Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4484results about How to "Adjustable position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

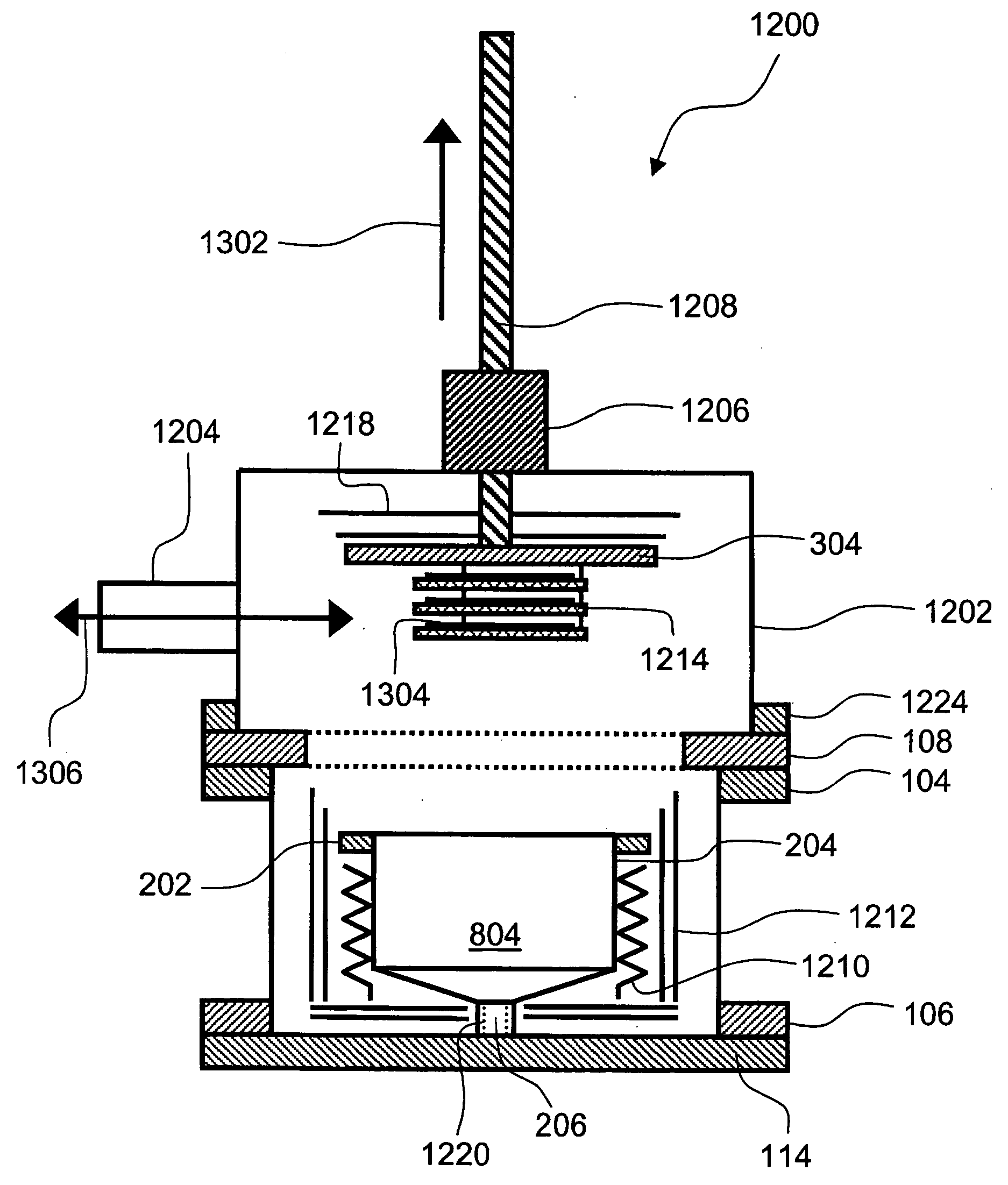

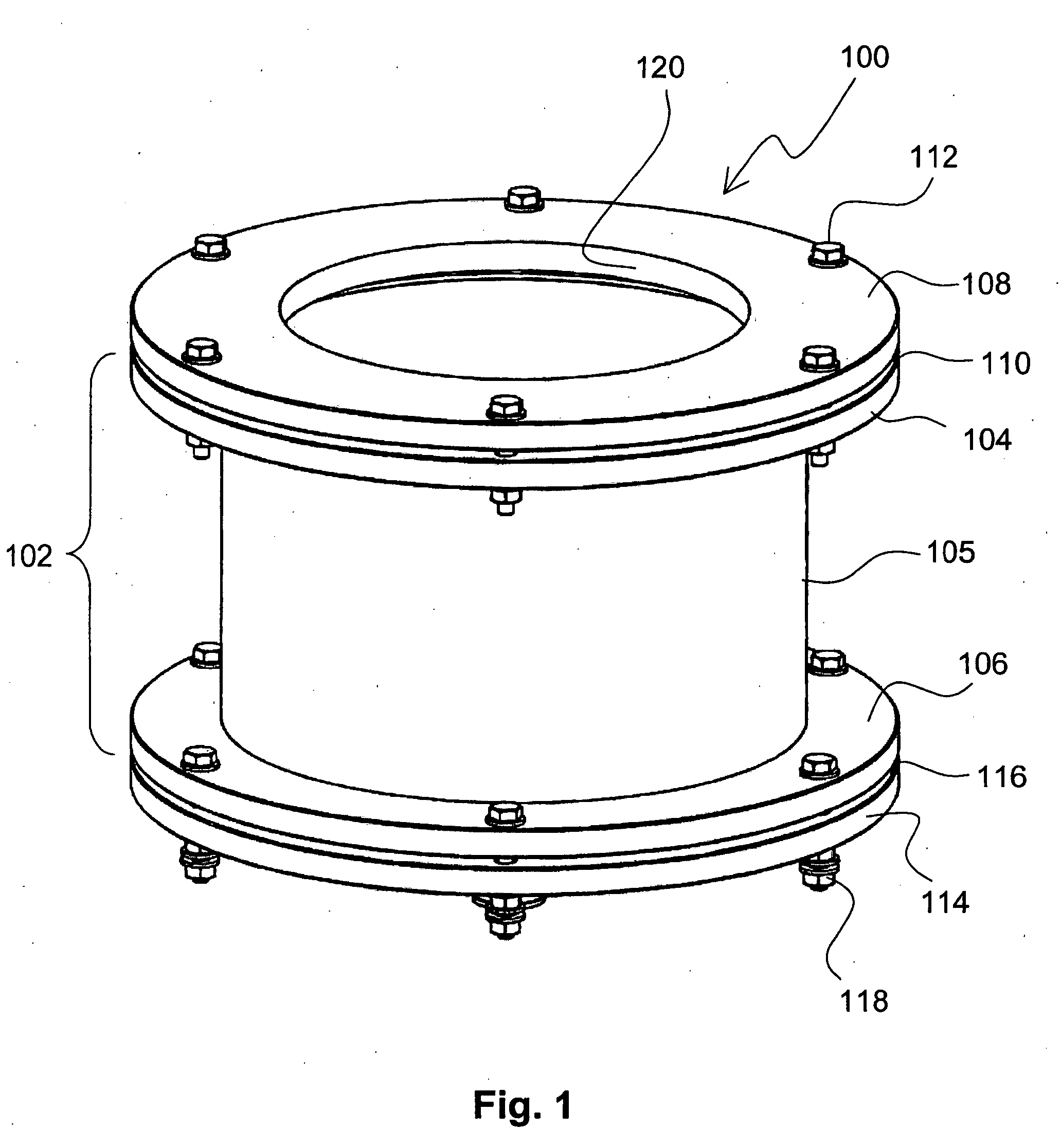

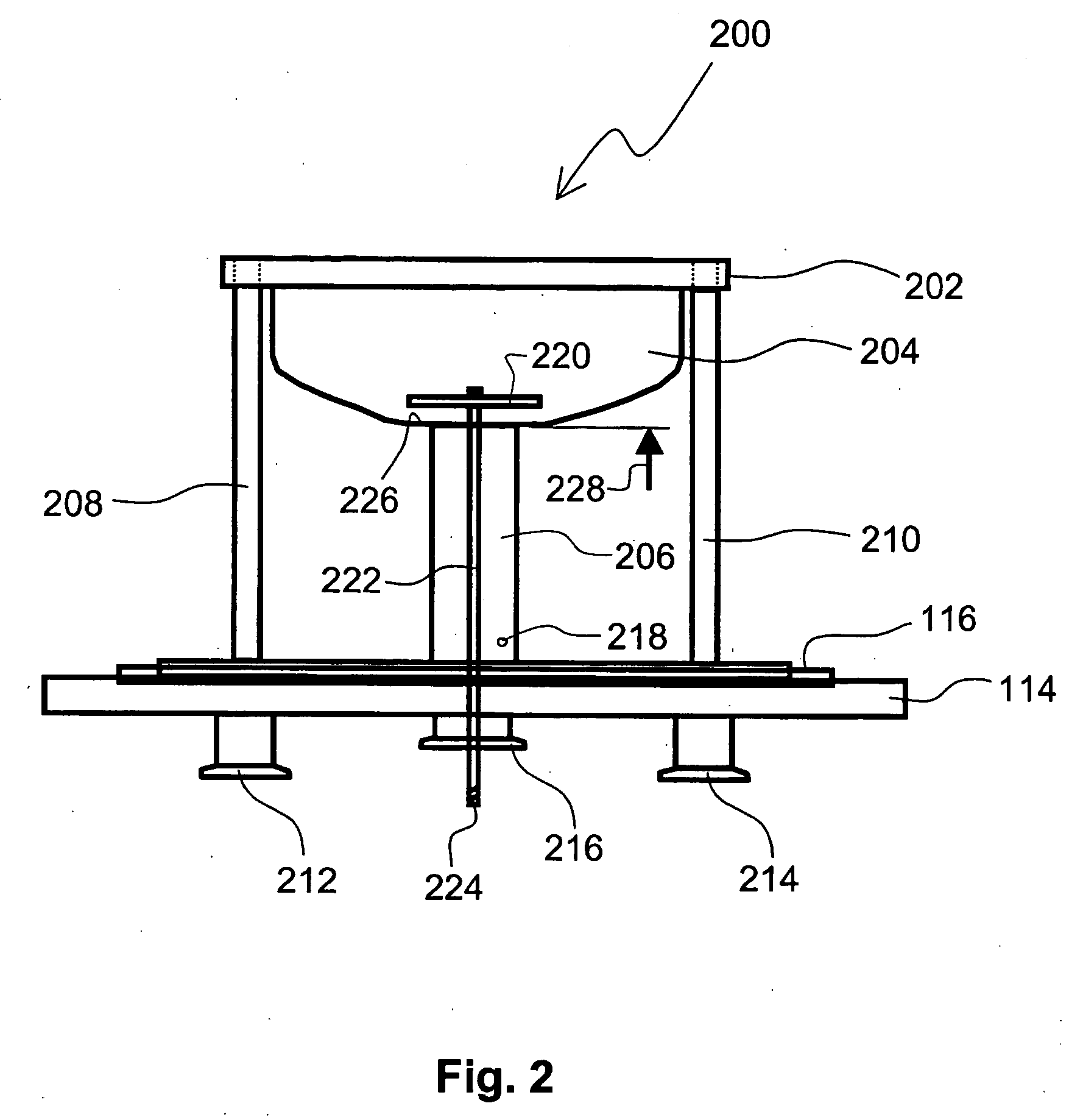

Apparatuses and methods for deposition of material on surfaces

ActiveUS20060196418A1Adjustable positionFrom chemically reactive gasesChemical vapor deposition coatingChemical reactionCompound (substance)

An apparatus for depositing conformal thin films by sequential self saturating chemical reactions on heated surfaces is disclosed. The apparatus comprises a movable single or dual-lid system that has a substrate holder attached to a reaction chamber lid. In other embodiments, the apparatus comprises an exhaust flow plug, a gas distribution insert, a local heater or a minibatch system. Various methods suitable for ALD (Atomic Layer Deposition) are also enclosed.

Owner:PICOSUN OY

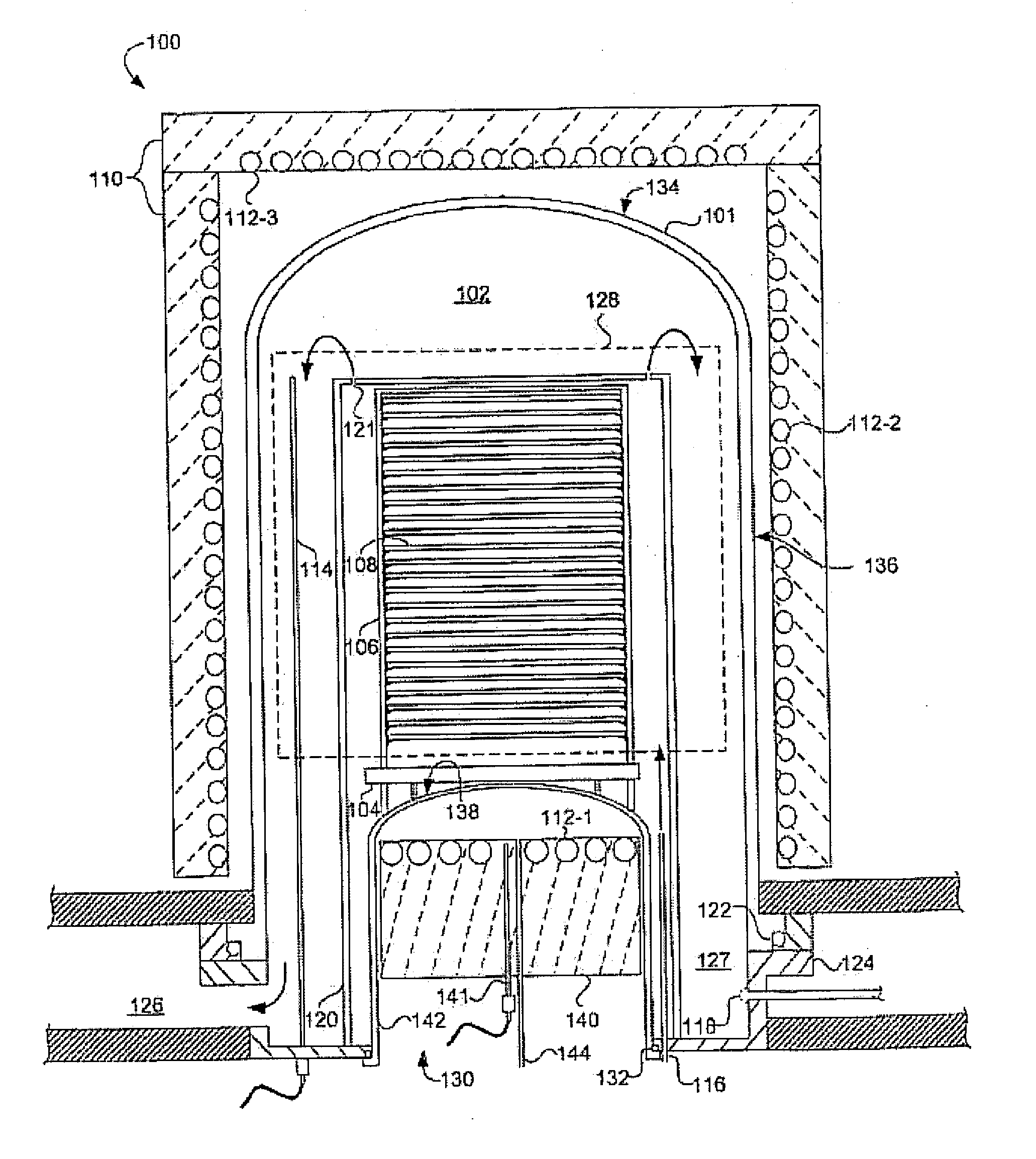

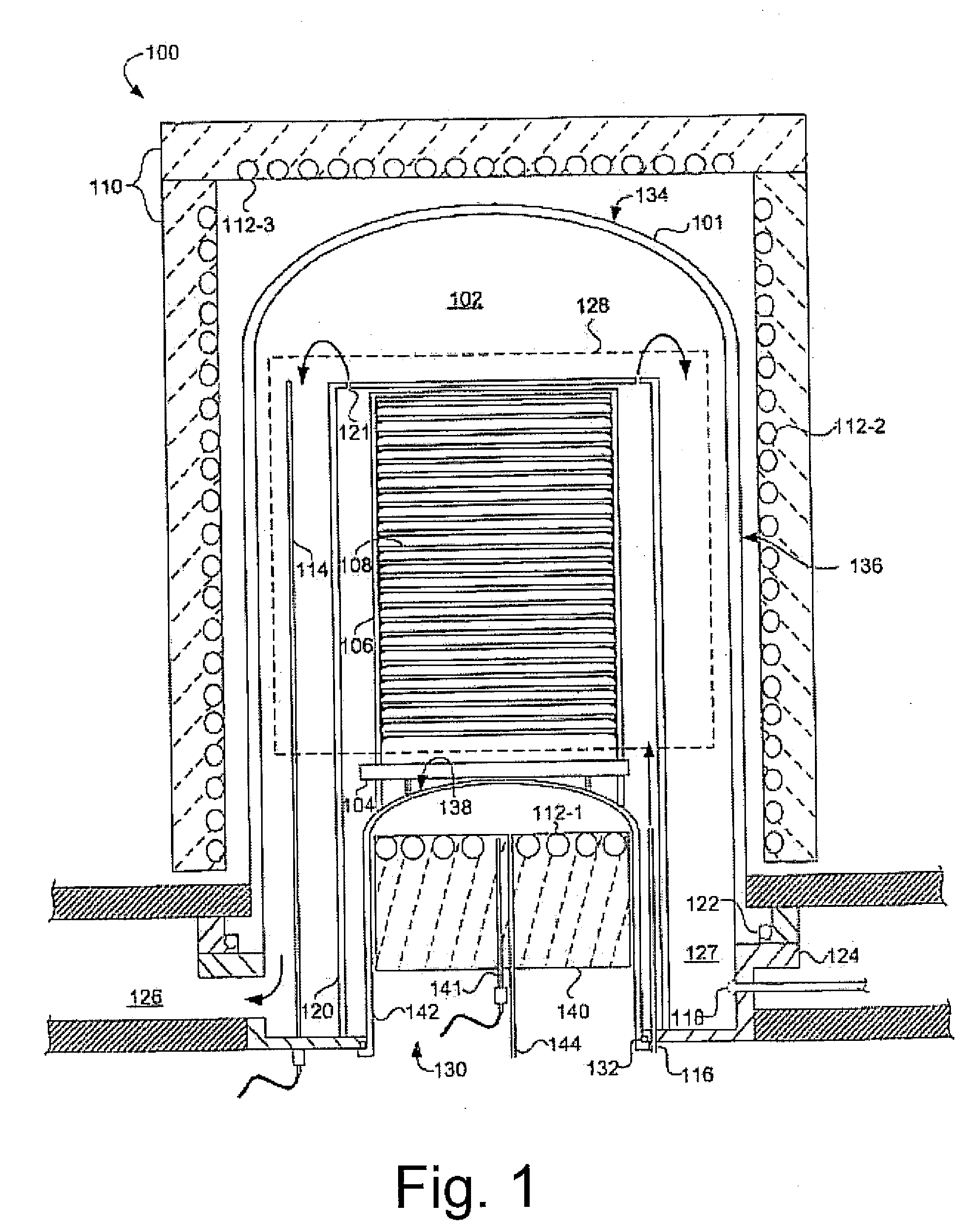

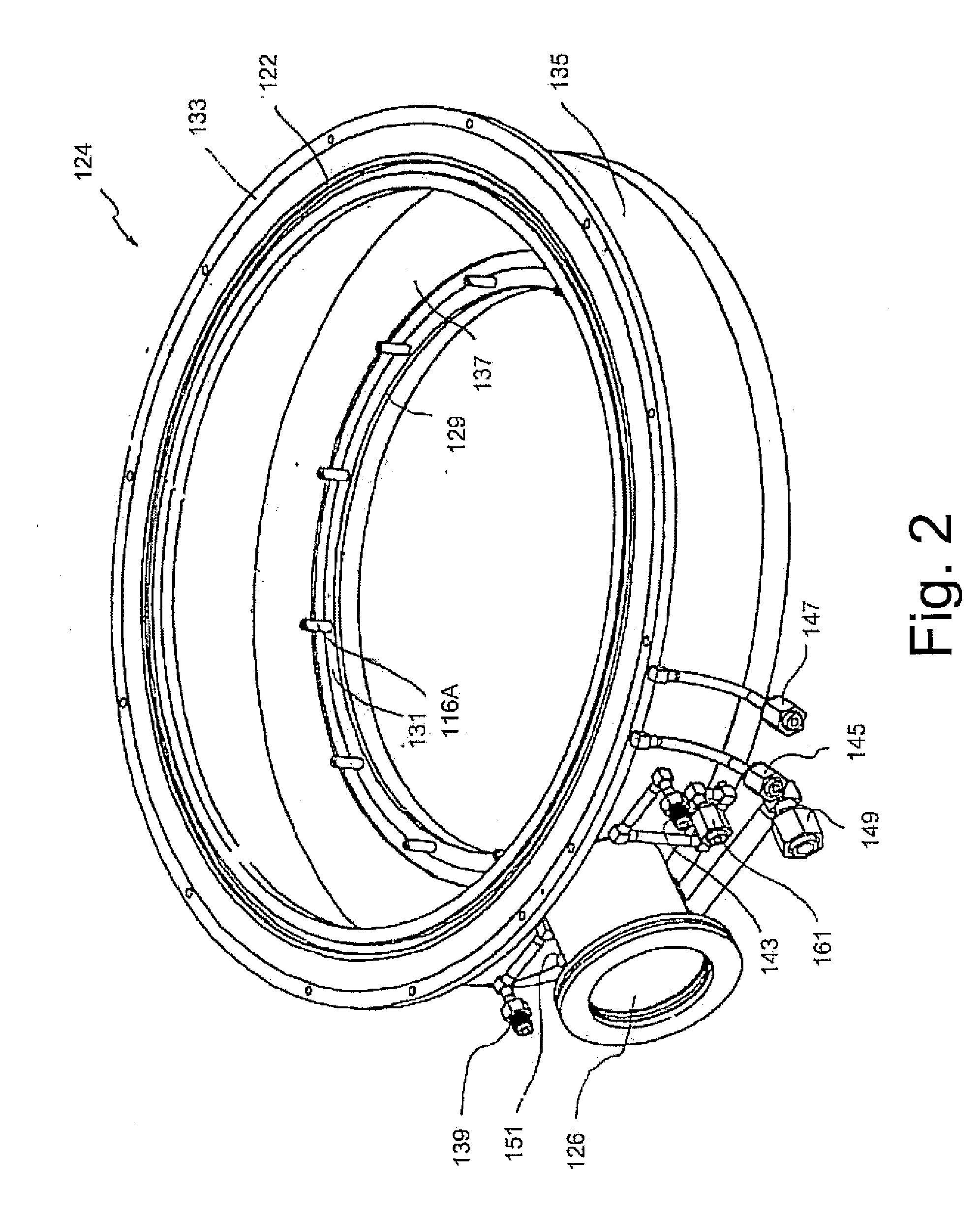

Thermal processing system with across-flow liner

InactiveUS20070137794A1Rapid evacuationRapid backfillingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAirflowElectrical and Electronics engineering

An apparatus is provided for thermally processing substrates held in a carrier. The apparatus includes an across-flow liner to improve gas flow uniformity across the surface of each substrate. The across-flow liner of the present invention includes a longitudinal bulging section to accommodate a across-flow injection system. The liner is patterned and sized so that it is conformal to the wafer carrier, and as a result, reduces the gap between the liner and the wafer carrier to reduce or eliminate vortices and stagnation in the gap areas between the wafer carrier and the liner inner wall.

