Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Removal from surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

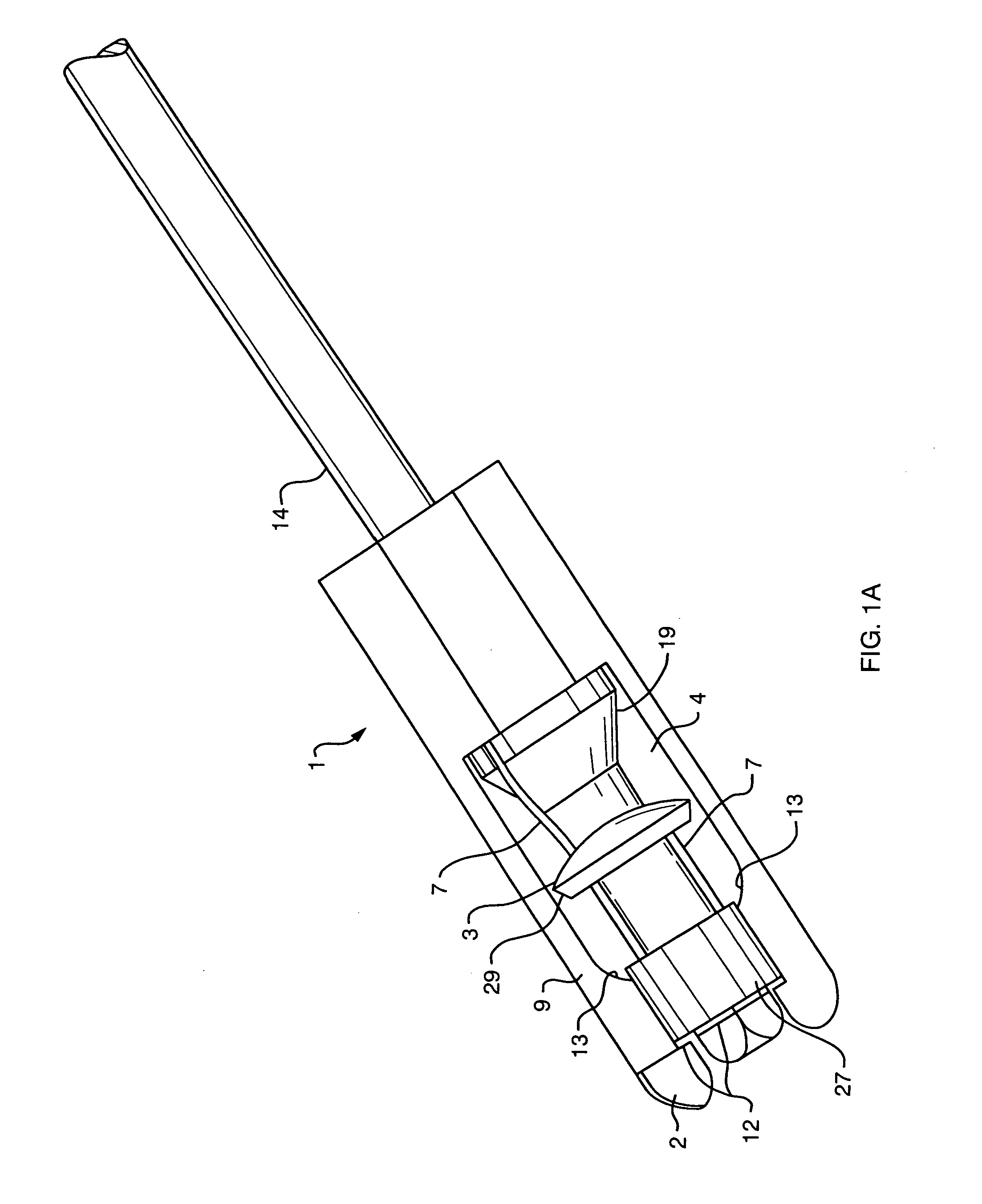

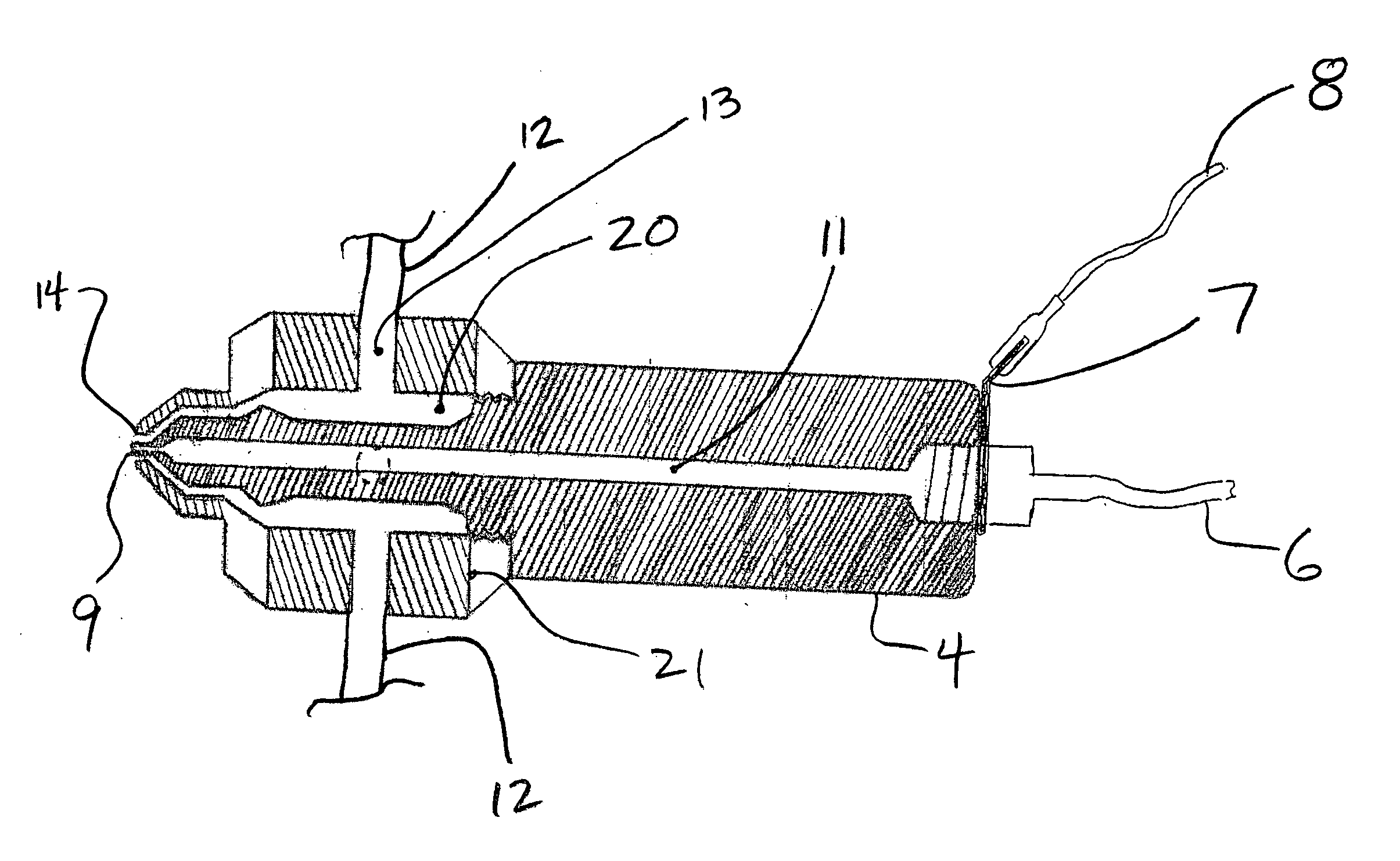

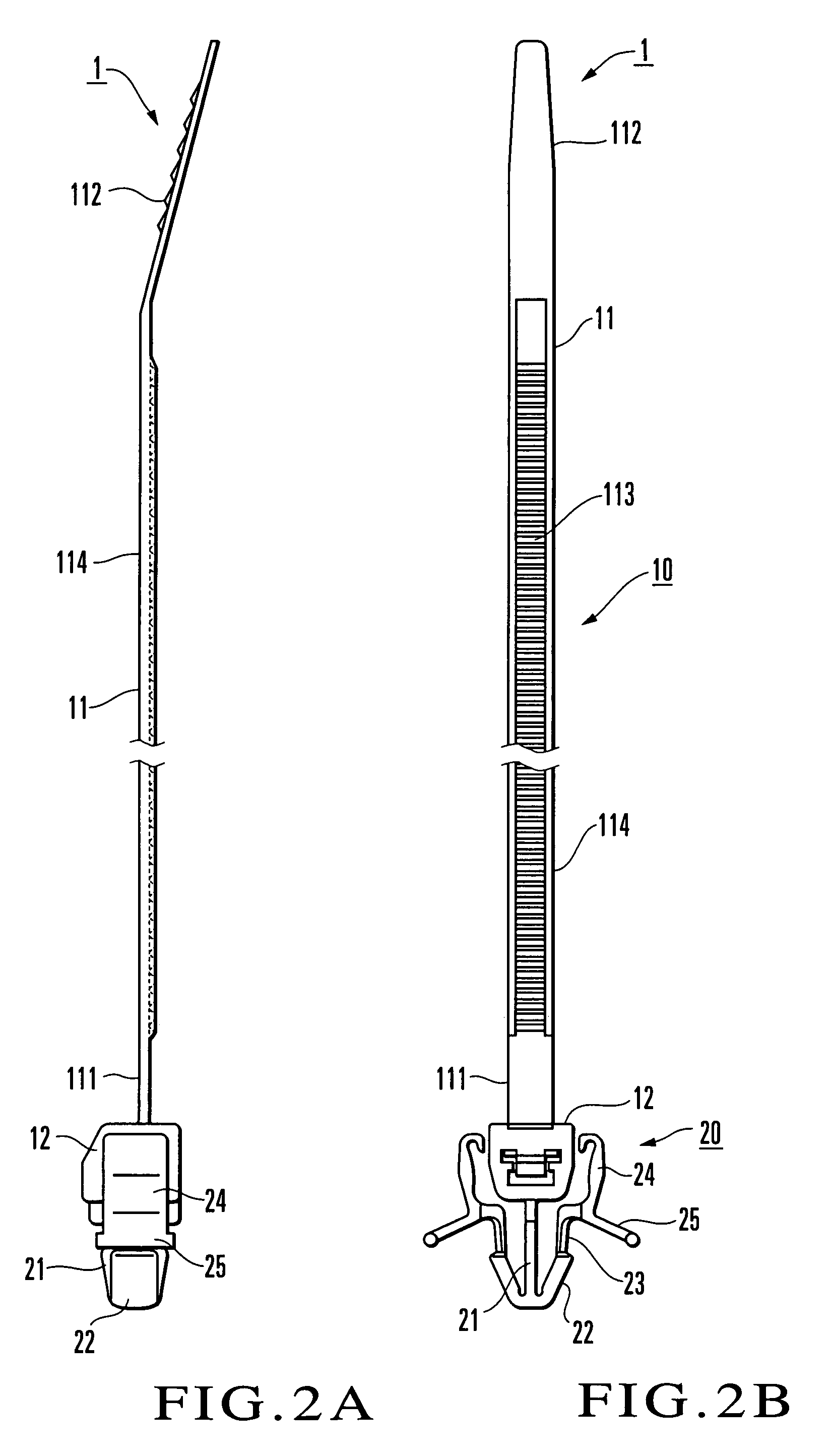

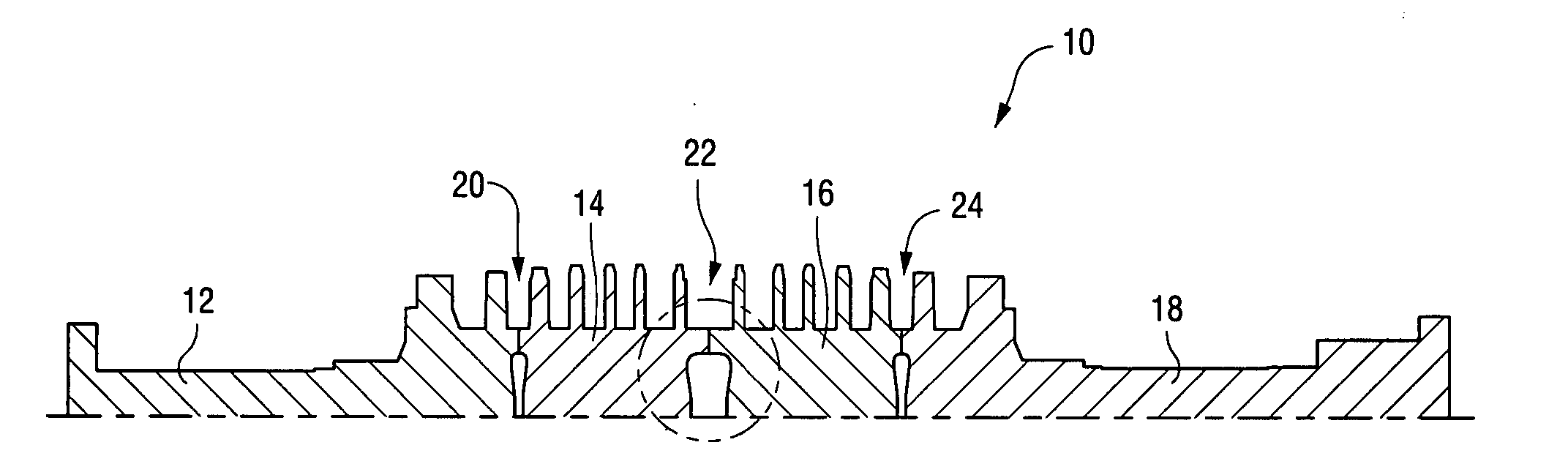

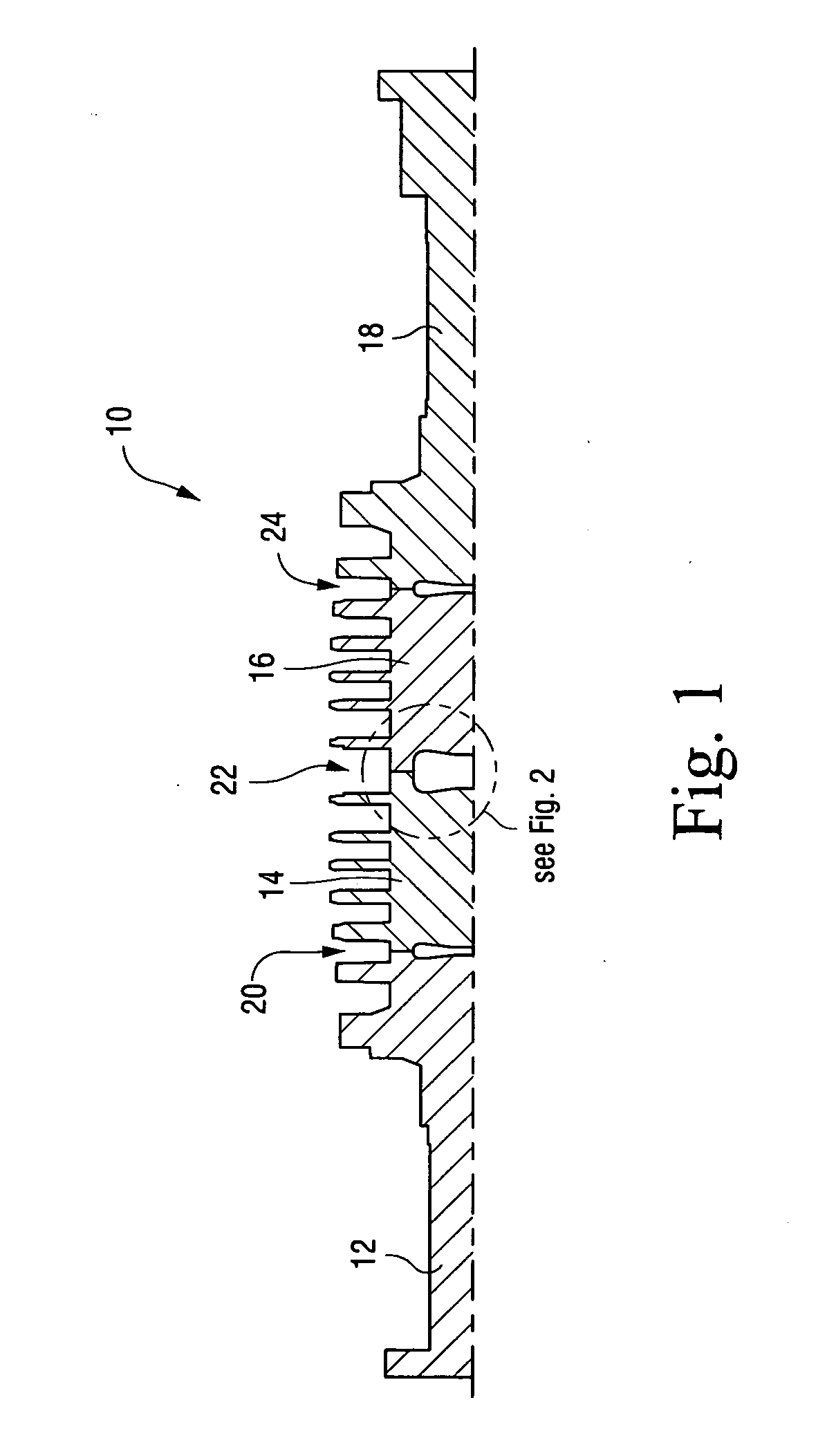

Suture clips, delivery devices and methods

InactiveUS7993368B2Removal from surfaceEliminate needSnap fastenersSuture equipmentsSuturing clipSuture clip

