Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191results about How to "Reduce sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

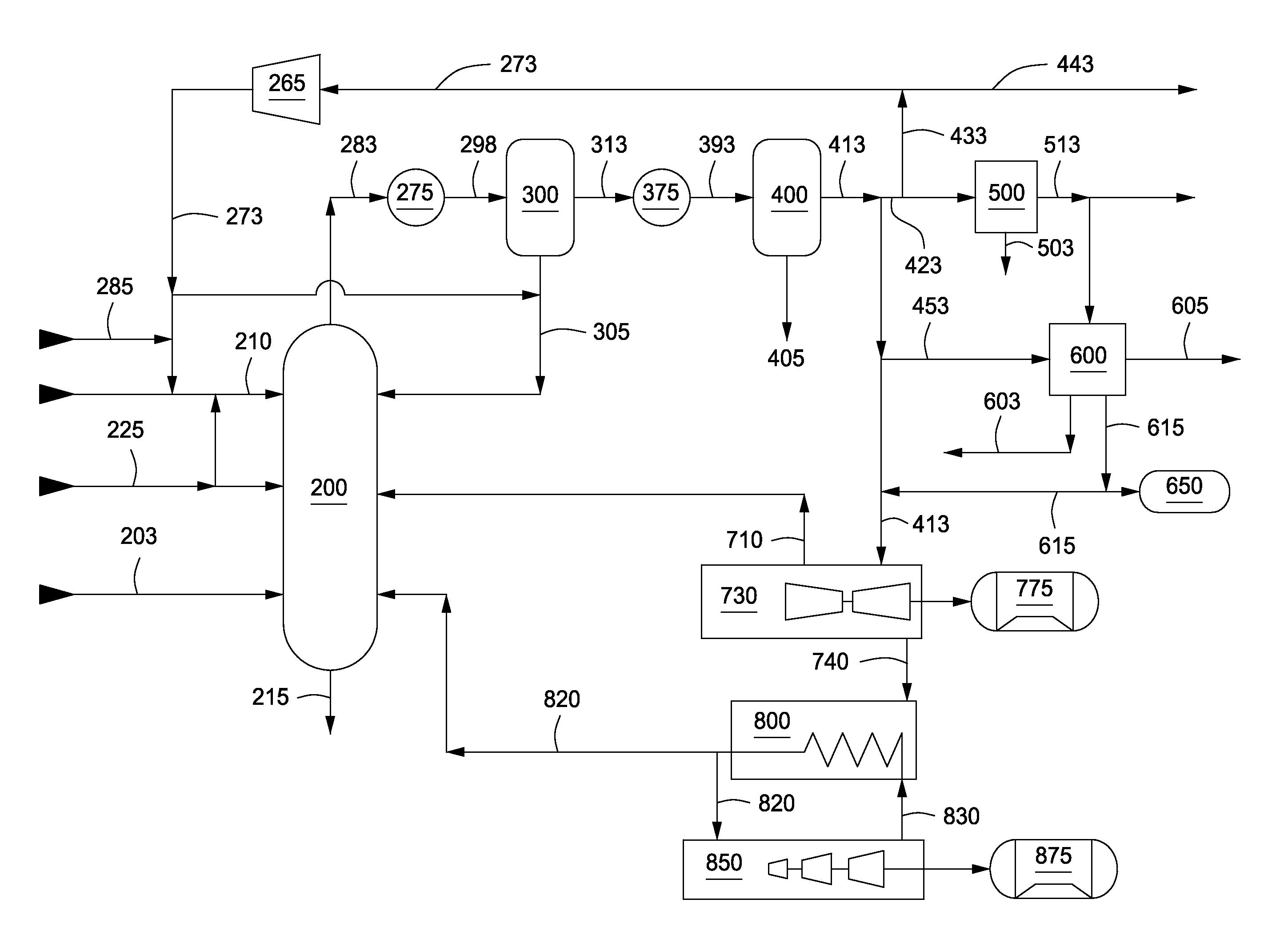

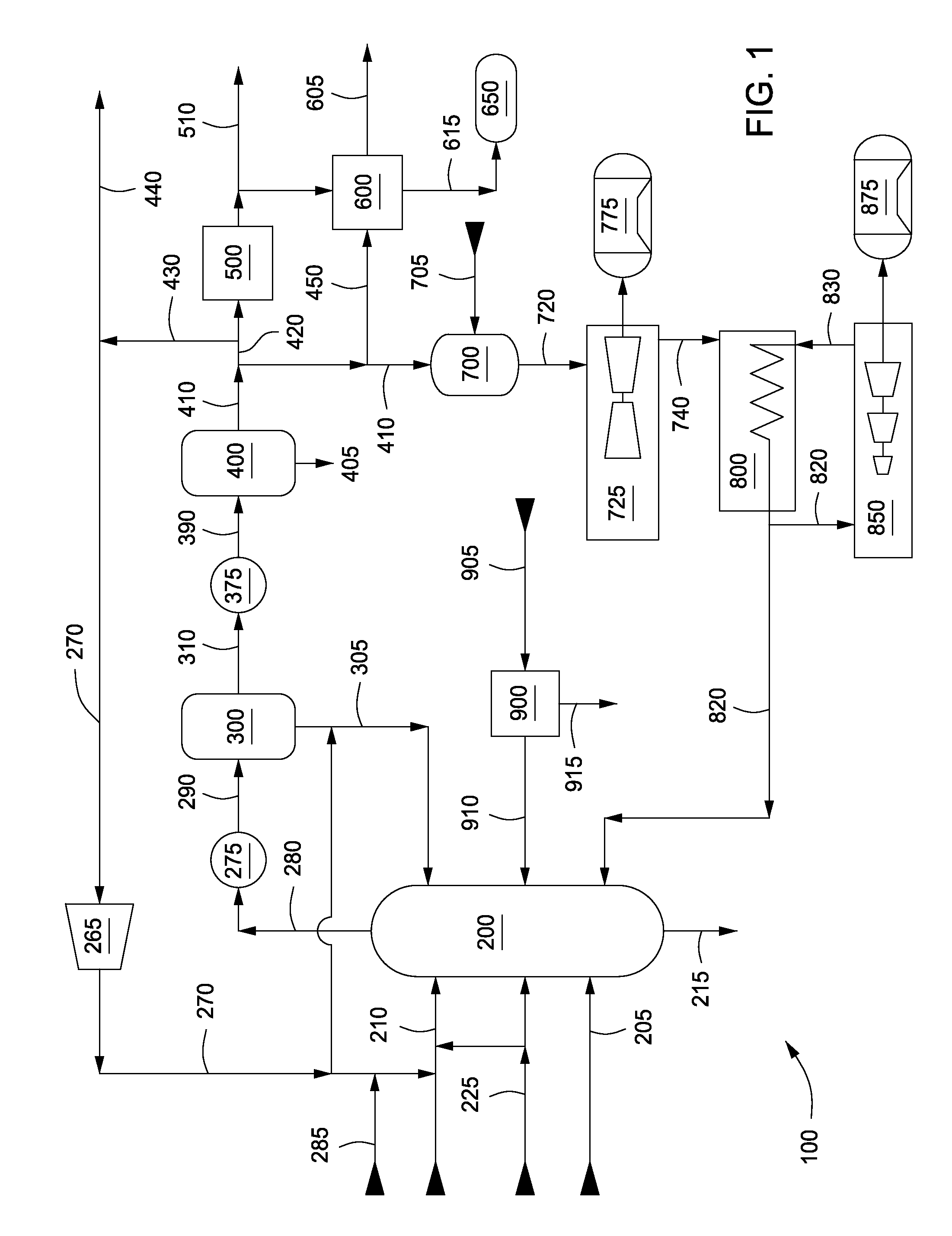

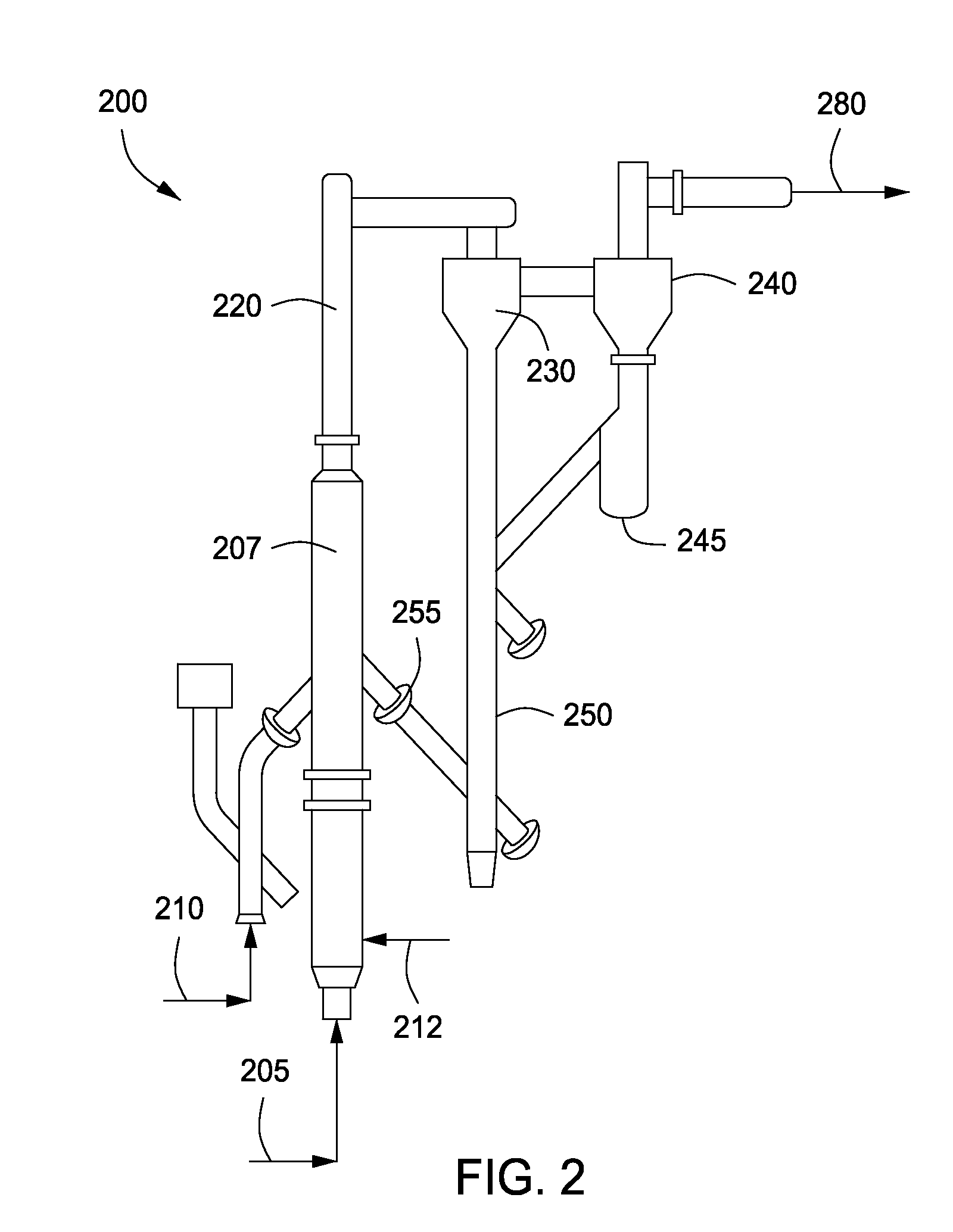

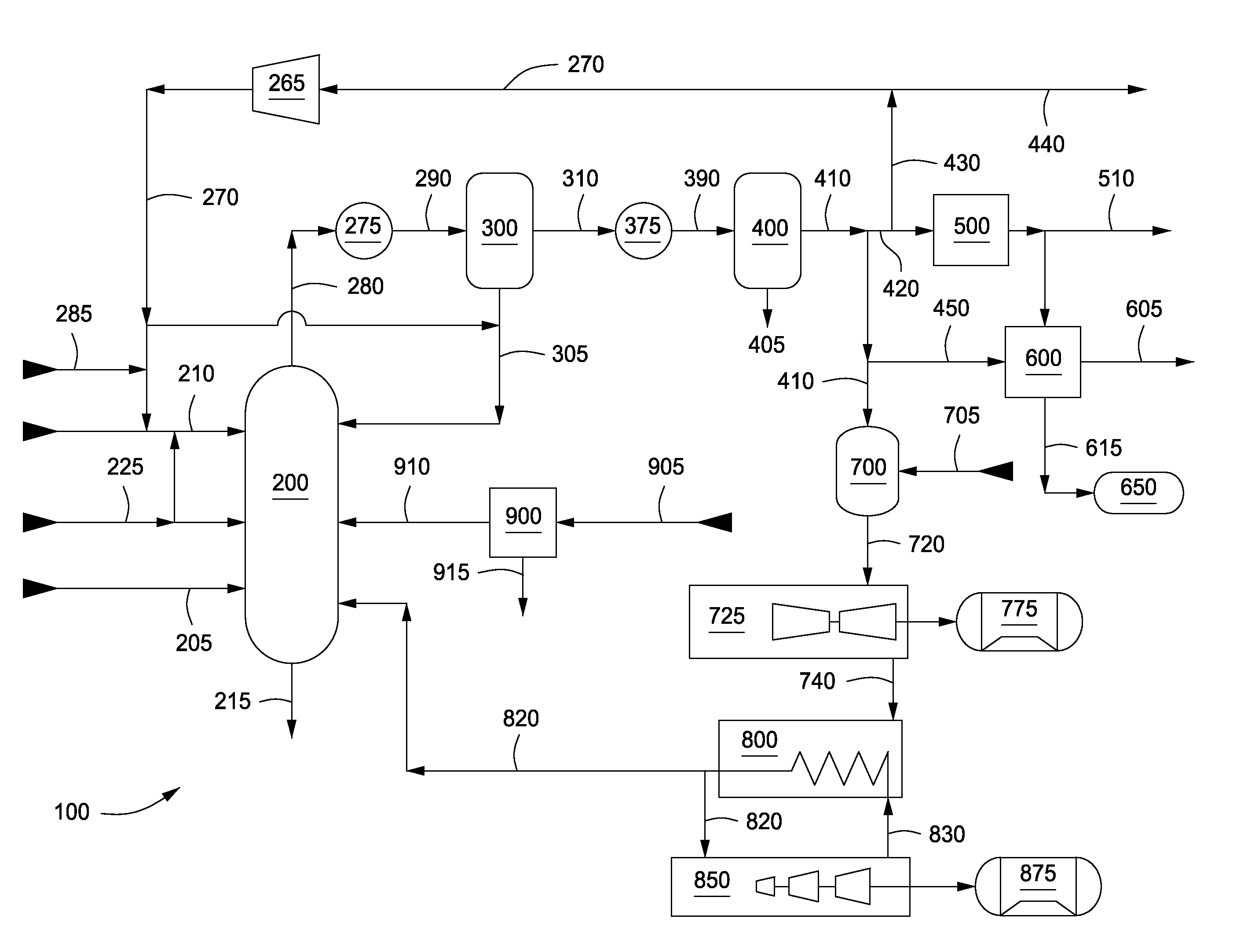

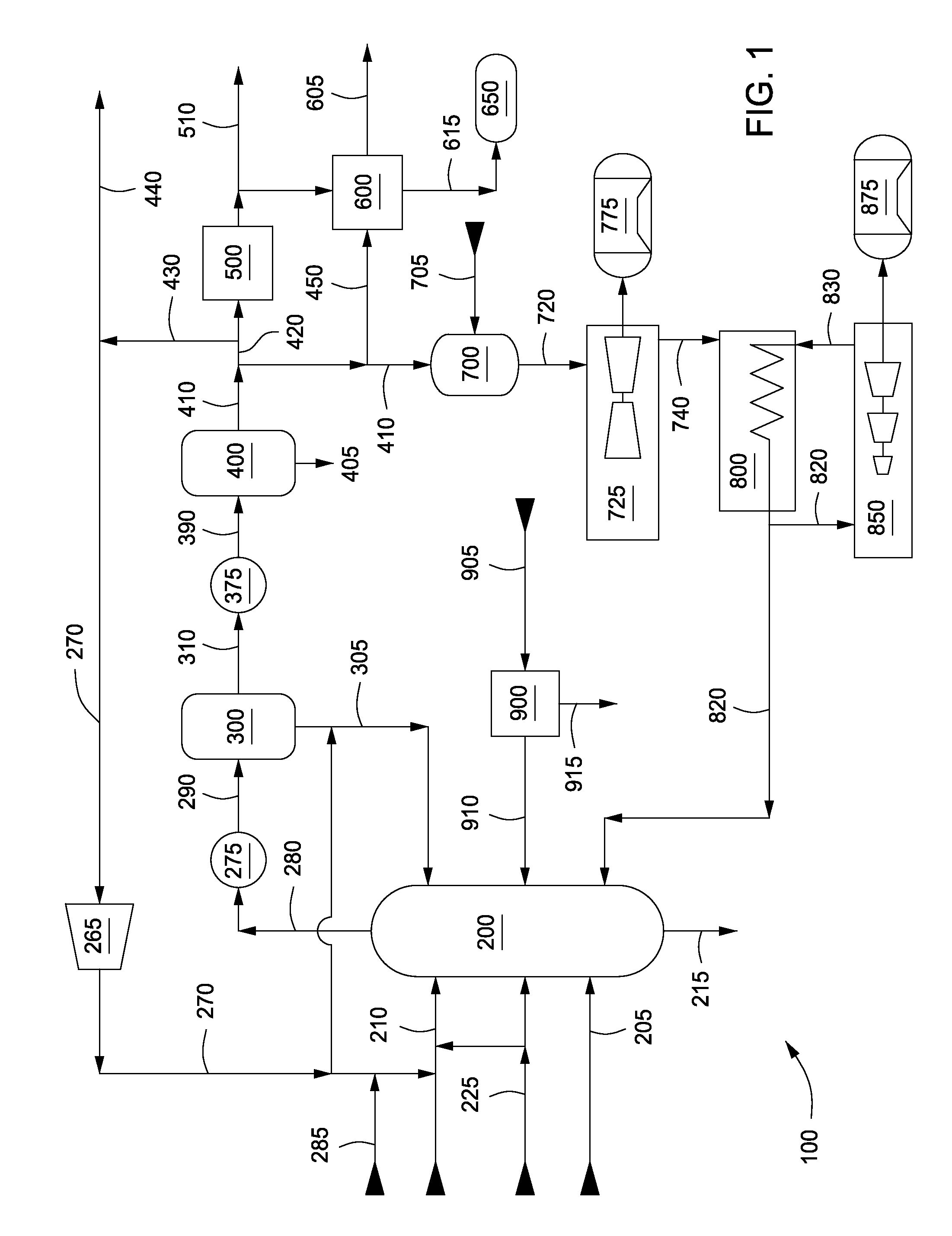

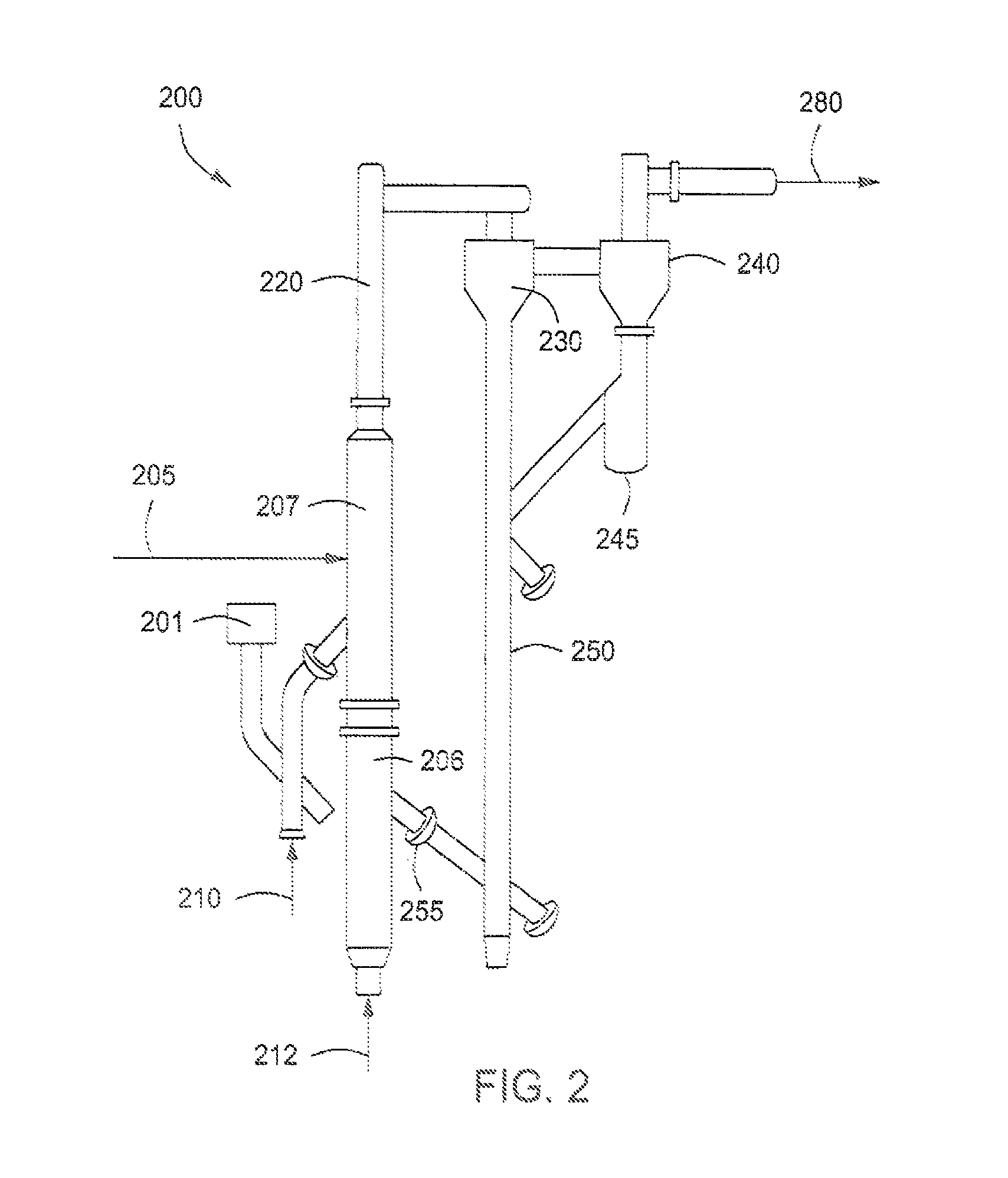

Low oxygen carrier fluid with heating value for feed to transport gasification

ActiveUS20090188165A1Reduce and eliminate partial and complete oxidationReduce and eliminate exothermic conversionMultiple metal hydridesCombustible gas catalytic treatmentCarrier fluidOxidizing agent

