Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

540 results about "Onium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An onium (plural: onia) is a bound state of a particle and its antiparticle. They are usually named by adding the suffix -onium to the name of the constituting particle except for muonium which, despite its name, is not a bound muon–antimuon onium, but an electron–antimuon bound state, and whose name was assigned by IUPAC. A muon–antimuon onium is called true muonium.

Intercalates formed via coupling agent-reaction and onium ion-intercalation pre-treatment of layered material for polymer intercalation

InactiveUS6407155B1Easy intercalationEasily co-intercalatedPigmenting treatmentPaper coatingOligomerPre treatment

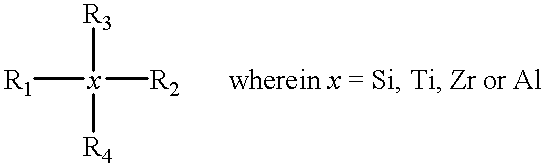

Intercalated layered materials prepared by reacting the layered material with a coupling agent and co-intercalating an onium ion and an oligomer or polymer between the planar layers of a swellable layered material, such as a phyllosilicate, preferably a smectite clay. The spacing of adjacent layers of the layered materials is expanded at least about 3 Å, preferably at least about 5 Å, usually preferably to a d-spacing of about 15-20 Å, e.g., 18 Å with the onium ion spacing / compatibilizing agent. The intercalation of the oligomer or polymer then increases the spacing of adjacent layers an additional at least 3 Å, e.g., to at least about 20 Å, preferably about 25 Å to about 30 Å, generally about 28 Å, and provides a nanocomposite having increased tensile strength, flexibility, and ductility (less brittle).

Owner:AMCOL INTERNATIONAL CORPORATION

Positive resist composition and patterning process

ActiveUS20080153030A1Good storage stabilityHigh resolutionOrganic chemistryPhotosensitive materialsHigh energyPhotoacid generator

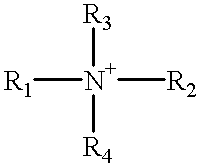

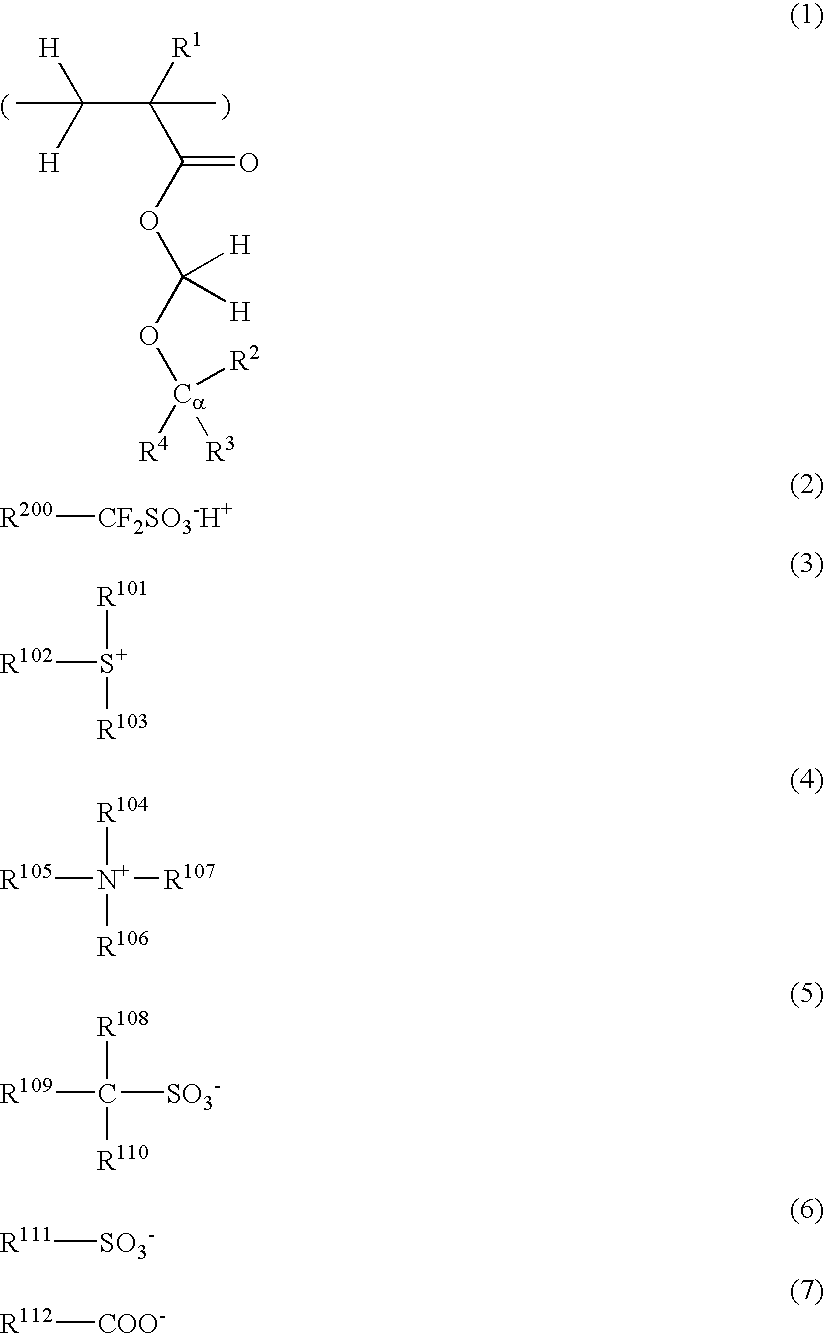

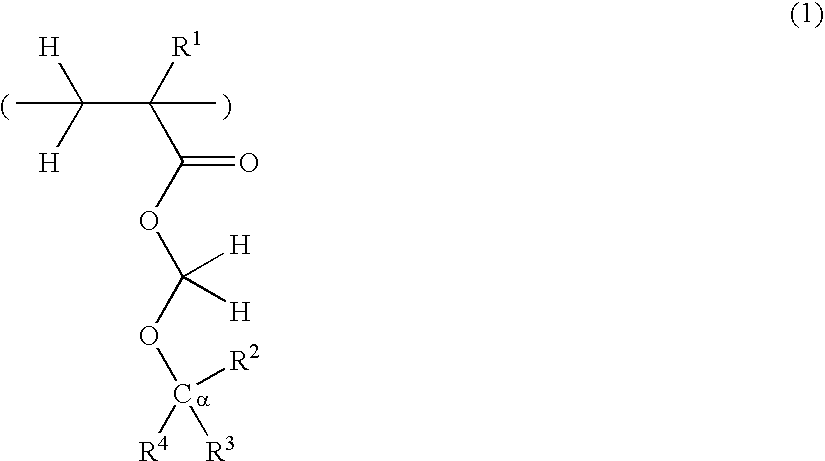

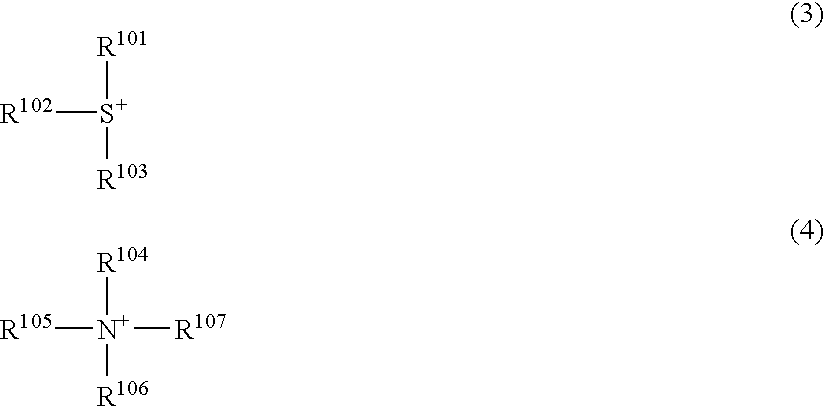

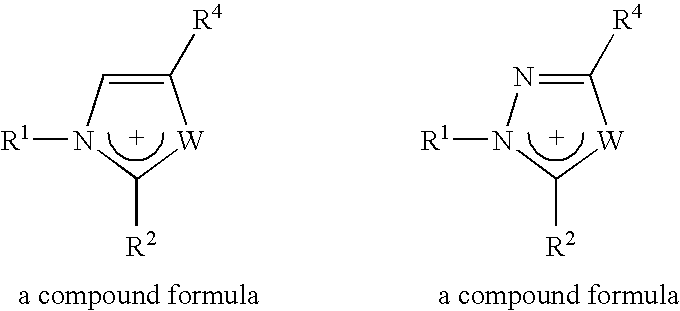

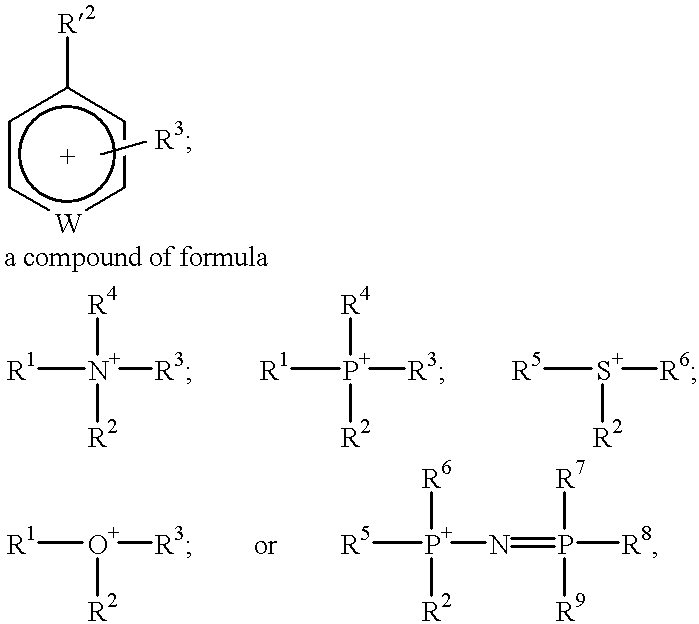

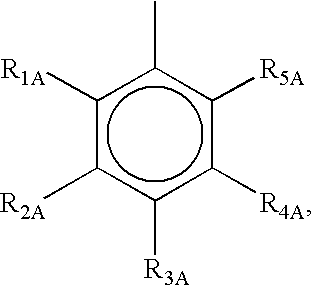

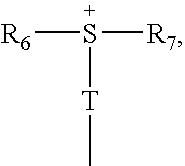

There is disclosed a resist composition that remarkably improves the resolution of photolithography using a high energy beam such as ArF excimer laser light as a light source, and exhibits excellent resistance to surface roughness and side lobe under use of a halftone phase shift mask; and a patterning process using the resist composition. The positive resist composition at least comprises (A) a resin component comprising a repeating unit represented by the following general formula (1); (B) a photoacid generator generating sulfonic acid represented by the following general formula (2) upon exposure to a high energy beam; and (C) an onium salt where a cation is sulfonium represented by the following general formula (3), or ammonium represented by the following general formula (4); and an anion is represented by any one of the following general formulae (5) to (7).

