Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

899 results about "Cyanogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyanogen is the chemical compound with the formula (CN)₂. It is a colorless, toxic gas with a pungent odor. The molecule is a pseudohalogen. Cyanogen molecules consist of two CN groups – analogous to diatomic halogen molecules, such as Cl₂, but far less oxidizing. The two cyano groups are bonded together at their carbon atoms: N≡C−C≡N, although other isomers have been detected. The name is also used for the CN radical, and hence is used for compounds such as cyanogen bromide (NCBr).

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

Integrated electroplating treatment method for waste water

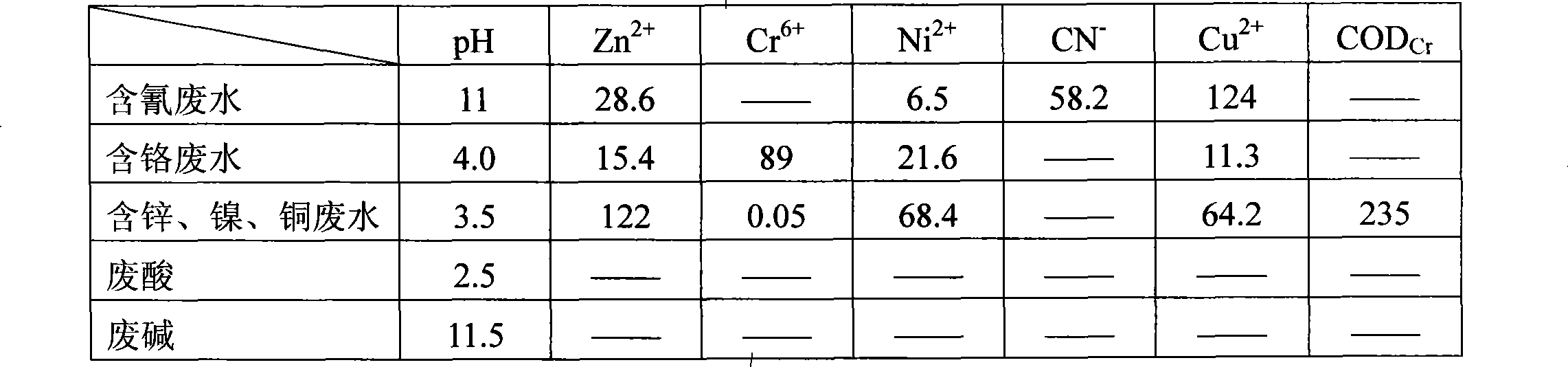

InactiveCN101234828AReduce manufacturing costWater contaminantsWaste water treatment from metallurgical processWater productionWater quality

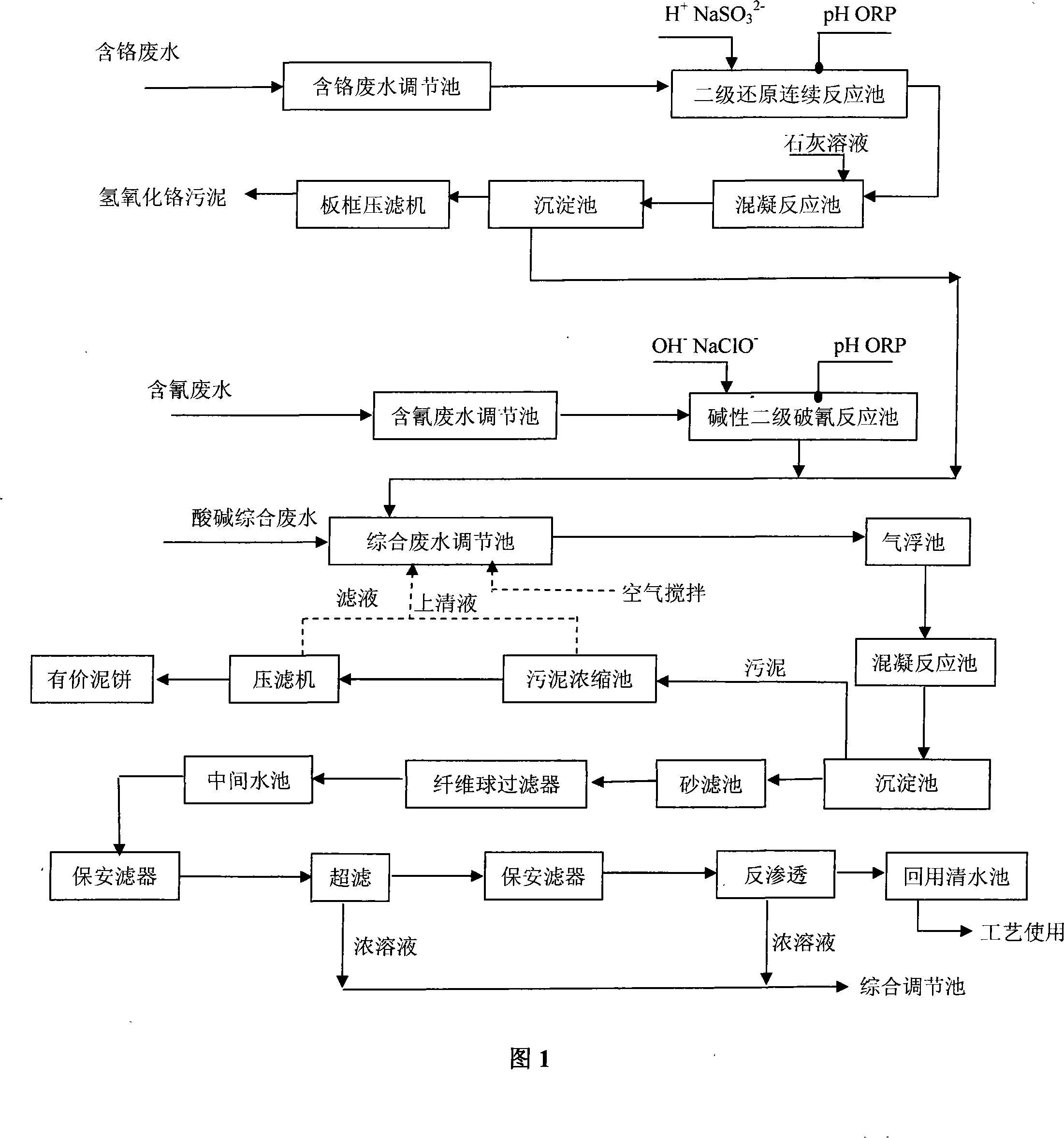

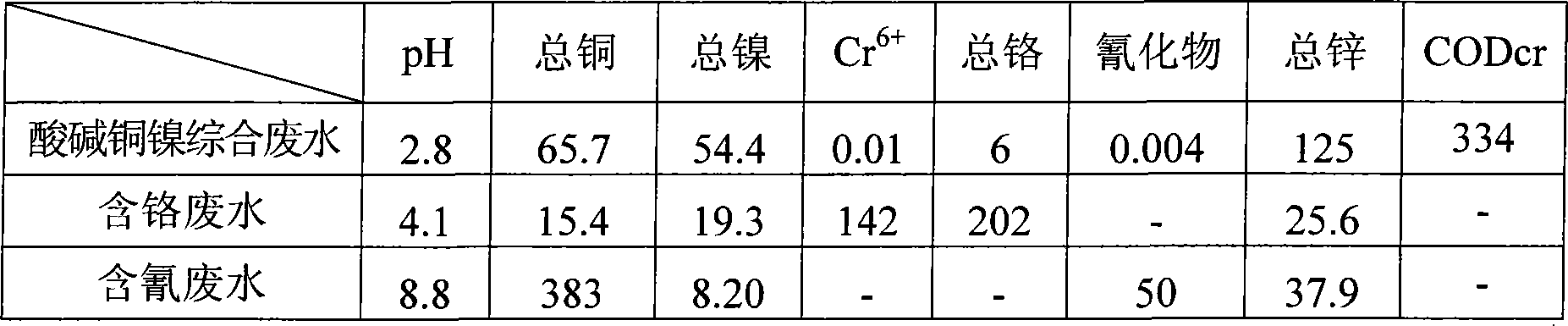

The invention relates to a method for treating comprehensive galvanization wastewater, particularly relating to a technique reclaiming resources of precious metal and recycly utilizing treated and comprehensively discharged galvanization wastewater. The method for treating the galvanization wastewater in the invention is characterized in that the following steps are included: (1) treating the wastewater containing chromium; (2) treating the wastewater containing cyanogen; (3) mixing and treating clear liquid obtained during treating the wastewater containing chromium in step (1) and the wastewater containing the cyanogen during treating the wastewater containing the cyanogen in step (2); (4) leading the clear liquid obtained during mixing and treating in step (3) into a reclaiming clean water pond; (5) leading the concentrated solution in step (4) into a comprehensive regulating pond of wastewater. Through treated by the technique of the method for treating comprehensive galvanization wastewater, each index of water quality of obtained water can reach or exceed the Drinking Water Sanitary Standard (GB5749-2006); the water can be reused in galvanization workshops; the water production rate of the reused water can reach over 80 percent; useful metal ions can be reclaimed; the target of environment protection can be met; benefits can be generated at the same time; the production cost can be reduced.

Owner:TIANJIN UNIV

Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

InactiveCN101172743AProcess Combination ScienceReasonable process combinationWater contaminantsWater/sewage treatment bu osmosis/dialysisIndustrial waste waterCombined technique

The invention relates to a combined technique of treating and reusing the organic sewage which is rich in cyanogen, ammonia and salt, and adopts the combined techniques of acidified decyanation (with the sodium cyanide recollected), basified ammonia blowing (with ammonium salt recollected), oxidation by adding chlorine, biological treatment, precipitation and clarification, deep oxidation, biological active carbon filtering, one-time brine refining, microstraining film, and other combined techniques, and then the chlorine alkali is produced after the secondary brine refining in the chlorine alkali industry and the entrance into the ionic membrane electrobath. The combined technique can be used for treating the industrial sewage in the tricyanogen chloride, chlorine alkali, gold mine, galvanization and other industries and conduct recovery of the resources, thereby overcoming the disadvantages that the prior art has narrow applicability and treatment function and disappointing treatment result, cannot recollect the resources, and has high treatment cost and unobvious economical benefit. The combination of the technique is scientific and reasonable, the technique is novel, unique and mature, the treatment is good, and the combined technique has a plurality of functions, strong applicability, wide use range and remarkable environmental and economical benefit.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

