Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11184 results about "Particle-size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The particle-size distribution (PSD) of a powder, or granular material, or particles dispersed in fluid, is a list of values or a mathematical function that defines the relative amount, typically by mass, of particles present according to size. Significant energy is usually required to disintegrate soil, etc. particles into the PSD that is then called a grain size distribution.

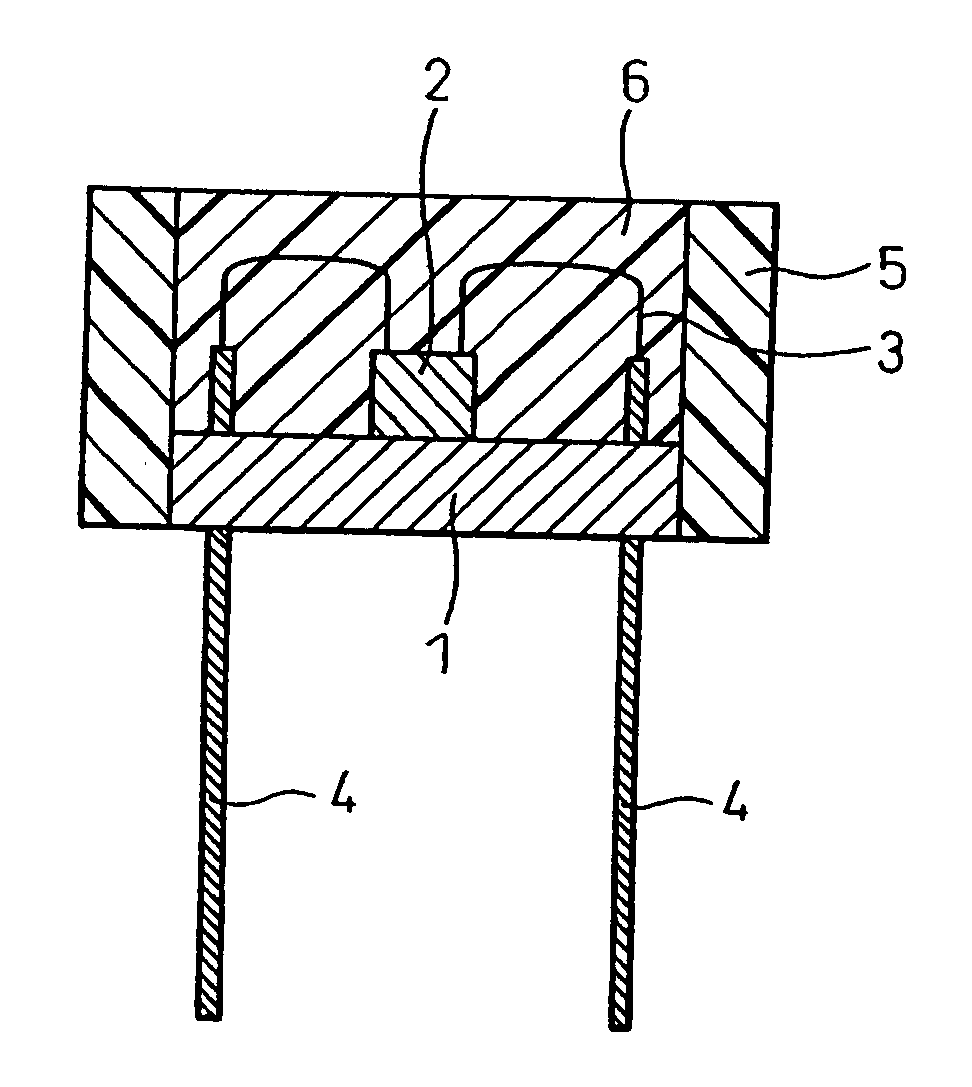

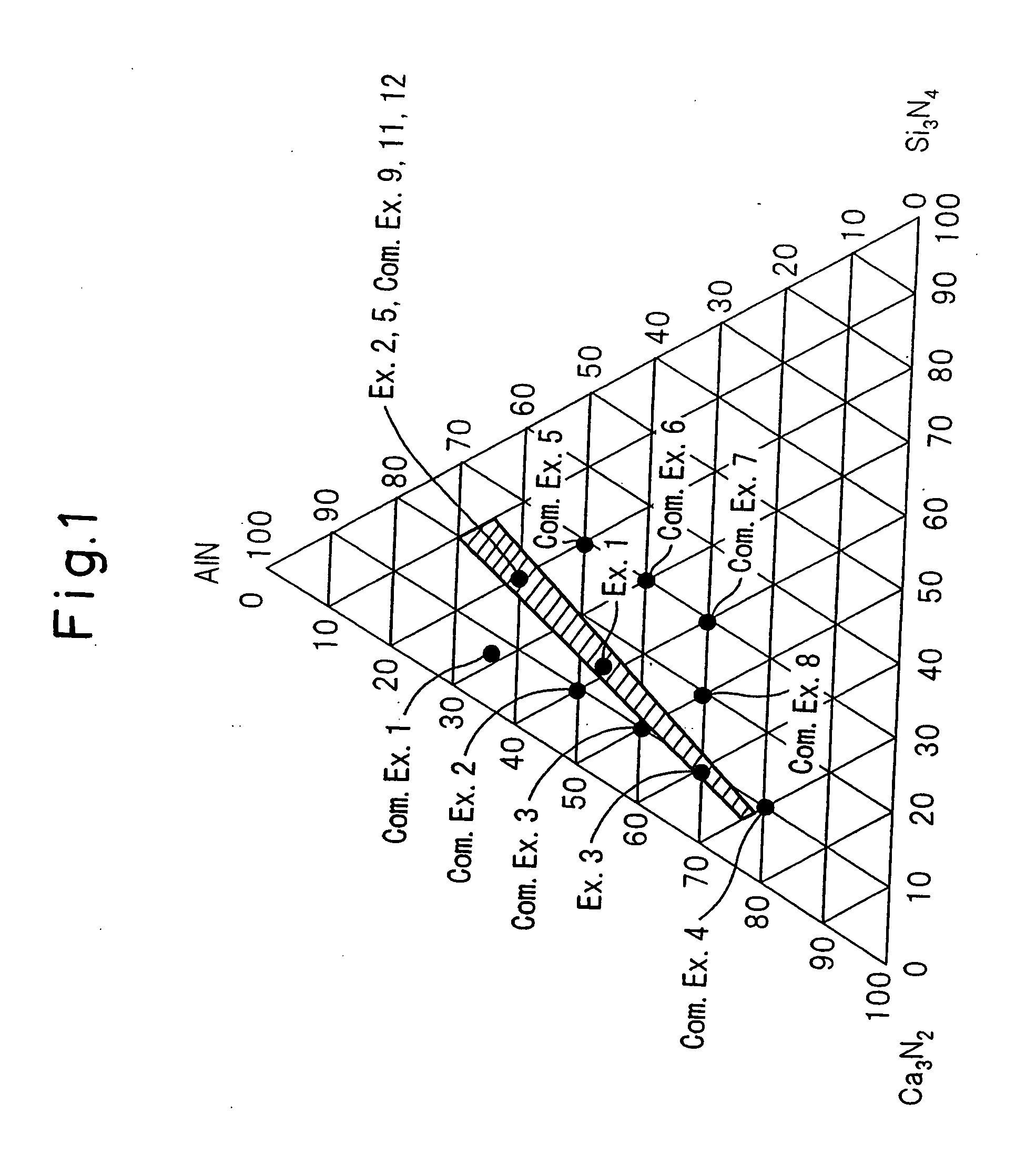

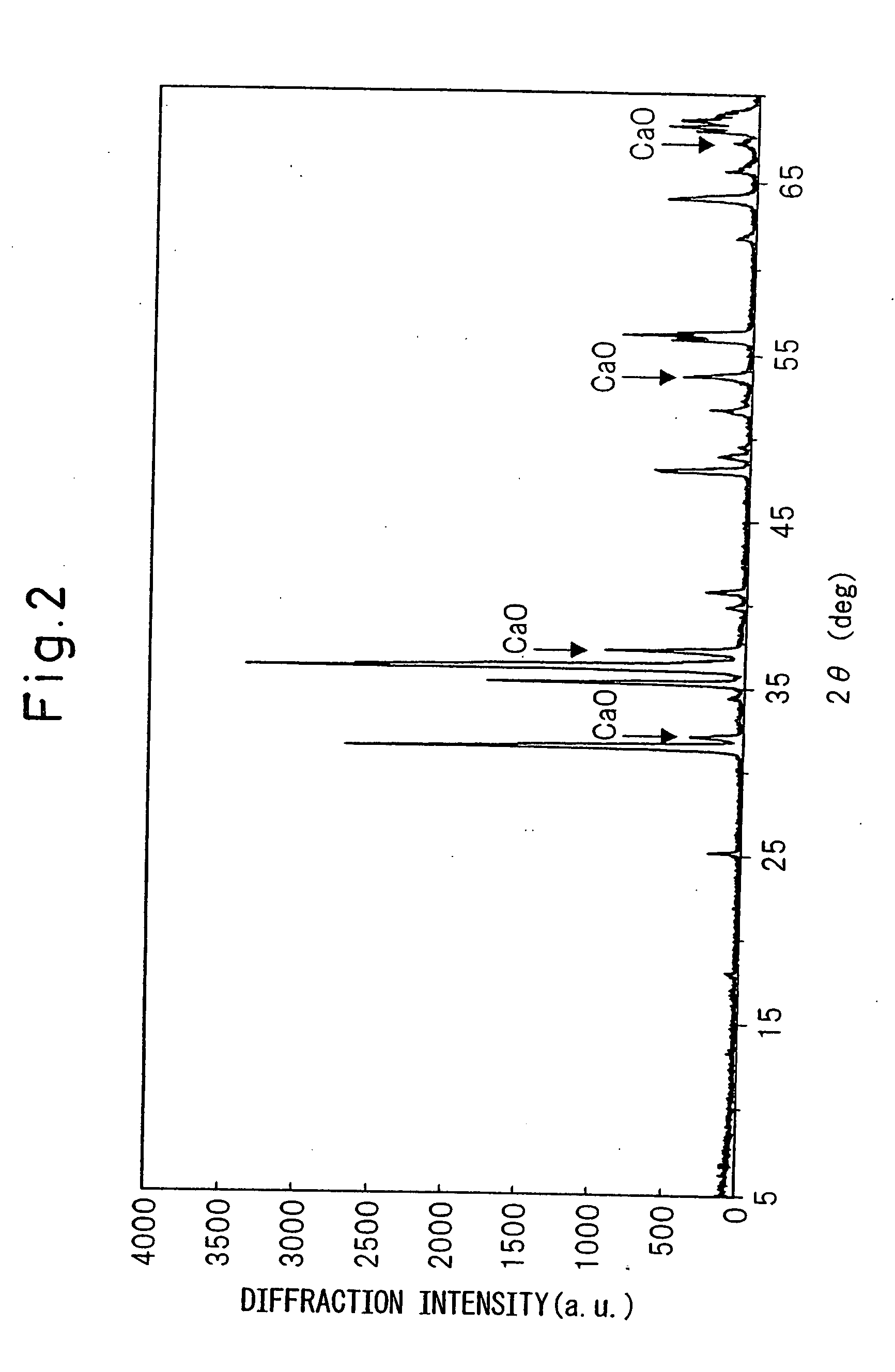

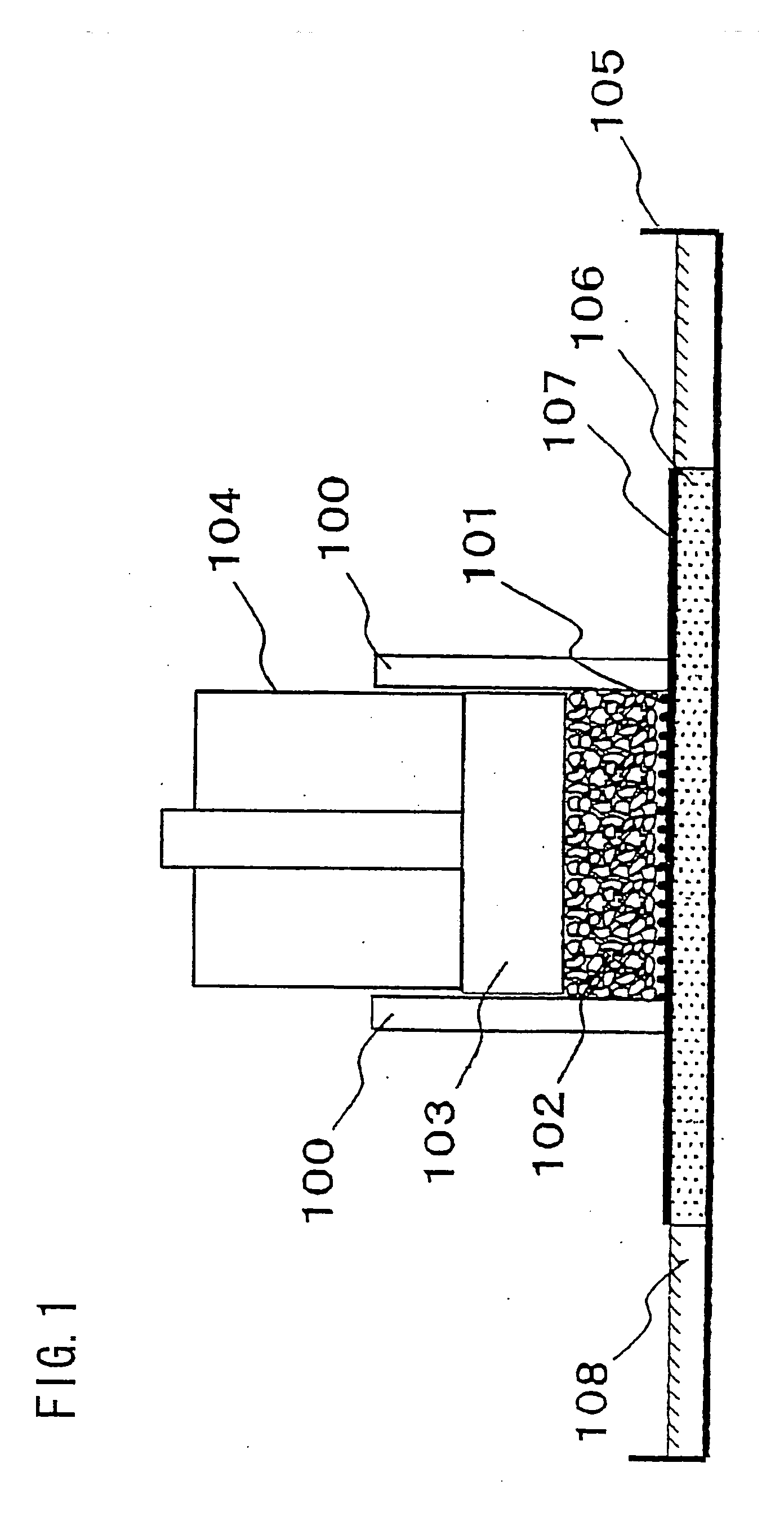

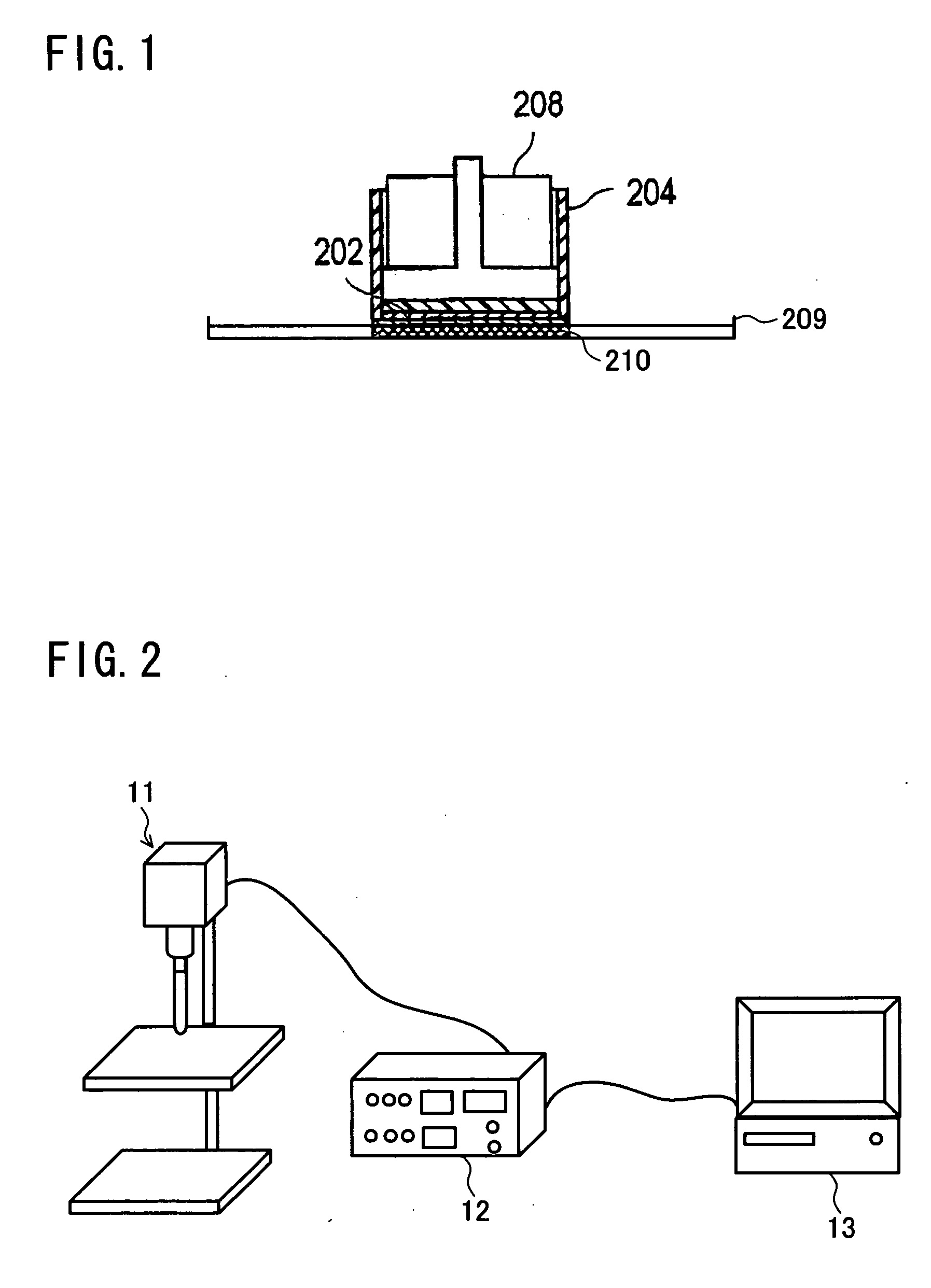

Red Nitride Phosphor and Production Method Thereof

A red phosphor where the crystal phase constituting the phosphor is monoclinic Eu-activated CaAlSiN3. A red phosphor which is Eu-activated CaAlSiN3 powder having an average particle diameter of 10 μm or less as measured in the non-pulverized state by the laser scattering particle size distribution analysis. A light-emitting device comprising a blue light-emitting element, a yellow phosphor capable of converting the blue light emitted from the blue light-emitting element into yellow light, and the above-described red phosphor capable of converting the blue light emitted from the blue light-emitting element into red light. A method for producing Eu-activated CaAlSiN3, comprising firing a raw material powder comprising Ca3N2, AlN, Si3N4 and EuN at 1,400 to 2,000° C. in a nitrogen-containing atmosphere, the Ca3N2, AlN and Si3N4 giving a composition falling in the region surrounded by a straight line connecting the following four points A to D in the composition diagram of FIG. 1 and EuN being contained in an amount of 0.01 to 10 parts by weight as Eu per 100 parts by weight in total of Ca3N2, AlN and Si3N4.

Owner:UBE IND LTD

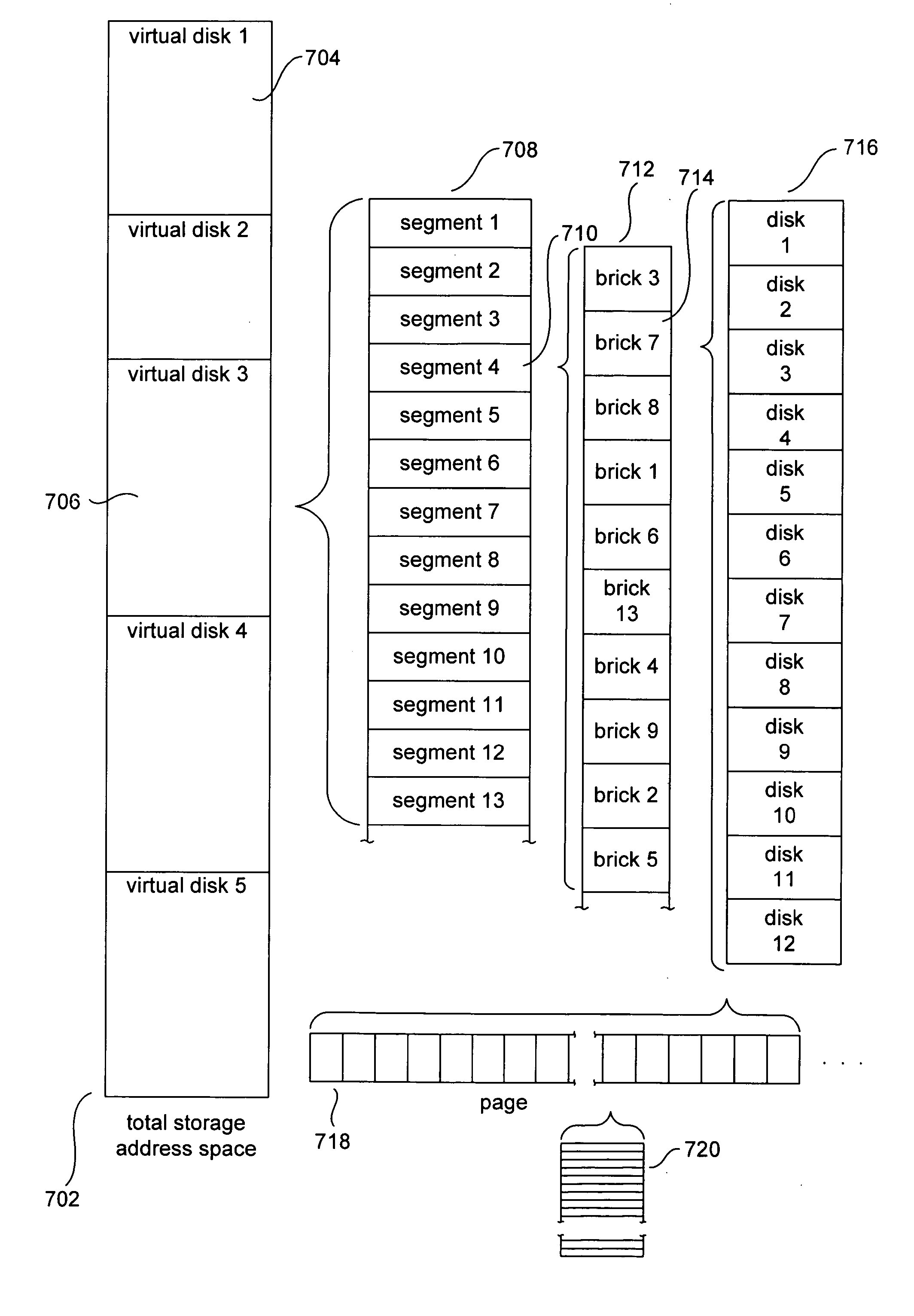

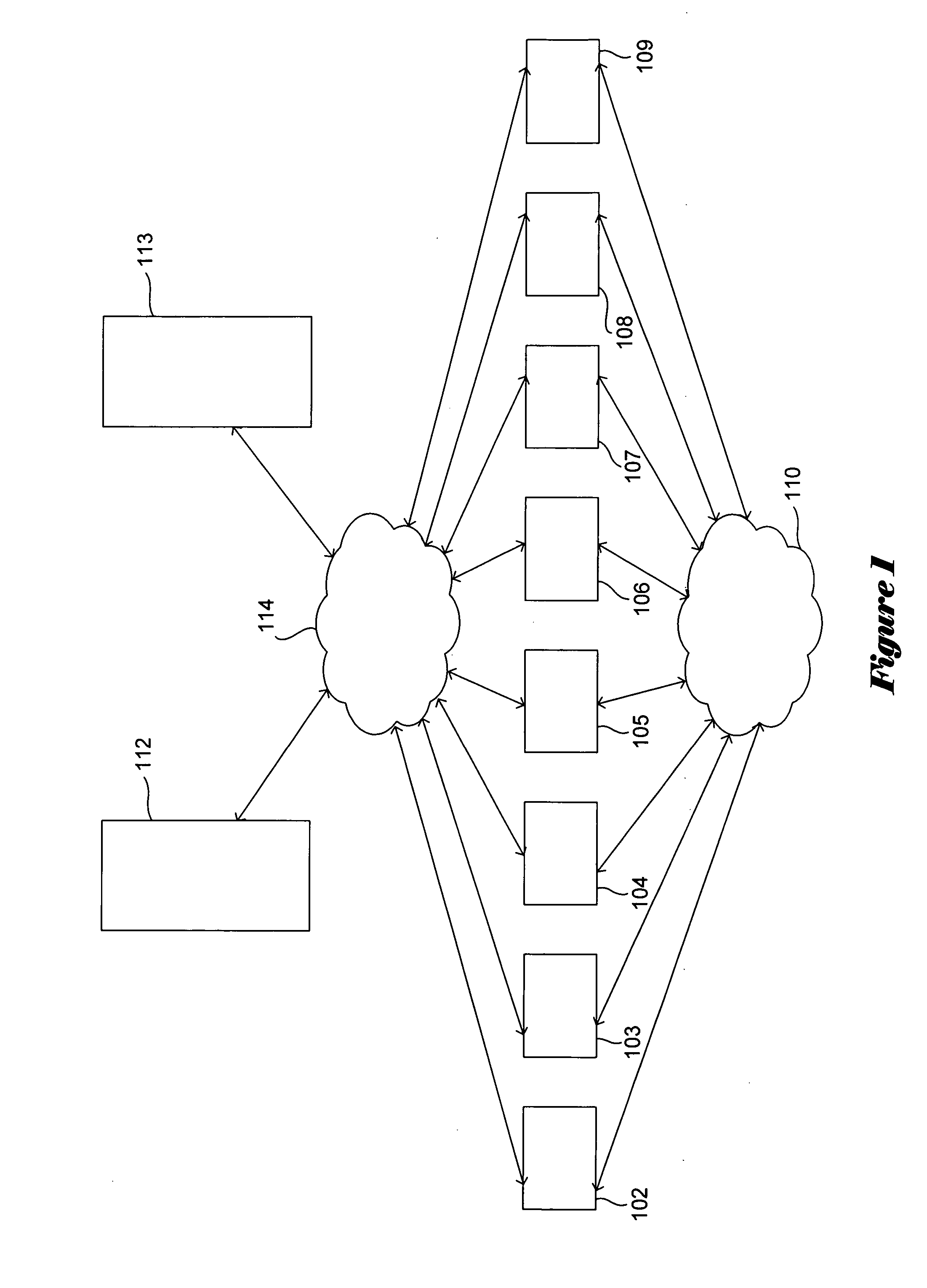

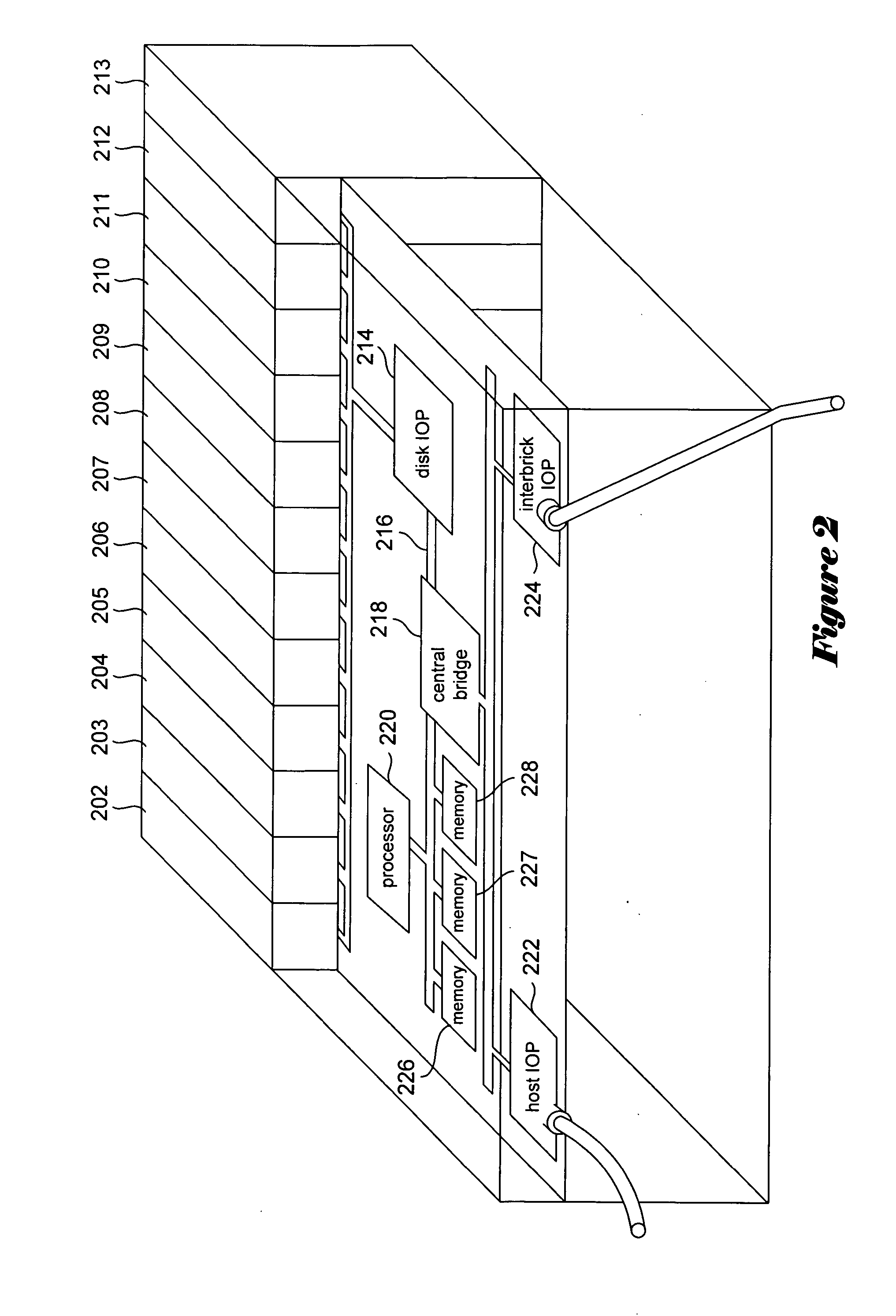

Methods and systems for hierarchical management of distributed data

Various method and system embodiments of the present invention are directed to hierarchical control logic within each component data-storage system of a distributed data-storage system composed of networked component data-storage systems over which virtual disks, optionally replicated as virtual-disk images, composed of data segments in turn composed of data blocks, are distributed at the granularity of segments. Each data segment is distributed according to a configuration. The hierarchical control logic includes, in one embodiment of the present invention, a top-level coordinator, a virtual-disk-image-level coordinator, a segment-configuration-node-level coordinator, a configuration-group-level coordinator, and a configuration-level coordinator.

