Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

434 results about "Electrochemical etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochemical etching is a chemical marking or etching with the use of low voltage electrical current. Electrochemical etching works with the electrical conductivity of the metal to remove the metal and redeposit it as an etch.

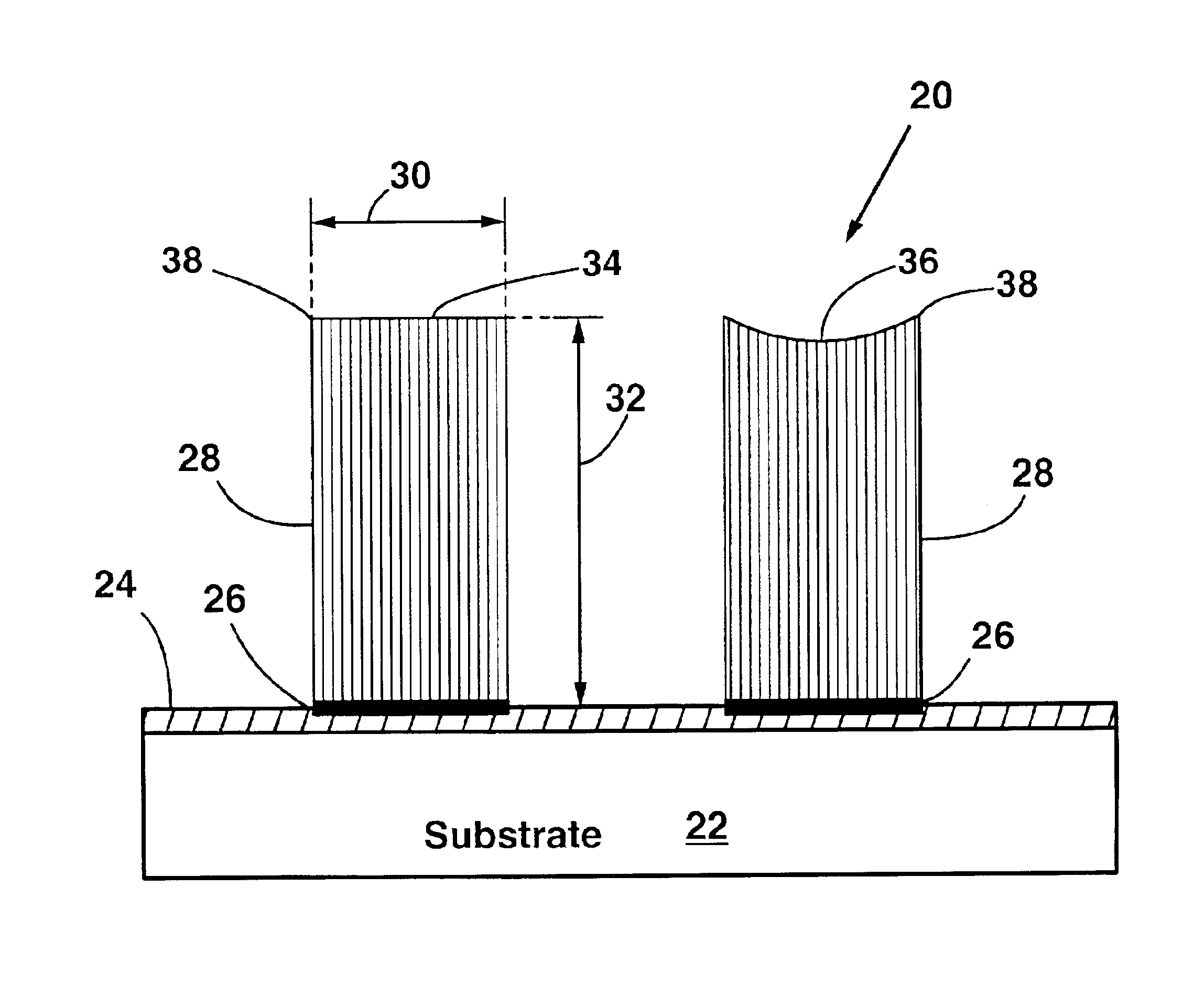

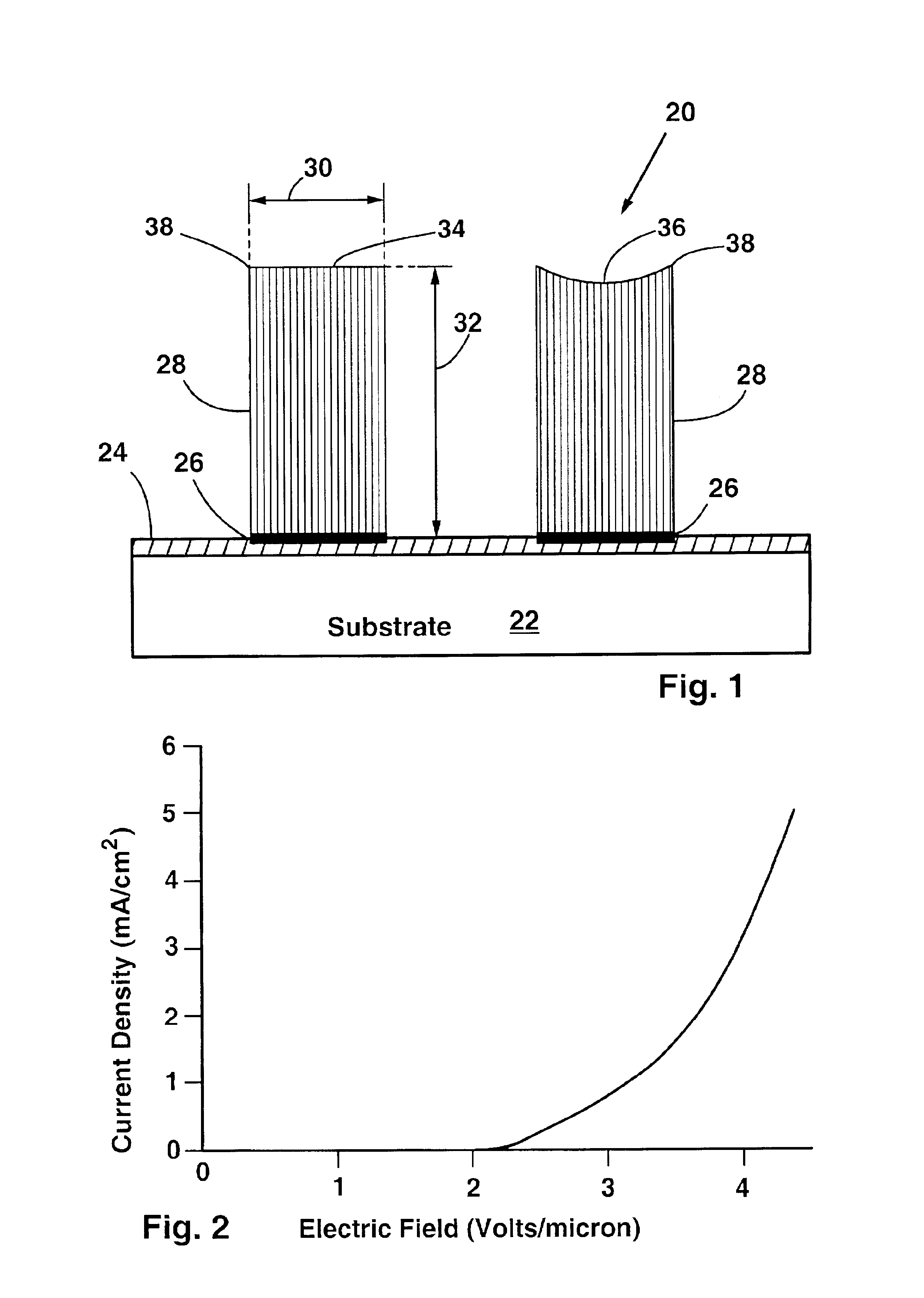

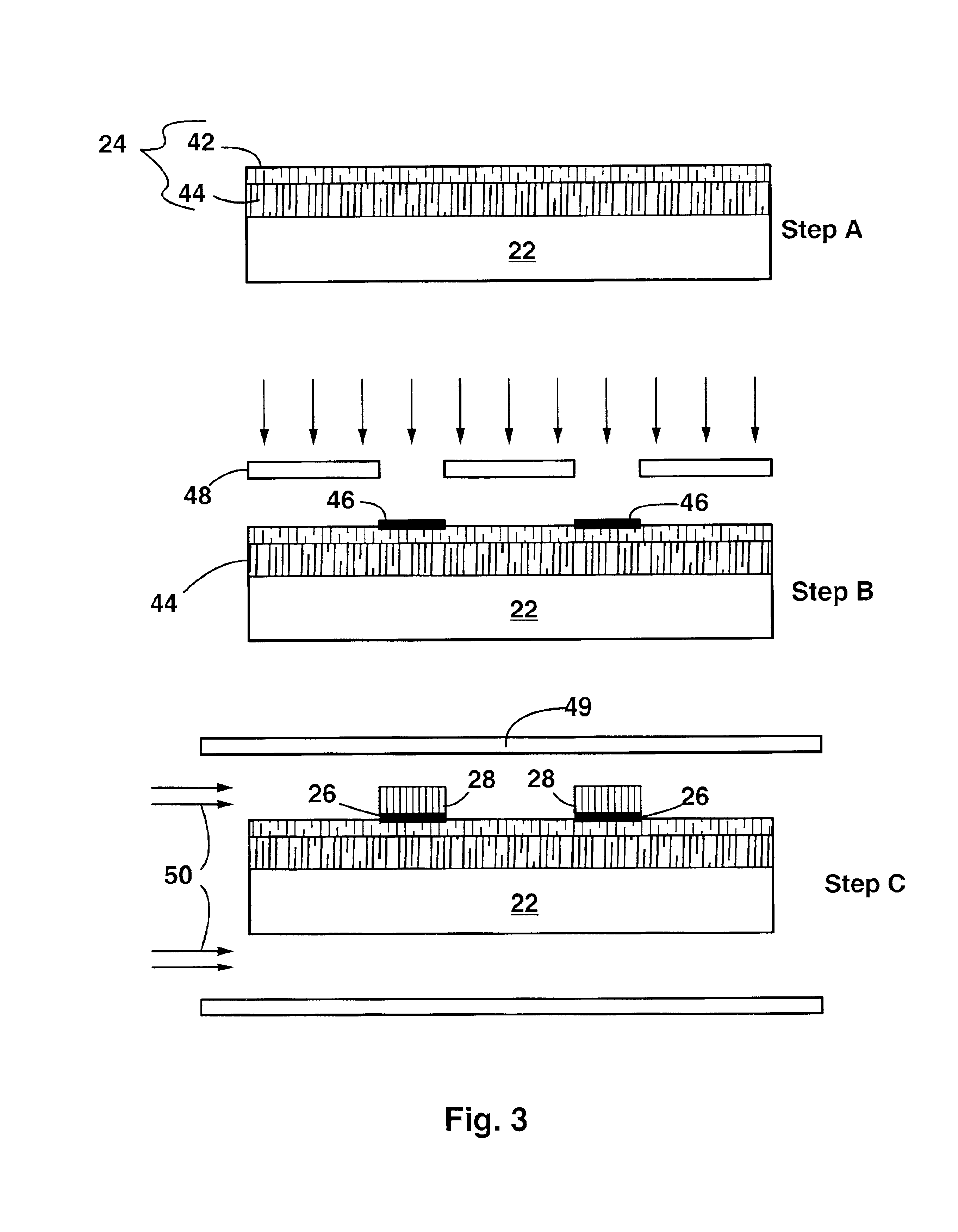

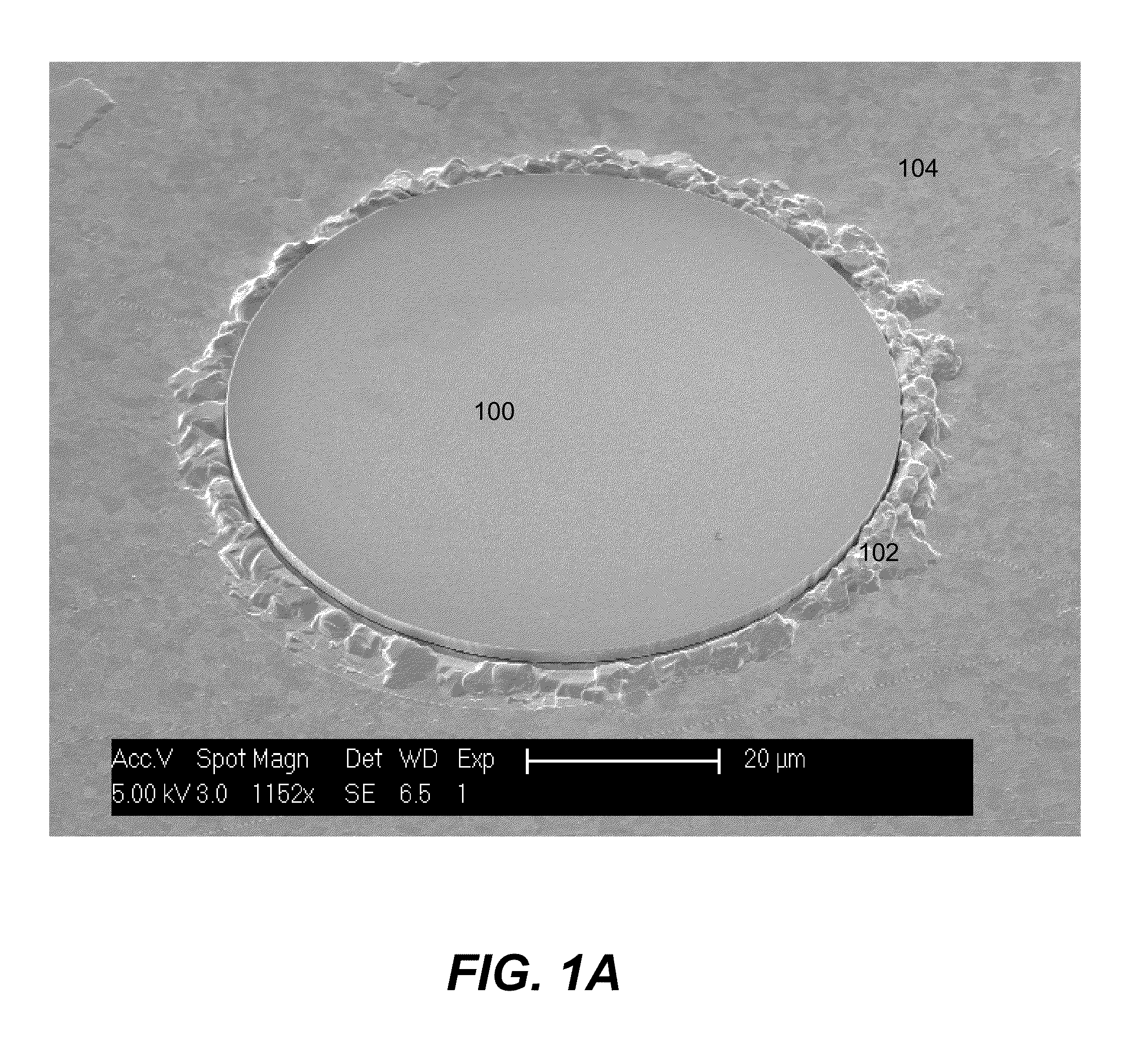

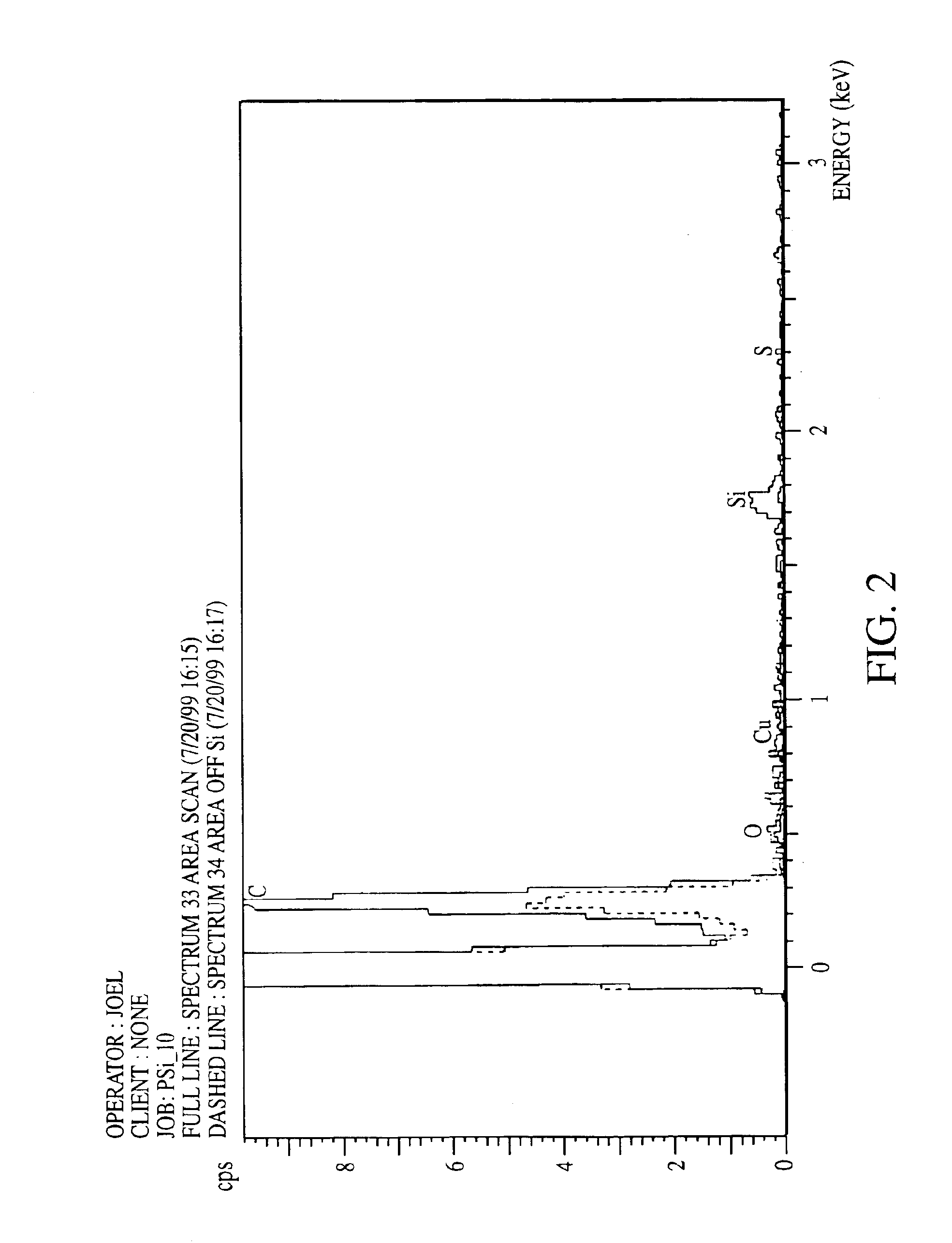

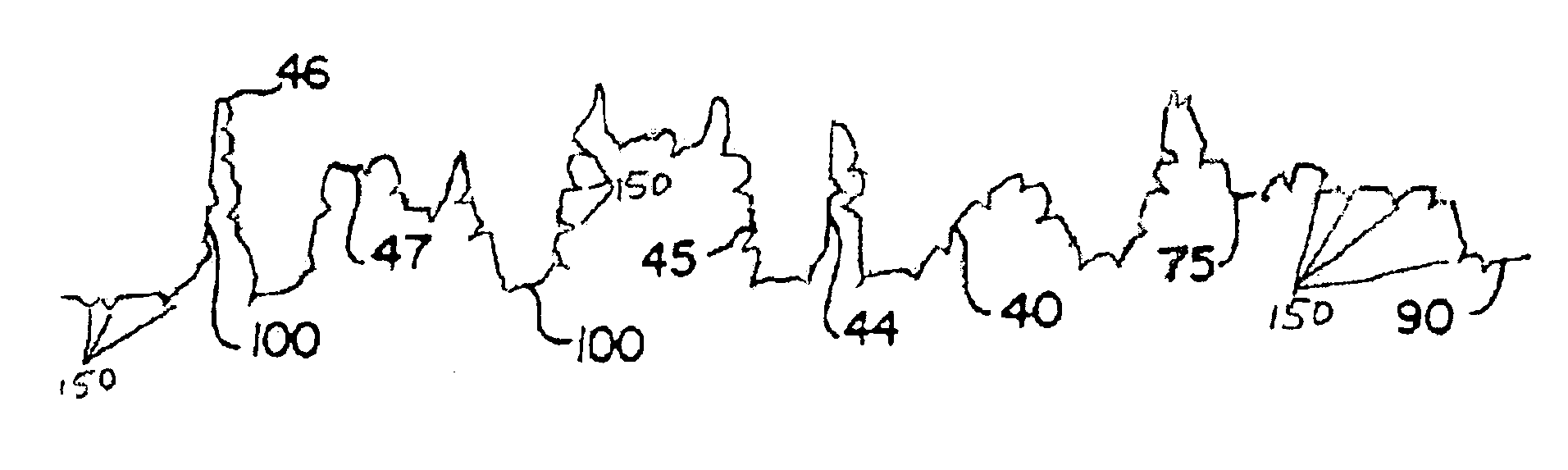

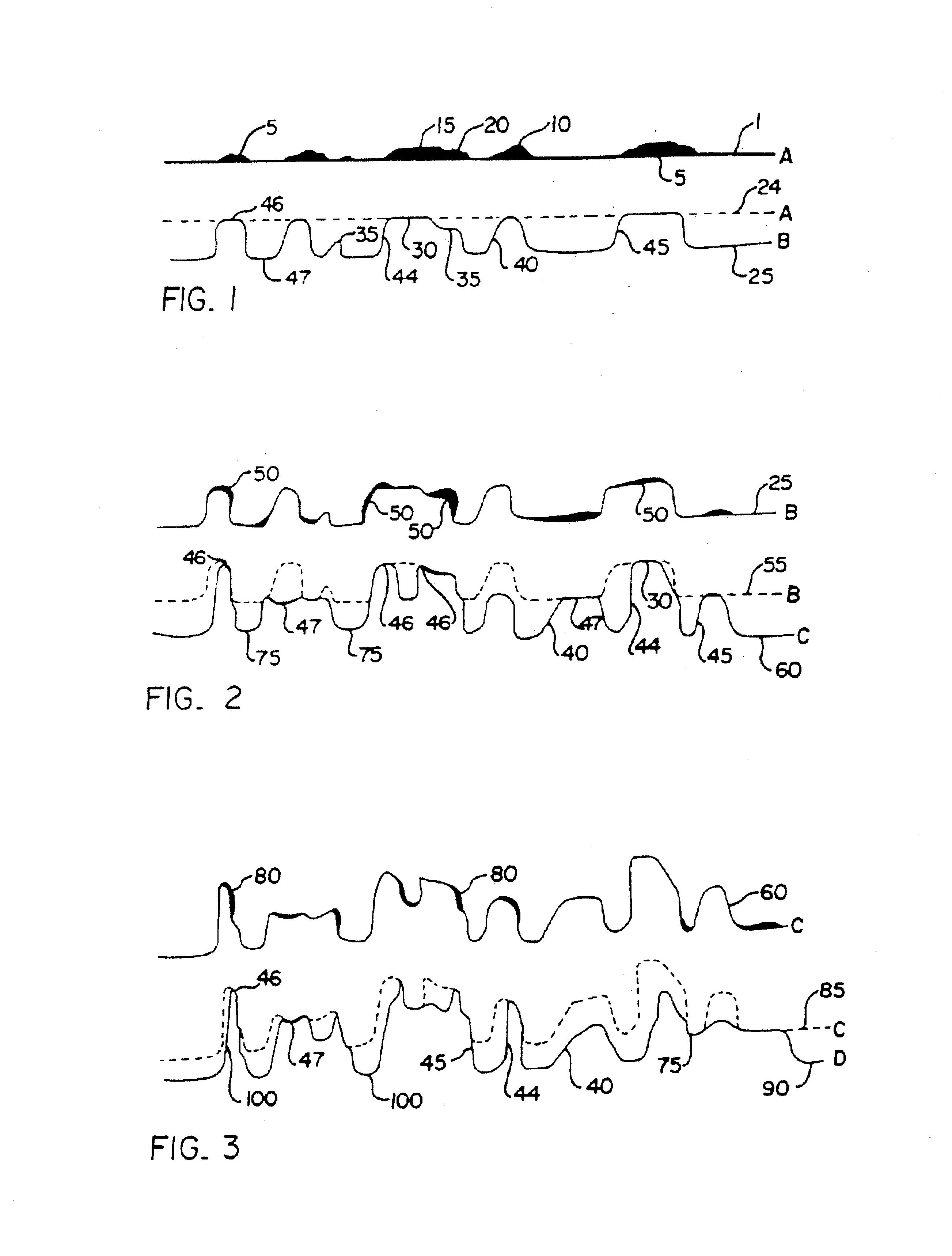

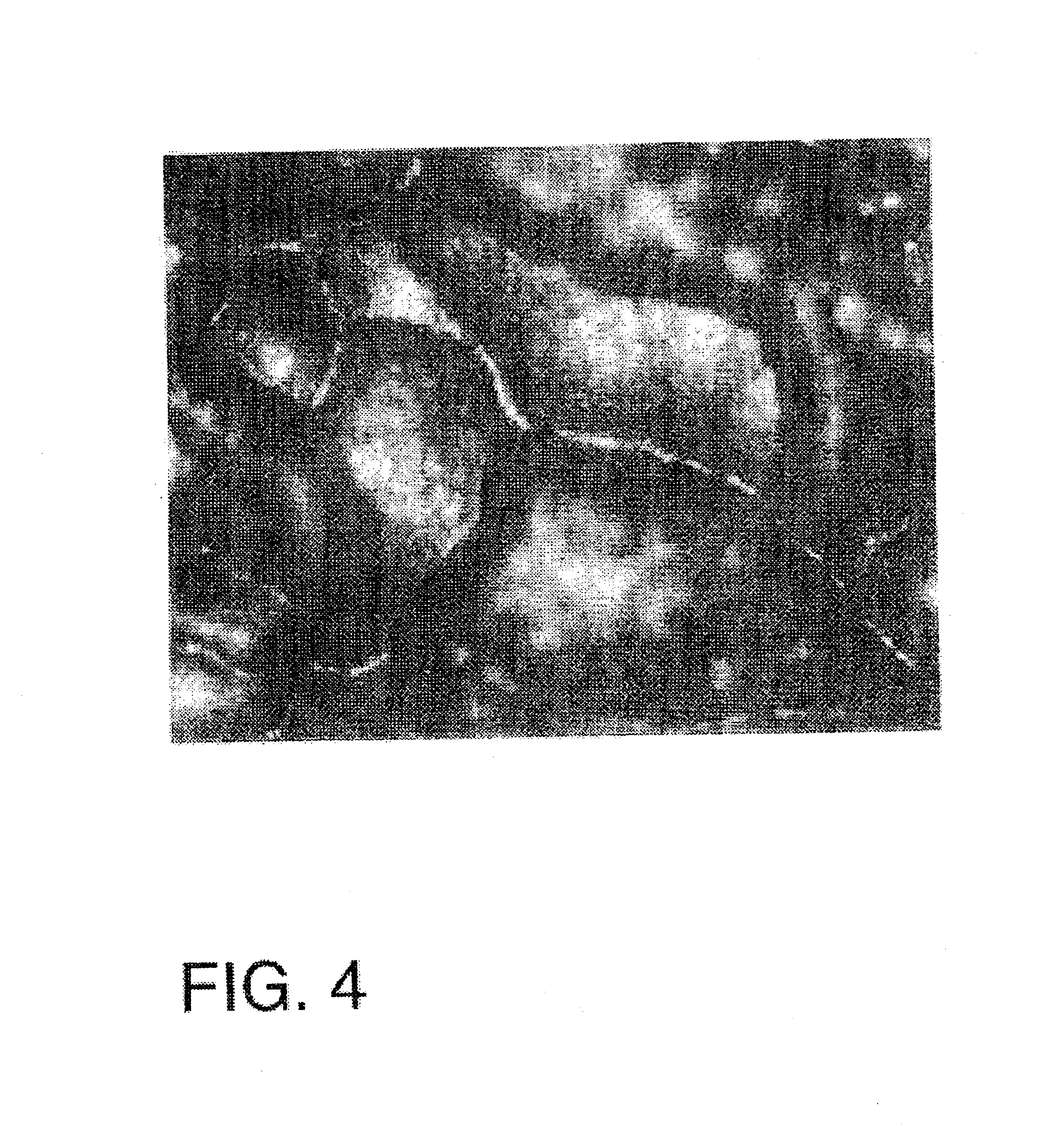