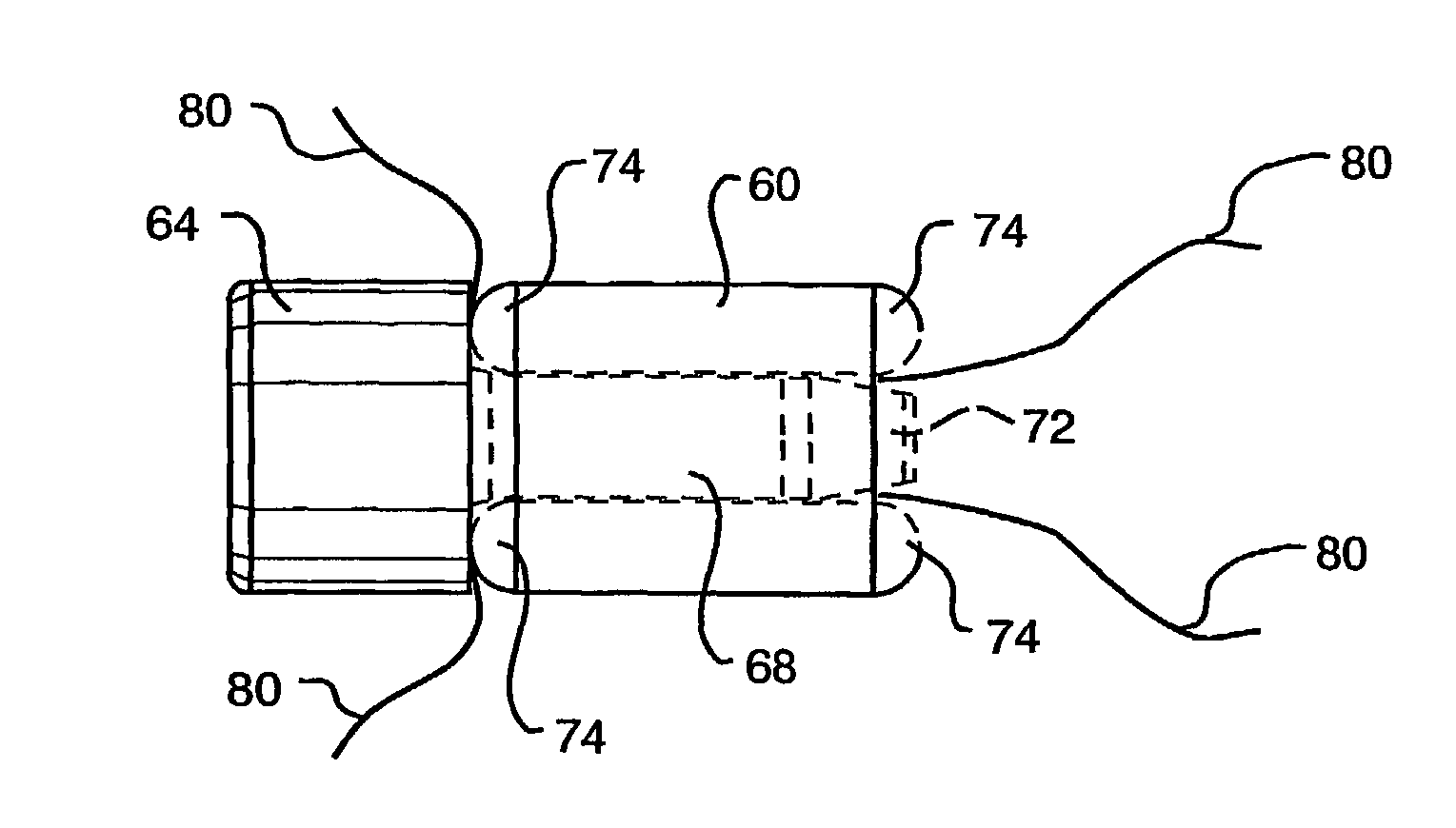

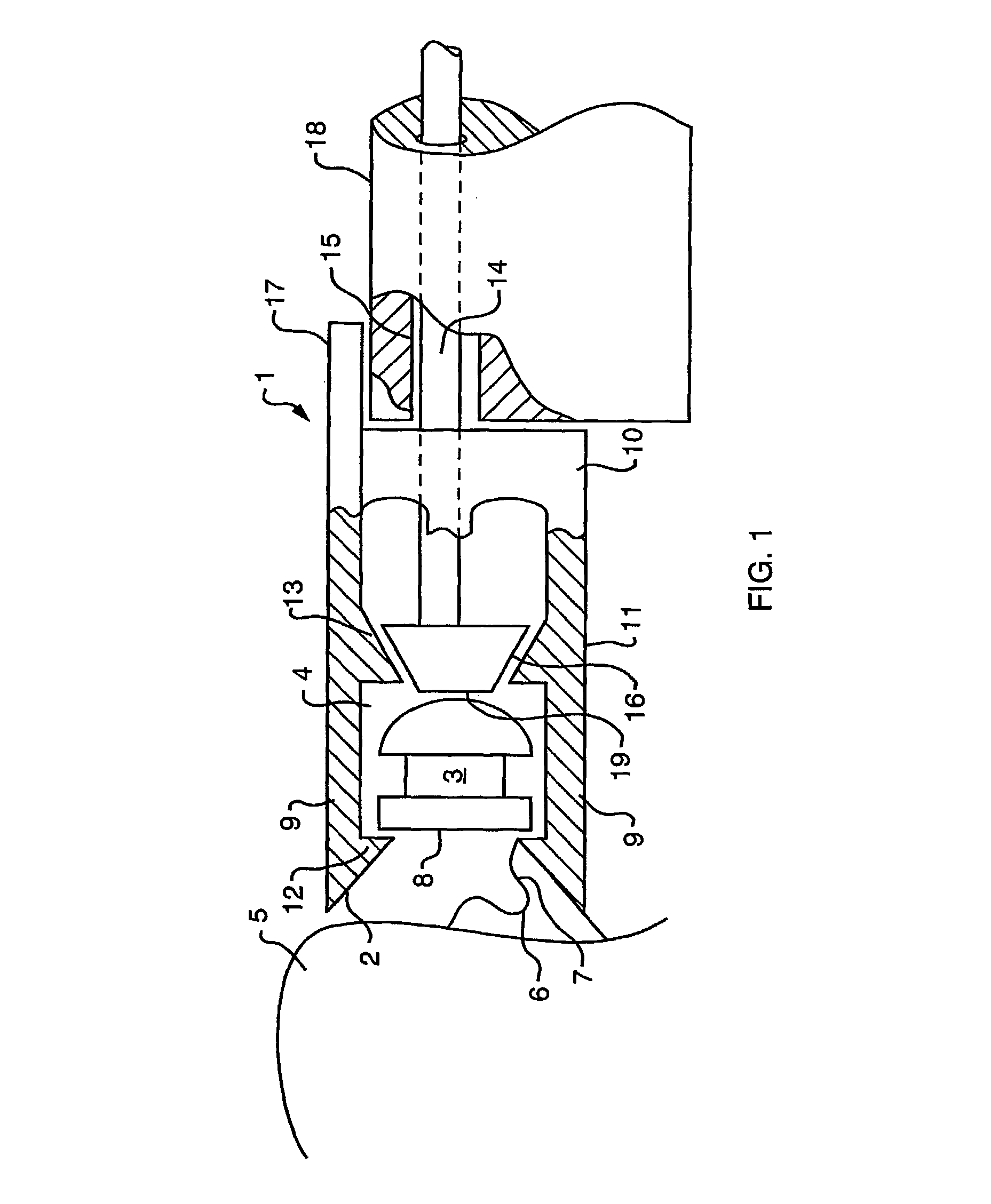

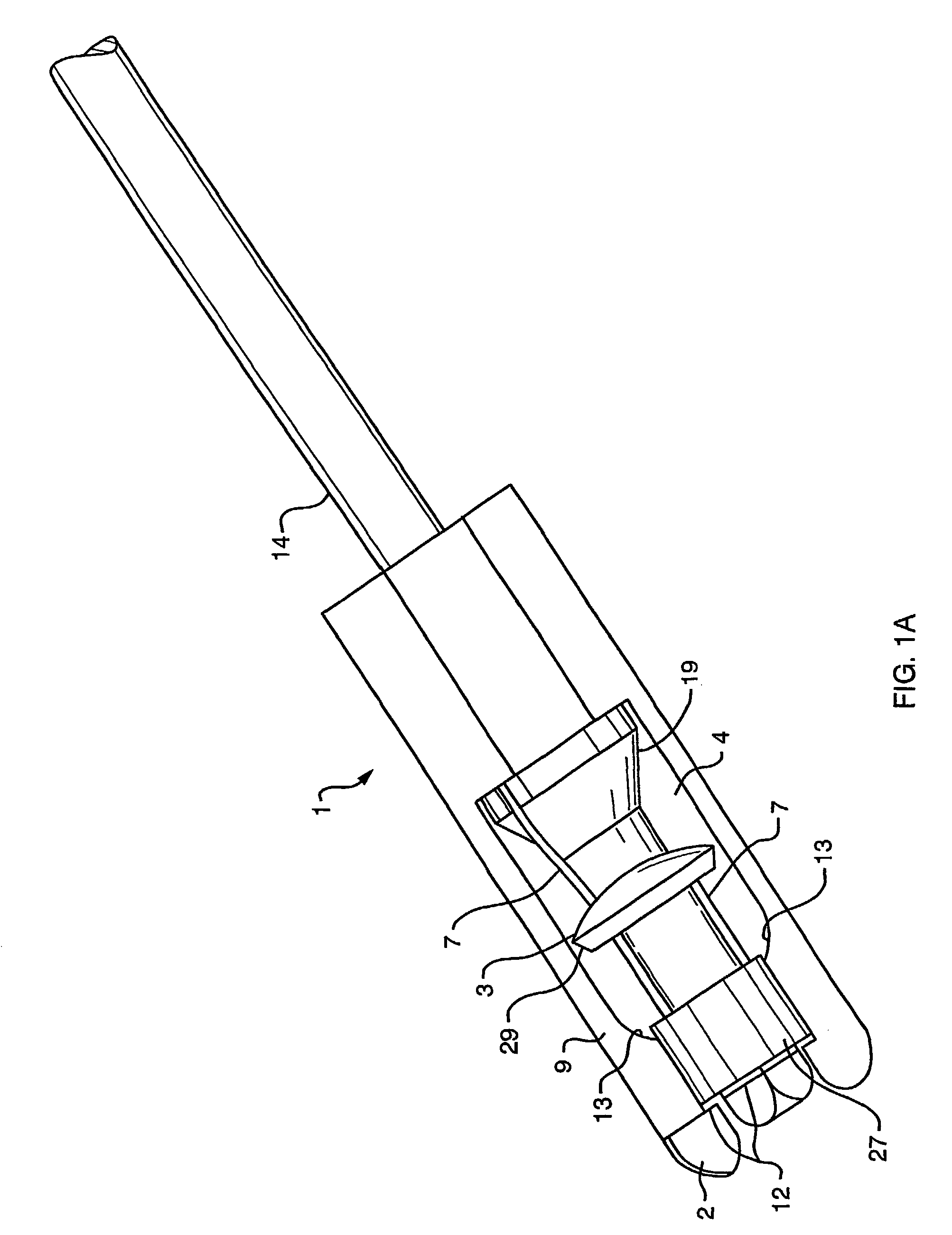

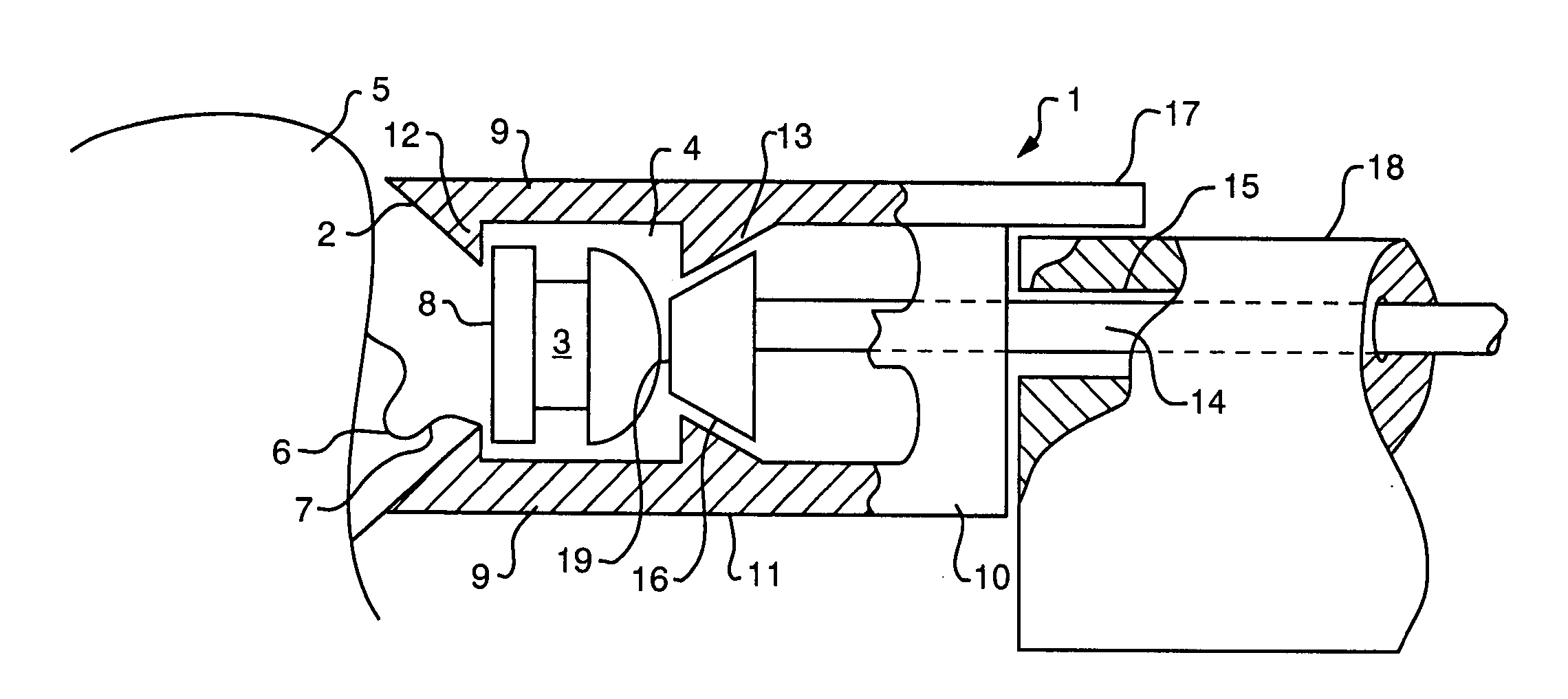

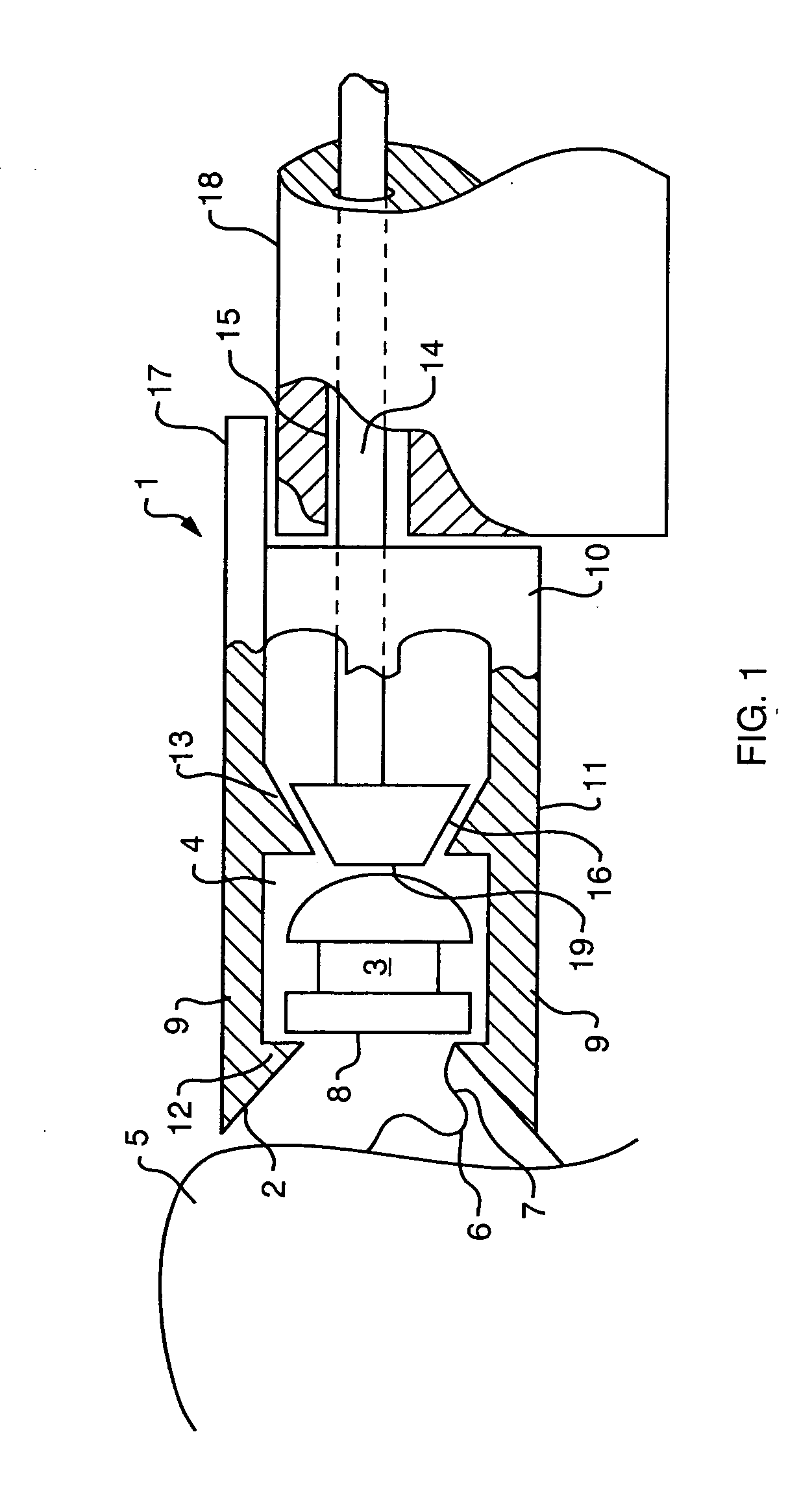

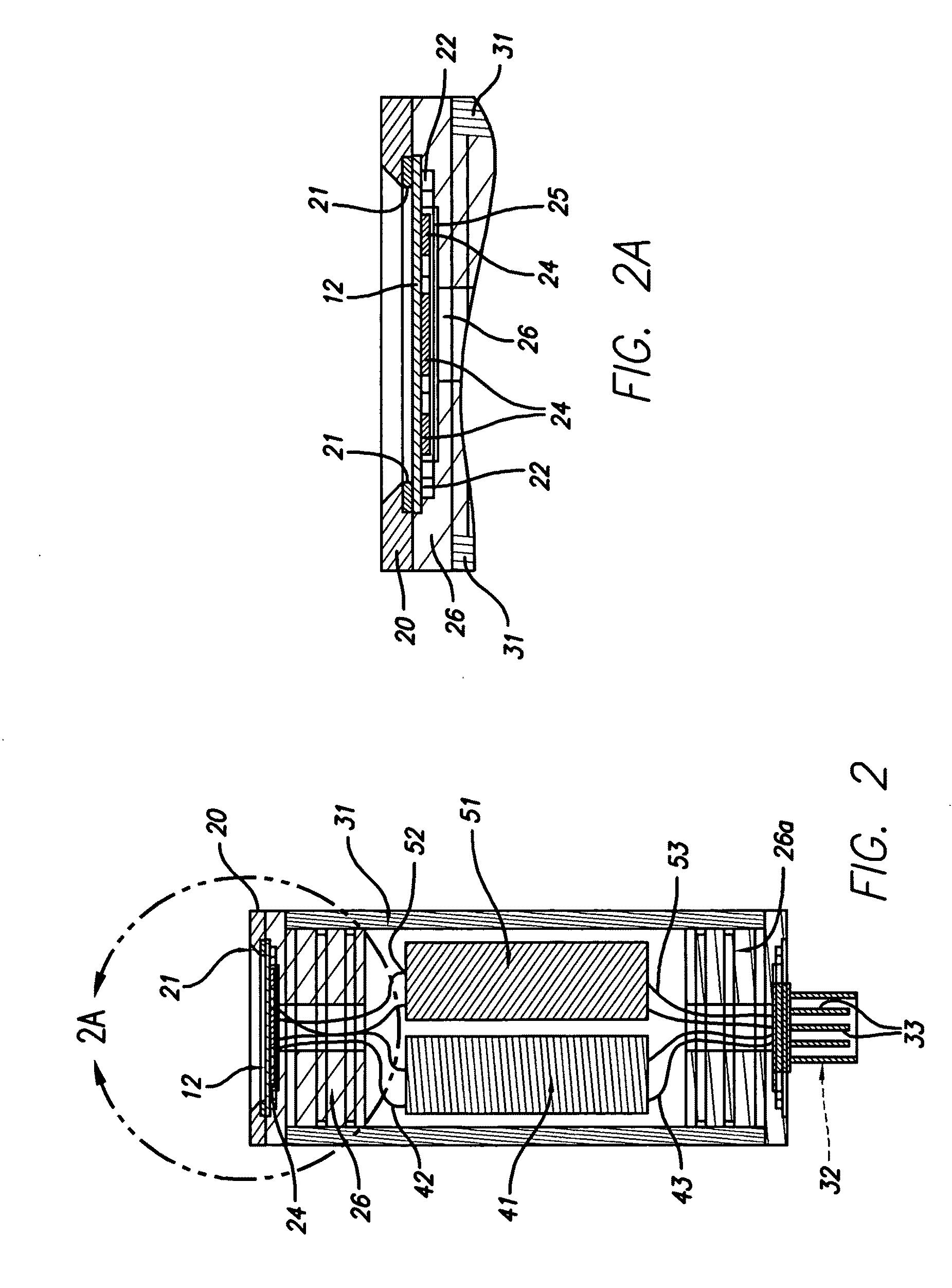

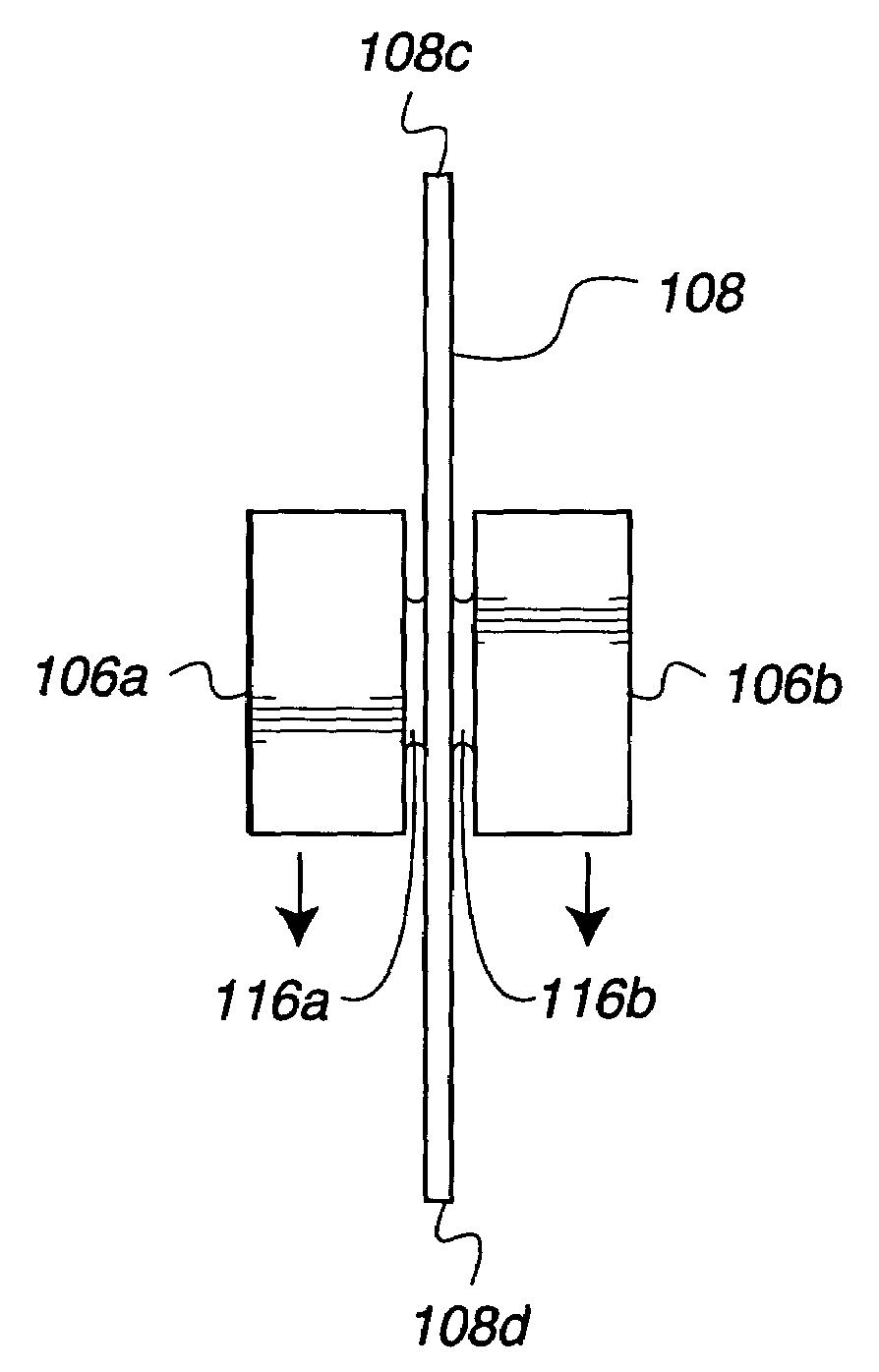

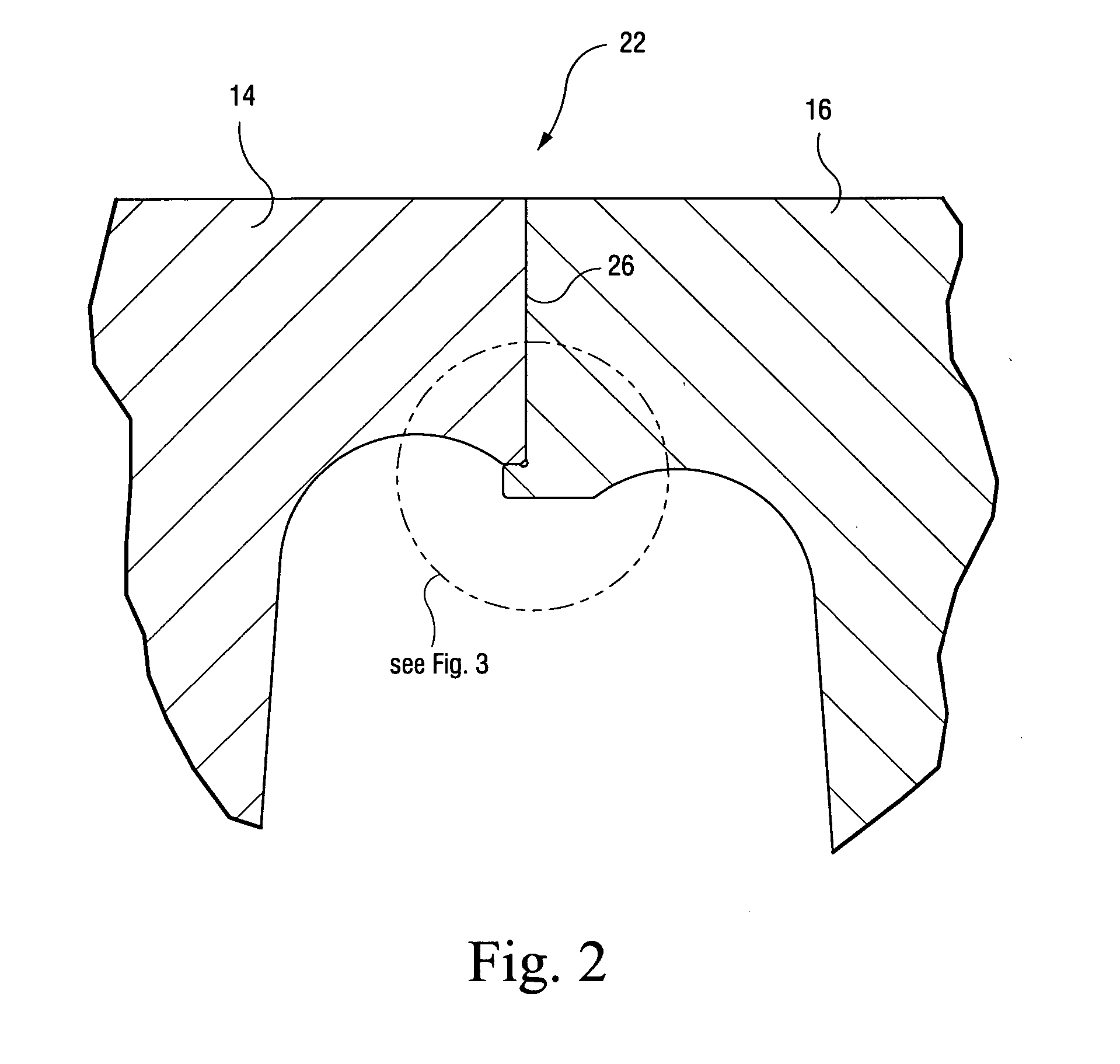

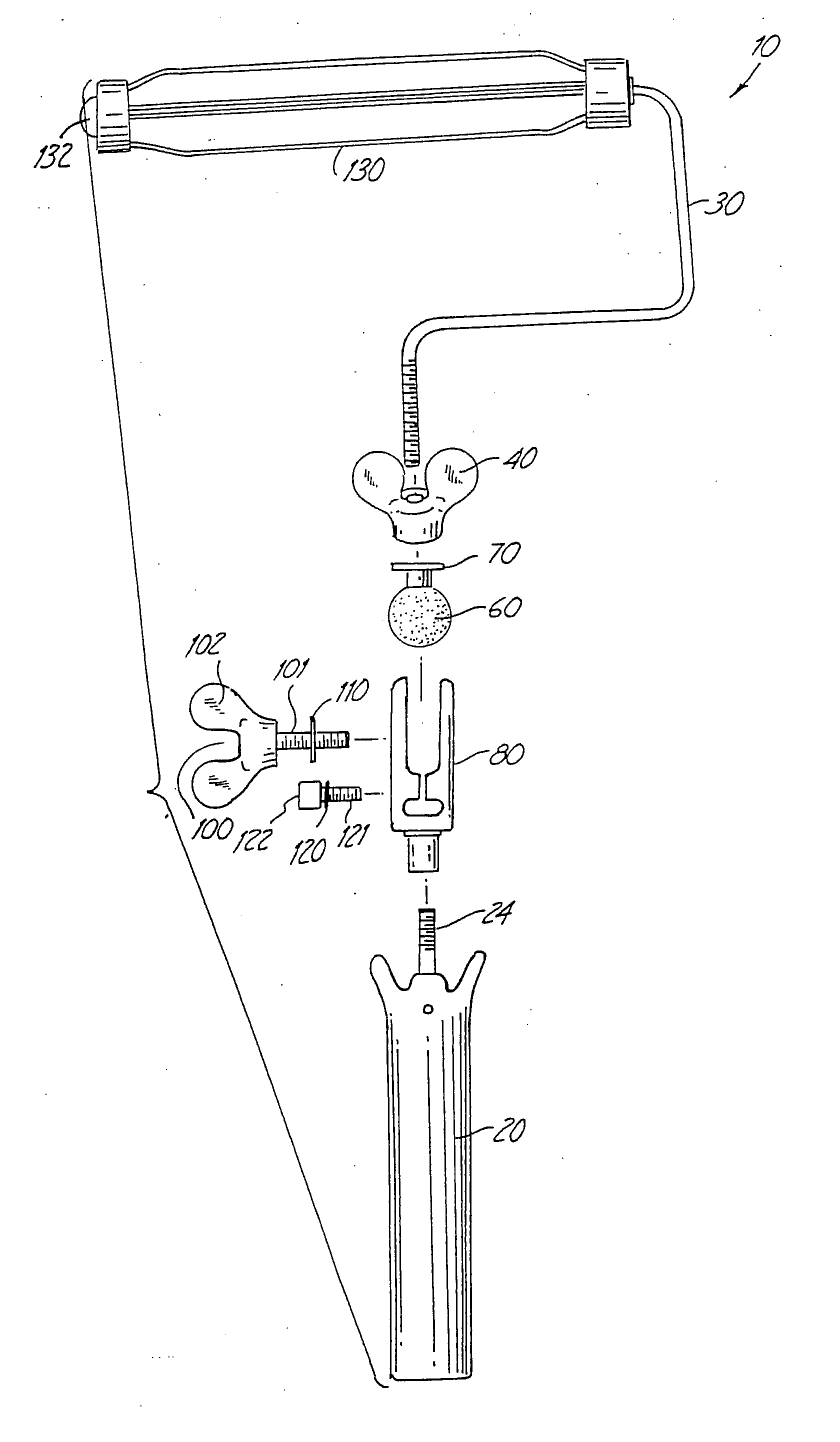

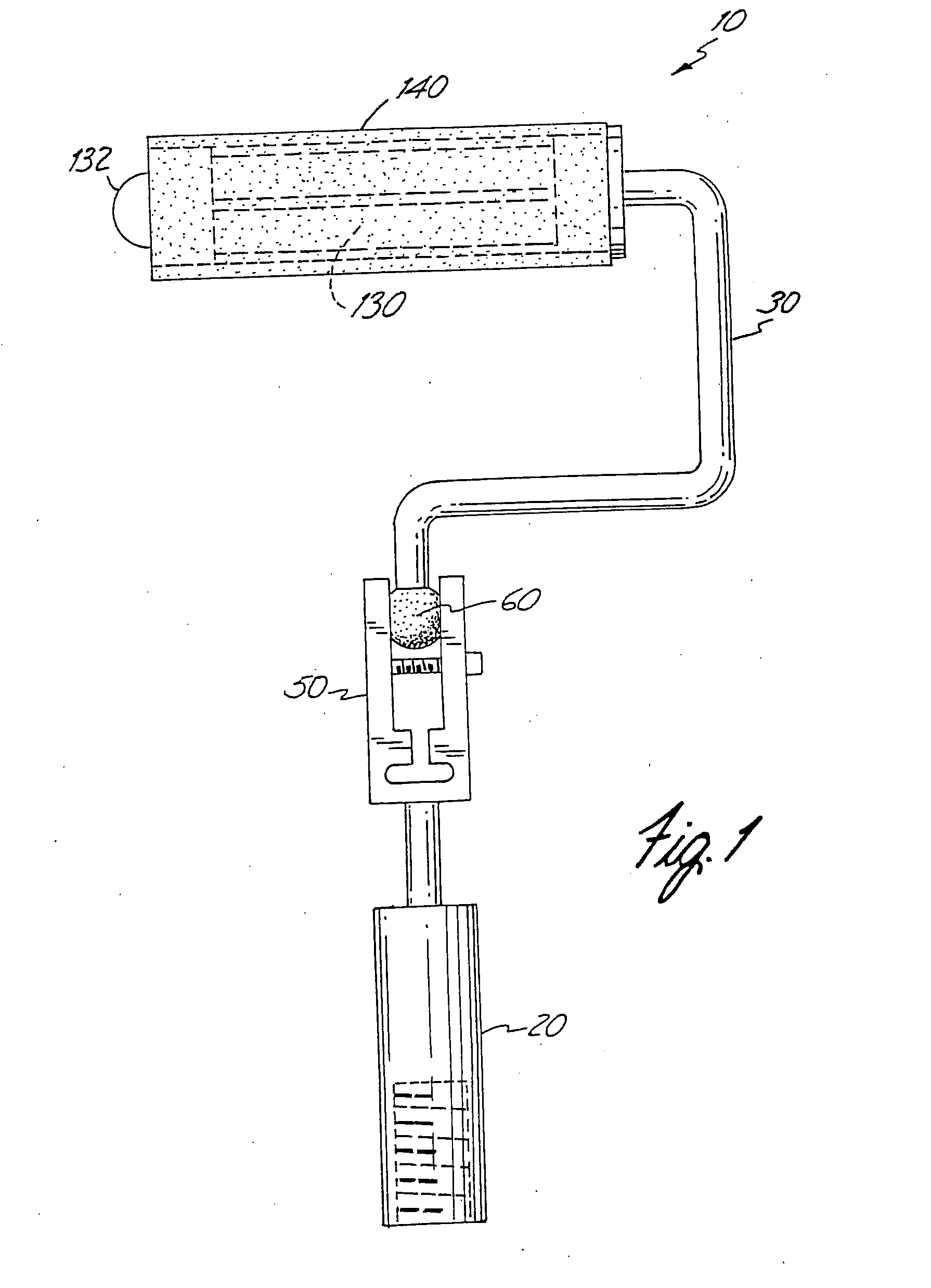

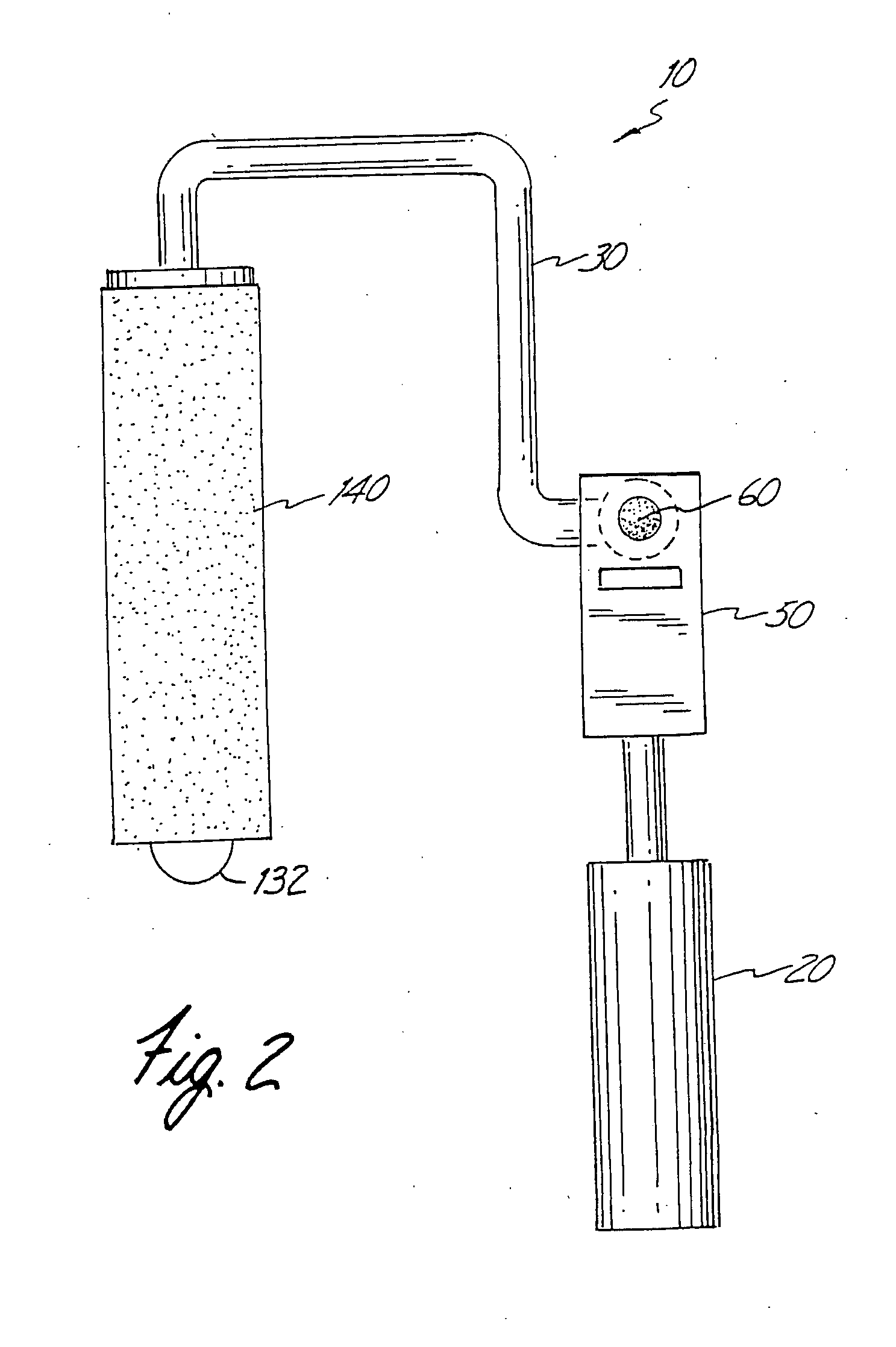

Provided herein are suture clips that include a plug, a ring, and a shaft. Also provided is a catheter that includes a collet cage with a plurality of flexible collet fingers that engage a suture clip ring and a suture clip plug for assembly with a suture. The catheter is designed to hold and assemble the suture clip in a first position and release the suture clip and sever the suture ends proximal to the suture clip in a second position.

Owner:CR BARD INC

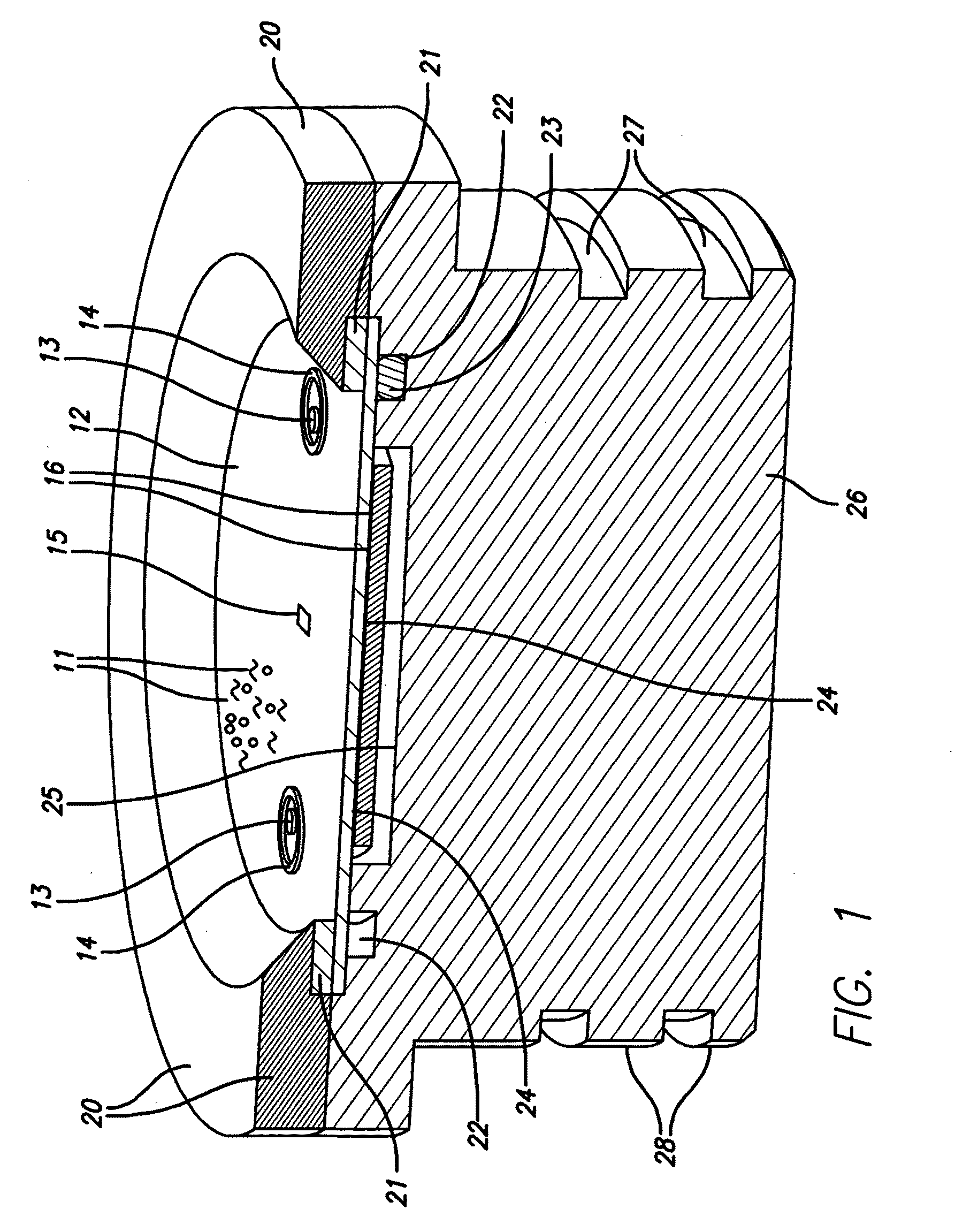

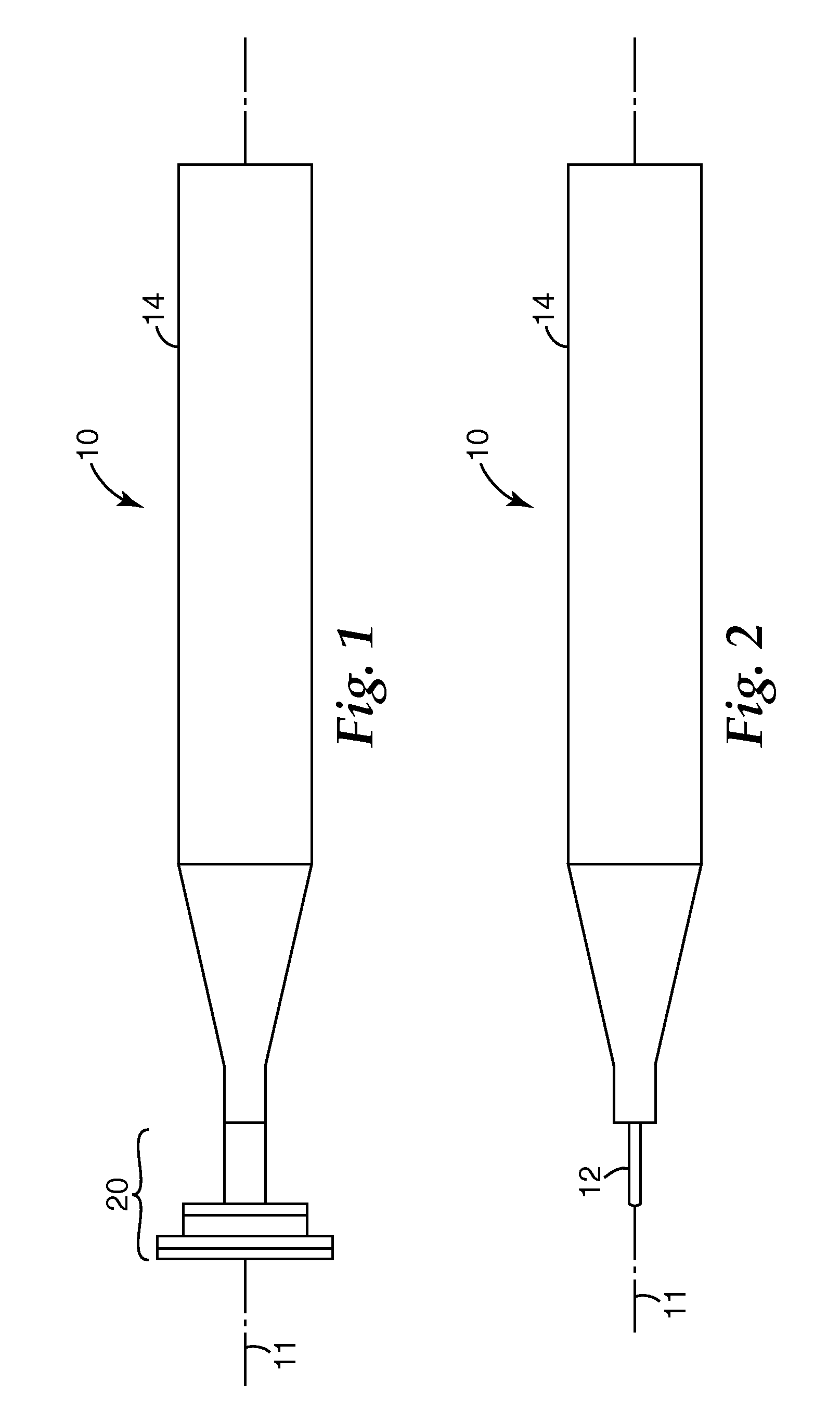

Method and apparatus for manufacturing a device

InactiveUS7052268B2Efficiently manufactureEfficient preparationConfectionerySweetmeatsDrug deliveryPolymer

A device, preferably a micro-device, is molded from a plastic material by injection molding, compression molding or embossing. A microabrader can be molded having microneedles for abrading the stratum corneum of the skin to form an abraded site in the tissue for enhancing drug delivery. The micro-device is molded using a mold assembly having a silicon molding surface. The silicon molding surface can include a recess corresponding to the desired shape and length of the microneedles. The silicon molding surface enables micron and submicron size features to be molded from polymeric materials without the polymeric material adhering to the mold surface. Micro-devices having molded features having micron and submicron dimensions can be rapidly produced without the use of a release agent.

Owner:BECTON DICKINSON & CO

Suture clips, delivery devices and methods

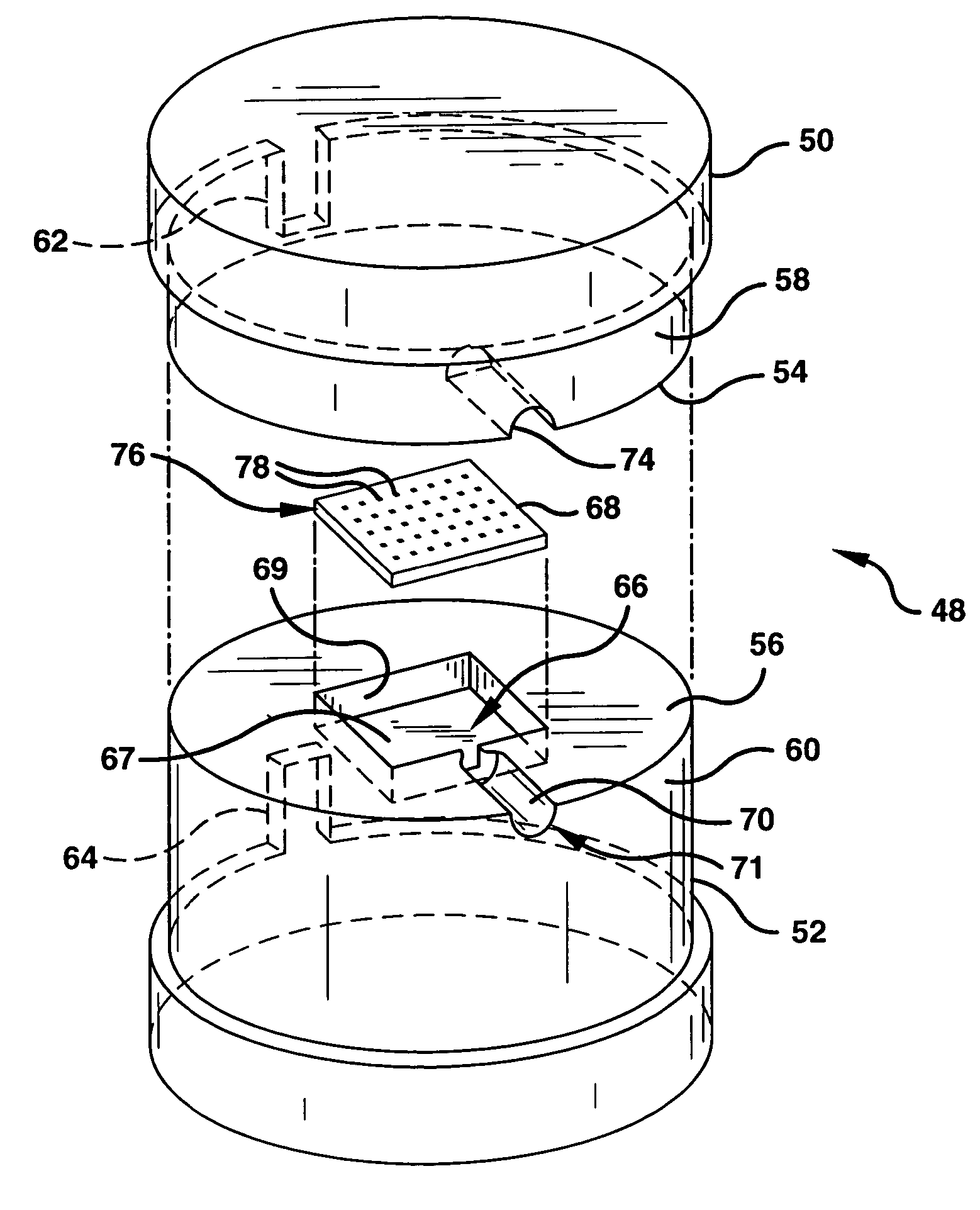

ActiveUS20070093858A1Enhancing suture capturing effectRemoval from surfaceSuture equipmentsHaberdasheryTwo stepEndoscope

Suture clips and suture clip loading, delivery, locking and severing devices in both catheter and endoscopic embodiments are disclosed that permit the delivery and application of suture clips directly in contact with or in close approximation to sutured tissue. The catheter or endoscopic versions incorporate a collet cage with a plurality of flexible collet fingers that captivate a suture clip ring and a suture clip plug for assembly with a suture. An outer sliding sleeve constrains the collet fingers when distally advanced to minimize potential trauma during delivery and assembly of the suture clip in close proximity to the stitched tissue. Proximal retraction of the sliding sleeve coupled with the distal advancement of a pusher against cam surfaces on the inner walls of the collet fingers causes the collet fingers to open. The catheter is designed to hold and assemble the suture clip in a first position and release the suture clip and sever the suture ends proximal to the suture clip in a second position. Single pusher two-step embodiments and double pusher three-step embodiments are disclosed. Suture clip designs with plugs having heads for use with the suture clip delivery catheter are also disclosed. A suture clip loading device for loading suture clip components into the delivery system as well as a threader for threading sutures into the suture clip systems are also disclosed. A method of loading, delivering and deploying suture clips is further disclosed.

