Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1153 results about "Electroforming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroforming is a metal forming process that forms parts through electrodeposition on a model, known in the industry as a mandrel. Conductive (metallic) mandrels are passivated (chemically) to preclude 'plating' and thereby to allow subsequent separation of the finished electroform. Non-conductive (glass, silicon, plastic) mandrels require the deposition of a conductive layer prior to electrodeposition. Conductive layers can be deposited chemically, or using vacuum deposition techniques (e.g., gold sputtering). The outer surface of the mandrel forms the inner surface of the form.

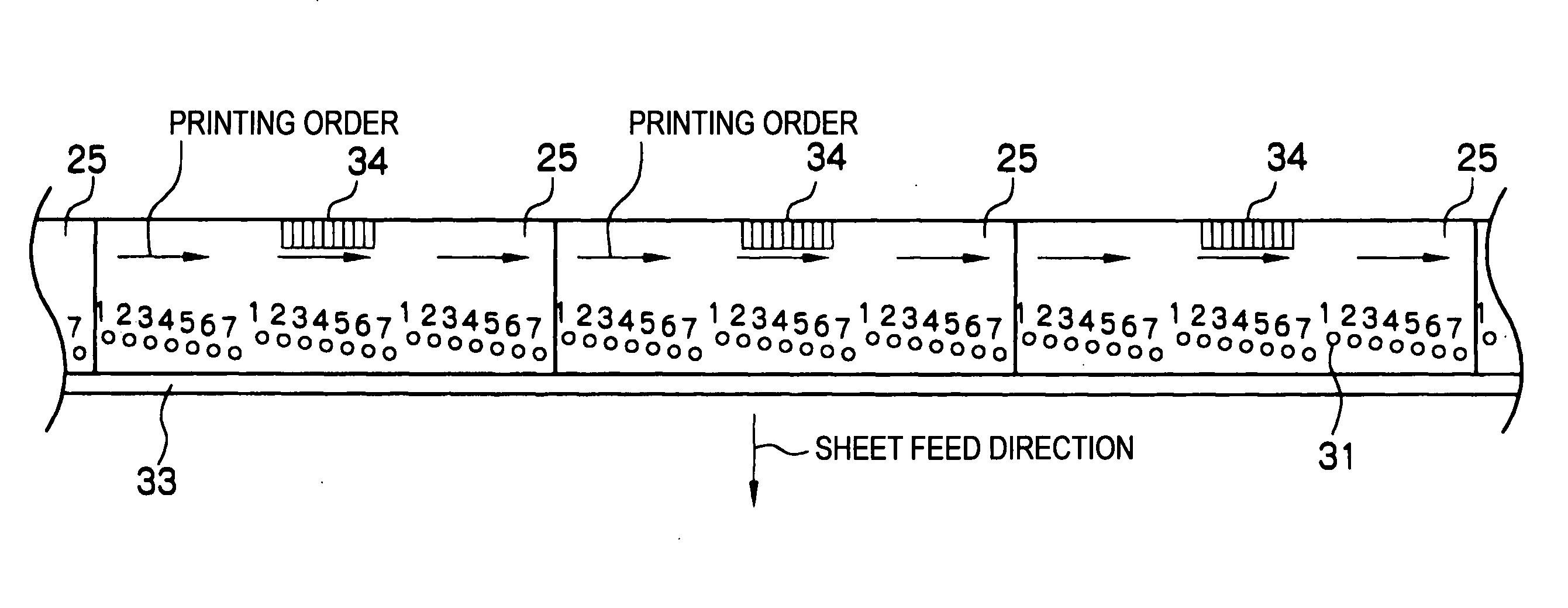

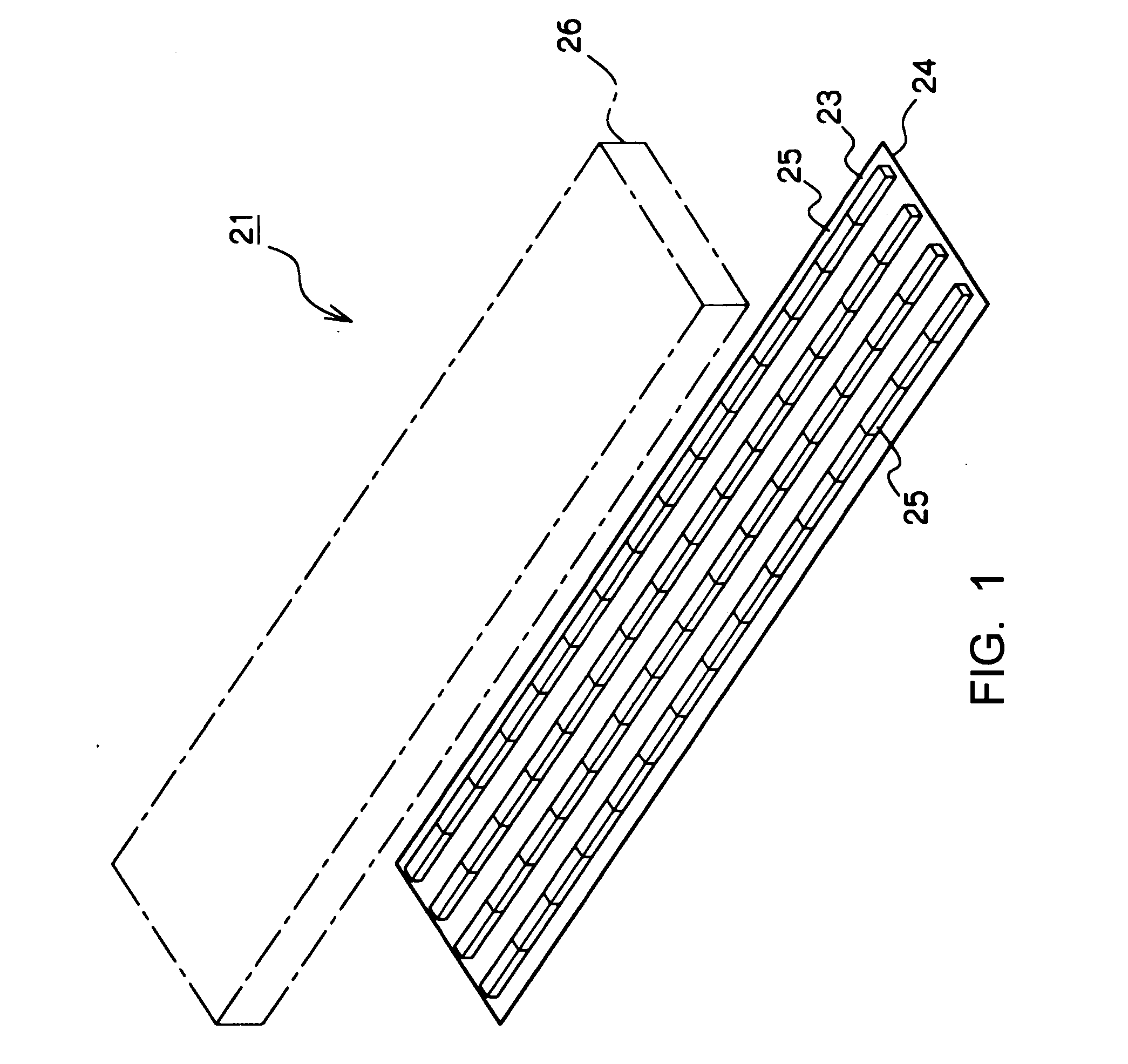

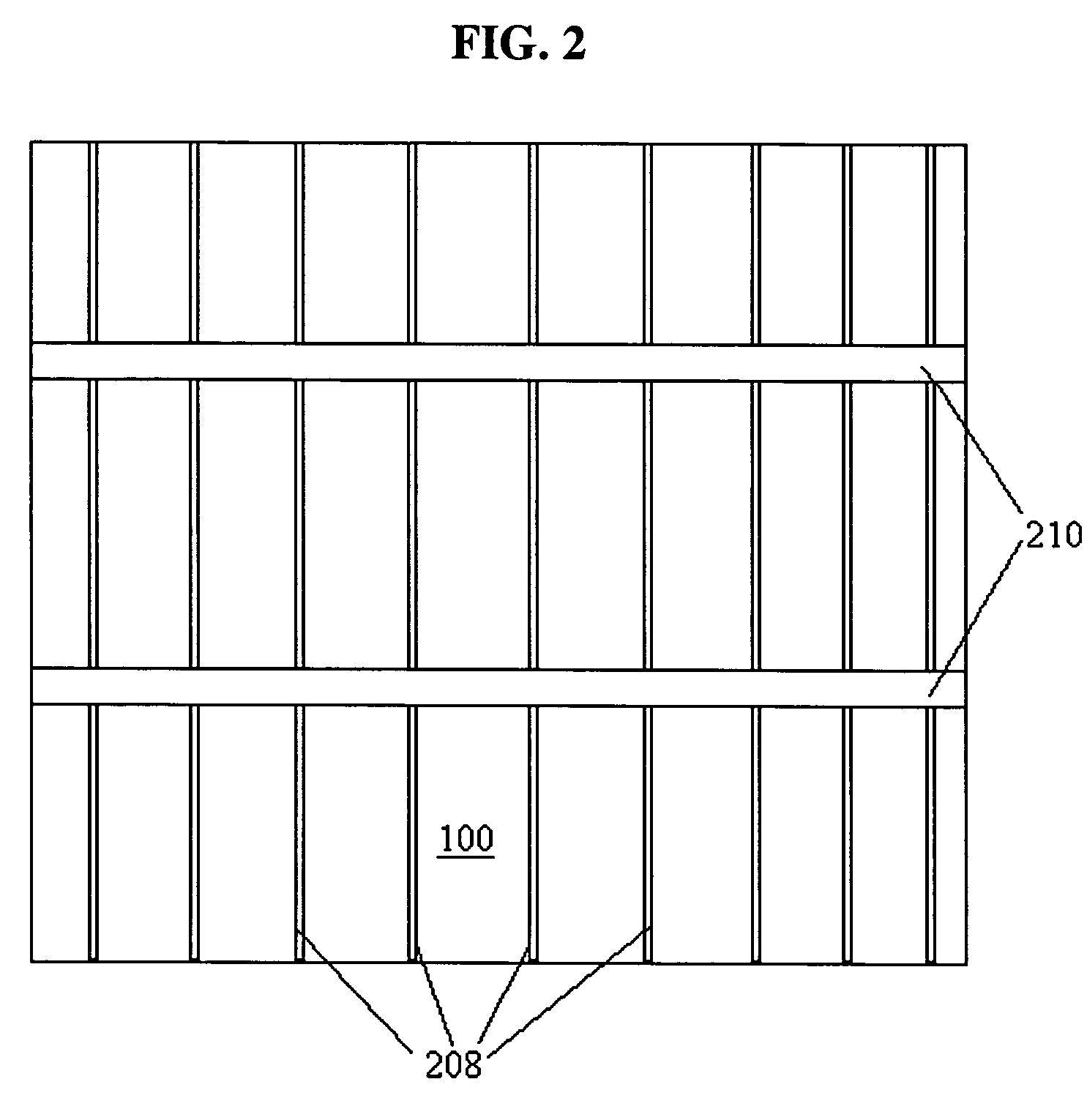

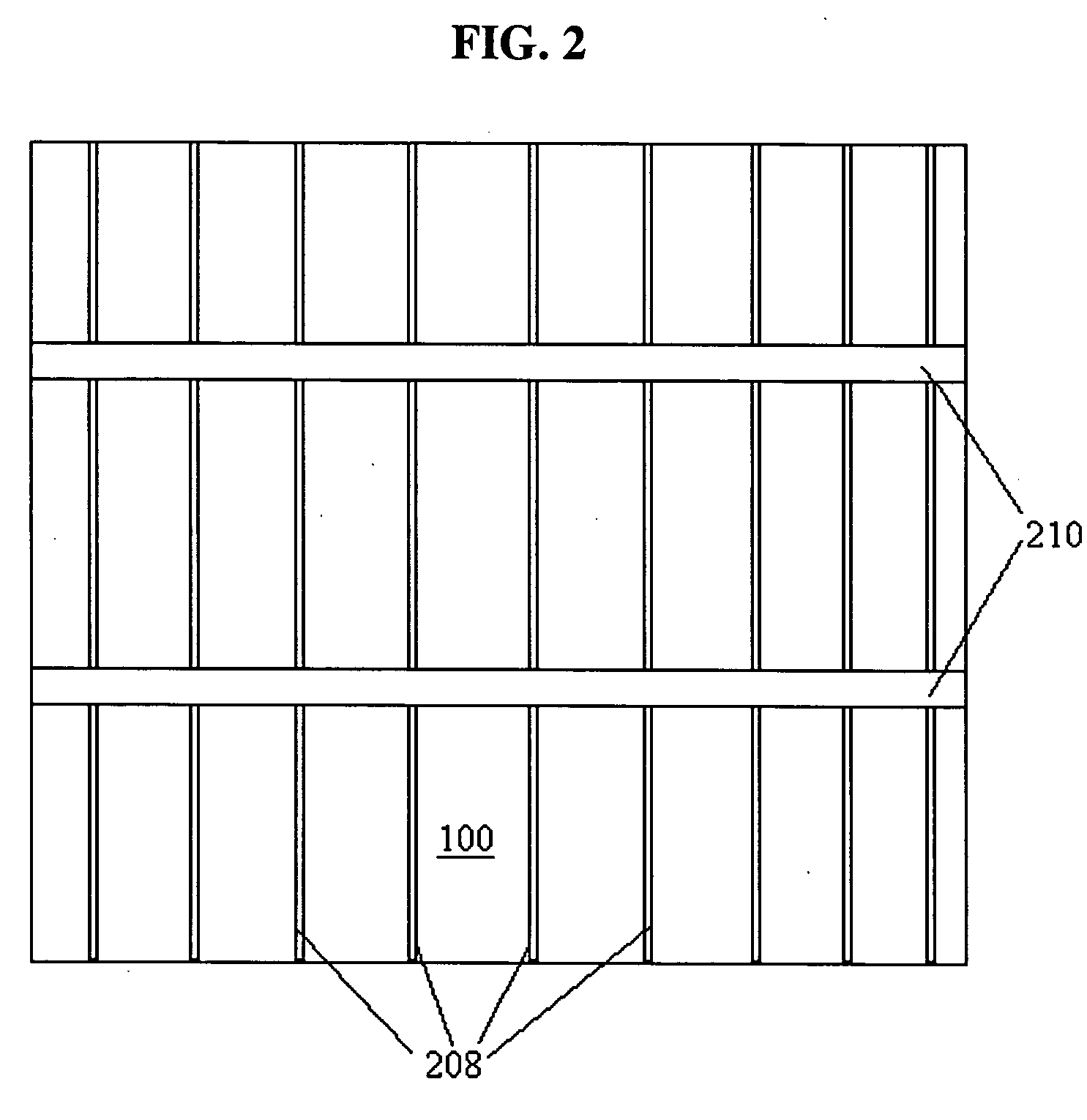

Ink jet print head, inkjet printer including the inkjet print head, and method of manufacturing inkjet print head

An inkjet print head includes one nozzle sheet (23) and a plurality of head chips (25) including a plurality of heaters. The nozzle sheet (23) is formed of an electroformed metal layer made of nickel or a material comprising nickel, and has discharge nozzle rows for respective colors disposed so that the discharge nozzles are in staggered arrangements and so that each set of discharge nozzles partly overlaps another set of discharge nozzles in a sheet-feed direction. The head chips are positioned at and affixed to a growth surface side of the nozzle sheet (23) in staggered arrangements so that the positions of the discharge nozzles and the positions of the heaters correspond to each other. Accordingly, reduction in printing quality caused by displacement of any of the discharge nozzles is prevented from occurring, and landing positions of discharged ink on a recording sheet are stabilized.

Owner:SONY CORP

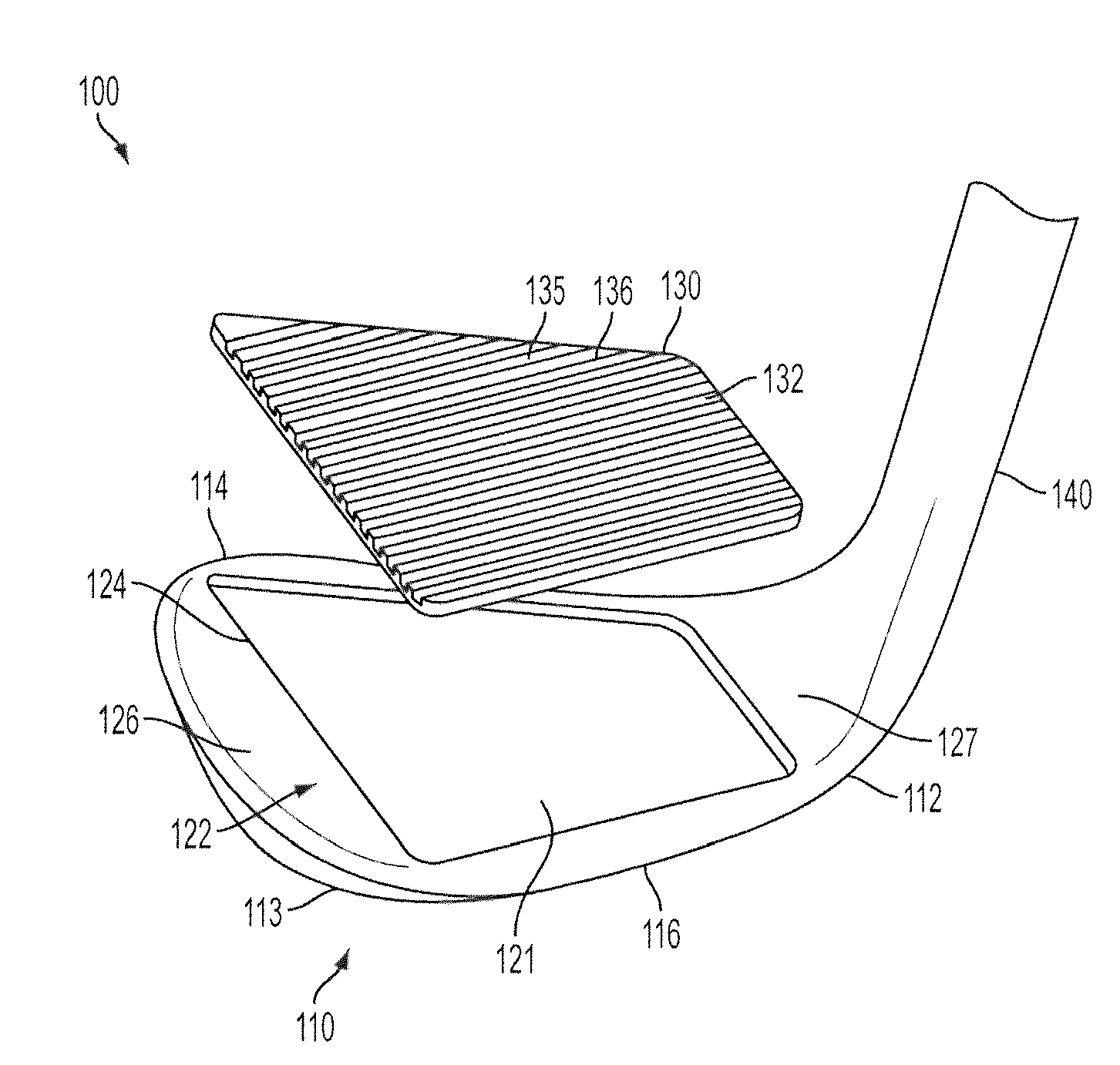

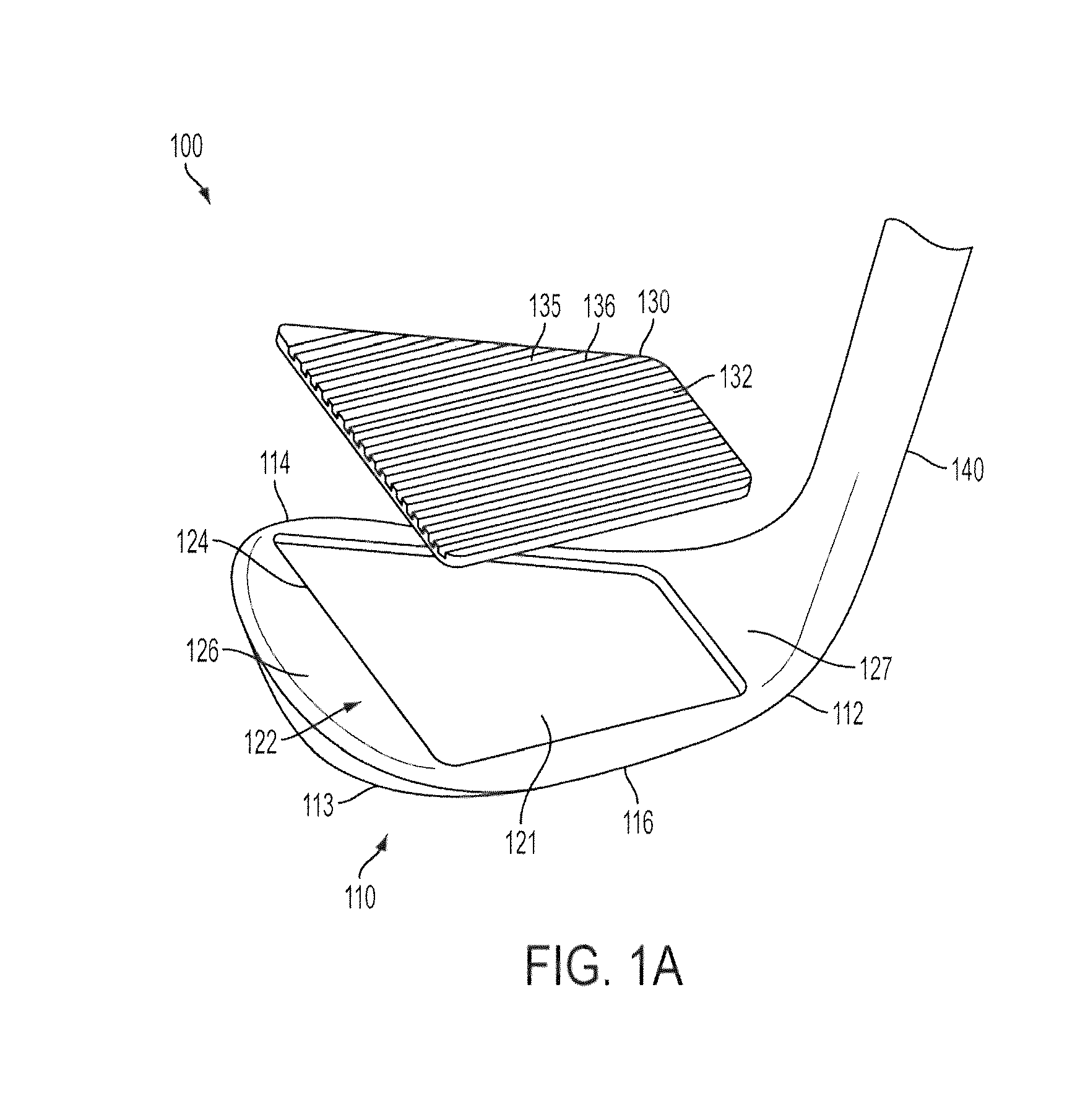

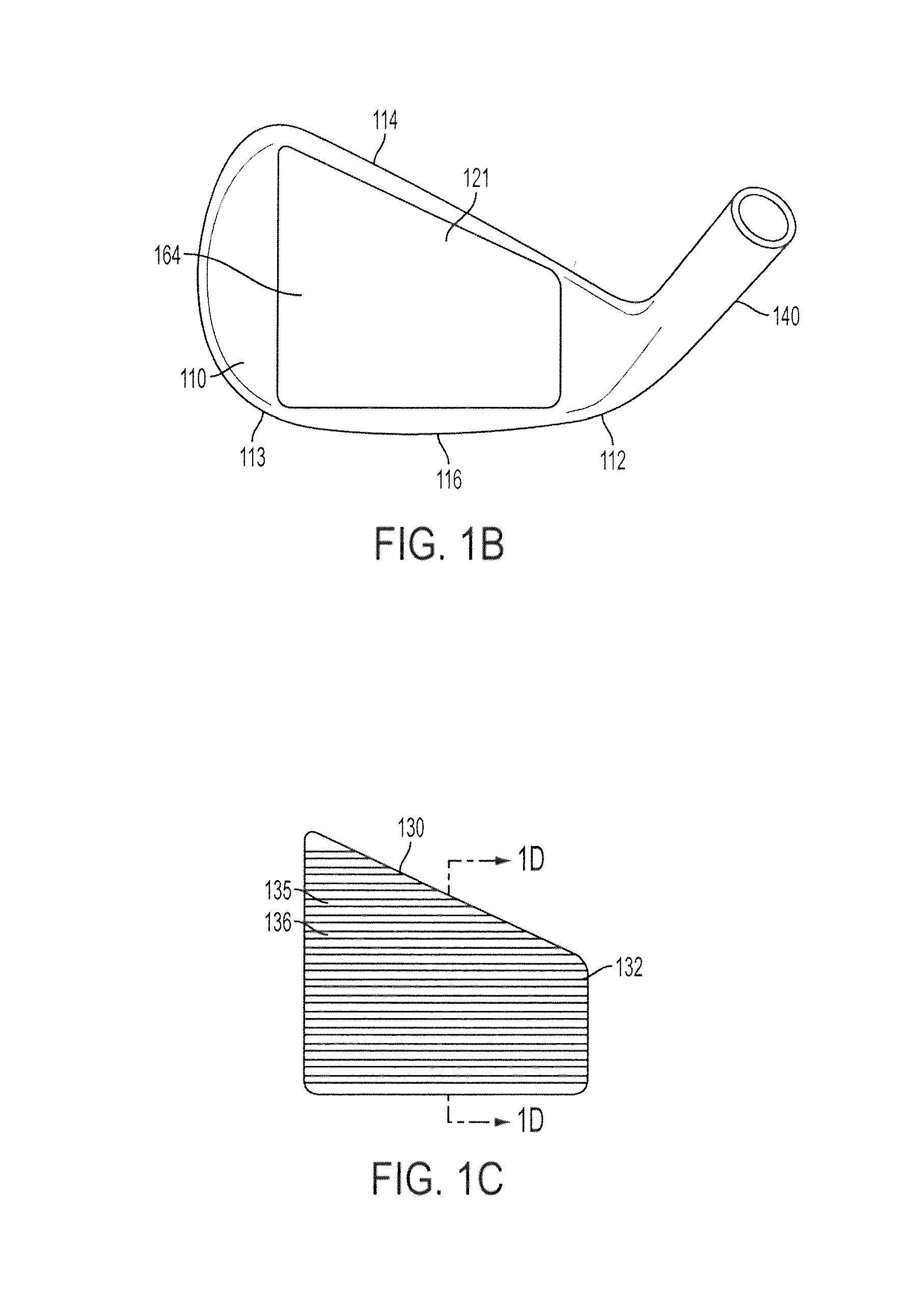

Golf club head with face insert

A golf club head is provided having a club body and a contact plate secured to the club body. The contact plate defines at least a portion of a striking surface having a plurality of striking surface grooves. The contact plate is formed using an electroforming process.

Owner:TAYLOR MADE GOLF

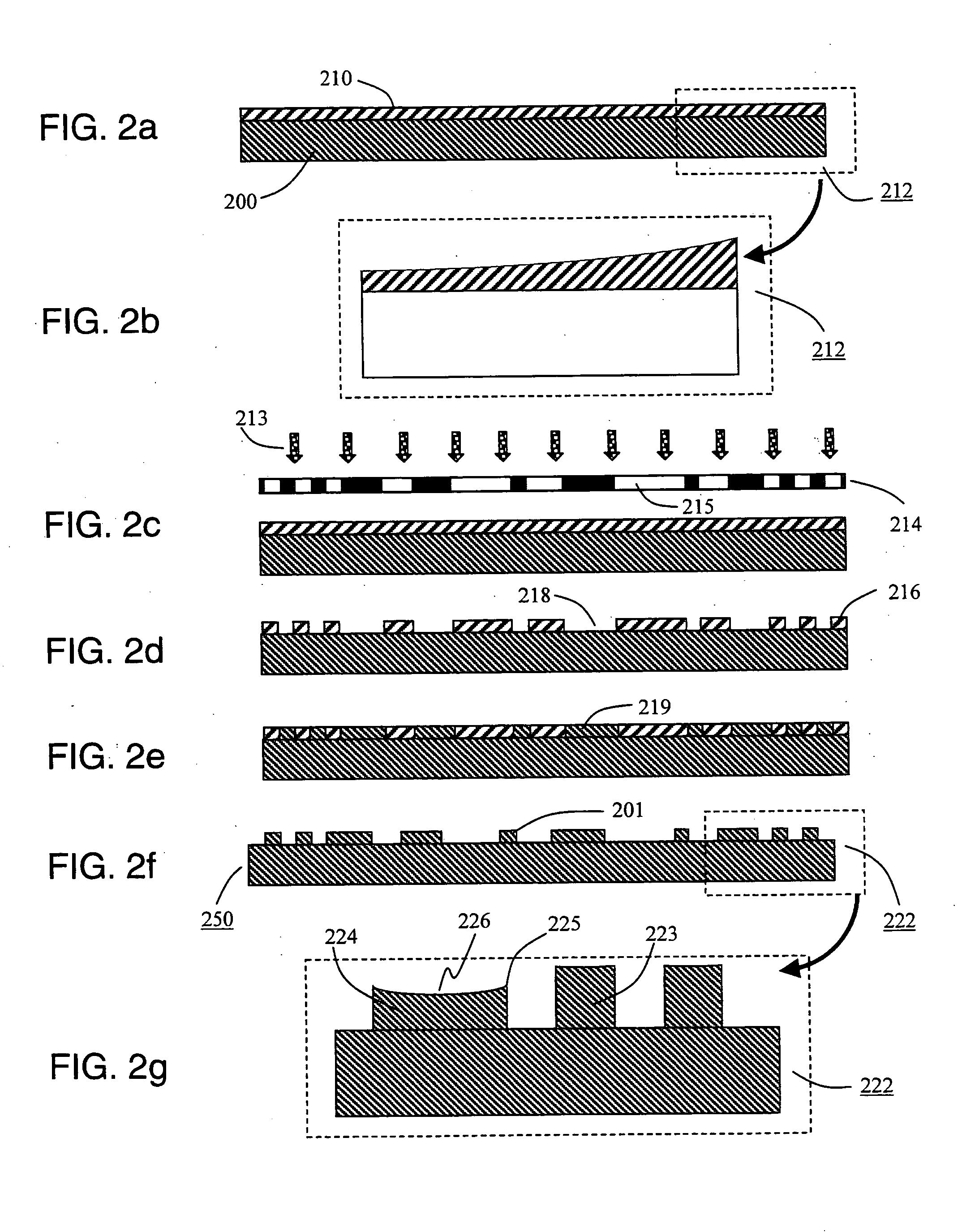

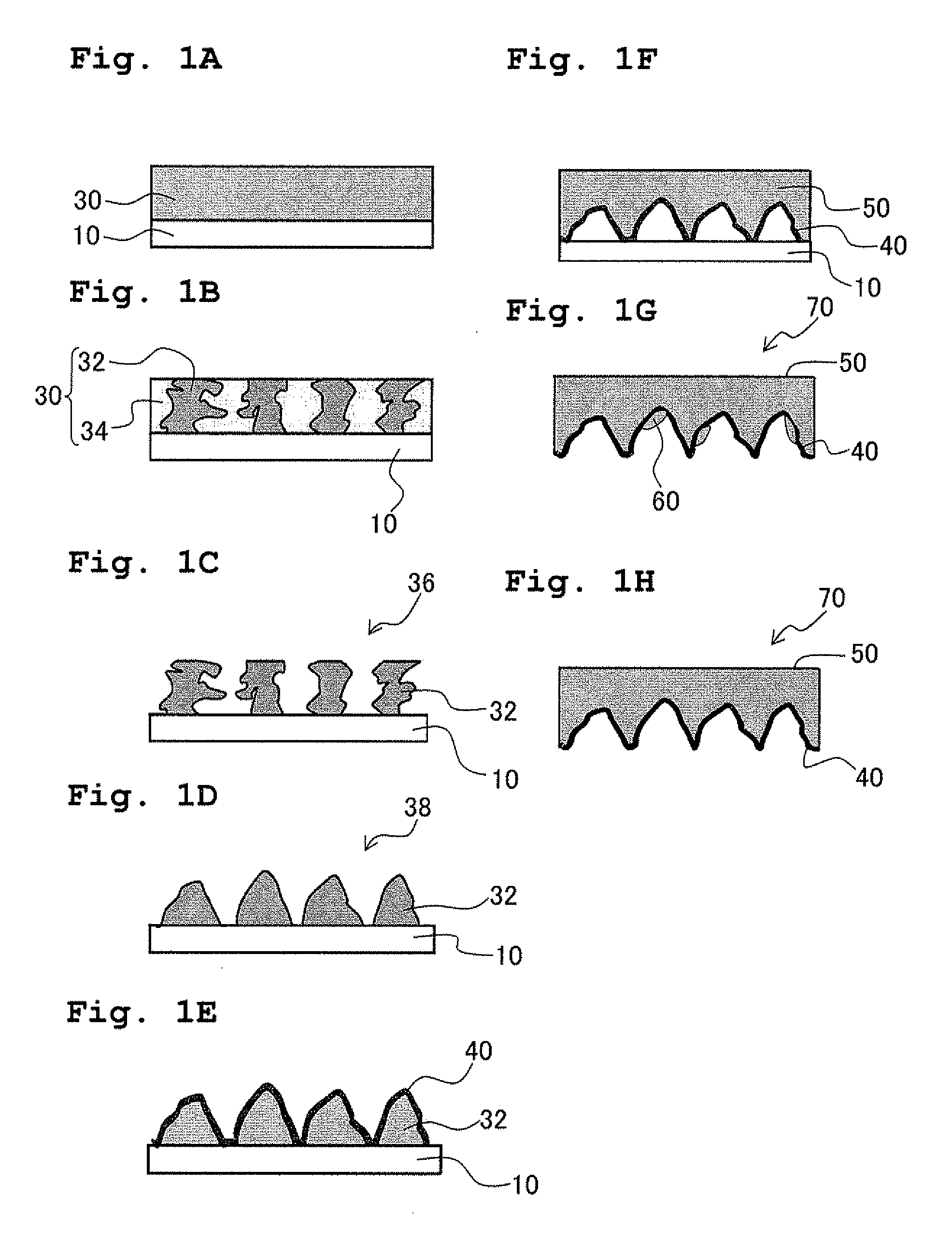

Microfabricated structures and processes for manufacturing same

InactiveUS20050067286A1Minimize surface roughnessEasy to controlElectroforming processesMicroelectromechanical systemsManufacturing technologyCompound (substance)

Various techniques for the fabrication of highly accurate master molds with precisely defined microstructures for use in plastic replication using injection molding, hot embossing, or casting techniques are disclosed herein. Three different fabrication processes used for master mold fabrication are disclosed wherein one of the processes is a combination of the other two processes. In an embodiment of the first process, a two-step electroplating approach is used wherein one of the metals forms the microstructures and the second metal is used as a sacrificial support layer. Following electroplating, the exact height of the microstructures is defined using a chemical mechanical polishing process. In an embodiment of the second process, a modified electroforming process is used for master mold fabrication. The specific modifications include the use of Nickel-Iron (80:20) as a structural component of the master mold, and the use of a higher saccharin concentration in the electroplating bath to reduce tensile stress during plating and electroforming on the top as well as sides of the dummy substrate to prevent peel off of the electroform. The electroforming process is also well suited towards the fabrication of microstructures with non-rectangular cross sectional profiles. Also disclosed is an embodiment of a simple fabrication process using direct deposition of a curable liquid molding material combined with the electroforming process. Finally, an embodiment of a third fabrication process combines the meritorious features of the first two approaches and is used to fabricate a master mold using a combination of the two-step electroplating plus chemical mechanical polishing approach and the electroforming approach to fabricate highly accurate master molds with precisely defined microstructures. The microstructures are an integral part of the master mold and hence the master mold is more robust and well suited for high volume production of plastic MEMS devices through replication techniques such as injection molding.