Owner:HEWLETT PACKARD DEV CO LP

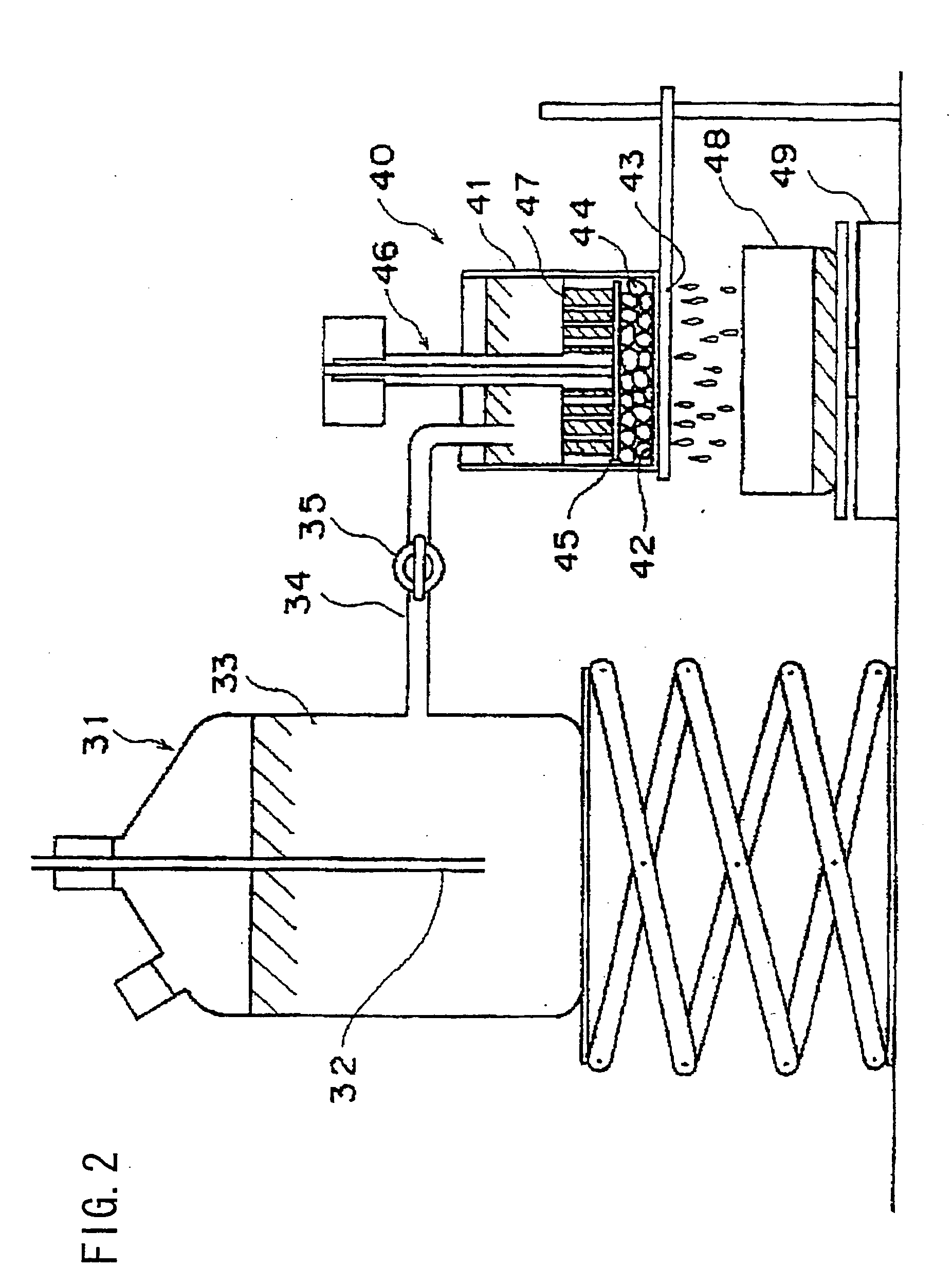

Methods of spray-drying a drug and a hydrophobic amino acid

InactiveUS6372258B1High level of stabilityEasy to manufacturePowder deliveryOrganic active ingredientsMoistureParticle-size distribution

According to the subject invention, dispersible dry powder pharmaceutical-based compositions are provided, including methods for their manufacture and dry powder dispersion devices. A dispersible dry powder pharmaceutical-based composition is one having a moisture content of less than about 10% by weight (% w) water, usually below about 5% w and preferably less than about 3% w; a particle size of about 1.0-5.0 mum mass median diameter (MMD), usually 1.0-4.0 mum MMD, and preferably 1.0-3.0 mum MMD; a delivered dose of about >30%, usually >40%, preferably >50%, and most preferred >60%; and an aerosol particle size distribution of about 1.0-5.0 mum mass median aerodynamic diameter (MMAD), usually 1.5-4.5 mum MMAD, and preferably 1.5-4.0 MMAD. Such composition are of pharmaceutical grade purity.

Owner:NOVARTIS FARMA

Water absorbent resin composition and production method thereof

The production method of a water absorbent resin composition including a particulate water absorbent resin, wherein: 95 wt % or more of particles whose particle diameter is less than 850 μm and not less, than 106 μm are contained, and a weight average particle diameter of the particles is less than 500 μm and not less than 300 μm and a logarithmic standard deviation (σξ) of a particle size distribution is 0.45 or less, and a water-soluble component of the water absorbent composition is 35 wt % or less, and a multivalent metal component is contained, and an extraction rate of the multivalent metal component is 5.0 wt % or more and less than 100 wt %, thereby providing the water absorbent resin composition, free from any coagulation of particles in high humidity, which has superior absorbent property in terms of an absorbency and a diffusing absorbency under pressure.

Owner:NIPPON SHOKUBAI CO LTD

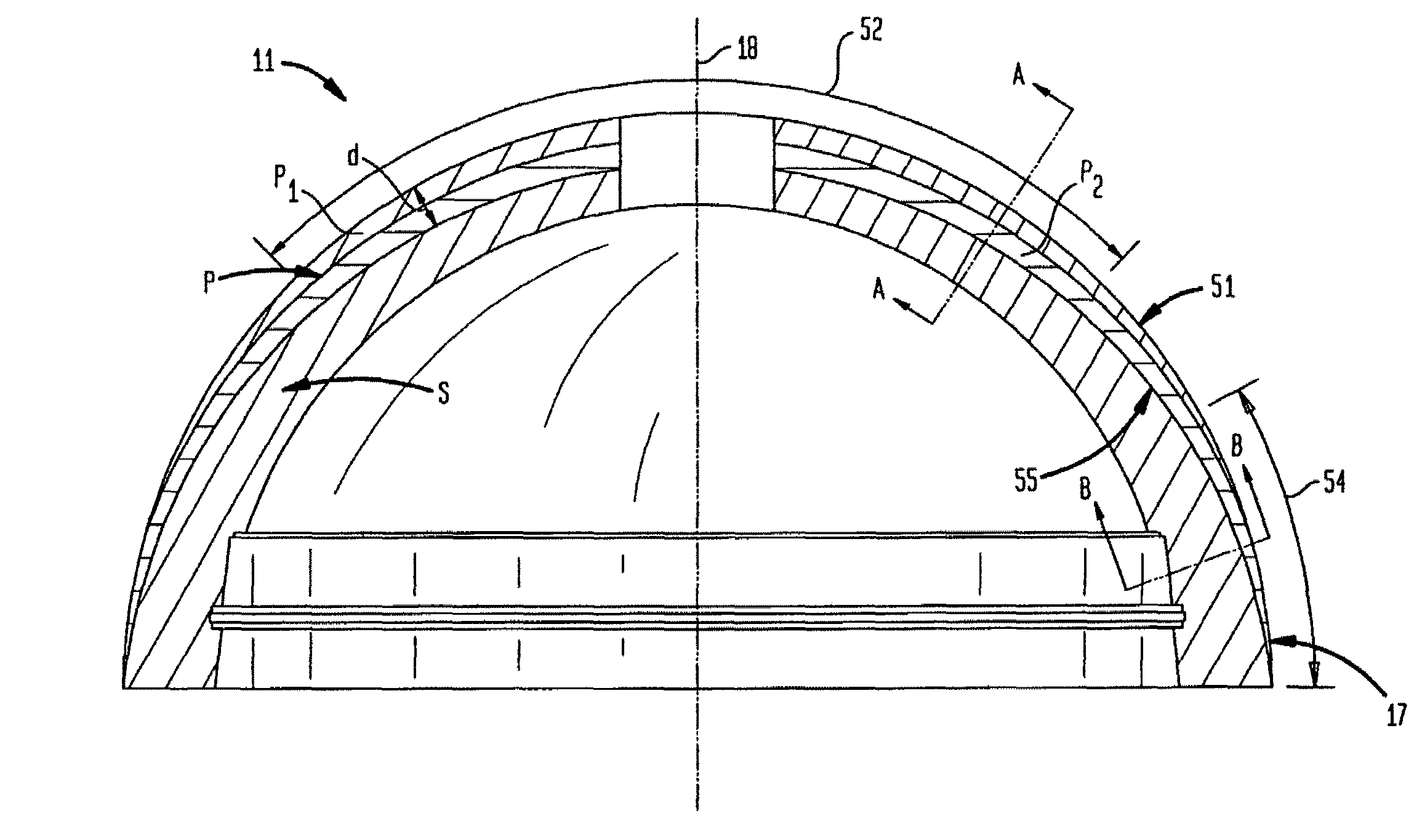

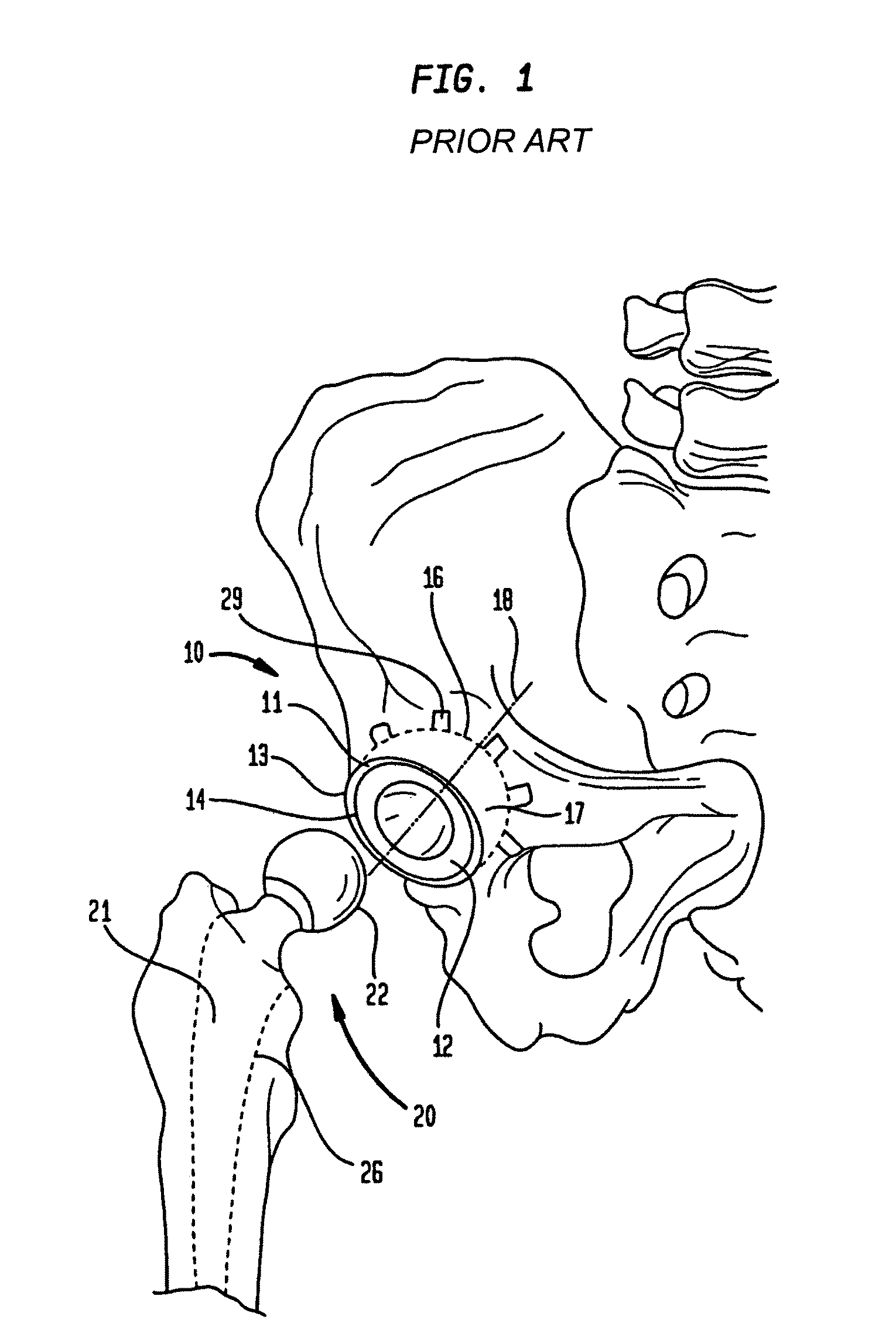

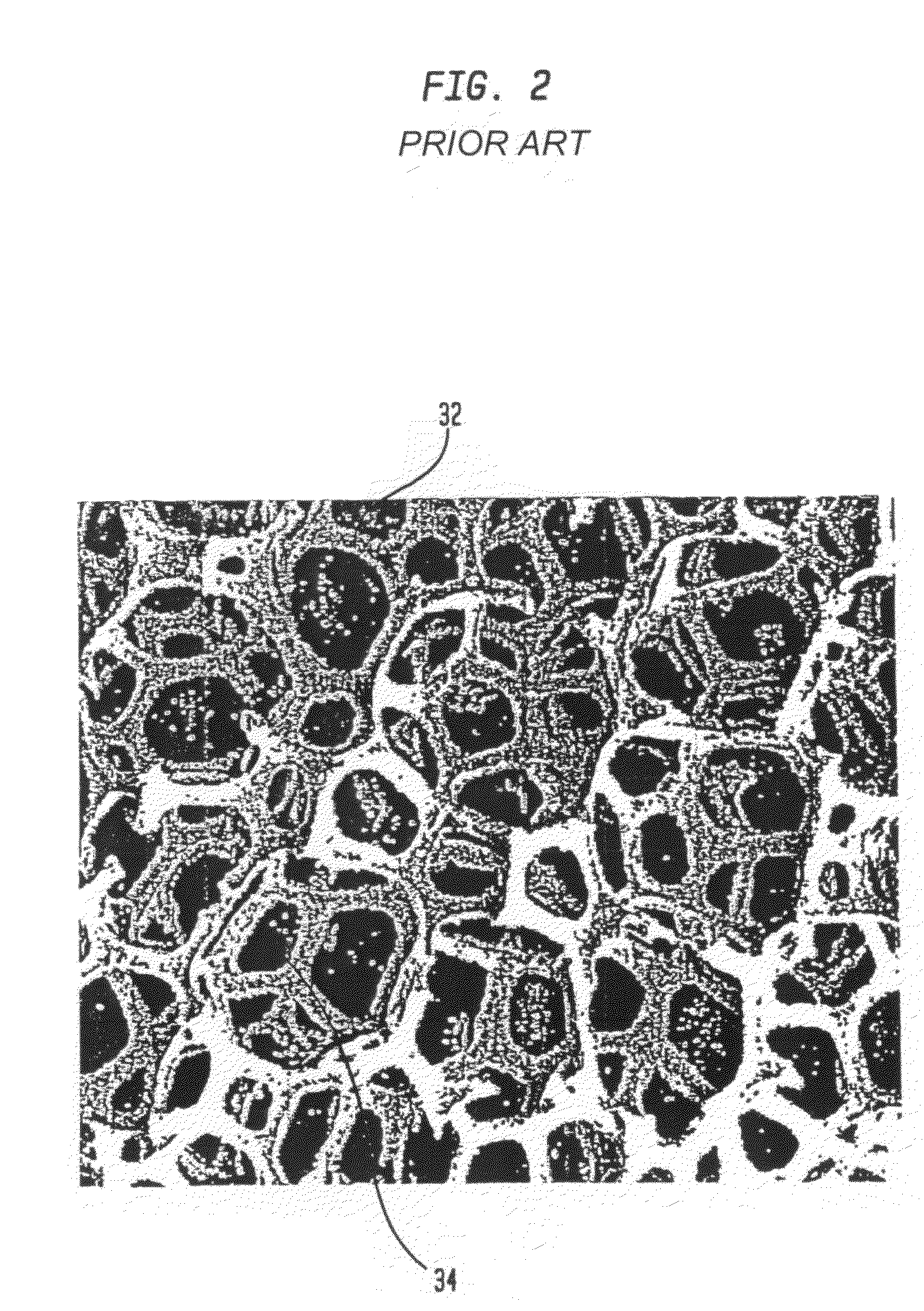

Gradient porous implant

ActiveUS7578851B2Optimizes various mechanical and biological requirements of the implants performanceIncreasing the thicknessAdditive manufacturing apparatusBone implantPorous implantMedical device

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

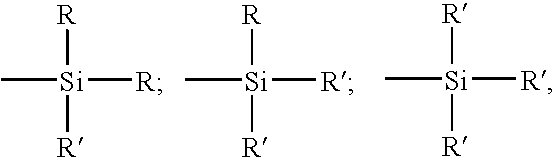

Catalyst components in use for polymerizing ethylene, and catalyst

This invention relates to a method for preparing catalyst for ethylene homopolymerization or copolymerization with other alpha-olefins. The catalyst comprises at least one Mg composite, at least one Ti compound, at least one organic alcohol compound, and at least one Si compound. The general formula of the Si compound is R1xR2ySi (OR3) z, where R1 and R2 are alkyl or halogen; R3 is alkyl; x is 0-2; y is 0-2; z is 0-4; x + y + z = 4. The catalyst has such advantages as high catalytic activity, high hydrogen sensitivity and narrow particle size distribution of polymer. The catalyst is suitable for slurry polymerization of ethylene, and combined polymerization process where catalyst with high activity is needed.

Owner:CHINA PETROLEUM & CHEM CORP +1

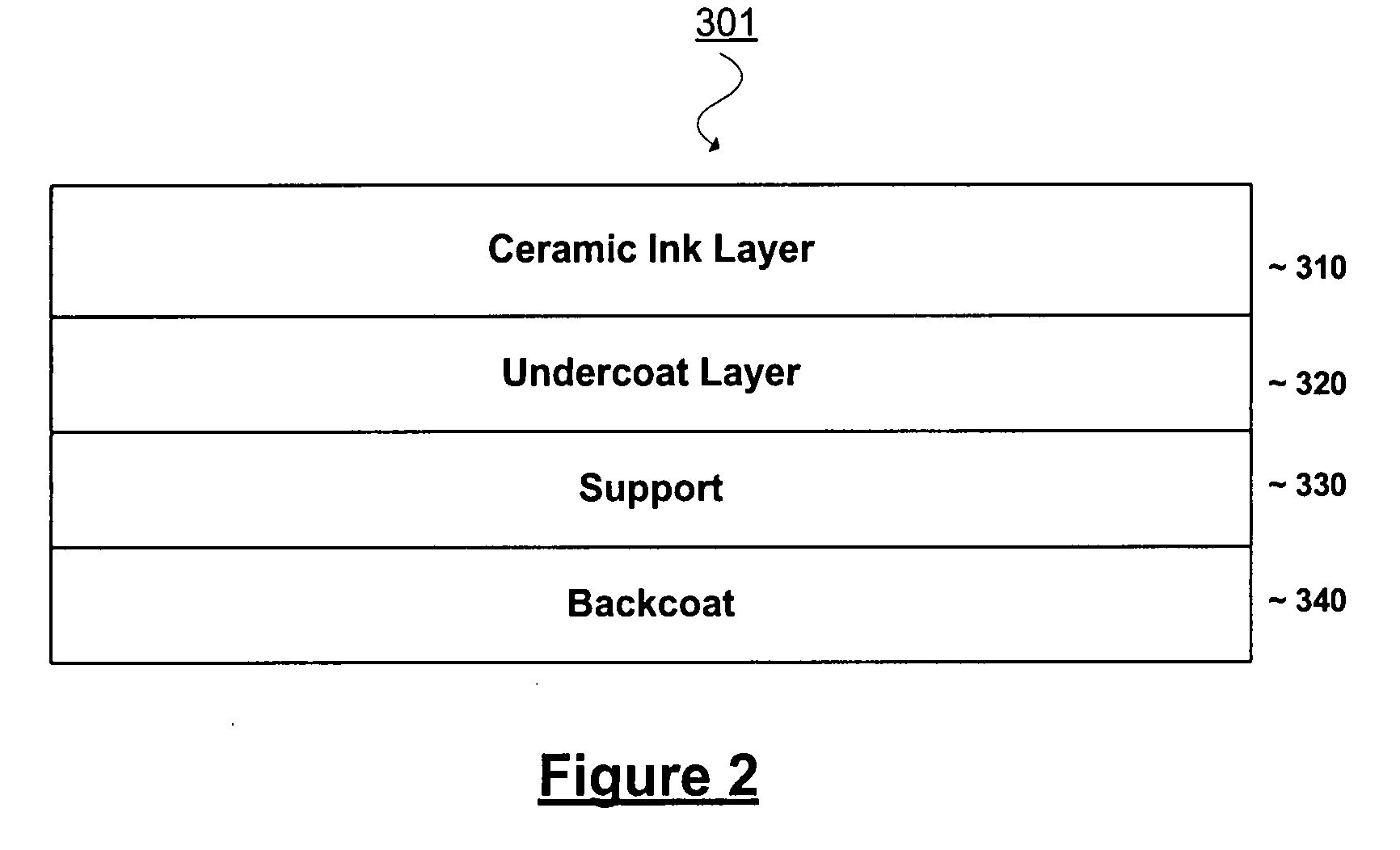

Magnetic recording medium and method of manufacturing the same

ActiveUS8535817B2Excellent characteristicsIncreased durabilityMagnetic materials for record carriersRecord information storageMetallurgyNon magnetic

An aspect of the present invention relates to a magnetic recording medium comprising a nonmagnetic layer containing a nonmagnetic powder and a binder and a magnetic layer containing a ferromagnetic powder and a binder in this order on a nonmagnetic support, whereinthe magnetic layer comprises a nonmagnetic powder of which coefficient of variation CV of a particle size distribution as denoted by the following formula (1):CV(%)=σ / φ×100 (1)is less than 20 percent, andthe magnetic layer has a thickness being equal to or less than 0.1 μm and falling within a range of 1.1≦φ / t≦8.0, wherein σ denotes a standard deviation of a particle diameter, φ denotes an average particle diameter of the nonmagnetic powder comprised in the magnetic layer being expressed in μm, and t denotes a thickness of the magnetic layer being expressed in μm.

Owner:FUJIFILM CORP

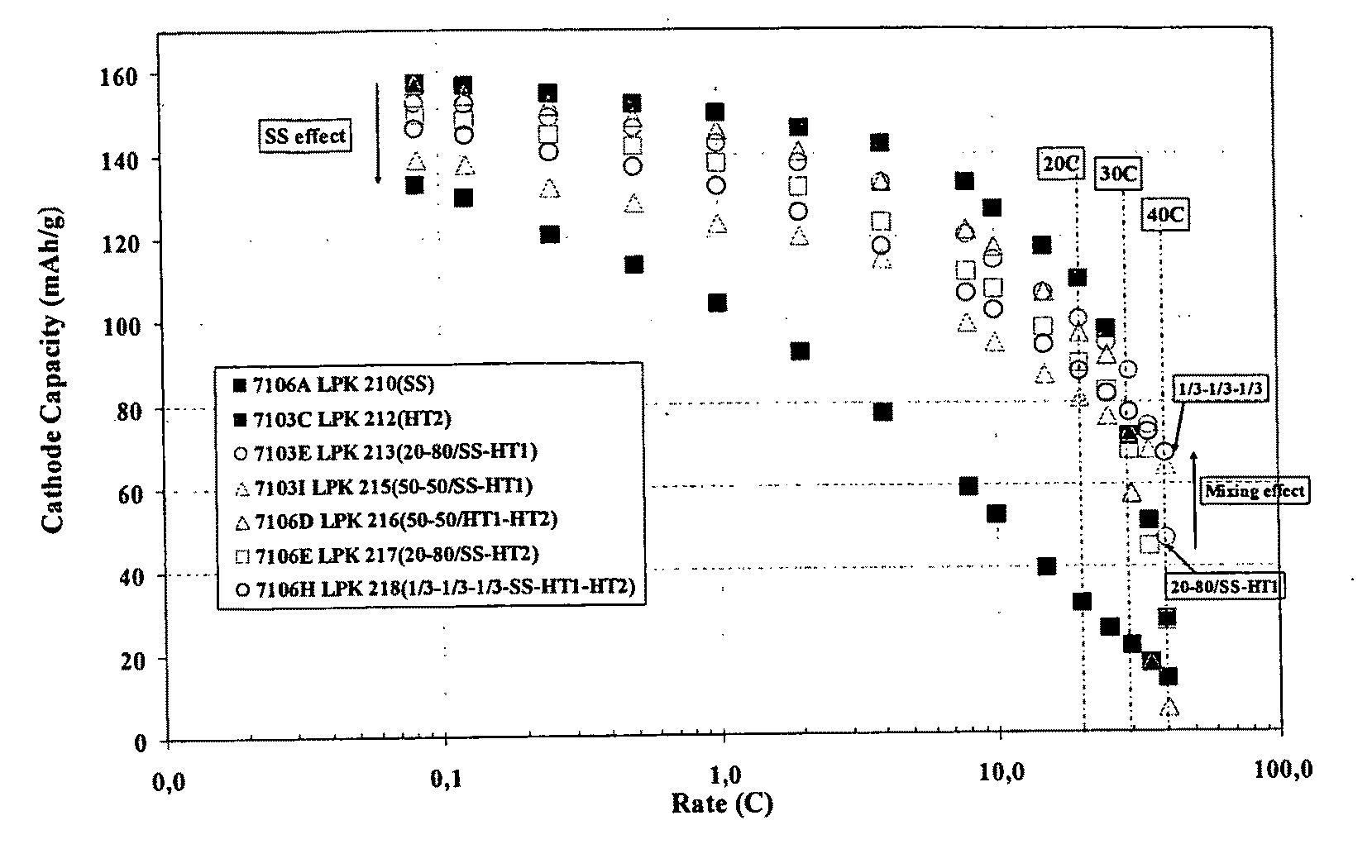

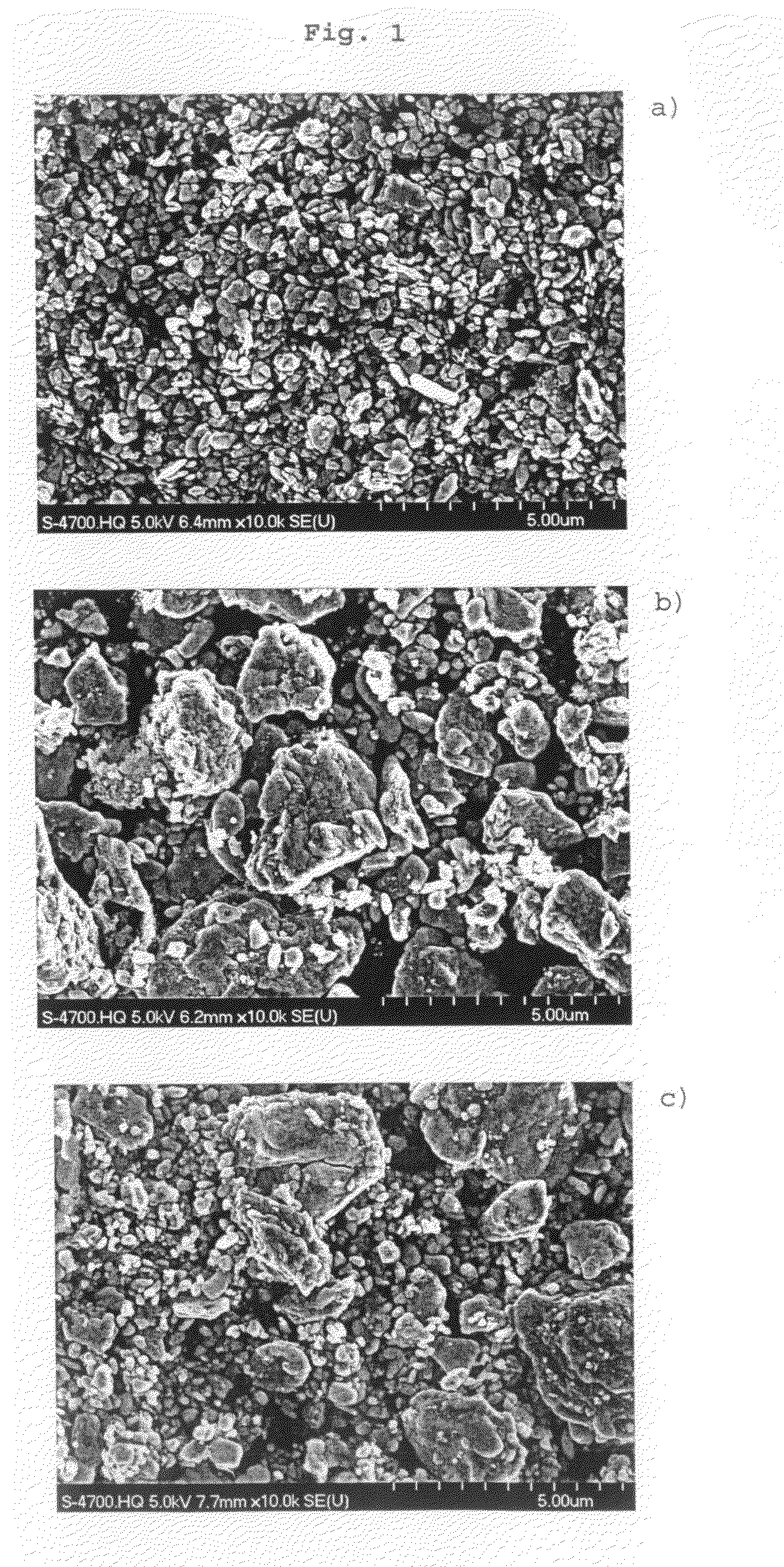

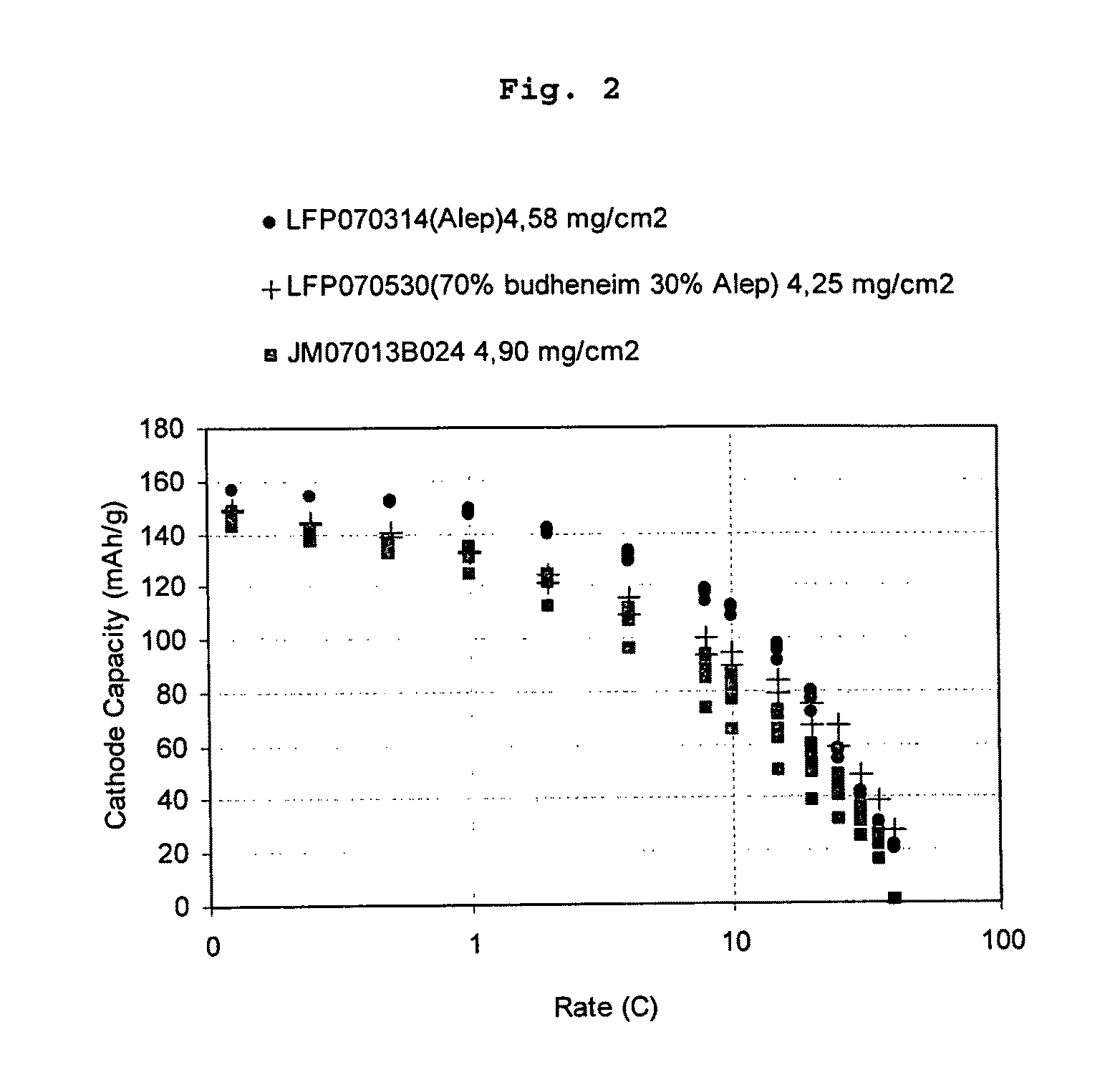

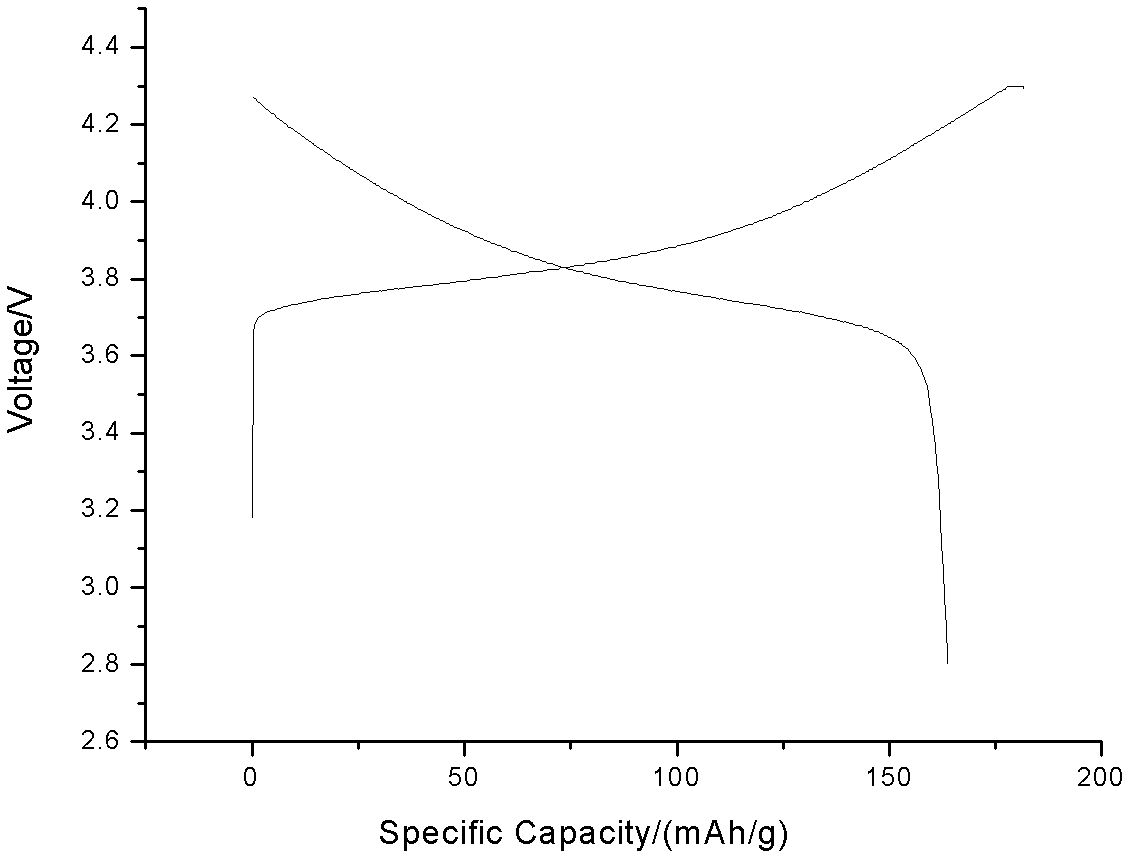

Lithium iron phosphate cathode materials with enhanced energy density and power performance

