Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127 results about "Metal lattice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

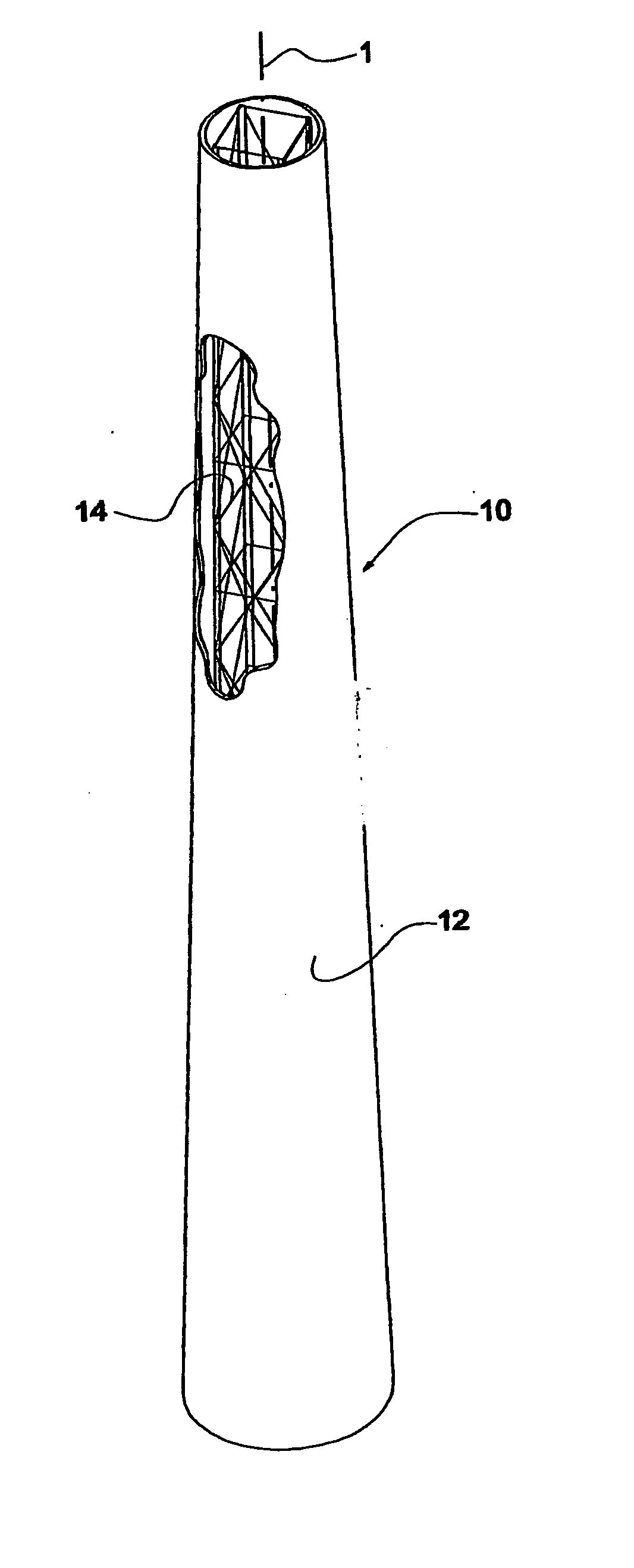

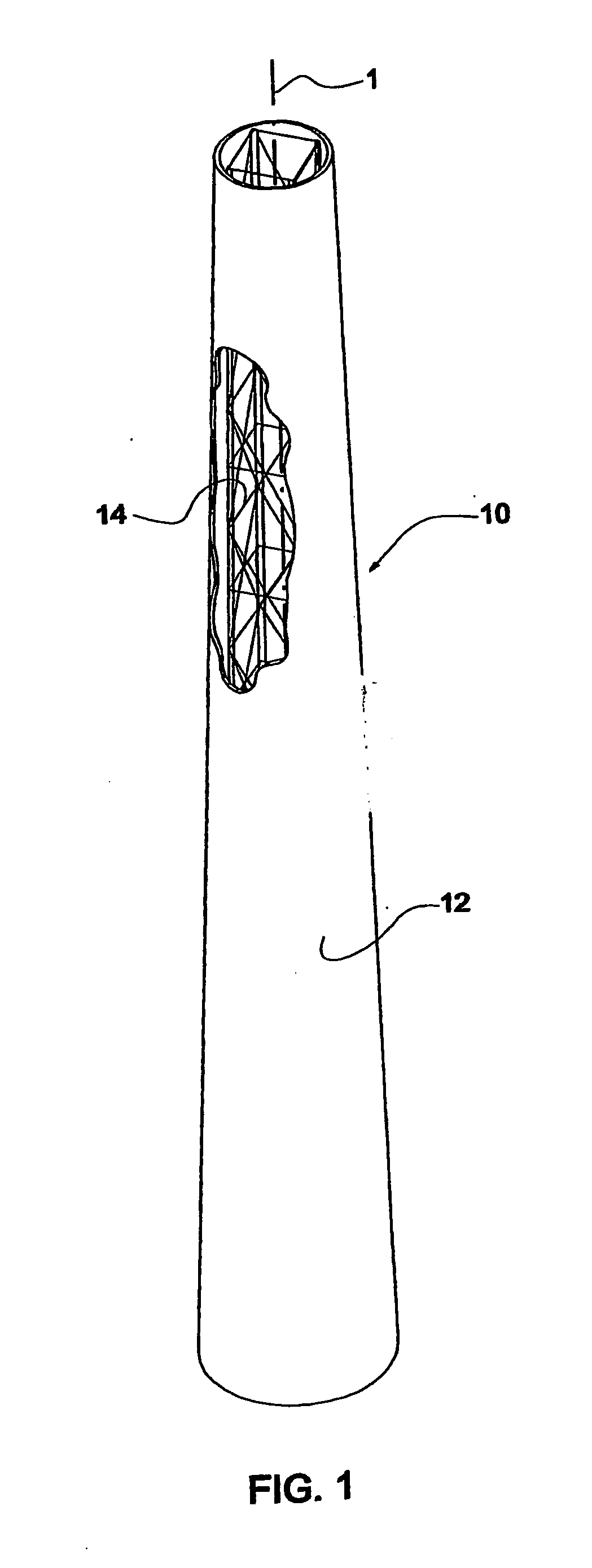

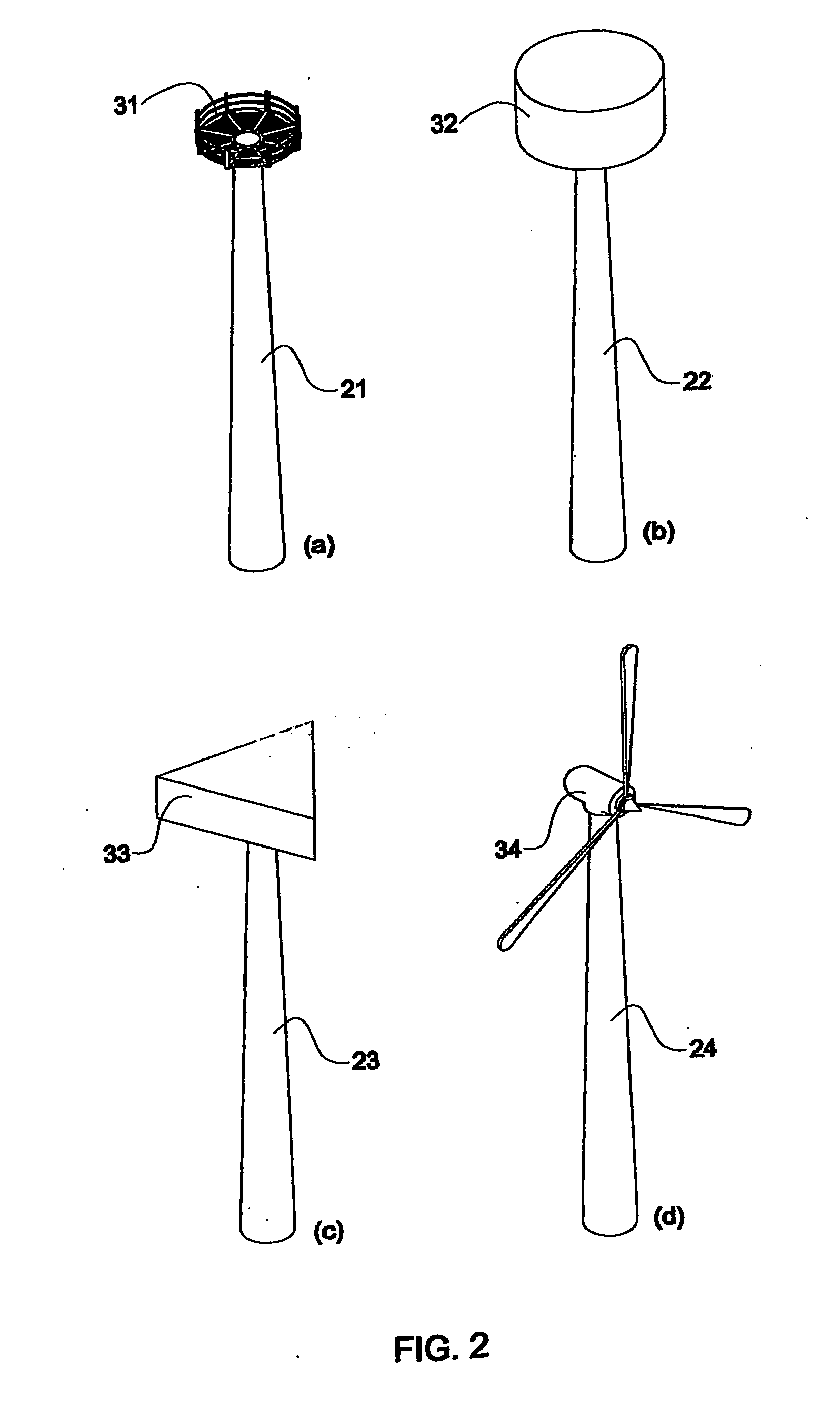

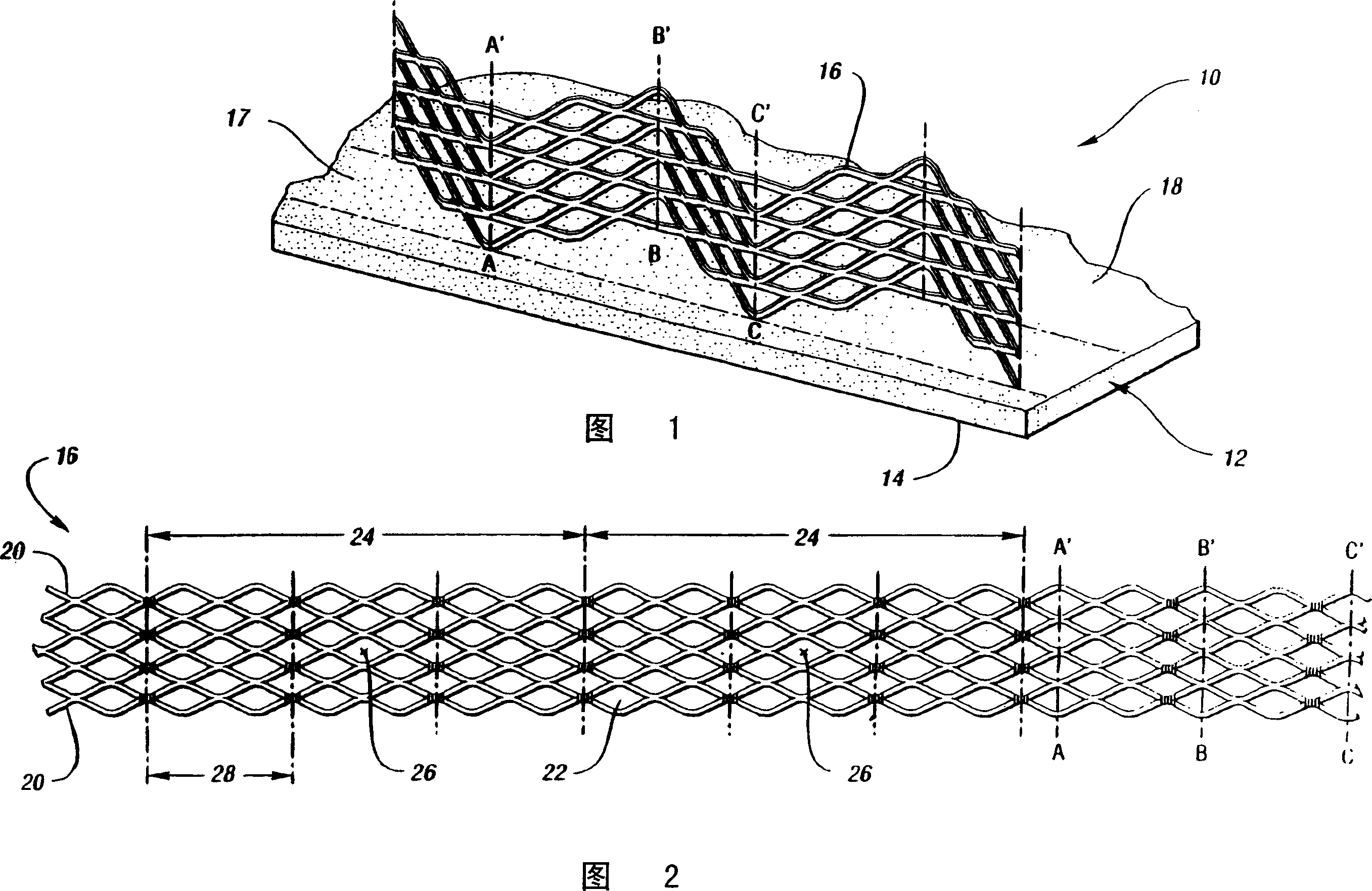

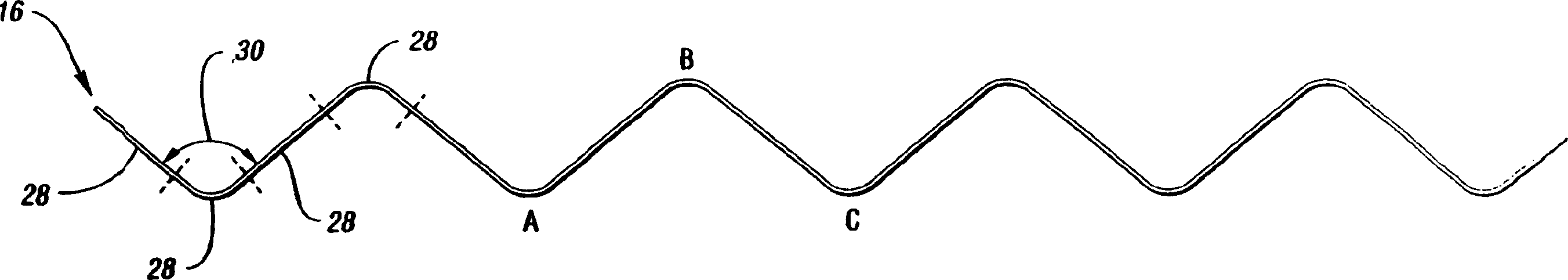

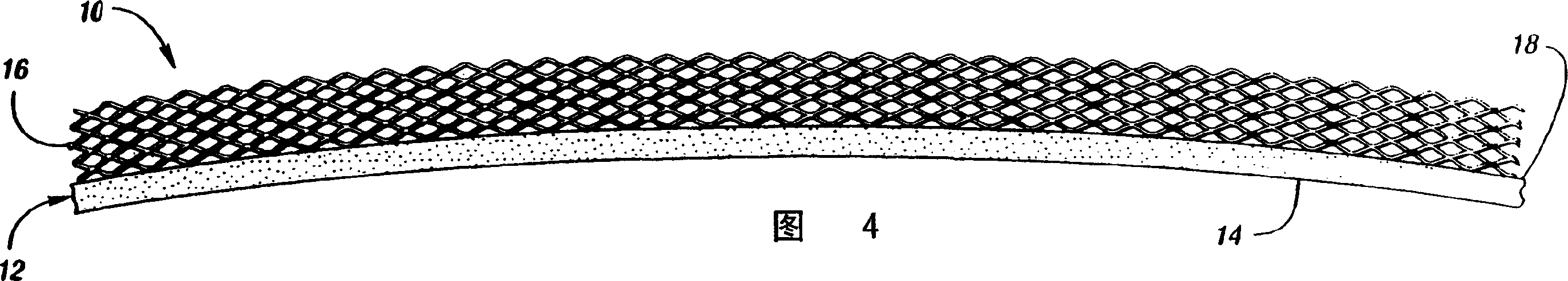

Lattice tower disguised as a monopole

InactiveUS20050166521A1Efficient solutionTransmission of vertical forceFloorsGirdersEngineeringMetal lattice

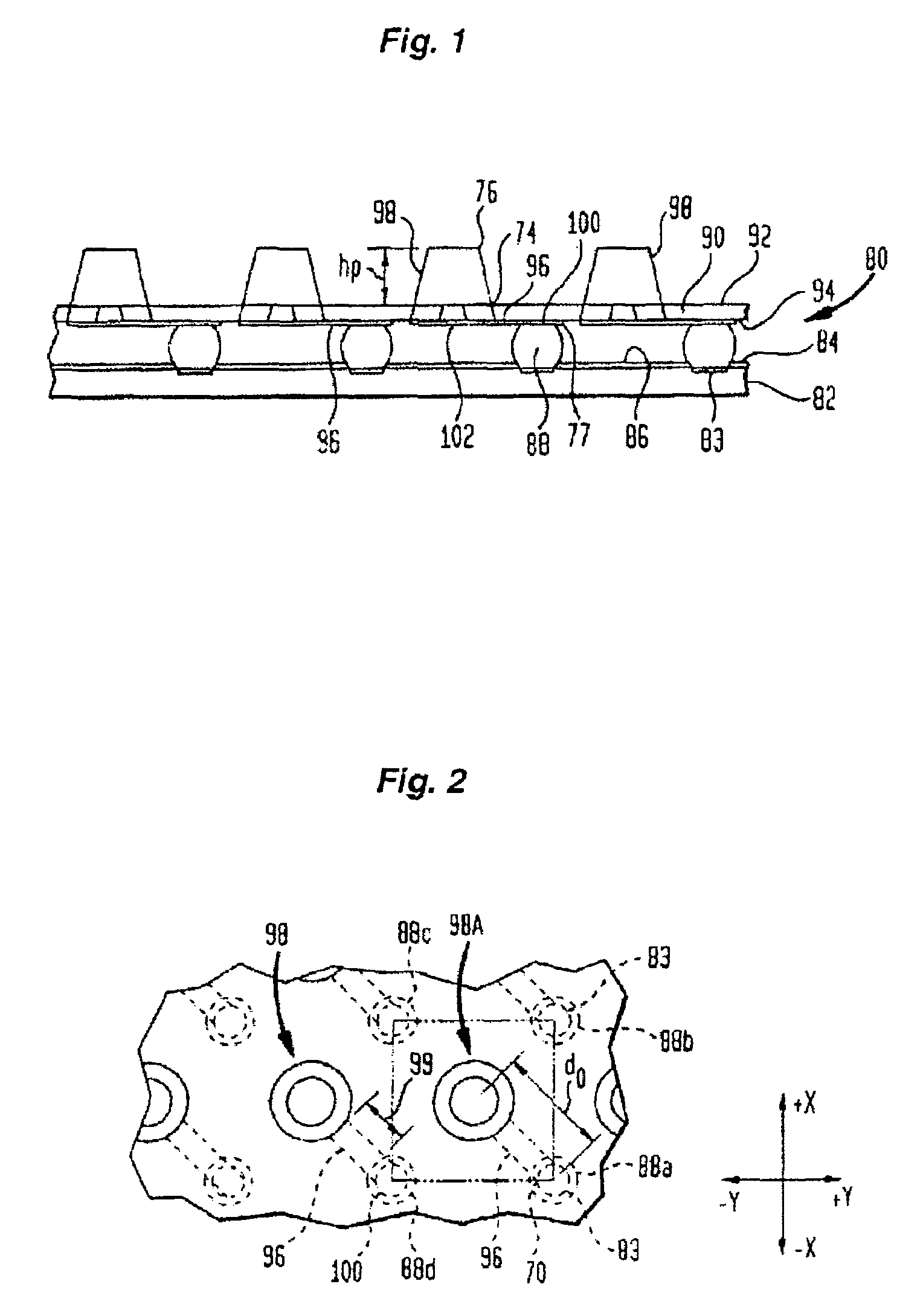

A solution for a tower (10) that may be substantially tall, characterized by the appearance of a monopole, the capacity to support large objects and consequently sustain great lateral loads generated by wind or earthquake, the facility to conceal vertical access ladder and all other installations, such as antenna feeder cables, and the availability at an acceptable cost level. The heart of the invention is the basic concept of separation between the structurally functioning elements, which are kept concealed, and a non-structural shell (12) which provides the tower (10) the shape of a monopole. The tower (10) comprises, therefore, a tall metal lattice structure (14) having a central vertical axis (1) and certain apparatus for its anchoring to a foundation, concealed within a shell (12) concentric with said central vertical axis (1) and further characterized, at any given level, by a closed cross-section which is either circular or equi-sided polygonal, said shell (12) being internally secured to and supported by said lattice metal structure (14) in an appropriate density throughout its area, so as to maintain its shape when subjected to wind loads or any other likely loads.

