Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1864results about How to "Improve discharge capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

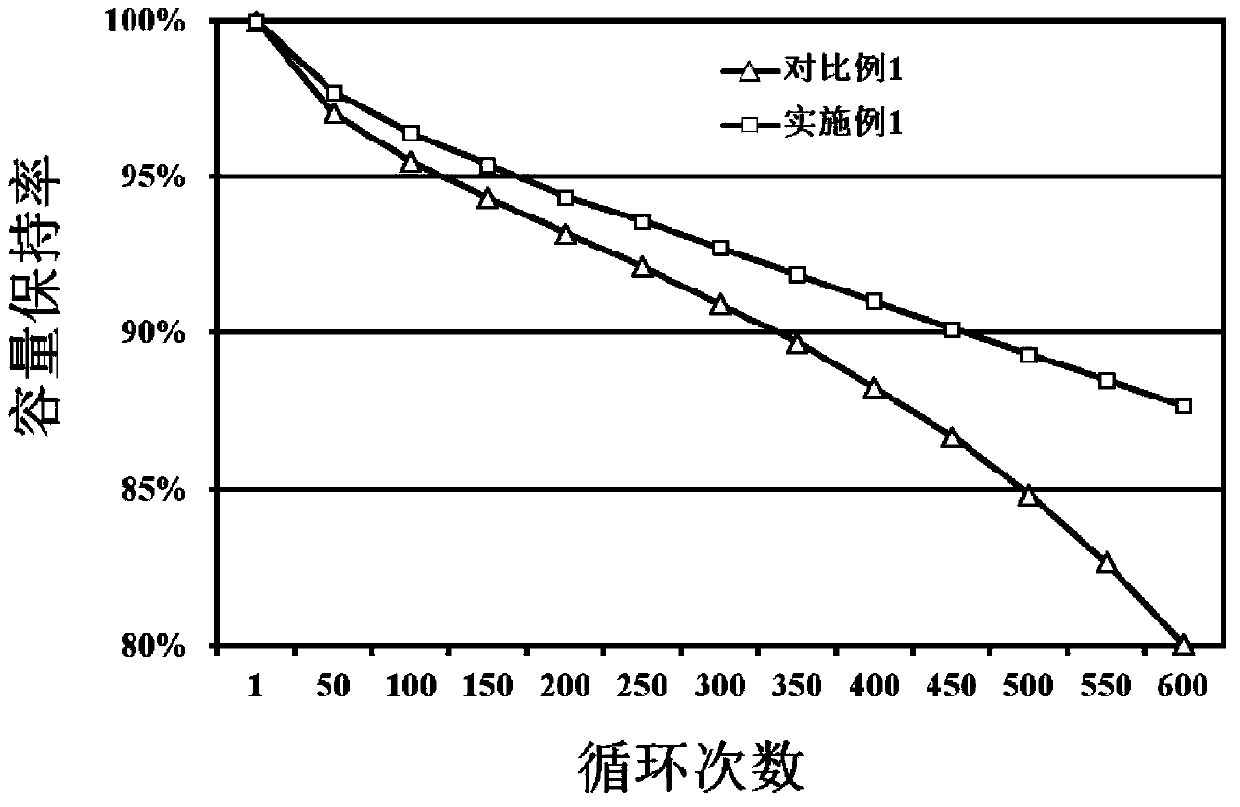

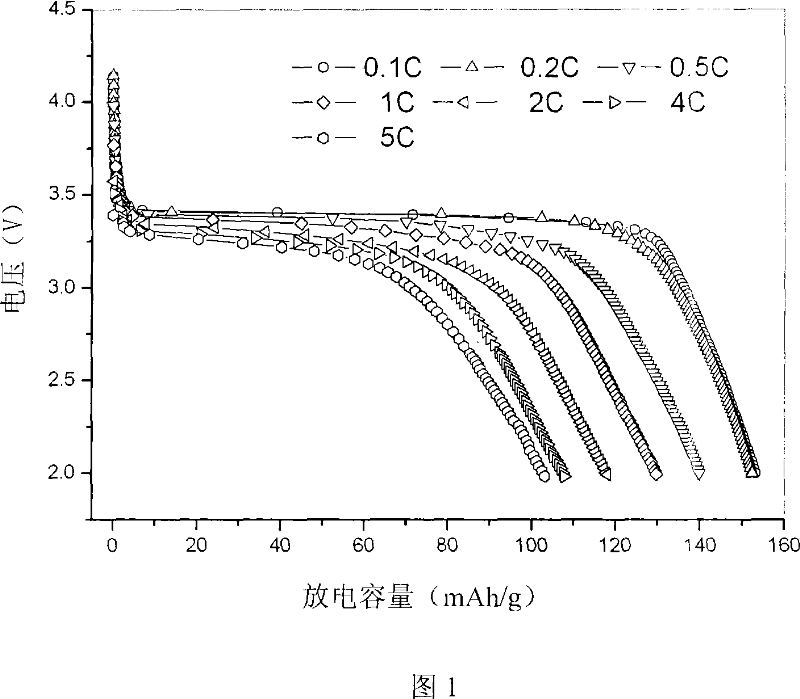

Preparation method for nickel-manganese-cobalt anode material of lithium ion battery

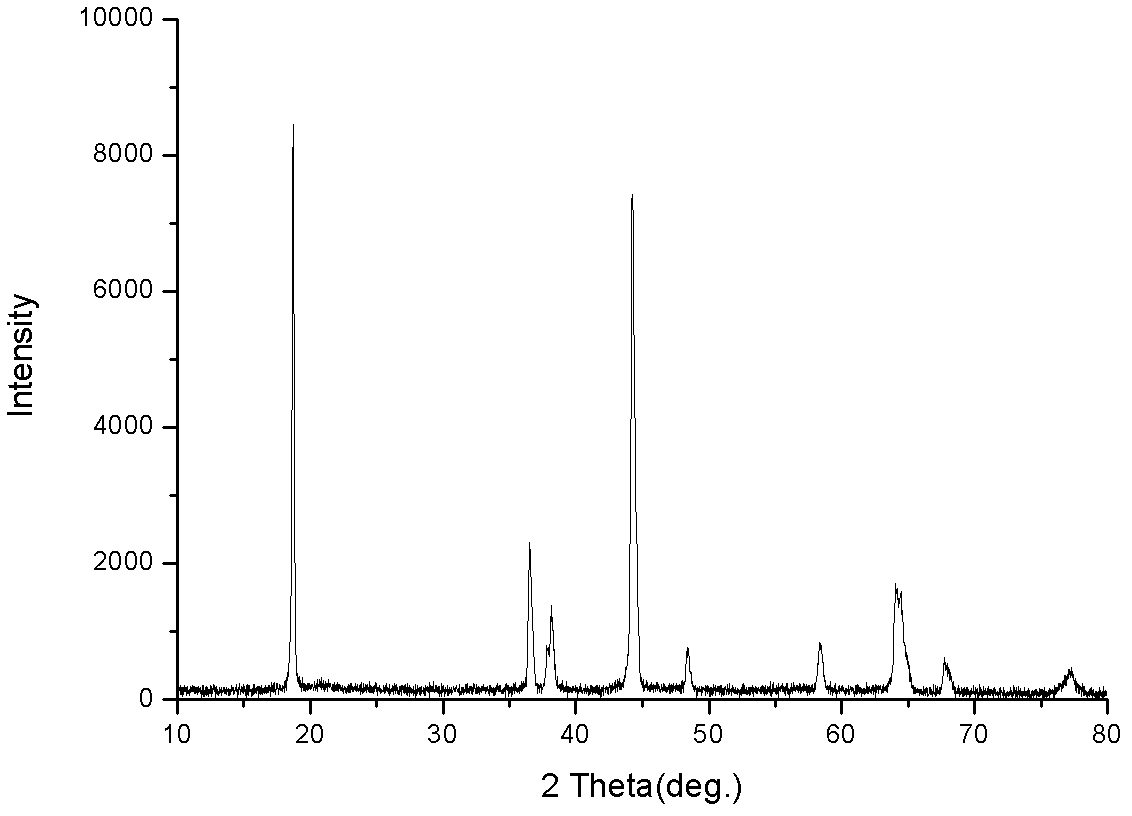

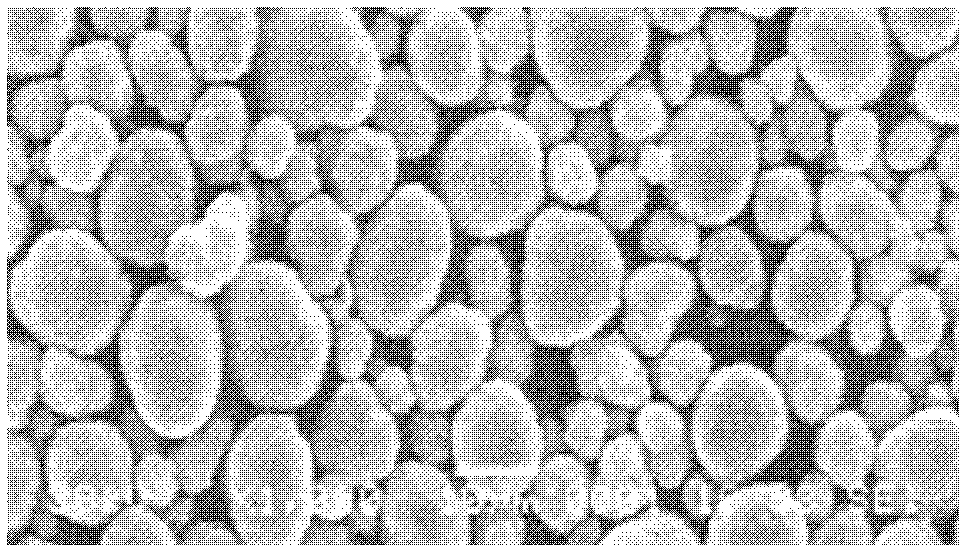

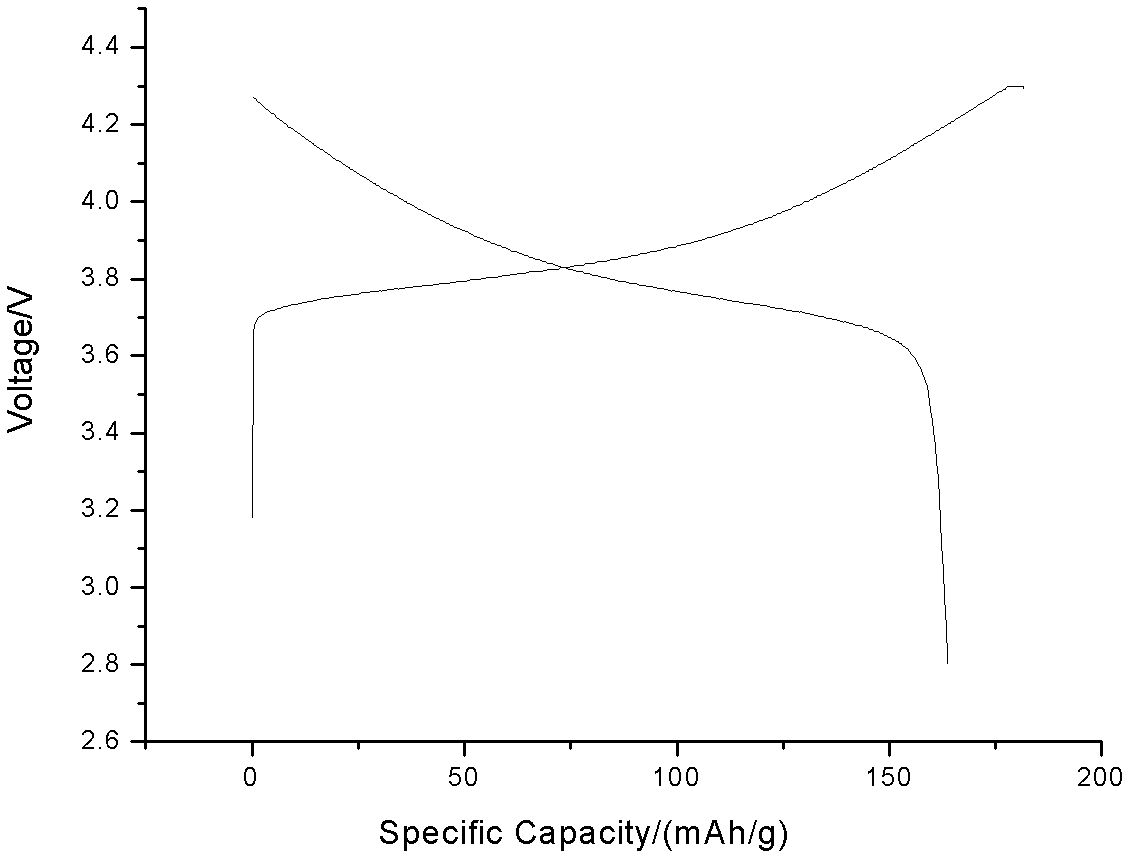

InactiveCN102306765AImprove discharge capacityImprove cycle performanceCell electrodesManganeseLithium compound

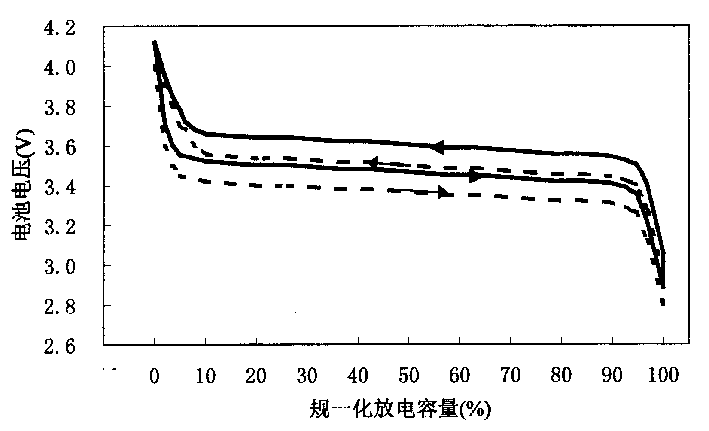

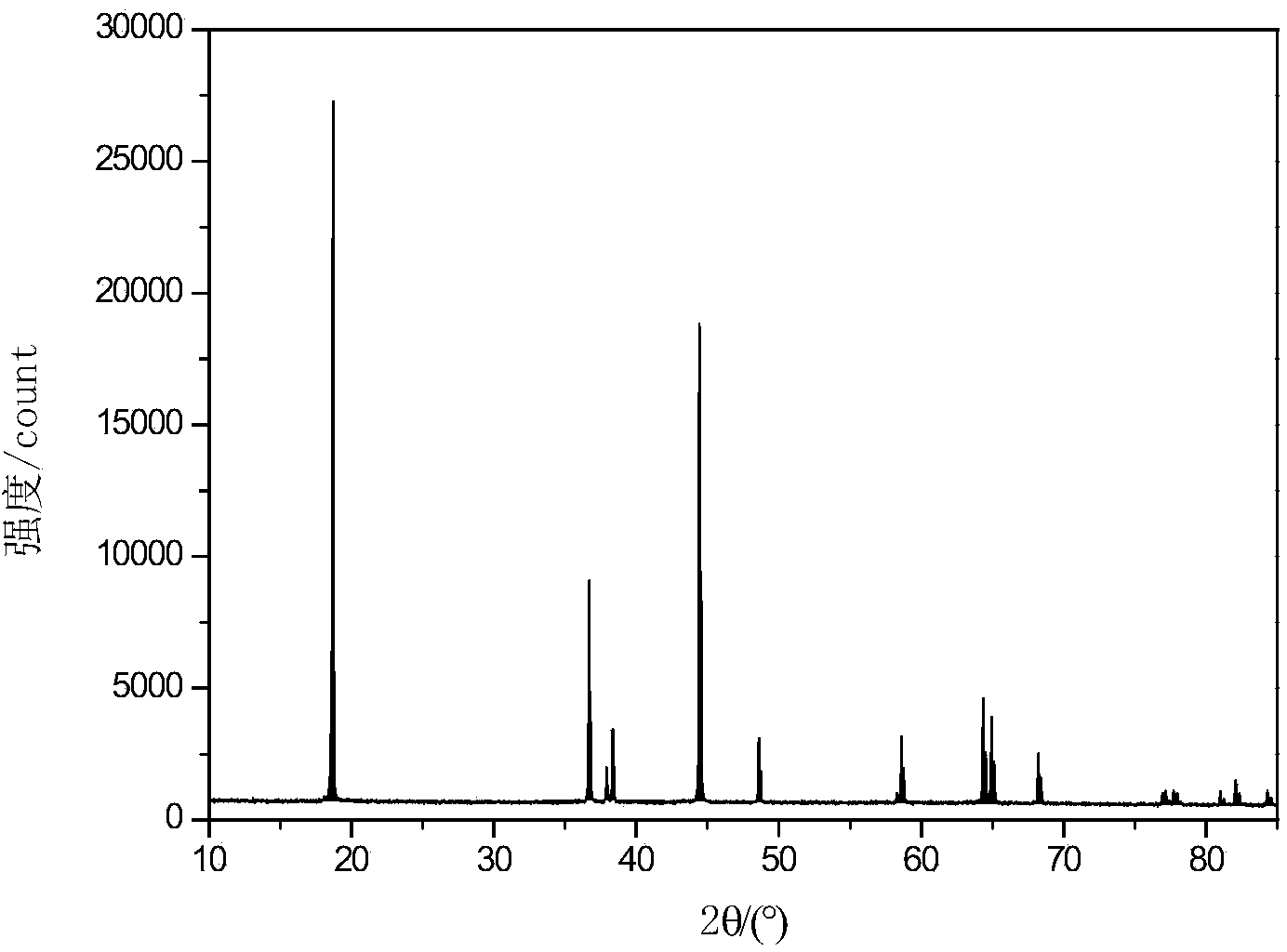

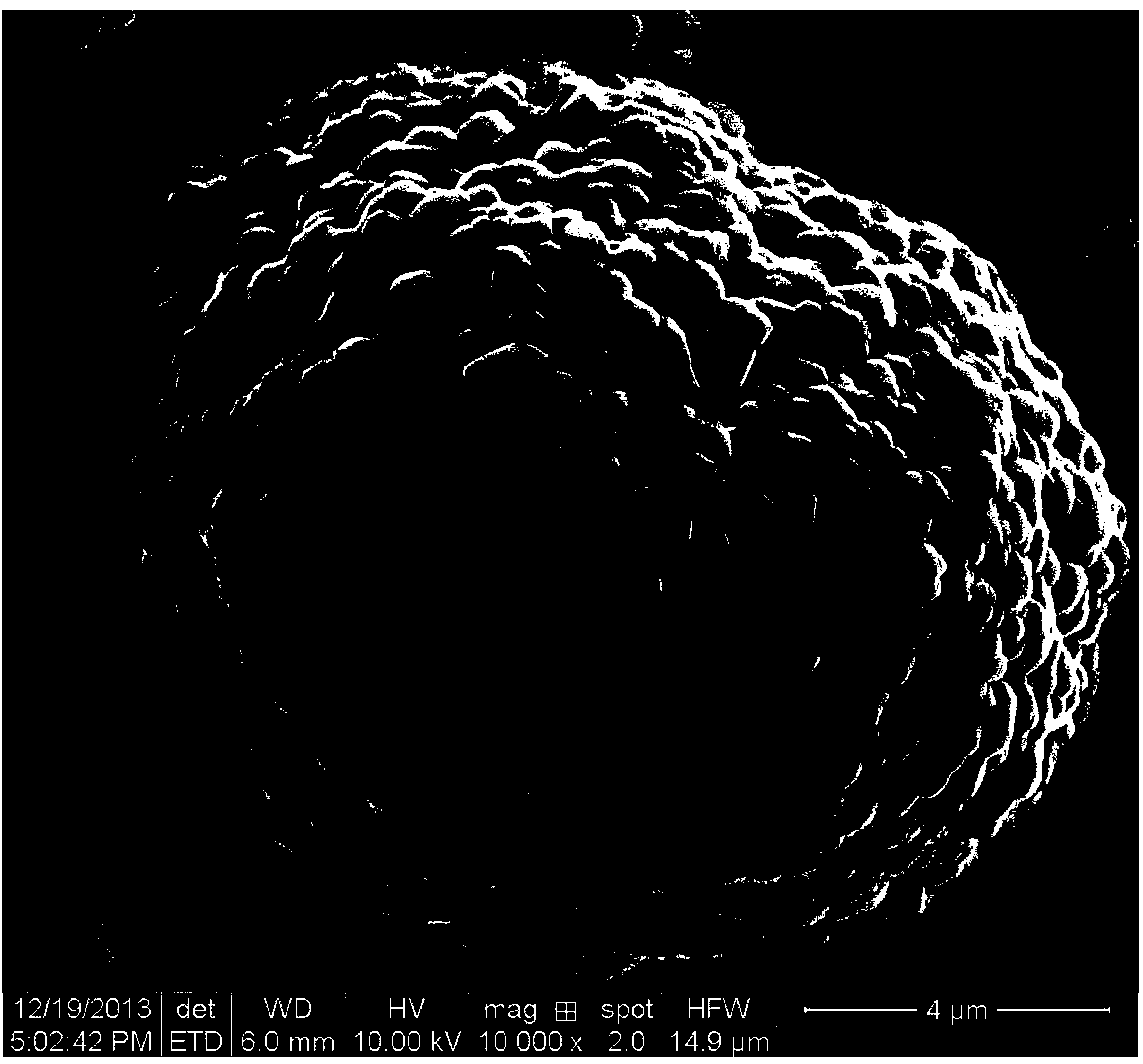

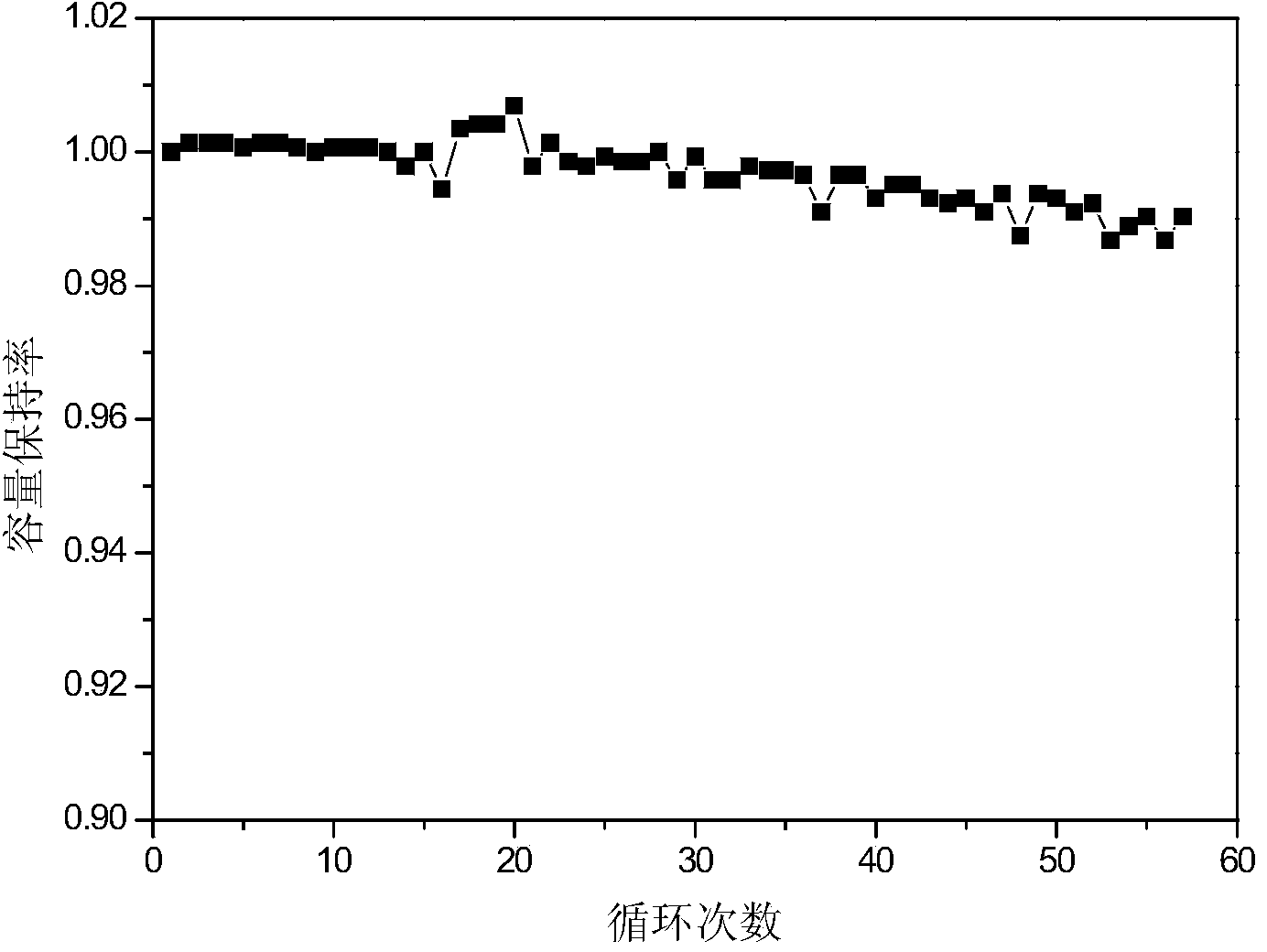

The present invention relates to a preparation method for a nickel-manganese-cobalt anode material of a lithium ion battery. According to the present invention, in the presence of nitrogen atmosphere, a mixed solution containing nickel iron, manganese iron and cobalt ion reacts with a precipitating agent, then processes of aging, washing, drying and the like are performed to obtain a nickel-manganese-cobalt hydroxide precursor, the synthesized precursor material has spherical morphology, ideal particle size distribution and high tap density; the precursor, a lithium compound and a doped compound are mixed, then the sintering processing is performed for twice to prepare the nickel-manganese-cobalt three-element composite anode material. The method has characteristics of simple synthesis process, easy process controlling, low energy consumption, high efficiency and low cost, and is applicable for the industrial production; the prepared precursor material has characteristics of spherical morphology, uniform particle distribution and high tap density; the discharge capacity of the battery is improved through doping the metals; the cycle performance of the battery is stable.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Negative active material for rechargeable lithium battery and method of preparing same

InactiveUS20020009646A1Increase energy densityImprove cycle lifeElectrode manufacturing processesNon-aqueous electrolyte accumulatorsCarbon filmGraphite particle

Owner:SAMSUNG SDI CO LTD

All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

ActiveCN103633329AImprove cycle lifeImprove discharge capacityCell electrodesSecondary cellsSolid state electrolyteTitanium disulfide

Embodiments of the present invention provide an all-solid state lithium ion battery composite positive electrode material, which comprises a positive electrode active material and a cladding layer arranged on the surface of the positive electrode active material, the positive electrode active material is one or a plurality of materials selected from a lithium cobalt oxide, lithium nickelate, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer material is one or a plurality of lithium-containing transition metal oxides. According to the present invention, with the cladding layer, formation of the space charge layer can be effectively inhibited, the electrode / inorganic solid state electrolyte interface can be improved, and the interface resistance of the all-solid state lithium ion battery can be easily reduced so as to improve cycle stability and durability of the all-solid state lithium ion battery. Embodiments of the present invention further provide a preparation method for the all-solid state lithium ion battery composite positive electrode material, and an all-solid state lithium ion battery containing the all-solid state lithium ion battery composite positive electrode material.