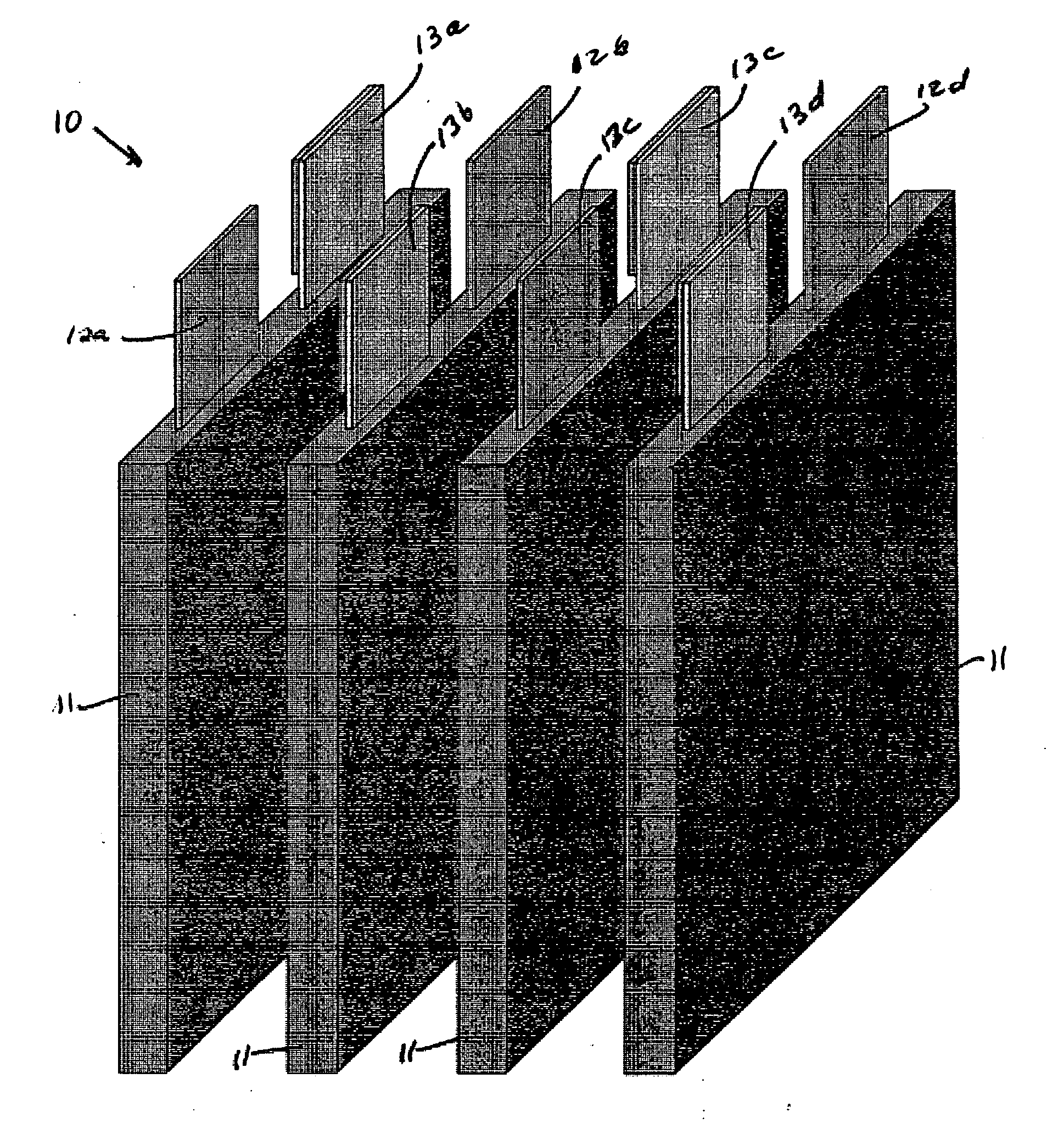

Self-oriented bundles of carbon nanotubes and method of making same

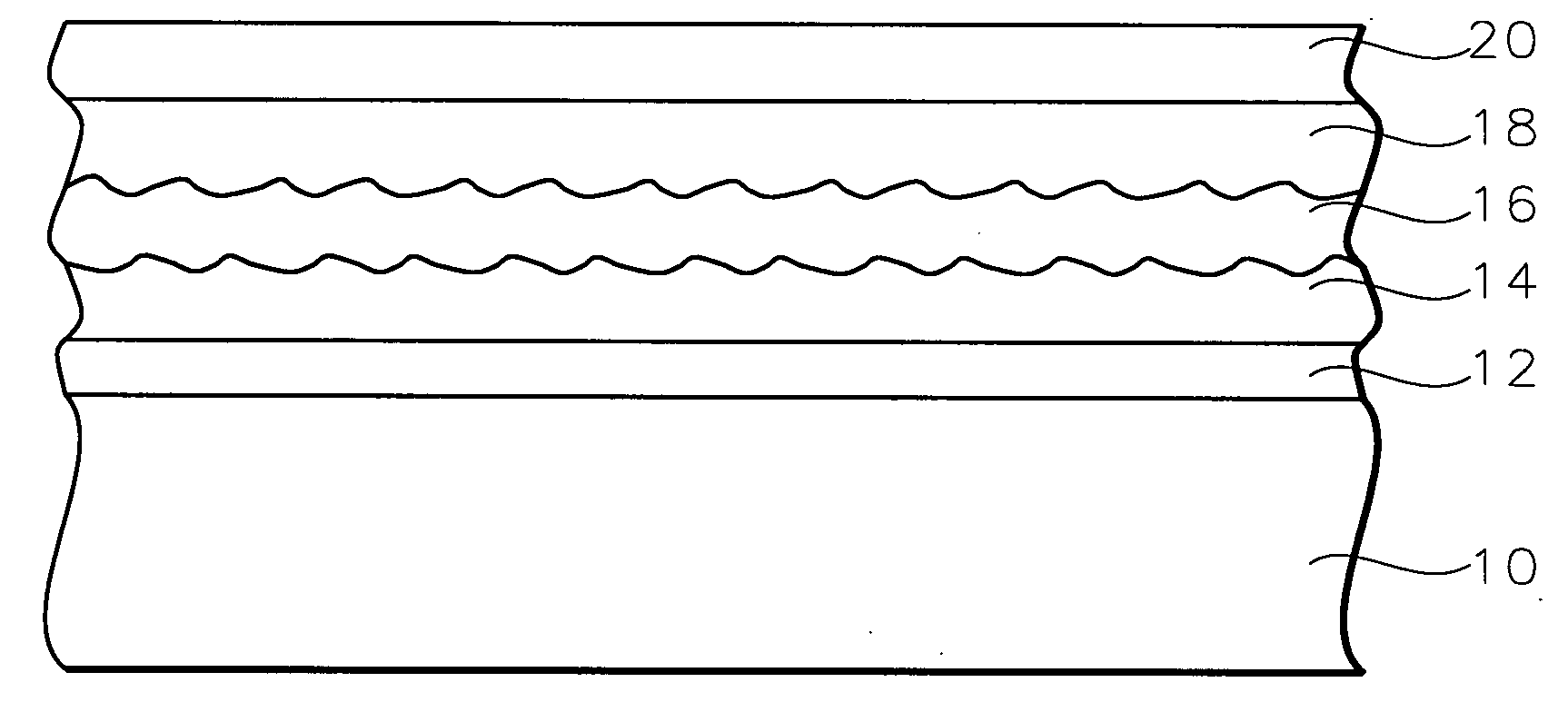

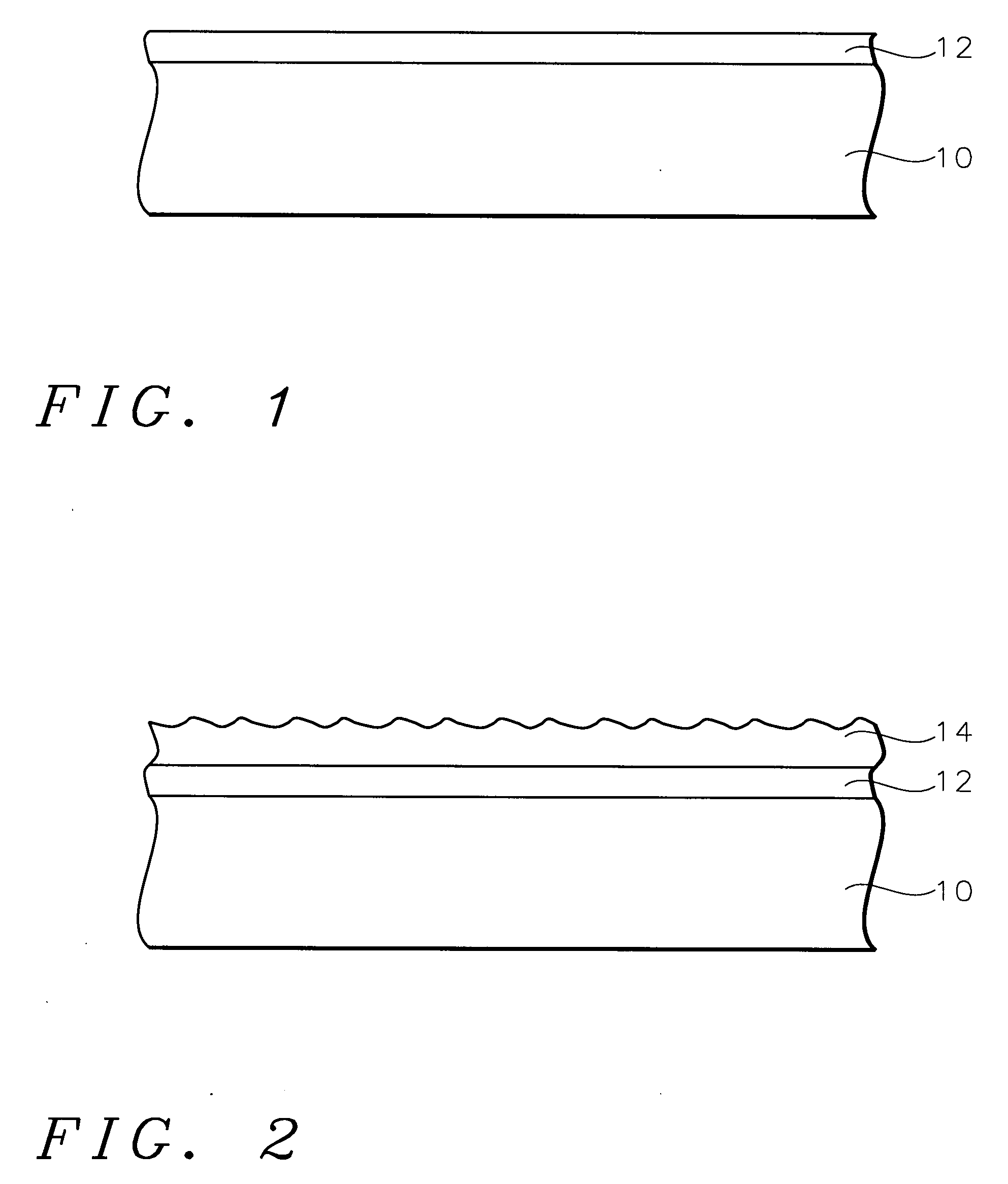

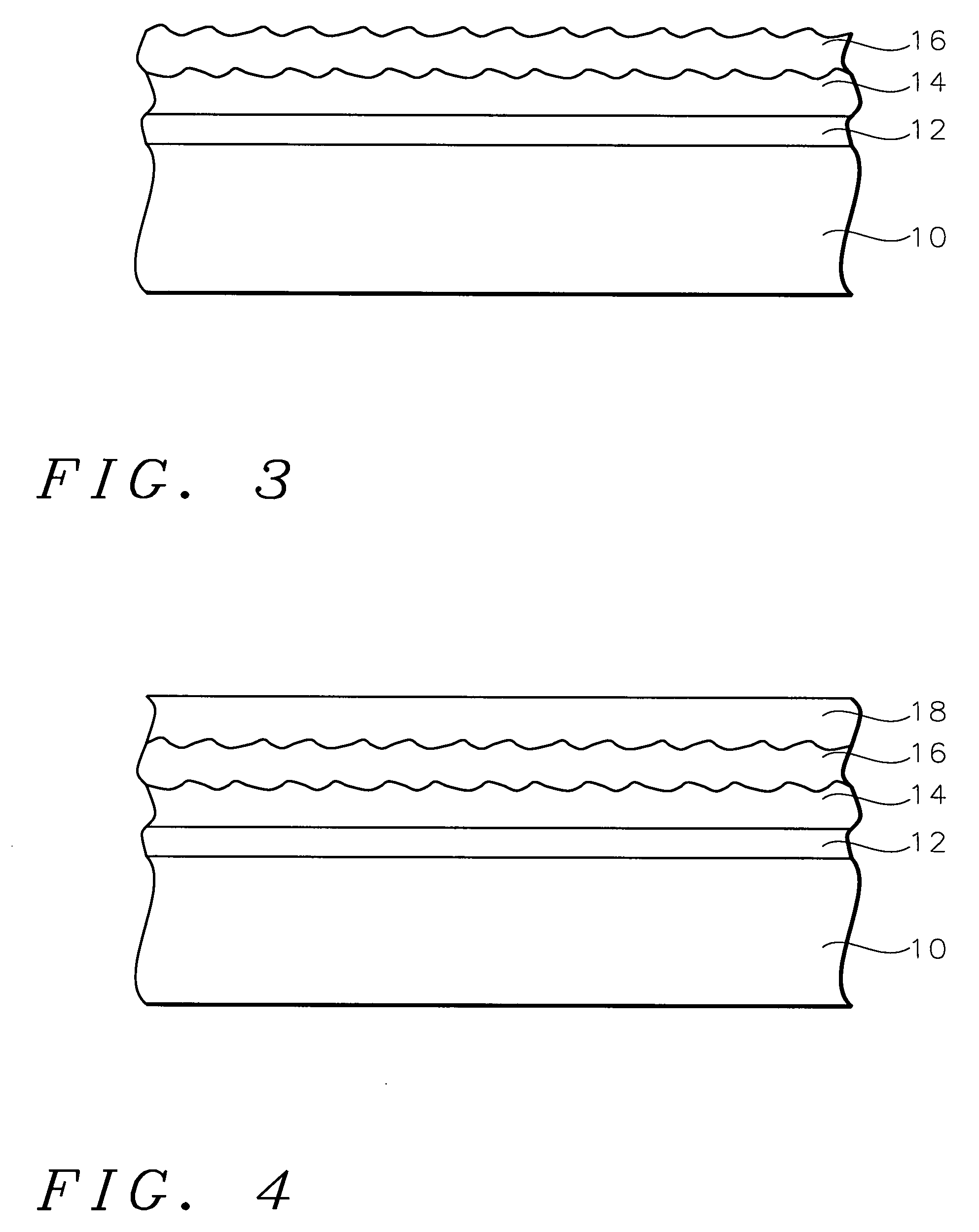

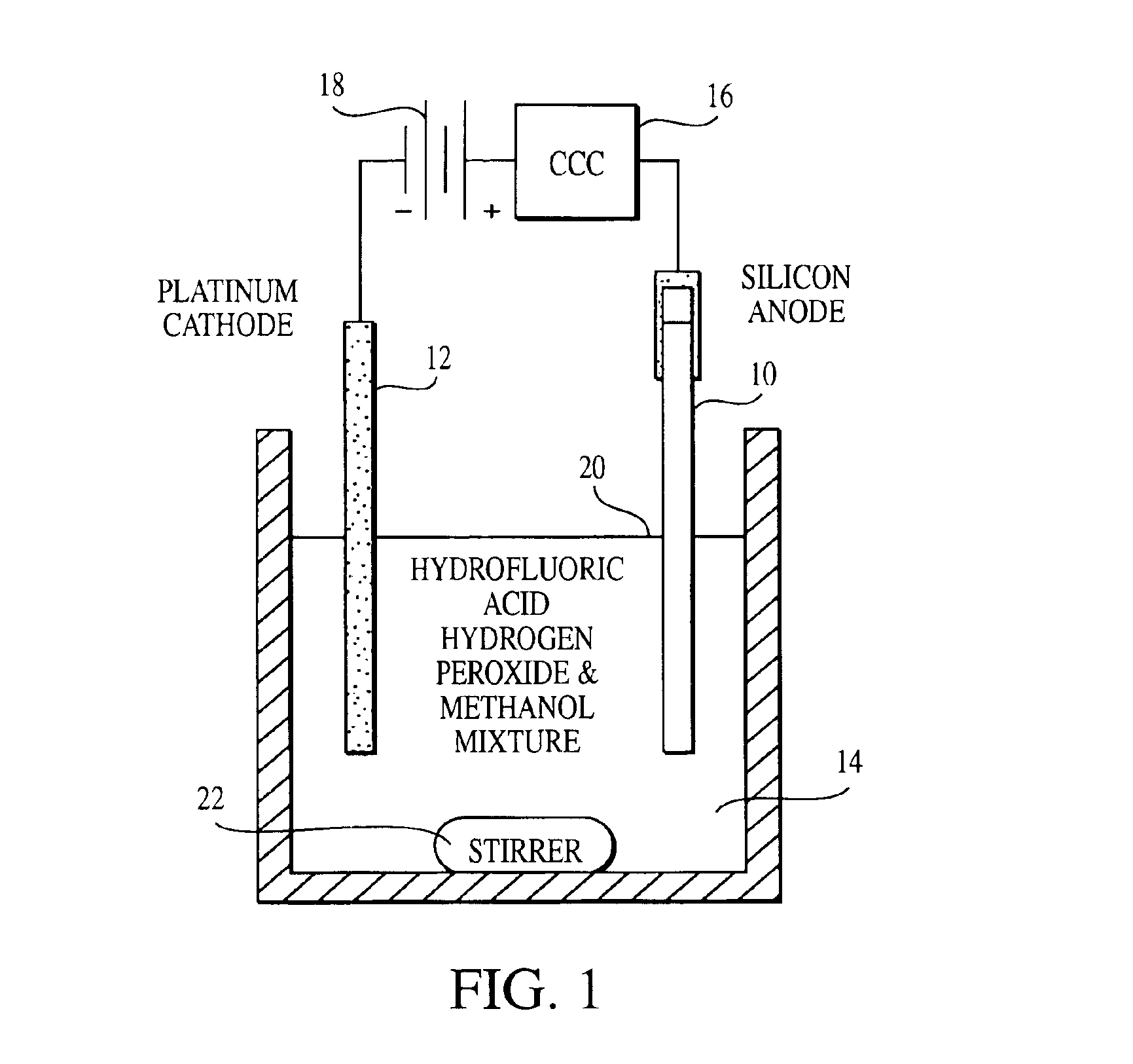

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

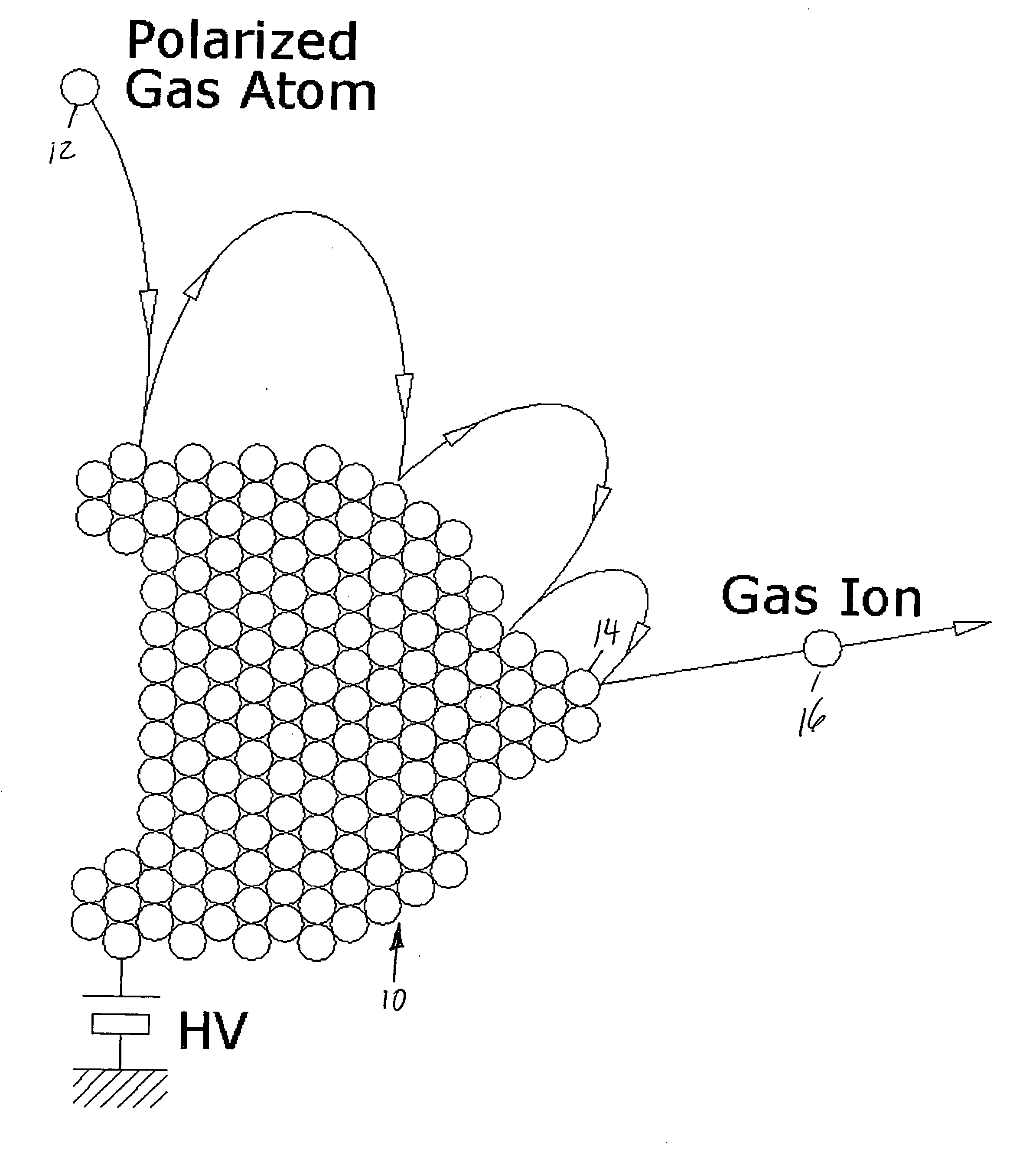

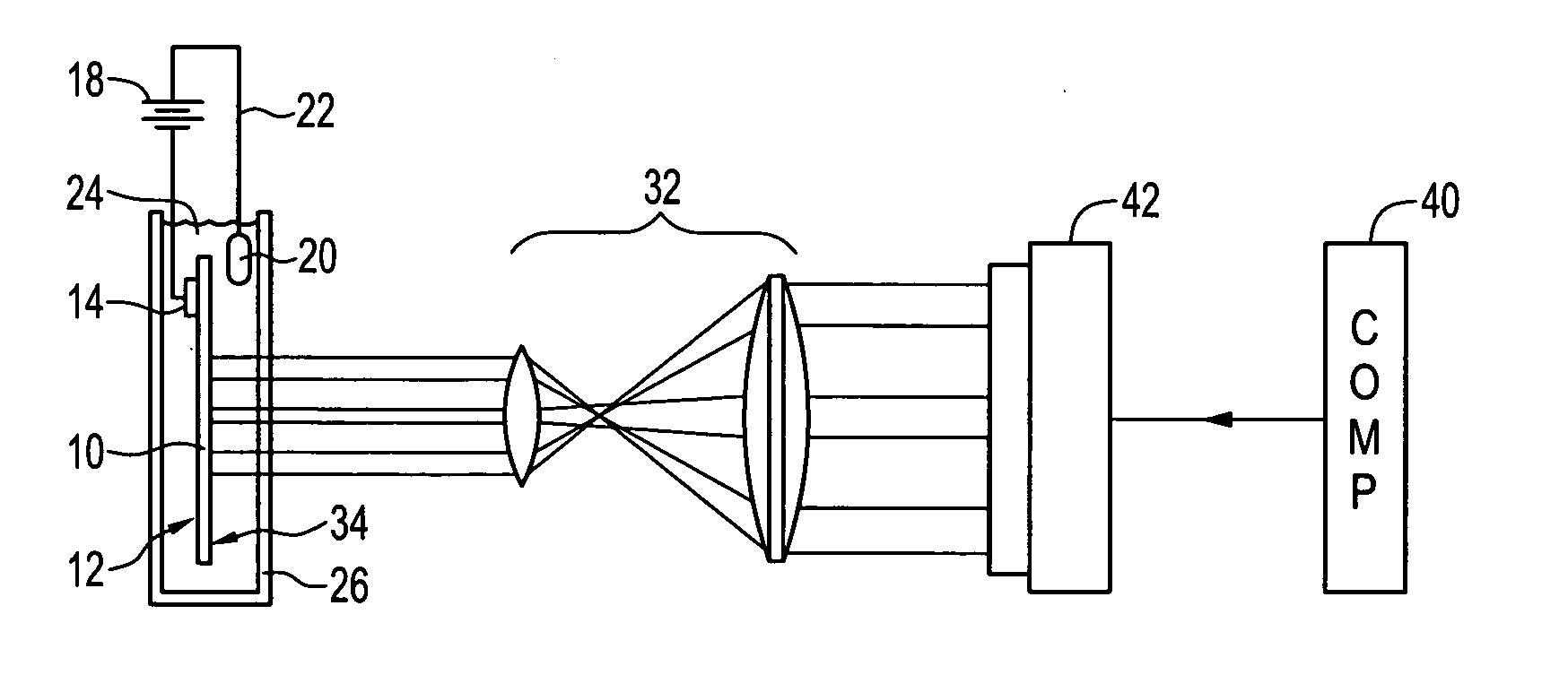

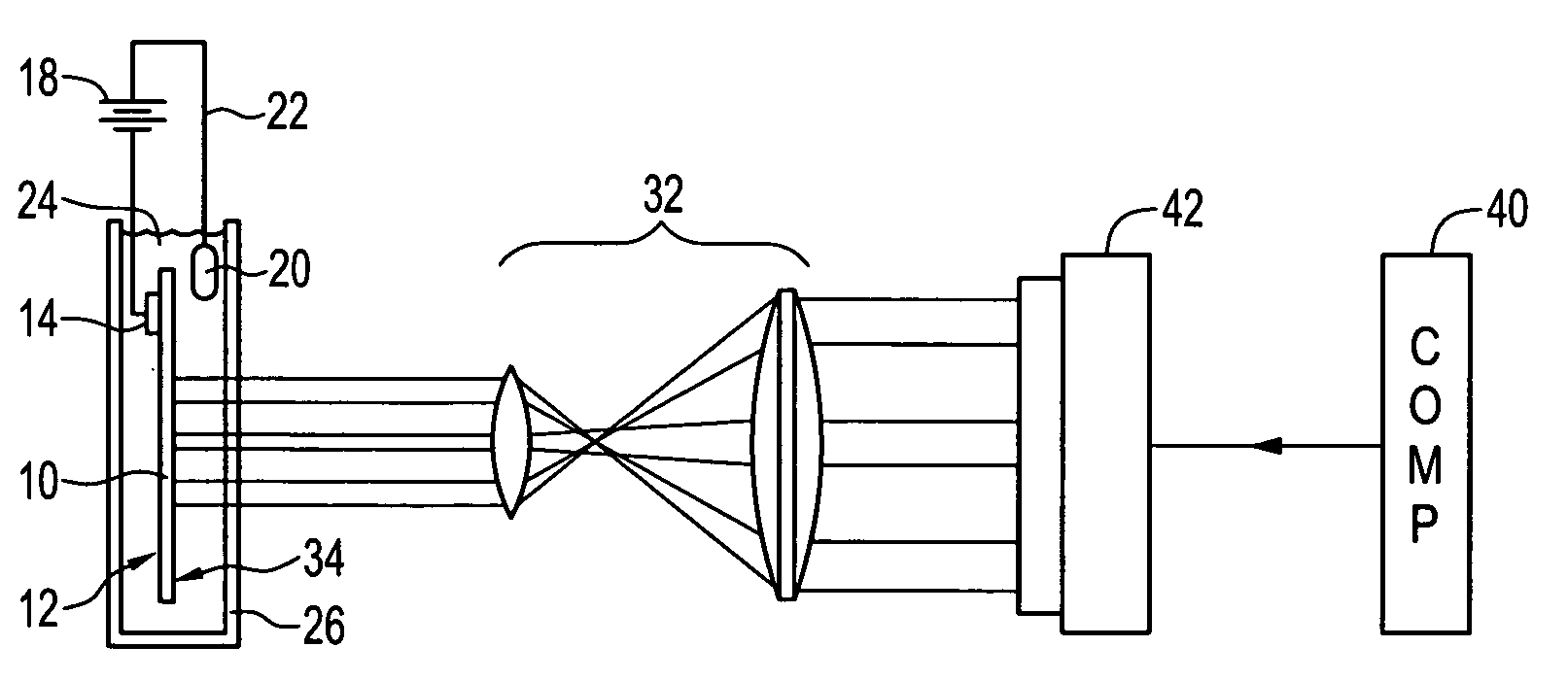

Atomic level ion source and method of manufacture and operation

ActiveUS20070051900A1Long-term performanceLong-term reliabilityMaterial analysis using wave/particle radiationMaterial analysis by optical meansElectrical conductorScanning electron microscope

