Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

504 results about "Beam laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

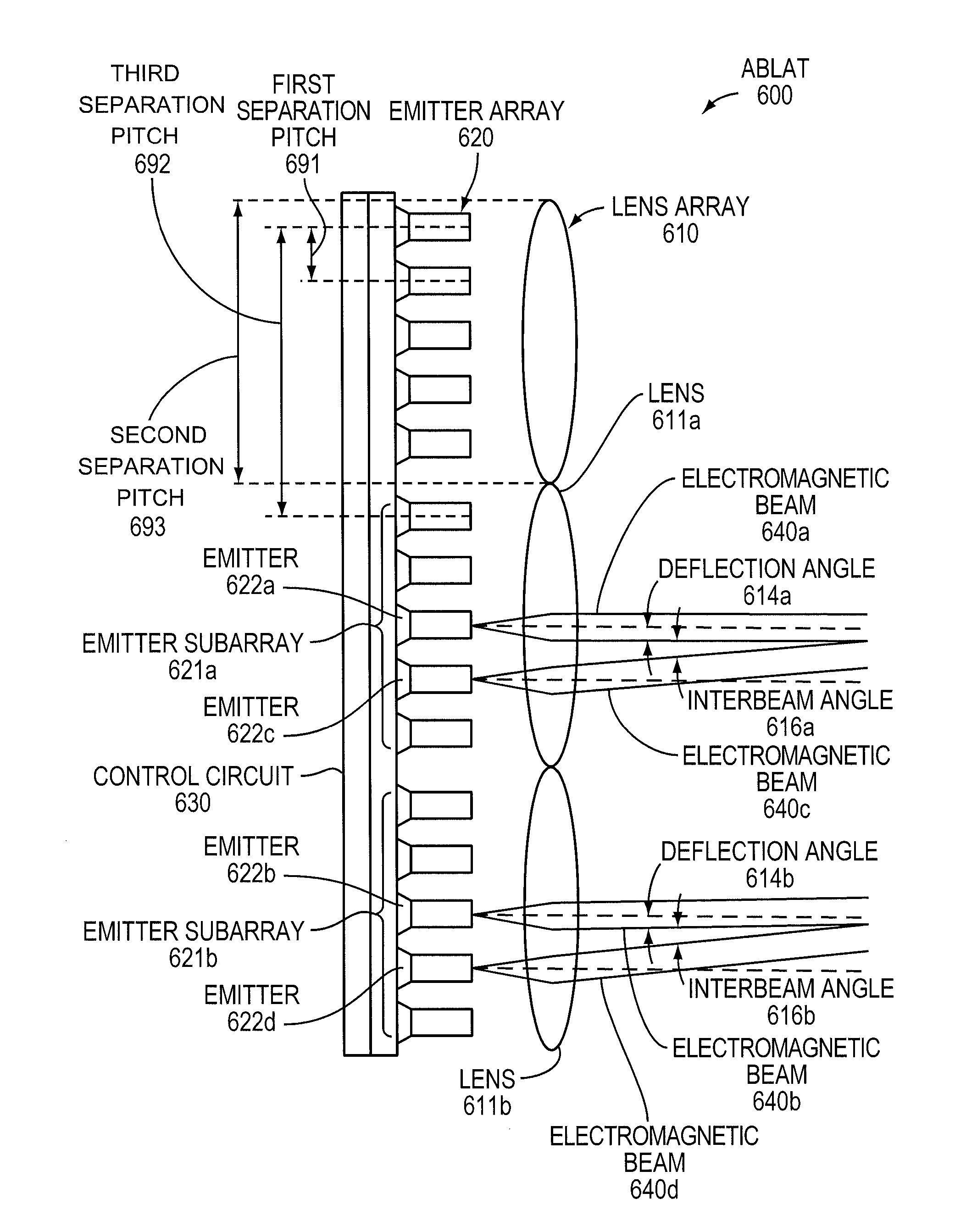

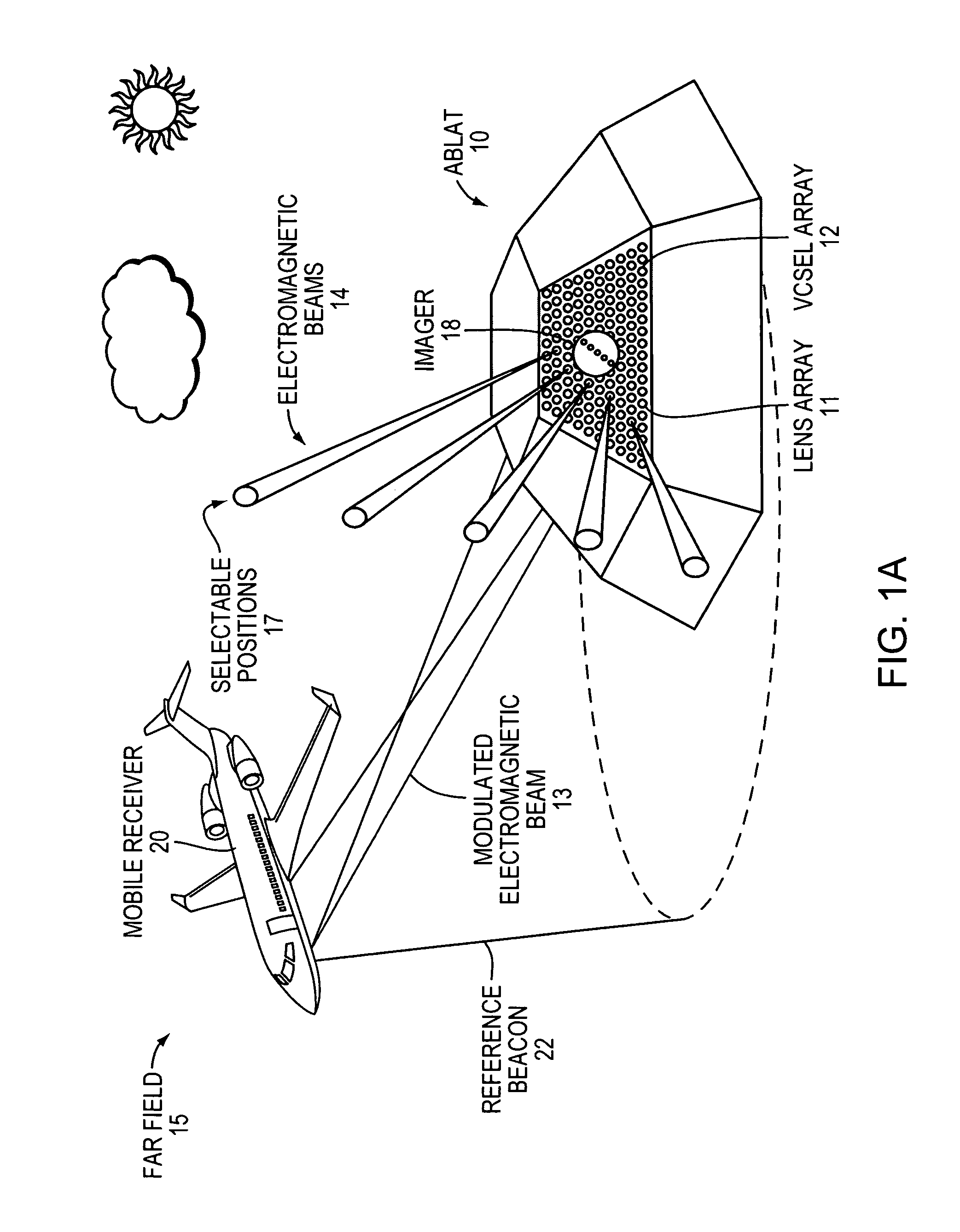

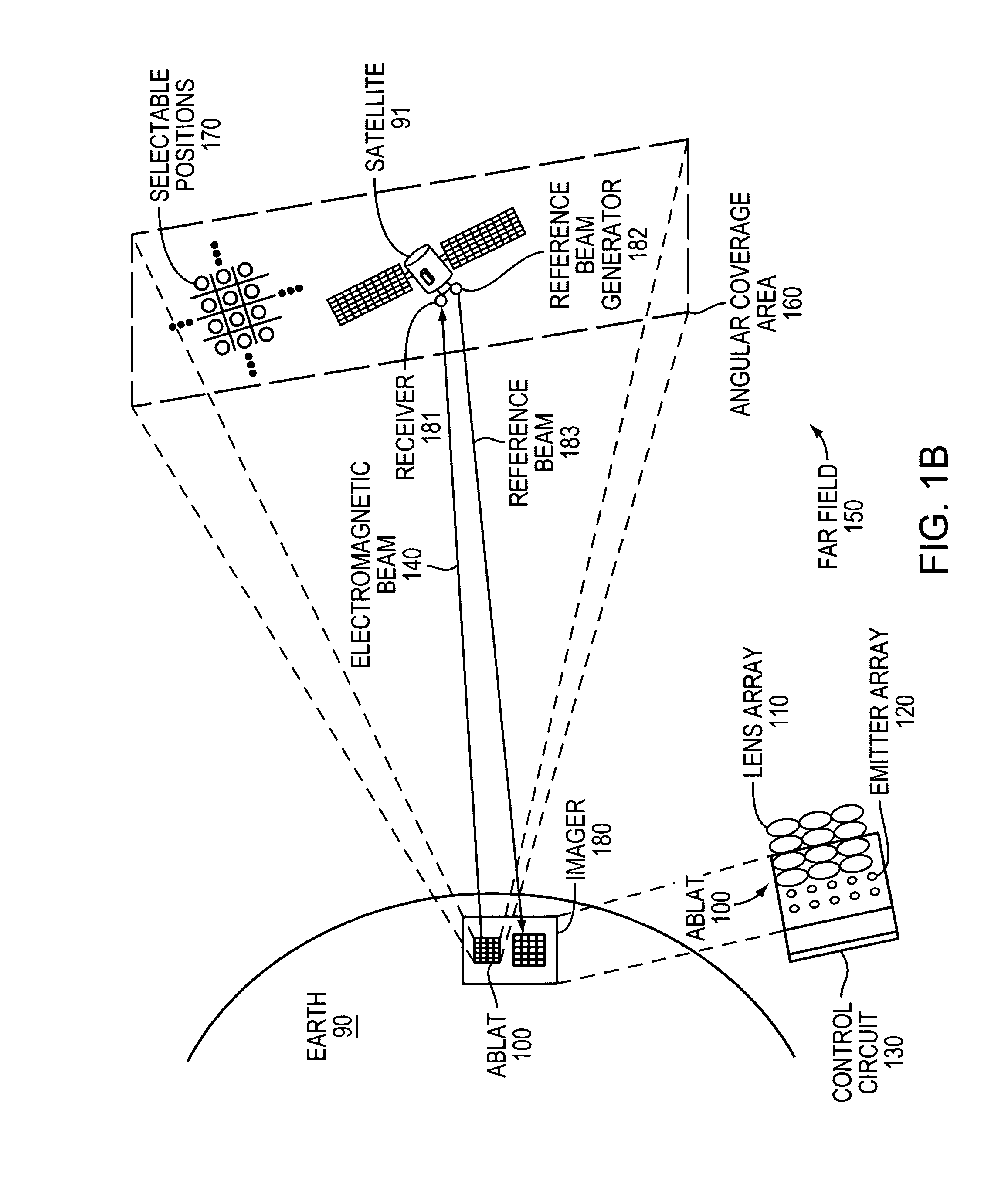

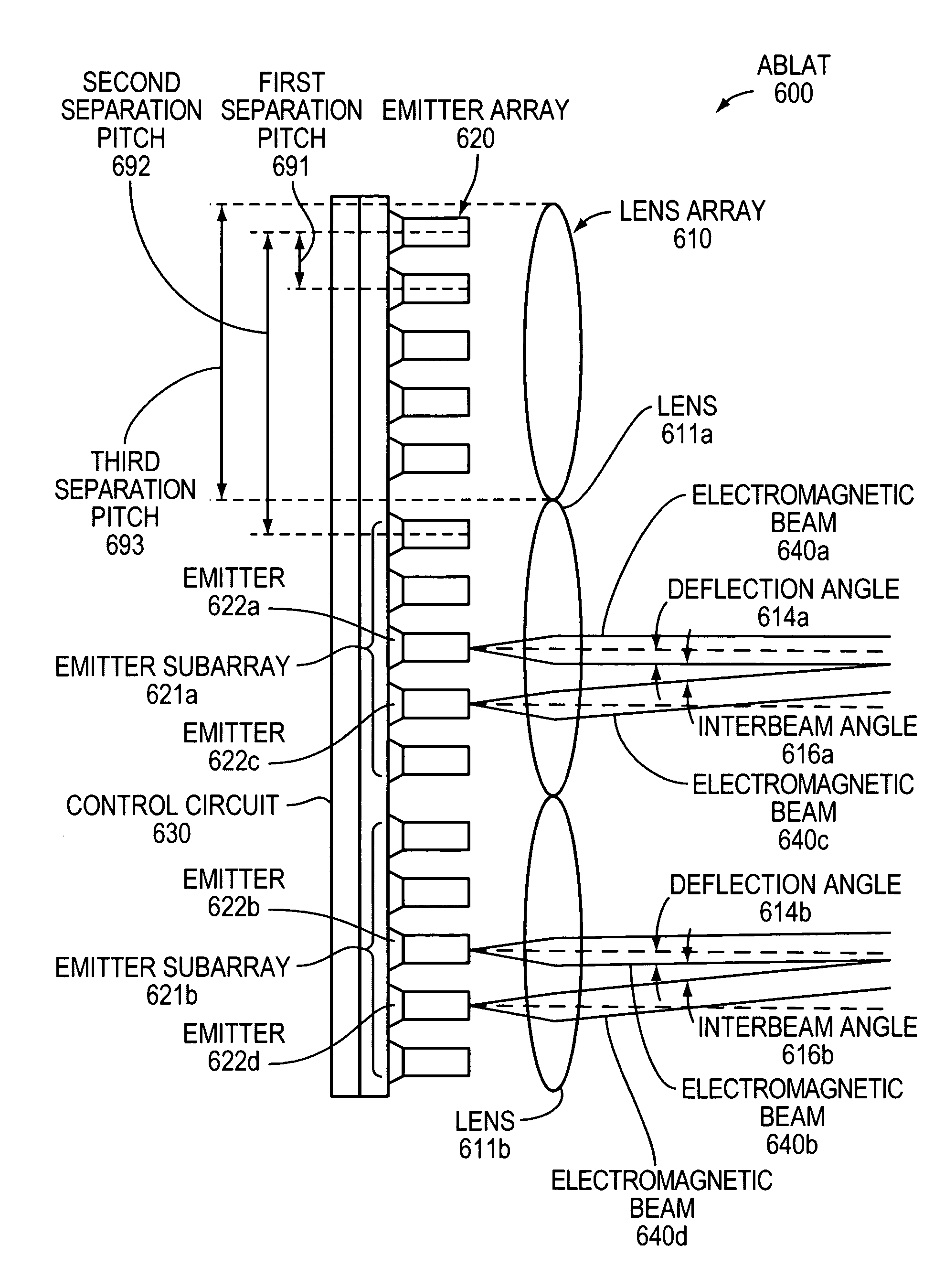

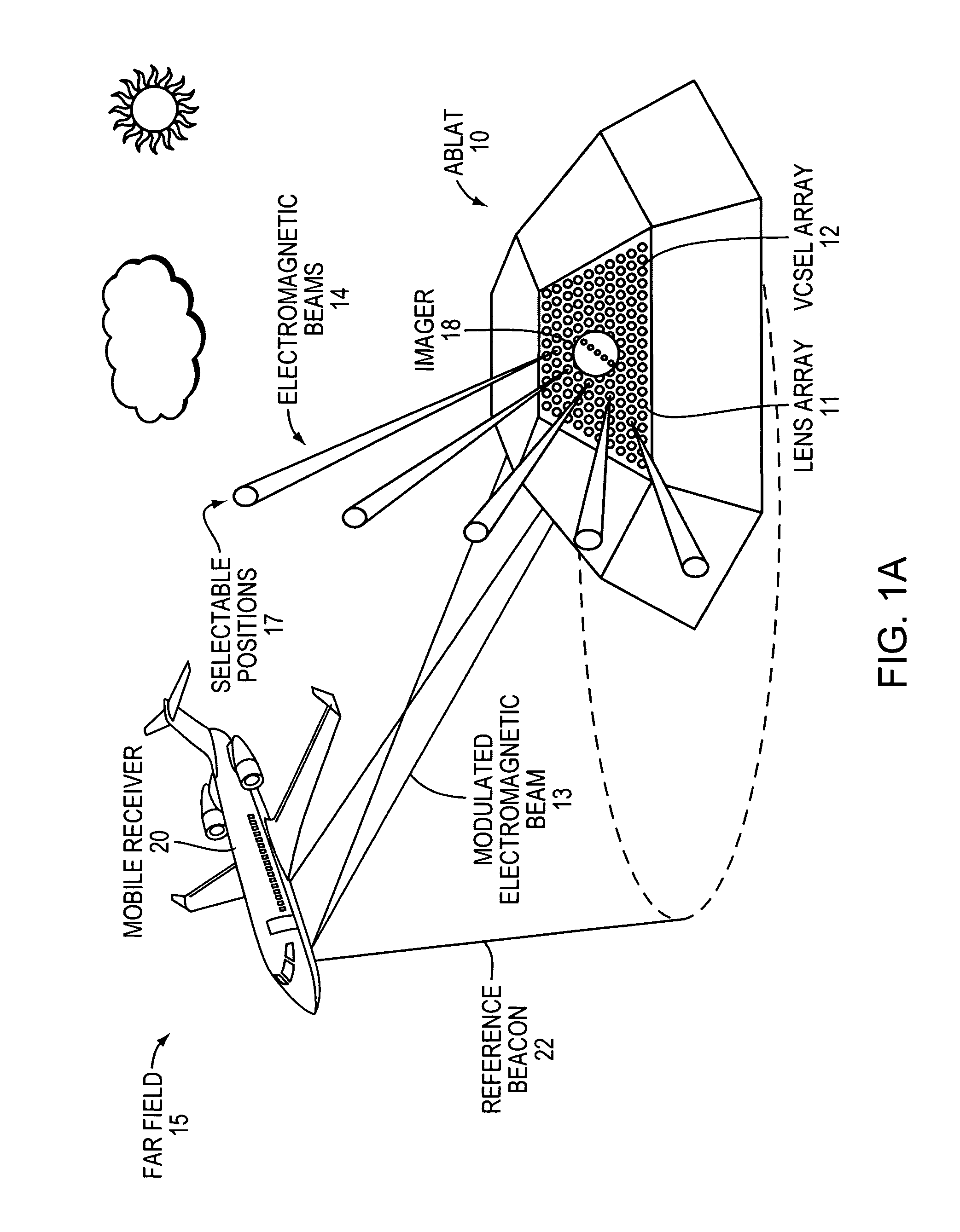

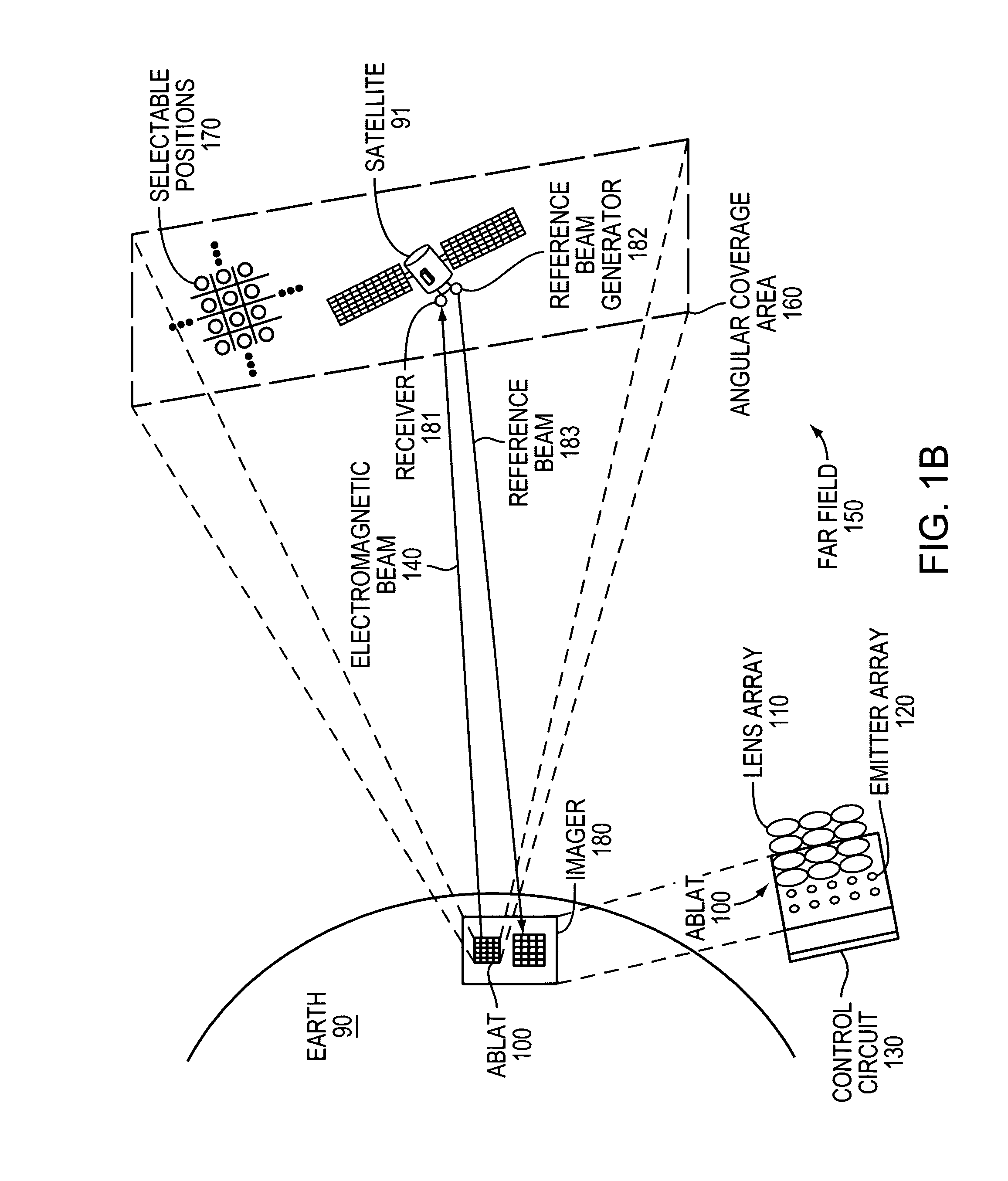

Agile-beam laser array transmitter

ActiveUS8301027B2Turn fasterWave based measurement systemsWavelength-division multiplex systemsLaser arrayBeam steering

An Agile-Beam Laser Array Transmitter (ABLAT) uses an array of emitters and an array of lenses to project electromagnetic beams over a wide angular coverage area in the far field. Differences in the separation pitches of the two arrays allows the ABLAT to project beams to contiguous and / or overlapping positions, depending on the ratio of the separation pitches and the lens focal length. Compared to other beam steering technology, the ABLAT is a smaller, lighter, and more efficient means of projecting beams over wider angular coverage areas. Various embodiments can be used in any beam steering application, including, but not limited to: free-space optical communications; light detection and ranging (lidar); optical scanning (e.g., retinal or bar-code scanning); display projection; image capture; optical character recognition; scanning laser microscopy; non-destructive testing; printing; facsimiles; map making; web inspection; color print processing; phototypesetting and platemaking; laser marking; material processing; DNA analysis; and drug discovery.