Owner:CINCINNATI UNIVERISITY OF THE

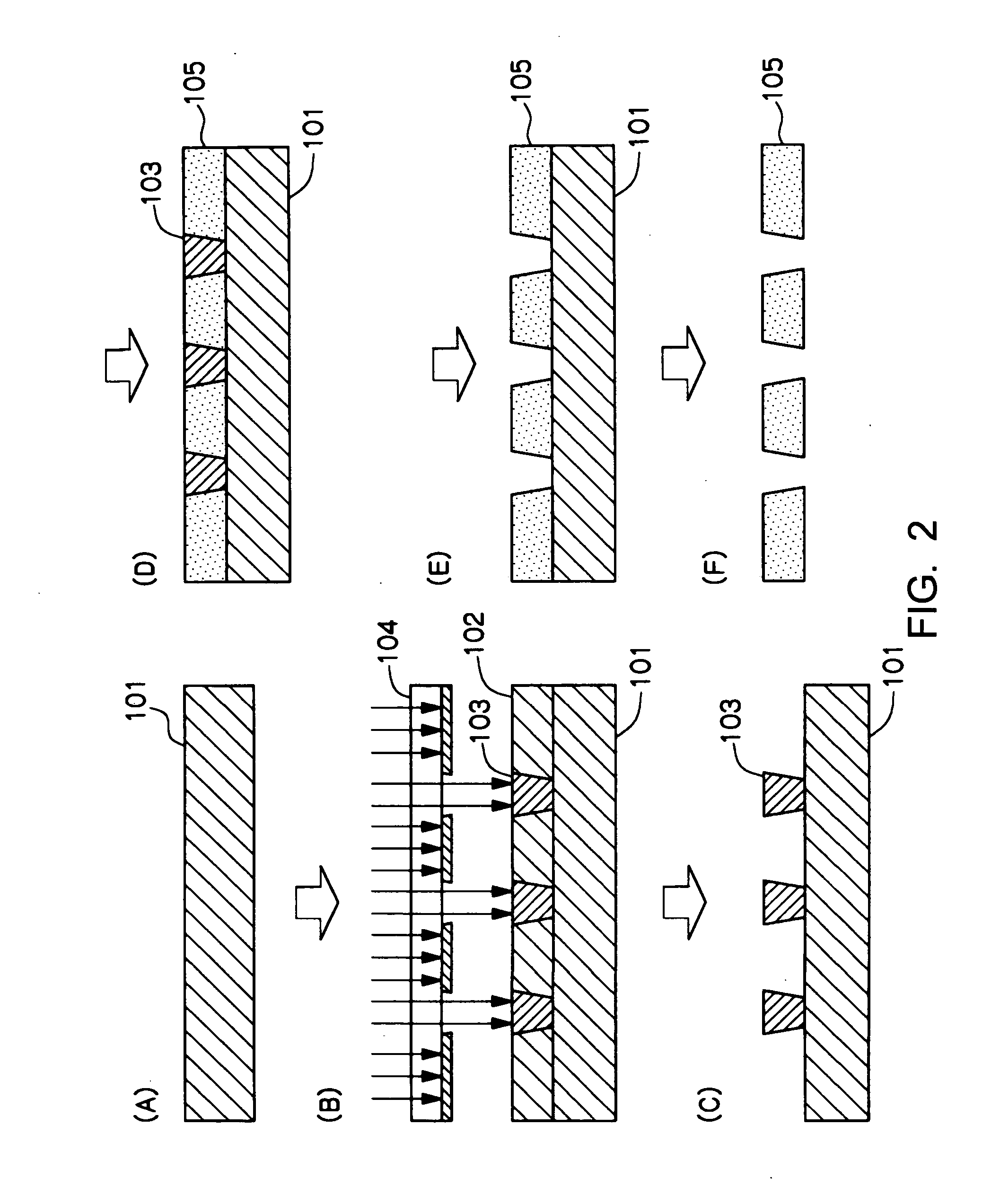

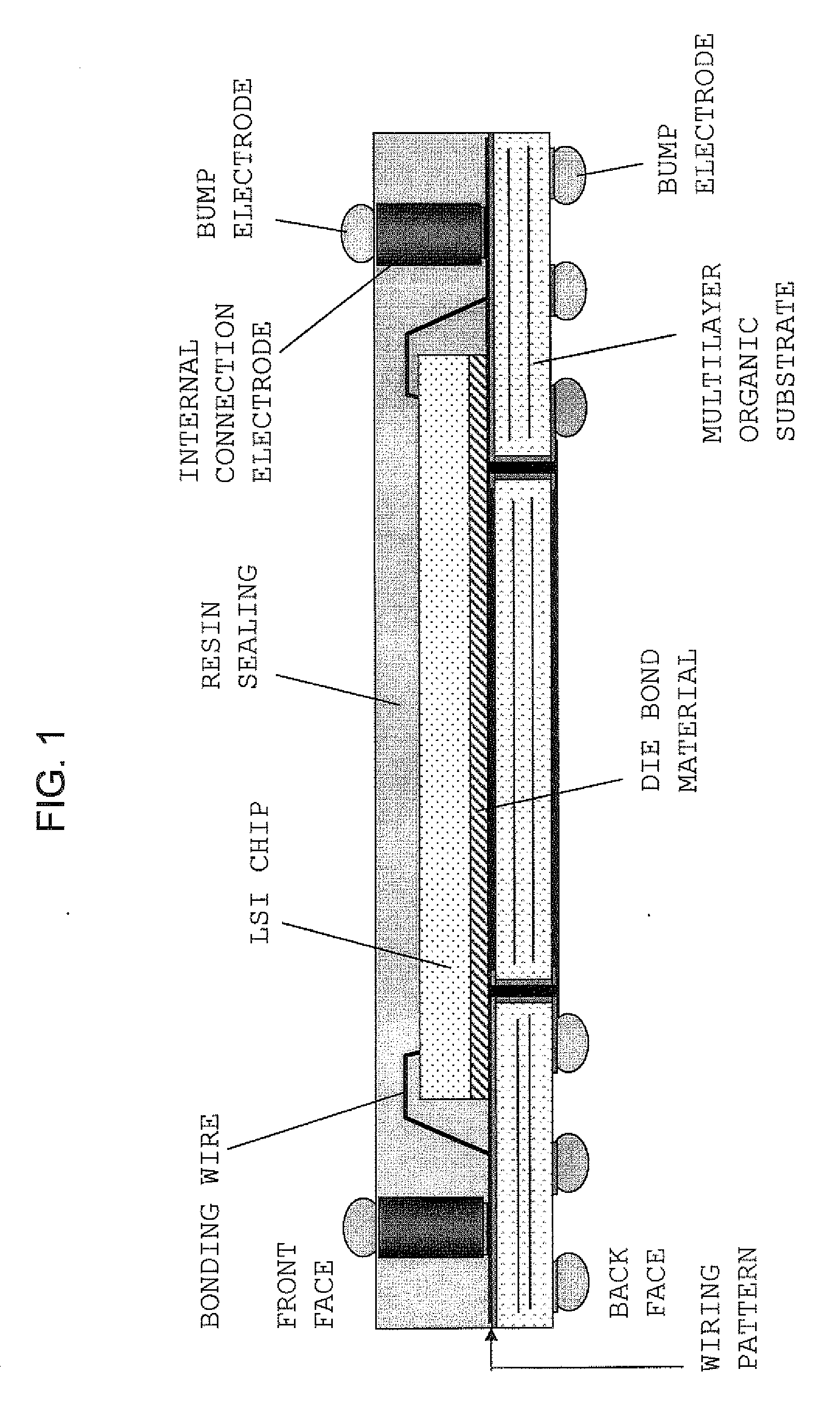

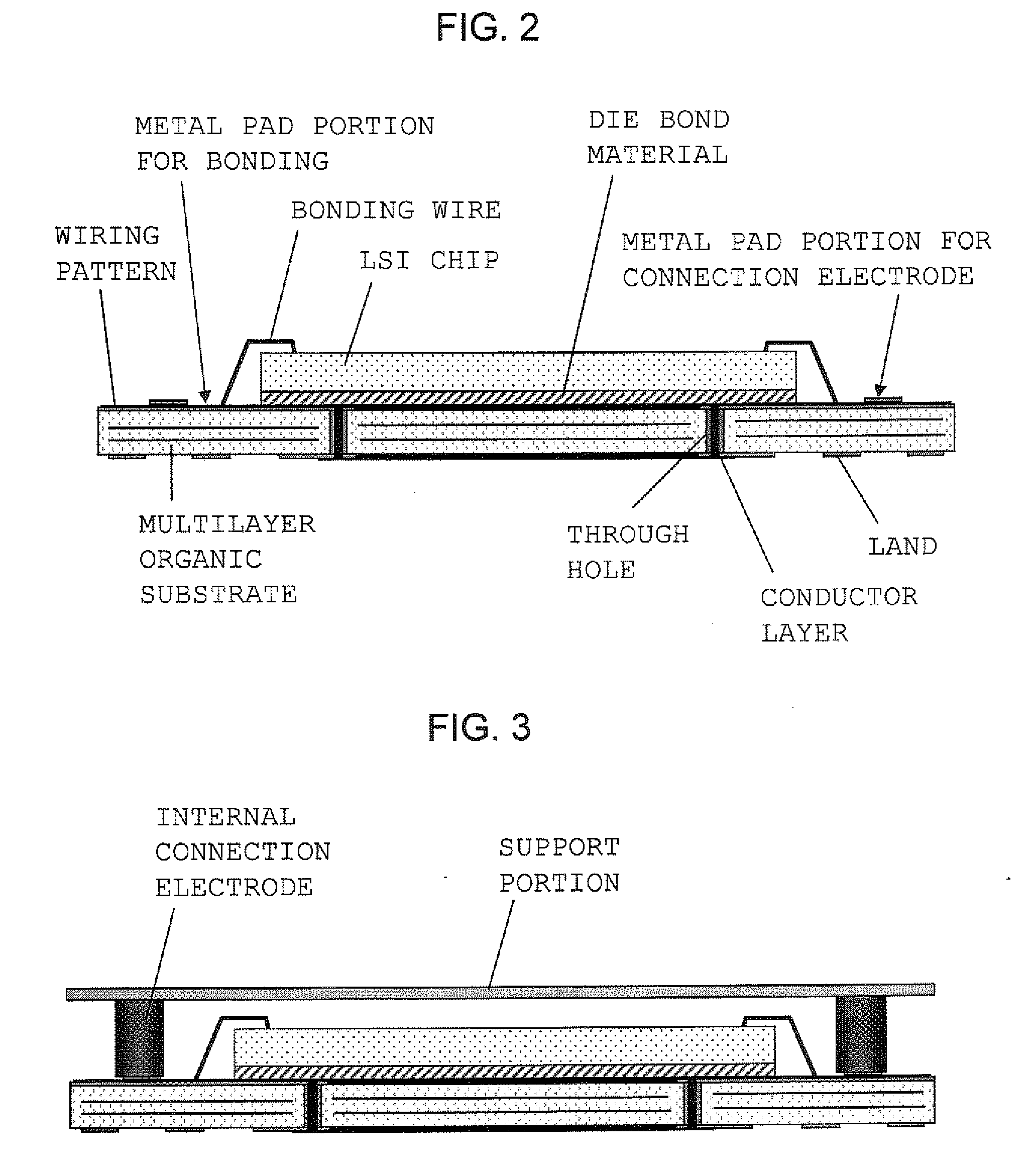

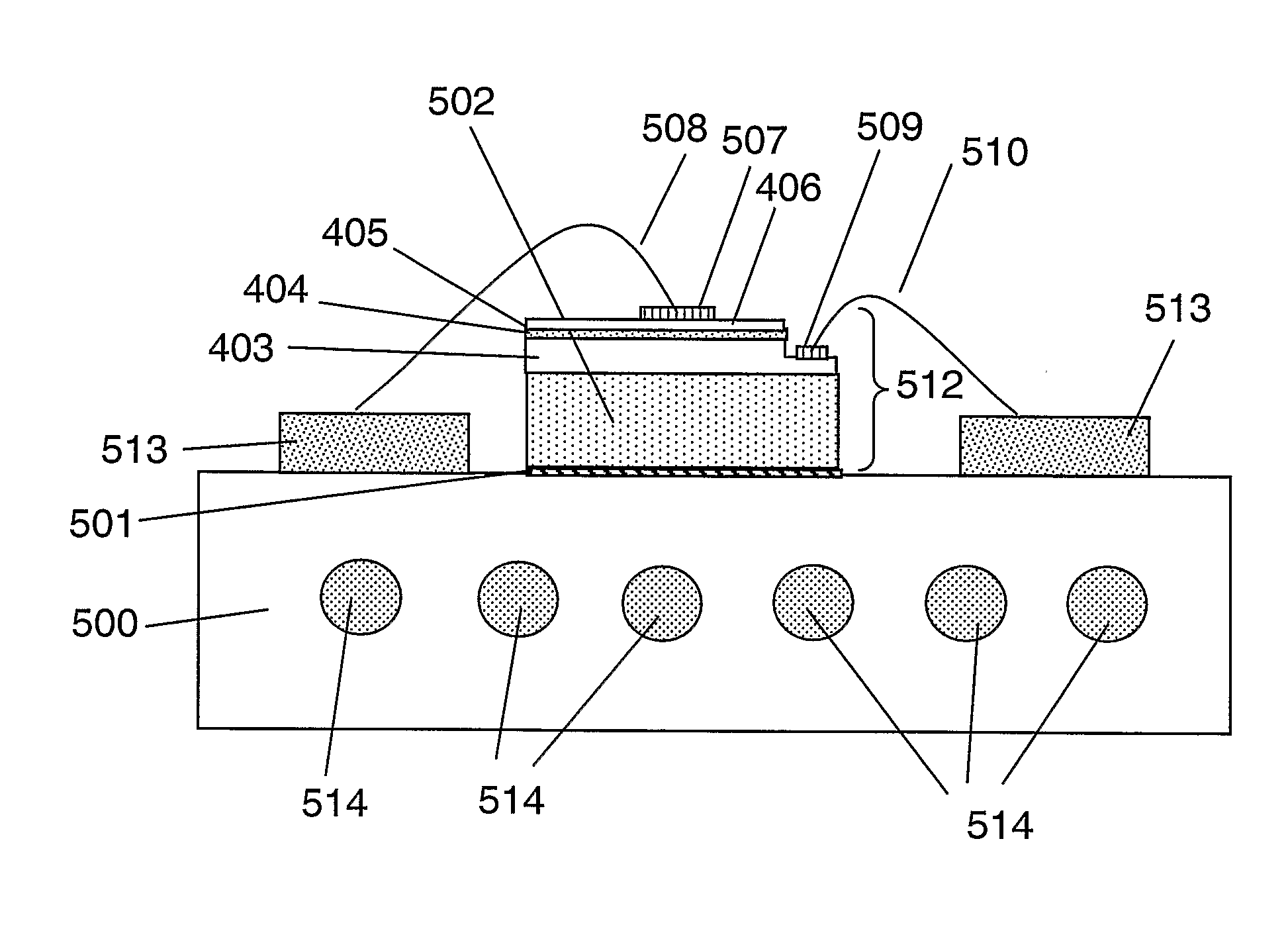

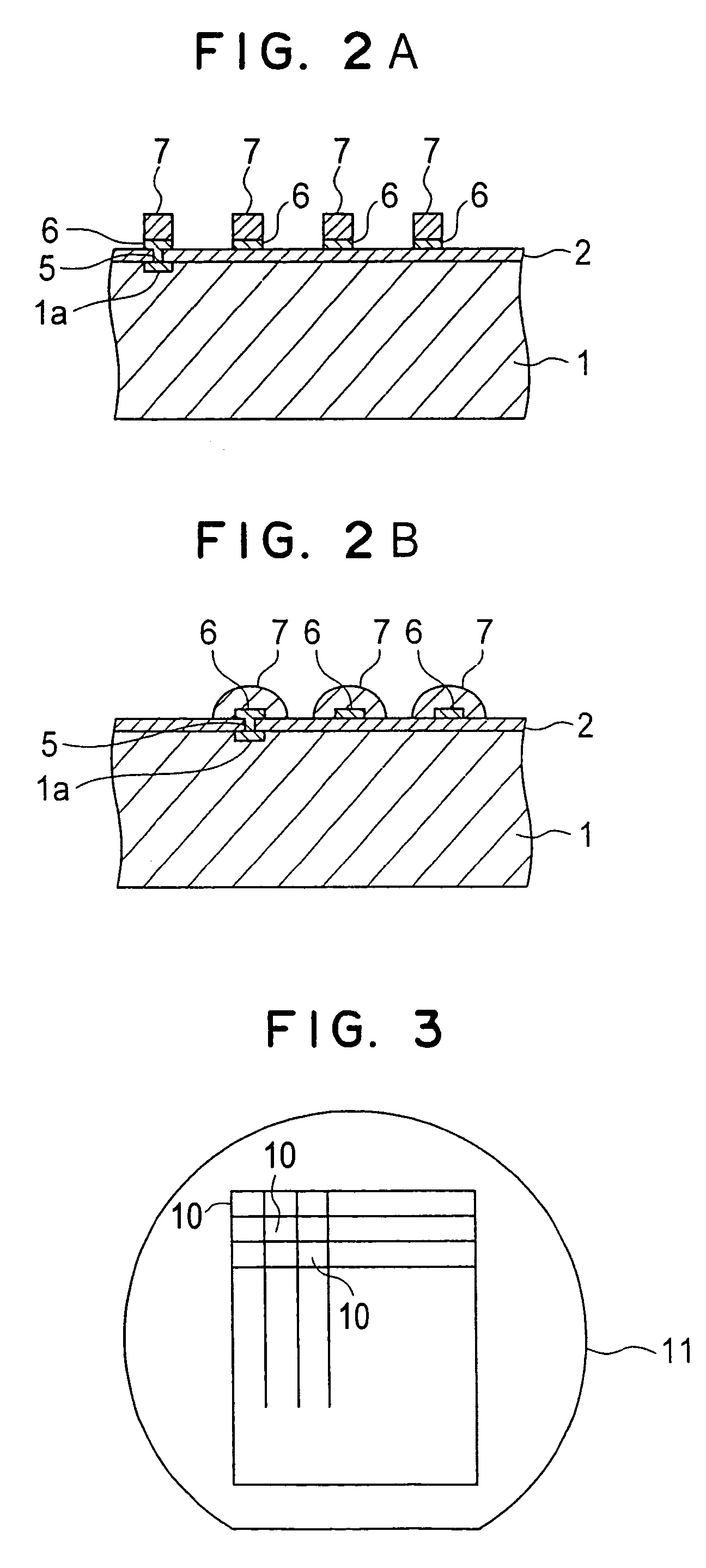

Method of manufacturing semiconductor device with electrode for external connection and semiconductor device obtained by means of said method

ActiveUS20090050994A1Low costEasy to useSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

A circuit element is disposed on an organic substrate and is connected to a wiring pattern provided on the organic substrate. Internal connection electrodes are formed on a support of a conductive material through electrofomiing such that the internal connection electrodes are integrally connected to the support. First ends of the internal connection electrodes integrally connected by the support are connected to the wiring pattern. After the circuit element is resin-sealed, the support is removed so as to separate the internal connection electrodes from one another. Second ends of the internal connection electrodes are used as external connection electrodes on the front face, and external connection electrodes on the back face are connected to the wiring pattern.

Owner:INVENSAS CORP

Mask electro-forming method for vaporization coating of organic light-emitting display

ActiveCN1804138AUniform openingEasy transferVacuum evaporation coatingPhotomechanical apparatusPosition toleranceDisplay device

The mask electroforming method for OLED comprises: preparing module core, pre-treating the core; sticking mask; exposing; developing; deoiling; cleaning in water; activating / passivating; cleaning; electroforming mask; cleaning; removing mask; peeling mask; bonding with silk screen; detecting the product; packing. This invention can prepare the high-precise mask for OLED with thickness less than 0.5mm, and has opening tolerance up to í‚0.005mm; for example, for a 370mmí‡470mm mask plate, the crosshole position tolerance just is í‚0.008mm.

Owner:KUN SHAN POWER STENCIL

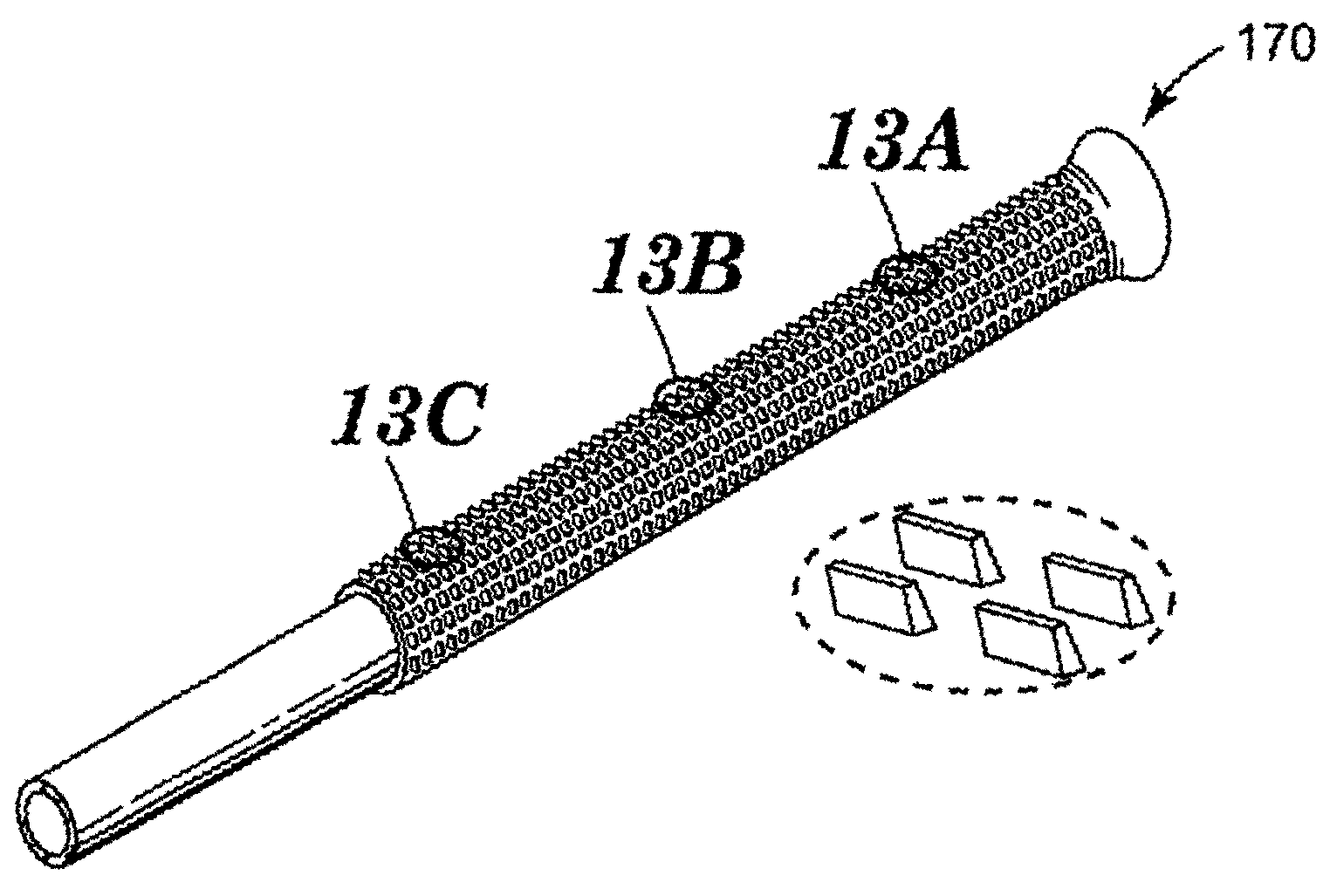

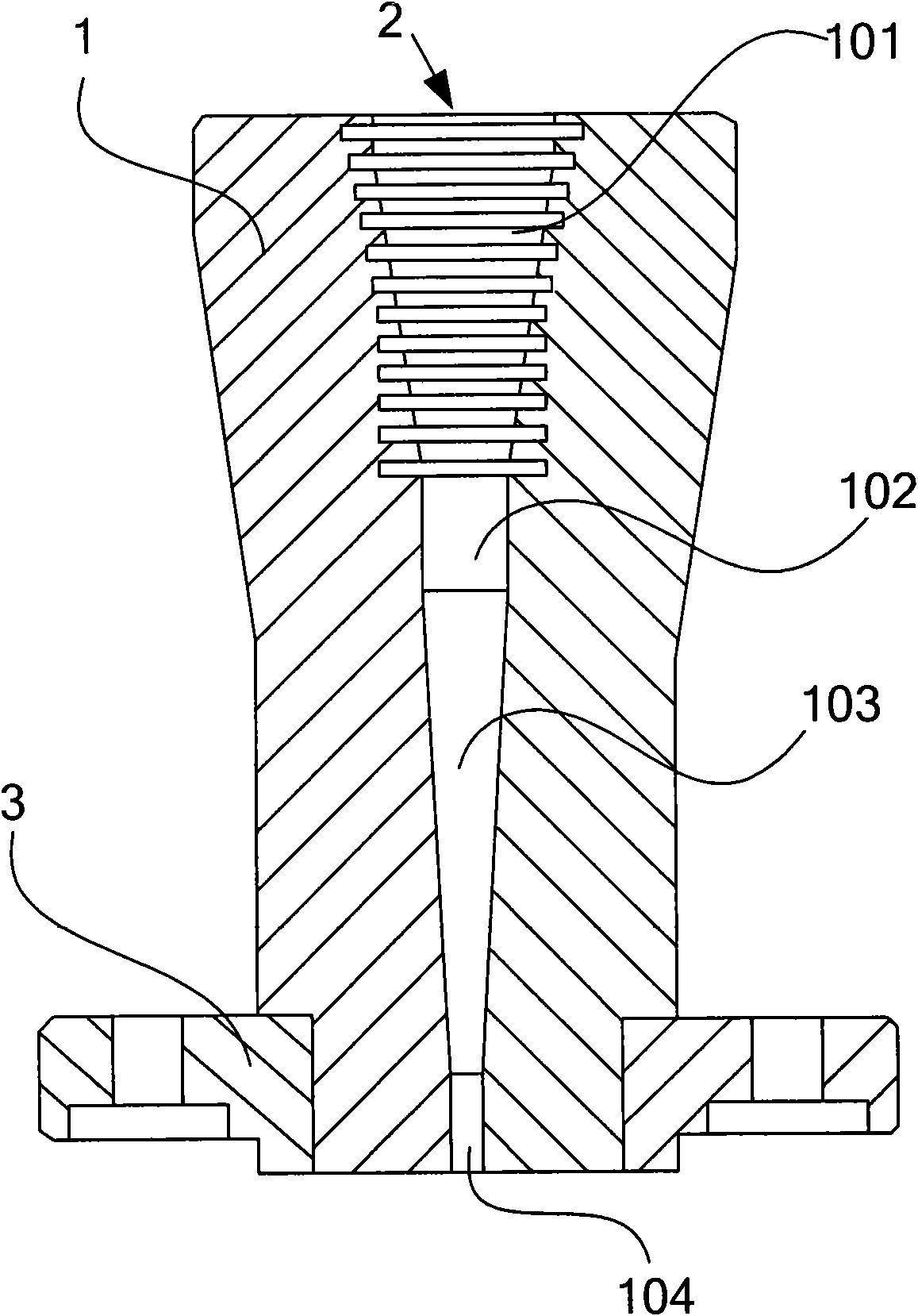

Method of manufacturing protruding-volute contact, contact made by the method, and inspection equipment or electronic equipment having the contact

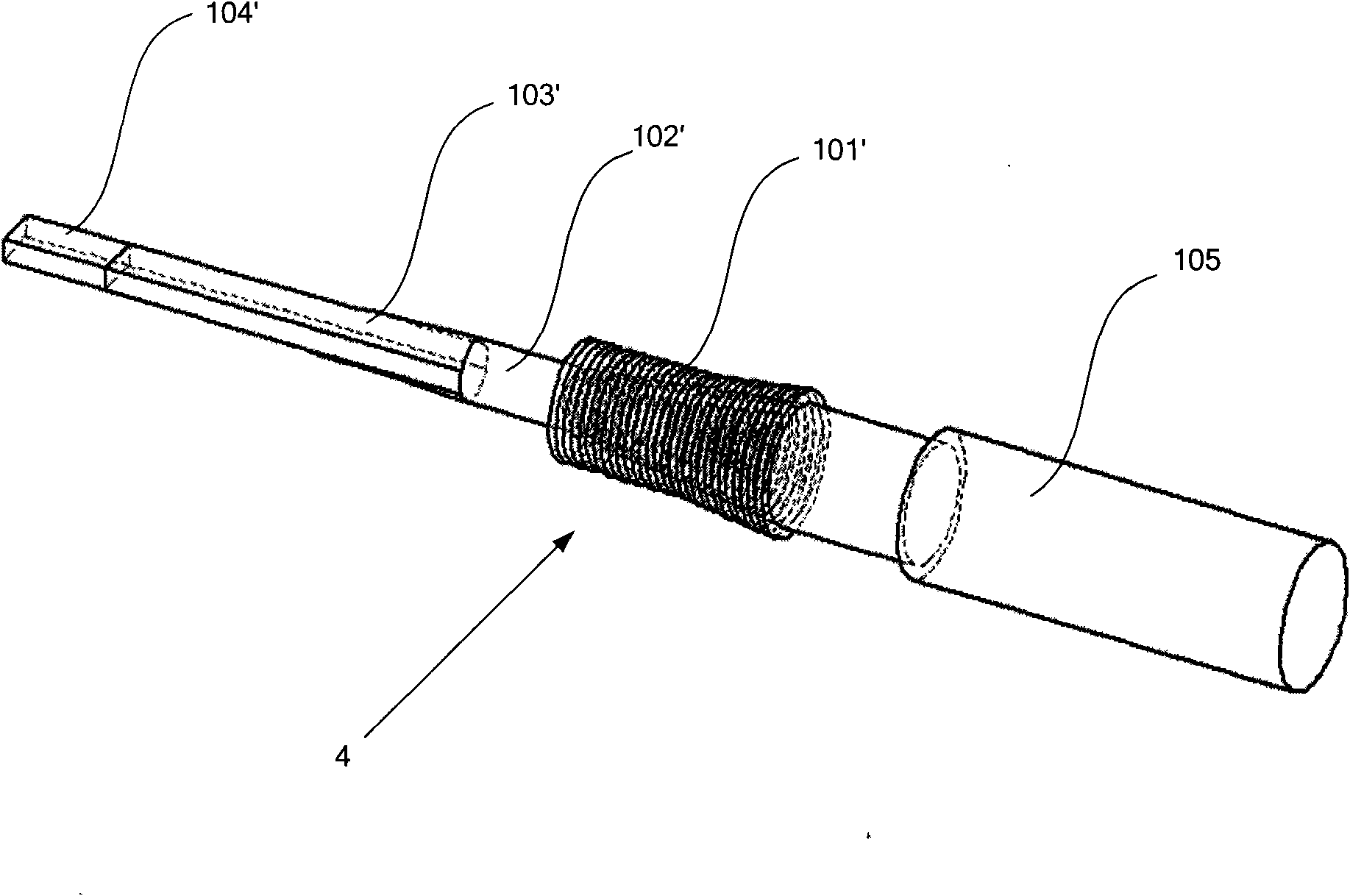

InactiveUS20050088193A1Low costImprove reliabilityContact member manufacturingManufacture of electrical instrumentsCouplingCoil spring