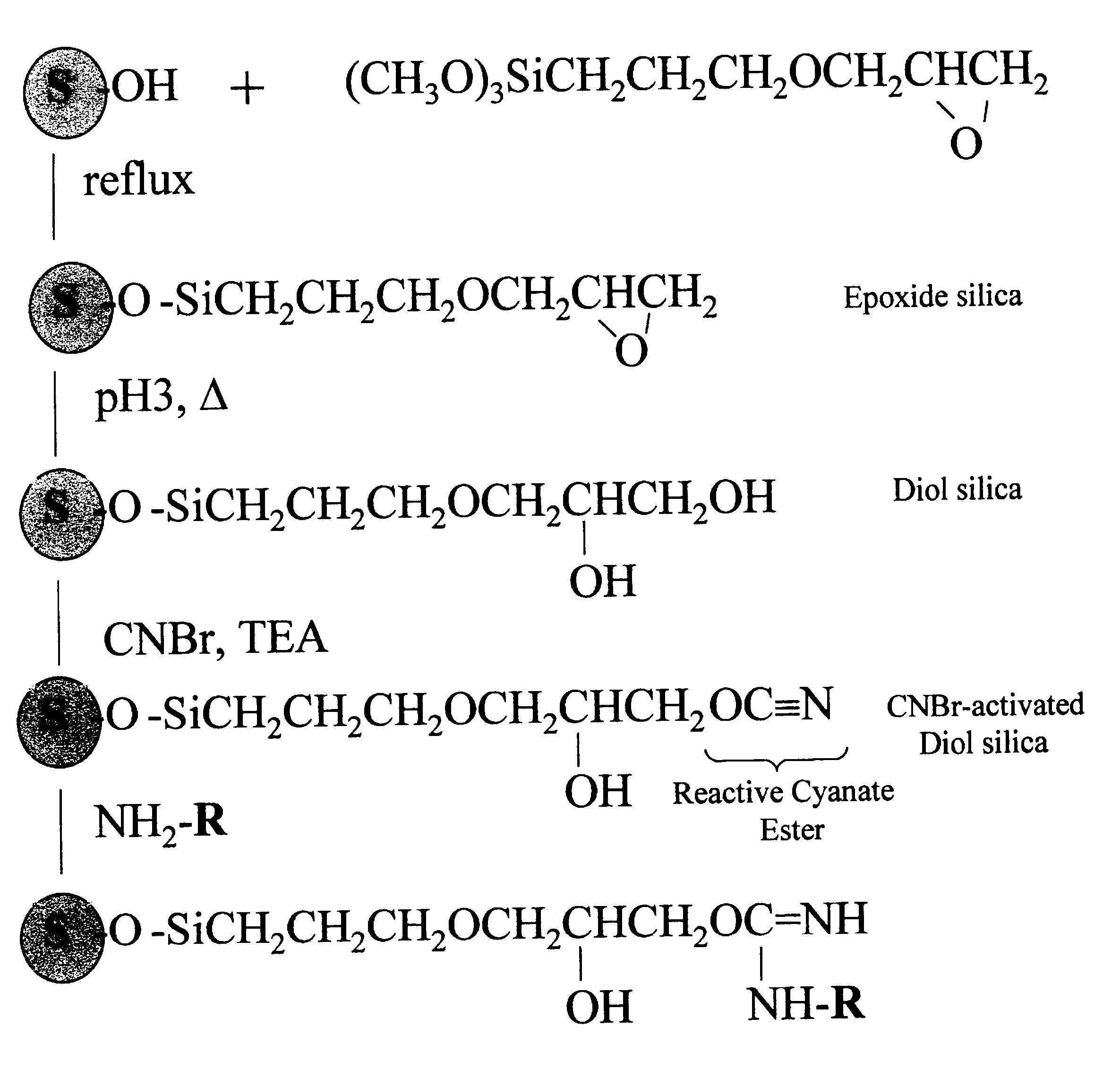

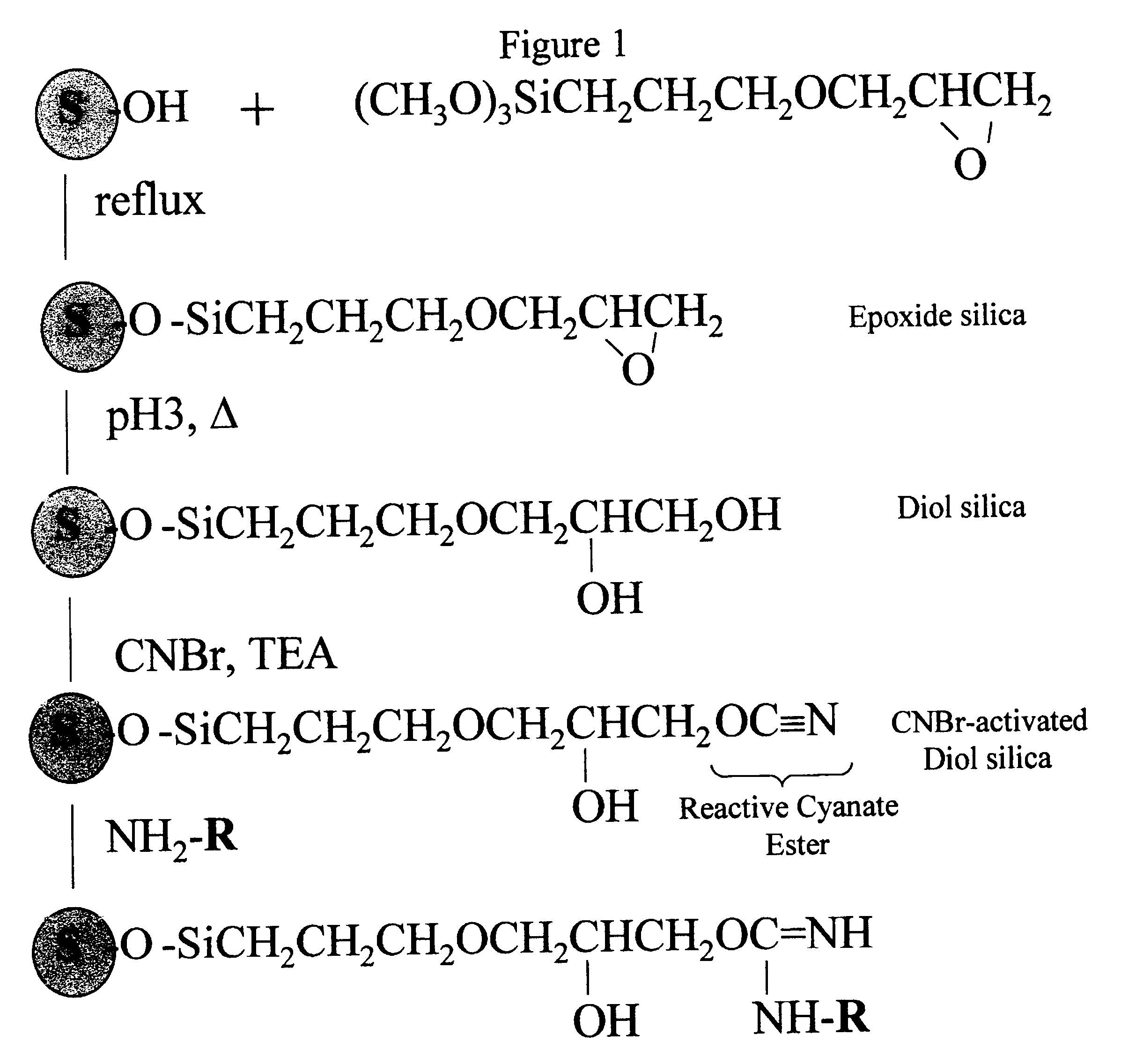

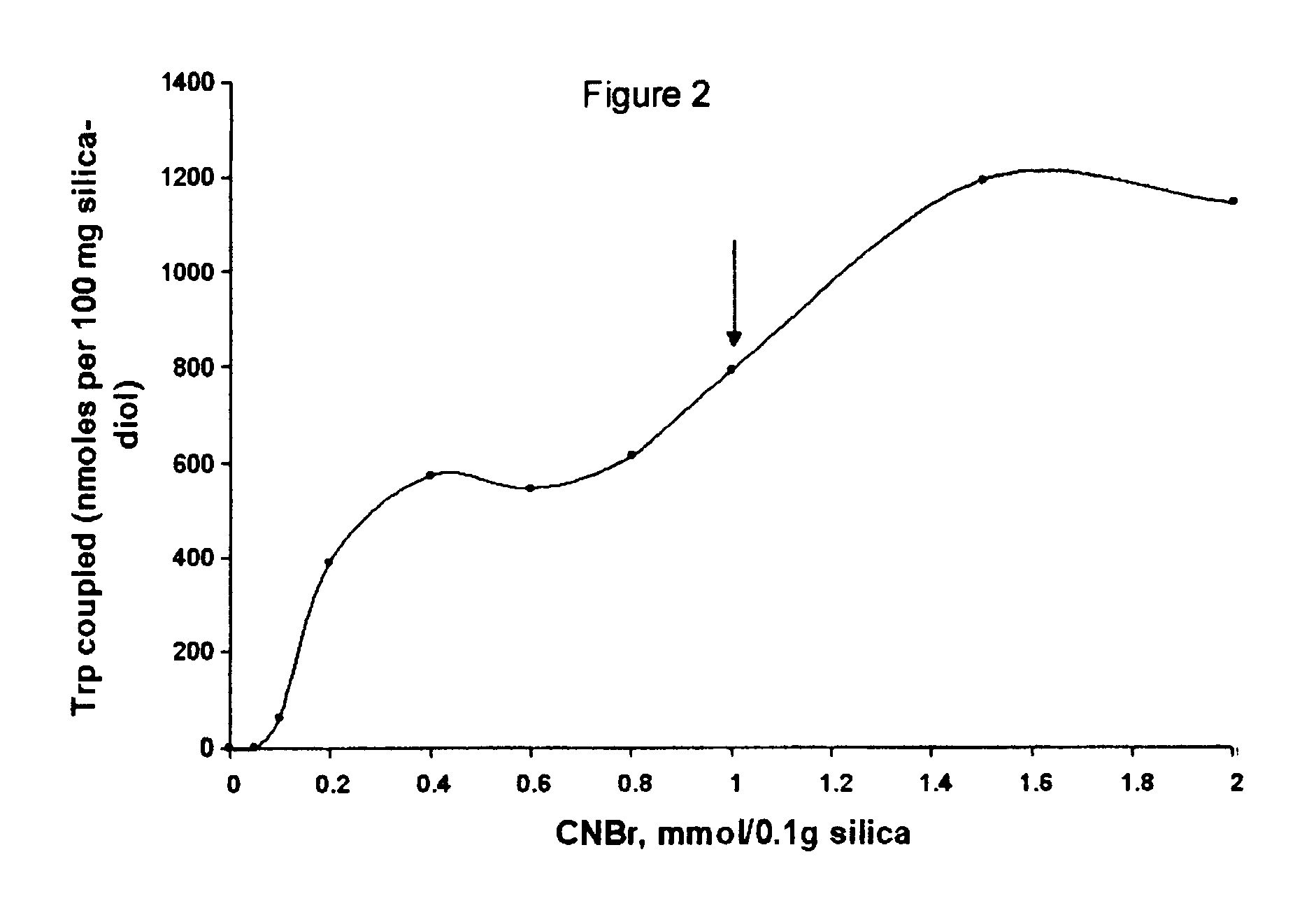

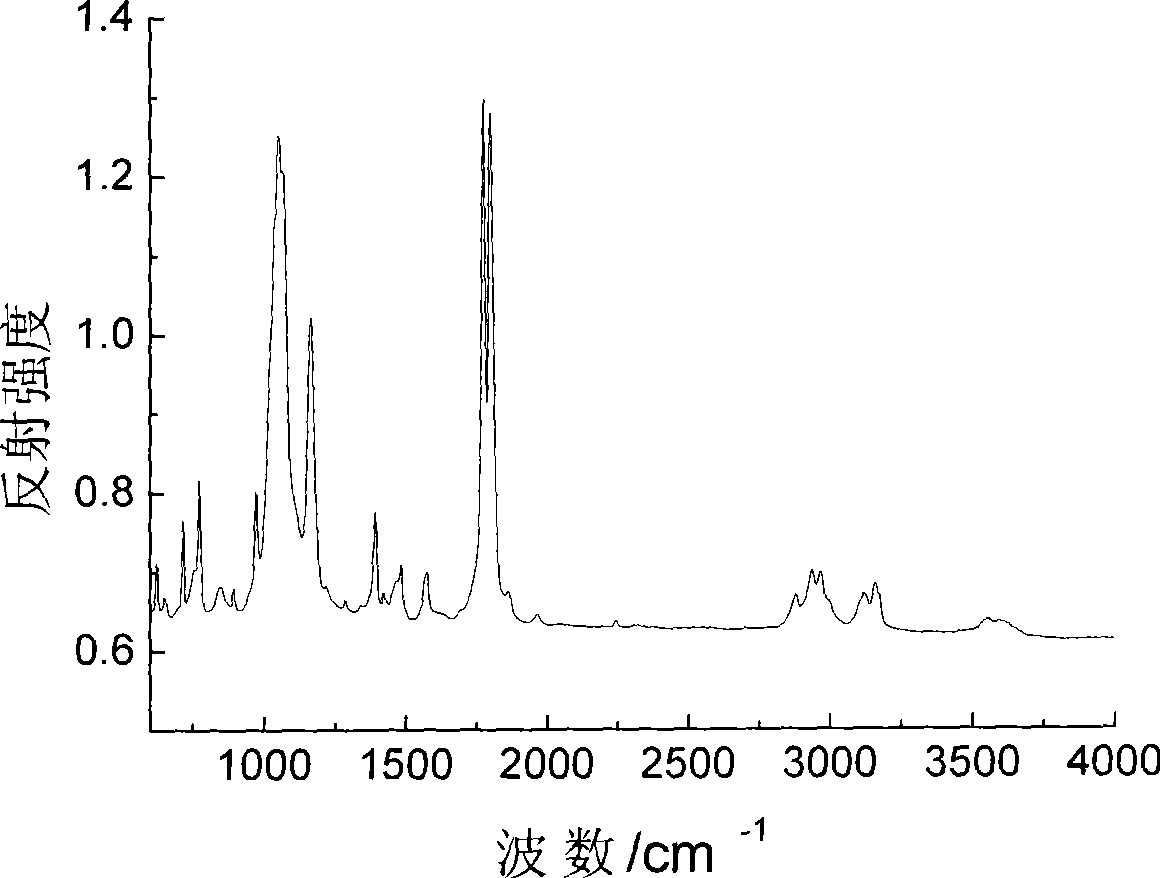

Cyanogen bromide-activation of hydroxyls on silica for high pressure affinity chromatography

InactiveUS6375846B1Excellent chromatographic performanceIon-exchange process apparatusOther chemical processesCyanogen halideCyanogen bromide

The present invention provides for a method to prepare a pressure stable and pH stable medium for use in high pressure (performance) affinity chromatography. The method includes the steps of treating hydroxyalkyl-silica with cyanogen halides or other cyanogen transfer reagents in the presence of an organic base in anhydrous solvents at temperatures in the range of from about -15° C. to about 20° C. for a period of time in the range of from about 1 minute to about 5 minutes, and washing the resulting medium in anhydrous solvent.

Owner:JARRETT HARRY WELLINGTON +1

Method for preparing ion liquid type gel polymer electrolyte and battery by in situ polymerization

ActiveCN101475663ASimple preparation processSimple manufacturing processFinal product manufactureSecondary cellsPolymer scienceTetrafluoroborate

The invention relates to a method for preparing ionic liquid type gel polymer electrolyte through home position polymerization. The method comprises the following steps: taking acrylonitrile and polyethylene glycol dimethyl acrylic acid ester as monomers, taking ethylene carbonate as an organic plasticizer, taking azo diisobutyl cyanogen as an initiator, taking lithium perchlorate as a lithium salt, adding ionic liquid 1-butyl-3-methylimidazole tetrafluoborate as the component of the electrolyte, and adopting a free radical initiation and home polymerization mode to prepare the stable ionic liquid type gel polymer electrolyte. The home polymerization mode has a simple and feasible process, and is