Owner:SILBER MEIR

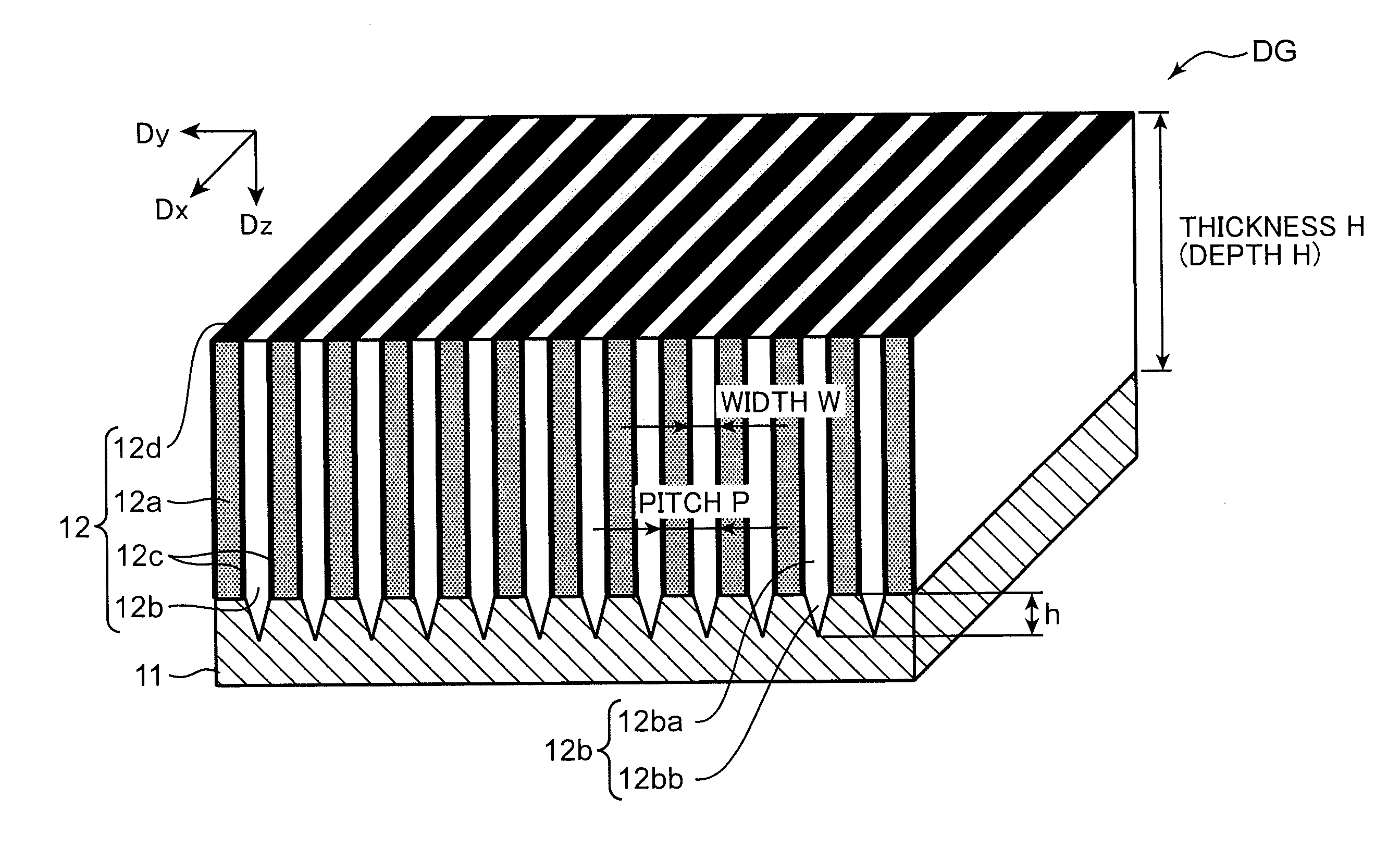

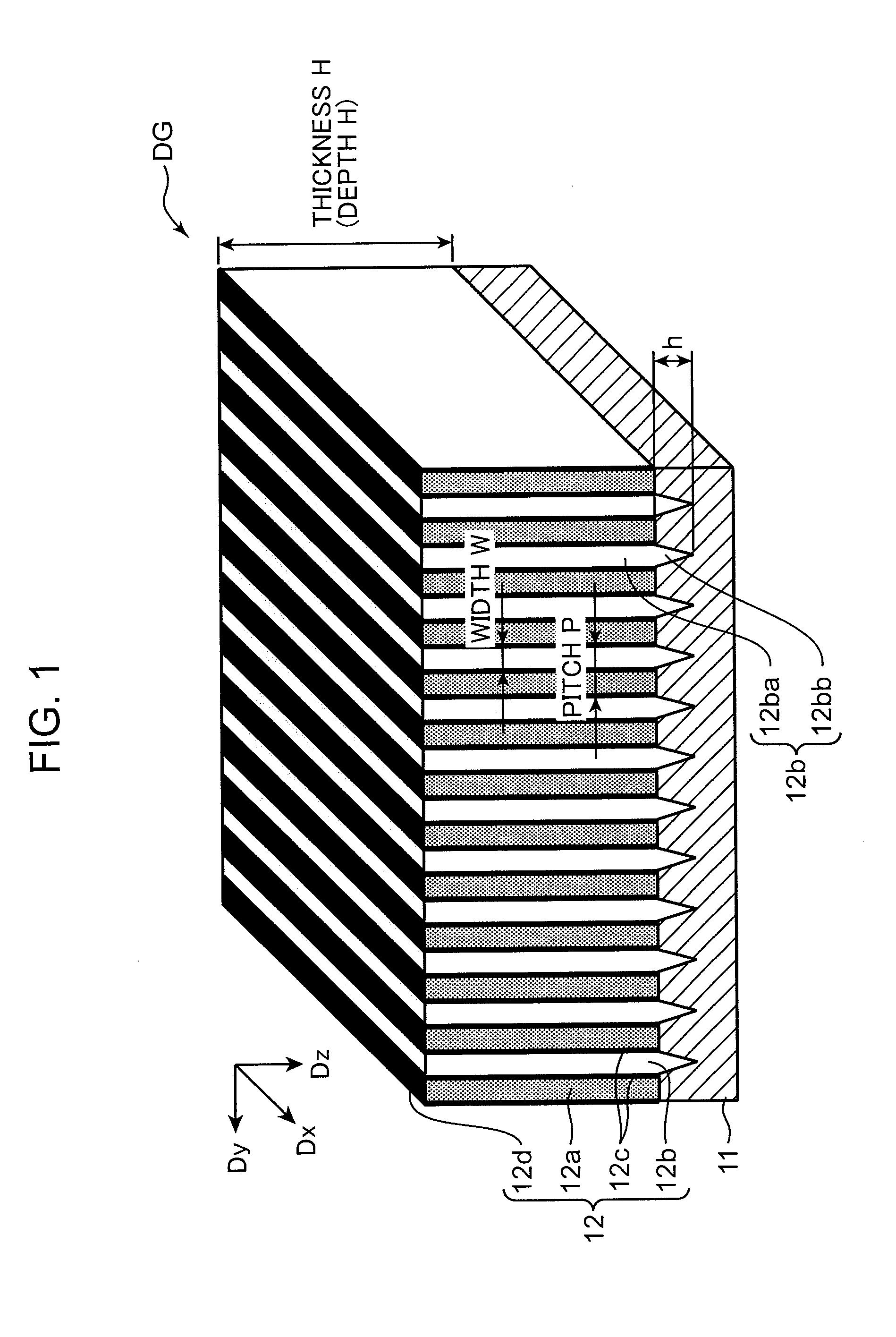

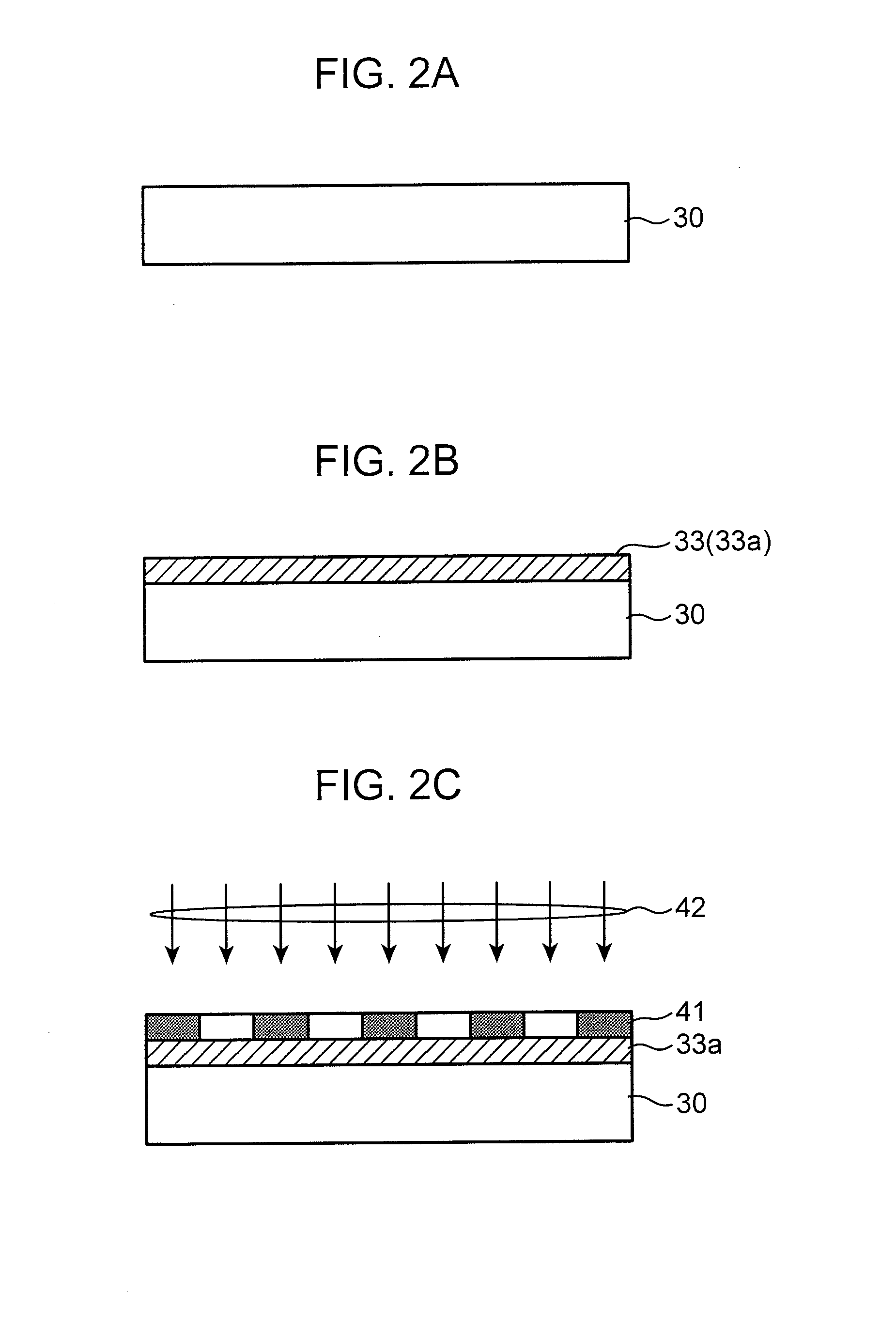

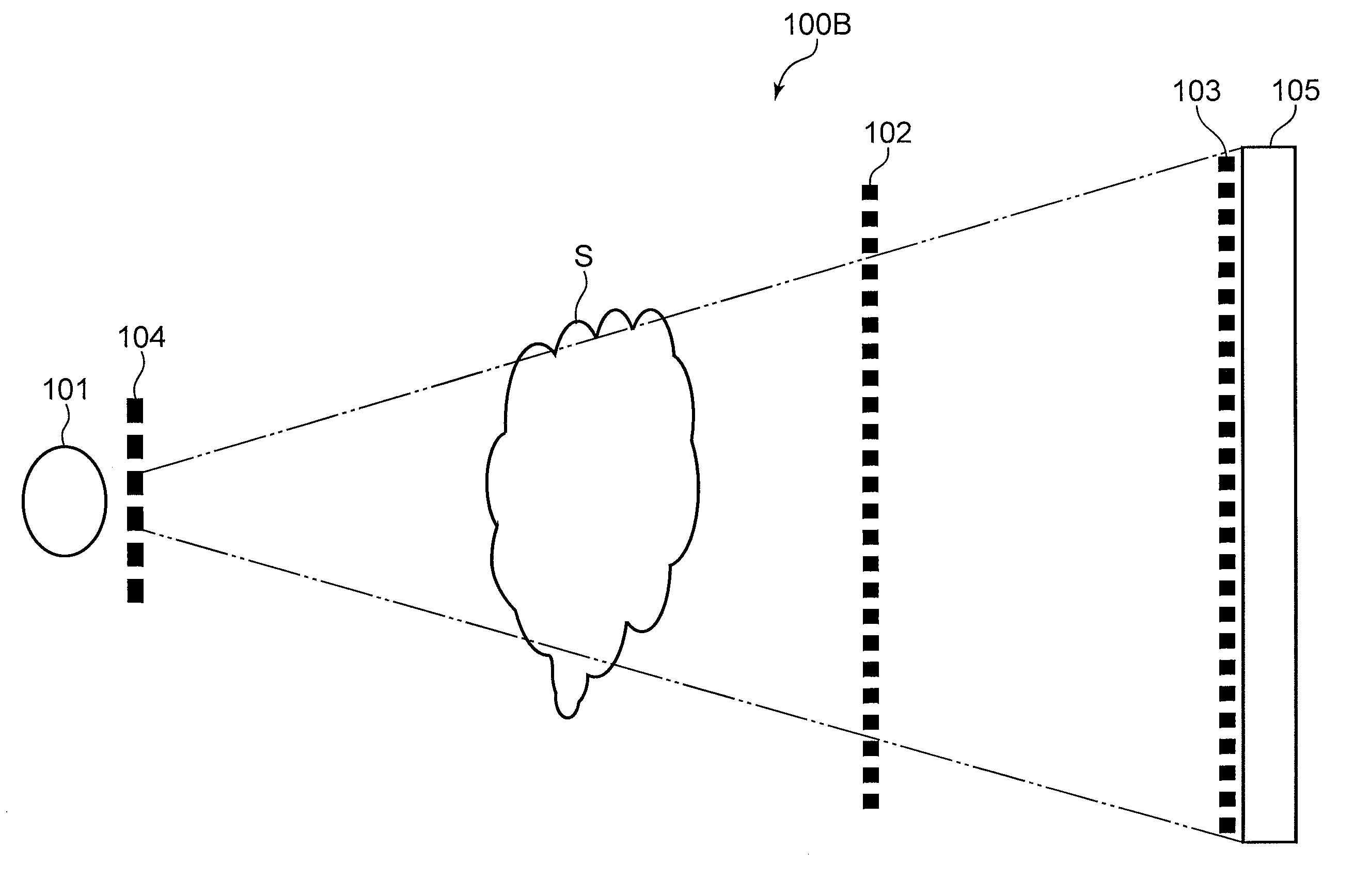

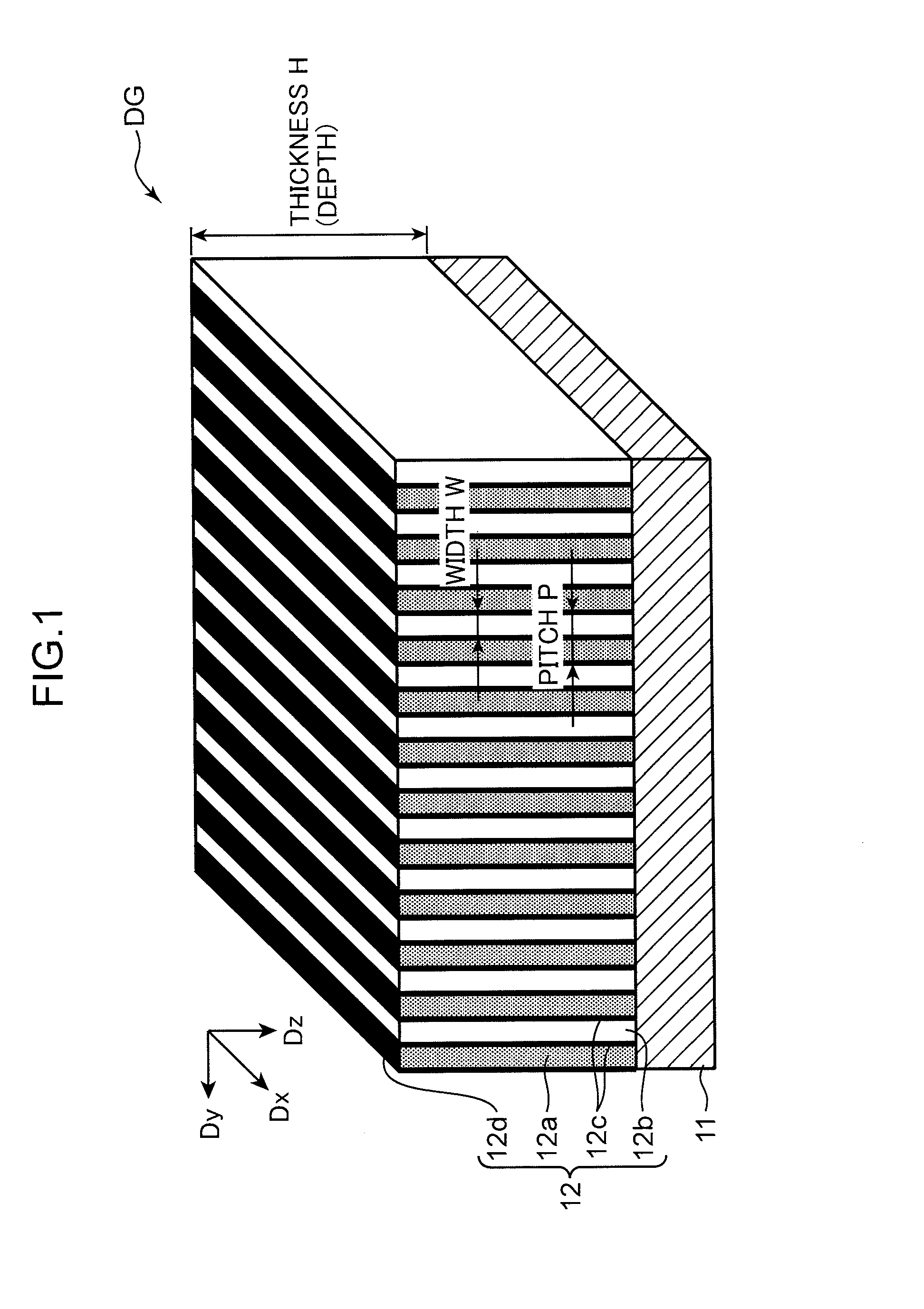

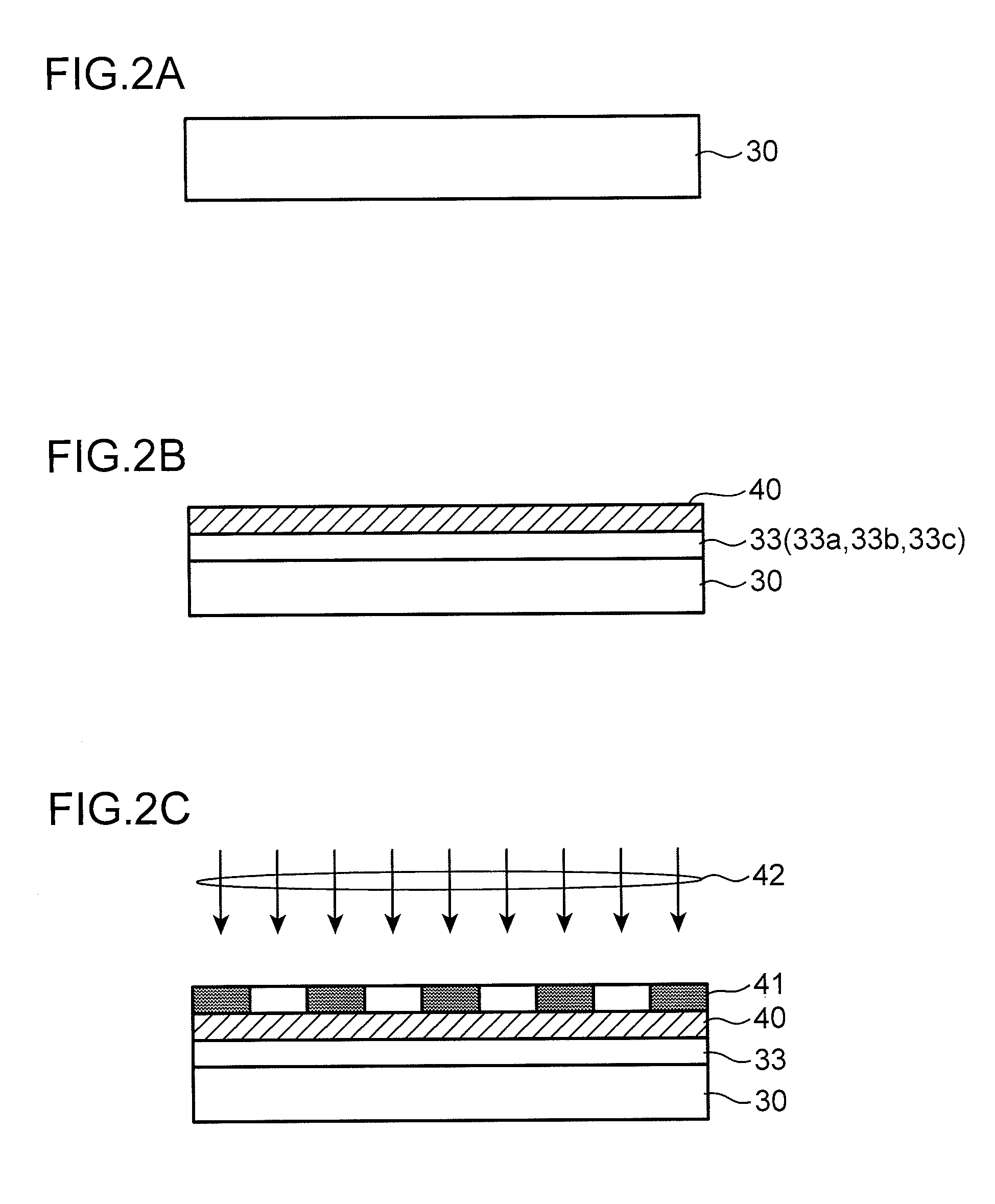

Metal Lattice Production Method, Metal Lattice, X-Ray Imaging Device, and Intermediate Product for Metal Lattice

InactiveUS20140241493A1Uniform deposition lengthHigh aspect ratioAnodisationImaging devicesX-rayMetal lattice

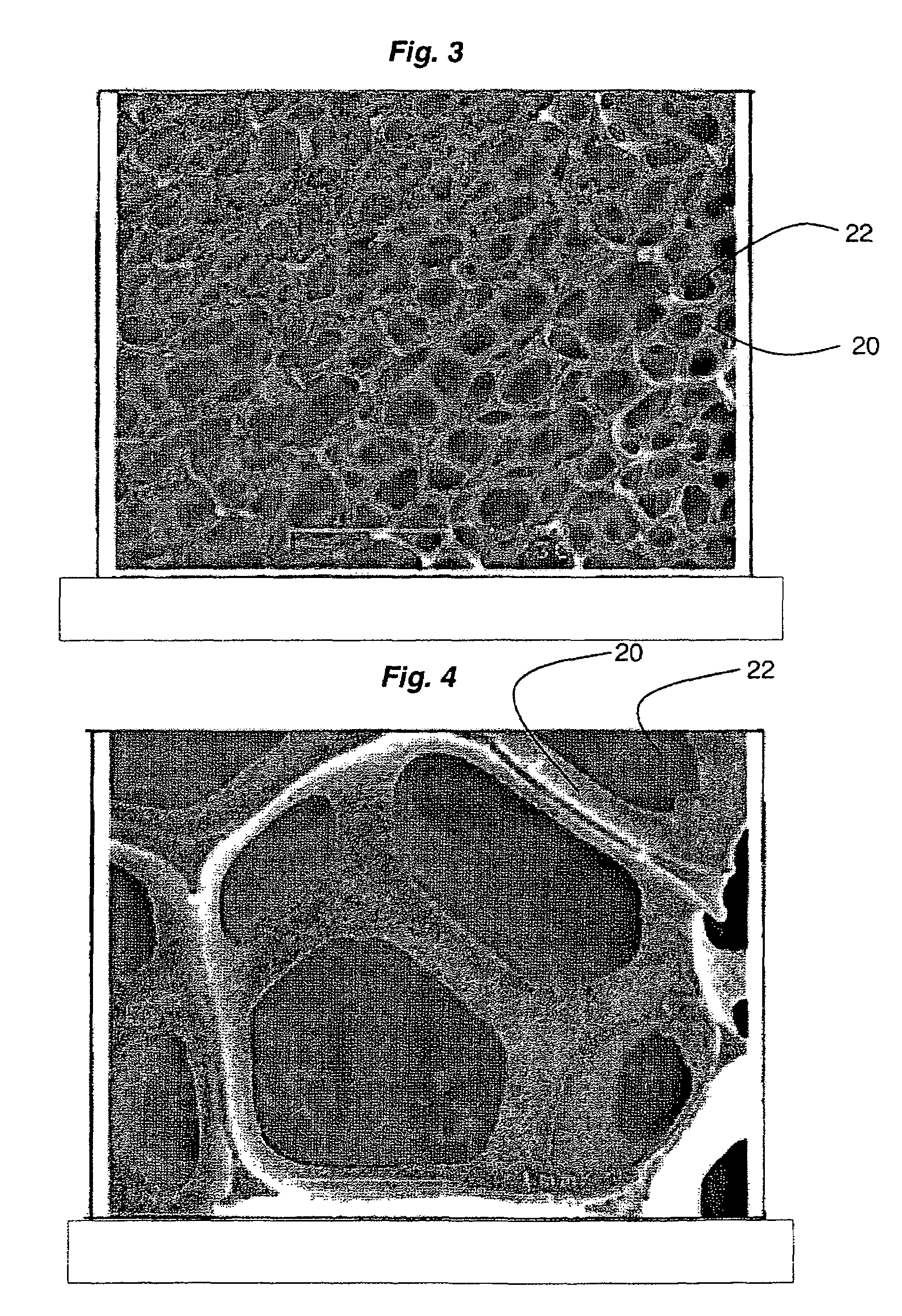

Method for manufacturing a metal grating structure, wherein, after a concave part having an insulating layer on an inner surface thereof is formed in a silicon substrate, a portion of the insulating layer formed on a bottom part of the concave part is removed, and the silicon substrate at the bottom part of the concave part is etched to increase the surface area of the bottom part of the concave part as compared with a state before the etching, followed by filling the concave part with metal by an electroforming method.

Owner:KONICA MINOLTA INC

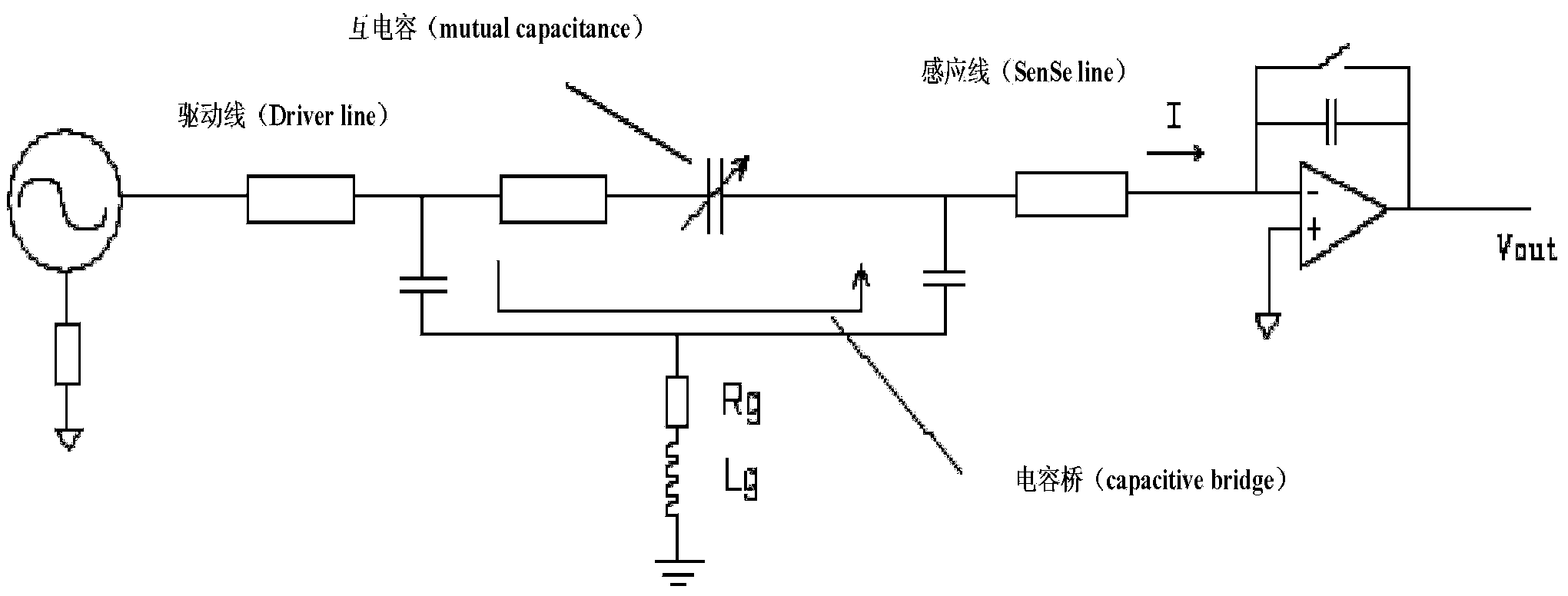

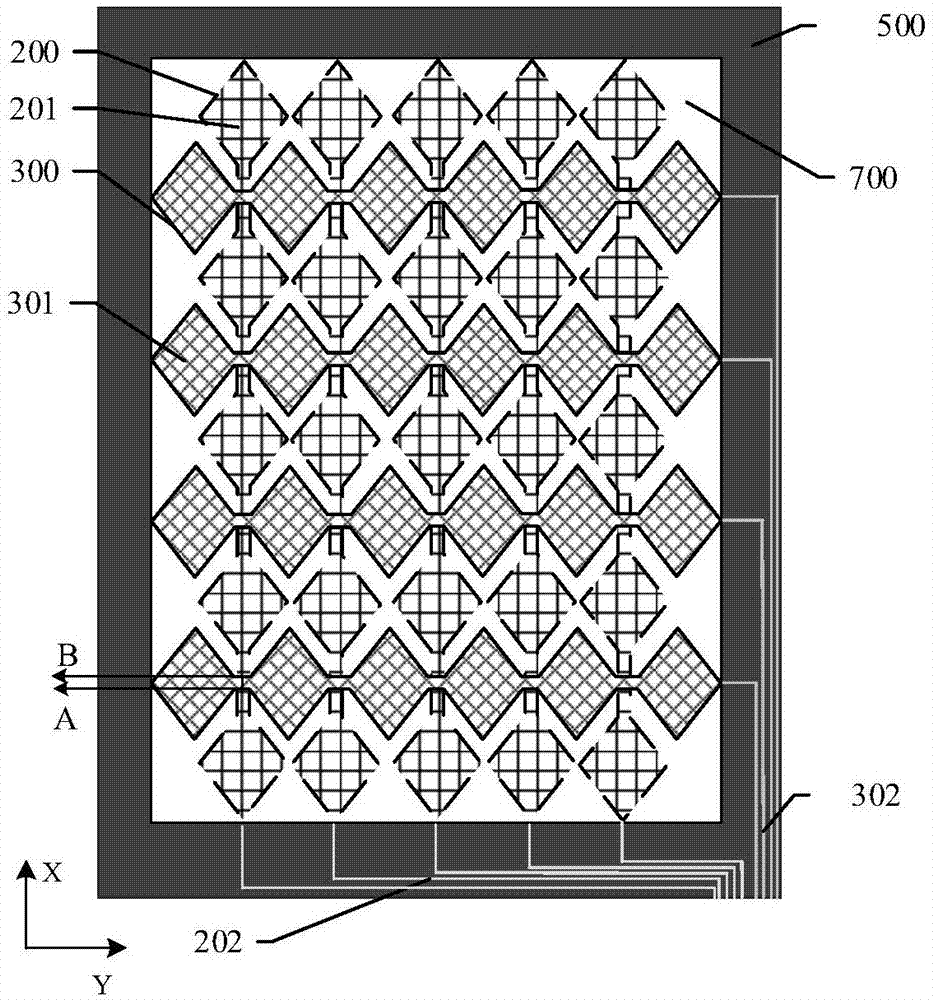

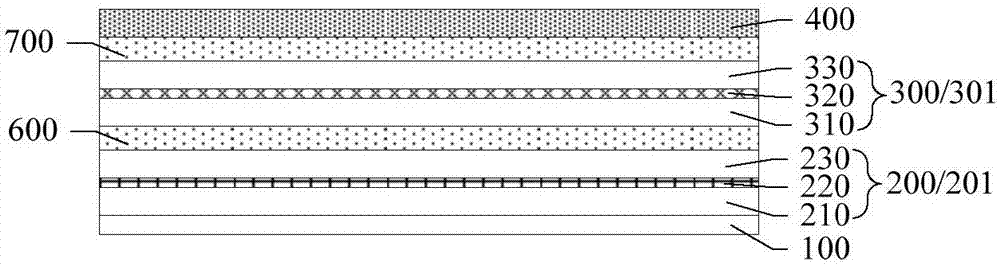

Embedded type touch control display device

ActiveCN103901650ALower resistanceReduce parasitic capacitanceStatic indicating devicesNon-linear opticsControl layerDisplay device

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

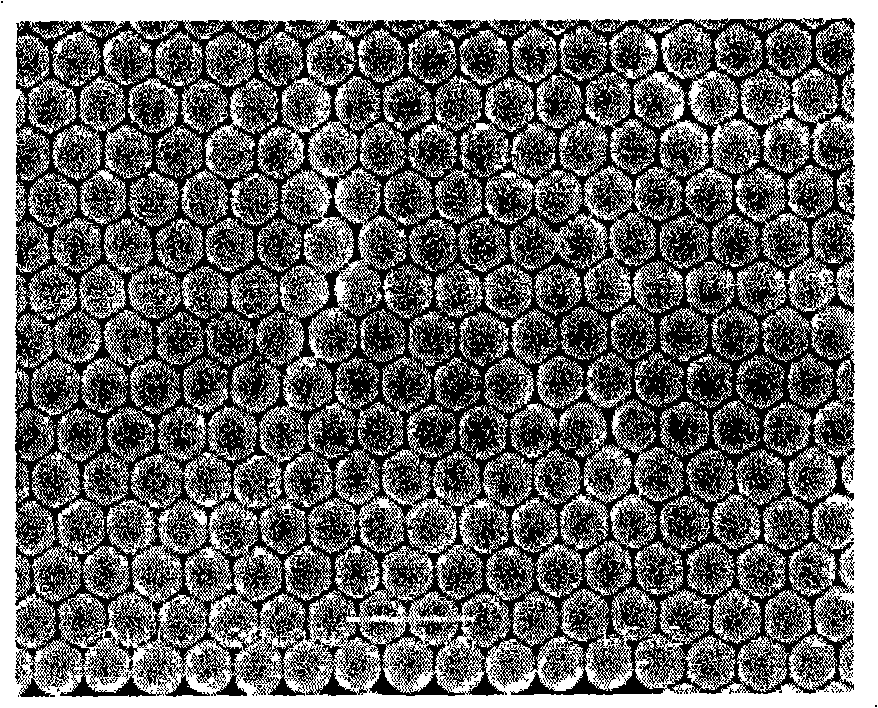

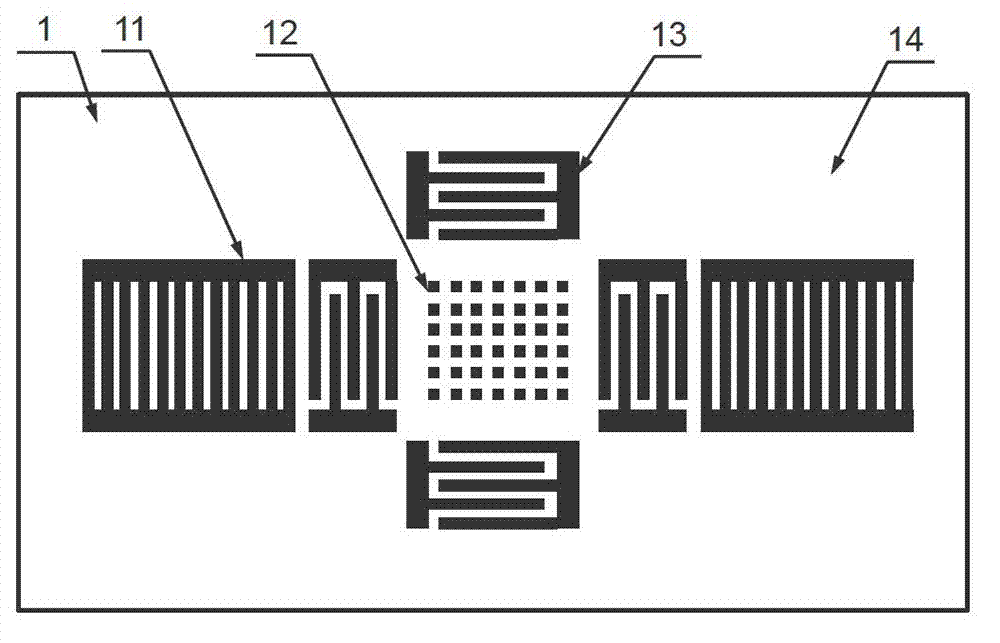

Surface plasma resonance image-forming nanostructure array chip preparation method

ActiveCN101339128AClear edgesImprove uniformityPhase-affecting property measurementsScattering properties measurementsPeriodic nanostructuresEvaporation

The invention relates to a preparation method of nanostructured array chip with surface plasma for resonance imaging. The preparation method is characterized by comprising the following steps: (1) selecting and cleaning a substrate; (2) using a vacuum evaporated coating to coat a first metal film on the substrate; (3) self-assembling a layer of polystyrene nanoparticles on the metal film; (4) coating a second metal film in a way of evaporation on the self-assembled layer so as to fill the gas between balls; (5) eliminating the nanoparticles with the Lift off technology; (6) using laser direct writing machine to manufacture a lattice mask plate of the level of micron; (7) adopting the photolithography to transmit the mask figure to the substrate; (8) acquiring the lattice figure through developing and stripping of photoresist; (9) using a chemical method to eliminate the excessive metal and photoresist; thus the metal lattice chip of the cyclical nanostructure can be formed. The method adopts the polystyrene nanoparticles for self-assembly so as to prepare the cyclical nanostructure, and thus is suitable for massive production of the nanostructure.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

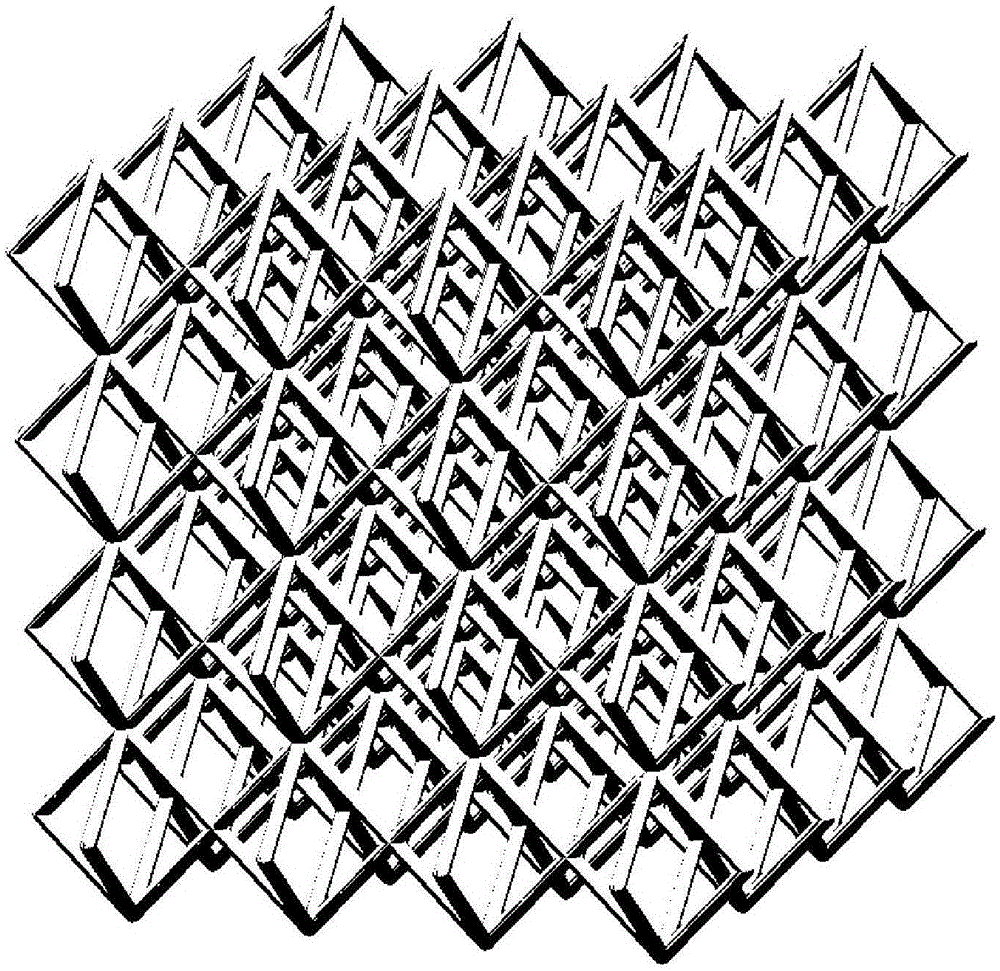

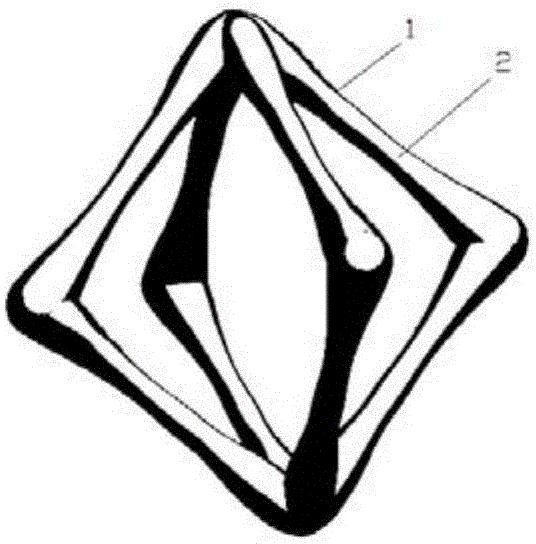

Section-variable metal lattice structure and machining method thereof

The invention discloses a section-variable metal lattice structure and a machining method thereof. The section-variable metal lattice structure comprises a plurality of section-variable lattice units arranged in the space. Each section-variable lattice unit is formed by connecting a plurality of section-variable rod pieces. The section-variable metal lattice structure is formed by conducting sintering layer by layer through a laser melting technology. A working bin of a metal powder sintering machine is kept sealed before machining with nitrogen being protection gas. For the internal force characteristics of all parts of the rod pieces, the rod pieces of the metal lattice units are optimized. Compared with an even lattice structure formed by weaving and welding metal wires, the section diameter of the section-variable rod pieces in the section-variable lattice structure is accurately determined by the internal force condition needing to be met under the load condition, materials forming the section-variable rod pieces are increased or decreased according to the stress gradient in the section-variable rod pieces, powder materials are saved, and the light characteristic is improved.