Owner:泰州市海通资产管理有限公司

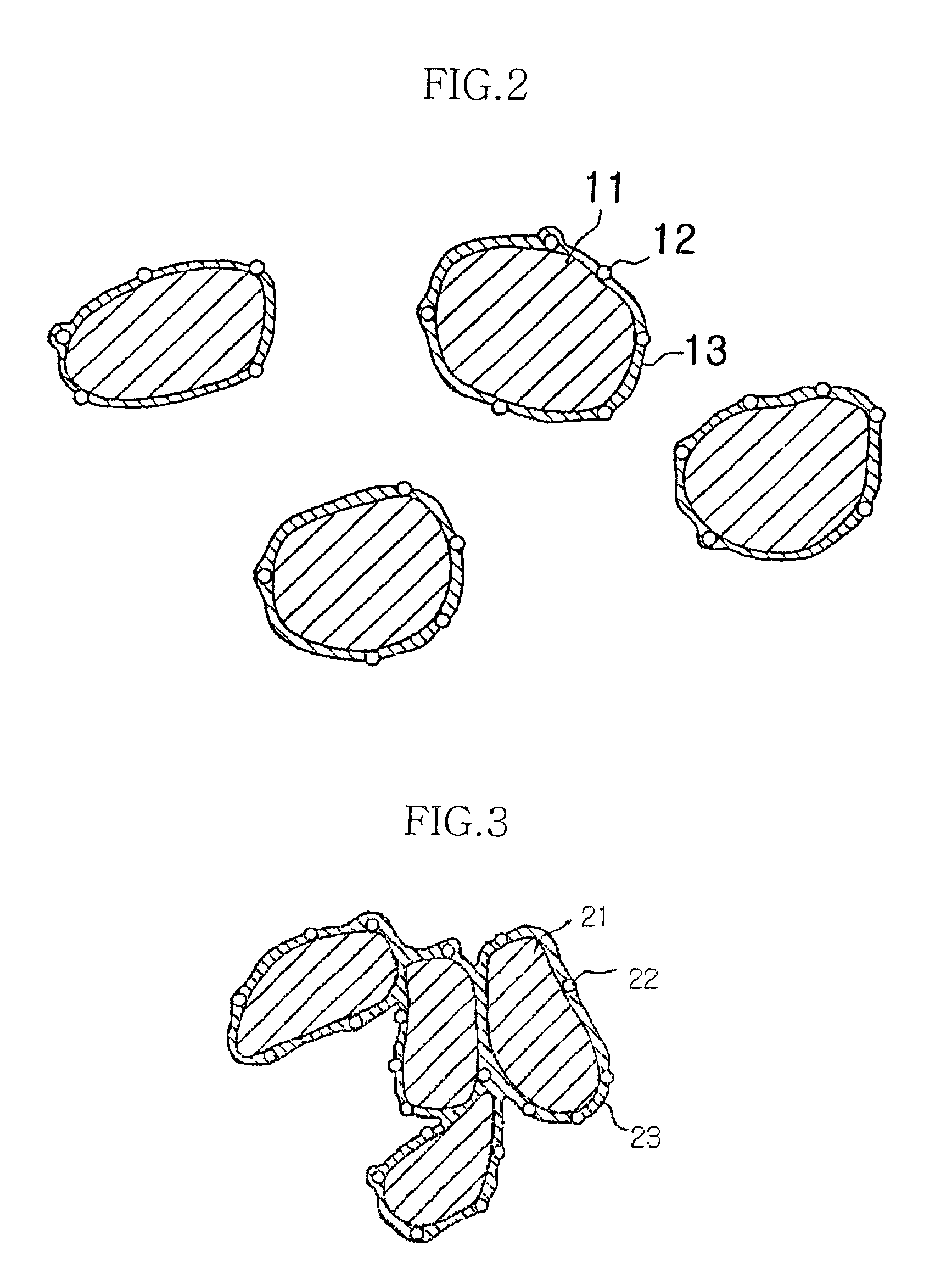

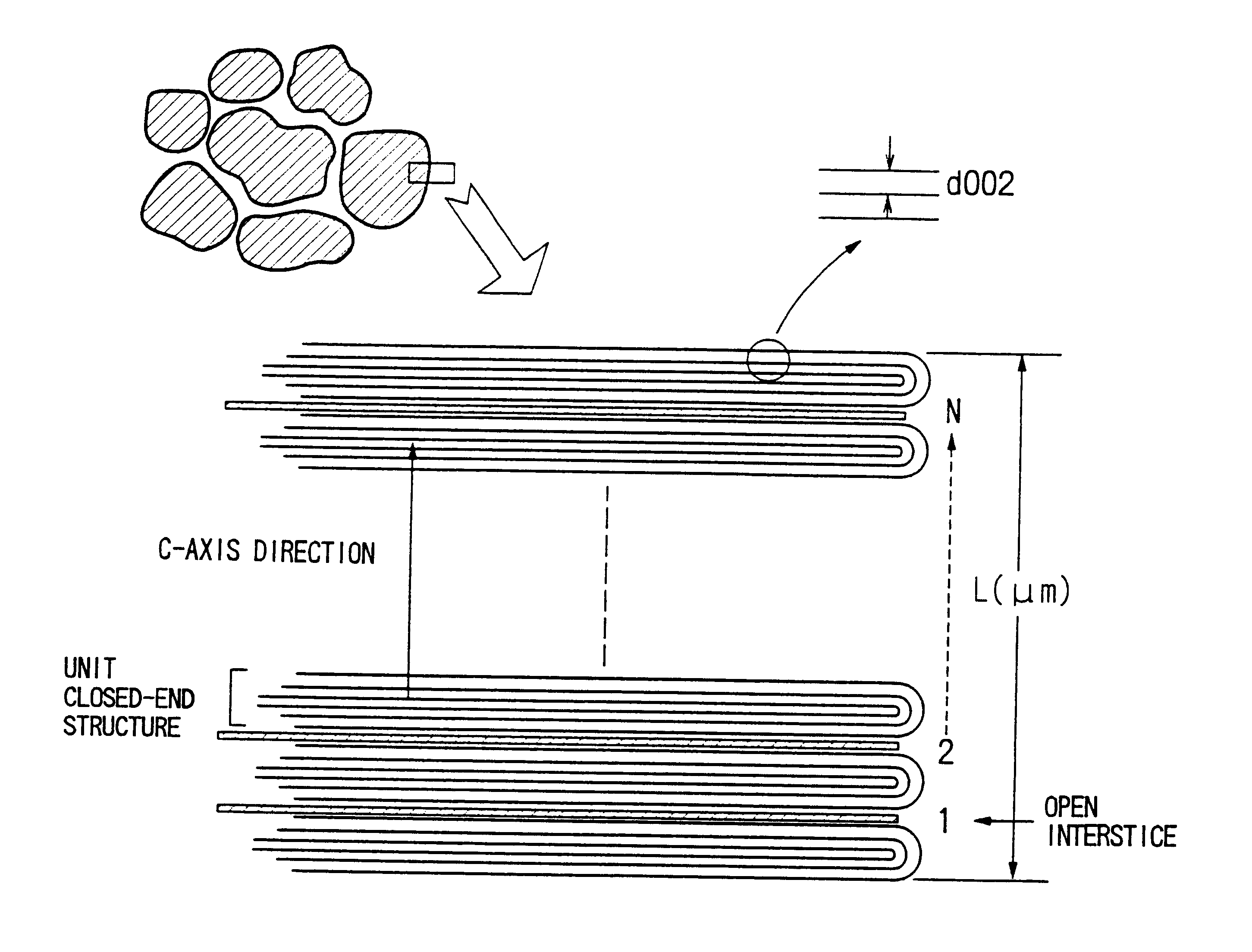

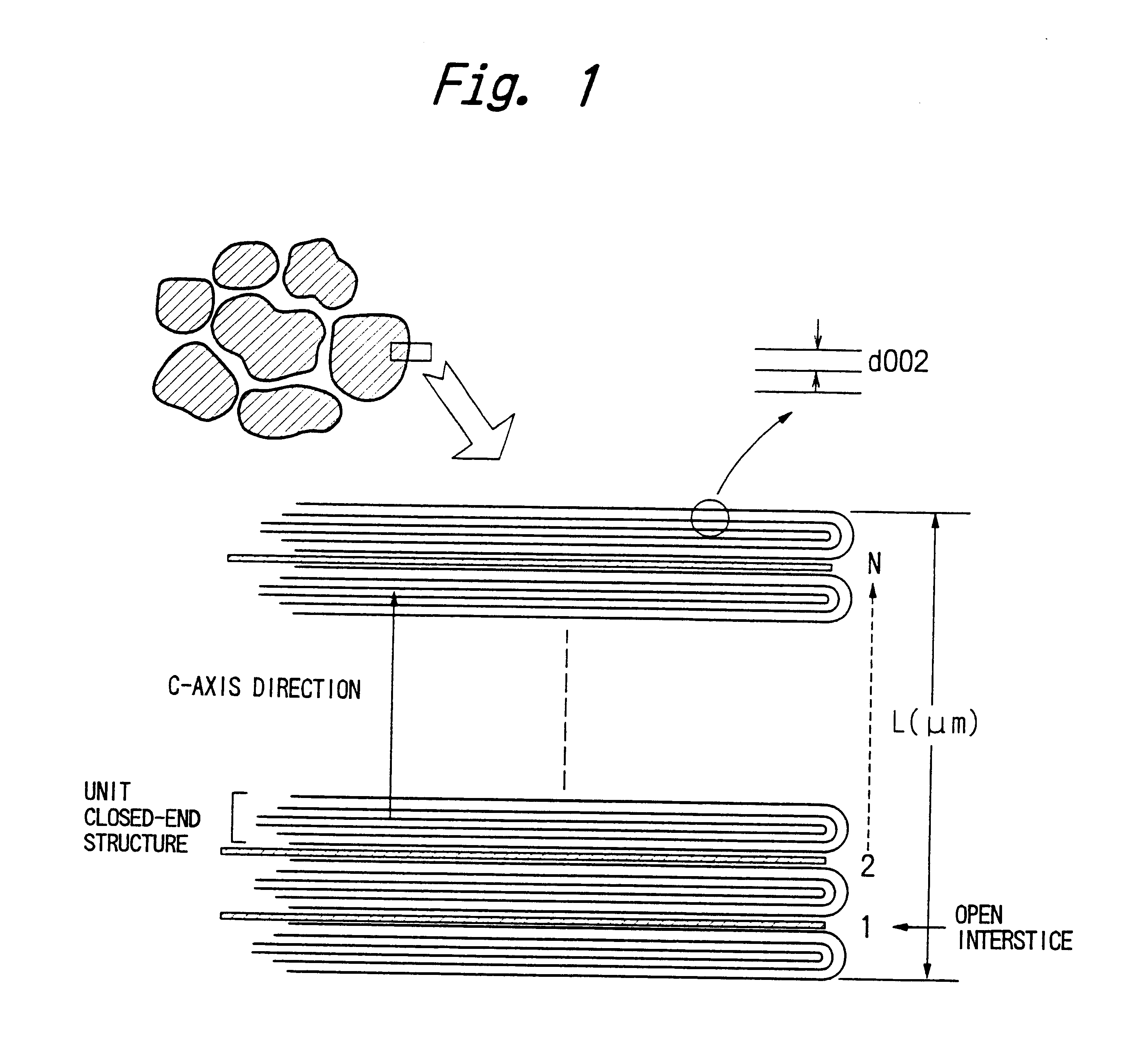

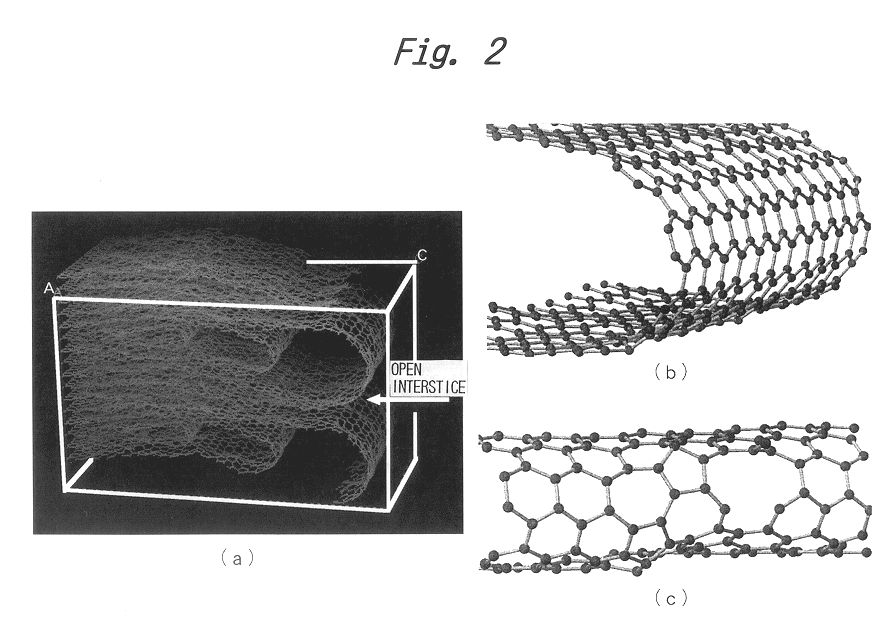

Graphite powder suitable for negative electrode material of lithium ion secondary batteries

InactiveUS6576369B1Improve discharge capacityImprove Coulombic efficiencyNon-aqueous electrolyte accumulatorsGraphiteLithiumMicrometer

A graphite powder has surface closed-end structures in which the graphite c-plane layers of the graphite layer crystal lattices have closed-ends on the surface of the graphite powder by linking the ends of one or more pairs of the c-plane layers, leaving interstices which are open on the surface of the graphite. The number of open interstices is at least 100 and at most 1500 per micrometer in a c-axis direction of the graphite. Preferably, the graphite powder has a specific surface area of 1.0 m2 / g or less. Such a graphite powder can be prepared either by graphitizing a carbon material, which has been pulverized at a high speed under well-controlled conditions before and / or after the carbonization, or by subjecting a carbon material, which has been pulverized under well-controlled conditions before and / or after the carbonization, to graphitization and then to oxidative heat treatment at a temperature of 600-800° C. and finally to heat treatment at a temperature of 800° C. or higher in an inert gas. The graphite powder can be used to produce negative electrodes of lithium ion secondary batteries having a high discharge capacity of at least 320 mAh / g and a high charge / discharge coulombic efficiency of at least 90%.