InactiveUS20090155689A1Powerful performanceHigh discharge ratePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiberPhosphate

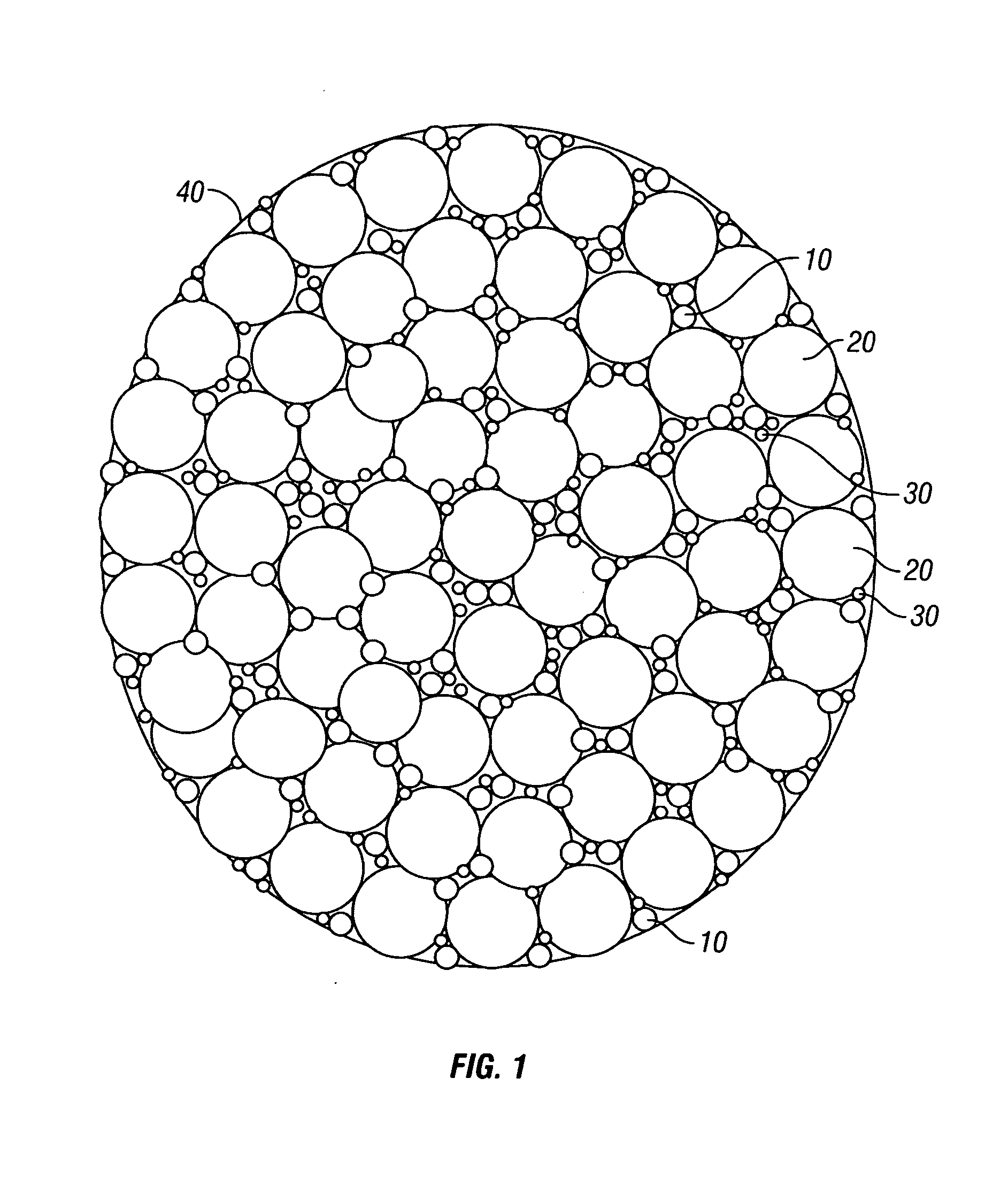

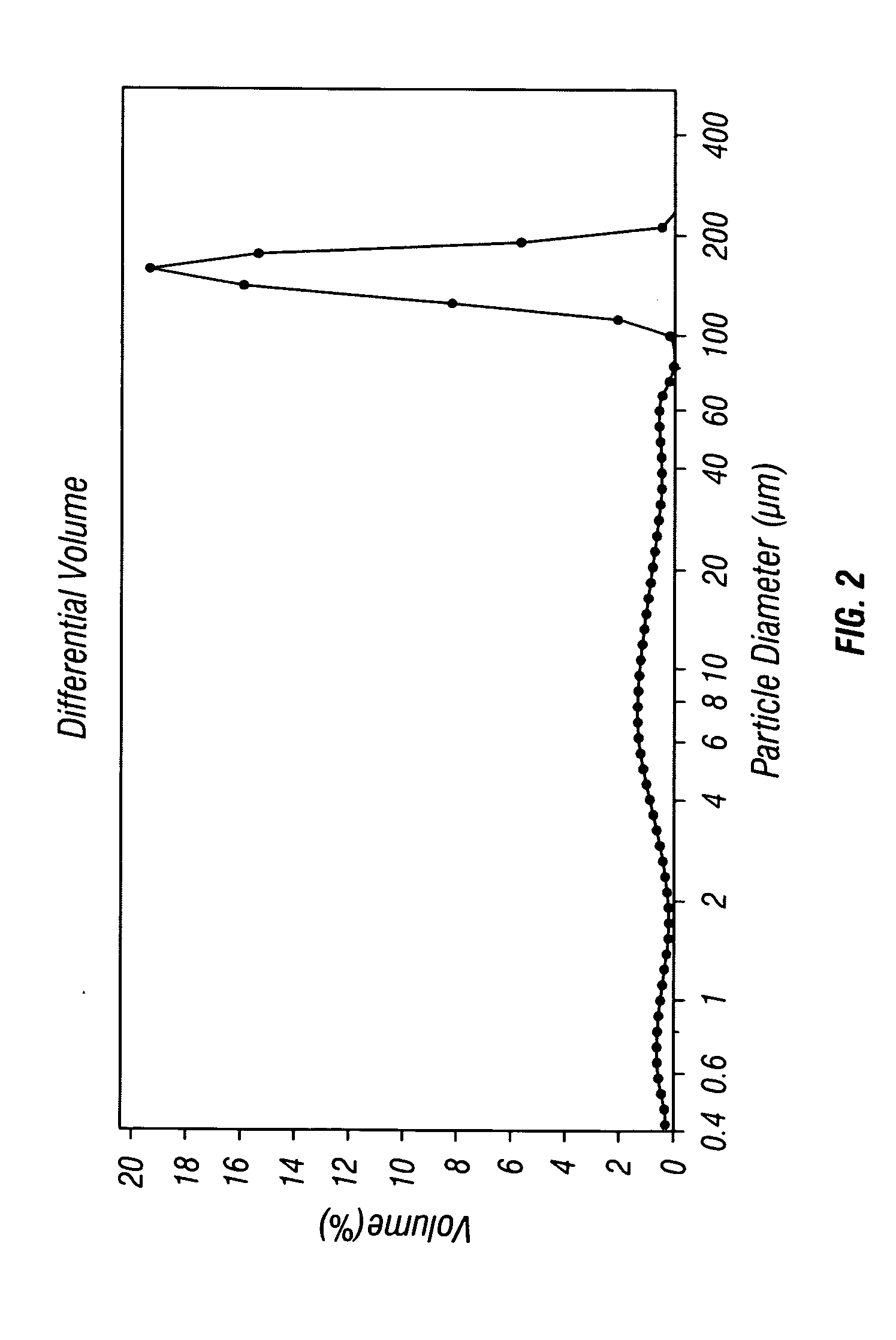

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:PHOSTECH LITHIUM

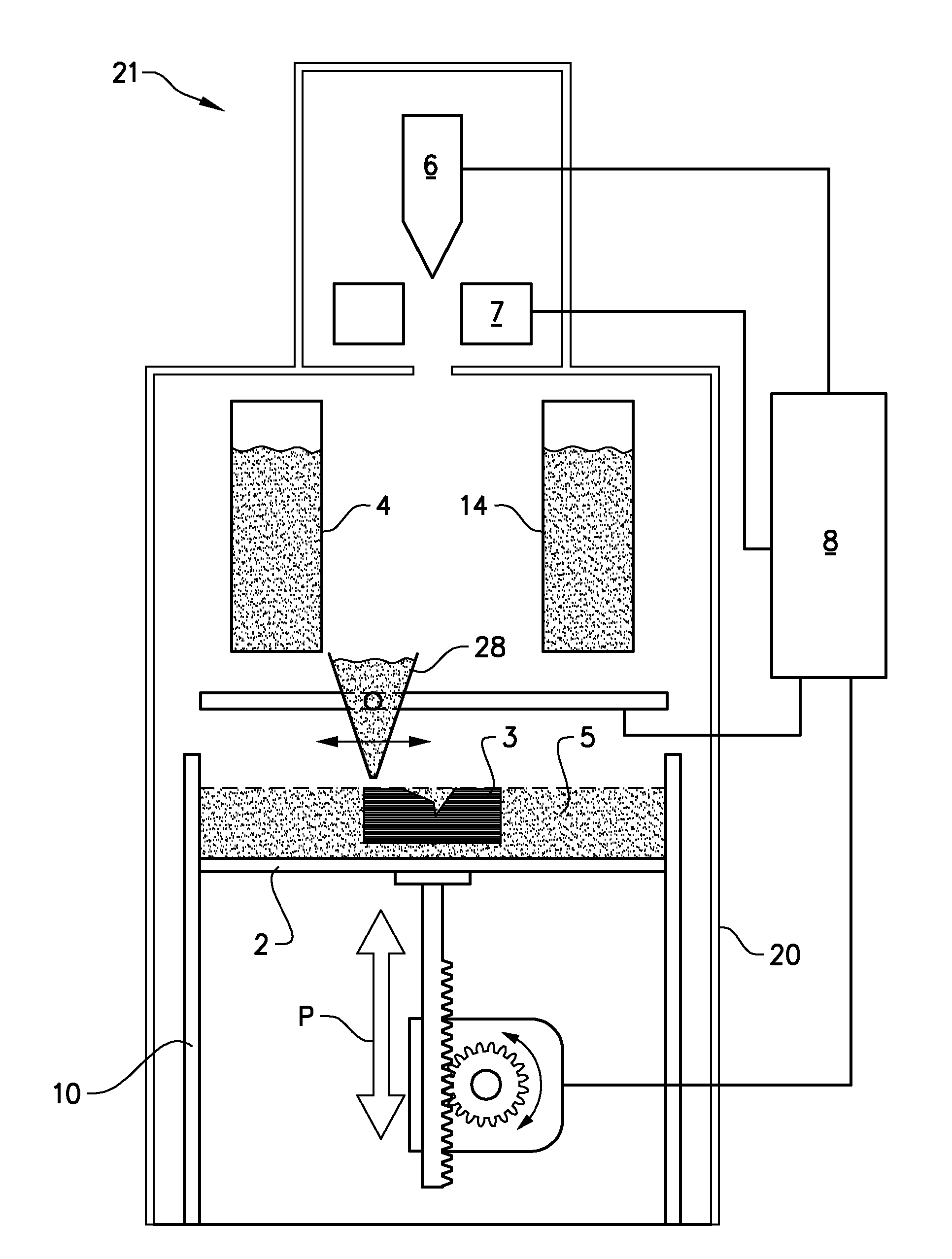

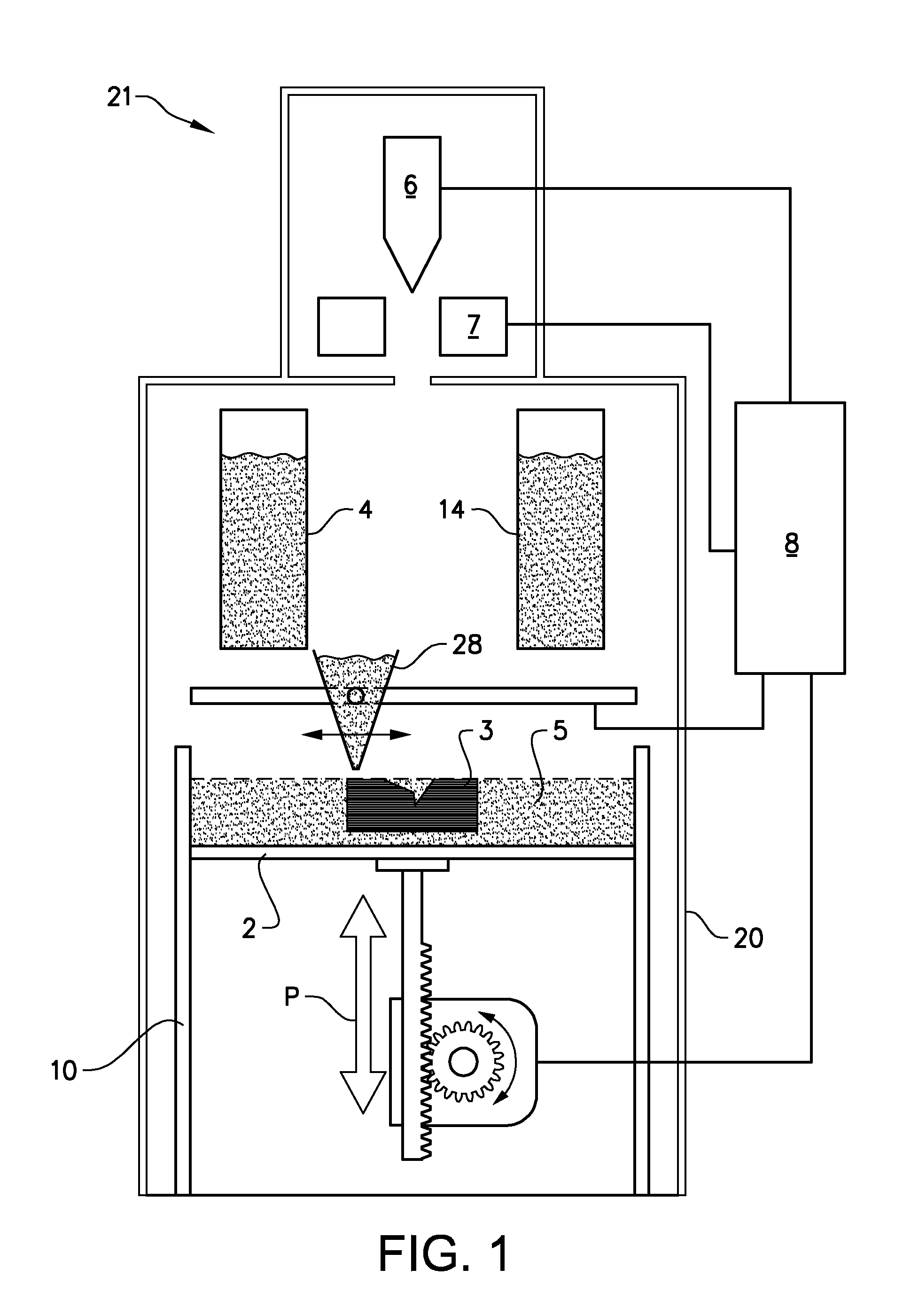

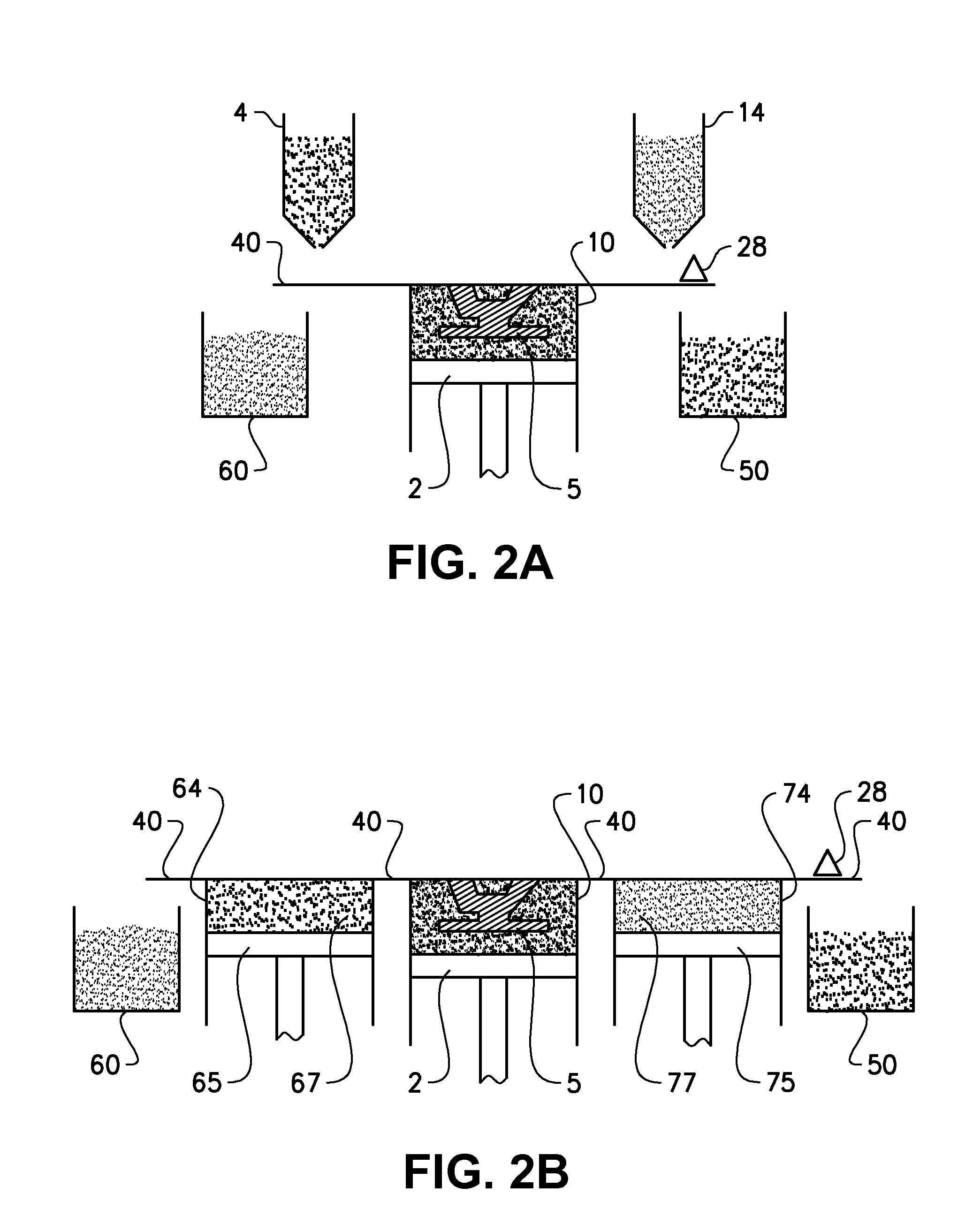

Powder distribution in additive manufacturing of three-dimensional articles

ActiveUS20150071809A1Additive manufacturing apparatusTransportation and packagingMetallurgyAdditive layer manufacturing

The present invention relates to a method for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table. Said method comprising the steps of: providing at least a first and second powder tank, providing a first type of powder in said first powder tank having a first particle size distribution, providing a second type of powder in said second powder tank having a second particle size distribution, providing a first sub-layer of said first type of powder on said work table, providing a second sub-layer of said second type of powder on top of said first layer of said first type of powder, fusing said first and second sub-layers simultaneously with a high energy beam from a high energy beam source for forming a first cross section of said three-dimensional article.

Owner:ARCAM AB

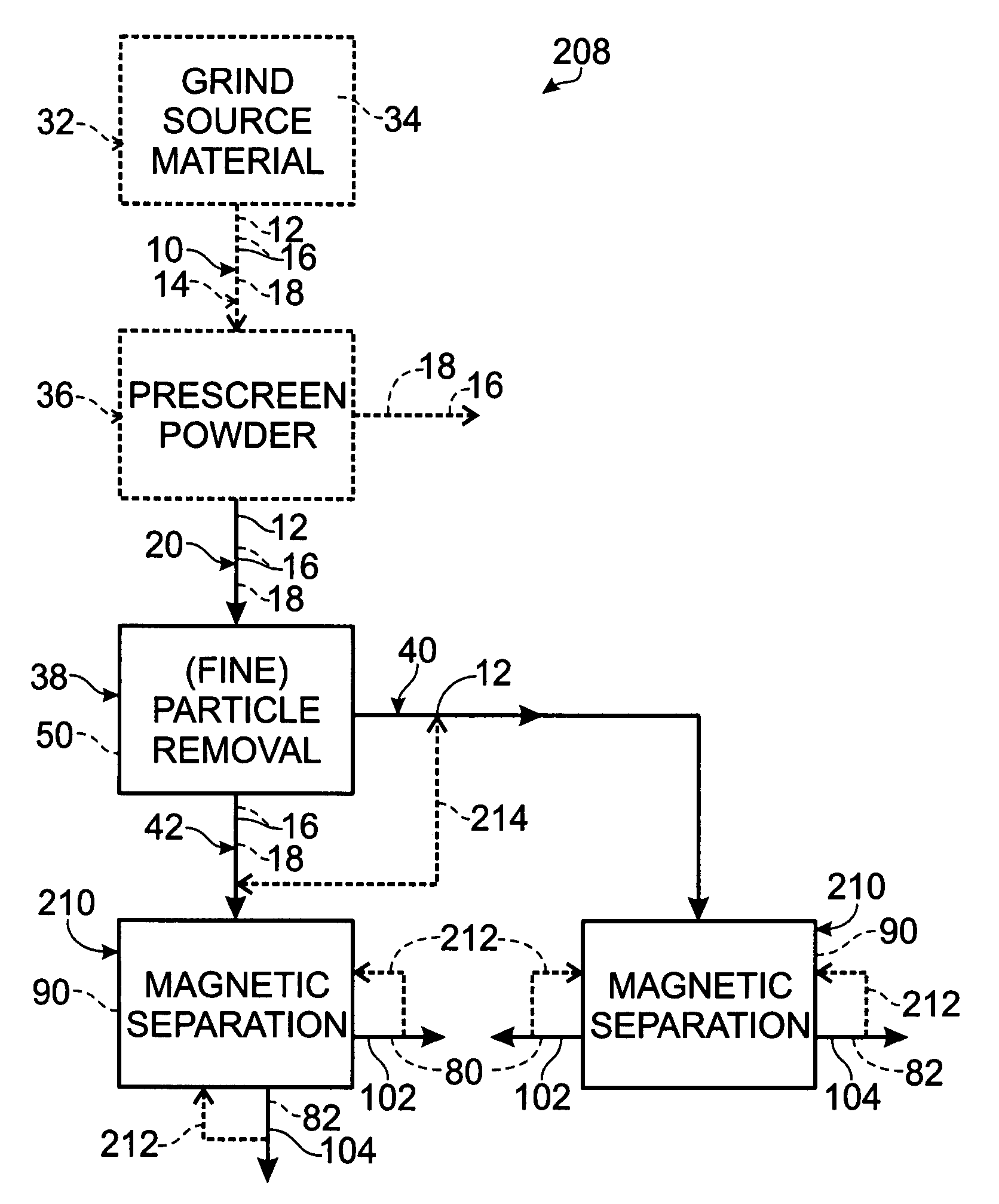

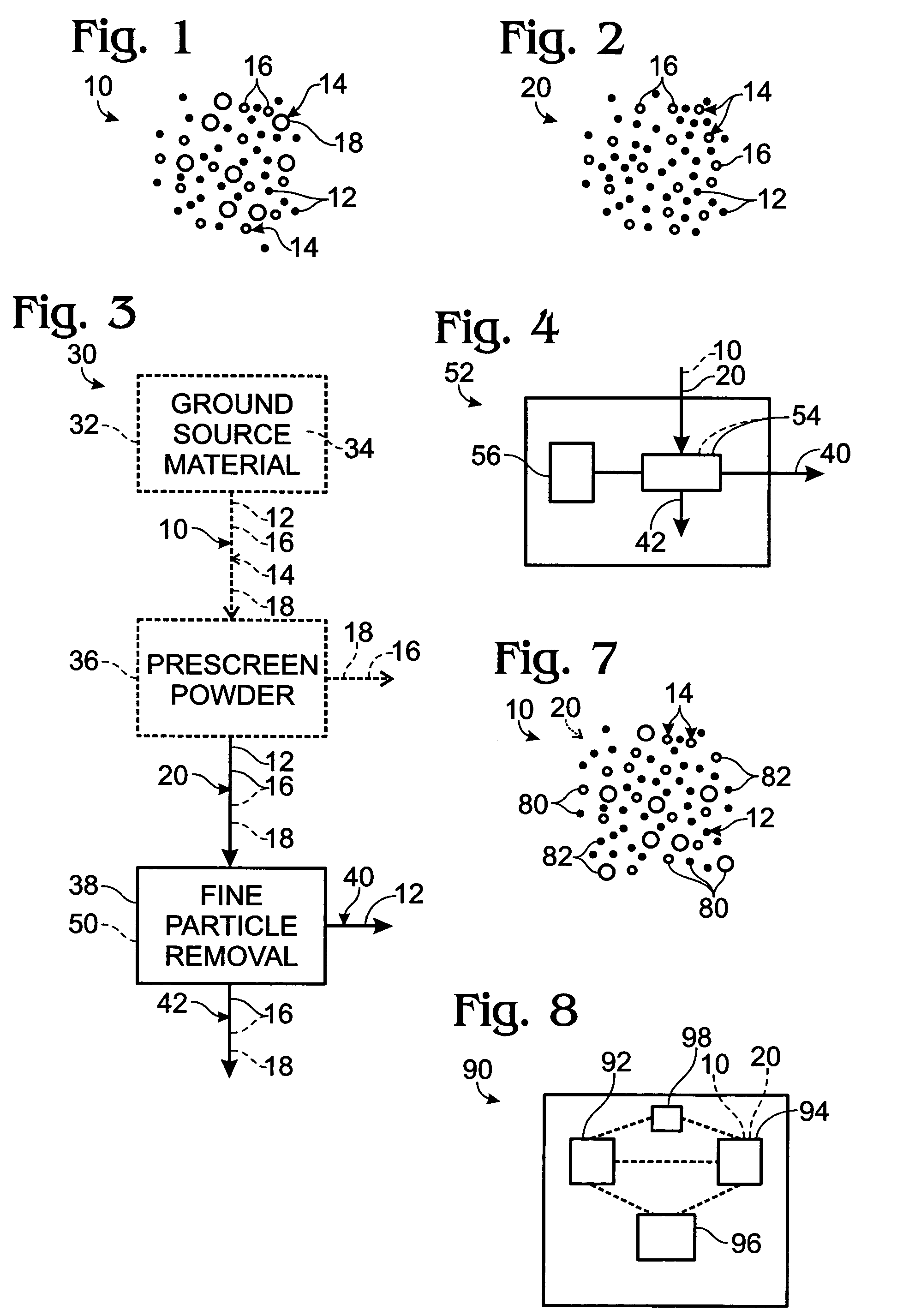

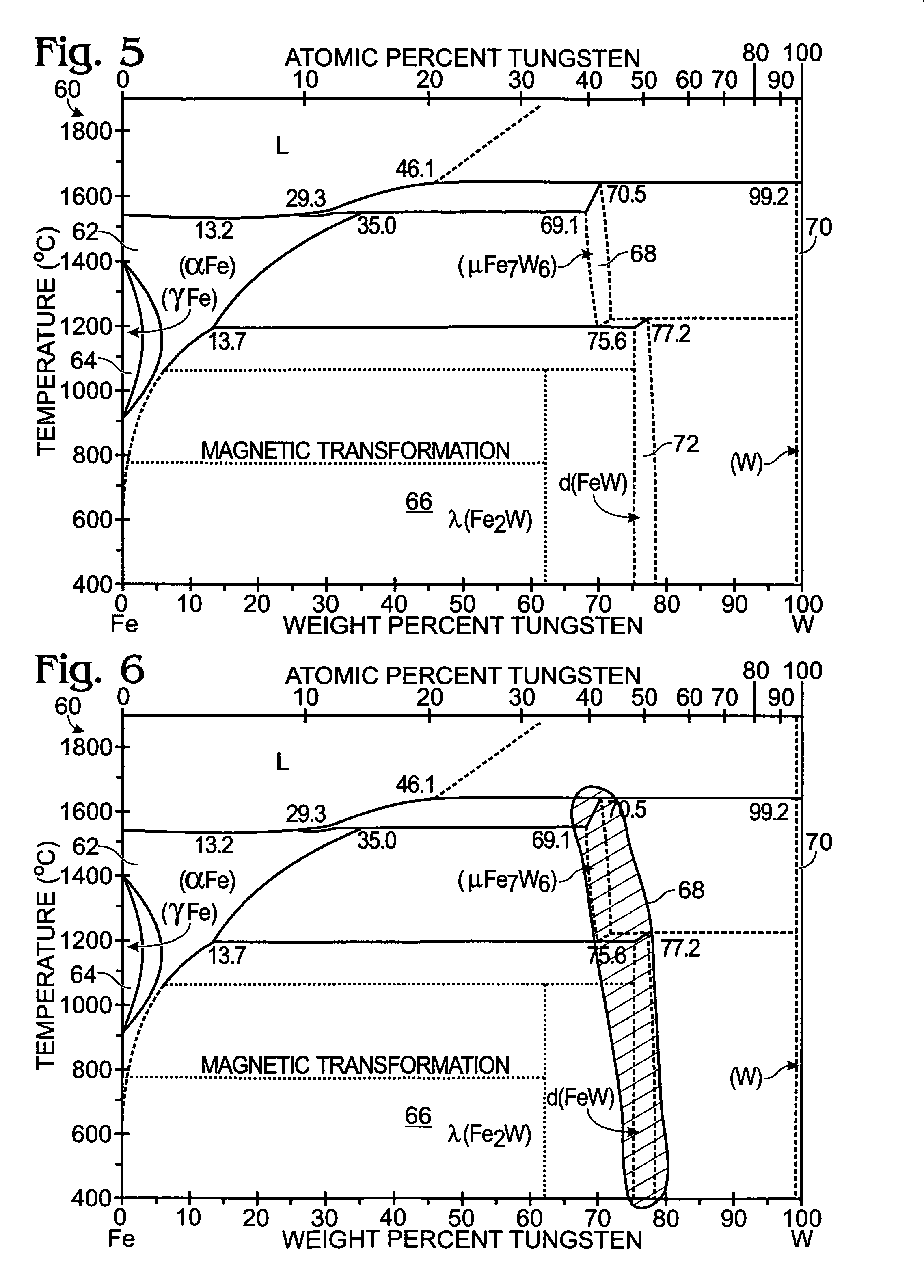

System and method for processing ferrotungsten and other tungsten alloys, articles formed therefrom and methods for detecting the same

Systems and methods for refining or otherwise processing tungsten alloys, including ferrotungsten powder and articles formed therefrom, and methods for detecting the presence of the same. The methods include at least one of magnetically-separating and particle-size-separating ferrotungsten or ferrotungsten-containing powder. In some embodiments, powder may be separated to remove fine particles, and optionally to separate the remaining particles into fractions containing selected particle size distributions. The powder additionally or alternatively may be separated into at least magnetic and non-magnetic fractions. In some embodiments, portions of two or more size and / or magnetism fractions are mixed to provide a ferrotungsten-containing feedstock. Selected fractions resulting from the size and magnetism separation steps may be utilized to provide a ferrotungsten-containing feedstock from which articles are produced and which may include additional components.