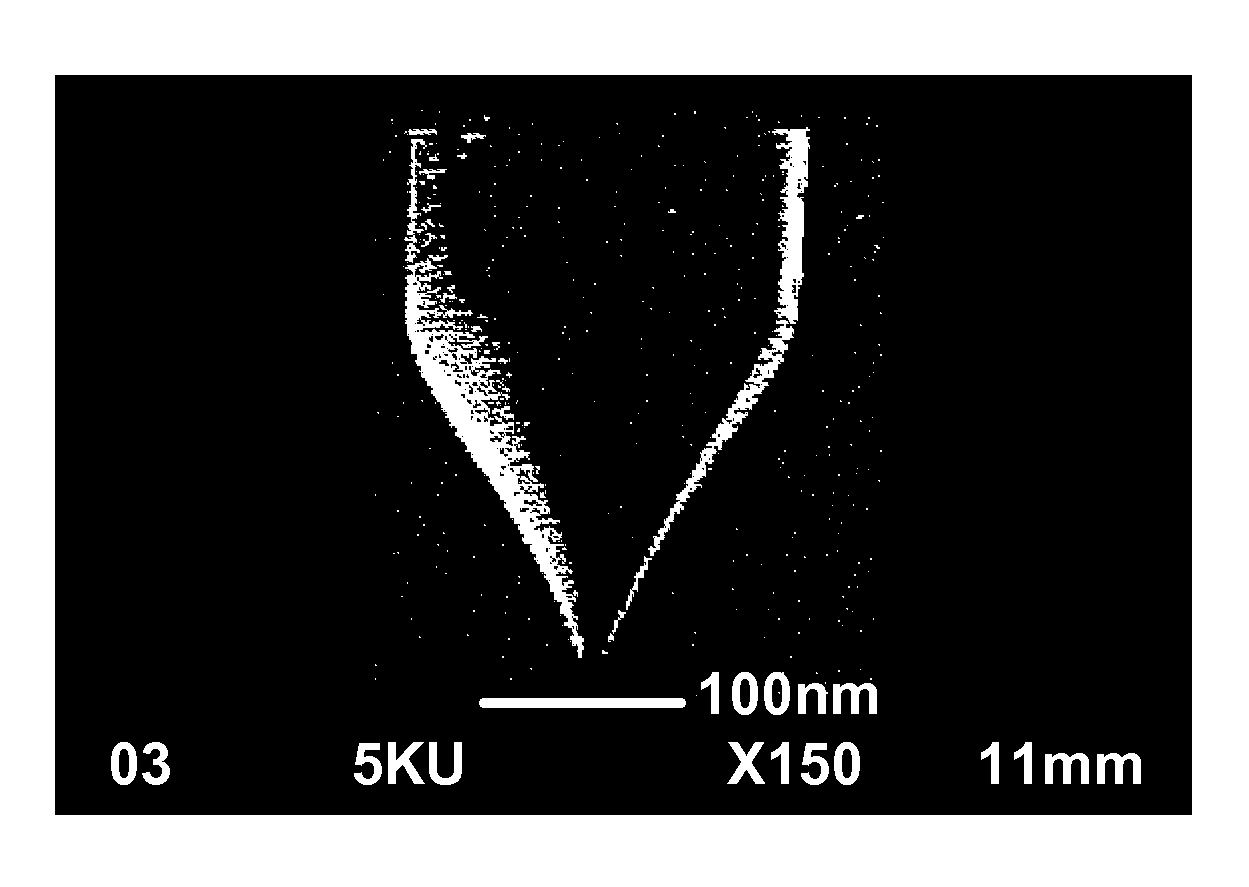

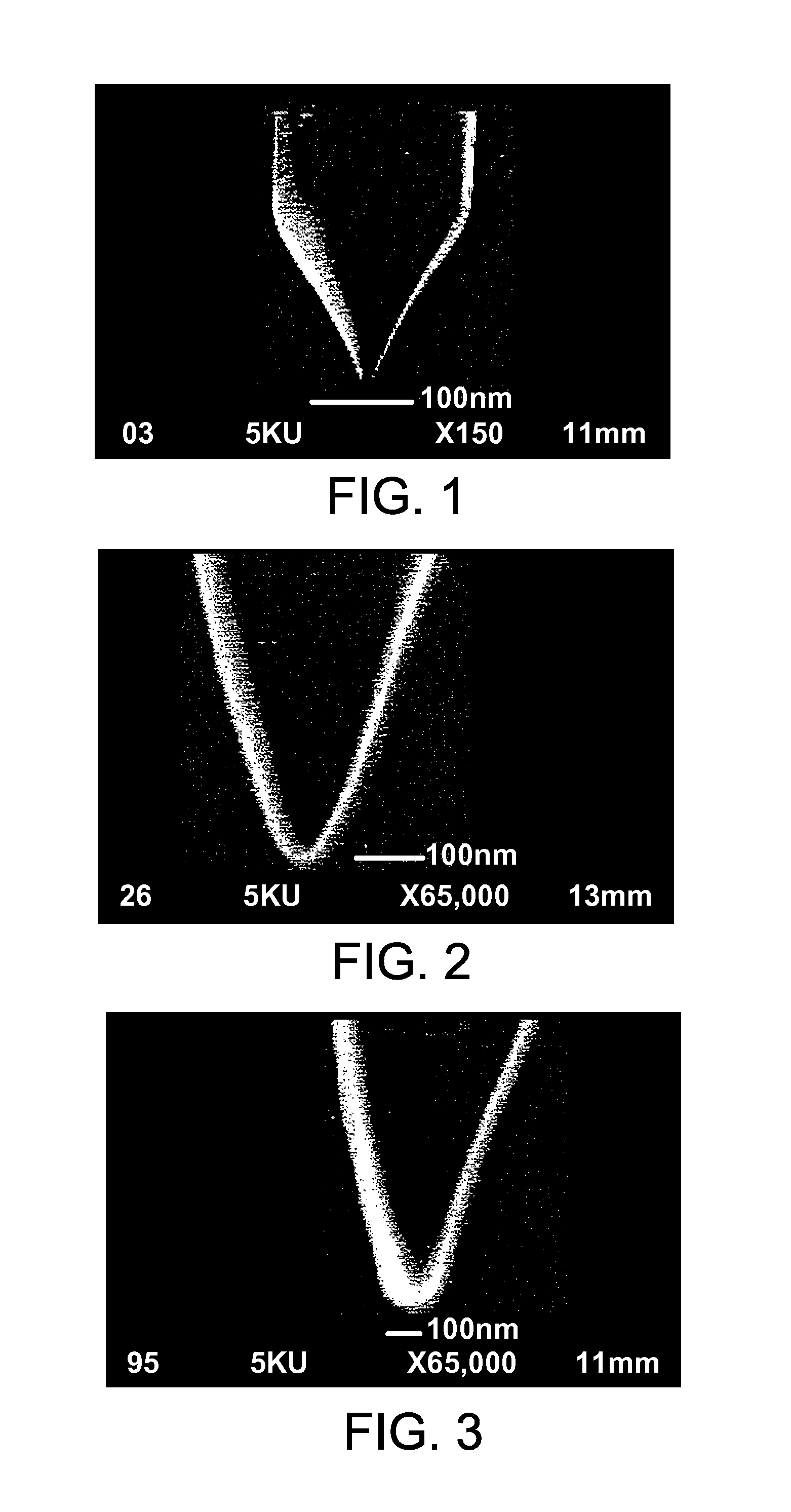

Ion source and method of making and sharpening. The ion source is a single crystal metal conductor having a substantially conical tip portion with substantial rotational symmetry. The tip portion terminates with a tip radius of curvature in the range of 50-100 nanometers. The ion source is made by electrochemical etching so that a conical tip of a selected geometry is formed. The ion source is then sharpened to provide a source of ions from a volume near the size of a single atom. Further, this ion source makes possible a stable and practical light ion microscope which will have higher resolution than existing scanning electron microscopes and scanning metal-ion microscopes.

Owner:ALIS CORP

Atomic level ion source and method of manufacture and operation

ActiveUS7368727B2Good symmetryLong-term performance and reliabilityMaterial analysis using wave/particle radiationMaterial analysis by optical meansElectrical conductorScanning electron microscope

Ion source and method of making and sharpening. The ion source is a single crystal metal conductor having a substantially conical tip portion with substantial rotational symmetry. The tip portion terminates with a tip radius of curvature in the range of 50–100 nanometers. The ion source is made by electrochemical etching so that a conical tip of a selected geometry is formed. The ion source is then sharpened to provide a source of ions from a volume near the size of a single atom. Further, this ion source makes possible a stable and practical light ion microscope which will have higher resolution than existing scanning electron microscopes and scanning metal-ion microscopes.

Owner:ALIS CORP

Small gauge pressure sensor using wafer bonding and electrochemical etch stopping

ActiveUS7493822B2Small sizeFluid pressure measurement using ohmic-resistance variationSemiconductor/solid-state device manufacturingEngineeringWafer bonding

A gauge pressure sensor apparatus and a method of forming the same. A constraint wafer can be partially etched to set the diaphragm size, followed by bonding to a top wafer. The thickness of the top wafer is either the desired diaphragm thickness or is thinned to the desired thickness after bonding. The bonding of top wafer and constraint wafer enables electrochemical etch stopping. This allows the media conduit to be etched through the back of the constraint wafer and an electrical signal produced when the etching reaches the diaphragm. The process prevents the diaphragm from being over-etched. The invention allows the die size to be smaller than die where the diaphragm size is set by etching from the back side.

Owner:HONEYWELL INT INC

Method for the reuse of gallium nitride epitaxial substrates

ActiveUS20130214284A1Low costFinal product manufactureSemiconductor/solid-state device manufacturingGallium nitrideBand gap

A method for the reuse of gallium nitride (GaN) epitaxial substrates uses band-gap-selective photoelectrochemical (PEC) etching to remove one or more epitaxial layers from bulk or free-standing GaN substrates without damaging the substrate, allowing the substrate to be reused for further growth of additional epitaxial layers. The method facilitates a significant cost reduction in device production by permitting the reuse of expensive bulk or free-standing GaN substrates.

Owner:RGT UNIV OF CALIFORNIA

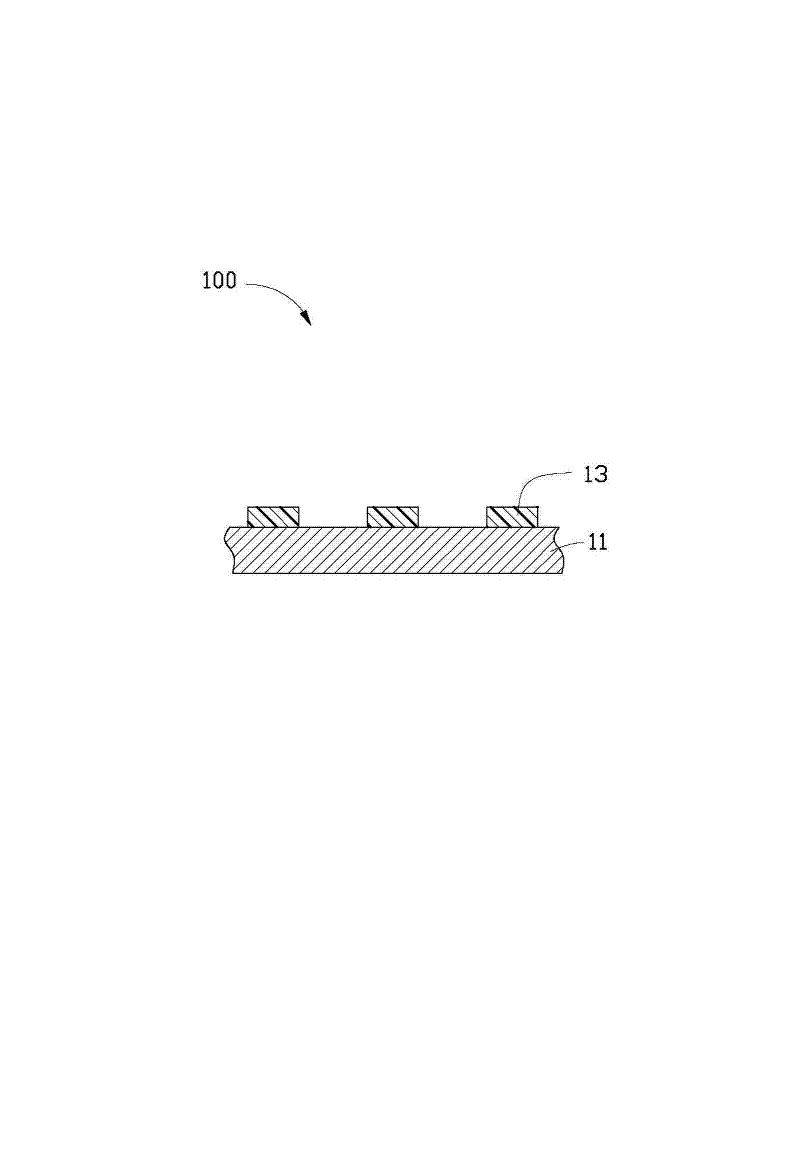

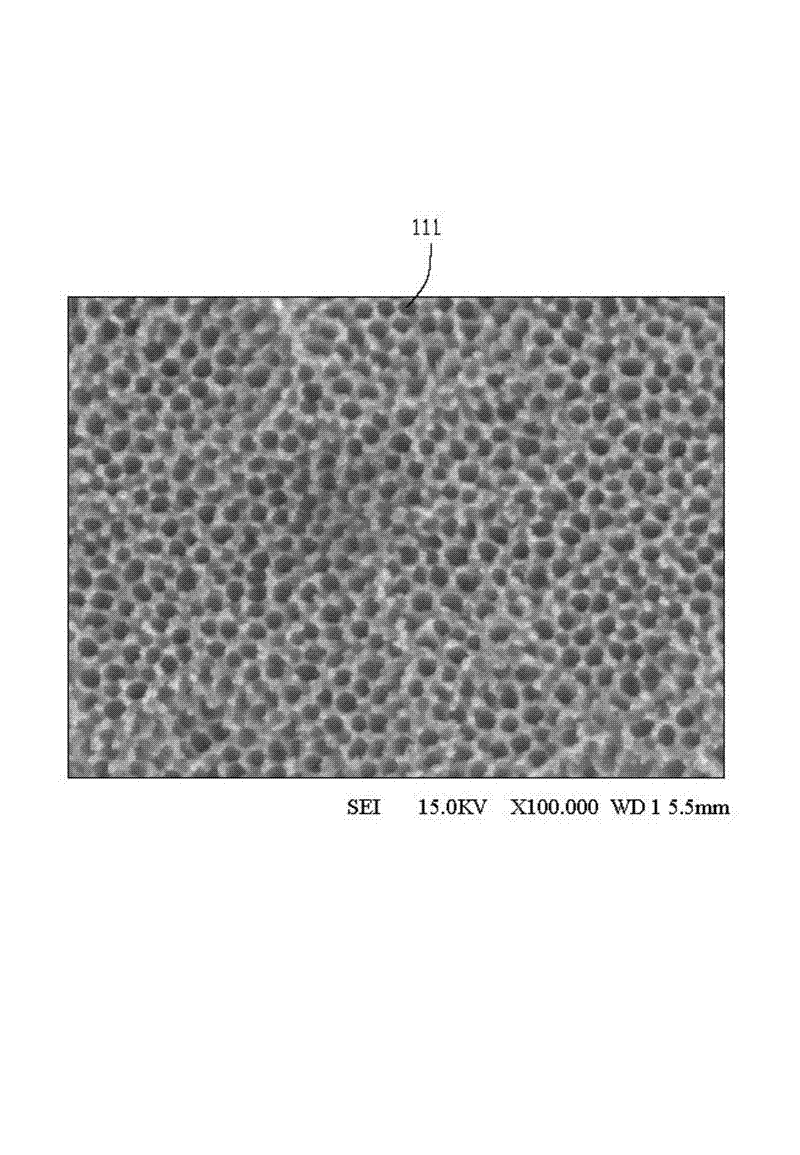

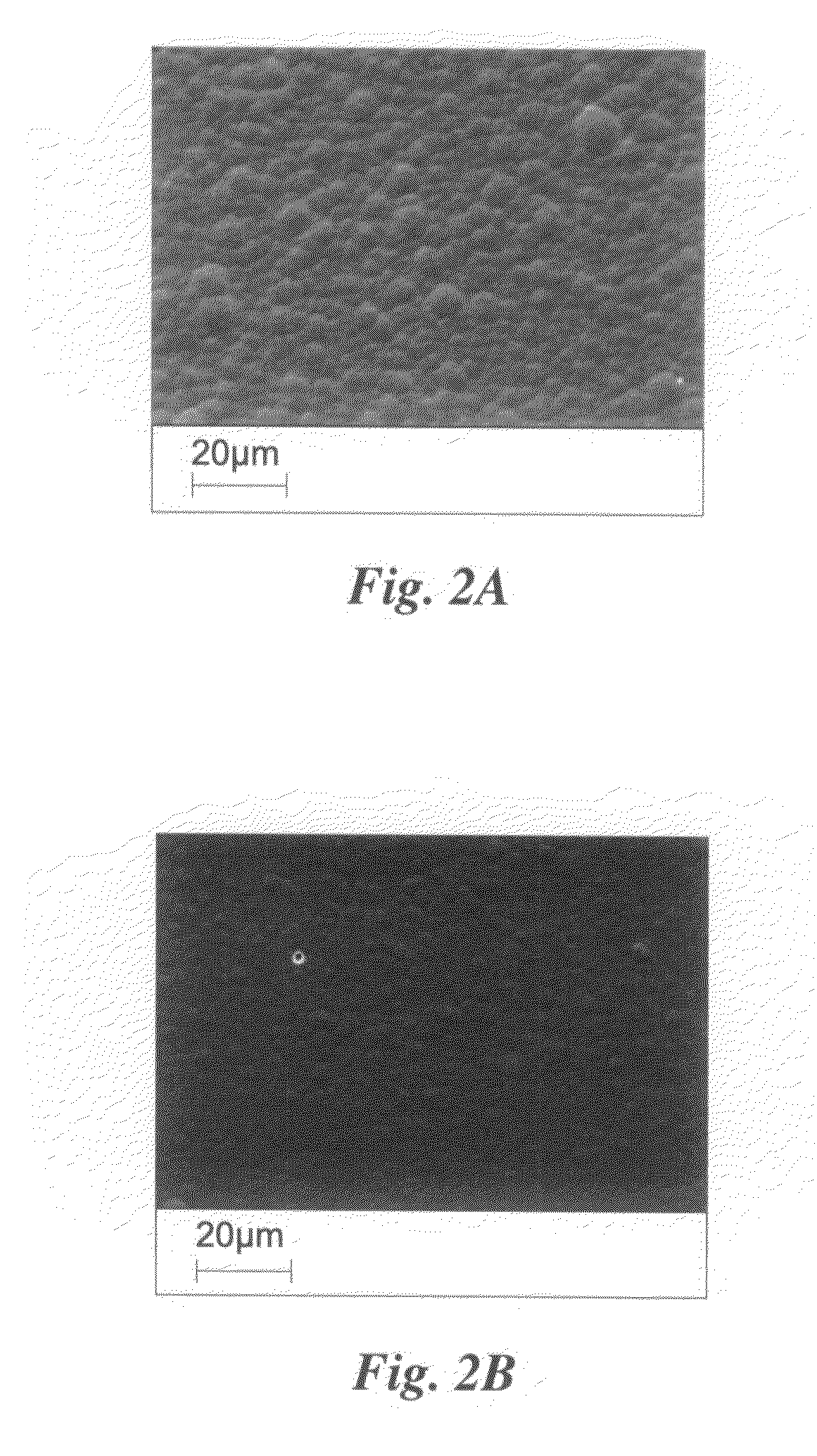

Growth of indium gallium nitride (InGaN) on porous gallium nitride (GaN) template by metal-organic chemical vapor deposition (MOCVD)

InactiveUS20090001416A1Increase indium incorporationLarge emissionsPolycrystalline material growthSemiconductor/solid-state device manufacturingIndiumGallium nitride

Si-doped porous GaN is fabricated by UV-enhanced Pt-assisted electrochemical etching and together with a low-temperature grown buffer layer are utilized as the template for InGaN growth. The porous network in GaN shows nanostructures formed on the surface. Subsequent growth of InGaN shows that it is relaxed on these nanostructures as the area on which the growth takes place is very small. The strain relaxation favors higher indium incorporation. Besides, this porous network creates a relatively rough surface of GaN to modify the surface energy which can enhance the nucleation of impinging indium atoms thereby increasing indium incorporation. It shifts the luminescence from 445 nm for a conventionally grown InGaN structure to 575 nm and enhances the intensity by more than two-fold for the growth technique in the present invention under the same growth conditions. There is also a spectral broadening of the output extending from 480 nm to 720 nm.

Owner:NAT UNIV OF SINGAPORE

Process method for preparing ultra-hydrophobic surface by electrochemical method

ActiveCN101665968AEndows the superior performance of "self-cleaning"Apparent nanostructureAnodisationSpecial surfacesPhysical chemistryElectrochemistry

The invention discloses a process method for preparing an ultra-hydrophobic surface by the electrochemical method. The process adopts two processing steps: forming the micro nanometer double-structurerough surface by first electrochemical etching and then oxalic acid anodic oxidation; and preparing the ultra-hydrophobic surface by modifying the surface with fluorosilane. The method is simple andpractical, uses mature electrochemical etching and anodic oxidation technology, allows for easy mass production and avoids environmental pollution.

Owner:甘肃中安瑞科科技有限公司

Silicon nanoparticle and method for producing the same

InactiveUS6846474B2Highly uniform in sizeEasily filtered outMaterial nanotechnologyNanostructure manufactureNanoparticleColloid

Highly uniform 1 nm silicon nanoparticles are provided by the invention. The nanoparticles exhibit beneficial properties. They are a source of stimulated emissions. They may be suspended in liquids, and solids. They can be formed into crystals, colloids and films. The nanoparticles of the invention are about 1 nm having about only one part in one thousand greater than 1 nm. A method for producing the silicon nanoparticle of the invention is a gradual advancing electrochemical etch of bulk silicon. Separation of nanoparticles from the surface of the silicon may also be conducted. Once separated, various methods may be employed to form plural nanoparticles into colloids, crystals, films and other desirable forms. The particles may also be coated or doped.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

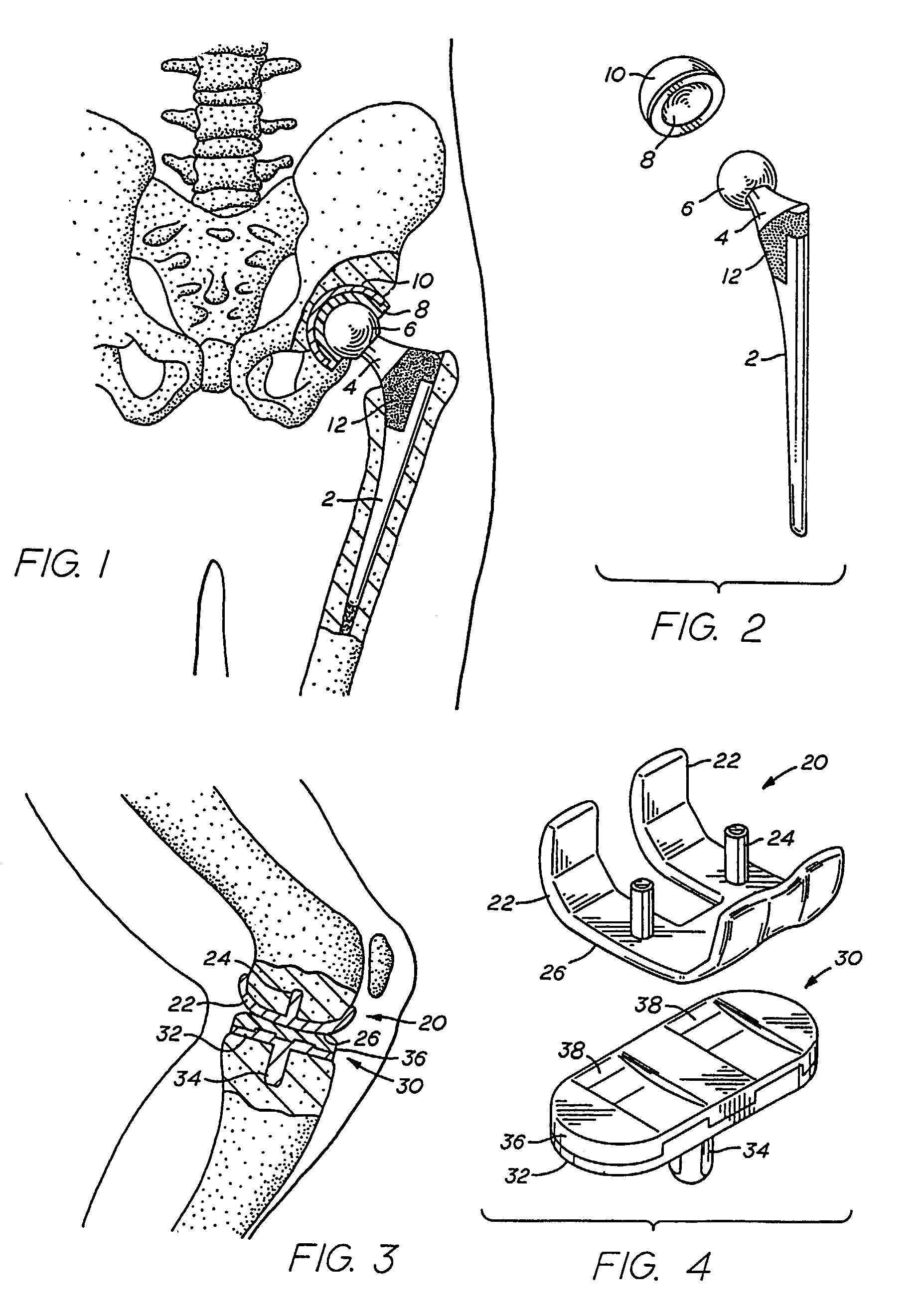

Surface for use on implantable device

InactiveUS6911249B2Reduce air resistancePromote absorptionLayered productsDecorative surface effectsImplanted deviceMaterials science

An attachment surface for an implantable device has an irregular pattern formed through a process including masking, chemical or electrochemical etching, blasting and debris removal steps. Surface material is removed from the implant surface without stress on the adjoining material and the process provides fully dimensional fillet radii at the base of the surface irregularities. This irregular surface is adapted to receive the ingrowth of bone material and to provide a strong anchor for that bone material which is resistant to cracking or breaking. The surface is prepared through an etching process which utilizes the random application of a maskant and subsequent etching in areas unprotected by the maskant. This chemical etching process is repeated a number of times as necessitated by the nature of the irregularities required in the surface. The blasting and debris removal steps produce microfeatures on the surface that enhance the ingrowth of bone material.

