Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

404 results about "Wax removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Using heat rather than cold remove more candle wax and is the best method for candle wax removal. Place a clean cotton cloth over the wax stain on the carpet, place a warm iron on the cloth and the wax will melt and be absorbed into the towel.

Wax for hot melt adhesive applications

InactiveUS6890982B2Produced economicallyProperty securityNon-macromolecular adhesive additivesFilm/foil adhesivesTG - TriglycerideStearic acid

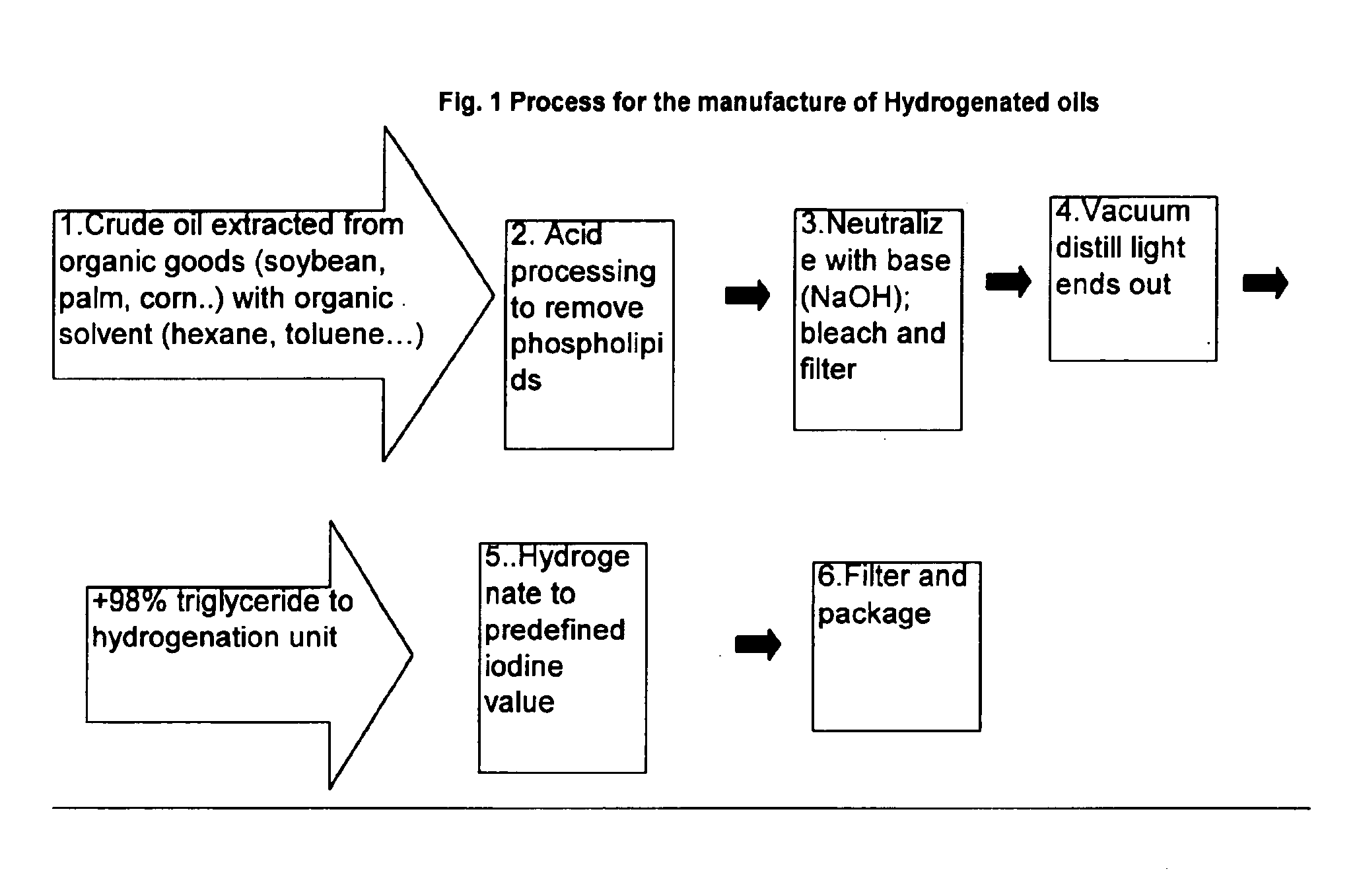

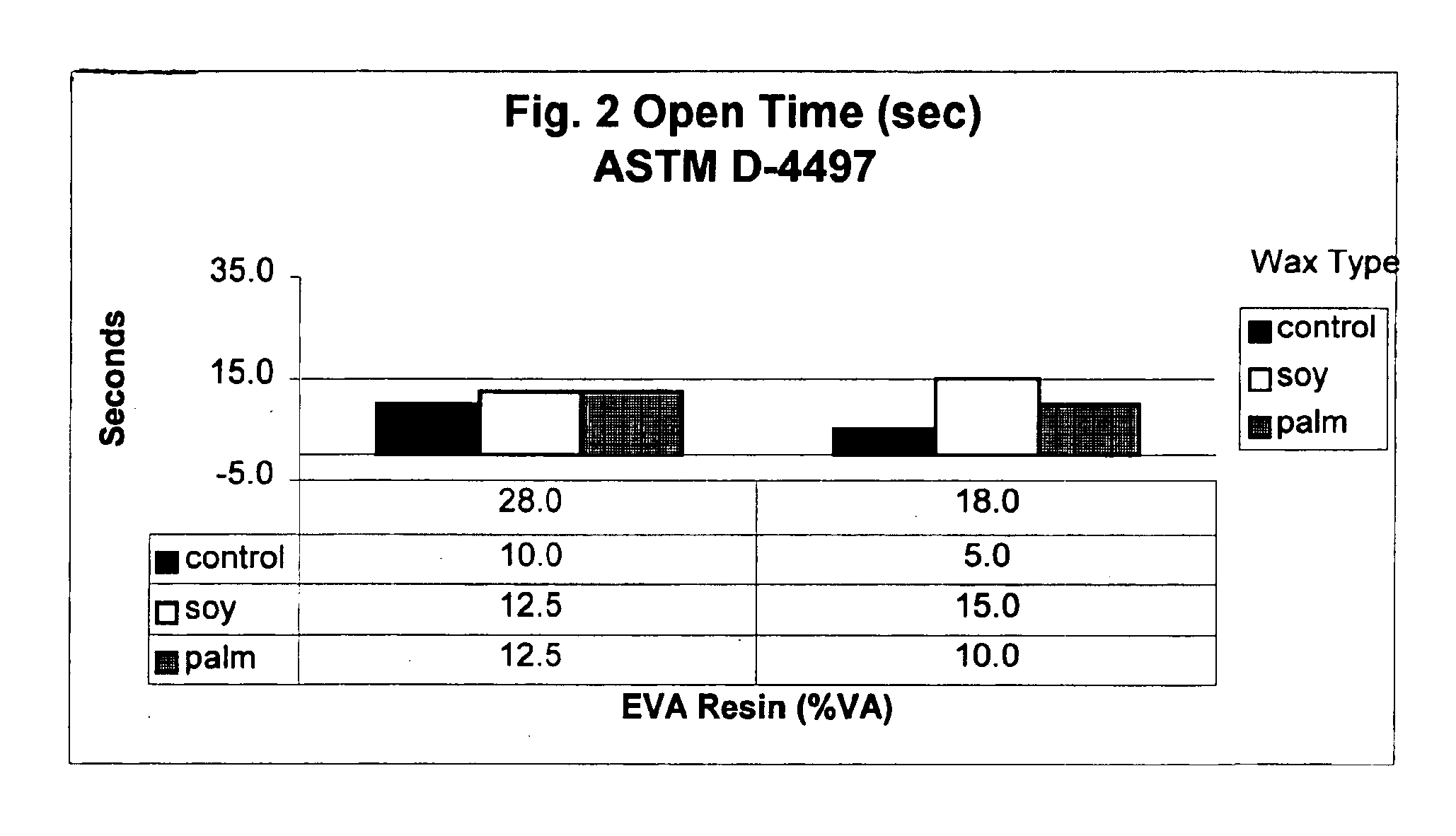

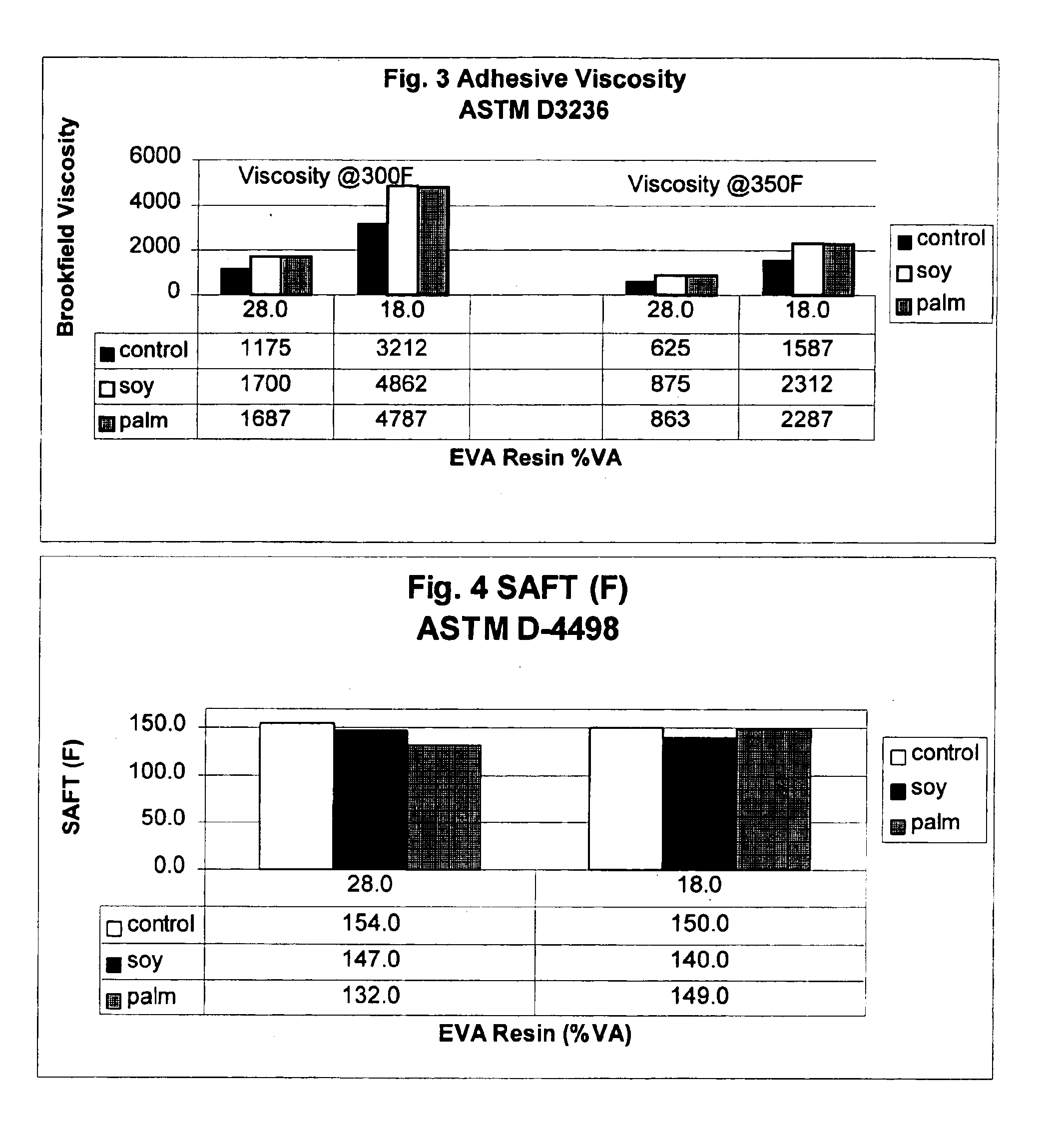

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used as substitutes for petroleum derived waxes in hot-melt adhesive compositions. Unlike petroleum-derived or synthetic waxes, adhesive compositions comprising these waxes, which are obtained from naturally derived, renewable resources, achieve adhesion performance similar to conventional adhesives containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-165 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid (C18). The naturally derived waxes are used as an alternative to petroleum and synthetically derived waxes in the manufacture of adhesives used to bond paper, wood, glass, plastic and metal in a variety of manufacturing operations.