Owner:AMICK FAMILY REVOCABLE LIVING TRUST

Medical aerosol formulations

InactiveUS6461591B1Improve dosage accuracyIncrease doseBiocideDispersion deliveryAlkaneAerosol spray

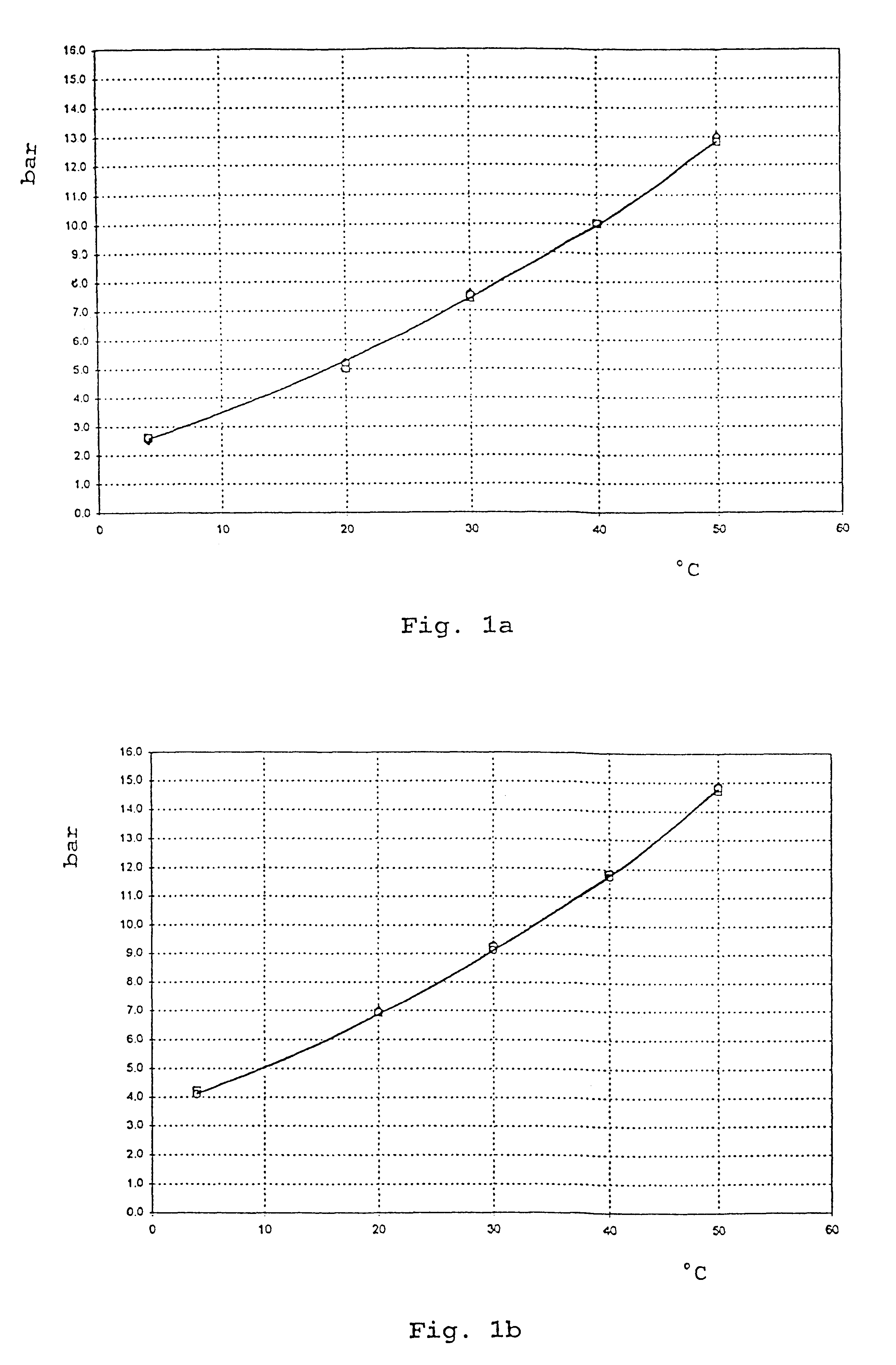

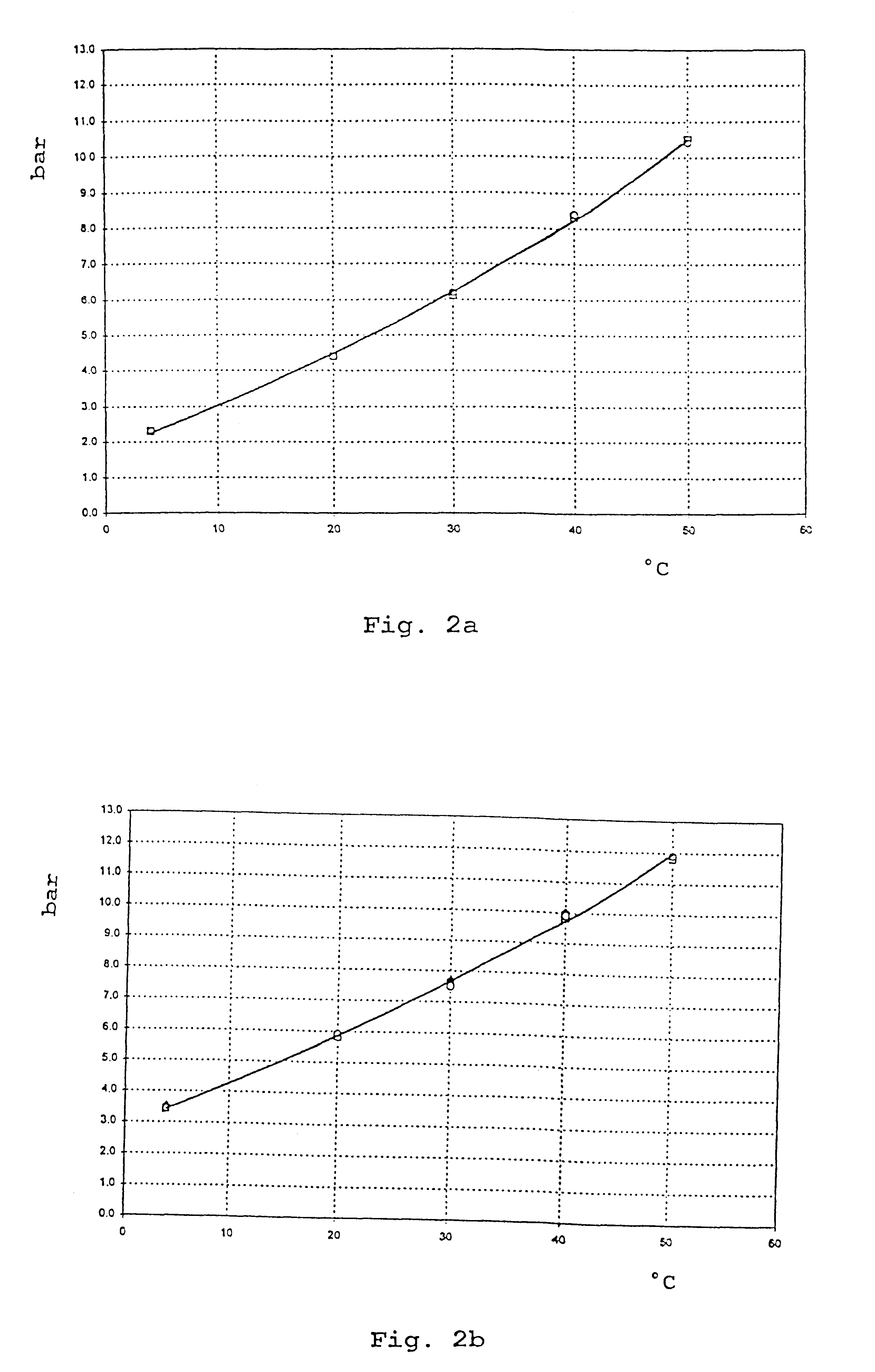

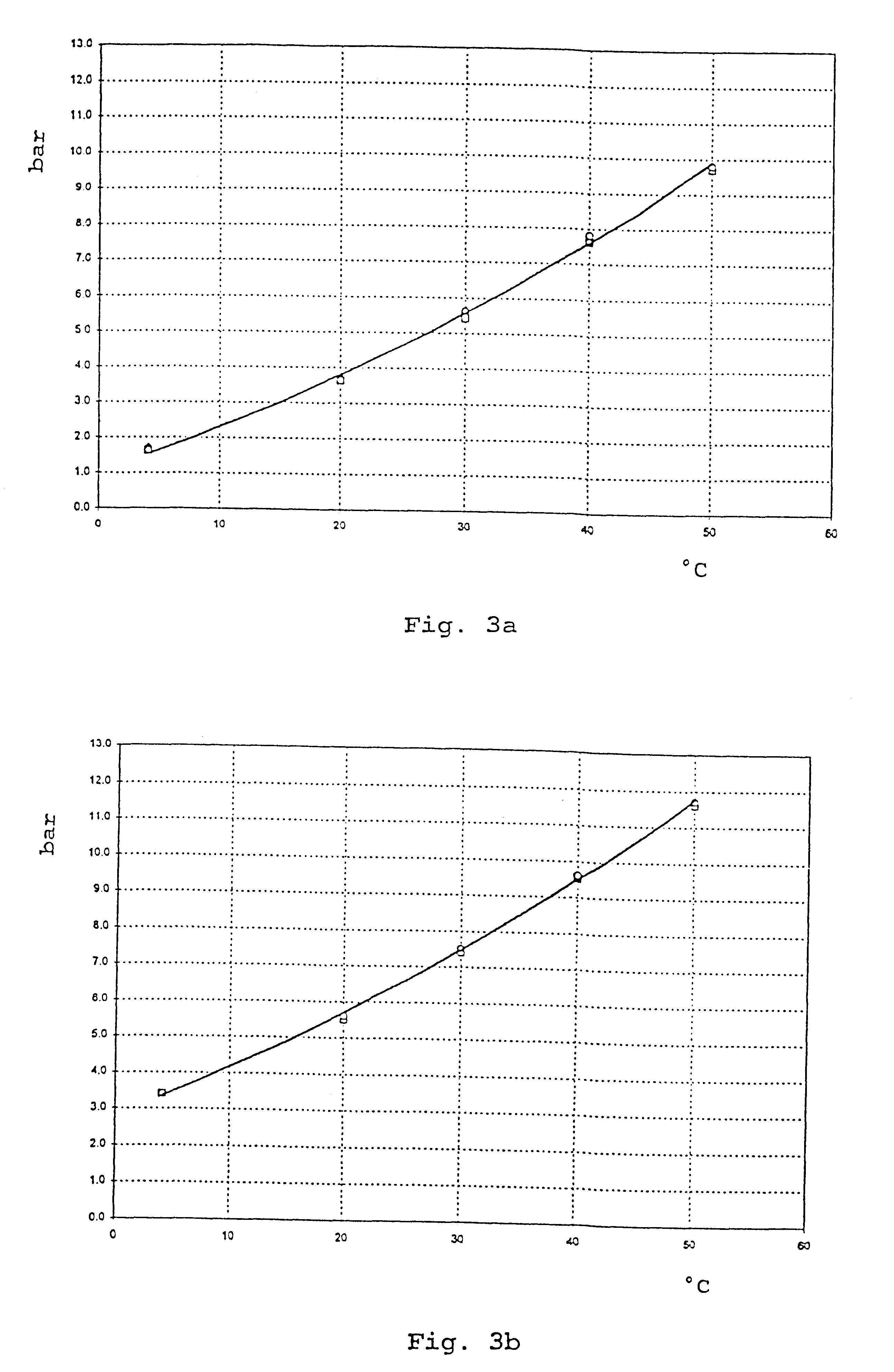

A pressure-liquefied propellant mixture for aerosols, comprising a fluorinated alkane, in particular 1,1,1,2-tetrafluoroethane and / or 1,1,1,2,3,3,3-heptafluoropropane, and carbon dioxide, makes possible an improvement of the wetting properties of pharmaceutically active compounds, with which the formulation problems existing with hydrofluoroalkanes in relation to suspension as well as solution aerosols can be overcome and thus improved medicinal aerosol formulations can be obtained. With the aid of carbon dioxide, it is also possible to specifically influence the pressure and thus the particle size distribution and also by displacement of oxygen from the hydrofluoroalkanes to improve the storage stability of oxidation-sensitive active compounds.

Owner:JAGOTEC AG

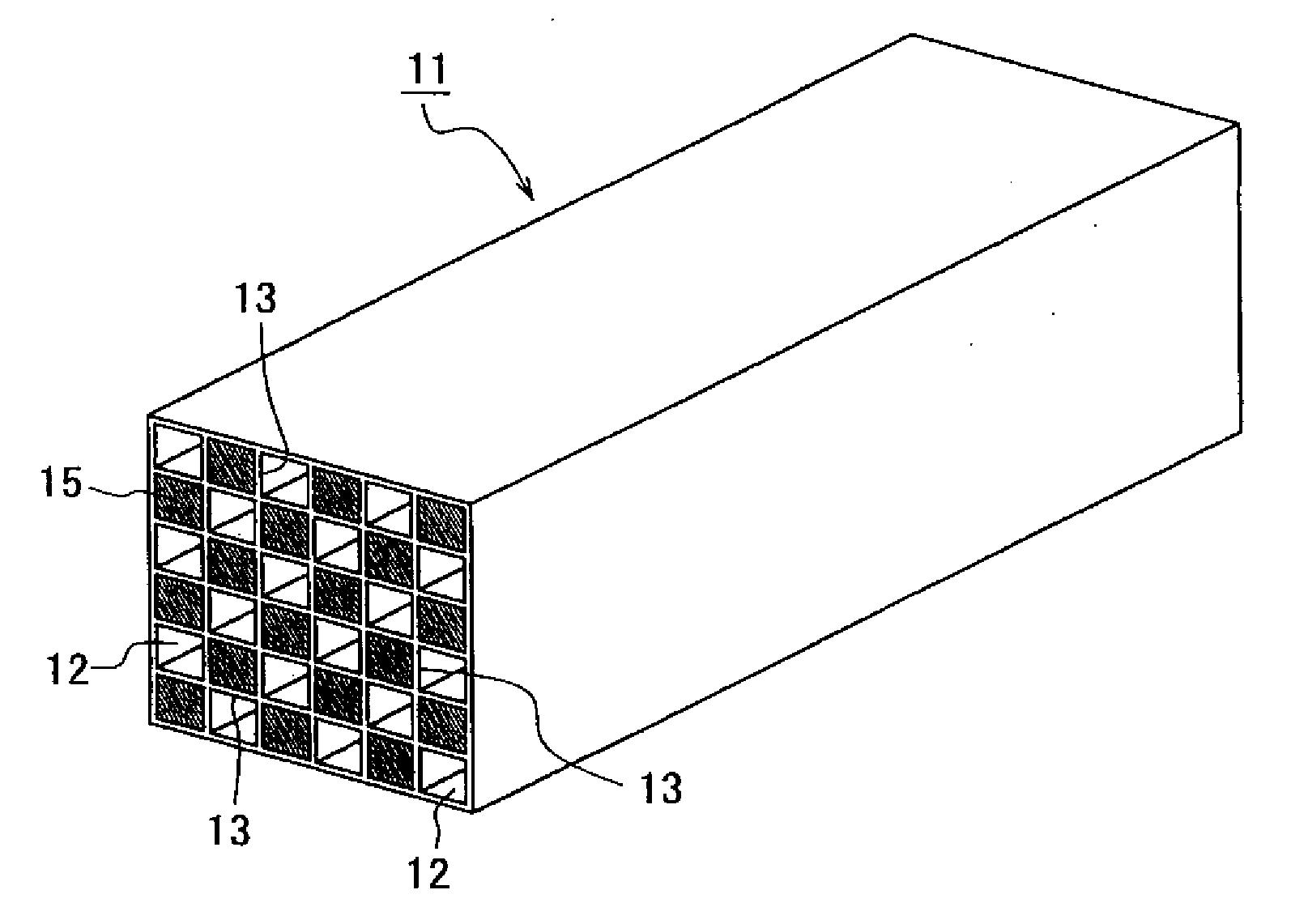

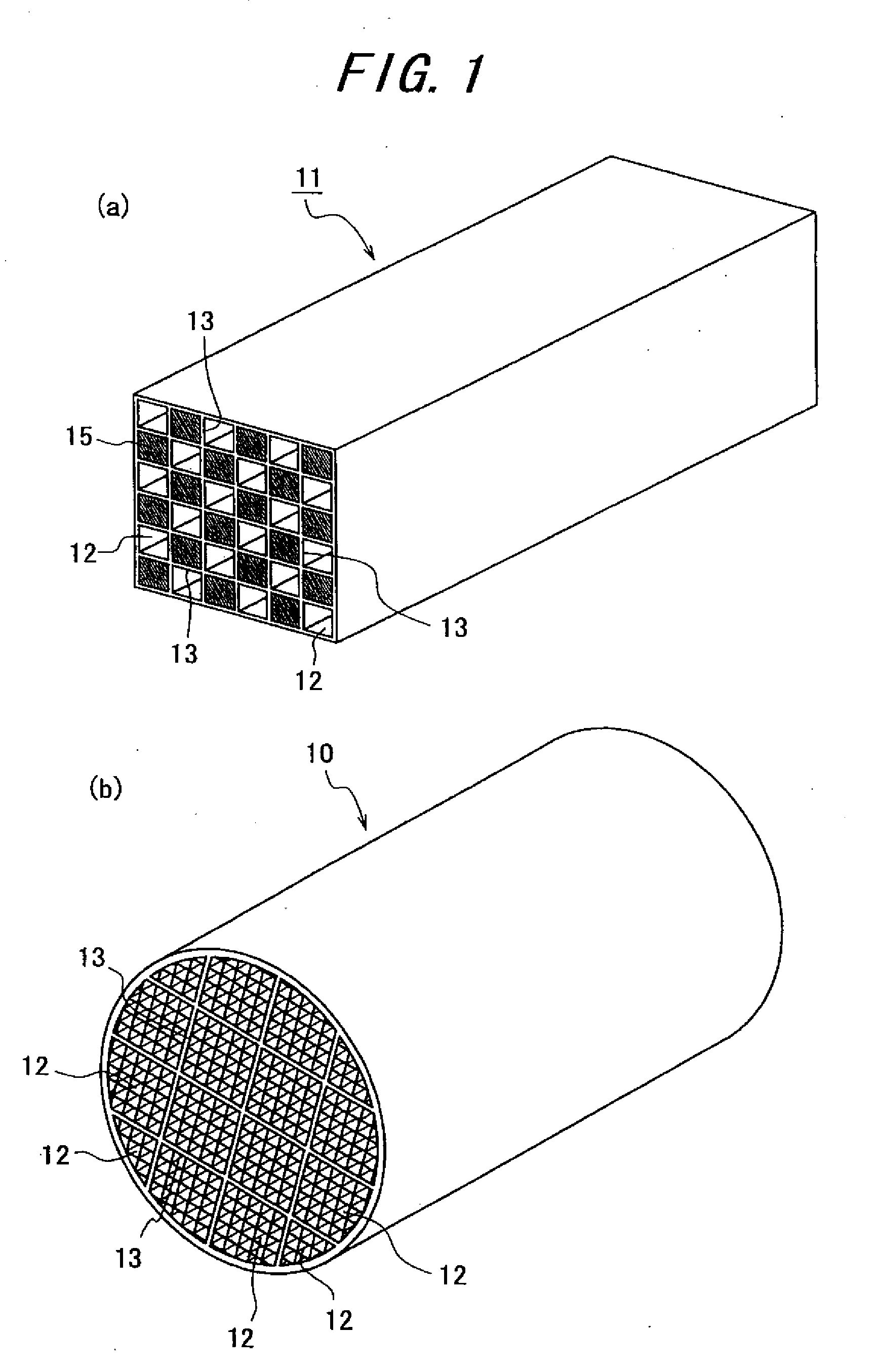

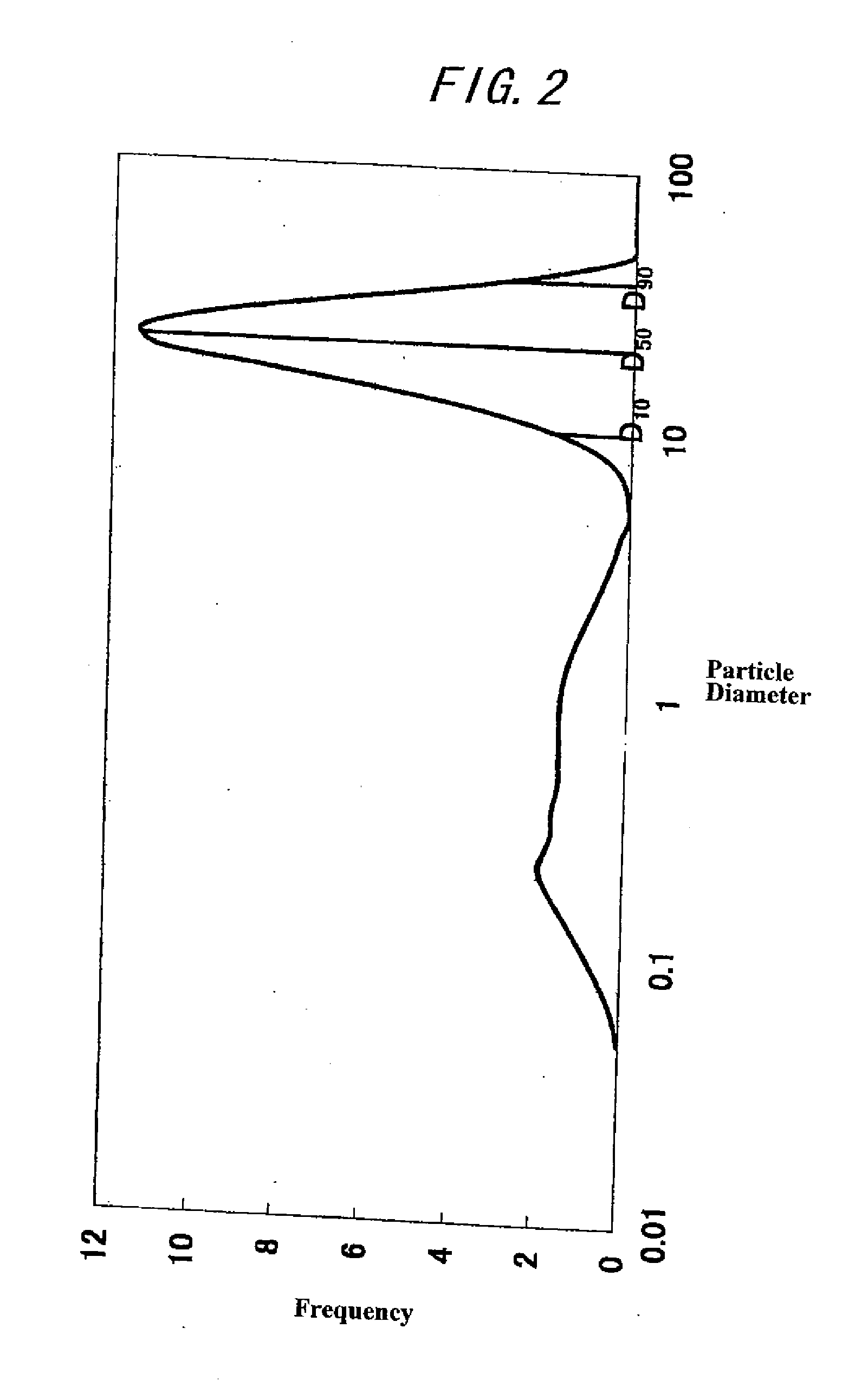

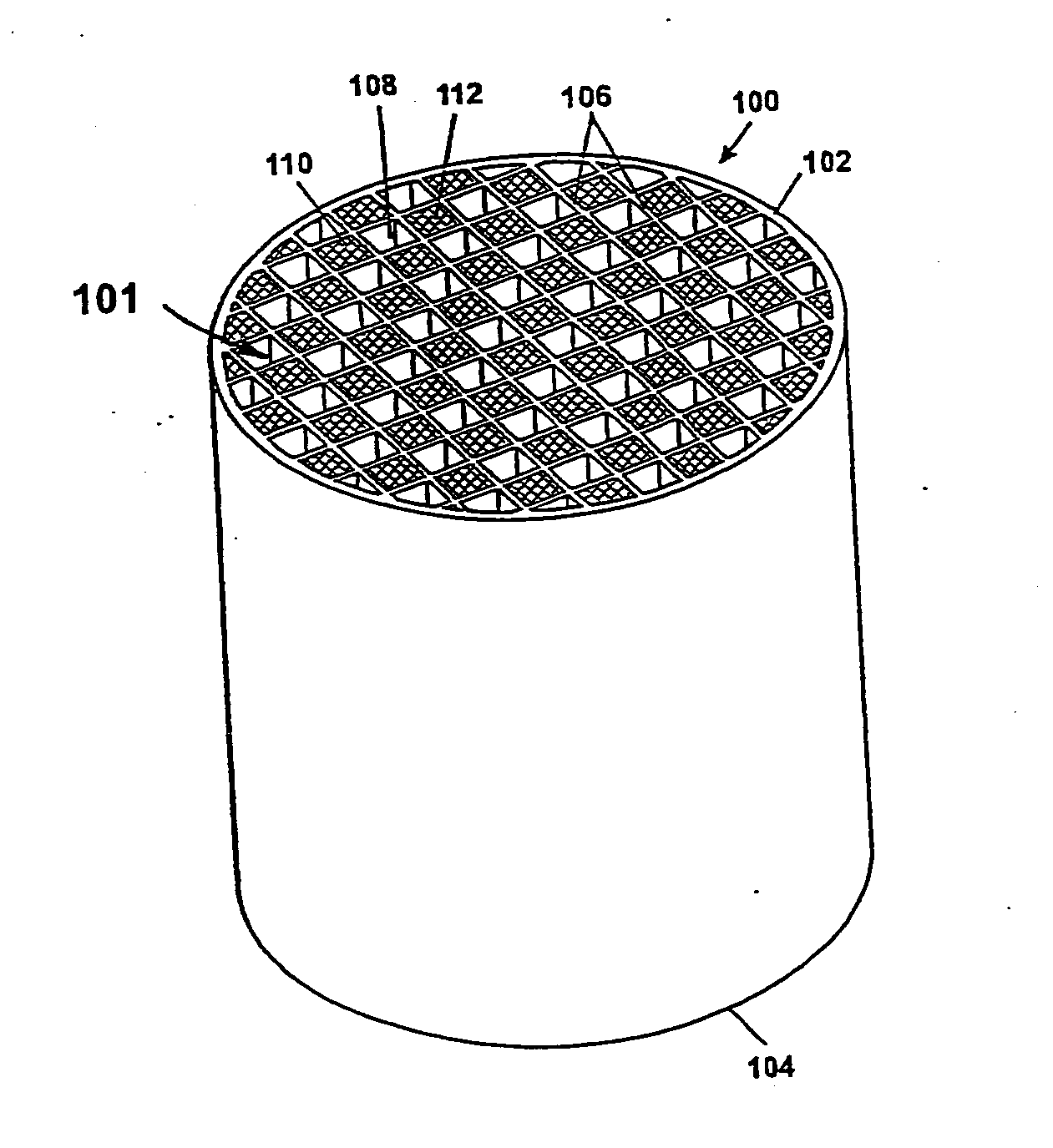

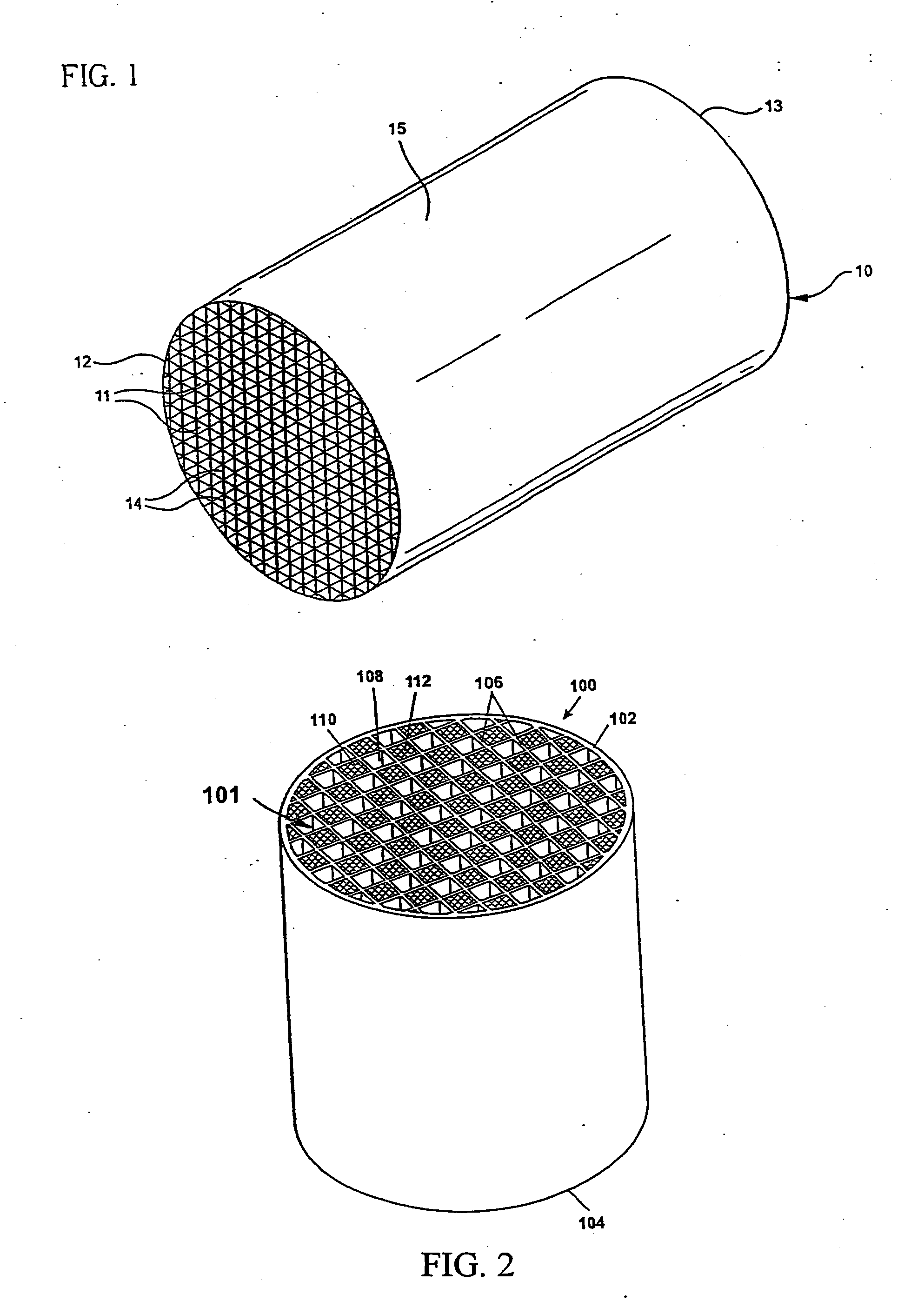

Ceramic Honeycomb Structural Body and Method of Manufacturing the Same

A ceramic honeycomb structural body is manufactured by molding silicon carbide raw powders into a honeycomb pillar shape and then firing it to form a sintered body. The silicon carbide raw powders are comprised of about 60 to about 80% by mass of particles of first particle group having one frequency peak in the particle size distribution and a particle size of 1.0 μm to about 100 μm, and about 20 to about 40% by mass of particles of a second particle group having a particle size of about 0.1 μm or more and less than 1.0 μm.

