Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30142results about "Ceramic shaping apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

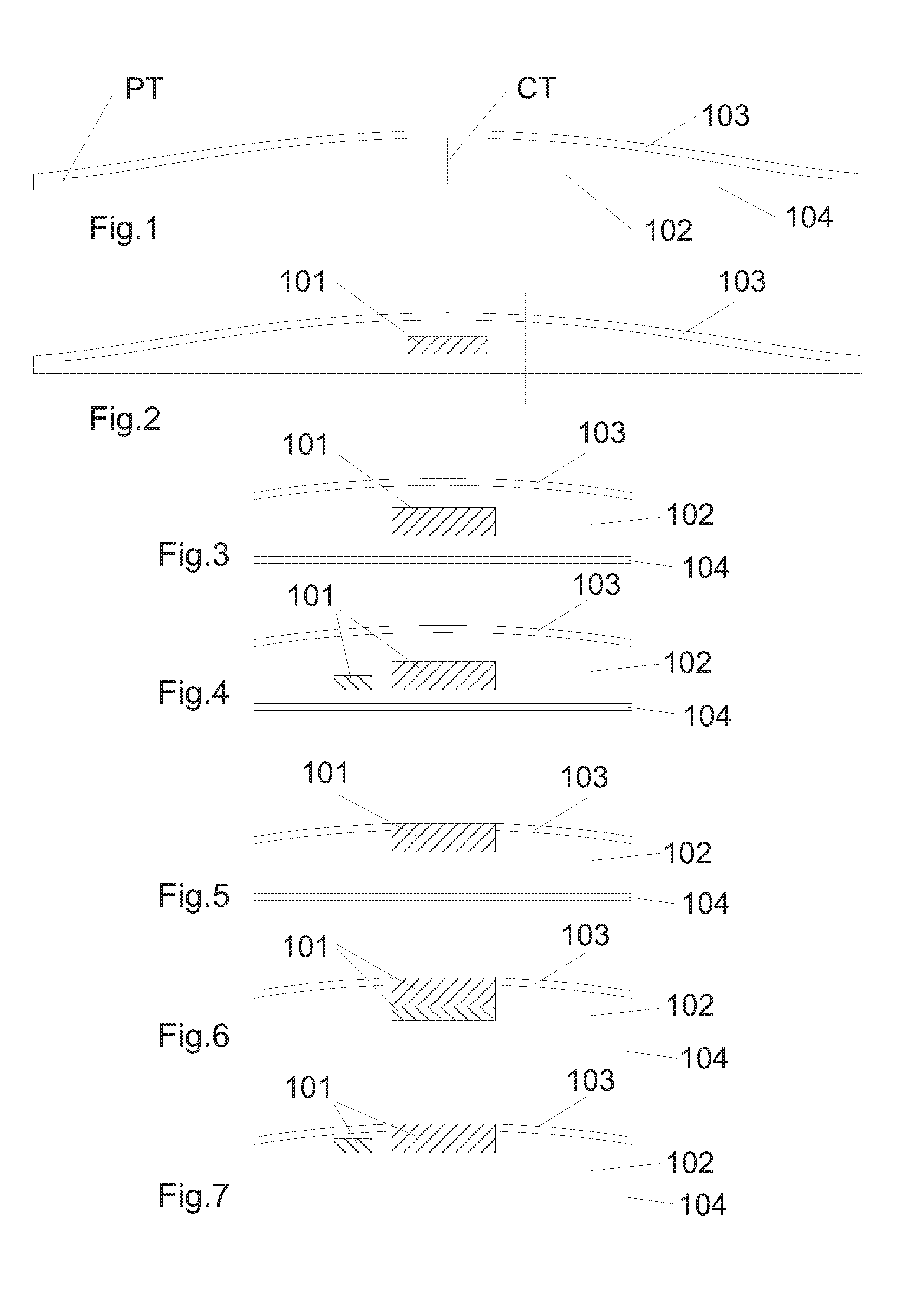

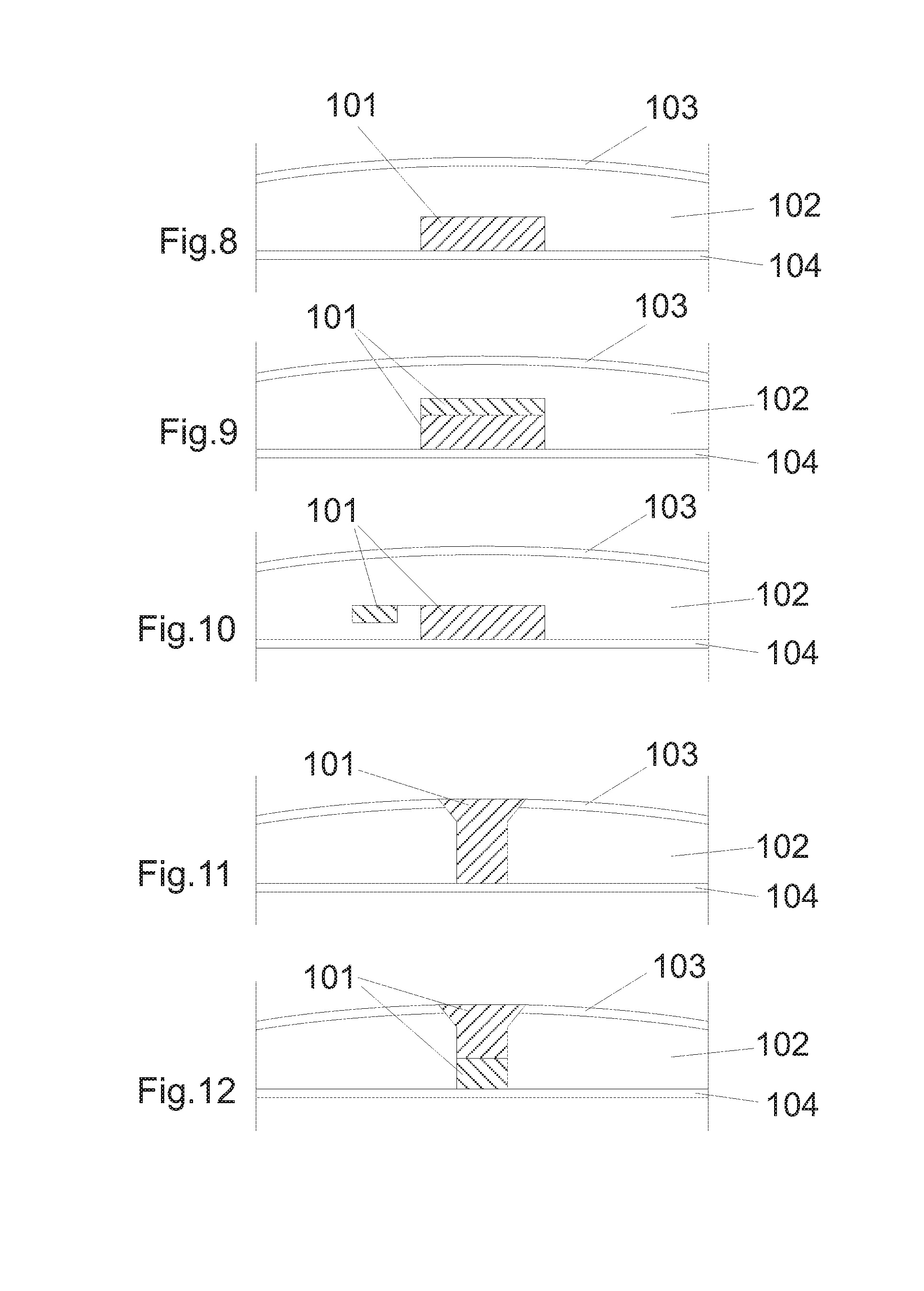

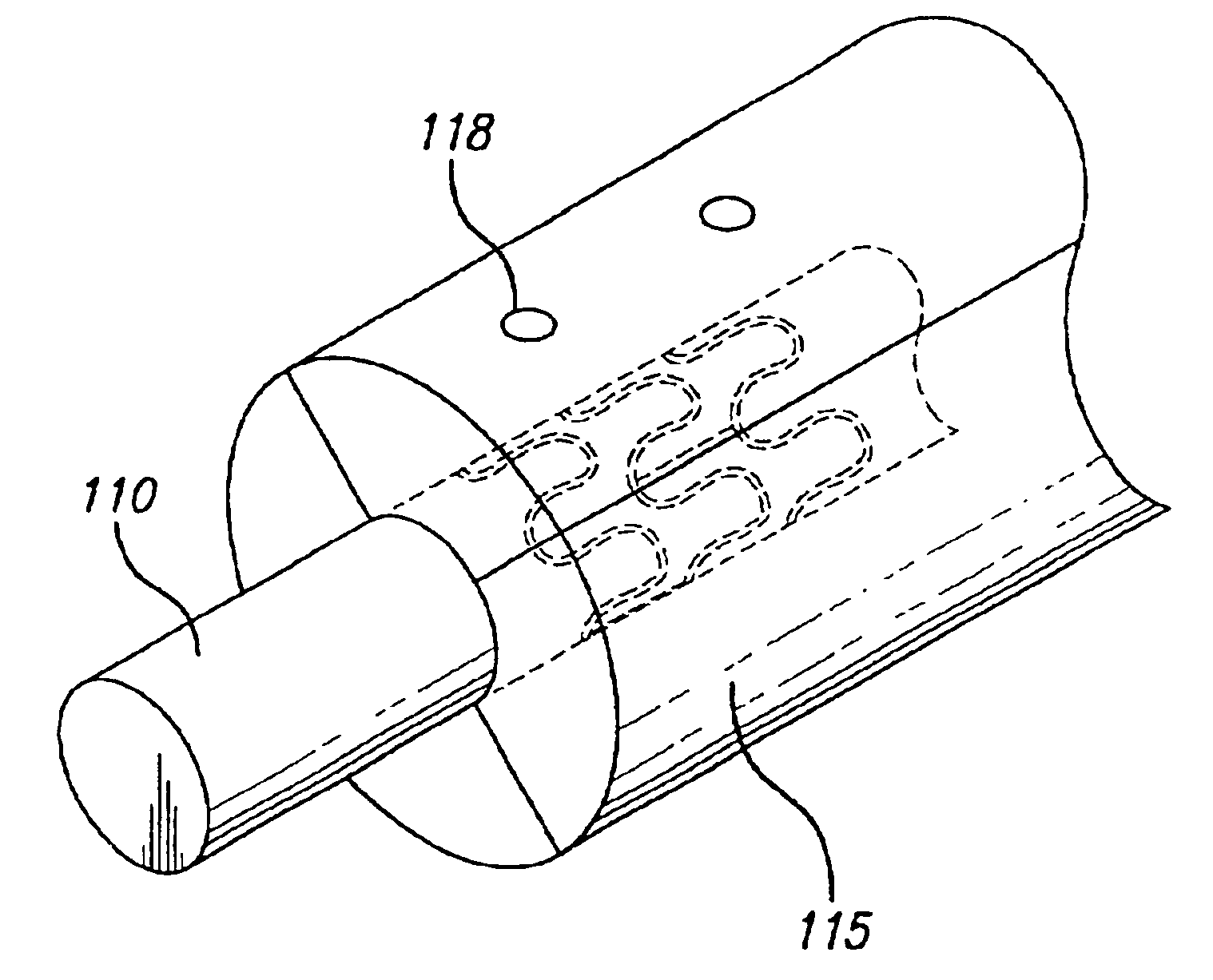

Wound closure material

Articles are provided having no orientation or a multi-directional orientation. Such articles may be in the form of films, ribbons, sheets, and / or tapes and may be utilized as buttresses with a surgical stapling apparatus or as reinforcing means for suture lines.

Owner:COVIDIEN LP

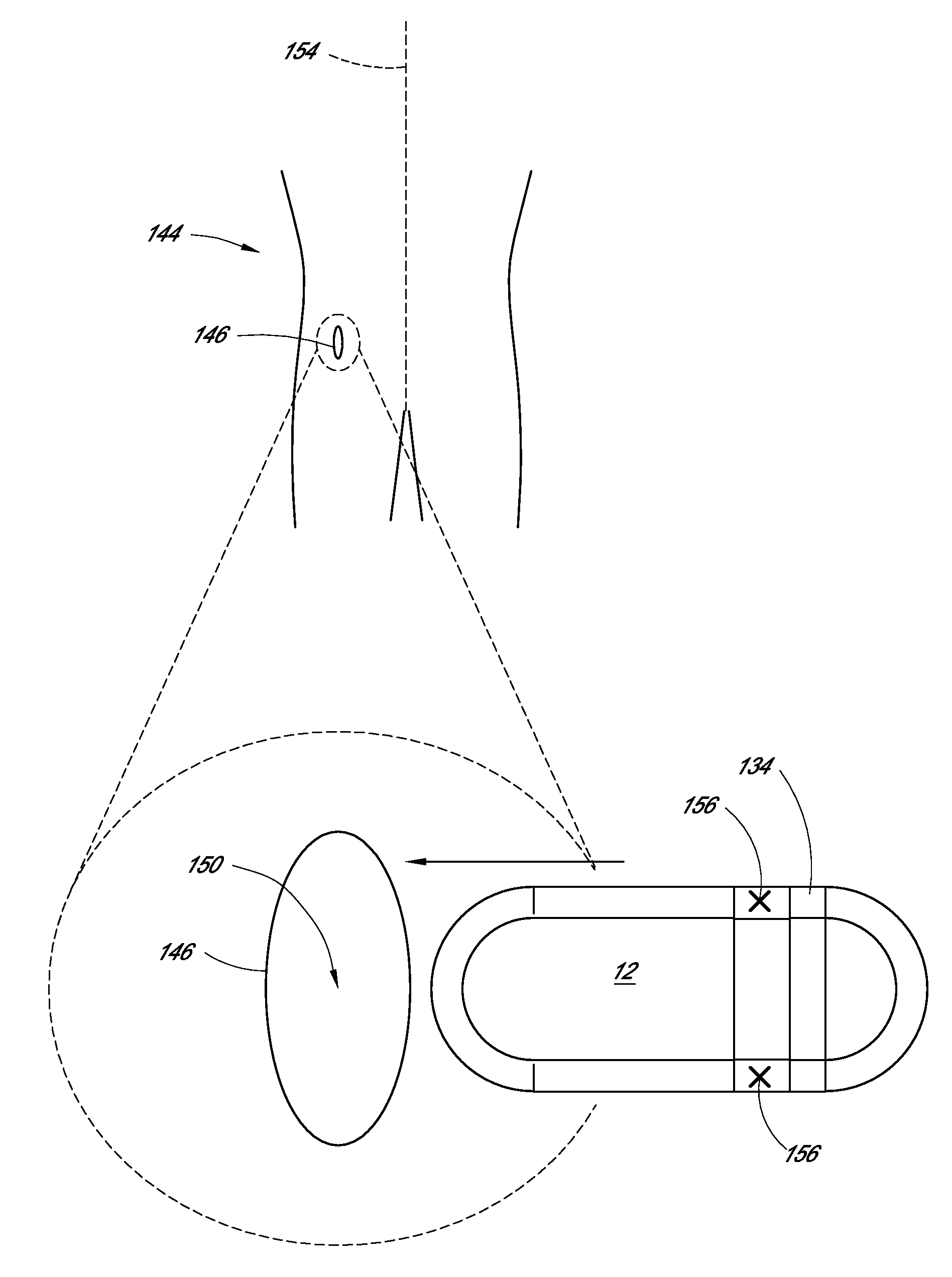

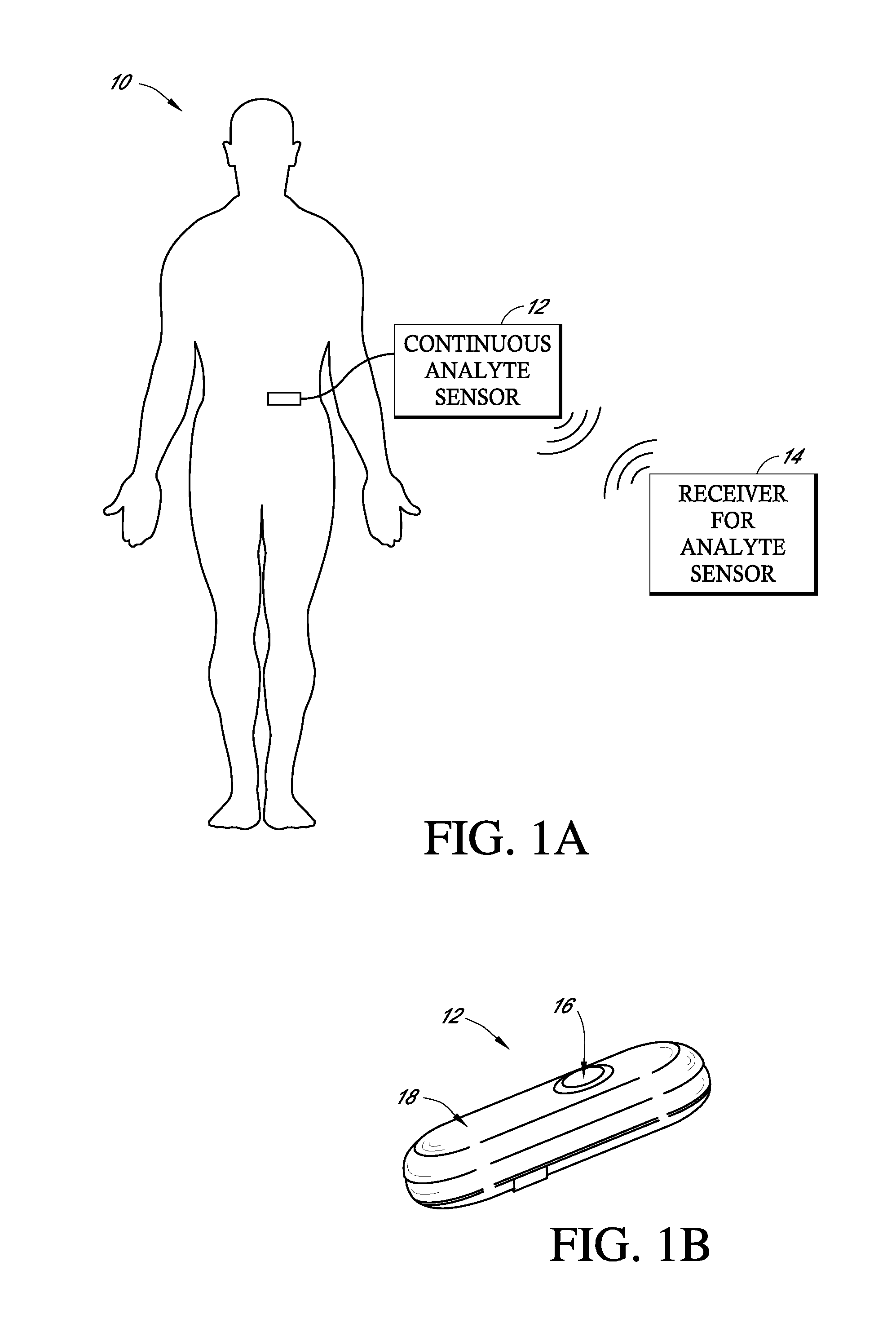

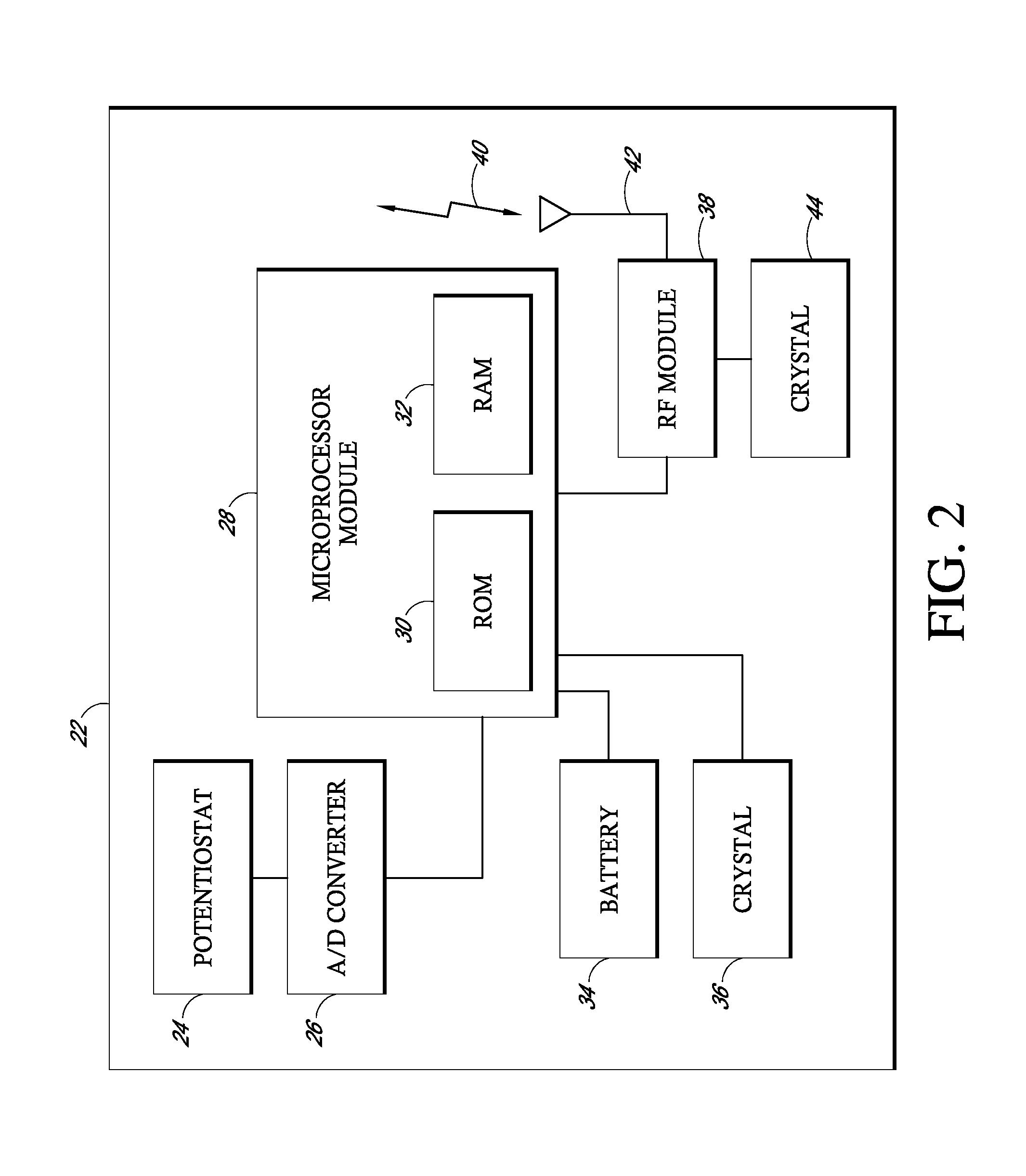

Implantable analyte sensor

InactiveUS20090030294A1Improve convenienceMinimize movementBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteMiniaturization

An implantable analyte sensor including a sensing region for measuring the analyte and a non-sensing region for immobilizing the sensor body in the host. The sensor is implanted in a precisely dimensioned pocket to stabilize the analyte sensor in vivo and enable measurement of the concentration of the analyte in the host before and after formation of a foreign body capsule around the sensor. The sensor further provides a transmitter for RF transmission through the sensor body, electronic circuitry, and a power source optimized for long-term use in the miniaturized sensor body.

Owner:DEXCOM INC

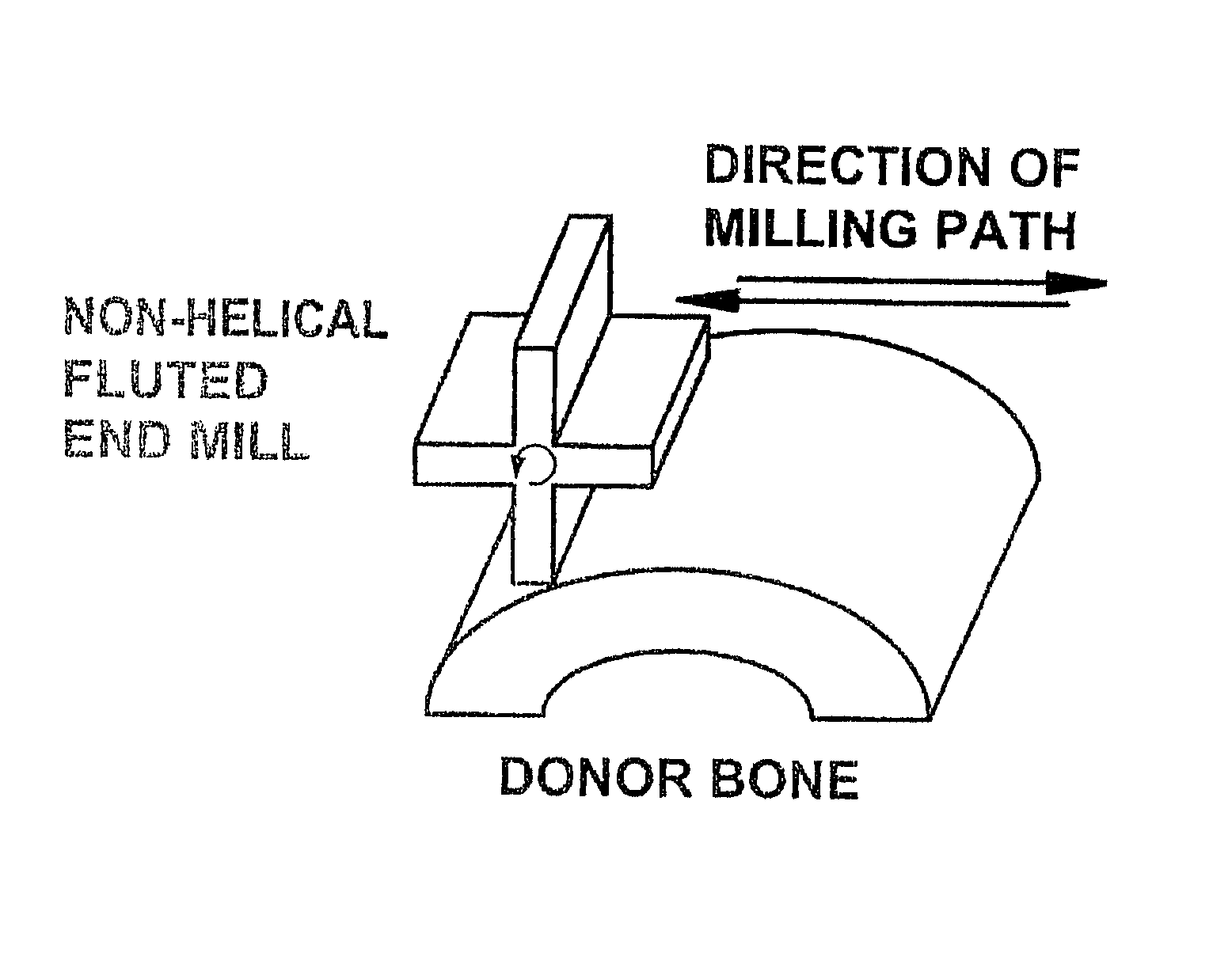

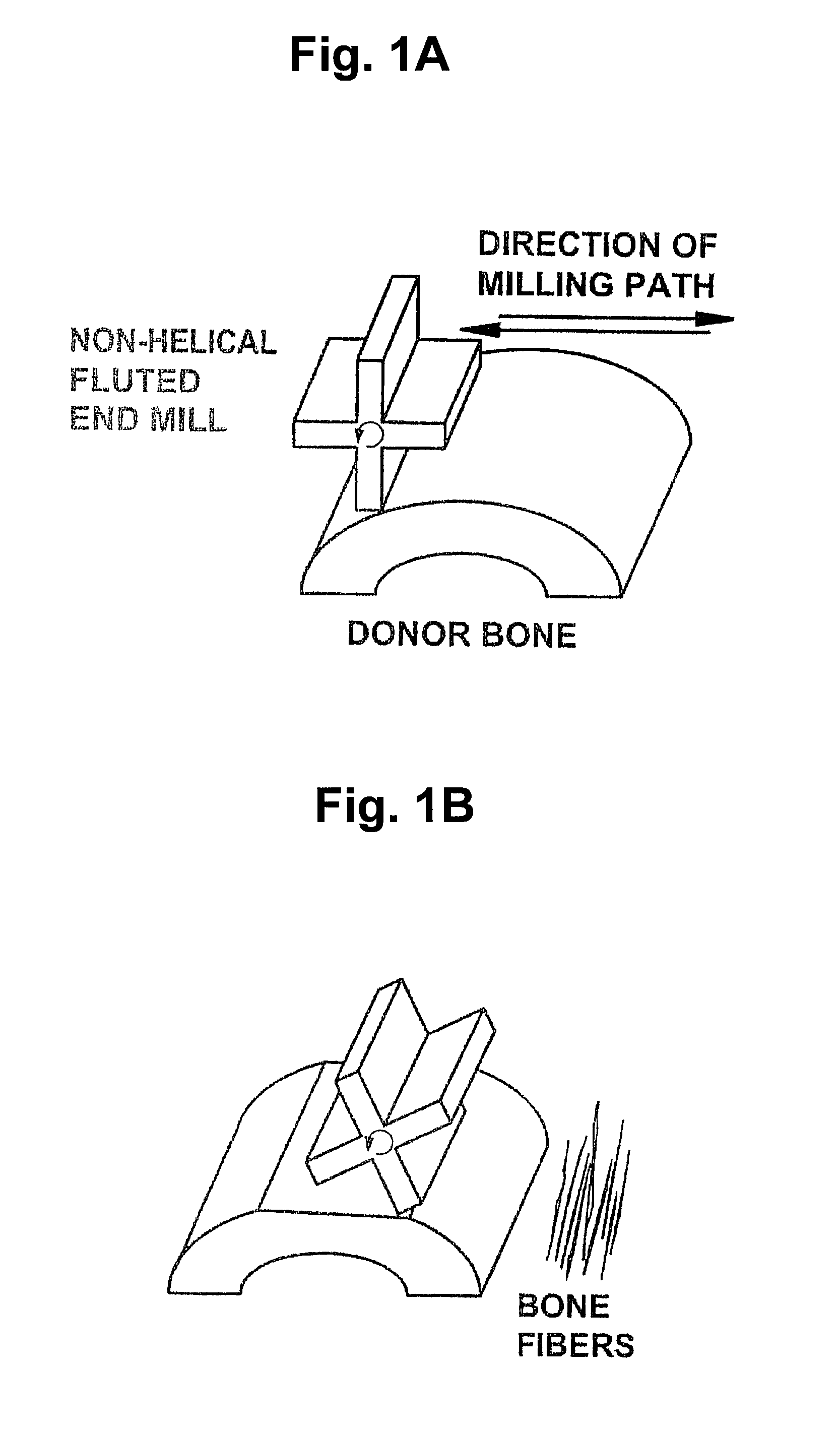

Tissue-derived mesh for orthopedic regeneration

An implant including a substantially cohesive aggregate comprising bone-derived particles. Cohesiveness is maintained by a member of mechanical interlocking, engagement of adjacent bone-derived particles with one another through engagement with a binding agent, thermal bonding, chemical bonding, or a matrix material in which the bone-derived particles are retained. The aggregate is shaped as a one-dimensional or two-dimensional body.

Owner:WARSAW ORTHOPEDIC INC

Long wearable soft contact lens

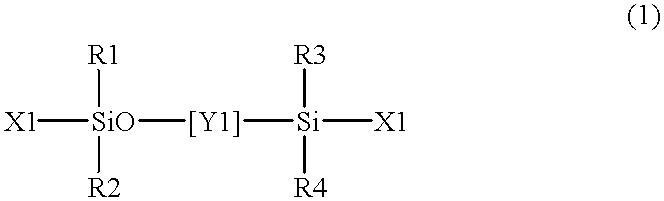

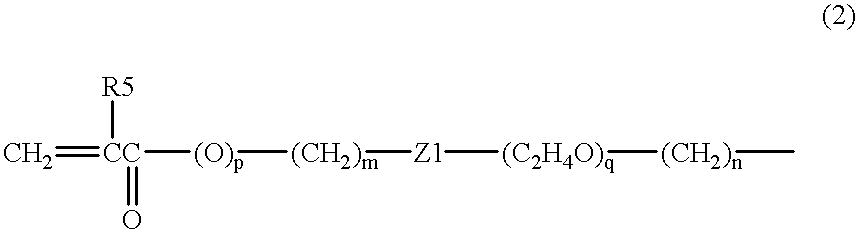

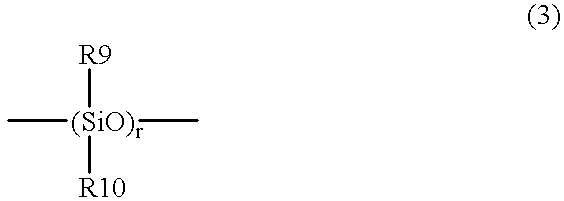

The present invention relates to a soft contact lens, and provides a contact lens which shows small and stable contact angle to water at its surface in water as well as in air, little deposition in wearing, high oxygen permeability, no adhesion of lens to a cornea and superior extended-wearing characteristics. The present invention provides a hydrogel soft contact lens which has contact angle at a lens surface in a range of 10-50° by the captive bubble method in water and 30-90° by the sessile drop method in air, oxygen permeability of not less than 30 and water content of not less than 5%, and also a hydrogel soft contact lens consisting of a polymer comprising a hydrophilic siloxanyl monomer shown by a specified general formula.