Owner:SHIN ETSU CHEM IND CO LTD

Preparation of elastomer with exfoliated clay and article with composition thereof

Owner:THE GOODYEAR TIRE & RUBBER CO +1

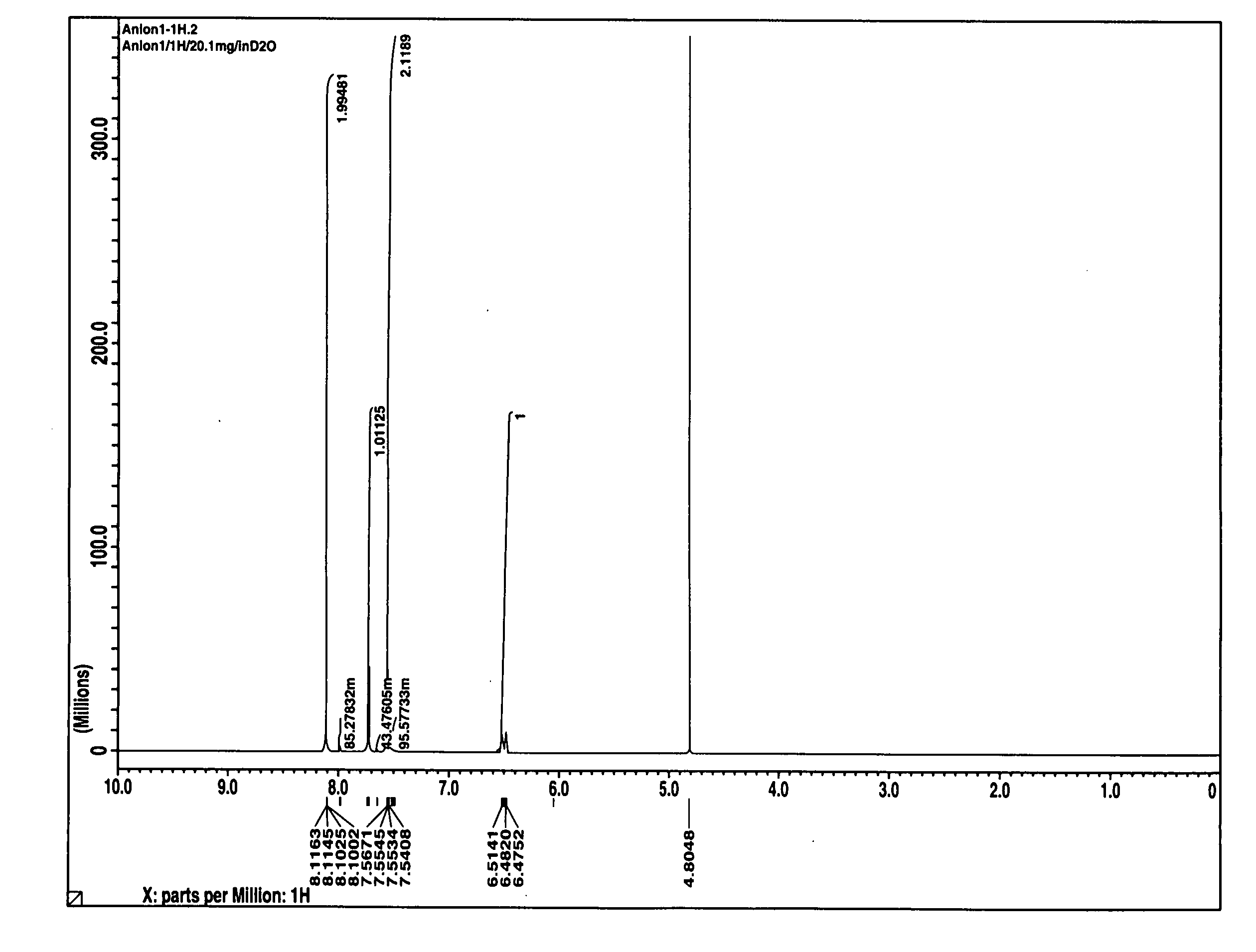

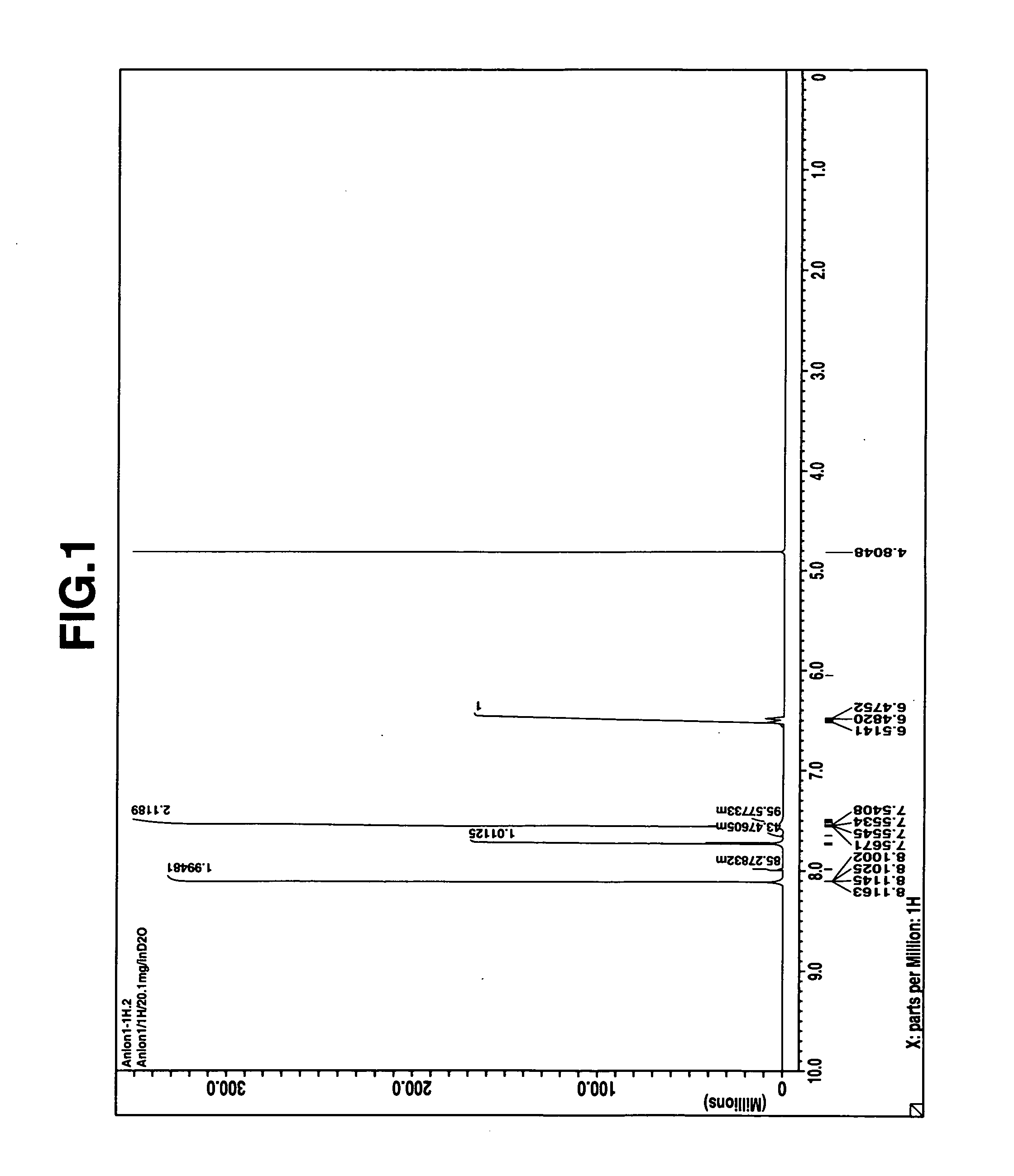

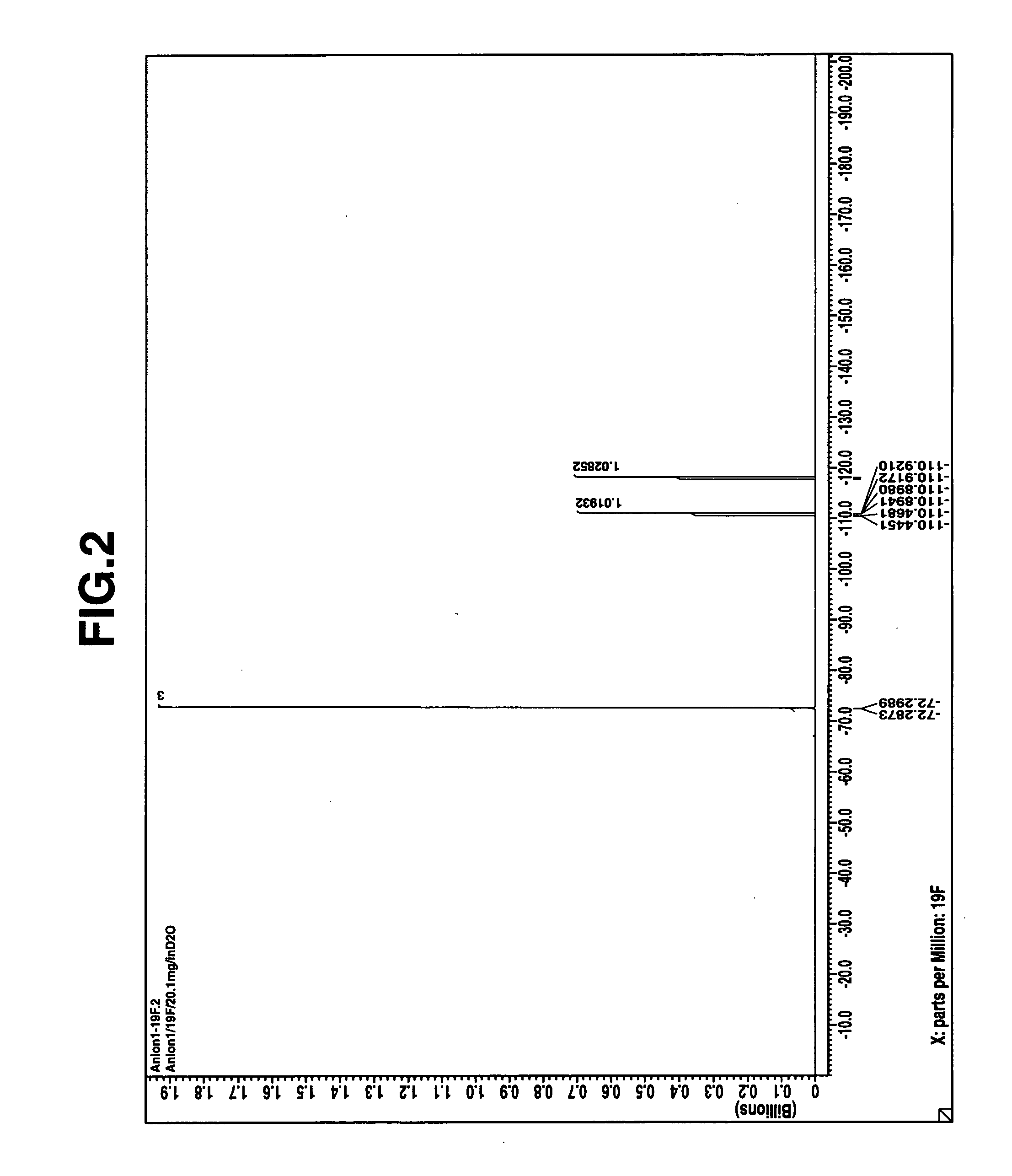

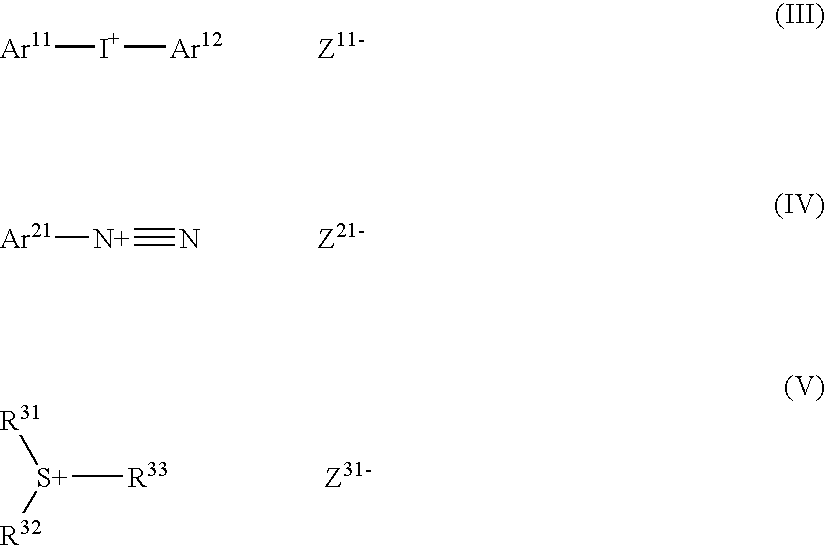

Novel sulfonate salts and derivatives, photoacid generators, resist compositions, and patterning process

ActiveUS20060228648A1Wide spectrum of molecular designReduce molecular weightOrganic chemistryPhotosensitive materialsResistSulfonate

Sulfonate salts have the formula: CF3—CH(OCOR)—CF2SO3−M+ wherein R is C1-C20 alkyl or C6-C14 aryl, and M+ is a lithium, sodium, potassium, ammonium or tetramethylammonium ion. Onium salts, oximesulfonates and sulfonyloxyimides and other compounds derived from these sulfonate salts are effective photoacid generators in chemically amplified resist compositions.

Owner:SHIN ETSU CHEM IND CO LTD

Elastomer composition which contains intercalated and exfoliated clay reinforcement formed in situ within the elastomer host and article, such as a tire, having at least one component thereof

This invention relates to a rubber composition which contains intercalated and at least partially exfoliated organophillic clay reinforcement formed in situ within the elastomer host from a hydrophilic clay. The invention particularly relates to an in situ modification of a hydrophilic clay to compatibilize the clay with a diene-based elastomer. The clay is converted from being hydrophilic in nature to being more hydrophobic in nature and therefore more compatible with the elastomer by bulk blending the elastomer host with a smectite clay, preferably a montmorillonite or hectorite clay, and a hydrocarbyl onium salt, such as for example a quaternary ammonium salt, and particularly in the absence of water addition to the elastomer host. Therefore, such in situ procedure of intercalation and at least partially exfoliation relies upon a bulk blending thereof with an elastomer host at an elevated temperature and under high shear conditions in contrast to pre-intercalating the clay in an aqueous based medium and in contrast to simple low viscosity melt processing of a thermoplastic polymer. The invention also relates to articles of manufacture, including tires, having at least one component comprised of such rubber composition. Such tire component may be, for example, a tire tread.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

Process for producing fluoroolefins

InactiveUS20030060670A1Preparation by hydrogen halide split-offOrganic chemistry methodsPhosphonium saltPtru catalyst