Owner:IBIDEN CO LTD

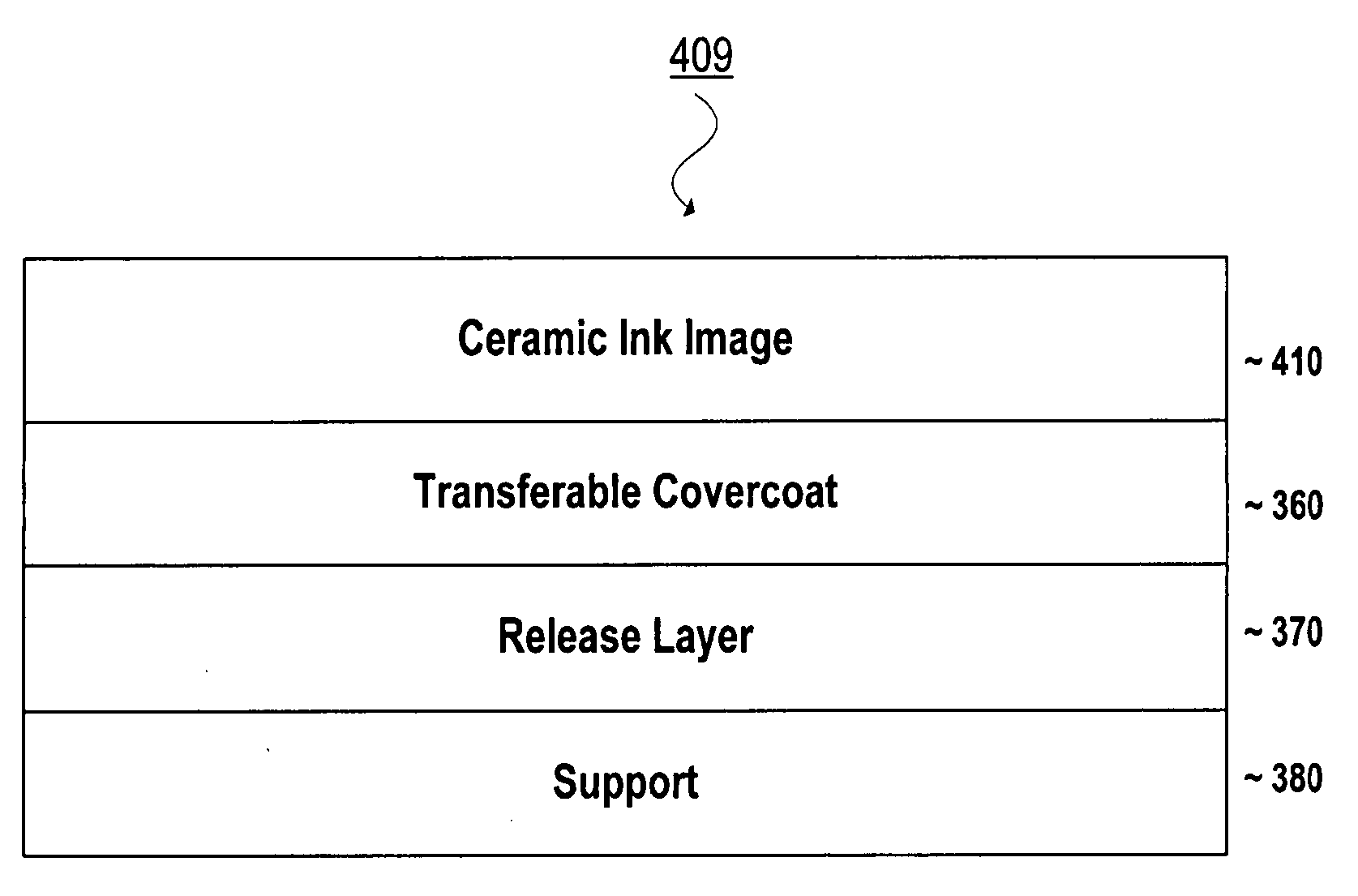

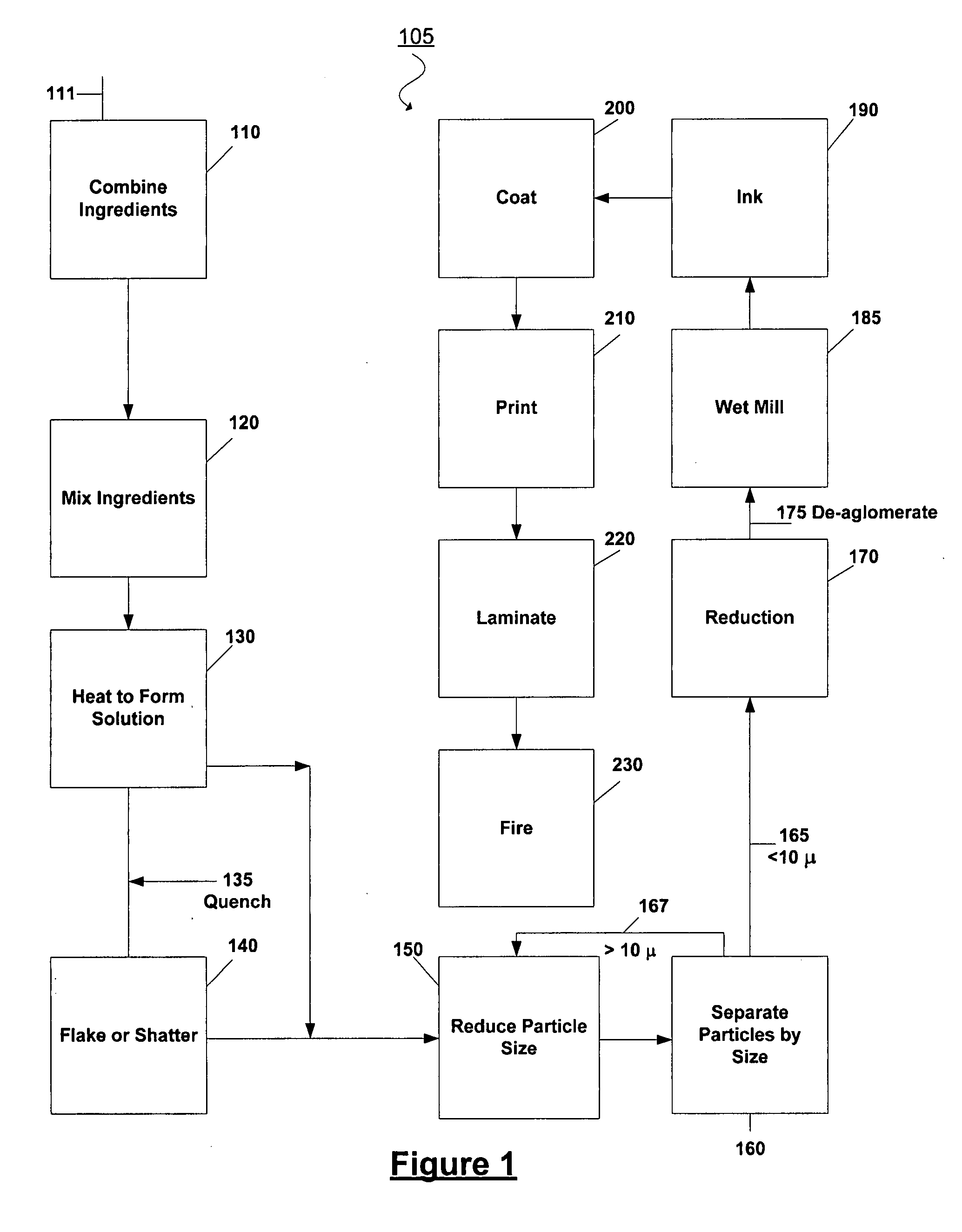

Colored glass frit

A colored glass frit with a specific surface area of less than 2 square meters per gram that contains from about 1 to about 80 weight percent of metallic element material and from about 30 to about 80 mole percent of glassy network forming oxide material. The frit has a transmission density per micron of thickness of at least about 0.1; when formed into a continuous film of 3 microns thickness and deposited onto a glass substrate, its transmission density is at least 0.3. The glassy network forming oxide material is homogeneously disposed in the flit, and the metallic element material is inhomogeneously dispersed within the glassy network forming oxide material. The metallic element material is in particulate form and has a particle size distribution such that at least 95 weight percent of its particles are smaller than 300 nanometers.

Owner:ALFRED UNIVERSITY

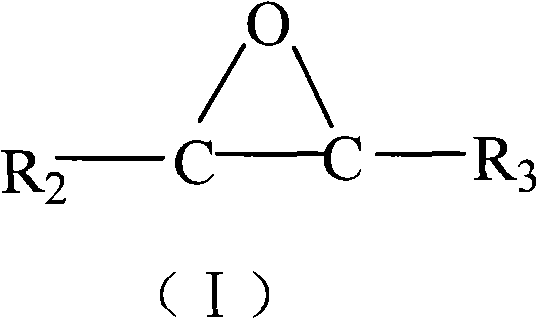

Spherical carriers for olefin polymerization catalyst and preparation method

ActiveCN102040683ANarrow particle size distributionParticles in good shapeParticle-size distributionPhotochemistry

The invention relates to spherical carriers for an olefin polymerization catalyst and a preparation method. Each spherical carrier comprises reaction products of the following components: (1) magnesium halide which is shown as the general formula MgX2, (2) alcohol compounds which are shown as the general formula ROH, and (3) ethylene oxide compounds which are shown as the general formula (I), wherein in the general formula (I), R2 and R3 are alkyls with a C1-C5 straight chain or branched chain; and hydrogen on the alkyls can be randomly substituted by a halogen atom. The spherical carriers have good particle shapes, adjustable particle sizes and narrow particle size distribution, and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

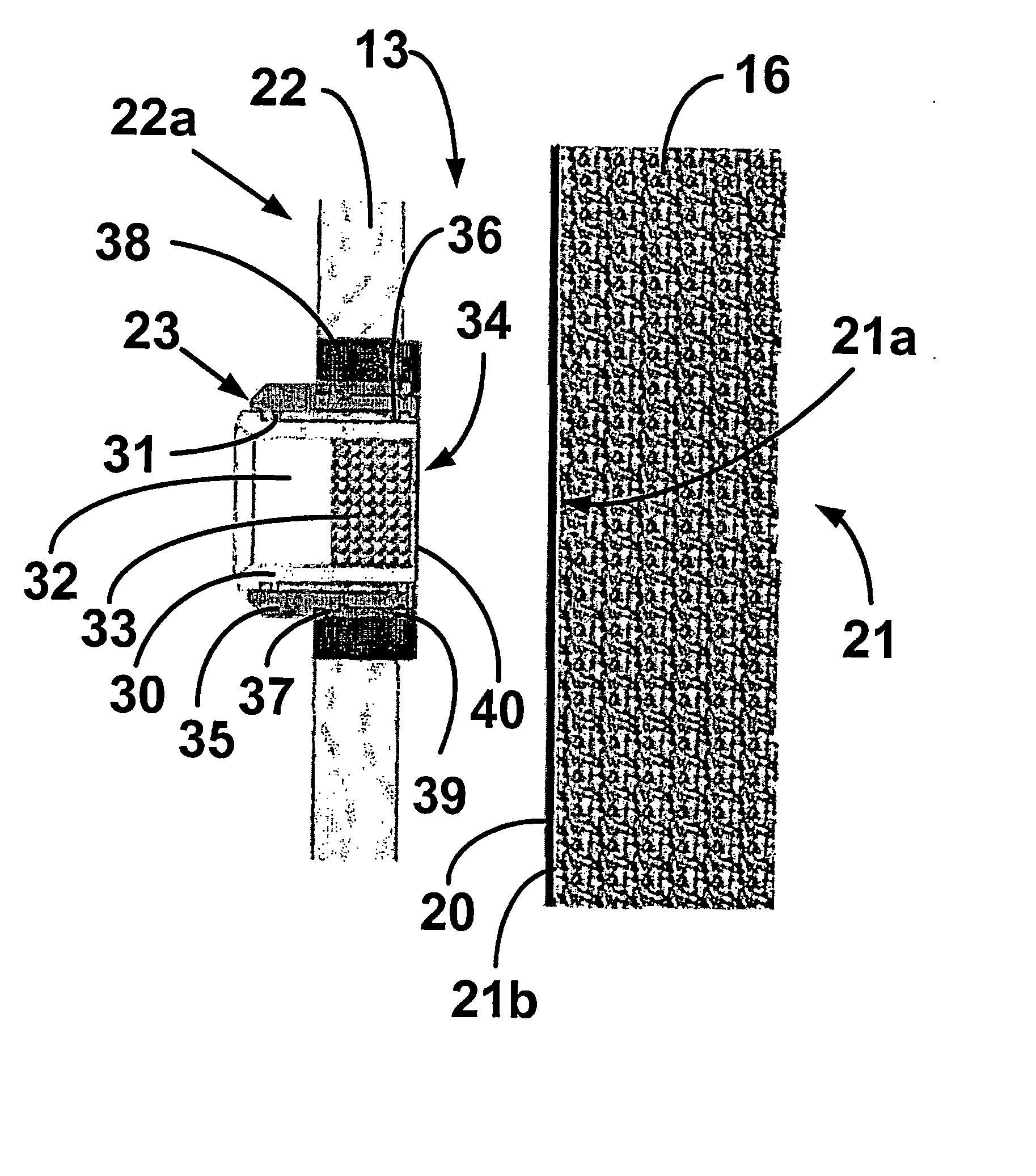

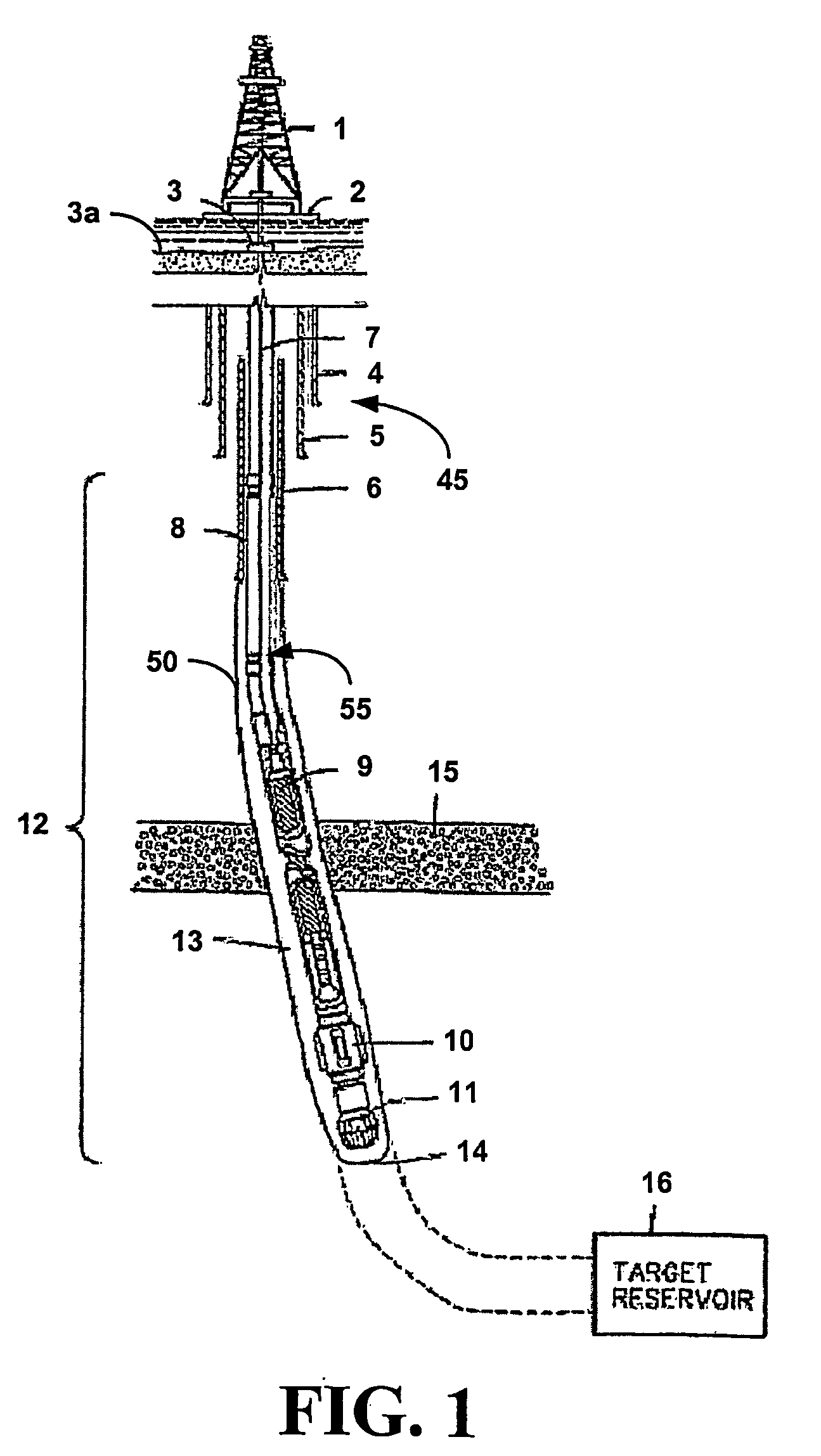

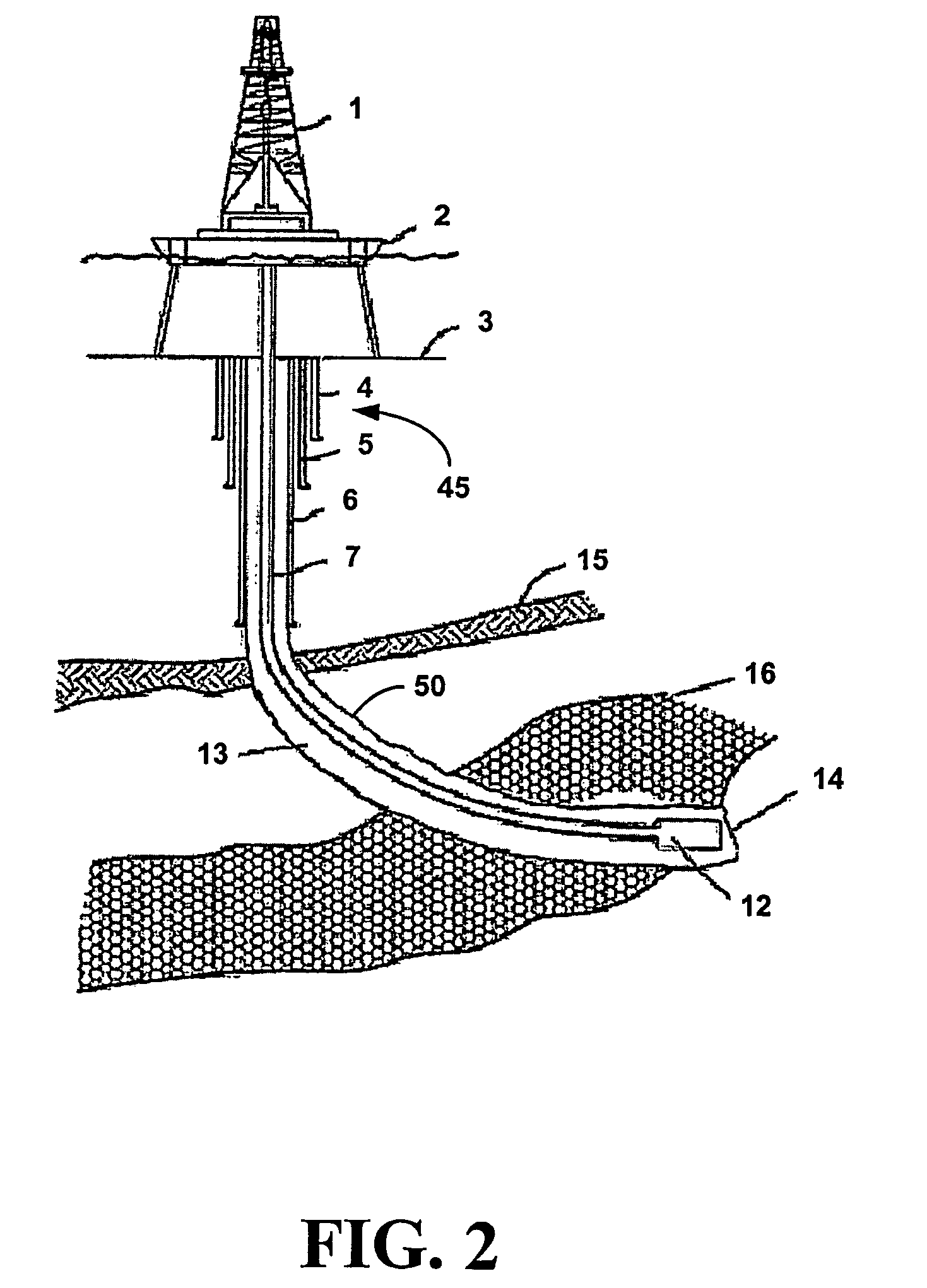

Drilling method for maintaining productivity while eliminating perforating and gravel packing

InactiveUS20060108114A1Improved formation productivityImprove productivityFluid removalProduction rateWell drilling

A method for well construction and completion is disclosed. First, a productive section of a well is drilled in the presence of a fluid system that controls fluid losses, is substantially non-damaging to the formation and includes particles in a particle size distribution sufficient to form a low permeability filter cake on a formation face and to allow the majority of the filter cake particles to flow back into the borehole after well completion. after drilling, a casing includes at least one and preferably a plurality of extendable permeable elements or member is run in the well so that the elements are positioned and aligned with sites in the producing formation and once extended form production conduits between the formation and an interior of the casing. A completed borehole is also disclosed including a casing having production conduits formed from the extendable members or elements.

Owner:BAKER HUGHES INC

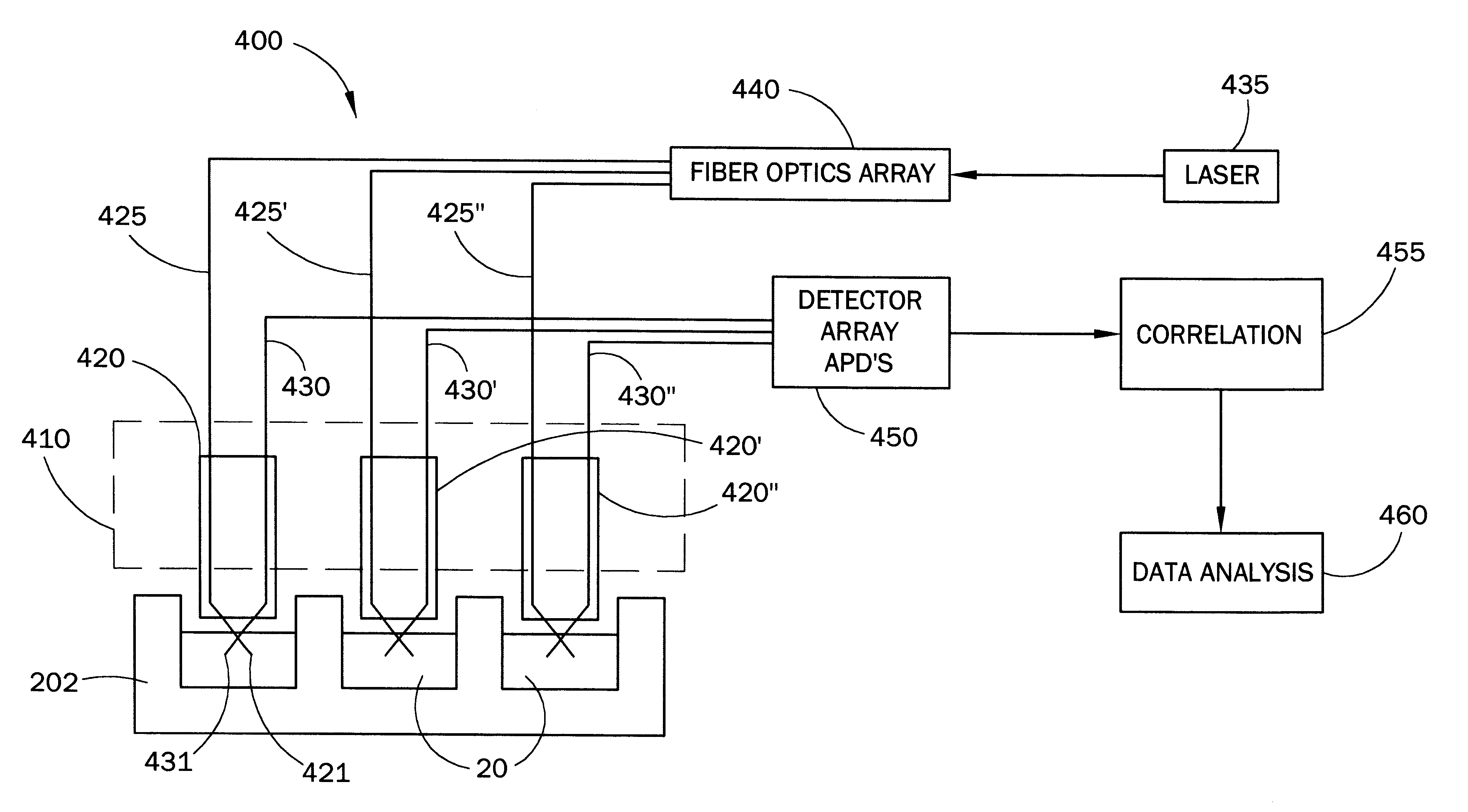

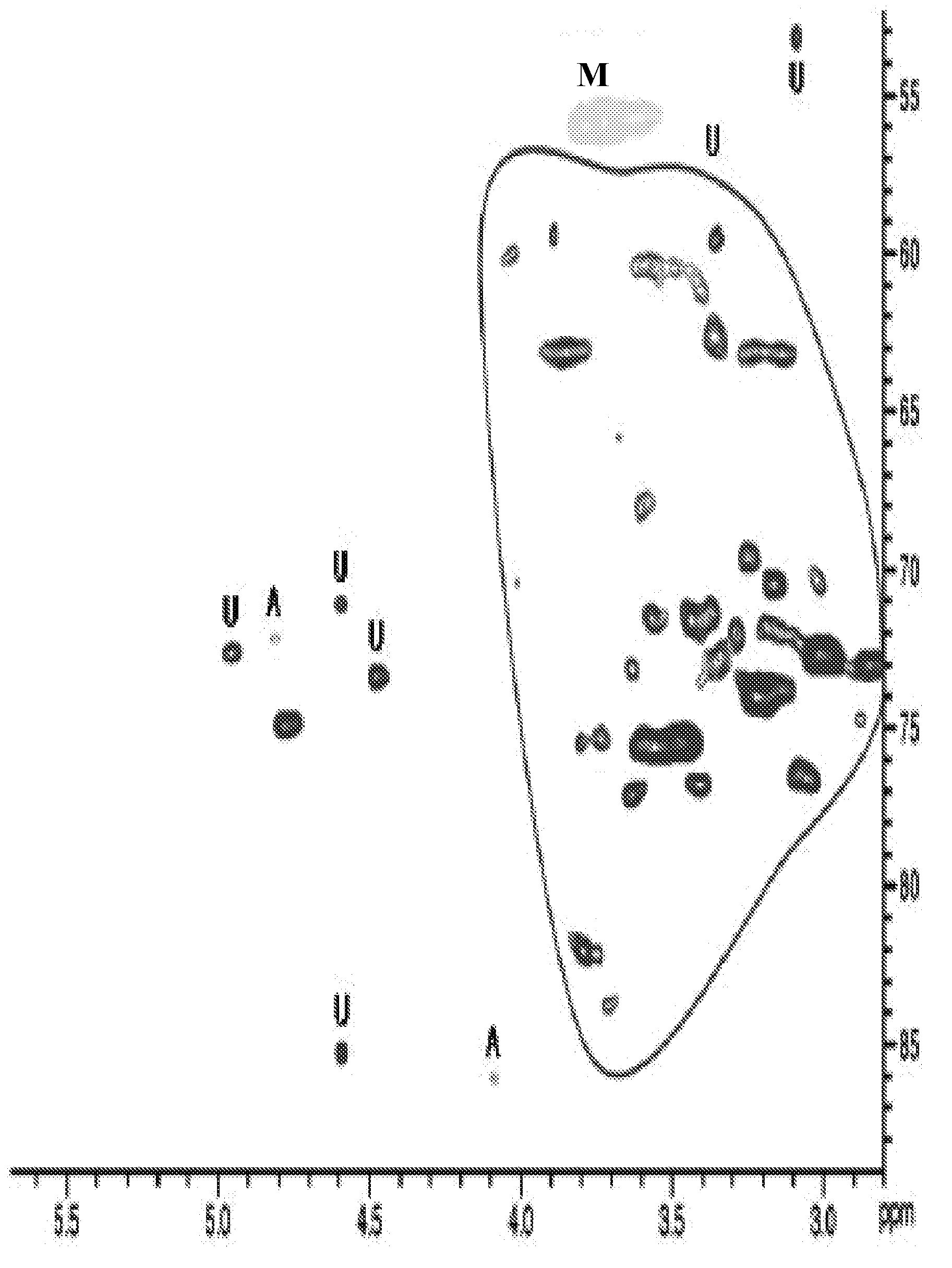

Fiber optic apparatus and use thereof in combinatorial material science

InactiveUS6519032B1Facilitate the discovery of commercially important polymericEffectively and efficiently characterizingSequential/parallel process reactionsComponent separationFiberHigh-Throughput Screening Methods

Methods, systems and devices are described for rapid characterization and screening of liquid samples to determine properties (e.g., particle size, particle size distribution, molar mass and / or molar mass distribution) thereof with static light scattering and / or dynamic light scattering. The liquid samples can be solutions, emulsions, suspensions or dispersions. One method, includes providing a vessel containing a liquid sample having an exposed surface that defines a gas-liquid sample interface, and analyzing the sample by light scattering methods that include transmitting light through the gas-liquid sample interface into the sample, and detecting light scattered from the sample or from a component thereof. Additional methods are directed to characterizing a plurality of liquid samples or components thereof. The methods, systems, and devices have applications in high-throughput screening, and particularly, in combinatorial materials research and in industrial process control.