Owner:MARCUS OIL & CHEM

Cyanogen-free plating method of zinc alloy die casting

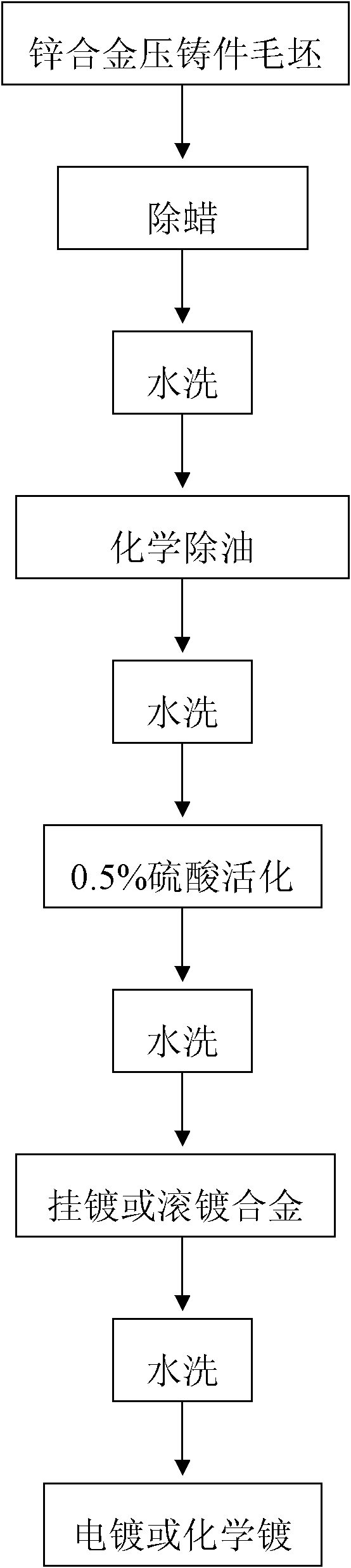

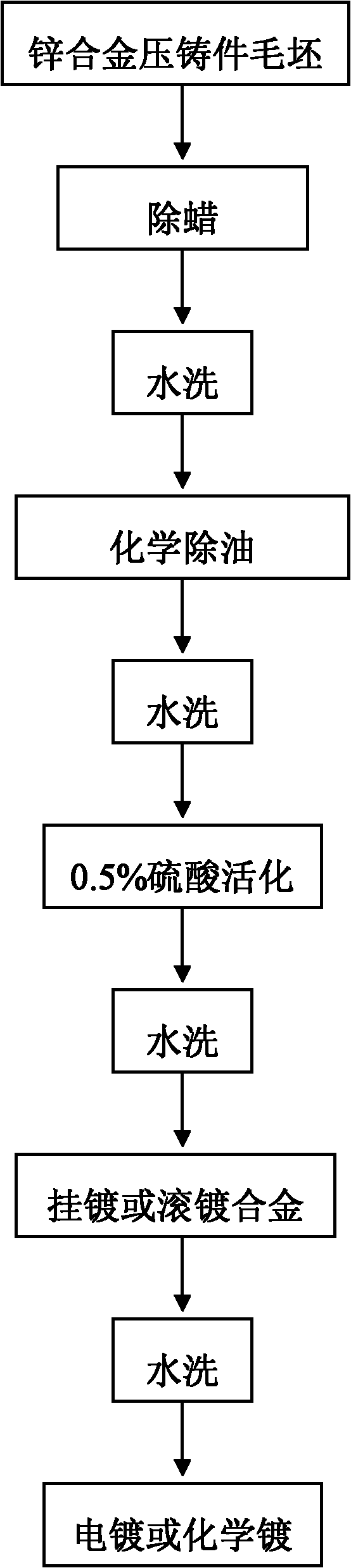

The invention discloses a cyanogen-free plating method of a zinc alloy die casting. The method is a plating method in which cyanogen-free copper-zinc alloy, copper-stannum alloy or ormolu is subjected to barrel plating or rack plating in a cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution as grounding layers so as to provide a pre-plating layer with good bonding force for subsequent plating or chemical plating. The method comprises the following steps: (1) carrying out ultrasonic wax removal or tumbling wax removal on a zinc alloy die casting blank; (2) washing; (3) chemically removing oil; (4) washing; (5) activating with 0.5% sulfuric acid; (6) washing; (7) carrying out barrel plating or rack plating on the alloys in the cyanogen-free copper-zinc alloy solution, copper-stannum alloy solution or ormolu solution; (8) washing; and (9) carrying out the subsequent plating or chemical plating. By using the method provided by the invention, cyanogen-free barrel plating or rack plating alloy is carried out on the zinc alloy die casting so that the obtained plating layer is semi-bright and has good bonding force.

Owner:广州市二轻研究所股份有限公司

Method for electroforming hard gold product

InactiveCN101560676AIncrease in sizeHigh hardnessElectroforming processesChemical structurePotassium

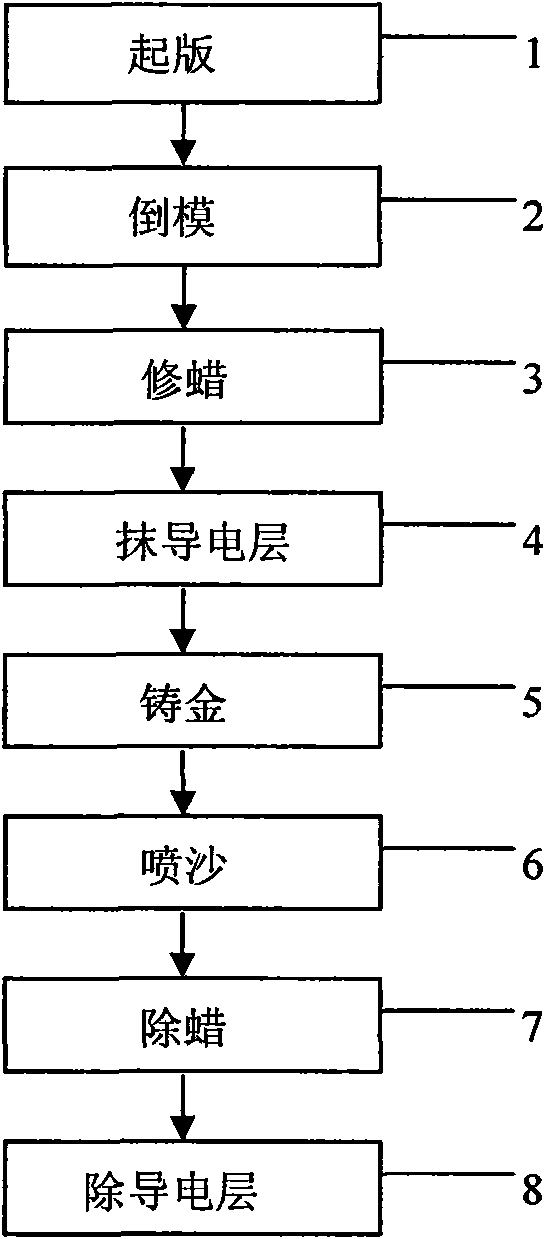

The invention relates to a method for electroforming hard gold products. The method comprises the following steps: template picking, mould pouring, wax repairing and electric conducting layer coating are carried out to obtain a wax mould of a gold product to be processed, and a layer of electric conductive oil is coated on the surface of the wax mould; and a titanium net is taken as anode in the gold electroforming step, the wax mould coated with the electric conductive oil is put in an electrotyping bath as cathode, the electroforming solution is put in the electrotyping bath and includes sulfurous acid gold potassium, ammonium sulfite and potassium citrate, wherein the sulfurous acid gold potassium is combined with the ammonium sulfite, a trivalent gold ion is reduced into a univalent gold ion, the univalent gold ion generates close crystal grains, the close crystal grains are combined through the potassium citrate to form complexing gold through PH buffer solution, the gold is deposited on the wax mould to form a casting gold layer, and the half-finished product is prepared; and the wax film in the half-finished product and the electric conductive layer are removed in the wax removal step and the electric conductive layer removal step to obtain the finished product. The volume and the hardness of the gold product are changed by using the variation of the chemical structure of the gold ion, so that the hardness, the volume and the toughness of the gold product meet the standards simultaneously.

Owner:武汉金凰珠宝股份有限公司

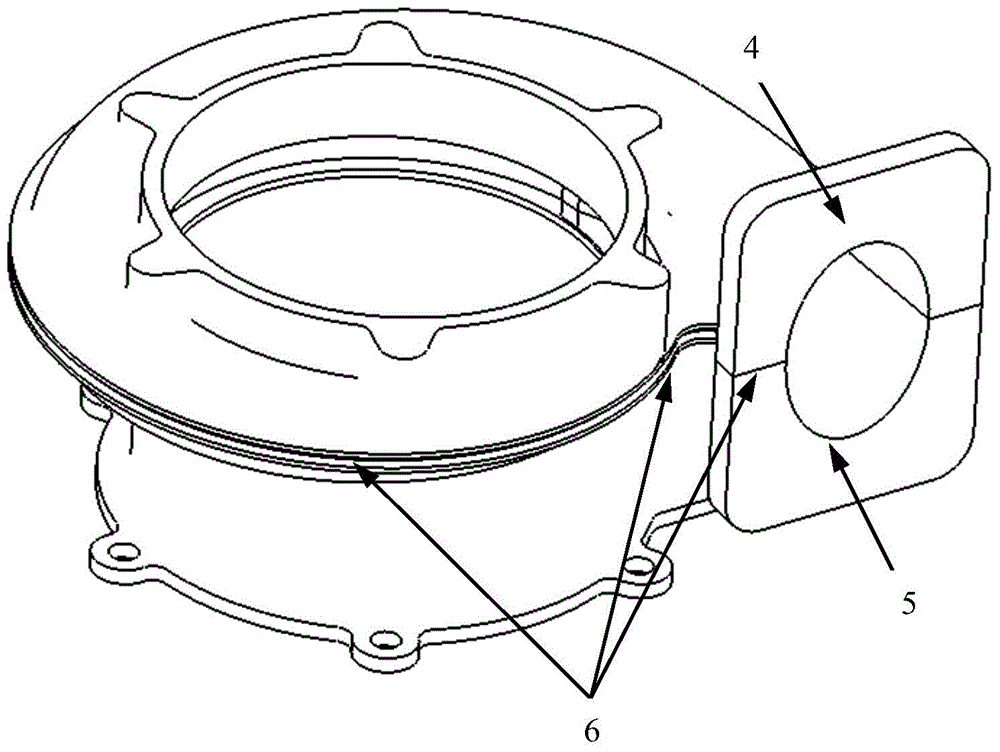

Combined wax pattern-based method of achieving precision investment casting for heat-resistant cast steel thin-wall turbine shell

ActiveCN104475682AImprove molding efficiencyReduce manufacturing costFoundry mouldsFoundry coresInvestment castingAlloy