Owner:NIPPON DENKO CO LTD +1

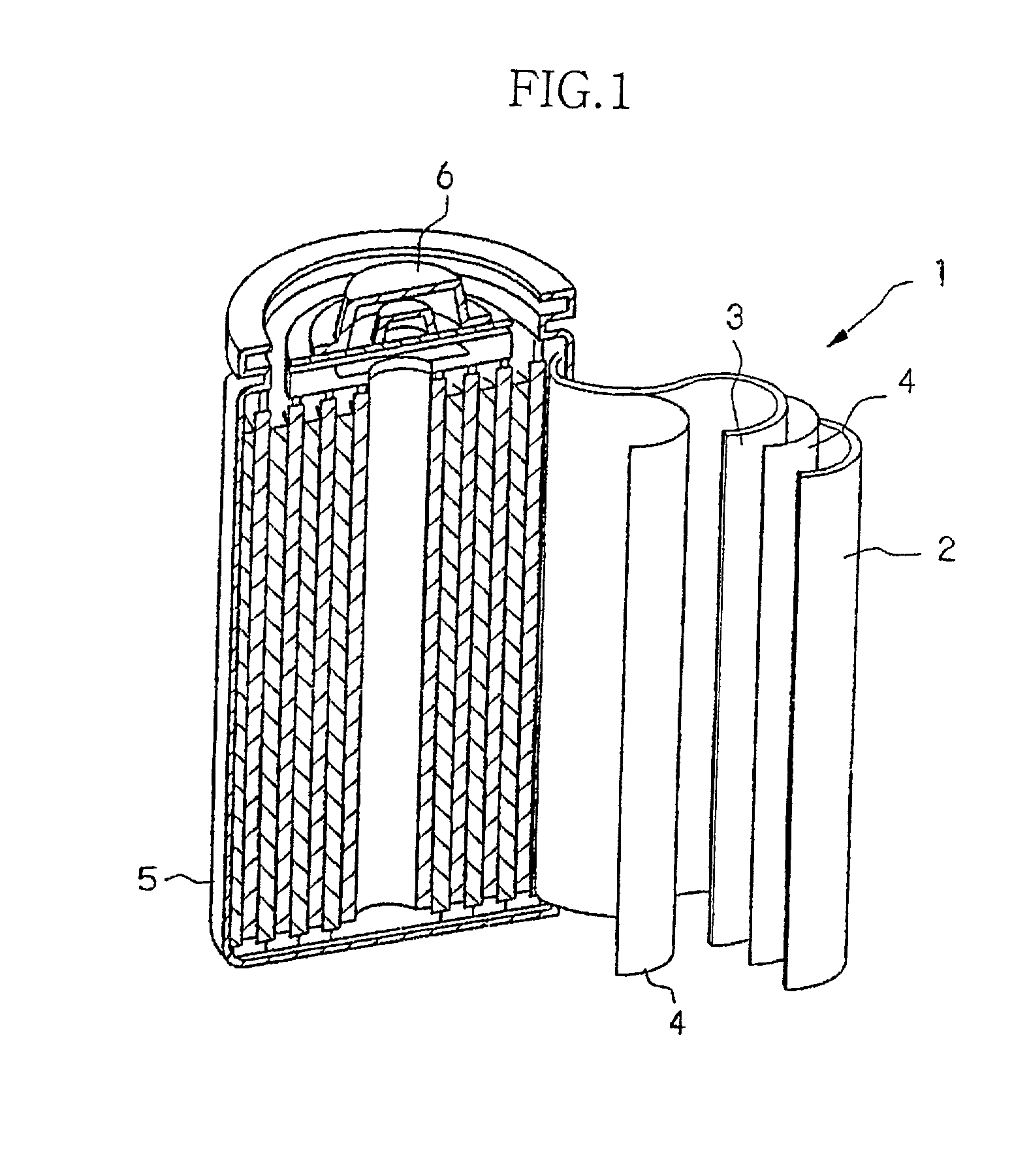

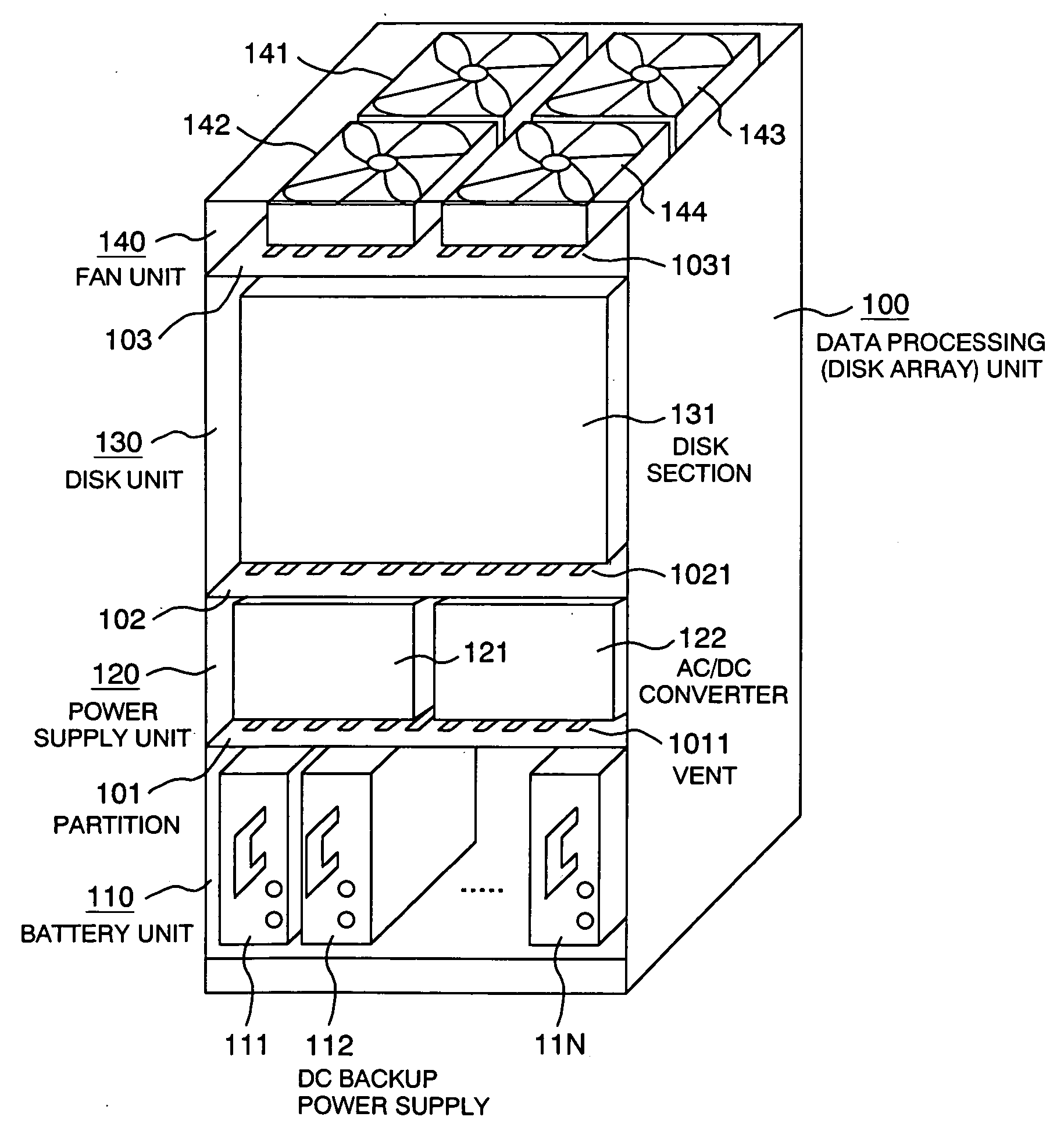

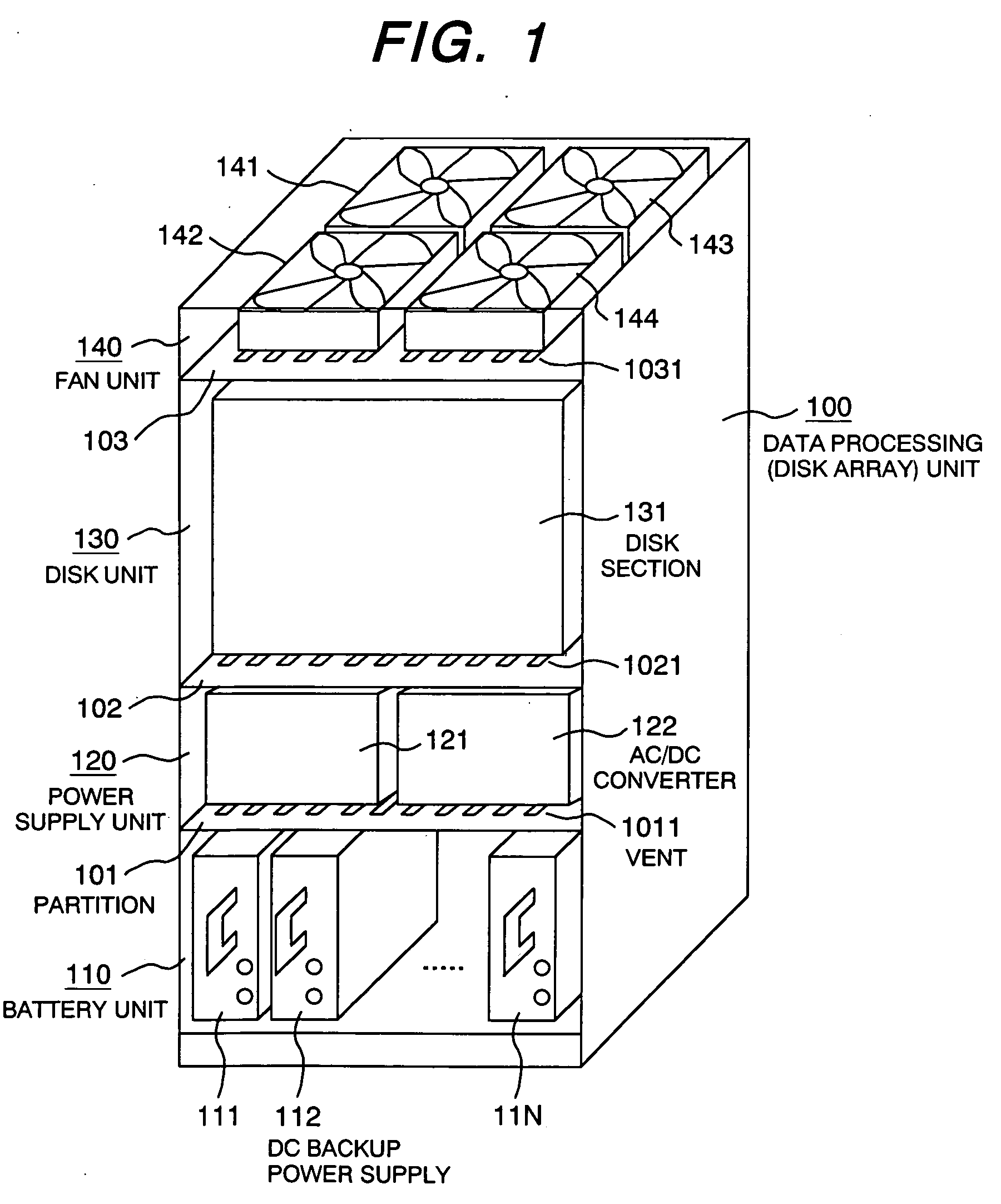

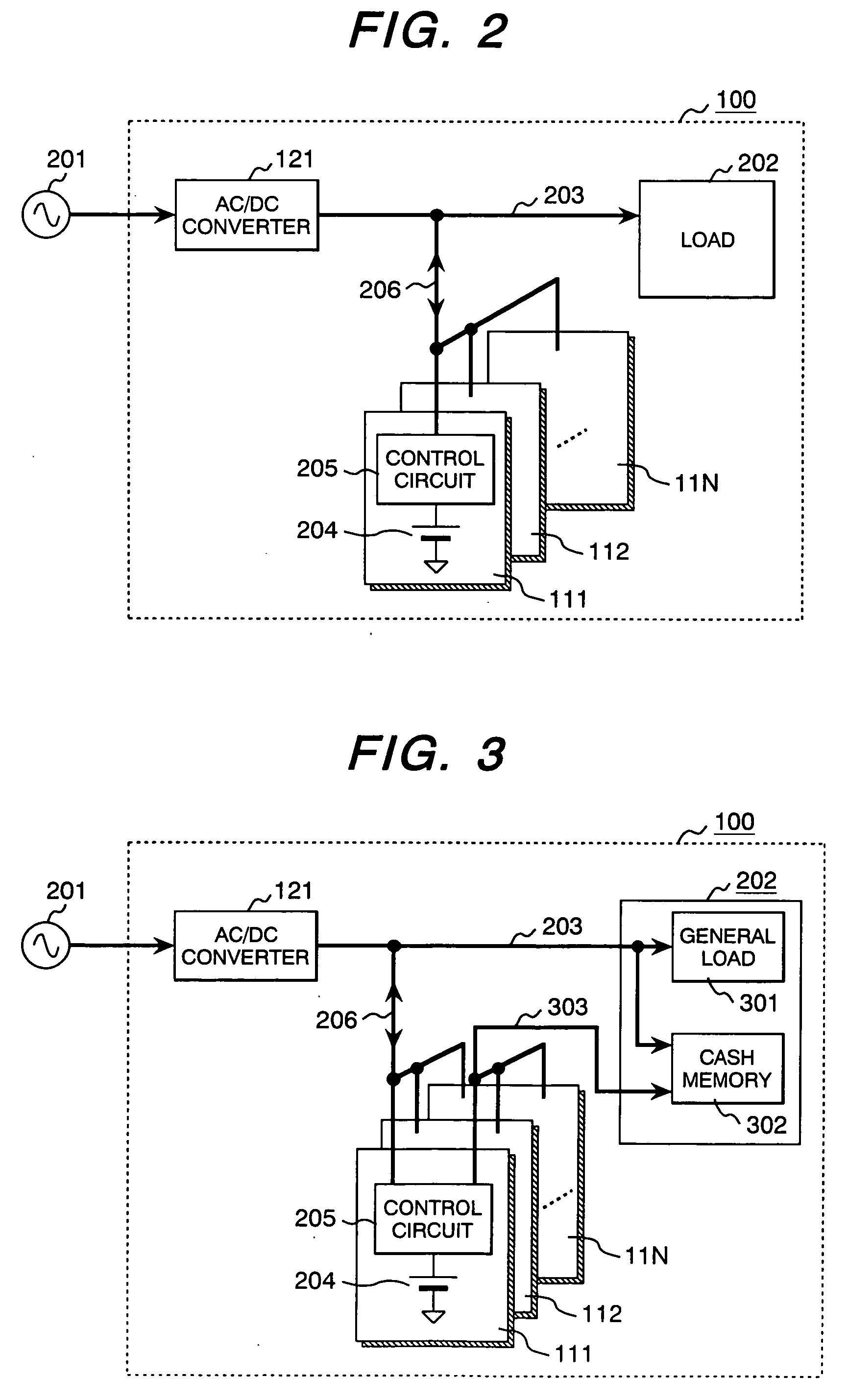

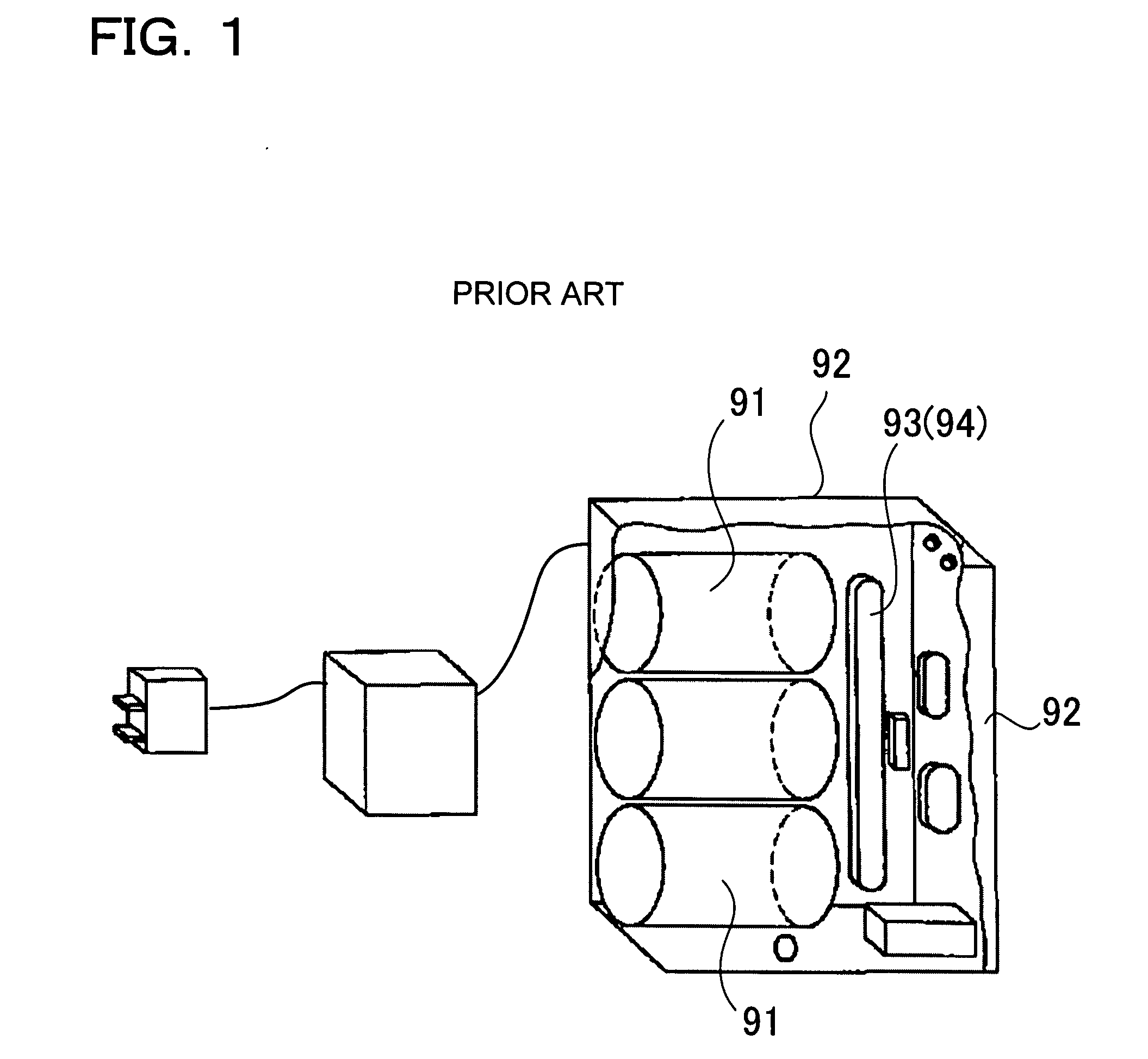

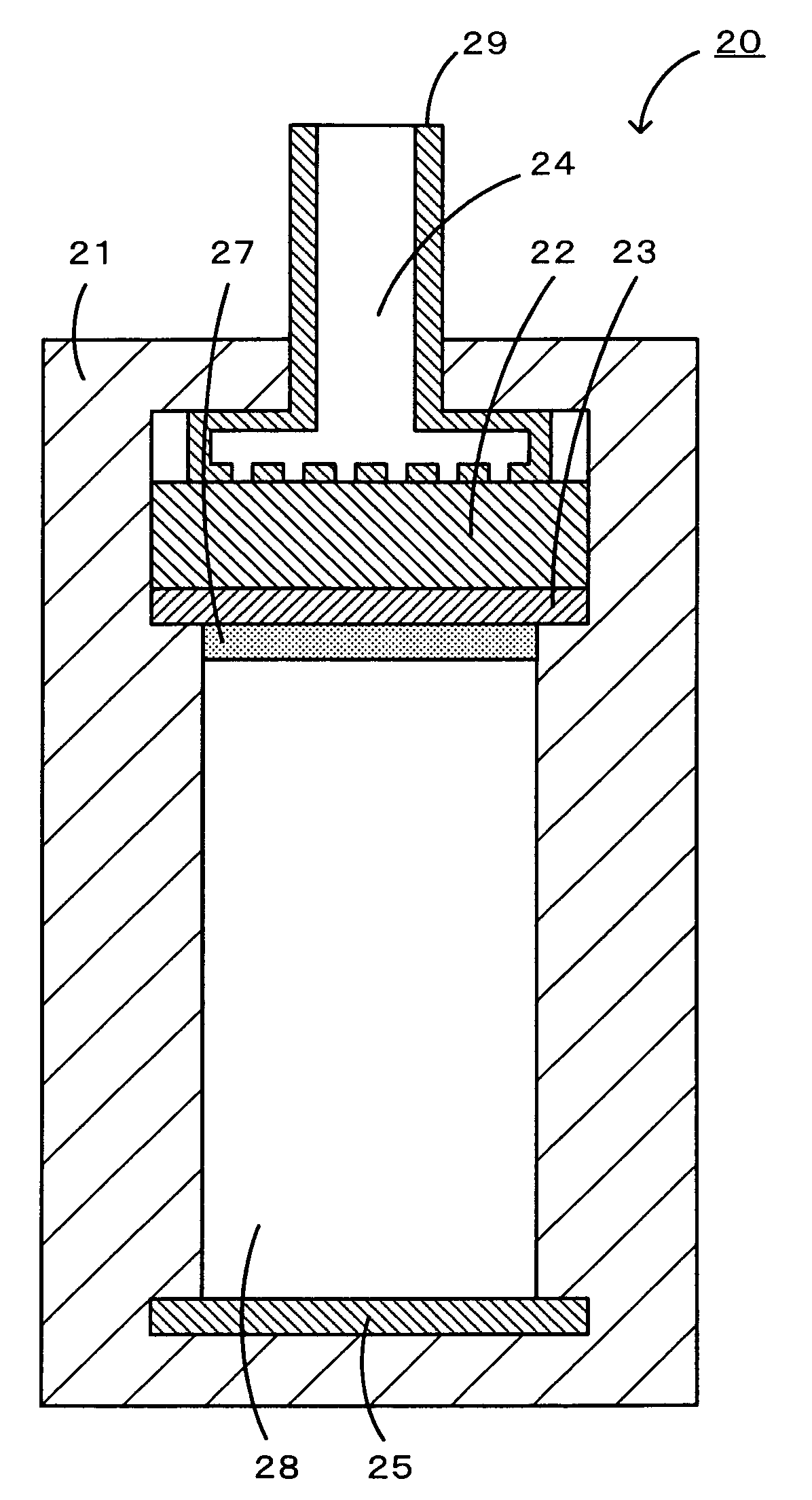

Data processing unit and DC backup power supply

InactiveUS20060056142A1Compact and economicImprove discharge capacityDigital data processing detailsVolume/mass flow measurementElectrical batteryStandby power

A backup power supply is so constructed that it is provided with multiple DC backup power supplies 111 to 11N, each containing nickel-metal hydride battery, stored upright on the bottom of the disk array unit 100; cooled by cooling air through the vents 1011 for ventilation from the bottom to the top; and connected with the output of the AC / DC converters 121, 122 with the backboard 151. Very compact disk array unit with an uninterruptible power supplying function can be realized.

Owner:HITACHI INFORMATION & TELECOMM ENG LTD

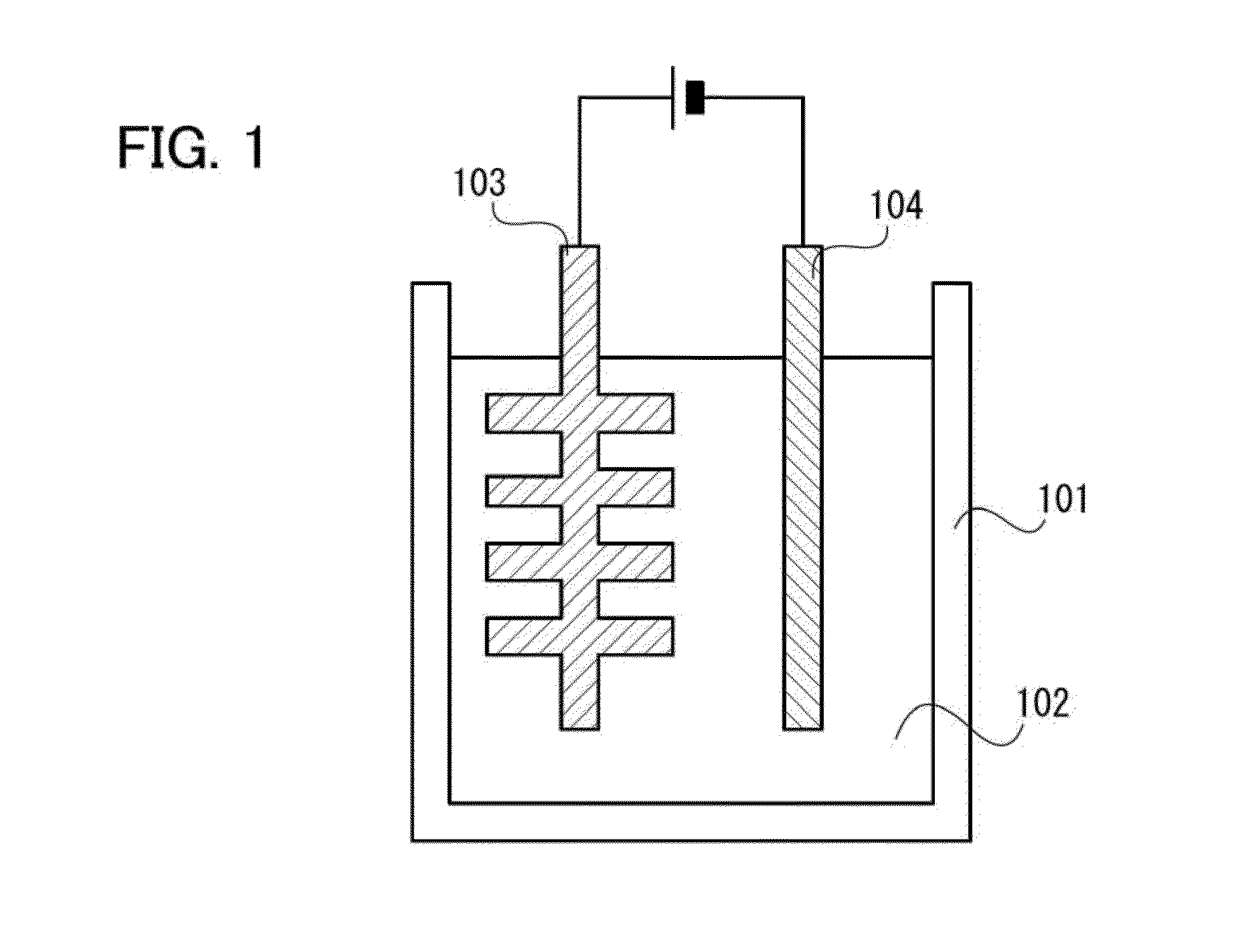

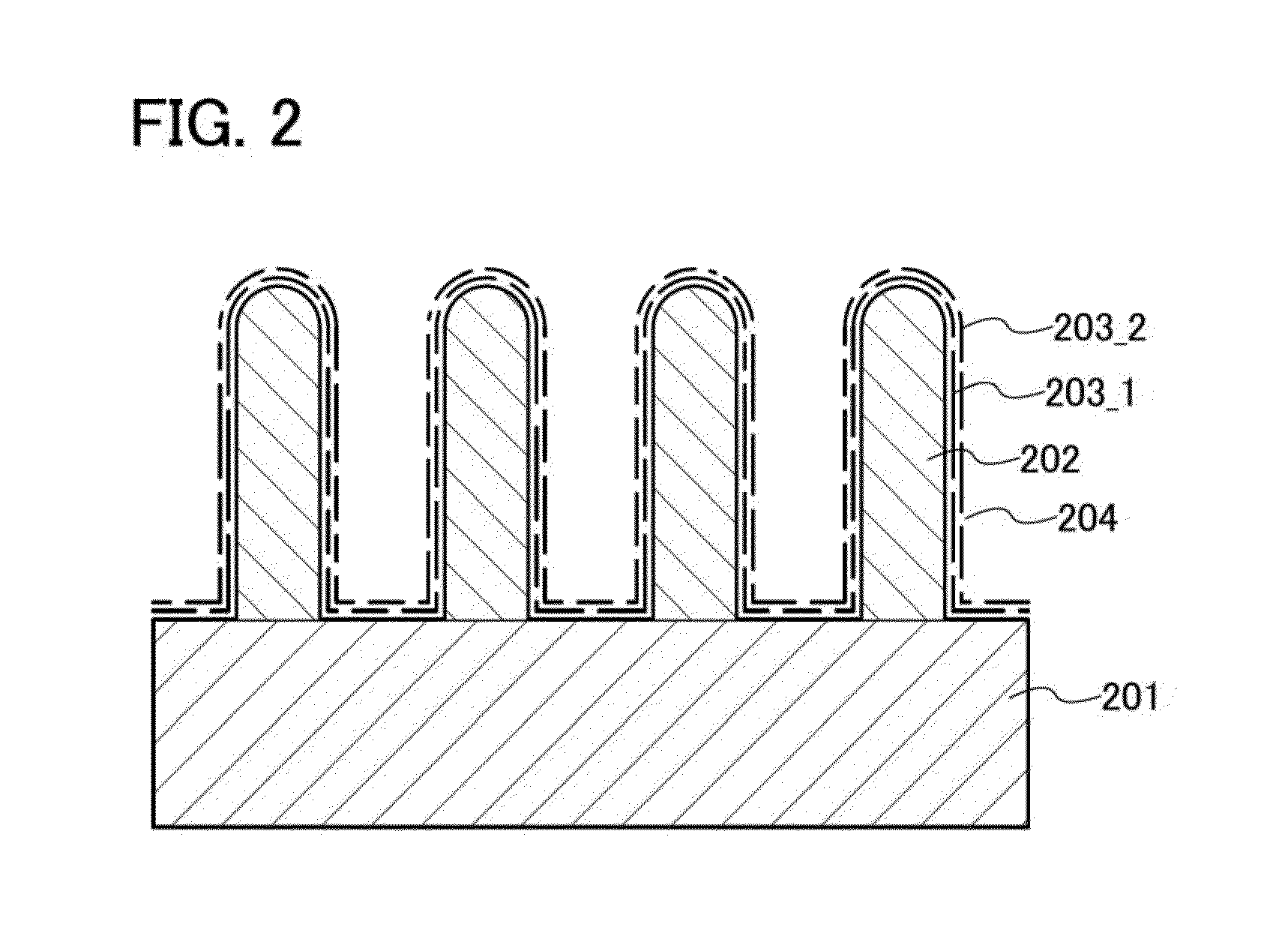

Single-layer and multilayer graphene, method of manufacturing the same, object including the same, and electric device including the same

ActiveUS20120308884A1High densityImprove discharge capacityElectrolysis componentsCarbon compoundsReducing atmosphereCvd graphene

Graphene is formed with a practically uniform thickness on an uneven object. The object is immersed in a graphene oxide solution, and then taken out of the solution and dried; alternatively, the object and an electrode are immersed therein and voltage is applied between the electrode and the object used as an anode. Graphene oxide is negatively charged, and thus is drawn to and deposited on a surface of the object, with a practically uniform thickness. After that, the object is heated in vacuum or a reducing atmosphere, so that the graphene oxide is reduced to be graphene. In this manner, a graphene layer with a practically uniform thickness can be formed even on a surface of the uneven object.

Owner:SEMICON ENERGY LAB CO LTD

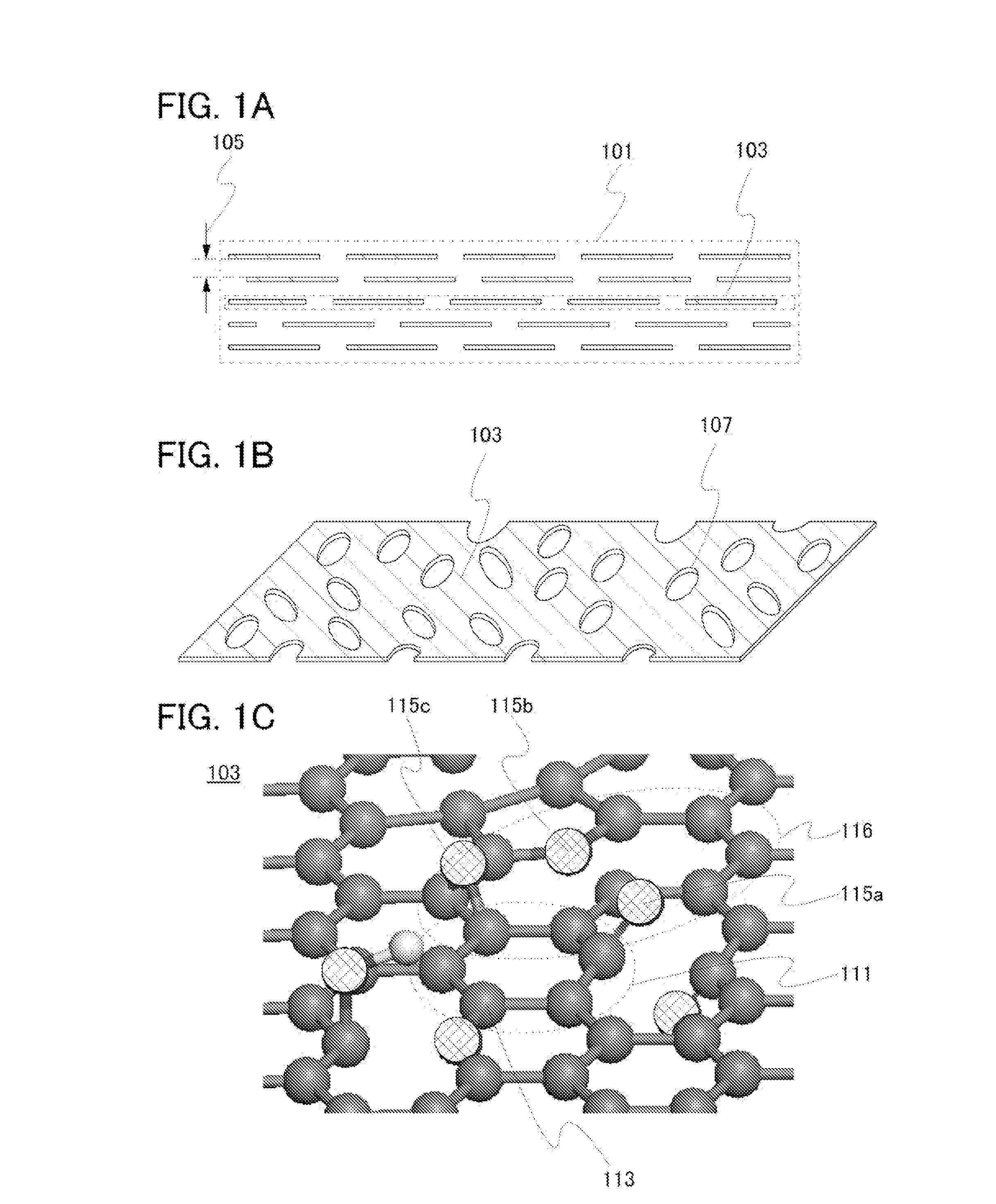

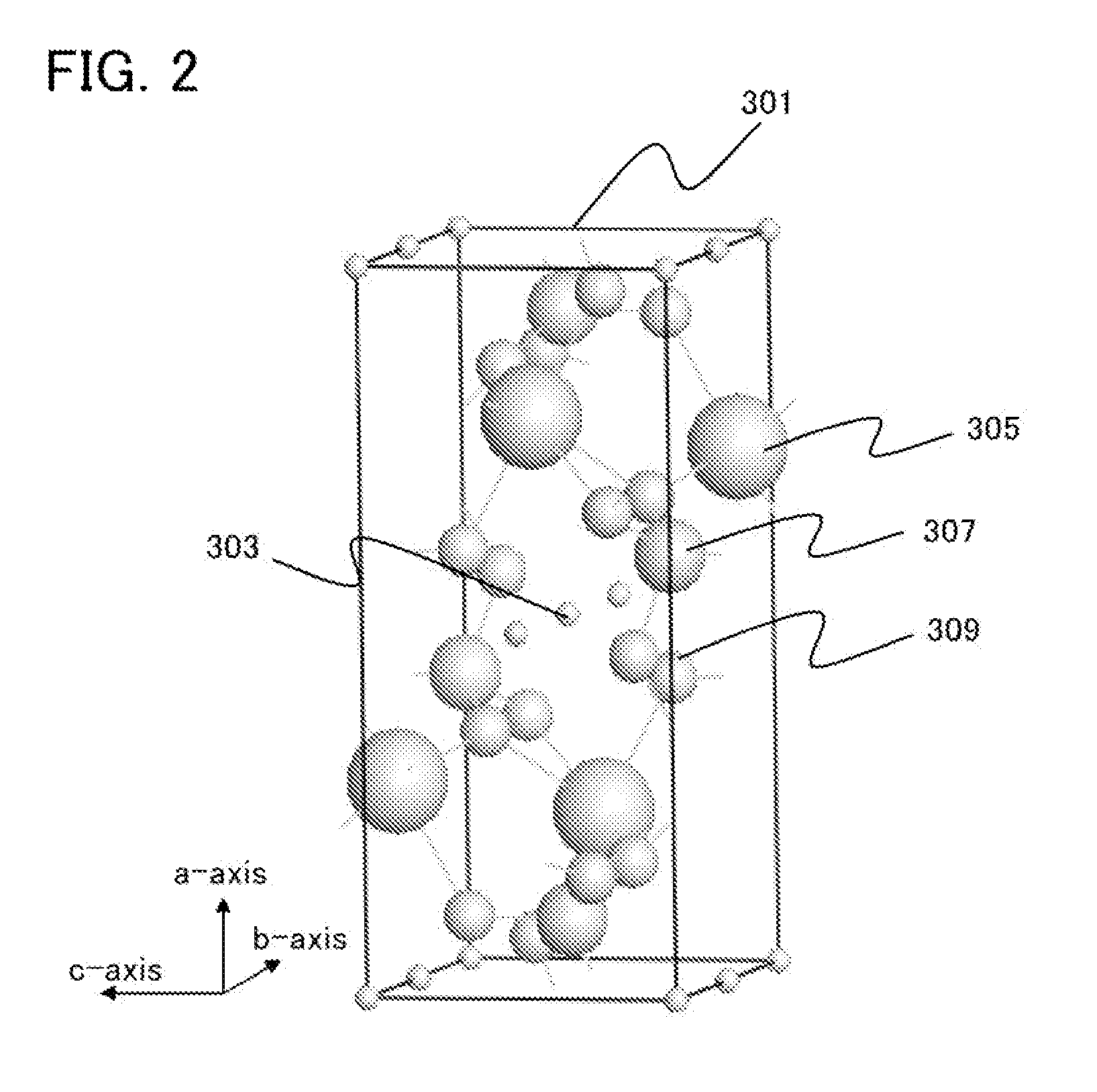

Multilayer graphene and power storage device

InactiveUS20120328956A1Reduce the amount requiredIncreased durabilityMaterial nanotechnologyCarbon compoundsGrapheneOxygen

To provide graphene through which ions can transfer in the direction perpendicular to a plane of the graphene. Multilayer graphene includes a plurality of graphenes stacked in a layered manner. The plurality of graphenes contain a six-membered ring composed of carbon atoms, a poly-membered ring which is a seven or more-membered ring composed of carbon atoms or carbon atoms and one or more oxygen atoms, and an oxygen atom bonded to one of the carbon atoms in the six-membered ring and the poly-membered ring, which is a seven or more-membered ring. The interlayer distance between adjacent graphenes of the plurality of graphenes is greater than 0.34 nm and less than or equal to 0.5 nm, preferably greater than or equal to 0.38 nm and less than or equal to 0.42 nm.

Owner:SEMICON ENERGY LAB CO LTD

Lithium cell positive electrode materials and preparing method thereof

InactiveCN1457111AImprove conductivityHigh conductivity at room temperatureElectrode thermal treatmentPositive electrodesNano structuringElectrical battery

The chemical general formula of the material is expressed as follows: LixM1-xFePO4, where M is selected from Mg2+, Ca2+...P5+ etc. With conduction adulterant added, reaction at 500-900 deg.C for 10 hr. by using metal oxide, phoshpate, fluoride etc. and non saturated crystal of Li-Fe phoshpate through nonstoichiometric method obtains the crystal of Li-Fe phosphate with high conductivity, which can be expressed as LiFePO4-y. The formula of material prepared by using method of pressurized type substitution ion is LixM1-xFezM'1-z. The formula of material of solid power prepared by using method of solid phase reaction is as LixM1-xFezMn1-zPO4. The formula of anode material in nano structure prepared by using method of vacuum sputter deposition is LixFePO4-y, whose conductivity and discharge capacity can reach 10 to the power -2 S / cm and 240 Ah / g.

Owner:徐瑞松

Gradient-doping positive material of lithium ion battery and preparation method of gradient-doping positive material of lithium ion battery

ActiveCN104241633AImprove discharge capacityHigh surface doping element concentrationCell electrodesSecondary cellsLithium-ion batteryLithium electrode

The invention discloses a gradient-doping positive material of a lithium ion battery and a preparation method of the gradient-doping positive material of the lithium ion battery. The structural formula of the positive material is shown as Li(1+alpha)Ni(x)M(y)M'(1-x-y)O(2), wherein alpha is greater than or equal to 0 and less than or equal to 0.2; x is greater than or equal to 0.3 and less than or equal to 1.0; y is greater than or equal to 0 and less than or equal to 0.475; 1-x-y is greater than 0 and less than or equal to 0.35; the concentration of doping element M' is subjected to gradient change from the surfaces of the material particles; on the surfaces of the material particles, the concentration of the element M' is relatively high, the concentration of element Ni is relatively low, and even the surfaces of the material particles are free of the element Ni; in the material particles, the concentration of the element Ni is relatively high, the concentration of the element M' is relatively low, and even the inside of the material particles are free of the element M'. The positive material is excellent in comprehensive performance and especially has the advantages of high discharge capacity, excellent cycle performance and the like. In addition, the method is simple; the industrial production is easy to implement.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

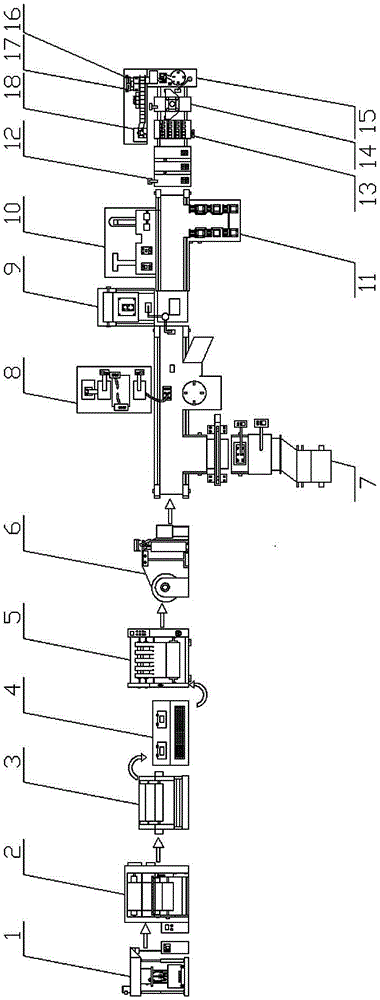

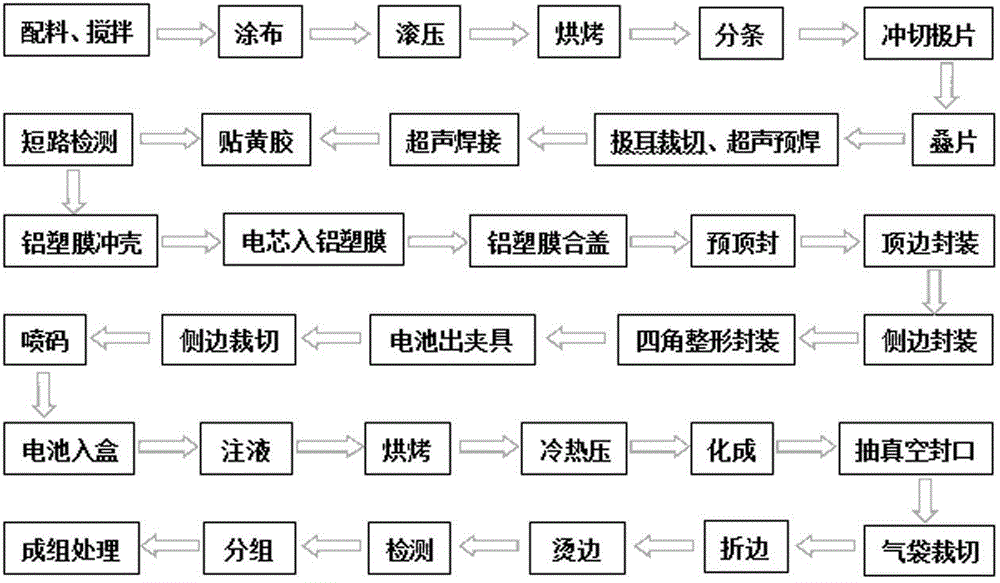

Power type lithium battery full-automatic production line and production technology thereof

ActiveCN105280957AStorableAchieve readFinal product manufactureElectrolyte accumulators manufactureProduction lineControl system

The invention relates to a power type lithium battery full-automatic production line and a production technology thereof. The power type lithium battery full-automatic production line mainly consists of a pole piece manufacturing unit, a battery assembling unit, a battery liquid injecting unit and a factory processing unit; each unit key equipment electrical control system is composed of a PLC, an industrial personal computer, a hydraulic and pneumatic component; the PLC controls each mechanism of the equipment to act in a coordinated manner; and the industrial personal computer collects data to realize the function that the data of the whole line can be stored, read and the like. The main effects lie in that mutual matching of production efficiency of each unit is realized through key debugging for production parameters, a conveyor is adopted in an intermediate link, and full automation of production process is finally realized; the production line is compatible with multi-standard battery production requirements, the production when the product is remodeled can be realized just by adjusting the equipment parameters and replacing partial work fixtures, and order form-based production requirement of the product is met; key equipment and technology on the line are independently researched and developed, the operation is reliable and stable, and the production line has higher cost performance.