Owner:MASSACHUSETTS INST OF TECH

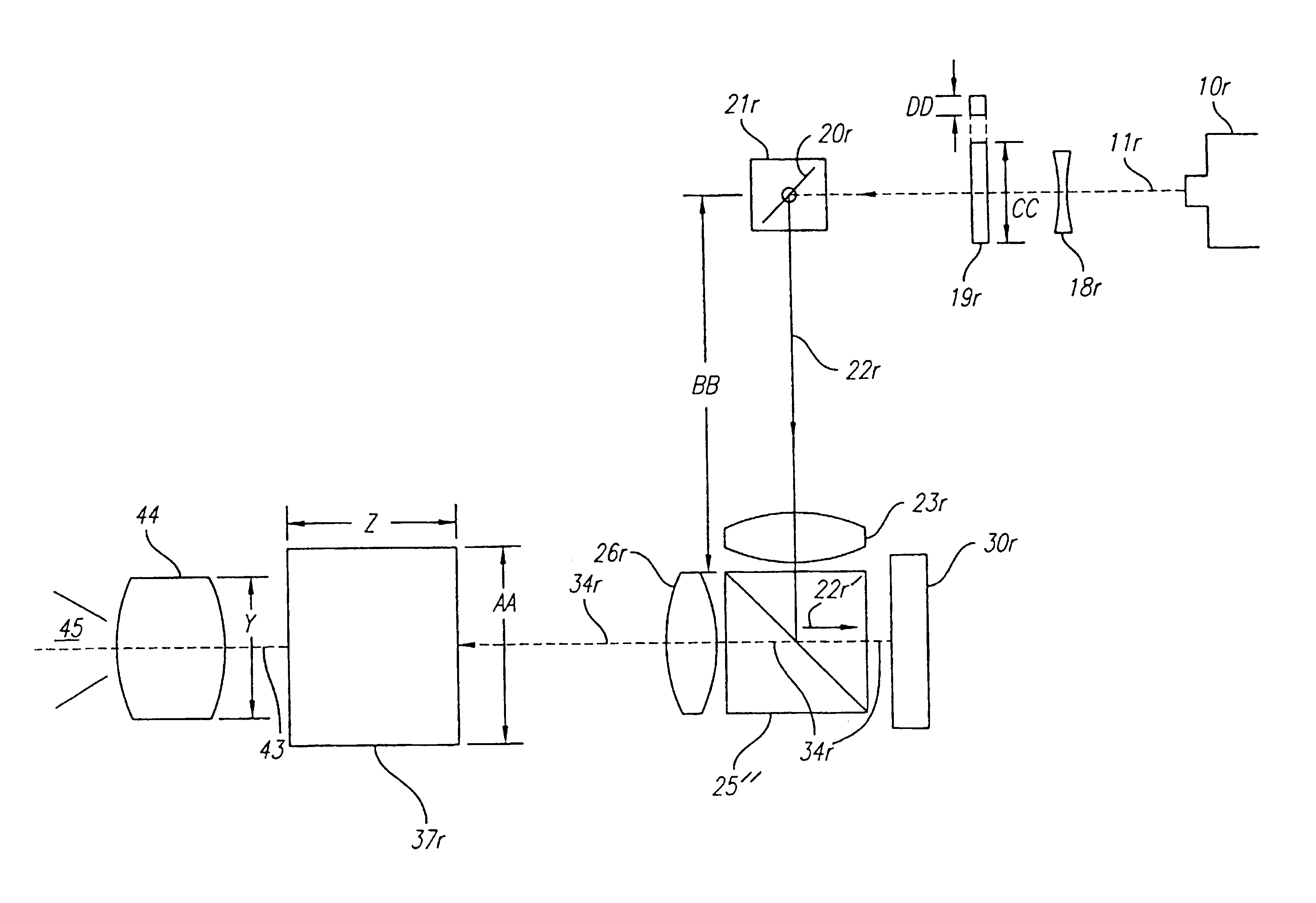

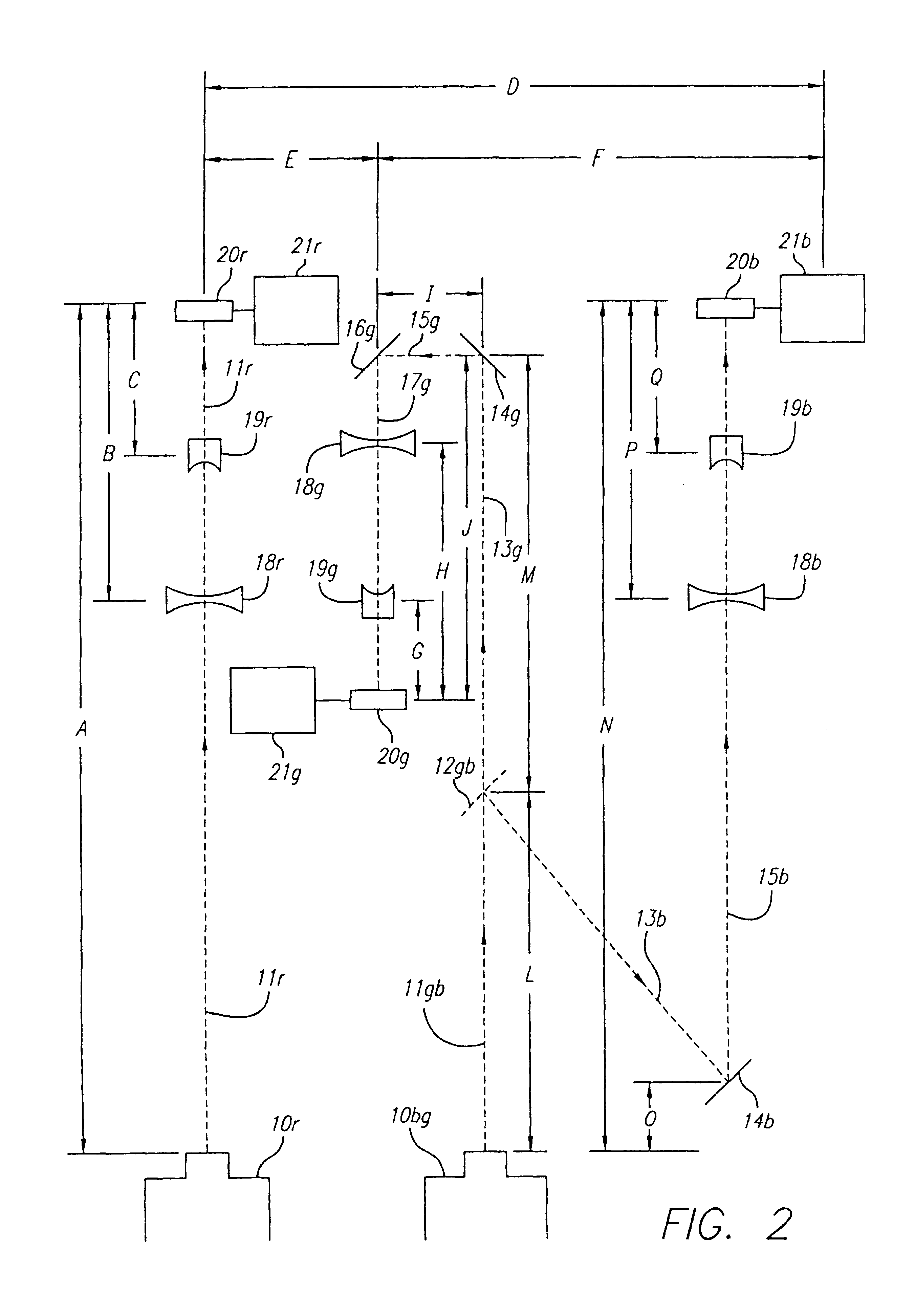

Agile-beam laser array transmitter

ActiveUS20100046953A1Turn fasterWide field of viewWave based measurement systemsWavelength-division multiplex systemsLaser arrayColor printing

An Agile-Beam Laser Array Transmitter (ABLAT) uses an array of emitters and an array of lenses to project electromagnetic beams over a wide angular coverage area in the far field. Differences in the separation pitches of the two arrays allows the ABLAT to project beams to contiguous and / or overlapping positions, depending on the ratio of the separation pitches and the lens focal length. Compared to other beam steering technology, the ABLAT is a smaller, lighter, and more efficient means of projecting beams over wider angular coverage areas. Various embodiments can be used in any beam steering application, including, but not limited to: free-space optical communications; light detection and ranging (lidar); optical scanning (e.g., retinal or bar-code scanning); display projection; image capture; optical character recognition; scanning laser microscopy; non-destructive testing; printing; facsimiles; map making; web inspection; color print processing; phototypesetting and platemaking; laser marking; material processing; DNA analysis; and drug discovery.

