Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

918 results about "Electrophoretic deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

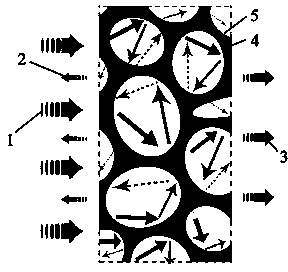

Electrophoretic deposition (EPD), is a term for a broad range of industrial processes which includes electrocoating, cathodic electrodeposition, anodic electrodeposition, and electrophoretic coating, or electrophoretic painting. A characteristic feature of this process is that colloidal particles suspended in a liquid medium migrate under the influence of an electric field (electrophoresis) and are deposited onto an electrode. All colloidal particles that can be used to form stable suspensions and that can carry a charge can be used in electrophoretic deposition. This includes materials such as polymers, pigments, dyes, ceramics and metals.

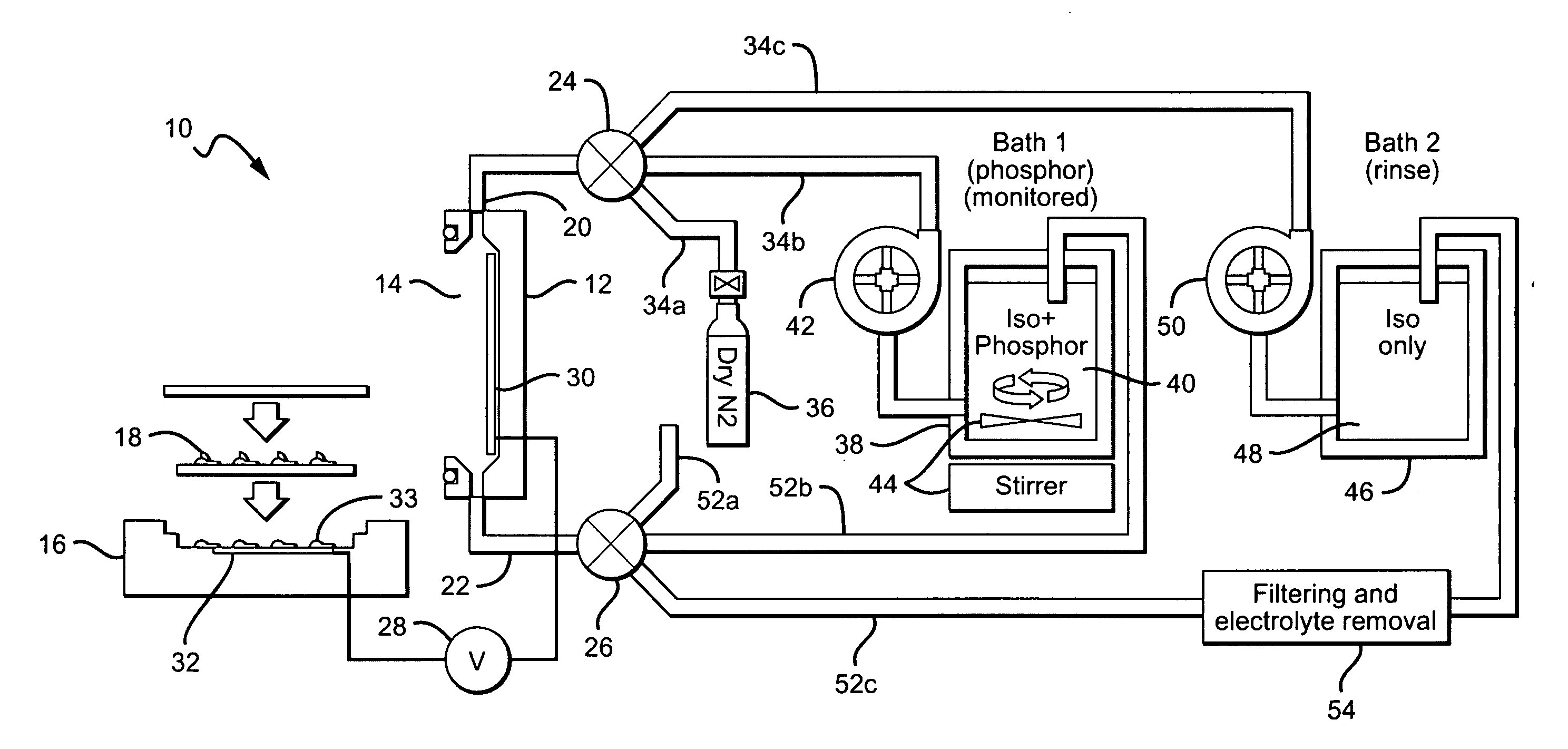

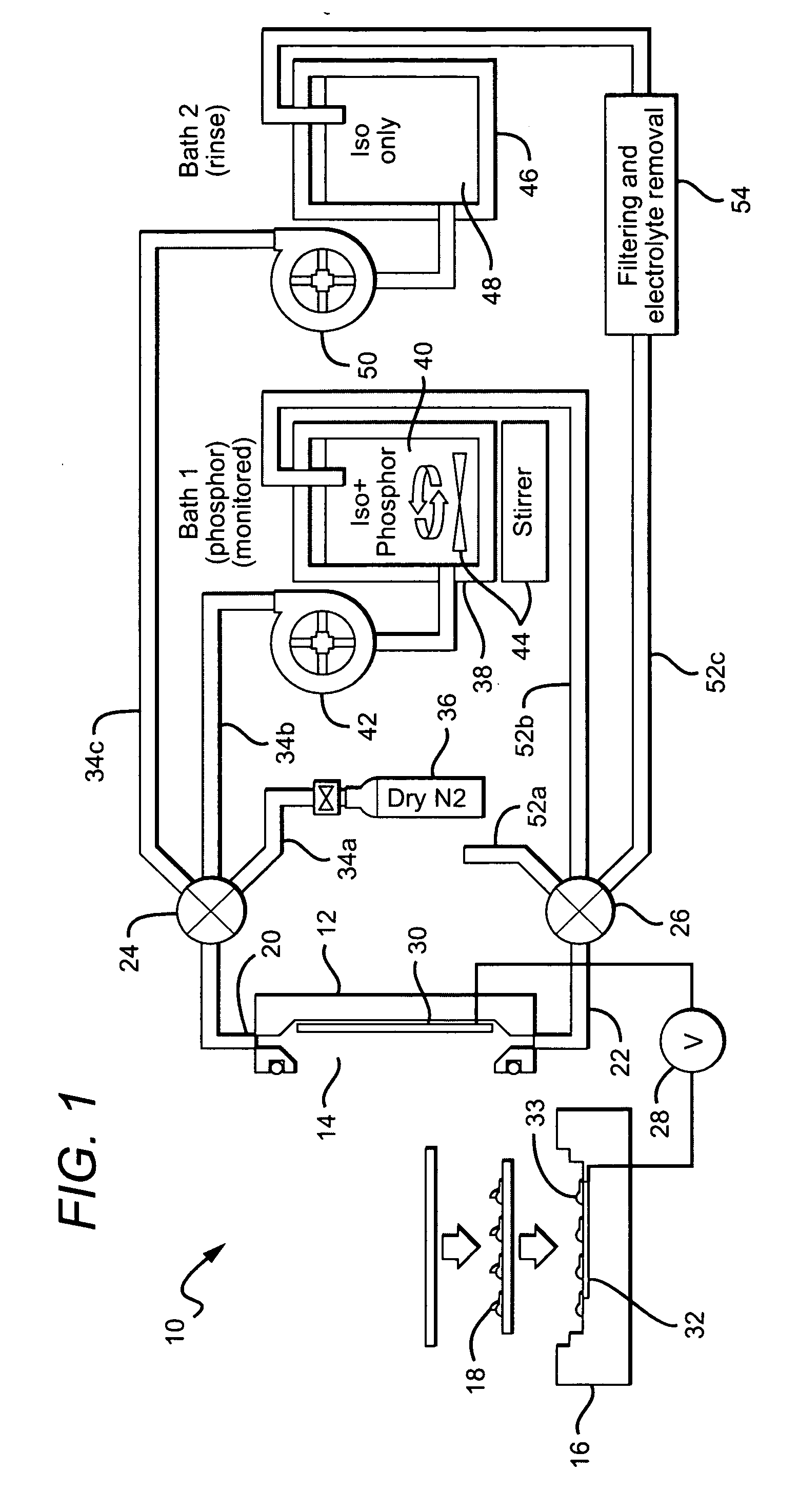

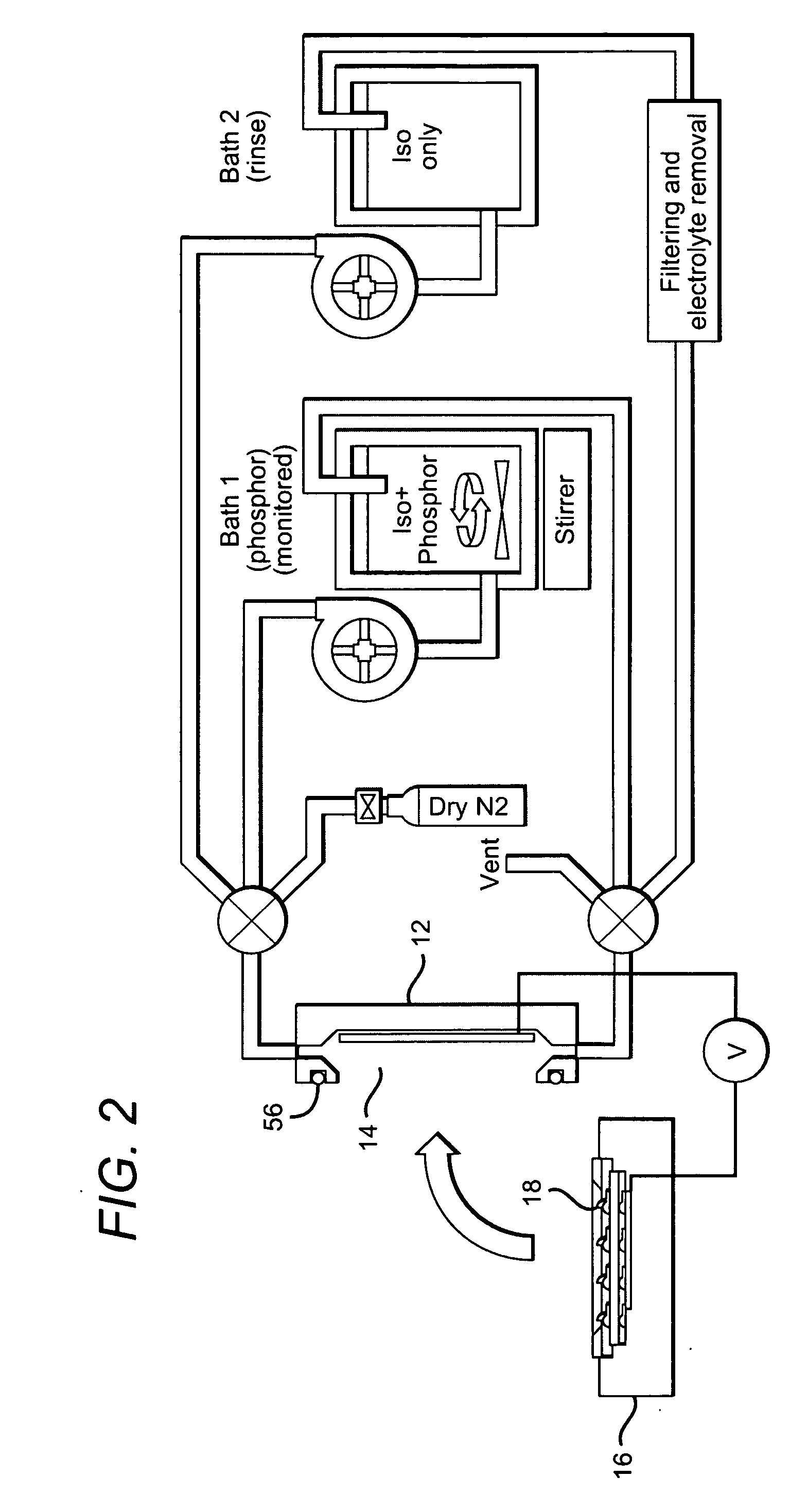

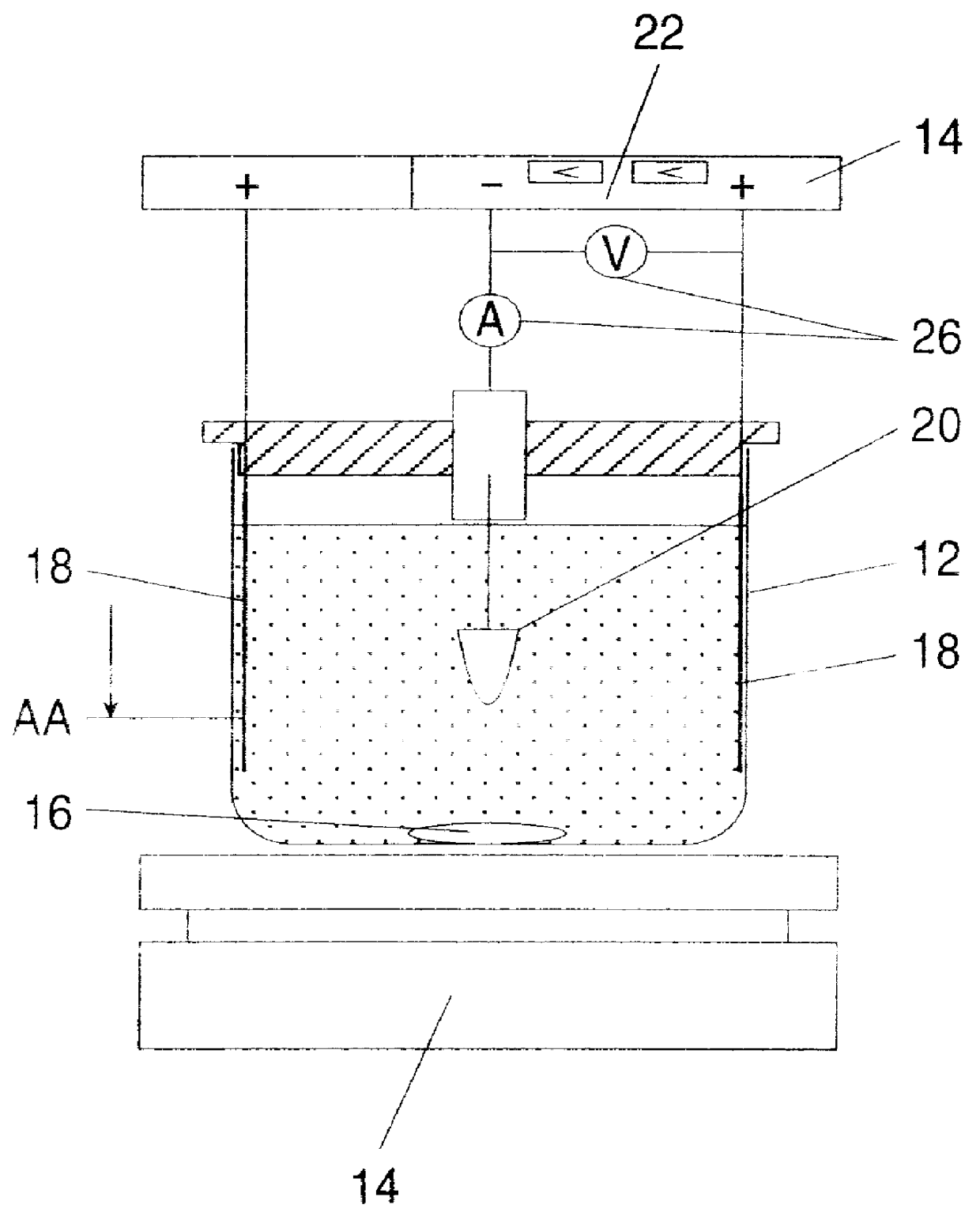

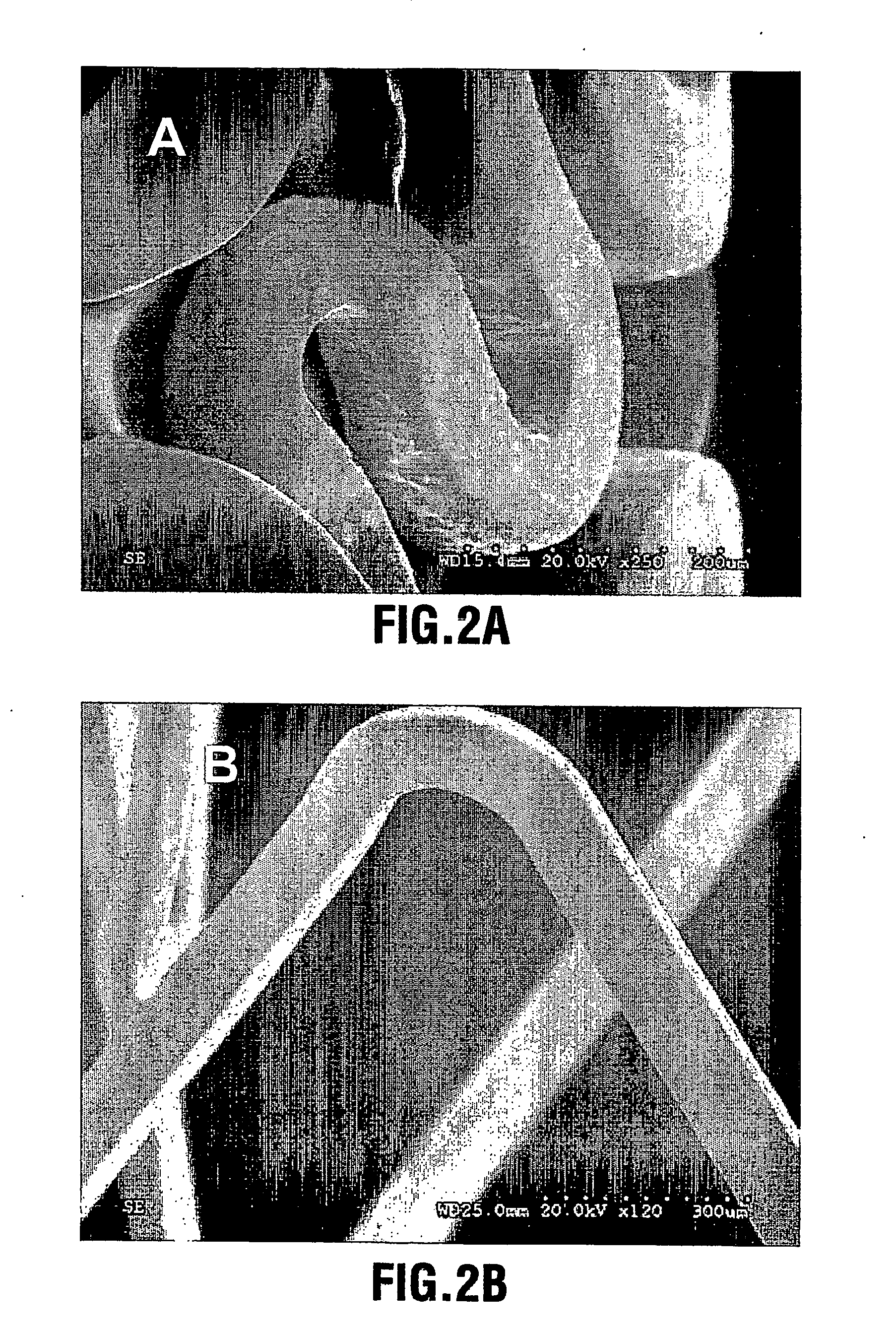

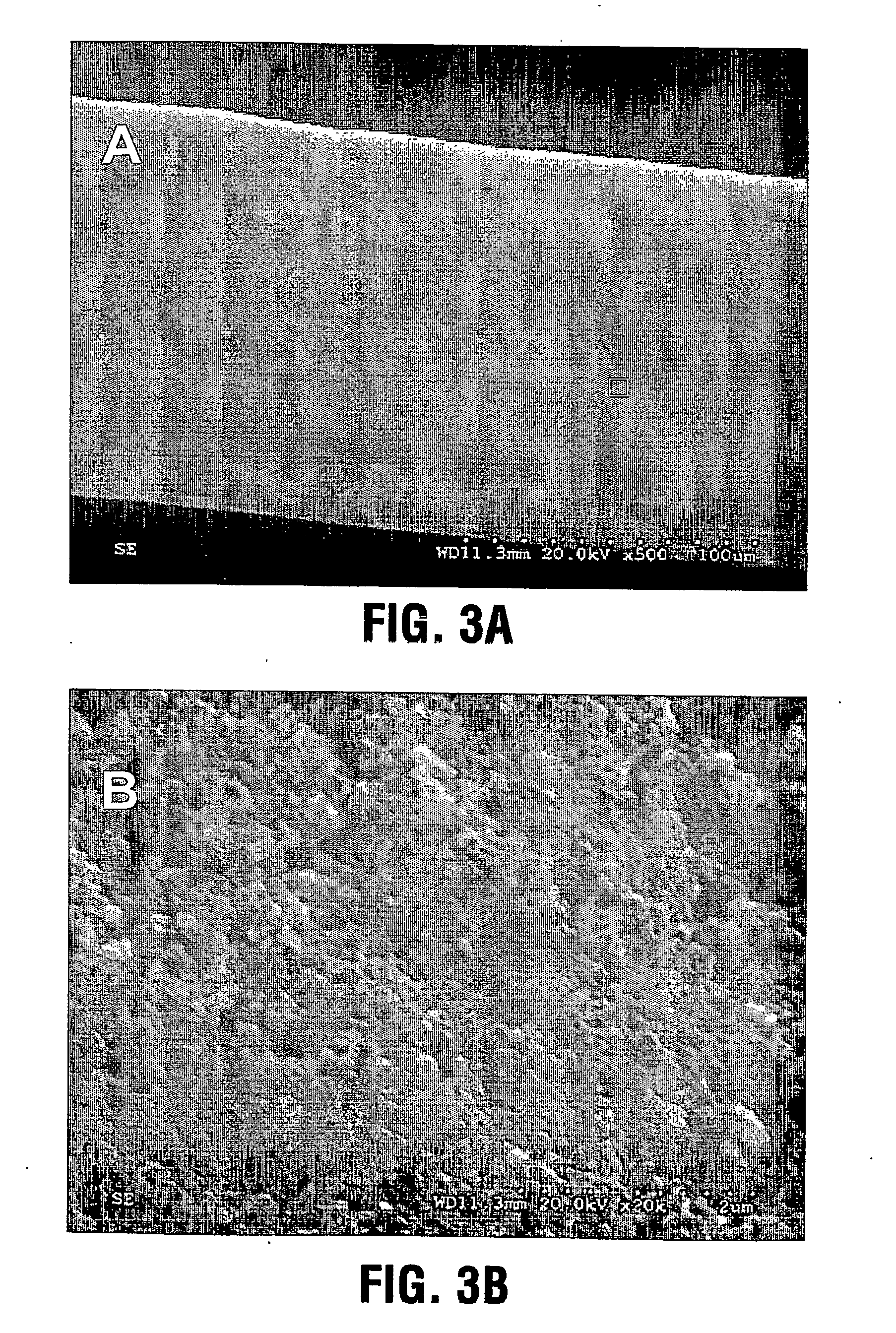

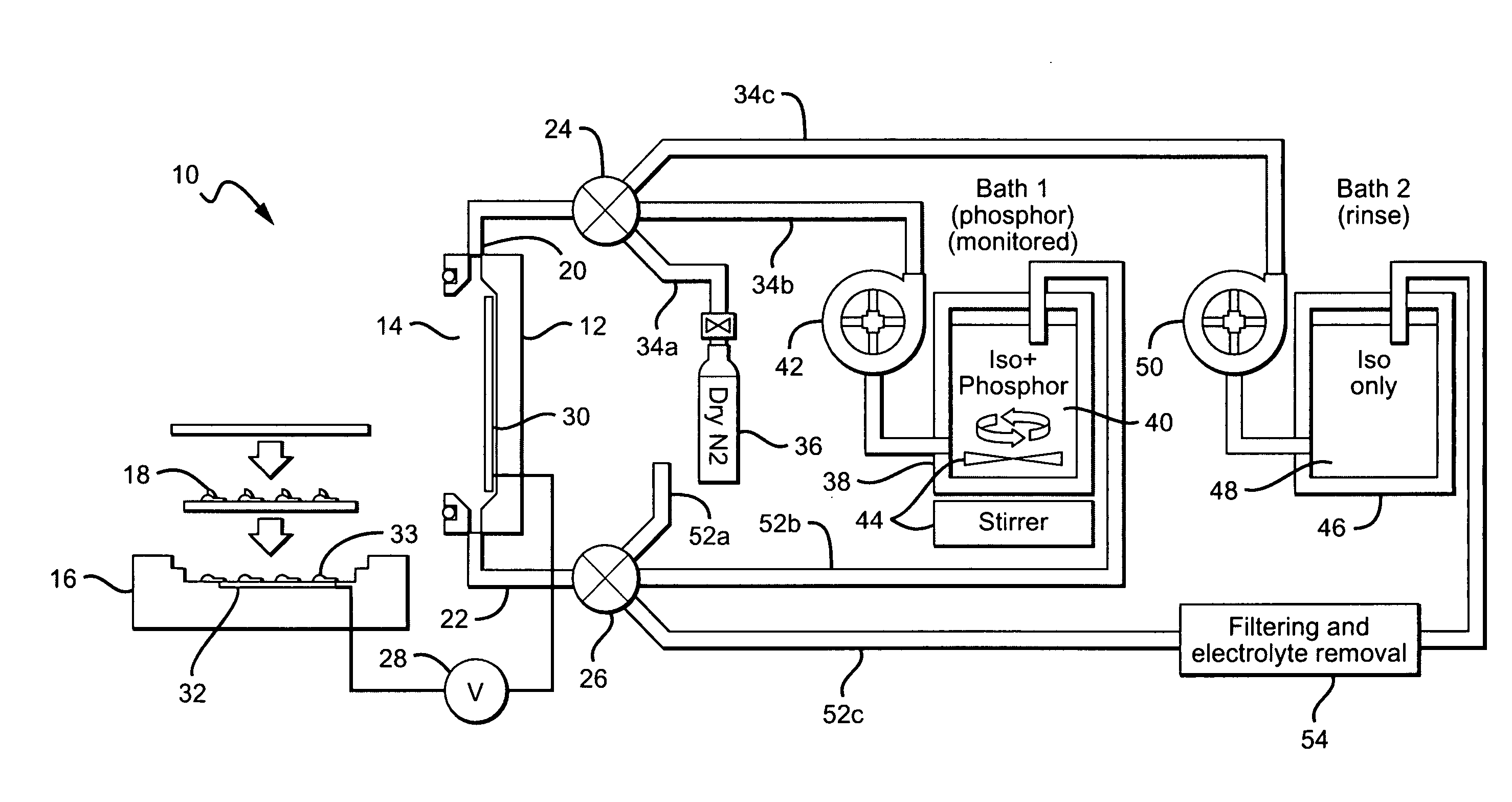

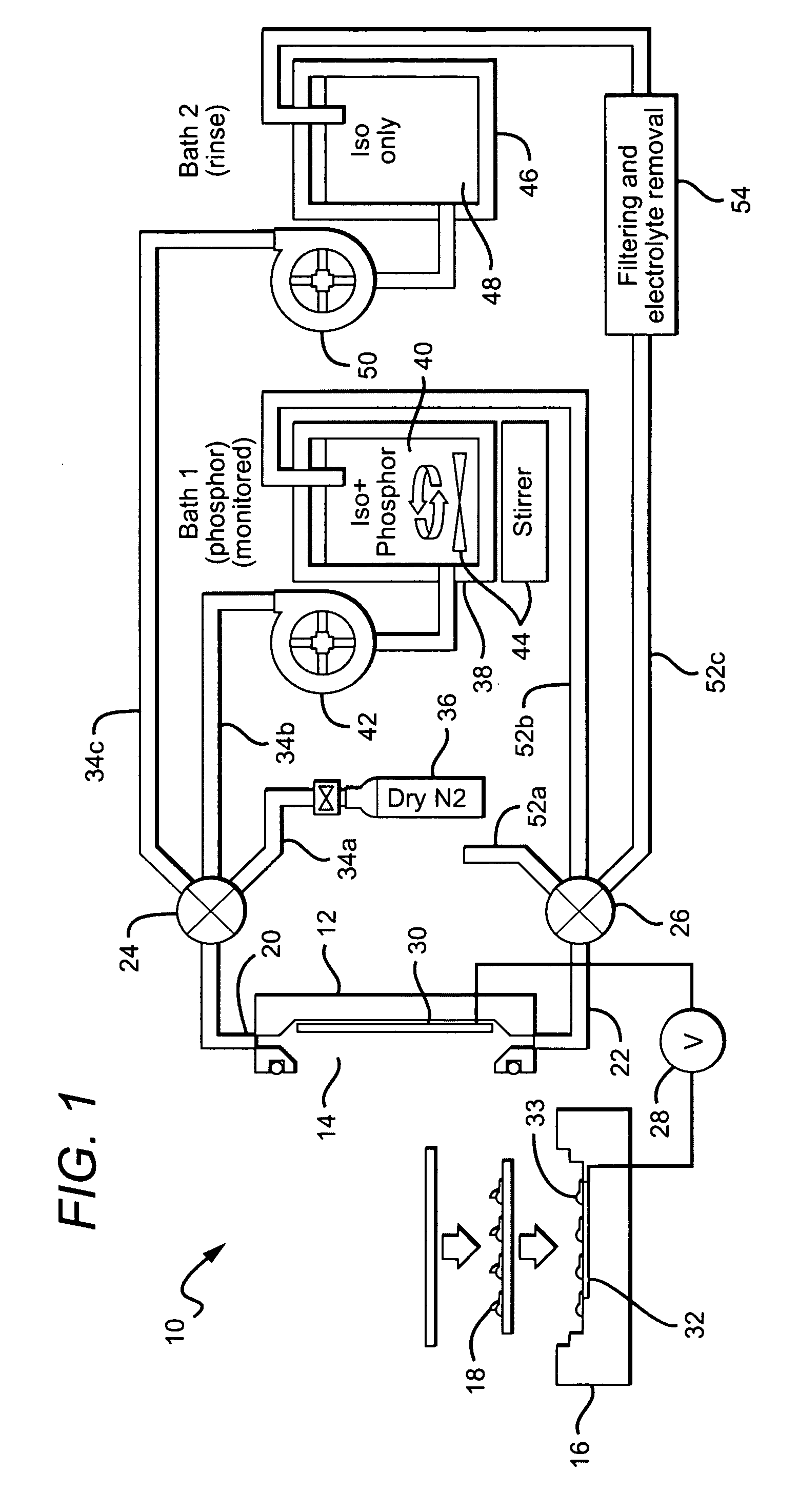

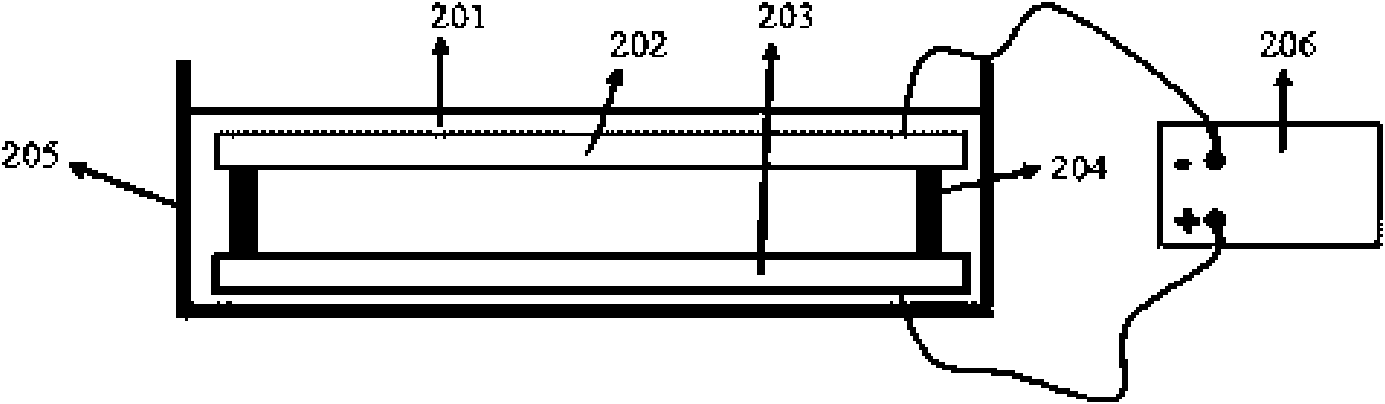

Close loop electrophoretic deposition of semiconductor devices

One close loop system and method for electrophoretic deposition (EPD) of phosphor material on light emitting diodes (LEDs). The system comprises a deposition chamber sealed from ambient air. A mixture of phosphor material and solution is provided to the chamber with the mixture also being sealed from ambient air. A carrier holds a batch of LEDs in the chamber with the mixture contacting the areas of the LEDs for phosphor deposition. A voltage supply applies a voltage to the LEDs and the mixture to cause the phosphor material to deposit on the LEDs at the mixture contacting areas.