Owner:东营黄蓝知识产权运营管理有限公司

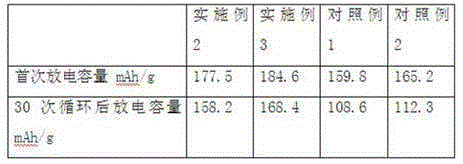

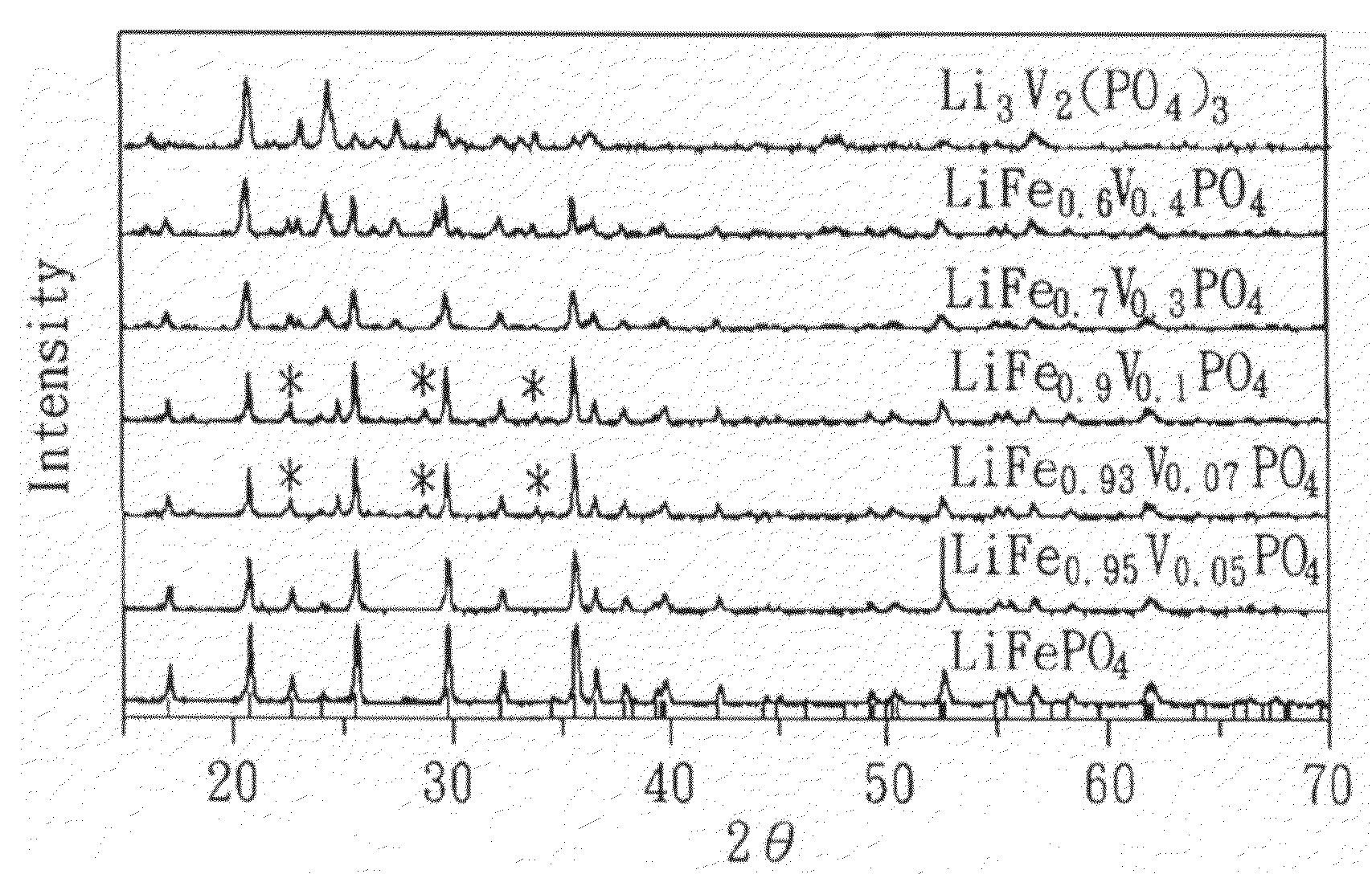

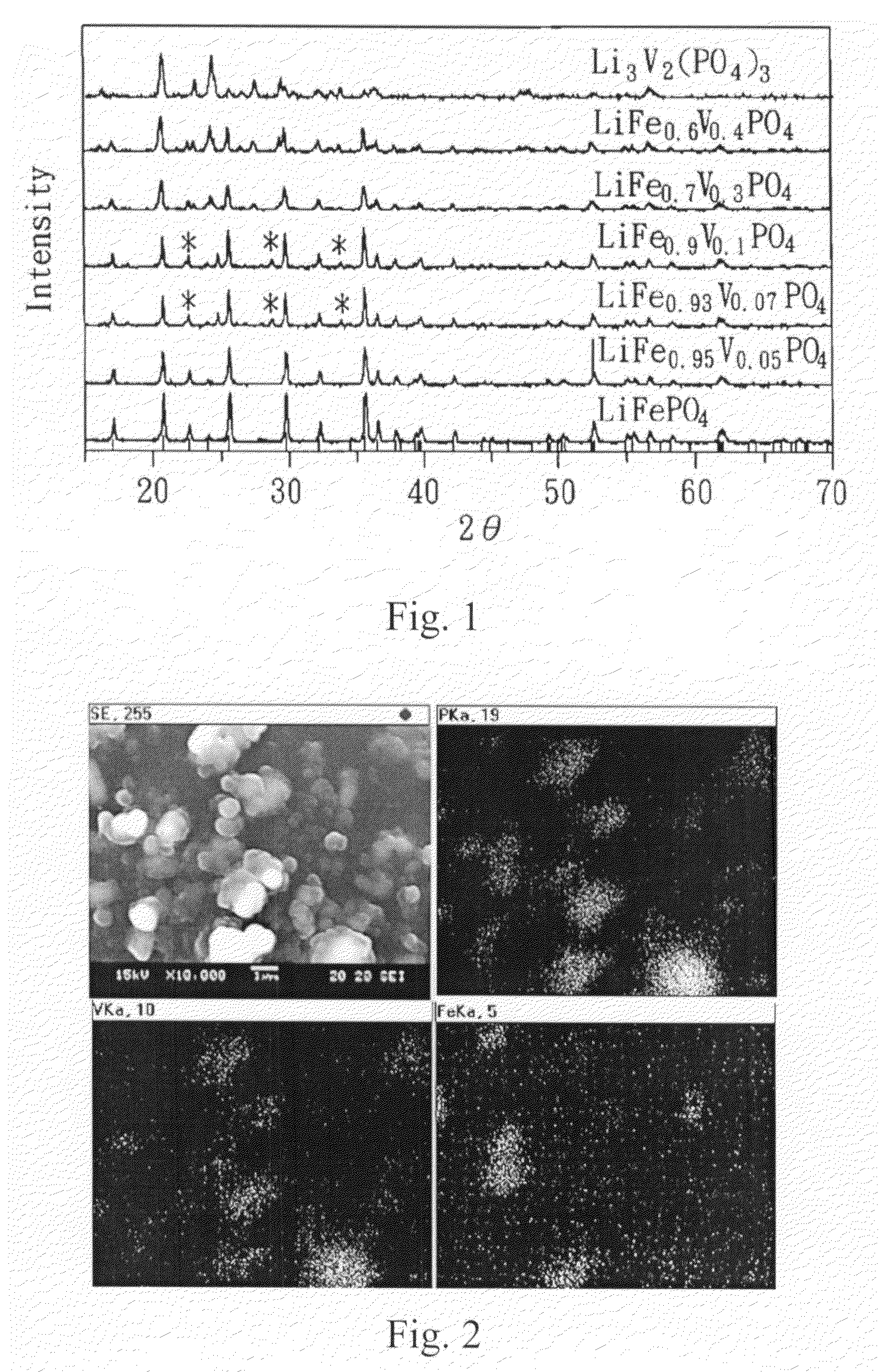

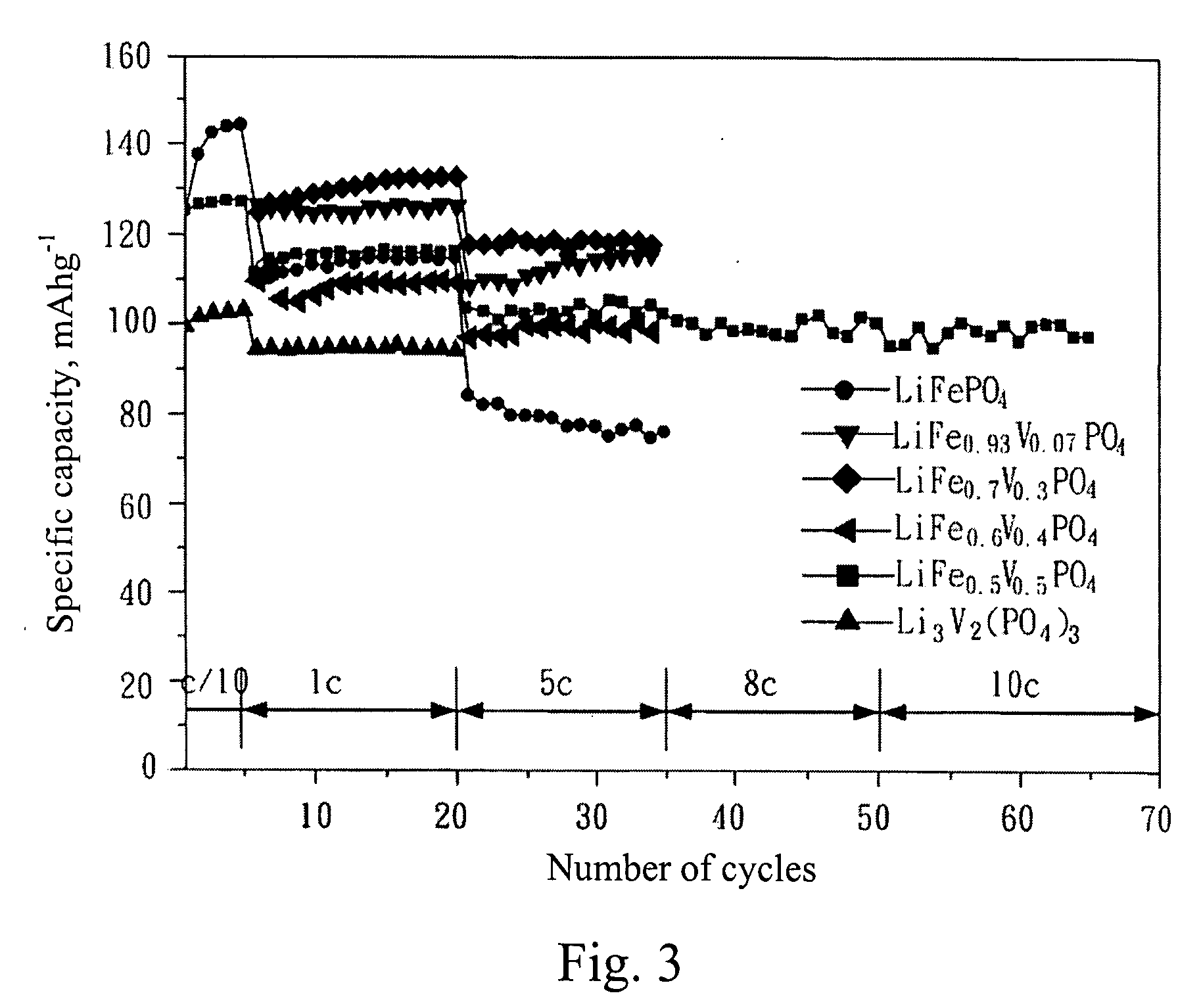

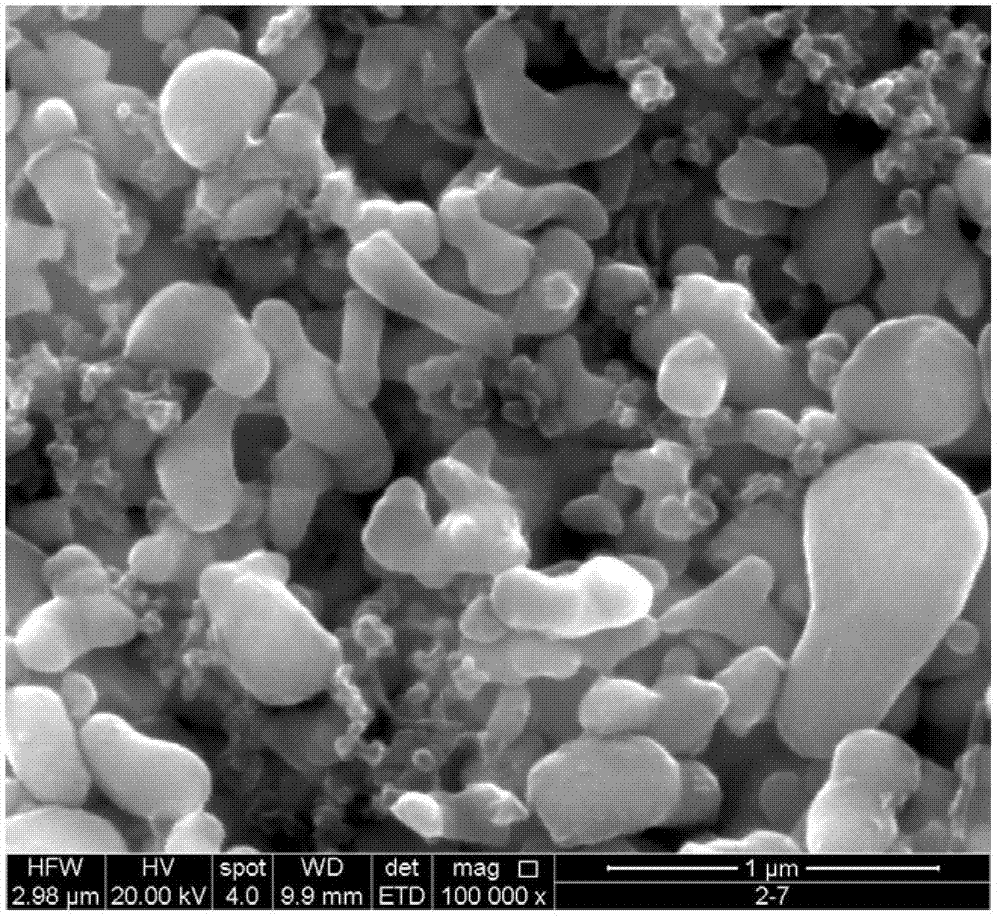

Preparation and application of LiFePO4/Li3V2 (PO4)3 composite cathode materials for lithium ion batteries

InactiveUS20080008938A1Improve conductivityCathode material of highElectrode manufacturing processesDuplicating/marking methodsComposite cathodeIron powder

A method of preparing LiFePO4 / Li3V2(PO4)3 composite cathode materials and their applications as cathode materials for lithium ion batteries are disclosed. The preparation method includes the following steps: (A) providing a mixture of iron powder, lithium salt, vanadium salt, and a phosphate salt whereafter these compounds are dissolved into a mixed acid solution; (B) drying the solution in order to obtain precursor powders; and (C) heating the precursor powders at a temperature ranging between 400 and 1000° C. to form LiFe1-y′Vy′PO4 / Li3V2-y″Fey″(PO4)3 composite powders. Alternatively, prepare the composite cathode by preparing olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y′Fey″(PO4)3 powders as in previous procedures followed by mixing adequately. The low cost of iron powder thus facilitates to prepared composite cathode materials exhibiting higher electrical conductivity and superior cycling performance at high C rates than those of olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y″Fey″(PO4)3. The invention will help the development of the lithium ion batteries and related industries.

Owner:TATUNG COMPANY

Non-water electrolyte for high-voltage lithium ion battery and preparation method

The invention relates to non-water electrolyte for a high-voltage lithium ion battery and a preparation method. The non-water electrolyte is characterized in that: respectively purifying sulphone compound, halogenated cyclic carbonic ester and carbonic ester through rectification and molecular sieving under the protection of argon or nitrogen; mixing the sulphone compound, the halogenated cyclic carbonic ester and the carbonic ester in the weight ratio of 1:1:2 to obtain a non-water mixed solvent from which impurities and water are removed; dissolving 10 to 18 percent of mixed lithium salt in 80 to 87 percent of non-water mixed solvent to obtain the electrolyte; adding 2 to 5 percent of additive into the electrolyte; and uniformly mixing at the temperature of 40 DEG C to obtain the non-water electrolyte for a 4.8 Vvs.Li+ / Li lithium ion battery. The electrolyte has higher compatibility with a cathode material under high voltage and can form a stable solid electrolyte interface (SEI) film on the surfaces of a positive electrode and a negative electrode. Besides, the invention has the advantages that: the preparation process is simple, and the method is easy to implement and suitable for industrialized production.

Owner:XIANGHE KUNLUN NEW ENERGY MATERIALS CO LTD

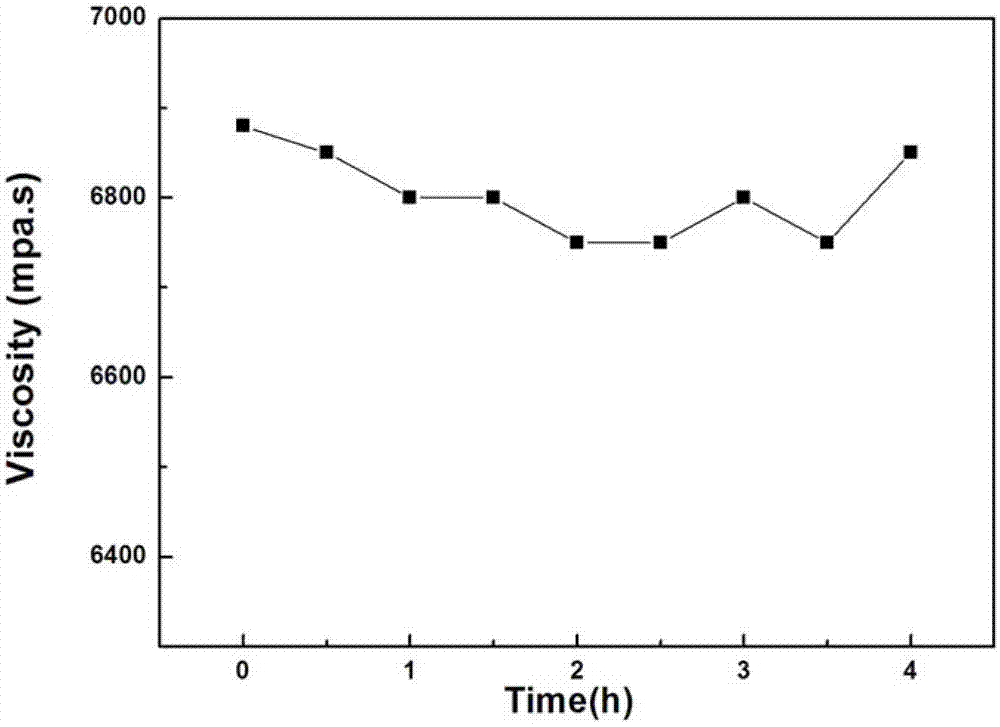

Cathode material of lithium ion battery, preparation method of cathode, and lithium ion battery

ActiveCN103199258APromote accumulationEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryNano carbon

The invention discloses a cathode material of a lithium ion battery, a preparation method of the cathode, and the lithium ion battery using the cathode material, belonging to the technical field of energy material. According to the invention, a chemical dispersant is added into the cathode of an aqueous lithium-ion battery, thereby solving problems of uniform dispersion for active materials of positive electrode and a nano-carbon mixed conductive agent; and a mechanical dispersion method is combined, preferably with a revolution speed of the mechanical dispersion being 15-35 HZ and a rotation speed being 10-30 HZ, thereby realizing uniform dispersion of the nano-active substances in a relatively short time. The cathode material of a lithium ion battery and the preparation method provide technical approach for solving uniform dispersion of the aqueous nano-active substances, and are high in production efficiency and low in cost; the prepared battery is high in discharge capacity, and is significantly improved in low temperature, multiplying power and cycling performances; and a new approach is provided for a large scale application of the nanometer lithium batteries which are limited to a high cost and a high-polluting oil system in the field.