Owner:AVIZA TECHNOLOGY INC

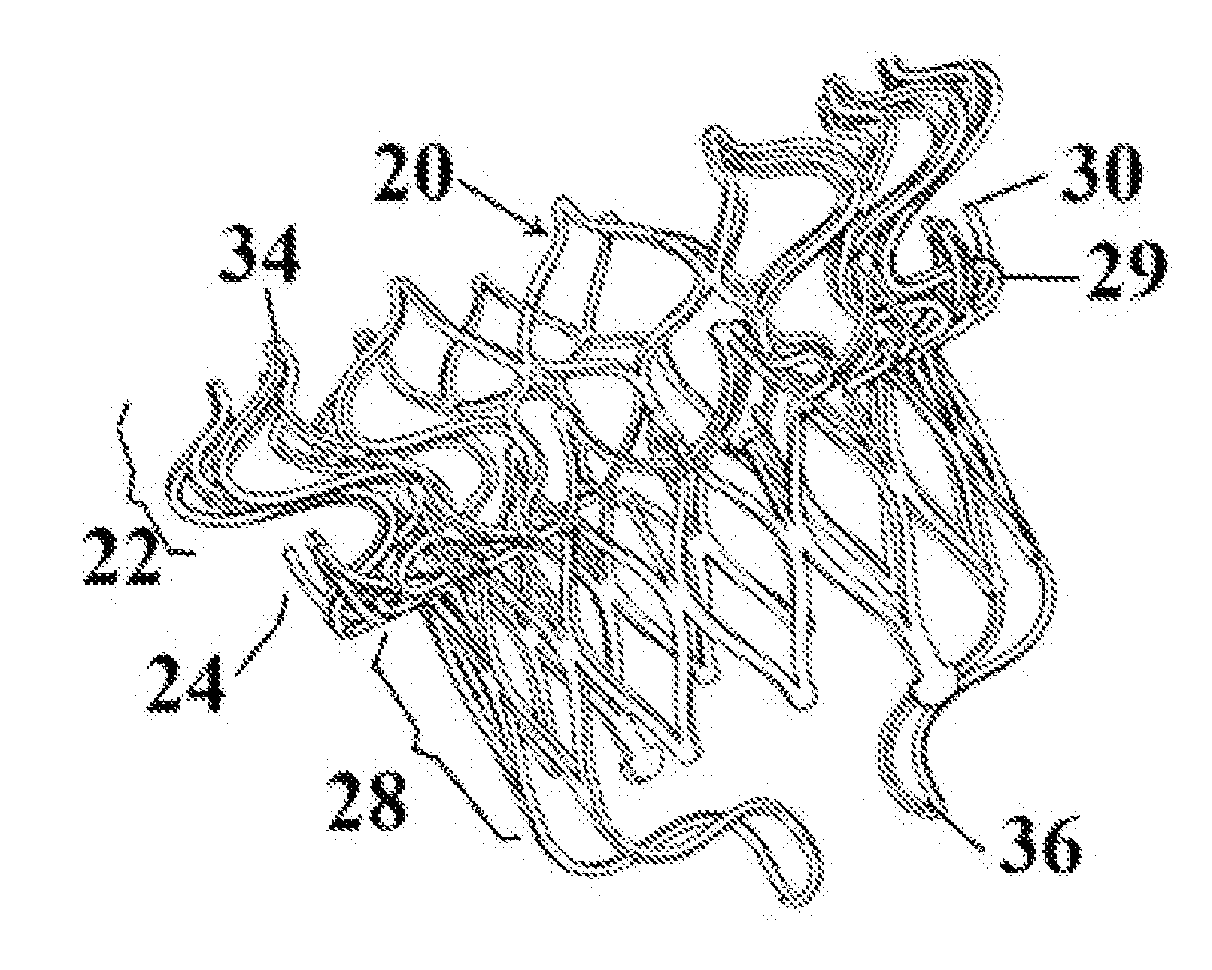

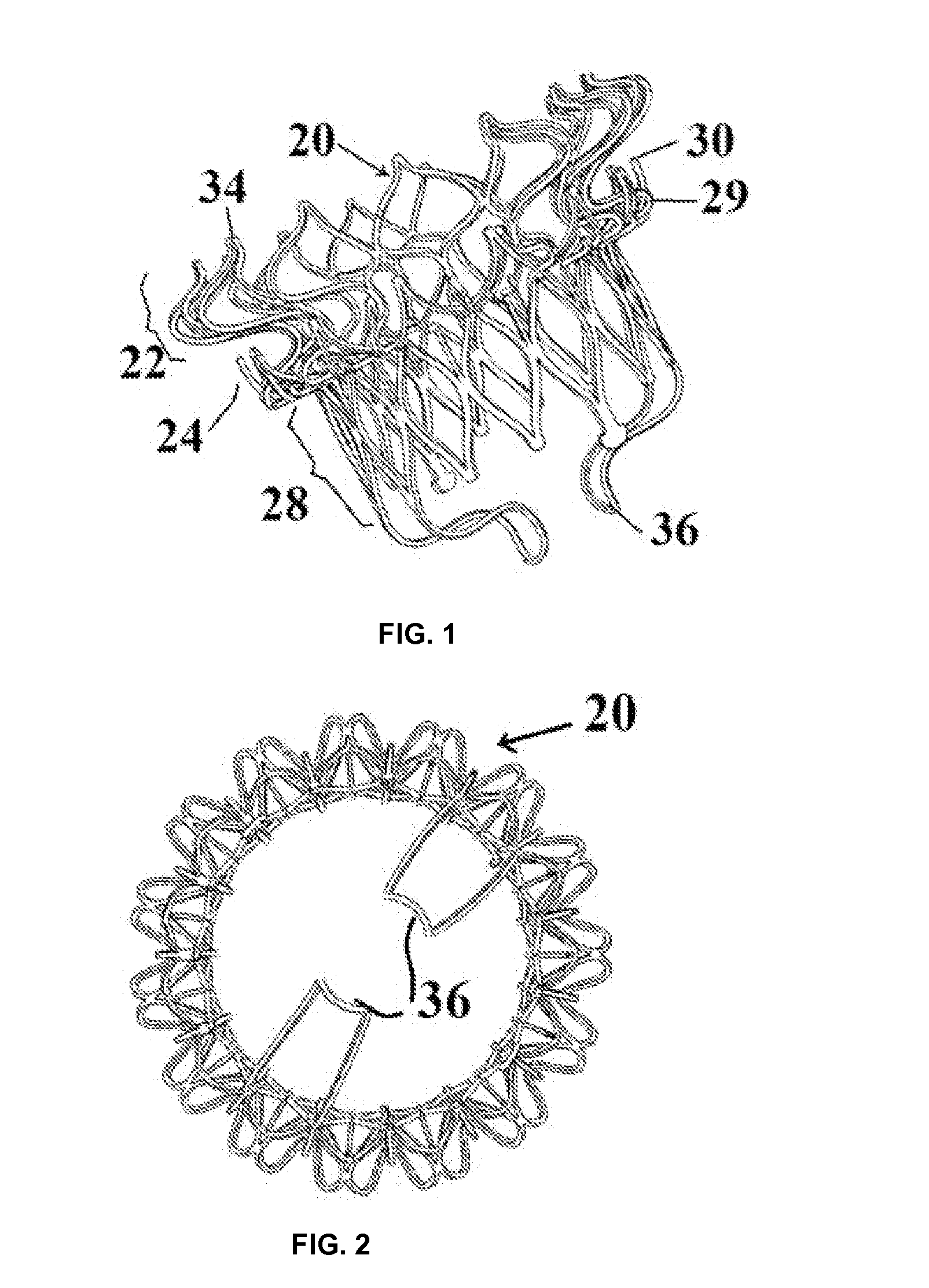

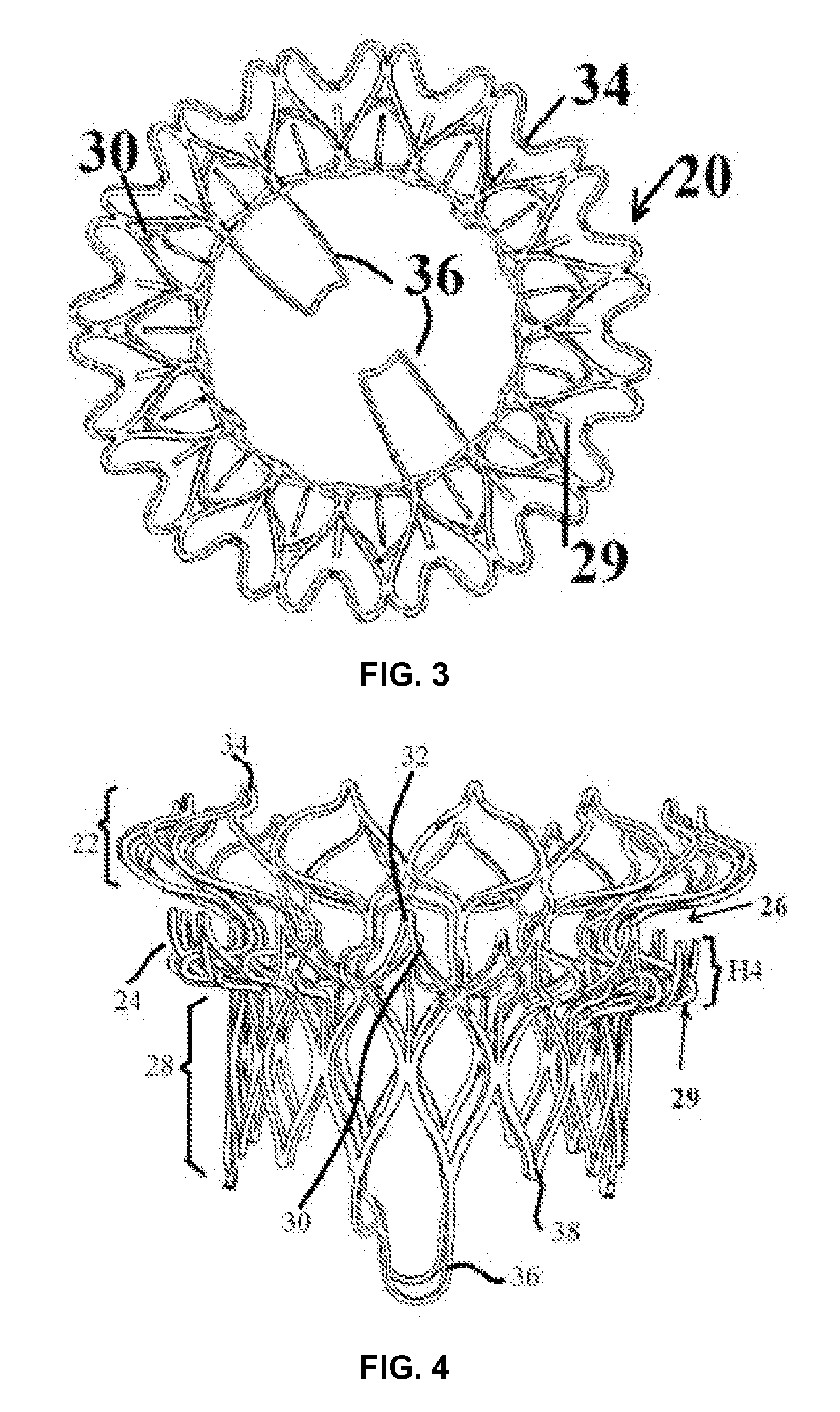

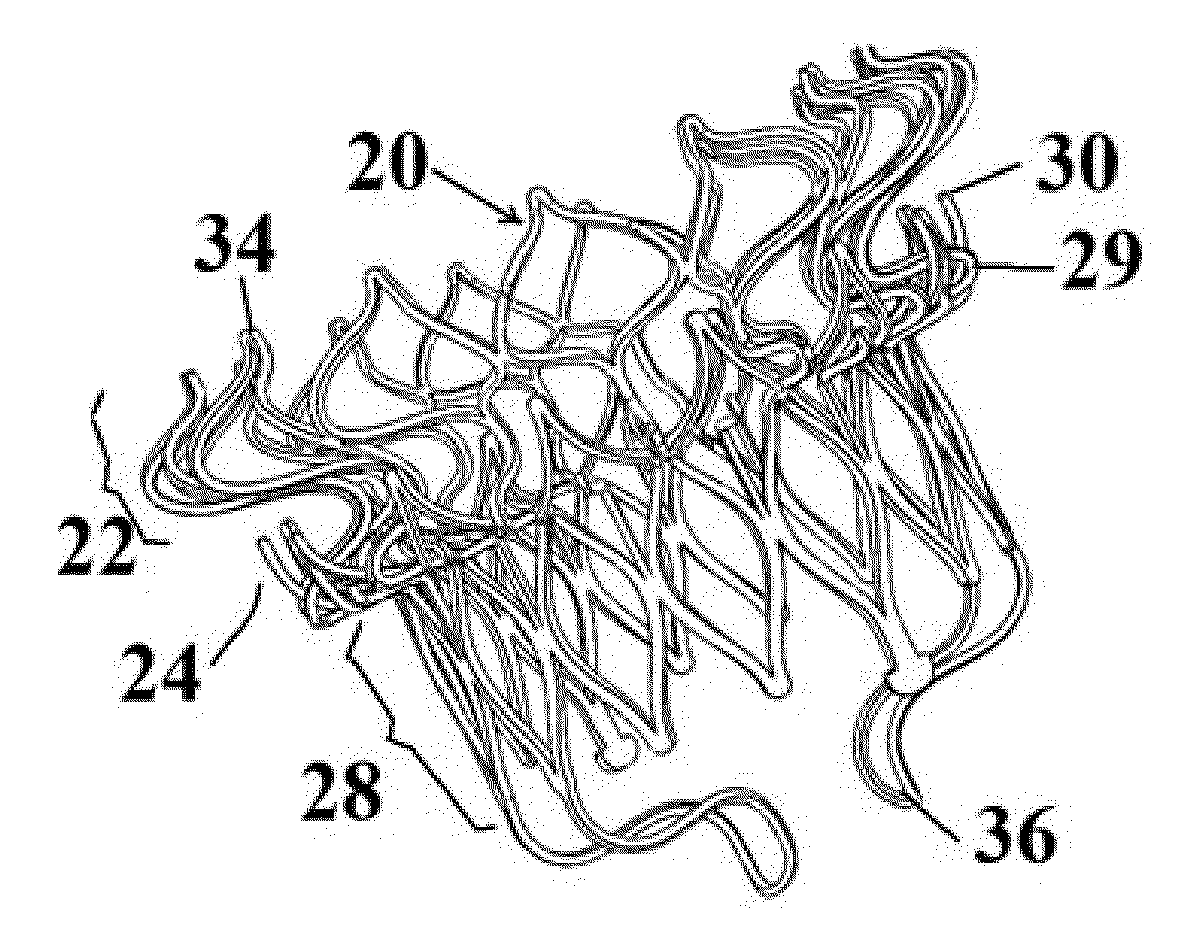

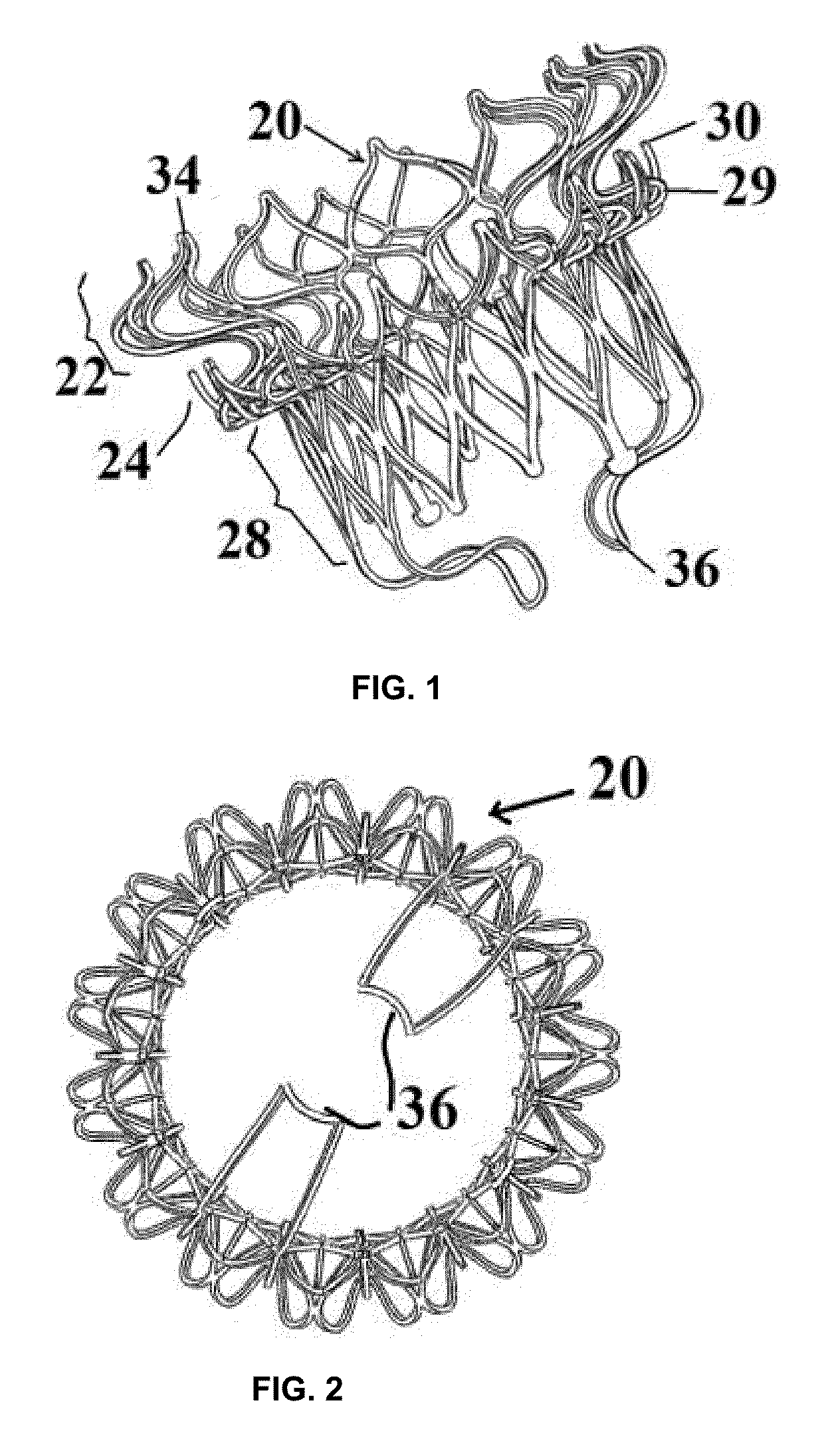

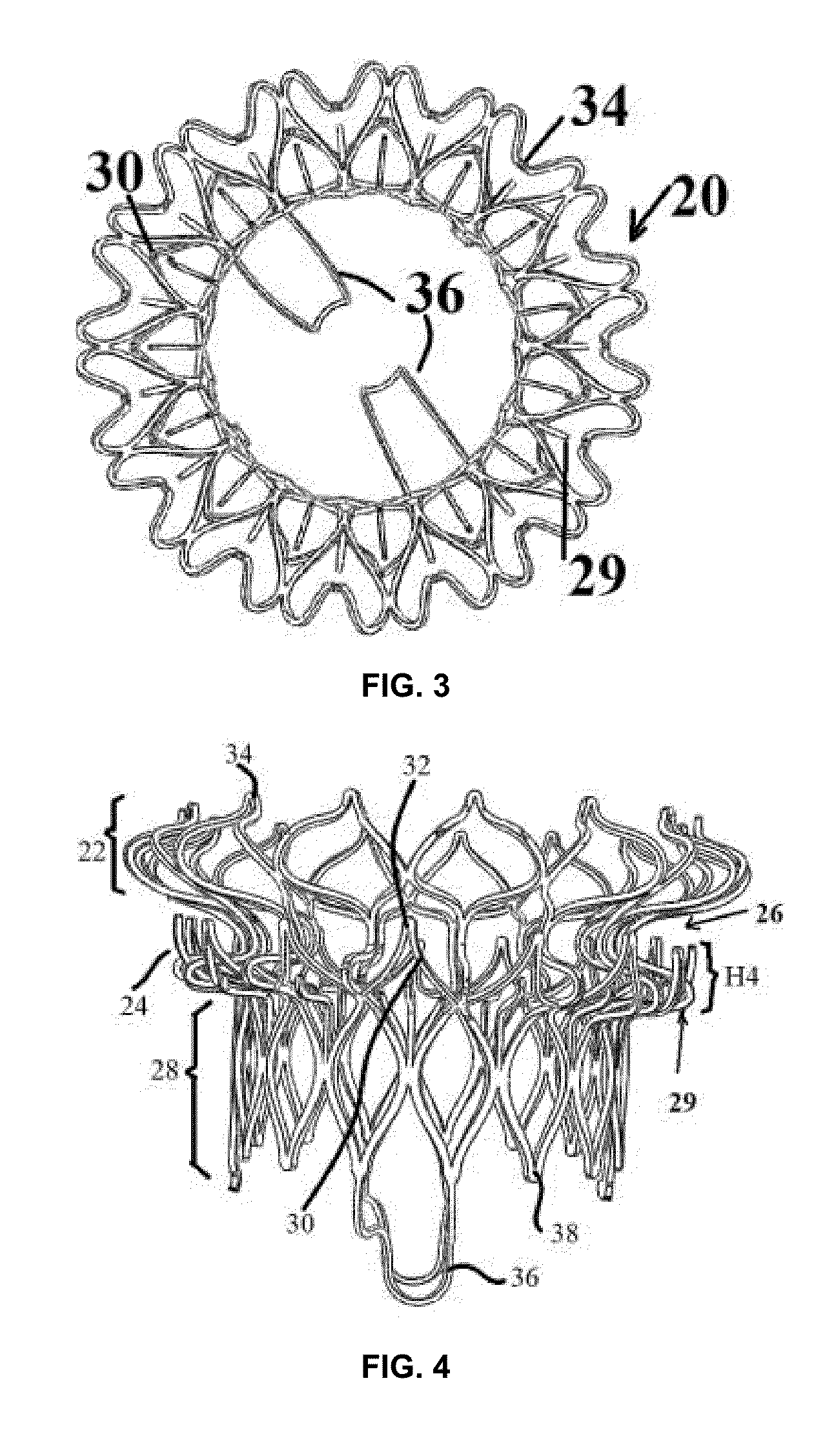

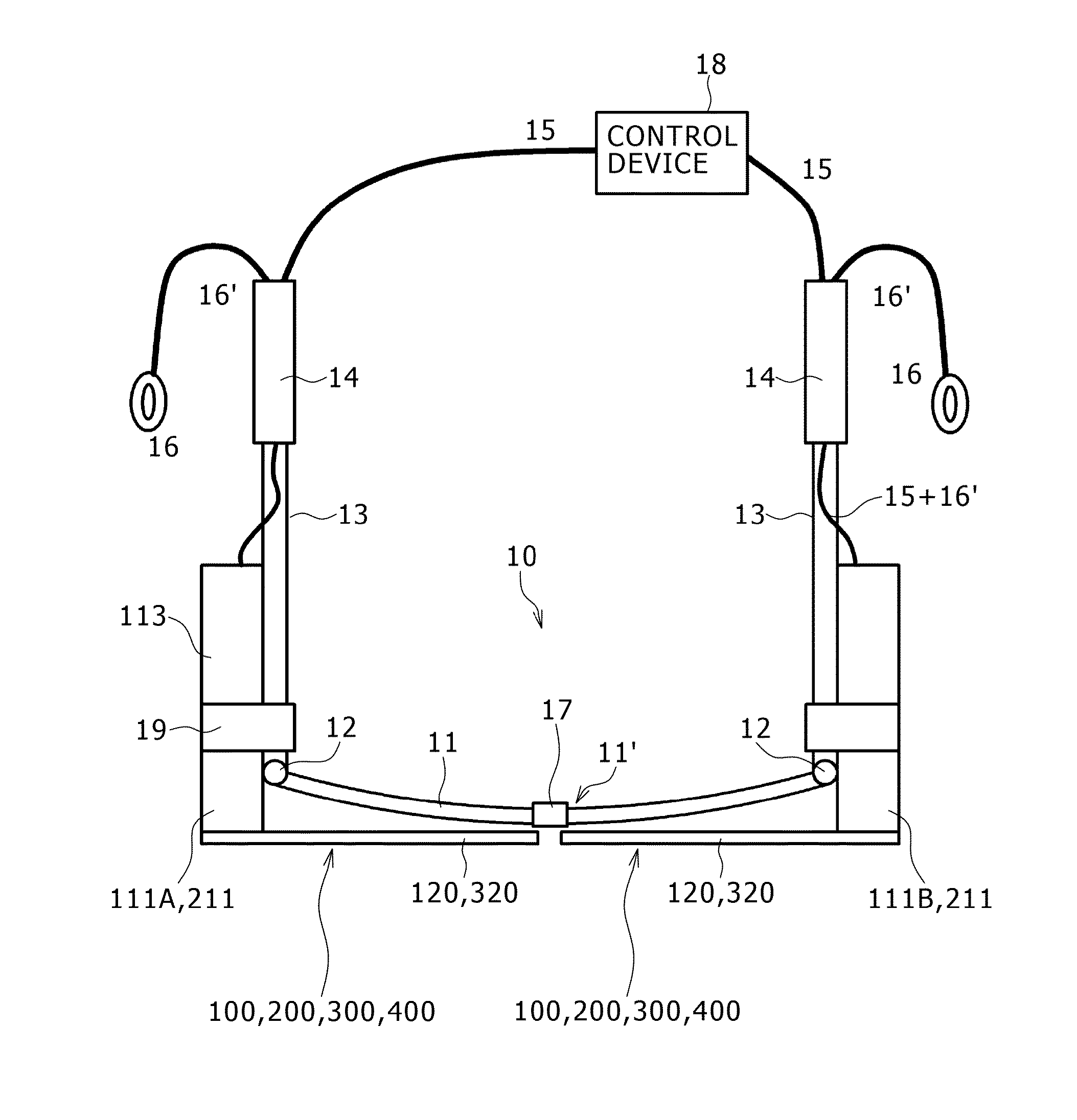

Device and Method for Mitral Valve Regurgitation Treatment

ActiveUS20150196390A1Effective protectionAdjustable positionHeart valvesBioprosthetic mitral valve replacementMitral valve leaflet

A mitral valve replacement device is adapted to be deployed at a mitral valve position in a human heart. The device has an atrial flange defining an atrial end of the device, a valve body defining a ventricular end of the device, and an annulus support that connects the atrial flange and the valve body, the annulus support including a ring of tabs extending radially therefrom and adapted to engage the native mitral annulus and / or the native leaflet(s) of the human heart. The atrial flange can be seated in the atrium above the native mitral valve annulus in a human heart, and the ring of tabs can engage the native mitral annulus in a manner where the atrial flange and tabs provide a clipping effect to secure the mitral valve replacement device at the native mitral valve position

Owner:SINOMED CARDIOVITA TECH INC

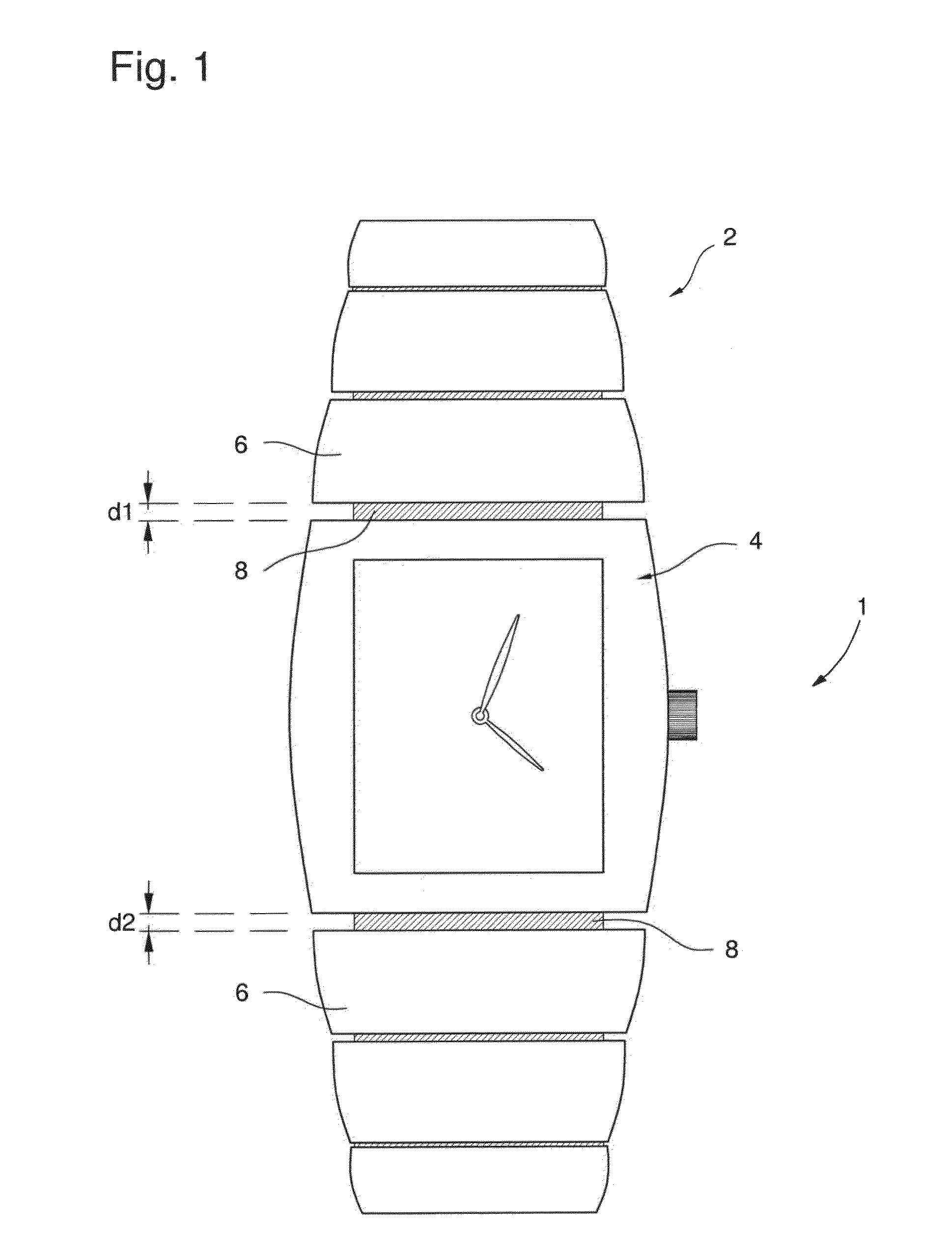

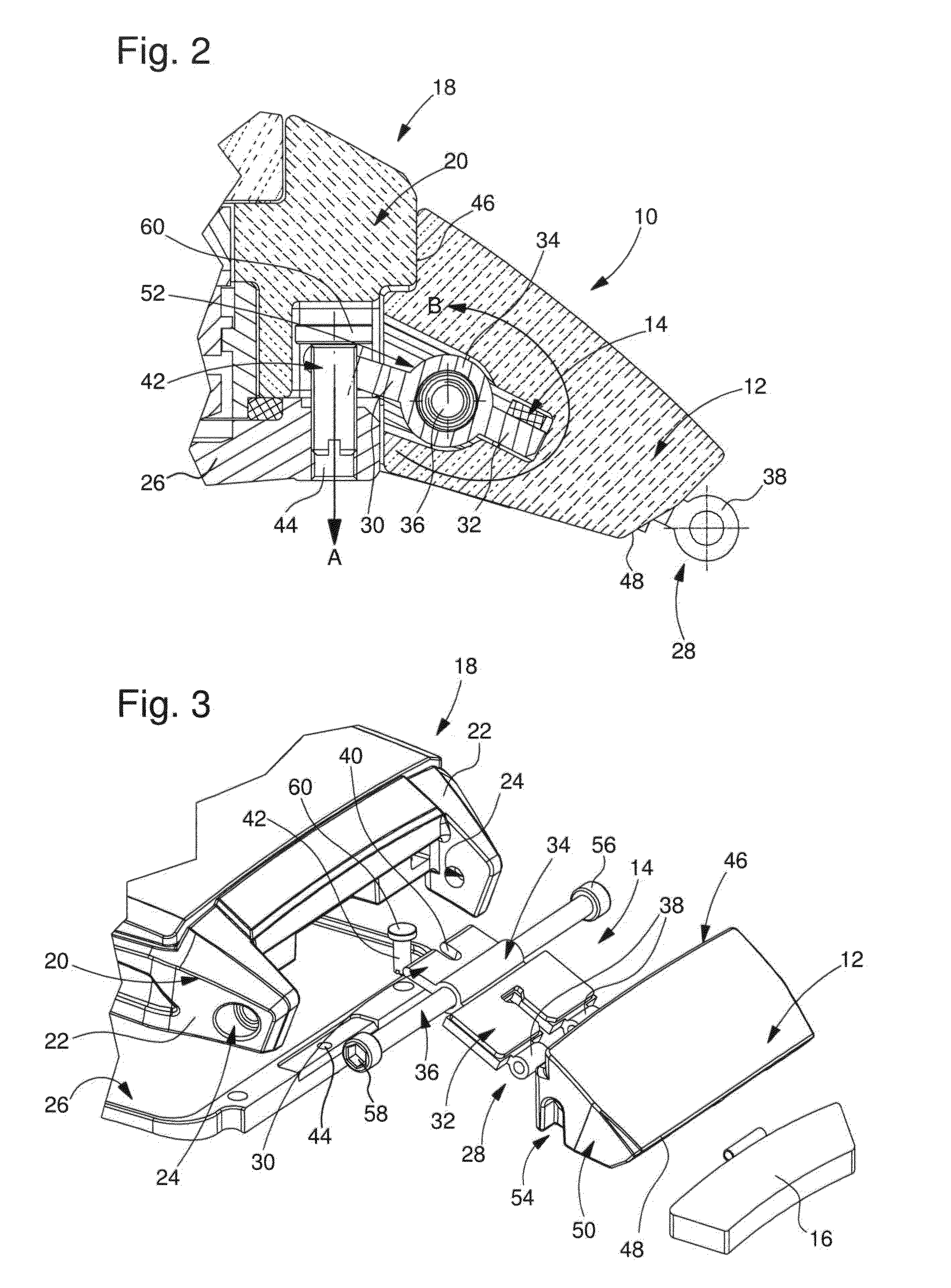

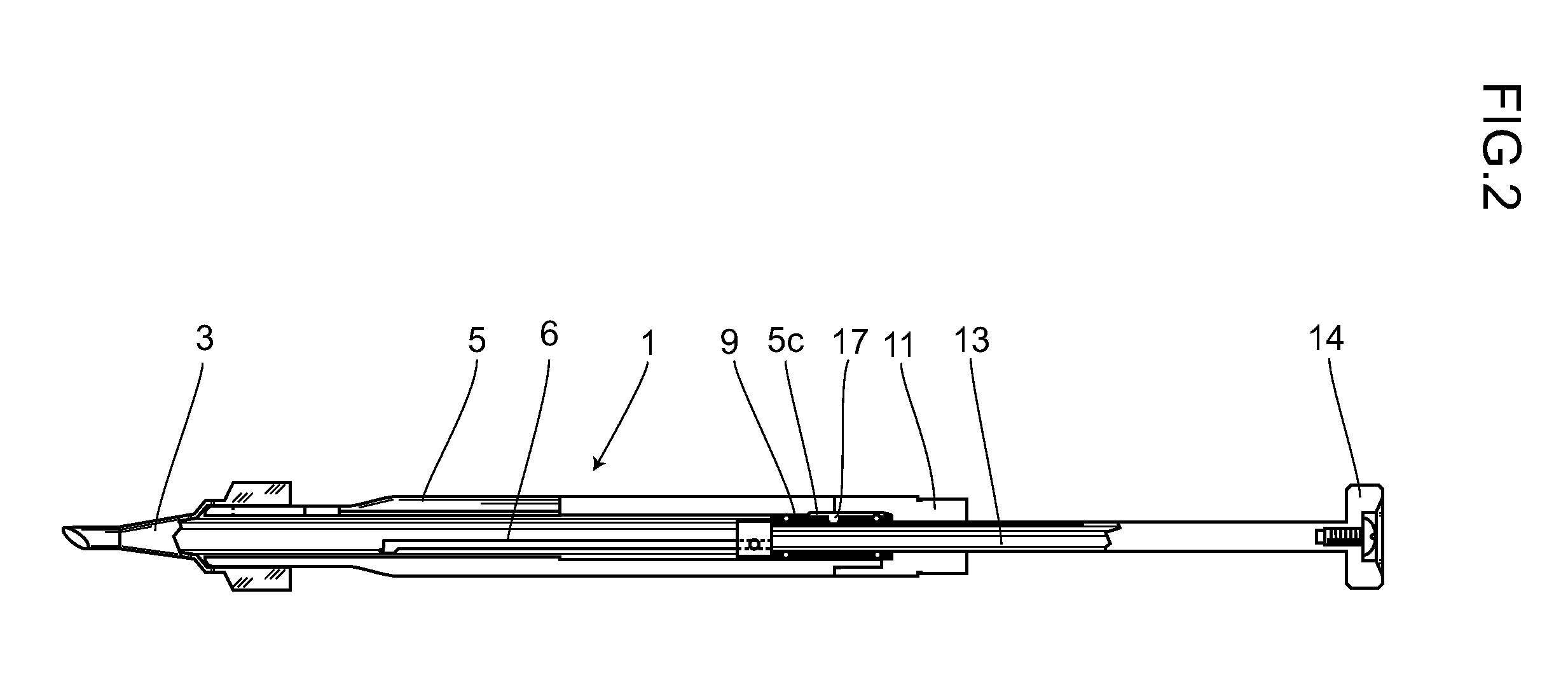

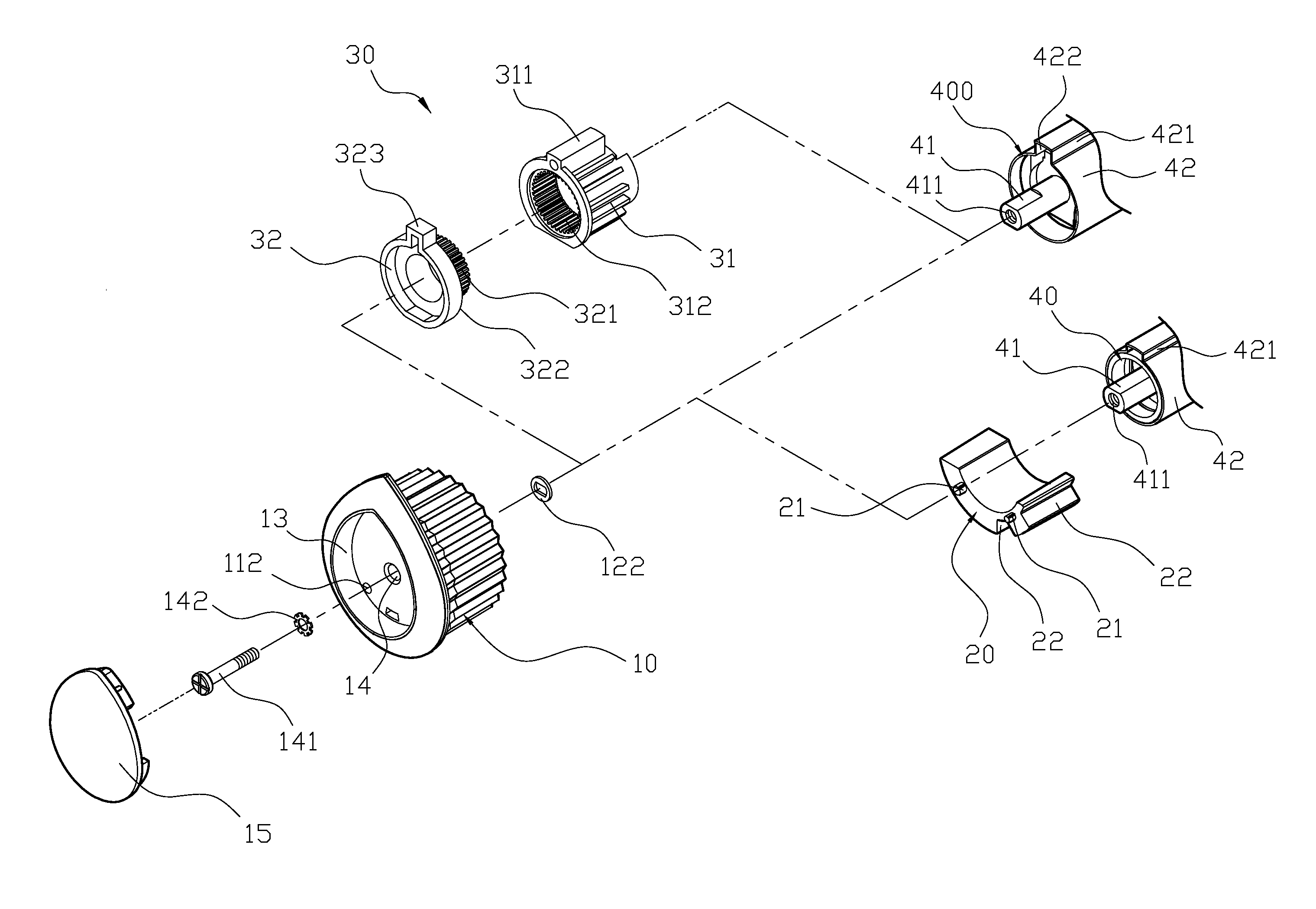

System for connecting a bracelet to a watch case

ActiveUS20140096345A1Adjustable positionInherent problemBraceletsClockwork casesTransverse axisEngineering

System for connecting a bracelet to a watch case by means of a link, the watch case comprising a caseband and a back cover, the link comprising a first hollow element and a second element partly nesting in the first hollow element, the first hollow element carrying a first means of fastening to the watch case and the second element carrying a second means of fastening to an adjacent bracelet link, characterized in that the watch case includes a mechanical device arranged to pivot the second element about a transverse axis to the longitudinal direction of the bracelet, the second element transmitting the pivoting motion thereof to the first element which pivots in turn and which is pressed against the caseband of the watch case.

Owner:THE SWATCH GROUP MANAGEMENT SERVICES

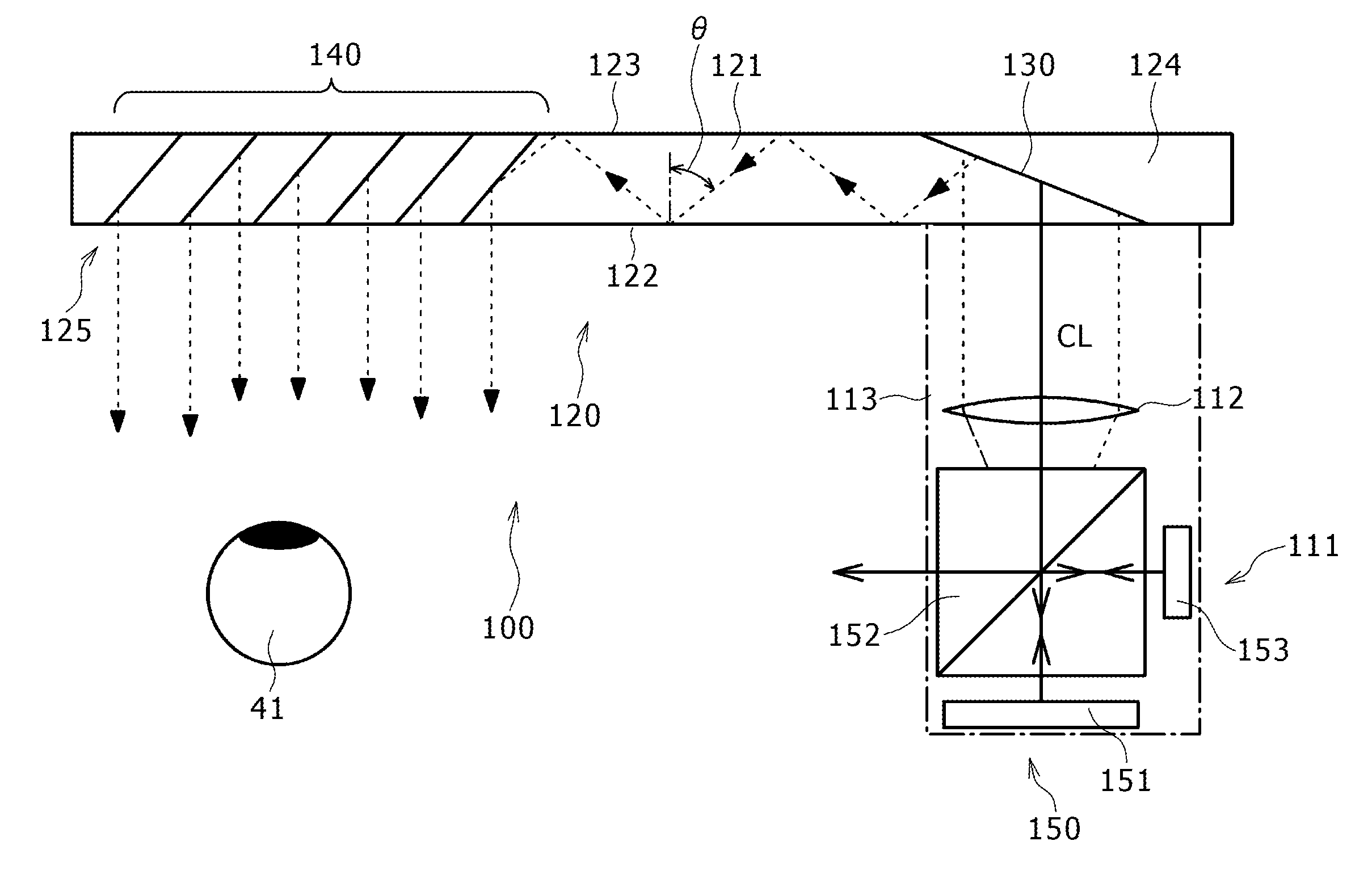

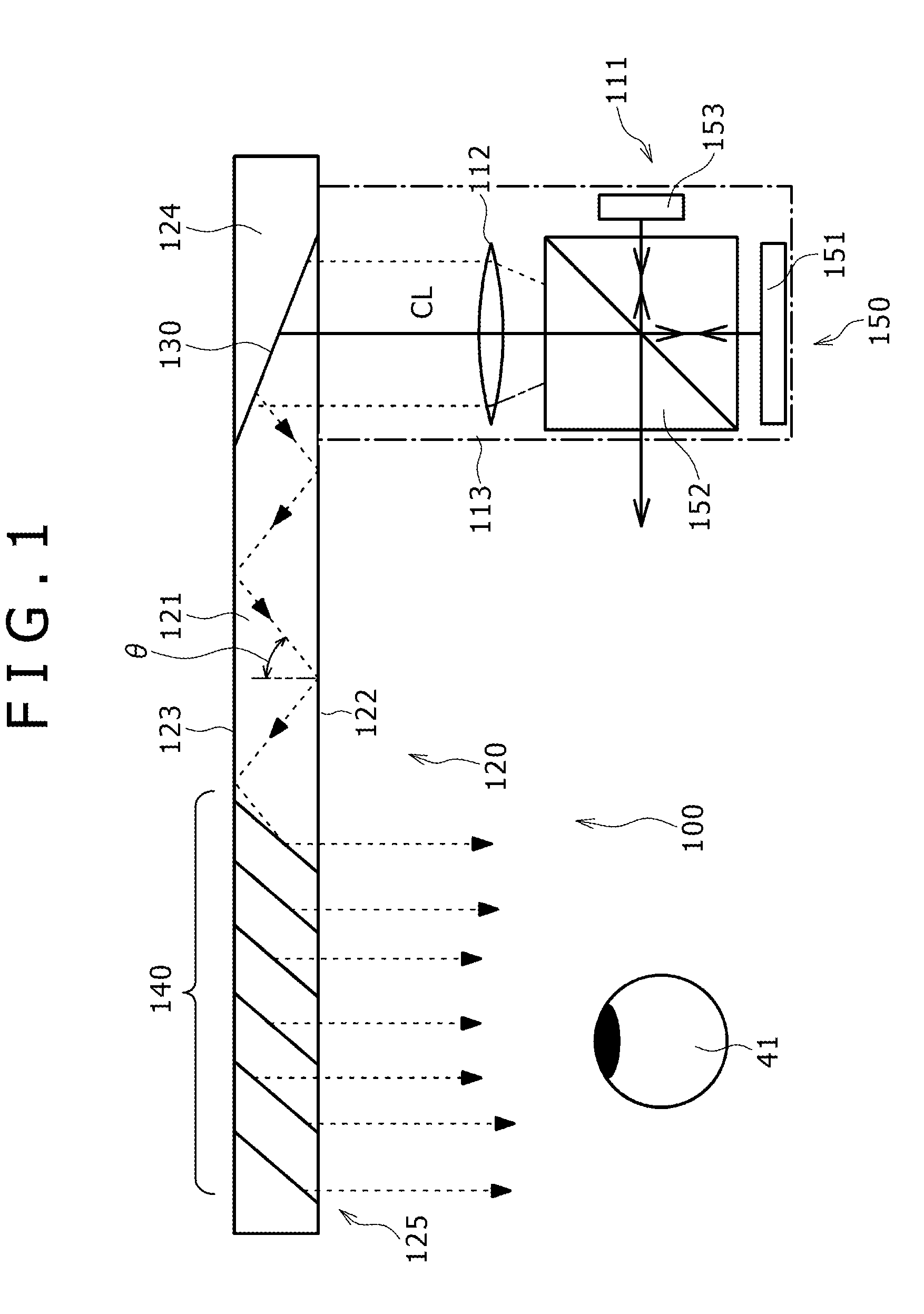

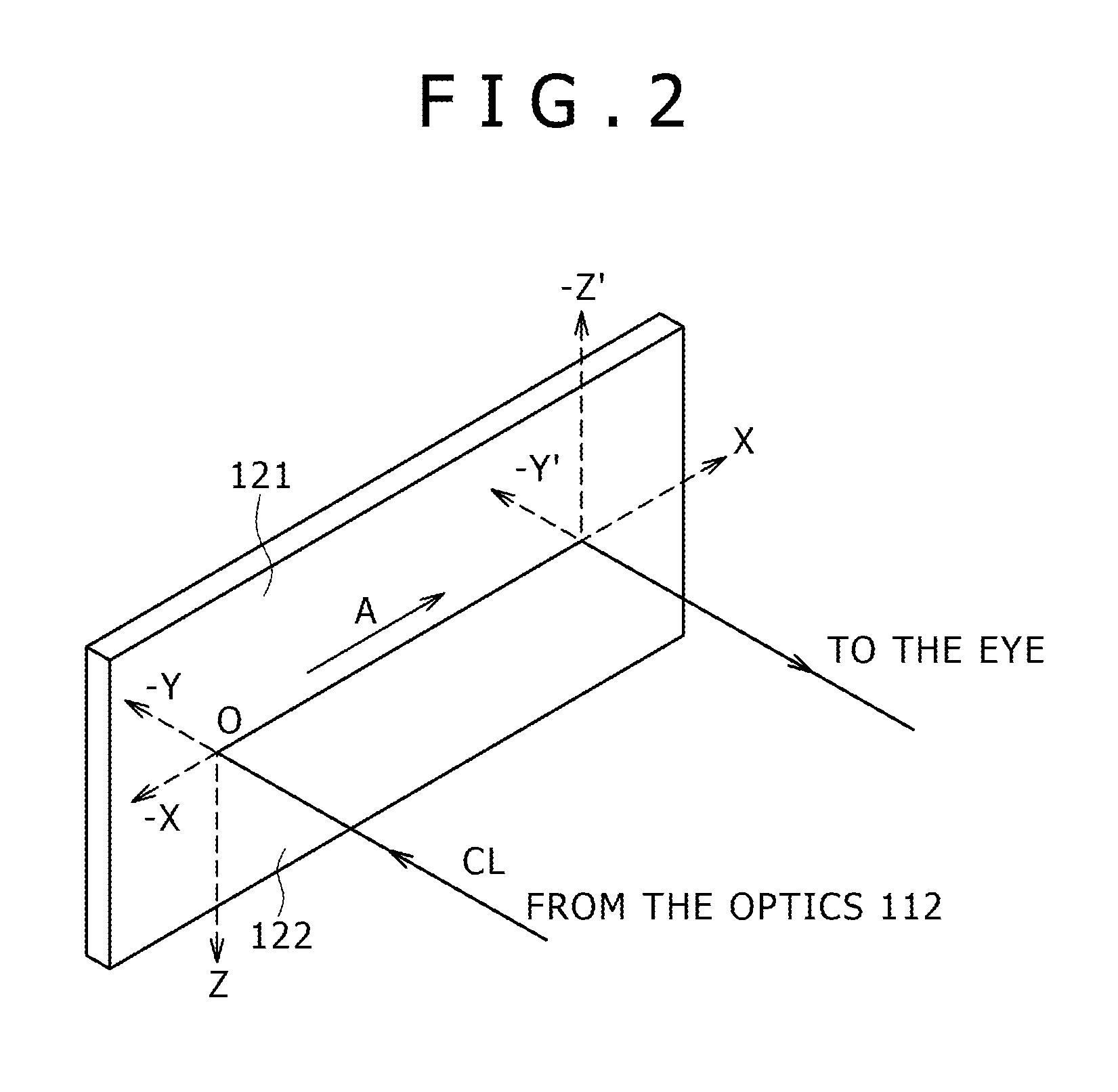

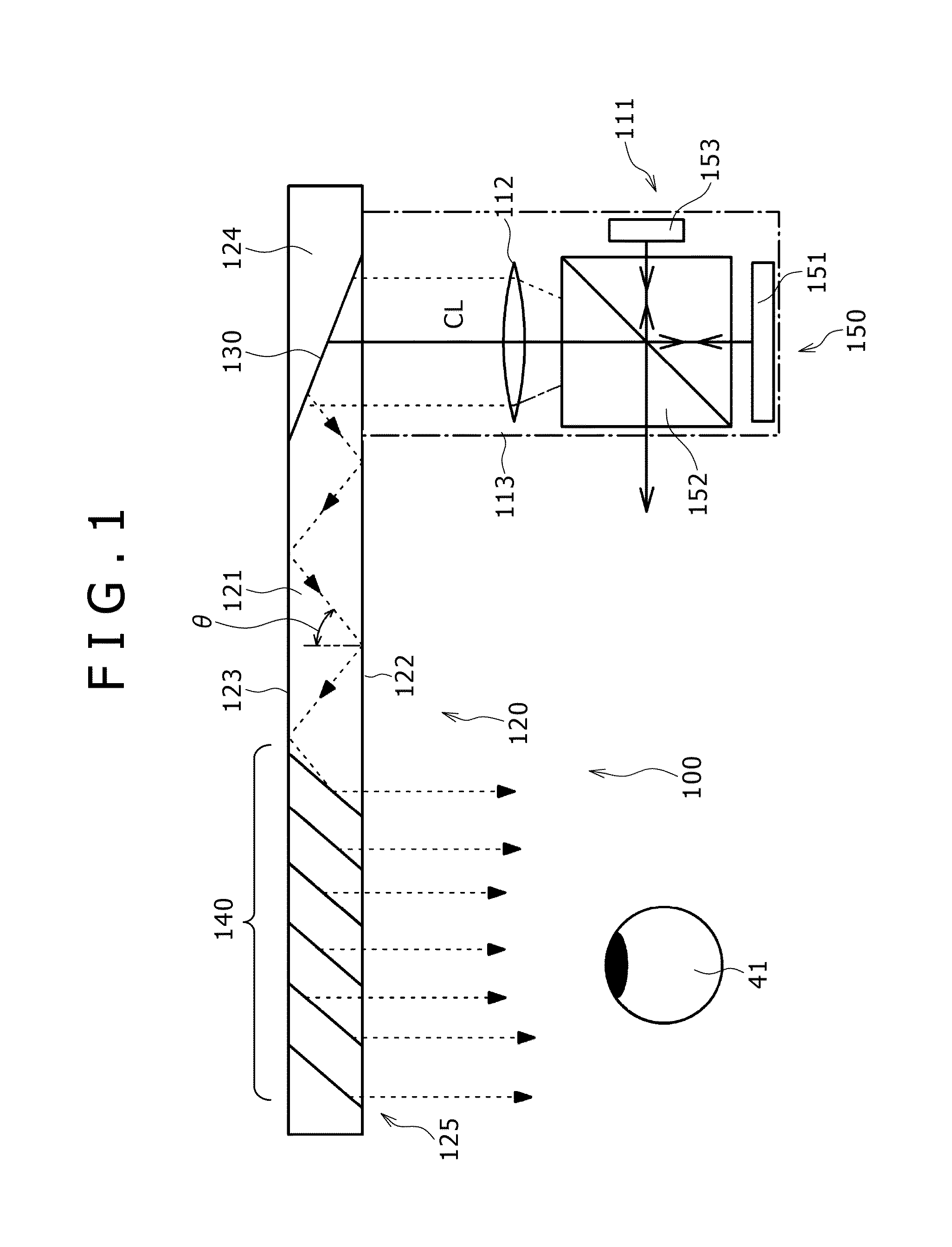

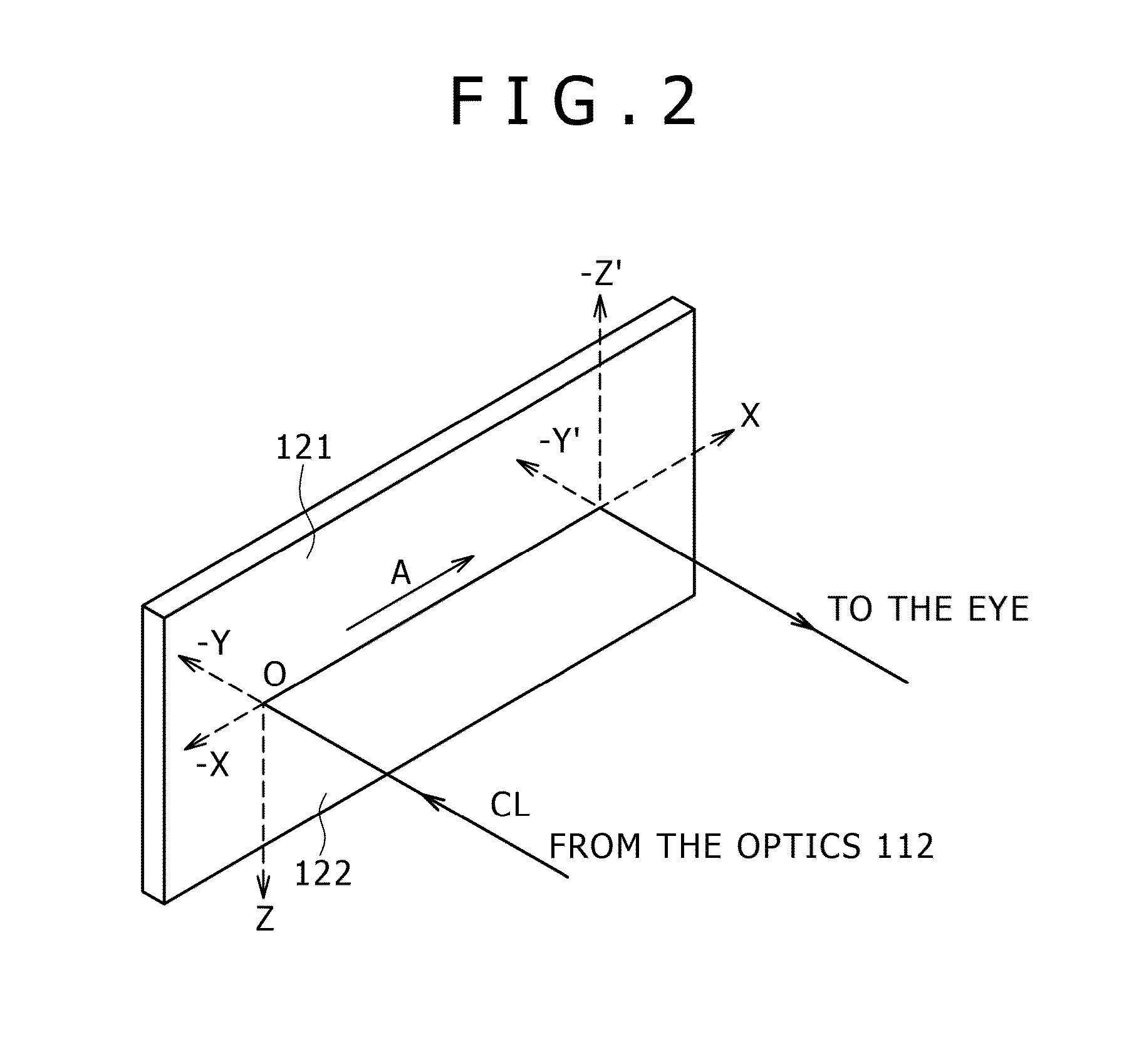

Head mounted display and optical position adjustment method of the same

ActiveUS20110248904A1Improve responseSmall sizeCathode-ray tube indicatorsImage data processingDisplay deviceImage signal

Disclosed herein is an optical position adjustment method of a head mounted display, the head mounted display including (a) an eyeglass type frame worn on the head of a viewer, and (b) two image display devices for the right and left eyes attached to the frame, and each of the image display devices including (A) an image forming device, and (B) an optical device adapted to receive, guide and emit light emitted from the image forming device, wherein the optical position adjustment method includes the step of: controlling an image signal that is supplied to the image forming device making up at least one of the image display devices so as to control the position of the image displayed on the optical device making up at least one of the image display devices and adjust the mutual positions of the two images.