Owner:CREELED INC

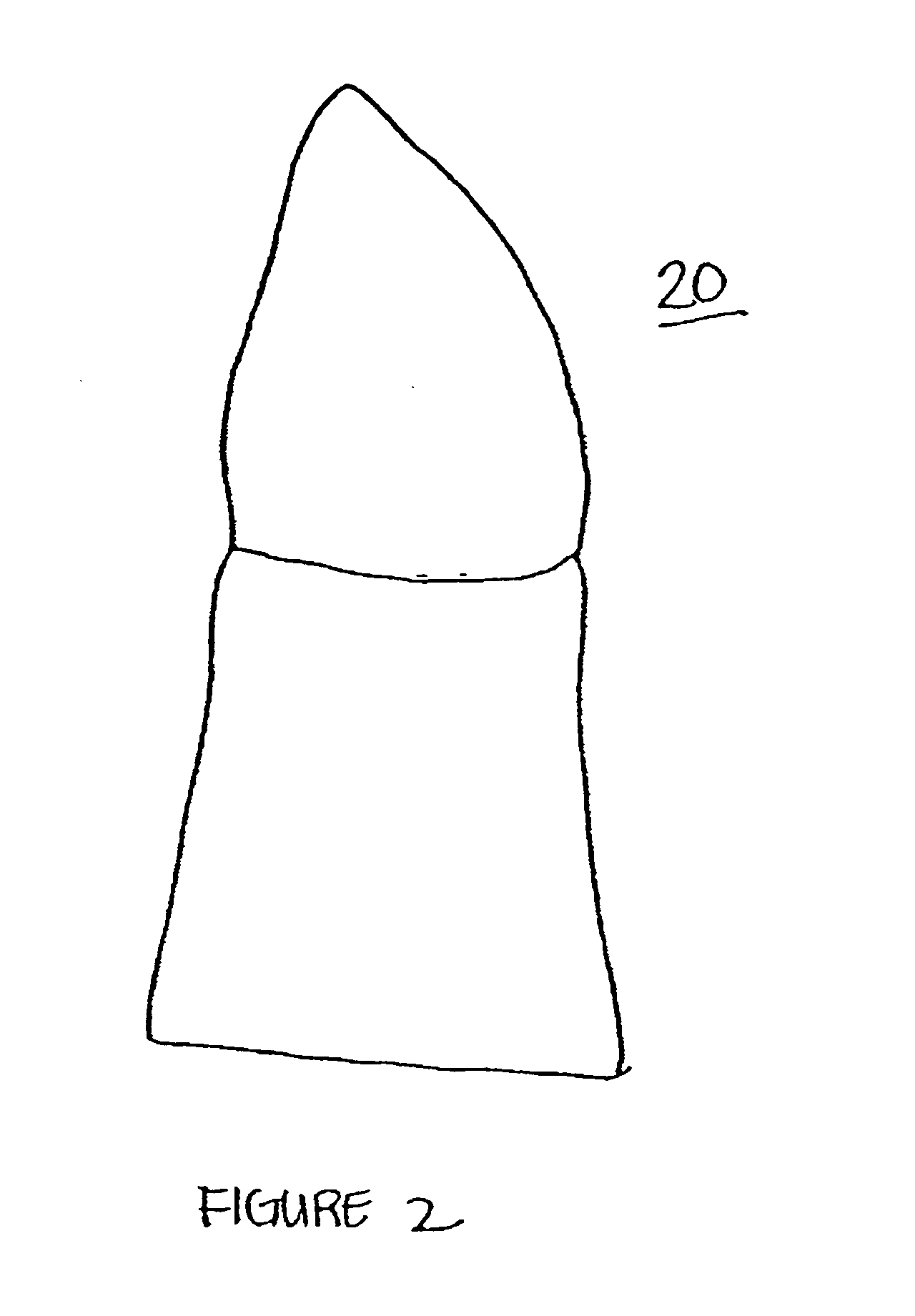

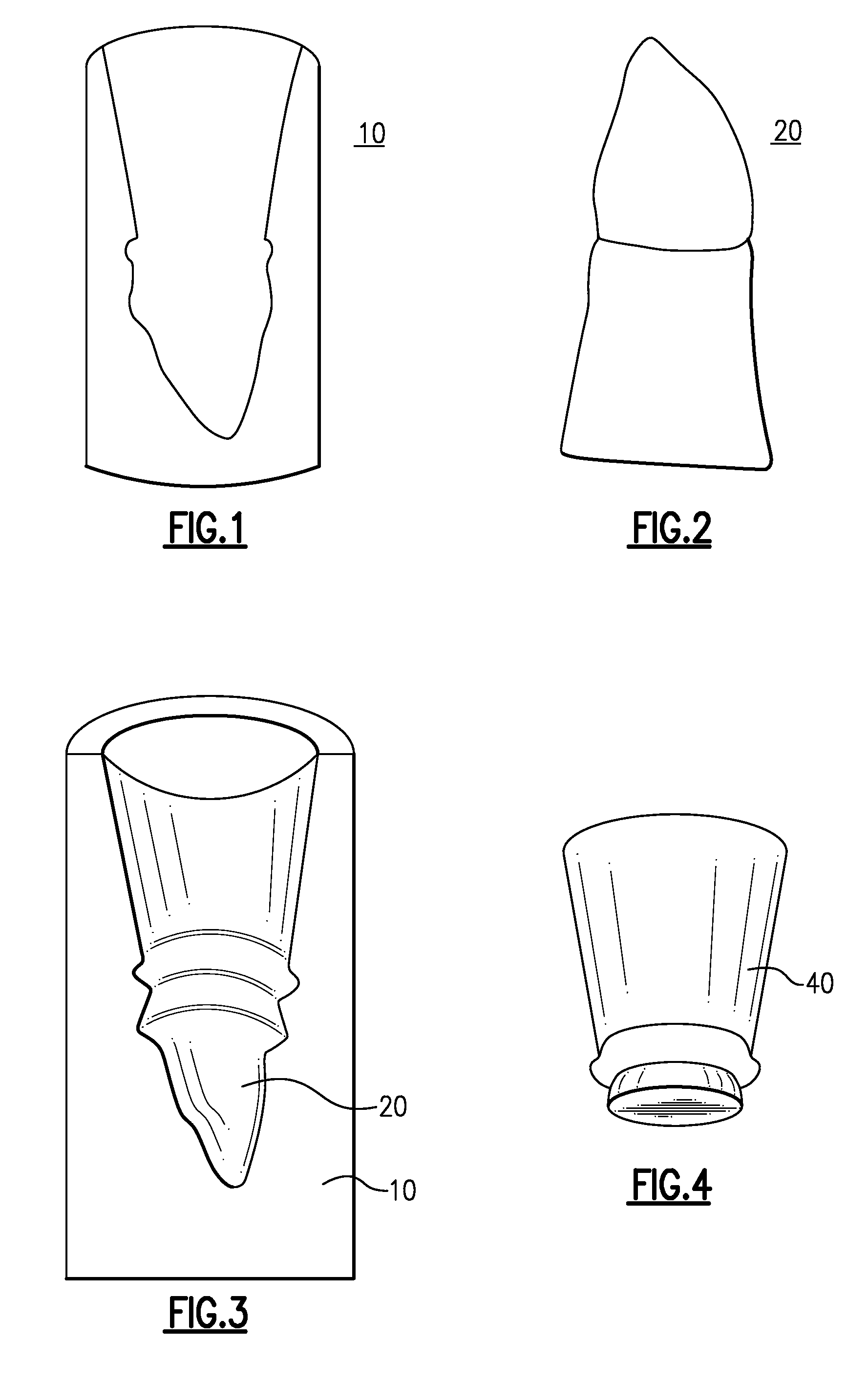

Solid free-form fabrication methods for the production of dental restorations

InactiveUS20050023710A1Improve bindingImpression capsCeramic shaping apparatusPolymer scienceFree form

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

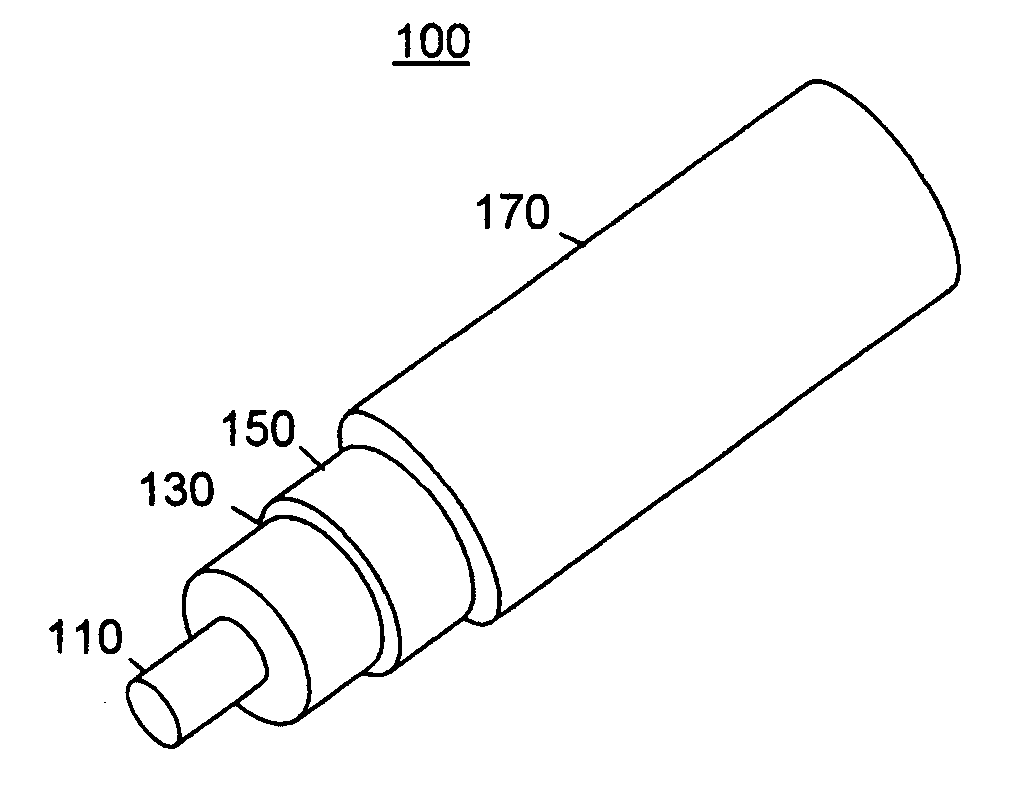

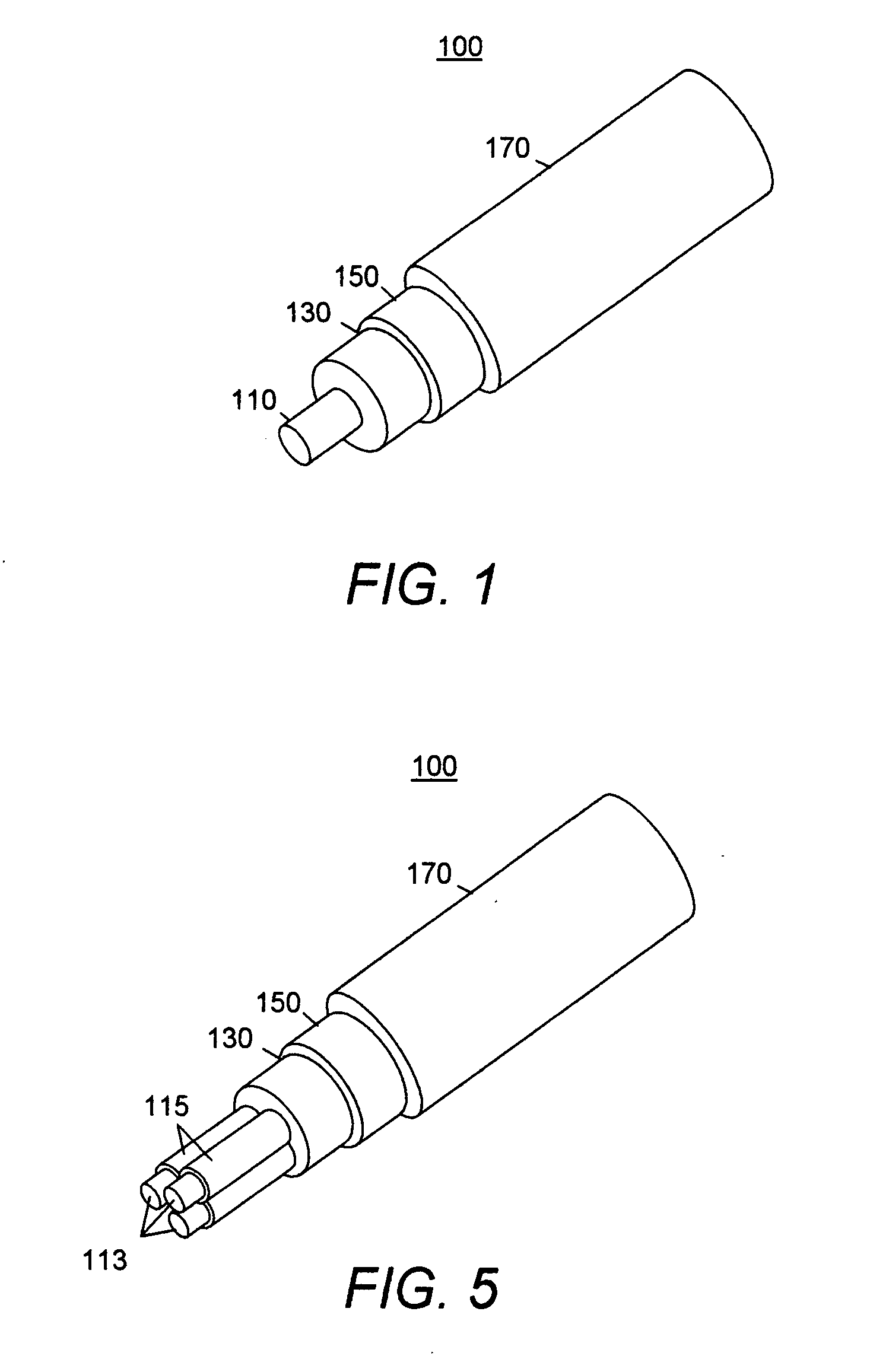

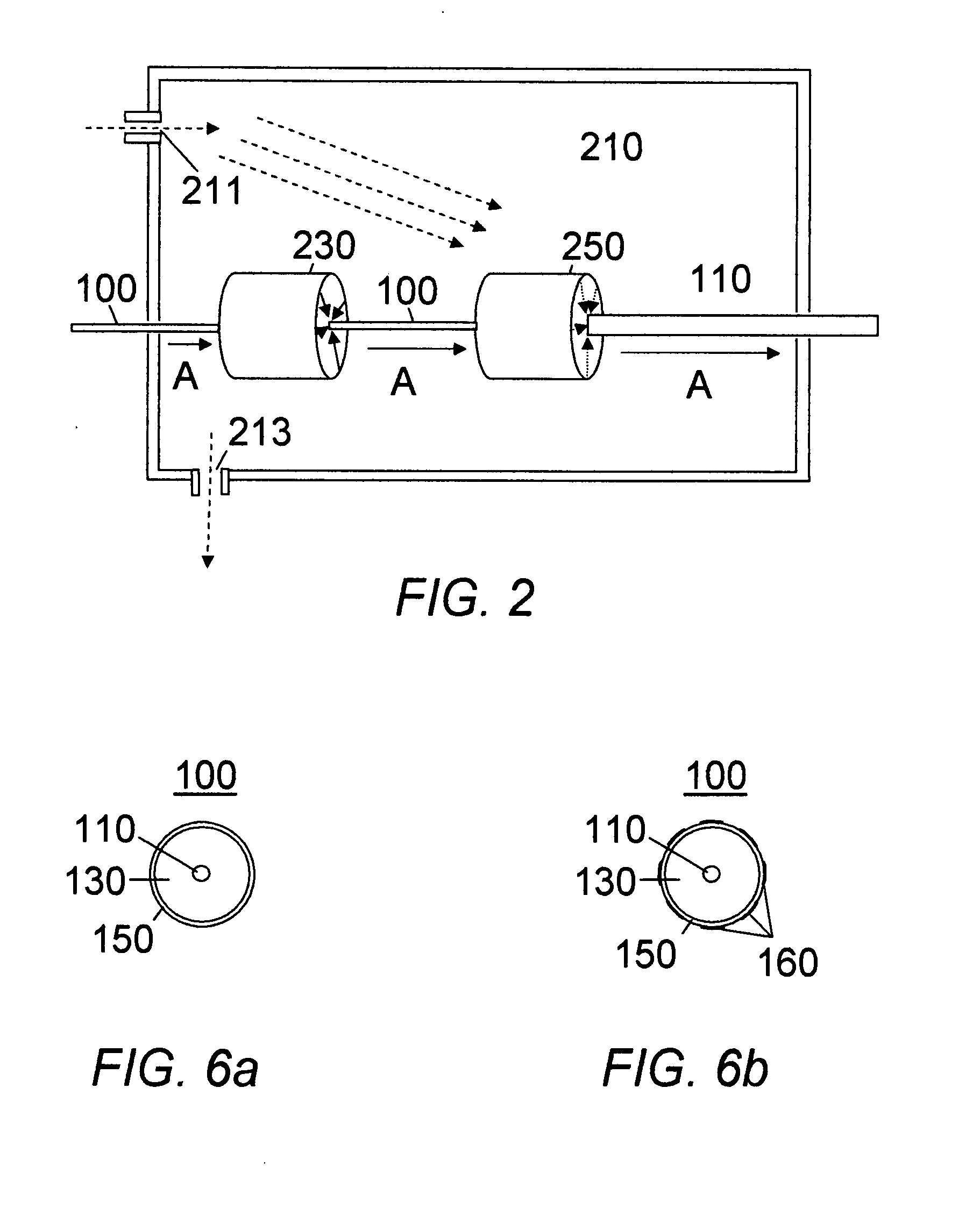

Multi-layer cable design and method of manufacture

InactiveUS20080060832A1Economically manufacturedVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsCathodic arc depositionFiber

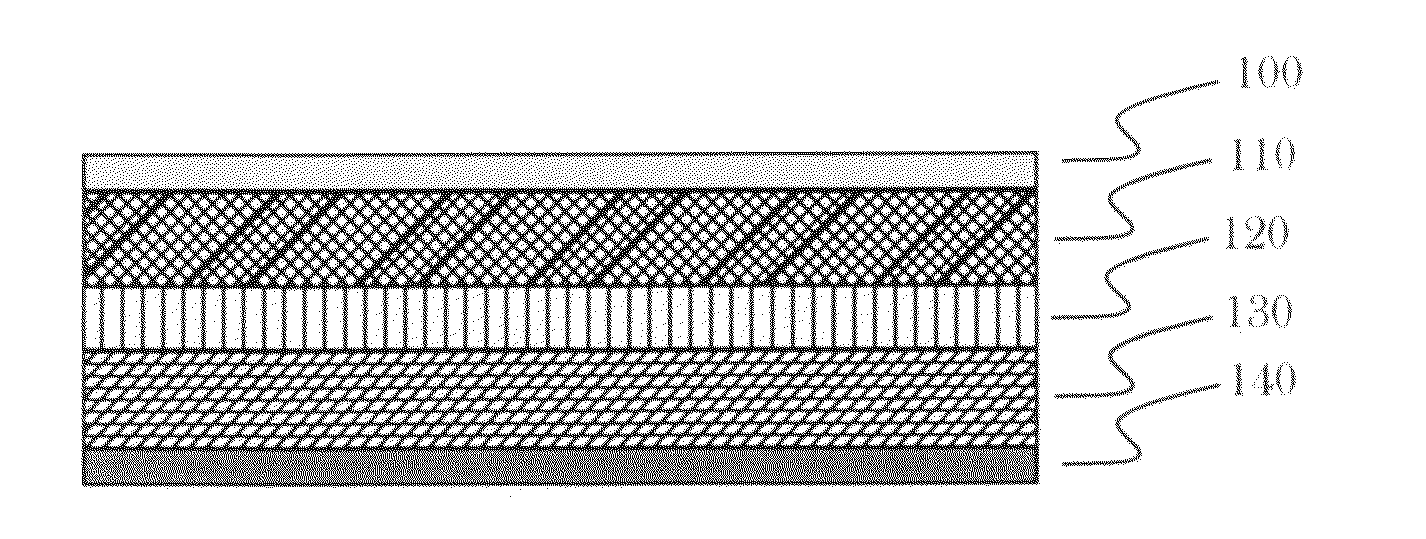

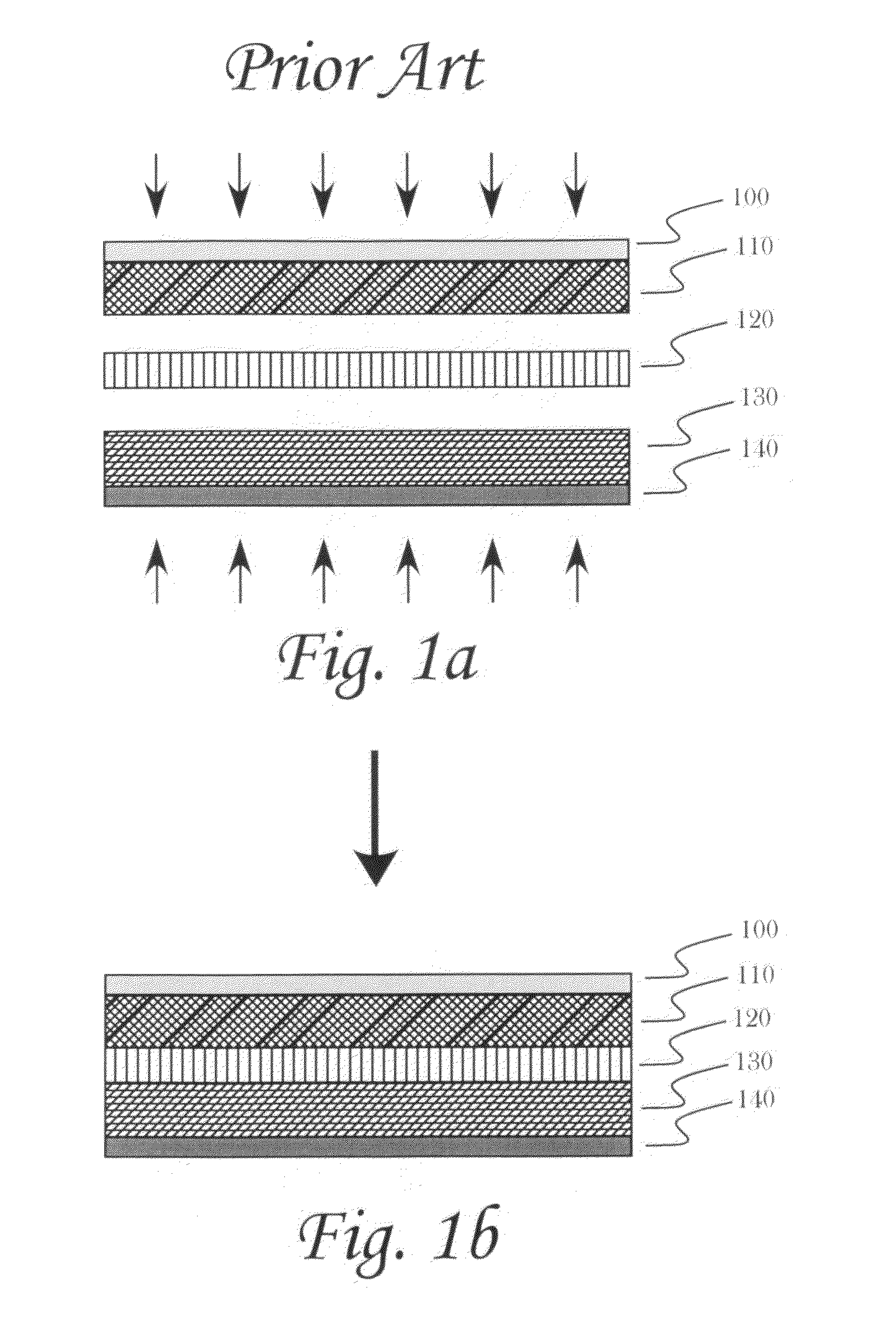

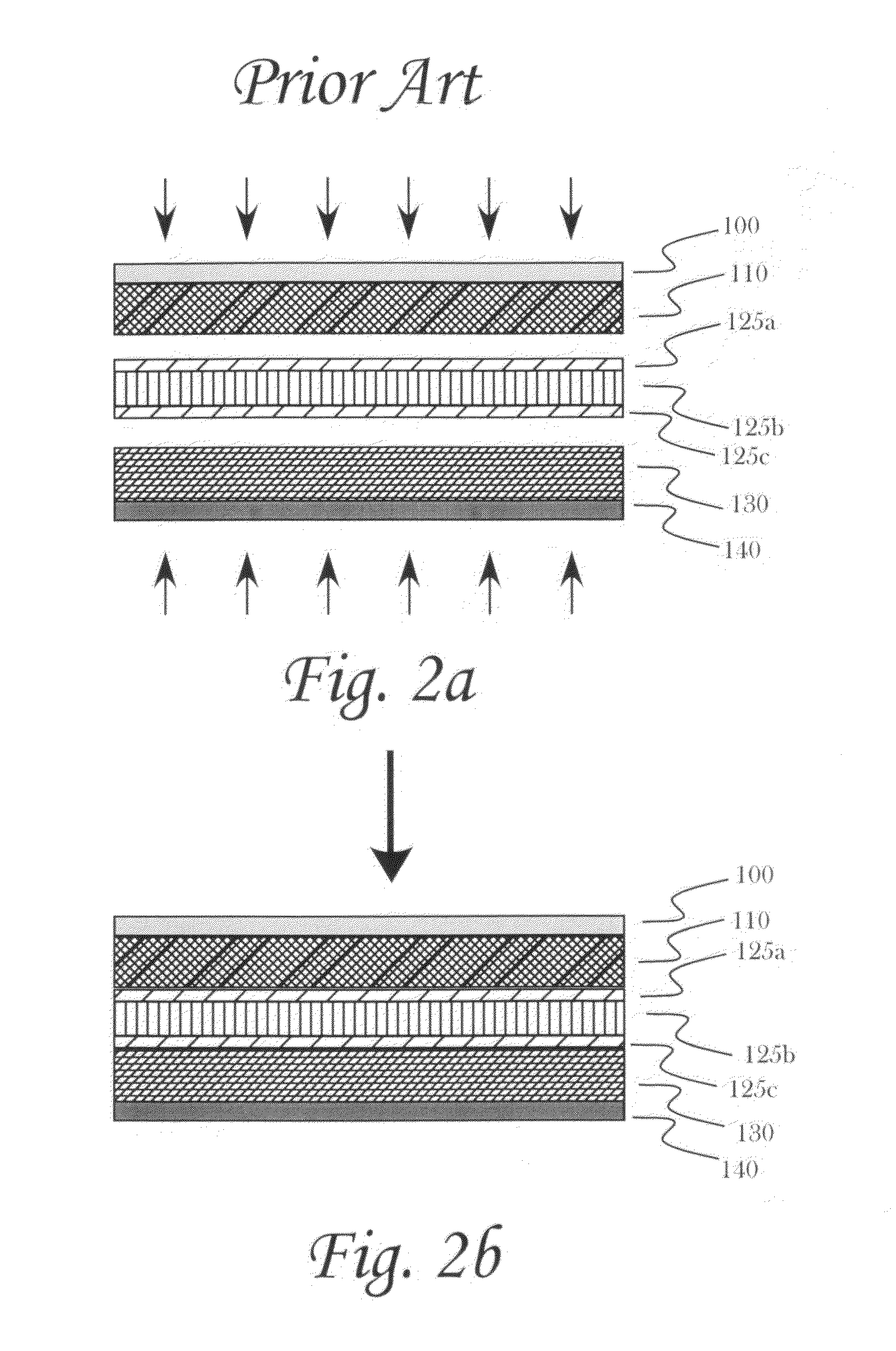

A novel method of designing and fabricating flexible and lightweight cable [100] having a central conductor [110], a dielectric layer [130], an outer conductor [150] and an insulation coating [170] using thin film technology is disclosed. The dielectric layer [130] is ‘grown’ on dielectric layer [130] using electrophoretic deposition to a specified thickness, based upon its intended use. It may include nano-diamonds. Ion beam assisted deposition is used to metalize the cable dielectric layer [130]. This may be ion beam assisted sputtering, ion beam assisted evaporative deposition or ion beam assisted cathodic arc deposition. In an alternative embodiment, the outer conductor may be etched to provide greater flexibility, or to add a piezoelectric layer. The central conductor [110] may be created from dielectric fibers [113] which are metalized as described above. The piezoelectric layer added to create ultrasonic transducer cables.