Owner:中创新航科技(江苏)有限公司

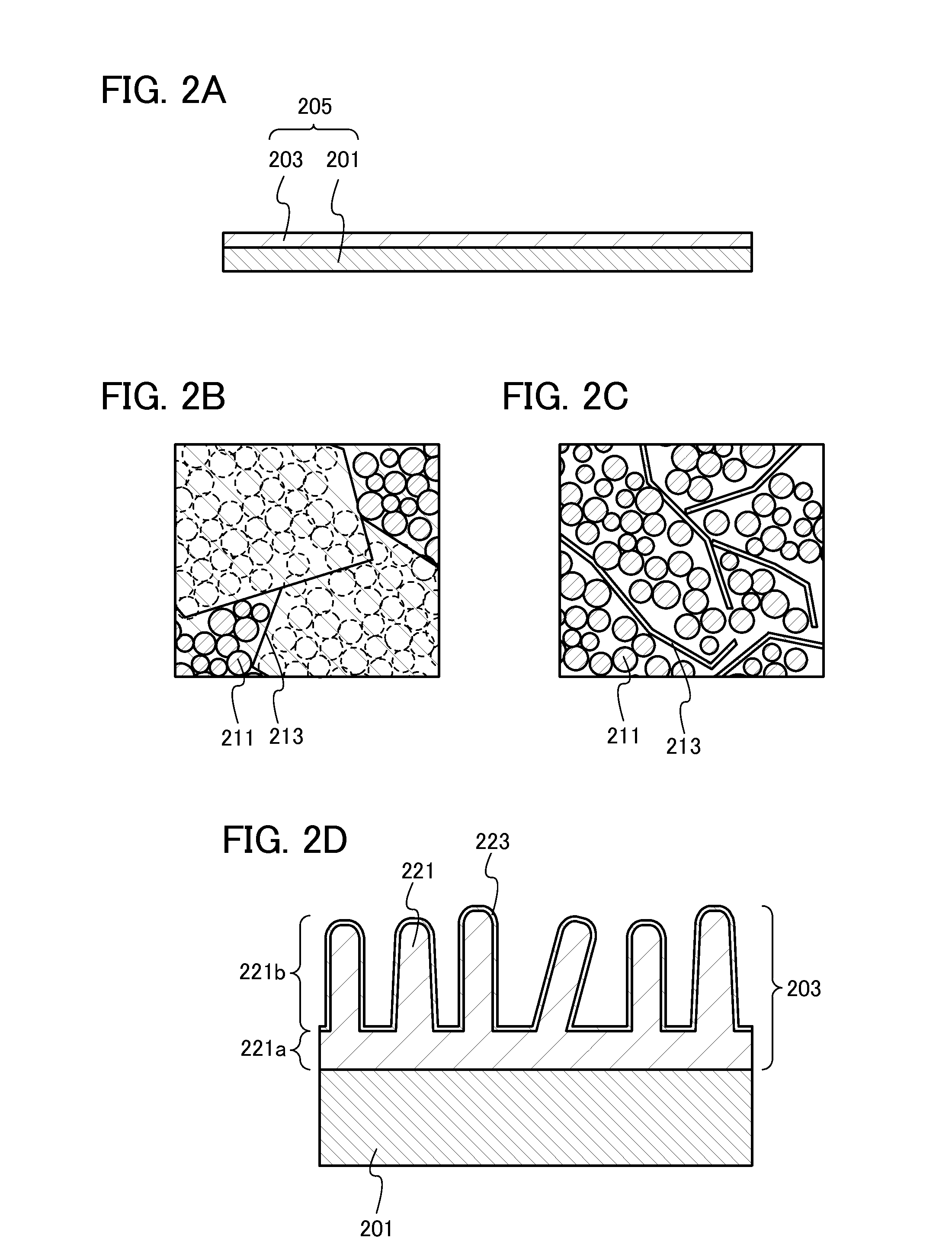

Lithium-ion secondary battery

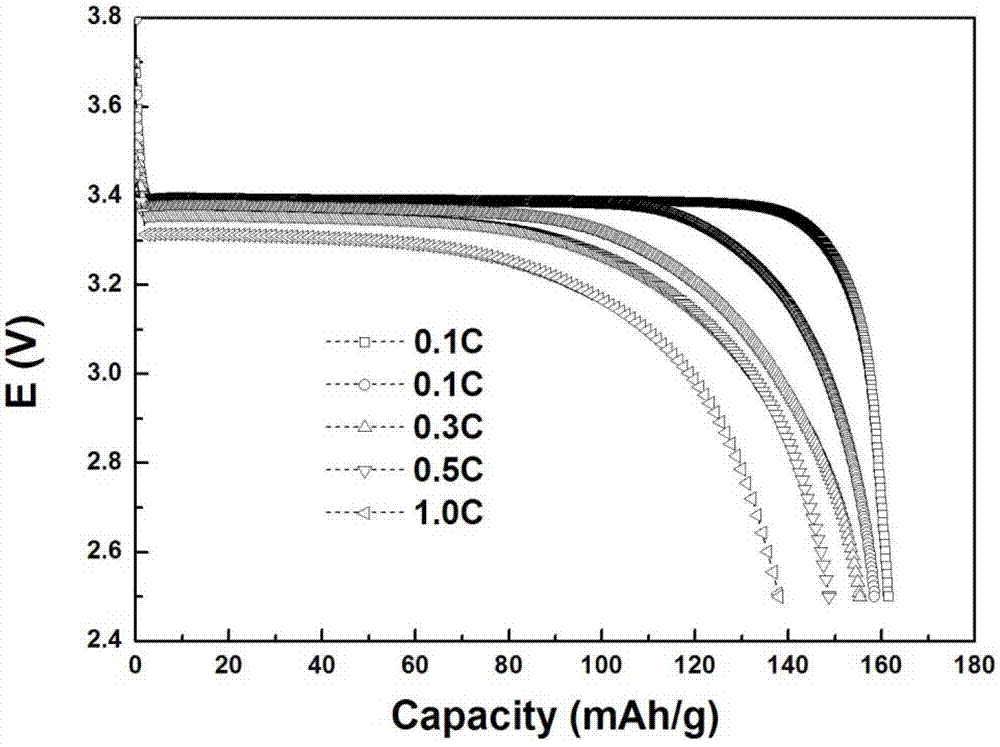

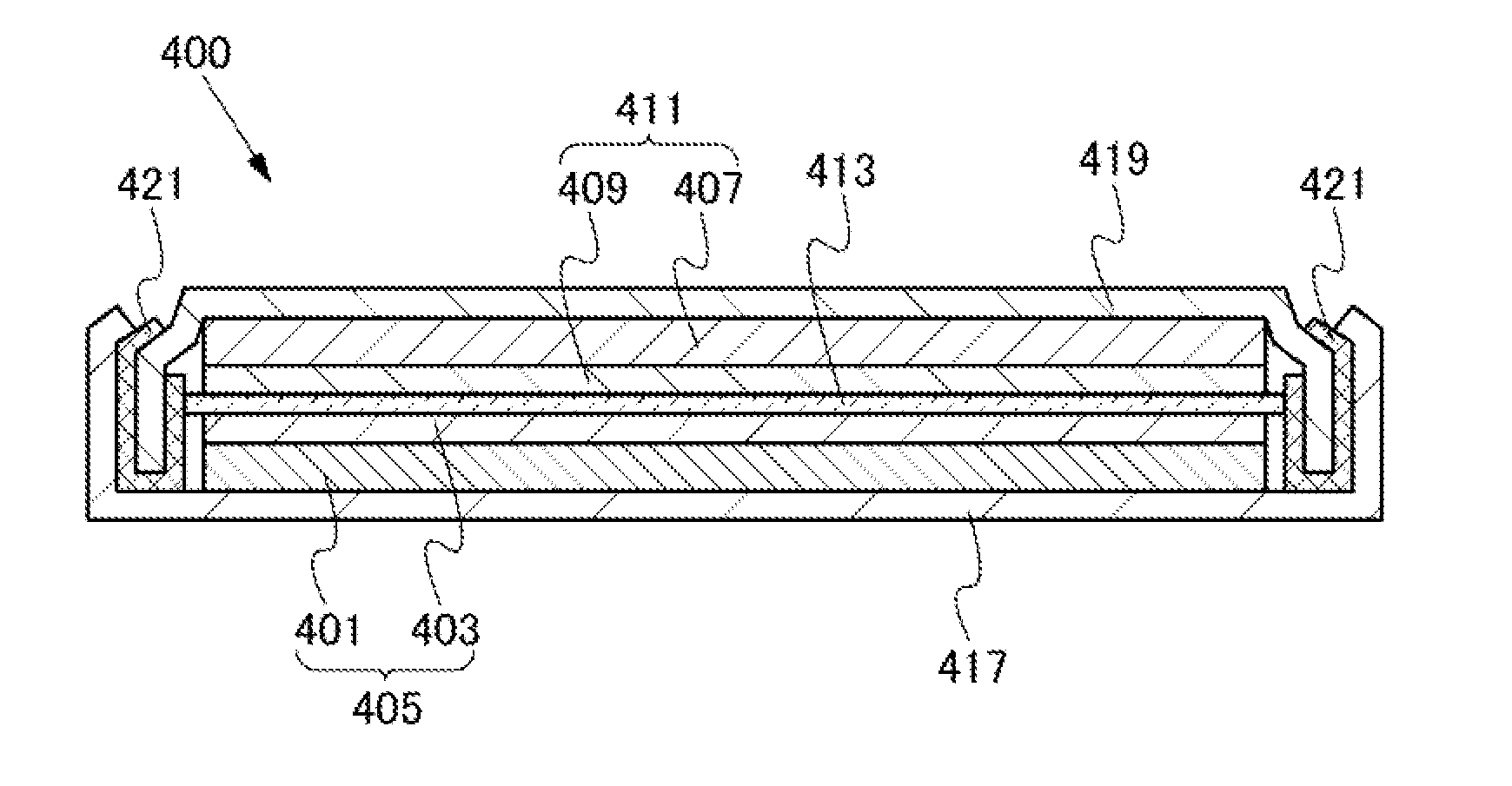

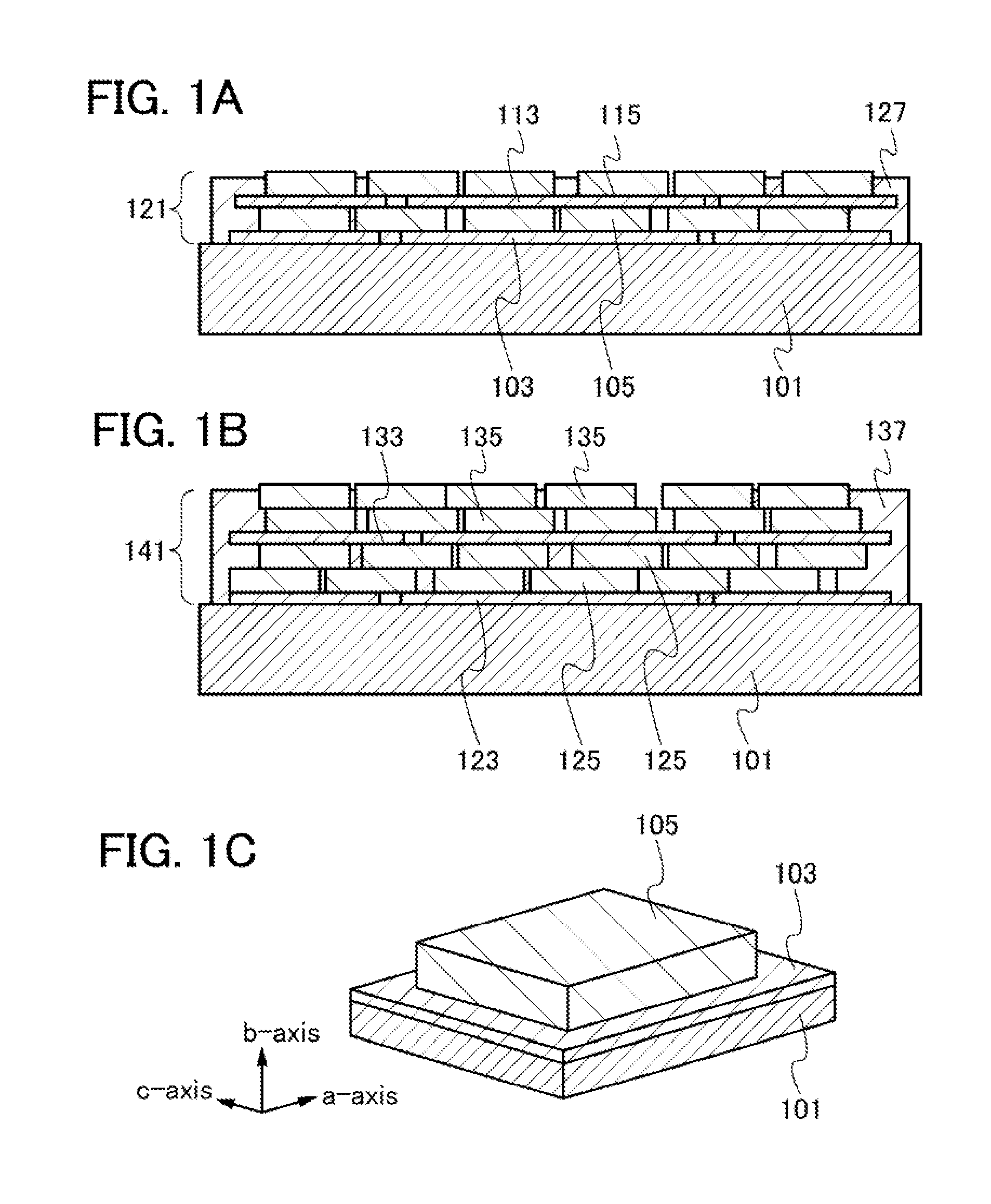

InactiveUS20120244430A1Easy to spreadRaise the ratioFinal product manufactureElectrode carriers/collectorsHigh energyElectrical battery

To provide a lithium-ion secondary battery having higher discharge capacity and higher energy density and a manufacturing method thereof. The lithium-ion secondary battery includes a positive electrode, a negative electrode, and an electrolyte provided between the positive electrode and the negative electrode. The positive electrode includes a positive electrode current collector and a positive electrode active material layer provided over the positive electrode current collector. In the positive electrode active material layer, graphenes and lithium-containing composite oxides are alternately provided. The lithium-containing composite oxide is a flat single crystal particle in which the length in the b-axis direction is shorter than each of the lengths in the a-axis direction and the c-axis direction. Further, the lithium-containing composite oxide is provided over the positive electrode current collector so that the b-axis of the single crystal particle intersects with a surface of the positive electrode current collector.

Owner:SEMICON ENERGY LAB CO LTD

Negative electrode material for quickly rechargeable graphite lithium-ion battery and preparation method of negative electrode material

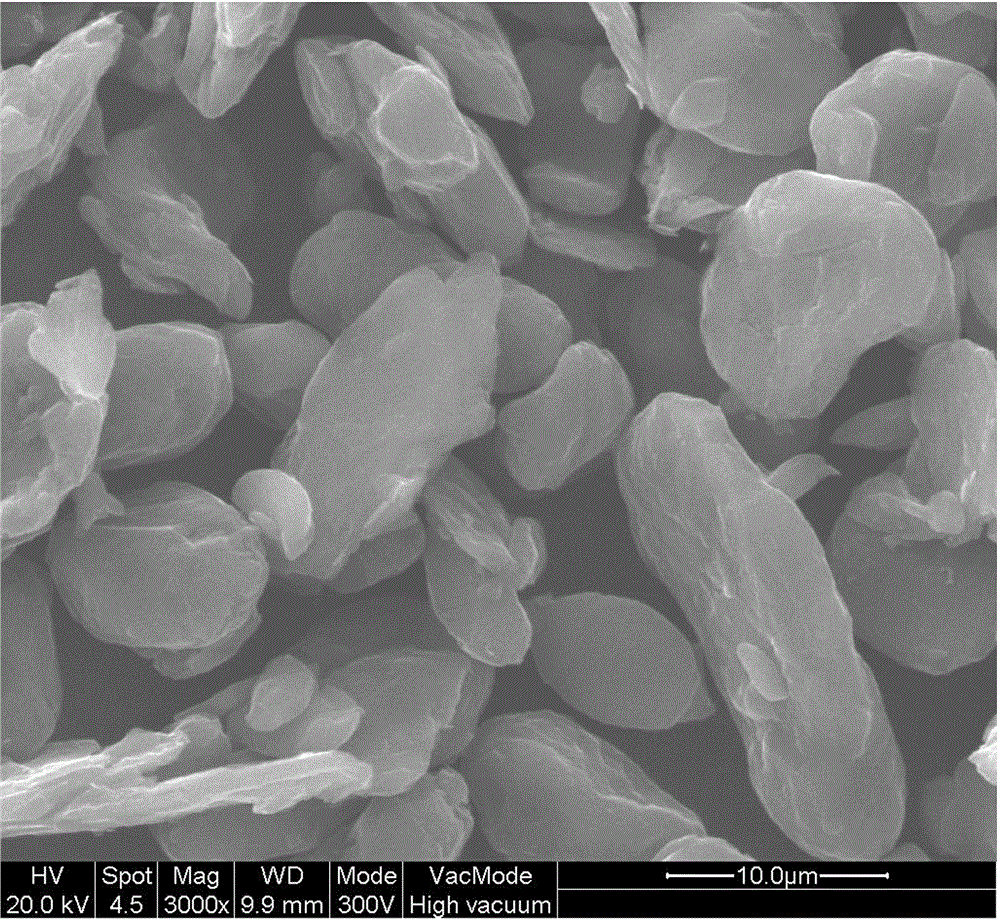

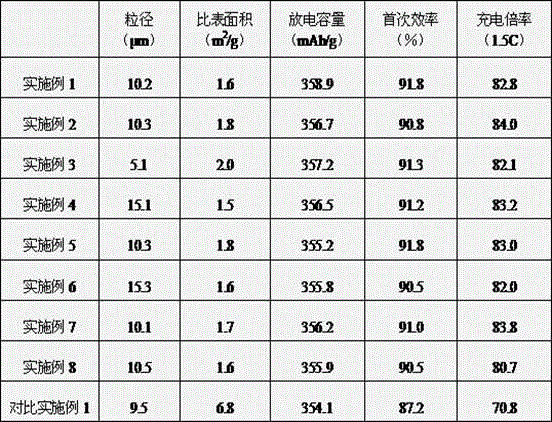

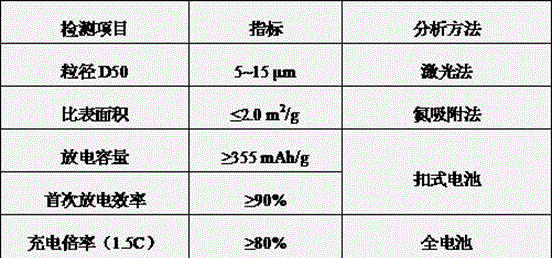

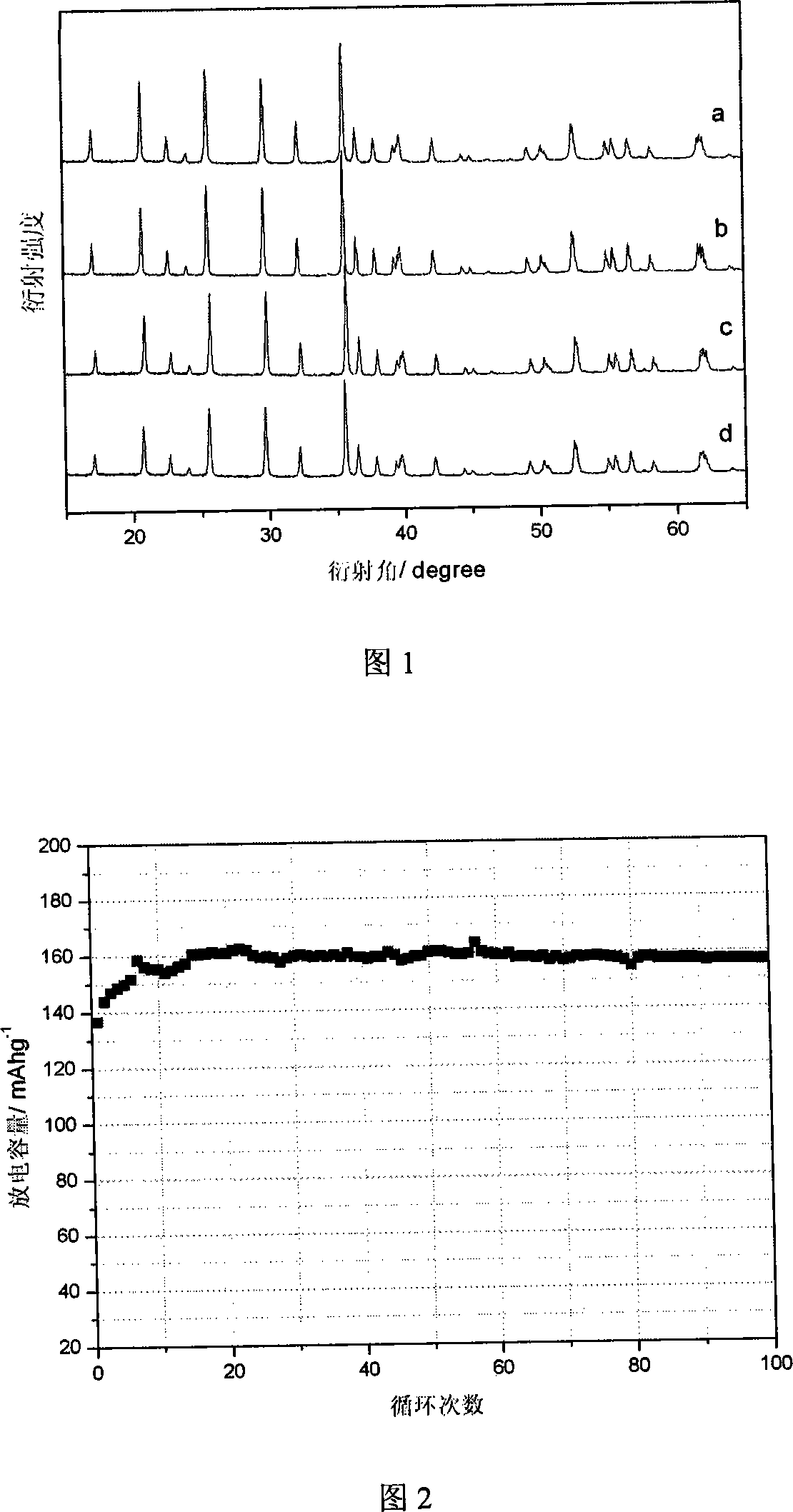

InactiveCN105024075ASmall specific surface areaIncrease charging rateCell electrodesSecondary cellsDischarge efficiencyElectrical battery

The invention discloses a negative electrode material for a quickly rechargeable graphite lithium-ion battery and a preparation method of the negative electrode material. The preparation method of the negative electrode material for the quickly rechargeable graphite lithium-ion battery comprises the following steps: (1) mixing a mixture containing a graphite precursor and bitumen and heating the mixture for kneading and crushing, wherein the mean grain size D50 of the graphite precursor ranges from 5 to 10 microns, and the mass ratio of the graphite precursor to the bitumen ranges from 50:50 to 90:10; (2) performing heat treatment at a temperature within the range of 300-700 DEG C under the protection of an inert gas; and (3) carrying out graphitizing. The mean grain size D50 of the negative electrode material prepared by use of the preparation method for the quickly rechargeable graphite lithium-ion battery is within the range of 5-15 microns and the specific surface area of the negative electrode material is below 2.0m2 / g; the first discharge capacity of a negative electrode, manufactured by use of the negative electrode material for the quickly rechargeable graphite lithium-ion battery, is more than 355mAh / g, and the initial charge-discharge efficiency of the battery is above 90%; if the battery is quickly charged (1.5C) for 45 minutes, the capacity of the battery can be above 80%; in short, the product is high in discharge capacity and charge / discharge efficiency, and good in rate capability. The invention also relates to a battery comprising the negative electrode material for the quickly rechargeable graphite lithium-ion battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Lithium element supplementing method for electrode of lithium ion battery

InactiveCN103943825AImprove discharge capacityEasy to scale applicationCell electrodesSecondary cellsElectrical batteryNickel–lithium battery

The invention aims at providing a method for supplementing lithium element in a new lithium ion battery. A liquid solution method is used for supplementing lithium for an electrode which needs to supplement with lithium element, and the lithium element supplementing method has better process feasibility. The method comprises the following steps: preparing a solvent which can dissolve metal lithium, and dissolving the metal lithium to form a lithium solution; enabling an electrode sheet to be in full contact with the lithium solution and enabling the lithium solution to infiltrate into the electrode; removing the solvent in the electrode sheet to obtain the electrode sheet after lithium supplementation. By adopting the method provided by the invention, the lithium element can be added into the electrode sheet, and the discharge capacity of the lithium ion battery assembled by the electrode can be improved.

Owner:徐兆清

Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

InactiveCN101237039AControl chemical compositionSmall particle sizeElectrode manufacturing processesChemical vapor deposition coatingGas phasePhosphate

The invention relates to a method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, namely, the method for preparing carbon coating lithium iron battery anode material, belonging to the Li-ion battery material preparation art technical field. The characteristics of the method for synthesizing LiFePO4 / C materials by solid phase and auxiliary chemical vapor deposition are that auxiliary chemical vapor deposition supporting the solid phase reaction method is adopted to synthesize the carbon coating phosphate lithium iron, namely, the LiFePO4 / C material. In the method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, a precursor comprising raw materials of lithium, iron and phosphor is adopted to prepare the carbon coating phosphate lithium iron after being blended, grinded by a globe mill, treated by preheating and calcined as well as vapor deposition. The method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method has the advantages that the chemical composition, carbon contents and grain size of LiFePO4 can be controlled effectively; the Li-ion battery anode material prepared has sound conductive performance and can improve the charge-discharge rate and cycling performance of the material.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

High-capacity graphite material and preparation method as well as application thereof

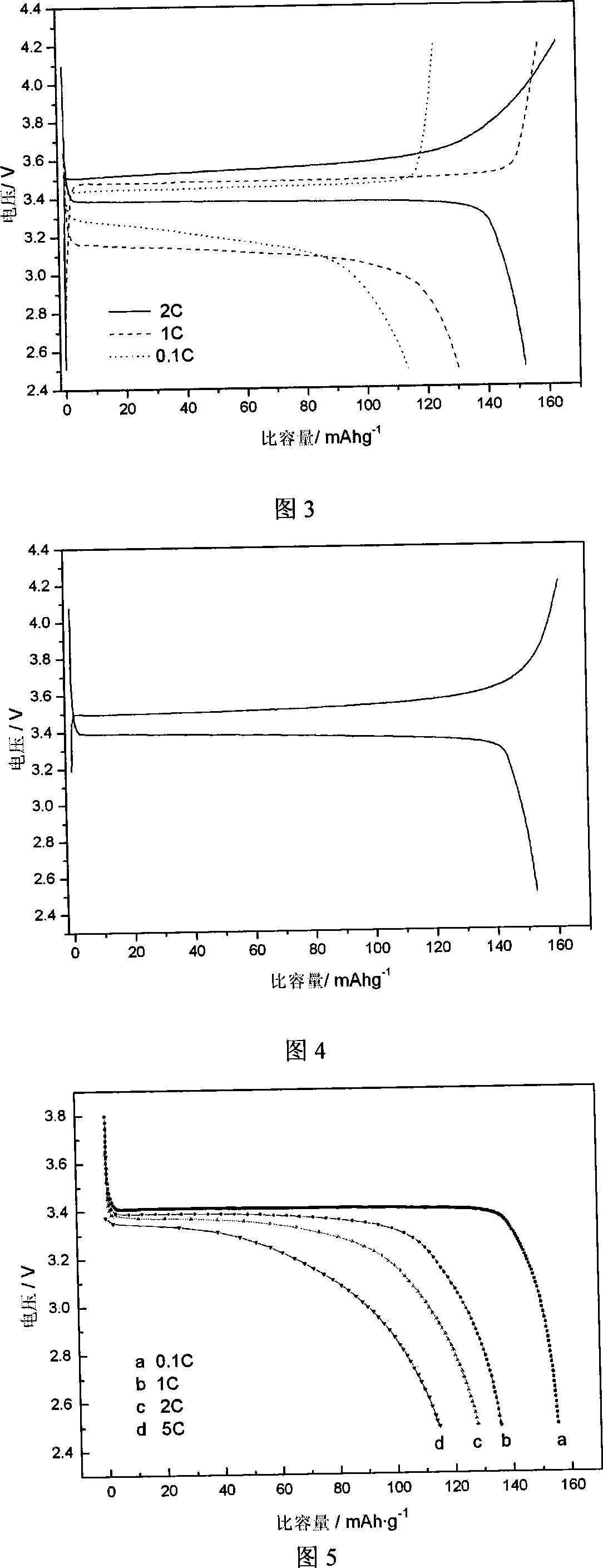

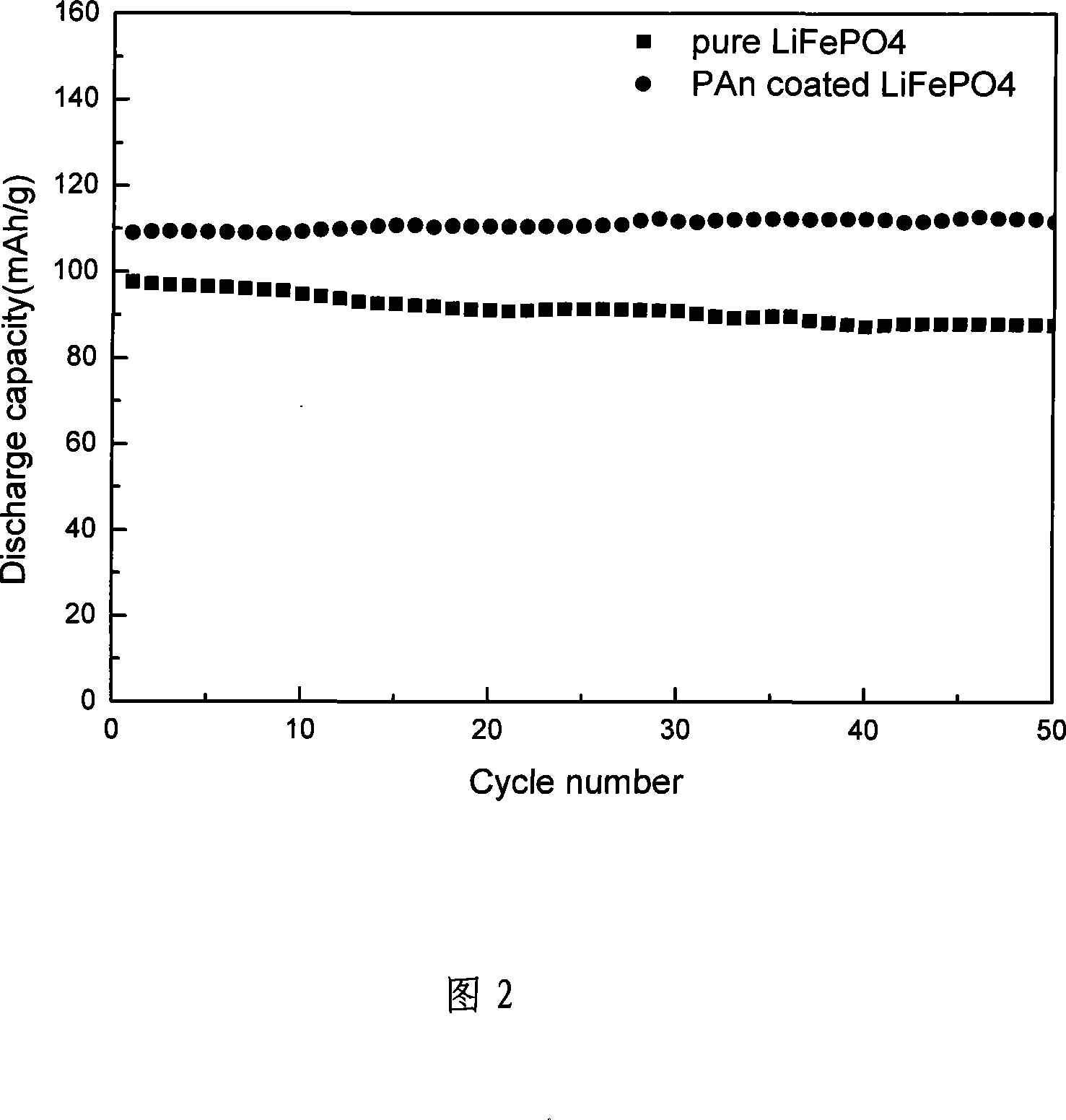

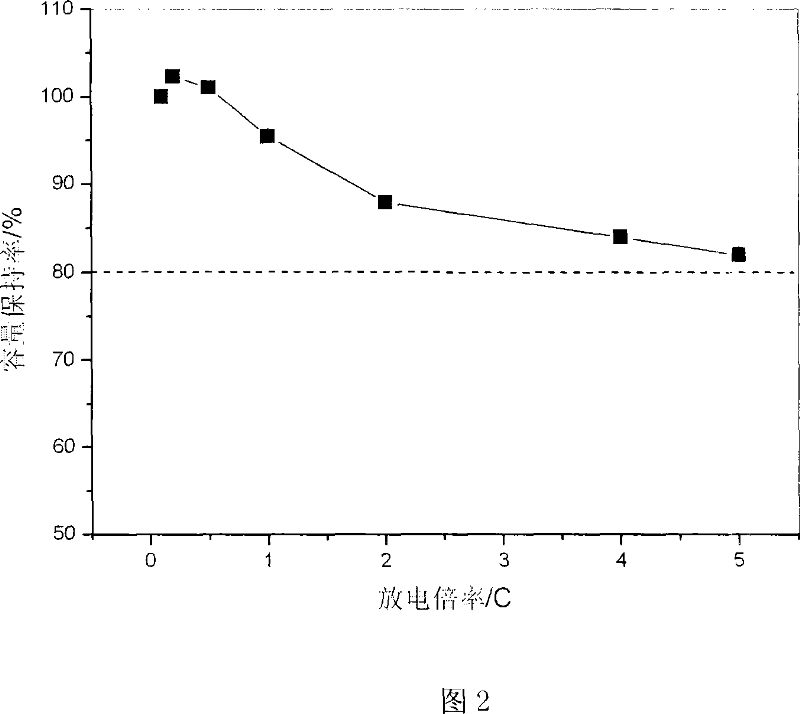

InactiveCN102659091AImprove discharge capacityImprove first-time efficiencyGraphiteCell electrodesMass ratioMetallurgy

The invention relates to a high-capacity graphite material and a preparation method as well as application thereof. The high-capacity graphite material comprises artificial graphite and natural graphite, wherein the mass ratio of artificial graphite to natural graphite is 20:1 to 1:1. According to the preparation method, the artificial graphite and the natural graphite are uniformly mixed according to a certain mass ratio, and then surface modification is carried out on the mixture. The prepared graphite material has the advantages of high discharge capacity, high first efficiency, long cycle life, low cost and the like; the discharge capacity of the high-capacity graphite material can reach up to more than 350mAh / g (even reach up to more than 368mAh / g); a half-cell of the high-capacity graphite material charges and discharges at the 1C multiple power; after the high-capacity graphite material cycles for 100 times, the capacity retention ratio of the high-capacity graphite material is still more than 90% (even reaches up to more than 96.3%); the first efficiency reaches up to more than 95.5%; and the manufacturing cost is reduced by about 1-10%. The high-capacity graphite material provided by the invention not only can meet the requirement of a lithium ion power battery for the high multiplying power charge-discharge of the material, but also reduces the manufacturing cost of the cathode material of the lithium ion battery.