Owner:SONY CORP

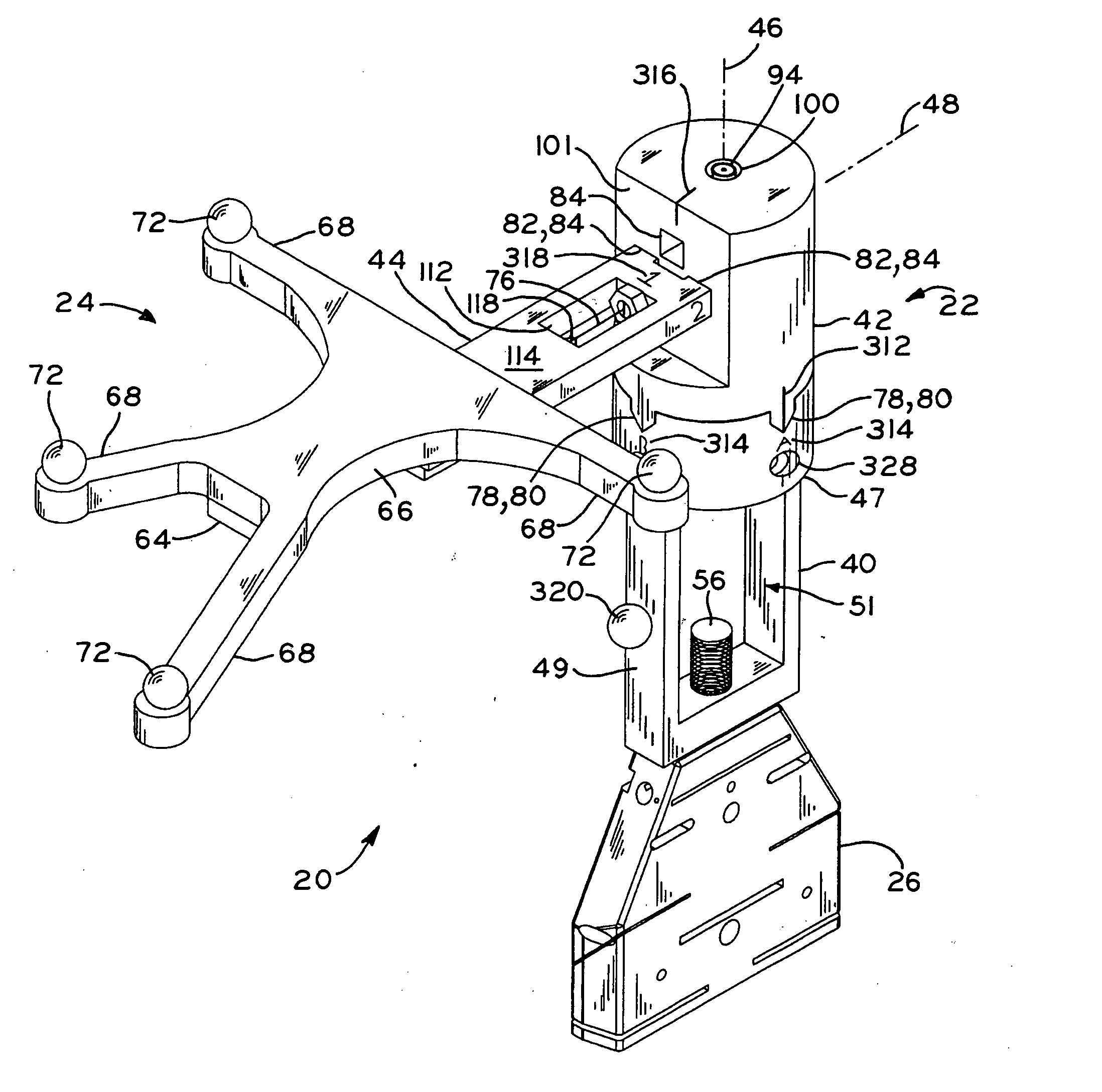

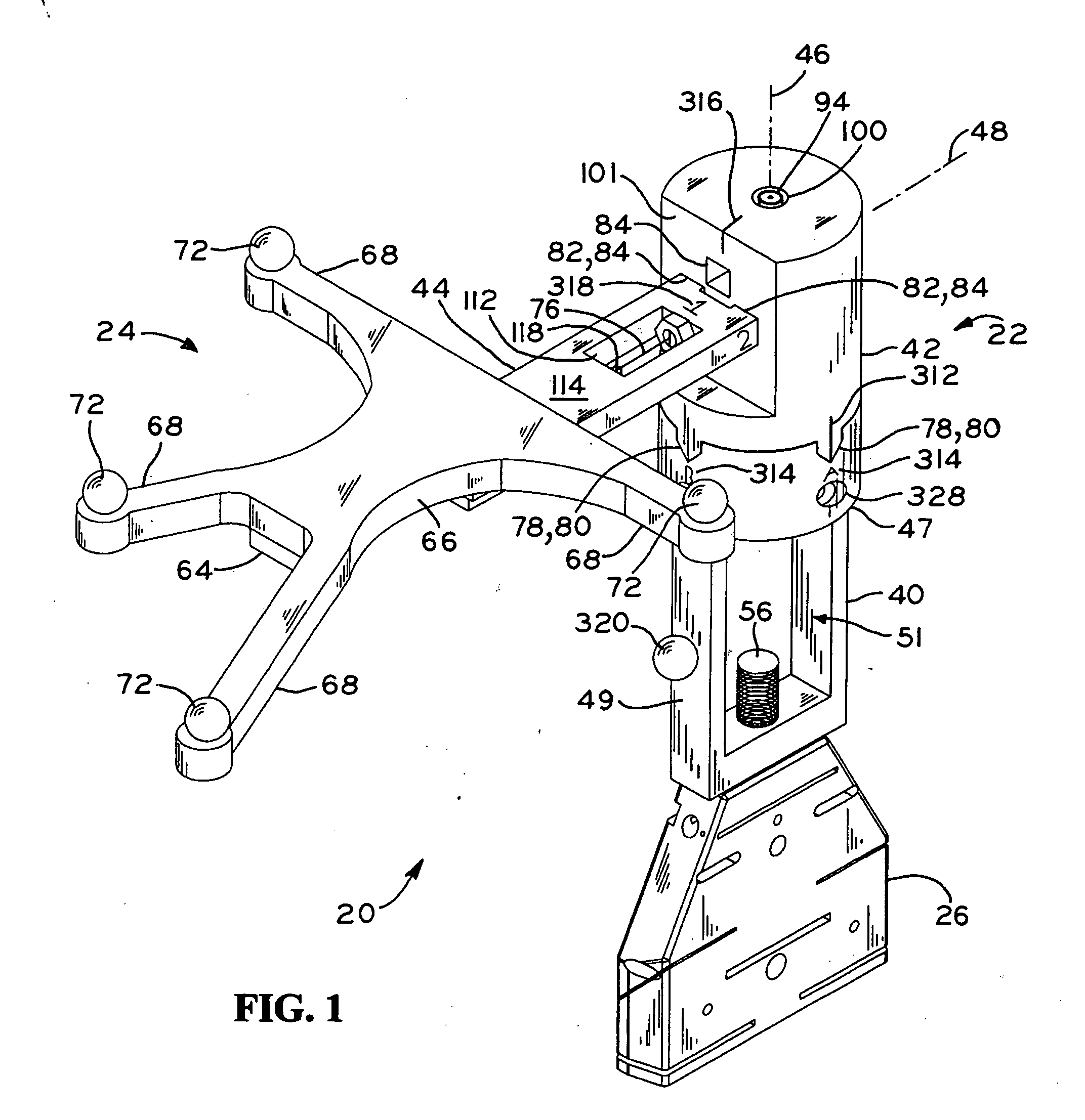

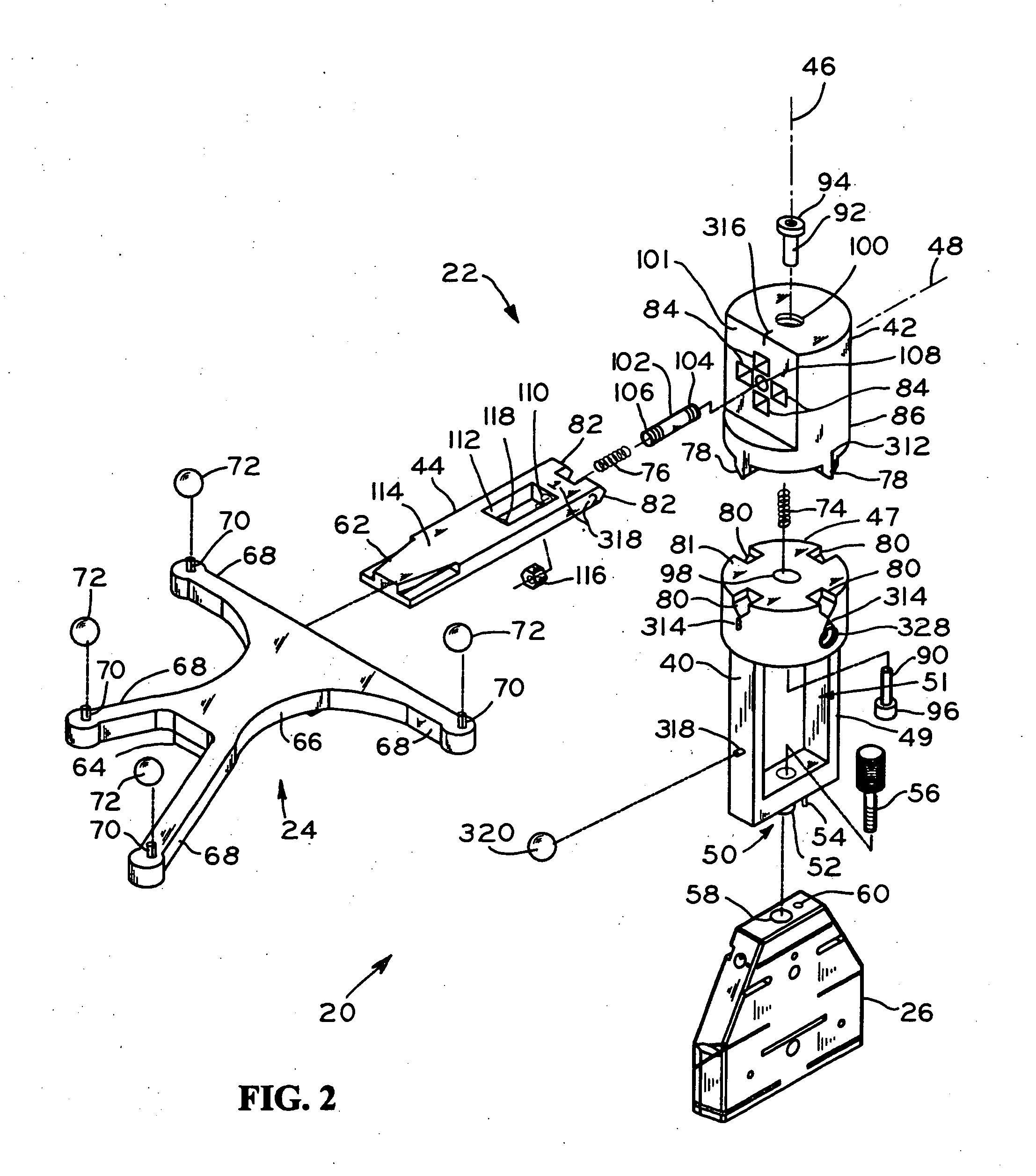

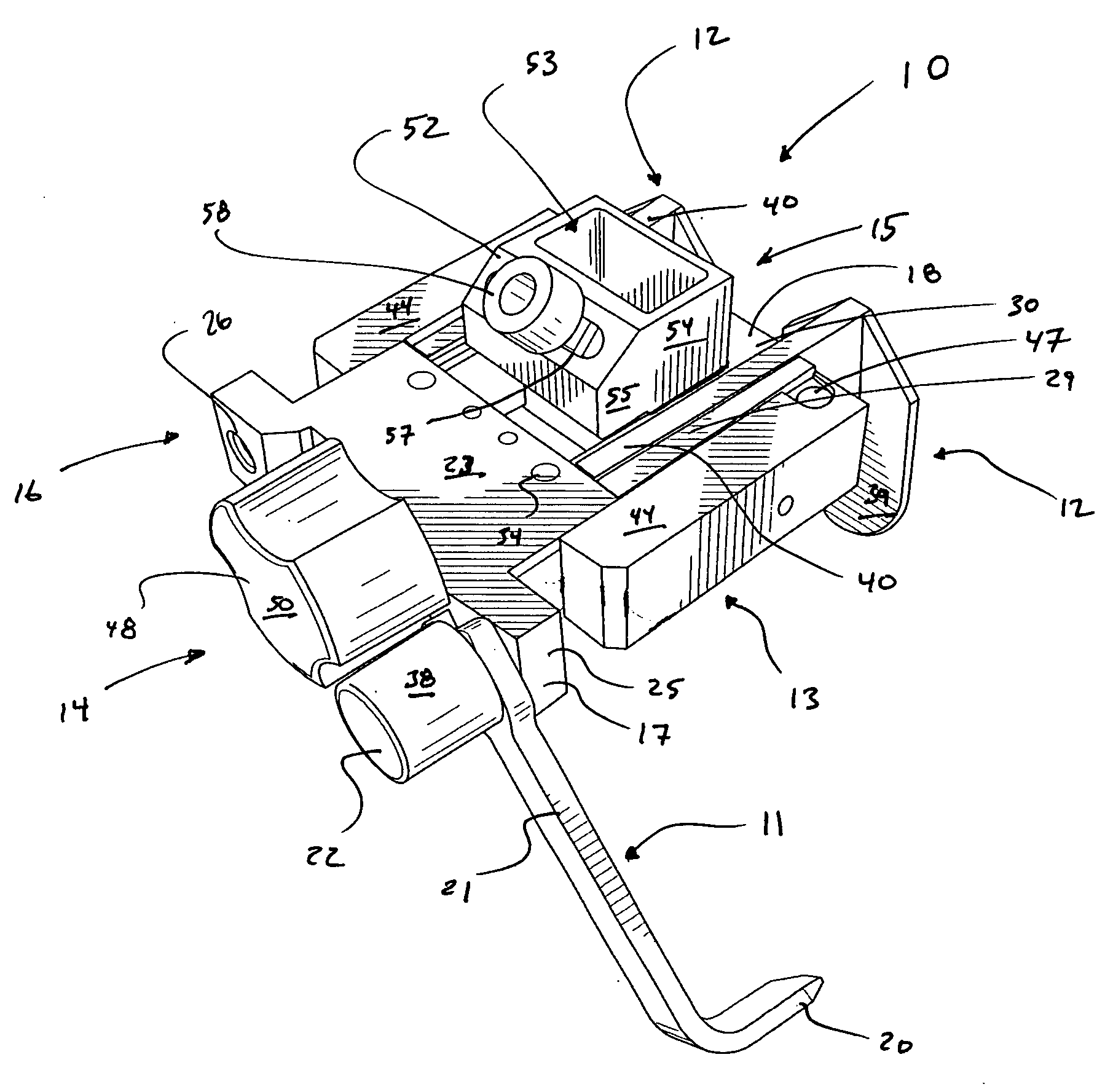

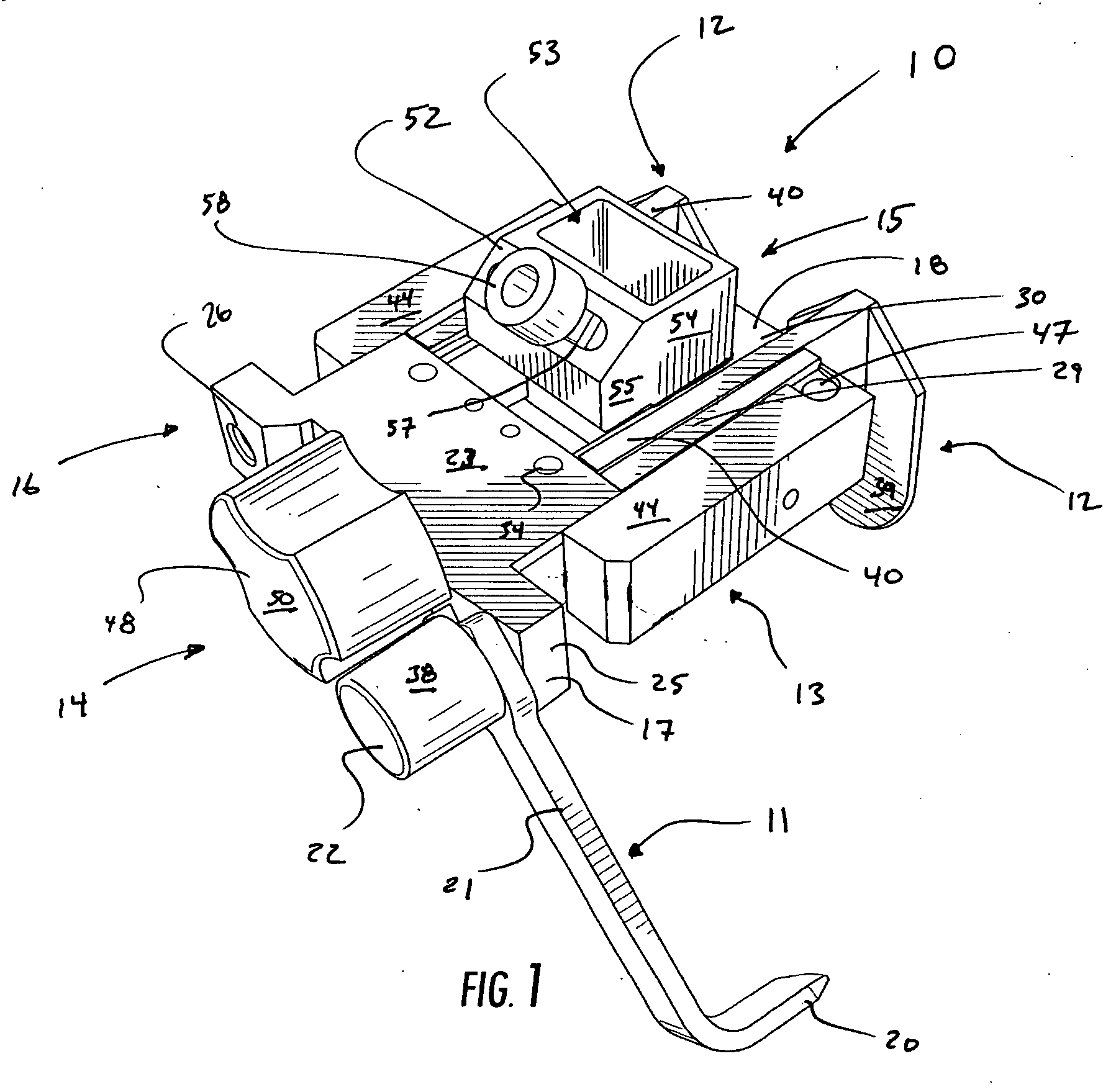

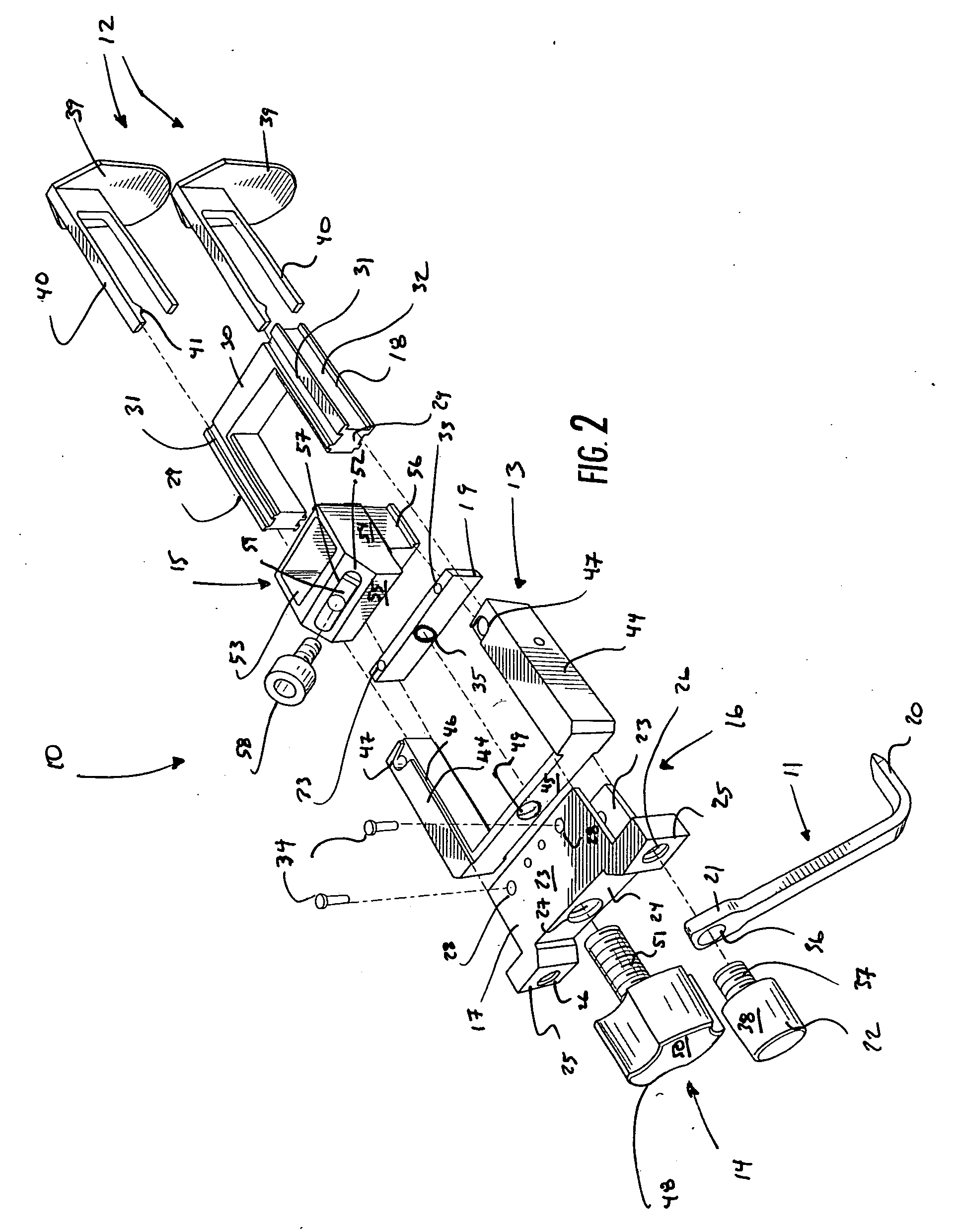

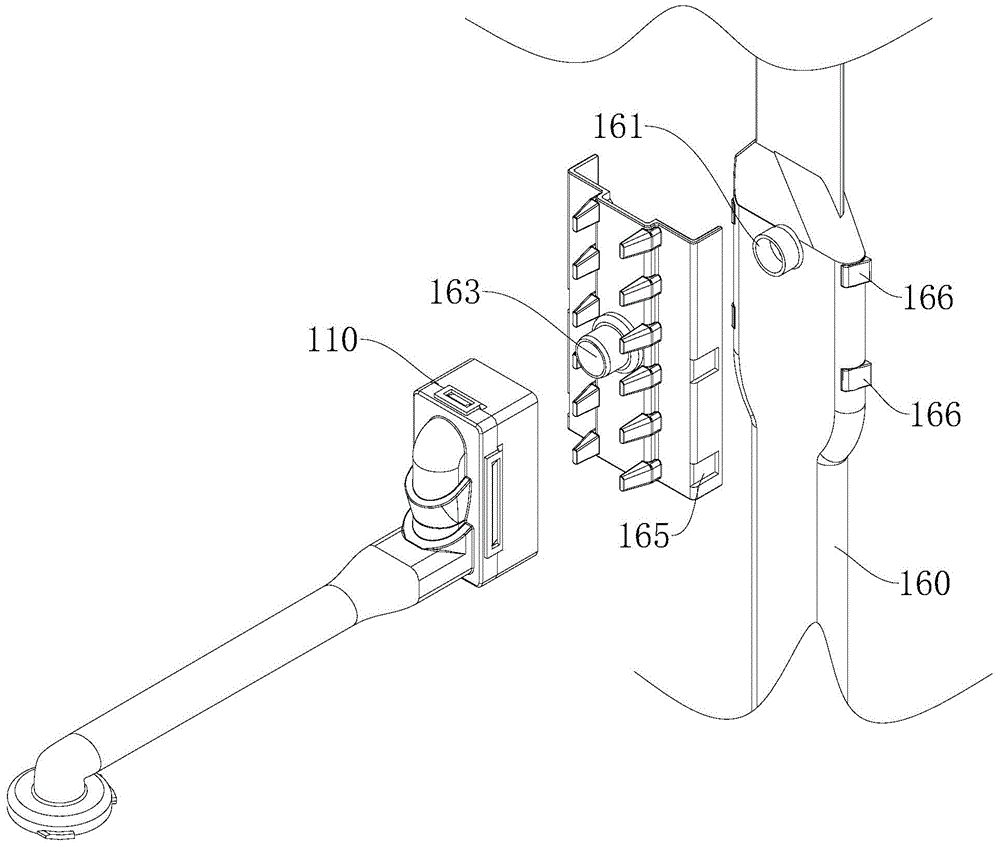

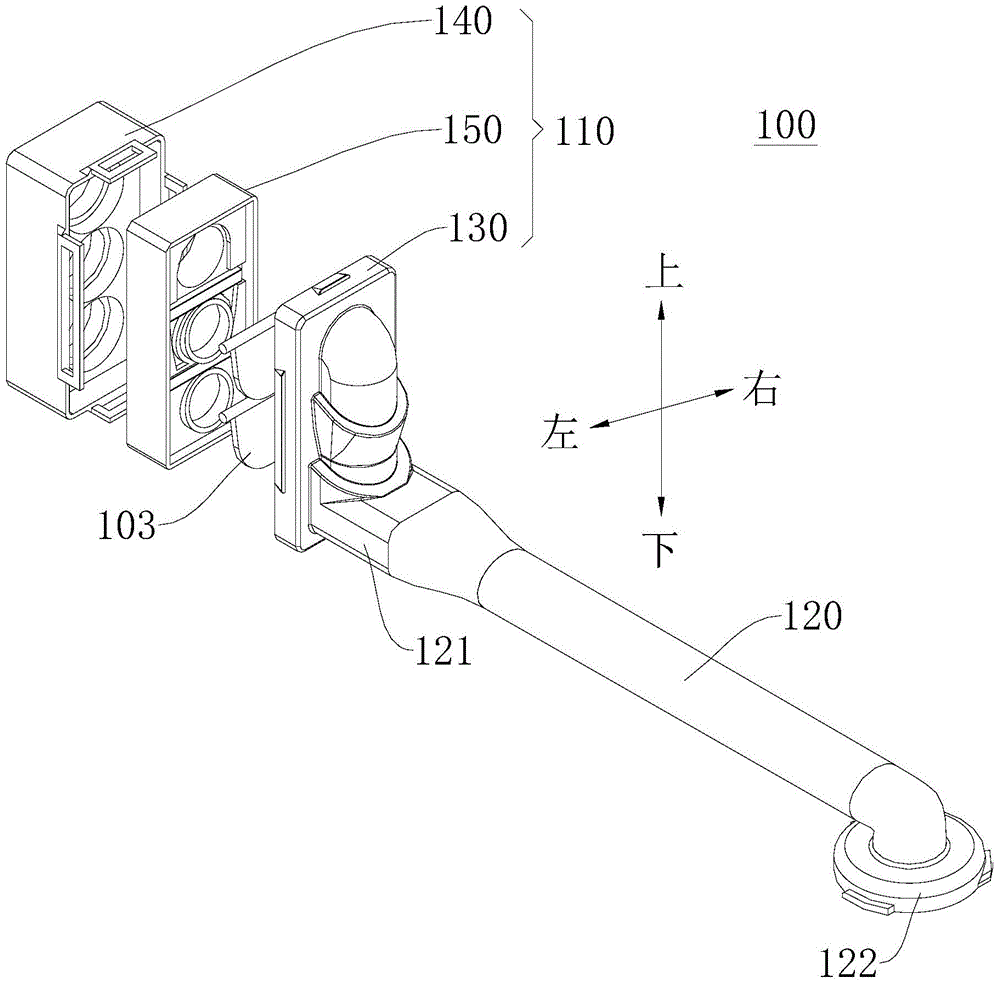

Universal support arm and tracking array

InactiveUS20050215888A1Precise definitionAdjustable positionDiagnostic markersDiagnostic recording/measuringCouplingLocation tracking

A universal tracking apparatus for a surgical instrument, the tracking apparatus including a support arm and tracking array. The support arm allows position adjustment of the tracking array between a number of predefined orientations relative to the instrument which are recognizeable and registerable in the navigation system. The support arm may be coupled with multiple types of surgical instruments and used to accurately define the position of the instrument in an anatomical model generated by the navigation system. The adjustable coupling between the tracking array and the support arm allows the surgeon to determine which orientation is best suited for the surgical application and also allows the surgeon to adjust the position of the tracking array during a surgical procedure without the need to re-register the tracking apparatus. The tracking array may also include at least one repositionable reference element to allow a single tracking array to be configured for use with a plurality of different instruments, wherein differing geometries defined by the tracking array and corresponding to particular instruments are recognizable and registerable by the navigation system.

Owner:ZIMMER TECH INC

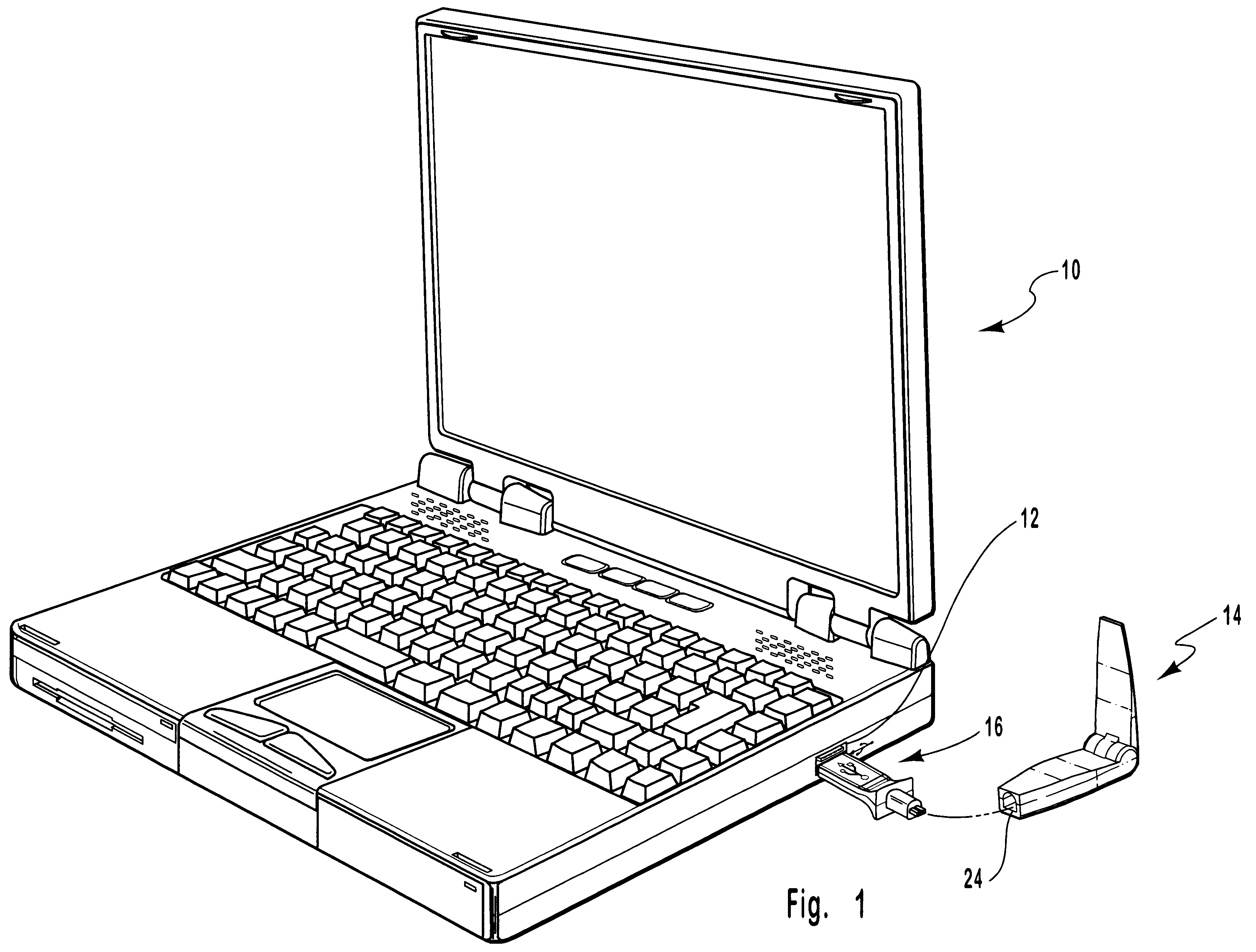

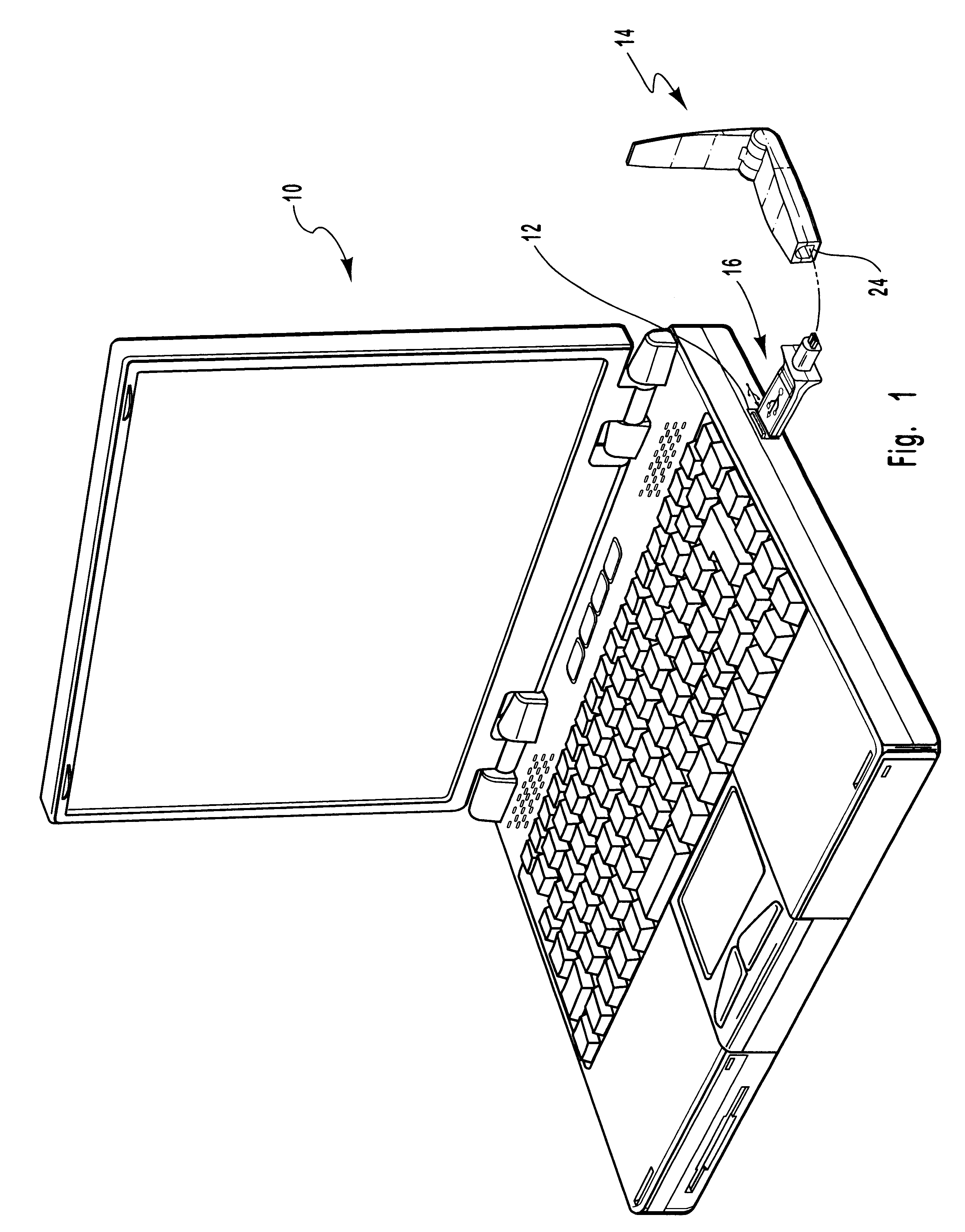

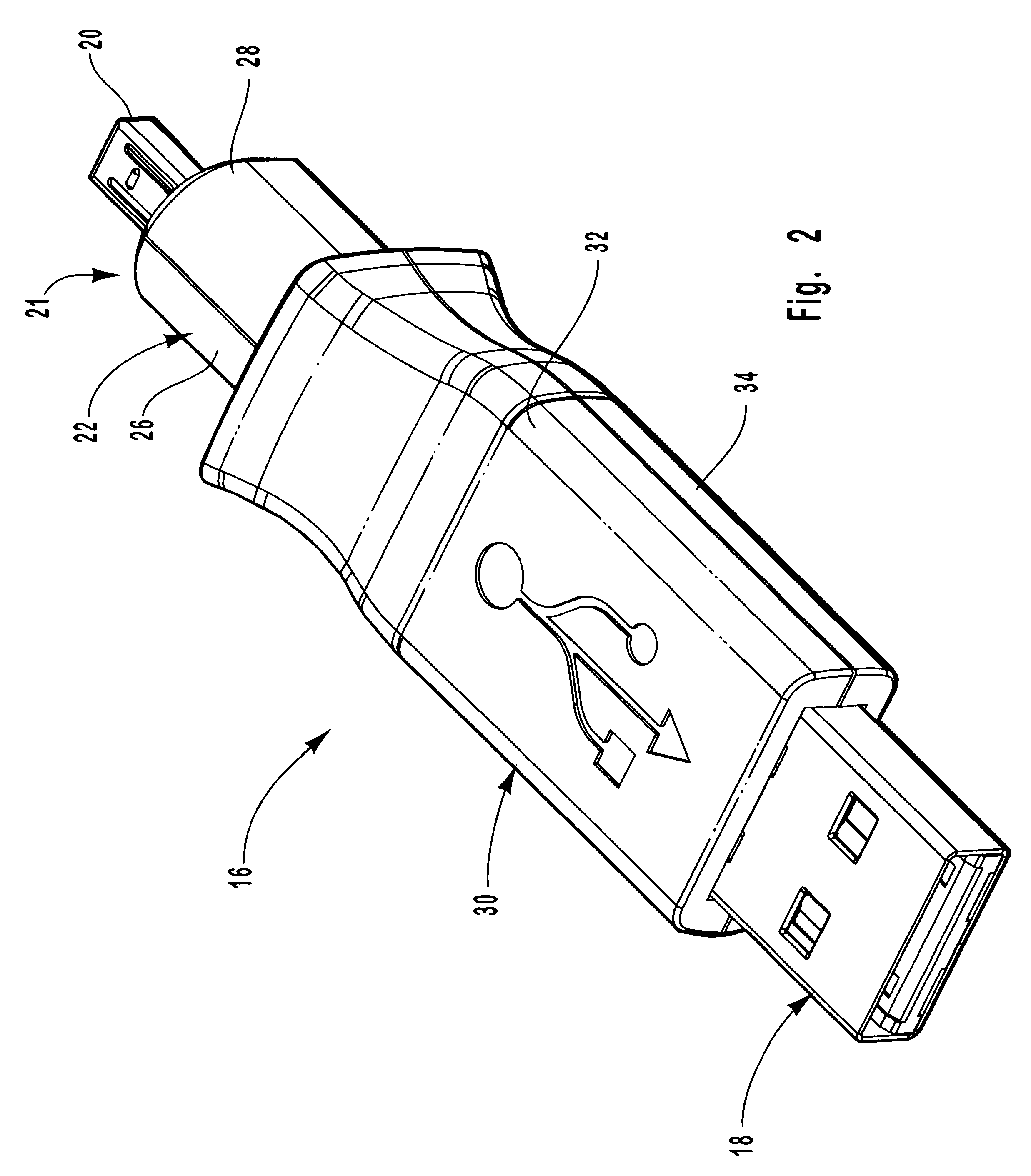

Rotating connector adapter with strain relief

InactiveUS6612874B1For direct connectionAdjustable positionCoupling device connectionsRotary current collectorEngineeringMechanical engineering

