Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8071results about "Pigmenting treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

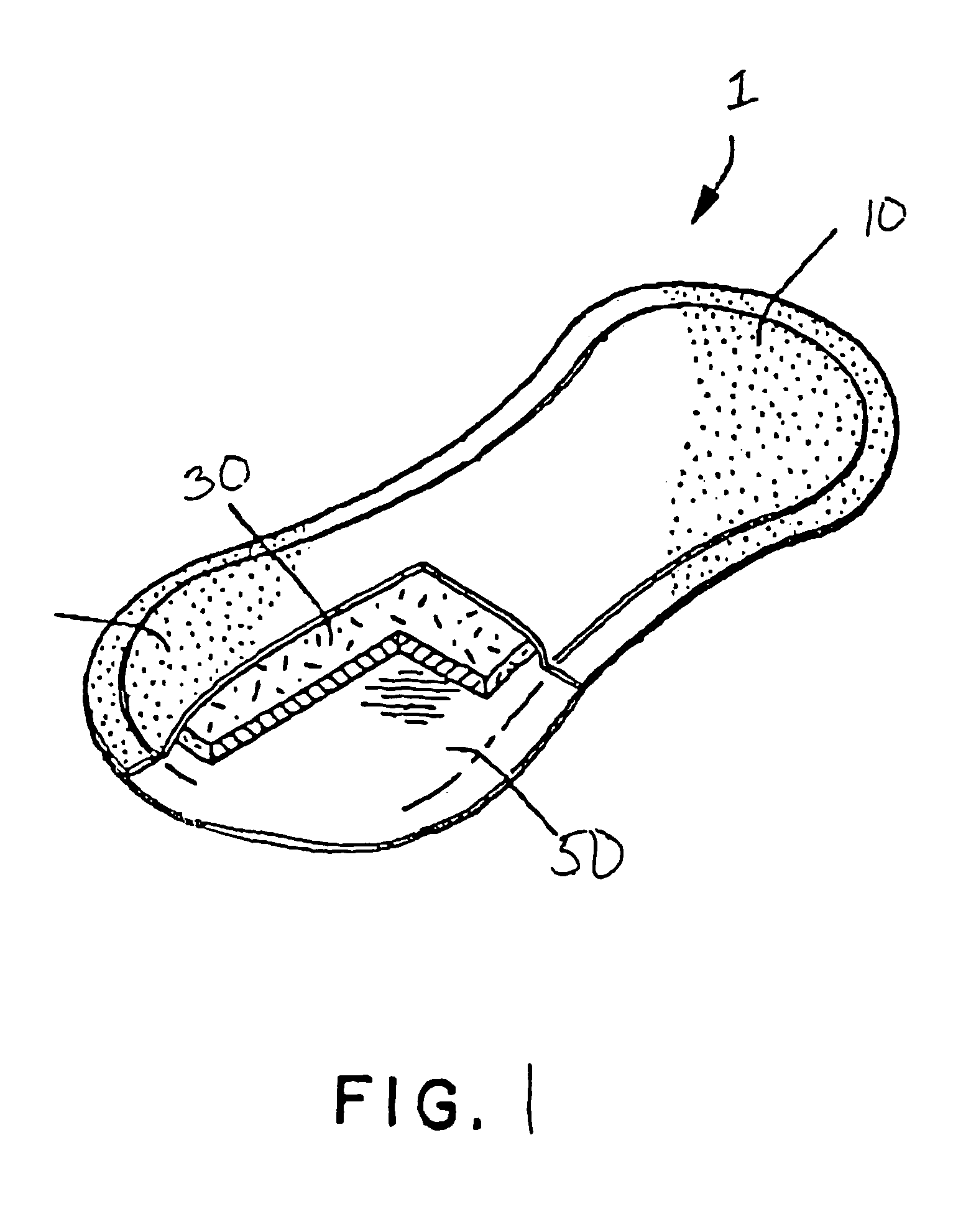

Absorbent articles comprising nanoparticles

Owner:NANO MET ZERO

Nano-scaled graphene plates

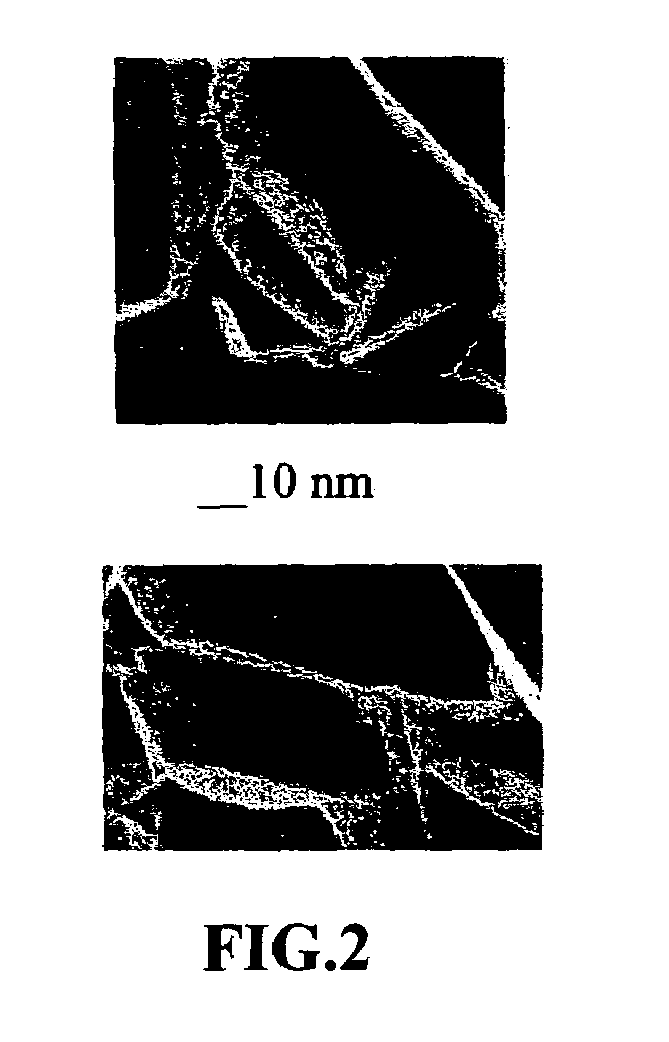

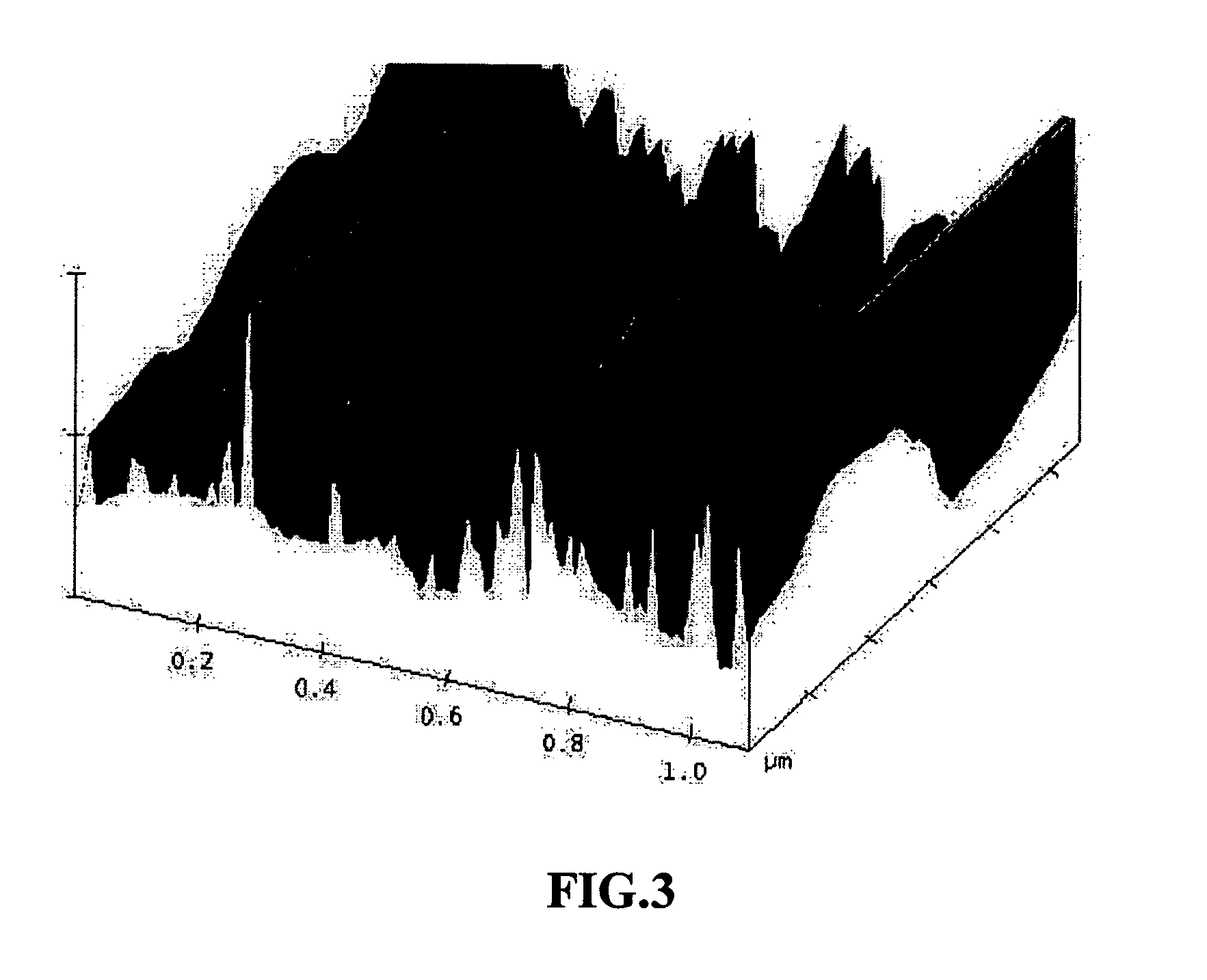

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

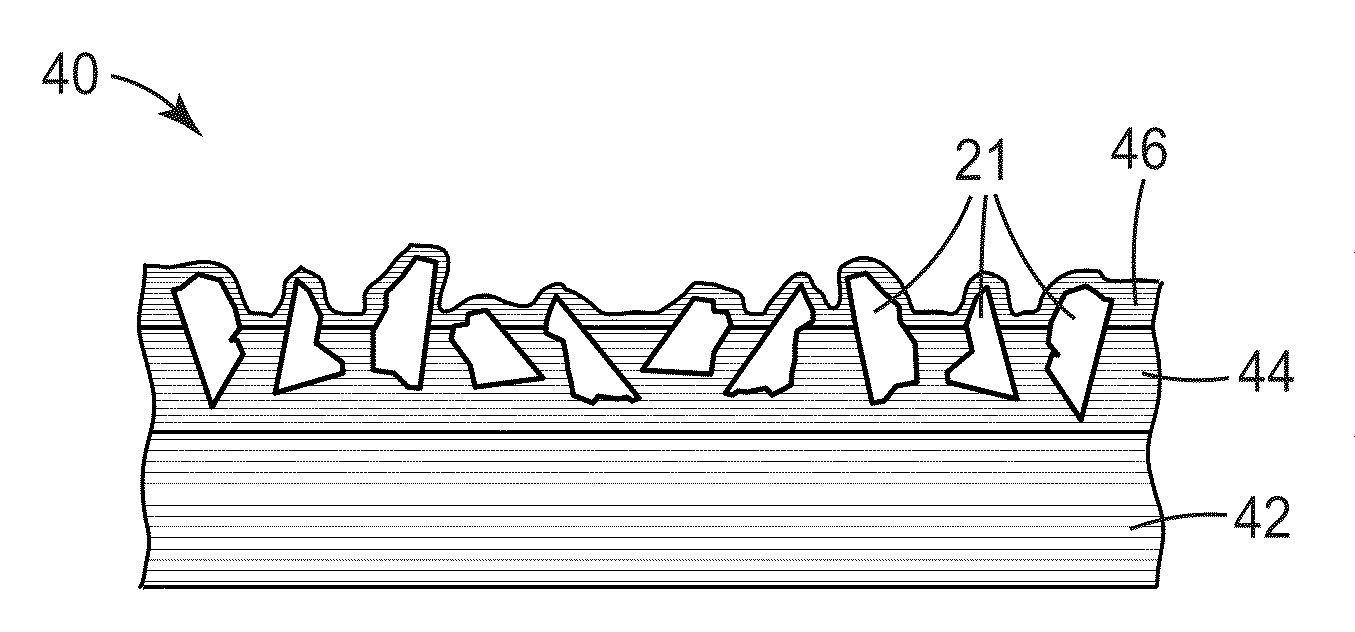

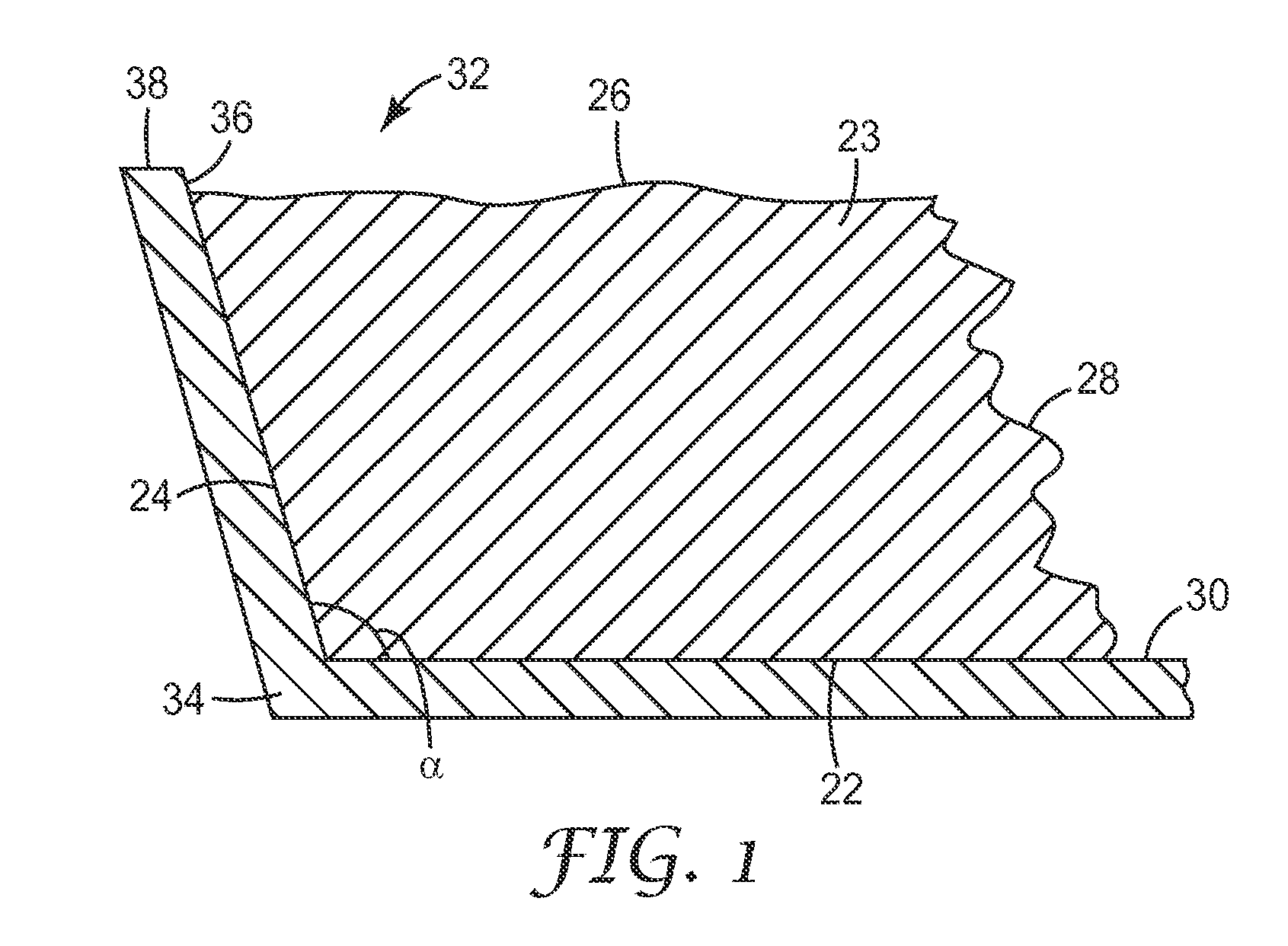

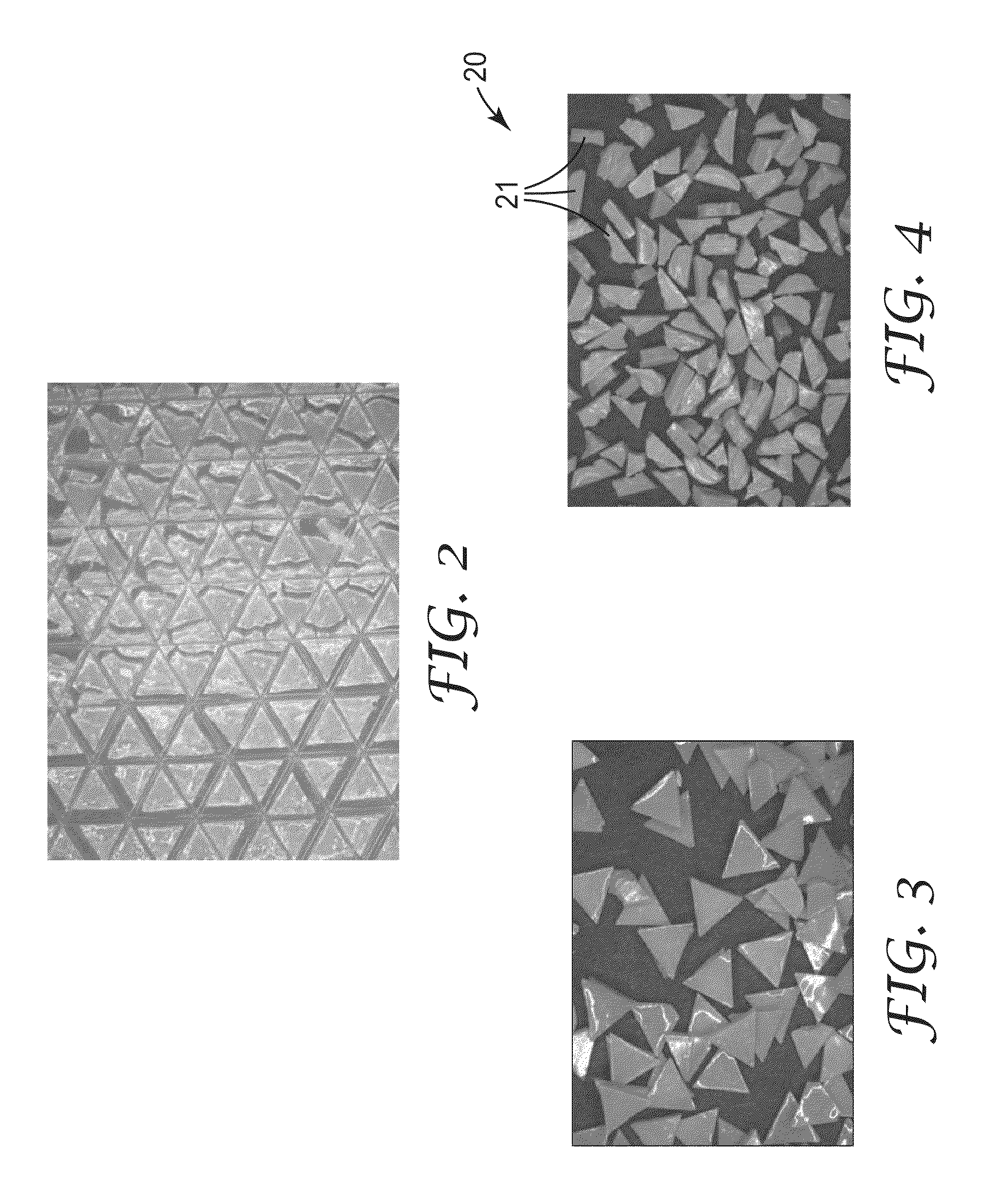

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

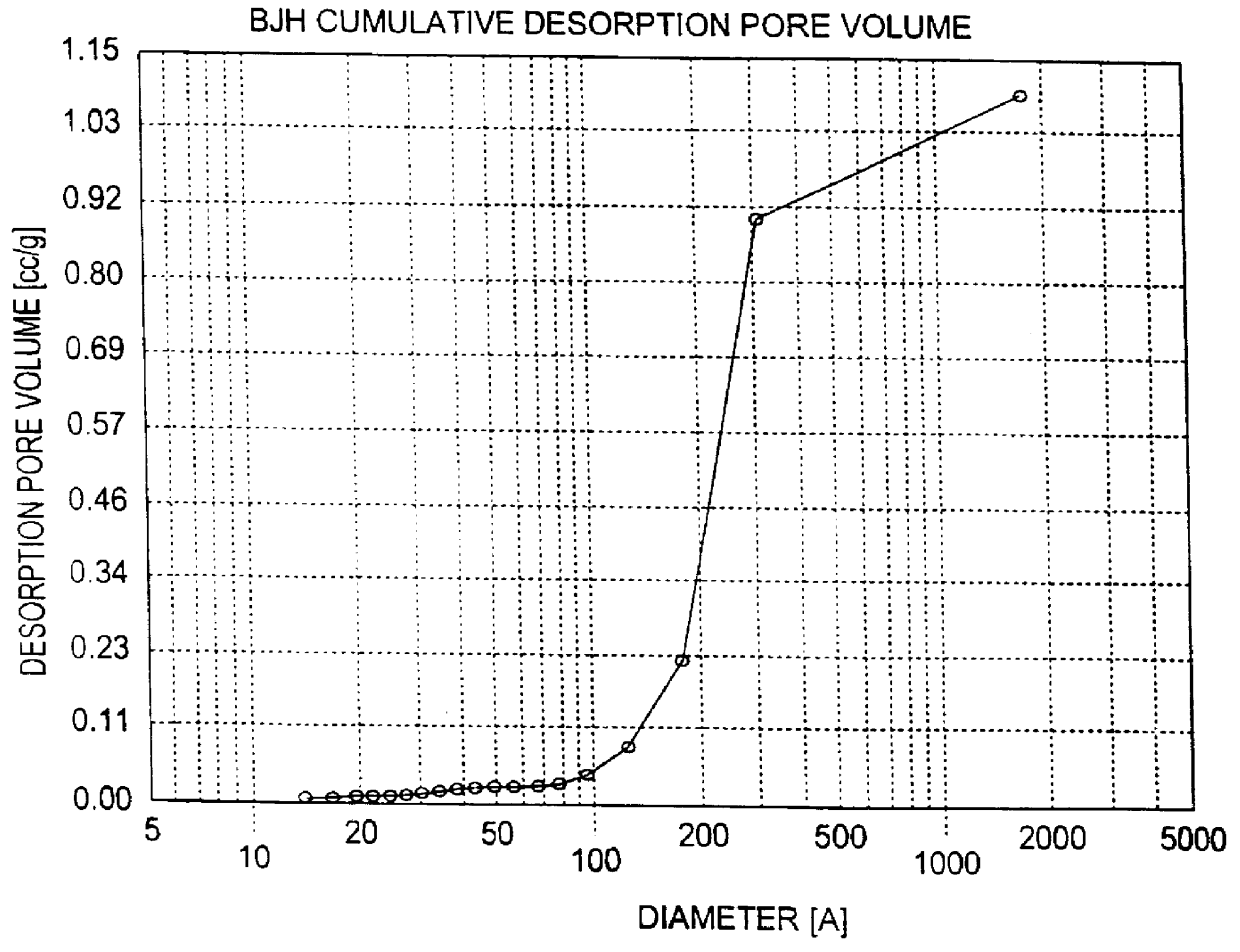

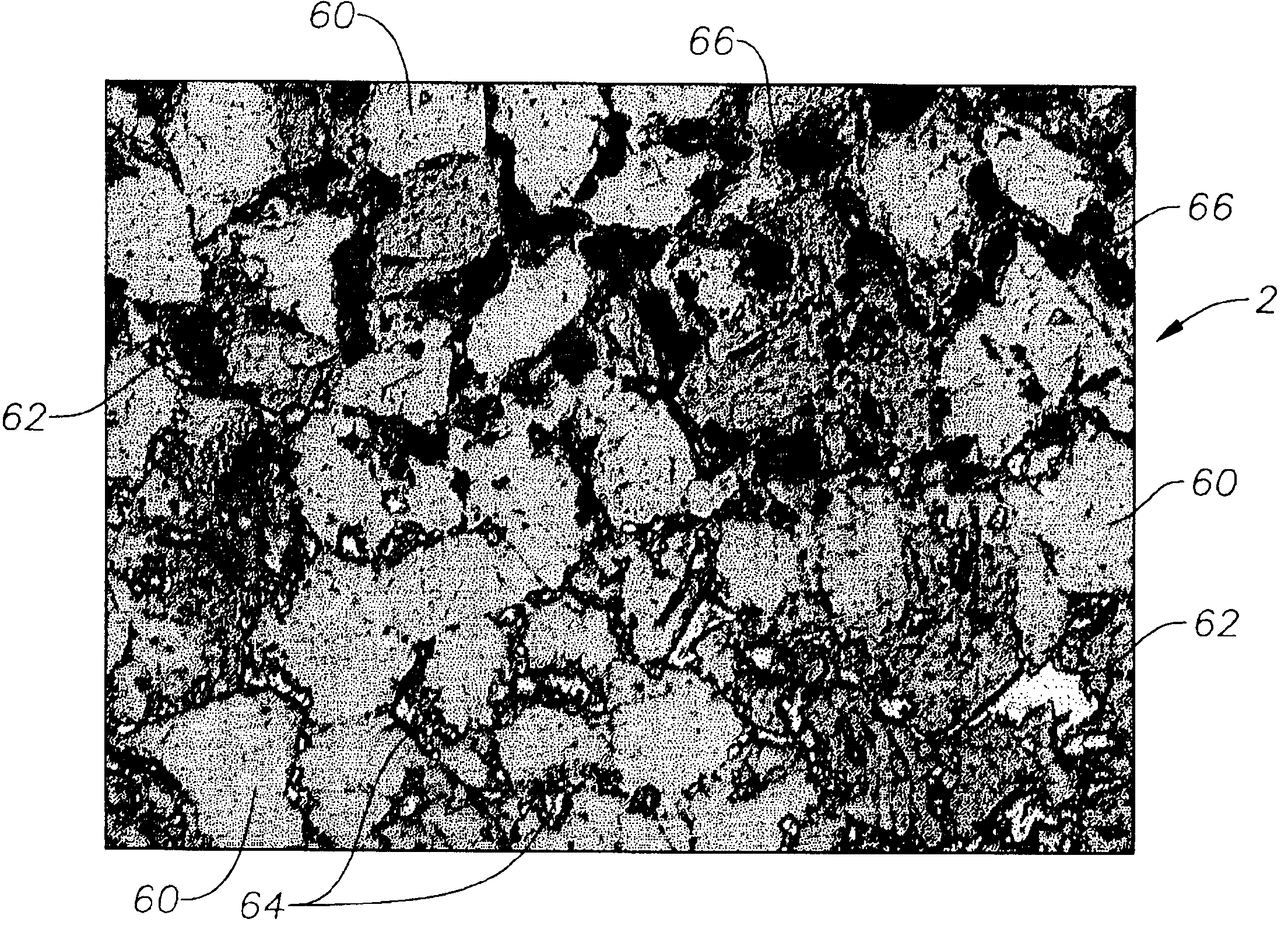

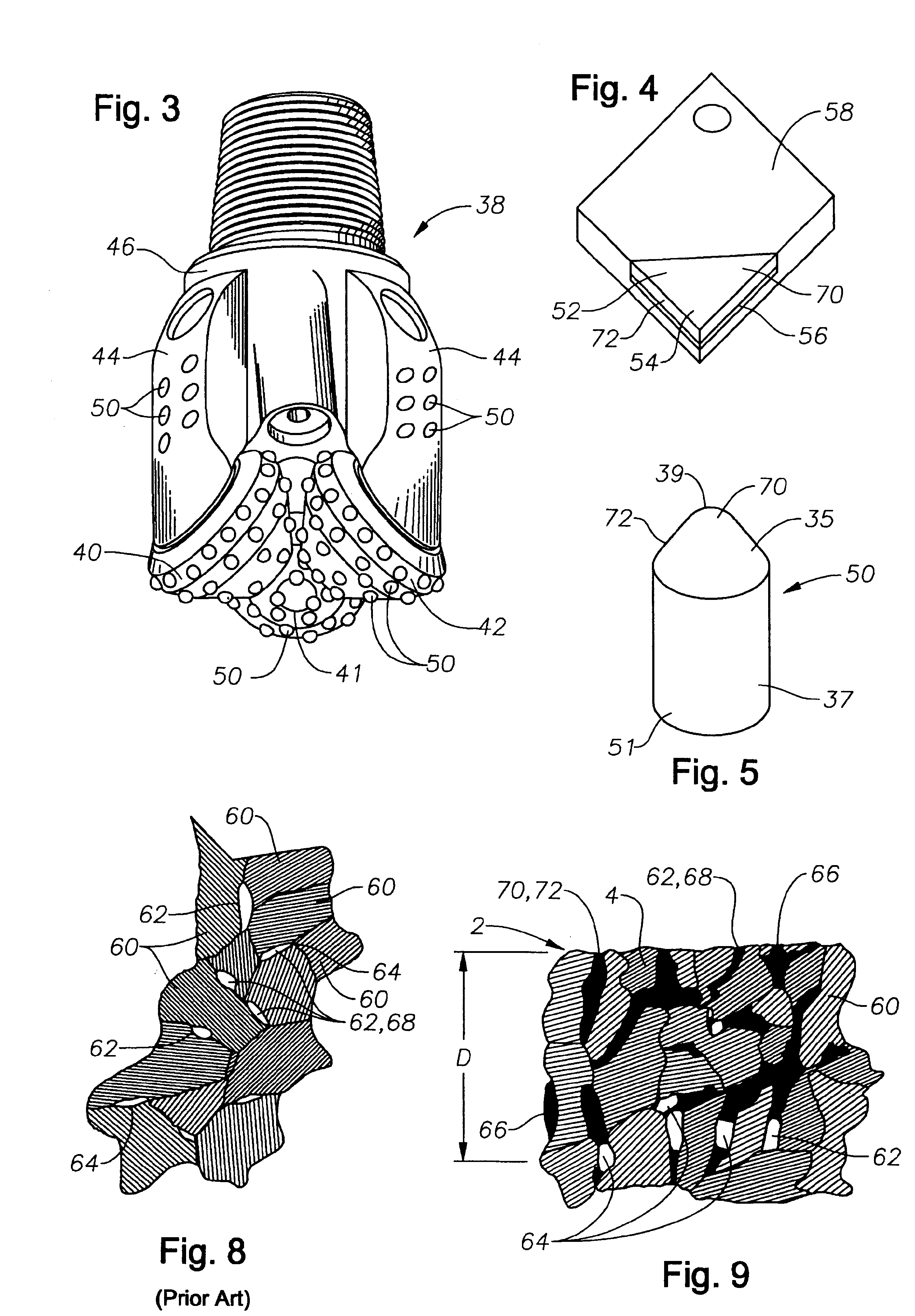

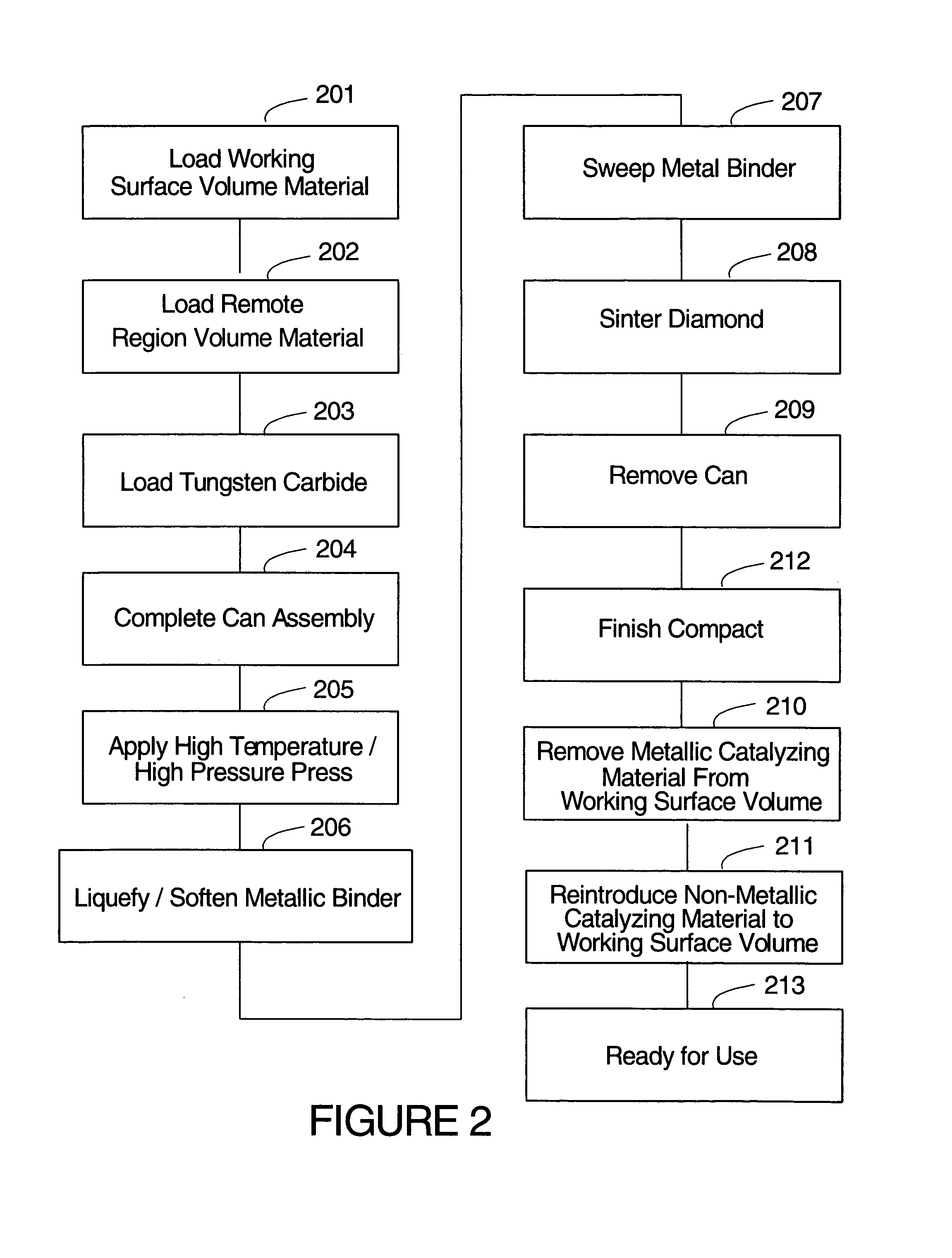

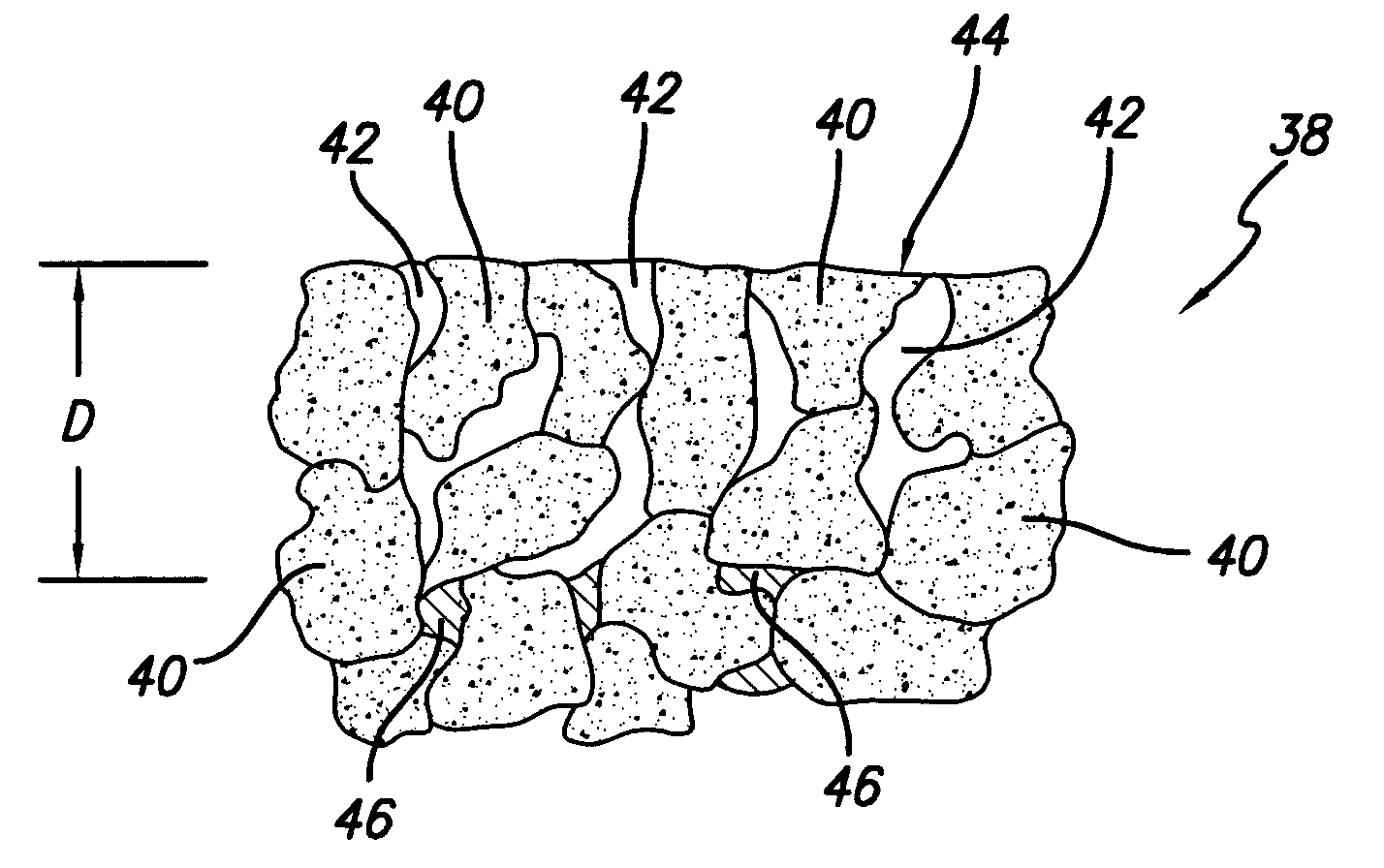

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

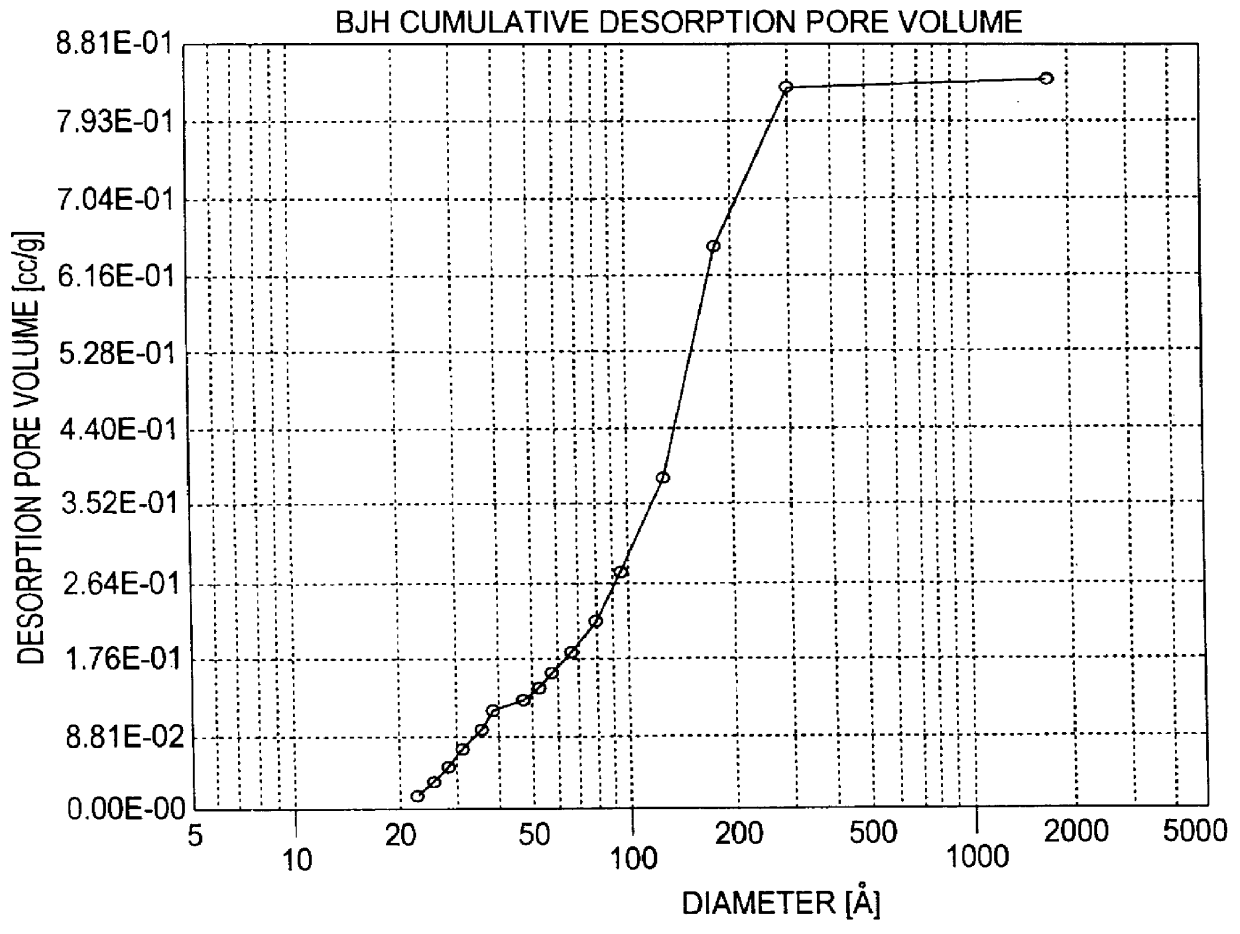

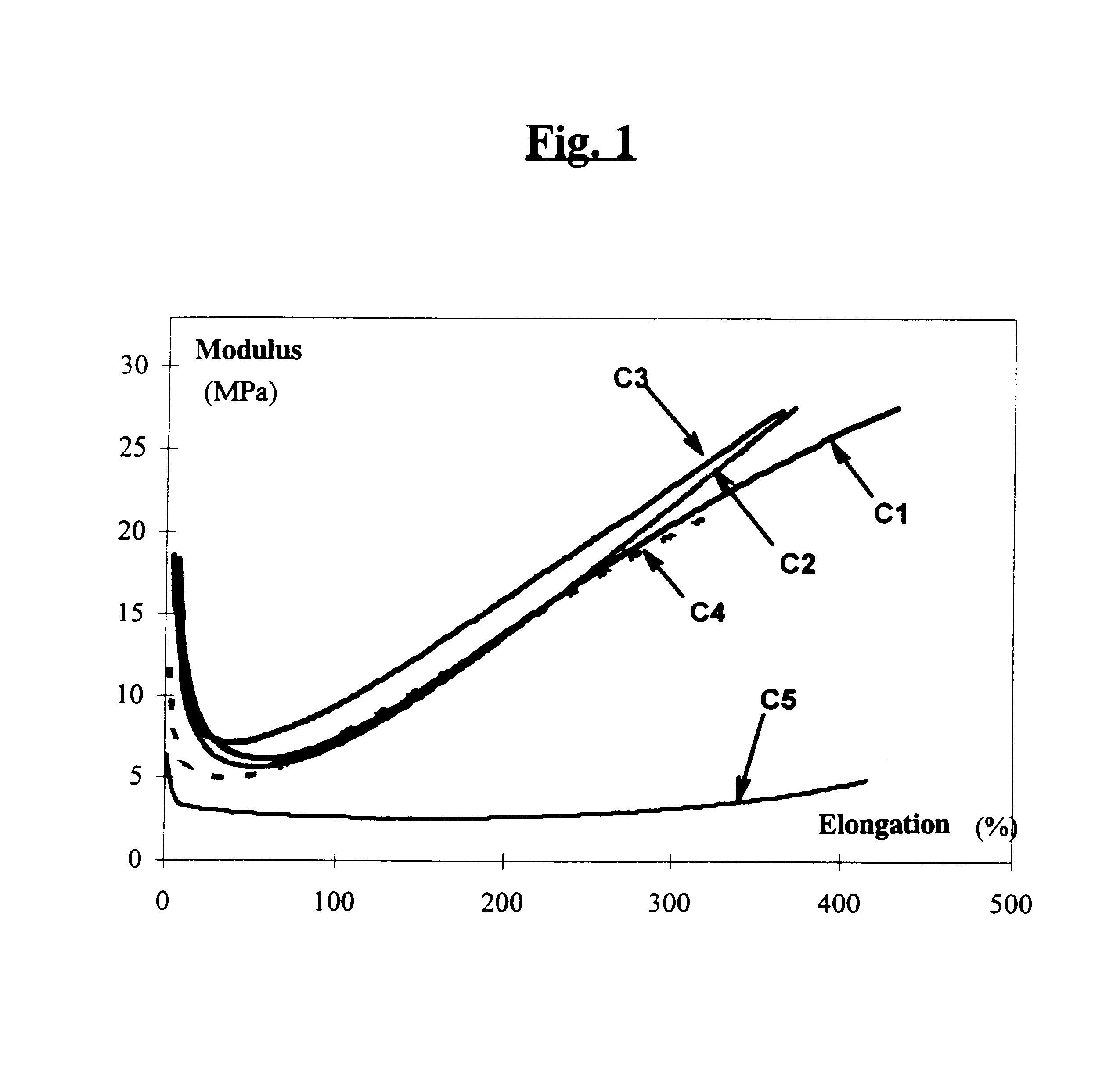

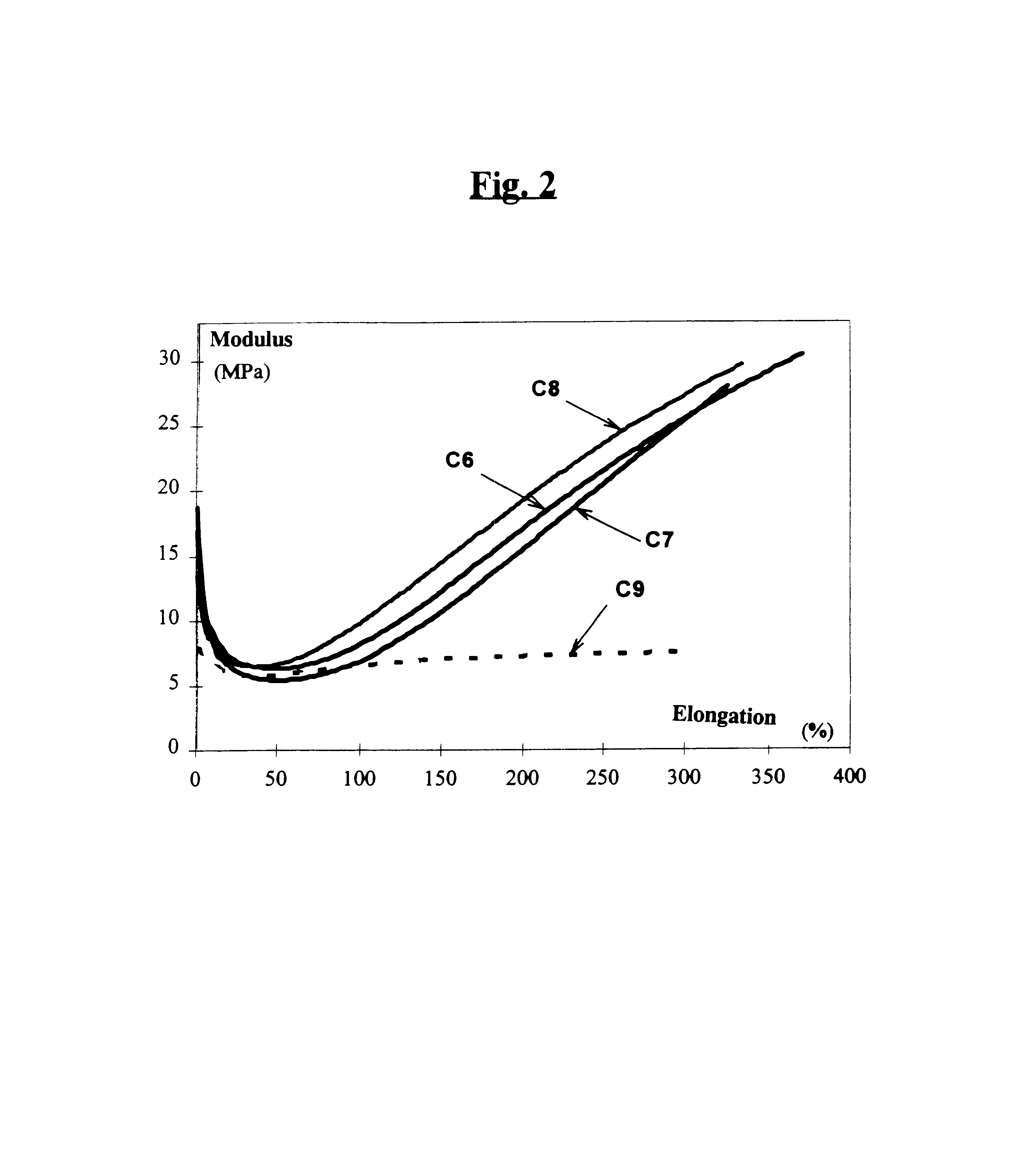

Reinforcing aluminum-based filler and rubber composition comprising such a filter

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers):the specific BET surface area of which is between 30 and 400 m2 / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10-3 mum-1 / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

PVC nanocomposite manufacturing technology and applications

InactiveUS20080194736A1Material nanotechnologyPigmenting treatmentPolymer scienceManufacturing technology

The present invention relates to a process and a product of forming polymer (especially PVC) nanocomposites with a variety of nanofillers. The present invention provides a method for forming a polymer nanocomposite, comprising powder mixing a composition comprising polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process. Additionally, the present invention relates to a polymer nanocomposite formed by a process, comprising powder mixing a polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process to achieve homogeneous dispersion of nanofillers in the polymer matrix.