Owner:天津市贝特瑞新能源科技有限公司

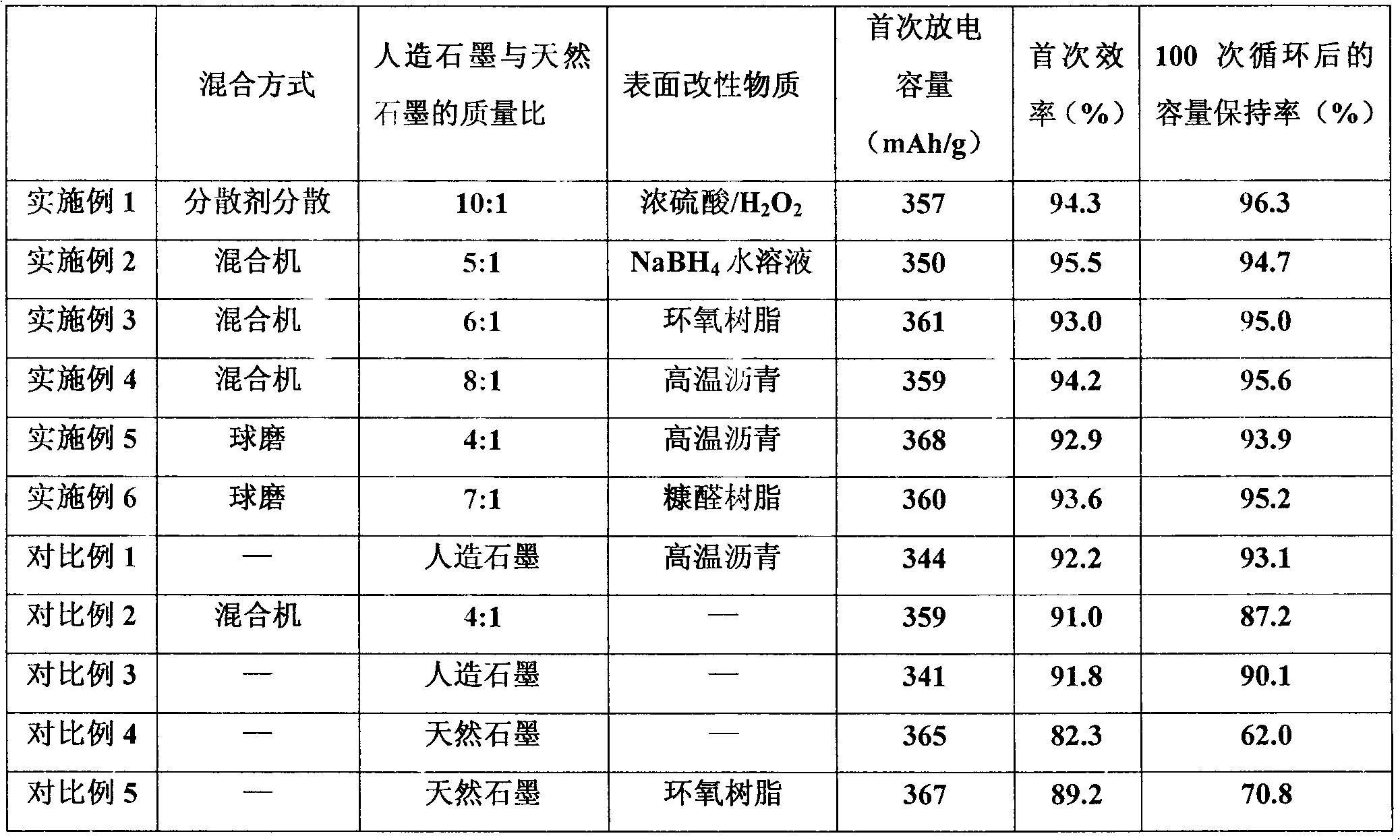

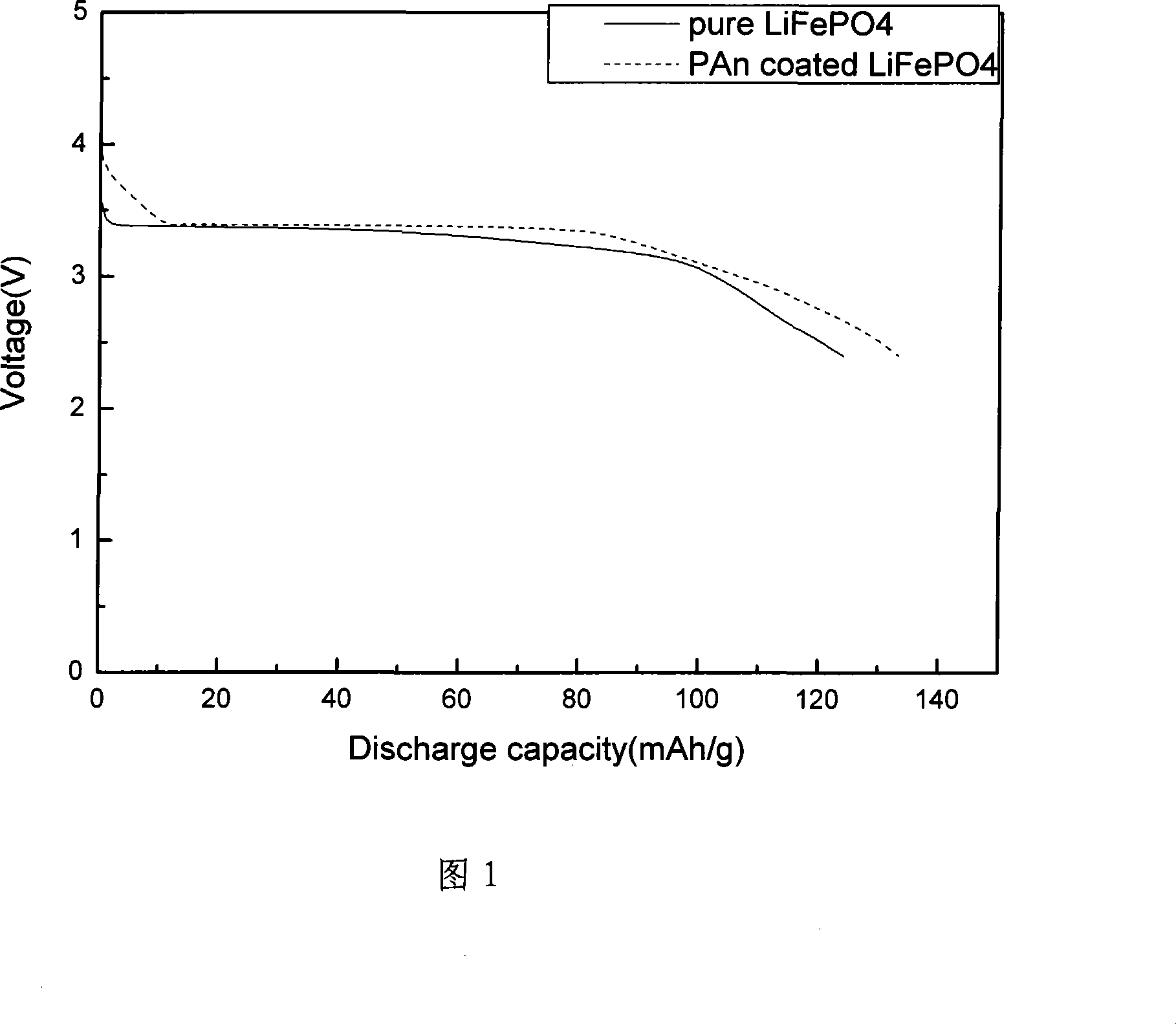

Making method for positive material LiFePO4 of poly-aniline coated lithium ion battery

InactiveCN101237036AStable discharge voltage platformHigh specific capacityElectrode manufacturing processesPhosphorus compoundsGranularitySodium-ion battery

The invention discloses a method for preparing polyaniline coating Li-ion battery anode material LiFePO4. The method is coating polyaniline on the in-situ surface of the powder of Li-ion battery anode material LiFePO4. The method has the following favorable effects: the discharging voltage platform of the polyaniline coating anode material LiFePO4obtained is stable, the battery has higher specific capacity up to one hundred and forty point three mAh / g, the granularity is distributed evenly, the grains are in good appearance and high in discharging capacity and long in cycling life, etc.

Owner:XIANGTAN UNIV

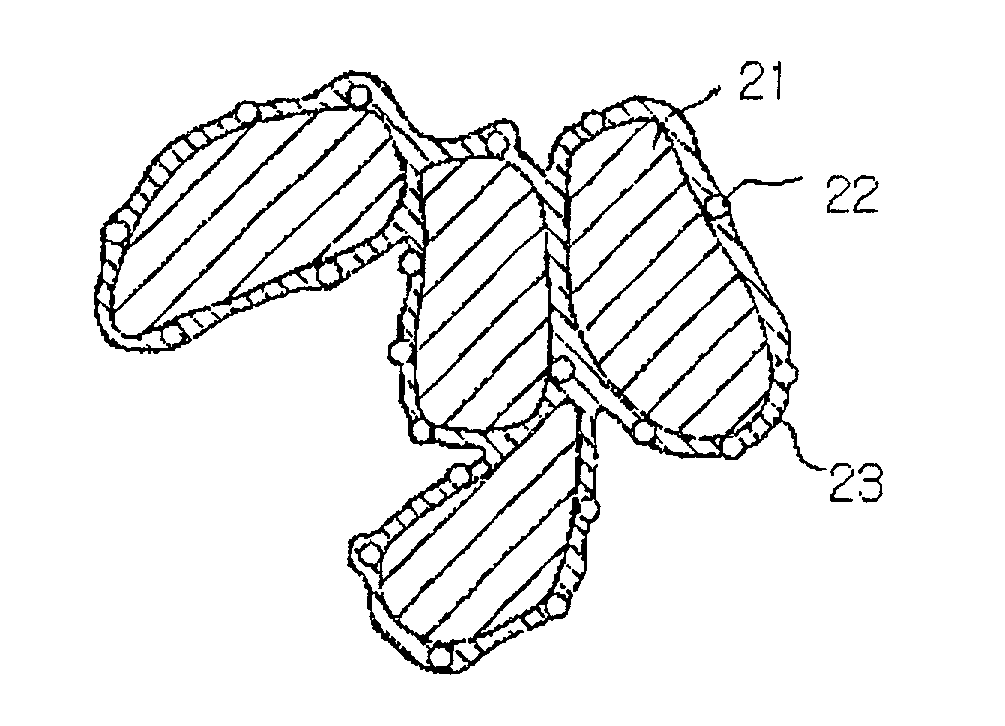

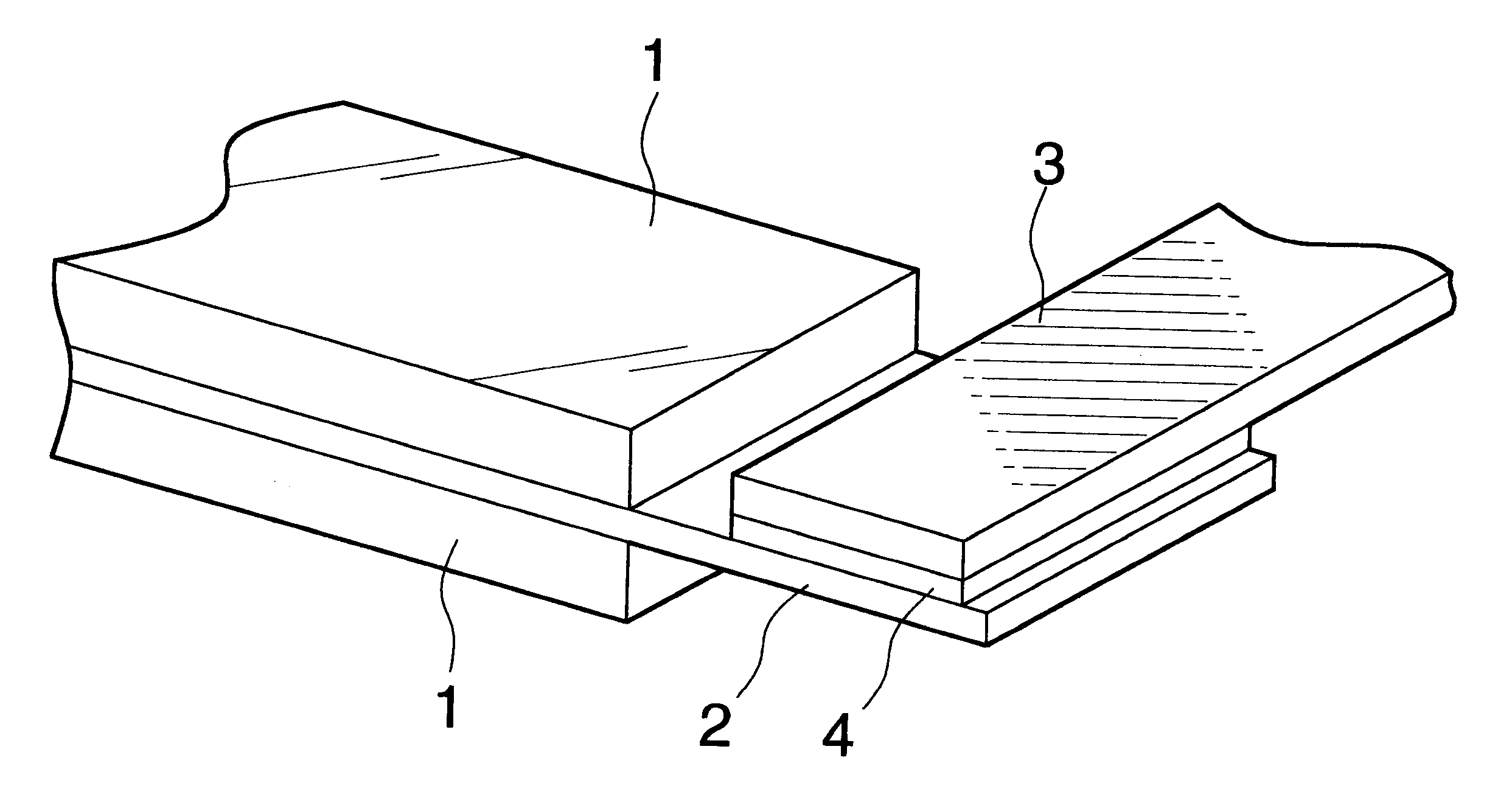

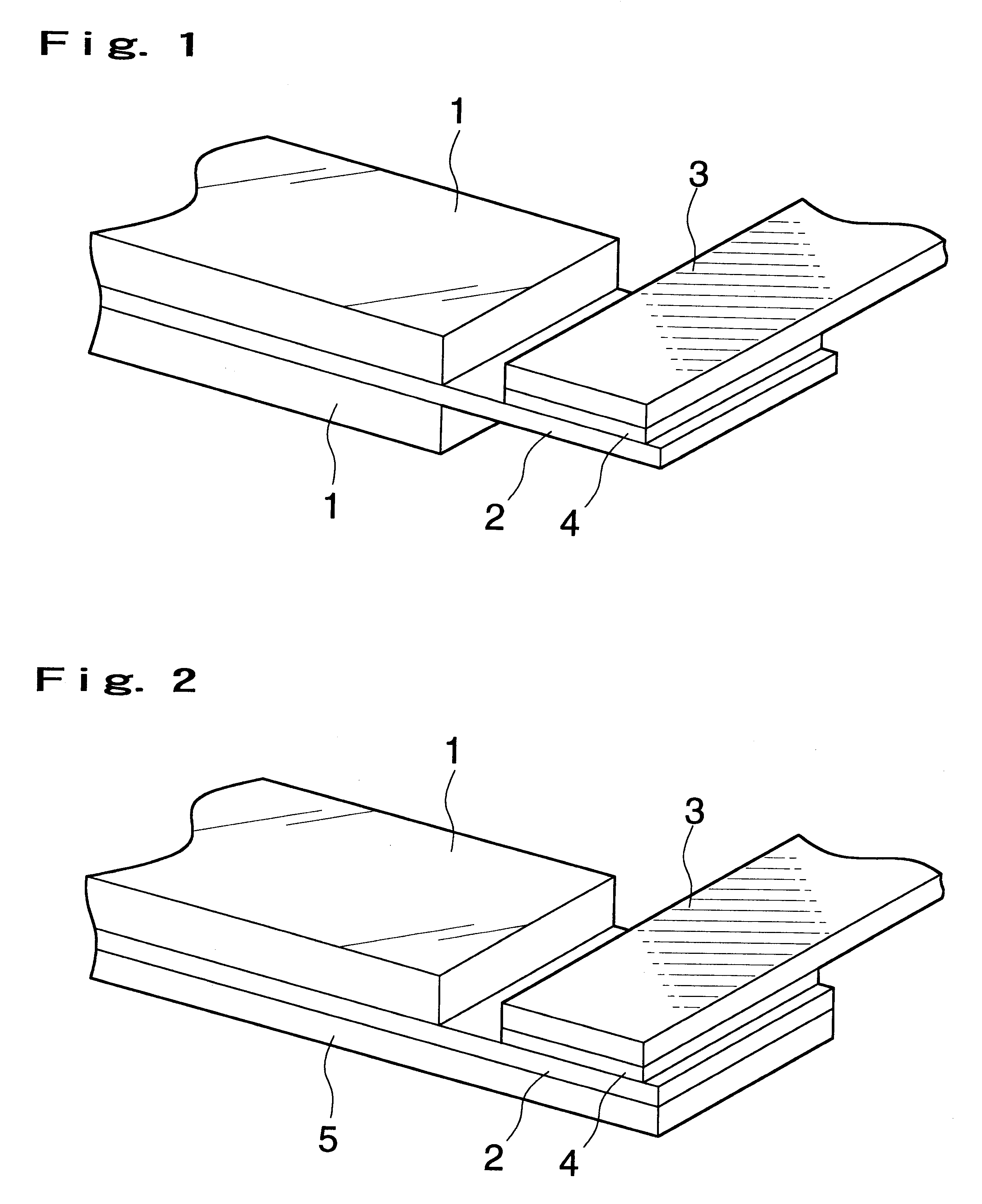

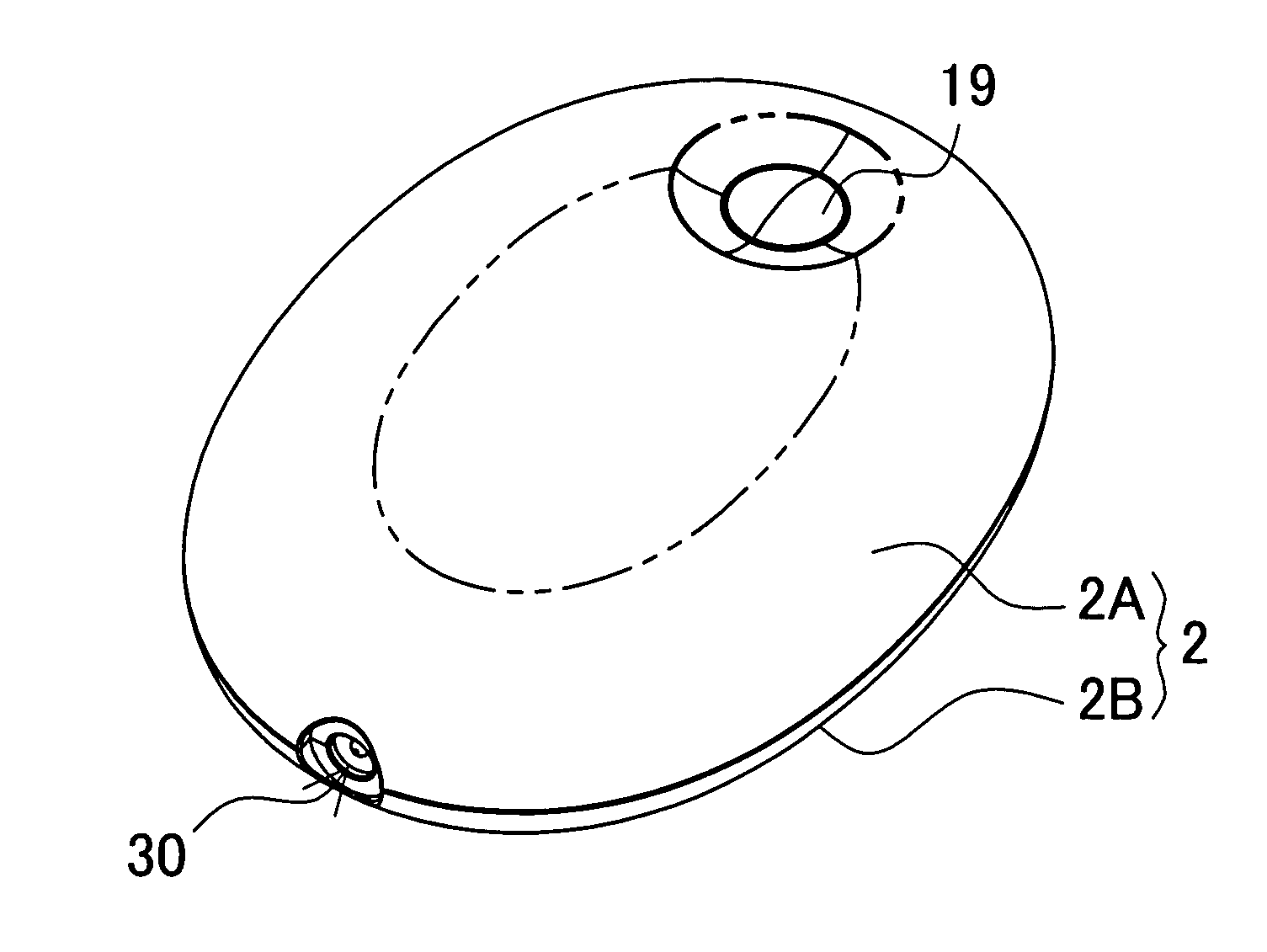

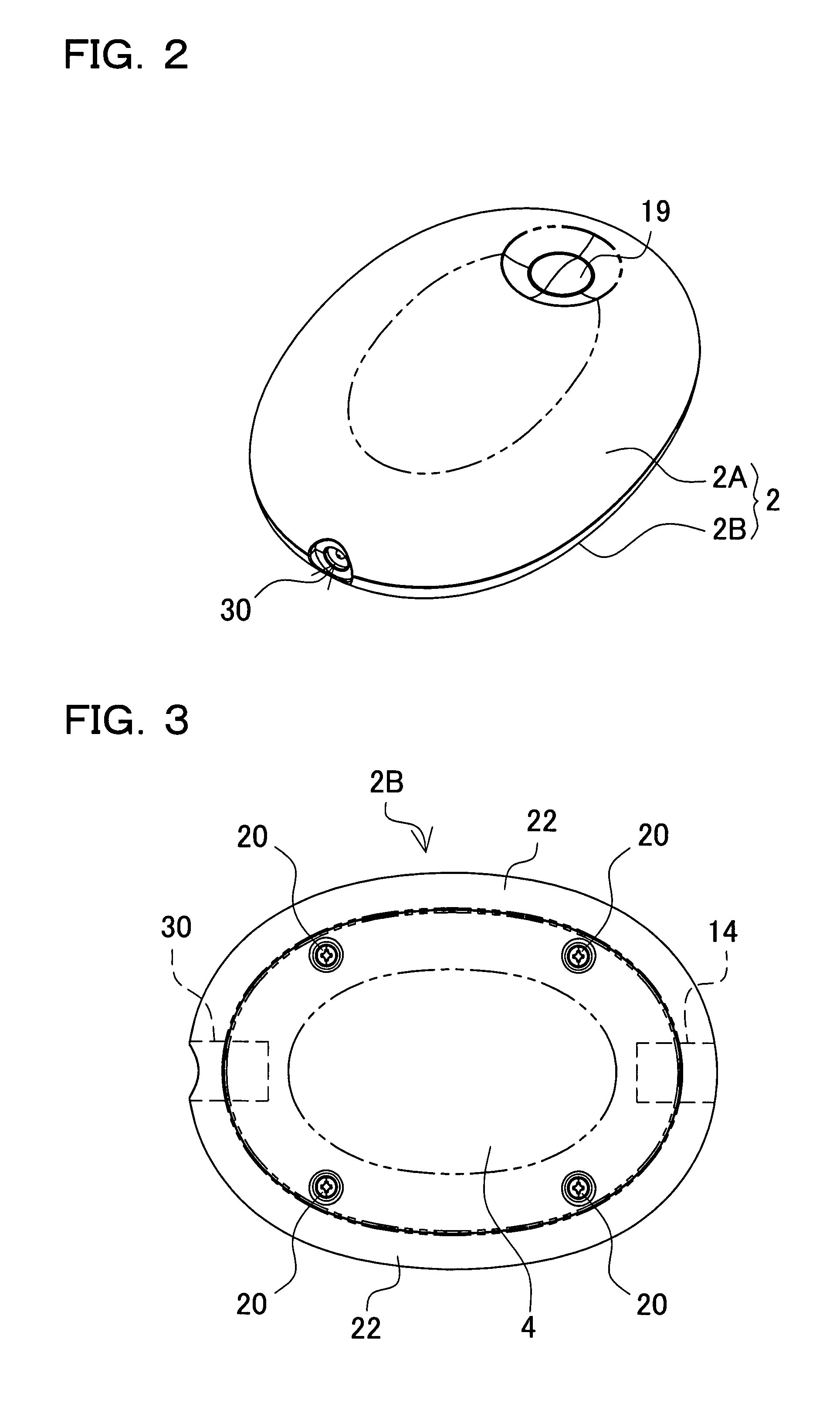

Electrode for battery, method of manufacturing the same and battery

InactiveUS6447950B1Simply manufactureGood effectElectrode manufacturing processesFinal product manufactureElectrical connectionGraphite

An electrode for a battery in which a collector and an electrode tab are connected with a novel connection structure without impairing electrical connection, and a method of manufacturing the electrode quite simply are provided. Further, a battery having this electrode for the battery is provided. A collector (2) and a tab (3) are connected via a graphite layer (4). The graphite layer is formed on the surface of the collector to be connected with the tab and / or the surface of the tab to be connected with the collector, the portions to be connected of the collector and the tab are overlapped on each other with the graphite layer interposed between the collector and the tab, and a pressure is applied to the overlapped portions to connect the collector (2) with the tab (3). It is preferable that the collector (2) is made of a conductive thin film formed on a resin film (5).