Owner:TITAN SPINE

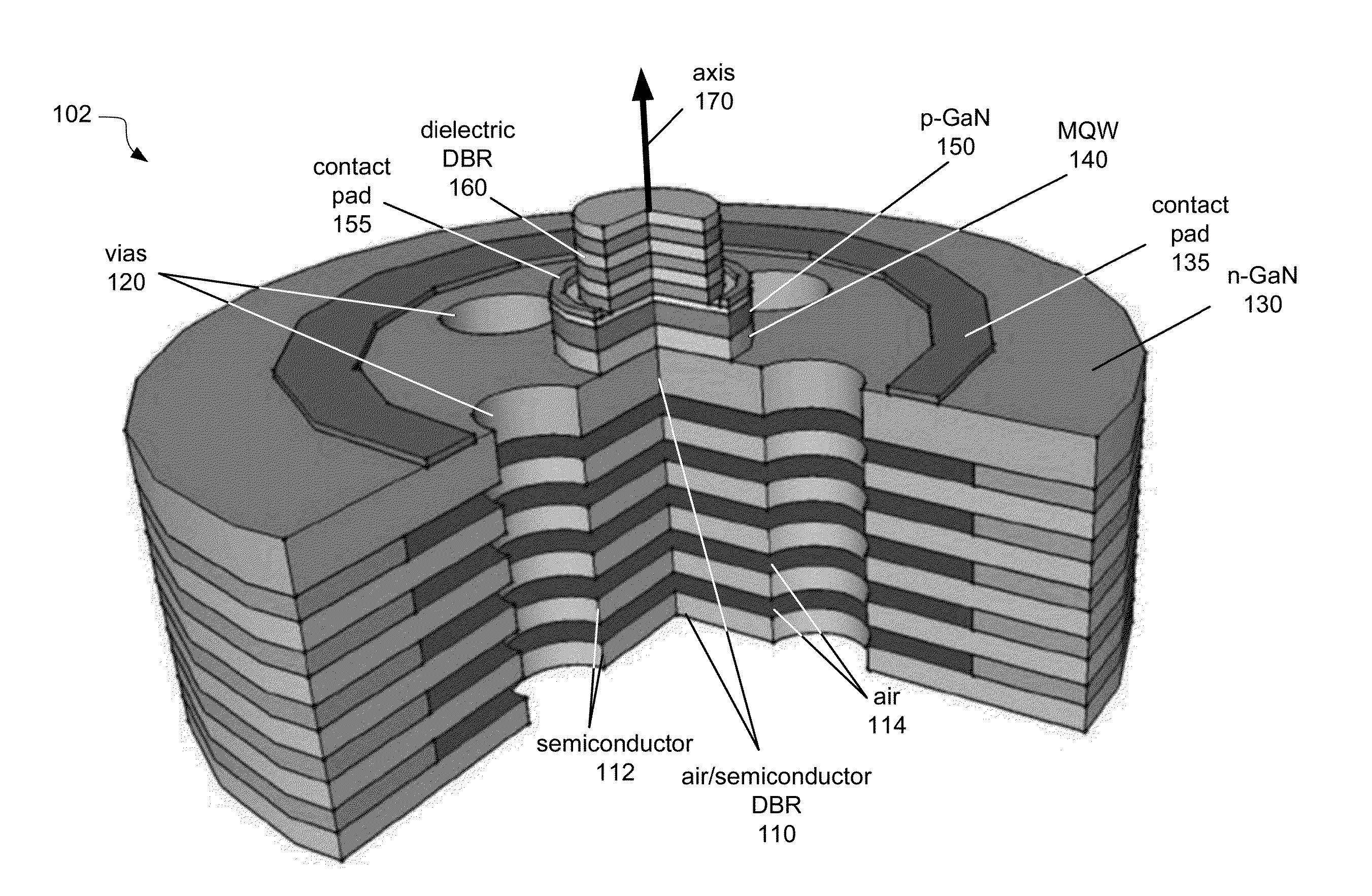

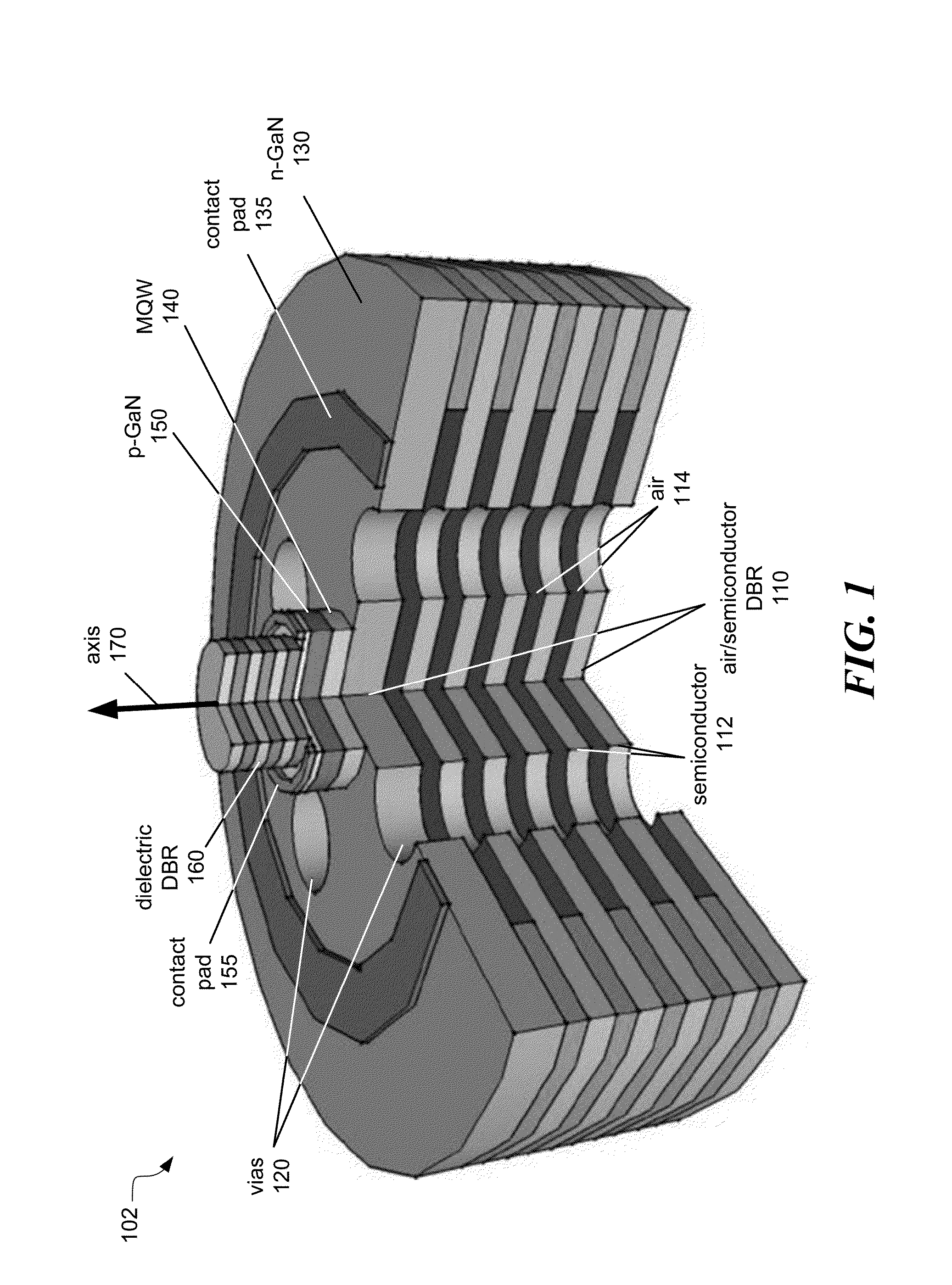

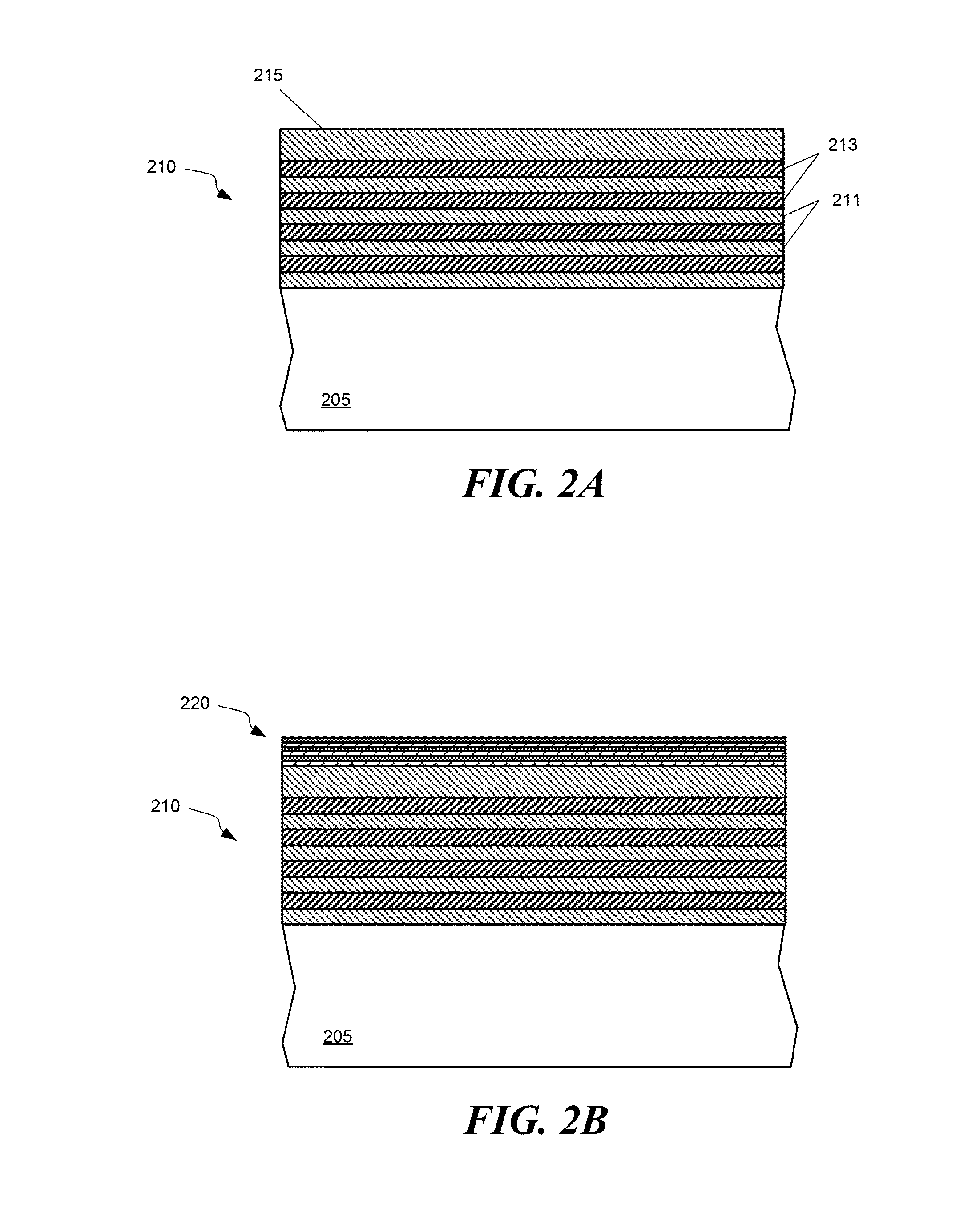

Lateral electrochemical etching of iii-nitride materials for microfabrication

ActiveUS20140003458A1High selectivityLaser detailsSolid-state devicesHigh volume manufacturingMicrofabrication

Conductivity-selective lateral etching of III-nitride materials is described. Methods and structures for making vertical cavity surface emitting lasers with distributed Bragg reflectors via electrochemical etching are described. Layer-selective, lateral electrochemical etching of multi-layer stacks is employed to form semiconductor / air DBR structures adjacent active multiple quantum well regions of the lasers. The electrochemical etching techniques are suitable for high-volume production of lasers and other III-nitride devices, such as lasers, HEMT transistors, power transistors, MEMs structures, and LEDs.

Owner:YALE UNIV

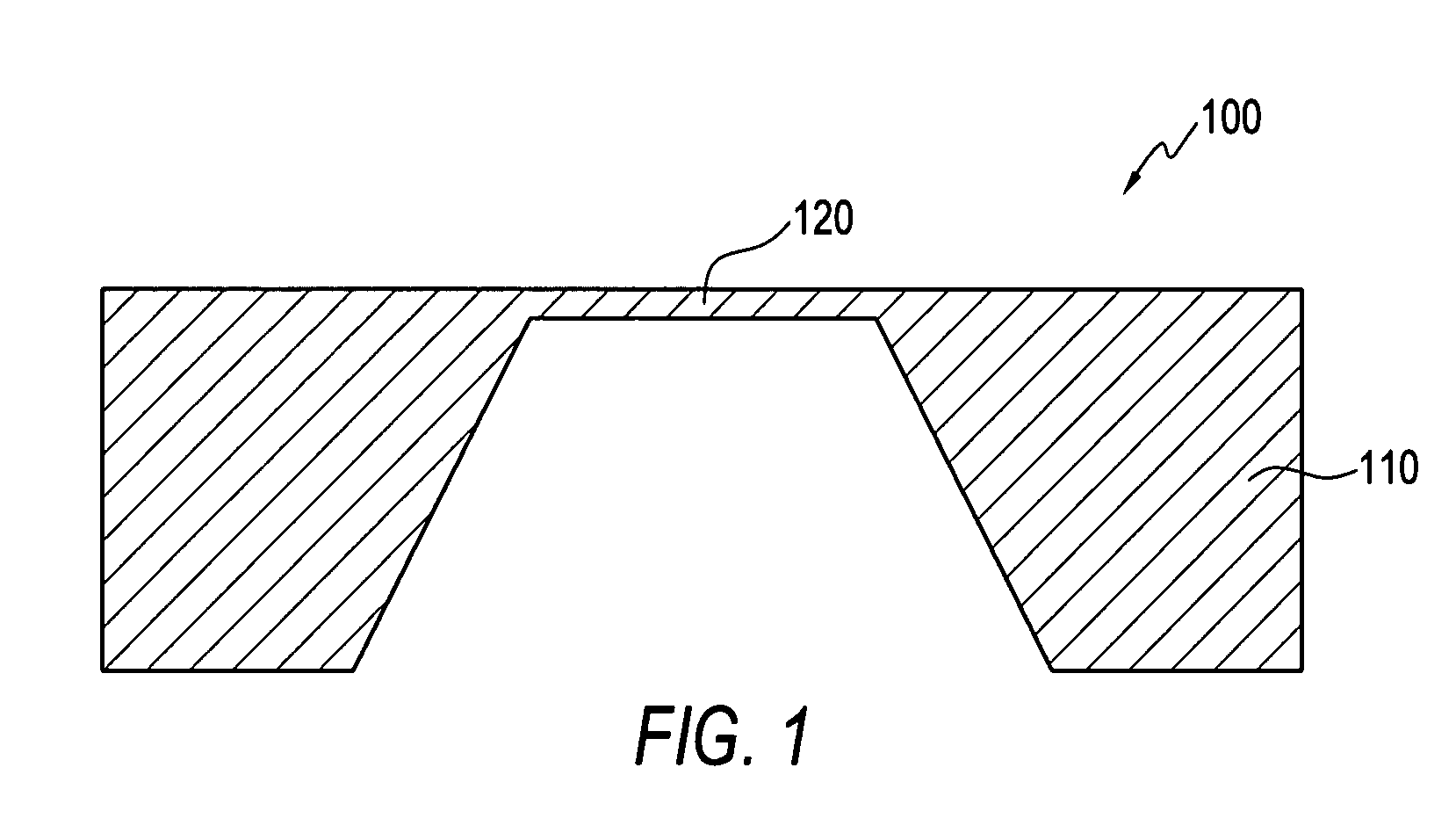

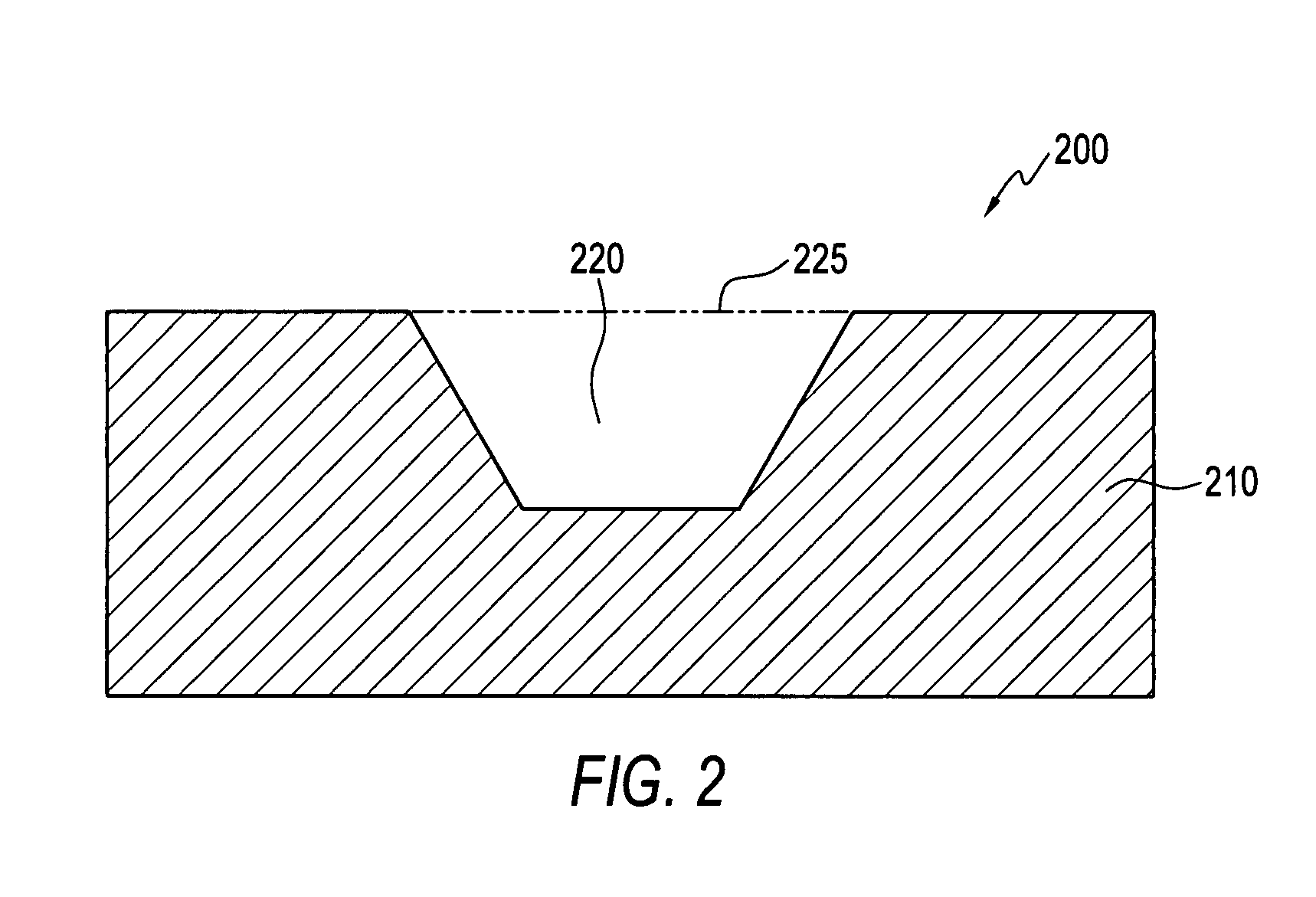

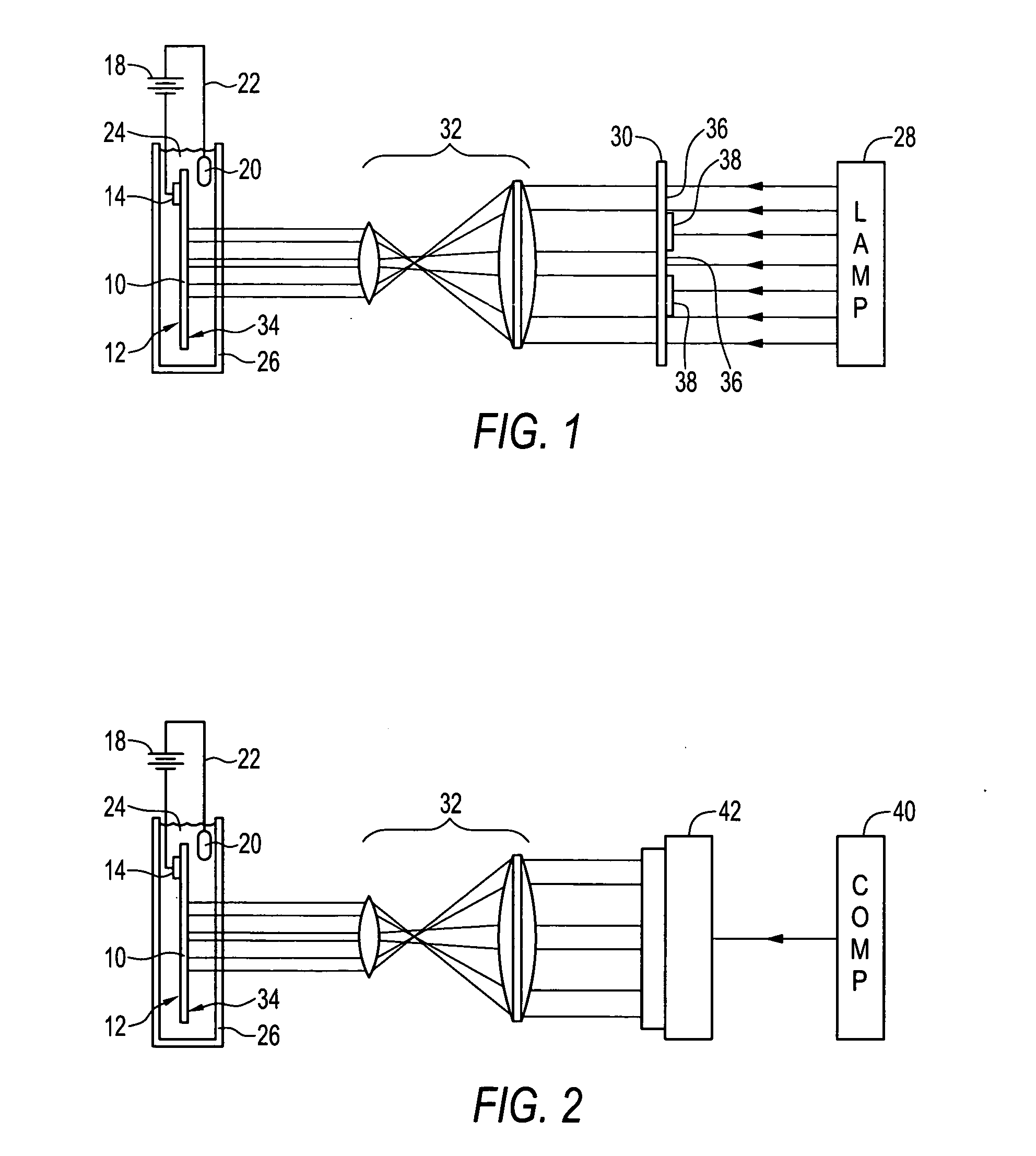

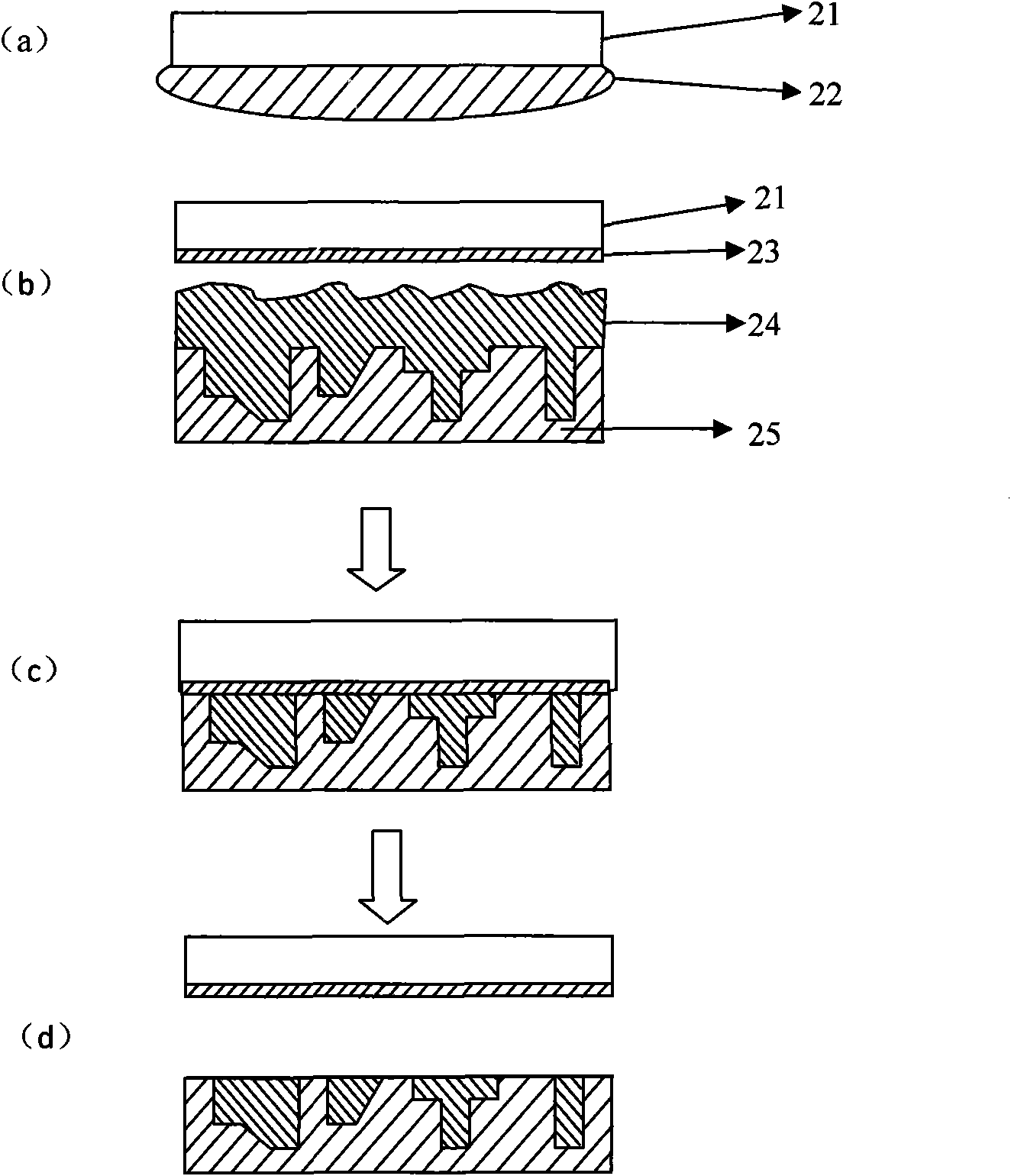

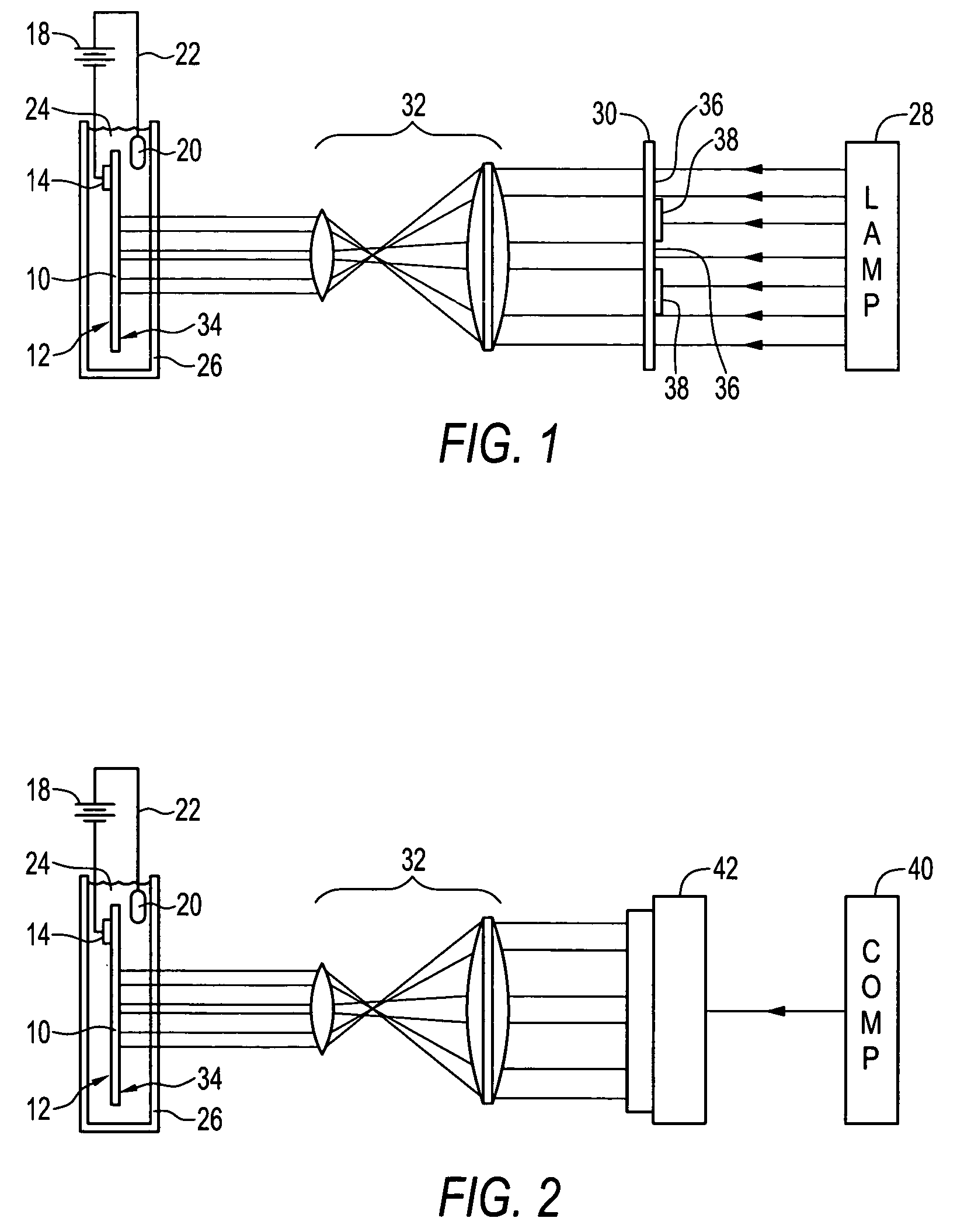

Direct patterning of silicon by photoelectrochemical etching

ActiveUS20050009374A1High resolutionComplex detailDecorative surface effectsAnalogue computers for chemical processesPhotoelectrochemical etchingSoft lithography