capable of directly assembling a lithium cell while simultaneously preparing the electrolyte. The prepared ionic liquid type gel polymer electrolyte has higher room temperature conductivity, good dimensional stability and mechanic properties, and can also be applied to dye sensitization solar cells. The prepared ionic liquid type gel polymer electrolyte cell can avoid the leakage and volatilization of the electrolyte and improve the safety of the cell.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

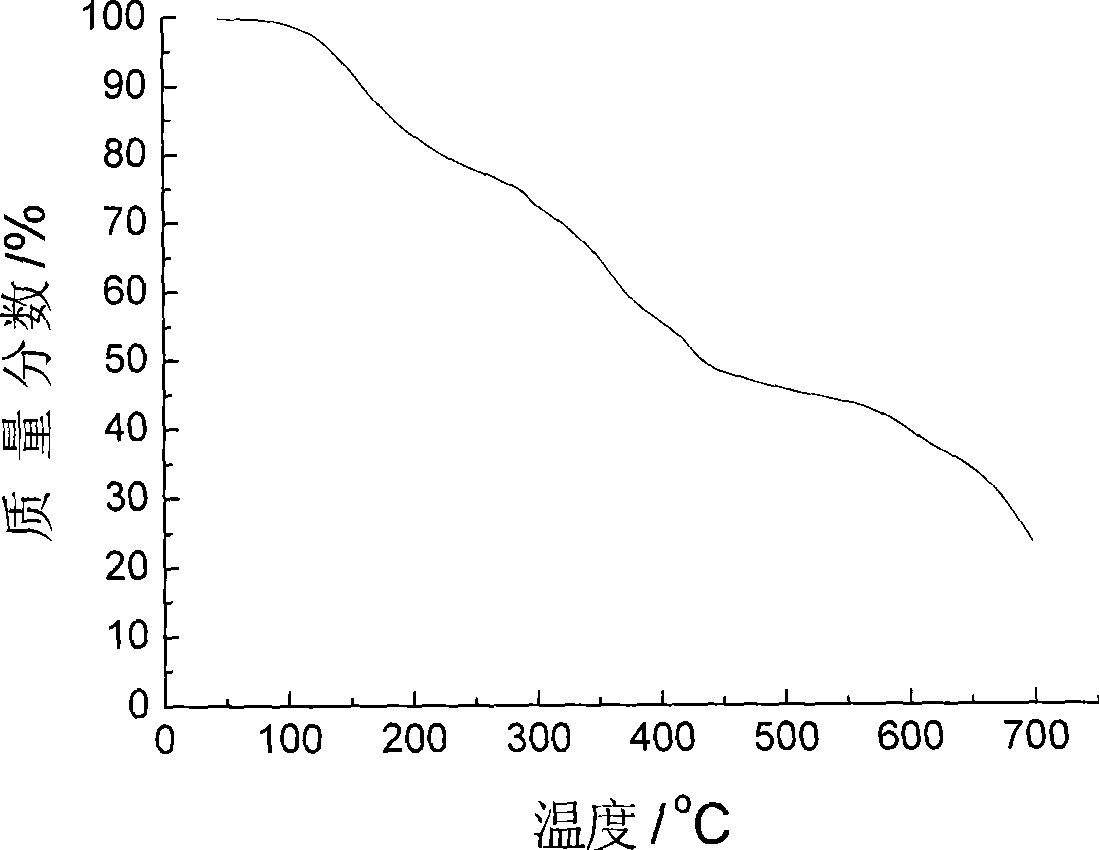

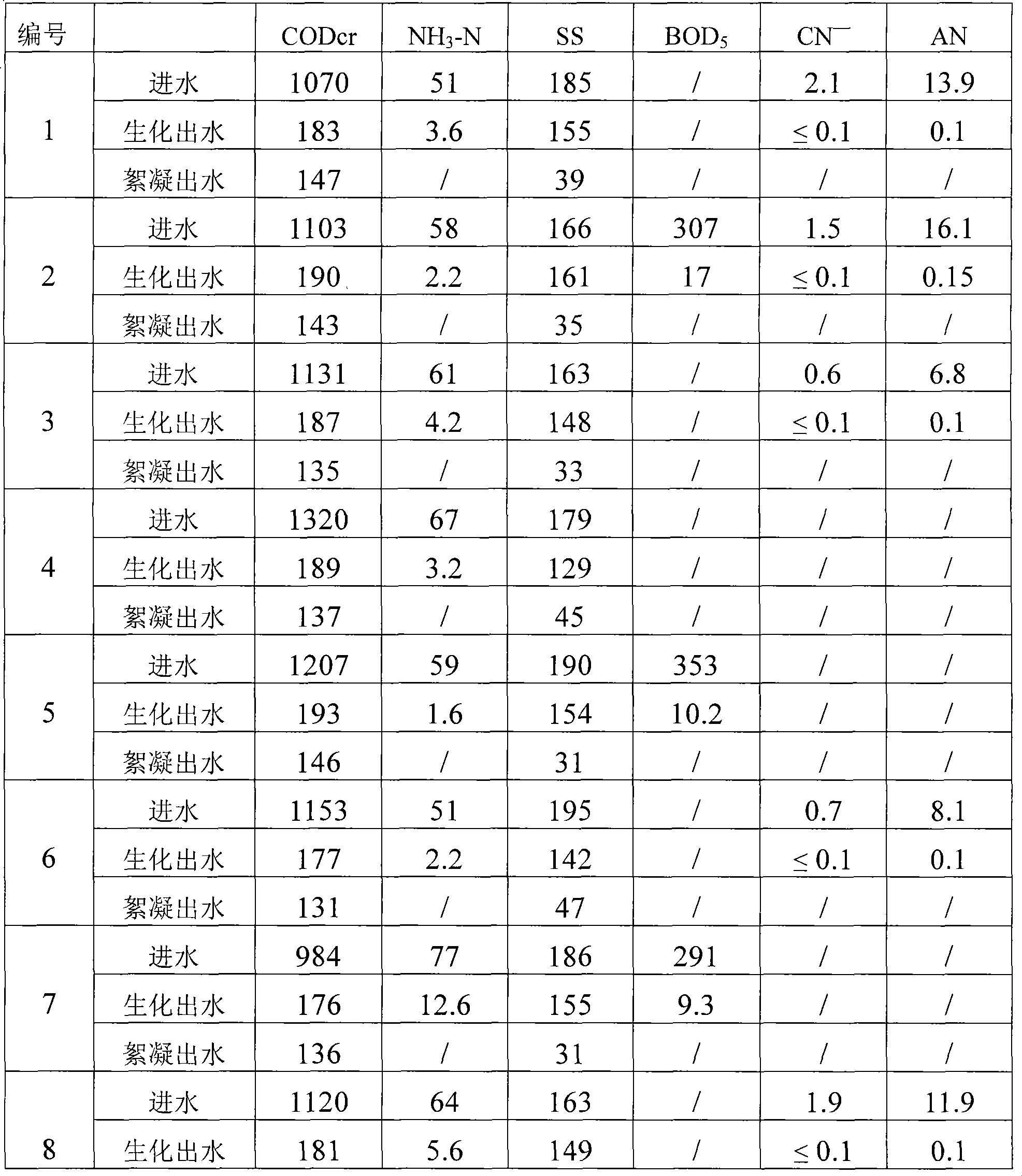

Treatment method of coking waste water

The invention discloses a treatment method of coking waste water, which comprises a biochemical treatment process of the coking waste water and an advanced treatment process of the coking waste water, wherein the biochemical treatment of the coking waste water adopts an A2O process; and the advanced treatment of the coking waste water adopts a method of internal electrolysis, Fenton oxidation coagulative precipitation and active carbon adsorption. In the method, an anaerobic pool, an anoxic pool and an aerobic pool are used for biochemical treatment; and internal electrolysis, Fenton oxidation coagulative precipitation and active carbon adsorption are used as an advanced section for treating the coking waste water. After the high-concentration coking waste water is treated by the method, the water quality of the effluent water can meet the sewage comprehensive discharge standard requirement that the COD (chemical oxygen demand) is no more than 50 mg / L, the ammonia nitrogen content is no more than 8 mg / L, the volatile phenol content is no more than 0.3 mg / L and the total cyanogen content is no more than 0.2 mg / L. Thus, the invention can protect the ecological environment, and has an important practical meaning for the sustainable development of coking enterprises.