Owner:WYATT TECH

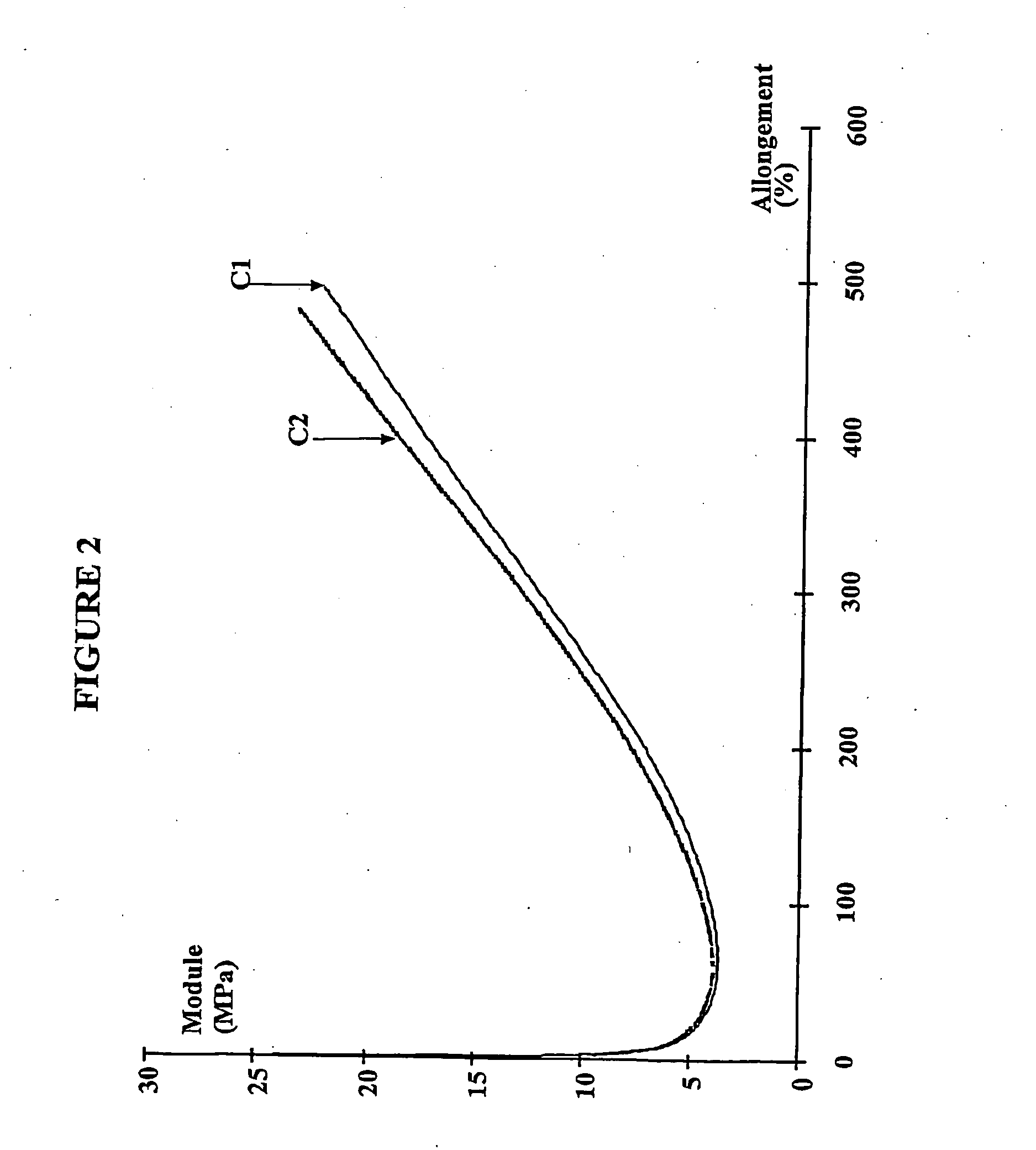

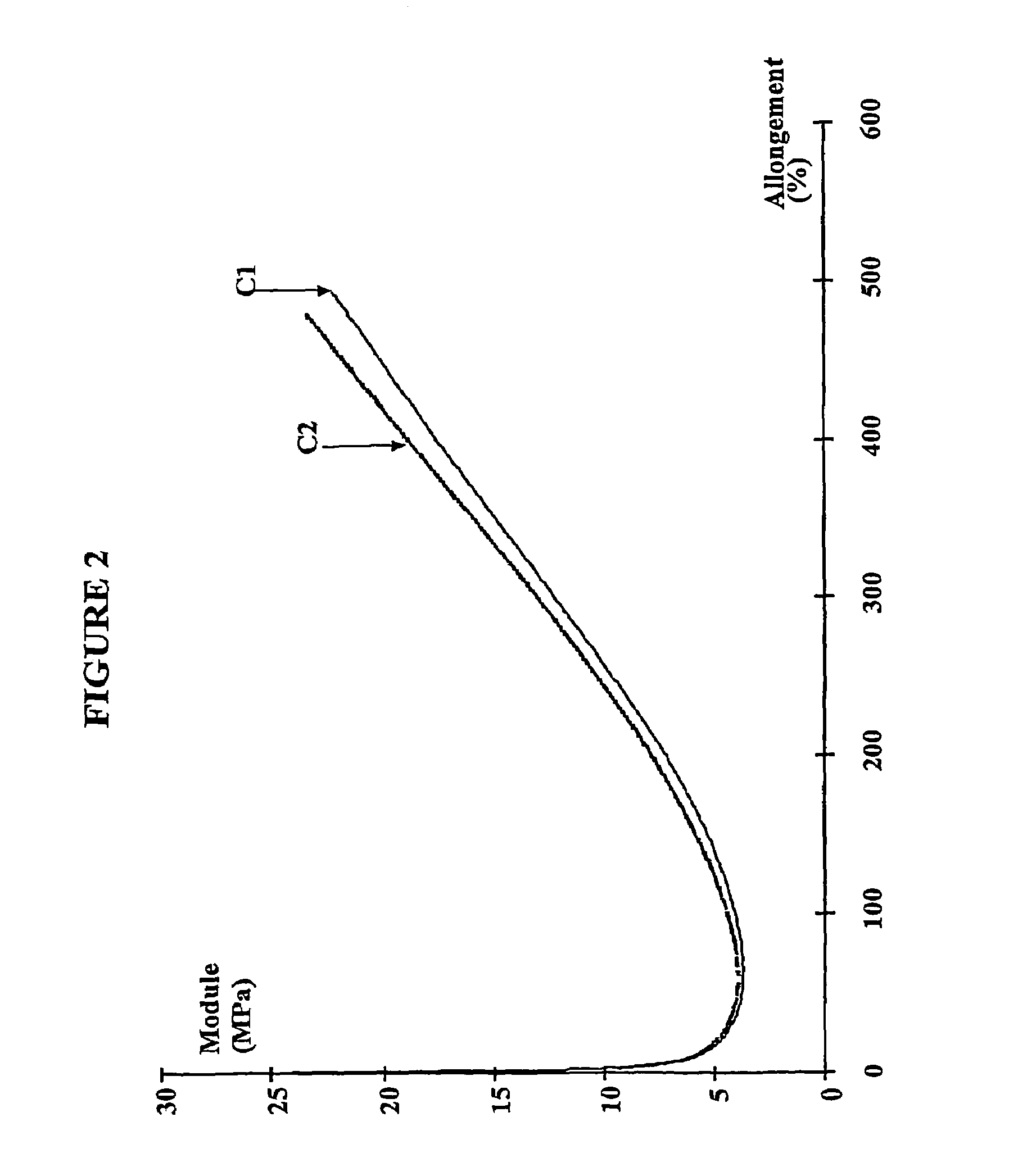

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS20050004297A1Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresElastomerPorosity

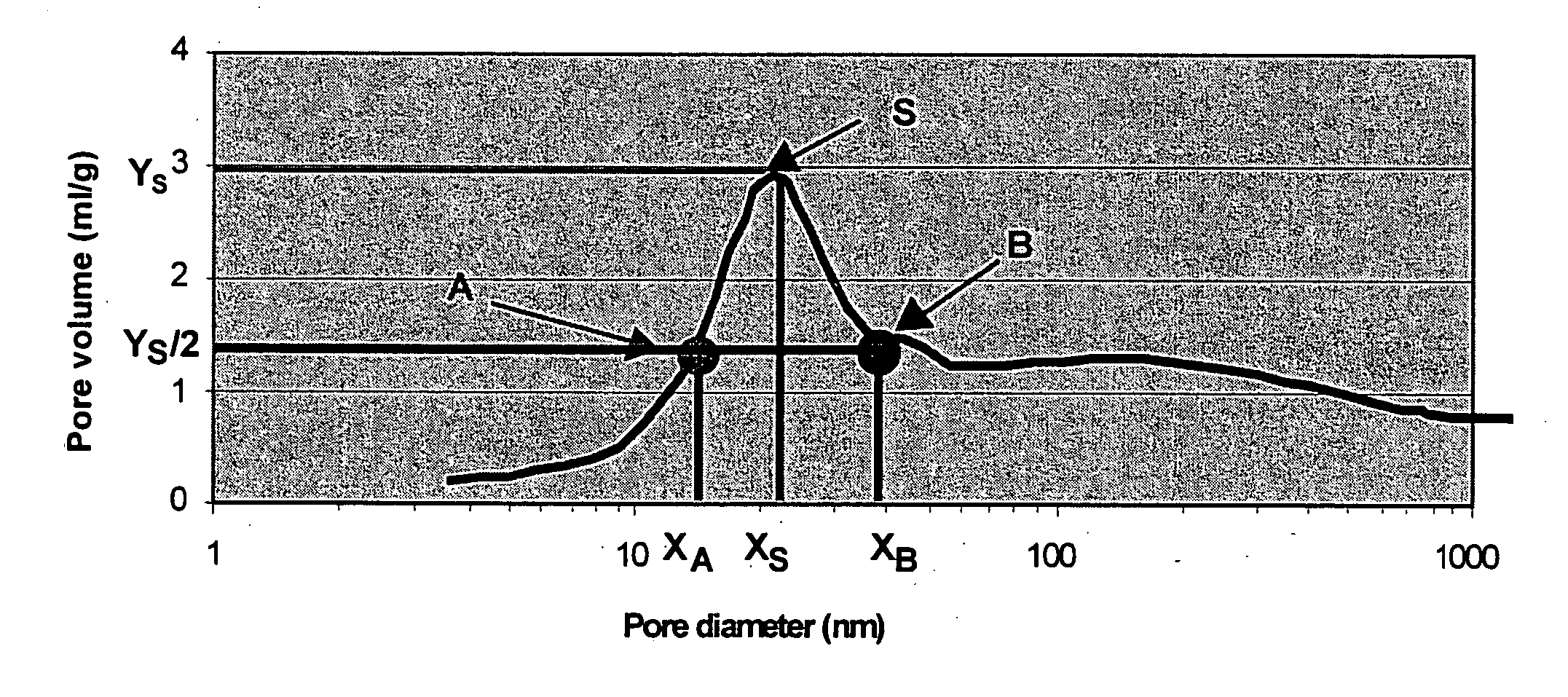

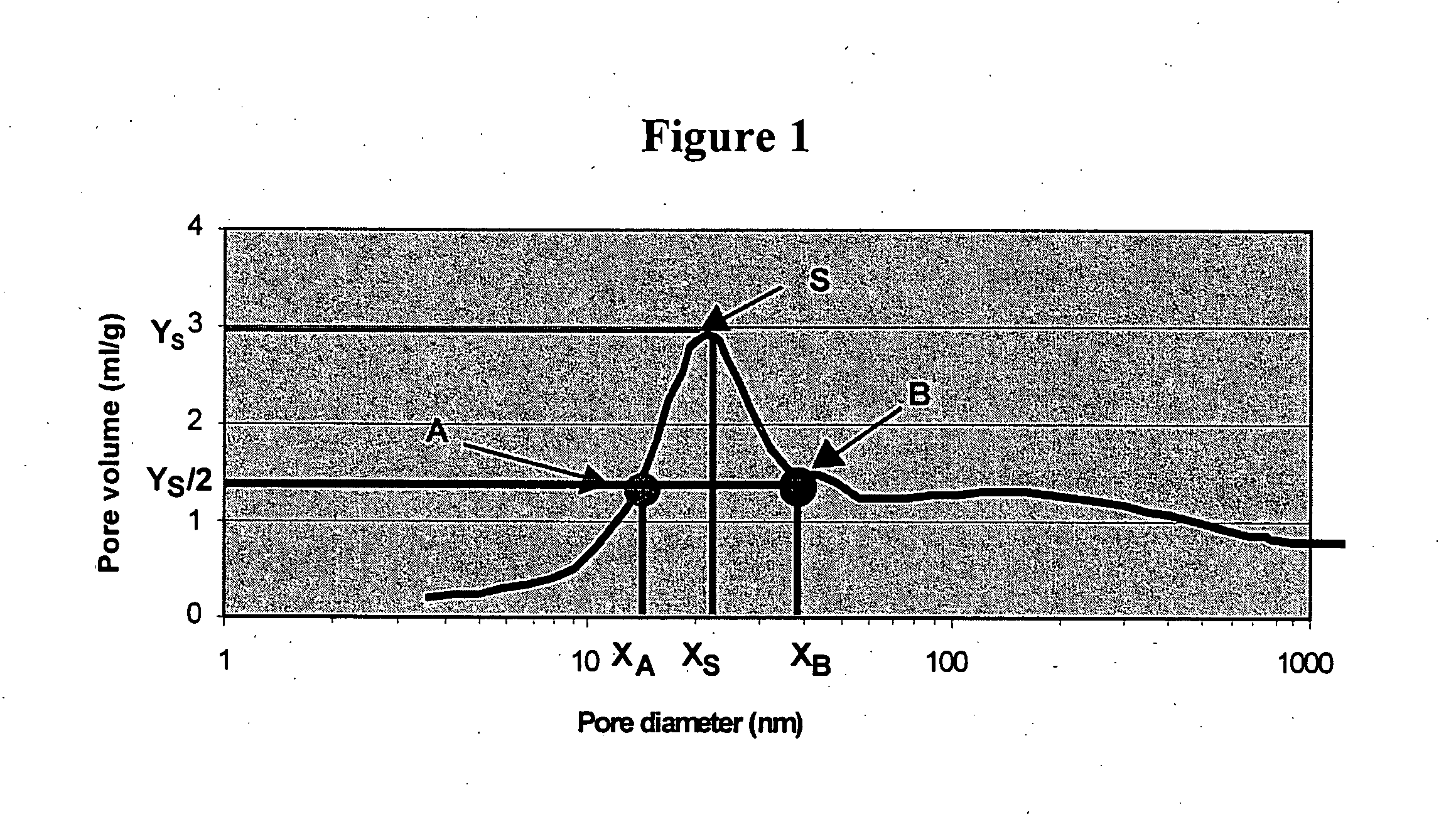

Diene rubber compositions are described containing a diene elastomer, a reinforcing inorganic filler, and a coupling agent wherein the inorganic filler includes a silica having the following characteristics: (a) a BET specific surface area between 45 and 400 m2 / g; (b) a CTAB specific surface area between 40 and 380 m2 / g; (c) an average particle size (by mass), dw, of 20 to 300 nm; and at least one of the following characteristics, preferably two and more preferably all three: (d) a particle size distribution such that dw≧ / CTAB)−30; (e) a porosity which meets the criterion L / FI≧−0.0025 CTAB+0.85; (f) an amount of silanols per unit of surface area, NSiOH / nm2; NSiOH / nm2≦−0.027 CTAB+10.5. These diene rubber compositions can be used for the manufacture of tires or of semi-finished products intended for tires.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

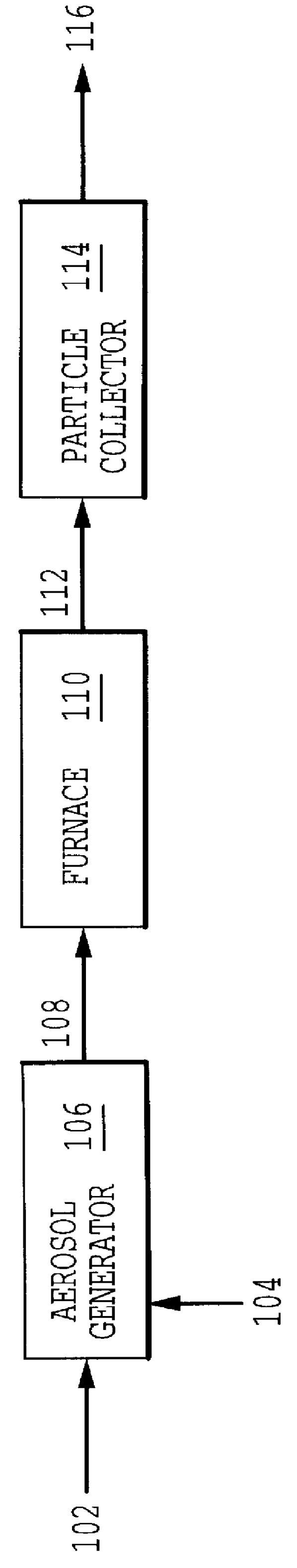

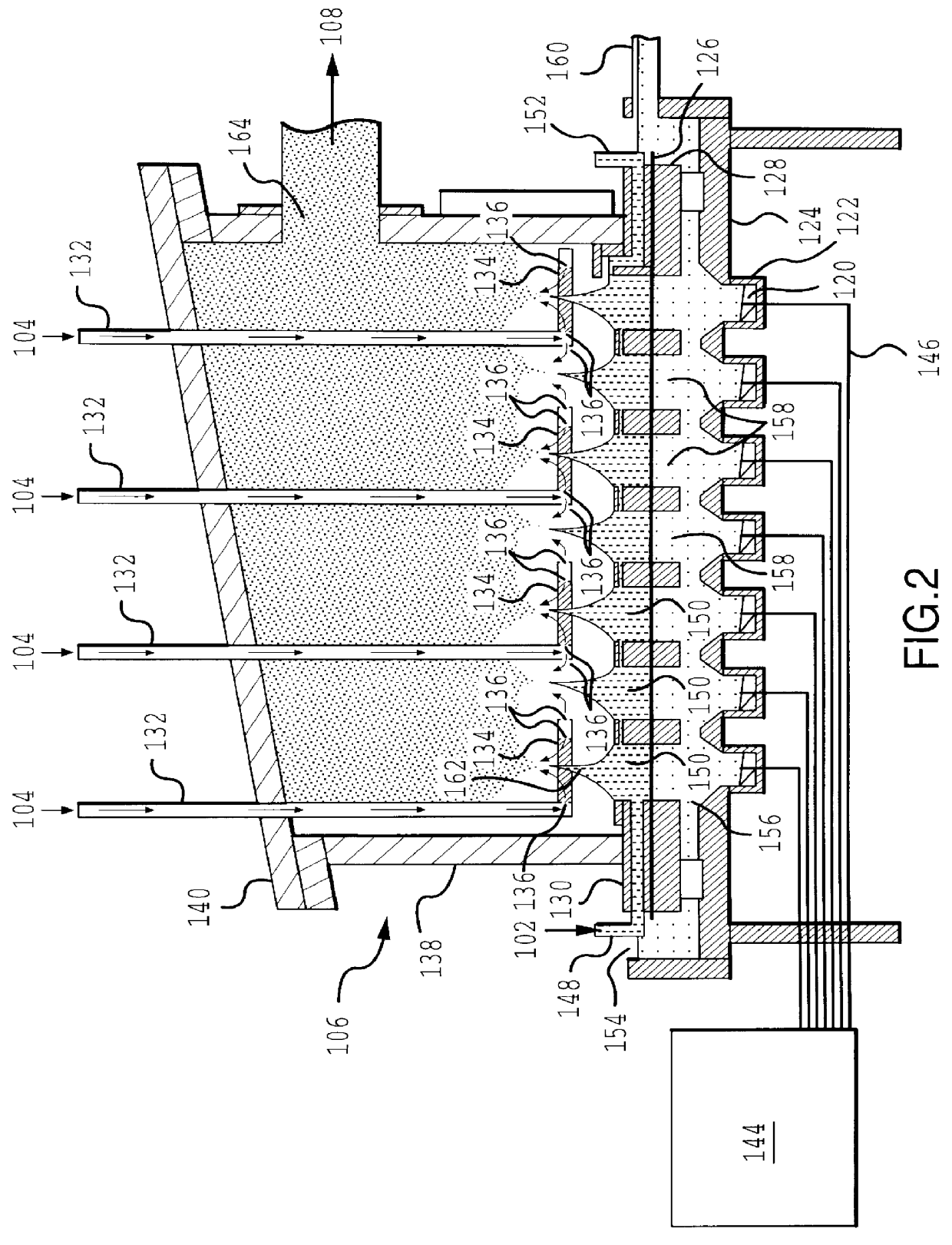

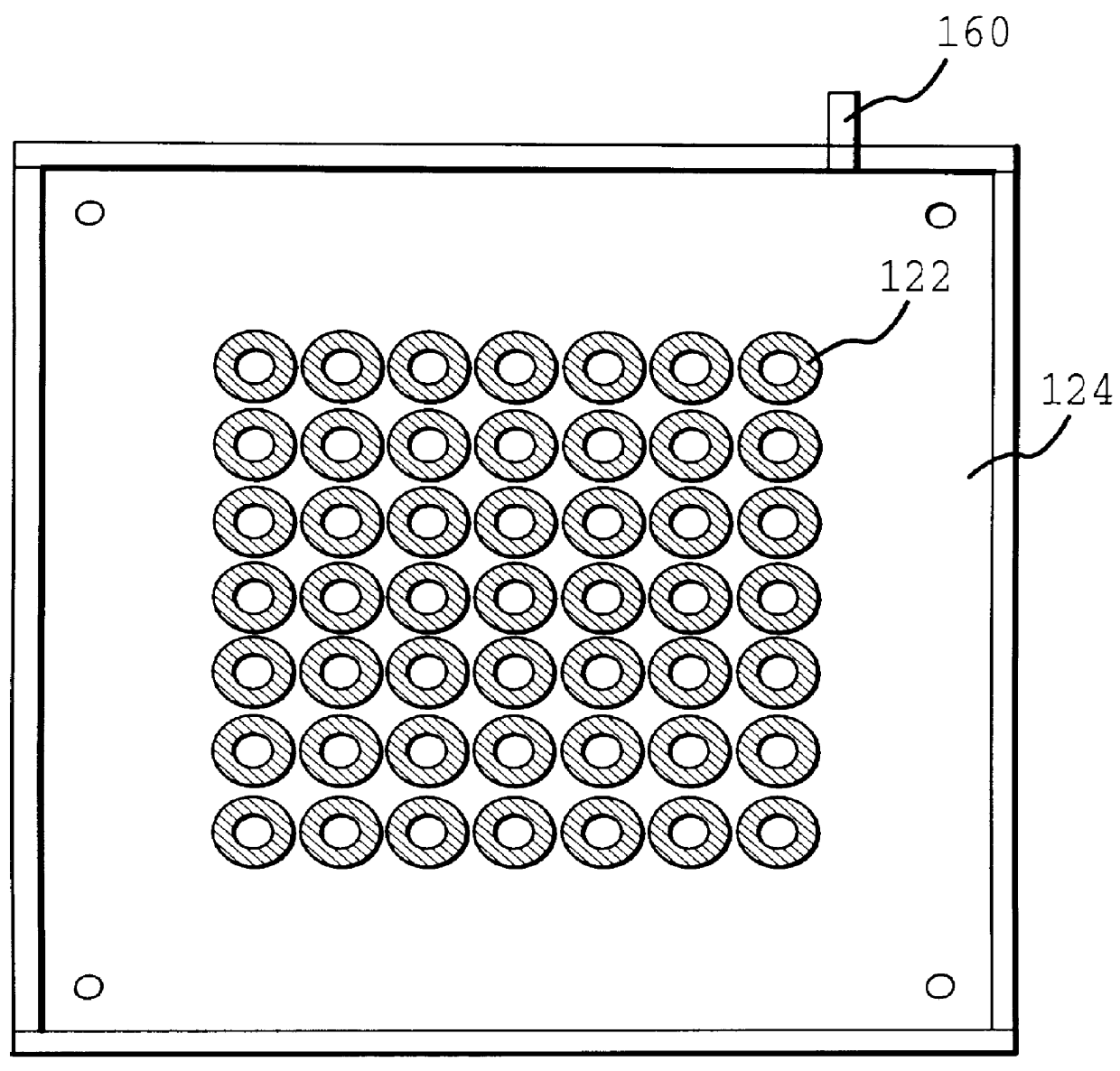

Powder batch of pharmaceutically-active particles and methods for making same

Powder batches of pharmaceutically-active particles and methods for making same. The pharmaceutically-active particles have a small particle size and a narrow particle size distribution and are particularly useful in devices such as medical inhalers. The present invention also provides an aerosol-based method for producing pharmaceutically-active particles wherein an aerosol is produced having a tightly controlled droplet size to produce pharmaceutically-active particles having a small particle size and narrow particle size distribution.

Owner:CABOT CORP

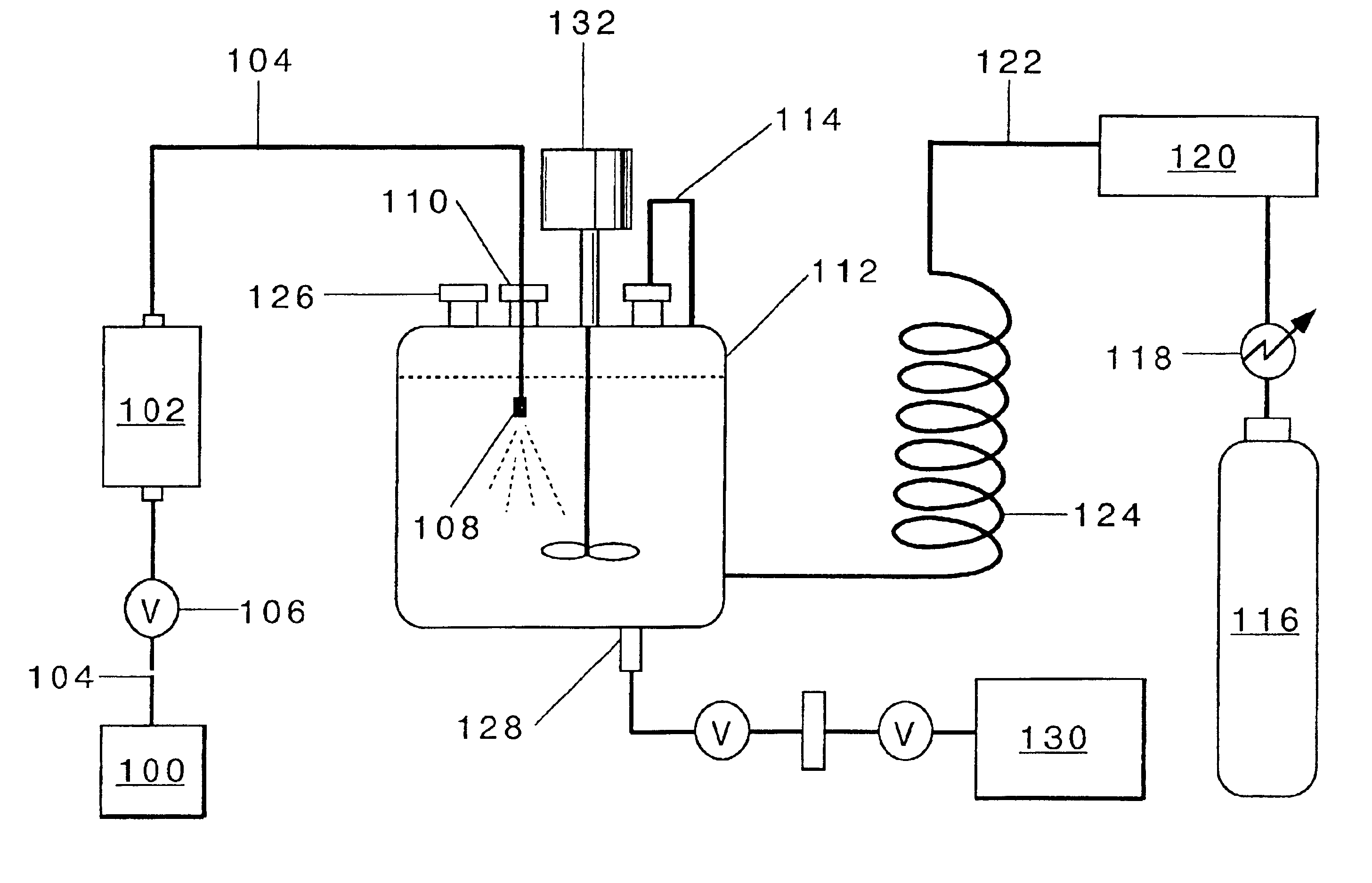

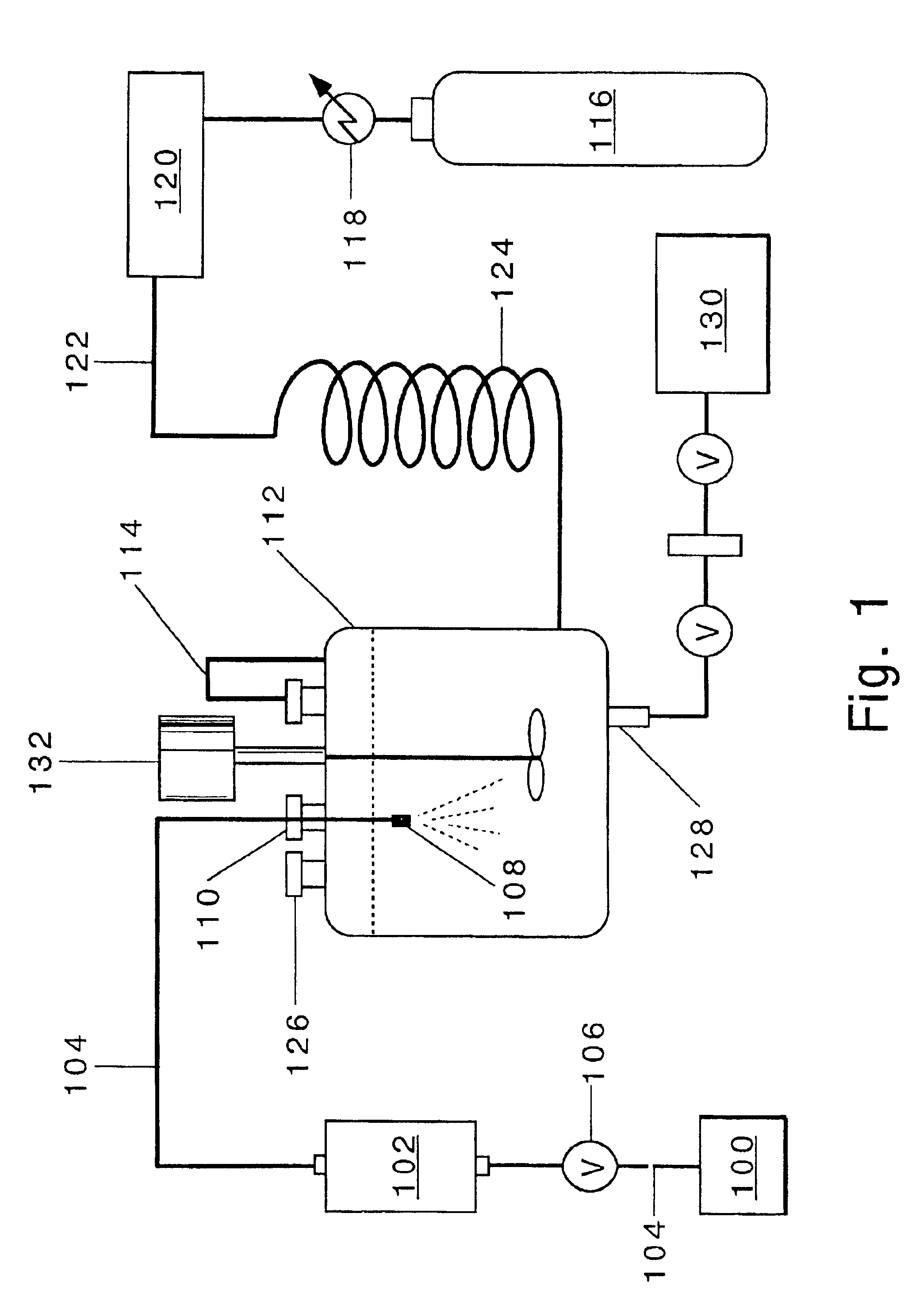

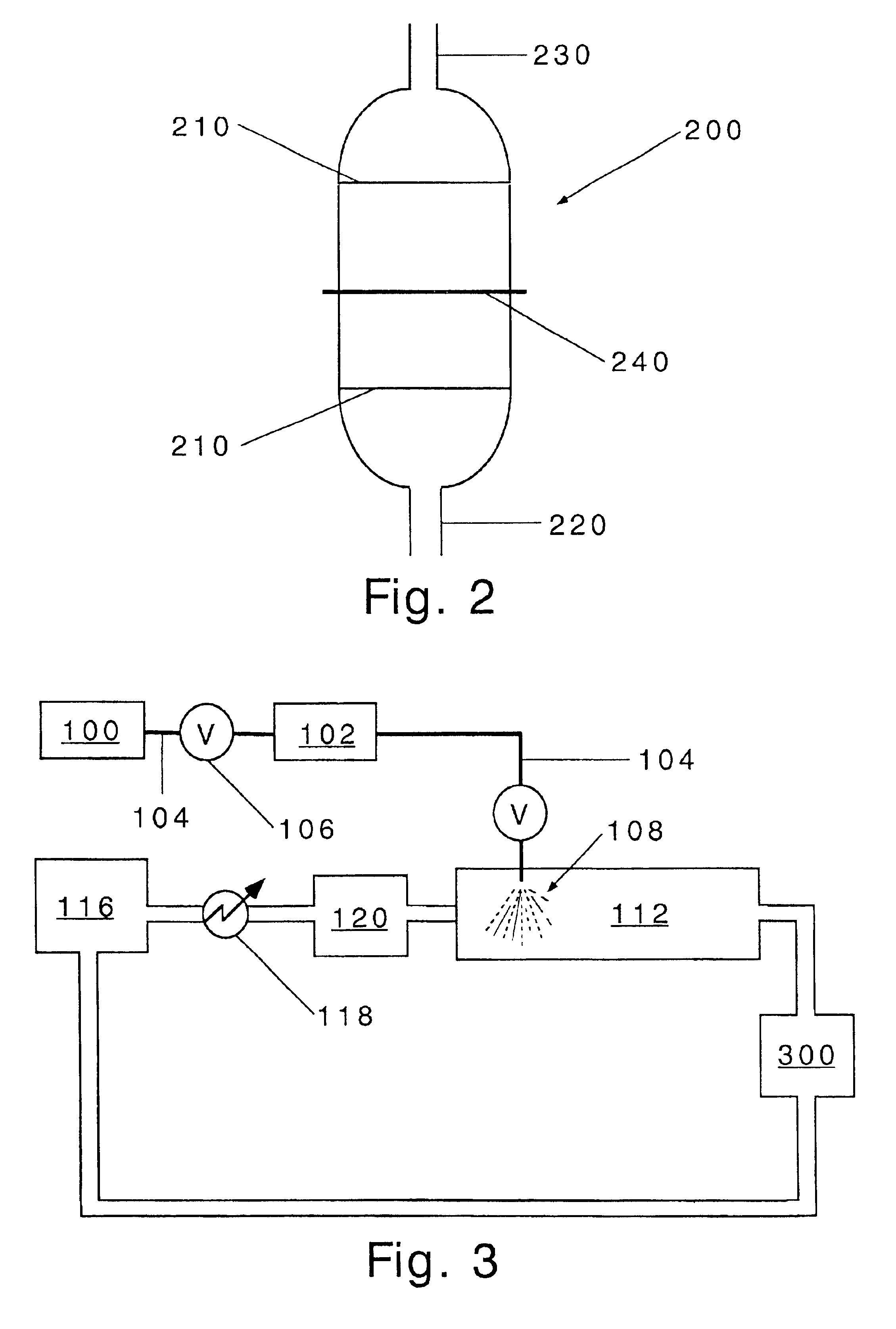

Process for production of nanoparticles and microparticles by spray freezing into liquid

InactiveUS6862890B2Improve efficiencyImprove efficacyPowder deliveryNervous disorderPorosityNanoparticle

The present invention provides a system and a method for the production of microparticles and nanoparticles of materials that can be dissolved. The system and method of the present invention provide quicker freezing times, which in turn produces a more uniform distribution of particle sizes, smaller particles, particles with increased porosity and a more intimate mixing of the particle components. The system and method of the present invention also produce particles with greater surface area than conventional methods. One form of the present invention provides a method for the preparation of particles. An effective ingredient is mixed with water, one or more solvents, or a combination thereof, and the resulting mixture is sprayed through an insulating nozzle located at or below the level of a cryogenic liquid. The spray generates frozen particles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Natural rubber master batch, production method thereof, and natural rubber composition

InactiveUS6841606B2Easy to processImprove propertiesPigmenting treatmentSpecial tyresPolymer scienceSlurry

The natural rubber master batch of the present invention is prepared by mixing a natural rubber latex having its amide linkages cleaved and an aqueous slurry having a filler dispersed in water. Alternatively, the natural rubber master batch is prepared by a method including a step for mixing a natural rubber latex and an aqueous slurry containing dispersed fillers having a specific particle size distribution and a limited range of 24M4DBP absorption. The natural rubber composition of the present invention is prepared by compounding natural rubber, which contains non-rubber components prepared by cleaving amide linkages of natural rubber latex, with silica and / or a particular inorganic filler.