Owner:COOPERVISION INT LTD

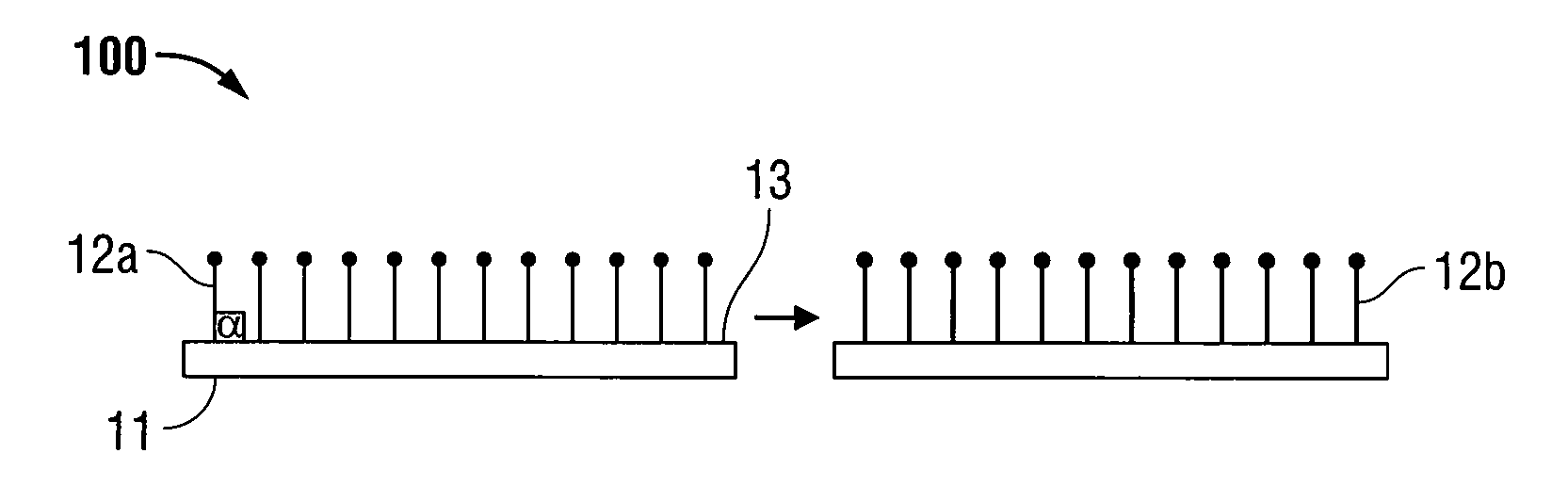

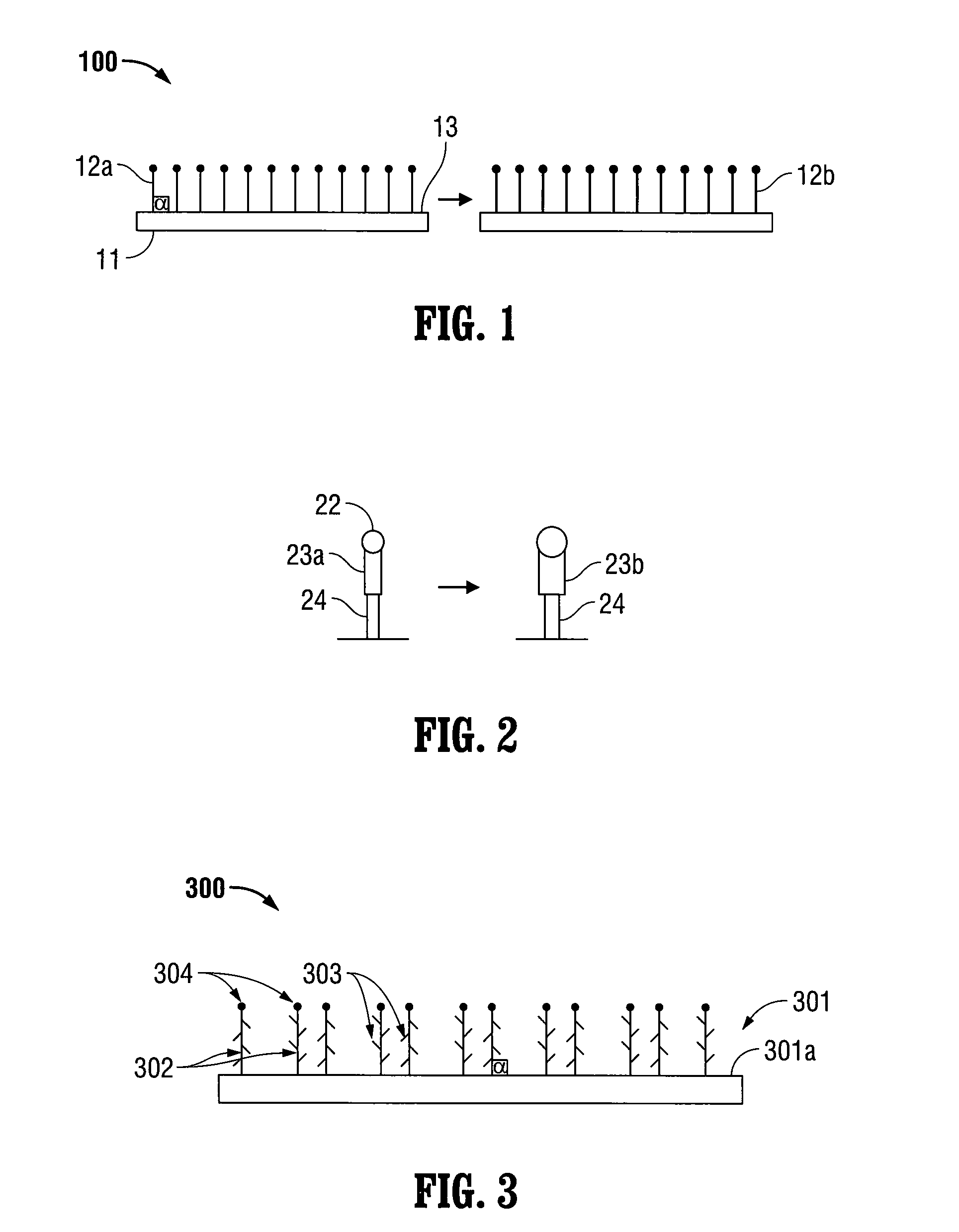

Implantable devices having swellable grip members

The present disclosure relates to implantable medical devices including swellable tissue gripping elements and methods of forming such devices. The implantable medical device may comprise a biocompatible substrate having a surface comprising at least one swellable grip member. The implantable medical device may take on the form of a surgical mesh, patch, buttress, or pledget and the swellable member may comprise spikes and / or spiked naps. The implantable medical device may also contain a bioactive agent.

Owner:TYCO HEALTHCARE GRP LP

Porous Substrates for Implantation

InactiveUS20100137990A1Easy to integrateGood biocompatibilitySuture equipmentsDental implantsPorous substrateAnimal body

A porous substrate or implant for implantation into a human or animal body constructed from a structural material and having one or more regions which when implanted are subjected to a relatively lower mechanical loading. The region(s) are constructed with lesser mechanical strength by having a lesser amount of structural material in said region(s) relative to other regions. This is achieved by controlling pore volume fraction in the regions. A spacer is adapted to define an open-cell pore network by taking a model of the required porous structure, and creating the spacer to represent the required porous structure using three-dimensional modelling. Material to form the substrate about the spacer in infiltrated the scaffold structure formed.

Owner:NATIONAL UNIVERSITY OF IRELAND

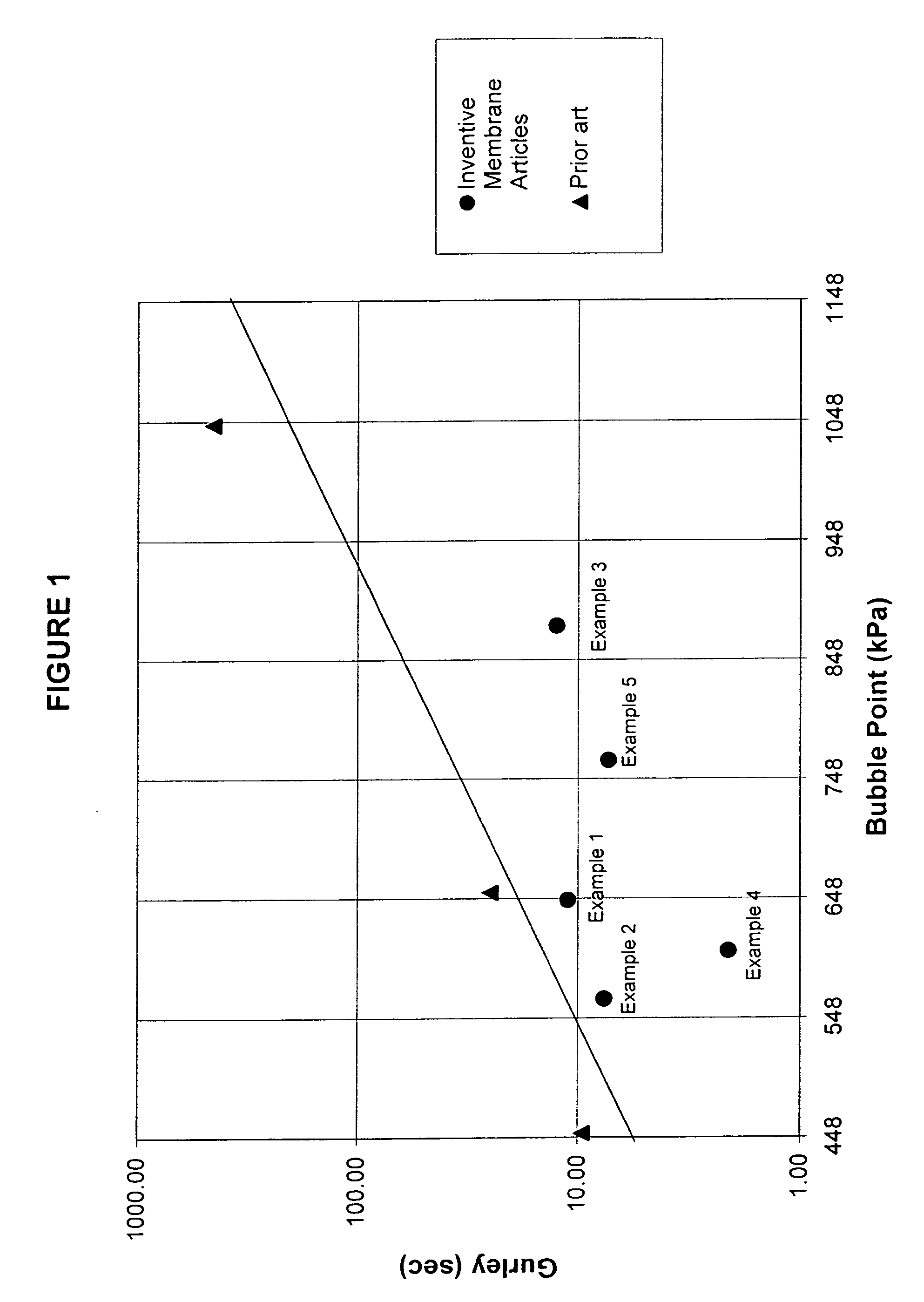

Porous PTFE materials and articles produced therefrom

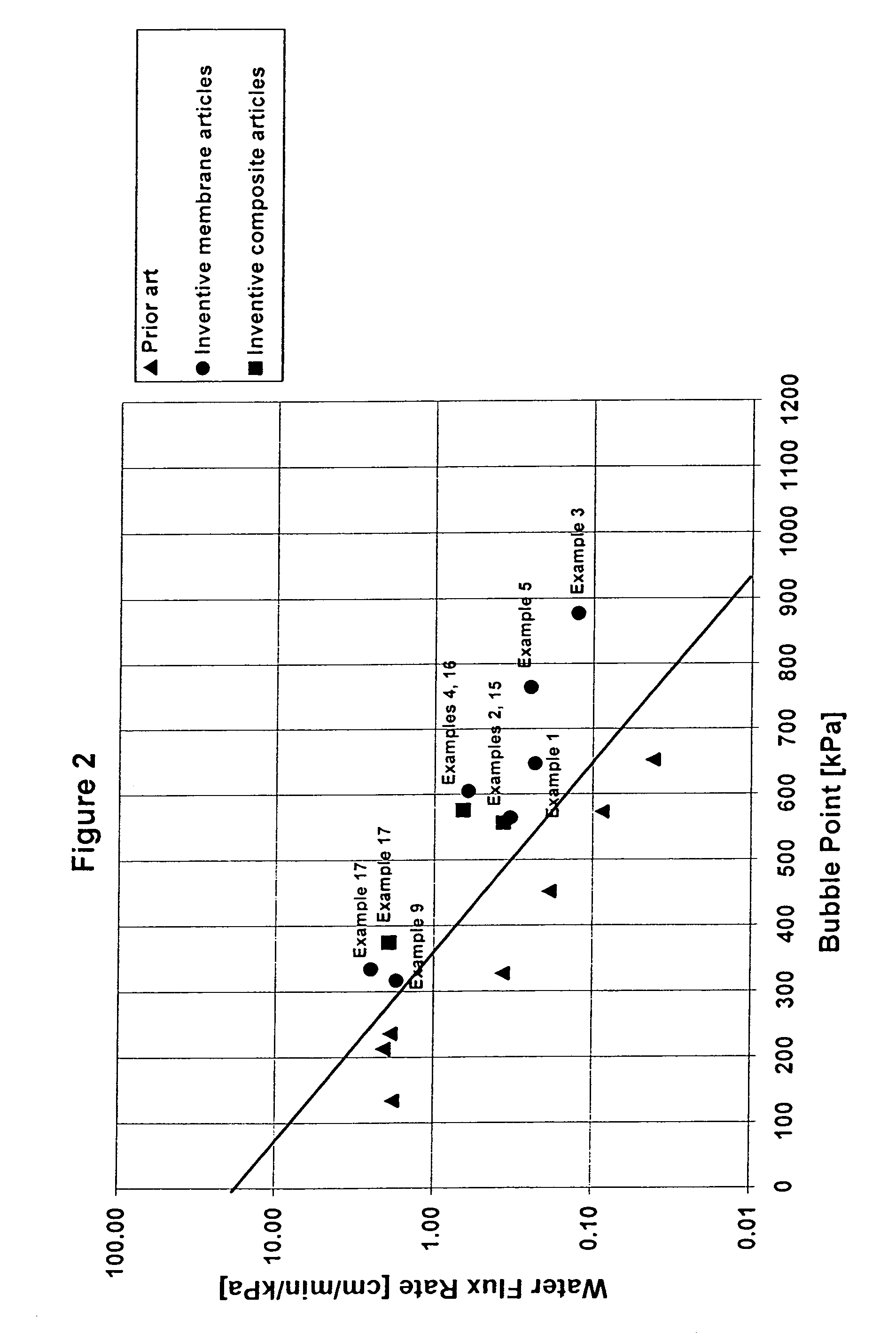

ActiveUS7306729B2High strengthLower overall flow resistanceMembranesSemi-permeable membranesFlow resistivityFiltration

Novel porous PTFE membranes are described possessing a unique combination of high strength, low flow resistance, and small pore size. Additionally, unique constructions with superior filtration and venting properties incorporating porous PTFE membranes are described.

Owner:WL GORE & ASSOC INC

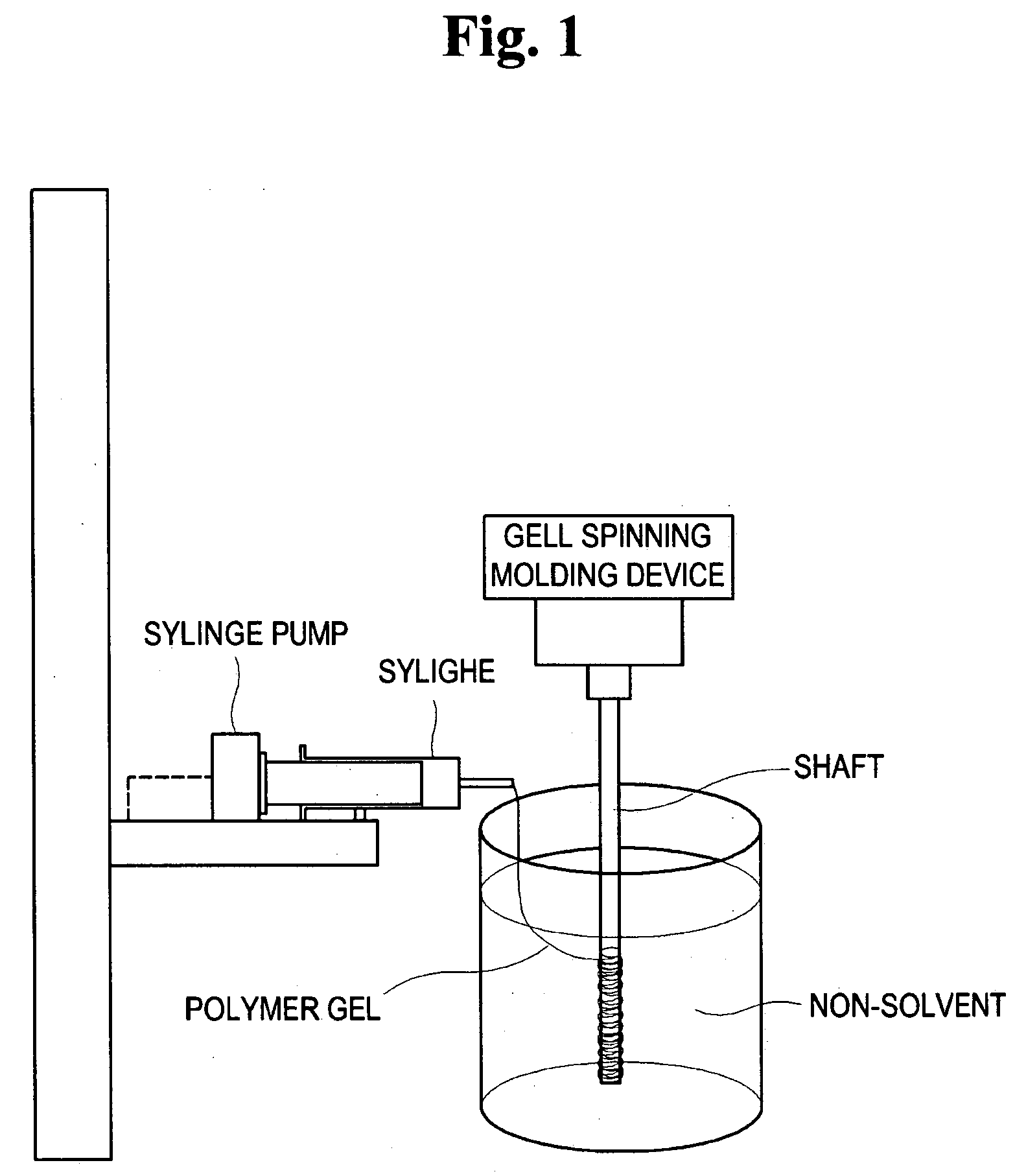

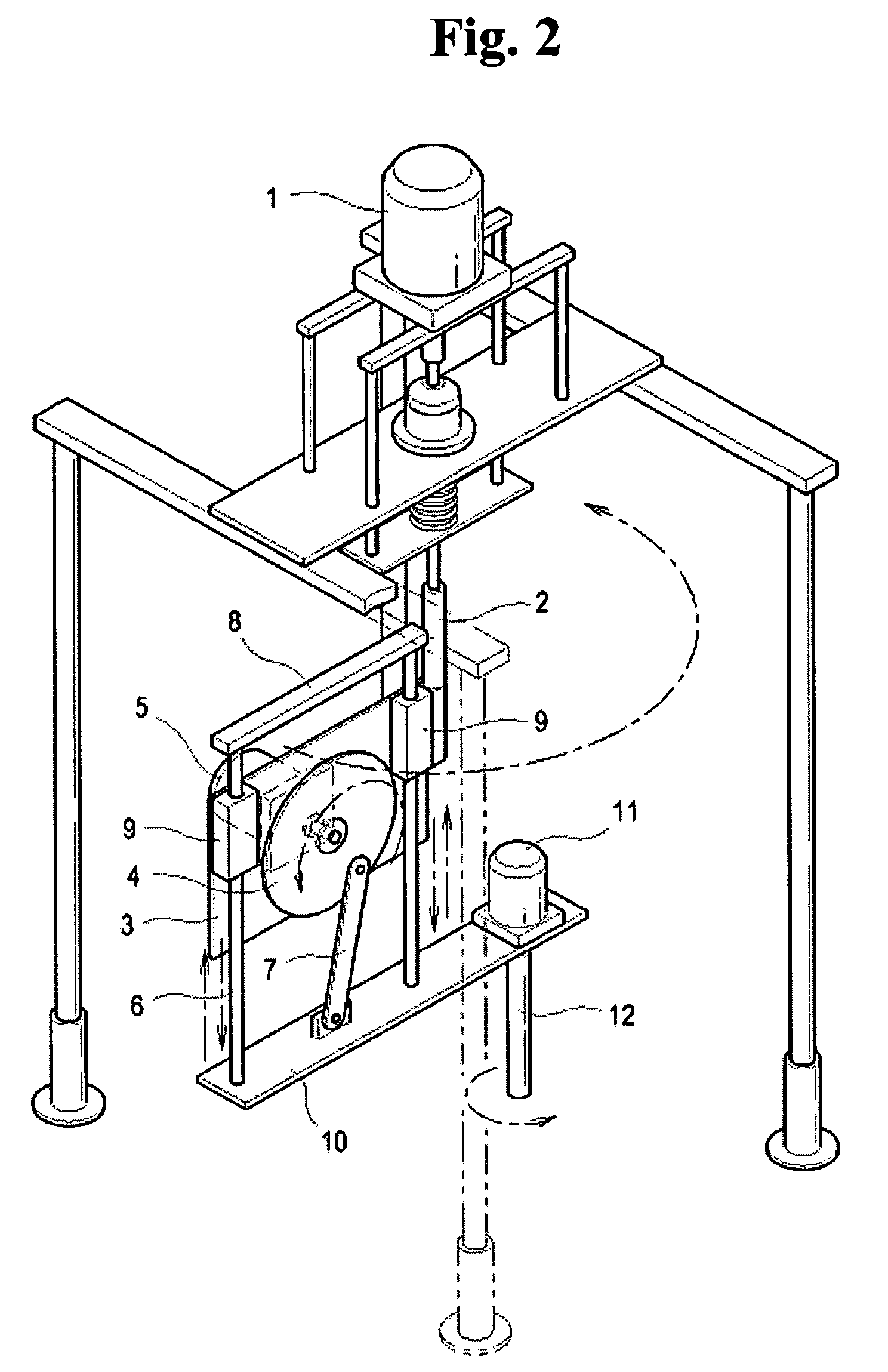

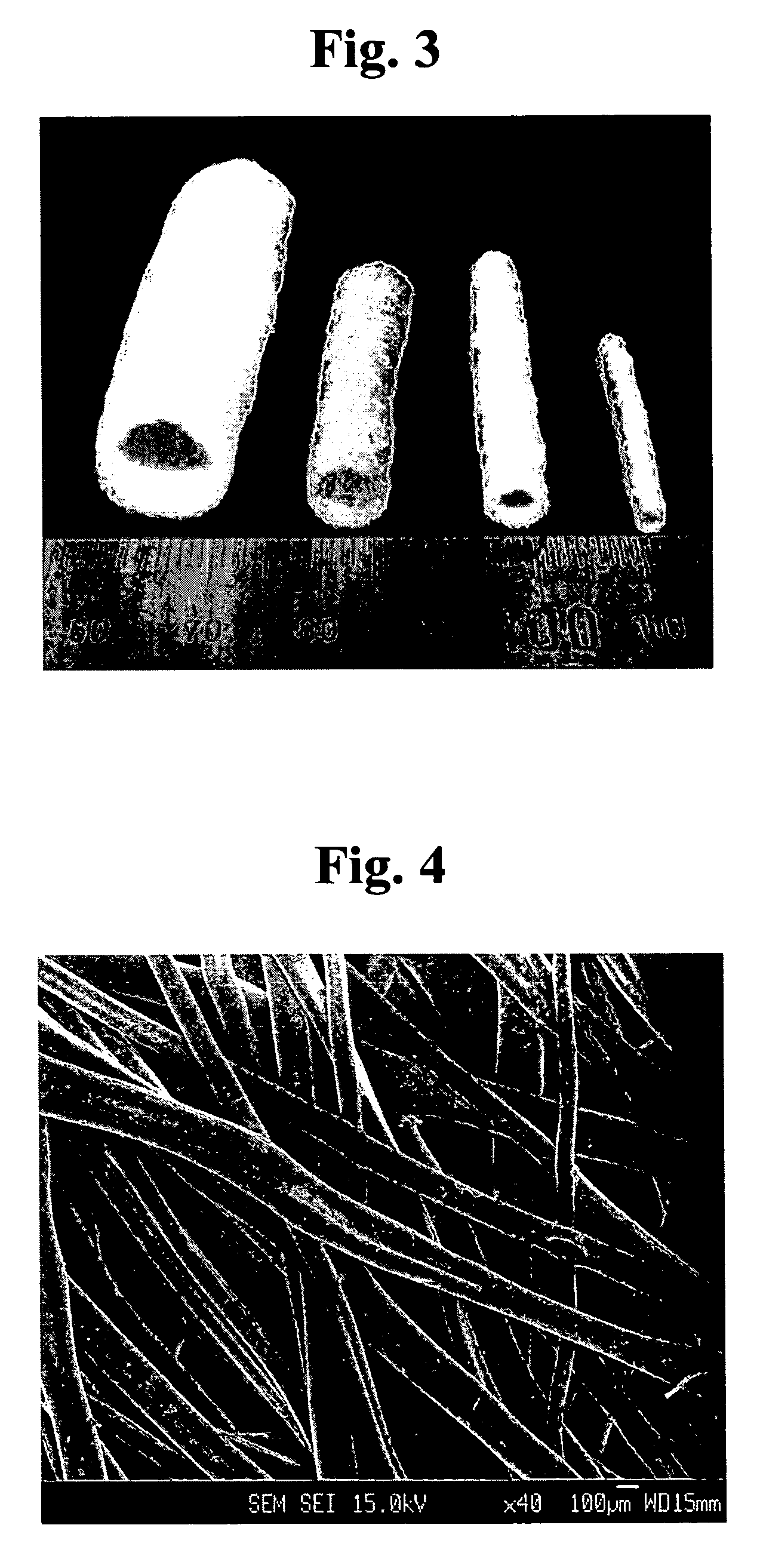

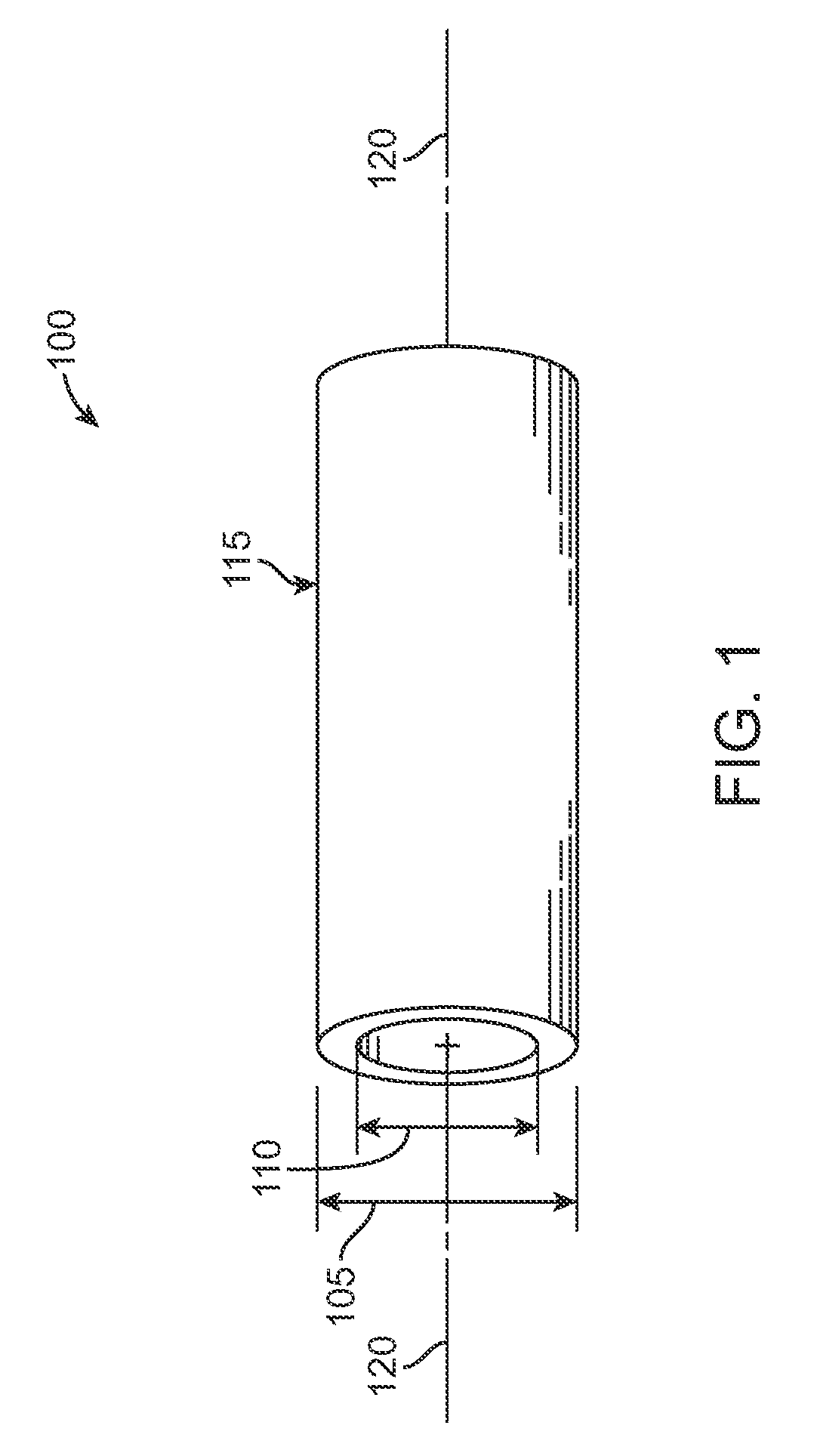

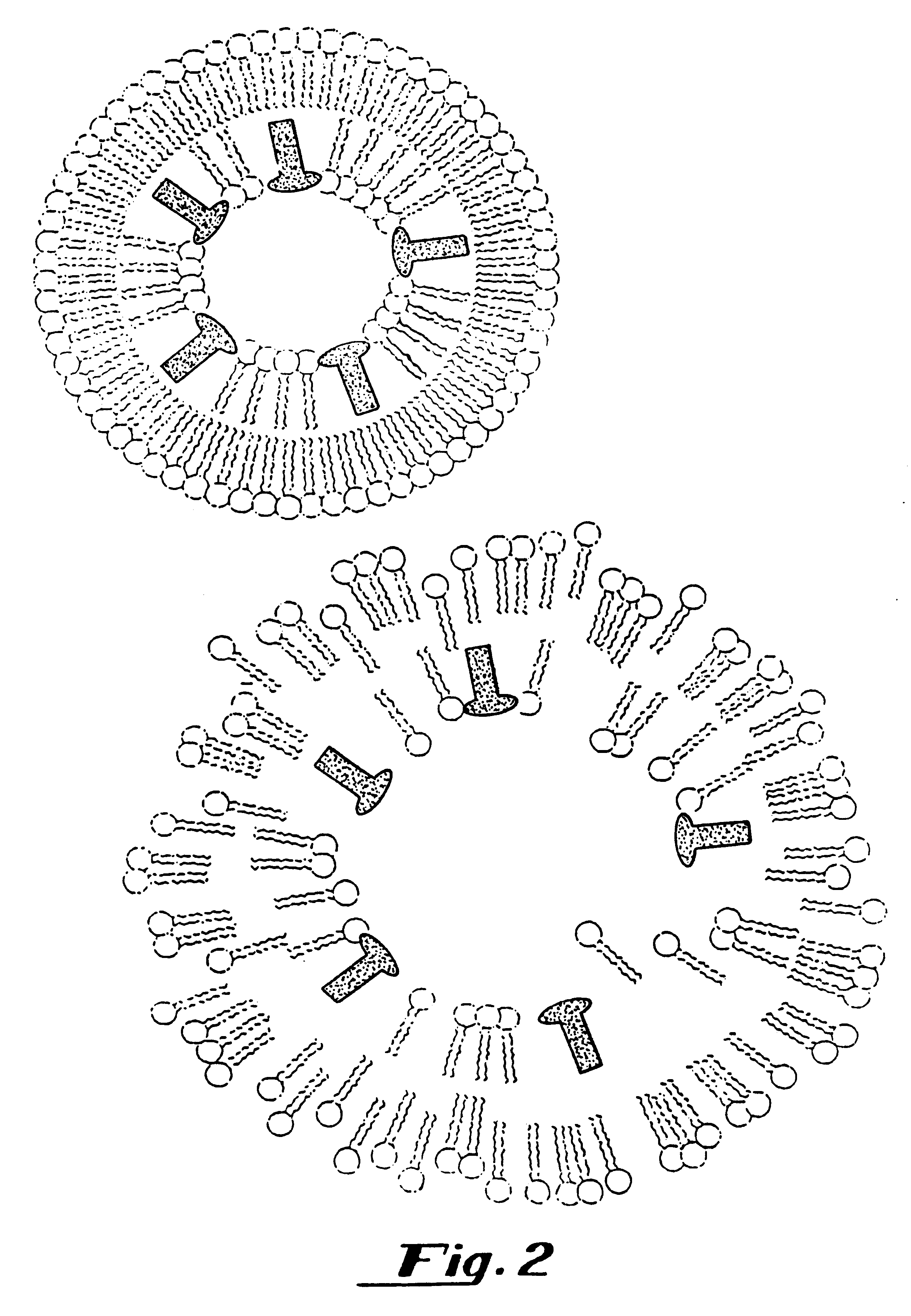

Method for preparing porous polymer scaffold for tissue engineering using gel spinning molding technique

InactiveUS20070009570A1Uniform pore sizeImprove interconnectivitySuture equipmentsCeramic shaping apparatusPolymer scienceSpinning

The present invention relates to a method of preparing a porous polymer scaffold for tissue engineering using a gel spinning molding technique. The method of the present invention can prepare a porous polymer scaffold having a uniform pore size, high interconnectivity between pores and mechanical strength, as well as high cell seeding and proliferation efficiencies, which can be effectively used in tissue engineering applications. Further, the method of the present invention can easily mold a porous polymer scaffold in various types such as a tube type favorable for regeneration of blood vessels, esophagus, nerves and the like, as well as a sheet type favorable for regeneration of skins, muscles and the like, by regulating the shape and size of a template shaft.