Owner:ANGANG STEEL CO LTD

Aluminum electrolytic cell overhaul dreg harmless treatment system and method

ActiveCN105728440AAchieve serializationImprove processing efficiencySolid waste disposalSlurryFluoride

The invention relates to an aluminum electrolytic cell overhaul dreg harmless treatment system and method and belongs to the technical field of electrolytic aluminum waste treatment. The aluminum electrolytic cell overhaul dreg harmless treatment system comprises a leaching bin used for leaching overhaul dregs and a reaction bin unit connected with the leaching bin and used for carrying out cyanogen removal and fluoride removal treatment. The aluminum electrolytic cell overhaul dreg harmless treatment system comprises the leaching bin and the reaction bin unit, slurry making and slurry leaching can be carried out in the leaching bin, and cyanogen removal and fluoride removal reactions are carried out in the reaction bin unit. The procedures are carried out separately. When one procedure is carried out, the other procedure is not affected and can be carried out simultaneously. Continuous cyanogen removal and fluoride removal treatment can be realized, and the treating efficiency is improved.

Owner:郑州鸿跃环保科技有限公司

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

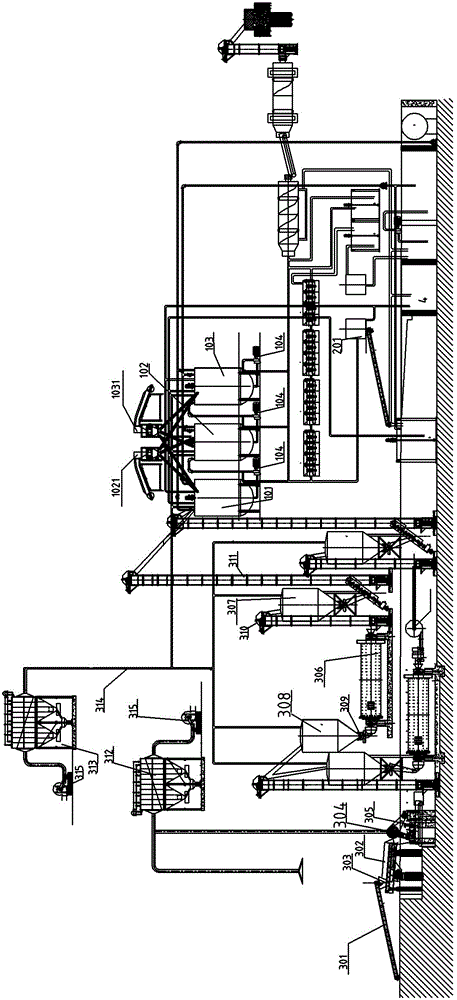

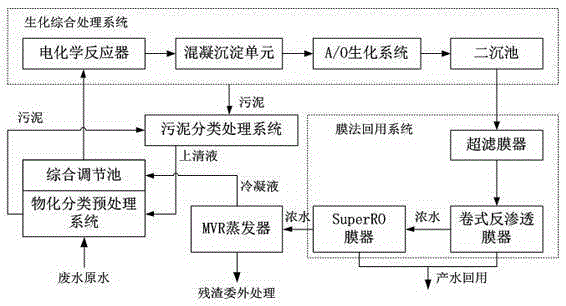

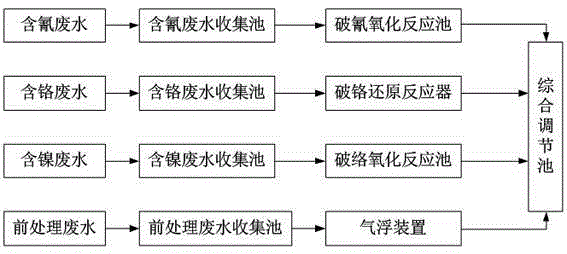

Technique and system for zero discharging treatment of electroplating effluent

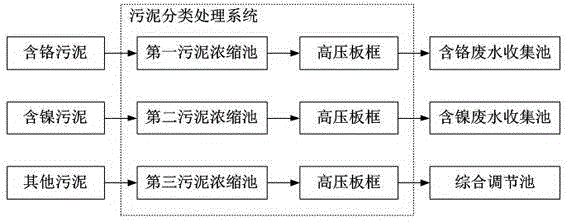

ActiveCN105271622AReduce processing costsAvoid wastingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgeWastewater

The invention discloses a technique and a system for zero discharging treatment of electroplating effluent. The system comprises a material classifying pre-treatment system, a biochemical comprehensive treatment system, a membrane method system, a membrane concentrated liquor vaporization system and a sludge classifying treatment system which are connected with each other in turn, wherein the sludge classifying treatment system is connected with the material classifying pre-treatment system and the biochemical comprehensive treatment system; the raw wastewater enters into the material classifying pre-treatment system; water generated by the membrane method system is recycled; the condensed liquid from the membrane concentrated liquor vaporization system is re-injected into the material classifying pre-treatment system. According to the technique provided by the invention, the wastewater is firstly treated in classifying form, so that the heavy pollution ions, such as, chromium, cyanogen, nickel, and the like, and the oily matters in the wastewater are effectively removed, and then the biochemical comprehensive treatment system is used for further treating, and lastly, the RO+SuperRo two-level combination mode is utilized to achieve the gross recovery at 94%, and meanwhile, the liquid amount for evaporation treatment is less than 6% of the gross wastewater quantity, the cost of the evaporation treatment is saved, the sludge is recycled, the waste of resources is avoided and the sludge treating cost is saved.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

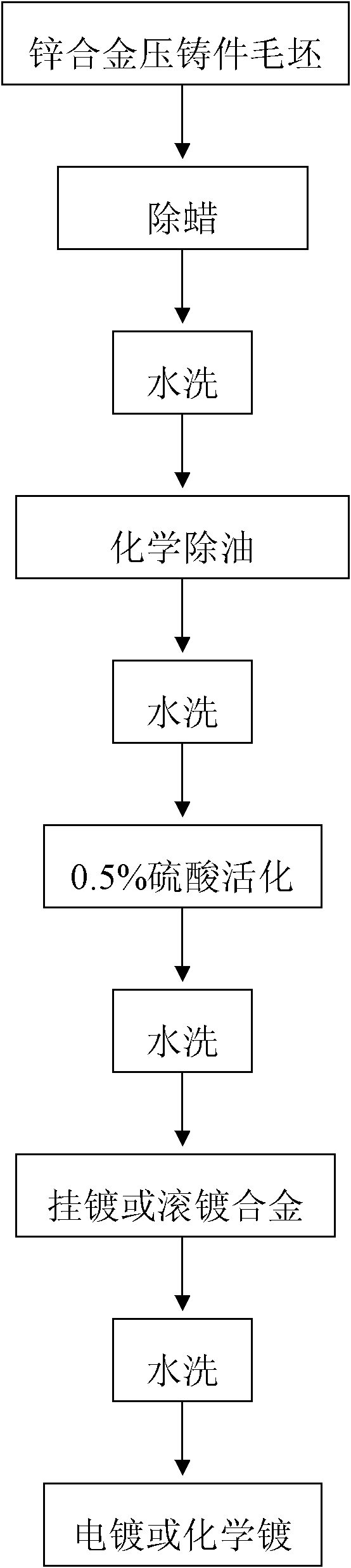

Cyanogen-free plating method of zinc alloy die casting

The invention discloses a cyanogen-free plating method of a zinc alloy die casting. The method is a plating method in which cyanogen-free copper-zinc alloy, copper-stannum alloy or ormolu is subjected to barrel plating or rack plating in a cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution as grounding layers so as to provide a pre-plating layer with good bonding force for subsequent plating or chemical plating. The method comprises the following steps: (1) carrying out ultrasonic wax removal or tumbling wax removal on a zinc alloy die casting blank; (2) washing; (3) chemically removing oil; (4) washing; (5) activating with 0.5% sulfuric acid; (6) washing; (7) carrying out barrel plating or rack plating on the alloys in the cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution; (8) washing; and (9) carrying out the subsequent plating or chemical plating. By using the method provided by the invention, cyanogen-free barrel plating or rack plating alloy is carried out on the zinc alloy die casting so that the obtained plating layer is semi-bright and has good bonding force.

Owner:广州市二轻研究所股份有限公司

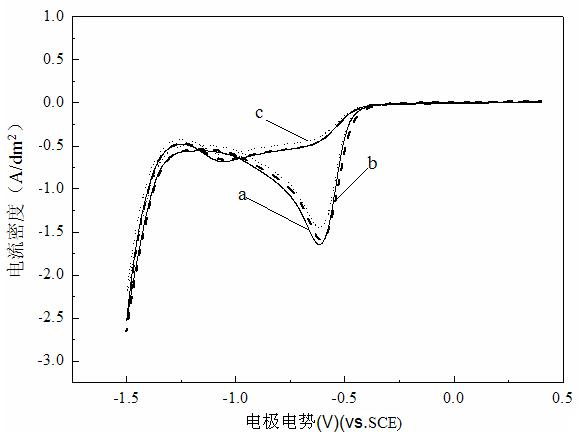

Cyanide-free silver plating solution containing auxiliary complexing agent

InactiveCN102277601AGood binding and brightPlating solution is stableSupporting electrolyteContinuous use

The invention discloses cyanogen-free silver-plating electroplating liquid containing an auxiliary complexing agent. The cyanogen-free silver-plating electroplating liquid containing the auxiliary complexing agent is composed of a silver ion source material, a complexing agent, the auxiliary complexing agent, a supporting electrolyte, an electroplating additive, a pH adjusting agent and the like;the components of the electroplating liquid and the contents are as follows: 30-60 g / L of silver ion source material, 140-200 g / L of complexing agent, 10-50 g / L of auxiliary complexing agent, 10-30 g / L of supporting electrolyte, 100-800 mg / L of electroplating additive and 10-30 g / L of pH adjusting agent. The cyanogen-free silver-plating electroplating liquid containing the auxiliary complexing agent provided by the invention has the advantages that: the electroplating liquid is stable and has low toxicity, the anodic passivation in the electroplating process can be better inhibited, the anodeis normally dissolved, the electroplating liquid can be continuously utilized for long time, the electroplating layer has a good bonding force and is bright, and the electroplating liquid can be applied to multiple fields including decorative electroplating, functional electroplating and the like.