Owner:BRIDGESTONE CORP

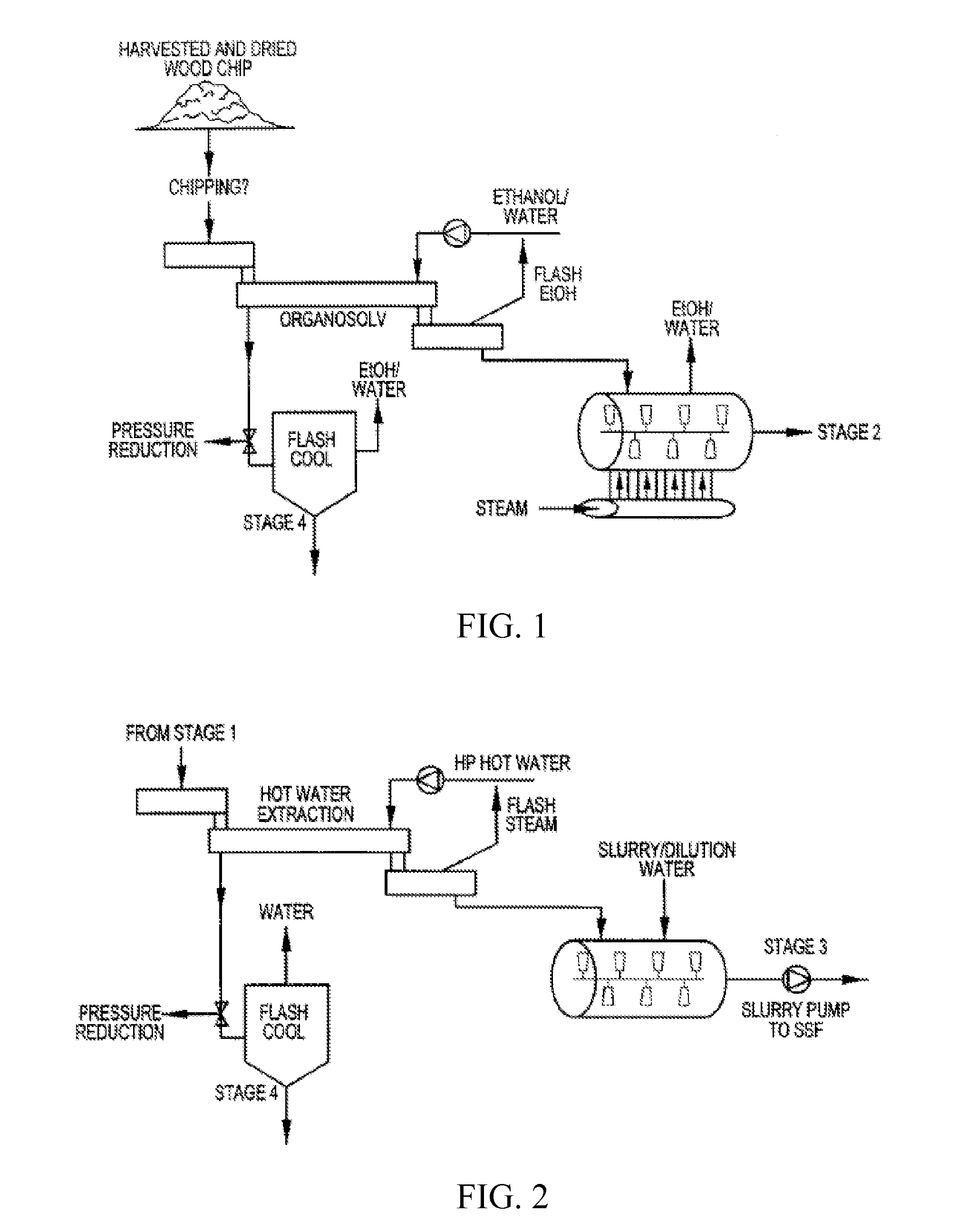

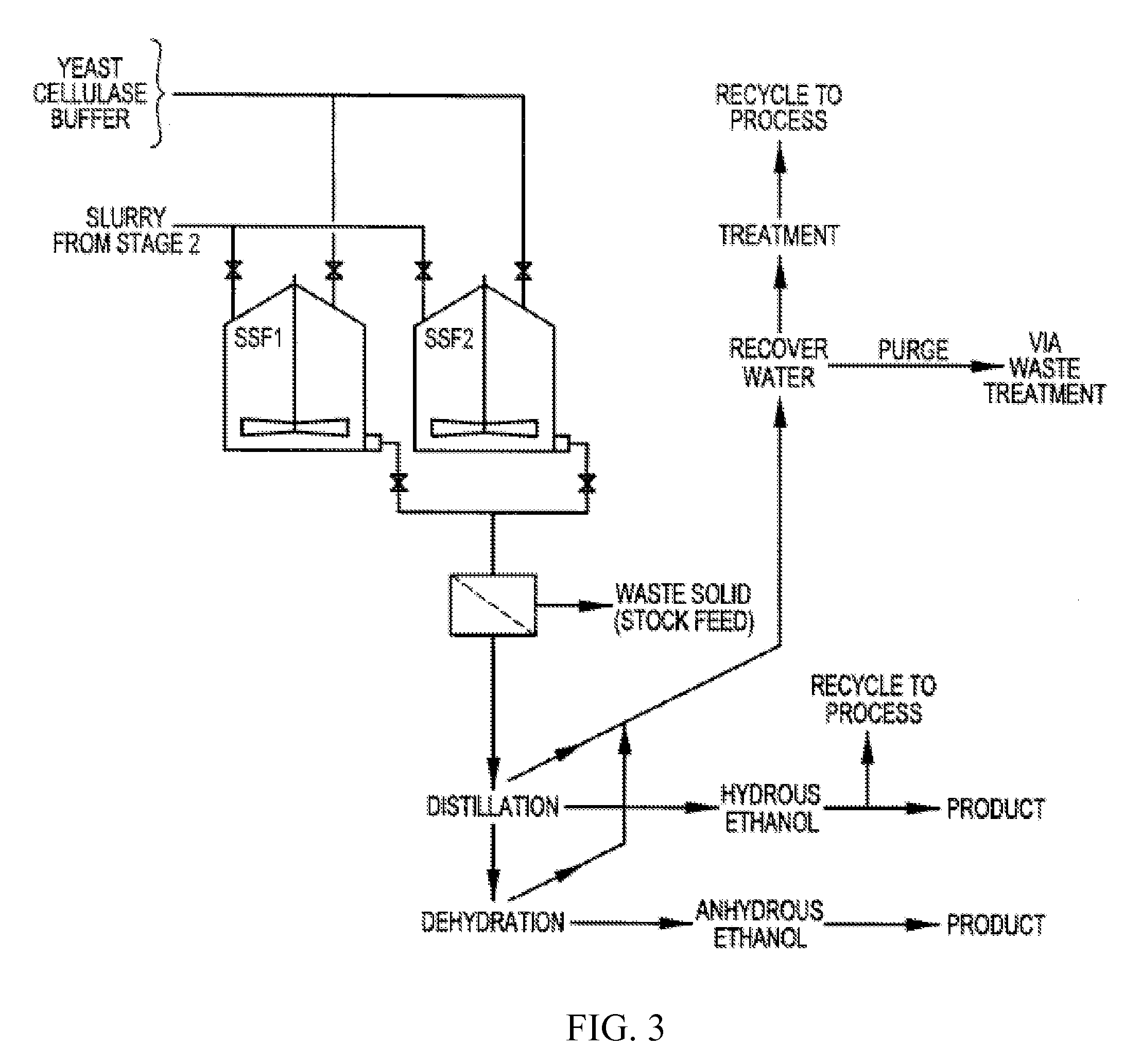

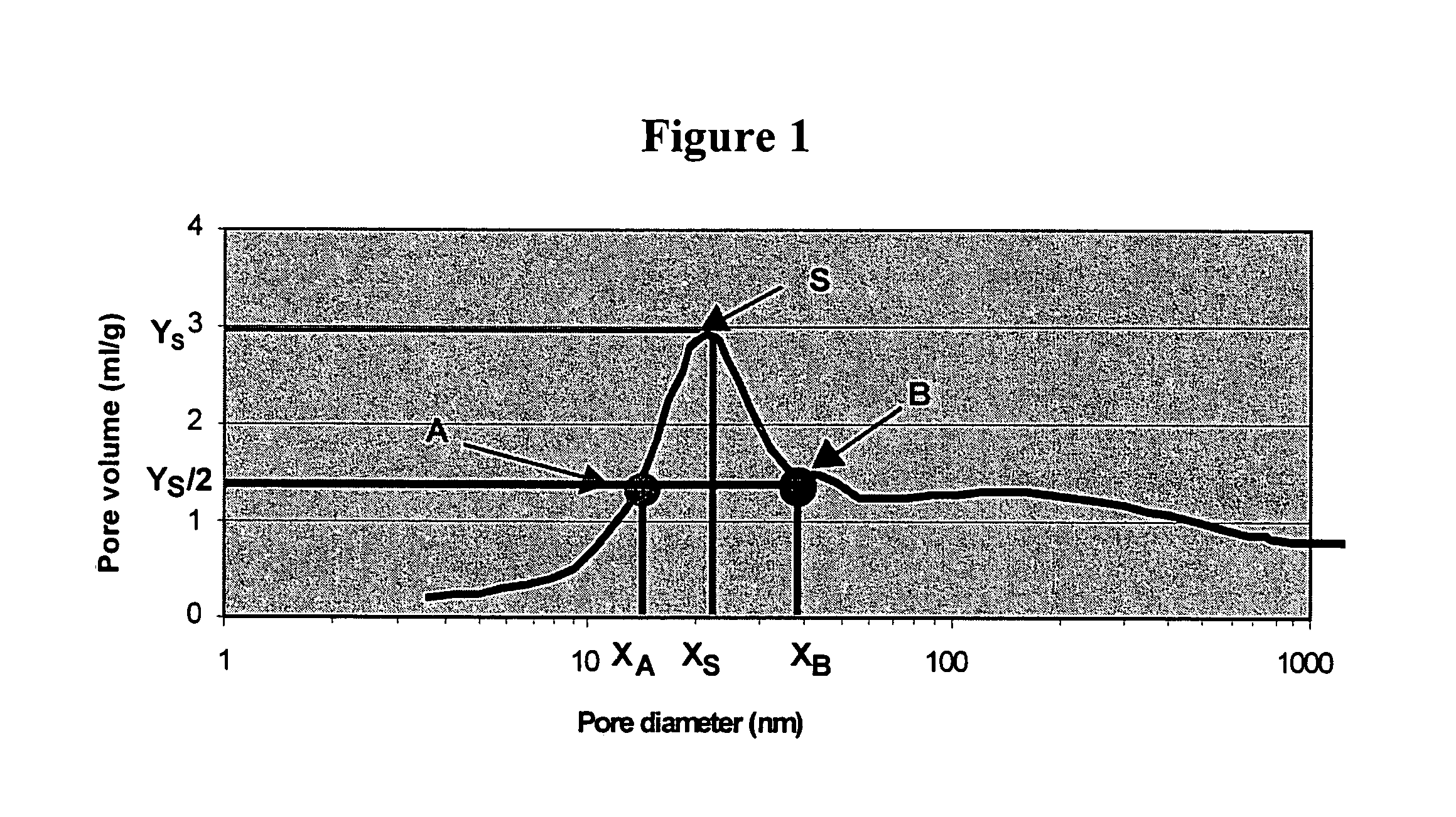

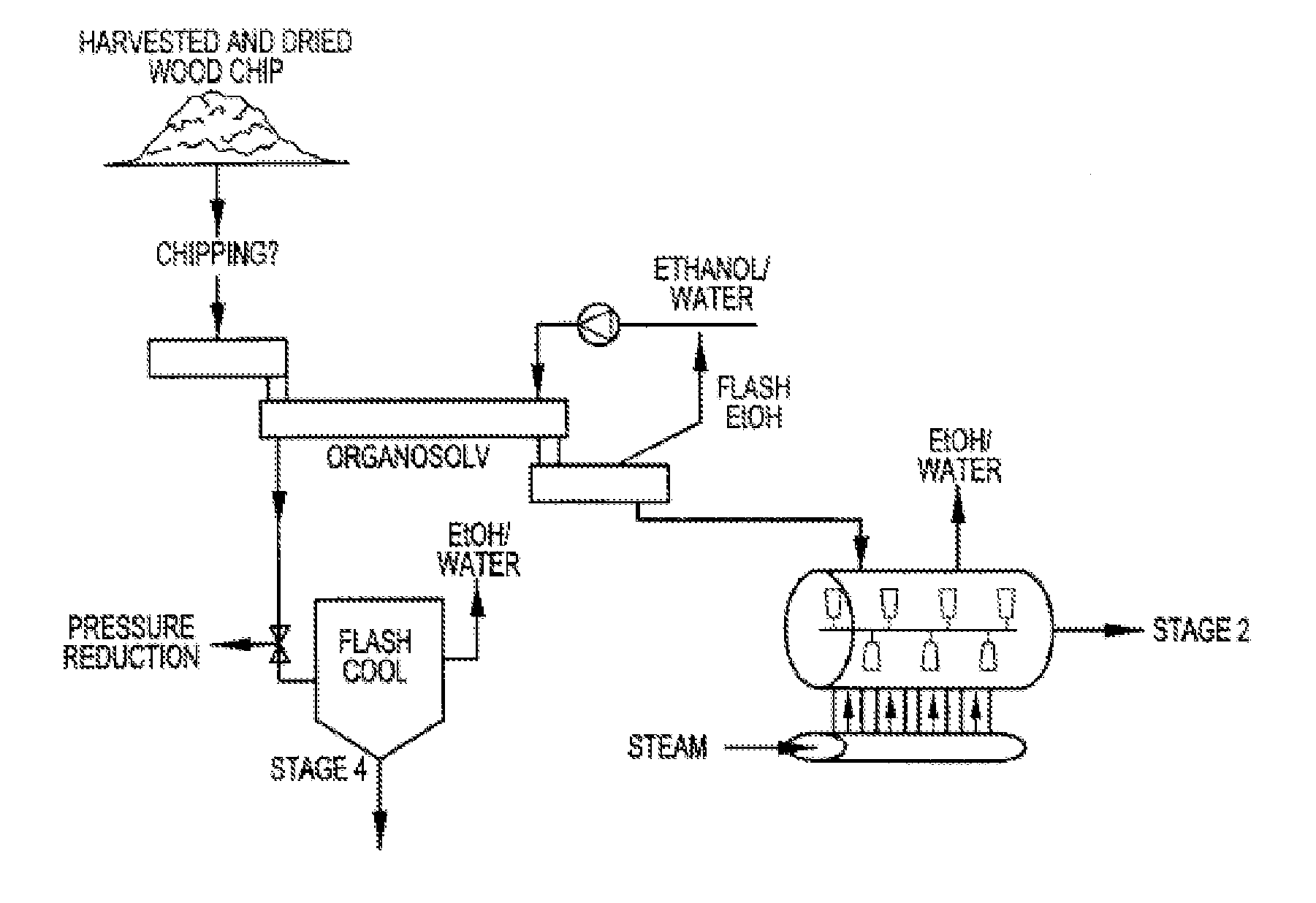

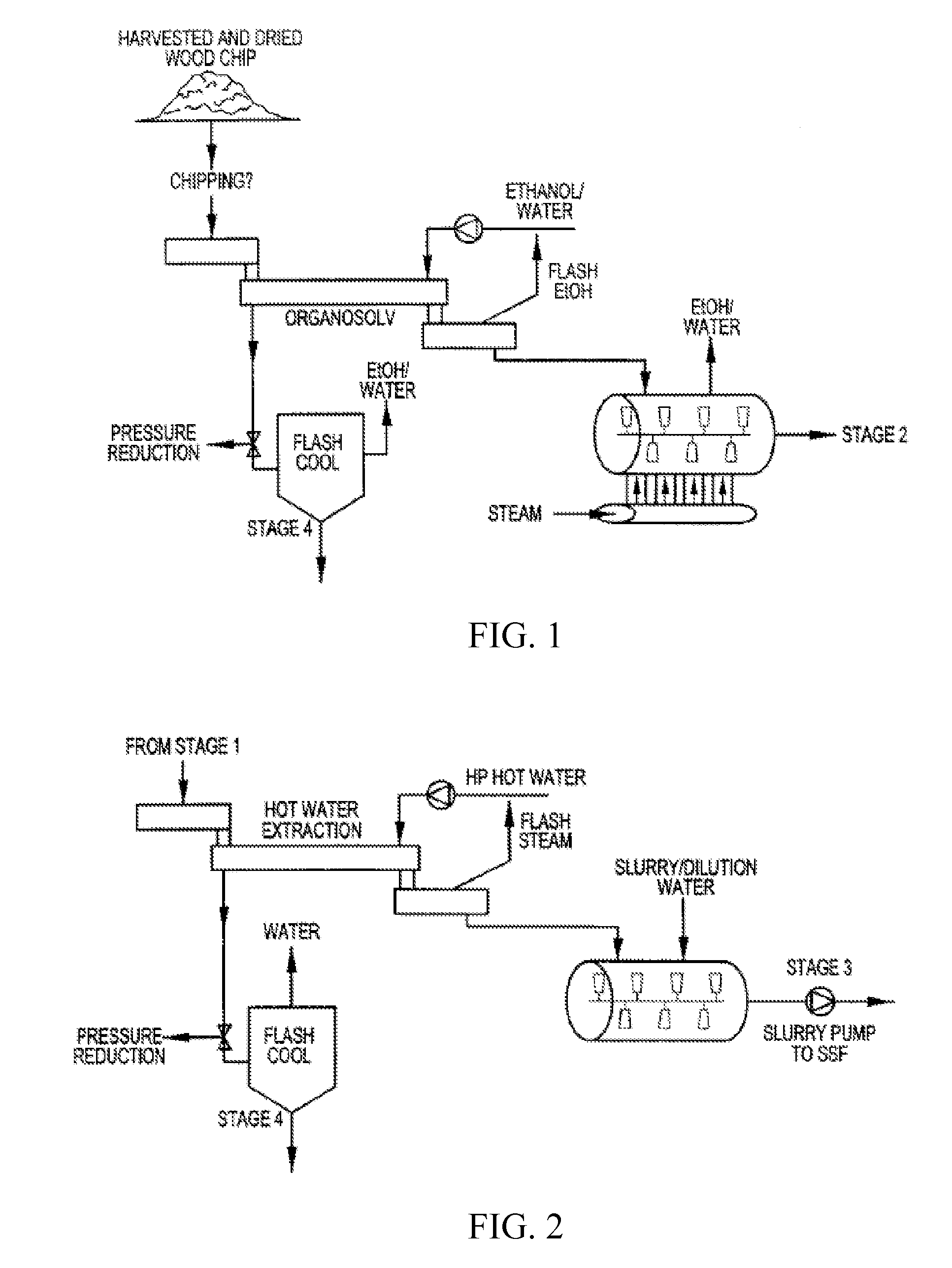

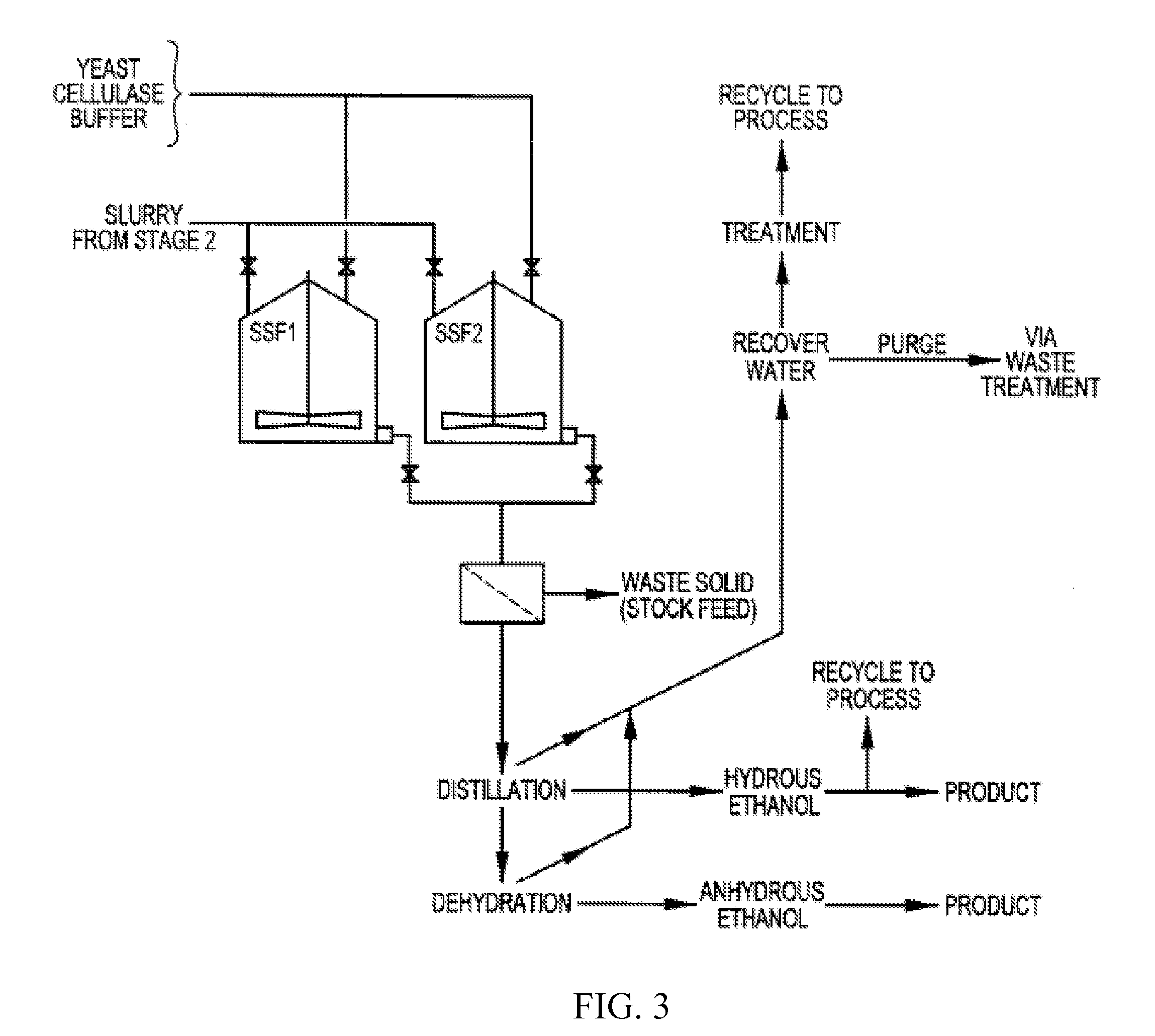

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090062516A1Good for healthImprove responseSugar derivativesOrganic compound preparationFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS7250463B2Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresPorosityElastomer

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

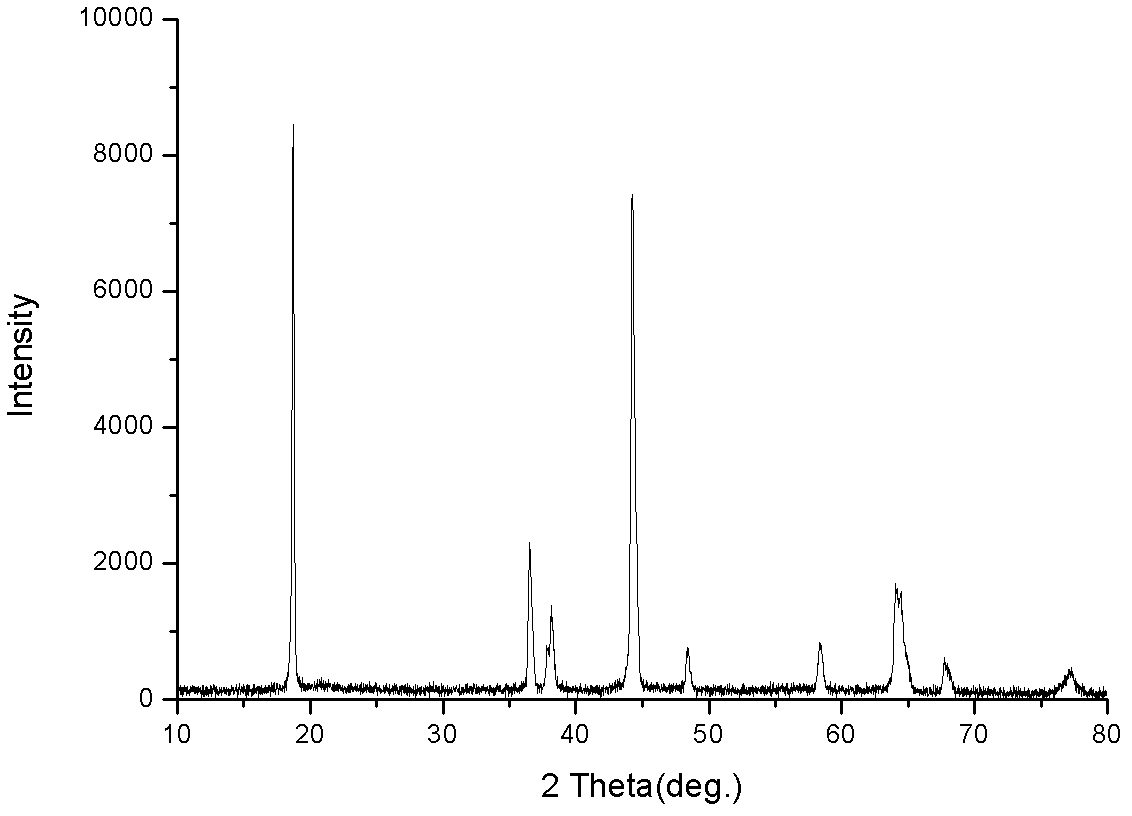

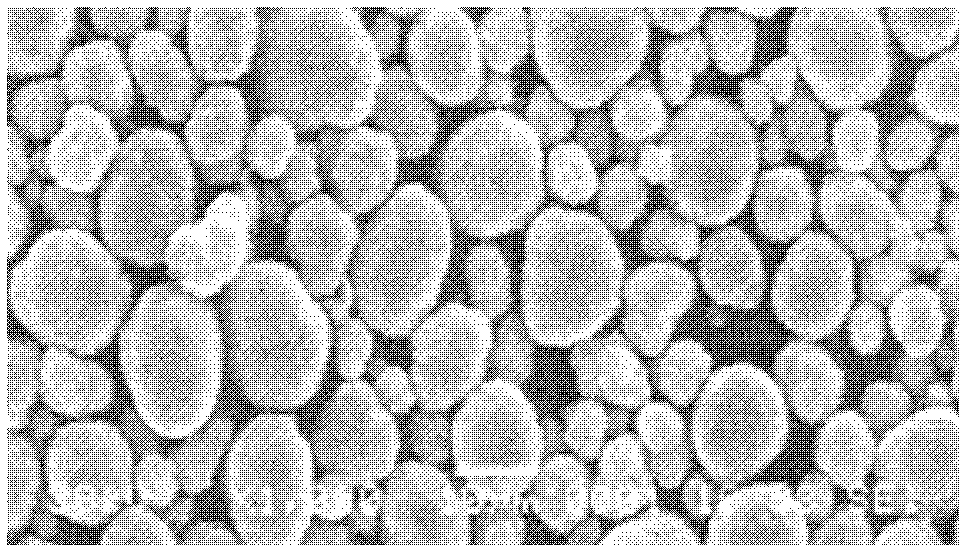

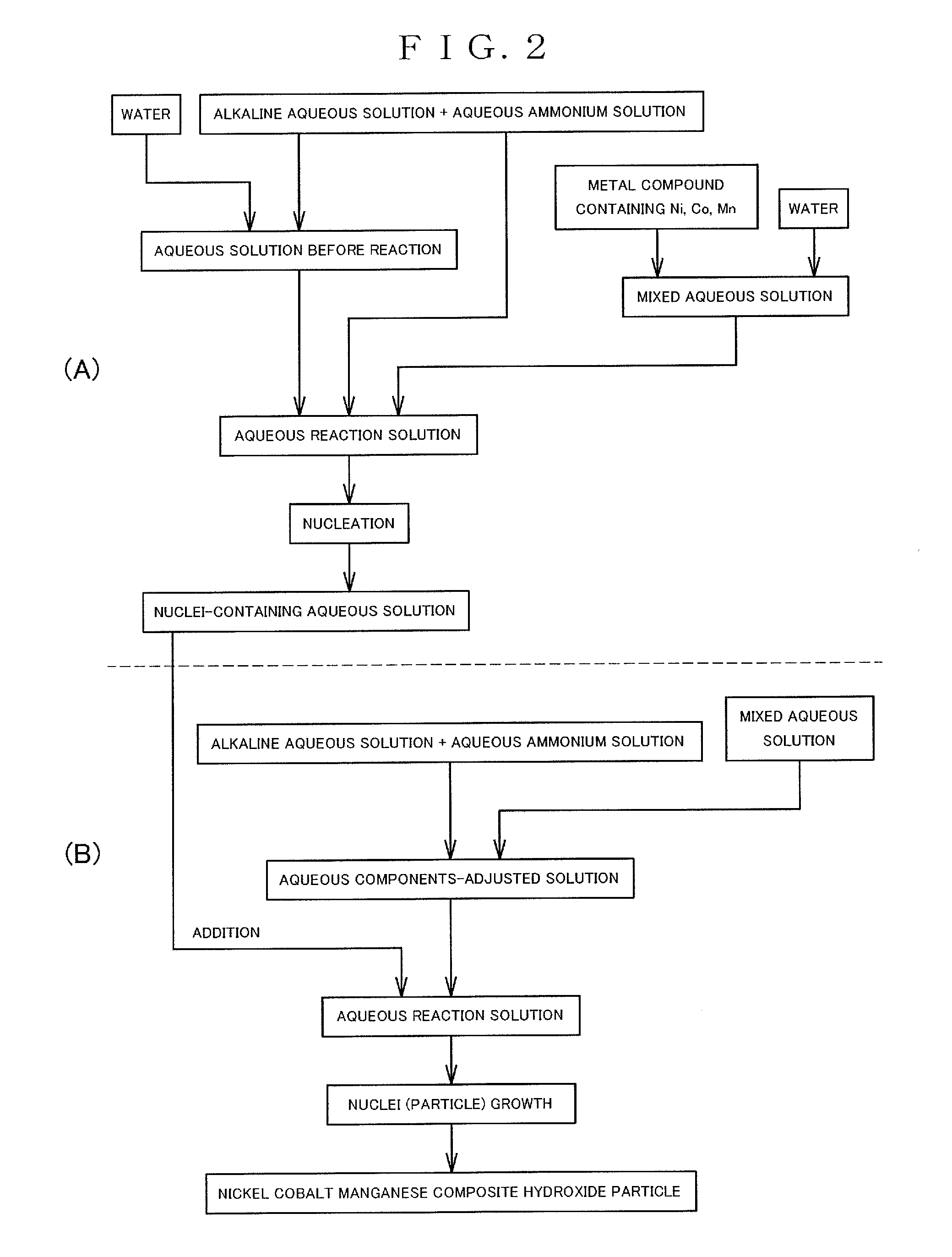

Preparation method for nickel-manganese-cobalt anode material of lithium ion battery

InactiveCN102306765AImprove discharge capacityImprove cycle performanceCell electrodesManganeseLithium compound

The present invention relates to a preparation method for a nickel-manganese-cobalt anode material of a lithium ion battery. According to the present invention, in the presence of nitrogen atmosphere, a mixed solution containing nickel iron, manganese iron and cobalt ion reacts with a precipitating agent, then processes of aging, washing, drying and the like are performed to obtain a nickel-manganese-cobalt hydroxide precursor, the synthesized precursor material has spherical morphology, ideal particle size distribution and high tap density; the precursor, a lithium compound and a doped compound are mixed, then the sintering processing is performed for twice to prepare the nickel-manganese-cobalt three-element composite anode material. The method has characteristics of simple synthesis process, easy process controlling, low energy consumption, high efficiency and low cost, and is applicable for the industrial production; the prepared precursor material has characteristics of spherical morphology, uniform particle distribution and high tap density; the discharge capacity of the battery is improved through doping the metals; the cycle performance of the battery is stable.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

ActiveUS20070119135A1Lower wash-coated pressure dropQuantity minimizationCombination devicesExhaust apparatusSago palmSource material

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1≧7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db≦1.00, wherein db=(d90−d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps≦0.90, wherein dps={(dp90−dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