The invention is directed to methods for direct patterning of silicon. The invention provides the ability to fabricate complex surfaces in silicon with three dimensional features of high resolution and complex detail. The invention is suitable, for example, for use in soft lithography as embodiments of the invention can quickly create a master for use in soft lithography. In an embodiment of the invention, electrochemical etching of silicon, such as a silicon wafer, for example, is conducted while at least a portion of the silicon surface is exposed to an optical pattern. The etching creates porous silicon in the substrate, and removal of the porous silicon layer leaves a three-dimensional structure correlating to the optical pattern.

Owner:RGT UNIV OF CALIFORNIA

Shell and manufacturing method thereof

ActiveCN103582329AImprove bindingCasings/cabinets/drawers detailsDomestic articlesBinding forceNanopore

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

Compound of aluminum or aluminum alloy and plastics and manufacturing method thereof

InactiveCN102229266AImprove bindingReduce usageAnodisationSynthetic resin layered productsThermoplasticAlloy substrate

The invention provides a compound of aluminum or an aluminum alloy and plastics and a manufacturing method thereof. The compound comprises an aluminum or aluminum alloy substrate and a plastic piece which is combined with the aluminum or aluminum alloy substrate through injection molding, wherein the aluminum or aluminum alloy substrate is subjected to electrochemical etching, thus the surface of the aluminum or aluminum alloy substrate is etched from the surface to the inside to form a plurality of nano holes; and the plastic piece is made of crystalline thermoplastic plastics. The manufacturing method of the compound comprises the following steps: providing the aluminum or aluminum alloy substrate; carrying out electrochemical etching treatment on the aluminum or aluminum alloy substrate, thus the surface of the aluminum or aluminum alloy substrate is etched from the surface to the inside to form the plurality of nano holes; and placing the aluminum or aluminum alloy substrate subjected to electrochemical etching into an injection molding mould, and combining the injection molding piece on the surface of the aluminum or aluminum alloy substrate, thus the compound is obtained, wherein the molding piece is made of crystalline thermoplastic plastics.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

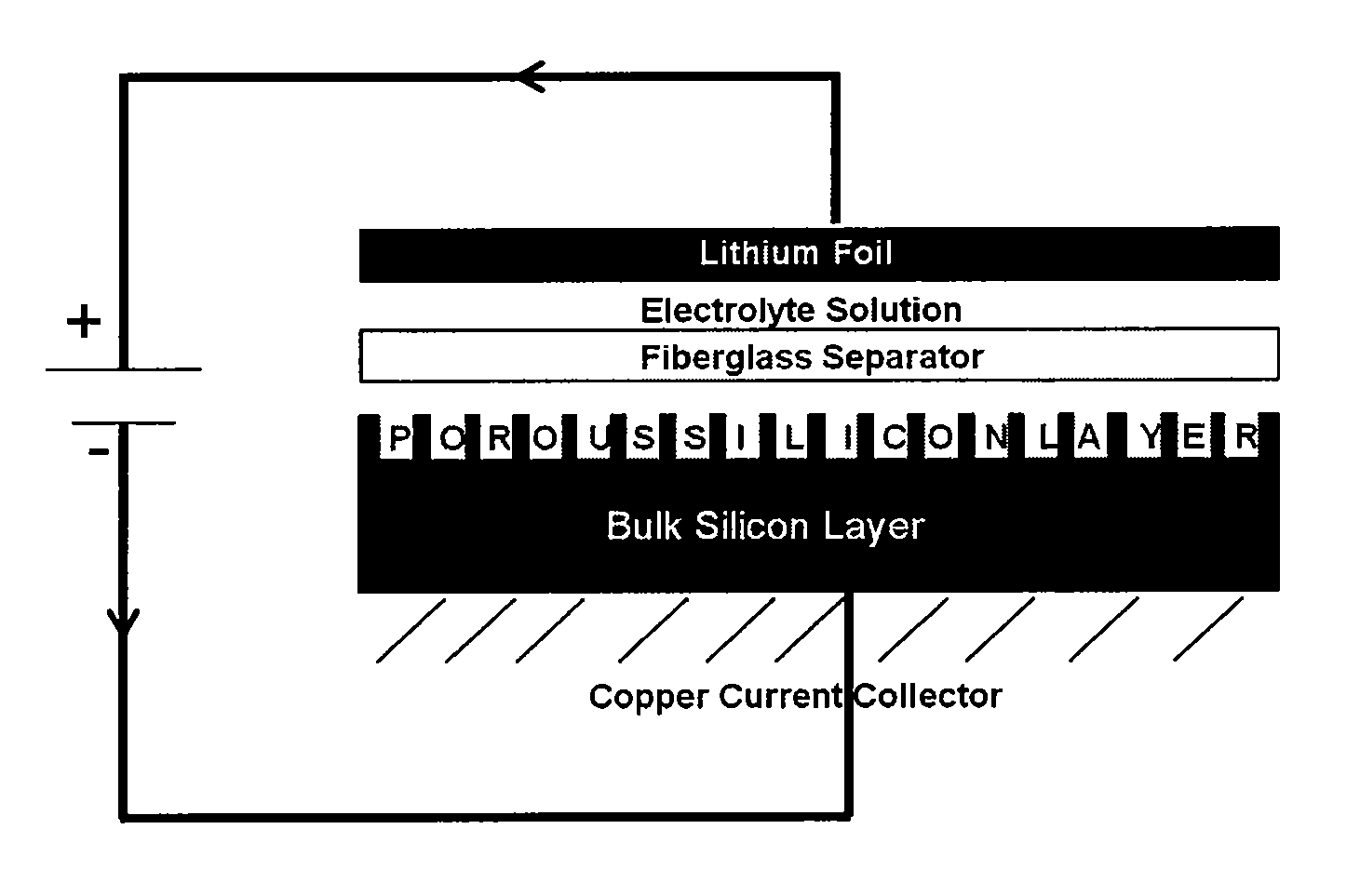

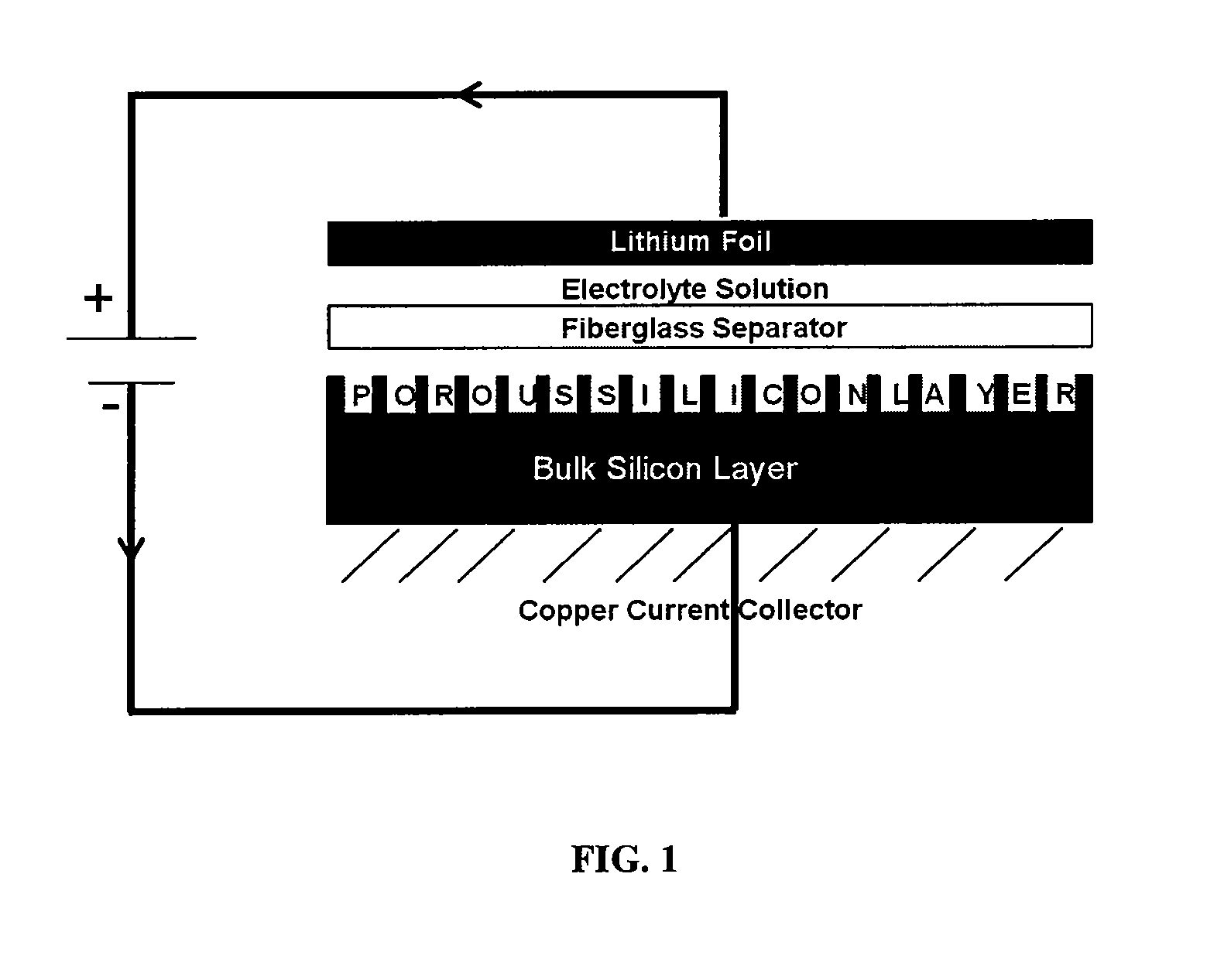

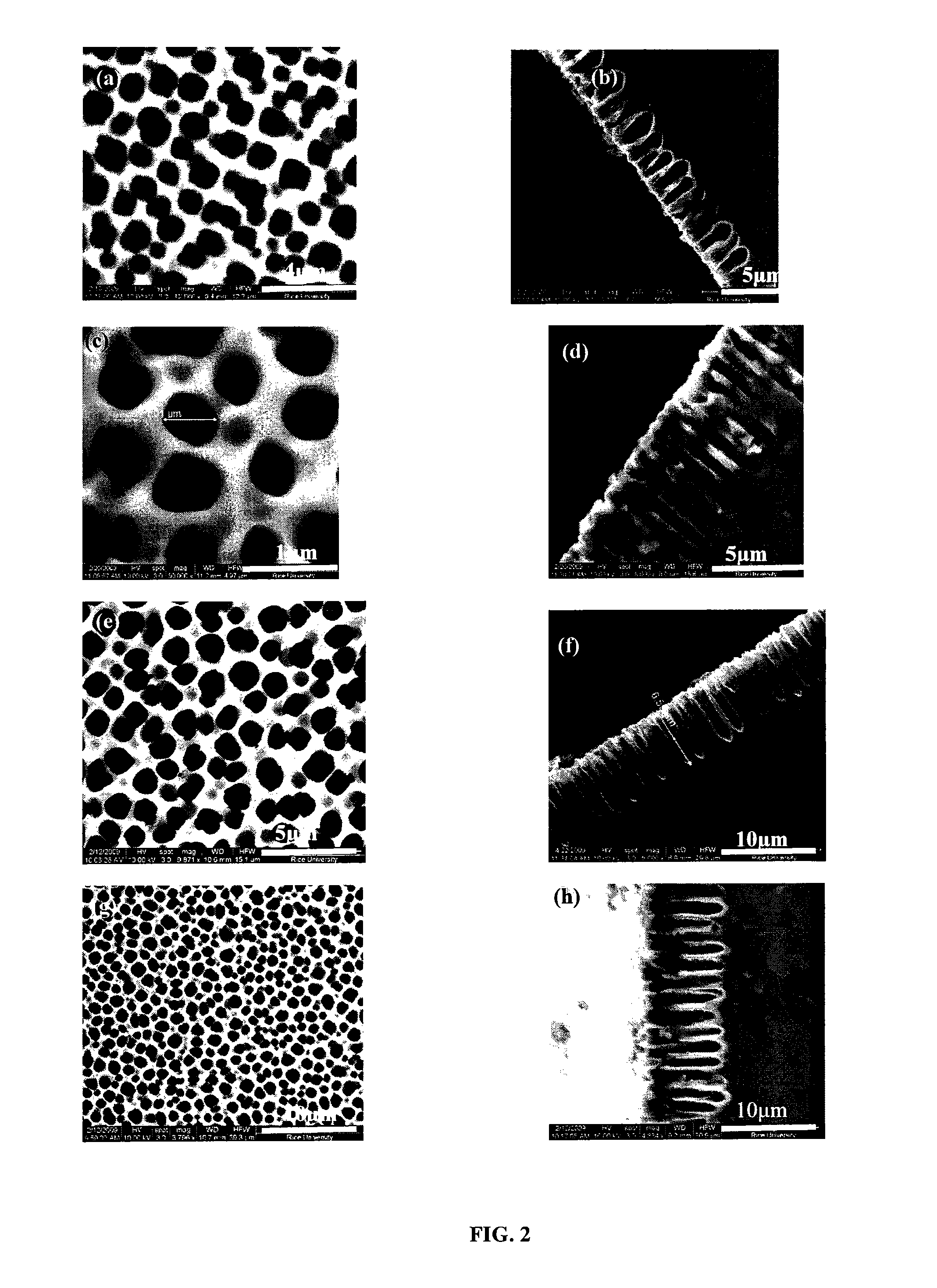

Structured silicon battery anodes

InactiveUS20120231326A1Large capacityLow costMaterial nanotechnologyElectrolysis componentsLithiumElectrochemistry

Methods of fabricating porous silicon by electrochemical etching and subsequent coating with a passivating agent process are provided. The coated porous silicon can be used to make anodes and batteries. It is capable of alloying with large amounts of lithium ions, has a capacity of at least 1000 mAh / g and retains this ability through at least 60 charge / discharge cycles. A particular pSi formulation provides very high capacity (3000 mAh / g) for at least 60 cycles, which is 80% of theoretical value of silicon. The Coulombic efficiency after the third cycle is between 95-99%. The very best capacity exceeds 3400 mAh / g and the very best cycle life exceeds 240 cycles, and the capacity and cycle life can be varied as needed for the application.