Owner:NANJING UNIV

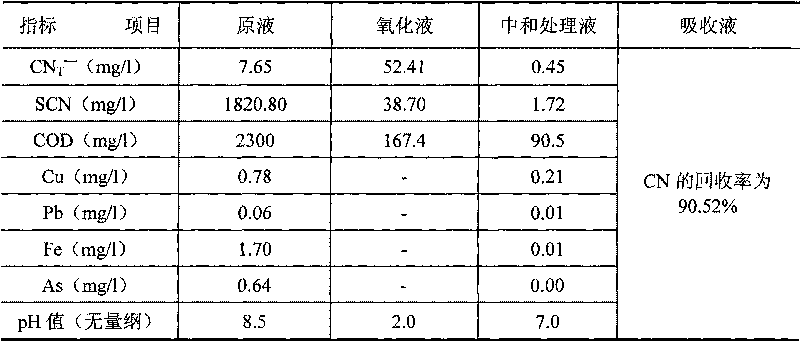

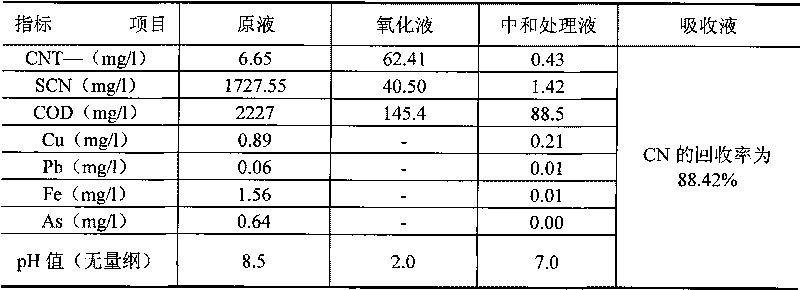

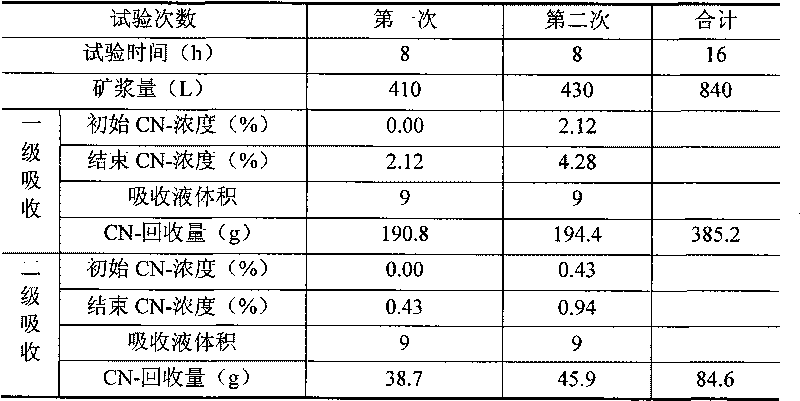

Recycling and harmless treatment method for cyaniding tailing slurry

ActiveCN101759274AIncrease contact areaToxicWaste water treatment from quariesWater contaminantsSlagGas phase

The invention discloses a recycling and harmless treatment method for cyaniding tailing slurry. In the method, the cyaniding tailing slurry containing cyanogen, thiocyanate, heavy metal and arsenic and liquid containing hydrogen peroxide are subjected to direct mixing treatment; the method utilizes high specific surface area of micro-fine granular ore to add the contact opportunity between the thiocyanate and the hydrogen peroxide and the contact area between gas phase and liquid phase through surface adsorption to accelerate a speed of oxidation-reduction reaction and an acidifying and stripping speed, utilizes metallic substances contained in slag to accelerate the reaction rate of the oxidation-reduction reaction without the addition of catalyst, and can reduce cost; meanwhile, in neutralization, Fe3+ in the slag is utilized to meet the requirement of arsenic precipitation without the addition of an arsenic precipitation reagent; when residual cyanides is removed from the hydrogen peroxide liquid, the hydrogen peroxide liquid and cyano complexes which are difficult to remove through the oxidation-reduction reaction form sediment so that the residual thiocyanate is further removed; the method can make the conversion rate of the thiocyanate in the ore slurry more than or equal to 88 percent; and compared with the treatment of filter pressing clear liquid of homogeneous ore slurry, the total reclaiming rate can be increased by over 20 percent.

Owner:CHANGCHUN GOLD RES INST +1

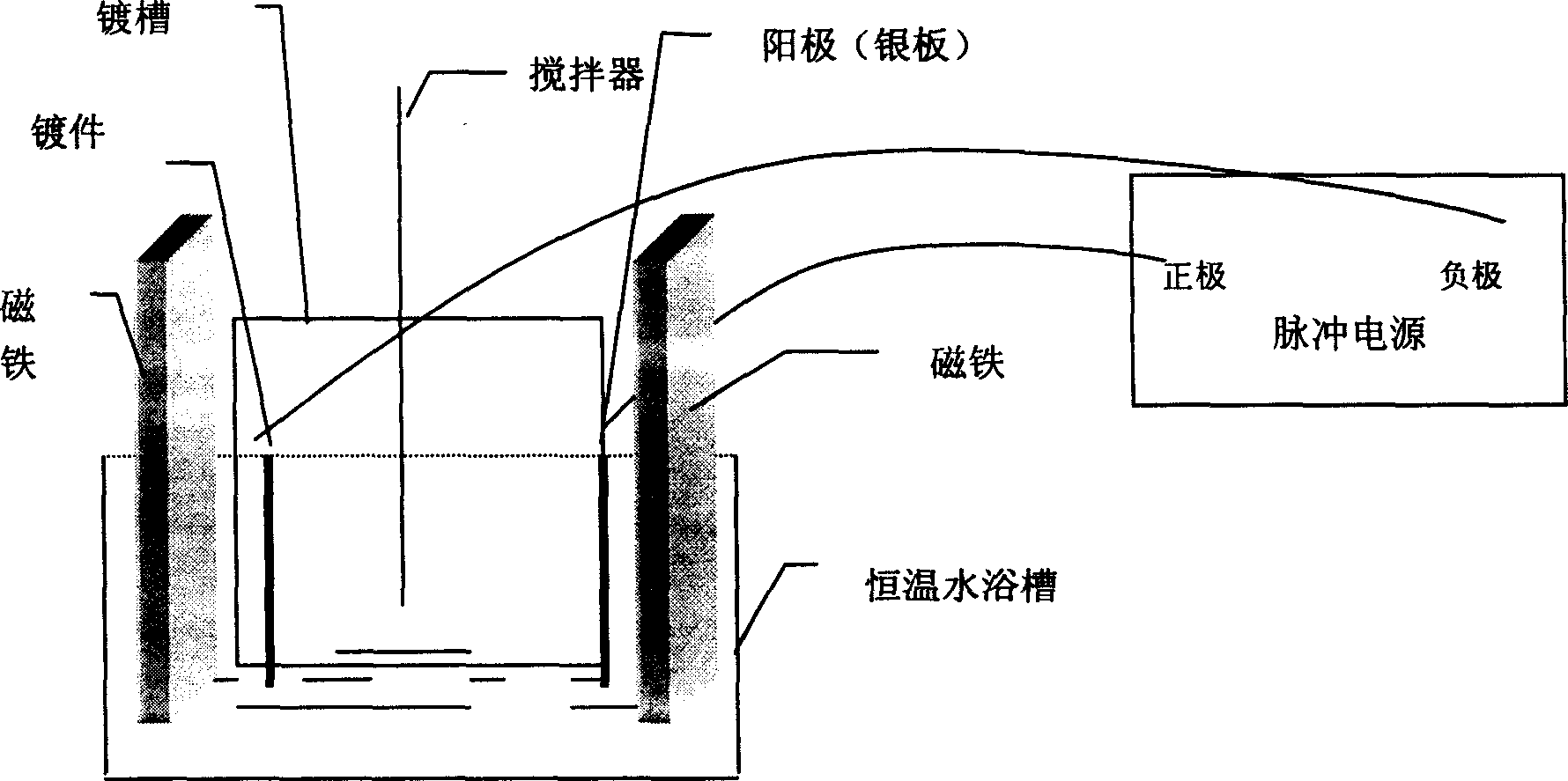

Technology of non-cyanide silver coating

A process of silver coating with no cyanogens at the action of magnetic field and impulse current. The main process is impulsive silver coating. Ingredients of the solution are as follow. AgNO3,50-60g / L; sodium thiosulfate, 250-350g / L; potassium, 90-110g / L; K2SO4,20-30g / L; boracic acid, 25-35g / L; brightener,5m / L. Stir at 20-40deg.C for 10min. pH of silvering solution is 4.2-4.8. Mean impulse current density is 0.5-1ms. Duty ratio is 5-15%. Orientation of magnetic field is parallel with that of impulse current. Square ratio of positive and negative pole is bigger than 2.

Owner:SHANGHAI UNIV

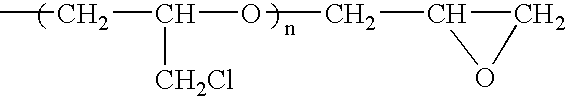

Pyrophosphoric acid bath for use in copper-tin alloy plating

InactiveUS20050166790A1Optimization rangeReduce SO3 generation rateAnti-corrosive paintsLiquid/solution decomposition chemical coatingGeneration rateAlloy coating

The invention relates to a pyrophosphoric acid bath for use in cyanogen-free copper-tin alloy plating that contains an additive (A) composed an amine derivative, an epihalohydrin and a glycidyl ether compound with ratios of epihalohydrin to glycidyl ether compound being 0.5-2 to 0.1-5 on mol basis, per 1 mol of the amine derivative, has a pH of 3 to 9, and optionally contains an additive (B) composed of an organic sulfonic acid and / or an organic sulfonic acid salt, and to a copper-tin alloy coating obtainable by using the bath. The invention provides a pyrophosphoric acid bath for use in copper-tin alloy plating of the cyanogen-free type utilizable on an industrial scale, particularly, capable of performing uniform treatment to exhibit low defective product generation rates even with the current density being incessantly changing between a high state and a low state, as a barrel plating method, and a copper-tin alloy coating obtainable by using the bath.