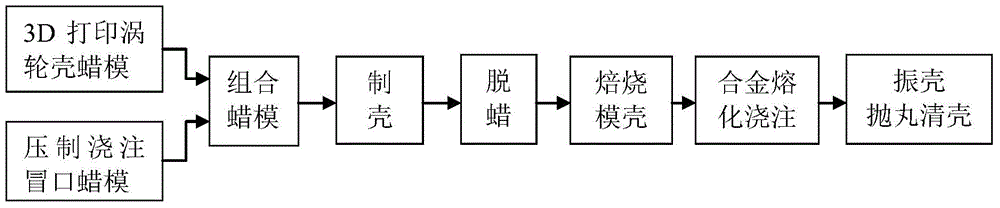

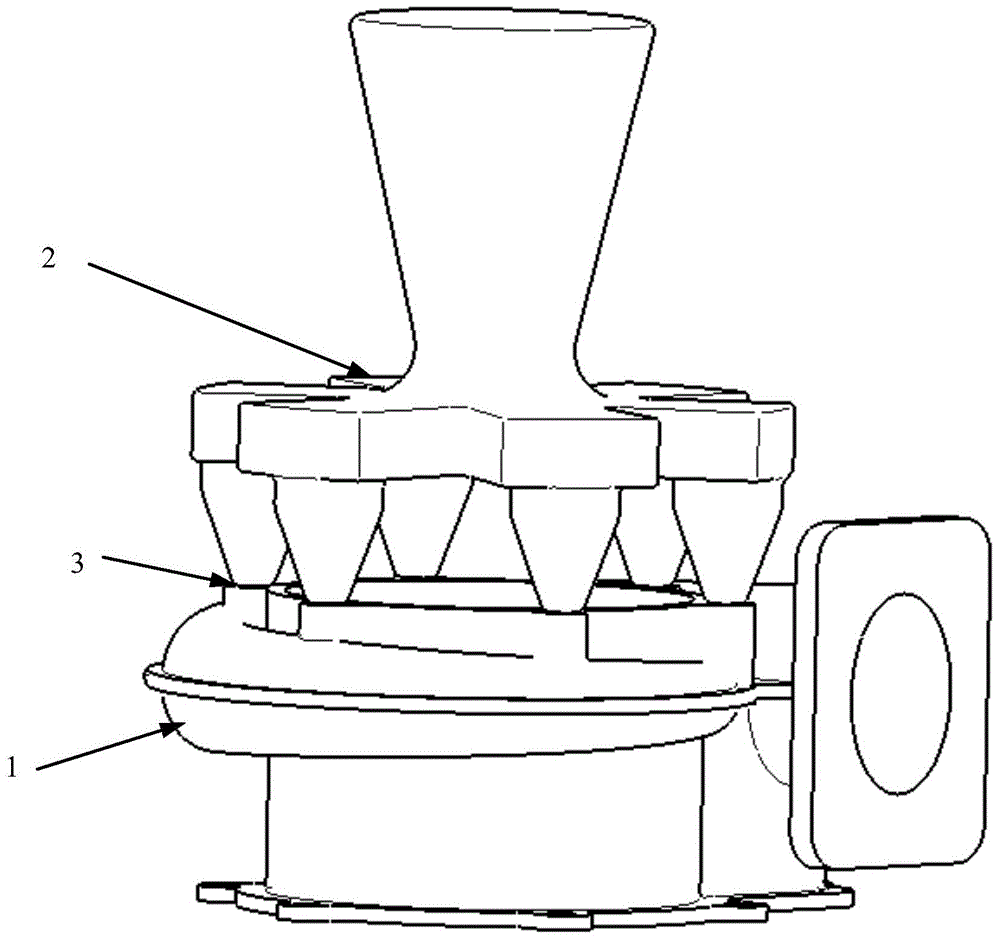

The invention discloses a combined wax pattern-based method of achieving precision investment casting for a heat-resistant cast steel thin-wall turbine shell, and belongs to the technical field of casting. In the method, the turbine shell is made of a heat-resistant cast steel material, a wax pattern of the turbine shell is three-dimensionally printed by adopting low-temperature wax, a riser wax pattern is poured by adopting medium-temperature wax through melt extrusion moulding, the combined wax pattern is formed by reliably bonding the wax pattern of the turbine shell with the riser wax pattern by bonding wax; an investment casting technical process based on the combined wax pattern comprises the following steps: preparing wax patterns, combining the wax patterns, producing a shell, carrying out investment wax removal, roasting a pattern shell, melting an alloy, pouring, compacting the shell, blasting shots, cleaning the shell, and the like. The method disclosed by the invention can be used for effectively increasing the wax pattern moulding efficiency of the turbine shell, reducing the cost, ensuring the casting accuracy of a runner of the turbine shell, improving the mould-filling capacity of heat-resistant cast steel, and achieving the thin-wall casting of the turbine shell; the wall thickness can be reduced to 3mm, and thus a light-weight purpose is achieved and the needs of an aircraft engine supercharger are met.

Owner:北京领动国创科技有限公司

Transparent Cold-Wax and Hot-Wax Depilatory Compositions with Three-Dimensional Suspended Particles

InactiveUS20040180014A1Convenient commercial manufacturing processBind more strongly with hairCosmetic preparationsHair removalHair removalSuspended particles

The present invention discloses cosmetic transparent hair removal (depilatory) compositions that: (1) Are transparent in appearance, (2) Can be made in cold wax or hot wax forms, (3) Manufactured at much less than 80 ° C., (4) Three-dimensional particles of visually attractive compositions can be added, (5) Bind more strongly with hair and less strongly with skin, (6) Can be applied either directly on the skin or applied on a piece of fabric, plastic, or paper first, which is then applied to skin for hair removal, and (7) Require minimal clean-up.

Owner:BIODERM RES

Process for carrying out vacuum cleaning, oil removal and wax removal by modified hydrocarbon cleaner

The invention relates to the technical field of electroplating pretreatment, in particular to a process for carrying out vacuum cleaning, oil removal and wax removal by a modified hydrocarbon cleaner. The process comprises degassing ultrasonic cleaning, vacuum cleaning, vacuum steam flushing, vacuum drying and the like. A plurality of flows are carried out in the vacuum environment with a certain vacuum degree and are matched with a degassing ultrasonic cleaning and vacuum cleaning technology and the modified hydrocarbon cleaner. For the cleaning process, in the whole process, harmful substances of halogen and the like, such as trichloroethylene, methylene chloride, tetrachloroethylene and the like, cannot be used and additional drying equipment is not required. Particularly, the process has excellent cleaning effect on irregular articles with blind holes, joints, gaps, cracks and the like. Meanwhile, the defects of oil removal and wax removal of the conventional process are overcome.

Owner:广东新球清洗科技股份有限公司

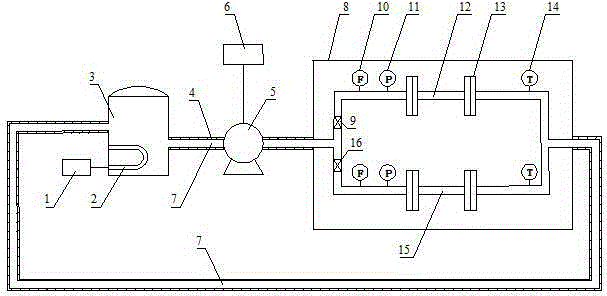

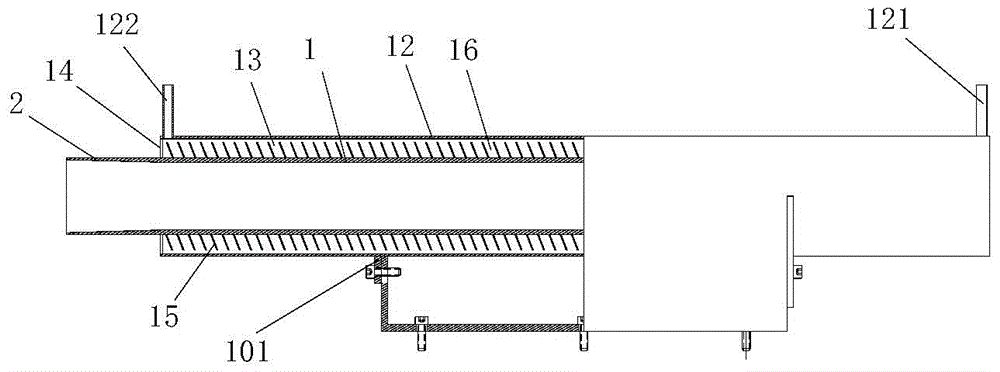

Apparatus and method for dynamic simulation of petroleum pipe scaling and wax precipitation

InactiveCN105277659AReduced over-pump shear strengthReduce distractionsWeighing by absorbing componentWater bathsLiquid storage tank

The present invention provides an experimental apparatus and a method for petroleum pipe scaling and wax precipitation, the apparatus comprises a liquid storage tank, a variable frequency motor, a screw pump, a constant temperature water bath tank, a first test tube, a second test tube, a cover plate and a lacing film test sample. The liquid storage tank is used for containing oil water needed for the experiment, and is connected with a temperature control system and a heater to ensure oil water temperature is constant at a preset value; a predetermined flow rate of oil output can be achieved by the variable frequency motor and the screw pump, the constant temperature water bath tank is used for simulation of test tube section wall temperature to study changing laws and mechanisms of sediment characteristics along with pipe wall temperature differences; the first test tube is a full size pipe segment, and is used for fully simulating pipe scaling and wax precipitation, and the second test tube is a pipe segment with an opening, and is used for study on the laws and mechanisms of the sediment characteristics along with time. The experimental apparatus and method can provide new methods and supports for research and development and evaluation of measures scaling and wax removal and prevention, and can ensure the petroleum pipe safe, economic and efficient operation.

Owner:SOUTHWEST PETROLEUM UNIV

Corrosion-release scale-proof wax-removal viscosity-reducing agent and preparation method thereof

ActiveCN101100601AMeet the requirements of wax removal and viscosity reductionMeet anti-corrosion and anti-fouling requirementsDrilling compositionSODIUM METAPHOSPHATESodium phosphates

A viscosity reducer with corrosion-inhibiting, scale-inhibiting and wax-cleaning functions consists of 2-alkyl-1-hydroxyethyl-3-hydroxypropyl-imidazoline sodium phosphate 5-10 wt%, lauryl dimethyl benzyl ammonium chloride 10-15 wt%, FC-NO1 fluorocarbon surface activator 0.05-0.2 wt%, alkylphenol ethoxylates(14) 3-8 wt%, methanal 3-7 wt%, hexamine 8-15 wt%, hexa-sodium metaphosphate 5-8 wt%, hydroxy-ethyl-crossing di-phosphoric acid 5-8 wt% and water residues. It has excellent coordination and corrosion protection and can be used in oil filed and oil well.

Owner:PETROCHINA CO LTD

Oil-in-water emulsions containing high wax content and a softpaste oily phase

A composition in the form of an oil-in-water (o / w) emulsion containing an oily phase dispersed in an aqueous phase, which contains a mixture of nonionic emulsifiers, the mixture being liquid at ambient temperature and having an HLB ranging from about 6 to 13, and in that the oily phase comprises at least about 5% by weight of one or more waxes based on the total weight of the composition, at least one of the waxes having a starting melting temperature of greater than or equal to about 50° C.

