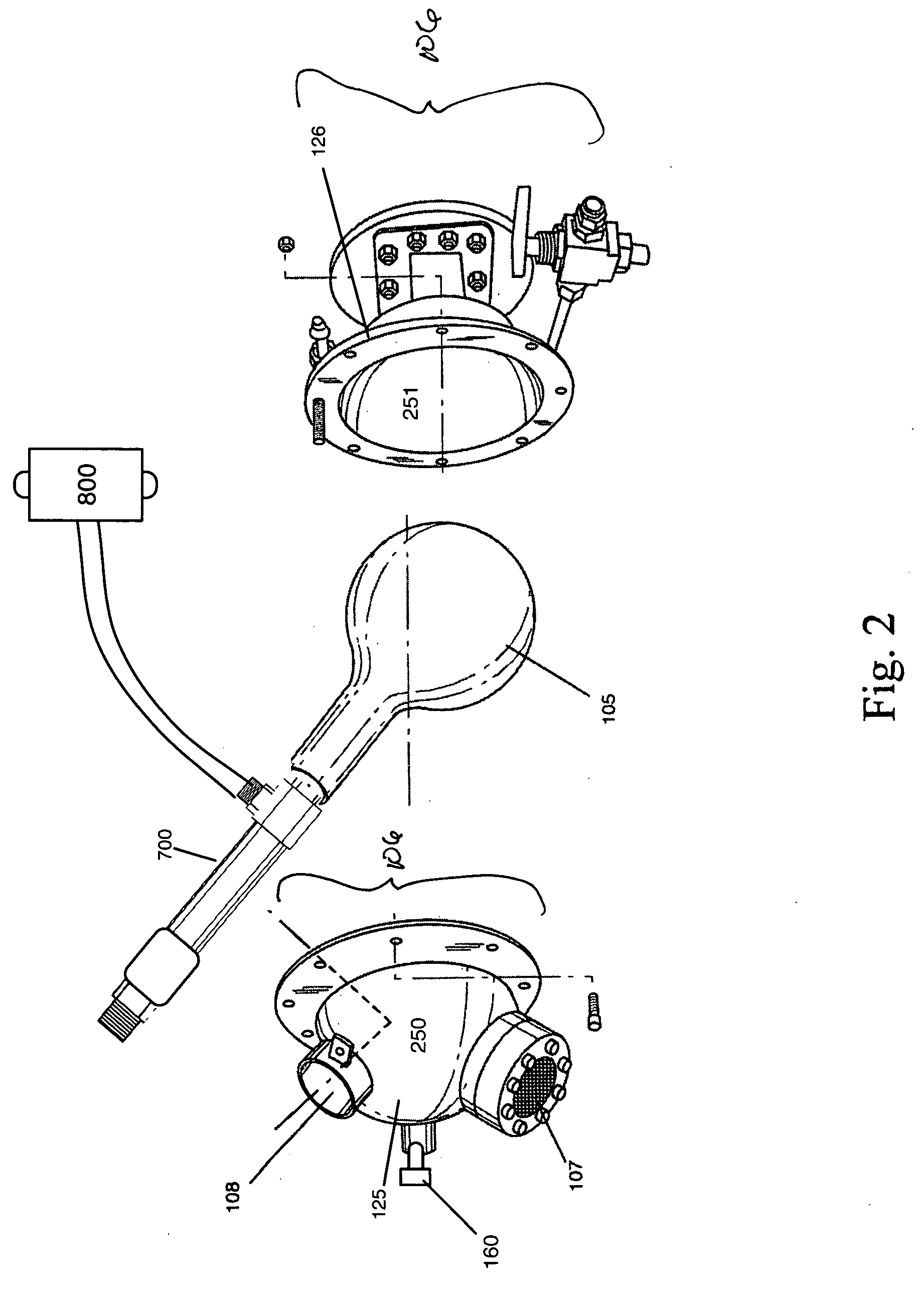

Radio frequency plasma-water dissociator

InactiveUS20090071816A1Generate efficientlySave a lot of costHydrogenOxygen/ozone/oxide/hydroxideRadio frequencyDummy load

A radio frequency plasma-water dissociator incorporates a plasma boiler, a RF Conduit, a dummy load, and a magnetron. The plasma boiler is in communication with the RF Conduit. The RF Conduit is in communication with the dummy load. And the dummy load is in communication with the magnetron. The magnetron is used for the purpose of generating the radio frequency waves.