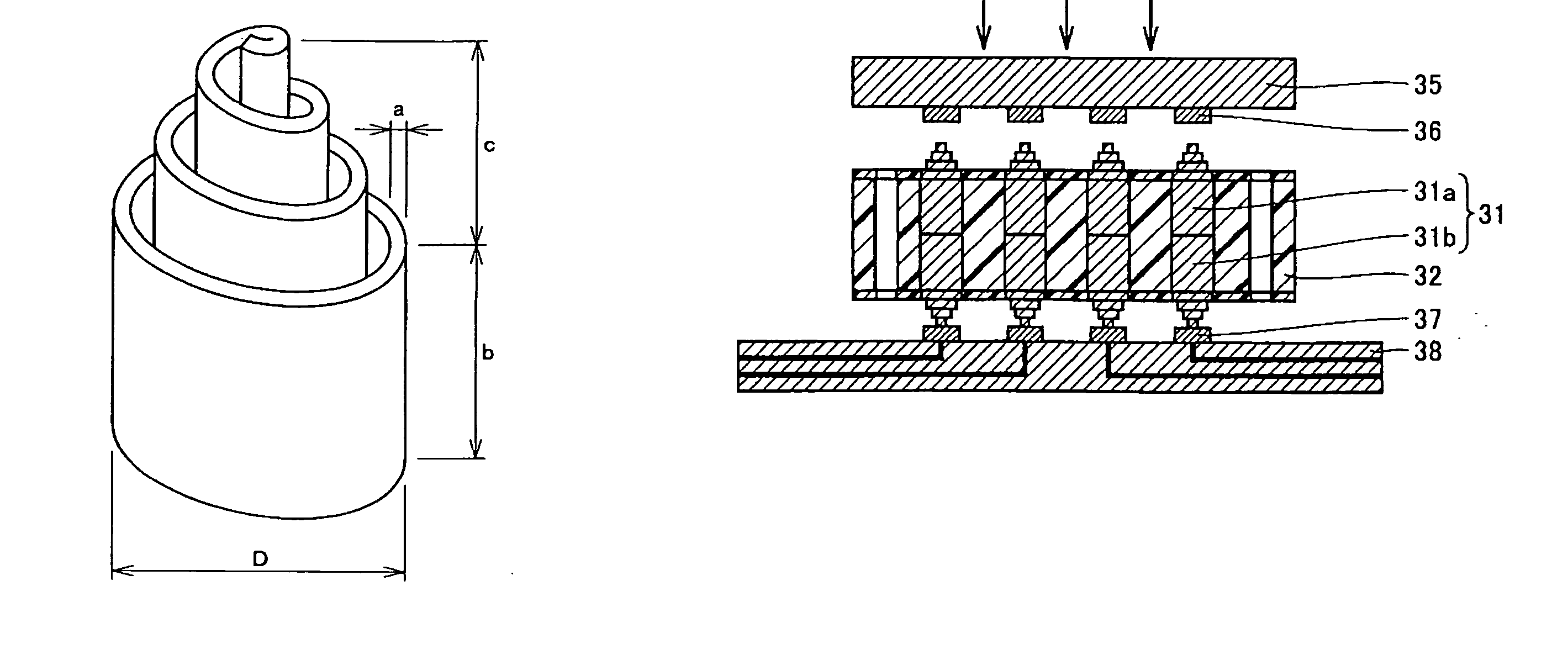

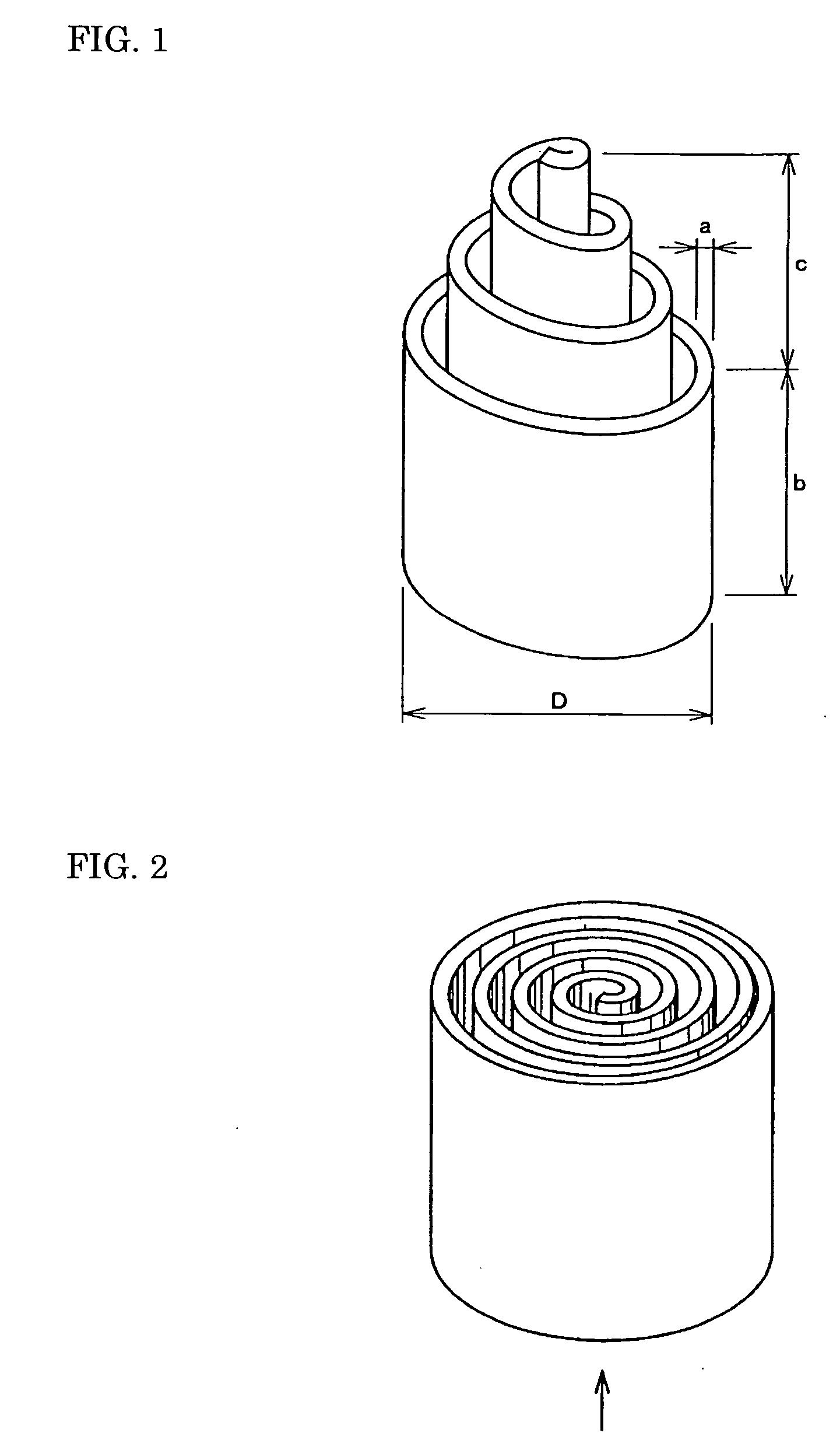

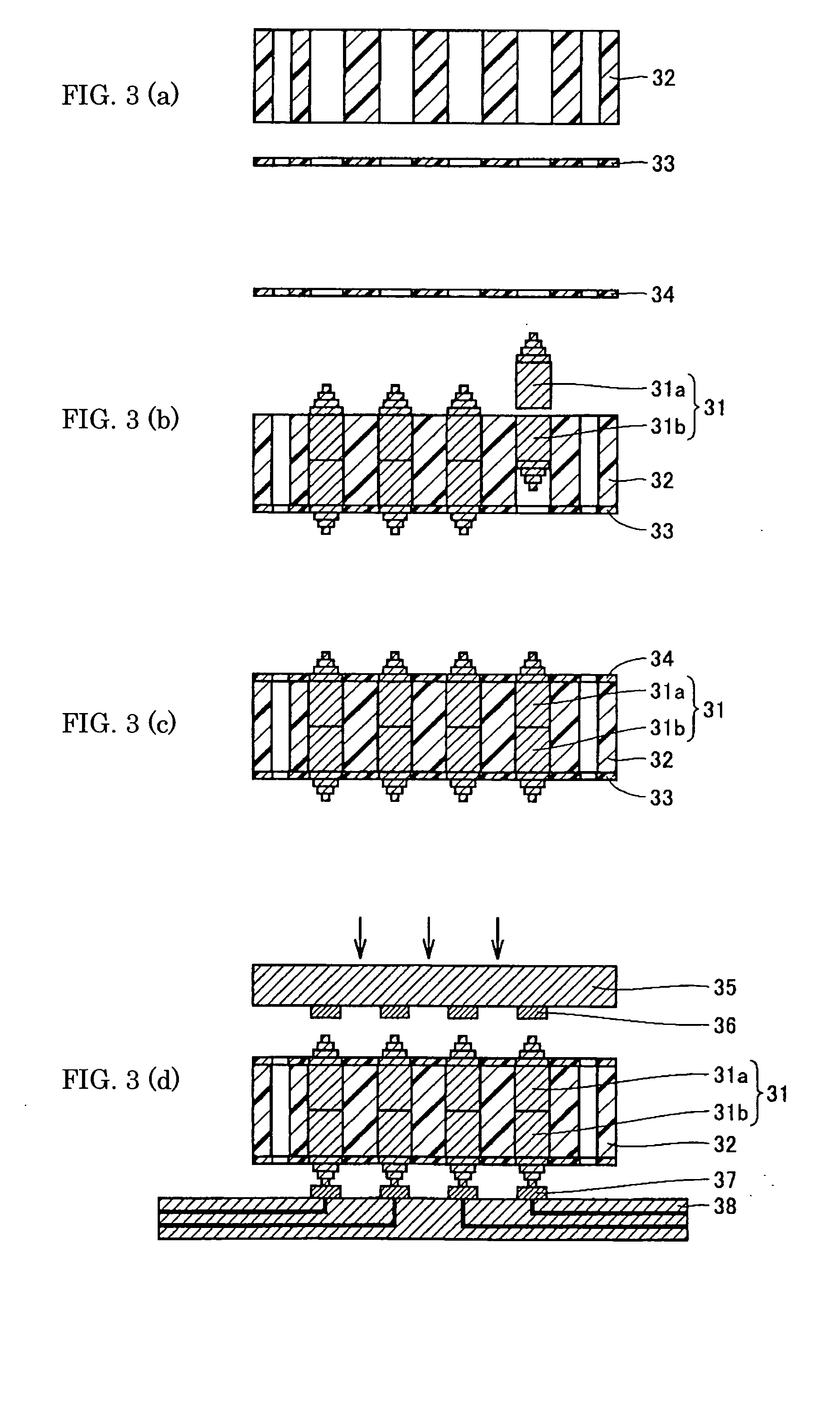

A method of manufacturing a protruding-volute contact for attaining electrical continuity with an electrode of electronic equipment or inspection equipment, the method comprising the steps of forming a plastic mold (resist structure) with a metal mold; forming a layer consisting of metallic material on the plastic mold (resist structure) by means of electroforming; and performing convex formation of a metal microstructure made from the layer consisting of metallic material so as to form a spiral spring that protrudes volutedly outward. With such method, an inspection contact or coupling contact having high reliability and capable of attaining electrical continuity of large electric current can be produced at low cost.

Owner:SUMITOMO ELECTRIC IND LTD

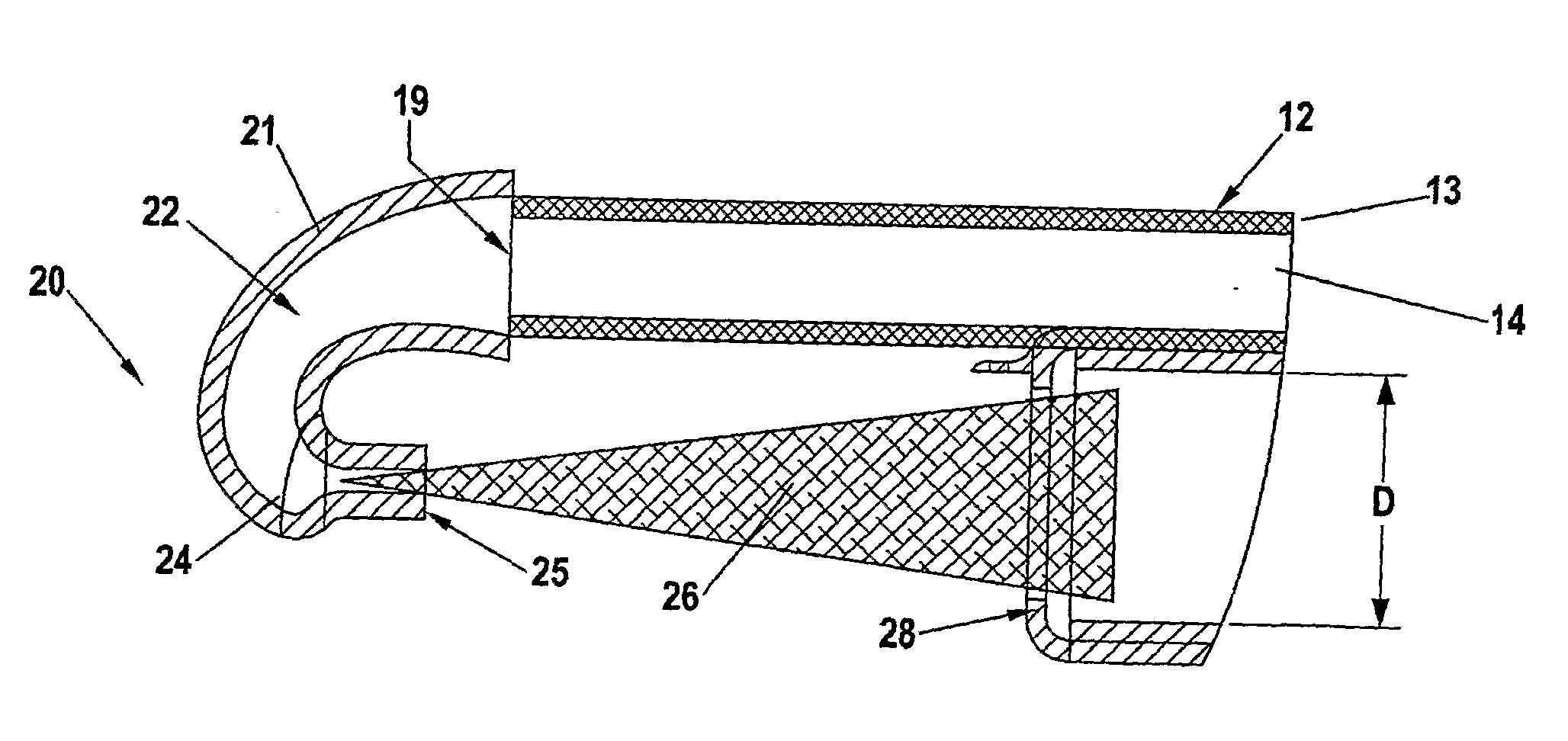

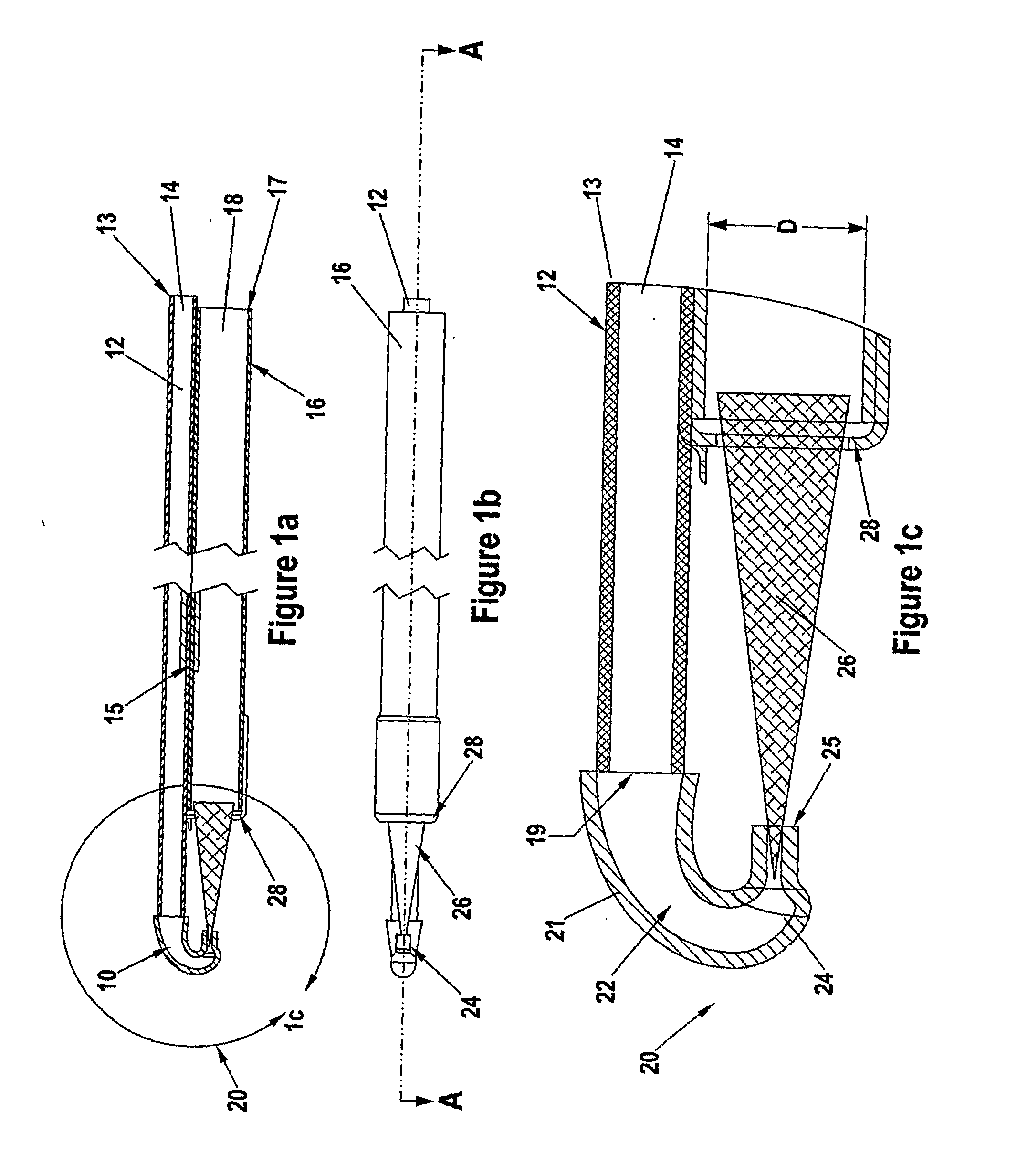

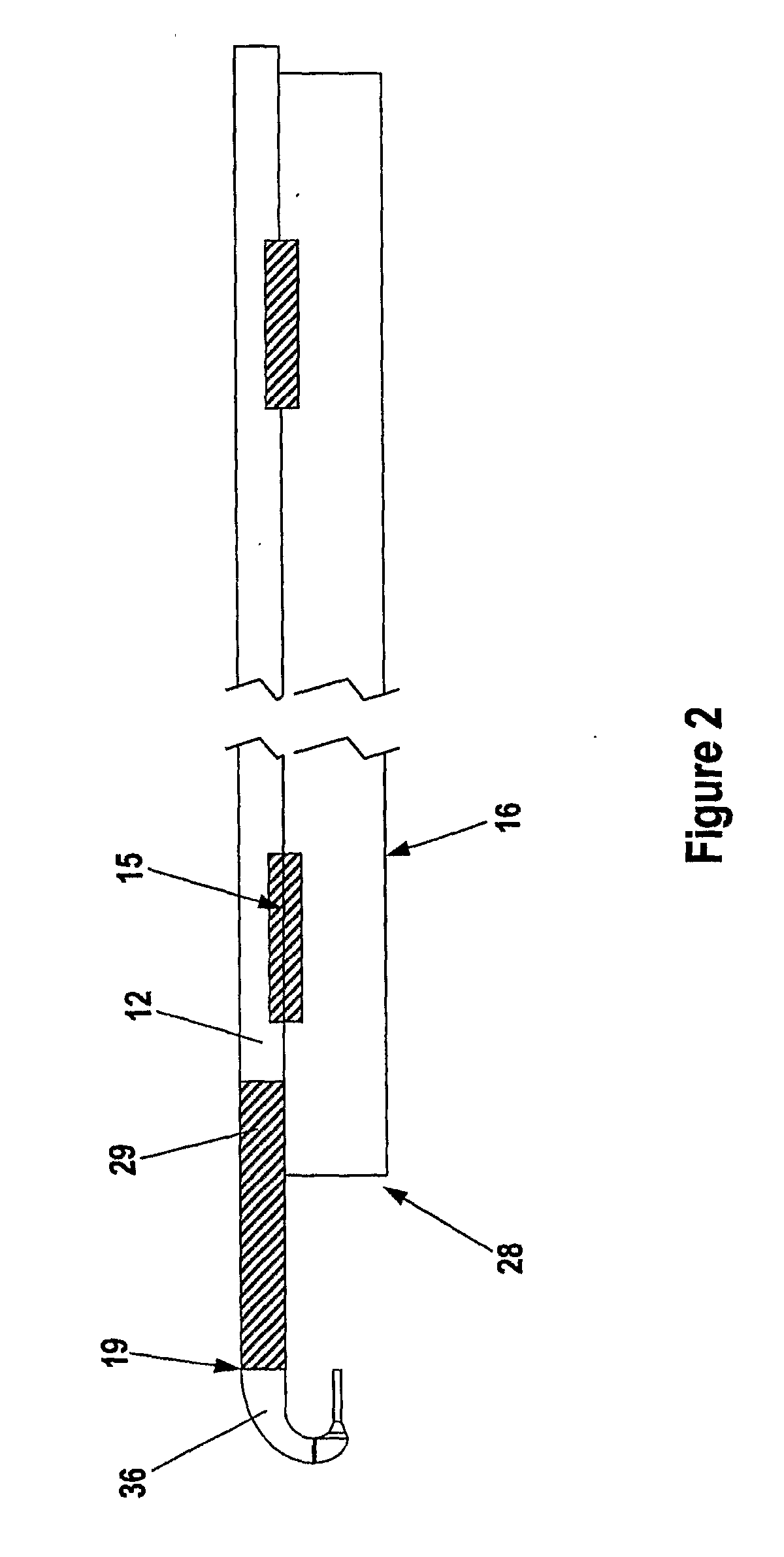

Electroformed liquid jet surgical instrument

InactiveUS20090306692A1Minimize the numberMinimize complexityMedical devicesSurgical instrument detailsLiquid jetEngineering

Certain embodiments of the invention provide a variety of methods of manufacturing a liquid jet-forming surgical instrument. According to these methods, a nozzle assembly of the instrument is electroformed on a mandrel. The nozzle assembly includes a nozzle providing a jet-opening, wherein the nozzle is shaped to form a liquid jet. In some embodiments, the mandrel includes a first mandrel portion and a second mandrel portion. Once the nozzle assembly is formed, the mandrel may be removed from the nozzle assembly. The nozzle assembly may in certain embodiments be coupled to an outlet of the pressure tube. In certain embodiments, an inlet of an evacuation tube is positioned such that a jet-receiving opening of the evacuation tube is positioned opposite the jet-opening of the nozzle.

Owner:HYDROCISION

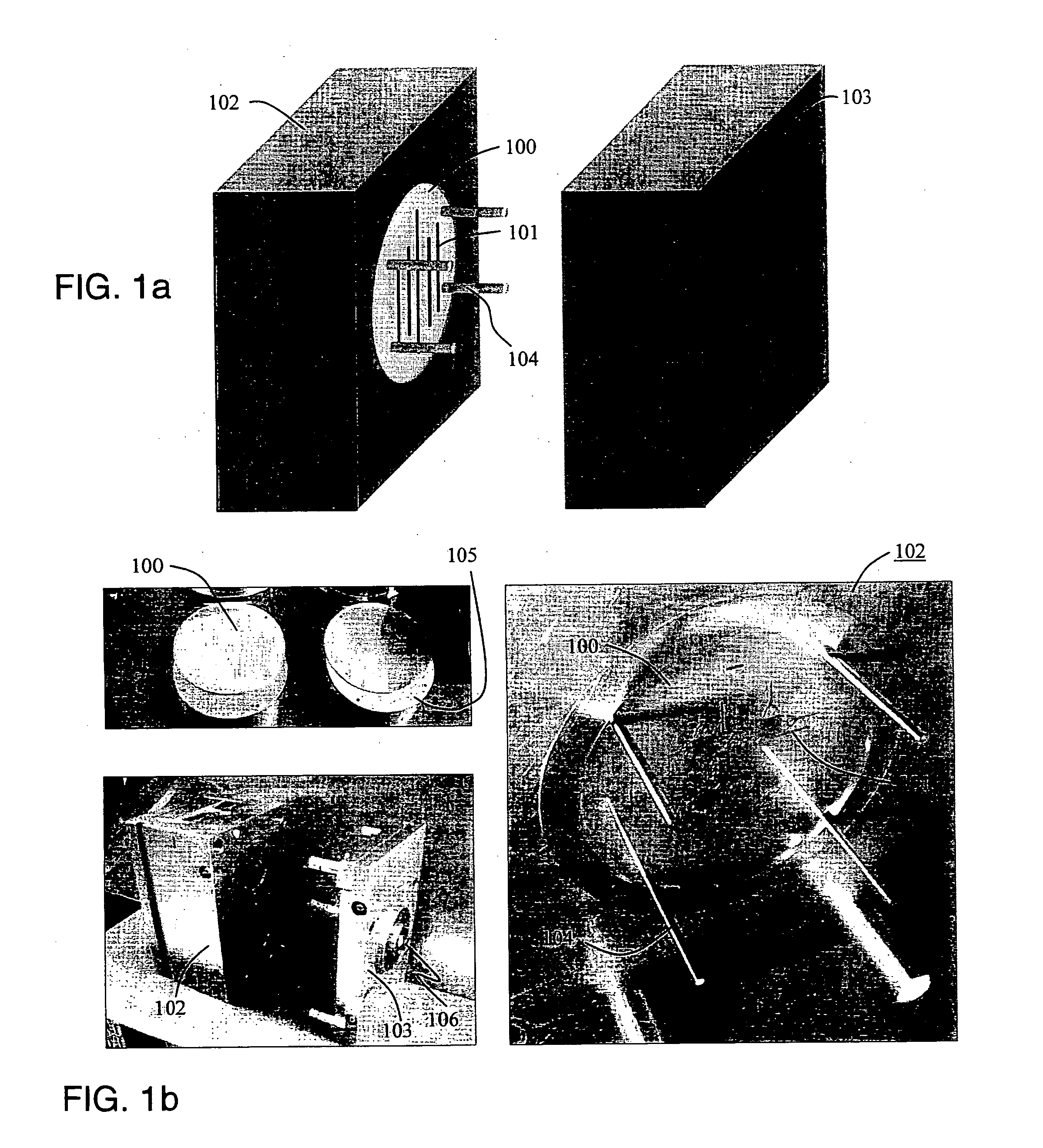

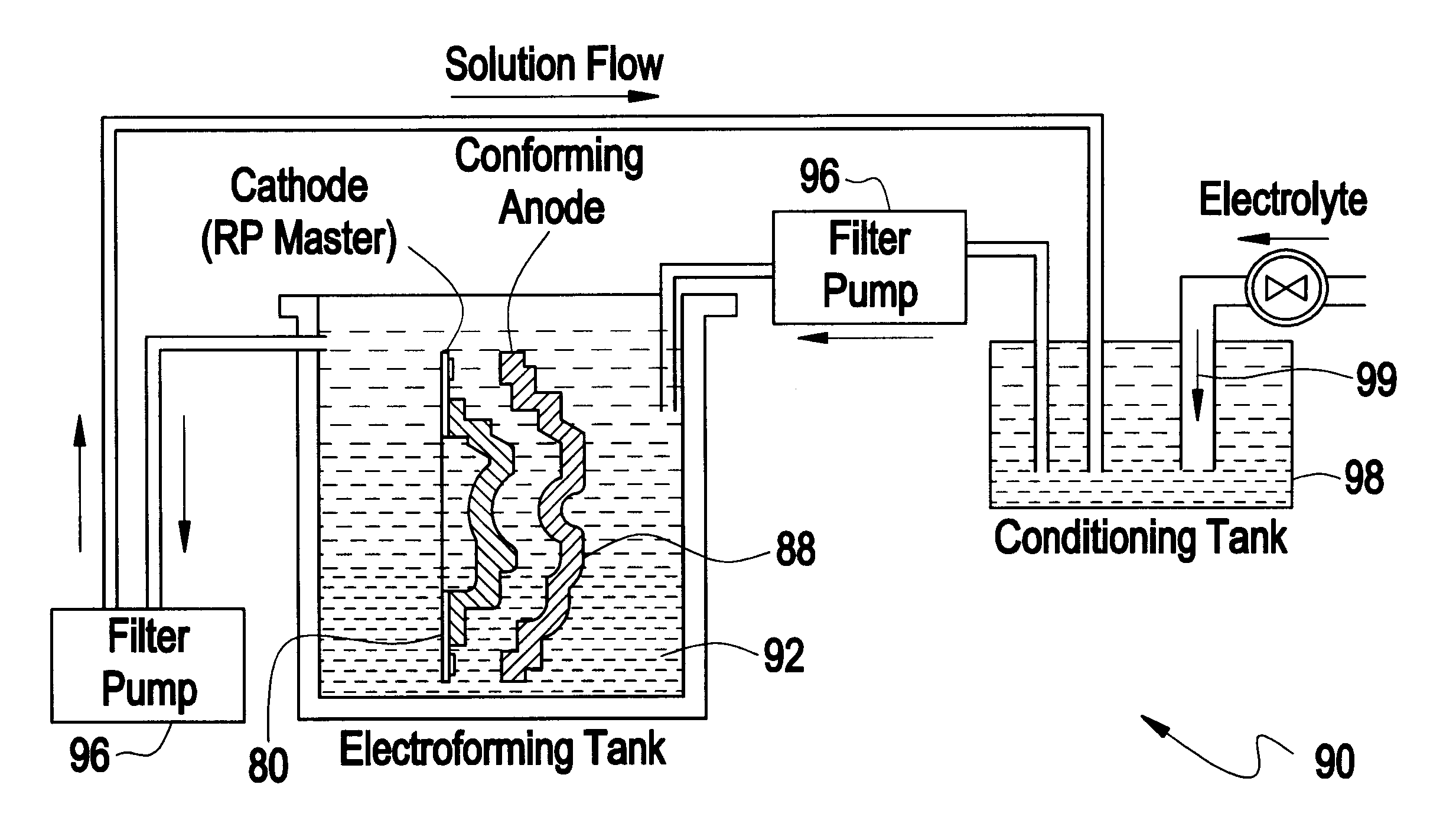

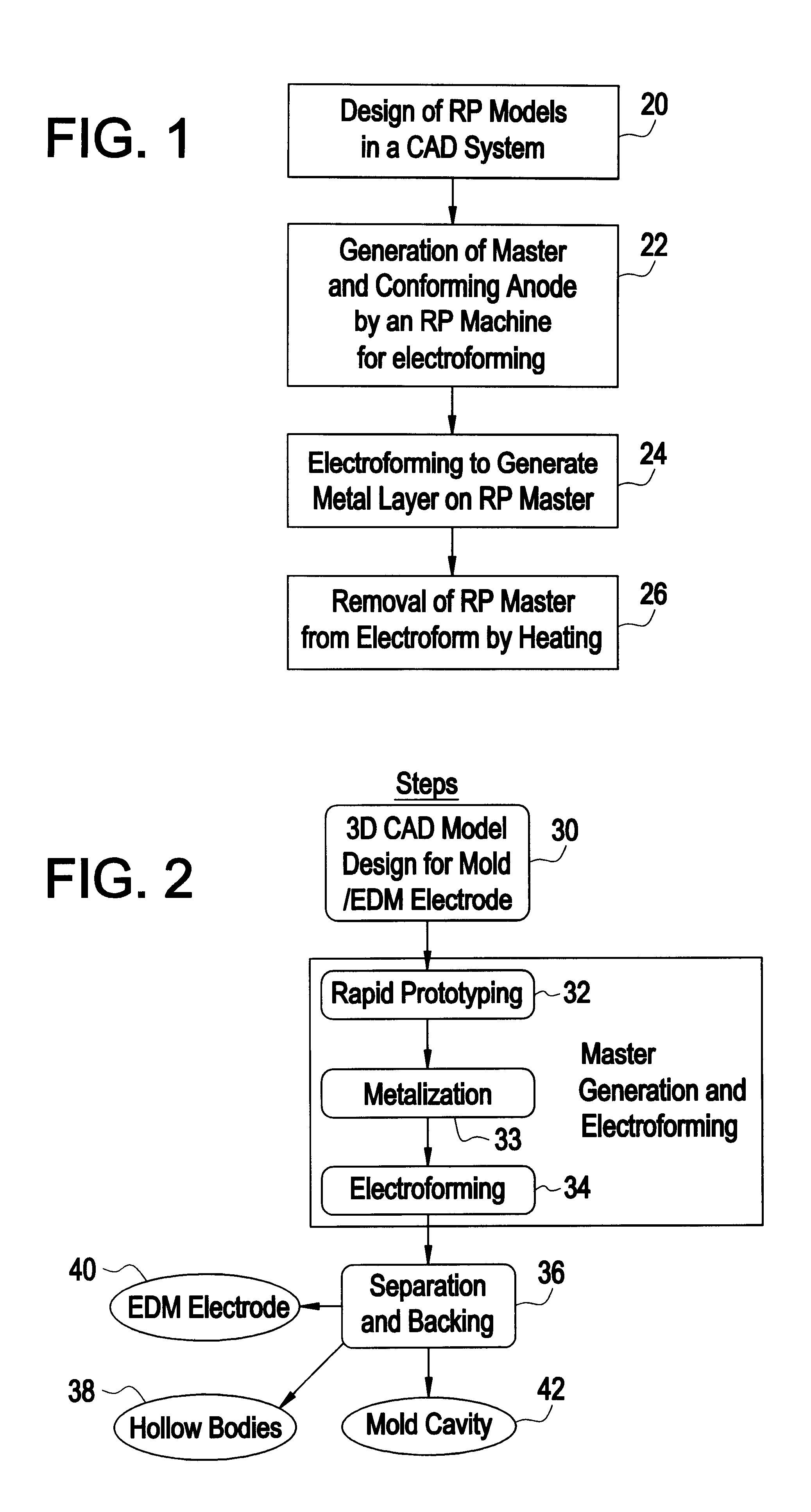

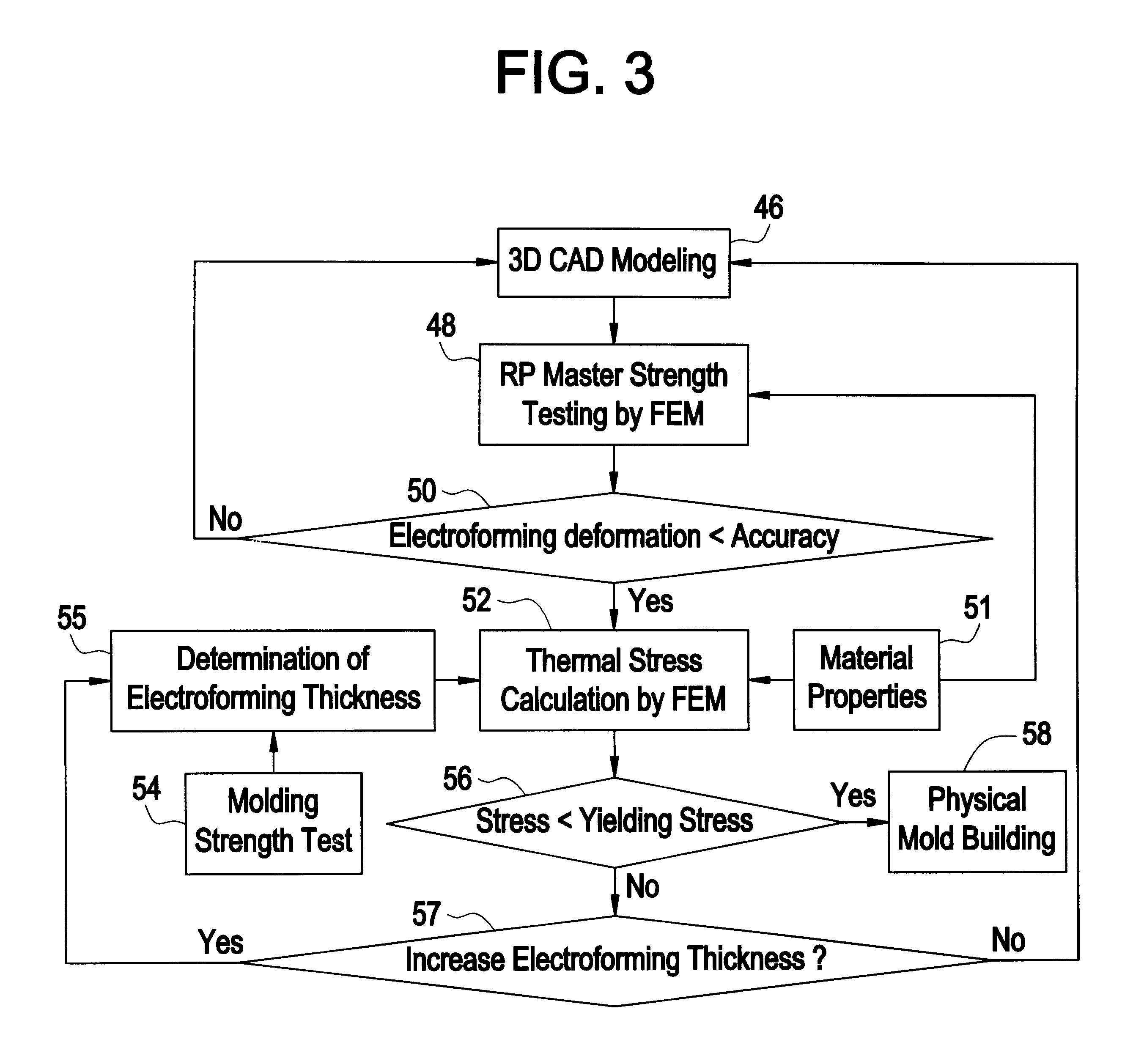

Rapid production of engineering tools and hollow bodies by integration of electroforming and solid freeform fabrication

InactiveUS6409902B1Stay in shapeAvoid insufficient thicknessAdditive manufacturing apparatusFoundry mouldsElectrolysisElement analysis

This invention describes a rapid tooling process that integrates solid freeform fabrication (SFF) with electroforming to produce metal tools including molds, dies, and electrical discharge machining (EDM) electrodes. An SFF part is metalized by electroless plating and then placed in an electroplating solution, where metal is deposited upon the part by electrolysis. When the desired thickness of metal has been reached, the SFF part is removed from the metal shell. The shell is then optionally backed with other materials to form a mold cavity, and EDM electrode, or other desired parts for tooling. Thermomechanical modeling and numerical simulation with finite element analysis (FEA) is used to determine the geometry of the SFF part and the electroform thickness for minimizing the manufacturing time and cost while satisfy the tooling requirement.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

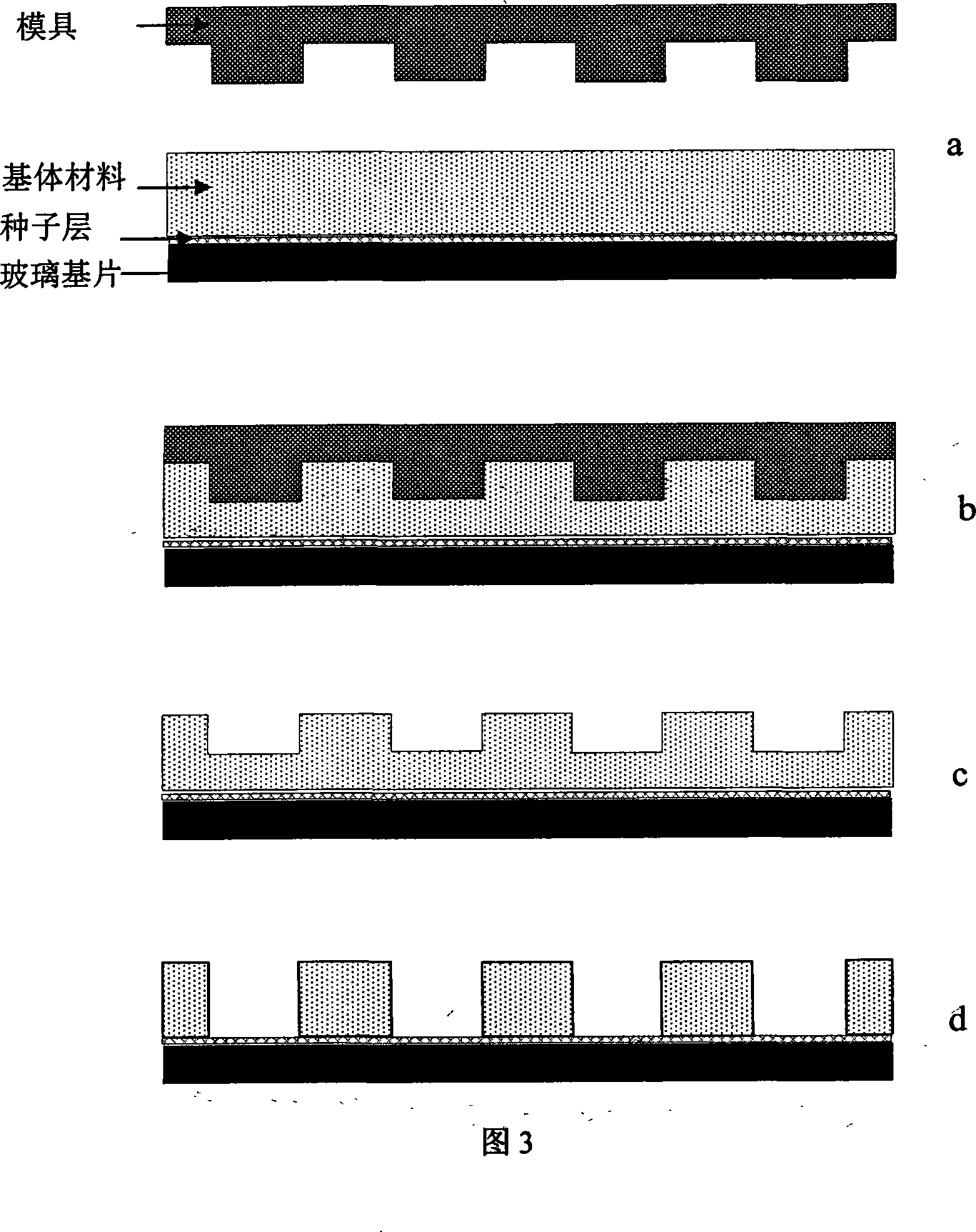

Minitype metal nickel mould producing method

InactiveCN101205054ASimple preparation processReduce manufacturing costDecorative surface effectsChemical vapor deposition coatingUltravioletElectron

The invention discloses a method for making a micro metal nickel mold. By adopting ultraviolet nano-imprint lithography and micro electroforming composite technology, the invention comprises the following basic technique flow: (1) a mother blank is lithographed by electron direct lithographing and dry etching; (2) a piece of glass taken as a substrate is cleaned and baked, with surface pretreated; (3) a Cr / Cu electroforming seed layer with a thickness of 90-110nm is sputtered on the glass substrate; (4) by taking the mother blank made by the step (1) as an imprint plate, a mold cavity microstructure is copied on ultraviolet organic light-cured substrate material by using a UV nano-imprint lithography technique; (5) a Cr / Cu or Au / Ti electroforming seed layer with a thickness of 8-12nm is deposited on the substrate material; (6) nickel with a depositional thickness of 300-500Mum is electroformed on the seed layer of the substrate material; (7) a metal backing is added; (8) after knockout, the metal nickel mold is obtained. The method has the advantages of low producing cost, simple technique and high producing effect, and can realize batch fabrication of submicron and nano-micro metal nickel mold with low cost.

