Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

331 results about "Pulse beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

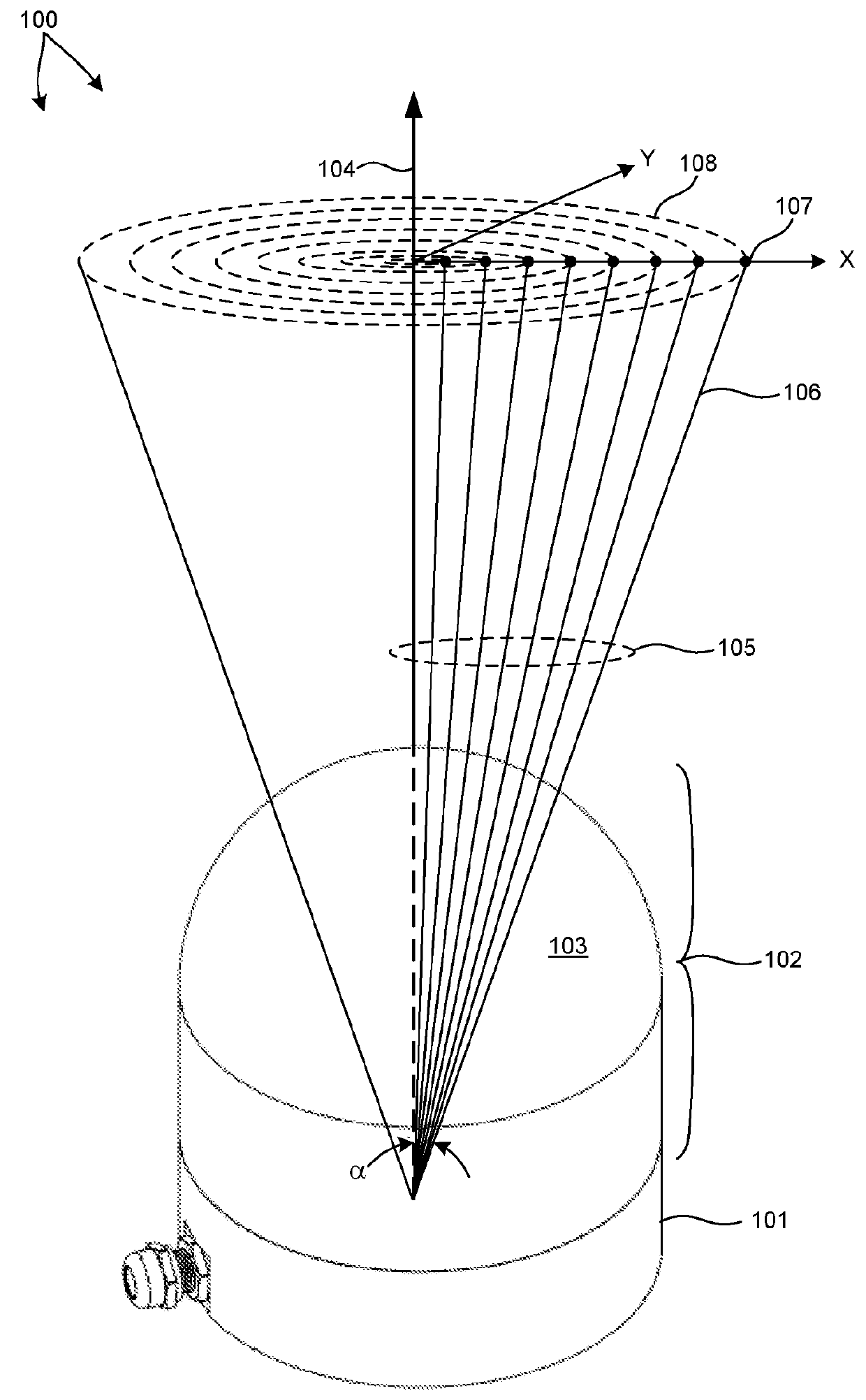

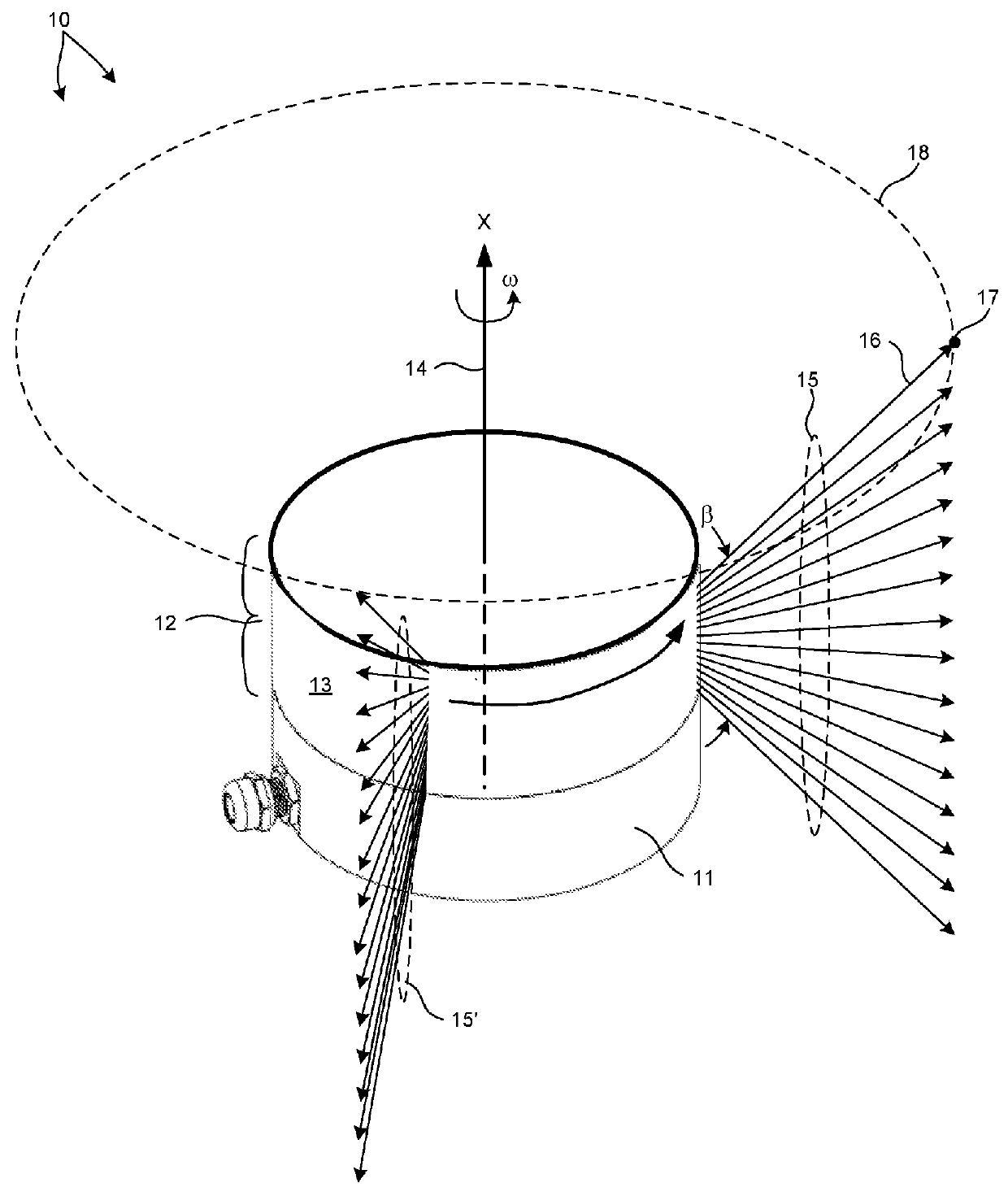

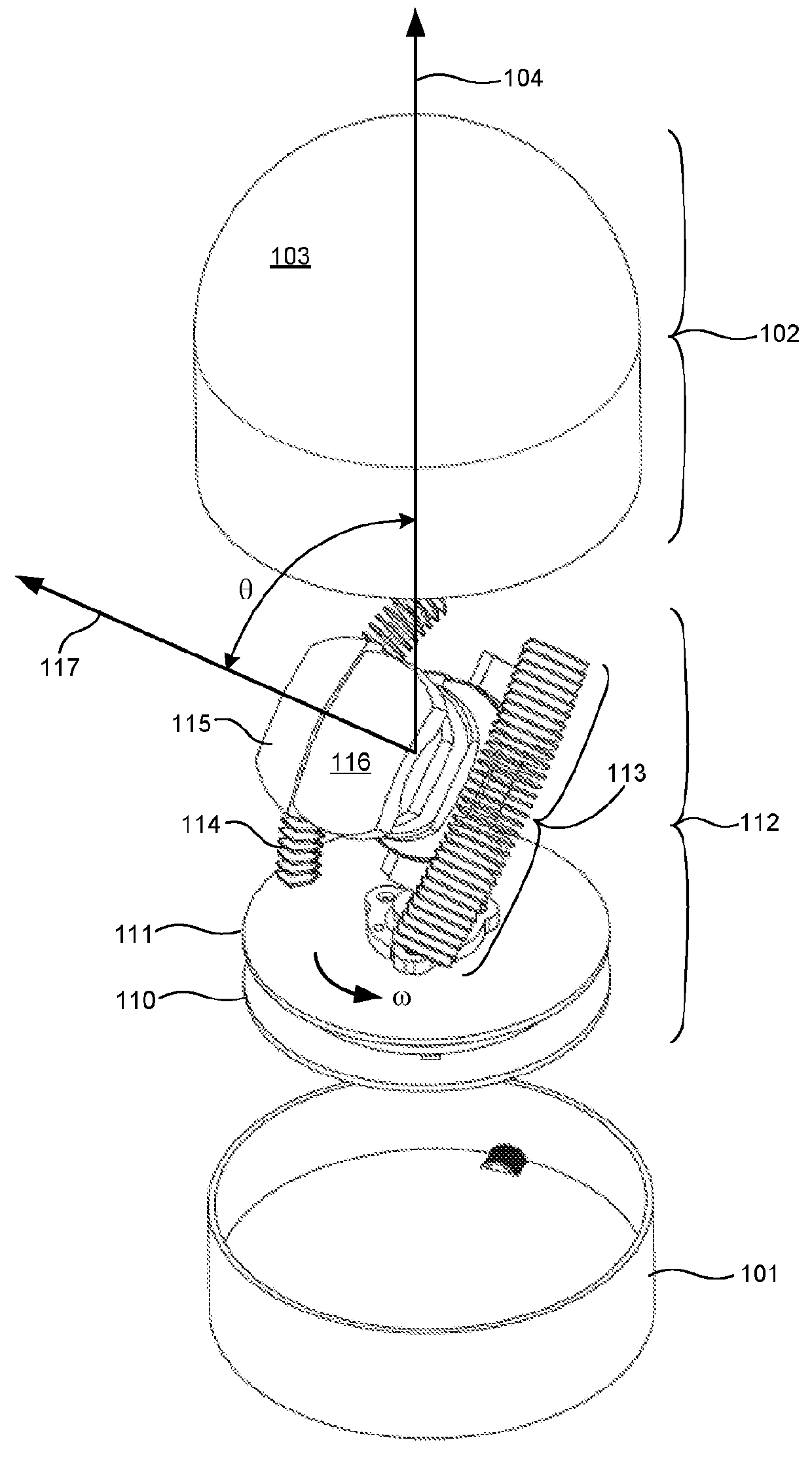

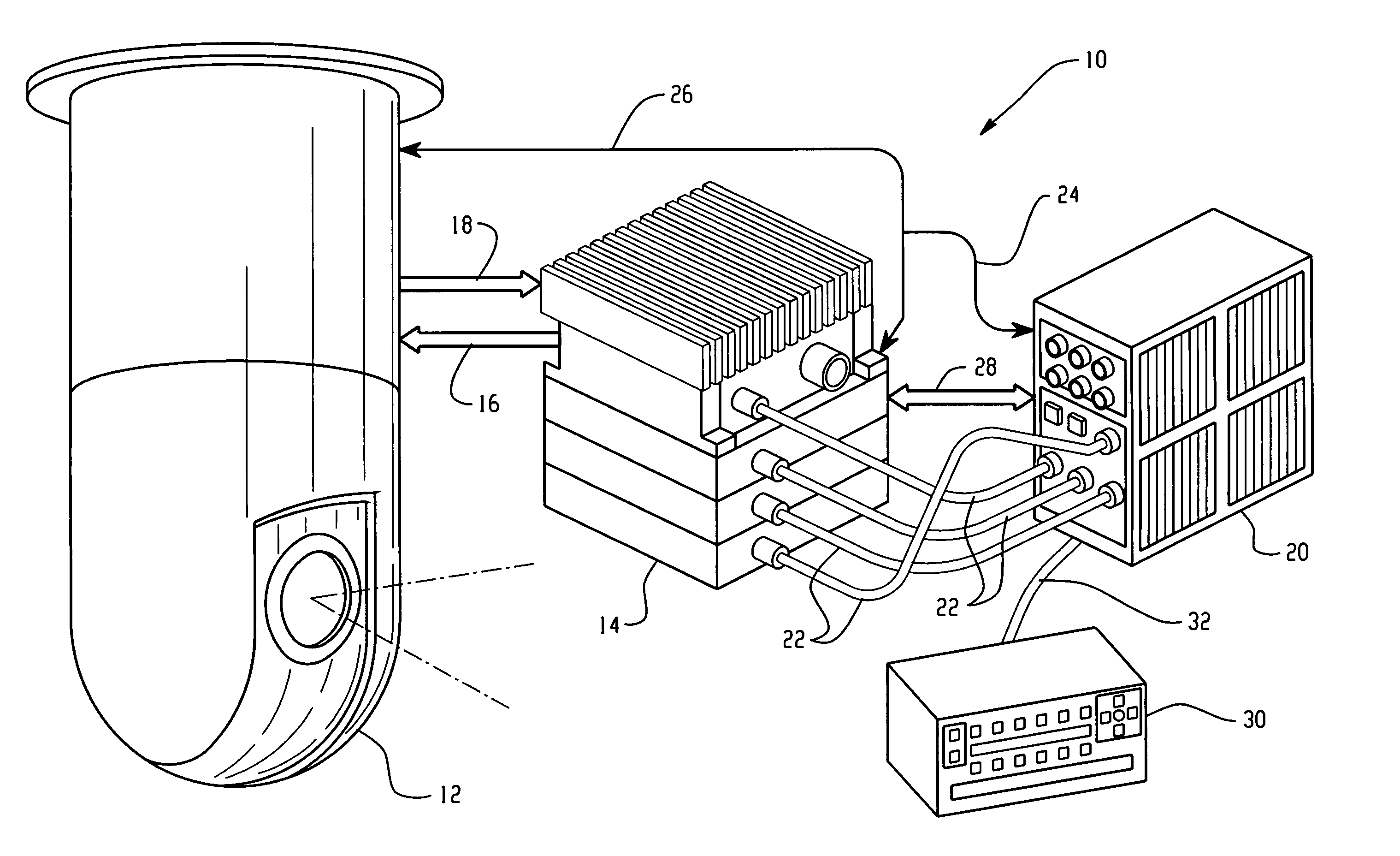

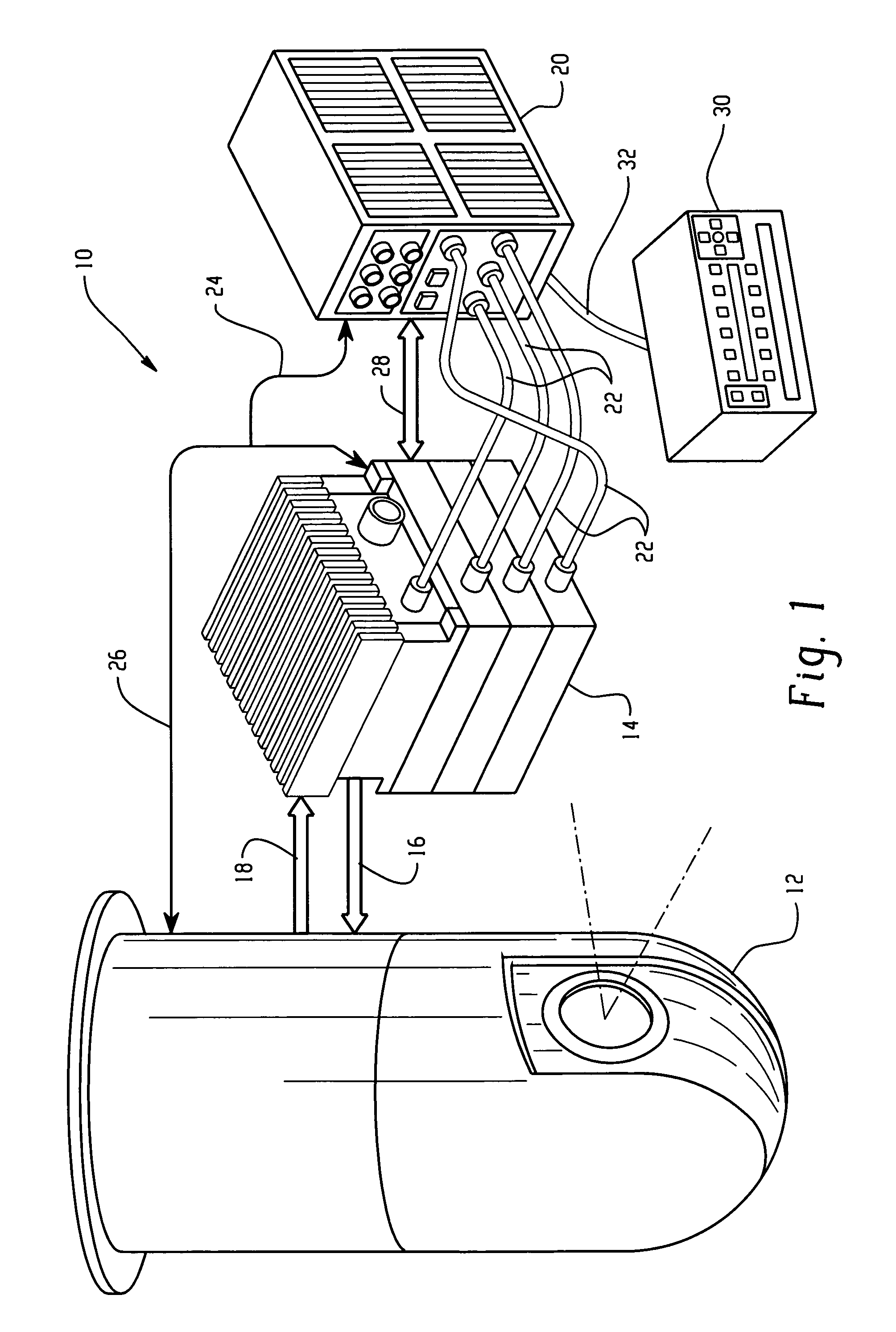

LIDAR Based 3-D Imaging With Varying Pulse Repetition

ActiveUS20170269209A1Reduce total energy consumption and heatReduce consumptionElectromagnetic wave reradiationSteroscopic systemsPulse beamRadar

Methods and systems for performing three dimensional LIDAR measurements with different pulse repetition patterns are described herein. Each repetitive pattern is a sequence of measurement pulses that repeat over time. In one aspect, the repetition pattern of a pulsed beam of illumination light emitted from a LIDAR system is varied to reduce total energy consumption and heat generated by the LIDAR system. In some examples, the repetitive pattern is varied by skipping a number of pulses. In some examples, the repetitive pattern of pulses of illumination light emitted from the LIDAR system is varied by changing a repetition rate of the sequence of emitted pulses. In some examples, the pulse repetition pattern is varied based on the orientation of the LIDAR device. In some examples, the repetition pattern is varied based on an object detected by the LIDAR device or another imaging system.

Owner:VELODYNE LIDAR USA INC

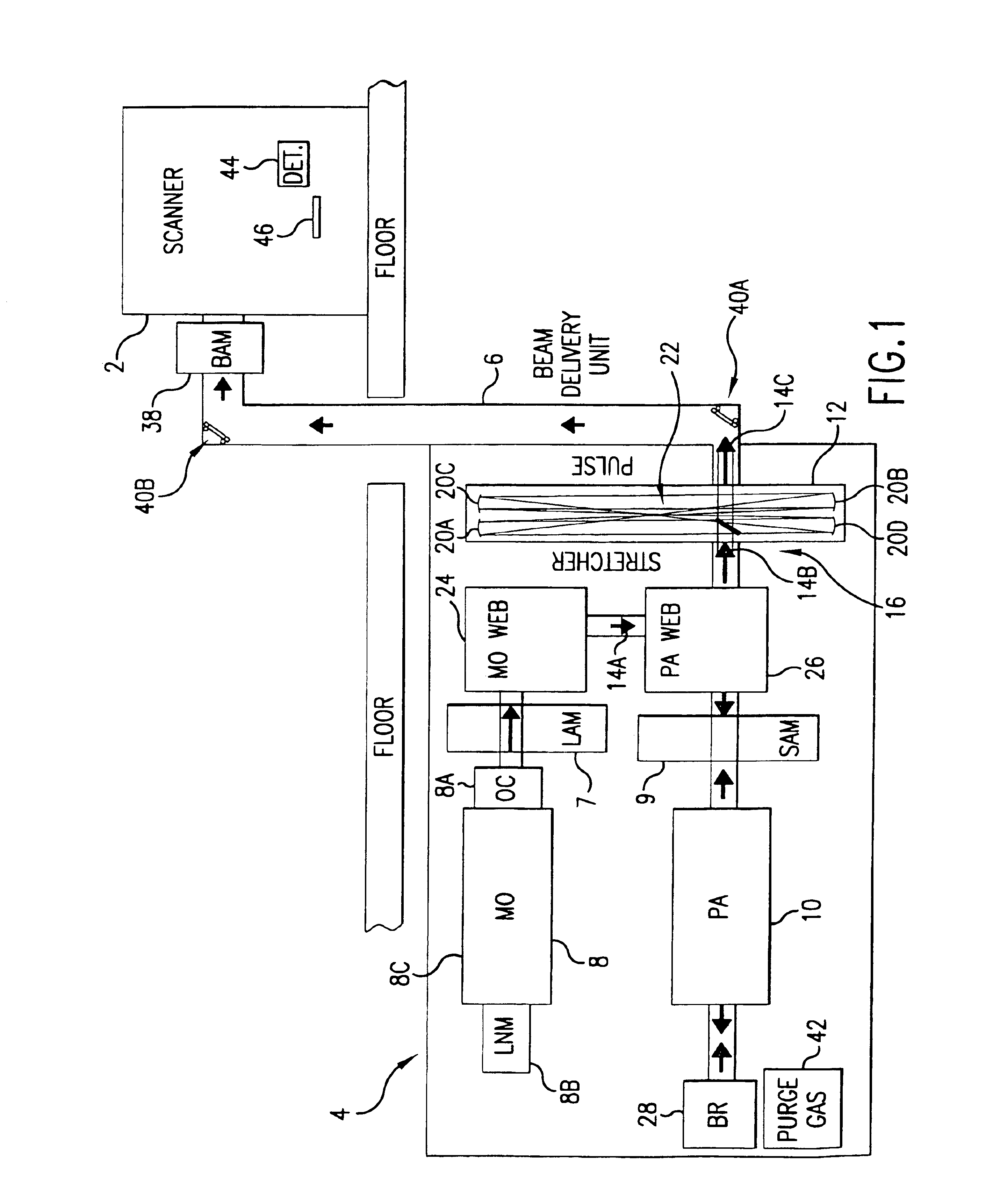

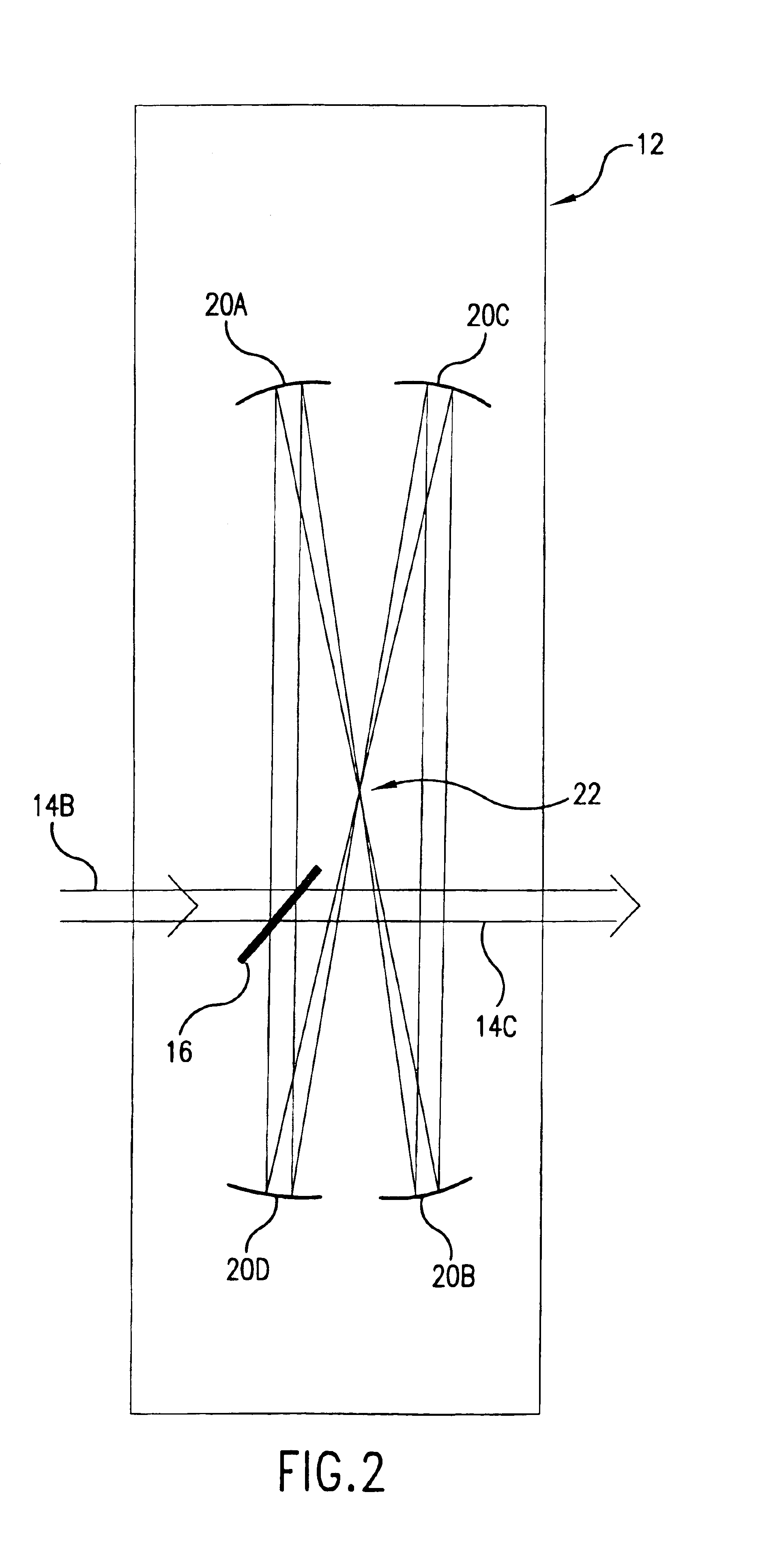

Long delay and high TIS pulse stretcher

A method and apparatus for laser light pulse stretching is disclosed which may comprise a beam splitter in the path of a laser output light pulse beam; selected to pass a first percent of the energy of a first input pulse of the laser output light pulse beam along a laser output light pulse beam output path as a first output pulse and to reflect a second percent of the energy of the laser output light pulse beam into a first delayed beam; an optical delay path receiving the first delayed beam and returning the first delayed beam to the beam splitter in an orientation such that a third percent of the first delayed beam is reflected into the output path as a second output pulse and a fourth percent is passed into the optical delay path as a second delayed beam; the optical delay path receiving the second delayed beam and returning the second delayed beam to the beam splitter in an orientation such that the third percent of the second delayed beam is reflected into the output path as a third output pulse and the fourth percent of the second delayed beam is passed into the optical delay path as a third delayed beam; the optical delay path receiving the third delayed beam and returning the third delayed beam to the beam splitter in an orientation such that the third percent of the third delayed beam is reflected into the output path as a fourth output pulse; the first input pulse being a first pulse in a plurality of pulses output from a prior pulse stretcher, each of a plurality of succeeding input pulses comprising the output of the prior pulse stretcher resulting from the stretching of a narrow band laser light output pulse, forming successive first, second, third and fourth output pulses, the combination of which forms a pulse stretcher having an output with TIS of at least 200 ns. The optical delay path may be formed of a plurality of at least eight reflecting mirrors and contained in an elongated enclosure having first and second end plates mounting a first group of at least four of the at least eight reflecting mirrors mounted on the first mounting surface symmetrically about a center axis of the optical delay path and a second group of at least four of the at least eight reflecting mirrors mounted on the second mounting surface symmetrically about the center axis. The mirrors may be staggered in a predefined pattern, e.g., a circular pattern. The delay path may lie in a plurality of planes. The apparatus may be part of a laser system, part of a beam delivery system or an interface between the two.

Owner:CYMER INC

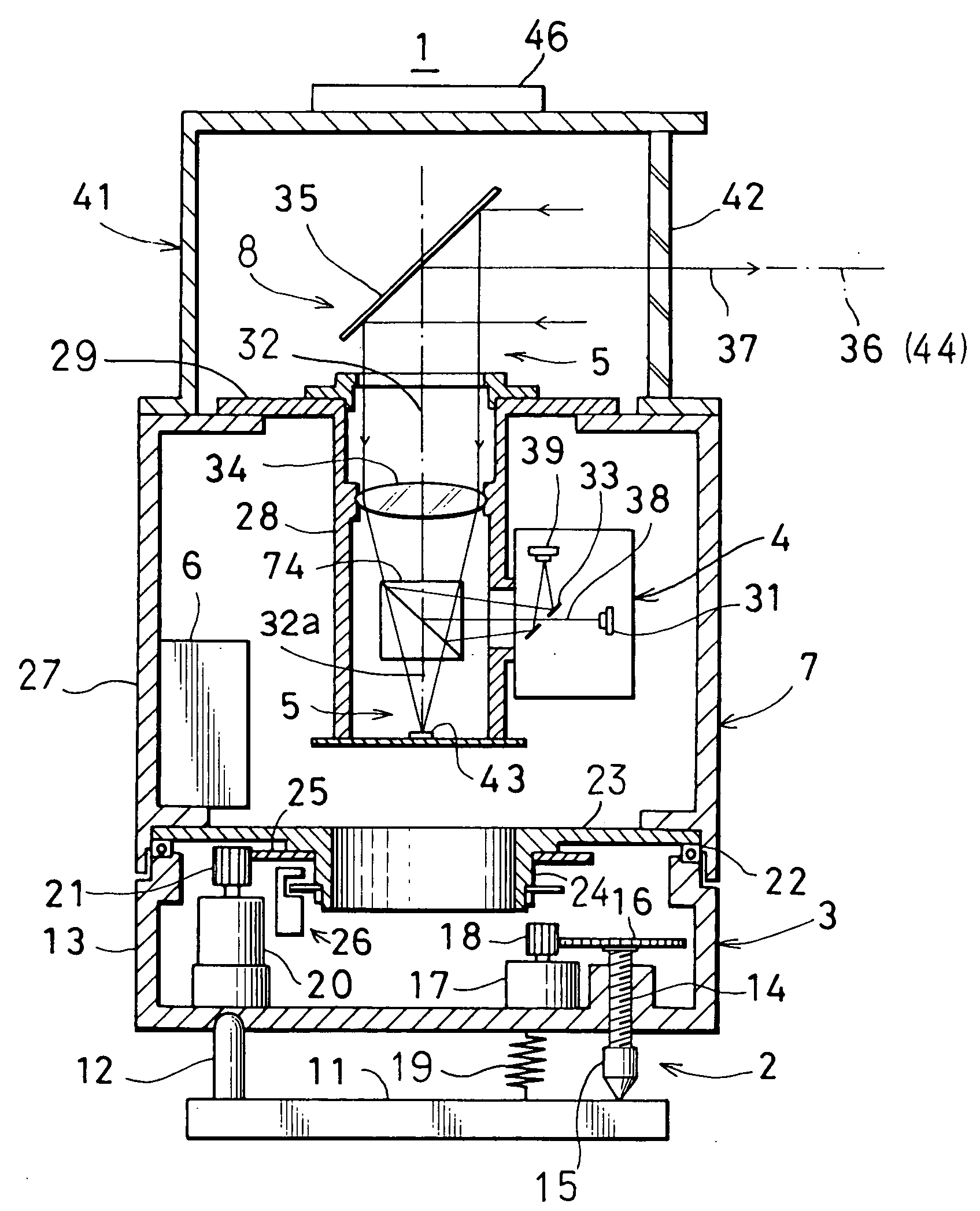

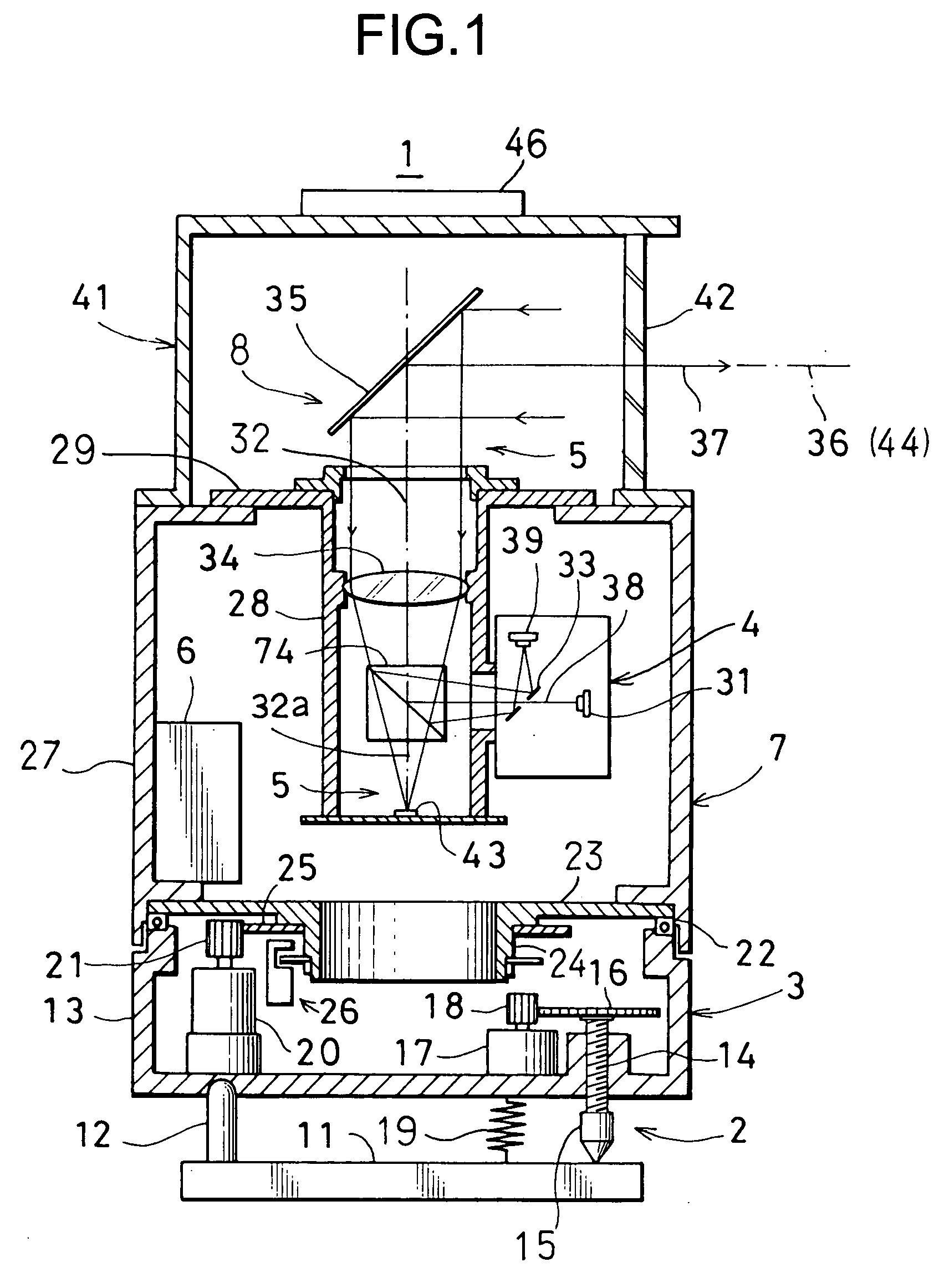

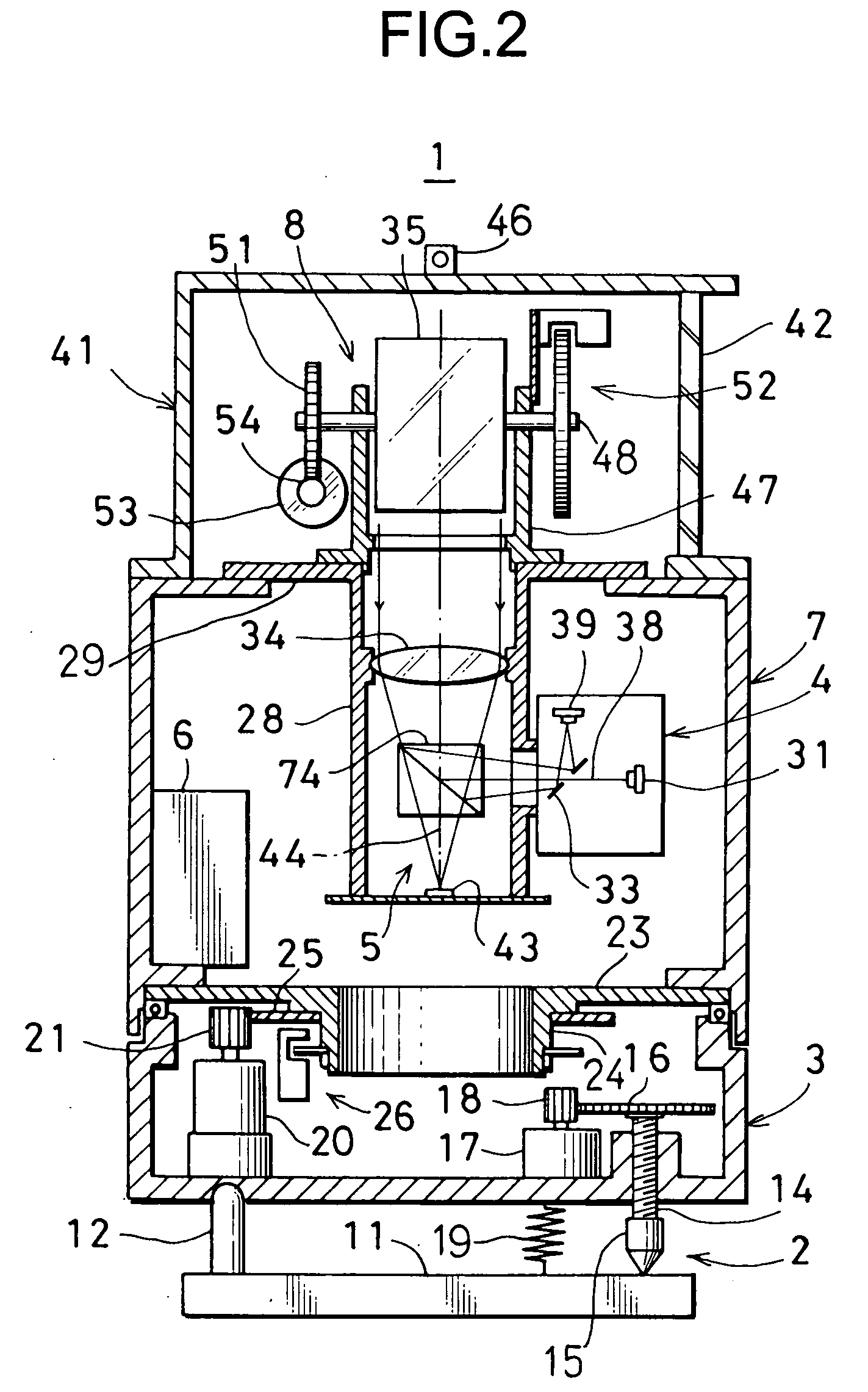

Position measuring system, position measuring method and position measuring program

ActiveUS20080075325A1Improve matchReduce the amount requiredOptical rangefindersActive open surveying meansPulse beamData matching

A position measuring system, comprising a distance measuring unit for projecting and scanning a pulsed beam for measurement to a measurement area and for measuring a distance based on a reflected light of the pulsed beam for measurement and for obtaining a position data group in the measurement area, a digital image pickup unit for acquiring an image data by taking an image of the measurement area, a storage unit for storing at least two sets of the position data groups and the image data acquired from at least two directions by interrelating and associating the position data groups with the image data, and an arithmetic unit for synthesizing the at least two position data groups through matching of the two images based on the two stored image data.