Owner:CR BARD INC

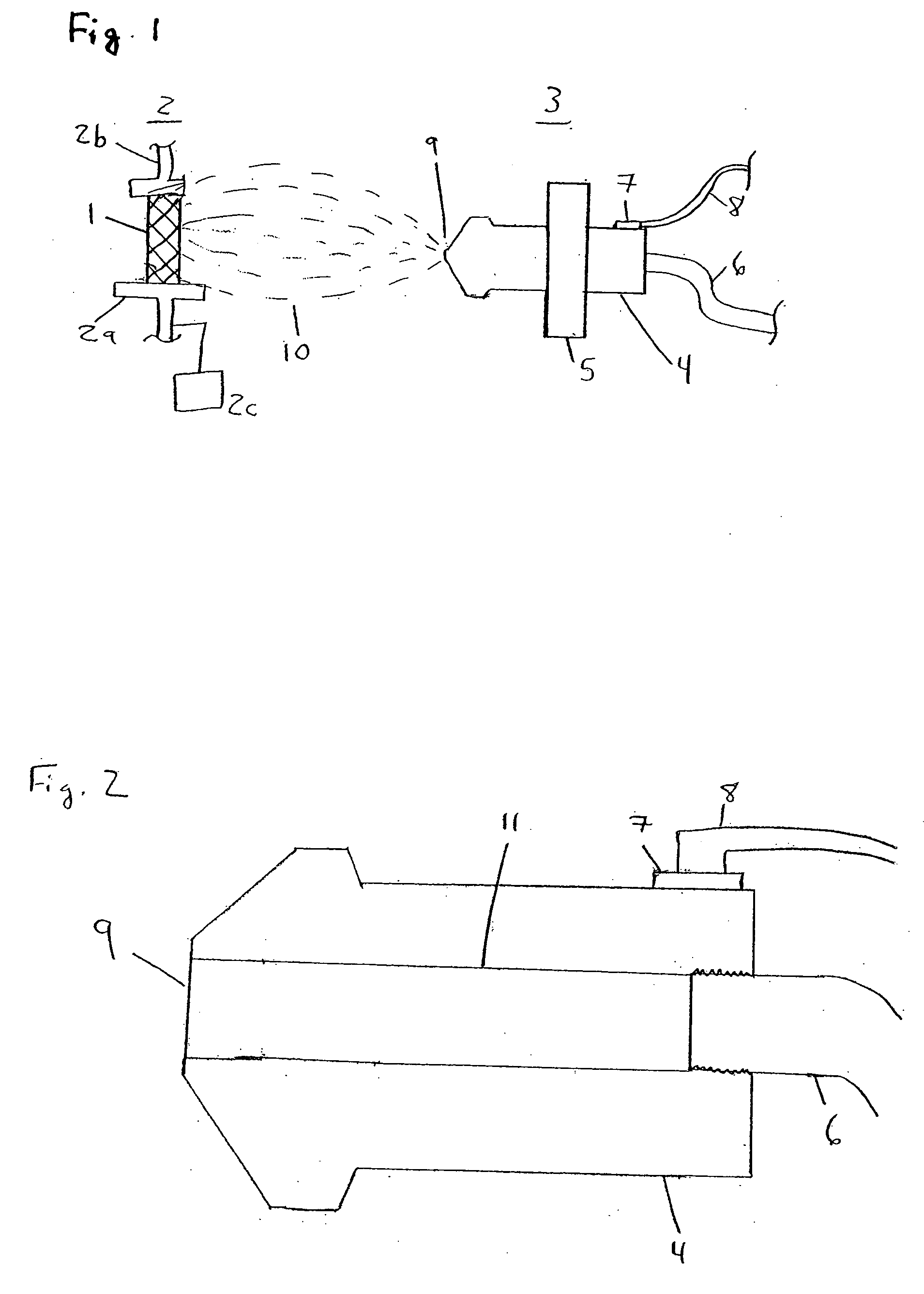

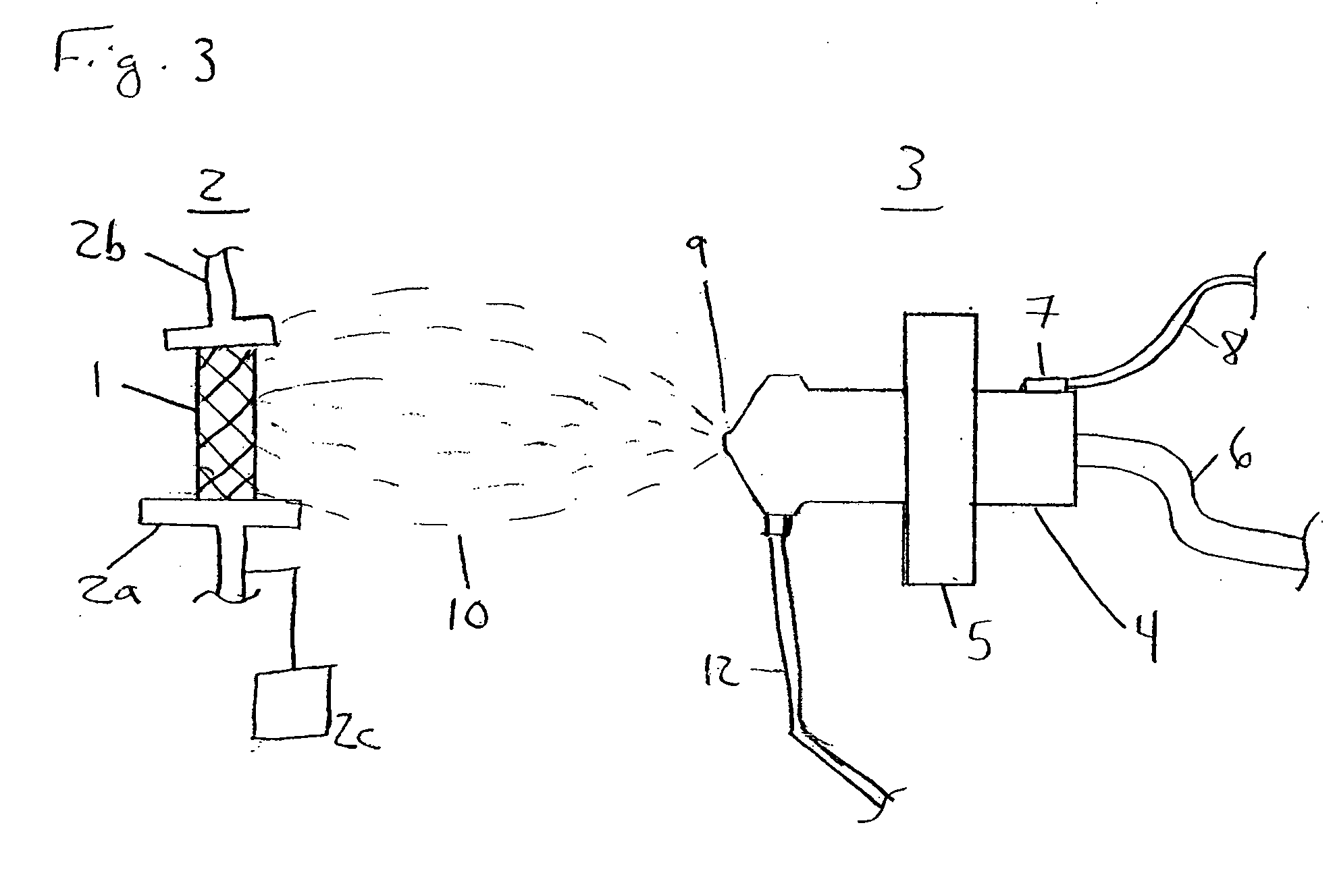

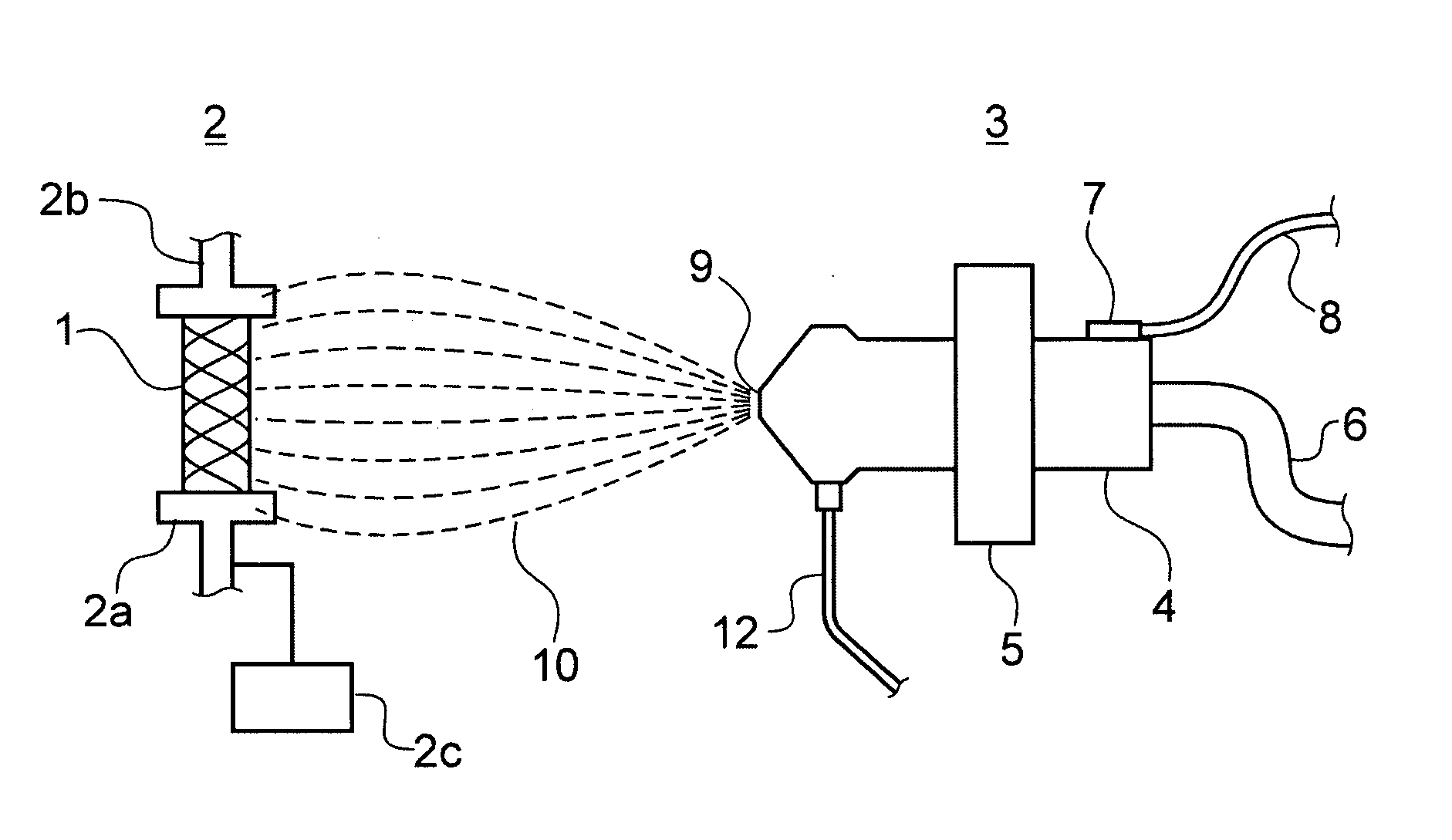

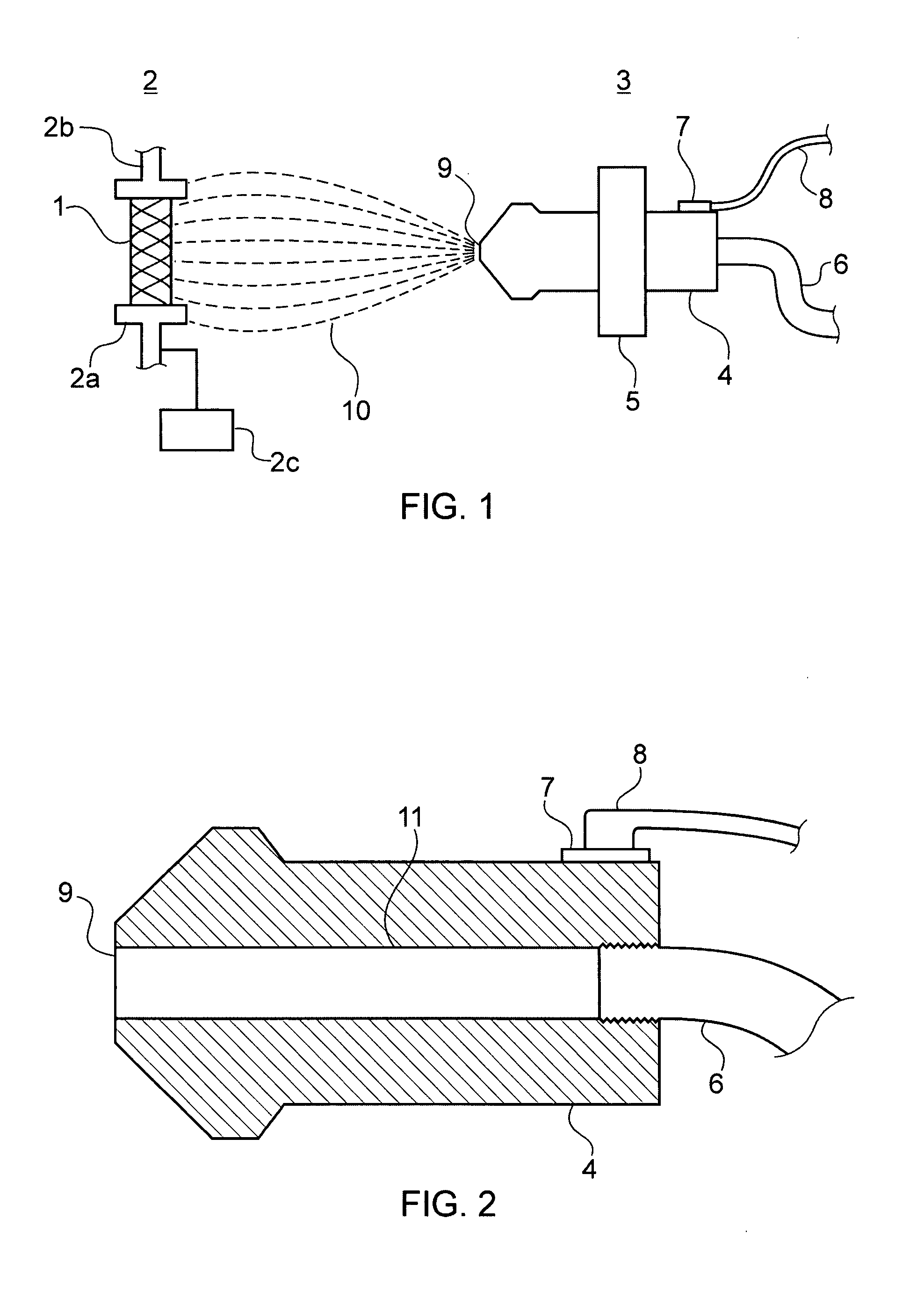

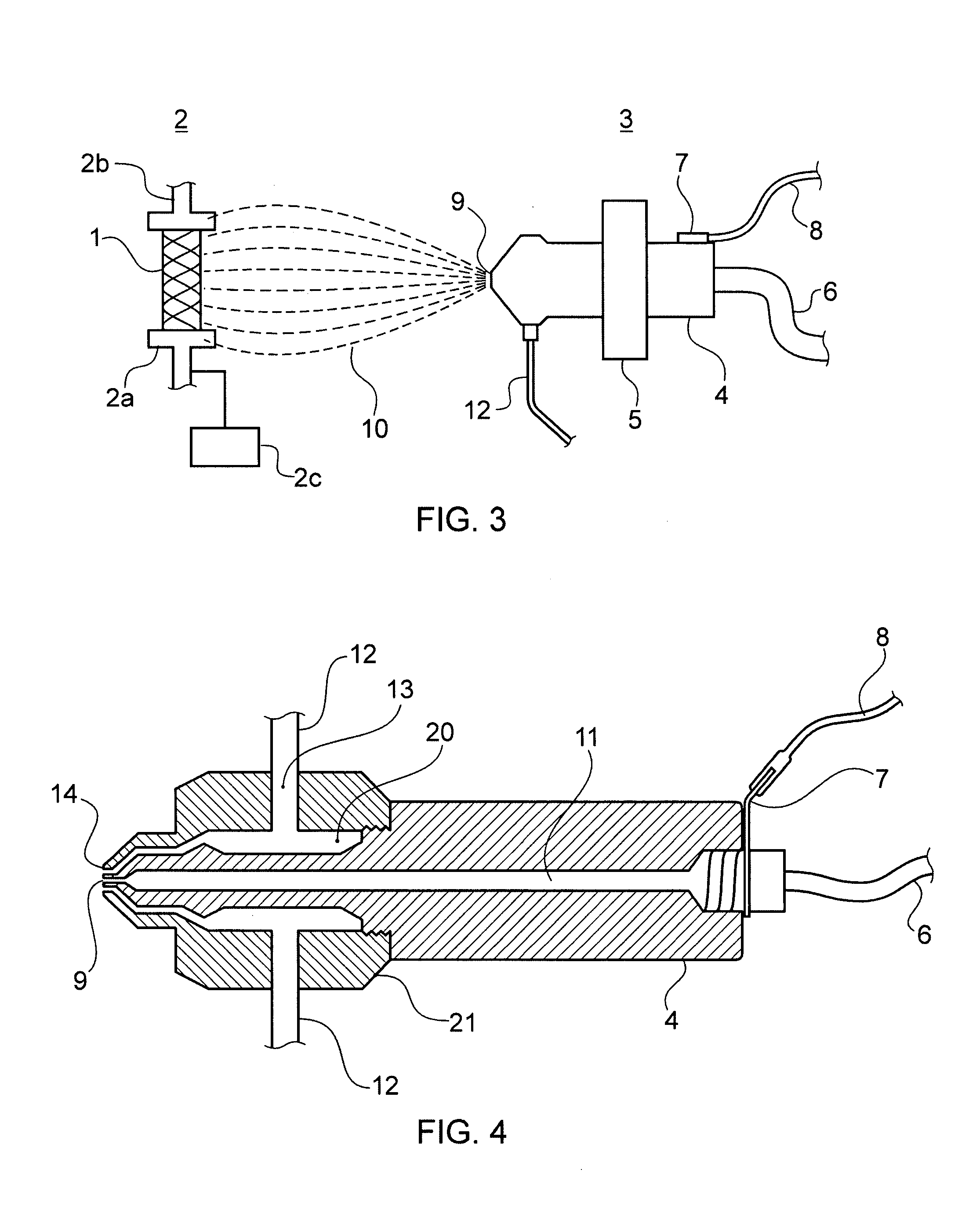

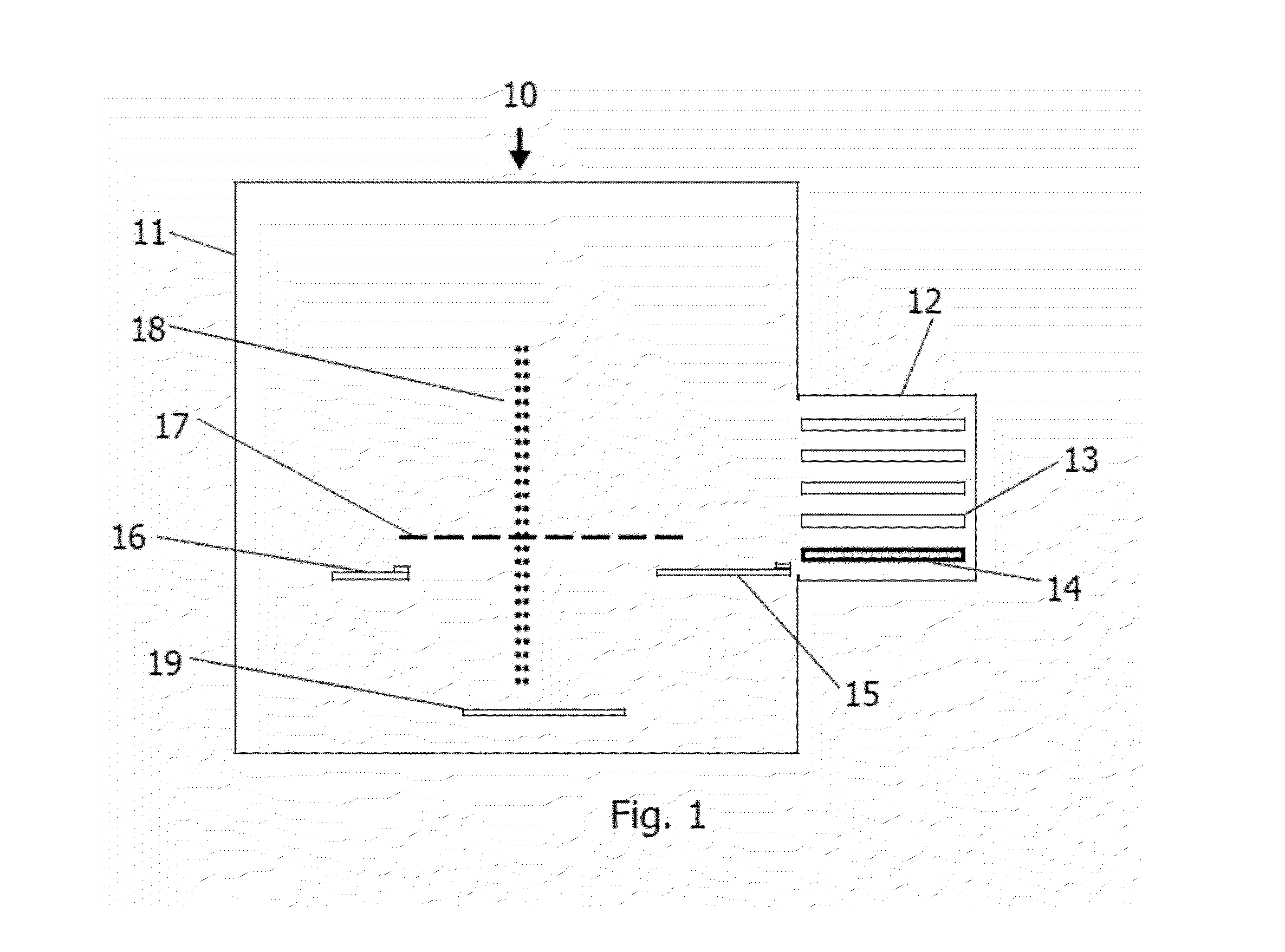

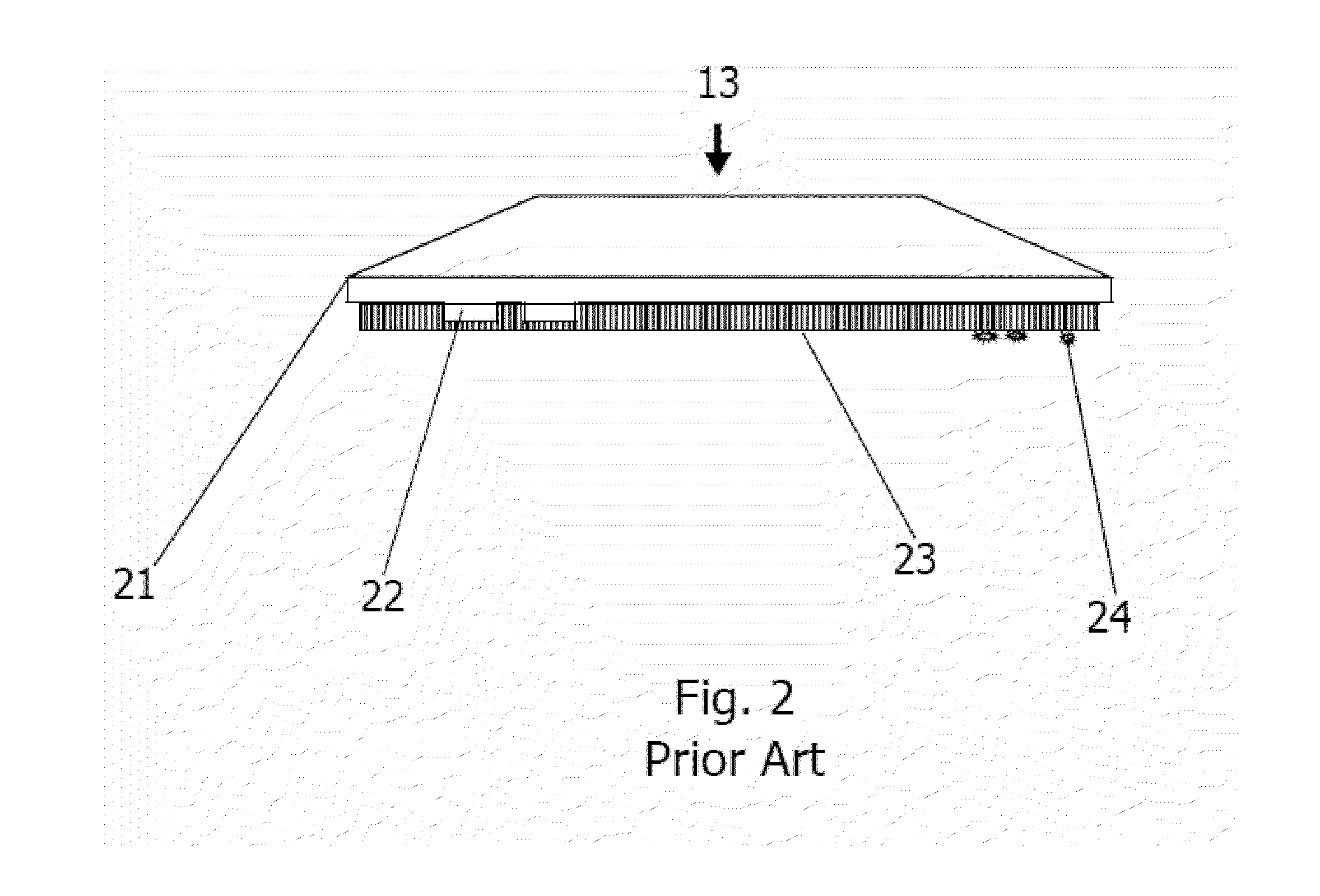

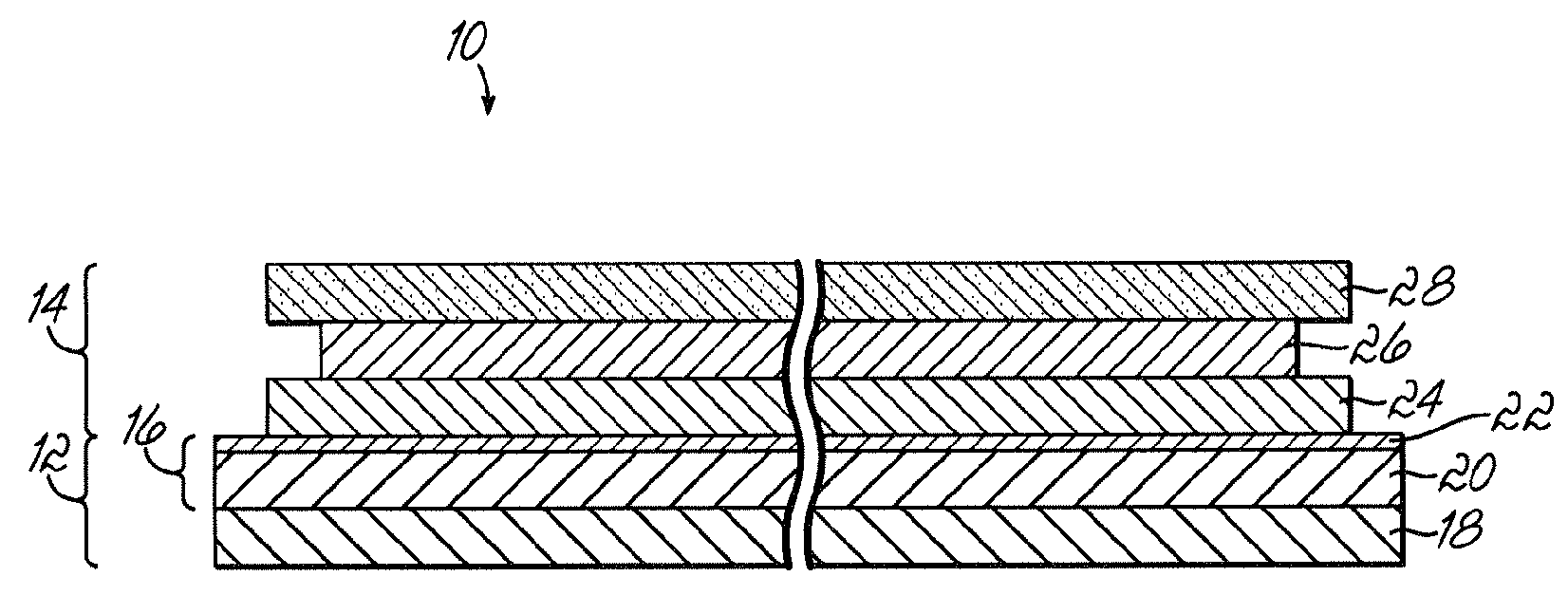

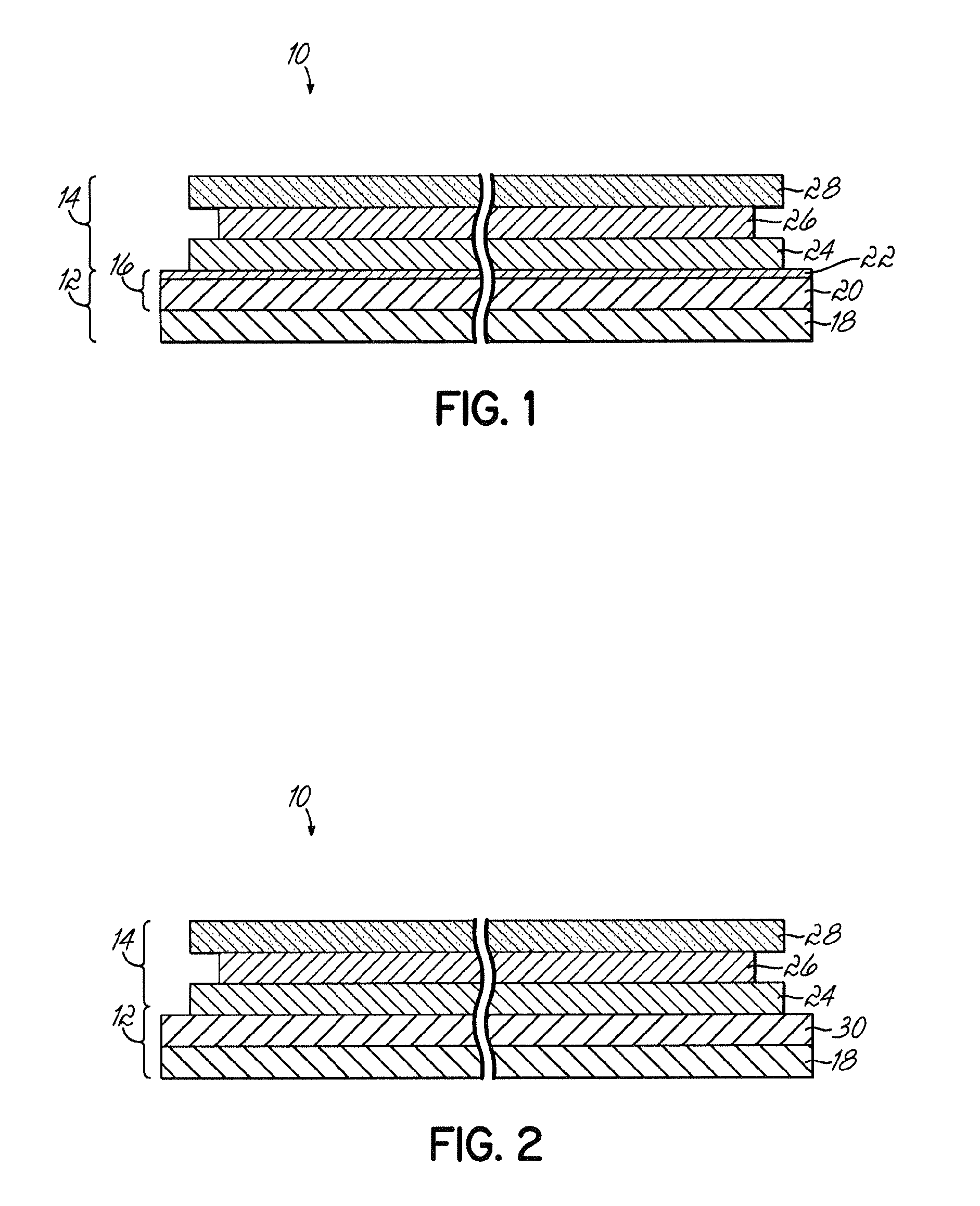

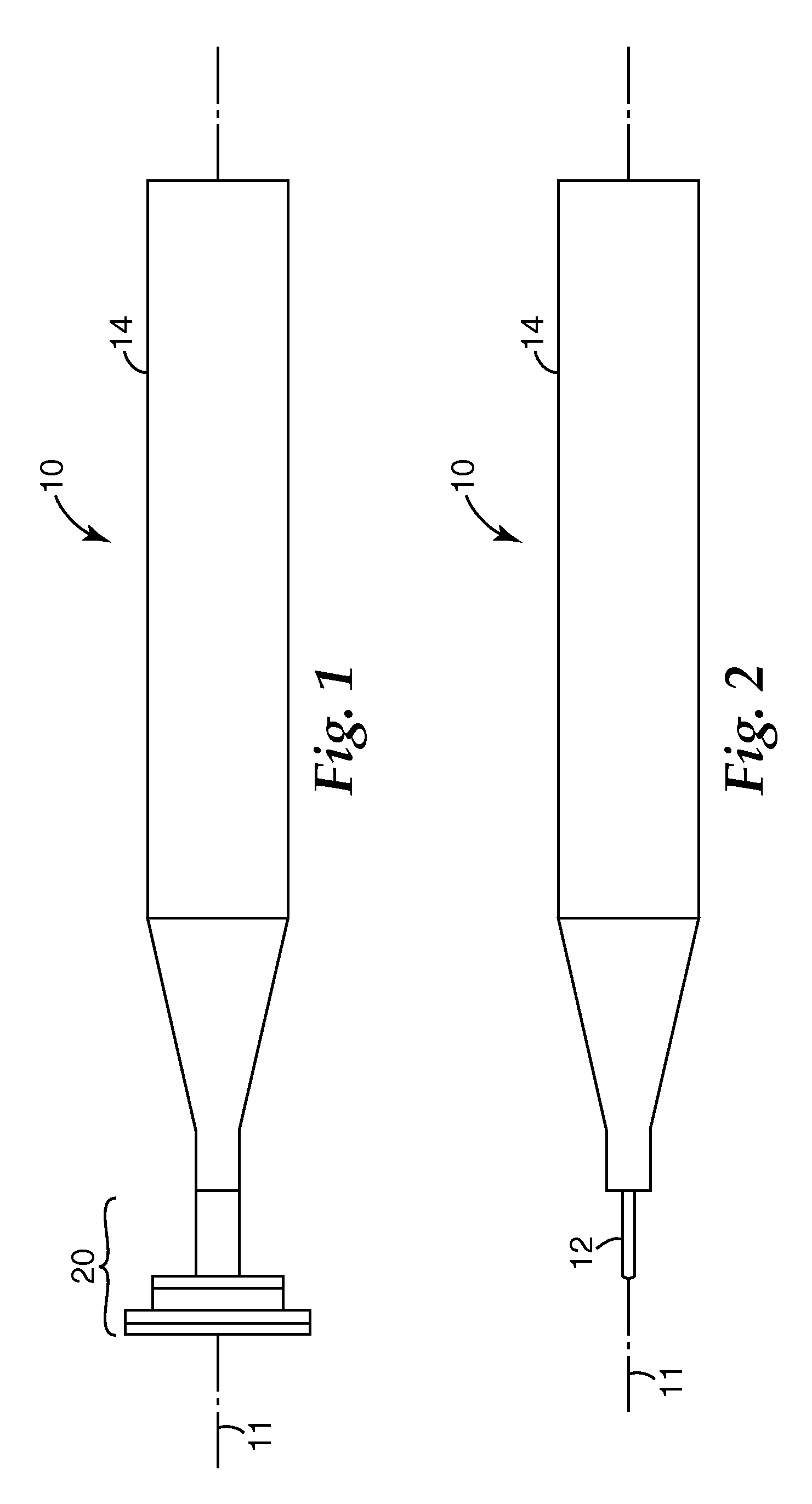

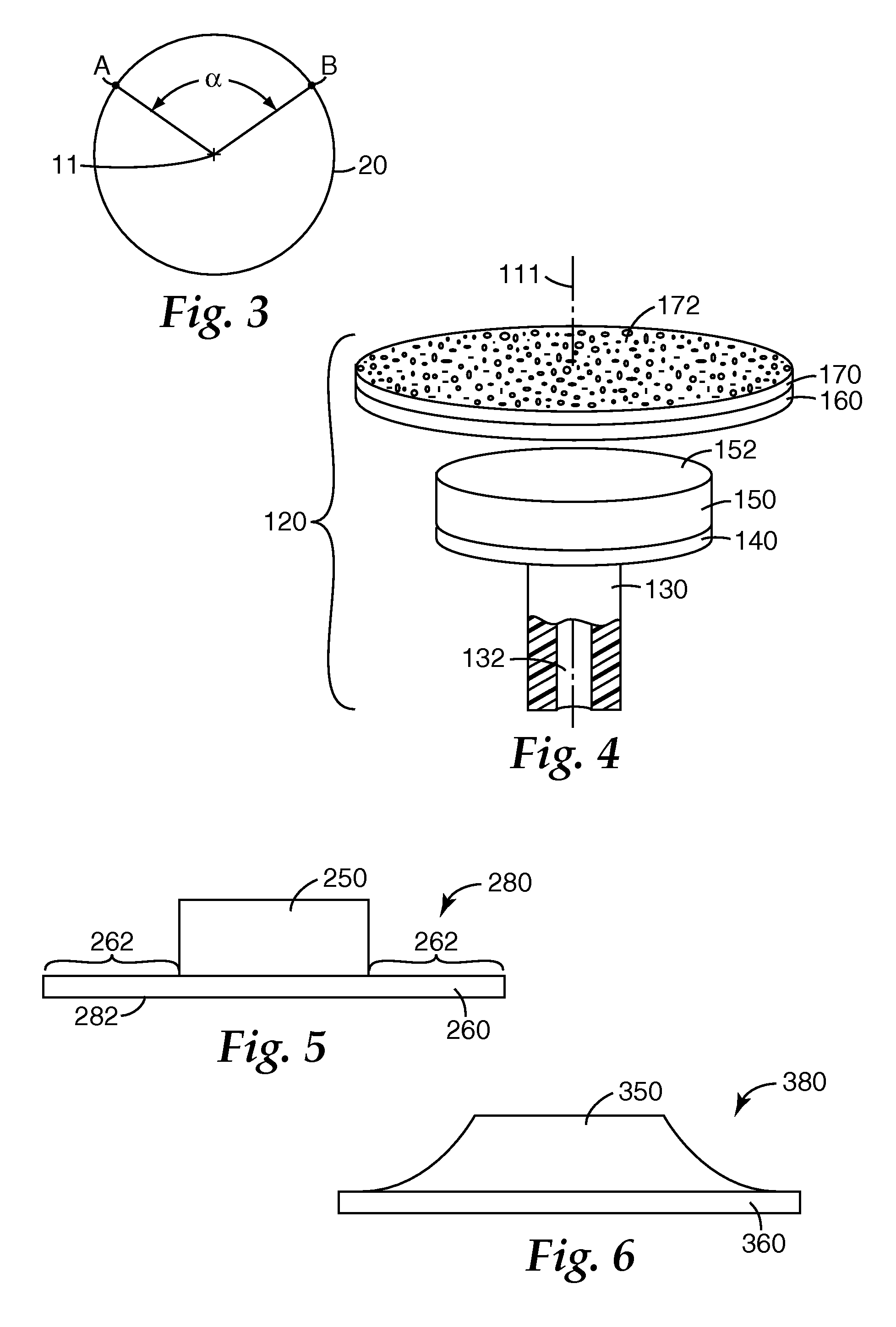

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS20050175772A1Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