Owner:TDK CORPARATION

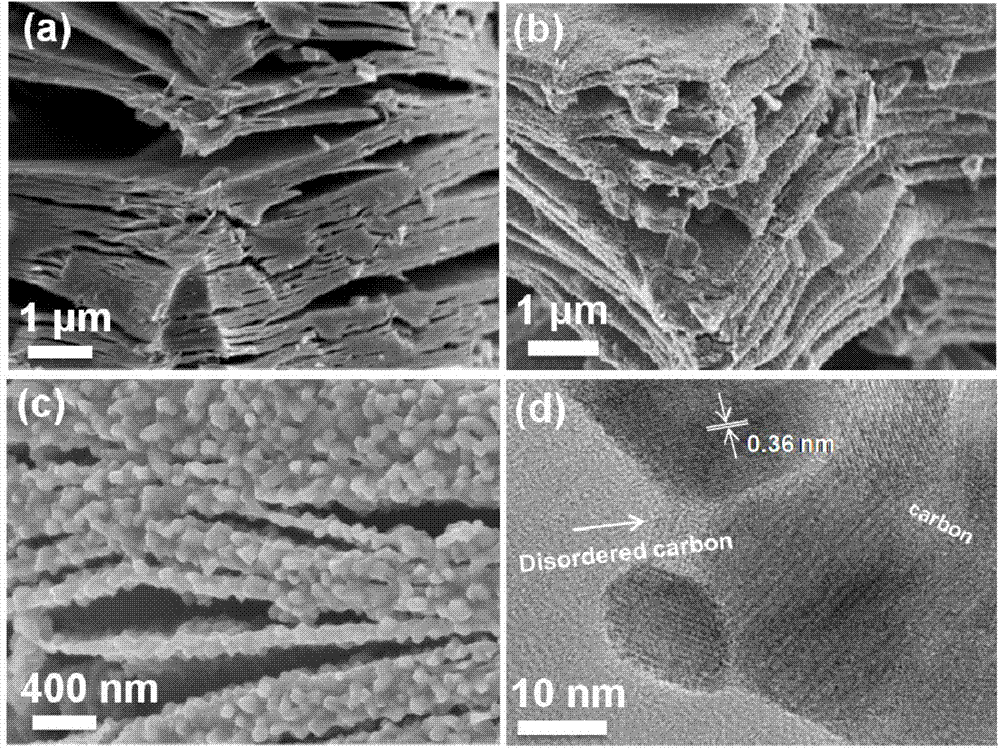

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

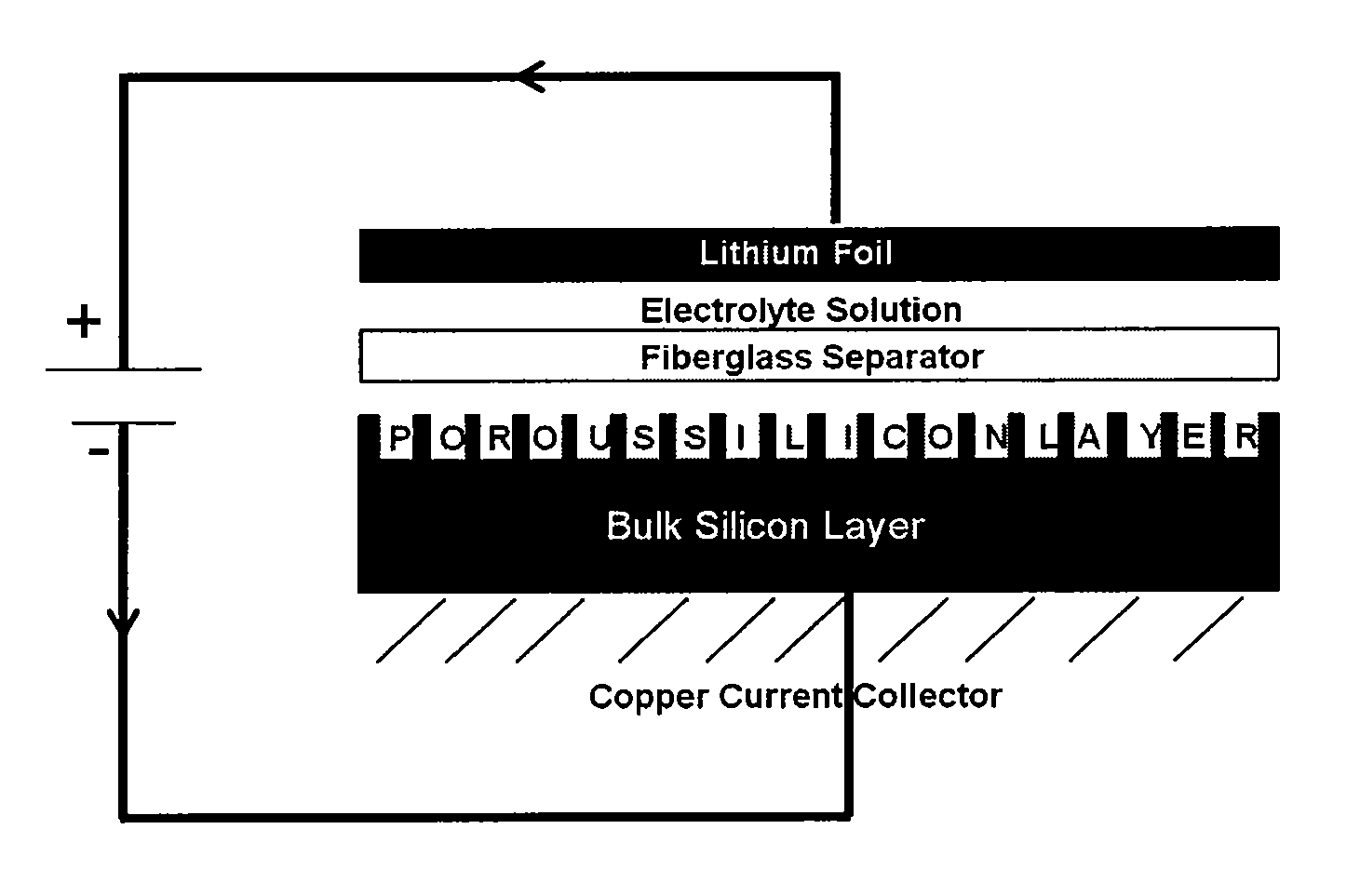

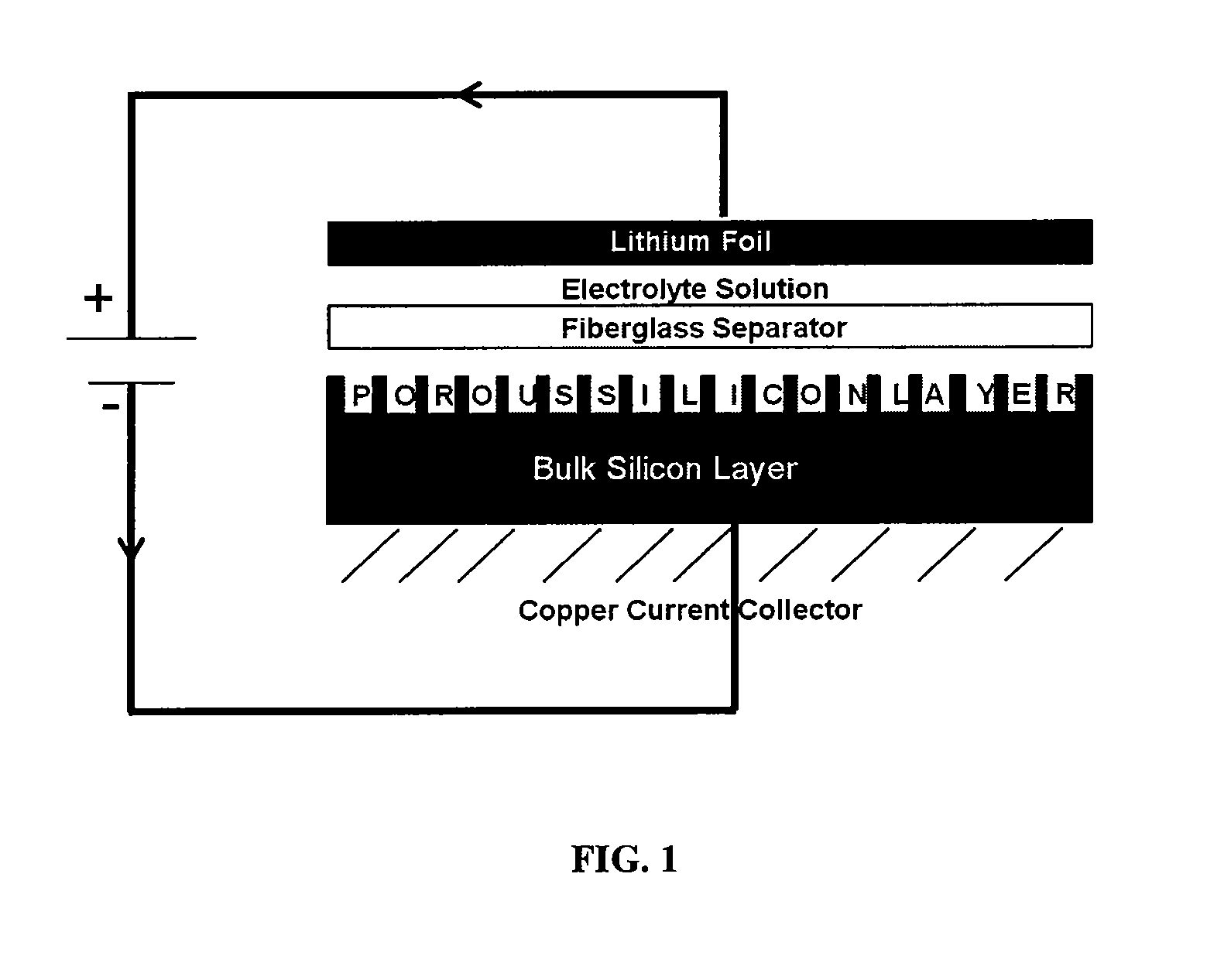

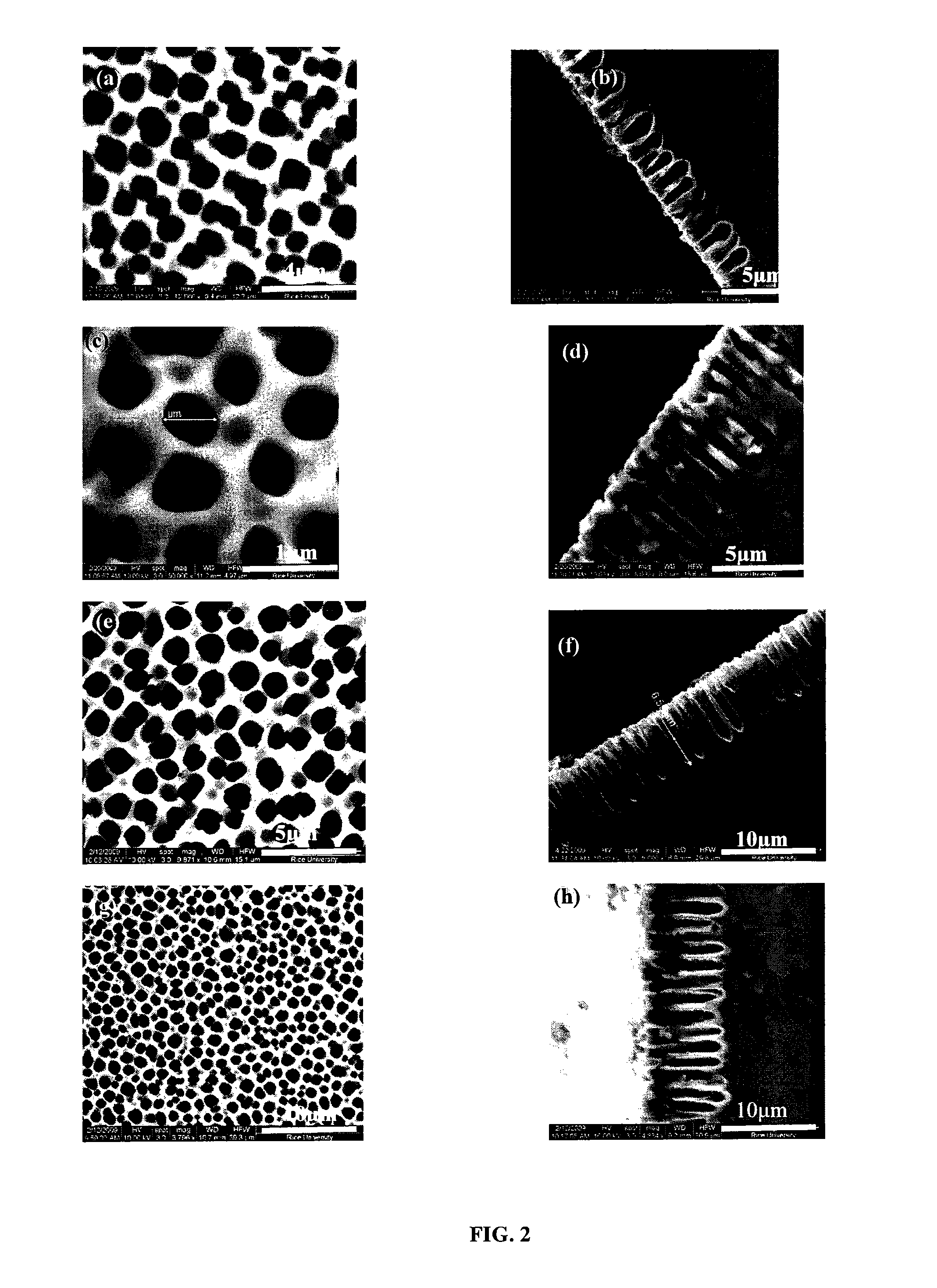

Structured silicon battery anodes

InactiveUS20120231326A1Large capacityLow costMaterial nanotechnologyElectrolysis componentsLithiumElectrochemistry

Methods of fabricating porous silicon by electrochemical etching and subsequent coating with a passivating agent process are provided. The coated porous silicon can be used to make anodes and batteries. It is capable of alloying with large amounts of lithium ions, has a capacity of at least 1000 mAh / g and retains this ability through at least 60 charge / discharge cycles. A particular pSi formulation provides very high capacity (3000 mAh / g) for at least 60 cycles, which is 80% of theoretical value of silicon. The Coulombic efficiency after the third cycle is between 95-99%. The very best capacity exceeds 3400 mAh / g and the very best cycle life exceeds 240 cycles, and the capacity and cycle life can be varied as needed for the application.

Owner:LOCKHEED MARTIN CORP +1

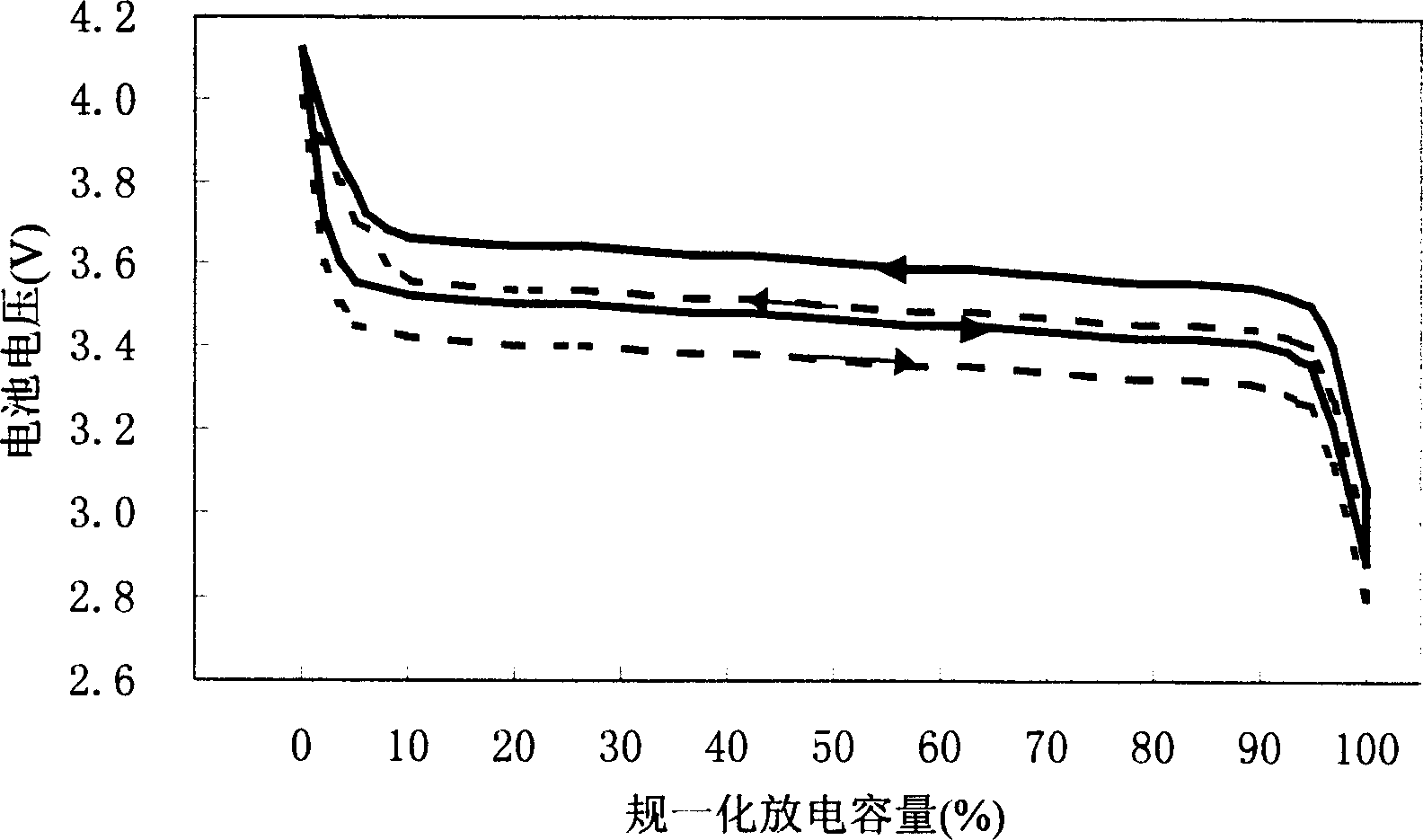

Positive electrode active material for lithium secondary battery, method of manufacturing the same, and lithium secondary battery using the same

InactiveUS20110200880A1Improve discharge capacityImprove discharge performanceNon-aqueous electrolyte accumulator electrodesSpecial surfacesLithiumBoron oxide

A positive electrode active material for lithium secondary batteries having a lithium-containing transition metal oxide having a layered structure and represented by the general formula Li1+xMn1-x-yMyO2, where 0<x<0.33, 0<y<0.66, and M is at least one transition metal other than Mn, the lithium-containing transition metal oxide having a boron oxide layer formed on the surface thereof.

Owner:SANYO ELECTRIC CO LTD

LiFePO4 cathode material based on P site doped and preparation method thereof

InactiveCN101037195AImprove rate discharge performanceImprove discharge capacityCell electrodesPhosphorus compoundsPhosphateFiltration

Disclosed is a phosphorus-doped lithium iron phosphate positive electrode material and a preparation method of the same, which relates to a positive electrode materials of lithium ion batteries. The present invention provides a phosphorus-doped lithium iron phosphate positive electrode material of lithium ion batteries with higher charge-discharge capacity, excellent multiplying power performance and cycle performance, and a preparation method of the same. The positive electrode material has a formula of LiyFe(P1-xMx)O4, wherein M is doping element of Ge, Sn, Se, Te or Bi. The preparation method comprises the steps of mixing the ferrite and phosphate with dopant; adding at least one of the water, alcohol, acetone serving as ball mill solvent; scrubbing and filtrating after ball milling; vacuum drying the filtration product to obtain the intermediate product which is mixed with lithium salt; adding ball mill solvent to ball mill again; drying the product and then heating calcining in the presence of inert gas or reducing atmosphere to obtain doping type lithium iron phosphate LiyFe(P1-xMx)O4 powder.

Owner:XIAMEN UNIV

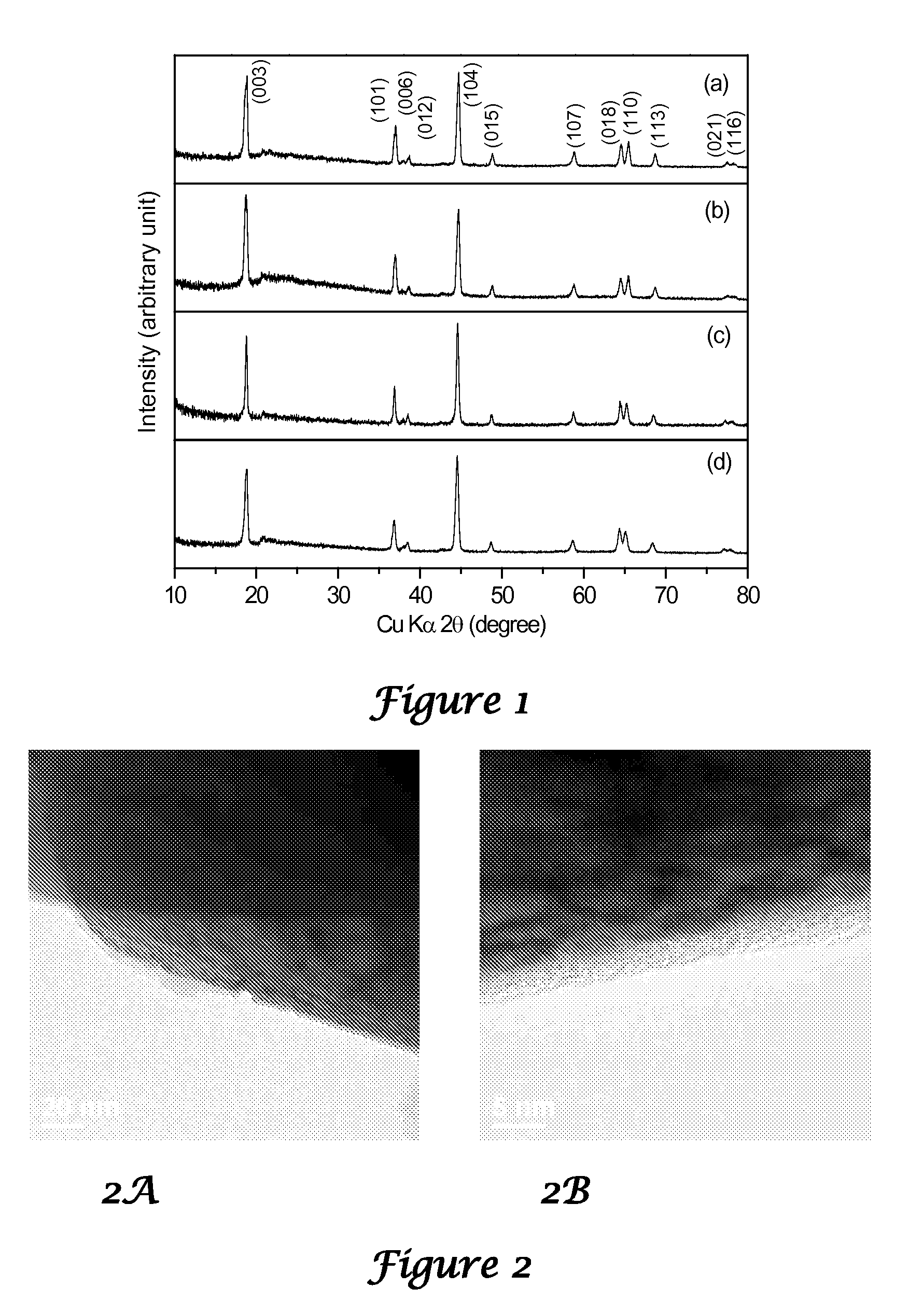

Active material for lithium secondary battery, electrode for lithium secondary battery, and lithium secondary battery

ActiveUS20130146808A1Improve discharge capacityCobalt compoundsNon-aqueous electrolyte accumulator electrodesMiller indexX-ray

[Object]There is provided an active material for a lithium secondary battery, which has a high initial efficiency and a high discharge capacity, and particularly has a high discharge capacity at a low temperature (excellent low-temperature characteristic), and a lithium secondary battery using the active material.[Solution]An active material for a lithium secondary battery, which contains a solid solution of a lithium transition metal composite oxide having an α-NaFeO2 crystal structure, wherein the composition ratio of metal elements contained in the solid solution satisfies, Li1+x−yNayCoaNibMncO2+d (0<y≦0.1, 0.4≦c≦0.7, x+a+b+c=1, 0.1≦x≦0.25, −0.2≦d≦0.2), the active material has an X-ray diffraction pattern attributable to a space group R3-m (P3112), and in the Miller index hkl, the half width of the diffraction peak of the (003) is 0.30° or less and the half width of the diffraction peak of the (114) plane is 0.50° or less. Further, the average of three oxygen position parameters determined from crystal structure analysis by the Rietveld method on the basis of the X-ray diffraction pattern is preferably 0.264 or less.

Owner:GS YUASA INT LTD

Hand warmer

InactiveUS20080053979A1Avoid failureImprove the temperature environmentMechanical apparatusSurgeryElectrical batteryRechargeable cell

In a hand warmer, a heat dissipating plate is thermally coupled to a heater that is supplied with current by a battery that is accommodated in a case. The battery is a box-shaped rechargeable battery of a box-shaped rechargeable lithium-ion battery or lithium-polymer battery that has flat surfaces opposed to each other. The heater is a heating element that is opposed to the flat surface of the battery. A shielding plate is arranged between the heating element and the flat surface of the battery. The heat dissipating plate that is thermally coupled to the heating element is secured to the case on the surface side of the case. In the hand warmer, the flat surface of the box-shaped rechargeable battery, the shielding plate and the heat dissipating plate are arranged in a stack structure. The heat dissipating plate is heated by the heating element.