Owner:KOREA INST OF SCI & TECH

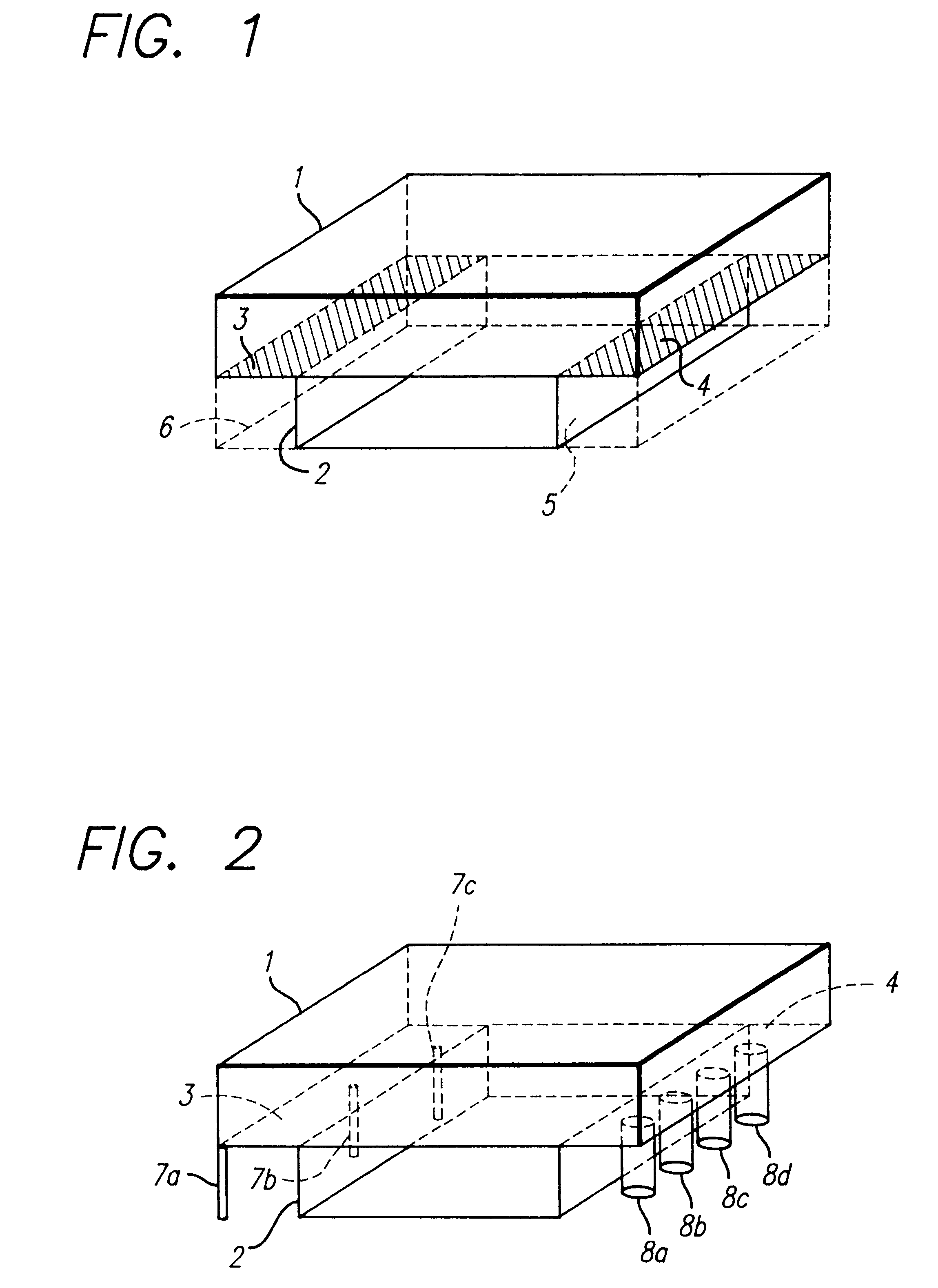

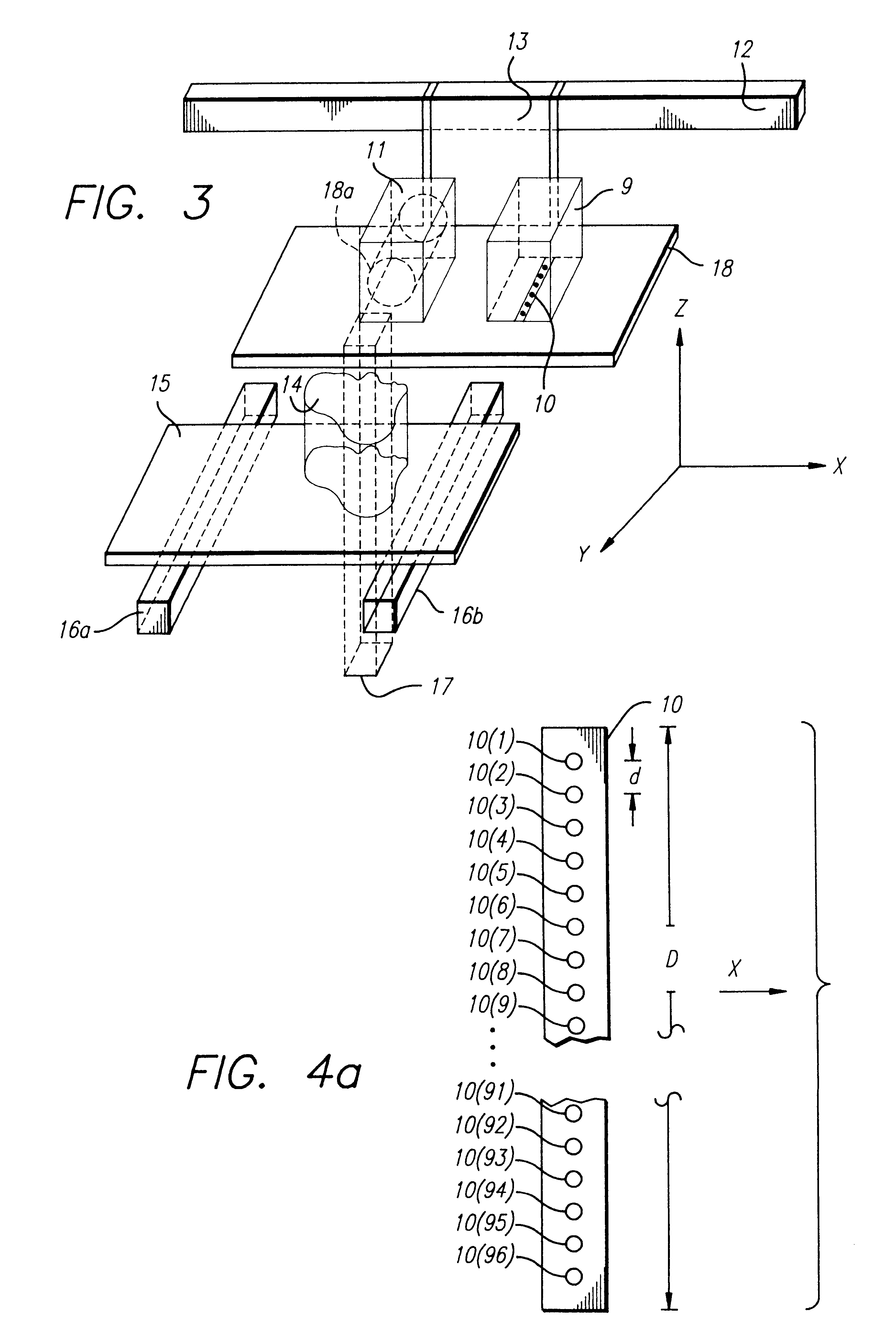

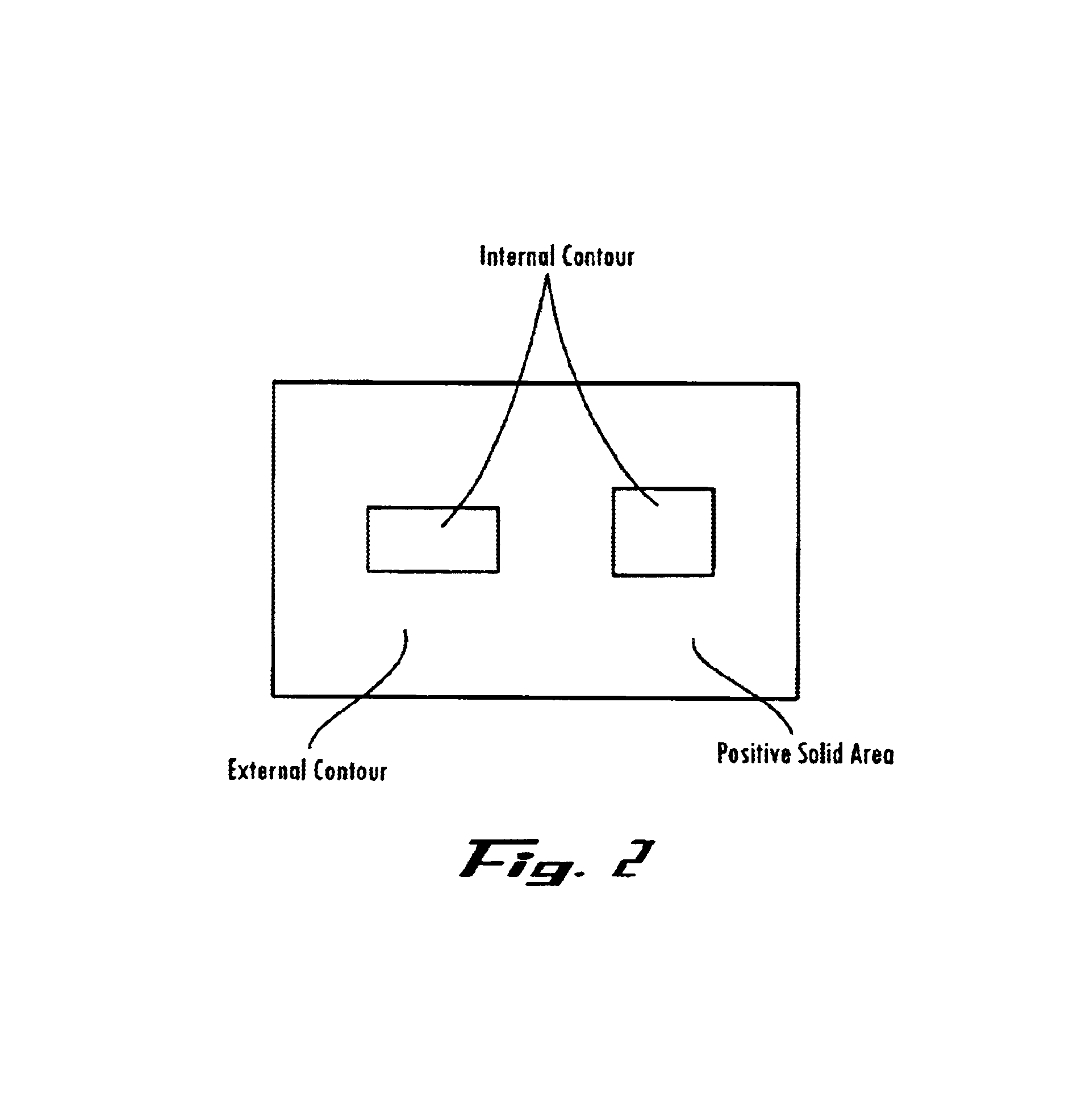

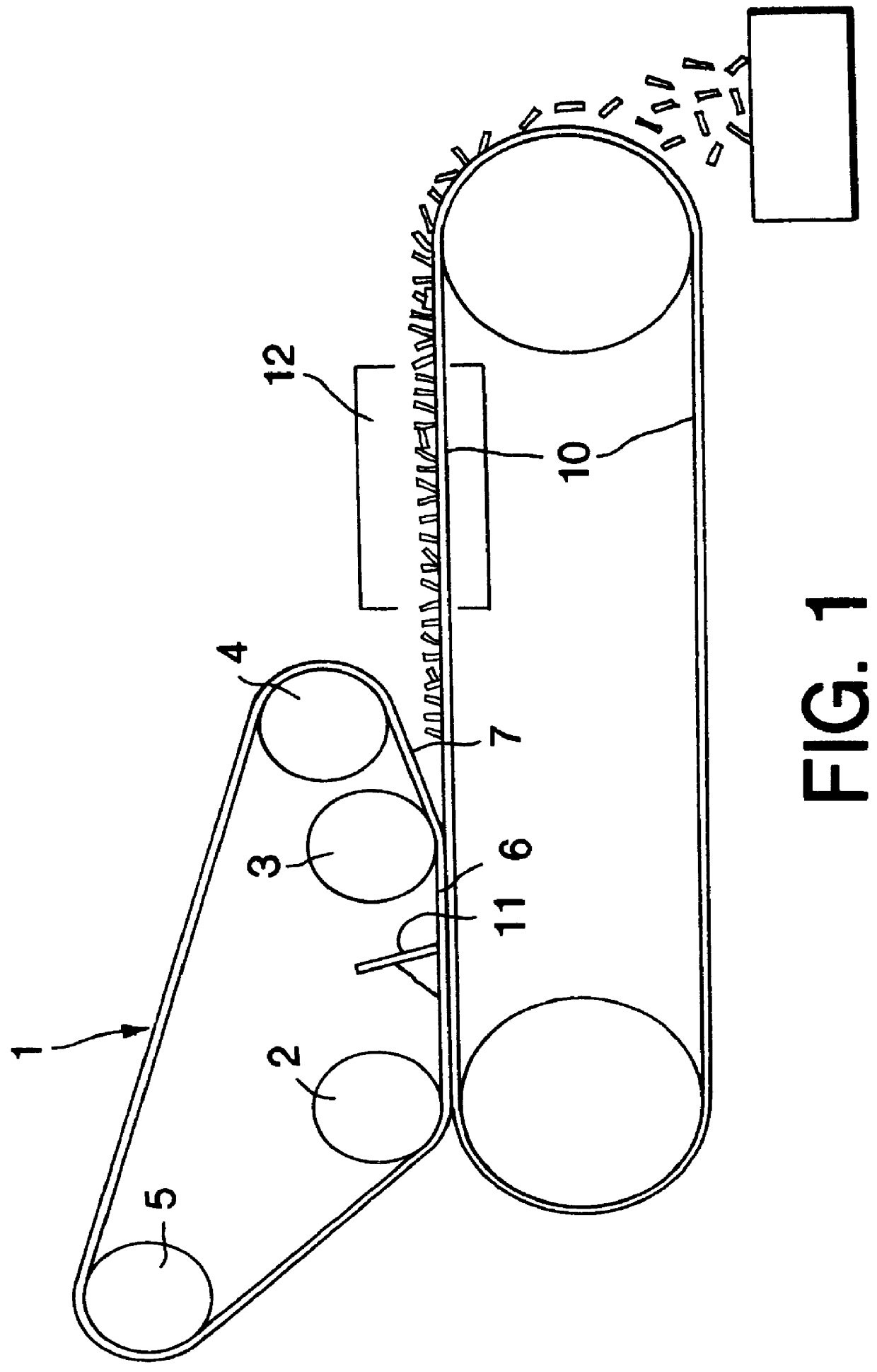

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6193923B1Easy to disassembleMinimal damageAdditive manufacturing apparatusCeramic shaping apparatusEngineeringSelective deposition

A variety of support structures and build styles for use in Rapid Prototyping and Manufacturing systems are described wherein particular emphasis is given to Thermal Stereolithography, Fused Deposition Modeling, and Selective Deposition Modeling systems, and wherein a 3D modeling system is presented which uses multijet dispensing and a single material for both object and support formation.