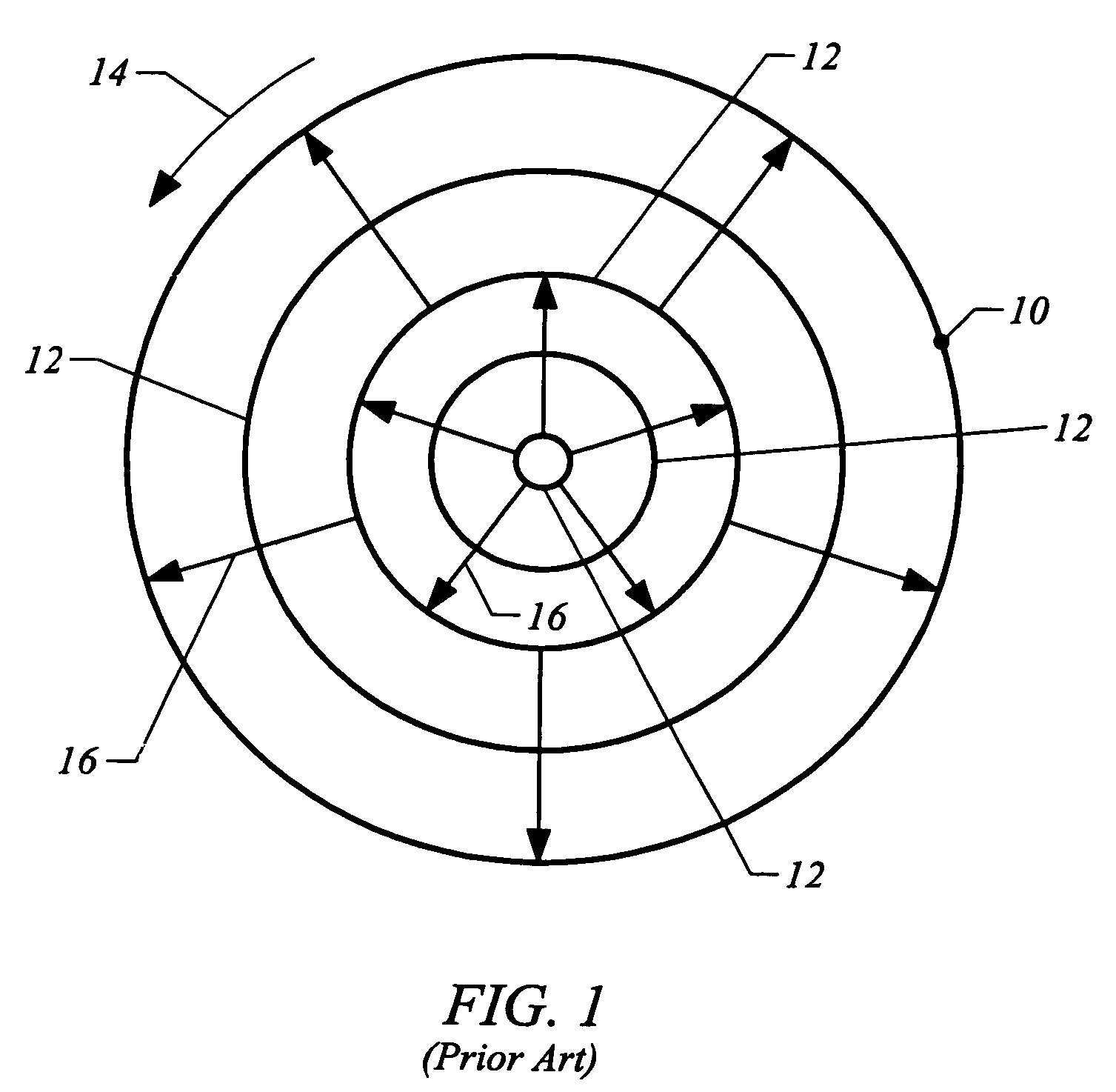

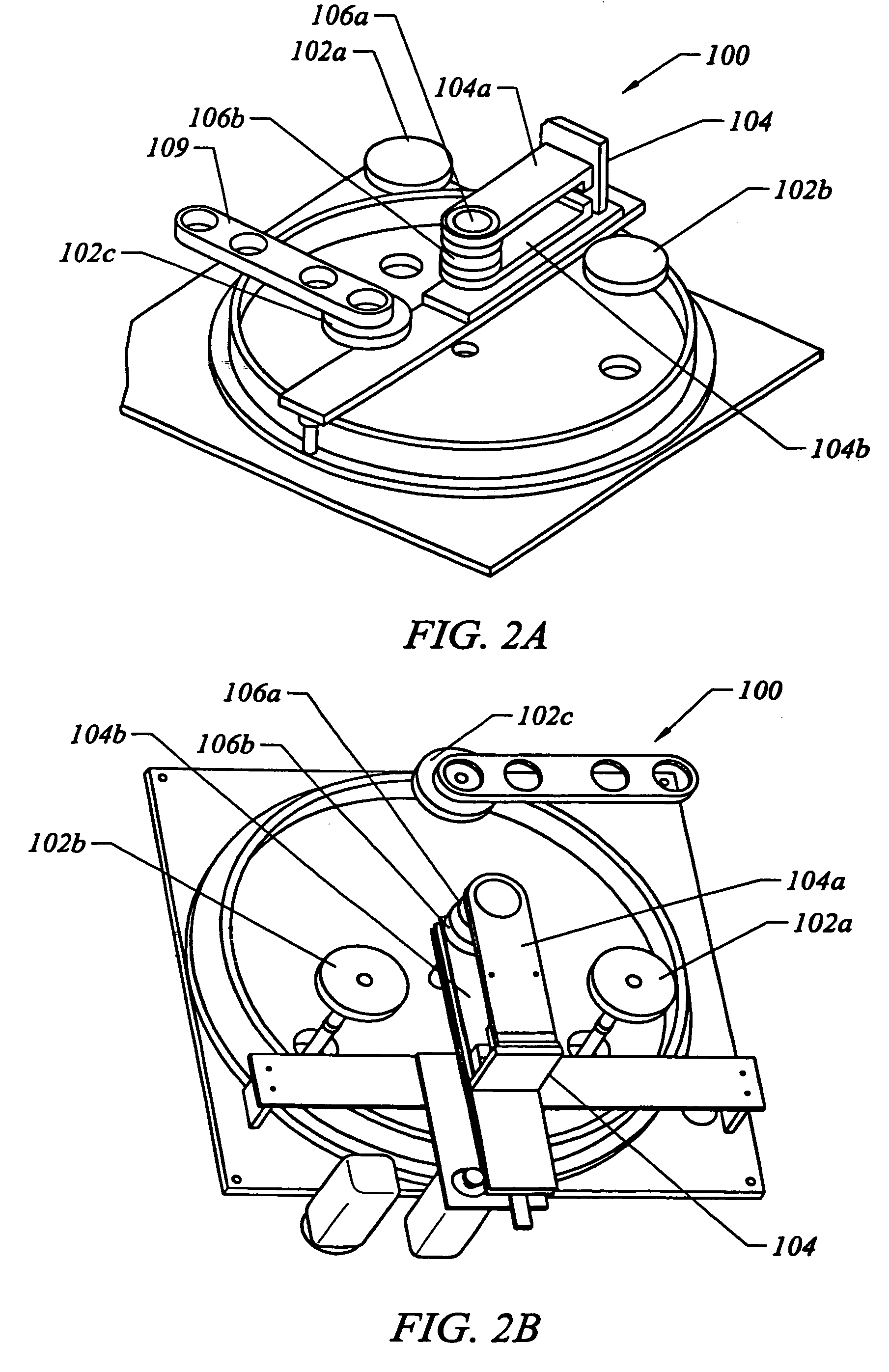

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS7241344B2Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

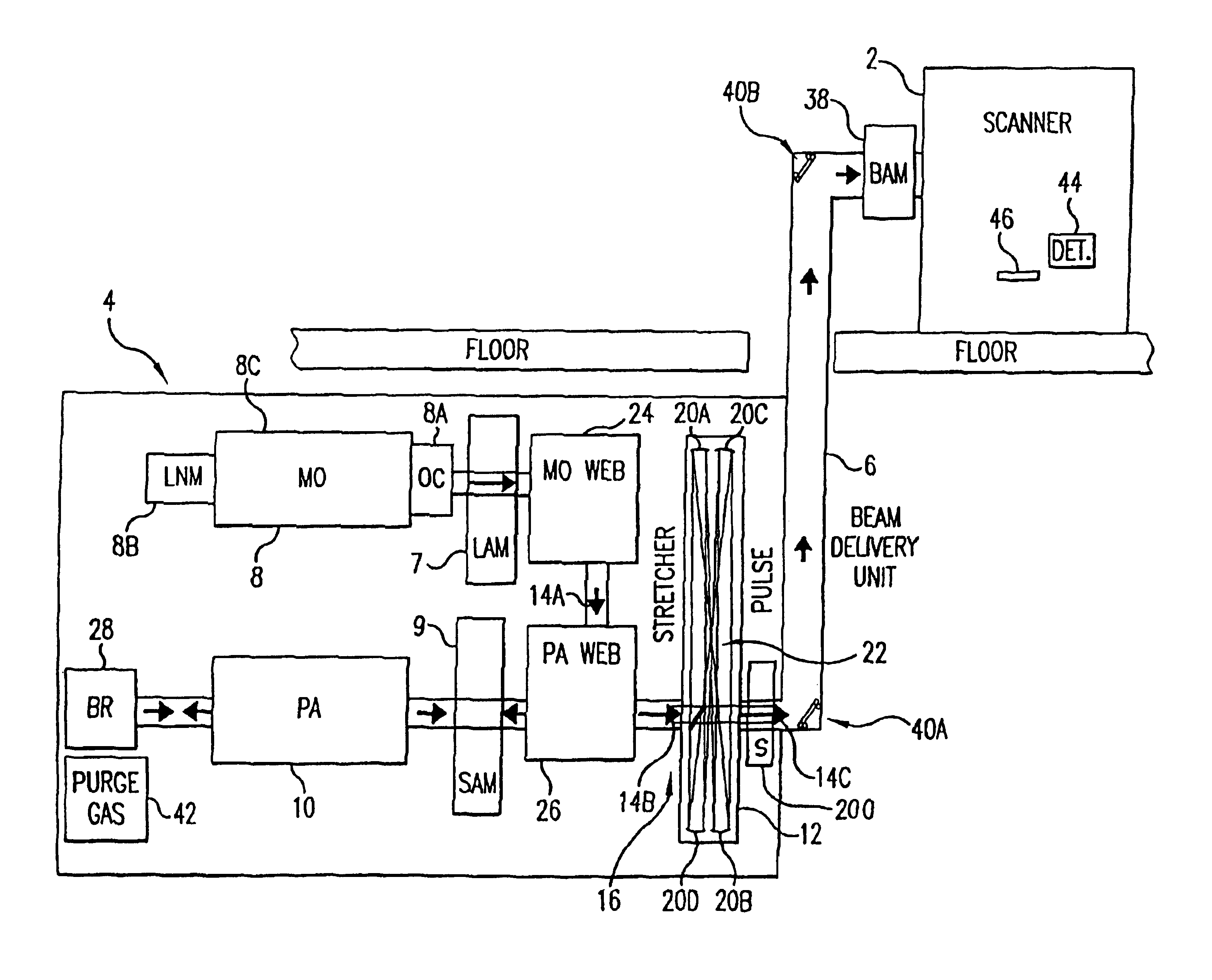

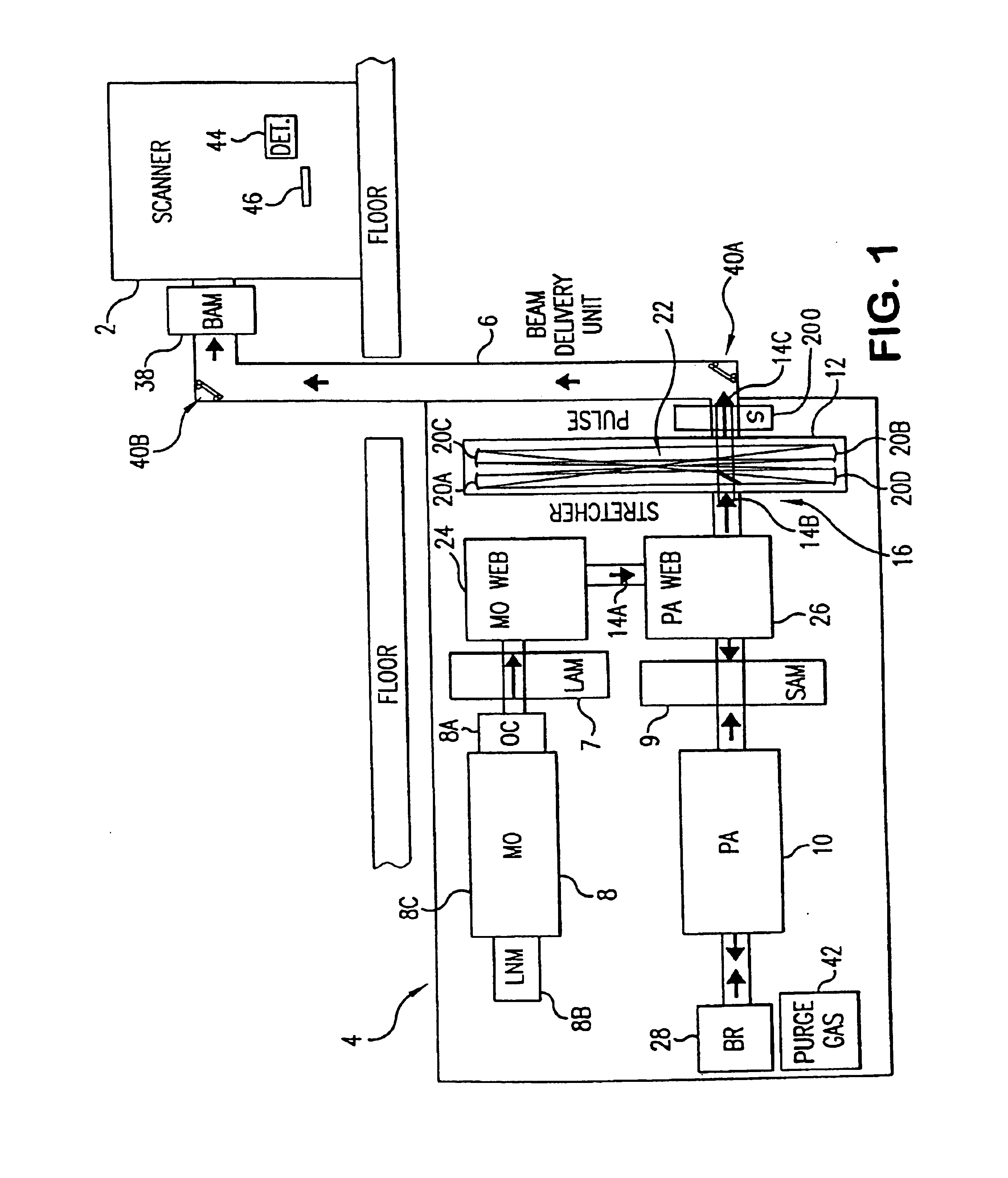

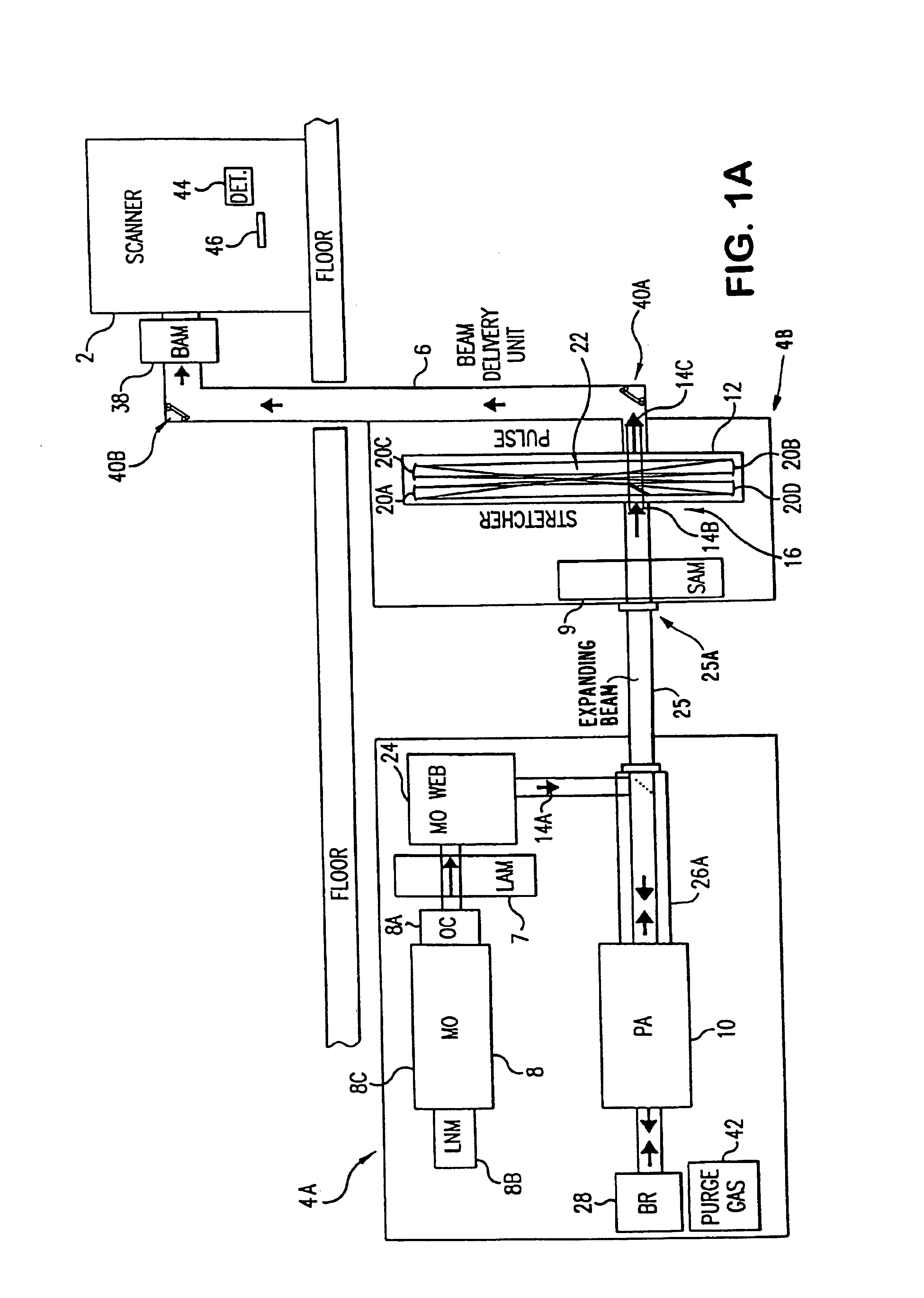

High power deep ultraviolet laser with long life optics

InactiveUS6904073B2Output powerBeam quality specificationOptical resonator shape and constructionLaser arrangementsPhysicsPulse energy density

The present invention provides long life optics for a modular, high repetition rate, ultraviolet gas discharge laser systems producing a high repetition rate high power output beam. The invention includes solutions to a surface damage problem discovered by Applicants on CaF2 optics located in high pulse intensity sections of the output beam of prototype laser systems. Embodiments include an enclosed and purged beam path with beam pointing control for beam delivery of billions of output laser pulses. Optical components and modules described herein are capable of controlling ultraviolet laser output pulses with wavelength less than 200 nm with average output pulse intensities greater than 1.75×106 Watts / cm2 and with peak intensity or greater 3.5×106 Watts / cm2 for many billions of pulses as compared to prior art components and modules which failed after only a few minutes in these pulse intensities. Techniques and components are disclosed for minimizing the potential for optical damage and for reducing the pulse energy density to less than 100×10−6 J / cm3. Important improvements described in this specification have been grouped into the following subject matter categories: (1) Solution to CaF2 surface damage discovered by Applicants, (2) description of a high power ArF MOPA laser system, (3) description of beam delivery units, (4) polarization considerations (5) a high speed water-cooled auto shutter energy detector module and (6) other improvements.

Owner:CYMER INC

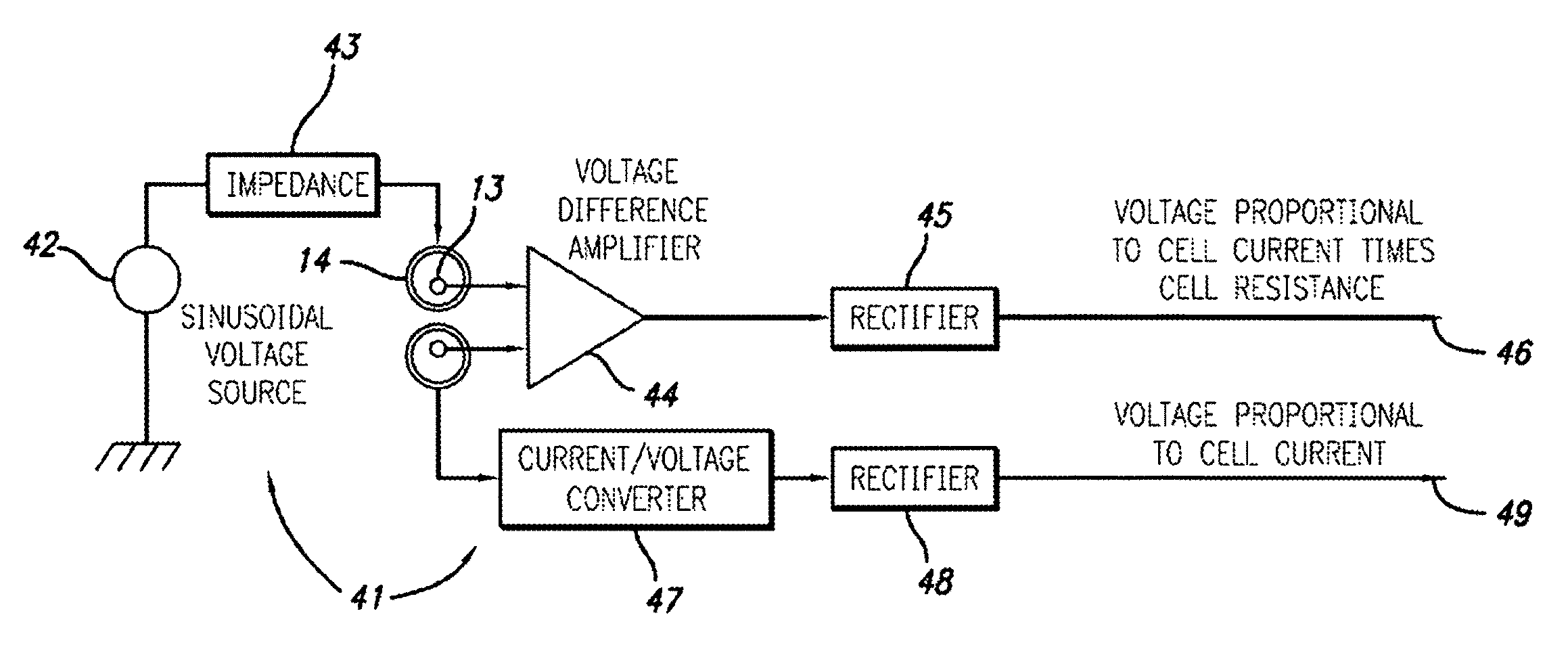

Self-cleaning submerged instrumentation

ActiveUS20100042389A1Reduce eliminateExtends optimum high-performance lifeFouling preventionResistance/reactance/impedenceBiofoulingAcoustics

Techniques and apparatus inhibit, limit, or remove biofouling and certain inorganic accumulations, to increase the longevity of accurate in-situ oceanographic and other underwater measurements and transducing processes. The invention deters formation of an initial bacterial layer and other precipitation, without harming the environment. The invention integrates an ultrasonic source into a sensor or other device, or its supporting structures. The ultrasonic source vibrates one or more critical surfaces of the device at a frequency and amplitude that dislodge early accumulations, thus preventing the rest of the fouling sequence. The ultrasonic driver is activated for short periods and low duty cycles, and in some cases preferably while the device is not operating.

Owner:ARETE ASSOCIATES INC

Vertical proximity processor

InactiveUS7069937B2Reducing wafer contaminationRemoval from surfaceElectrolysis componentsElectrostatic cleaningEngineering

A method for processing a substrate is provided which includes generating a fluid meniscus on the surface of the vertically oriented substrate, and moving the fluid meniscus over the surface of the vertically oriented substrate to process the surface of the substrate.

Owner:LAM RES CORP

Compact Device for Dual Transmutation for Isotope Production Permitting Production of Positron Emitters, Beta Emitters and Alpha Emitters Using Energetic Electrons

InactiveUS20080240330A1Promote coolingEasily removeConversion outside reactor/acceleratorsHigh energyRadiochemistry

A method and apparatus for directing high energy electrons to a converter material that emits gamma rays, which, in turn interact directly with parent isotopes to produce unstable, short-lived medical isotopes and product isotopes by the gamma, n reaction, or which interact with high-z materials to produce neutrons that then produce valuable isotopes by neutron capture in parent isotopes.

Owner:HOLDEN CHARLES S

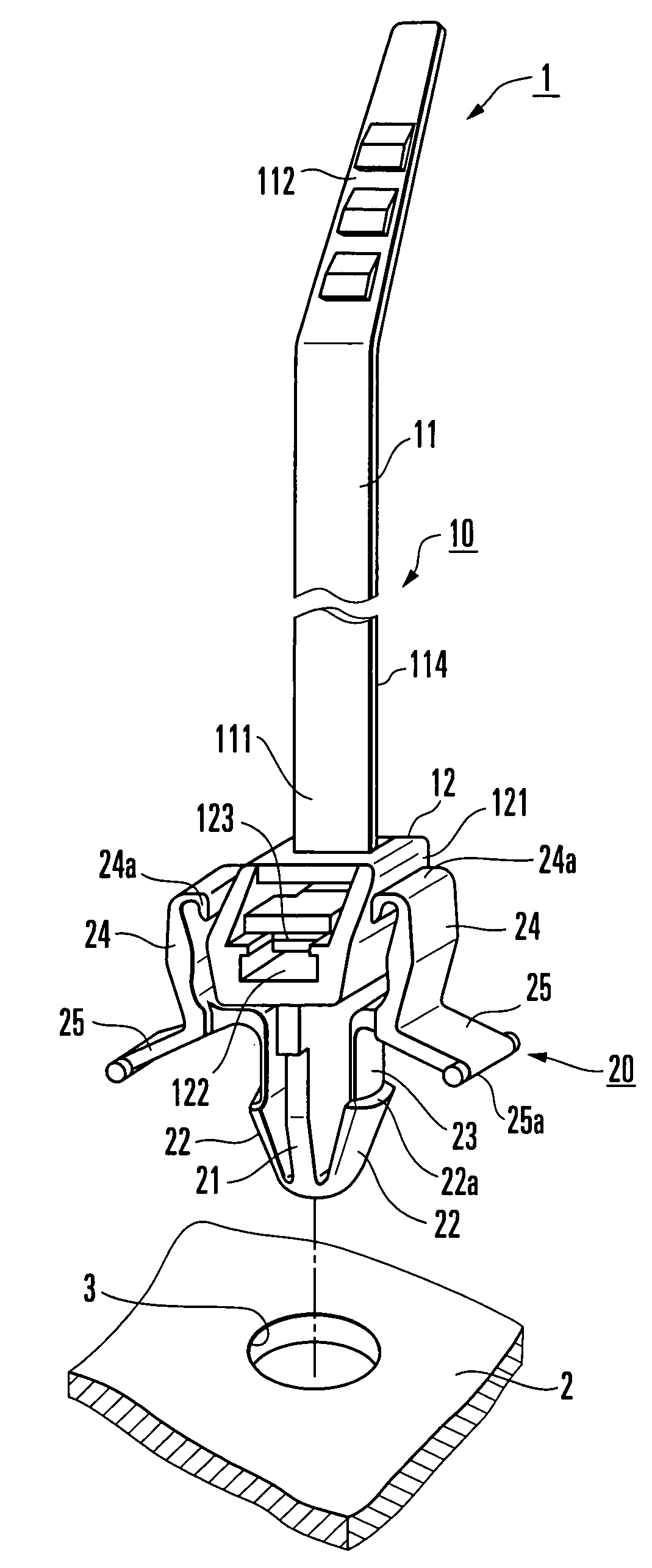

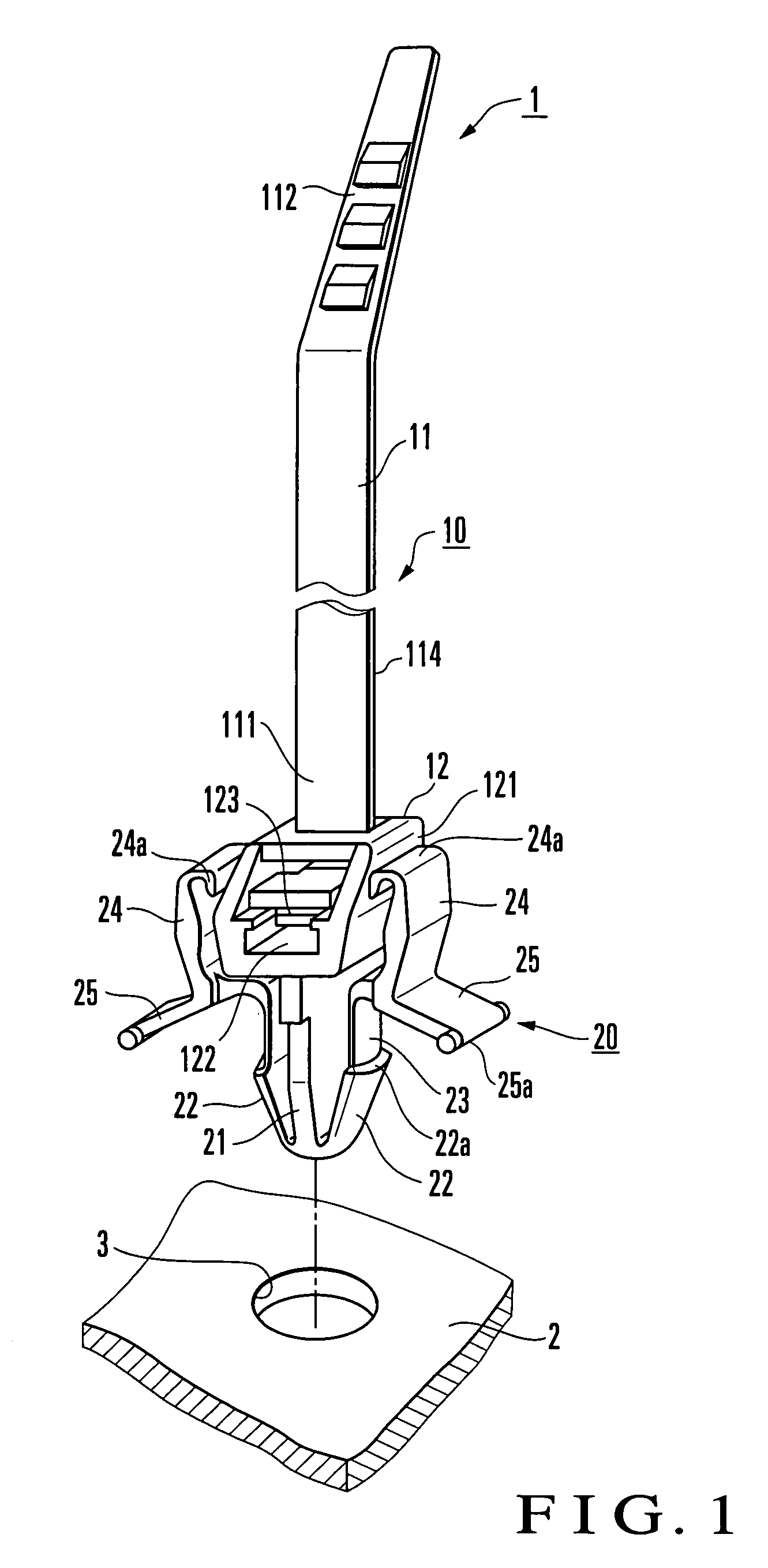

Fixing tool

InactiveUS7229052B2Removal from surfaceNot easy to dropPipe supportsSnap-action fastenersEngineeringChassis

A fixing tool includes a holding portion and fitting portion. The holding portion allows a chassis to hold a component. The fitting portion is integrally formed with the holding portion and is to be fitted in a through hole formed in the chassis, so that the holding portion is fixed to the chassis. The fitting portion has a post, a pair of fitting pieces, a pair of disengaging pieces, and a pair of leg pieces. The post projects downward from one side of the holding portion. The fitting pieces are formed at a distal end of the post to have an arrowhead-like shape, and elastically deform outwardly in diameter so as to be fitted in the through hole. The disengaging pieces extend from distal ends of the fitting pieces along two side surfaces of the holding portion, and elastically deform the fitting pieces, when operated manually, to disengage them from the through hole. The leg pieces have proximal ends connected to part of the disengaging pieces, and distal ends that can abut against an upper surface of the chassis. The disengaging pieces have extending ends which are close to or connected to the side surfaces of the holding portion.