A connector adapter that can be used to directly connect a peripheral device to a host device. The connector adapter is adjustable so as to allow selective reorientation of the peripheral with respect to the host device. The connector adapter includes a limiting mechanism that restricts the degree to which the adapter can be selectively rotated. In addition, the adapter includes an indexing mechanism that allows the position of the adapter to be locked in predetermined positions. In one embodiment, the connector adapter is partially formed from a compliant material so that the adapter can bend when submitted to an external force, and thereby resist breakage. The connector adapter may also have a physical geometry that provides additional strain relief, such as a plurality of serrations formed on the outer surface. An extension spring can be positioned within the connector adapter so as to return the adapter to substantially its original shape when the external force is removed.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Device and method for mitral valve regurgitation treatment

ActiveUS9393111B2Effective protectionAdjustable positionHeart valvesMitral valve leafletMitral valve replacement

Owner:SINOMED CARDIOVITA TECH INC

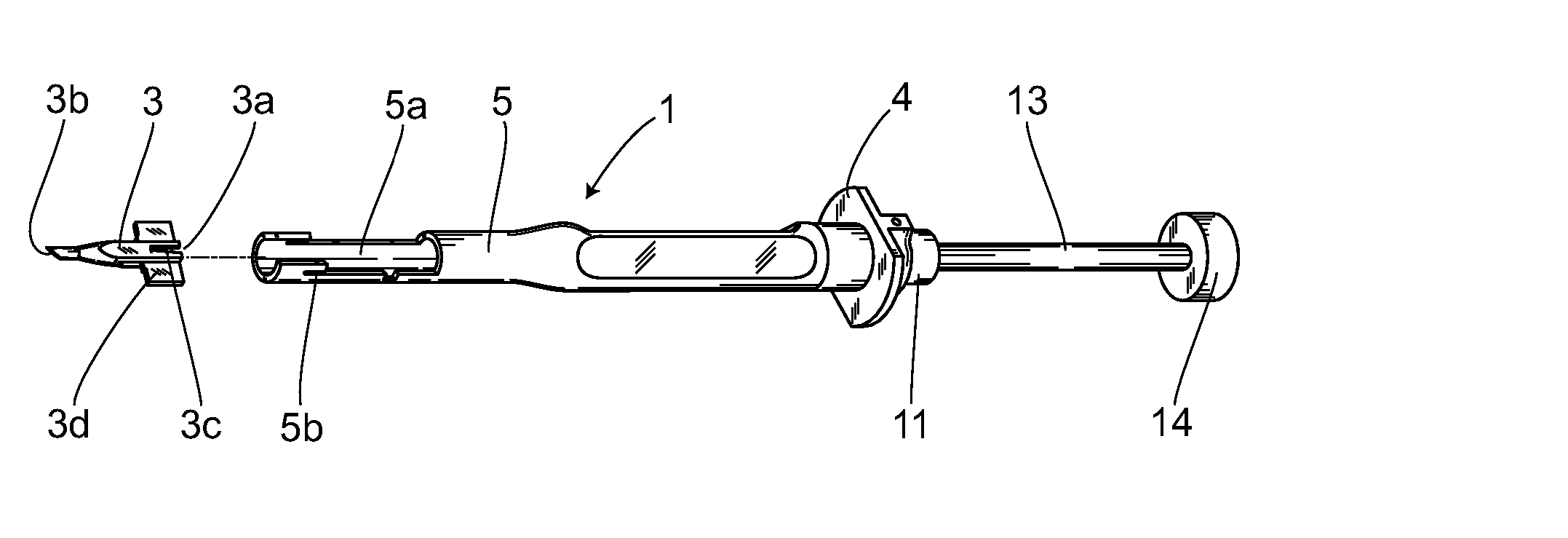

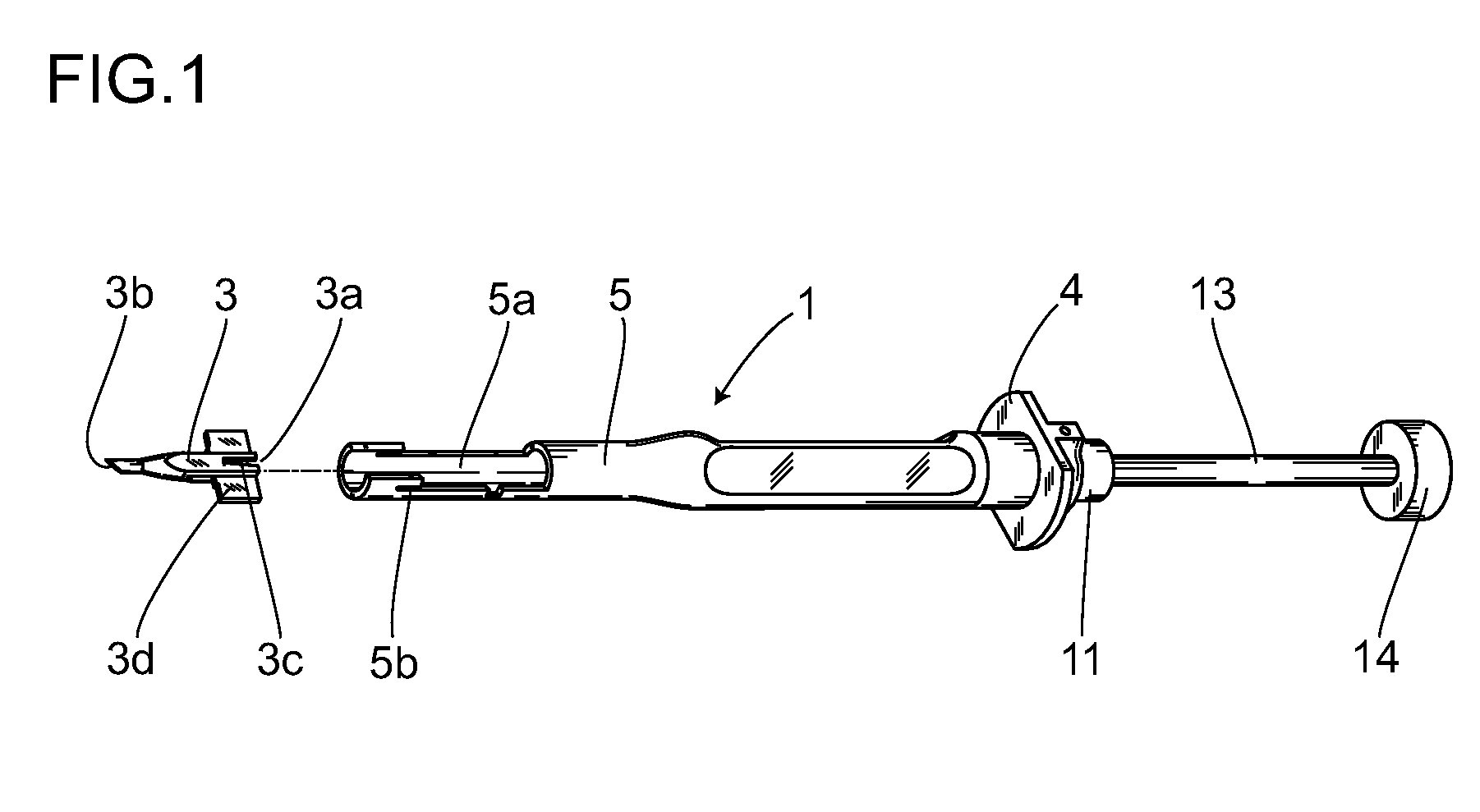

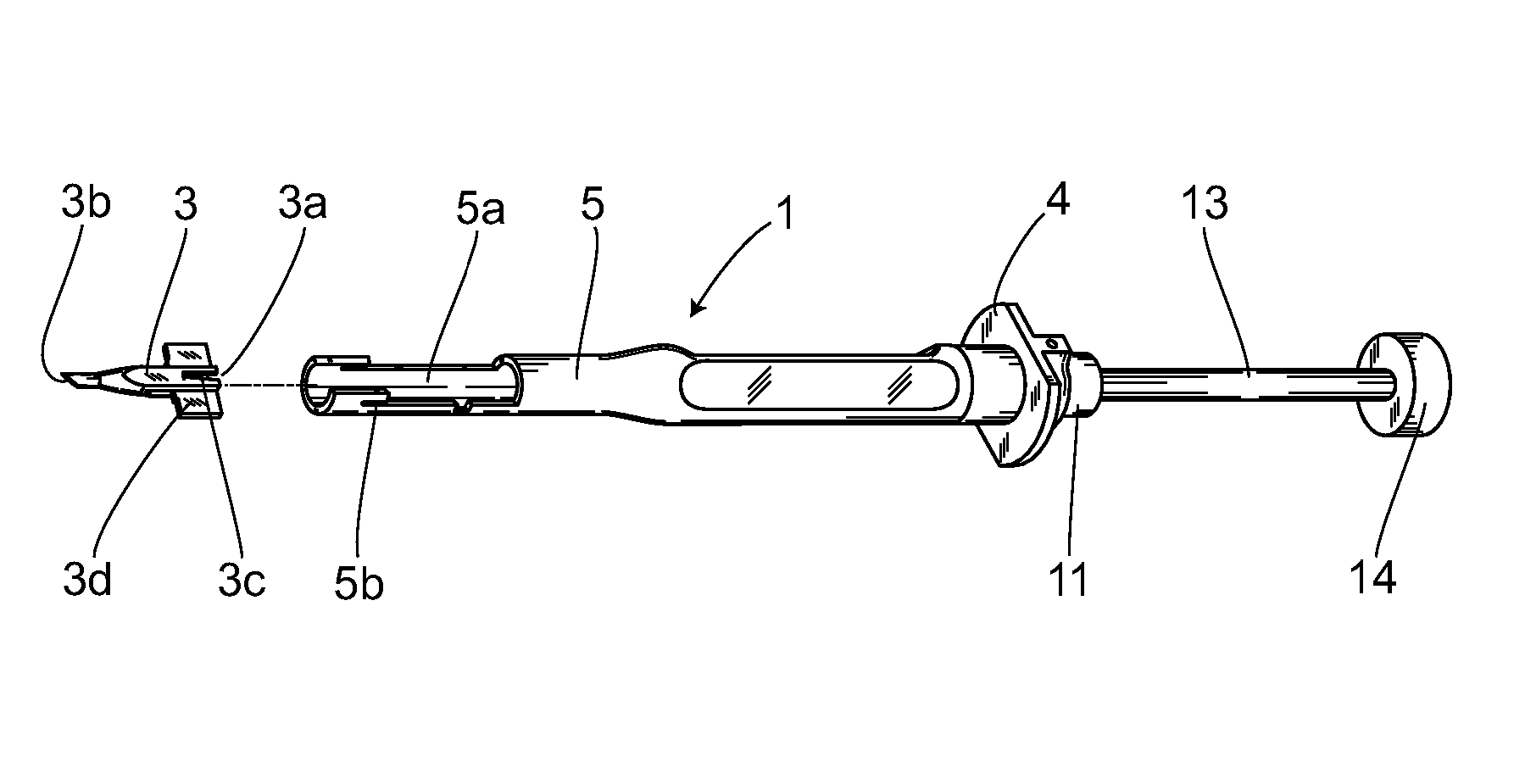

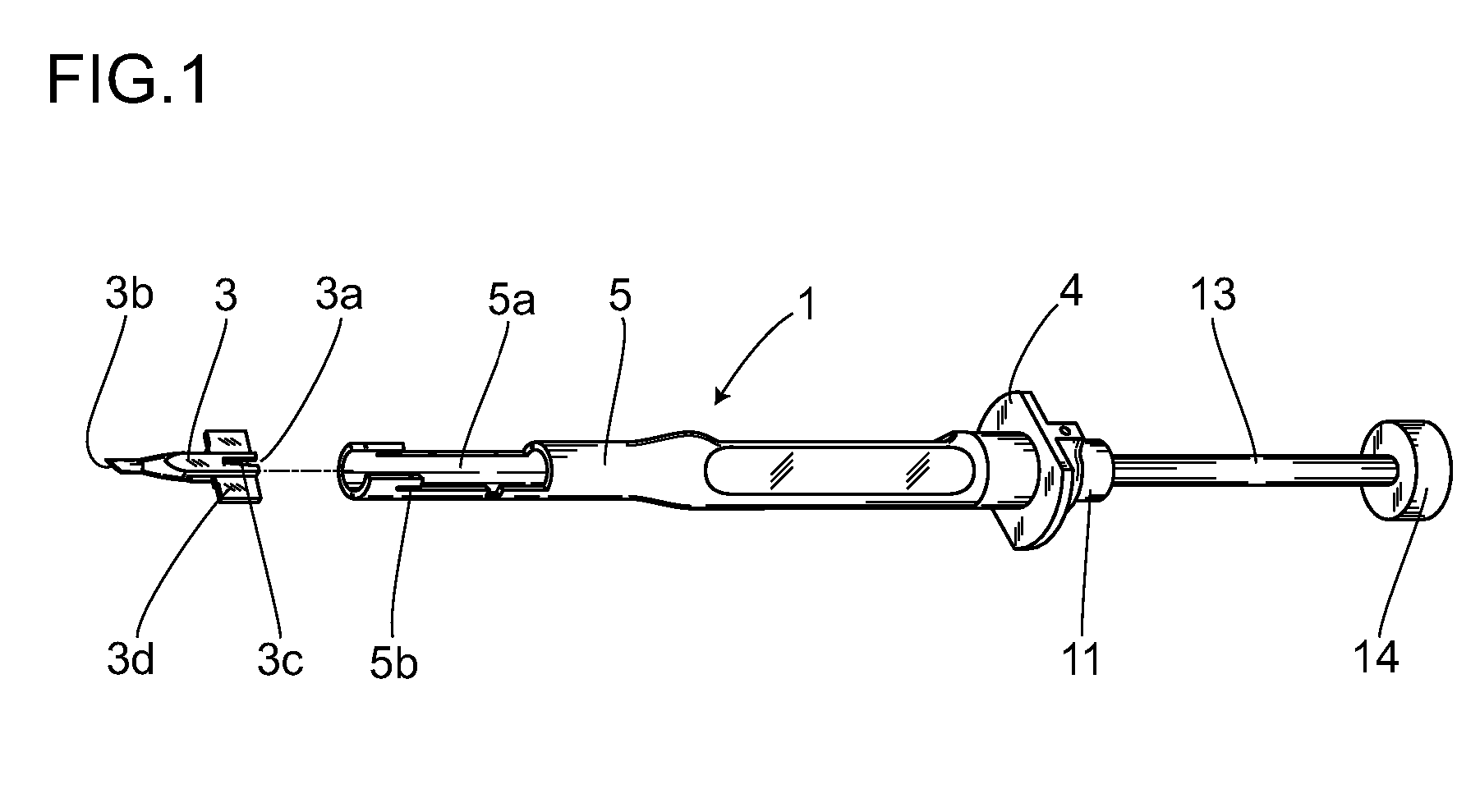

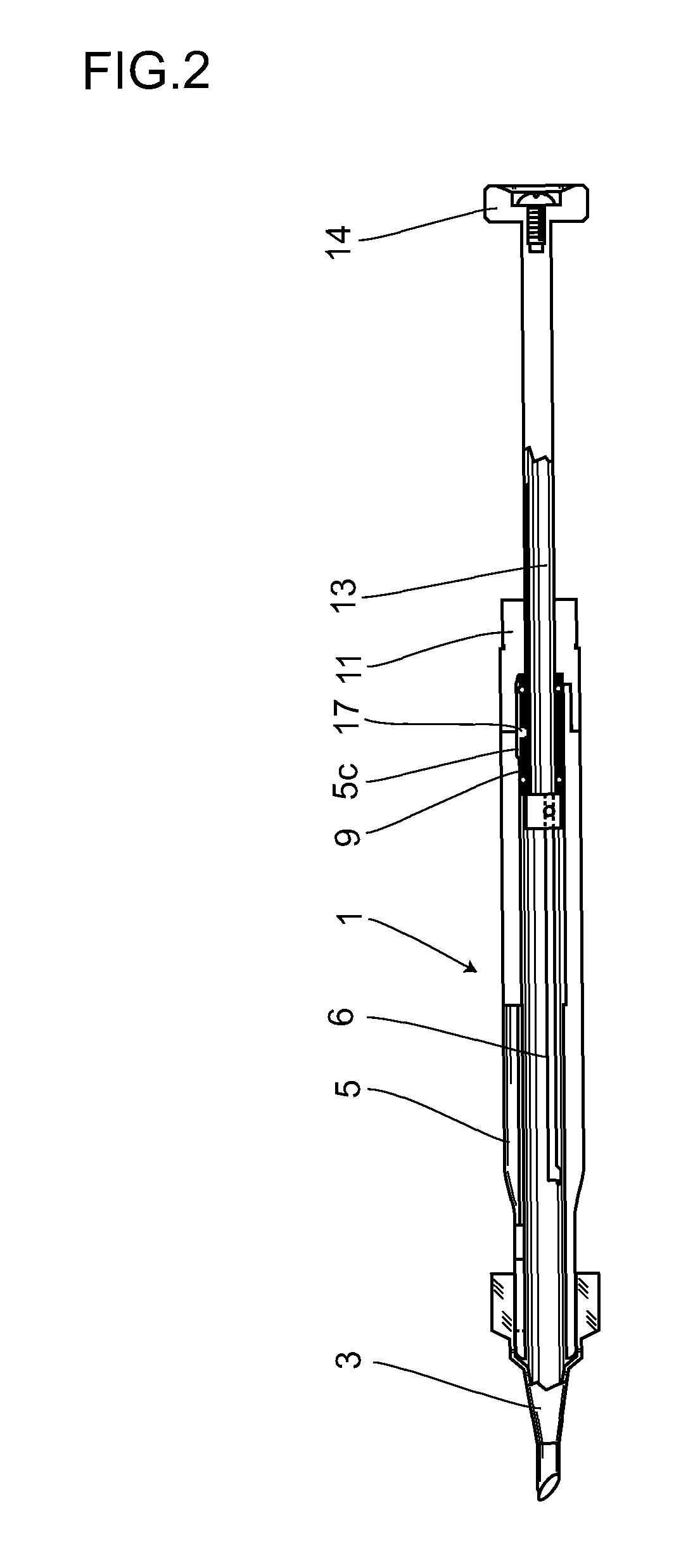

Intraocular Lens Implanting Device

ActiveUS20080086146A1Safely and reliably inserted into eyeballAdjustable positionEye surgeryIntraocular lensMedicineIntraocular lens insertion

An intraocular lens implanting device capable of inserting an intraocular lens surely in safety into an eyeball and having an ophthalmic hooking function capable of adjusting the position of the intraocular lens. The intraocular lens implanting device for inserting an intraocular lens into an eyeball through an incision in the eyeball tissue comprises a tubular main body, a storage part for the intraocular lens integrated with the main body or separated therefrom, and a plunger for pressing the intraocular lens placed in the containing section and discharging it into the eyeball, wherein the distal end of the plunger has a base part and a protuberance.

Owner:HOYA CORP

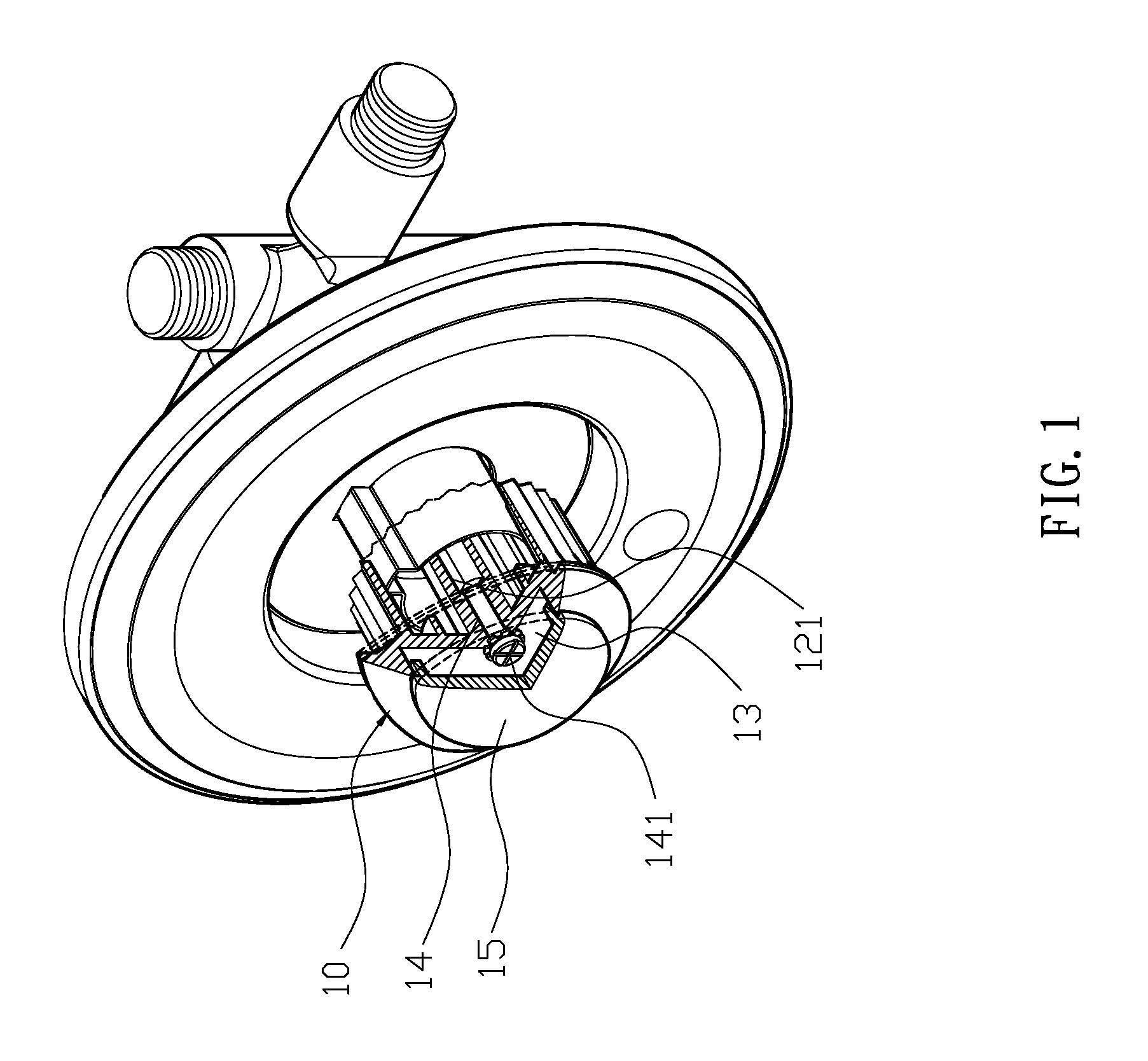

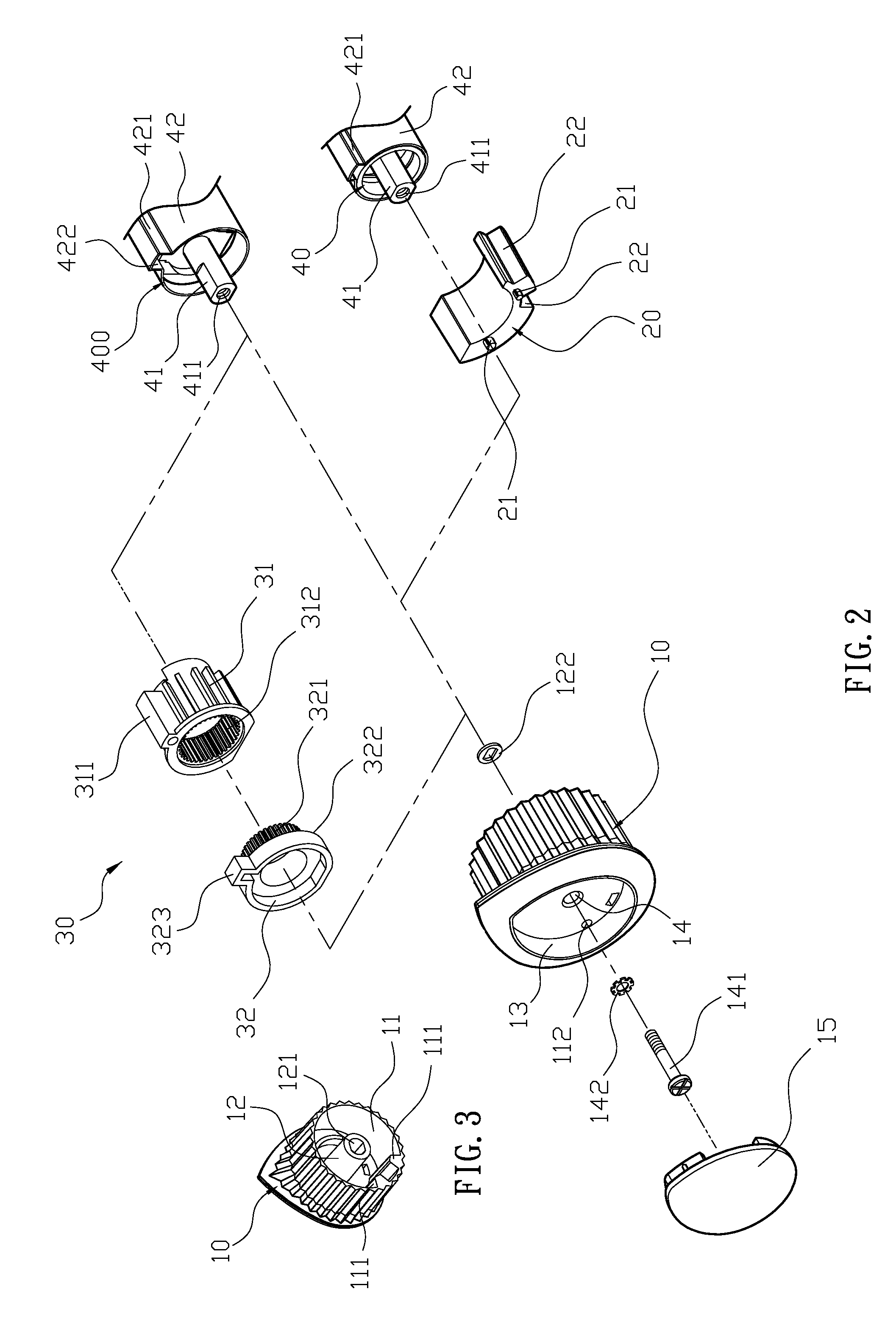

Wall-mounted faucet control components

ActiveUS8607662B2Improve practicalityReduction in rotation angleControlling membersOperating means/releasing devices for valvesEngineeringMechanical engineering

Owner:ALEXANDER YEH IND

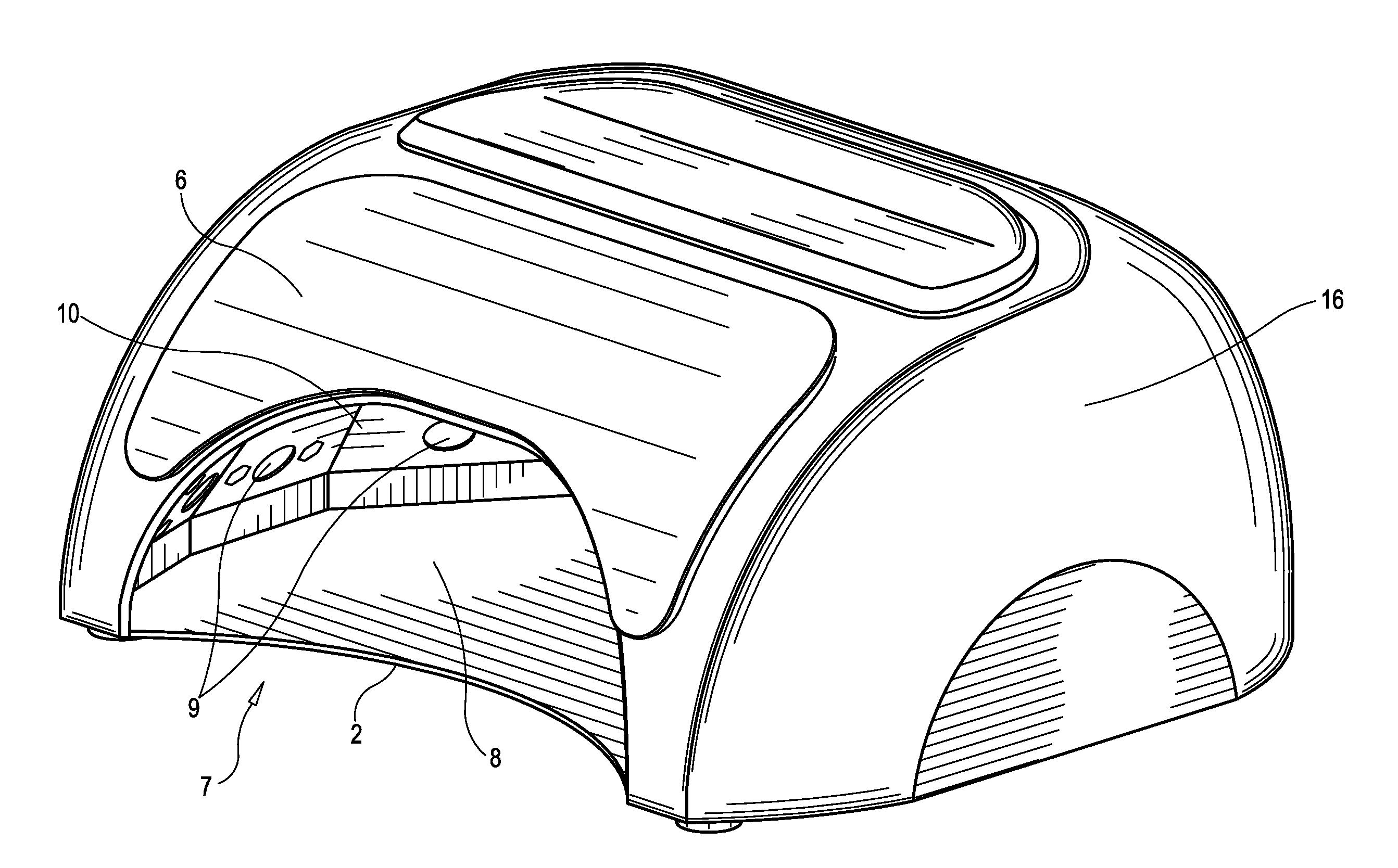

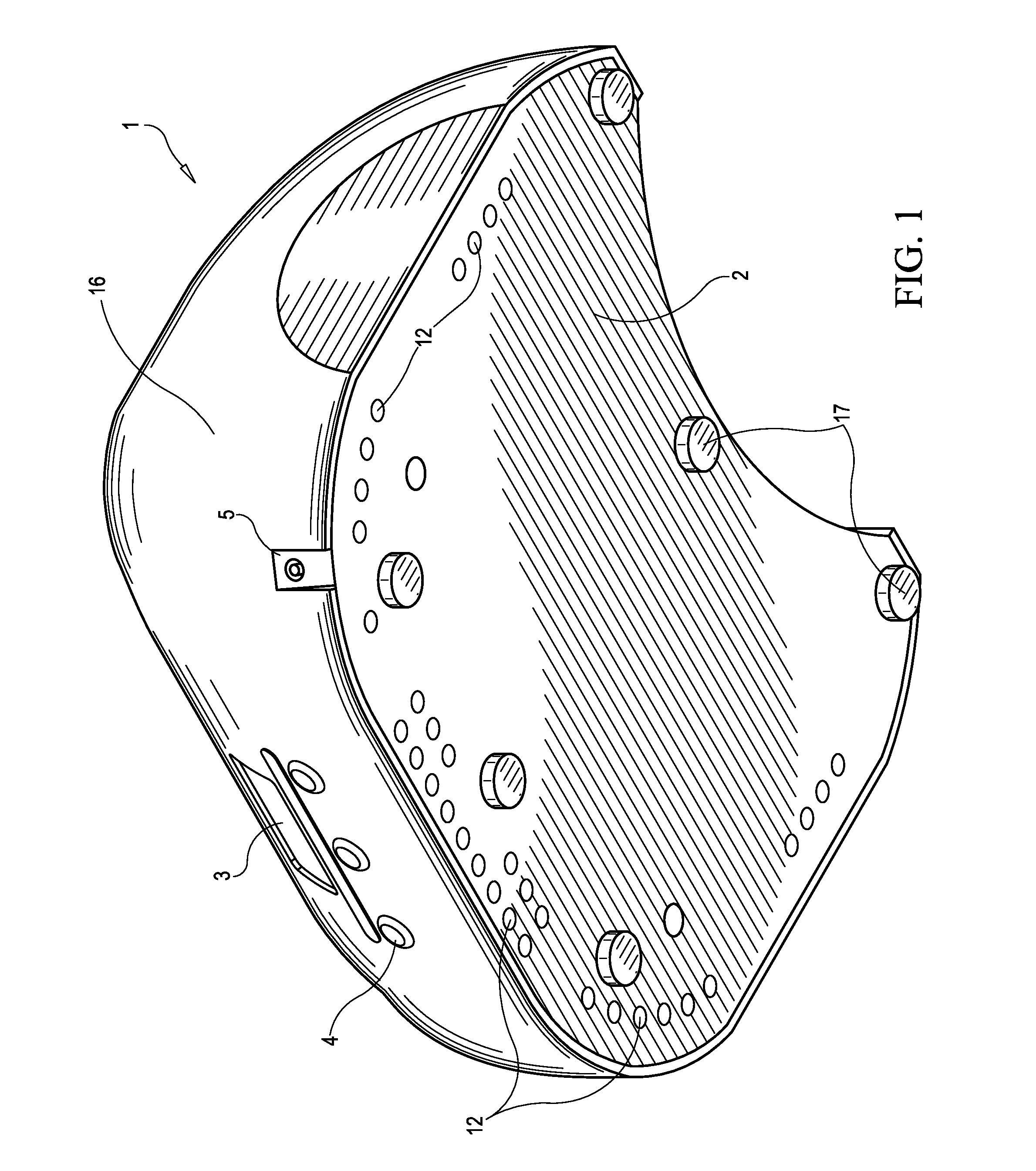

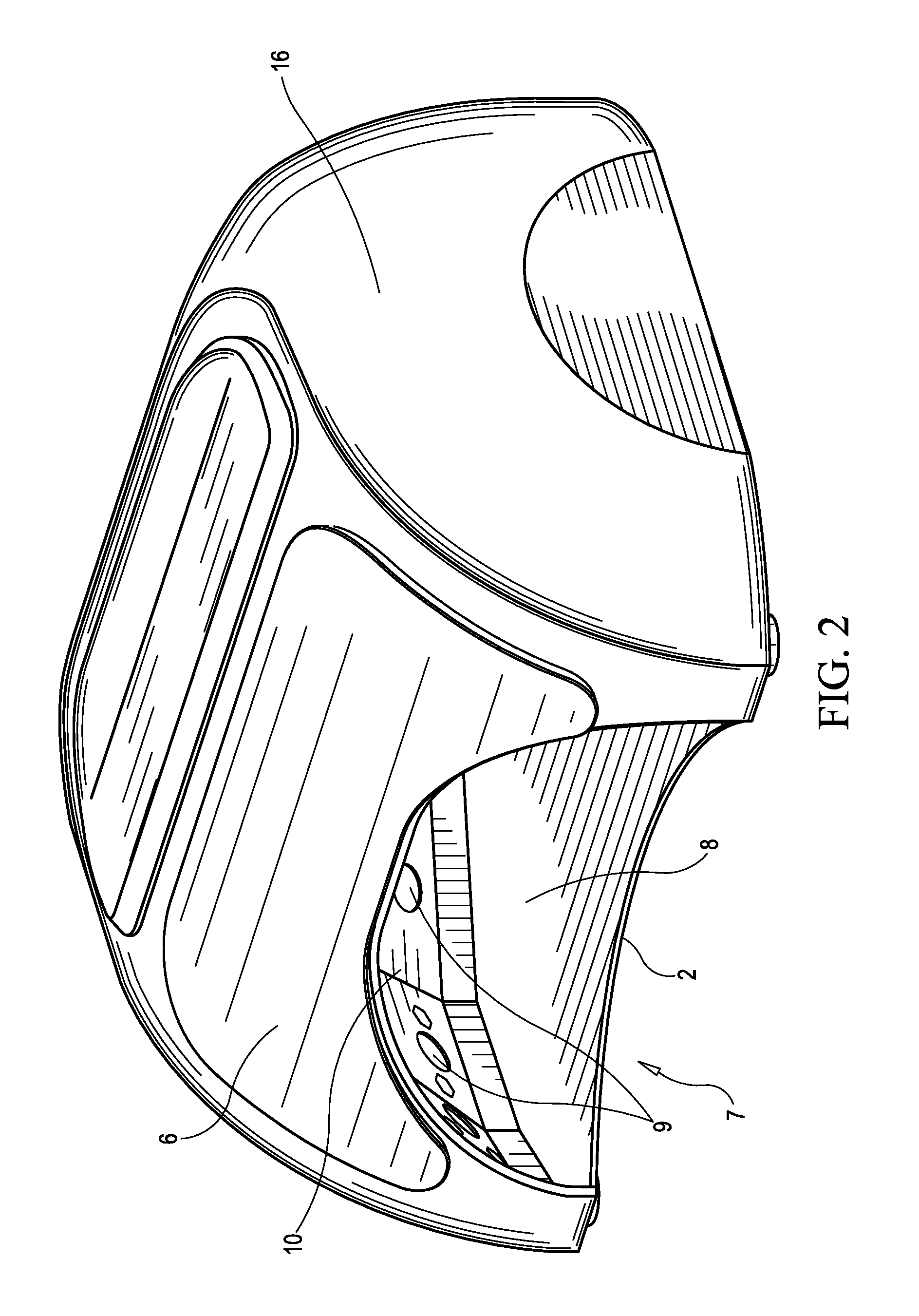

Devices and methods for curing nail gels

InactiveUS20130161531A1Minimizing durabilityMinimizing a user's overexposureMaterial analysis using wave/particle radiationElectric discharge tubesLight-emitting diodeBiomedical engineering

Novel nail gel curing devices and methods of their use are disclosed. Novel shields for nail gel curing devices and methods of their use are also disclosed. The devices and shields are useful for curing nail gels and more particularly where light emitting diode “LED” equipped devices are used to cure UV-VIS curable nail gel resins.