Owner:MASSACHUSETTS INST OF TECH

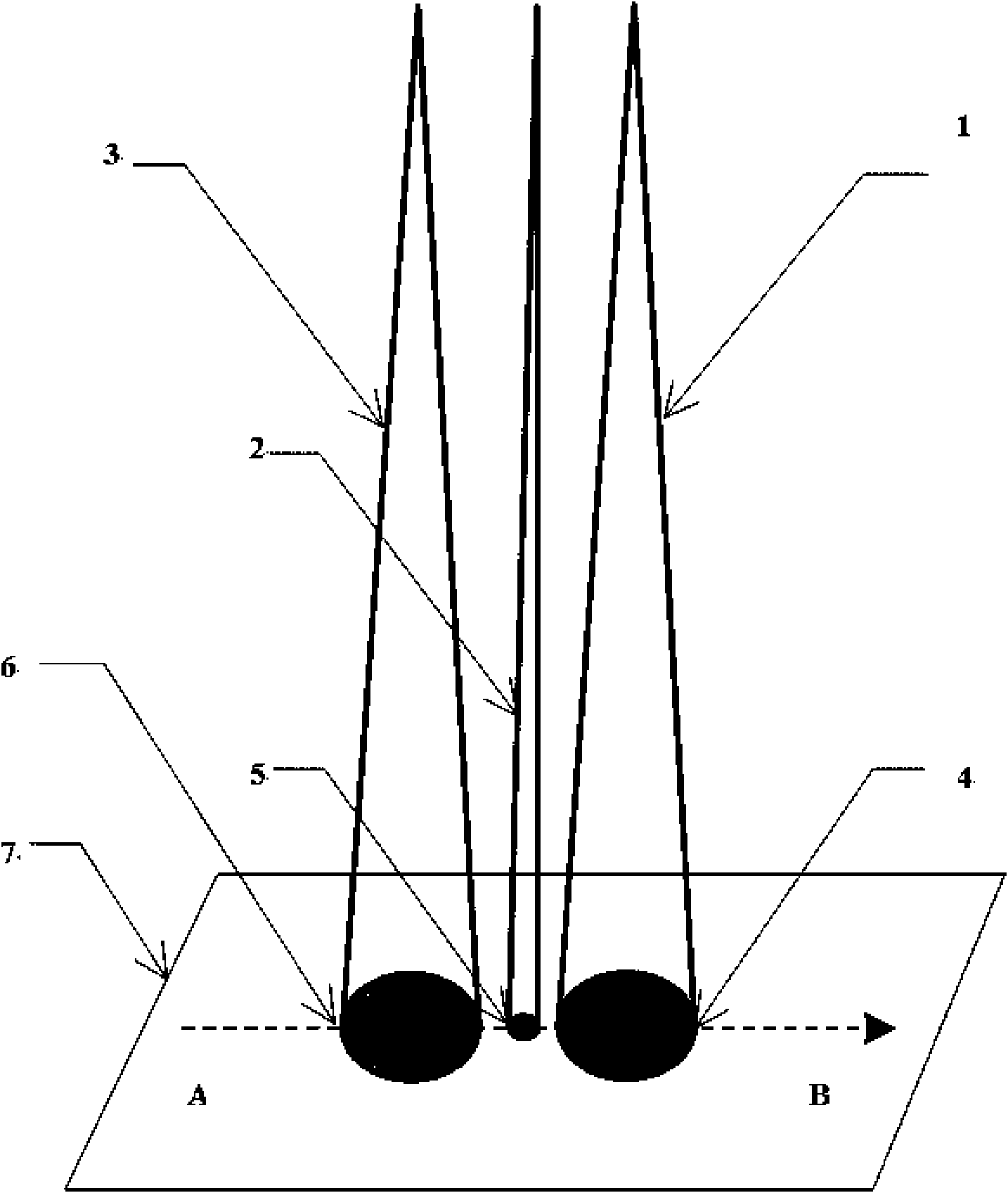

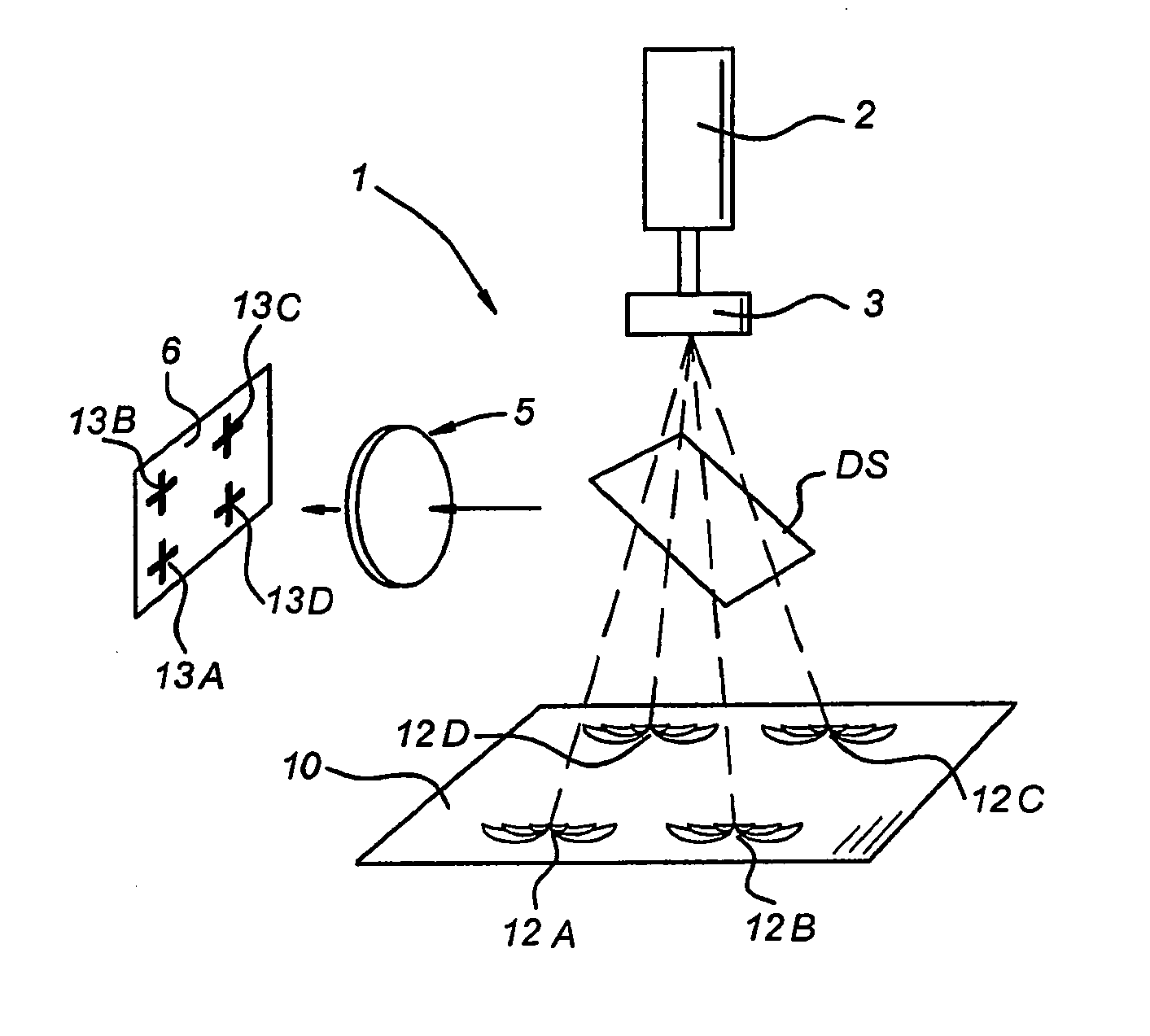

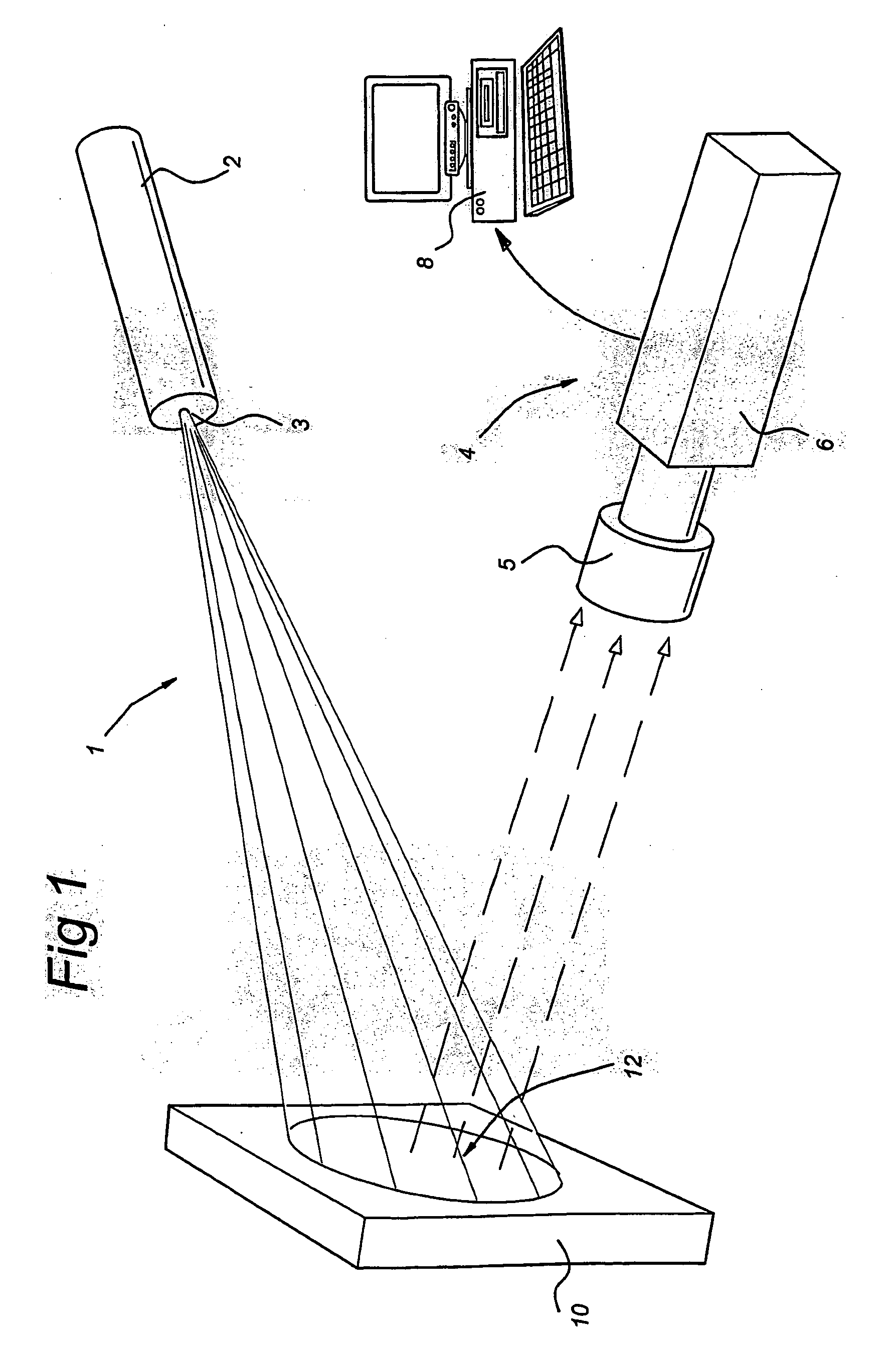

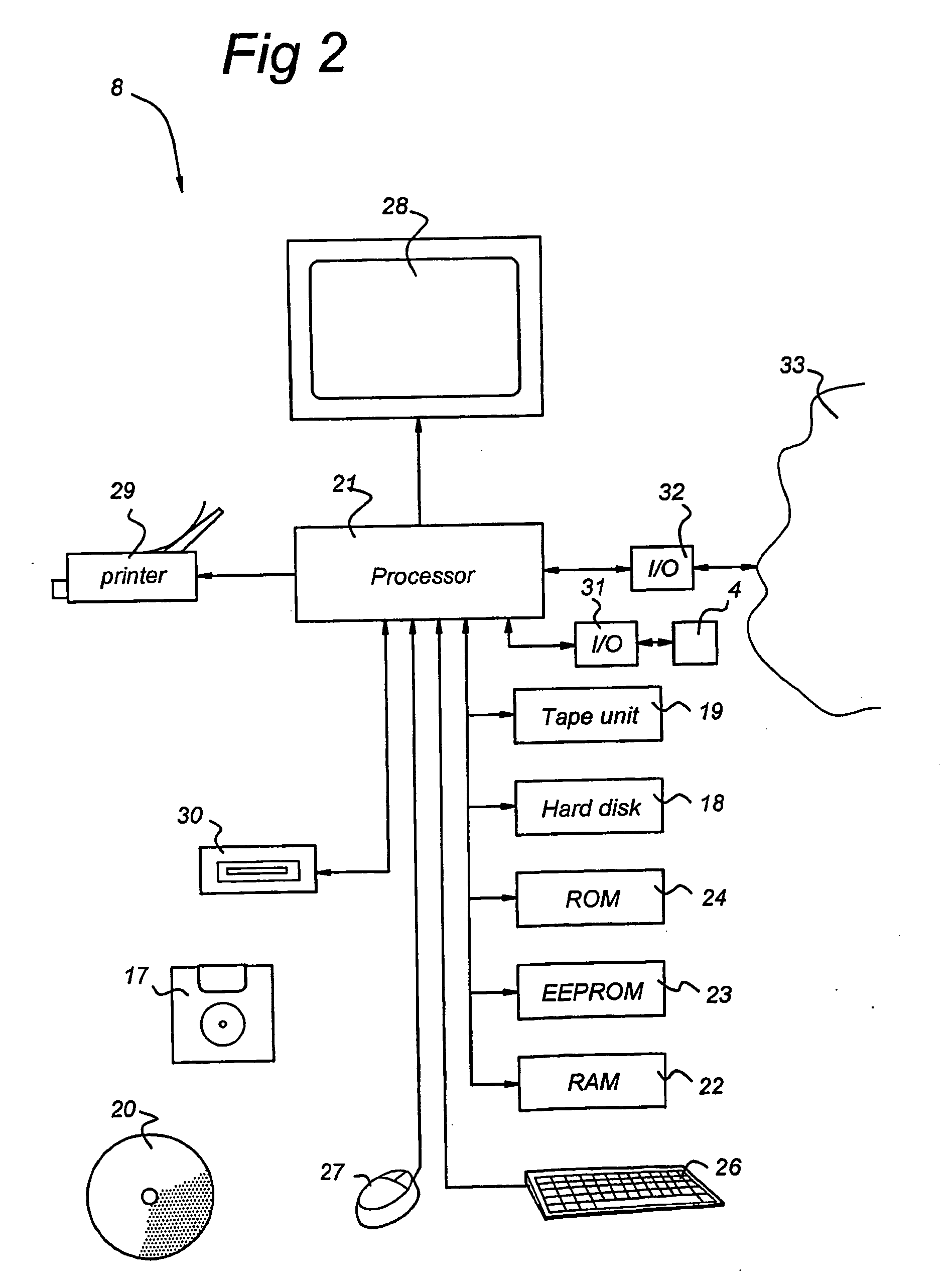

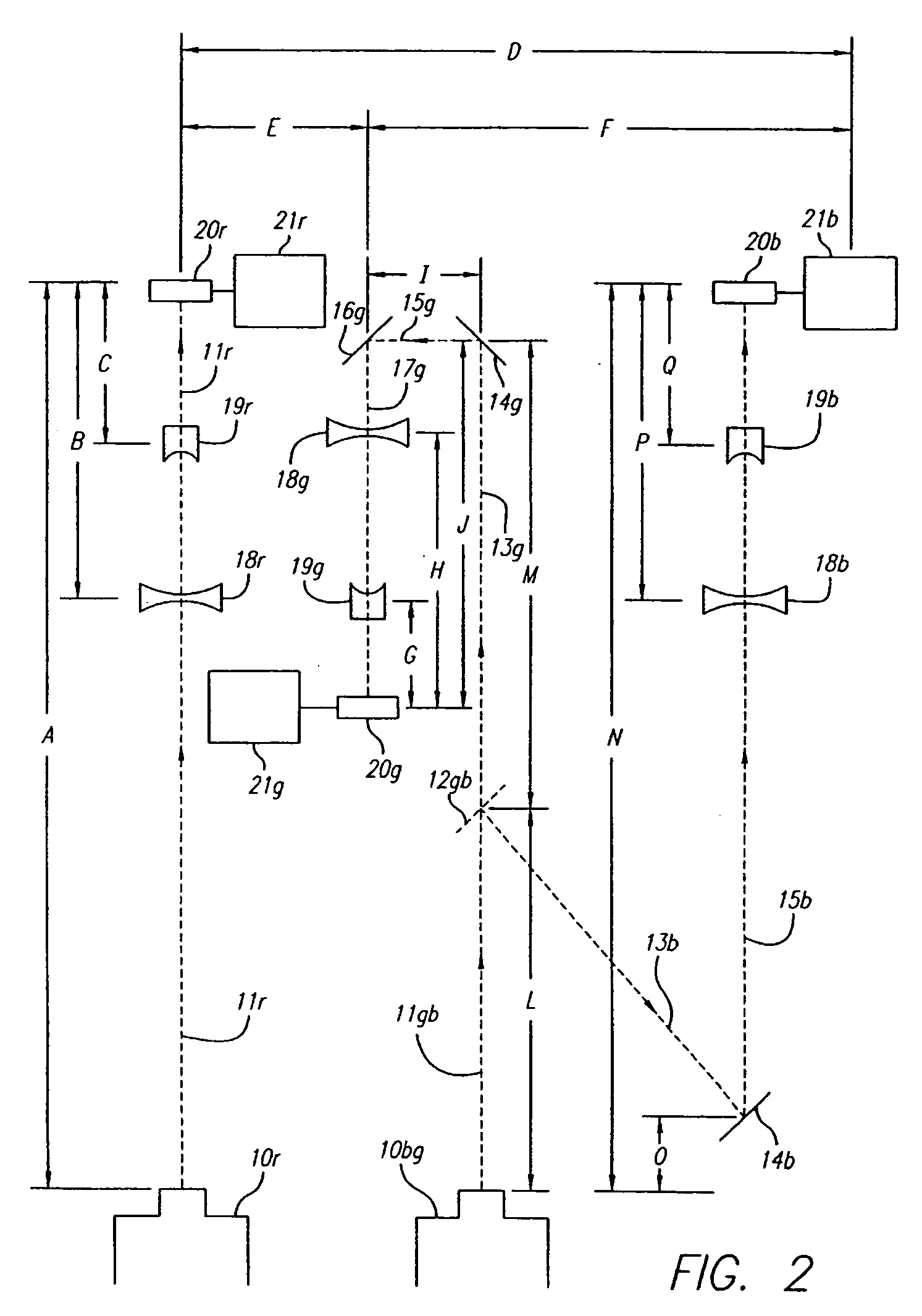

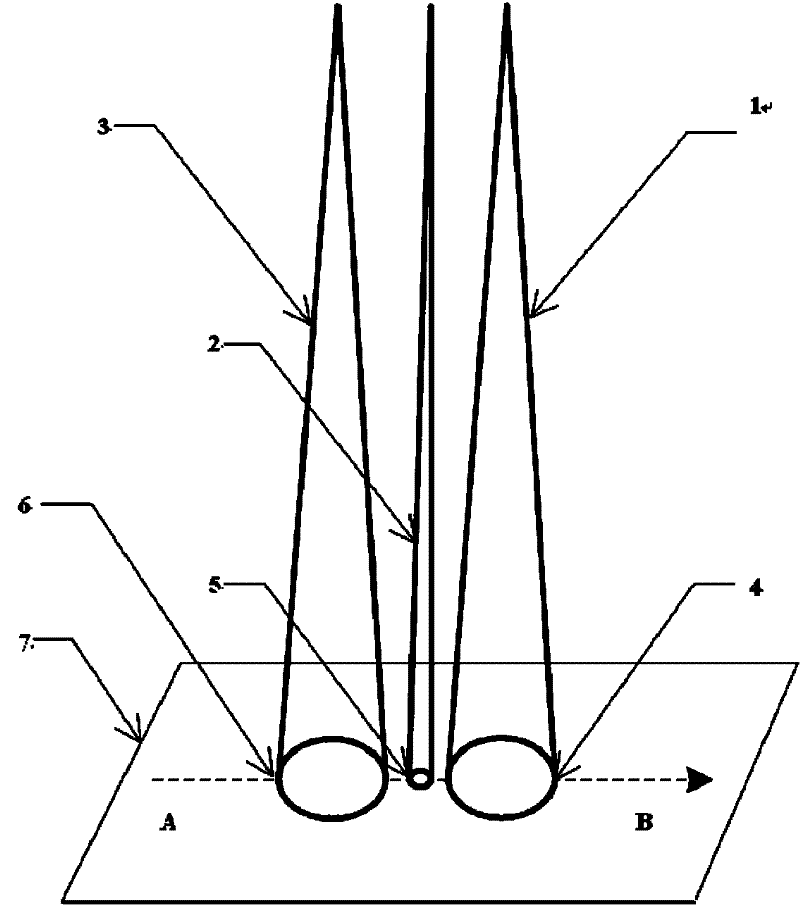

Laser doppler perfusion imaging with a plurality of beams

InactiveUS20050187477A1High strengthImprove signal-to-noise ratioScattering properties measurementsIndication/recording movementLight beamLaser light

Laser Doppler Perfusion Imaging system including a laser light source (2), an image detector (4), and signal detector (6); the laser light source (2), in use, being arranged for illuminating a selected area of interest (12) on a sample (10) for determining perfusion related data of the sample (10), the image detector, in use, being arranged for capturing an image of the sample (10), and the signal detector (6), in use, being arranged for detecting a laser Doppler signal from the selected area of interest (12) on the sample (10), wherein the laser light source (2) comprises optical means (3) for creating a laser beam comprising a plurality of beams.

Owner:PERIMED

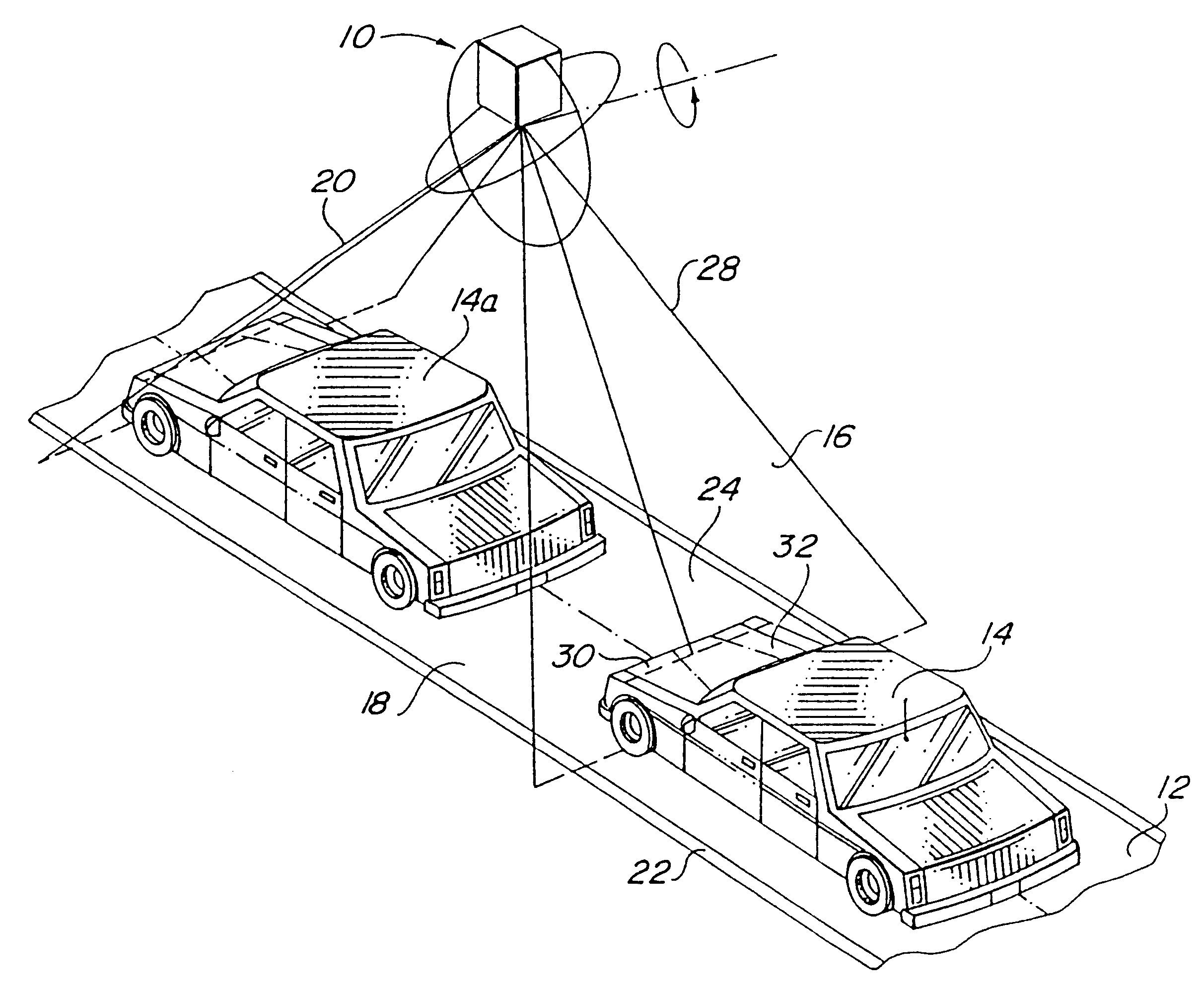

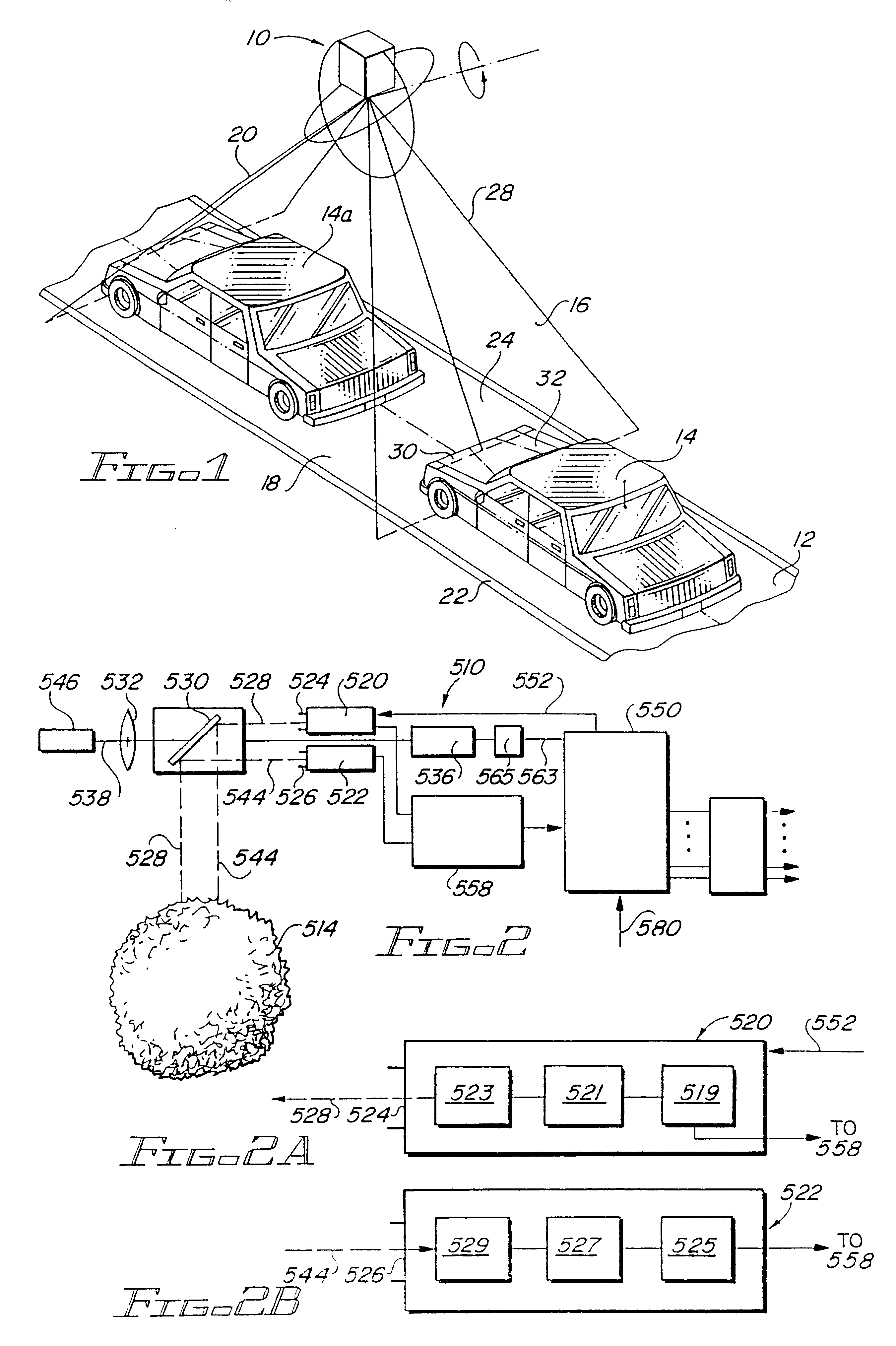

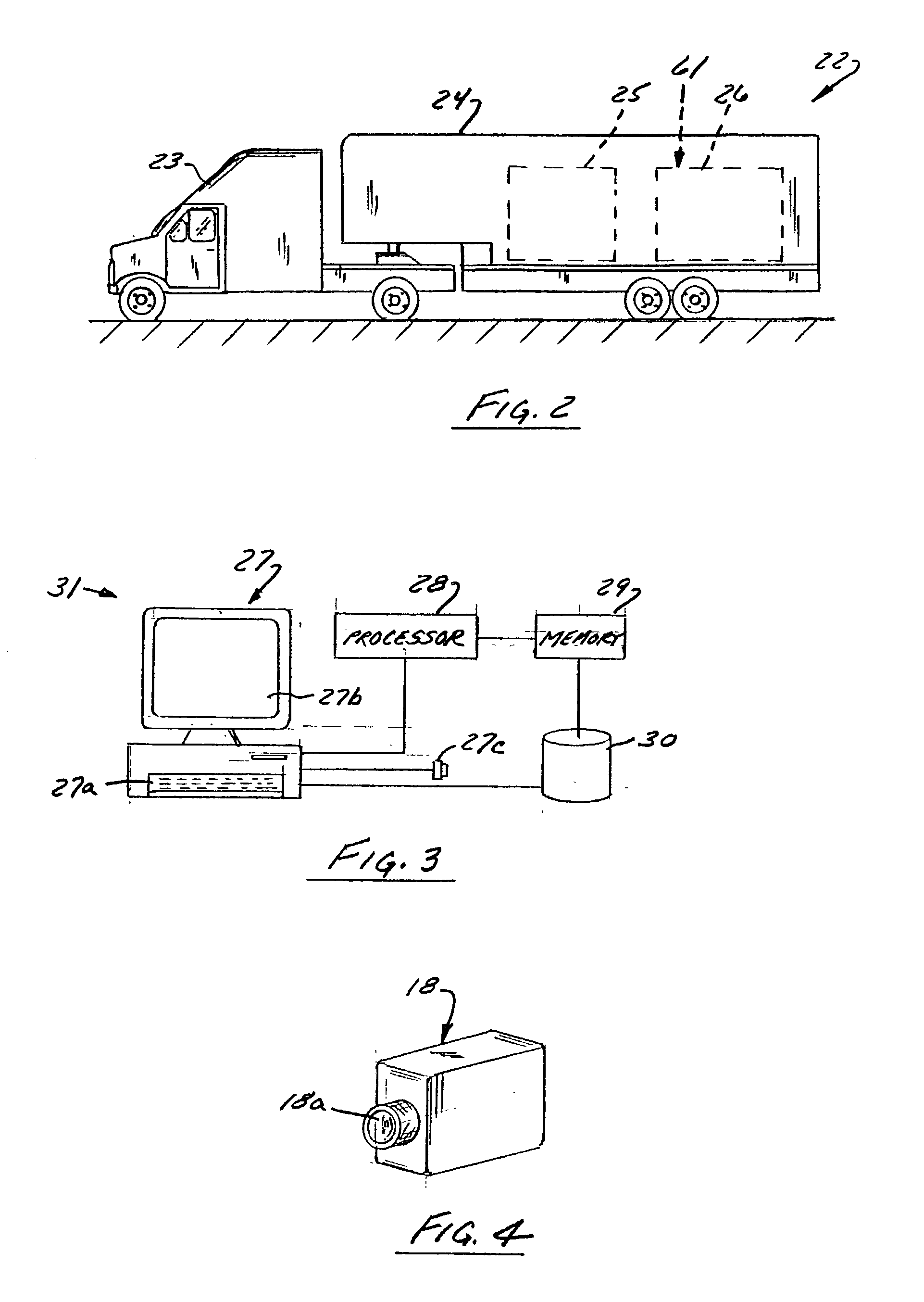

Vehicle classification and axle counting sensor system and method

InactiveUS6304321B1Accurately determineAccurate detectionOptical rangefindersDetection of traffic movementLight beamRoad surface

A vehicle detection and classification sensor provides accurate 3D profiling and classification of highway vehicles for speeds up to 100 mph. A scanning time-of-flight laser rangefinder is used to measure the distance to the highway from a fixed point above the road surface and then measure the distance to the surfaces of any vehicle that is viewed by the sensor. A rotating polygon scans a beam laser into two beams projected across the road surface at a fixed angle between them. The beam is pulsed at a high repetition rate for determining vehicle speeds with a high accuracy and uses the calculated speed and consecutive range measurements as the vehicle moves past the sensor to develop a three-dimensional profile of the vehicle. An algorithm is applied to the three-dimensional profile for providing a vehicle-classification.