Owner:TAKEUCHI KOUGIYOU KK

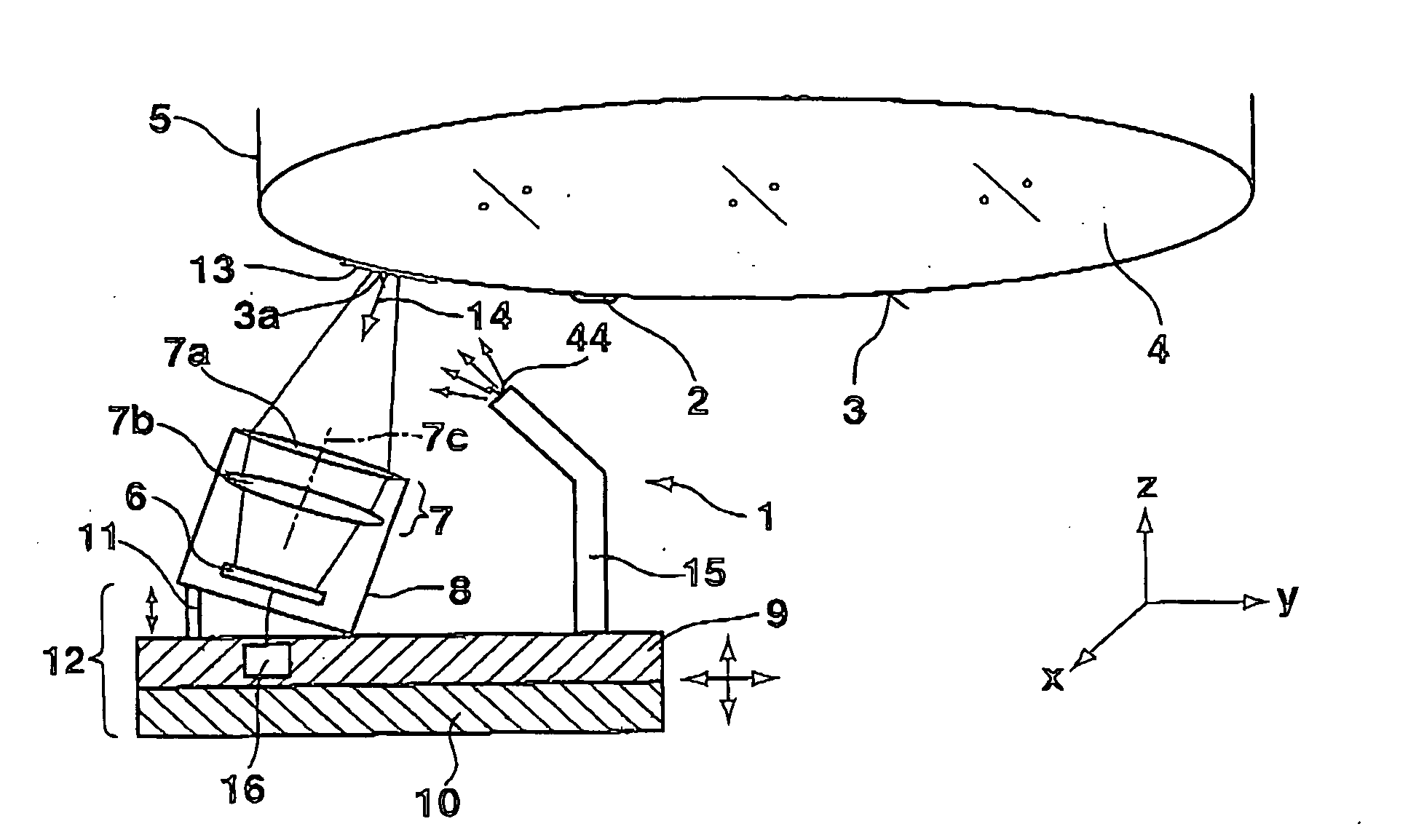

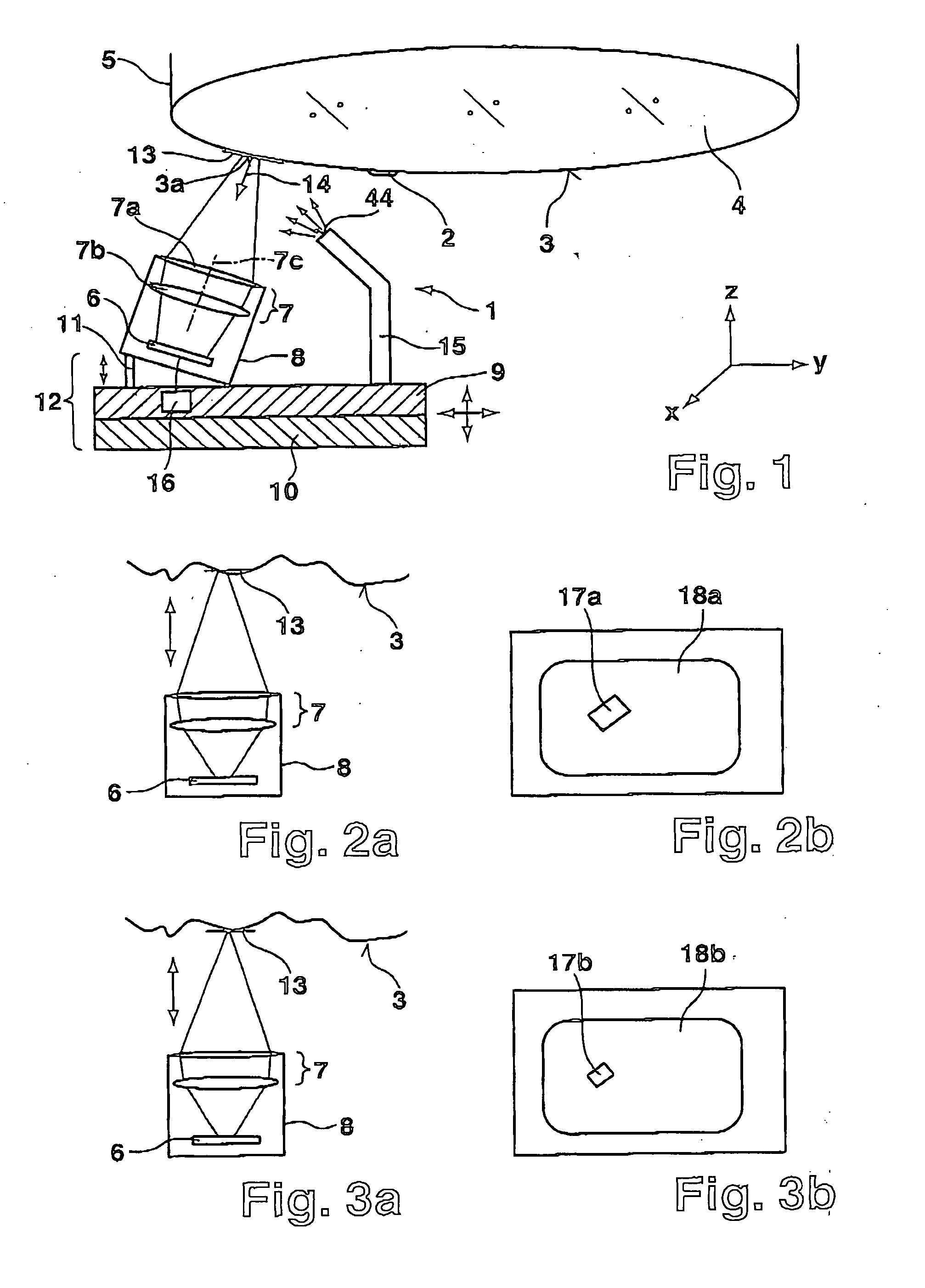

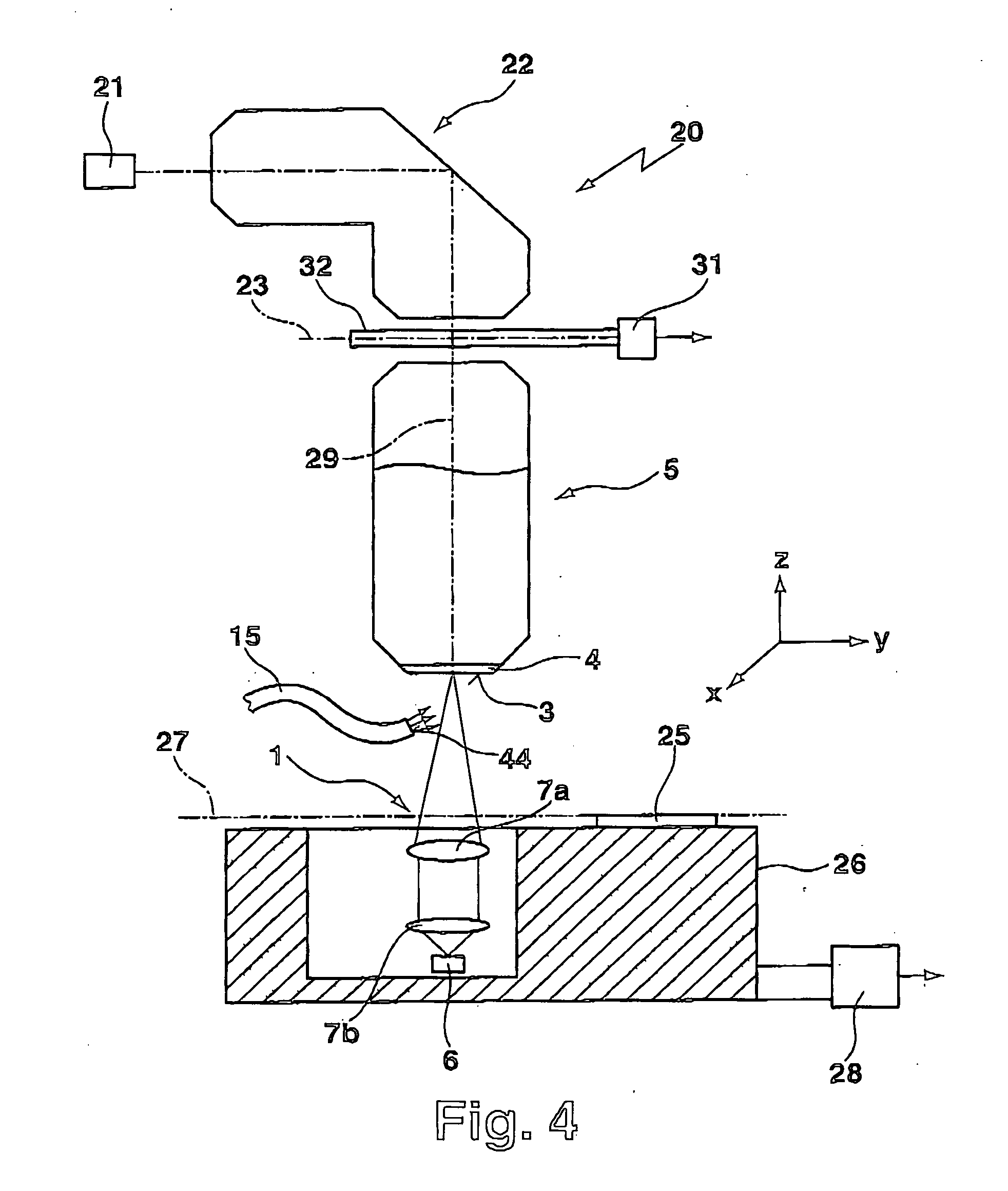

Devices and methods for inspecting optical elements with a view to contamination

InactiveUS20070132989A1Removal from surfaceReduce impactPhotomechanical apparatusOptical articlesMagnificationOptic system

Described is an examination system (1) for locating contamination (2) on an optical element (4) installed in an optical system (5), which examination system (1) comprises: a spatially resolving detector (6); imaging optics (7) that magnify in particular at a magnification of between 2 times and 100 times, for magnified imaging of a surface sub-region (3a) of the optical element (4) on the spatially resolving detector (6); as well as a movement mechanism (12), in particular a motorised movement mechanism (12), for displacing the imaging optics (7) together with the detector (6) relative to the surface (3) of the optical element (4) such that any desired surface sub-region of the surface (3) can be imaged at magnification.

Owner:CARL ZEISS SMT GMBH

Abrasive articles, rotationally reciprocating tools, and methods

InactiveUS20080233845A1Surface defectControl impactEdge grinding machinesSupport wheelsMaterials sciencePolishing

Methods of abrading surfaces by rotationally reciprocating abrasive surfaces in contact with the surfaces, abrasive articles for use in rotationally reciprocating tools, and methods of removing defects in a surface, where the methods include sanding using a rotationally reciprocating abrasive surface followed by one or more polishing operations are disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Support assemblies for pipes, conduits and tubes

ActiveUS20060178246A1Resists contaminationEasy to checkPipe supportsMining devicesCatheterGuide tube

Wall-mounted type and trapeze type support strut assemblies attach pipes, conduit, and tubes to vertical and horizontal surfaces in a sanitary manner. The strut assemblies repel contaminants, are easy to inspect, and easy to clean. Structures to provide seismic stability to trapeze type support strut assemblies may also be used.

Owner:FOOD GRADE SOLUTIONS LLC

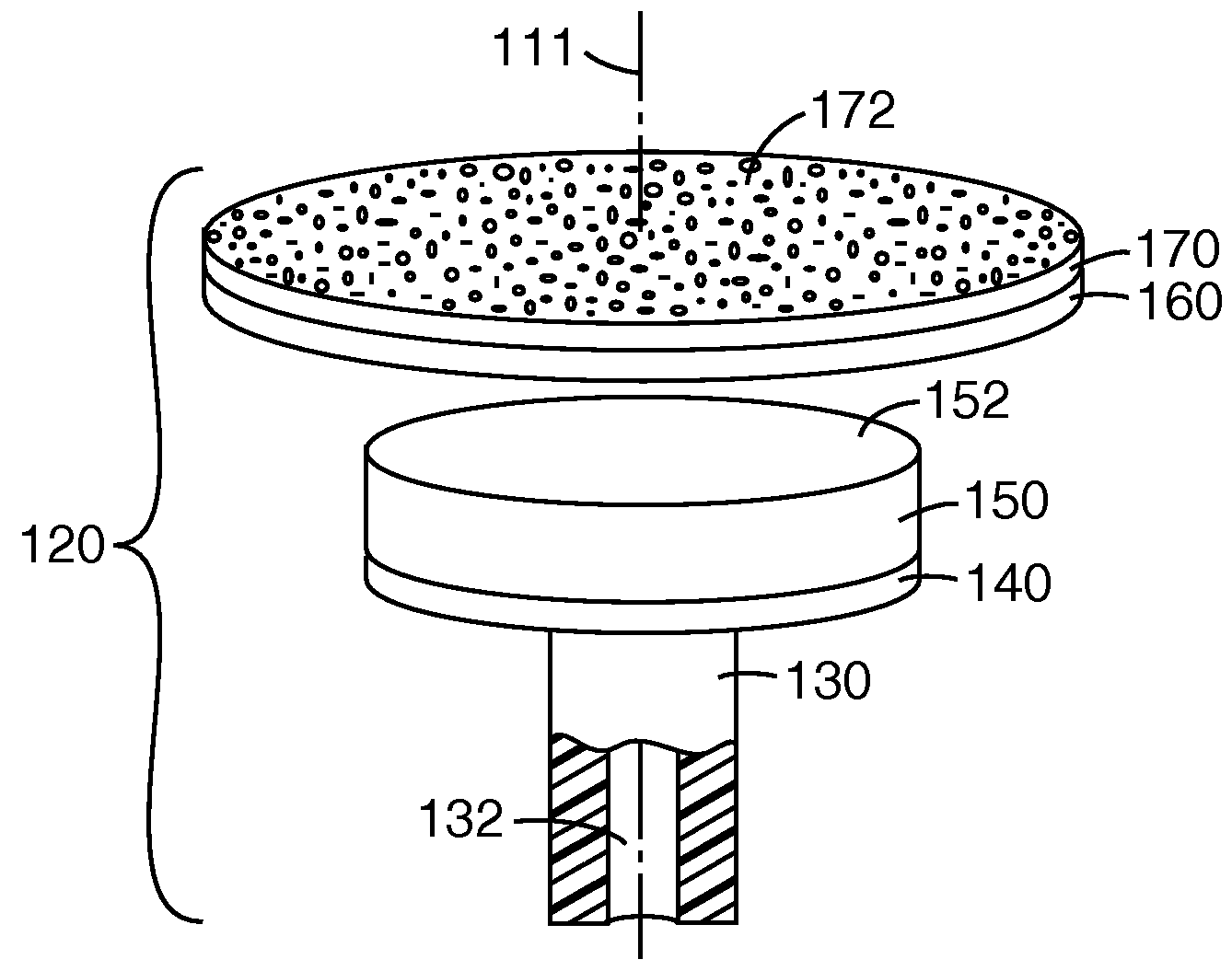

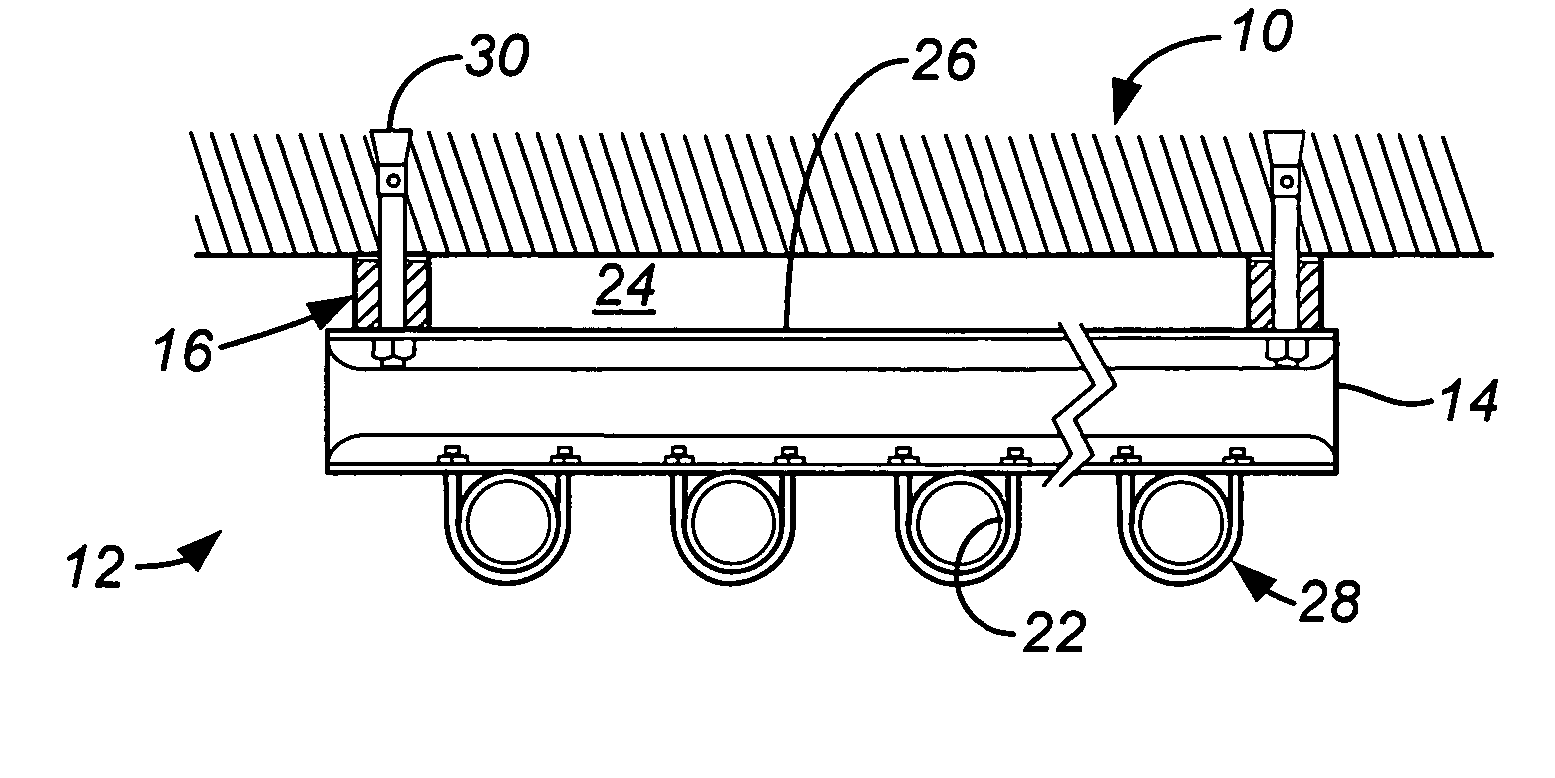

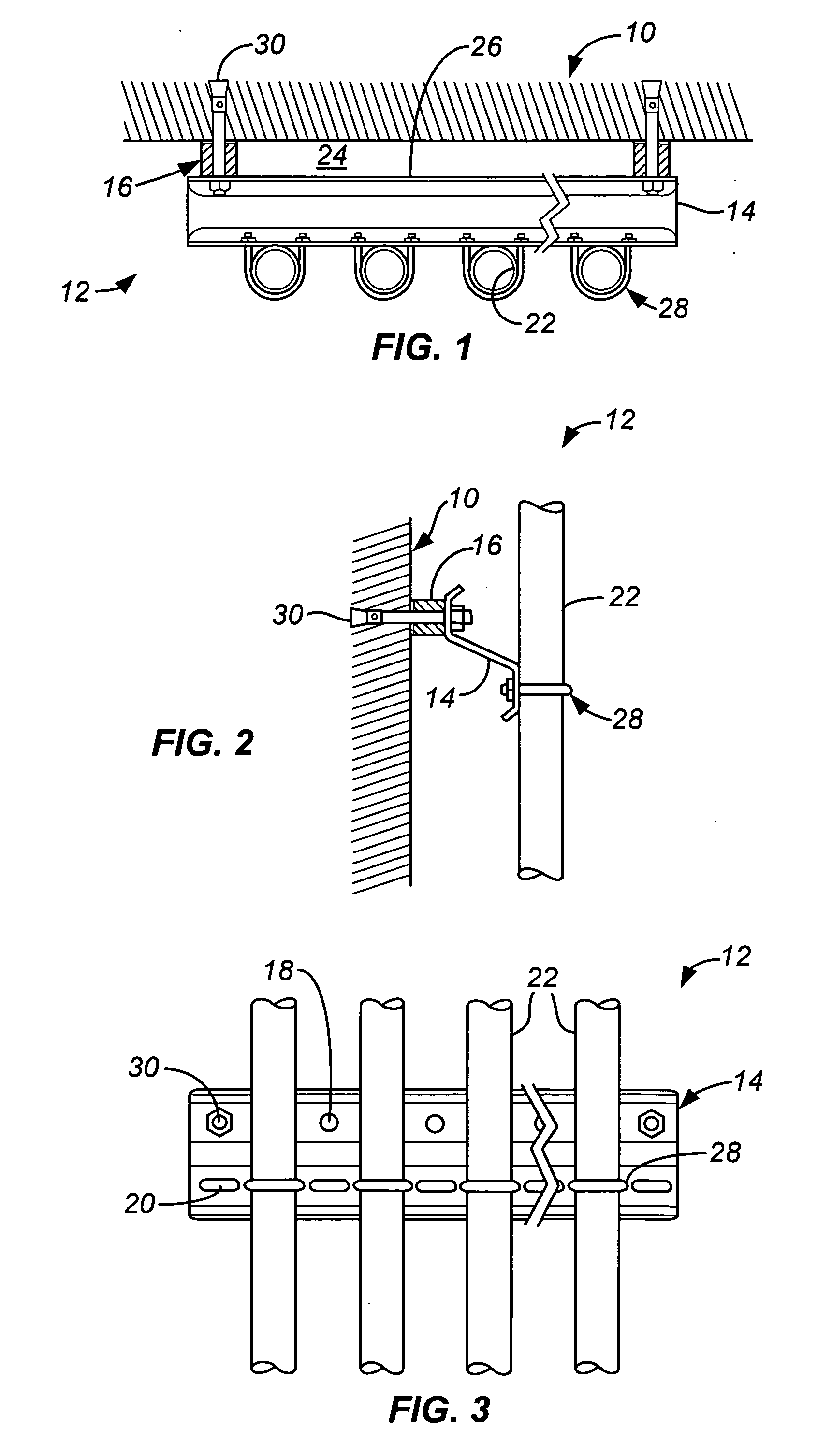

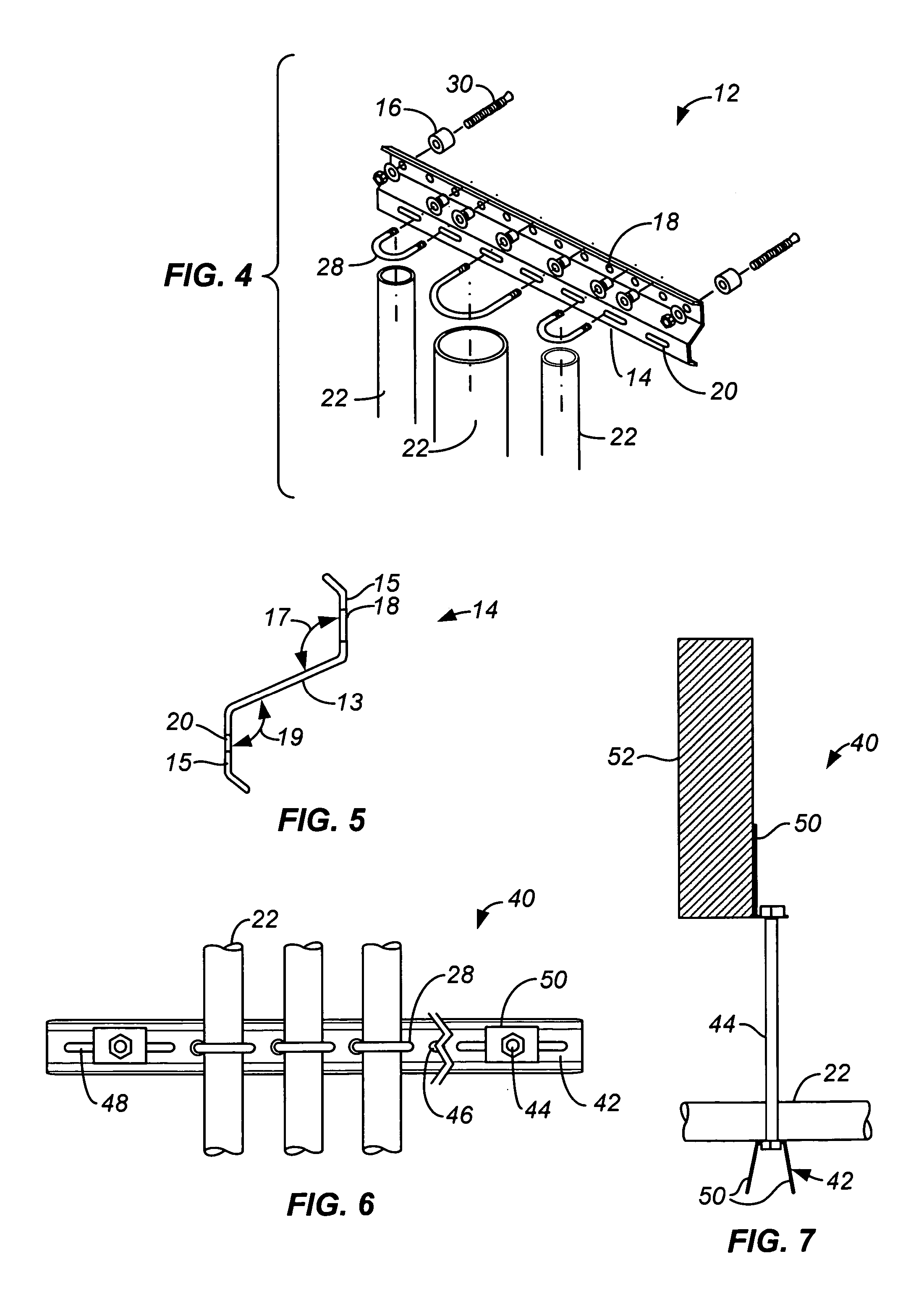

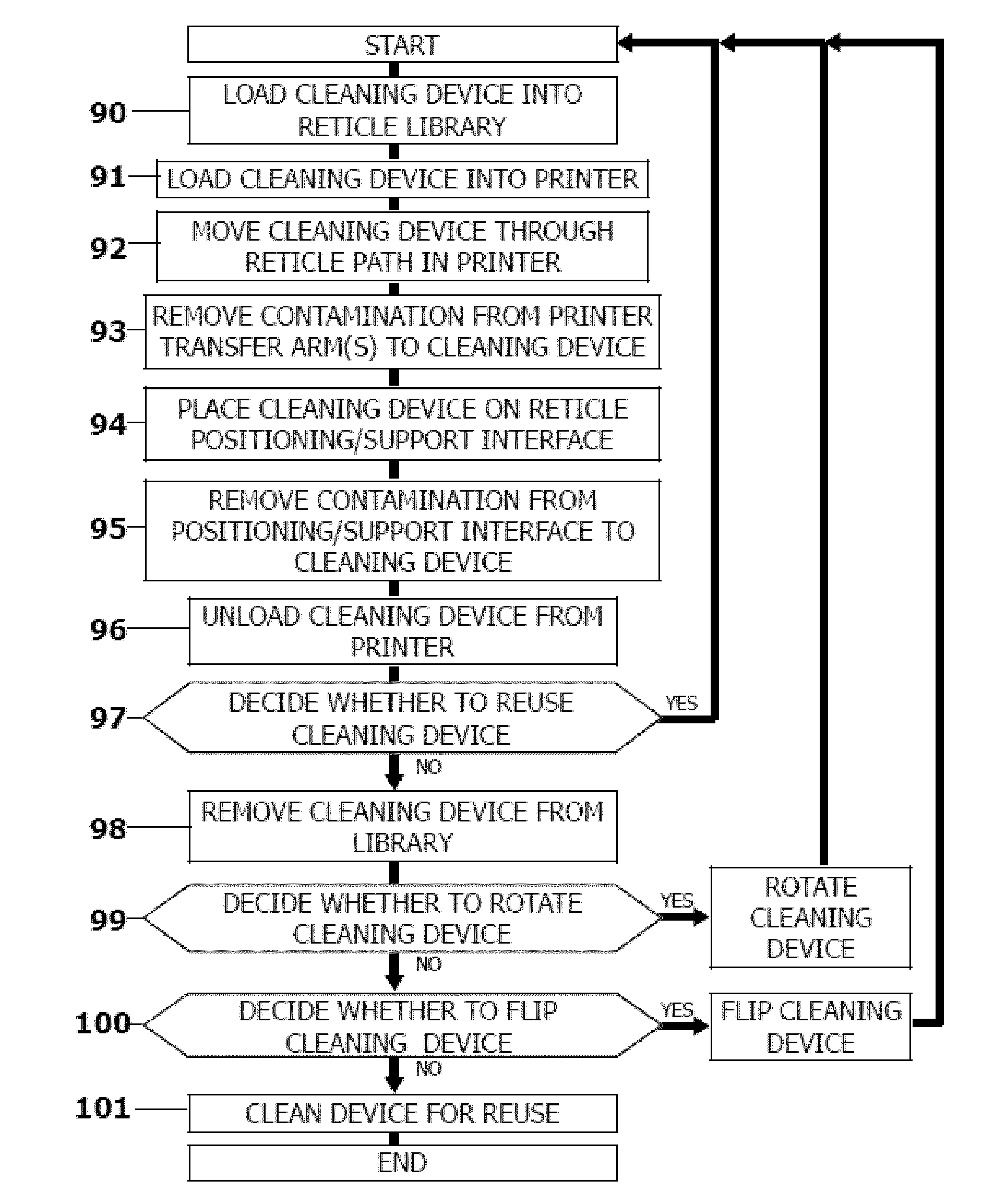

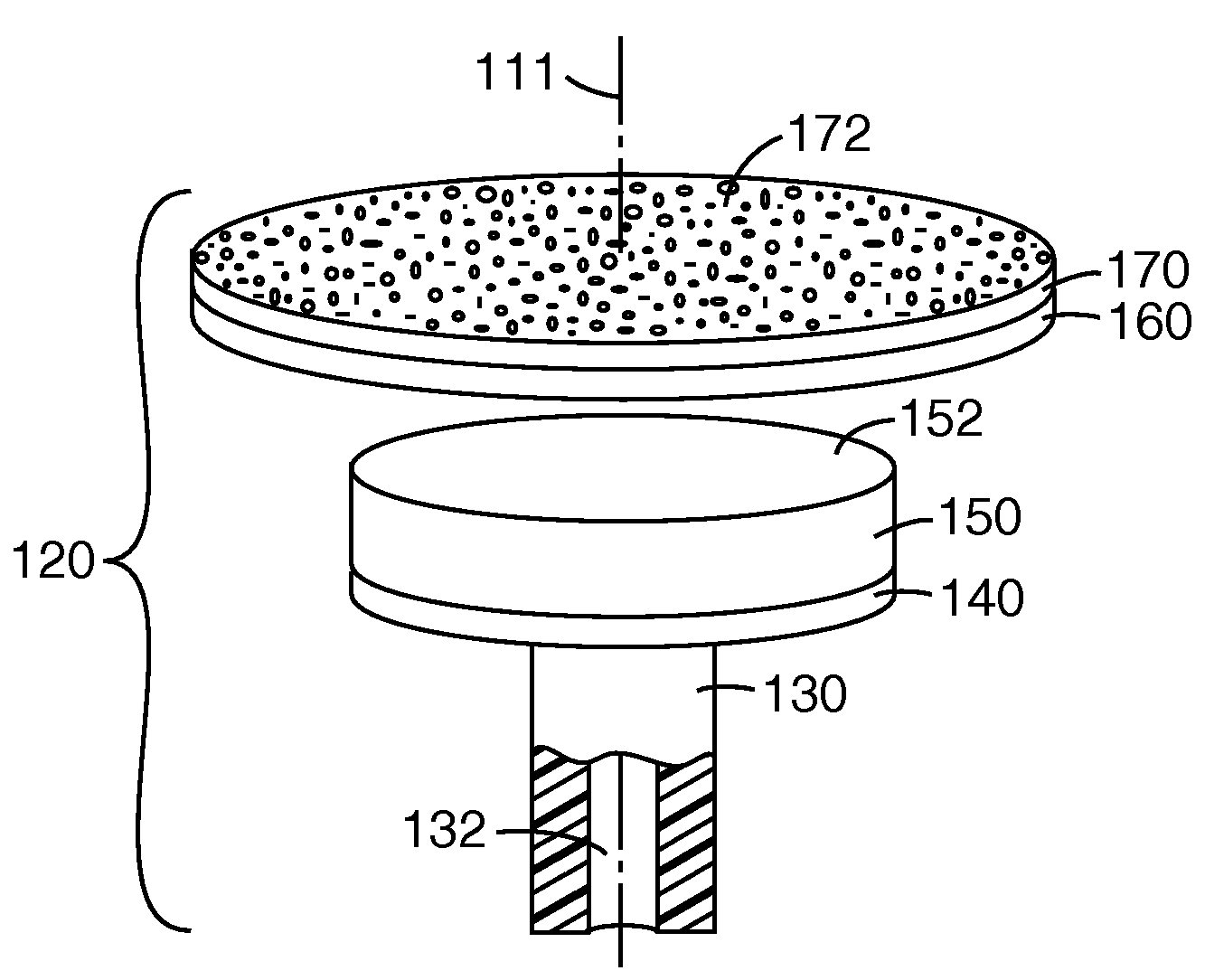

Method and apparatus for cleaning photomask handling surfaces

InactiveUS20140226136A1Remove contaminationRemoval from surfaceOriginals for photomechanical treatmentPhotographic printingStepperEngineering

The cleaning device may clean the handling and support interface for a reticle inside a reticle handling tool, such as a micrographic scanner / stepper printer, without opening the tool. The cleaning device may have the same or approximate form factor as either a reticle without a pellicle or a reticle with a pellicle. The cleaning device is transported through the reticle handling tool in the same manner and along the same path as a reticle, contacted against surfaces that a reticle touches, and transferred out of the reticle handling tool. The cleaning device comprises a cleaning pad, secured to the base substrate, the cleaning pad having predetermined characteristics that cause the cleaning pad to remove contamination and particulates from the reticle transfer and placement equipment when the cleaning device contacts the robot transfer arm(s) and reticle positioning / support interface.

Owner:SEMICON PHOTOMETROLOGY SOLUTIONS

Heat transfer label

ActiveUS7622171B2Removal from surfaceDecorative surface effectsSynthetic resin layered productsMicrocrystalline waxAcrylonitrile

A heat transfer label comprising a support portion and a transfer portion for transfer of the transfer portion from the support portion to an article. The article may be untreated polyethylene, polypropylene, PET, or acrylonitrile. Heat is applied to the support portion while the transfer portion is placed into contact with the untreated polyethylene, polypropylene, or acrylonitrile article. The transfer portion comprises an adhesive layer comprising a vinyl acetate resin, a tackifying petroleum hydrocarbon resin, and a microcrystalline wax.