Owner:CHONGQING UNIV

Method for Manufacturing Metal Lattice, Metal Lattice Manufactured by the Method, and X-ray Imaging Device using the Metal Lattice

ActiveUS20130279651A1Imaging devicesHandling using diffraction/refraction/reflectionX-rayMetal lattice

According to a method for manufacturing a metal grating structure of the present invention, in filling a concave portion formed in a silicon substrate (30), for instance, a slit groove (SD) with metal by an electroforming method, an insulating layer (34) is formed in advance on an inner surface of the slit groove (SD) as an example of the concave portion by a thermal oxidation method. Accordingly, the metal grating structure manufacturing method is advantageous in finely forming metal parts of the grating structure. A metal grating structure of the present invention is manufactured by the above manufacturing method, and an X-ray imaging device of the present invention is incorporated with the metal grating structure.

Owner:KONICA MINOLTA INC

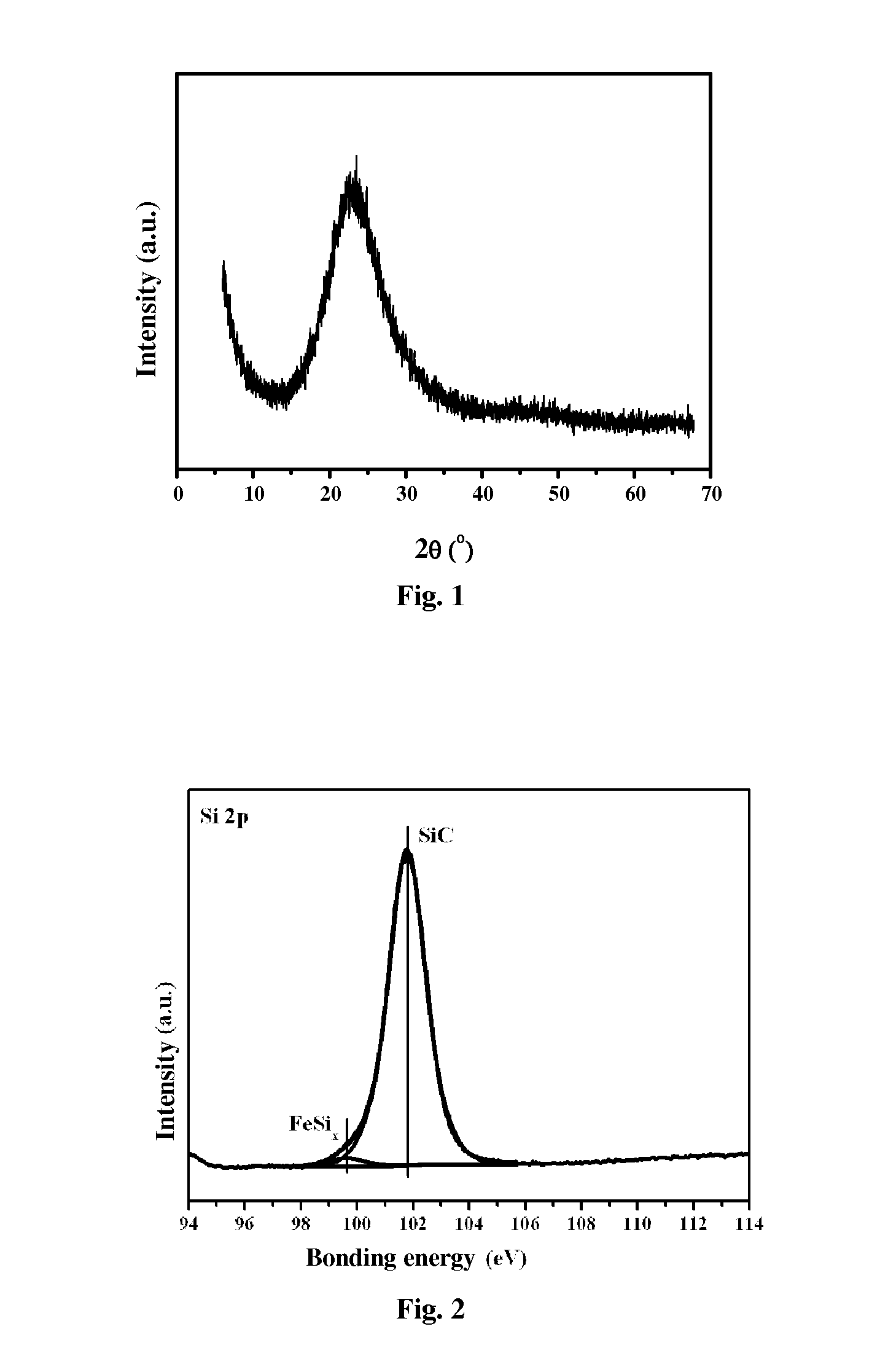

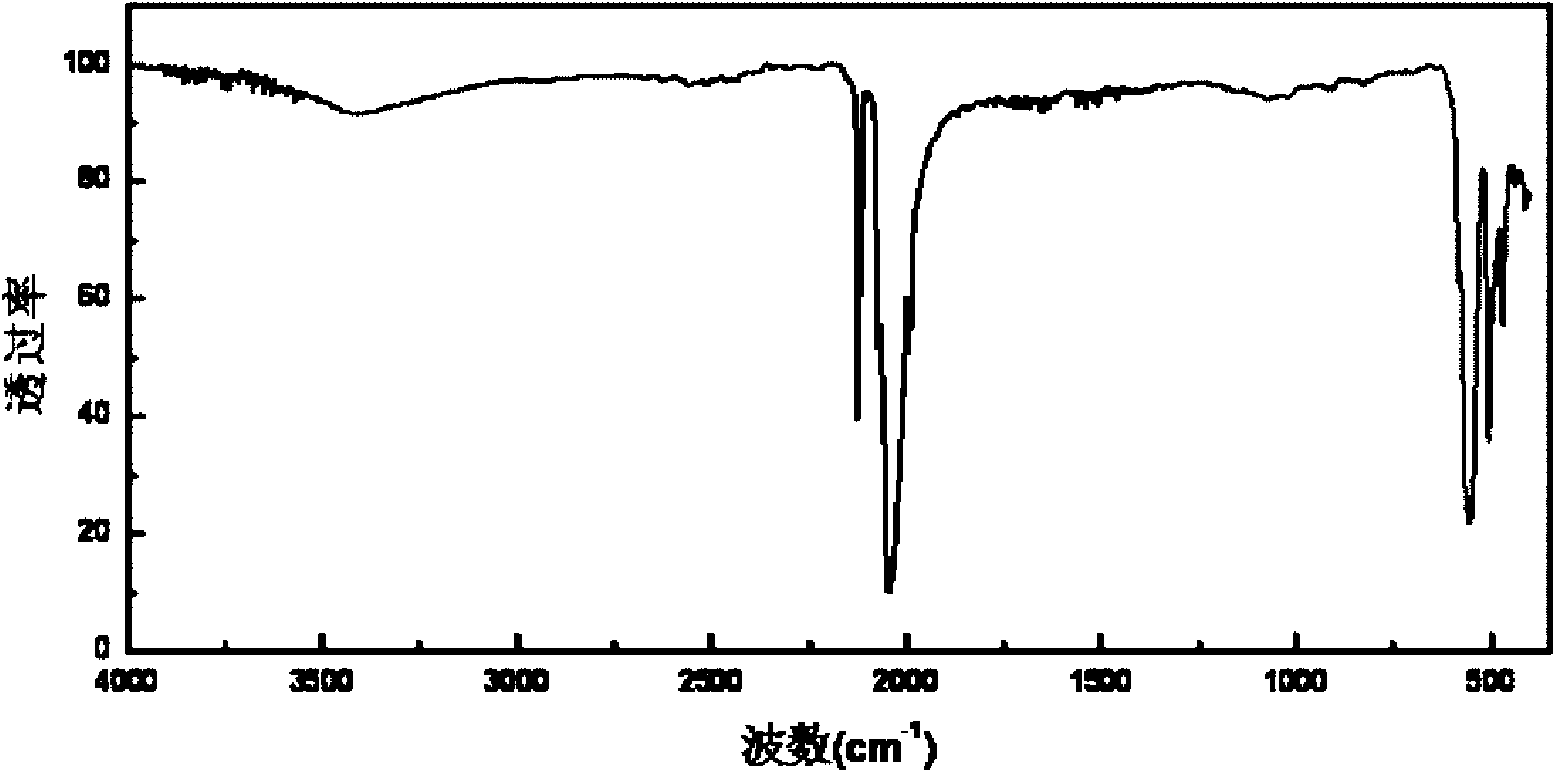

Synthesis of olefins from oxygen-free direct conversion of methane and catalysts thereof

ActiveUS20140336432A1Specific performanceGood dispersionOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPtru catalystFixed bed

The present invention is related to the preparation of a metal lattice-doping catalyst in an amorphous molten state, and the process of catalyzing methane to make olefins, aromatics, and hydrogen using the catalyst under oxygen-free, continuous flowing conditions. Such a process has little coke deposition and realizes atom-economic conversion. Under the conditions encountered in a fixed bed reactor (i.e. reaction temperature: 750˜1200° C.; reaction pressure: atmospheric pressure; the weight hourly space velocity of feed gas: 1000˜30000 ml / g / h; and fixed bed), conversion of methane is 8-50%. The selectivity of olefins is 30˜90%. And selectivity of aromatics is 10˜70%. There is no coking. The reaction process has many advantages, including a long catalyst life (>100 hrs), high stability of redox and hydrothermal properties under high temperature, high selectivity towards target products, zero coke deposition, easy separation of products, good reproducibility, safe and reliable operation, etc., all of which are very desirable for industrial application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

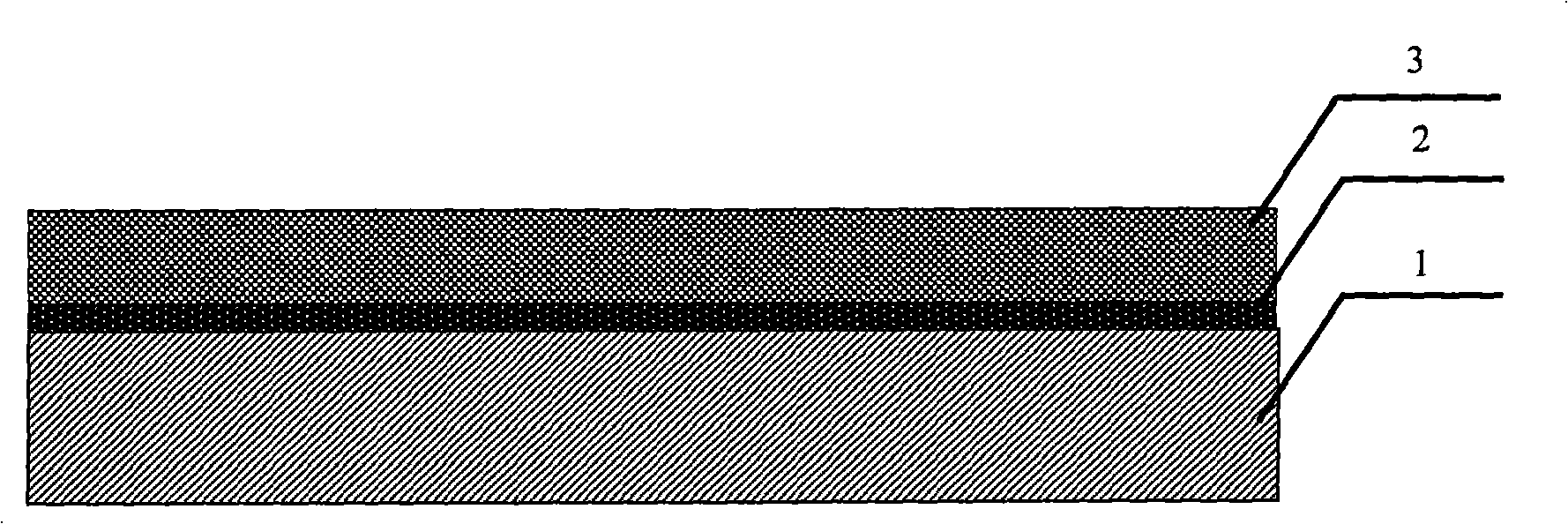

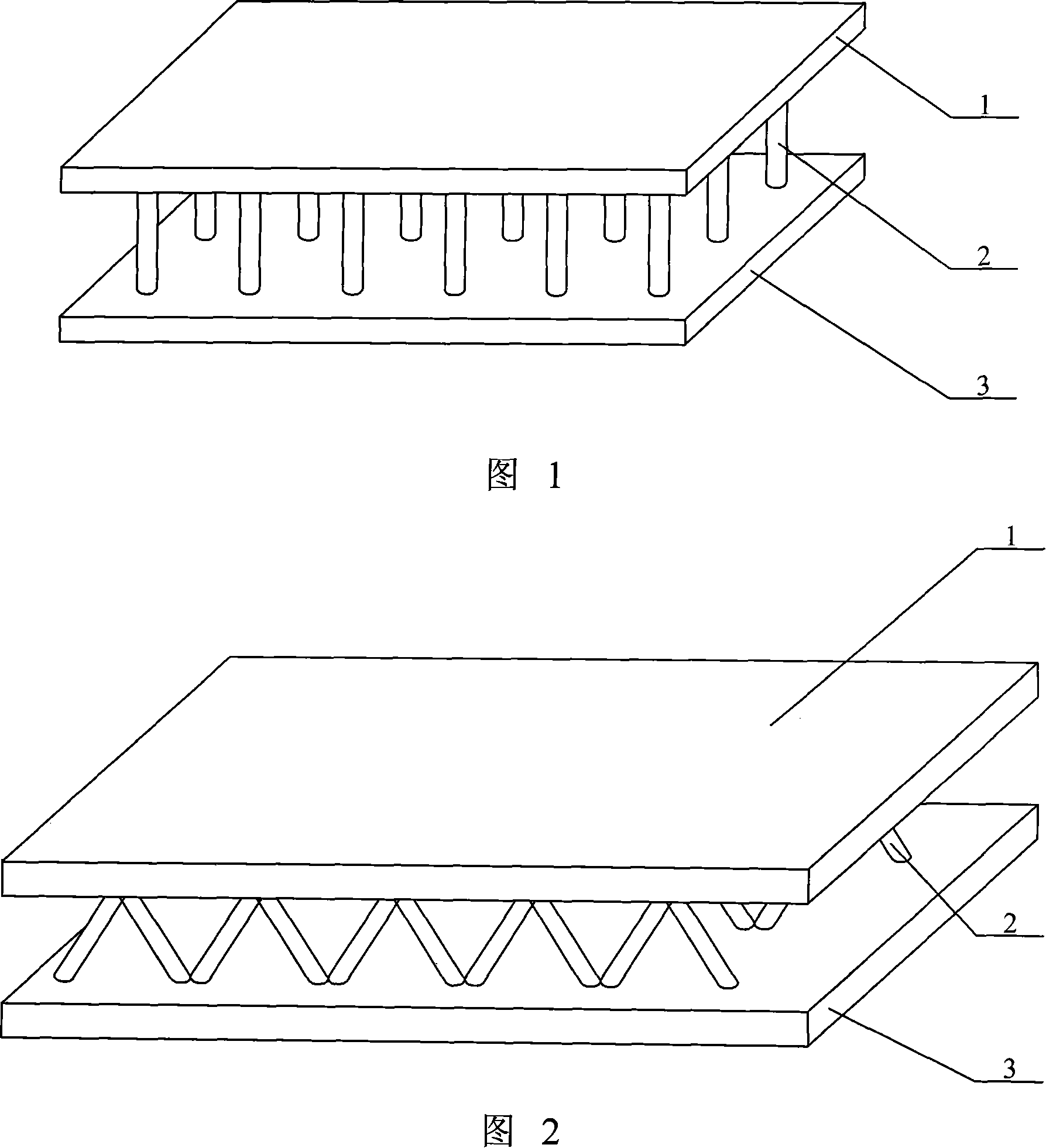

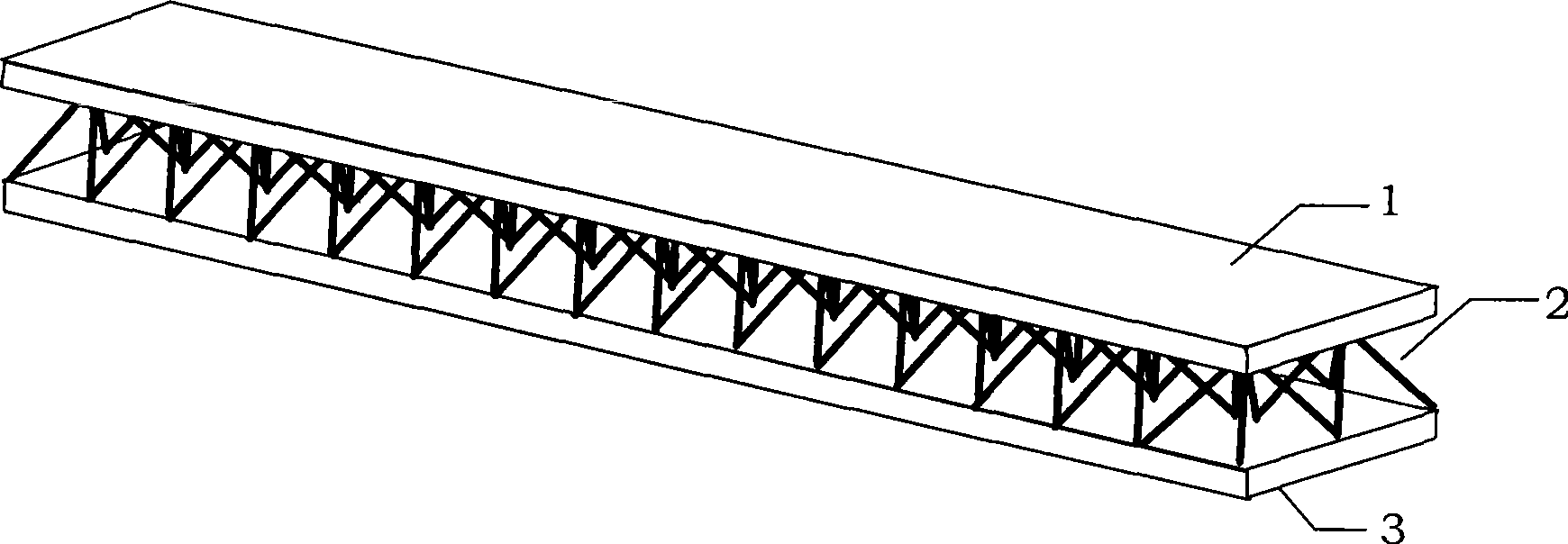

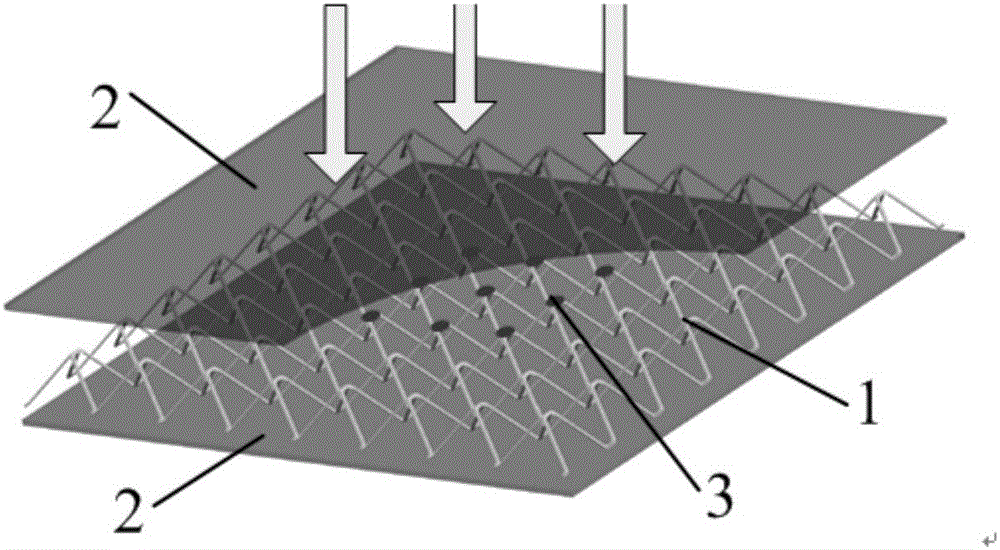

Fibre-reinforced composite lattice sandwich plate and its preparing process

The invention is a lattice sandwich plate made of reinforced composite fiber material and a manufacture method of the sandwich plate, and relates to a lattice sandwich plate and a manufacture method of the sandwich plate. The invention settles the problem that a prior lattice sandwich plate is difficult to be molded and materials used are limited to metal materials. A lattice of the invention is arranged between an upper fiber composite panel (1) and a lower fiber composite panel (3), and consists of a plurality of fiber composite columns (2). The upper ends of the fiber composite columns (2) are connected with the upper fiber composite panel (1) in a fixing way, while the lower ends of the fiber composite columns (2) is connected with the lower fiber composite panel (3) in a fixing way. The manufacture method is as follows: 1. a cleaning mould is designed and a demoulding agent is applied on the mould; 2. a pre-immersed material is cut into the designed size and filed into a pole, which is put into a mould hole; 3. the upper panel and the lower panel are laid; (4) solidification by heating and pressurizing is done, and the reinforced composite fiber material lattice sandwich plate is made. Compared with a traditional metal lattice sandwich plate, the reinforced composite fiber material lattice sandwich plate of the invention is provided with the higher intensity and rigidity, and can be designed easily.

Owner:HARBIN INST OF TECH

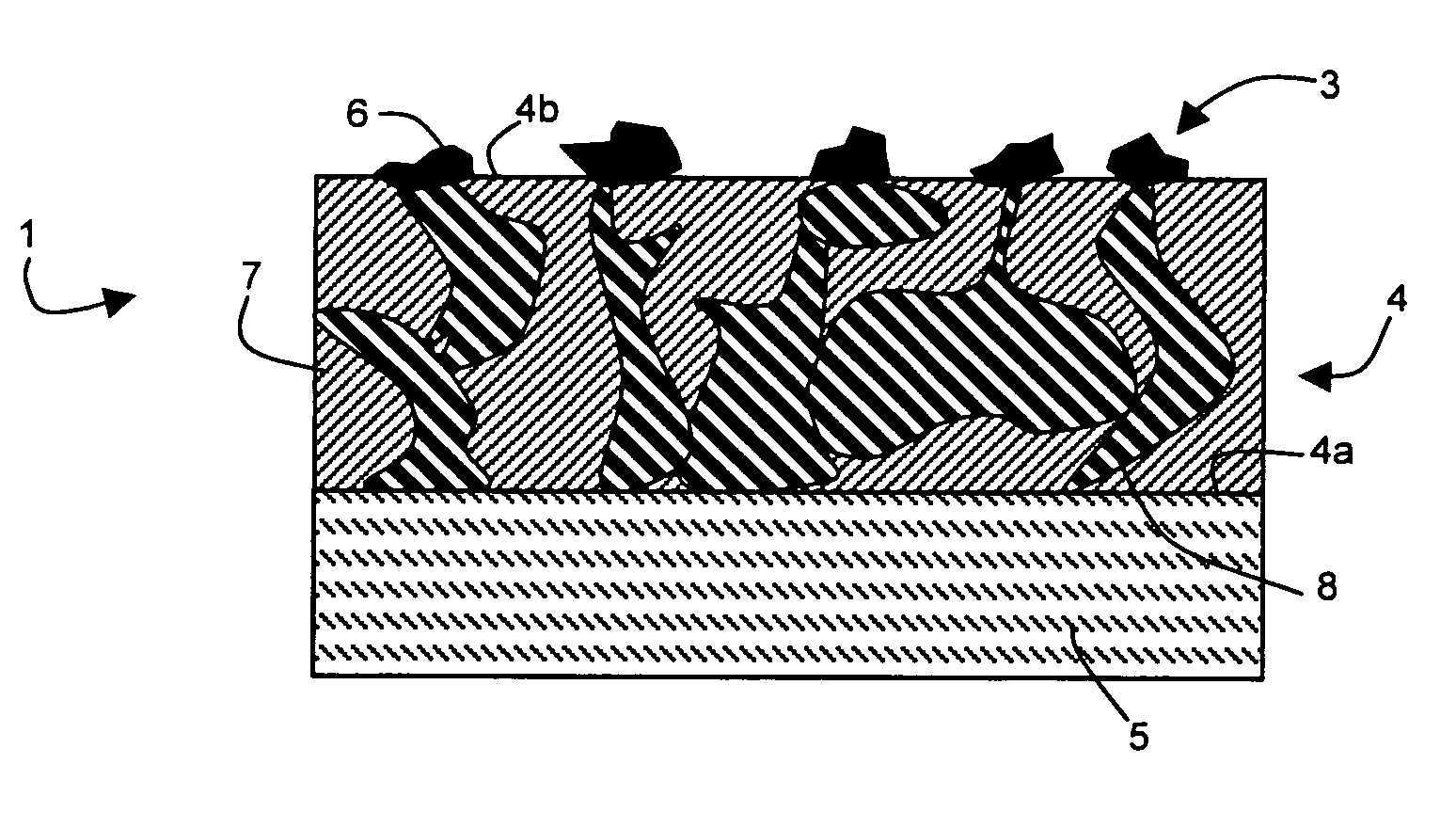

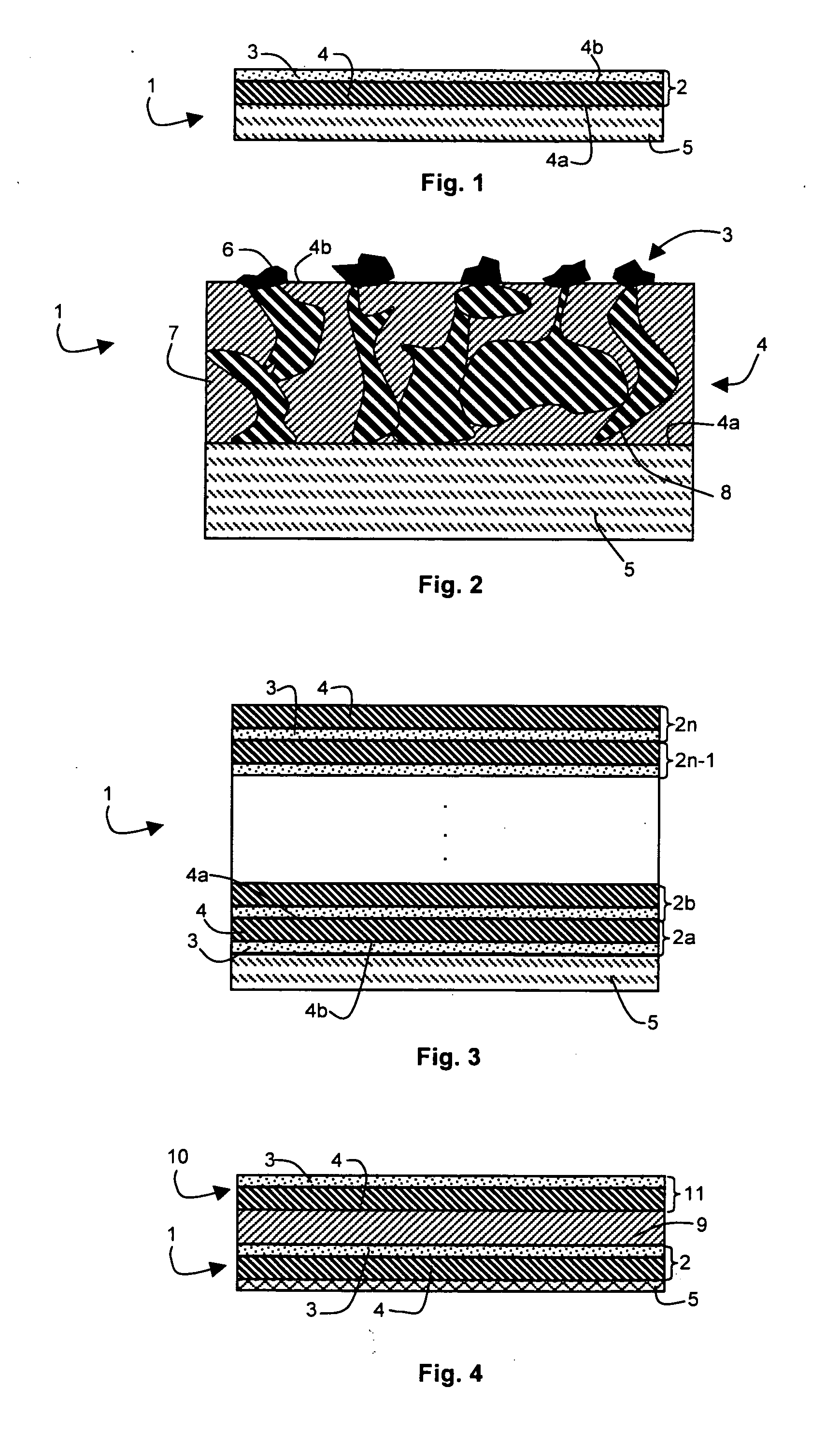

Electrode for Alkali Fuel Cell and Method for Making a Fuel Cell Including at Least One Step of Making Such an Electrode

InactiveUS20090042092A1Improve efficiencyEasy to implementFinal product manufacturePrimary cellsNano sizeElectron

An electrode for an alkali fuel cell comprises an active layer formed by a bilayer or by a stack of a plurality of bilayers. Each bilayer is composed of a catalytic layer comprising catalyst particles of nanometric size and of a porous layer comprising two opposite faces one of which is in contact with the catalytic layer. The porous layer is made from a porous composite material comprising a hydroxide ion conducting polymer matrix in which a metallic lattice is formed constituting a plurality of electronically conducting paths connecting the two opposite faces of the porous layer. Advantageously, fabrication of such an electrode is obtained by successively performing vacuum deposition of the catalyst particles and vacuum co-deposition of the hydroxide ion conducting polymer and of the metal on a free surface of a support.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