Owner:SHANDONG UNIV

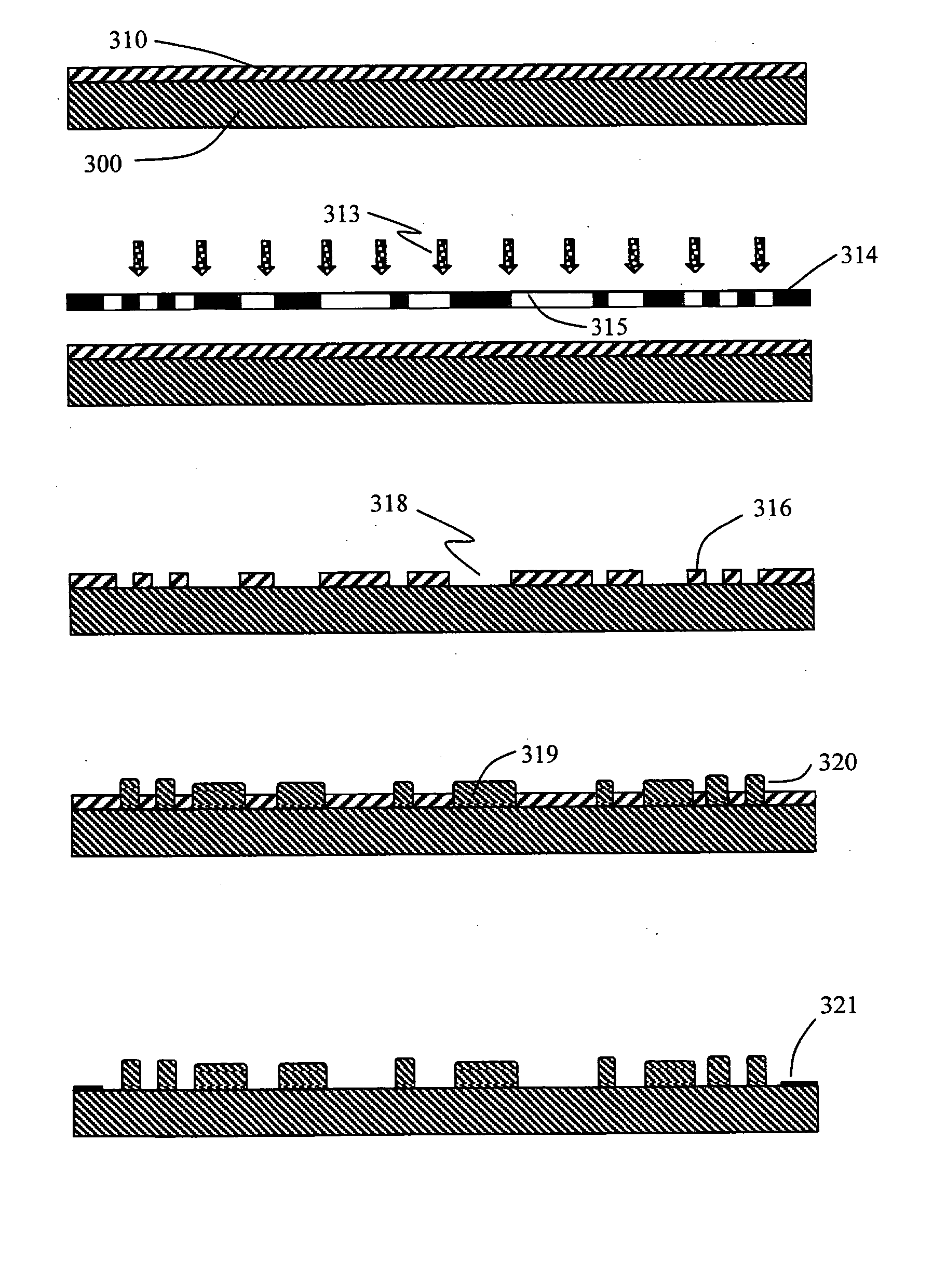

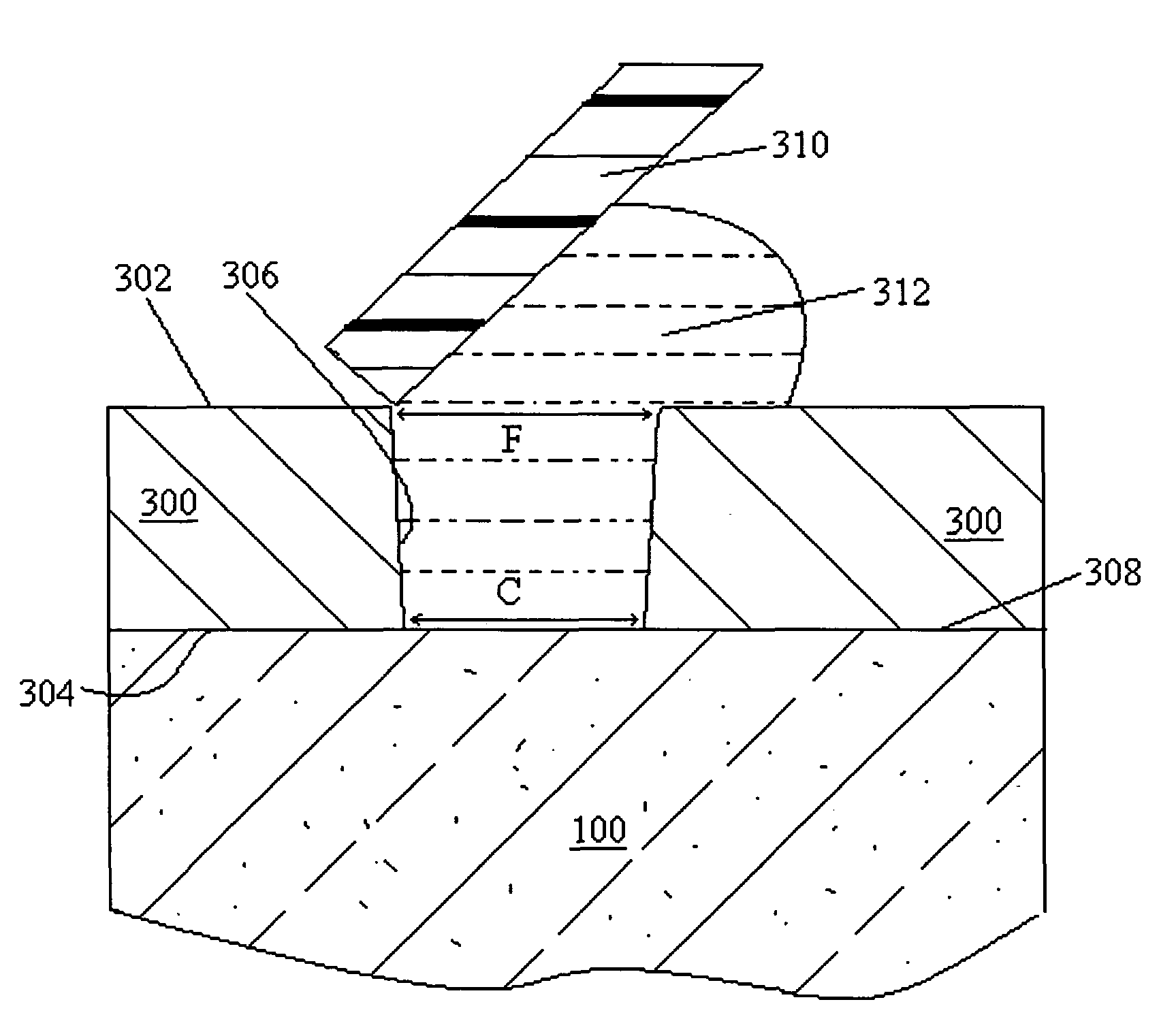

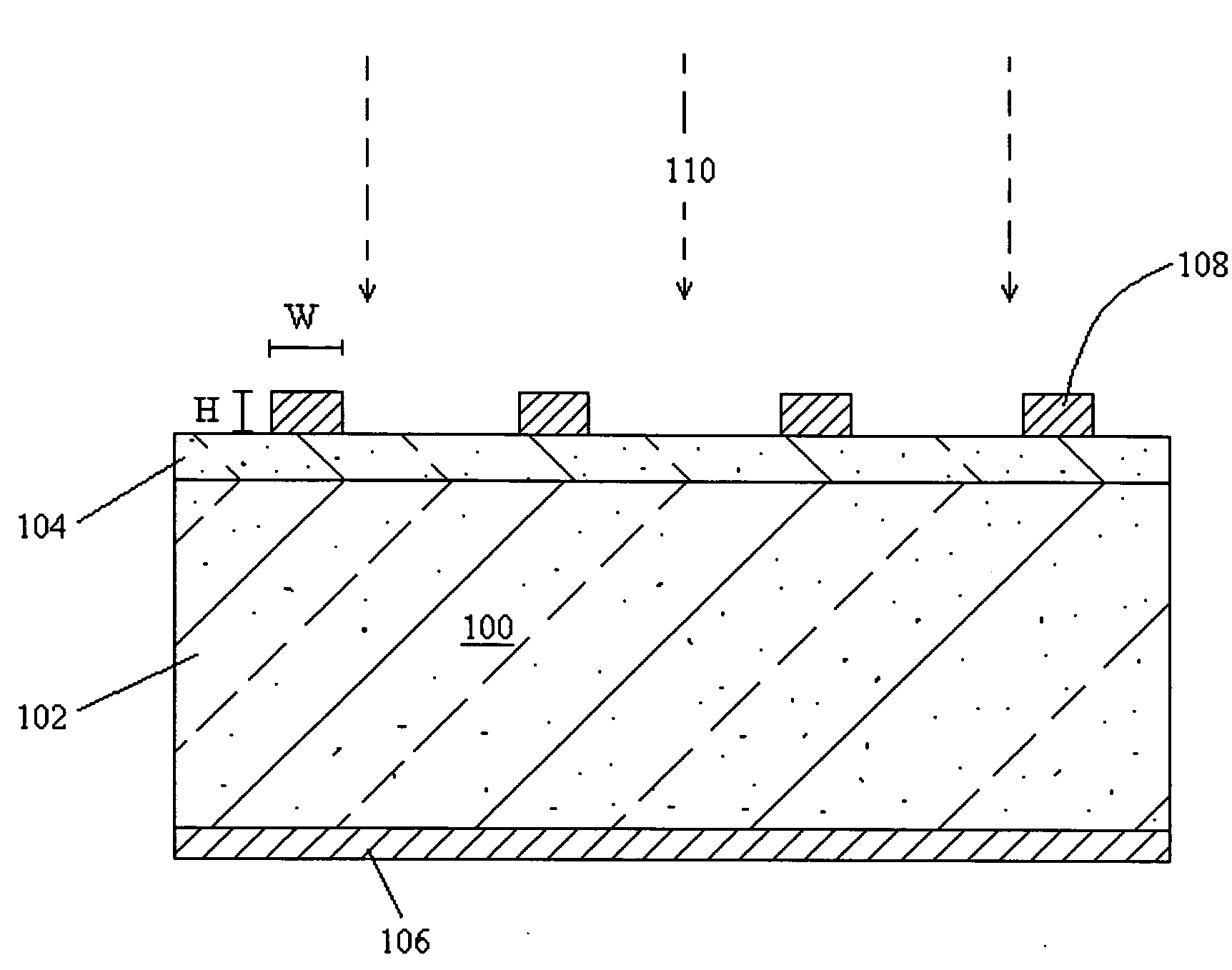

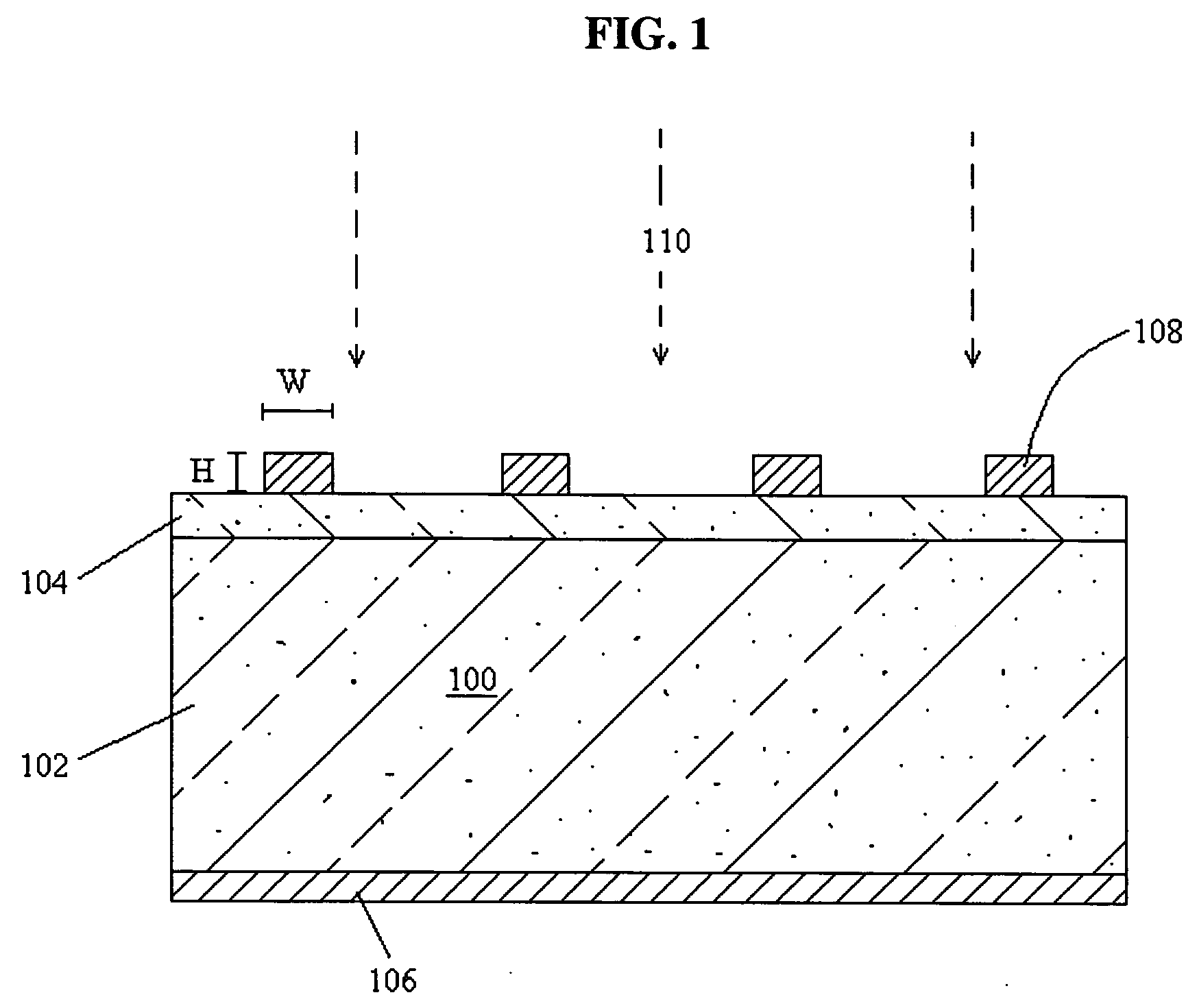

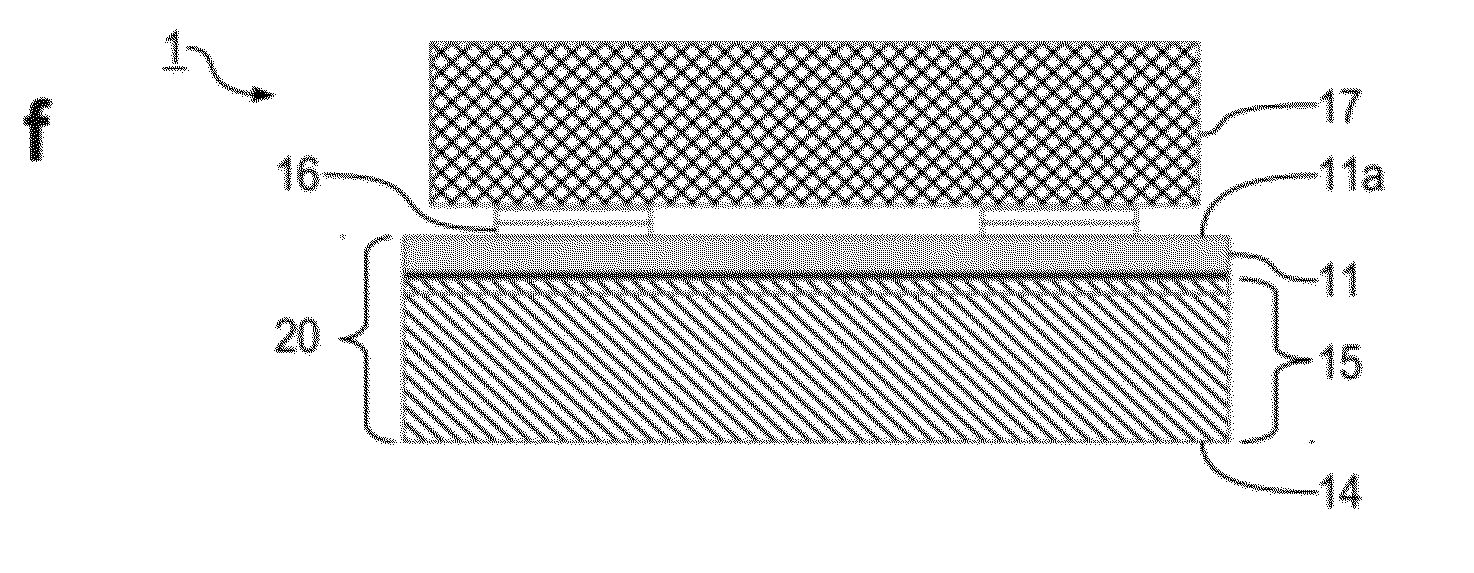

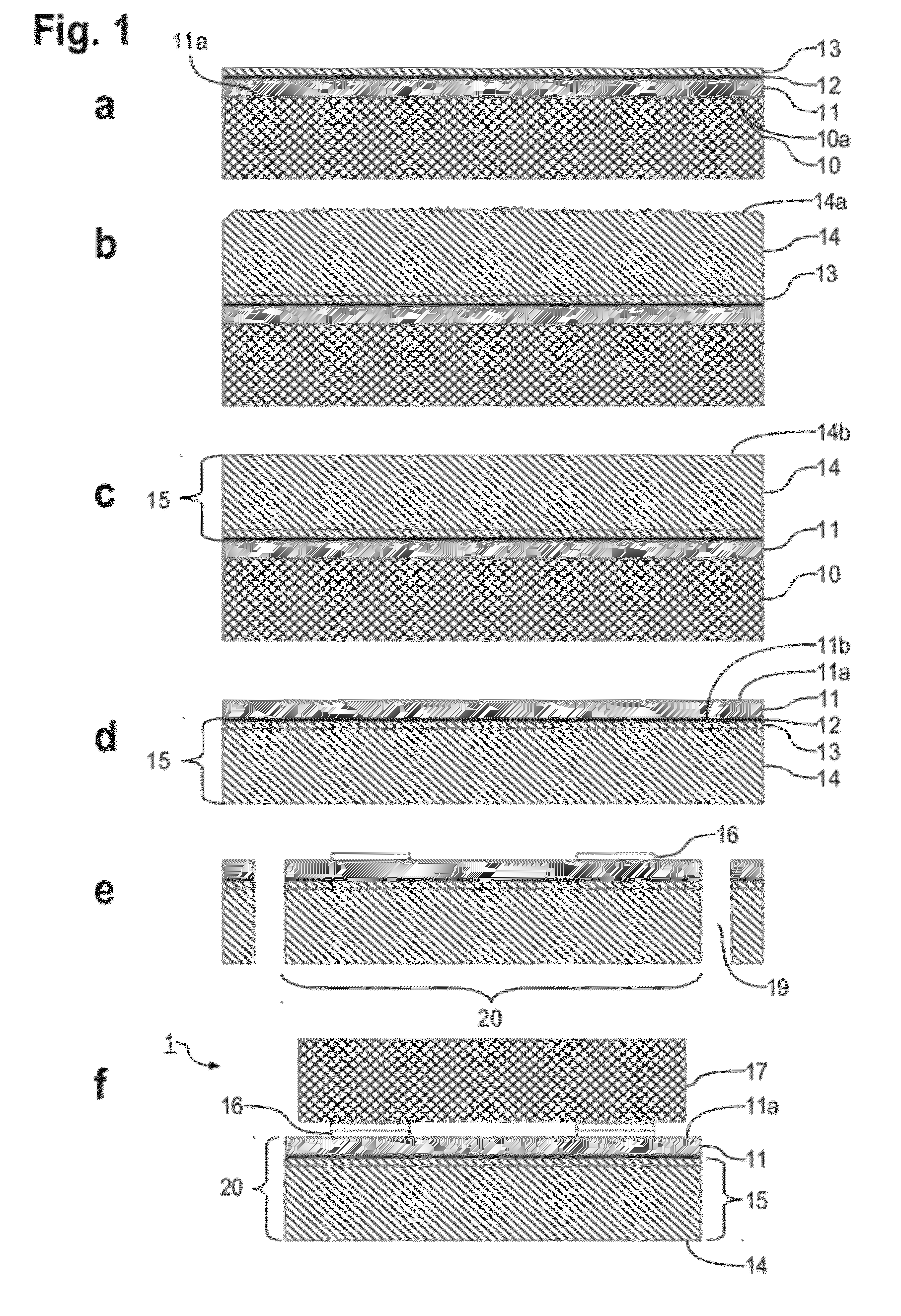

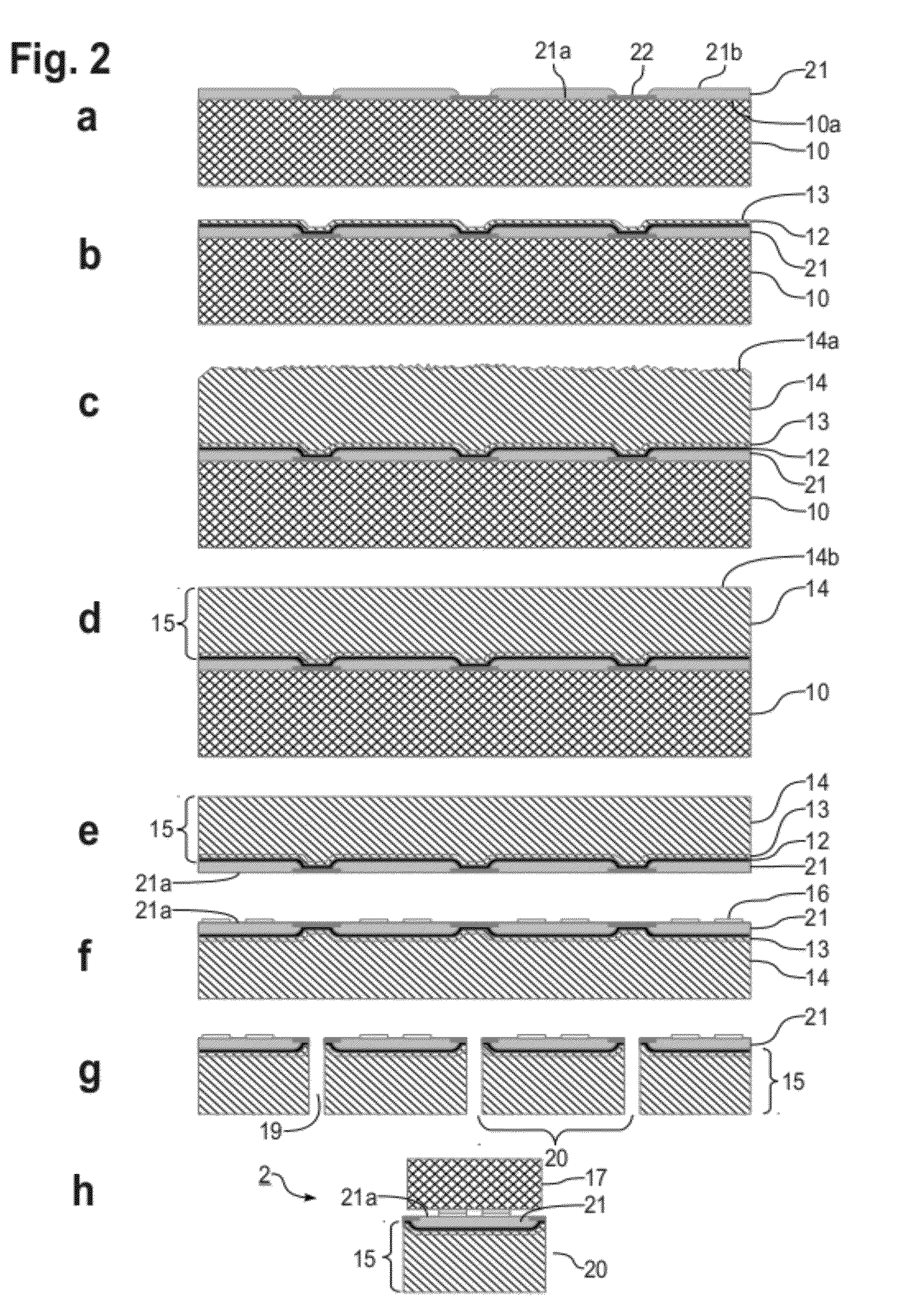

Electroformed stencils for solar cell front side metallization

A method for providing metallization upon a semiconductor substrate utilizing a stencil having at least one aperture extending from the contact side to the fill side, the contact side of the stencil being substantially flat and forming a sharp edge with a wall of the at least one aperture, the at least one aperture being tapered such that an area of a cross-section of the at least one aperture at the fill side is larger than an area of the cross-section of the at least one aperture at the contact side. A method of forming a stencil for depositing metallization lines on a semiconductor substrate is also disclosed.

Owner:FRY S METALS INC

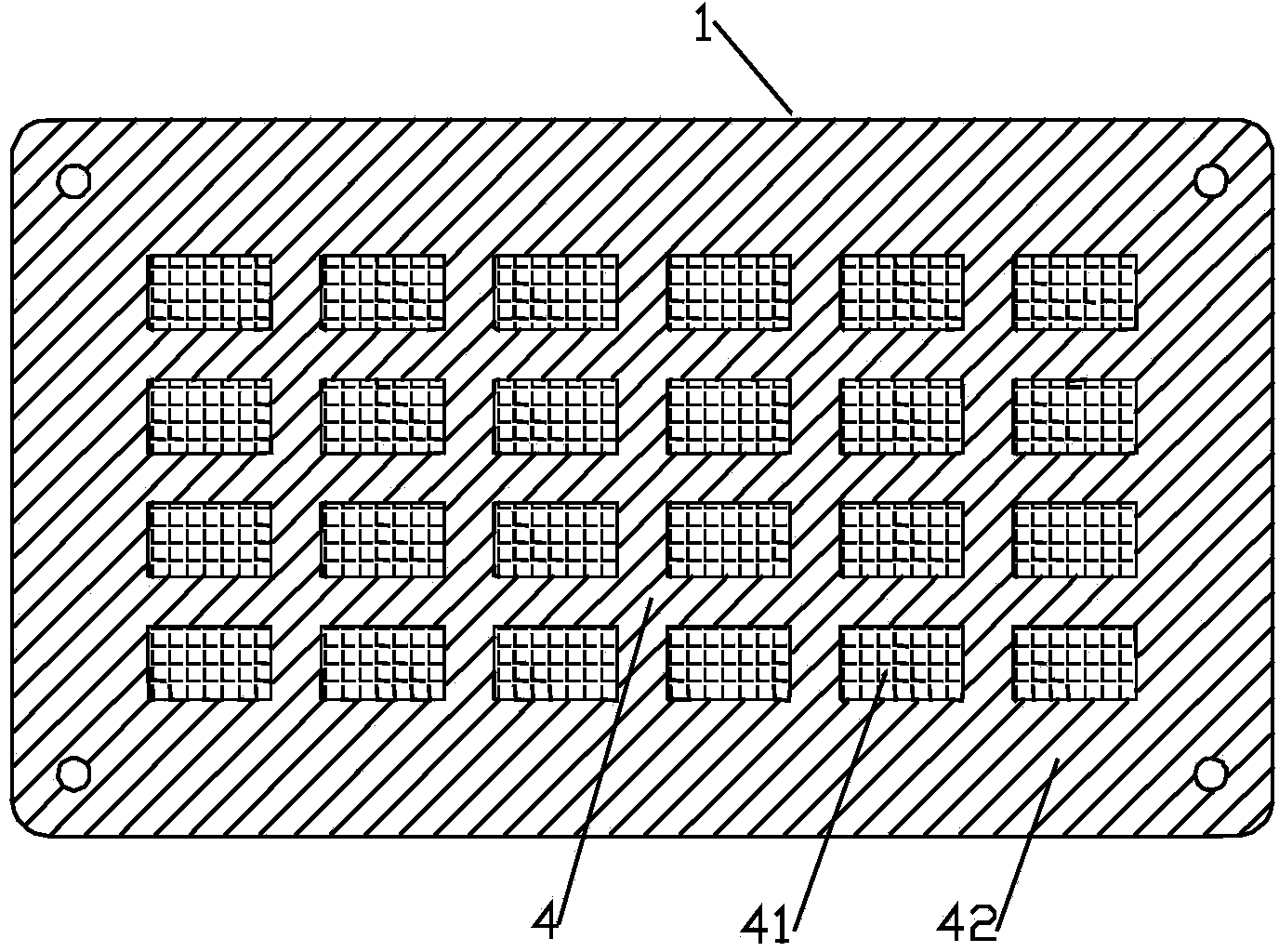

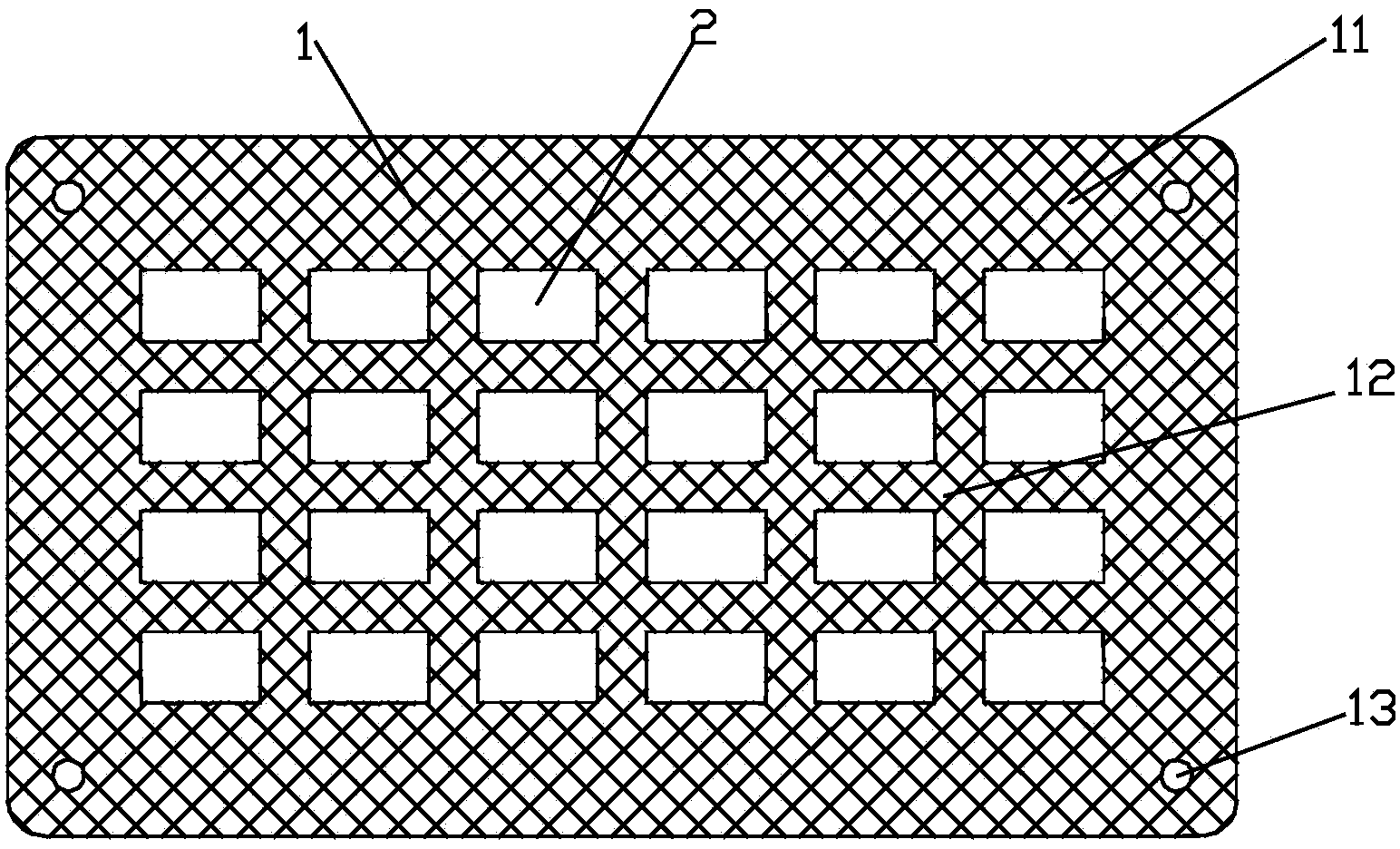

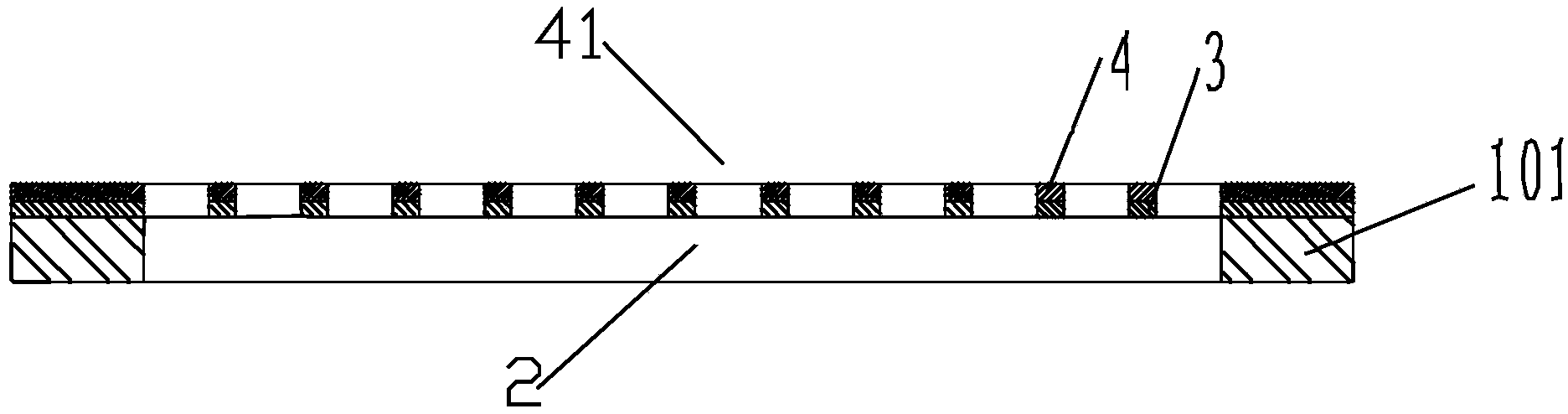

Novel fine metal mask plate for producing organic light emitting diode (OLED) display panel and fabrication method of novel fine metal mask plate

ActiveCN103451598AHigh strengthSave the process of welding to the frameVacuum evaporation coatingPhotomechanical apparatusInvar alloyFine structure

The invention discloses a novel fine metal mask plate for producing an organic light emitting diode (OLED) display panel and a fabrication method of the novel fine metal mask plate. The novel fine metal mask plate comprises a border formed by a plurality of through holes formed in a metal substrate, wherein a layer of fine mask is electroformed on the upper surface of the border, so that the fine mask and the border are combined into a whole; the fine mask divides a pattern area and a border area, on which a part with a fine structure is formed; the through holes in the pattern area and the border correspond to each other. The fabrication method comprises the following steps: A, preparing the metal substrate, namely carrying out rough shape cutting on an invar alloy plate or a stainless steel plate, so as to accord with the design size and form the metal substrate; B, fabricating the fine mask, namely coating a photoresist layer on the metal substrate, developing required patterns on the photoresist layer on the metal substrate, and orderly electroforming a metal substrate layer and a metal layer with a low coefficient of thermal expansion, so as to form the fine mask of the mask plate; and C, etching the substrate, namely dividing the pattern area on the refine mask, etching off the metal substrate in a district corresponding to the back part of the pattern area by a chemical etching method, so as to form the through holes, and leaving an external border and an internal partition frame, so that the external border and the internal partition frame jointly support the fine mask.