Owner:NIHON NEW CHROME

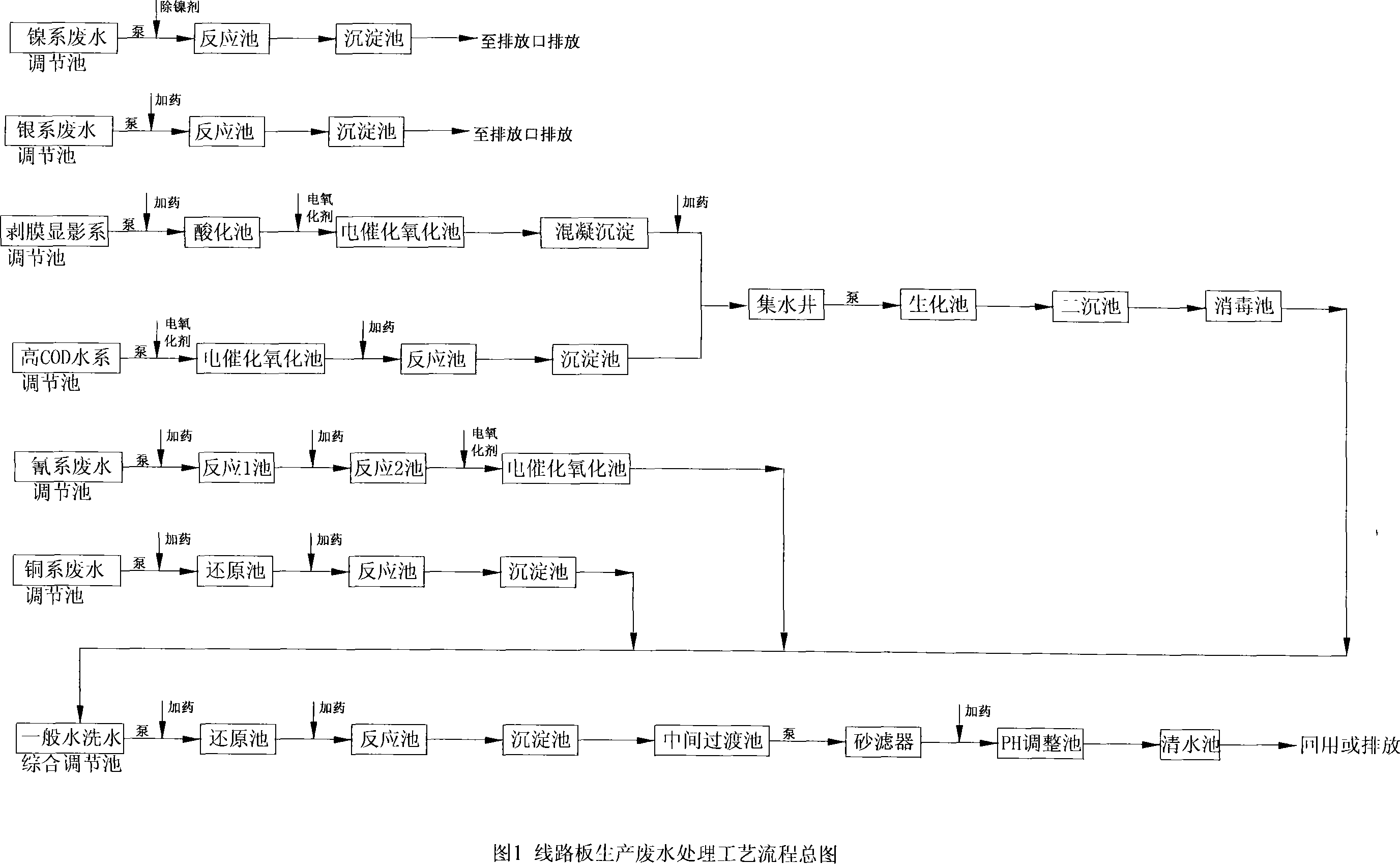

Integrated processing technique for waste water in breadboard production

InactiveCN101054247AThe process principle is clearComplete process principleWater/sewage treatment by electrochemical methodsWaste water treatment from metallurgical processElectricityWater processing

The invention relates to an efficient process technology for processing plenty of waste water generated in circuit board production, in particular to a pretreatment technology of high copper waste water and difficult biochemical degradation waste water with high COD in the process technology and entire waste water processing technology. First, sorting waste water reasonably according to nature thereof, dividing into as gold thread cyanogen waste water, nickel waste water, silver waste water, copper waste water, peel ink development waste water, high COD waste water and general aqueous washing water, collecting and specially processing the seven kinds of waste water independently, which key technology is the pretreatment technology for copper waste water, peel ink development waste water and high COD waste water. For copper, the key of waste water processing lies in to break complex compound and prevent secondary complexation of remnant Cu2+ and EDTA when adjusting pH to alkaline value; the key of peeling ink development waste water and high COD waste water lies in the foundation that carries out electrocatalysis oxidize to remove partial CODs, on with raise BOD / COD ratio thereof to improve biochemicalness radically.

Owner:深圳市宇力科技有限公司

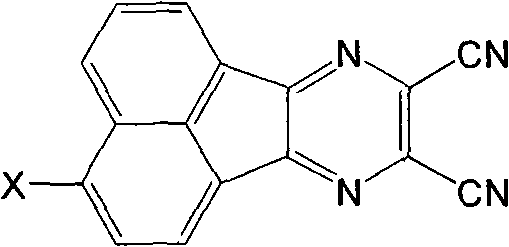

O-dicyano-acenaphtho pyrazine compound and anti-tumor application thereof

InactiveCN101723907AEnhanced inhibitory effectOrganic active ingredientsOrganic chemistryQuinonePyrazine

The invention relates to a DNA-targeted o-dicyano-acenaphtho pyrazine compound in the field of application of antineoplastic medicaments. The compound is prepared by taking acenaphthene quinone as a raw material and performing bromination, cyclization and aromatic nucleophilic substitution reaction. The compound is characterized in that: one end takes an amino straight chain of a flexible side chain or an annular group as an electron-donating group, while the other end takes two cyanogen groups as electron-withdrawing groups; the two ends form an electron deficient large-plane conjugated system; and the structure accords with an ideal DNA intercalator. The compound shows obvious inhibitory activity to an in vitro test of MCF-7 (human mammary cancer cells).

Owner:DALIAN UNIV OF TECH

Catalytic wet oxidation method of cyanogen-containing industrial wastewater

ActiveCN102452710AHigh strengthAvoid crackingWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureOxygen

The invention relates to a catalytic wet oxidation method of cyanogen-containing industrial wastewater. With the method, problems of catalysts in existing technologies, such as difficult shaping, low activity, easy crushing, short service life, low COD removing rate, and complicated technology, can be solved. According to the invention, industrial wastewater and gas containing elementary oxygen are adopted as raw materials. Under a reaction temperature of 230-300 DEG C, a reaction pressure of 3-10MPa, and a liquid space velocity of 0.5-2.5h<-1>, the raw materials contact a catalyst, such tat a COD removing rate is higher than 95%. After the treatment, a total cyanogen content is smaller than 5ppm. The adopted catalyst is a composite carrier loaded with at least one metal selected from Pt,Pd, Ru, Ir, or Rh, or an oxide of the metals. With the method provided by the invention, the problem is well solved. The method can be used in industrial treatment of cyanogen-containing industrial wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

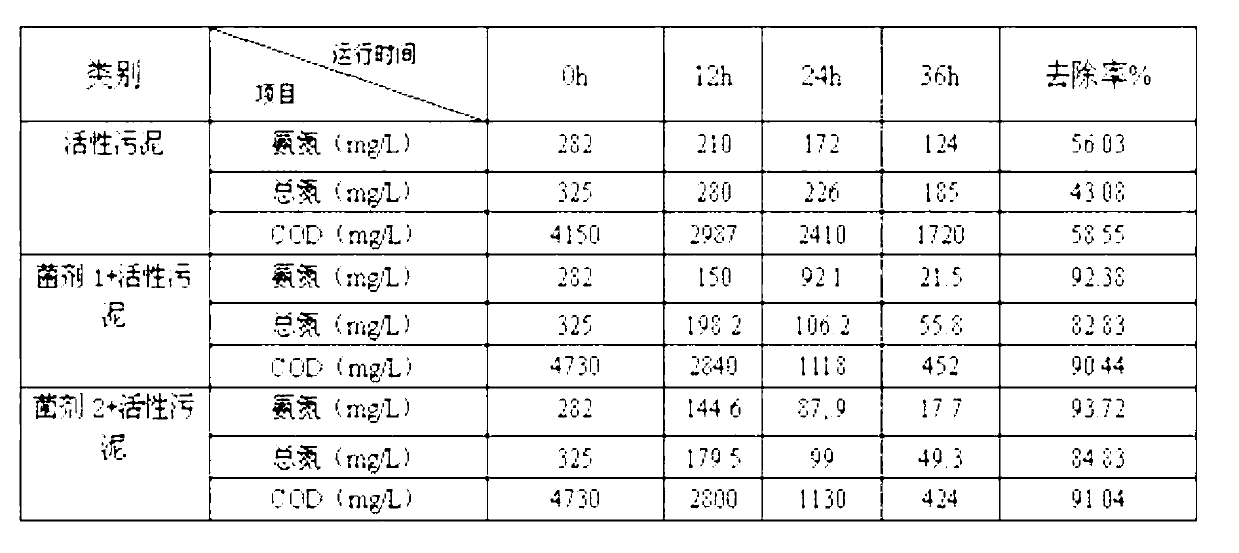

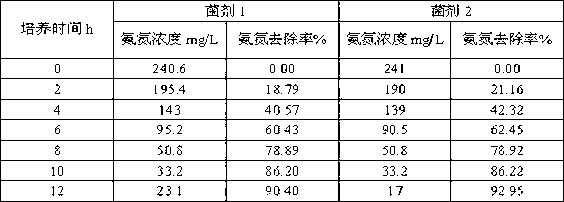

Achromobacter xylosoxidans subsp.xylosoxidans LH-N25 and heterotrophic nitrification and aerobic denitrification microorganism bactericide and preparation method and use thereof

ActiveCN103122332ASolve the difficult removal of total nitrogenFacilitate large-scale production applicationBacteriaMicroorganism based processesToxic materialTotal nitrogen

The invention discloses achromobacter xylosoxidans subsp.xylosoxidans LH-N25 with CGMCC No.6972. The invention also discloses a heterotrophic nitrification and aerobic denitrification microorganism bactericide. The microorganism bactericide comprises achromobacter xylosoxidans subsp.xylosoxidans LH-N25 or also comprises paracoccus aminovorans LH-N40; and the strains are combined according to any ratio. The invention also discloses a preparation method of the microorganism bactericide. The microorganism bactericide disclosed by the invention not only can solve the problem that total nitrogen cannot be easily removed in the traditional reactor, but also can effectively remove ammonia nitrogen and total nitrogen in a water body in the same reactor, and has tolerance and degradation ability on the toxic substances such as phenols, amines, hetercyclics, cyanogens and polyaromatic hydrocarbon in the wastewater at the same time. The microorganism bactericide is especially suitable for chemical wastewater containing nitrogen, is simple in treatment process, stable in effect, and resistant to impact of environmental toxic substances, and has a wide application prospect in treatment of chemical wastewater containing nitrogen.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Aluminum electrolysis waste tank lining harmless treatment device and treatment method

ActiveCN107377592AImprove processing efficiencyGood effectSolid waste disposalElectrolysisFiltration