Owner:OSI DEFENSE SYST

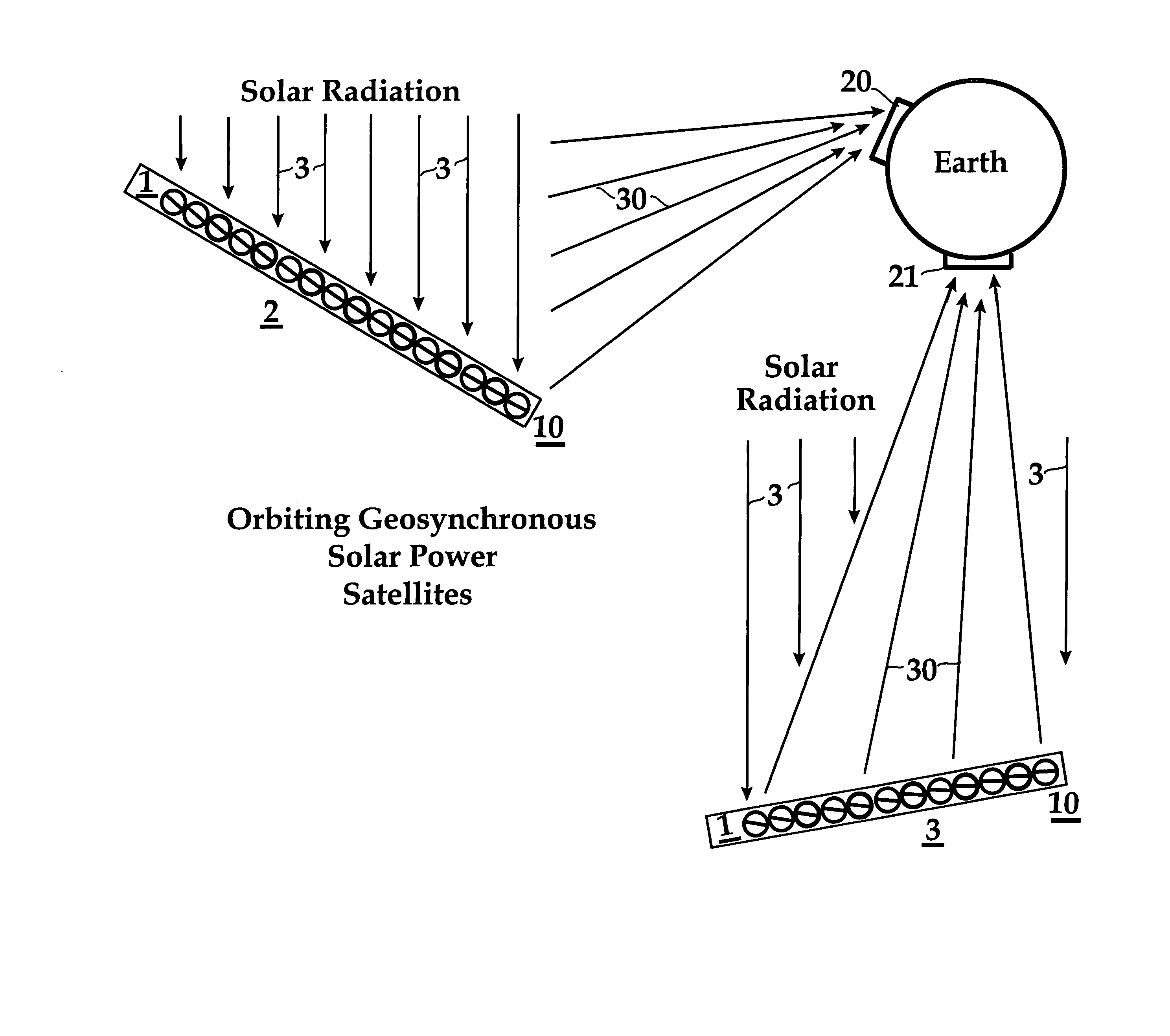

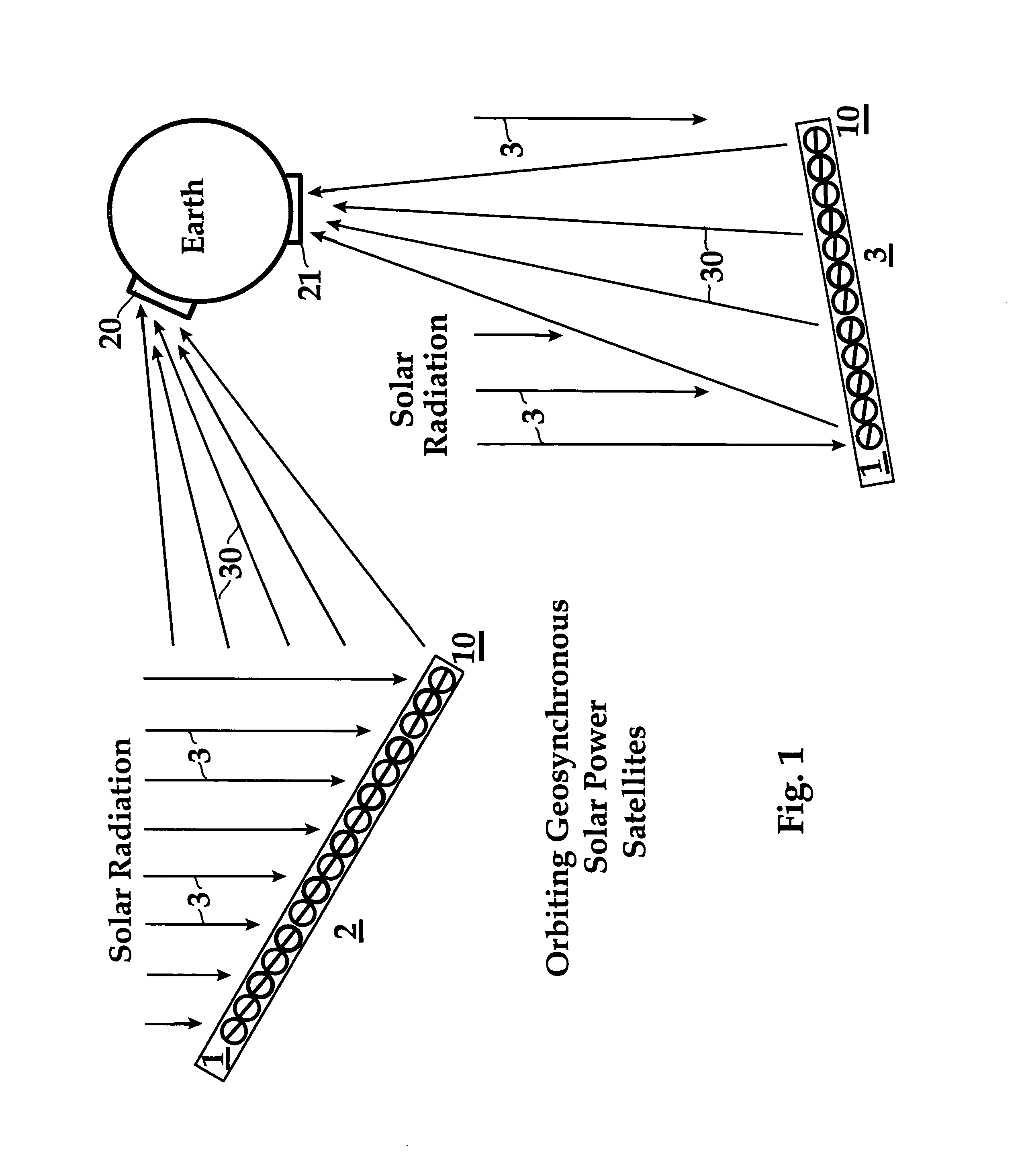

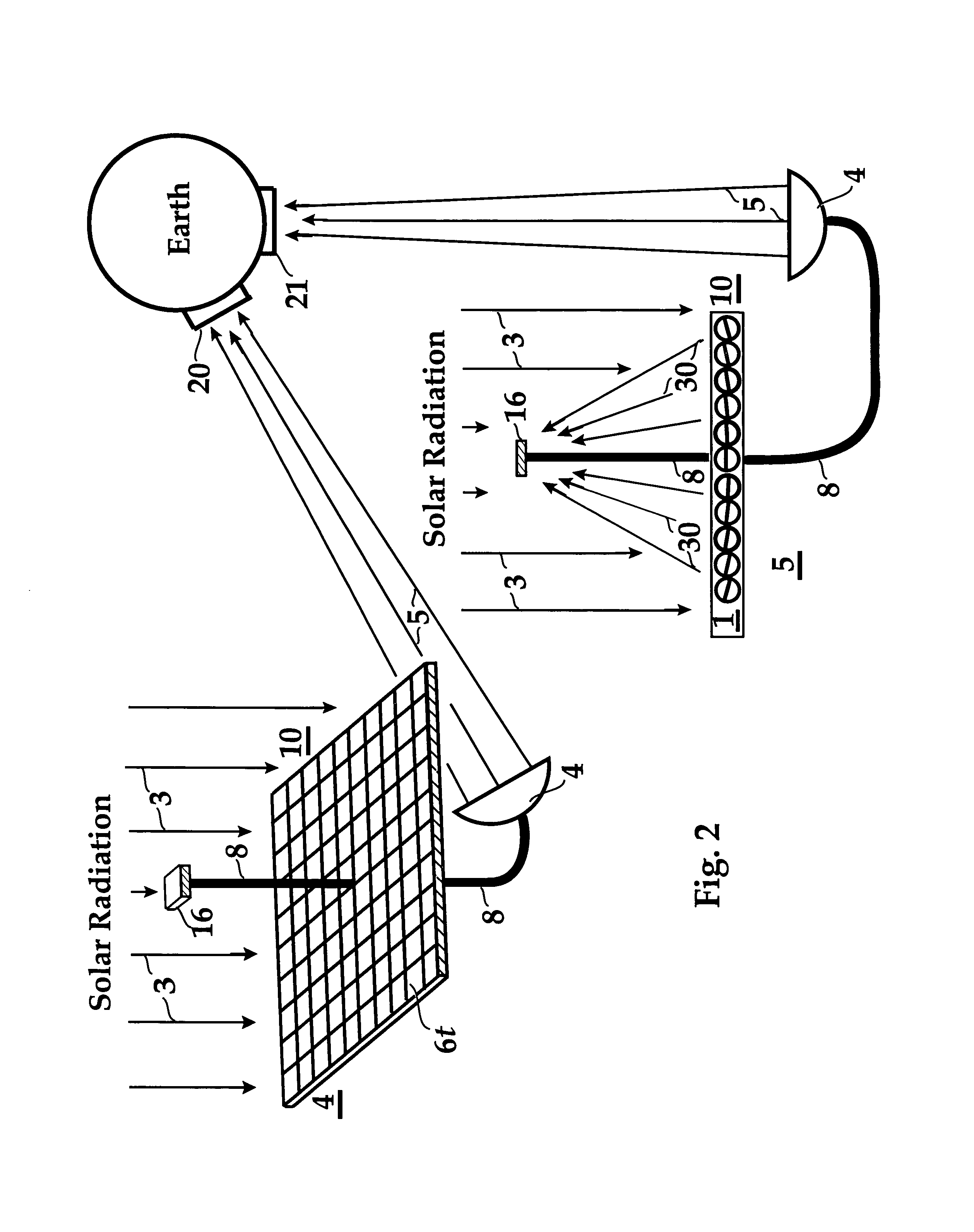

Micro-optics concentrator for solar power satellites

InactiveUS7077361B1Low costAffordable solar energySolar heating energyCosmonautic vehiclesSolar powerSolar power satellites

There is an increasingly intense need to harness solar energy due to an ever growing shortage of conventional energy sources, The instant invention is concerned with method and apparatus for solar concentrator micro-mirrors on solar power satellites and the moon to focus and reflect large quantities of solar energy. Method and apparatus are taught for directly reflecting solar energy to the Earth; reflecting solar energy to a microwave converter in space which transmits microwave energy to the Earth; and reflecting solar energy to a laser radiation converter which beams laser radiation to the Earth. The concentrated energy received at the Earth may be converted directly to electricity or indirectly by thermo-mechanical means. The advantages and disadvantages of the different means of sending such concentrated energy to the Earth are discussed. A particularly important objective of this invention is the focussing of sunlight for solar power conversion and production. The instant invention can contribute to the goal of achieving environmentally clean solar energy on a large enough scale to be competitive with conventional energy sources.

Owner:RABINOWITZ MARIO

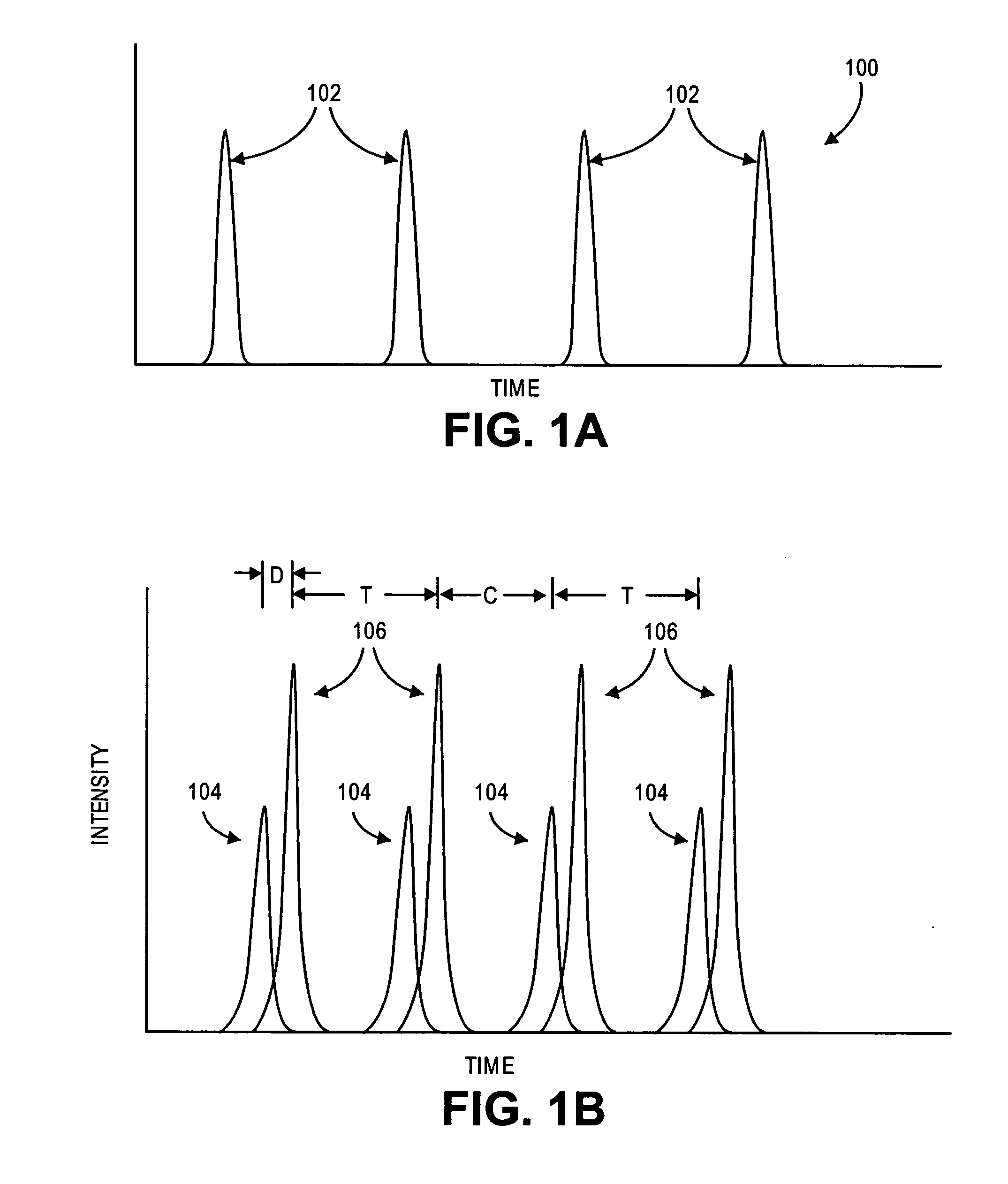

Dual pulsed beam laser micromachining method

InactiveUS20060249816A1Semiconductor/solid-state device detailsSolid-state devicesOptoelectronicsLaser scribing