Owner:RAZAVI ALI

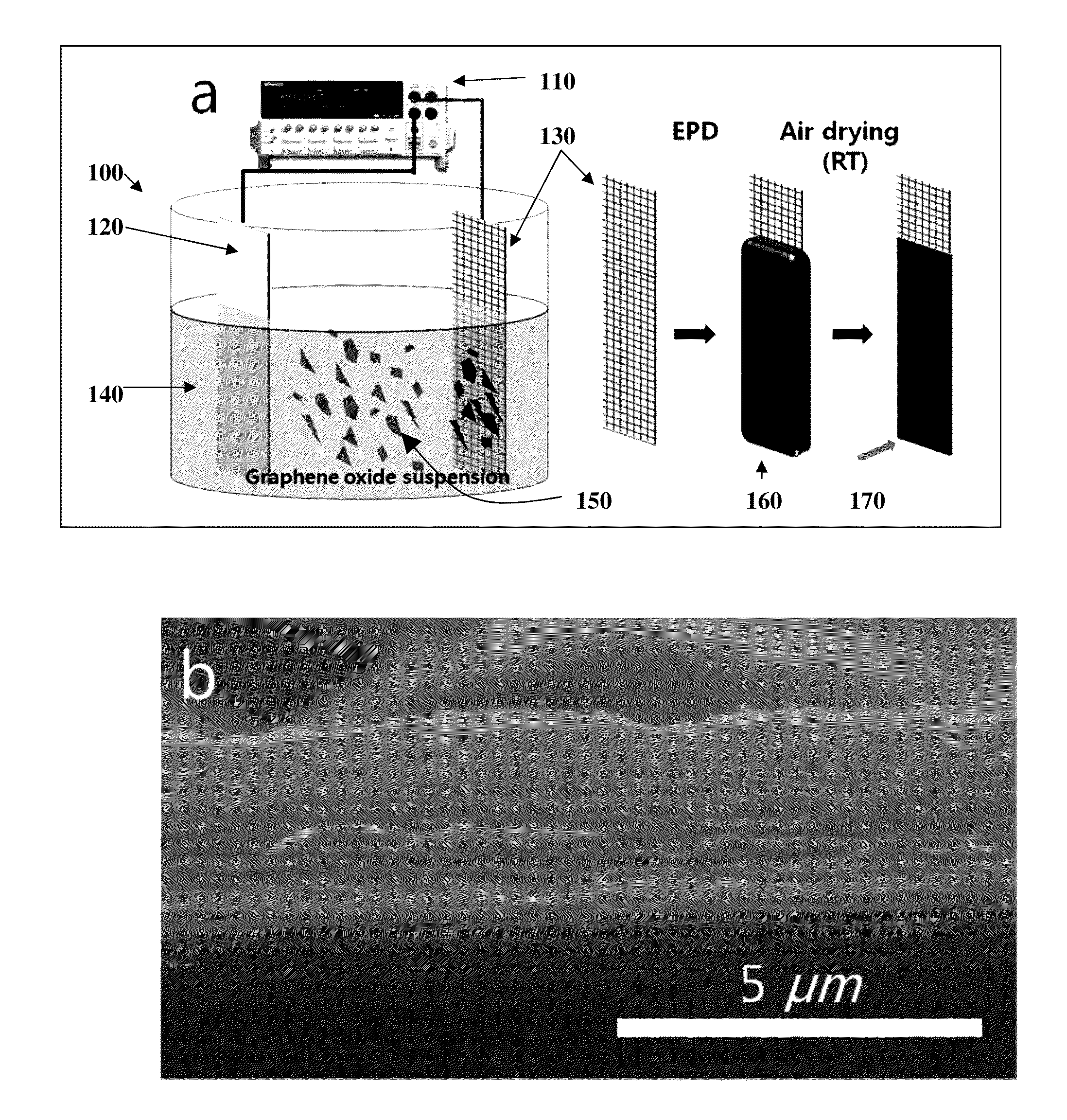

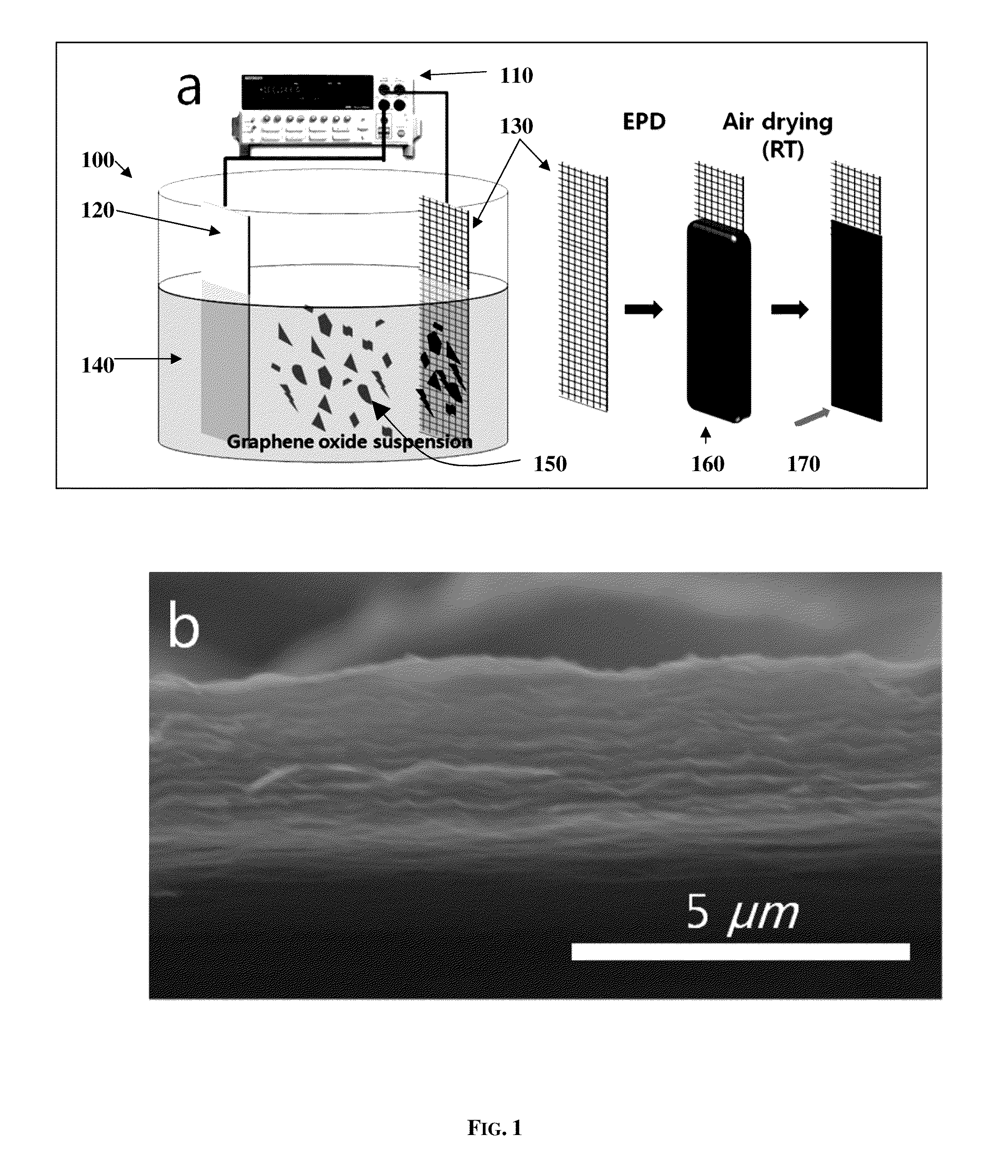

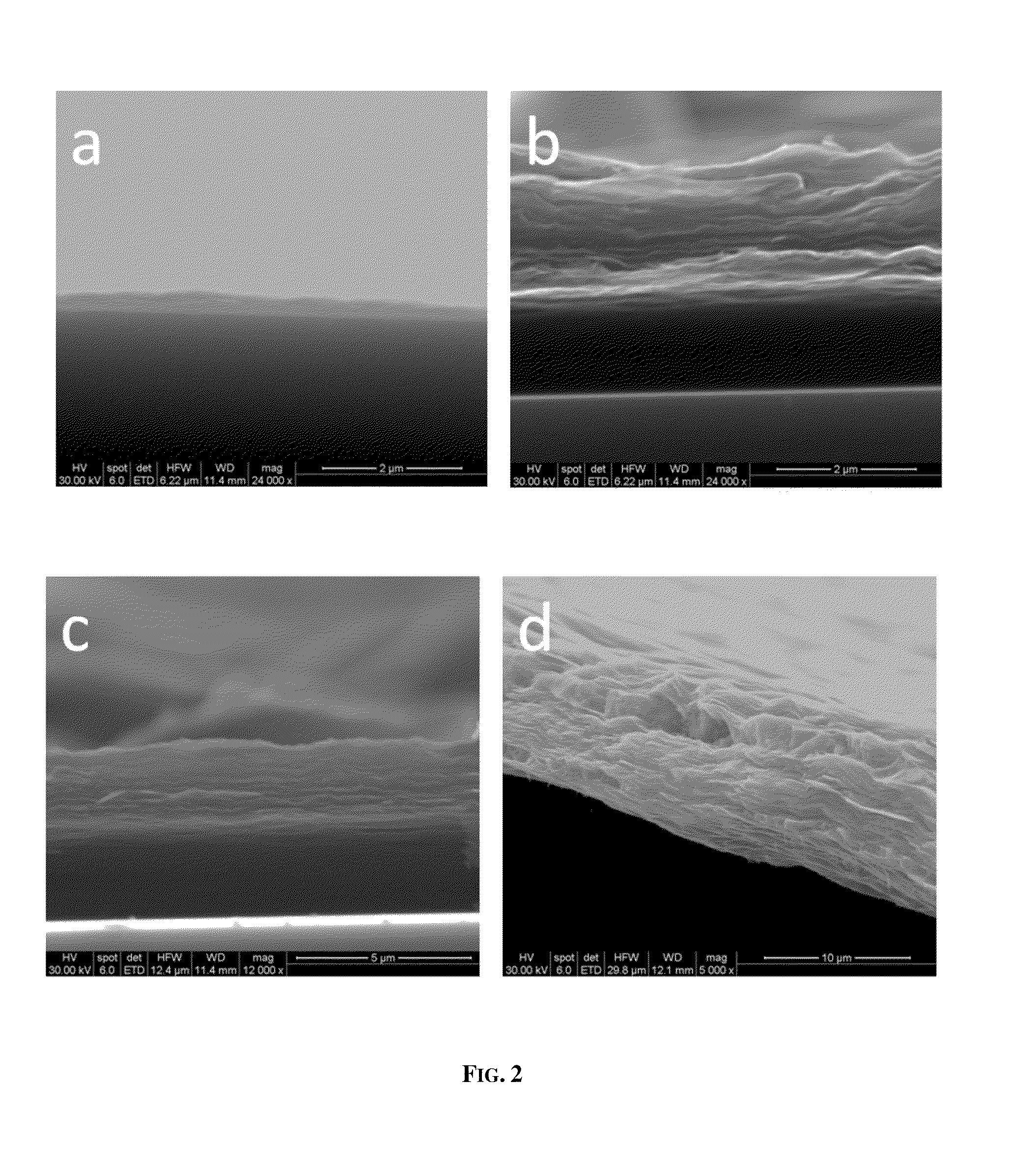

Electrophoretic deposition and reduction of graphene oxide to make graphene film coatings and electrode structures

Owner:RUOFF RODNEY S +4

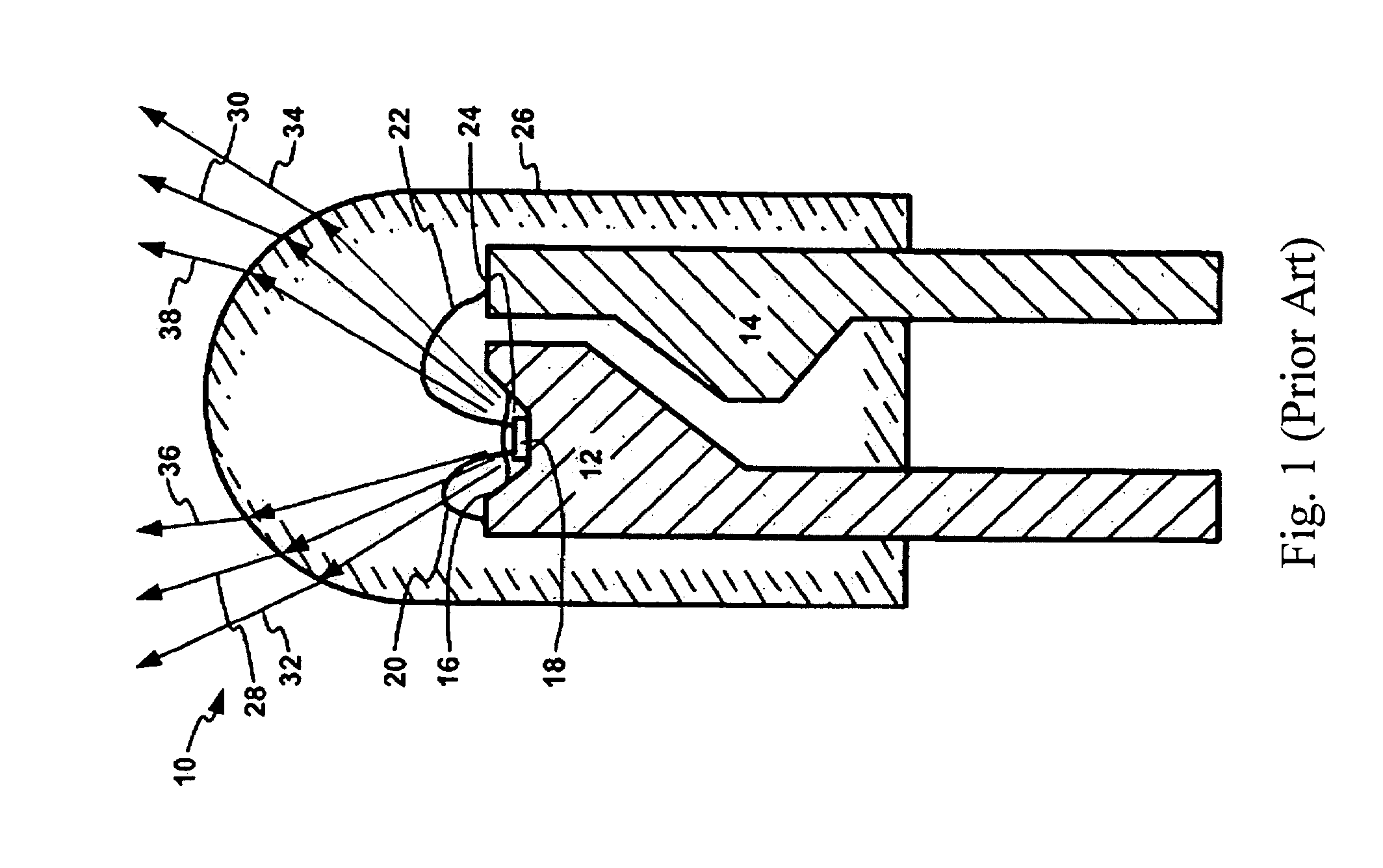

Electrophoretic diamond coating and compositions for effecting same

InactiveUS6258237B1Effective engineering evaluation of material strengthImprove adhesionElectrolysis componentsVolume/mass flow measurementSubstrate surfaceMaterials science

A method of depositing diamond particles on a surface of a substrate is provided. The method is effected by (a) charging the diamond particles by a positive charge to obtain positively charged diamond particles; and (b) electrophoretically depositing the positively charged diamond particles on the surface of the substrate, for obtaining a green diamond particles coat on the surface of the substrate.

Owner:ISCAR LTD

Graphene Films and Methods of Making Thereof

ActiveUS20130156678A1Material nanotechnologyElectrolysis componentsPlanar substrateConformal coating

Provided are methods for forming graphene or functionalized graphene thin films. Also provided are graphene and functionalized graphene thin films formed by the methods. For example, electrophoretic deposition methods and stamping methods are used. Defect-free thin films can be formed. Patterned films can be formed. The methods can provide conformal coatings on non-planar substrates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

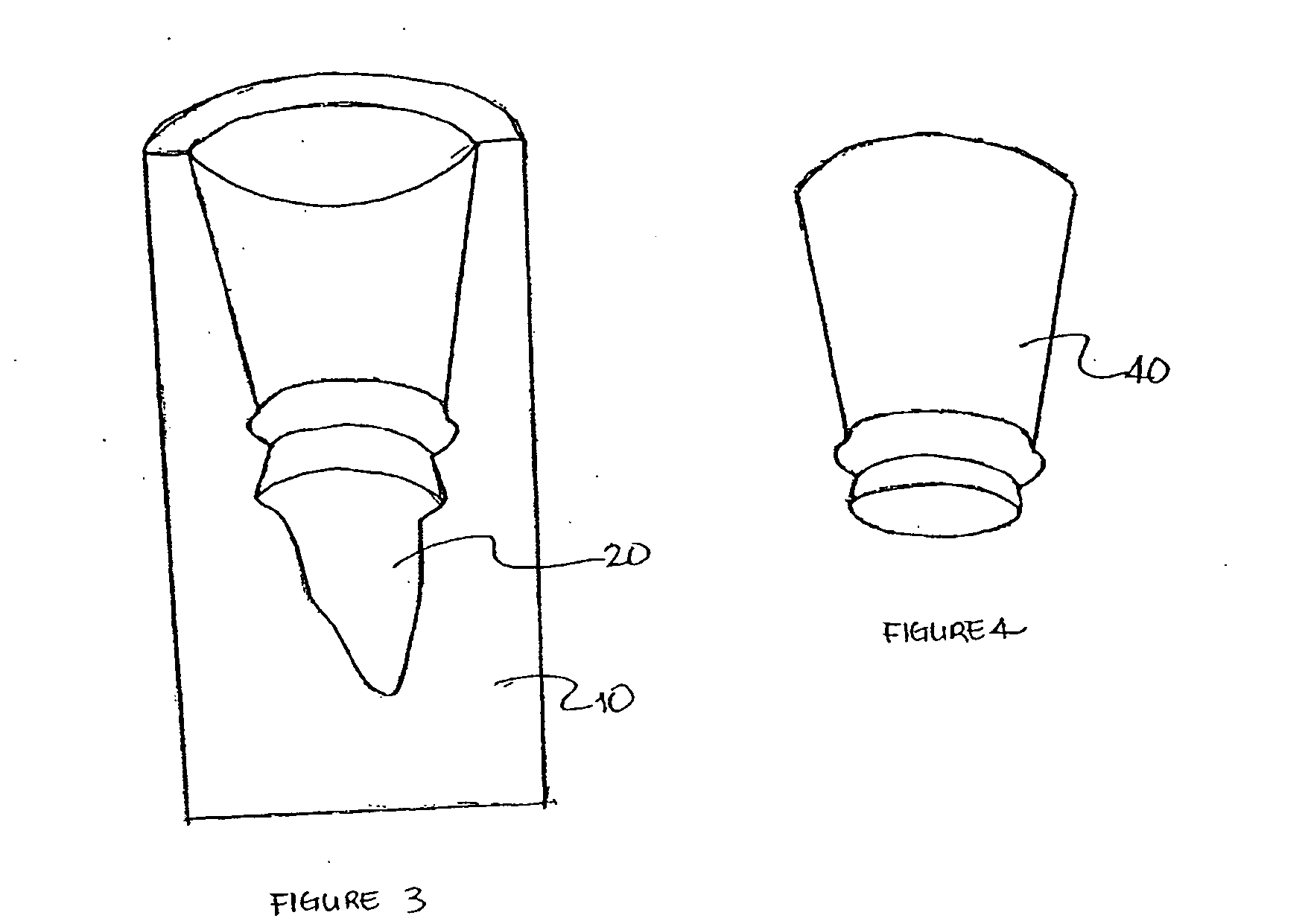

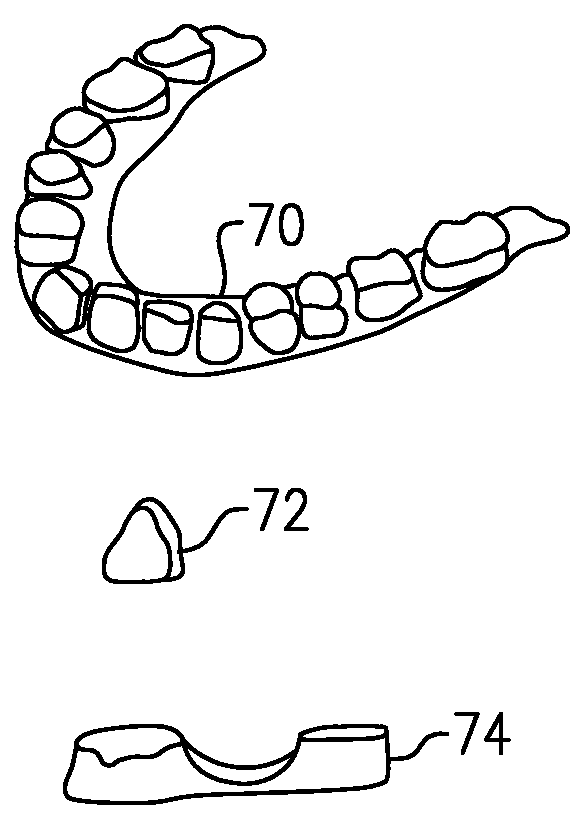

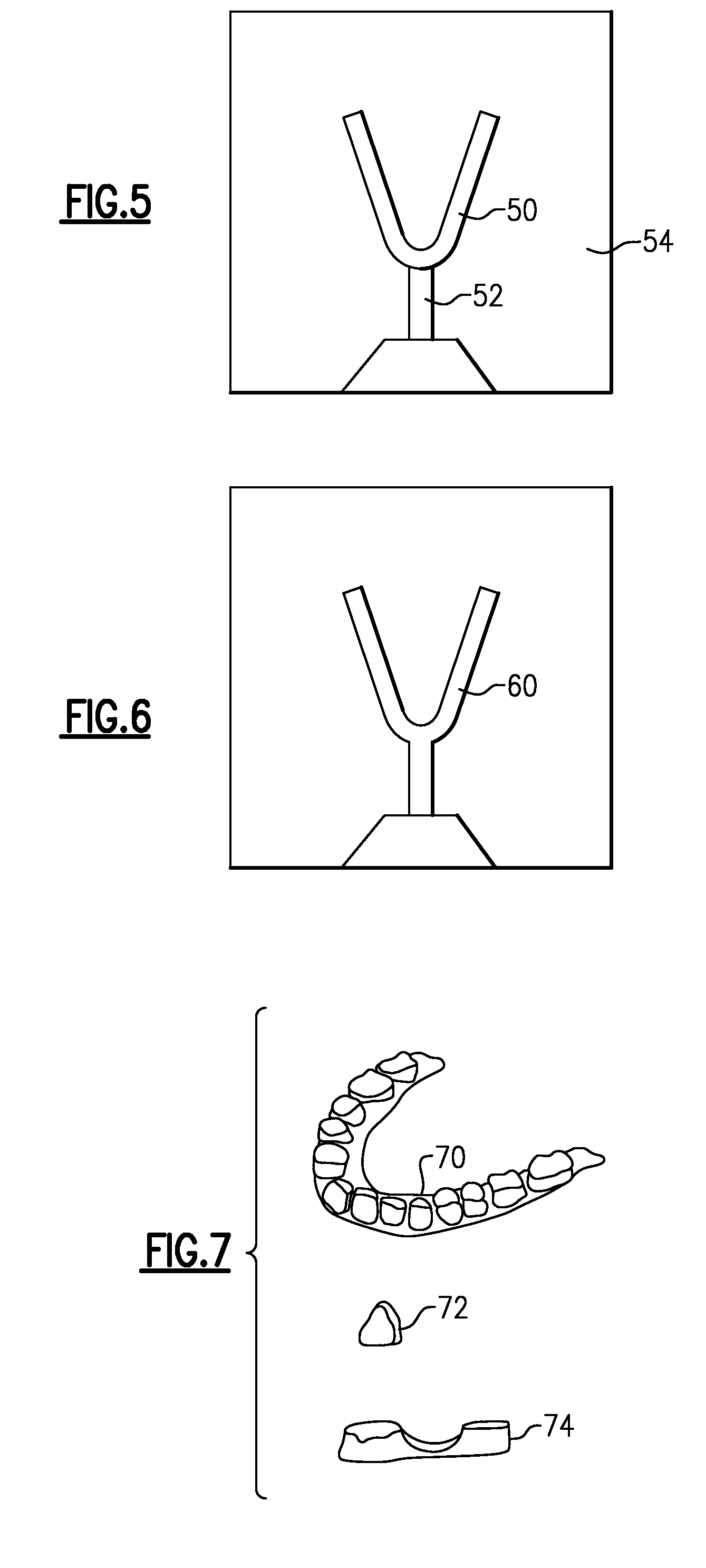

Method of electrophoretic deposition of ceramic bodies for use in manufacturing dental appliances

InactiveUS6059949AHigh strengthImprove toughnessElectrolysis componentsTeeth fillingMetallurgyElectrophoresis

A method for electrophoretic deposition of ceramic particles as a green body shaped as a dental appliance, the method comprising the steps of (a) forming a suspension of the ceramic particles in a first polar solvent, the ceramic particles constituting at least about 5% of the first suspension by weight; (b) passing a direct electrical current through the first suspension, using a deposition electrode shaped as the dental appliance to form a green body; (c) coating the green body with glass particles; and (d) sintering the resultant coated body for obtaining a glass coated all-ceramic dental appliance.