Owner:NAIL ALLIANCE

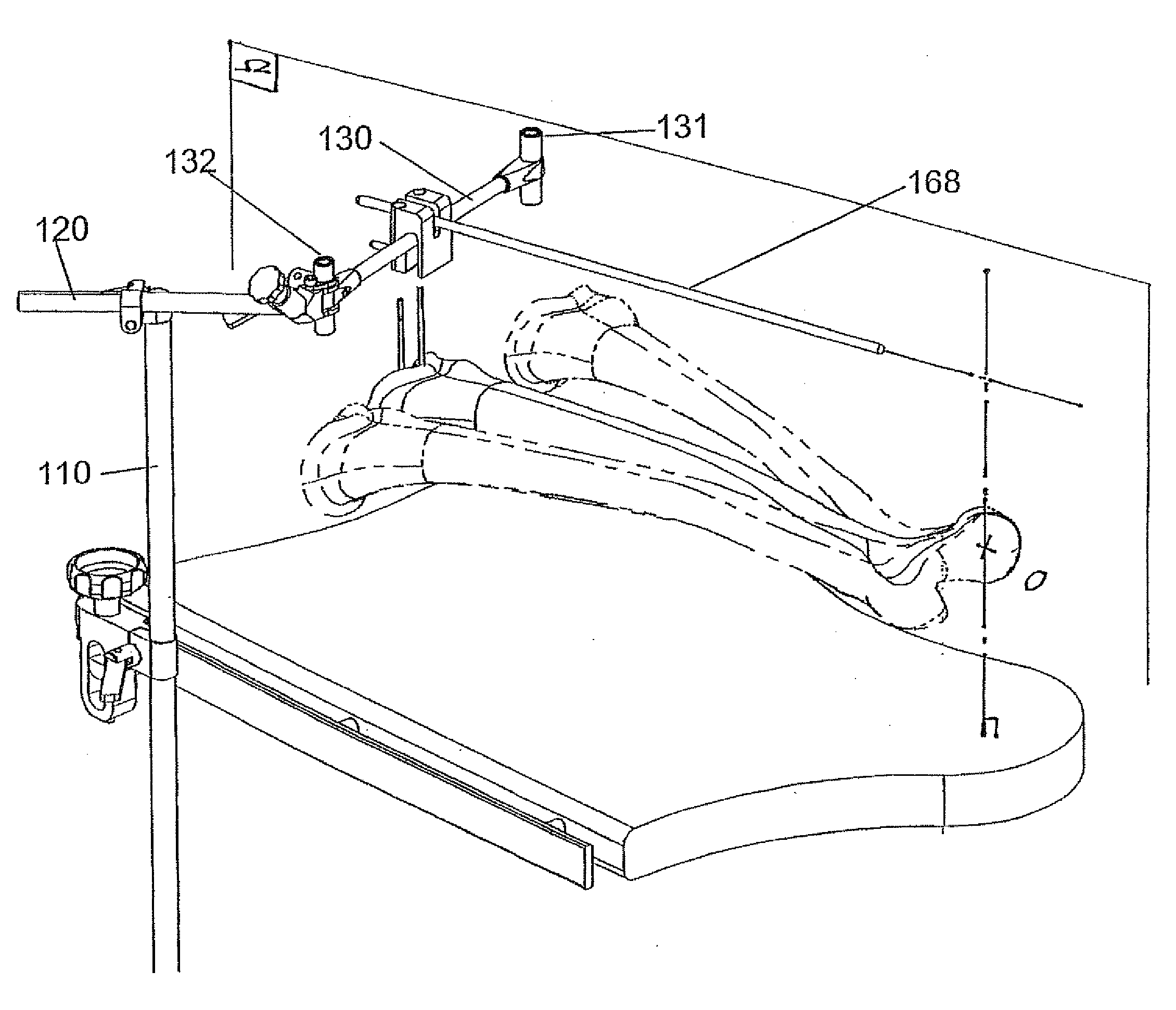

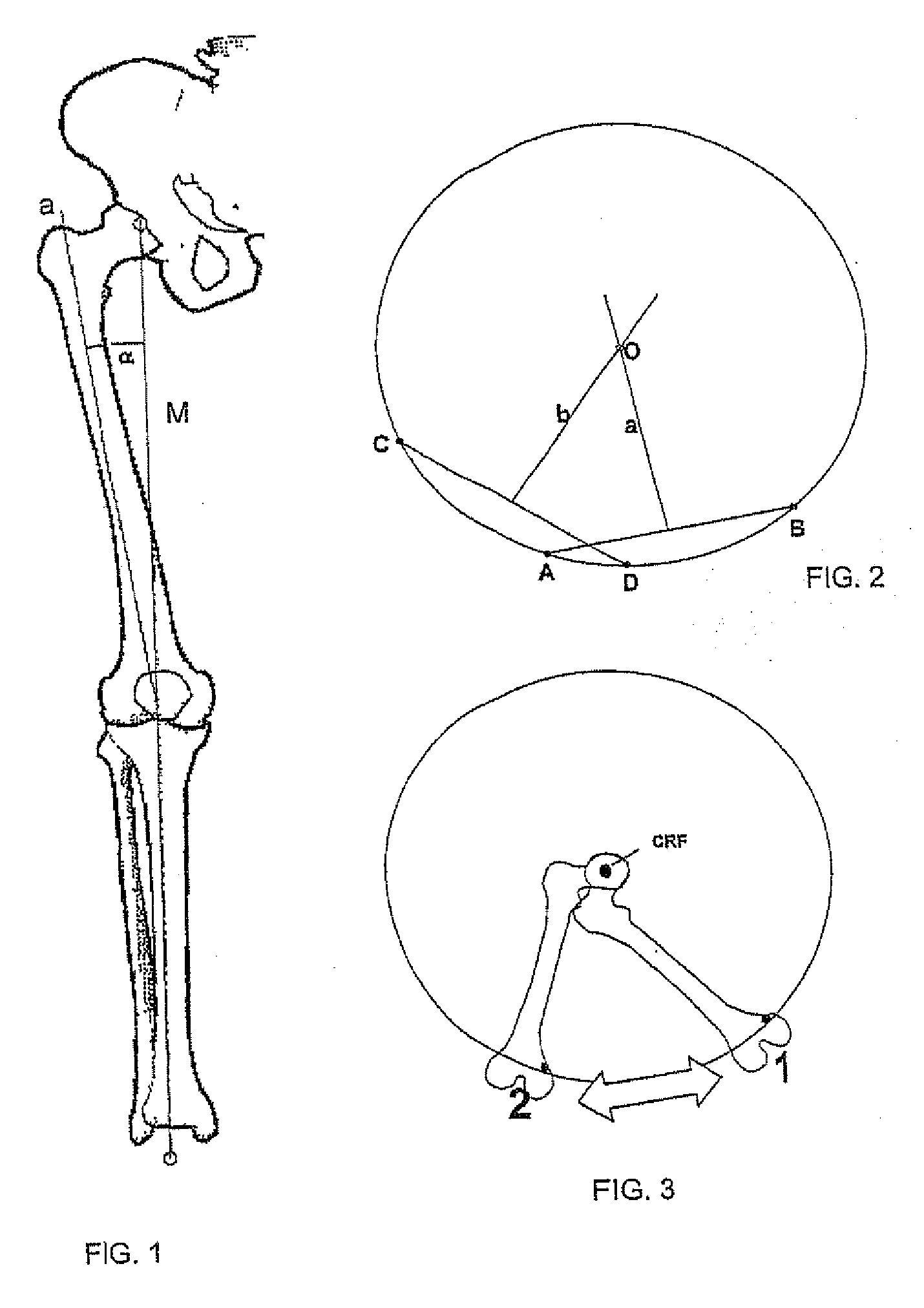

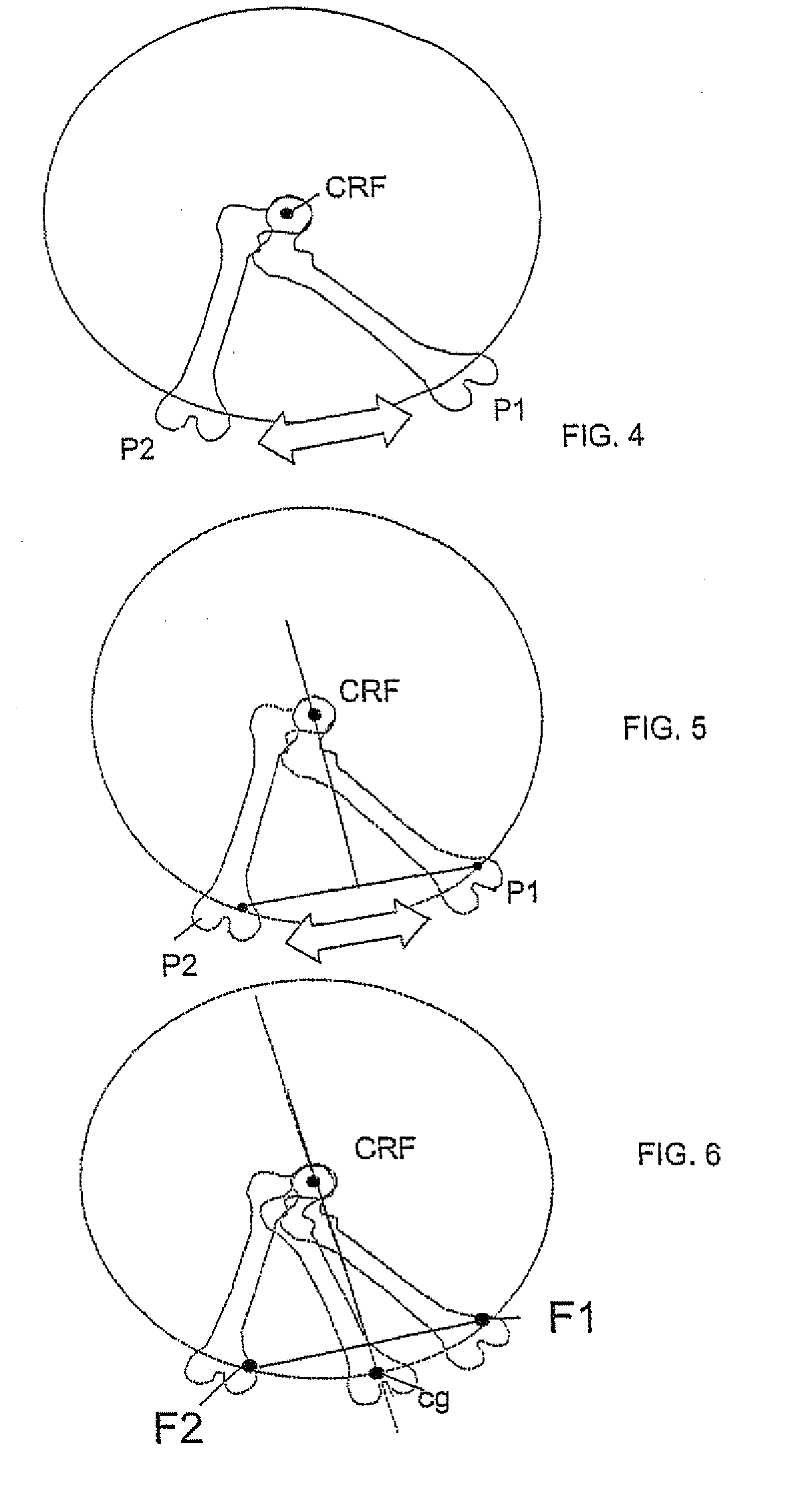

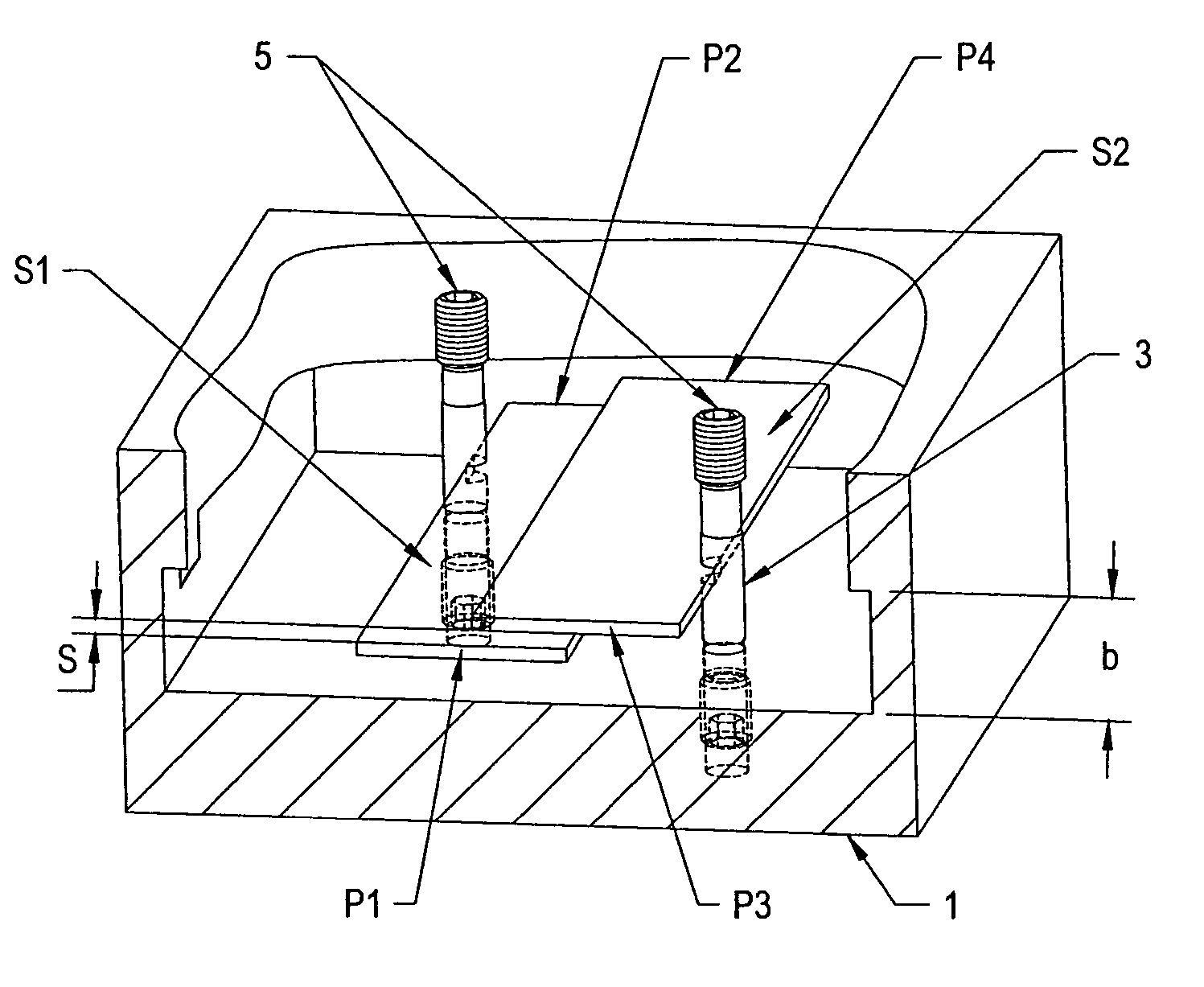

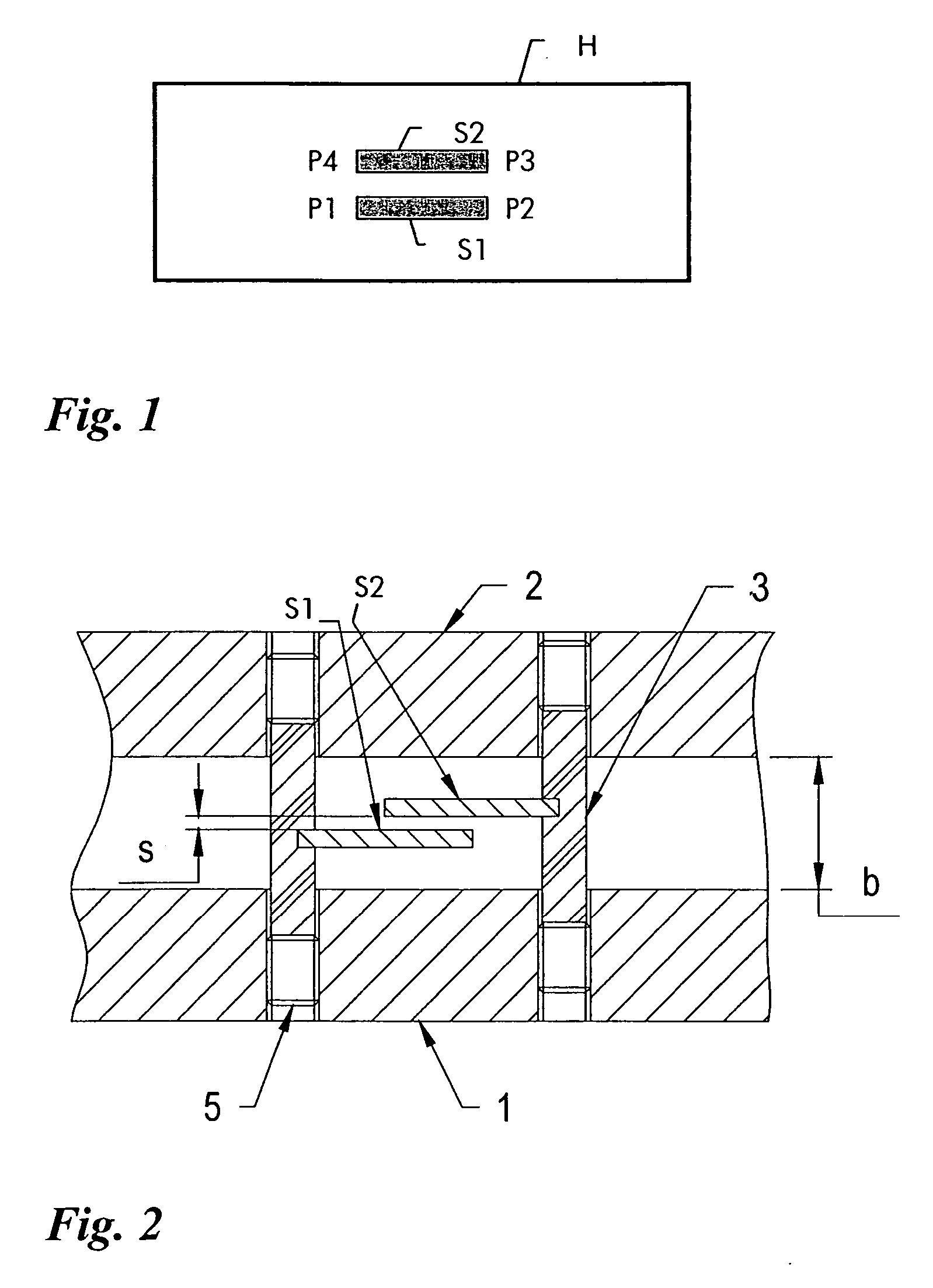

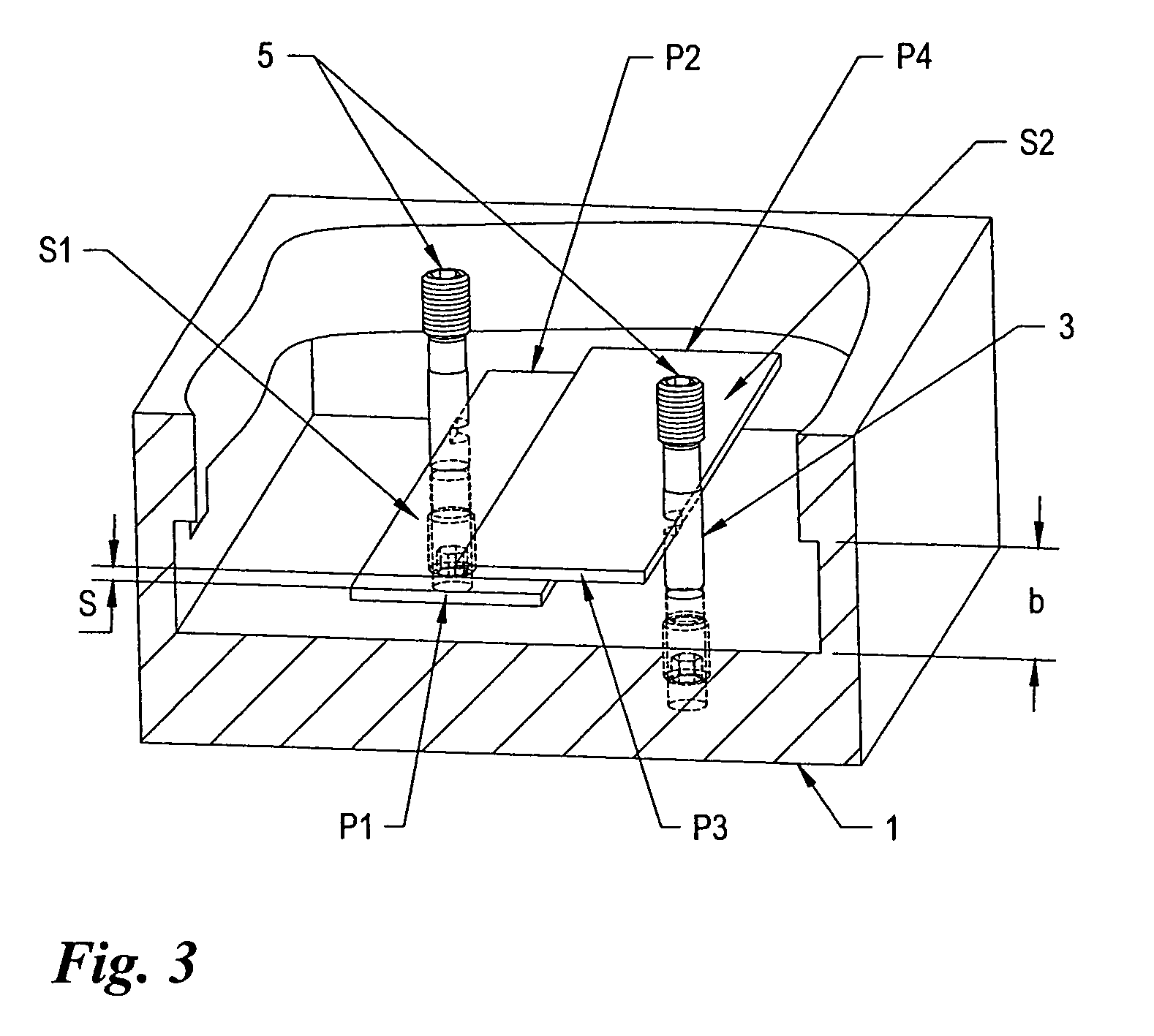

Sighting instrument for determining the mechanical axis of the femur

ActiveUS20090216247A1Simple fast and less-costlyGood precisionMeasurement devicesOperating tablesRight femoral headSagittal plane

A device for the determination of a plane containing the mechanical axis of the femur includes a mechanical member of articulated and or / sliding elements for the determination and memorization of two positions in space (F1 and F2) of the same point (F) of the knee, freely selected, when the knee is in position P1 and P2, relative to a referential system. These positions are obtained by rotation of the inferior limb from position P1 to position P2, about the centre of the femoral head. The orientation of an omega plan perpendicular to the frontal or sagittal plane containing the centre of the femoral head and the centre of the knee can be materialized by a rod contained in this plane, which rod is fixed perpendicularly and in the middle of the arm having at the ends two localization elements for points F1 and F2.

Owner:BREVEXCO S P R L

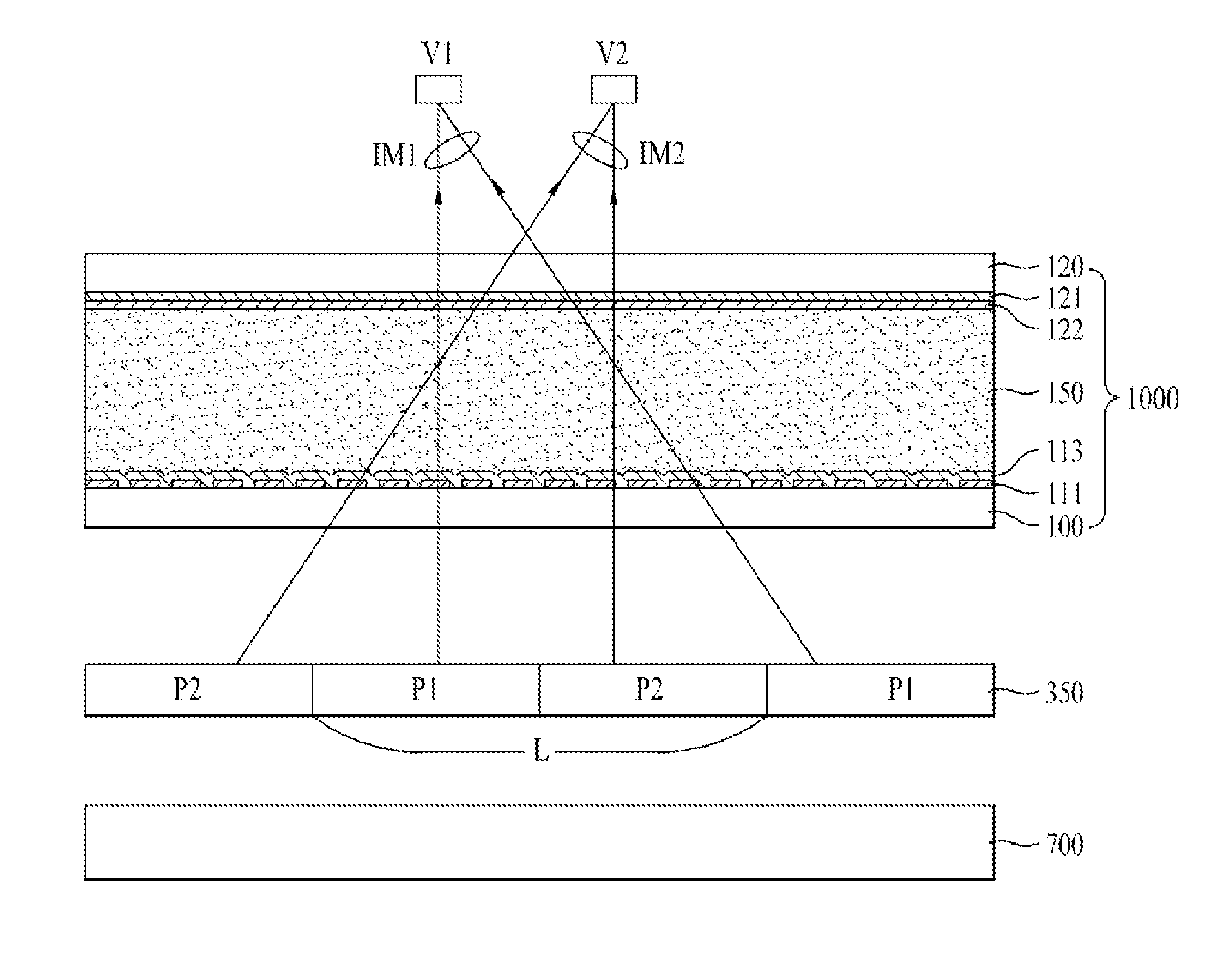

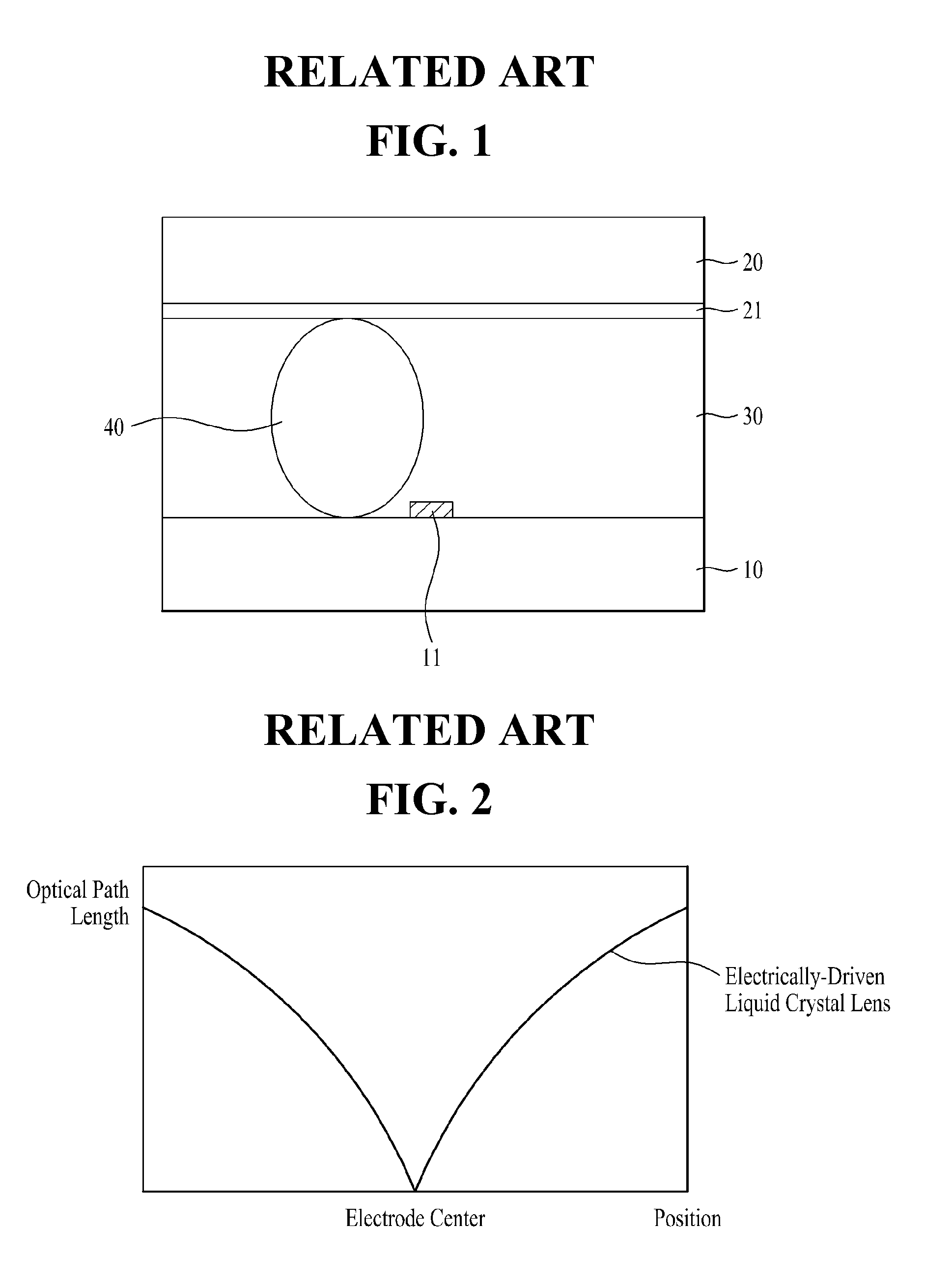

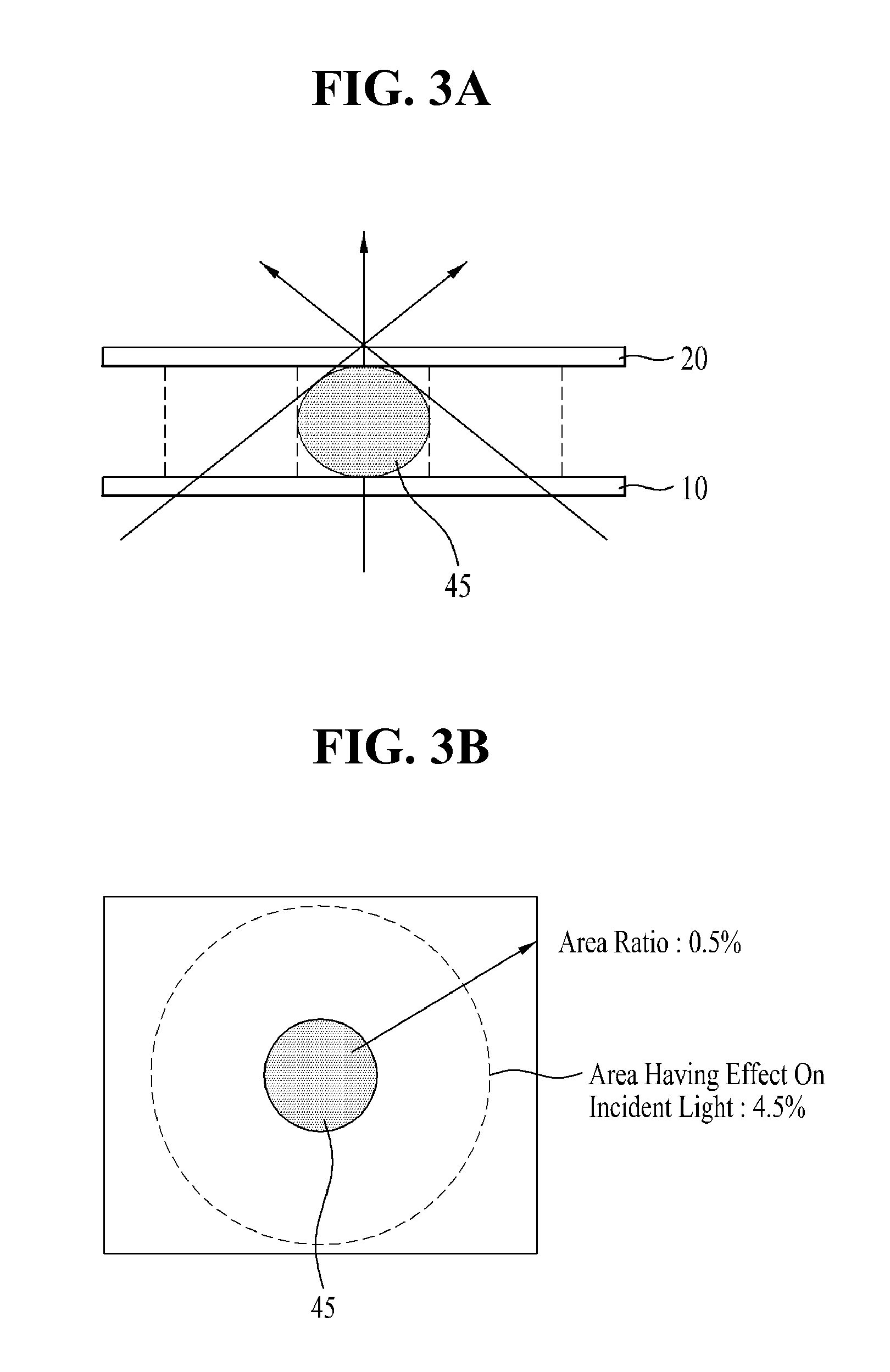

Electric field driven liquid crystal lens cell and stereoscopic image display device using the same

ActiveUS20110157499A1Adjustable positionSurface errorStatic indicating devicesSteroscopic systemsEngineeringVoltage source

An electric field driven liquid crystal lens cell including a first substrate and a second substrate arranged opposite each other, a first plurality of split electrodes formed on the first substrate, each of the first plurality of split electrodes corresponding to one of a plurality of lens regions, a second electrode formed over an entire first surface of the second substrate, a voltage source to apply differing voltages to the first and second plurality of split electrodes, a spacer formed between the first substrate and the second substrate, the location of the spacer corresponding to the vertex of the lens when voltages are applied to at least one of the first plurality of split electrodes and the second electrode, and a liquid crystal layer disposed between the first substrate and the second substrate.