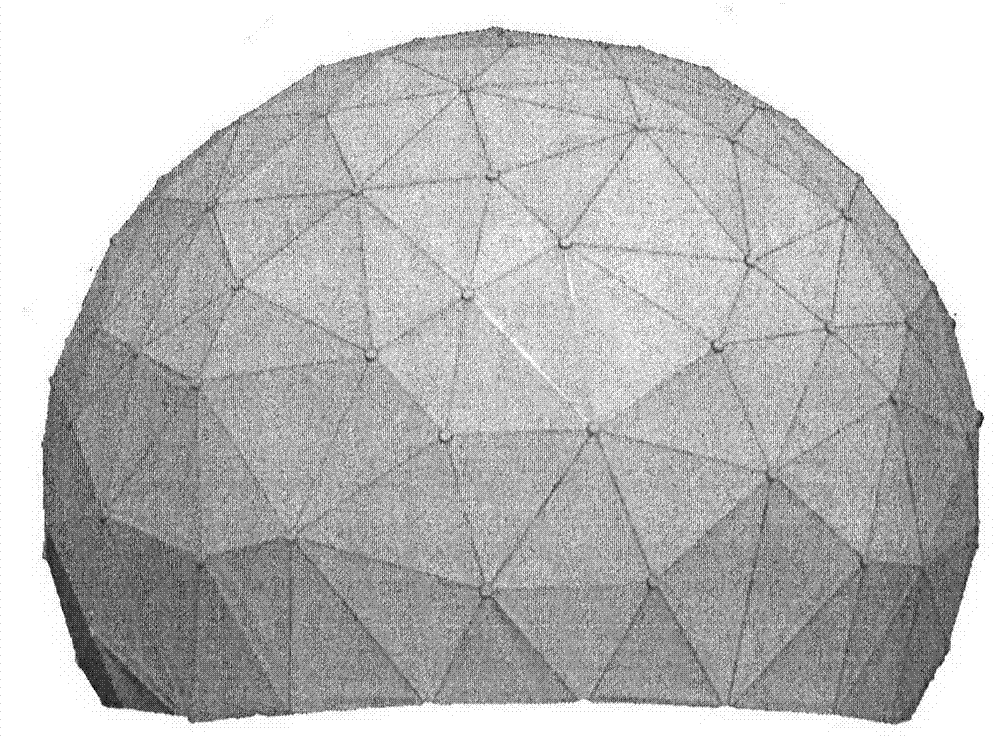

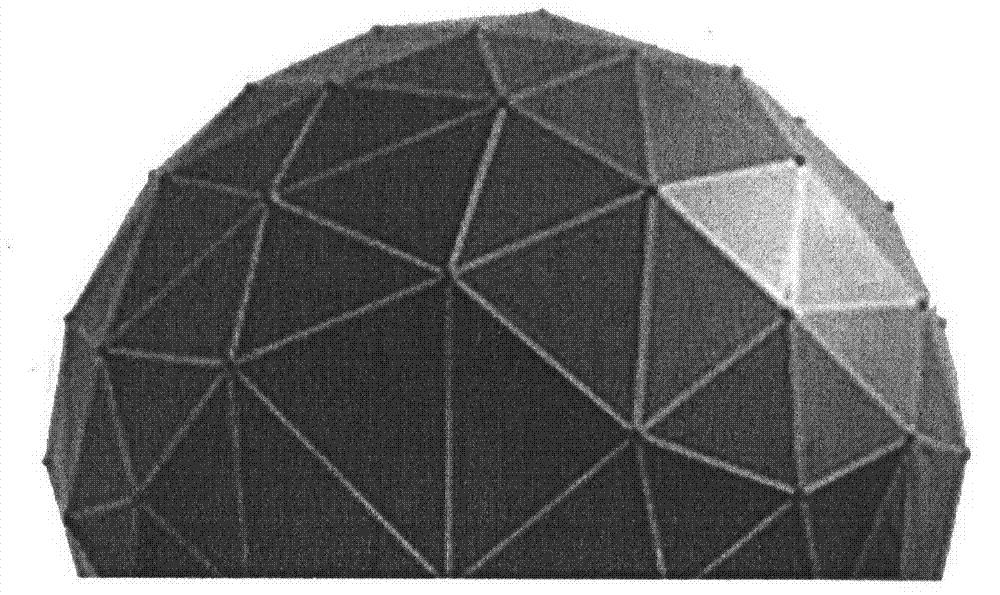

Method for quickly establishing spherical antenna cover with metal latticed shell structure

InactiveCN104752821ACompact structureEasy and fast processing and installationRadiating element housingsPolyesterRadiation loss

The invention discloses a method for quickly establishing a spherical antenna cover with a metal latticed shell structure and belongs to the crossing field of civil engineering metal latticed shell mechanics and electronic engineering. The method comprises the steps of firstly establishing a 32-face body and a variant of the 32-face body, selecting pentagonal synchronous rotation random element and establishing planer variation elements through pentagonal rotation angle control; adopting a geodesic projection method on the new planer variation elements to perform topological mapping transformation towards the external spherical surface of the variant of the 32-face body through the center of a variation element plane, a boundary center and a pentagonal center and performing random triangular spherical polyhedral main body establishment; finally giving spherical antenna cover whole topological structure design. The whole antenna cover is composed of shed face film plates and node base assembling members, the film plates with polyester film opening structures and the triangular metal frame structure design are combined with the antenna cover whole topological structure design, so that the metal antenna cover has good mechanical property and electromagnetic property and has very high wind and snow resisting capacity and a small radiation loss characteristic.

Owner:周丰峻

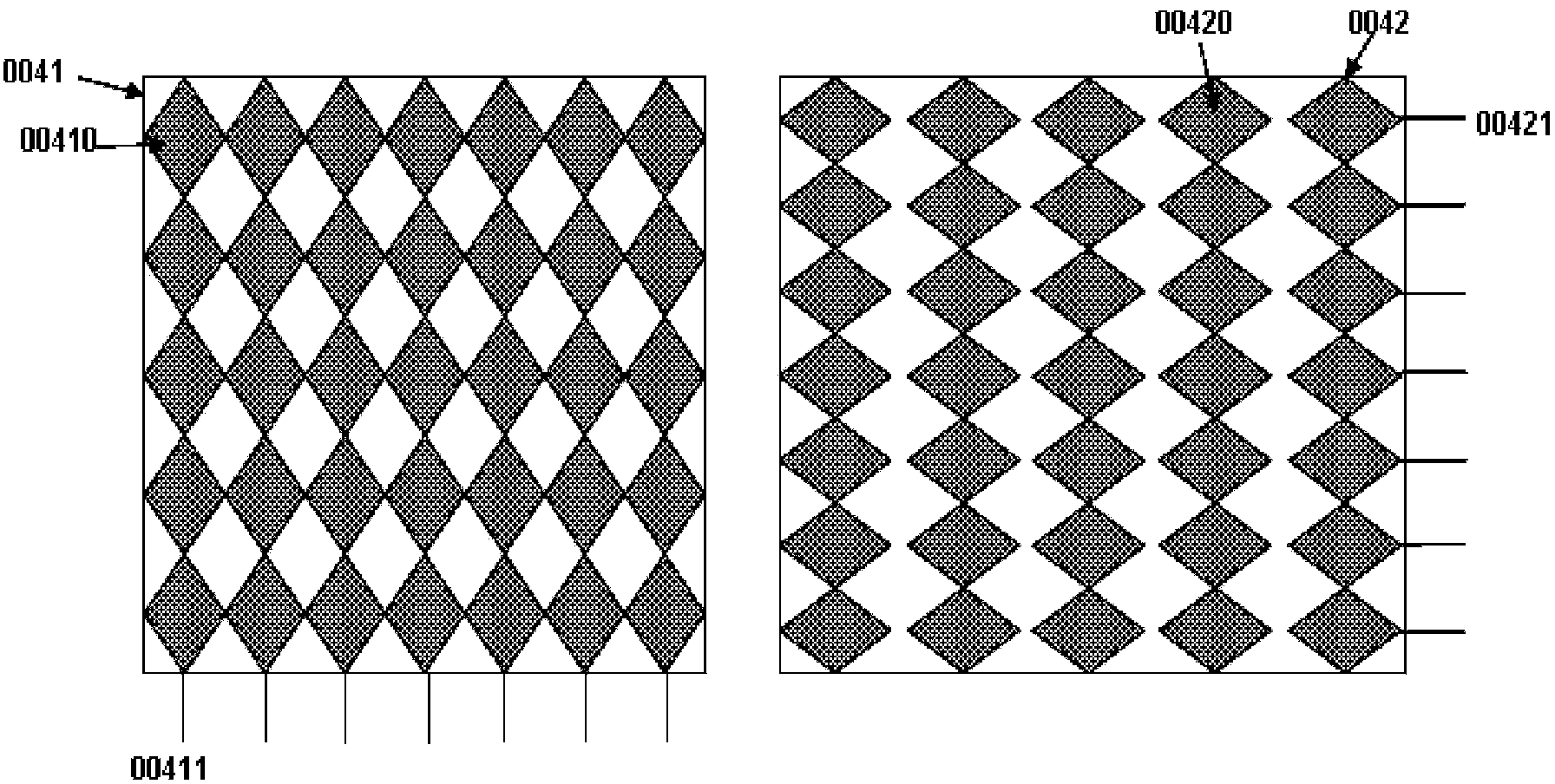

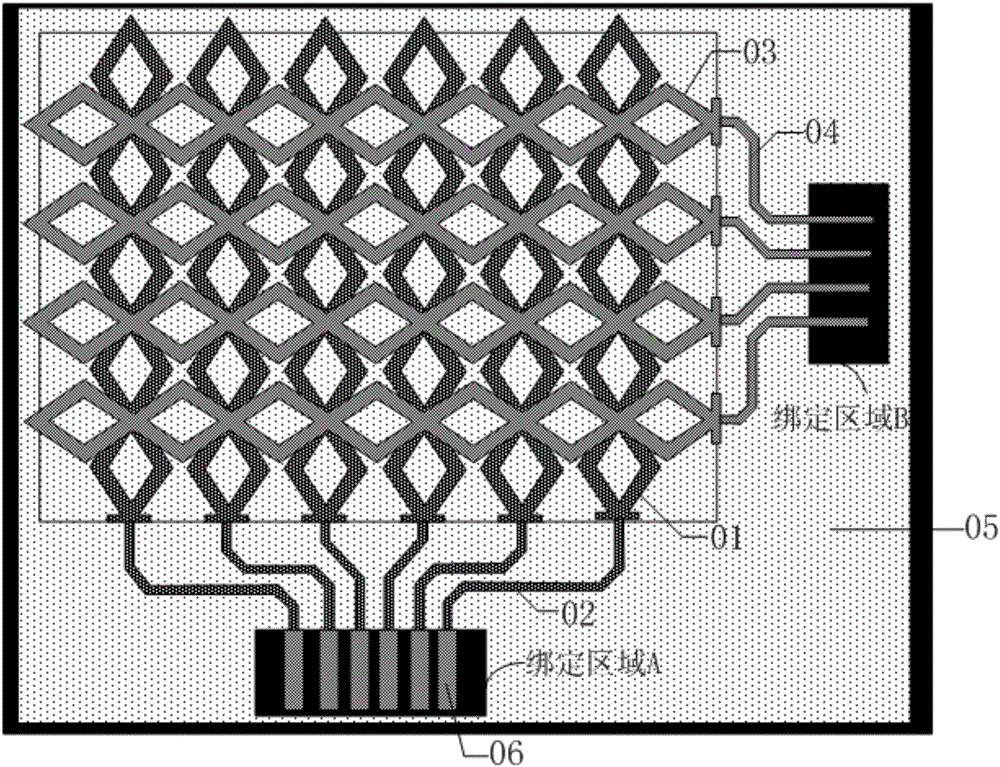

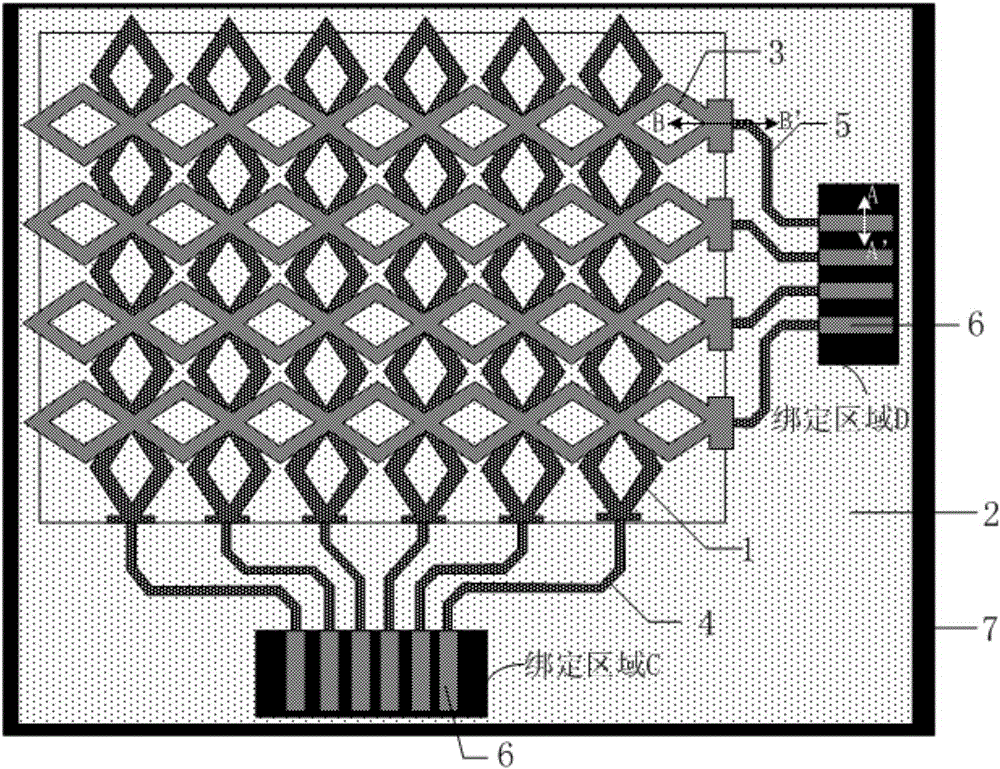

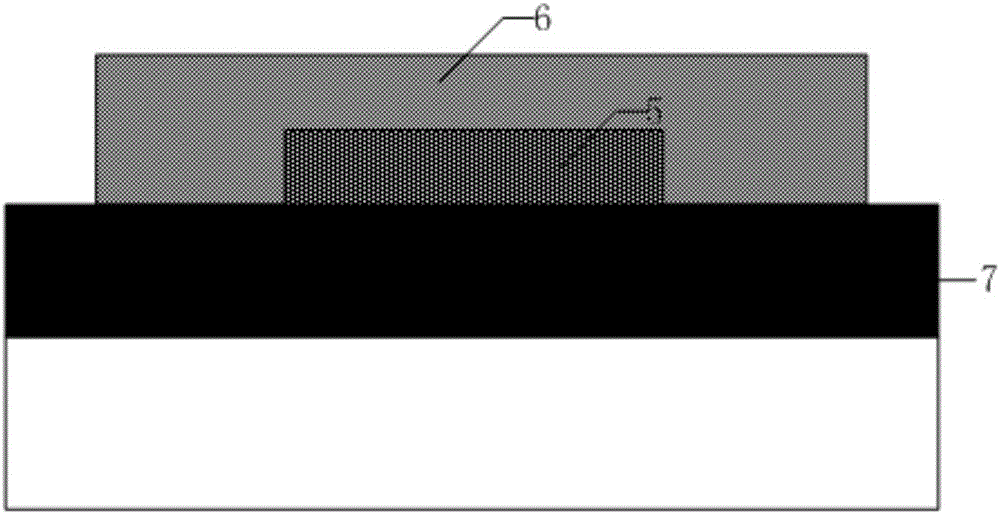

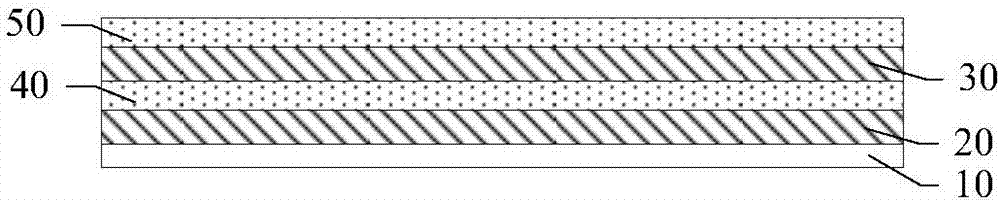

Touch screen and manufacturing method thereof as well as display device

ActiveCN106201145AImprove corrosion resistancePlay a protective effectInput/output processes for data processingDisplay deviceEngineering

The invention discloses a touch screen and a manufacturing method thereof as well as a display device. The touch screen comprises a substrate base plate, and a first touch electrode, a first insulating layer and a second touch electrode which are arranged on the substrate base plate in sequence, wherein the first touch electrode and the second touch electrode are mutually crossed and are of a metal lattice shape; the touch screen further comprises a first signal line which is electrically connected with the first touch electrode, and a second signal line which is electrically connected with the second touch electrode; and metal protection layers are arranged on the first signal line and the second signal line located in a binding region of the touch screen. The metal protection layers are arranged on the first signal line and the second signal line located in the binding region of the touch screen and can be used for protecting the first signal line and the second signal line, so that the anti-corrosion capability of the touch screen is integrally improved, and furthermore, the final yield of a product can be improved through corrosion resistance dependence authentication.

Owner:BOE TECH GRP CO LTD +1

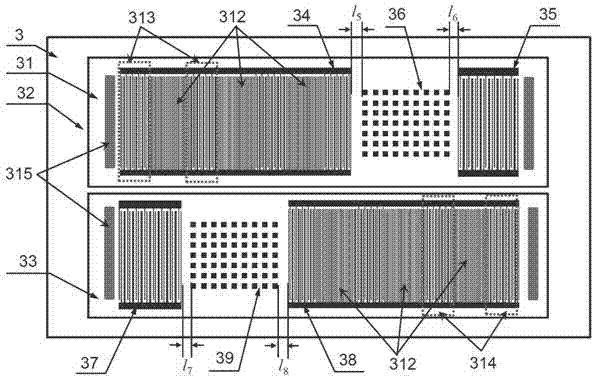

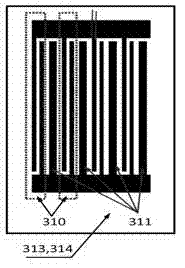

Surface acoustic wave gyroscope based on traveling wave mode

InactiveCN103196438AEasy to detectImprove stabilitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesElectricityGyroscope

The invention relates to a surface acoustic wave (SAW) gyroscope based on a traveling wave mode. The SAW gyroscope (3) comprises a piezoelectric substrate (32), a first delay line (31) and a second delay line (33) arranged on the surface of the piezoelectric substrate (32), and sound-absorbing rubbers (35) distributed at both ends of the first delay line (31) and the second delay line (33). The SAW gyroscope is characterized in that a first metal lattice (36) is distributed between two interdigital transducers of the first delay line (31), and a second metal lattice (39) is distributed between two interdigital transducers of the second delay line (33), the first delay line (31) and the second delay line (33) are parallelly and reversely arranged and has a same structure. The piezoelectric substrate (32) is a LiTaO3 piezoelectric substrate rotating around a Y direction for 112 DEG and cut, and spreading along an X direction. Through the above structure, a detection sensitivity of the gyroscope is effectively improved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

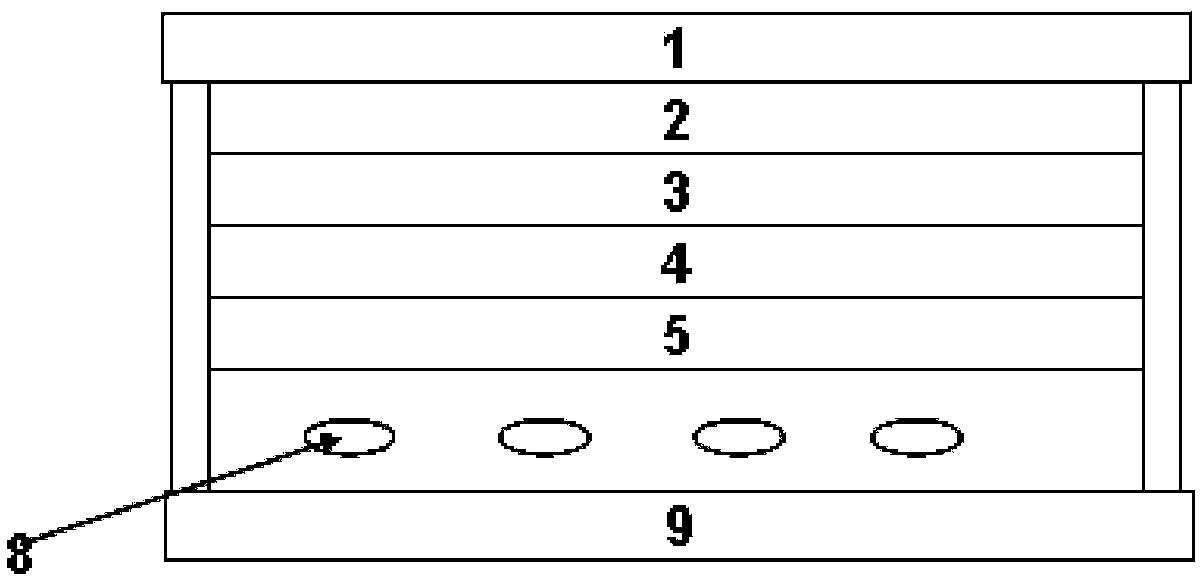

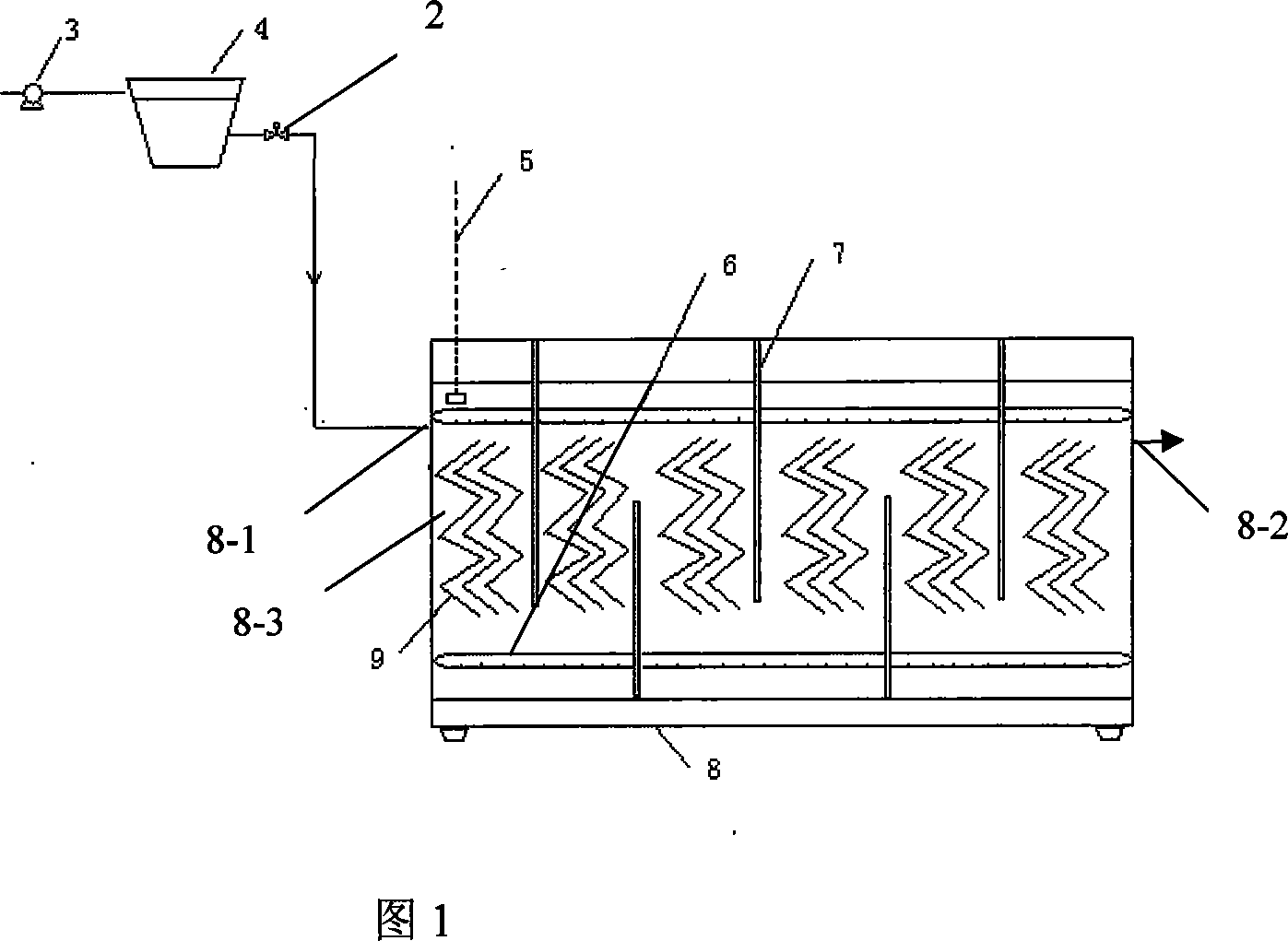

Helminth attaching biological bed for deweighting city sewage sludge

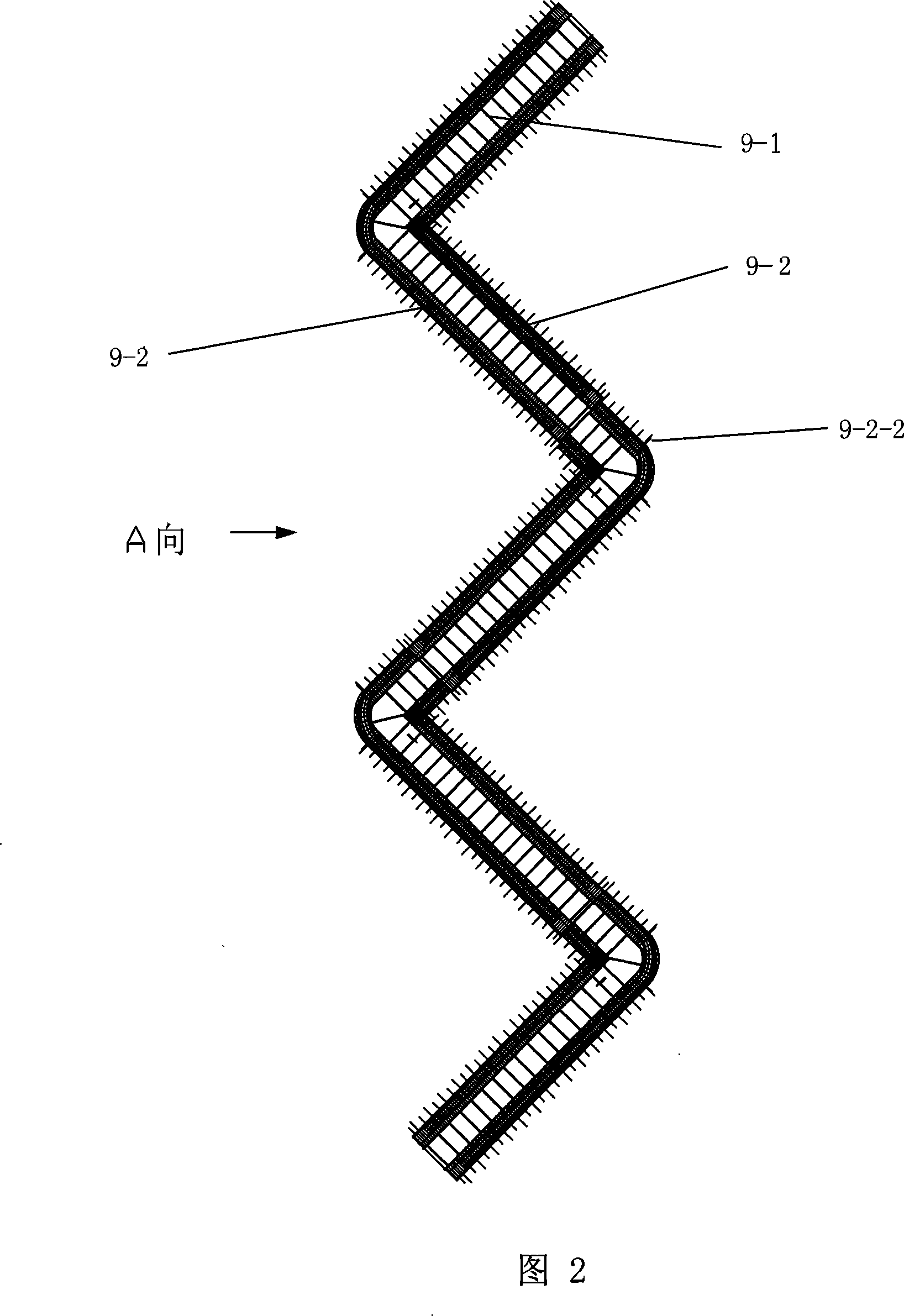

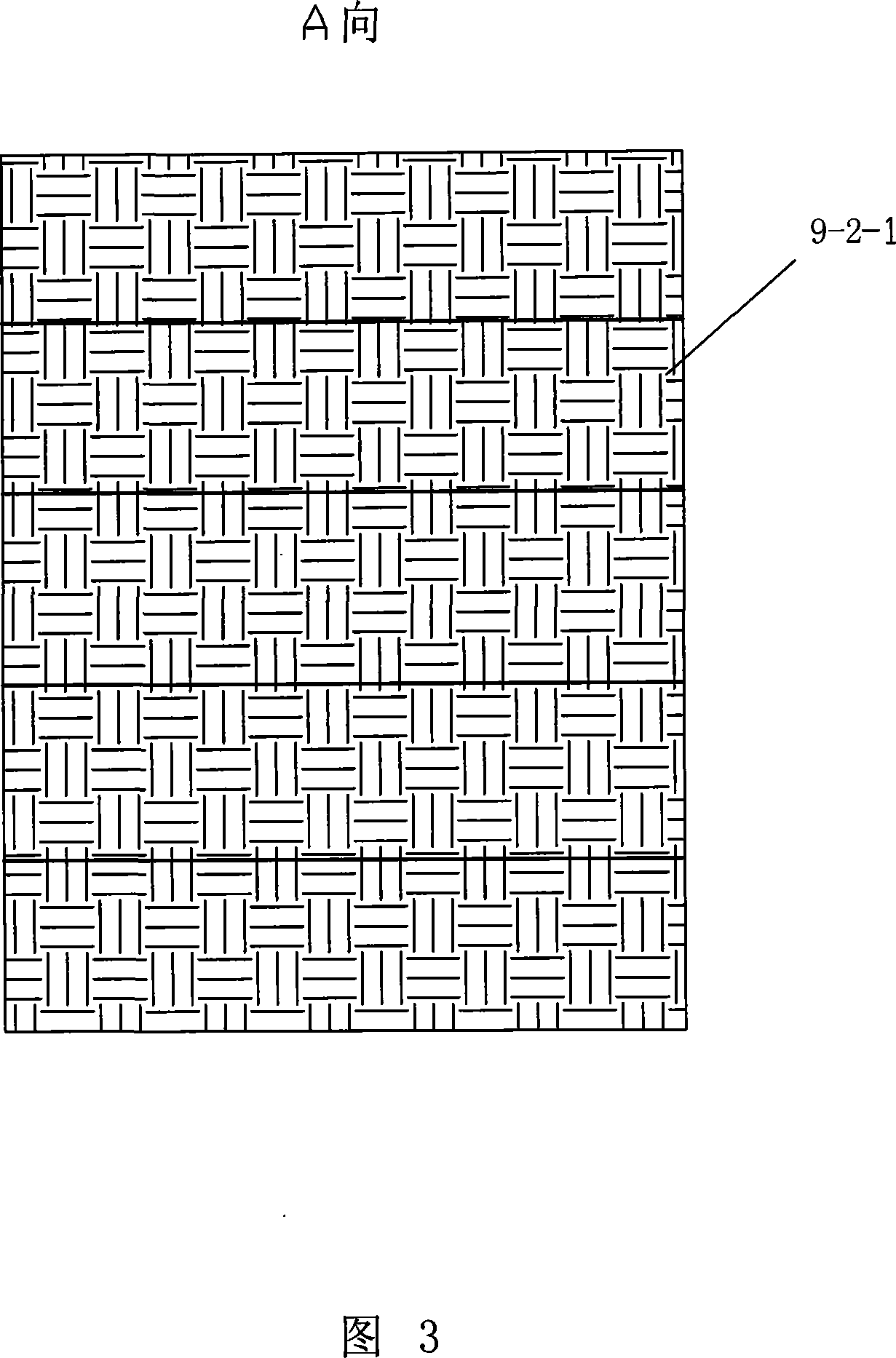

ActiveCN101157501AReduce impactStrong ability to workSustainable biological treatmentBiological water/sewage treatmentFiber bundleWave shape

A worm attaching type biological bed for sludge decrement treatment of city sewage is disclosed. The invention belongs to the technical field of sludge treatment with biological technology and overcomes the shortcomings of low attaching worm quantity, unstable population, low working capacity and low water-impact resisting ability of the prior art. The bed comprises a container, a plurality of baffles and an aerating device, wherein, the baffles can baffle the water entered the container before flowing out; the spaces among vertically baffles as well as between the baffles and the lateral wall of the container are used as overflowing passages. The bed also comprises a plurality of worm attaching plates, which are arranged in the overflowing passages along the length direction thereof. The worm attaching plates consist of metal lattice screens and filling membranes, wherein, the metal lattice screens are made into wave shapes along the length direction; the filling membranes are elastic panels made by crisscrossing and rolling polypropylene fiber bundles and polyethylene fiber bundles with orifices or clearances left between, and the diameter and the width of the orifices or clearances is 0.1-0.5 mm; the surfaces of the filling membranes have attaching polyethylene fiber bundles or polyethylene cilia.