Systems and processes for producing synthesis gas. A carbonaceous feedstock can be combined with one or more low-oxygen carrier fluids having a high heating value. The feedstock and carrier fluid, in the presence of one or more oxidants, can be gasified to provide a synthesis gas. In one or more embodiments, at least a portion of the synthesis gas can be recycled for use as the carrier fluid.

Owner:KELLOGG BROWN & ROOT LLC

Sintered quartz glass products and methods for making same

InactiveUS6012304AReduce sinteringLonger sintering timeGlass shaping apparatusCeramic shaping apparatusSilica particleDevitrification

A number of unique processes are disclosed for manufacture of sintered high-purity quartz glass products in which a shaped silica body or preform is made from an aqueous slurry of micronized silica particles by gel casting, slip casting or electrophoretic deposition. The silica particles may comprise a major portion by weight of crystalline silica. In one embodiment of the invention the sintered quartz glass is transparent, substantially bubble-free and suitable for scientific or optical uses. In another embodiment the porous silica preform is fired in steam to increase the hydroxyl content and then nitrided in a nitrogen-hydrogen reducing atmosphere. A minute amount of chemically-combined nitrogen in the high-purity quartz glass is sufficient to provide a tremendous improvement in physical properties and an incredible increase in the resistance to devitrification.

Owner:LOXLEY TED A +2

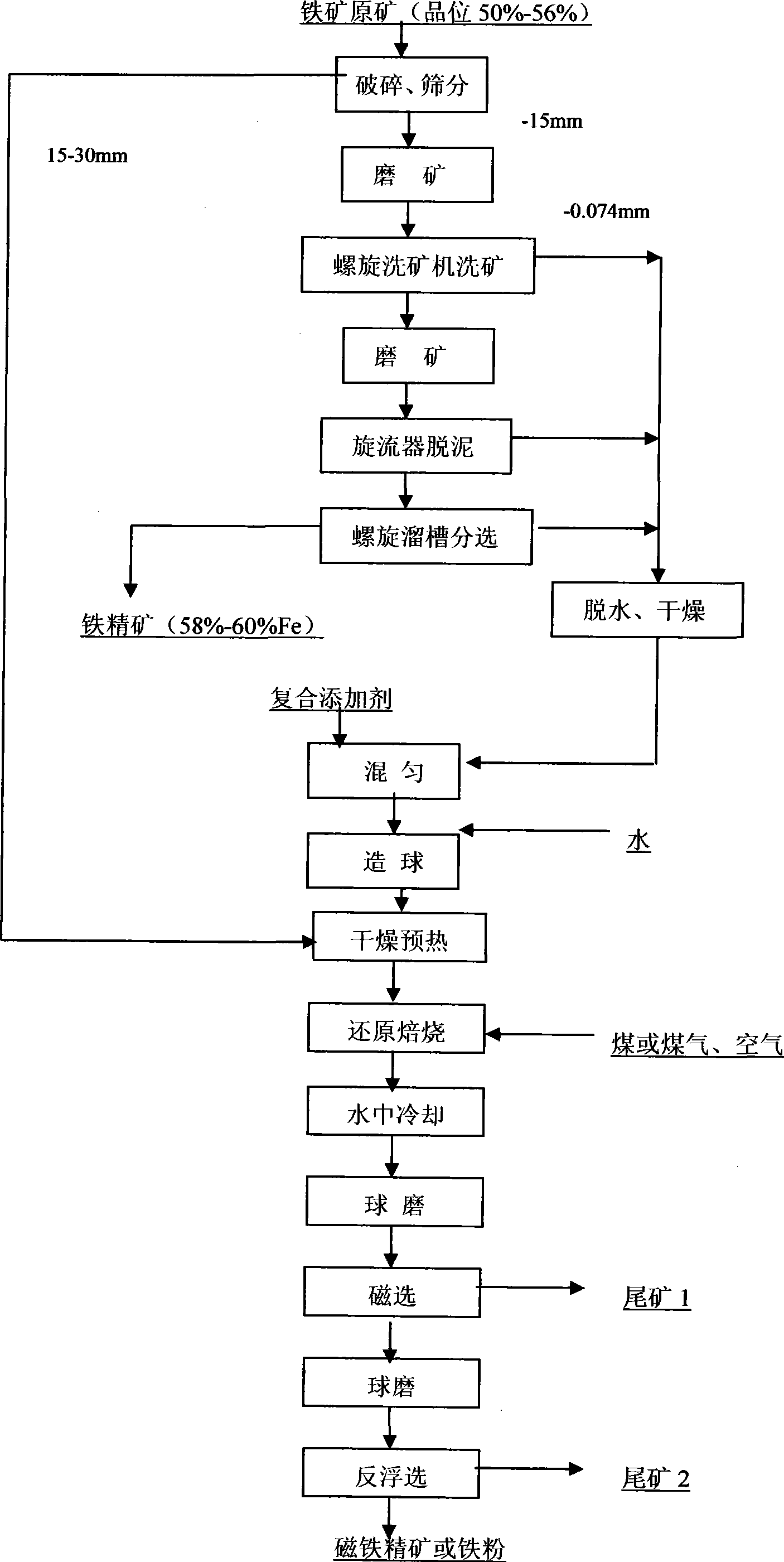

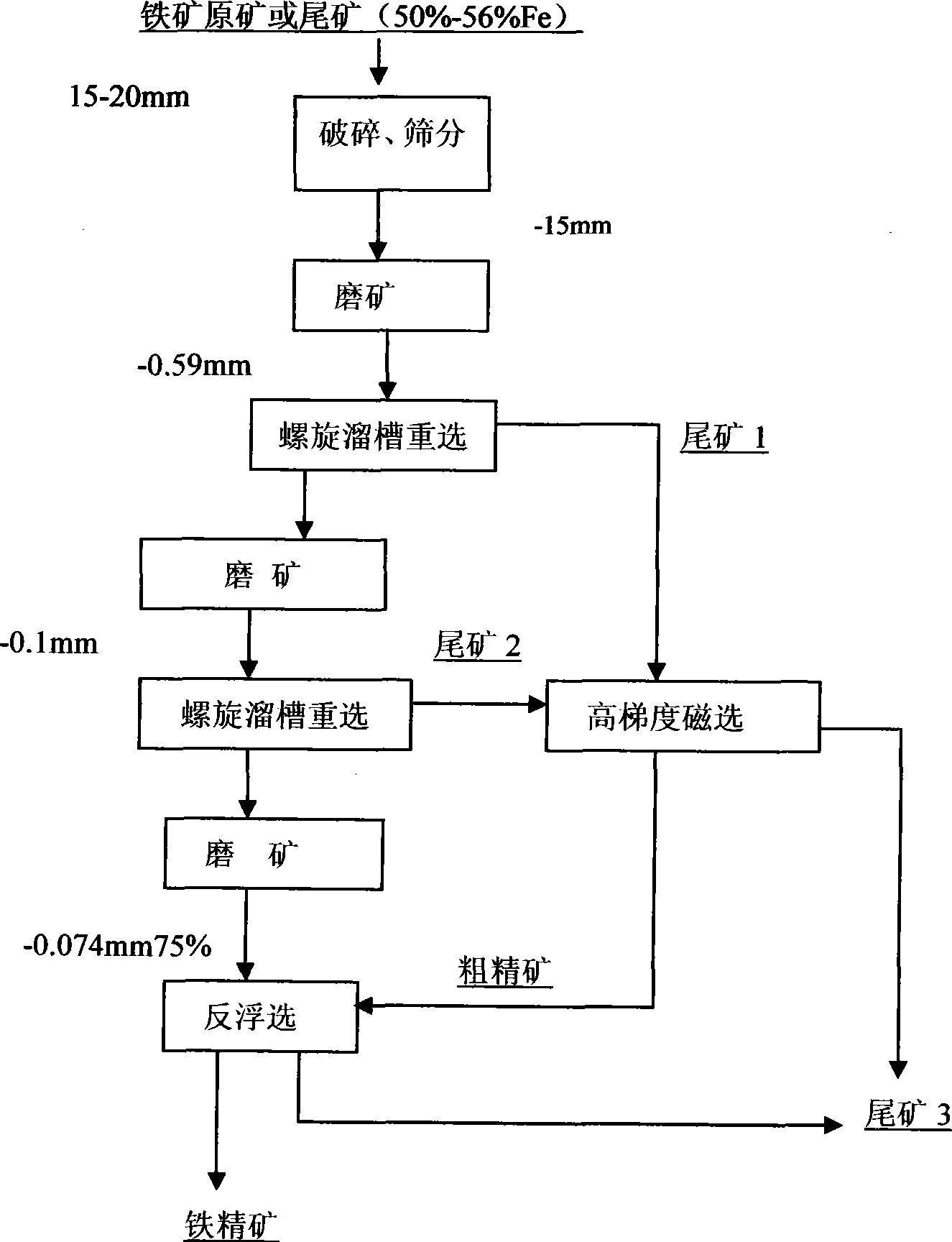

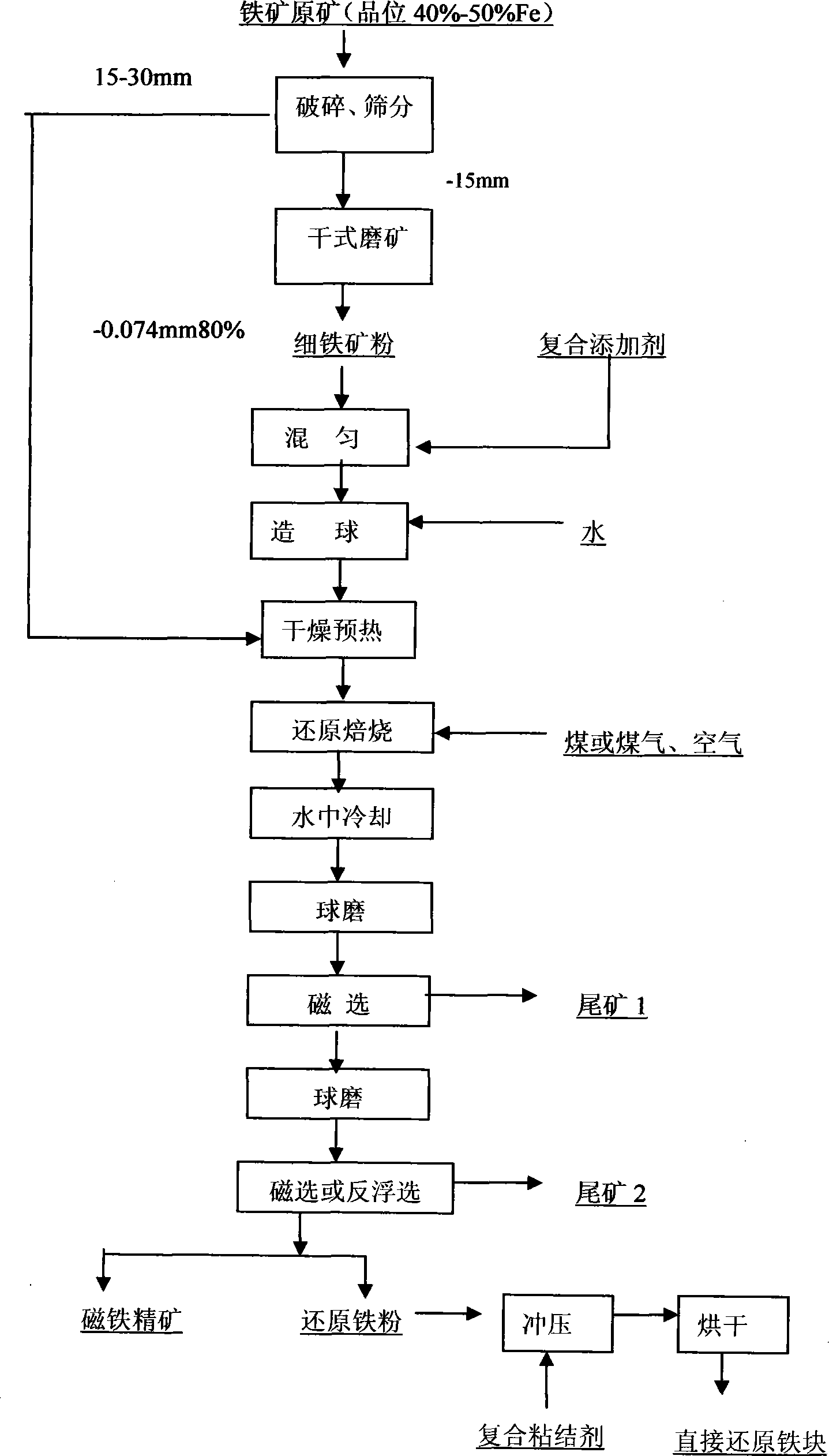

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

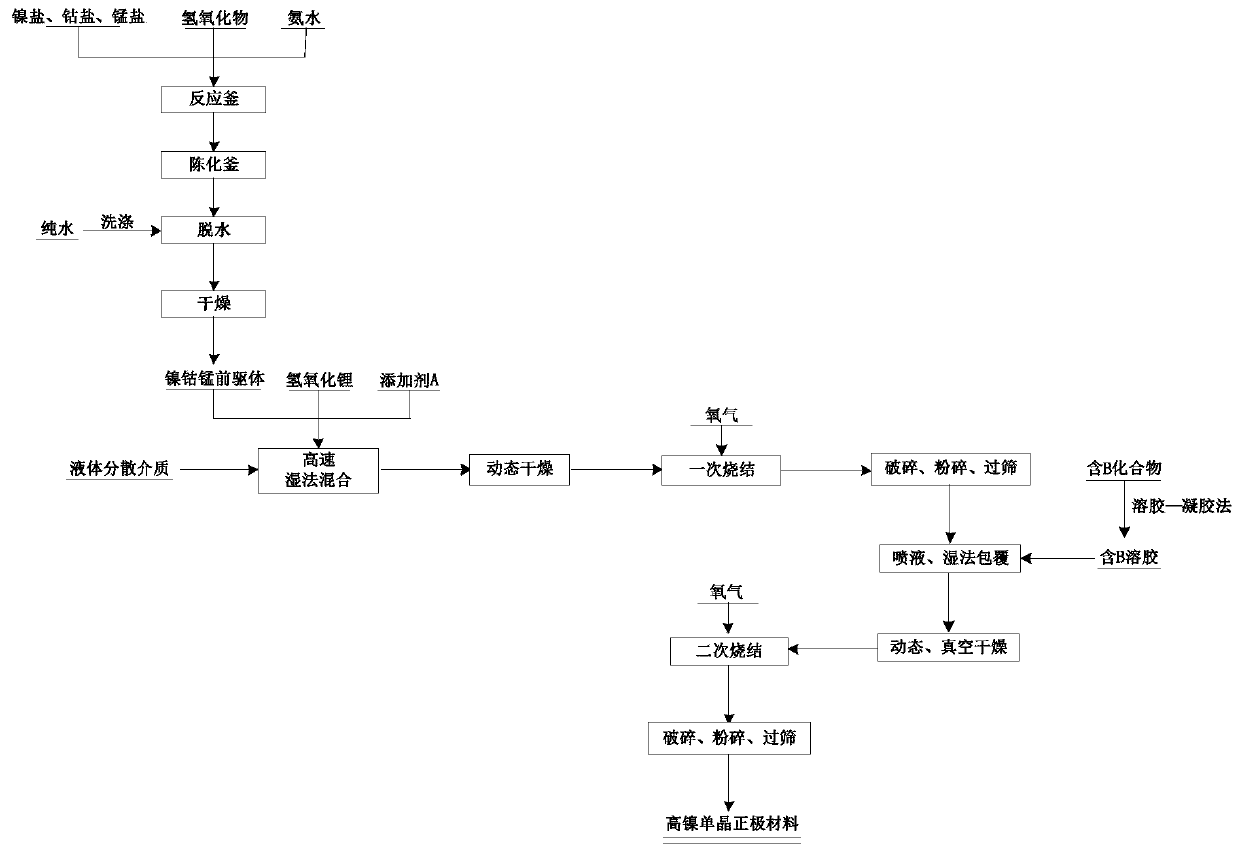

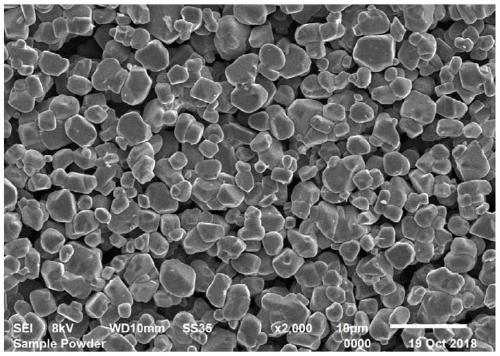

Method for preparing high-nickel long-cycle single-crystal lithium ion battery positive-pole material

InactiveCN110451585AImprove uniformityImprove stabilityCell electrodesSecondary cellsNickel saltLithium hydroxide