Owner:KK TOPCON

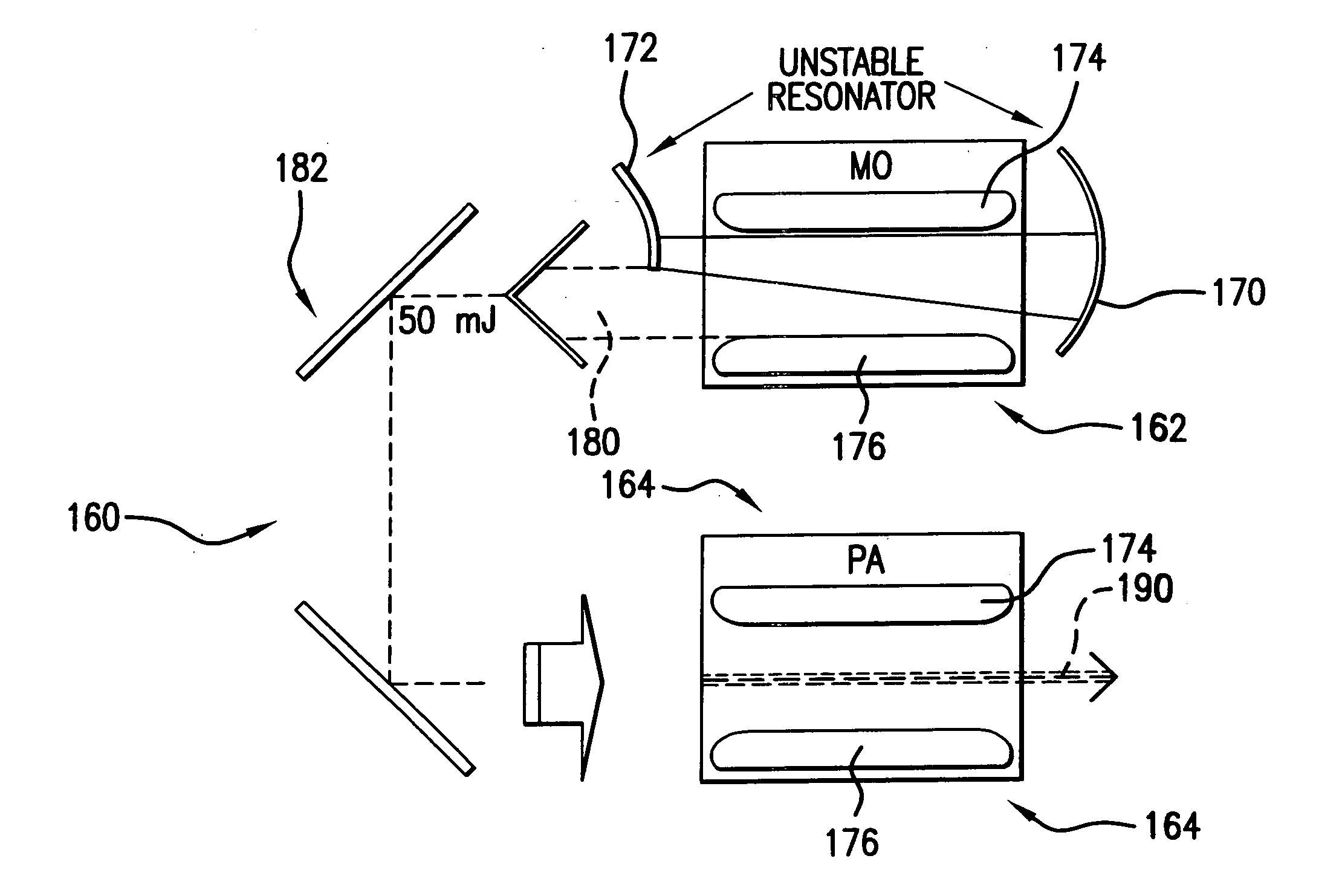

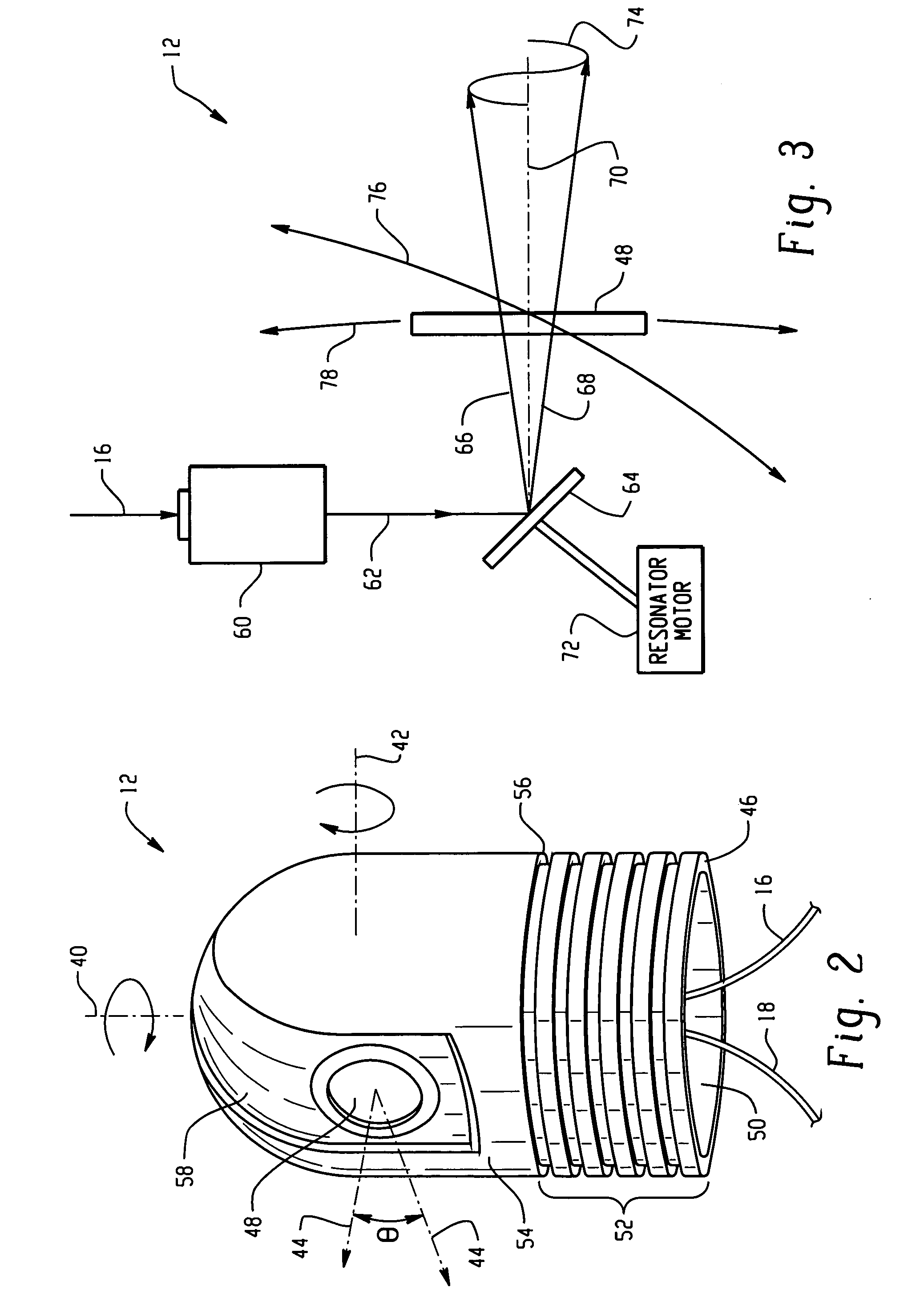

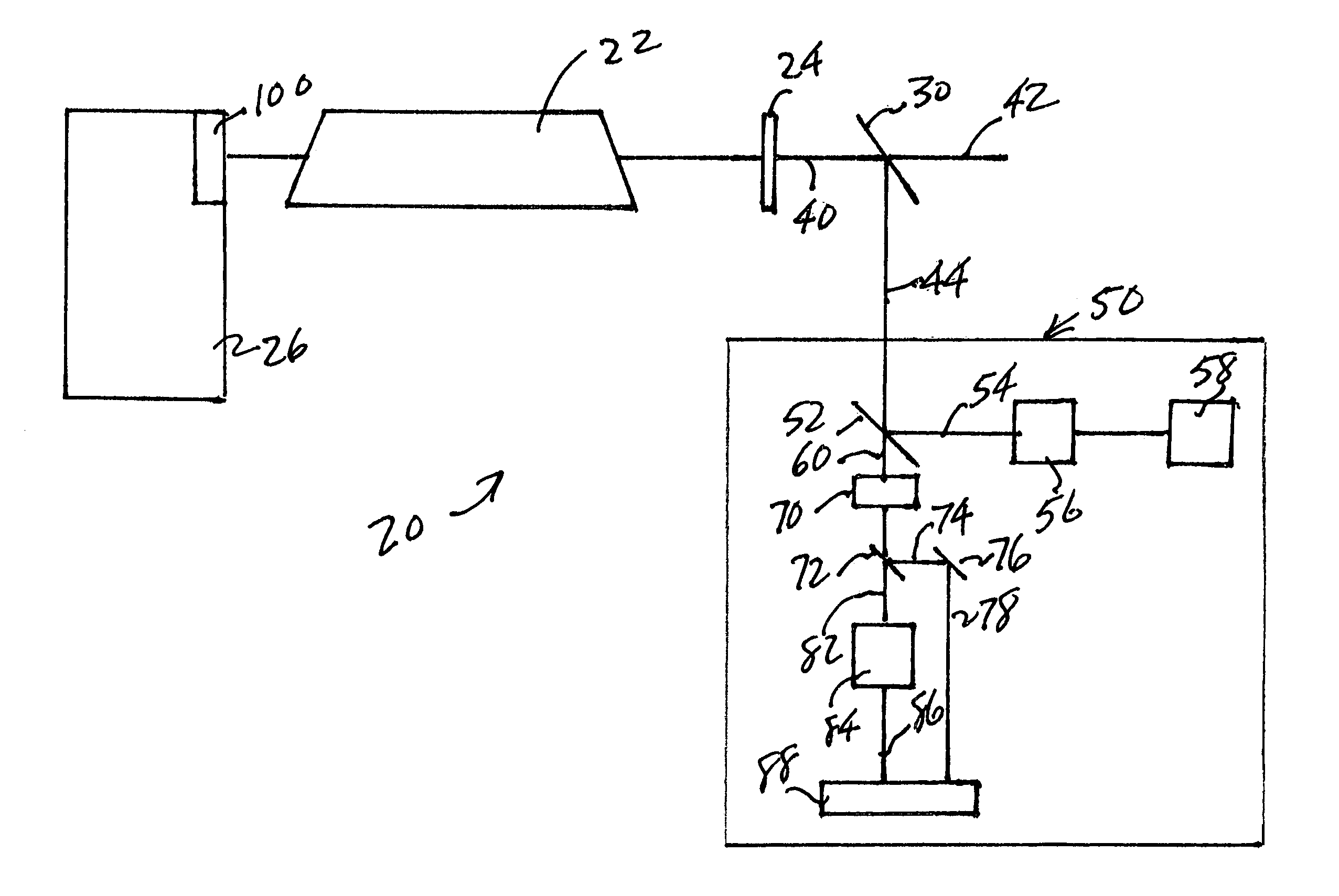

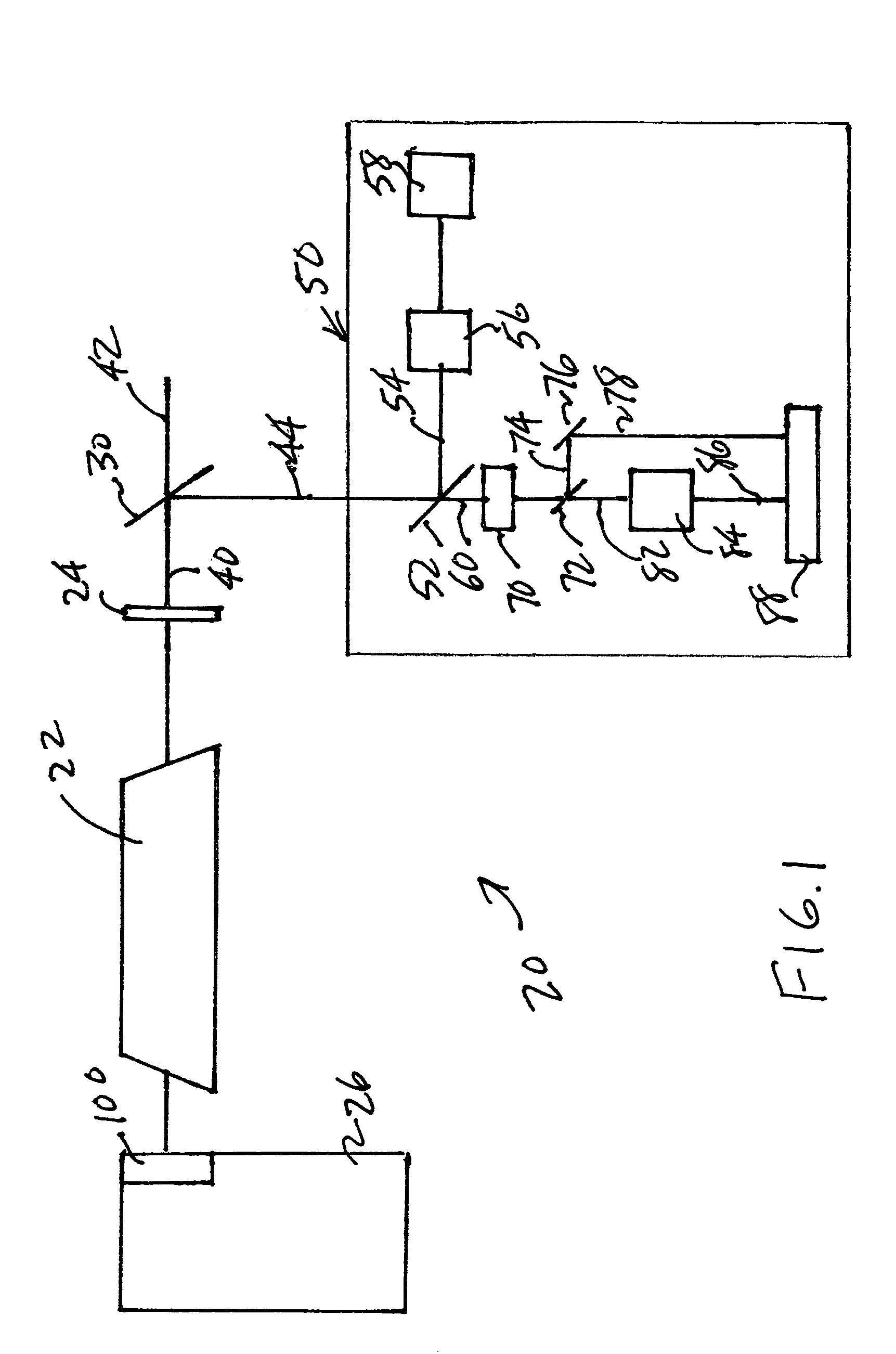

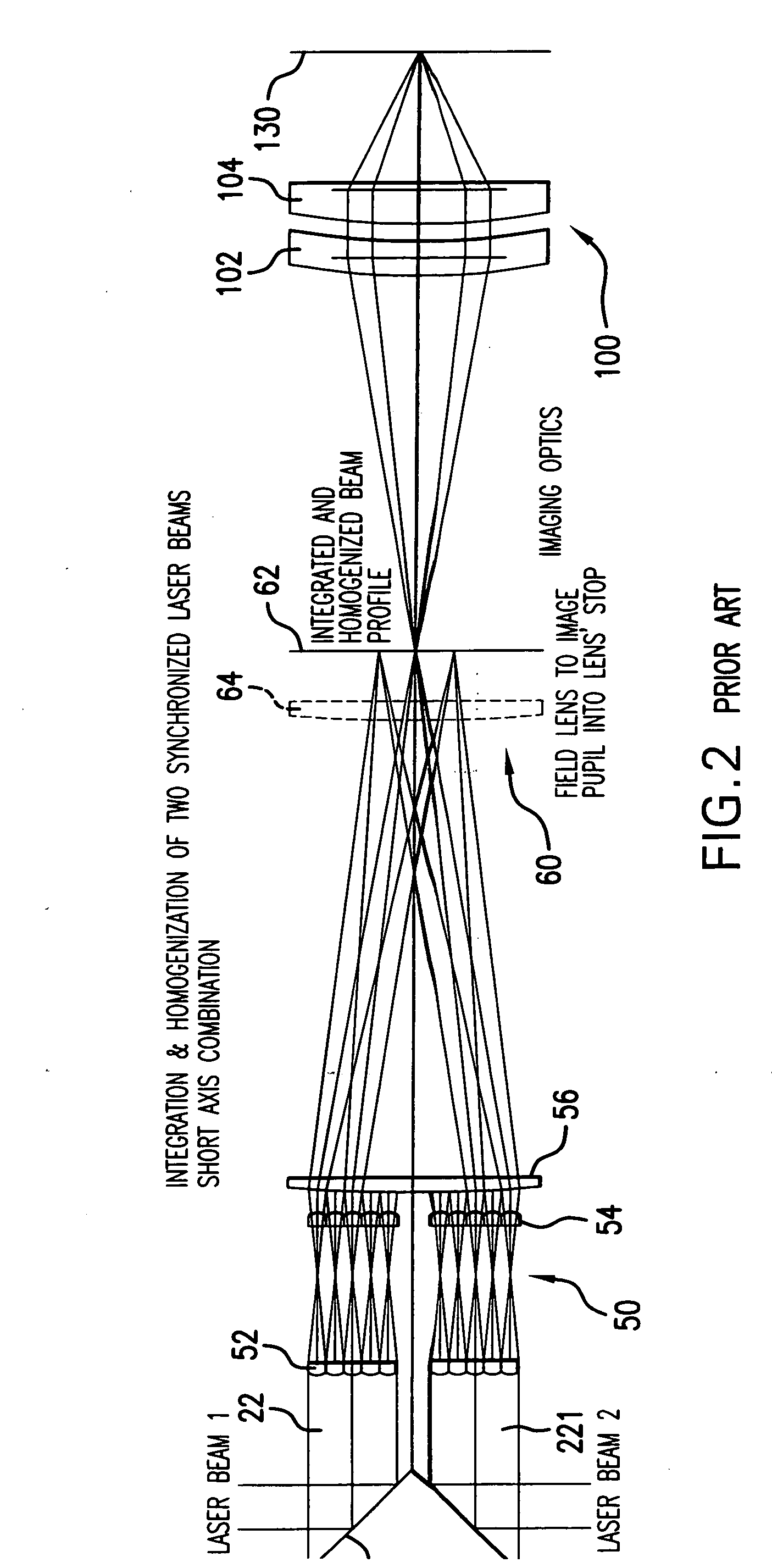

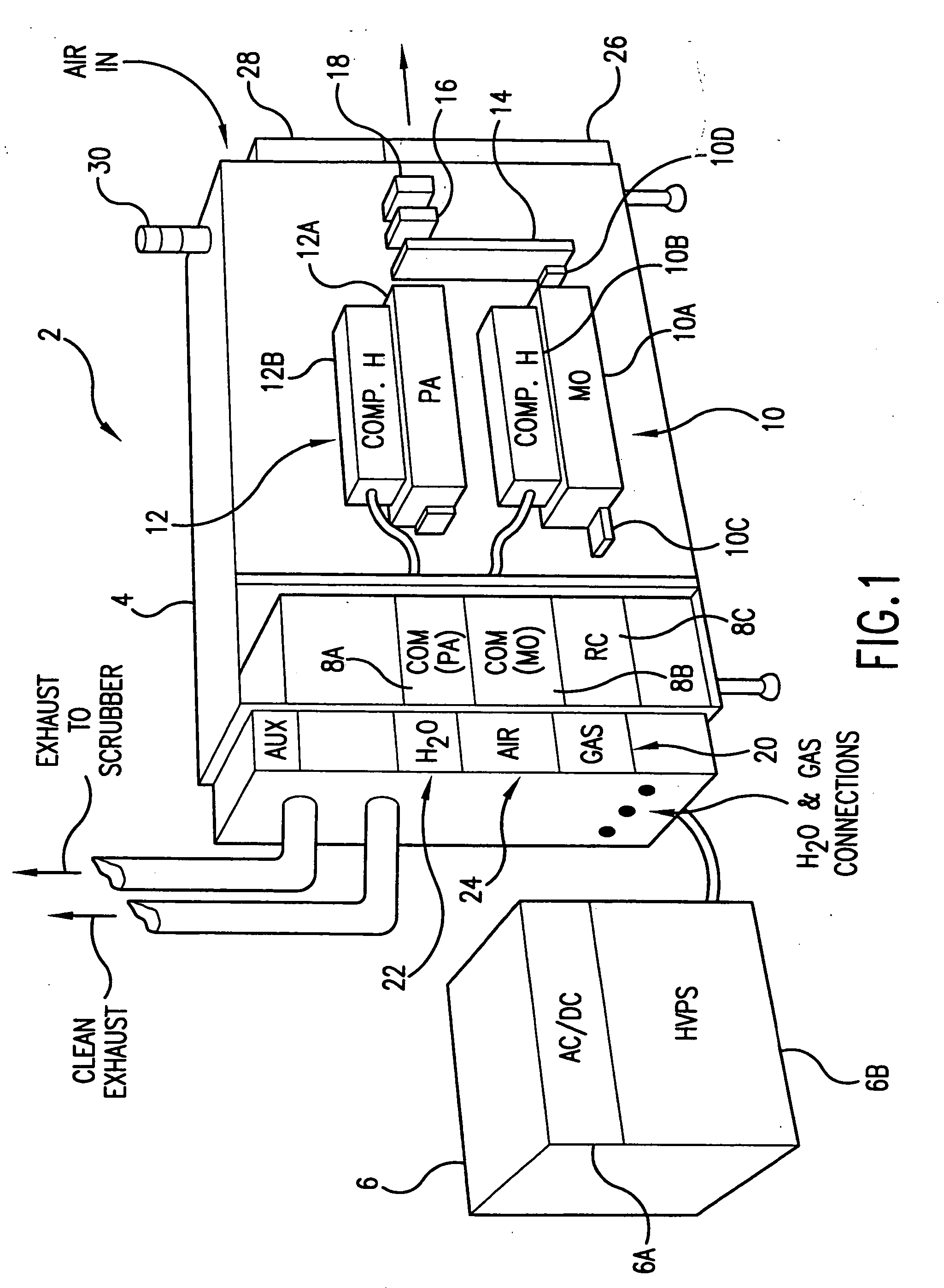

Laser thin film poly-silicon annealing system

InactiveUS20050141580A1High repetition rateIncrease powerSemiconductor/solid-state device manufacturingLaser arrangementsPulse beamMetrology