A process for producing a fluoroolefin of the formula: CF.sub.3CY.dbd.CX.sub.nH.sub.p wherein Y is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); X is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); n and p are integers independently equal to 0, 1 or 2, provided that (n+p)=2; comprising contacting, in the presence of a phase transfer catalyst, a compound of the formula: CF.sub.3C(R.sup.1.sub.aR.sup.2.sub.b) C(R.sup.3.sub.cR.sup.4.sub.d), wherein R.sup.1, R.sup.2, R.sup.3, and R.sup.4 are independently a hydrogen atom or a halogen selected from the group consisting of fluorine, chlorine, bromine and iodine, provided that at least one of R.sup.1, R.sup.2, R.sup.3, and R.sup.4 is halogen and there is at least one hydrogen and one halogen on adjacent carbon atoms; a and b are independently=0, 1 or 2 and (a+b)=2; and c and d are independently=0, 1, 2 or 3 and (c+d)=3; and at least one alkali metal hydroxide. The alkali metal hydroxide can be, for example, potassium or sodium hydroxide and the phase transfer catalyst can be, for example, at least one: crown ether such as 18-crown-6 and 15-crown-5; or onium salt such as, quaternary phosphonium salt and quaternary ammonium salt. The olefin is useful, for example, as an intermediate for producing other industrial chemicals and as a monomer for producing oligomers and polymers.

Owner:HONEYWELL INT INC

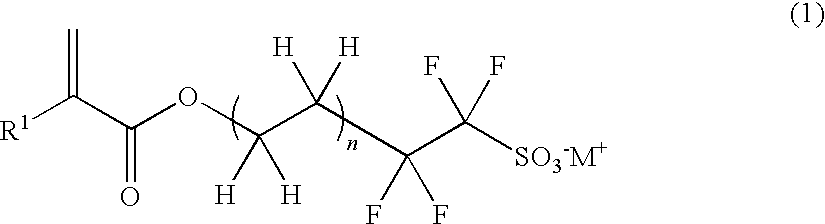

Novel sulfonate salts and derivatives, photoacid generators, resist compositions, and patterning process

ActiveUS20080124656A1Increase acidityInhibits the formation of defectsLithium organic compoundsOrganic compound preparationResistPhotoacid

Sulfonate salts have the formula: R1COOCH2CH2CF2CF2SO3−M+ wherein R1 is alkyl, aryl or hetero-aryl, M+ is a Li, Na, K, ammonium or tetramethylammonium ion. Onium salts, oxime sulfonates and sulfonyloxyimides derived from these salts are effective photoacid generators in chemically amplified resist compositions.

Owner:SHIN ETSU CHEM IND CO LTD

Materials useful as electrolytic solutes

The invention concerns novel ionic compounds with low melting point whereof the onium type cation having at least a heteroatom such as N, O, S or P bearing the positive charge and whereof the anion includes, wholly or partially, at least an ion imidide such as (FX1O)N−(OX2F) wherein X1 and X2 are identical or different and comprise SO or PF, and their use as solvent in electrochemical devices. Said composition comprises a salt wherein the anionic charge is delocalised, and can be used, inter alia, as electrolyte.

Owner:ACEP +2

Photoimageable dielectric material for circuit protection

InactiveUS6489042B2Sharp contrastReduce swellingGroup 4/14 element organic compoundsInsulating substrate metal adhesion improvementEpoxySolvent

An electronic circuit device comprising at least one substrate having a photoimageable covercoat, comprising at least 95 weight percent of at least one epoxy-modified aromatic vinyl-conjugated diene block copolymer and a catalyst comprising an onium salt selected from a triarylsulfonium salt and a diaryliodonium salt, wherein the covercoat is formed by solvent coating or extrusion and then heat laminated onto at least a portion of the substrate.