The invention relates to a method for preparing a high-nickel long-cycle single-crystal nickel-cobalt-manganese (NCM) lithium ion battery positive-pole material. The preparation method comprises the following steps: (1) mixing a soluble nickel salt, a cobalt salt, a manganese salt, an alkali metal hydroxide and ammonia water, and enabling the mixture to flow into a reaction kettle for constant-temperature coprecipitation to obtain a high-nickel NCM ternary precursor material; (2) uniformly mixing the high-nickel NCM ternary precursor, lithium hydroxide and an additive A in a wet high-speed mixing mode, carrying out drying, then carrying out primary sintering in an oxygen-enriched atmosphere to obtain a spherical high-nickel NCM ternary positive-pole material; (3) carrying out crushing, smashing and sieving to obtain a high-nickel NCM ternary positive-pole material; and (4) carrying out wet mixing and drying on the high-nickel NCM ternary positive-pole material with a coating agent B, carrying out secondary sintering in an oxygen-enriched atmosphere, and carrying out crushing, smashing and sieving to obtain the high-nickel single-crystal NCM lithium ion battery positive-pole material. The positive-pole material prepared by the method has the advantages of high capacity, good cycle performance, high compaction density and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

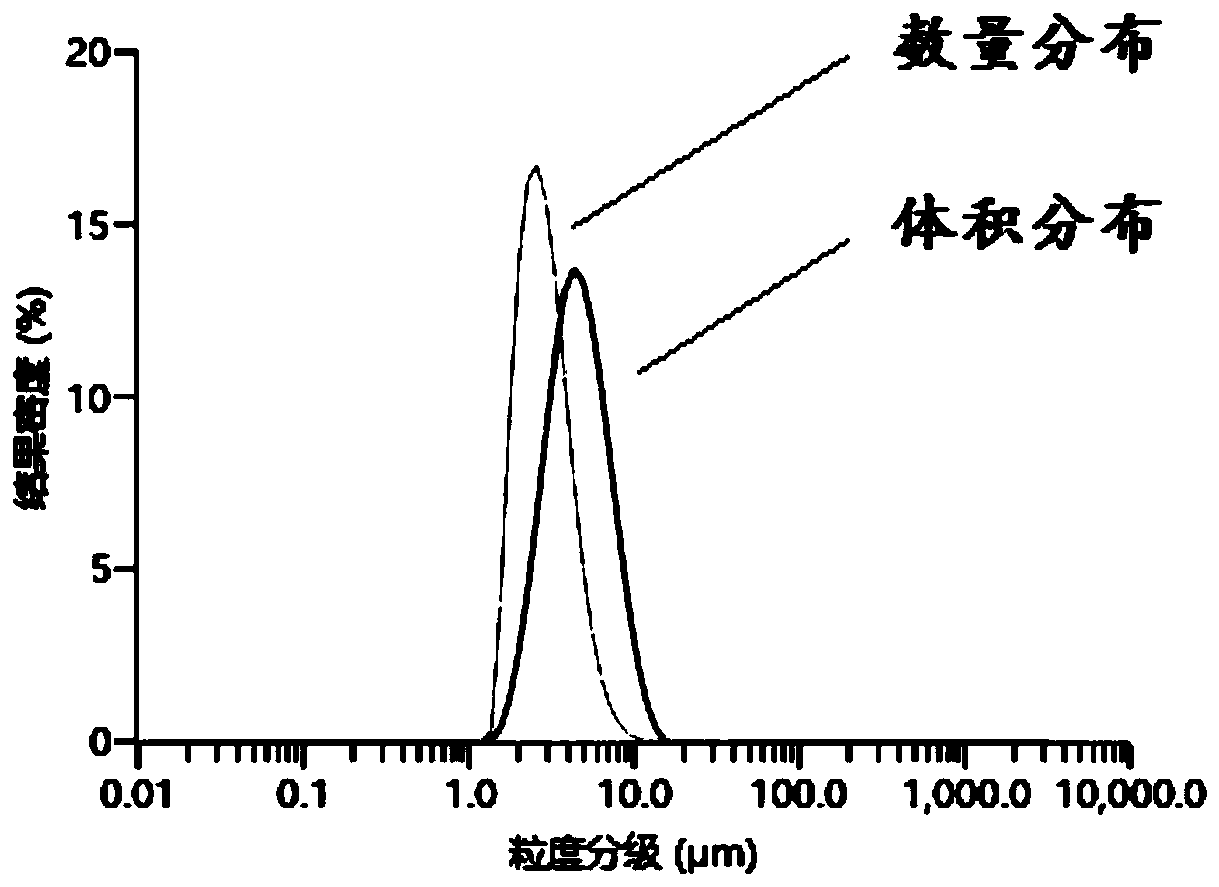

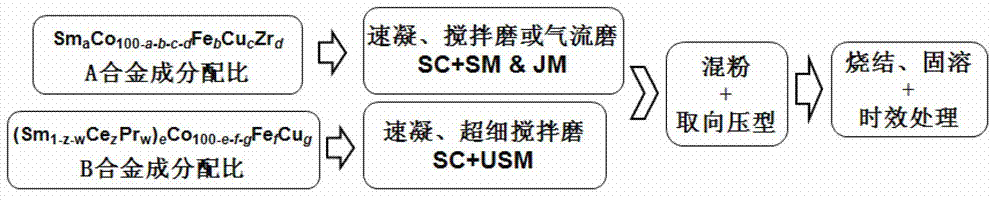

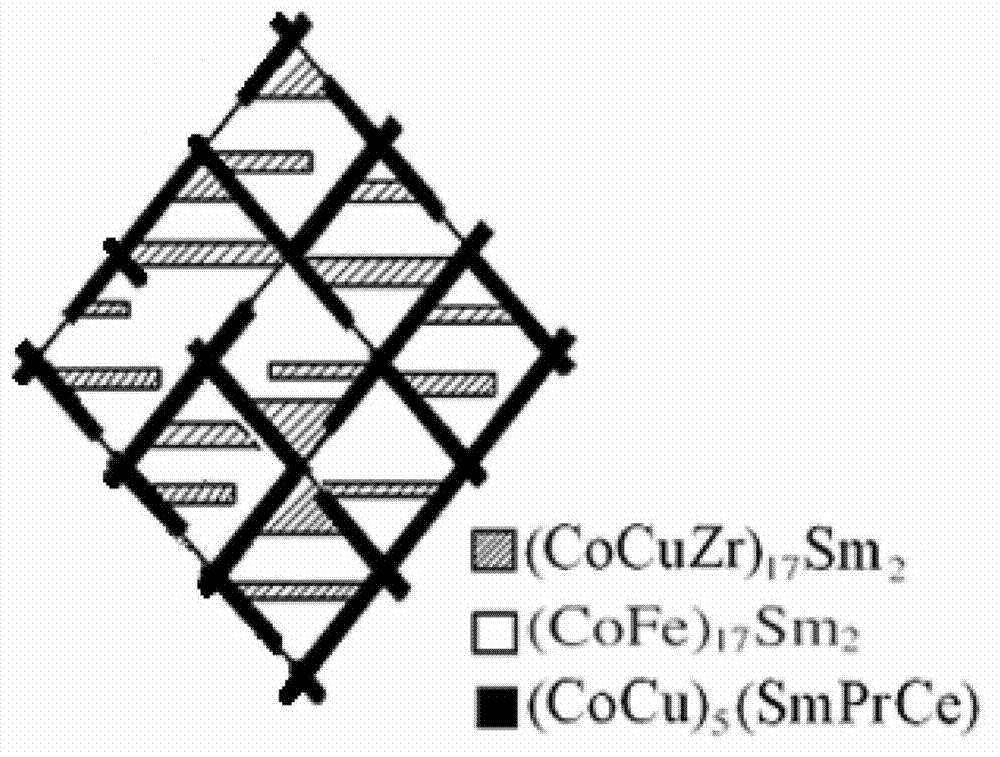

High-remanence low-coercivity samarium cobalt permanent magnetic material and preparation method

ActiveCN102760545AHigh surface magnetic fieldReduce sinteringMagnetic materialsRemanenceChemical composition

The invention belongs to the field of rare earth permanent magnetic material manufacturing, and relates to a high-remanence low-coercivity samarium cobalt permanent magnetic material and a preparation method. The chemical components of the permanent magnetic material by mass percent are shown as follows: 23-26.5% of [Sm1-x-y(Prx, Cey)], 17-20% of Fe, 3-6% of Cu, 1-3% of Zr, and the balance of Co, wherein x is not less than 0 and not more than 0.1, and y is not less than 0 and not more than 0.1. In the preparation method, a double main phase alloying method and a rapid hardening technology are used, a rapid hardening belt with two components is needed only, and a high-remanence low-coercivity magnet can be prepared; an anti-oxidation lubricant is added in a jet milling process so as to prevent agglomeration and oxidation of magnetic powder, and the oxygen content of the magnet is less than 1500ppm. By addition of Ce and Pr, the thermal treatment temperature of the samarium cobalt permanent magnetic material is reduced. The magnet performance is shown as follows: Br=11.0-11.5kGs, Hcj=10-20kOe, and (BH)max=28-33MGOe.