Owner:3D SYST INC

Imprint mold and method for making using sidewall spacer line doubling

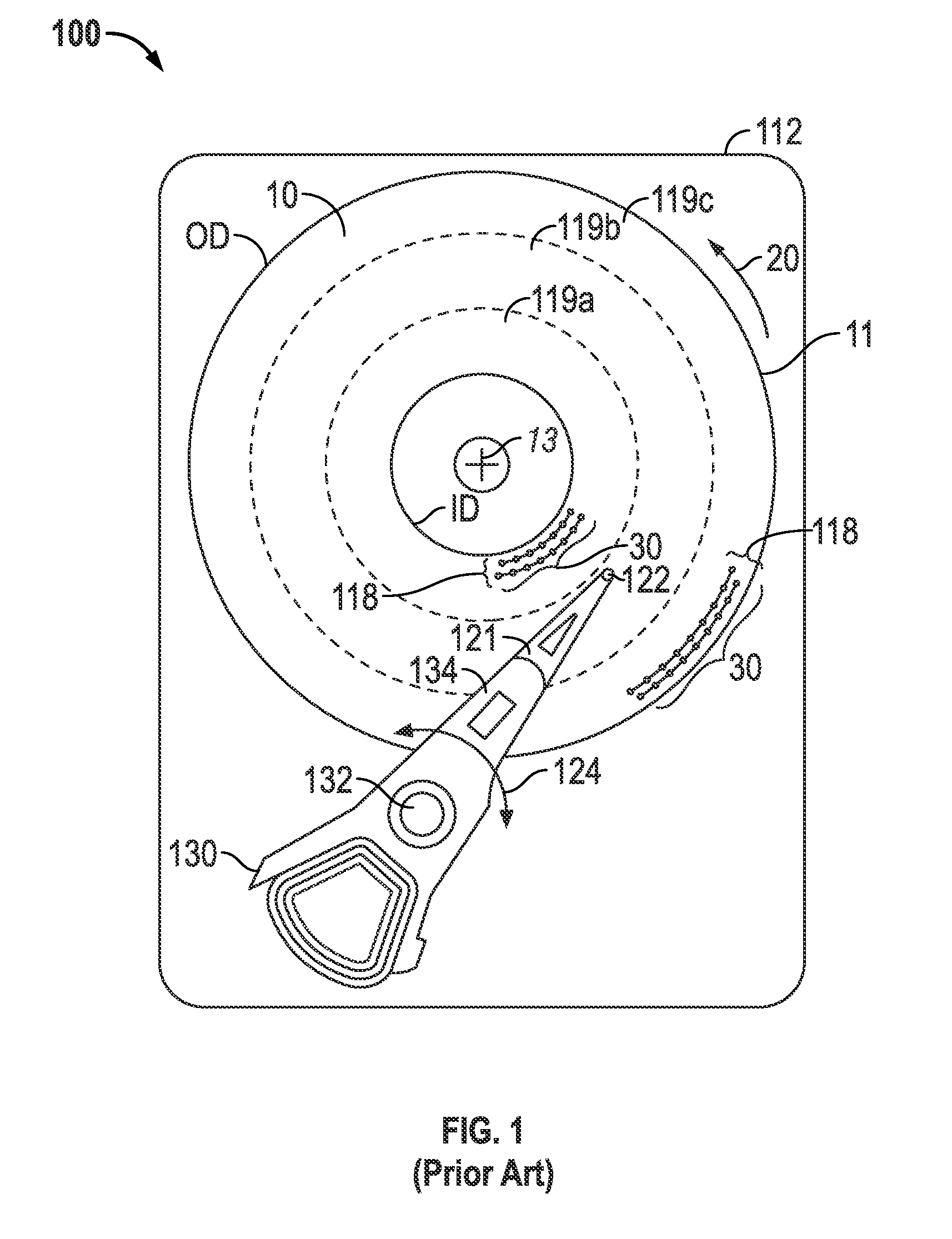

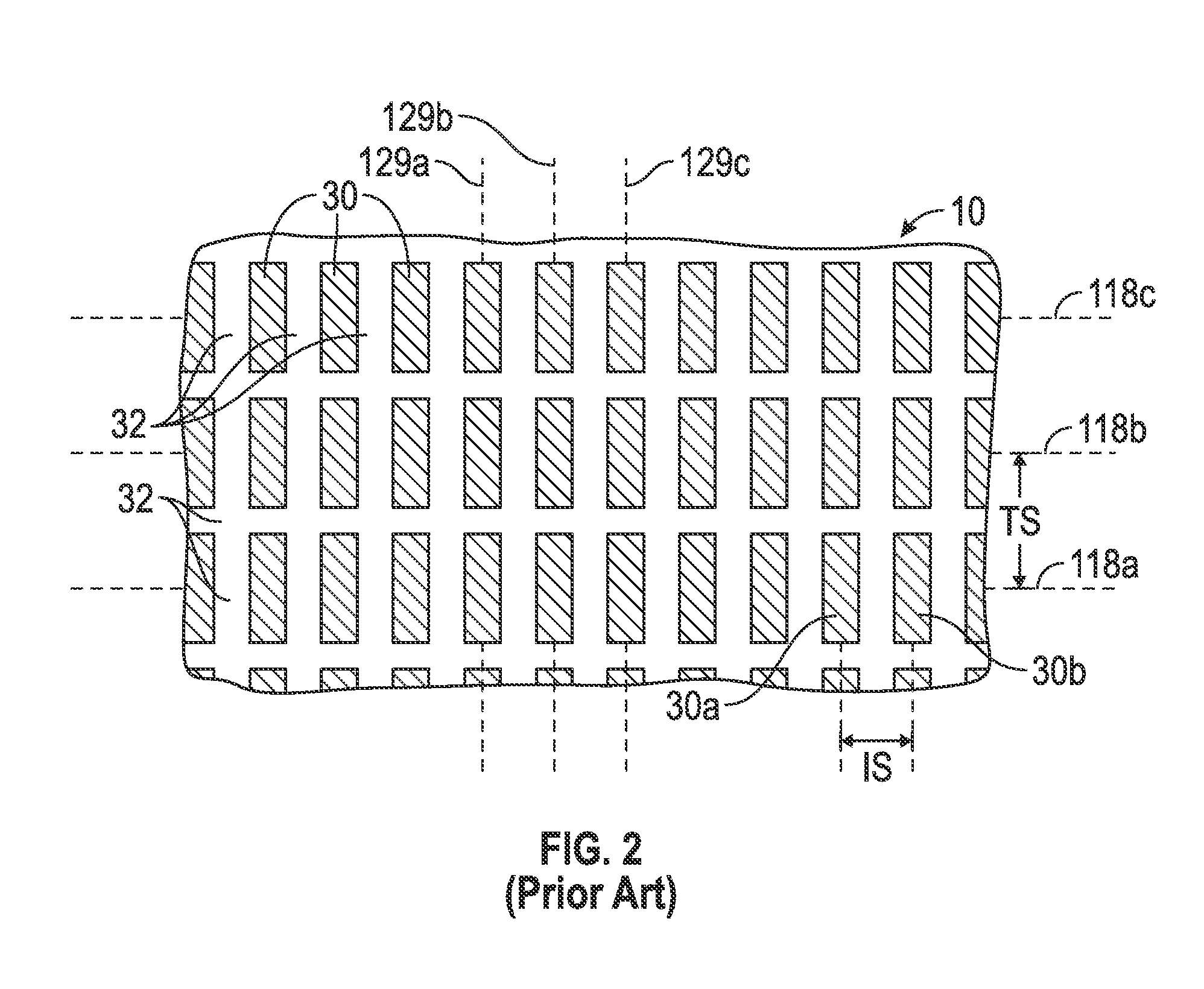

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

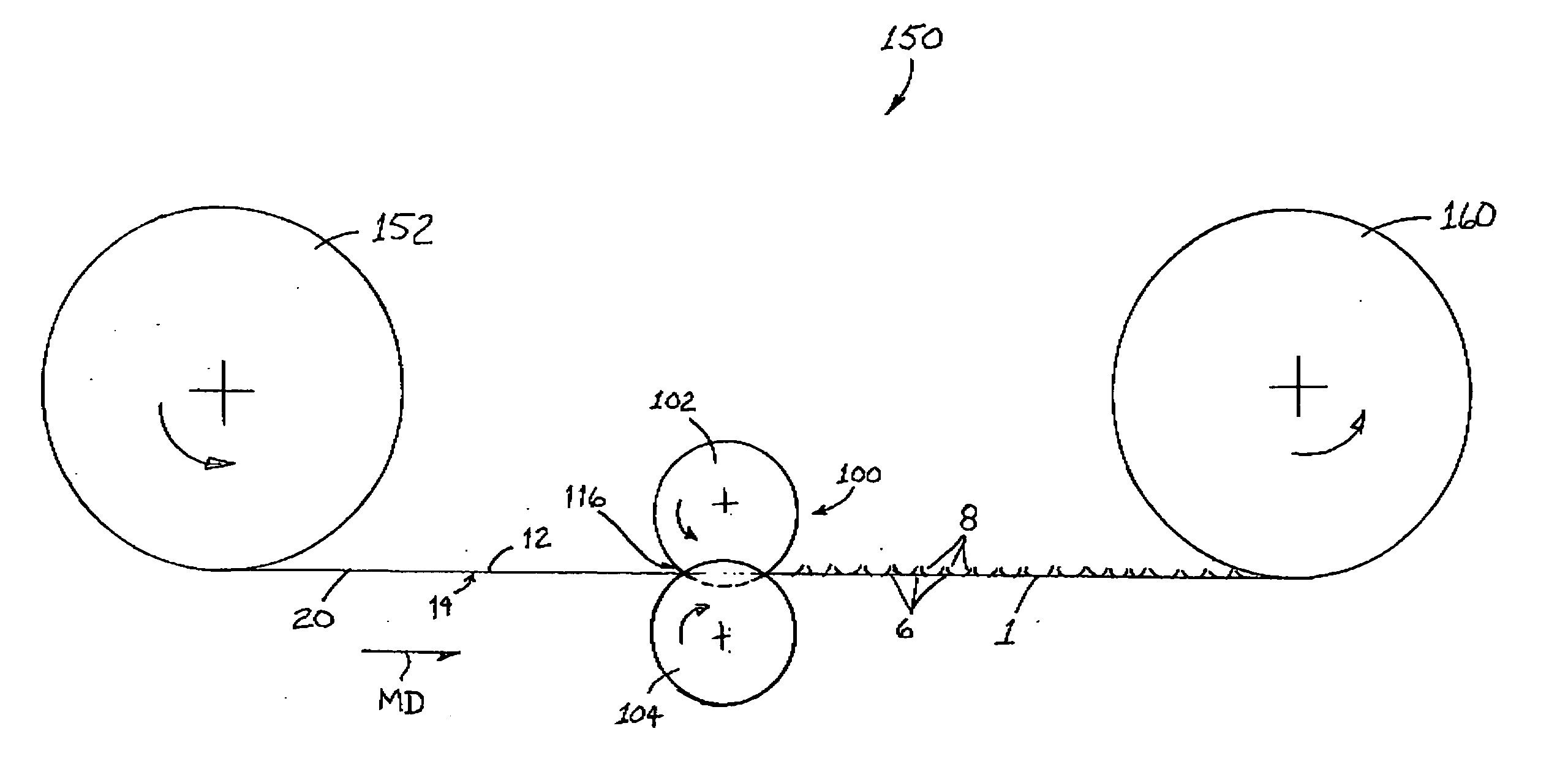

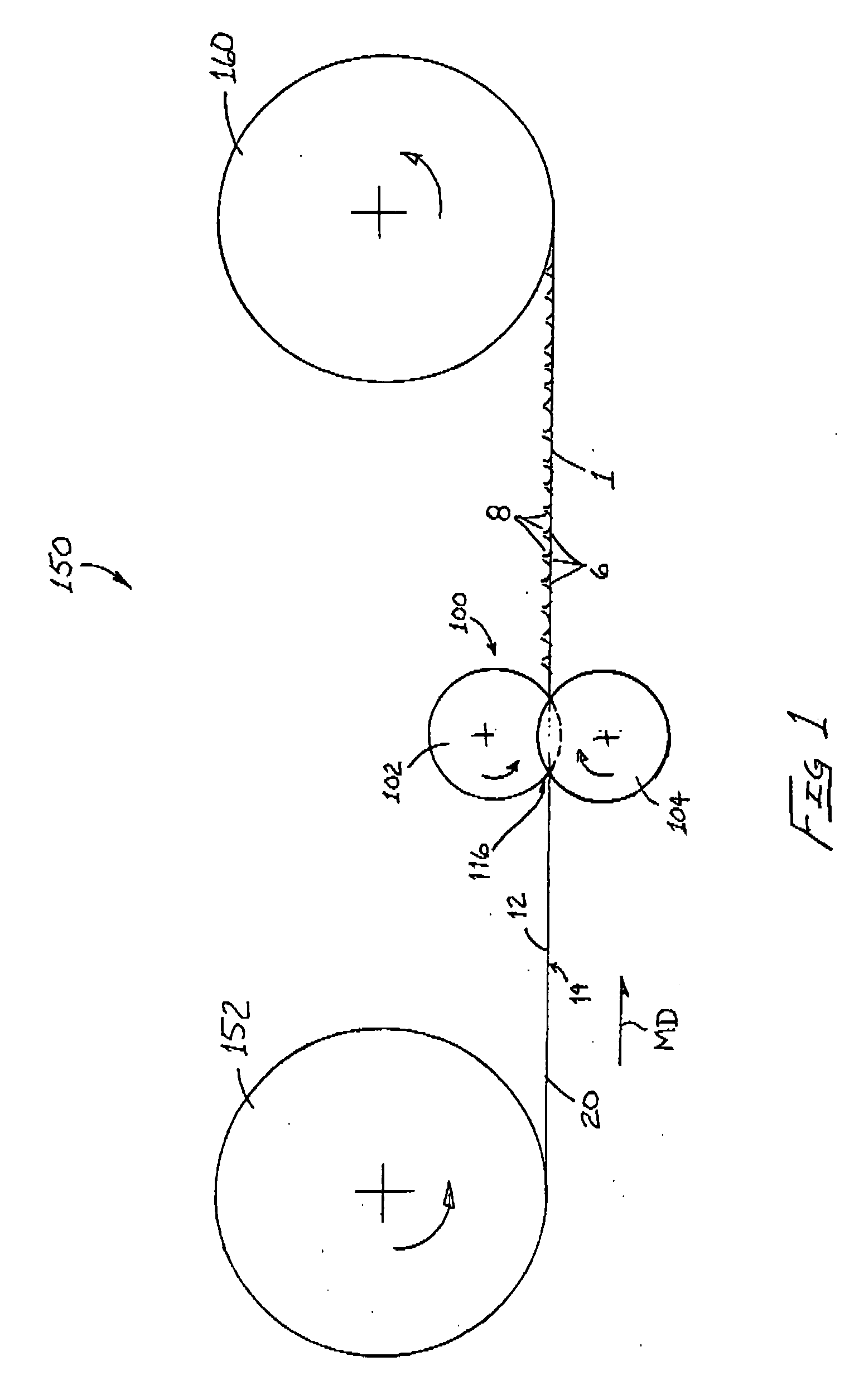

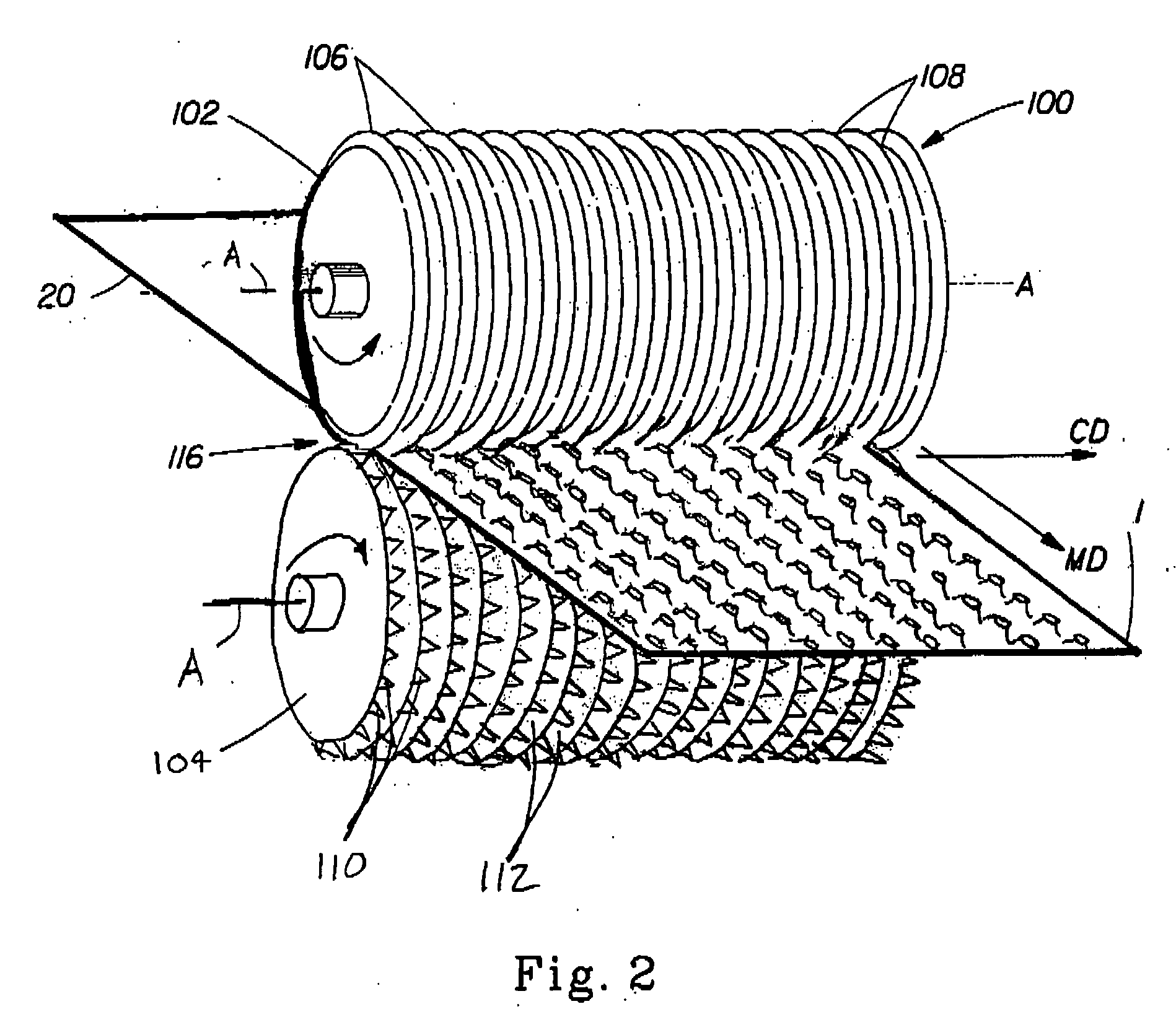

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

Polymer solution for nanoimprint lithography to reduce imprint temperature and pressure

InactiveUS20040110856A1Reduce pressureReduce the temperatureNanostructure manufactureDecorative surface effectsCross-linkVitrification

A method of forming features on substrates by imprinting is provided. The method comprises: (a) forming a polymer solution comprising at least one polymer dissolved in at least one polymerizable monomer; and (b) depositing the polymer solution on a substrate to form a liquid film thereon; and then either: (c) curing the liquid film by causing the monomer(s) to polymerize and optionally cross-linking the polymer(s) to thereby form a polymer film, the polymer film having a glass transition temperature (Tg); and imprinting the polymer film with a mold having a desired pattern to form a corresponding negative pattern in the polymer film, or (d) imprinting the liquid film with the mold and curing it to form the polymer film. The temperature of imprinting is as little as 10° C. above the Tg, or even less if the film is in the liquid state. The pressure of the imprinting can be within the range of 100 to 500 psi.

Owner:HEWLETT PACKARD DEV CO LP

Three-Dimensional Adhesive Device Having a Microelectronic System Embedded Therein

InactiveUS20080275327A1Simple and inexpensive wayModerate viscosityWave amplification devicesLayered productsCapacitanceElectronic systems

Accordingly, the present invention relates to a three-dimensional adhesive device to be attached to the body surface of a mammal comprising a microelectronic sensing system characterized by(a) a three-dimensional adhesive body made of a pressure sensitive adhesive having an upper surface and a bottom surface;(b) a microelectronic system embedded in the body of the pressure sensitive adhesive;(c) one or more cover layer(s) attached to the upper surface; and(d) optionally a release liner releasable attached to the bottom surface of the adhesive device.Suitably the microelectronic system is a microelectronic sensing system capable of sensing physical input such as pressure, vibration, sound, electrical activity (e.g. from muscle activity), tension, blood-flow, moisture, temperature, enzyme activity, bacteria, pH, blood sugar, conductivity, resistance, capacitance, inductance or other chemical, biochemical, biological, mechanical or electrical properties.

Owner:BRAEMAR MFG +2

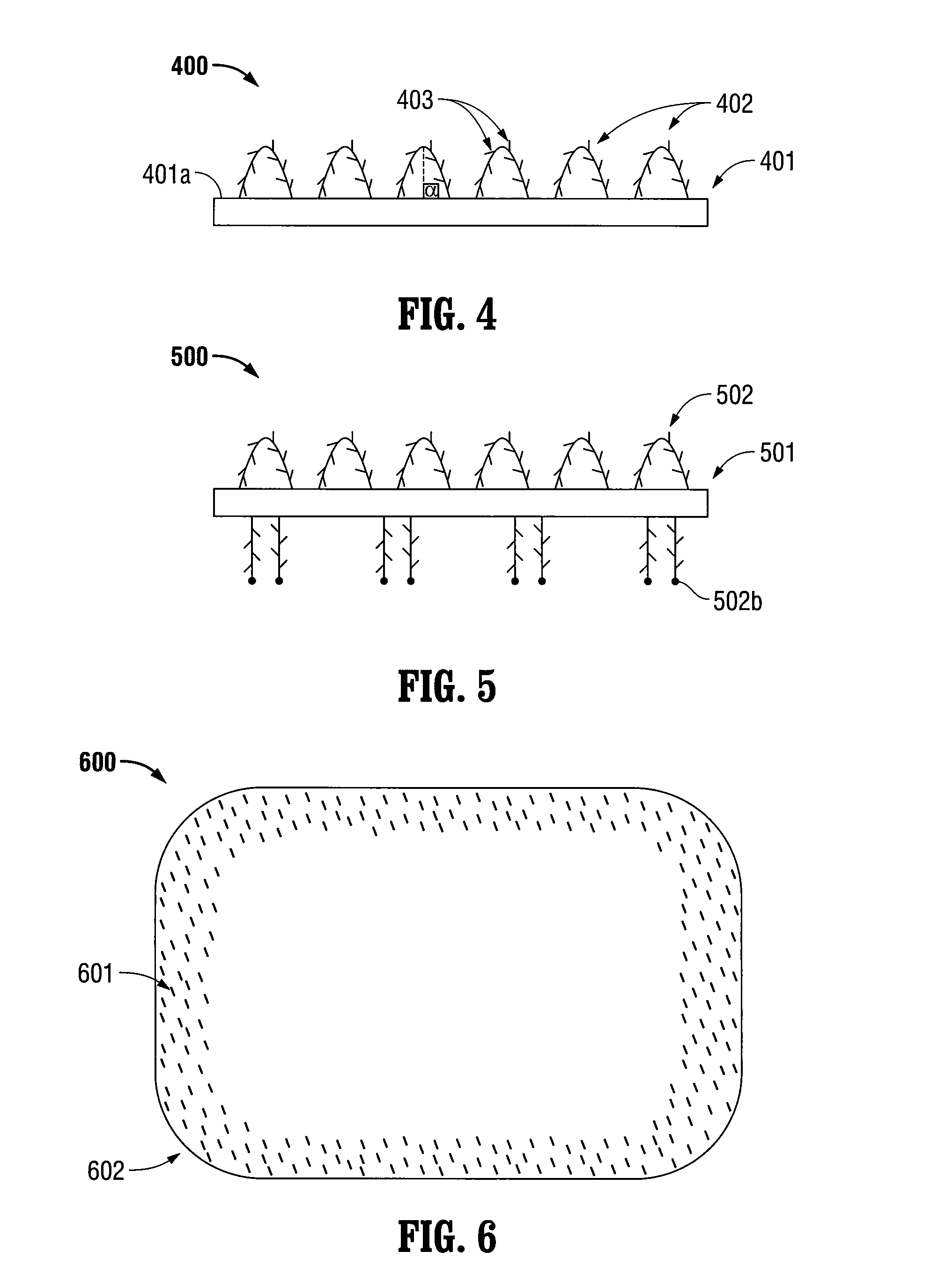

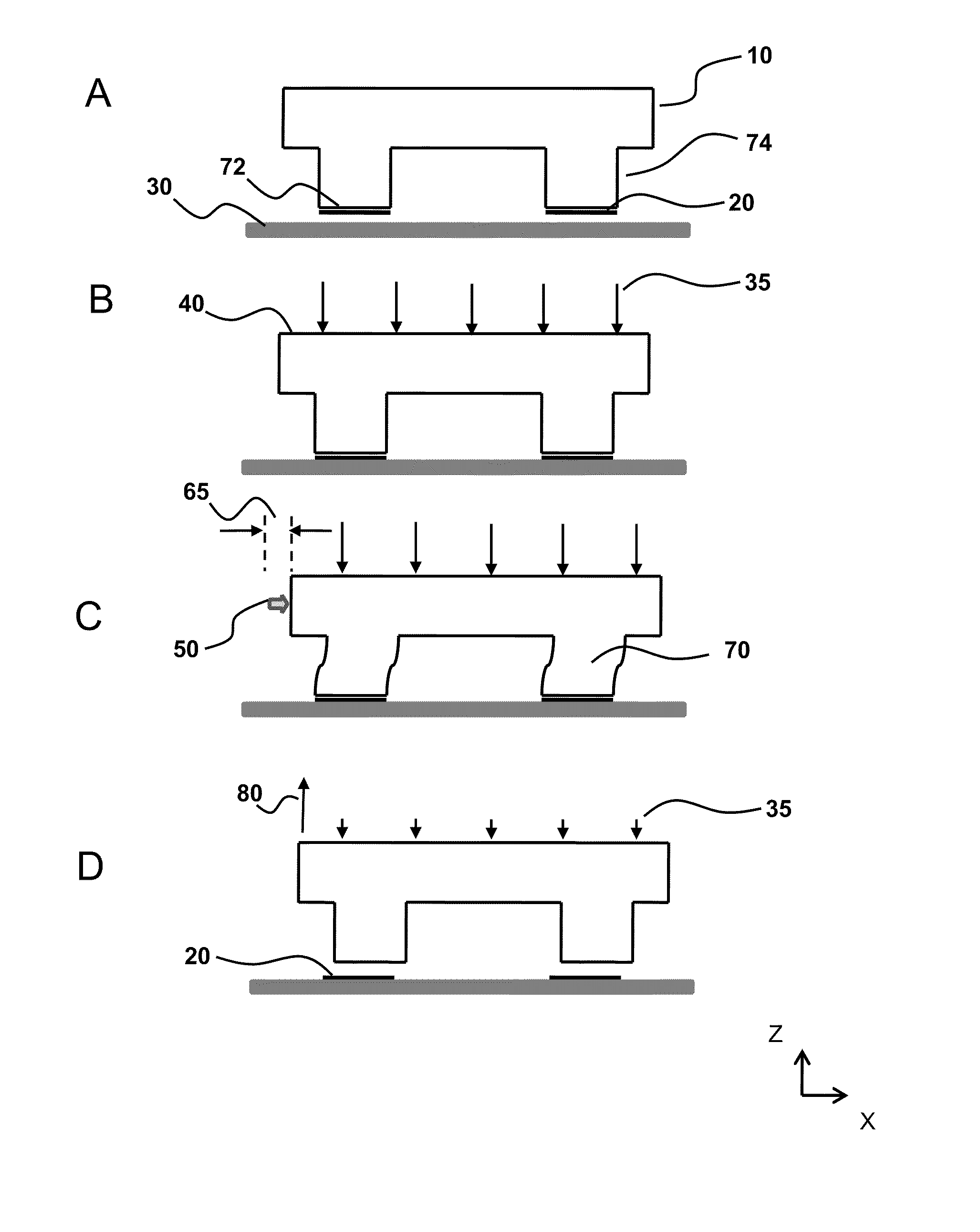

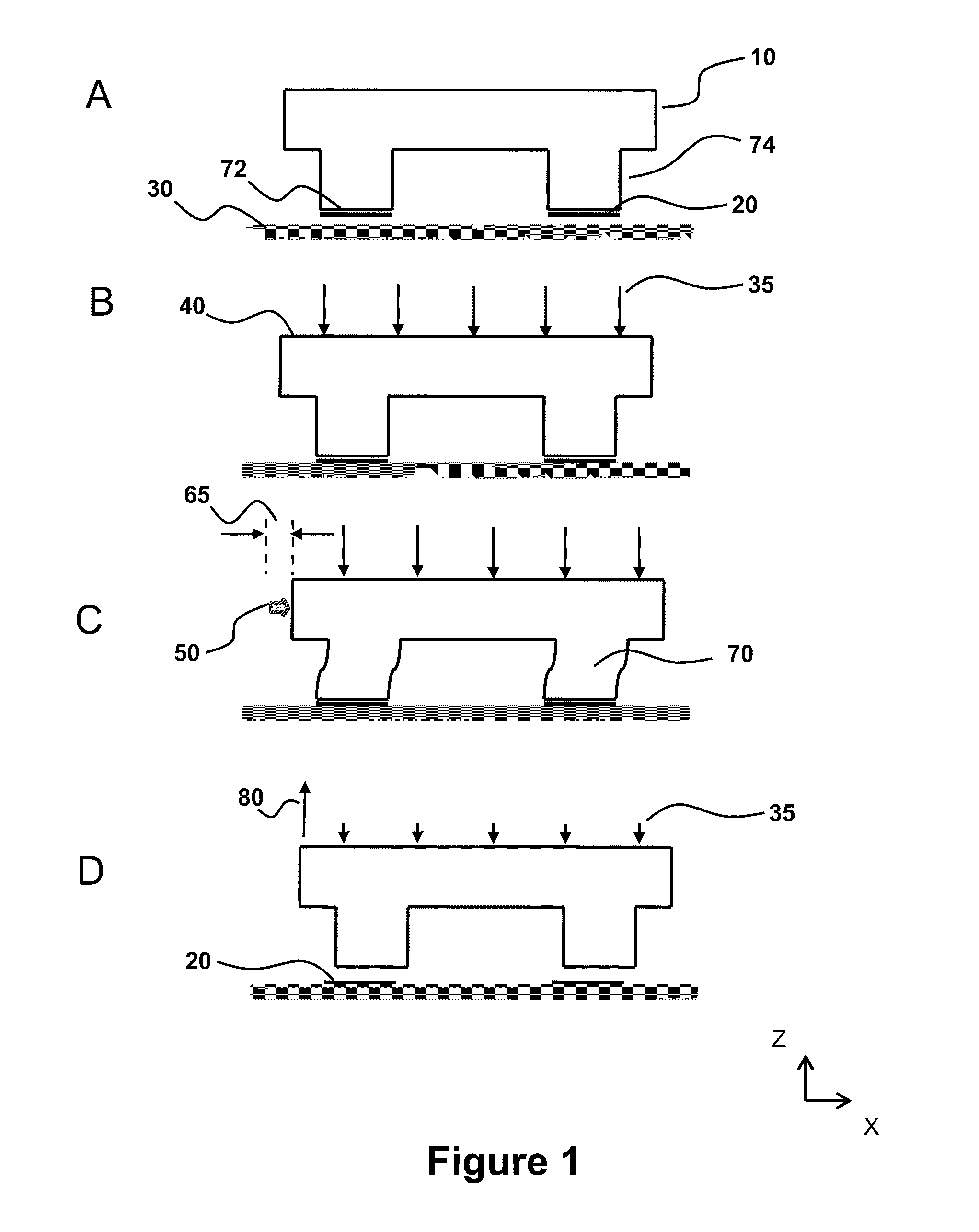

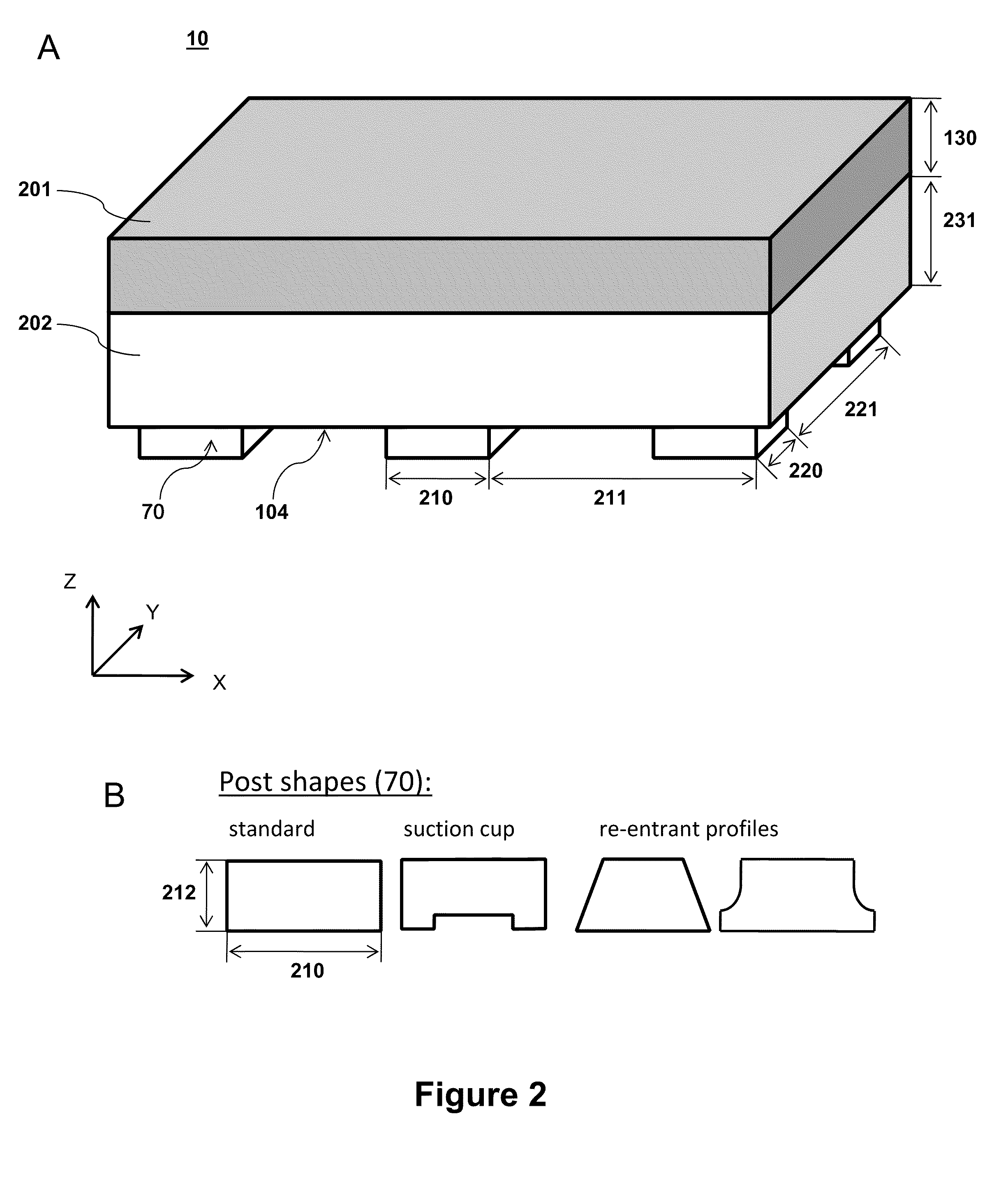

Printing semiconductor elements by shear-assisted elastomeric stamp transfer

ActiveUS8506867B2Sacrificing printing yield and accuracyIncrease chanceConfectionerySolid-state devicesEngineeringVertical displacement

Provided are methods and devices for transfer printing of semiconductor elements to a receiving surface. In an aspect, the printing is by conformal contact between an elastomeric stamp inked with the semiconductor elements and a receiving surface, and during stamp removal, a shear offset is applied between the stamp and the receiving surface. The shear-offset printing process achieves high printing transfer yields with good placement accuracy. Process parameter selection during transfer printing, including time varying stamp-backing pressure application and vertical displacement, yields substantially constant delamination rates with attendant transfer printing improvement.

Owner:X DISPLAY CO TECH LTD

Solid free-form fabrication methods for the production of dental restorations

InactiveUS20050023710A1Improve bindingImpression capsCeramic shaping apparatusPolymer scienceFree form

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

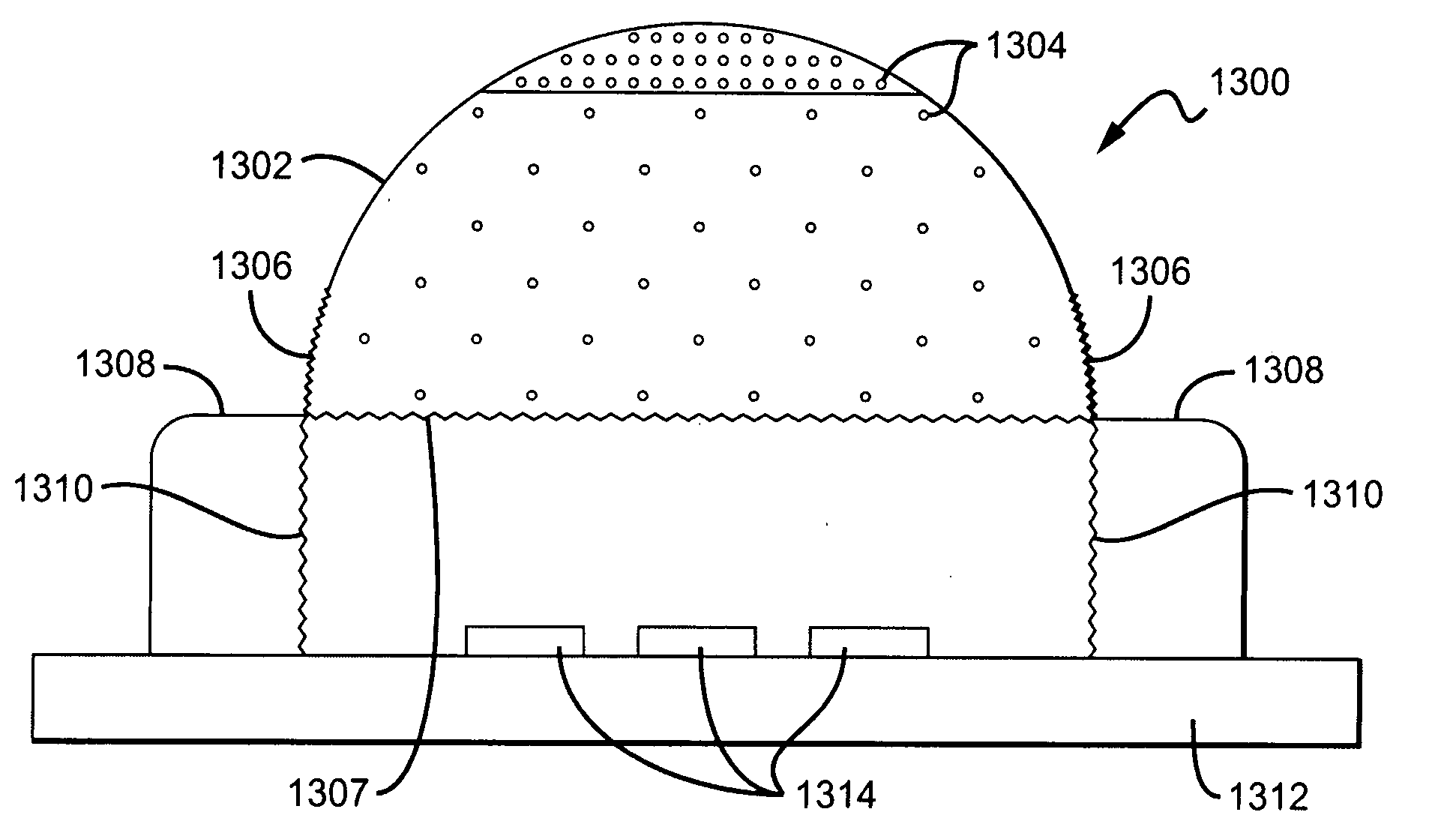

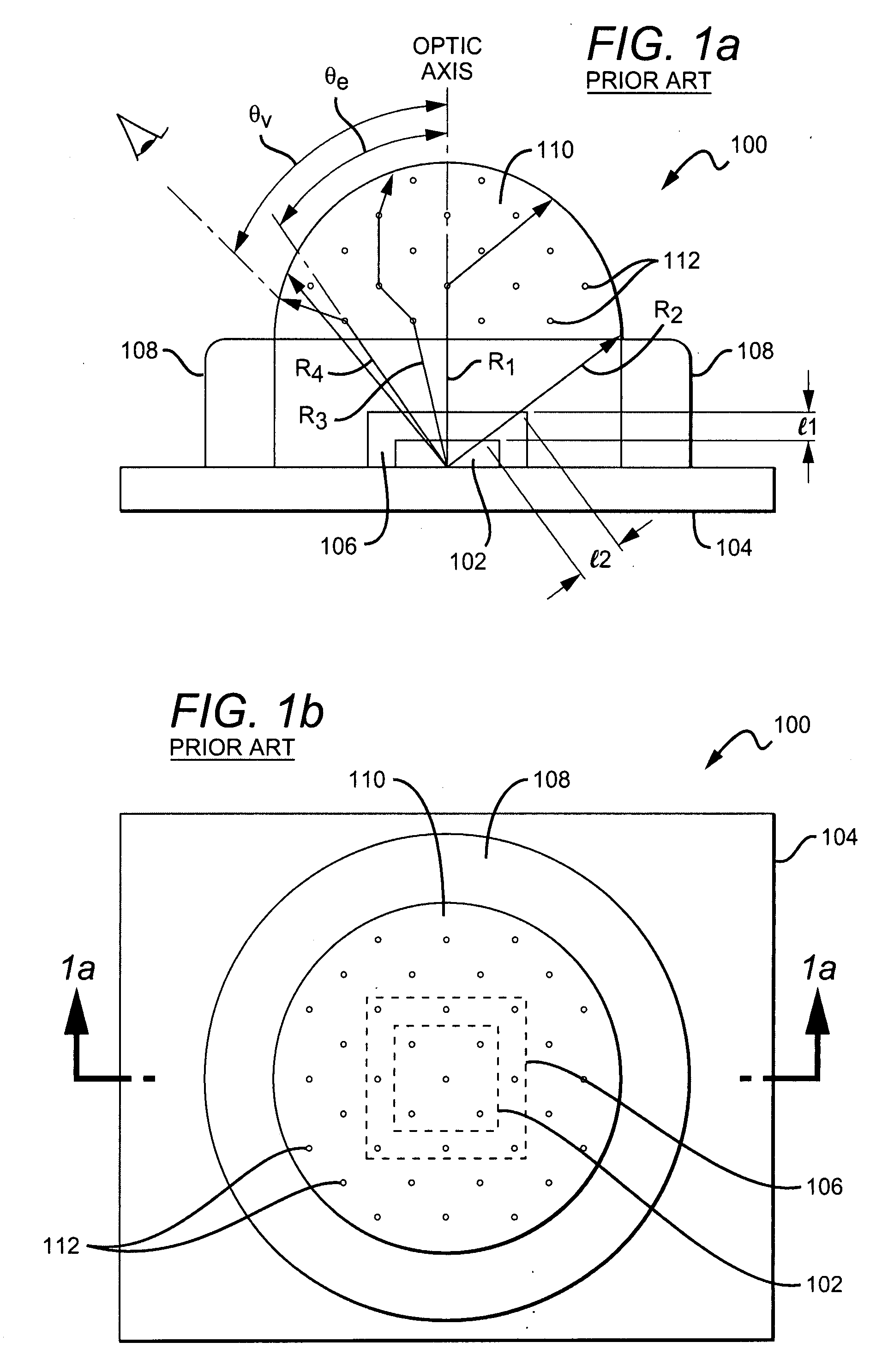

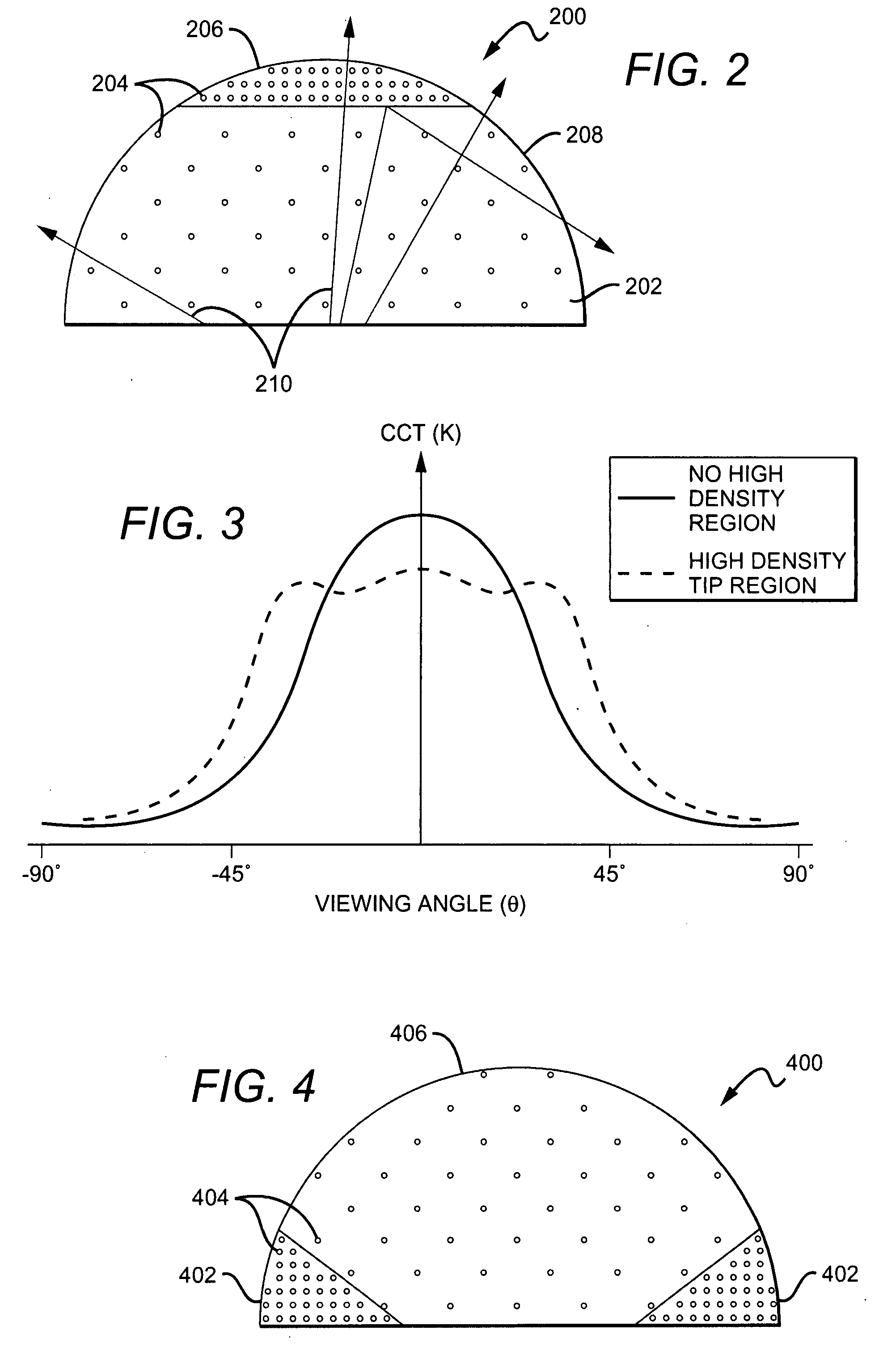

Encapsulant with scatterer to tailor spatial emission pattern and color uniformity in light emitting diodes

ActiveUS20080308825A1Solid-state devicesSemiconductor/solid-state device manufacturingHigh densityLight beam

A light emitting device having an encapsulant with scattering features to tailor the spatial emission pattern and color temperature uniformity of the output profile. The encapsulant is formed with materials having light scattering properties. The concentration of these light scatterers is varied spatially within the encapsulant and / or on the surface of the encapsulant. The regions having a high density of scatterers are arranged in the encapsulant to interact with light entering the encapsulant over a desired range of source emission angles. By increasing the probability that light from a particular range of emission angles will experience at least one scattering event, both the intensity and color temperature profiles of the output light beam can be tuned.