Owner:LG DISPLAY CO LTD

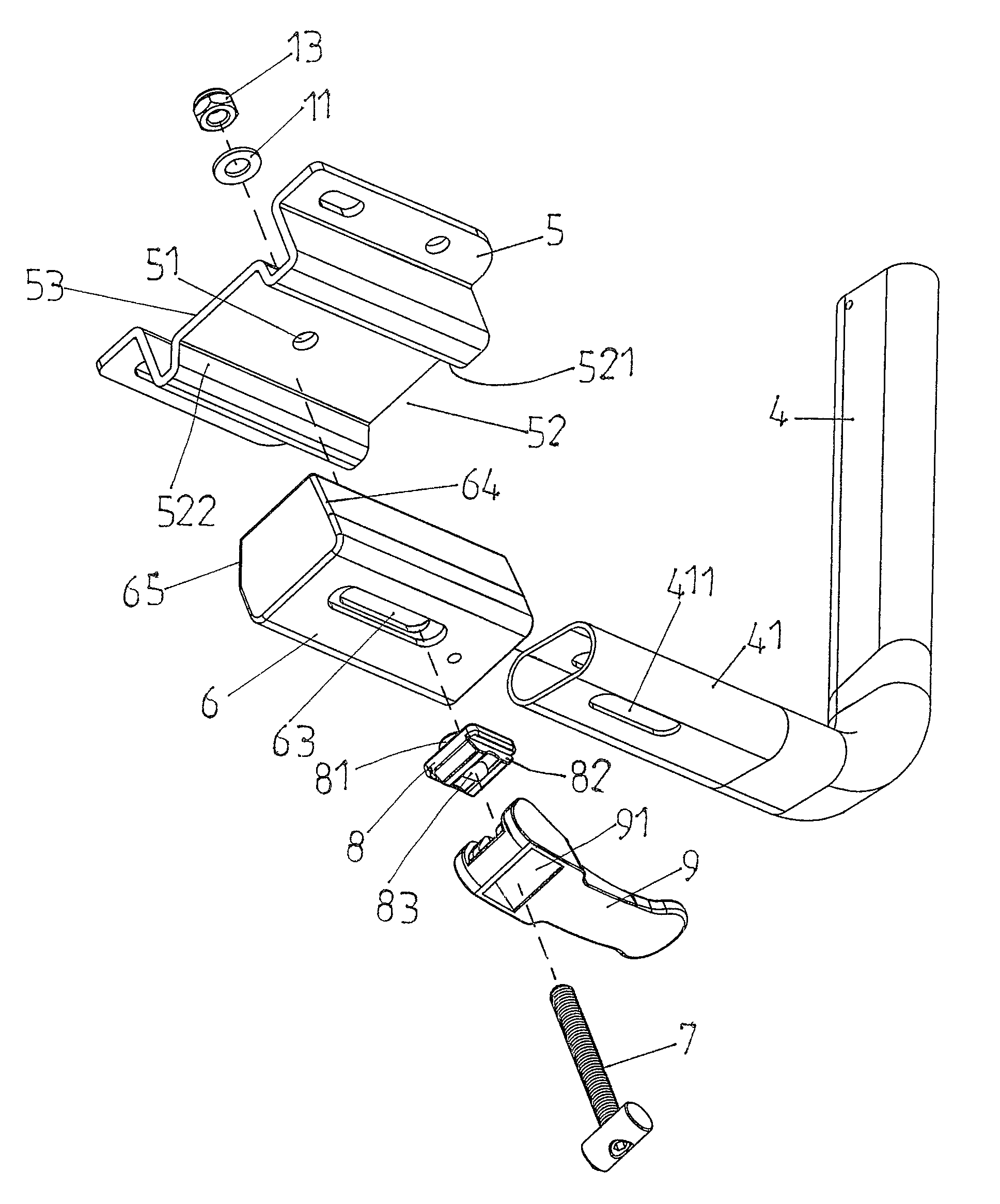

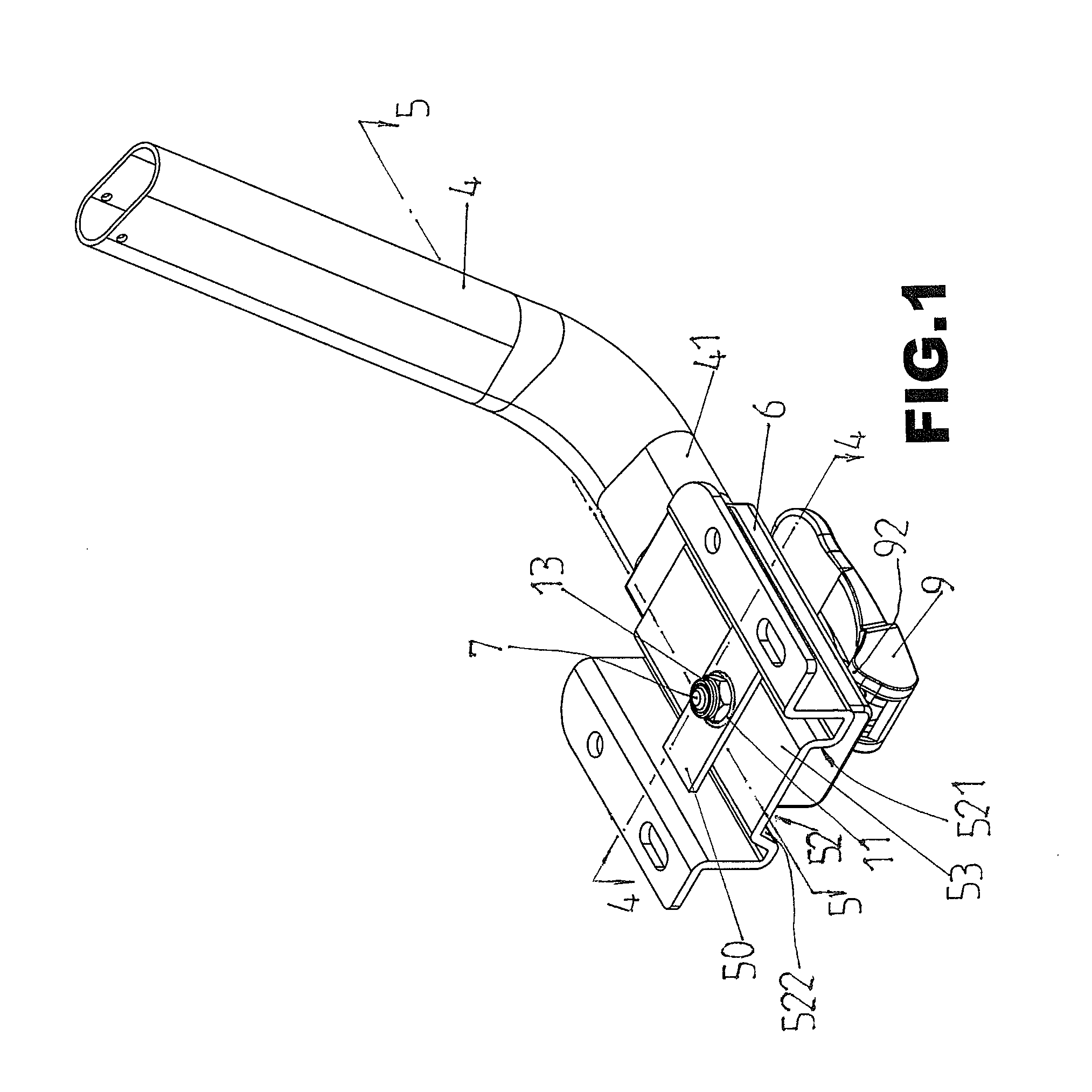

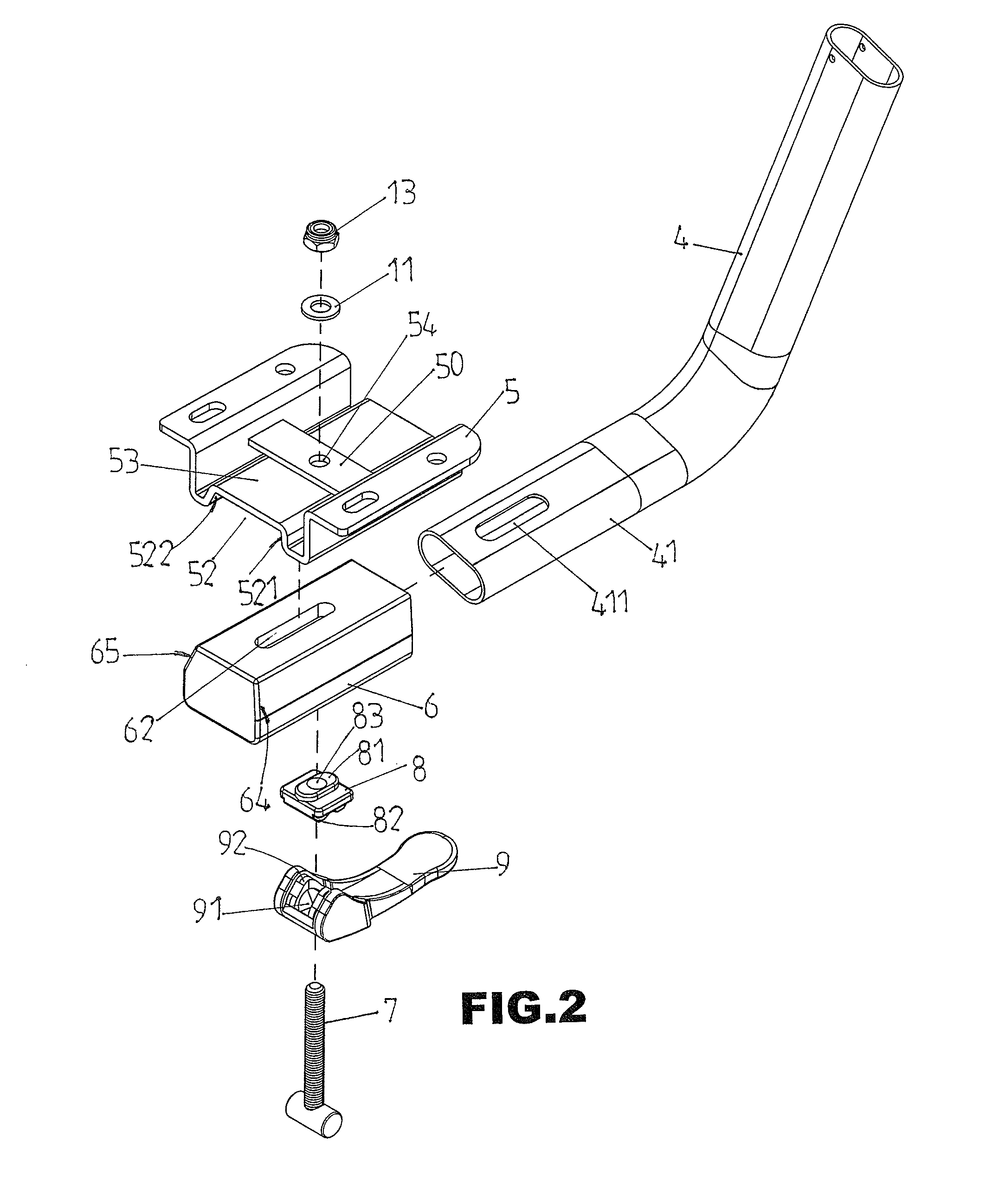

Armrest assembly that can adjust its leftward and rightward positions

An armrest assembly includes a mounting bracket, a limit member mounted on the mounting bracket, and an armrest support mounted on the limit member. The bottom of the mounting bracket is provided with a slideway which has a first side provided with an upright limit face and a second side provided with an oblique limit face. The limit member has a first side provided with an upright mating face abutting the upright limit face and a second side provided with an oblique mating face abutting the oblique limit face. Thus, the upright mating face and the oblique mating face are limited by the upright limit face and the oblique limit face respectively, so that the limit member is moved in the slideway smoothly and stably without producing any vibration to facilitate movement of the armrest support relative to the mounting bracket.

Owner:TSAI PO CHUAN

Reference mark adjustment mechanism for a femoral caliper and method of using the same

ActiveUS20050209600A1Easy to prepareAdjustable positionJoint implantsKnee jointsAnterior cortexFemoral condyles

A femoral caliper having one or more anatomical referencing members for placement against portions of the femur, such as the anterior cortex and posterior portion of the femoral condyles, to measure the femur for sizing of the femoral component. A reference mark positioning guide of the femoral caliper is connected to the anatomical referencing member and is capable of guiding placement of a reference mark on the femur that facilitates positioning of the femoral component. The femoral caliper includes an adjustment mechanism capable of displacing the reference mark positioning guide relative to the anatomical referencing member. This allows adjustment of the position of the reference mark (and hence the femoral component) on the femur to account for the up or down sizing of the femoral component. Preferably, the adjustment mechanism adjusts the reference mark positioning guide in the anterior-posterior direction to allow balancing of the tightness or laxity of the selected component.

Owner:MICROPORT ORTHOPEDICS HLDG INC

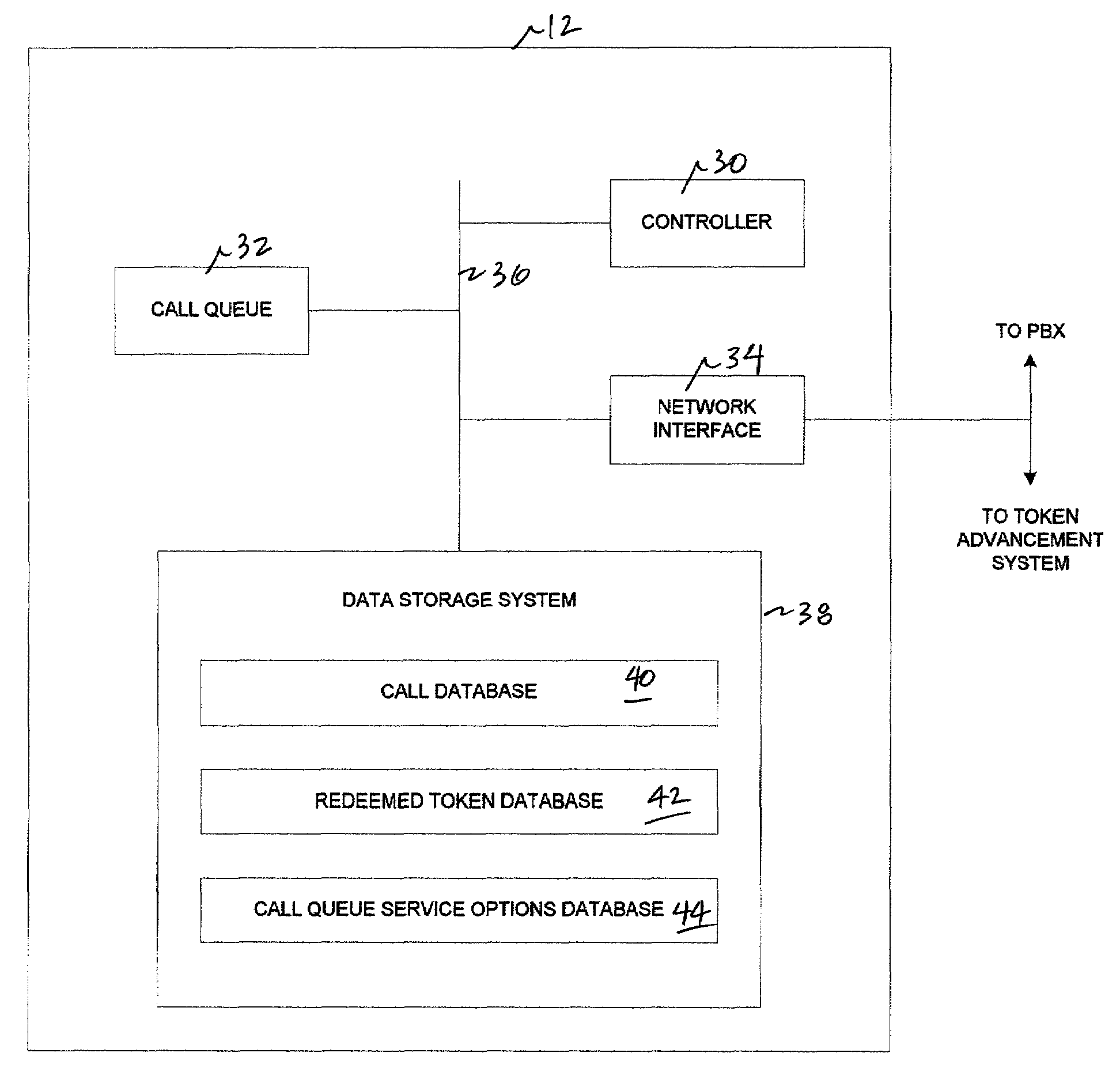

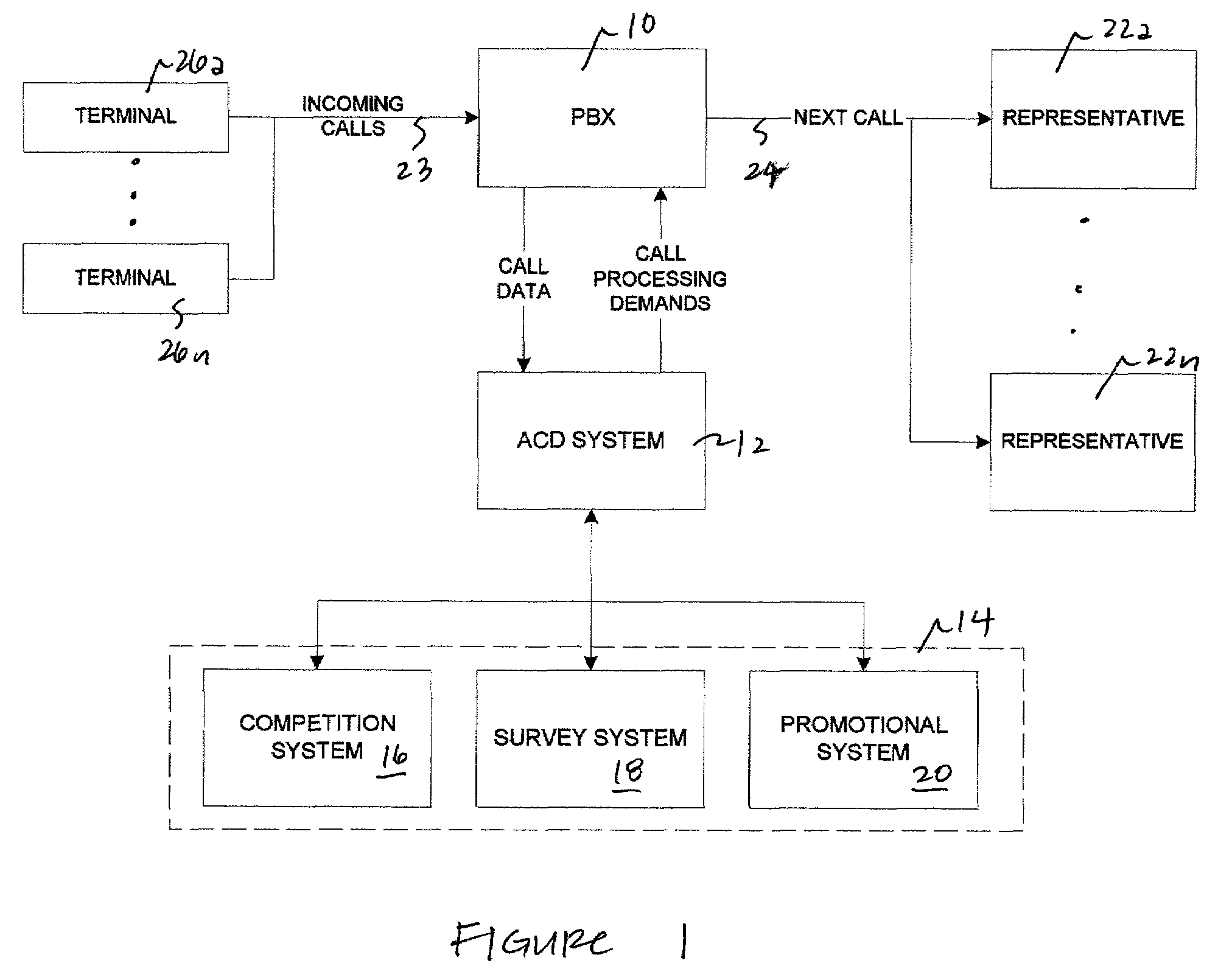

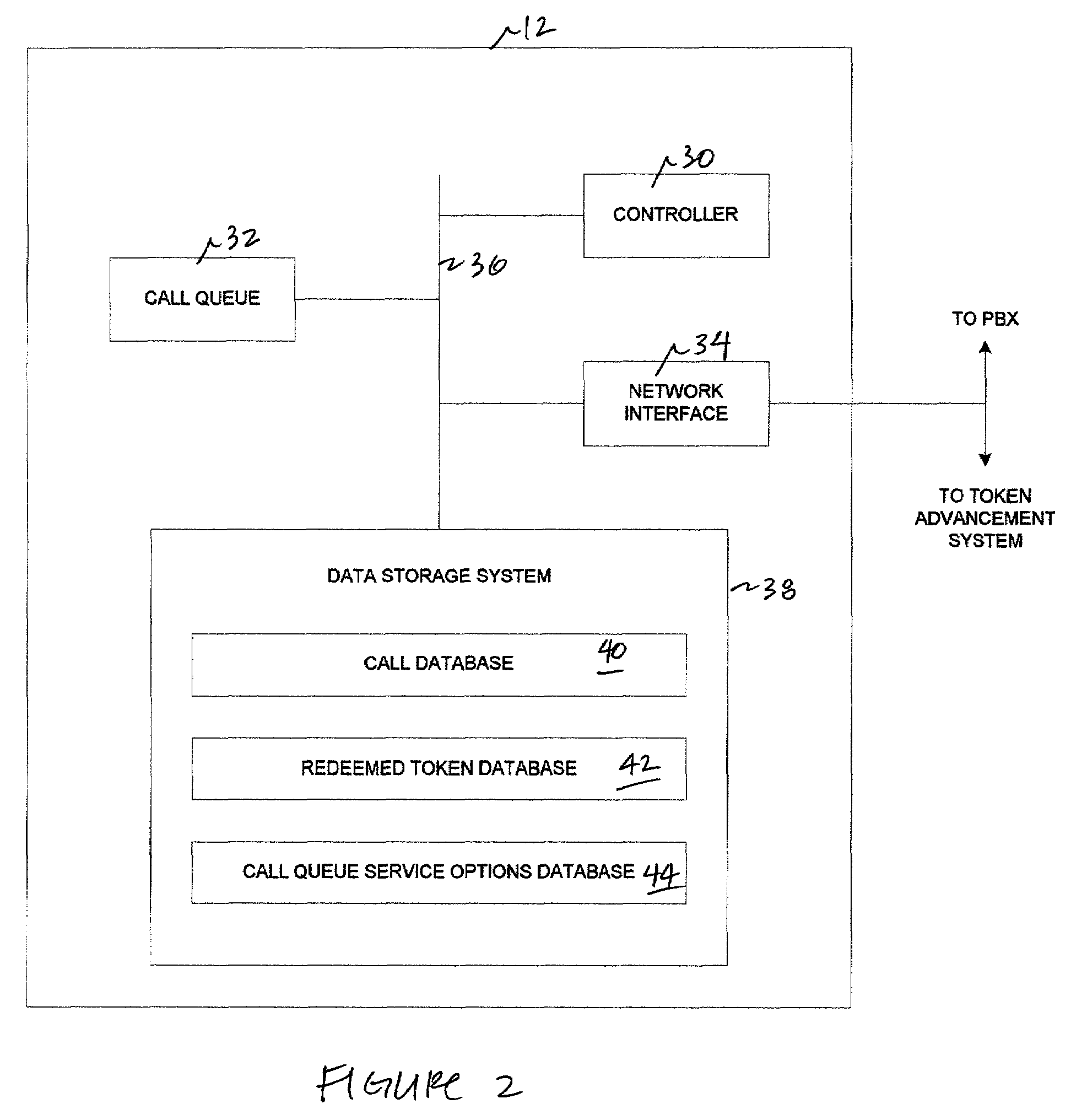

Enabling caller controlled hold queue position adjustment

A method, system, and program for allowing callers to adjust in position within a call hold queue are provided. An advancement token earned by a caller is detected at a calling queue. The position of the caller within the calling queue is adjusted, in response to redemption of the advancement token, such that the caller is allowed control over the position within the calling queue by earning advancement tokens. In particular, a caller may earn advancement tokens by participation in competitions or surveys or by redemption of membership points.

Owner:IBM CORP

Height adjustable arm assembly

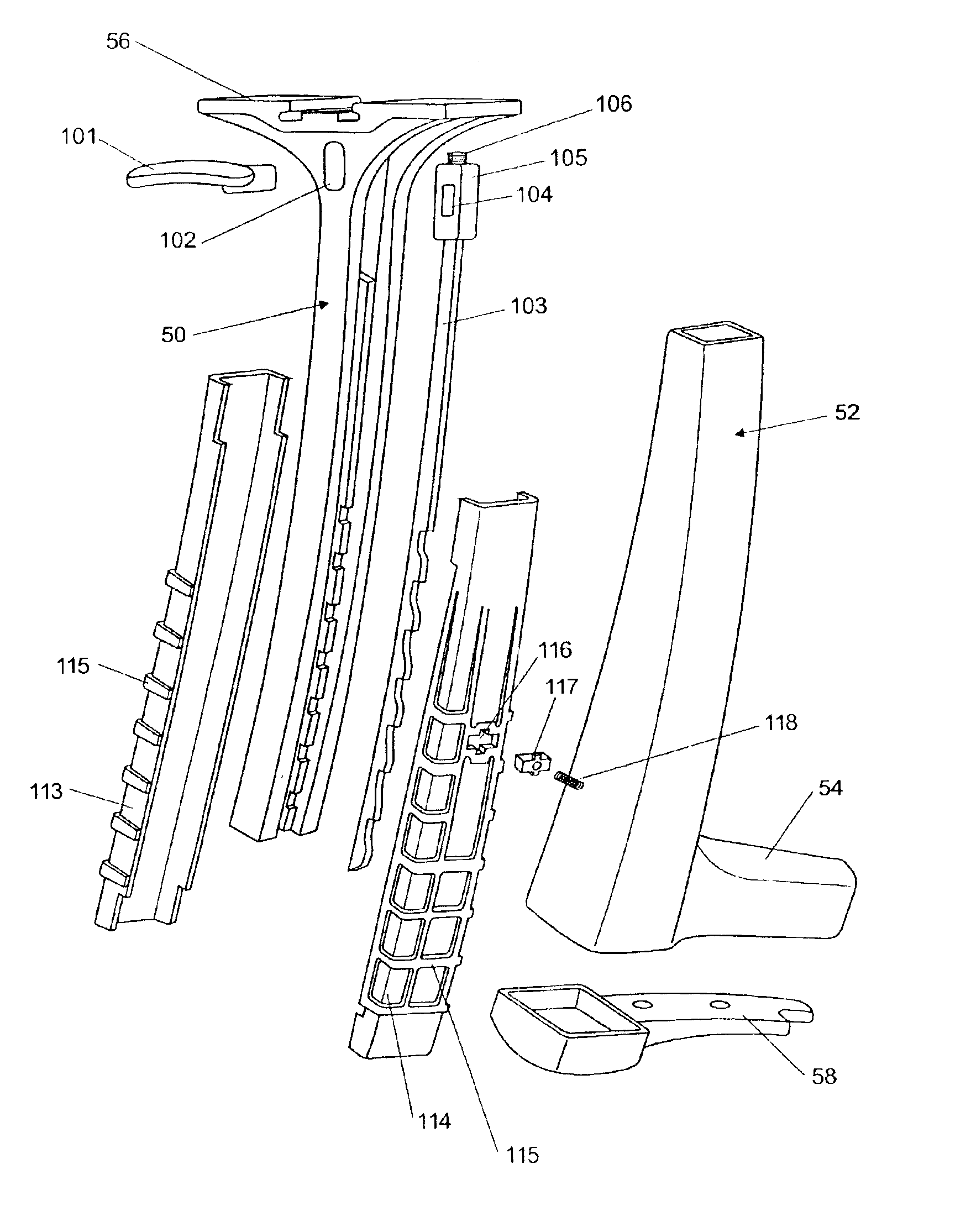

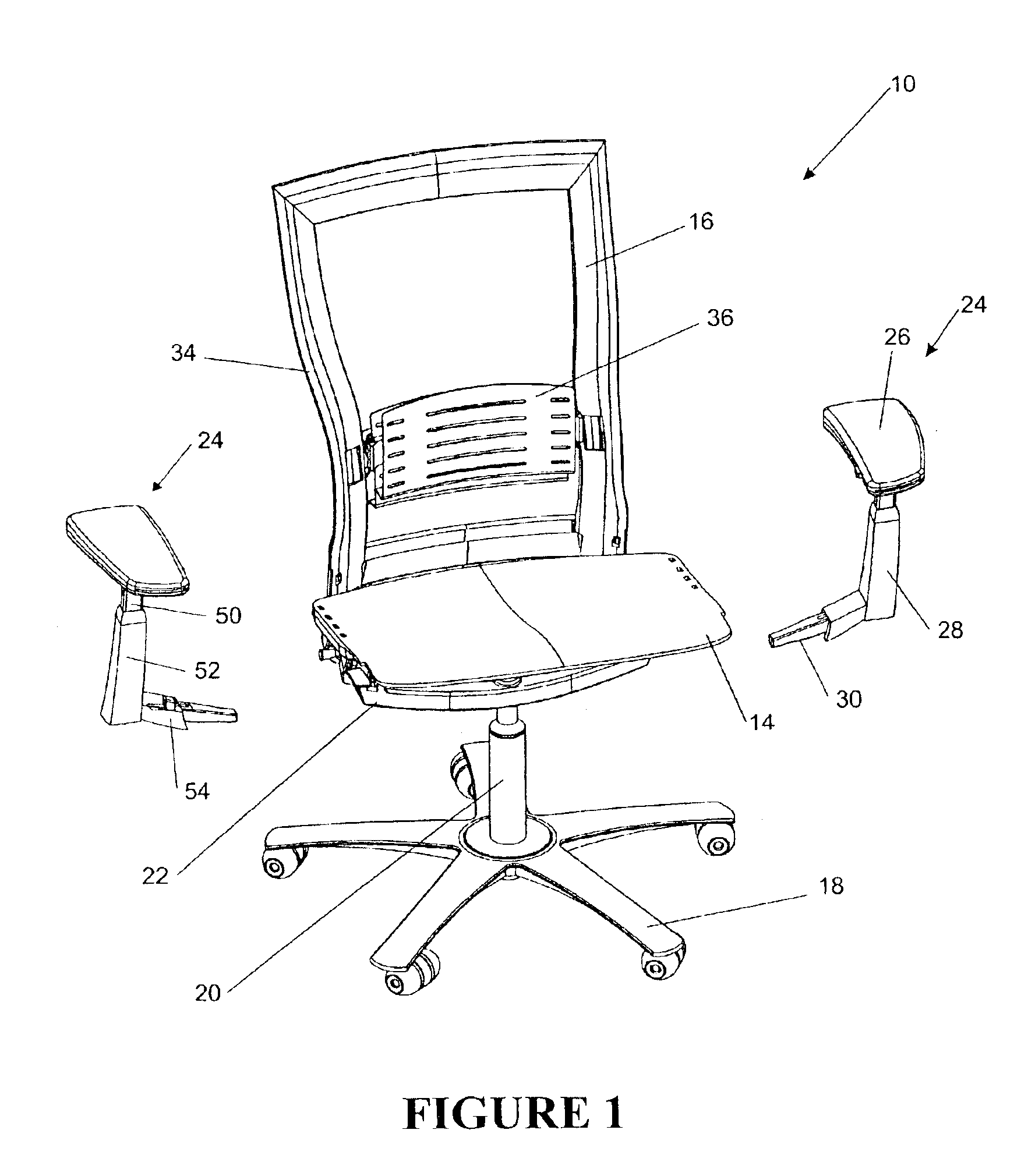

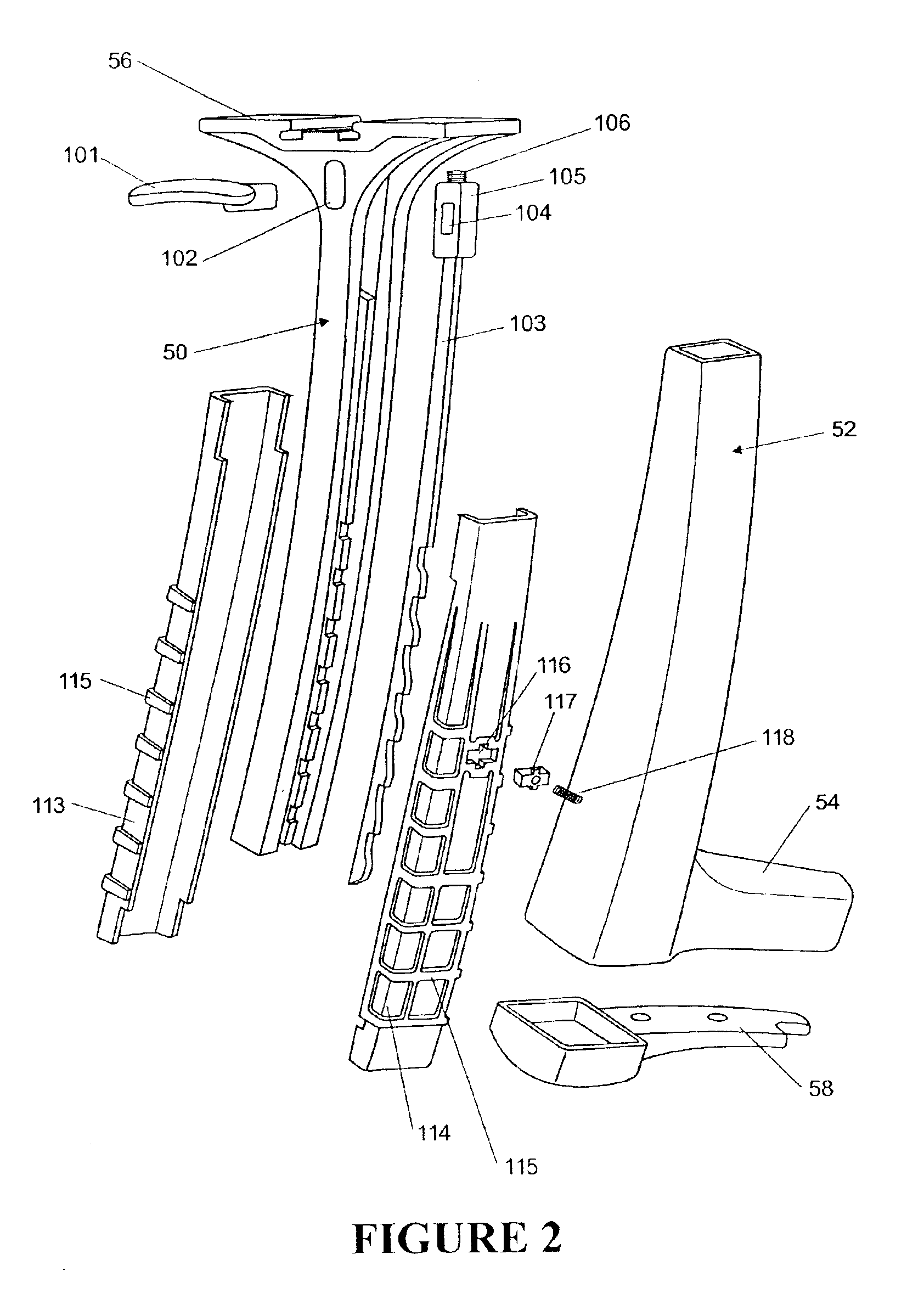

An arm assembly includes an outer stem (52) and an inner stem (50) slidable in the outer stem and including a number of recesses (107) along its length. A biased locking device (117) engages one or more of the recesses (107) to lock the position of the inner stem (50) relative to the outer stem (52). A release member (103) operably connected to an actuator (101) has a number of recesses (110) and raised surfaces (112), the release member (103) slidable relative to the inner stem (50) between a first position in which recess(es) (110) in the release member is / are aligned with recess(es) (107) of the inner stem and the locking device (117) engages recess(es) in the stem (50) to inhibit movement thereof relative to the outer stem, and a second position in which raised surface(s) (112) of the release member align(s) with recess(es) (107) of the stem (50) to disengage the locking device from the recess(es) of the stem.

Owner:FORMWAY FURNITURE

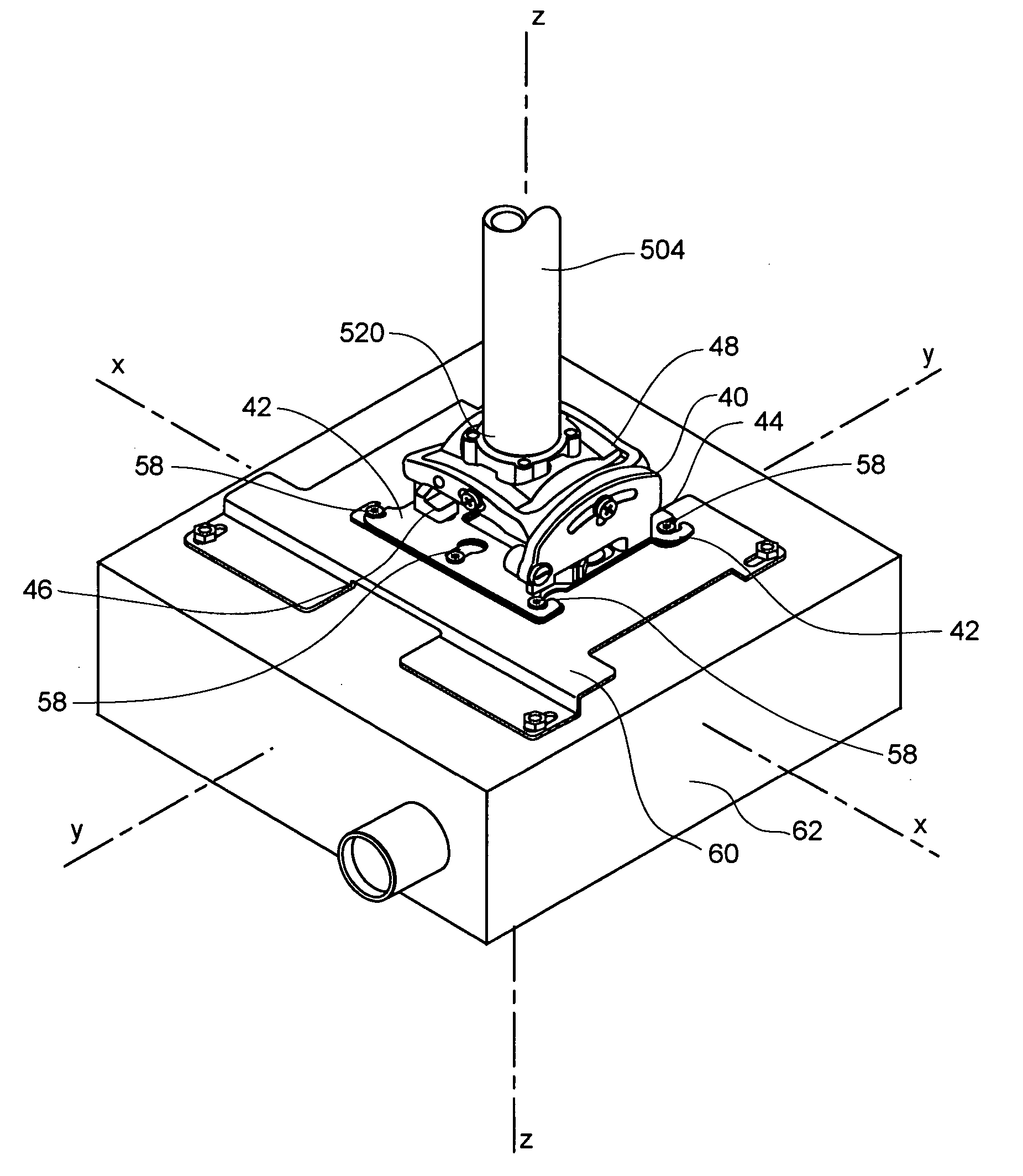

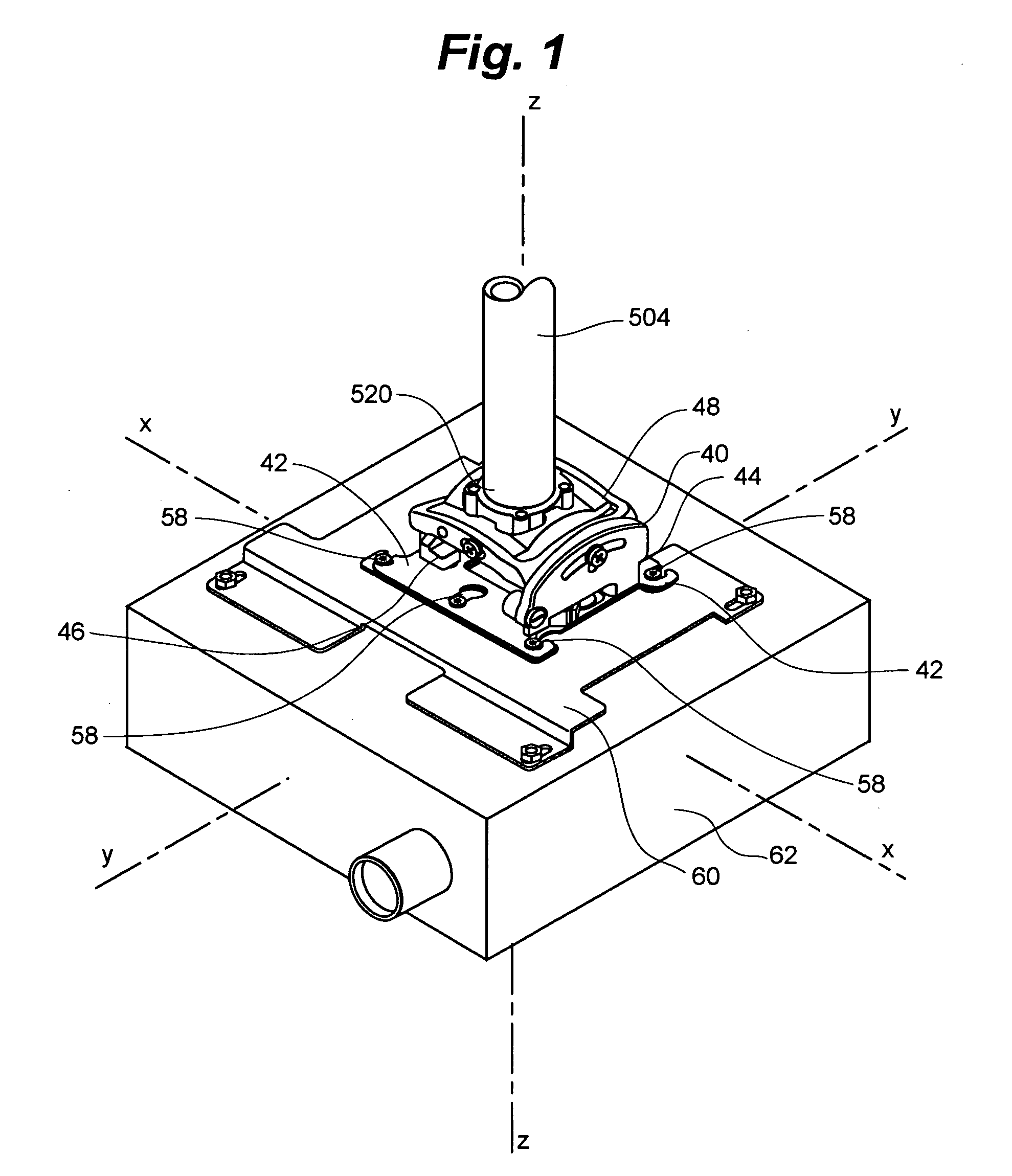

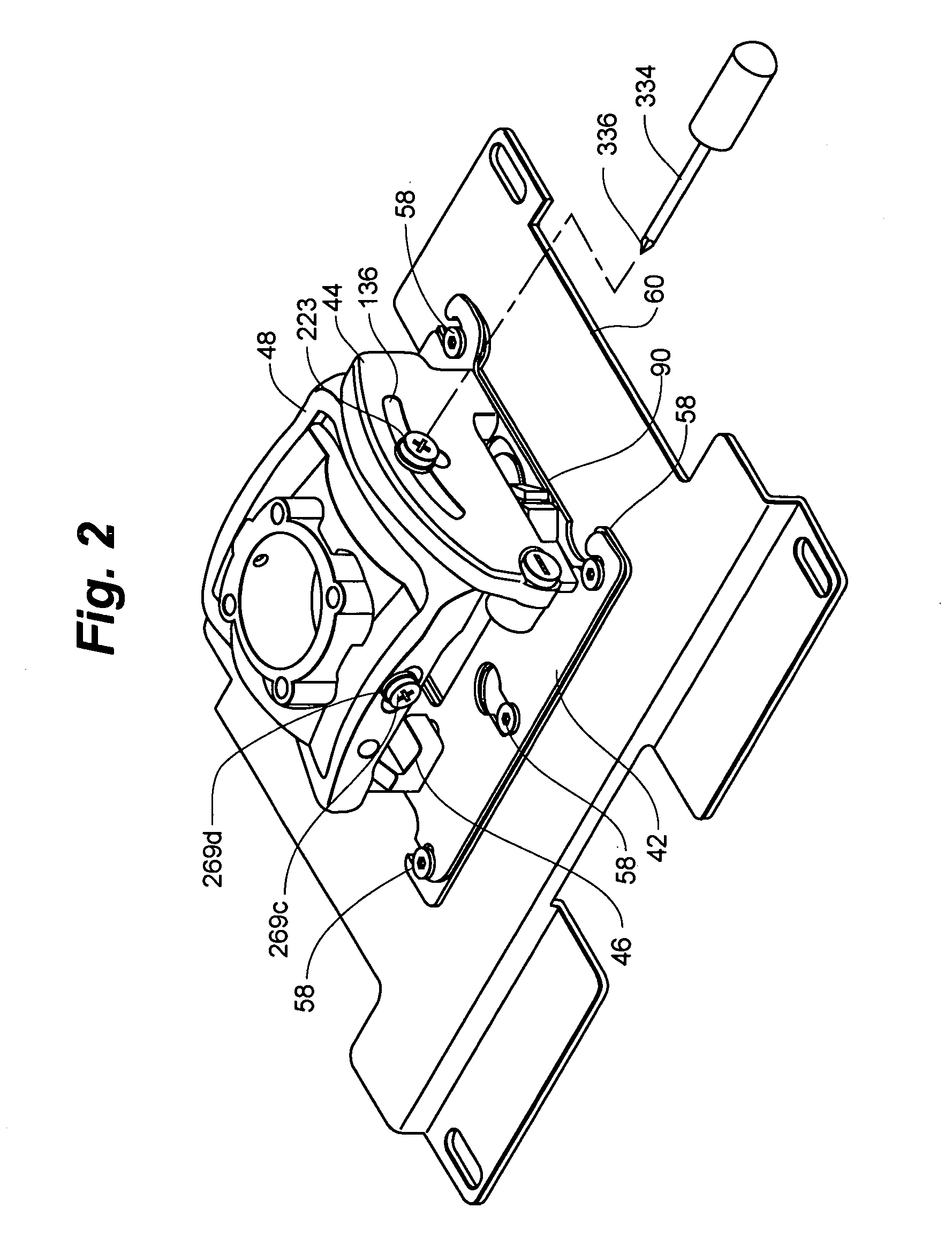

Adjustable projector mount

ActiveUS20070257181A1Quick and easy precision projectorImprove securityPortable framesProjectorsEngineeringGravity center

A mount for attaching a projection device to an overhead structure includes a device interface operably attachable to the projection device and a device orientation adjustment structure operably coupled with the device interface. The device orientation adjustment structure has structure defining up to three independent axes for adjustment of projector pitch, roll, and yaw. A single selectively adjustable friction element may be provided to enable projector position to be fixed about for any one or all of the independent axes. A gear adjustment mechanism may be provided to enable fine adjustment of projector position. Moreover, any one or all of the independent axes may pass through the projector device, preferably proximate its center of gravity so that it is self balanced on the mount to ease adjustment.