Owner:CENT IRON & STEEL RES INST

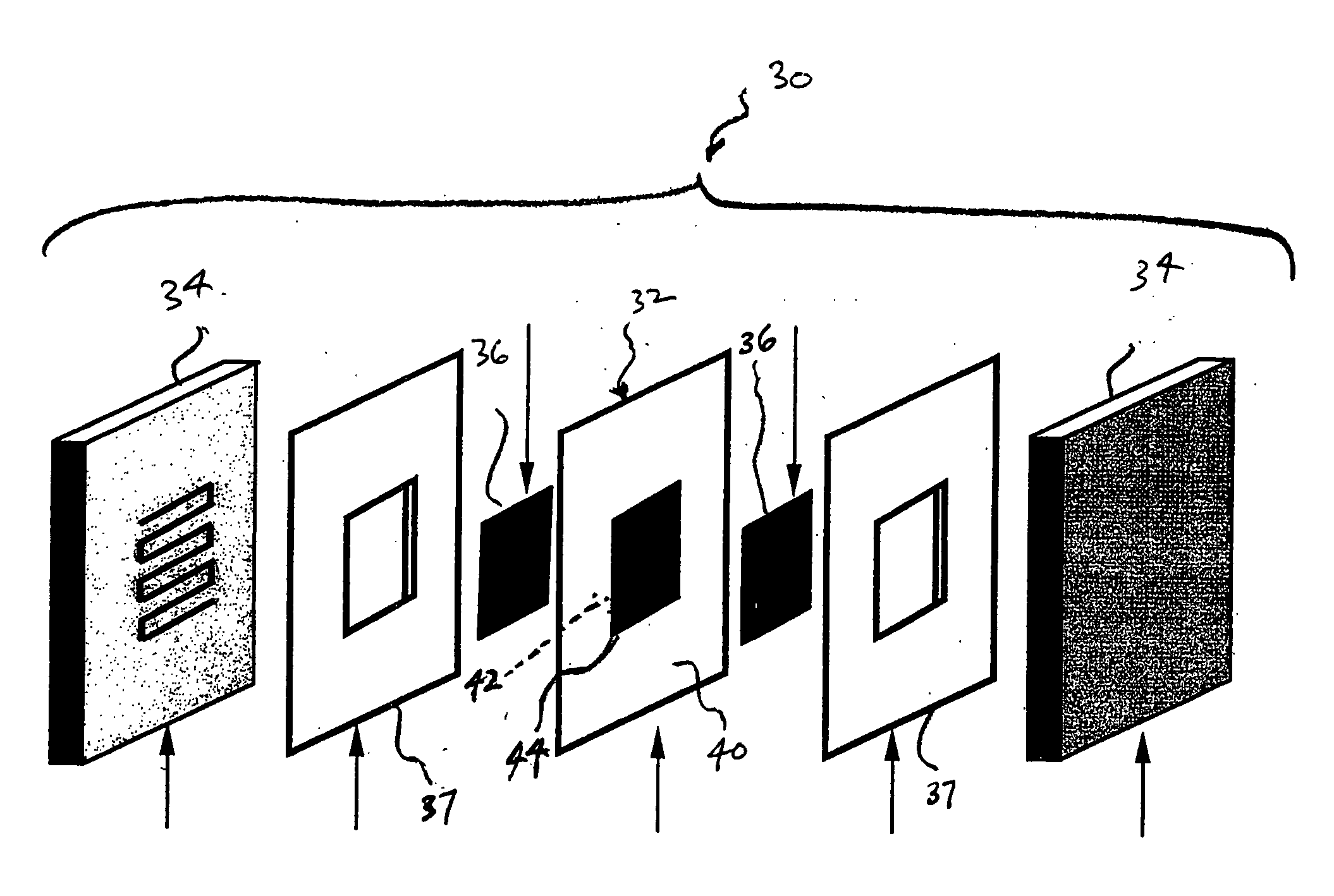

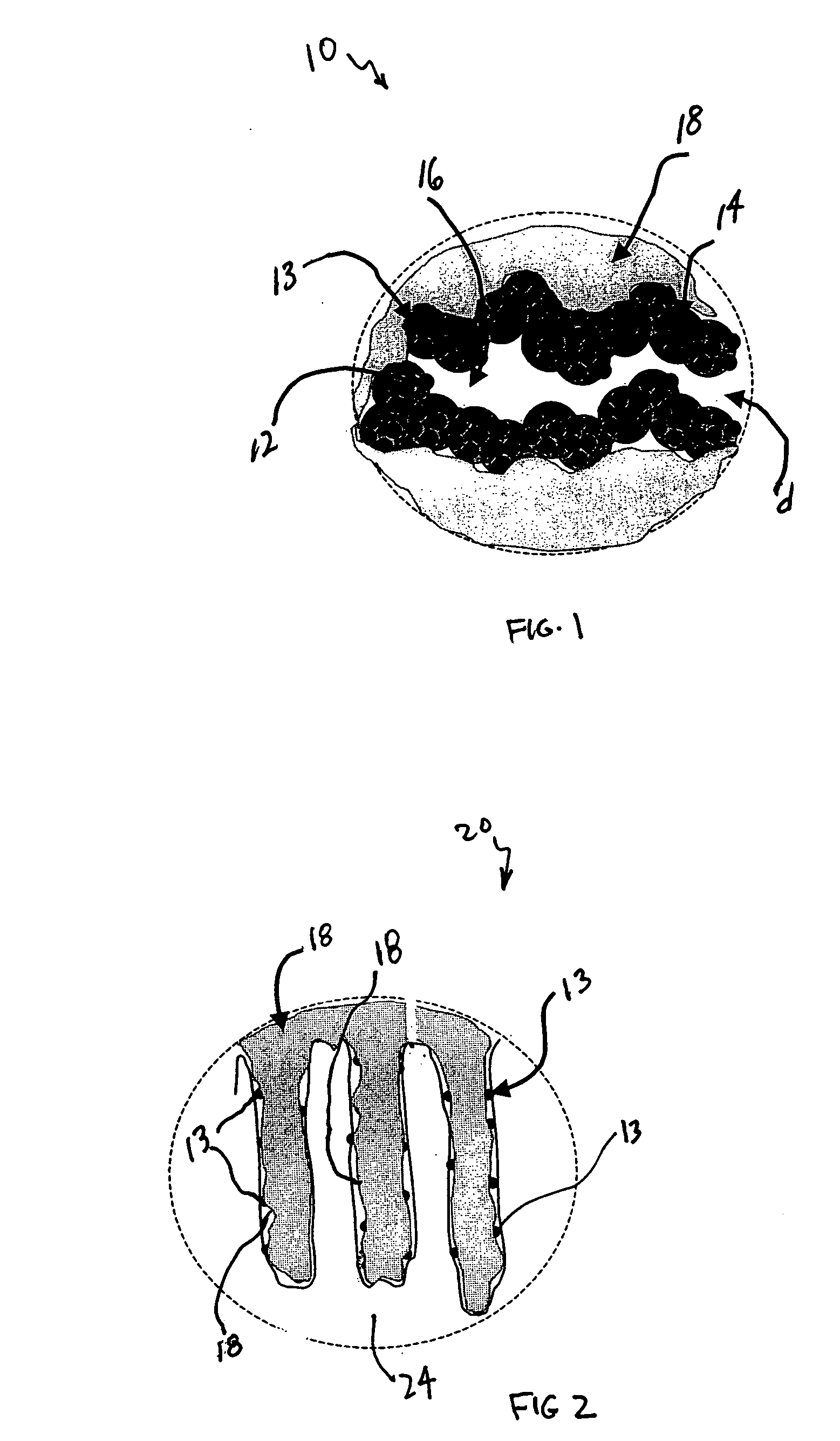

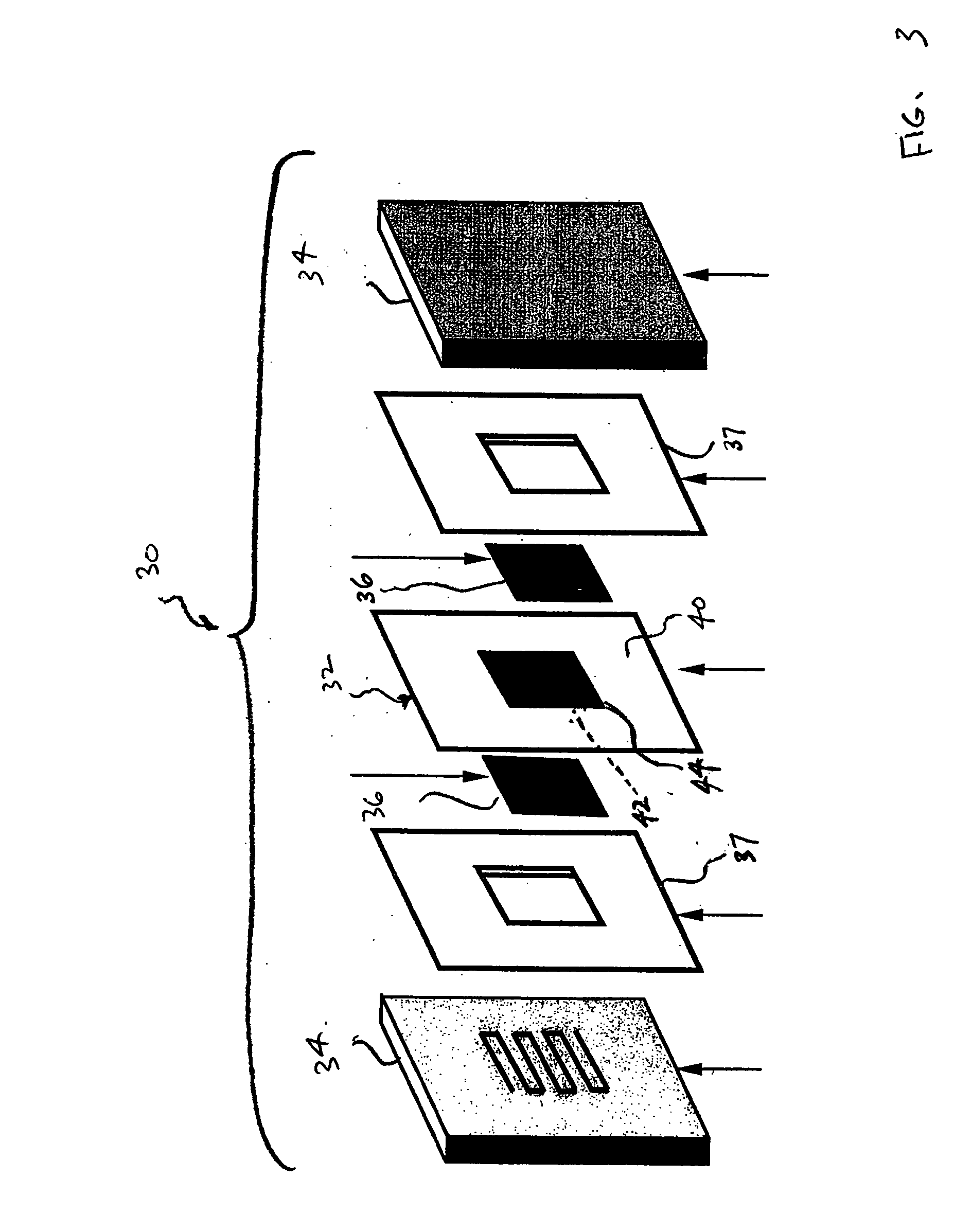

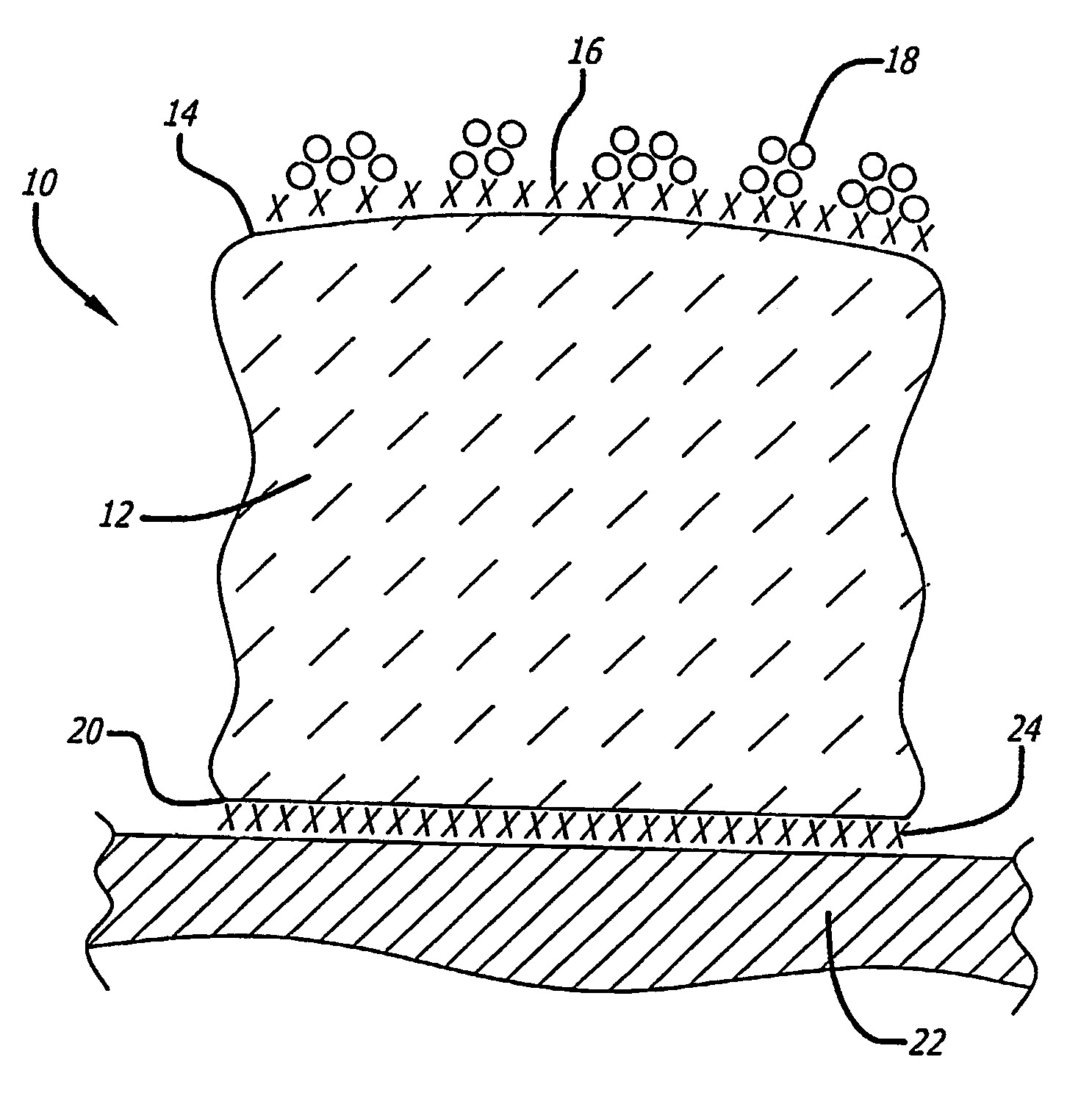

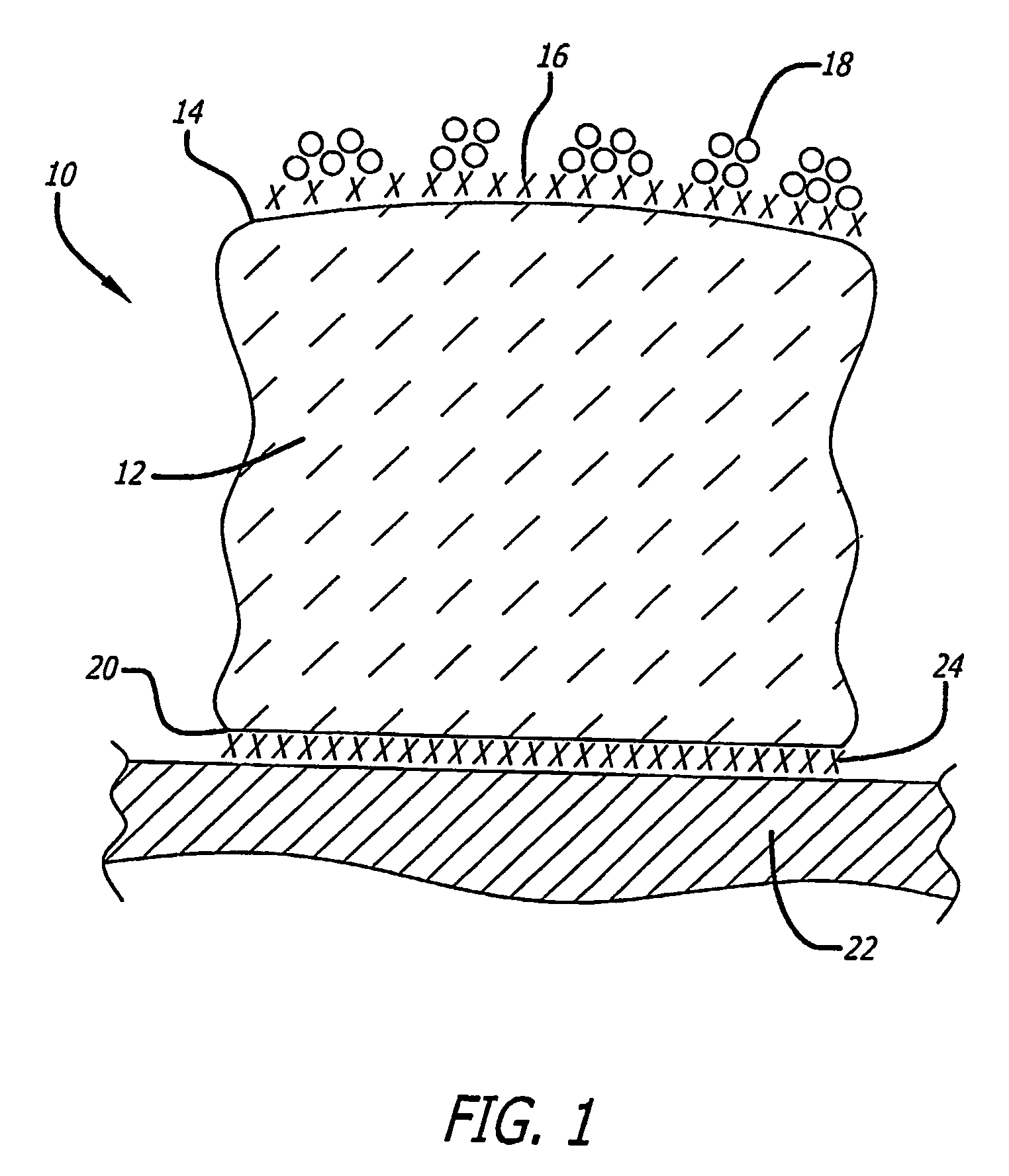

Method of preparing membrane electrode assemblies with aerogel supported catalyst

InactiveUS20050200040A1Pore size can be alteredIncrease contactFinal product manufactureCell electrodesVitrificationPolymer science

A process of manufacturing a membrane electrode assembly comprises the steps of preparing an electrode-forming catalyst ink comprising porous aerogel supported catalyst and an electrolyte; depositing the prepared catalyst ink on a polymer film to form one or more catalyst layers; hot-pressing the one or more catalyst layers deposited on the polymer film at a temperature that is higher than a glass transition temperature of the electrolyte; decreasing the temperature of the hot-pressed catalyst layer and the polymer film; and removing the polymer film from the one or more catalyst layers.

Owner:HARA HIROAKI S +1

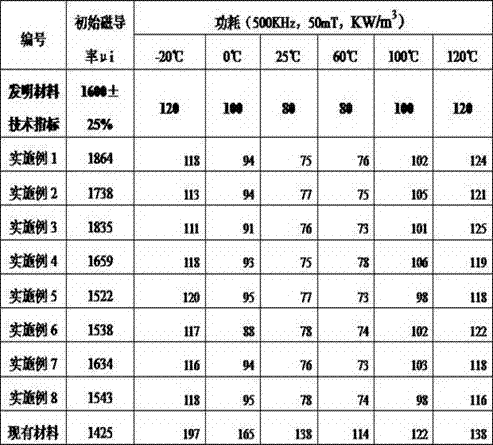

Wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

InactiveCN107540363AReduce lossImprove workabilityInorganic material magnetismInductances/transformers/magnets manufactureWork performanceRoom temperature

A wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material comprises a main component, an auxiliary component A and an auxiliary component B, wherein, according to weight percentage, the main component comprises Fe2O3, MnO and ZnO; based on the weight of the main component, the auxiliary component A comprises at least two of CaCO3, V2O5, TiO2 and Co3O4, and the auxiliary component B comprises at least three of CaCO3, Nb2O5, TiO2, Co3O4, CuO, MoO and SiO2; the SiO2 amount in the auxiliary component B is determined according to the total amount of SiO2 impurities in the main component so as to ensure that in the whole material, the SiO2 amount is 0.025-0.035% of the total weight of the main component. A preparation method of the wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material sequentially comprises the following steps: performing component analysis on the main component, primarily dosing, primarily sanding, presintering, secondarily dosing, moulding and sintering. The wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material has excellent working performance under the conditions of 500KHz and 50mT and within the temperature range from -20 DEG C to 120 DEG C, has relatively low loss, saves more energy than the conventional material, and has lower standby loss at low temperature and room temperature.

Owner:郴州市久隆旺高科电子有限公司

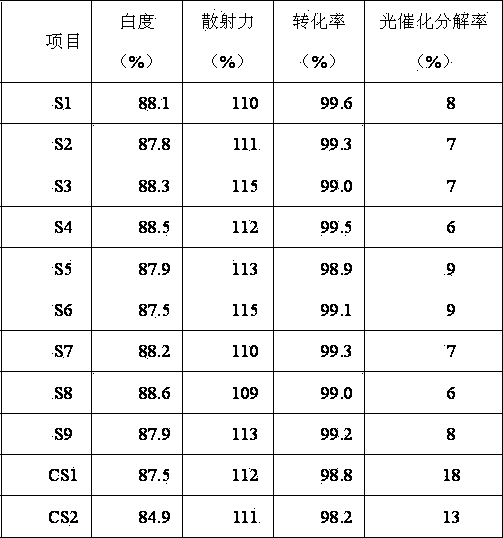

Preparation method of weather-resistant titanium dioxide

InactiveCN103496739AReduce photochemical activityGood weather resistanceTitanium dioxidePigment treatment with organosilicon compoundsLithium compoundAqueous solution

The invention provides a preparation method of weather-resistant titanium dioxide. The method includes doping metatitanic acid subjected to bleaching and secondary washing. The doping method includes sequentially adding water solution of phosphorus compound, magnesium compound, stibium compound, aluminum compound, lithium compound and potassium compound, and well mixing. By the method, iron content in the titanium dioxide is lowered, the prepared titanium dioxide is good in each quality index, and photocatalytic activity is lowered greatly.

Owner:湖南永利化工股份有限公司

High-strength aluminum oxide ceramic metalized paste and preparation method thereof

The invention discloses high-strength aluminum oxide ceramic metalized paste and a preparation method thereof. The metalized paste disclosed by the invention is prepared from the following substances by weight percent: 70-85% of molybdenum powder, 5-15% of manganese powder, 5-15% of Al2O3 powder; 5-10% of silica powder, 0.2-1.2% of calcium oxide, 0.2-1.5% of magnesium oxide, 0.2-1.5% of zirconium oxide powder, and 0.2-1.0% of titanium dioxide powder. The preparation method comprises the steps of respectively putting the substances into an oven according to the ratio; baking for 1-2 hours at the temperature of 100-110 DEG C; putting the molybdenum powder into a ball grinder; adding absolute ethyl alcohol to grind for 24-48 hours; baking at 100-110 DEG C; and putting the manganese powder, the Al2O3 powder, the silica powder, the calcium oxide, the magnesium oxide, the zirconium oxide powder and the titanium dioxide powder into the ball grinder to grind for 4-6 hours; adding the grinded molybdenum powder to grind for 36-48 hours, so as to obtain the mixed powder of the materials; and adding a binder to the mixed powder to grind for 24-48 hours, so as to obtain the metalized paste.

Owner:JINZHOU METAL CERAMICS

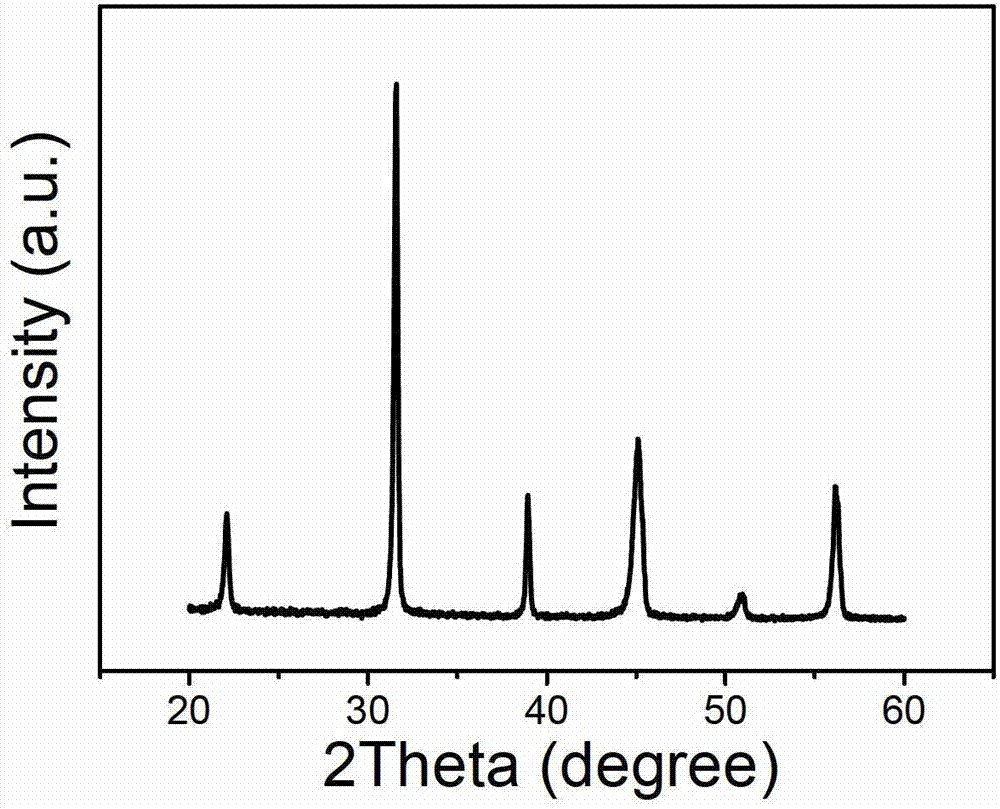

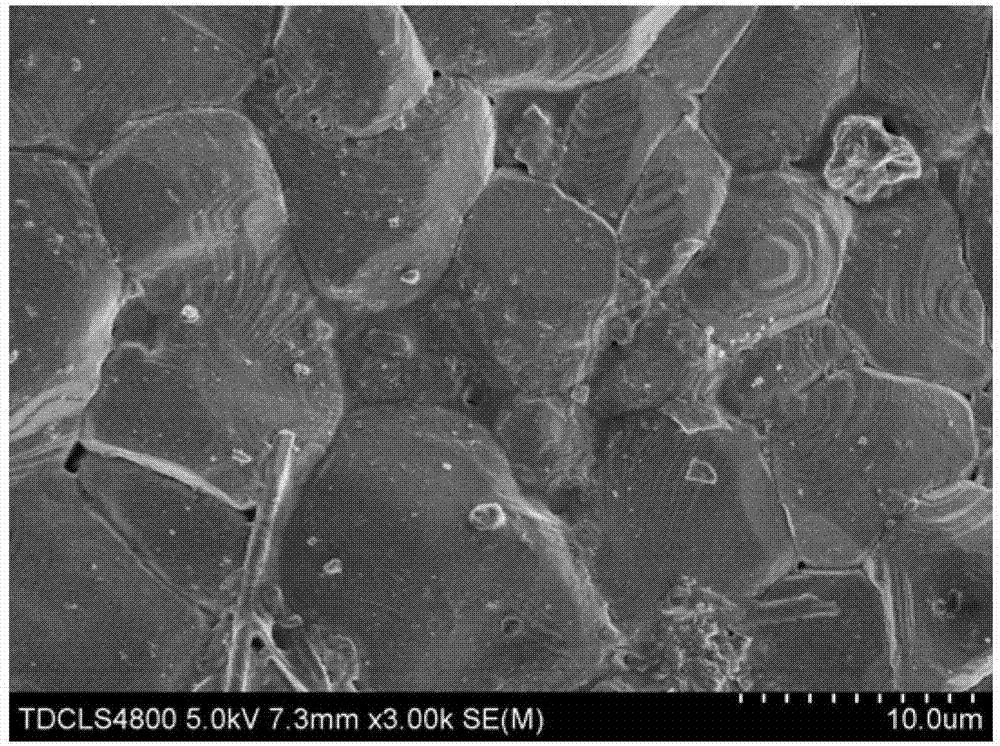

BCTZ-based perovskite system multi-component lead-free piezoelectric ceramic and preparation method thereof

InactiveCN102924078AStable piezoelectric performanceReduce sintering and pre-firing temperatureIonPerovskite

The invention discloses BCTZ-based perovskite system multi-component lead-free piezoelectric ceramic and a preparation method thereof. Raw material components in molar percent are represented by (1-y)[(1-x)Ba(Zr0.2Ti0.8)O3-x(Ca0.7Ca0.3)O3]-y[(Na0.52K0.44Li0.04)(Nb0.88-Sb0.08Ta0.04)O3], wherein x is 0.40 to 0.50; and y is 0.001 to 0.05. A principal crystalline phase of the material has a perovskite structure, the piezoelectric constant d33 is up to 464pC / N, the electromechanical coupling factor kp is up to 0.5, the performance of the traditional lead-containing piezoelectric ceramic is reached, and the preparation process is stable and repeatable; and the existence of Na, K and Li ions can reduce sintering and calcining temperature, and the piezoelectric ceramic has a good application prospect.