Owner:CEREL CERAMIC TECH

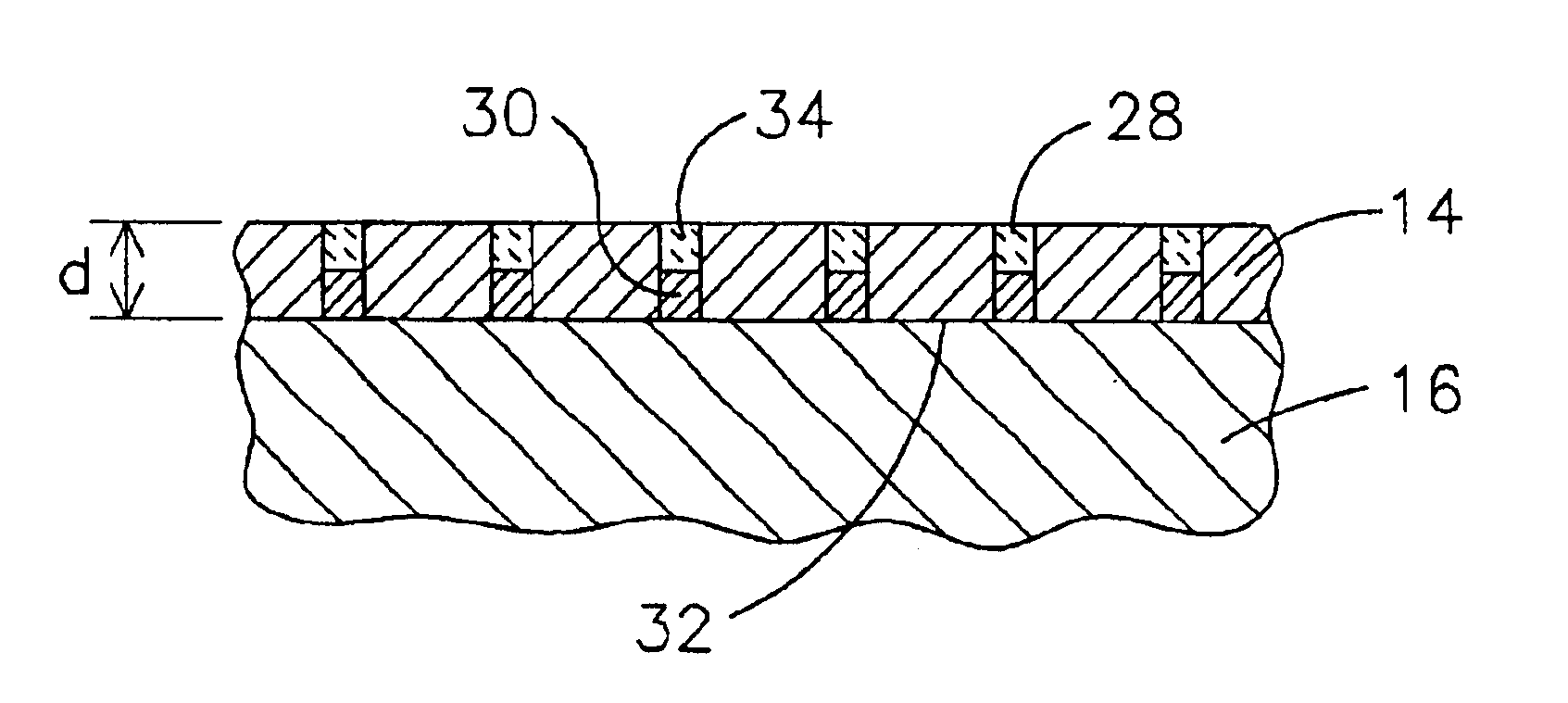

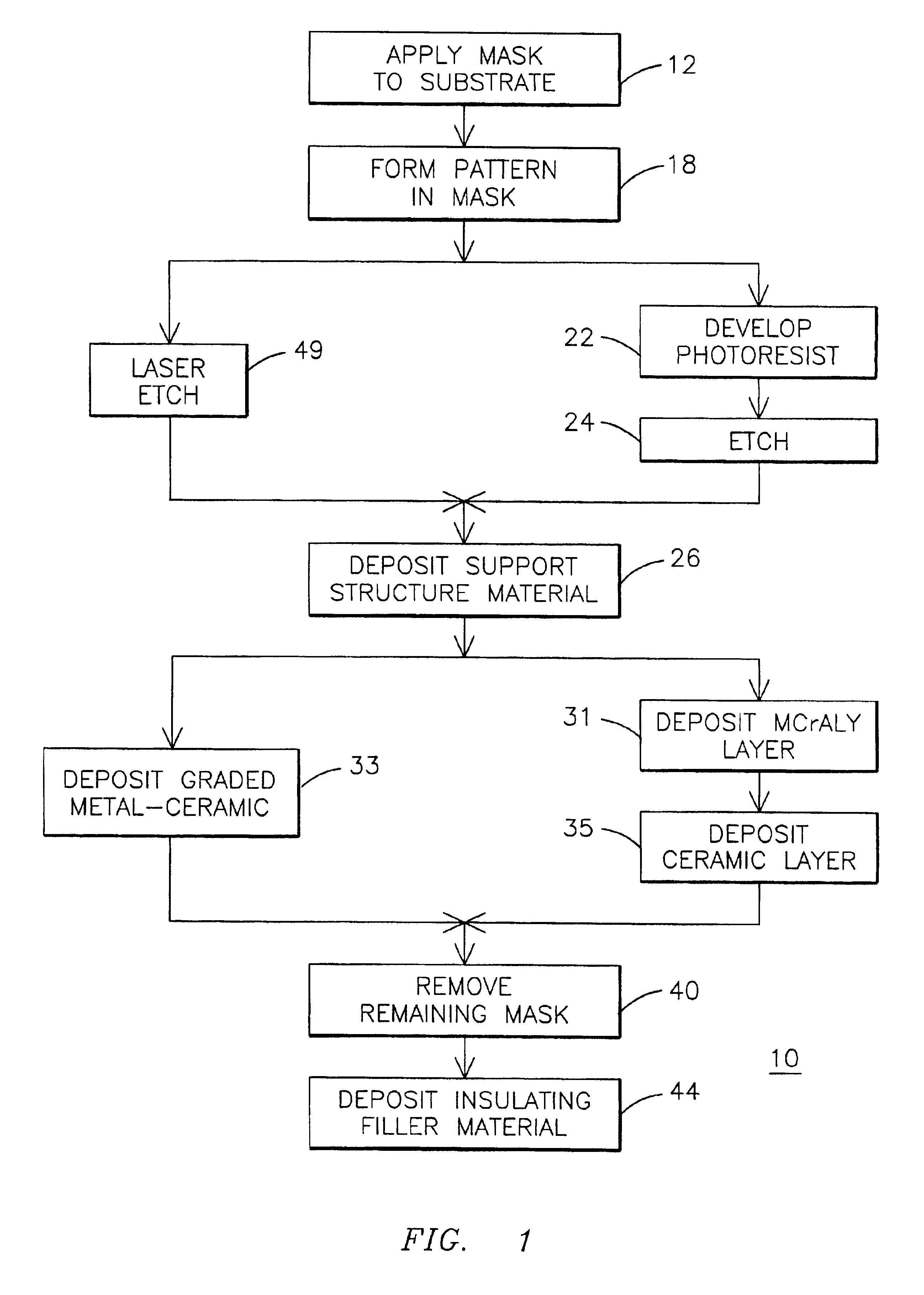

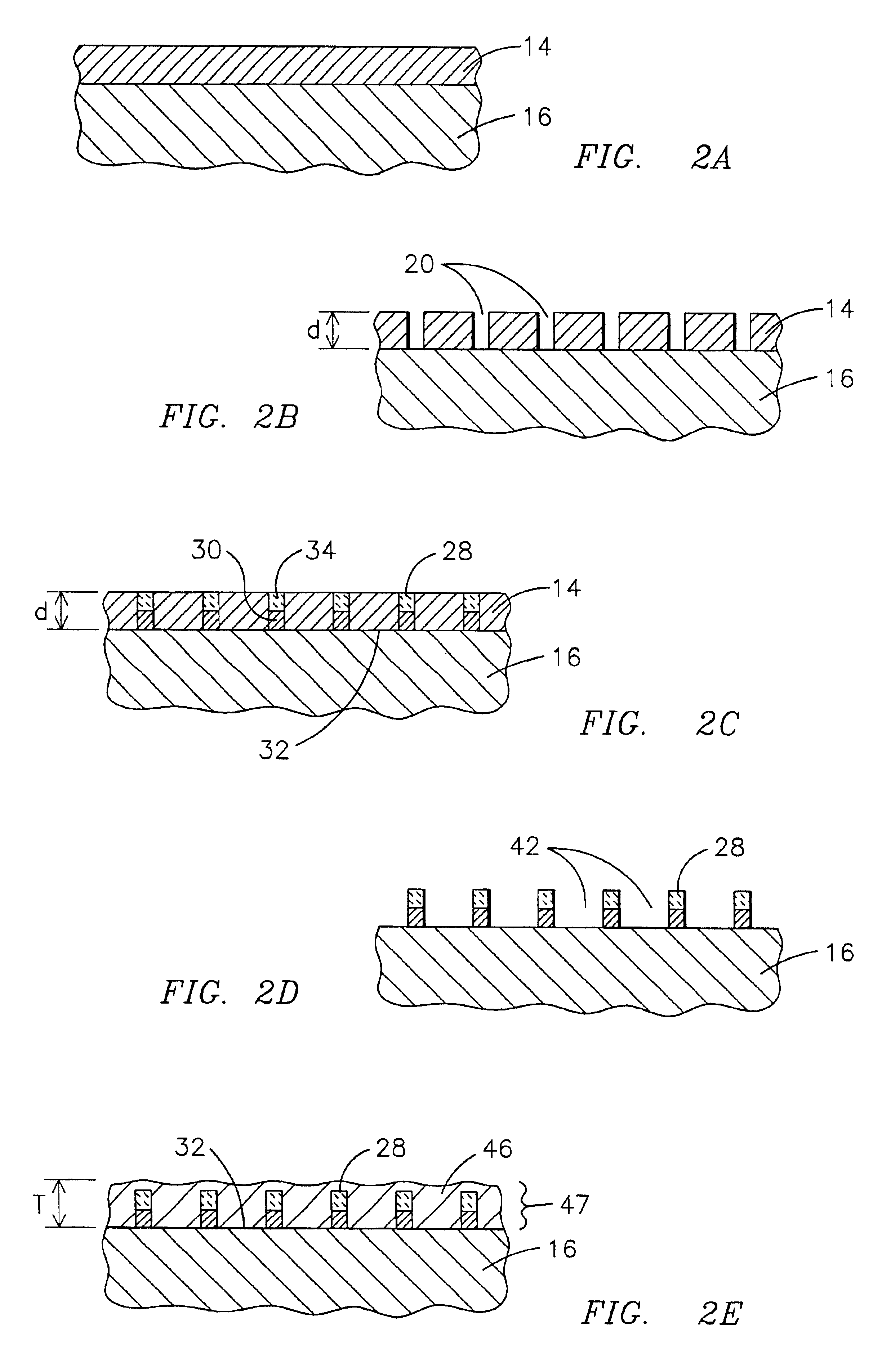

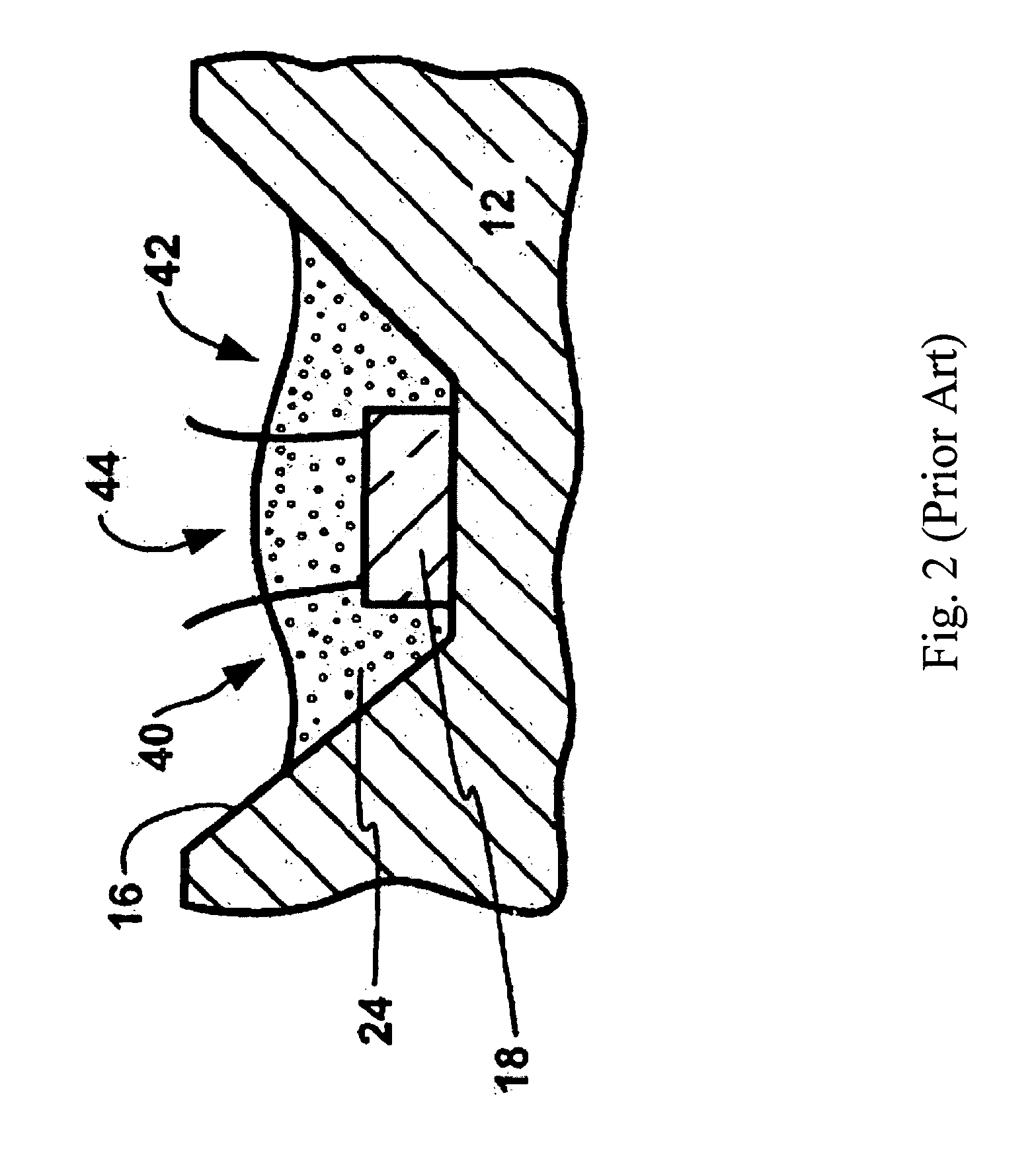

Honeycomb structure thermal barrier coating

InactiveUS6846574B2Minimize heat transfer rateConvenient coatingMolten spray coatingRecord information storageForeign matterLaser etching

A device having an improved thermal barrier coating (46) and a process for manufacturing the same. A support structure (28) for retaining a ceramic insulating material (46) on a substrate (16) is formed by the deposition of a support structure material through a patterned masking material (14). The support structure can define cells into which the ceramic insulating material is deposited following removal of the masking material. The masking material may be patterned by known photolithographic techniques (22,24) or by laser etching (48). The support structure (28) may be a composite metal-ceramic material having either discreet layers (30,34) or a graded composition and may be deposited by an electro-desposition process followed by a heat treatment to form a solid state diffusion bond with the substrate. The ceramic filler material may be deposited (44) by the electrophoretic deposition of ceramic particles coated with a bonding material that is subsequently heated to oxidize and to bond the particles together. The support structure may be provided with included walls in order to improve its resistance to foreign object impact damage.

Owner:SIEMENS ENERGY INC

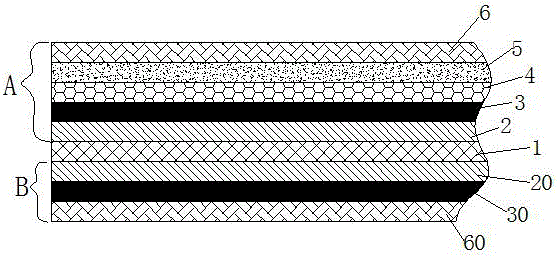

Polymer supported electrodes

InactiveUS20110183203A1Prevent thermal runawayInhibit growthMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSpray coatingPolymer supported

Methods and devices arising from the practice thereof for making and using battery electrodes formed onto ion permeable, electrically non-conductive substrates, preferably battery separators are disclosed herein. Electrodes are formed onto substrates using a variety of methods including, but not limited to, spray coating and electrophoretic deposition. Electrically conductive layers may be applied to the electrode coating layer side opposite or adjacent to the substrate to act as current collectors for the battery. Multilayer devices having alternating layers of conductive layers, electrode layers and substrates, wherein the conductive layers may be in electrical communication with other conductive layers to form a battery.

Owner:MOLECULAR NANOSYST

Calcium phosphate coated implantable medical devices and processes for making same

InactiveUS20060134160A1Reduce porosityControlled release rateBiocideInorganic phosphorous active ingredientsCalcium phosphate coatingCardiovascular stent

This invention relates to novel calcium phosphate-coated implantable medical devices and processes of making same. The calcium-phosphate coatings are designed to minimize the immune response to the implant (e.g. restenosis in stenting procedures) and can be used to store and release a medicinally active agent in a controlled manner. Such coatings can be applied to any implantable medical devices and are useful for a number of medical procedures including (but not limited to) balloon angioplasty in cardiovascular stenting, ureteral stenting and catheterisation. The calcium phosphate coatings can be applied to a substrate as one or more coatings by a sol-gel deposition process, an aerosol-gel deposition process, a biomimetic deposition process, a calcium phosphate cement deposition process, an electro-phoretic deposition process or an electrochemical deposition process. The coating can contain and elude a drug in an engineered manner.