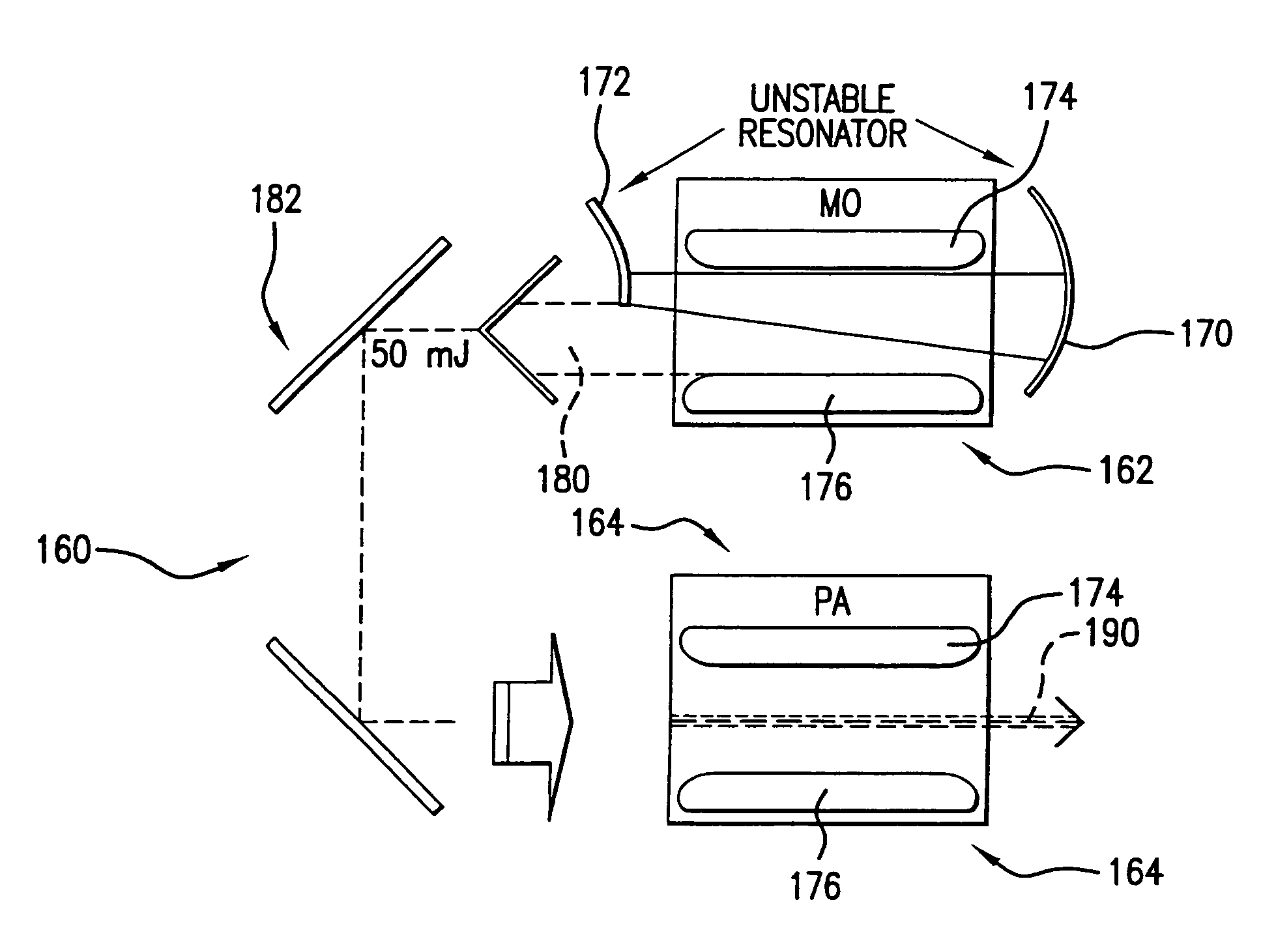

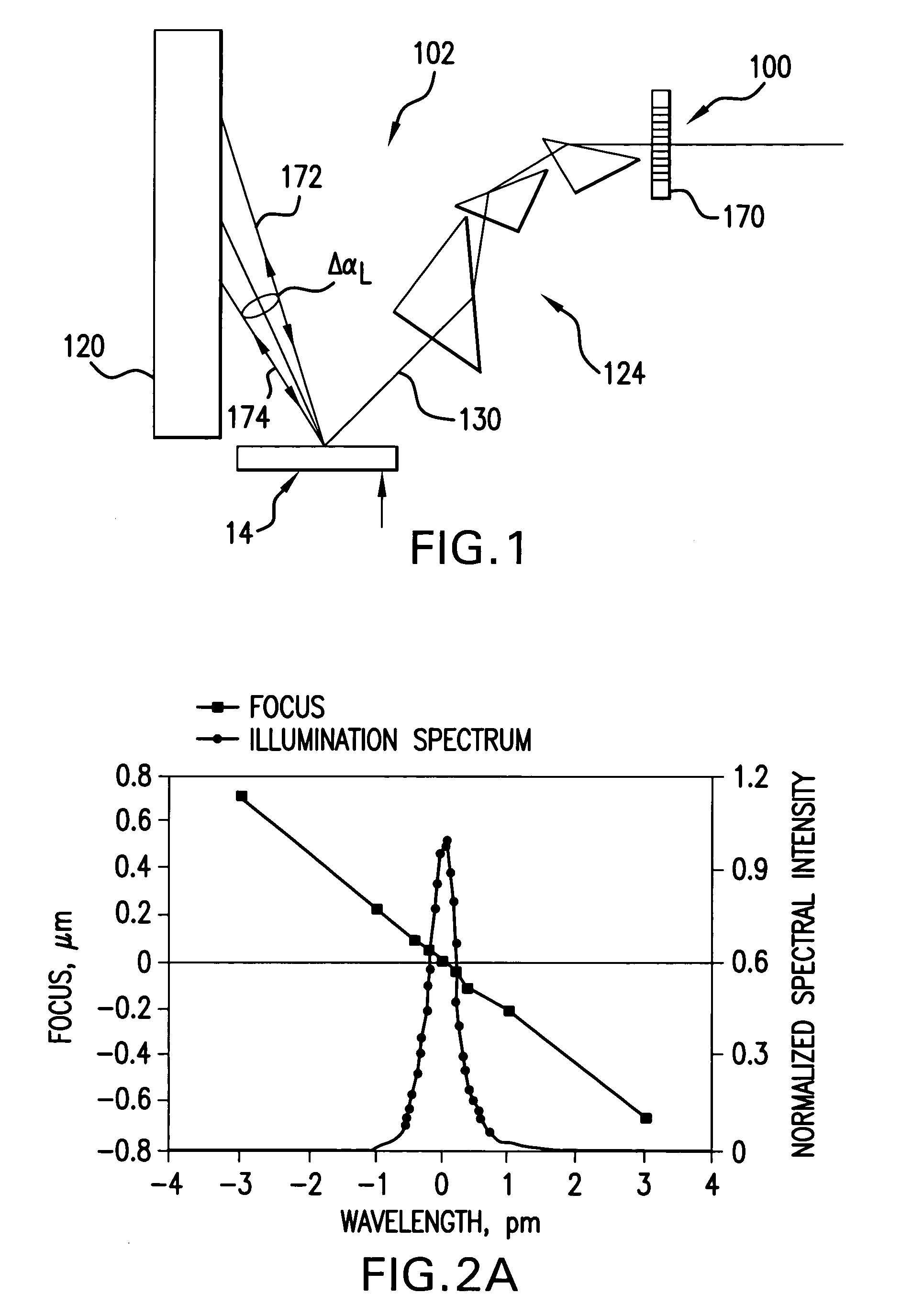

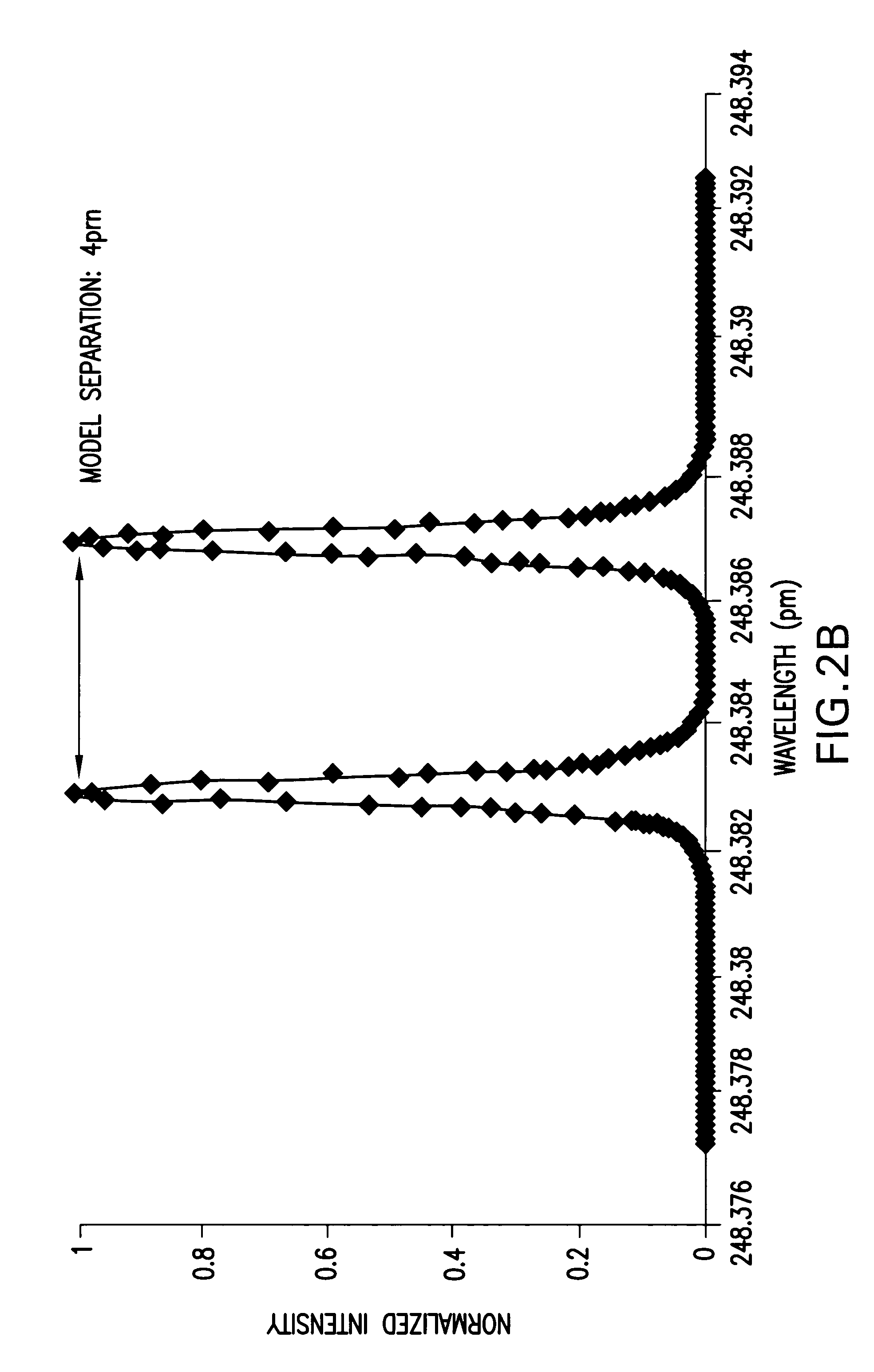

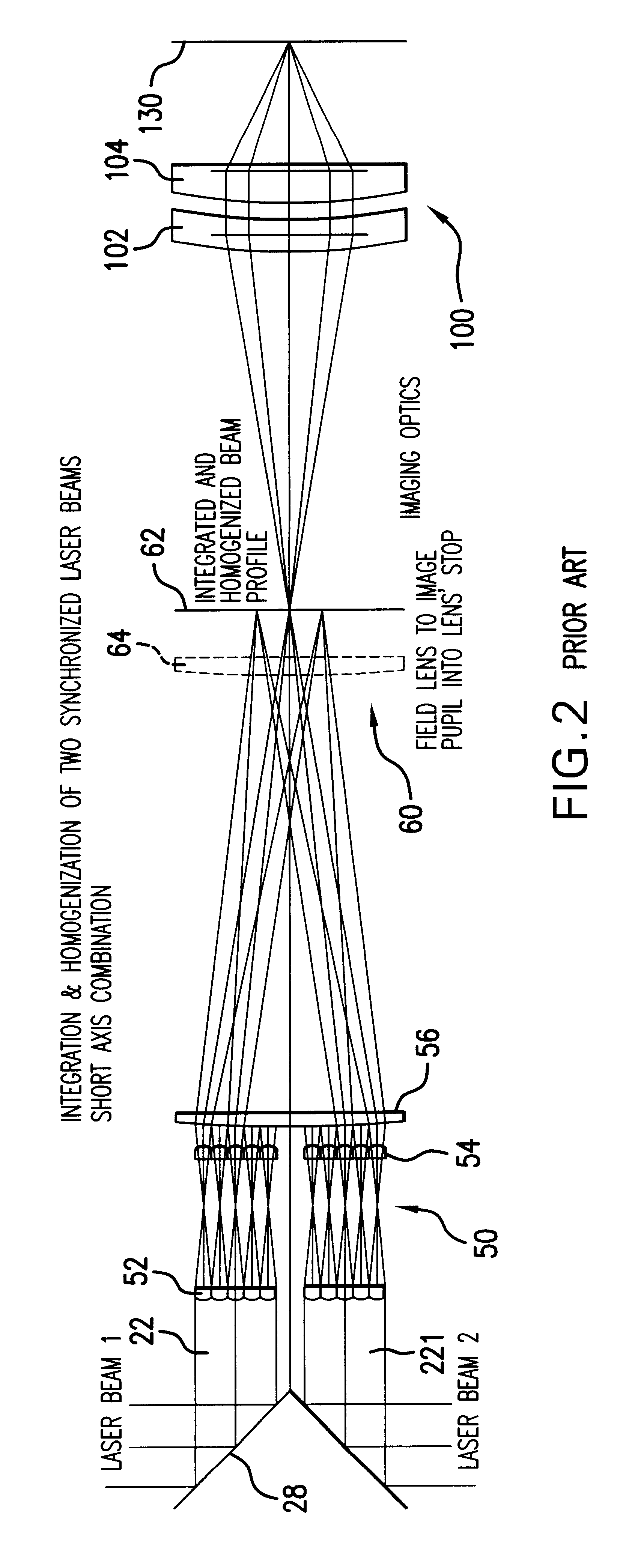

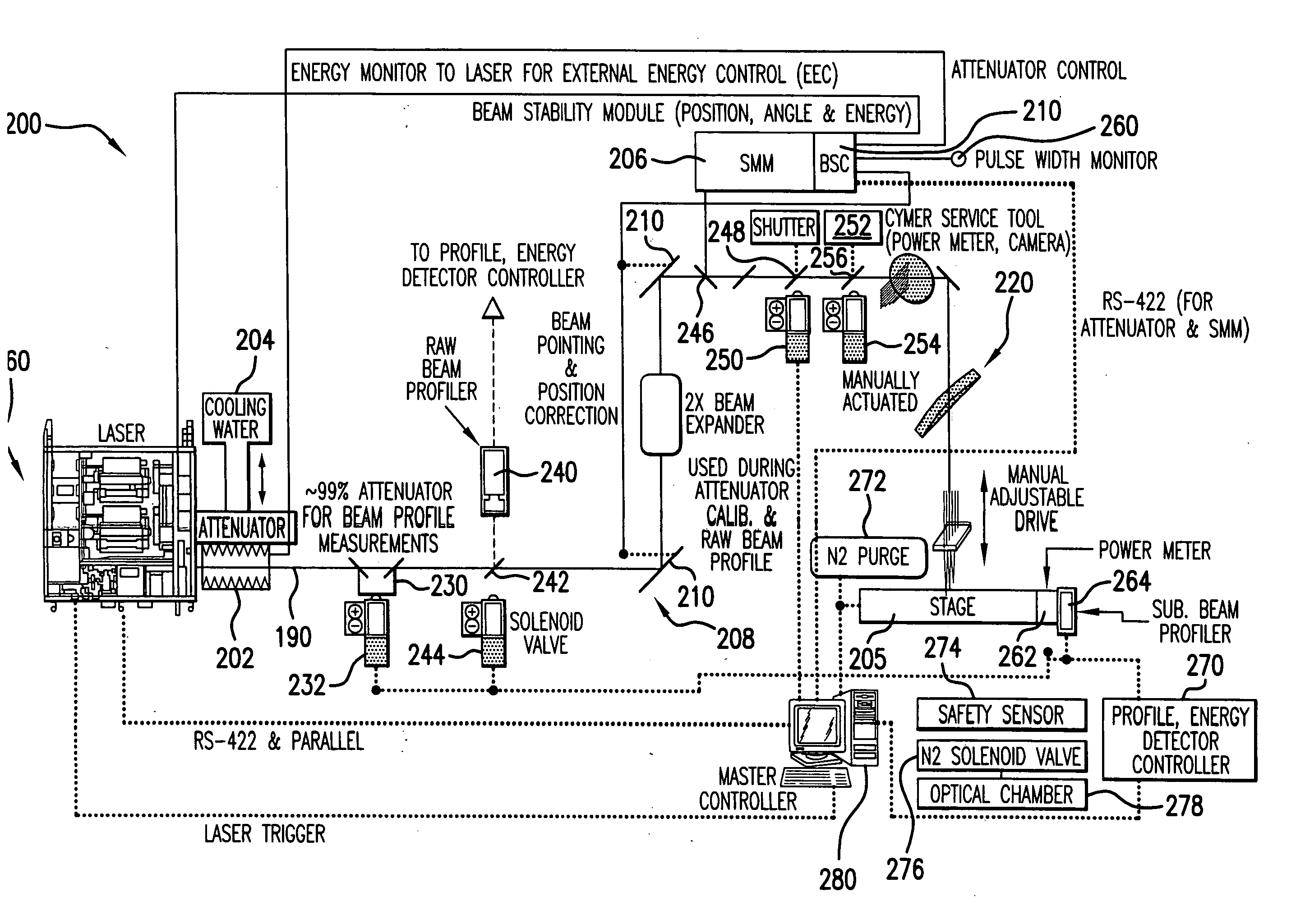

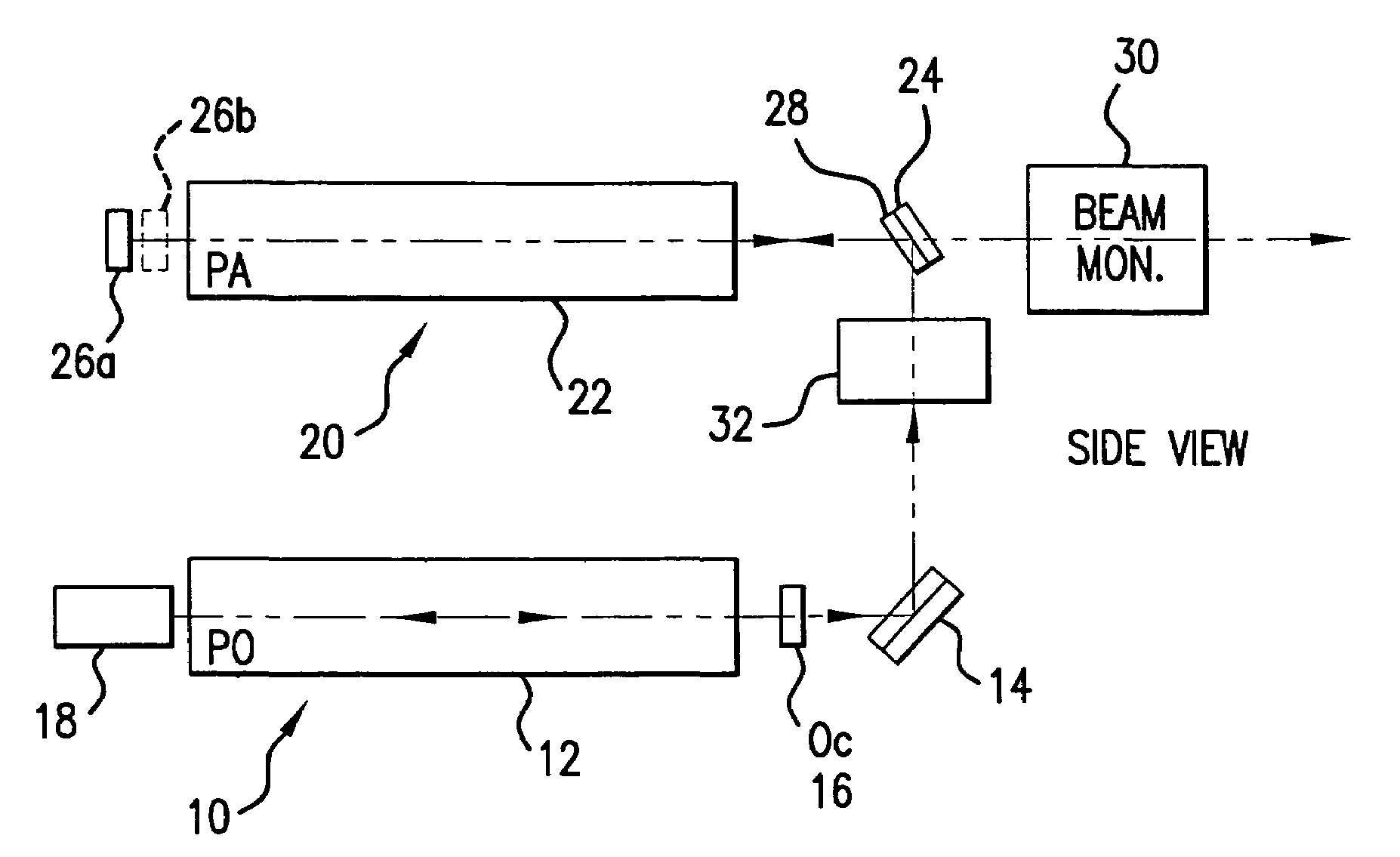

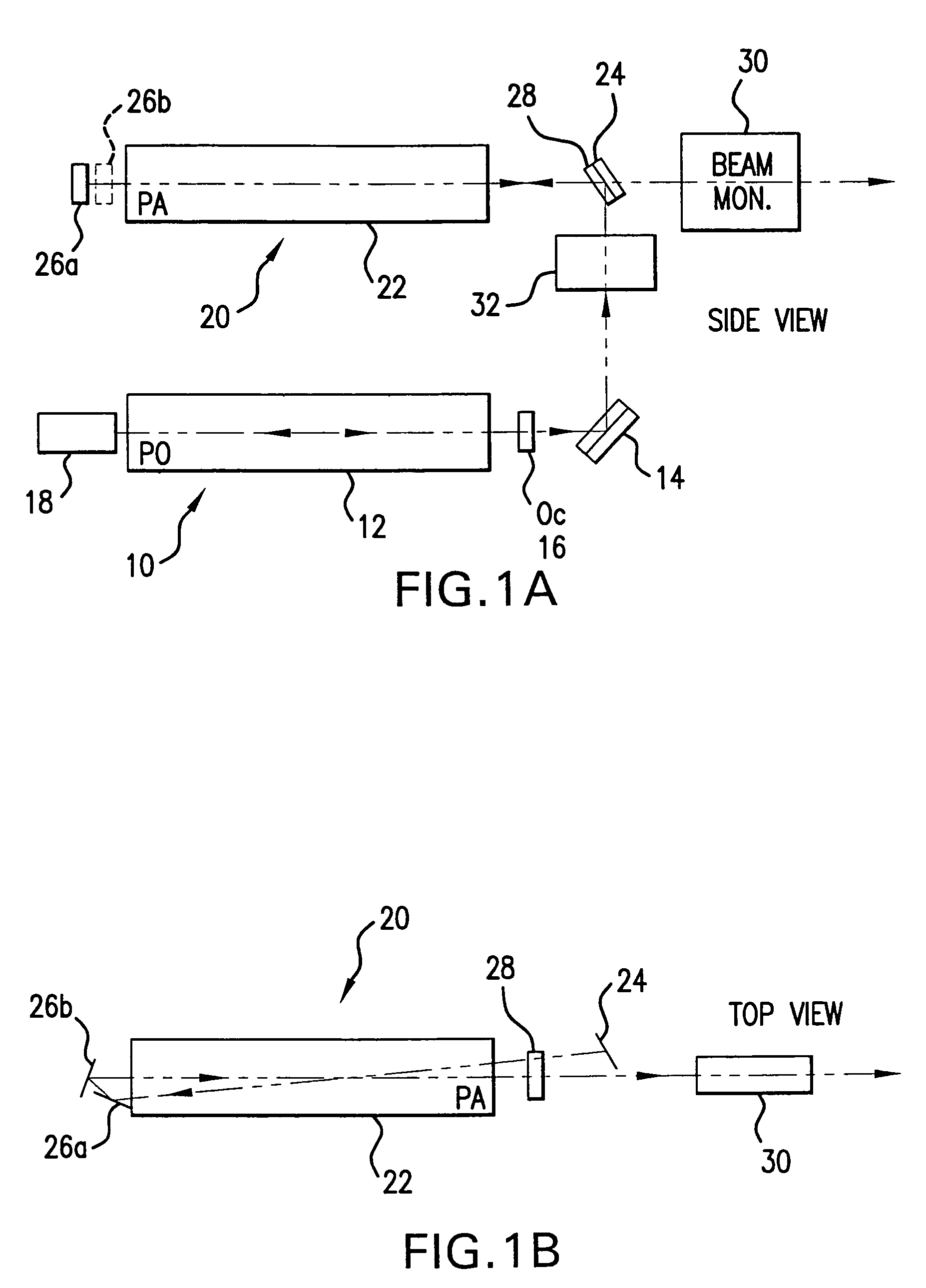

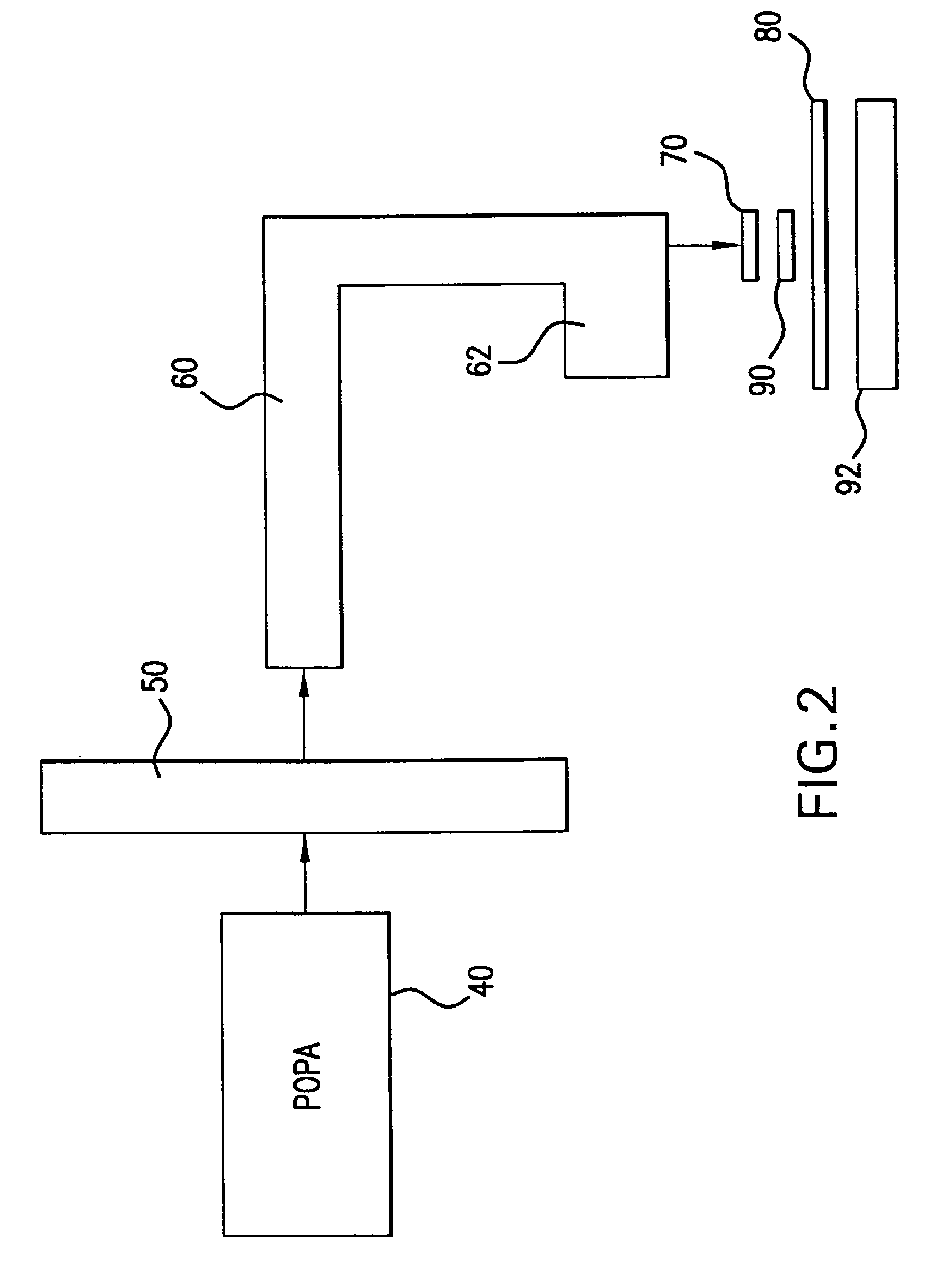

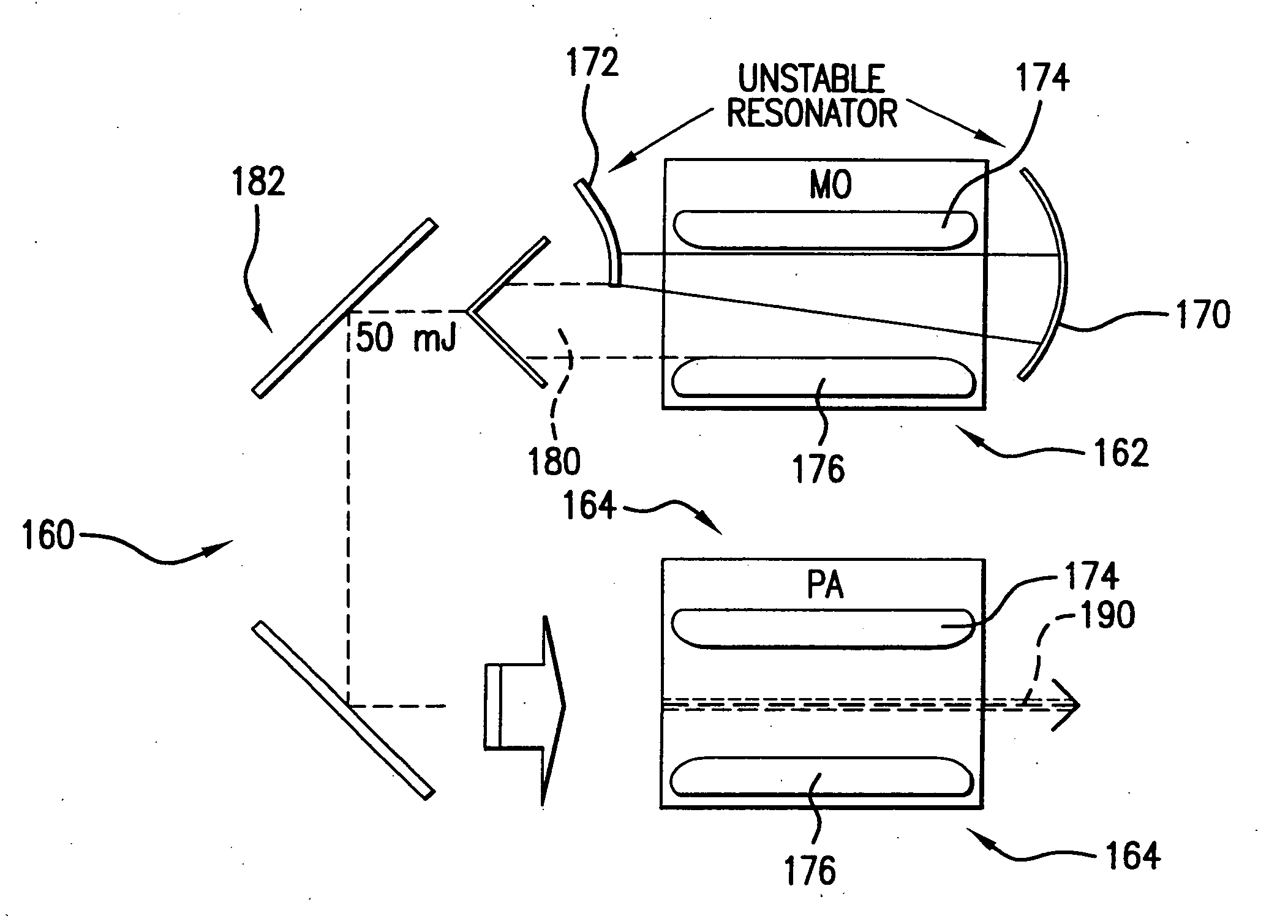

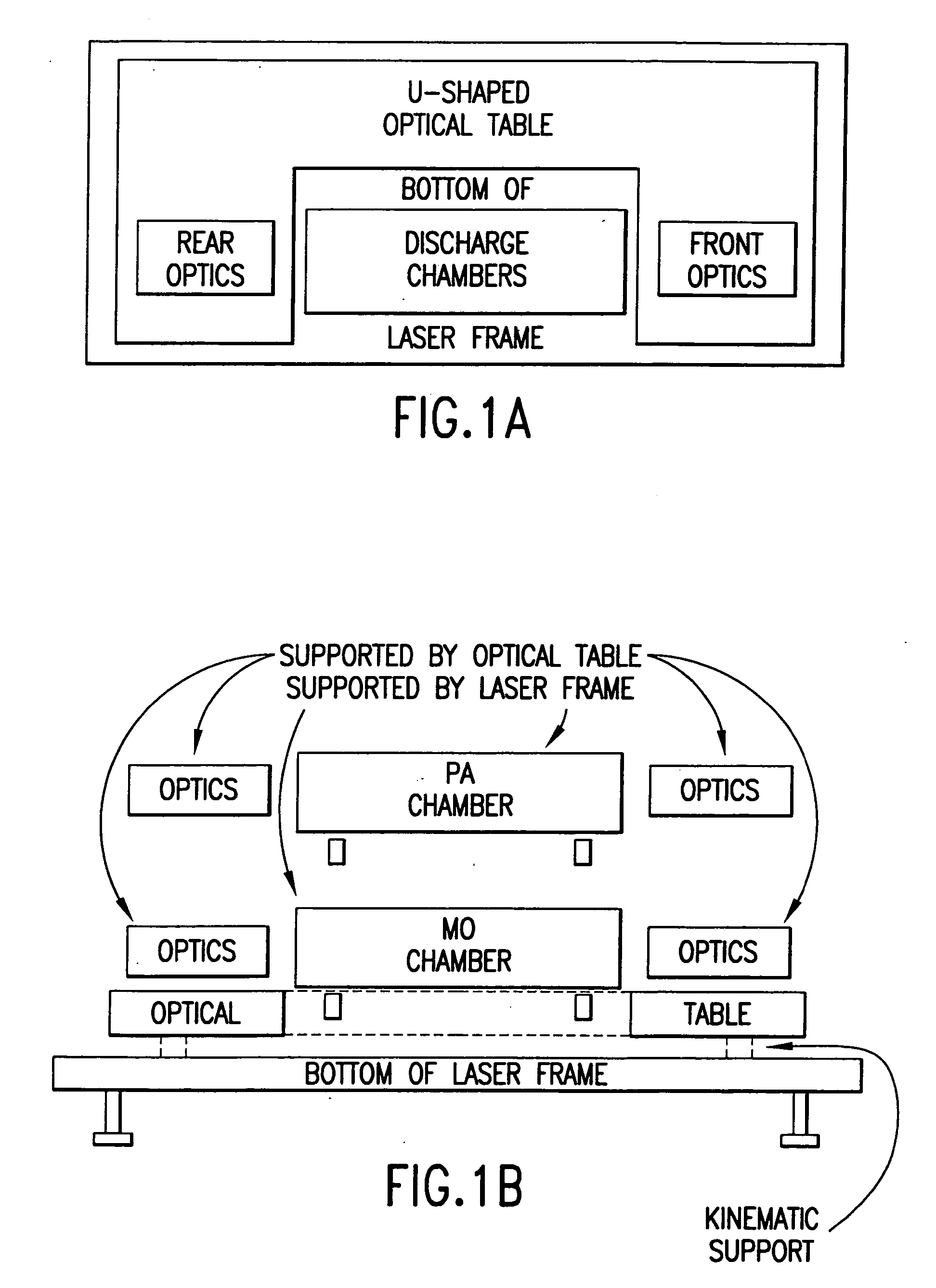

A gas discharge laser crystallization apparatus and method for performing a transformation of a crystal makeup or orientation in a film on a workpiece is disclosed, which may comprise a master oscillator power amplifier MOPA or power oscillator power amplifier configured XeF laser system producing a laser output light pulse beam at a high repetition rate and high power with a pulse to pulse dose control; an optical system producing an elongated thin pulsed working beam from the laser output light pulse beam. The apparatus may further comprise the laser system is configured as a POPA laser system and further comprising: relay optics operative to direct a first output laser light pulse beam from a first laser PO unit into a second laser PA unit; and, a timing and control module timing the creation of a gas discharge in the first and second laser units within plus or minus 3 ns, to produce the a second laser output light pulse beam as an amplification of the first laser output light pulse beam. The system may comprise divergence control in the oscillator laser unit. Divergence control may comprise an unstable resonator arrangement. The system may further comprise a beam pointing control mechanism intermediate the laser and the workpiece and a beam position control mechanism intermediate the laser and the workpiece. Beam parameter metrology may provide active feedback control to the beam pointing mechanism and active feedback control to the beam position control mechanism.

Owner:CYMER INC

Laser thin film poly-silicon annealing system

InactiveUS7061959B2Semiconductor/solid-state device manufacturingLaser arrangementsPulse beamMetrology

A gas discharge laser crystallization apparatus and method for performing a transformation of a crystal makeup or orientation in a film on a workpiece is disclosed, which may comprise a master oscillator power amplifier MOPA or power oscillator power amplifier configured XeF laser system producing a laser output light pulse beam at a high repetition rate and high power with a pulse to pulse dose control; an optical system producing an elongated thin pulsed working beam from the laser output light pulse beam. The apparatus may further comprise the laser system is configured as a POPA laser system and further comprising: relay optics operative to direct a first output laser light pulse beam from a first laser PO unit into a second laser PA unit; and, a timing and control module timing the creation of a gas discharge in the first and second laser units within plus or minus 3 ns, to produce the a second laser output light pulse beam as an amplification of the first laser output light pulse beam. The system may comprise divergence control in the oscillator laser unit. Divergence control may comprise an unstable resonator arrangement. The system may further comprise a beam pointing control mechanism intermediate the laser and the workpiece and a beam position control mechanism intermediate the laser and the workpiece. Beam parameter metrology may provide active feedback control to the beam pointing mechanism and active feedback control to the beam position control mechanism.

Owner:CYMER INC

Laser output beam wavefront splitter for bandwidth spectrum control

ActiveUS7154928B2Optical resonator shape and constructionActive medium materialPulse beamFrequency spectrum

Apparatus / method providing bandwidth control in narrow band short pulse duration gas discharge laser output light pulse beam producing systems, producing a beam comprising pulses at selected pulse repetition races, e.g., comprising a dispersive bandwidth selection optic selecting at least one center wavelength for each pulse determined at least in part by the angle of incidence of the beam containing the respective pulse on the optic; a tuning mechanism operative to select at least one angle of incidence of the beam containing the respective pulse upon the optic; the tuning mechanism comprising a plurality of incidence angle selection elements each defining an angle of incidence for a different spatially separated but not temporally separated portion of the pulse to return from the optic a laser light pulse comprising a plurality of spatially separated but not temporally separated portions, each having one of at least two different selected center wavelengths.