Owner:HARBIN INST OF TECH

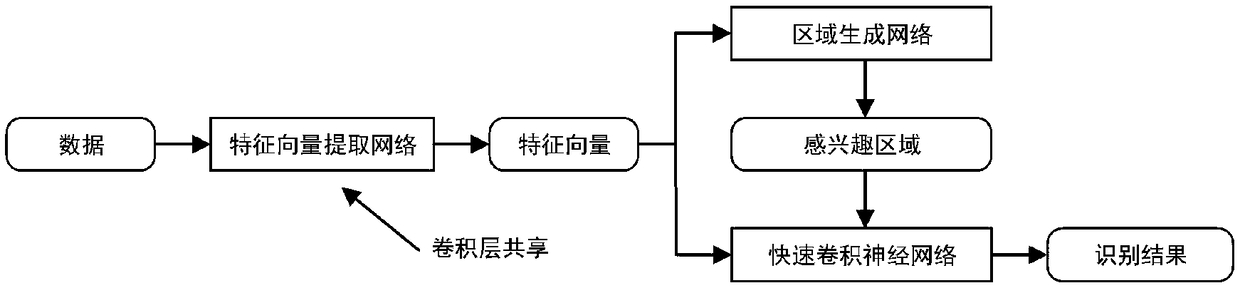

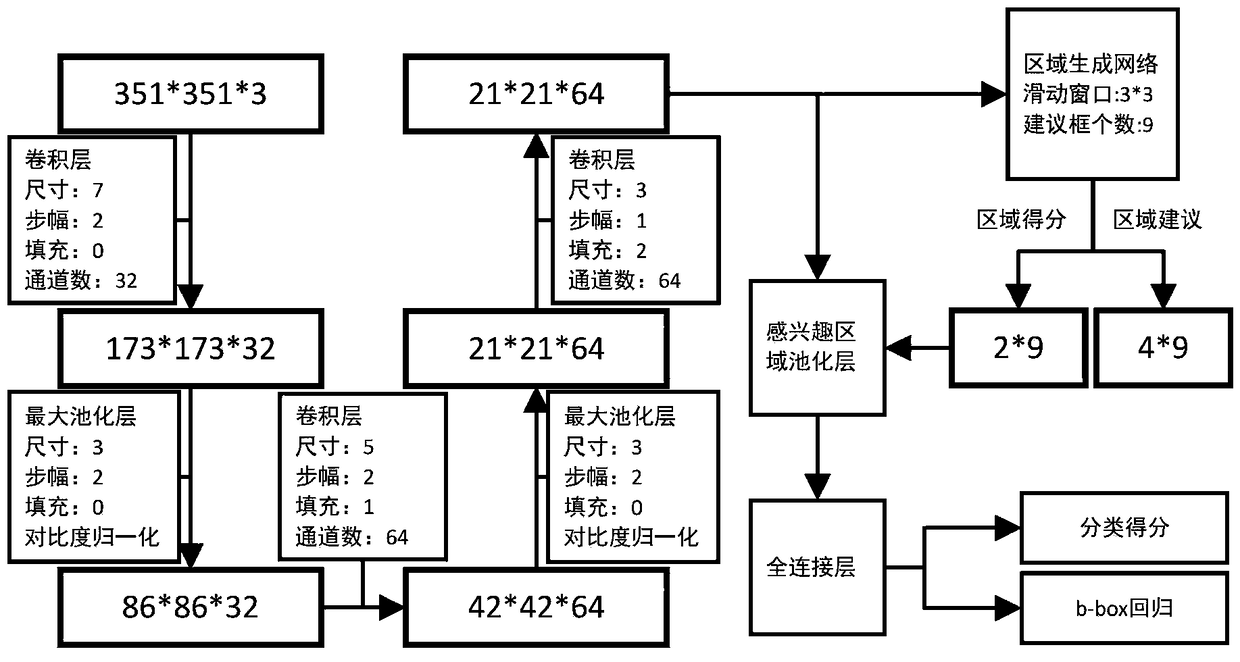

An internal defect detection method for a multilayer metal lattice structure material based on Faster R-CNN

Owner:YANSHAN UNIV

Method for making modular energy-absorbing assembly

InactiveCN1443108AMaximize absorptionPedestrian/occupant safety arrangementDomestic articlesEnergy absorptionEngineering

A method is provided for making an energy-absorbing assembly for decelerating an object that impacts the assembly. The assembly comprises a base and at least energy-absorbing module associated therewith. To provide predetermined energy-absorption characteristics, the at least one energy-absorbing module is formed from a group consisting of a first structure (A) and a second structure (B). Structure (A) is a metal lattice which supported by the base. Structure (B) comprises a plurality of recesses, each having a floor and a wall. Together, structures (A) and (B) and combinations thereof afford a user-determinable resistance to impact.

Owner:OAKWOOD ENERGY MANAGEMENT

Graphene/metal composite material and preparation method thereof

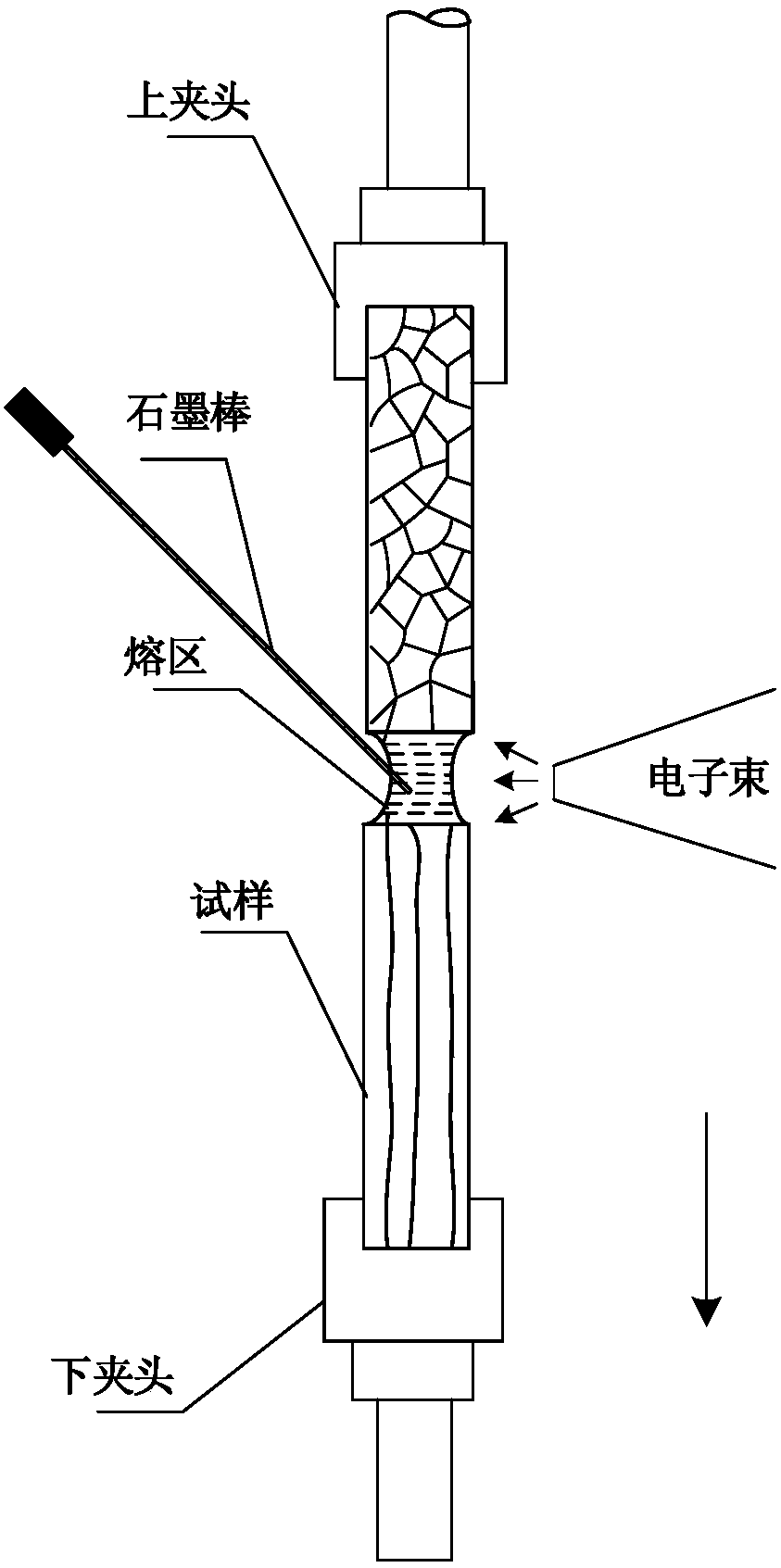

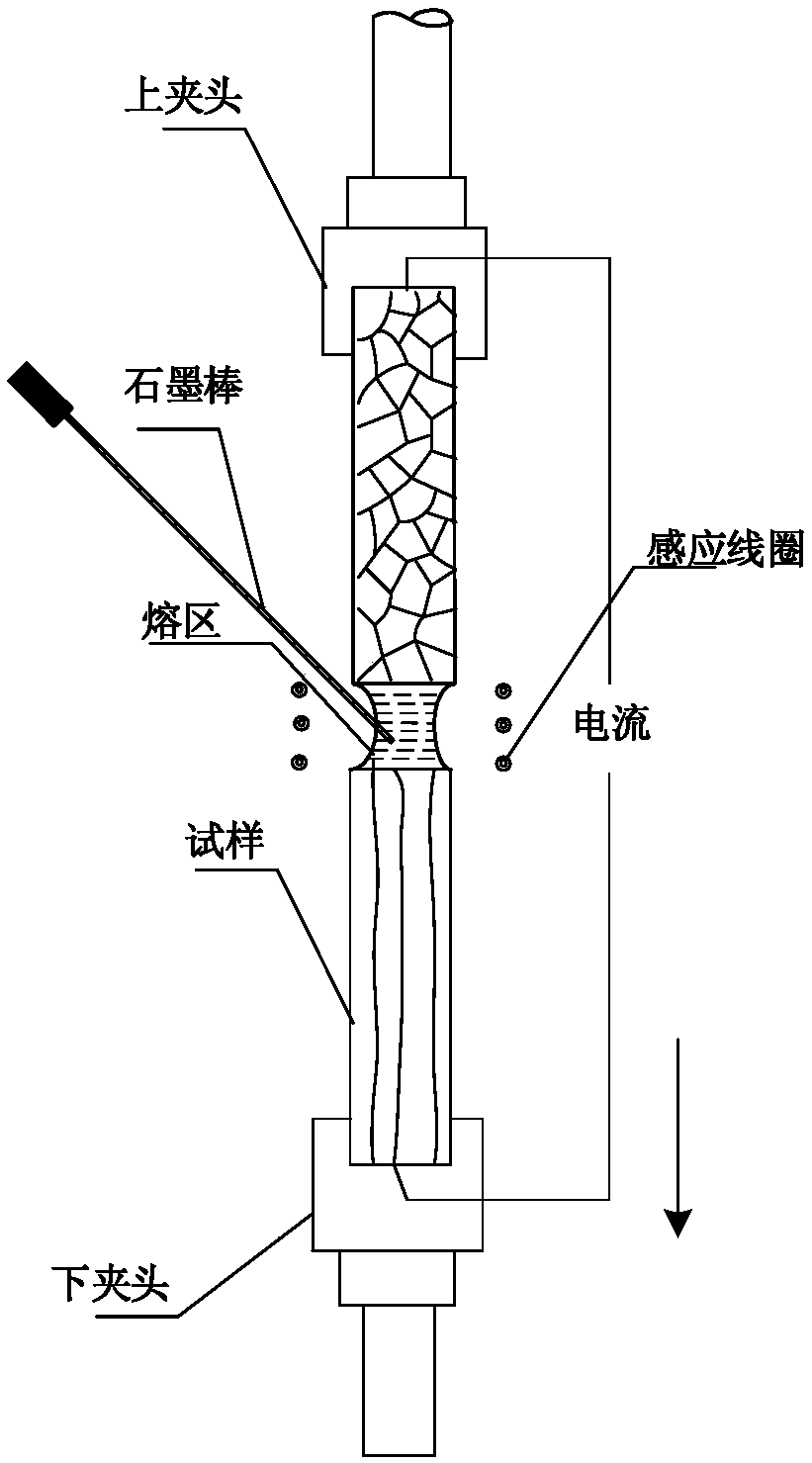

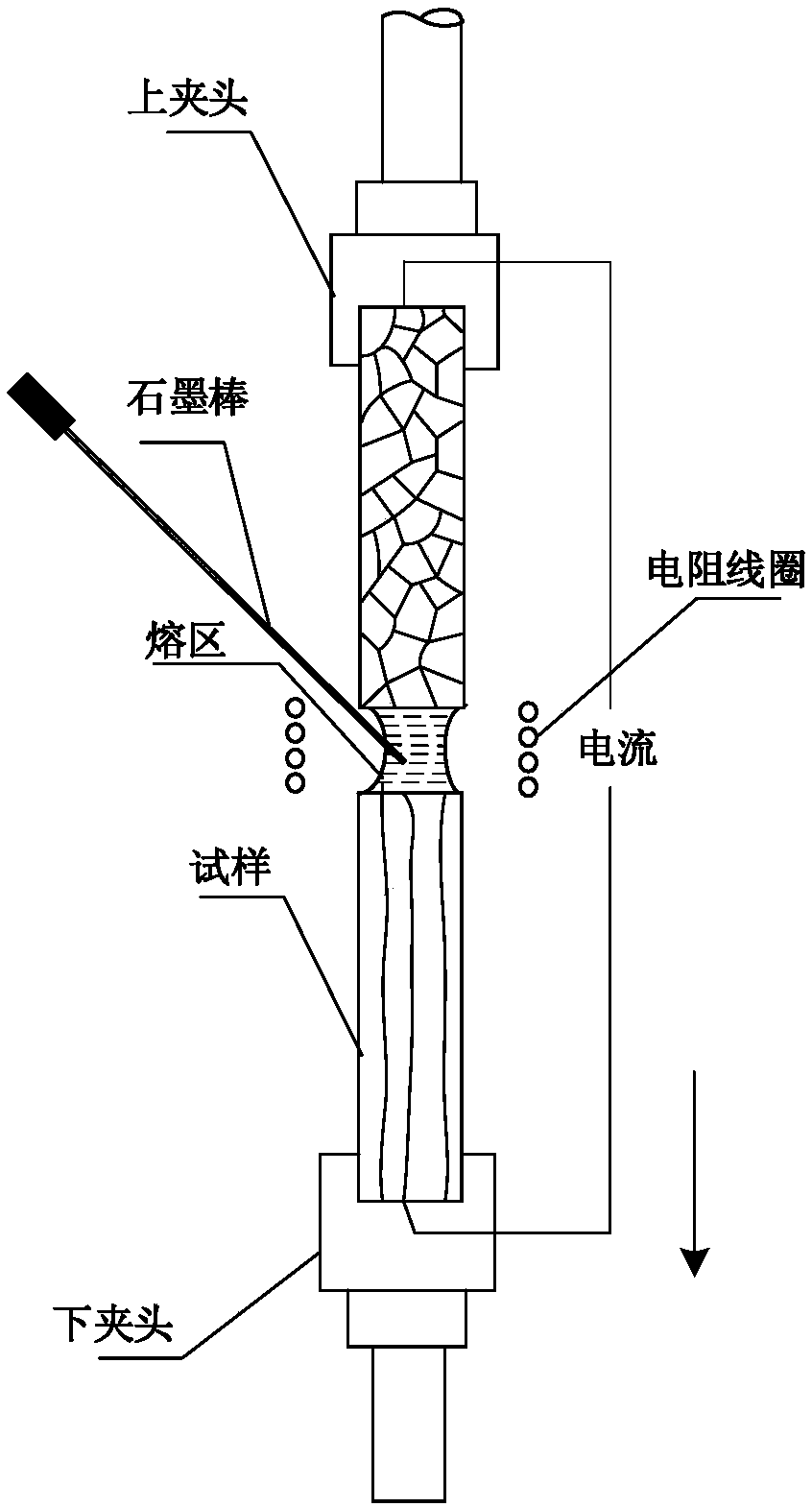

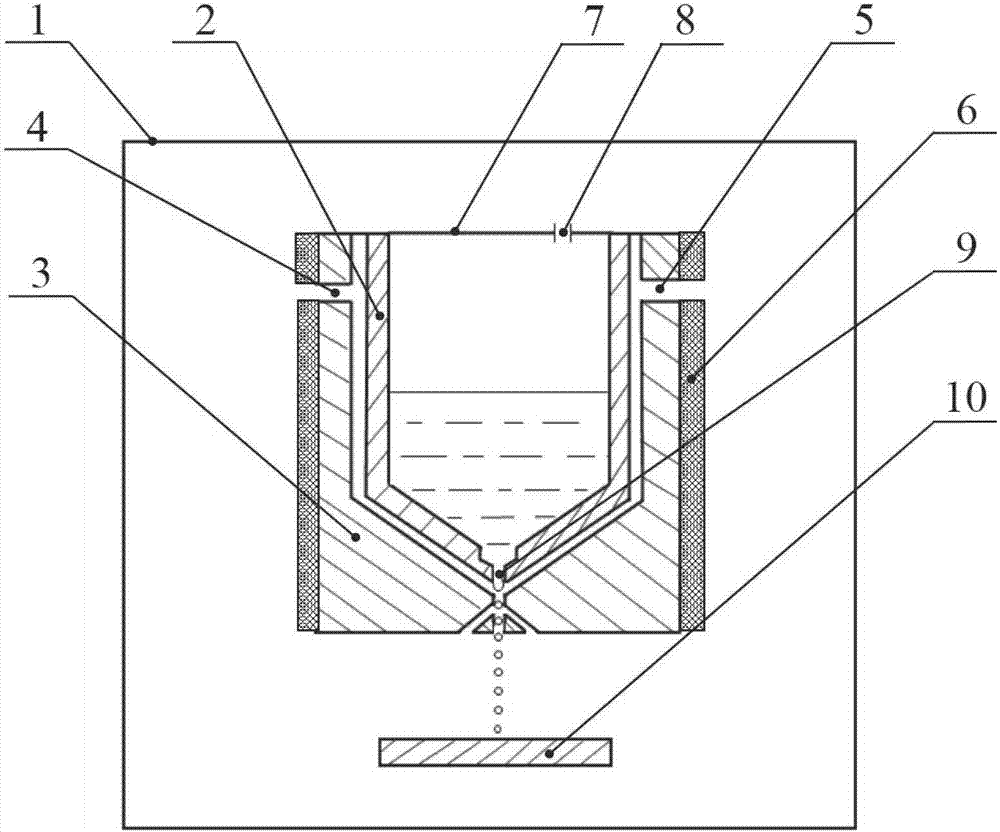

The invention discloses a graphene / metal composite material and a preparation method thereof. The method comprises the following steps of: (1) weighing a metal rod and a high-purity carbon rod in percentage by mass, wherein the high-purity carbon rod accounts for 1%-30%; (2) clamping the cleaned metal rod on an upper chuck and a lower chuck of a withdrawing system of a directional solidification furnace adopting a floating zone method, clamping the high-purity carbon rod on a clamp beside the withdrawing system, and enabling the bottom end of the high-purity carbon rod to be in contact with amelting zone of the metal rod; and (3) performing vacuum-pumping on the directional solidification furnace adopting the floating zone method, performing directional solidification on the metal rod, controlling length of a melting zone to be 1-50 mm, moving the metal rod from top to bottom at a rate of 1-5000 [mu]m / s, and rotating along the axis of the withdrawing system; and enabling the bottom end of the high-purity carbon rod to be within the melting zone of the metal rod all the time. According to the graphene / metal composite material obtained by the method disclosed by the invention, carbon exists in a metal lattice in the form of graphene, and the two-phase interface is good in combination, so that conductivity of the material is favorably improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

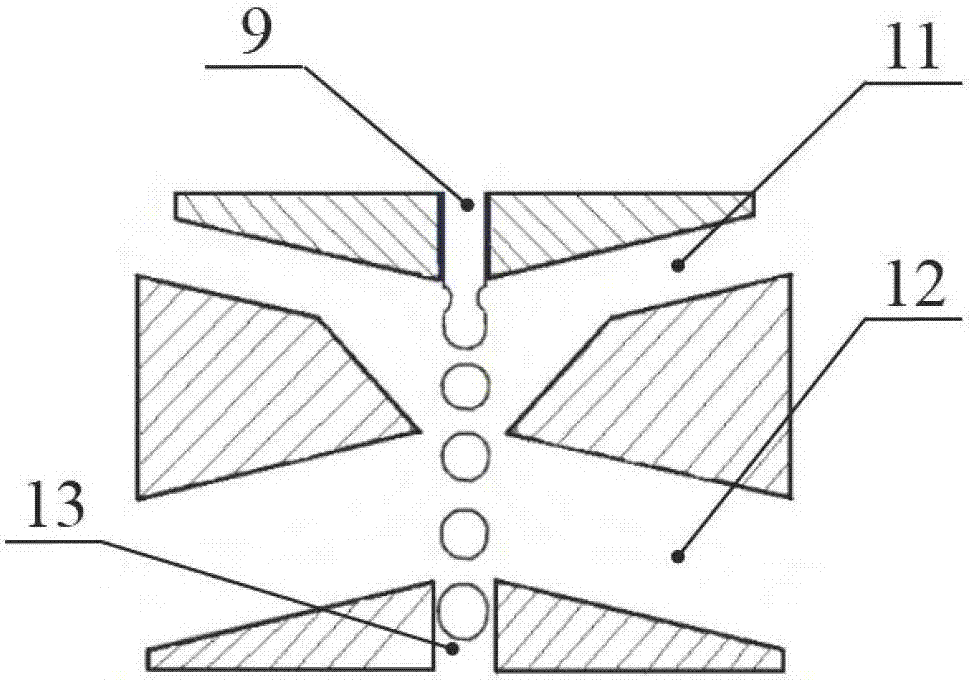

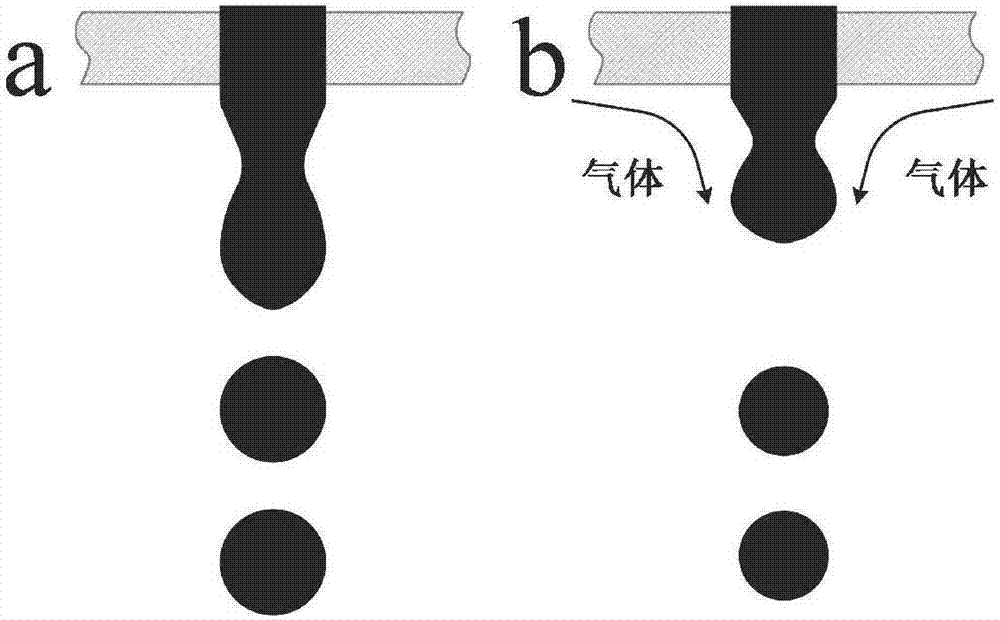

Vapor-assisted metal micro-droplet manufacturing device and method

ActiveCN107127345AUniform structureHigh precisionAdditive manufacturing apparatusManufacturing technologyGas phase

The invention discloses a vapor-assisted metal micro-droplet manufacturing device and method and belongs to a micro-droplet jetting additive manufacturing technology. The inside of a seal box body is kept in a closed environment to keep an internal temperature invariable; a liquid metal is stored in an inner crucible, an inert gas with pulsating pressure is introduced from a pulsating pressure gas inlet, and the liquid metal is extruded to flow outside from a liquid outlet; a certain distance is kept between an outer crucible and the inner crucible; a heater wraps the outside of the outer crucible to keep the temperature of an internal environment constant; a high-pressure gas flows from an air inlet passage and a flowing metal liquid is extruded and sheared at a liquid outlet; the high-pressure gas flows outside from an air leakage passage and generated micro-droplets flow outside from a droplet outlet and fall to a deposition platform. Through the viscous shearing action of the gas around the liquid outlet, advanced shear fracture of the liquid is achieved at a droplet formation stage, smaller uniform micro-droplets are generated, improvement of the accuracy and the compactness of a formed part is facilitated, a metal lattice structure is more uniform and the mechanical property is better.