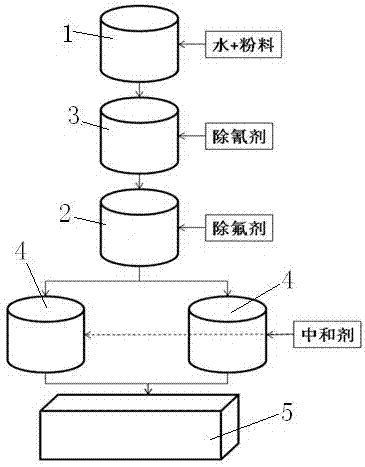

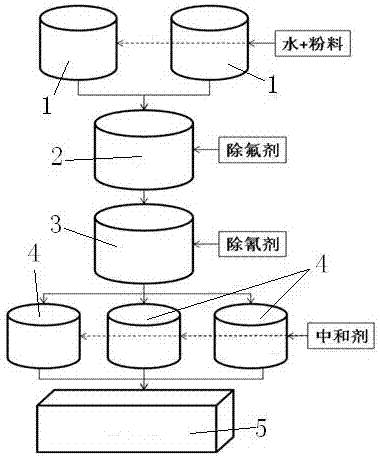

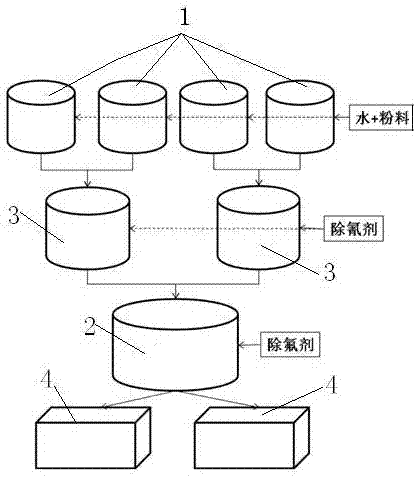

The invention relates to an aluminum electrolysis waste tank lining harmless treatment device and a treatment method. The treatment device is characterized by comprising a water adding reaction bin, a cyanogen removing agent or fluorine removing agent adding reaction bin, a fluorine removing agent or cyanogen removing agent adding reaction bin, a neutralizing agent adding reaction bin and a collecting bin connected in sequence. The treatment method comprises the following process: an aluminum electrolysis waste tank lining is crushed and milled as powder to feed in the water adding reaction bin, the cyanogen removing agent or fluorine removing agent adding reaction bin, the fluorine removing agent or cyanogen removing agent adding reaction bin, the neutralizing agent adding reaction bin and the collecting bin in sequence; charging, reaction and discharge are performed at the same time to form continuous aluminum electrolysis waste tank lining harmless treatment process; treated slurry is totally poured in the collecting bin, and is injected in a filter press by the collecting bin for pressing and filtration; harmless slag is carried out; and filtrate is recycled, so that the waste tank lining harmless treatment is realized, the treatment efficiency is high, the effect is good, and the operation is flexibility, simple and convenient.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Non-cyanogen high-density copper plating solution and Aluminium alloy wheel hub electroplating technique using same

The invention discloses a high density copper electroplating liquid without cyanogen and aluminum alloy boss electroplating craft, which is characterized by the following: allocating 250-400ml / l high density copper opening jar agent without cyanogen, 80-120 ml / l high density copper accelerant without cyanogen, 0-5 ml / l high density copper additive without cyanogen and surplus as water; adjusting pH value at 9. 2-10. 0; getting the electroplating liquid; adding following steps between twice depositing zinc step and acid bright coppering step; pre-coating the high density copper without cyanogen; petting the aluminum alloy boss into high density coppering liquid without cyanogen; electroplating; thick-plating; putting the aluminum alloy boss into thick coating liquid; proceeding thick electroplating. This craft can decrease cost and modify electroplating quality.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

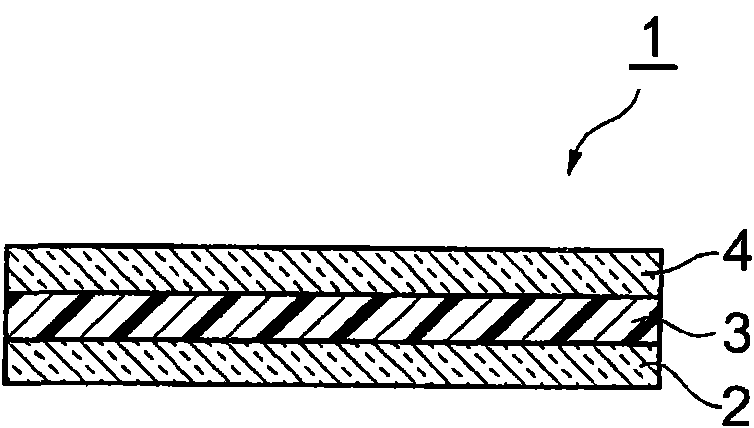

Light-sensitive resin composite and method for manufacturing printed circuit board using same

ActiveCN101738861AHigh sensitivityImprove resolutionPrinted circuit manufacturePhotosensitive materials for photomechanical apparatusCarbon numberChemical compound

The invention relates to a light-sensitive resin composite and a method for manufacturing a printed circuit board using the same. The resin composition comprises the following components: (A) an adhesive polymer, (B) a light polymeric compound with an ethylene unsaturated bond and (C1) a stilbazole compound represented by the following general formula (1); in the formula (1), R1, R2 and R3 respectively represent alkyl with the carbon number of 1-20, alkoxyl with the carbon number of 1-6, alkyl ester with the carbon number of 1-6, amido, and alkyl amido, carboxyl, cyanogen group, nitryl or (methyl) acryloyl group with the carbon number of 1-20 independently, m and n respectively represent the integer of 1-3 independently, and a, b and c respectively represent the integer of 0-5 independently.

Owner:株式会社力森诺科 +1

Integrative electroplating waste treatment process

InactiveCN101475274ALow investment costReduce processing costsWaste water treatment from metallurgical processMultistage water/sewage treatmentReduction treatmentWaste treatment

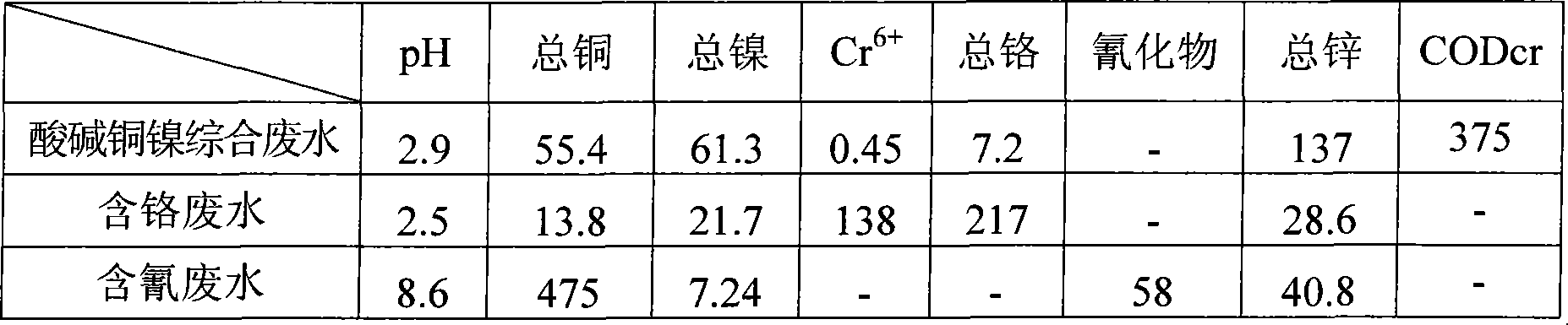

The invention discloses a process for treating comprehensive electroplating wastewater, which solves the technical problems existing in the prior process for treating the comprehensive electroplating wastewater. The process comprises the following steps: (1) establishing wastewater disposal basins for the electroplating wastewater by classification, and automatically adding waste acid and waste alkali into the basins; (2) reducing hexavalent chrome for pretreatment; (3) carrying out secondary oxidation decyanation and reduction treatment on wastewater containing cyanogen; (4) mixing pretreated wastewater containing chromium and wastewater subjected to the secondary oxidation decyanation treatment without cyanogen with the comprehensive electroplating wastewater containing copper, nickel and zinc, adjusting the mixed wastewater to neutrality, and adding an NTC coagulating agent into the mixed wastewater; (5) after coagulation, carrying out solid-liquid separation on the wastewater in a high-speed sedimentation tank; and (6) filtering the wastewater which is subjected to the solid-liquid separation in an intermediate water tank, and recycling the qualified wastewater or discharging the qualified wastewater in accordance to standard. The process has the advantages that the problem that different metal ions require respective treatment or multiple circulating treatments because of different concentrations can be solved, the problem of independently setting air flotation to remove oil can be solved, the problem of recycling the waste acid and the waste alkali can be solved; and investment, operating cost and floor area are saved.

Owner:LIDA ENVIRONMENT ENG DALIAN ECONOMIC TECH DEV ZONE

Hazard-free treatment and utilization method for aluminium electrolysis waste slot liner

ActiveCN106565120AEfficient and reasonable useAvoid wasting timeSolid waste managementAluminium electrolysisBrick

The invention relates to a hazard-free treatment and utilization method for an aluminium electrolysis waste slot liner. The hazard-free treatment and utilization method is characterized by comprising the steps of (1) performing sorting and separating on the aluminium electrolysis waste slot liner based on an aluminium electrolysis waste negative electrode carbon material and a waste fireproof material; (2) performing smashing separately; (3) performing powder grinding separately; (4) measuring content values of cyanogen and fluorine;(5) adding a solid cyanogen removal agent and a solid fluorine removal agent, and performing material mixing; (6) performing a cyanogen removal and fluorine removal and neutral reaction on the waste fireproof material; (7) performing a cyanogen removal and fluorine removal reaction on the waste negative electrode carbon material; (8) pressing and filtering material slurry obtained in the step (6), recycling the filtering liquid, and taking filtering slag for road pavement; and (9) pressing and filtering material slurry obtained in the step (7), recycling the filtering liquid, and taking filtering slag as carbon brick for manufacturing a blast furnace. By adoption of the hazard-free treatment and utilization method, different kinds of waste materials in the waste slot liner are processed, respective optimal technological parameters specific to different kinds of waste materials are selected, and the hazard-free slag can be sorted and reasonably recycled.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