Owner:CYMER INC

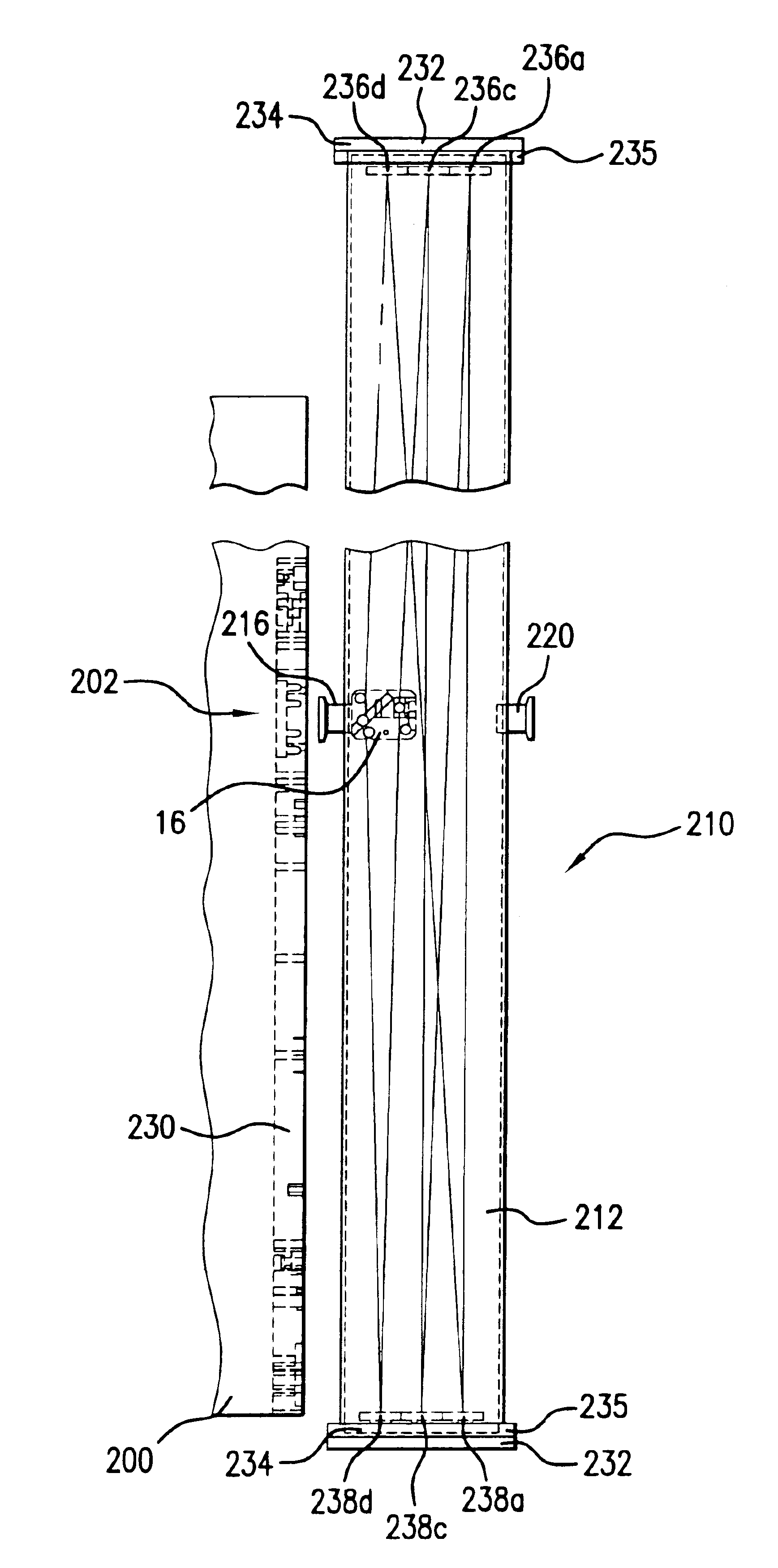

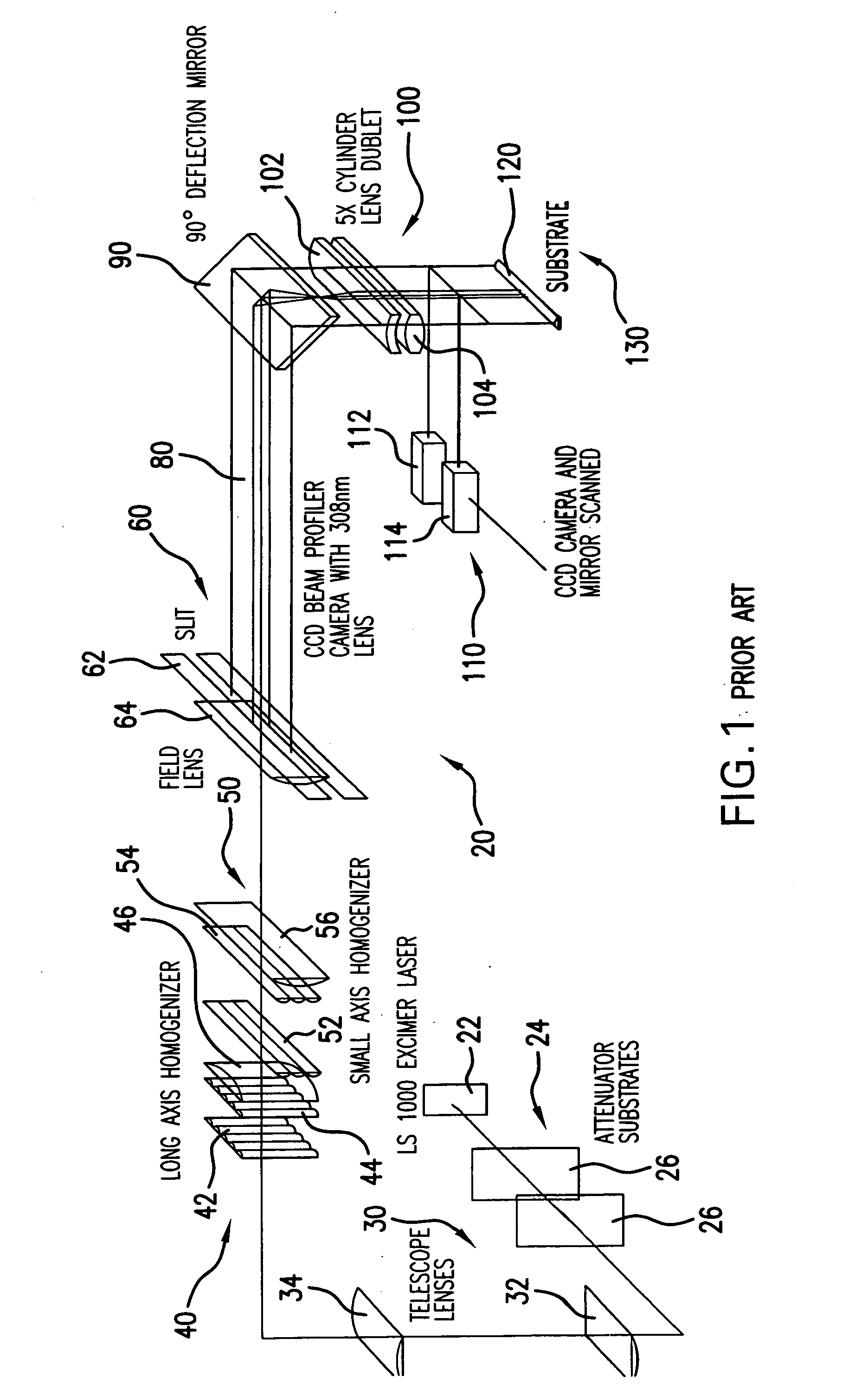

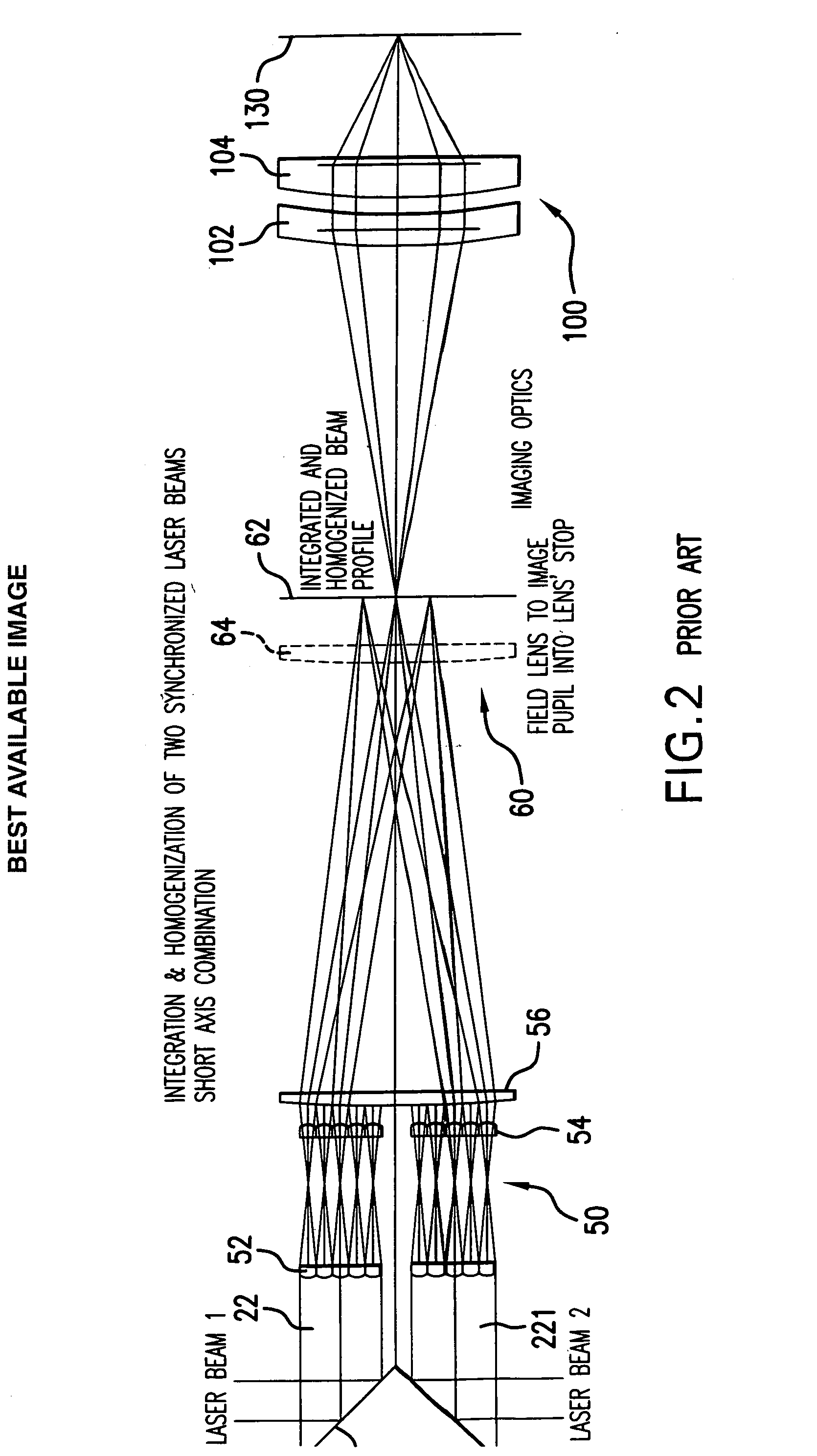

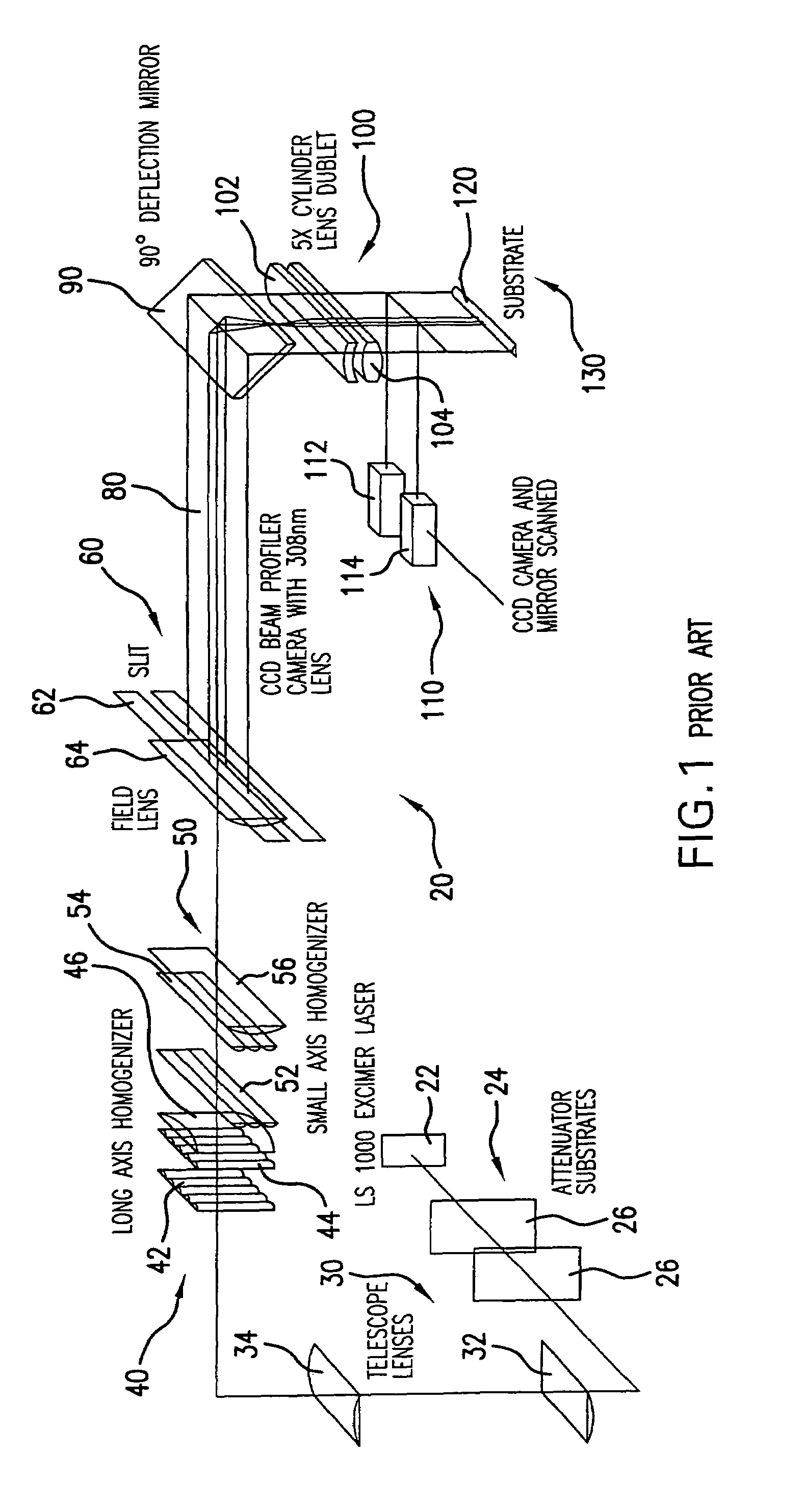

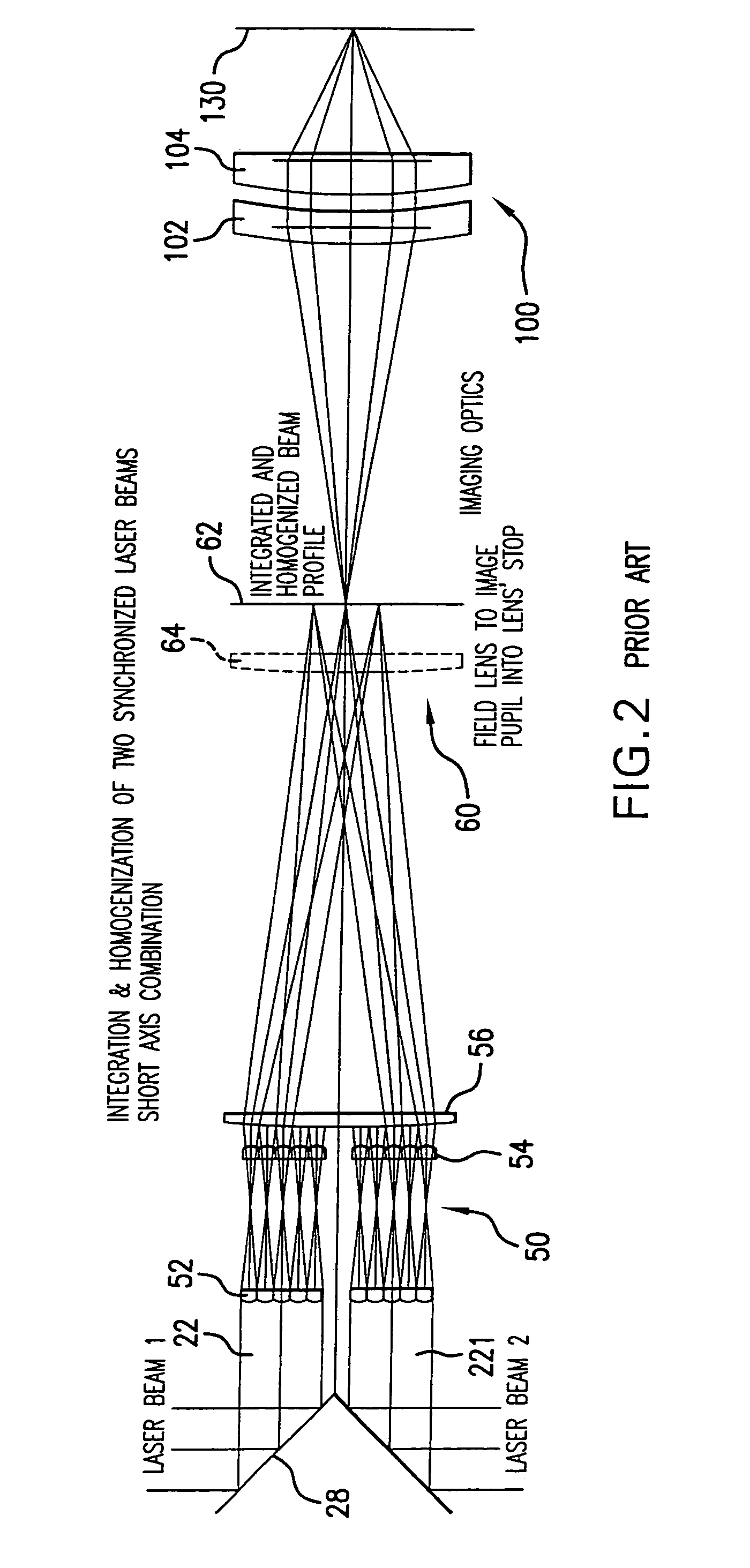

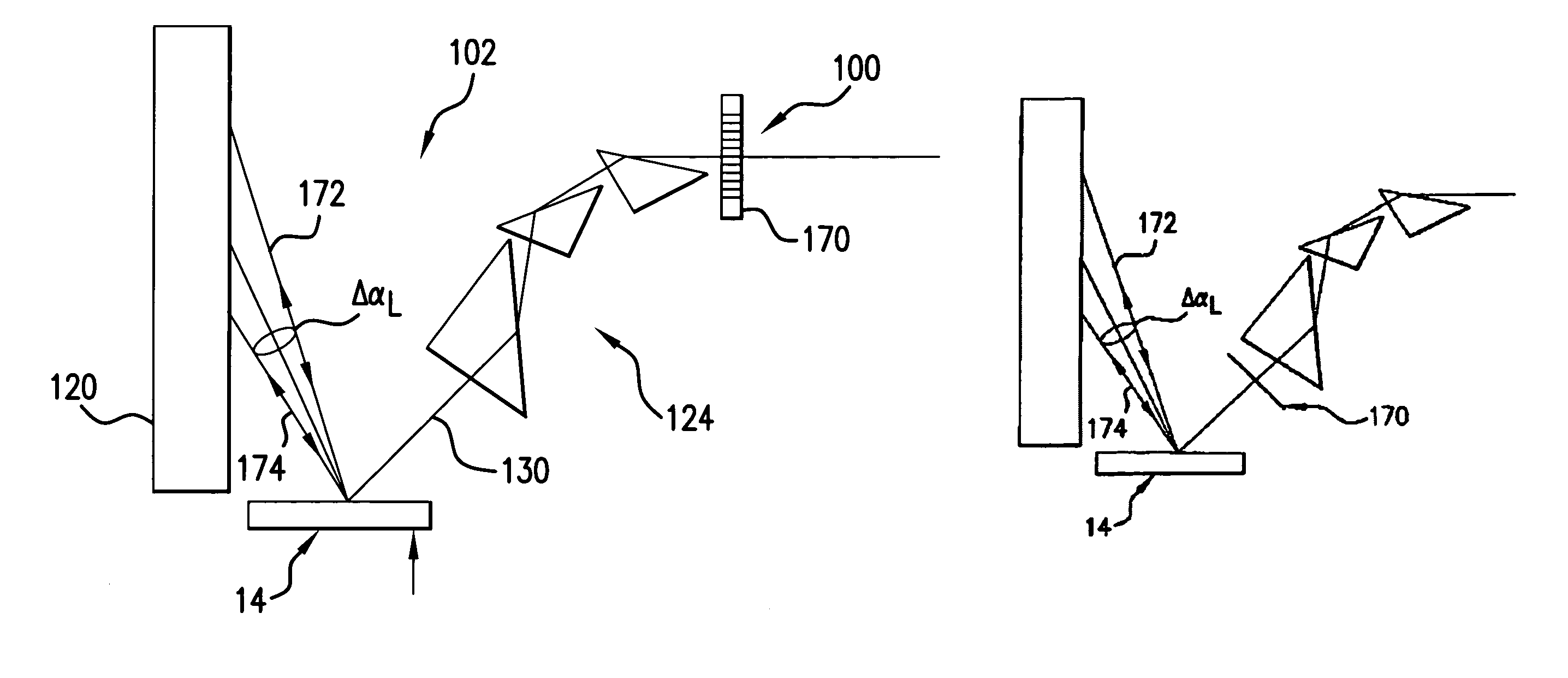

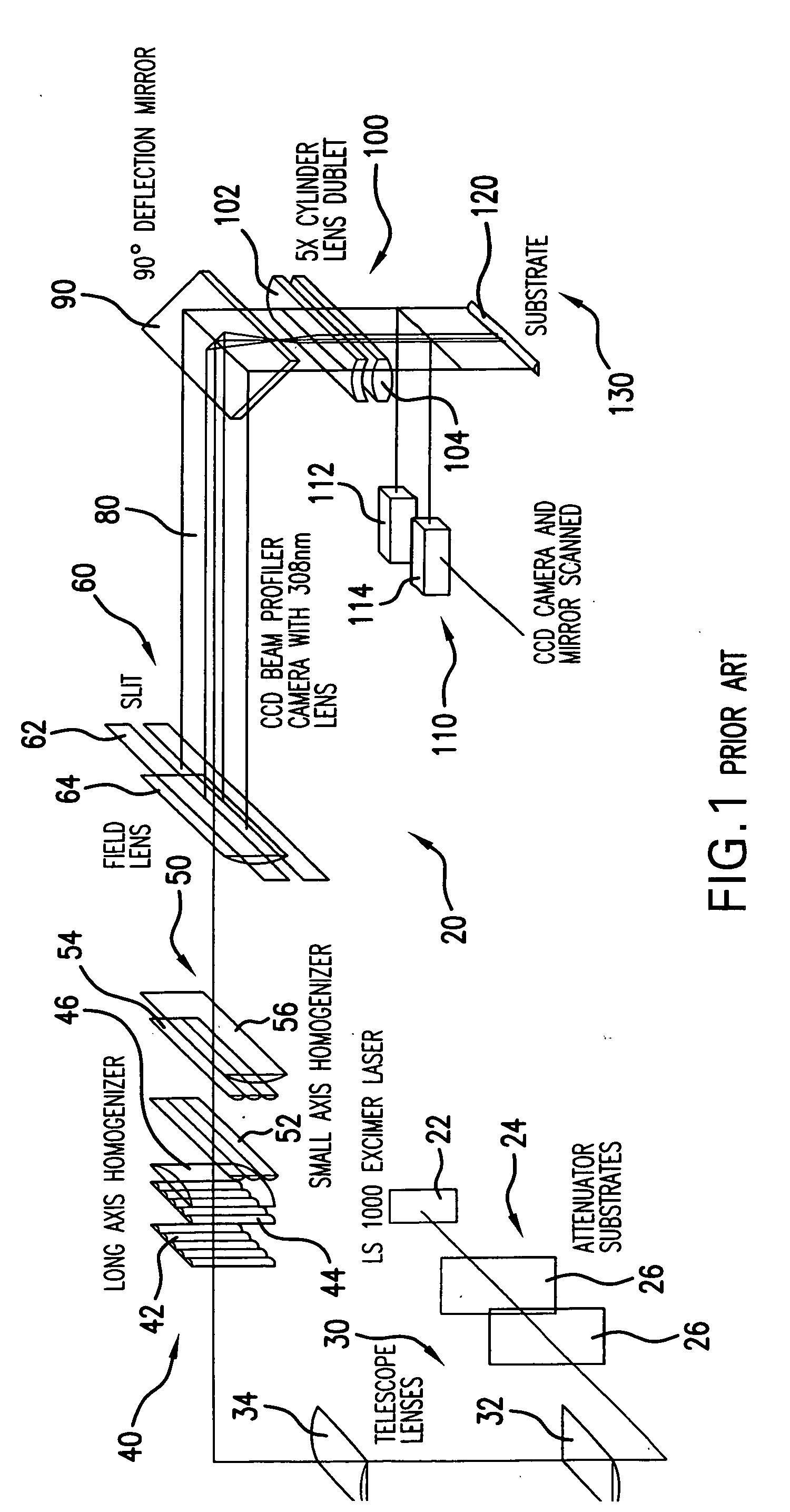

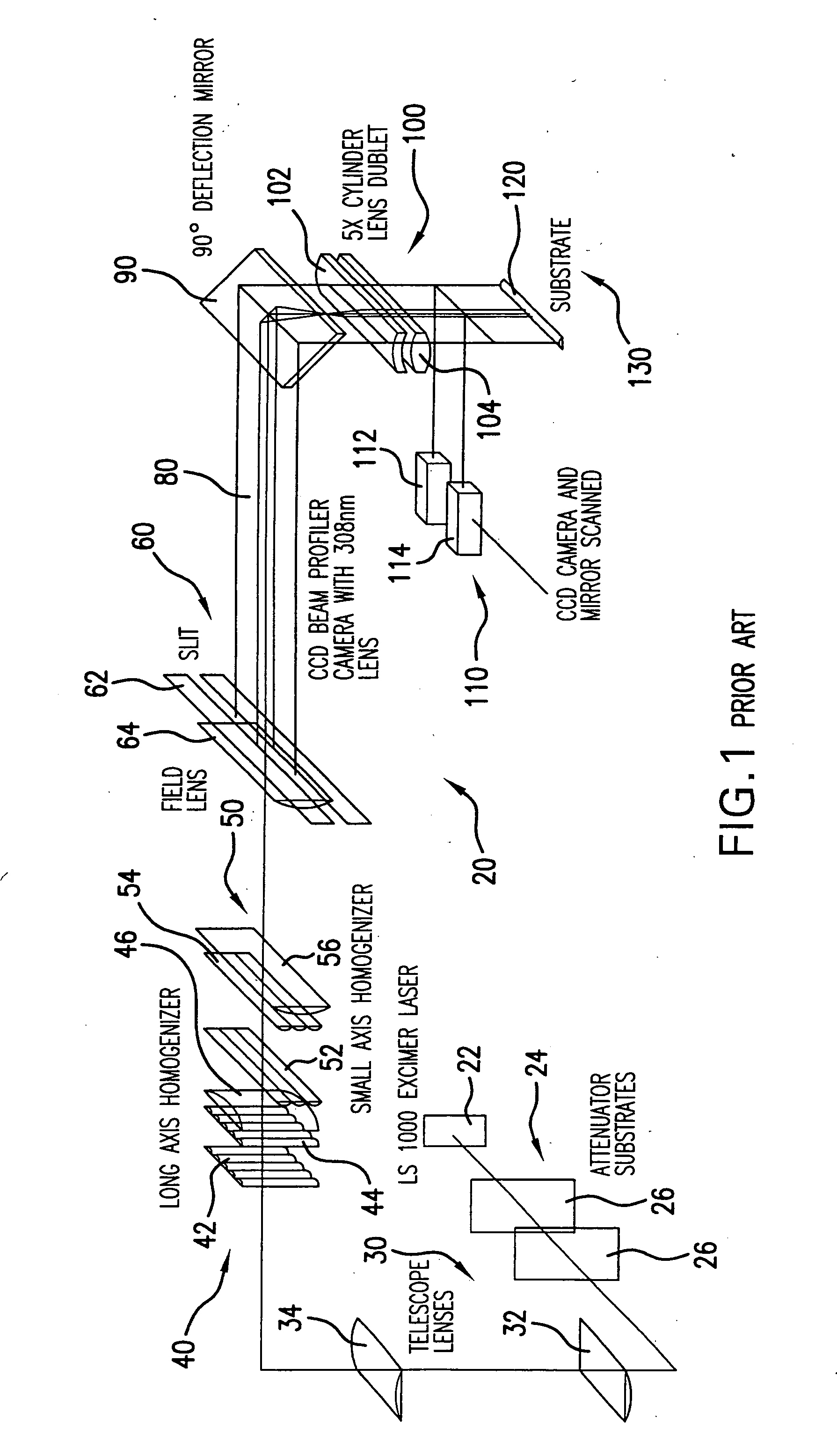

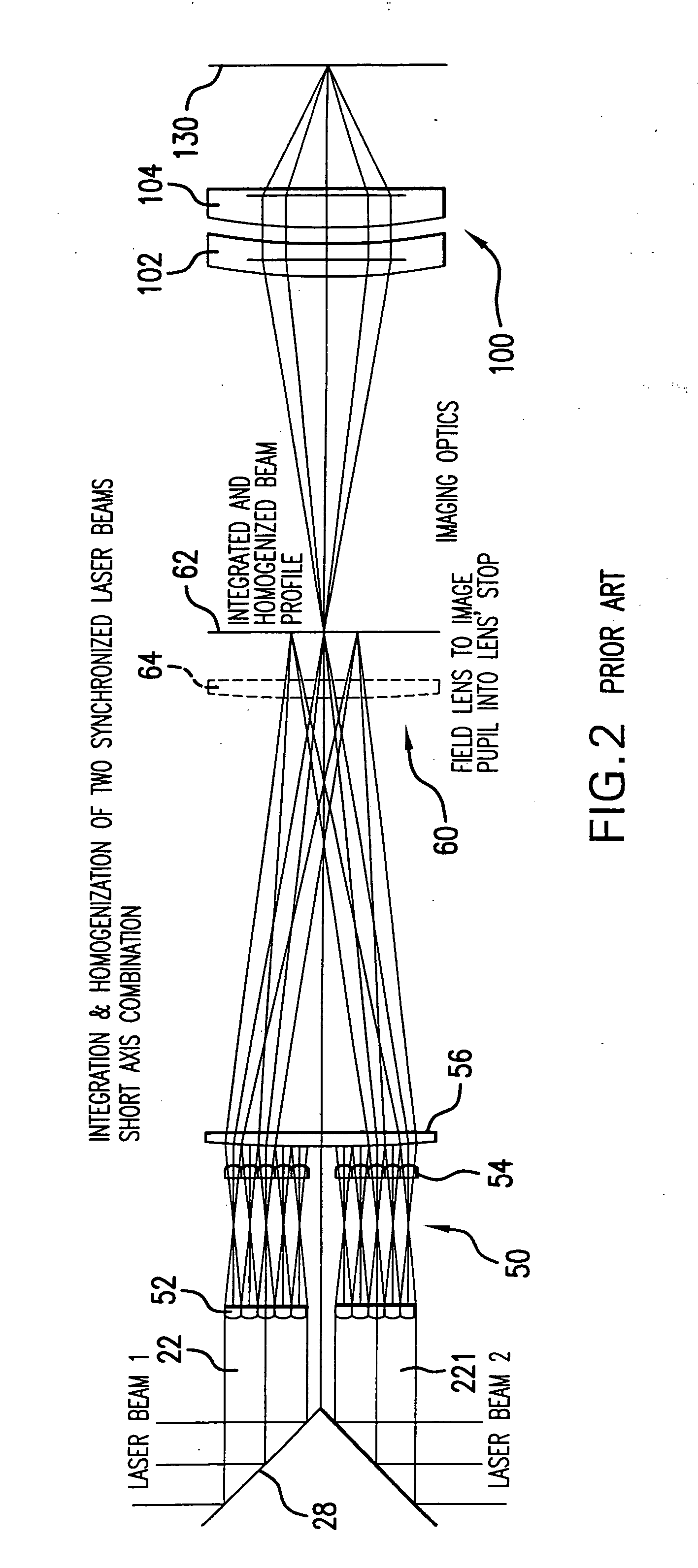

Laser thin film poly-silicon annealing optical system

A high energy, high repetition rate workpiece surface heating method and apparatus are disclosed which may cmprise a pulsed XeF laser operating at or above 4000 Hz and producing a laser output light pulse beam at a center wavelength of about 351 nm; an optical system narrowing the laser output light pulse beam to less than 20 μm in a short axis of the laser output light pulse beam and expanding the laser output light pulse beam to form in a long axis of the beam a workpiece covering extent of teh long axis; the optical system including a field stop intermediate the laser and the workpiece; the workpiece comprising a layer to be heated; wherein the optical system focuses the laser output light pulse beam at a field stop with a magnification sufficient to maintain an intensity profile that has sufficiently steep sidewalls to allow the field stop to maintain a sufficiently steep beam profile at the workpiece without blocking the beam profile at too high an intensity level. 2. The apparatus may also have a high average power in the laser ouput light pulse beam as delivered to the workpiece and a a linebow correction mechanism in a short axis optical assembly. The linebow correction mechanism may comprise a plurality of weak cross cylinders. The system may comprise a catadioptric projection system. The linewidth due to laser diffraction and divergence may be less than geometric limitations. The system may project adjacent peaks of the nominal XeF spectrum to improve overall depth of focus through the separate center wavelengths of each respective adjacent peak having a different focal plane at the workpiece. The system may comprise a linebow is correction mechanism within a field stop optical assembly correcting linebow at the field stop plane and within a workpiece projection optical assembly correcting linebow at the workpiece plane.

Owner:CYMER INC

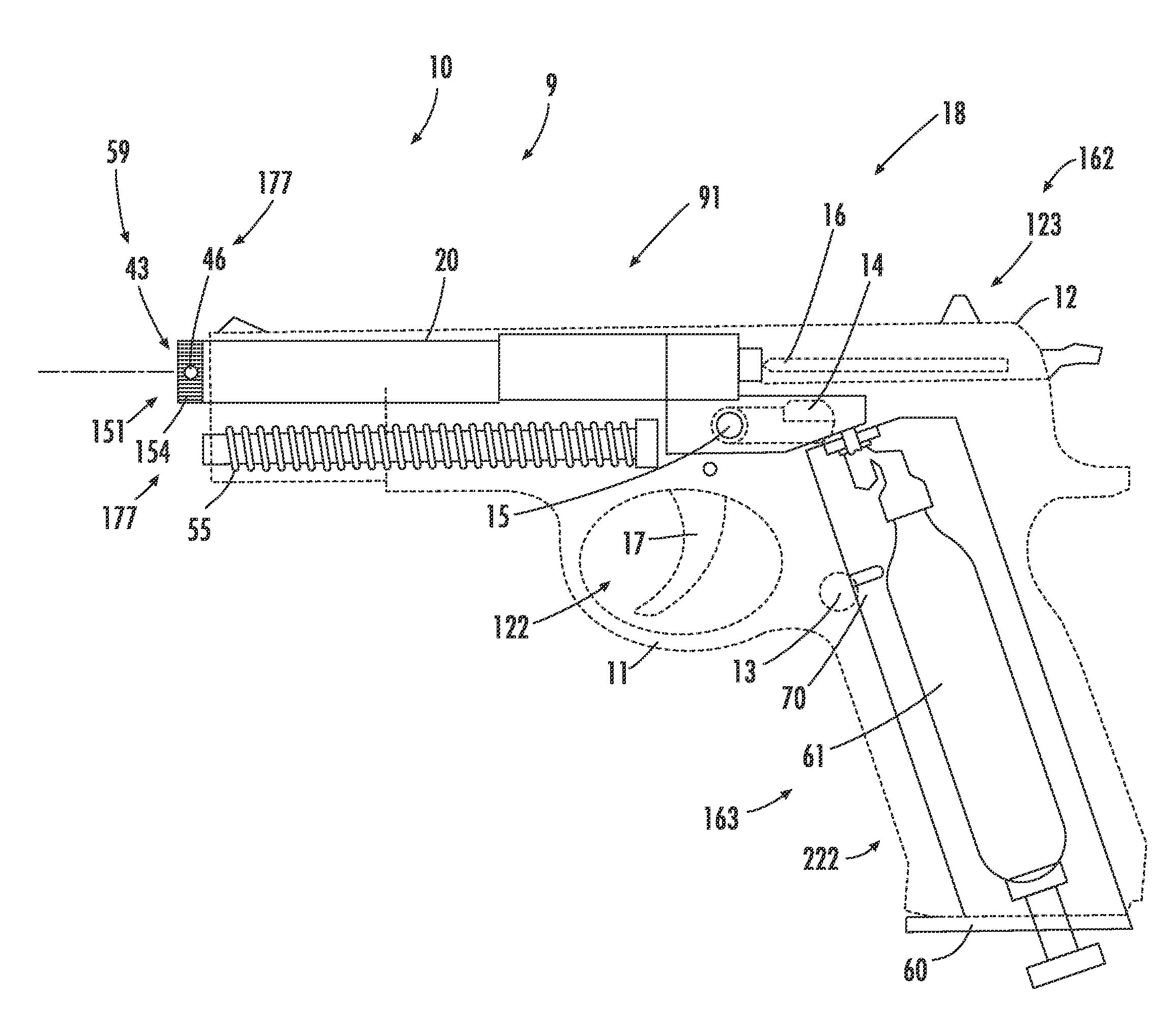

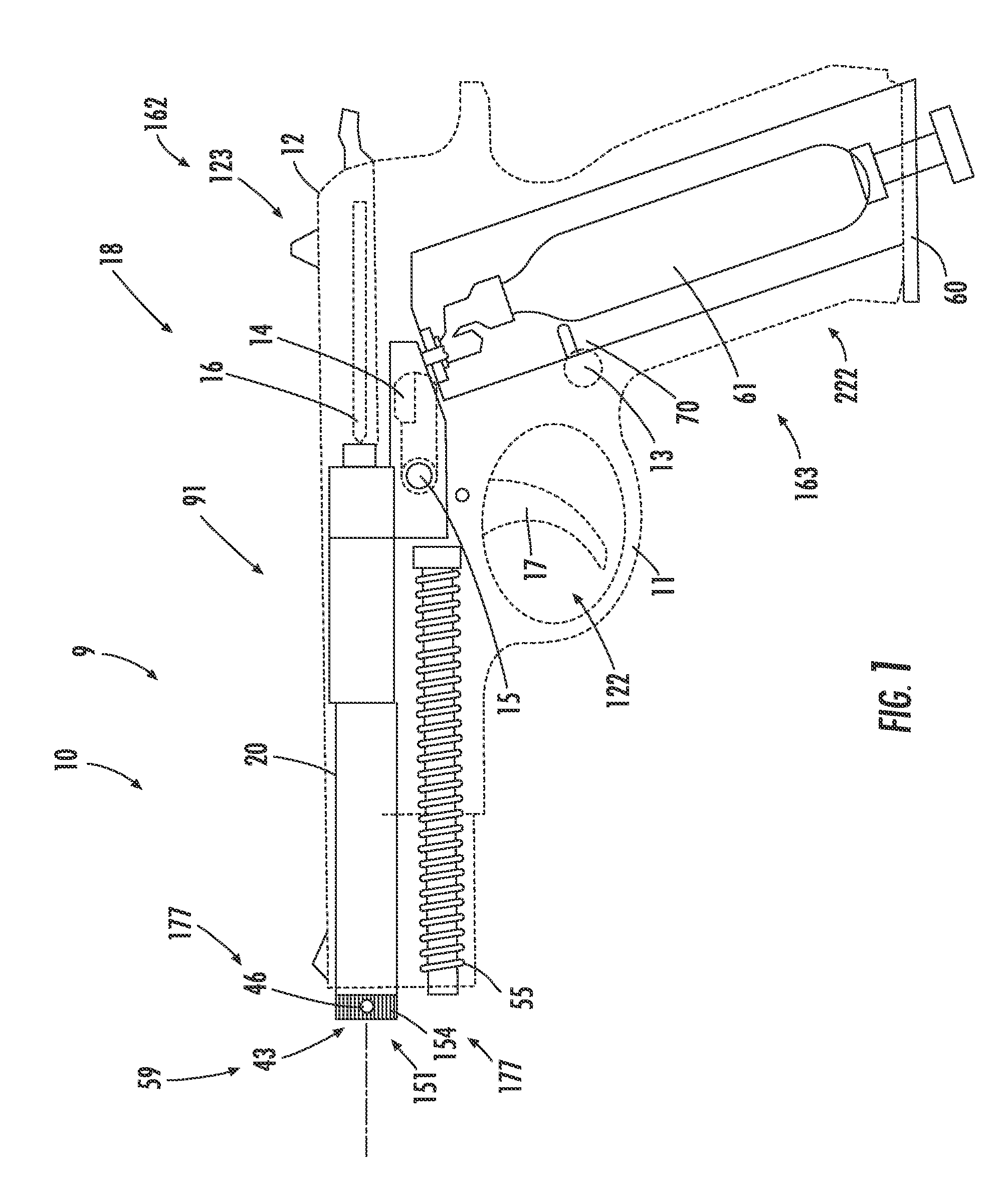

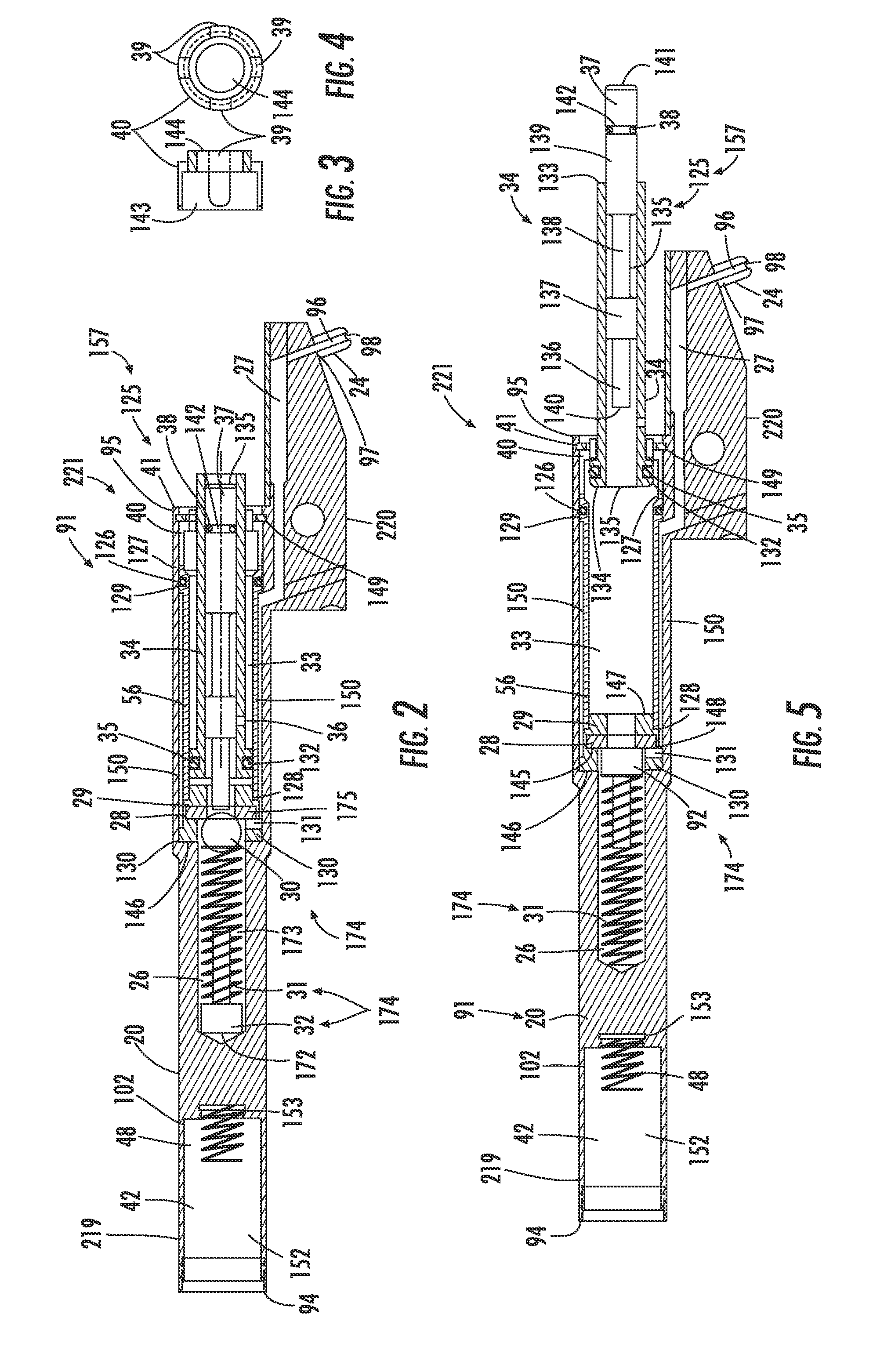

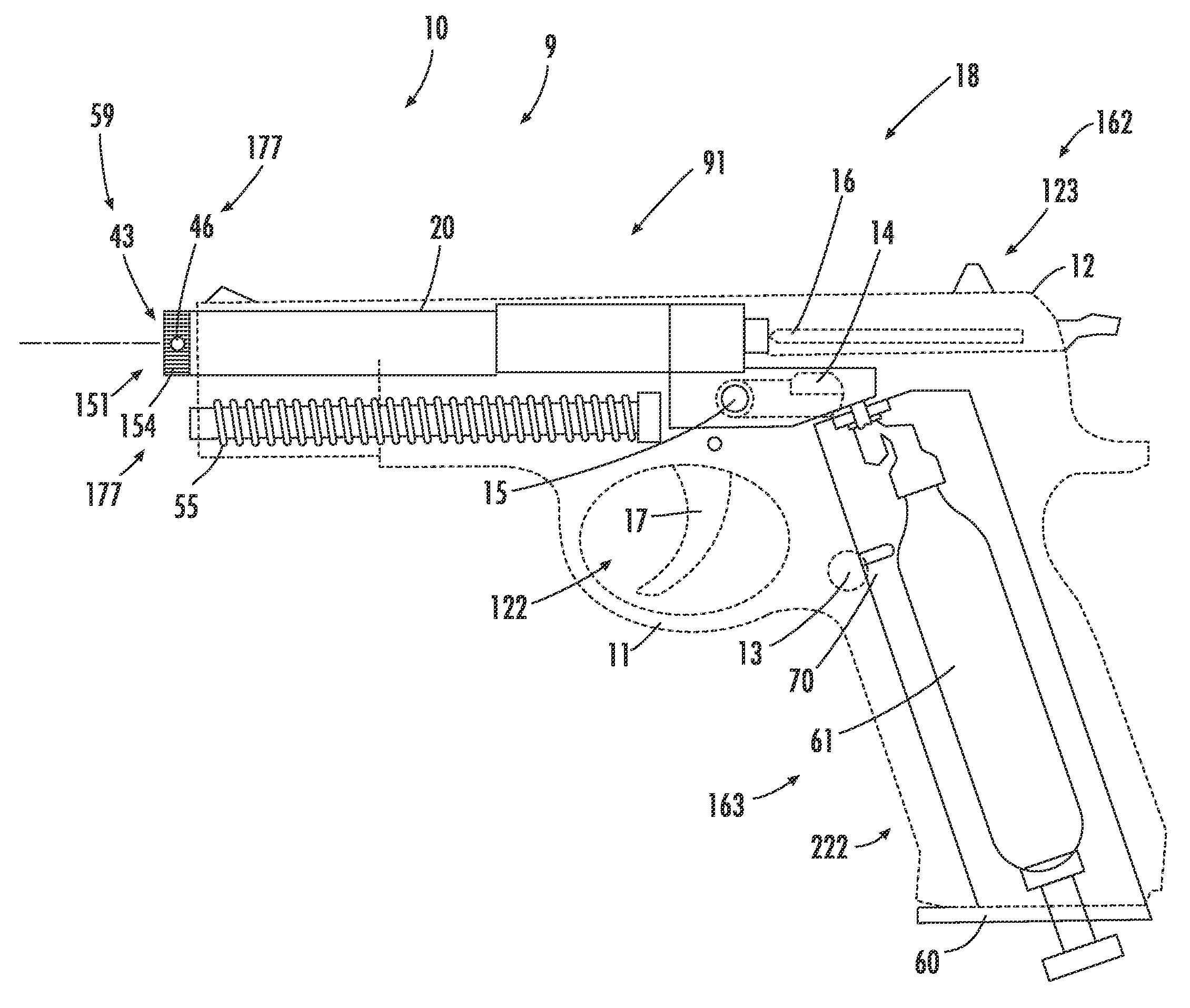

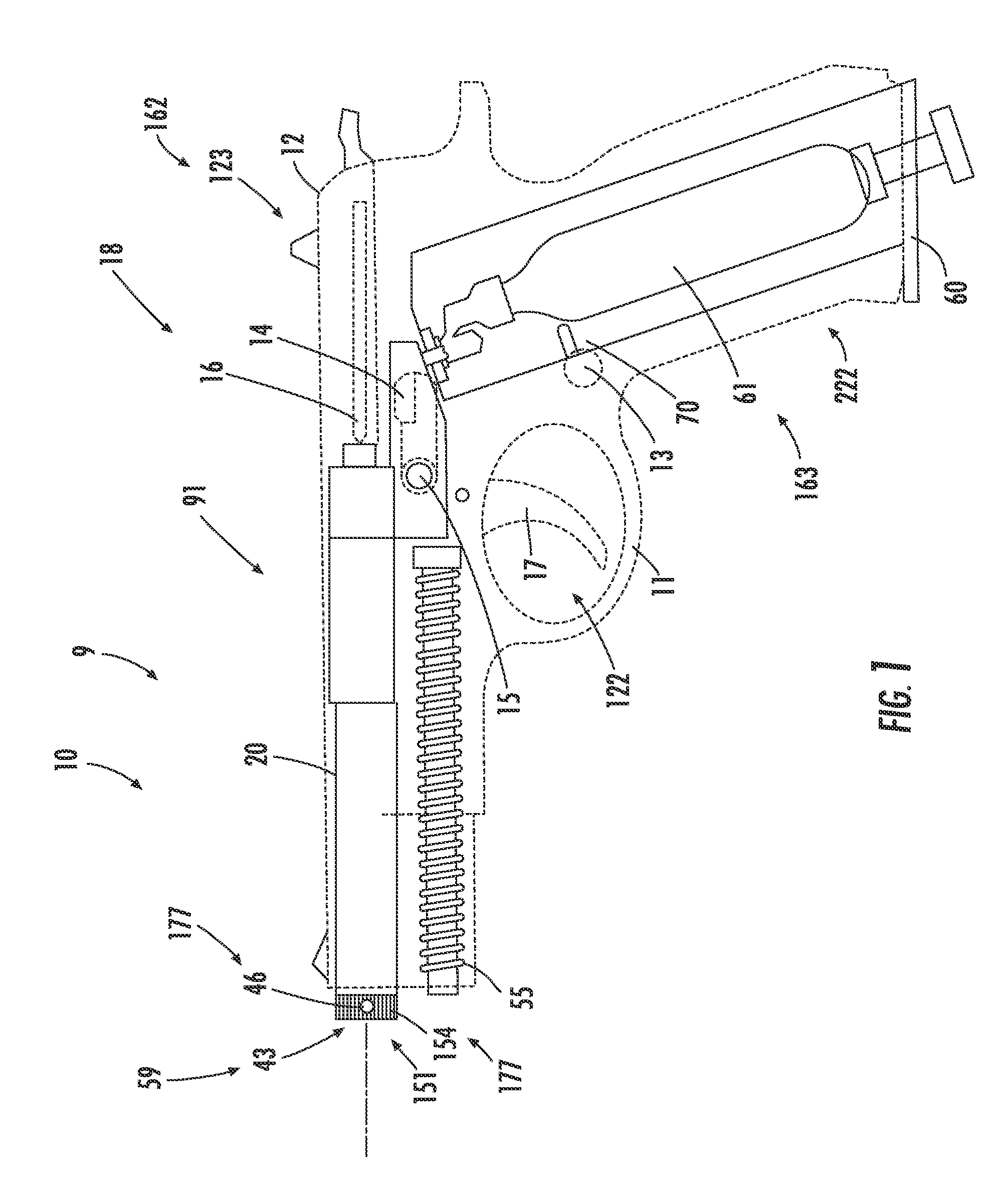

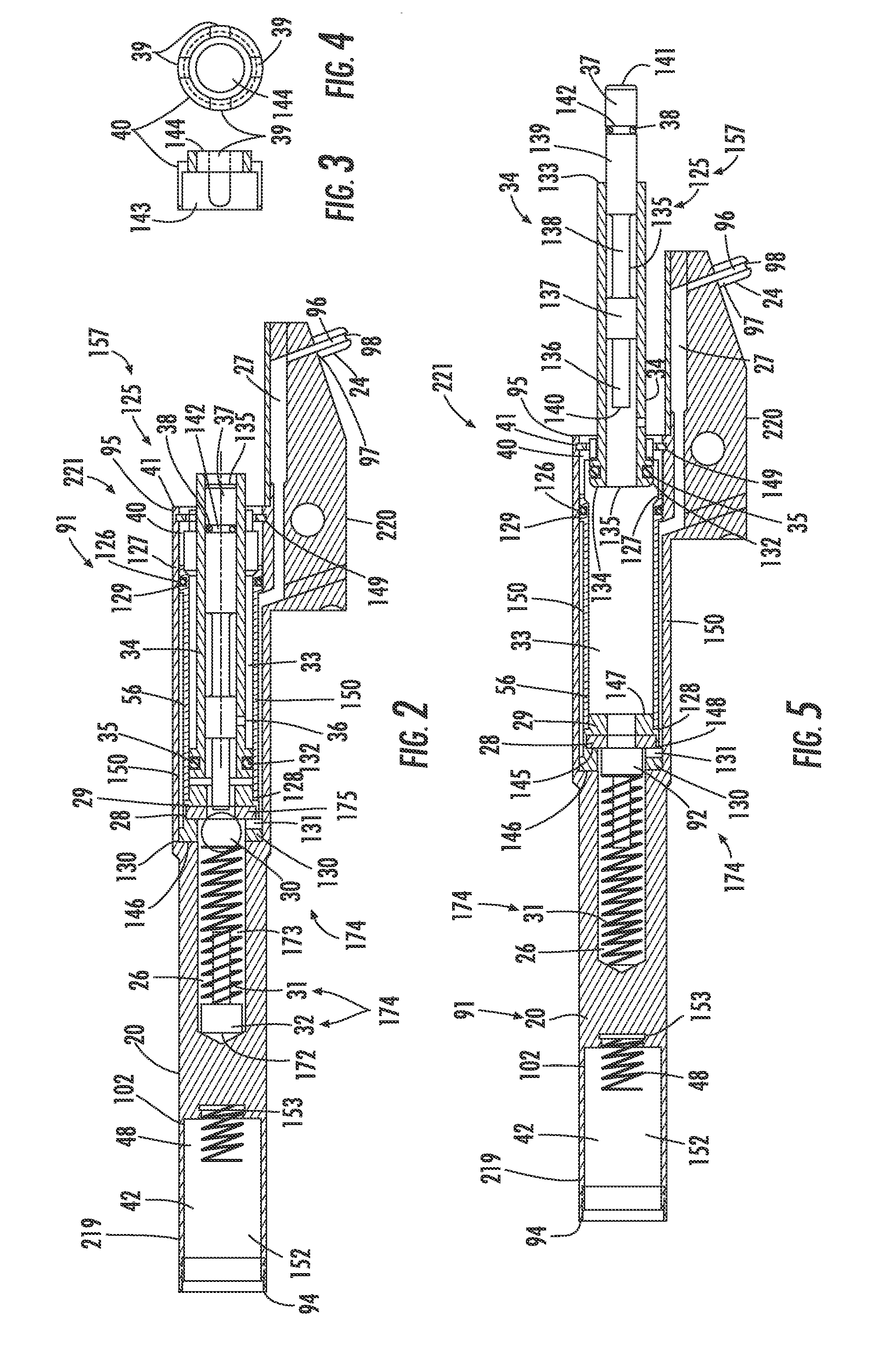

Apparatus for converting a pistol into a weapon simulator

ActiveUS20120129136A1Easy to disassembleRealistic sensationCompressed gas gunsTraining adaptationPulse beamEngineering

An apparatus for non-permanent conversion of a semiautomatic pistol into a compressed gas powered weapon simulator. The apparatus replaces the pistol's barrel, recoil spring and magazine with no modification of the pistol, which allows retaining the operational functions of the pistol's remaining components. Compressed gas, from the simulation magazine unit, is used in the compressed gas valve means, in the barrel unit, to operate the slide mechanism, to compress the simulation recoil spring, and to emit a laser pulse beam on a target when activated by the firing mechanism; and battery power, from the simulation magazine unit, is used to count the number of shots, lock the slide after a predetermined number of shots and transmit information from the weapon simulator to a remote data system. The compressed simulation recoil spring returns the slide mechanism back to its original position, unless locked open by the apparatus.

Owner:DVORAK VOJTECH

System and method of identifying an object in a laser beam illuminated scene based on material types

Owner:ROSEMOUNT AEROSPACE

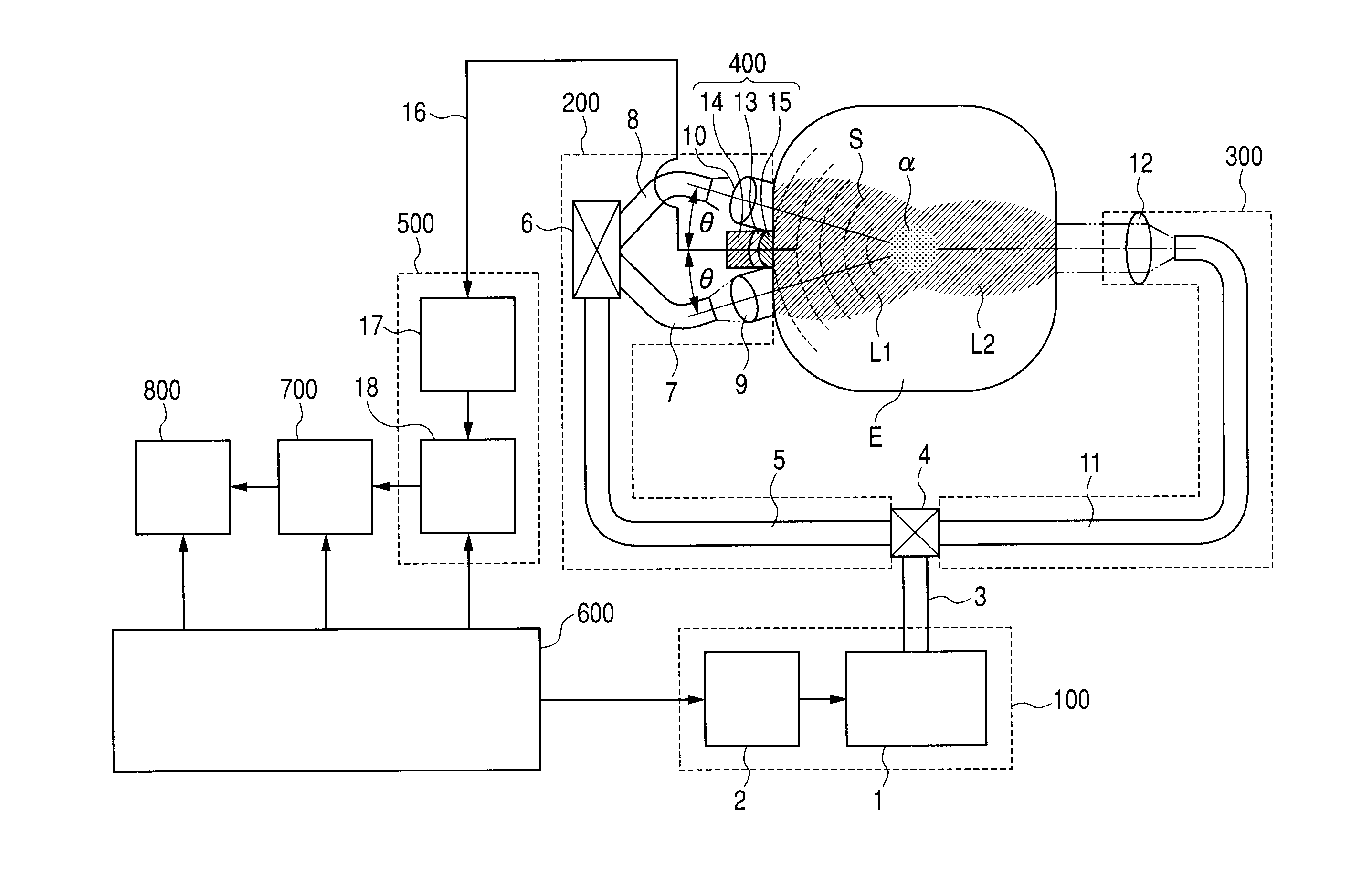

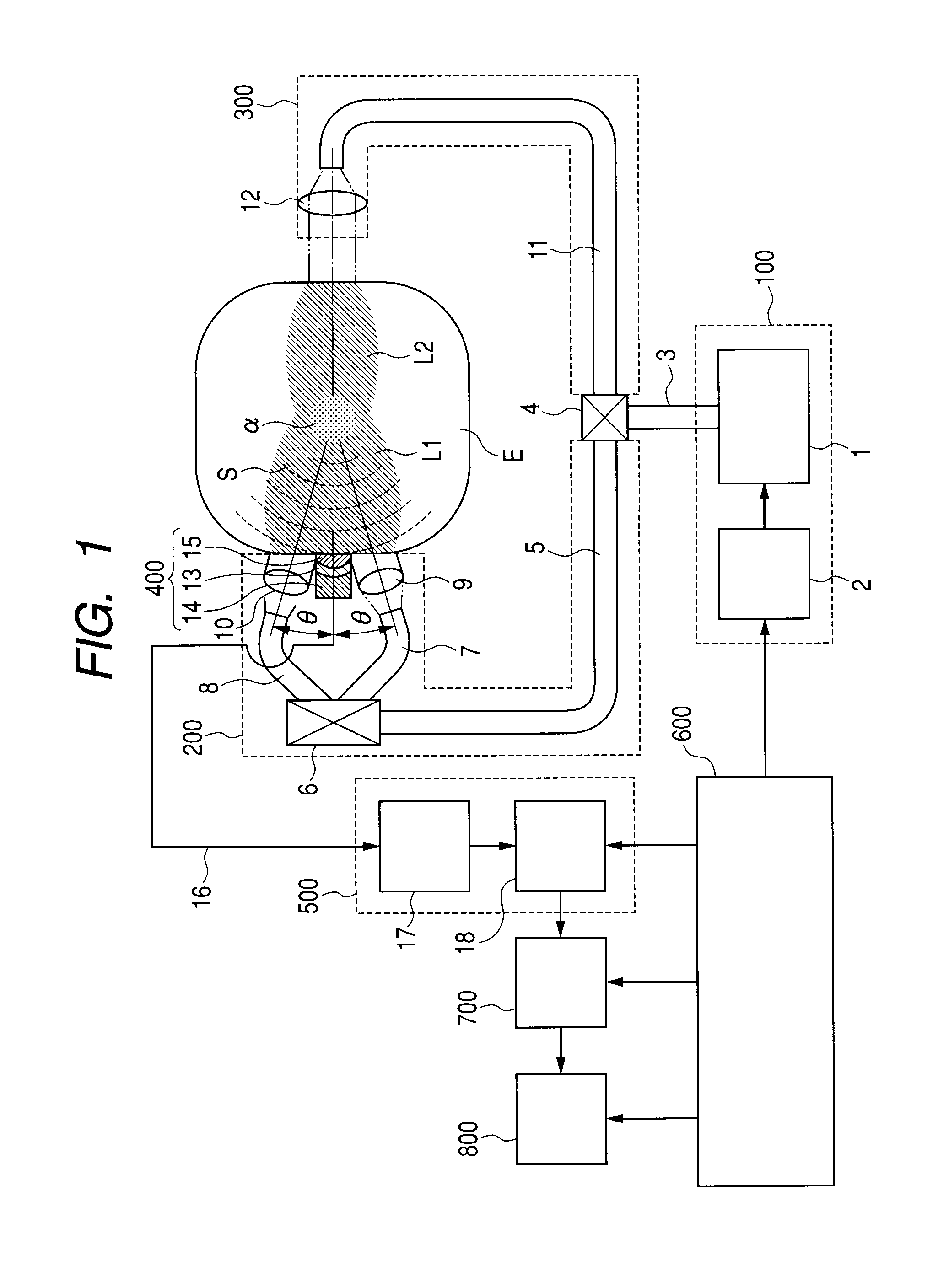

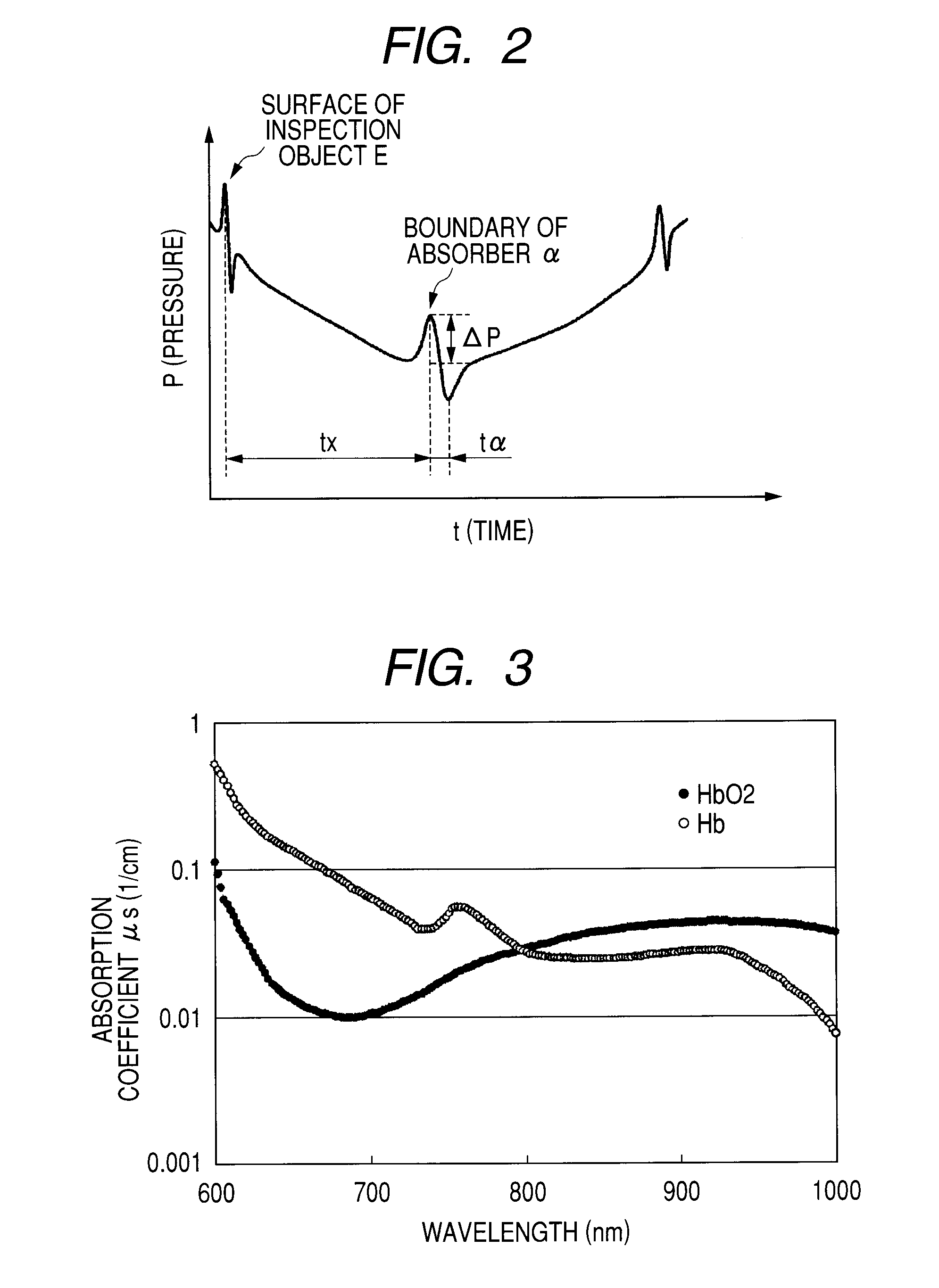

Photoacoustic measurement apparatus

InactiveUS20110112391A1Improve accuracyAccurate measurementDiagnostics using lightMaterial analysis by optical meansPulse beamLight beam

A measurement apparatus capable of measuring a position and a size of an absorber with high accuracy, which includes: a light source unit for emitting a pulse beam; an illumination optical unit for leading the pulse beam emitted by the light source unit to an inside of an inspection object; and an acoustic signal detection unit for detecting a photoacoustic signal generated by the pulse beam in which the illumination optical unit includes a first and second illumination optical units that are arranged so that the inspection object is irradiated with the pulse beam from both sides thereof opposingly; and the acoustic signal detection unit is provided so that a detection surface of the acoustic signal detection unit is positioned on the same side as that of one of irradiation surfaces of the inspection object which the first and second illumination optical units irradiate with the pulse beam.

