Shell and manufacturing method thereof

A manufacturing method and shell technology, which can be applied to other household appliances, cabinets/cabinets/drawer parts, electrical equipment shells/cabinets/drawers, etc., can solve the problem of weak bonding force, low shell processing efficiency, time-consuming issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

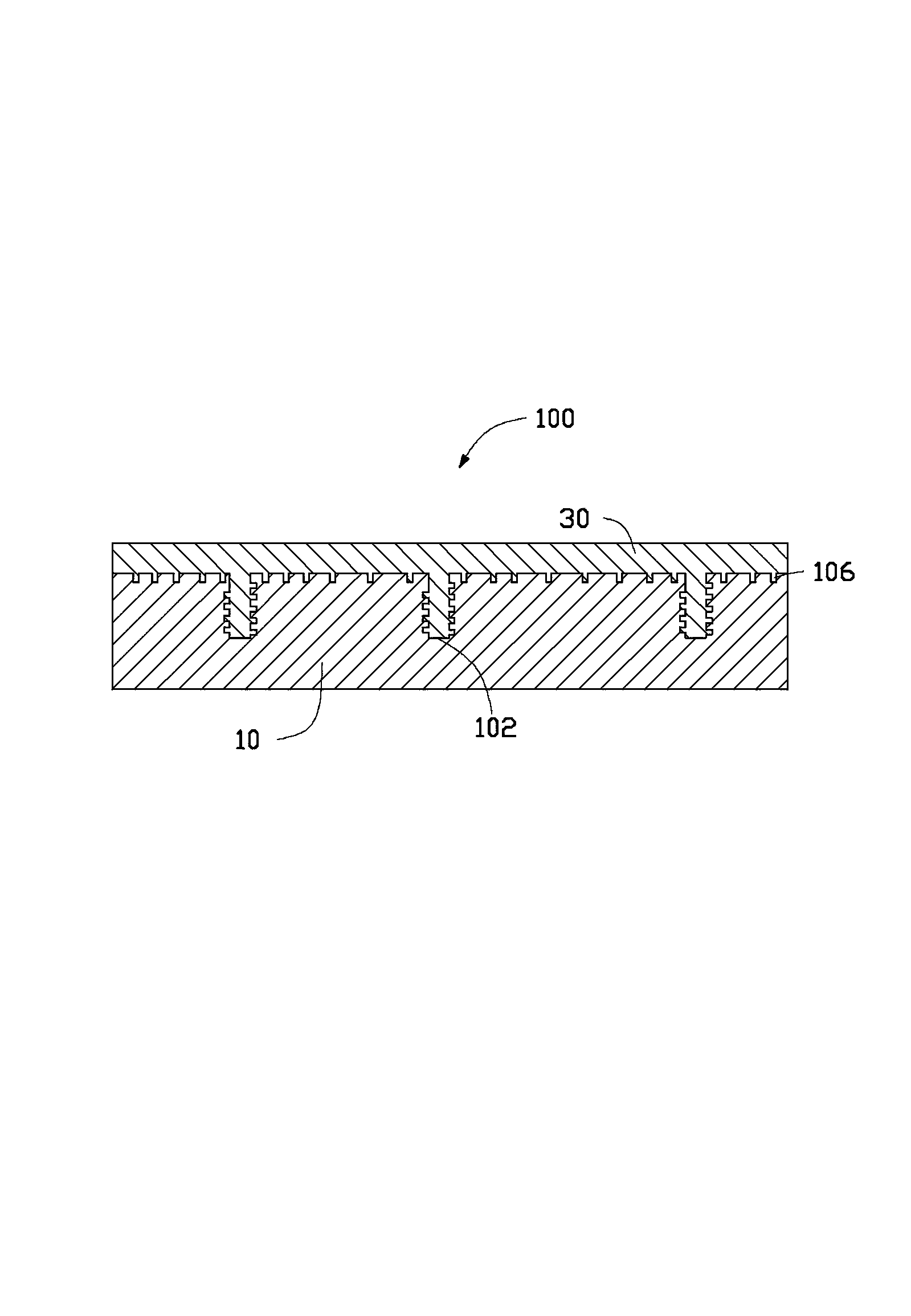

[0018] see Figure 1 to Figure 3 , the casing 100 according to the first embodiment of the present invention includes a metal part 10 and a plastic part 30 combined with the metal part 10 . In the embodiment of the present invention, the housing 100 is a mobile phone housing. It can be understood that the casing 100 may also be a casing of other electronic devices such as a tablet computer and a notebook computer.

[0019] The metal piece 10 is a rectangular frame made of aluminum alloy. It can be understood that the metal piece 10 can also be made of aluminum, magnesium / magnesium alloy, stainless steel and other metals or alloys. A plurality of laser holes 102 formed after laser treatment and a plurality of nanoholes 106 formed after electrochemical etching are formed on the inner surface of the metal piece 10 .

[0020] Please also see Figure 5 and Figure 7 , a plurality of laser holes 102 in this embodiment are connected to each other to form interlaced strip grooves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com