Owner:ZHONGSHAN XINNUO MICROELECTRONICS CO LTD

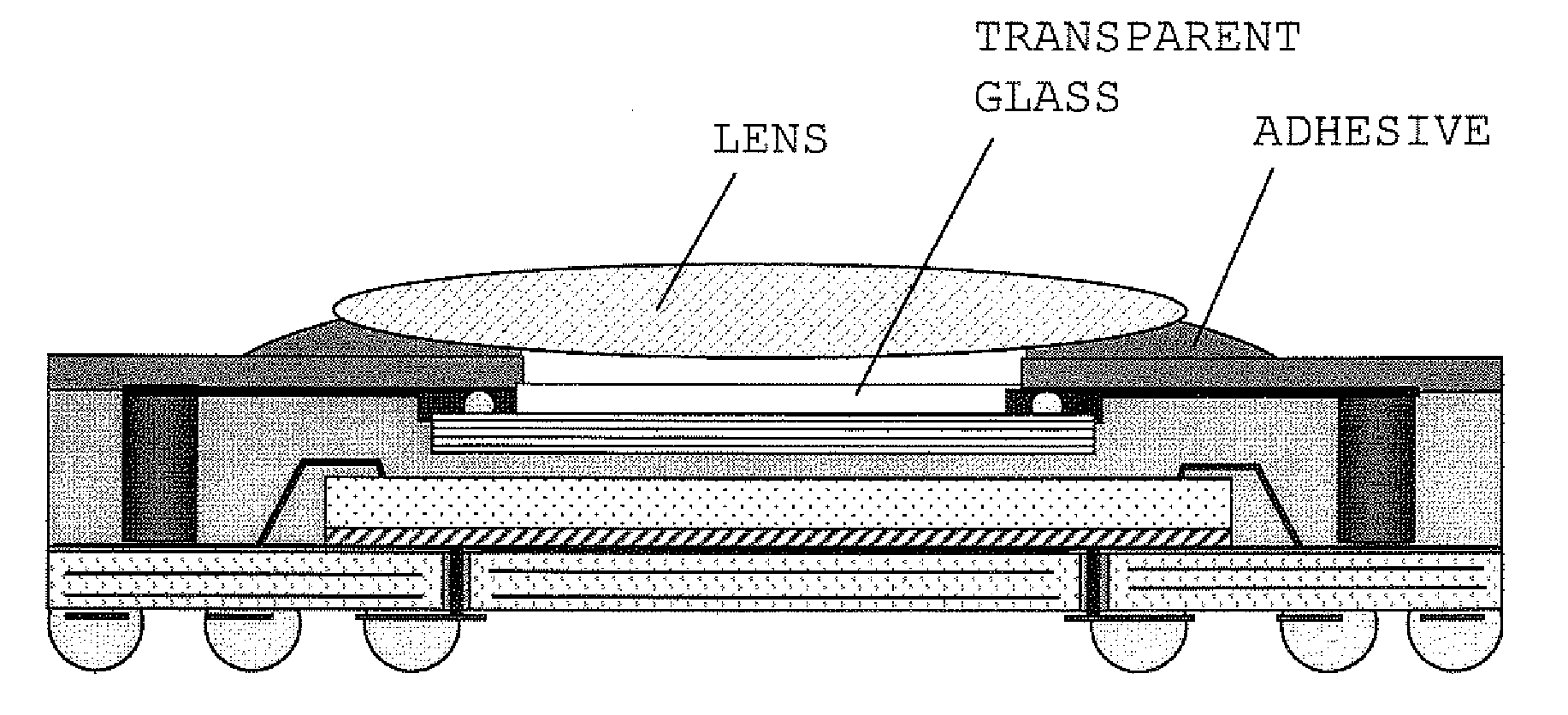

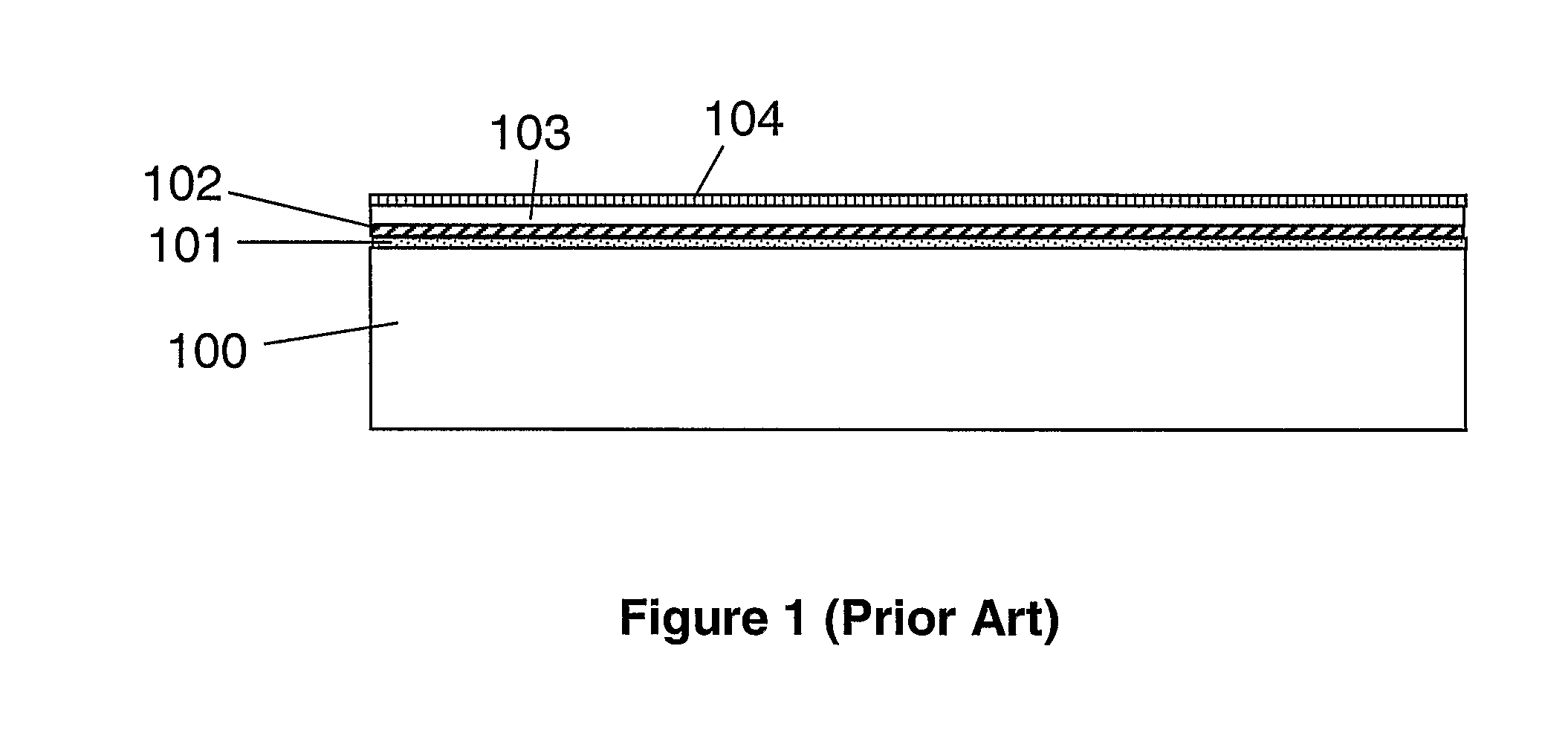

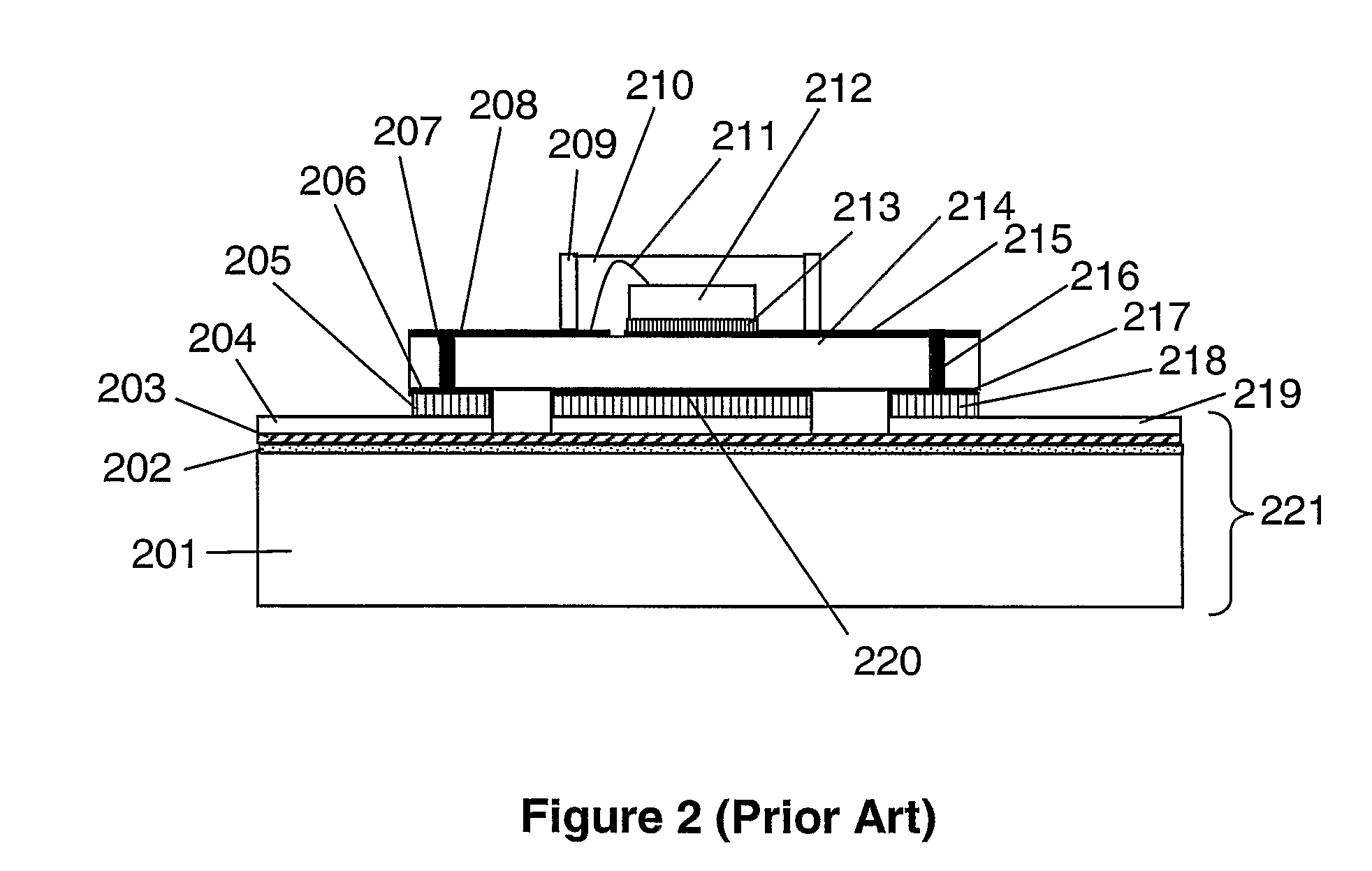

Ultra high thermal performance packaging for optoelectronics devices

ActiveUS8324633B2Thermal resistance minimizationReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesLight emitting deviceElectron

A light emitting module comprises a light emitting device (LED) mounted on a high thermal dissipation sub-mount, which performs the traditionally function of heat spread and the first part of the heat sinking. The sub-mount is a grown metal that is formed by an electroplating, electroforming, electrodeposition or electroless plating process, thereby minimizing thermal resistance at this stage. An electrically insulating and thermally conducting layer is at least partially disposed across the interface between the grown semiconductor layers of the light emitting device and the formed metal layers of the sub-mount to further improve the electrical isolation of the light emitting device from the grown sub-mount. The top surface of the LED is protected from electroplating or electroforming by a wax or polymer or other removable material on a temporary substrate, mold or mandrel, which can be removed after plating, thereby releasing the LED module for subsequent processing.

Owner:LUMILEDS HLDG BV

Process for fabricating a monolayer or multilayer metal structure in LIGA technology, and structure obtained

ActiveCN101038440AImprove qualityEasy thickness controlSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistIon bombardment

The invention relates to a process for fabricating a monolayer or multilayer metal structure in LIGA technology, in which a photoresist layer is deposited on a flat metal substrate, a photoresist mold is created by irradiation or electron or ion bombardment, a metal or alloy is electroplated in this mold, the electroformed metal structure is detached from the substrate and the photoresist is separated from this metal structure, wherein the metal substrate is used as an agent involved in the forming of at least one surface of the metal structure other than that formed by the plane surface of the substrate.

Owner:ROLEX SA

Large area periodic array three-dimensional microstructure preparation method

InactiveCN101101441ASimple preparation processReduce manufacturing costSemi-permeable membranesDecorative surface effectsThree dimensional microstructureSilicon rubber

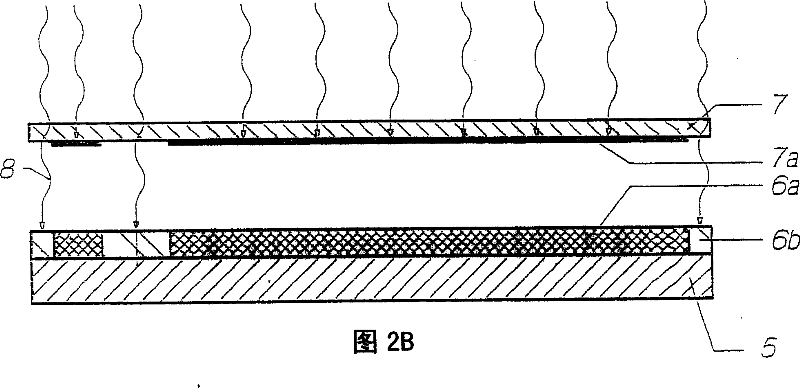

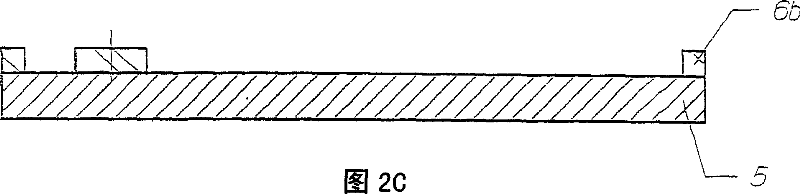

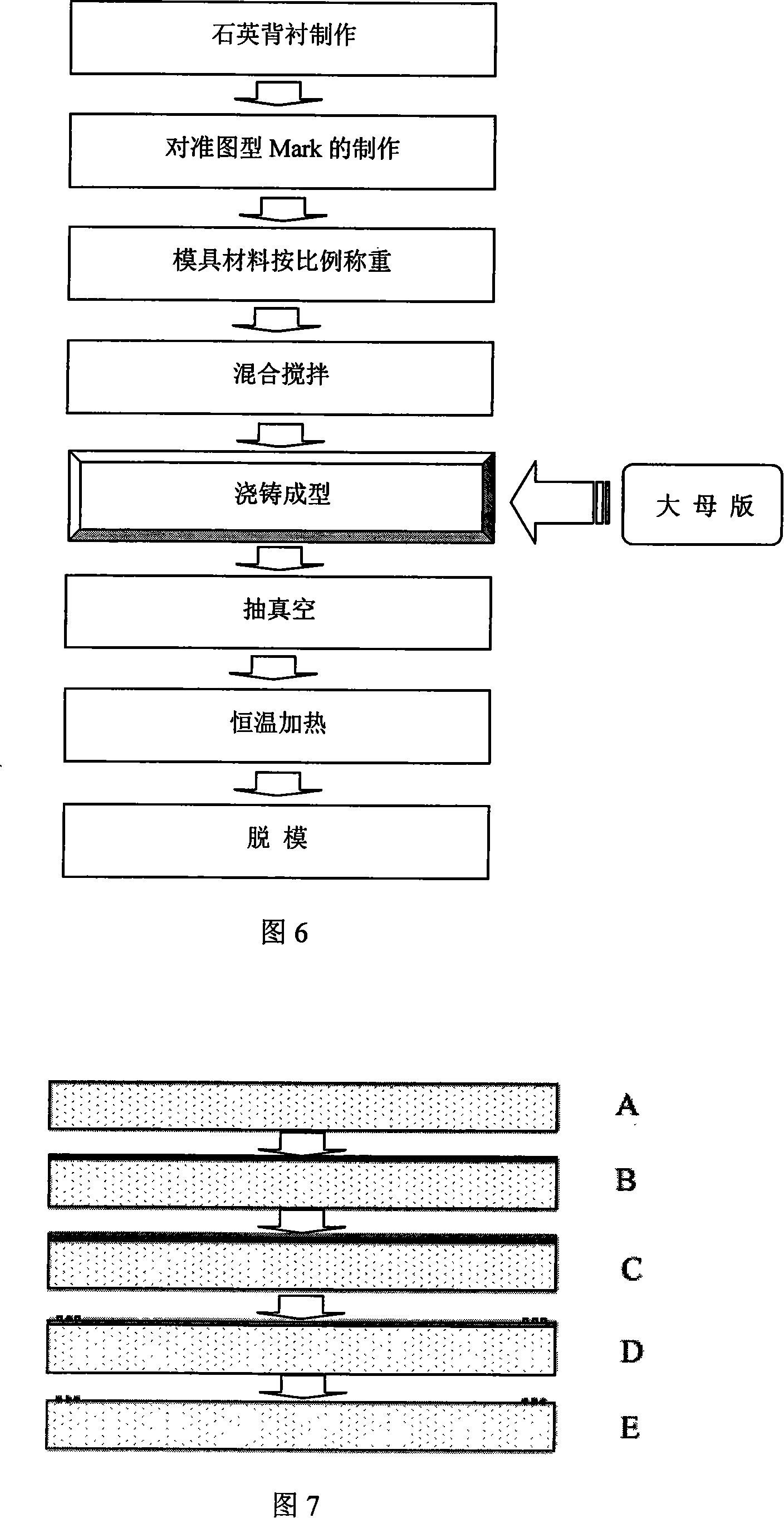

The invention discloses a large-area periodical array 3D microstructure preparing method, based on UV nano press printing technique, adopting soft mould and inverse pressure printing to implement low-cost preparation of large-area periodical array 3D microstructure and its basic process flow includes: 1. making small master by electron beam direct write photoetching and dry etching; 2. making large master by small master step-pressure printing and accurate micro-electroforming; 3. pouring liquid PDMS material to large master by vacuum assistance to make silicon rubber soft mould; 4. using quartz glass as substrate and making anti-adhesion surface preprocessing on the substrate; 5. using the ready-made silicon rubber soft mould, and combining with the inversing pressure printing to prepare large area periodical array 3D microstructure on the substrate. And the method has advantages of low cost, process simple, suitable to large batch production, and low cost preparation.

Owner:SHANDONG UNIV

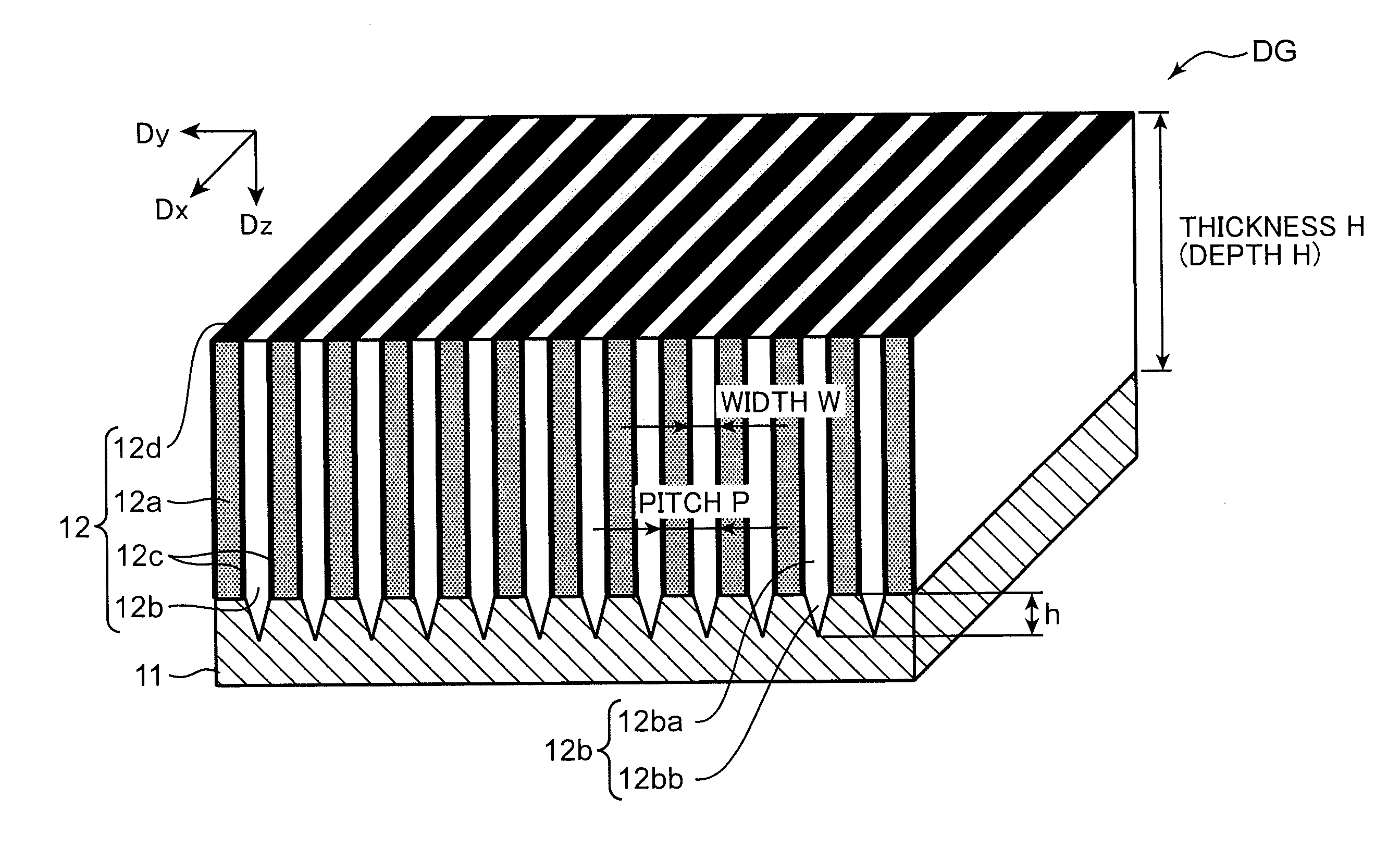

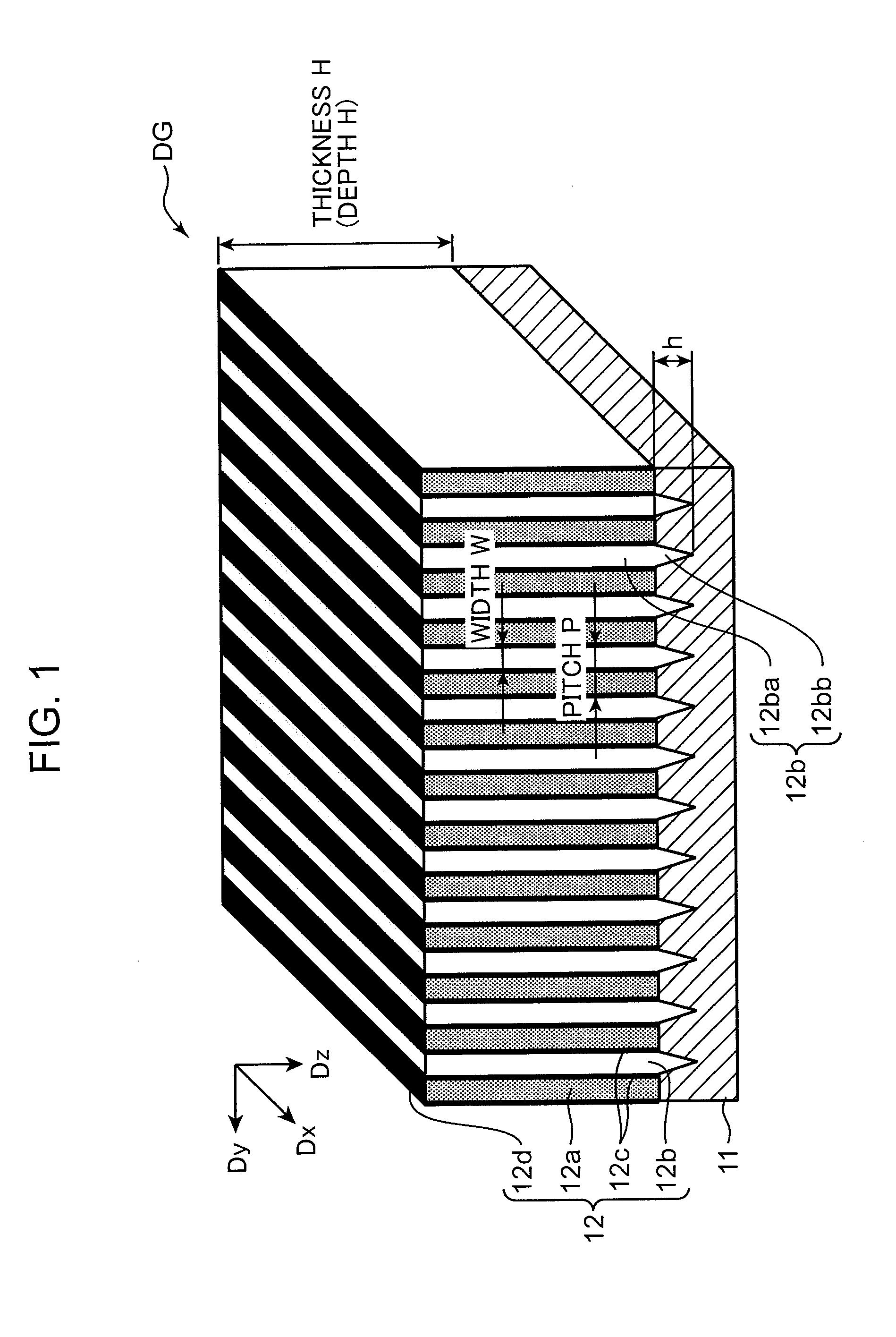

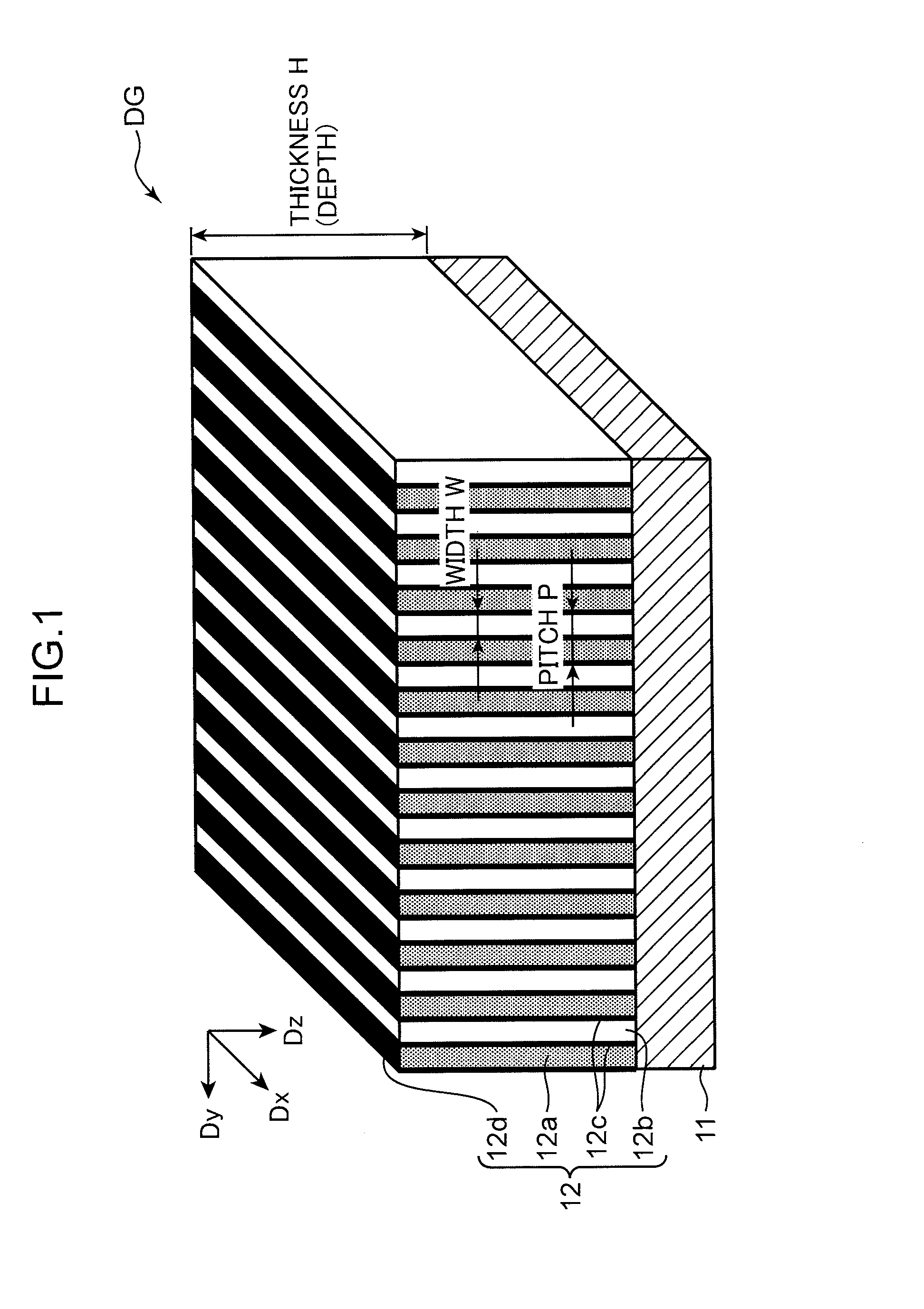

Metal Lattice Production Method, Metal Lattice, X-Ray Imaging Device, and Intermediate Product for Metal Lattice

InactiveUS20140241493A1Uniform deposition lengthHigh aspect ratioAnodisationImaging devicesX-rayMetal lattice

Method for manufacturing a metal grating structure, wherein, after a concave part having an insulating layer on an inner surface thereof is formed in a silicon substrate, a portion of the insulating layer formed on a bottom part of the concave part is removed, and the silicon substrate at the bottom part of the concave part is etched to increase the surface area of the bottom part of the concave part as compared with a state before the etching, followed by filling the concave part with metal by an electroforming method.

Owner:KONICA MINOLTA INC

Electroformed stencils for solar cell front side metallization

ActiveUS20090081823A1Increase the areaPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringSolar cell

A method for providing metallization upon a semiconductor substrate utilizing a stencil having at least one aperture extending from the contact side to the fill side, the contact side of the stencil being substantially flat and forming a sharp edge with a wall of the at least one aperture, the at least one aperture being tapered such that an area of a cross-section of the at least one aperture at the fill side is larger than an area of the cross-section of the at least one aperture at the contact side. A method of forming a stencil for depositing metallization lines on a semiconductor substrate is also disclosed.