Owner:FORMOSA PLASTICCS CORP

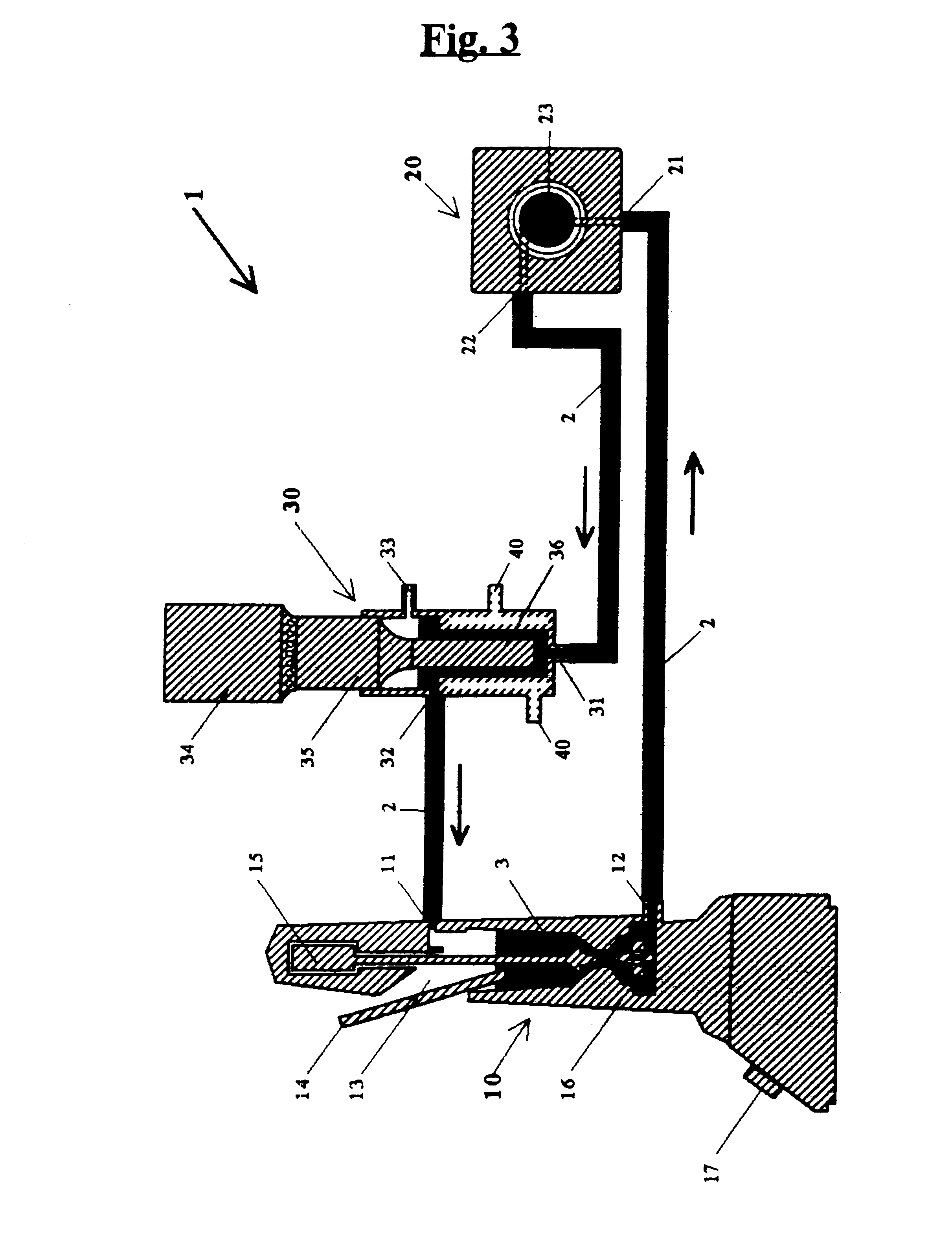

Walter-absorbing agent

There is disclosed a water-absorbing agent which combines both performances of the capillary suction force and the liquid permeability. This water-absorbing agent is a particulate water-absorbing agent comprising water-absorbent resin particles (α) and a liquid-permeability-enhancing agent (β), wherein the water-absorbent resin particles (α) are surface-crosslink-treated particles of a crosslinked polymer of a monomer including acrylic acid and / or its salt; with the water-absorbing agent being characterized in that the particulate water-absorbing agent has: a mass-average particle diameter (D50) in the range of 234 to 394 gm, a logarithmic standard deviation (σξY) of a particle diameter distribution in the range of 0.25 to 0.45, an absorption capacity without load (CRC) of not less than 15 g / g, and a water-extractable component content of not higher than 15 mass %; and further a liquid-permeability-enhancing agent (β) content in the range of 0.01 to 5 mass parts per 100 mass parts of the water-absorbent resin particles (α).