Owner:INTEL CORP

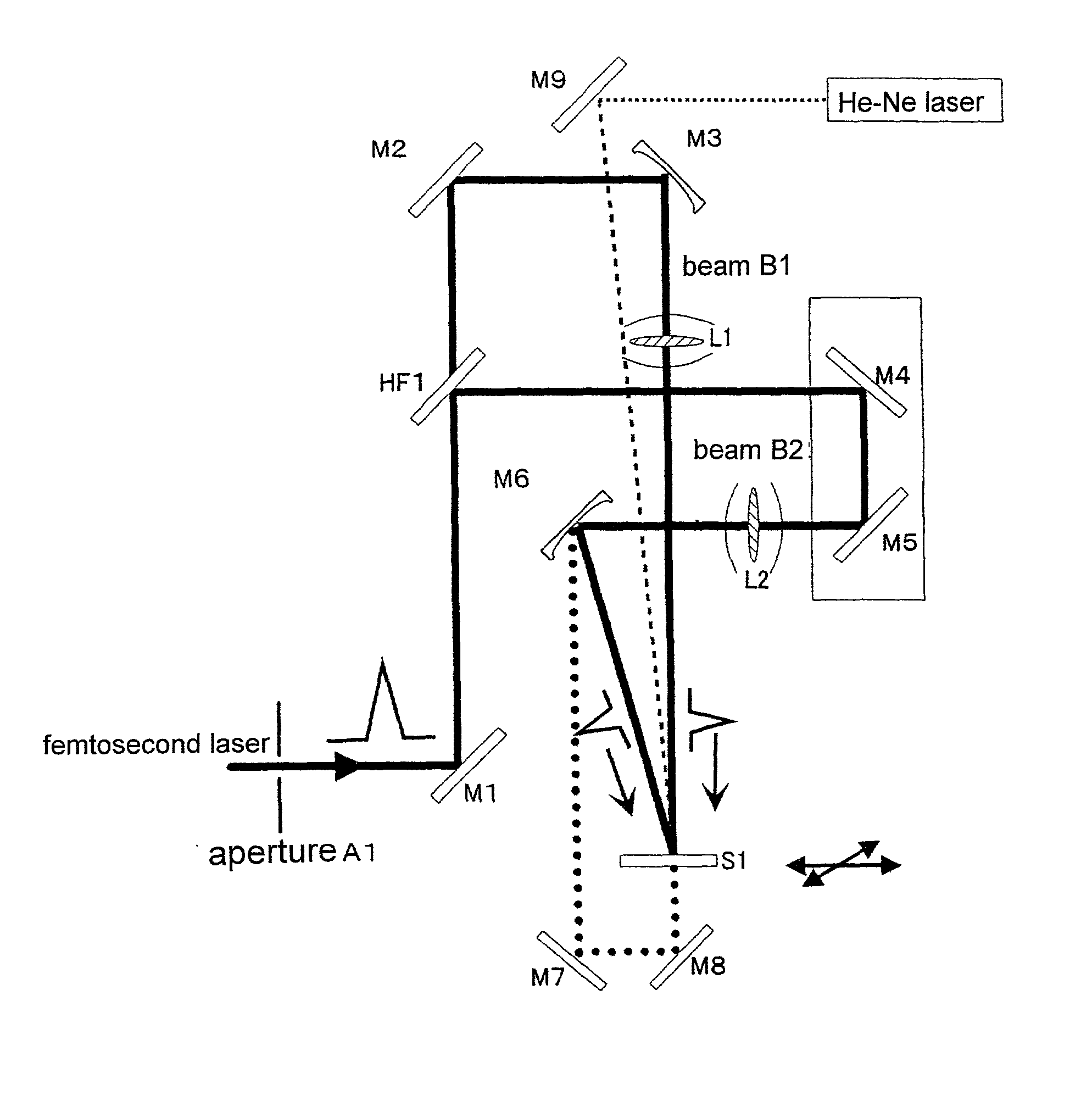

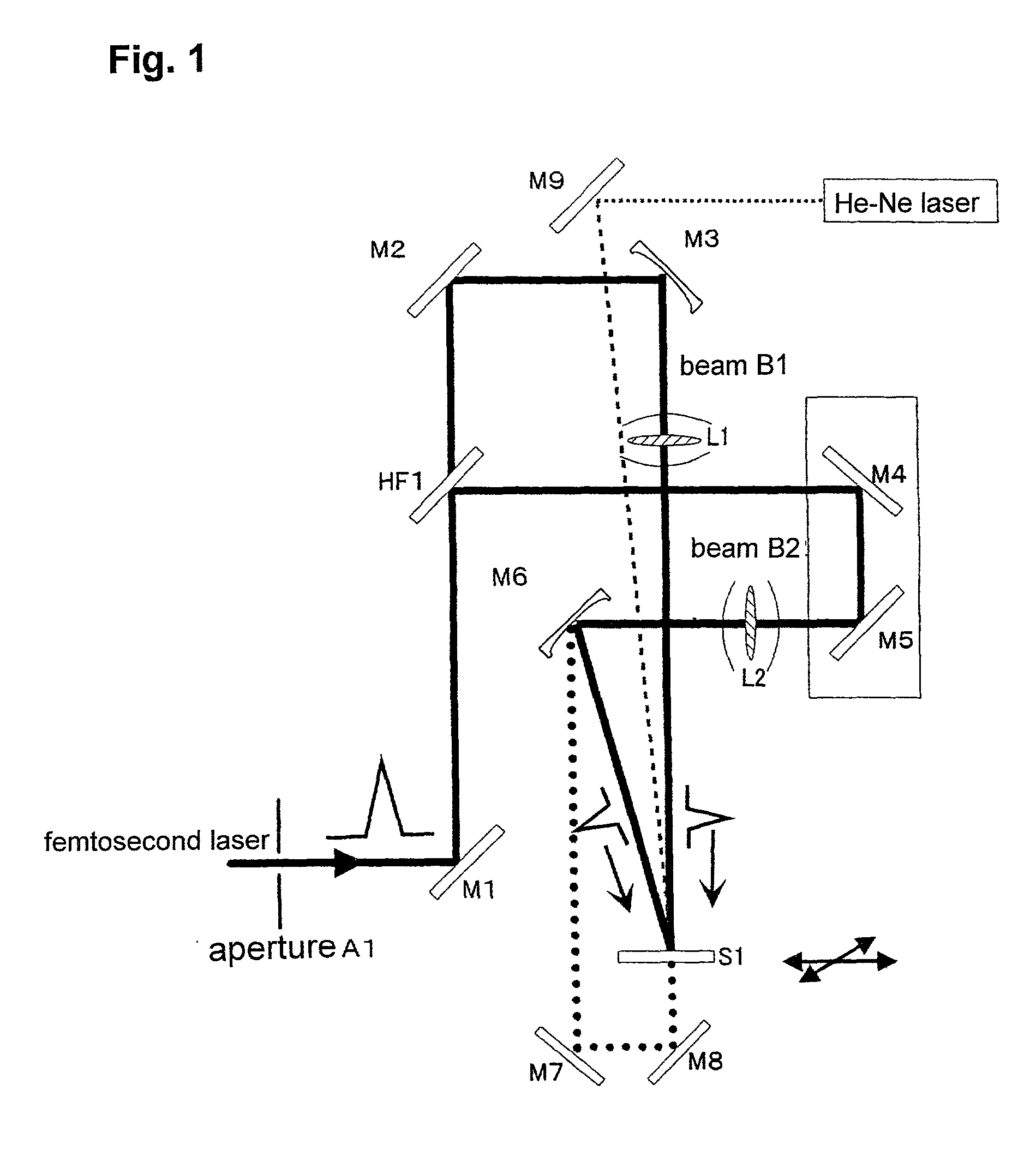

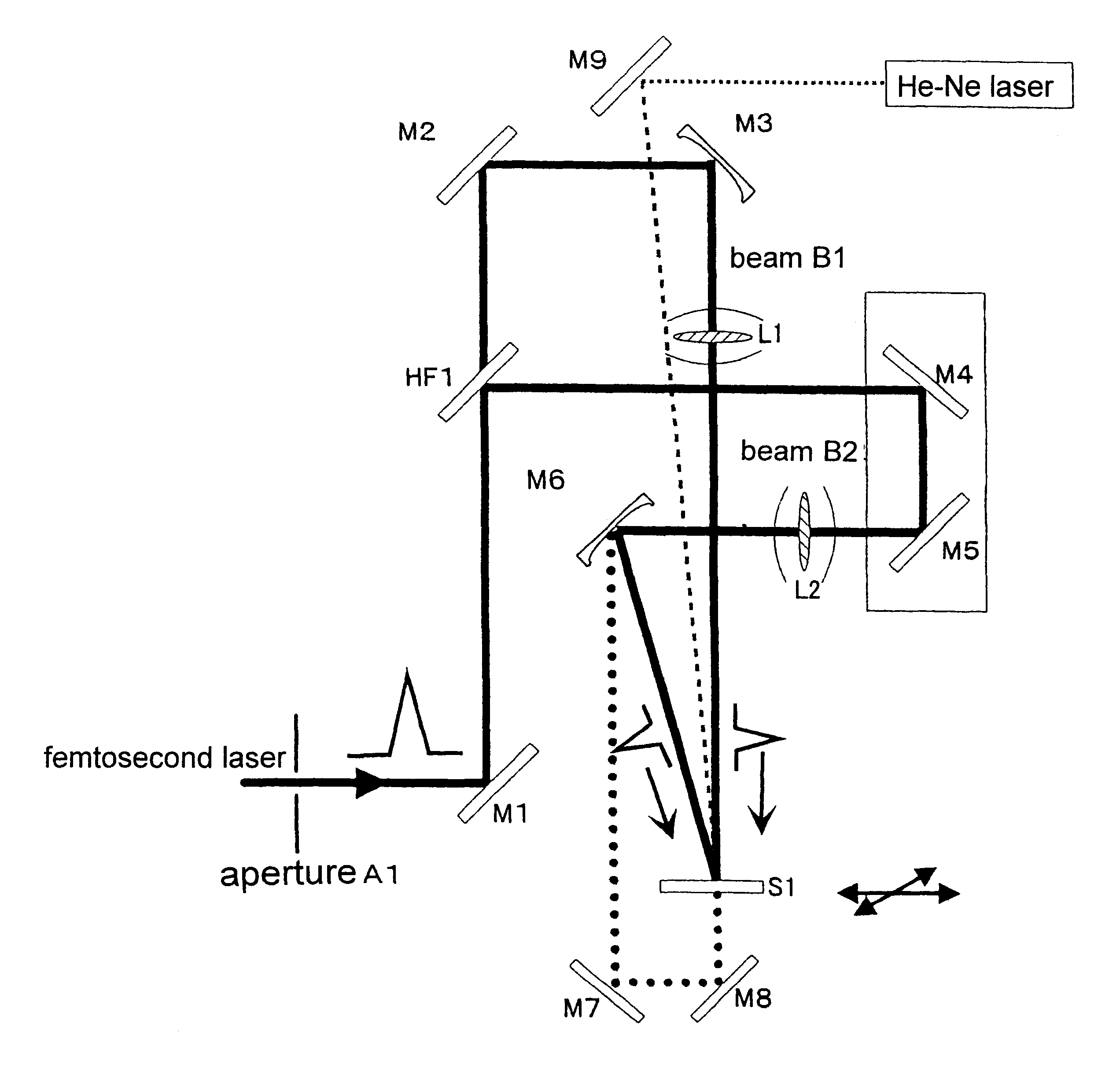

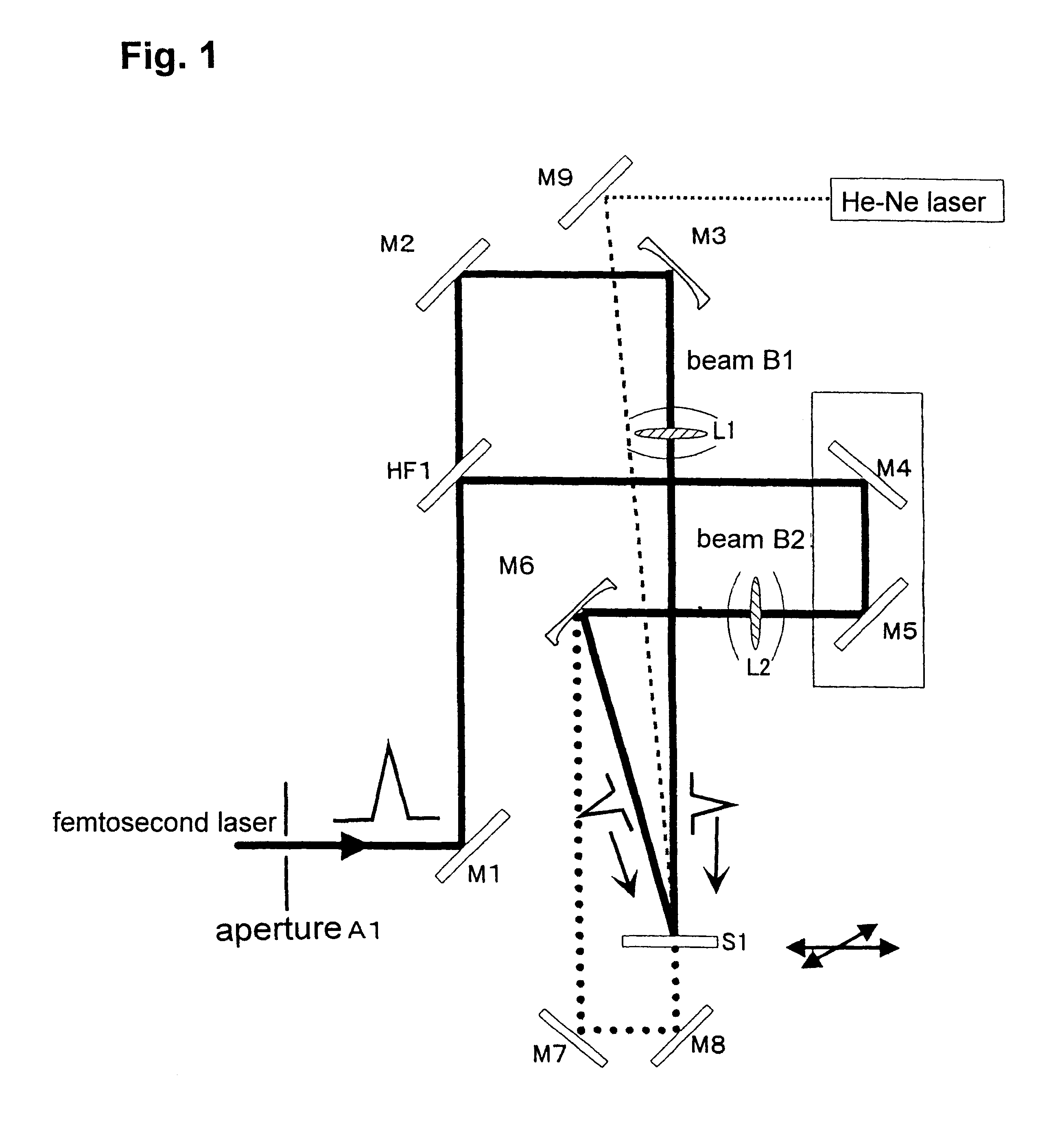

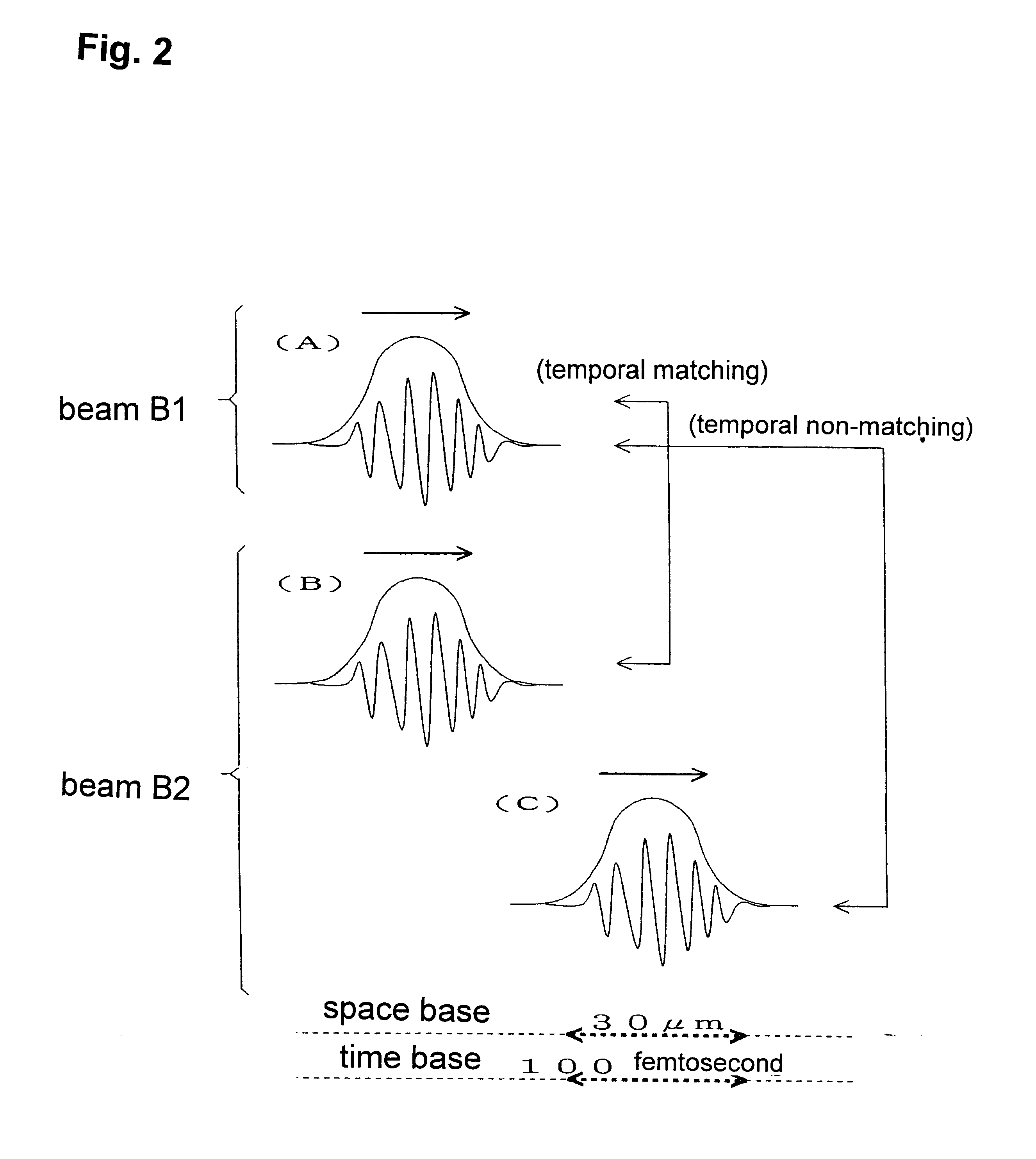

Production method and device for hologram

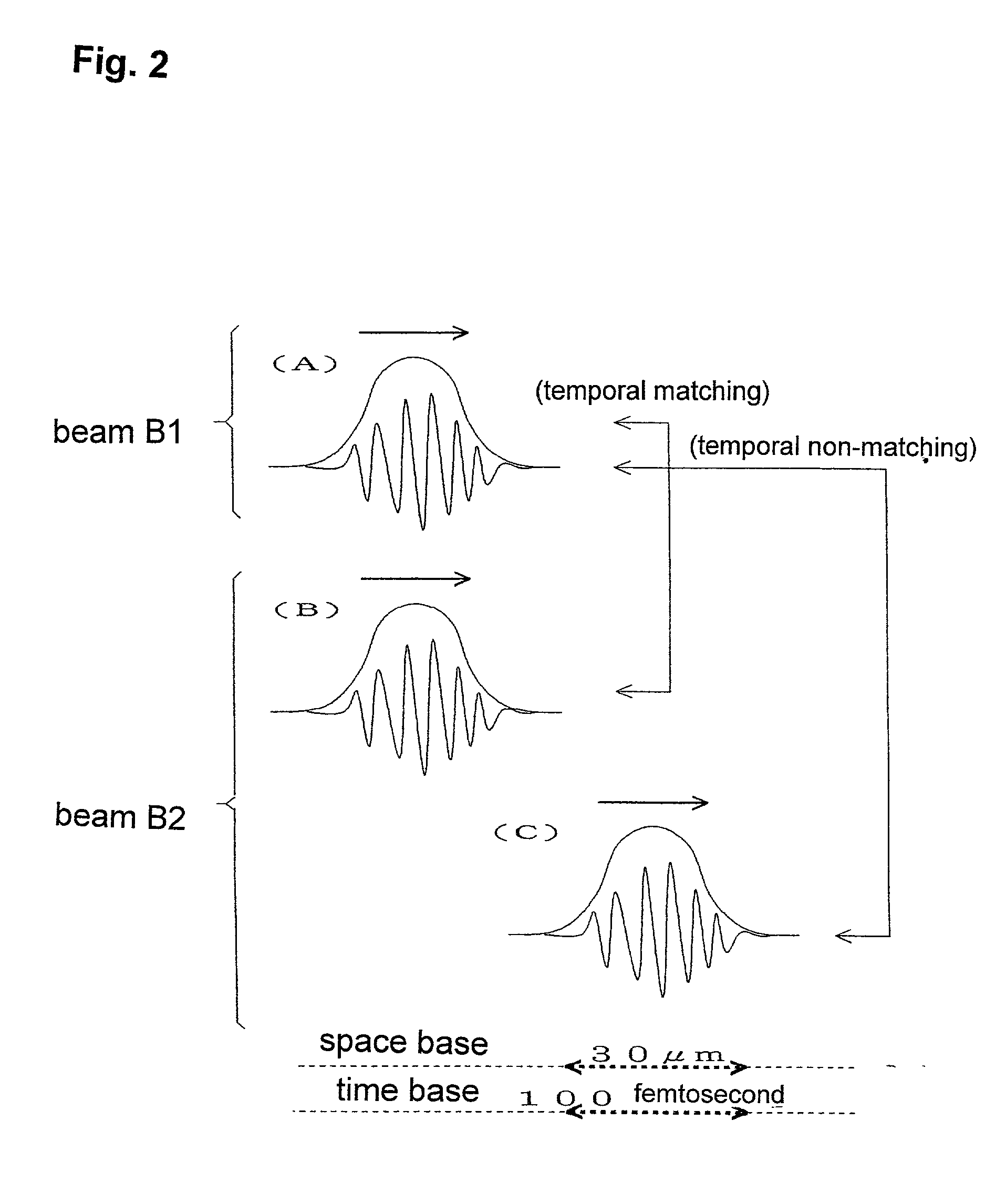

InactiveUS20020126333A1Improve interferenceReduce coherenceLaser detailsHolographic light sources/light beam propertiesPulse beamSemiconductor materials