Owner:3M INNOVATIVE PROPERTIES CO

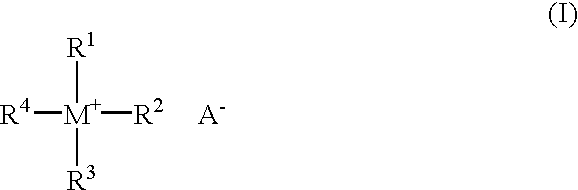

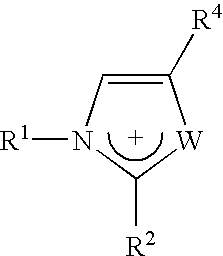

Onium salt compound, polymer compound comprising the salt compound, chemically amplified resist composition comprising the polymer compound, and method for patterning using the composition

ActiveUS20100075256A1Improve adhesionLess dependentOrganic chemistryPhotosensitive materialsResistAryl

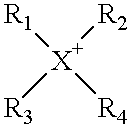

A compound represented by the following formula (1) is provided:wherein R1 represents a hydrogen atom, a trifluoromethyl group, an alkyl group, or an alkoxy group; and A represents a group represented by the following formula (2) or formula (3):wherein R2, R3, R4, R5 and R6 each independently represent a substituted or unsubstituted alkyl group, a substituted or unsubstituted allyl group, a substituted or unsubstituted perfluoroalkyl group, a substituted or unsubstituted benzyl group, or a substituted or unsubstituted aryl group; and two or more of R2, R3 and R4 may be linked to each other to form a saturated or unsaturated carbon ring or a saturated or unsaturated heterocyclic ring.The chemically amplified resist composition comprising a polymer compound which is produced from the compound of formula 1 according to the present invention provides a chemically amplified resist sensitive to far-ultraviolet radiation, which is represented by KrF excimer laser or ArF excimer laser.

Owner:SK MATERIALS PERFORMANCE CO LTD

Photoactive compounds

The present application relates to a compound of formula A-X-B, where (i) A-X-B form an ionic compound Ai Xi Bi where Ai and Bi are each individually an organic onium cation; and Xi is anion of the formula Q-R500—SO3− or (ii) A-X-B form a non-ionic compound Ac-Xc-Bc, where Ai, Bi, Q, R500, Ac, Bc, and Xc are defined herein. The compounds are useful as photoactive materials.

Owner:MERCK PATENT GMBH

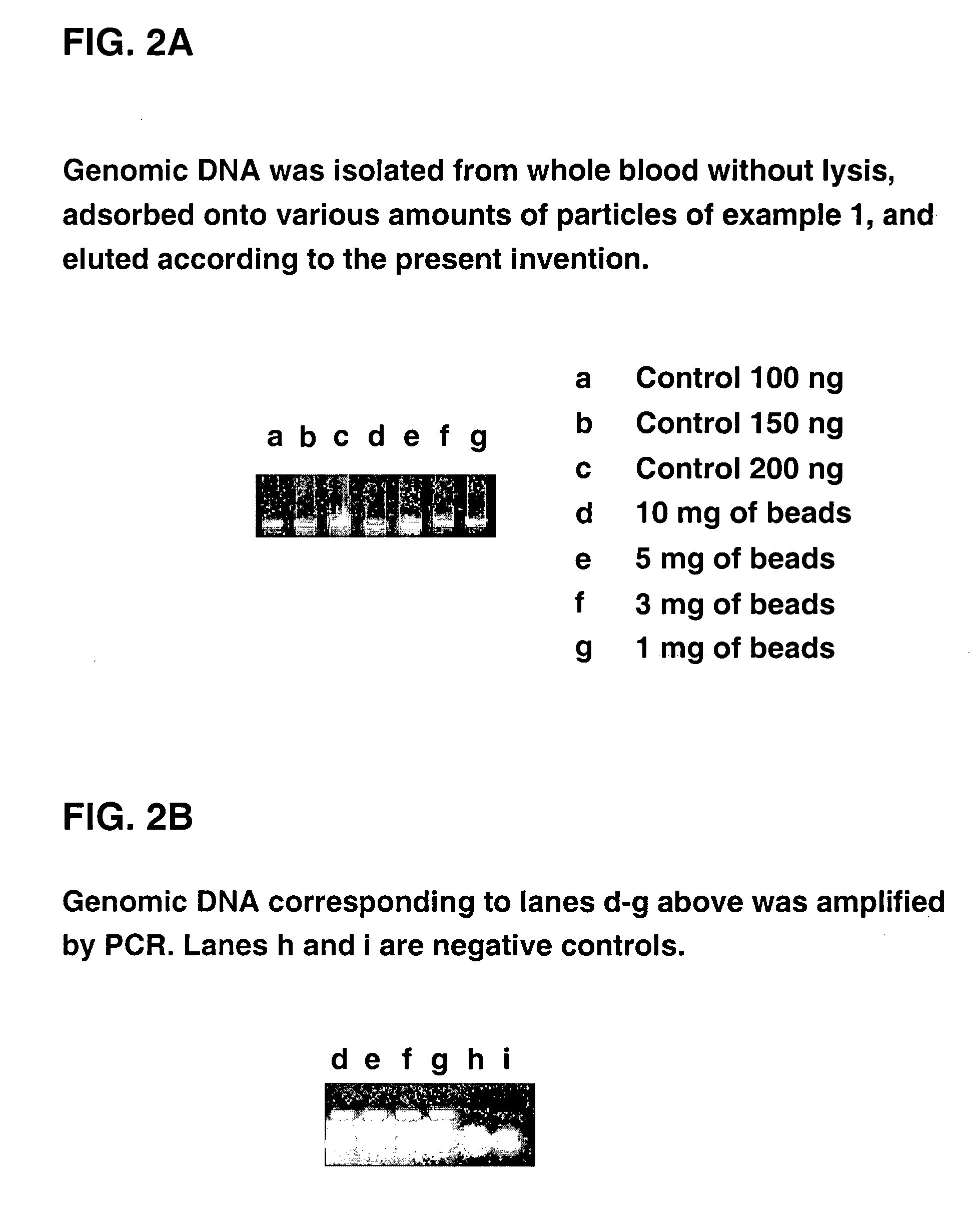

Simplified methods for isolating nucleic acids from cellular materials

Methods of isolating nucleic acids from samples of cellular material are disclosed which use solid phase binding materials and which avoid the use of a lysis solution. The use of the solid phase binding materials unexpectedly allow the nucleic acid content of cells to be freed and captured directly and in one step. The new methods represent a significant simplification over existing methods. Preferred solid phase materials for use with the methods and compositions of the invention comprise a quaternary onium nucleic acid binding portion.

Owner:NEXGEN DIAGNOSTICS LLC

Onium salt compound and radiation-sensitive resin composition

An onium salt compound having a cation moiety of the following formula (1) is disclosed. wherein A represents I or S, m is 1 or 2, n is 0 or 1, x is 1-10, and Ar1 and Ar2 are (substituted) aromatic hydrocarbon group, and P represents —O—SO2R, —O—S(O)R, or —SO2R, wherein R represents a hydrogen atom, a (substituted) alkyl group, or a (substituted) alicyclic hydrocarbon group. The onium salt compound is suitable as a photoacid generator for photoresists of a positive-tone radiation-sensitive resin composition. The positive-tone radiation-sensitive resin composition containing this compound is useful as a chemically-amplified photoresist exhibiting high resolution at high sensitivity, responsive to various radiations, and having outstanding storage stability.

Owner:JSR CORPORATIOON

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

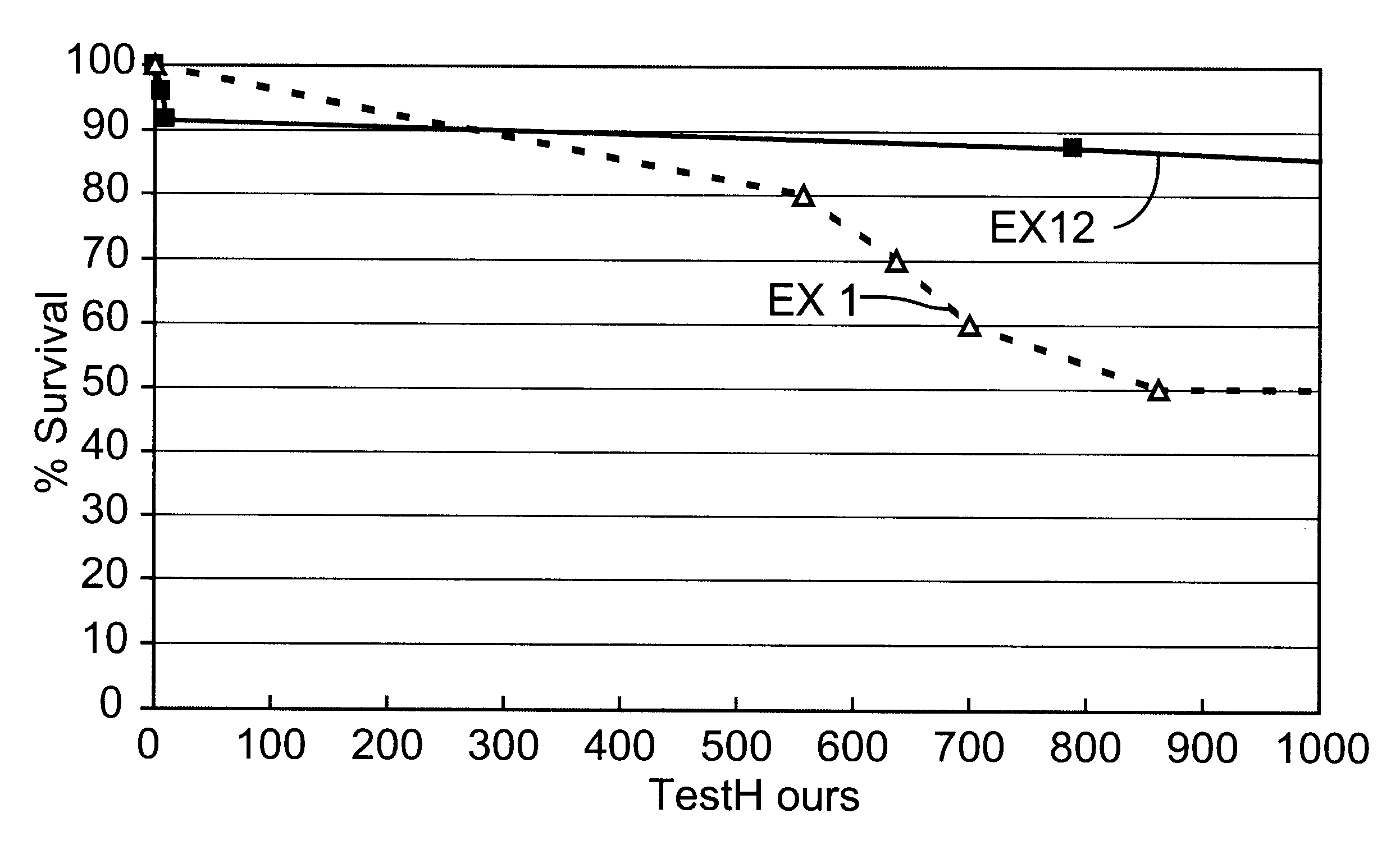

Onium-modified polymer and method for manufacturing same

InactiveUS20060047054A1Improve conductivityGood hygroscopicitySpecial tyresBulk chemical productionCompound (substance)Solvent

Onium-modified polymers, such as polyethers and alkylimidazolium-modified polymers are provided. The polymers have desirable properties such as moisture absorbing capability, low volatile organic compounds (VOCs) emission, and enhanced electrical conductivity. A method to prepare the polymers is also provided, in which green solvents such as ionic liquids are utilized as both reaction media and reactants.