Owner:FRY S METALS INC

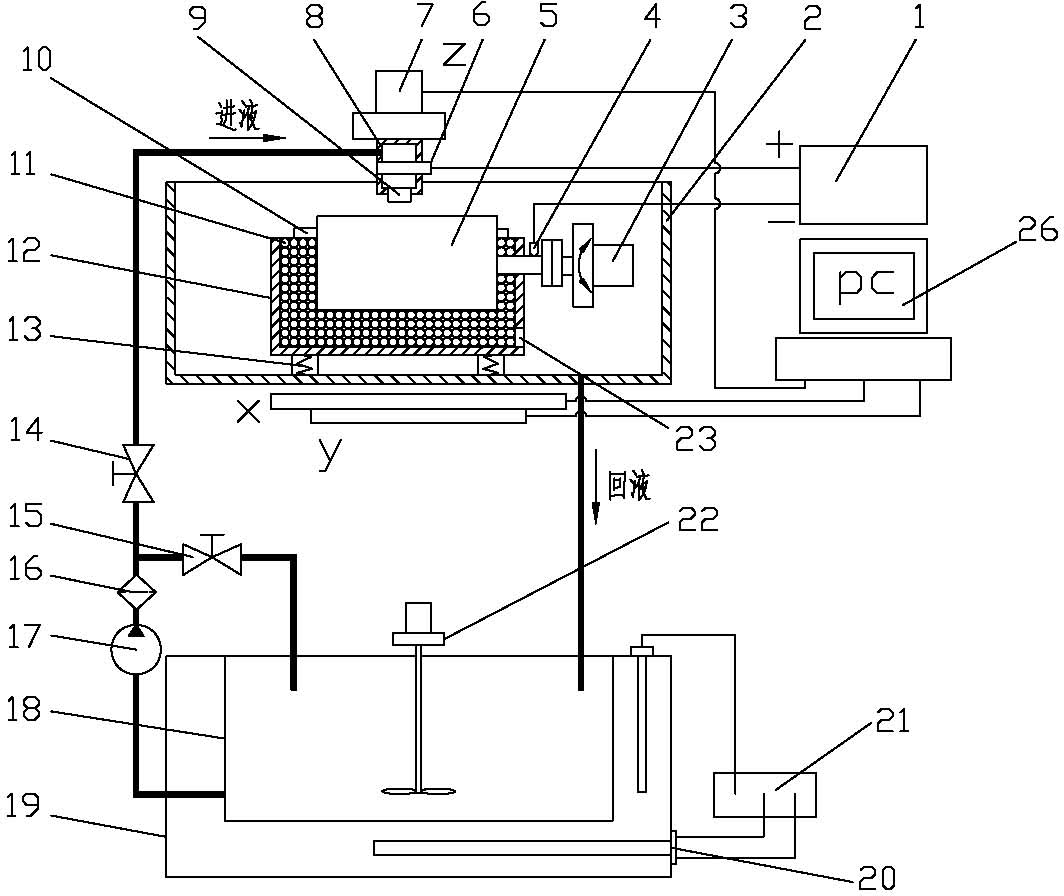

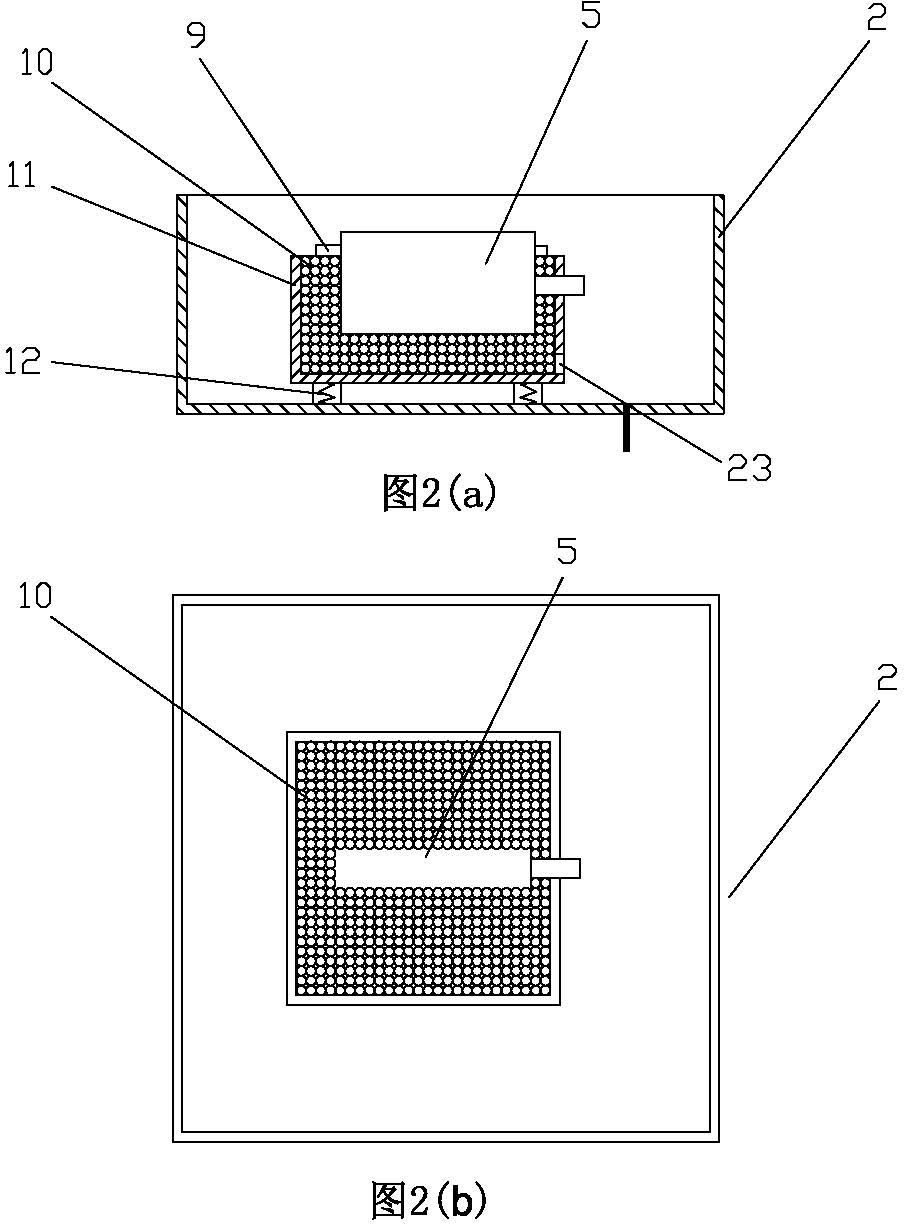

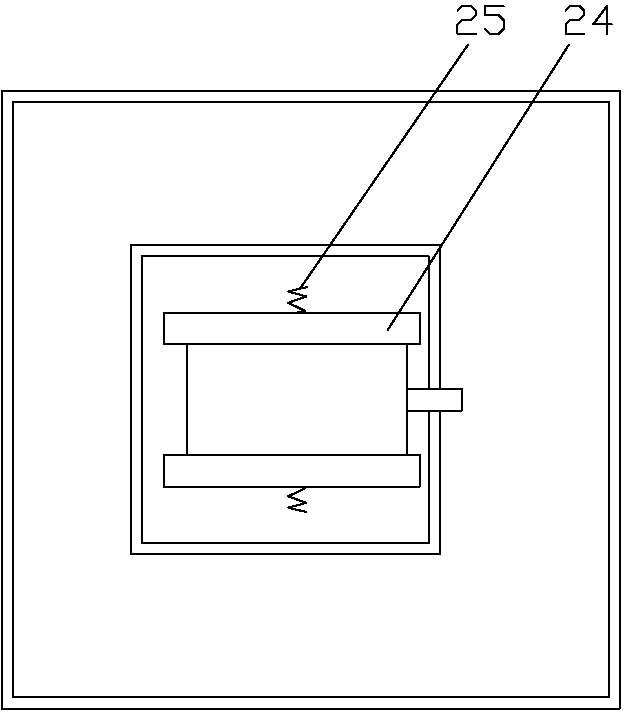

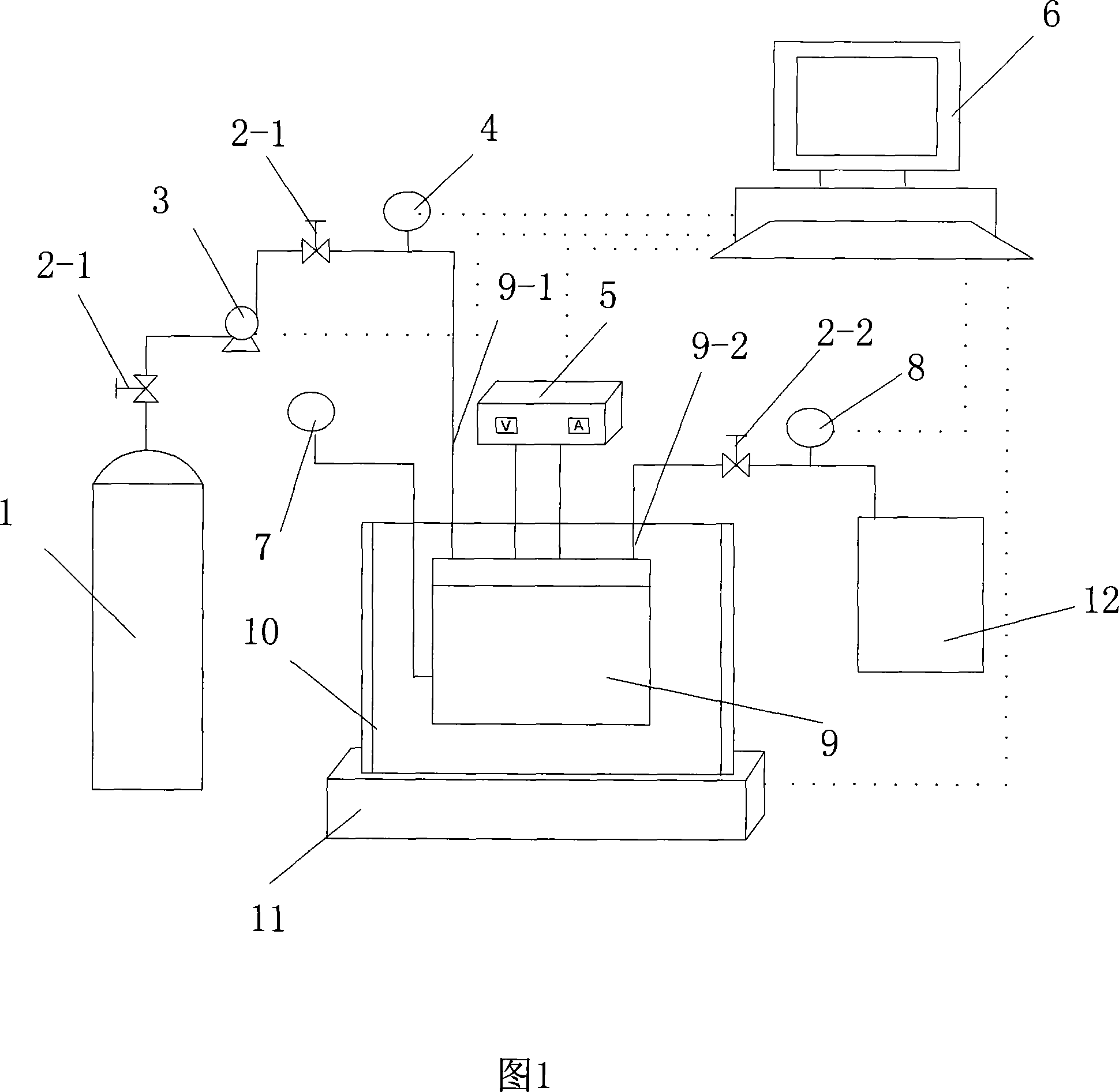

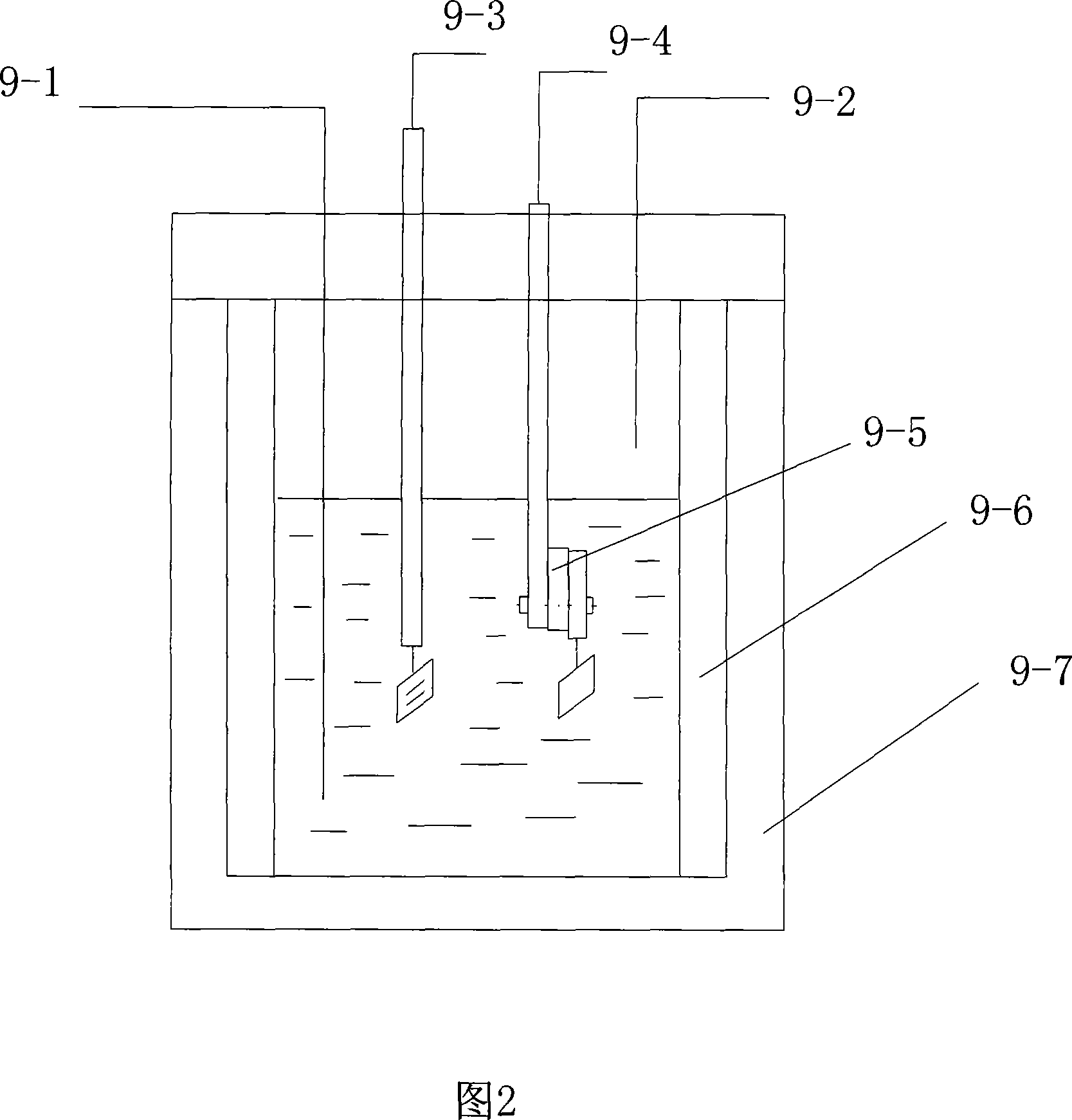

Method and device for processing revolving parts by high-speed jet injection electroforming

InactiveCN101994137AReduce thicknessOvercome timeElectroforming processesTemperature controlControl system

The invention provides a method and device for processing revolving parts by high-speed jet injection electroforming. The method is characterized in that an electroforming core mould is partially buried in an electroforming groove which is filled with hard particles or is in direct contact with a plated negative pole surface through a friction piece, so that the defects of accumulated tumors, burrs and the like on a deposition surface can be effectively removed by the friction of the hard particles or the friction piece on an electroforming layer; and a computer is used for controlling a jet nozzle to scan along with a certain track and cooperates with the rotary motion of the electroforming core mould at the same time, so that the exposed electroforming core mould surface is subjected to selective scanning electroforming so as to pile up the required parts layer by layer. The device of the invention mainly comprises a table movement mechanism, a negative pole rotation drive device, a control system, a temperature control device, an electroforming liquid circulating filter system and the like. The method and device for processing the revolving parts by high-speed jet injection electroforming of the invention are adopted, thus not only effectively removing the defects of hard spots, air holes, accumulated tumors and the like on the electroforming layer surface and manufacturing the electroforming layer with compact and even texture at higher deposition speed, but also abandoning the complicated negative pole female die of the traditional electroforming and rapidly and efficiently forming the revolving parts with different shapes and wall thicknesses by one step.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Optical fiber connector, ferrule used therefor and method for manufacturing ferrule

Electroforming is performed in an electroforming bath with a cathode of a metal wire member immersed in an electroforming solution to electrodeposit nickel around the aluminum alloy wire member. The aluminum alloy wire member is removed by dissolution with an alkaline solution from an obtained nickel electroformed product. Accordingly, a nickel cylinder is obtained, which has a through-hole formed corresponding to the wire member. The cylinder is cut into those having a predetermined length. The outer circumference is subjected to cutting based on the through-hole to obtain a ferrule. The inner diameter accuracy of the through-hole of the ferrule is determined by the outer diameter accuracy of the wire member. Therefore, it is unnecessary to perform polishing for the through-hole. The highly accurate ferrule is obtained in accordance with the simple process at low cost. The PC polishing for the ferrule for effecting PC junction of optical fibers is extremely easy, because the ferrule is made of metal. Thus, it is possible to provide a high performance optical fiber connector.

Owner:TETABUO TANAKA

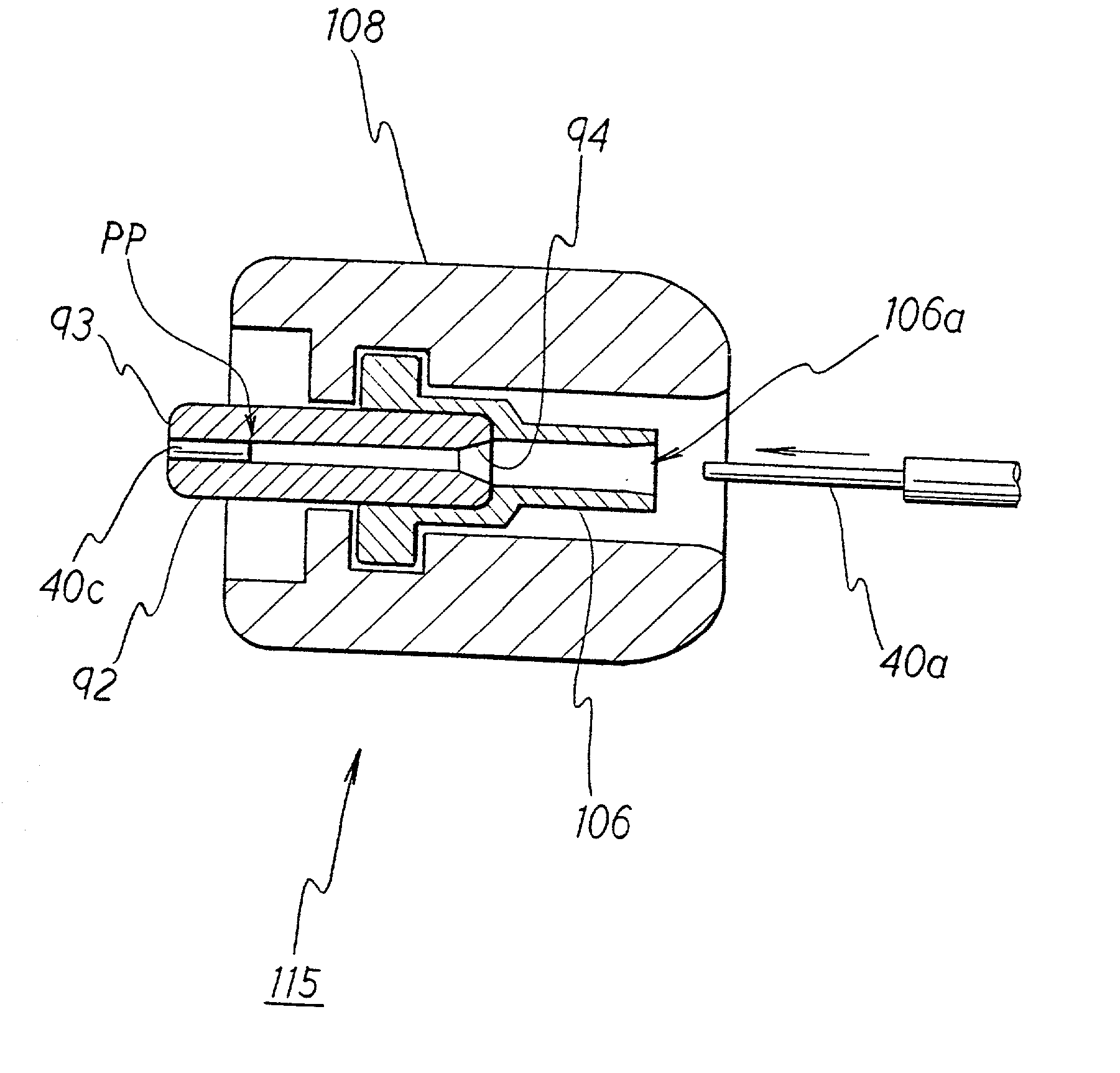

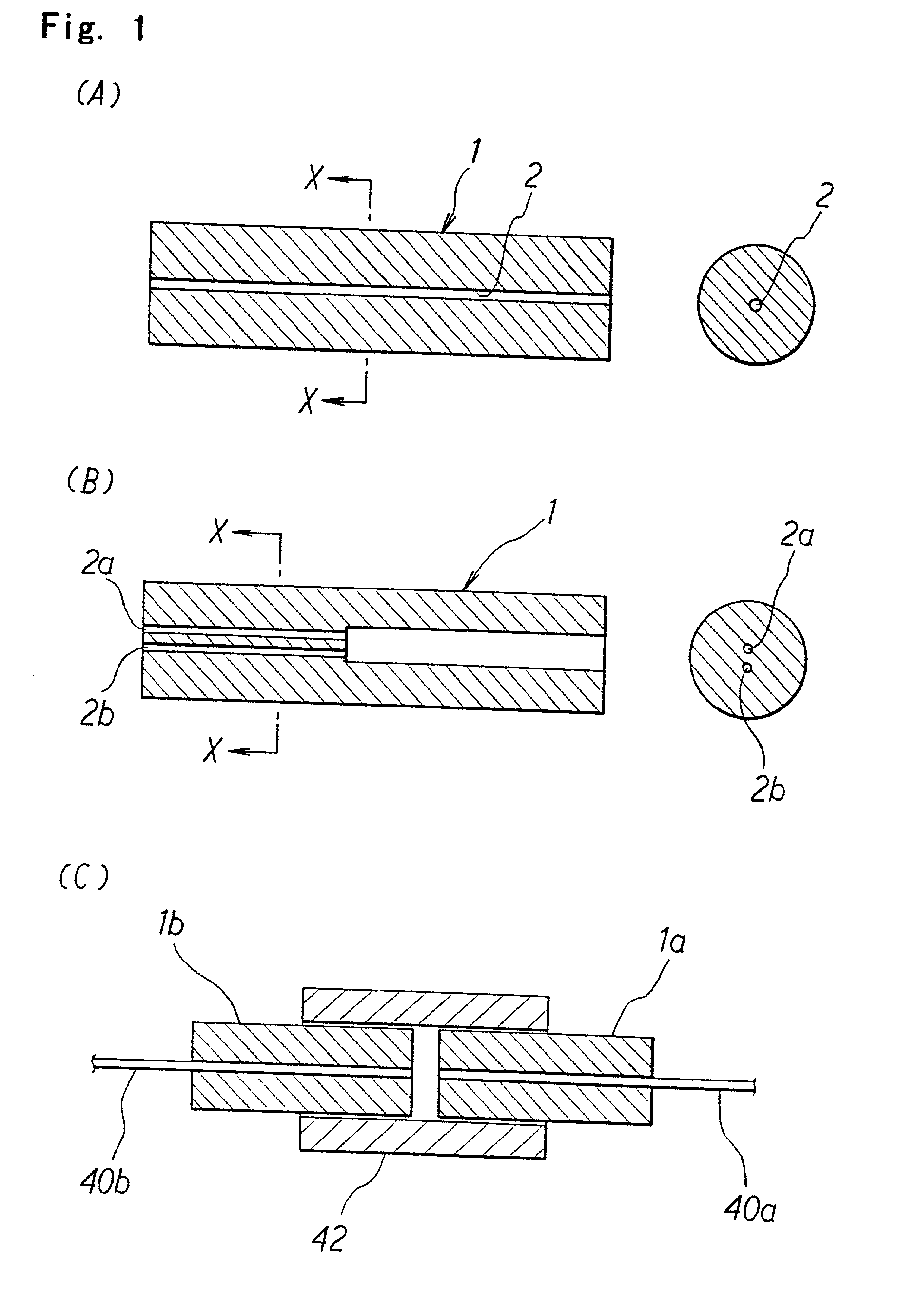

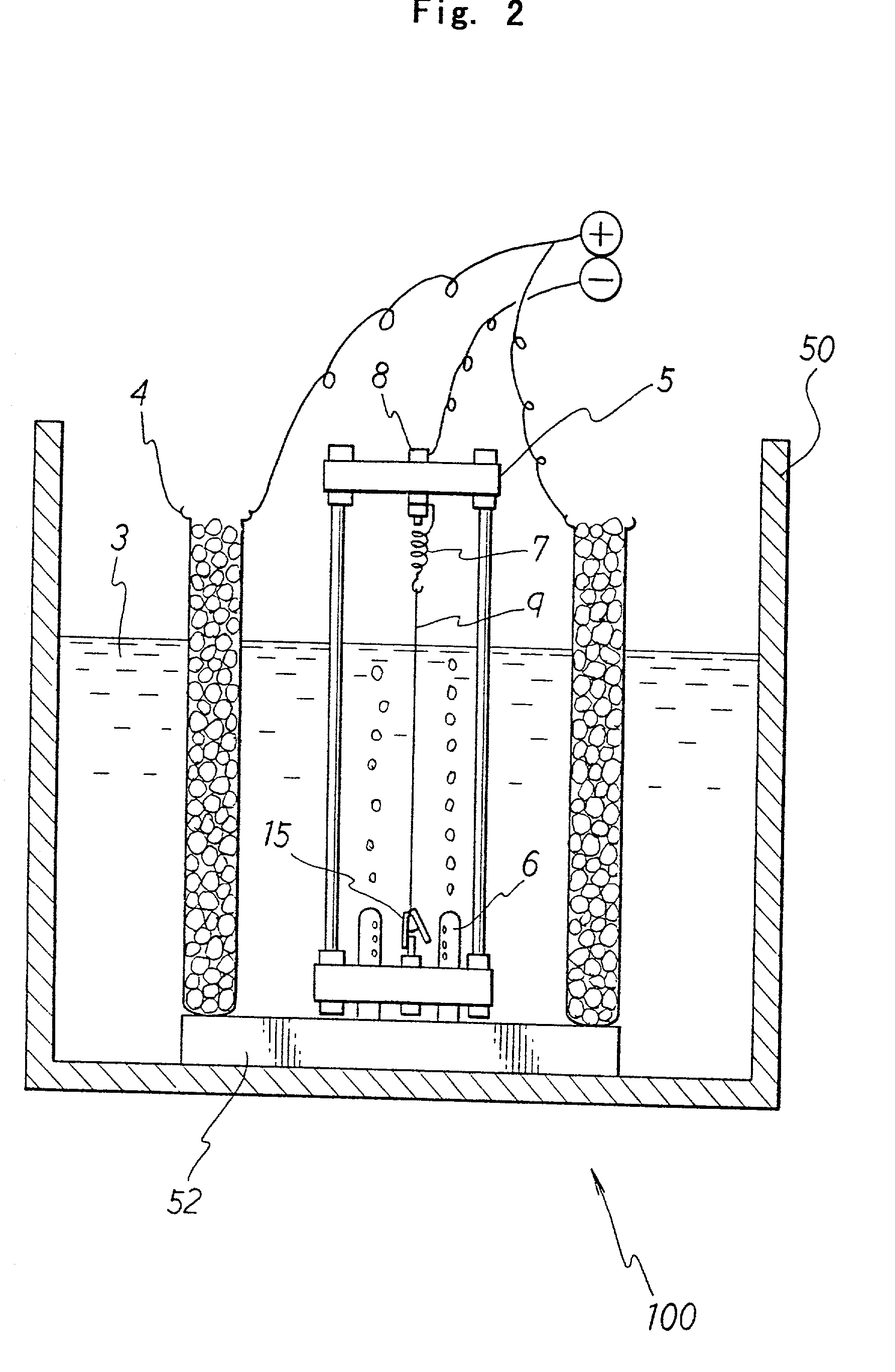

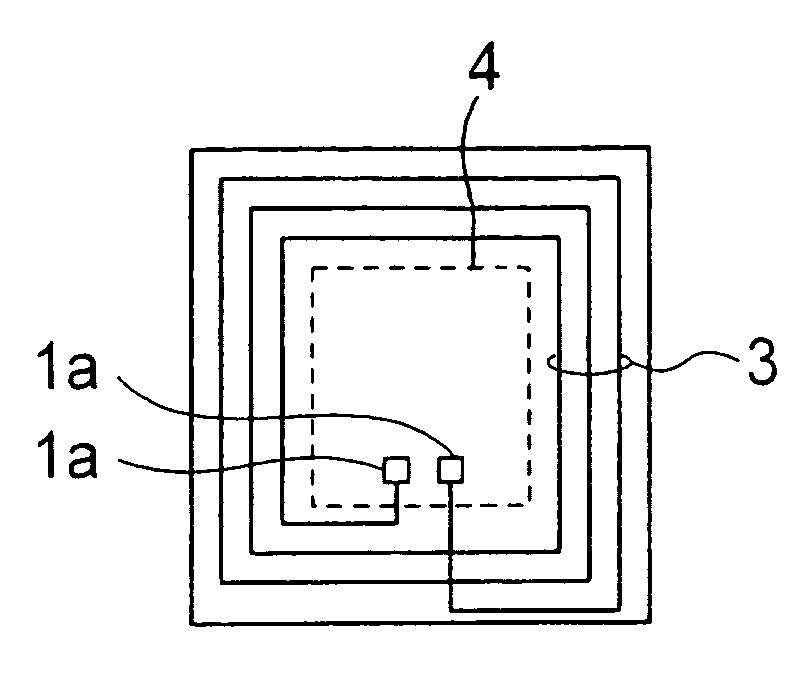

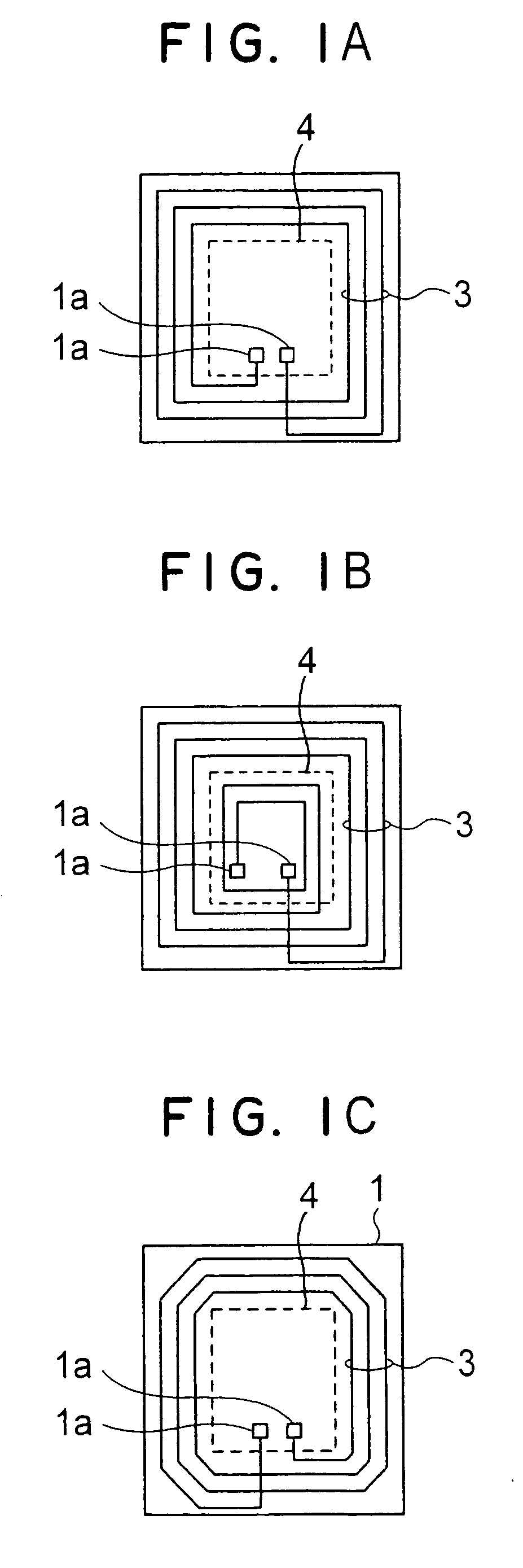

Method of manufacturing an IC coil mounted in an information carrier

InactiveUS7129145B2Energy lossReduce lossesSemiconductor/solid-state device detailsSolid-state devicesMulti materialElectrical conductor

An information carrier in which an IC element formed integrally with a coil is mounted and which has an extended communication range and a method of manufacturing the same and a structure of the IC element appropriately suited for this sort of information carrier and a method of manufacturing the same. In the IC element, a conductor constituting the coil 3 is implemented in a multilayer structure including a metal-sputtered layer or alternatively a metal-evaporated layer 6 and a metal-plated layer 7. In the method of manufacturing the IC element, a precision electroforming method is employed as a means for forming the metal-plated layer 7. The information carrier is implemented in such a structure in which the IC element 1 is disposed at a center portion in a planar direction of a substrate 21. In a method of manufacturing the information carrier, strip material or materials 41 to 45 a given one of which has mounted thereon desired parts inclusive of the IC elements are manufactured, whereon desired information carriers 20a, . . . , 20h are formed by punching the strip material(s).