Owner:TIANJIN UNIV

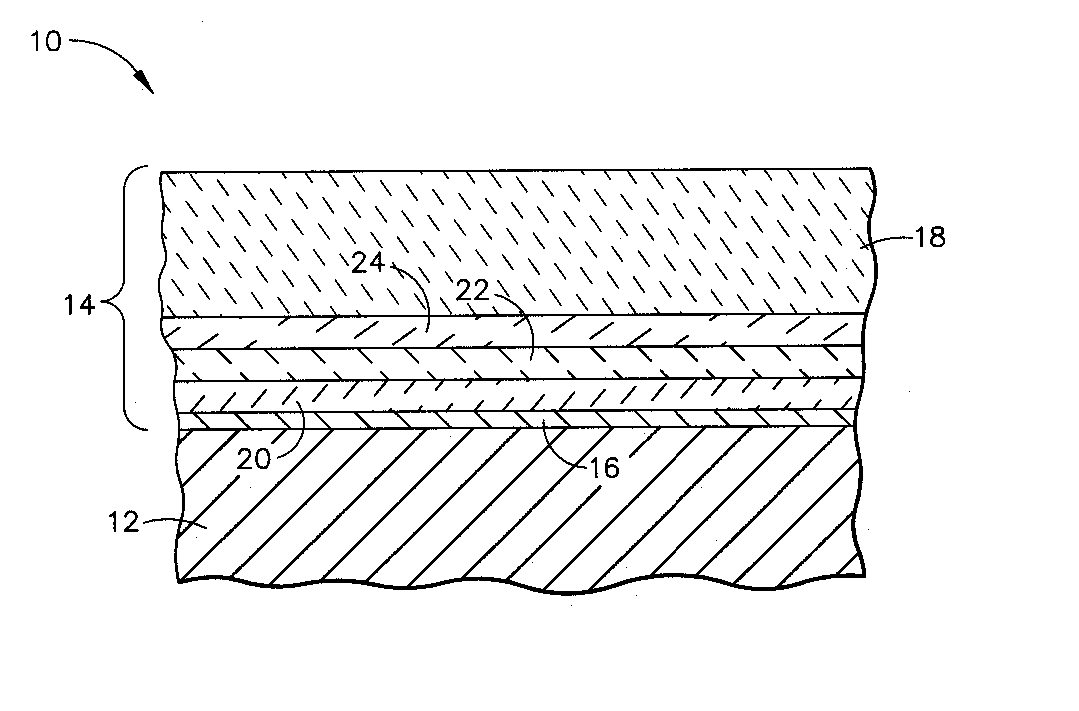

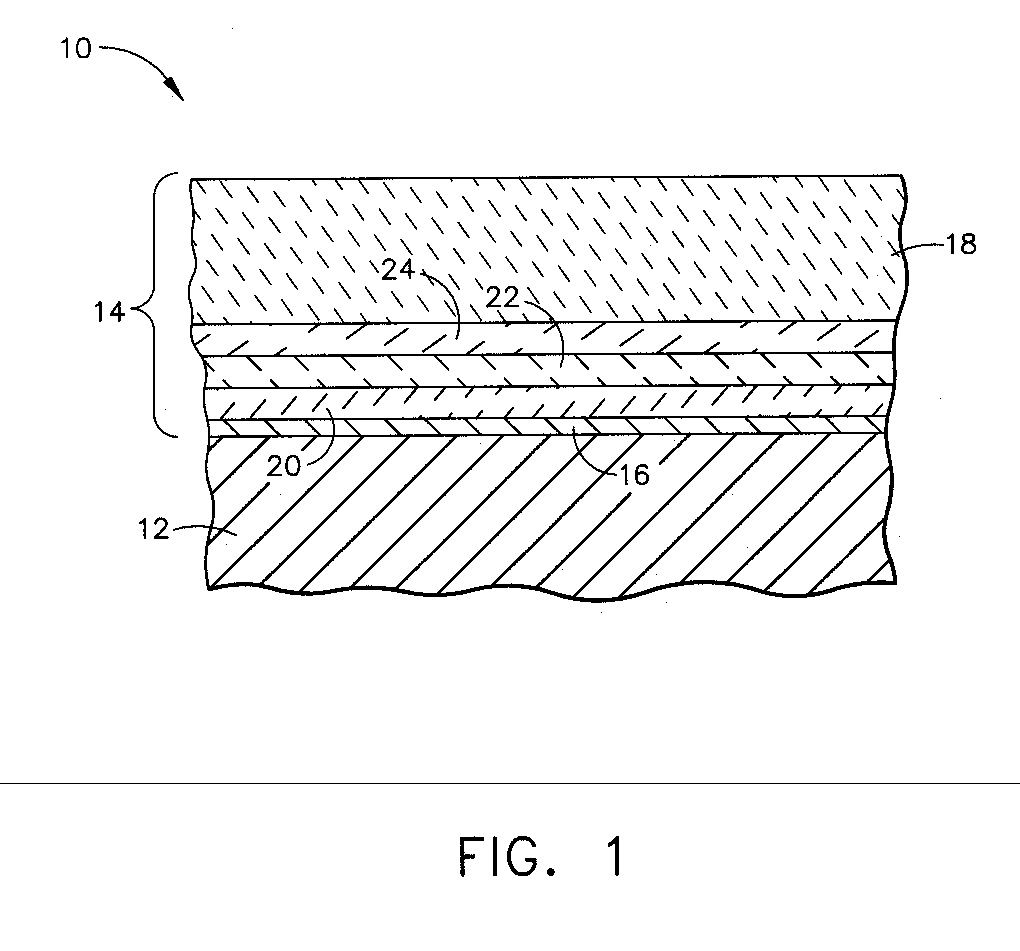

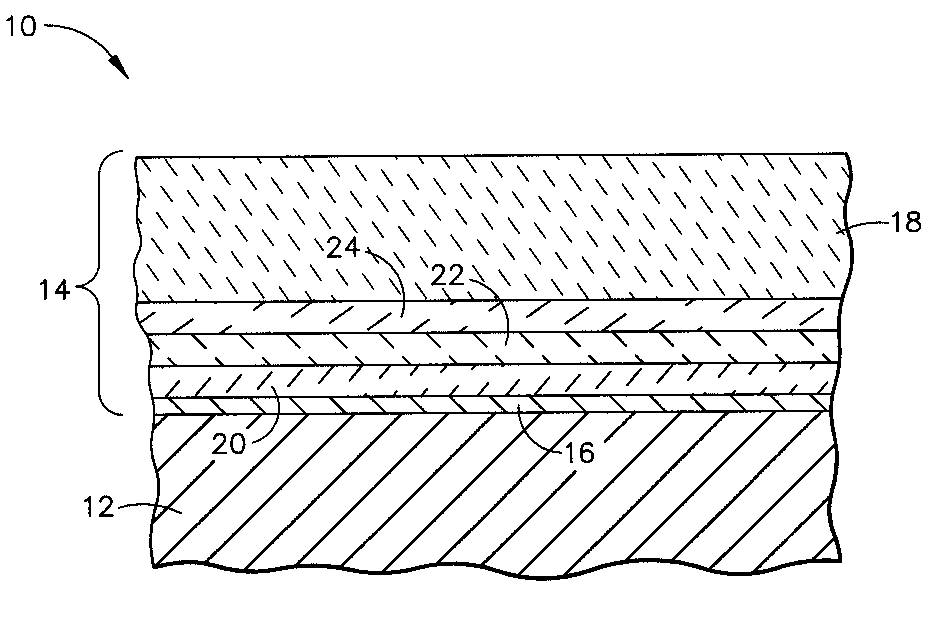

Thermal/environmental barrier coating system for silicon-containing materials

ActiveUS20060280962A1Improve the immunityHigh temperature capabilityBlade accessoriesMachines/enginesAlkaline earth metalCoating system

A coating system for Si-containing materials, particularly Si-based composites used to produce articles exposed to high temperatures. The coating system is a compositionally-graded thermal / environmental barrier coating (T / EBC) system that includes an intermediate layer containing yttria-stabilized hafnia (YSHf) and mullite, alumina and / or an aluminosilicate, which is used in combination with an inner layer between a Si-containing substrate and the intermediate layer and a thermal-insulating top coat overlying the intermediate layer. The intermediate layer provides environmental protection to the silicon-containing substrate, and has a coefficient of thermal expansion between that of the top coat and that of the inner layer so as to serve as a transition layer therebetween. The intermediate layer is particular well suited for use in combination with an inner layer of an alkaline earth metal aluminosilicate (such as BSAS) and a top coat formed of YSZ or YSHf.

Owner:GENERAL ELECTRIC CO

A method for direct reduction of industrial waste slag in rotary hearth furnace

InactiveCN102277461ALow mechanical strength requirementIncrease flexibilityProcess efficiency improvementHearthProcess conditions

The invention relates to a direct reduction method for treating industrial waste slag in a rotary hearth furnace, belonging to a new direct reduction ironmaking process in the metallurgical industry. The main process is: ingredients - mixing - pellets - drying - preheating - reduction - metallized pellets. Metallized pellets with a metallization rate of over 80% can be obtained after reduction in a rotary hearth furnace. The present invention comprehensively recycles and utilizes valuable elements in iron-containing industrial waste residues, economically obtains reducing agent resources, and solves the problem of low falling strength of cold solidified carbon-containing pellets prepared in the process of comprehensive recycling of industrial waste residues It has the advantages of high metallization rate, simple operation, easy control of process conditions, less equipment investment, low production cost, easy to meet raw material conditions, etc., and the overall process is more energy-saving than the furnace smelting process. It is also more environmentally friendly, and more importantly, the method can comprehensively recycle industrial waste, reduce its pollution to the environment, and save energy and protect the environment.

Owner:UNIV OF SCI & TECH BEIJING

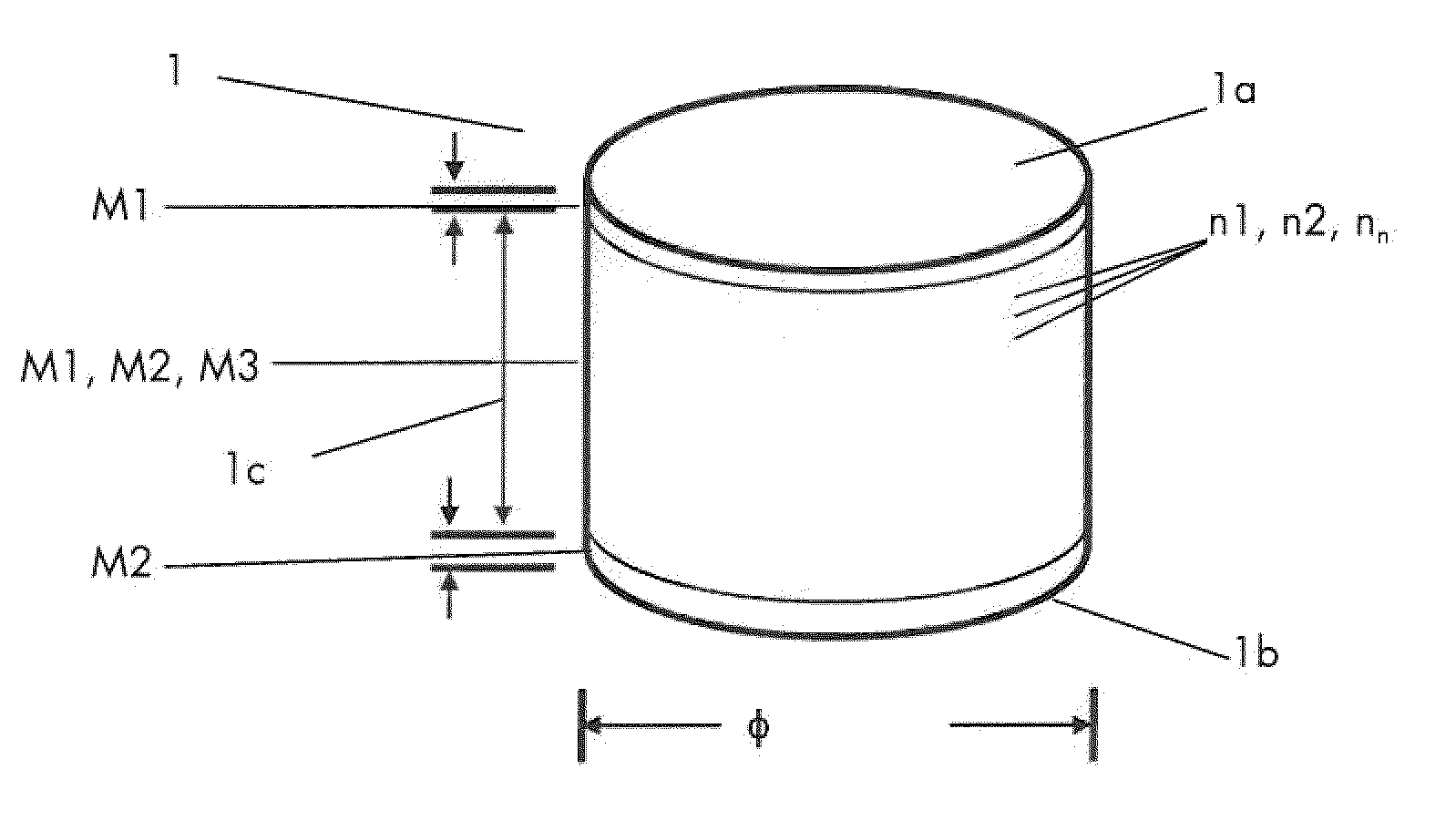

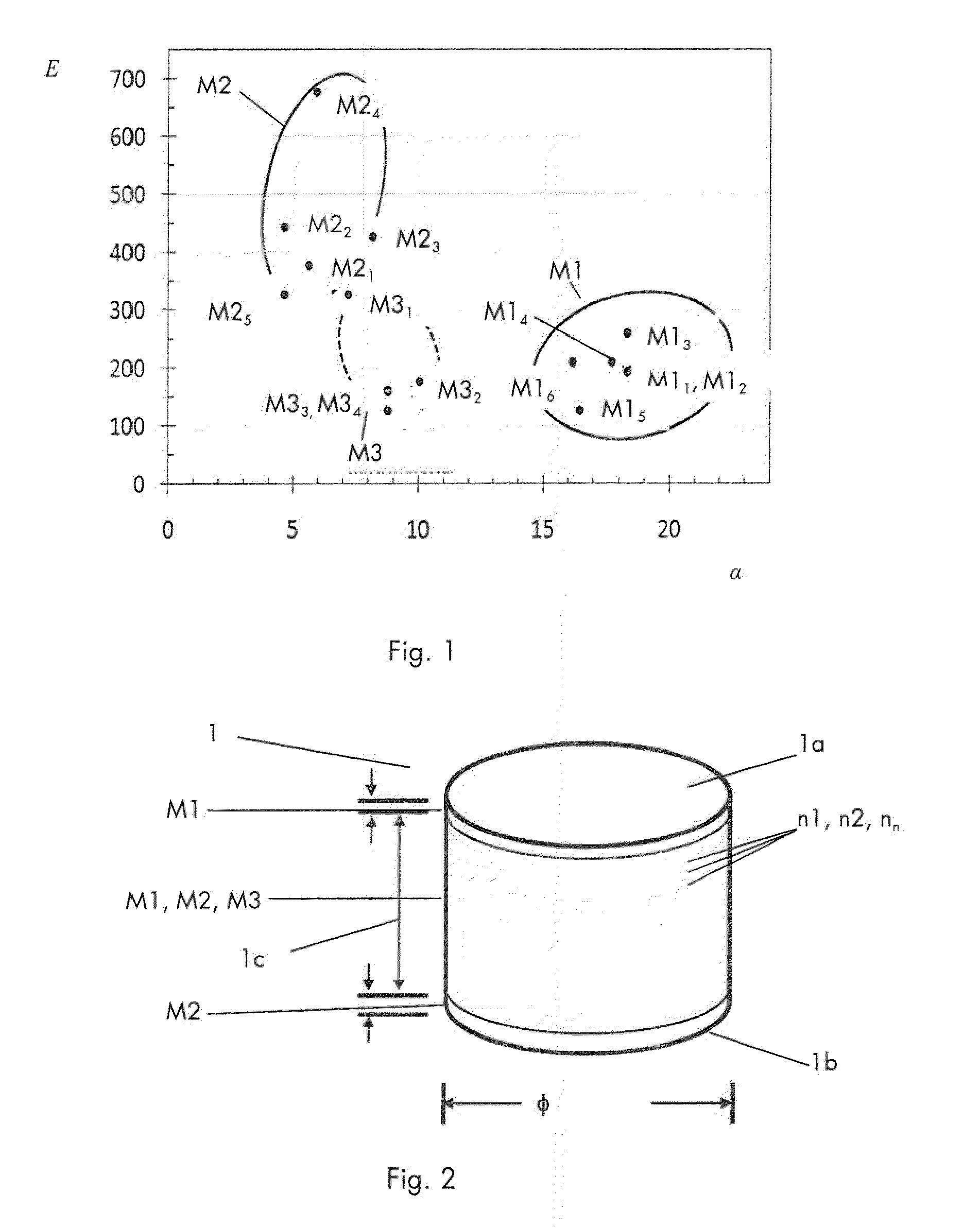

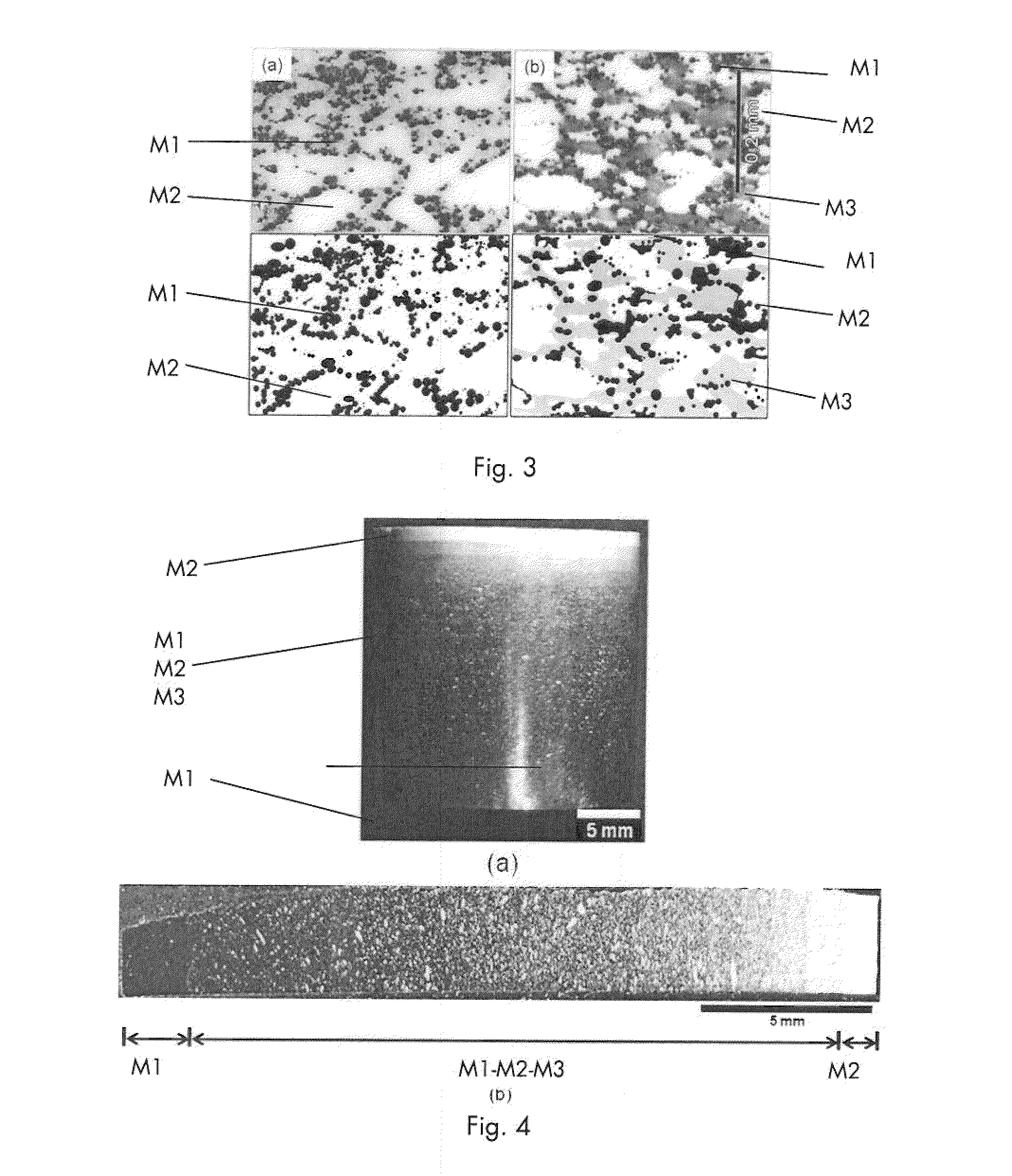

Functionally graded material shape and method for producing such a shape

InactiveUS20110236713A1Minimize interfaceWeakening rangeMaterial nanotechnologyThin material handlingFunctionally graded materialMethods of production

The invention relates to a functionally graded material shape (1) where a first material (M1) is fused with a second material (M2) through sintering and a method of production of said functionally graded material shape (1). Said first material (M1) has a first coefficient of thermal expansion (α1) and said second material (M2) has a second coefficient of thermal expansion (α2), differing from the first coefficient of thermal expansion (α1). The invention is characterized in that the shape (1) further comprises a third material (M3) adapted to, together with M1 and M2, create an intermediate composite material phase intermixed between the first and the second materials (M1, M2). Said third material (M3) has a coefficient of thermal expansion (α3) intermediate between the first coefficient of thermal expansion (α1) of the first material (M1) and the second coefficient of thermal expansion (α2) of the second material (M2).