Owner:LOREAL SA

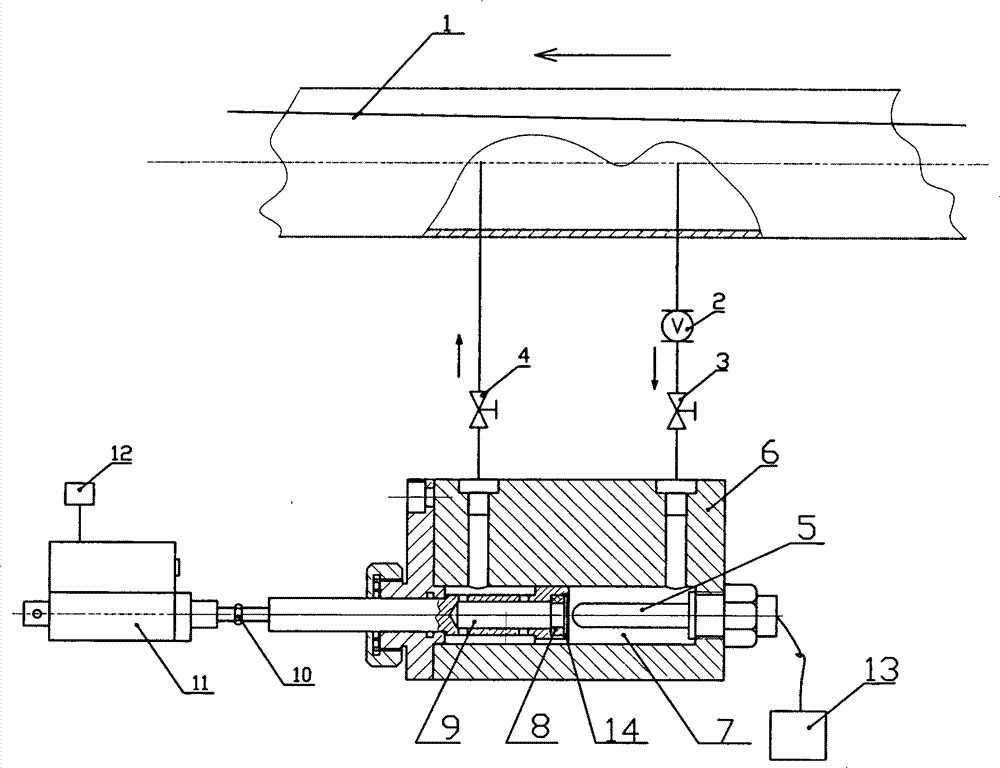

Method for wax removal and measurement of wax thickness

ActiveUS20100300486A1Situation is differentEffective installationCleaning heat-transfer devicesHollow article cleaningEngineeringWax removal

A method for removal of wax deposited on an inner wall in contact with a fluid stream. The method includes the steps of cooling the inner wall and the fluid stream to a temperature of or below the wax appearance temperature, enabling wax to dissolve and precipitate on the inner wall, and heating of the inner wall for a short period of time to release the deposited wax from the surface of the inner wall, mainly in the form of solid parts. The thickness of wax deposits in a pipe section can be determined by computing the temperatures obtained upstream and downstream in the said pipe section, before and after applying heat pulse.

Owner:DEN NORSKE STATS OLJESELSKAP AS

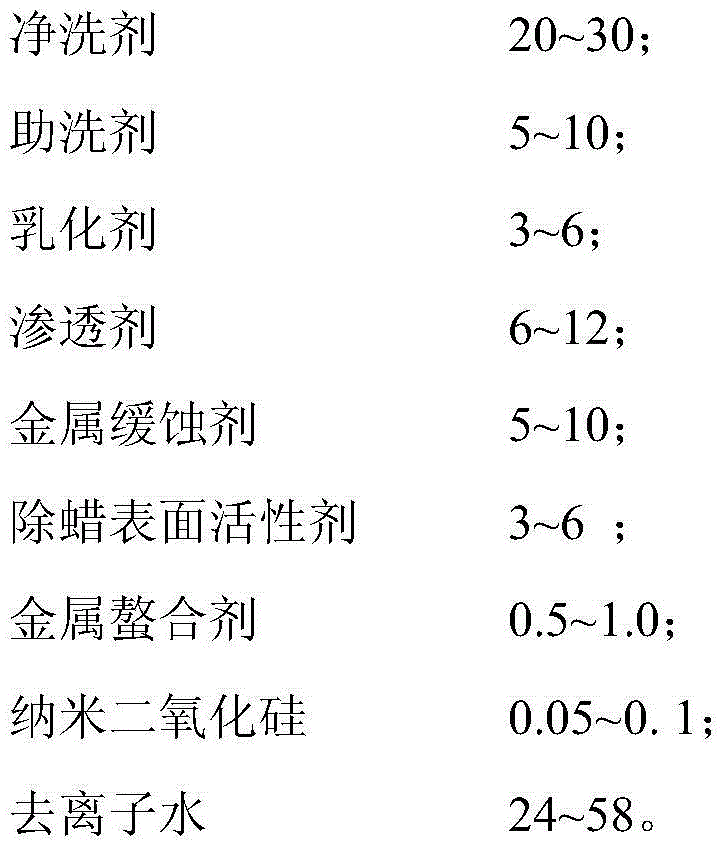

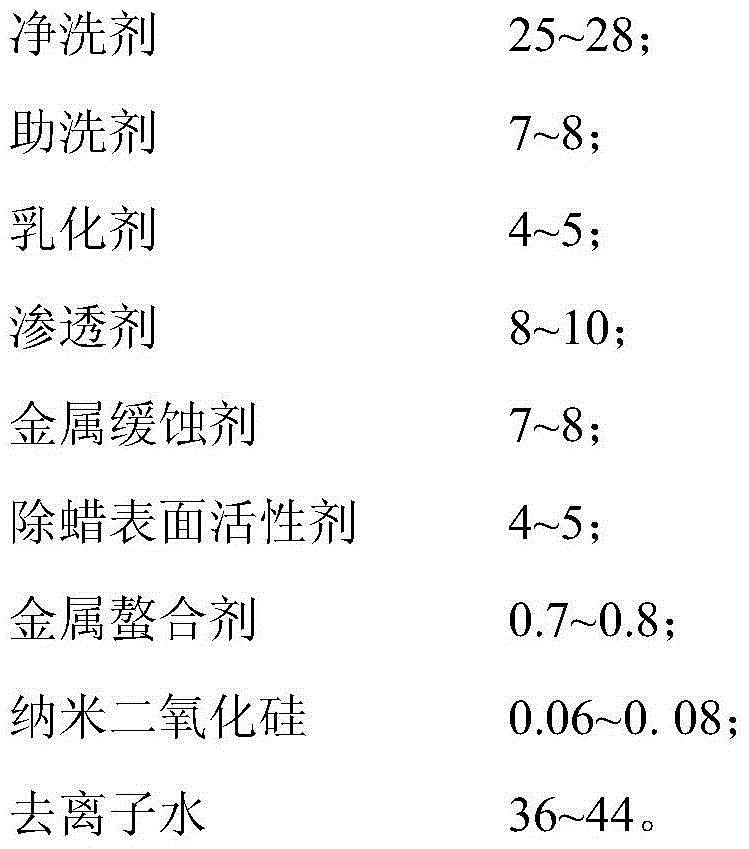

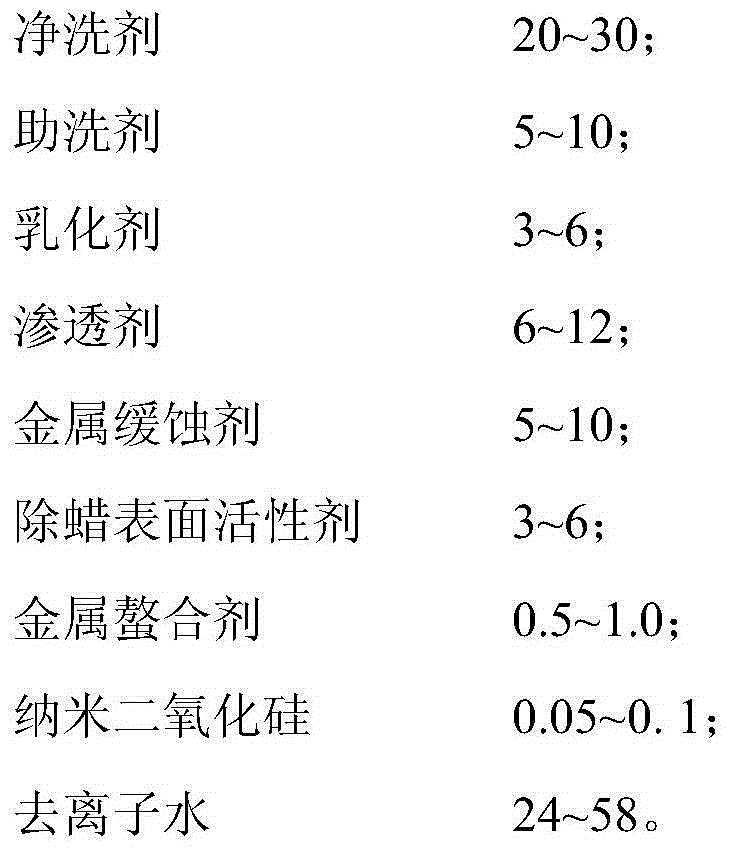

Nanometer wax-removal degreasing cleaning agent and preparation method thereof

InactiveCN104560447AEasy to cleanUnique nanoporous structureOrganic detergent compounding agentsSurface-active detergent compositionsSilicon oxideLotion

The invention relates to a nanometer wax-removal degreasing cleaning agent and a preparation method thereof and relates to cleaning agents. The nanometer wax-removal degreasing cleaning agent is prepared from the following raw materials in mass ratio: 20-30 of detergent, 5-10 of a builder, 3-6 of an emulsifier, 6-12 of a penetrating agent, 5-10 of a metal corrosion inhibitor, 3-6 of a wax-removal surfactant, 0.5-1.0 of a metal chelating agent, 0.05-0.1 of nanometer silicon oxide and 24-58 of deionized water. The preparation method comprises the following steps of (1) adding the metal chelating agent in deionized water to obtain an aqueous solution of the metal chelating agent; and 2) adding the emulsifier, the metal corrosion inhibitor and the nanometer silicon oxide into a reactor, adding deionized water and the detergent, adding the penetrating agent, the wax-removal surfactant and nanometer silicon oxide, stirring and adding the aqueous solution of the metal chelating agent obtained in the step (1), supplementing the residual deionized water and further stirring to obtain the nanometer wax-removal degreasing cleaning agent. The cleaning agent has the advantages of high wax-removal and degreasing speeds, long application period, good cleaning effect and environmental friendliness.