Owner:BRIDGESTONE CORP

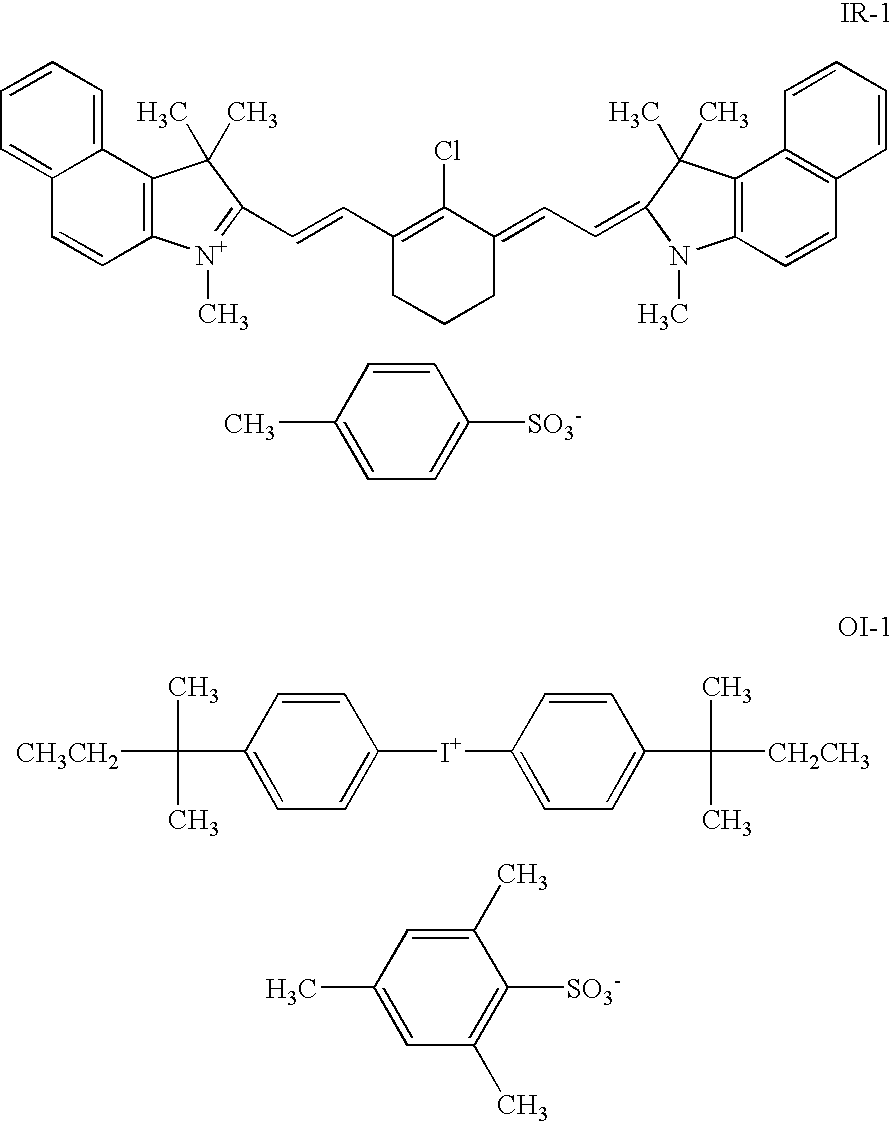

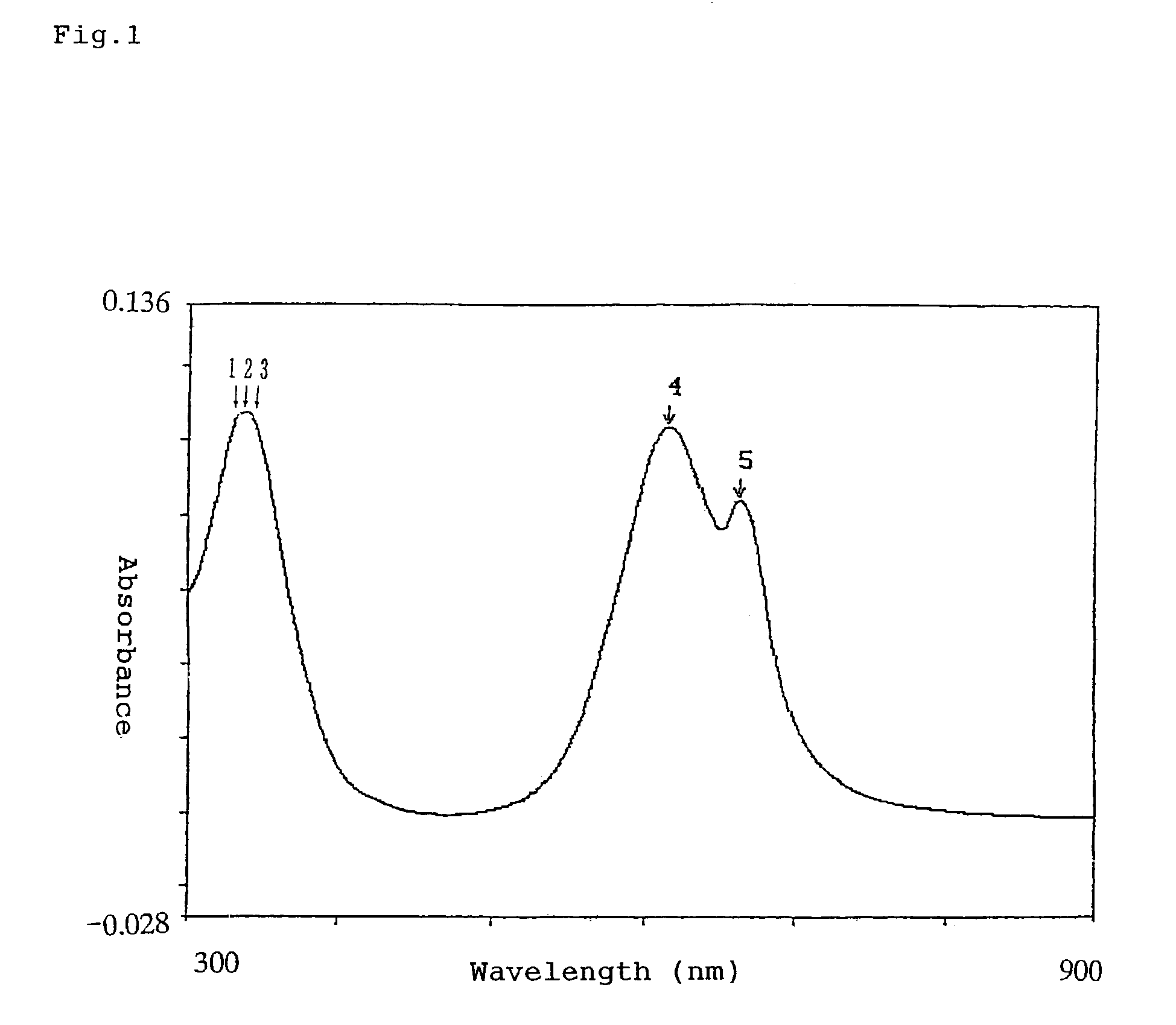

Negative-working photosensitive composition and negative-working photosensitive planographic printing plate

InactiveUS20050287466A1Good storage stabilityGood visible image qualityPhotoprinting processesSilver halide emulsionsChemical compoundPlanographic printing

A negative-working photosensitive composition comprises (a) an alkali-soluble resin, (b) a compound which causes a crosslinking reaction by an acid, (c) a compound which generates an acid by heating, and (d) a photothermal converting agent, wherein the compound (c) which generates an acid by heating described above is an onium salt of an acidic dye having a sulfonic group in a molecule. A negative-working photosensitive planographic printing plate is provided with a photosensitive layer comprising the negative-working photosensitive composition, on a surface of a support.

Owner:EASTMAN KODAK CO +1

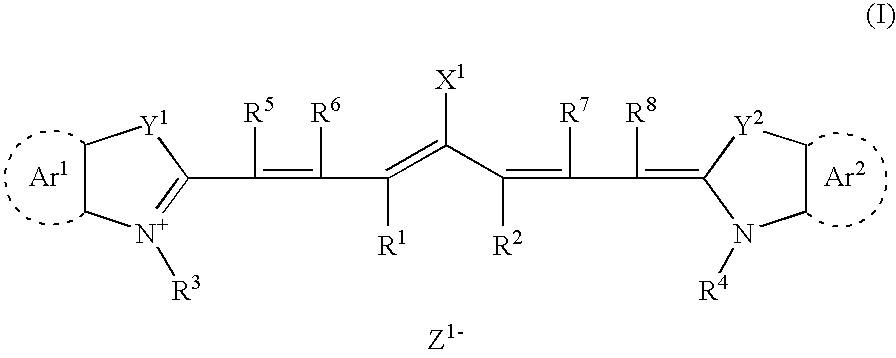

Lithographic printing plate precursor

InactiveUS6858374B2Semiconductor/solid-state device manufacturingDiazo compound compositionsChemical compoundOrganic dye

A lithographic printing plate precursor is disclosed, comprising a support having provided thereon a photosensitive layer containing at least (A) an infrared ray absorbing agent, (B) an onium salt, (C) a radically polymerizable compound, (D) a binder polymer and (E) an organic dye or the precursor thereof capable of undergoing change in color tone upon exposure.