Owner:NIPPON SHOKUBAI CO LTD

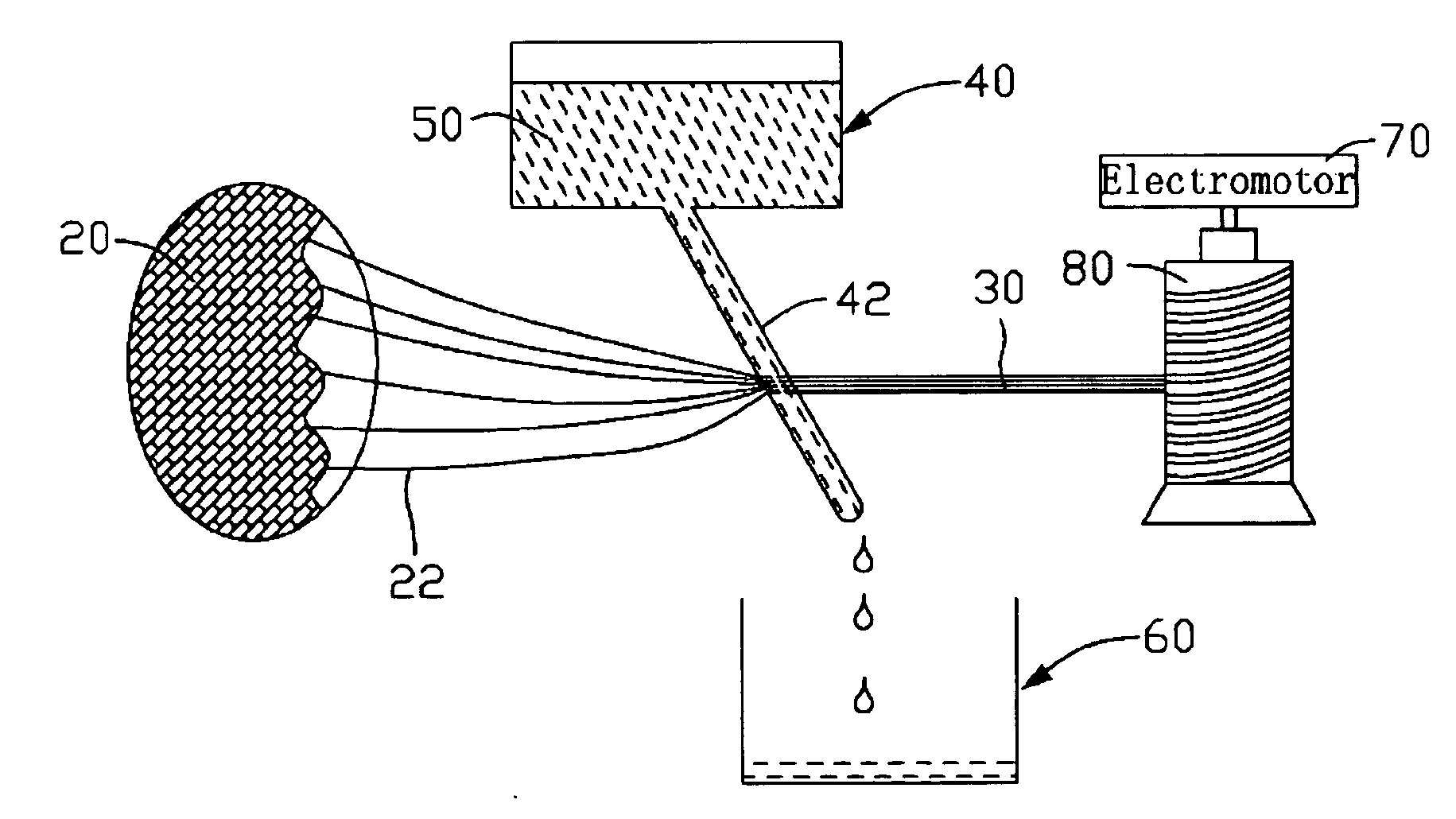

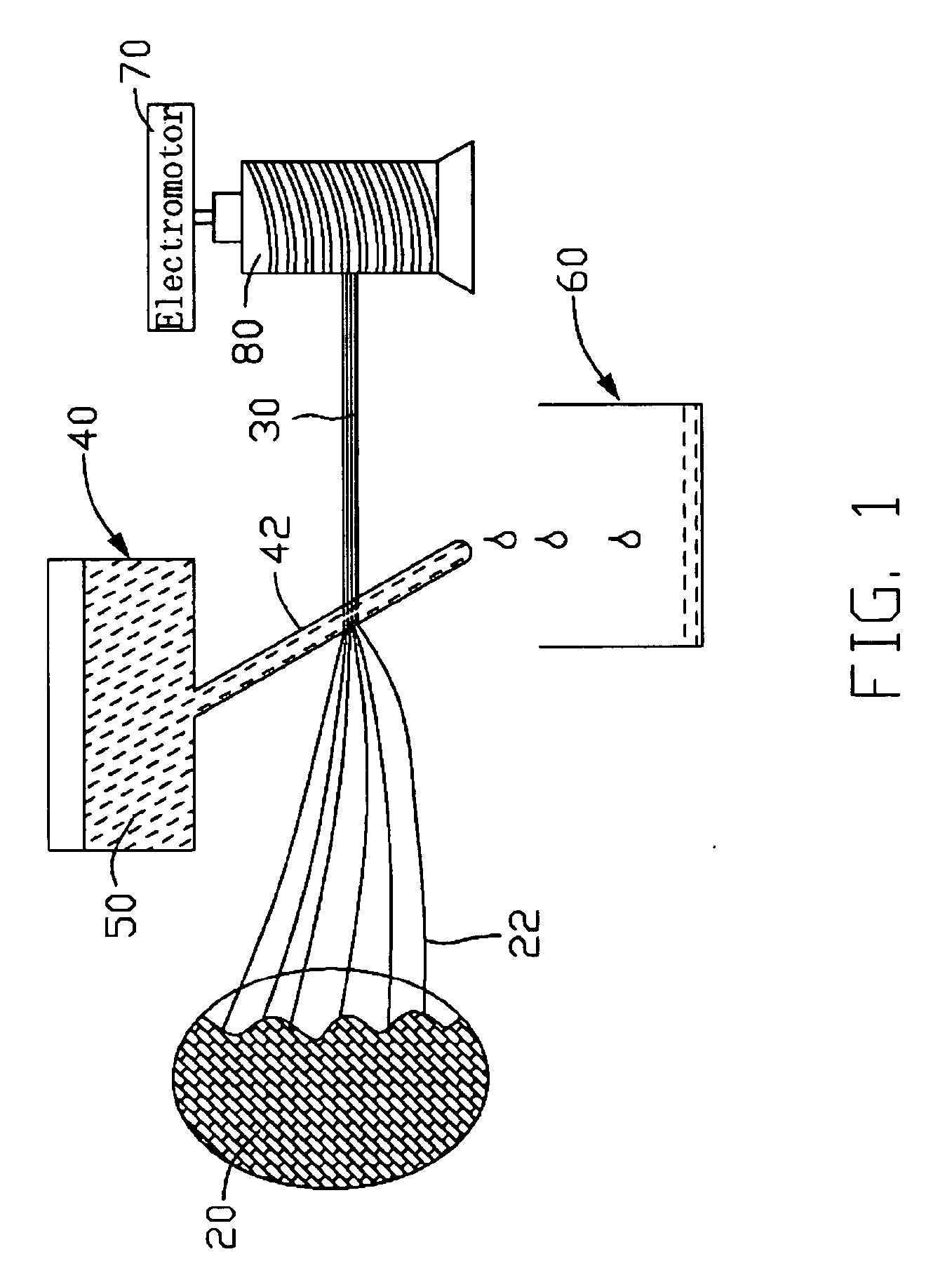

Carbon nanotube yarn and method for making the same

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

Abrasive grain, abrasive articles, and methods of making and using the same

Owner:3M INNOVATIVE PROPERTIES CO

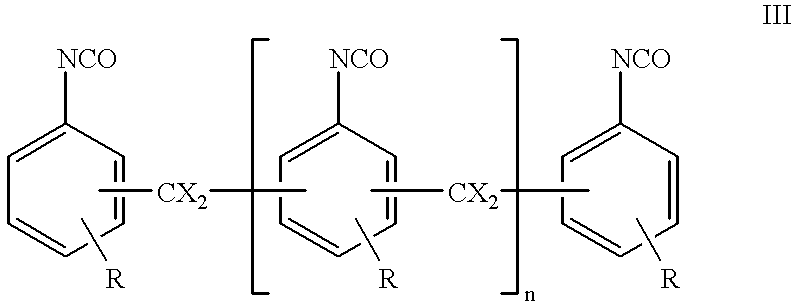

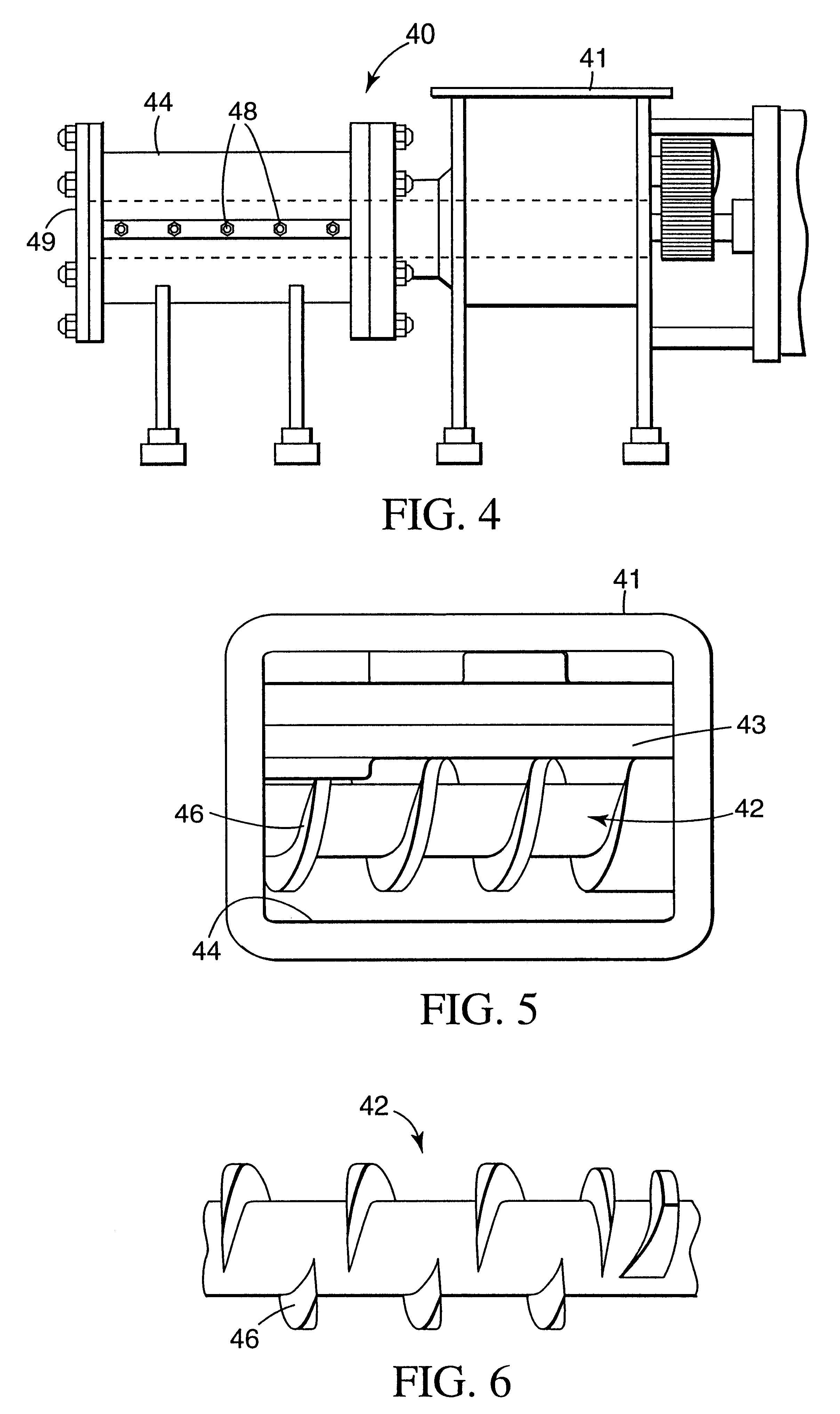

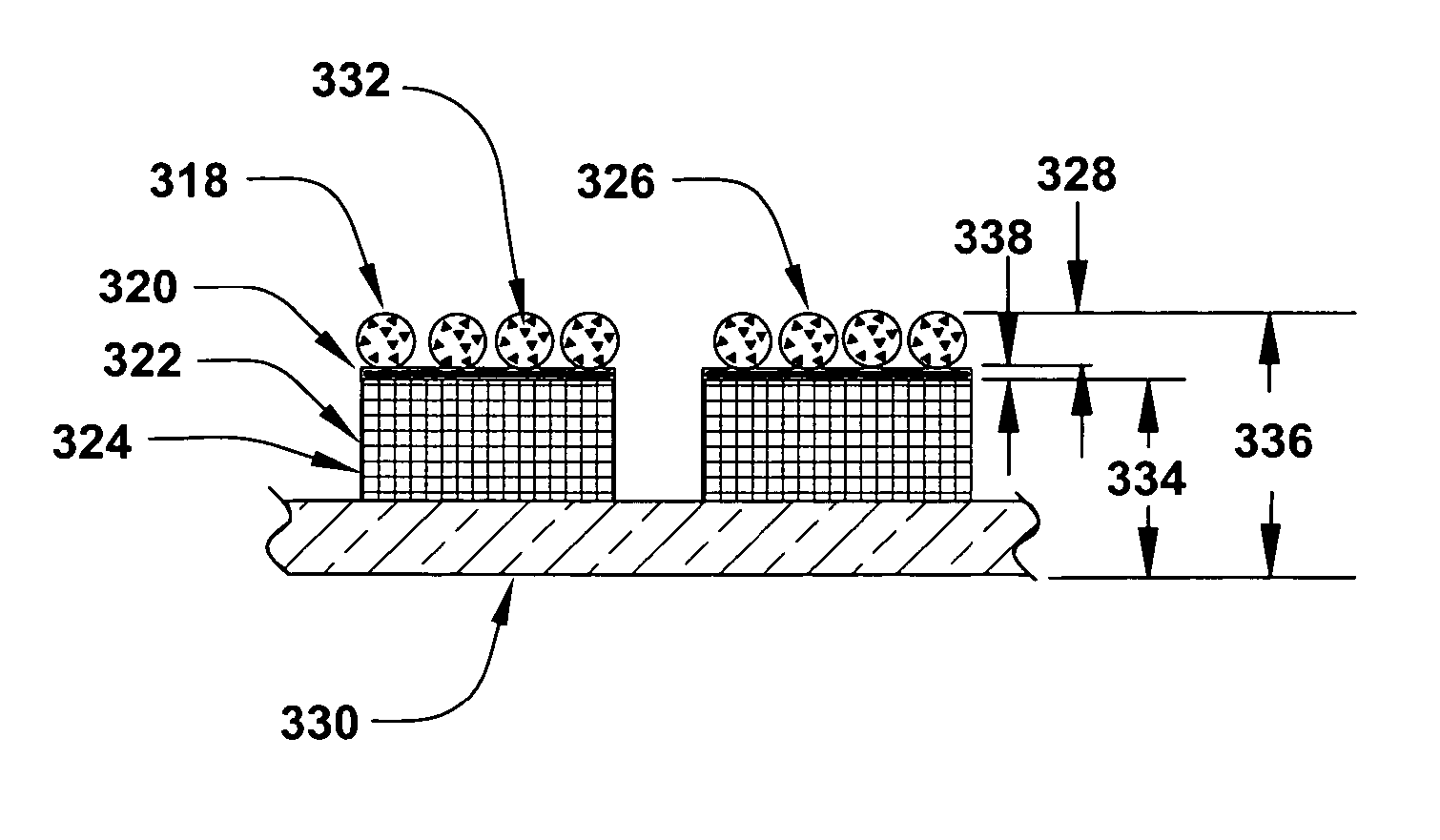

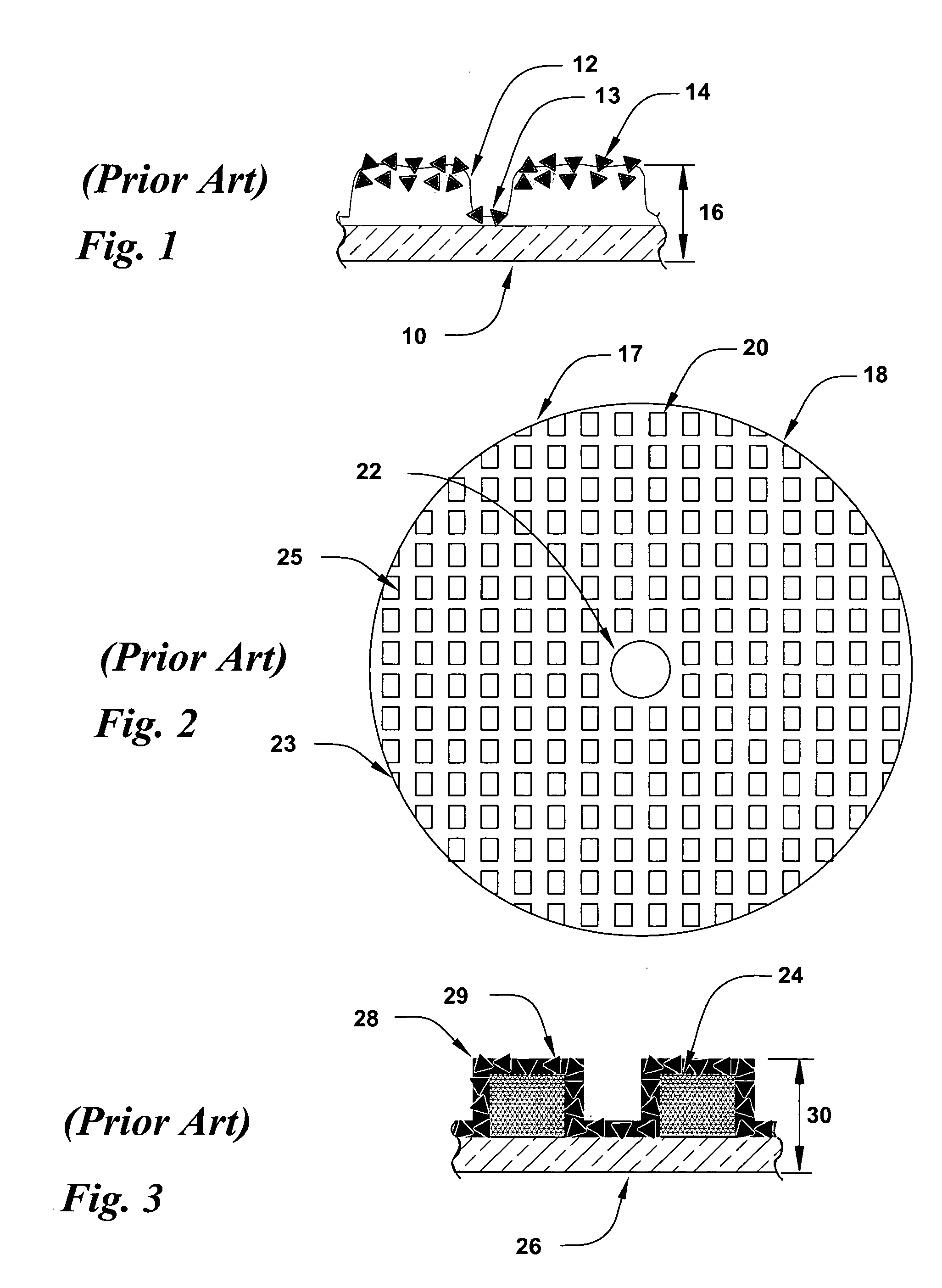

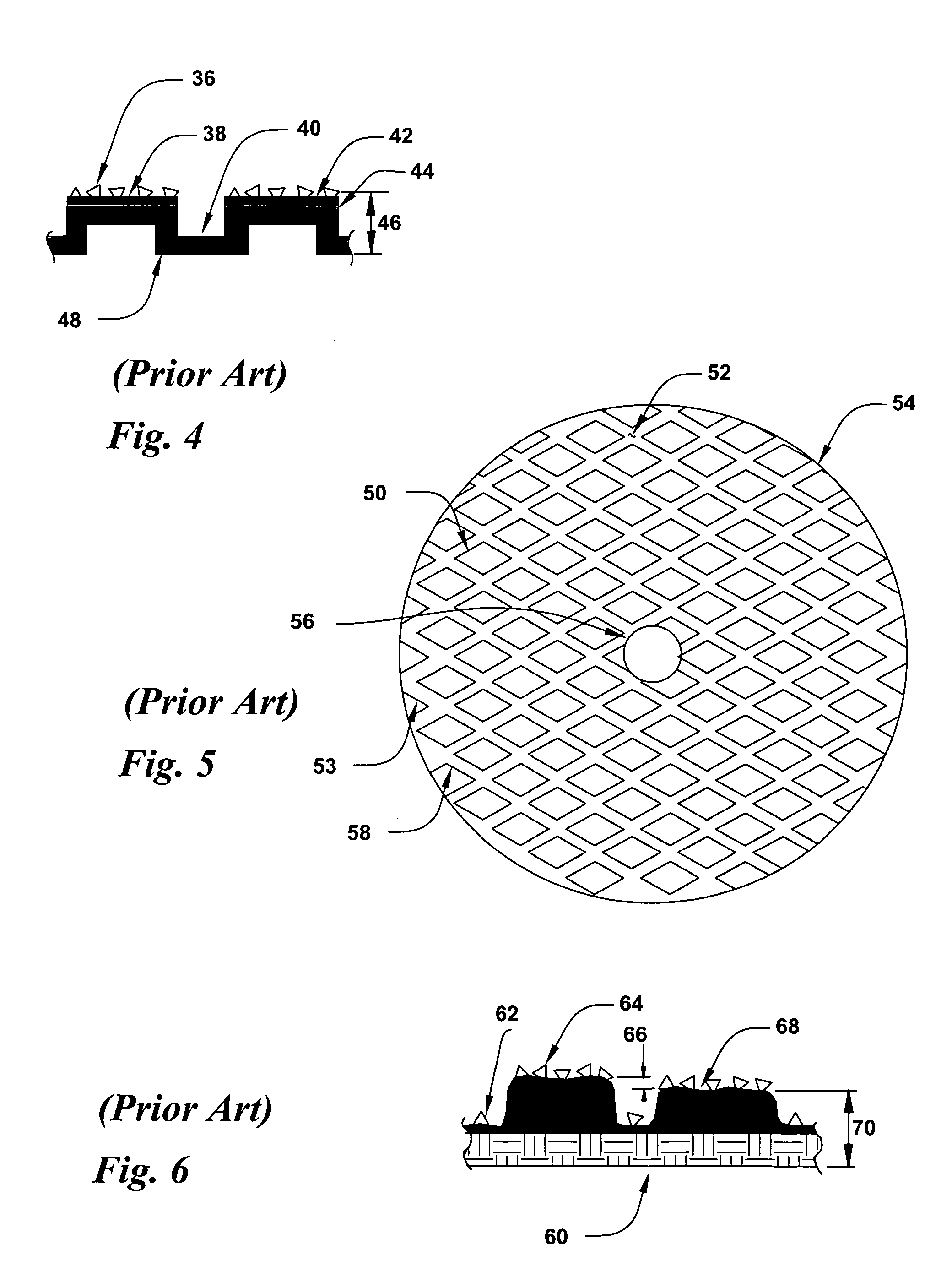

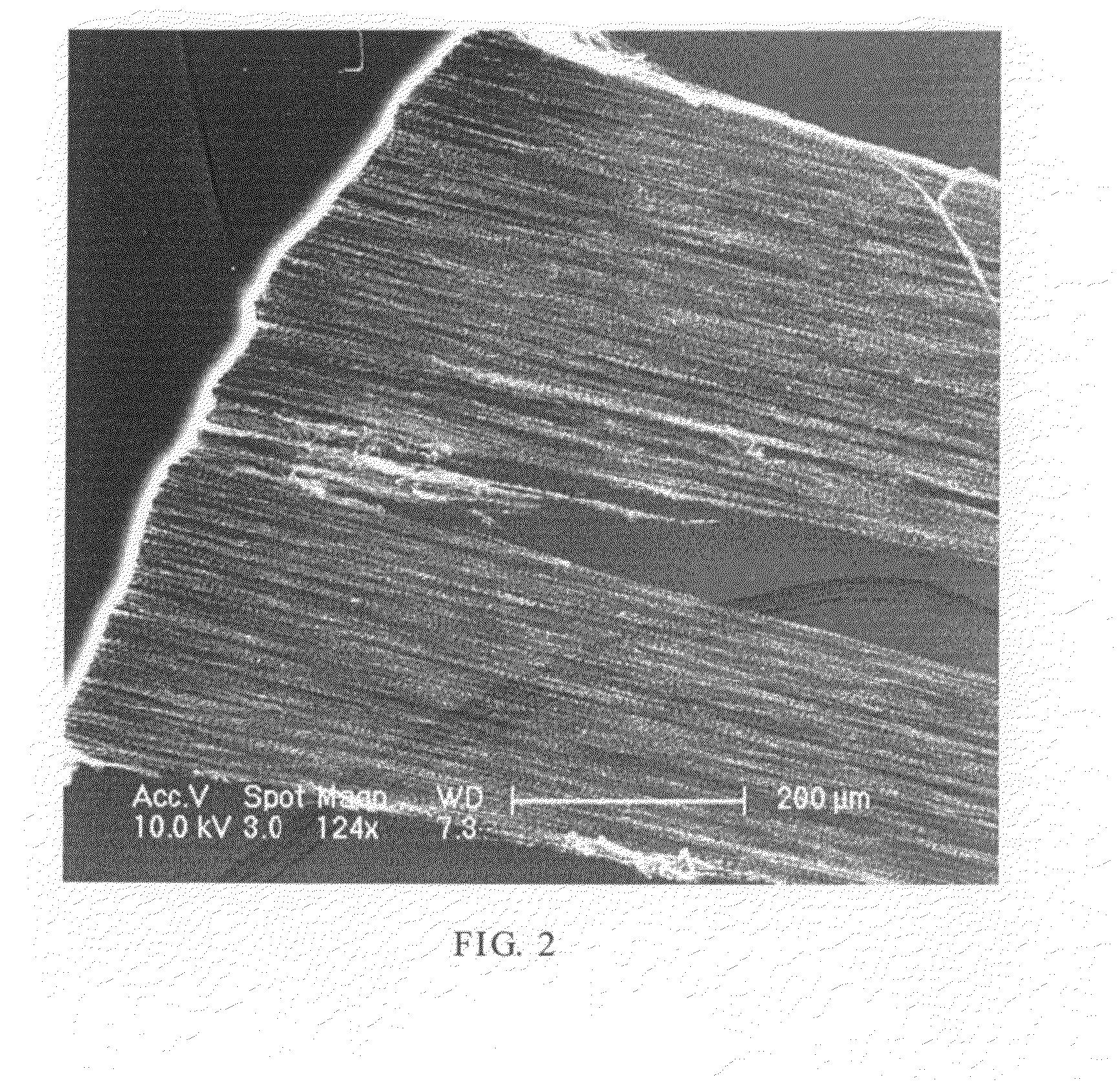

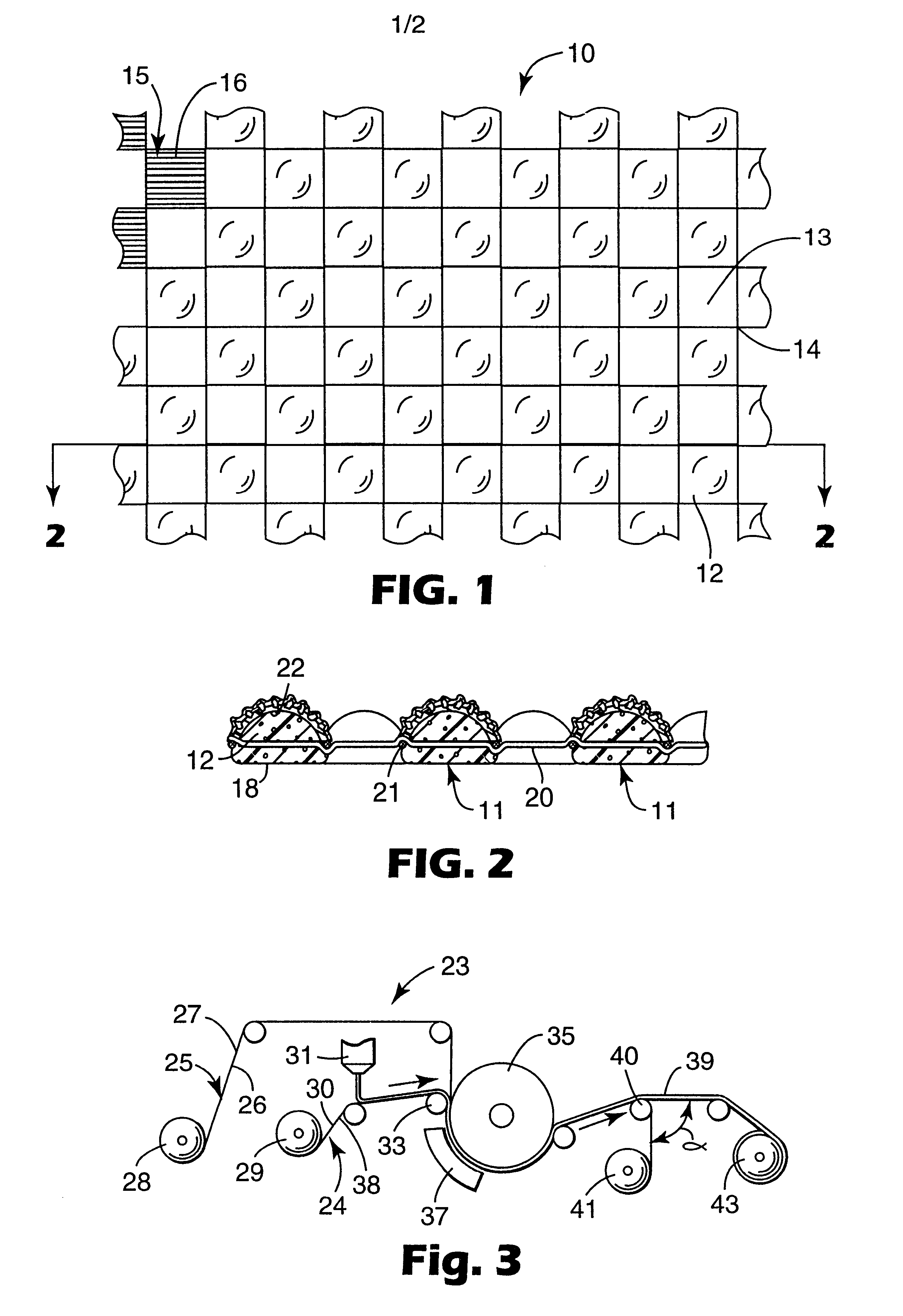

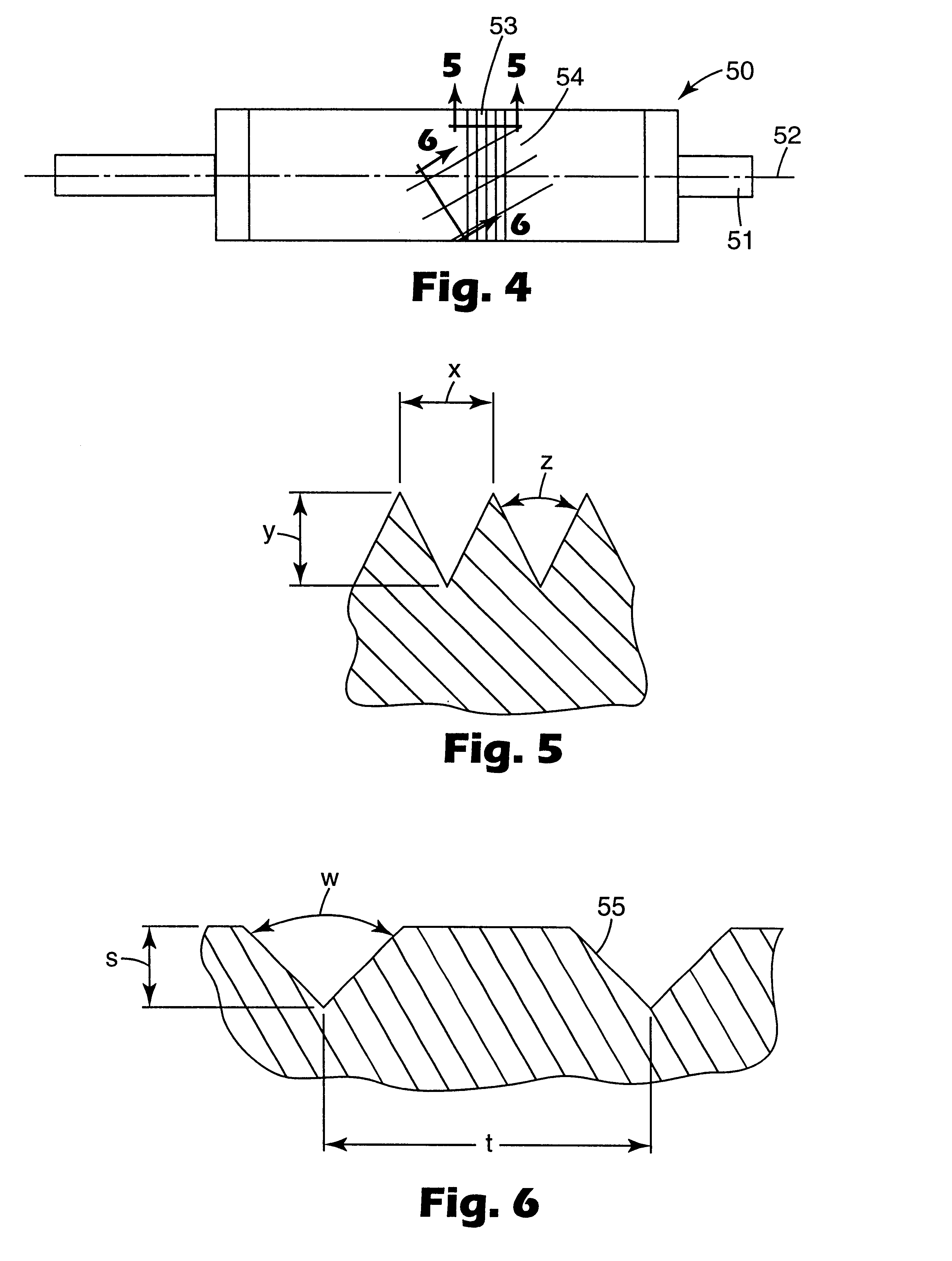

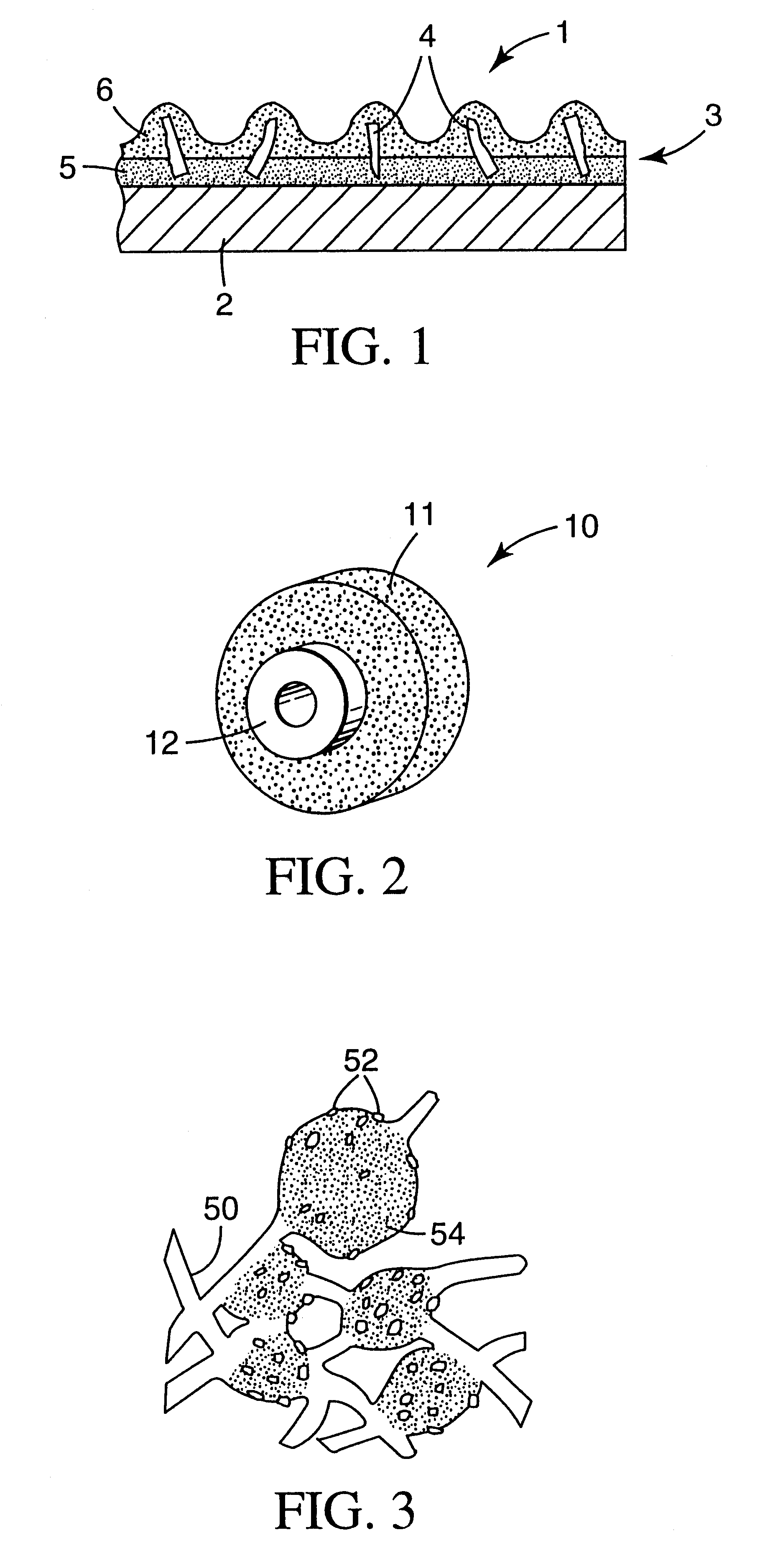

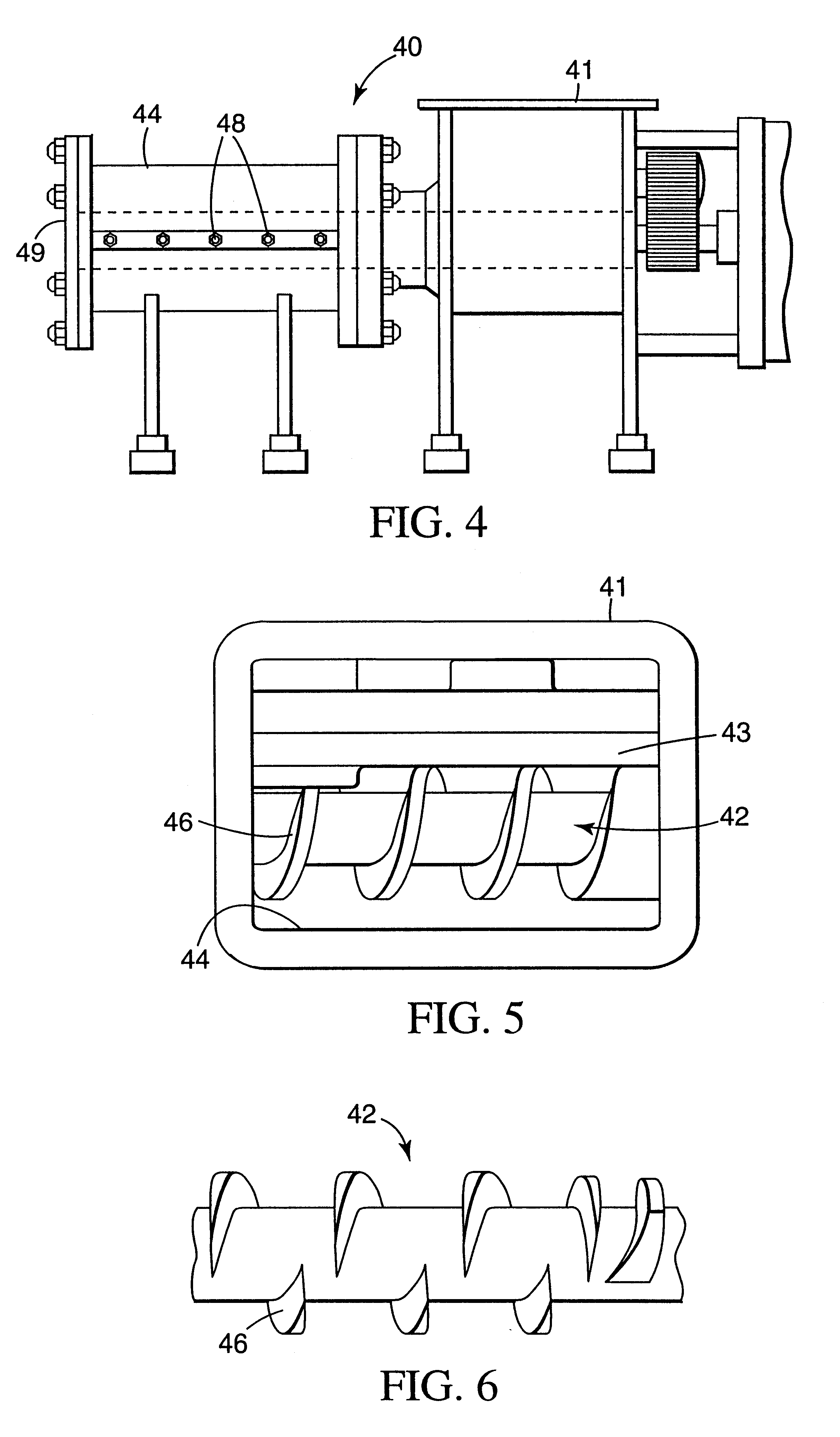

Abrasive bead coated sheet and island articles

InactiveUS20050118939A1Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedSlurry

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

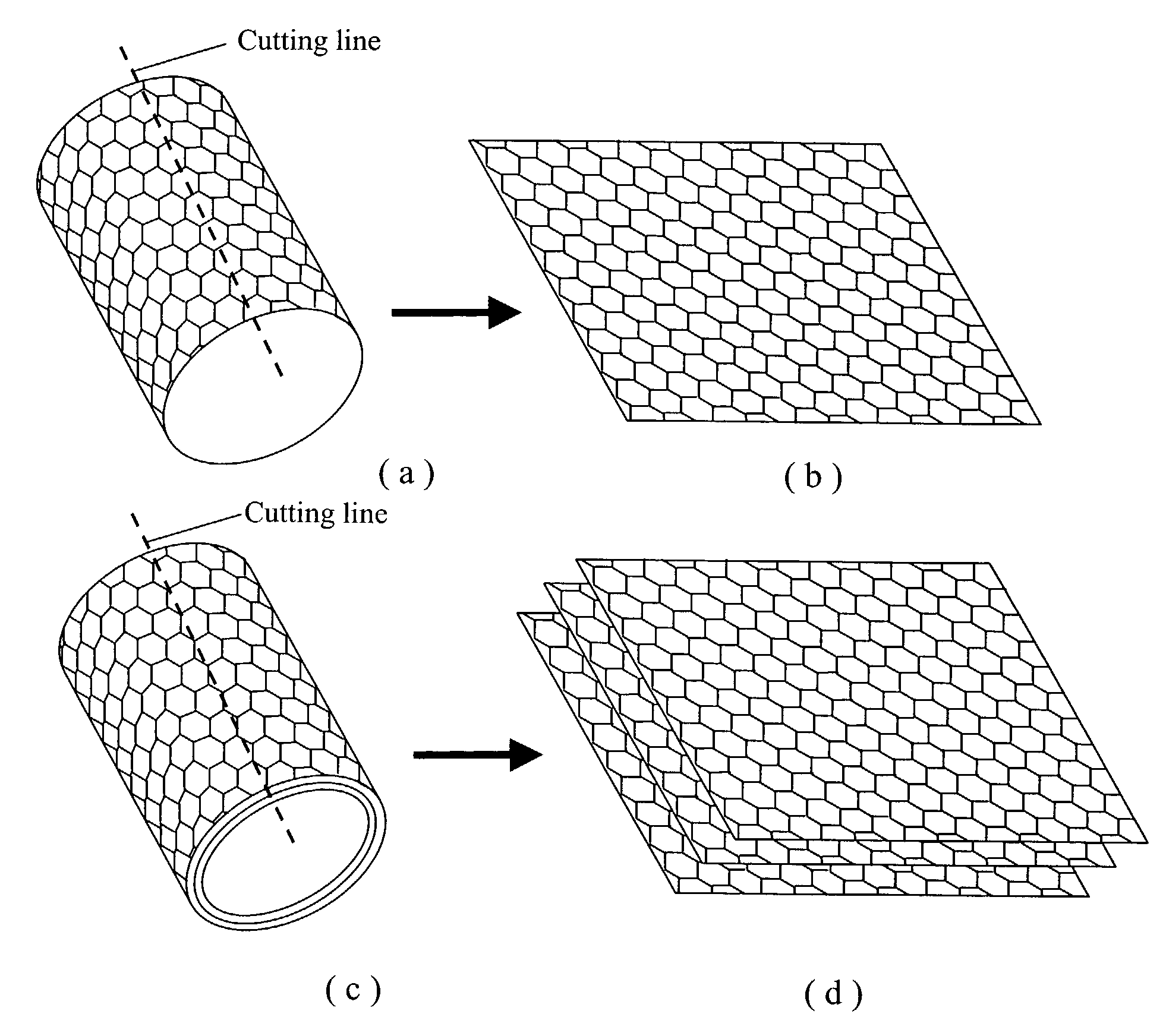

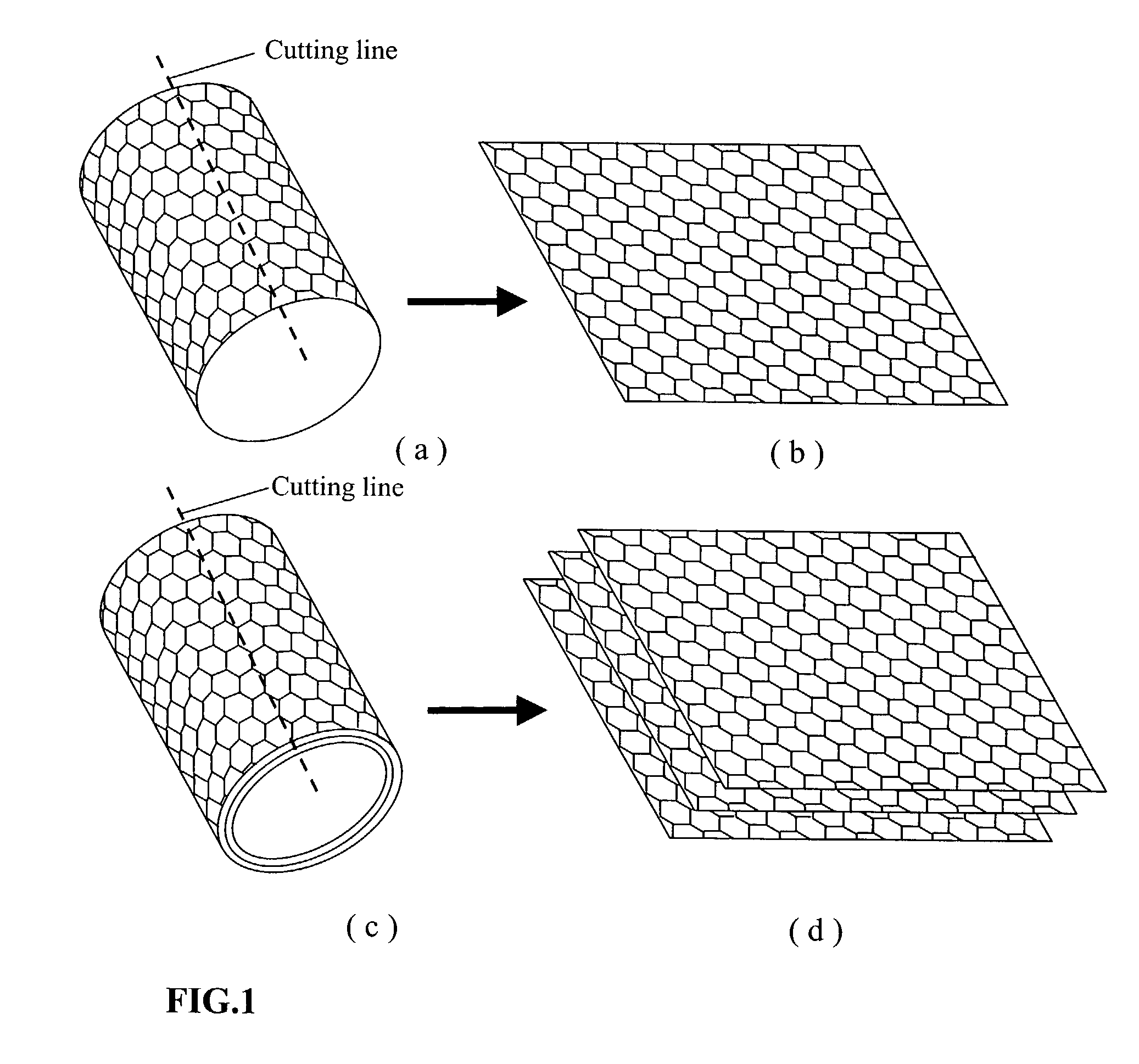

Process for producing nano-scaled platelets and nanocompsites

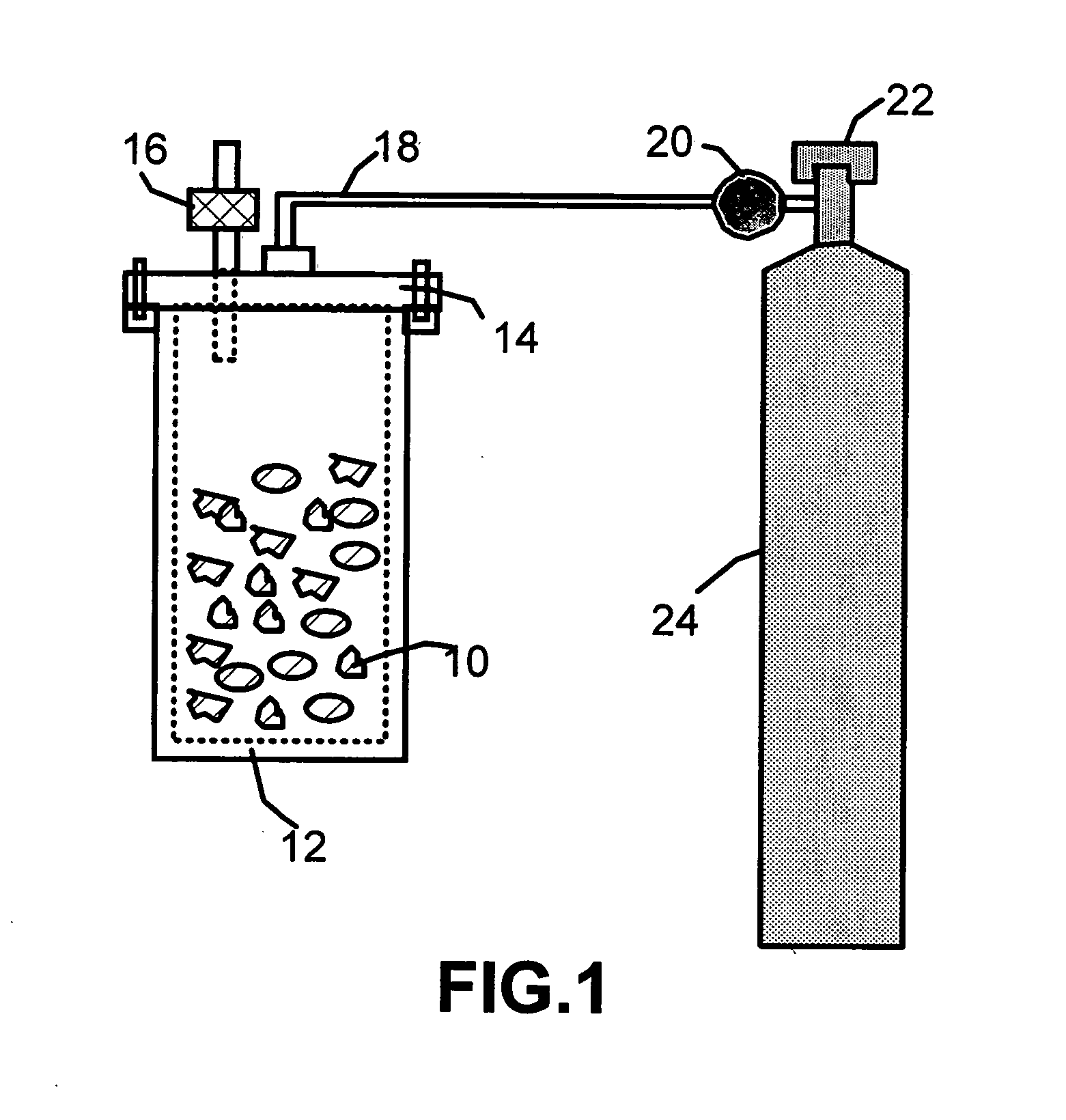

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) subjecting a layered material to a gaseous environment at a first temperature and first pressure sufficient to cause gas species to penetrate between layers of the layered material, forming a gas-intercalated layered material; and (b) subjecting the gas-intercalated layered material to a second pressure, or a second pressure and a second temperature, allowing gas species to partially or completely escape from the layered material and thereby exfoliating the layered material to produce partially delaminated or totally separated platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can also include dispersing the platelets in a matrix material to form a nanocomposite.

Owner:GLOBAL GRAPHENE GRP INC

Water-absorbing agent

There is disclosed a water-absorbing agent which combines both performances of the capillary suction force and the liquid permeability. This water-absorbing agent is a particulate water-absorbing agent comprising water-absorbent resin particles (α) and a liquid-permeability-enhancing agent (β), wherein the water-absorbent resin particles (α) are surface-crosslink-treated particles of a crosslinked polymer of a monomer including acrylic acid and / or its salt; with the water-absorbing agent being characterized in that the particulate water-absorbing agent has: a mass-average particle diameter (D50) in the range of 234 to 394 gm, a logarithmic standard deviation (σζ) of a particle diameter distribution in the range of 0.25 to 0.45, an absorption capacity without load (CRC) of not less than 15 g / g, and a water-extractable component content of not higher than 15 mass %; and further a liquid-permeability-enhancing agent (β) content in the range of 0.01 to 5 mass parts per 100 mass parts of the water-absorbent resin particles (α).

Owner:NIPPON SHOKUBAI CO LTD

Method for making carbon nanotube yarn

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

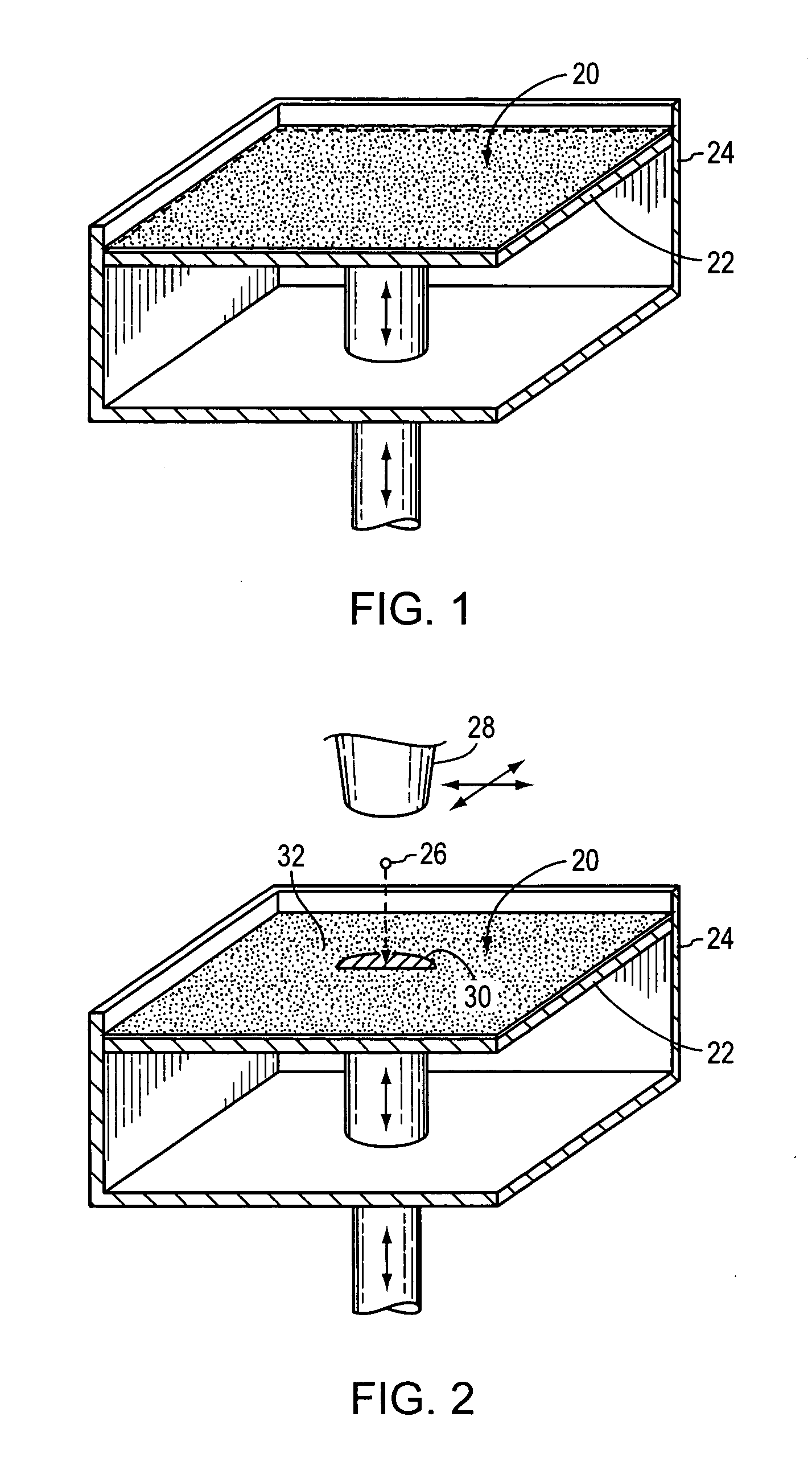

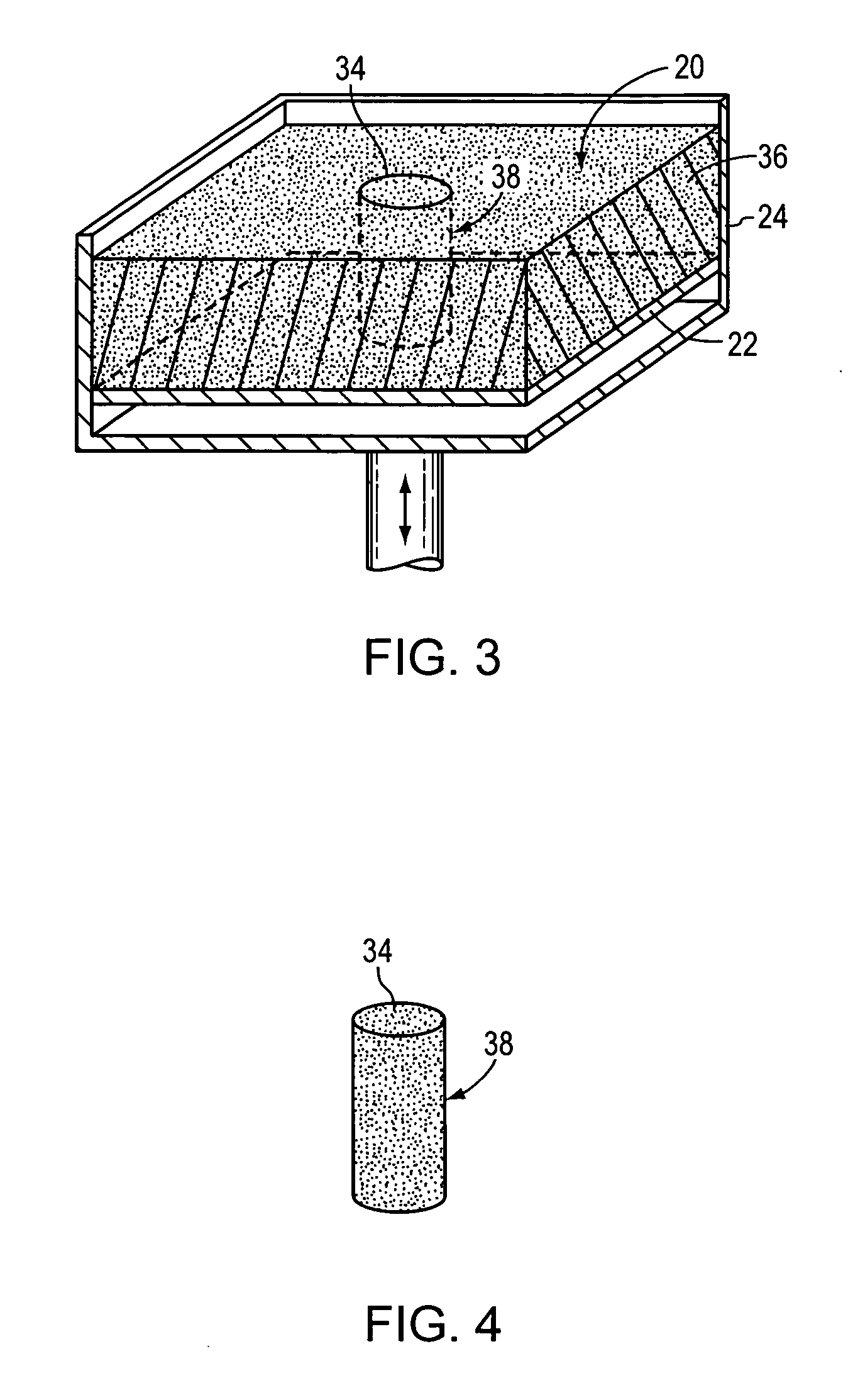

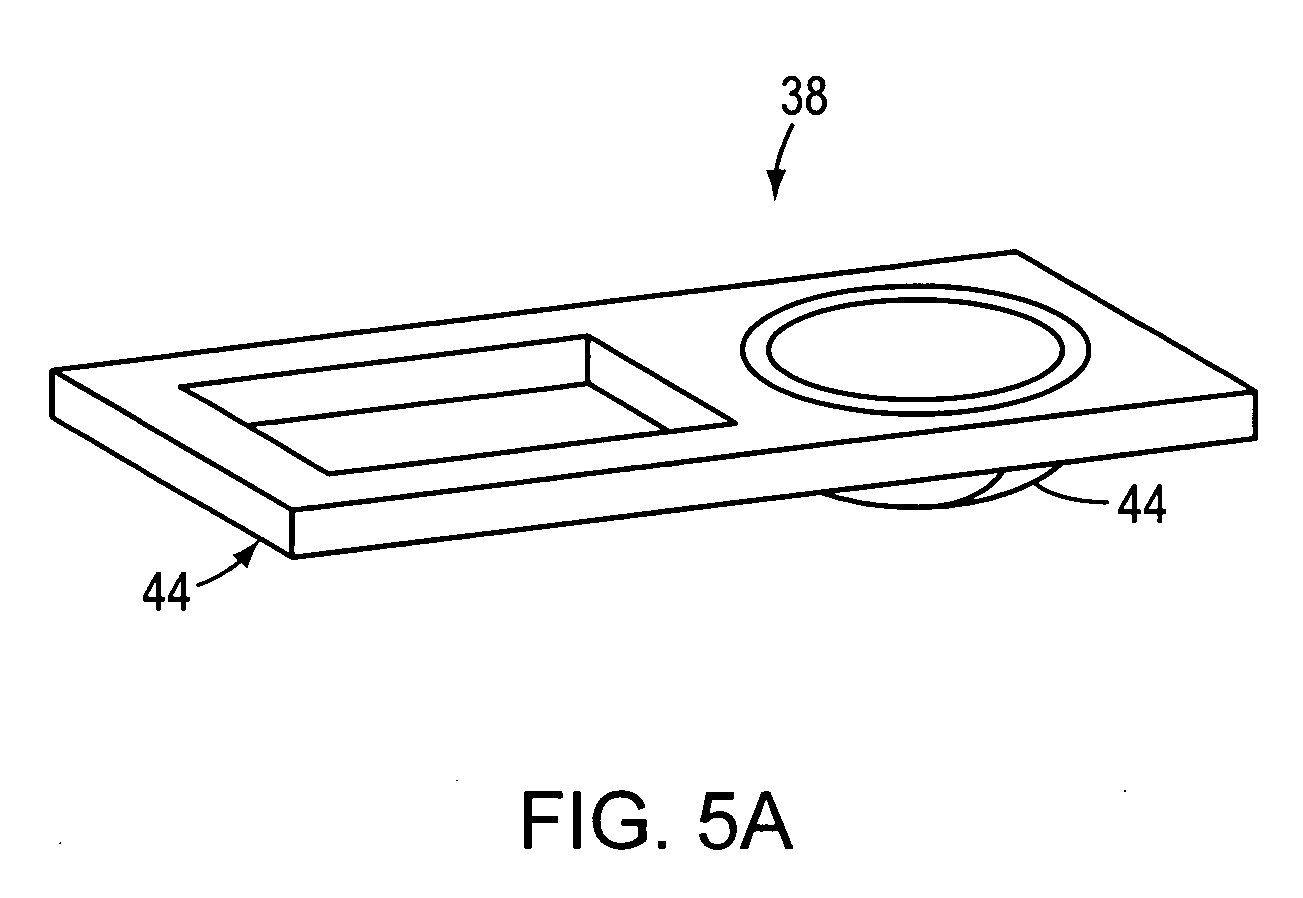

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

Superabsorbent polymers having anti-caking characteristics

InactiveUS6124391ALittle and no caking problemEliminate the problemPigmenting treatmentAbsorbent padsPolymer scienceSuperabsorbent polymer

A particulate material composition of superabsorbent polymer particles, wherein less than about 60% by weight of the superabsorbent polymer particles will pass through a U.S. Standard 50 mesh sieve. The composition has anti-caking properties and also reduced dusting. The composition can be produced by mixing the superabsorbent polymer particles with an inorganic powder, such as clay.