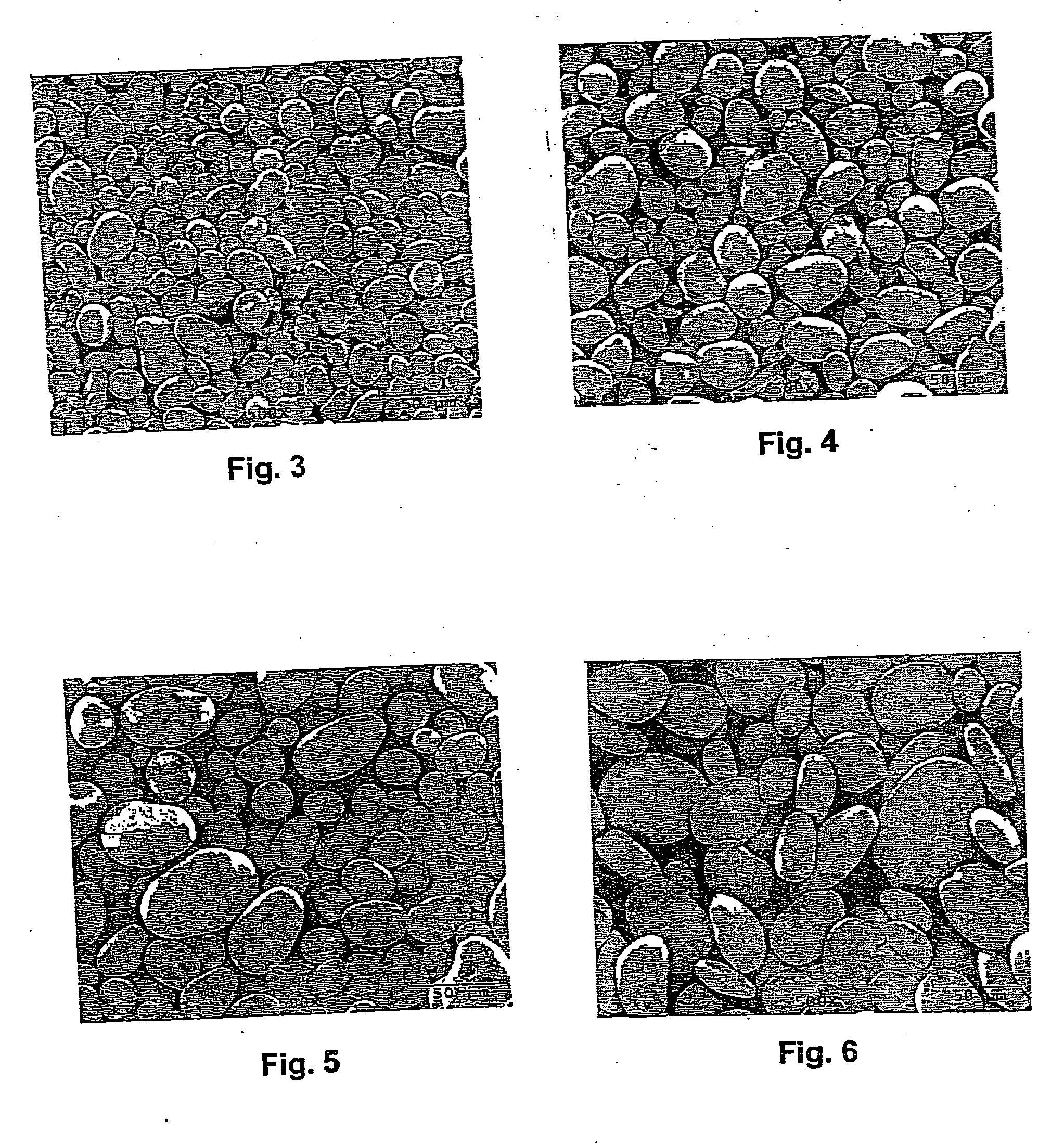

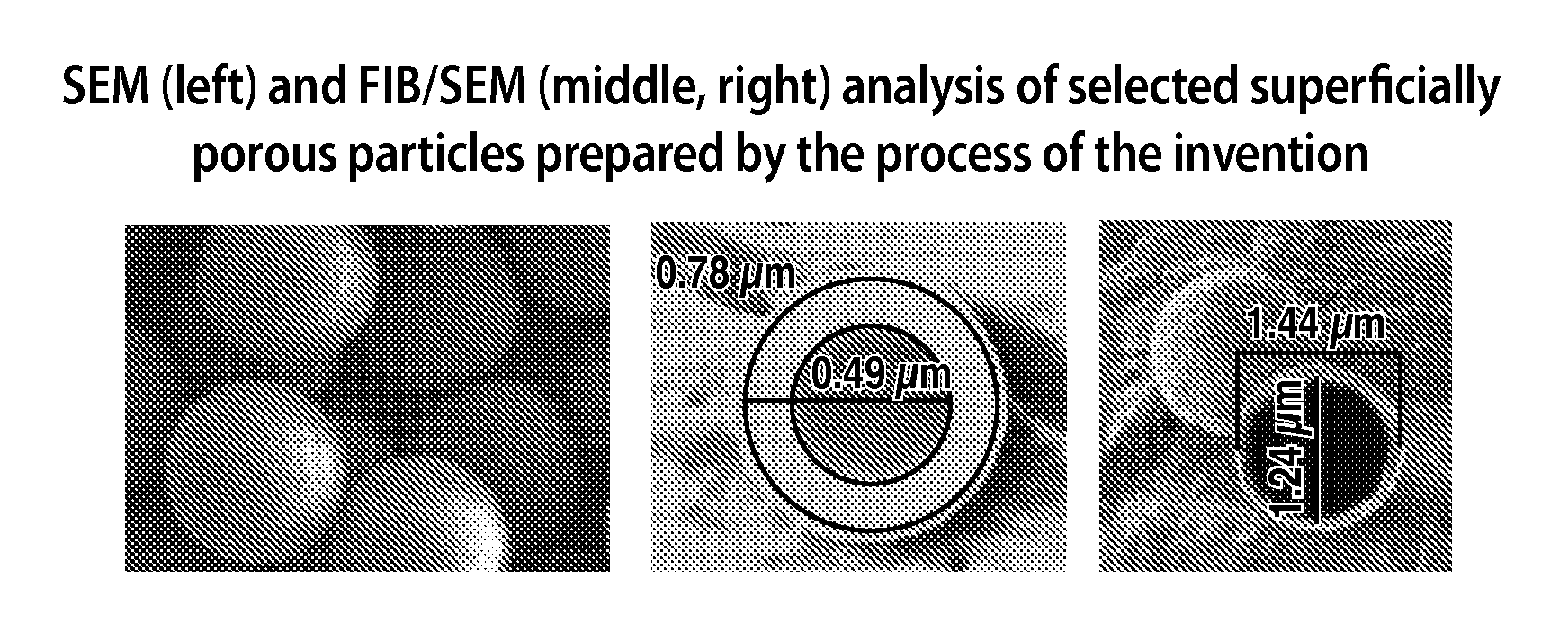

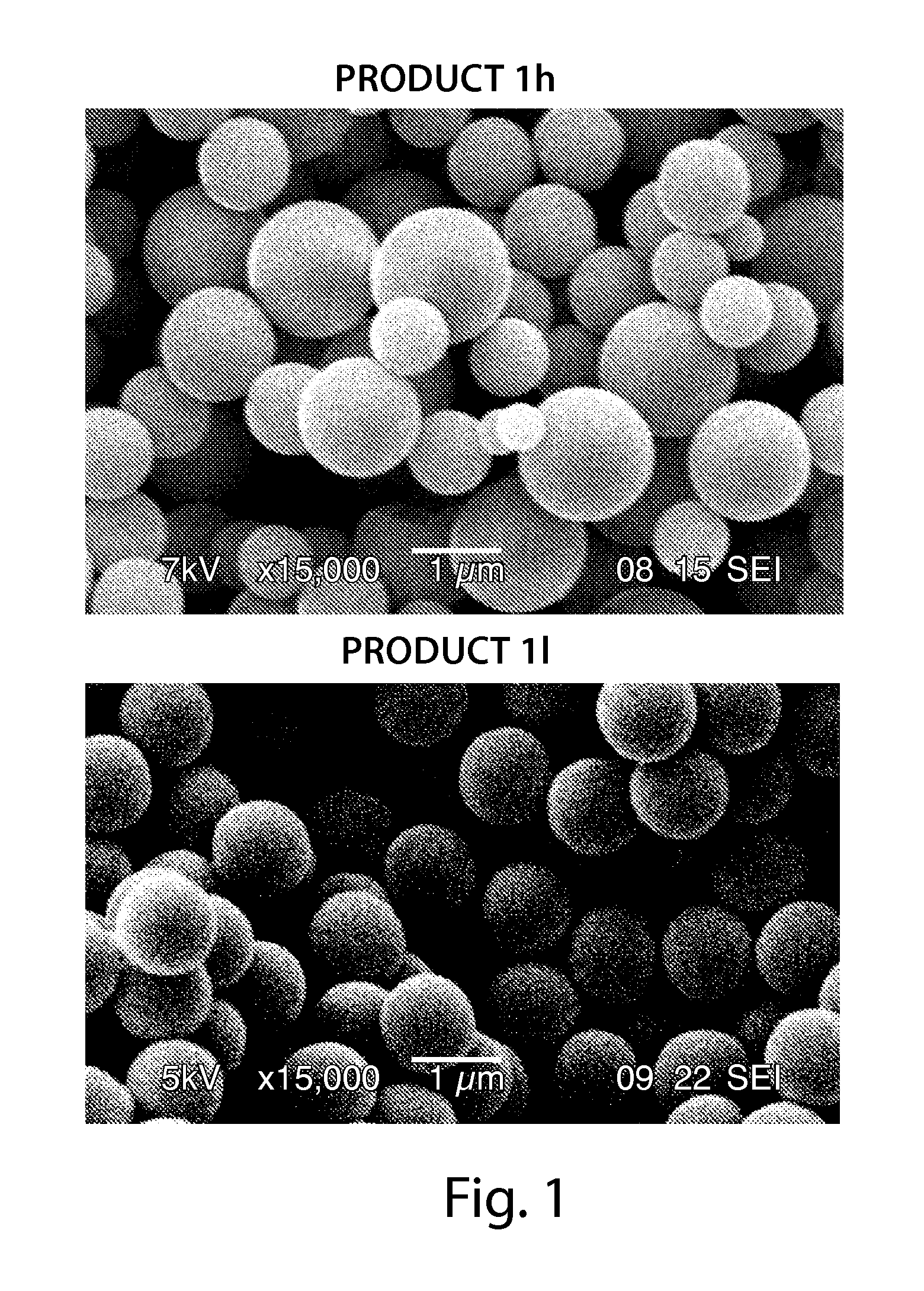

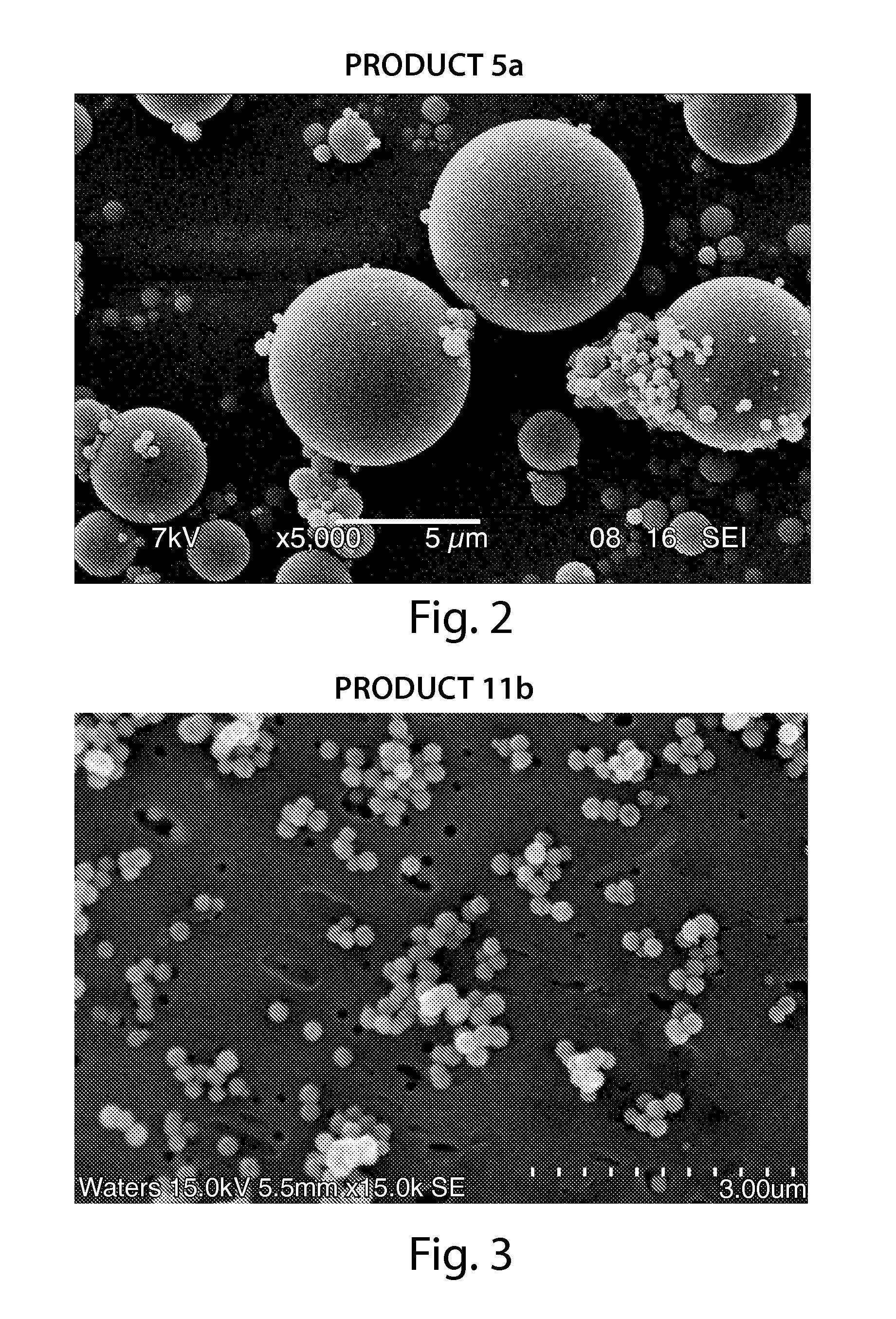

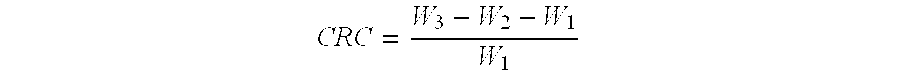

Superficially porous materials comprising a substantially nonporous core having narrow particle size distribution; process for the preparation thereof; and use thereof for chromatographic separations

InactiveUS20130112605A1Prevent fine generationInhibit aggregationIon-exchanger regenerationPretreated surfacesChromatographic separationHybrid material

Novel chromatographic materials for chromatographic separations, columns, kits, and methods for preparation and separations with a superficially porous material comprising a substantially nonporous core and one or more layers of a porous shell material surrounding the core. The material of the invention is comprised of superficially porous particles and a narrow particle size distrution. The material of the invention is comprised of a superficially porous monolith, the substantially nonporous core material is silica; silica coated with an inorganic / organic hybrid surrounding material; a magnetic core material; a magnetic core material coated with silica; a high thermal conductivity core material; a high thermal conductivity core material coated with silica; a composite material; an inorganic / organic hybrid surrounding material; a composite material coated with silica; a magnetic core material coated with an inorganic / organic hybrid surrounding material; or a high thermal conductivity core material coated with an inorganic / organic hybrid surrounding material.

Owner:WATERS TECH CORP

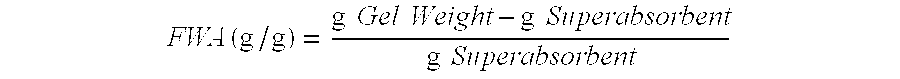

Superabsorbent polymers having delayed water absorption characteristics

InactiveUS6514615B1Shorten drying timeReduce removalNon-fibrous pulp additionPaper/cardboardMicrometerSuperabsorbent polymer

A superabsorbent polymer comprising a delayed absorption superabsorbent polymer having a free water absorbency property of absorbing less than about 3 grams of aqueous saline per gram of superabsorbent polymer in about 6 seconds, for a full particle size distribution of superabsorbent polymer ranging from about 40 micrometers to about 890 micrometers.

Owner:EVONIK OPERATIONS GMBH

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090069550A1Great potentialTotal calories lowLignin derivativesPulp by-products recoveryFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

Particulate water absorbent agent and production method thereof, and water absorbent article

ActiveUS20050209352A1Improve liquidityImprove water absorptionOther chemical processesAbsorbent padsParticulatesSaline water

A particulate water absorbing agent of the present invention includes a water absorbent resin, having a cross-linking structure, whose surface has been cross-linked by adding a surface treatment agent, wherein: (i) a mass average particle diameter (D50) ranges from 200 to 600 μm and 95 to 100 wt % of a particulate water absorbing agent whose particle diameter ranges from less than 850 μm to not less than 150 μm is contained with respect to 100 wt % of whole the particulate water absorbing agent, and (ii) a logarithmic standard deviation (σζ) of particle size distribution ranges from 0.25 to 0.45, and (iii) a compressibility rate defined by a following equation ranges from 0 to 18%, and (iv) a surface tension of a supernatant liquid obtained in 4 minutes after dispersing 0.5 g of the particulate water absorbing agent in 50 ml of physiological saline whose temperature is 20° C. is 55 mN / m or more, the compressibility rate (%)=(P−A) / P×100 where P represents a tapped bulk density of the particulate water absorbing agent and A represents a loose bulk density of the particulate water absorbing agent.

Owner:NIPPON SHOKUBAI CO LTD

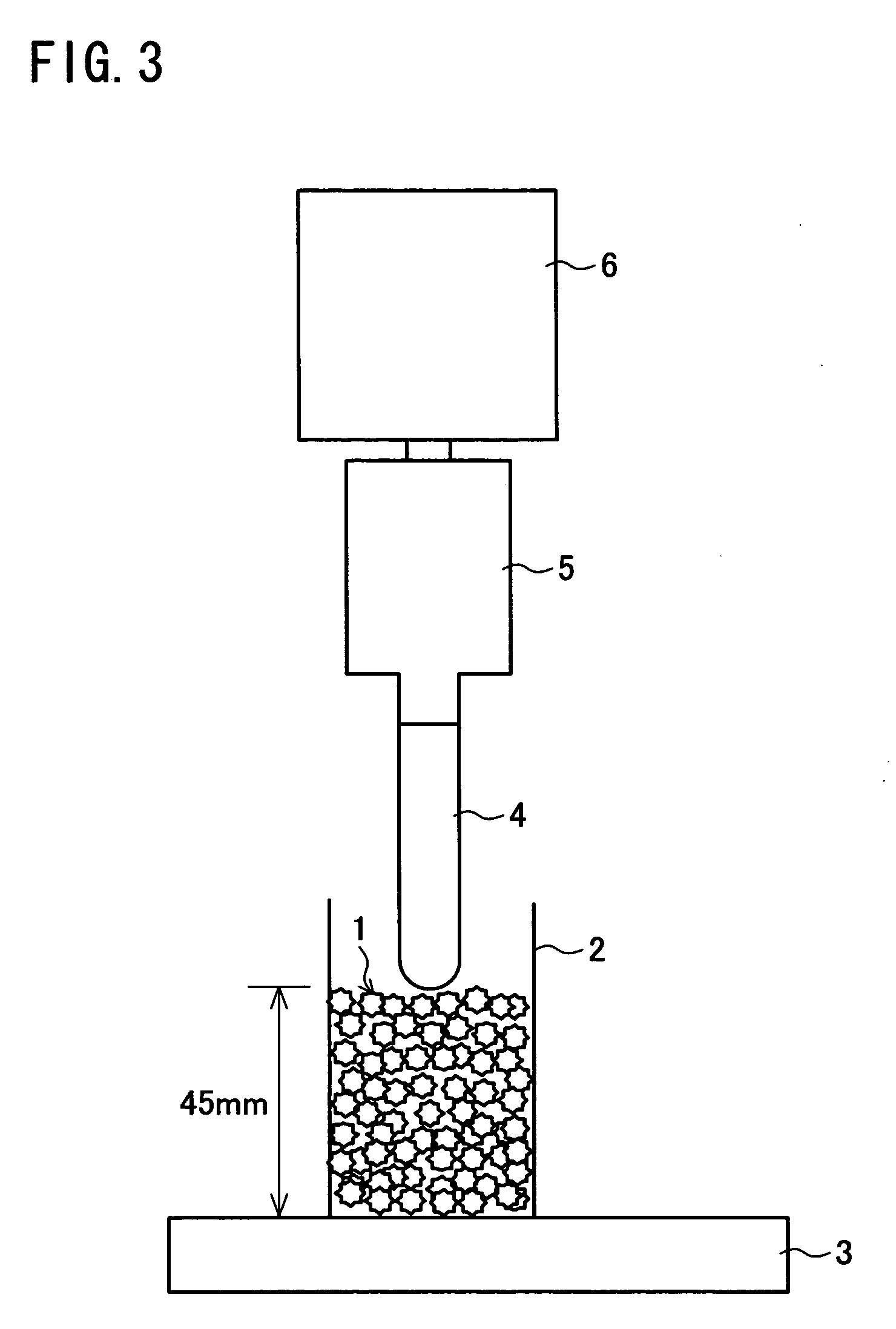

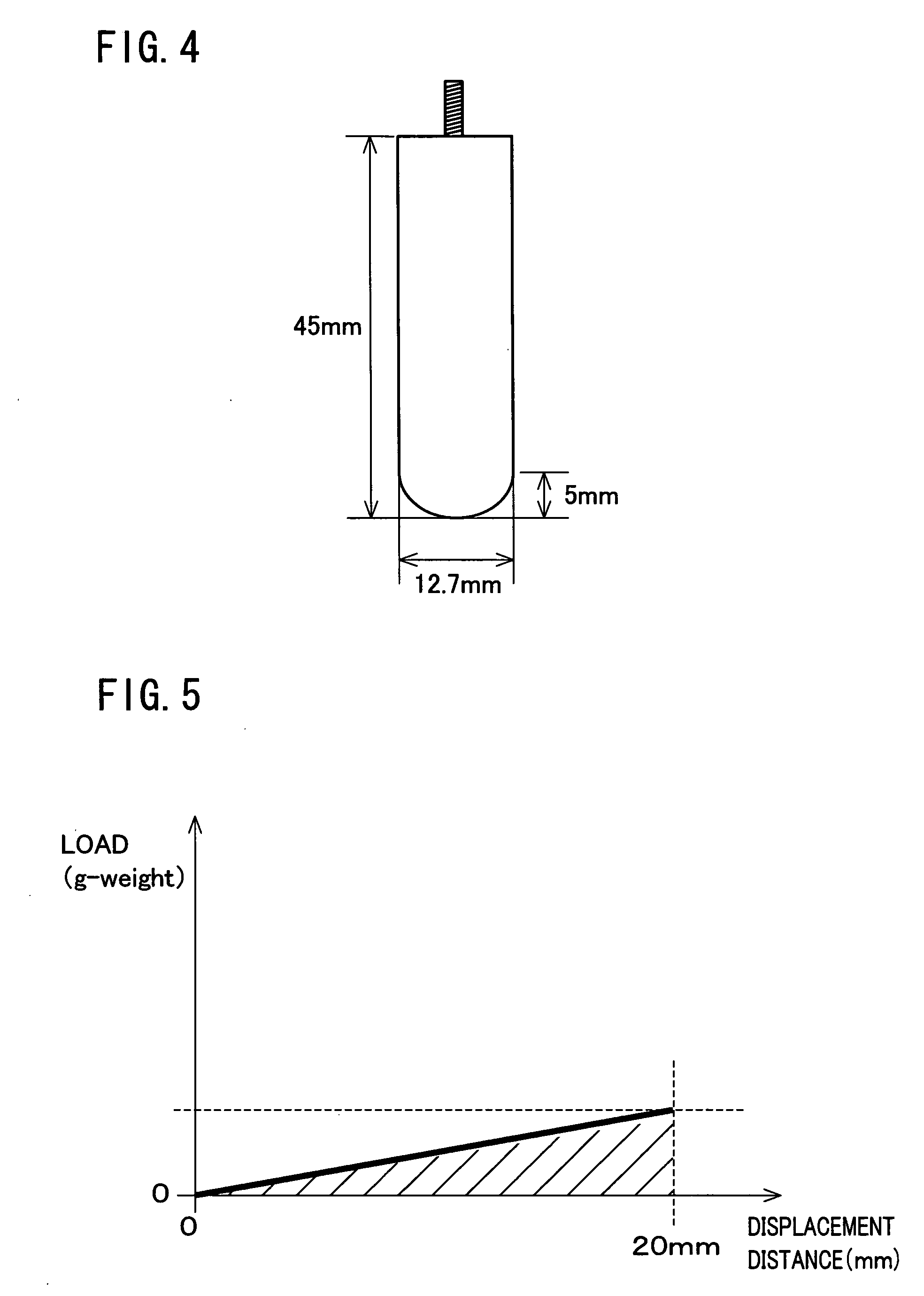

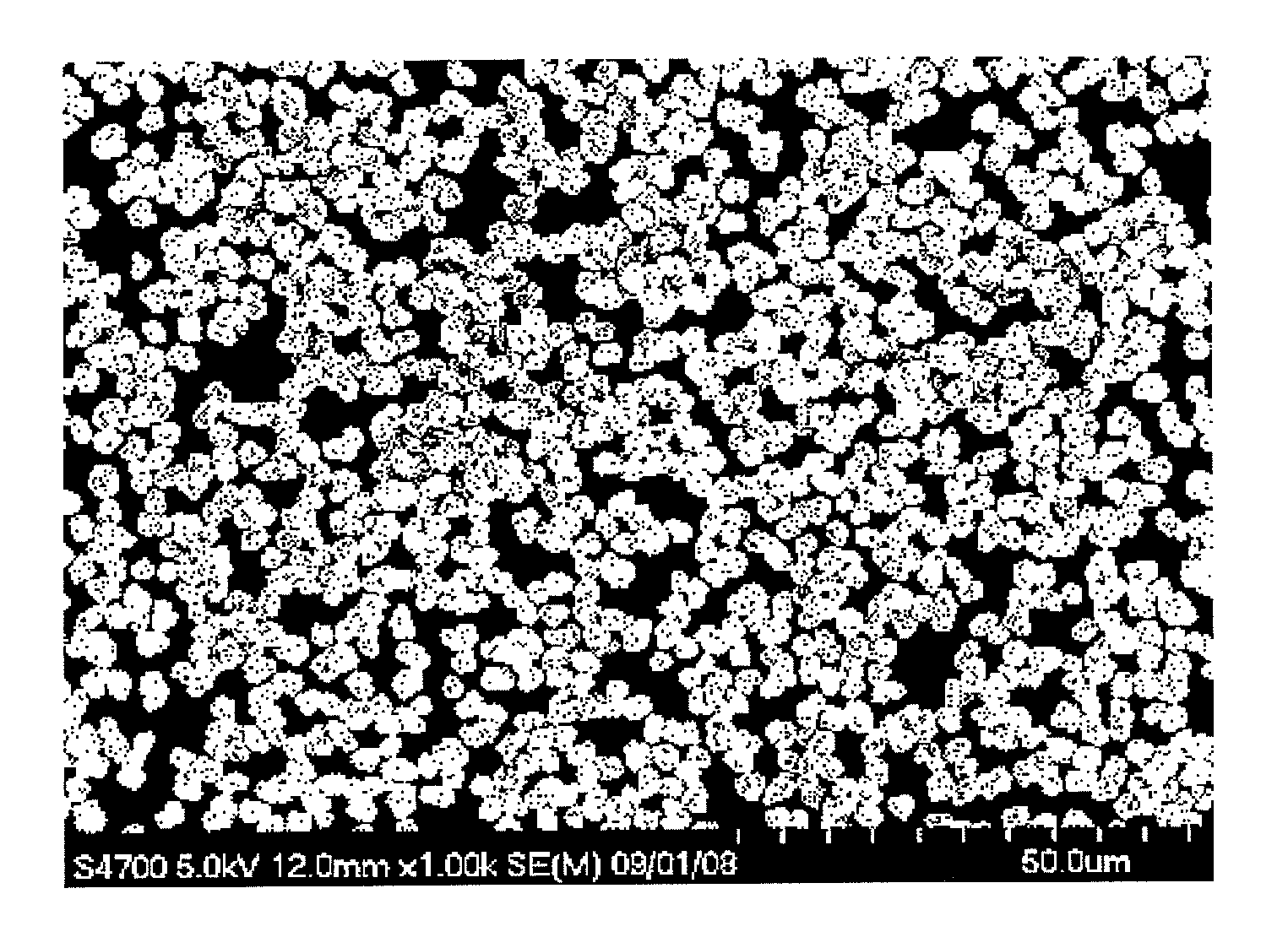

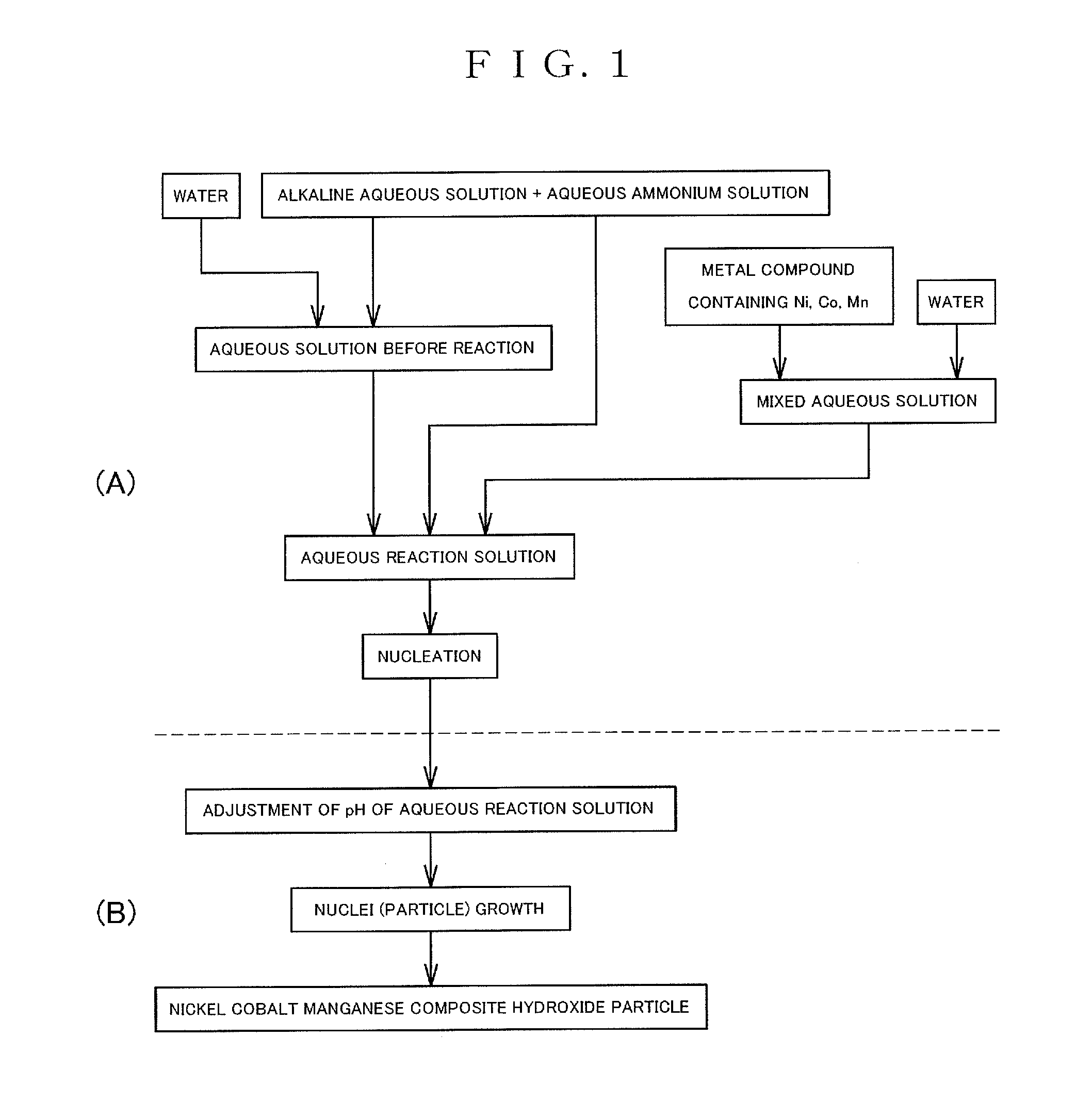

Nickel-cobalt-manganese complex hydroxide particles and method for producing same, positive electrode active material for nonaqueous electrolyte secondary battery and method for producing same, and nonaqueous electrolyte secondary battery

ActiveUS20120270107A1Growth inhibitionFast executionNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLiquid temperatureManganese

An object of the present invention is to provide nickel cobalt manganese composite hydroxide particles having a small particle diameter and a uniform particle size distribution, and a method for producing the same.[Solution]A method for producing a nickel cobalt manganese composite hydroxide by a crystallization reaction is provided. The method includes: a nucleation step of performing nucleation by controlling a pH of an aqueous solution for nucleation including metal compounds containing nickel, cobalt and manganese, and an ammonium ion donor to 12.0 to 14.0 in terms of the pH as measured at a liquid temperature of 25° C. as a standard; and a particle growth step of growing nuclei by controlling a pH of an aqueous solution for particle growth containing nuclei formed in the nucleation step to 10.5 to 12.0 in terms of the pH as measured at a liquid temperature of 25° C. as a standard.

Owner:SUMITOMO METAL MINING CO LTD +1

Structured composite compositions for treatment of subterranean wells

ActiveUS20060258546A1Reinforce strength (or modulus)Improve stress resistancePretreated surfacesFlushingParticulatesBi modal

A structured composite is comprised of particulates having particle size distribution of at least two modes and a binder. The particle size distribution is preferably bi-modal or tri-modal. The composite may further contain a density-modifying agent for modifying the density of the composite. The particulates are preferably substantially spherical and may be ultra lightweight (ULW) materials. The resulting composites exhibit the requisite strength to survive downhole imposed stresses and temperatures.

Owner:BJ SERVICES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com