Owner:FUJIFILM CORP +1

Cyan dye mixture, water-based cyan ink composition, and method of ink-jet recording

The present invention relates to a cyan dye mixture, an ink composition containing the mixture and a method of ink-jet recording with the ink composition. The print obtained by the method is characterized by discoloring or fading little even when allowed to stand in a well ventilated shade or in an ozone gas. The cyan dye mixture comprises compounds which are obtained by chlorosulfonating, as a starting material, copper phthalocyanine or a sulfonated copper phthalocyanine and then aminating the chlorosulfonation product with an aminating agent used in an amount of at least 2.5 mol per mol of the starting material, and which are represented by the following formula (1): wherein M represents a proton, alkali metal ion, alkaline earth metal ion, onium ion of an organic amine, or ammonium ion; m is an integer of 1 to 4; and n is an integer of 0 to 3; provided that m+n is an integer of 1 to 4.

Owner:NIPPON KAYAKU CO LTD

Aromatic fluorine-free photoacid generators and photoresist compositions containing the same

InactiveUS20090181319A1Good optical clarityImprove thermal stabilityOrganic chemistryOrganic compound preparationSulfonatePhotoacid generator

Fluorine-free photoacid generators and photoresist compositions containing fluorine-free photoacid generators are enabled as alternatives to PFOS / PFAS photoacid generator-containing photoresists. The photoacid generators are characterized by the presence of a fluorine-free aromatic sulfonate anionic component having one or more electron withdrawing groups. The photoacid generators preferably contain a fluorine-free onium cationic component, more preferably a sulfonium cationic component. The photoresist compositions preferably contain an acid sensitive imaging polymer having a lactone functionality. The compositions are especially useful for forming material patterns using 193 nm (ArF) imaging radiation.

Owner:GLOBALFOUNDRIES INC

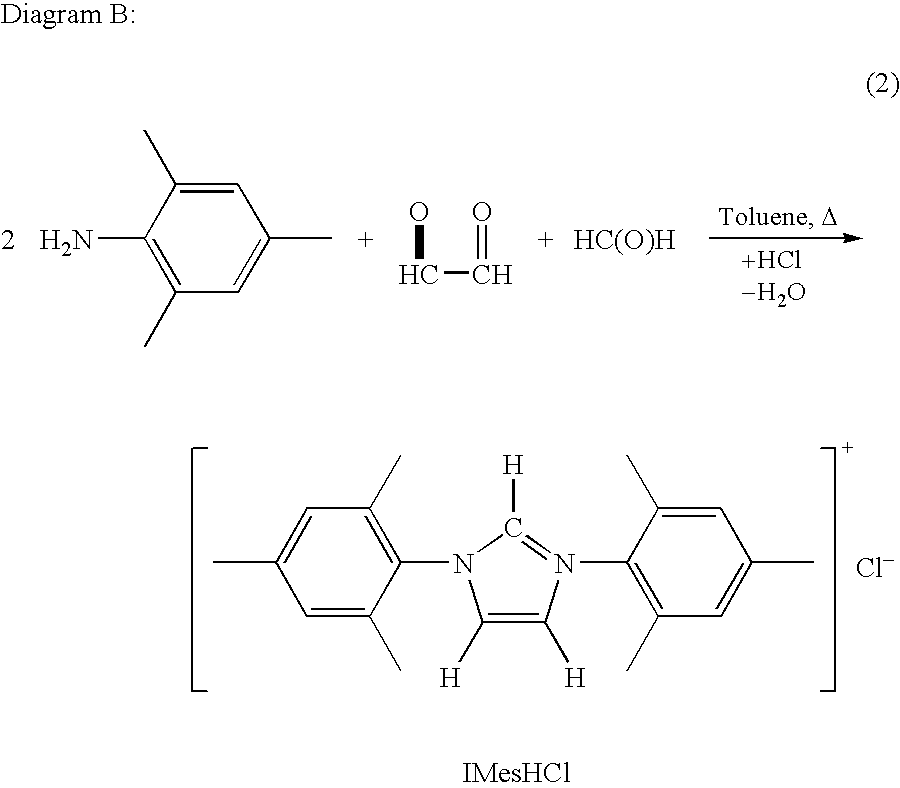

Synthesis of 1,3 distributed imidazolium salts

Imidazolium salts are the immediate precursors to N-heterocyclic carbenes (NHC) yet a simple, general synthetic route to a wide variety of imidazolium salts is not yet available. Such a straightforward route is described for two specific members of this family of ligand precursor: 1,3-Bis(2,4,6-trimethylphenyl)imidazolium chloride (IMes.HCl) and 1,3-Bis(2,6-diispropylphenyl)imidazolium chloride (IPr.HCl). The procedure appears general and similar protocols can be used to isolate various imidazolium salts.

Owner:UNIV OF NEW ORLEANS RES & TECH FOUND INC A NON PROFIT LOUISIANA

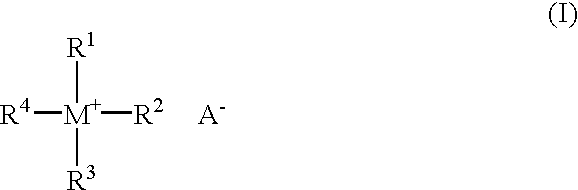

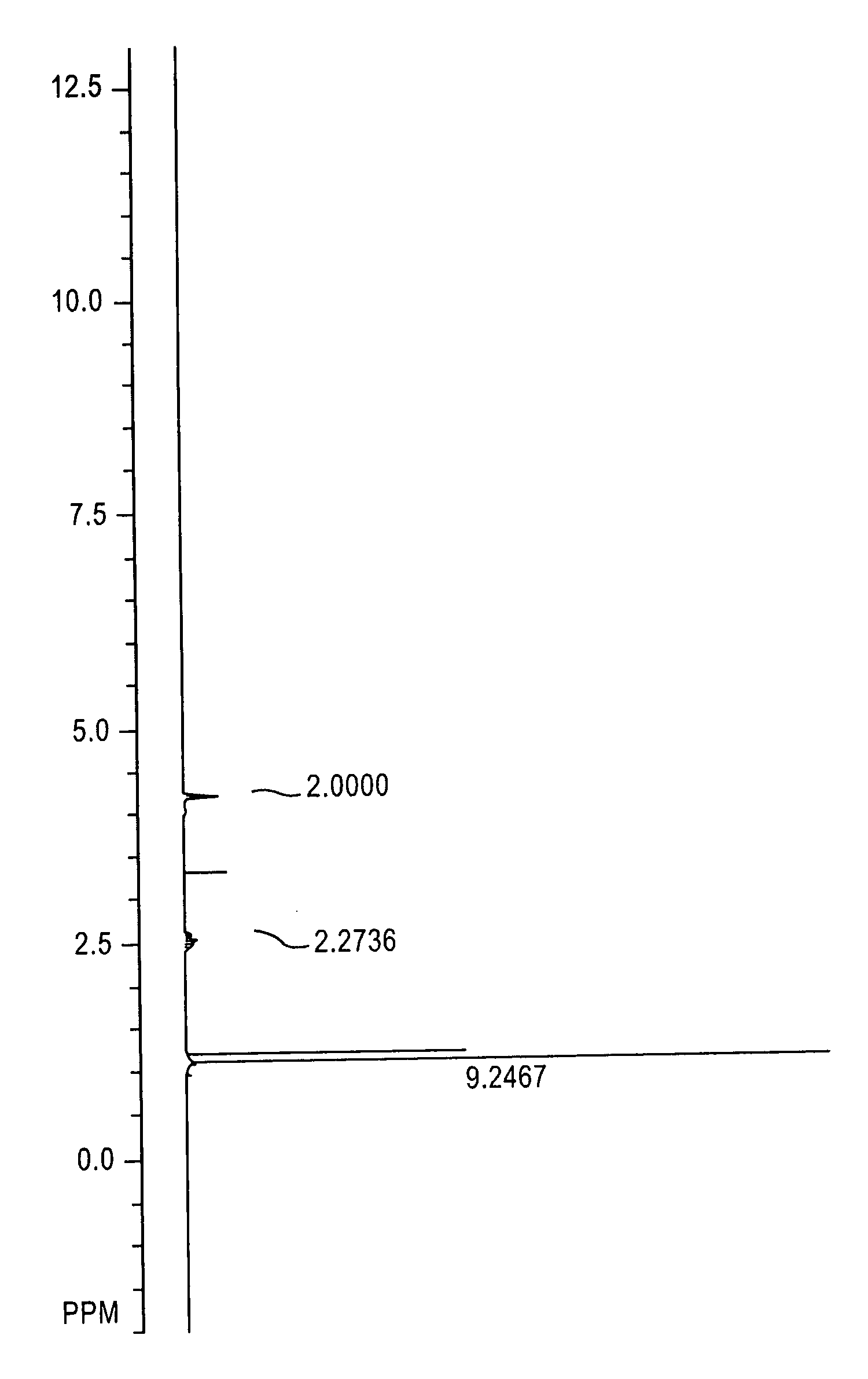

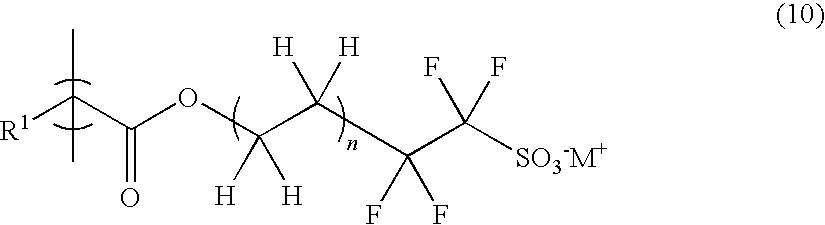

Polymerizable sulfonic acid onium salt and resin

ActiveUS20100063232A1Increase acidityImprove combustion performanceOrganic chemistryPhotomechanical apparatusHydrogen atomRadiation sensitivity

A resin that includes a repeating unit shown by the following formula (10) has an excellent performance as a radiation sensitive acid generator, and exhibits only a small adverse effect on the environment and a human body.wherein R1 represents a hydrogen atom or the like, M+ represents a specific cation, and n is an integer from 1 to 5.