Owner:MULTI COLOR CORP

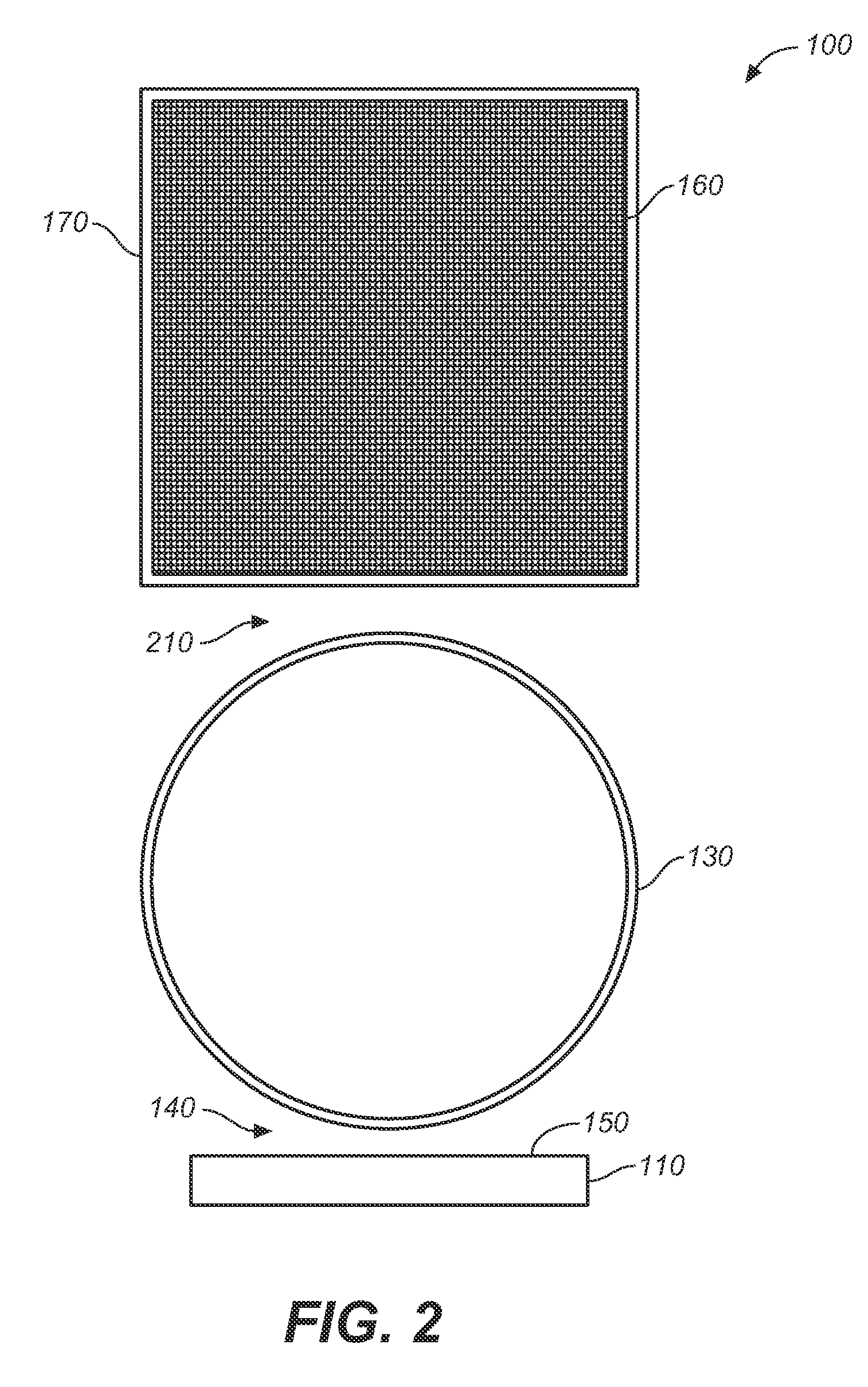

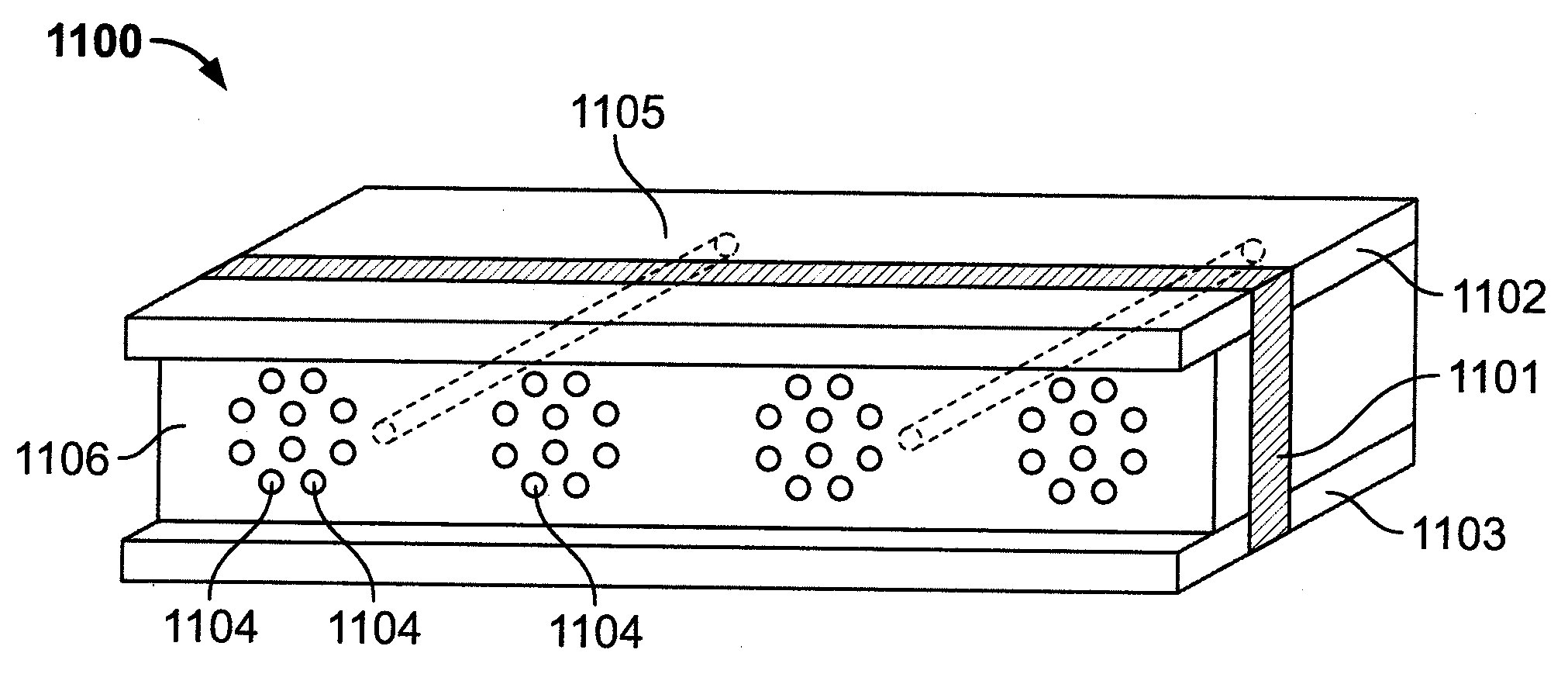

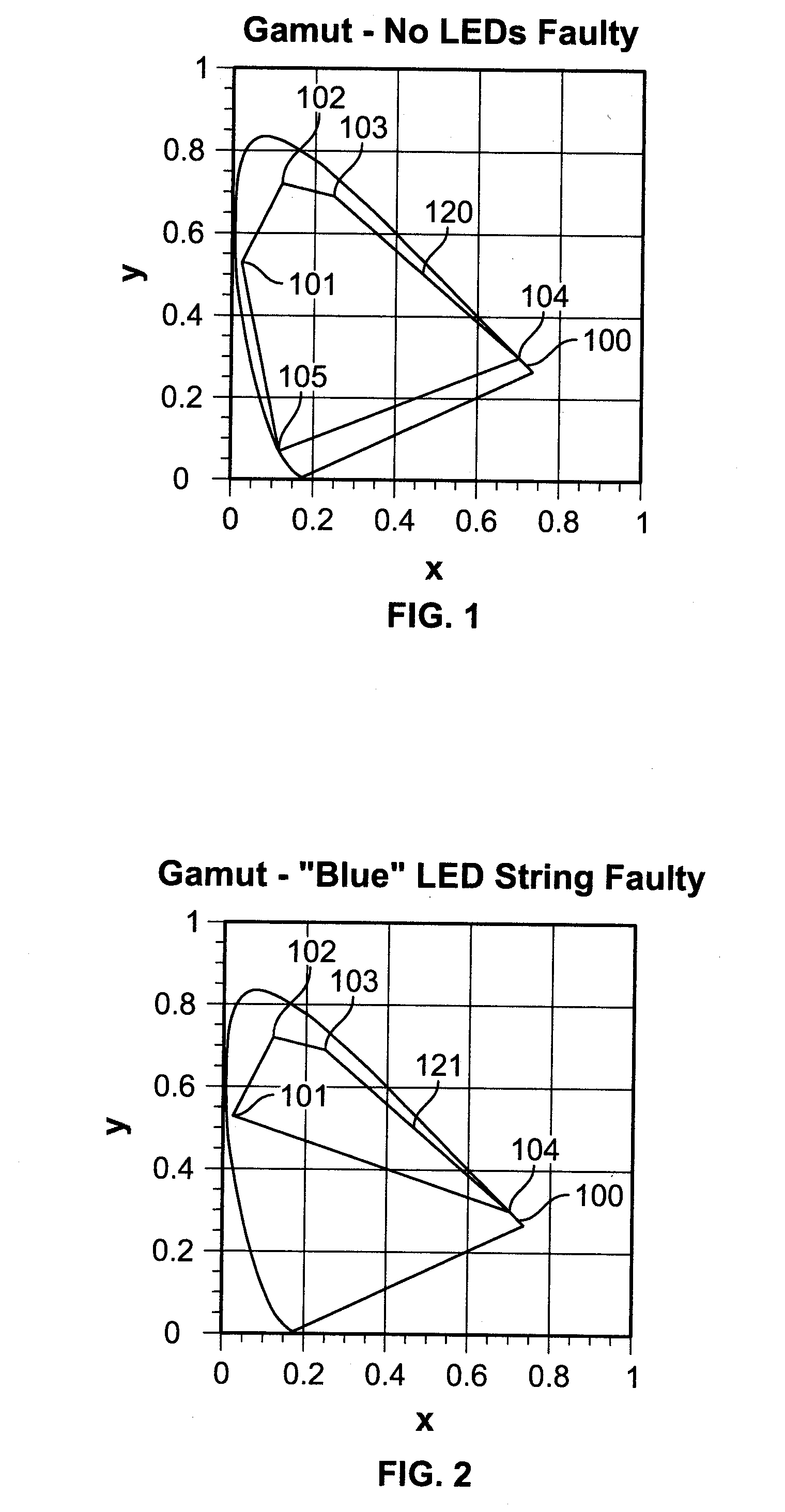

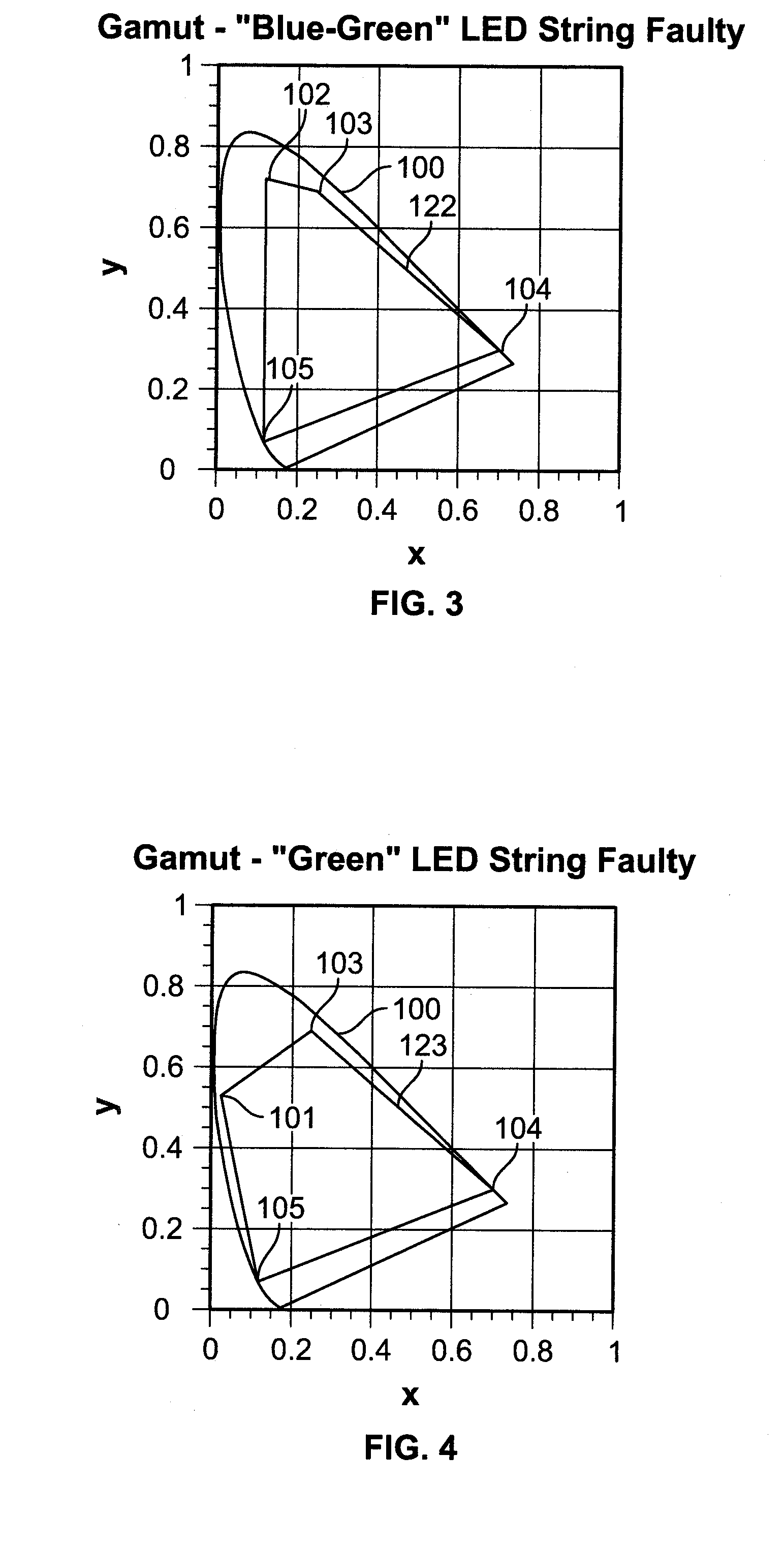

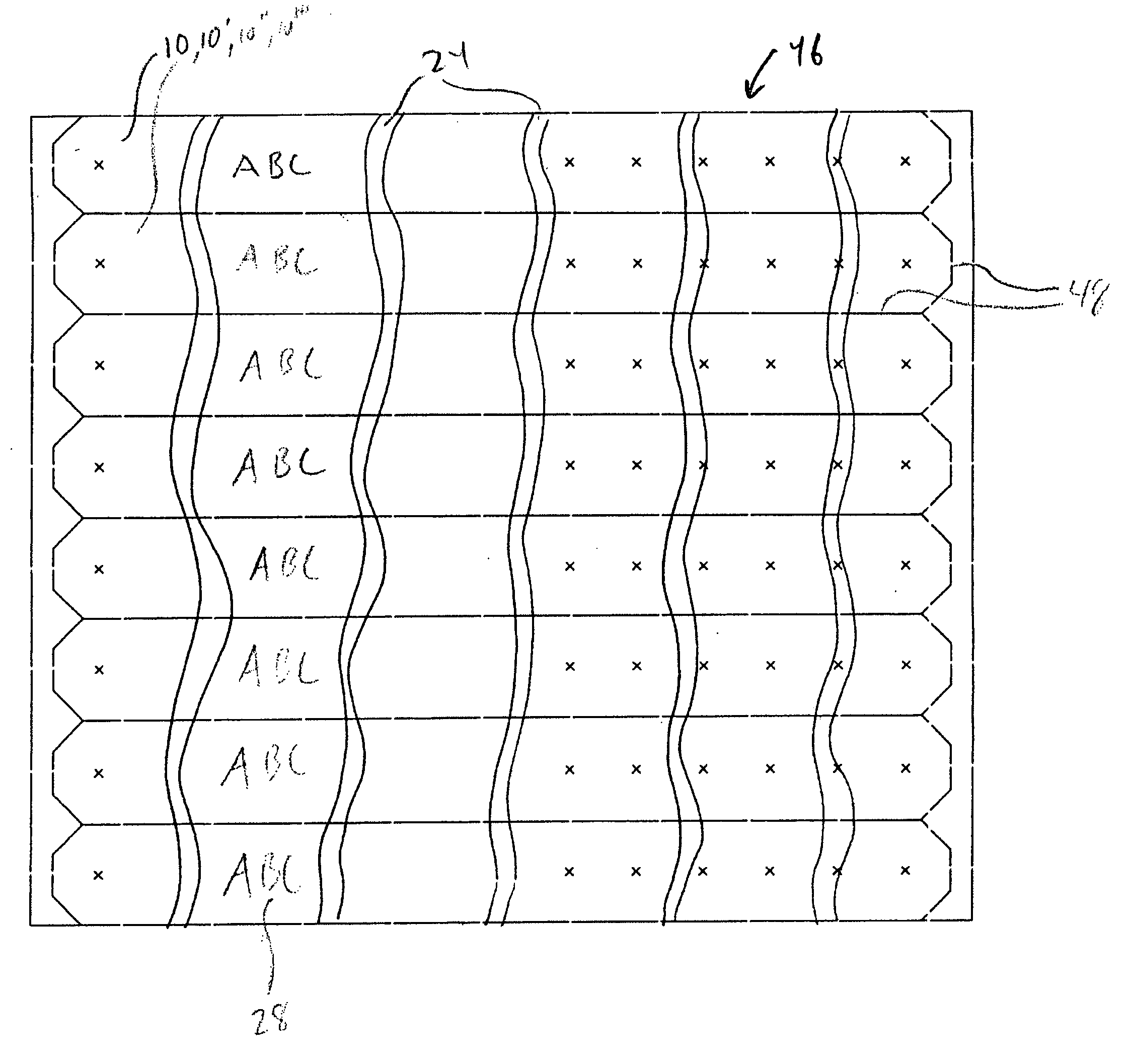

Enclosure for housing a plurality of pixels of a graphical display

ActiveUS20090040775A1Reduce humidityRemoval from surfaceElectric discharge tubesLighting heating/cooling arrangementsGraphicsElectrical conductor

An enclosure is provided for housing pixels of a graphical display. The enclosure provides one or more laminar structures at a first surface of the enclosure. The laminar structure may be made up of a first material of a predetermined thickness at the first surface and a second material in sufficiently close proximity with the first material to allow heat conduction. The second material preferably has a thermal conductivity greater than the thermal conductivity of the first material. Thermal conductors are provided in or attached to the second material in the laminar structure to conduct heat to a second surface of the enclosure. The first material may be, for example, a polymer. The second material may be, for example, a heat wick, a metal mesh or heat pipes. The second surface may be cooled by an air stream, which may also reduce humidity at the surface.

Owner:LANDMARK SCREENS

Polishing particles and a polishing agent

InactiveUS20030186634A1Reduced strengthControl rateMaterial nanotechnologyGrinding drivesVolumetric Mass DensitySilicon dioxide

In the polishing particles each having a core-shell structure, the polishing rate can be controlled by adjusting the thickness and / or density of the shell portion. The polishing particles having the core-shell structure with the average diameter (D) in the range from 5 to 300 nm, and the shell portion of the polishing particles comprises silica with the thickness (ST) in the range from 1 to 50 nm, and the density of the shell portion is in the range from 1.6 to 2.2 g / cc, while the Na content of the shell portion is less than 10 ppm.

Owner:JGC CATALYSTS & CHEM LTD

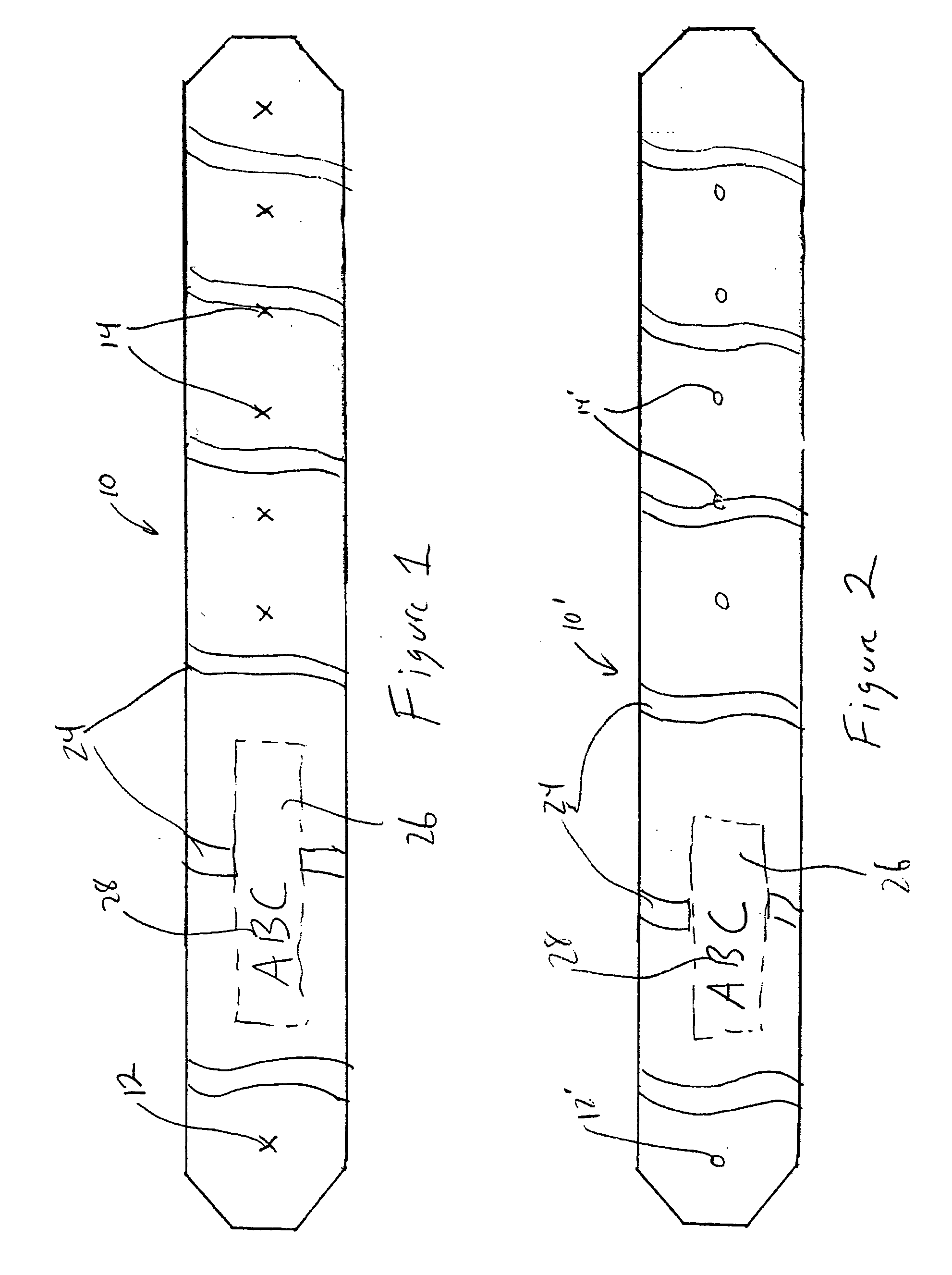

Printed identification band and method of manufacturing same

InactiveUS20070283607A1Efficient and economical to produceAesthetically pleasingStampsPerson identificationEngineeringDigital printing

An identification band includes an elongated member having a front face and a rear face, and having a first opening therein adjacent a first end and a series of openings therein adjacent a second end, the elongated member being formed from a material adapted to accept digital printing ink. A stud is disposed in the first opening, the stud adapted to be passed through one of the series of openings after the band is wrapped around an object. A digital image is printed on at least one of the front face and the rear face of the elongated member, the digital image being composed of digital printing ink.

Owner:PRINTMARK INDS

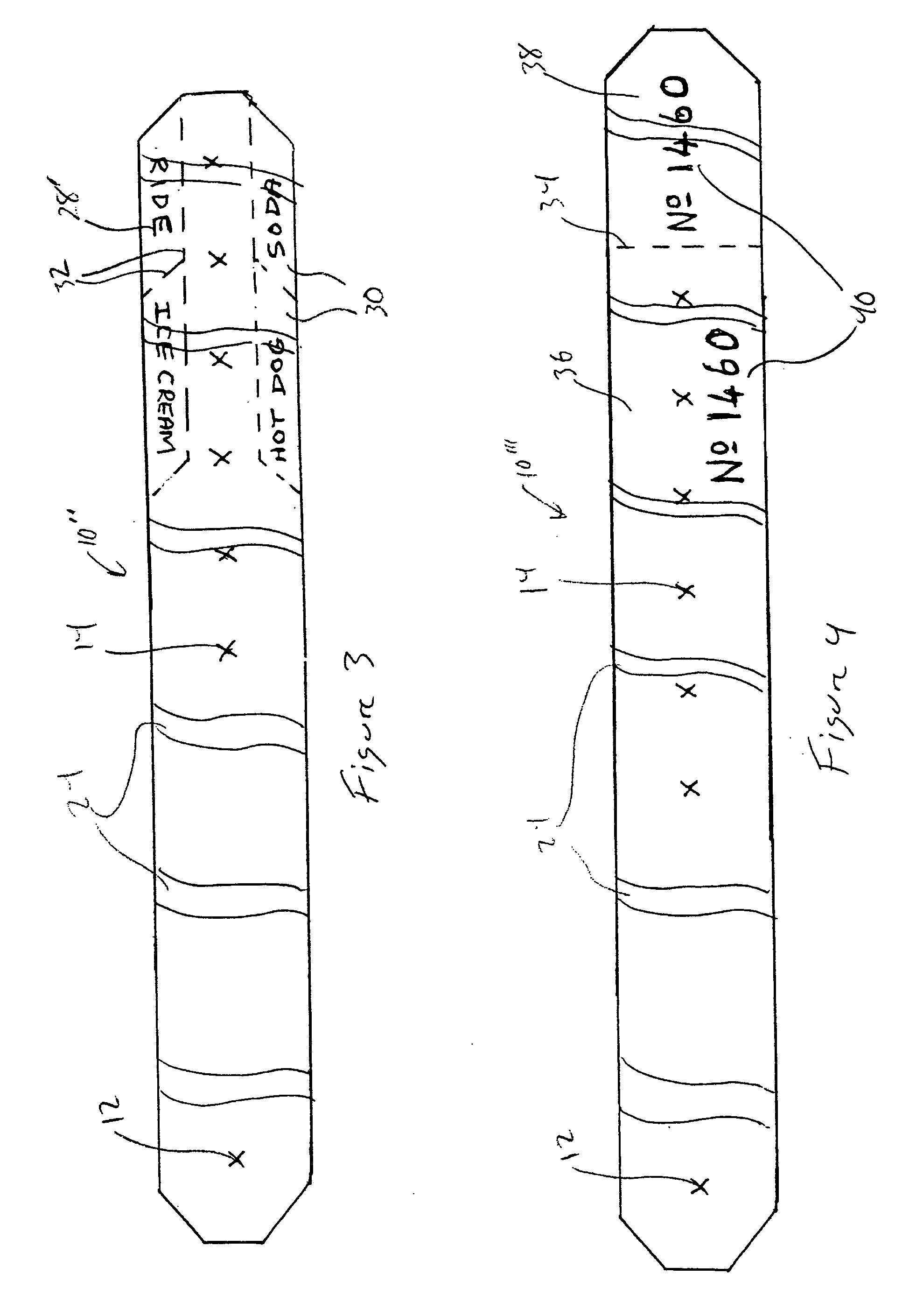

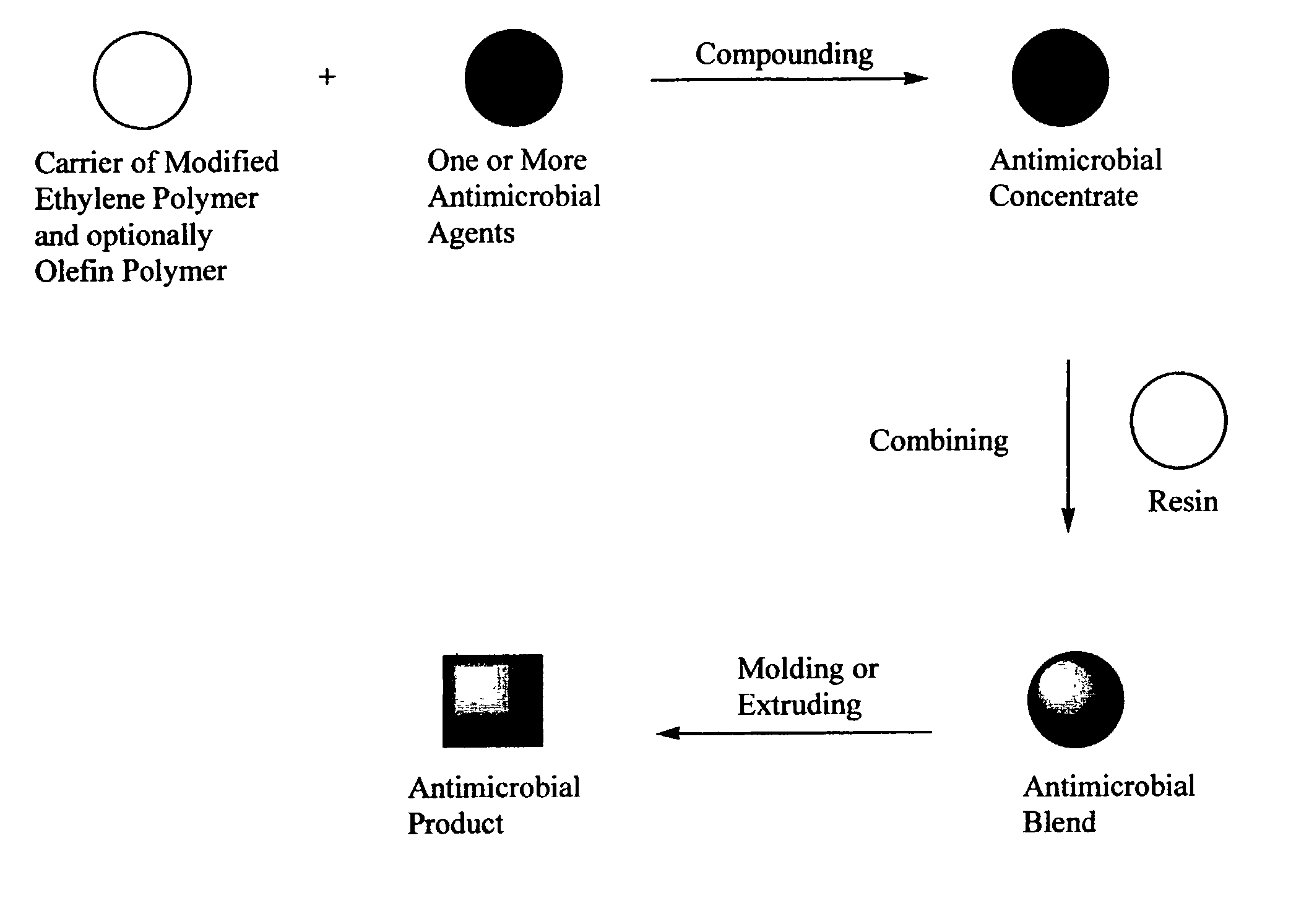

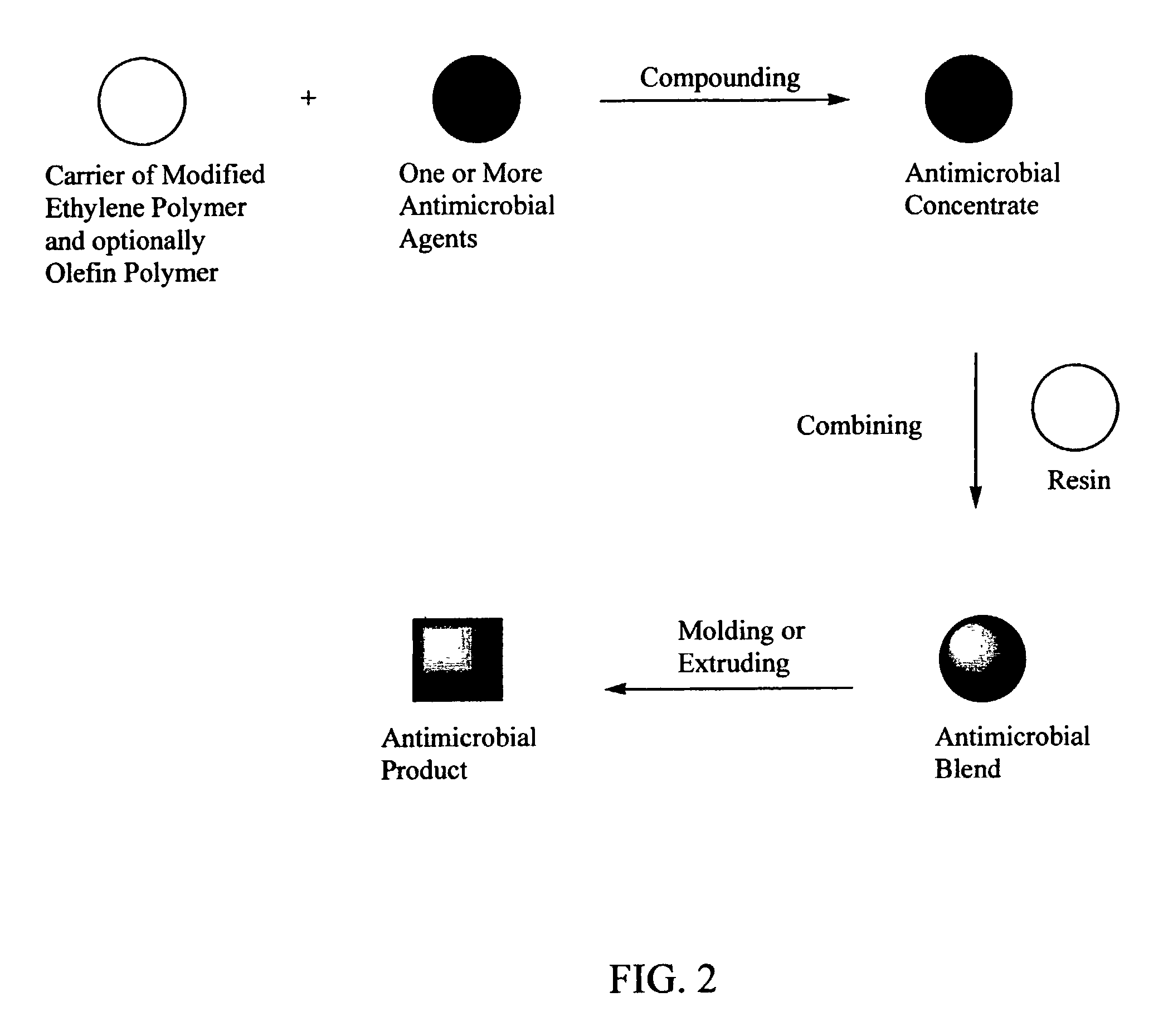

Antimicrobial concentrates

InactiveUS6979455B2High degreeImprove solubilityBiocidePowder deliveryMicrobial agentEthylene Polymers

An antimicrobial concentrate is manufactured from a carrier, one or more antimicrobial agents and optionally one or more modifiers, the carrier having a modified ethylene polymer and optionally an olefin polymer and a method of producing the concentrate by producing the carrier, having the modified ethylene polymer and optionally the olefin polymer, then compounding the carrier with one or more antimicrobial agents and optionally one or more modifiers, to form the concentrate, which does not exhibit chalking and clumping of antimicrobial agent on the surface thereof. An antimicrobial blend that is manufactured from the antimicrobial concentrate, a resin and optionally an additive and a method of producing the blend by combining the concentrate with the resin. An antimicrobial product that is formed by producing a blend, then molding or extruding the blend to form the product, which provides desired antimicrobial efficacy and does not exhibit taste and odor issues associated with food and liquids meant for human consumption, due to leaching of the antimicrobial agent from the surface of the polymeric matrix.