Owner:LOCKHEED MARTIN CORP +1

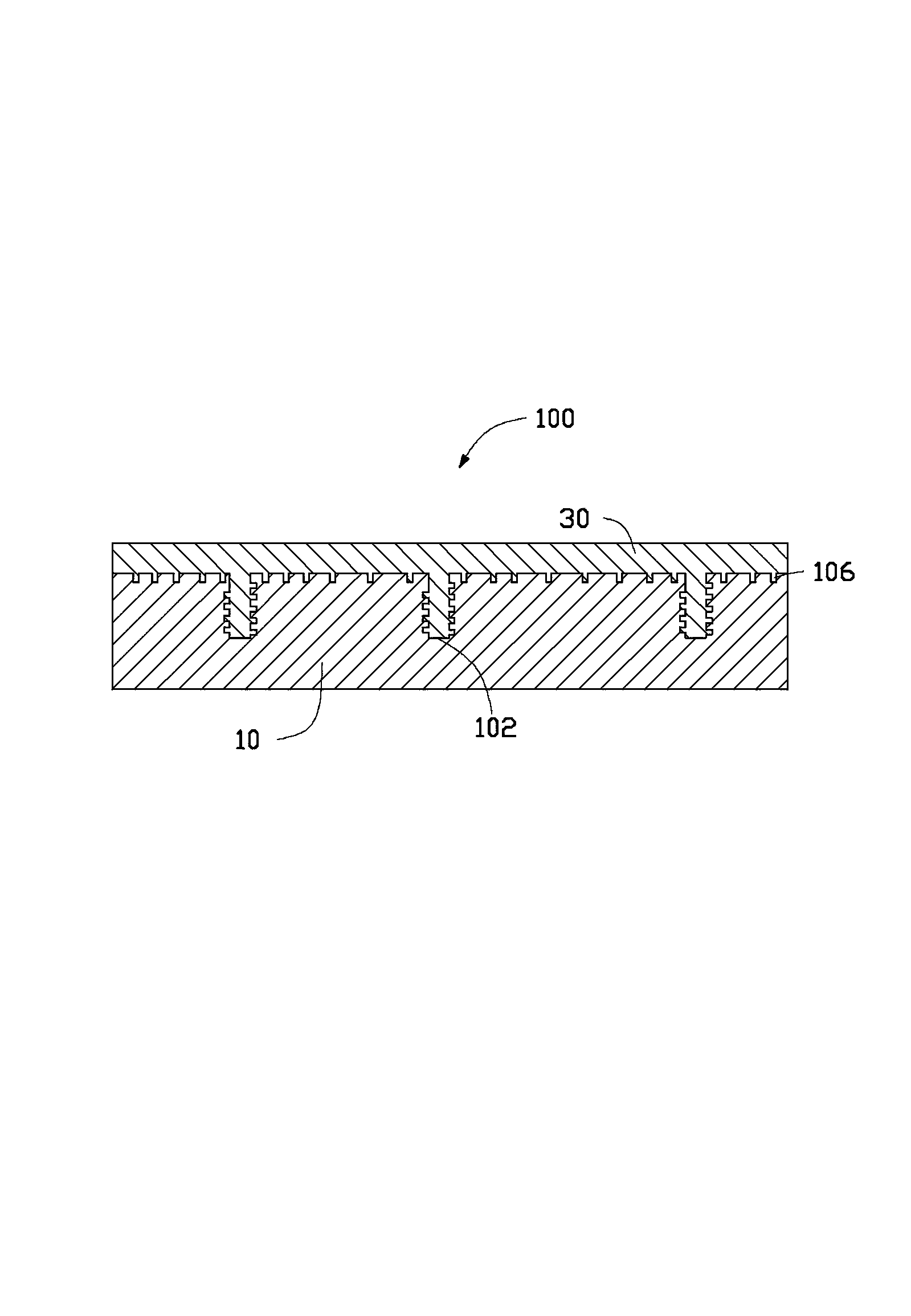

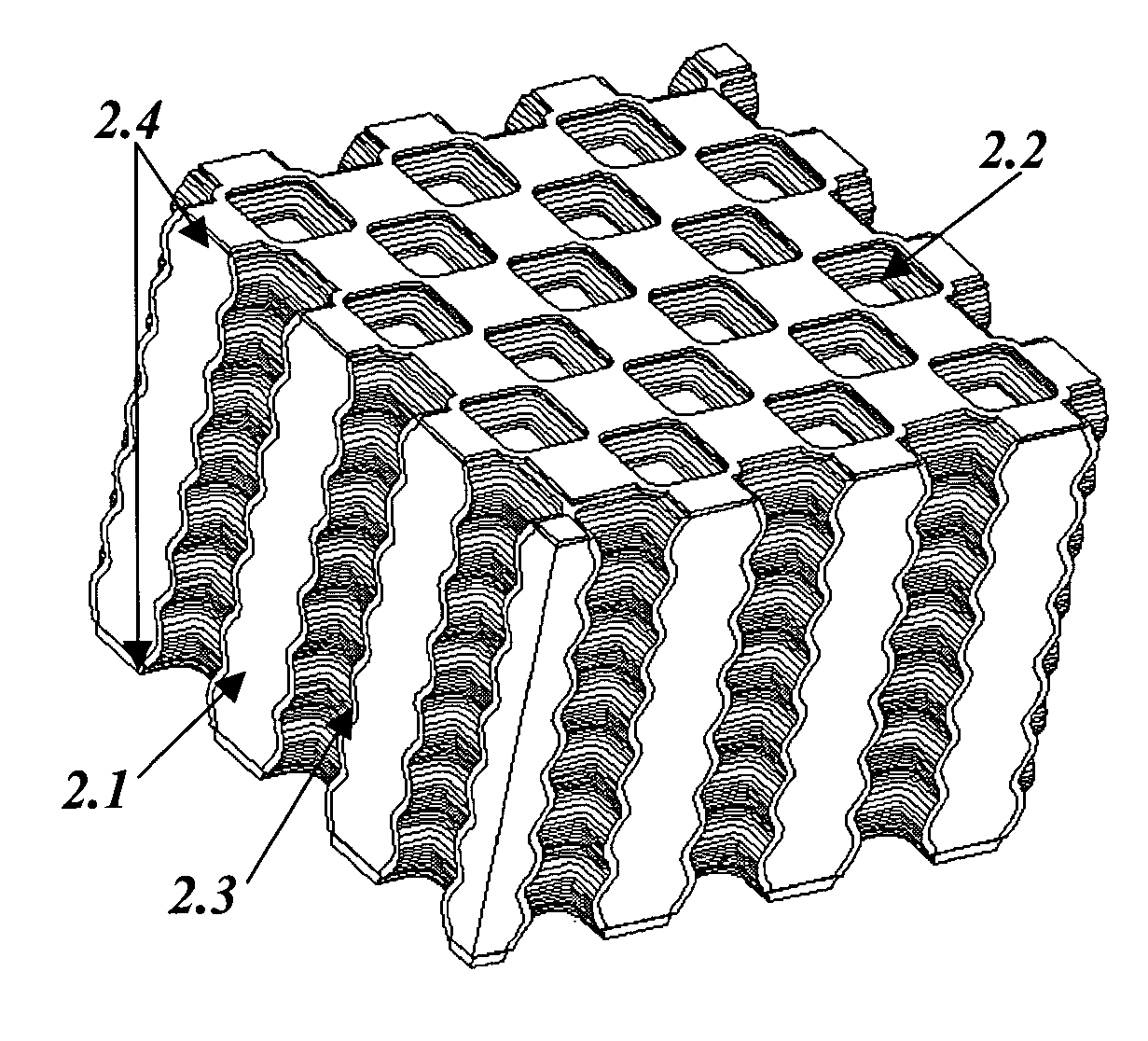

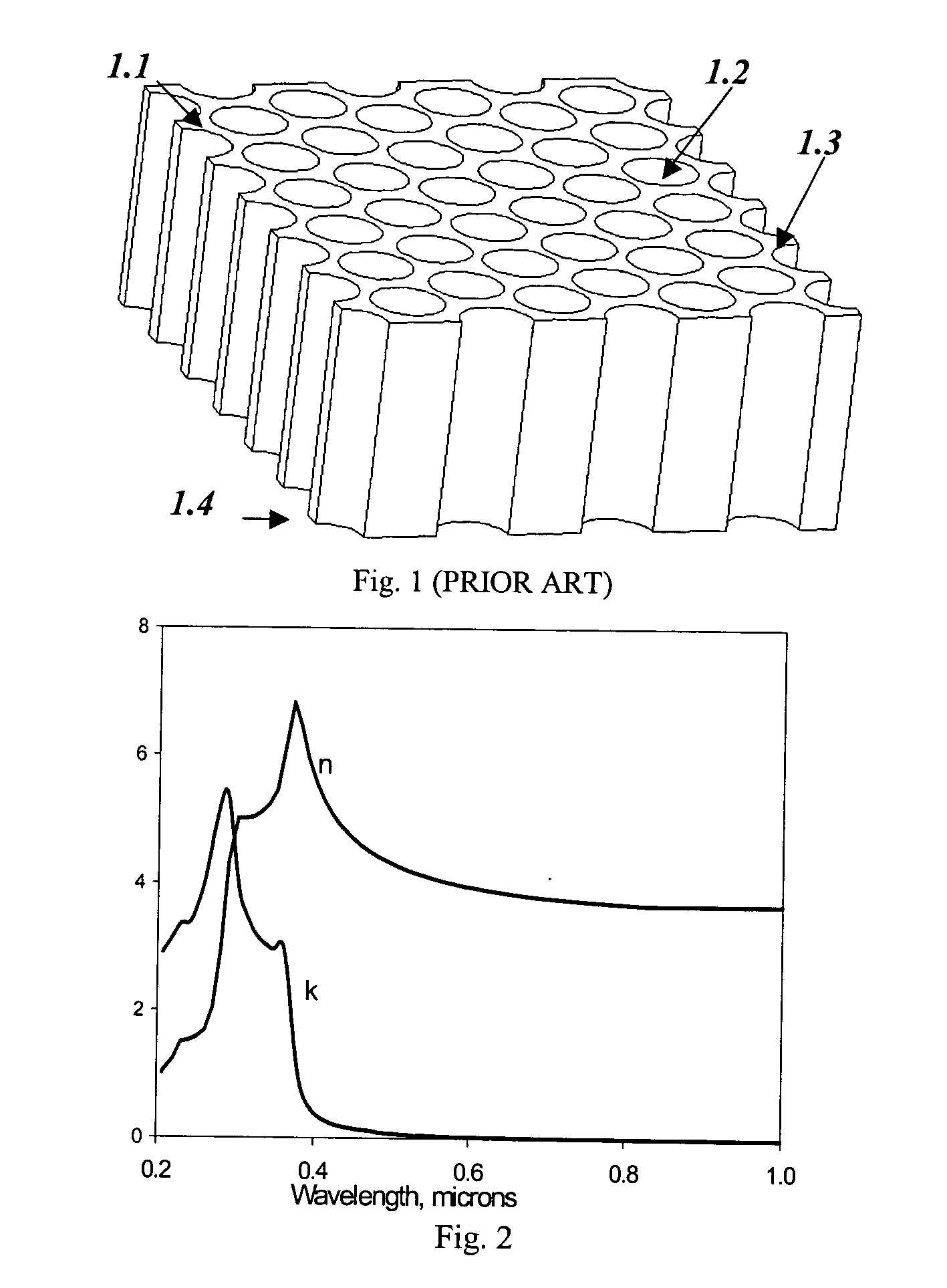

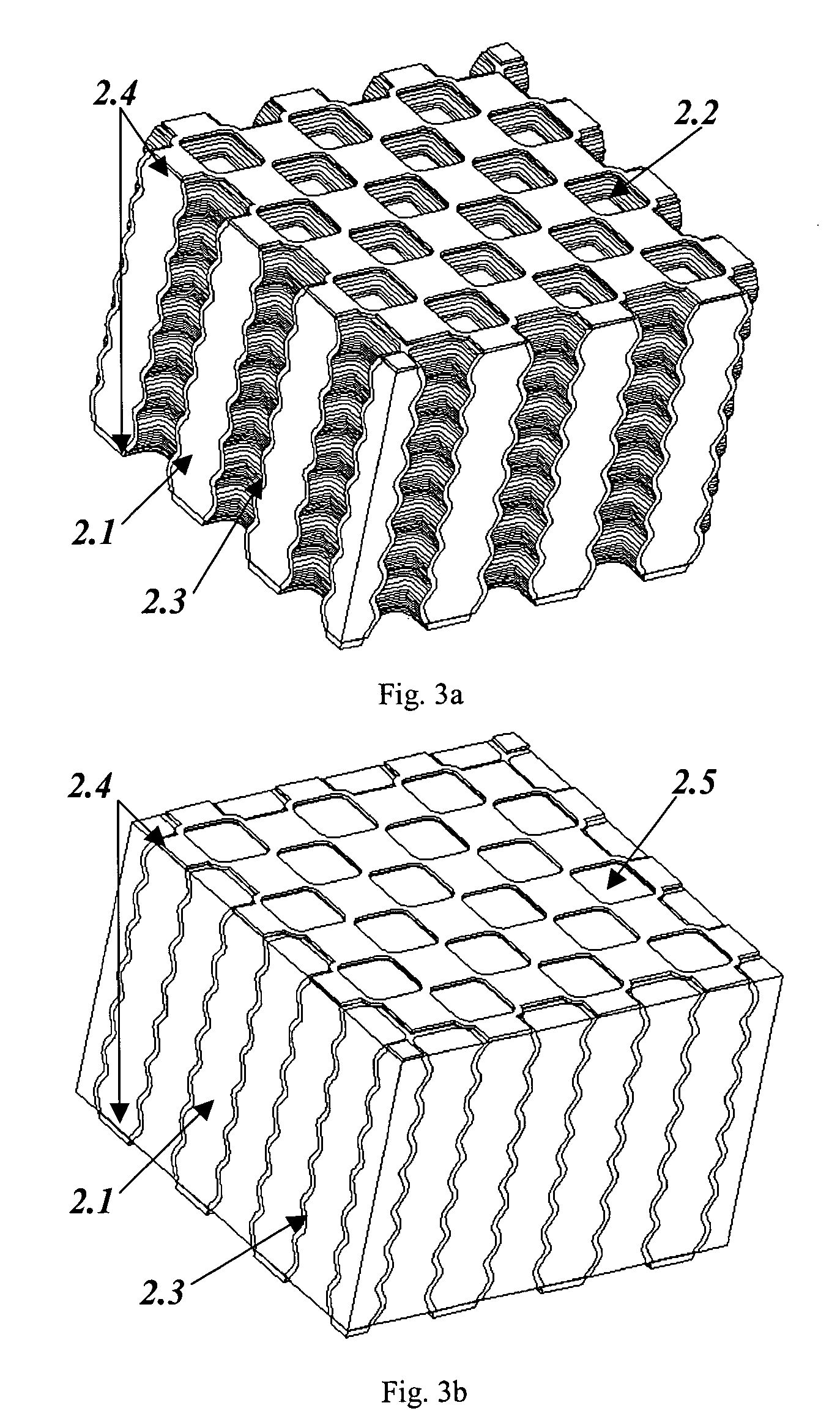

Method of manufacturing a spectral filter for green and longer wavelengths

InactiveUS20040134879A1Low level of lossIncrease the sectionElectrolysis componentsPaper/cardboard articlesBandpass filteringElectrochemistry

A method of manufacture for optical spectral filters with omnidirectional properties in the visible, near IR, mid IR and / or far IR (infrared) spectral ranges is based on the formation of large arrays of coherently modulated waveguides by electrochemical etching of a semiconductor wafer to form a pore array. Further processing of said porous semiconductor wafer optimizes the filtering properties of such a material. The method of filter manufacturing is large scale compatible and economically favorable. The resulting exemplary non-limiting illustrative filters are stable, do not degrade over time, do not exhibit material delamination problems and offer superior transmittance for use as bandpass, band blocking and narrow-bandpass filters. Such filters are useful for a wide variety of applications including but not limited to spectroscopy, optical communications, astronomy and sensing.

Owner:LAKE SHORE CRYOTRONICS INC

Preparation method for superamphiphobic surface of aluminum and alloy thereof

InactiveCN103290418AEasy to prepareMild process conditionsLiquid/solution decomposition chemical coatingMicro nanoMicron scale

The present invention relates to a preparation method for a superamphiphobic surface of aluminum and an alloy thereof. According to the present invention, a two-step method is adopted to prepare a superhydrophobic surface, and a low surface energy material is adopted to modify the hydrophobic surface, wherein an electrochemical etching method is adopted to prepare an aluminum micron-scale rough surface, then a hydrothermal synthesis method is adopted to synthesize a zinc oxide micro-nano double rough structure, and the prepared superhydrophobic surface provides a contact angle of more than 156 DEG for water, and provides an oleophobic angle of more than 150 DEG C for lubricating oil; and the method has the following characteristics that: simpleness and practicality are provided, equipment requirements are low, the used electrochemical etching technology and the used hydrothermal synthesis technology are mature, the large-area superamphiphobic surface is easily prepared, and industrial manufacturing is easily achieved.

Owner:HARBIN INST OF TECH

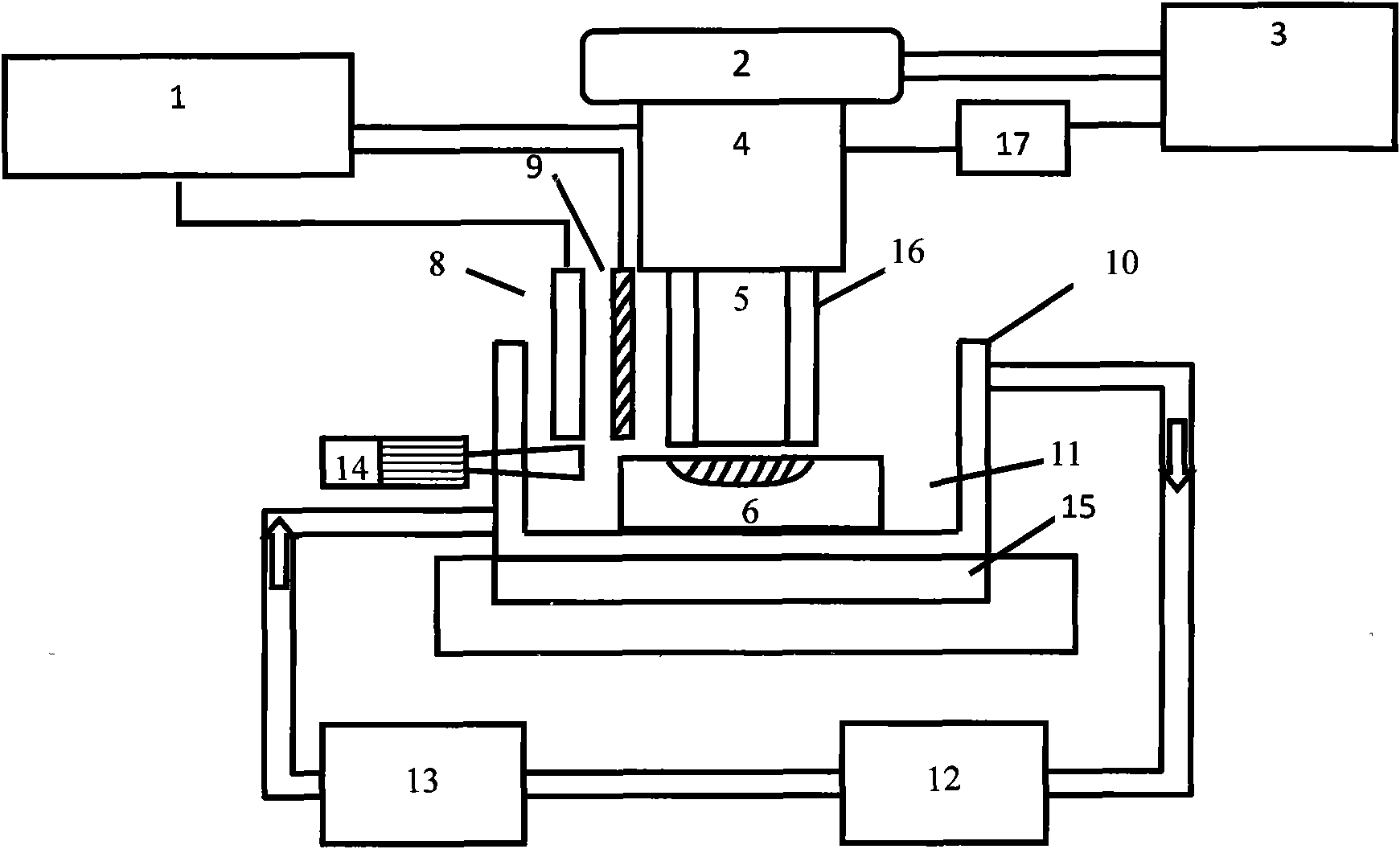

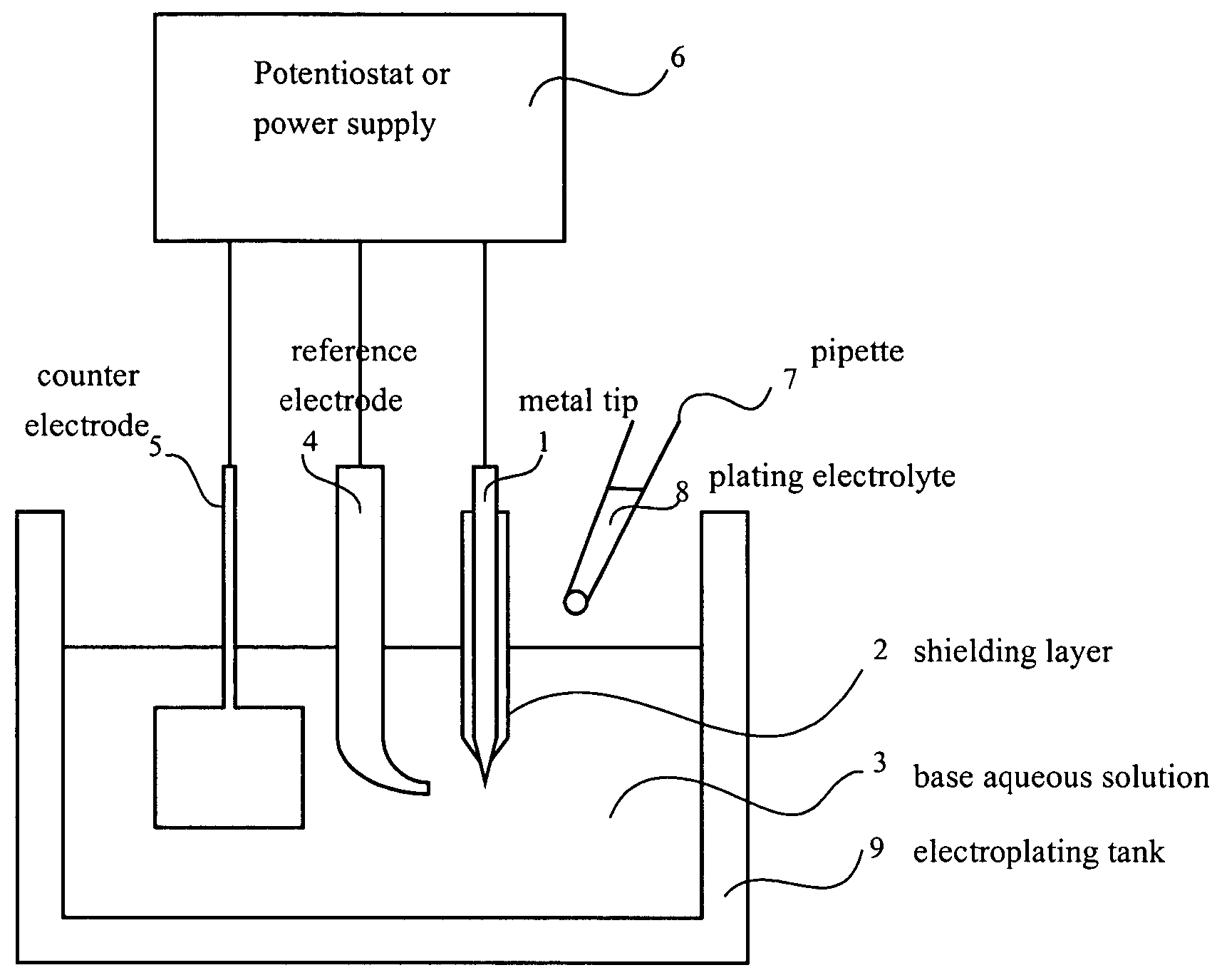

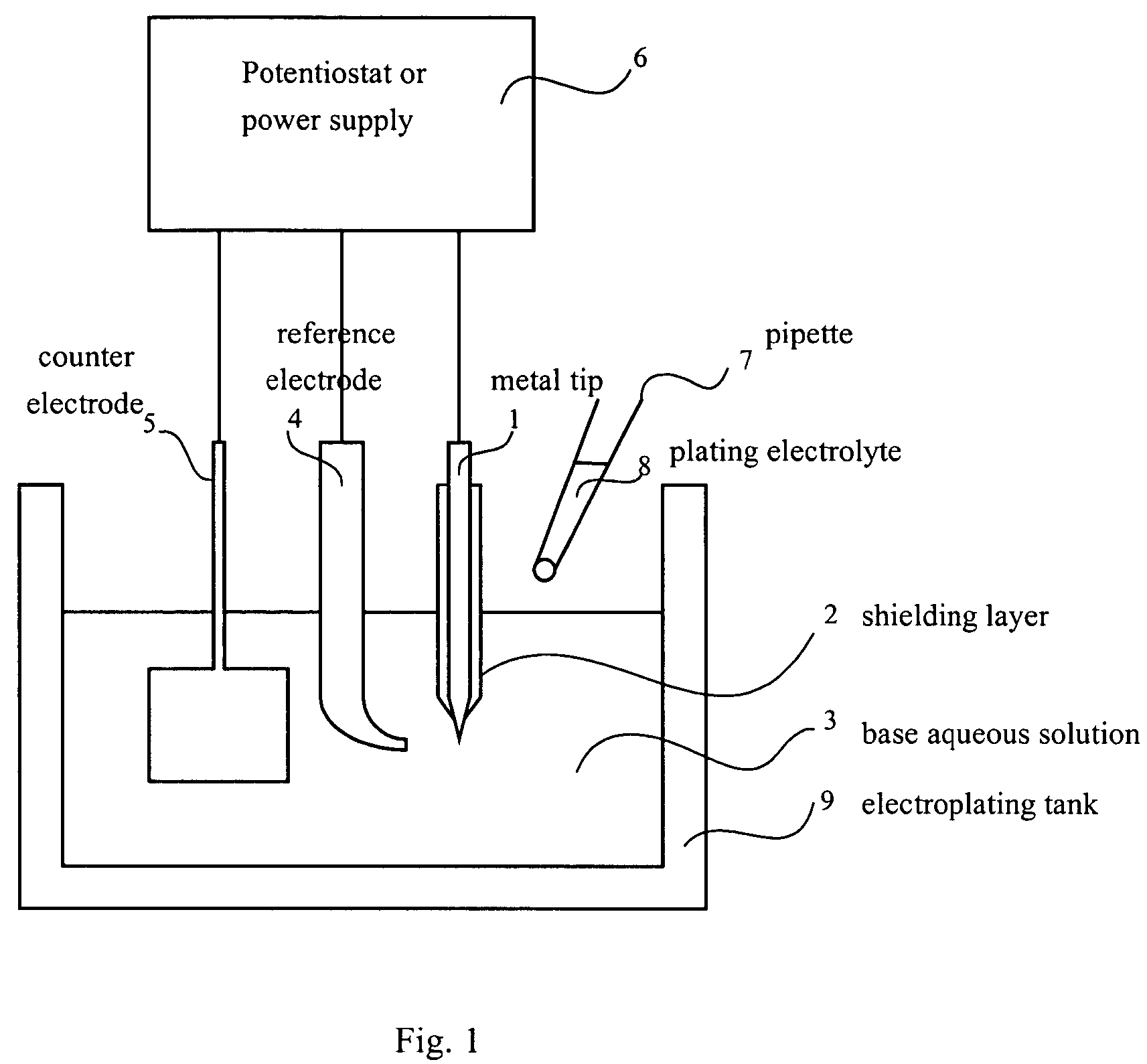

Electrochemical levelling and polishing processing method with nanometer precision and device thereof

ActiveCN101880907ANo mechanical damageNo pollution problemElectrolysis componentsSemiconductor/solid-state device manufacturingElectrochemical responseLiquid layer

The invention provides an electrochemical levelling and polishing processing method with nanometer precision and a device thereof, relating to an electrochemical etching levelling and polishing technology. The device is provided with a cutter with nanometer levelling precision, an electrochemical reaction control system capable of accurately controlling the thickness of an etching levelling agent liquid layer in nanoscale, a solution circulating device, a solution thermostat and an automatic control system. The method is implemented by the following steps: preparing the cutter with nanometer levelling precision to serve as an electrochemical working electrode, and placing the cutter at the bottom of a container together with a workpiece; immersing the cutter in a solution, starting an electrochemical system, generating the etching levelling agent on the surface of the cutter, compressing the etching levelling agent liquid layer on the cutter surface into a nanoscale thickness, and regulating and controlling the thickness of the etching levelling agent liquid layer; driving a tri-dimensional micro-drive device, leading the cutter to approach the workpiece gradually, and regulating and controlling the distance and parallelism between the workpiece surface and the cutter; and leading the cutter to move toward the workpiece surface, and enabling the constraint etching levelling agent liquid layer on the cuter surface to contact with the workpiece surface until the whole workpiece is etched, leveled and polished.

Owner:XIAMEN UNIV

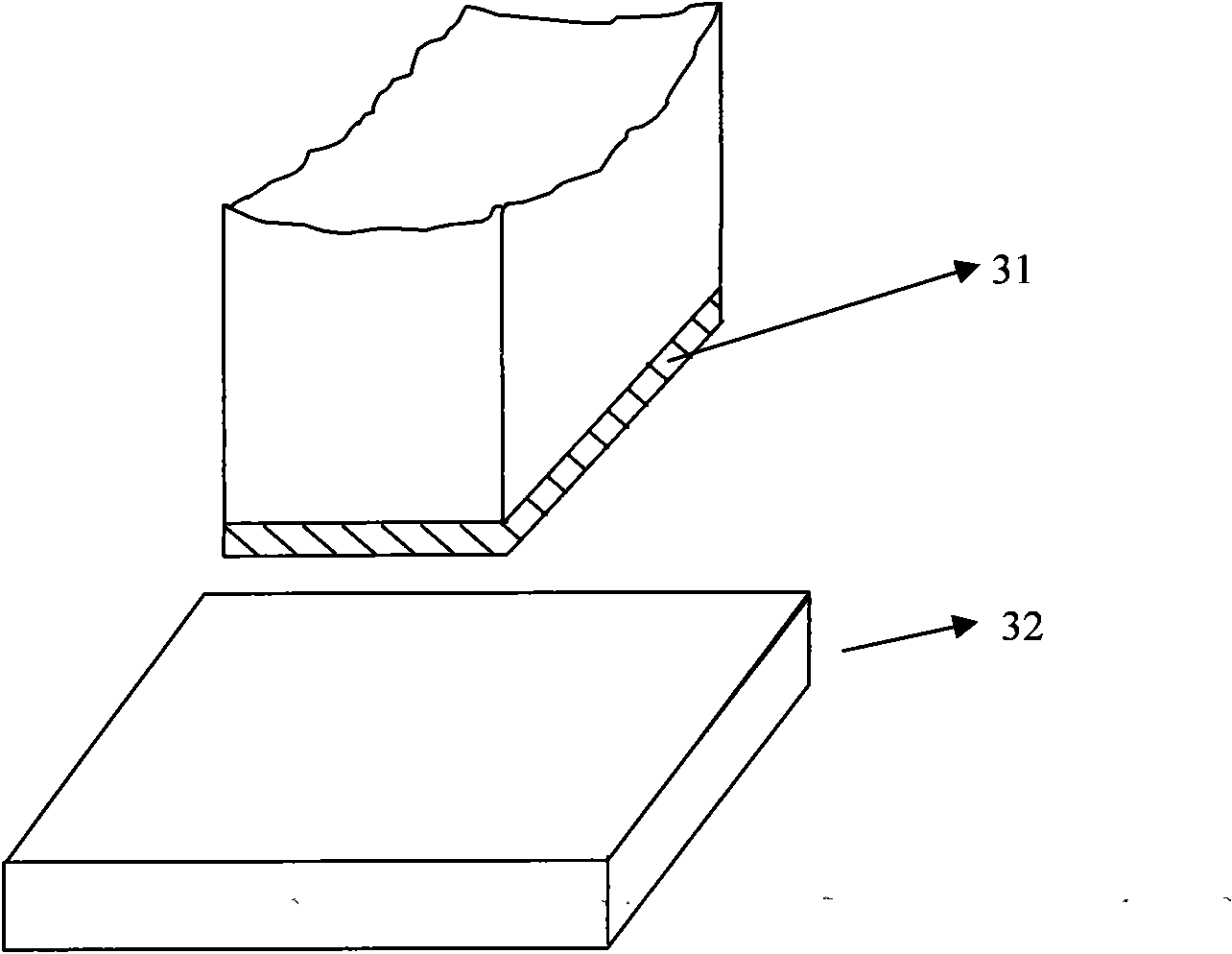

Single-atom tip and preparation method thereof

ActiveUS7507320B2Simple methodElectrolysis componentsWave amplification devicesSingle crystalElectrochemistry

Owner:ACAD SINIC

In-situ oxidized textured surfaces for prosthetic devices and method of making same

A textured surface and oxidation layer coating on a metallic material is accomplished through the chemical and / or electrochemical etching of the surface to modify the surface texture and an in-situ oxidation procedure. The surface is useful for the fabrication of prosthetic devices, particularly medical implants, due to the corrosion and wear resistance imparted by the oxidation layer and the ability to enhance grafting of the implant onto bone imparted by the surface texture.

Owner:SMITH & NEPHEW INC

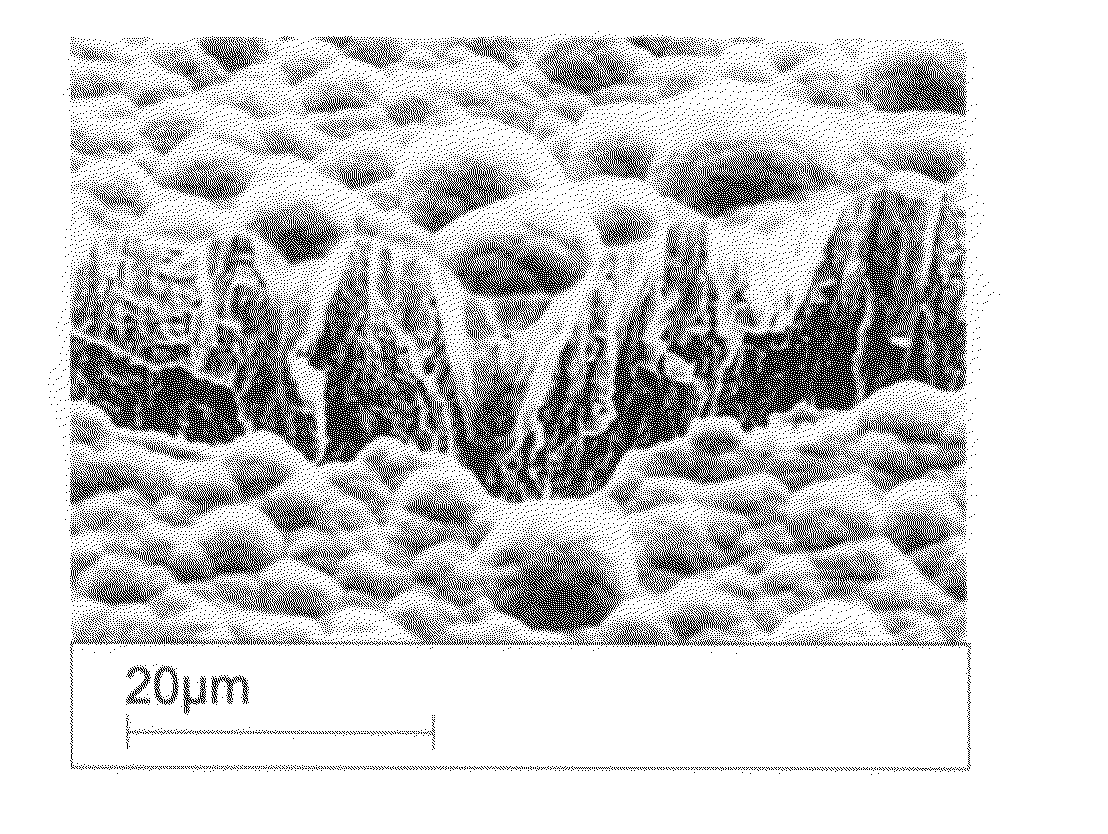

Methods for tailoring the surface topography of a nanocrystalline or amorphous metal or alloy and articles formed by such methods

InactiveUS20100282613A1Reducing width and depthHigh depositionElectrolysis componentsSemiconductor/solid-state device manufacturingNumber densityTopography

Electrochemical etching tailors topography of a nanocrystalline or amorphous metal or alloy, which may be produced by any method including, by electrochemical deposition. Common etching methods can be used. Topography can be controlled by varying parameters that produce the item or the etching parameters or both. The nanocrystalline article has a surface comprising at least two elements, at least one of which is metal, and one of which is more electrochemically active than the others. The active element has a definite spatial distribution in the workpiece, which bears a predecessor spatial relationship to the specified topography. Etching removes a portion of the active element preferentially, to achieve the specified topography. Control is possible regarding: roughness, color, particularly along a spectrum from silver through grey to black, reflectivity and the presence, distribution and number density of pits and channels, as well as their depth, width, size. Processing parameters that have been correlated in the Ni—W system to topography features include, for both the deposition phase and the etching phase of a nanocrystalline surface: duty cycle, current density, deposition duration, plating chemistry, polarity ratio. The relative influence of the processing parameters can be noted and correlated to establish a relationship between values for processing parameters and degree of topography feature. Control can be established over the topography features. Correlation can be made for any such system that exhibits a definite spatial distribution of an active element that bears a predecessor spatial relationship to a desired topography feature.