Owner:WALLIN TODD WILLIAM

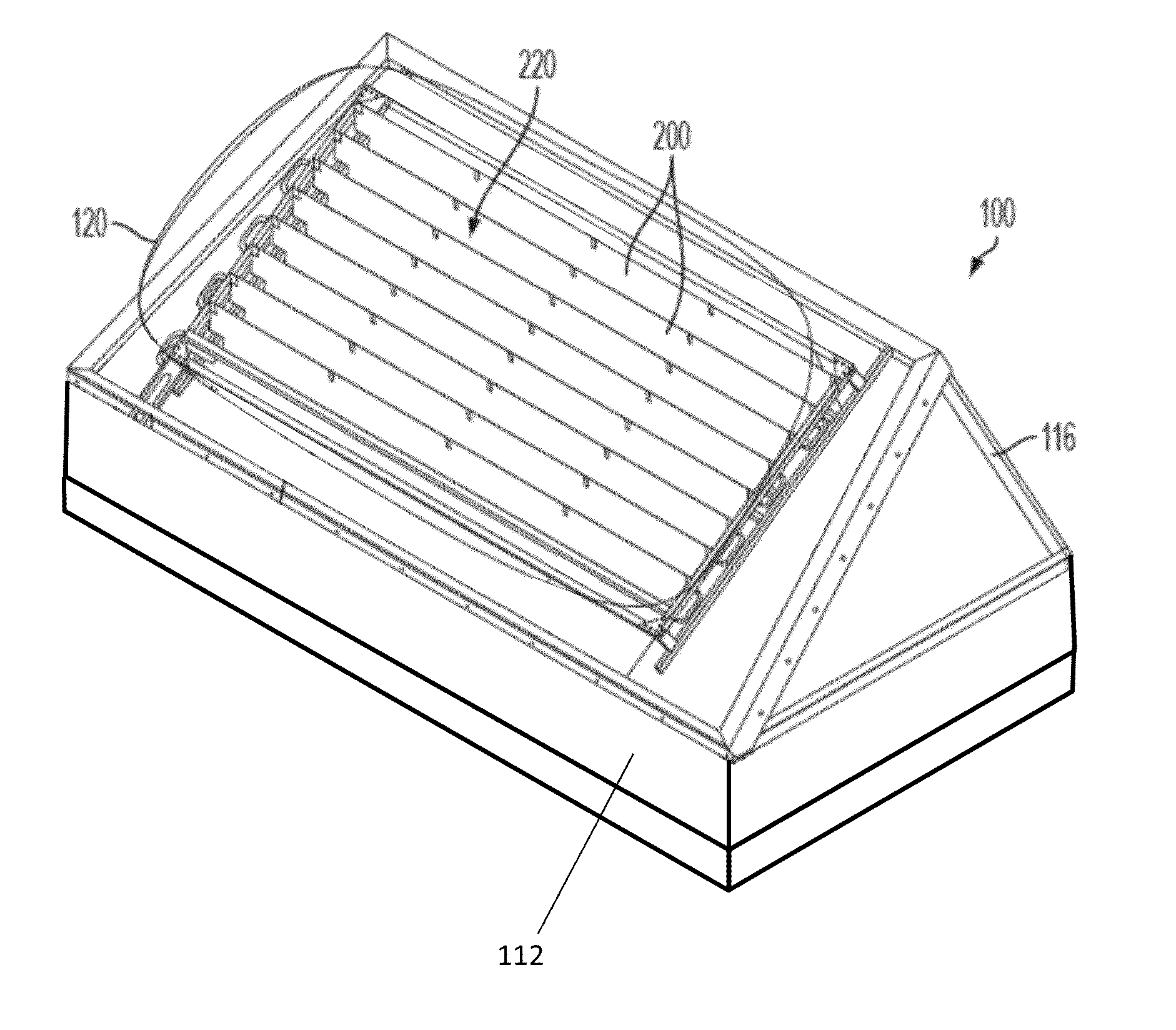

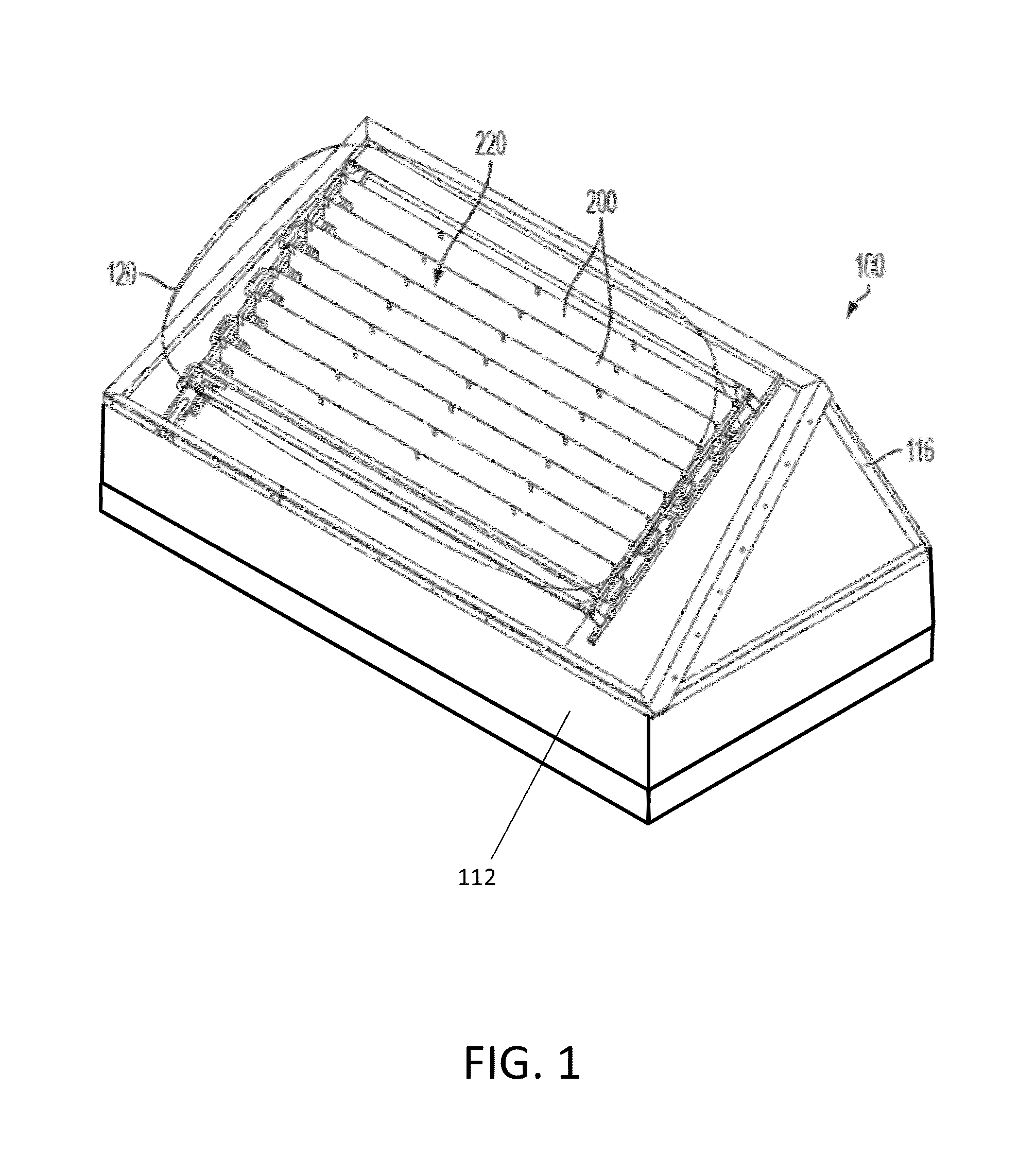

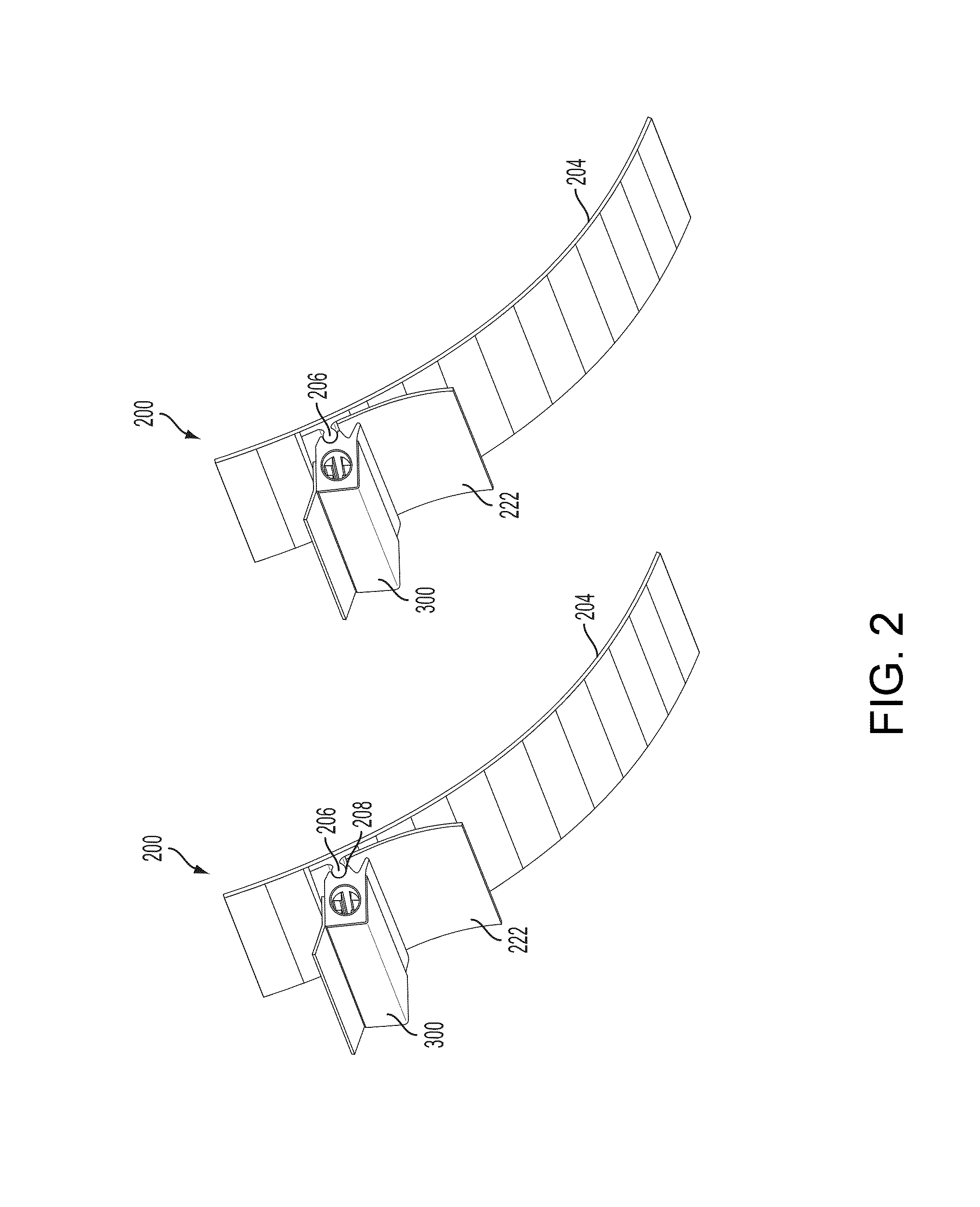

Housing and mounting assembly for skylight energy management system

InactiveUS20140165482A1Increases light availableSave a lot of costSolar heating energyBuilding roofsComputer moduleEngineering

Disclosed is a housing and mounting assembly for a skylight module, and particularly for a skylight module that incorporates an energy management system. The housing and mounting assembly is configured to efficiently capture both direct solar and diffuse ambient light, and deliver light that is diffuse to the space below the skylight that provides even illumination and no unpleasant glare spots. The walls of the skylight module may be formed of multi-wall polycarbonate panels configured to redirect both the upward- and downward-shining light through the aperture into the space below. Moreover, the curb of the assembly may include a flexible flashing strip provided with a reflective coating configured to reflect sunlight upward through the walls of the assembly and into the skylight module, such that the advantages of collecting and using such reflected light can be achieved even in a retrofit installation on a non-reflective roofing surface.

Owner:MBC VENTURES INC

Systems and methods for participant controlled communications regarding financial accounts

ActiveUS7949594B2Save a lot of costAvoid communicationComplete banking machinesFinanceControl communicationsDirect communication

Owner:FIRST DATA

Structure for monitoring semiconductor polysilicon gate profile

InactiveUS20060024853A1Promote generationSave a lot of costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringPolysilicon gate

Detection of a profile drift of a polysilicon line is enhanced by a test structure that (1) measures a bottom width and an average width of a cross sectional area of the same polysilicon line (2) correlates the two measurements, and (3) compares such correlation with a previous correlation of bottom width to average width of cross sectional area of the same polysilicon line.