Owner:XIAMEN UNIV

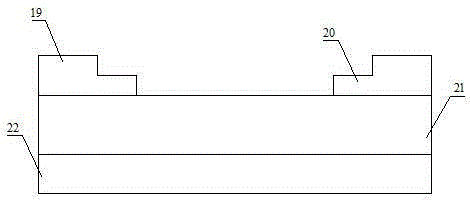

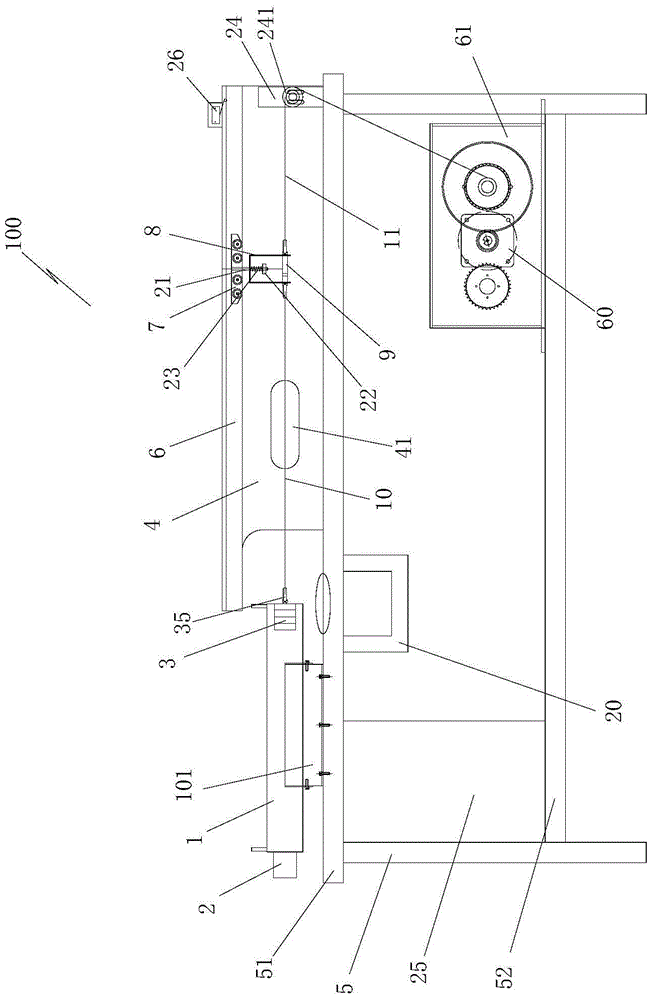

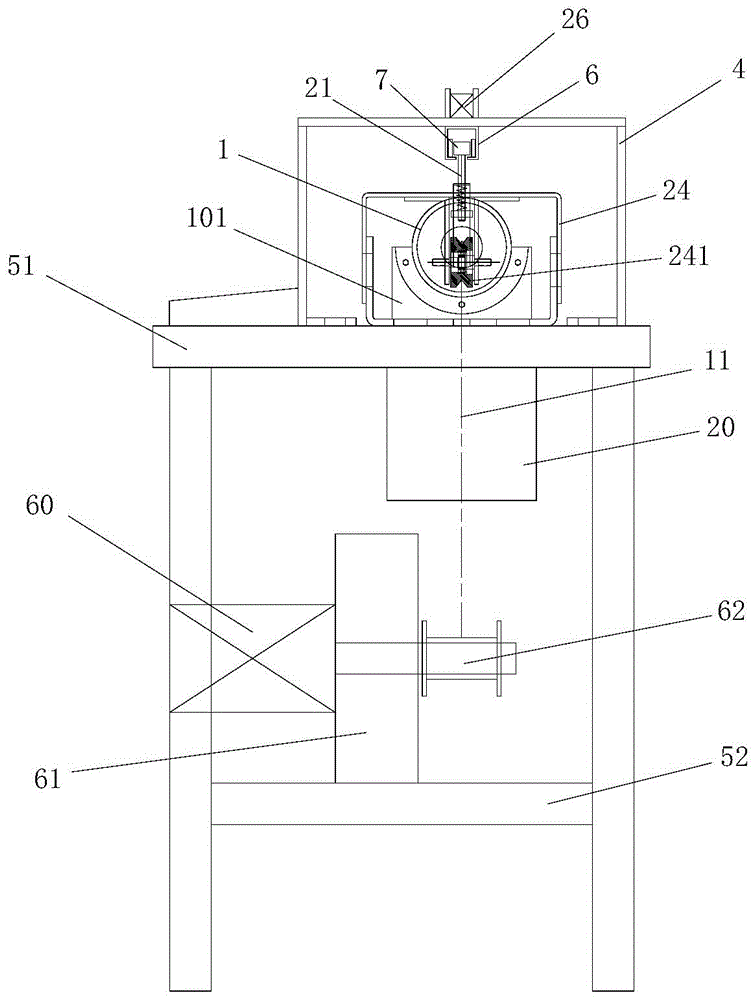

Crude oil pipeline ball passing and wax removal simulation experiment device and experiment method

ActiveCN104568625AMeasuring changes in wax removal resistanceUsing mechanical meansInvestigating material hardnessElectricityData acquisition

The invention relates to a crude oil pipeline ball passing and wax removal simulation experiment device which comprises an operation desk, wherein a test pipeline is fixed on the operation desk; a ball serving barrel is coaxially arranged at the rear end of the test pipeline; a pipeline cleaner is coaxially arranged in the ball serving barrel; an acrylic cover body is arranged on the operation desk; a hanger rail is fixedly arranged on the inner side of the top of the acrylic cover body; a guide pulley block is slidingly arranged on the hanger rail; a sensor hanging bracket capable of adjusting tension is fixedly arranged under the guide pulley block; a tension sensor is horizontally arranged on the sensor hanging bracket; the front end of the pipeline cleaner is connected with the tension sensor via a first hauling rope; the front end of the tension sensor is connected with a hauling driving system via a second hauling rope; the tension sensor is electrically connected with a measurement and data acquisition system; and the hauling driving system is electrically connected with a servo control system. The device can measure the strength of a wax deposit on a wall of a crude oil pipeline and change of wax removal resistance in a pigging process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Crude oil water-content on-line tester

ActiveCN102830219AAccurate dataSimple and reliable online moisture determinationMaterial testing goodsLine tubingPush pull

The invention discloses a crude oil water-content on-line tester. The crude oil water-content on-line tester comprises a valve body with a valve cavity. The valve body is provided with an oil inlet and an oil return opening communicated with the valve cavity. The oil inlet is connected to an oil inlet pipe which is provided with a circulating oil pump and an oil inlet pipe stop valve and is connected to an oil transportation main pipe. The oil return opening is connected to an oil return pipe which is provided with an oil return stop valve and is connected to the oil transportation main pipe. A water-content tester probe is arranged at one of two opposite sides of the valve body and a push-pull rod is arranged at the other one of the two opposite sides of the valve body. Front parts of the water-content tester probe and the push-pull rod stretch into the valve cavity. A rear part of the push-pull rod stretches out of the valve body. A fluorine rubber sleeve with a centre hole is fixed to a front end of the push-pull rod. The centre hole of the fluorine rubber sleeve aims at the water-content tester probe and sizes of the centre hole and the water-content tester probe are matched. A rear end of the push-pull rod is connected to a push-pull power plant. The crude oil water-content on-line tester realizes automatic timing and regular wax removal, avoids stopping of the oil transportation main pipe, avoids dismounting and manual cleaning of the water-content tester probe, realizes accurate water-content tester detection data, and realizes simple and reliable crude oil water-content on-line detection.

Owner:北京永兴精佳仪器有限公司

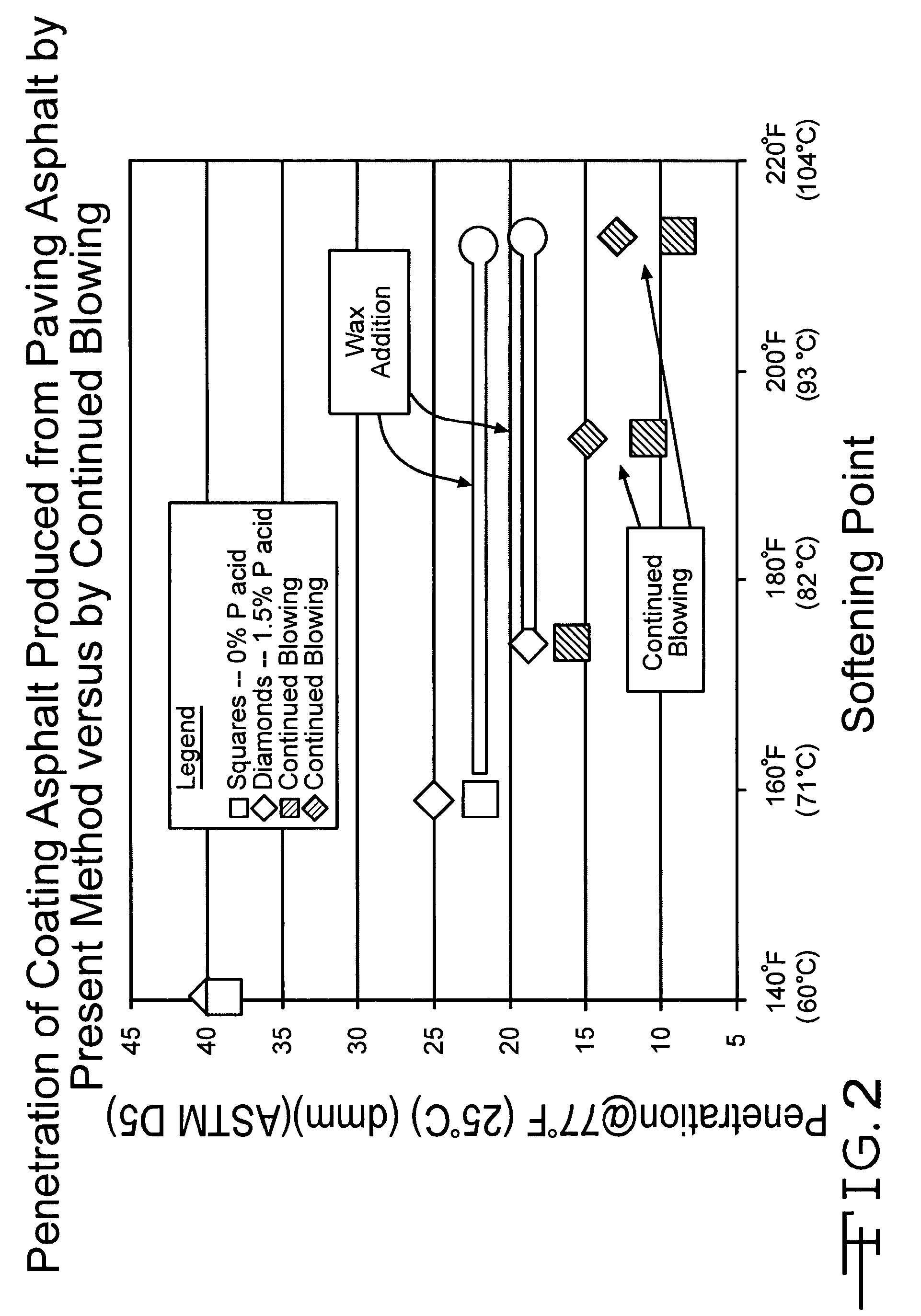

Roofing coating asphalt composition

ActiveUS8753442B2Excellent indexImprove stabilityRoof covering using tiles/slatesWorking-up pitch/asphalt/bitumen by chemical meansWax removalAsphalt

A method of producing a roofing shingle coating asphalt from a non-coating grade asphalt feedstock includes the following steps. The non-coating grade asphalt feedstock is partially blown to lower its penetration to a first penetration that is within or close to a target penetration range of the coating asphalt, and to raise its softening point to a first softening point that is lower than a target softening point range of the coating asphalt. A wax is added to the partially blown non-coating grade asphalt to further raise its softening point to a second softening point that is within the target softening point range to produce the coating asphalt. The wax may also be added during the blowing process. Resulting roofing coating asphalt compositions may comprise a paving grade asphalt and a wax, and yet still has desirable penetration, softening point and viscosity.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Wax removing water for cleaning wax scale on surface of polished workpiece and preparation method thereof

The invention discloses wax removing water for cleaning wax scale on the surface of a polished workpiece and a preparation method thereof. The wax removing water comprises the following components: 3 to 5 g / L of linear alkylbenzene sodium sulfonate, 5 to 10 g / L of secondary alkyl sulfate, 5 to 10 g / L of alkanolamide, 30 to 40 g / L of fatty alcohol polyoxyethylene ether sulfate, 100 to 150 g / L of sodium tripolyphosphate, and 3 to 5 g / L of ethylene diamine tetraacetic acid (EDTA). The wax removing water has good emulsifying effect and very strong solubilizing and dispersion effects, and can thoroughly clean the wax scale on the surface of the polished workpiece.

Owner:HUBEI DE MEI TECH

Glass wax solvent and adhesive wax cleaning method

PendingCN109370801AHigh cloud pointImprove emulsificationInorganic/elemental detergent compounding agentsCationic surface-active compoundsInorganic saltsAdhesive

The invention provides a glass wax solvent which comprises 2-6wt% of weakly alkaline inorganic salt, 3-6wt% of chelating agents, 10-25wt% of surfactants, 2-10wt% of cosolvents and the balance water. The surfactants are anionic surfactants and nonionic surfactants, and the weight ratio of the anionic surfactants to the nonionic surfactants is (2-8):(10-20). The glass wax solvent is designed according to characteristics of adhesive wax, a formula of the glass wax solvent is free from strongly alkaline auxiliaries such as sodium hydroxide and potassium hydroxide, the anionic surfactants and the nonionic surfactants are compounded, the turbidity point of the wax solvent can be increased under the combined action of the components of the wax solvent, and the emulsifying and cleaning capacity ofthe wax solvent can be improved. The invention further provides an adhesive wax cleaning method.