Owner:THE UNIV OF BRITISH COLUMBIA

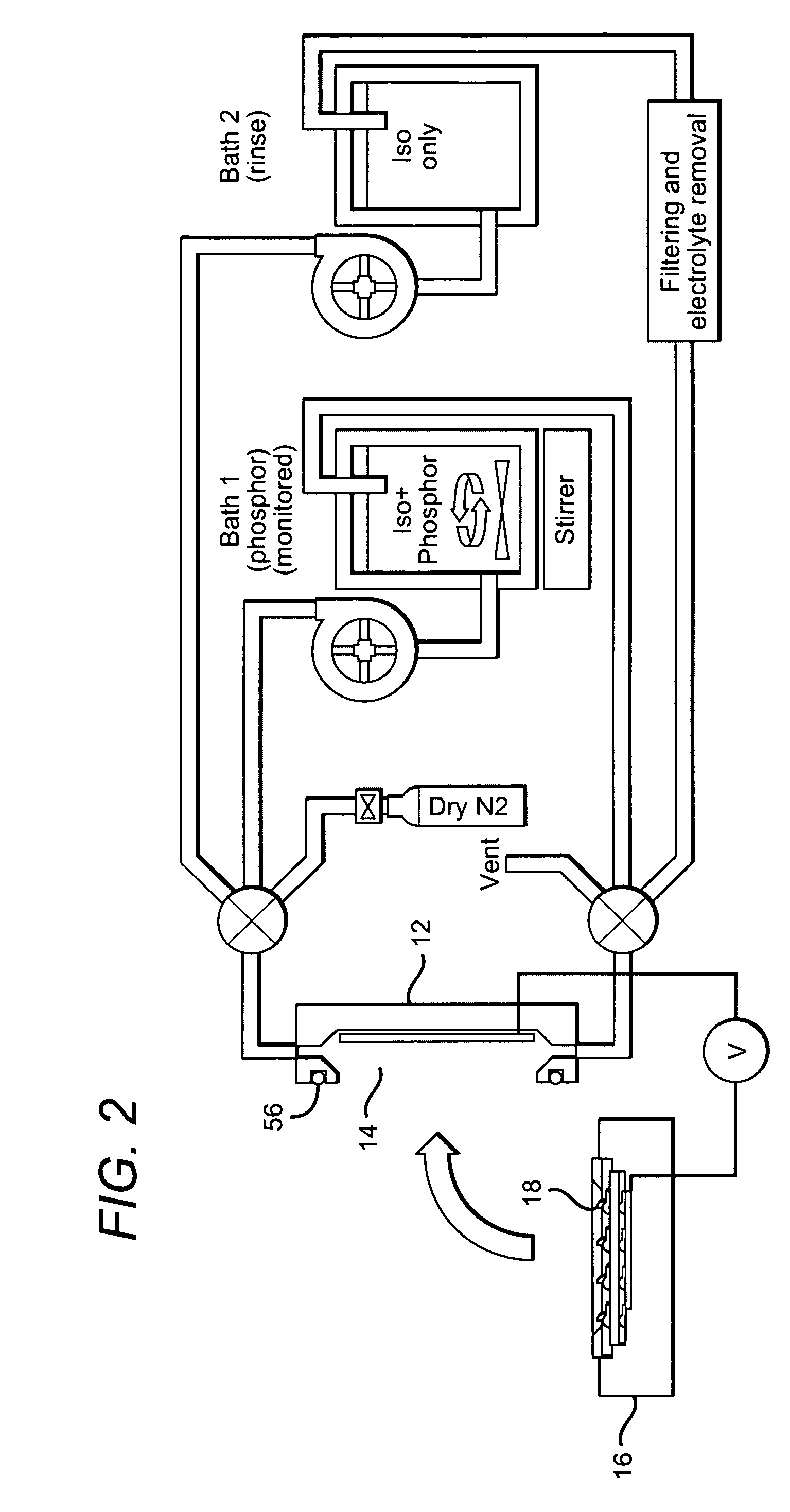

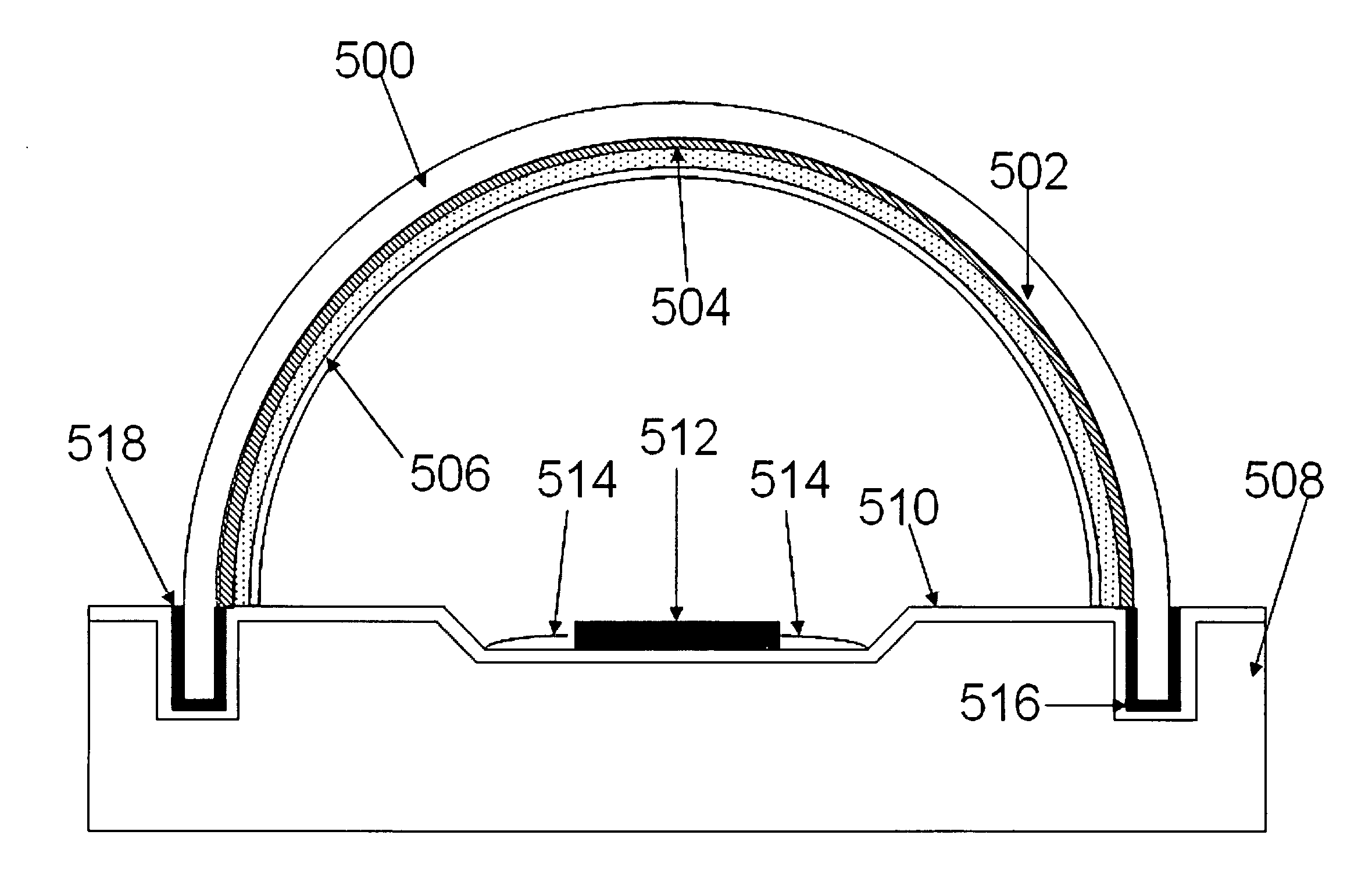

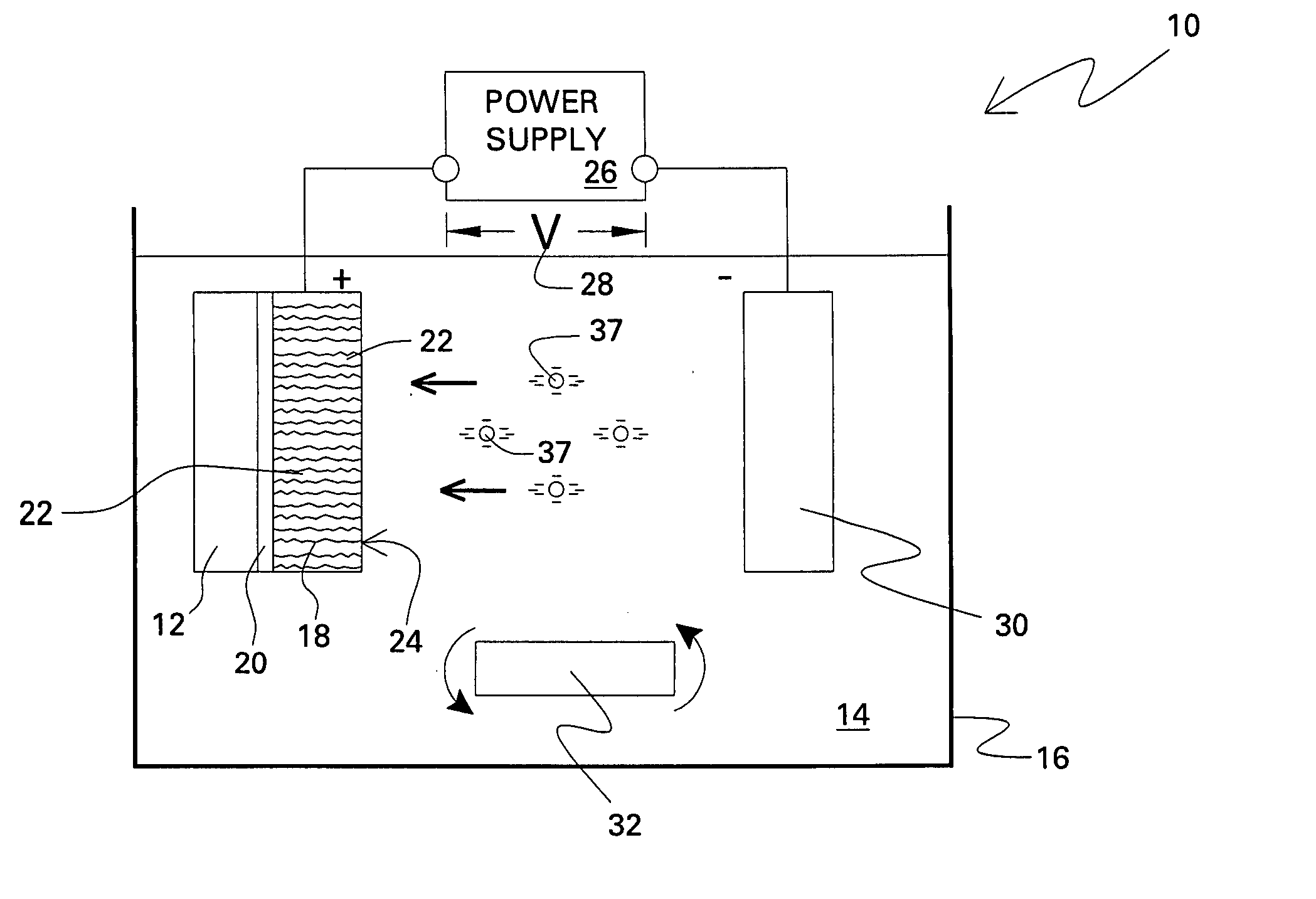

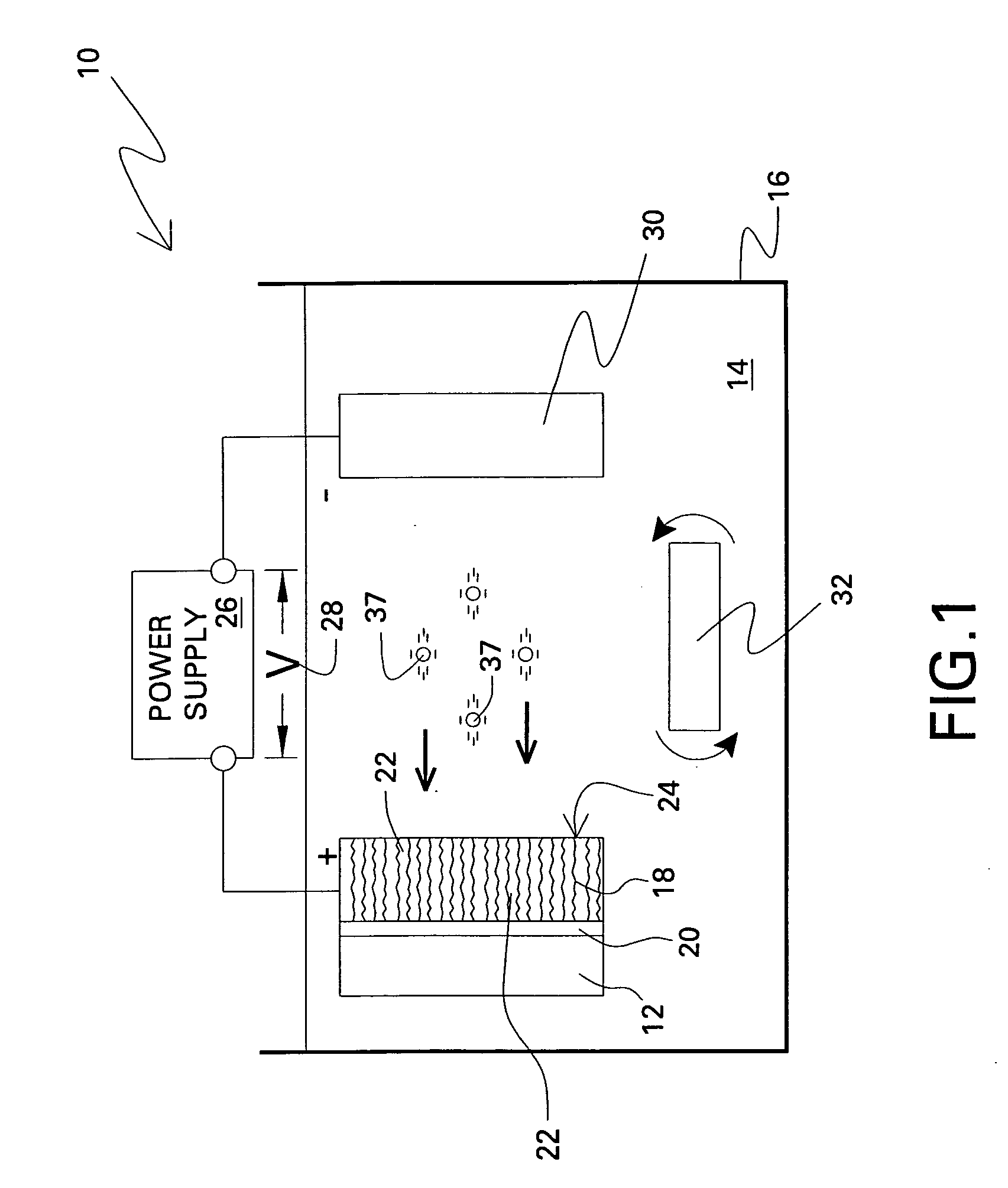

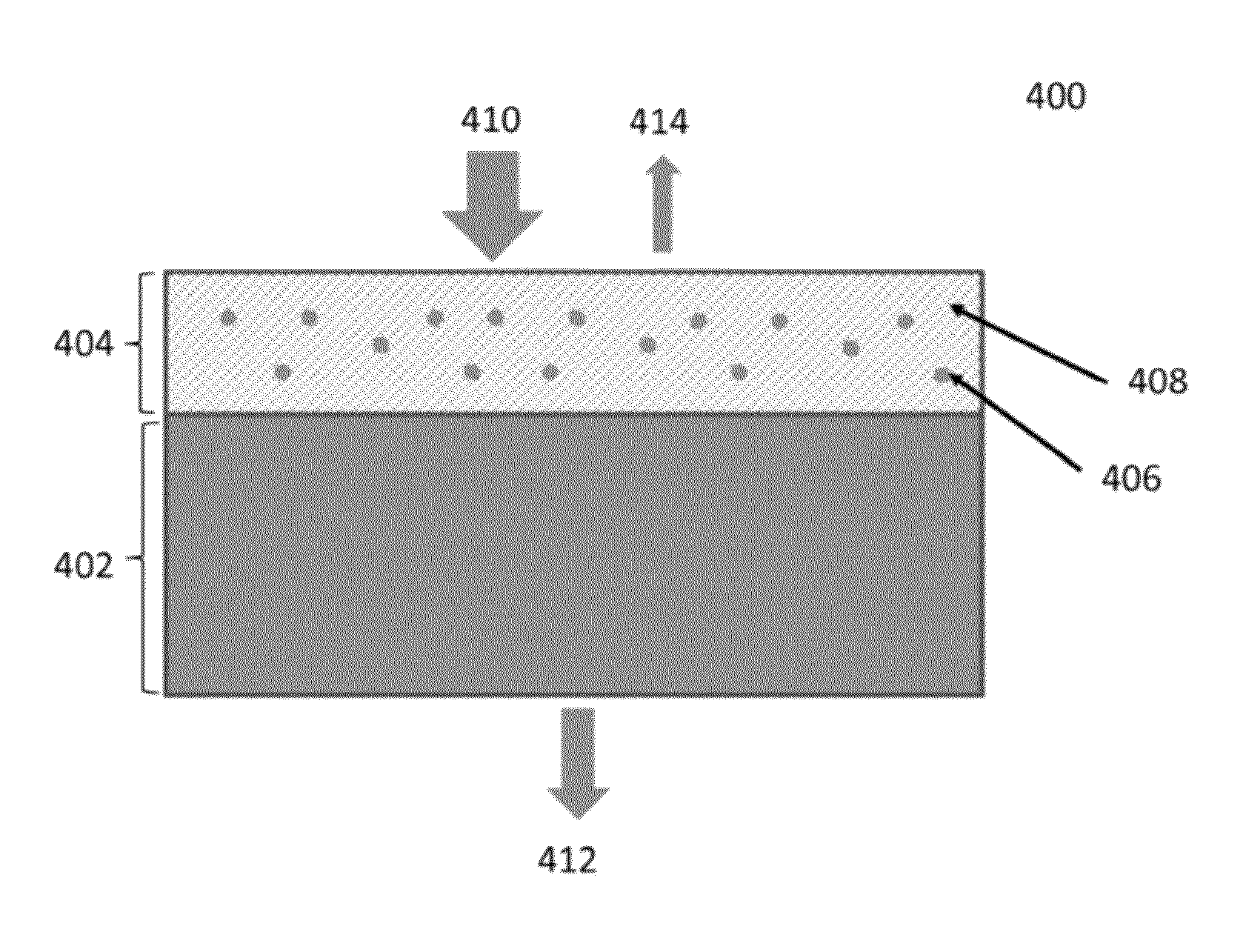

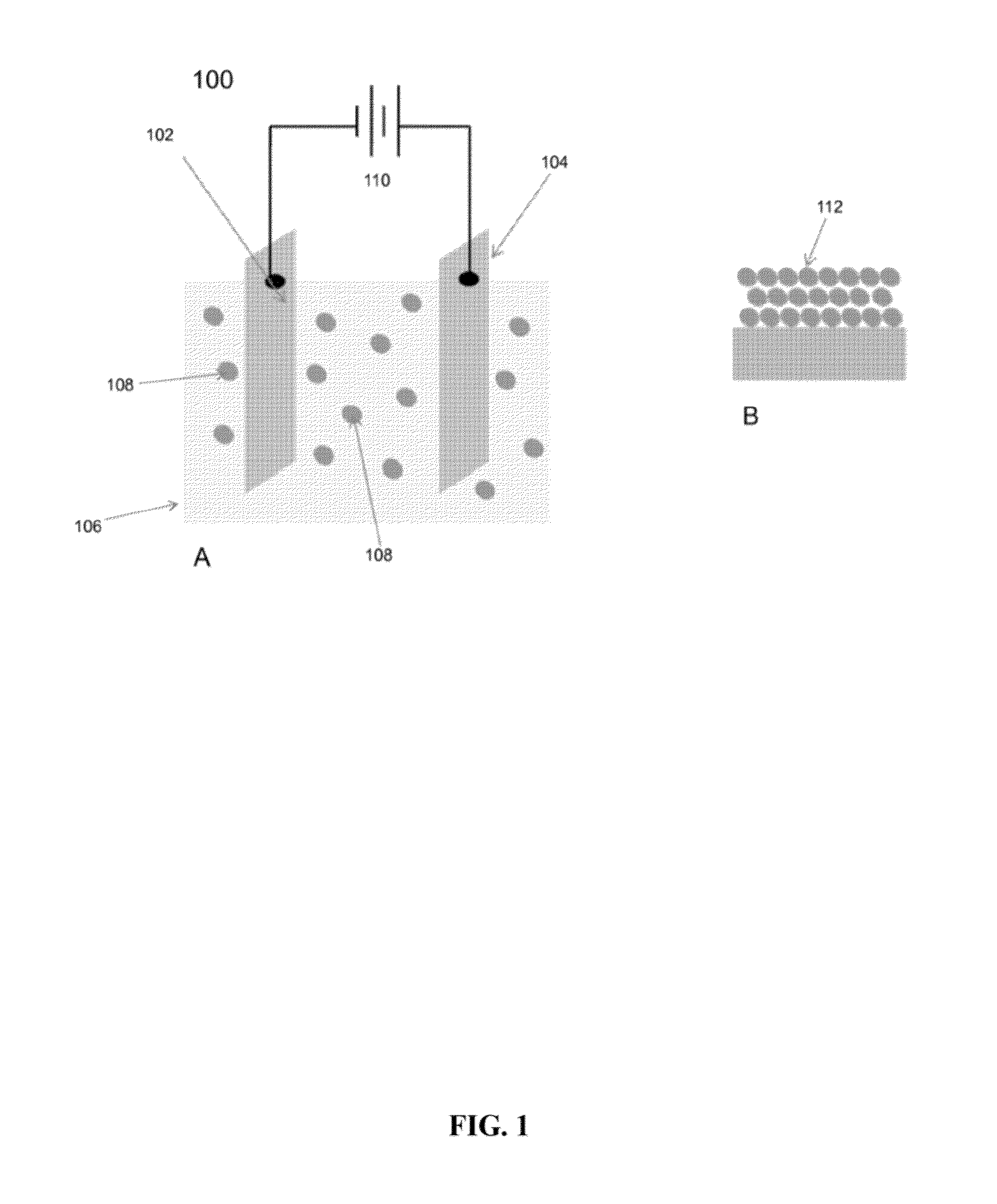

System for and method for closed loop electrophoretic deposition of phosphor materials on semiconductor devices

One close loop system and method for electrophoretic deposition (EPD) of phosphor material on light emitting diodes (LEDs). The system comprises a deposition chamber sealed from ambient air. A mixture of phosphor material and solution is provided to the chamber with the mixture also being sealed from ambient air. A carrier holds a batch of LEDs in the chamber with the mixture contacting the areas of the LEDs for phosphor deposition. A voltage supply applies a voltage to the LEDs and the mixture to cause the phosphor material to deposit on the LEDs at the mixture contacting areas.

Owner:CREELED INC

Sintered quartz glass products and methods for making same

InactiveUS6012304AReduce sinteringLonger sintering timeGlass shaping apparatusCeramic shaping apparatusSilica particleDevitrification

A number of unique processes are disclosed for manufacture of sintered high-purity quartz glass products in which a shaped silica body or preform is made from an aqueous slurry of micronized silica particles by gel casting, slip casting or electrophoretic deposition. The silica particles may comprise a major portion by weight of crystalline silica. In one embodiment of the invention the sintered quartz glass is transparent, substantially bubble-free and suitable for scientific or optical uses. In another embodiment the porous silica preform is fired in steam to increase the hydroxyl content and then nitrided in a nitrogen-hydrogen reducing atmosphere. A minute amount of chemically-combined nitrogen in the high-purity quartz glass is sufficient to provide a tremendous improvement in physical properties and an incredible increase in the resistance to devitrification.

Owner:LOXLEY TED A +2

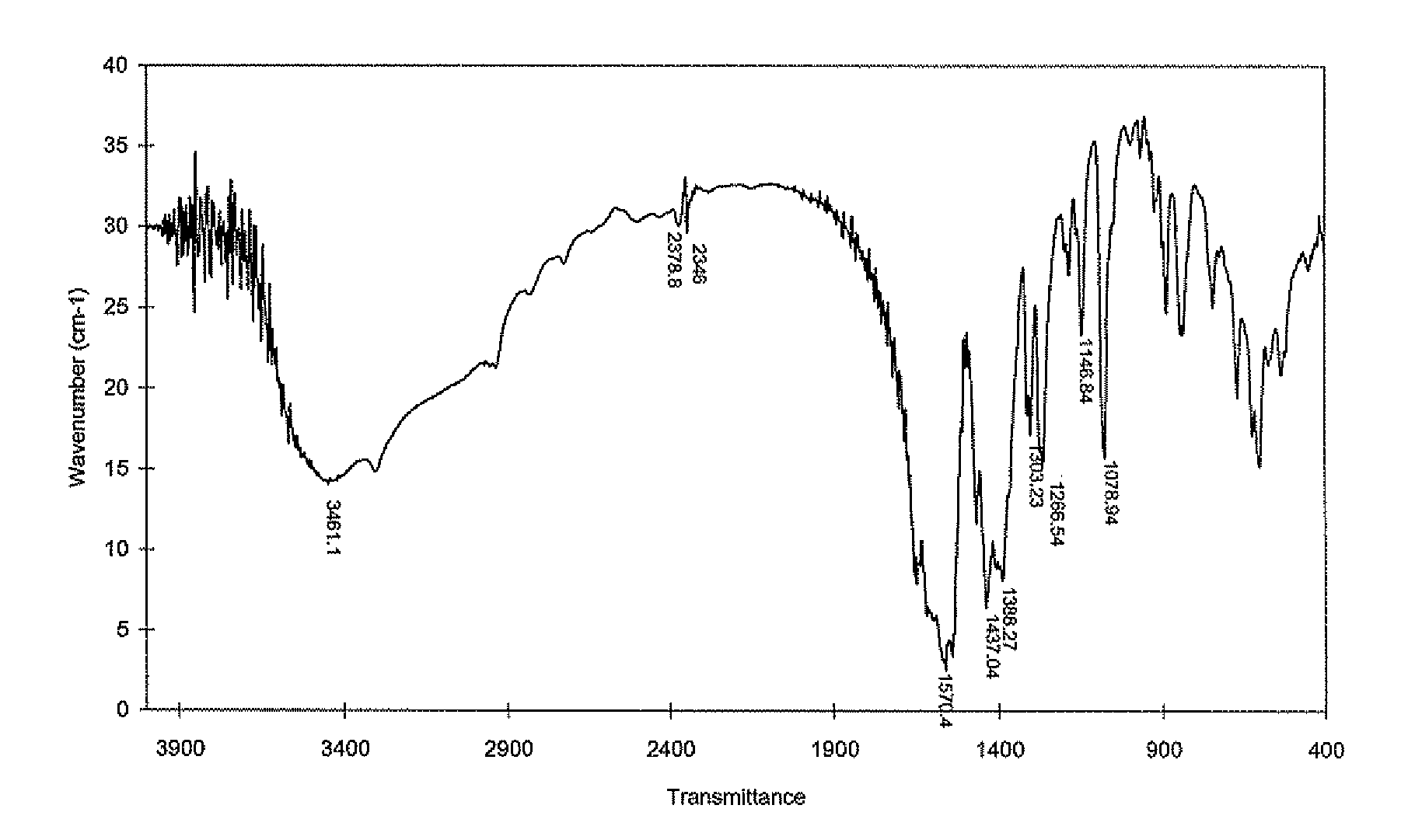

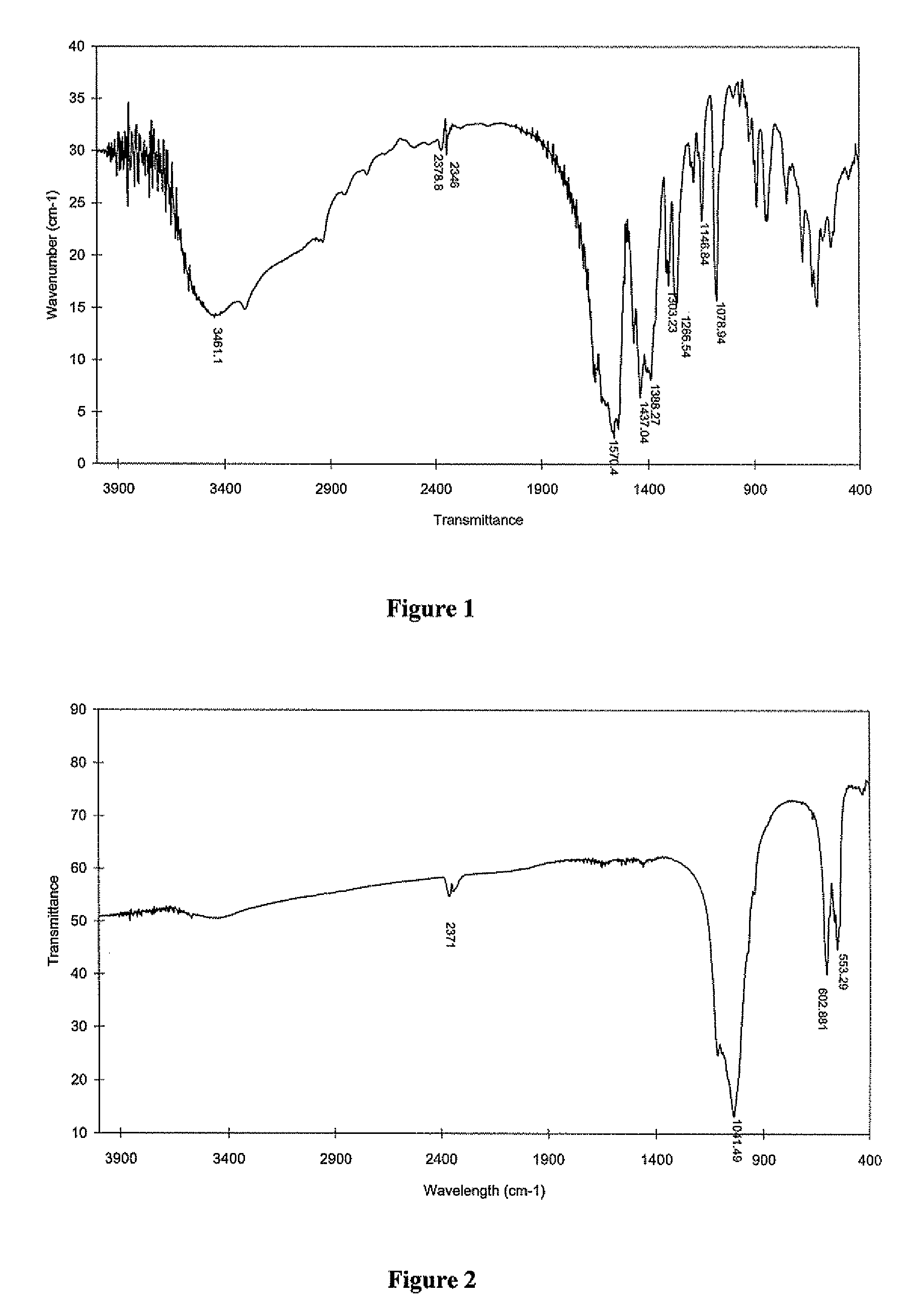

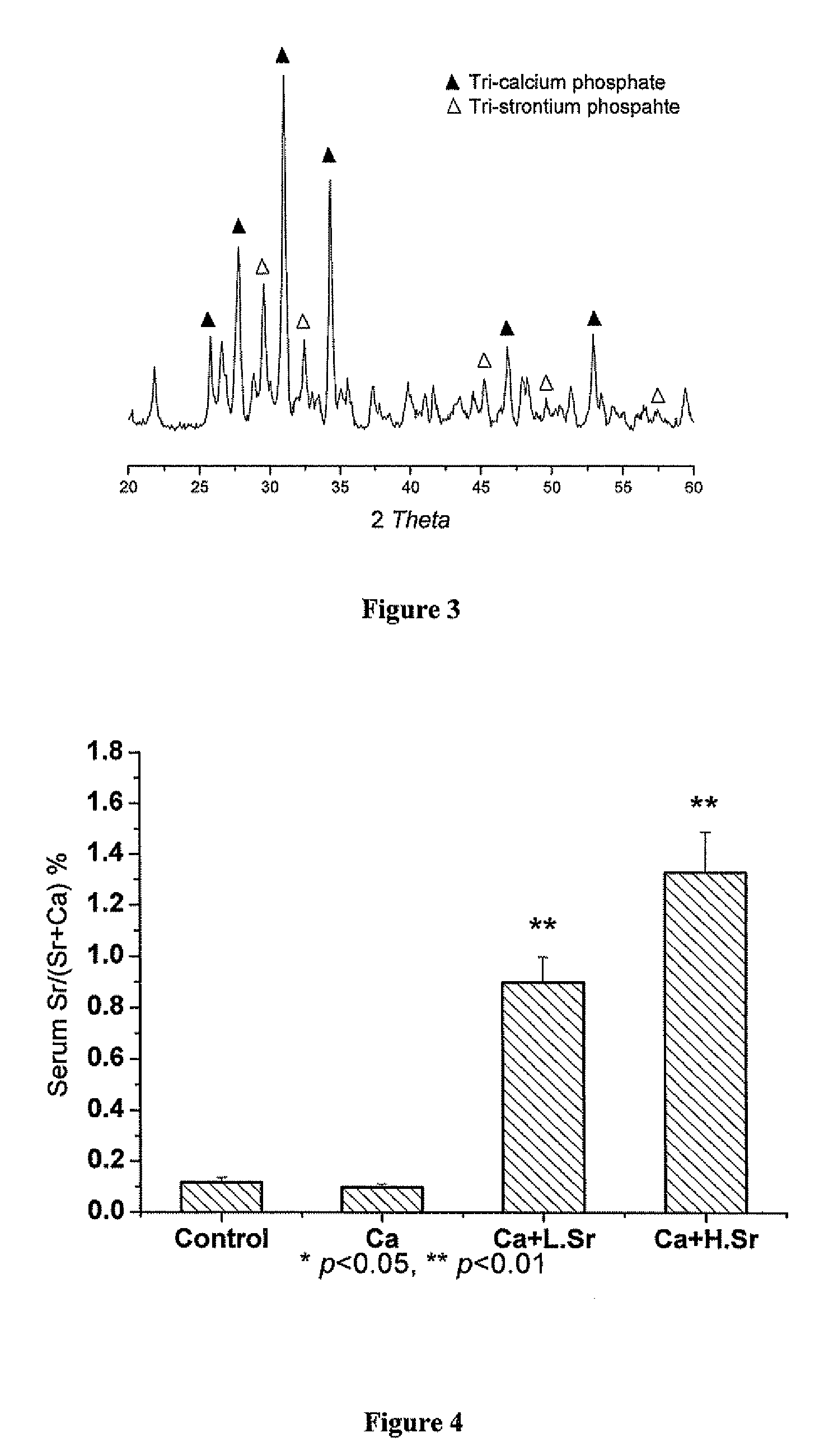

Strontium fortified calcium nano-and microparticle compositions and methods of making and using thereof

InactiveUS20080317807A1Good biocompatibilityPrevent looseningHeavy metal active ingredientsBiocideDiseasePhosphate

Compositions containing strontium fortified calcium nanoparticles and / or microparticles, and methods of making and using thereof are described herein. The strontium fortified calcium compounds contain calcium ions, calcium atoms, strontium ions, strontium atoms, and combinations thereof and one or more anions. Exemplary anions include, but are not limited to, citrate, phosphate, carbonate, and combinations thereof. The particles can be formulated for enteral or parenteral administration by incorporating the particles into a pharmaceutically carrier. The compositions can further contain one or more active agents useful for bone diseases or disorders, such as vitamin D, growth factors, and combinations thereof. The compositions can be used to treat or prevent one or more bone diseases or disorders of the bone, such as osteoporosis. Alternatively, the particles can be coated onto a substrate, such as the surface of an implant. The coatings can be used to improved biocompatibility of the implant, prevent loosening of the implant, reducing leaching of metal ions from metallic implants, and reduce corrosion. The coatings can be applied to the substrate using a variety of techniques well known in the art. In one embodiment, the coating is applied using electrophoretic deposition. The use of nano- and / or microparticles that provide high surface area helps to improve interfacial strength between the coating and the implant, which allows for the use of lower sintering temperatures. Lowering sintering temperatures minimizes or prevents thermal decomposition of the coating material and / or degradation of the implant material.

Owner:THE UNIVERSITY OF HONG KONG

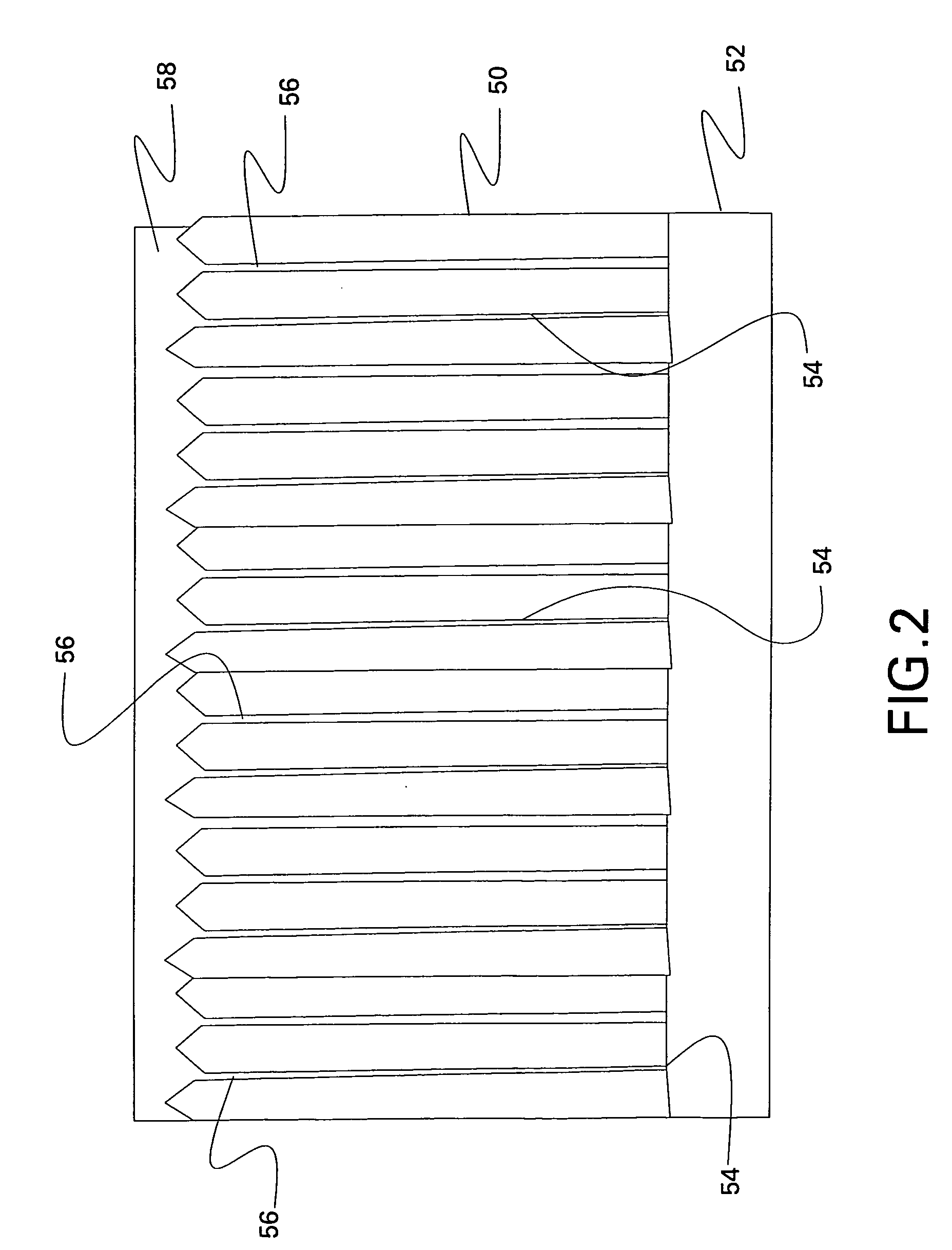

FED cathode structure using electrophoretic deposition and method of fabrication

InactiveUS6902658B2High densityVolume/mass flow measurementNanoinformaticsField emission deviceElectrophoresis