Owner:SANYO ELECTRIC CO LTD

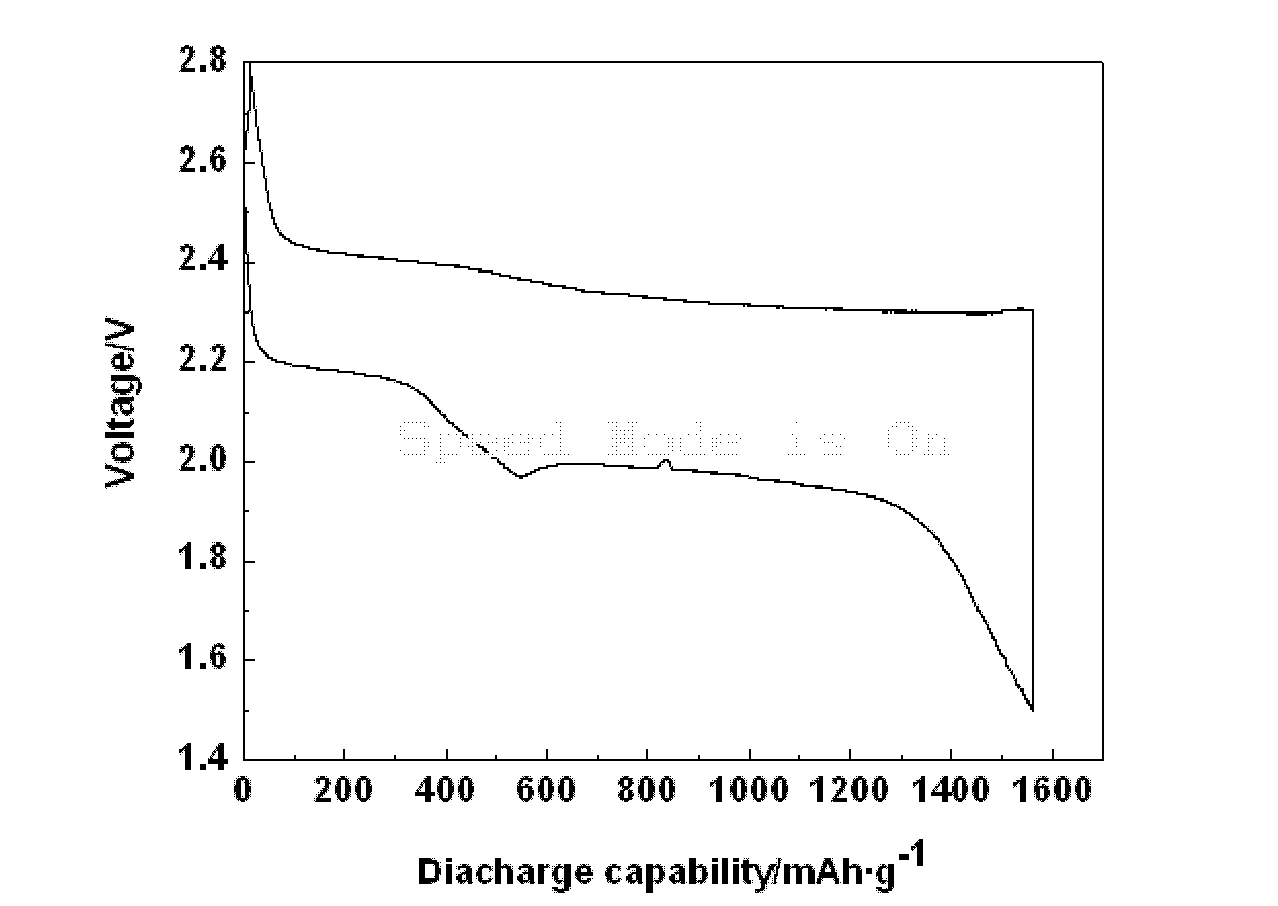

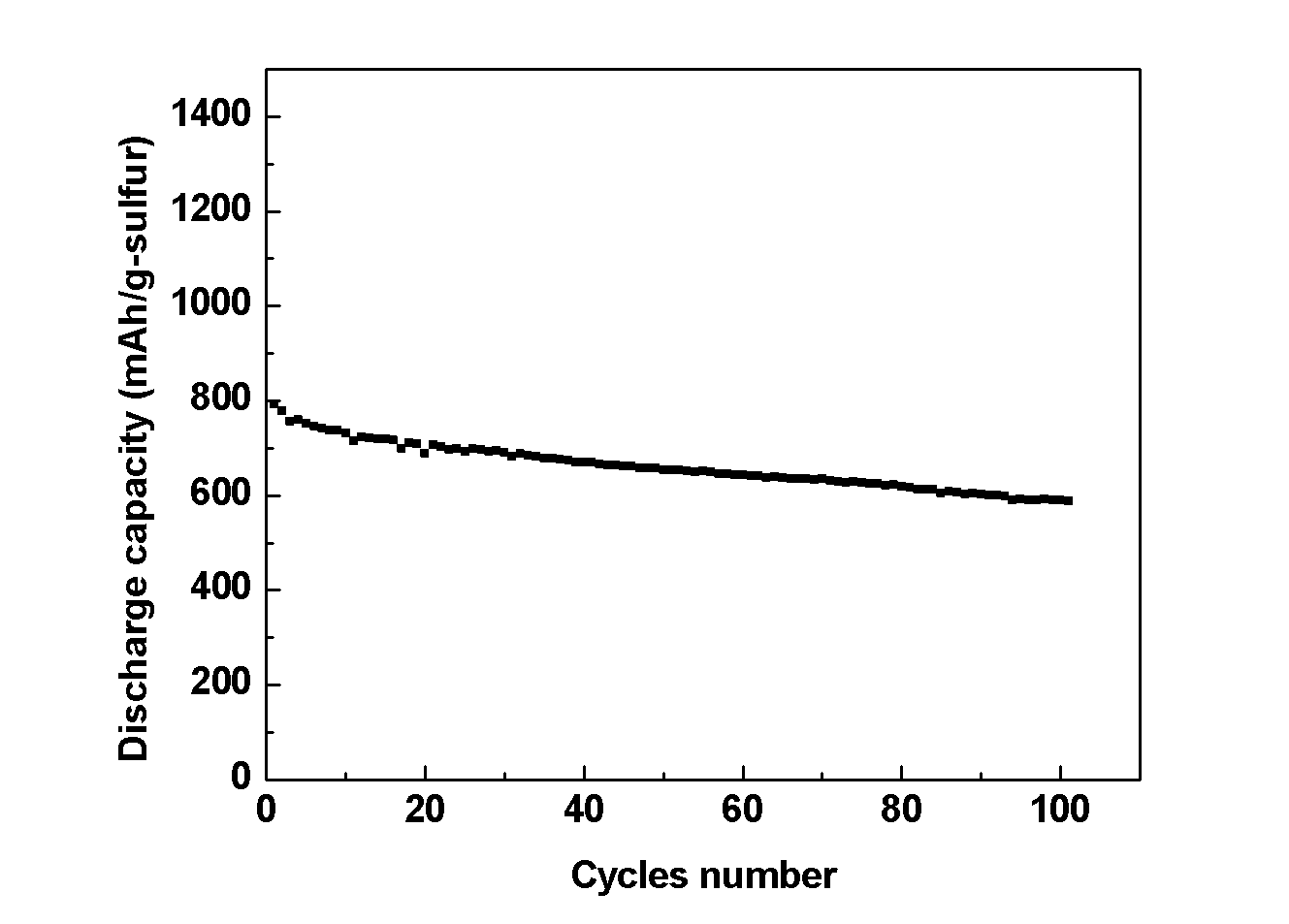

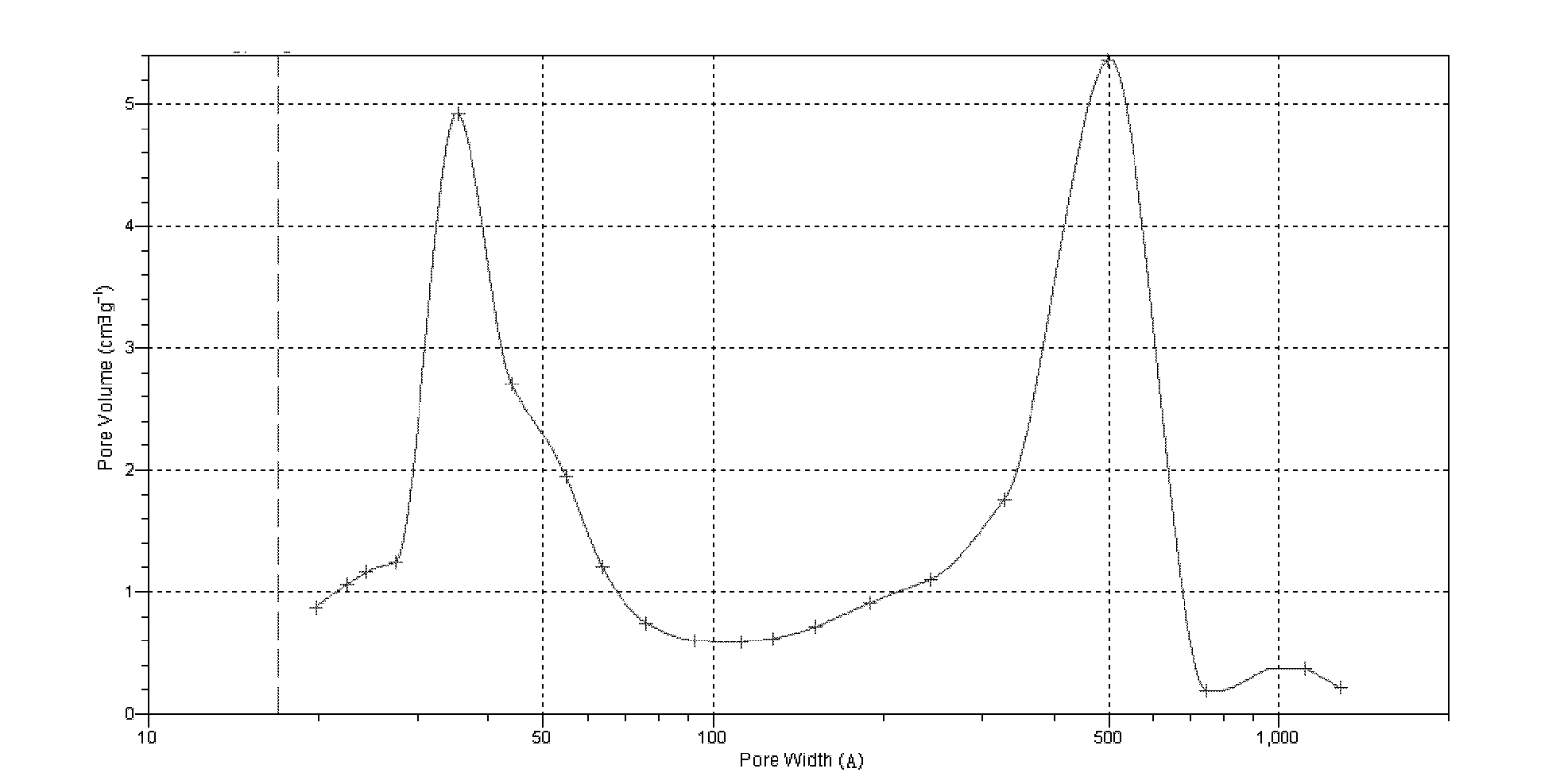

Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

ActiveCN103050669AImprove discharge capacityLarger than surfaceNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur electrode

The invention relates to a carbon-sulphur composite used for a cathode material of a lithium sulphur battery as well as a preparation method and application thereof. The carbon-sulphur composite comprises a carbon material and elemental sulphur, wherein the carbon material is formed by doping mesoporous carbon with the aperture of 2-5nm and electroconductive carbon with the aperture of 30-70nm, and the electroconductive carbon with the aperture of 30-70nm contains micropores with the aperture of 0.5-1.7nm; and the elemental sulphur accounts for 10-90wt% of the total quantity of the composite. Abundant micropores guarantee that the carbon material has larger specific surface, adsorption capacity to polysulphide is stronger, and dissolution of the polysulphide can be effectively limited, so that stability of a sulphur electrode is improved. Meso pores in porous distribution can load more sulphur active substances, electrochemical capacity of a composite material is improved, and diffusion and transmission of lithium ions and electrolyte solution can be facilitated, so that reduction polarization of the elemental sulphur is reduced and discharge plateau of the elemental sulphur is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

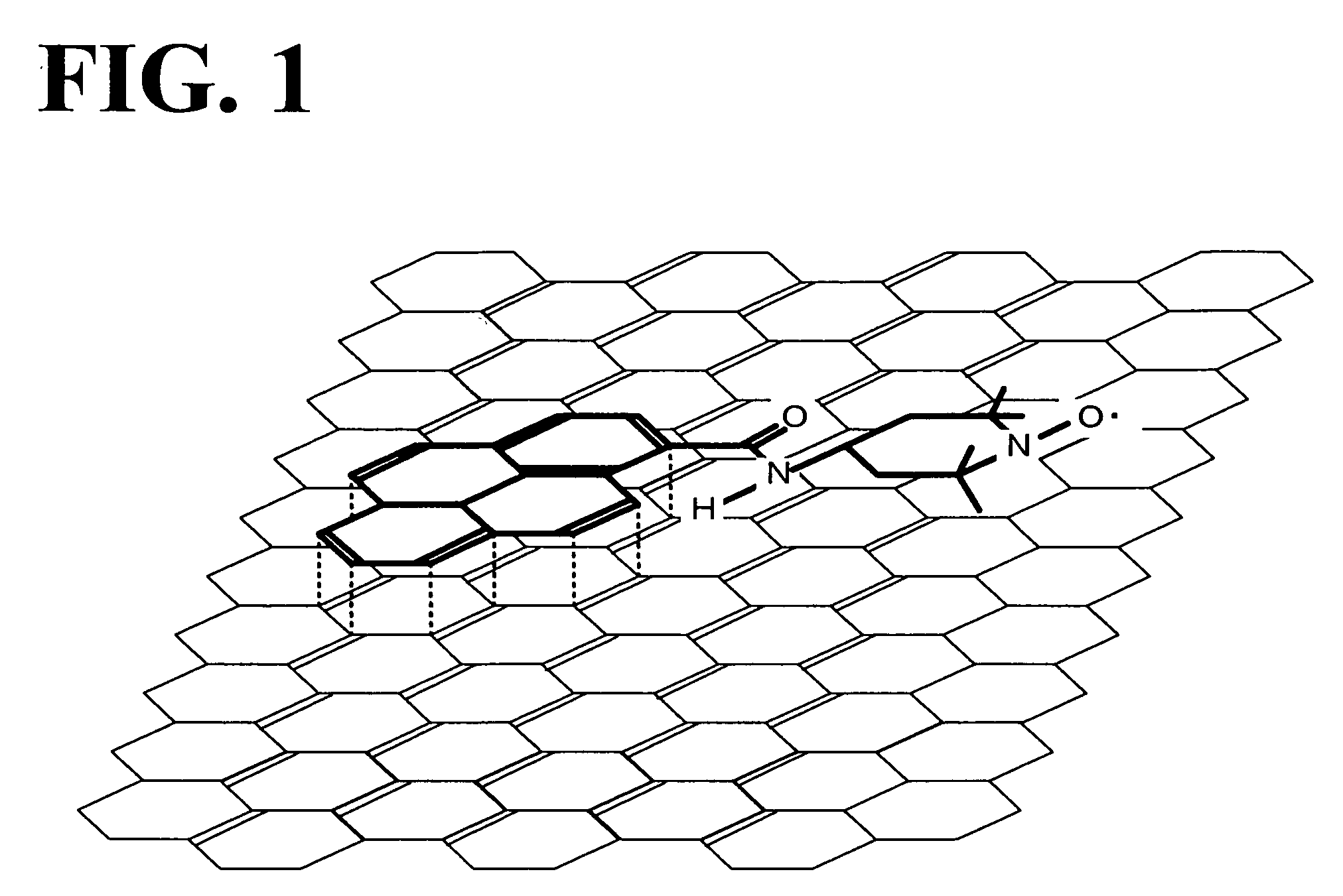

Alkali metal air battery

InactiveUS20090239113A1Raise the discharge potentialCharge capacityFuel and secondary cellsActive material electrodesMetallic lithiumLithium–air battery

A F-type electrochemical cell, which is a lithium air battery, includes a positive electrode facing a negative electrode composed of metallic lithium with a separator provided therebetween in a casing. Air is capable of flow to the positive electrode. A nonaqueous electrolytic solution is charged into a space between the positive electrode and the negative electrode. At least one of the positive electrode and the nonaqueous electrolytic solution of the lithium air battery contains a compound having a stable radical skeleton. The compound also serves as a redox catalyst for oxygen.

Owner:TOYOTA CENT RES & DEV LAB INC

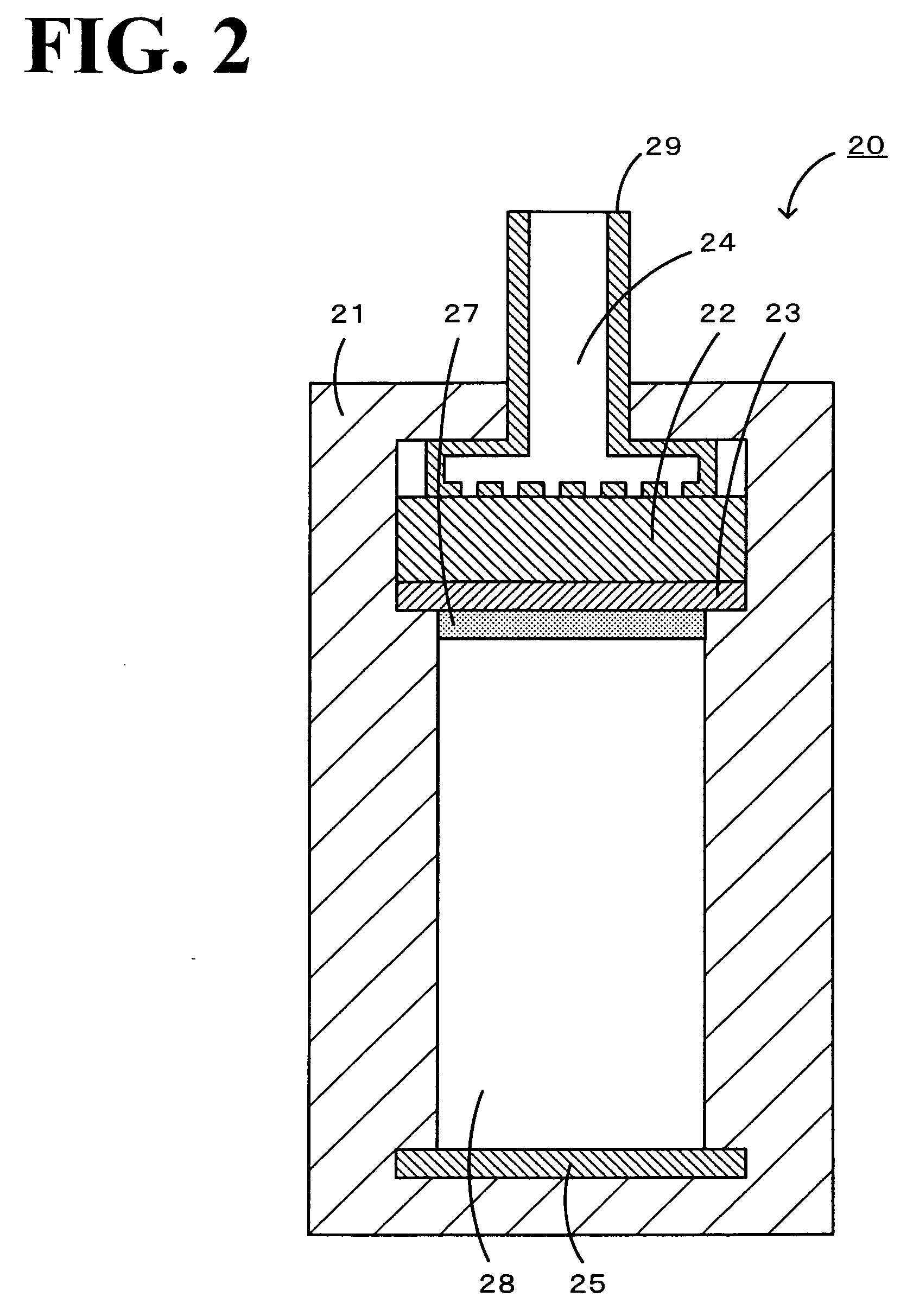

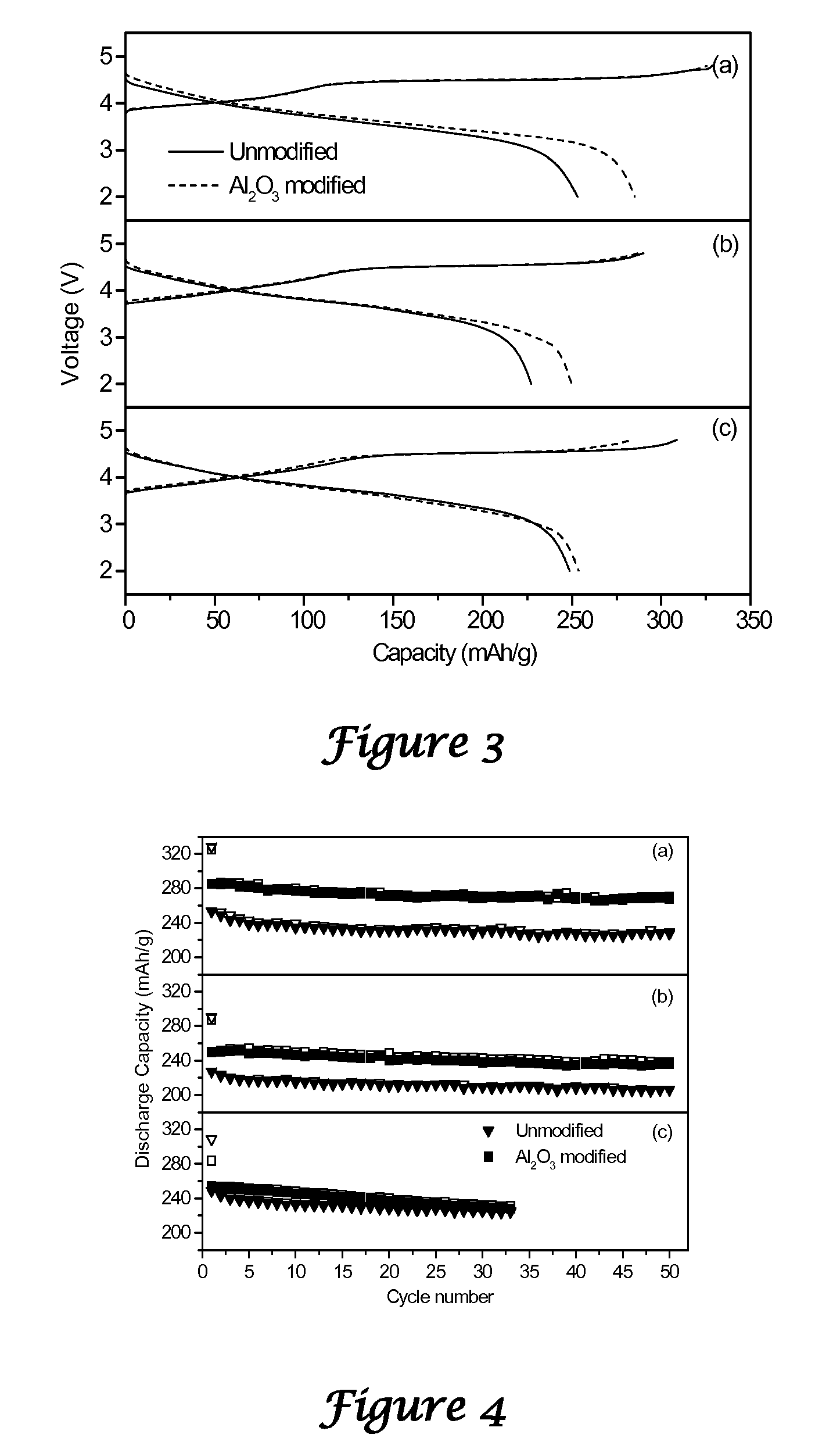

Surface and Bulk Modified High Capacity Layered Oxide Cathodes with Low Irreversible Capacity Loss

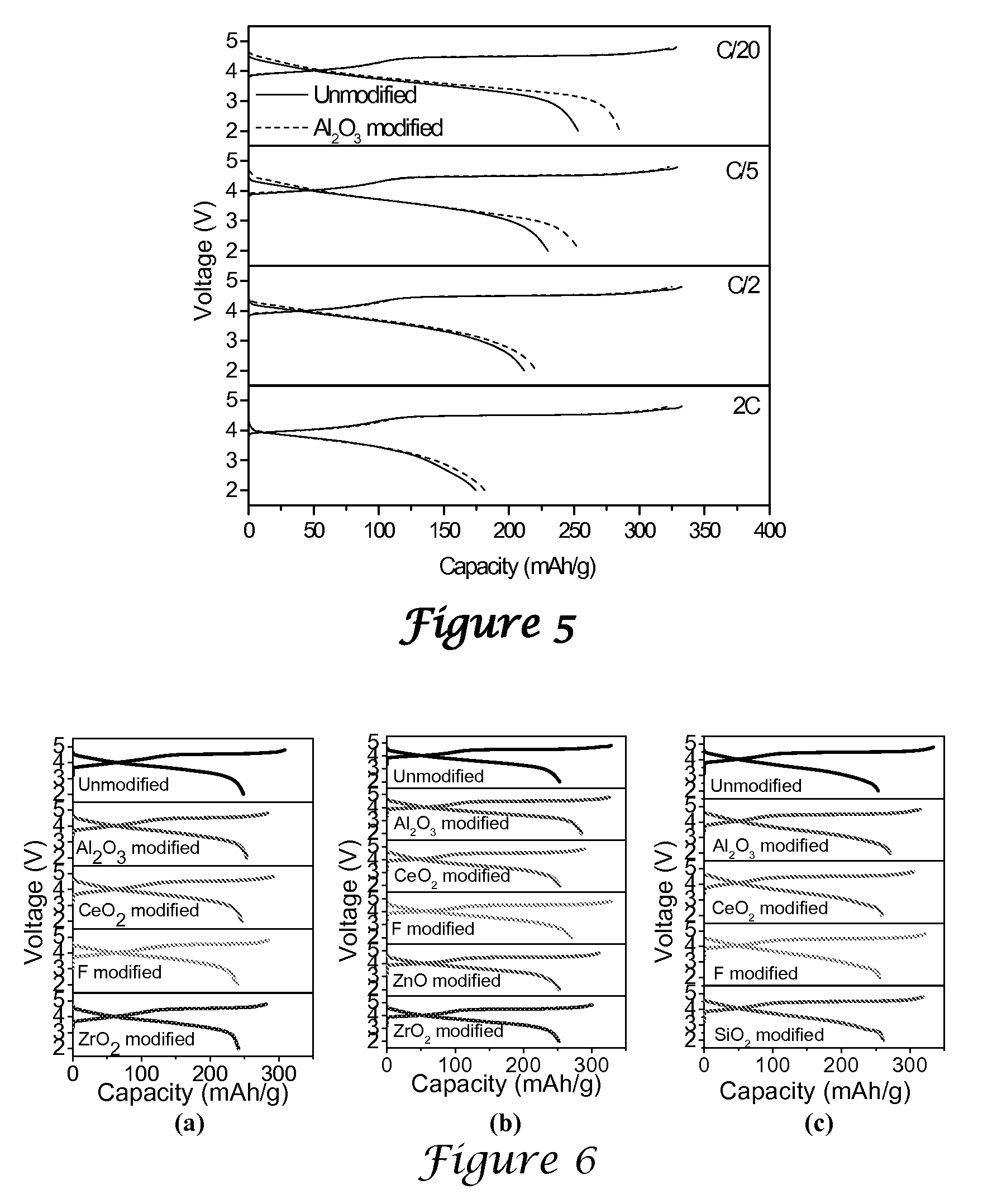

InactiveUS20090224212A1Large capacityLow costNon-metal conductorsConductive materialCapacity lossCrystal structure

The present invention includes compositions, surface and bulk modifications, and methods of making of (1−x)Li[Li1 / 3Mn2 / 3]O2.xLi[Mn0.5-yNi0.5-yCo2y]O2 cathode materials having an O3 crystal structure with a x value between 0 and 1 and y value between 0 and 0.5, reducing the irreversible capacity loss in the first cycle by surface modification with oxides and bulk modification with cationic and anionic substitutions, and increasing the reversible capacity to close to the theoretical value of insertion / extraction of one lithium per transition metal ion (250-300 mAh / g).

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Limiting amplitude protection circuit used in non-contact IC card and radio frequency identification label

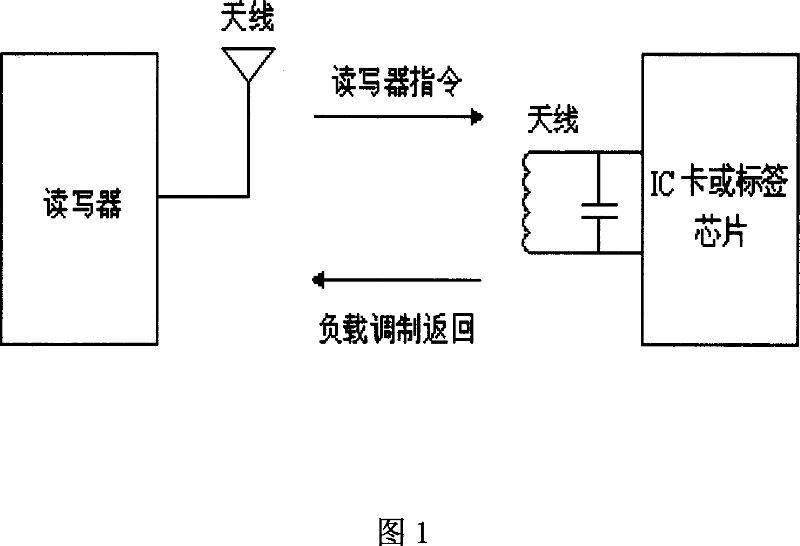

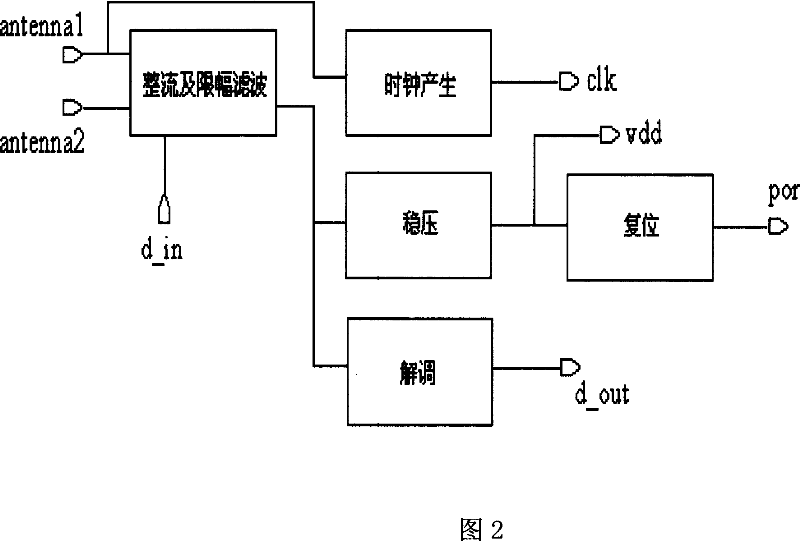

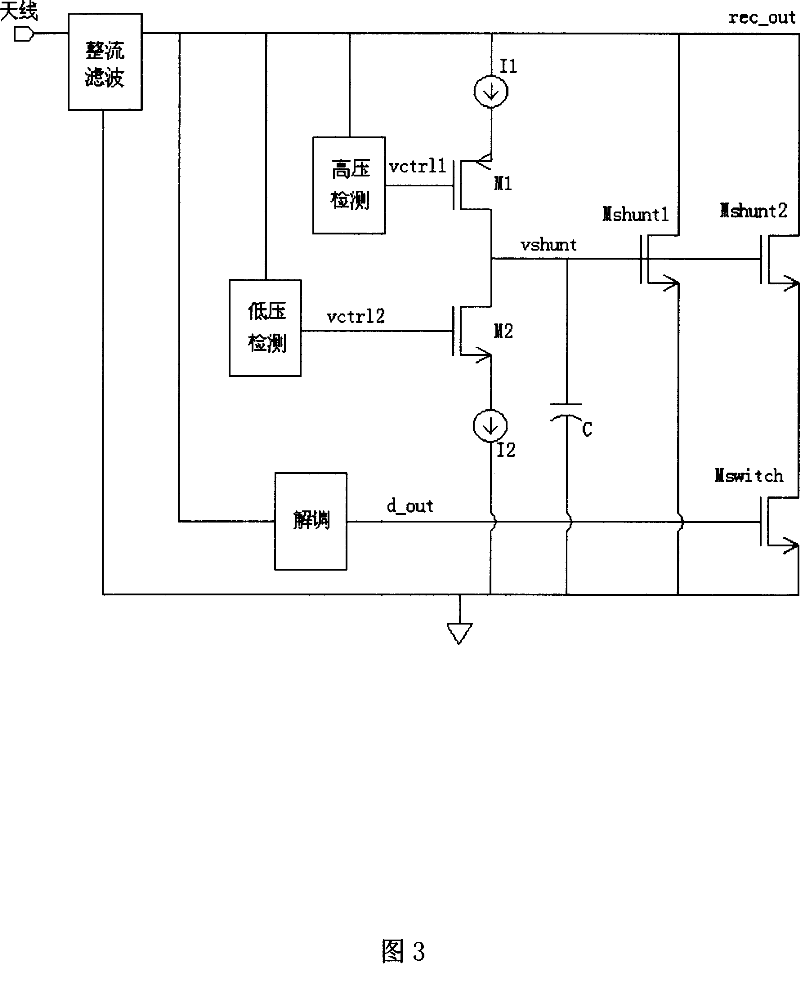

ActiveCN101038616AAvoid the problem of easy power offExpand the scope of workElectronic switchingSensing record carriersCapacitanceControl signal

The invention discloses an amplitude-limiting circuit used for the non-contact type IC card and the radio frequency identified tag chip comprising a bypass grounding transistor being paralleled to the rectified filter circuit of the chip radio frequency interface, a high voltage and a low voltage detection circuits for detecting the output signal from the rectified filter circuit, wherein the high voltage and low voltage circuit controls the opening of a charging current source for charging a capacitor and a discharging current source, the capacitor forms an amplitude-limiting signal by discharging, and the amplitude-limiting signal controls the opening of the bypass grounding transistor. The invention can implement amplitude-limiting function without affecting the posterior demodulation, voltage stabilization, and normal operation of the clock and the reset circuit.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com