Owner:JSR CORPORATIOON +1

Infrared-sensitive composition containing a metallocene derivative

The present invention provides an initiator system including an infrared-absorbing compound that exhibits an electronic transition band in the near-infrared region, an initiator, and a metallocene compound. Upon exposure to infrared radiation, the initiator system is capable of producing radicals sufficient to initiate a photopolymerization reaction. Suitable infrared-absorbing compounds include indocyanine dyes, for example. Trihalomethyl triazine compounds and onium compounds are suitable initiators. Suitable metallocene compounds include ferrocenes and titanocenes. The present invention also provides an infrared-sensitive composition including an ethylenically unsaturated polymerizable component, an infrared-absorbing compound that exhibits an electronic transition band in the near-infrared region, an initiator, and a metallocene compound. The infrared-sensitive composition provides improved photospeed and sensitivity in some embodiments. A printing plate precursor including an infrared-sensitive coating is also provided. The printing plate precursor exhibits enhanced shelf life in some embodiments. A method of making a printing plate precursor and a method for making a printable lithographic printing plate are further provided by the invention.

Owner:KODAK POLYCHROME GRAPHICS

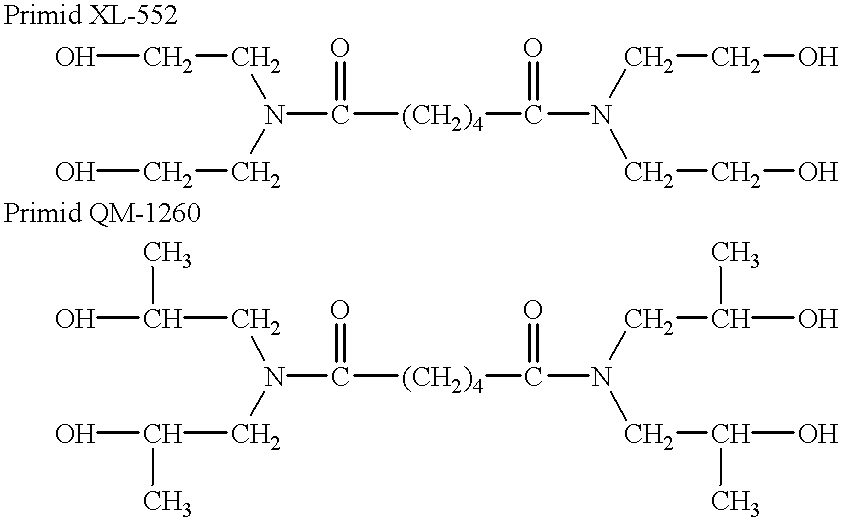

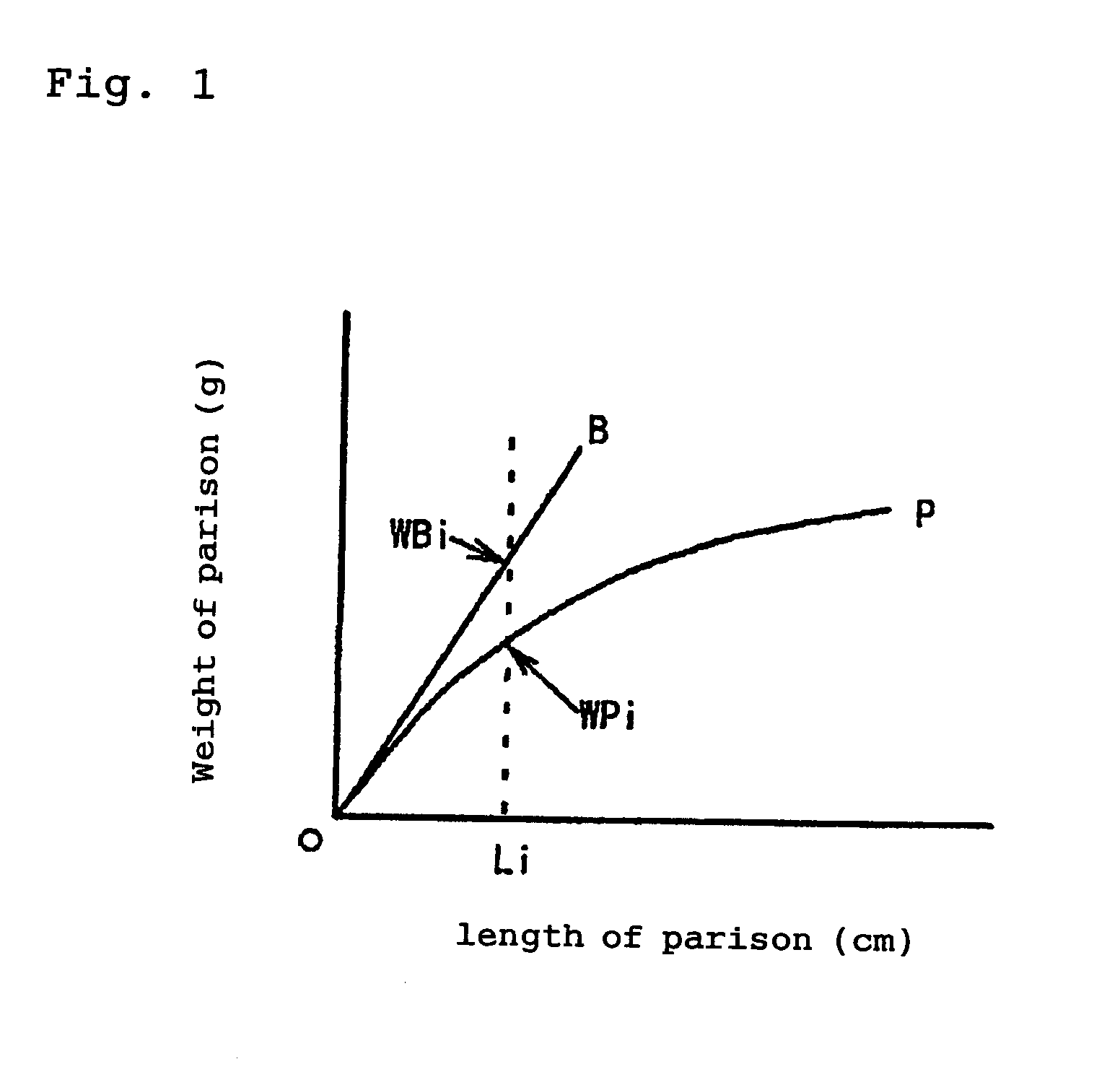

Thermoplastic resin composition, molded article, and process for producing the same

InactiveUS20040030021A1Good light transmissionEnhance reflexesPigmenting treatmentMicaCation-exchange capacityShell molding

A thermoplastic resin composition comprising: (A) 100 parts by weight of a noncrystalline thermoplastic resin component (component A); (B) 0.1 to 50 parts by weight of a layered silicate (component B) which satisfies the following (i) to (iii): (i) it has a cation exchange capacity of 50 to 200 milliequivalents / 100 g, and at least 40% of the cation exchange capacity being exchanged with an organic onium ion, (ii) 60% or more of the layered silicate particles have a thickness of 100 nm or less in the resin composition, and (iii) the interlayer spacing of the layered silicate (component B) in the resin composition is smaller than the interlayer spacing of the layered silicate alone by 0.5 nm or more; and (C) 0 to 50 parts by weight of a compound (component C) having affinity for the noncrystalline thermoplastic resin component as the component A and a hydrophilic component; and molded articles thereof. According to the present invention, a noncrystalline thermoplastic resin composition having excellent stiffness, surface appearance and heat stability, especially a polycarbonate resin composition and molded articles thereof are obtained.

Owner:TEIJIN KASEK KK

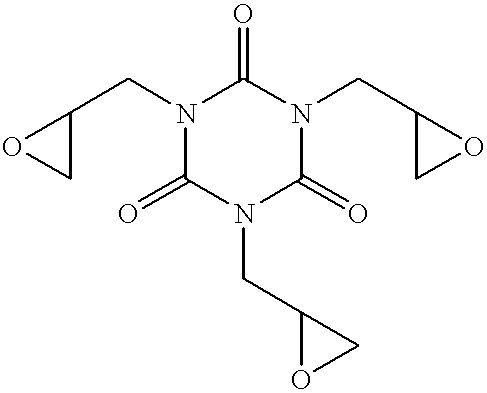

Photopolymerizable compositions for electroless plating methods

ActiveUS9188861B2Low efficiencyEasy to usePhotomechanical coating apparatusPhotosensitive materials for photomechanical apparatusPhotosensitizerElectron donor