Owner:EVONIK DEGUSSA GMBH

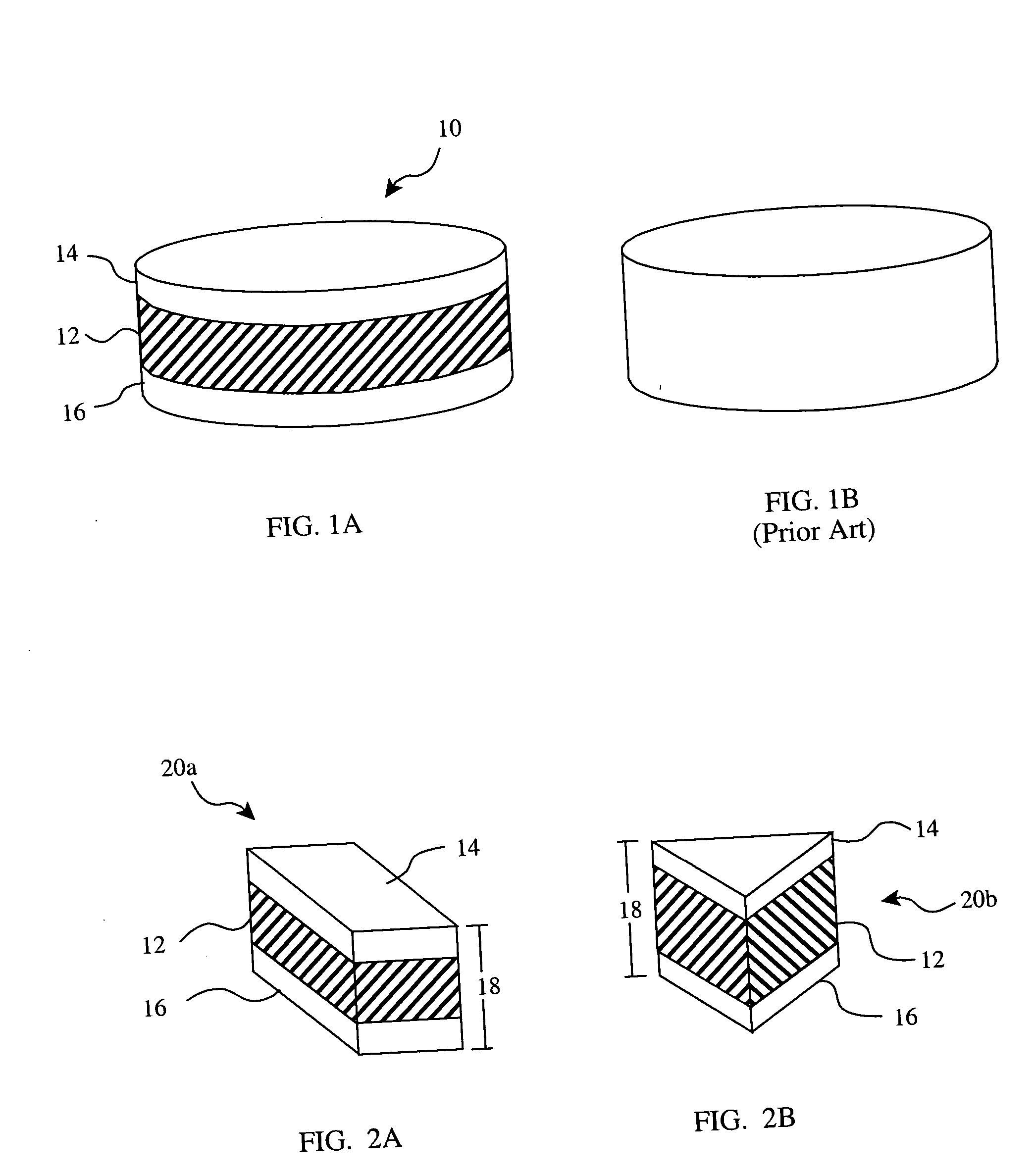

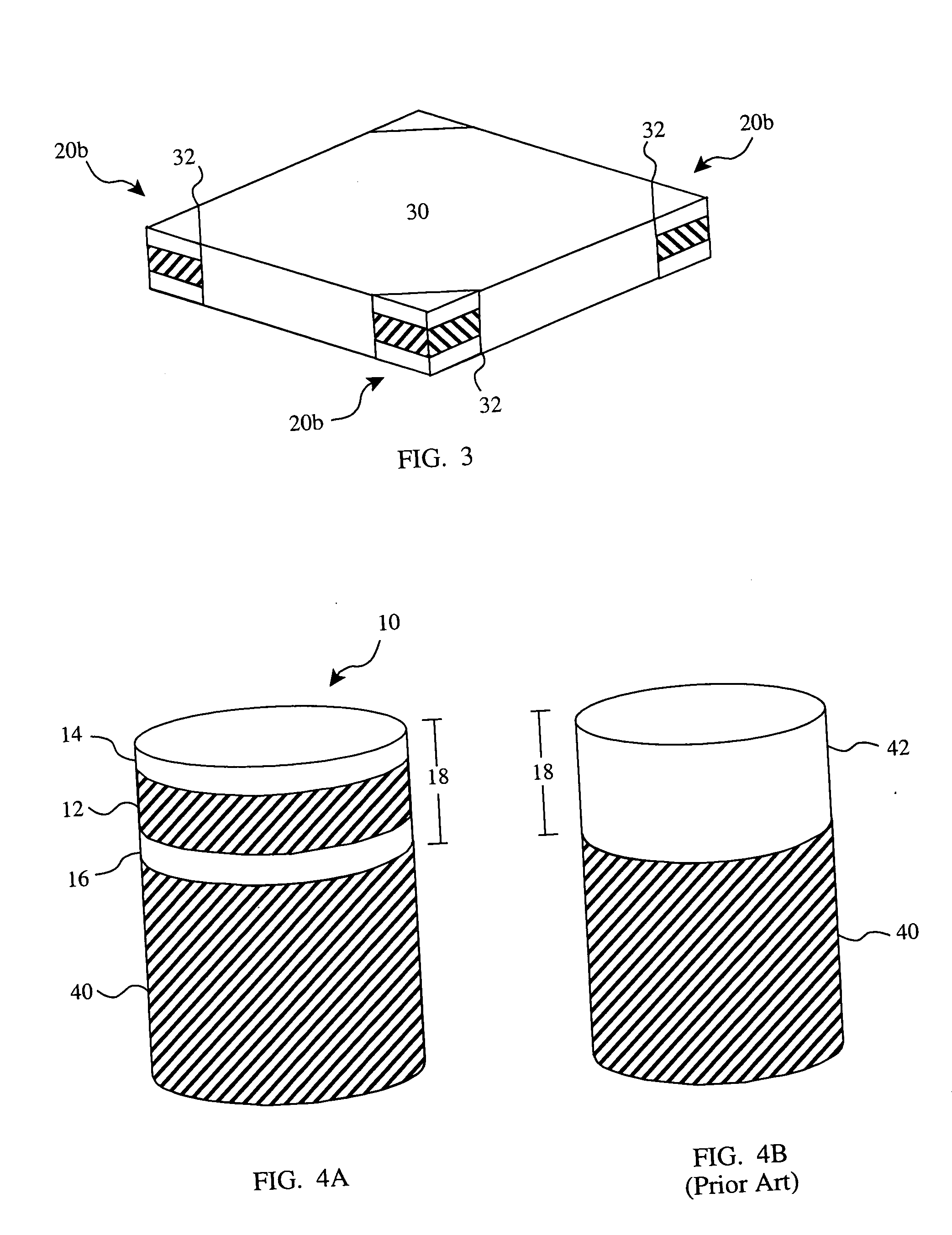

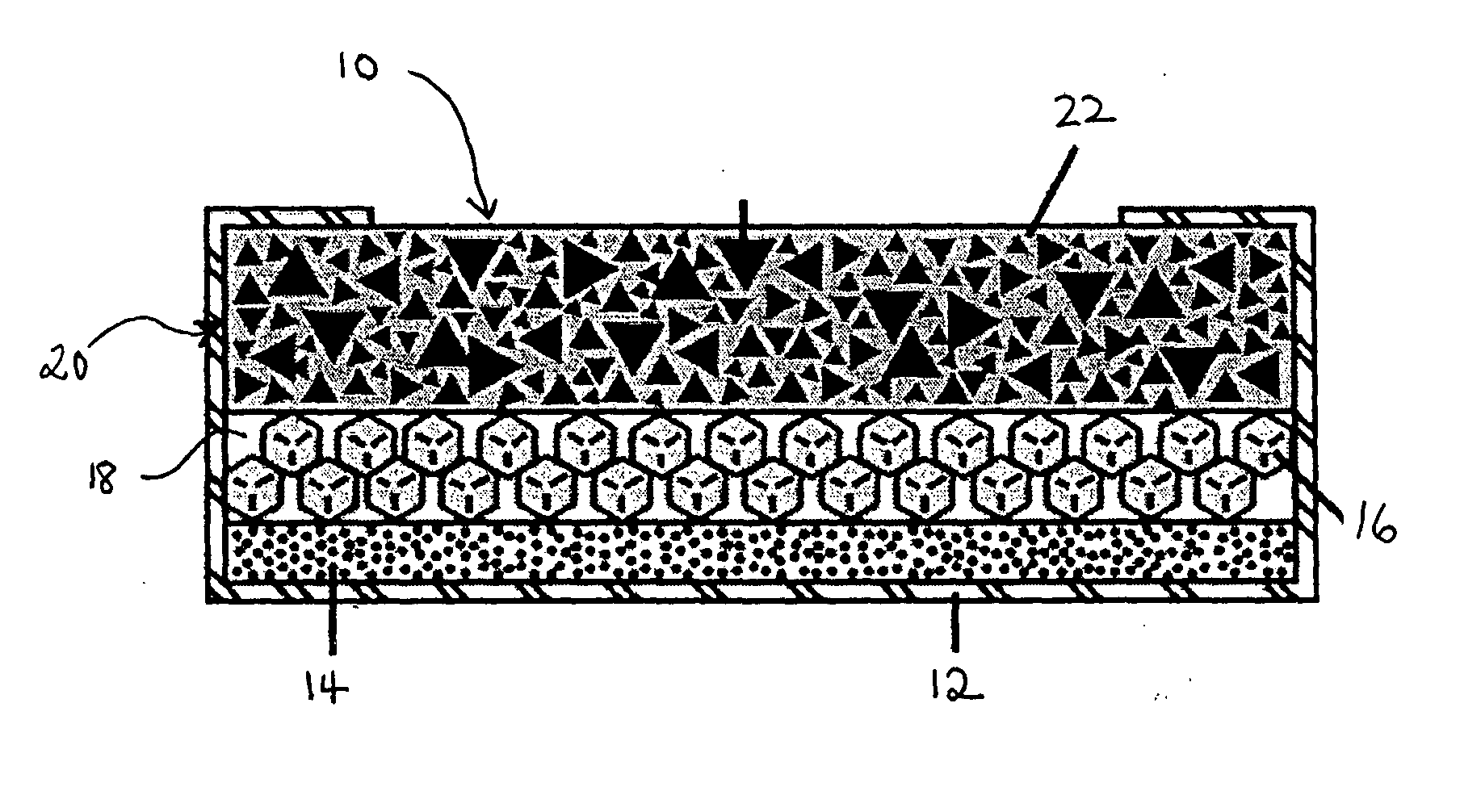

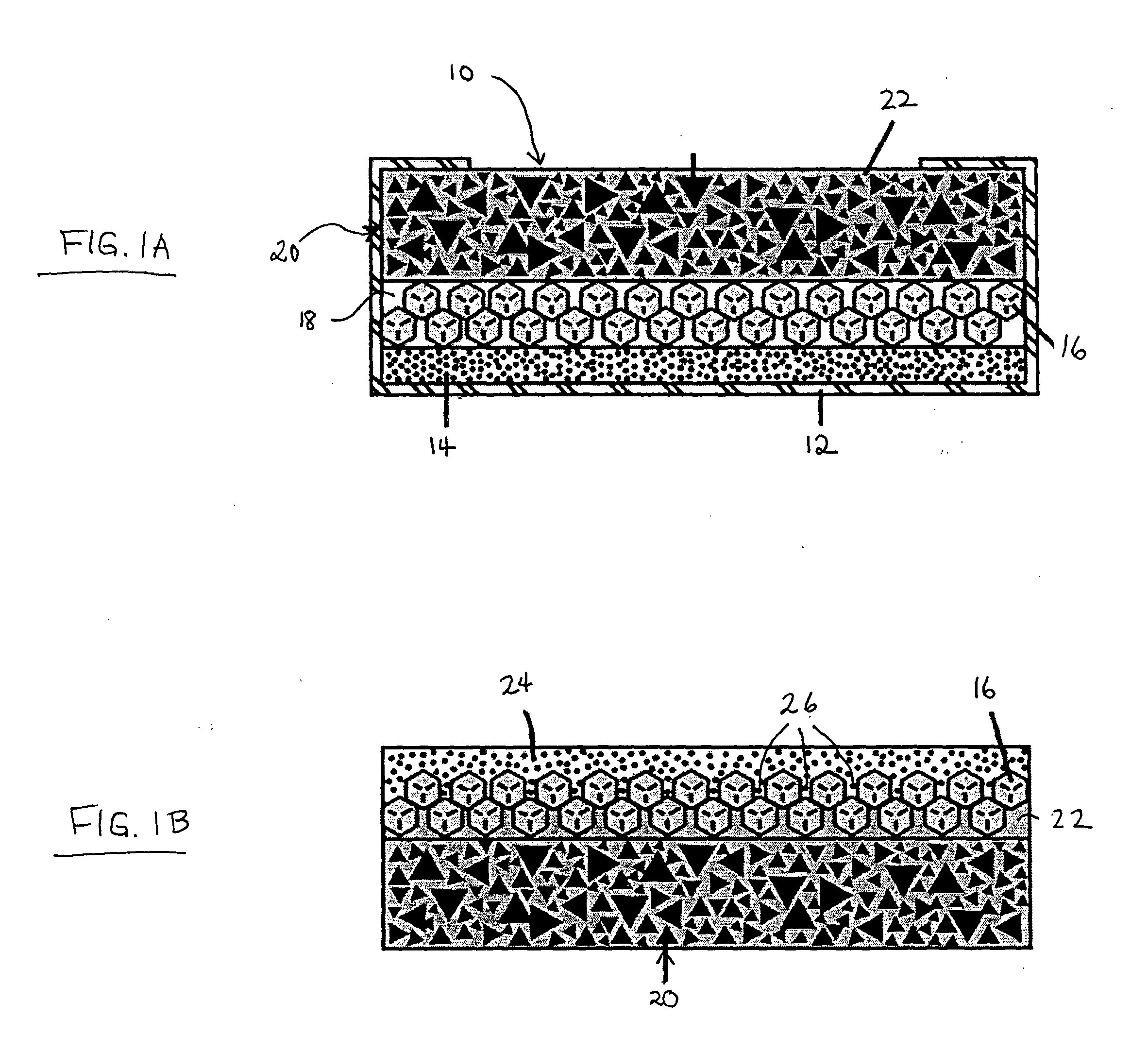

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

Polymer compositions, method of manufacture, and articles formed therefrom

ActiveUS20060142455A1High tensile modulusImprove ductilityPigmenting treatmentMaterial nanotechnologyPolymer scienceFluoropolymer

A polymer composition is disclosed, which comprises a matrix polymer, a fluoropolymer that may be at least partially encapsulated by an encapsulating polymer, and a filler. Methods for making the polymer compositions and articles made of such compositions are also disclosed. The compositions and article can have improved tensile modulus, ductility, and / or impact properties.

Owner:SABIC INNOVATIVE PLASTICS IP BV

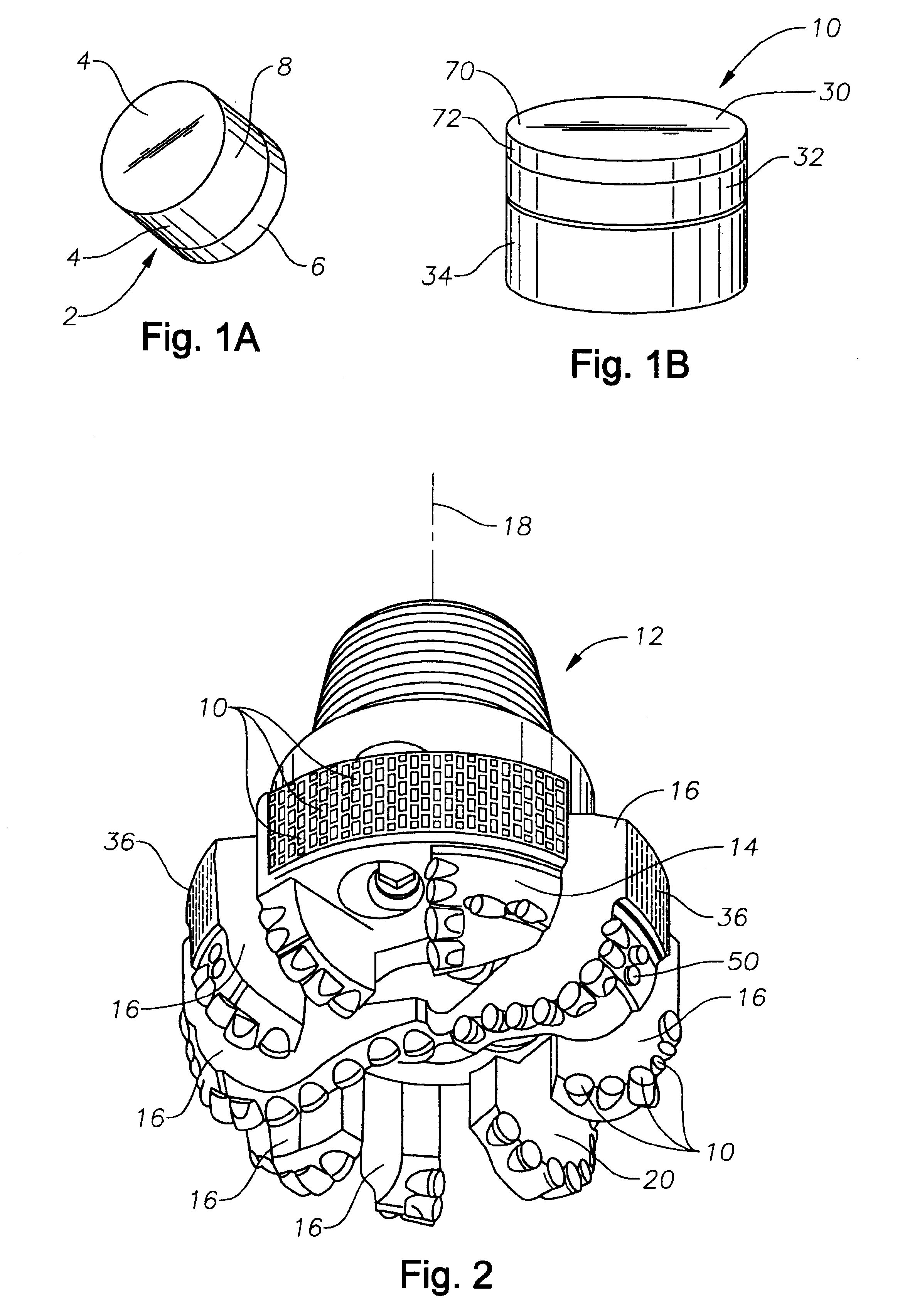

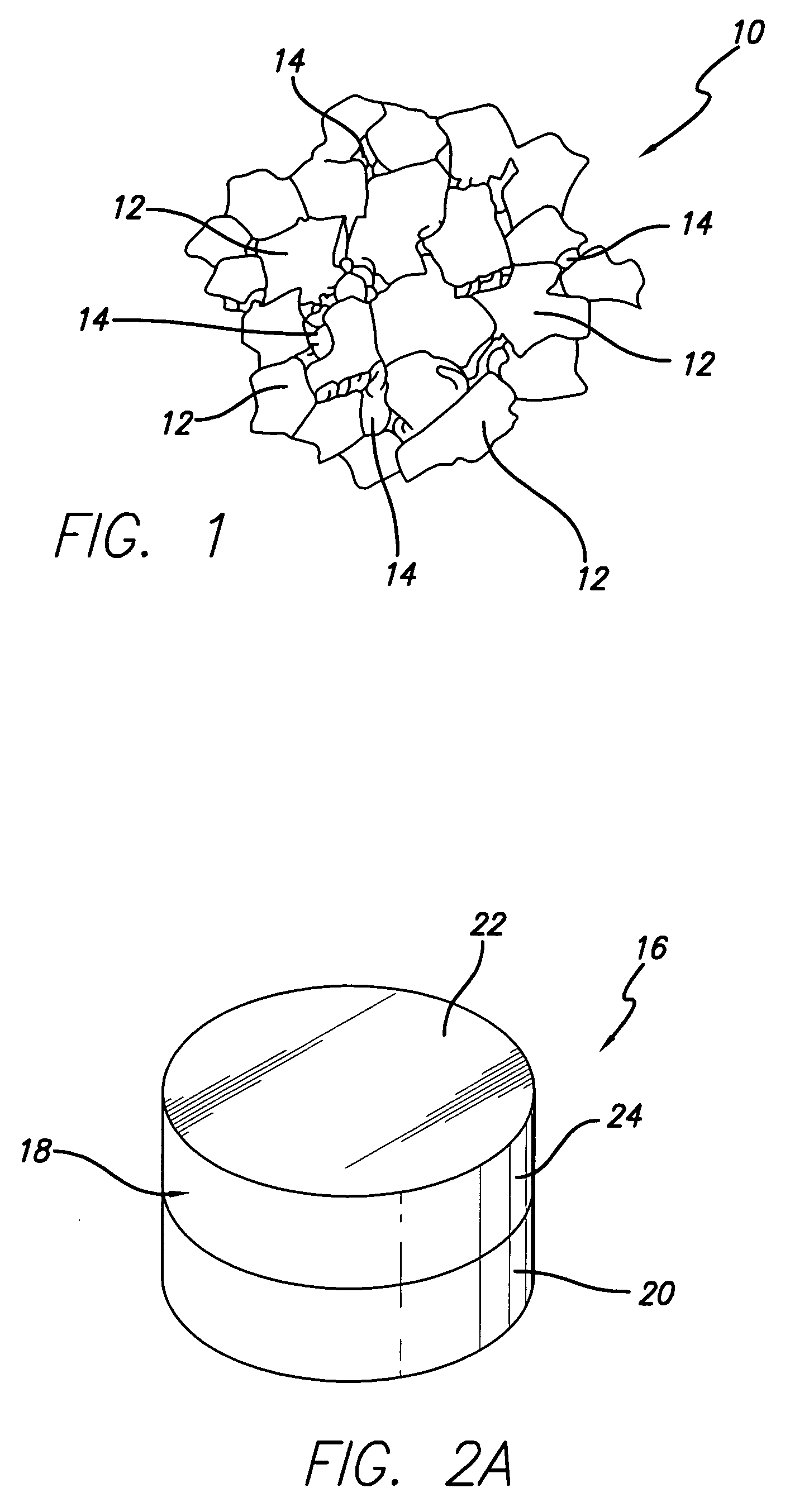

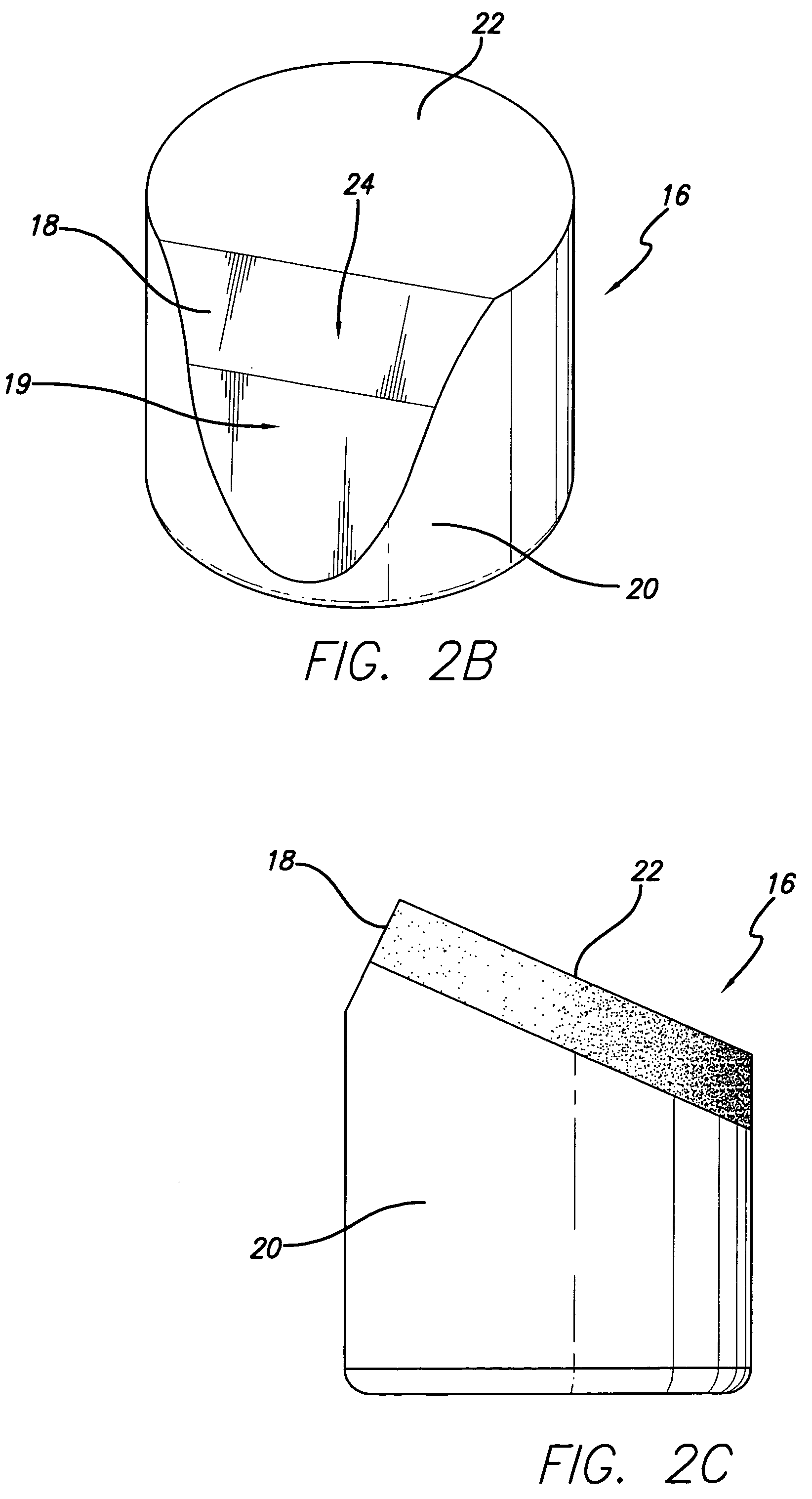

Polycrystalline diamond compact (PDC) cutting element having multiple catalytic elements

InactiveUS7635035B1Improve thermal stabilityPigmenting treatmentDrill bitsPolycrystalline diamondThermal stability

A polycrystalline diamond compact useful for wear, cutting, drilling, drawing and like applications is provided with a first diamond region remote from the working surface which has a metallic catalyzing material and a second diamond region adjacent to or including the working surface containing a non-metallic catalyst and the method of making such a compact is provided. This compact is particularly useful in high temperature operations, such as hard rock drilling because of the improved thermal stability at the working surface.

Owner:US SYNTHETIC CORP

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060390A1Improve thermal stabilityGood adhesionPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body. The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

Abrasive product and method of making the same

InactiveUS6613113B2Effectively removing the sanding dust from the abrasive surfaceLess abrasive surfacePigmenting treatmentOther chemical processesElastomerMaterials science

The invention provides a flexible abrasive product comprising a flexible sheet-like substrate comprising a multiplicity of separated resilient bodies connected to each other in a generally planar array in a pattern which provides open spaces between adjacent connected bodies, each body having a first surface and an opposite second surface; and abrasive particles to cause at least the first surface to be an abrasive surface. A method of making the abrasive is provided by providing the substrate and providing abrasive particles to at least the first surface to provide an abrasive surface.