Owner:CANON KK

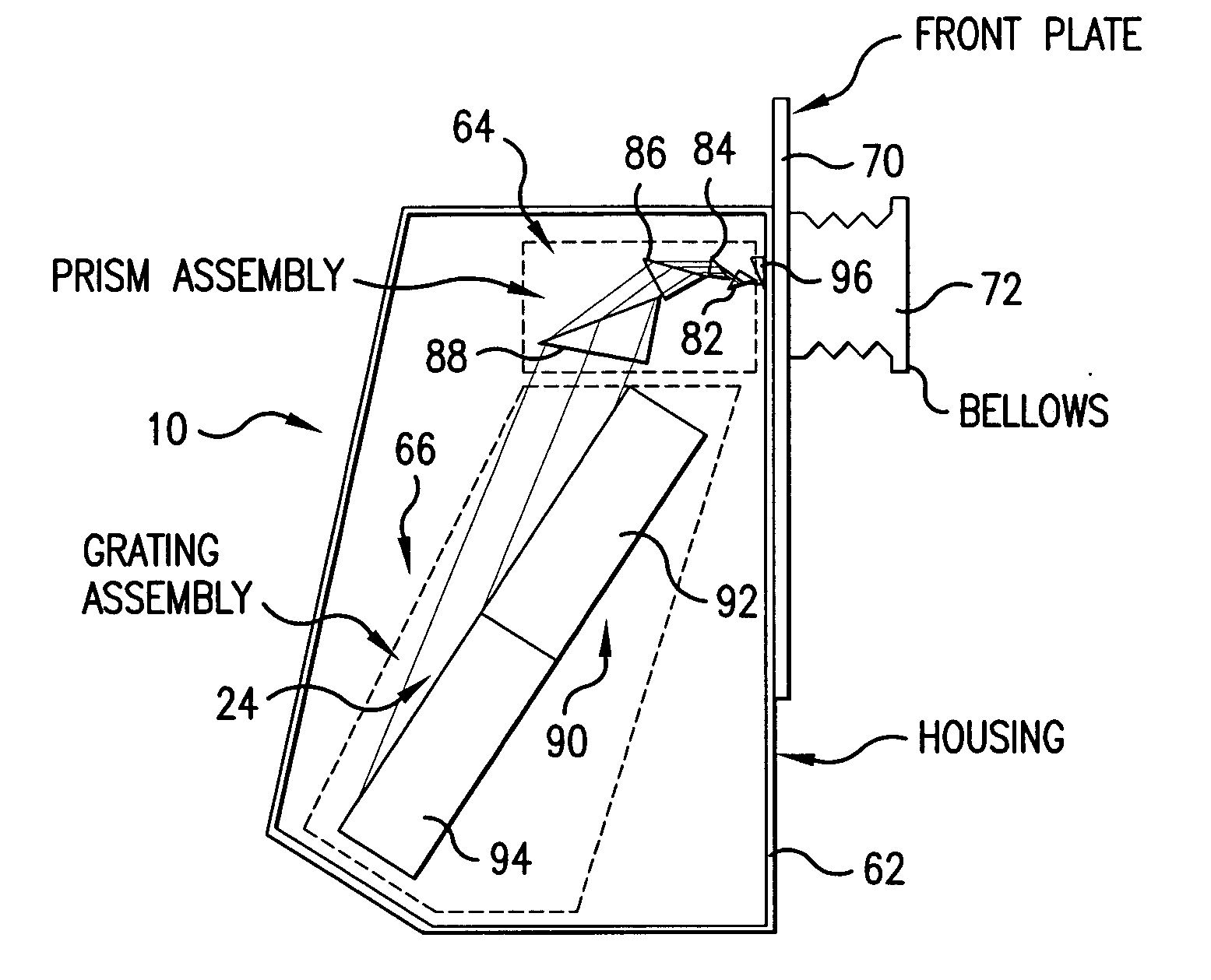

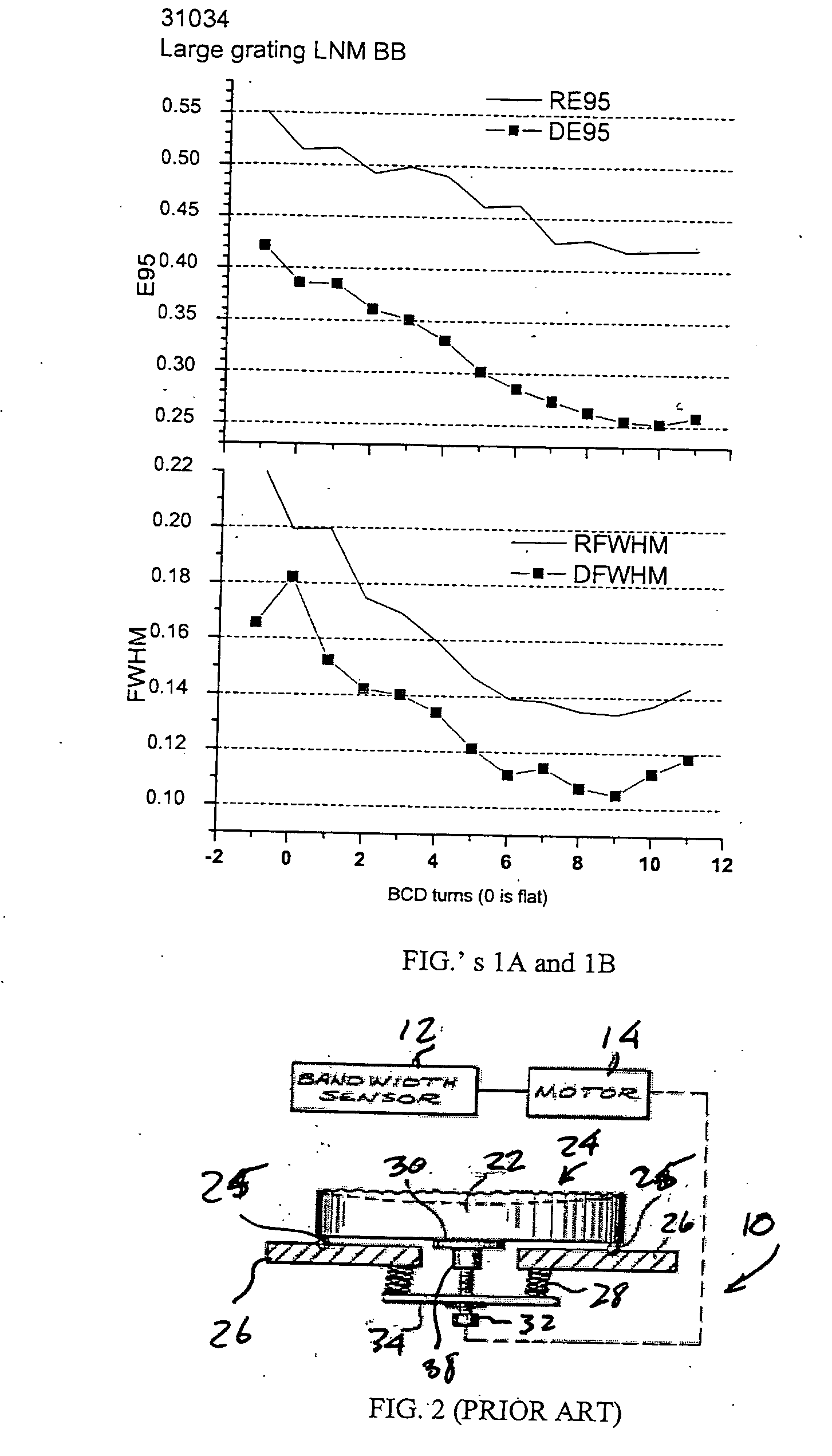

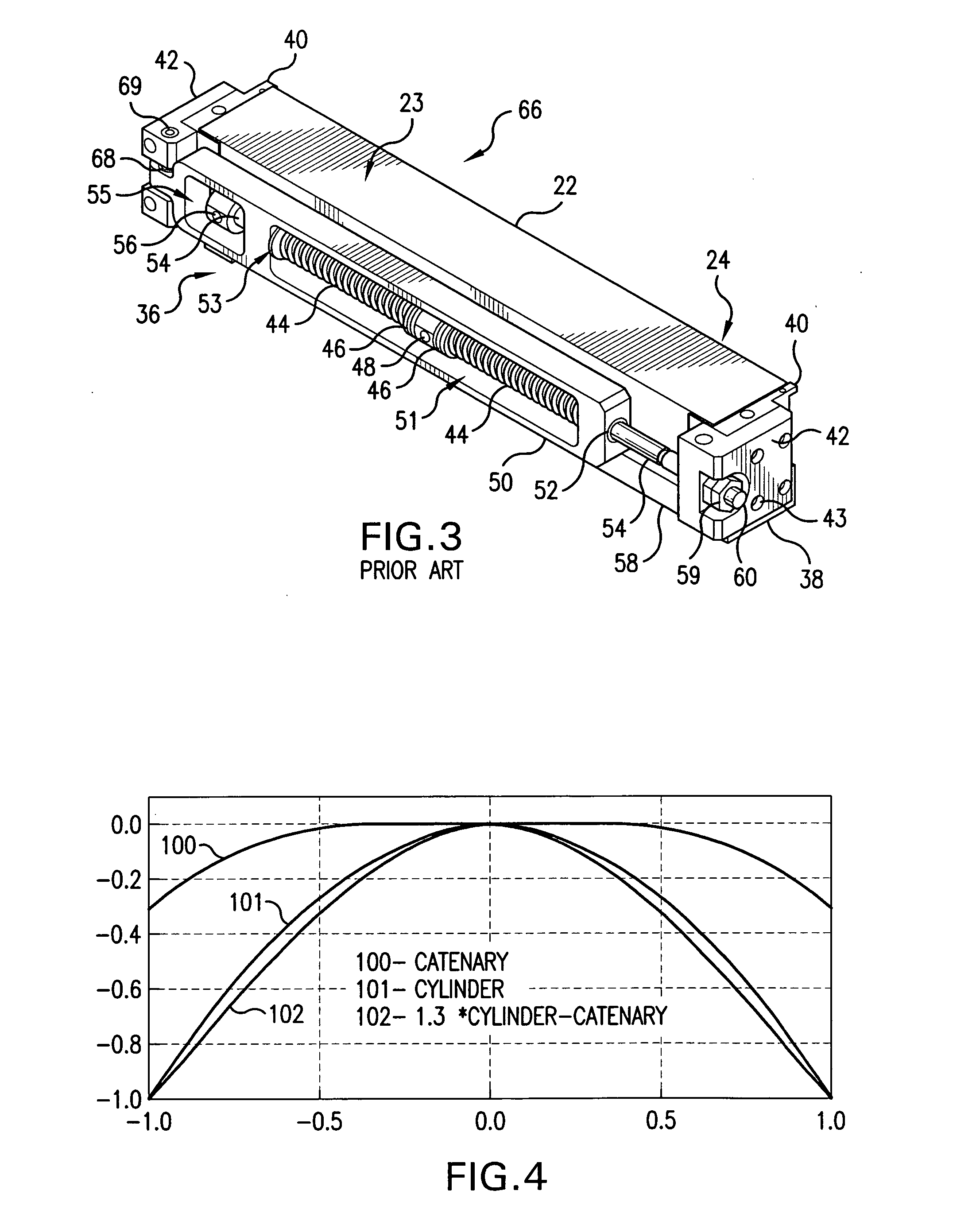

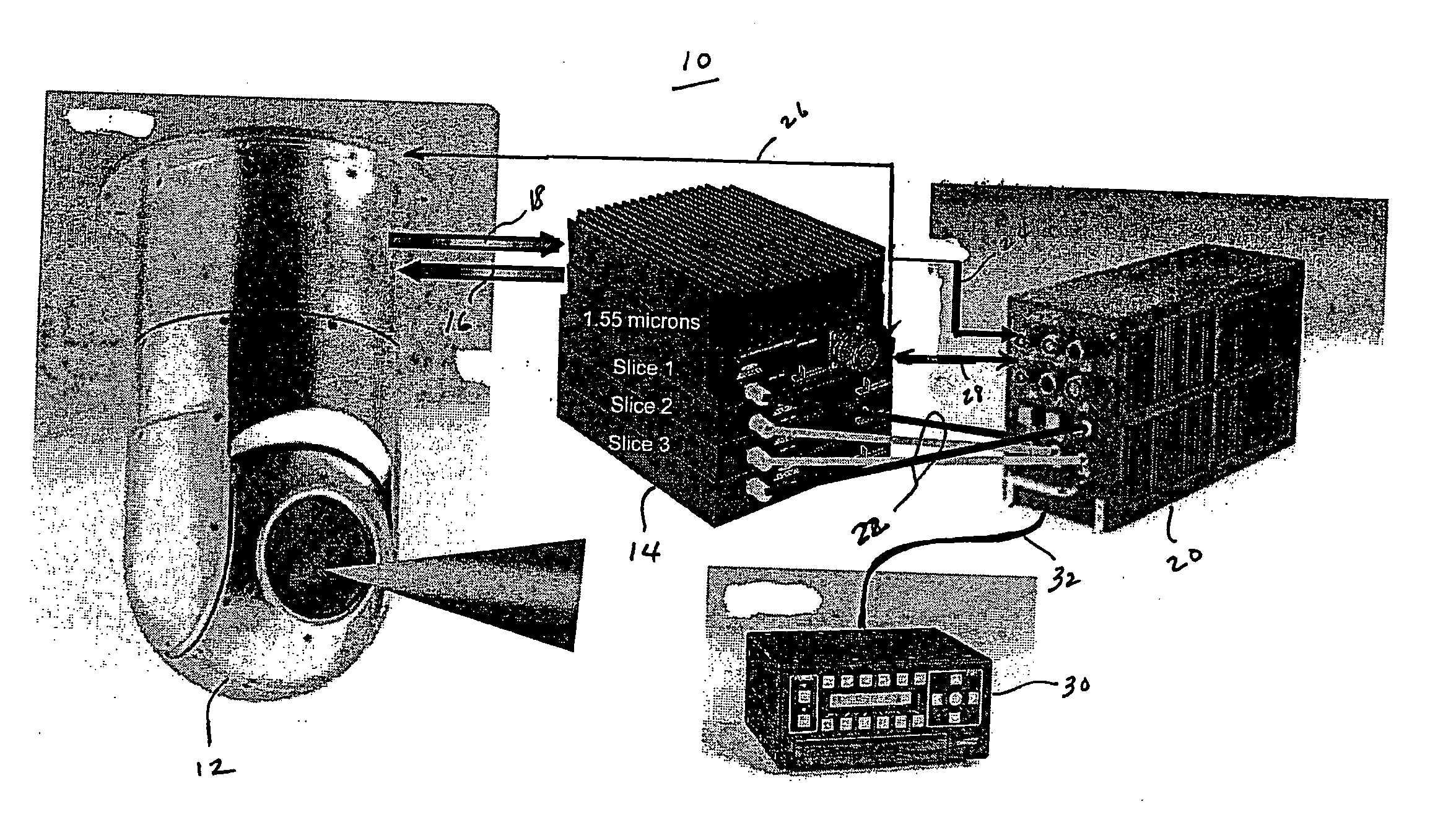

High power high pulse repetition rate gas discharge laser system bandwidth management

InactiveUS20060114956A1Minimize Fresnel lossHigh repetition rateActive medium materialPulse beamAngle of incidence

A line narrowing apparatus and method for a narrow band DUV high power high repetition rate gas discharge laser producing output laser light pulse beam pulses in bursts of pulses is disclosed, which may comprise a dispersive center wavelength selection optic contained within a line narrowing module, selecting at least one center wavelength for each pulse determined at least in part by the angle of incidence of the laser light pulse beam containing the respective pulse on a dispersive wavelength selection optic dispersive surface; a first dispersive optic bending mechanism operatively connected to the dispersive center wavelength selection optic and operative to change the curvature of the dispersive surface in a first manner; and, a second dispersive optic bending mechanism operatively connected to the dispersive center wavelength selection optic and operative to change the curvature of the dispersive surface in a second manner. The first manner may modify a first measure of bandwidth and the second manner may modify a second measure of bandwidth such that the ratio of the first measure to the second measure substantially changes. The first measure may be a spectrum width at a selected percentage of the spectrum peak value (FWX % M) and the second measure may be width within which some selected percentage of the spectral intensity is contained (EX %). The first dispersive optic bending mechanism may change the curvature of the dispersive surface in a first dimension and the second in a second dimension generally orthogonal to the first dimension. The laser system may comprise a beam path insert comprising a material having an different index of refraction and an index of refraction thermal gradient opposite from that of a neighboring optical element. The first dispersive optic bending mechanism may change the curvature of the dispersive surface in a first dimension and the second a second dimension generally parallel to the first dimension. An optical beam twisting element in the lasing cavity may optically twist the laser light pulse beam to present a twisted wavefront to the dispersive center wavelength selection optic. Bending may change the curvature and wavelength selection, e.g., in a burst may create two center wavelength peaks to select FWX % M and EX % independently.

Owner:CYMER INC

System and method of identifying an object in a laser beam illuminated scene based on material types

A method of identifying an object in a laser beam illuminated scene based on material types comprises the steps of: emitting a pulsed beam of laser energy, each beam pulse comprising a plurality of different discrete wavelength emission components; illuminating a predetermined scene with the pulsed beam; receiving return laser pulses from objects within the illuminated scene, each return laser pulse comprising return components corresponding to the plurality of different discrete wavelength emission components; determining spectral reflectance values for the plurality of return components of each return laser pulse; determining a material type for each return laser pulse of the illuminated scene based on the plurality of reflectance values of the corresponding return pulse; indexing each determined material type to a position in the illuminated scene; and identifying an object in the illuminated scene based on material types and indexed positions thereof in the scene. A counterpart system for carrying out the method is also disclosed.

Owner:ROSEMOUNT AEROSPACE

Relax gas discharge laser lithography light source

An apparatus and method are disclosed for operating a narrow band short pulse duration gas discharge laser output light pulse beam producing system, producing a beam comprising laser output light pulses at a selected pulse repetition rate, which may comprise: a dispersive center wavelength selection optic selecting at least one center wavelength for each pulse determined at least in part by the angle of incidence of the laser light pulse beam containing the respective pulse on the dispersive wavelength selection optic; a tuning mechanism operative to select at least one angle of incidence of a first spatially defined portion of the laser light pulse beam containing the respective pulse upon the dispersive center wavelength selection optic; and, the tuning mechanism comprising a variably refractive optical element defining a plurality of refractive angular displacements of the first spatially defined portion of the laser light pulse beam passing through the variably refractive optical element at one of a plurality of positions of incidence of the laser light pulse beam on the variably refractive optical element. The variably refractive optical element may comprise: a first generally flat face defining a surface of incidence for the laser light pulse beam; and, a second multifaceted or curved face defining a plurality of generally flat surfaces of exit or a continuously varying surface of exit for the laser light beam. Other aspects of pulse parameter metrology and pulse modulation control, including in response to signals from the utilization tool are disclosed, e.g., relating to proper dose control with differing center wavelength spectra.

Owner:CYMER INC

Position measuring system, position measuring method and position measuring program

ActiveUS8218131B2Reduce defectsOptical rangefindersActive open surveying meansPulse beamData matching

A position measuring system, comprising a distance measuring unit for projecting and scanning a pulsed beam for measurement to a measurement area and for measuring a distance based on a reflected light of the pulsed beam for measurement and for obtaining a position data group in the measurement area, a digital image pickup unit for acquiring an image data by taking an image of the measurement area, a storage unit for storing at least two sets of the position data groups and the image data acquired from at least two directions by interrelating and associating the position data groups with the image data, and an arithmetic unit for synthesizing the at least two position data groups through matching of the two images based on the two stored image data.

Owner:KK TOPCON

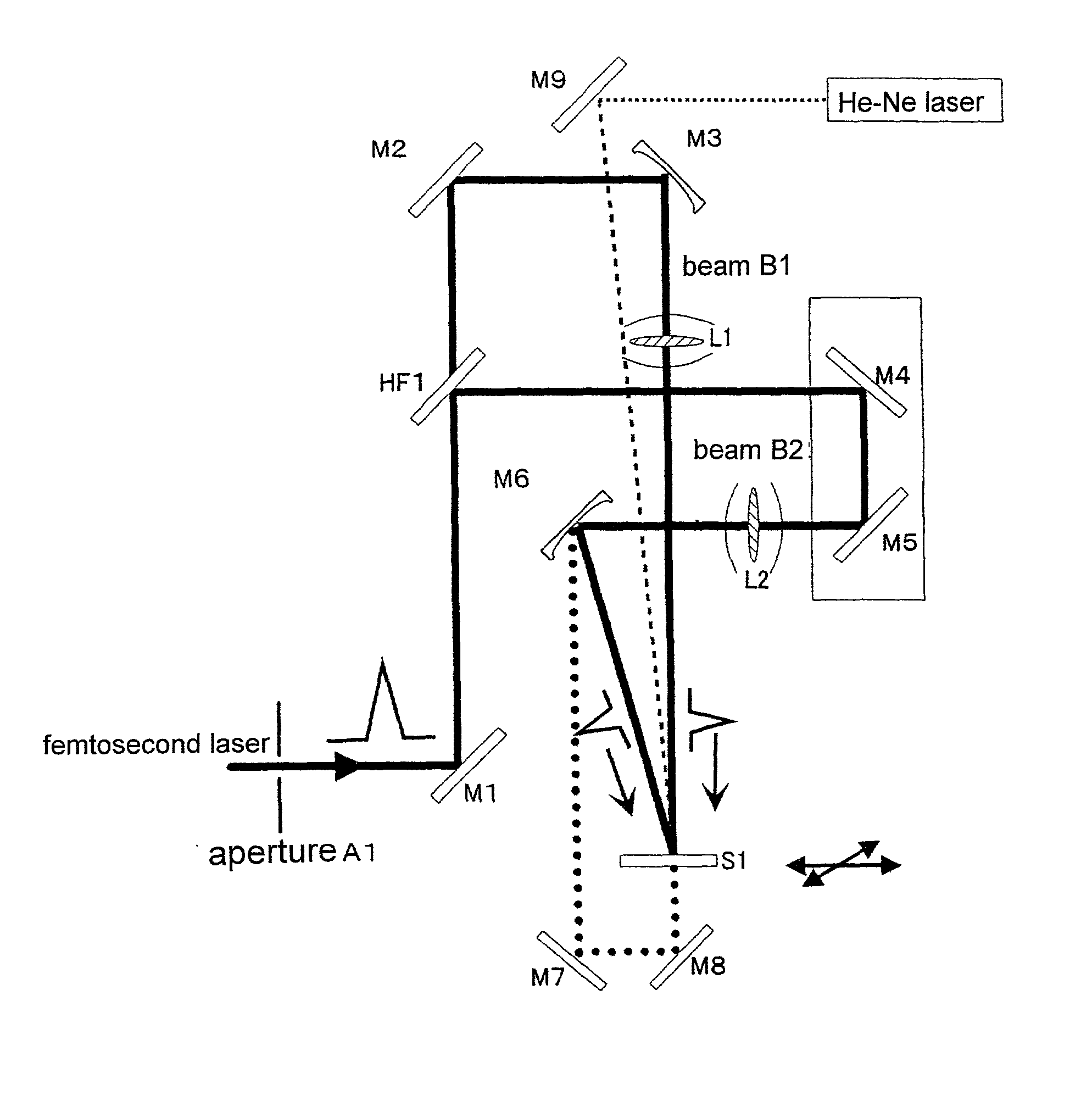

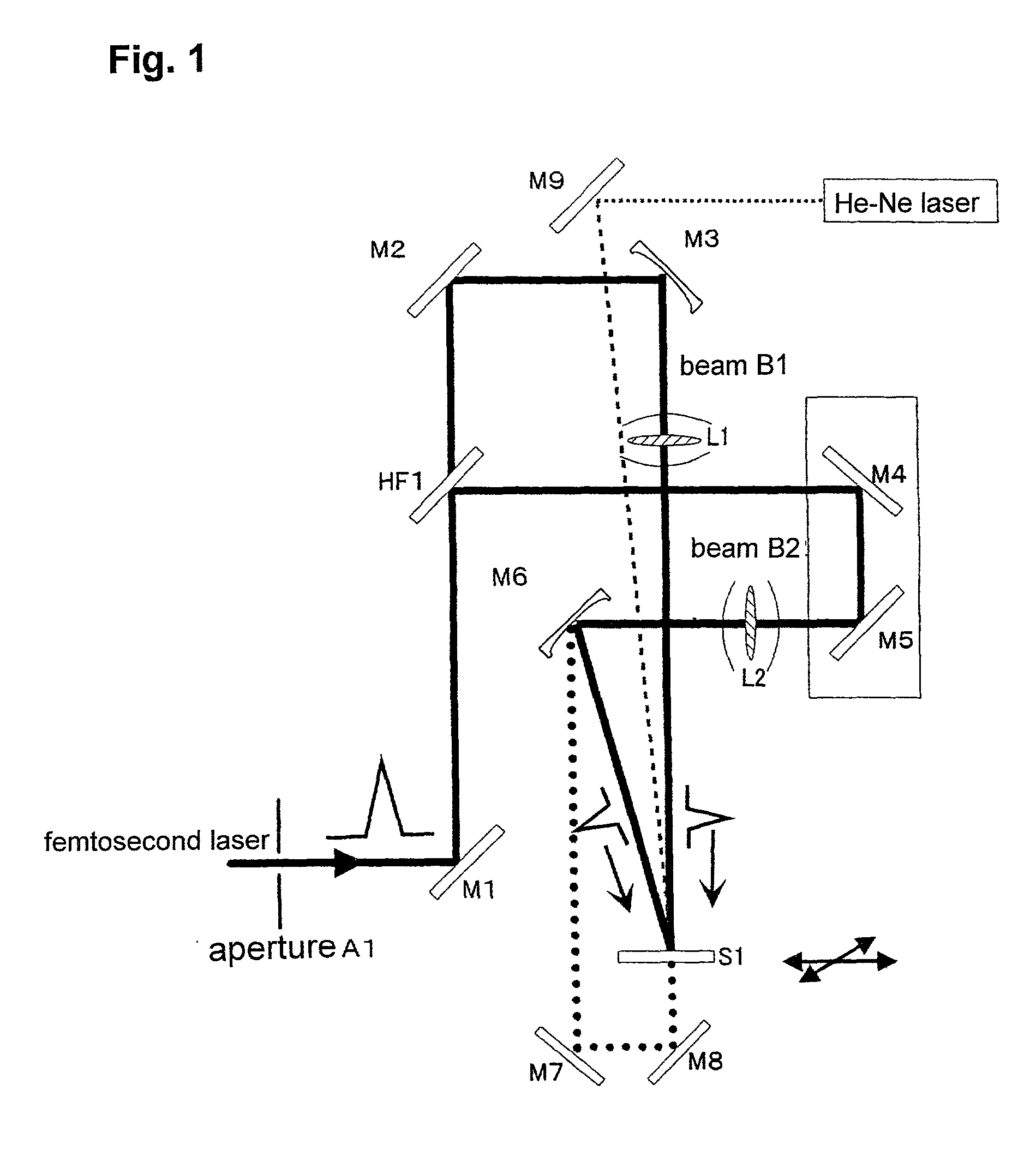

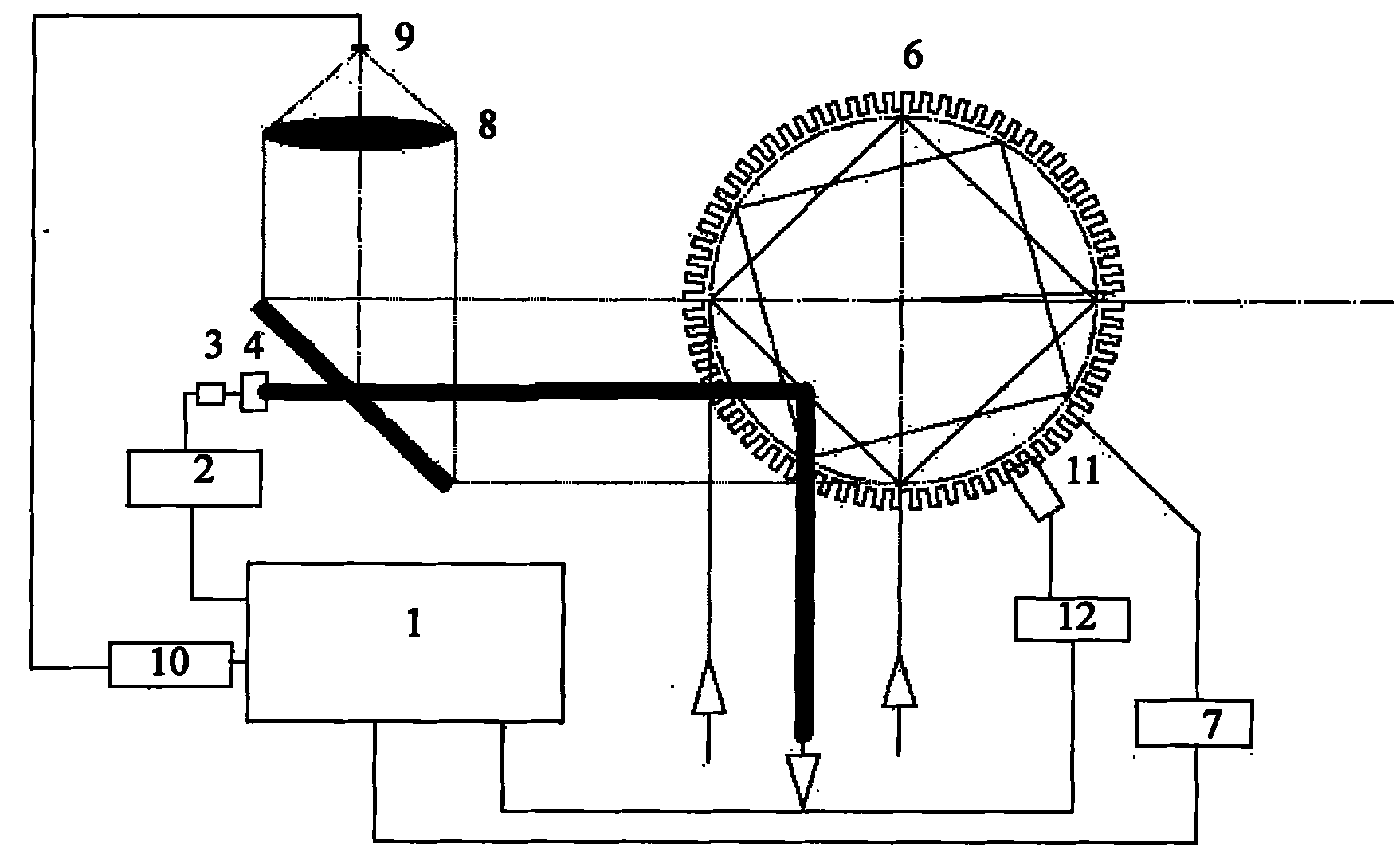

Production method and device for hologram

InactiveUS20020126333A1Improve interferenceReduce coherenceLaser detailsHolographic light sources/light beam propertiesPulse beamSemiconductor materials

A method and apparatus for producing a hologram using a two-beam laser interference exposure process, comprising the steps of using as a light source a femtosecond laser having a pulse width of 900-10 femtoseconds and a peak output of 1 GW or more and capable of generating a pulse beam at or close to the Fourier transform limit, dividing the pulse beam from the laser into two by a beam splitter, controlling the two beams temporally through an optical delay circuit and spatially using plane and concave mirrors each having a slightly rotatable reflection surface to converge the beams on a surface of or within a substrate for recording a hologram at an energy density of 100 GW / cm.sup.2 or more with keeping each polarization plane of the two beams in parallel so as to match the converged spot of the two beams temporally and spatially, whereby a hologram is recorded irreversibly on the substrate formed of a transparent material, semiconductor material or metallic material.

Owner:JAPAN SCI & TECH CORP

Detecting photons in the presence of a pulsed radiation beam

InactiveUS20110006212A1Reduces and avoids interferenceReduce sensitivityMaterial analysis using wave/particle radiationSurgeryPulse beamBeam source

A detector system adapted for monitoring a radiation treatment system comprising a pulsed beam radiation source for treating a body with a given beam intensity and beam configuration, with pulse times and intervals between pulses less than 100 milliseconds, using at least one monitoring radiation source located inside or outside the body, the detector system comprising; a) a detector designed to detect radiation from the monitoring source, and subject to interference radiation from the beam source; and b) control circuitry that creates a data record of radiation received by the detector, to provide information about the body; wherein, when the detector detects radiation in real time during operation of the beam, the data record selectively excludes data for radiation received by the detector during the pulses, as opposed to data for radiation received by the detector between pulses.

Owner:NAVOTEK MEDICAL

Laser thin film poly-silicon annealing optical system

InactiveUS20050035103A1High energyIncrease heightFrom solid stateBy zone-melting liquidsPulse beamHigh energy

A high energy, high repetition rate workpiece surface heating method and apparatus are disclosed which may cmprise a pulsed XeF laser operating at or above 4000 Hz and producing a laser output light pulse beam at a center wavelength of about 351 nm; an optical system narrowing the laser output light pulse beam to less than 20 μm in a short axis of the laser output light pulse beam and expanding the laser output light pulse beam to form in a long axis of the beam a workpiece covering extent of teh long axis; the optical system including a field stop intermediate the laser and the workpiece; the workpiece comprising a layer to be heated; wherein the optical system focuses the laser output light pulse beam at a field stop with a magnification sufficient to maintain an intensity profile that has sufficiently steep sidewalls to allow the field stop to maintain a sufficiently steep beam profile at the workpiece without blocking the beam profile at too high an intensity level. 2. The apparatus may also have a high average power in the laser ouput light pulse beam as delivered to the workpiece and a a linebow correction mechanism in a short axis optical assembly. The linebow correction mechanism may comprise a plurality of weak cross cylinders. The system may comprise a catadioptric projection system. The linewidth due to laser diffraction and divergence may be less than geometric limitations. The system may project adjacent peaks of the nominal XeF spectrum to improve overall depth of focus through the separate center wavelengths of each respective adjacent peak having a different focal plane at the workpiece. The system may comprise a linebow is correction mechanism within a field stop optical assembly correcting linebow at the field stop plane and within a workpiece projection optical assembly correcting linebow at the workpiece plane.

