Method for preparing acetylene selective hydrogenation catalyst

A hydrogenation catalyst, selective technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the lack of controllable nanostructure of metal oxides, wide particle size distribution of Pd, and uneven distribution uniformity. In order to achieve the effect of rich catalyst structure, narrow size distribution, and high controllability of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example provides a method for preparing a small-scale, highly dispersed Pd / metal oxide catalyst with a three-dimensional nanostructure. The specific steps are:

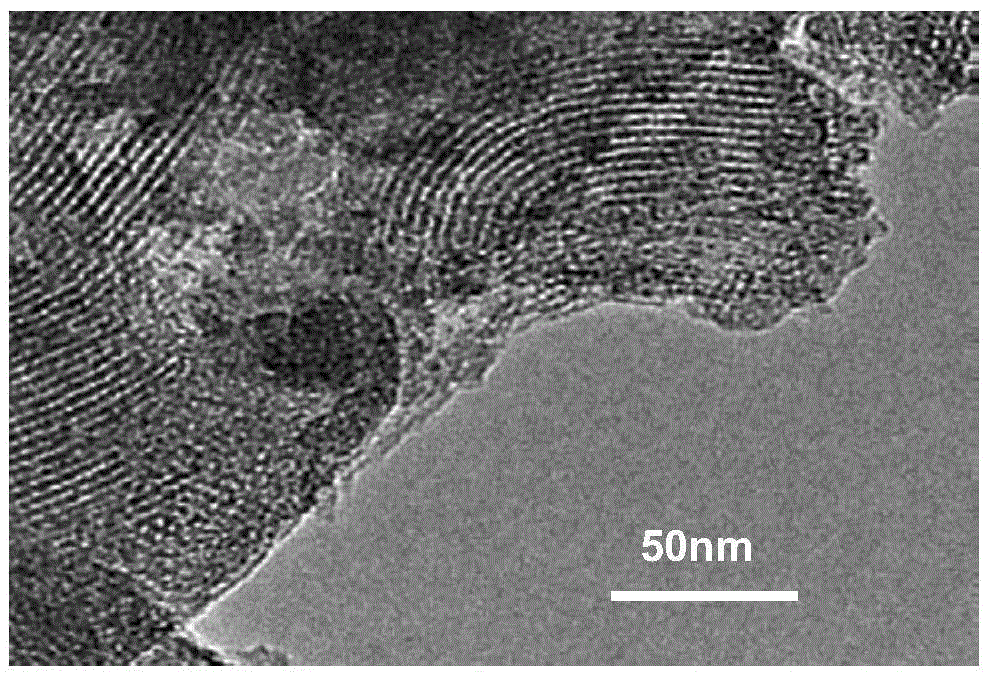

[0029] Step 1: Put 0.5g of MCM-41 molecular sieve carrier in a fixed bed, seal the reactor, feed nitrogen and adjust the pressure of the reactor to 130Pa, and heat the carrier to keep the temperature at 150°C. The structure of MCM-41 molecular sieve is shown in Figure 1.

[0030] Step 2: Perform a cycle of TiO on the carrier 2 Atomic layer deposition, a cycle includes the following four links:

[0031] 1) Inject Ti(OPr) into the reaction chamber 4 Saturating surface chemistry with the substrate and displacing surface functional groups;

[0032] 2) Clean unreacted Ti(OPr) with inert carrier gas 4 and by-products;

[0033] 3) Inject H into the reaction chamber 2 o 2 Surface reaction with the first reactive precursor adsorbed on the surface of the substrate to replace the surface functional groups agai...

Embodiment 2

[0045] This embodiment provides a method for preparing a small-scale, highly dispersed Pd / metal oxide catalyst with a three-dimensional nanostructure. The specific steps of the method are:

[0046] Step 1: Put 0.5g of MCM-41 molecular sieve carrier in a fixed bed, seal the reactor, feed nitrogen and adjust the pressure of the reactor to 150Pa, and heat the carrier to keep the temperature at 150°C.

[0047] Step 2: Perform a cycle of TiO on the carrier 2 Atomic layer deposition, a cycle includes the following four links:

[0048] 1) Inject Ti(OPr) into the reaction chamber 4 Saturating surface chemistry with the substrate and displacing surface functional groups;

[0049] 2) Clean unreacted Ti(OPr) with inert carrier gas 4 and by-products;

[0050] 3) Inject H into the reaction chamber 2 o 2 Surface reaction with the first reactive precursor adsorbed on the surface of the substrate to replace the surface functional groups again;

[0051] 4) Passing in an inert carrier ga...

Embodiment 3

[0062] This example provides a method for preparing a small-scale, highly dispersed Pd / metal oxide catalyst with a three-dimensional nanostructure. The specific steps are:

[0063] Step 1: Put 0.5g of MCM-41 molecular sieve carrier in a fixed bed, seal the reactor, feed nitrogen and adjust the pressure of the reactor to 150Pa, and heat the carrier to keep the temperature at 150°C.

[0064] Step 2: Perform a cycle of TiO on the carrier 2 Atomic layer deposition, a cycle includes the following four links:

[0065] 1) Inject Ti(OPr) into the reaction chamber 4 Saturating surface chemistry with the substrate and displacing surface functional groups;

[0066] 2) Clean unreacted Ti(OPr) with inert carrier gas 4 and by-products;

[0067] 3) Inject H into the reaction chamber 2 o 2 Surface reaction with the first reactive precursor adsorbed on the surface of the substrate to replace the surface functional groups again;

[0068] 4) Passing in an inert carrier gas to clean the un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com