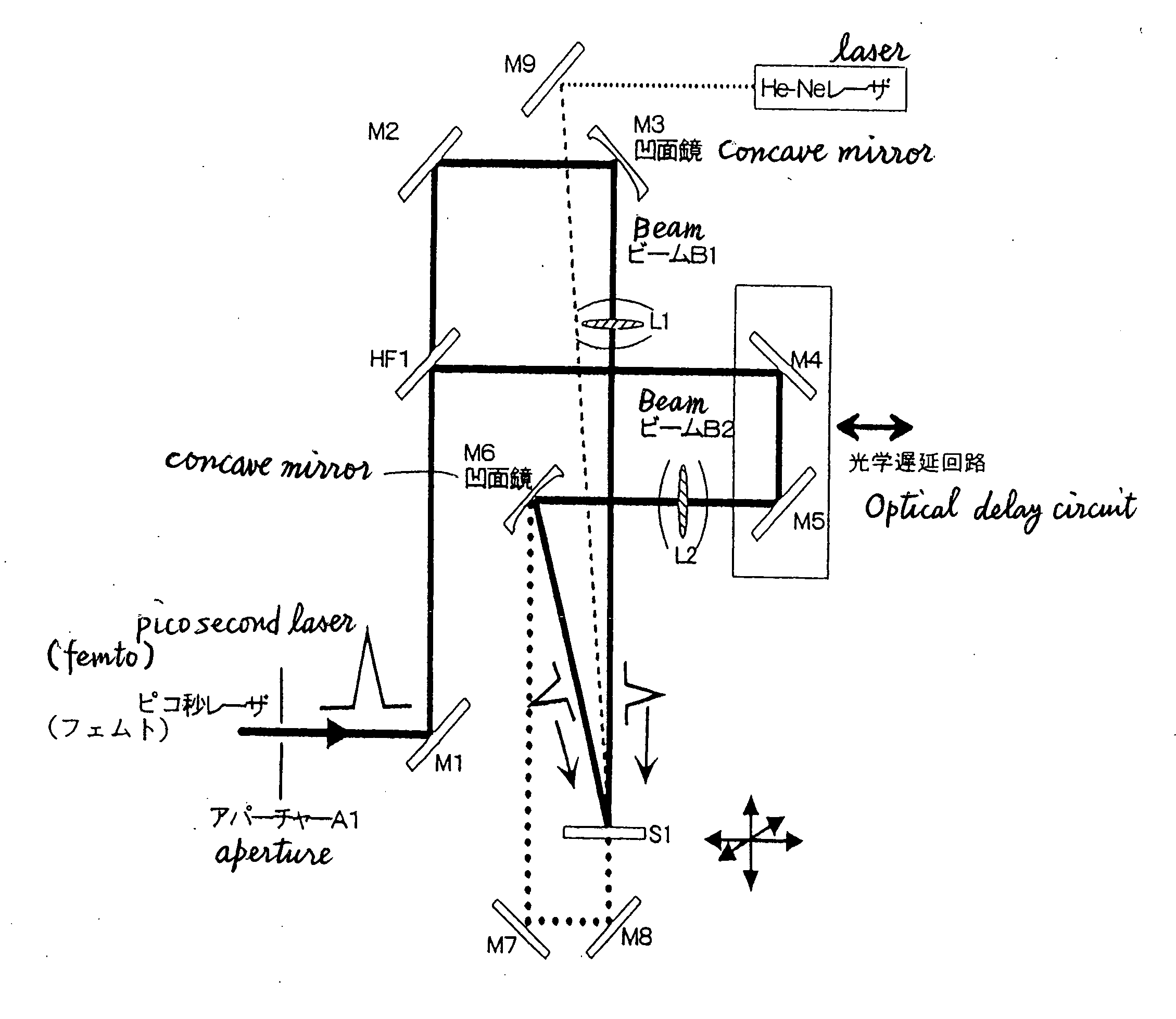

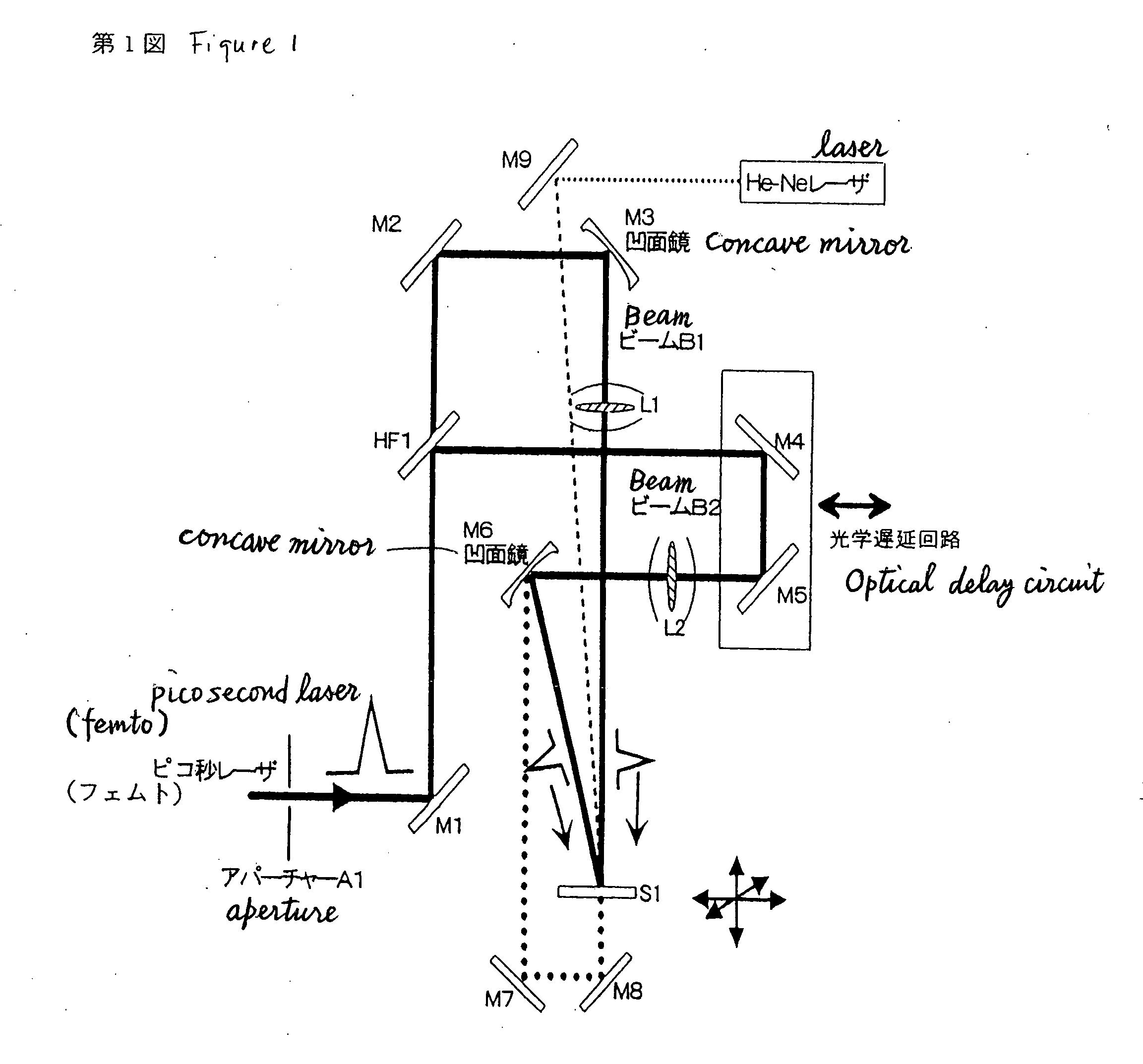

A method and apparatus for producing a hologram using a two-beam laser interference exposure process, comprising the steps of using as a light source a femtosecond laser having a pulse width of 900-10 femtoseconds and a peak output of 1 GW or more and capable of generating a pulse beam at or close to the Fourier transform limit, dividing the pulse beam from the laser into two by a beam splitter, controlling the two beams temporally through an optical delay circuit and spatially using plane and concave mirrors each having a slightly rotatable reflection surface to converge the beams on a surface of or within a substrate for recording a hologram at an energy density of 100 GW / cm.sup.2 or more with keeping each polarization plane of the two beams in parallel so as to match the converged spot of the two beams temporally and spatially, whereby a hologram is recorded irreversibly on the substrate formed of a transparent material, semiconductor material or metallic material.

Owner:JAPAN SCI & TECH CORP

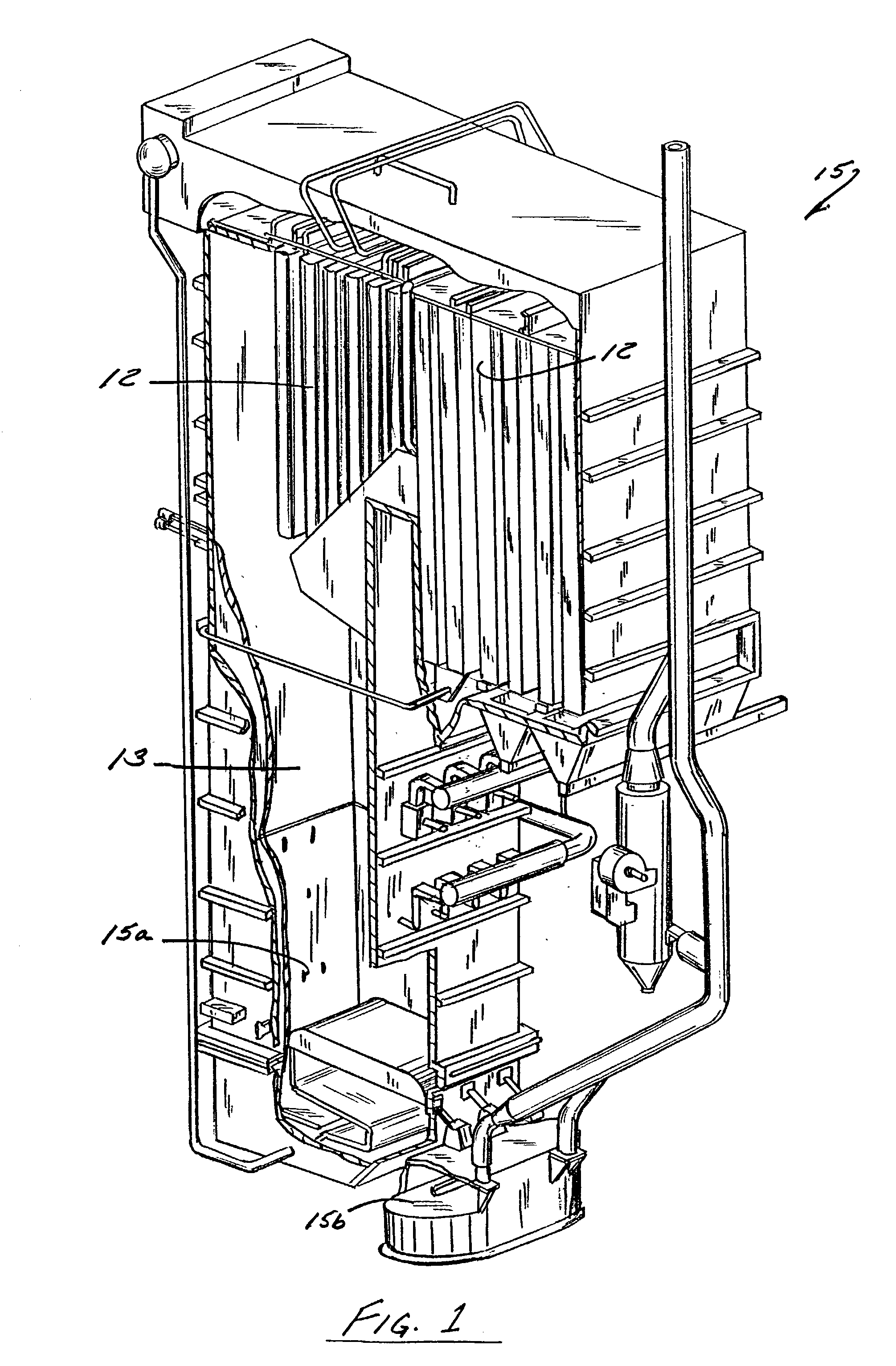

Laser system for slag removal

InactiveUS6710285B2Eliminates slagConsiderable riskCleaning heat-transfer devicesHollow article cleaningFiberSlag

A system for removing slag from a boiler includes a laser, a targeting system, and a computer system for controlling the operation of the laser and targeting system. Preferably, the laser includes chemicals contained in a mixing pre-chamber. A pump connects to the pre-chamber, and an iodine laser diode connects to the pump. The laser unit also has a power source, cooling system, and a raw beam laser. The targeting system is driven by targeting software and includes an optical targeting system. Preferably, the system also includes a mobile trailer with a computer control room, a main laser operating unit, and a portable optical targeting system connected to the laser unit. Fiber optic cable connects the targeting system and the laser. The online deslagging method includes transporting and setting-up the system, relaying set-up information, feeding targeting information, activating and operating the laser to remove slag from within the boiler.

Owner:FIRST CALL EXPLOSIVE SOLUTIONS

Laser system slag removal

InactiveUS20030222062A1Removal from surfaceEliminates slagCleaning heat-transfer devicesHollow article cleaningFiberSlag

A system for removing slag from a boiler includes a laser, a targeting system, and a computer system for controlling the operation of the laser and targeting system. Preferably, the laser includes chemicals contained in a mixing pre-chamber. A pump connects to the pre-chamber, and an iodine laser diode connects to the pump. The laser unit also has a power source, cooling system, and a raw beam laser. The targeting system is driven by targeting software and includes an optical targeting system. Preferably, the system also includes a mobile trailer with a computer control room, a main laser operating unit, and a portable optical targeting system connected to the laser unit. Fiber optic cable connects the targeting system and the laser. The online deslagging method includes transporting and setting-up the system, relaying set-up information, feeding targeting information, activating and operating the laser to remove slag from within the boiler.

Owner:FIRST CALL EXPLOSIVE SOLUTIONS

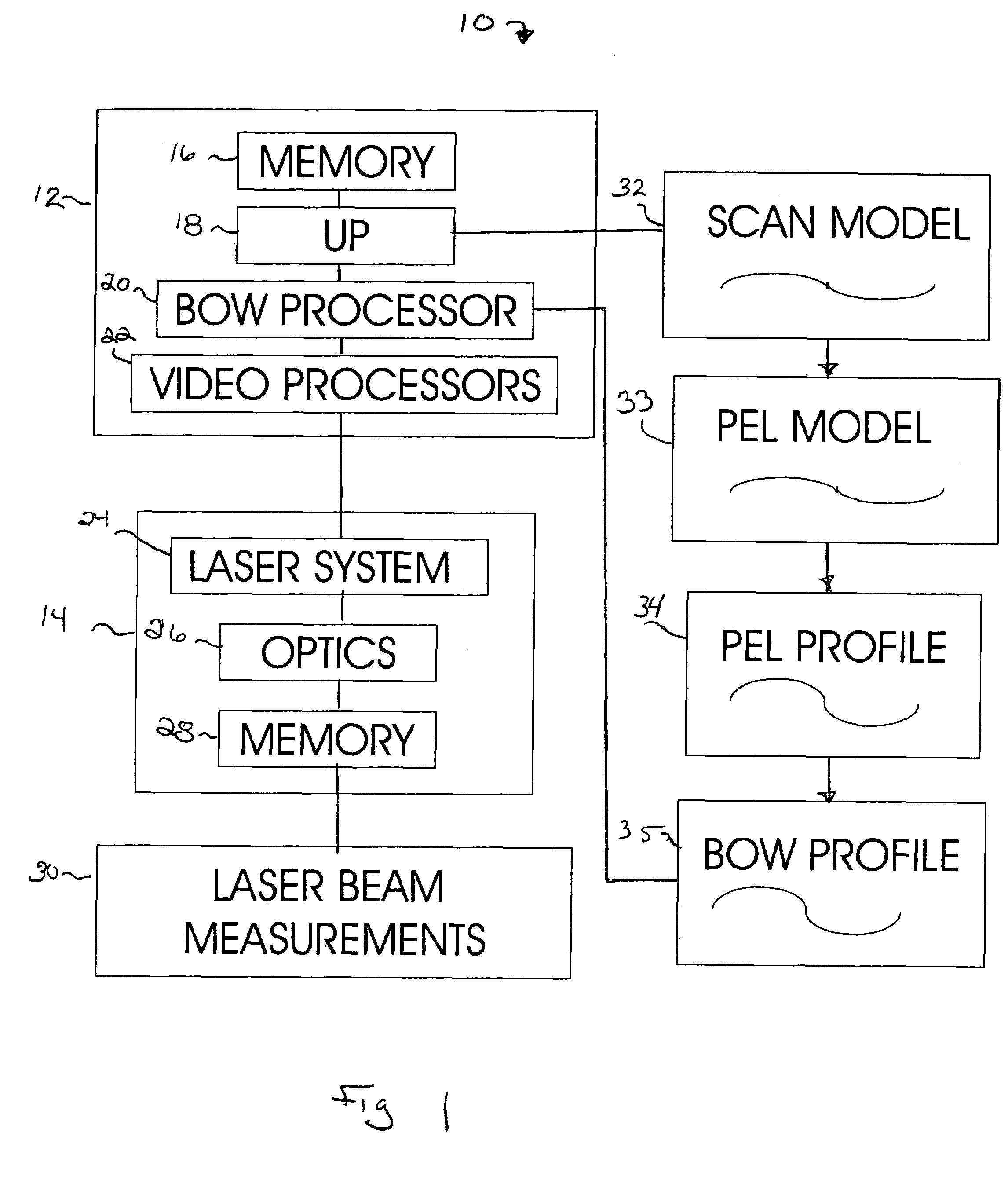

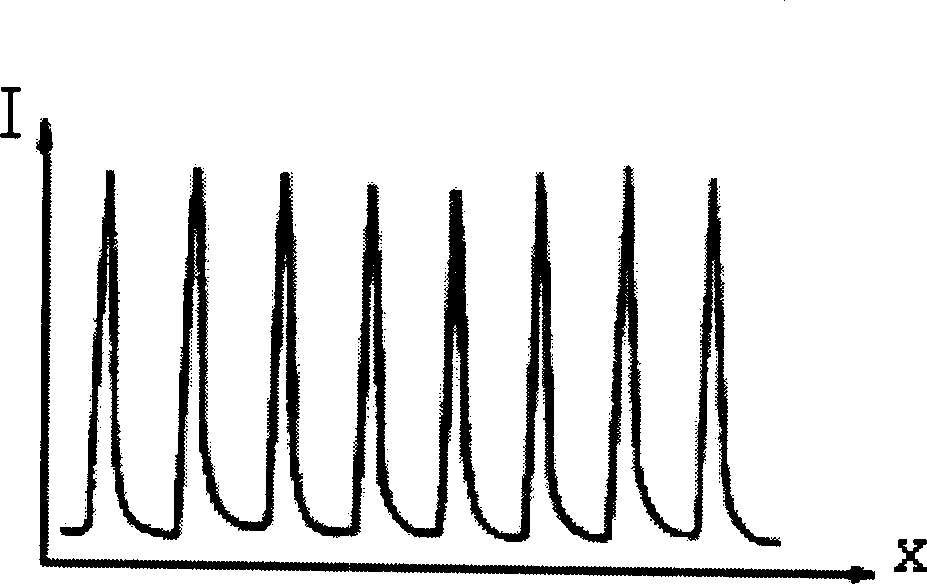

Algorithms and methods for determining laser beam process direction position errors from data stored on a printhead

Systems and methods are provided for characterizing laser beam process direction position errors in an electrophotographic device. Once the process direction position errors of a given beam laser beam system have been characterized, an image is adjusted or warped prior to being processed by the laser beam system to compensate for laser beam process direction position errors, e.g., bow and skew.

Owner:LEXMARK INT INC

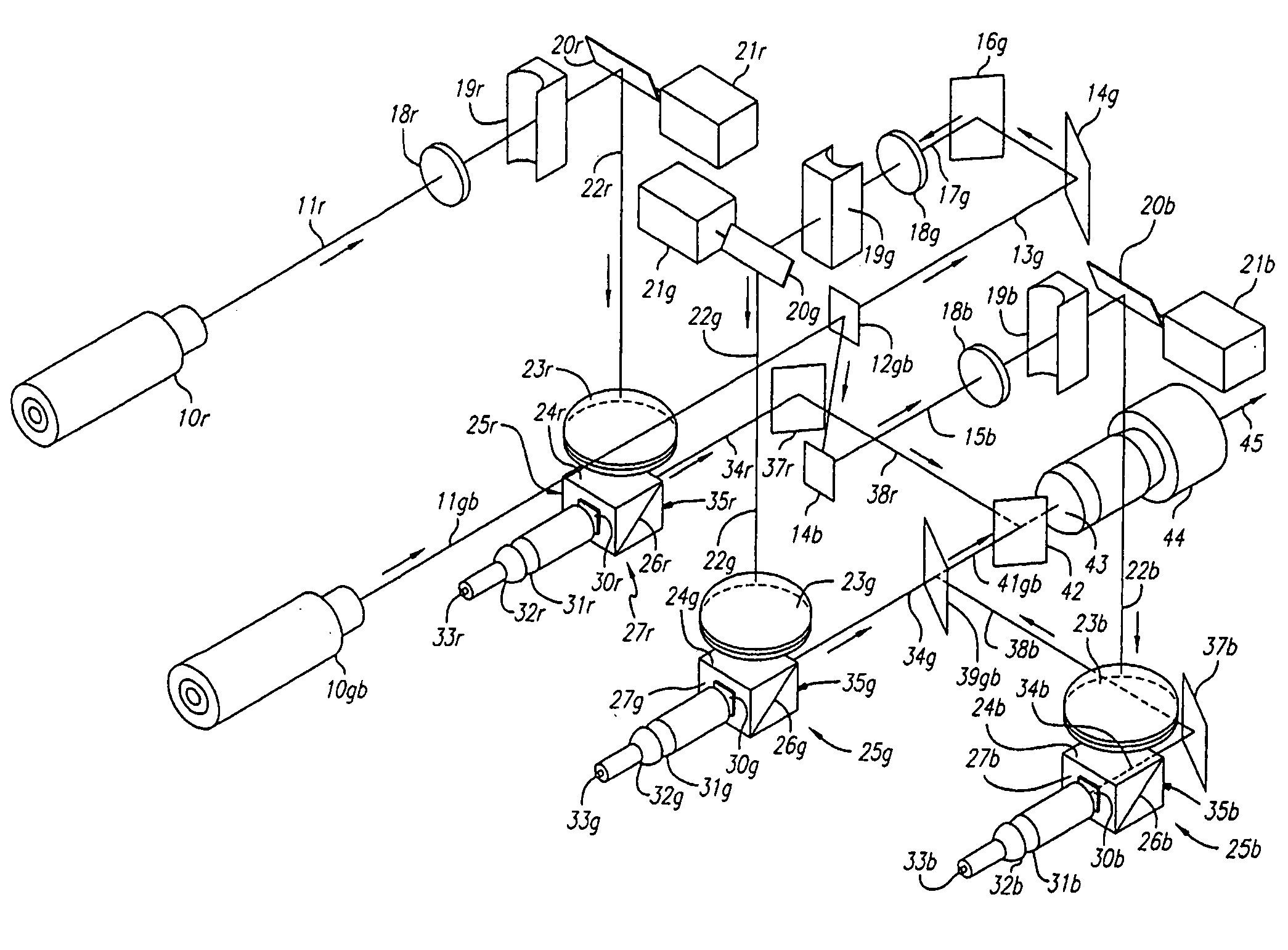

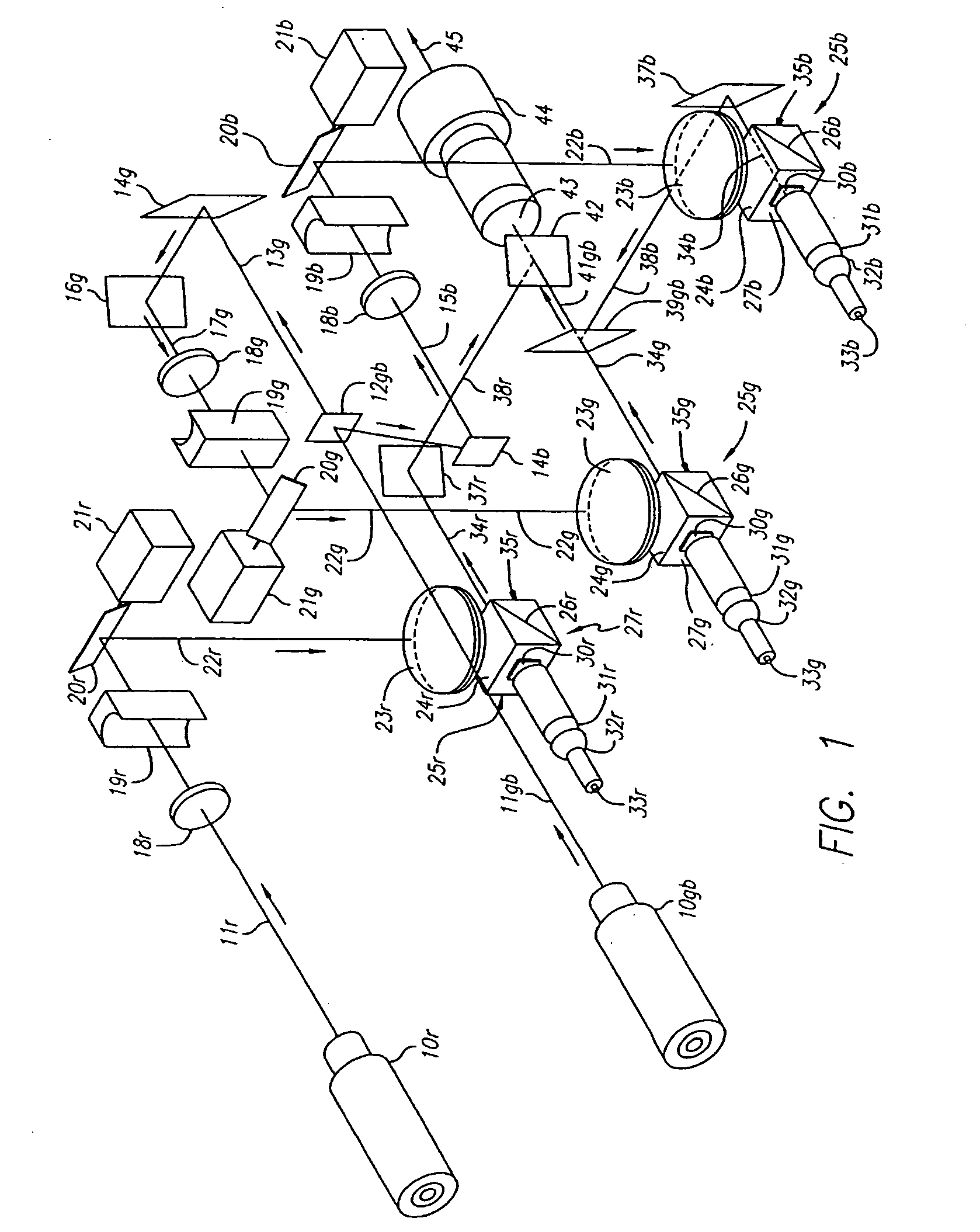

Laser projection apparatus with liquid-crystal light valves and scanning reading beam