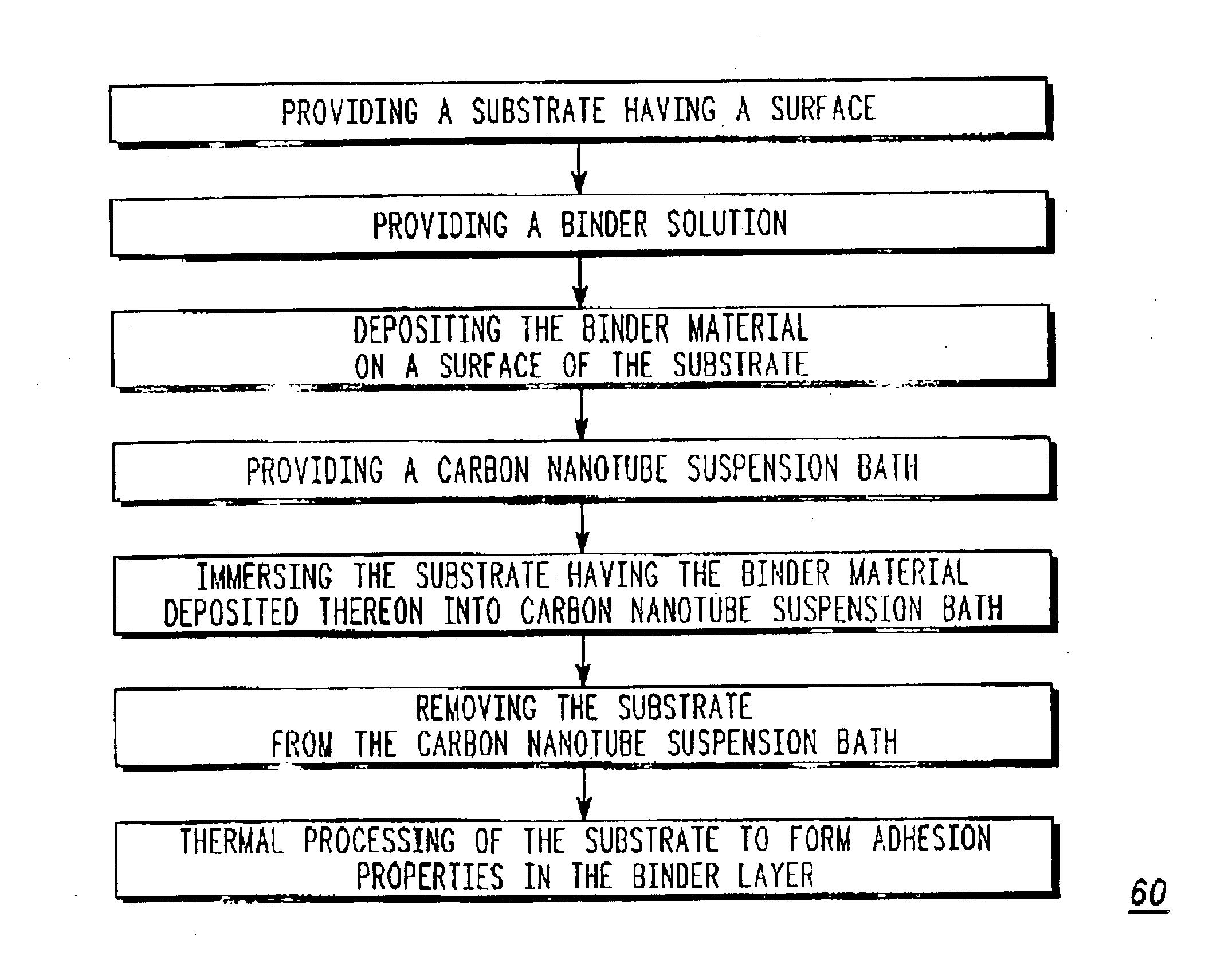

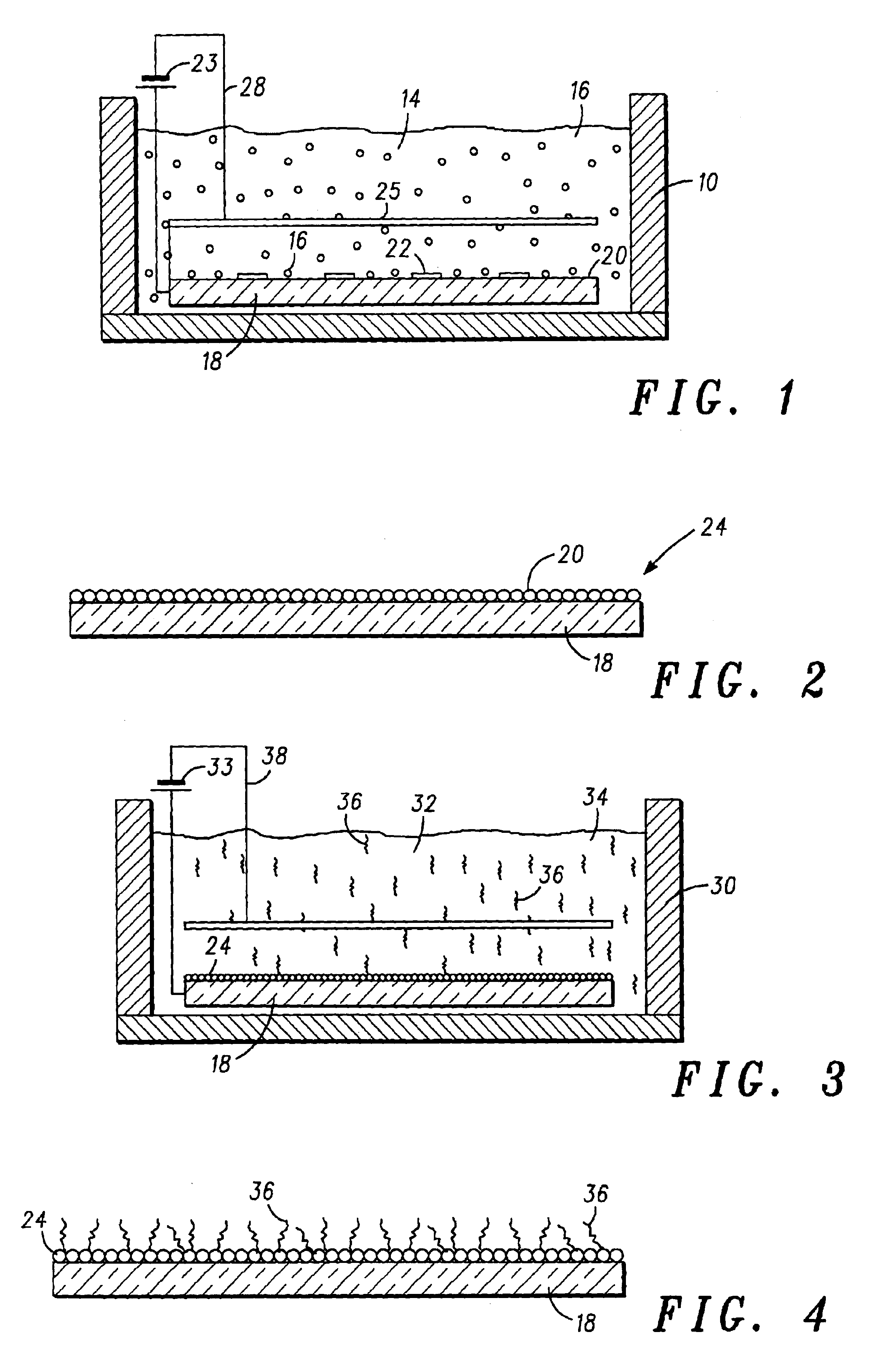

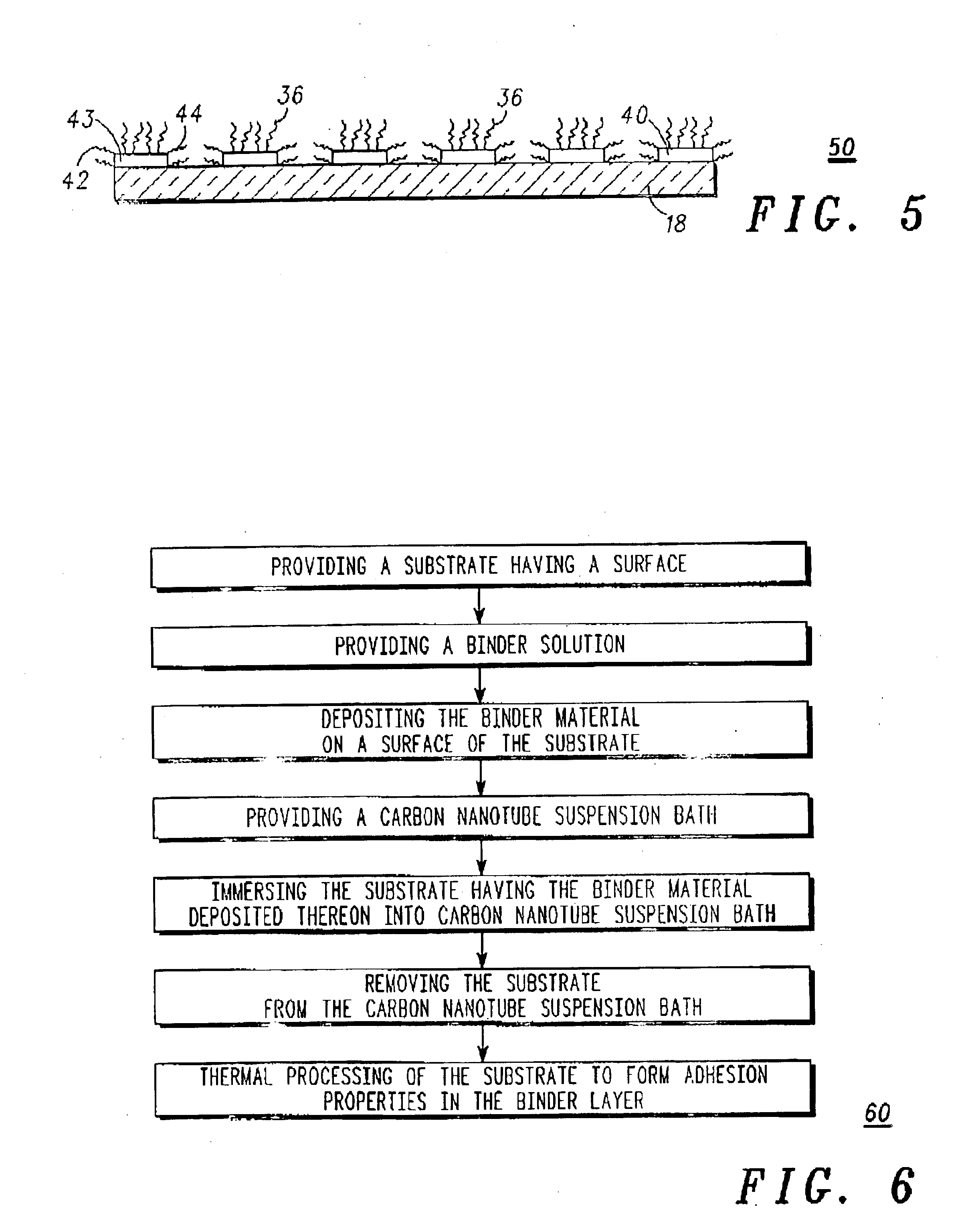

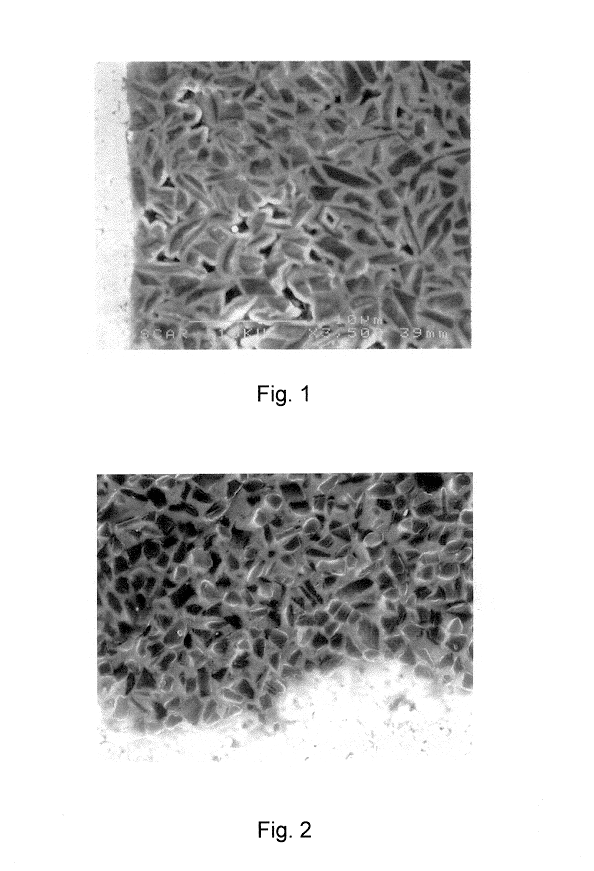

A method of fabricating a field emission device cathode using electrophoretic deposition of carbon nanotubes in which a separate step of depositing a binder material onto a substrate, is performed prior to carbon nanotube particle deposition. First, a binder layer is deposited on a substrate from a solution containing a binder material. The substrate having the binder material deposited thereon is then transferred into a carbon nanotube suspension bath allowing for coating of the carbon nanotube particles onto the substrate. Thermal processing of the coating transforms the binder layer properties which provides for the adhesion of the carbon nanotube particles to the binder material.

Owner:MOTOROLA SOLUTIONS INC

Metallic structures incorporating bioactive materials and methods for creating the same

InactiveUS20060051397A1Reduce riskEconomical and scaleableSurgeryCatheterElectrophoresisMedical device

Disclosed herein are methods to create medical devices and medical devices including bioactive composite structures. The methods include using electroless and electrophoretic deposition and codeposition methods for providing implantable medical devices coated with bioactive composite structures. In one use, the implantable medical devices of the present invention include stents with bioactive composite structures.

Owner:MEDLOGICS DEVICE CORP

Method for forming high performance surface coatings and compositions of same

InactiveUS6410086B1Improve performanceHigh mechanical strengthPhotography auxillary processesElectrolysis componentsGas phaseCompound (substance)

A method of forming on an object a surface coating having a high mechanical strength and chemical and physical stability above 700° C. is disclosed. The method comprises (a) electrophoretically depositing at least one surface coating material on a surface of the object for obtaining a green coating on the surface; and (b) infiltrating into and depositing onto the green coating at least one additional surface coating material by a gas-phase infiltration / deposition method, thereby forming a high performance surface coating, wherein, the at least one surface coating material and the at least one additional surface coating material are chemically and physically stable above 700° C.

Owner:CEREL CERAMIC TECH +1

Foam metal-graphene composite material and preparation method thereof

ActiveCN103436939ALarge specific surface areaImprove conductivityElectrophoretic coatingsDielectricElectrophoreses

The invention discloses a foam metal-graphene composite material and a preparation method thereof. The composite material comprises a foam metal substrate and a graphene film layer positioned on the substrate. The foam metal-graphene composite material is prepared by means of electrophoresis. Specifically, the preparation method comprises the following steps: removing greasy dirt and oxides from the surface of a foam metal substrate, preparing graphene by the oxidation-reduction method, modifying graphene, and performing electrophoretic deposition on the graphene on the surface of the foam metal substrate. Within a certain of electromagnetic waveband, on one hand, the foam metal-graphene composite material has the structural advantages of light weight and porosity, large specific surface area and good conductivity of a foam metal, and on the other hand, the composite material integrates excellent electrical conductivity and high dielectric constant, a capacity of being more conducive to absorbing electromagnetic waves due to a large amount of defects and functional group residues of the self-made graphene, and other properties of self-made graphene. The composite material has a higher electromagnetic shielding performance and can serve as an excellent electromagnetic shielding material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method of manufacturing light emitting diode packaging lens and light emmiting diode package

InactiveUS20110068356A1Solid-state devicesSemiconductor/solid-state device manufacturingPhosphorLight-emitting diode

A method of manufacturing light emitting diode packaging lens and packages made by using the method are disclosed in the present invention. By using electrophoretic deposition, one or more layers of phosphors are coated onto one surface of a cup which has a curved portion. The cup is used for the packaging lens. Thickness of phosphor layer can be controlled and distribution of phosphor particles is uniform. Therefore, light emitting diode packages with the lens can be a uniform light source.

Owner:WALSIN LIHWA

Methods for applying mitigation coatings, and related articles

InactiveUS20070119713A1Electrolysis componentsVolume/mass flow measurementThermal barrier coatingTurbine

A method for protecting a thermal barrier coating (TBC) which comprises voids is described. The method involves the step of electrophoretically depositing a mitigation coating material such as alumina to fill at least a portion of the voids. The TBC is often applied over a metal substrate, such as a turbine engine component. The voids can be in the form of vertical cracks within the TBC. A thermal barrier coating is also described, containing voids which extend into the coating from a top surface, wherein at least a portion of the voids is filled with a mitigation coating material.

Owner:GENERAL ELECTRIC CO

Hydroxylapatite coating magnesium alloy medical inner implantation material and method of preparing the same

The invention relates to a hydroxyapatite coating magnesium alloy medical implantation material and a preparation method thereof. The hydroxyapatite coating magnesium alloy medical implantation material is characterized in that: the surface of a magnesium alloy substrate is attached with a hydroxyapatite coating layer. The preparation method of the hydroxyapatite coating magnesium alloy medical implant material can adopt the bionic solution growing method, the ion beam deposition method, the coating and sintering process, the plasma spray method, the discharge plasma sintering method or the electrophoresis deposition method. The magnesium alloy material with the hydroxyapatite coating structure which is provided by the invention can effectively slow down the degradation rate of the magnesium alloy; at the same time, the coating layer can not only have great tissue compatibility, but can also be conductive to connective tissue attachment and the growth of the bone tissues, improve the bone healing rate and shorten the healing time.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH +1