Owner:HITACHT MAXELL LTD

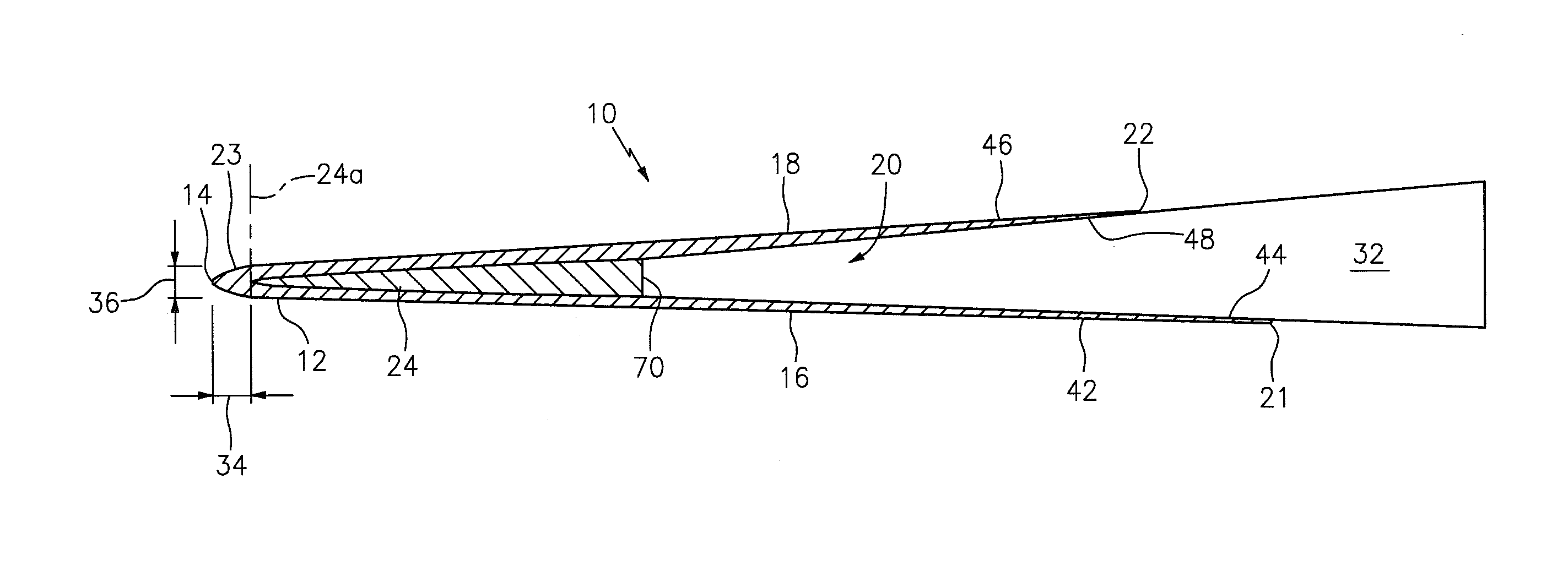

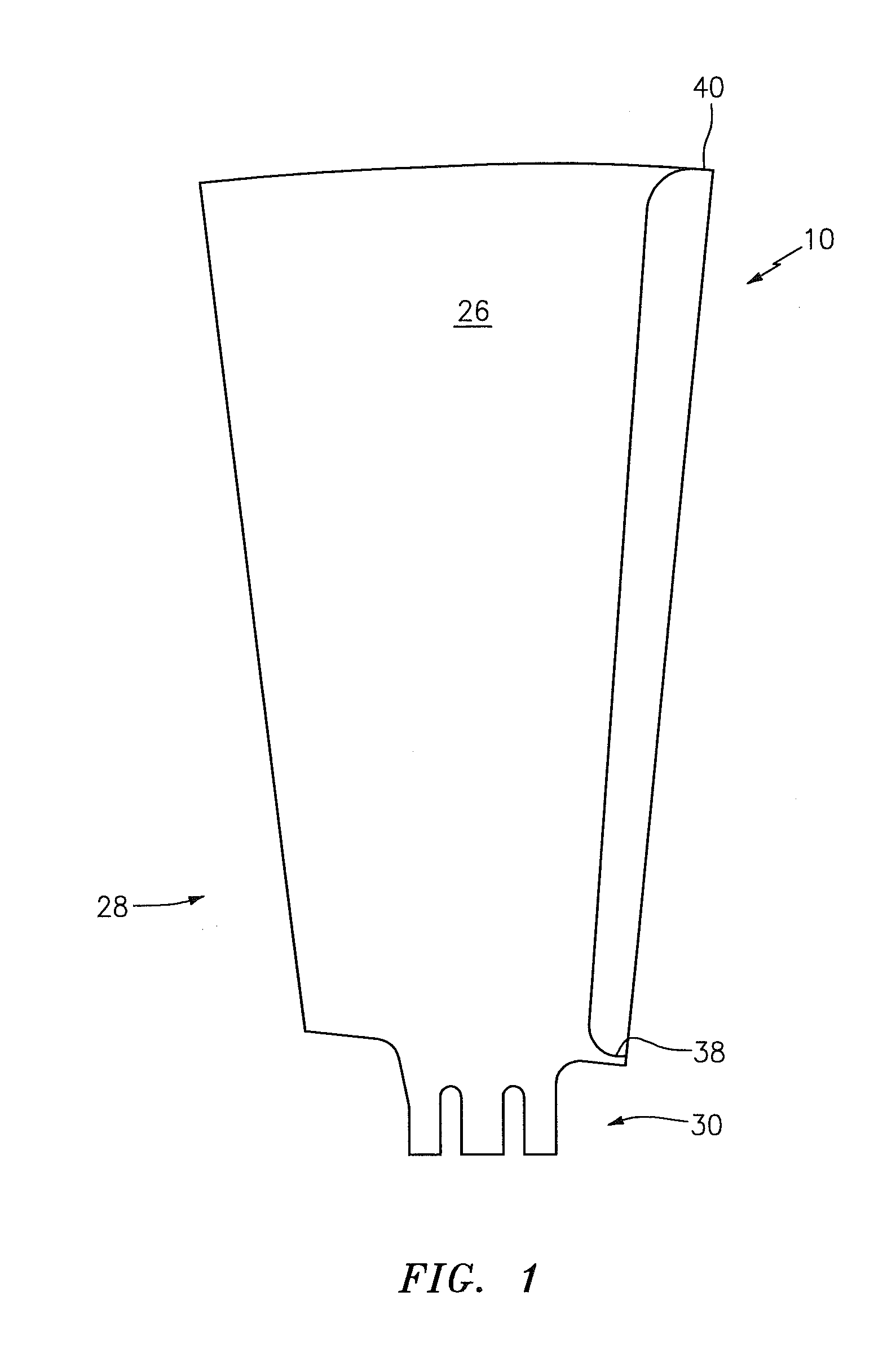

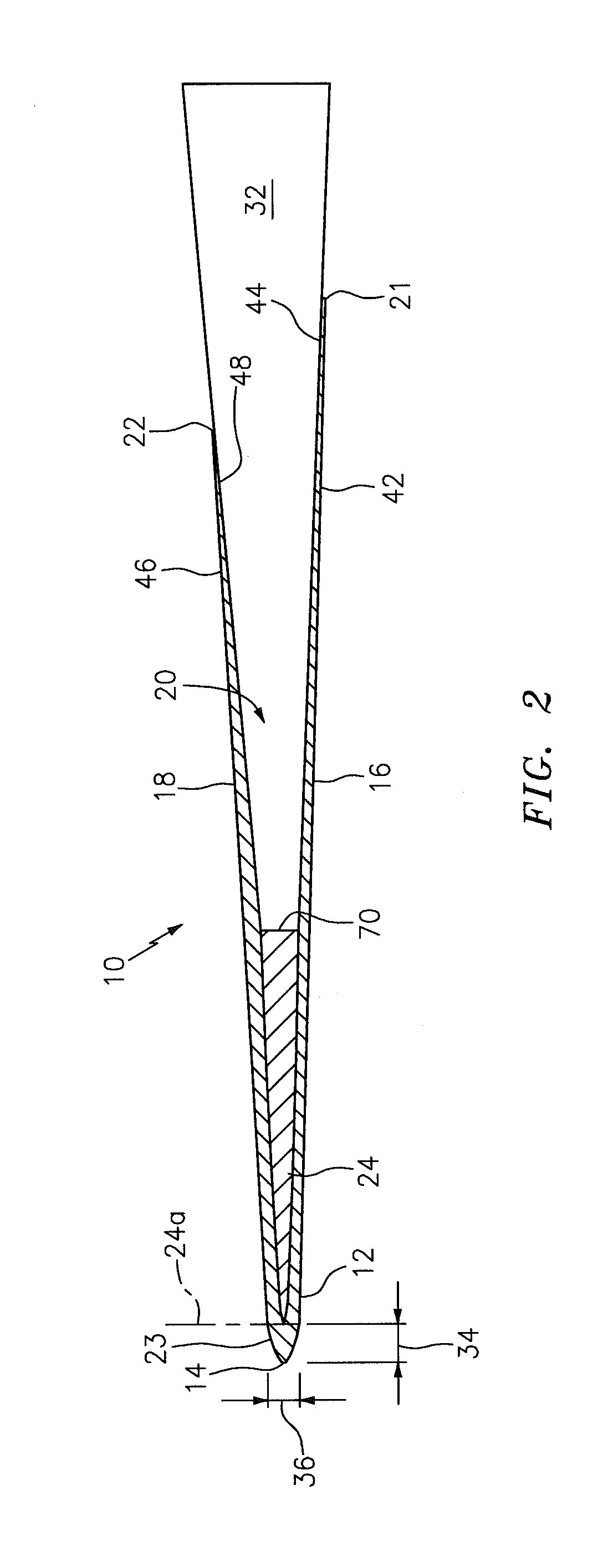

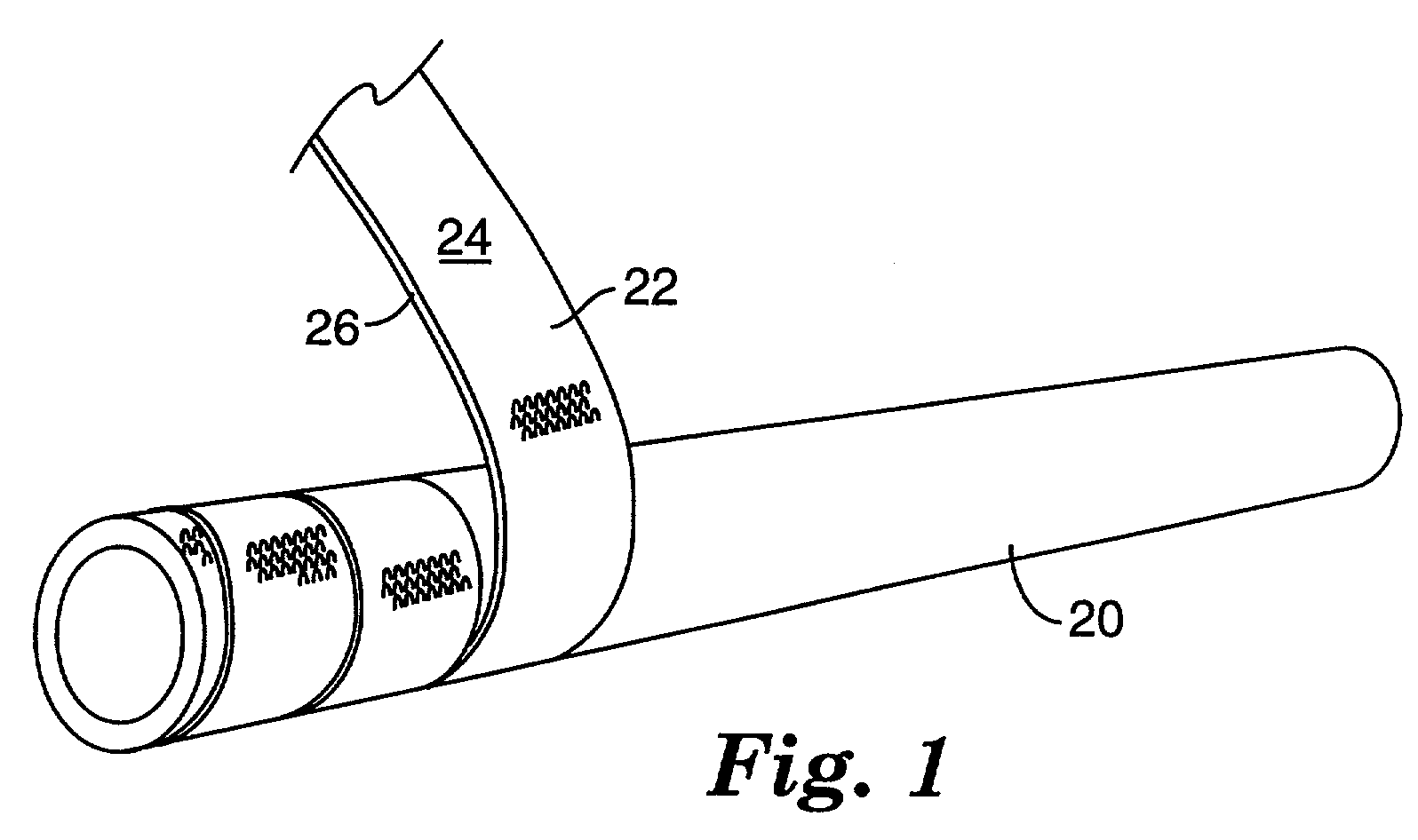

Electroformed sheath

An electroformed sheath for protecting an airfoil includes a sheath body and a mandrel insert is provided. The sheath body includes a leading edge. The sheath body includes a pressure side wall and an opposed suction side wall, which side walls meet at the leading edge and extend away from the leading edge to define a cavity between the side walls. The sheath body includes a head section between the leading edge and the cavity. The mandrel insert is positioned between the pressure side and suction side walls, and includes a generally wedge-shaped geometry. A method for protecting an airfoil includes: 1) securing a mandrel insert to a mandrel; 2) electroplating a sheath body onto the mandrel and the mandrel insert; 3) removing the mandrel from the sheath body so that a sheath cavity is defined within the sheath body; and 4) securing the airfoil within the sheath cavity.

Owner:RAYTHEON TECH CORP

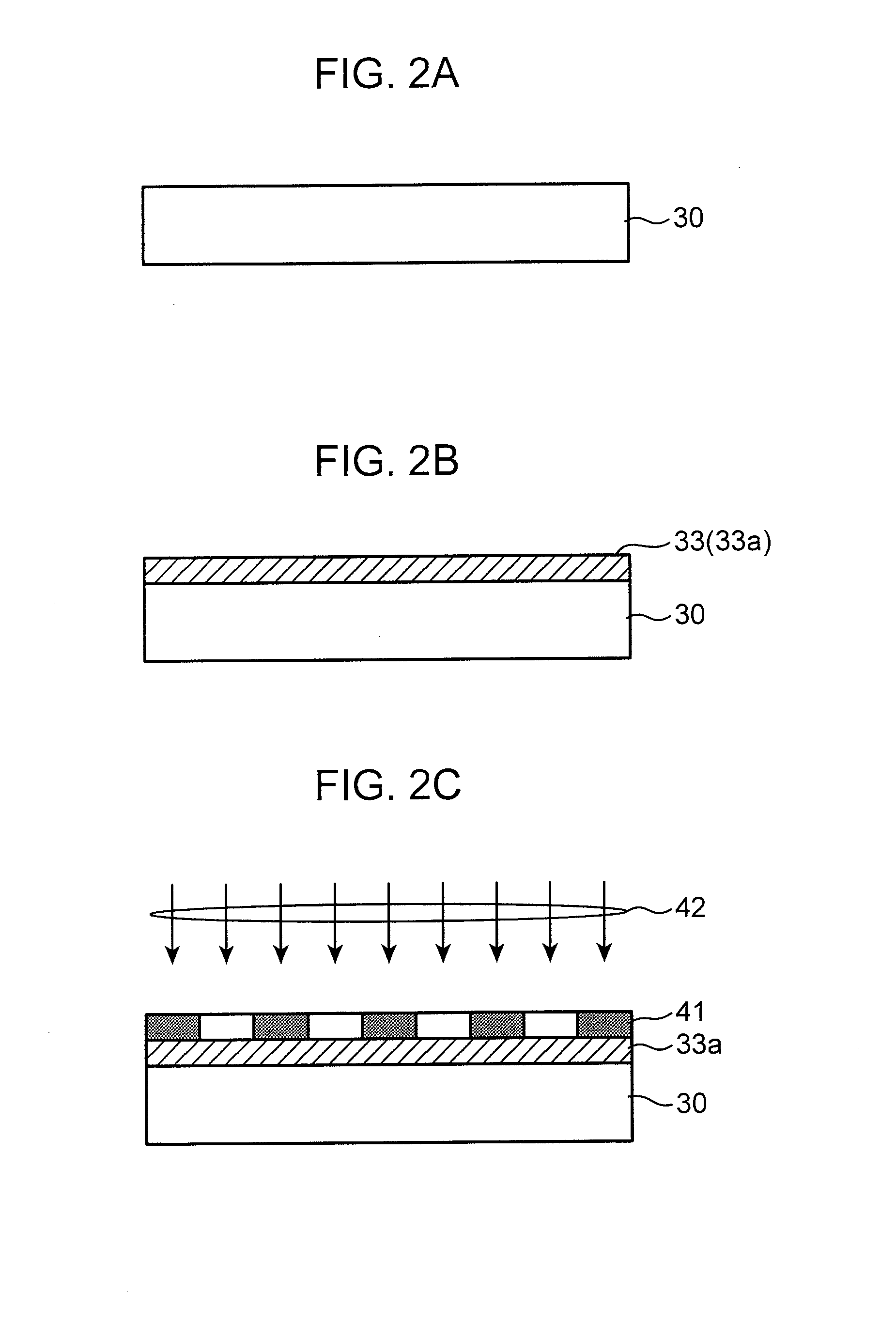

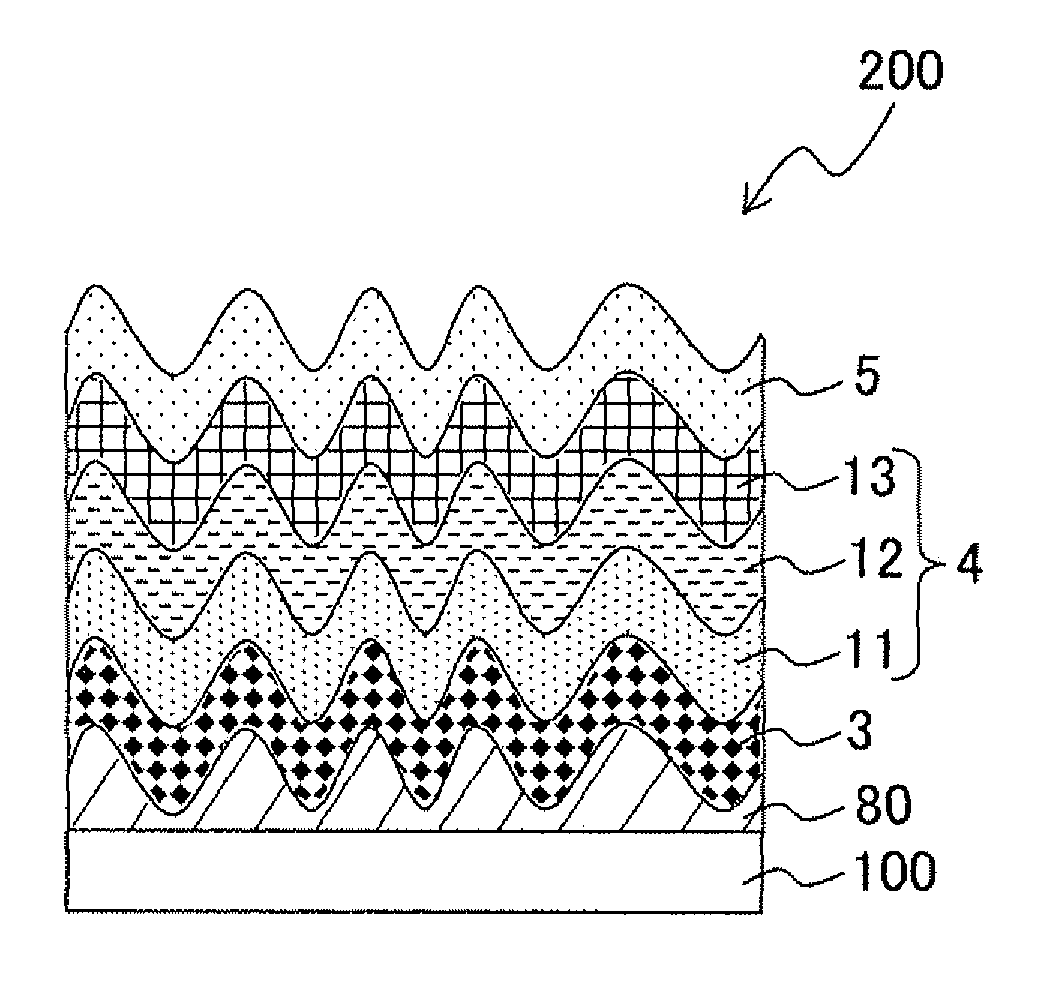

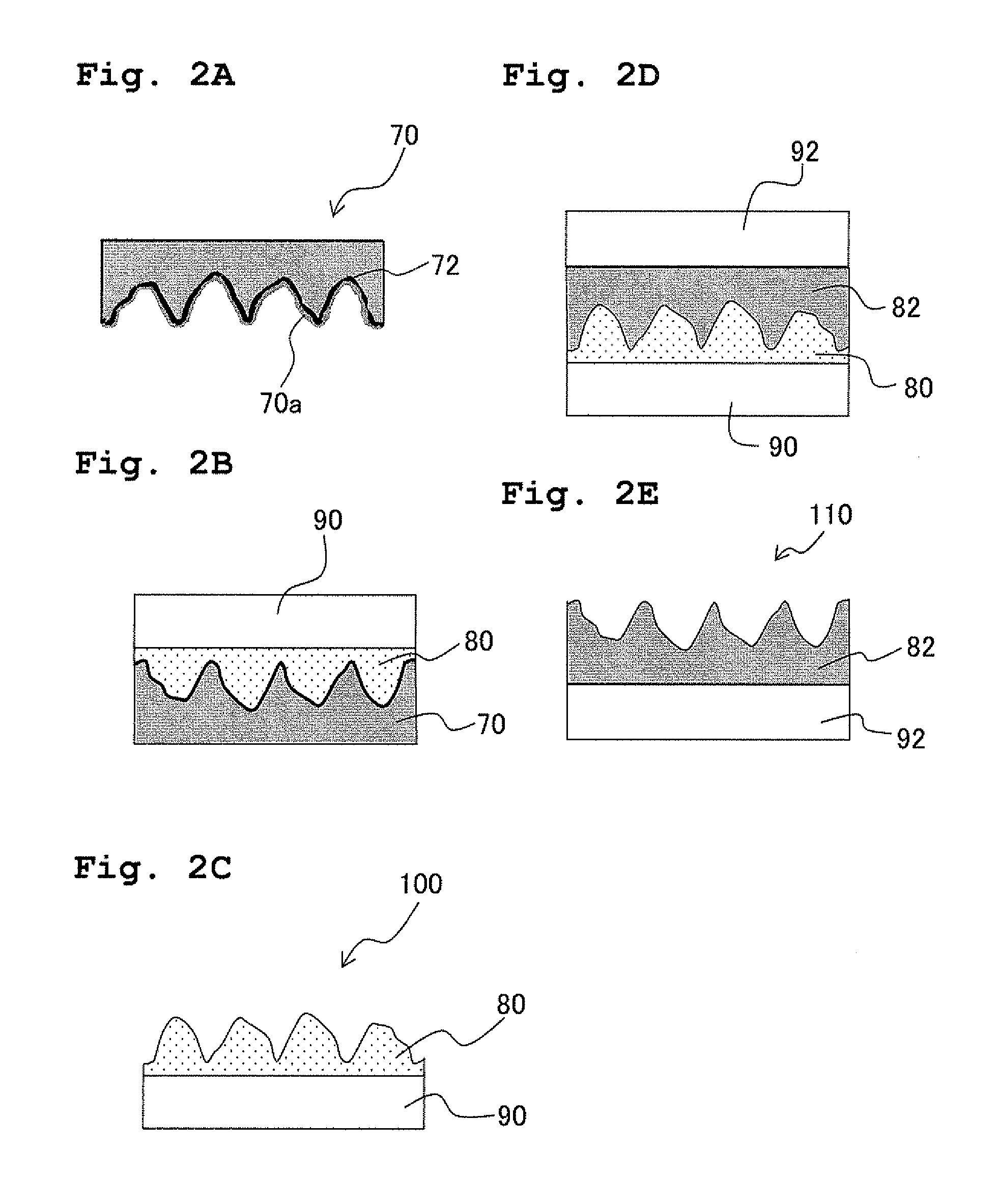

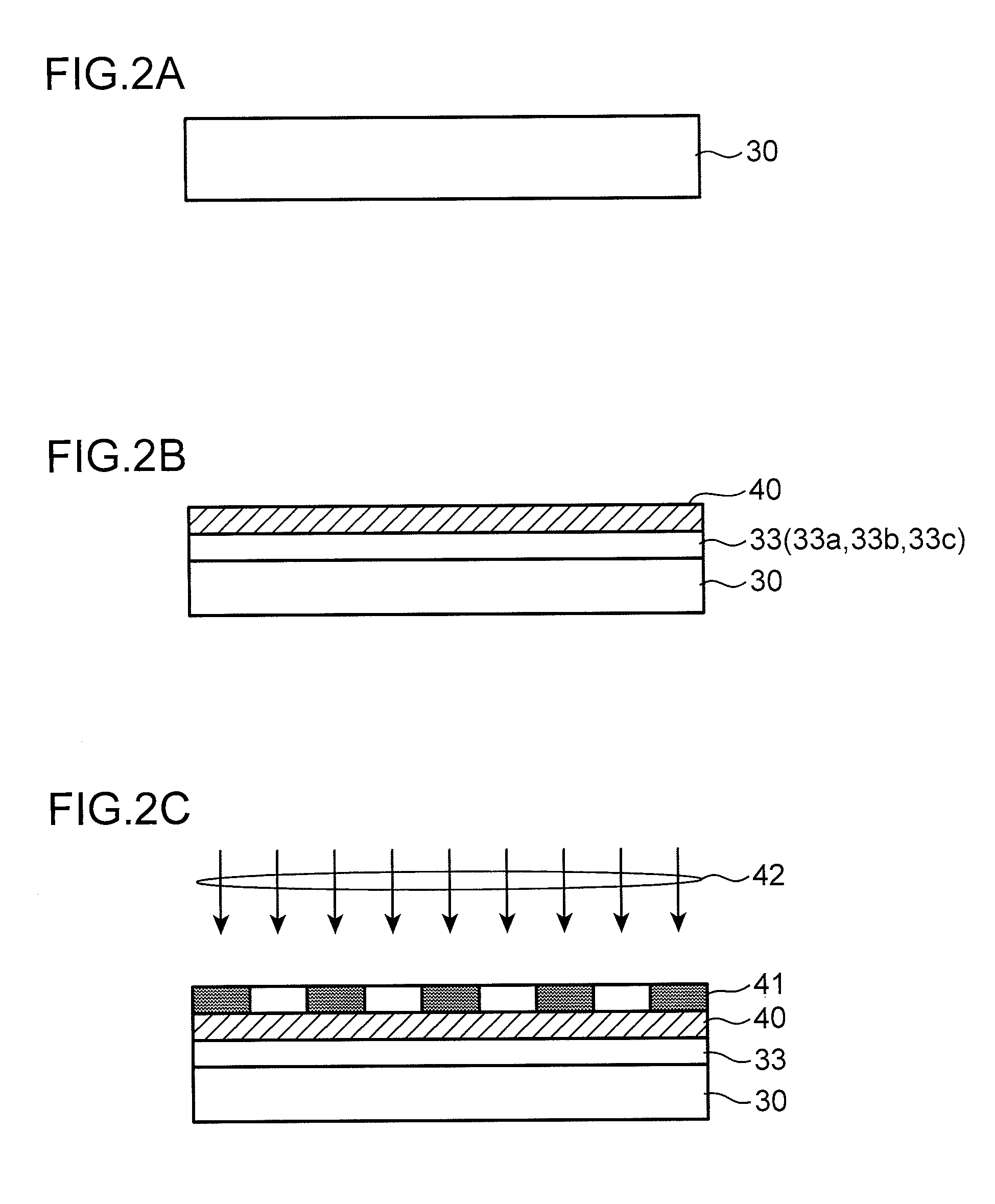

Method for producing mold for minute pattern transfer, method for producing diffraction grating using the same, and method for producing organic el element including the diffraction grating

InactiveUS20130299796A1High mechanical strengthReduce directivityMaterial nanotechnologyNanoinformaticsCopolymerMetal

A method for producing a mold includes: applying a block copolymer solution made of first and second polymers on a base member; performing a first annealing process at a temperature higher than Tg of the block copolymer after drying the coating film; forming a concavity and convexity structure on the base member by removing the second polymer by an etching process; performing a second annealing process of the concavity and convexity structure at a temperature higher than Tg of the first polymer; forming a seed layer on the structure; laminating or stacking a metal layer on the seed layer by an electroforming; and peeling off the metal layer from the base member. The second annealing process enables satisfactory transfer of a concavity and convexity structure on the base member onto the metal layer.

Owner:JX NIPPON OIL & ENERGY CORP +1

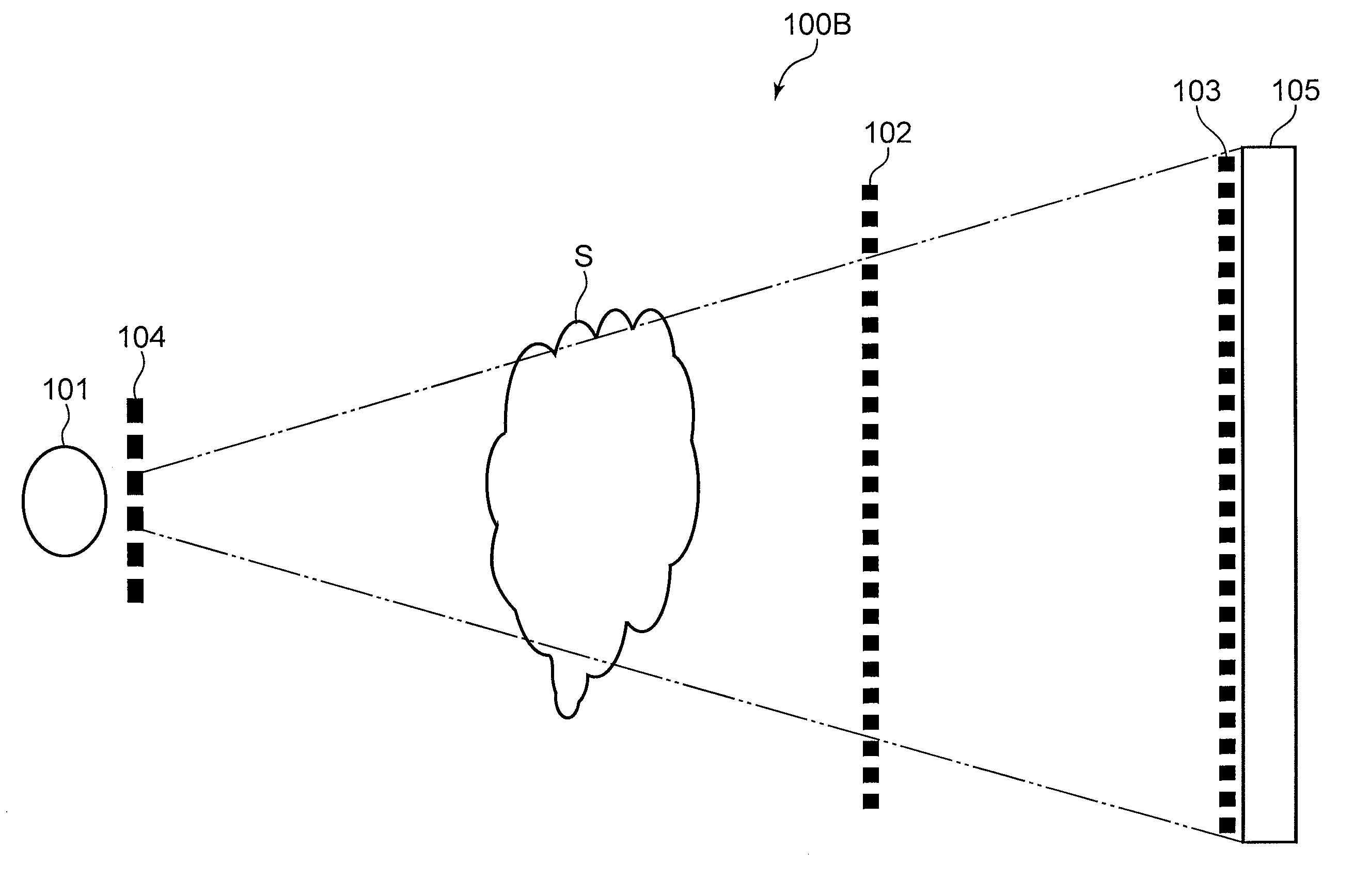

Method for Manufacturing Metal Lattice, Metal Lattice Manufactured by the Method, and X-ray Imaging Device using the Metal Lattice

ActiveUS20130279651A1Imaging devicesHandling using diffraction/refraction/reflectionX-rayMetal lattice

According to a method for manufacturing a metal grating structure of the present invention, in filling a concave portion formed in a silicon substrate (30), for instance, a slit groove (SD) with metal by an electroforming method, an insulating layer (34) is formed in advance on an inner surface of the slit groove (SD) as an example of the concave portion by a thermal oxidation method. Accordingly, the metal grating structure manufacturing method is advantageous in finely forming metal parts of the grating structure. A metal grating structure of the present invention is manufactured by the above manufacturing method, and an X-ray imaging device of the present invention is incorporated with the metal grating structure.