Owner:MASSACHUSETTS INST OF TECH

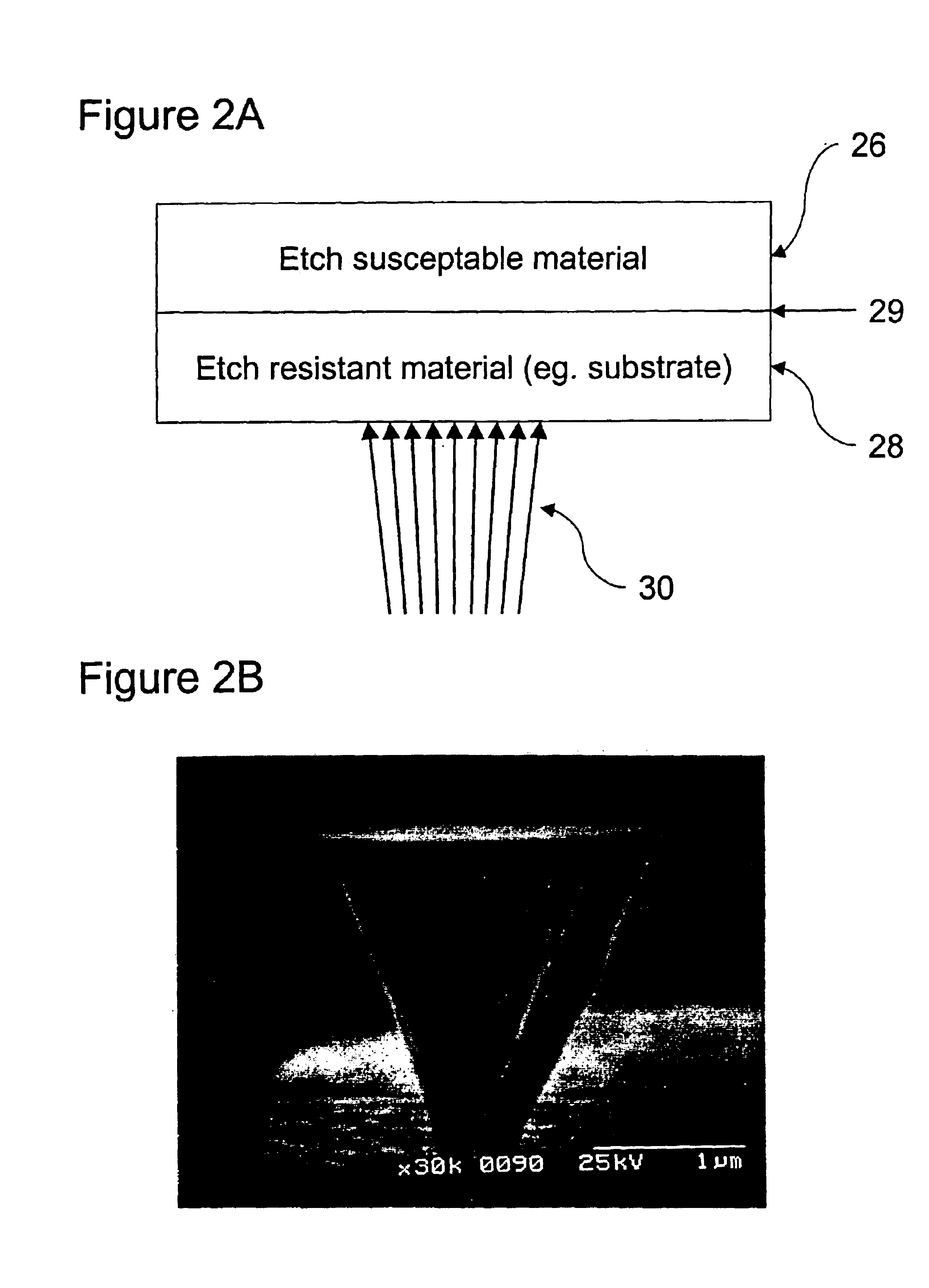

Photoelectrochemical undercut etching of semiconductor material

InactiveUS6884740B2Strong undercutKeep energy smallDecorative surface effectsSemiconductor/solid-state device manufacturingPreferential etchingSemiconductor materials

Photoelectrochemical (PEC) etching is restricted to a group III nitride semiconductor-barrier interface to laterally etch or undercut the target group III nitride. The barrier interface is provided by the transparent sapphire substrate on which the target group III nitride is epitaxially grown or by a layer of material in intimate contact with the target group III nitride material and having a bandgap sufficiently high to make it resistant to PEC etching. Due to the first orientation in which this effect was first observed, it has been named backside-Illuminated photoelectrochemical (BIPEC) etching. It refers to a preferential etching at the semiconductor-barrier layer interface. The assembly can be exposed to light from any direction to effectuate bandgap-selective PEC etching. An opaque mask can be applied to limit the lateral extent of the photoelectrochemical etching.

Owner:RGT UNIV OF CALIFORNIA

Metallic implants

InactiveUS20090204213A1Pharmaceutical delivery mechanismJoint implantsBiocompatibilityElectrochemistry

Disclosed is a method of preparing a medical implant. The biocompatible metal surface of the implant is subjected to electrochemical etching in an electrolyte solution to which a current has been applied.

Owner:DEPUY SYNTHES PROD INC

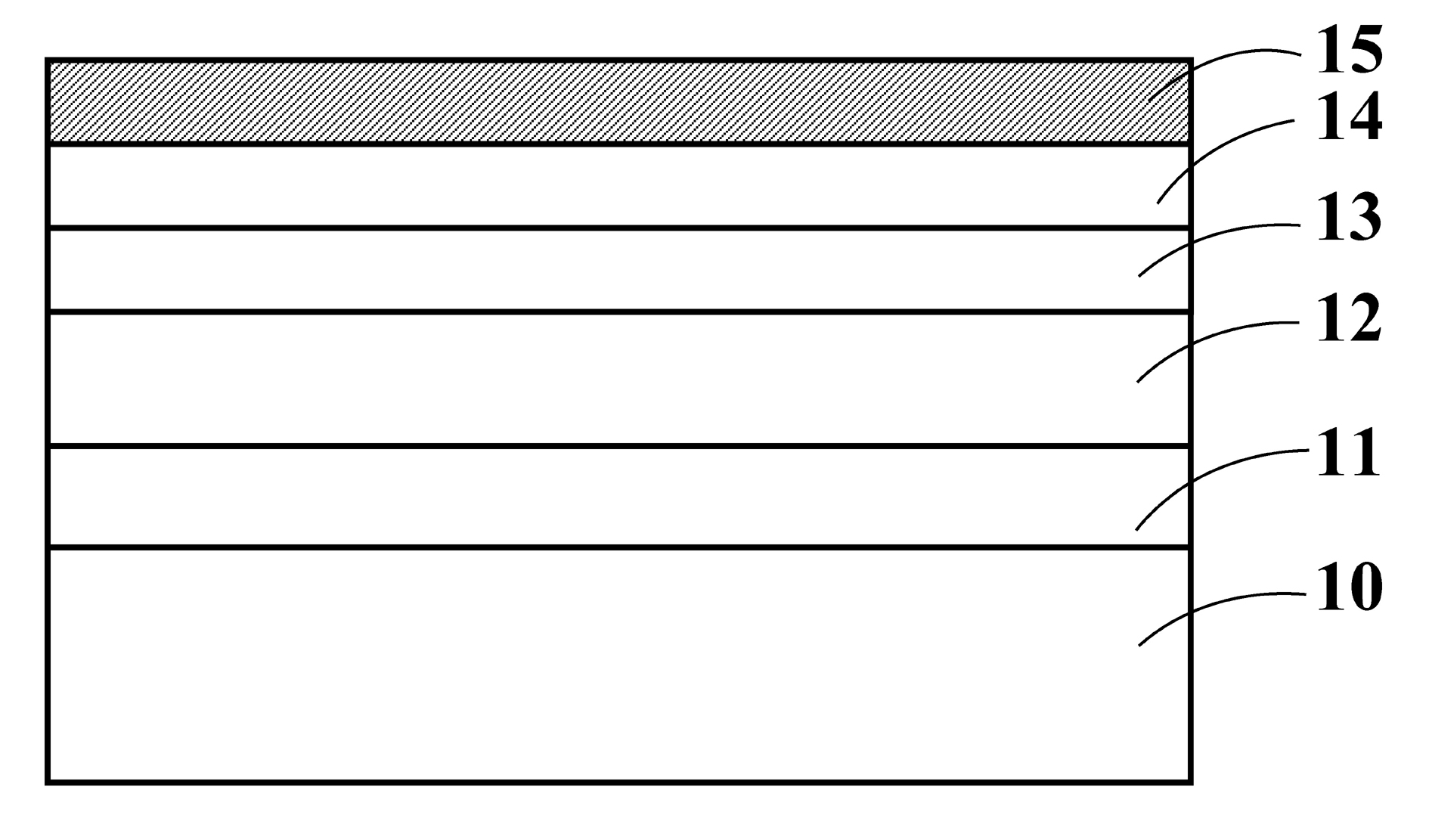

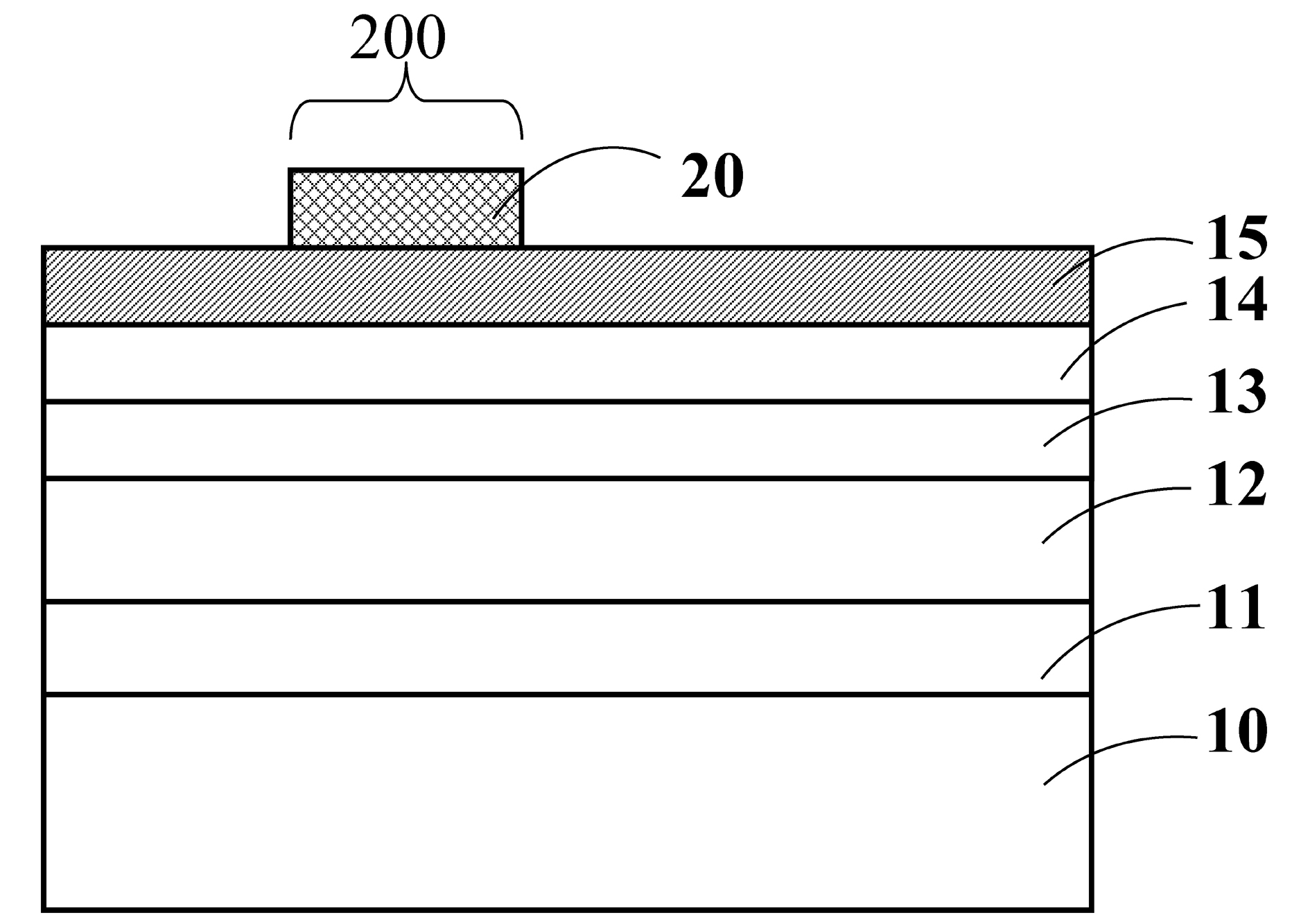

Method for manufacturing gallium nitride-based light-emitting diode with current barrier layer

ActiveCN101969089AHas a current blocking effectAvoid damageSemiconductor devicesGallium nitrideLight-emitting diode

The invention discloses a method for manufacturing a gallium nitride-based light-emitting diode with a current barrier layer. The method comprises the following steps of: constituting a gallium nitride-based luminous epitaxial layer by using an n-type gallium nitride-based epitaxial layer, an active layer, a p-type gallium nitride-based epitaxial layer and an undoped gallium nitride-based epitaxial layer from top to bottom in turn on a sapphire substrate; defining a current blocking area on the gallium nitride-based luminous epitaxial layer and coating a metal layer serving as a mask on the undoped gallium nitride-based epitaxial layer of the current blocking area so as to cover the entire current blocking area; removing the undoped gallium nitride-based epitaxial layer outside the current blocking area by electrochemical etching; removing the metal layer serving as the mask; manufacturing a transparent conductive layer on the p-type gallium nitride-based epitaxial layer and the undoped gallium nitride-based epitaxial layer; and manufacturing a p electrode on the transparent conductive layer in the current blocking area. The current barrier layer is defined selectively by the electrochemical etching, so that the problems of damage and passivation caused by dry etching are solved and an undoped epitaxial layer-based gallium nitride-based light-emitting diode with current blocking effect is obtained.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

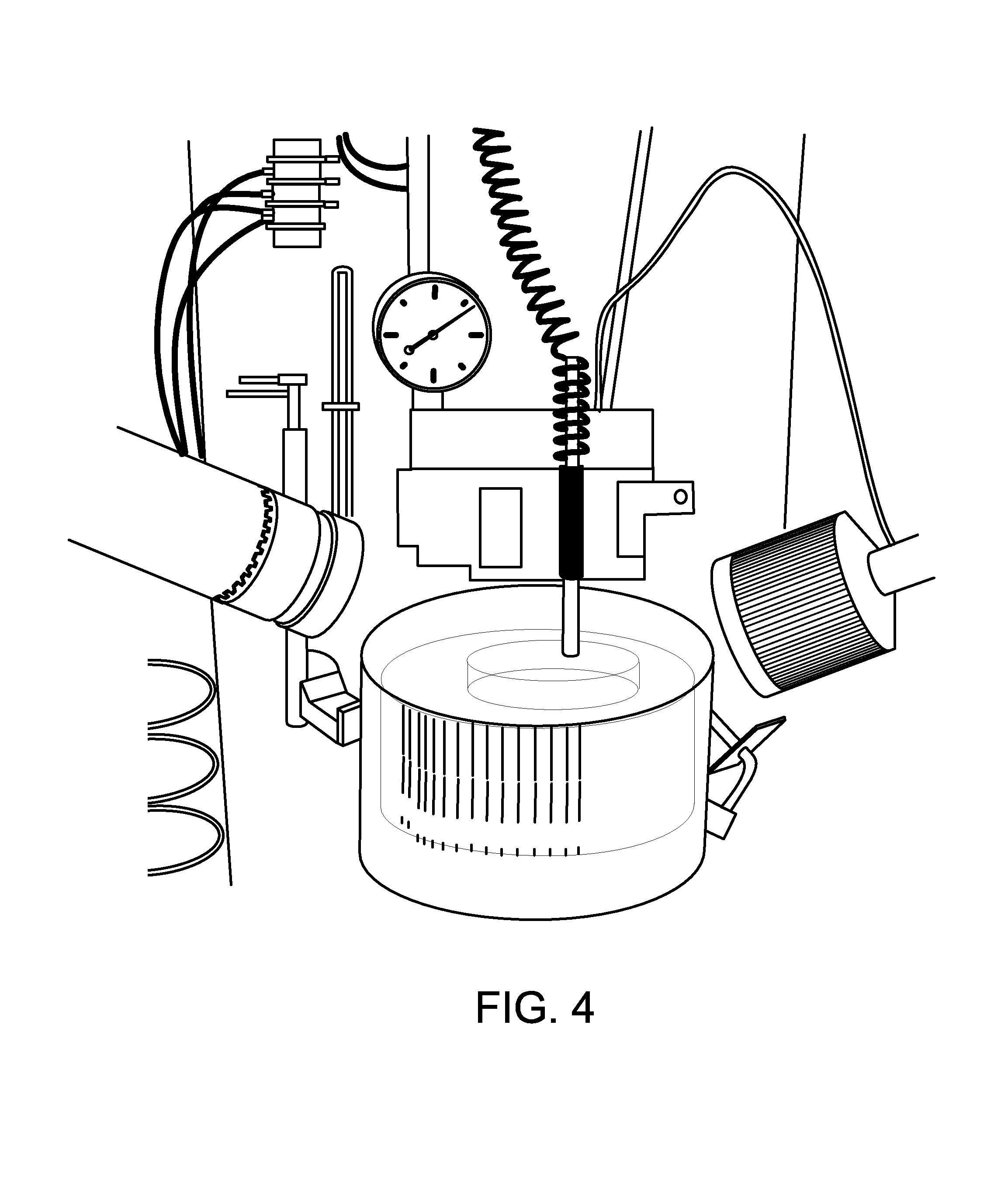

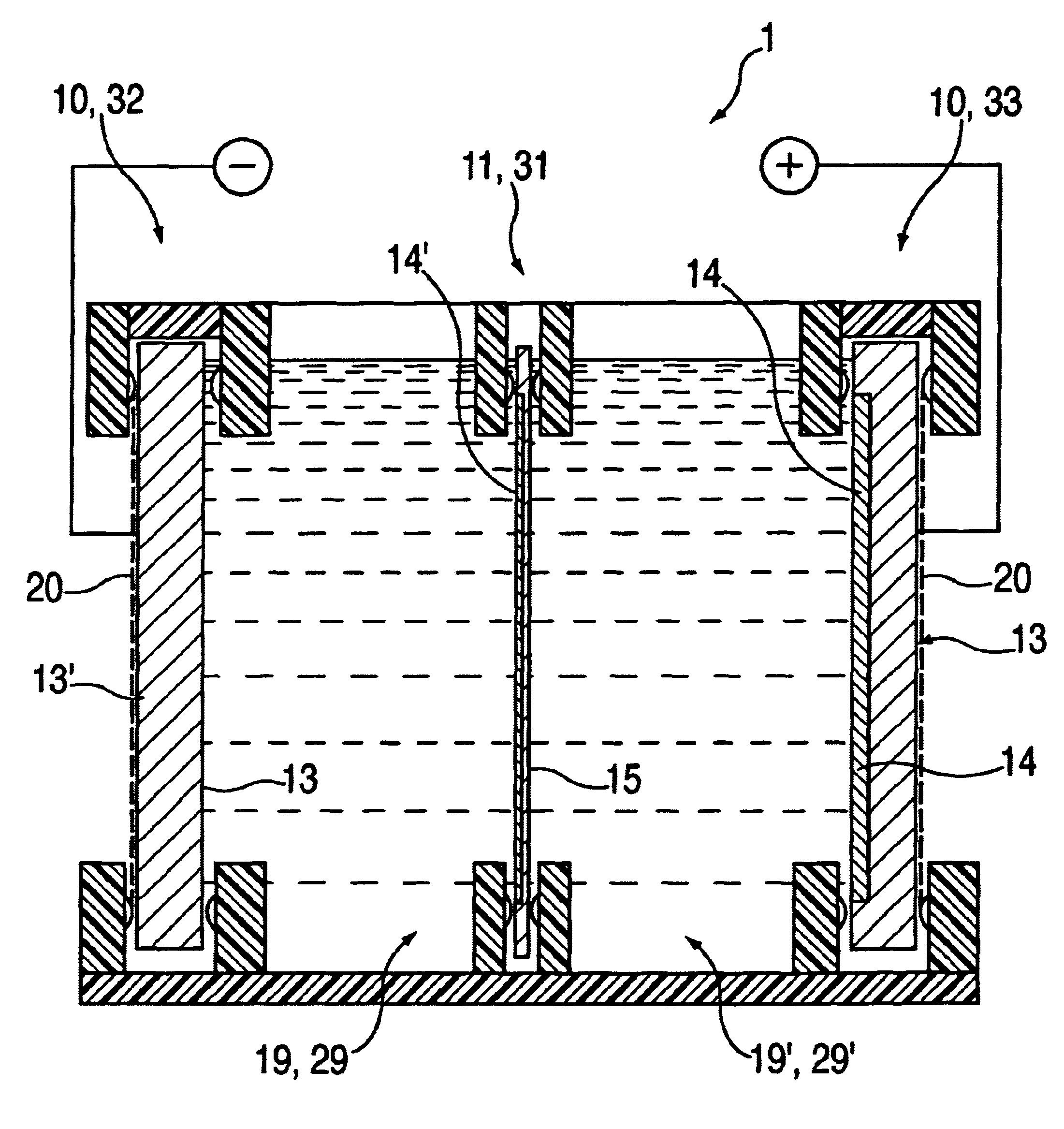

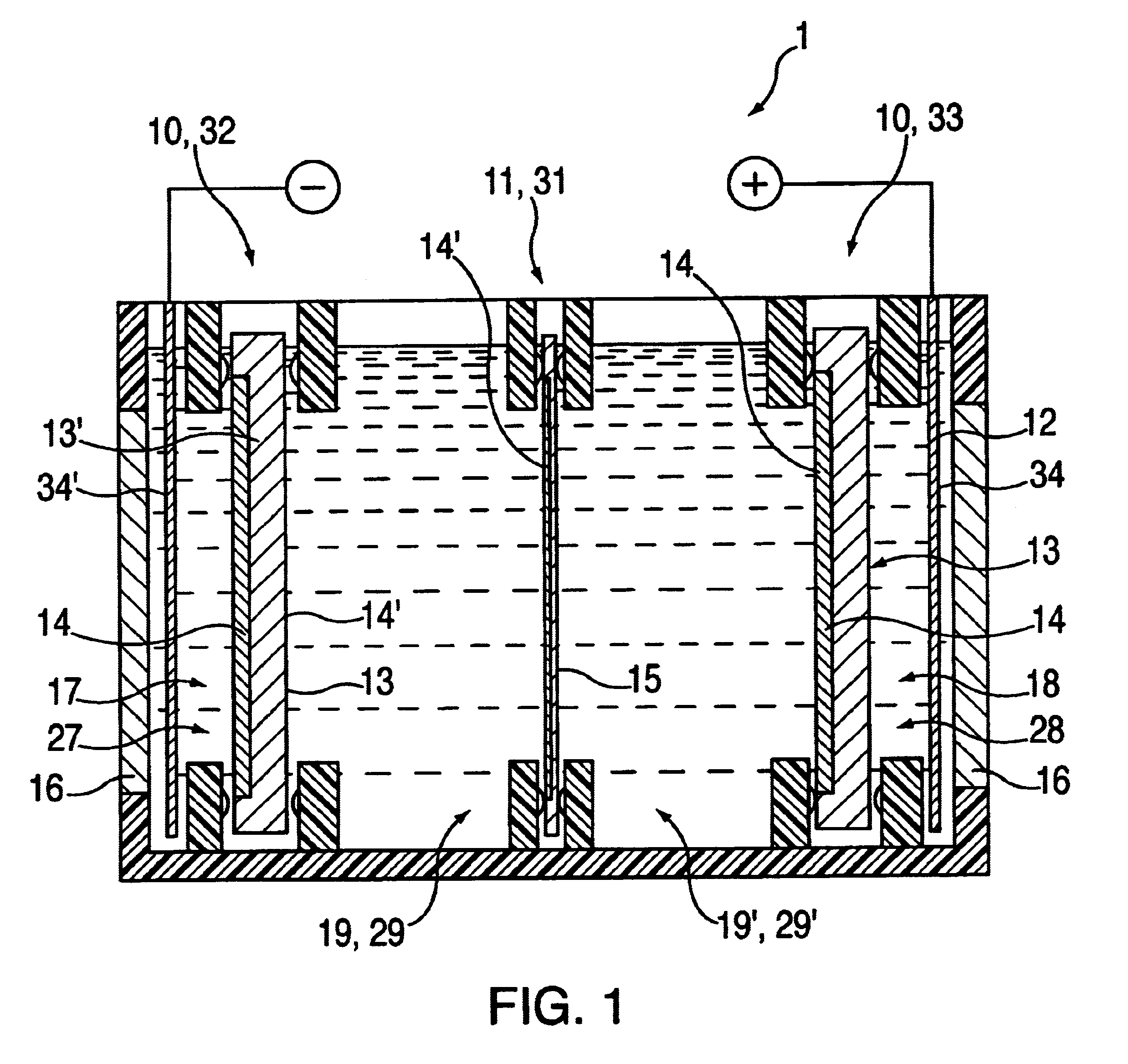

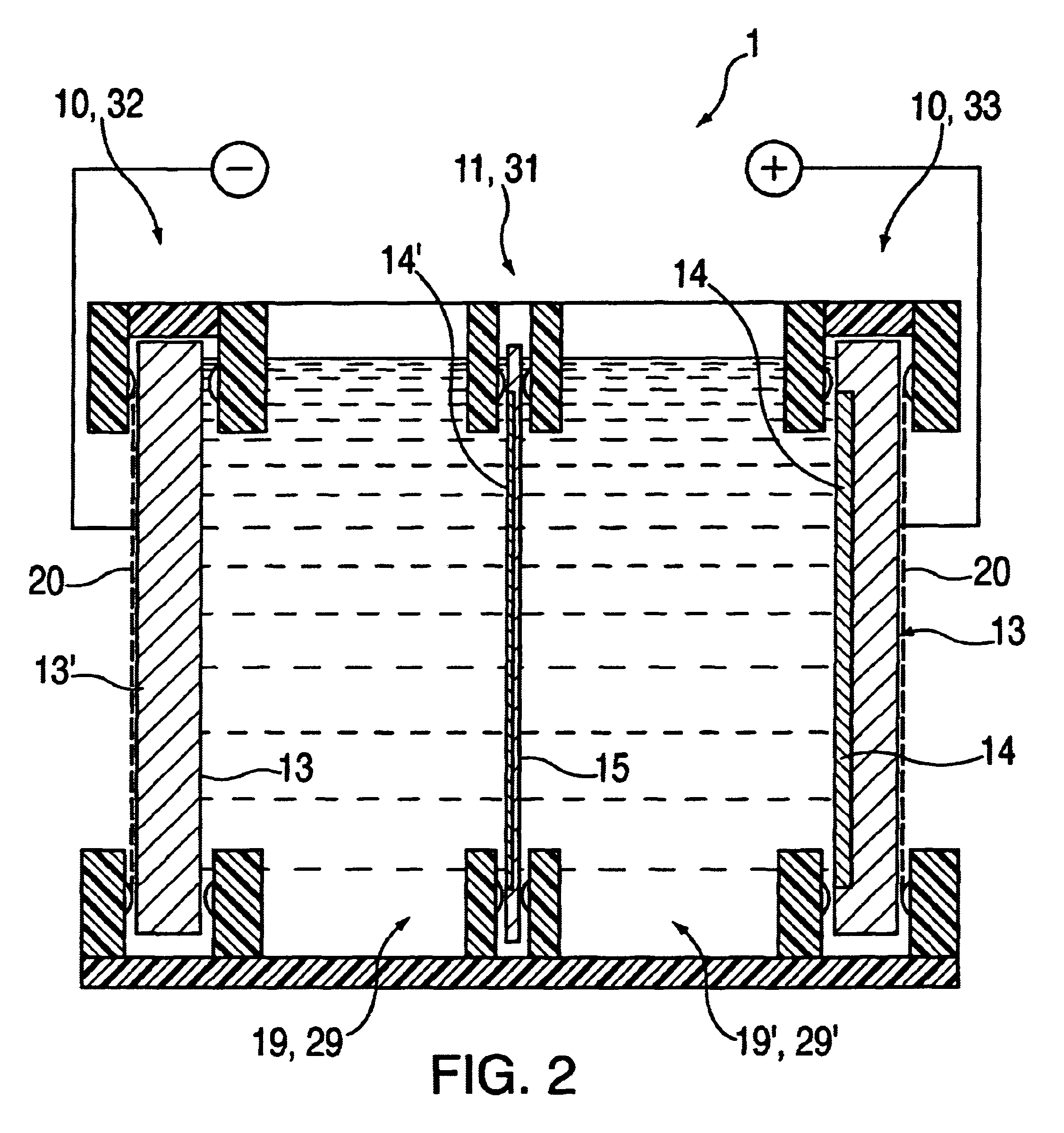

Electrochemical etching cell

InactiveUS6726815B1Simplifies electrical contactSimple structure designCellsCell componentsElectrolyteElectrochemical etching

An electrochemical etching cell (1) is proposed for etching an etching body (15) made at least superficially of an etching material. The etching cell (1) has at least one chamber filled with an electrolyte, and is provided with a first electrode (13), which at least superficially has a first electrode material, and with a second electrode (13') which at least superficially has a second electrode material. Furthermore, the etching body (15) is in contact, at least region-wise, with the electrolyte. In this context, the first electrode material and the second electrode material are selected such that, after the etching, the etching body (15) is not contaminated and / or is not impaired in its properties by the electrode materials. In particular, the electrode materials are the same materials as the etching material. Also proposed is a method for etching an etching body (15) using this etching cell (1), the first and / or the second electrode (13, 13') being used as a sacrificial electrode. The proposed etching cell is particularly suitable for etching silicon wafers in a CMOS-compatible production line.