Owner:CREELED INC

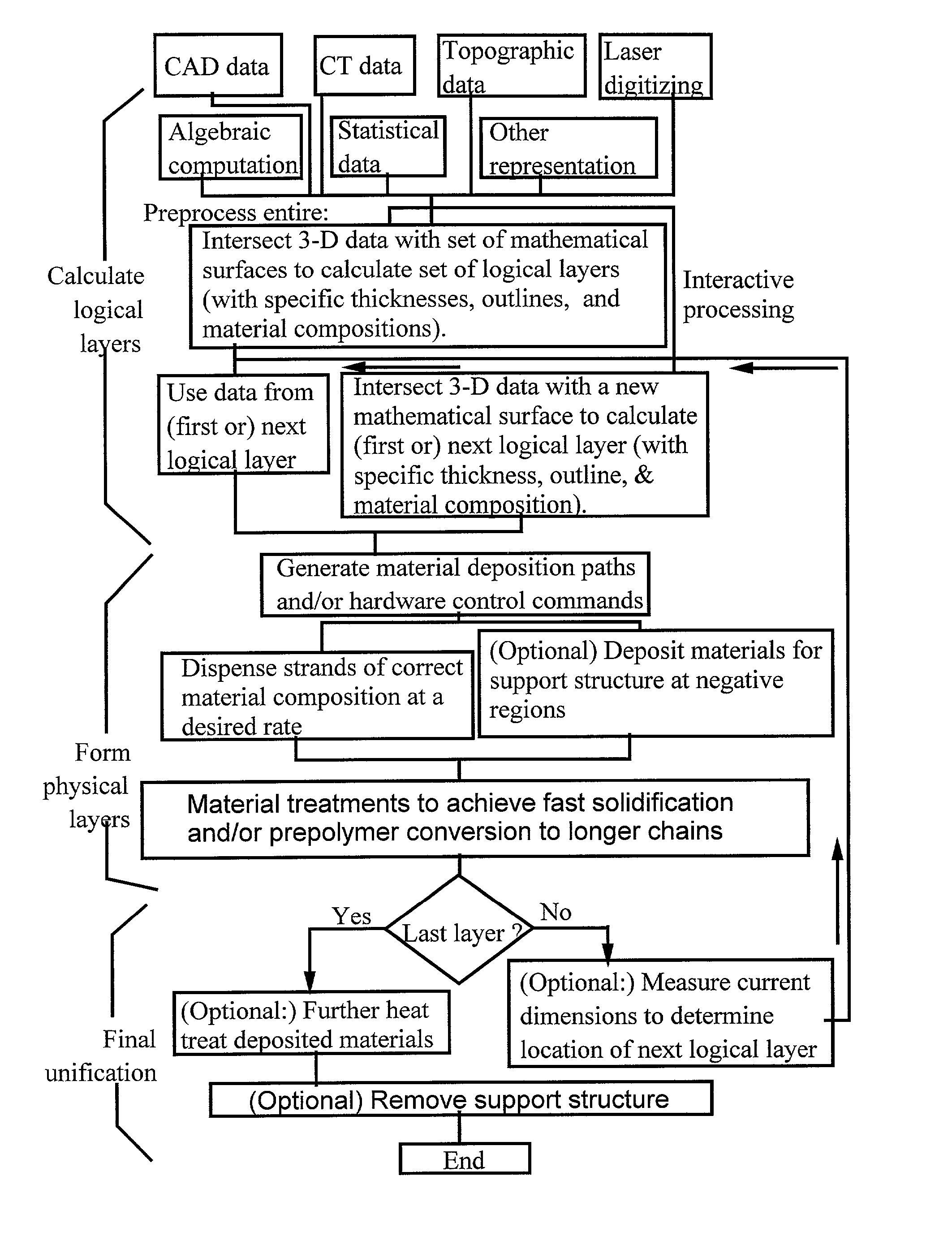

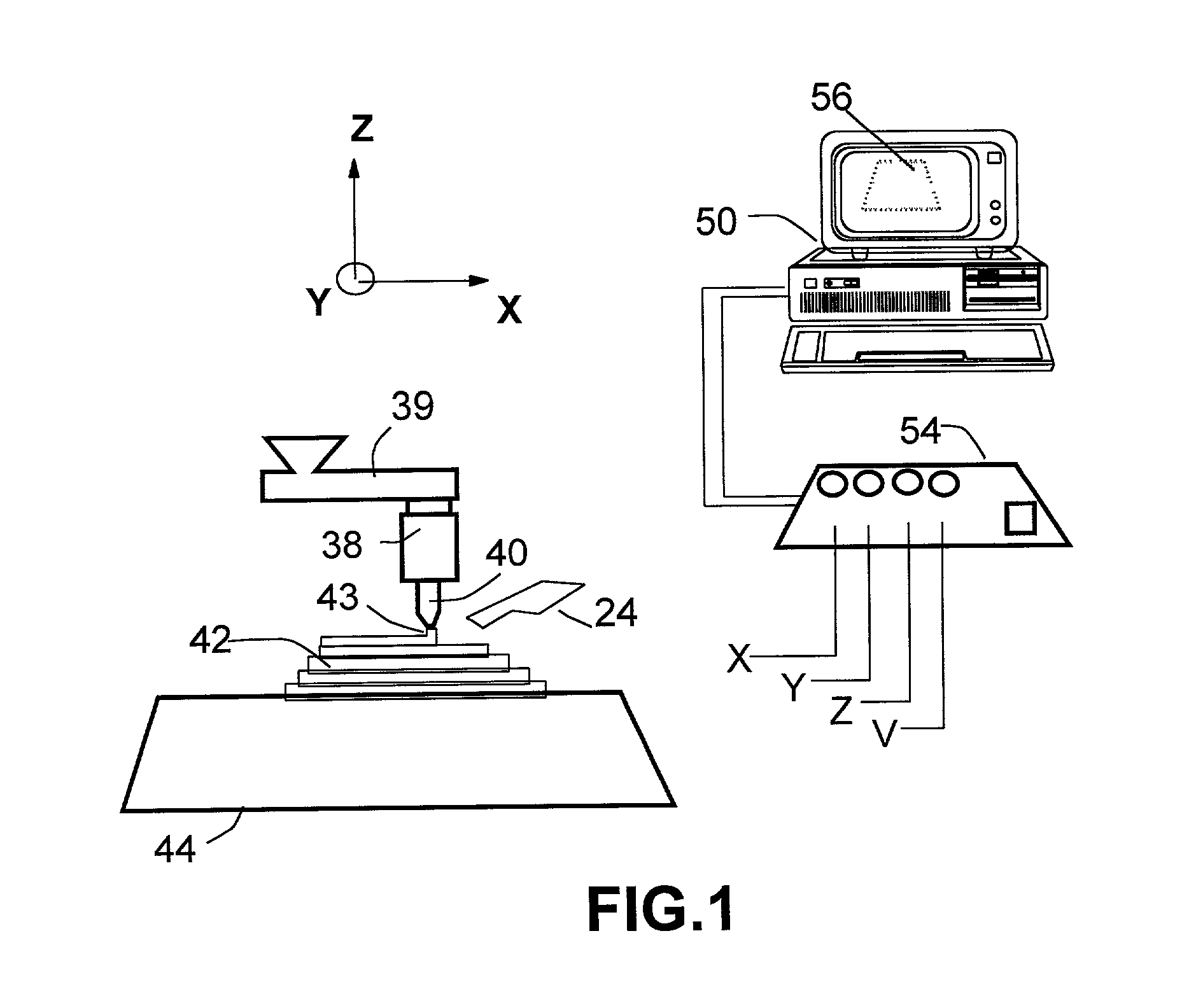

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

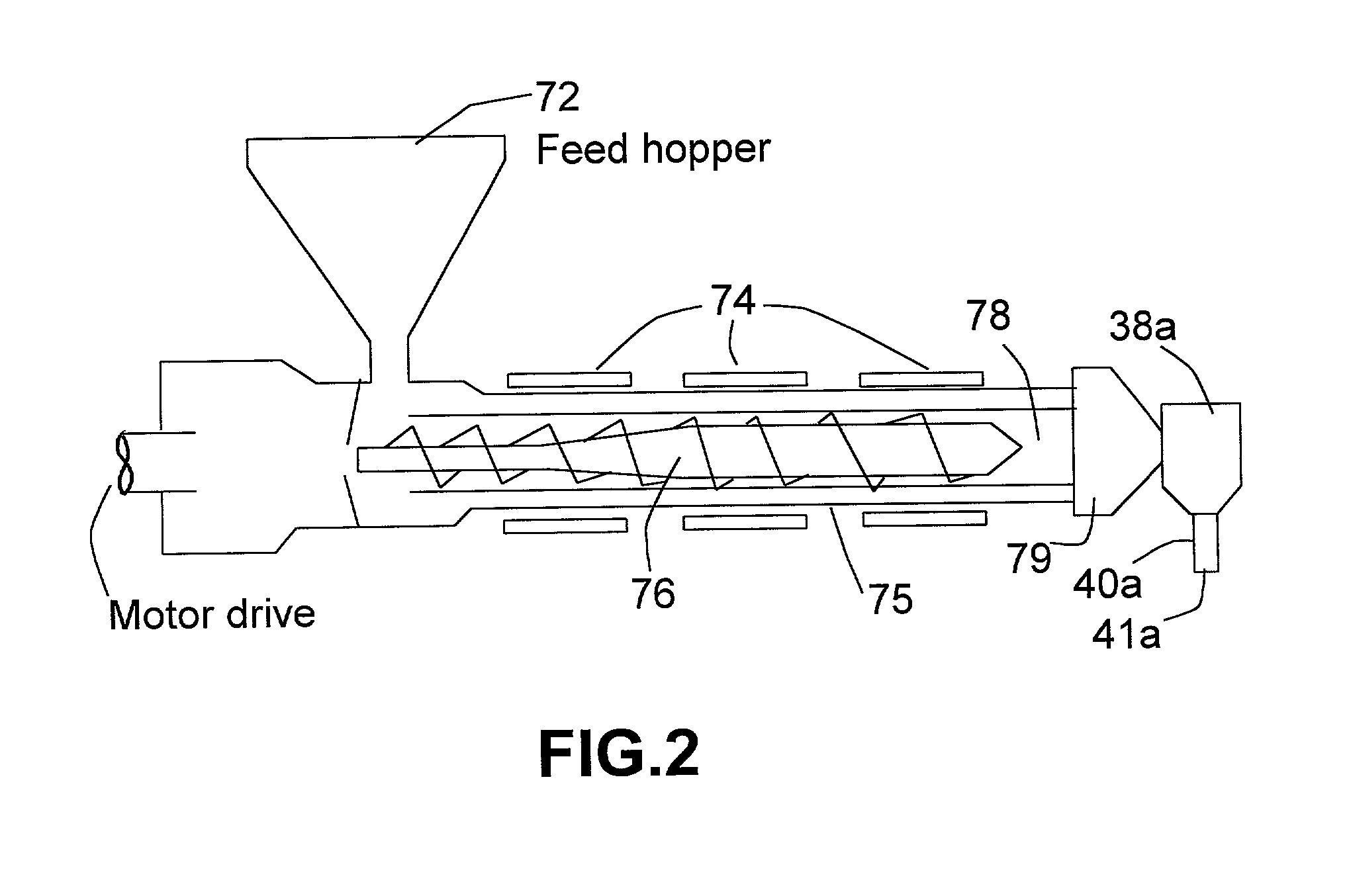

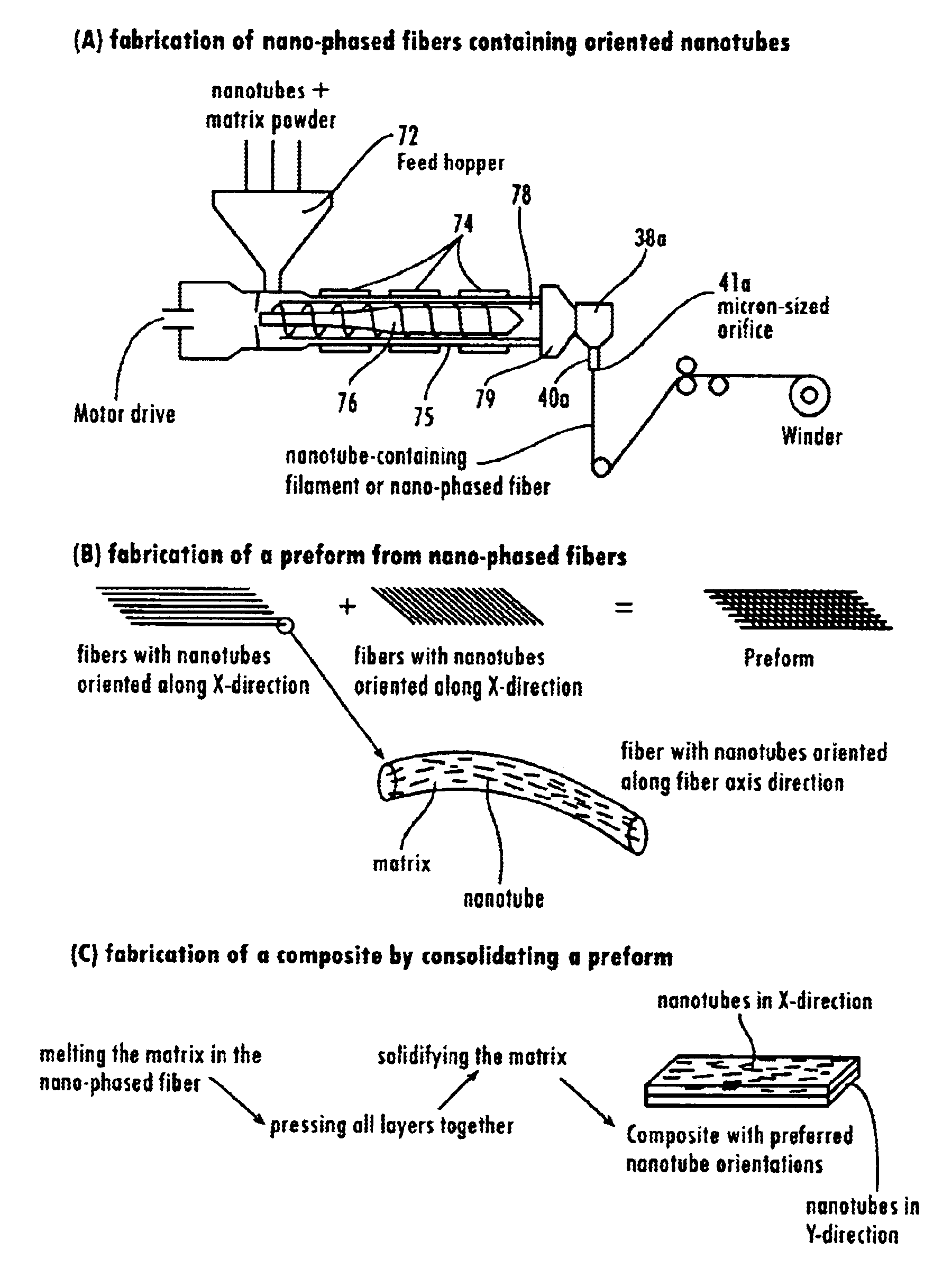

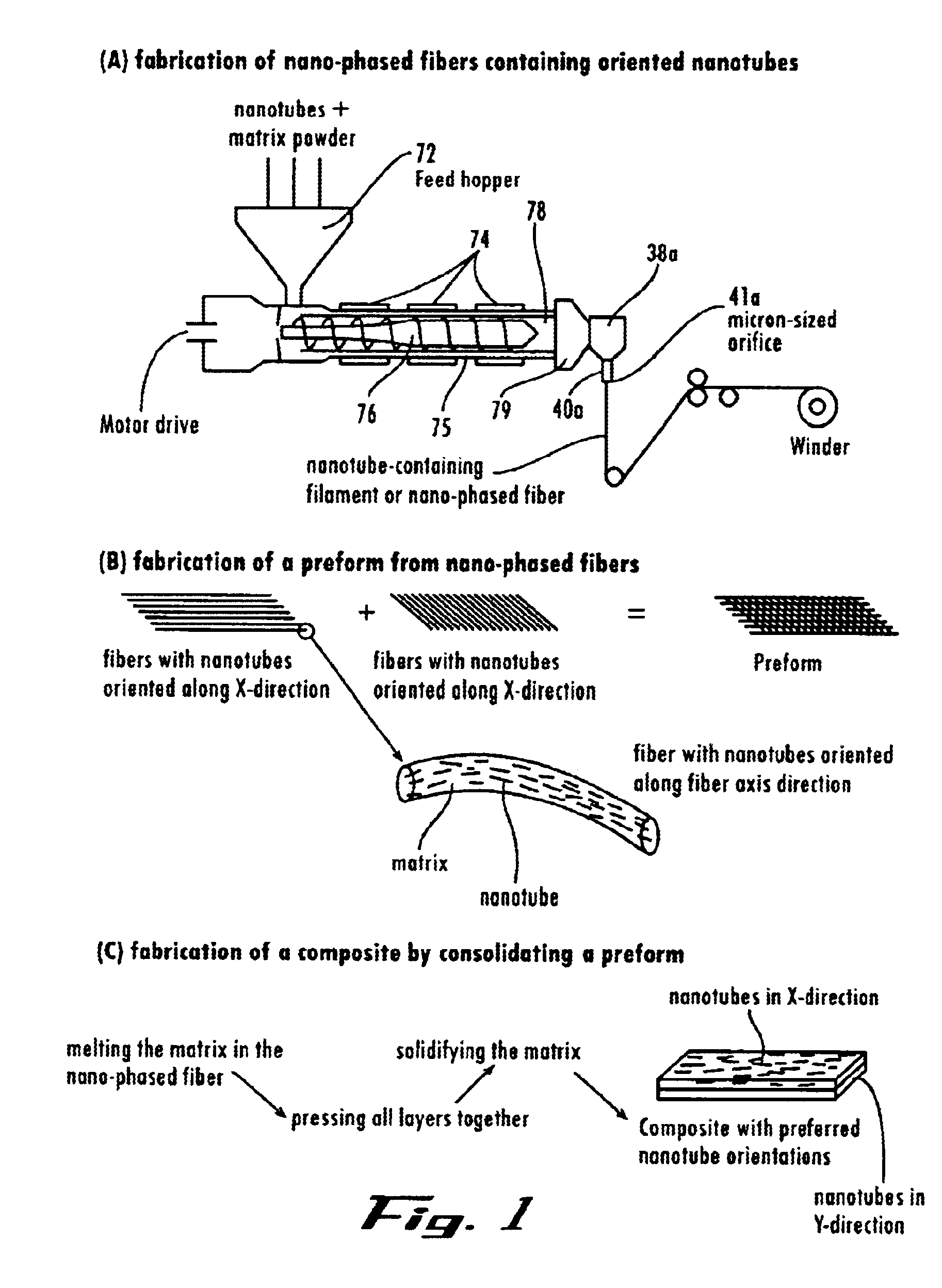

Nanotube fiber reinforced composite materials and method of producing fiber reinforced composites

InactiveUS6934600B2Requires minimizationGenerate efficientlyMaterial nanotechnologyAdditive manufacturing apparatusFiber-reinforced compositeMotion controller

Owner:AUBURN UNIV

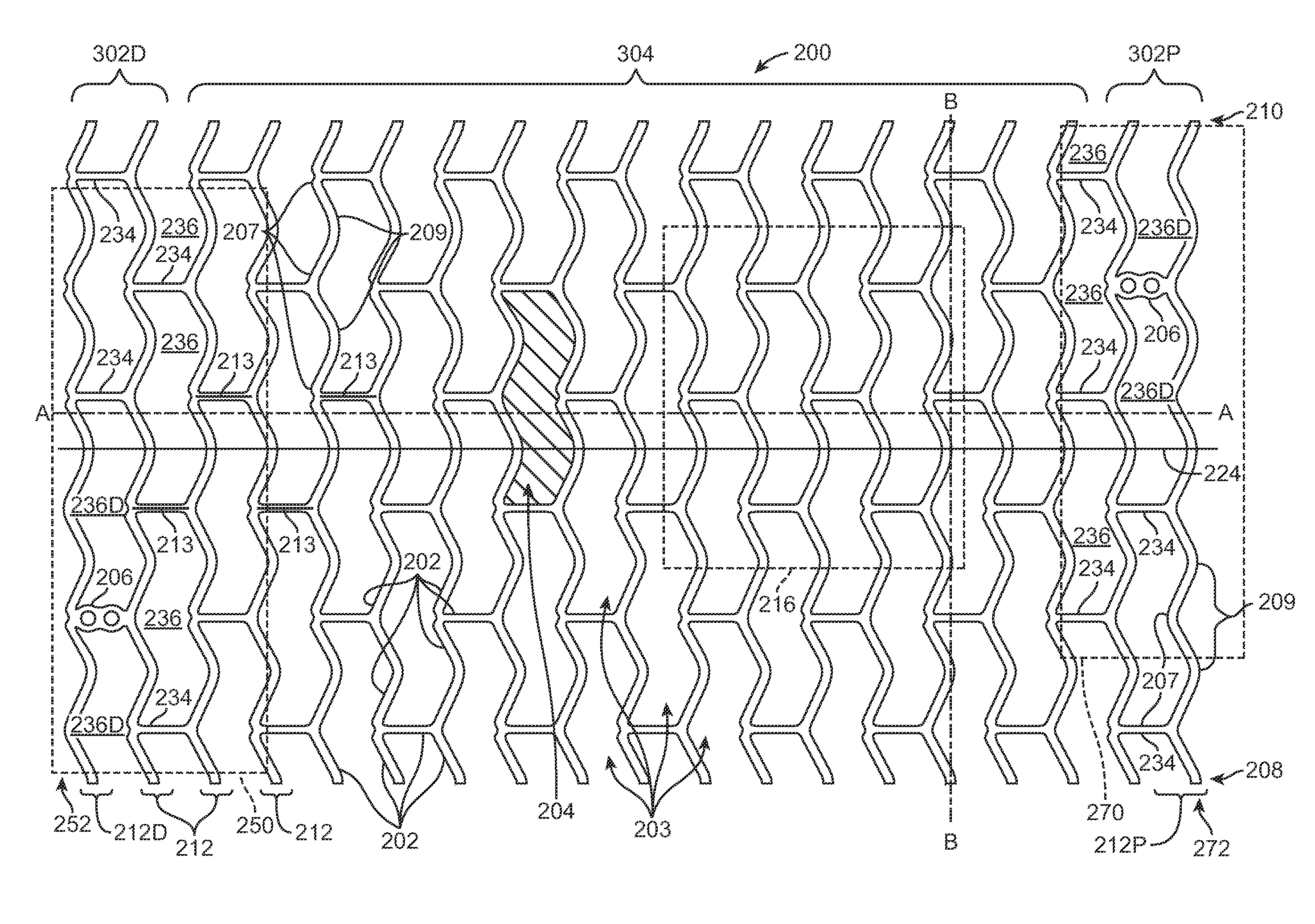

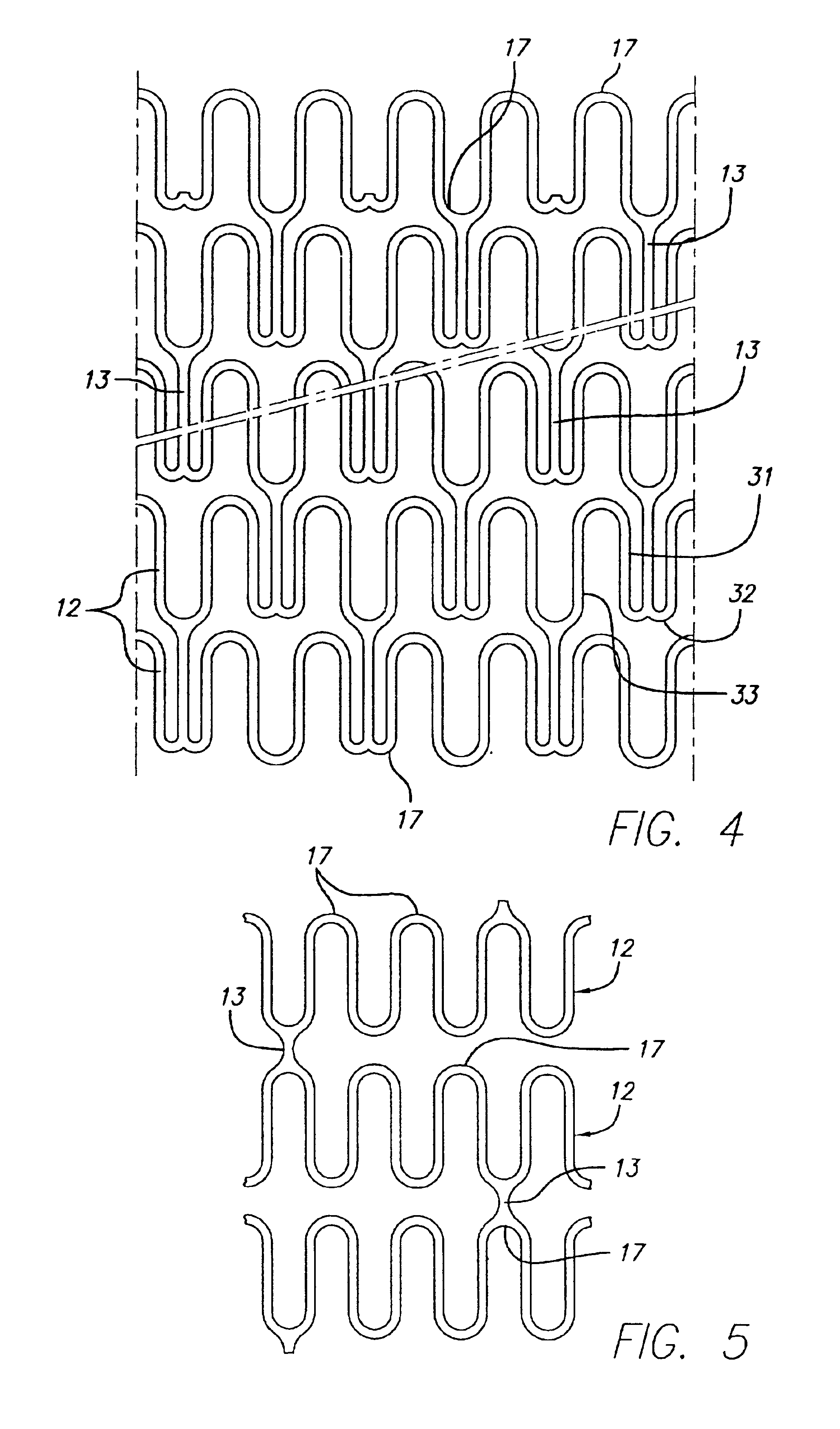

Polymeric Stent

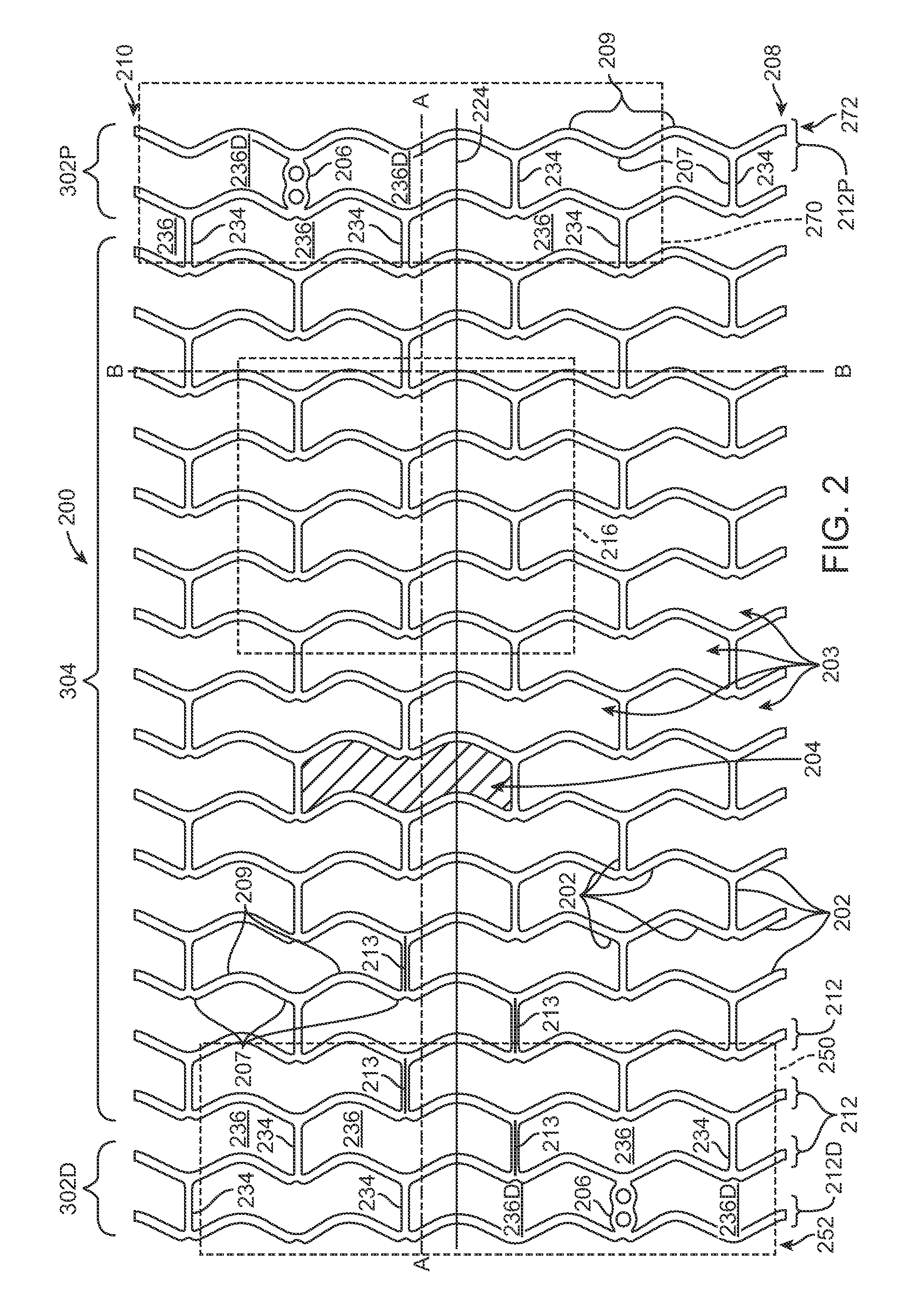

A strut pattern of an endoprosthesis includes a plurality of W-shape cells that define a tubular body, the W-shaped cells at the opposite ends of the tubular body have a modified configuration that is different than the W-shaped cells at the middle portion of the tubular body. At the distal end of the tubular body, the W-shaped cells have crests with axial positions that are axially spaced apart, and have troughs with circumferential positions that are spaced apart. At the intermediate and distal end of the tubular body, the W-shaped cells crests with axial positions that coincide and have troughs with circumferential positions that coincide. The strut pattern is cut from a tubular precursor construct made of PLLA that has been radially expanded and axially extended by blow molding.