Owner:LENS TECH CHANGSHA

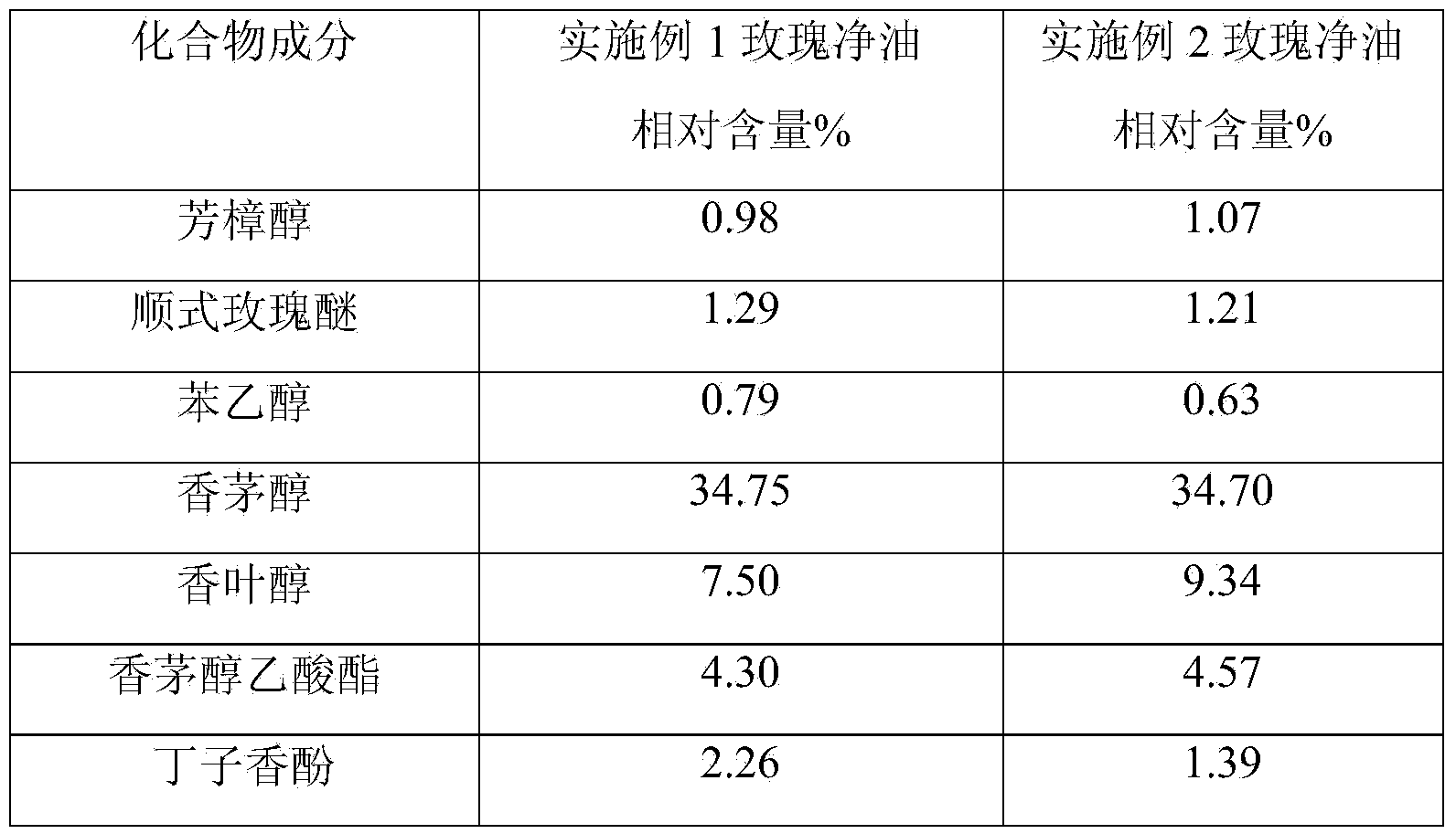

Preparation method for rose absolute oil

ActiveCN104140889ANatural Pure Fragrance ProtectionDoes not destroy aroma componentsEssential-oils/perfumesOrganic solventAlcohol

The invention discloses a preparation method for rose absolute oil. The preparation method comprises the following steps of: extracting: leaching fresh rose petals by virtue of a non-polar organic solvent; combining extracting liquor, filtering, and concentrating filtrate under reduced pressure to obtain rose extract; dissolving the rose extract in absolute ethyl alcohol or 95% alcohol, filtering to remove insoluble raw wax to obtain rose-dissolved filtrate, and continuously freezing for 15-20 hours; centrifuging the frozen rose-dissolved filtrate at a high speed, so that the wax is deposited to obtain rose wax and rose liquid supernatant; concentrating the wax-removed rose liquid supernatant in vacuum to obtain the rose absolute oil. According to the preparation method disclosed by the invention, a molecular distillation step is omitted by virtue of secondary wax removal, so that the prepared rose absolute oil is clear and transparent, and low in moisture and wax content, and thus, defects that the conventional rose oil is relatively sharp in aroma, more in aroma component loss, incomplete in aroma characteristics, relatively great in variation between the aroma and the aroma of fresh flowers, and easy to oxidize and deteriorate are overcome.

Owner:无锡悦禧玫瑰科技有限公司

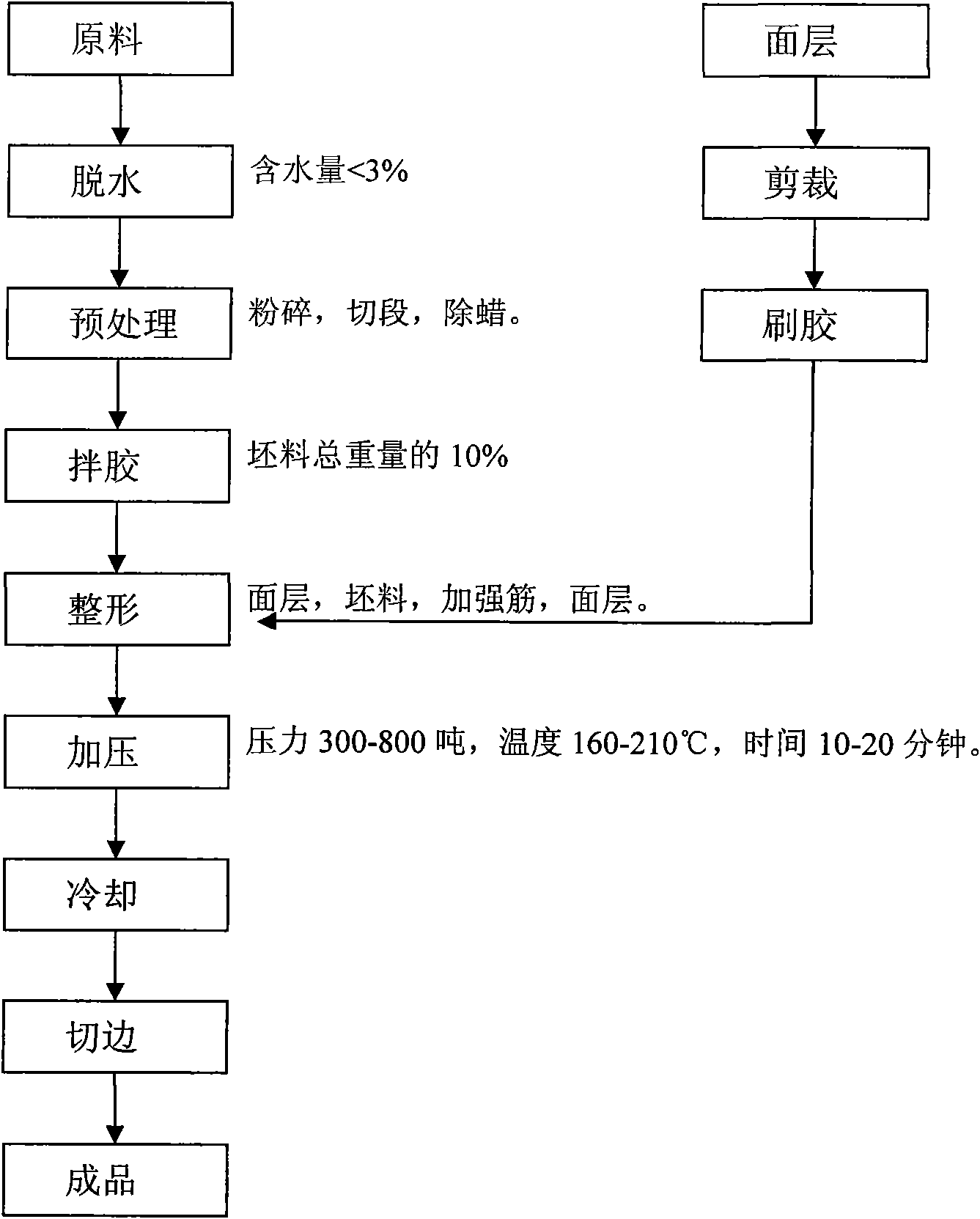

Process for selecting, using and producing cotton straw composite board raw materials

InactiveCN101574827AHigh strengthReduce manufacturing costFlat articlesDomestic articlesWood veneerFiber

The invention relates to a process for selecting, using and producing cotton straw composite board raw materials, belonging to the production industry of non-wood boards. The process takes cotton straws as main materials, uses reed canes, cornstalks, sorghum straws and bamboos as reinforcing ribs to produce non-wood boards instead of woods. The process is a method for selecting, using and producing raw materials aiming at various defects in the production process of non-wood boards; laid papers or wood thin slices are adopted as veneers aiming at the traditional process of secondary veneering; the veneers and blanks are formed by once heat pressing so that the process flows are simplified; reed canes after wax removal, cornstalks, sorghum straws and bamboo strips are arranged and paved in the blanks as the reinforcing ribs in a staggered form aiming at the defect that the strength of the non-wood boards is lower, thereby the strength of the boards is improved; the cotton straws are adopted as main materials aiming at the characteristics that straws of other plants contain less wood fiber and the cotton straws contain more wood fiber, thus waste is changed into valuable, and the cost of the raw materials is reduced; the waxiness on the surfaces of the straws is removed by a mechanical or chemical method, and the requirement for using common gel is achieved, thereby the manufacturing cost of the boards is reduced, and specific practices are narrated in detail in a specification.