Owner:ROBERT BOSCH GMBH

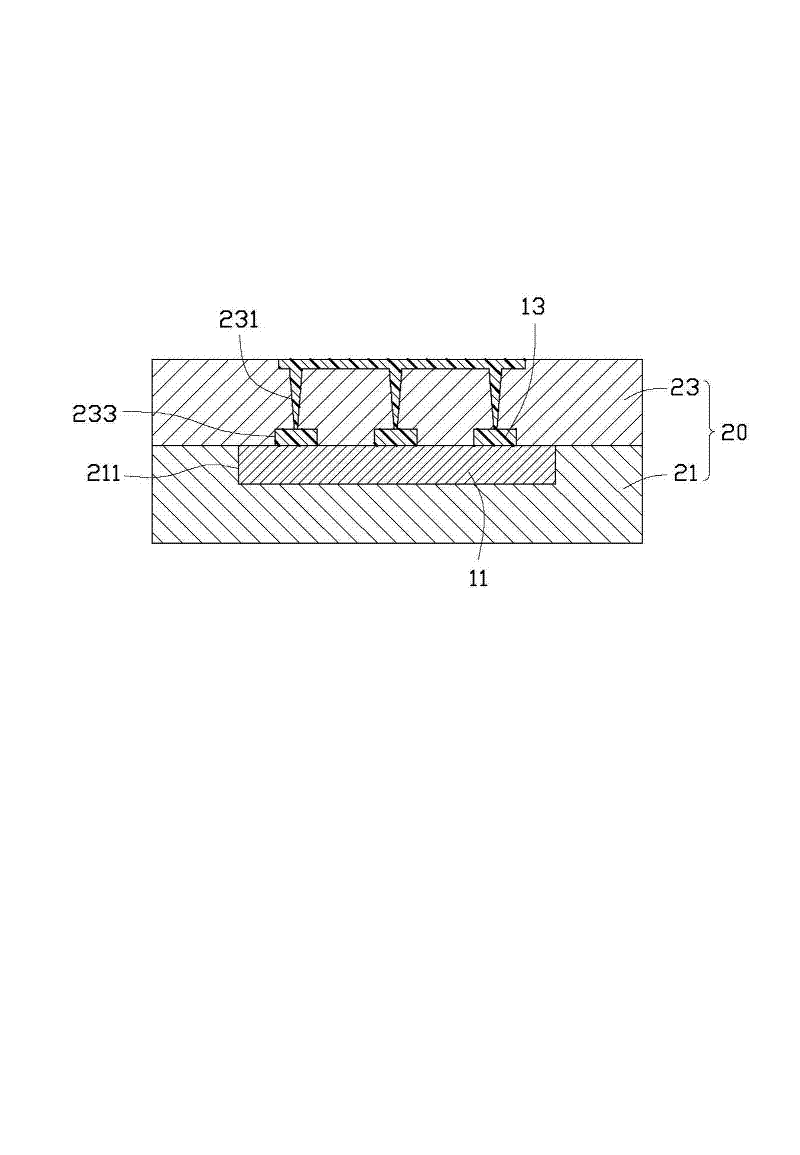

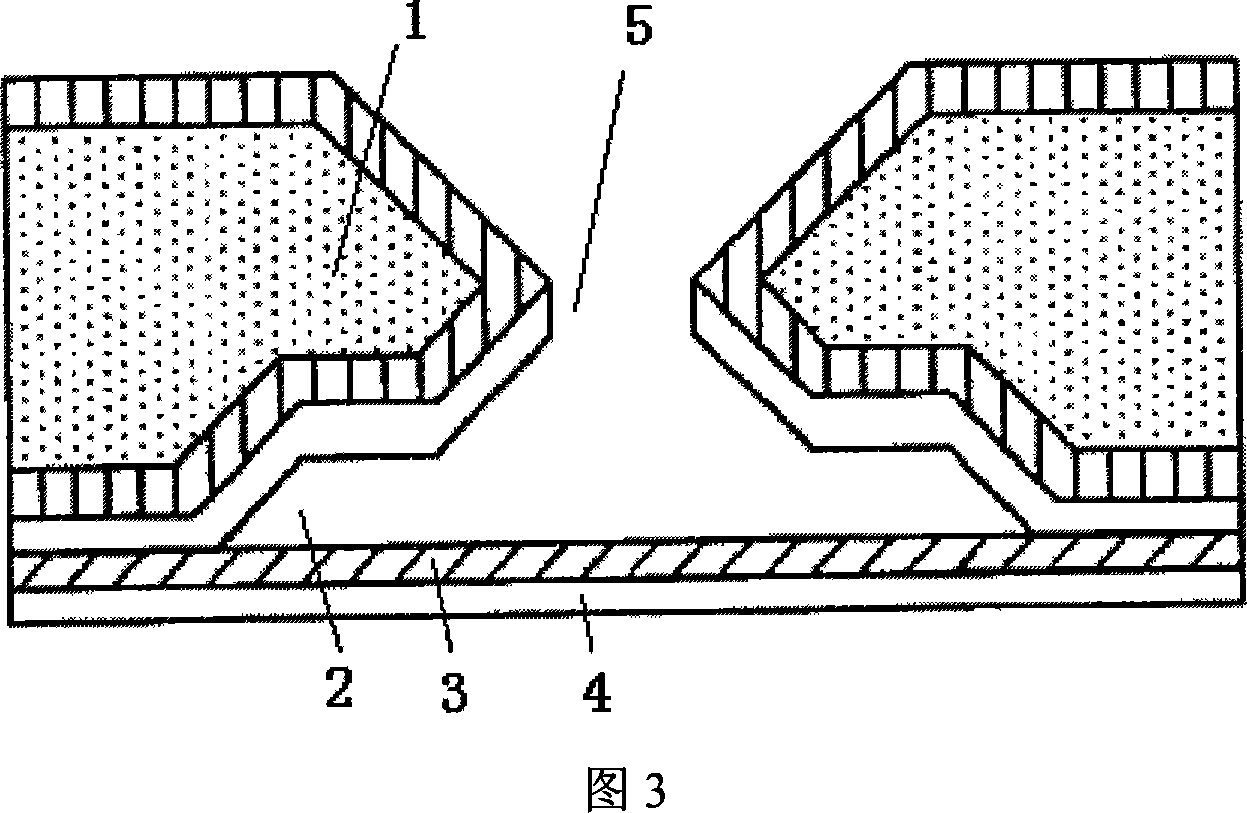

Piezoelectric combining jet device and its making process

InactiveCN101066542AImprove reliabilityImprove consistencyLiquid spraying apparatusVibrating membraneEngineering

The piezoelectric combining jet device includes a silicon base, a cavity, a jet, a vibrating membrane and a piezoelectric actuator. It features the piezoelectric actuator comprising piezoelectric material, and one upper electrode and one lower electrode adhered separately to the upper and lower surfaces of the piezoelectric material. The piezoelectric combining jet device is made through an electrochemical etching process, which includes preparing a porous silicon layer, releasing porous silicon to form cavity, inducing coupled plasma etching to form the jet, low pressure chemical vapor depositing the vibrating silicon diaphragm, and sol-gel process to prepare the piezoelectric film. The piezoelectric combining jet device with cavity, jet, vibrating silicon diaphragm and piezoelectric film prepared on the identical silicon base has high reliability and consistency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

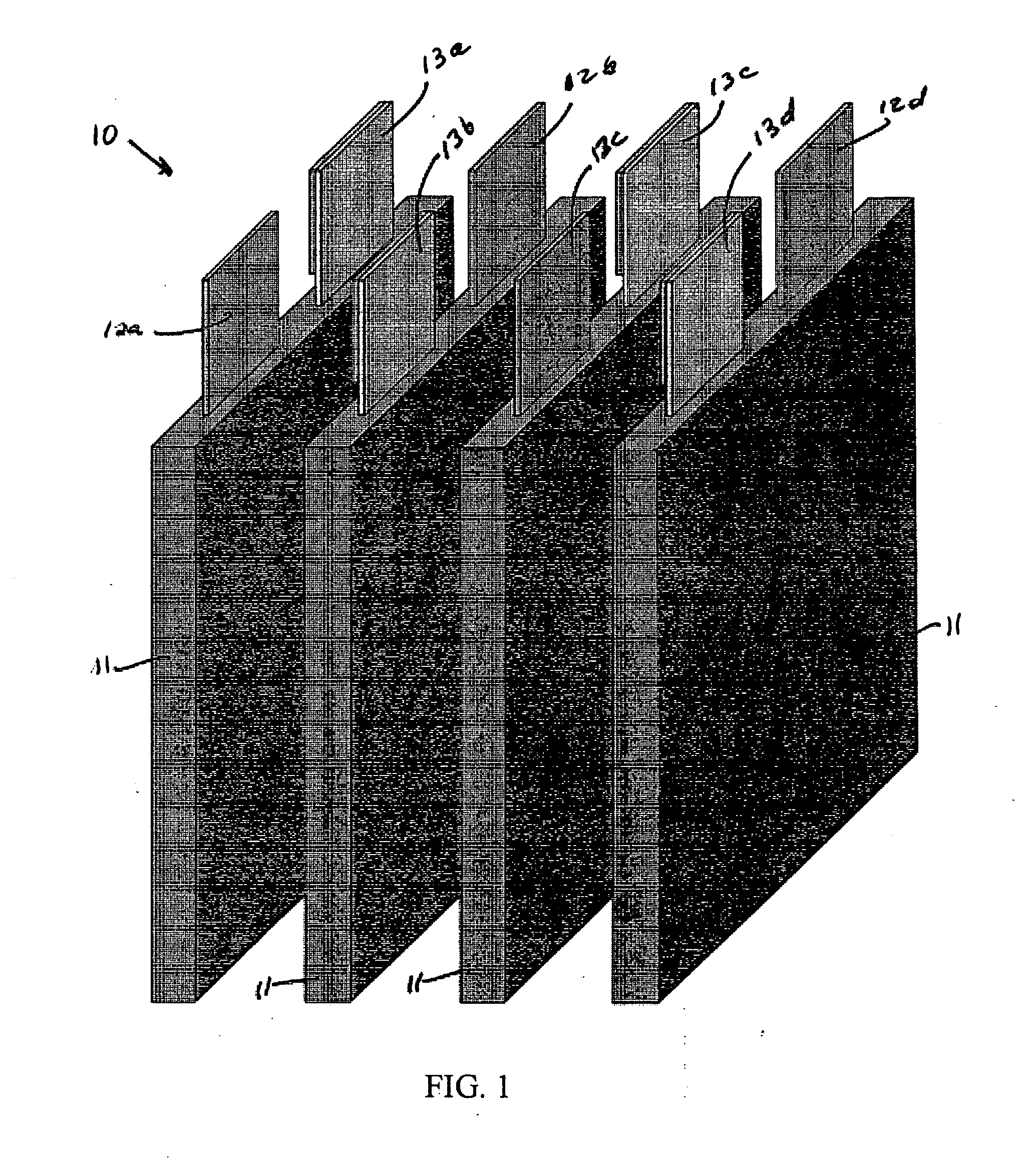

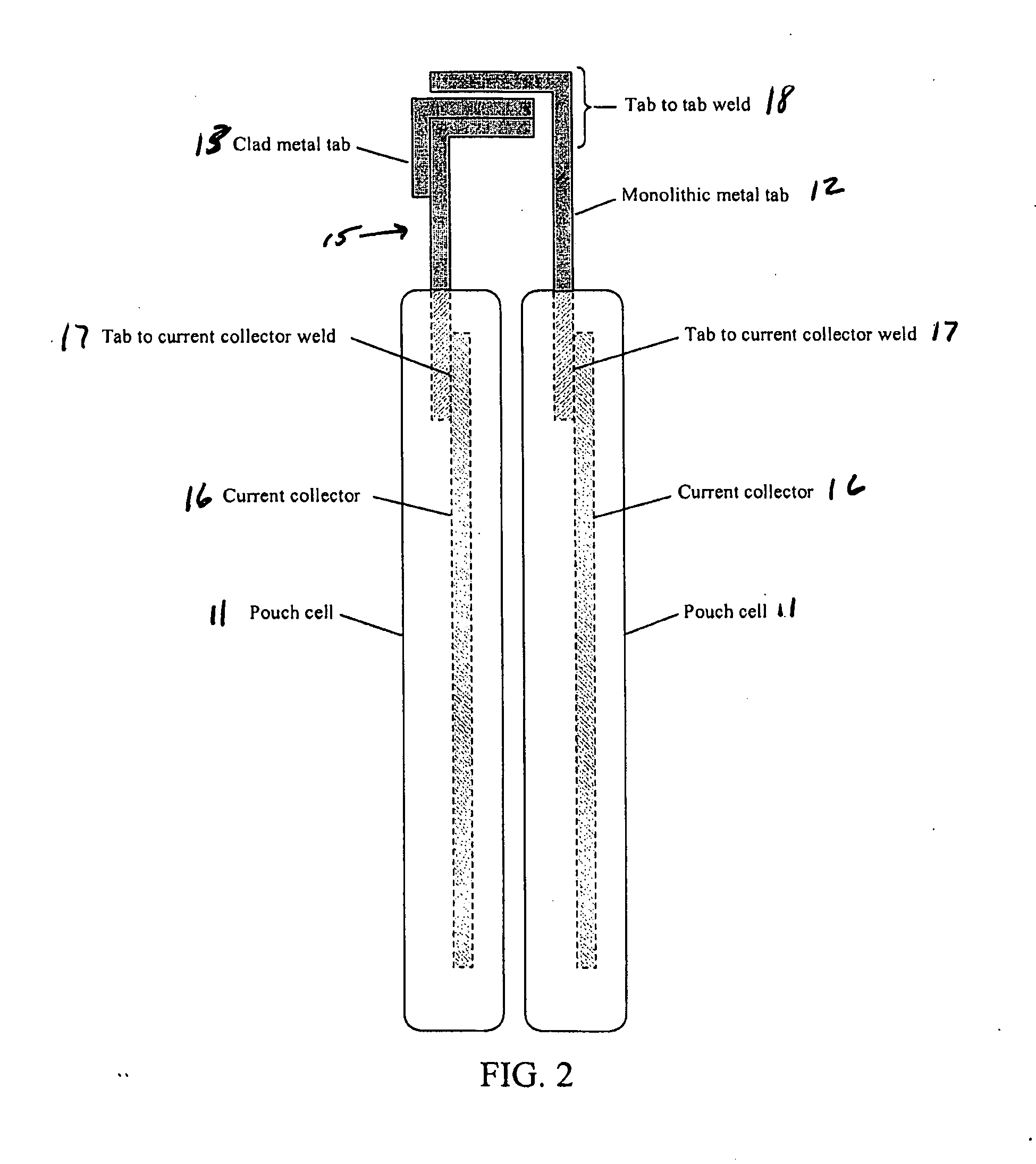

Battery Tabs and Method of Making the Same

InactiveUS20110274964A1Improve corrosion resistanceLess-robustPrimary cell to battery groupingCell electrodesMechanical millingEngineering

A terminal for a Li-ion battery cell utilizes a bimetallic strip formed from the materials used as the Li-ion cell current collectors, such as copper and aluminum. The bimetallic strip is to be used as, at least one, of the Li-ion pouch cell terminals. At least one portion of the bimetallic strip has one of the metallic components removed by such means as chemical or electrochemical etching, mechanical milling, skiving, or grinding, the remaining component being connected to the collector and the other end of the strip serving as the terminal.

Owner:EMS ENGINEERED MATERIALS SOLUTIONS LLC

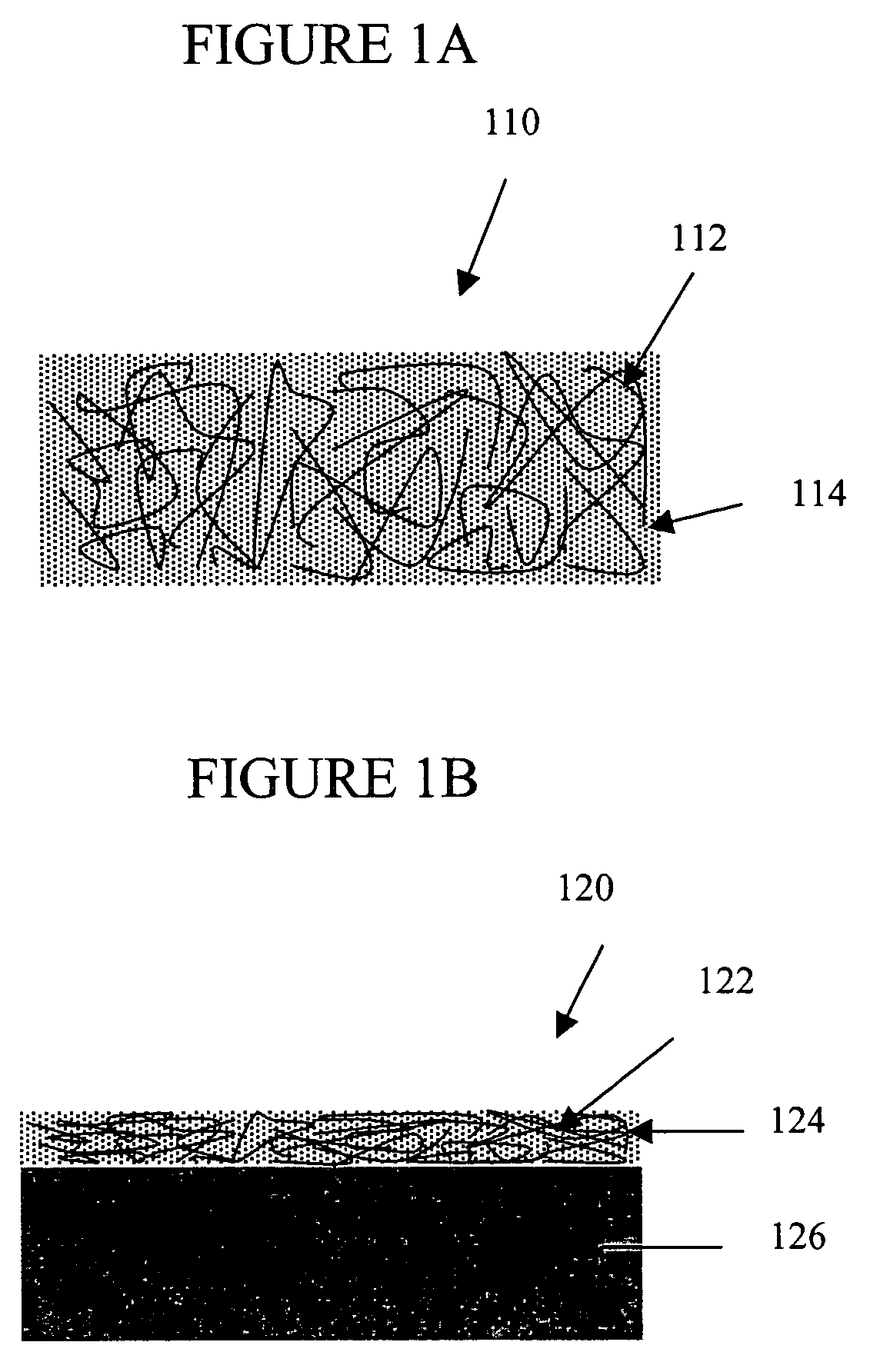

Fabrication and activation processes for nanostructure composite field emission cathodes

ActiveUS7294248B2Improve adhesionImprove conductivityVolume/mass flow measurementNanoinformaticsComposite fieldMetallurgy

A method of forming an electron emitter includes the steps of: (i) forming a nanostructure-containing material; (ii) forming a mixture of nanostructure-containing material and a matrix material; (iii) depositing a layer of the mixture onto at least a portion of at least one surface of a substrate by electrophoretic deposition; (iv) sintering or melting the layer thereby forming a composite; and (v) electrochemically etching the composite to remove matrix material from a surface thereof, thereby exposing nanostructure-containing material.

Owner:NURAY TECH

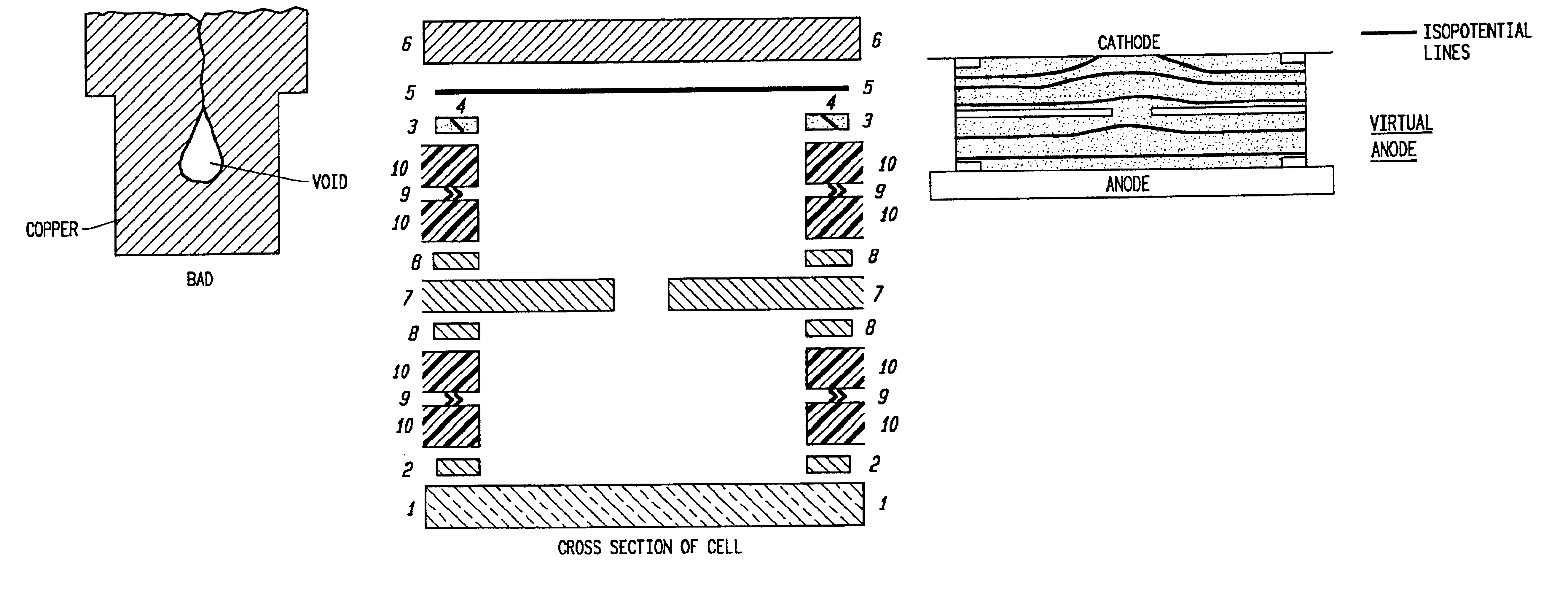

Electrodeposition apparatus with virtual anode

InactiveUSRE37749E1Inhibited DiffusionCellsSemiconductor/solid-state device manufacturingCapacitanceElectrochemistry

An electrochemical etching step in a semiconductor device fabrication process increases the radius of curvature of edges of metal lines deposited on the semiconductor device. The metal lines are fabricated by forming a mask, electrodepositing the metal, and removing the mask, and the electro-chemical etching step in performed subsequently. The increased radius of curvature of the metal lines simplifies subsequent planarization and decreases line-to-line capacitance, thereby enhancing device performance. In an apparatus for performing the fabrication process, wires sown into a gasket which secures the semiconductor wafer and prevents electrolyte leakage, allows the gasket to function also as a component of the cathode. A more uniform metal deposition is created by a virtual anode, i.e., a metal plate having an aperture and being located between the anode and the cathode.

Owner:PORIS JAIME

Electrochemical metallographic etching method universal for nickel-based alloys

InactiveCN101655426AFlat surfaceClear grain boundariesPreparing sample for investigationGlycerolPhosphoric acid

The invention discloses an electrochemical metallographic etching method universal for nickel-based alloys and relates to the electrochemical etching of the metallographic structure of a metal material. The method adopts the electrochemical metallographic etching method and takes an etching solution as a conducting medium, a metallographic specimen to be observed as an anode and a platinum electrode as cathode; the etching-control conditions comprise: the constant etching voltage: 2V / cm<2>-8Vcm<2>, the etching time: 1min-5min, the etching solution thereof contains in percentage by weight, 65%-85% of phosphoric acid, 5%-15% of sulfuric acid, 8%-15% of chromic acid and 3%-8% of glycerol, the prepared high-temperature corrosion-proof nickel-based alloys such as G-3, 825, X750 and the like have flat surface of metallograph, clear crystal boundary and clear crystal grain. Compared with chemical etching method, the electrochemical metallographic etching method has easily-controlled experimental conditions, good experimental repeatability and high experimental efficiency and is suitable for Ni-Fe-Cr alloys.

Owner:UNIV OF SCI & TECH BEIJING

Direct patterning of silicon by photoelectrochemical etching

ActiveUS7433811B2High resolutionComplex detailDecorative surface effectsSemiconductor/solid-state device manufacturingPhotoelectrochemical etchingSoft lithography

The invention is directed to methods for direct patterning of silicon. The invention provides the ability to fabricate complex surfaces in silicon with three dimensional features of high resolution and complex detail. The invention is suitable, for example, for use in soft lithography as embodiments of the invention can quickly create a master for use in soft lithography. In an embodiment of the invention, electrochemical etching of silicon, such as a silicon wafer, for example, is conducted while at least a portion of the silicon surface is exposed to an optical pattern. The etching creates porous silicon in the substrate, and removal of the porous silicon layer leaves a three-dimensional structure correlating to the optical pattern.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com