Owner:ABBOTT CARDIOVASCULAR

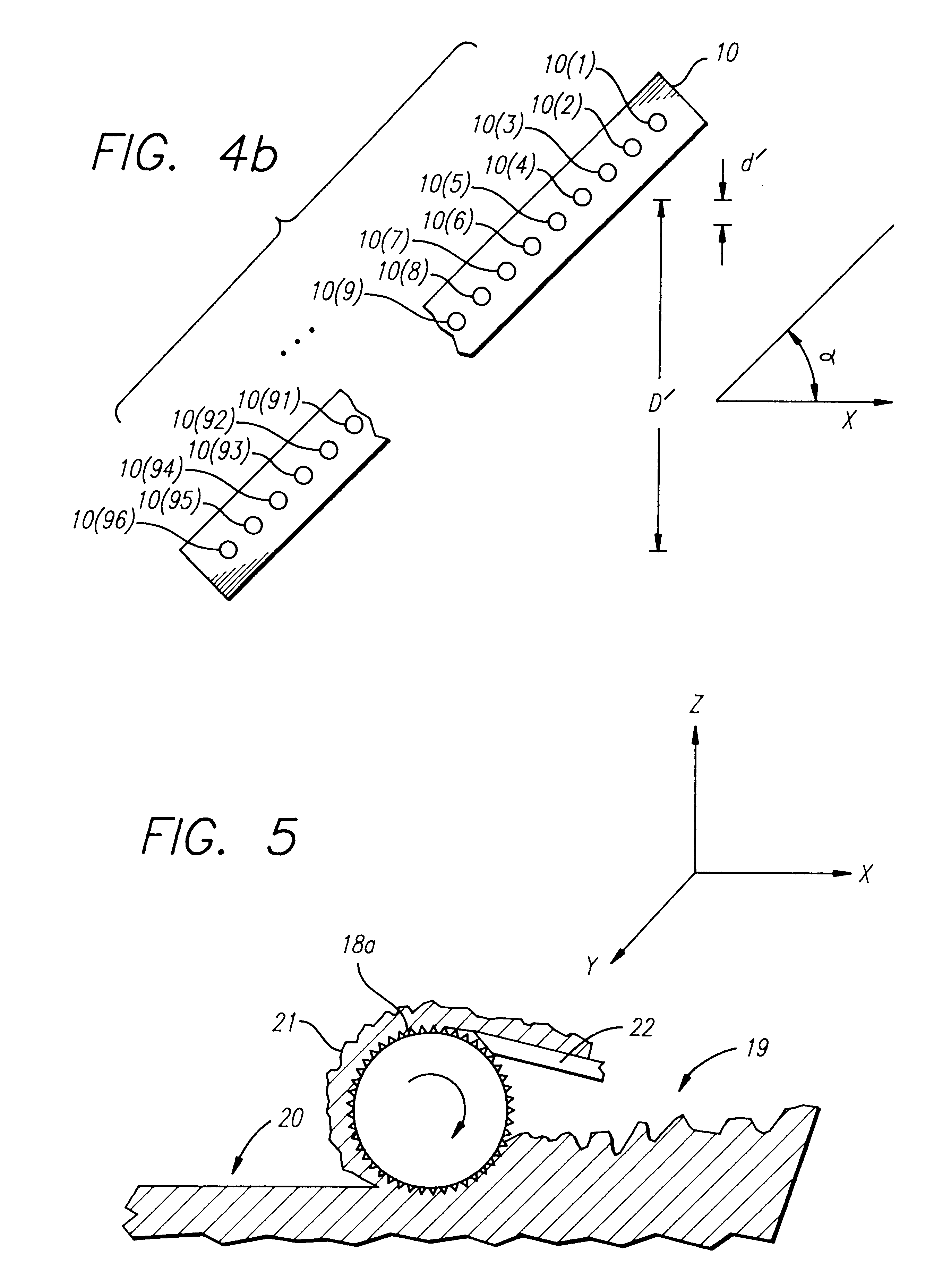

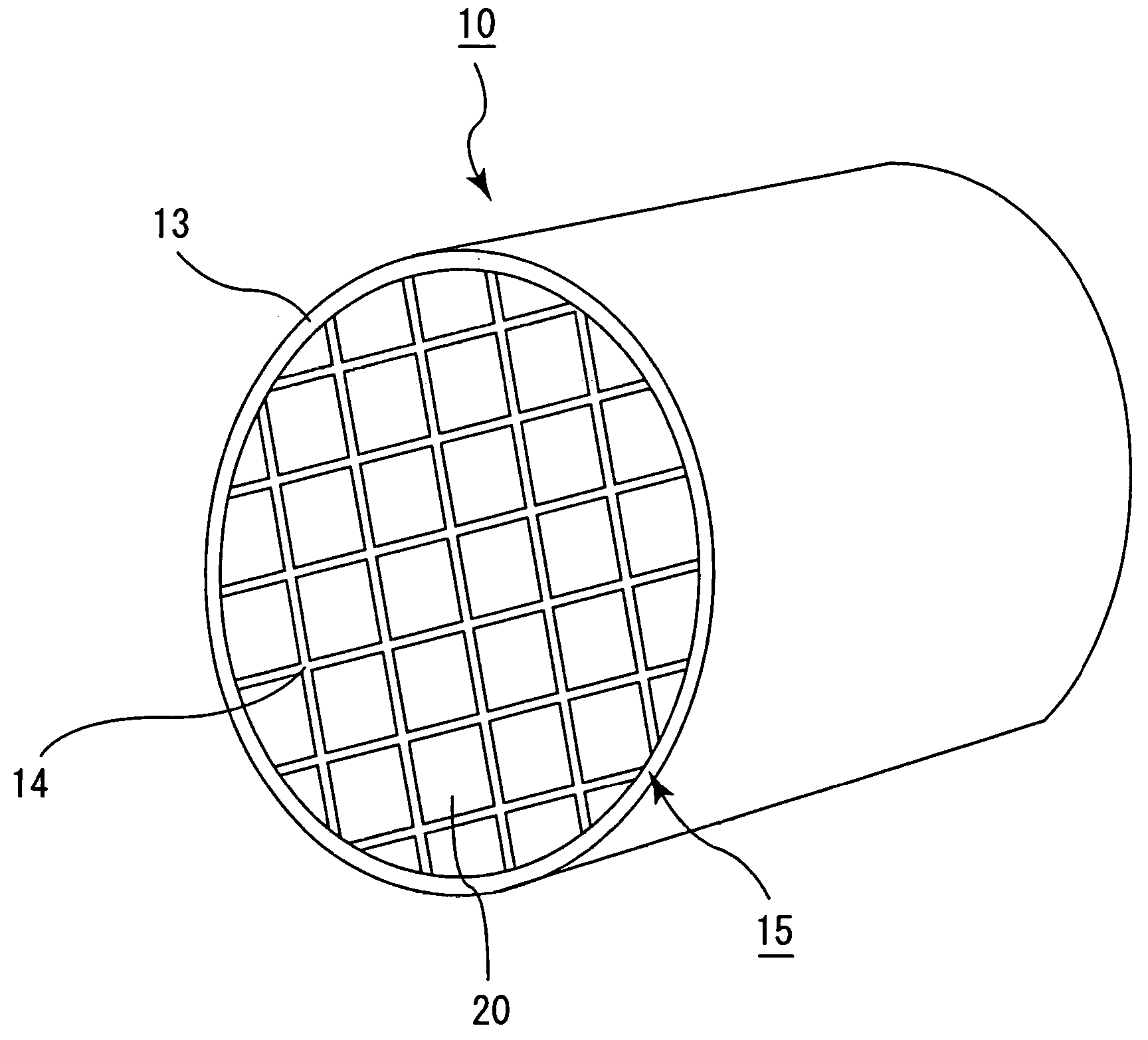

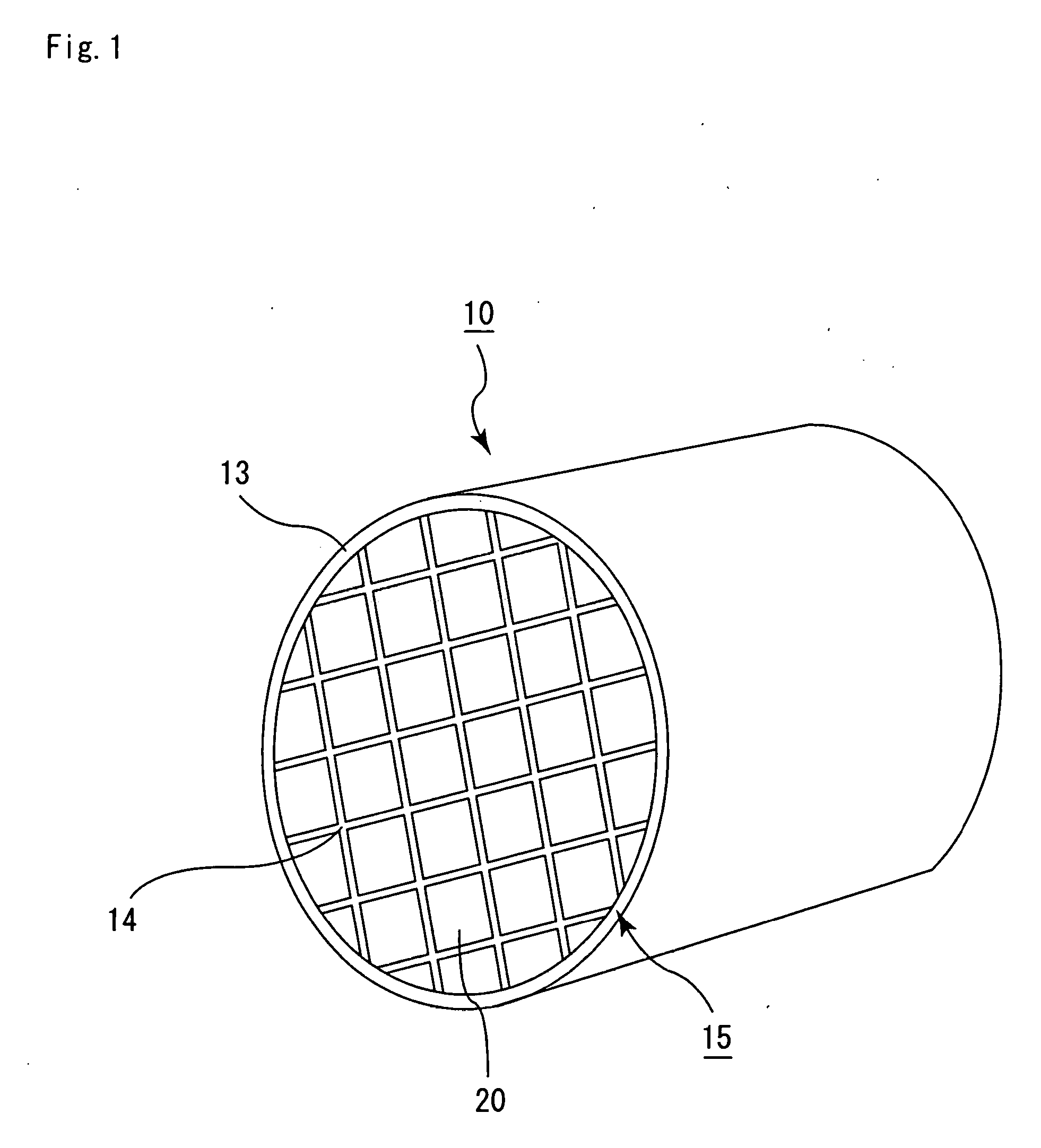

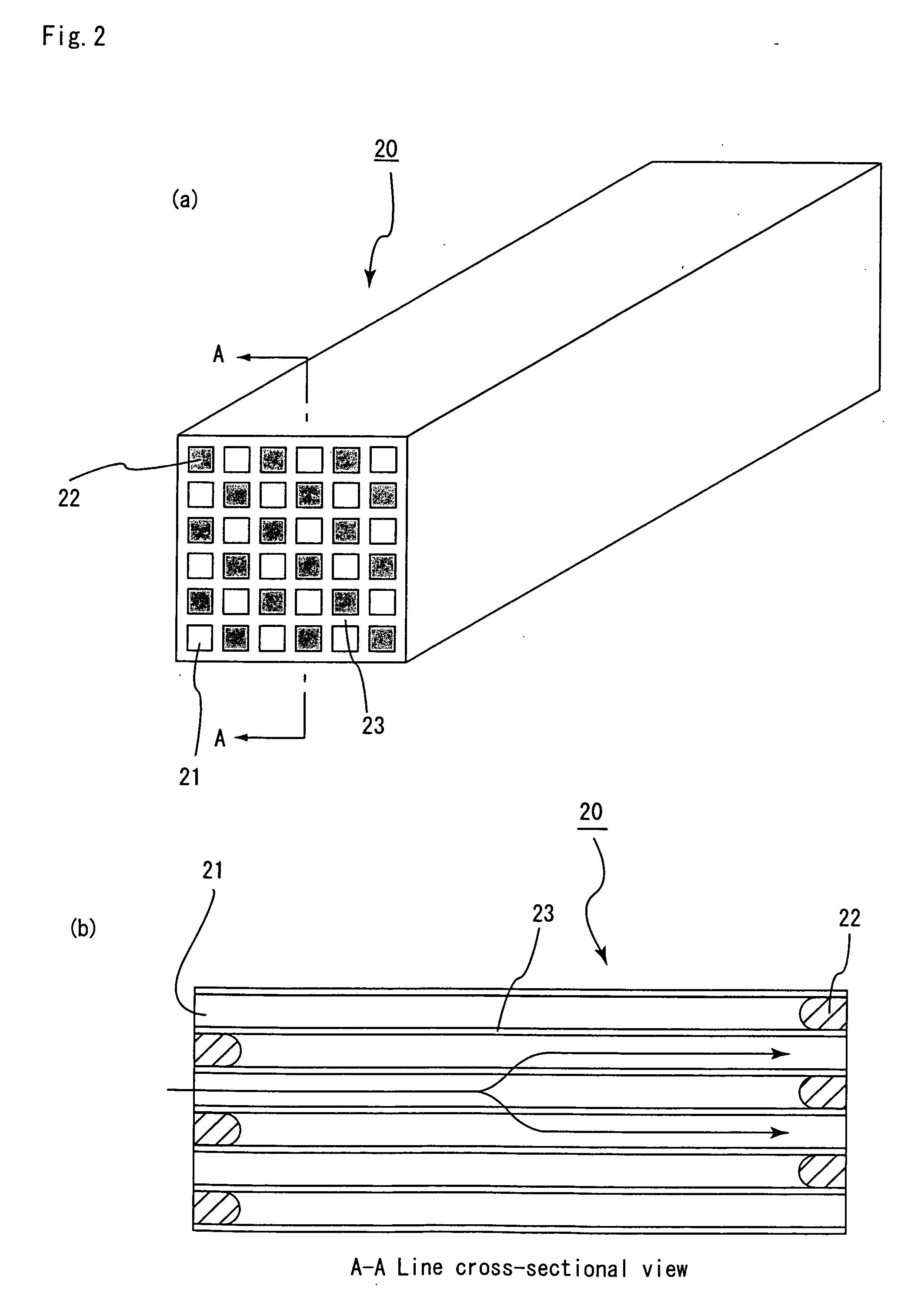

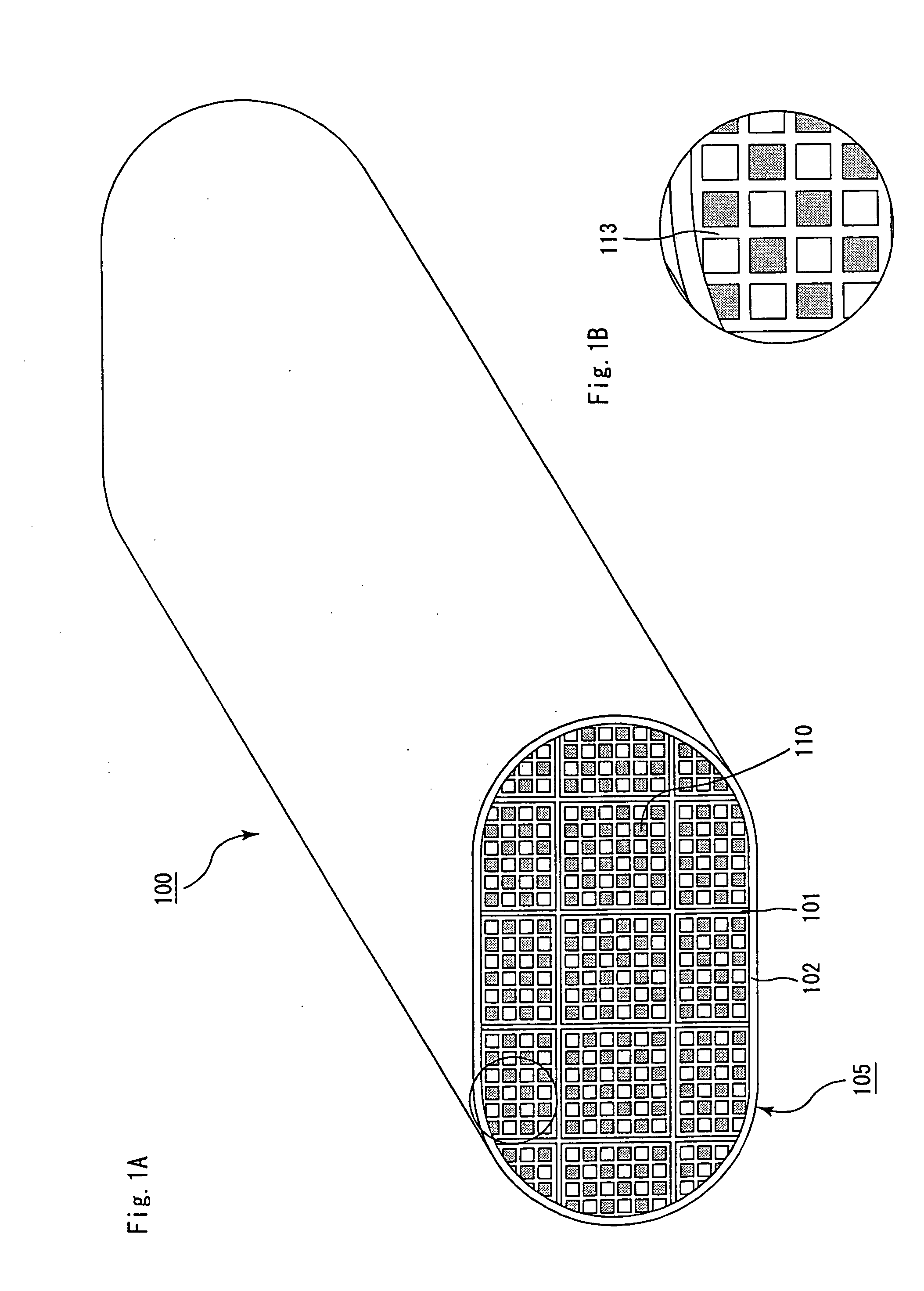

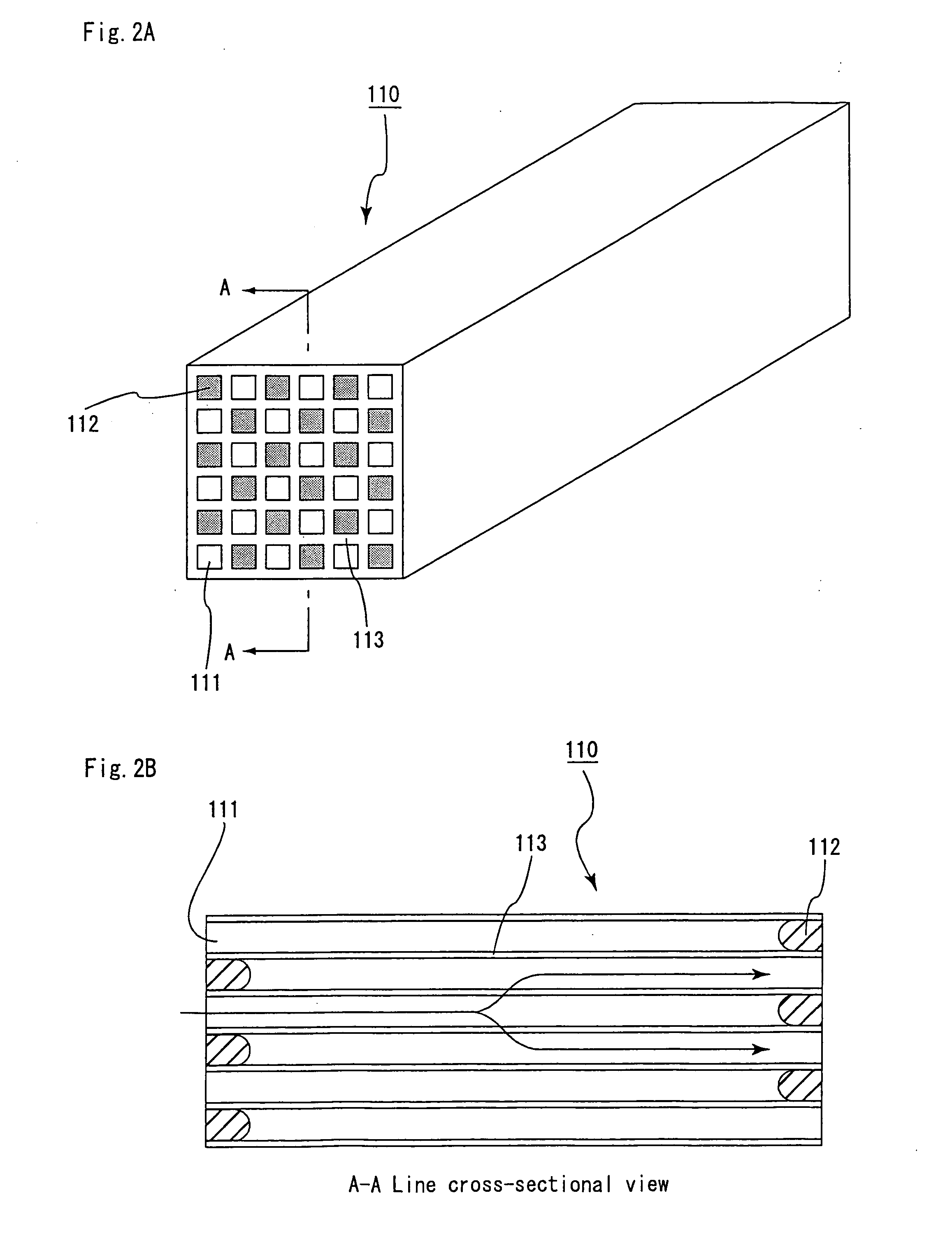

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

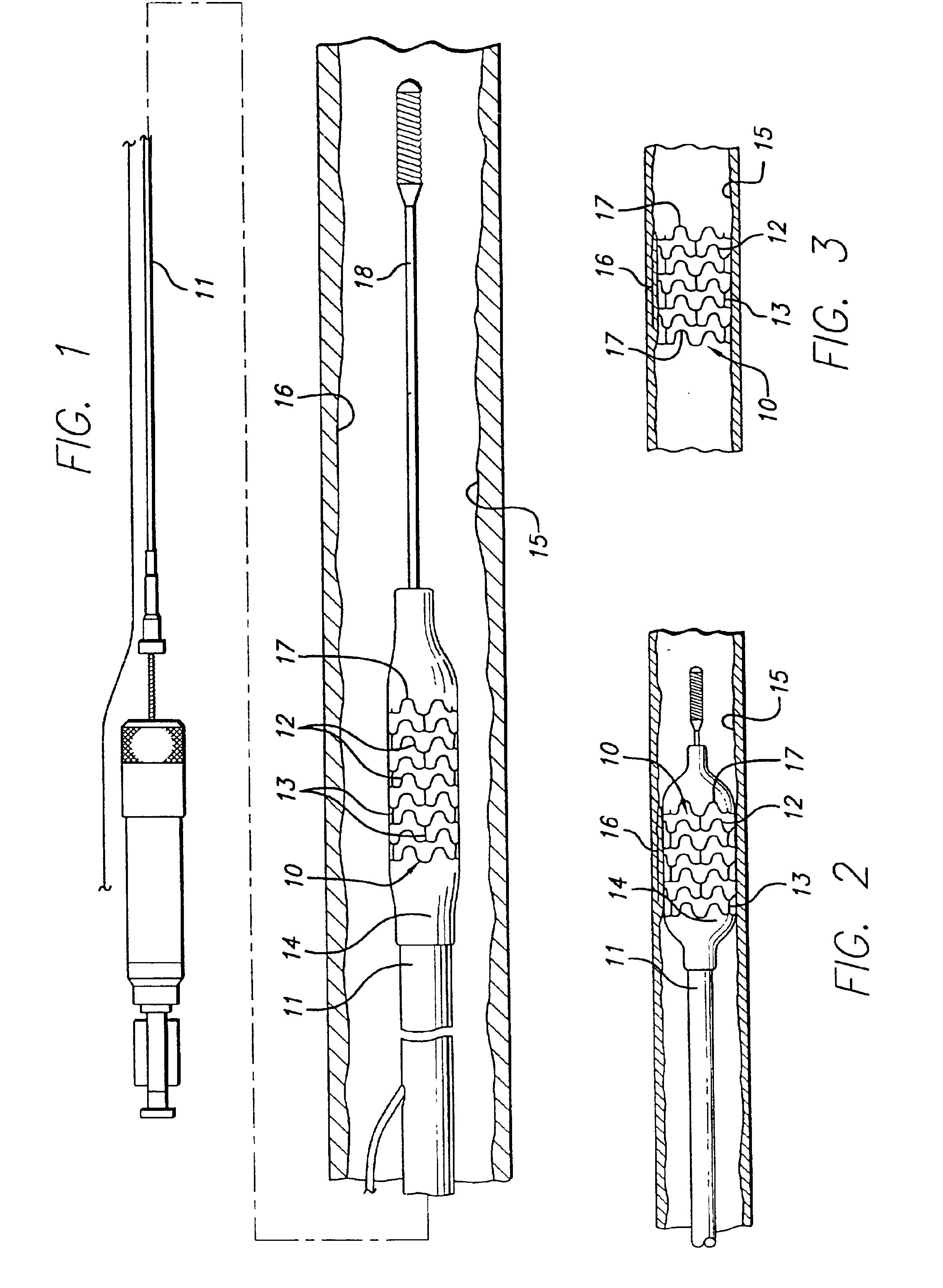

Hybrid intravascular stent

InactiveUS6866805B2Increase flexibilityImprove radial strengthStentsSurgeryCoronary arteriesIntravascular stent

A hybrid stent is formed which exhibits both high flexibility and high radial strength. The expandable hybrid stent for implantation in a body lumen, such as a coronary artery, consists of radially expandable cylindrical rings generally aligned on a common longitudinal axis and interconnected by one or more links. In one embodiment, a dip-coated covered stent is formed by encapsulating cylindrical rings within a polymer material. In other embodiments, at least some of the rings and links are formed of a polymer material which provides longitudinal and flexural flexibility to the stent. These polymer rings and links are alternated with metallic rings and links in various configurations to attain sufficient column strength along with the requisite flexibility in holding open the target site within the body lumen. Alternatively, a laminated, linkless hybrid stent is formed by encapsulating cylindrical rings within a polymer tube.