Owner:DIAMORPH AB

Low oxygen carrier fluid with heating value for feed to transport gasification

ActiveUS8221513B2Reduce and eliminate partial and complete oxidationReduce and eliminate exothermic conversionMultiple metal hydridesCombustible gas catalytic treatmentCarrier fluidOxidizing agent

Systems and processes for producing synthesis gas. A carbonaceous feedstock can be combined with one or more low-oxygen carrier fluids having a high heating value. The feedstock and carrier fluid, in the presence of one or more oxidants, can be gasified to provide a synthesis gas. In one or more embodiments, at least a portion of the synthesis gas can be recycled for use as the carrier fluid.

Owner:KELLOGG BROWN & ROOT LLC

Method for producing molten iron with high-phosphorus and low-iron refractory iron ore

InactiveCN101643806AEfficient desulfurizationImprove reducibilityFluidised-bed furnacesIronstoneHigh energy

The invention provides a method for producing molten iron with high-phosphorus and low-iron refractory iron ore, comprising the following steps: taking high-phosphorus and low-iron refractory iron oreas raw material; taking wood coal as reducing agent; oxidizing roasting; directly reducing; magnetically separating and separating; melting and separating; dephosphorizing molten iron; and obtainingthe low-phosphorus molten iron. The method can process the extremely refractory iron ore with high P content, high S content, high SiO2 content and low iron level, has high ore iron recovery rate, completely solves the difficulties of the high-phosphorus and low-iron refractory iron ore such as ore selecting and smelting, removing coke, and eliminating high-energy consumption and high-pollution technical process such as ore selecting, sintering, palletizing, coking, etc. Phosphorus-containing slag can realize resource comprehensive utilization. A great number of experiments and semi-industrialproduction demonstrate that the technical economic effect of the method is remarkable and effectively solves the current problem of ore resources supply-demand contradiction in China.

Owner:KUNMING IRON & STEEL HLDG CO LTD

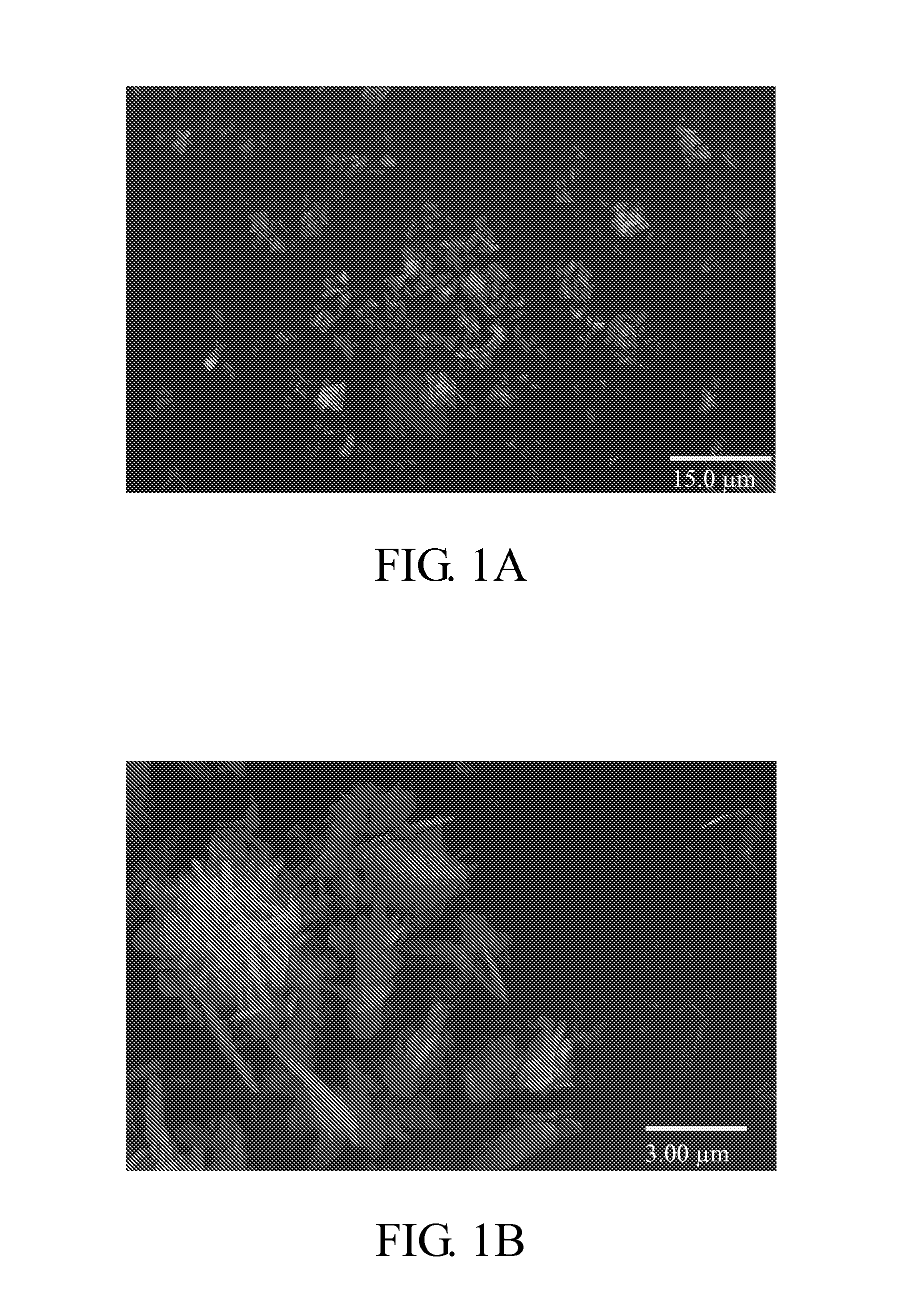

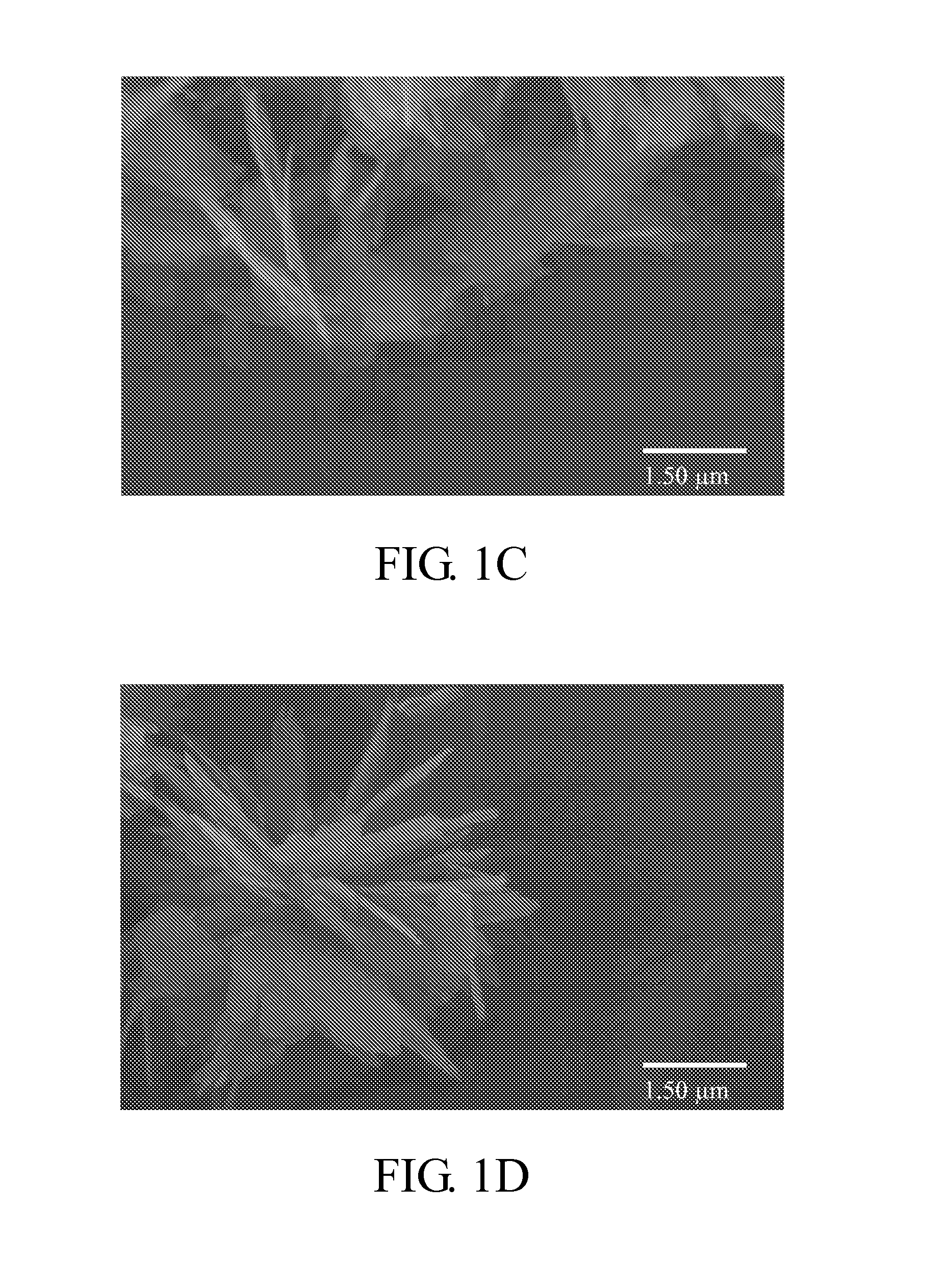

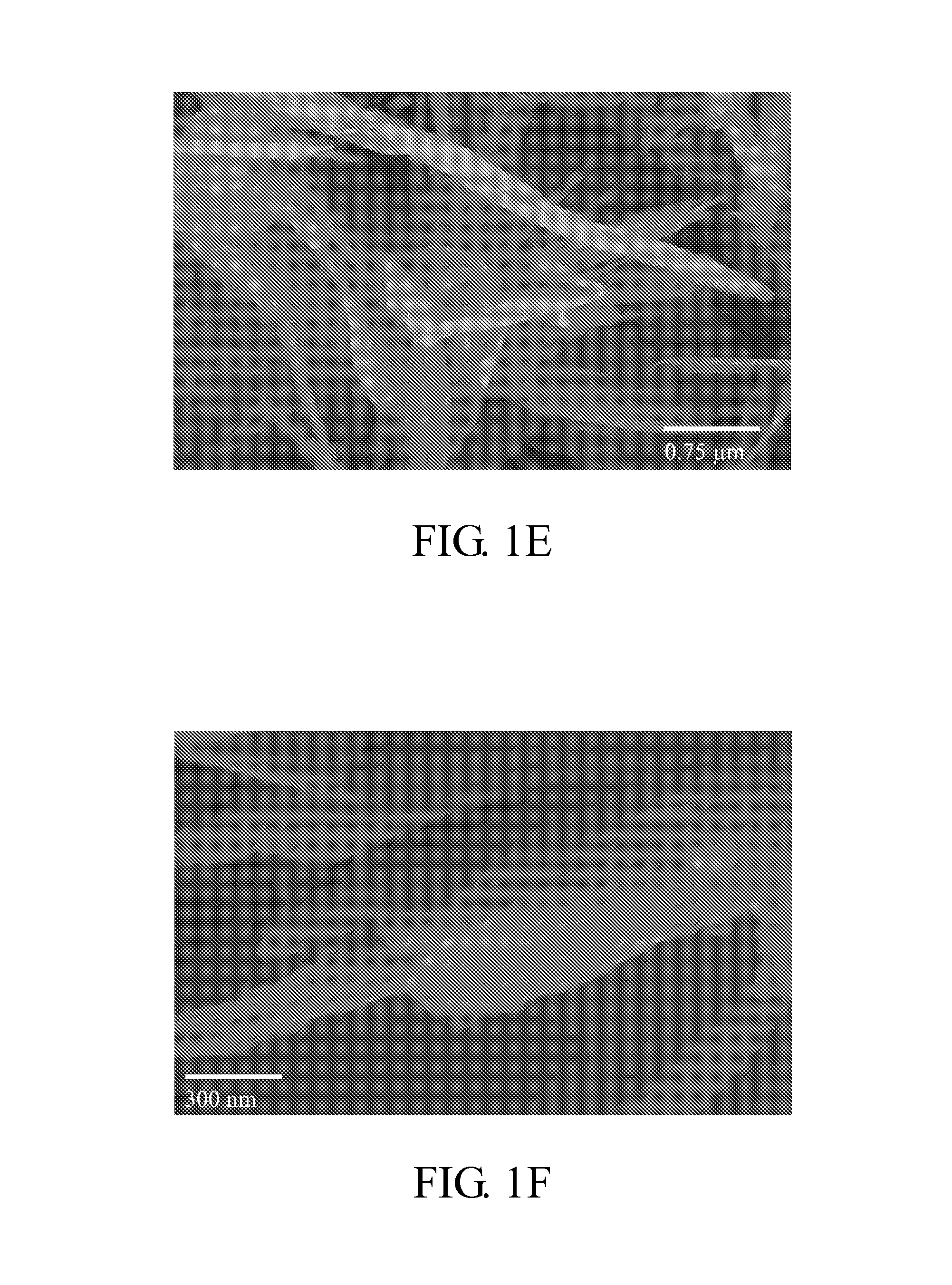

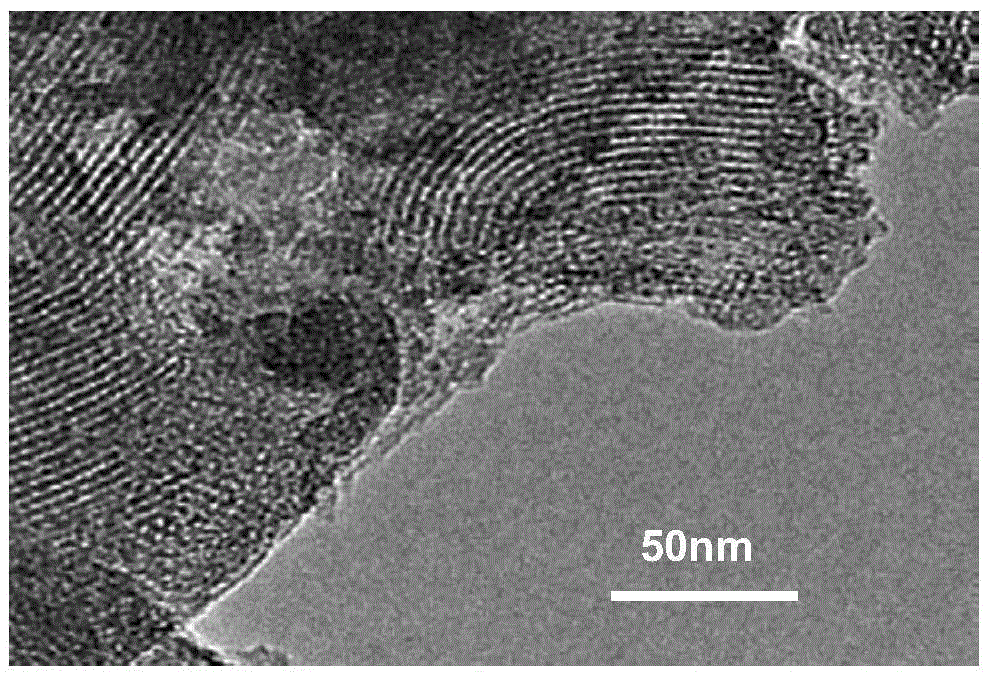

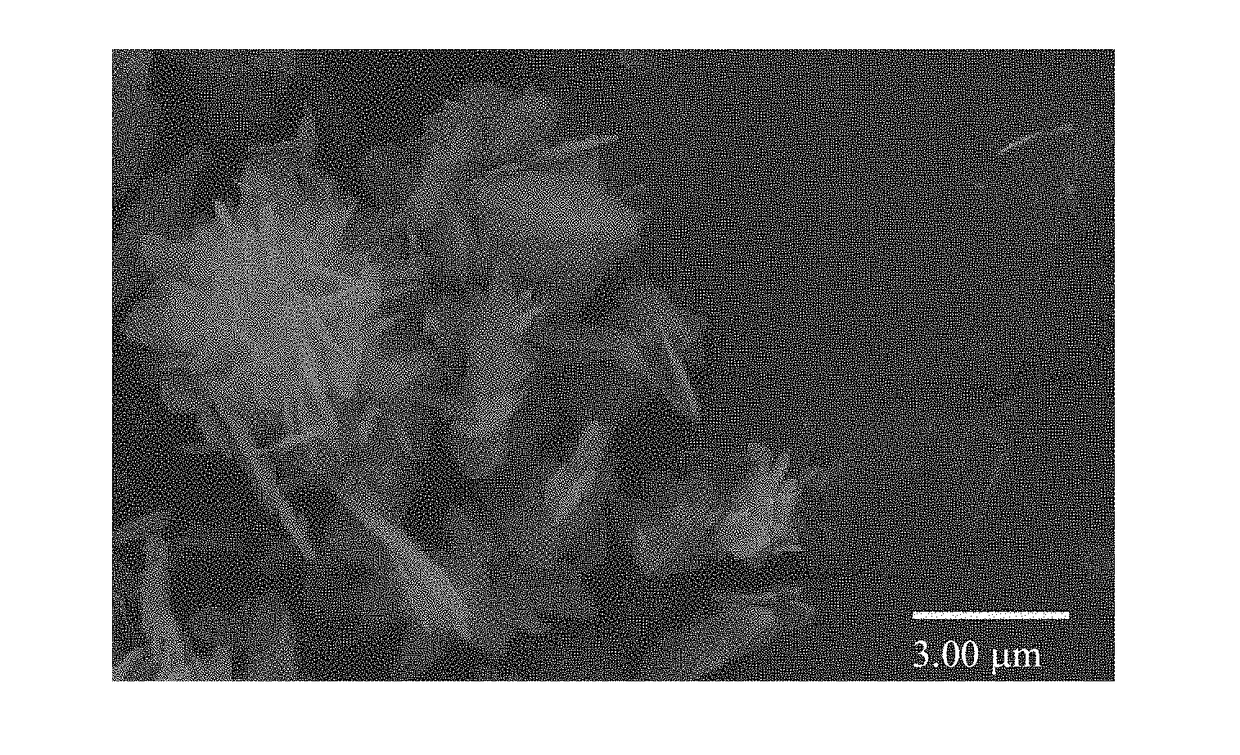

Ferrous phosphate powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

ActiveUS20150232338A1Improve conductivitySmall sizeNon-metal conductorsCell electrodesLithium iron phosphatePhosphate

Ferrous (II) phosphate (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The lithium iron phosphate powders are represented by the following formula (II):LiFe(1-a)MaPO4 (II)wherein, M, and a are defined in the specification, the lithium iron phosphate powders are composed of plural flake powders, the length of each of the flake powders is 0.1-10 μm, and a ratio of the length and the thickness of each of the flake powder is in a range from 11 to 400.