Solid Free-Form Fabrication Methods For The Production of Dental Restorations

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

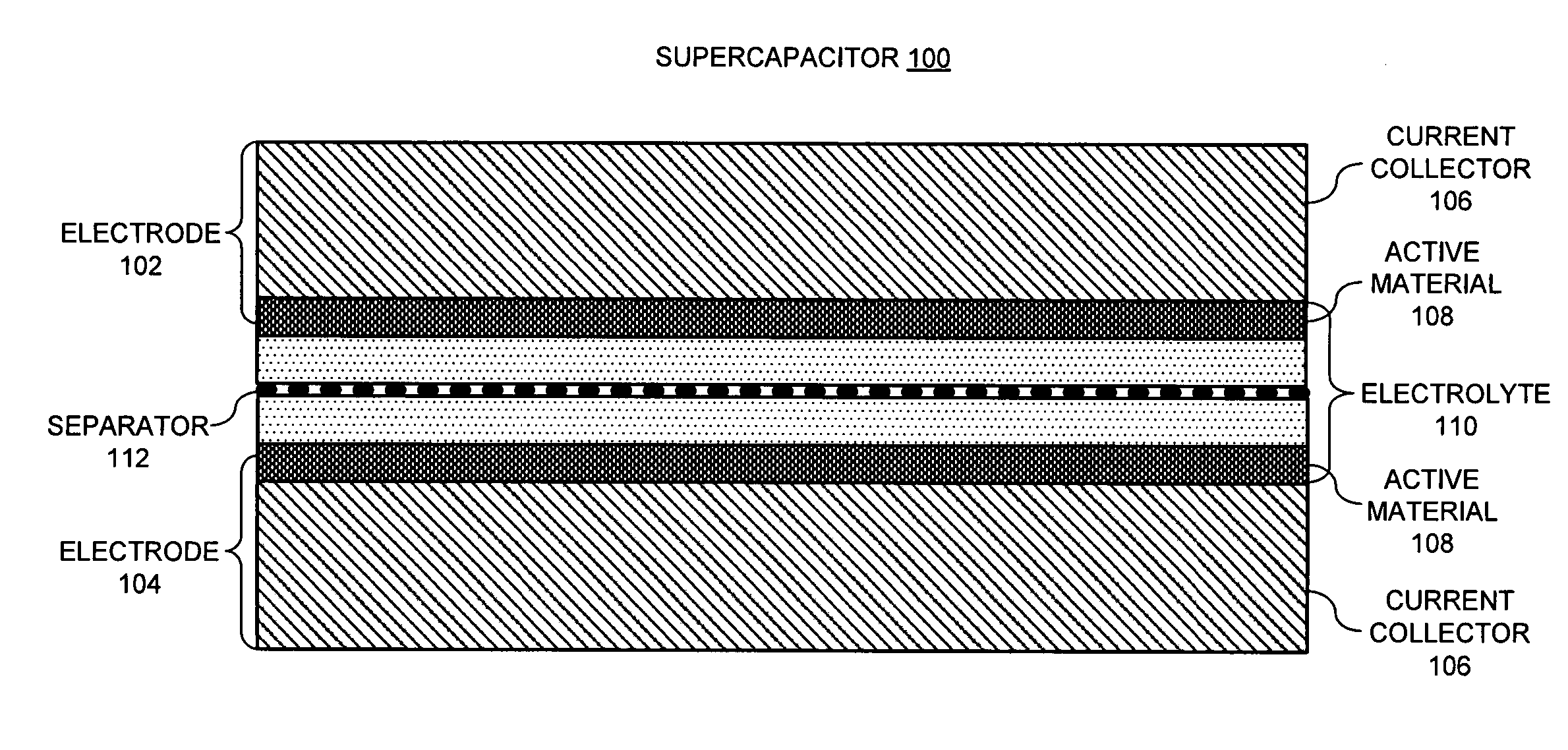

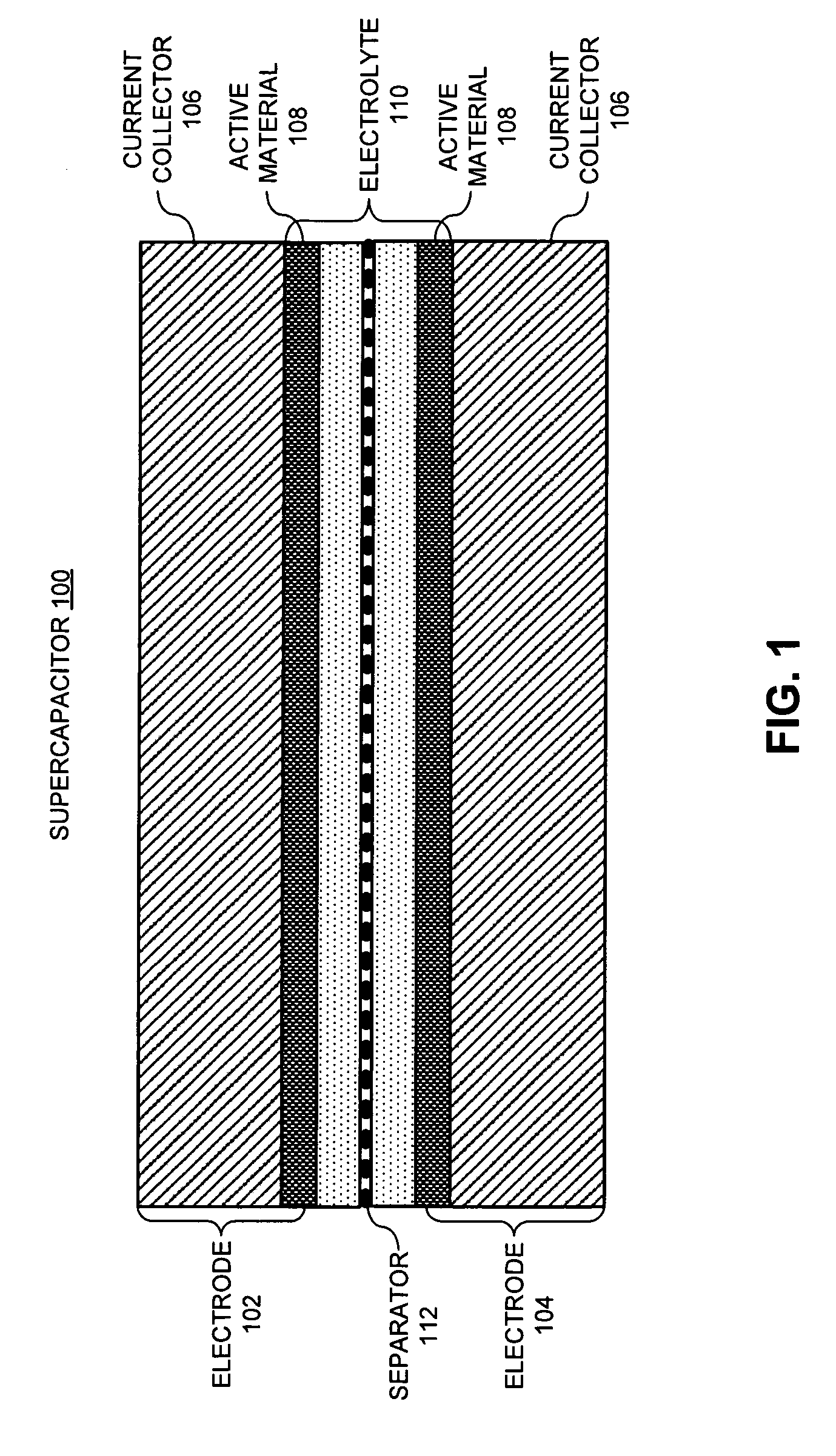

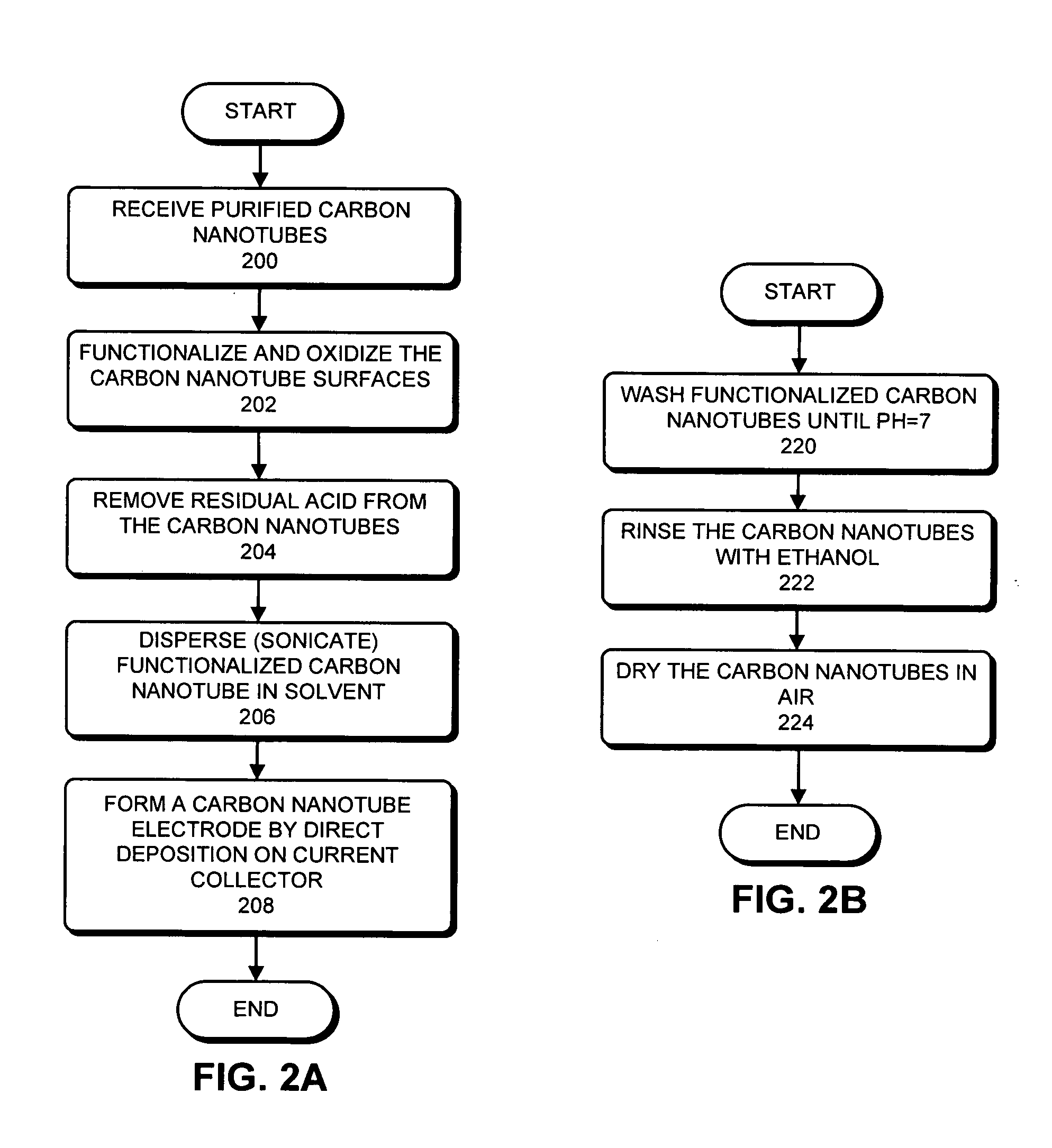

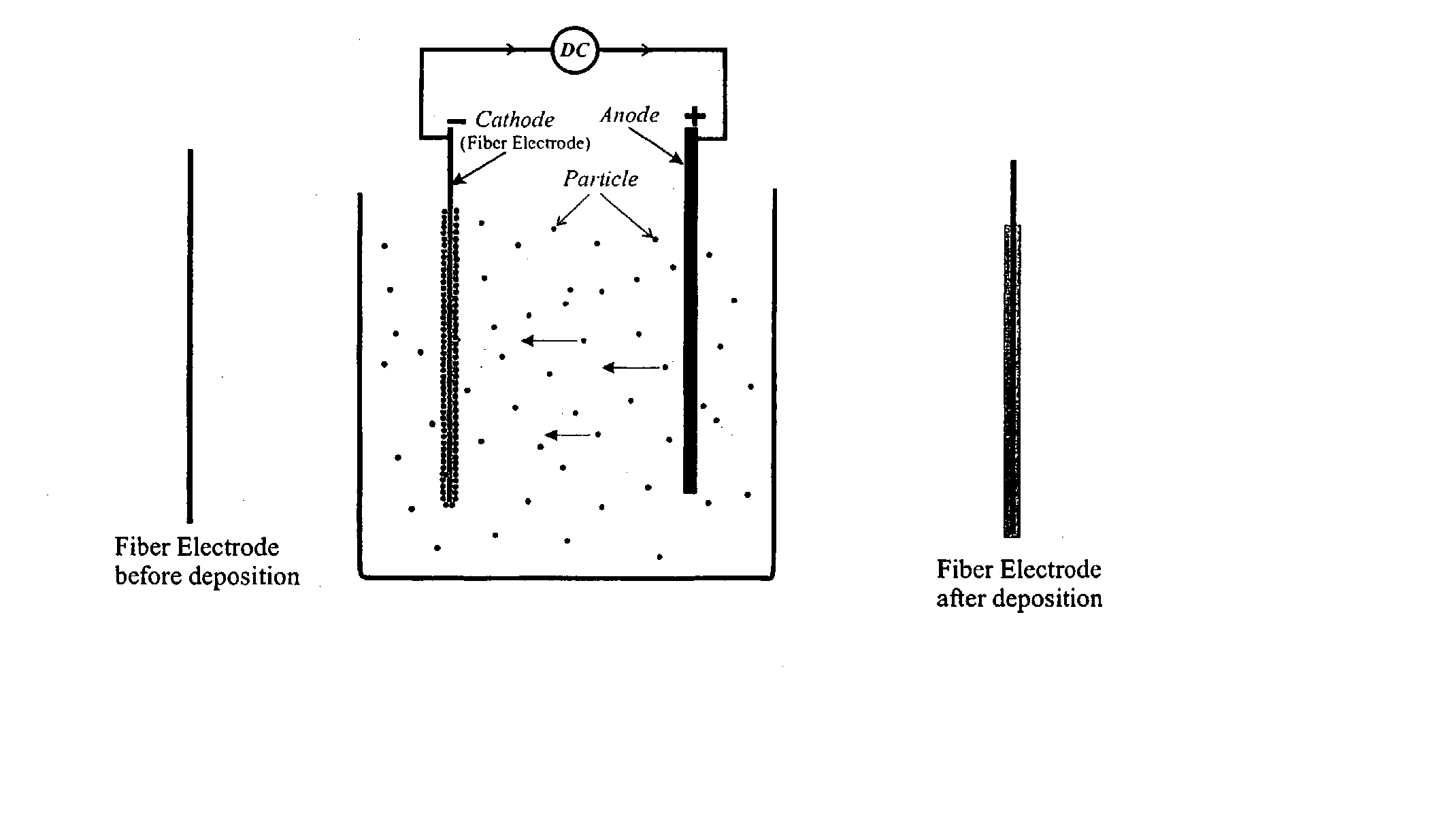

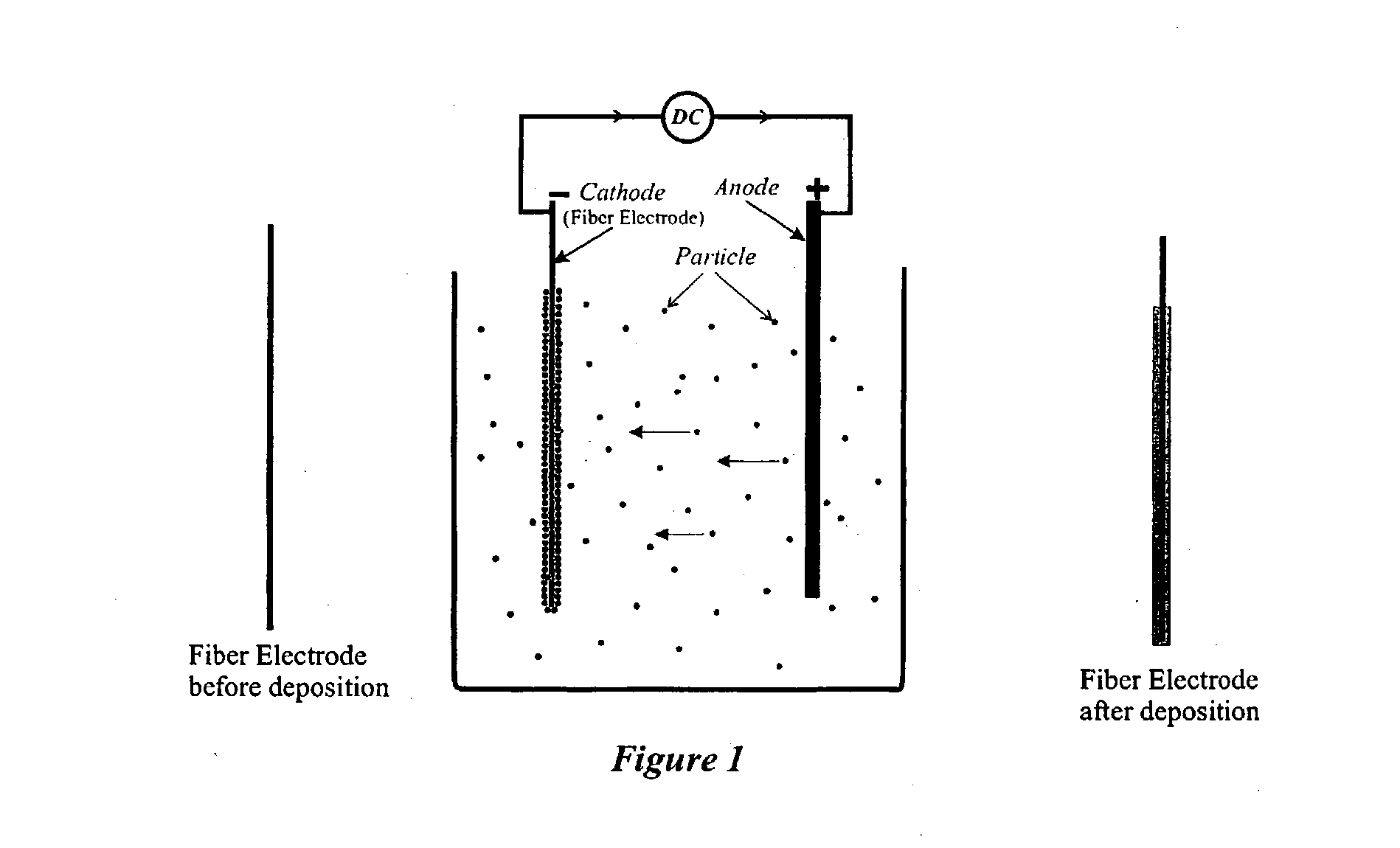

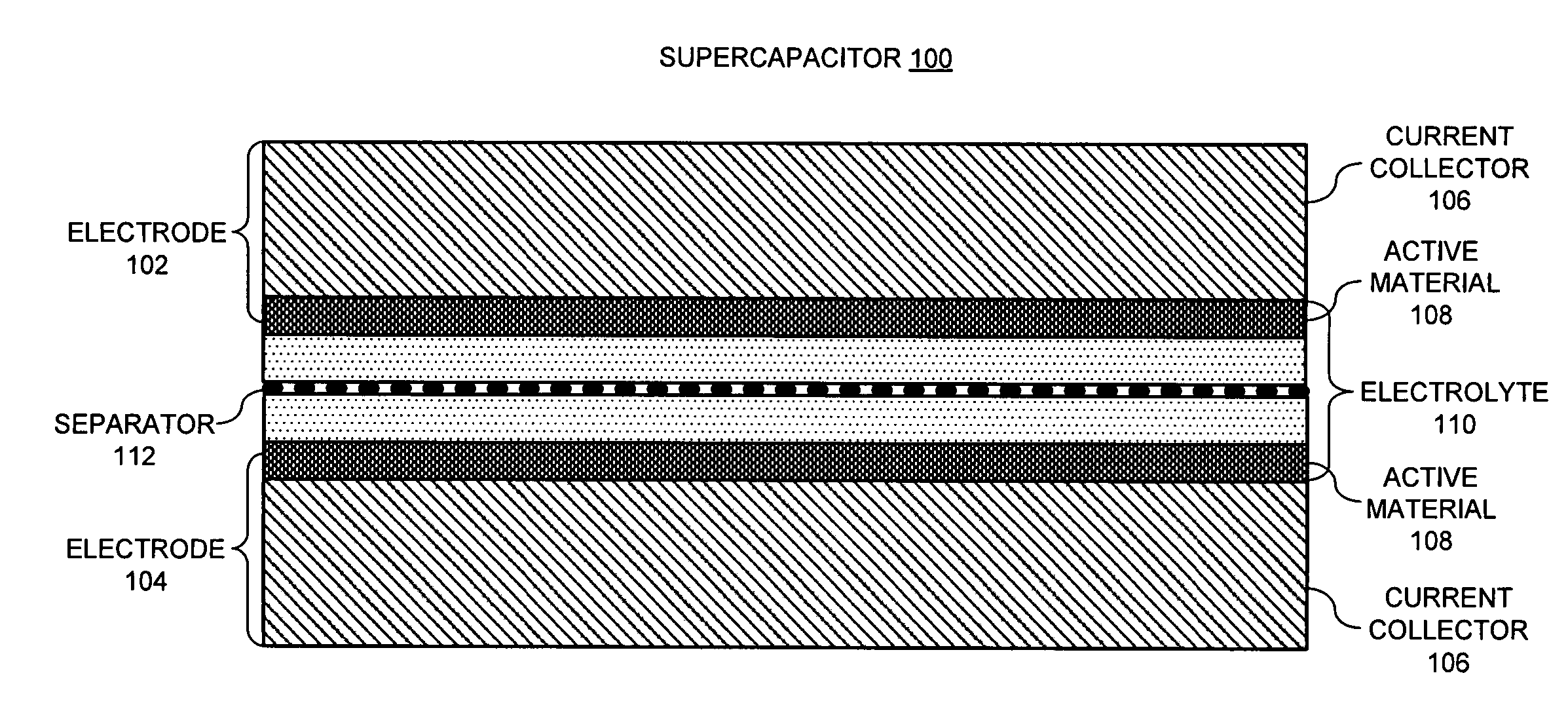

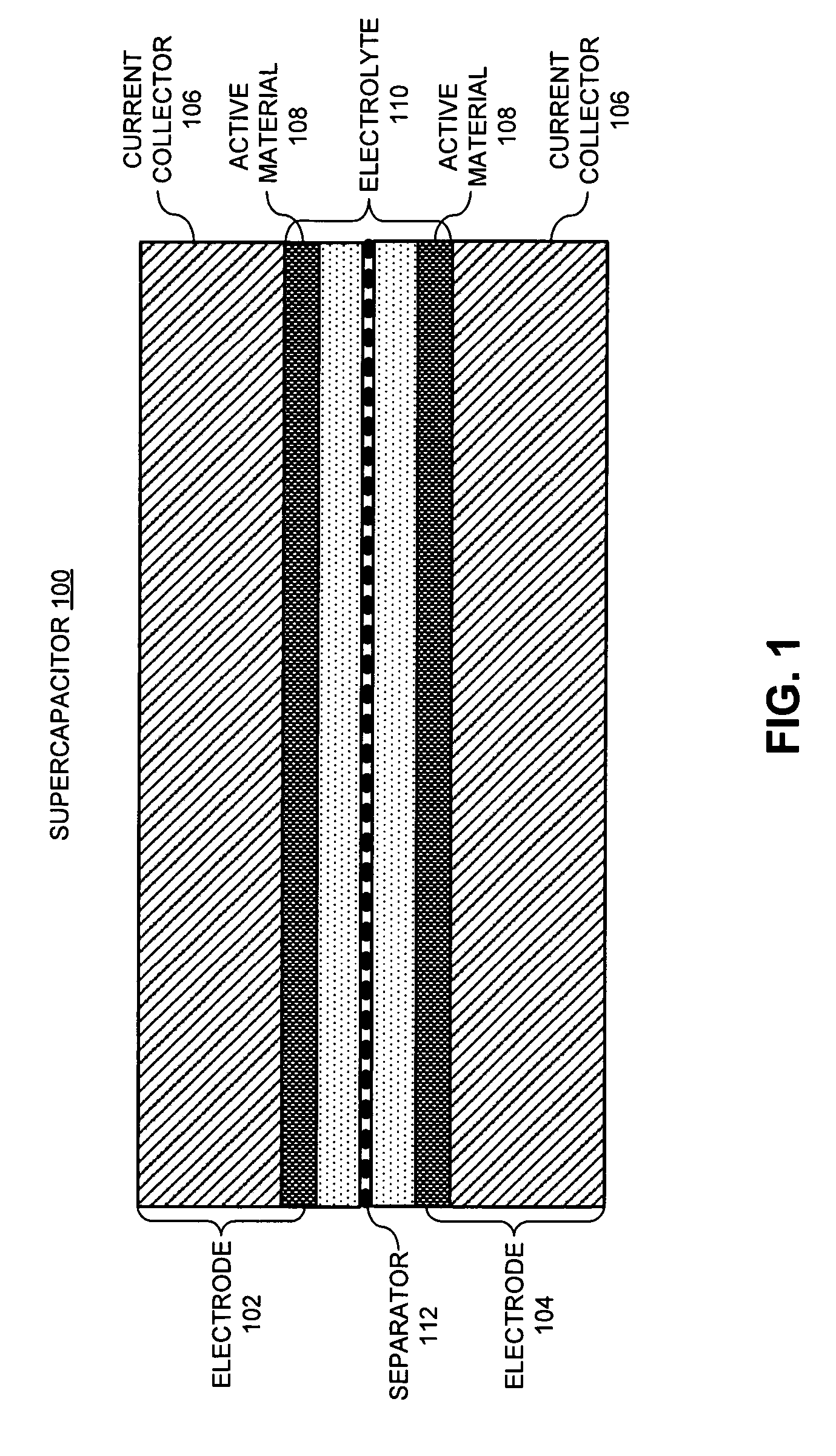

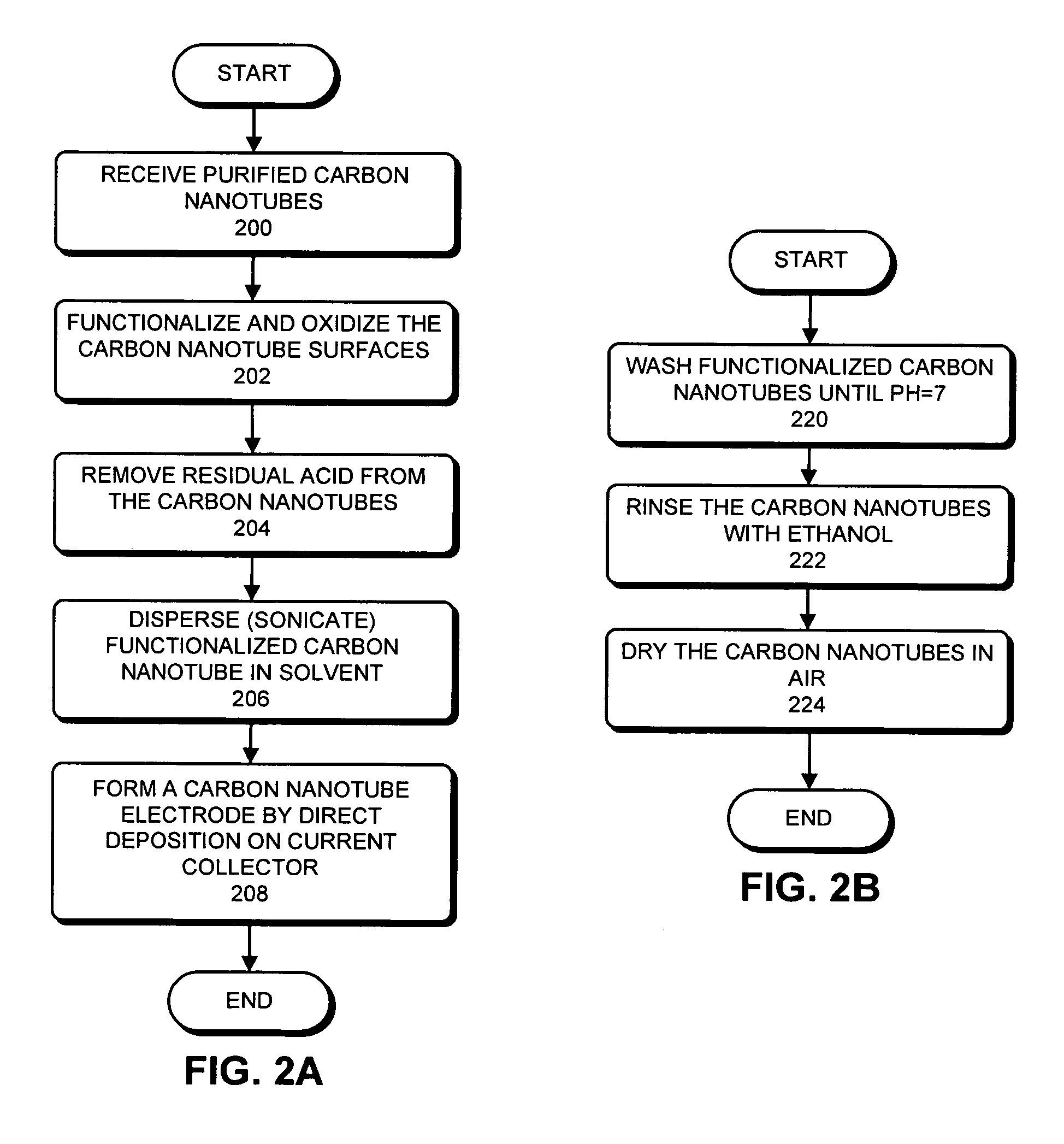

High power density supercapacitors with carbon nanotube electrodes

InactiveUS20080010796A1Reduce contact resistanceHigh bulk densityLiquid electrolytic capacitorsHybrid capacitor electrodesCarbon nanotubeSupercapacitor

One embodiment of the present invention provides a process for fabricating an electrode for a capacitor using carbon nanotubes (CNTs), wherein the electrode comprises a metal substrate and a layer of active material (CNTs) coated onto the metal substrate. Specifically, the process starts by dispersing CNTs in a solvent to form a suspension. Next, the CNTs are charged in the suspension. The metal substrate is then immersed in the suspension. Next, the CNTs are deposited onto the metal substrate using electrophoretic deposition (EPD) to form the layer of active material on the metal substrate. In particular, the layer of active material is formed on the metal substrate without using a binder, which effectively reduces contact resistance between the active material and the metal substrate.

Owner:RGT UNIV OF CALIFORNIA

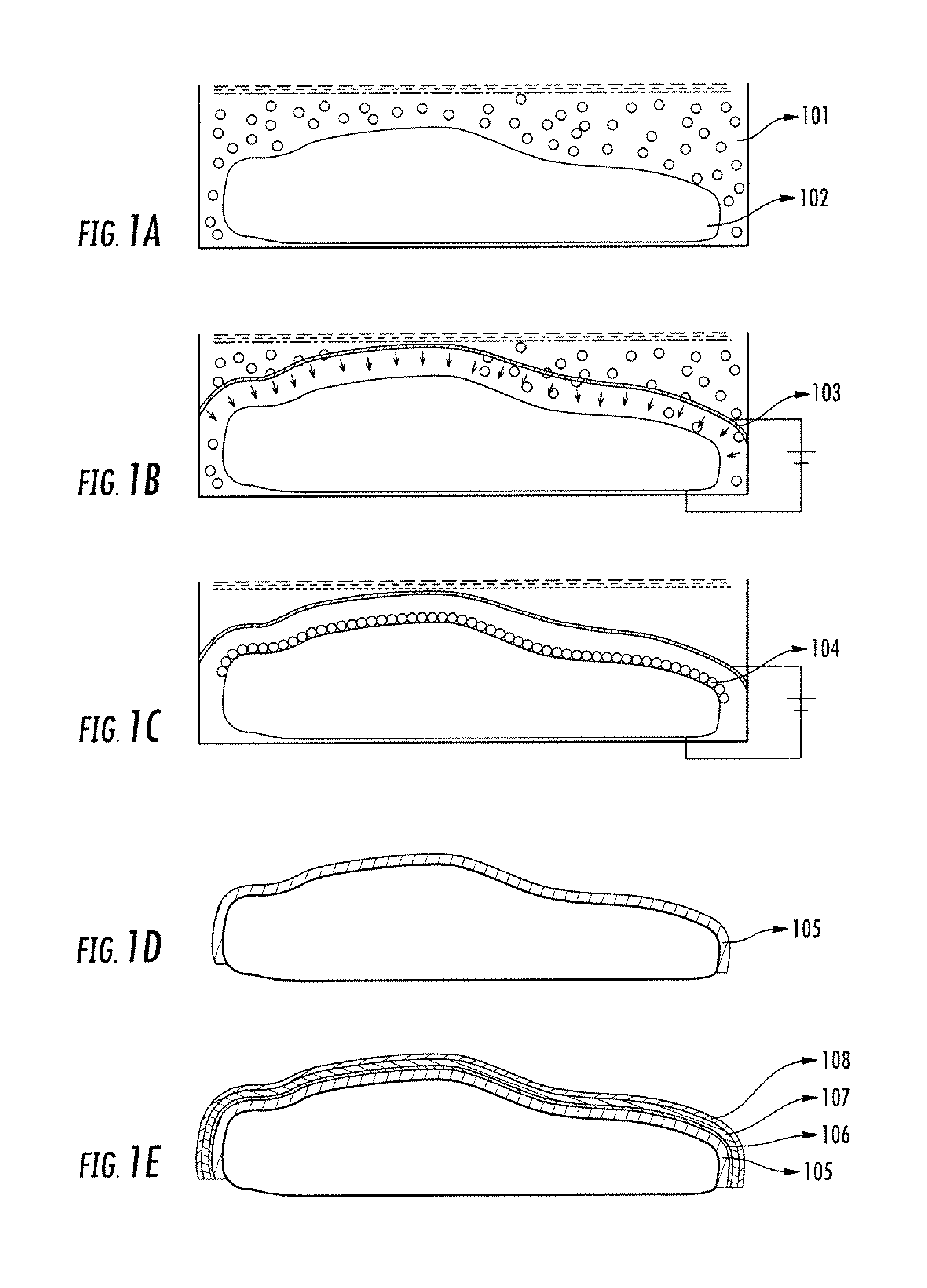

Method for preparation of metal chalcogenide solar cells on complexly shaped surfaces

InactiveUS20120100660A1Electrolytic coatingsSemiconductor/solid-state device manufacturingIndiumMetal chalcogenides

Methods for fabricating a photovoltaic device on complexly shaped fabricated objects, such as car bodies are disclosed. Preferably the photovoltaic device includes absorber layers comprising Copper, Indium, Gallium, Selenide (CIGS) or Copper, Zinc, Tin, Sulfide (CZTS). The method includes the following steps: a colloidal suspension of metal surface-charged nanoparticles is formed; electrophoretic deposition is used to deposit the nanopartieles in a metal thin film onto a complexly shaped surface of the substrate; the metal thin film is heated in the presence of a chalcogen source to convert the metal thin film into a metal chalcogenide thin film layer; a buffer layer is formed on the metal chalcogenide thin film layer using a chemical bath deposition; an intrinsic zinc oxide insulating layer is formed adjacent to a side of the buffer layer, opposite the metal chalcogenide thin film layer, by chemical vapor deposition; and finally, a transparent conducting oxide is formed adjacent to a side of the intrinsic zinc oxide, opposite the buffer layer, by chemical vapor deposition.

Owner:IMRA AMERICA

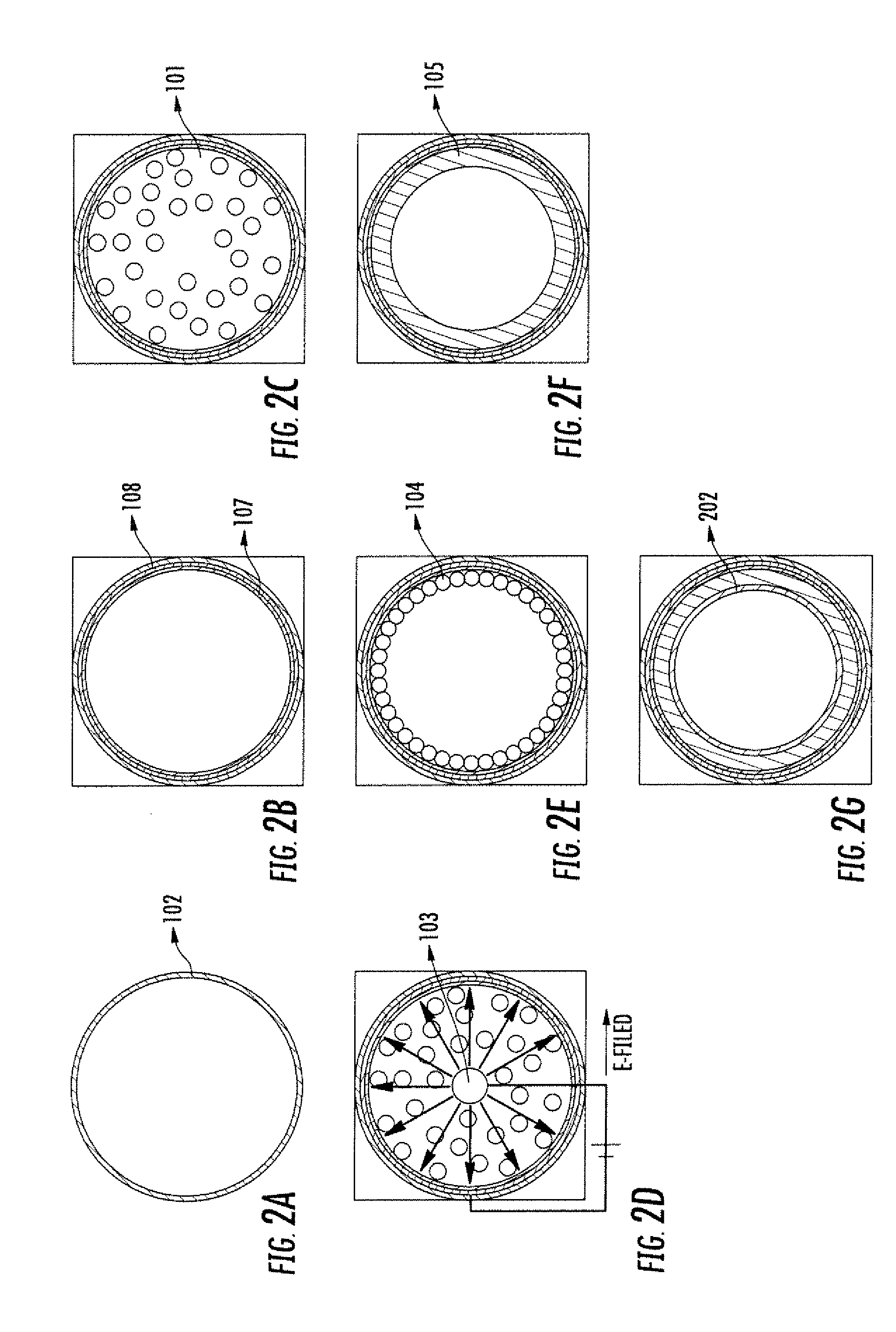

Production of hollow ceramic membranes by electrophoretic deposition

InactiveUS20030178307A1Prevent penetrationReduce porosityFinal product manufactureCell electrodesMetallurgyElectrophoresis

The present invention provides methods for producing hollow ceramic membranes by electrophoretic deposition. The hollow ceramic membranes may have a small cross-sectional area of about 1.0x10<-5 >mm<2 >to about 25 mm<2>. The cross-sectional configuration of the hollow ceramic membranes may be any geometry such as circular, square, rectangular, triangular or polygonal. The hollow ceramic membranes produced by the methods of the present invention may have multiple layers but always the innermost layer, or the first deposited layer is porous and made by electrophoretic deposition. Subsequent layers may be porous or non porous and deposited before or after sintering the first layer. If it is deposited after sintering, it may require additional sintering steps. Additional layers may be deposited by further electrophoretic deposition, sol-gel coating, dip coating, vacuum casting, brushing, spraying or other known techniques.

Owner:INNOTECH ALBERTA INC

High power density supercapacitors with carbon nanotube electrodes

InactiveUS7553341B2Reduce contact resistanceHigh bulk densityHybrid capacitor electrodesLiquid electrolytic capacitorsCarbon nanotubeSupercapacitor

One embodiment of the present invention provides a process for fabricating an electrode for a capacitor using carbon nanotubes (CNTs), wherein the electrode comprises a metal substrate and a layer of active material (CNTs) coated onto the metal substrate. Specifically, the process starts by dispersing CNTs in a solvent to form a suspension. Next, the CNTs are charged in the suspension. The metal substrate is then immersed in the suspension. Next, the CNTs are deposited onto the metal substrate using electrophoretic deposition (EPD) to form the layer of active material on the metal substrate. In particular, the layer of active material is formed on the metal substrate without using a binder, which effectively reduces contact resistance between the active material and the metal substrate.