Owner:刘金忠

Method for extracting high-purity solanesol from potato leaf, tobacco leaf and/or tobacco stem

ActiveCN101182284ASimple processEasy to industrializeHydroxy compound separation/purificationSaponificationMethanol

A method of extracting high-purified solanesol from potato leaves, tobacco leaves and / or tobacco stems is that the solanesol is extracted from the raw materials by extracting solvent, solanesol extract is obtained after solid-liquid separation; the solanesol extract is processed for the phase-transfer catalytic saponification reaction inside an organic-solvent-buck-phase-transfer catalyst system; the solanesol extract after saponification is completely dissolved in mixed alcohol-acetone solvent under 50 DEG C to 75 DEG C for stationary placing, cooling and filtering; filtrate is steamed to be dry to obtain the solanesol extract after wax removal, and the solanesol extract is dissolved in methanol or acetonitrile in reflux to be frozen and crystallized for obtaining white solid which is dried to obtain the solanesol. The present invention has the advantages of gentle reaction condition, simple technology, short production period, large batch, the high yield and purity of the solanesol and being convenient for industrialization.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

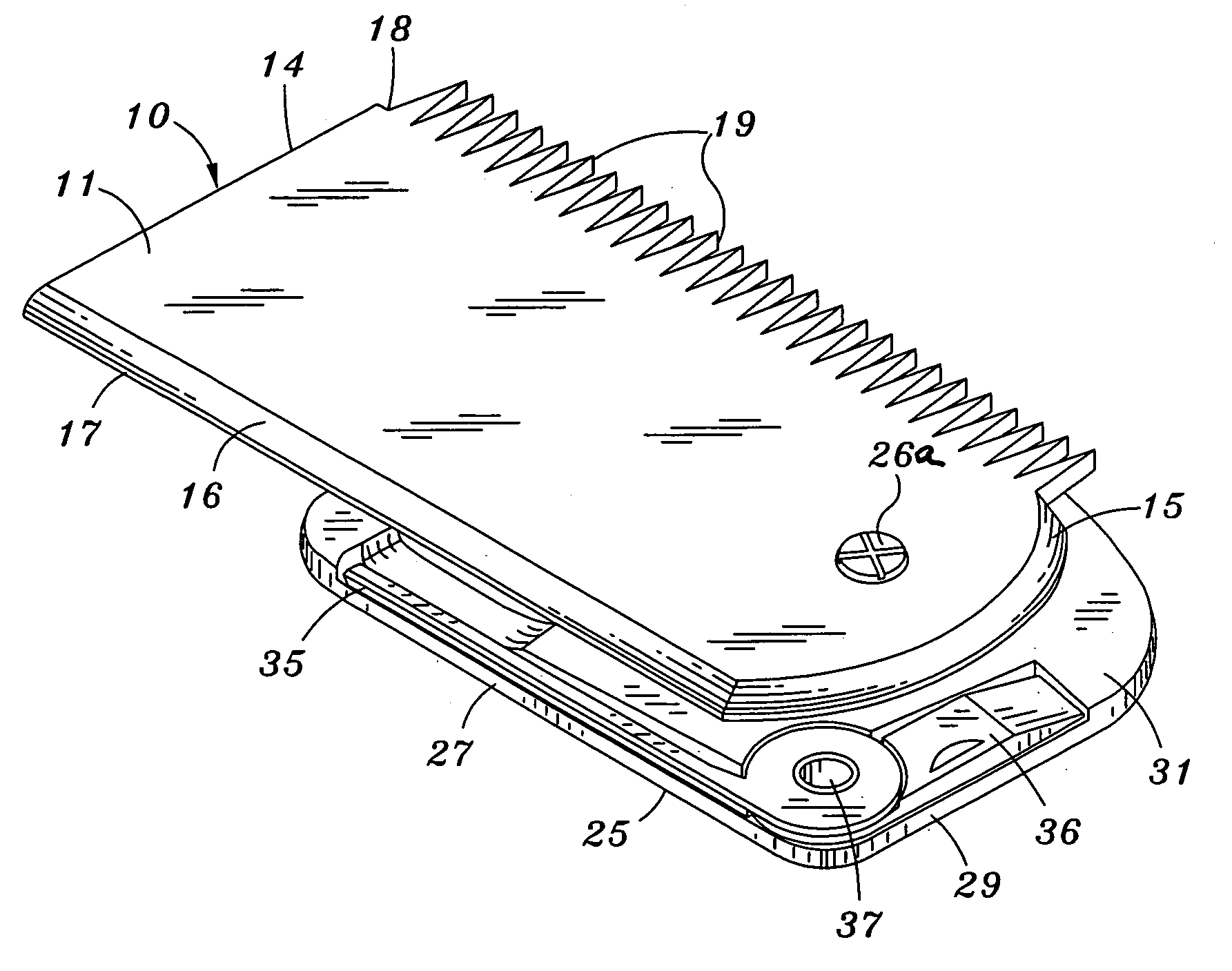

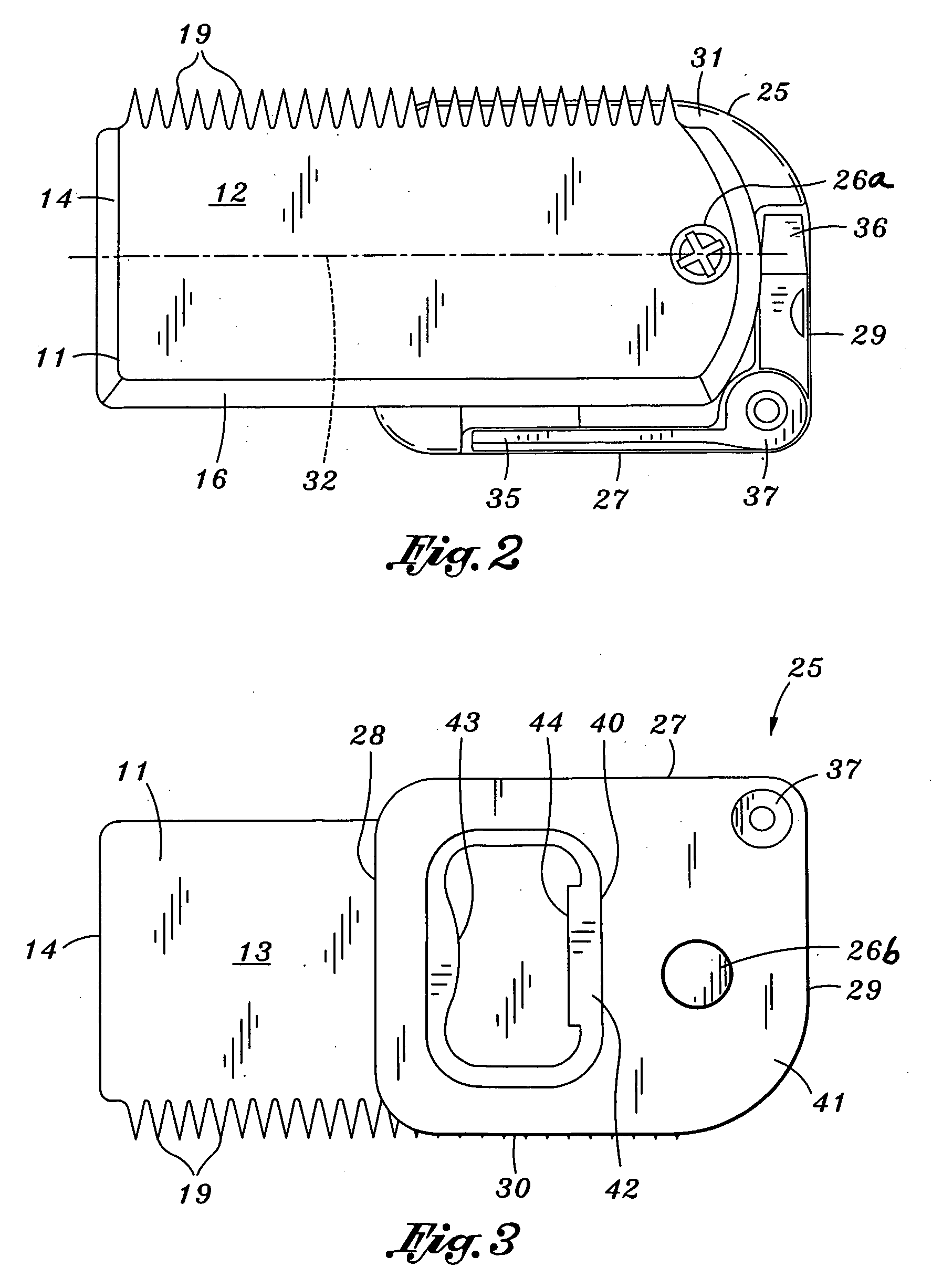

Hand tool for removal of wax from a surfboard incorporating manual accessories

InactiveUS20070277336A1Uniform applicationEasy to storePower operated devicesWater sport boardsEngineeringHand tool

A hand tool used for removing wax from a surfboard incorporating associated accessories. The wax removal element of the present invention constitutes a substantially rectangular scraping panel that can be resiliently flexed along the elongated axis of the panel. One of the elongated edges of the panel is extended into a plurality of uniform gouging members that are adapted to penetrate the wax to prepare the wax mounted on the surfboard to be removed. The edge of the panel opposed to the scraping members is beveled to provide an edge that is adapted to remove the wax from the surfboard. Rotatably coupled to the bottom surface of the scraping panel are one or more accessories and hand tools used for maintenance of the surfboard and for the personal employment of the user.

Owner:JILDI

Wax-resin surface polishes

InactiveUS6258882B1Easy to useLow of applicationNon-fibrous pulp additionPaper coatingAcrylic resinAliphatic hydrocarbon

Polish formulations are provided which comprise:a) an aliphatic hydrocarbon solvent comprising 0-10% aromatic hydrocarbons;b) an acrylic resin; andc) a wax product that is thermoplastic, transparent, a solid at room temperature and has a melting / softening point of about 60° to about 90° C.; wherein wt:wt ratio of said acrylic resin and wax is about 1:3 to about 1:8 and the wt:wt ratio of said resin and wax to said solvent is about 1:1 to about 1:9. The formulations function as surface polishes that can be used on any hard surface including wood, metal, stone, and other non-porous surfaces.

Owner:SMITHSONIAN INSTION THE

Viscosity reducting, de-waxing, deoiling auxiliary agent in use for extracting petroleum, and preparation method

InactiveCN101092558ATo achieve the purpose of reducing viscositySolve process problemsDrilling compositionSludgeCis-Butenedioic Acid

This invention discloses additive used in petroleum exploitation. The additive is a milky or yellow viscose liquid, and the pH value is 7-8. The additive comprises: dispersant (dodecyl benzene) 18.0-38.0%, emulsifier (nonyl phenol polyoxyethylene ether) 8.0-18.0%, water 35.0-65.0%, penetrant (diethylhexyl sulfosuccinate) 5.0-11.0%, and catalyst (cobalt acetate) 1.0-3.0%. When the additive is combined with crude oil, colloid asphalt and wax in crude oil can be rapidly dispersed, and the sludge can be precipitated and separated, thus the viscosity can be reduced, wax and sludge can be removed, and the fluidity of crude oil can be improved. The viscosity reduction rate is 96.0-99.8%, the wax removal rate is 90-95%, and the sludge removal rate is 60-70%. The additive can avoid steam hot-exploitation of highly viscose crude oil.

Owner:大连四方电泵有限公司

Wax removal water for cleaning automobile aluminum wheel hub and preparing method thereof

This invention relates to a wax-removing water for cleaning car Al wheel hubs and its preparation method, in which, the components and weight proportions are: TEA 10-20, oleic acid 12-25, fatty alcohol polyethenoxy ether 6-13, coconut oil diethanolamide 8-15, absolute ethanol 2-5 and a penetrating agent 2-7 including the following preparation method: first of all mixing the TEA with oleic oil uniformly, then adding coconut oil diethanolamide, the penetrating agent, the absolute alcohol and the fatty alcohol polyethenoxy ether orderly and mixing them uniformly to get a wax-removing water widely used in wax-removing for Al alloy especially car wheel hubs.