Owner:ABBOTT CARDIOVASCULAR

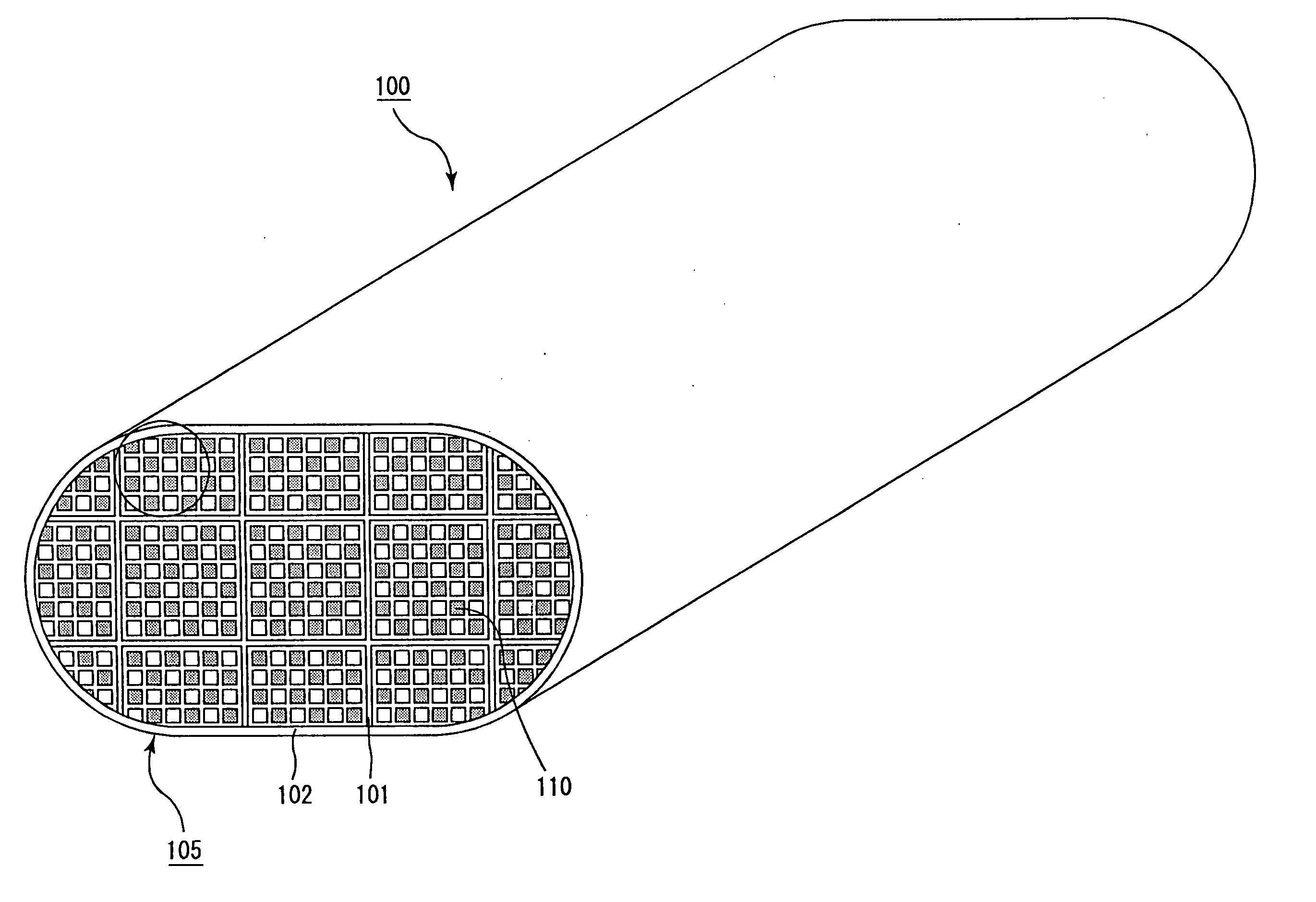

Honeycomb structural body and manufacturing method thereof

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

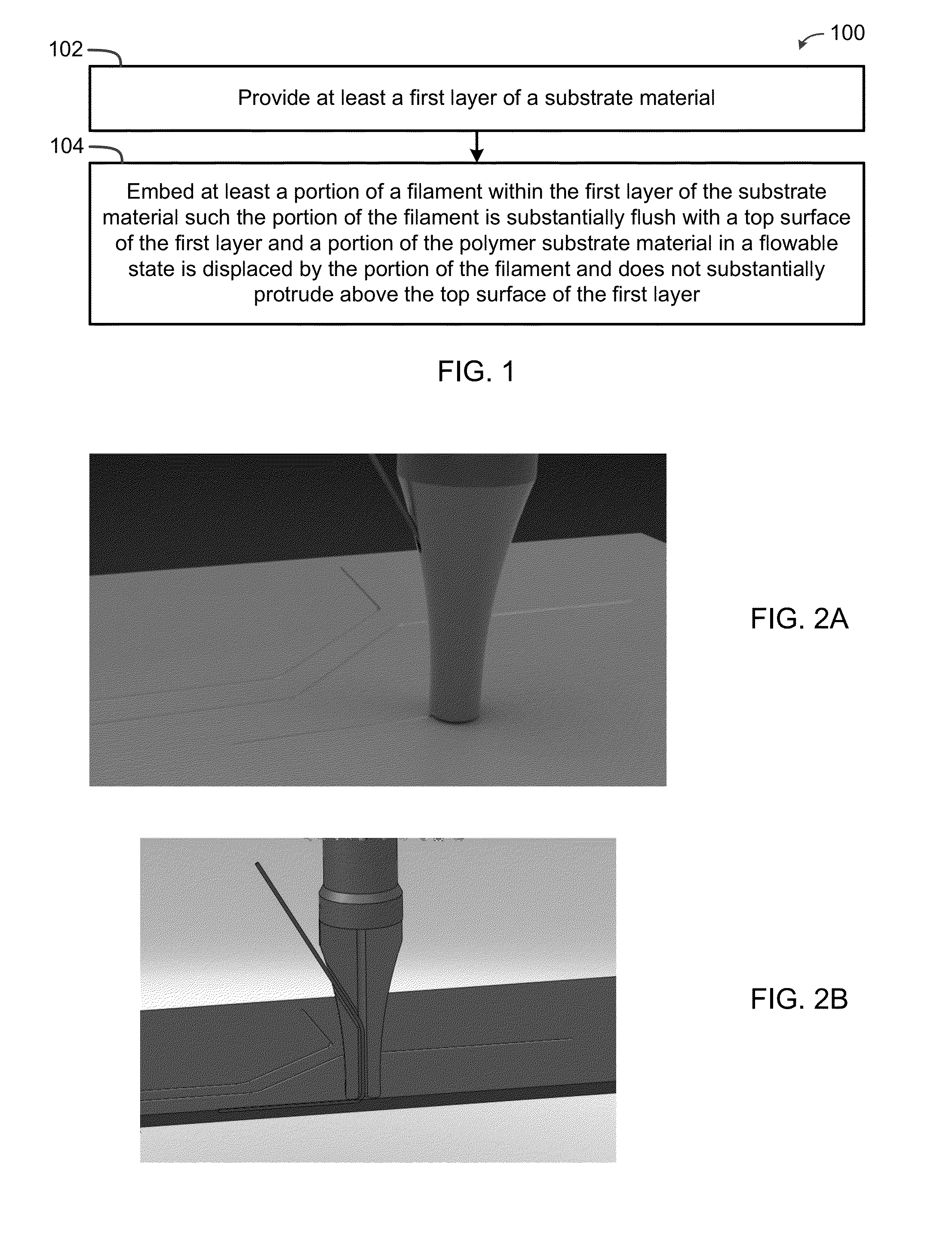

Methods and Systems For Embedding Filaments in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

ActiveUS20140268604A1High mechanical strengthElectric discharge heatingCeramic shaping apparatusElectricityEngineering

The present invention provides systems and methods for embedding a filament or filament mesh in a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device by providing at least a first layer of a substrate material, and embedding at least a portion of a filament or filament mesh within the first layer of the substrate material such the portion of the filament or filament mesh is substantially flush with a top surface of the first layer and a substrate material in a flowable state is displaced by the portion of the filament and does not substantially protrude above the top surface of the first layer, allowing the continuation of an additive manufacturing process above the embedded filament or filament mesh. A method is provided for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

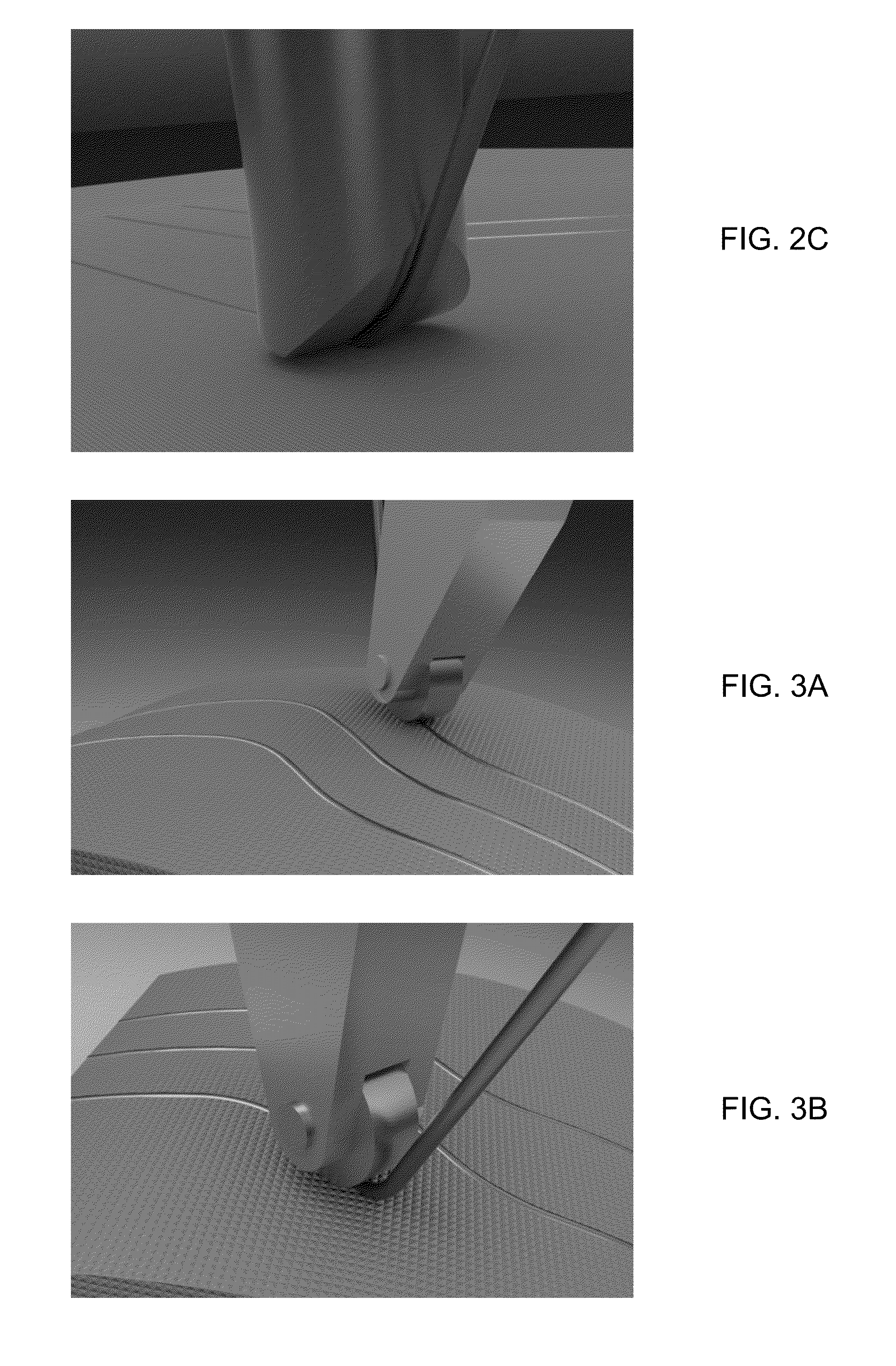

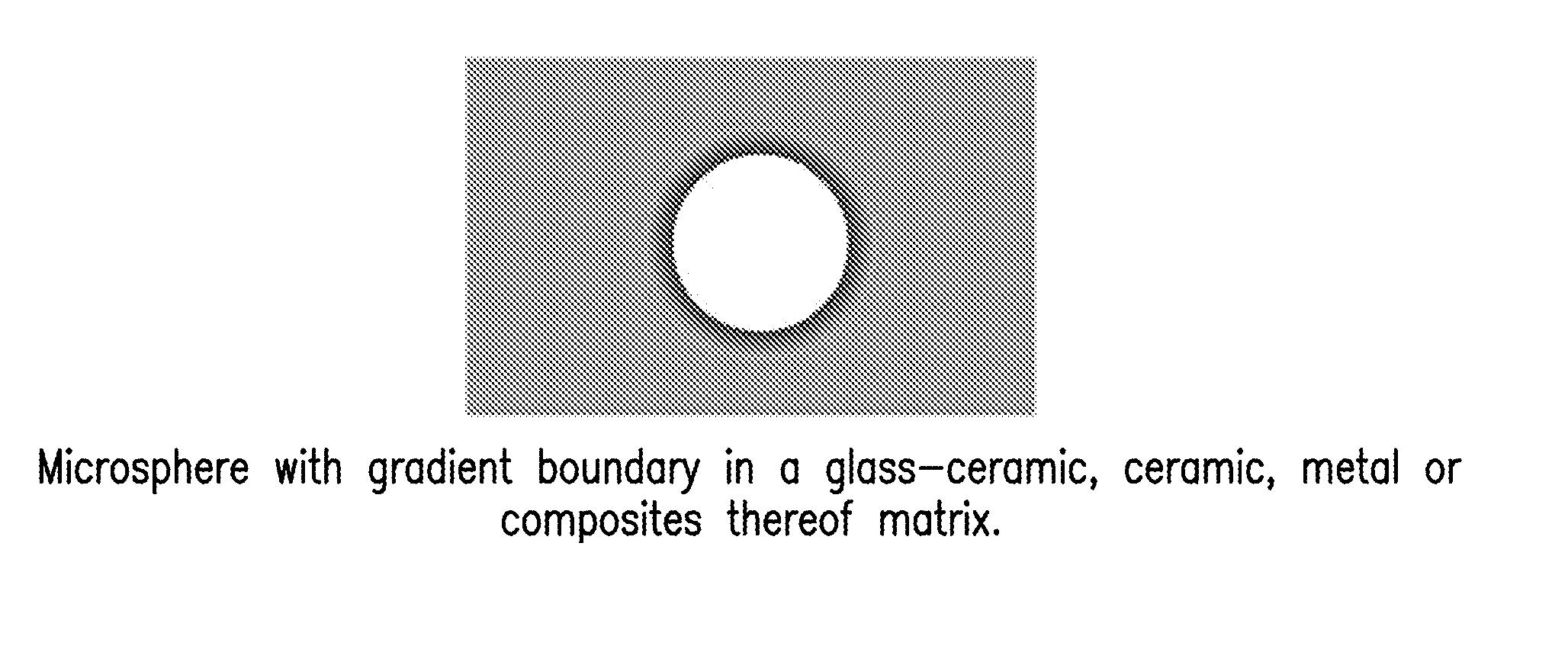

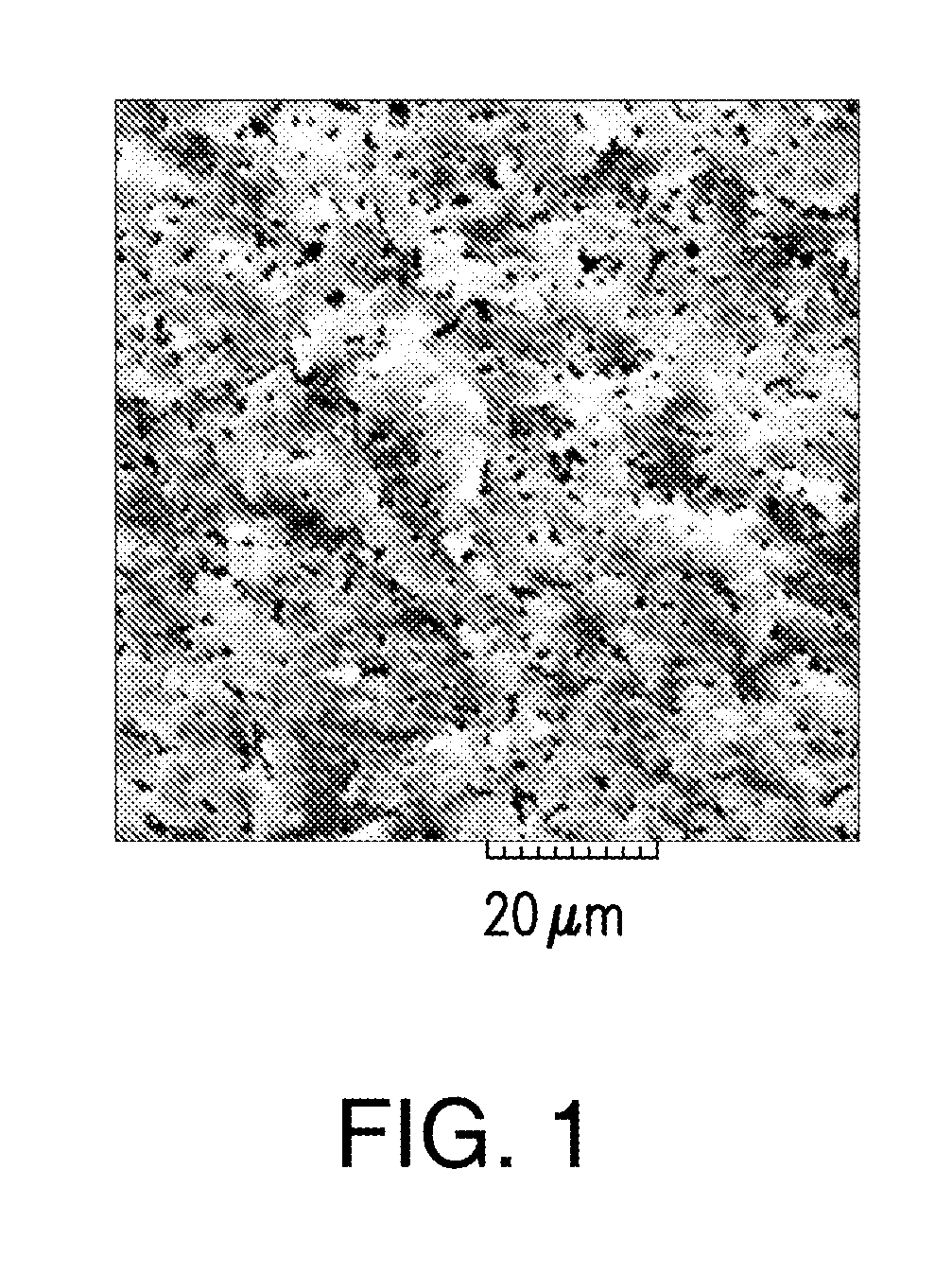

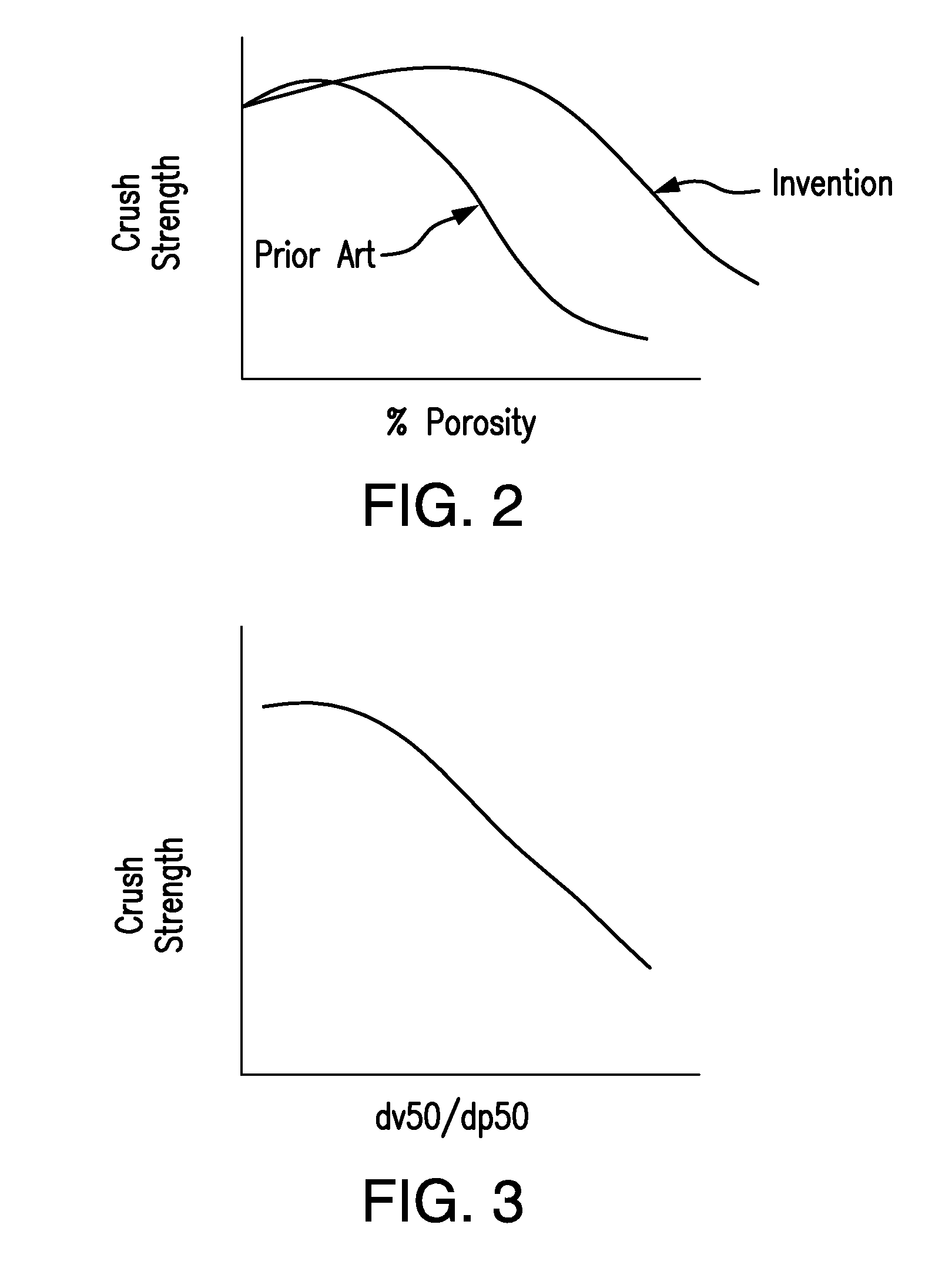

Ceramic Particles With Controlled Pore and/or Microsphere Placement and/or Size and Method Of Making Same

InactiveUS20110160104A1Improve balanceFluid removalCeramic shaping apparatusMicrosphereHigh intensity

The present invention relates to lightweight high strength microsphere containing ceramic particles having controlled microsphere placement and / or size and microsphere morphology, which produces an improved balance of specific gravity and crush strength such that they can be used in applications such as proppants to prop open subterranean formation fractions. Proppant formulations are further disclosed which use one or more microsphere containing ceramic particles of the present invention. Methods to prop open subterranean formation fractions are further disclosed. In addition, other uses for the microsphere containing ceramic particles of the present invention are further disclosed, as well as methods of making the microsphere containing ceramic particles.

Owner:HALLIBURTON ENERGY SERVICES INC

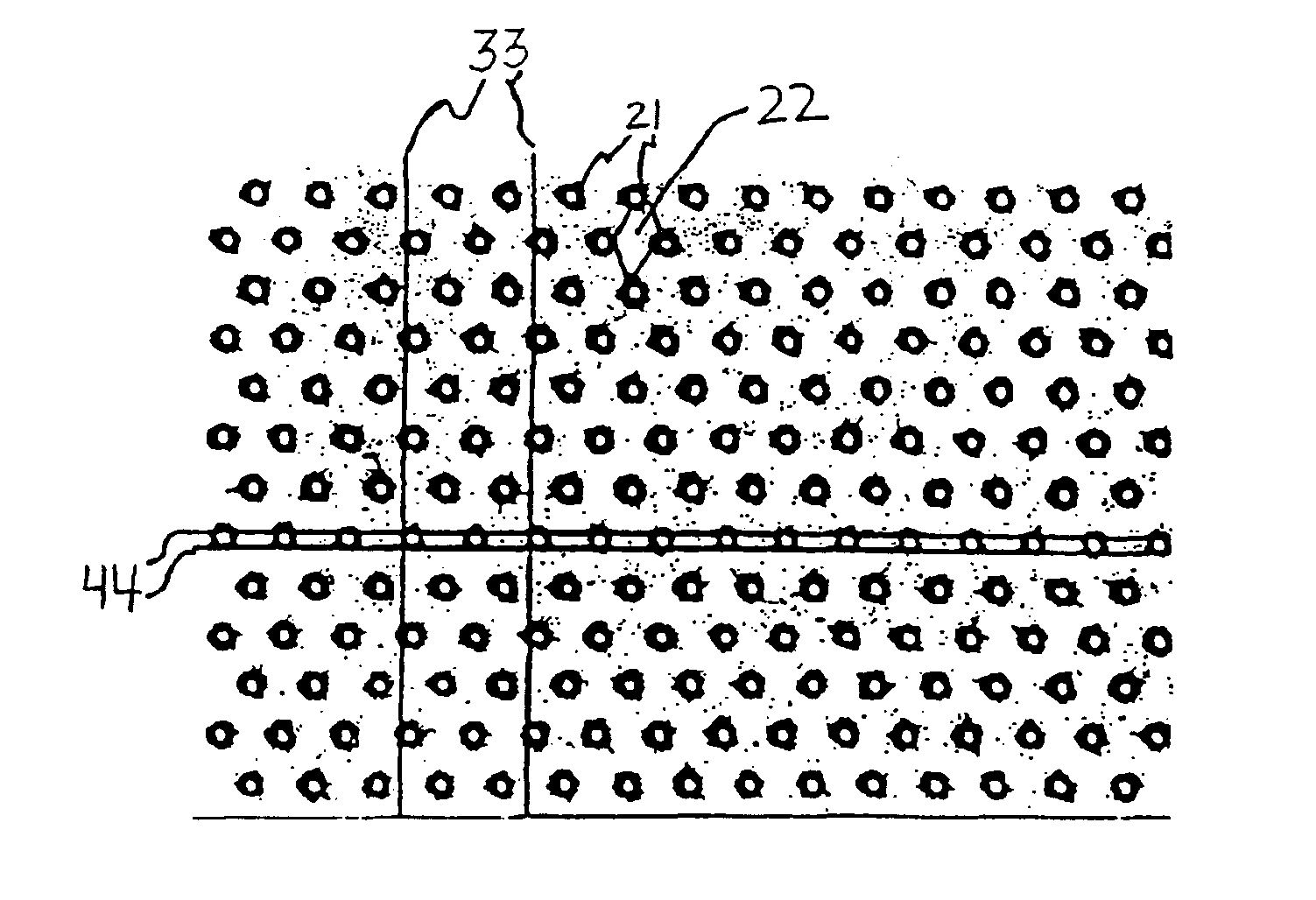

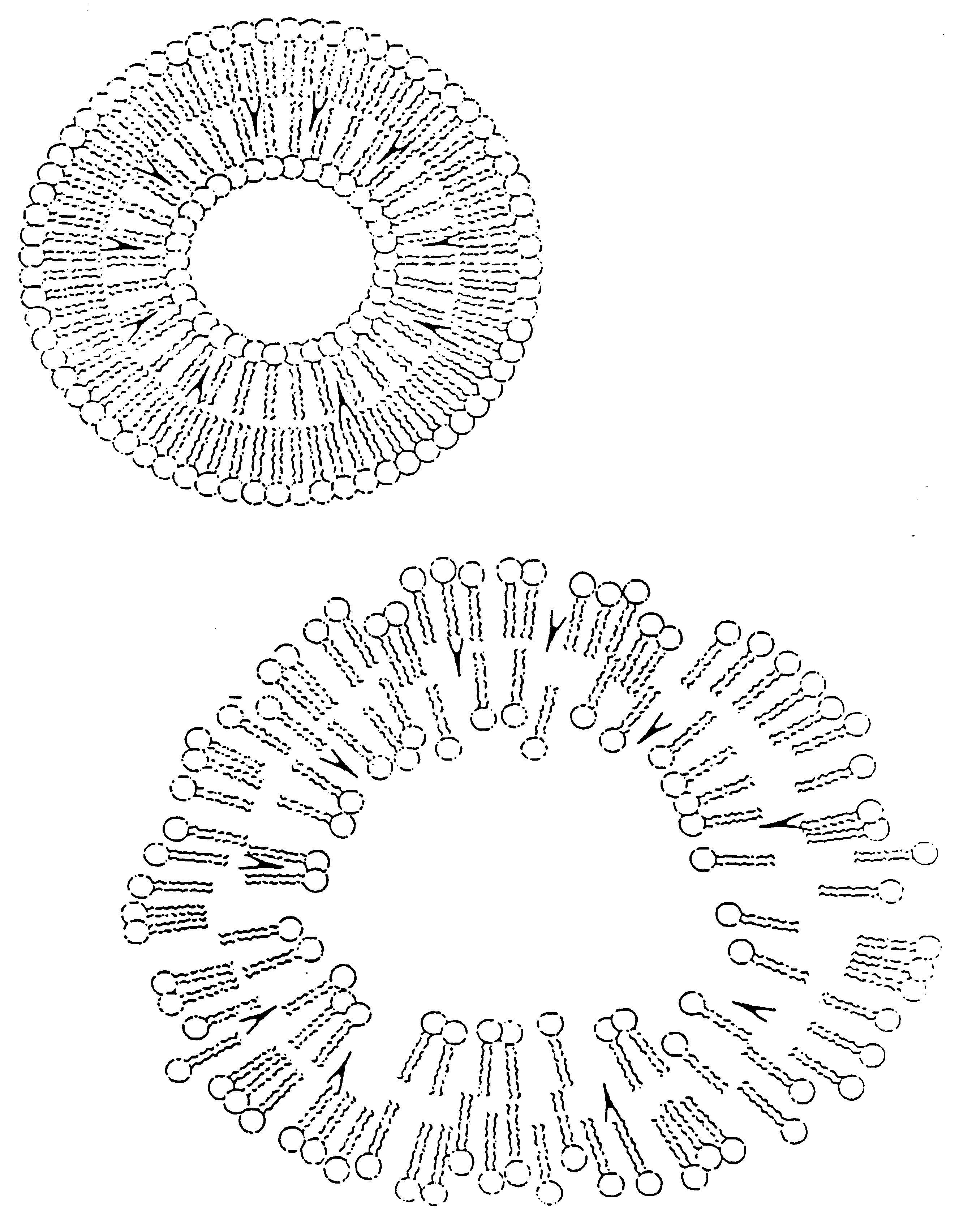

Neovascularization promoting membrane for bioimplants

A method of producing a biocompatible microporous membrane comprising the steps of providing a biocompatible membrane and using an energy beam to form a set of pores having a minor axis of less than 15 μm through the biocompatible membrane. One embodiment includes the steps of producing a first layer of material, defining a first set of pores; producing a second layer of material, defining a second set of pores and wherein the second set of pores is defined so as to cooperatively engage the first set of pores; and aligning and joining the first layer of material to the second layer of material to form a laminated membrane, having through-passageways formed by the first set of pores at least partially aligned with the second set of pores.

Owner:WAVEFORM TECH INC

Screen printing shaped articles

Shaped ceramic articles can be obtained by screen printing the desired shapes from a dimensionally stable dispersion of a precursor of the ceramic onto a surface, drying the screen printed shapes so obtained and firing them to generate the shaped ceramic articles.