Owner:RGT UNIV OF CALIFORNIA

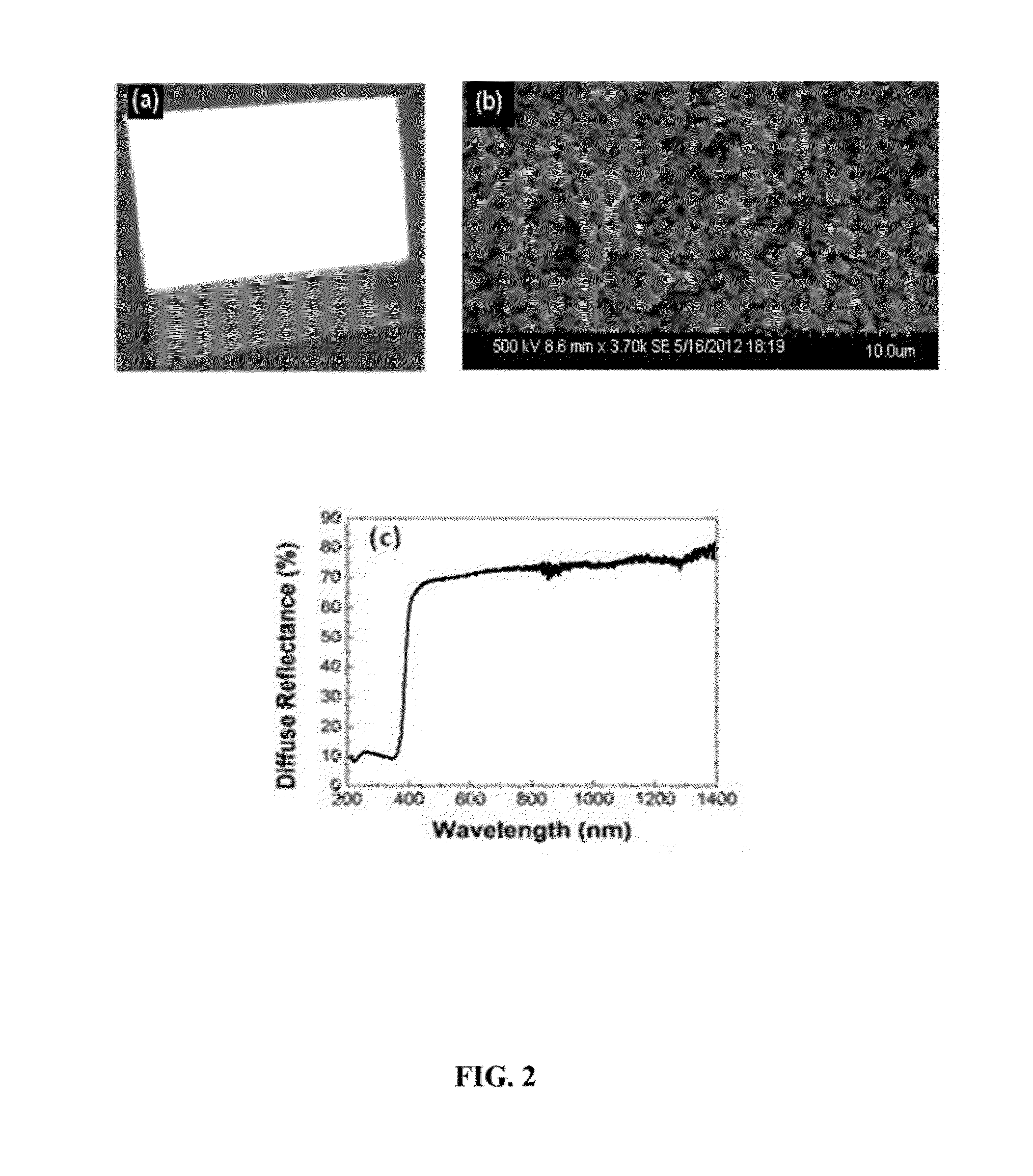

Nanoparticle films for use as solar cell back reflectors and other applications

Disclosed are methods for forming nanoparticle films using electrophoretic deposition. The methods comprise exposing a substrate to a solution, the solution comprising substantially dispersed nanoparticles, an organic solvent, and a polymer characterized by a backbone comprising Si—O groups. The methods further comprise applying an electric field to the solution, whereby a nanoparticle film is deposited on the substrate. Suitable polymers include polysiloxanes, polysilsesquioxanes and polysilicates. Coated glass windows and methods of forming the coated glass windows using the solutions are also disclosed. The methods may be adapted to form nanoparticle films suitable for use as back reflectors in solar cells, where such nanoparticle-based back reflectors exhibit high reflection and light scattering properties, including use of such back reflectors to fabricate solar cells and other photovoltaic-based and light dependent devices such as television screens, computer monitors, portable systems such as mobile phones, handheld games consoles and PDAs.

Owner:THE SOUTH DAKOTA BOARD OF REGENTS

Flexible electrochemical electrode, continuous glucose monitoring sensor and preparation method thereof

InactiveCN105943058ASimple processReduce manufacturing costCatheterLiquid/solution decomposition chemical coatingElectrophoretic depositionCarbon nanotube

The invention discloses a flexible electrochemical electrode, a continuous glucose monitoring sensor equipped therewith and a preparation method thereof. Golden layers on two sides of a chemical gold-plating film are utilized as a working electrode and a comparison-counter electrode in order to form an electrochemistry electrode system. Petal-shaped platinum nanoparticles are subjected to electro-deposition on the surface of the working electrode as a catalysis layer. Then, electrophoretic deposition carbon nanotube / Nafion mesh layer is utilized as an anti-interference layer. An enzyme biochemical sensitive layer is formed through static adsorption on the anti-interference layer and coated with a polyurethane mass transfer restriction protection layer after cross-linking and solidity of glutaraldehyde. Therefore, the continuous glucose monitoring sensor is prepared. Without lithography or screen printing and other technologies, an electrochemical electrode system can be constructed so that processing technology is effectively simplified and large scale production is easily achieved and production cost is lowered. In the meantime, advantages such as broad linear range, high interference immunity, high response sensitivity and long term stability are obtained.

Owner:ZHEJIANG UNIV

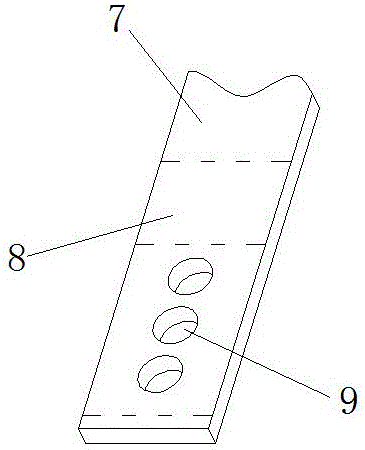

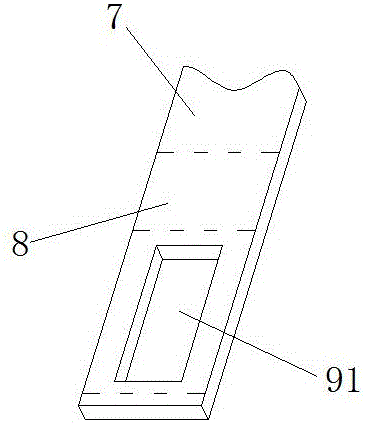

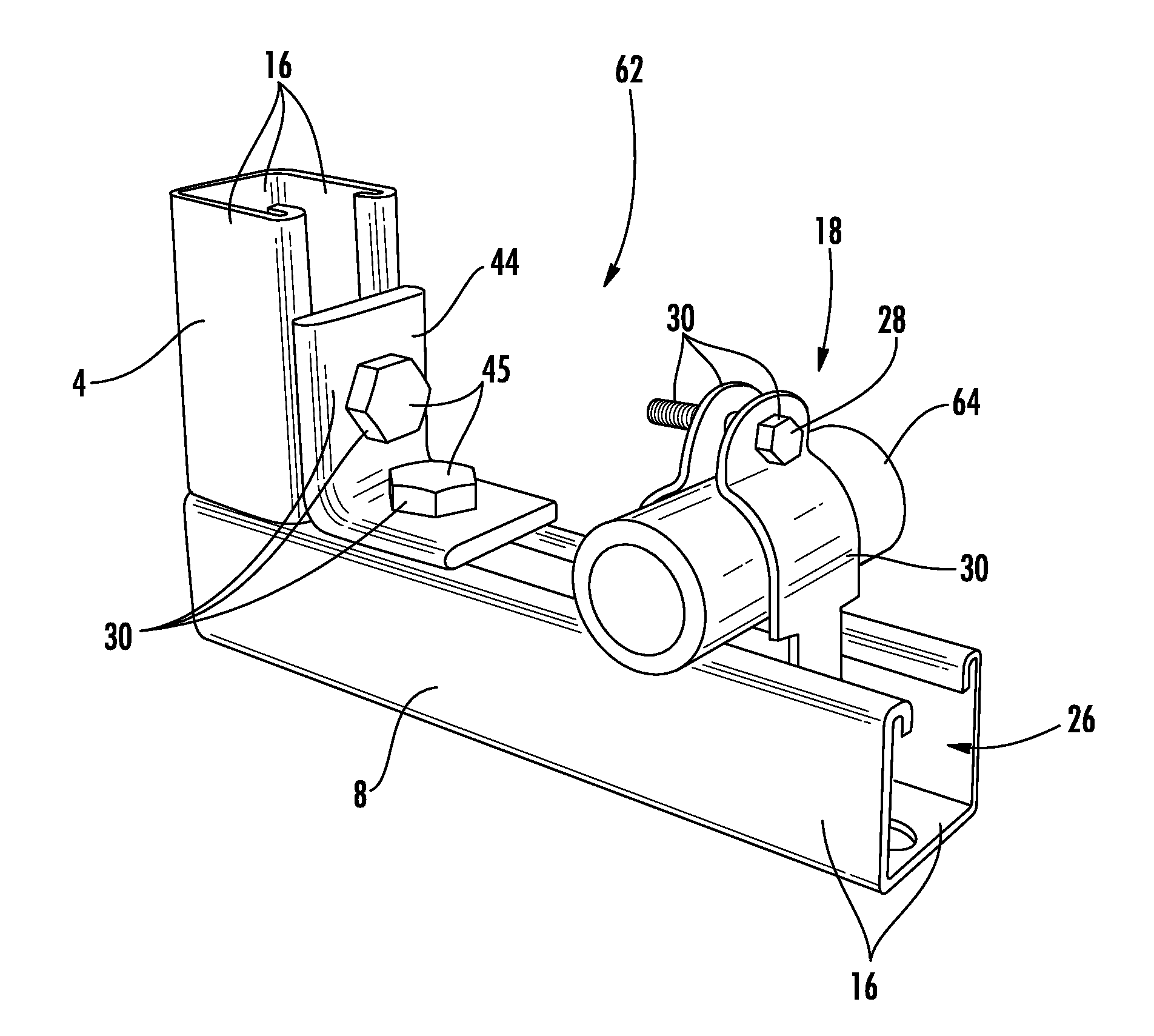

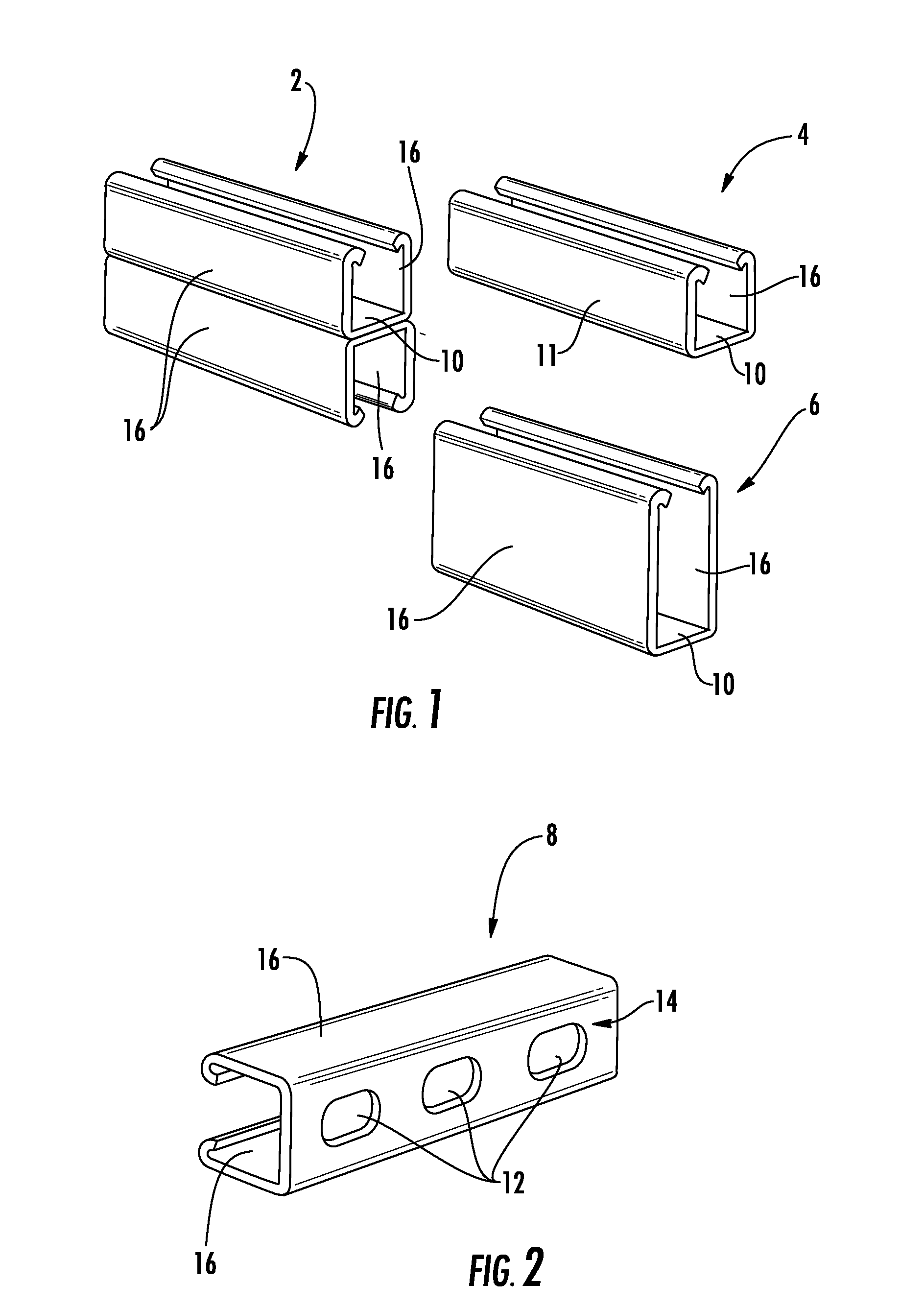

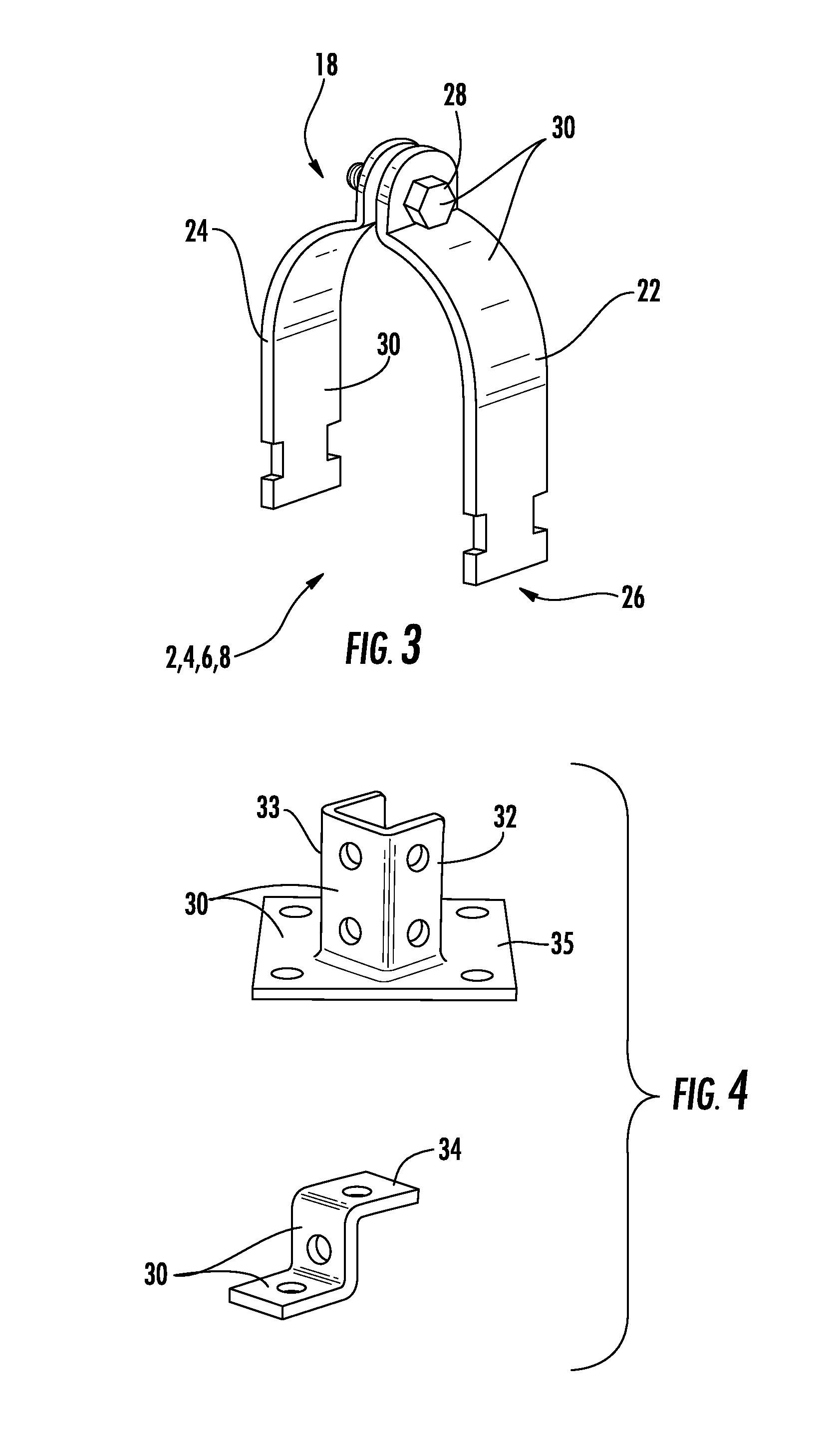

Enhanced corrosion resistant channels, fittings and fasteners

A corrosion resistant support system includes a first channel member having a first corrosion resistant coating. The first corrosion resistant coating is a zinc-aluminum-magnesium coating. A fitting is engageable with said channel member and a first mechanical fastener to couple the fitting to the channel member, the fitting and the first mechanical fastener having a second corrosion resistant coating. The second corrosion resistant coating is a thermal diffusion galvanized coating or a zinc-aluminum-magnesium coating. The first channel member and the first mechanical fastener may also have a third corrosion resistant coating disposed over the first and second corrosion resistant coatings, respectively. The third corrosion resistant coating can be a Perma-Green™ coating, a powder coating, an electrocoating (E-coat or Electrophoretic deposition coating), a paint coating, an epoxy coating, a polyvinyl chloride (PVC) coating, a trivalent chromium coating, a hexavalent chromium coating, a zinc coating, and / or a copper coating.

Owner:UNISTRUT INT CORP

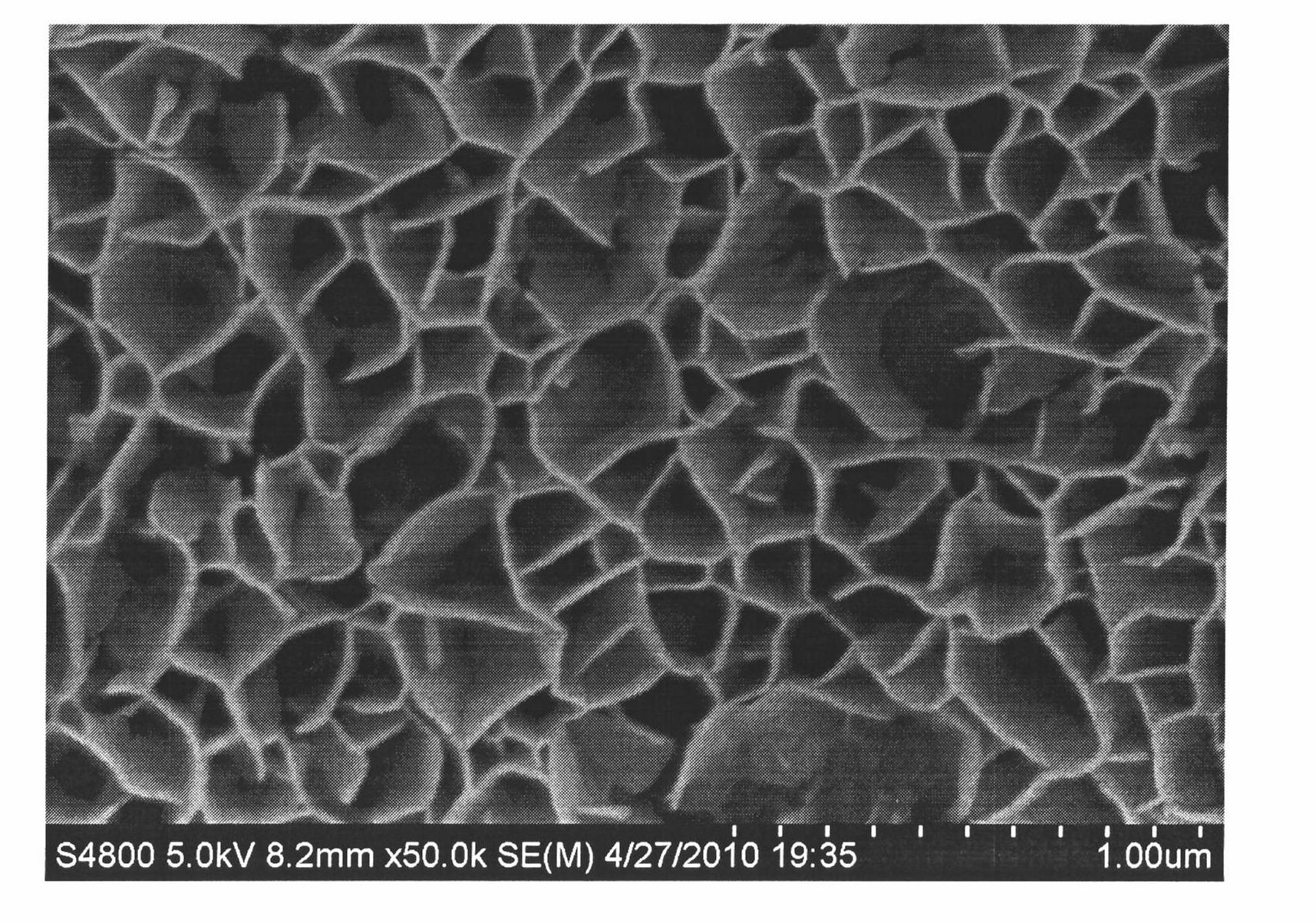

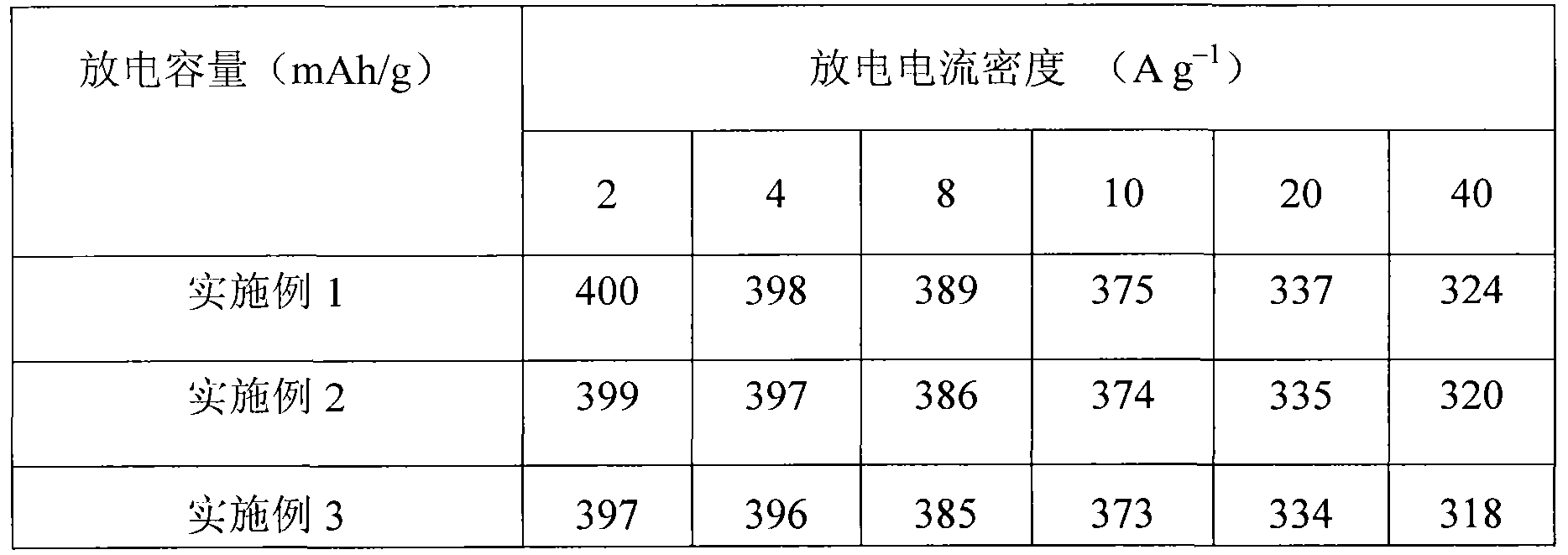

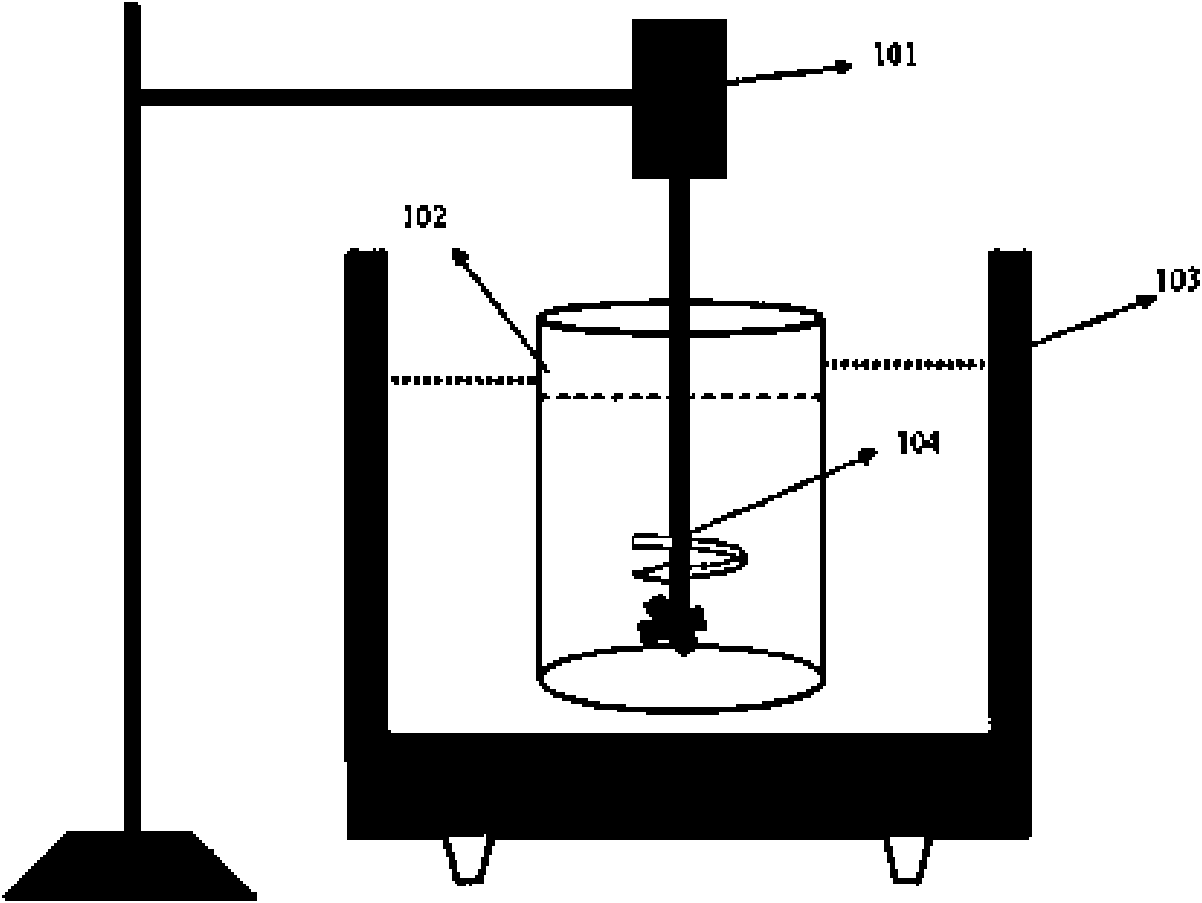

Film for graphene/porous nickel oxide composite super capacitor and preparation method thereof

InactiveCN102013330AIncrease contact areaShorten the diffusion distanceCapacitor electrodesCapacitanceElectron

The invention discloses a film for a graphene / porous nickel oxide composite super capacitor. The invention is characterized in that the film is of a disordered nano porous structure, the aperture range is 10 to 350nm, the thickness of the film is 1 to 5 mu m, and the weight ratio of graphene to nickel oxide is (0.5:100) to (2:100). The method for preparing the film comprises the following steps: dissolving graphite oxide sheets and magnesium nitrate into an isopropanol solution so as to form a positively-charged graphite oxide sheet sol, then carrying out electrophoretic deposition on the obtained sol so as to obtain a graphene film; and through taking the graphene film as a deposition carrier, preparing a three-dimensional porous film for the graphene / porous nickel oxide composite super capacitor by using a chemical bath film-coating method. The porous composite thin film prepared by the method has the advantages of good mechanical capacity and super-capacitance property, high-discharge specific capacitance, high-ratio charge-discharge properties, high cycle life and the like, and has wide application prospects in the fields such as electric automobiles, communication, consumer electronics, signal control and the like.

Owner:ZHEJIANG UNIV

Surface chemical metal plating carbon nanotube field-emission cathode preparation method

ActiveCN101661858AImprove stabilityFacilitates electron conductionCold cathode manufactureState of artChemical plating

The invention provides a surface chemical metal plating carbon nanotube field-emission cathode preparation method, which belongs to a carbon nanotube field emission cathode technology, solves the shortcomings of the existing technology, improves the electronic conduction and emission capabilities of the carbon nanotube and enhances the contact between a carbon nanotube film and a substrate electrode. The preparation method comprises the following steps: the carbon nanotube is processed through purification, cutting, scattering, and then through sensitization and activation, the carbon nanotubesurface forms a noble metal catalytic center; then the carbon nanotube surface forms a metal layer through a chemical plating method, the surface chemical metal plating carbon nanotube is prepared into evenly and stably dispersed carbon nanotube electrophoresis liquid, and finally pulse electrophoresis deposition is used for preparing the cathode of the carbon nanotube. The surface chemical metalplating carbon nanotube has good electronic conduction and emission capabilities, the carbon nanotube field-emission cathode and a substrate electrode can form good attachment, and the invention canrealize large-area, imaging and uniform preparation for the carbon nanotube field-emission cathode.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com