Owner:NATIONAL TSING HUA UNIVERSITY

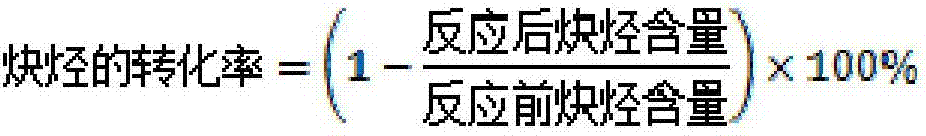

Method for preparing acetylene selective hydrogenation catalyst

ActiveCN105536851ASimple structureUniform film formationMolecular sieve catalystsCatalyst activation/preparationDispersityNano structuring

The invention discloses a method for preparing an acetylene selective hydrogenation catalyst. The method mainly overcomes the defects that in the prior art, Pd particle size distribution is wide, distribution uniformity is poor, and a metallic oxide serving as a substrate lacks a controllable nano structure. Firstly, a three-dimensional nano structure is provided through a mesoporous material, a metallic oxide is deposited on the structure, and a metallic oxide substrate with the three-dimensional nano structure same as the mesoporous material is obtained; then, by means of the atomic layer deposition, nano Pd metal particles are loaded and deposited on the surface of the metallic oxide substrate, and the loading amount of Pd and the metallic oxide can be adjusted according to different deposition period numbers. The catalyst prepared through the method is of the three-dimensional nano structure and large in specific surface area, the Pd metallic particles are high in dispersity, uniform in distribution, uniform in size and good in activity, selectivity and stability in the acetylene selective hydrogenation catalysis reaction. The method avoids the characteristics that metallic particle size distribution is wide and distribution is not uniform in the preparation process of an impregnation method and a chemical plating method.

Owner:XIAN MODERN CHEM RES INST

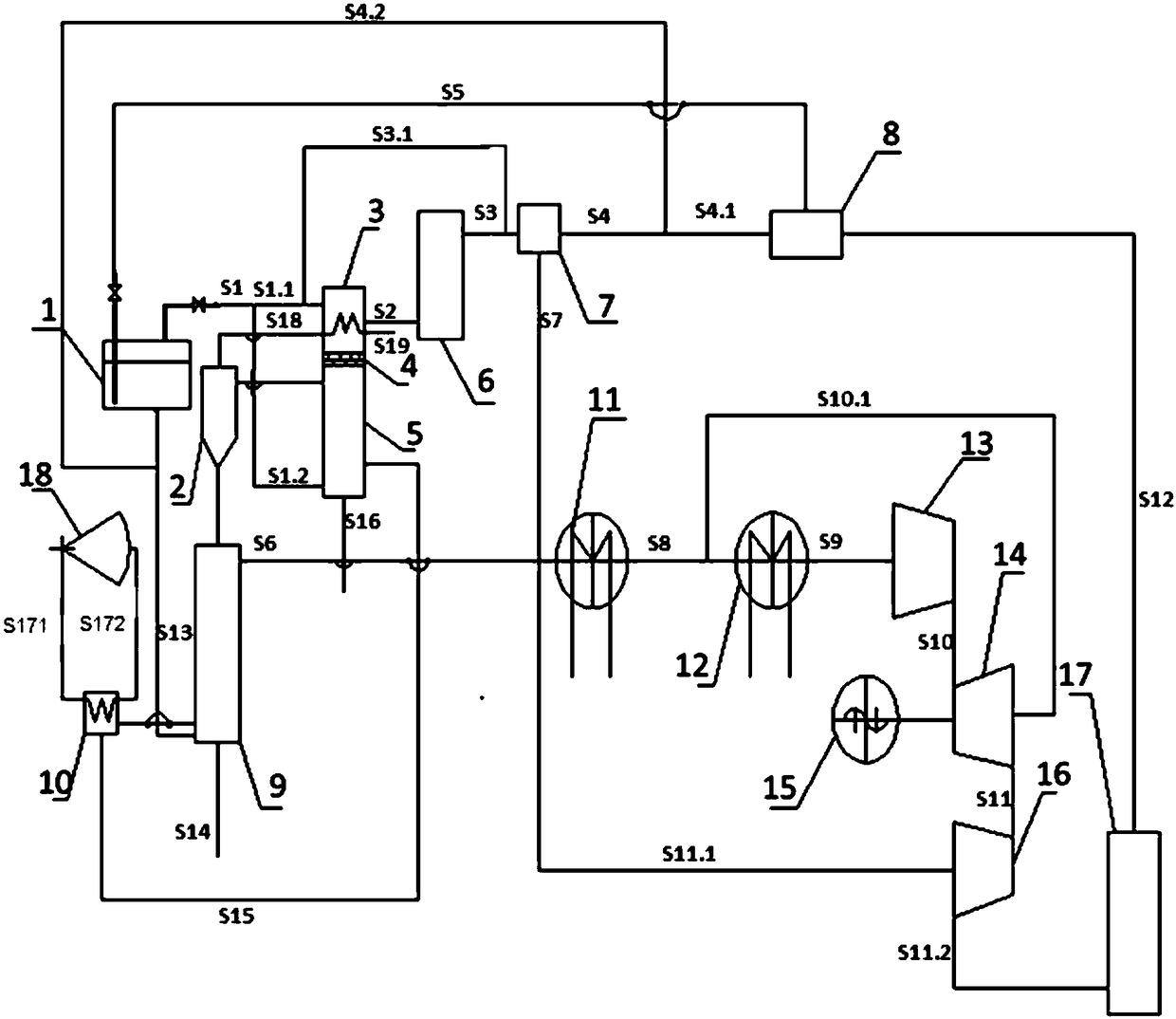

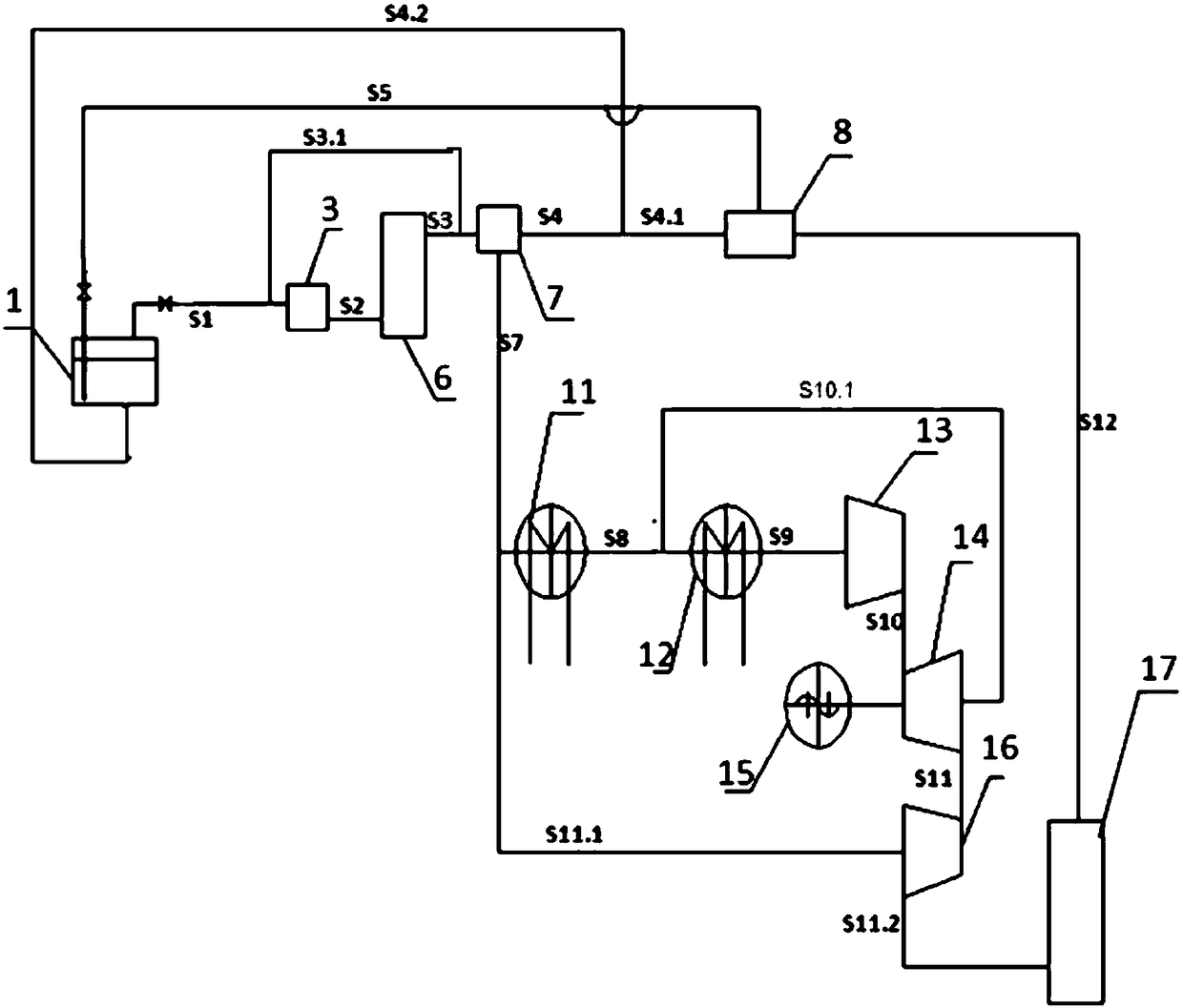

Combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and working method thereof

InactiveCN108507188AReduce sinteringBig investmentBioreactor/fermenter combinationsSolar heating energyHigh energyPower cycle

The invention discloses a combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and a working method thereof. A solar thermal chemistry process and a fuel power cycle are organically coupled by the system, so that the step utilization of the solar energy is realized; on one hand, a reduced oxygen-carrying body is usedfor converting the solar energy into chemical energy to be stored in an oxygen-carrying body heat accumulator, necessary heat energy is provided for the chemical looping combustion; and on the one hand, the characteristic that the CO2 is released by absorbing CO2 through the photosynthesis of microalgae under light illumination is utilized, pure O2 is provided for the oxygen-enriched combustion, and secondary air is provided for an air reactor; in addition, by complementary integration of the oxygen-enriched combustion system and the chemical looping combustion system, and the reasonable and efficient utilization of the fuel is realized; and meanwhile, the pure CO2 generated through oxygen-enriched combustion and chemical looping combustion is used for pushing a turbine to generate electricity for heat supply, so that the problem of high energy consumption and high cost due to the fact that CO2 is trapped and separated is solved, the CO2 flue gas waste heat can be effectively utilized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Ferrous phosphate powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

ActiveUS20180118569A1Improve conductivitySmall sizeNon-metal conductorsCell electrodesLithium iron phosphatePhosphate

Ferrous (II) phosphate (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The lithium iron phosphate powders are represented by the following formula (II):LiFe(1-a)MaPO4 (II)wherein, M, and a are defined in the specification, the lithium iron phosphate powders are composed of plural flake powders, the length of each of the flake powders is 0.1-10 μm, and a ratio of the length and the thickness of each of the flake powder is in a range from 11 to 400.

Owner:NATIONAL TSING HUA UNIVERSITY

Anti-erosion iron runner castable for large blast furnace

InactiveCN111574206APrevent penetrationLow apparent porosityCeramicwareOxidation resistantCarbon black

The invention relates to an anti-erosion iron runner castable for a large blast furnace. The material comprises, according to weight percentage, 58-64 parts of compact brown fused alumina particles, 2-5 parts of white corundum particles, 16-23 parts of silicon carbide, 5-7 parts of aluminum oxide micro-powder, 2-3 parts of pure calcium aluminate cement, 2-3 parts of silicon dioxide micro-powder, 1.5-2.5 parts of spherical asphalt particles, 0.5-1.2 parts of carbon black powder, 1.5-3.5 parts of metal silicon powder, 0.2-0.6 part of boron carbide, 0.1-0.2 part of metal aluminum powder, 0.15-0.2part of a water reducing agent, 0.6-1 part of an anti-erosion agent and 0.05-0.08 part of explosion-proof fibers. According to the castable, the service life of a primary runner of a main runner is prolonged, and the stability of safe operation of an iron runner is improved. It is verified that the requirements for rapid baking without cracking, erosion resistance, oxidation resistance, slag adhesion resistance and iron flux can be met, the iron flux can reach 180000 tons or above without repairing, and good application prospects are achieved.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

Supported metal catalyst with improved thermal stability

InactiveUS7504355B2Improve adhesionGood metal adhesionCatalyst carriersCatalyst activation/preparationAdditive ingredientHafnium

Catalytic systems are provided that include a metallic catalyst attached to a ceramic support that has alumina as a principal ingredient. The ceramic support is doped with an adhesive agent so that the surface of the support includes the adhesive agent. The adhesive agent is designed to form an open-shell electronic structure at the interface between the metallic catalyst and the support. The open-shell structure promotes extended useful catalyst lifetimes. The adhesive agents are early transition metals that include titanium, zirconium, scandium, hafnium, lanthanum and yttrium. Doping of the ceramic support surface with the adhesive agent also increases the adhesion between the ceramic support and metallic monoliths to which the ceramic support may be attached.

Owner:PRINCETON UNIV

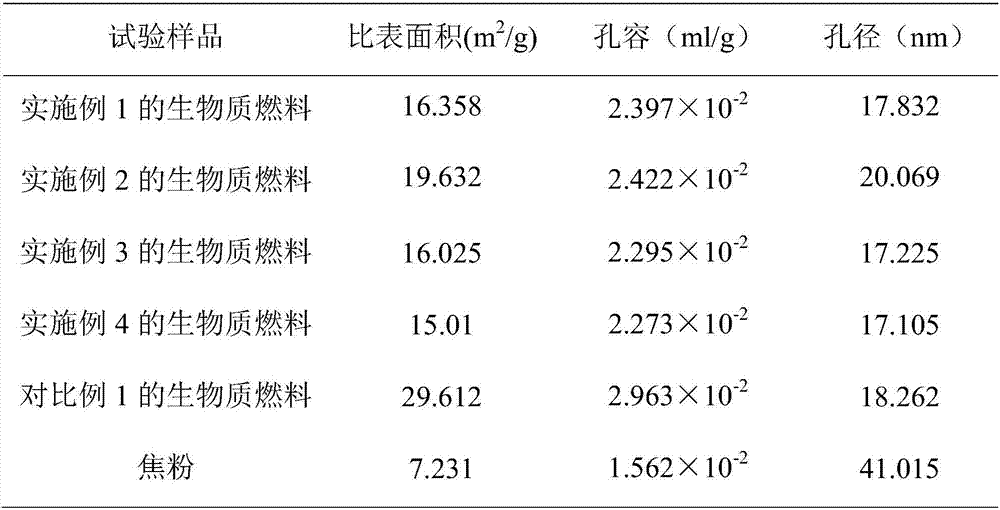

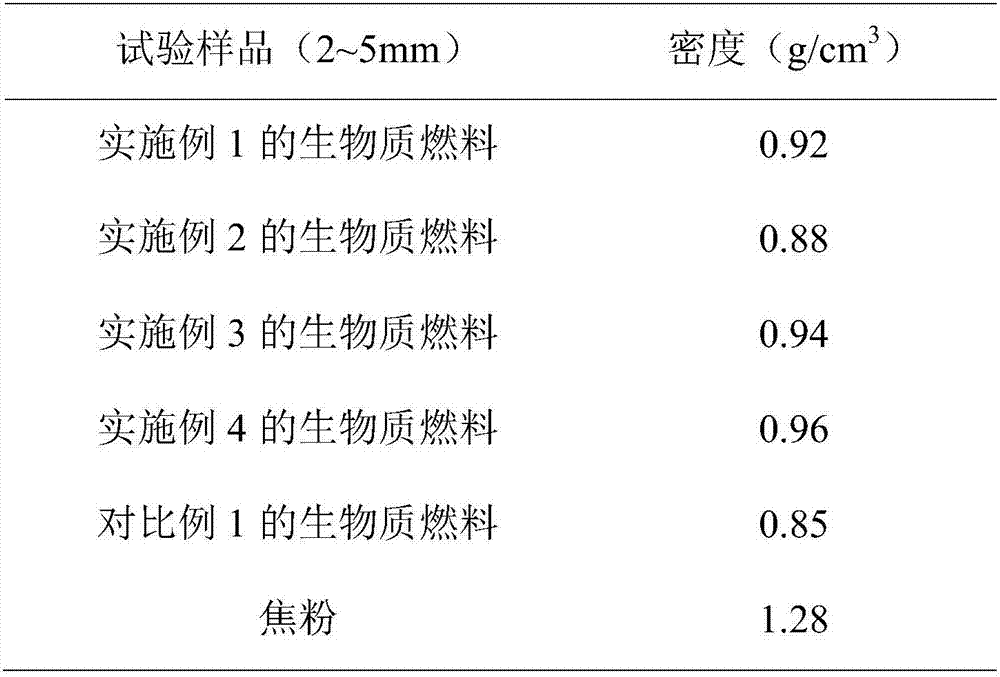

Biomass fuel for iron ore sintering and preparation method and application of biomass fuel

The invention discloses biomass fuel for iron ore sintering and a preparation method and application of the biomass fuel. The biomass fuel is prepared through the steps that molding and carbonizing are conducted on the biomass fuel, and then filling and packing are conducted on the biomass fuel by means of a urea solution and CaO powder according to the requirements of iron ore sintered fuel. Theproblems that biomass is loose, porous, large in specific surface area, low in fixed carbon content, too fast in reaction and the like are solved, the performance index of the prepared biomass fuel isclose to that of coke powder, part of the coke powder can be replaced to conduct sintering production, and meanwhile the discharge amount of pollutant in the iron ore sintering production process canbe effectively inhibited.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Engine cleaning lubricant and preparation method thereof

The invention discloses an engine cleaning lubricant and a preparation method thereof. The engine cleaning lubricant is prepared through combining high-base-number sulfurized alkylphenol calcium, polyacrylate, polyisobutylene, polyisobutylene succinimide, organic molybdenum and cleaning oil, is used for cleaning an engine, can decompose quickly and is used for removing various colloids, stubborn scales, carbon deposits and attachments, such as metal powder and the like generated through metal friction from the interior of the engine, so that good lubricating property is guaranteed, the frictional resistance is reduced, the power of an automobile is increased, the elasticity of various sealing gaskets and cushions inside the engine is recovered, and the sealing performance is enhanced; and a layer of protective film is formed inside the engine, so that the rust preventing and wear resisting functions of the engine are improved, the oil consumption and engine wear are reduced, and the service lives of engine oil and the engine are prolonged.

Owner:ANHUI CHEWEISHI AUTOMOBILE ACCESSORIES

Method for preparing low-oxygen high-pure metal hafnium powder

ActiveCN104646659ALow content of interstitial elementsGuaranteed complete deoxygenationCrucibleMolten salt

The invention relates to a method for preparing low-oxygen high-pure metal hafnium powder; the low-oxygen high-pure metal hafnium powder has the purity of greater than 99.5wt% and the oxygen content being smaller than 0.15 wt%. The preparation method comprises the following steps: a. filling metal hafnium powder, a deoxidizing agent and a molten salt into a crucible; b, putting the crucible into a reaction tank, sealing the equipment, vacuumizing and inflating argon gas to wash the crucible, heating and deoxidizing, then performing constant-temperature and thermal-insulating deoxidization, cooling and discharging at the end of the deoxidization; c, pickling the discharged product, then washing with de-ionized water, sieving and drying the obtained product, namely, the product of the low-oxygen high-pure metal hafnium powder. The molten salt system is capable of effectively removing impurities in the metal hafnium powder, in particular, remarkably reducing the oxygen content in the hafnium powder; and the prepared low-oxygen high-pure metal hafnium powder satisfies the material requirement of high-end products.