Owner:CYMER INC

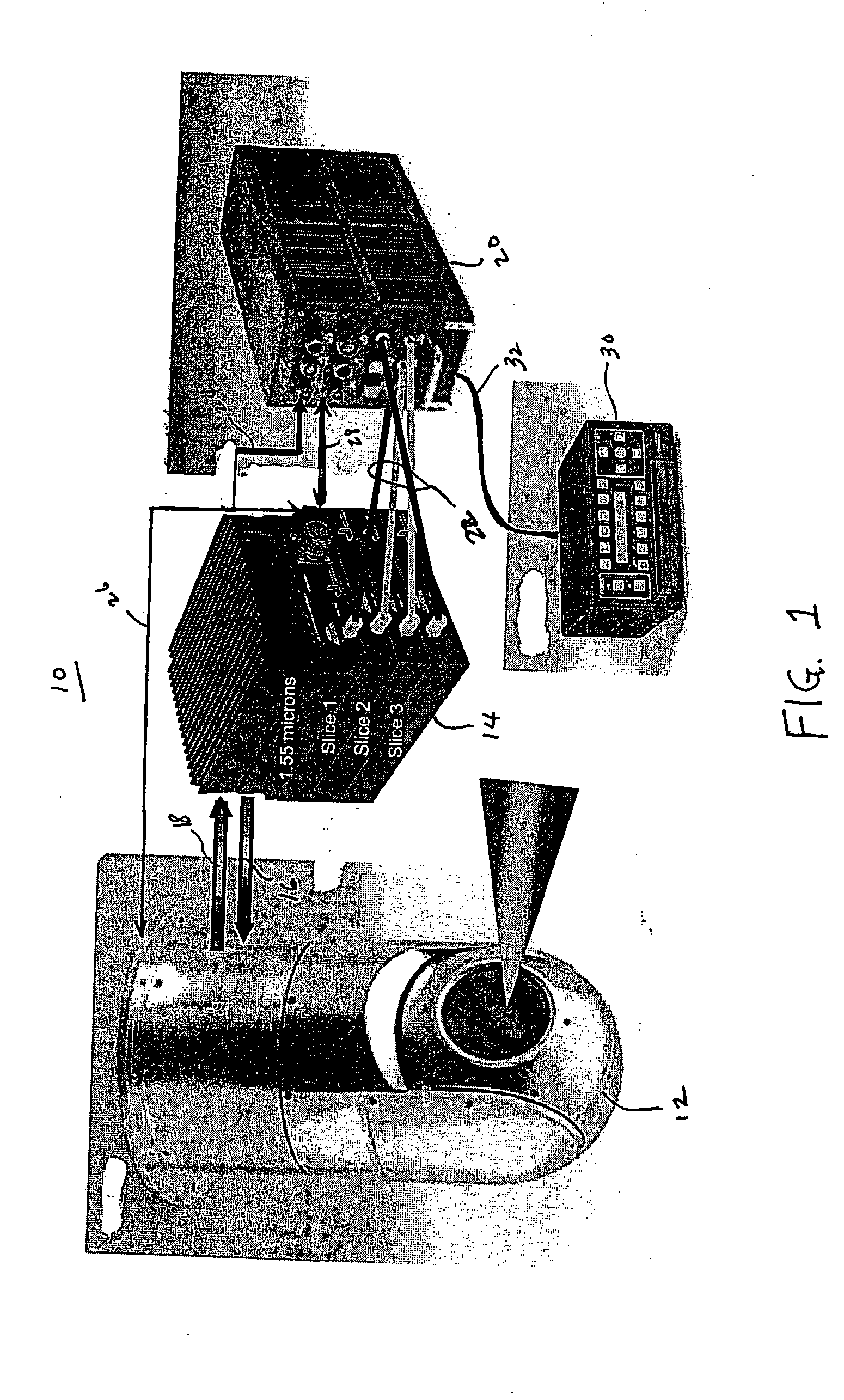

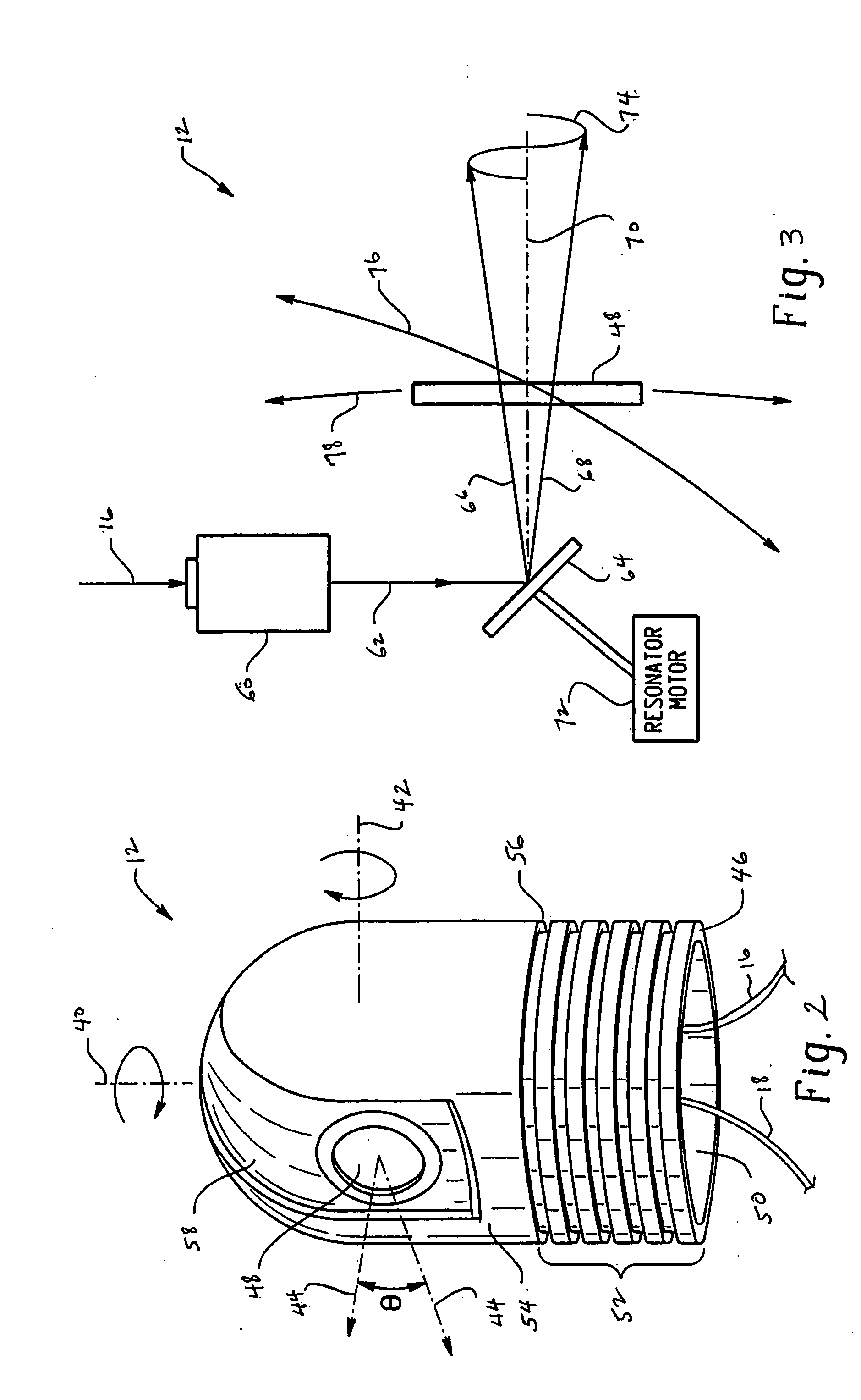

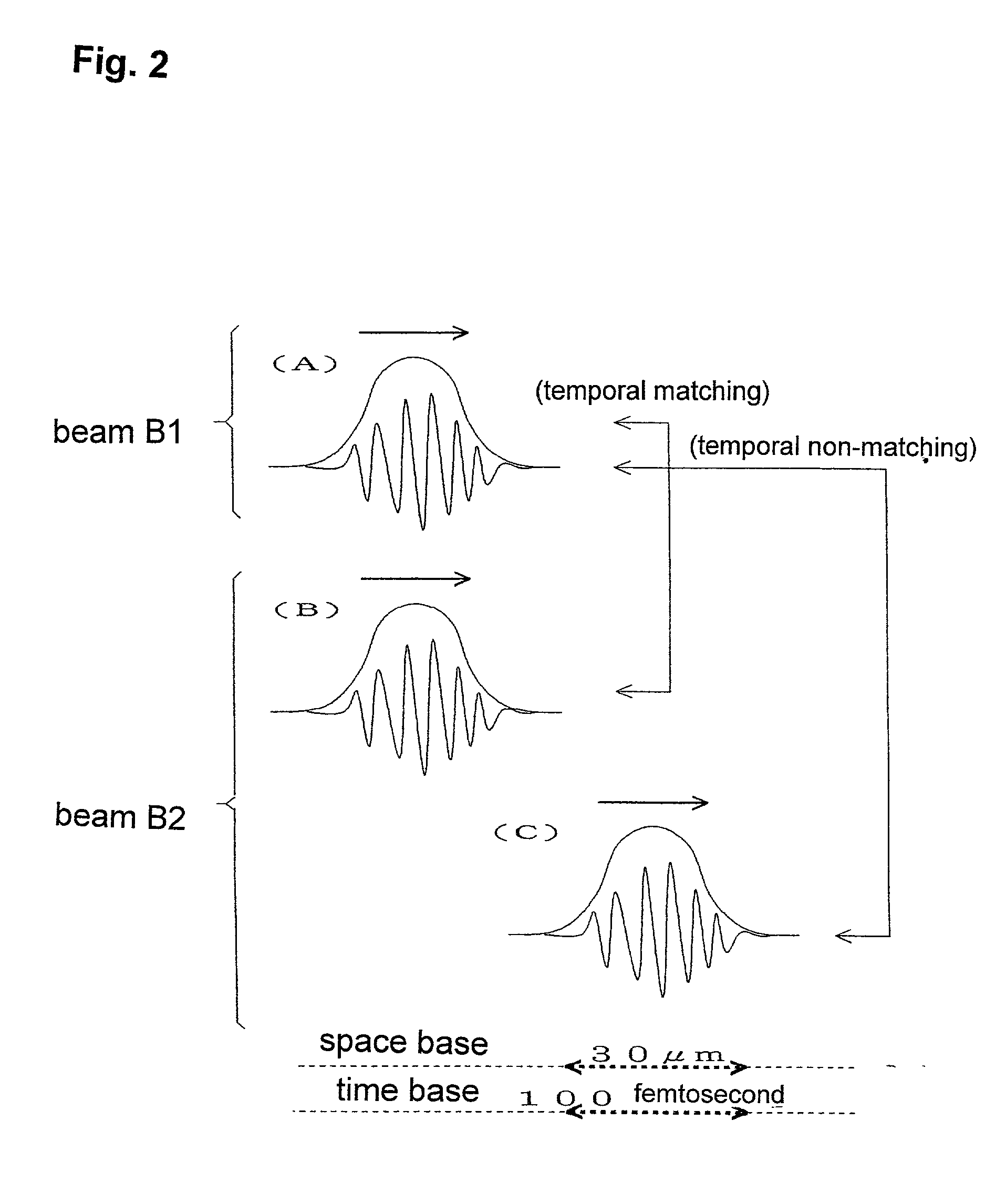

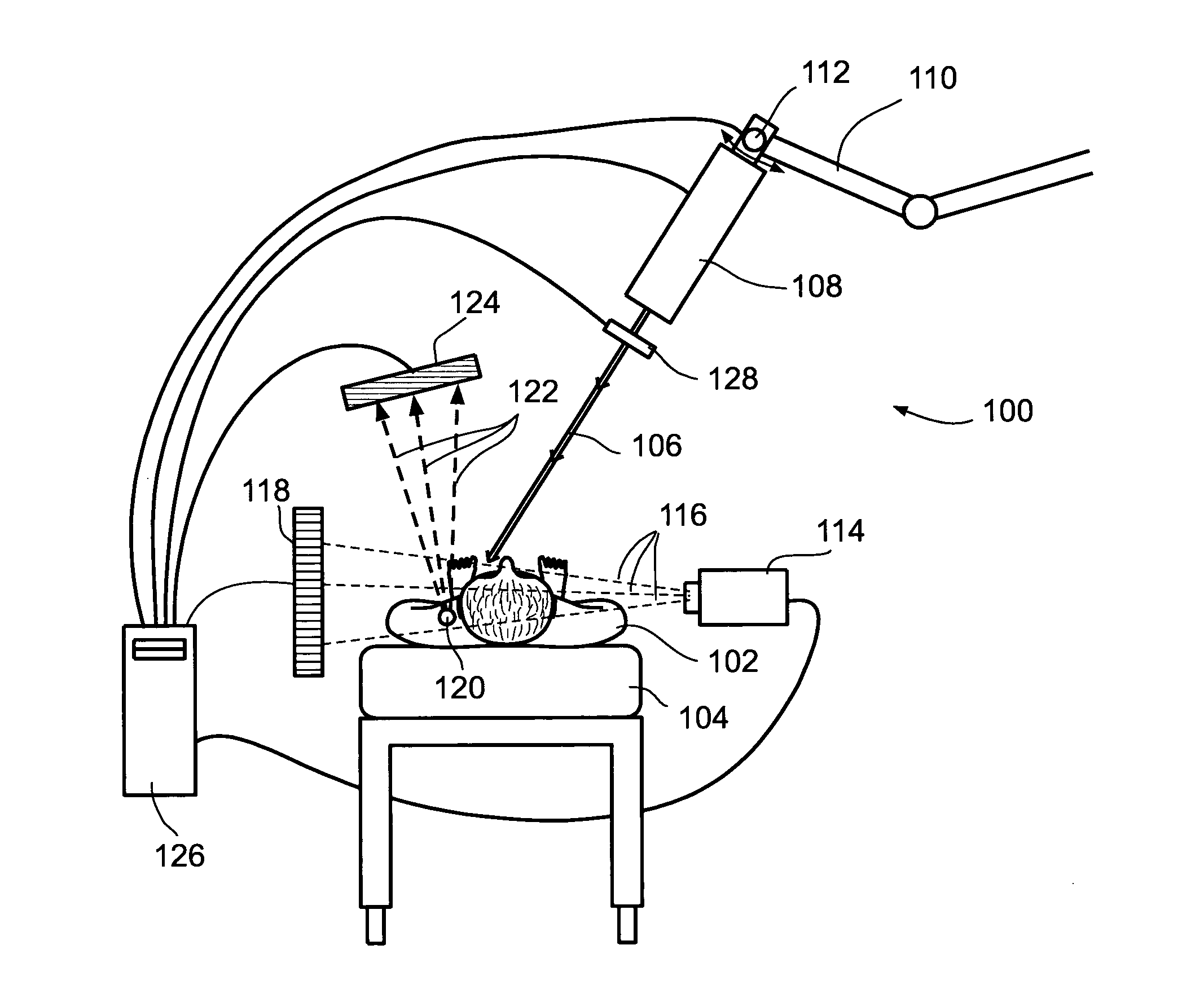

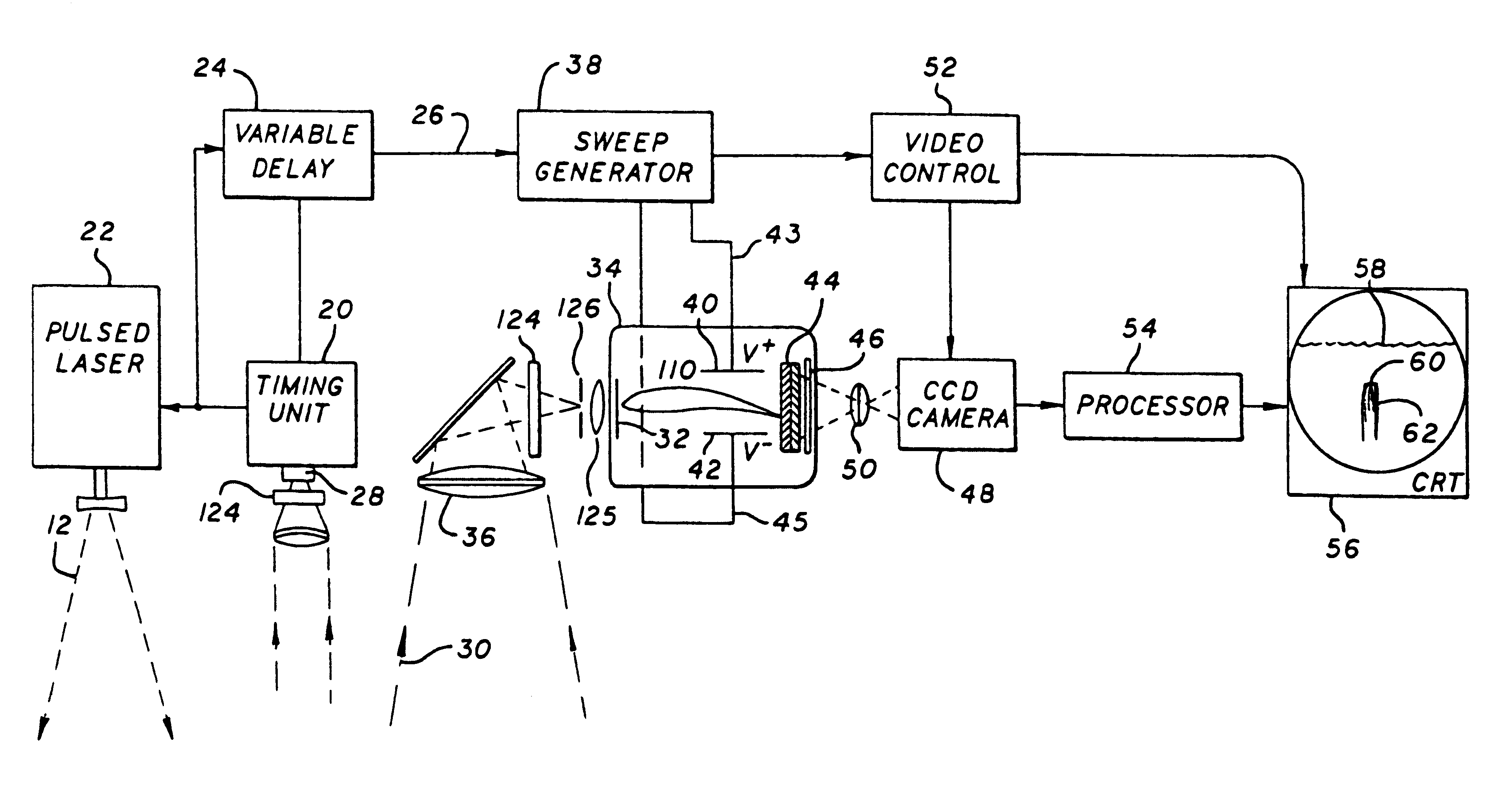

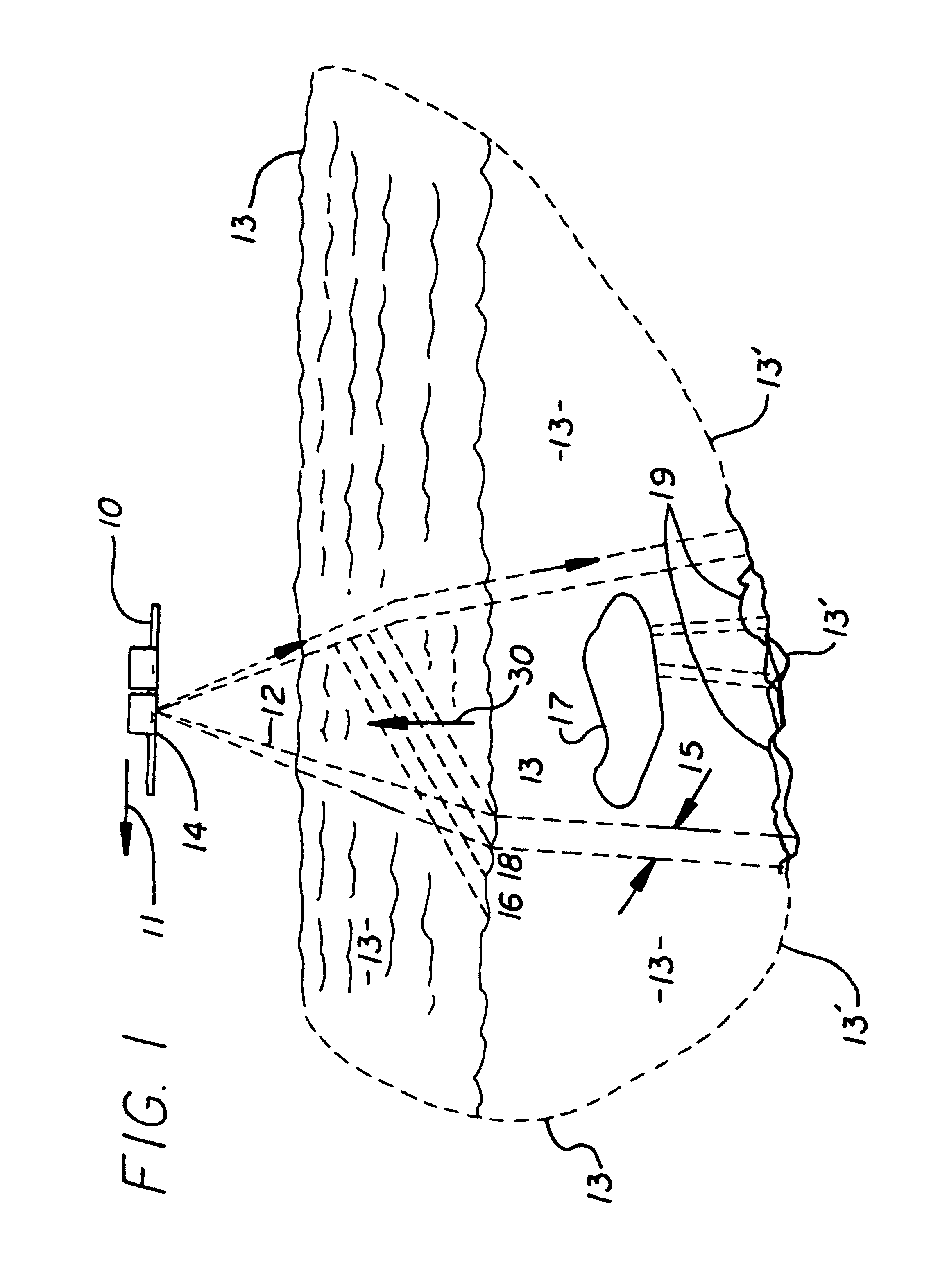

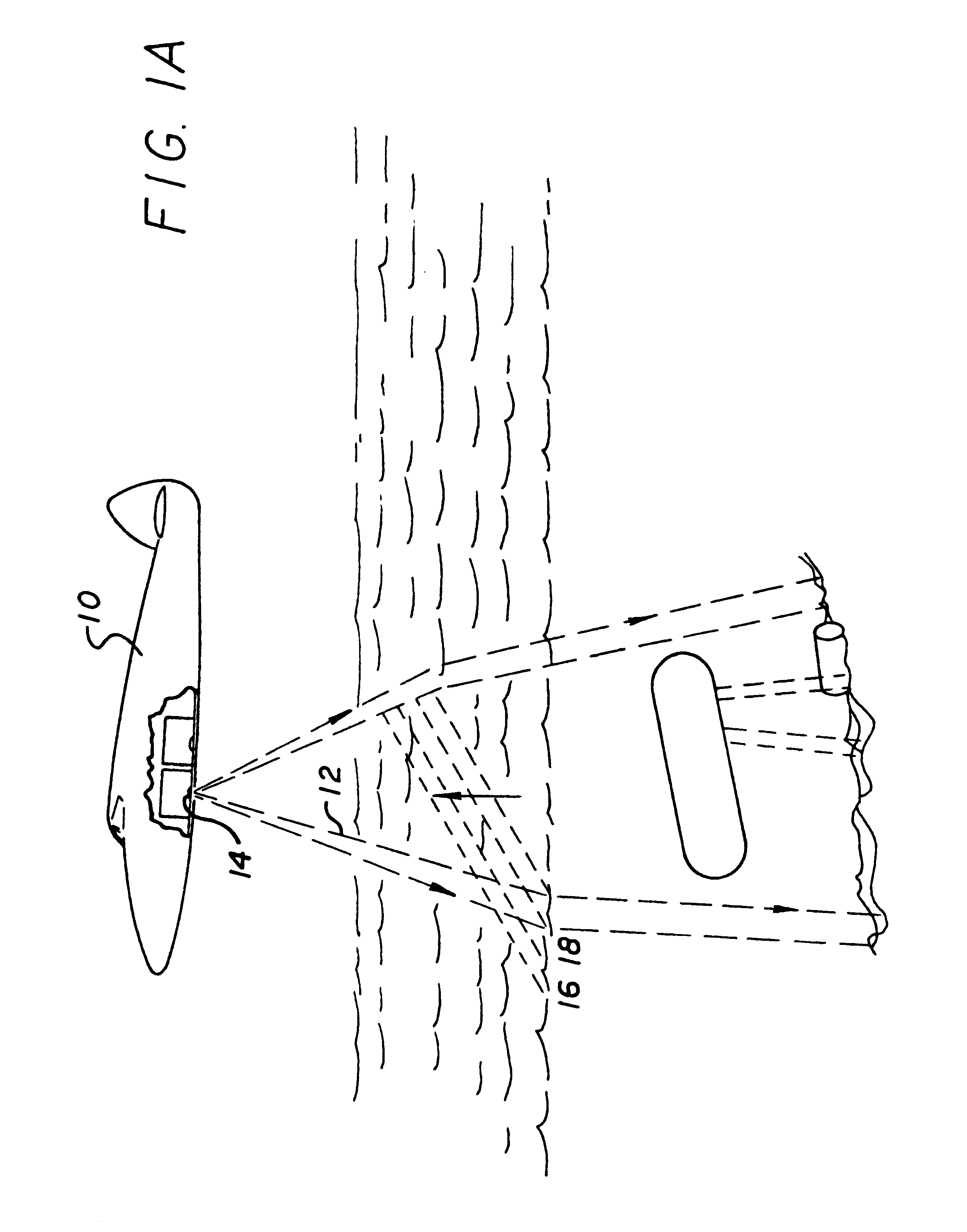

Confocal-reflection streak lidar apparatus with strip-shaped photocathode, for applications at a wide range of scales

InactiveUS6873716B1Eliminate needEnhances target signatureUltrasonic/sonic/infrasonic diagnosticsSurgeryPulse beamPhotocathode

The system images the volume of a turbid medium and detects the contents. The medium can be water or air, or living tissue, or almost any other material which is at least partially light-transmissive. The system includes a light source for producing a series of discrete fan-shaped pulse beams that are substantially uniform in intensity or have been peaked at the edges of the fan to illuminate sections of the medium, a streak tube with a large, thin-slit-shaped photocathode for collecting the maximum amount of light from weak returns, a field-limiting slit disposed in front of the cathode for removing multiply scattered light, a large-aperture optical element for collecting and focusing the reflected portions of the pulse beam on the field-limiting slit and the cathode, and an array of detectors. A volume display of the medium is generated by translating the transmitter and receiver normal to the longitudinal axis of the pulse beam, to illuminate adjacent sections of the medium, and combining the sections to provide a volume display. All, or substantially all, of the light returned from each pulse beam is used. Vehicle motion can be used to provide the scan of the beam. Applications range from foggy sky surveillance at multiple-kilometer scale to location of fractional-millimeter tumors in a human breast.

Owner:ARETA ASSOC

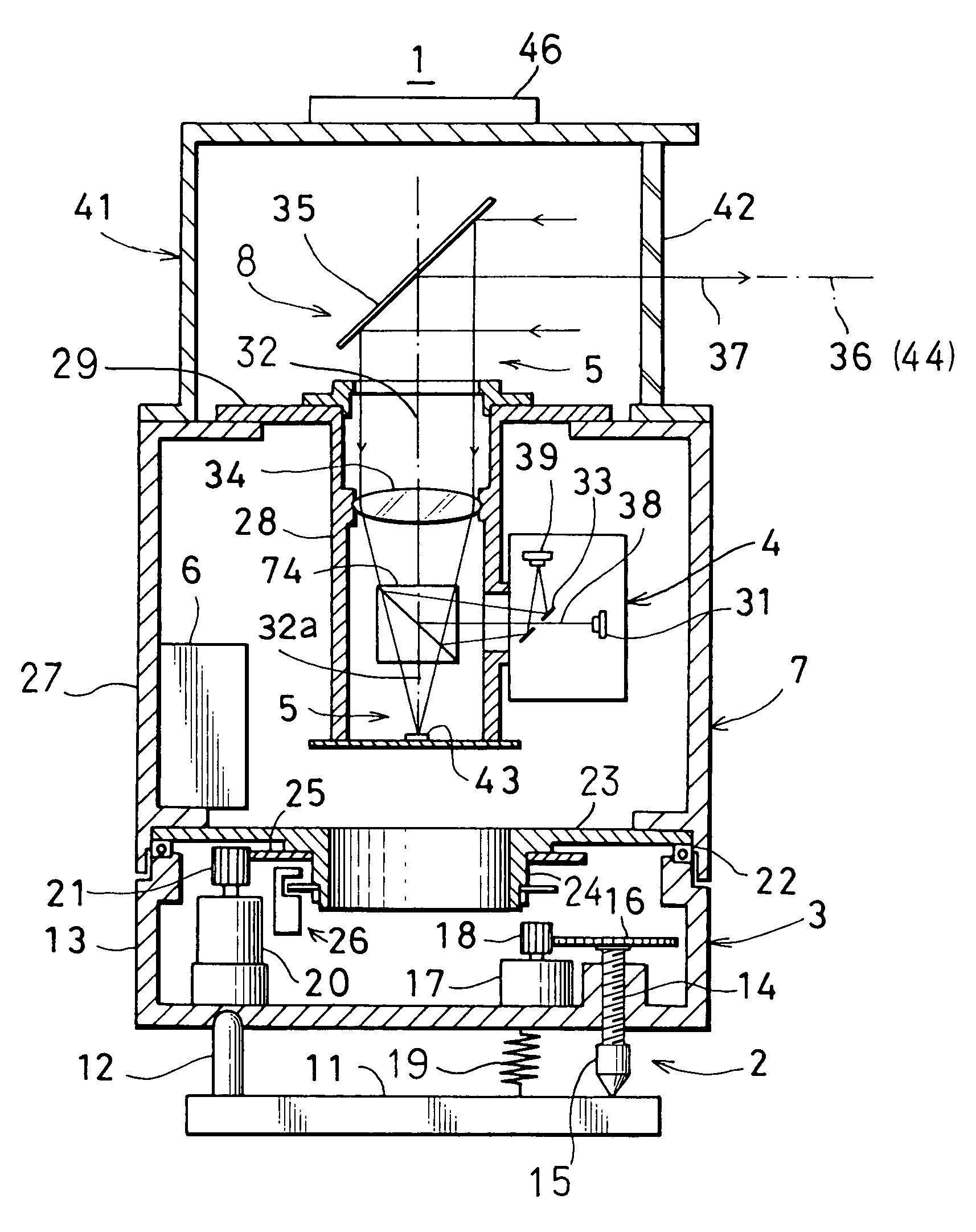

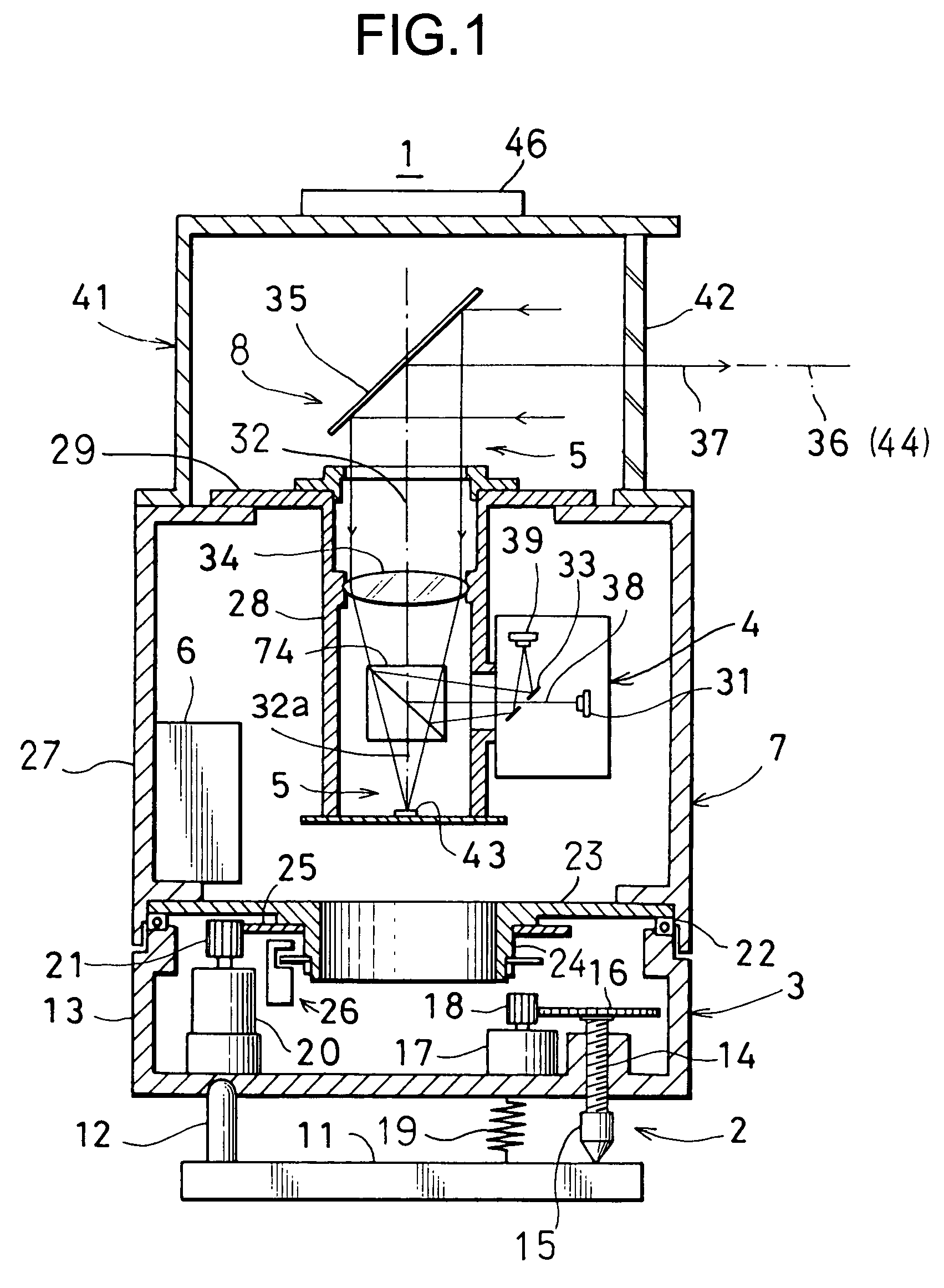

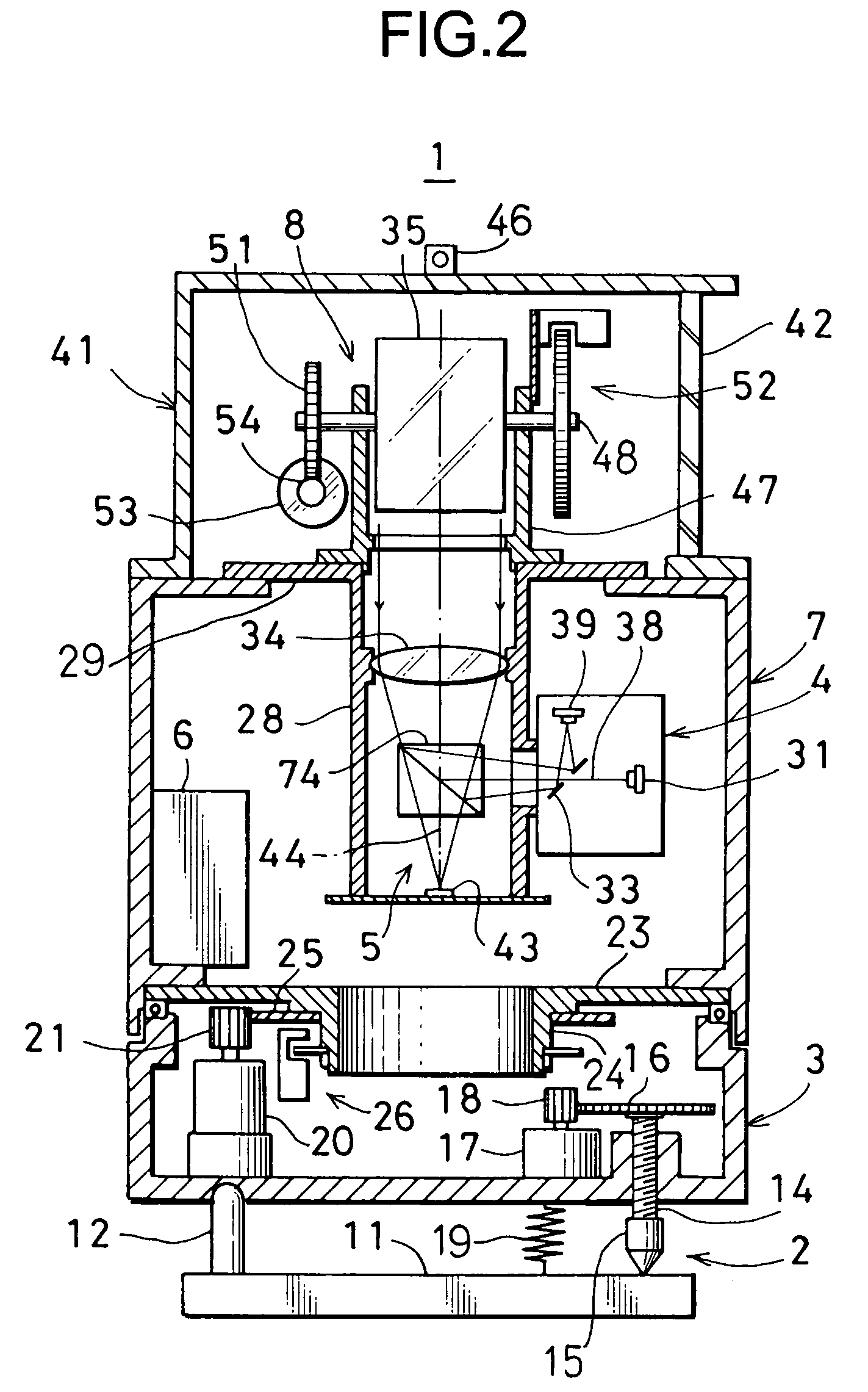

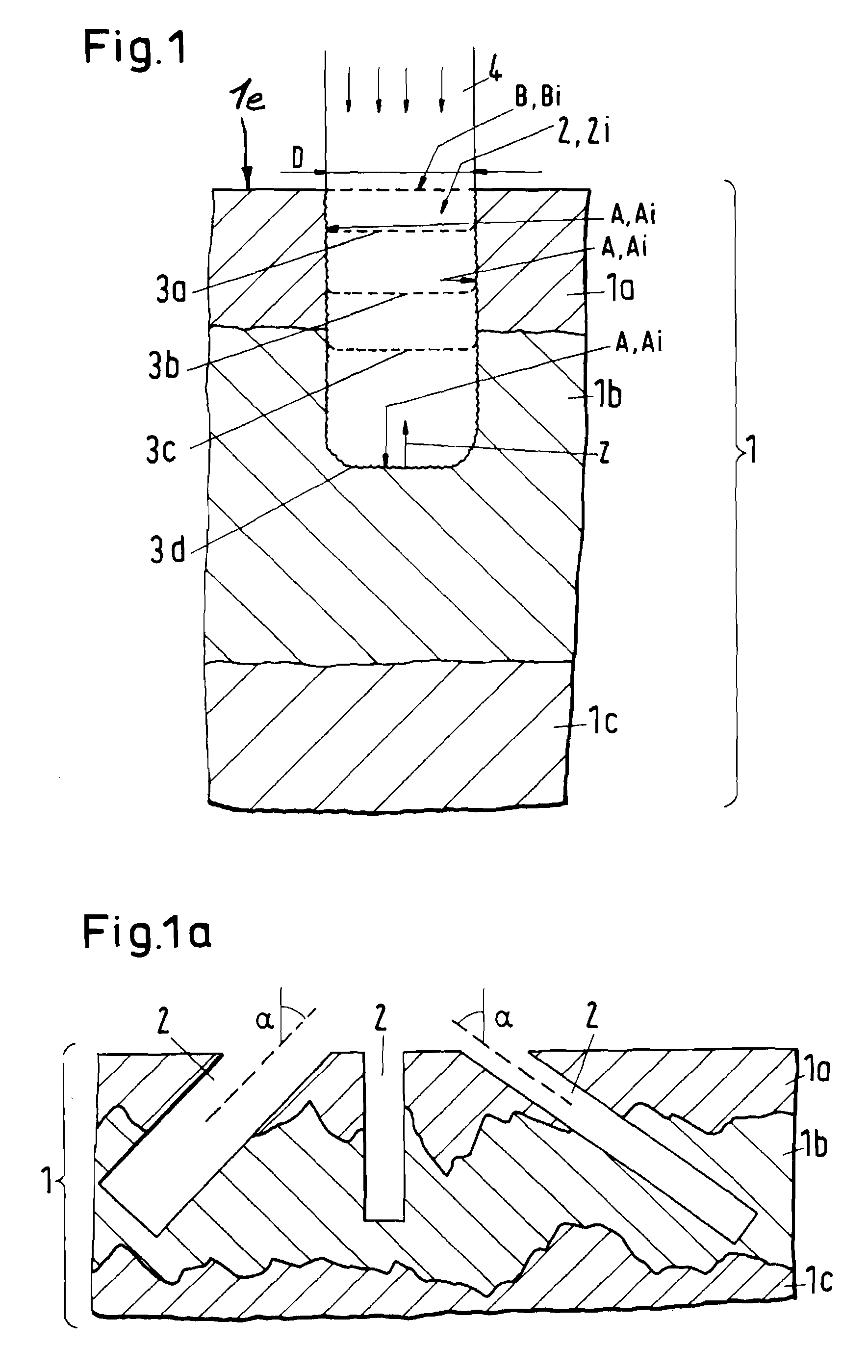

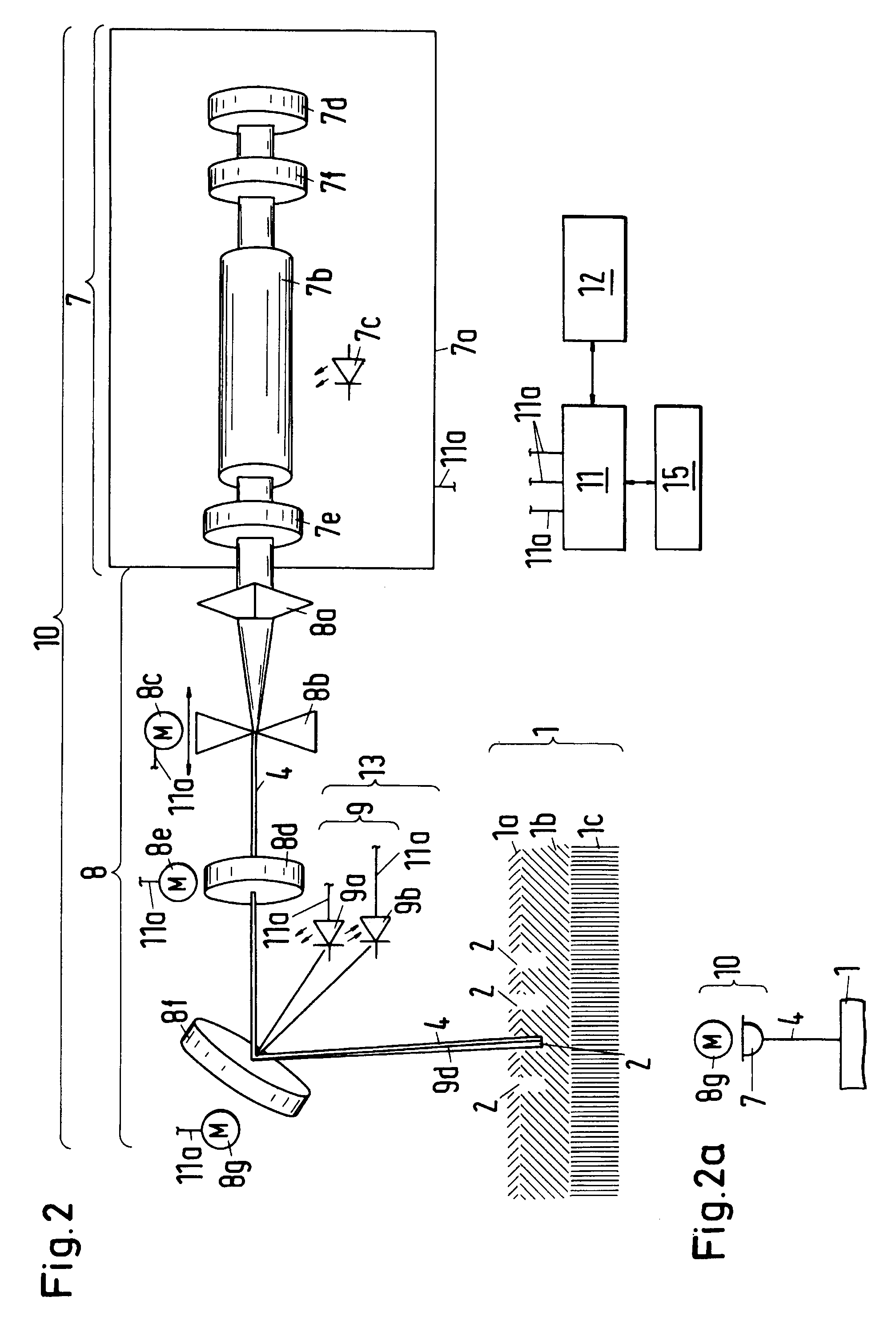

Laser Microporator

ActiveUS20080208104A1Negligible damageDestroys surfaceElectrotherapyMedical devicesPulse beamOptoelectronics

The laser micro-porator (10) for porating a biological membrane (1), comprises: a) a laser source (7) that emits a pulsed beam (4), the laser source (7) comprising a laser diode (7c); b) optics (8a,8b,8x) that modify the pulsed beam to direct a laser beam (4) of less that 1 mm width on the biological membrane (1); c) a deflector (8f) oriented to direct the laser beam (4) in various directions; d) a laser beam shaping device that reshapes the energy intensity distribution of the laser beam (4); and e) a poration controller (11) that controls the laser source (7) to create a poration consisting of a plurality of individual pores (2) in the biological membrane (1).