Owner:3M INNOVATIVE PROPERTIES CO

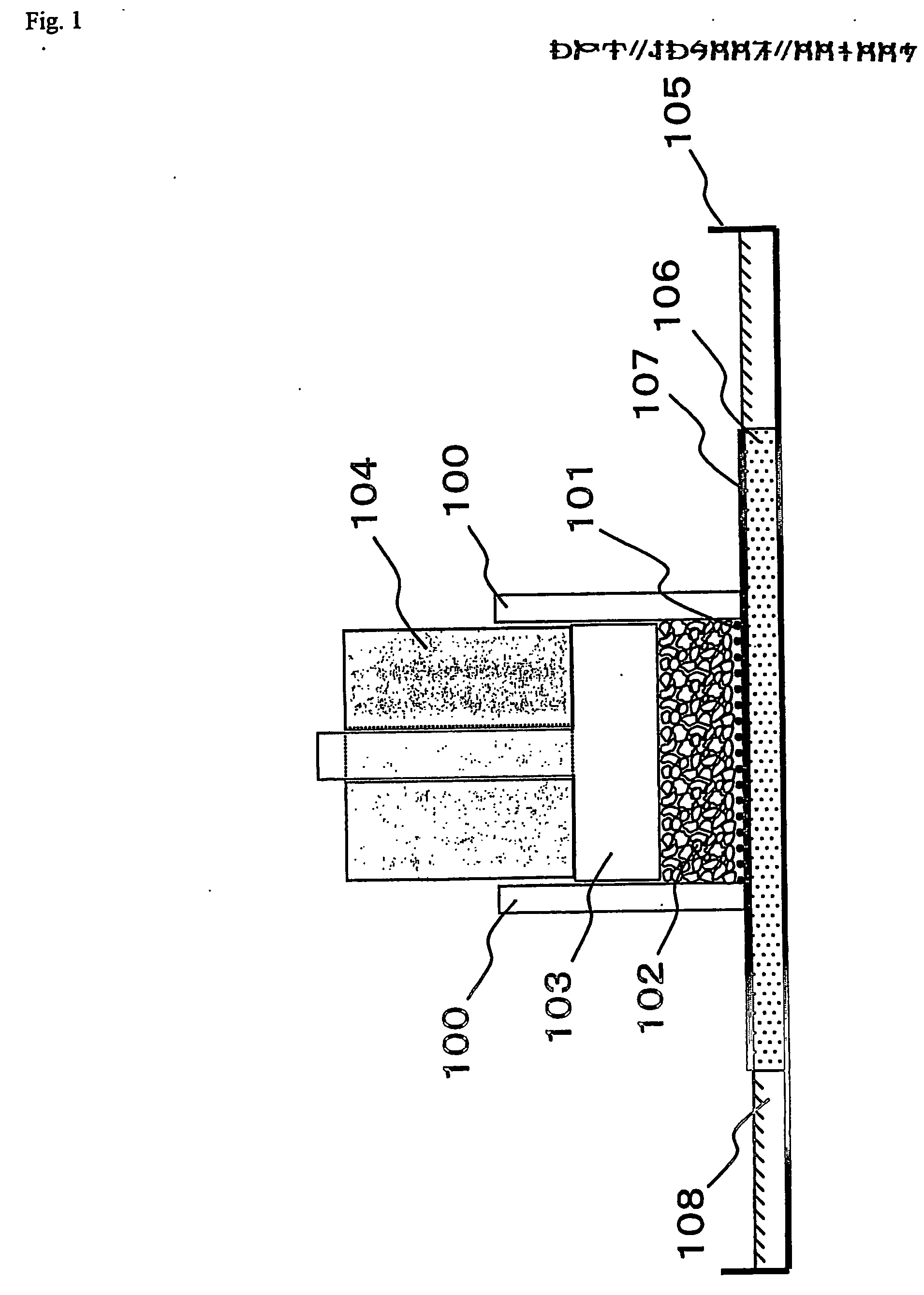

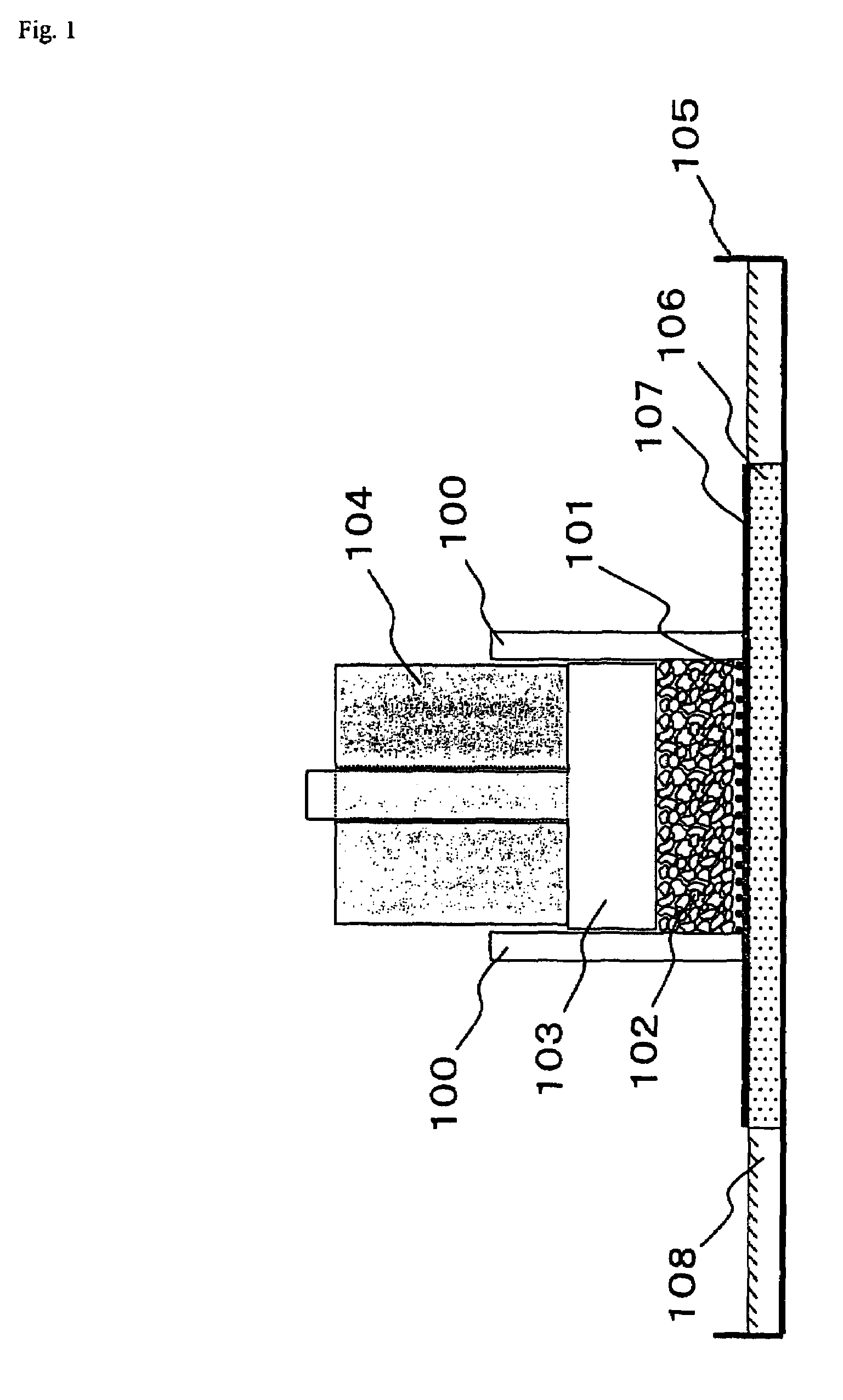

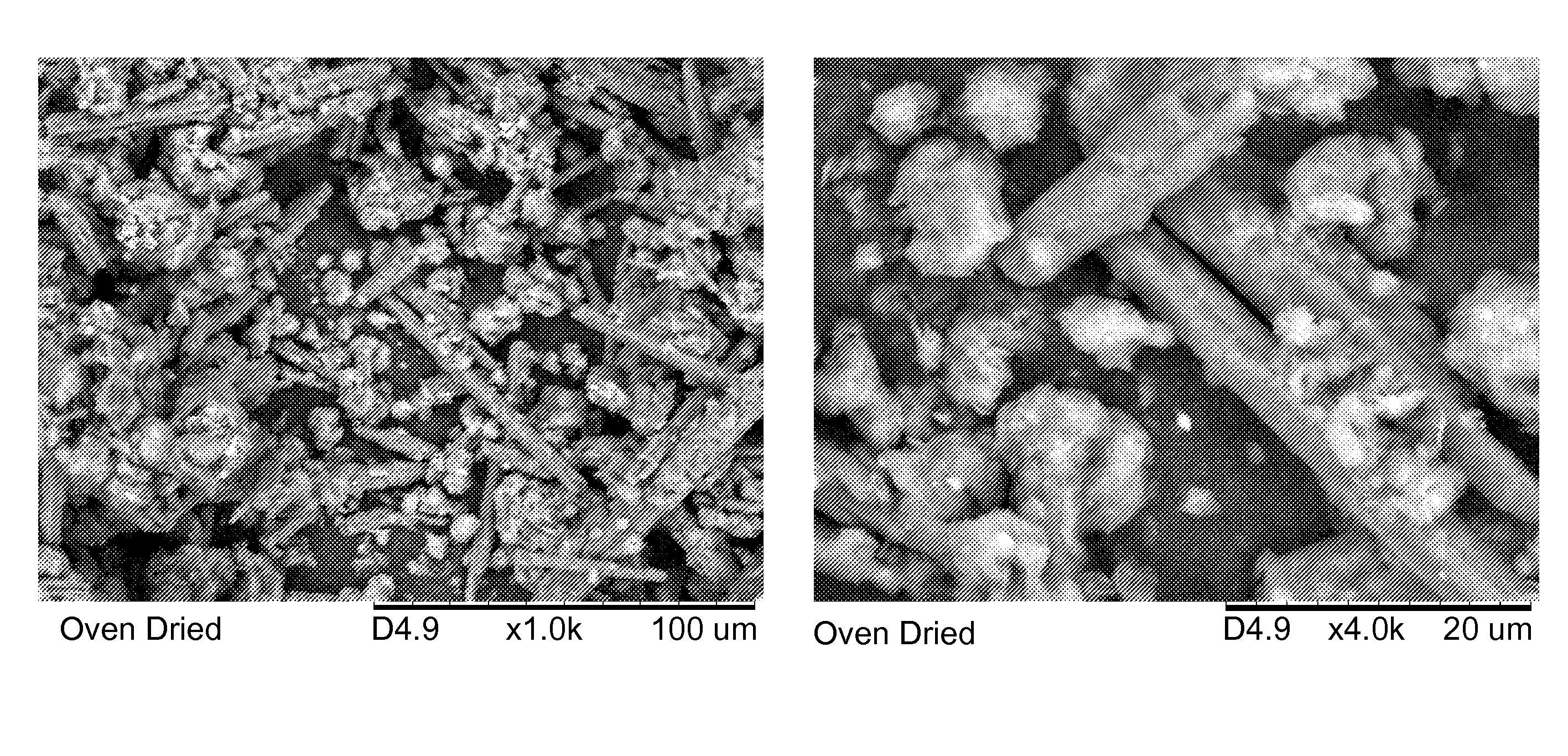

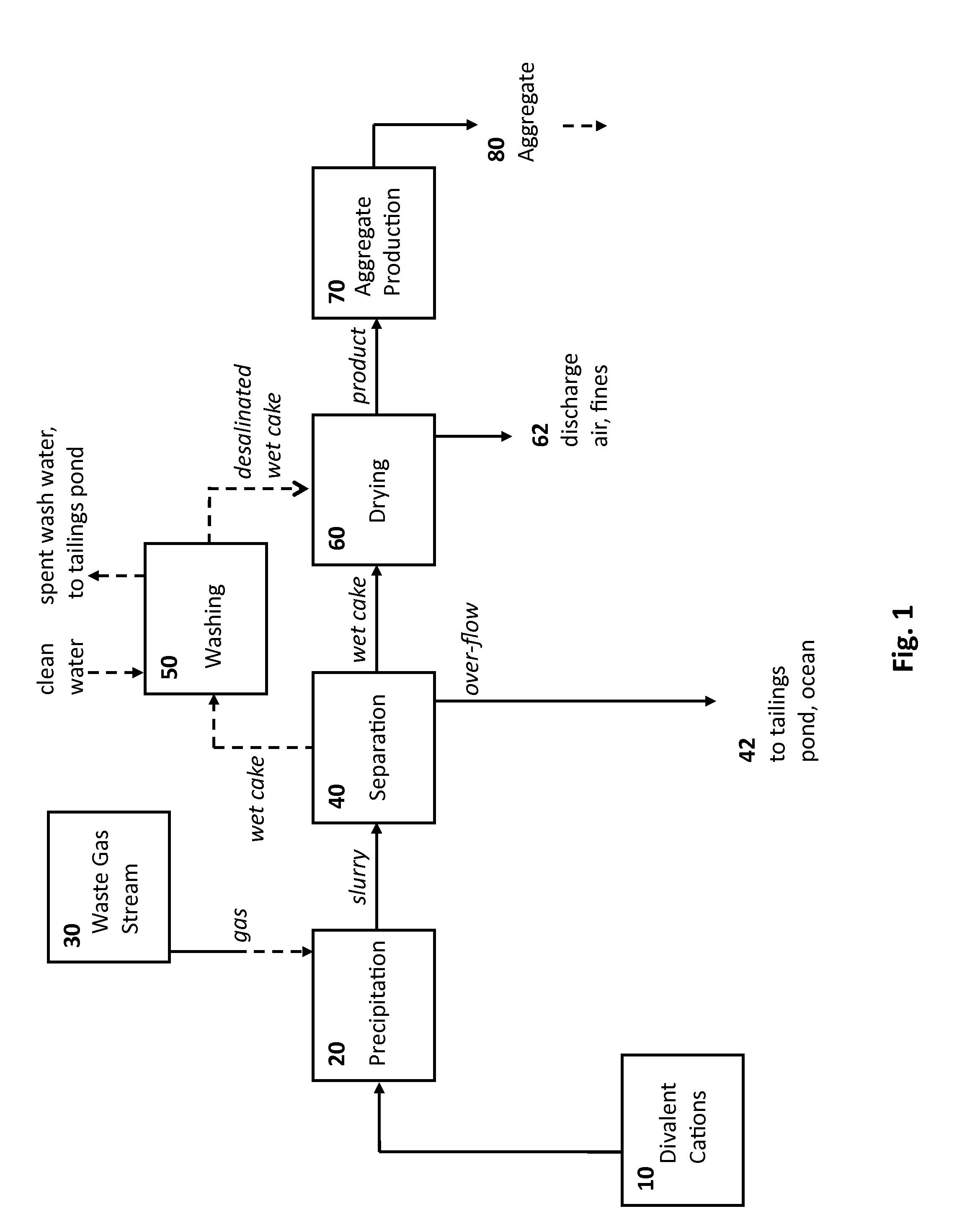

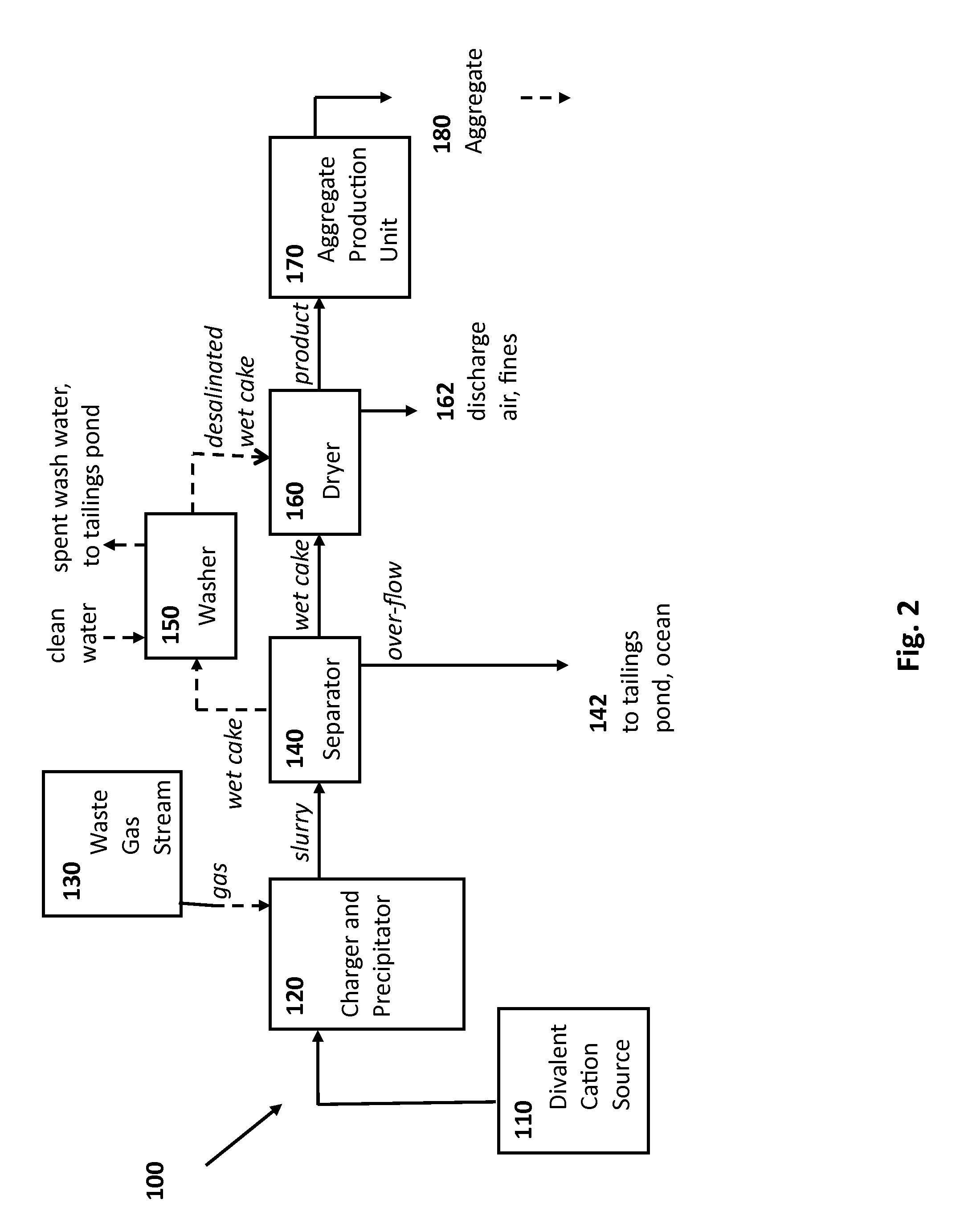

Rocks and aggregate, and methods of making and using the same

ActiveUS20100024686A1Calcium/strontium/barium carbonatesPigmenting treatmentCarbonateToxic industrial waste

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:ARELAC INC

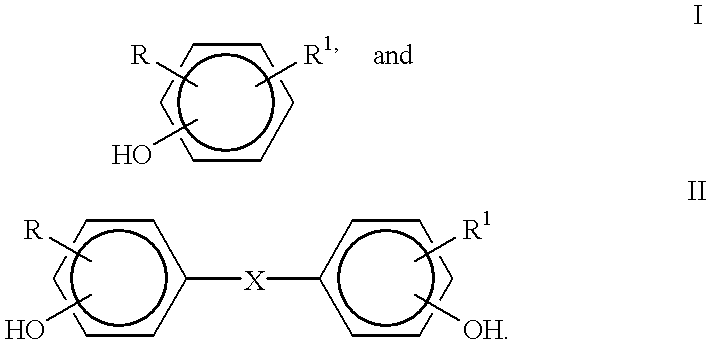

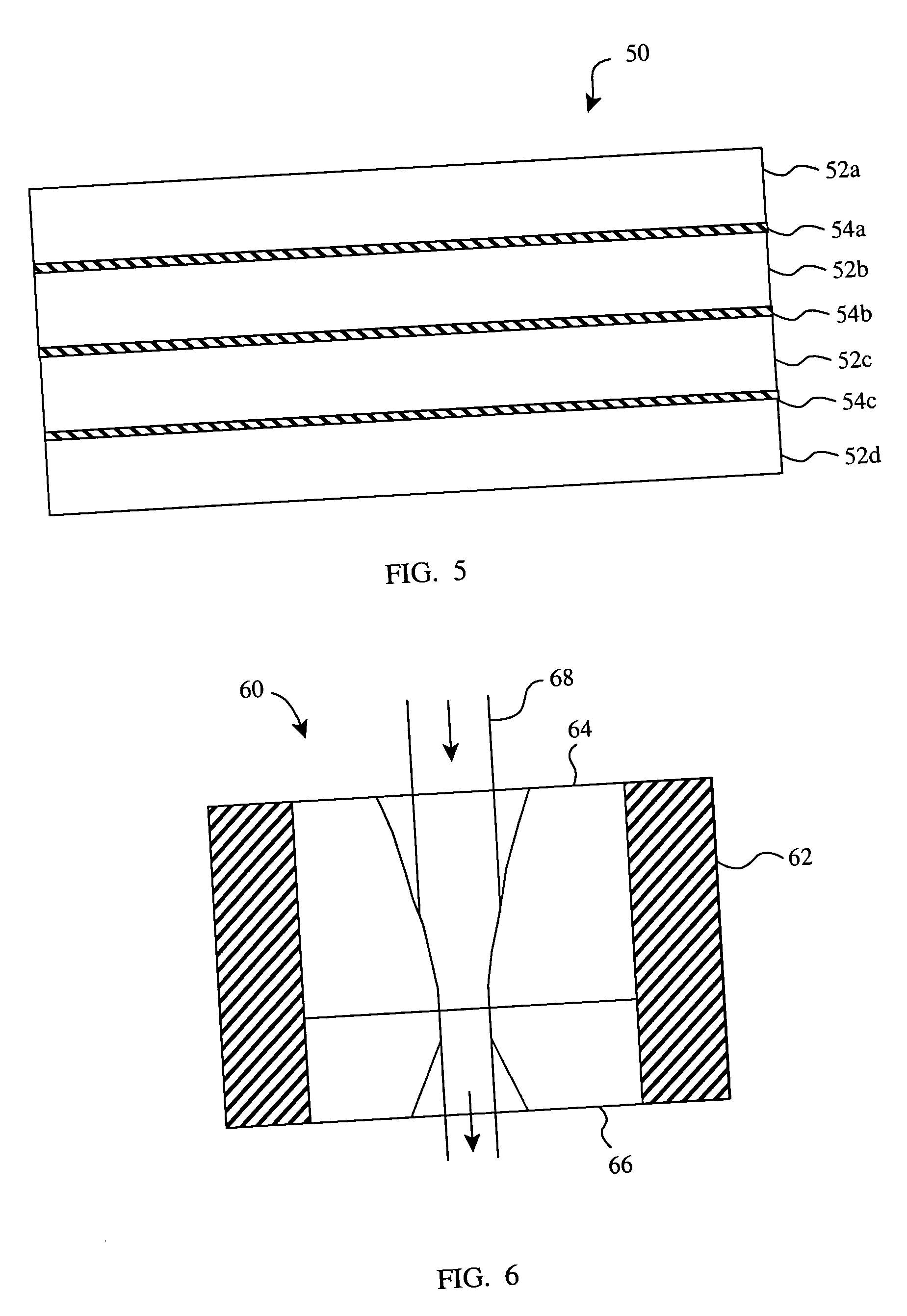

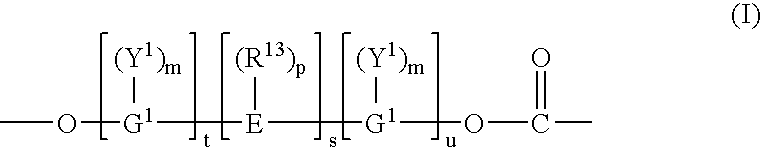

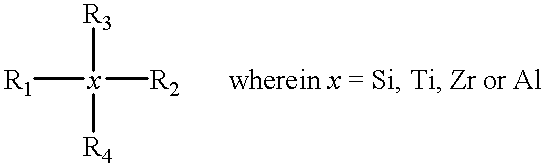

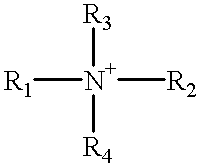

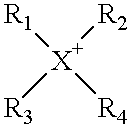

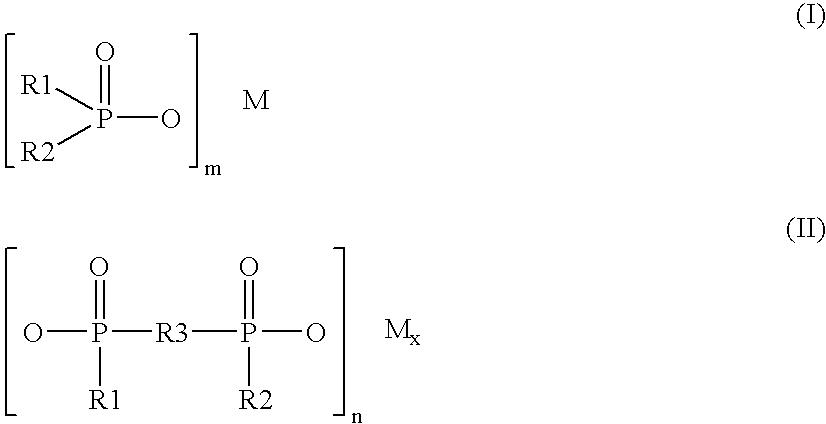

Intercalates formed via coupling agent-reaction and onium ion-intercalation pre-treatment of layered material for polymer intercalation

InactiveUS6407155B1Easy intercalationEasily co-intercalatedPigmenting treatmentPaper coatingOligomerPre treatment

Intercalated layered materials prepared by reacting the layered material with a coupling agent and co-intercalating an onium ion and an oligomer or polymer between the planar layers of a swellable layered material, such as a phyllosilicate, preferably a smectite clay. The spacing of adjacent layers of the layered materials is expanded at least about 3 Å, preferably at least about 5 Å, usually preferably to a d-spacing of about 15-20 Å, e.g., 18 Å with the onium ion spacing / compatibilizing agent. The intercalation of the oligomer or polymer then increases the spacing of adjacent layers an additional at least 3 Å, e.g., to at least about 20 Å, preferably about 25 Å to about 30 Å, generally about 28 Å, and provides a nanocomposite having increased tensile strength, flexibility, and ductility (less brittle).