Owner:LEGRAND AV INC

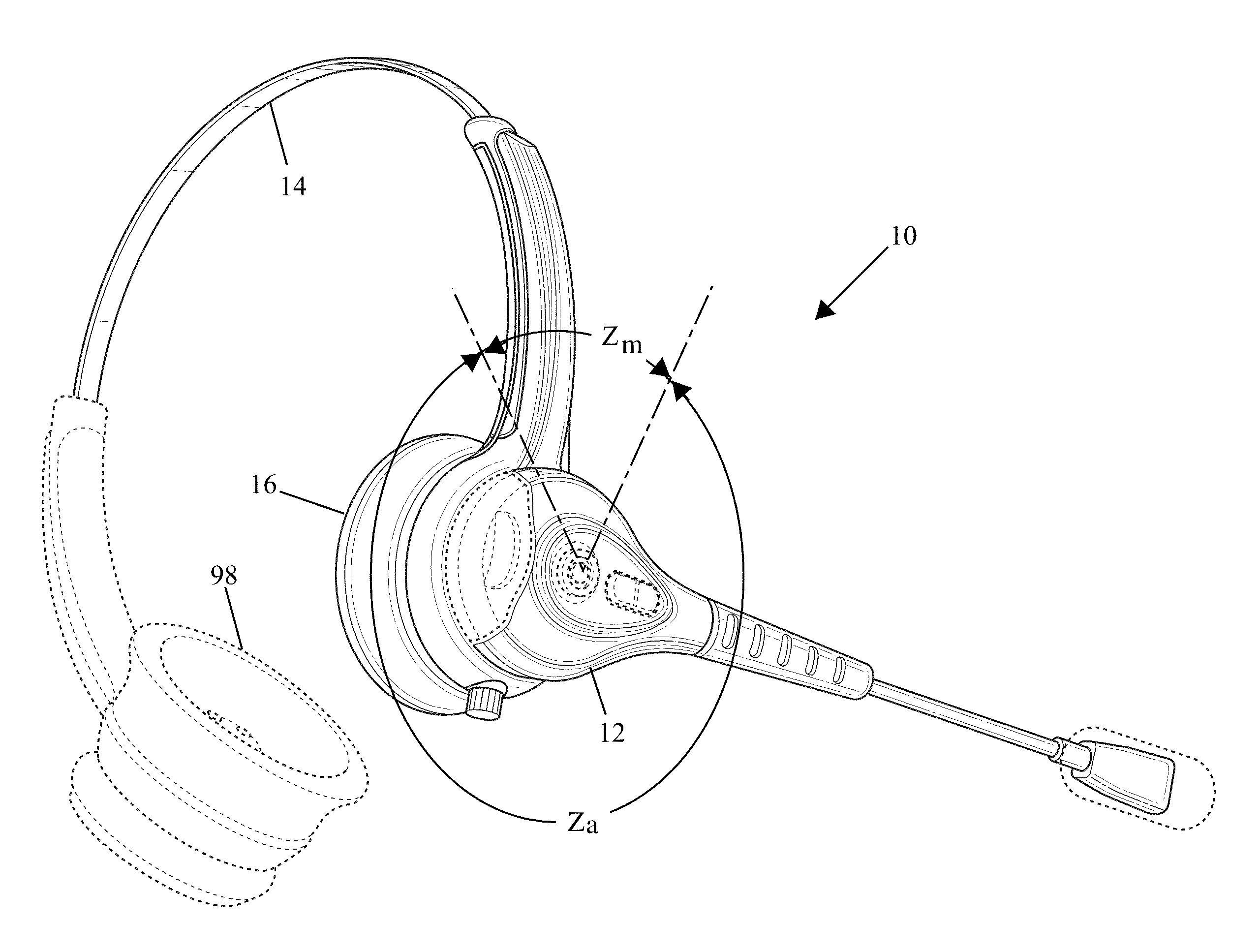

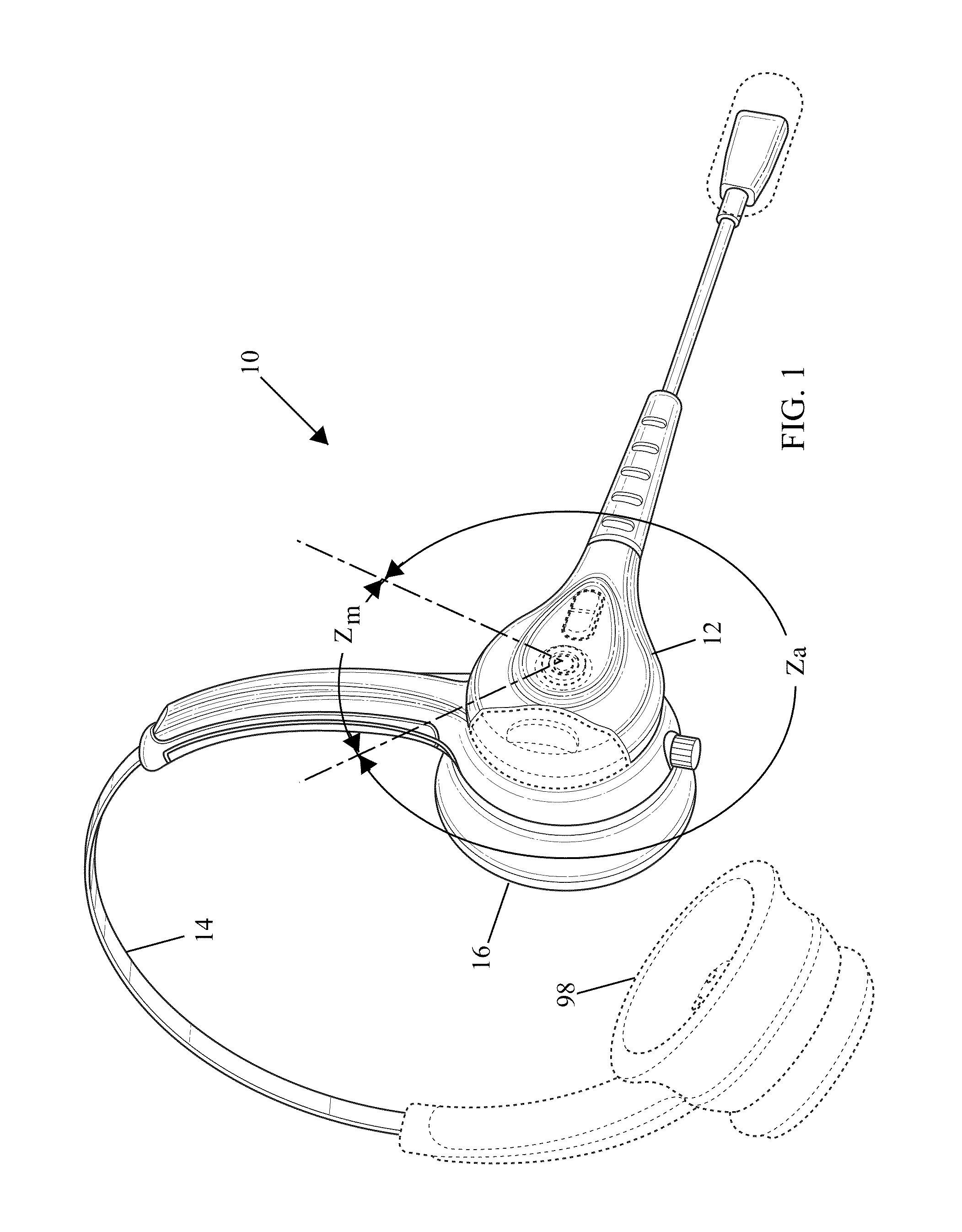

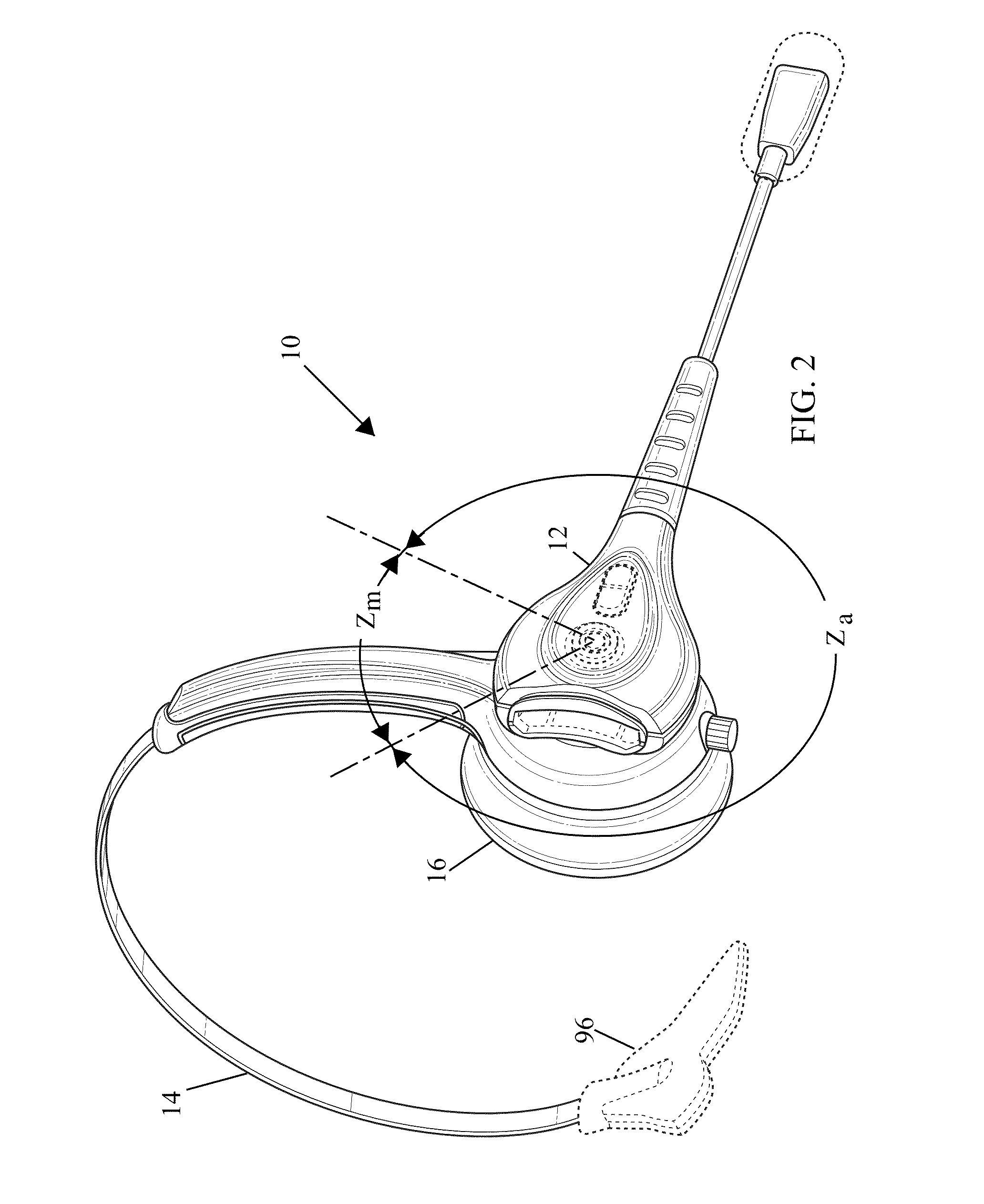

Modular Headset with Pivotable Boom and Speaker Module

ActiveUS20160198254A1Adjustable positionHeadphones for stereophonic communicationSupra/circum aural earpiecesModularityEngineering

A modular headset with a microphone boom module selectively engageable with a headband module. The microphone boom module has a speaker housing, a microphone boom, a microphone retained by the microphone boom, and a speaker retained by the speaker housing. An annular hub projects from the speaker housing, and an aperture is disposed in the headband module for receiving the hub in a pivotable engagement. Positive and negative electrical contact surfaces, such as conductive rings, are disposed over the hub, and electrical contacts project from the aperture to travel along the electrical contact surfaces. The microphone boom module has an active angular zone Za wherein the microphone boom module is active and a mute angular zone Zm. The mute angular zone Zm can include a range of angles encompassing alignment of a longitudinal orientation of the microphone boom module with a plane of the headband.

Owner:GECAWICZ RAYMOND +1

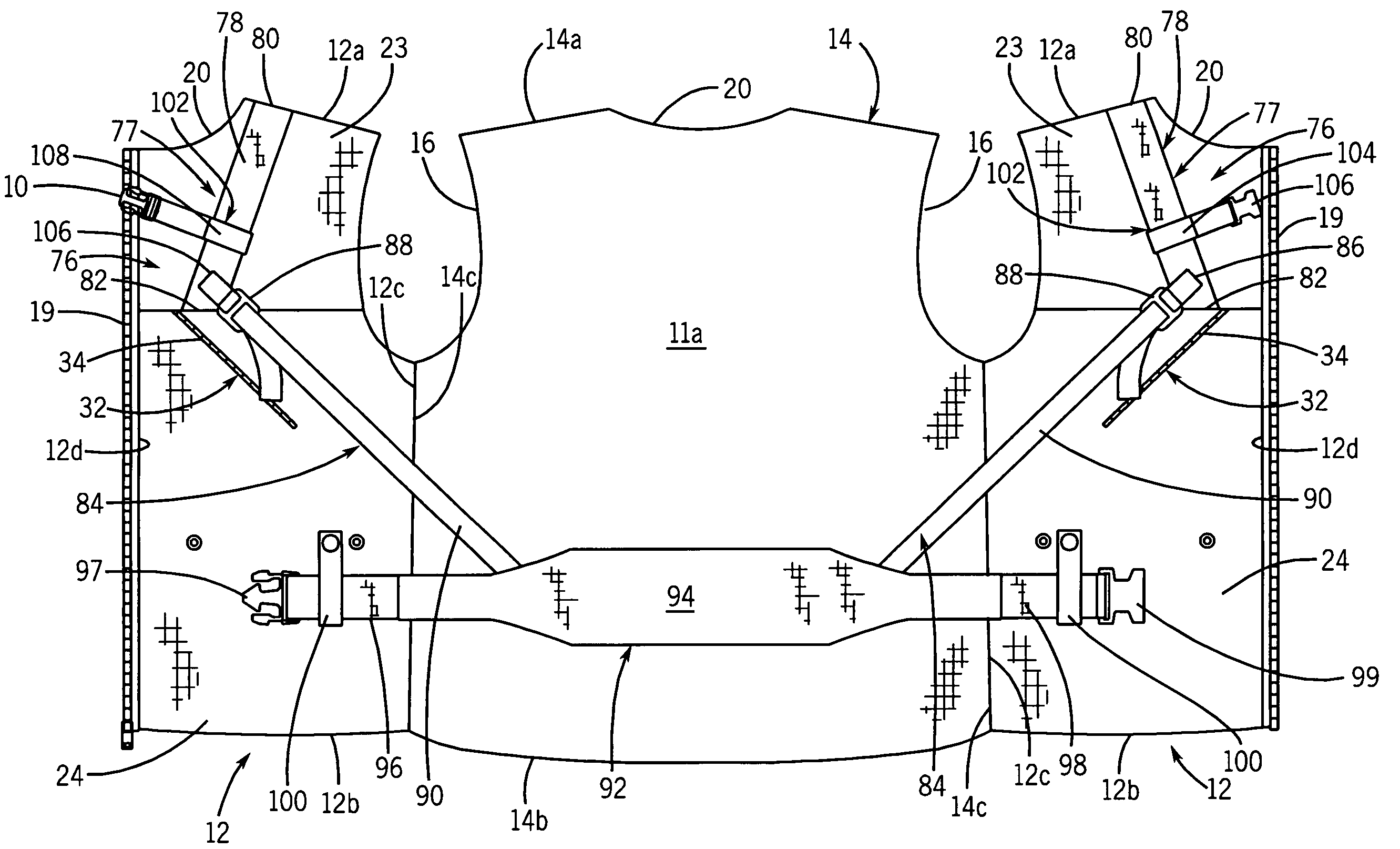

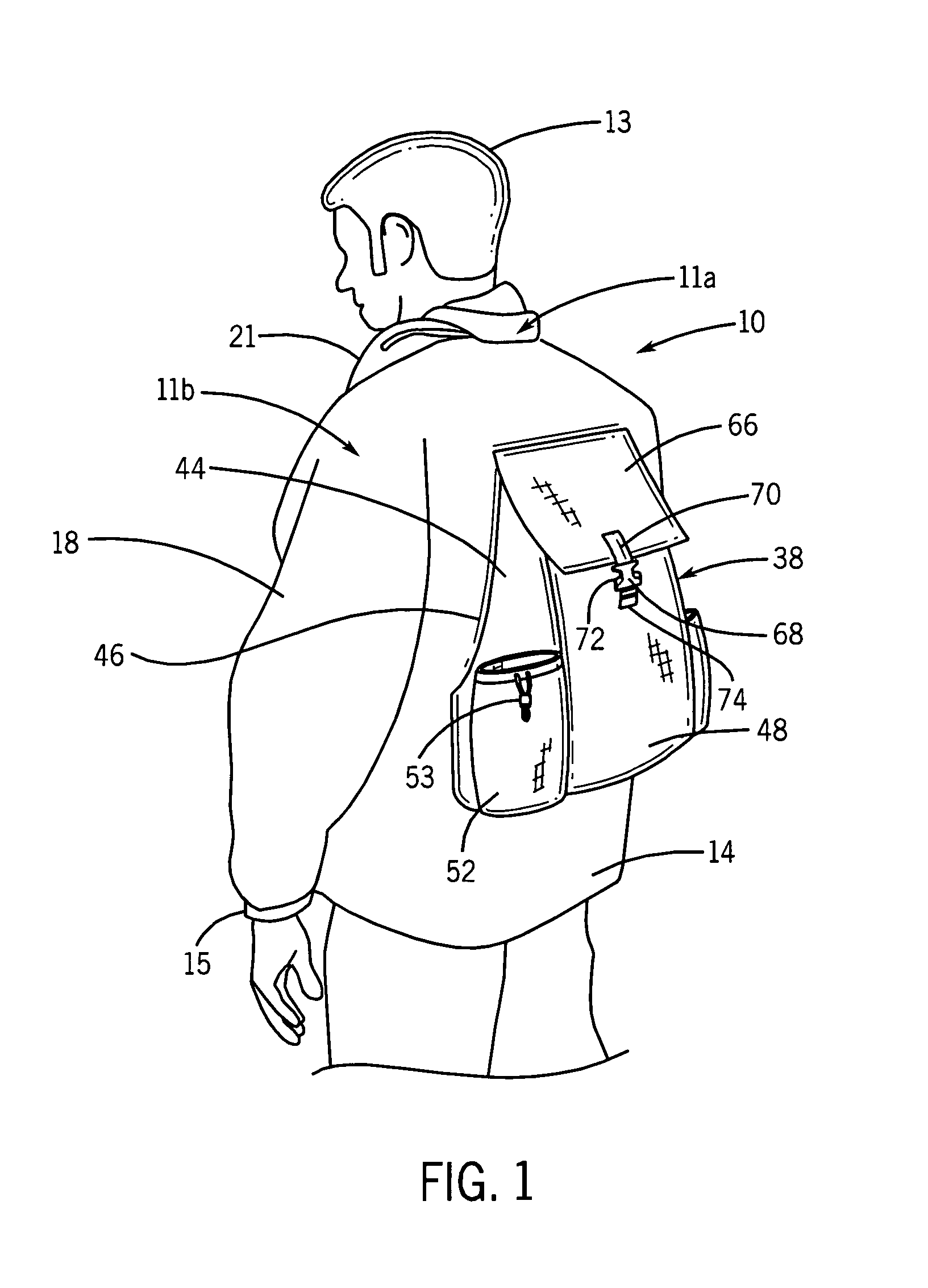

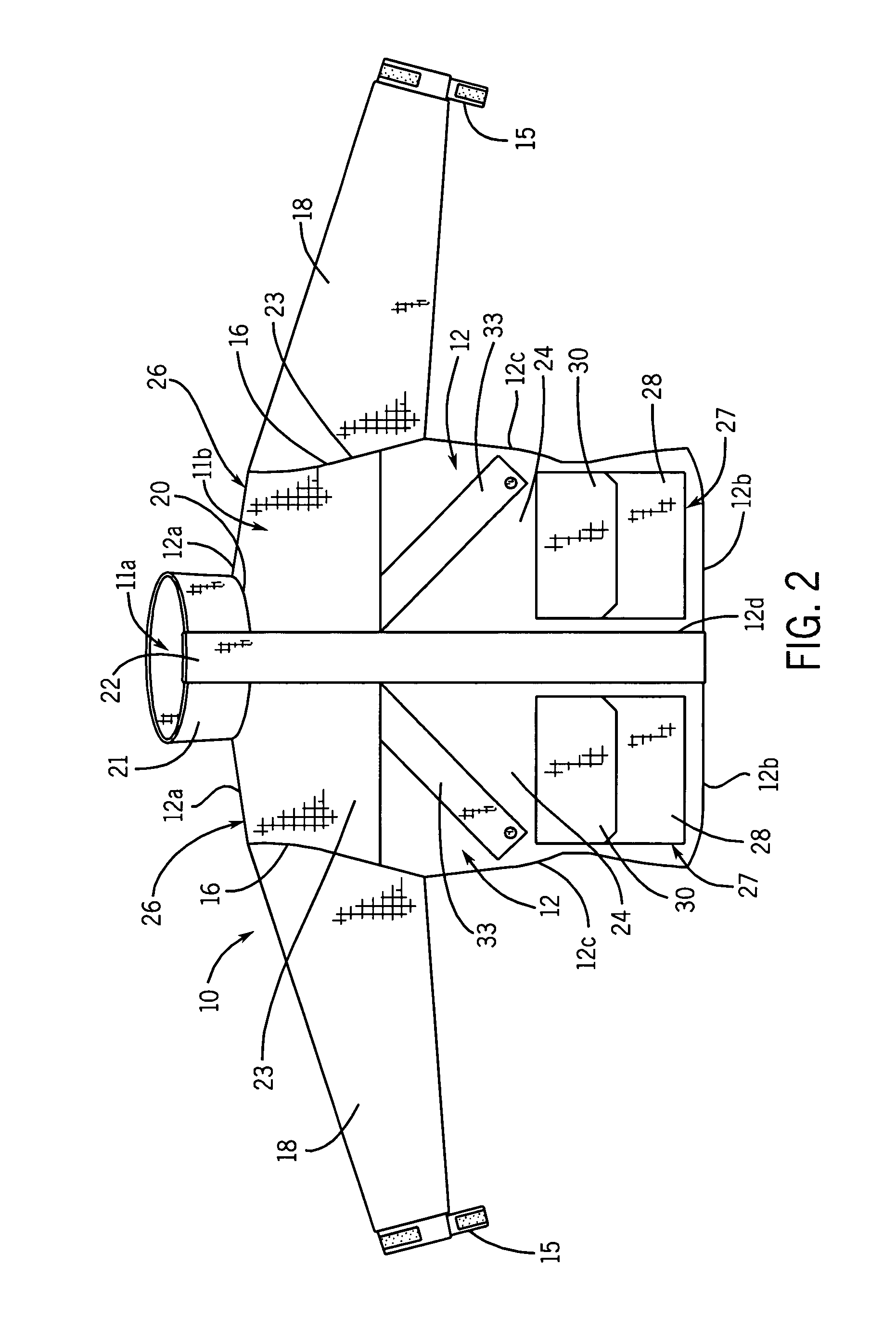

Garment with adjustable weight support mechanism

InactiveUS7000255B1Adjustable positionEasy constructionOvergarmentsProtective garmentEngineeringLow back

A garment including an adjustable weight support mechanism used to shift the weight and position of objects contained within pockets disposed on the garment is provided. The garment has a number of pockets including a storage pouch releasably attached to the rear of the garment. The support mechanism is attached to the garment and includes a pair of strap assemblies which extend from the shoulders of the garment downwardly towards the bottom of front and rear panels forming the garment. The first strap of each assembly is connected between the shoulder of the garment and the front panel. The second strap assembly is connected between the rear panel and the first strap, and is adjustable in length. When the second strap is pulled to shorten the length of the second strap, the second strap pulls the first strap downwardly and forwardly to pull the shoulders and rear panel of the garment upwardly and move the weight contained in the storage pouch upwardly onto the shoulders of the wearer of the garment, and off of the lower back.

Owner:BAACKE DENNIS R

Working device setted on one place and engineering machinery using it

InactiveCN1831253AShorten the timeImprove operational skillsMechanical machines/dredgersVehiclesState of artEngineering

The invention is a working device arranged in some place, composed of two or above working devices arranged in some place, back-to-back, side-arranged, opposite, staggered, side-by-side, up and down, rotatable, inclinable, turnable, movable, liftable or in other form. And an engineering machine applying it is composed by arranging it in corresponding position on a corresponding vehicle or chassis or connecting it with the correspond position. And it can compose various engineering machines by various vehicles or chassises, compact, multifunctional, low-cost, high-efficiency and energy-saving, and having strong practicality.

Owner:姚实现

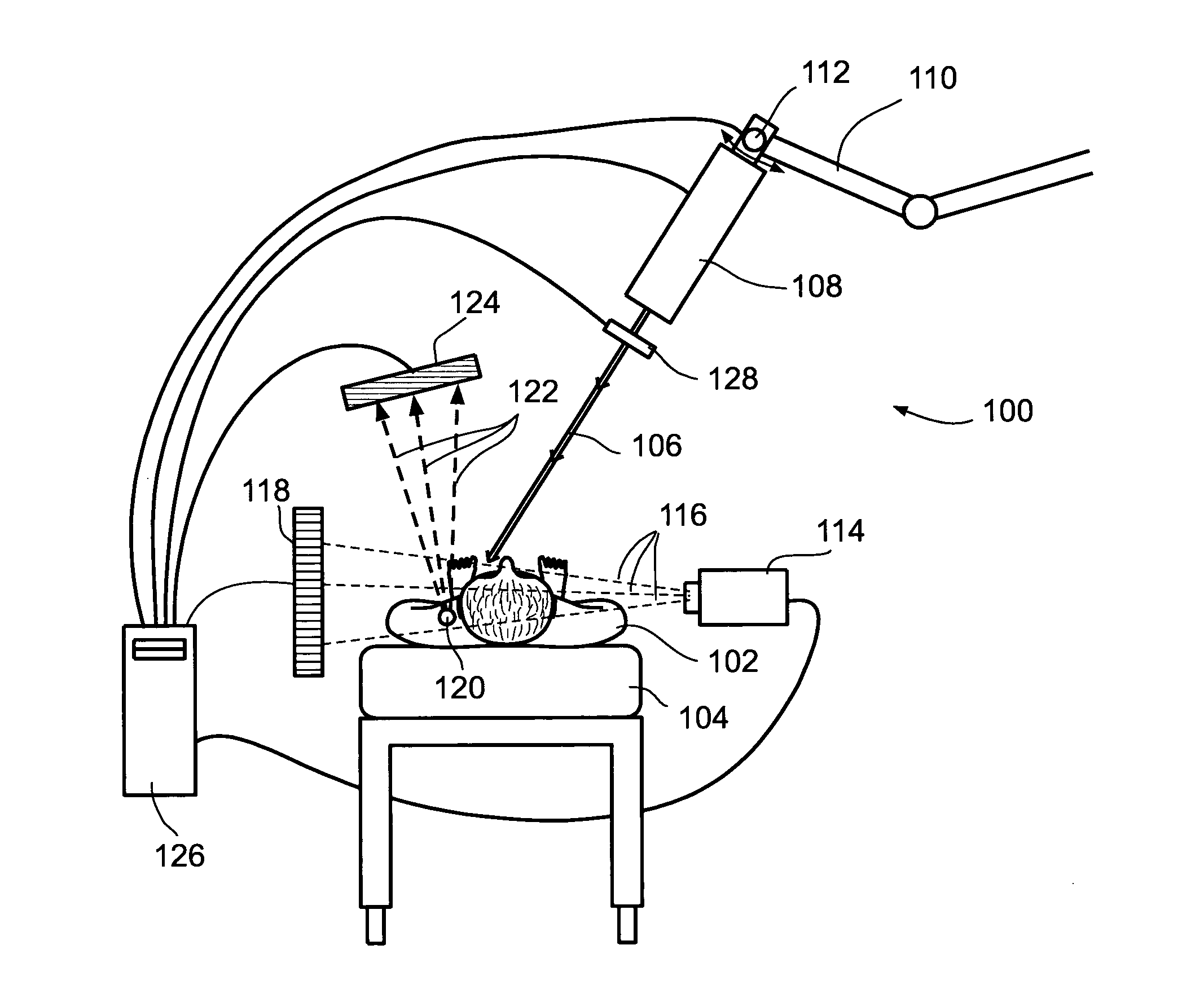

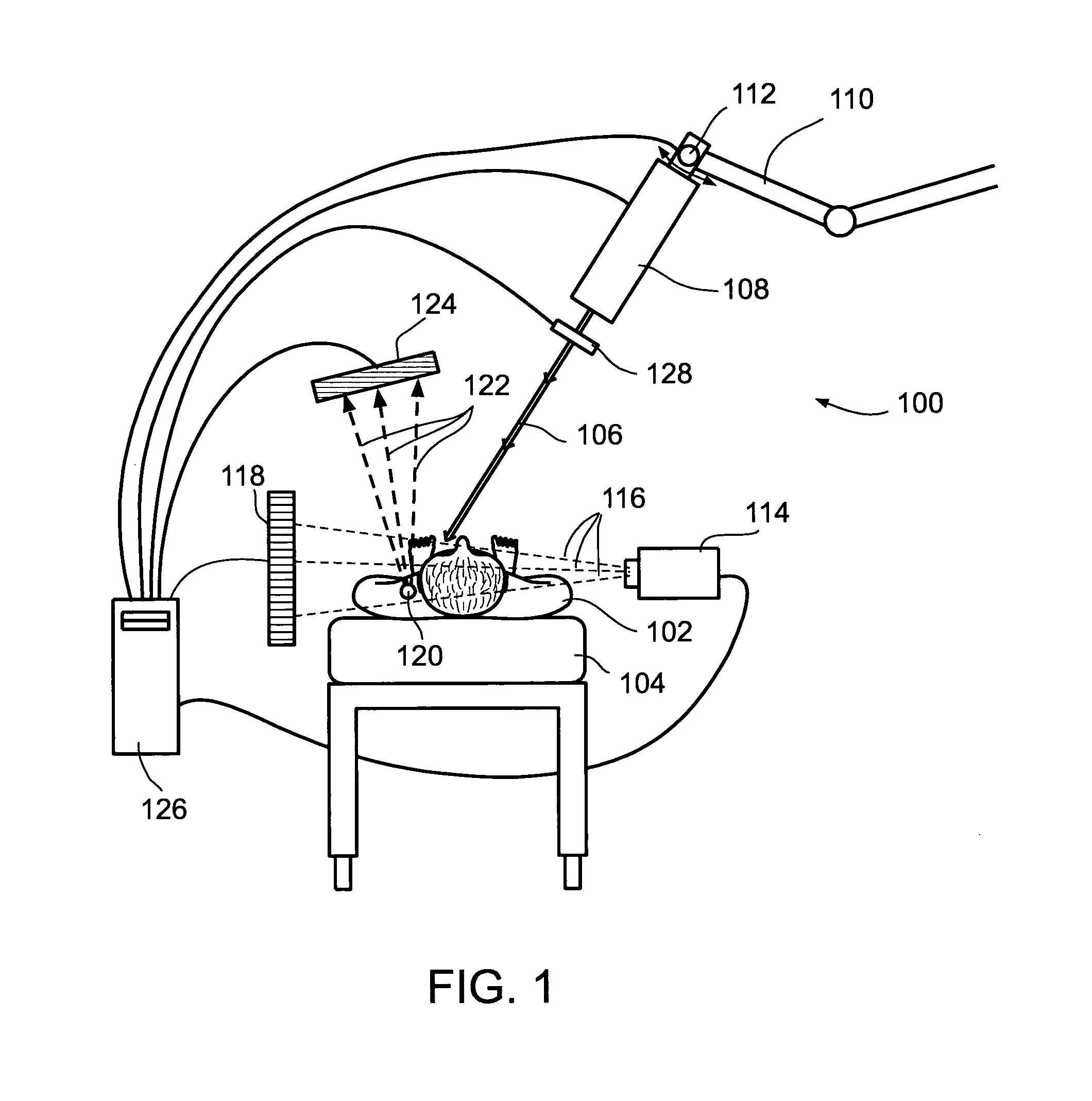

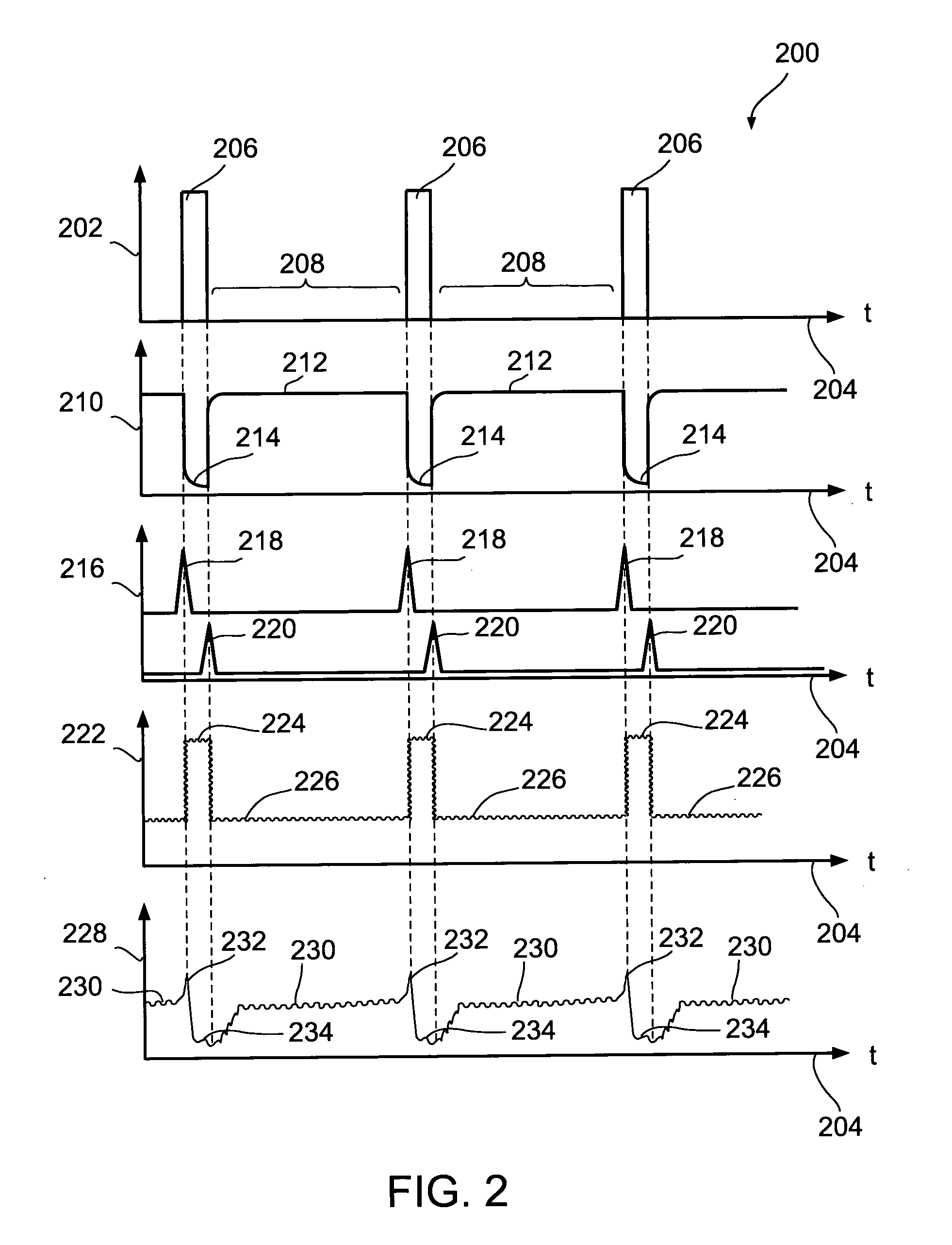

Detecting photons in the presence of a pulsed radiation beam

InactiveUS20110006212A1Reduces and avoids interferenceReduce sensitivityMaterial analysis using wave/particle radiationSurgeryPulse beamBeam source

A detector system adapted for monitoring a radiation treatment system comprising a pulsed beam radiation source for treating a body with a given beam intensity and beam configuration, with pulse times and intervals between pulses less than 100 milliseconds, using at least one monitoring radiation source located inside or outside the body, the detector system comprising; a) a detector designed to detect radiation from the monitoring source, and subject to interference radiation from the beam source; and b) control circuitry that creates a data record of radiation received by the detector, to provide information about the body; wherein, when the detector detects radiation in real time during operation of the beam, the data record selectively excludes data for radiation received by the detector during the pulses, as opposed to data for radiation received by the detector between pulses.