Owner:JIANGSU DEMEI TECH

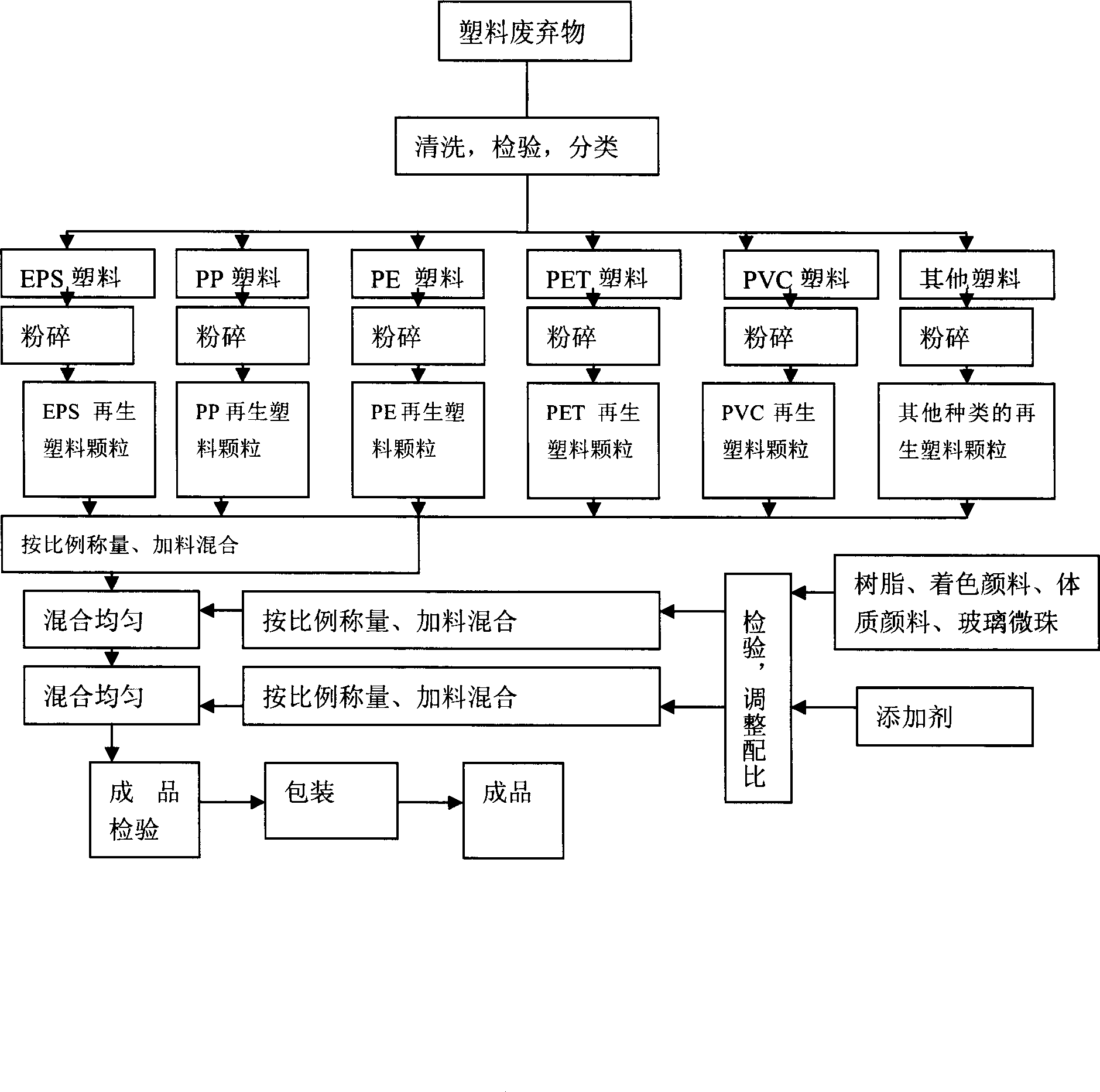

Hot-melting road mark paint prepared by employing waste plastics

The invention discloses a heat-fusing road mark coating made from waste plastic and a preparation method thereof, relating to a chemistry coating and a preparation method thereof, in particular to a coating used for road traffic safety mark and a preparation method thereof. The invention is characterized in that: the heat-fusing road mark comprises the following materials by weight: 5.0 to 20.0 proportions of regeneration waste plastic particle, 3.0 to 10.0 proportions of C5 petroleum resin, 0.5 to 13.0 proportions of acrylic resin, 3.0 to 5.0 proportions of titanium pigment, 9.0 to 14.5 proportions of quartz sand, 15.0 to 27.0 proportions of light calcium carbonate powder, 24.0 to 28.0 proportions of heavy calcium carbonate powder, 0.5 to 1.0 proportion of polyethylene wax, 0.5 to 4.0 resin EVA, 20.0 to 22.0 glass micro-beads, 0.5 to 1.0 proportion of dioctyl phthalate and 1.0 to 2.5 proportions of other additives. The preparation method has following steps: (1) classifying and grinding waste plastic, (2) adding materials according to prescription, (3) adding additive and evenly mixing. The invention solves the problems of high cost, large energy consumption of the traditional heat-fusing road mark coating, also provides a new method of directly utilizing waste plastic, which finds a new way for saving energy and eliminating 'white pollution'.

Owner:吕耀康

Soft mlcrocrystalline wax composition

The invention relates to a soft crystallitic wax combination containing crystallitic wax as the substrate, malthene and tackifier. The soft crystallitic wax combination disclosed in the invention has reduced rigidity and enhanced viscosity, and adjusts the product properties according to needs. Being capable of effectively overcoming the defects of the common crystallitic wax such as weak toughness and easy breakage, etc., the crystallitic wax composite relating to the invention is in particular suitable for the fields of moisture protection, insulation, sealing and gift candles, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

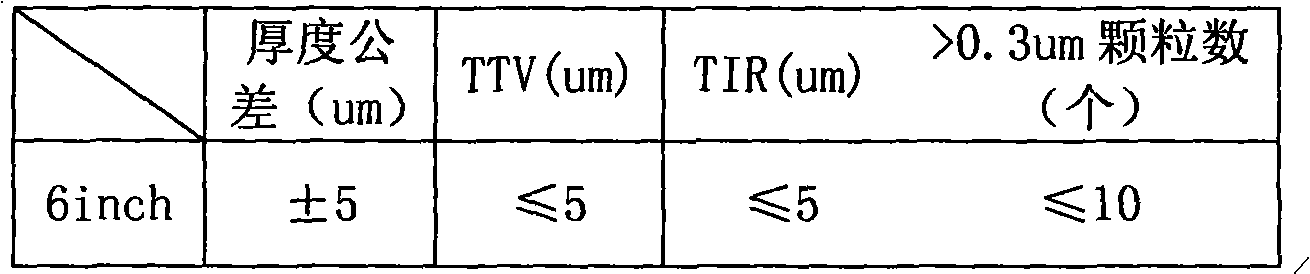

Polishing process for ultrahigh-resistivity silicon polished wafer

The invention relates to a polishing process for an ultrahigh-resistivity zone-melting silicon polished wafer. Wax-free single-surface polishing is adopted in the process and comprises rough polishing and fine polishing; the rough polishing and the fine polishing are respectively carried out according to pressure and time parameters set in four steps; the polishing solution temperature of the rough polishing and the fine polishing is controlled in a range of 30-40 DEG C; and the large disk temperature of a polishing machine is controlled in a range of 40-60 DEG C. In the process, polishing pressure and time suitable for producing an ultrahigh-resistivity silicon wafer are worked out, quality indexes of flatness, and the like of the polished surface of the silicon wafer are improved by adopting wax-free polishing, especially, an wafer adhering agent is discarded, the contamination of organic matter, and the like is reduced to the greatest extent and the polishing wafer is easy to clean, thereby simplifying wax removal cleaning program and equipment, reducing the cost of the polishing silicon wafer and improving the labor productivity.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

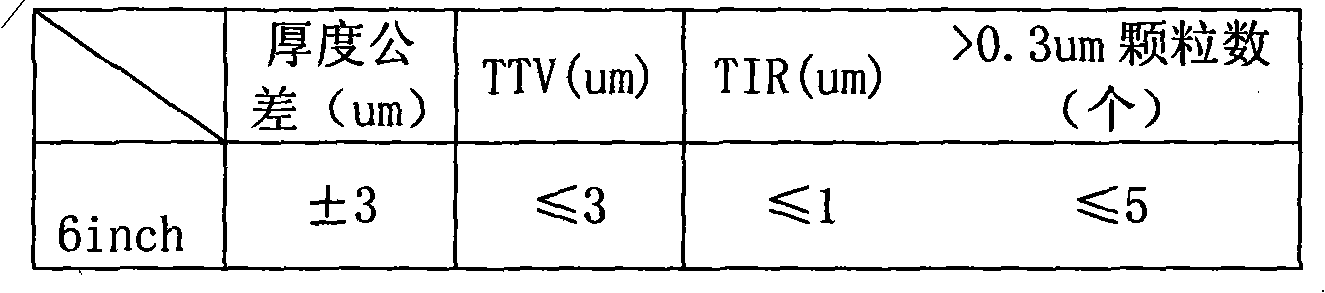

Sanitary product surface treatment method

InactiveCN103361688AImprove surface densityImprove coating qualityVolumetric Mass DensityWax removal

The invention aims to provide a sanitary product surface treatment method which can be adopted to strengthen density of a coating on the surface of a sanitary product, raise quality of the coating of the product and prolong service life of the product. The method provided by the invention comprises the following steps: wax removal step, oil removing step, electrode electrolysis step, activating treatment step, nickel plating processing step and chrome plating step. By the adoption of the method for processing a sanitary product, density of the surface of the sanitary product is higher, the thicknesses of a nickel coating and a chromium coating are increased, and quality of the coating of the sanitary product is improved. Thus, the service life of the sanitary product in a general environment is prolonged, the sanitary product can be suitable for more other complex environments, and the service life can be guaranteed. The Sanitary product surface treatment method provided by the invention can be applied in the field of production of sanitary equipment.

Owner:ZHUHAI XIANGJIN HARDWARE & ELECTRICAL APPLIANCE

Grease, oil and wax resistant paper composition

InactiveUS7833915B2Eliminating most surfactantsNatural cellulose pulp/paperSpecial paperOil and greaseFluorocarbon

In order to provide grease, oil and wax resistance to a paper substrate, a coating containing a binder, a filler material and calcium carbonate is used. The coating of the invention is essentially free from fluorocarbons, which are considered harmful to human and animal populations, and surfactants and other chemicals which may alter the color of the coated paper. The coated paper has a GE brightness level between approximately 50 and approximately 90, while providing superior grease, oil and wax resistance.

Owner:SKC ACQUISITION +1

Hardware chromium plating technology

The invention discloses a hardware chromium plating technology which comprises the following steps: performing degreasing so as to remove grease from the surface of hardware; performing cleaning repeatedly so as to further remove grease from the surface of the hardware; performing wax removal so as to remove a wax layer from the surface of the hardware; performing oil removal so as to remove an oil layer from the surface of the hardware through a surfactant; performing anodic electrolysis oil removal so as to further remove the oil layer from the from the surface of the hardware; performing acid activation repeatedly so as to increase the electroplating efficiency; performing bright copper plating so that a final plating has adhesive force, corrosion resistance, wear resistance and glossiness; performing acid copper plate so that the final plating has adhesive force, corrosion resistance, wear resistance and glossiness; performing nickel plating so that the final plating has adhesive force, corrosion resistance, wear resistance and glossiness; performing golden nickel so that co-deposition of particles and nickel is realized to form a composite plating; performing chromium plating so that the final plating has adhesive force, corrosion resistance, wear resistance and glossiness; performing passivation; performing air blowing; and performing baking and the like so as to improve the adhesive force, corrosion resistance, wear resistance and glossiness of a chromium plating.

Owner:苏州市美能五金镀饰有限公司

Wax print cloth wax veins producing prescription and technique

InactiveCN101144251AElasticFlexibleFibre treatmentDyeing processParaffin waxOxidation-Reduction Agent

The present invention discloses a print production prescription and a process of the wax print fabric. The production prescription used adopts rosin, paraffin wax, beeswax, and macromolecule resin as wax material. The process flow is as follows: firstly, an original grey cloth is processed through singeing, desizing, scouring, bleaching, mercerizing, stenter tentering of weft ripe or padding Naphthol liquid Naphthol, the wax liquid melted and mixed under the condition of 50 DEG C to 200 DEG C on a wax printing machine is uniformly printed on the fabric through a rotary screen on the condition of constant temperature, after the air-cooled or water-cooled solidification, the dyeing redox is dyed blue with flora on the indigo machine or the color flora machine is dyed with color through padding the azoic dyestuff, and then a wax swinging machine is pulled over the small circular hole in a rope shape. Under 40 DEG C, and by the machinery outside force, the wax membrane is cracked naturally, and through processing the wax-dyeing by using indigo, insoluble azo dyes, and India blue IBN etc., the wax print fabric with various glaze and different style of wax print can be obtained.

Owner:王化斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com