Owner:MICROBAN PROD CO INC

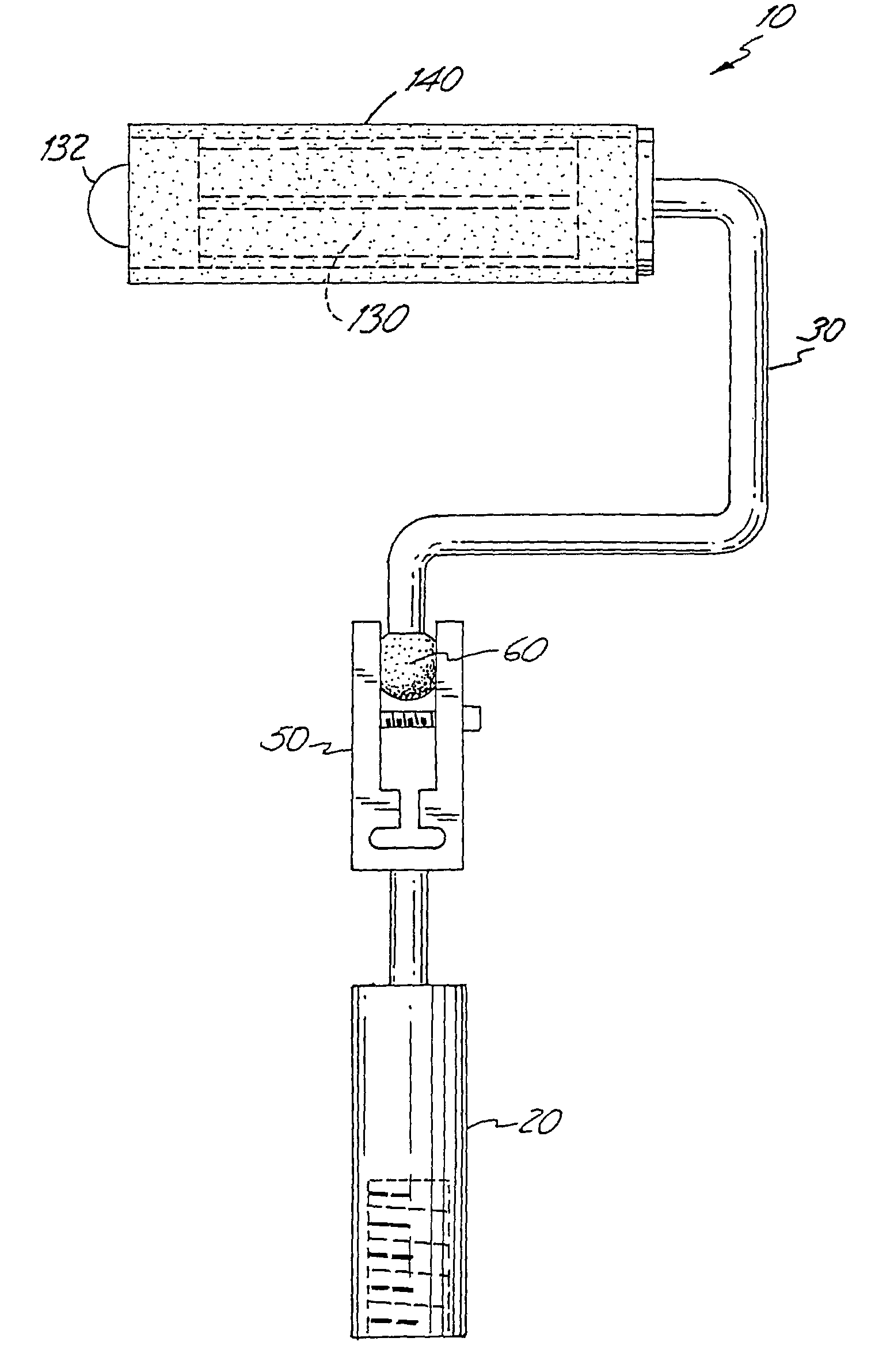

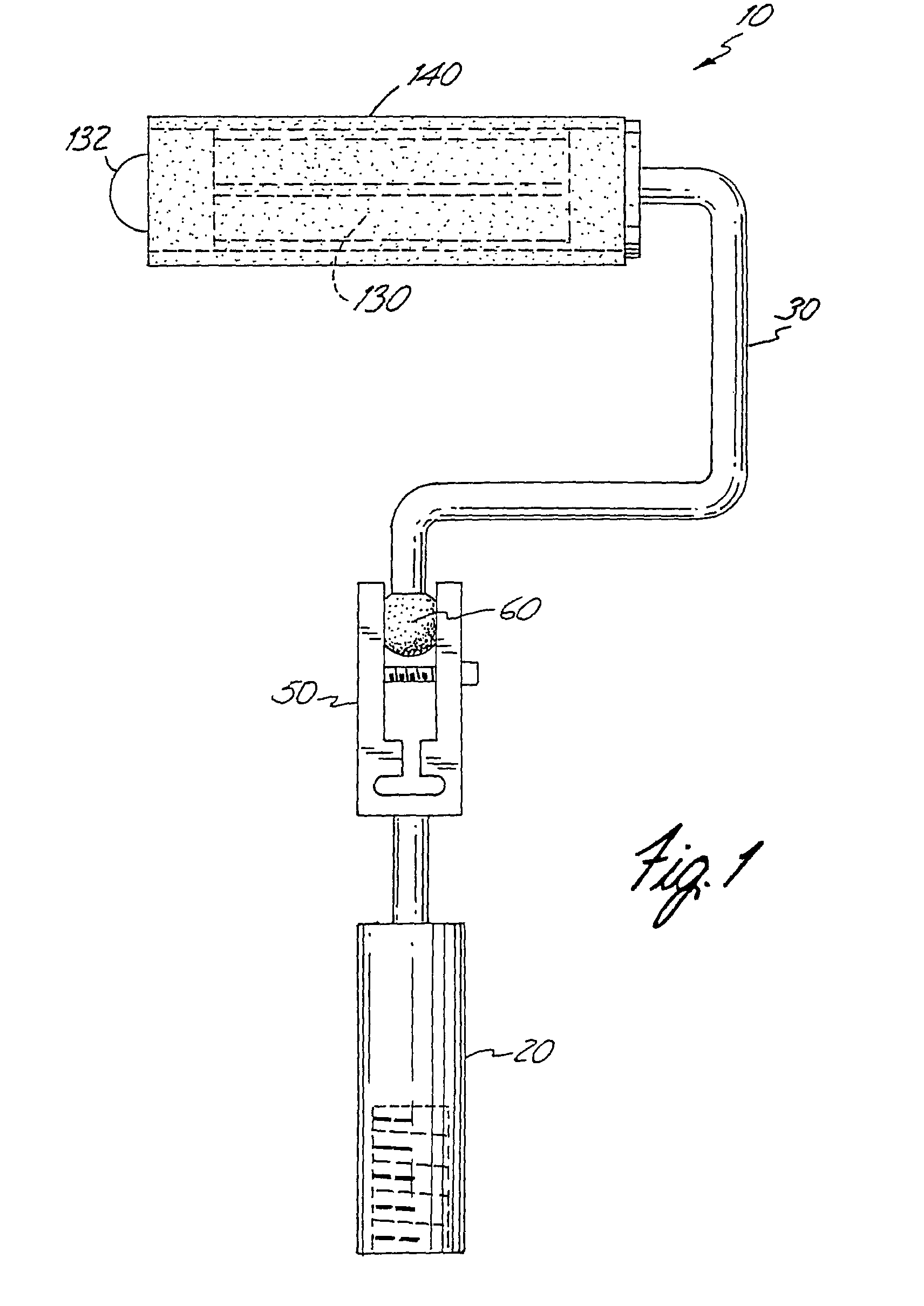

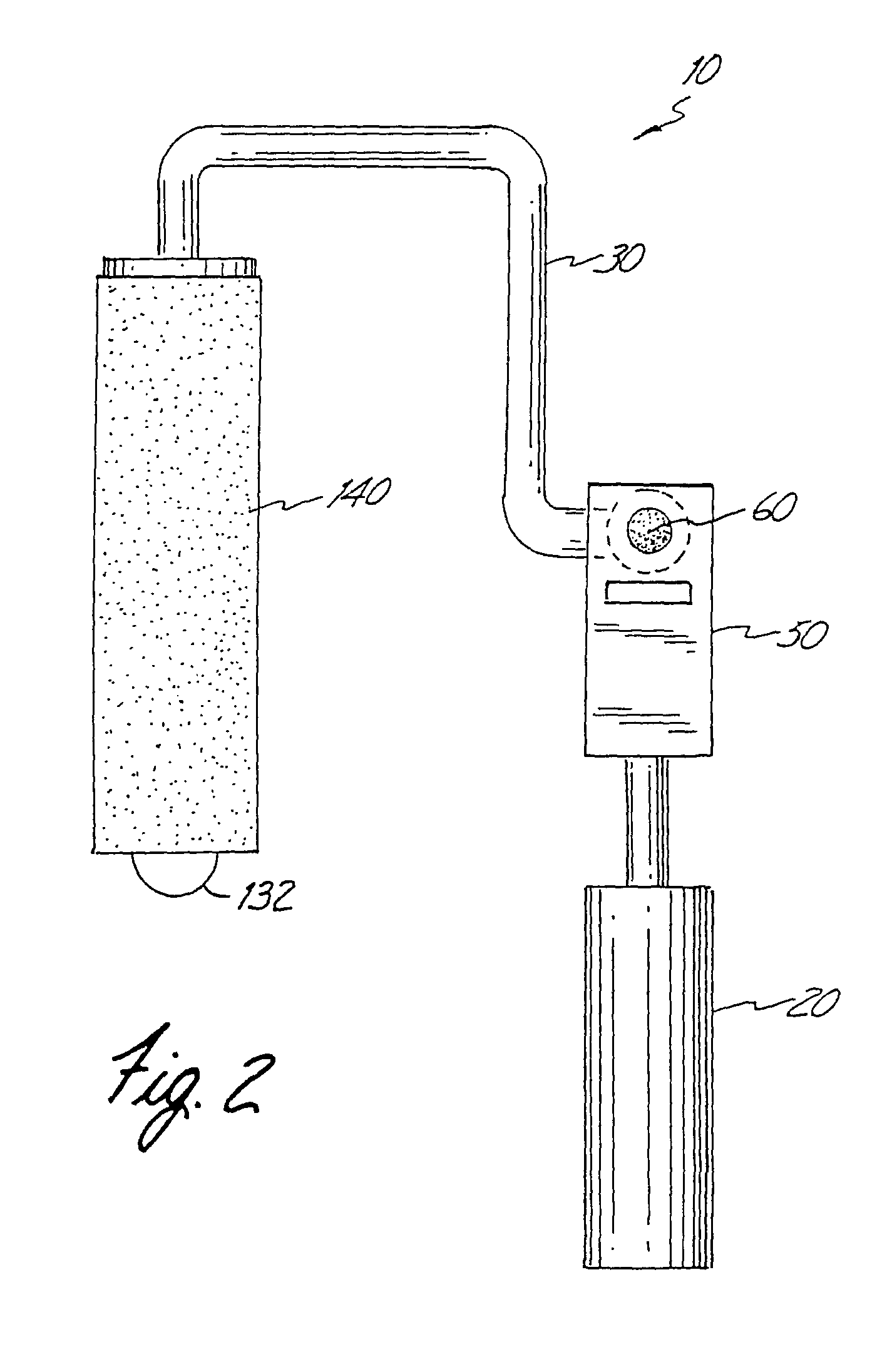

Paint roller

InactiveUS8060975B2Reduce laborRemoval from surfaceLiquid surface applicatorsBrush bodiesEngineeringPaint roller

Owner:WILLIAMS MAKOLLE

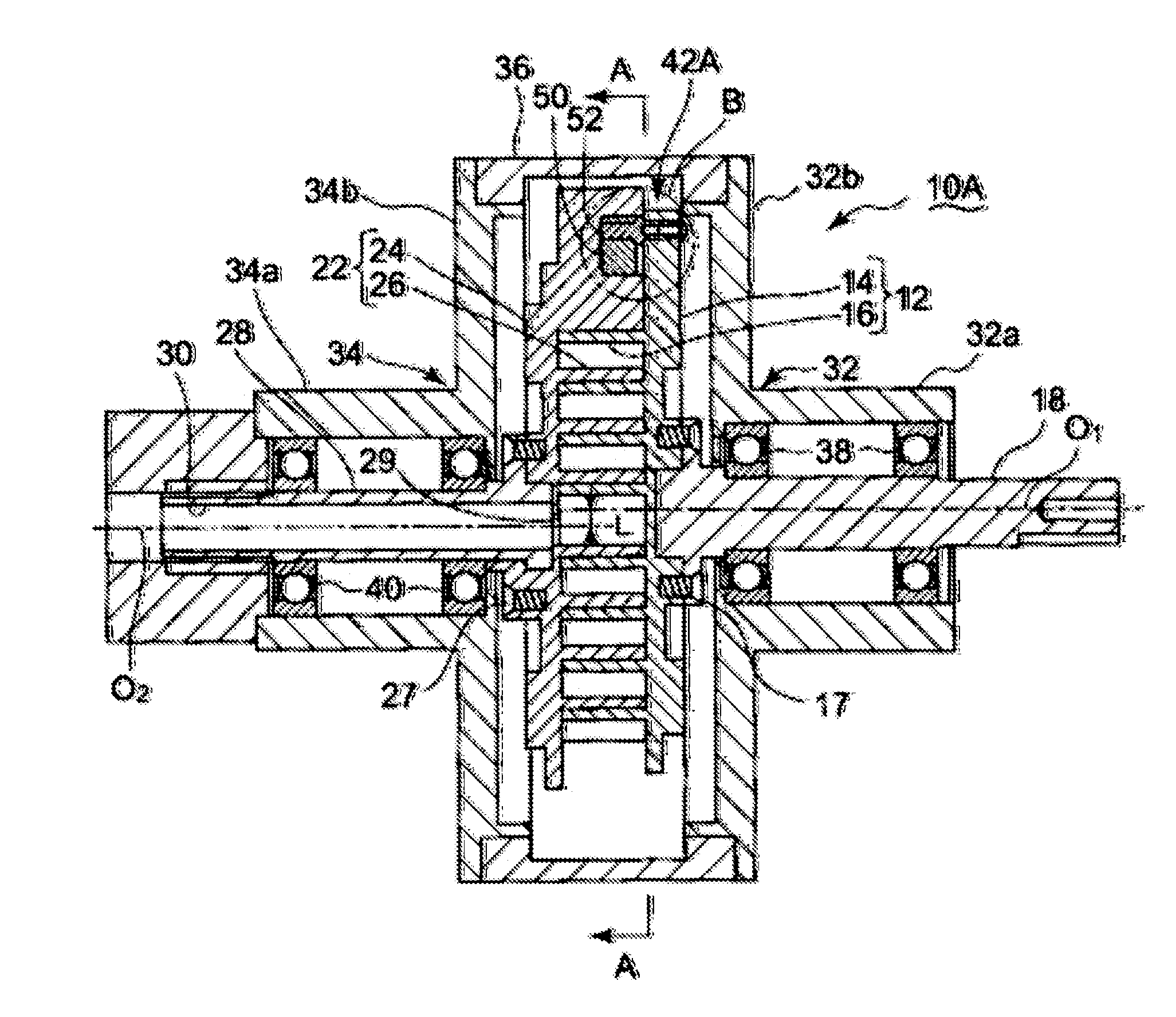

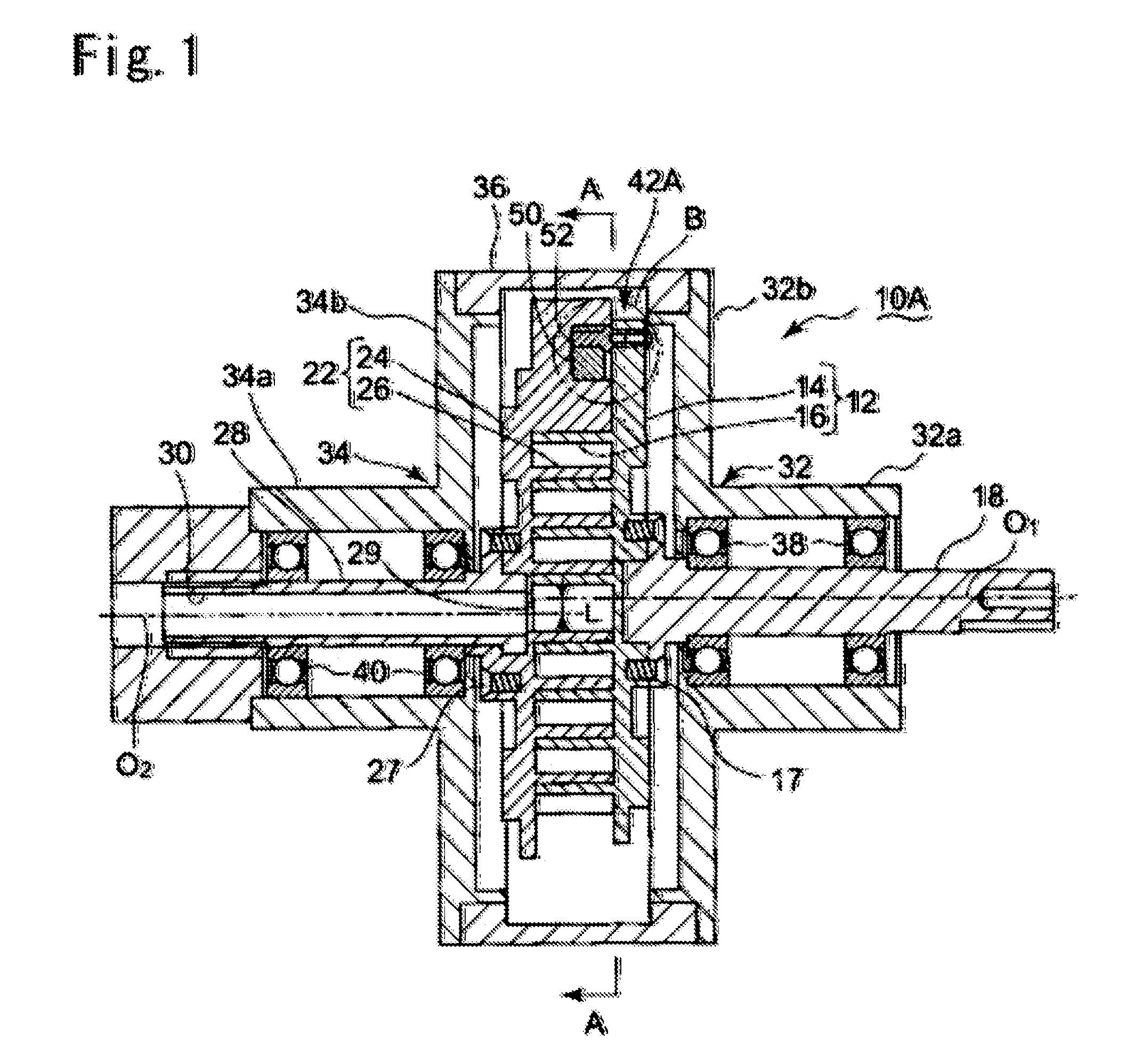

Scroll type fluid machine

InactiveUS20120288393A1Easy to slideIncreased durabilityEngine of arcuate-engagement typePump componentsEngineeringSolid of revolution

To realize an increase in lifespan and a reduction in cost in an interlocking mechanism that causes a driving scroll and a driven scroll to rotate synchronously, a through hole is drilled into a peripheral edge portion of a driving scroll side end plate, and a pin member is fixed to the through hole. A base is provided on a driven scroll side spiral projection that faces the through hole. A columnar recessed portion is carved into an opposing surface of the base, and an aluminum rotary body is loosely fitted into the recessed portion. An eccentric hole is drilled into the rotary body, and the pin member is loosely fitted into the eccentric hole. The interlocking mechanism is disposed in an odd number at equal intervals on an outer edge portion of the scroll end plate such that loads exerted on the rotary body act in an identical plane.

Owner:ANEST IWATA CORP

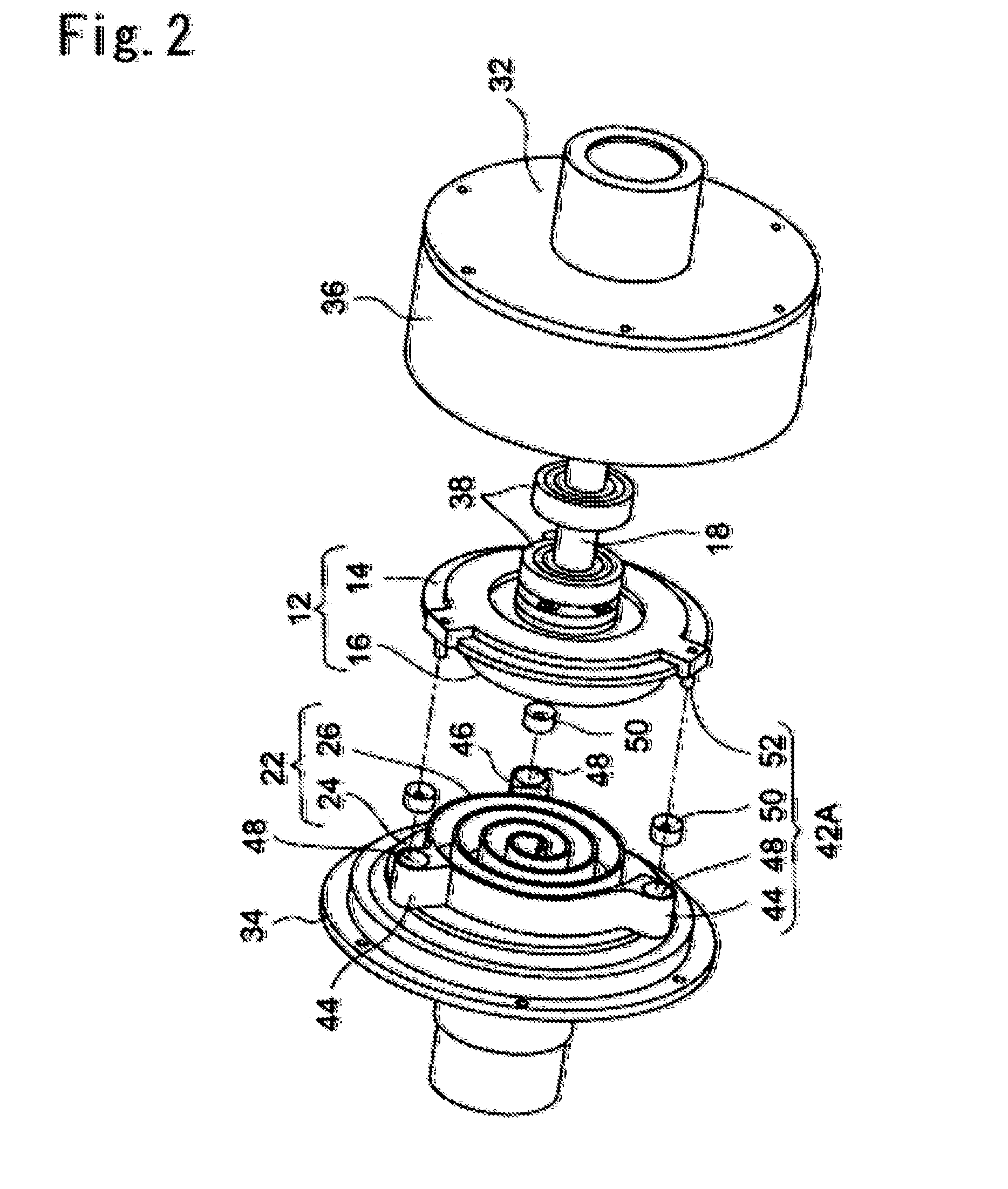

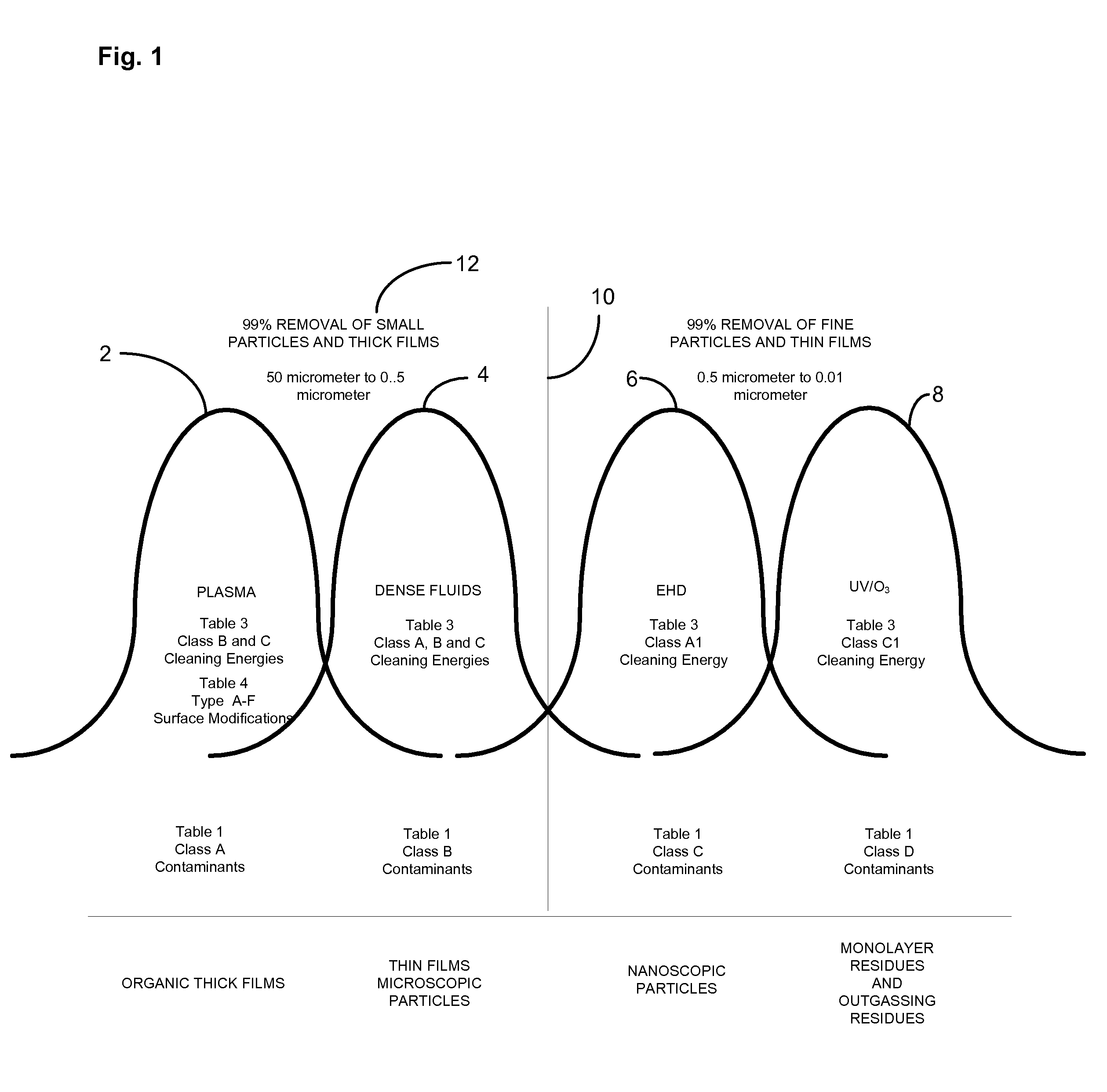

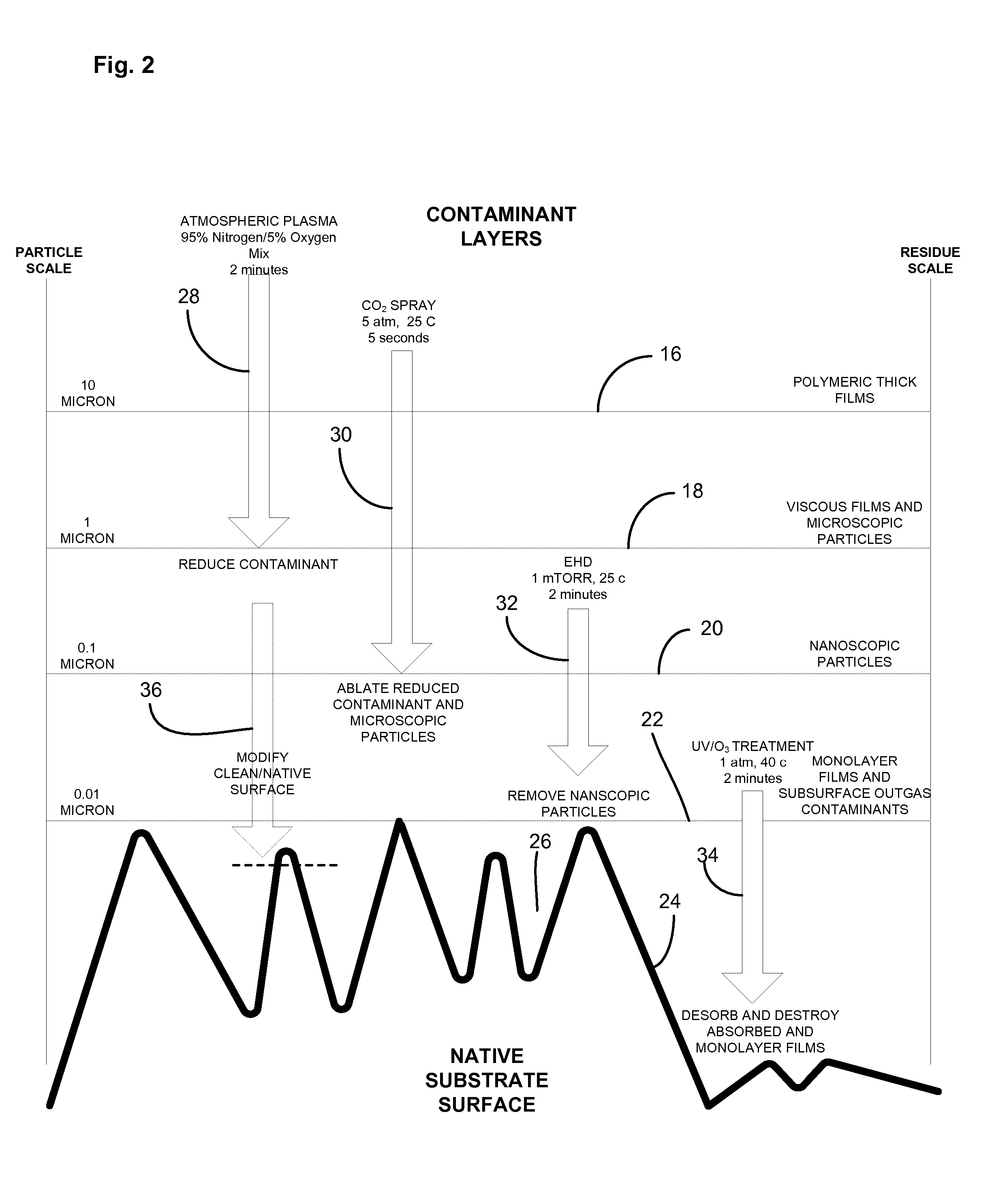

Method of treating a substrate

InactiveUS20070246064A1Reduce repollutionEliminates wet processingElectrostatic cleaningSemiconductor/solid-state device manufacturingTime segmentEngineering

A method of cleaning a substrate within a controlled environment includes placing the substrate into a high pressure vessel. The high pressure vessel is then supplied with a dense fluid under pressure. The dense fluid is contacted with the substrate for a selected period of time to at least partially remove a contaminant contained on the substrate. After the selected period of time, the vessel is depressurized to at least partially convert the dense fluid into a vapor. The vapor is then subjected to an energy field to form a plasma within the vessel which is used to treat the substrate for a second selected period of time. The thus cleaned substrate is then removed from the vessel.

Owner:JACKSON DAVID P

Weld prep joint for electron beam or laser welding

InactiveUS20060231531A1Preventing burn-throughRemoval from surfaceTurbinesBlade accessoriesEngineeringRabbet

A weld prep joint for welding a pair of axially aligned first and second machine rotor forgings includes a first weld joint configuration in an end of the first rotor forging including a first radial weld surface and a first axial rabbet surface; a second weld joint configuration on an end of the second rotor forging including a second radial weld surface adapted to engage the first radial weld surface, a second axial rabbet surface adapted to engage the first axial rabbet surface, and a third radial non-weld surface extending radially inwardly of the second rabbet surface and axially offset from the second radial weld surface.

Owner:GENERAL ELECTRIC CO

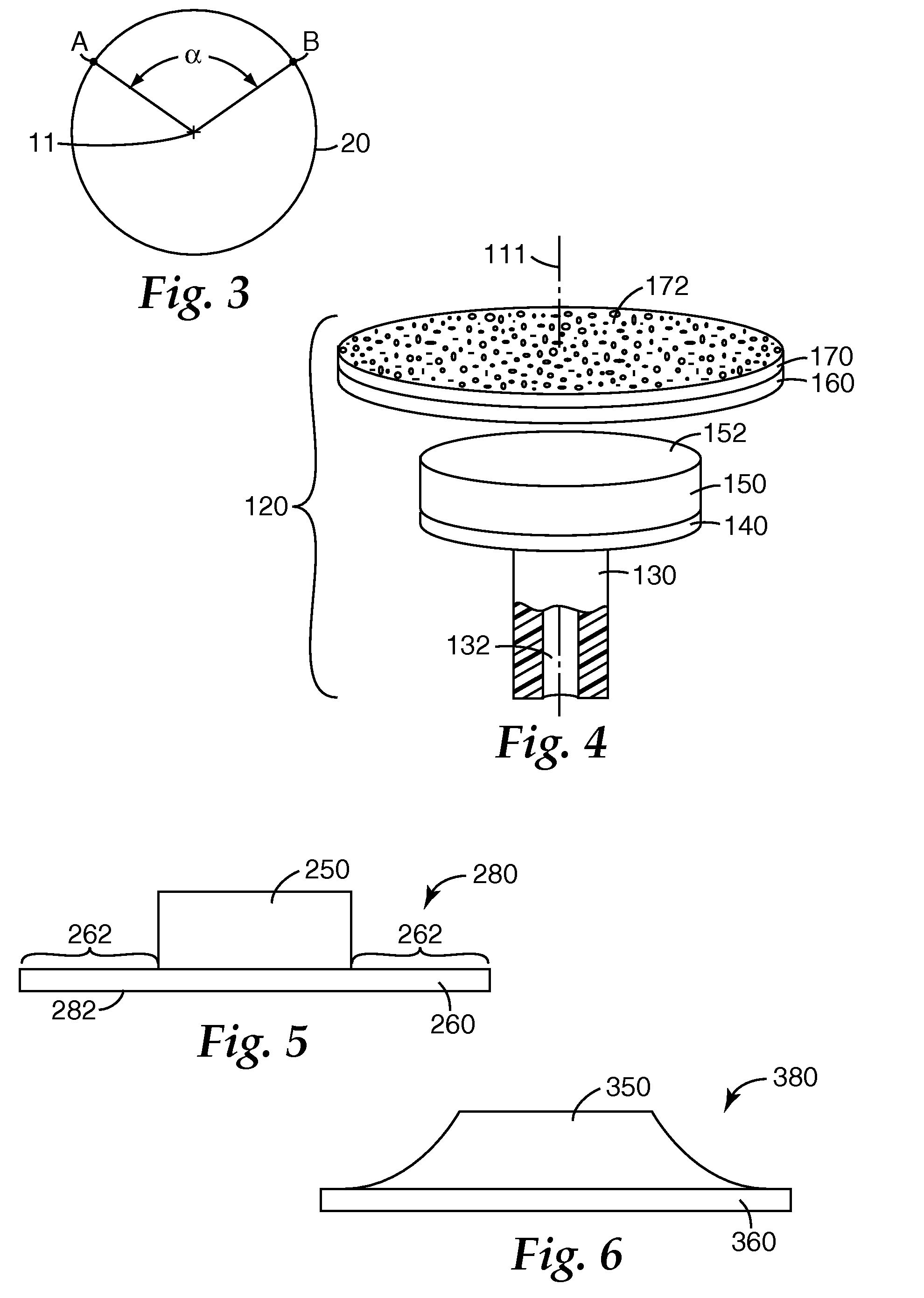

Paint roller

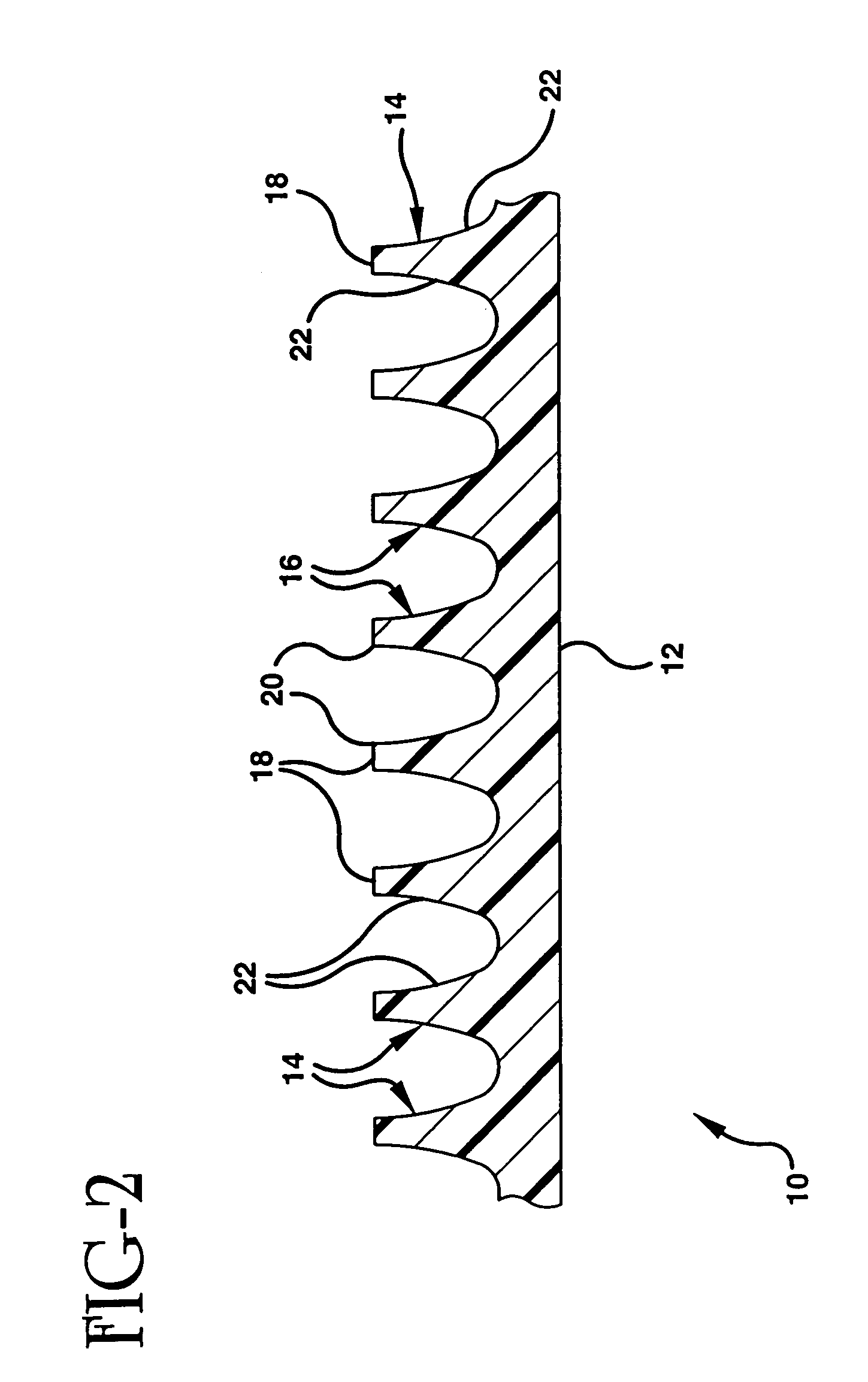

InactiveUS20070130714A1Reduce laborRemoval from surfaceLiquid surface applicatorsBrush bodiesEngineeringPaint roller

A paint roller including a shaft, a handle attached to a first end of the shaft, and at least one of (a) a frame with an axial protrusion, and (b) a flexure joint with one or more functional elements. The frame is configured and arranged to be rotatably secured to a second end of the shaft for operably engaging a paint roller head and rotating the paint roller head about an axis. The protrusion extends in a second axial direction from the distal end of the frame so as to prevent a distal end of a paint roller head operably engaged upon the frame from contacting a surface perpendicular to the axis of rotation. The flexure joint is configured and arranged to be interposed between and connect the second end of the handle and the first end of the shaft. The functional element is configured and arranged to be secured to a second end of the shaft. The flexure joint includes a receiving member with first and second transversely spaced opposing arms defining a transverse gap between the arms, a spherical member positioned within the gap, a connector in communication with the arms for adjusting the transverse width of the gap occupied by the spherical member and a spacing adjustment mechanism also in communication with the arms for adjusting the transverse width of the gap occupied by the spherical member.