Owner:有研资源环境技术研究院(北京)有限公司

Sintering prevention vanadium-containing stone coal microwave roasting method

The invention relates to a sintering prevention vanadium-containing stone coal microwave roasting method. According to the technical scheme, the method includes: crushing vanadium-containing stone coal into coarse-grained vanadium-containing stone coal with the grain size less than 6mm and greater than 1mm and fine-grained vanadium-containing stone coal with the grain size less than 1mm; adding water to the fine-grained vanadium-containing stone coal to be mixed according to the mass ratio of the fine-grained vanadium-containing stone coal to the water of 1:0.06-0.09 to produce small balls 3-8mm in grain size and drying the small balls; placing the dried small balls in an industrial microwave roasting device as bedding materials, placing the coarse-grained vanadium-containing stone coal on the bedding materials prior to microwave roasting, and cooling to indoor temperature to obtain vanadium-containing stone coal roasting materials, wherein the microwave roasting is characterized in that the temperature rate ranging from 25 DEG C / min to 55 DEG C / min is increased rapidly to the temperature rate ranging from 750 DEG C to 850 DEG C, 25-40 min constant-temperature microwave roasting is performed, and the industrial microwave roasting device is 2400 to 2500 MHz (megahertz) in frequency. With the method, sintering during microwave roasting of the vanadium-containing stone coal is obviously reduced, and the effect of microwave roasting is good.

Owner:WUHAN UNIV OF SCI & TECH

Nano-ceramic compound bonding agent

The invention relates to a ceramic compound bonding agent, in particular to a nano-ceramic compound bonding agent, which is suitable for manufacturing super-hard grinding tools with various granularity and belongs to the technical field of materials. The bonding agent is prepared by adding second phases, such as nano-grade granules, nano-grade lamellas, nano-grade whiskers, nano-grade fibers and the like to a ceramic bonding agent matrix to form a nano-compound material, wherein at least one phase of the nano-compound material is of nano-size. Because the of small granularity and large specific surface area, the nano-ceramic material presents evident small size effect, quantum size effect and surface interface effect, which ensures that the nano-ceramics have special properties different from traditional ceramics, such as high intensity, good tenacity, low sintering temperature and the like. Thus, when the nano-powder is adopted to carry out sintering, the densifying speed is high, the sintering temperature is lower and is 400-600 DEG C lower than that of the traditional ceramics manufacturing, and the sintering process is greatly shortened.

Owner:薛维

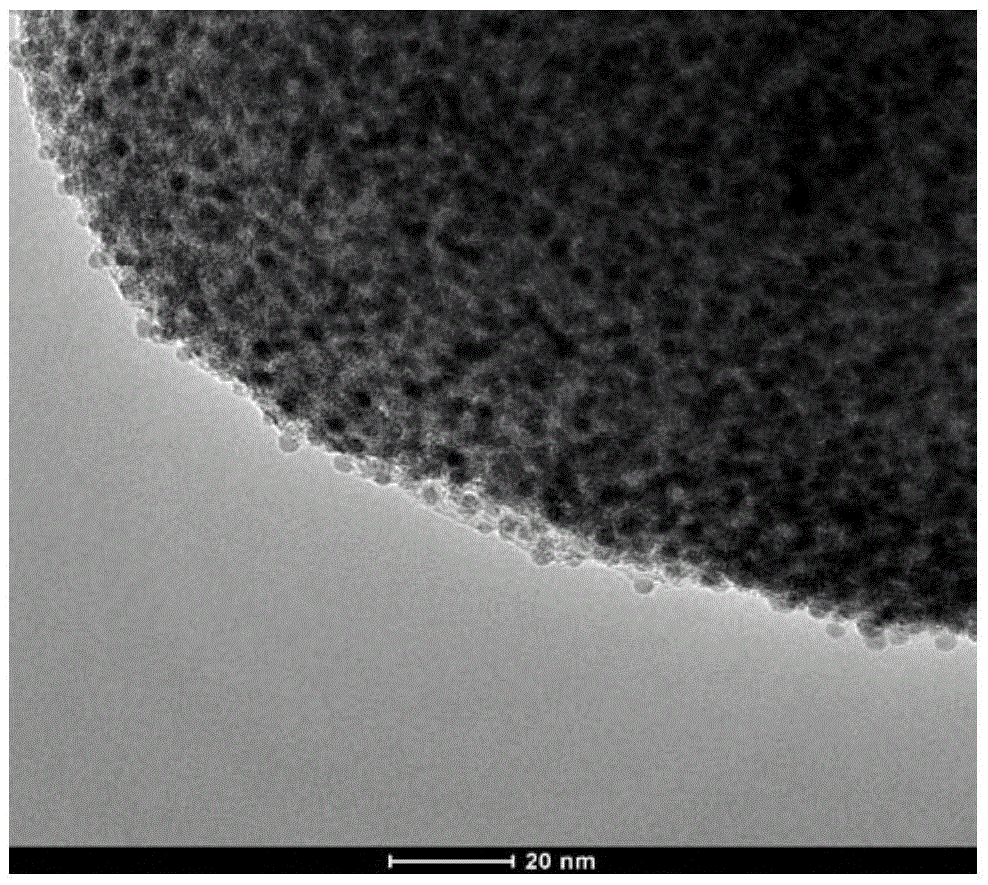

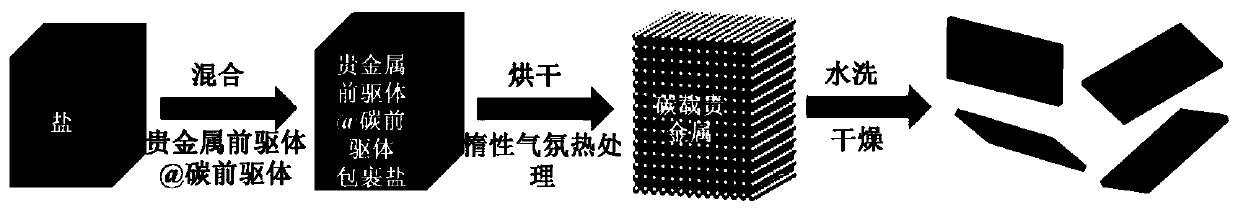

Carbon-nanosheet-loaded noble metal nanoparticle catalyst and preparation method and application thereof

InactiveCN110280240AWide variety of sourcesThe process is simple and easy to controlCell electrodesNanotechnologyInorganic saltsInstability

The invention discloses a carbon-nanosheet-loaded noble metal nanoparticle catalyst and a preparation method and application thereof. According to the method, an inorganic salt is taken as a template, a commercial carbon source is provided, noble metal at least having multi-catalytic prospects is at least deposited on the commercial carbon precursor to form a composite, then the carbon-nanosheet-loaded noble metal nanoparticle catalyst is obtained by a chemical or physical method; the method is characterized by comprising the following steps: (1) dissolving or dispersing a commercial noble metal precursor in a solvent to form a noble metal precursor solution or suspension; (2) mixing the commercial carbon precursor with the noble metal precursor solution or suspension evenly, then mixing with the inorganic salt template, drying and then calcining in an inert atmosphere to obtain the carbon-nanosheet-loaded noble metal nanoparticle catalyst. According to the catalyst, the problem of instability of noble metal nanoparticles in commercial application can be solved, the catalytic performance is improved significantly, the preparation process is controllable, environmental friendliness is realized, and the catalyst is suitable for mass production.

Owner:EAST CHINA UNIV OF TECH

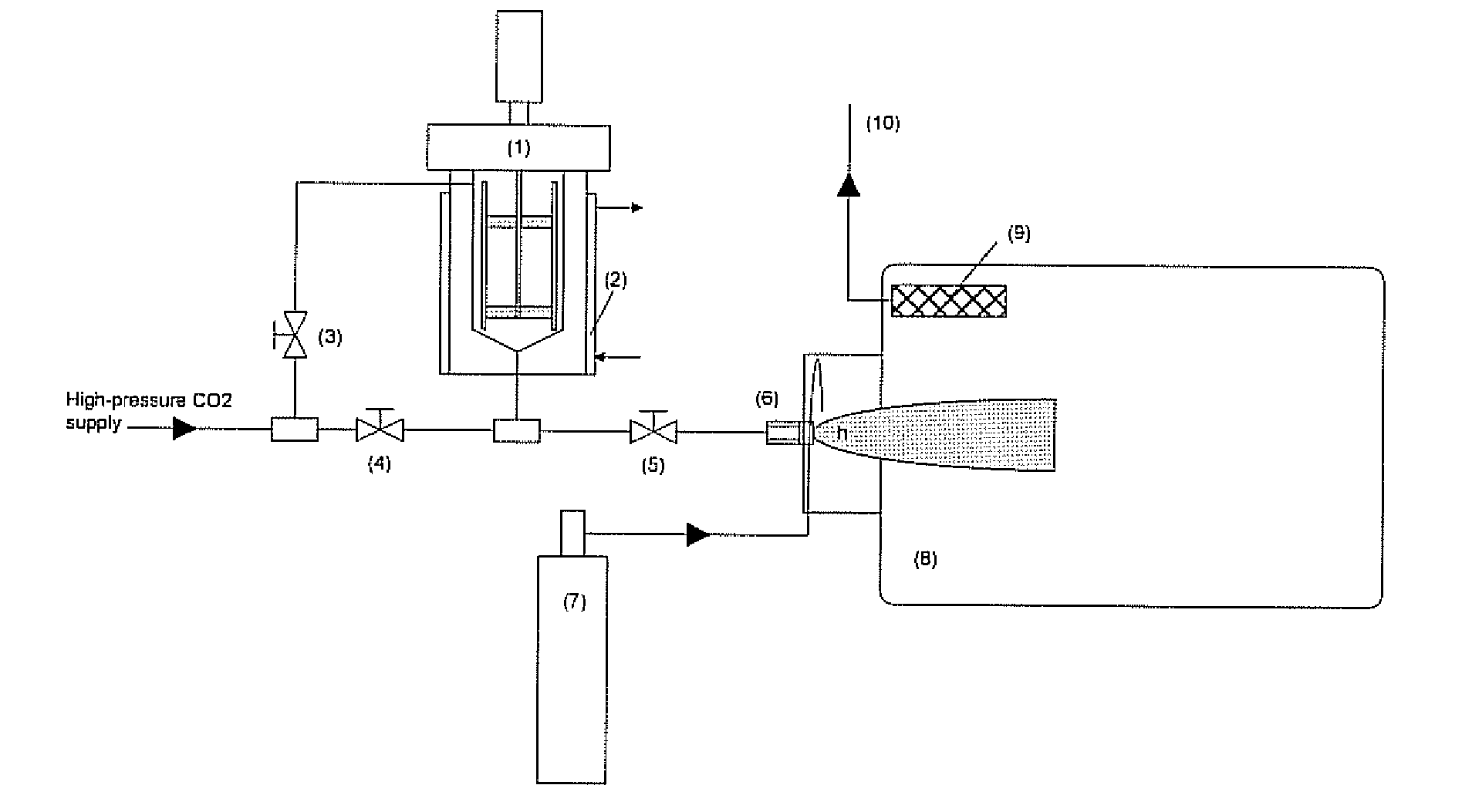

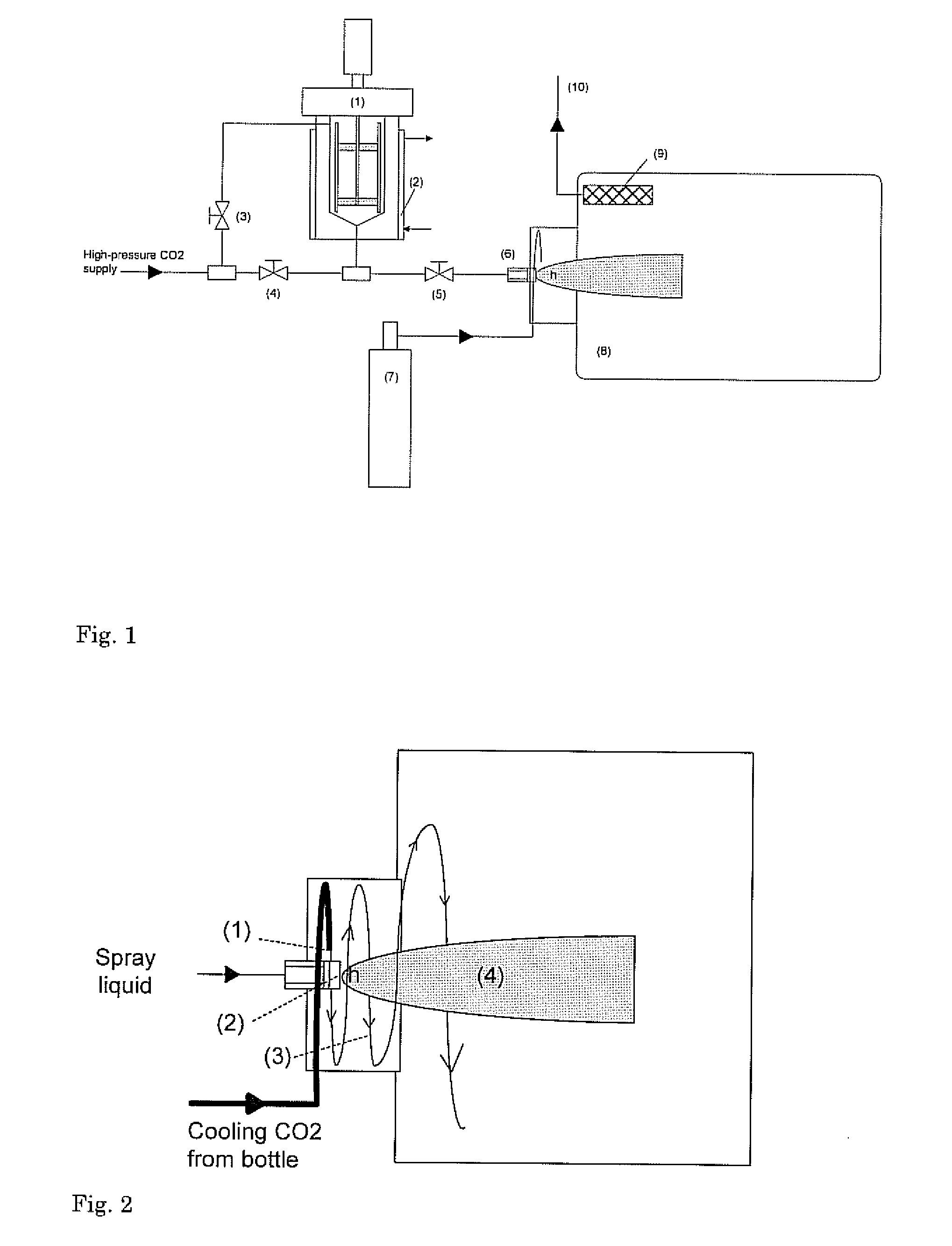

Dispersion structuring agent

ActiveUS20120018535A1Promote recoveryIncrease relative volatilityCosmetic preparationsToilet preparationsEmulsionLiquid gas

Disclosed is a novel method of making a structuring agent for edible dispersions such as margarines or spreads. Fat, or another structuring component, is subjected to a process involving mixing it with liquefied gas or supercritical gas, and expanding the mixture through an orifice. In the invention, water is added to the mixture prior to expansion, so as to provide a spray liquid in the form of a fat and water emulsion.

Owner:FEYECON DEV & IMPLEMENTATION

Thermal/environmental barrier coating system for silicon-containing materials

ActiveUS7407718B2Good mechanical integrityImprove the immunityPropellersRotary propellersAlkaline earth metalCoating system

Owner:GENERAL ELECTRIC CO

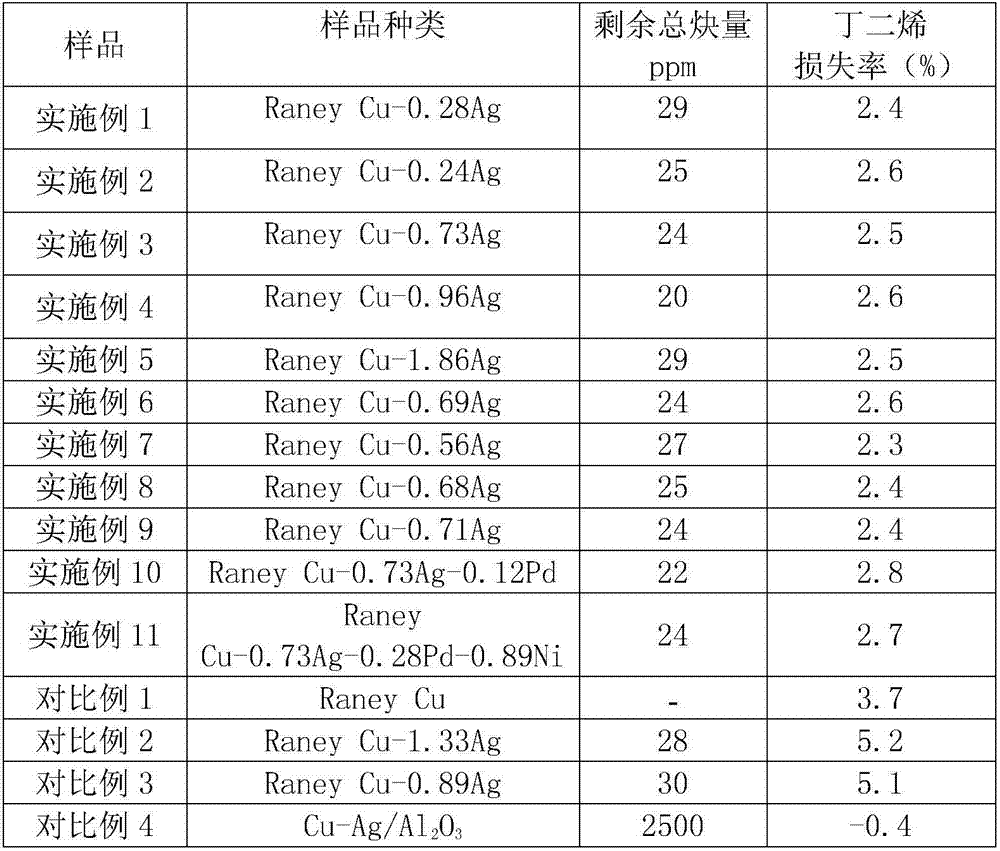

Method for preparing silver carbonized Raney copper catalyst, catalyst and application

ActiveCN107952450AHigh activityExtended service lifeHydrocarbon purification/separationHydrocarbonsAlkyneAlloy

The invention discloses a method for preparing a silver carbonized Raney copper catalyst, a catalyst and an application. The method comprises the steps: (1) uniformly mixing Raney alloy particles witha curing system of carbonizable organic matters, and carrying out curing, so as to obtain a catalyst precursor; (2) carbonizing the obtained catalyst precursor at a high temperature under the protection of inert gas, and then, carrying out activation, so as to obtain a carbonized Raney copper catalyst; (3) preparing a mixed solution from soluble organic amine and water, and then, dissolving a soluble silver salt and soluble salts of other auxiliaries, so as to prepare a silver source solution; and (4) adding the carbonized Raney copper catalyst into deionized water, carrying out stirring to form a suspension solution, dropwise adding the silver source solution obtained in the step (3) into the carbonized Raney copper catalyst solution, and carrying out a reaction and washing, thereby preparing the silver carbonized Raney copper catalyst. According to the catalyst disclosed by the invention, alkyne in liquid-phase C4 distillate can be removed until the concentration is 30ppm or less, and the loss rate of 1,3-butadiene is controlled to be 3% or less.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com