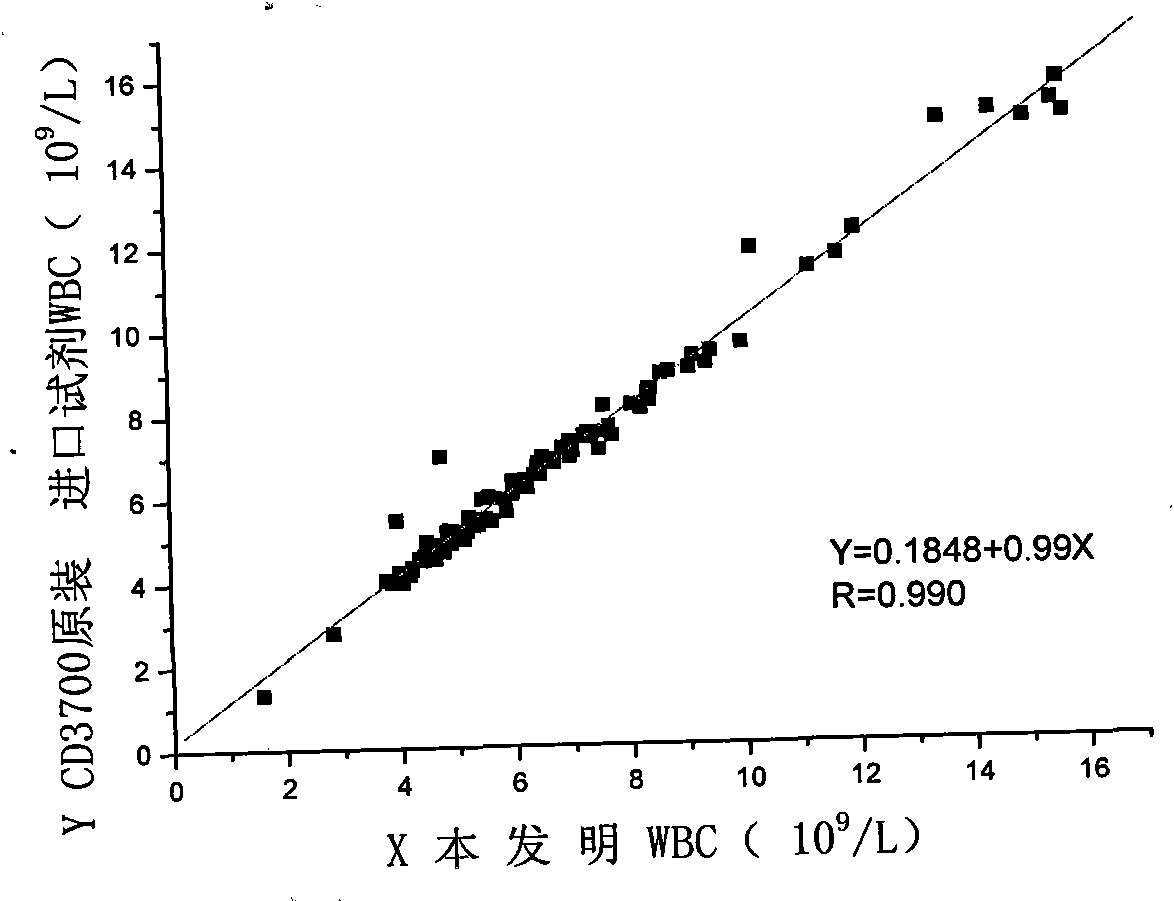

Reagent for hemocyte analyzers

The invention discloses a reagent for hemocyte analyzers, which is prepared from diluent, hemolytic agent, sheath flow liquid and cleaning fluid. Compared with the prior art, the invention changes the actual state of long-term dependence on import of the reagent for hemocyte analyzers in China, and is produced and sold in China, thereby greatly reducing the production cost; the hemolytic agent in the reagent does not contain cyanogen, thereby greatly reducing the injury to health of the personnel and experiment operators in manufacturing factories, and avoiding the environment pollution of prussiates; the reagent is especially suitable for the CD3700 / 3500, CD3000 and CD3200 differential count full-automatic hemocyte analyzers of Abbott Laboratories in America, and the hemolytic agent A750test indicates the reagent achieves the ICSH standard; and the correlation coefficients of leucocyte, erythrocyte, hemoglobin, thrombocyte and the like relative to the imported ABBOTT CELL-DYN3700 / 3500 reagent are respectively greater than 0.95.

Owner:URIT MEDICAL ELECTRONICS CO LTD

Acrylon production waste water treatment method

ActiveCN101423312ASolve the problem of chelation poisoningEasy to handleMultistage water/sewage treatmentSustainable biological treatmentAcrylonitrileTherapeutic effect

The method discloses a method for treating wastewater generated during the production of acrylic fibers. The method is to treat comprehensive wastewater generated during the production of acrylic fibers taking acrylonitrile as a first monomer by steps of uniform settlement, pH value adjustment, aerobic biochemical treatment and flocculation precipitation. The method adds iron ions, magnesian ion, calcium ion and other metallic ions during the biochemical treatment to react the ions with cyanogens, nitrile, amine and other substances in the wastewater to form chelate complexs, thereby preventing the substances form damaging enzymes of microorganisms, solving the problem of chelating poisoning of microorganisms during water treatment, improving activities of microorganisms and wastewater treatment effect, shortening treatment process, reducing treatment cost and having the characteristics of simpleness, practicality, stable treatment effect, high removal efficiency and wide application range, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of 2-mercaptobenzothiazole modified activated carbon

ActiveCN107215872ASimple processLow modification costOther chemical processesCarbon compoundsActivated carbonOrganic solvent

The invention discloses a preparation method and application of 2-mercaptobenzothiazole modified activated carbon, belonging to the fields of wet metallurgy and precious metal recovery. The preparation method comprises the steps of dissolving 2-mercaptobenzothiazole as an activated carbon modifying agent with an organic solvent or a strong base solution, and preparing 2-mercaptobenzothiazole modified activated carbon by virtue of an impregnation method, wherein the 2-mercaptobenzothiazole modified activated carbon is used for adsorbing Au(S2O3)2<3->. According to the preparation method, the disadvantages that cyanogen is polluted during adsorption recovery of activated carbon supported copper cyanide complex ions (Cu(CN)4<2->), a modifying process of loaded prussian blue is complicated, and continuous adsorption is difficultly realized, and the like are solved; the modified activated carbon is capable of adsorbing gold in thiosulfate gold leaching and has the advantages of multistage adsorption capacity and the like.

Owner:KUNMING UNIV OF SCI & TECH

Closed circulation processing technique for cyanide-containing waste water

The invention relates to a treatment method of wastewater with cyanogen, in particular to a closed circulation treatment method of wastewater with cyanogen. The wastewater with cyanogen is first treated with cyanogen breaking by oxidation; the wastewater after reaction is then made into pure water to be reused in a zero-emission closed circulation process of the production. The process involves that the wastewater is first treated with cyanogen breaking by secondary oxidation with NaClO as oxidant so as to ensure that CN<-> is thoroughly oxidized to be N2 and CO2; coagulation sedimentation, filtration and ion exchange treatment are then followed to ensure that effluent with the electric conductivity below 10Mus after treatment is reused as the pure water and other impurities form floc units and are recycled after pressure filtration dehydration. The closed circulation treatment method of the invention is proved to have remarkable effects after verification by experiments.

Owner:甘晓明 +7

Cyanogens-free gold plating solution and method for plating gold by adopting same

The invention provides cyanogens-free gold plating solution and a method for plating gold by adopting the cyanogens-free gold plating solution, relating to a plating solution and a gold electroplating method. The invention solves the problems that cyanide is toxic and the stability of sulphite gold plating solution is poor. The cyanogens-free gold plating solution of the invention is composed of coordinating agent, auric chloride, potassium carbonate, potassium pyrophosphate and compound additive. The gold plating method of the invention includes the following steps: sodium hydroxide is used for regulating the pH value of cyanogens-free gold plating solution, then constant current mode is adopted, and plating is carried out under the conditions that the distance of cathode and anode is 5-20cm and the temperature is 30-60 DEG C. The cyanogens-free gold plating solution of the invention contains no highly toxic substance, and the stability of plating solution is good, the plating solution is not muddy or changed in colour when being used in 30 days (including plating and ingredient compensation). Meanwhile 10ml plating solution is used for continuous plating and 0.15Ah of electric quantity passes through, and a coating in good surface state still can be obtained.

Owner:WUXI HAITE NEW MATERIAL RES INST

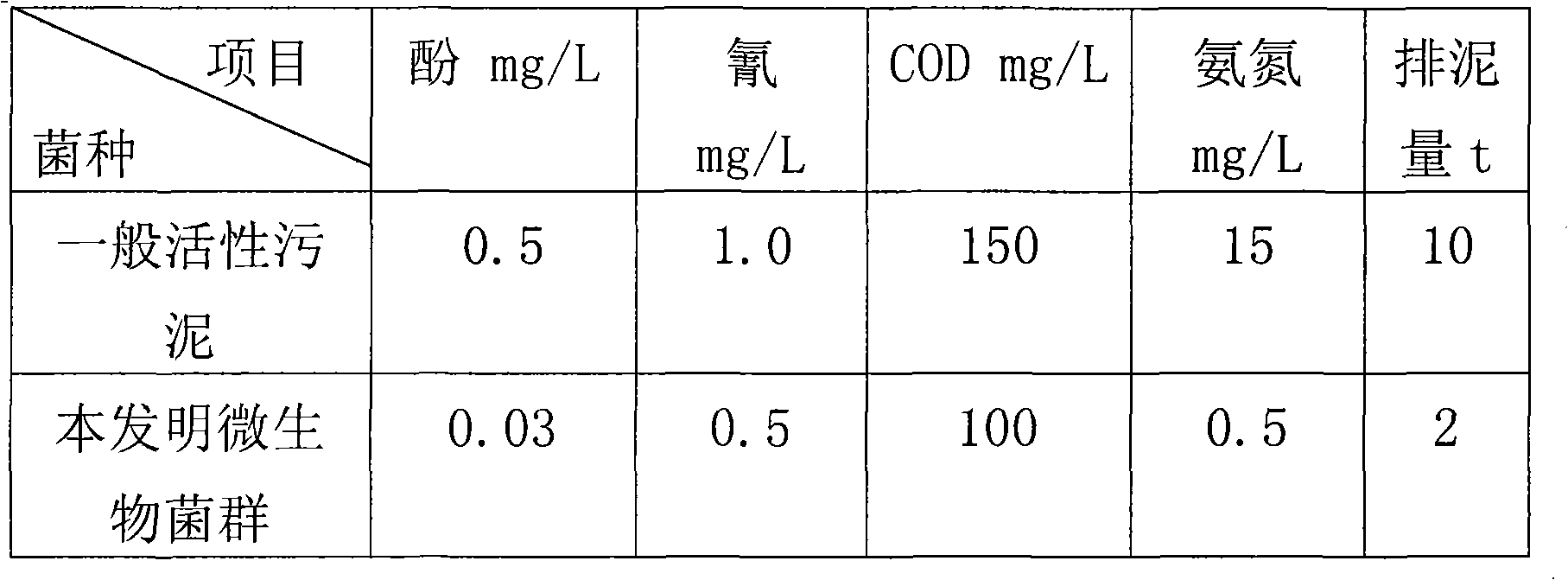

Method for culturing microbial flora for purifying waste water

InactiveCN101914441AReduce CODReduce ammonia nitrogen contentBacteriaBiological water/sewage treatmentActivated sludgeOperation mode

The invention discloses a method for culturing a microbial flora for purifying waste water, which comprises the following steps: A, filtering, settling and concentrating active sludge, adding coking wastewater at the temperature of below 33 DEG C, adding nutrients, proteins and microbial growth hormone at the same time, aerating for 3 to 5 days under a constant-temperature condition, settling, discharging supernatant, adding glucose solution and domesticating according to the operation mode of a batch reactor activated sludge process; B, at the end of domestication, screening cocci, bacilli and spirilla, placing into containers for low-temperature storage respectively, injecting 10 percent glucose solution into the containers for repair, and taking the bacterial strains out 24 hours later for mixing; and C, performing aerobic and anaerobic culture of the mixed bacterial strains, and adding a stabilizer and strain protective agent. For common active sludge, the method can reduce the phenol, cyanogens, COD and ammonia nitrogen content of coking wastewater more effectively and reduce sludge discharge obviously.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com