Owner:PANTEC BIOSOLUTIONS

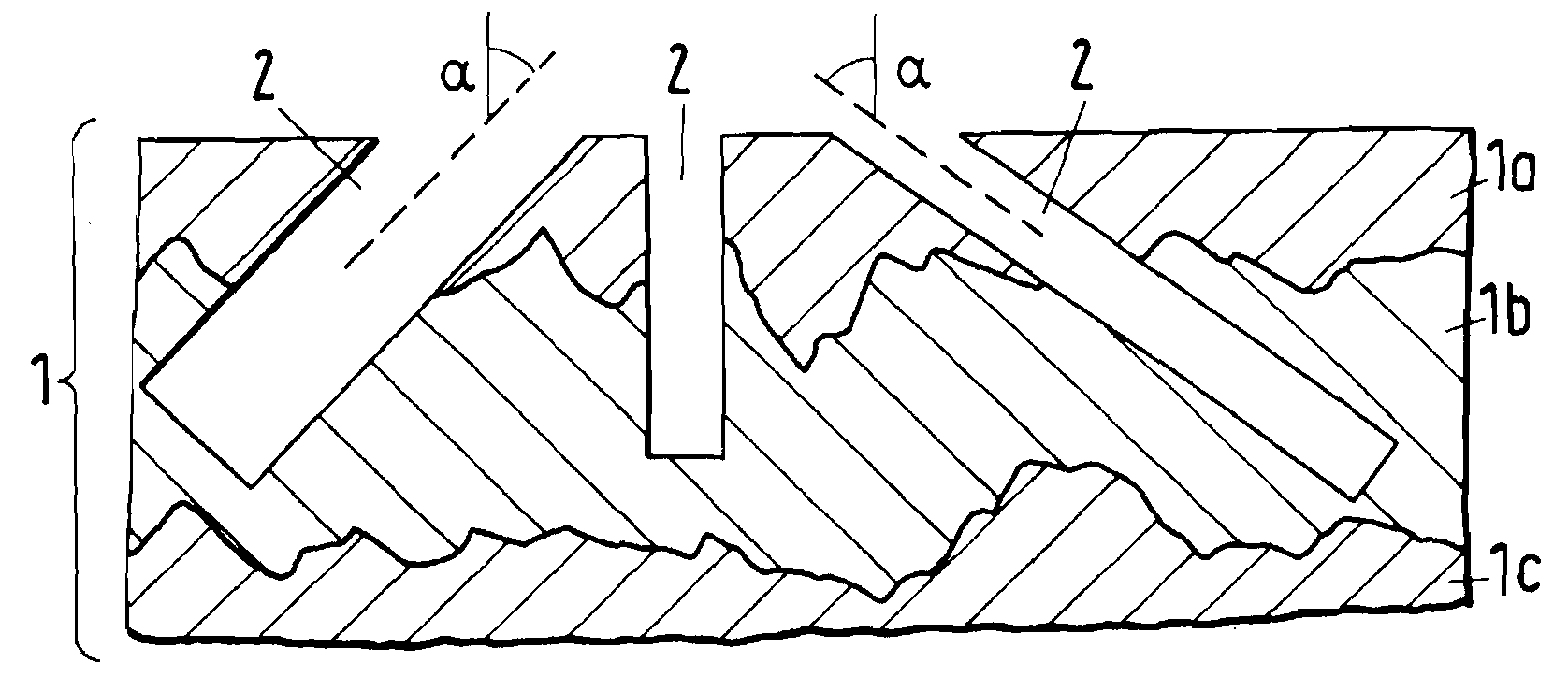

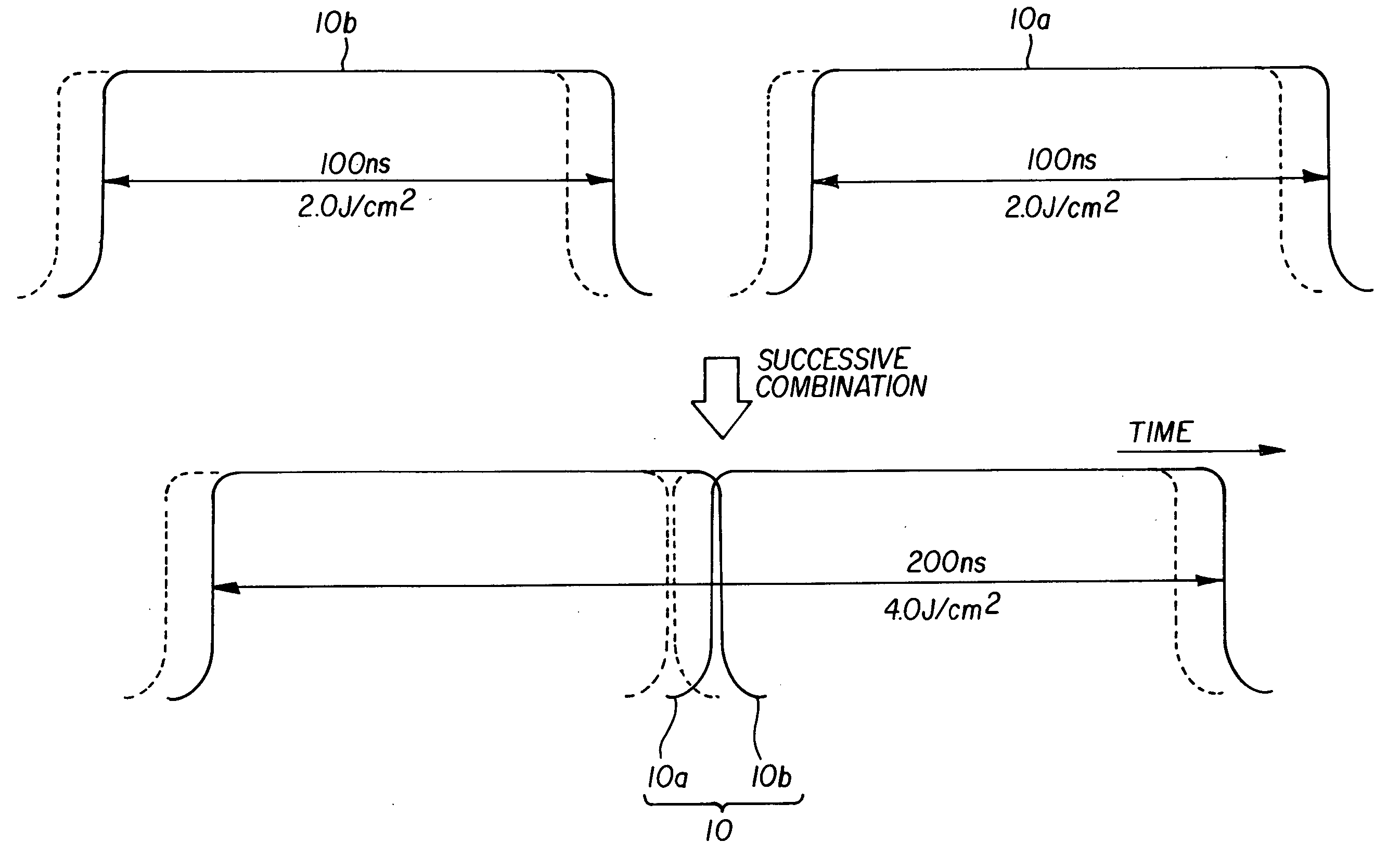

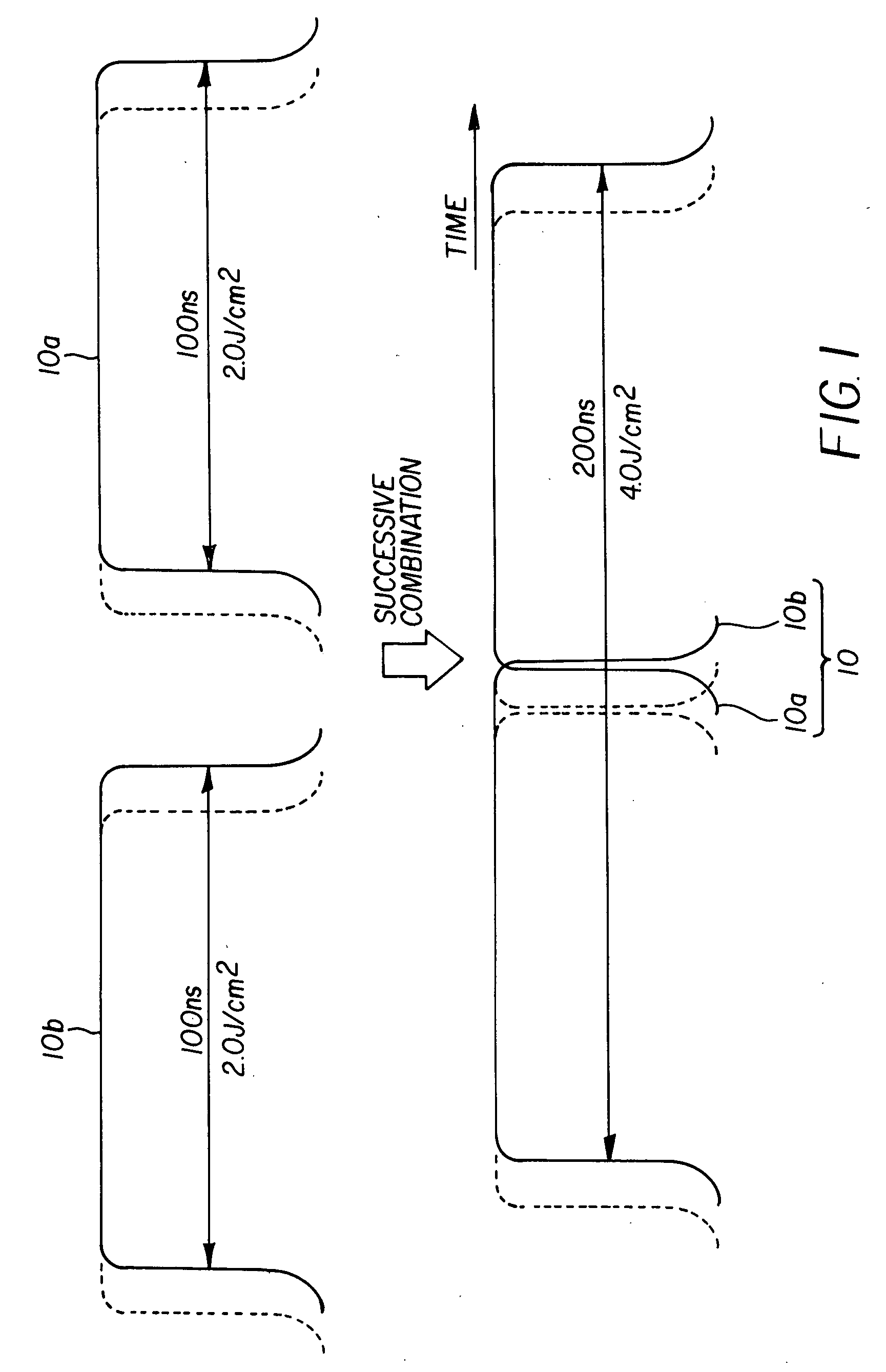

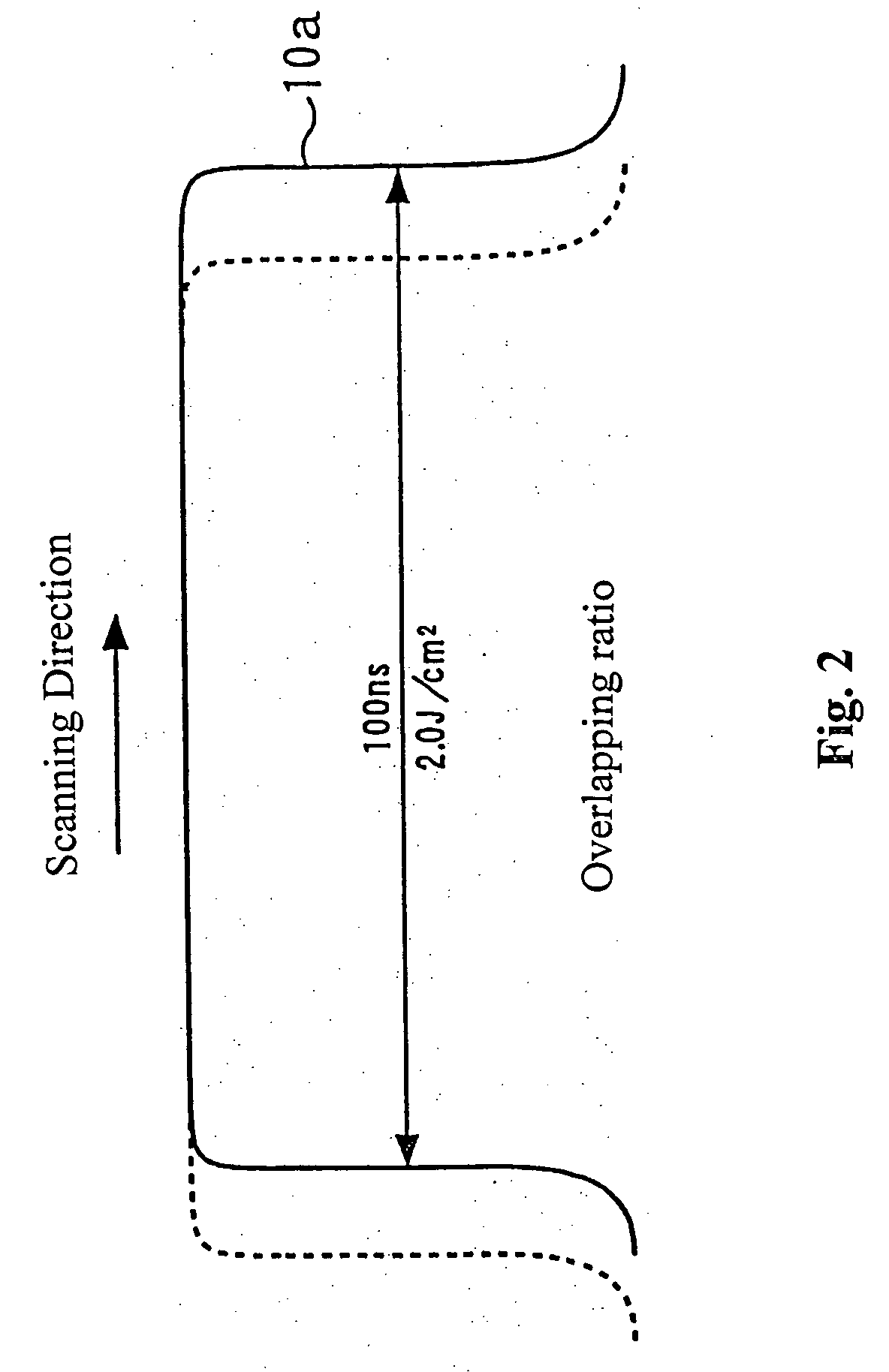

Method of manufacturing semiconductor element

ActiveUS20050059263A1Stably activate in a short time a regionSemiconductor/solid-state device manufacturingSemiconductor devicesPulse beamHigh activation

A method for stably activating pn-successive layers in a semiconductor element in a short time is disclosed. Pulsed beams, each of which has a pulse shape that is approximately rectangular, are projected from respective laser irradiation devices and successively combined into a pulsed beam equivalent to one pulse, with which the doped layer region is irradiated. By successively projecting the pulsed beams onto the doped layer region in this way, an effect is obtained which is the same as that of irradiating the doped layer region with a single pulsed beam having a long full-width at half maximum. A high activation ratio from a shallow region to a deep region of the doped layer region is enabled. This can stably activate the semiconductor element having the pn-successive layers as the doped layer region in a short time, making possible the manufacture of semiconductor elements having superior device characteristics.

Owner:FUJI ELECTRIC CO LTD

Very high energy, high stability gas discharge laser surface treatment system

InactiveUS7167499B2Semiconductor/solid-state device manufacturingLaser arrangementsPulse beamNoble gas

A gas discharge laser crystallization apparatus and method for performing a transformation of a crystal makeup or orientation in the substrate of a workpiece is disclosed which may comprise, a multichamber laser system comprising, a first laser unit comprising, a first and second gas discharge chamber; each with a pair of elongated spaced apart opposing electrodes contained within the chamber, forming an elongated gas discharge region; a laser gas contained within the chamber comprising a halogen and a noble gas selected to produce laser light at a center wavelength optimized to the crystallization process to be earned out on the workpiece; a power supply module comprising, a DC power source; a first and a second pulse compression and voltage step up circuit connected to the DC power source and connected to the respective electrodes, comprising a multistage fractional step up transformer having a plurality of primary windings connected in series and a single secondary winding passing through each of the plurality of primary windings, and a solid state trigger switch; and a laser timing and control module operative to time the closing of the respective solid state switch based upon operating parameters of the respective first and second pulse compression and voltage step up circuit to effect operation of the first and second laser units as either a POPA configured laser system or a POPO configured laser system to produce a single output laser light pulse beam. As a POPA laser system relay optics may be operative to direct a first output laser light pulse beam from the first laser unit into the second gas discharge chamber; and, the timing and control module operates to create a gas discharge between the second pair of electrodes while the first output laser light pulse beam is transiting the second discharge region, within plus or minus 3 ns and as a POPO, combining optics combine the output beams, and timing creates pulse separation in the combined output a preselected time plus or minus 3 ns.

Owner:CYMER INC

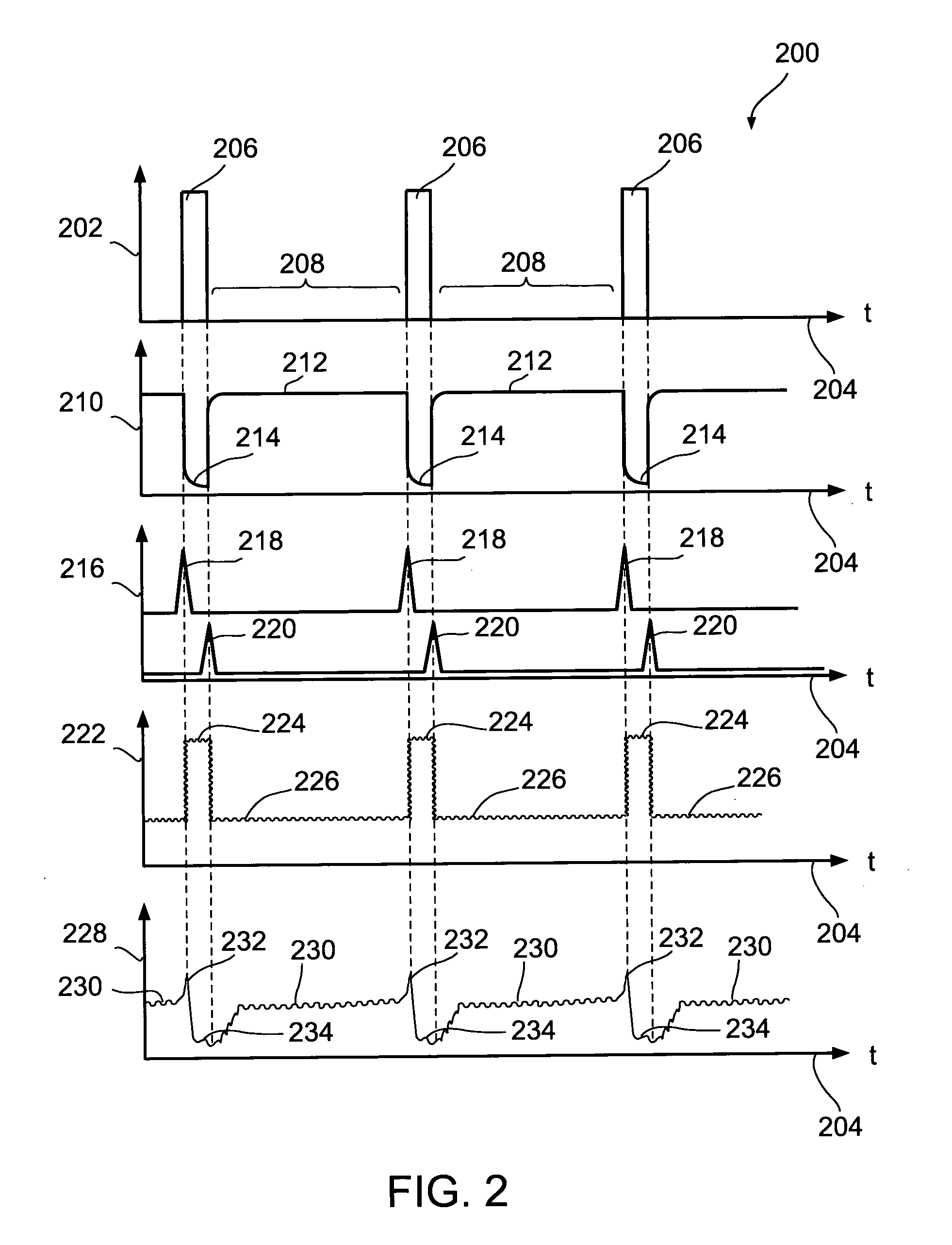

Laser pulse energy control systems and methods

Systems and methods provide laser pulse energy control and / or monitoring. An example laser processing apparatus includes a laser system to generate a beam of laser pulses and a pulse energy control system to adjust the pulse energy of each laser pulse in the beam on a pulse-by-pulse basis. The pulse energy control system includes an open loop feedforward control path that selects a pulse energy transmission value for each laser pulse based on a calibrated transmission curve that maps laser pulse energy as a function of pulse repetition frequency. A laser energy monitor measures the laser pulse energy of each laser pulse in the beam of laser pulses. A power control loop may further adjust the pulse energy of one or more laser pulses in the beam of laser pulses based on feedback from the laser energy monitor.

Owner:ELECTRO SCI IND INC

Laser thin film poly-silicon annealing optical system

A high energy, high repetition rate workpiece surface heating method and apparatus are disclosed which may comprise a pulsed XeF laser operating at or above 4000 Hz and producing a laser output light pulse beam at a center wavelength of about 351 nm; an optical system narrowing the laser output light pulse beam to less than 20 μm in a short axis of the laser output light pulse beam and expanding the laser output light pulse beam to form in a long axis of the beam a workpiece covering extent of the long axis; the optical system including a field stop intermediate the laser and the workpiece; the workpiece comprising a layer to be heated; wherein the optical system focuses the laser output light pulse beam at a field stop with a magnification sufficient to maintain an intensity profile that has sufficiently steep sidewalls to allow the field stop to maintain a sufficiently steep beam profile at the workpiece without blocking the beam profile at too high an intensity level. 2. The apparatus may also have a high average power in the laser output light pulse beam as delivered to the workpiece and a a line bow correction mechanism in a short axis optical assembly. The line bow correction mechanism may comprise a plurality of weak cross cylinders. The system may comprise a catadioptric projection system. The linewidth due to laser diffraction and divergence may be less than geometric limitations. The system may project adjacent peaks of the nominal XeF spectrum to improve overall depth of focus through the separate center wavelengths of each respective adjacent peak having a different focal plane at the workpiece. The system may comprise a line bow is correction mechanism within a field stop optical assembly correcting line bow at the field stop plane and within a workpiece projection optical assembly correcting line bow at the workpiece plane.

Owner:CYMER INC

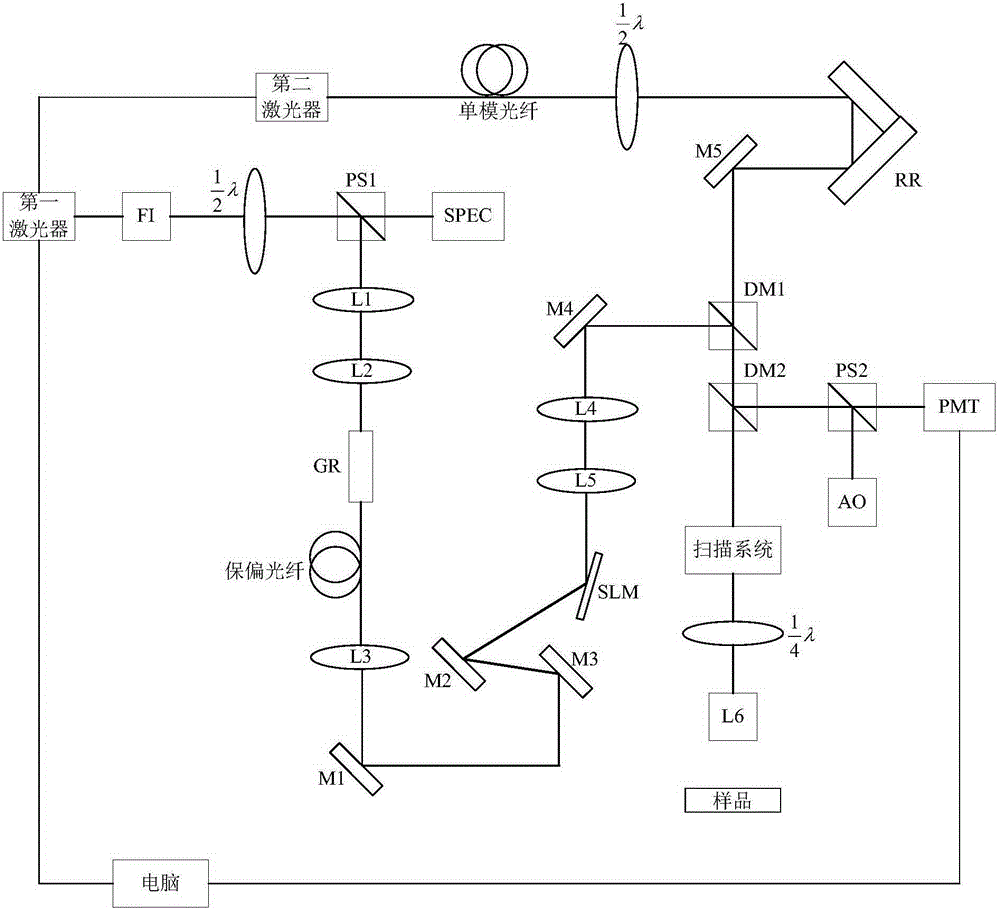

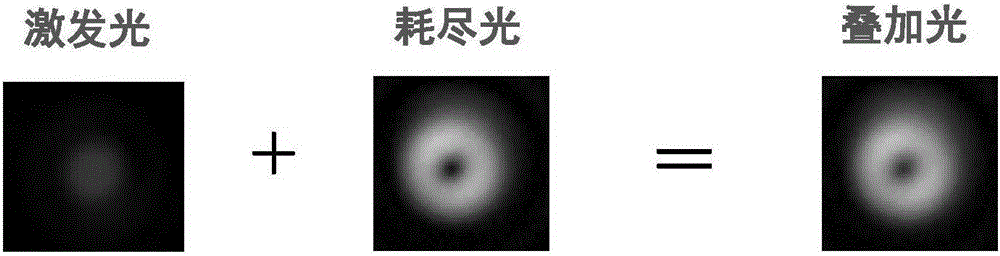

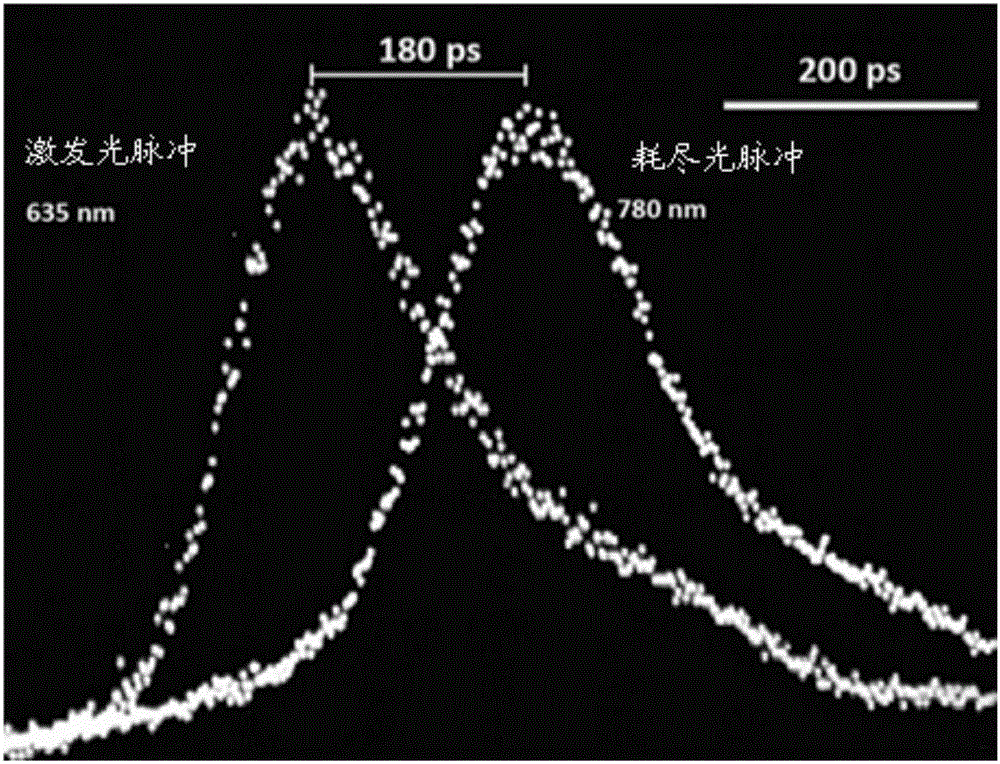

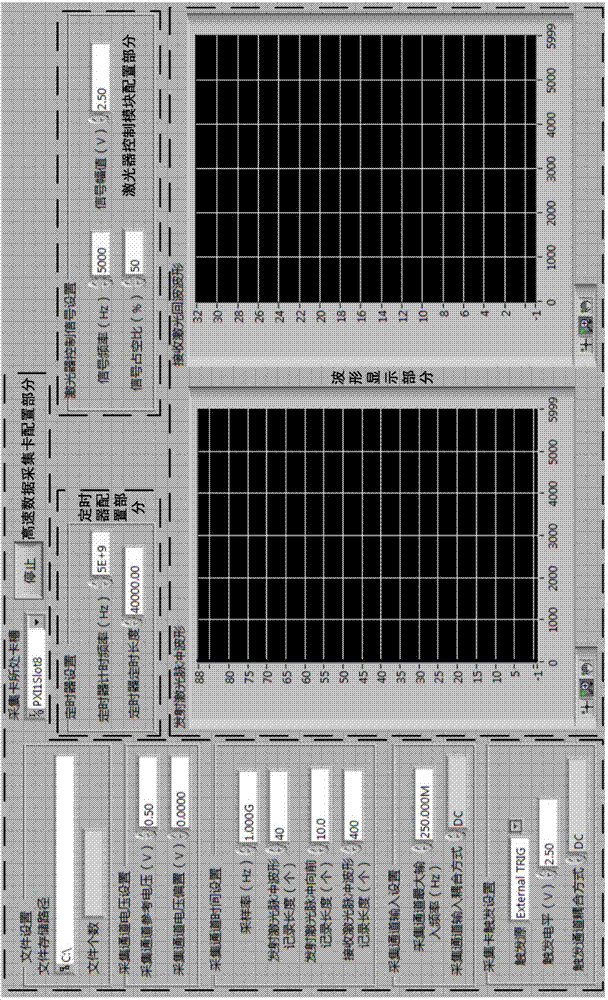

Super-resolution imaging system

InactiveCN105241857ARealize aberration correctionImprove spatial resolutionFluorescence/phosphorescencePulse beamSpatial light modulator

The invention discloses a super-resolution imaging system. The imaging system comprises a first laser, a second laser, a first half-wave plate, a first pulse beam splitter, a spectrometer, a first battery of lens, a glass rod, polarization maintaining optical fibers, a spatial light modulator, a first object lens, a battery of reflectors, a second battery of lens, a reflector, single mode fibers, a second half-wave plate, a retroreflector, a reflector, a first dichroic mirror, a second dichroic mirror, a scanning system, a one fourth slide, a spacial object lens, a second pulse beam splitter, and a photomultiplier. A coherent optical adaptive technique is adopted to carry out aberration correction so as to increase the spatial resolution of a STED super-resolution microscopic imaging system, thus the aberration caused by uneven surface of a biological sample and uneven distribution of inner refractive index of a sample is eliminated, and the spacial resolution is increased.

Owner:SHENZHEN UNIV

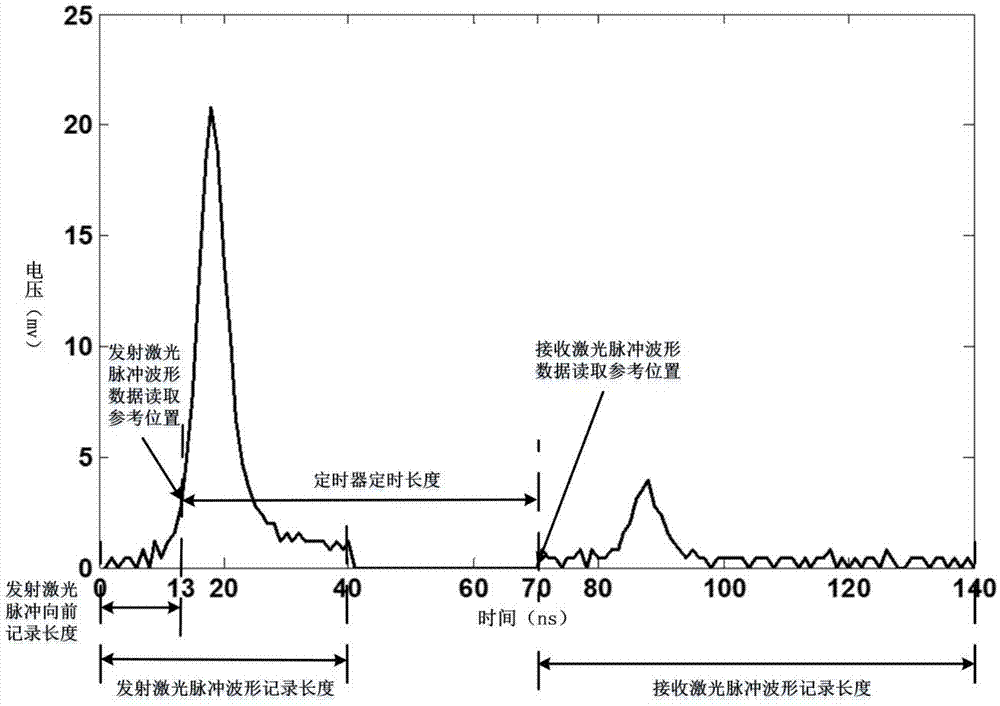

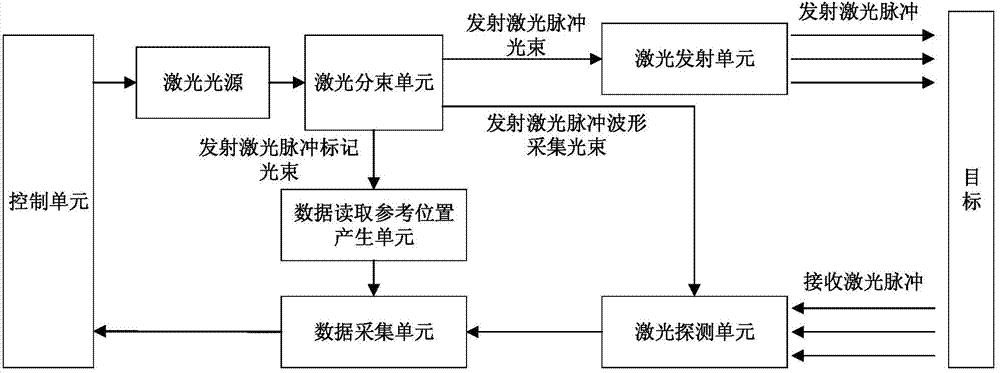

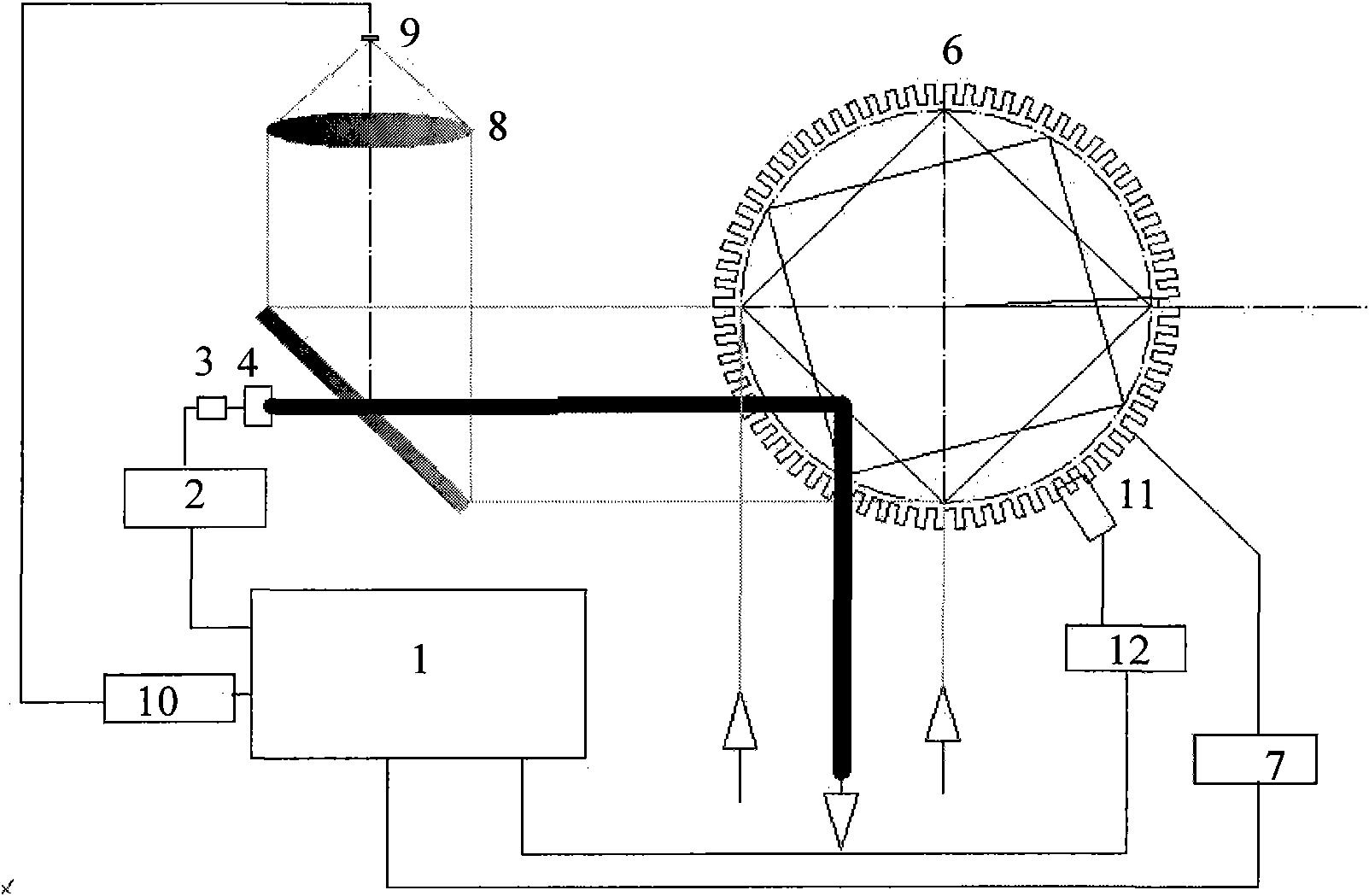

Full-fiber optical path full-waveform laser radar system

The invention discloses a full-fiber optical path full-waveform laser radar system. The laser radar system comprises a control unit, a laser source, a laser beam splitting unit, a laser emitting unit, a data reading reference position generating unit, a laser detecting unit, a data acquiring unit and a software unit. The control unit controls a pulse laser to emit laser pulses, and the laser pulses are divided into an emitted laser pulse beam, an emitted laser pulse waveform acquisition beam and an emitted laser pulse marking beam through the laser beam splitting unit; after being subjected to target scattering, the emitted laser pulse beam enters the data acquiring unit through the laser detecting unit to serve as the received laser pulse waveform to be acquired, and a human-computer interaction interface is provided by the software unit. The laser radar system breaks through the limitation that a convectional laser radar can only measure a limited amount of distance and intensity data, complete fiberization of a full-waveform laser radar optical path is achieved through fiber components, and the debugging flexibility and the system integration simplification of a full-waveform laser radar are effectively enhanced.