InactiveUS20050057727A1Image contrast superiorHigh resolutionProjectorsPicture reproducers using projection devicesBeam splitterLiquid crystal light valve

Laser lines at 635 nm or longer (ideally 647 nm) are preferred for red, giving energy-efficient, bright, rapid-motion images with rich, full film-comparable colors. Green and blue lines are used too—and cyan retained for best color mixing, an extra light-power boost, and aid in speckle suppression. Speckle is suppressed through beam-path displacement—by deflecting the beam during projection, thereby avoiding both absorption and diffusion of the beam while preserving pseudocollimation (noncrossing rays). The latter in turn is important to infinite sharpness. Path displacement is achieved by scanning the beam on the liquid-crystal valves (LCLVs), which also provides several enhancements—in energy efficiency, brightness, contrast, beam uniformity (by suppressing both laser-mode ripple and artifacts), and convenient beam-turning to transfer the beam between apparatus tiers. Preferably deflection is performed by a mirror mounted on a galvanometer or motor for rotary oscillation; images are written incrementally on successive portions of the LCLV control stage (either optical or electronic) while the laser “reading beam” is synchronized on the output stage. The beam is shaped, with very little energy loss to masking, into a shallow cross-section which is shifted on the viewing screen as well as the LCLVs. Beam-splitter / analyzer cubes are preferred over polarizing sheets. Spatial modulation provided by an LCLV and maintained by pseudocollimation enables imaging on irregular projection media with portions at distinctly differing distances from the projector—including domes, sculptures, monuments, buildings; waterfalls, sprays, fog, clouds, ice; scrims and other stage structures; trees and other foliage; land and rock surfaces; and even assemblages of living creatures including people.

Owner:TROYER DIANE

Process method for welding aluminum and aluminum alloy material by laser

InactiveCN101850472ASmall sizeEasy to closeGrinding machinesWelding/soldering/cutting articlesOrganic solventHigh energy

The invention relates to laser welding and discloses a process method for welding aluminum and aluminum alloy material by laser. The process method comprises steps of: (1) selecting an Nd:YAG laser with high beam quality and high energy density; (2) adopting double-beam laser to weld aluminum and aluminum alloy material, wherein the distance between the two beams is 0.6-1.0 mm, and the energy ratio of the two beams is larger than 1:1; (3) surface treatment of a material to be welded: removing greasy dirt and dust with an organic solvent and removing an oxidation film by mechanical cleaning and / or chemical cleaning; and (4) utilizing the two-beam laser to weld the aluminum and the aluminum alloy material. A needle body, a sleeve and a lead of the invention are manufactured into a whole; therefore, the invention solves adaptability of the laser welding to assembly precision, enhances the stability of welding process and improves welding line quality.

Owner:武汉楚天激光(集团)股份有限公司

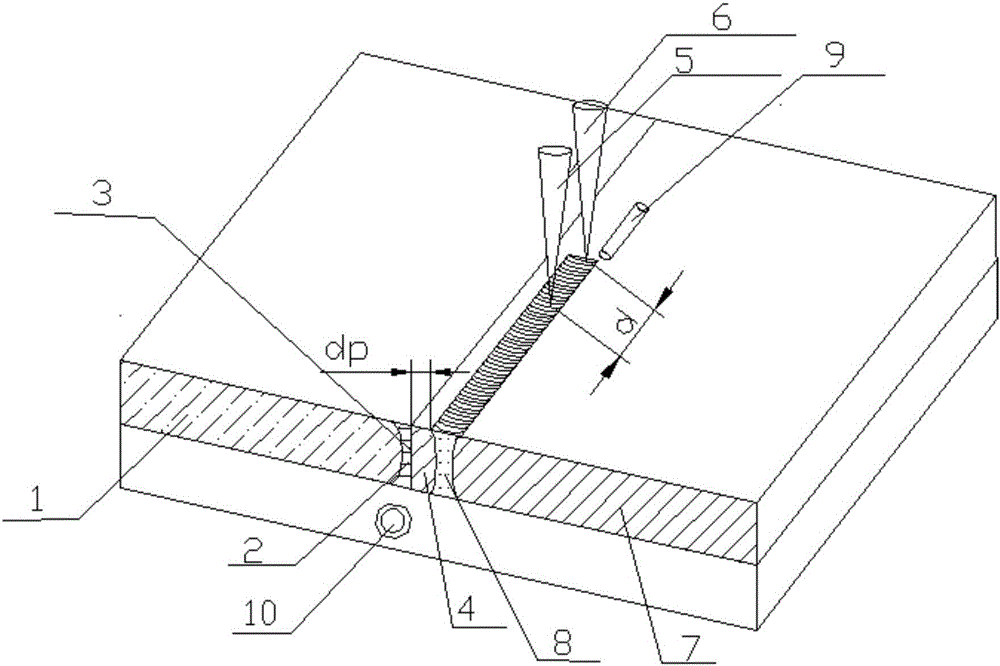

Fast forming method of fusion of metal powder of three beams of laser compound scanning

ActiveCN101607311BSlow down drastic changesUniform temperature fieldIncreasing energy efficiencyLength waveMetal powder

Owner:HUAZHONG UNIV OF SCI & TECH

Laser induced nanometer brazing method of silicon carbide particle reinforced aluminum matrix composite with high volume fraction

ActiveCN102699465AEnhanced BrazingImprove compactnessWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalElectron

The invention provides a laser induced nanometer brazing method of a silicon carbide particle reinforced aluminum matrix composite with high volume fraction, which relates to a brazing method of the silicon carbide particle reinforced aluminum matrix composite with high volume fraction. The method comprises the following steps of: (1) preparing nano-crystal particle layers at brazed surfaces of an upper matrix and a lower matrix; (2) preparing a silver matrix, aluminum matrix or zinc matrix brazing filler metal; (3) assembling a piece to be brazed, to be specific, placing the brazing filler metal prepared in the step (2) between the brazed surfaces of the upper matrix and the lower matrix, which are treated in the step (1), so as to form the piece to be brazed; and (4) under the protection of argon, carrying out double-beam laser brazing on the piece to be brazed, so as to achieve laser induced nanometer brazing of the composite. According to the invention, high temperature cannot be generated in the welding process; the shear strength of an obtained joint can reach about 260 MPa, so as to completely satisfy electronic packaging requirements or welding requirements of other materials, which contain a large quantity of ceramic phases and for which high brazing temperature is not allowed, and products thereof. The brazing method provided by the invention is used for brazing the silicon carbide particle reinforced aluminum matrix composite with high volume fraction.

Owner:TIGER TECH CO LTD

Production method and device for hologram

InactiveUS6633419B2Increase energy densityImprove interferenceLaser detailsHolographic light sources/light beam propertiesPulse beamSemiconductor materials

A method and apparatus for producing a hologram using a two-beam laser interference exposure process, comprising the steps of using as a light source a femtosecond laser having a pulse width of 900-10 femtoseconds and a peak output of 1 GW or more and capable of generating a pulse beam at or close to the Fourier transform limit, dividing the pulse beam from the laser into two by a beam splitter, controlling the two beams temporally through an optical delay circuit and spatially using plane and concave mirrors each having a slightly rotatable reflection surface to converge the beams on a surface of or within a substrate for recording a hologram at an energy density of 100 GW / cm<HIL><2 < / SP><PDAT>or more with keeping each polarization plane of the two beams in parallel so as to match the converged spot of the two beams temporally and spatially, whereby a hologram is recorded irreversibly on the substrate formed of a transparent material, semiconductor material or metallic material.< / PTEXT>

Owner:JAPAN SCI & TECH CORP

Method for producing hologram by pico-second laser

InactiveUS20060019171A1Reduce waveform distortionStable recordHolographic light sources/light beam propertiesPhotomechanical apparatusPicosecond laserOptical interaction

Disclosed is a method of producing a hologram through a two-beam laser interfering exposure process, which comprises emitting a coherent laser light with a pulse width (τ) ranging from greater than 900 femtoseconds to 100 picoseconds and a laser power of 10 μJ / pulse or more using a solid-state laser as a light source, dividing the pulses light from the laser into two beams, controlling the two beams temporally and spatially in such a manner that the two beam are converged on a surface of or inside a workpiece for recording a hologram while matching the respective converged spots of the two beams with one another temporally and spatially to create the interference therebetween so as to record a surface-relief hologram on the surface of the workpiece or an embedded hologram inside the workpiece in an irreversible manner. The present invention can solve a problem with a conventional process of recording a hologram in a non-photosensitive material in an irreversible manner using interfering femtosecond laser pulses, specifically, distortion in the waveforms of pulsed laser beams and resulting instability in recording of an embedded hologram due to a non-linear optical interaction between the femtosecond laser pulses and air / the material.

Owner:JAPAN SCI & TECH CORP

Method for processing double-beam laser cladding tool

InactiveCN104388929AImprove performance compared toDense tissueMetallic material coating processesLaser processingManufacturing technology

The invention discloses a method for processing a double-beam laser cladding tool. Laser is divided into two beams of lasers having equal energy by virtue of a laser beam splitter, the two beams of lasers are respectively focused and simultaneously act on recesses formed in both sides of the substrate of the tool and high-hardness iron-based alloy powder is fed to focal points by virtue of paraxial powder-feeding nozzles for cladding so as to achieve the requirements on set width and thickness. According to the method, the laser processing efficiency can be increased by 20 times compared with that of the conventional tool manufacturing technology, and the method is convenient to operate and high in degree of automation; by the double beams, both sides of the substrate of the tool are simultaneously clad, no need of complex fixtures during cladding is ensured and the substrate of the tool almost has no deformation after cladding.

Owner:JIANGSU ZHONGKESIXIANG LASER TECH

Laser-based irradiation apparatus and methods for monitoring the dose-rate response of semiconductor devices

InactiveUS7019311B1Electric discharge tubesElectroluminescent light sourcesOperational systemDose rate

A scanned, pulsed, focused laser irradiation apparatus can measure and image the photocurrent collection resulting from a dose-rate equivalent exposure to infrared laser light across an entire silicon die. Comparisons of dose-rate response images or time-delay images from before, during, and after accelerated aging of a device, or from periodic sampling of devices from fielded operational systems allows precise identification of those specific age-affected circuit structures within a device that merit further quantitative analysis with targeted materials or electrical testing techniques. Another embodiment of the invention comprises a broad-beam, dose rate-equivalent exposure apparatus. The broad-beam laser irradiation apparatus can determine if aging has affected the device's overall functionality. This embodiment can be combined with the synchronized introduction of external electrical transients into a device under test to simulate the electrical effects of the surrounding circuitry's response to a radiation exposure.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

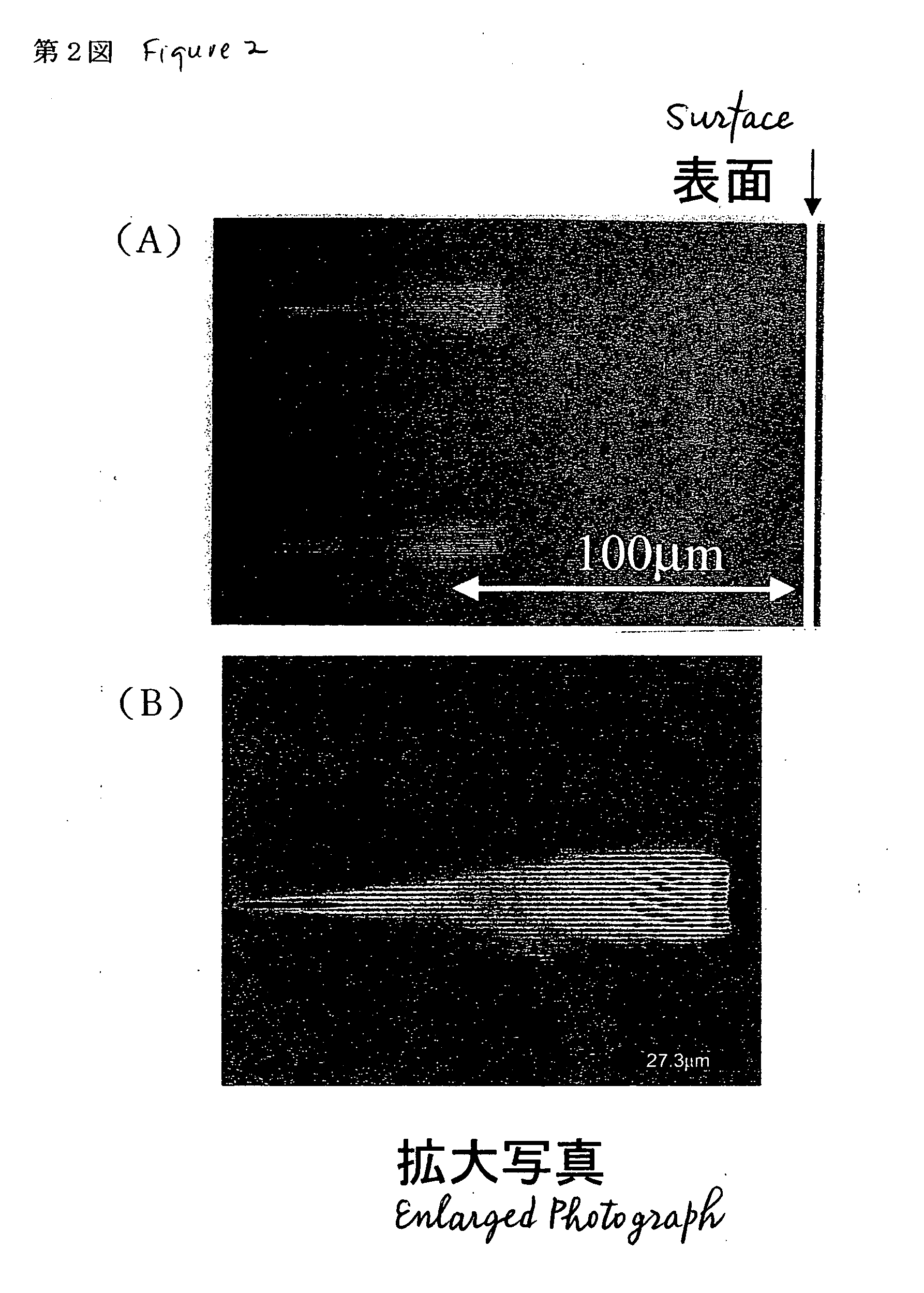

A multi-beam laser radar with non-uniform pulse energy

ActiveCN109116366BImprove energy utilizationImprove performanceElectromagnetic wave reradiationPulse energyControl cell

Owner:HESAI TECH CO LTD

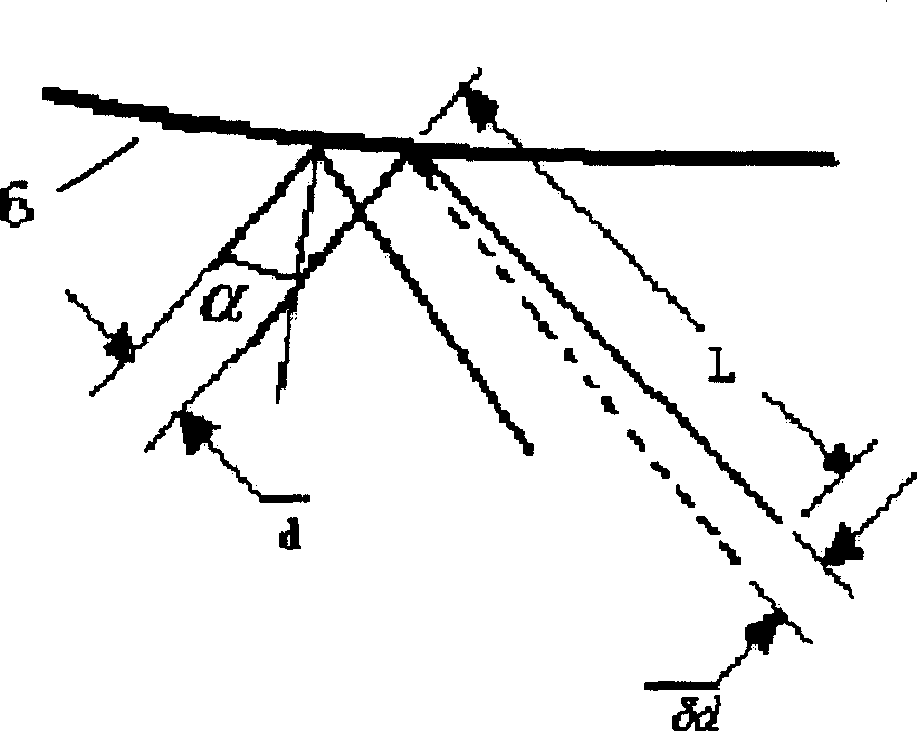

Double-beam laser deep penetration brazing method applicable to moderately thick plate aluminum/steel dissimilar alloy connection

InactiveCN106513892APremium connectionMeet welding needsSoldering apparatusWelding/soldering/cutting articlesForms of energyThick plate

The invention provides a double-beam laser deep penetration brazing method applicable to moderately thick plate aluminum / steel dissimilar alloy connection, and belongs to the field of laser machining of dissimilar alloy connection. According to the double-beam laser deep penetration brazing method, two laser beams with different forms of energy are arranged in series, and act on the steel side; through the main laser beam, deep penetration is achieved on the steel side; a solid-state steel intermediate layer is acquired by controlling the offset dp of the laser beams with a steel / aluminum interface and the heat input on a regulating joint interface, the heat input for welding is transferred through the solid-state steel intermediate layer, an aluminum alloy is molten, and the molten aluminum alloy is wetted and spread, thereby achieving laser deep penetration brazing of an aluminum / steel dissimilar alloy; when the auxiliary laser beam goes before, the stability of laser deep penetration welding is improved and the effect of preheating treatment before welding is achieved; and when the auxiliary laser beam follows after, the wetting and spreading properties of aluminum are improved, and the effect of heat treatment after welding on the joint interface is achieved. By adoption of the double-beam laser deep penetration brazing method provided by the invention, the distribution of welding temperature fields can be controlled, the interfacial intermetallic compound distribution and thickness uniformity can be improved, and the high-quality and efficient dissimilar alloy connection can be achieved.

Owner:BEIJING UNIV OF TECH

Device for calibrating dynamic balance parameter of helicopter rotor blade

InactiveCN102944361AMeasurement results have no effectGuaranteed accuracyStatic/dynamic balance measurementDynamic balanceComplex programmable logic device

The invention discloses a device for calibrating a dynamic balance parameter of a helicopter rotor blade and relates to a test and calibration technology of a helicopter rotor blade, and the device is used for solving the problems such as big error in measurement result and poor reliability in the dynamic balance test calibration of the helicopter rotor blade in the prior background art. A laser measurement platform is formed by a three-beam laser device of a dynamic balance test table; the flapping parameter of the rotor blade is measured in a non-contact way through a method of cutting laser beams by the blade; a pulse time sequence measuring and controlling system is designed by taking a CPLD (Complex Programmable Logic Device) and a DSP (Digital Signal Processor) as cores; and the flapping and shimmy characteristic parameters of the rotor blade are measured. A simulated blade with fixed height difference is adopted in a calibration device and rotated at a stable rotation speed through a servo motor, the dynamic balance test platform of the rotor blade is calibrated on site through a method of cutting the laser beams by the simulated blade, the calibration result is traced to national length standard, the accuracy and traceability of the measurement result are ensured, and a quality guarantee is provided for the development and test of the helicopter rotor blade.

Owner:HARBIN INST OF TECH

Optical sensor for thin film detection

InactiveCN1821748ARealize real-time detectionRealize industrial scale productionForce measurement by measuring optical property variationMaterial analysis by optical meansBeam splitterSemiconductor materials

This invention discloses an optical sensor composed of pump diode lasers, a chopper and a beam splitter prism, in which, the first pump diode laser and the second pump diode laser output two beams of laser of different frequencies and output a beam laser by regulation of the chopper to irradiate on a dual grid splitter to form a 2-D beam array to be reflected on a CCD focal plane and imaged by a film sample to display the light spot position distribution information and the light intensity variety information of each spot of the reflection beam array to get the growing rate of the film by computing the transformation information of said light intensity, evaluate the film stress by beam offset information and Stoney equation and evaluate components of the material based on the incident light vacuum wavelength lambda< 0 > put forward by Brunner and function of the Al component x.