Owner:IBM CORP

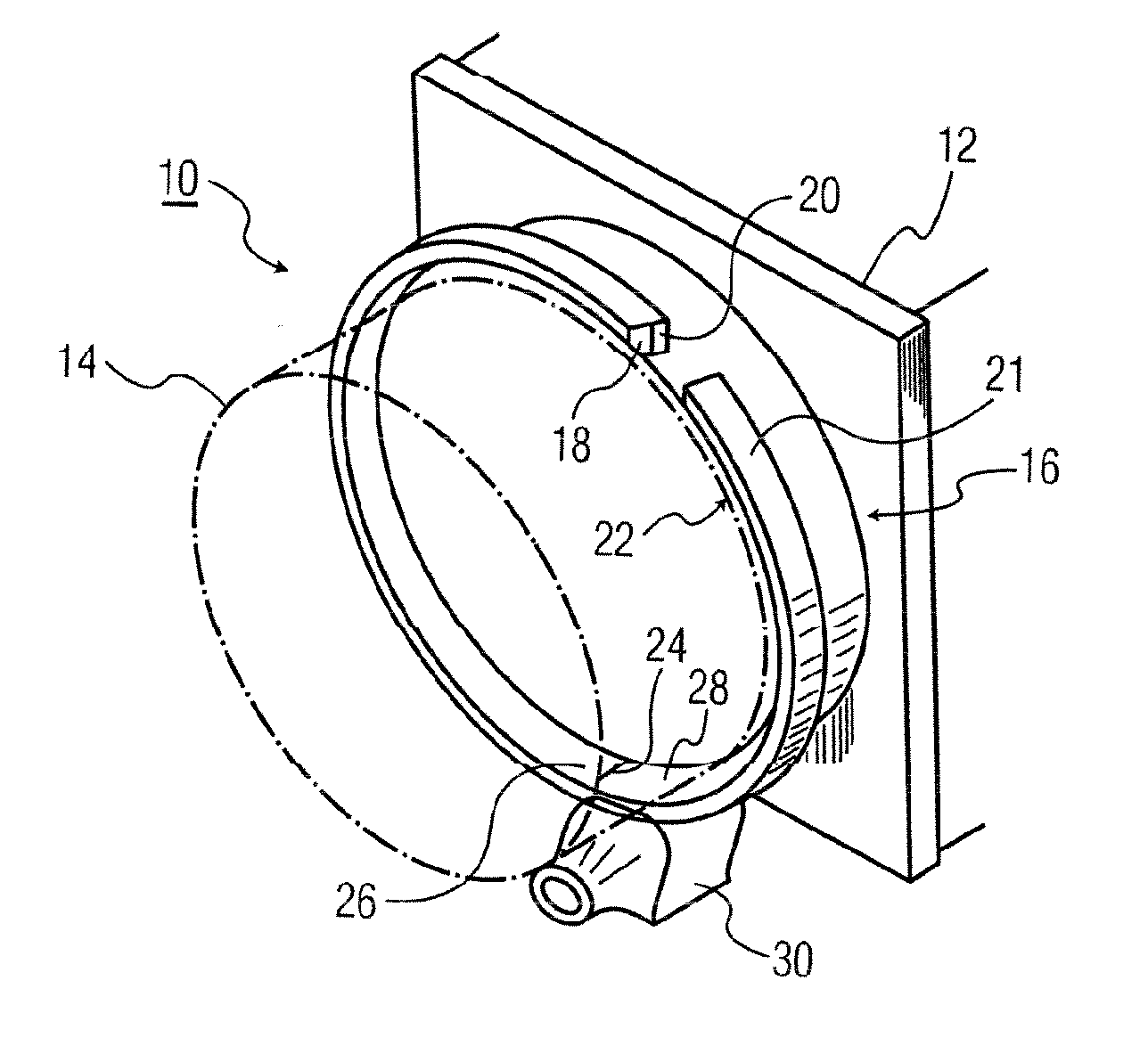

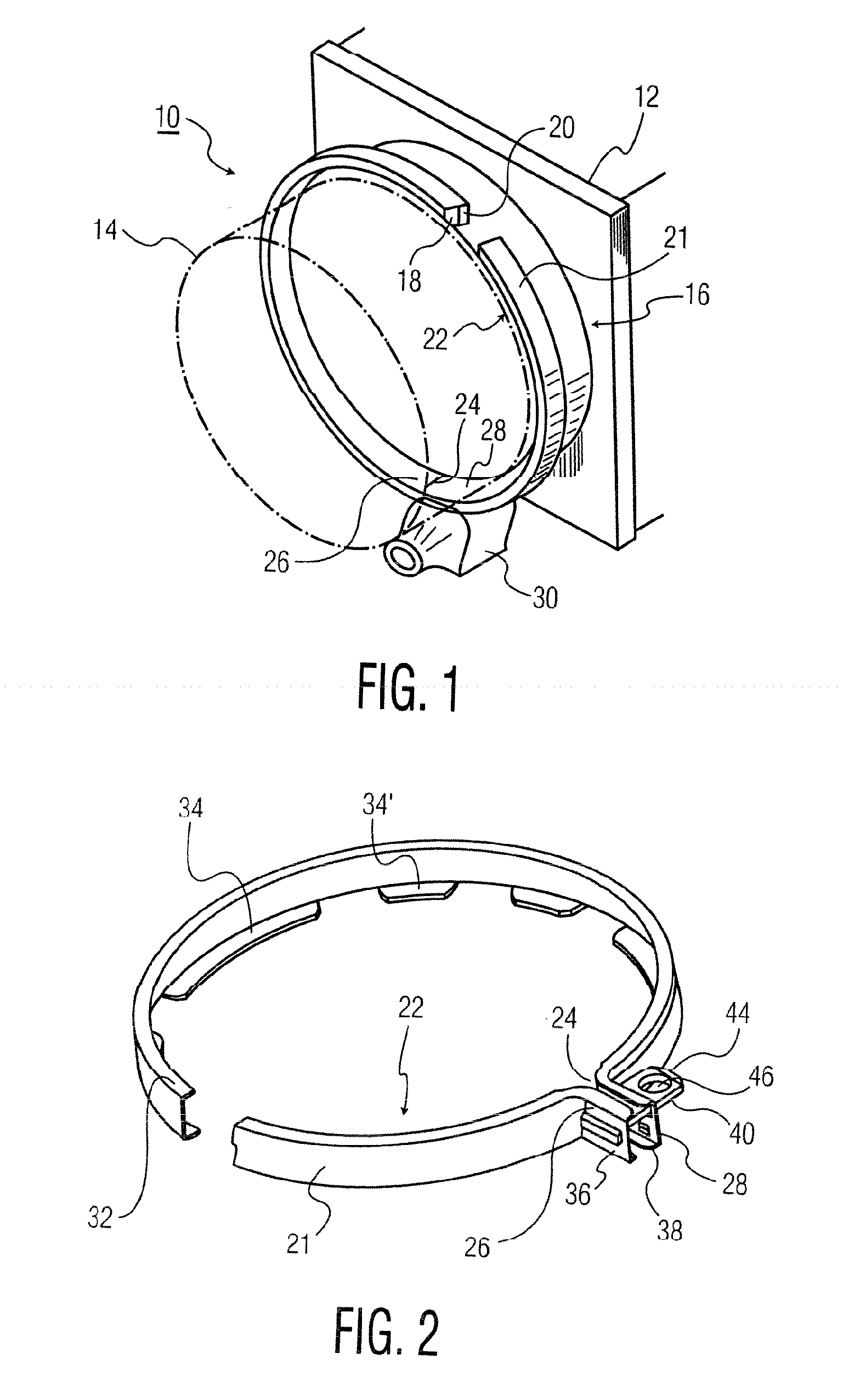

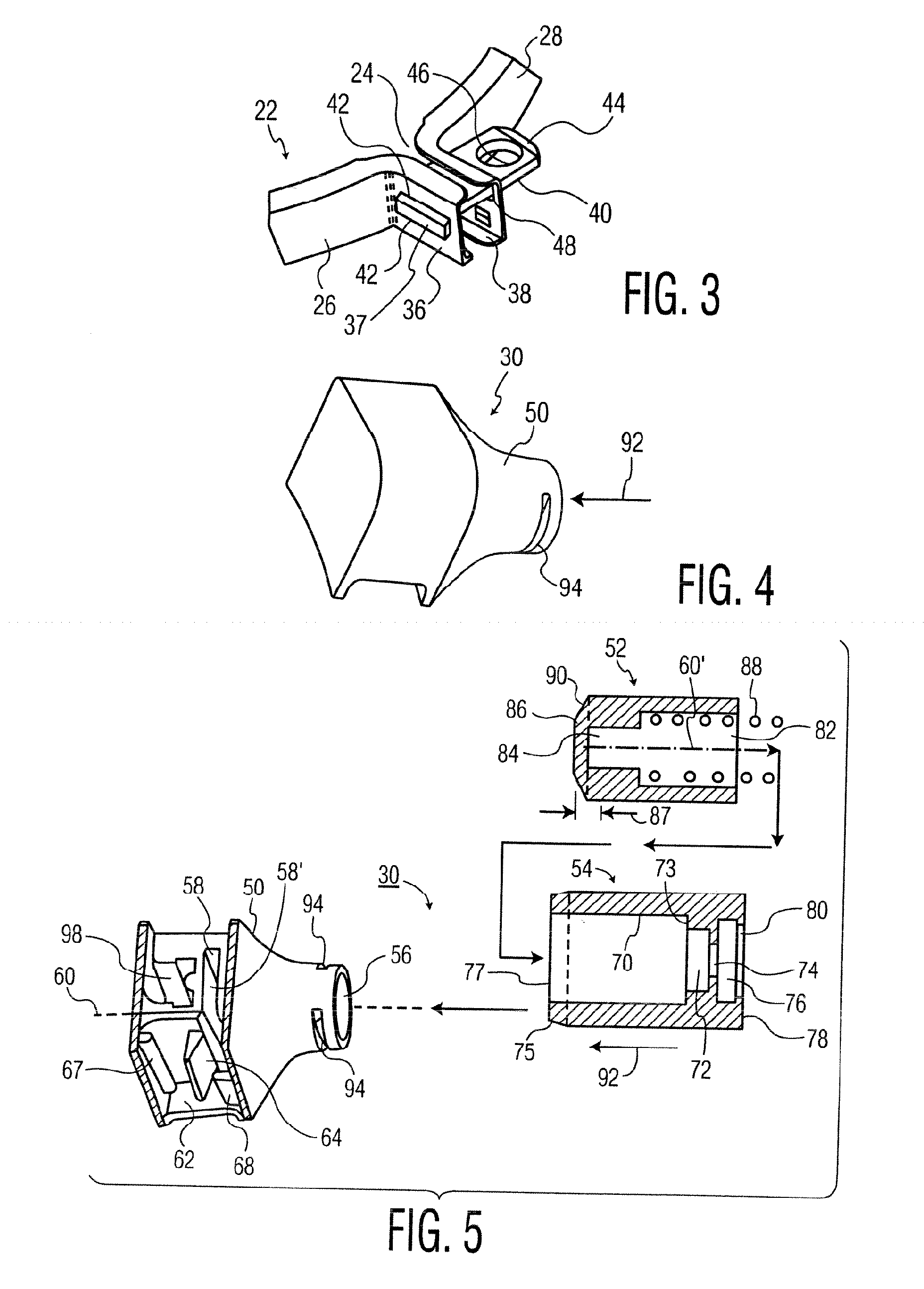

Meter ring locking device

InactiveUS20060277955A1Minimize extentSave a lot of costBuilding locksVolume meteringEngineeringPlunger

A utility meter clamping ring is locked to the meter by a locking device that locks the free ends of the ring together automatically without the use of a separate plunger device. A latch is spring loaded in the locking device housing in a normally biased lock position. The lock device is secured to one free end of the clamping ring. An apertured blade is attached to the other free end of the clamping ring. The ring is placed about the flanges of the meter cover and base flanges and the blade is then inserted into the locking device housing where its aperture is engaged automatically by the spring loaded latch and locked to the housing upon insertion. A conventional plunger key may optionally be used to unlock the latch and release the blade from the locked position to free the ends for removal of the meter cover via an optional bore in the latch engaged by the key. The latch may be optionally permanently locked to the blade so that either the locking device or the ring has to be destroyed. Weakening grooves are in the ring of the latter embodiment to facilitate breaking the ring open. Embodiments are disclosed for use with F and G type plunger unlock keys and include an anti-tampering sleeve for use in the lock to preclude tampering disengagement of the lock of the type used with an F type key.

Owner:DEBRODY ROBERT F +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com