Owner:BEIHANG UNIV

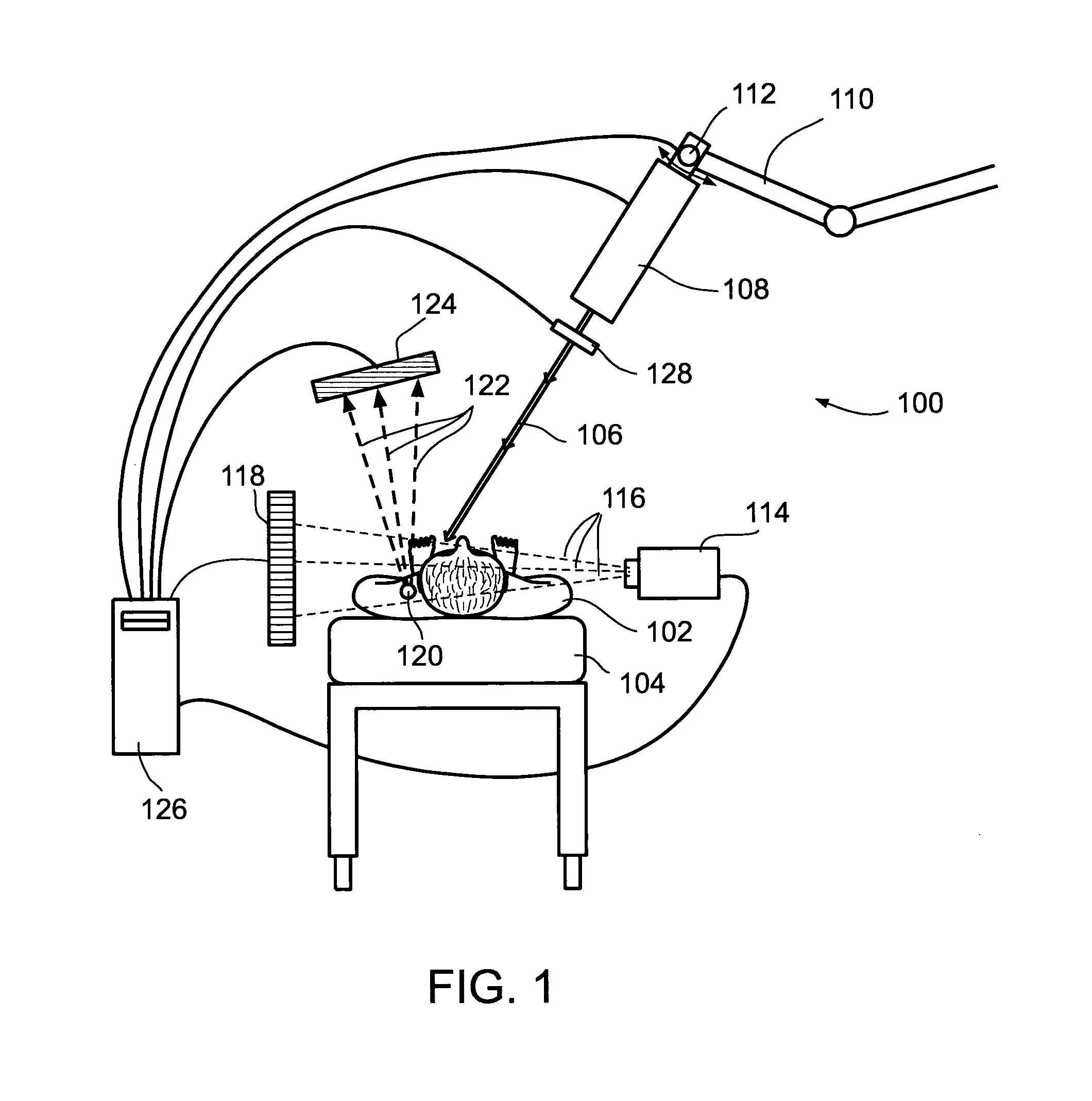

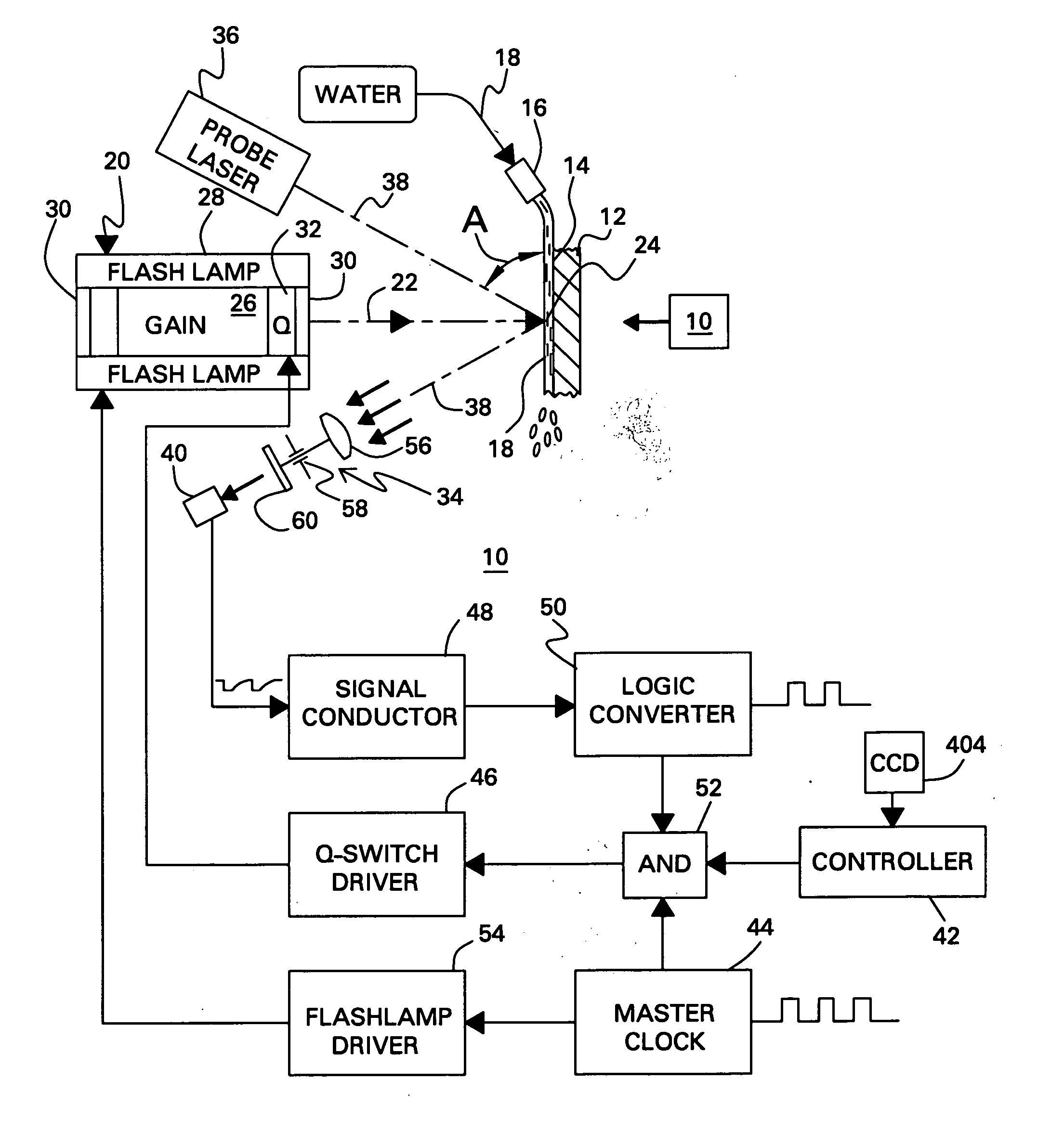

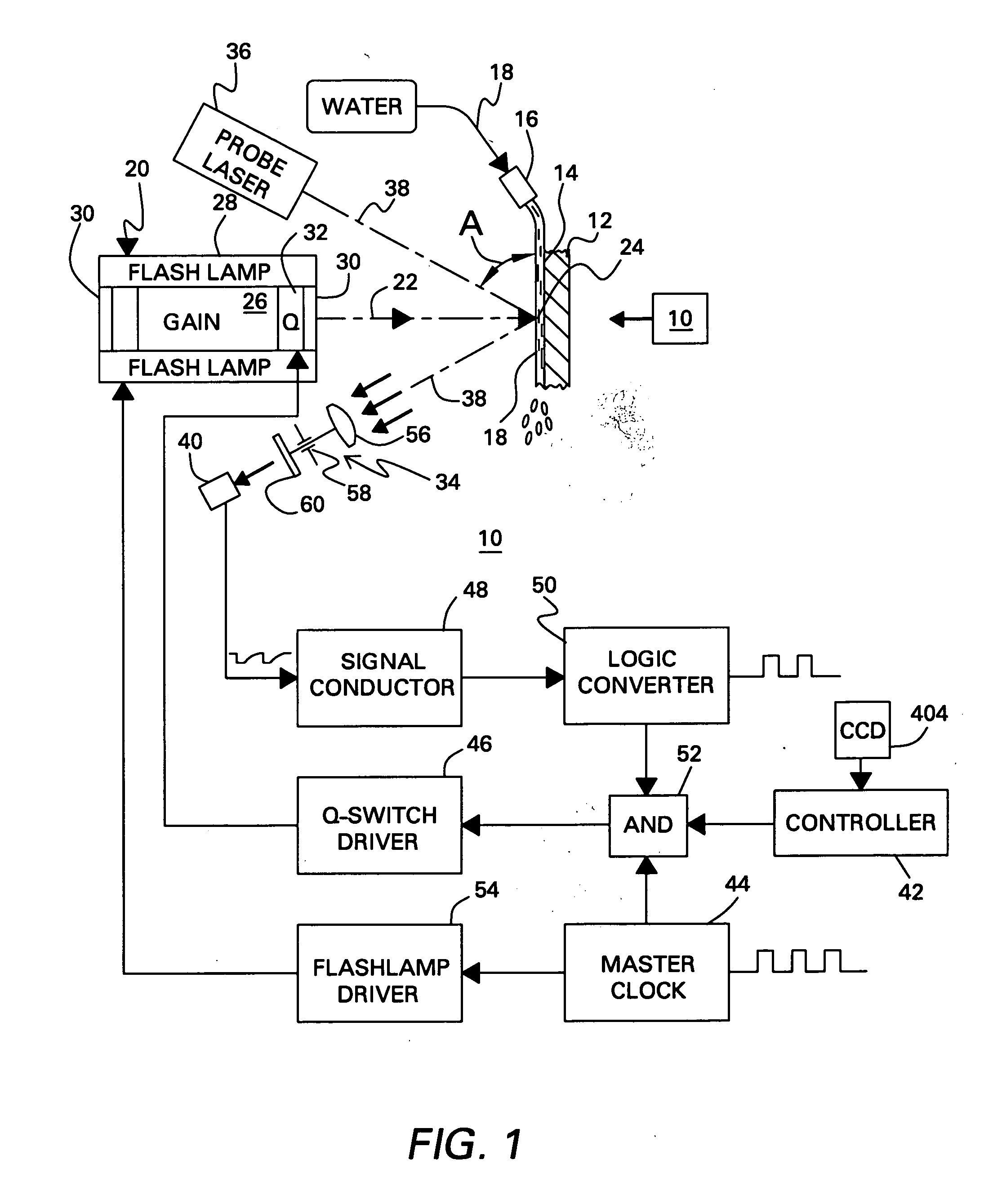

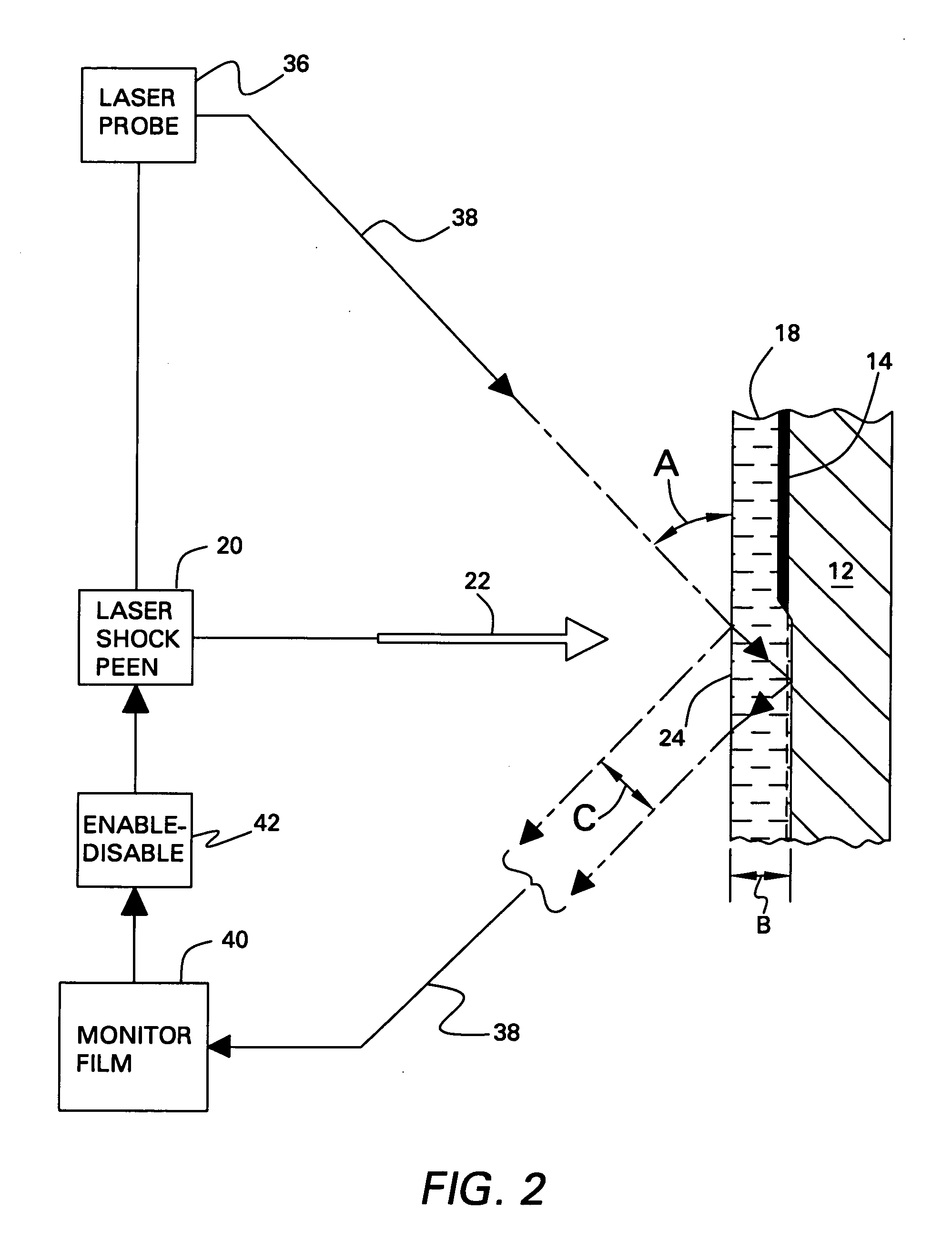

Monitored laser shock peening

A pulse laser is configured for projecting a pulsed laser beam at a target site on a fluid film atop a workpiece for laser shock peening the workpiece. The fluid film is monitored by a probe laser which projects a probe laser beam at the target site, and an optical detector which detects reflection of the probe beam from the target site. The pulse laser is coordinated by the detector in order to emit the pulsed beam in response to the condition of the monitored film.

Owner:GENERAL ELECTRIC CO

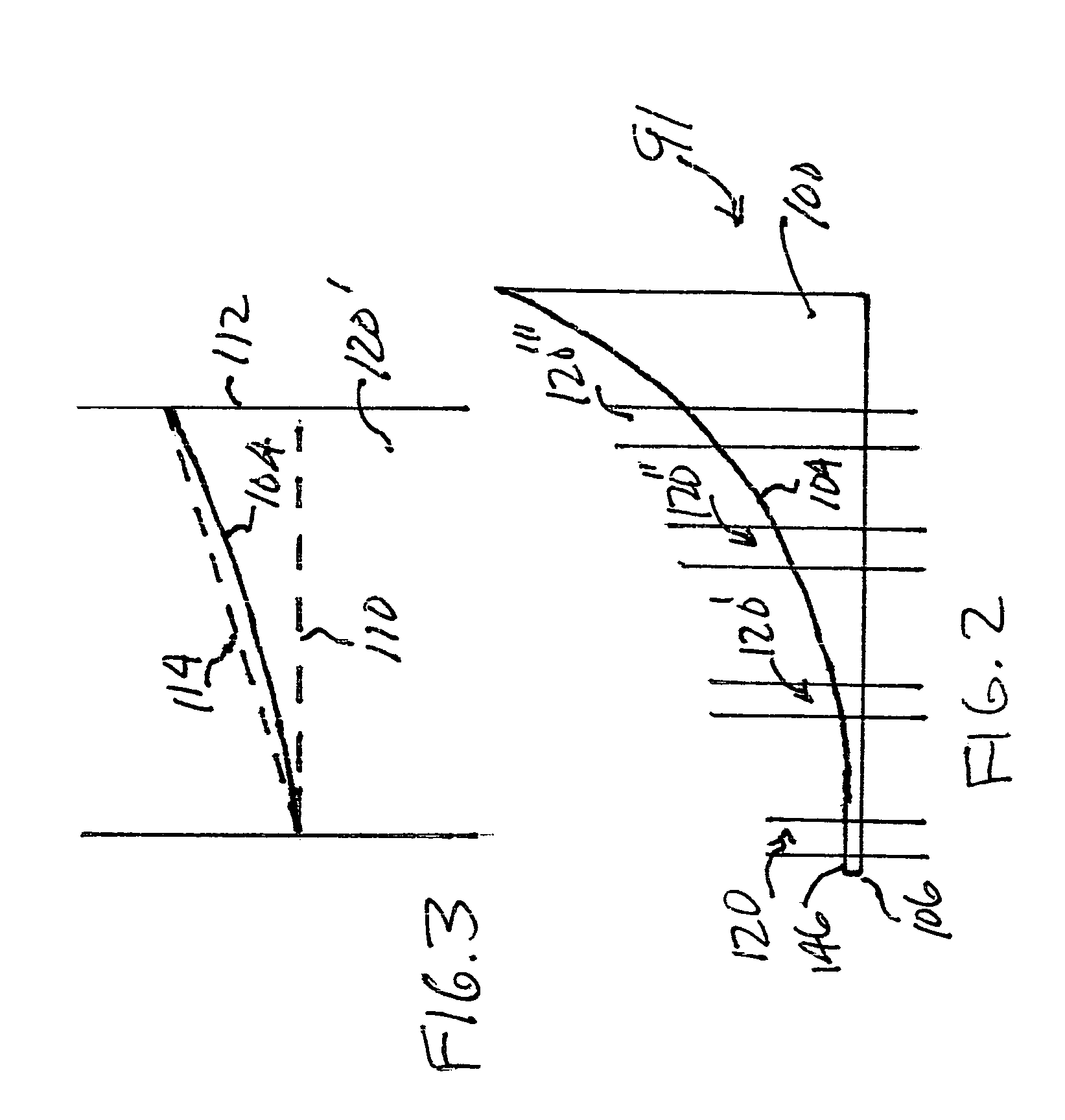

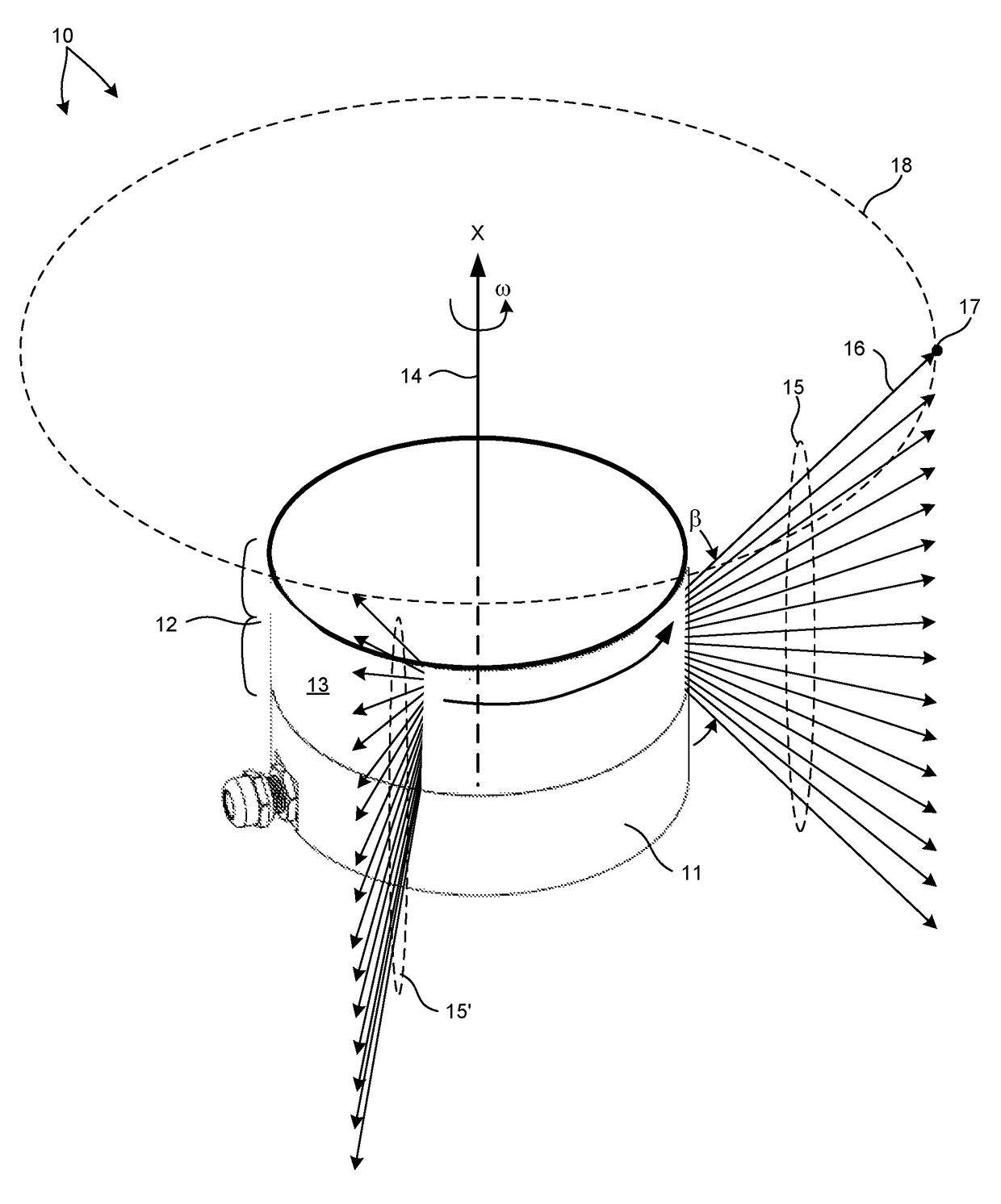

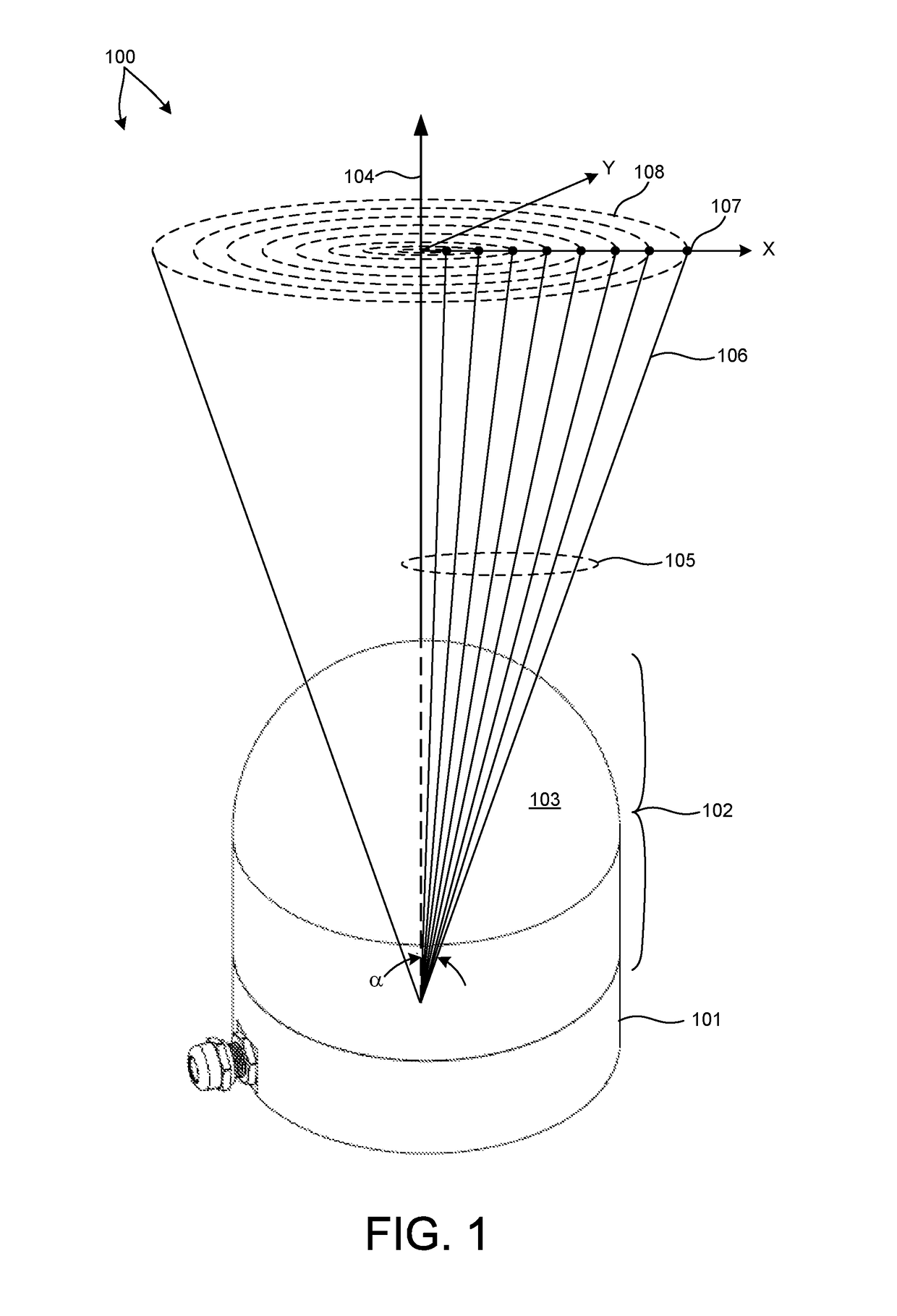

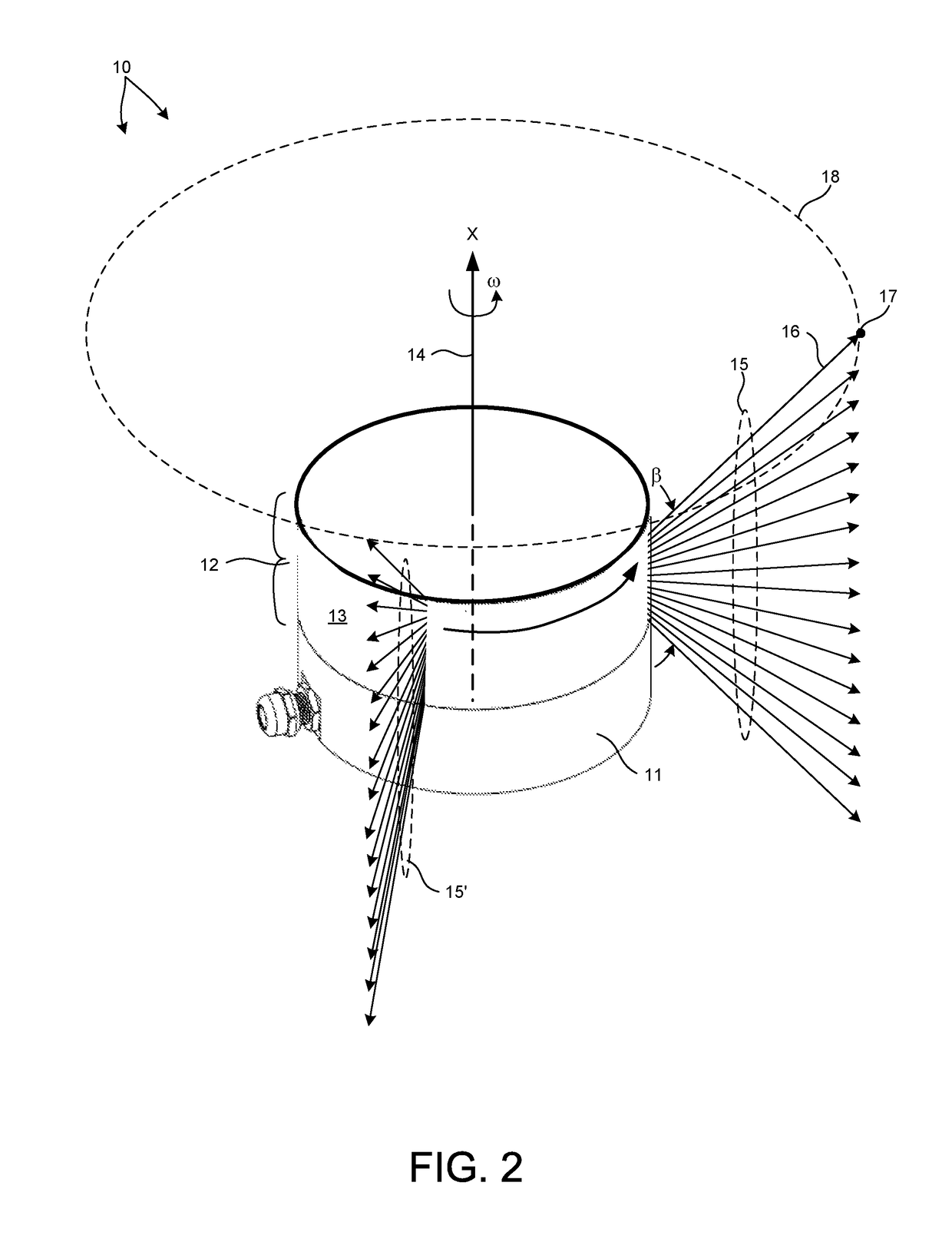

LIDAR based 3-D imaging with varying pulse repetition

ActiveUS10048374B2Reduce total energy consumption and heatReduce consumptionElectromagnetic wave reradiationSteroscopic systemsPulse beamRadar

Methods and systems for performing three dimensional LIDAR measurements with different pulse repetition patterns are described herein. Each repetitive pattern is a sequence of measurement pulses that repeat over time. In one aspect, the repetition pattern of a pulsed beam of illumination light emitted from a LIDAR system is varied to reduce total energy consumption and heat generated by the LIDAR system. In some examples, the repetitive pattern is varied by skipping a number of pulses. In some examples, the repetitive pattern of pulses of illumination light emitted from the LIDAR system is varied by changing a repetition rate of the sequence of emitted pulses. In some examples, the pulse repetition pattern is varied based on the orientation of the LIDAR device. In some examples, the repetition pattern is varied based on an object detected by the LIDAR device or another imaging system.

Owner:VELODYNE LIDAR USA INC

Apparatus for converting a pistol into a weapon simulator

ActiveUS8602784B2Easy to disassembleRealistic sensationCompressed gas gunsTraining adaptationPulse beamEngineering

An apparatus for non-permanent conversion of a semiautomatic pistol into a compressed gas powered weapon simulator. The apparatus replaces the pistol's barrel, recoil spring and magazine with no modification of the pistol, which allows retaining the operational functions of the pistol's remaining components. Compressed gas, from the simulation magazine unit, is used in the compressed gas valve means, in the barrel unit, to operate the slide mechanism, to compress the simulation recoil spring, and to emit a laser pulse beam on a target when activated by the firing mechanism; and battery power, from the simulation magazine unit, is used to count the number of shots, lock the slide after a predetermined number of shots and transmit information from the weapon simulator to a remote data system. The compressed simulation recoil spring returns the slide mechanism back to its original position, unless locked open by the apparatus.

Owner:DVORAK VOJTECH

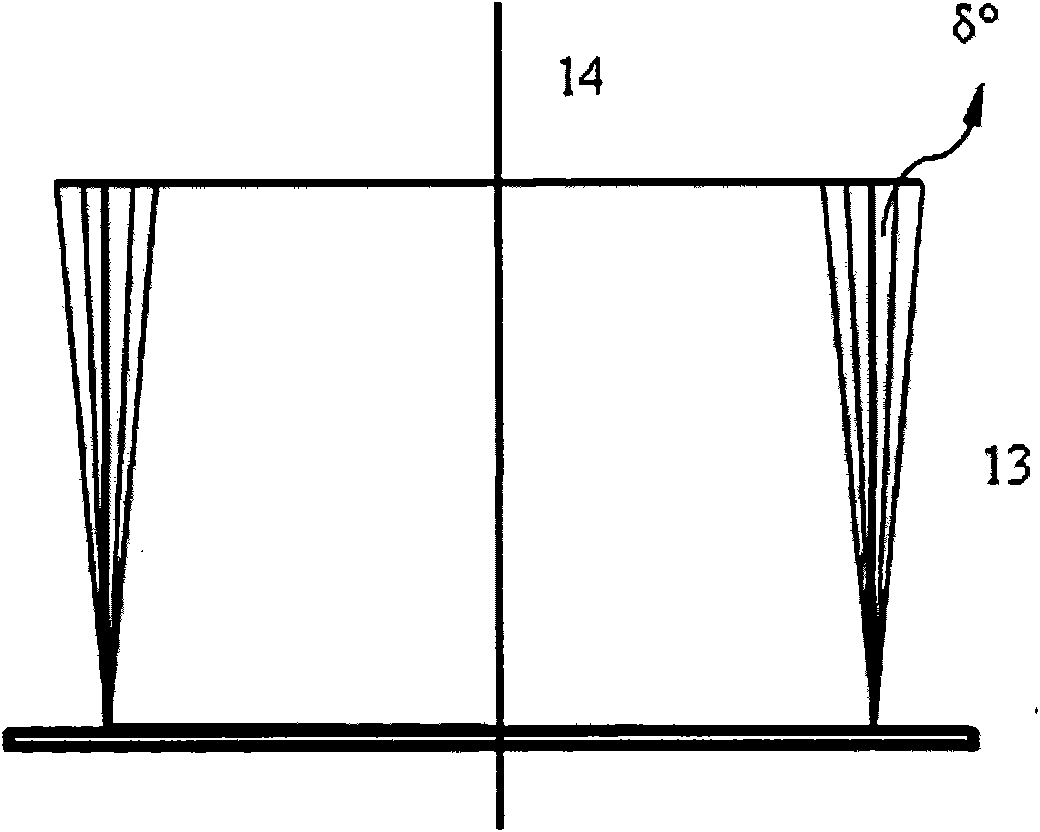

Multi-spectral scanning foresight anti-collision laser radar device and application thereof

InactiveCN102338875ALarge field of view scanning rangeDetect intrusion obstaclesElectromagnetic wave reradiationPulse beamWide field

The invention discloses a multi-spectral scanning foresight anti-collision laser radar device and application thereof. The multi-spectral scanning foresight anti-collision laser radar device comprises a laser emission system, a polyhedral rotary scanning system, a laser reception and detection system and a control drive system; the laser emission system, the polyhedral rotary scanning system and the laser reception and detection system are sequentially connected; and the laser emission system, the polyhedral rotary scanning system and the laser reception and detection system are also respectively connected with the control drive system. The application method of the multi-spectral scanning foresight anti-collision laser radar device comprises the following steps of: transmitting narrow-pulse beams on a polyhedral reflector (13) by a laser (3), wherein multiple spectrums can be scanned in a vertical foresight road direction because the relative rotating shaft of each surface of the polyhedral reflector (13) has different small inclinations; and giving out related alarms based on data by a control system (1). Compared with the prior art, the multi-spectral scanning foresight anti-collision laser radar device has the advantages of capabilities of obtaining a wide field scanning range, detecting the height and position information of a barrier, and the like.

Owner:李少勤

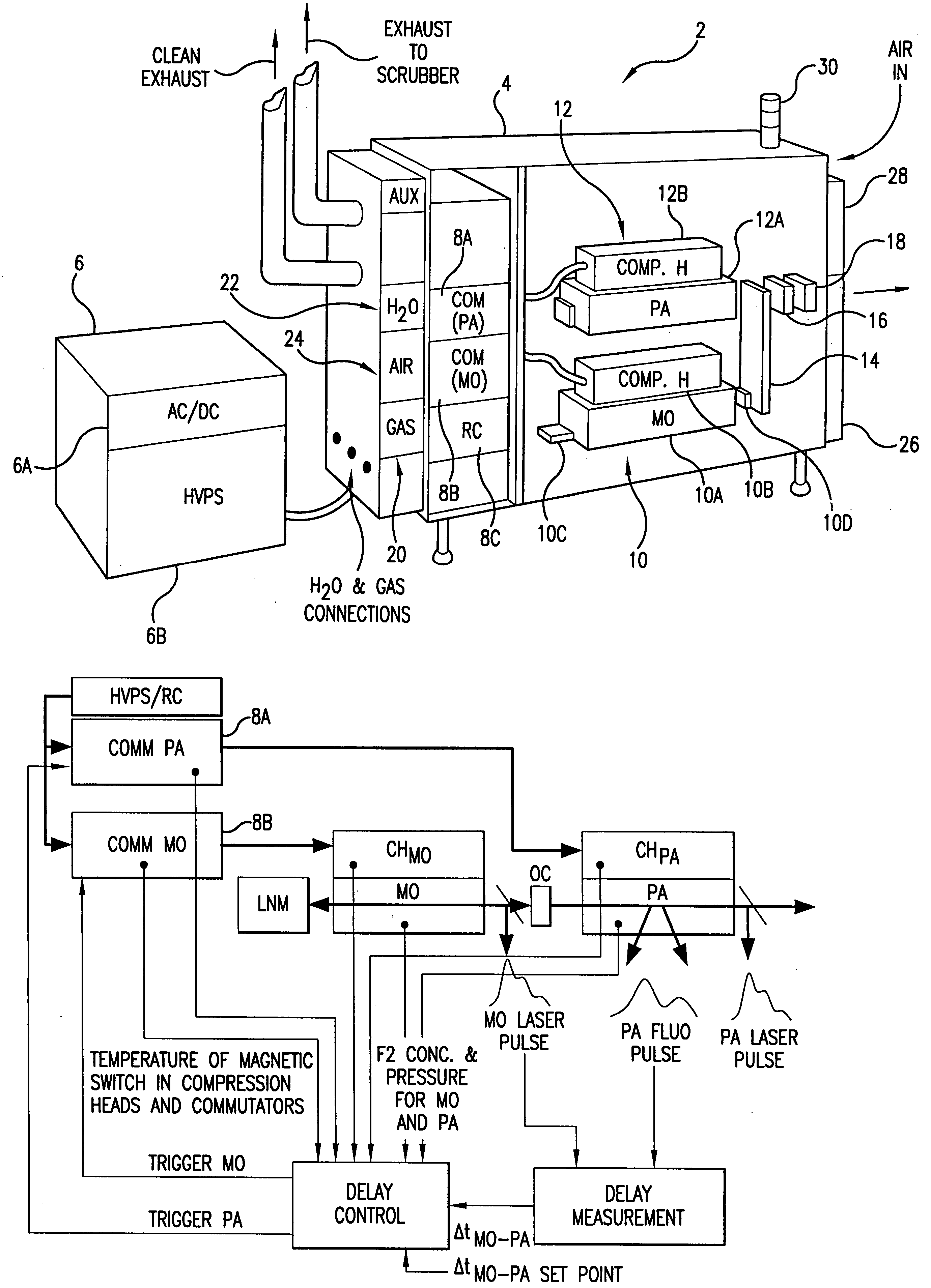

Very narrow band, two chamber, high rep-rate gas discharge laser system

InactiveUS20050271109A1Output powerBeam quality specificationOptical measurementsOptical resonator shape and constructionPulse beamSpectral bands

An oscillator-amplifier gas discharge laser system and method is disclosed which may comprise a first laser unit which may comprise a first discharge region which may contain an excimer or molecular fluorine lasing gas medium; a first pair of electrodes defining the first discharge region containing the lasing gas medium, a line narrowing unit for narrowing a spectral bandwidth of output laser light pulse beam pulses produced in said first discharge region; a second laser unit which may comprise a second discharge chamber which may contain an excimer or molecular fluorine lasing gas medium; a second pair of electrodes defining the second discharge region containing the lasing gas medium; a pulse power system providing electrical pulses to the first pair of electrodes and to the second pair of electrodes producing gas discharges in the lasing gas medium between the respective first and second pair of electrodes, and laser parameter control mechanism modifying a selected parameter of a selected laser output light pulse beam pulse produced by said gas discharge laser system by controlling the timing of the occurrence of the gas discharge between the first pair of electrodes and the occurrence of the gas discharge between the second pair of electrodes.

Owner:CYMER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com