Owner:BEIJING UNIV OF TECH

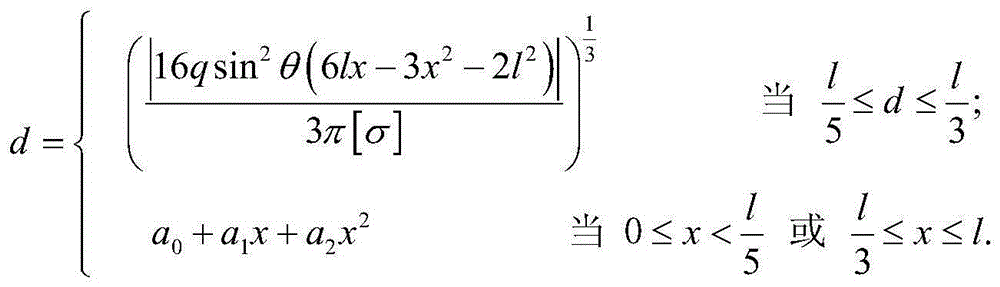

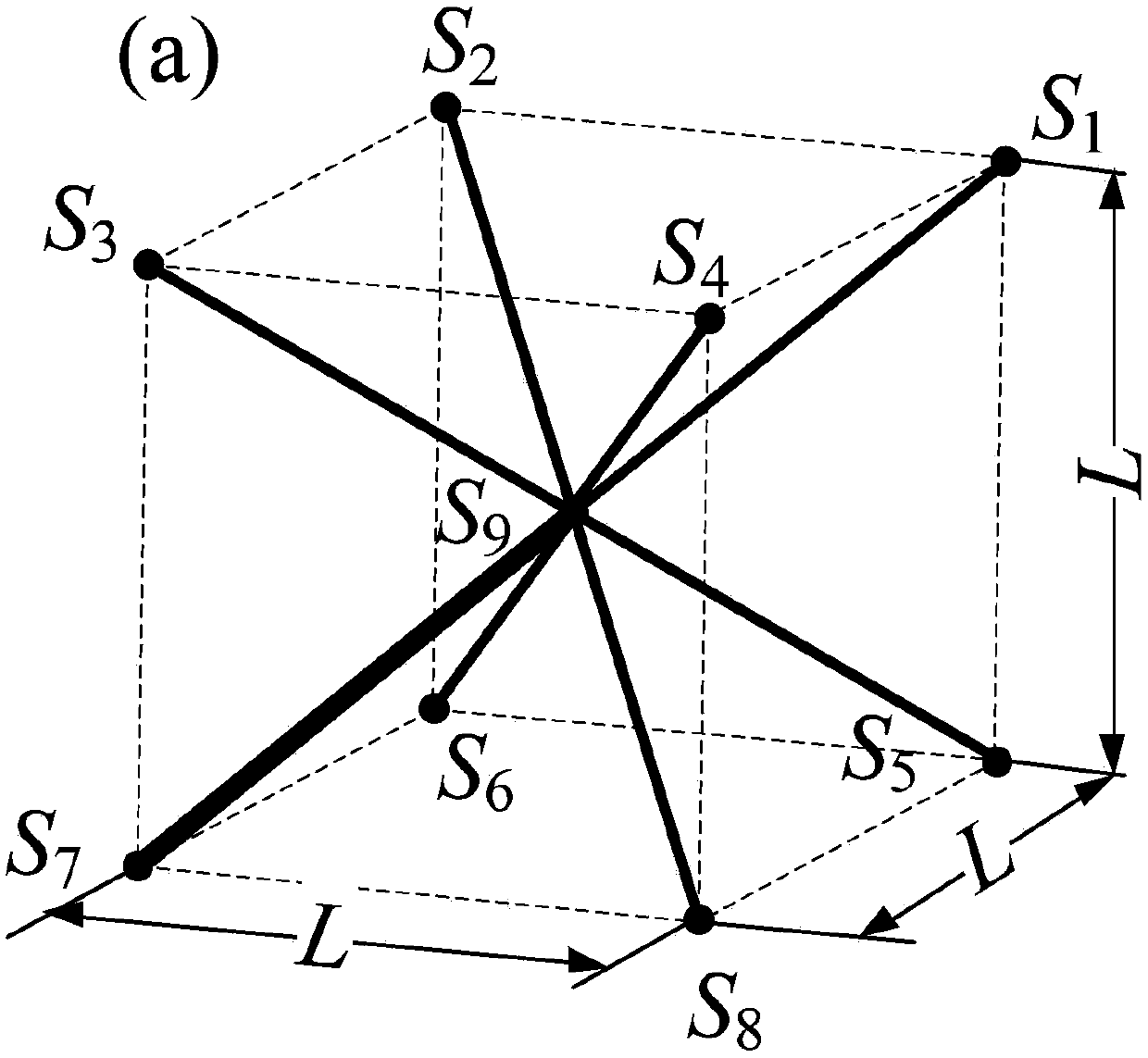

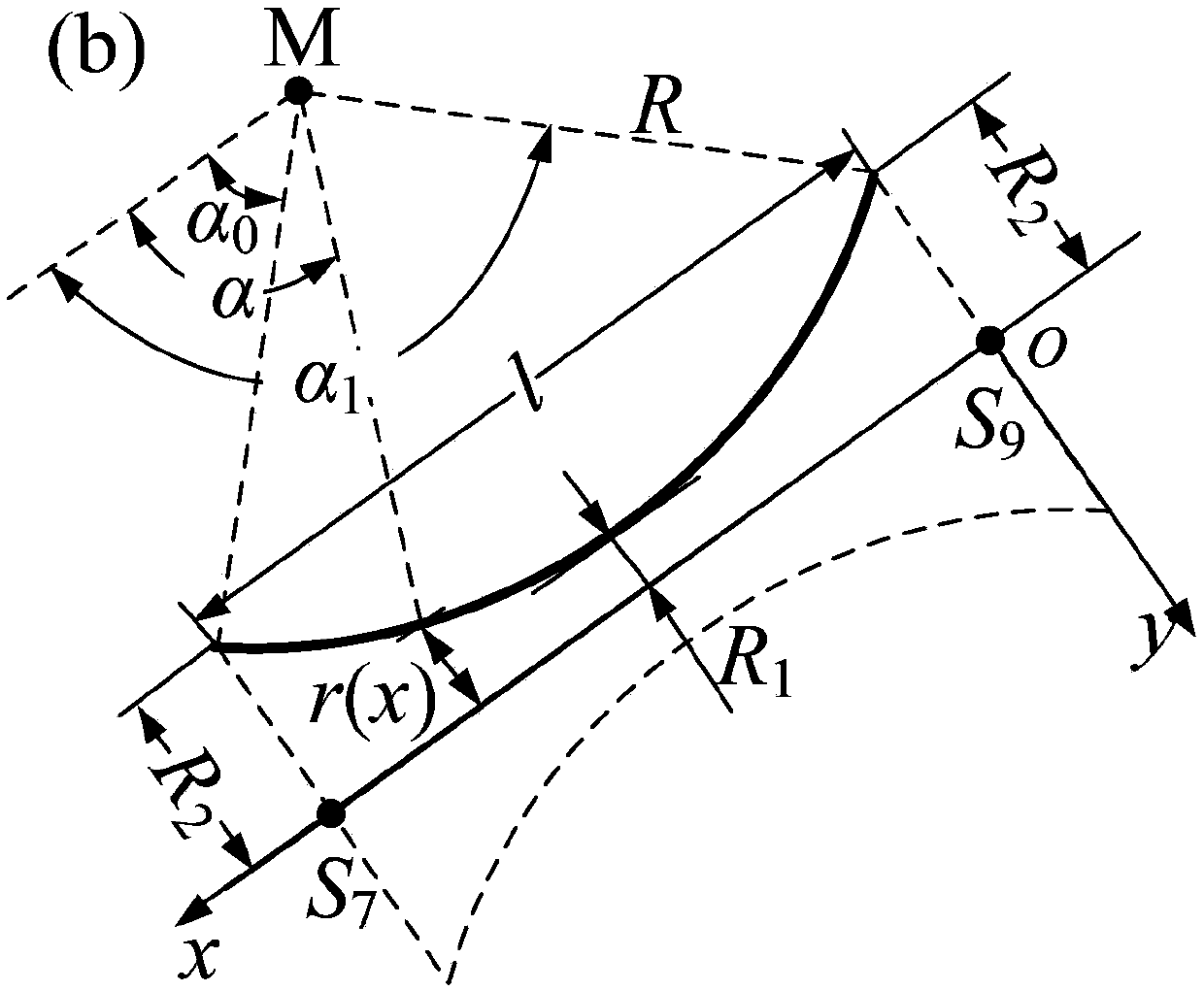

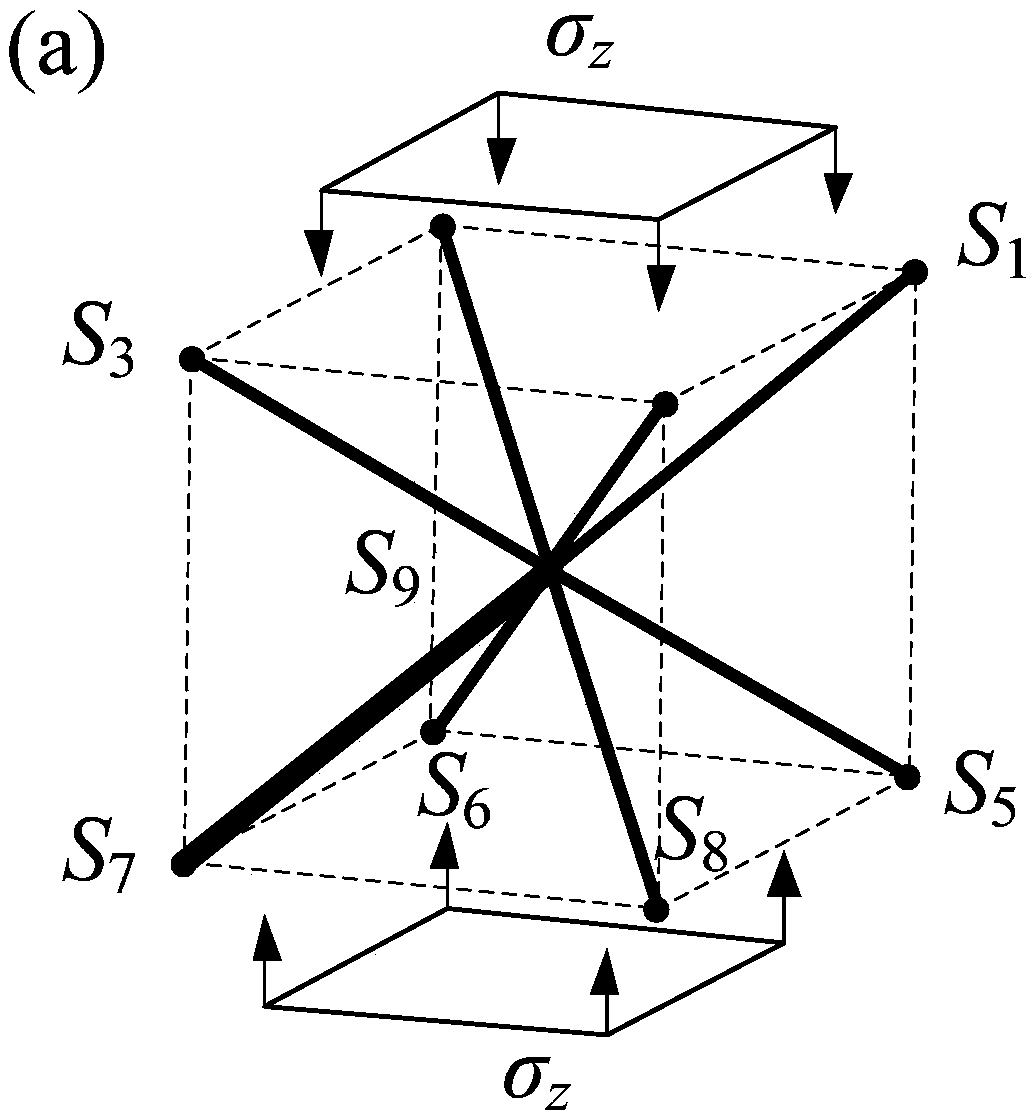

Algorithm for calculating initial rigidity and plastic failure strength of variable-section metal lattice structure

ActiveCN108038318AAccurate section changeCalculate initial stiffnessDesign optimisation/simulationSpecial data processing applicationsTangential forceMetal lattice

The invention discloses an algorithm for calculating the initial rigidity and plastic failure strength of a variable-section metal lattice structure. The algorithm includes the steps of s1, building aplane-coordinate system, and using the plane-coordinate system and the section size of a BCC variable-section metal lattice unit cell rod to obtain the radius expression of the section of the BCC variable-section metal lattice unit cell rod; s2, building a space coordinates system, and using the space coordinates system, the Hooke's law and a bending and compression combined deformation formula to obtain the relational expression of spatial tangential force, bending moment and spatial displacement borne by the node of the unit cell rod; s3, using the energy conservation law and the relationalexpression of spatial tangential force, bending moment and spatial displacement to obtain a quadratic equation in one unknown related to the tangential force of the node of the unit cell rod, solvingthe quadratic equation in one unknown to obtain a tangential force expression which does not contain the spatial displacement of the node, and using the tangential force expression and the relation between the tangential force at the node and axial force and the bending moment to obtain the expression of the axial force and the bending moment; s4, using the Hooke's law and the expression of the tangential force, the bending moment and the axial force to obtain the initial rigidity and plastic failure strength of the BCC variable-section metal lattice structure.

Owner:CHONGQING UNIV

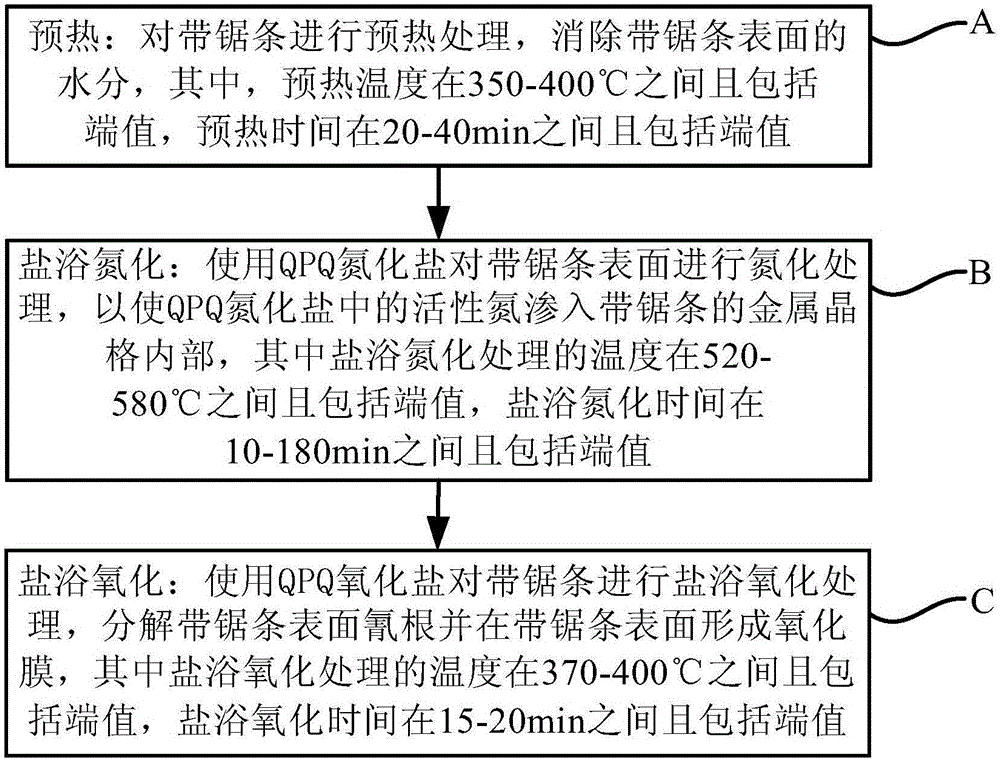

Band saw blade heat treatment technology

ActiveCN105063325AHigh hardnessImprove rust resistanceSolid state diffusion coatingFurnace typesTime rangeCyanide

The invention provides band saw blade heat treatment technology. The technology comprises the following steps: A. preheating: preheating a band saw blade and removing the moisture on the surface of the band saw blade, wherein the temperature ranges from 350 DEG C to 400 DEG C and comprises 350 DEG C and 400 DEG C; the time ranges from 20 minutes to 40 minutes and comprises 20 minutes and 40 minutes; B. salt bath nitriding: carrying out salt bath nitriding treatment on the surface of the band saw blade by using QPQ (quench-polish-quench) nitriding salt so that active nitrogen in the QPQ nitriding salt permeates a metal lattice of the band saw blade, wherein the temperature ranges from 520 DEG C to 580 DEG C and comprises 520 DEG C and 580 DEG C; the salt bath nitriding time ranges from 10 minutes to 180 minutes and comprises 10 minutes and 180 minutes; C. salt bath oxidizing: carrying out salt bath oxidizing treatment on the band saw blade by using QPQ oxidizing salt to decompose cyanides on the surface of the band saw blade and form an oxidation film on the surface of the band saw blade, wherein the temperature ranges from 370 DEG C to 400 DEG C and comprises 370 DEG C and 400 DEG C; the time ranges from 15 minutes to 20 minutes and comprises the end value. The hardness and corrosion resistance of the band saw blade can be reinforced by adopting the band saw blade heat treatment technology.

Owner:湖南台锯科技有限公司

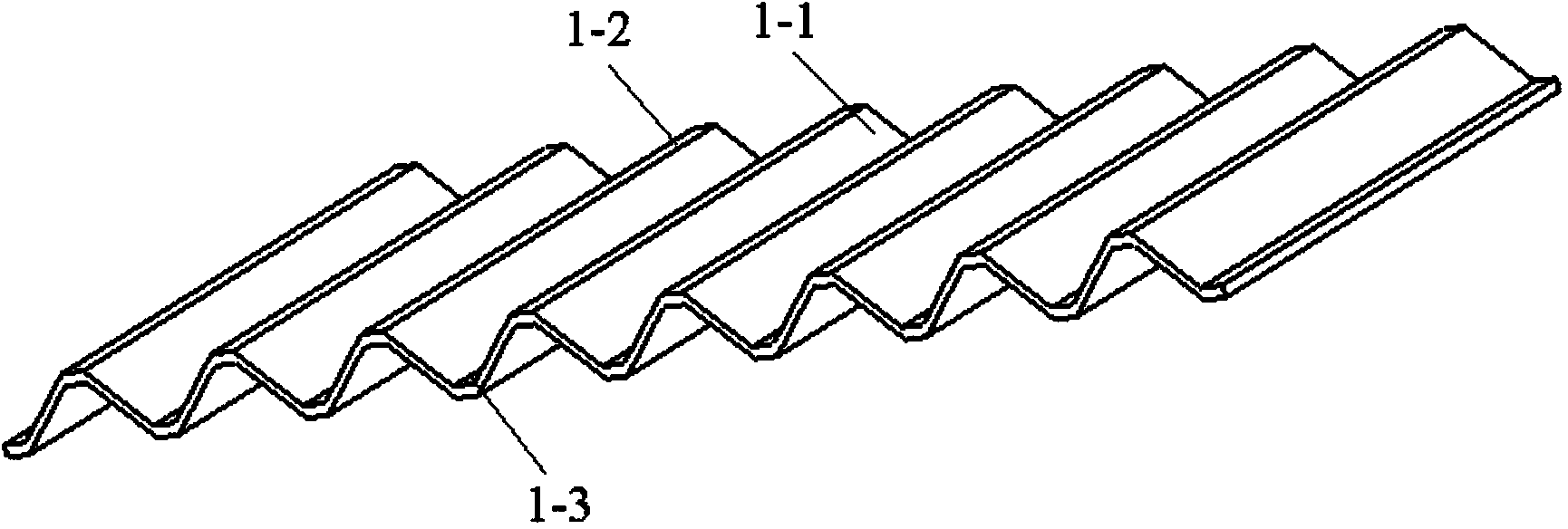

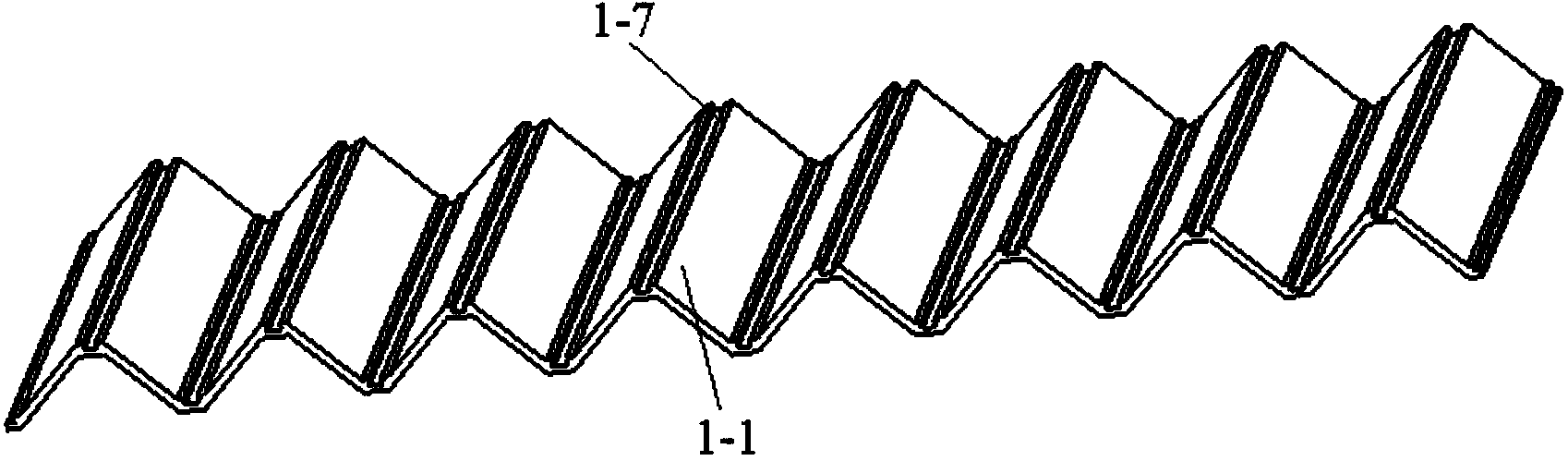

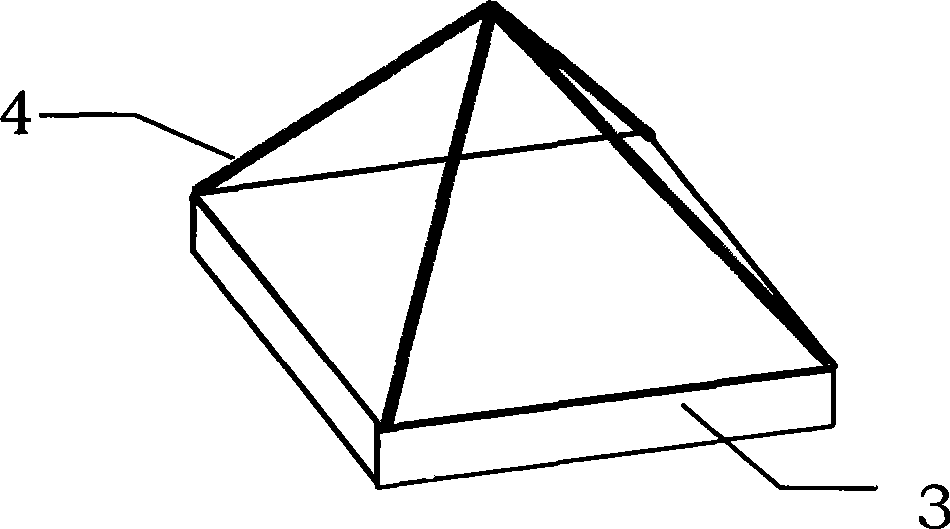

Metal pyramid type lattice sandwich plate and preparation method thereof

The invention discloses a metal pyramid type lattice sandwich plate and a preparation method thereof, relates to a lattice sandwich plate and a preparation method thereof, and aims to solve the problems that an existing metal lattice structure is high in preparation cost, low in material utilization rate, long in preparation process and complicated in manual operation and more preparation defects are introduced into the metal lattice structure in the preparation process. The metal pyramid type lattice sandwich plate comprises a pyramid type lattice core, an upper metal panel and a lower metal panel. The preparation method comprises the following steps: 1, preparing a metal corrugated plate; 2, preparing metal pyramid type lattice structure unit cells; 3, preparing the pyramid type lattice core; 4, preparing the metal pyramid type lattice sandwich plate. The prepared metal pyramid type lattice sandwich plate has the advantages of low cost, high material utilization rate and short preparation process. Compared with the preparation cost of the existing metal lattice structure, the preparation cost of the metal pyramid type lattice sandwich plate is reduced by 20-30 percent. By virtue of the preparation method, the metal pyramid type lattice sandwich plate can be obtained.

Owner:HARBIN INST OF TECH

Touch control panel, manufacturing method of touch control panel and touch control display device

ActiveCN107512050AInput/output processes for data processingMetal layered productsManufacturing gridDisplay device

The invention provides a touch control panel, a manufacturing method of the touch control panel and a touch control display device. The touch control panel comprises a substrate base plate and a plurality of first touch control electrodes, wherein the first touch control electrodes are positioned on the substrate base plate; each first touch control electrode comprises a plurality of first touch control electrode wires in crossed arrangement; in addition, the first touch control electrode wires comprise at least two layers of transparent conductive layers in laminated arrangement in the direction vertical to the substrate base plate; the transparent conductive layers comprise a first metal oxide layer and a first metal layer, or the first metal oxide layer and a first graphene layer. The touch control panel uses at least two transparent conductive layers in pairwise laminated arrangement for replacing the metal lattice for manufacturing grid touch control electrode wires in the touch control electrode; the moire is eliminated, so that the optical quality of the touch control panel is improved.

Owner:BOE TECH GRP CO LTD +1

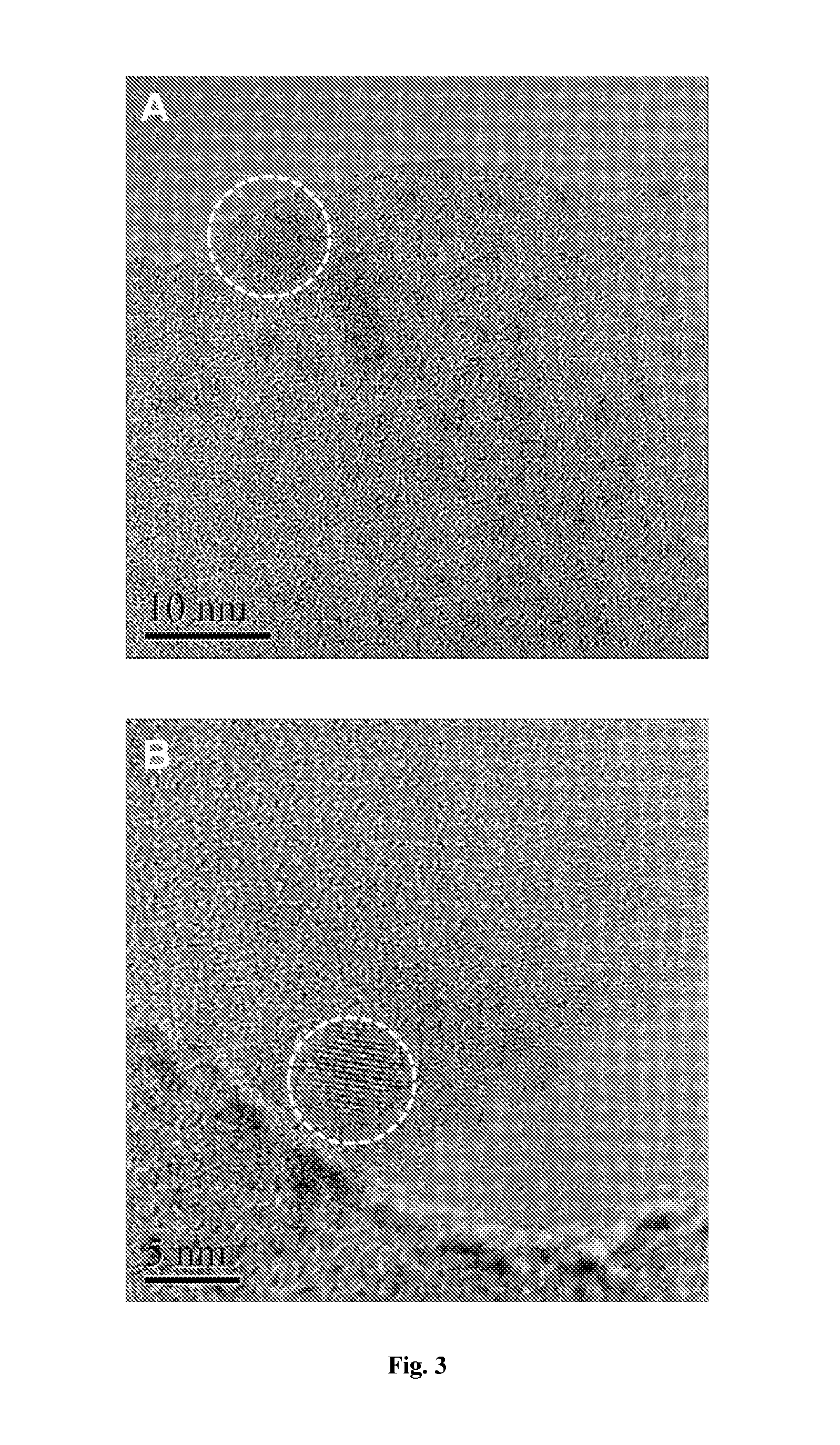

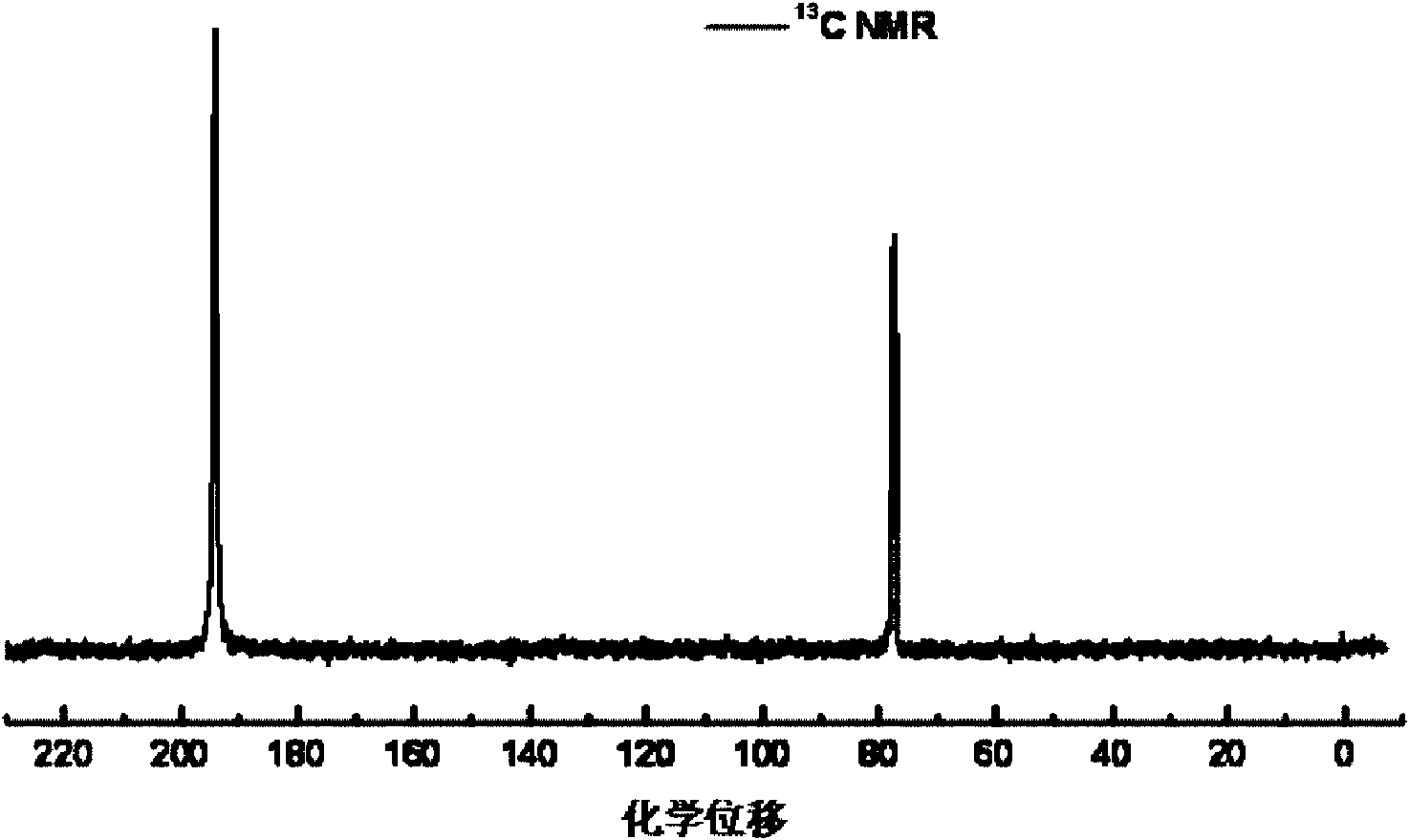

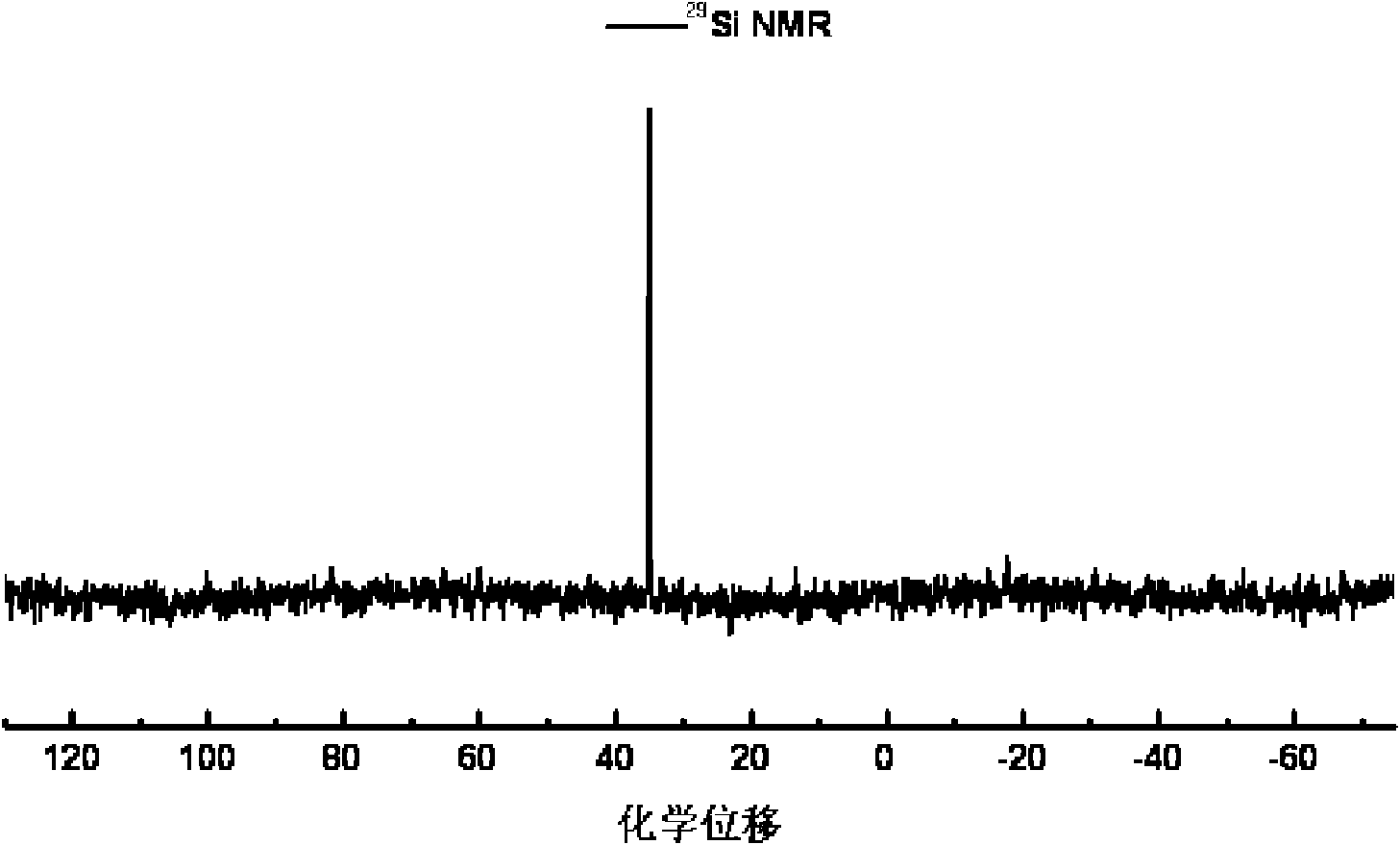

Preparation method of high-performance supported metal silicide catalyst and application thereof

ActiveCN101658804AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsHydrocarbon by hydrogenationMetal silicideAlkyne

The invention discloses a preparation method of a high-performance supported metal silicide catalyst and application thereof, and belongs to the field of catalytic science and technology. In the catalyst, silicon atoms enter metal lattices, and cause the metal lattices to be expanded and metallic bond length to be increased, and structural changes, physical property changes and the like provide metal silicides with special catalytic properties. The preparation method comprises the following steps: a carbonyl compound and an organic silicon compound are used as raw materials, and a metal organic silicide precursor is obtained after low temperature reaction and purification by sublimation; and the metal organic silicide precursor is sublimated to a carrier in a fluidized bed reactor for metal organic chemical vapor deposition, thus obtaining the high-performance supported metal silicide catalyst. The catalyst can be applied to multi-phase hydrogen-related catalytic reactions such as naphthalene hydrogenation, selective hydrogenation of alkyne or diene, hydrodesulfurization and hydrodenitrogenation reactions. The preparation method solves the problem of low surface area of metal silicides prepared by traditional methods, and has advantages of simple operation and easy control.