Owner:SAINT GOBAINNORTON INDAL CERAMICS

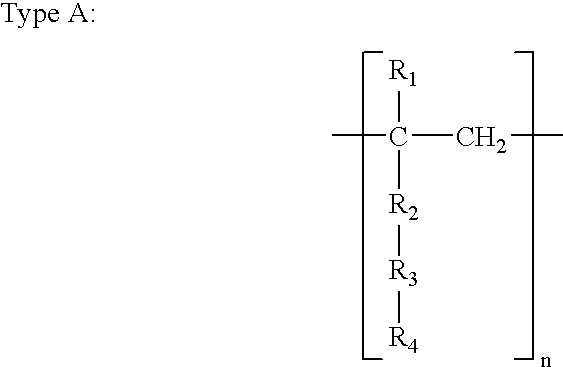

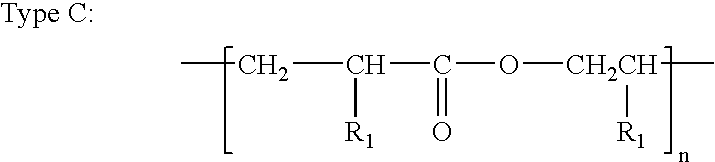

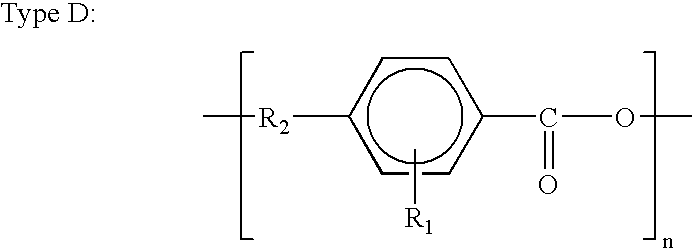

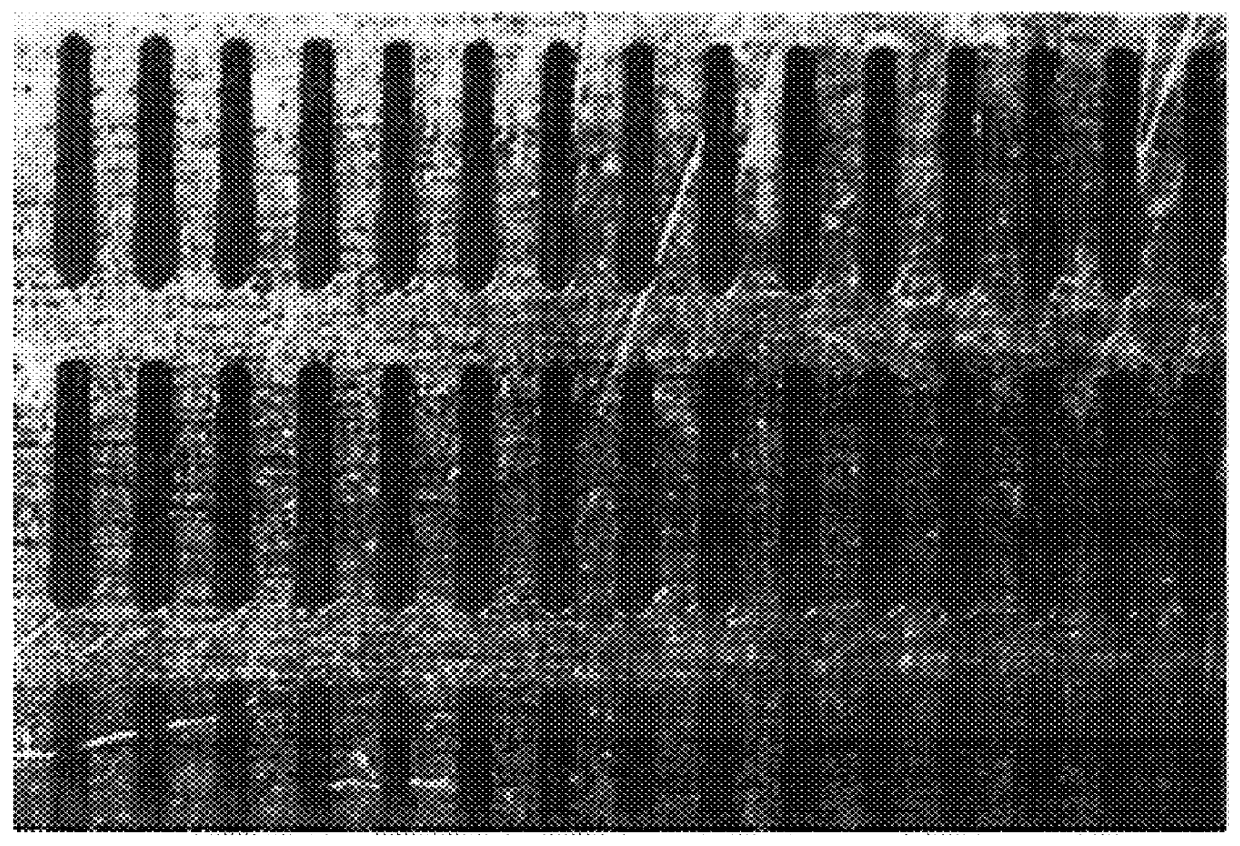

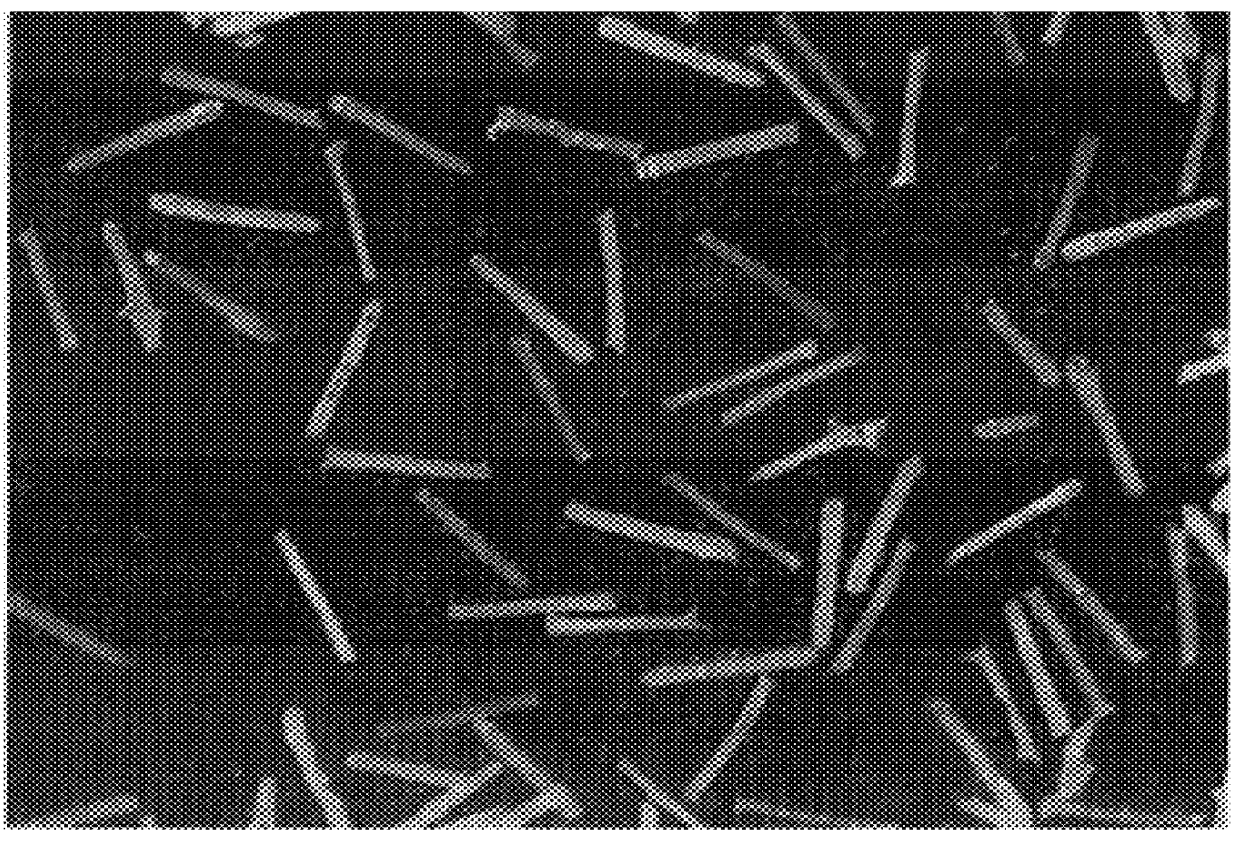

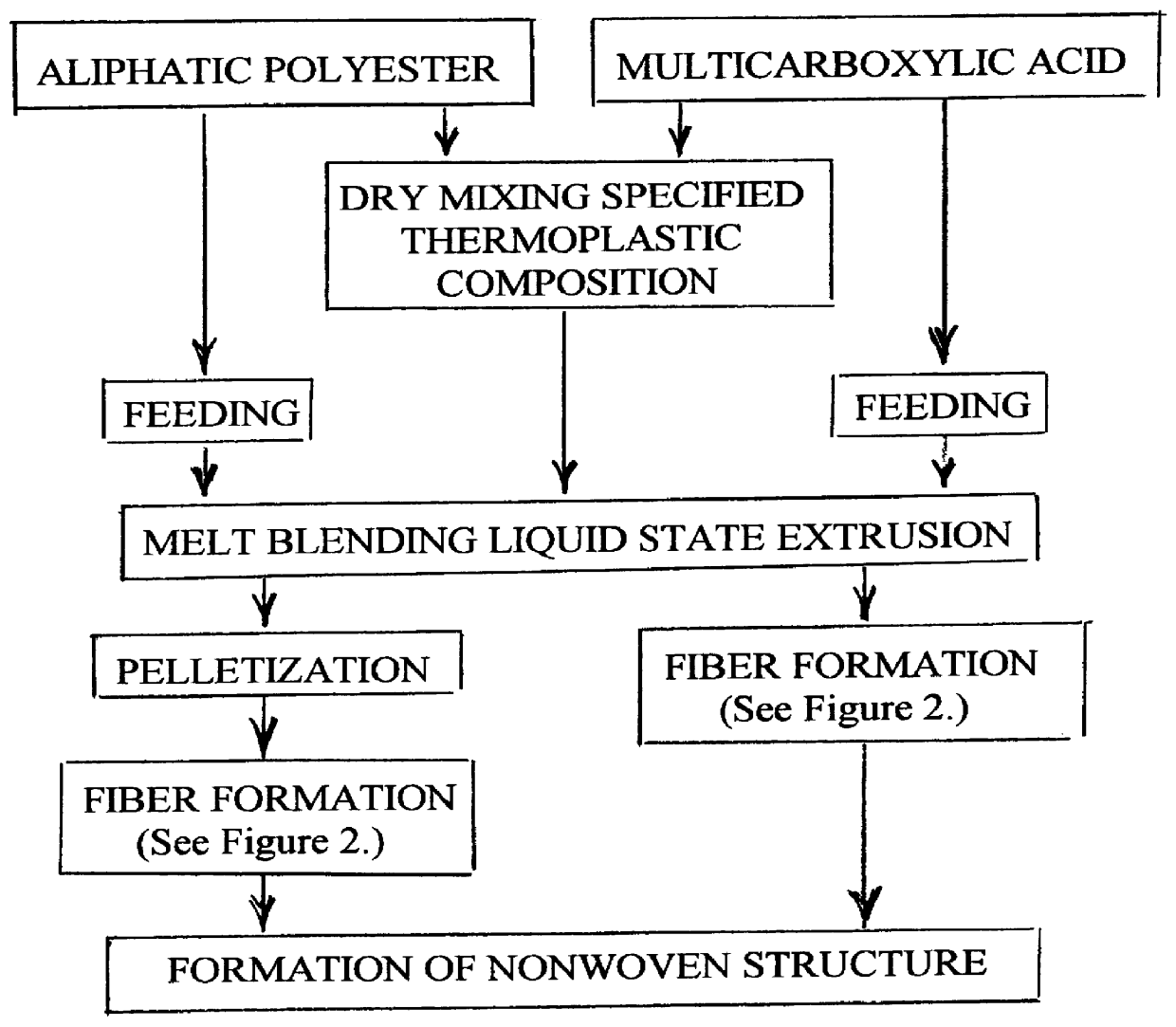

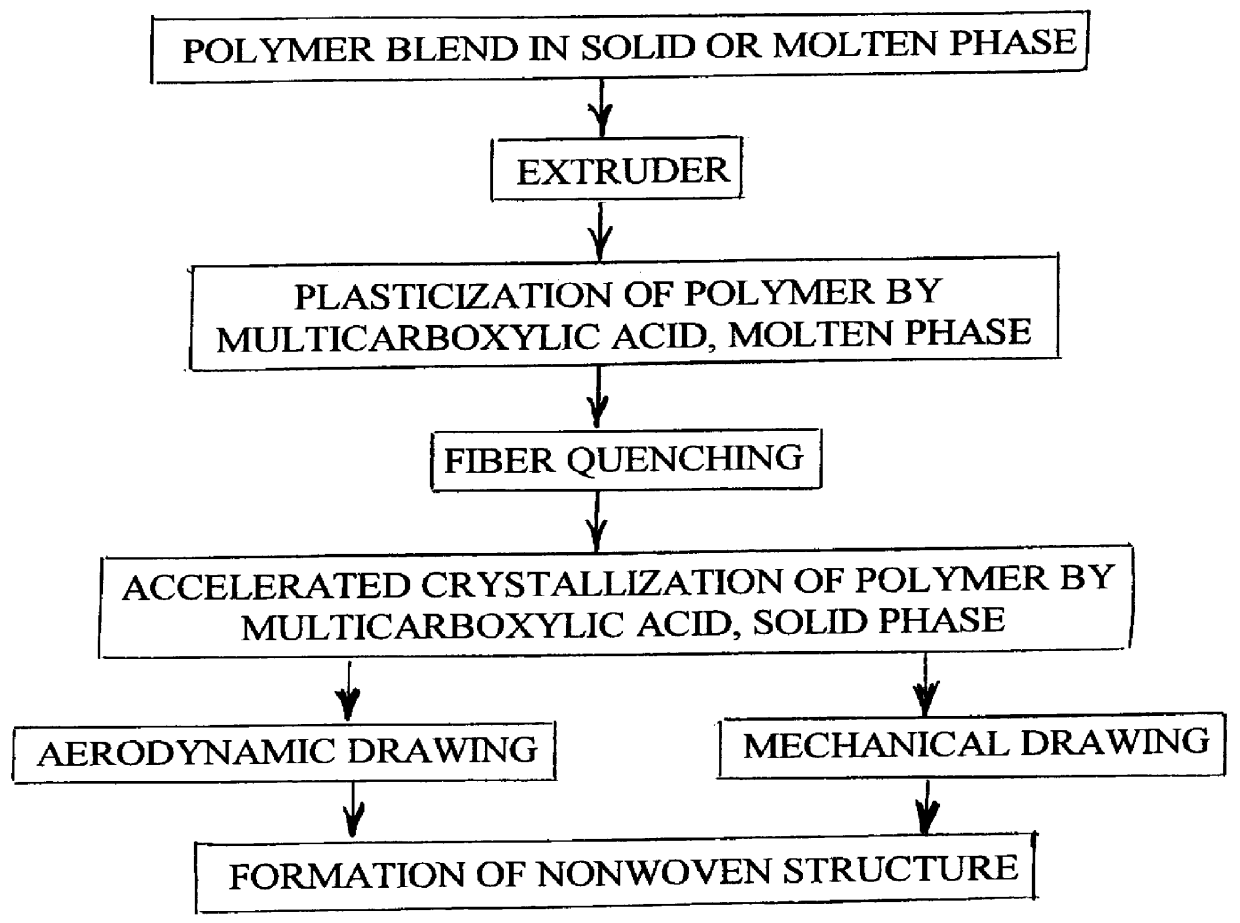

Synthetic fiber

InactiveUS6135987AFormed easily and efficientlyCeramic shaping apparatusBaby linensPolyesterVitrification

A process is disclosed for forming a synthetic fiber including providing a first component of an aliphatic polyester polymer a second component of a multicarboxylic acid, mixing the first component aliphatic polyester polymer and the second component multicarboxylic acid to form an unreacted specified thermoplastic composition, and melt blending the unreacted specified thermoplastic composition in an extruder or a mixer. The second component multicarboxylic acid lubricates the extruder and provides a nucleating agent for crystallizing the specified thermoplastic composition to form a mean crystal size less than about 120 Angstroms. Fiber composed of the specified thermoplastic composition has a mean crystal size less than about 120 Angstroms. The fiber has a glass transition temperature (Tg) less than about 55 DEG C. In one aspect, a first component of polylactic acid and a second component of adipic acid provide synthetic fibers in a nonwoven structure used in a biodegradable and compostable disposable absorbent product for the absorption and removal of body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

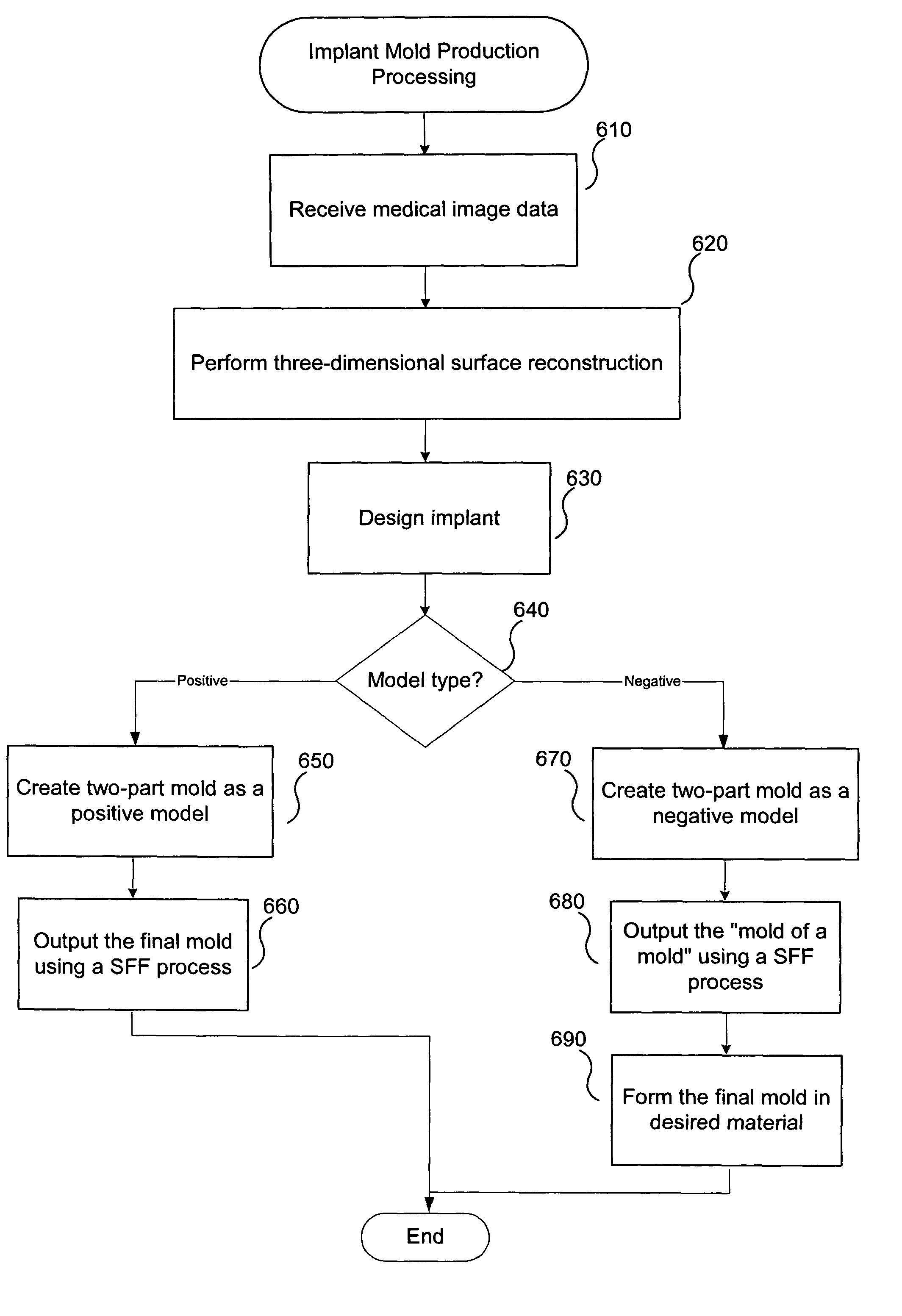

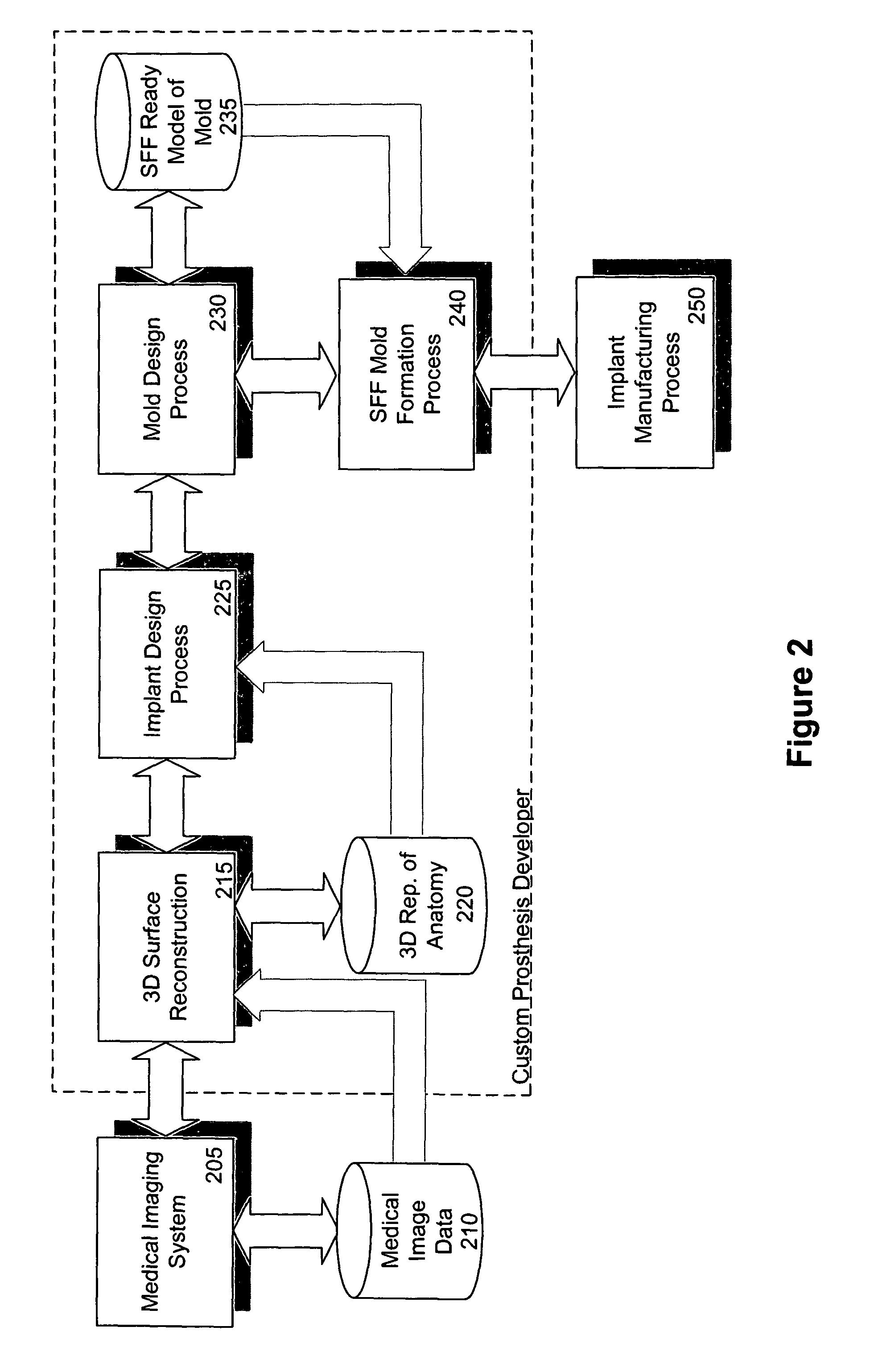

Method for design and production of a custom-fit prosthesis

Systems and methods are provided for designing and producing a custom-fit prosthesis. According to one embodiment, a mold is produced from which a custom-fit implant may be directly or indirectly manufactured. Medical image data representing surrounding portions of a patient's anatomy to be repaired by surgical implantation of the custom-fit implant are received. Then, three-dimensional surface reconstruction is performed based on the medical image data. Next, the custom-fit implant is designed based on the three-dimensional surface reconstruction and a positive or negative representation of a two-part mold is created with a void in the shape of the custom-fit implant by subtracting a representation of the custom-fit implant from a representation of a mold. Finally, the two-part mold is output from which the custom-fit implant may be directly manufactured; or an implant is directly output. Alternatively, an intermediate mold is created from which a two-part mold may be directly manufactured.

Owner:3D SYST INC

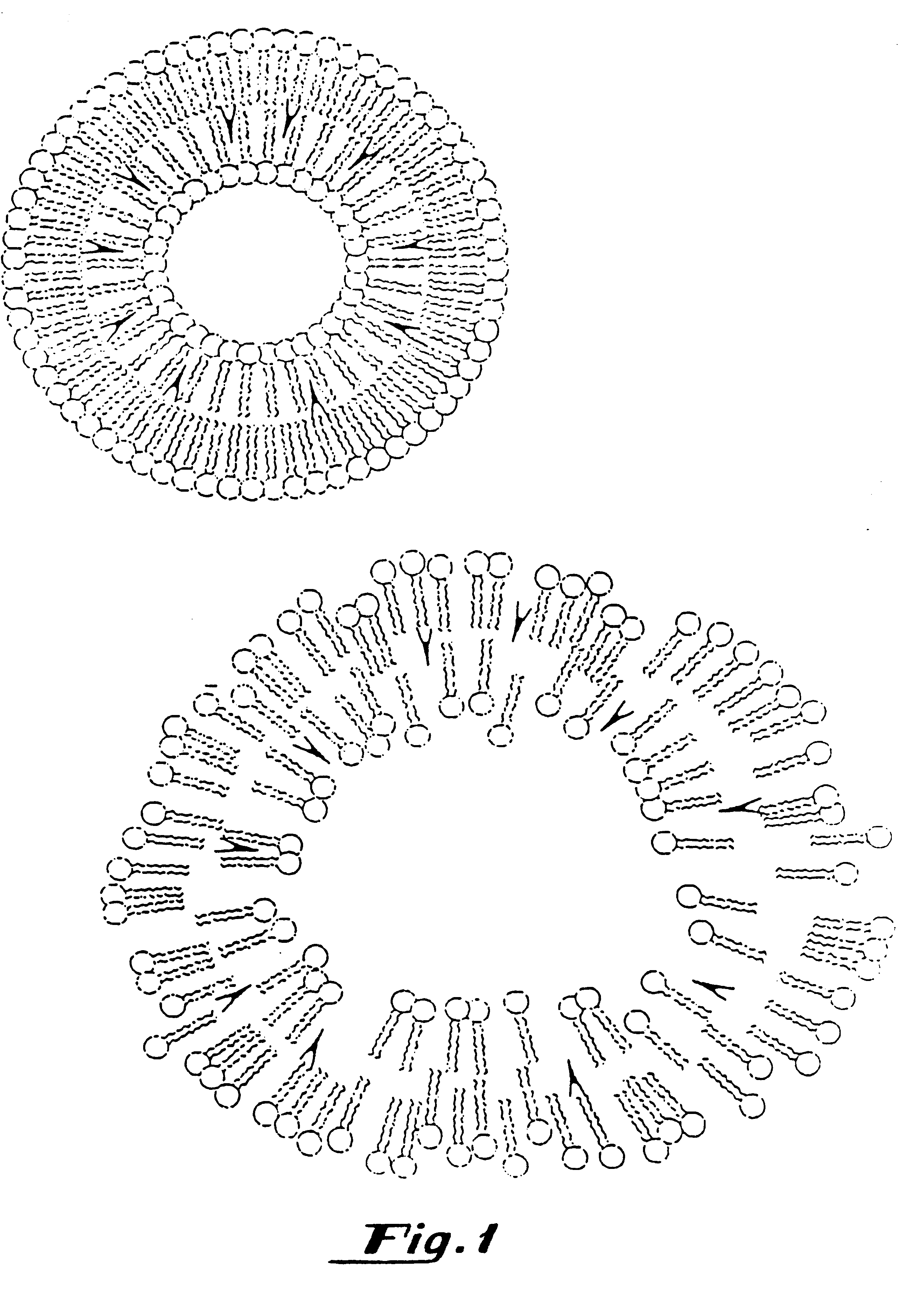

Therapeutic delivery systems

InactiveUS6443898B1Low costSuitable for useUltrasonic/sonic/infrasonic diagnosticsPowder deliveryMicrosphereLiposome

Therapeutic delivery systems comprising gaseous precursor-filled microspheres comprising a therapeutic are described. Methods for employing such microspheres in therapeutic delivery applications are also provided. Therapeutic delivery systems comprising gaseous precursor-filled liposomes having encapsulated therein a contrast agent or drug are preferred. Methods of and apparatus for preparing such liposomes and methods for employing such liposomes in therapeutic delivery applications are also disclosed.

Owner:CEREVAST MEDICAL

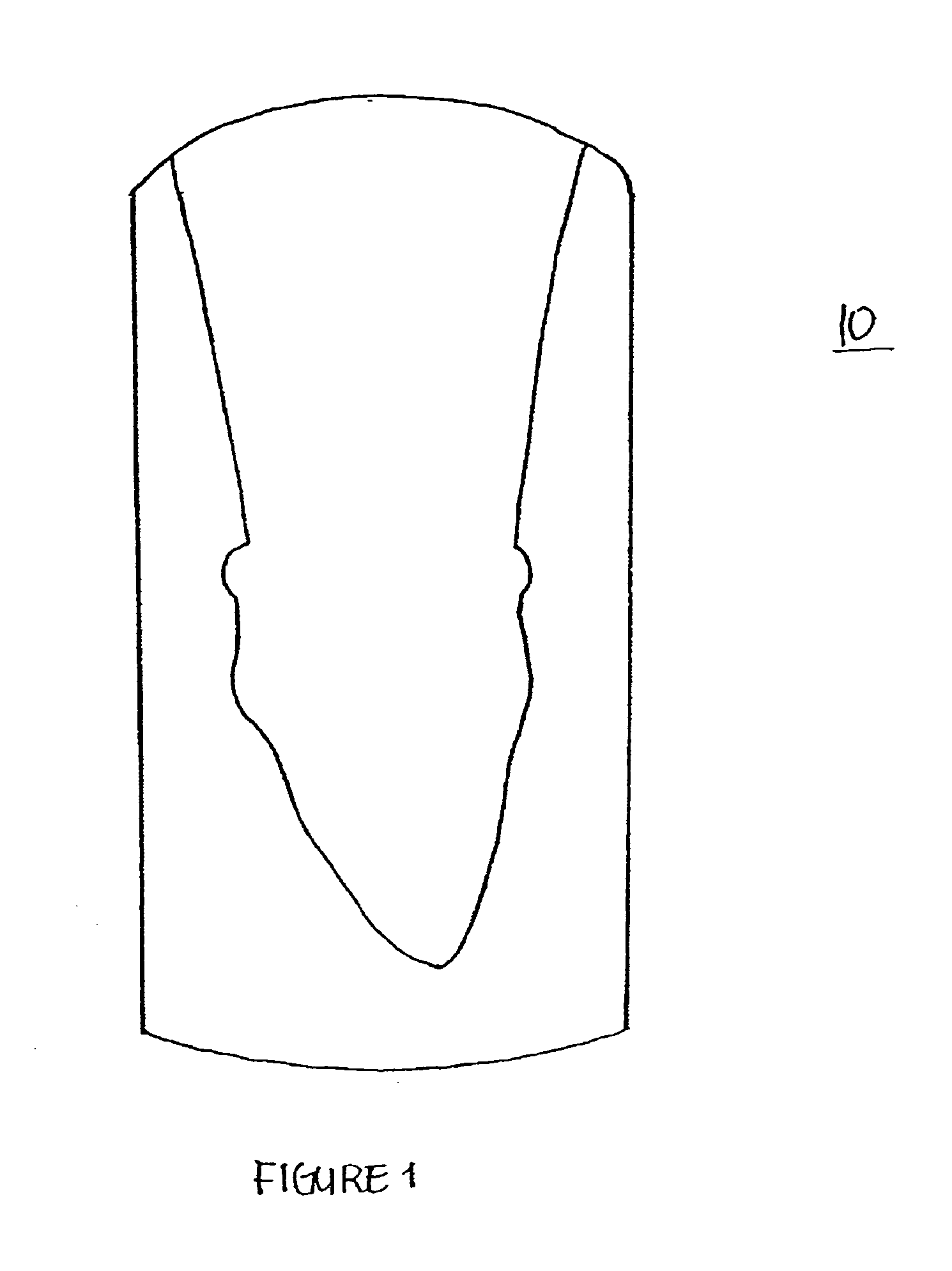

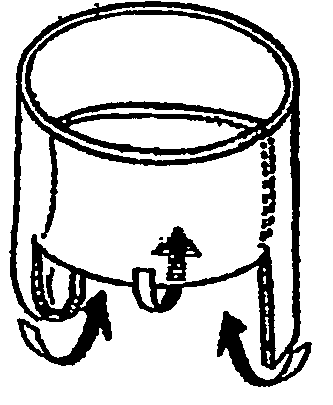

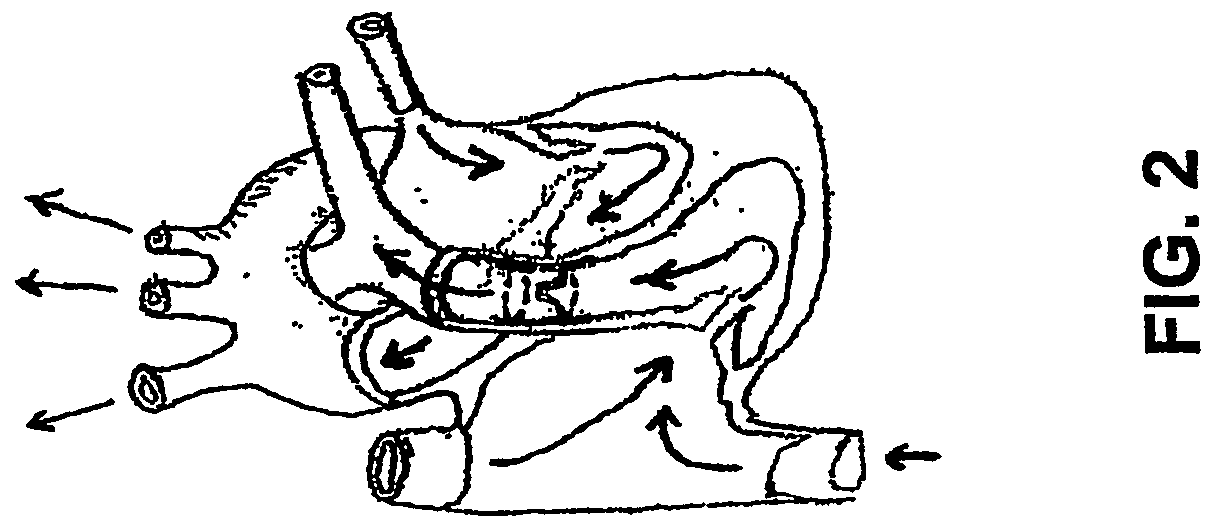

Involuted endovascular valve and method of construction

ActiveUS20050240262A1Increase potential strengthIncreased durabilityHeart valvesCeramic shaping apparatusProsthesisBiological materials

A prosthetic tri-leaflet valve formed by involuting a portion of a tubular structure inside itself. The valve can be made by a method comprising providing a tubular segment in which three equidistant longitudinal incisions are made in one end of the tube creating three flaps which are involuted, i.e., folded, in toward the inside of the tube and the edges of the flaps secured to the inner wall of the tube to form leaflets. The tube can be formed of a single sheet of synthetic, organic or biological material and can be solid, woven, braided or the like. A braided configuration permits the valve to be annularly compressed and delivered to the site using a minimally invasive delivery mechanism, then expanded at the implantation site.

Owner:EDWARDS LIFESCIENCES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com