Owner:XIDIAN UNIV

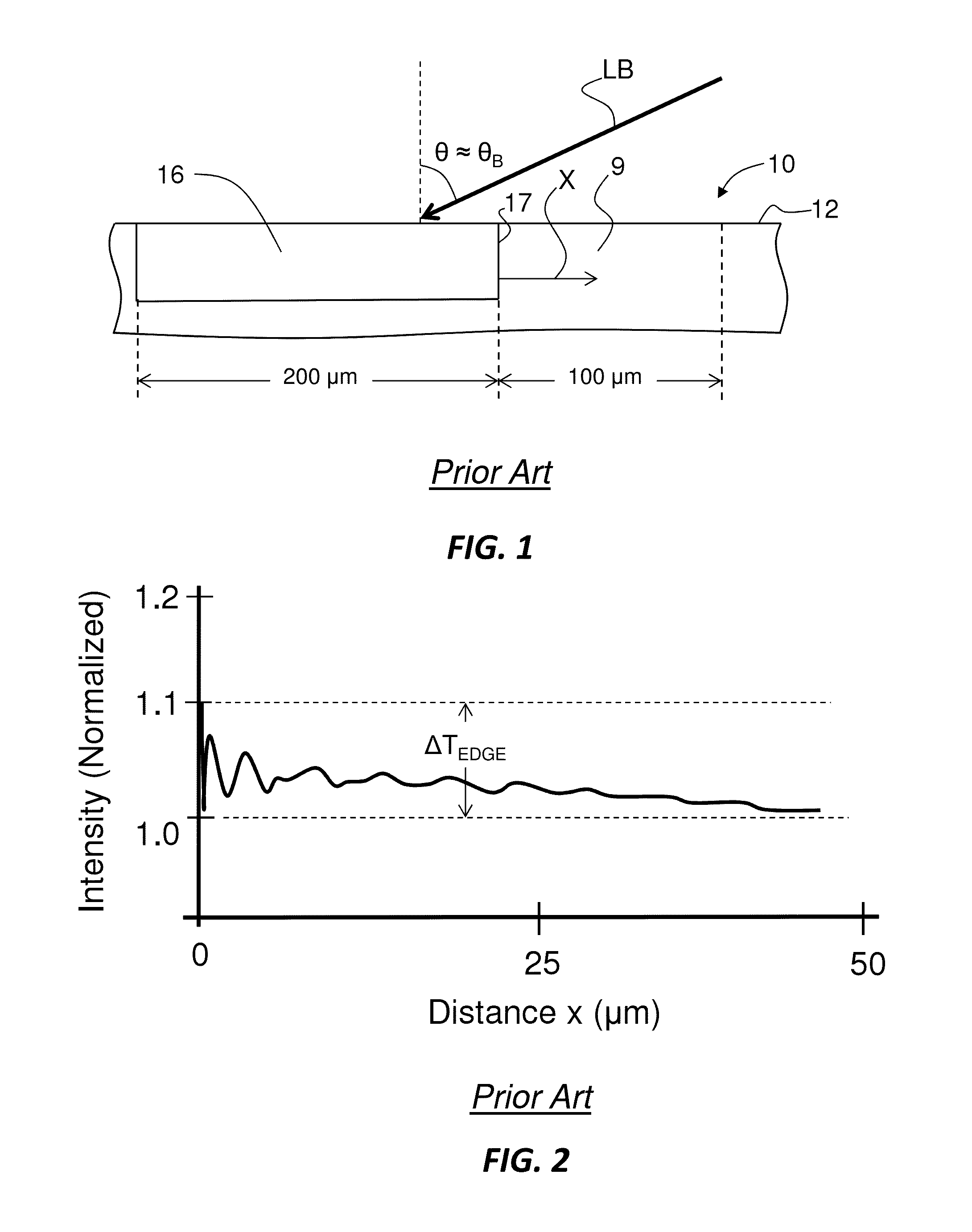

Two-beam laser annealing with improved temperature performance

ActiveUS8546805B2Improve temperature uniformityImprove surface reflectivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsLight beamOptoelectronics

Systems and methods are disclosed for performing laser annealing in a manner that reduces or minimizes wafer surface temperature variations during the laser annealing process. The systems and methods include annealing the wafer surface with first and second laser beams that represent preheat and anneal laser beams having respective first and second intensities. The preheat laser beam brings the wafer surface temperate close to the annealing temperature and the anneal laser beam brings the wafer surface temperature up to the annealing temperature. The anneal laser beam can have a different wavelength, or the same wavelength but different orientation relative to the wafer surface. Reflectivity maps of the wafer surface at the preheat and anneal wavelengths are measured and used to select first and second intensities that ensure good anneal temperature uniformity as a function of wafer position.

Owner:VEECO INSTR

Narrow gap three-beam laser welding method

ActiveCN102059452AReasonable distributionAdjustable positionLaser beam welding apparatusLaser processingLight spot

The invention discloses a narrow gap three-beam laser welding method, and belongs to the technical field of laser processing. The method solves the problem of poor transition stability of welding wire metal molten drops in the conventional swinging or rotating double-beam welding method. In the welding process of the method, a main beam emitted by a laser device is split into three welding beams, the energy of the three welding beams is one third of the energy of the main beam respectively, and three focusing light spots of the three welding beams in a narrow gap weld groove are arranged in parallel or in a regular triangle. The method is suitable for narrow gap laser welding.

Owner:HARBIN INST OF TECH

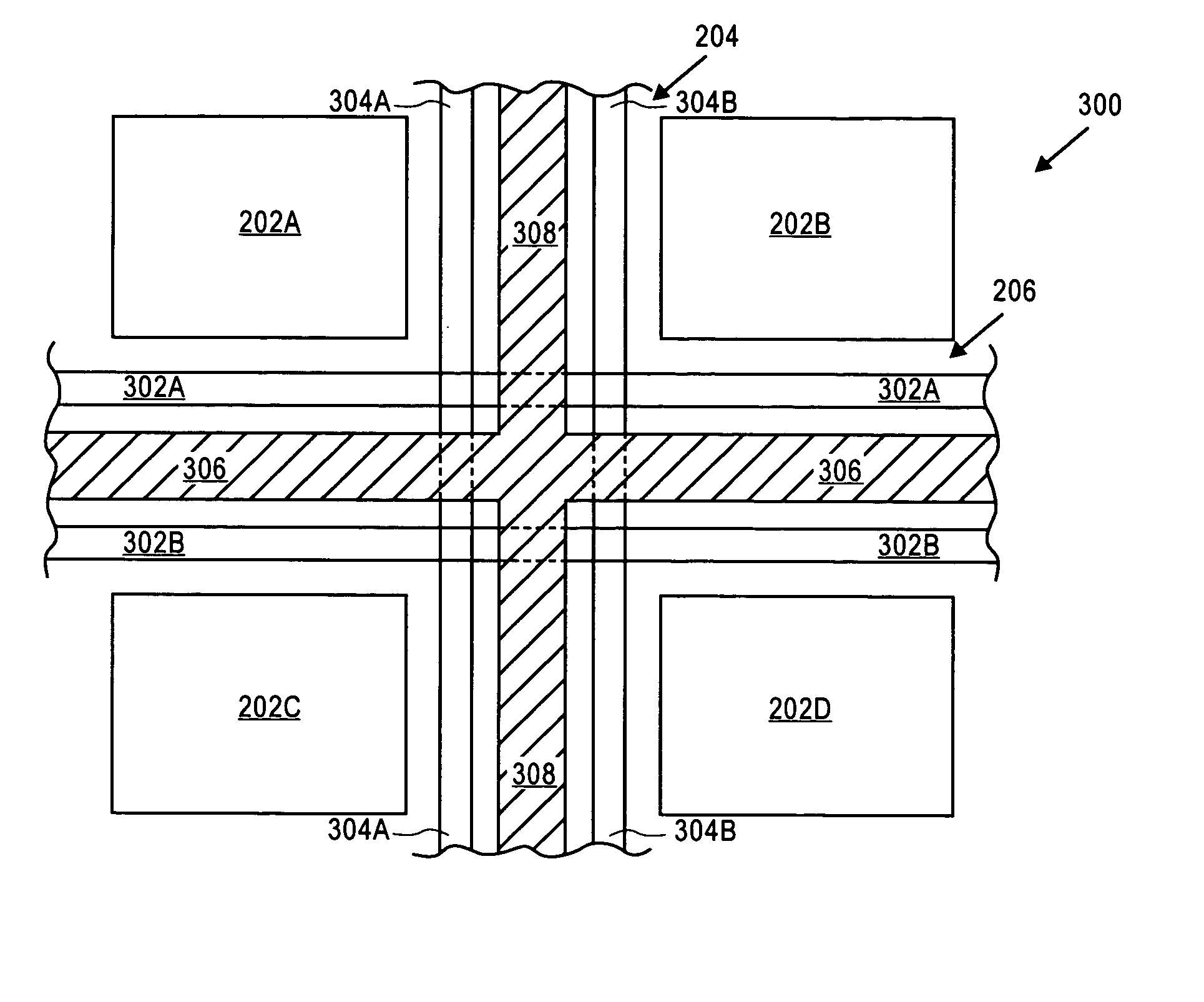

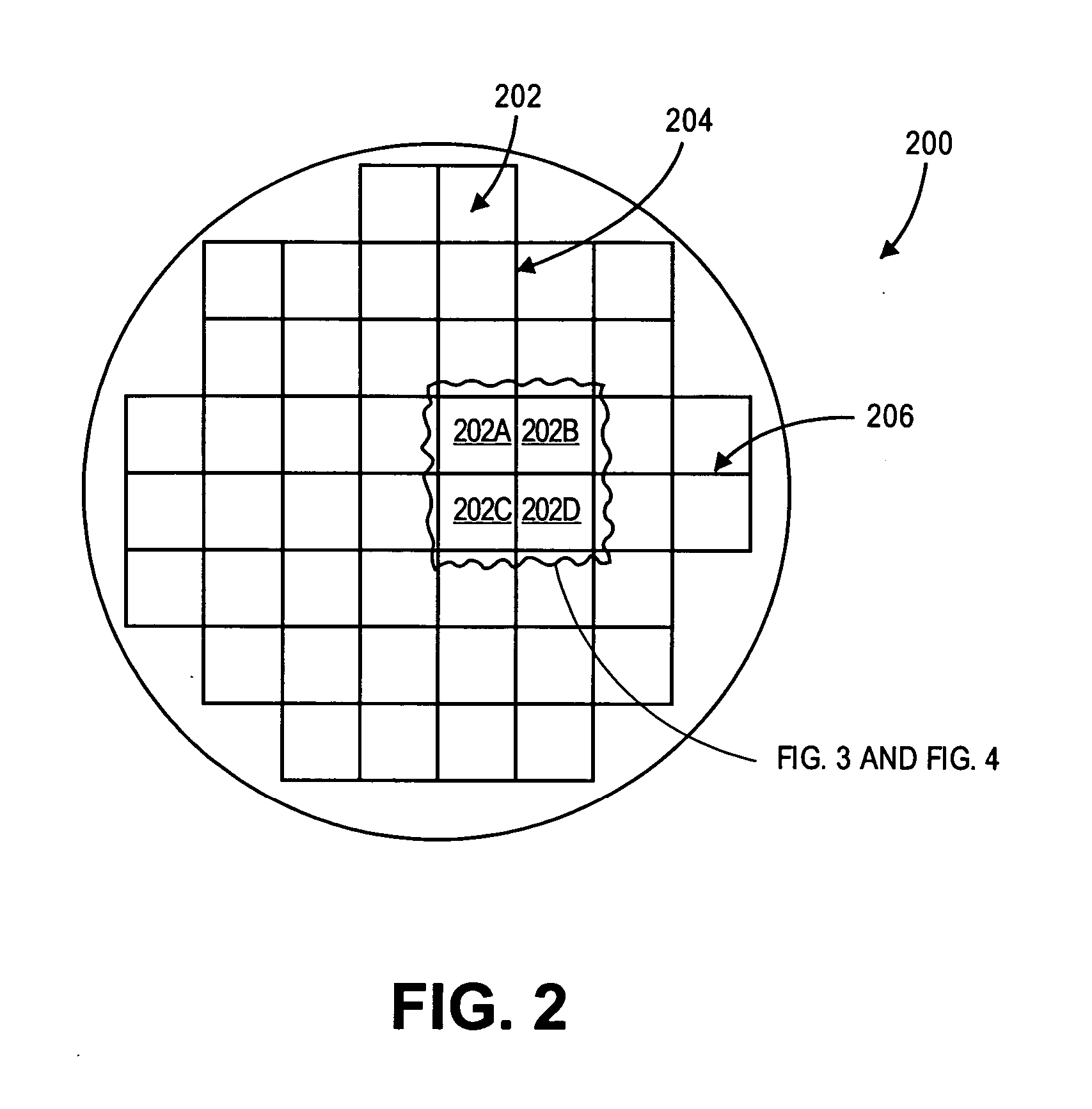

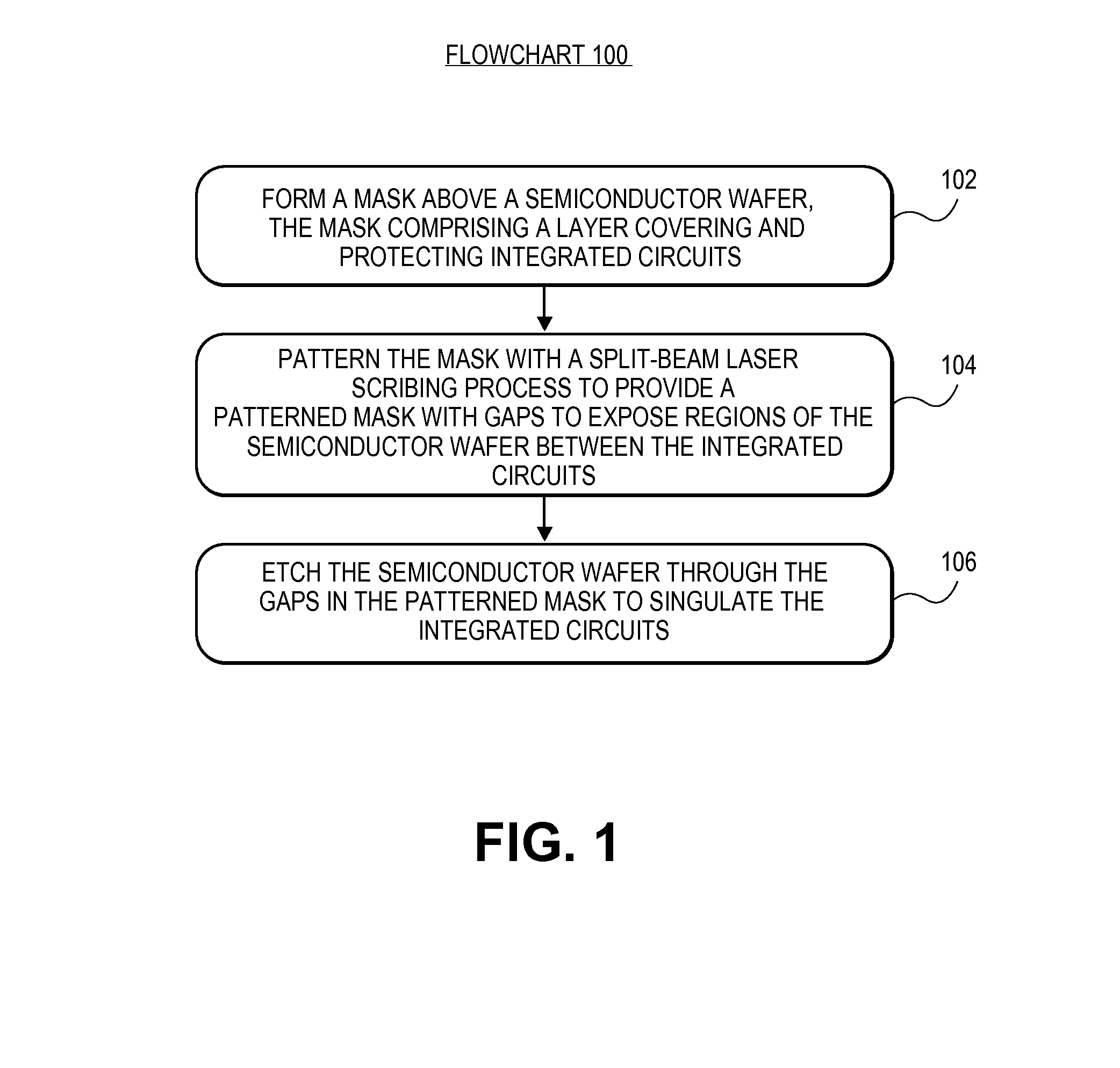

Wafer dicing using hybrid split-beam laser scribing process with plasma etch

ActiveUS20130017668A1Welding/cutting auxillary devicesSemiconductor/solid-state device manufacturingWafer dicingEngineering

Methods of dicing semiconductor wafers, each wafer having a plurality of integrated circuits, are described. A method includes forming a mask above the semiconductor wafer. The mask is composed of a layer covering and protecting the integrated circuits. The mask is patterned with a split-beam laser scribing process to provide a patterned mask with gaps. The patterning exposes regions of the semiconductor wafer between the integrated circuits. The semiconductor wafer is then etched through the gaps in the patterned mask to singulate the integrated circuits.

Owner:APPLIED MATERIALS INC

Laser projection apparatus with liquid-crystal light valves and scanning reading beam

InactiveUS6910774B2Achievement of good whites and blacks more awkwardIncrease powerStatic indicating devicesProjectorsBeam splitterLiquid crystal light valve

Laser lines at 635 nm or longer (ideally 647 nm) are preferred for red, giving energy-efficient, bright, rapid-motion images with rich, full film-comparable colors. Green and blue lines are used too—and cyan retained for best color mixing, an extra light-power boost, and aid in speckle suppression. Speckle is suppressed through beam-path displacement—by deflecting the beam during projection, thereby avoiding both absorption and diffusion of the beam while preserving pseudocollimation (noncrossing rays). The latter in turn is important to infinite sharpness. Path displacement is achieved by scanning the beam on the liquid-crystal valves (LCLVs), which also provides several enhancements—in energy efficiency, brightness, contrast, beam uniformity (by suppressing both laser-mode ripple and artifacts), and convenient beam-turning to transfer the beam between apparatus tiers. Preferably deflection is performed by a mirror mounted on a galvanometer or motor for rotary oscillation; images are written incrementally on successive portions of the LCLV control stage (either optical or electronic) while the laser “reading beam” is synchronized on the output stage. The beam is shaped, with very little energy loss to masking, into a shallow cross-section which is shifted on the viewing screen as well as the LCLVs. Beam-splitter / analyzer cubes are preferred over polarizing sheets. Spatial modulation provided by an LCLV and maintained by pseudocollimation enables imaging on irregular projection media with portions at distinctly differing distances from the projector—including domes, sculptures, monuments, buildings; waterfalls, sprays, fog, clouds, ice; scrims and other stage structures; trees and other foliage; land and rock surfaces; and even assemblages of living creatures including people.

Owner:TROYER DIANE

Light splitting model test device capable of measuring transparent spoil internal three dimensional displacement field

InactiveCN105758324ARealize monitoringThe instrument structure is simpleUsing optical meansNatural stateLight beam

The invention discloses a light splitting model test device capable of measuring a transparent spoil internal three dimensional displacement field, and a test method thereof. The light splitting model test device comprises an optical platform and a laser light splitting system, a transparent soil model test device and a PIV test system which are all arranged on the optical platform. The test device can split a single beam laser source into double beam laser sources, form vertical planar light beams through a lens assembly, and vertically slice soil samples. The device can truly realize monitoring of a spoil body internal three dimensional deformation field in a spoil body natural state; referred instruments have simple structures, and are convenient to operate and easy to master.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

All-fiber axisymmetric polarized beam laser based on less-mode fiber bragg grating and generating method thereof

InactiveCN102544999AConvenient and controllable switchingIncreased Polarization PurityActive medium shape and constructionFiberResonant cavity

The invention relates to an all-fiber axisymmetric polarized beam laser based on a less-mode fiber bragg grating and a method for generating an axisymmetric polarized laser beam. The characteristic of the less-mode fiber bragg grating that wavelength and transverse mode are in one-to-one correspondence is utilized, and a wavelength selection device is combined in a fiber resonant cavity, so that axial polarized beam laser output is realized. The laser mainly comprises a pumping source, a gain medium, the wavelength selection device and a mode selector unit containing the less-mode fiber bragggrating. The output has the characteristics of high polarization purity, single wavelength, narrow linewidth, convenience in realizing controlled switchover between radial polarization laser and poloidal polarization laser, and the like. The invention provides the truly all-fiber axisymmetric polarized beam laser with the advantages of more stable structure and convenience in movement and productization without adopting any special coupled devices.

Owner:UNIV OF SCI & TECH OF CHINA

Alternating Beam Laser Imaging System with Reduced Speckle

An imaging system (200) is configured to reduce perceived speckle in images (201) produced by the imaging system. The imaging system (200) includes one or more laser source pairs (205,206), with each laser source pair being configured to produce two beams (209,210) of a color. A spatial light modulator (211) is configured to produce the images (201) with light (212) from the source pairs by scanning the light (212) in a raster pattern (213) along a projection surface (202). A beam translator (225) is configured to cause lines of successive sweeps of the raster pattern (213) to be scanned with the two beams (221,222) on an alternating basis such that a line scanned by a first of the two beams in one sweep is scanned by a second of the two beams in a sequentially subsequent sweep. Other optical elements can introduce angular diversity to further reduce speckle, such as a beam shifter (2200) and a light translation element (990).

Owner:MICROVISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com