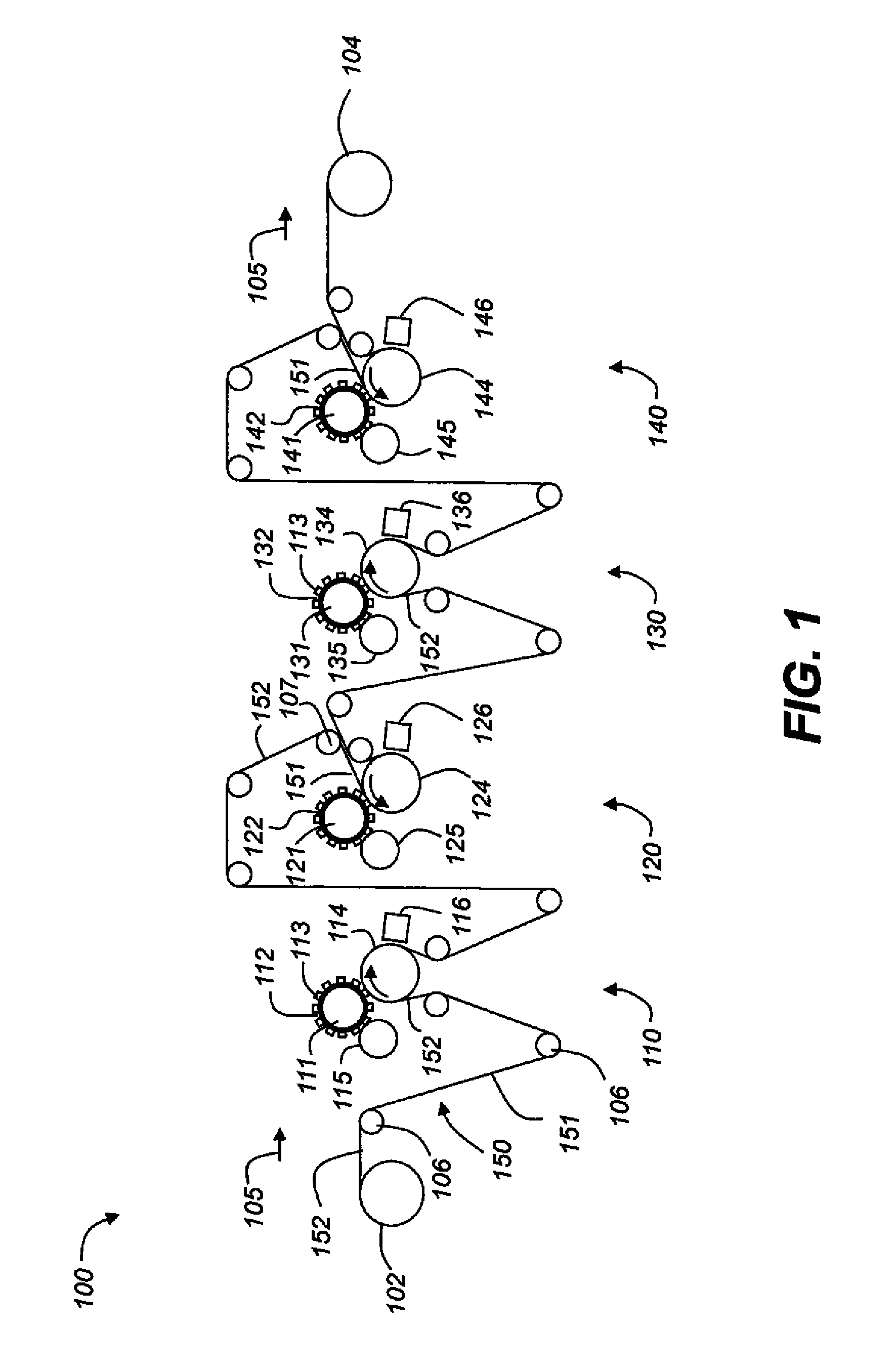

A photopolymerizable composition has five essential components: (a) a photopolymerizable epoxy material, (b) a photoacid generator such as an onium salt, (c) electron donor photosensitizer having an oxidation potential of at least 0.4 V and up to and including 3 V vs. SCE, and (d) metal particles. This photopolymerizable composition can be applied or printed onto one or both sides of various substrates to form articles that can be used to form electrically conductive materials. Methods for using the photopolymerizable compositions include electroless plating methods that can be carried out in roll-to-roll printing systems once various photocured patterns are formed from the photopolymerizable compositions.

Owner:EASTMAN KODAK CO

Polymer composition, method, and article

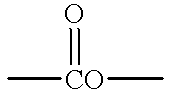

A synergistic flame retardant combination includes (a) a phosphorus salt having the formulawherein Md+ is a metal ion or an onium ion; d is 1, 2, 3, or 4 according to the identity of M and its oxidation state; each occurrence of R1 and R2 is independently C1-C18 hydrocarbyl; and each occurrence of m and n is independently 0 or 1; and (b) a phosphine compound selected from trihydrocarbylphosphines, trihydrocarbylphosphine oxides, and combinations thereof. Polymer compositions utilizing the flame retardant combination are described.

Owner:SABIC GLOBAL TECH BV

Photopolymerizable compositions for electroless plating methods

ActiveUS9207533B2Low efficiencyEasy to usePhotosensitive materials for photomechanical apparatusPhotosensitizerElectron donor

Owner:EASTMAN KODAK CO

Methods of using cleavable solid phases for isolating nucleic acids

Solid phase materials for binding nucleic acids and methods of their use are disclosed. The materials feature a cleavable linker portion which can be cleaved to release bound nucleic acids. The solid phase materials comprise a solid support portion comprising a matrix selected from silica, glass, insoluble synthetic polymers, and insoluble polysaccharides to which is attached a nucleic acid binding portion for attracting and binding nucleic acids, the nucleic acid binding portion (NAB) being linked by a cleavable linker portion to the solid support portion. Preferred nucleic acid binding portions comprise a ternary or quaternary onium group. The materials can be in the form of microparticles, fibers, beads, membranes, test tubes or microwells and can further comprise a magnetic core portion. Methods of binding nucleic acids using the cleavable solid supports are disclosed as are their use in methods of isolating or purifying nucleic acids.

Owner:NEXGEN DIAGNOSTICS LLC

Resist underlayer film forming composition containing silicone having onium group

ActiveUS20110143149A1Small film thicknessDry etching rateSilicon organic compoundsPhotosensitive materialsResistAnti-reflective coating

There is provided a resist underlayer film forming composition for lithography for forming a resist underlayer film capable of being used as a hard mask or a bottom anti-reflective coating, or a resist underlayer film causing no intermixing with a resist and having a dry etching rate higher than that of the resist. A film forming composition comprising a silane compound having an onium group, wherein the silane compound having an onium group is a hydrolyzable organosilane having, in a molecule thereof, an onium group, a hydrolysis product thereof, or a hydrolysis-condensation product thereof. The composition uses as a resist underlayer film forming composition for lithography. A composition comprising a silane compound having an onium group, and a silane compound having no onium group, wherein the silane compound having an onium group exists in the whole silane compound at a ratio of less than 1% by mol, for example 0.01 to 0.95% by mol. The hydrolyzable organosilane may be a compound of Formula: R1aR2bSi(R3)4-(a+b). A resist underlayer film obtained by applying the composition as claimed in any one of claims 1 to 14 onto a semiconductor substrate and by baking the composition.

Owner:NISSAN CHEM IND LTD

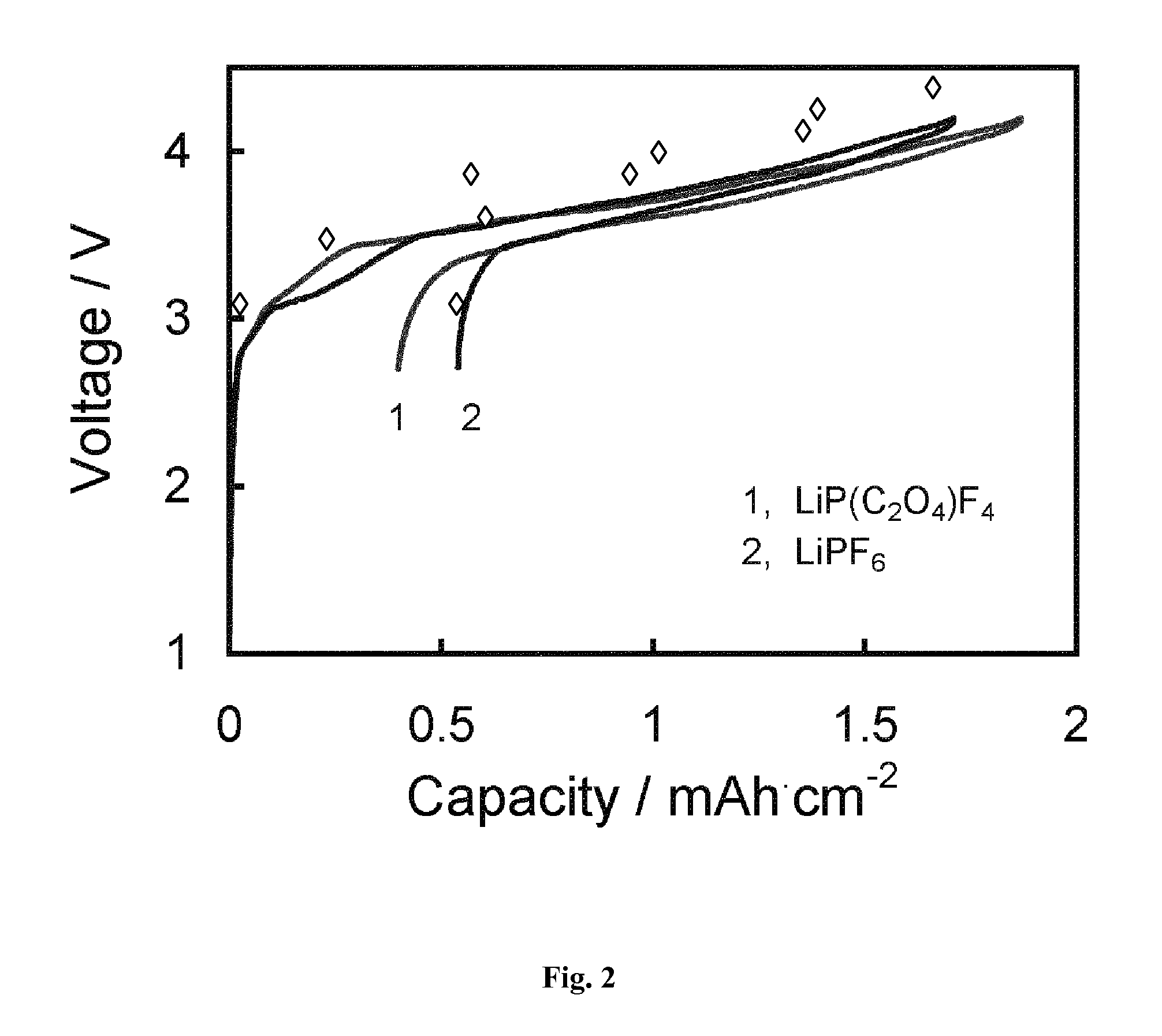

Oxyfluorophosphate synthesis process and compound therefrom

An electrolyte compound has the formulawhere p is an integer from 1 to 3 inclusive; and Yp+ is a metal ion, onium species, or proton; j is an integer value between 0 and 4 inclusive; k is an integer between 1 and 3 inclusive; and the sum 2k and j equals 6; Z is independently in each occurrence CR1R2 or C(O); R1 and R2 are independently in each occurrence H, F or CH3. A process for preparing an oxyfluorophosphate is also provided.

Owner:ARMY US SEC THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com