Owner:DALIAN UNIV OF TECH

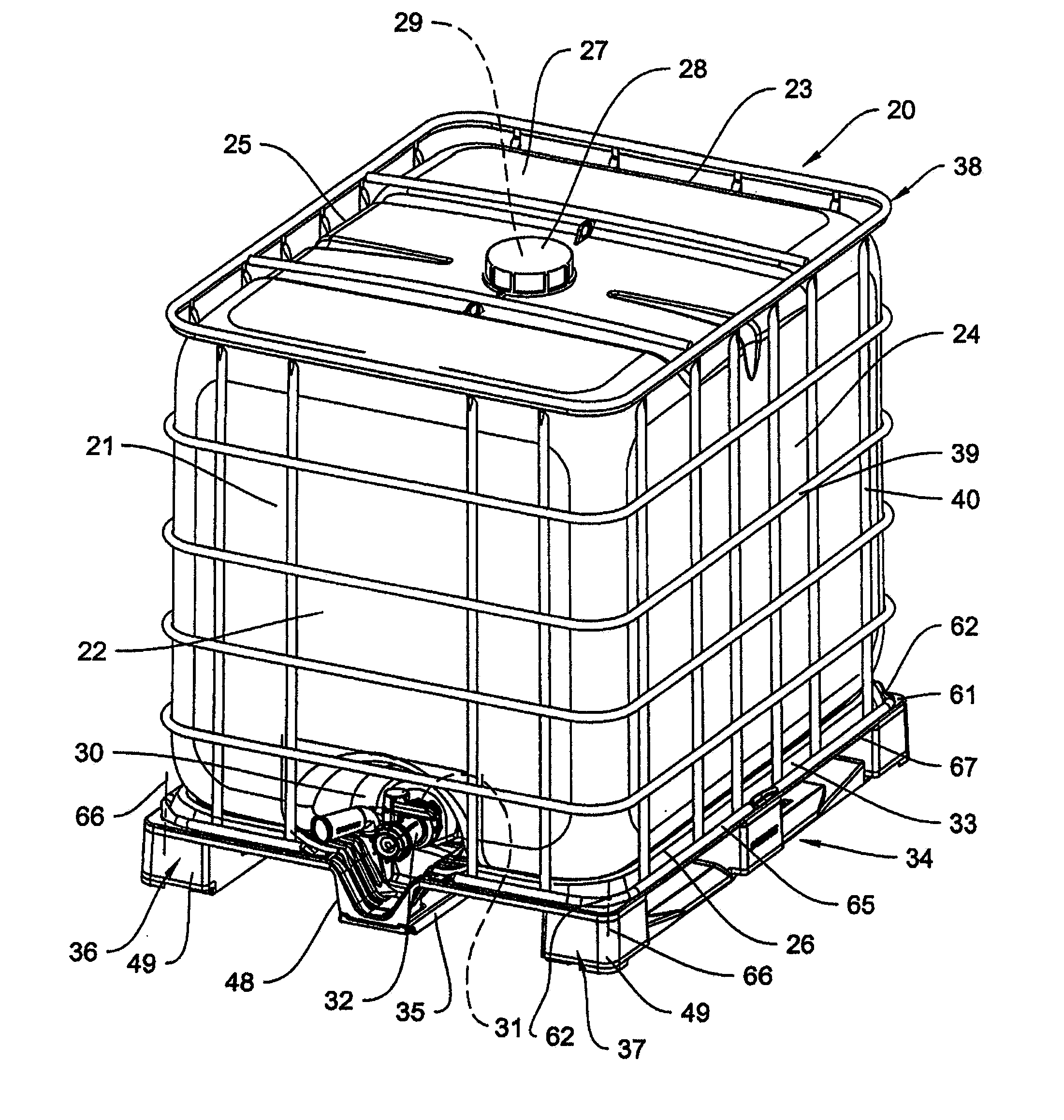

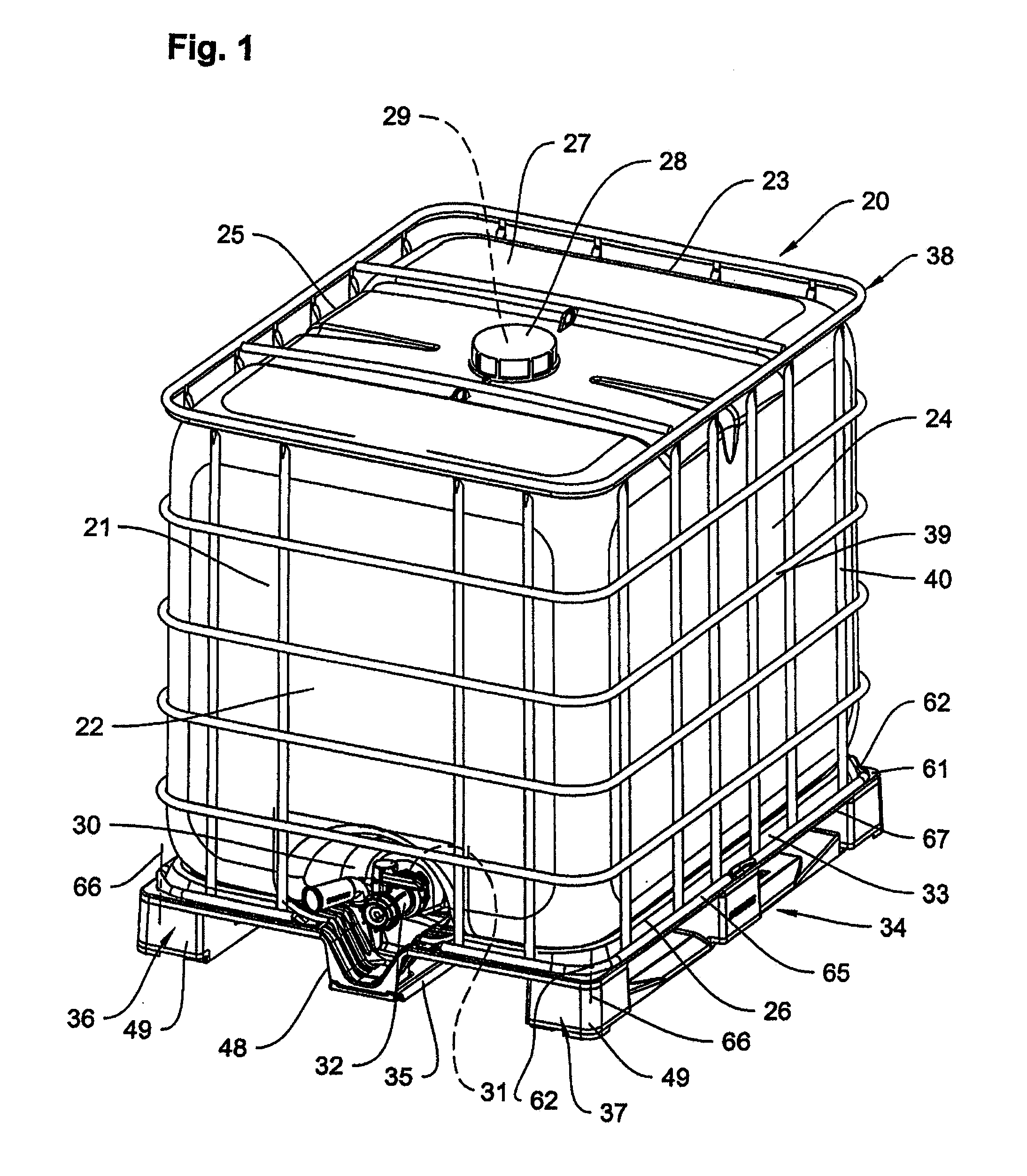

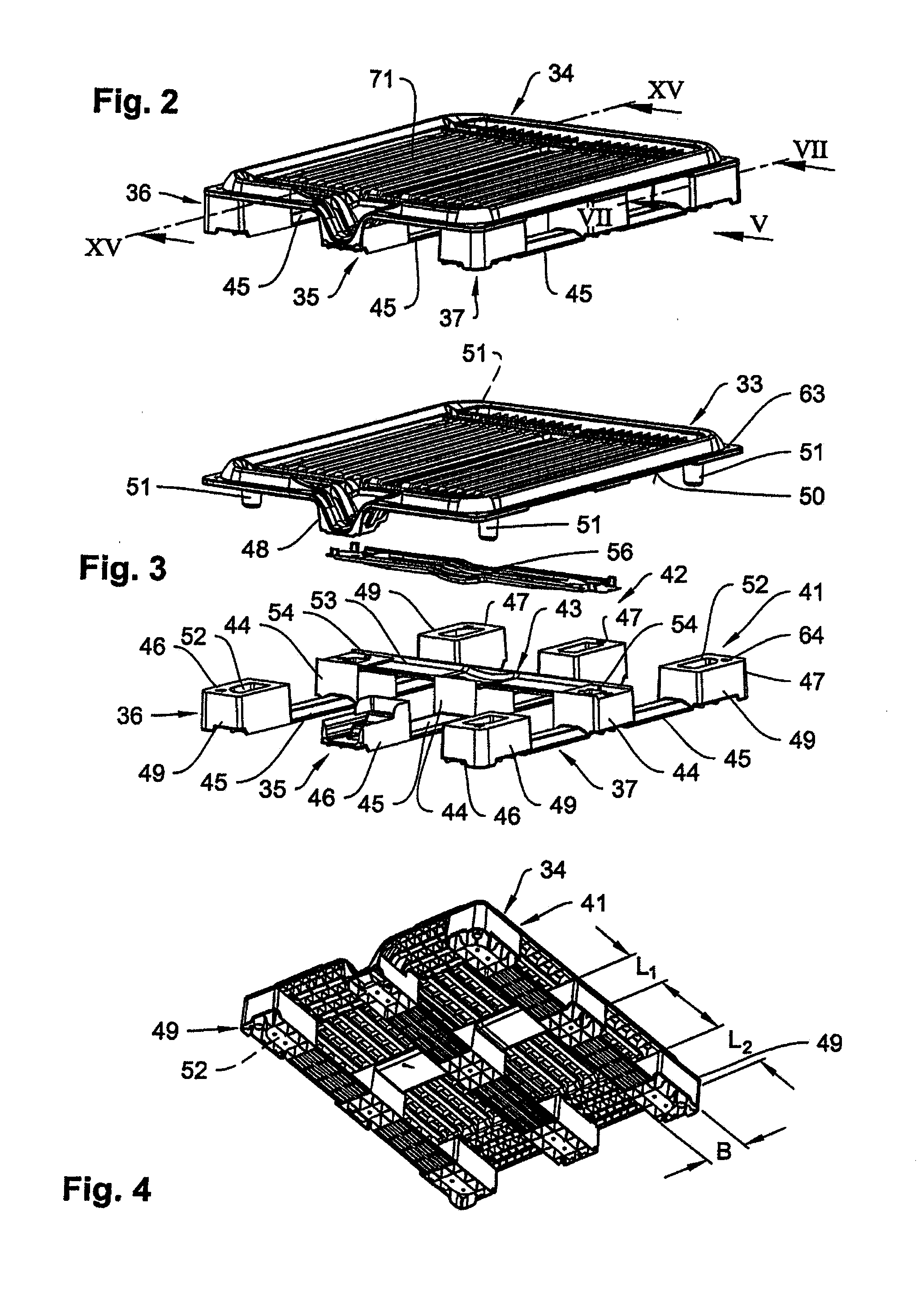

Skid Pallett For Transport And Storage Containers For Liquids

ActiveUS20120279885A1Reduce riskSimplifying ready-to-use productionLarge containersOther accessoriesEngineeringSlide plate

A skid pallet comprising an inner container made of plastic, comprising a lockable filler neck and a discharge nozzle for connecting a removal fitting as well as an outer jacket made of a metal lattice or metal plate. The skid pallet is equipped to be handled by forklifts, a storage and retrieval machine or similar transport equipment and is equipped with a pallet floor, which is supported on support feet of a central skid and two outer skids. The central skid and the outer skids are connected to one another by a skid bridge forming a pallet base, which can be handled independent from the pallet floor, and that, for establishing a non-positive plug-in connection with the pallet base, the pallet floor furthermore encompasses engagement devices, which are assigned to the support feet and which interact with assigned engagement devices of the support feet.

Owner:PROTECHNA SA

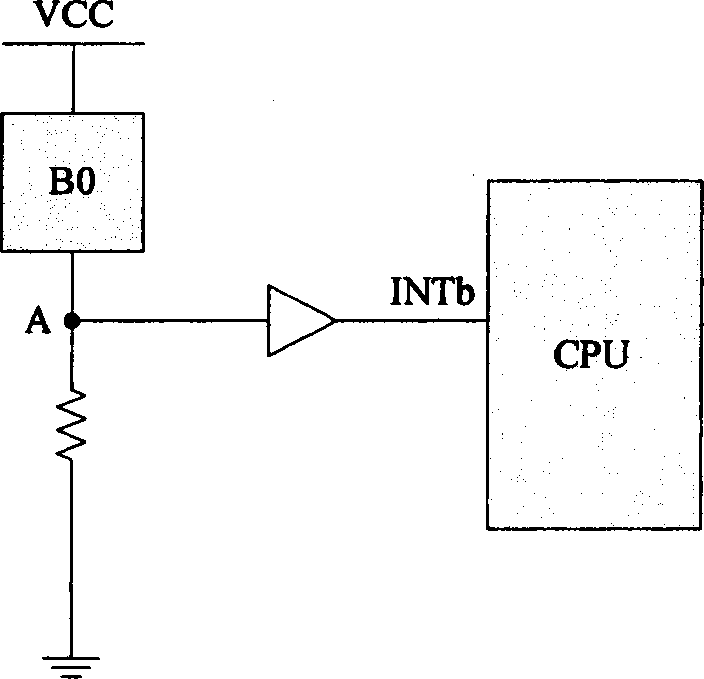

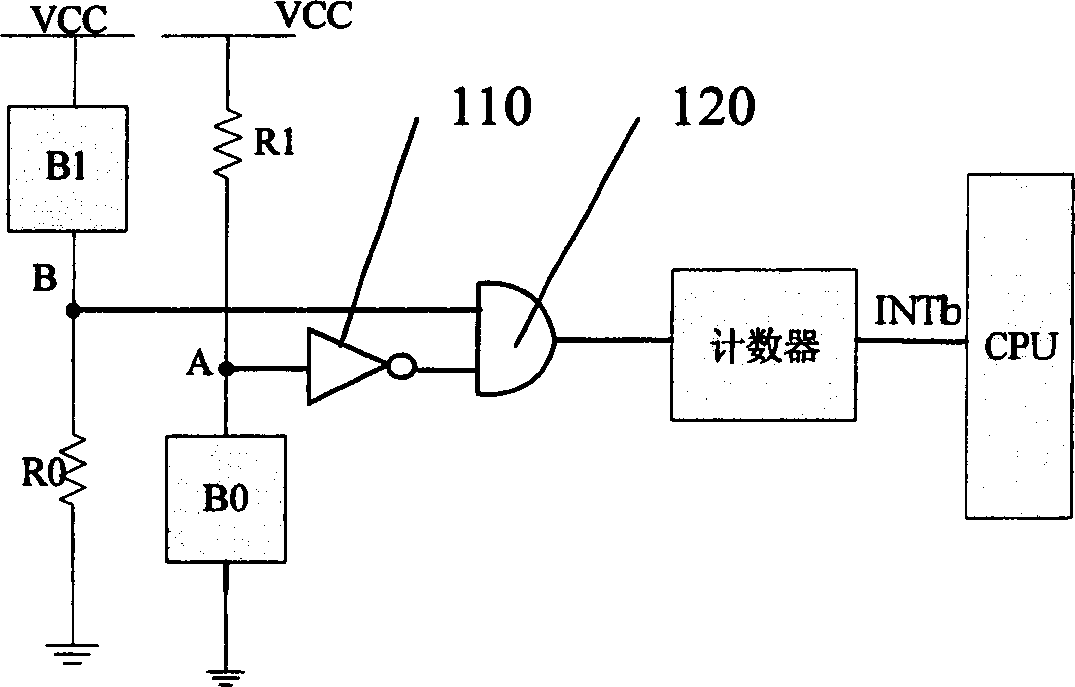

Multi layer gridding detector of chip, and method for anti attack

ActiveCN1696863AEffective protectionIncrease the difficultyDigital data processing detailsSolid-state devicesElectricityDetector circuits

A lattice detector consists of metal lattice for providing voltage and detection signal, CPU triggering pin for zero clearing and resetting of storage. The present invention realizes efficient protection of core data by applying protective method of setting metal lattice and detector circuit on safety chip.

Owner:SHENZHEN SINOSUN TECH

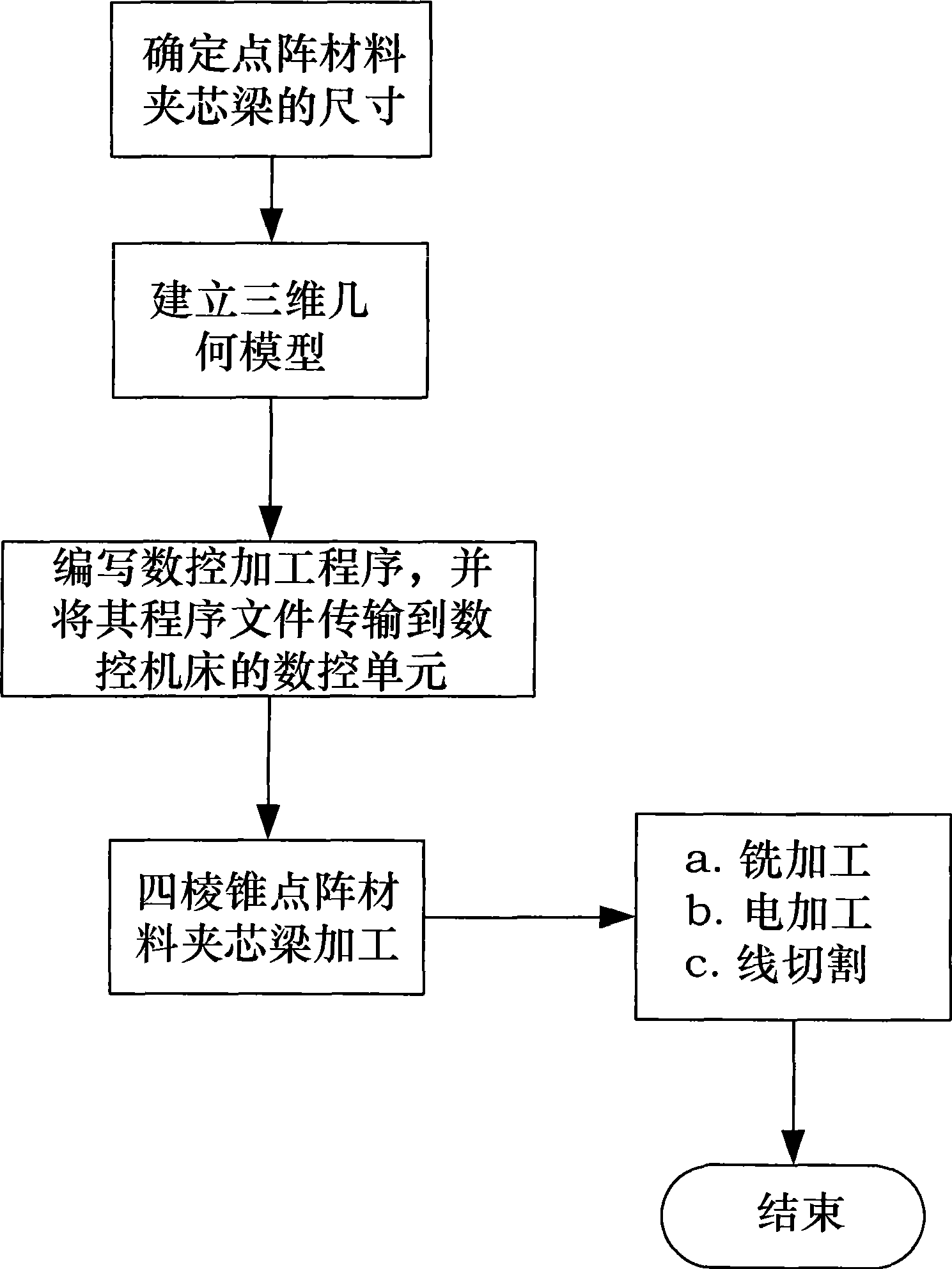

Preparation method of rectangular pyramid metal lattice material

InactiveCN101417386AHigh strengthTroubleshoot Connection Strength IssuesMilling equipment detailsIn planeNumerical control

The invention discloses a preparation method of a rectangular pyramid metal lattice material and includes the following steps of: defining geometric size of a sandwich beam of the lattice material; building a three-dimensional geometric model of the sandwich beam of the rectangular pyramid lattice material; writing a numerical control machining program and transferring a program file to a numerical control unit of a numerical control machine; and finally, processing the sandwich beam of the rectangular pyramid lattice material through the numerical control machine. The preparation method of the invention has the advantages of high automation degree and short manufacturing cycle; in addition, the rectangular pyramid metal lattice material prepared with the method is high in strength, level in plane, good in periodicity of rectangular pyramid cell elements and widespread in application.

Owner:BEIHANG UNIV

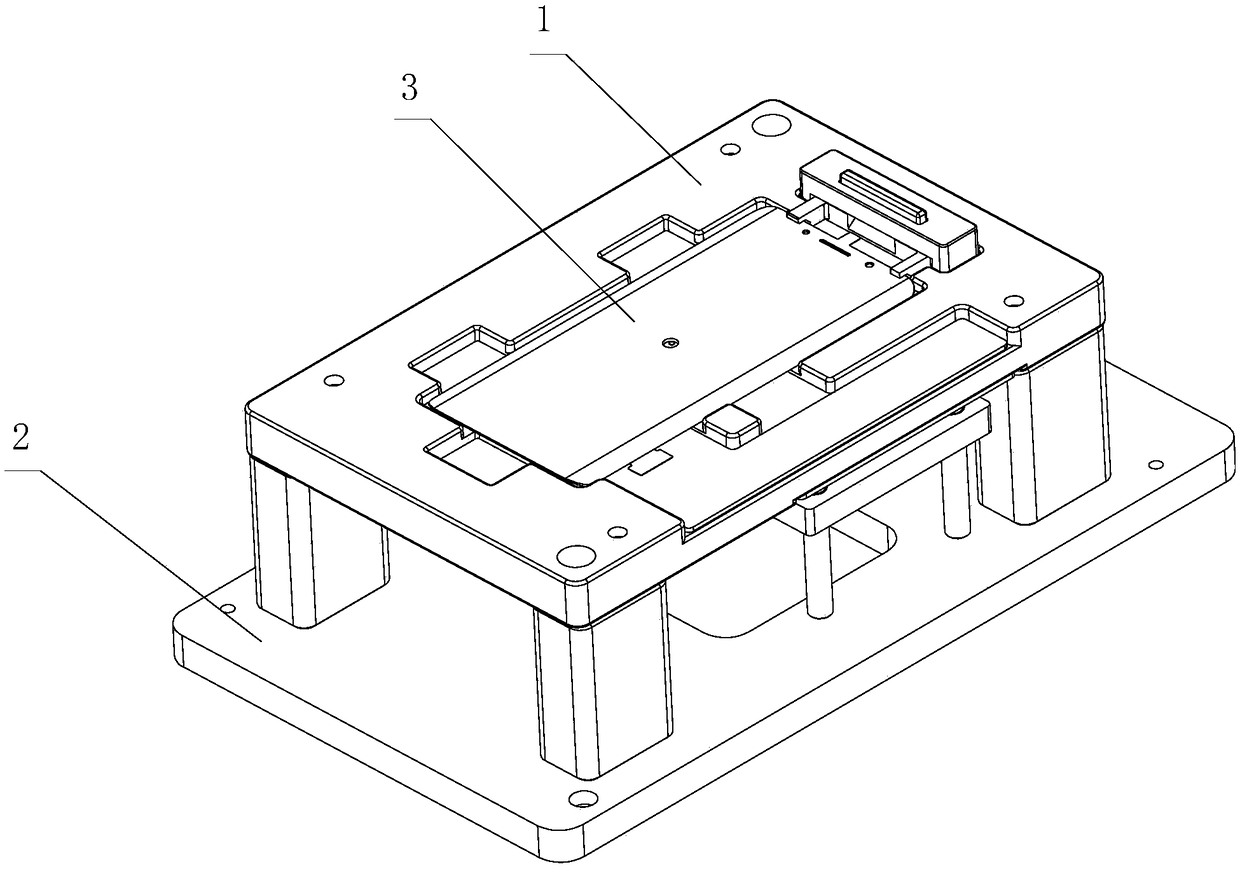

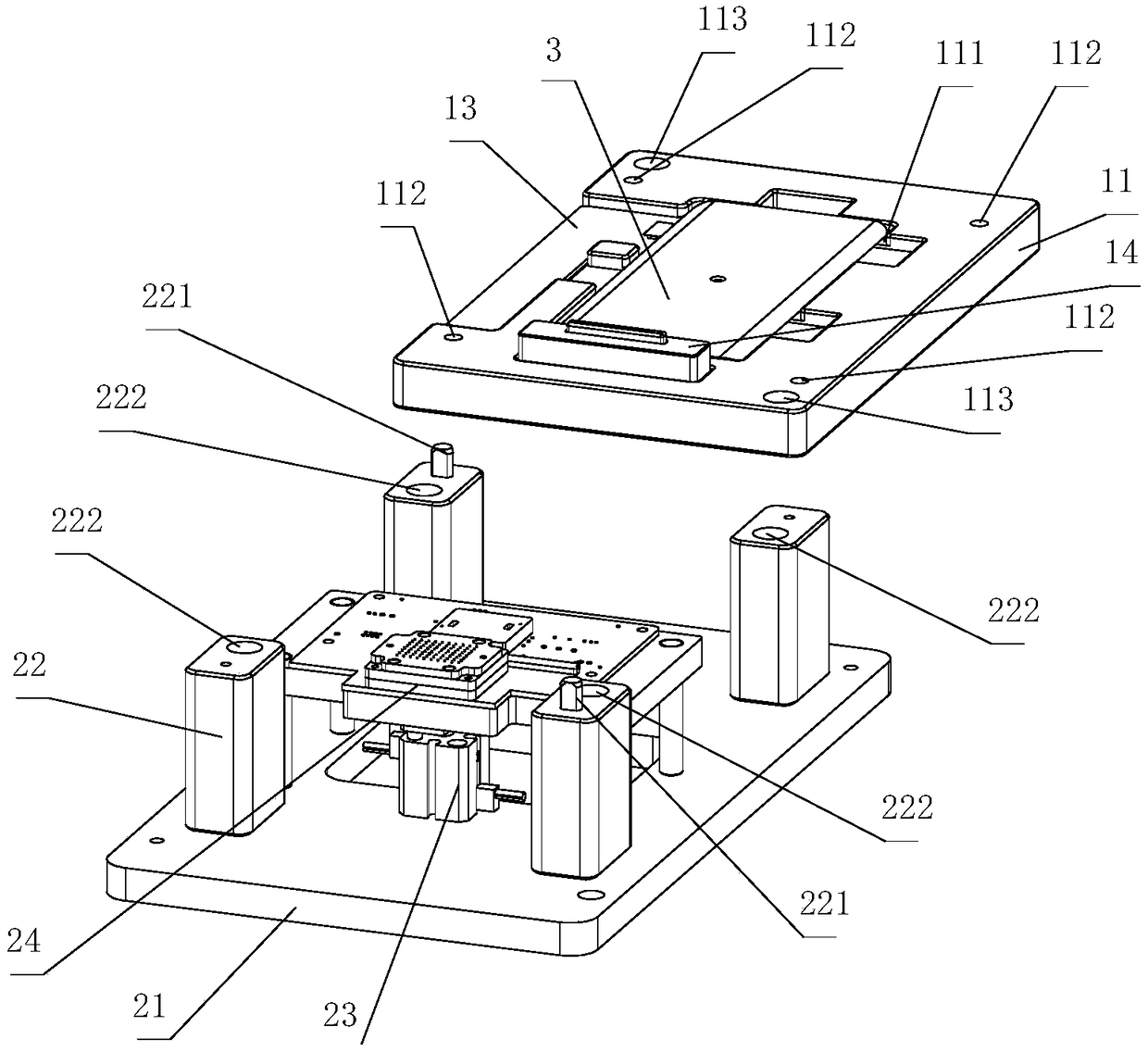

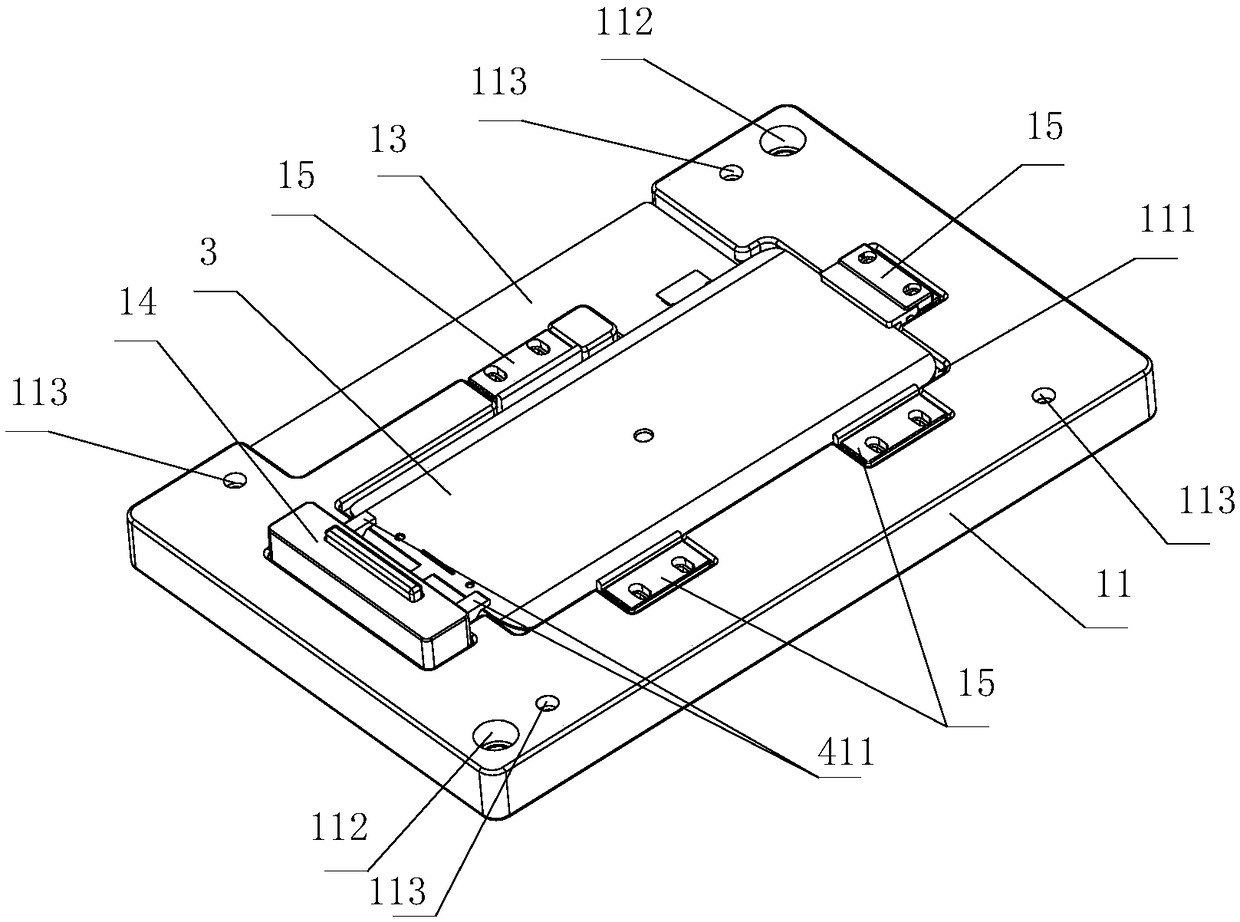

Bearing device for display panel test

PendingCN109342020AThe test result is accurateReduce harmOptical apparatus testingSignal onMetal lattice

The invention relates to a bearing device for display panel test. The bearing device includes a carrier and a test base. The bearing device is connected with a connector of a display panel through a PCB signal adapter plate, and transmits a detection signal of the display panel to a metal lattice of the PCB signal adapter plate. The display panel can be detected by making the bearing device and the metal lattice of the PCB signal adapter plate form a circuit directly, which reduces the damage caused by repeated pressing of products. The metal lattice of PCB signal adapter plate is detected directly, which avoids an inaccurate test result caused by conduction failure of the connector of the display panel. Support pillars are arranged at the four corners of the base to locate the hold the carrier and make the carrier connected accurately. A cylinder drives a probe component to move up and down to complete signal on / off operation. The bearing device for display panel test has the advantages of simple operation, high success rate of conduction and high detection efficiency. The structure of the bearing device can be compatible with non-testable workstations.