Owner:AMCOL INTERNATIONAL CORPORATION

Nanodiamond PCD and methods of forming

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

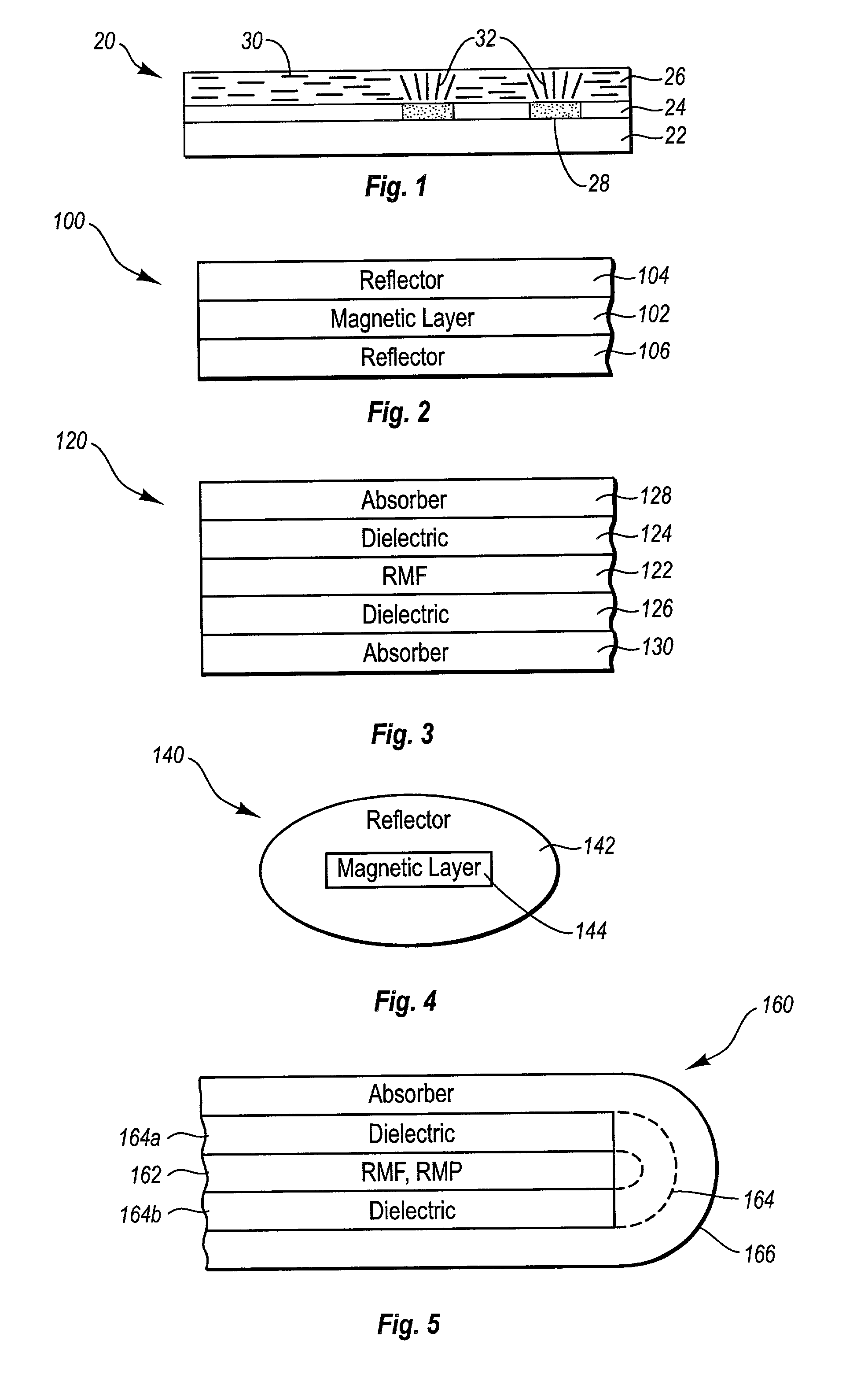

Methods for producing imaged coated articles by using magnetic pigments

InactiveUS20020182383A1Good colorGood optical performancePigmenting treatmentNon-fibrous pulp additionPigmentMagnetic field

Methods and devices for producing images on coated articles are provided. The methods generally comprise applying a layer of magnetizable pigment coating in liquid form on a substrate, with the magnetizable pigment coating containing a plurality of magnetic non-spherical particles or flakes. A magnetic field is then applied to selected regions of the pigment coating while the coating is in liquid form, with the magnetic field altering the orientation of selected magnetic particles or flakes. Finally, the pigment coating is solidified, affixing the reoriented particles or flakes in a non-parallel position to the surface of the pigment coating to produce an image such as a three dimensional-like image on the surface of the coating. The pigment coating can contain various interference or non-interference magnetic particles or flakes, such as magnetic color shifting pigments.

Owner:VIAVI SOLUTIONS INC

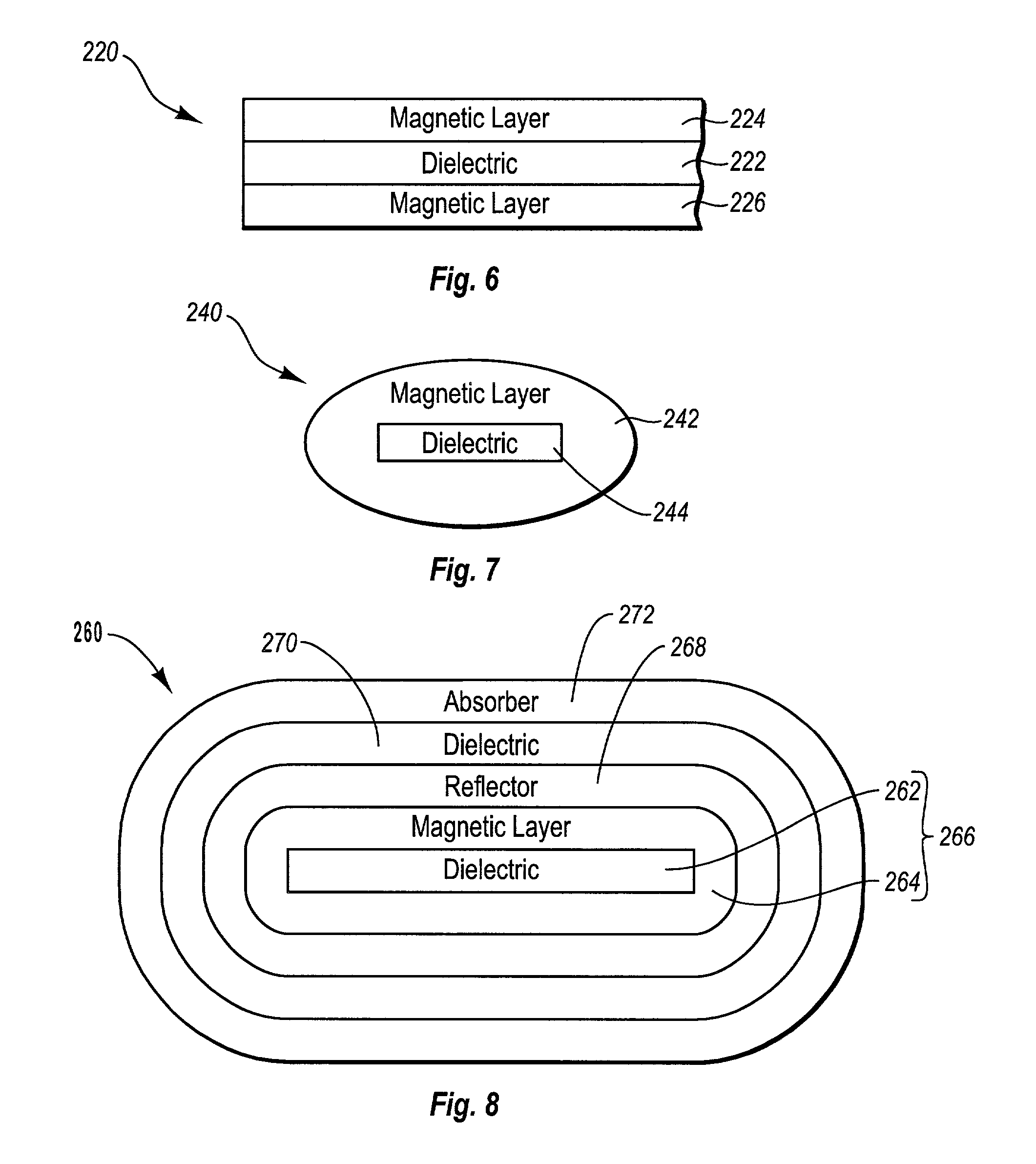

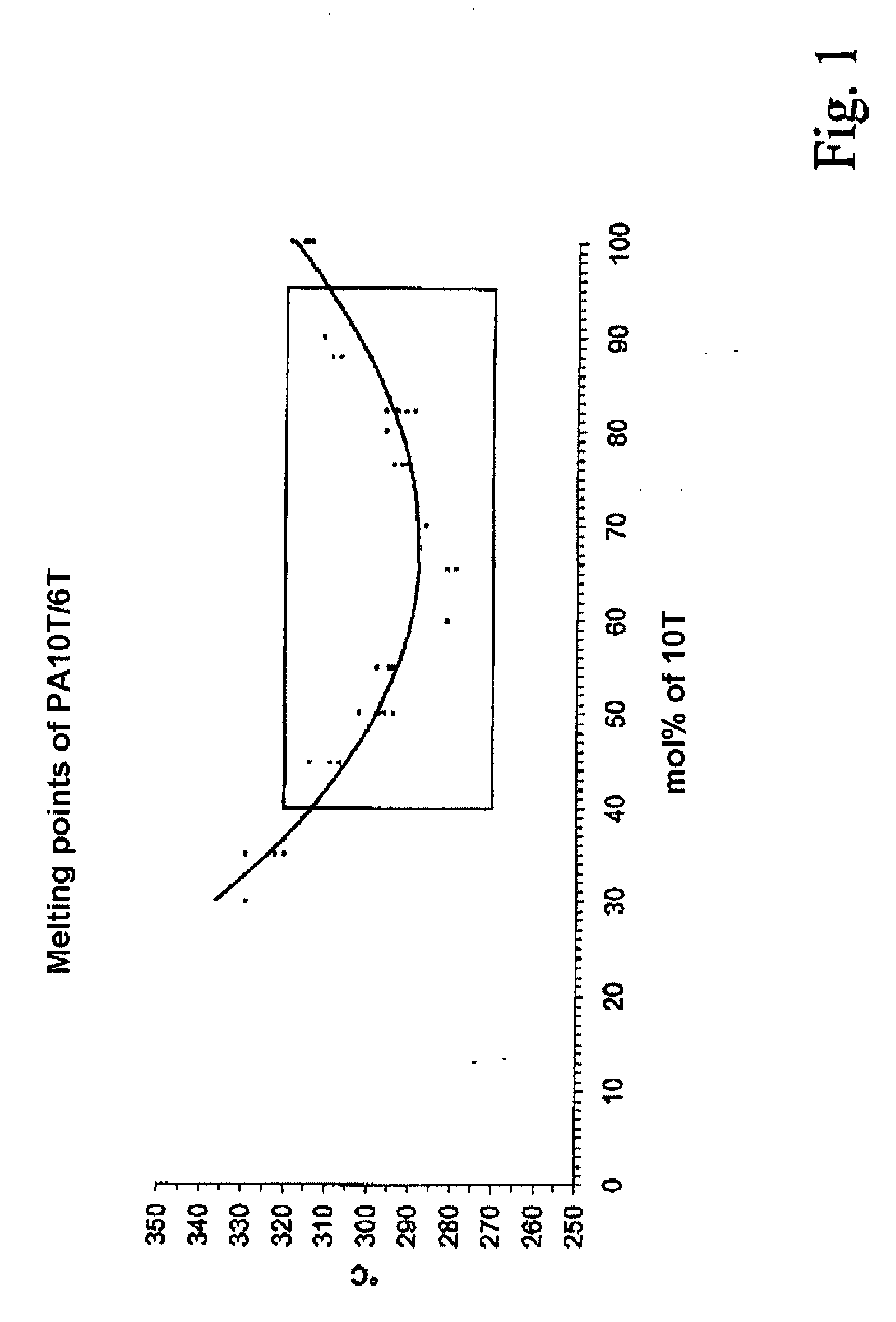

Semiaromatic polyamide molding compositions and their use

ActiveUS20080274355A1High strengthLow water absorptionPigmenting treatmentNon-fibrous pulp additionHexamethylenediamineAramides

A polyamide molding composition with the following constitution is described:(A) from 30 to 100% by weight of at least one 10T / 6T copolyamide, where this is composed of(A1) from 40 to 95 mol % of 10T units, formed from the monomers 1,10-decanediamine and terephthalic acid(A2) from 5 to 60 mol % of 6T units, formed from the monomers 1,6-hexanediamine and terephthalic acid(B) from 0 to 70% by weight of reinforcing materials and / or fillers(C) from 0 to 50% by weight of additives and / or further polymerswhere the entirety of components A to C is 100%, with the proviso that in component (A) up to 30 mol %, based on the entirety of the dicarboxylic acids, of the terephthalic acid can have been replaced by other aromatic, aliphatic, or cycloaliphatic dicarboxylic acids, and with the proviso that in component (A) up to 30 mol % of 1,10-decanediamine and respectively 1,6-hexanediamine, based on the entirety of the diamines, can have been replaced by other diamines, and with the proviso that not more than 30 mol % in component (A), based on the entirety of the monomers, can have been formed via lactams or amino acids. Uses of this polyamide molding composition are moreover described, as also are processes for the preparation of these polyamide molding compositions.

Owner:EMS PATENT AG

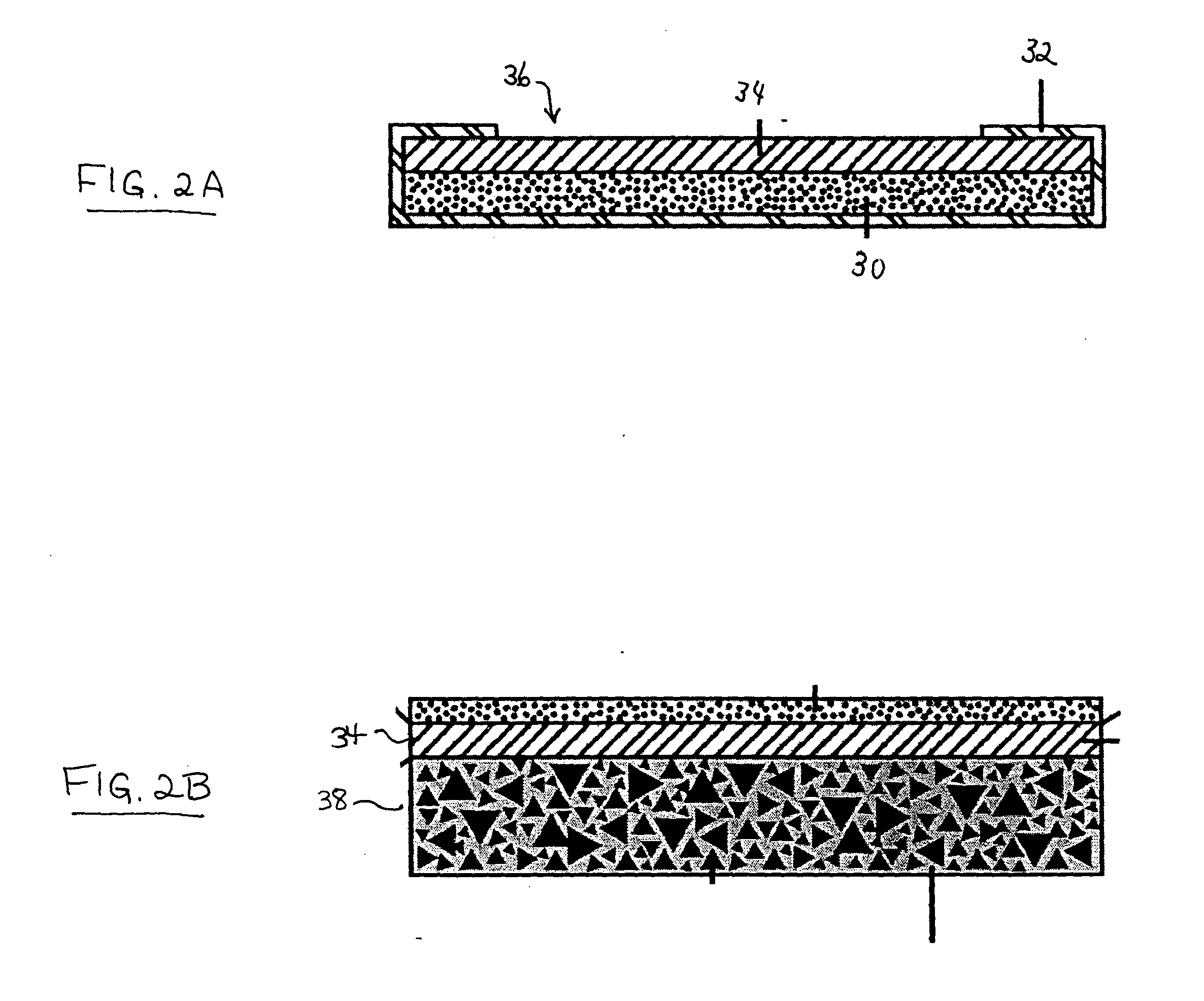

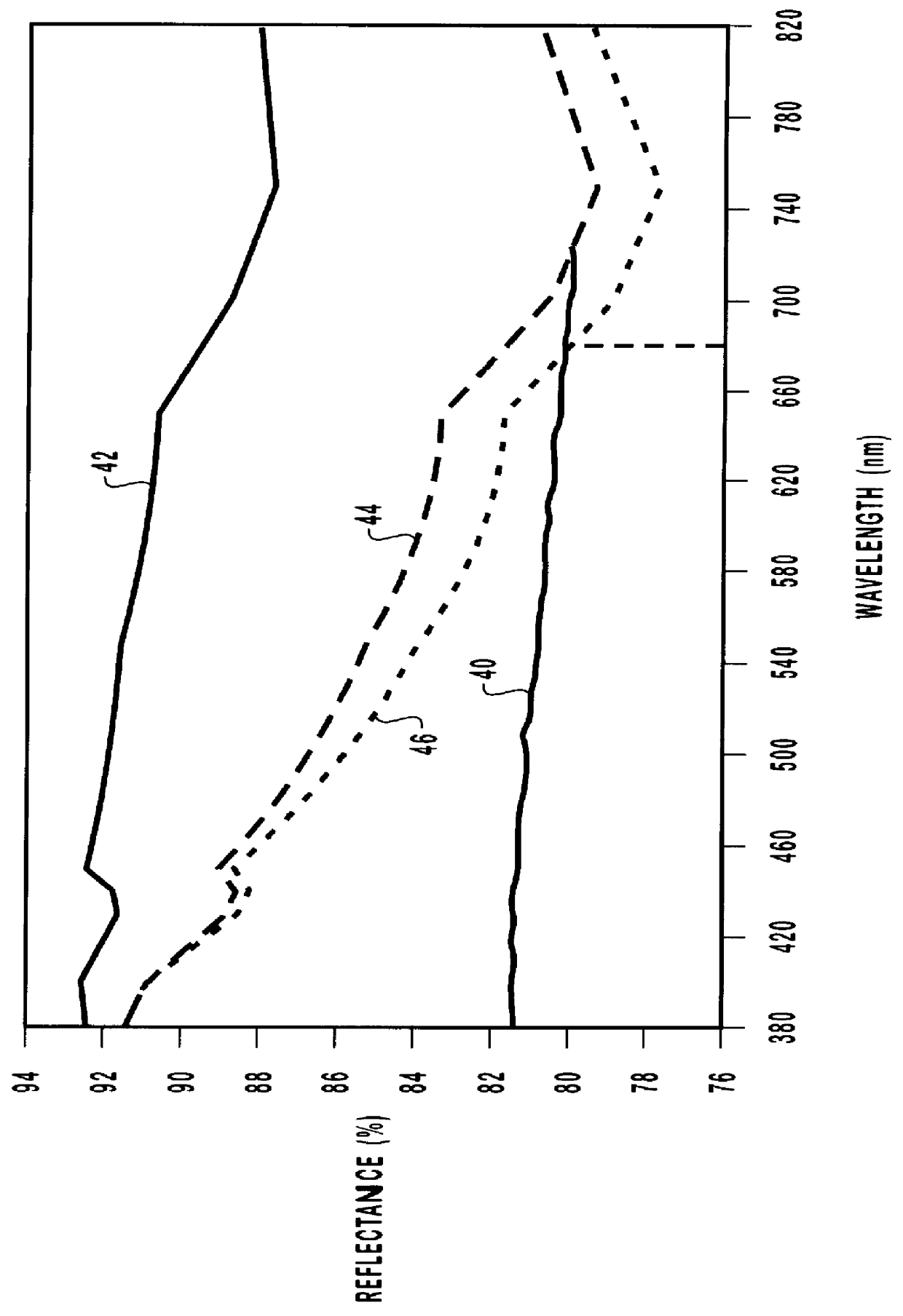

Bright metal flake

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

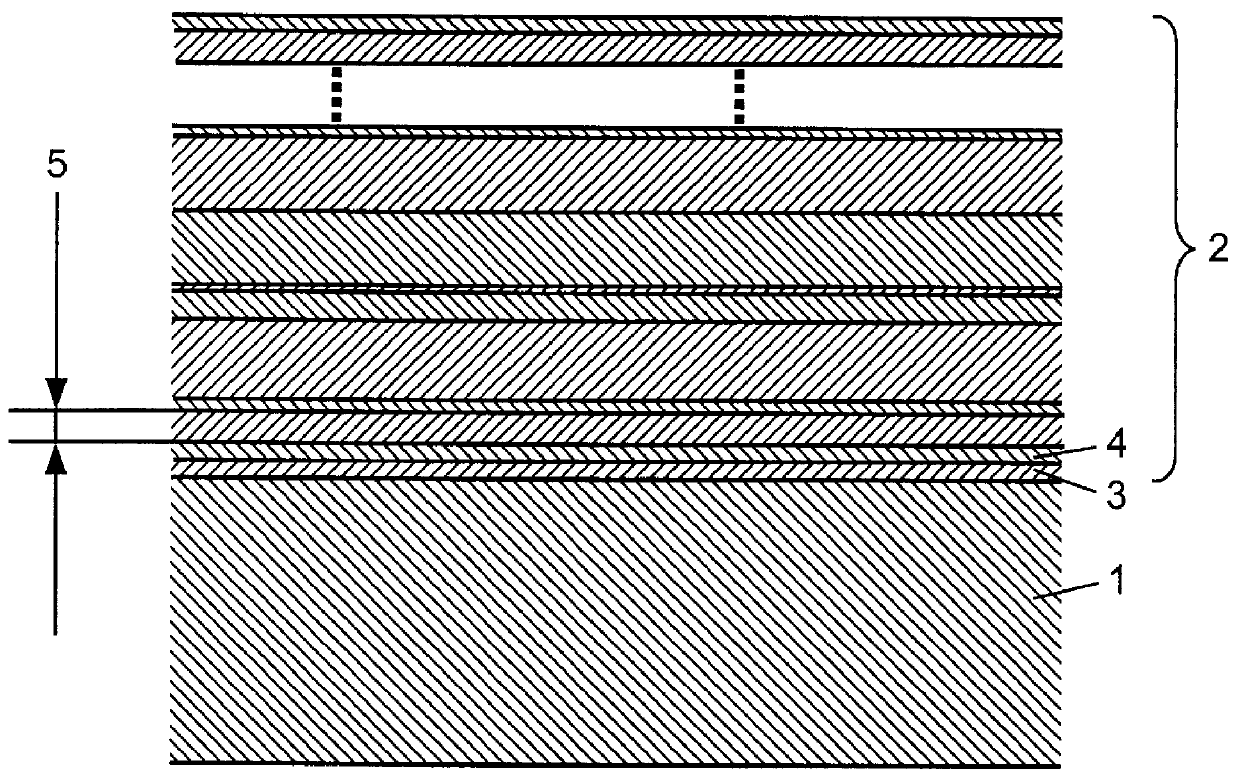

Multilayered coated cutting tool

The present invention relates to a cutting tool comprising a body of sintered cemented carbide or cermet, ceramic or high speed steel on which at least one of the functioning parts of the surface of the body, a thin, adherent, hard and wear resistant coating is applied. The coating comprises a laminar, multilayered structure of refractory compounds in polycrystalline, non-repetitive form, MX / NX / MX / NX where the alternating layers MX and NX are metal nitrides or carbides with the metal elements M and N selected from the group consisting of Ti, Nb, Hf, V, Ta, Mo, Zr, Cr, Al and W. The sequence of individual layer thicknesses is essentially aperiodic throughout the entire multilayered structure, and layer thicknesses are larger than 0.1 nanometer but smaller than 30 nanometer, preferably smaller than 20 nanometer. The total thickness of said multilayered coating is larger than 0.5 mu m but smaller than 20 mu m.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Abrasive grain, abrasive articles, and methods of making and using the same

InactiveUS6287353B1Easy accessImprove grinding efficiencyPigmenting treatmentOther chemical processesComposite materialCeramic materials

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com