Owner:NAVOTEK MEDICAL

Intraocular lens implanting device

ActiveUS8460311B2Safely and reliably inserted into eyeballAdjustable positionEye treatmentIntraocular lensMedicineIntraocular lens insertion

An intraocular lens implanting device capable of inserting an intraocular lens surely in safety into an eyeball and having an ophthalmic hooking function capable of adjusting the position of the intraocular lens. The intraocular lens implanting device for inserting an intraocular lens into an eyeball through an incision in the eyeball tissue comprises a tubular main body, a storage part for the intraocular lens integrated with the main body or separated therefrom, and a plunger for pressing the intraocular lens placed in the containing section and discharging it into the eyeball, wherein the distal end of the plunger has a base part and a protuberance.

Owner:HOYA CORP

Directional coupler

ActiveUS20050040912A1Tight manufacturing toleranceAdjustable positionMultiple-port networksWaveguidesEngineeringElectrical and Electronics engineering

A directional coupler uses non-metallic slotted spacers at the edges of a pair of coupled lines. The spacers are adjustable in their vertical position and thereby provide continuous coupling fine-adjustment. The spatial relationship between the coupled lines is therefore adjustable and does not depend upon extremely tight manufacturing tolerances.

Owner:RPX CORP

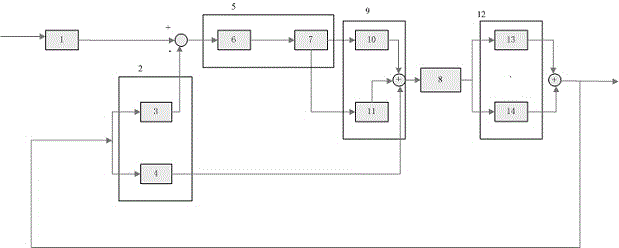

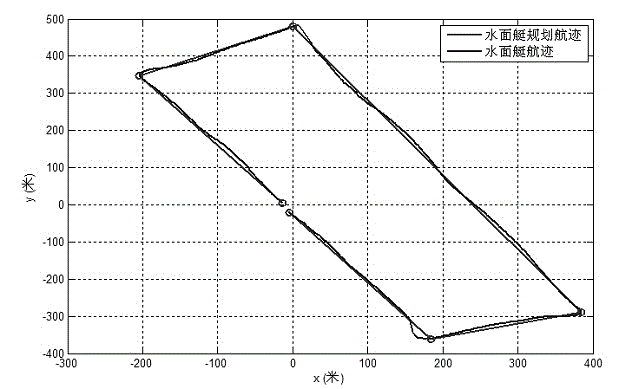

Unmanned surface vehicle trajectory tracking control device and method based on nonlinear control theory

ActiveCN103955218AGuaranteed uptimeReduce consumption costPosition/course control in two dimensionsState variablePath generation

The invention provides an under-actuated unmanned surface vehicle self-adaptive trajectory tracking control device and method. The device comprises a reference path generator, a state sensor, a differential converter, a parameter estimator, a virtual controller and a longitudinal thrust and bow steering torque controller. According to the unmanned surface vehicle actual position and course angle collected by the state sensor (2) and the reference position and reference course angle information generated by the reference path generator (1), the new state variable is obtained through the differential converter (5), the new state variable and the speed and angle speed information collected by a sensor (4) are transmitted to the parameter estimator (8) and the longitudinal thrust and bow steering torque controller (12), a control instruction is obtained through calculation to drive an execution mechanism, and the longitudinal thrust and bow steering torque of an unmanned surface vehicle are adjusted. According to the device and method, the unmanned surface vehicle can reach the specific position within specific time at specific speed. Due to the under-actuated unmanned surface vehicle, energy consumption and manufacturing cost of a system can be lowered, and the weight of the system is reduced.

Owner:精海智能装备有限公司

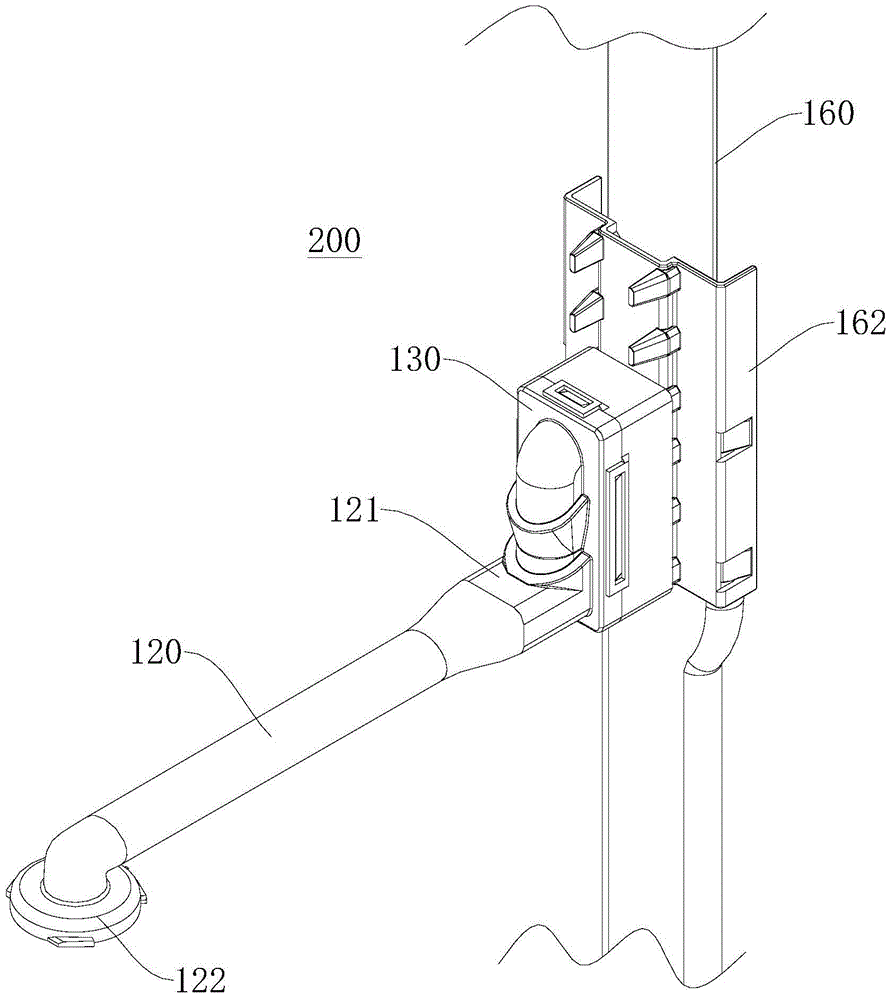

Spray arm water pipe assembly of dish-washing machine and dish-washing machine provided therewith

PendingCN105231971AAdjustable positionImprove comfortTableware washing/rinsing machine detailsEngineeringWater pipe

The invention discloses a spray arm water pipe assembly of a dish-washing machine and a dish-washing machine provided therewith. The spray arm water pipe assembly of the dish-washing machine comprises a water regulator and a spray arm water pipe. One end of the spray arm water pipe is connected with the water regulator. The other end of the spray arm water pipe is used for being connected with a spray arm. Multiple water inlets are arranged on the water regulator at intervals. The water regulator is provided with a reversing device which is used for one of the multiple water inlets at most and communicated with the spray arm water pipe. The spray arm water pipe assembly of the dish-washing machine and the dish-washing machine provided therewith have following beneficial effects: the multi-step adjustment of the position of the spray arm water pipe assembly of the dish-washing machine is achieved; and the use of comfort is enhanced.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

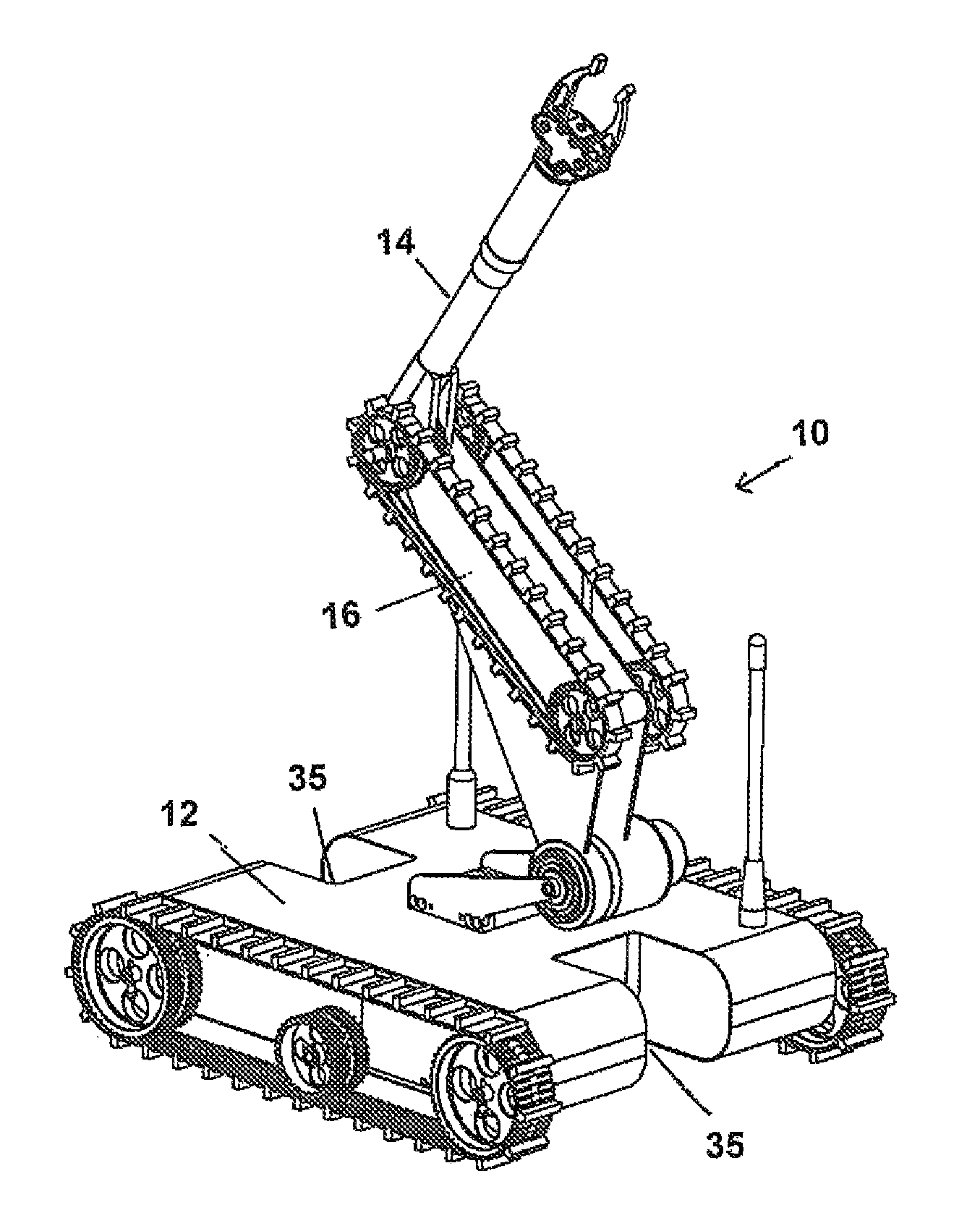

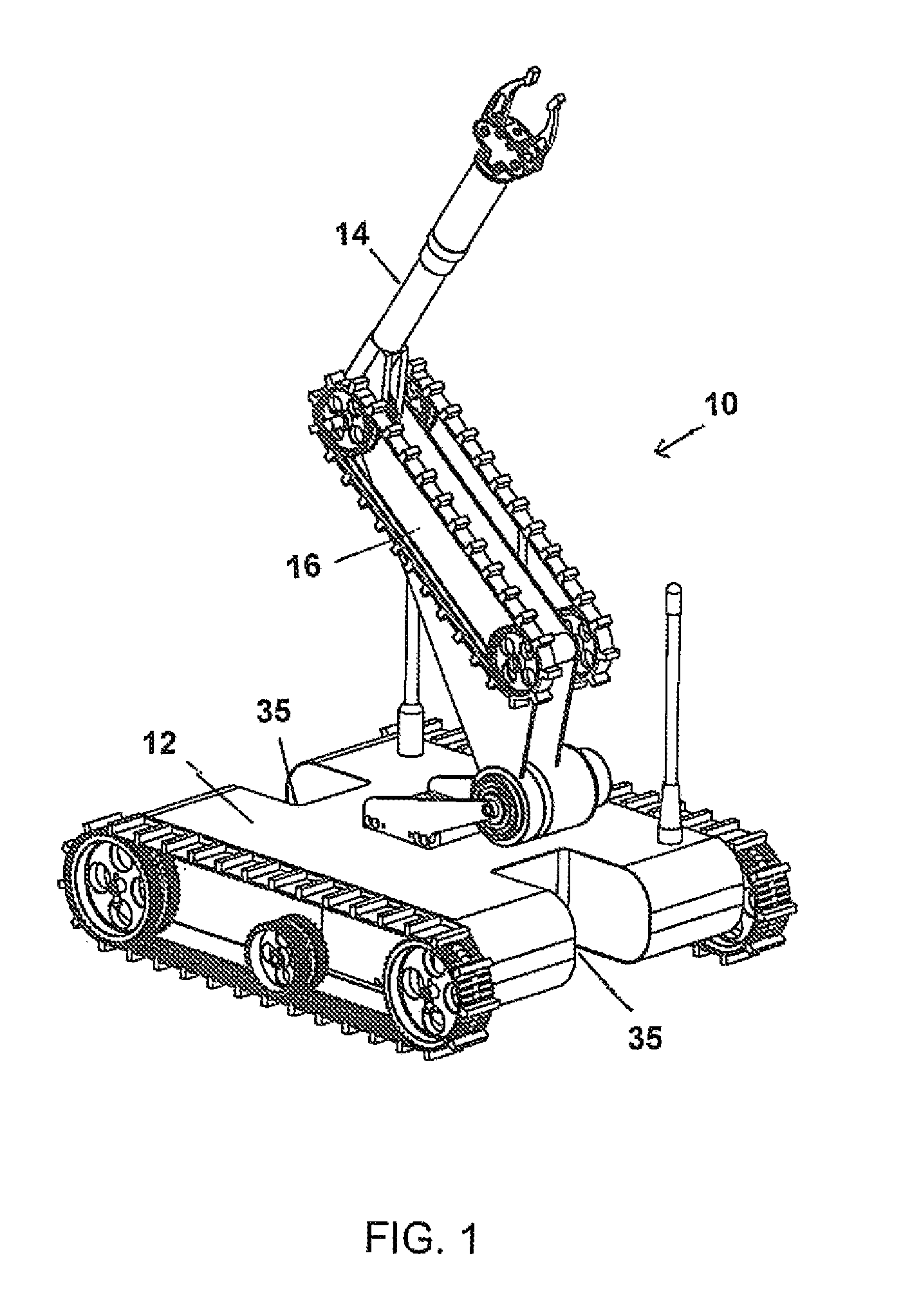

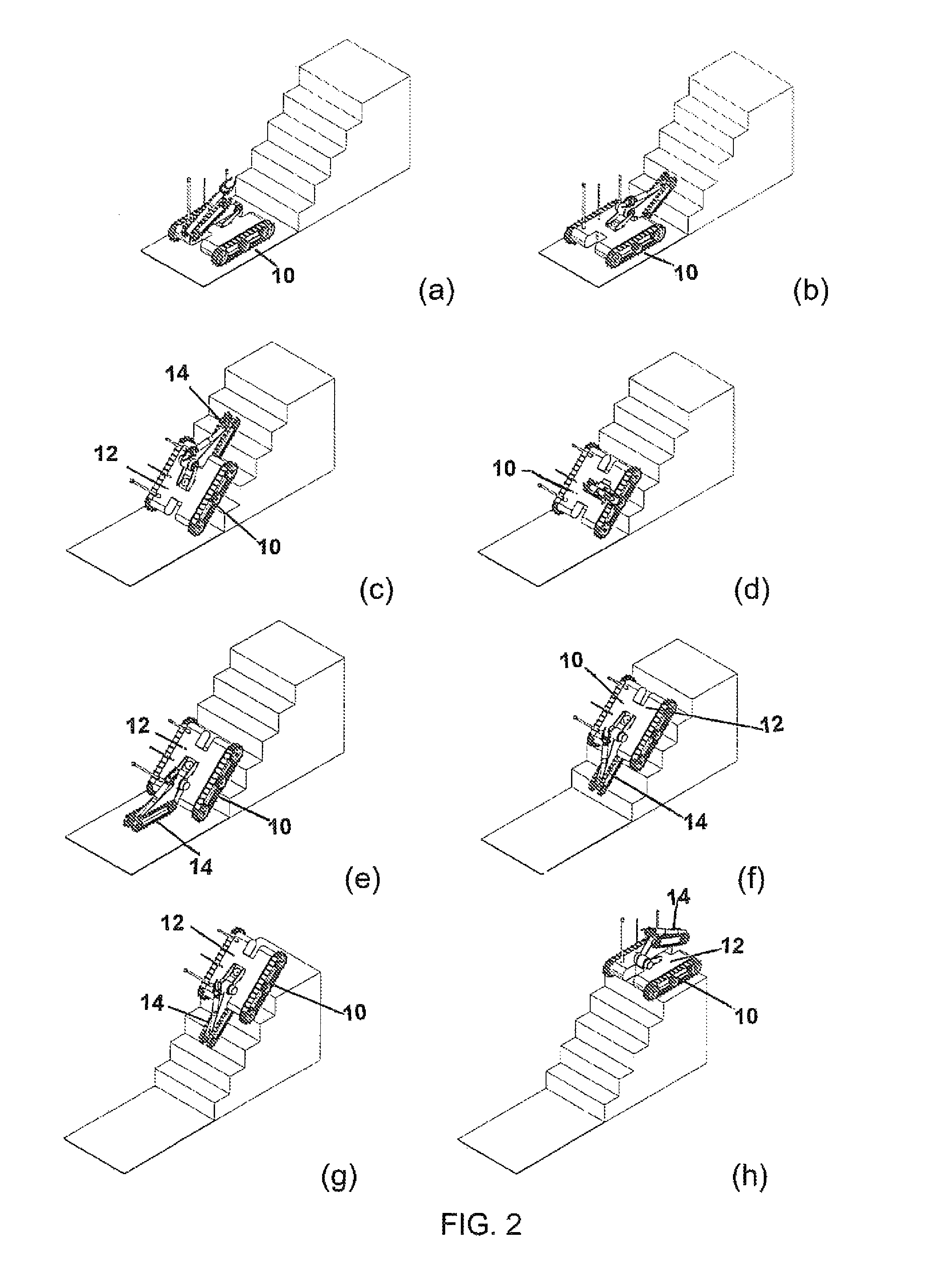

Mobile robot

ActiveUS8360178B2Improve abilitiesEasy to trackCarriage/perambulator accessoriesMechanical apparatusEngineeringManipulator

The mobile robot includes a chassis, a pair of drive system, a manipulator arm with a turret. The pair of drive systems is operably connected to opposed sides of the chassis. The turret is rotationally attached to the platform. The first link of the manipulator arm is attached to the turret at a first joint. The manipulator arm has at least a first link, and the first link is adapted to function as a traction device.

Owner:CHINA SUPERROBOTICS LTD

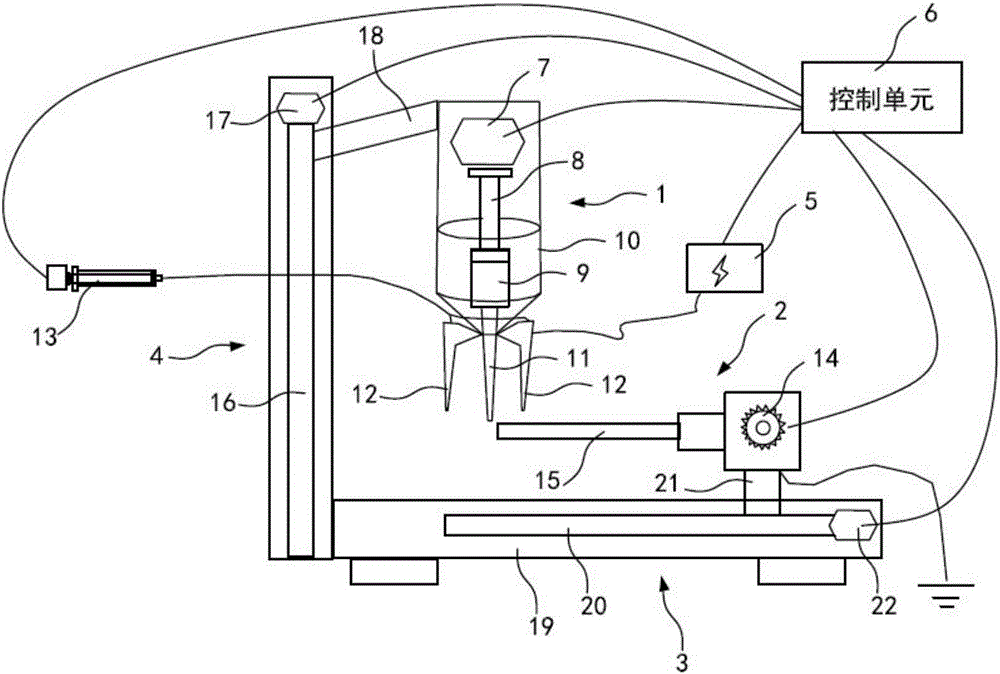

Device for manufacturing artificial blood vessel through combination of bio-printing and electro-spinning technologies

InactiveCN106012052AAdjustable positionStentsAdditive manufacturing apparatusRelative displacementMotor control

The invention discloses a device for manufacturing an artificial blood vessel through combination of bio-printing and electro-spinning technologies. The device comprises a material release unit, a rotary receiving unit, a horizontal moving platform, a vertical moving platform, a high-voltage power supply and a control unit, wherein the rotary receiving unit is located below the material release unit and comprises a rotary motor and a receiving rod; the rotary motor can drive the receiving rod to conduct rotary operation. The device has the following benefits: during operation, when the material release unit uses a bio-printing nozzle, a first stepping motor controls an extrusion pump to extrude out a cell-containing hydrogel material in a storage tank, and the extrusion pump can realize setting and controlling of the material release speed and quantity by the control unit; the vertical moving platform controls relative displacement of the whole material release unit to the rotary receiving unit, and can conduct vertical up-and-down displacement (such as 0.1 mm, 0.5 mm, 5 mm and continuous displacement), the displacement can be adjusted according to the extrusion requirement, and the distance between the bio-printing nozzle and the rotary receiving unit is adjusted through the displacement; the bio-printing nozzle and electro-spinning nozzles can work simultaneously or alternately, which is adjusted by the control unit according to actual demands.

Owner:THE SECOND HOSPITAL AFFILIATED TO SUZHOU UNIV

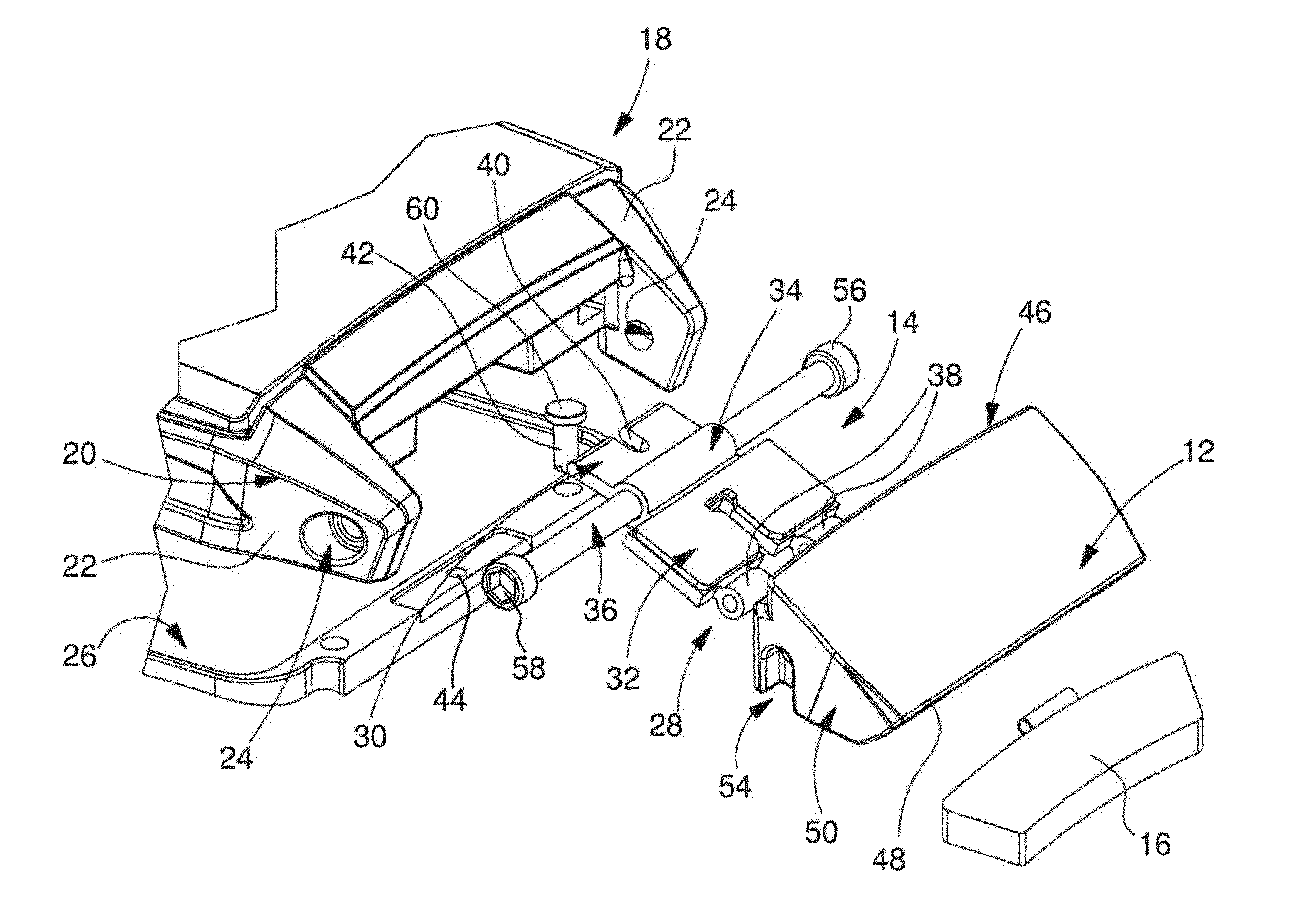

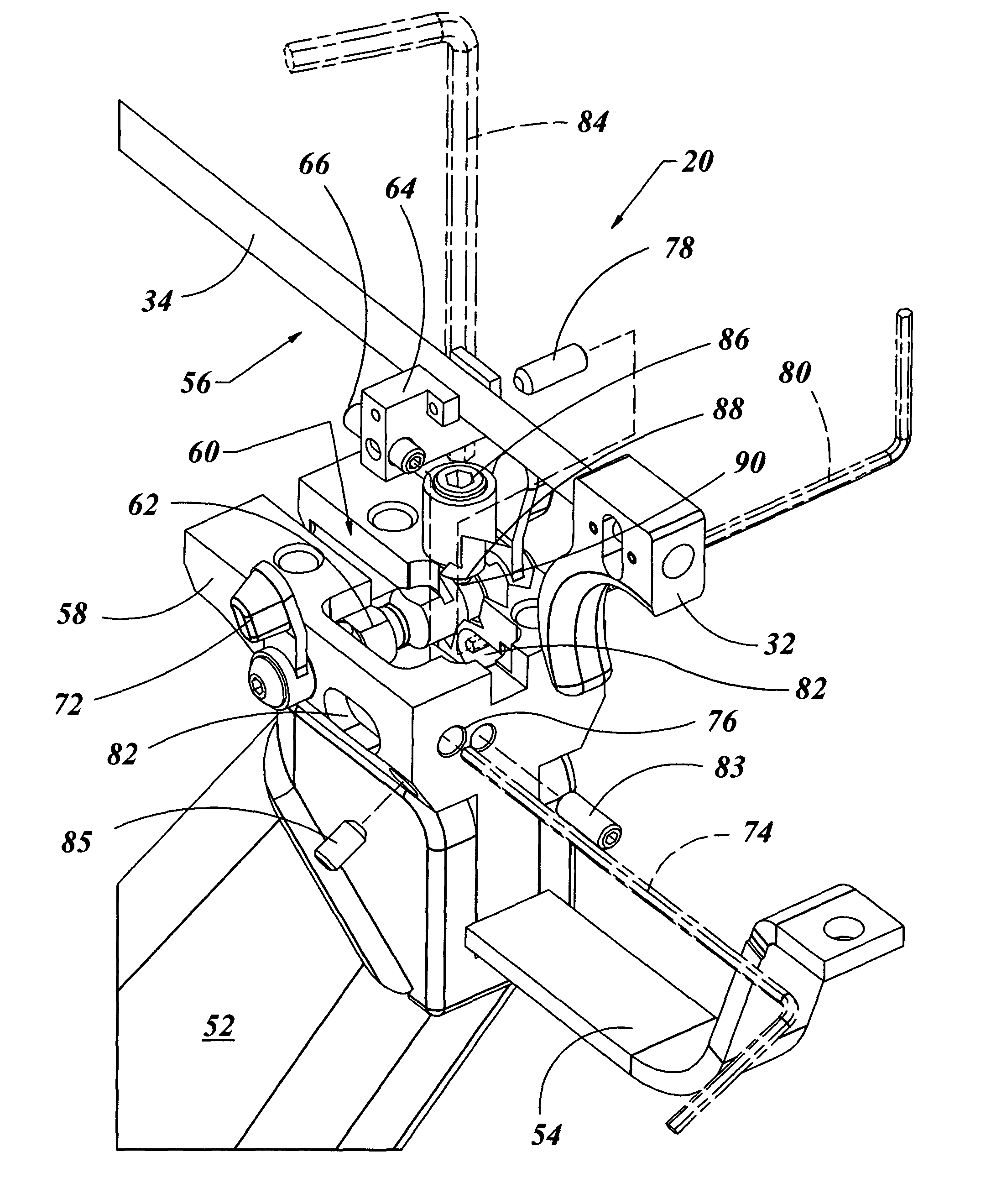

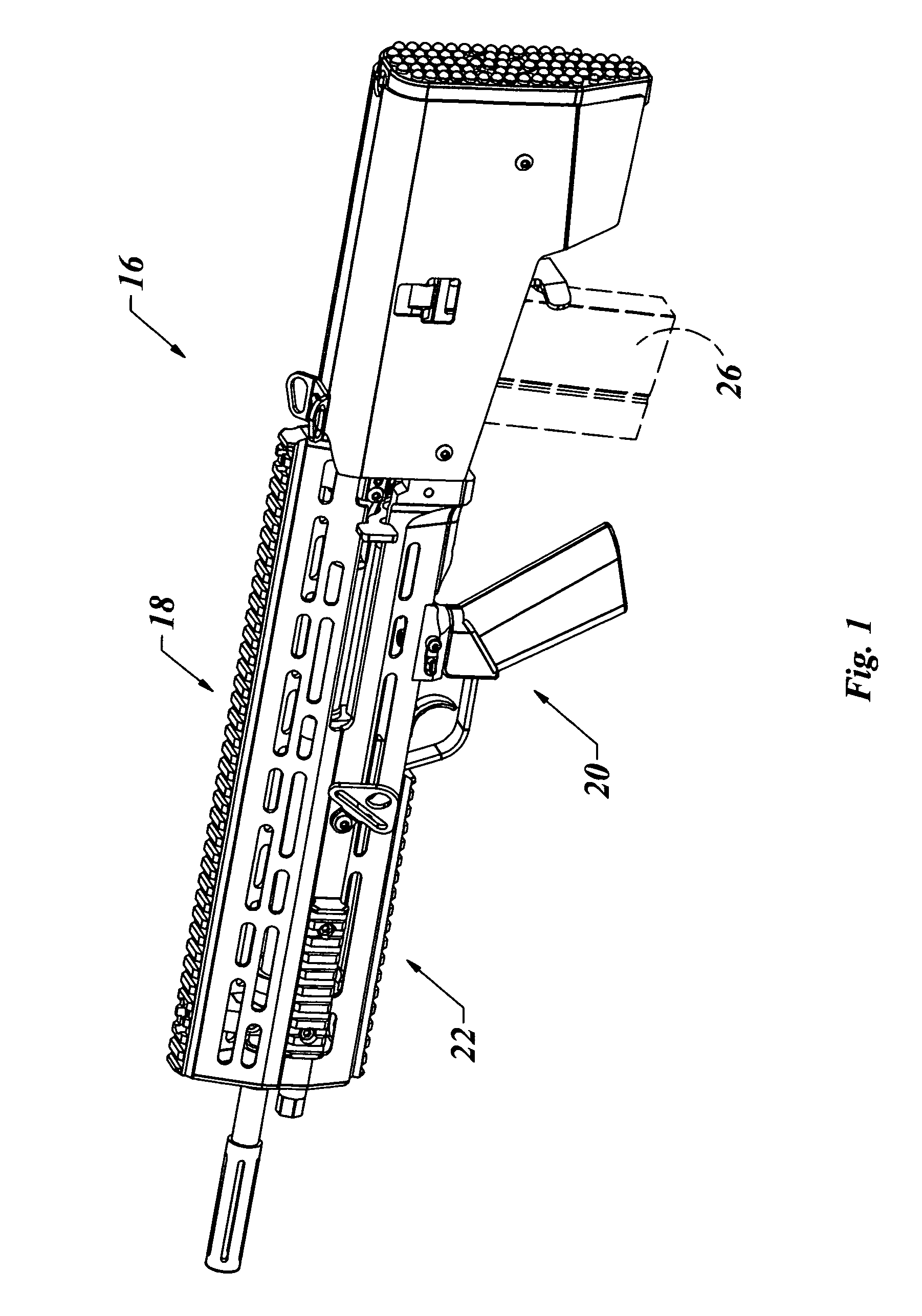

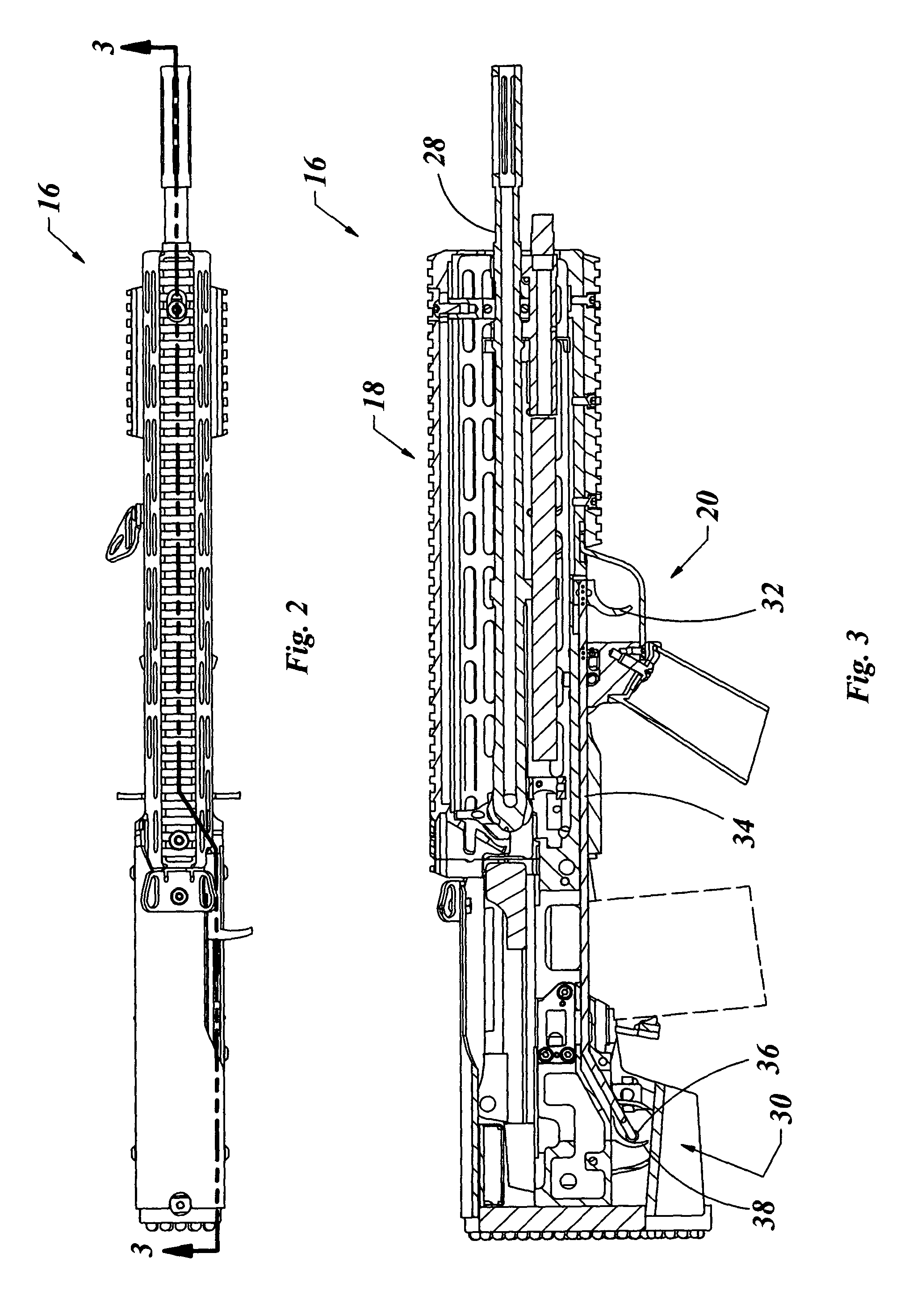

Replacement stock system for rifle

InactiveUS8931393B1Significant riskAdjustable positionSafety arrangementFiring/trigger mechanismsEngineeringLocking plate

A trigger assembly group of the type used with a rifle stock replacement system is provided. The trigger assembly group and may include a trigger assembly, including a trigger coupled to a trigger rod, a locking plate coupled to the trigger rod and a preload cylinder coupled to the locking plate. This in combination with the firing elements of the existing rifle may comprise a firing control mechanism. The trigger assembly group may also include a trigger block with a recess adapted to receive the trigger rod and the locking plate. A safety spool may be a part of the trigger assembly group and include a cross hole, which may be adapted to receive the preload cylinder when the safety spool is in a first position and not receive the preload cylinder when the safety spool is in a second position.

Owner:VINCENT JEFF +1

Head mounted display and optical position adjustment method of the same

ActiveUS20140347252A1Improve responseSmall sizeInput/output for user-computer interactionCathode-ray tube indicatorsMedicineComputer graphics (images)

Disclosed herein is an optical position adjustment method of a head mounted display, the head mounted display including (a) an eyeglass type frame worn on the head of a viewer, and (b) two image display devices for the right and left eyes attached to the frame, and each of the image display devices including (A) an image forming device, and (B) an optical device adapted to receive, guide and emit light emitted from the image forming device, wherein the optical position adjustment method includes the step of: controlling an image signal that is supplied to the image forming device making up at least one of the image display devices so as to control the position of the image displayed on the optical device making up at least one of the image display devices and adjust the mutual positions of the two images.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com