Owner:武汉精毅通电子技术有限公司

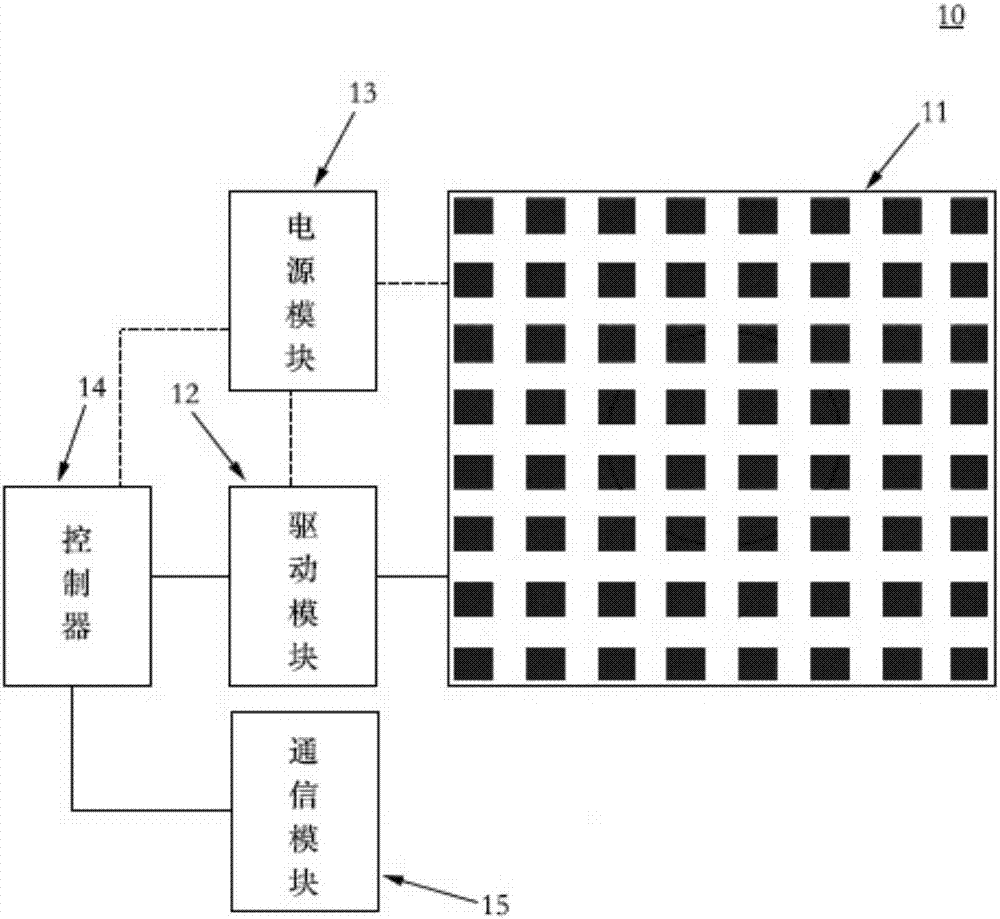

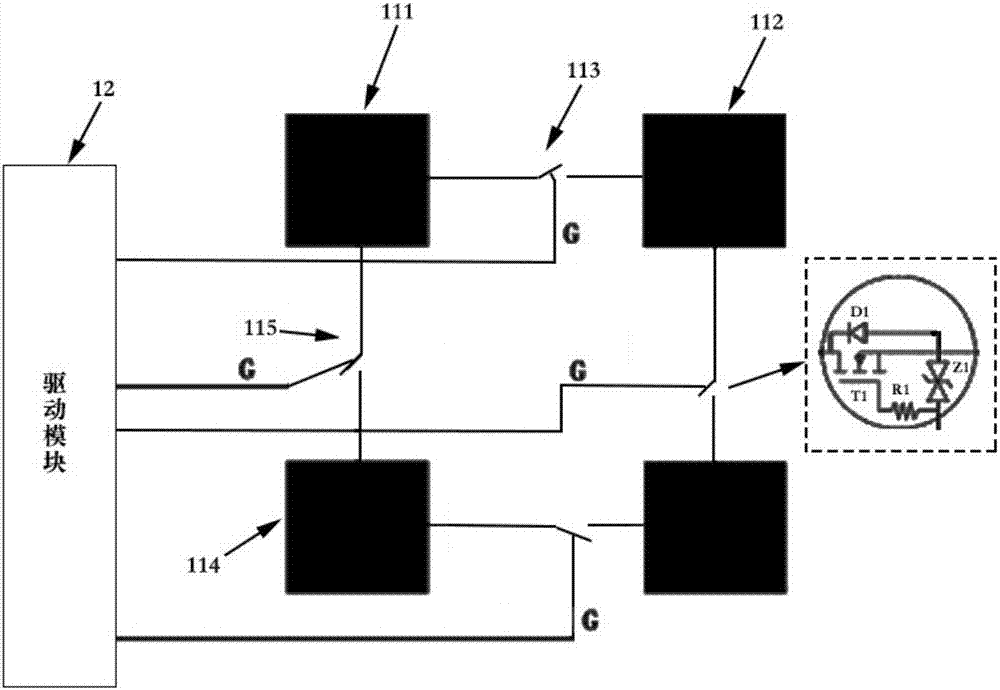

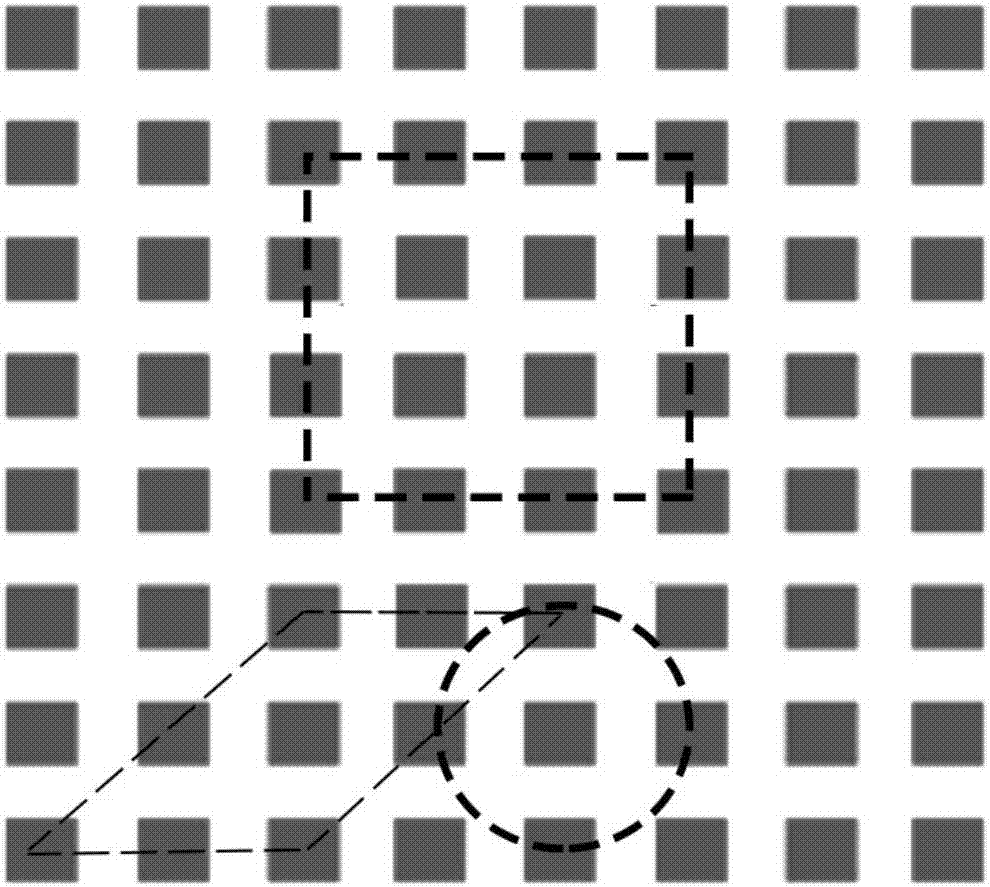

Wireless charger and charging control method thereof

InactiveCN107171391AImprove usabilityAdjustable positionElectric powerArrangements for several simultaneous batteriesElectricityControl signal

The invention discloses a wireless charger and a charging control method thereof. The wireless charger comprises a metal lattice, a driving module and a controller, wherein the metal lattice, the driving module and the controller are electrically connected with a power supply module. The metal lattice comprises a plurality of metal points. Adjacent metal points in the metal lattice are connected through a controllable switch. The control end of the controllable switch is connected with the driving module. The controller generates a first control signal to the driving module. The driving module drives the controllable switches in a first area of the metal lattice according to the first control signal for realizing conduction so that the metal points in the first area of the metal lattice are started for forming a first transmitting coil. According to the wireless charger and the charging control method thereof, through forming the coil by means of connecting the plurality of metal points and adjusting the controllable switches, charging coil position adjustment can be realized, thereby realizing free placement of to-be-charged equipment in the wireless charger, realizing high suitability for different kinds of to-be-charged equipment, and improving wireless charging availability and user experience.

Owner:里程

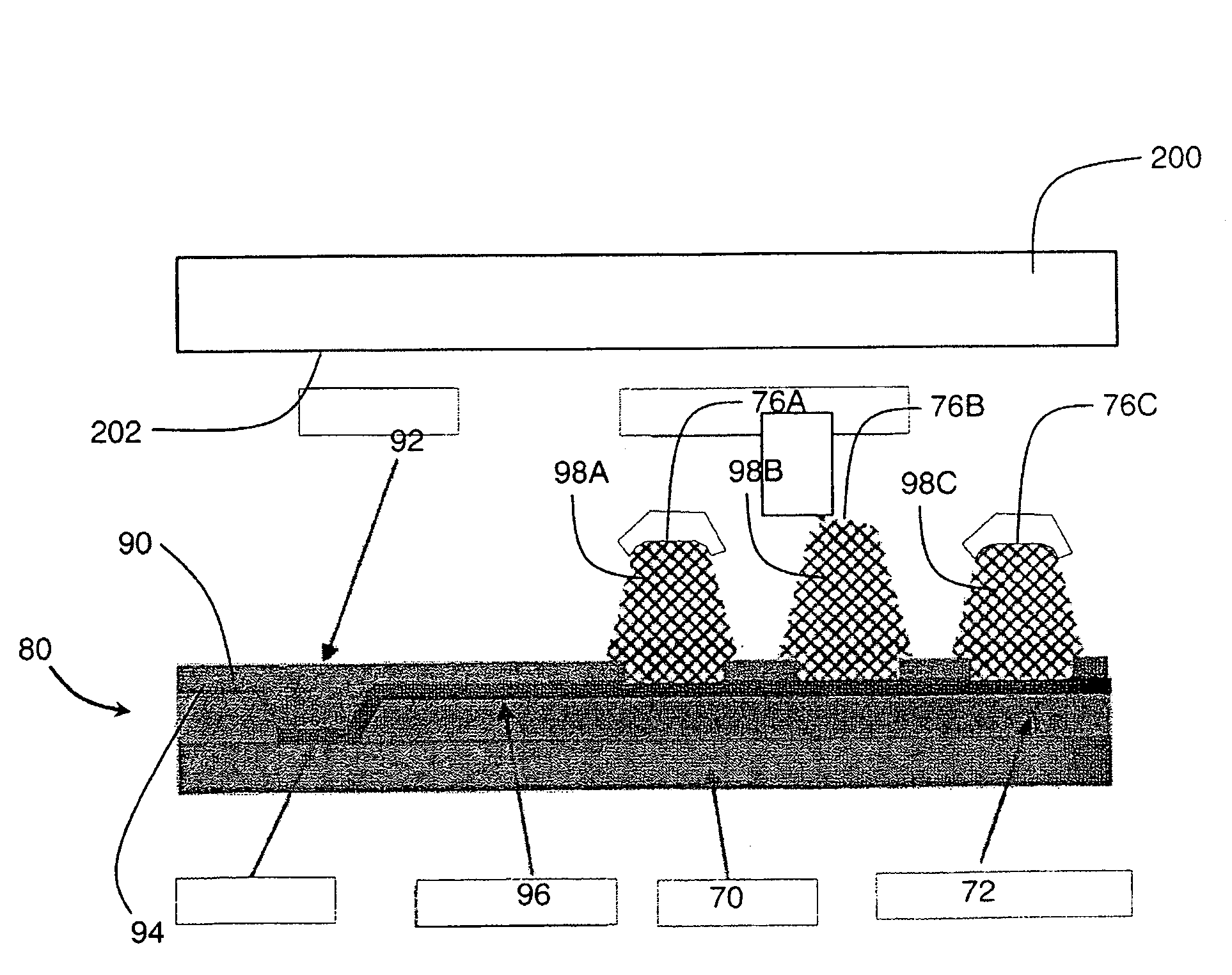

Microelectronic component with foam-metal posts

ActiveUS7510401B2Semiconductor/solid-state device detailsSolid-state devicesMetal latticeEngineering

A microelectronic component having a base and a plurality of conductive posts extending from said base. Each of the posts is formed from a connected lattice of metal having voids therein. The lattice may be formed by depositing metal onto a sacrificial element such as an open-celled polymeric foam. During use or during processing, the posts may be deformed , as by crushing the lattice.

Owner:TESSERA INC

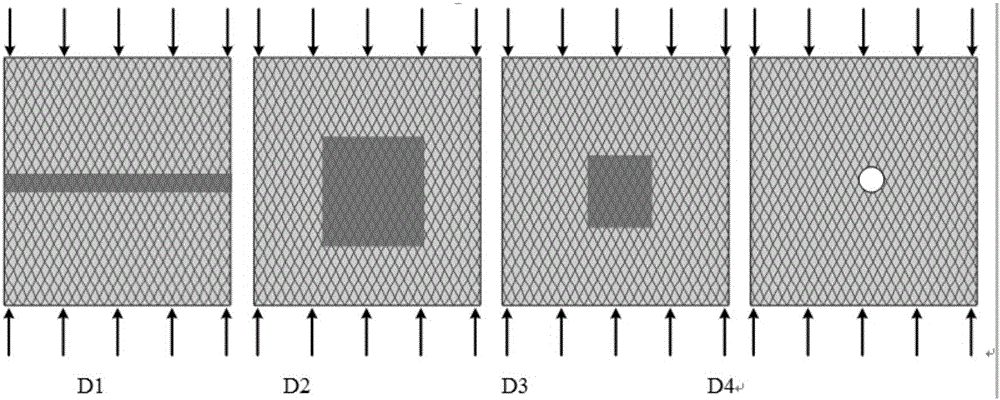

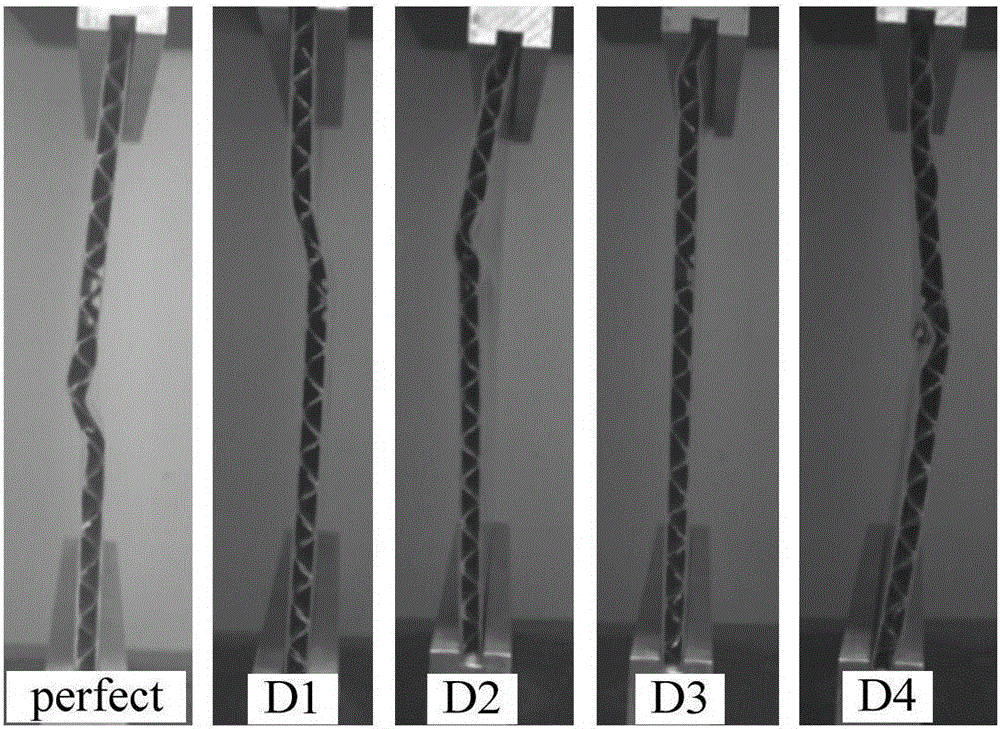

Metal lattice interlayer plate with embedded defects and mechanical property detection method thereof

InactiveCN106124327AMechanical property testingSimple preparation processPreparing sample for investigationMaterial strength using tensile/compressive forcesWire gauzeMetal lattice

The invention discloses a metal lattice interlayer plate with embedded defects and a mechanical property detection method thereof. The preparation process is simple, low in cost and applicable to preparation of various metal lattice materials. By means of the mechanical property detection method, the mechanical property of the metal lattice interlayer plate with the embedded defects can be comprehensively detected. The method comprises the steps that 1, a wire mesh of a two-dimensional planar structure of a periodic rhombus structure is stamped at joints to obtain a lattice material with a three-dimensional pyramid structure; 2, defects are embedded on the lattice material or metal panels, the lattice material is used as a core material to be arranged between the two metal panels in an overlaid mode, the lattice material and the two metal panels are brazed at a high temperature after being overlapped, and the metal lattice interlayer plate with the embedded defects is obtained. The defect embedding process comprises the steps that some joints of the lattice material are coated with protective materials, partial metal lattice sandwich is cut away, or one metal panel is punched.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

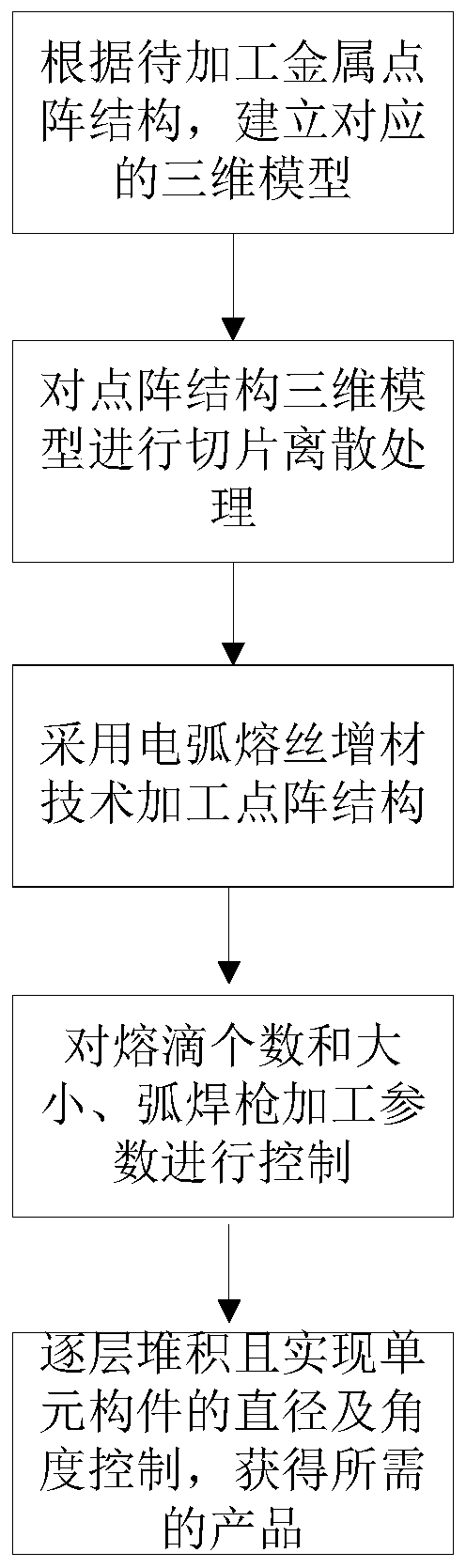

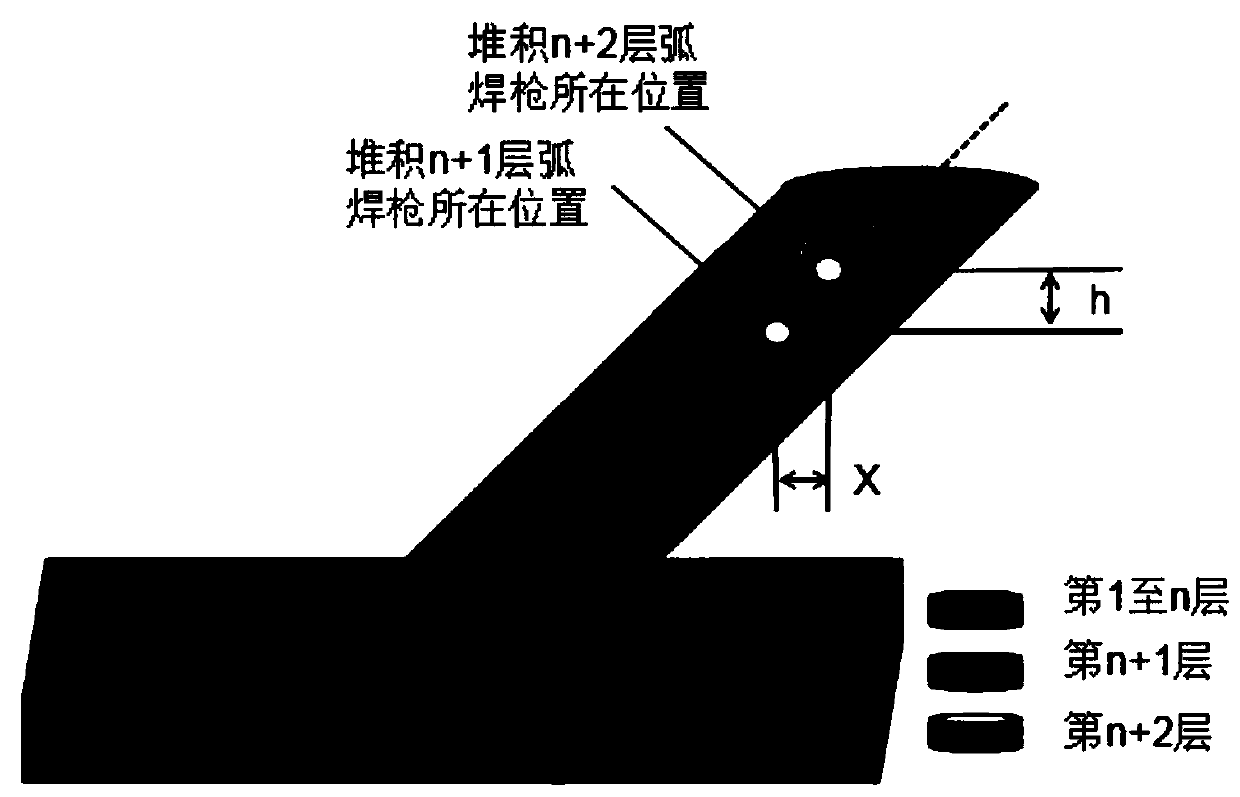

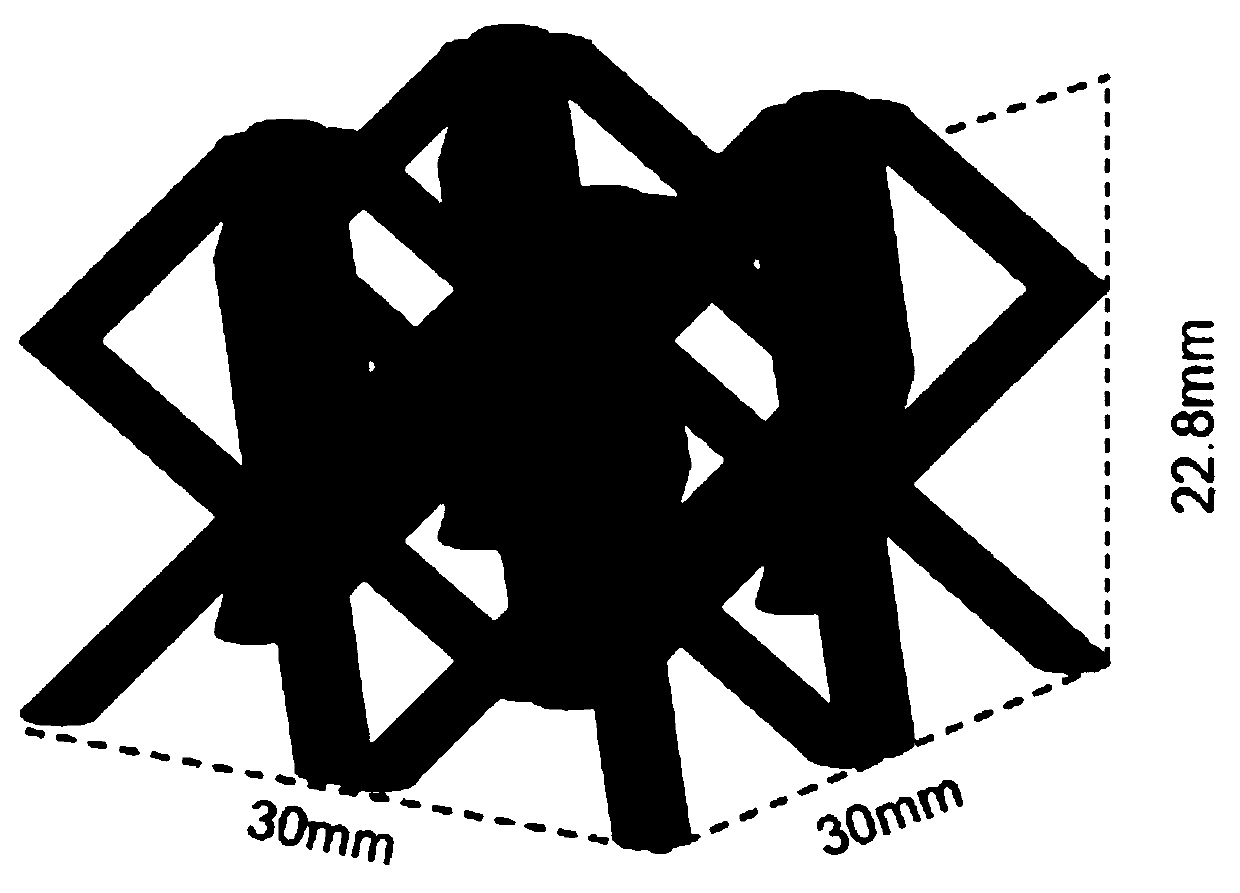

Method of electric arc fuse additive manufacturing of metal lattice structure and product

ActiveCN110560837AImprove material requirementsImprove material qualityAdditive manufacturing apparatusArc welding apparatusLifting capacityEngineering

The invention belongs to the related technical field of lattice structure manufacturing and processing, and discloses a method of electric arc fuse additive manufacturing of a metal lattice structure.On one hand, the pulse waveform of power output is controlled, so that the transition of one pulse and one drop is realized, the size and number of molten drops can be accurately controlled, and thediameter of a unit rod of the lattice structure is controlled; on the other hand, the lifting capacity and offset in a printing path are controlled, so that the angle of the unit rod of the lattice structure can be accurately controlled, and the electric arc fuse additive manufacturing of the lattice structure of any structure is realized. The invention further discloses a corresponding product. According to the method, the defects and deficiencies of various preparation lattice structures in the prior art can be effectively overcome, and additionally, the method has the advantages of high processing quality and low material requirement and is suitable for any complex form and large sizes.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com