Cyanogen-free plating method of zinc alloy die casting

A die-casting and zinc alloy technology, applied in the field of electrochemical surface science and engineering, can solve problems such as weak bonding force of the coating, friction and corrosion of the coating, and unsatisfactory anode dissolution, and achieve the effect of optimizing the electroplating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

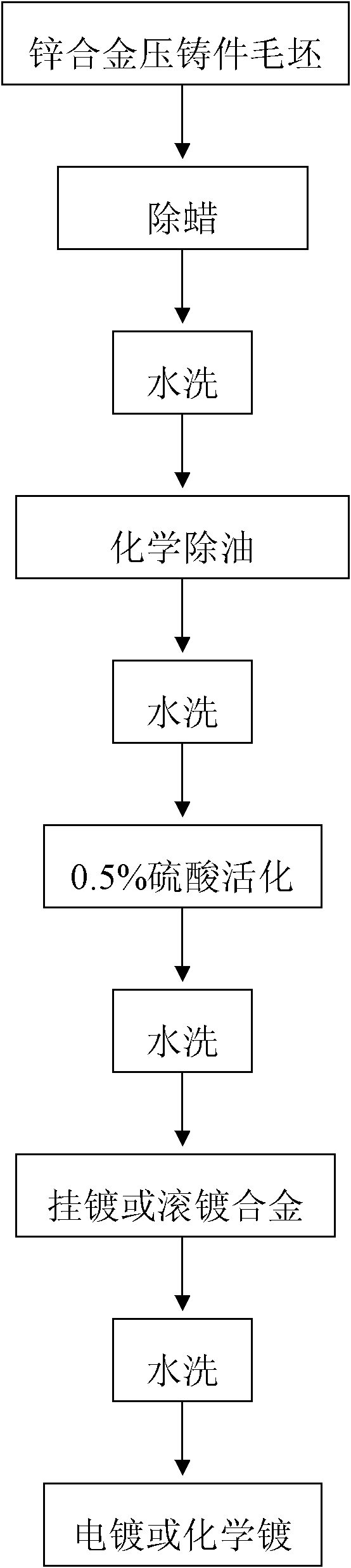

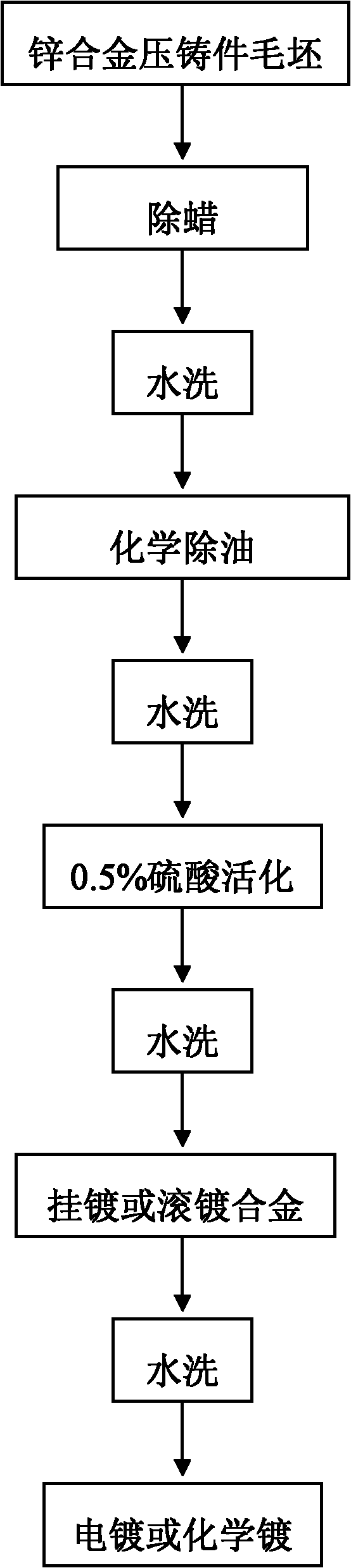

[0032] like figure 1 Shown, a kind of zinc alloy die-casting part cyanide-free electroplating method comprises the steps:

[0033] (1) Waxing removal of zinc alloy die-casting blanks: Soak zinc alloy die-casting blanks in BH-20 wax remover solution of Guangzhou Second Light Industry Science and Technology Research Institute at 80°C and a concentration of 30ml / L for 12 minutes to remove zinc Wax on the surface of alloy die casting blanks to obtain zinc alloy die castings after wax removal.

[0034] (2) Water washing: wash the zinc alloy die-casting part after wax removal in step (1) three times at 20° C. to remove the residual wax remover solution on the surface.

[0035] (3) Chemical degreasing: the zinc alloy die-casting part cleaned in step (2), soaked in the degreasing agent solution of 40 ℃ for 12min, remove the grease on the surface of the zinc alloy die-casting part, and obtain the zinc alloy die-casting part after degreasing pieces; the concentration of trisodium phos...

Embodiment 2

[0043] Such as figure 1 Shown, a kind of zinc alloy die-casting part cyanide-free electroplating method comprises the steps:

[0044] (1) Wax removal of zinc alloy die-casting blanks: Soak the zinc alloy die-casting blanks in BH-20 wax remover solution of Guangzhou Second Light Industry Science and Technology Research Institute at 75°C and a concentration of 50ml / L for 20min to remove zinc Wax on the surface of alloy die casting blanks to obtain zinc alloy die castings after wax removal.

[0045] (2) Water washing: wash the zinc alloy die-casting part after wax removal in step (1) three times at 35° C. to remove the residual wax remover solution on the surface.

[0046] (3) Chemical degreasing: The zinc alloy die-casting parts cleaned in step (2) are immersed in a degreaser solution at 35°C for 20 minutes to remove the grease on the surface of the zinc alloy die-casting parts to obtain the zinc alloy die-casting parts after degreasing pieces; the concentration of trisodium p...

Embodiment 3

[0054] Such as figure 1 Shown, a kind of zinc alloy die-casting part cyanide-free electroplating method comprises the steps:

[0055] (1) Wax removal of zinc alloy die-casting blanks: Soak zinc alloy die-casting blanks in BH-20 wax remover solution at 85°C and a concentration of 40ml / L Guangzhou Second Light Industry Science and Technology Institute for 8 minutes to remove zinc alloy Wax on the surface of the die-casting blank to obtain a zinc alloy die-casting after wax removal.

[0056] (2) Water washing: wash the zinc alloy die-casting part after wax removal in step (1) three times at 30° C. to remove residual wax remover solution on the surface.

[0057] (3) Chemical degreasing: the zinc alloy die-casting part cleaned in step (2), soaked in a degreaser solution at 55°C for 8 minutes, removes the grease on the surface of the zinc alloy die-casting part, and obtains the zinc alloy die-casting part after degreasing pieces; the concentration of trisodium phosphate in the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com