Owner:KONICA MINOLTA INC

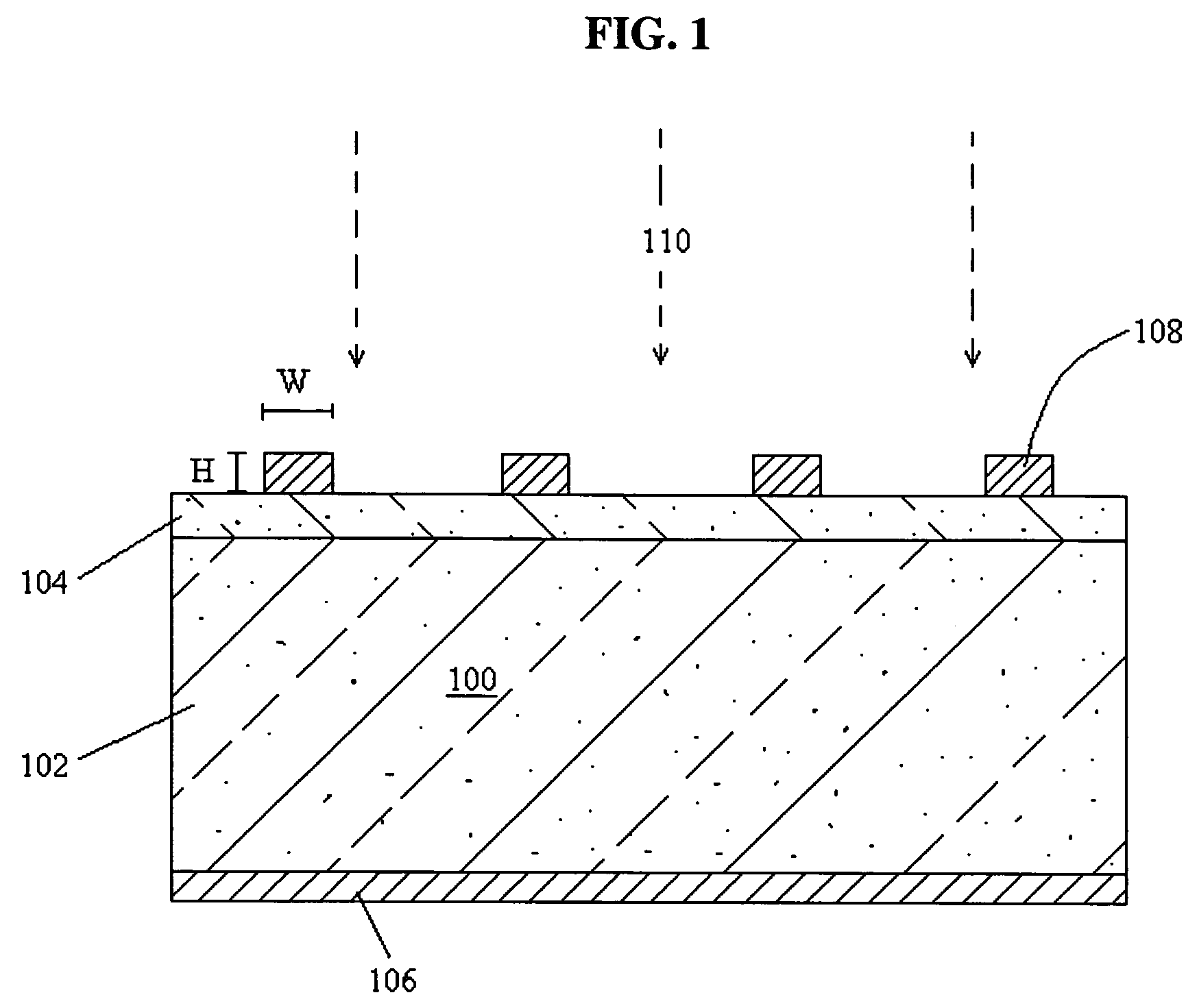

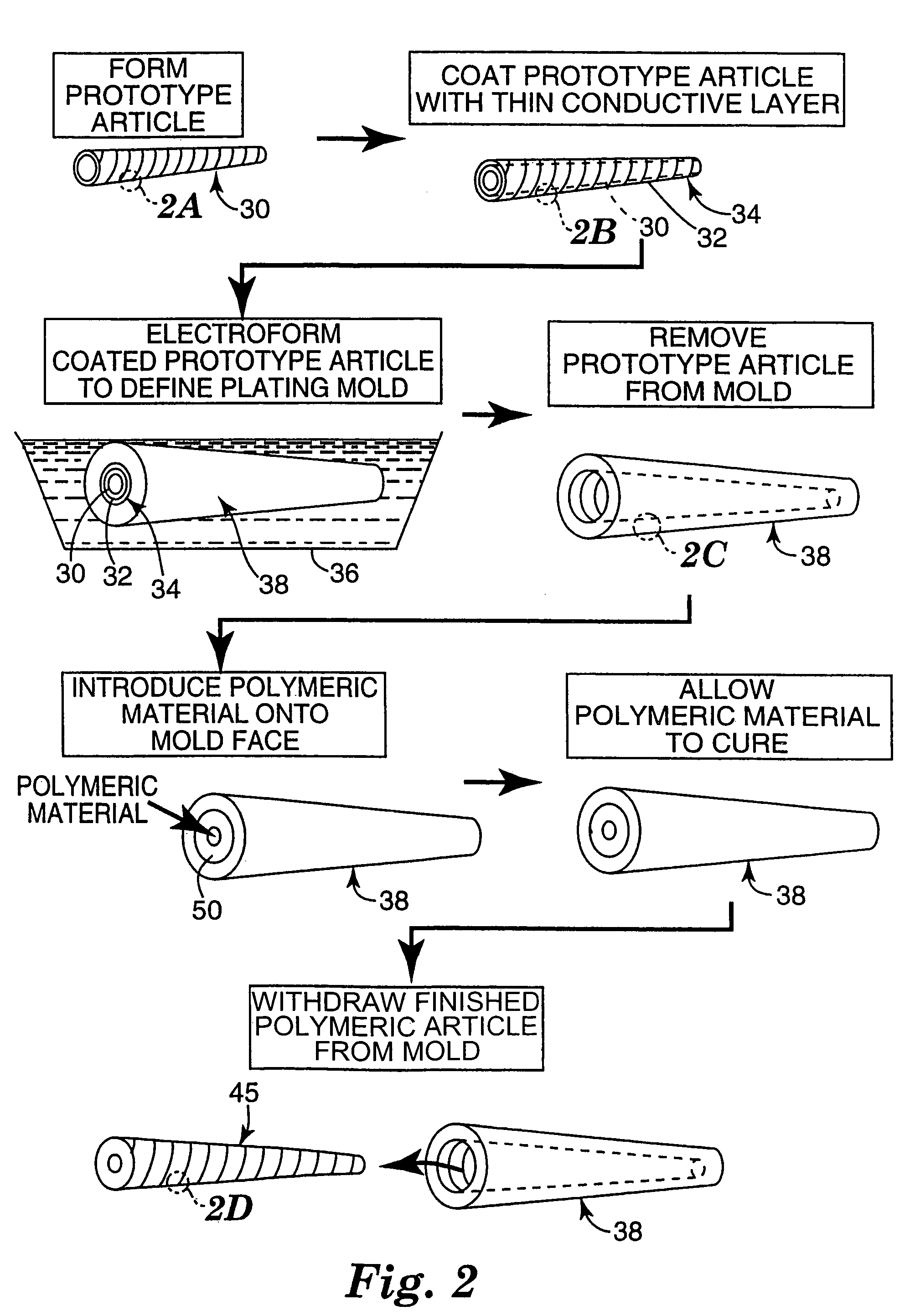

Microreplicated surface

InactiveUS7703179B2Increase heightImprove toleranceTravelling carriersHoldersPolymer scienceSurface structure

This disclosure relates to a method for making a polymeric article mold, a method for making a polymeric article with that mold, and improved surface topography features for a polymeric article. A prototype article is formed and then coated with a thin conductive layer. The coated prototype article is then electroformed until nickel plated to a sufficient depth to define a nickel plating tool. After the prototype article has been removed from the mold face of the nickel tool, the tool can be used as a mold for forming finished polymeric articles which replicate the original prototype article. The use of fine topography features such as a dense upstanding stem array on the surface of the prototype article facilitates accurate and complete electroforming by increased surface area presentation. The disclosure also presents improvements to microreplicated surface structures such as stem arrays. The improvements include the formation on a stem array having separate zones of stems of differing heights, and the formation of directional microreplicated features (e.g., stems) which are oriented and shaped to promote or restrict frictional interaction in one or more particular directions.

Owner:3M INNOVATIVE PROPERTIES CO

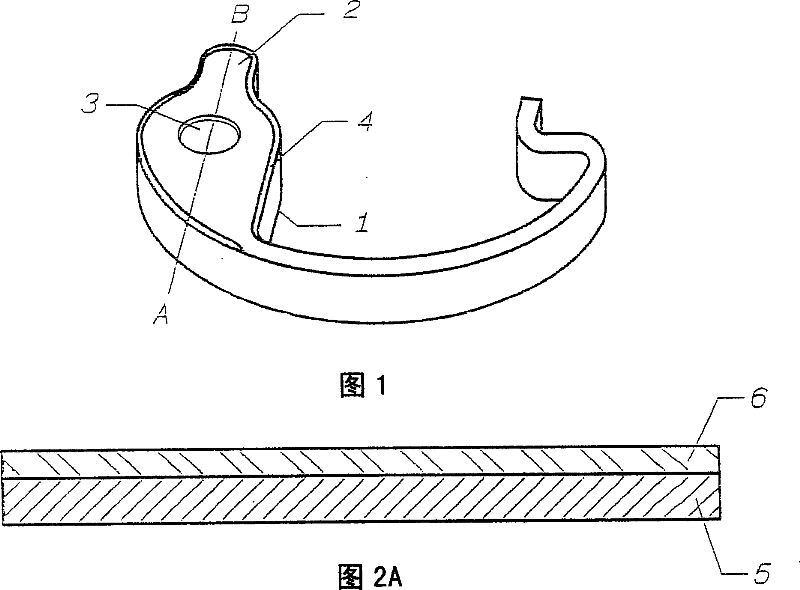

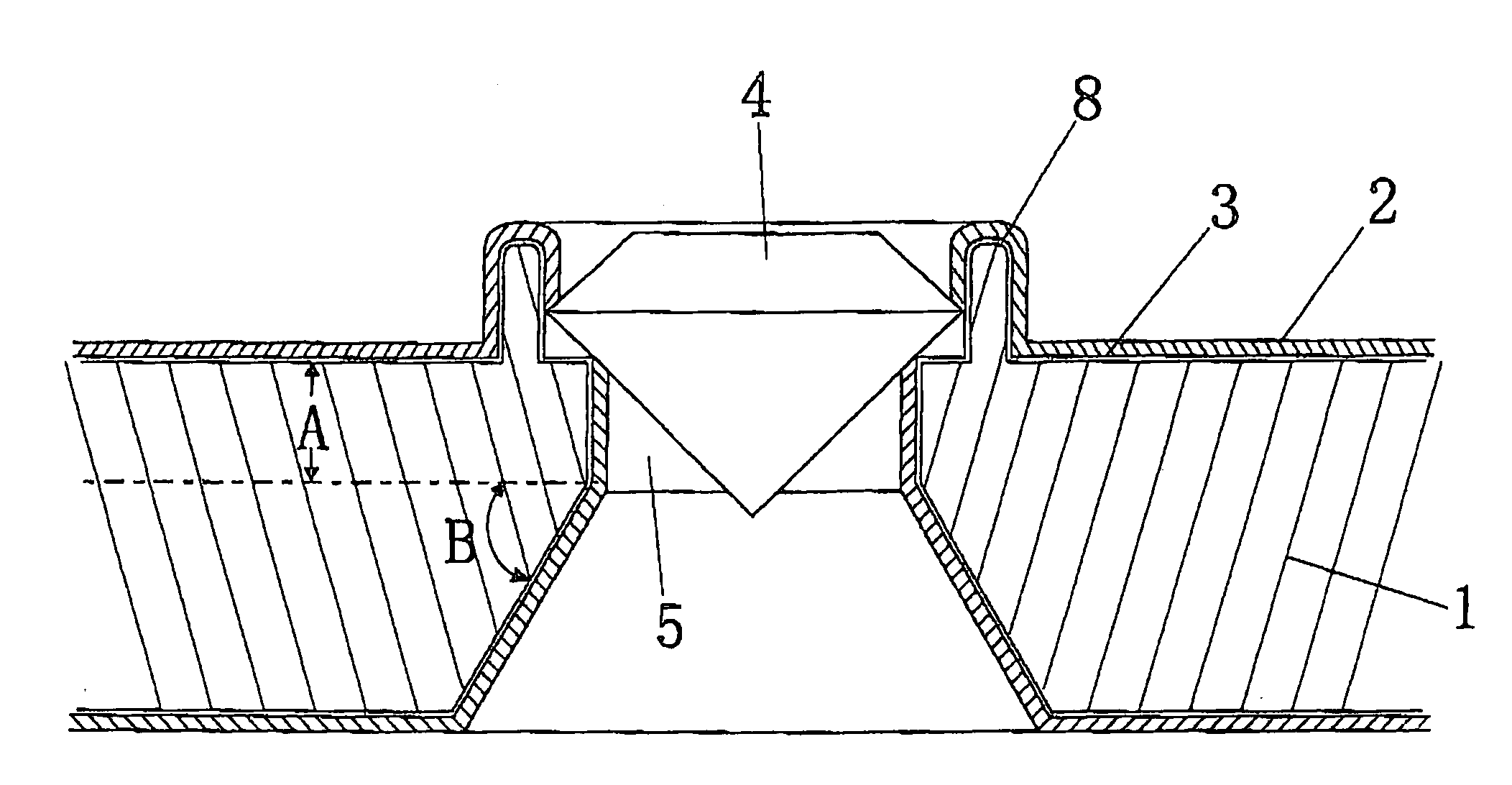

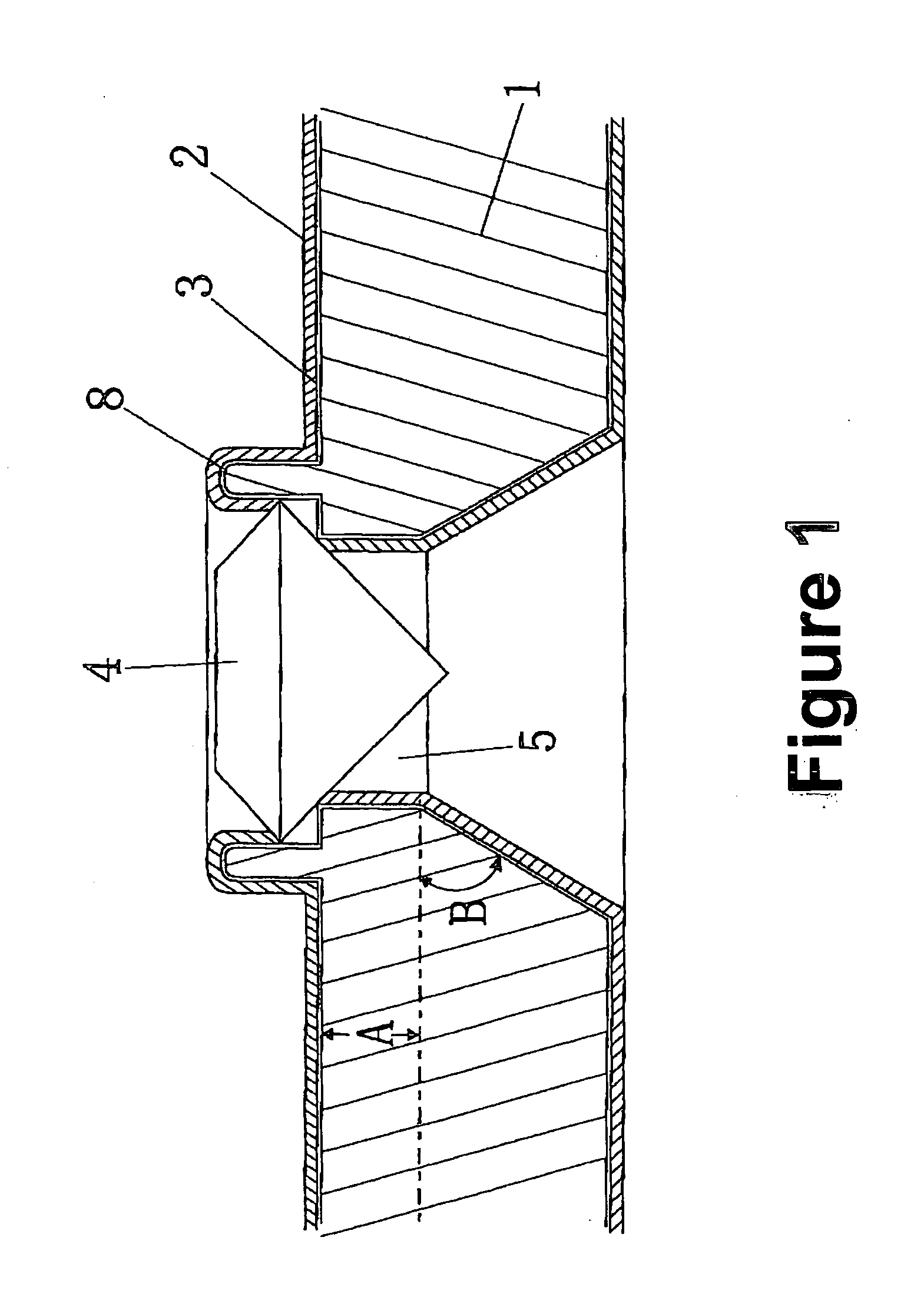

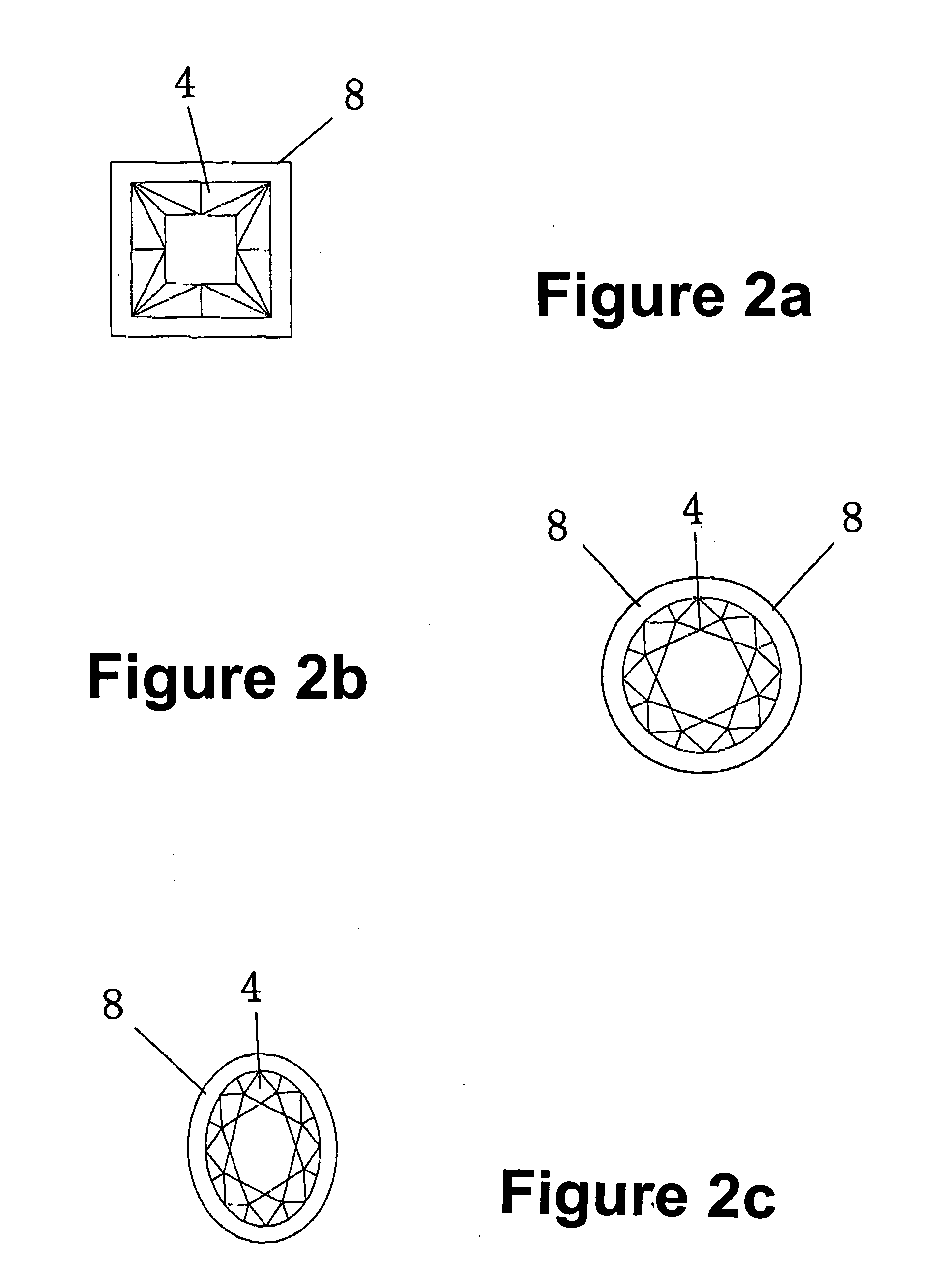

Setting stones in the surface of electroformed piece

A method for setting at least one stone (4) in the surface of a jewelry and / or sculpture produced by electroforming comprising: a wax mandrel (1) which has a particularly designed tubular seat (5) and setting means (7, 8, 9). The wax mandrel (1) is then thoroughly painted with conductive coating (3) on its surface for conducting electricity. The stone (4) is then put in said tubular seat (5). During electroforming process, electroforming metal is deposited on said conductive coating (3) layer by layer and fills the gap between the stone (4) and the inlay position thus holds and sets the stone (4) in position. After electroforming, any redundant metal flake is removed by a scraper. Finally, said wax mandrel (1) and said conductive coating (3) are removed thermally and chemically. The method does not need to pre-set the stone (4) on a metal piece before electroforming, therefore the processing is simplified and thus greatly reduces the cost.

Owner:K & M JEWELRY

Technical for manufacturing jewelry by using hard gold

InactiveCN101810387AHigh hardnessIncrease elasticityJewelleryElectroforming processesManufacturing technologyEngineering

The invention provides a process for manufacturing jewelry by using hard gold. The technique mainly comprises the following steps of: 1, molding; 2, opening a jelly mould; 3, injecting wax; 4, trimming the wax; 5, applying silver oil; 6, manufacturing a raw blank; 7, removing the wax; 8, removing silver; 9, welding; 10, modifying the mould; 11, picking stones and embedding stones; 12, treating the surface; and 13, carving by laser. The method ensures that the molecular structure of gold changes by utilizing hard gold jewelry manufacturing technology and applying the metal reinforcing technology in aerospace science and technology to jewelry manufacture and adjusting temperature, pH value, current, pulse power supply, additive and other technical parameters of electrotyping solution in an electrotyping process, thereby effectively improving the hardness and the elasticity of the gold. On the premise of ensuring the purity of the gold, the hardness of the gold is 4 times that of the traditional gold, so that the technique requirements of the fashion jewelry design are met. The gold jewelry and art decorations manufactured by the method cannot be easily scratched or deform, so that the artistic quality of the jewelry and decorations can be greatly improved.

Owner:惠州市博艺黄金珠宝有限公司

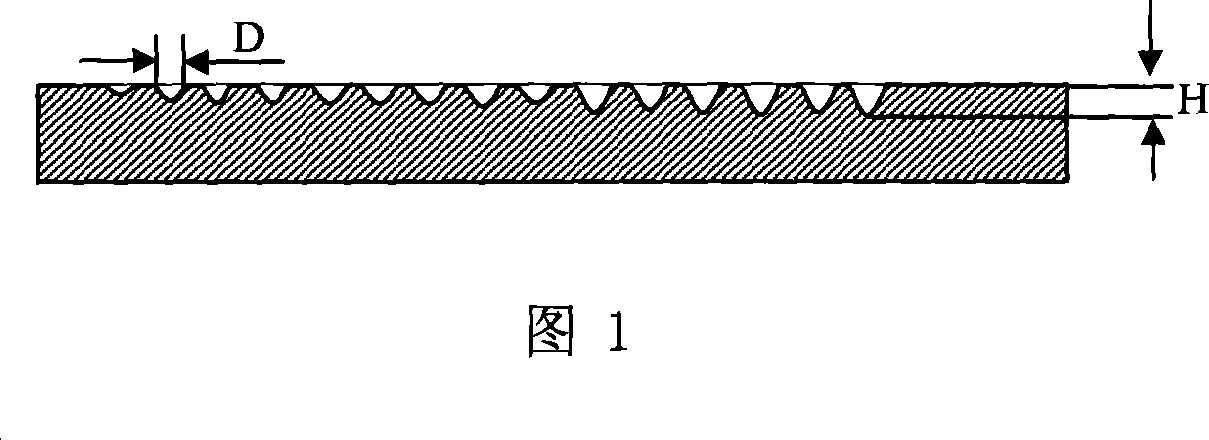

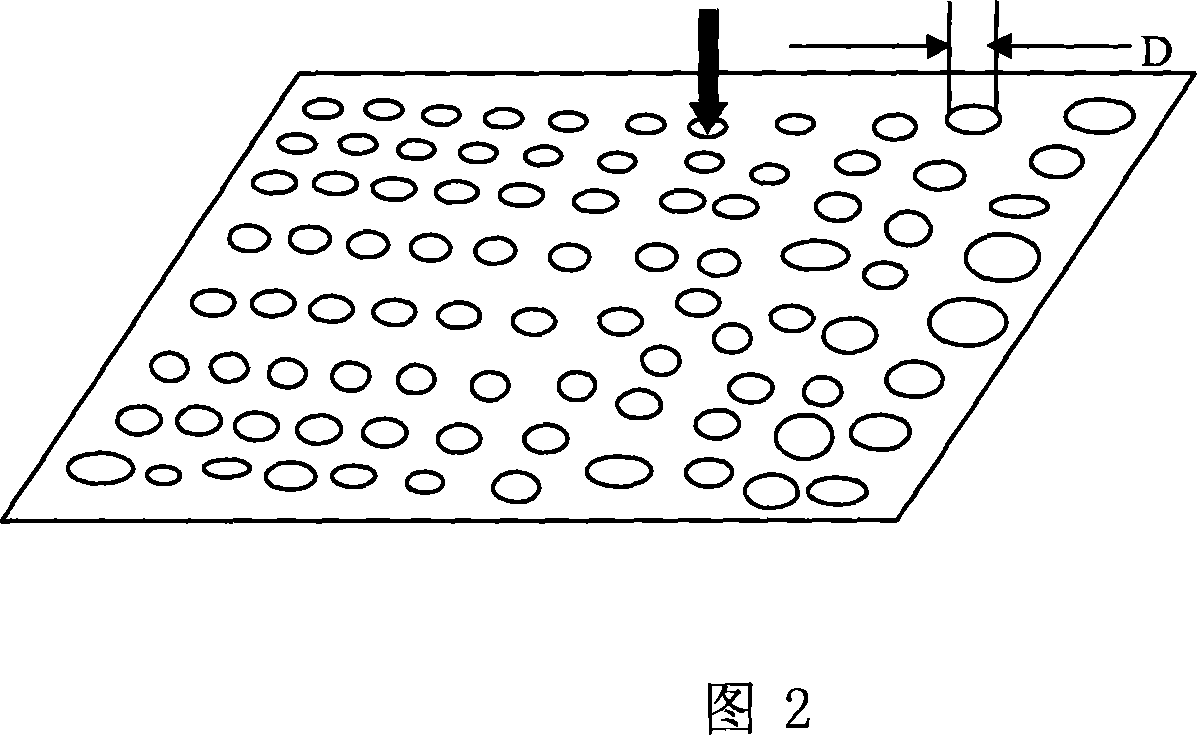

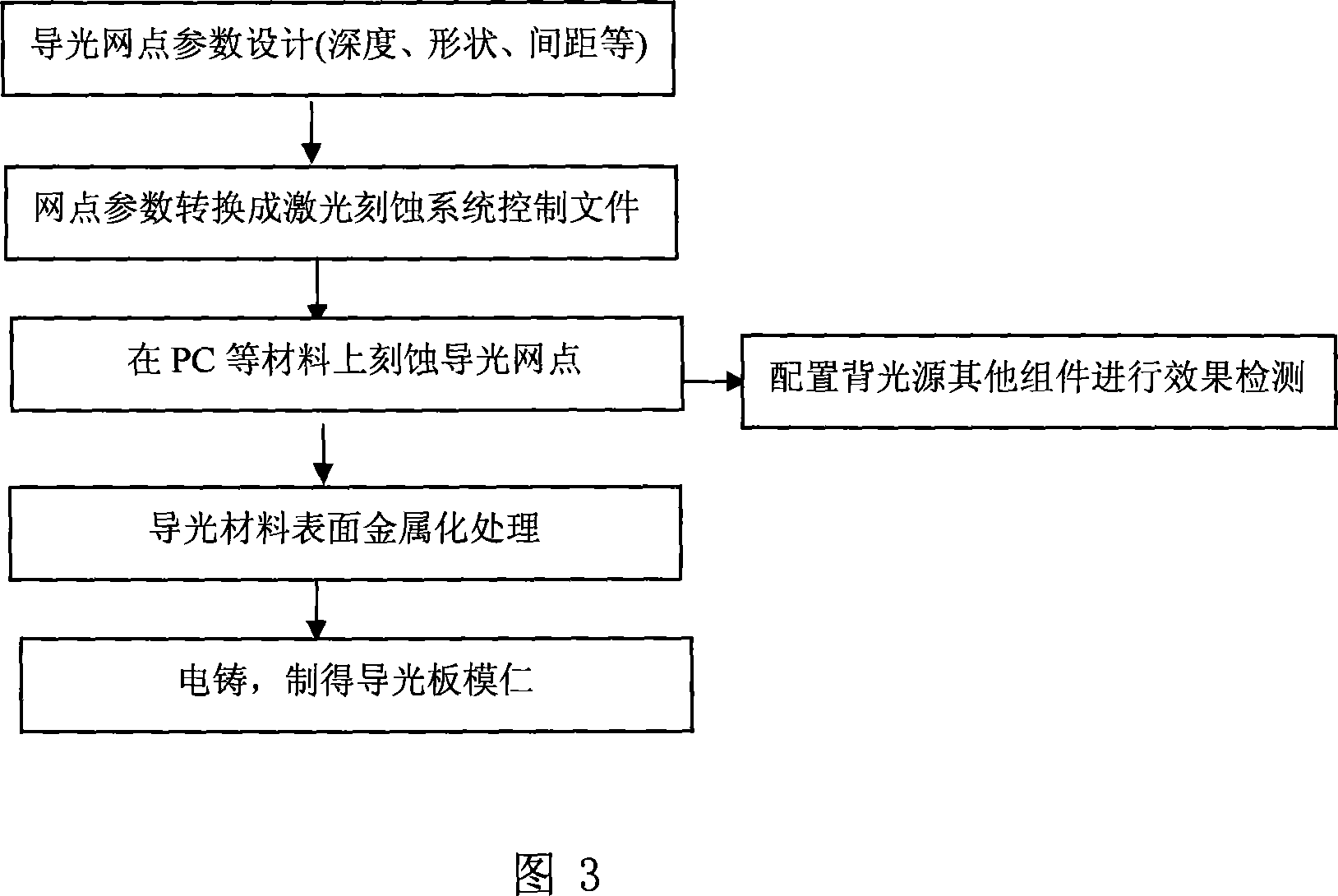

Manufacturing method of light guiding board/ light guiding film mould core

InactiveCN101034183AQuick responseEasy to adjustLaser detailsOptical light guidesLight guideLight beam

This invention discloses a method of producing lightguide plate / lightguide membrane mode kernel, according to the lightguide-demand, form lightguide network structure on the surface of the lightguide substrate, the features are: use of high-power pulsed lasers, through beam shaping, collimate light focused directly on the substrate surface etching lightguide networks, obtain lightguide plate monomeric unit, metallizing the surface of the lightguide plate monomeric unit etched, Further electroforming, meanwhile, In nickel metal deposited on the surface, make nickel metal deposited and lightguide substrate separated, then get the lightguide plate / lightguide membrane mode kernel needed. At the same time, the lightguide plate monomeric unit etched can be used as backlight module, dispose other backlight module; the invention can detect the lightguide performance. This invention can be carried out rapid for evaluating the design of networks and providing samples, after metal processing and electroforming process, the lightguide plate / lightguide membrane mode kernel can be made, greatly reducing the production cycle, simplify the process and reduce the cost ,have a faster market response capability.

Owner:SVG TECH GRP CO LTD +1

Method of fabrication, device structure and submount comprising diamond on metal substrate for thermal dissipation

InactiveUS20120288698A1Hinder device functionalityHinder subsequent processingSemiconductor/solid-state device detailsSolid-state devicesDevice materialElectroforming

A method of fabrication, a device structure and a submount comprising high thermal conductivity (HTC) diamond on a HTC metal substrate, for thermal dissipation, are disclosed. The surface roughness of the diamond layer is controlled by depositing diamond on a sacrificial substrate, such as a polished silicon wafer, having a specific surface roughness. Following deposition of the diamond layer, an adhesion layer, e.g. comprising a refractory metal, such as tantalum, and at least one layer of HTC metal is provided. The HTC metal substrate is preferably copper or silver, and may be provided by electroforming metal onto a thin sputtered base layer, and optionally bonding another metal layer. The electrically non-conductive diamond layer has a smooth exposed surface, preferably ≦10 nm RMS, suitable for patterning of contact metallization and / or bonding to a semiconductor device. Methods are also disclosed for patterning the diamond on metal substrate to facilitate dicing.

Owner:ADVANCED DIAMOND TECH

Millimeter wave rectangular-circular transition integrated corrugated horn antenna and processing method

InactiveCN101662072AAvoid discontinuitiesSmall VSWRWaveguide hornsWaveguide type devicesHorn antennaStanding wave ratio

The invention discloses a millimeter wave rectangular-circular transition integrated corrugated horn antenna and a processing method and adopts integrated disposable electroforming for processing. A shell is internally provided with an inner cavity communicating from top to bottom in the shell, and the inner cavity consists of a corrugated inner wall radiation section, a circular waveguide extension section, a rectangular-circular transition waveguide section and a rectangular waveguide extension section from top to bottom, and one end of the port of the rectangular waveguide extension sectionin the shell is assembled with a connection part through sleeve joint. The corrugated horn antenna is electroformed by an inner core with the structure the same as that of the inner cavity, the integrated structure is adopted instead of various independent parts, the discontinuity of inner section change and deteriorated smoothness of a transition part caused by the processing dimension difference of all components, assembly and positioning error and other reasons are avoided, voltage standing wave ratio is reduced and antenna performance is improved, and compared with the traditional discrete part scheme, the scheme also reduces the requirement on processing accuracy properly. In the invention, the antenna performance, production technology complexity and time cost are all improved.

Owner:BEIHANG UNIV

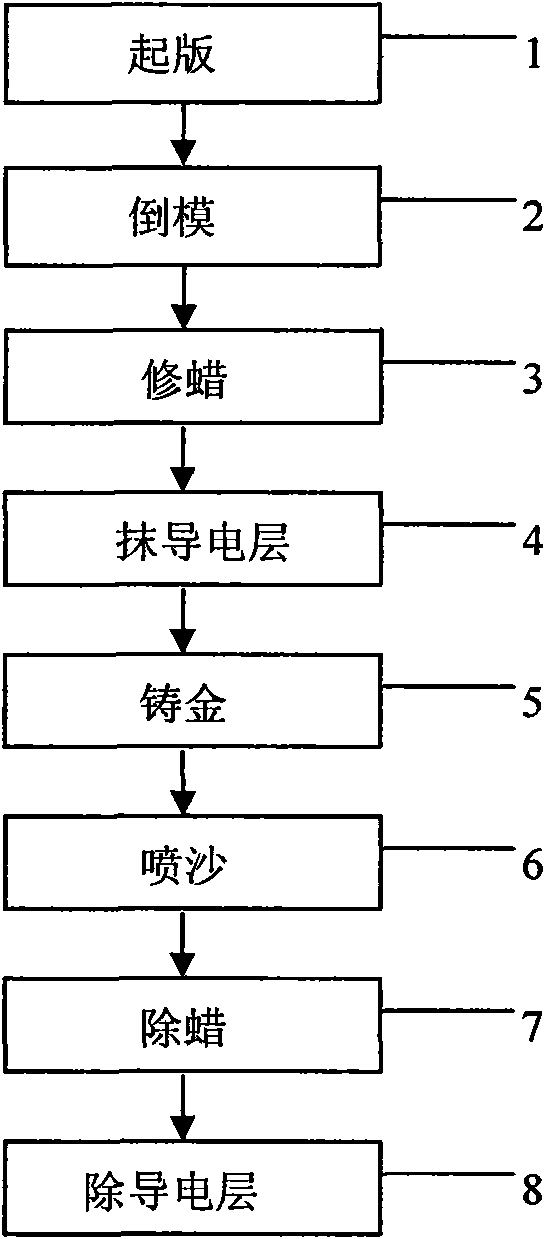

Method for electroforming hard gold product

InactiveCN101560676AIncrease in sizeHigh hardnessElectroforming processesChemical structurePotassium

The invention relates to a method for electroforming hard gold products. The method comprises the following steps: template picking, mould pouring, wax repairing and electric conducting layer coating are carried out to obtain a wax mould of a gold product to be processed, and a layer of electric conductive oil is coated on the surface of the wax mould; and a titanium net is taken as anode in the gold electroforming step, the wax mould coated with the electric conductive oil is put in an electrotyping bath as cathode, the electroforming solution is put in the electrotyping bath and includes sulfurous acid gold potassium, ammonium sulfite and potassium citrate, wherein the sulfurous acid gold potassium is combined with the ammonium sulfite, a trivalent gold ion is reduced into a univalent gold ion, the univalent gold ion generates close crystal grains, the close crystal grains are combined through the potassium citrate to form complexing gold through PH buffer solution, the gold is deposited on the wax mould to form a casting gold layer, and the half-finished product is prepared; and the wax film in the half-finished product and the electric conductive layer are removed in the wax removal step and the electric conductive layer removal step to obtain the finished product. The volume and the hardness of the gold product are changed by using the variation of the chemical structure of the gold ion, so that the hardness, the volume and the toughness of the gold product meet the standards simultaneously.

Owner:武汉金凰珠宝股份有限公司

Superfine electroform technique of supercutical fluid, and equipment

InactiveCN101092716AImprove deposition conditionsQuality improvementElectroforming processesEngineeringBottle

This invention discloses process and apparatus for micro electroforming by using supercritical fluid. The process comprises: (1) generating supercritical fluid electroforming solution in the reactor of a fine deposition unit; (2) controlling the power source by a control unit, selecting appropriate electric parameters, and depositing metal ions onto the photoresist patterns of the cathode of the fine deposition unit; (3) removing residual photoresist to obtain fine component. The apparatus comprises a CO2 steel bottle, a high-pressure pump, a DC power source, a control unit, a fine deposition unit, a magnetic stirrer, a thermostatic bath, a backpressure valve and a recovery device. The method and apparatus in this invention can deposit compact, smooth and clear fine component, and the waste supercritical fluid electroforming solution can be recovered and recycled.

Owner:HAIAN GASOLINEEUM SCI RES INSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com