Owner:WILLIAMS MAKOLLE

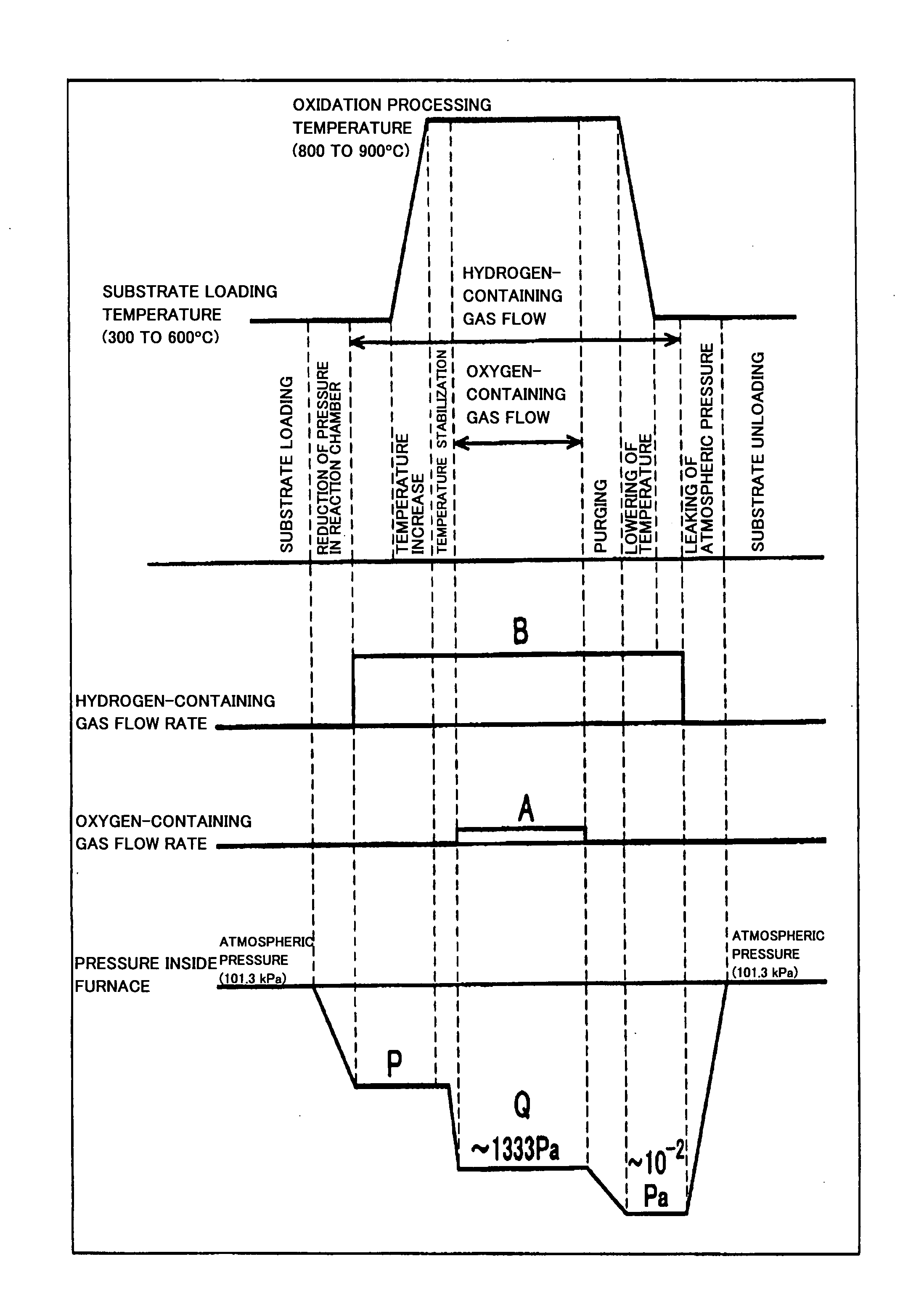

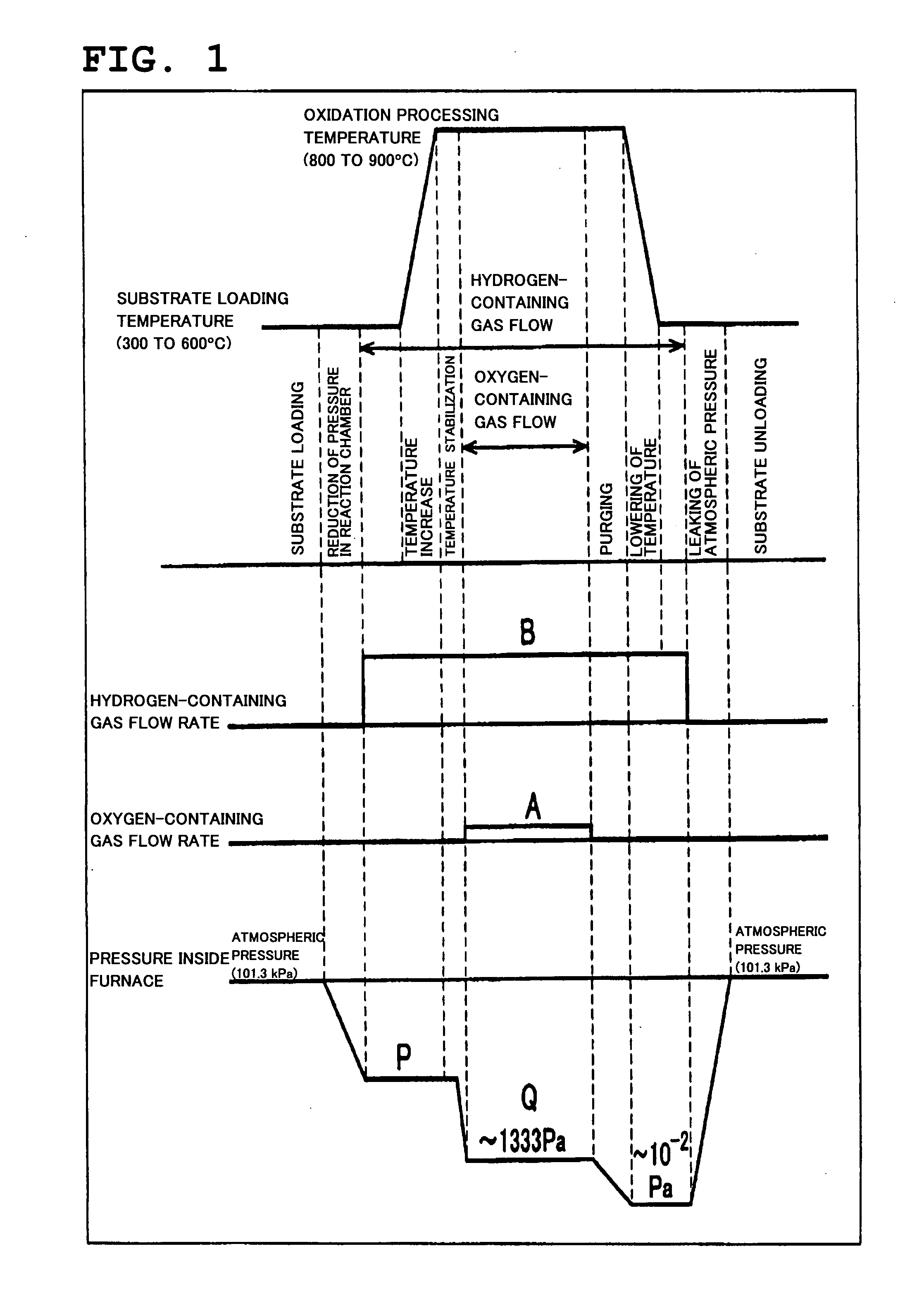

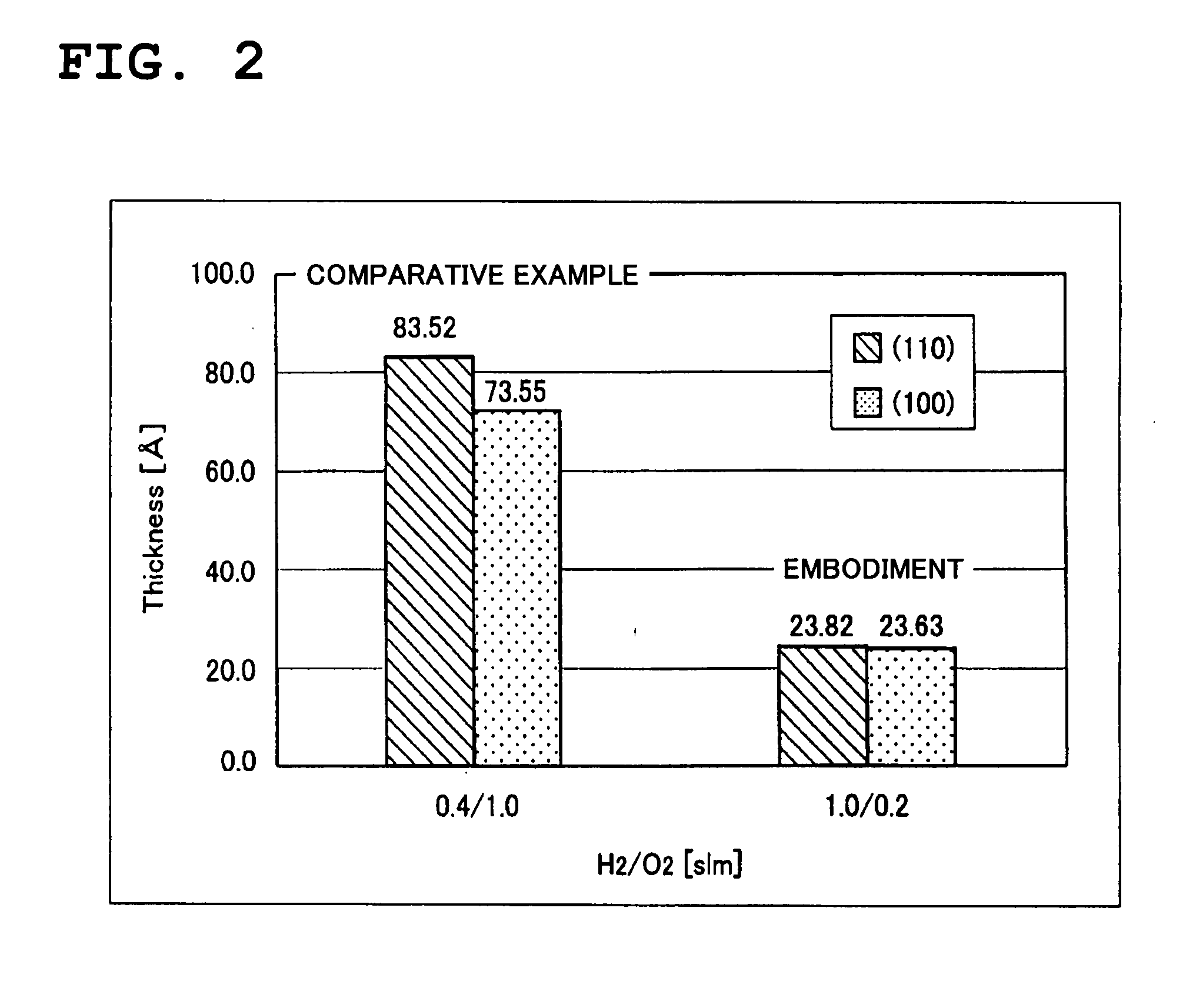

Manufacturing Method of a Semiconductor Device, and Substrate Processing Apparatus

ActiveUS20080124943A1Prevent oxidationRemoval from surfaceSemiconductor/solid-state device manufacturingHydrogenOxygen

An object of this invention is to make it possible to suppress early-stage oxidation of a substrate surface prior to oxidation processing, and to remove a natural oxidation film. For this reason, a method is provided comprising the steps of loading a substrate into a processing chamber, supplying a hydrogen-containing gas and an oxygen-containing gas into the processing chamber, and subjecting a surface of the substrate to oxidation processing, and unloading the substrate subjected to oxidation processing from the processing chamber. In the oxidation processing step, the hydrogen-containing gas is introduced in advance into the processing chamber, with the pressure inside the processing chamber set at a pressure that is less than atmospheric pressure, and the oxygen-containing gas is then introduced in the state in which the introduction of the hydrogen-containing gas is continued.

Owner:KOKUSA ELECTRIC CO LTD

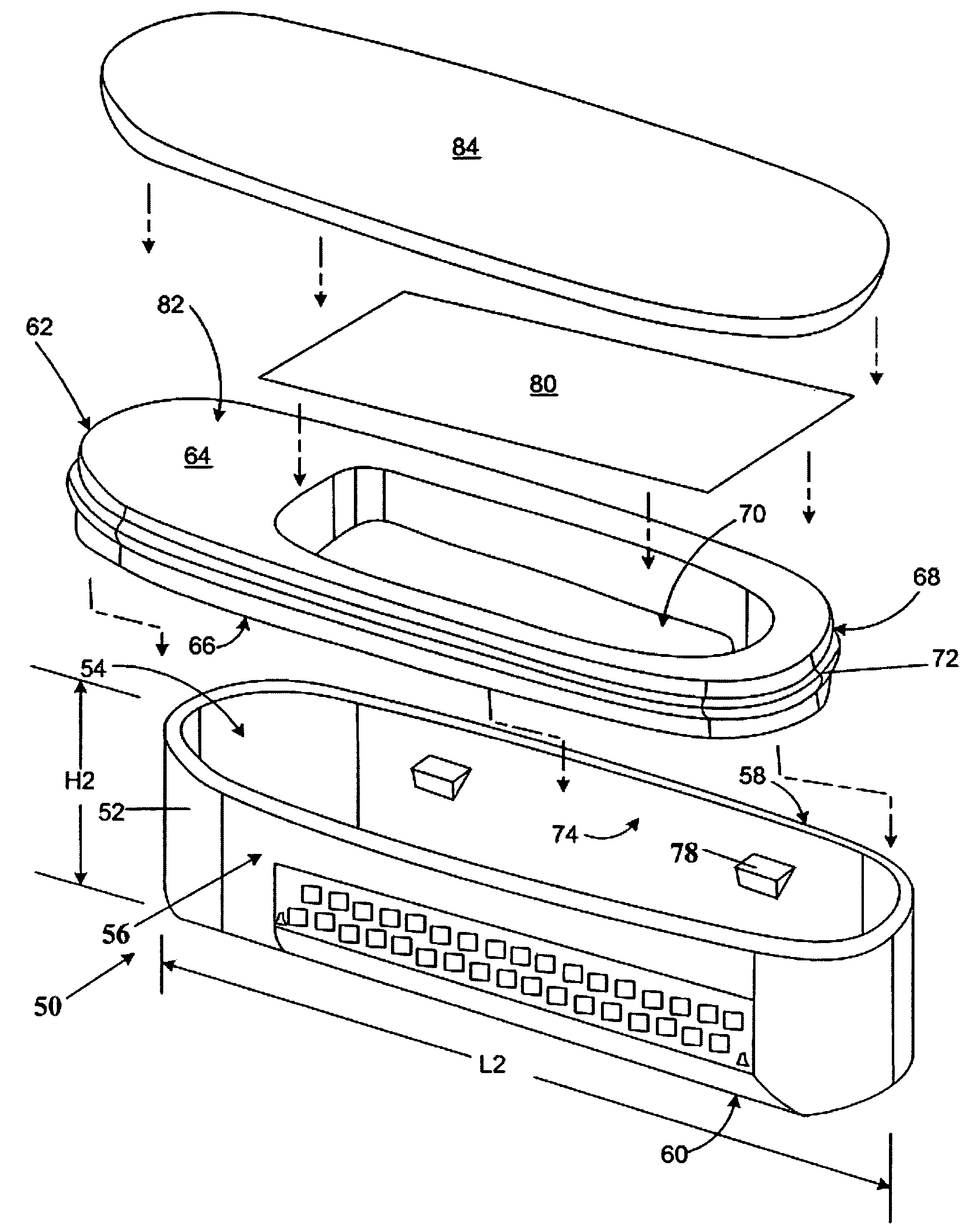

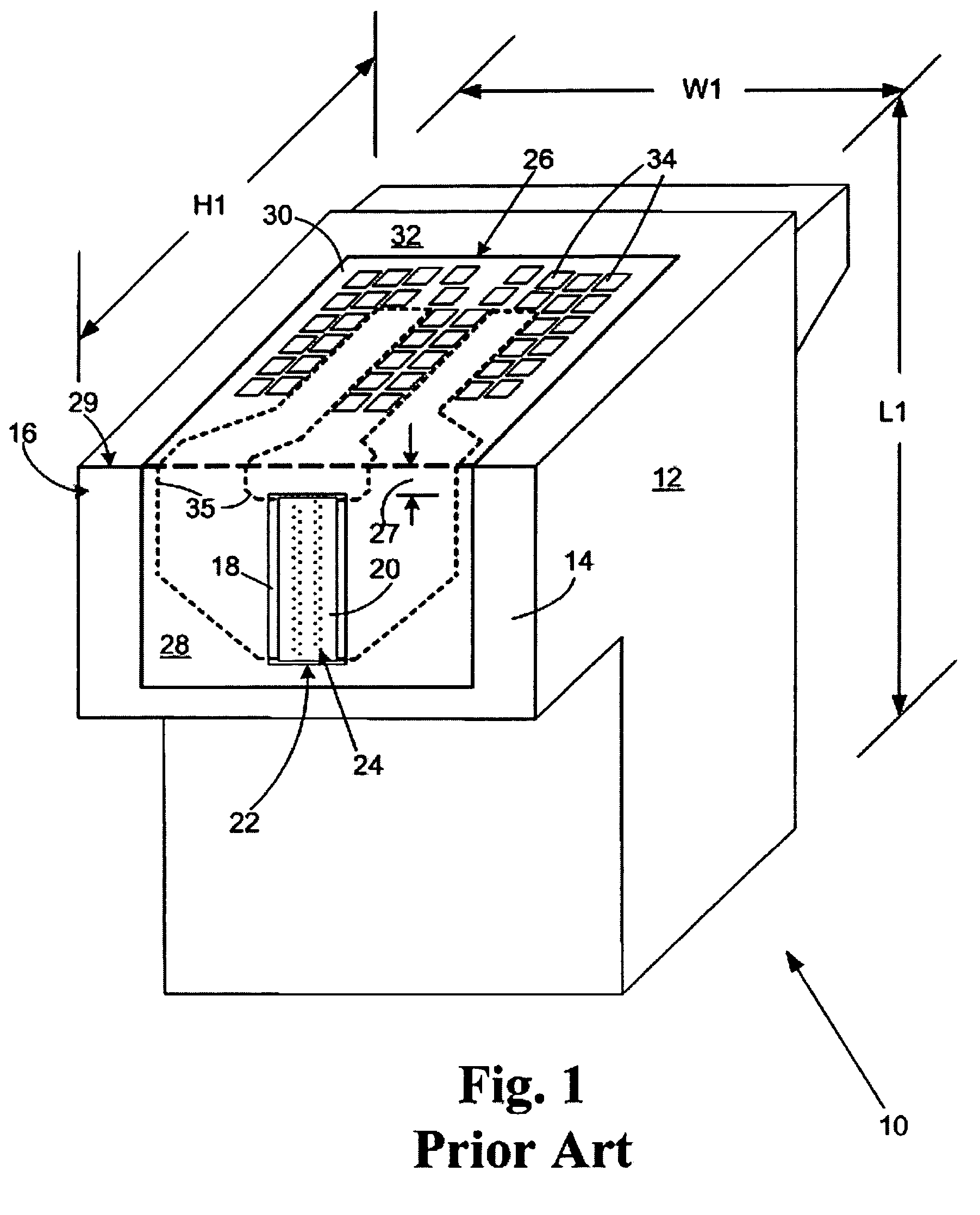

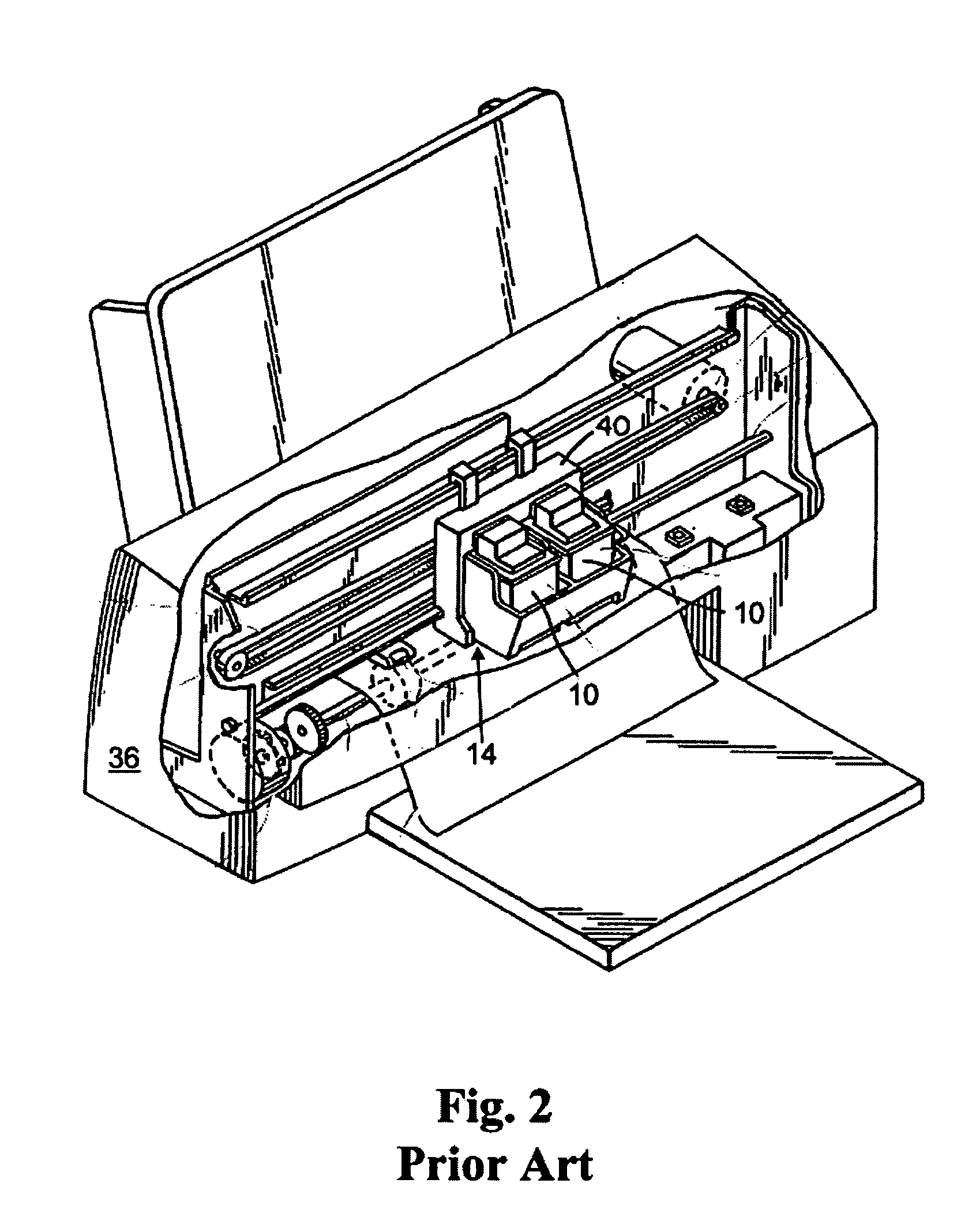

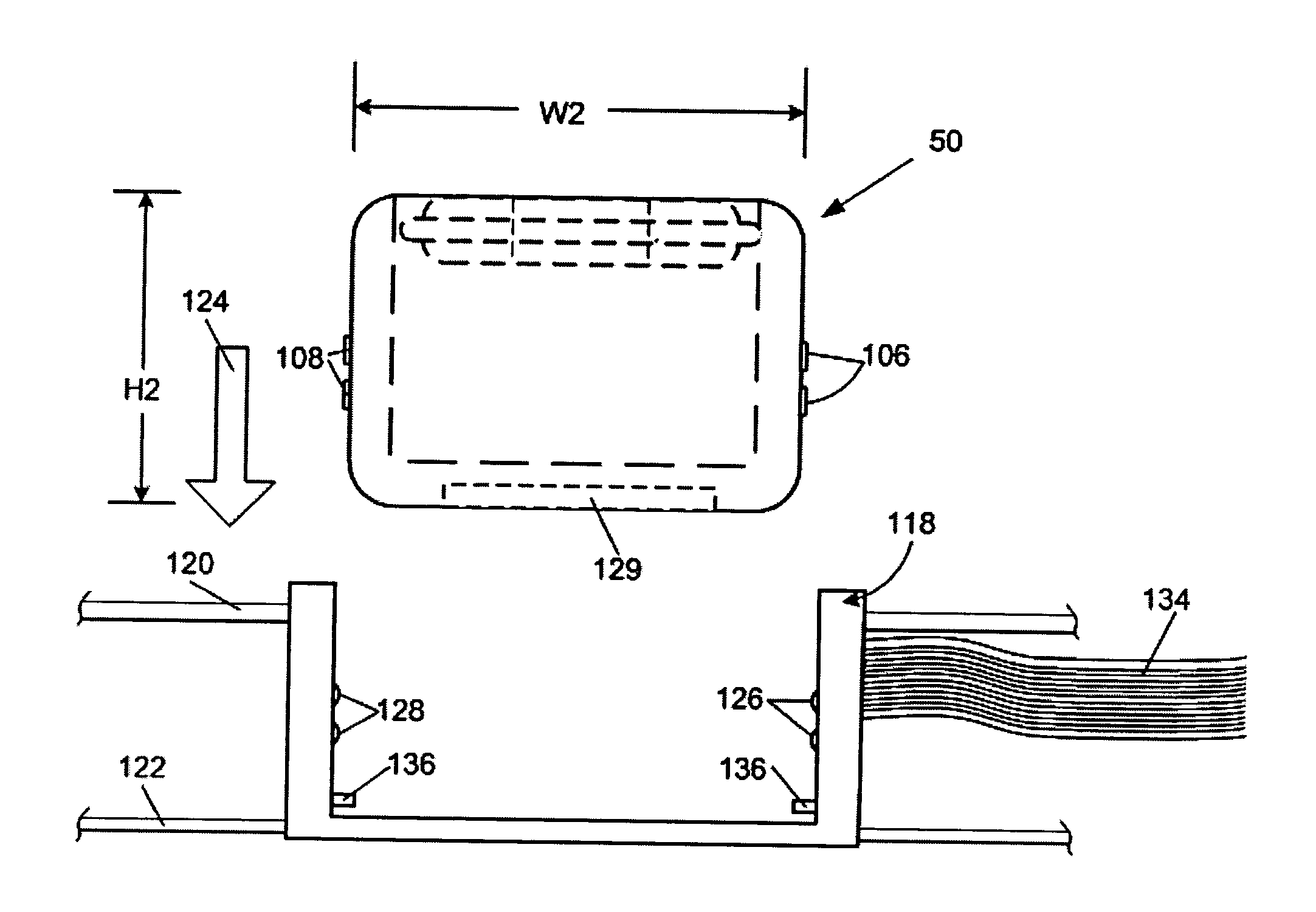

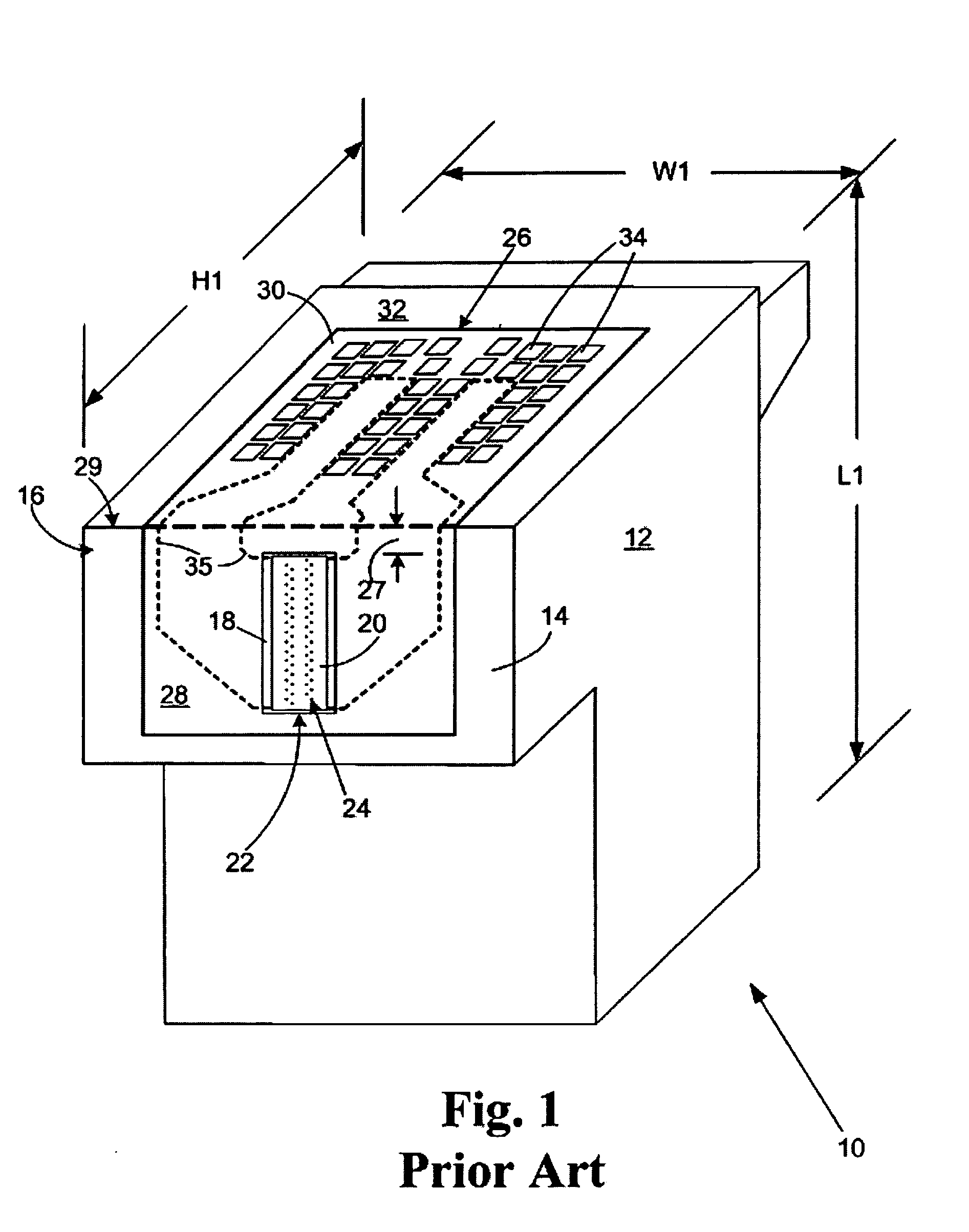

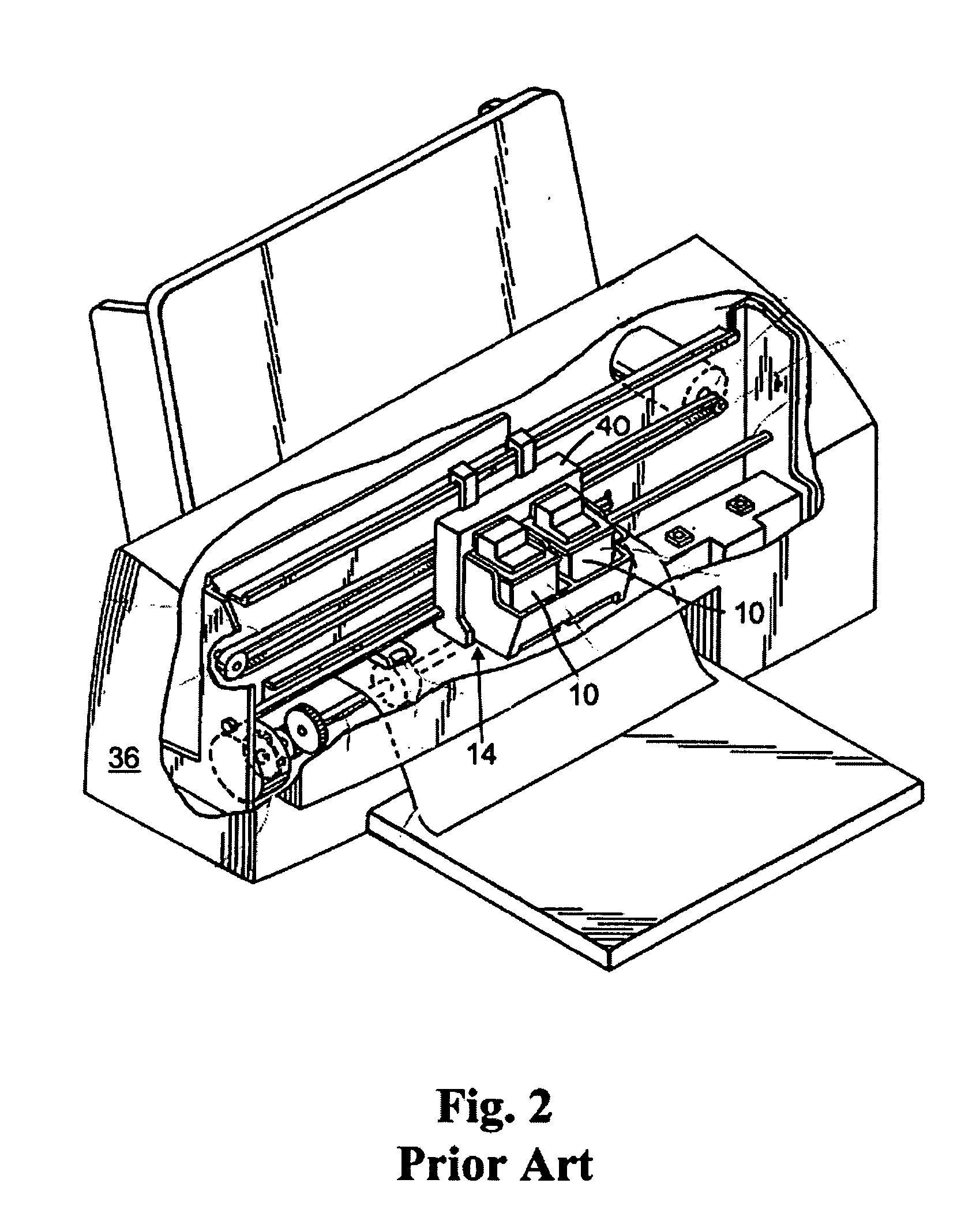

Low profile ink jet cartridge assembly

A low-profile ink jet cartridge assembly for an ink jet printer. The low profile ink jet cartridge assembly includes a substantially rectangular ink jet cartridge body having a printhead side, opposing side surfaces attached to the printhead side and a length, a height, and a width, wherein the length is greater than the height and the width. A printhead containing a semiconductor substrate is attached to the printhead side of the ink cartridge. A flexible circuit having a width, a length, a first edge along the length thereof, a second edge along the length thereof, first printer contact pads along at least a portion of the length thereof adjacent the first edge, and second printer contact pads along at least a portion of the length thereof adjacent the second edge is attached to the ink cartridge on the opposing side surfaces of the cartridge body.

Owner:FUNAI ELECTRIC CO LTD

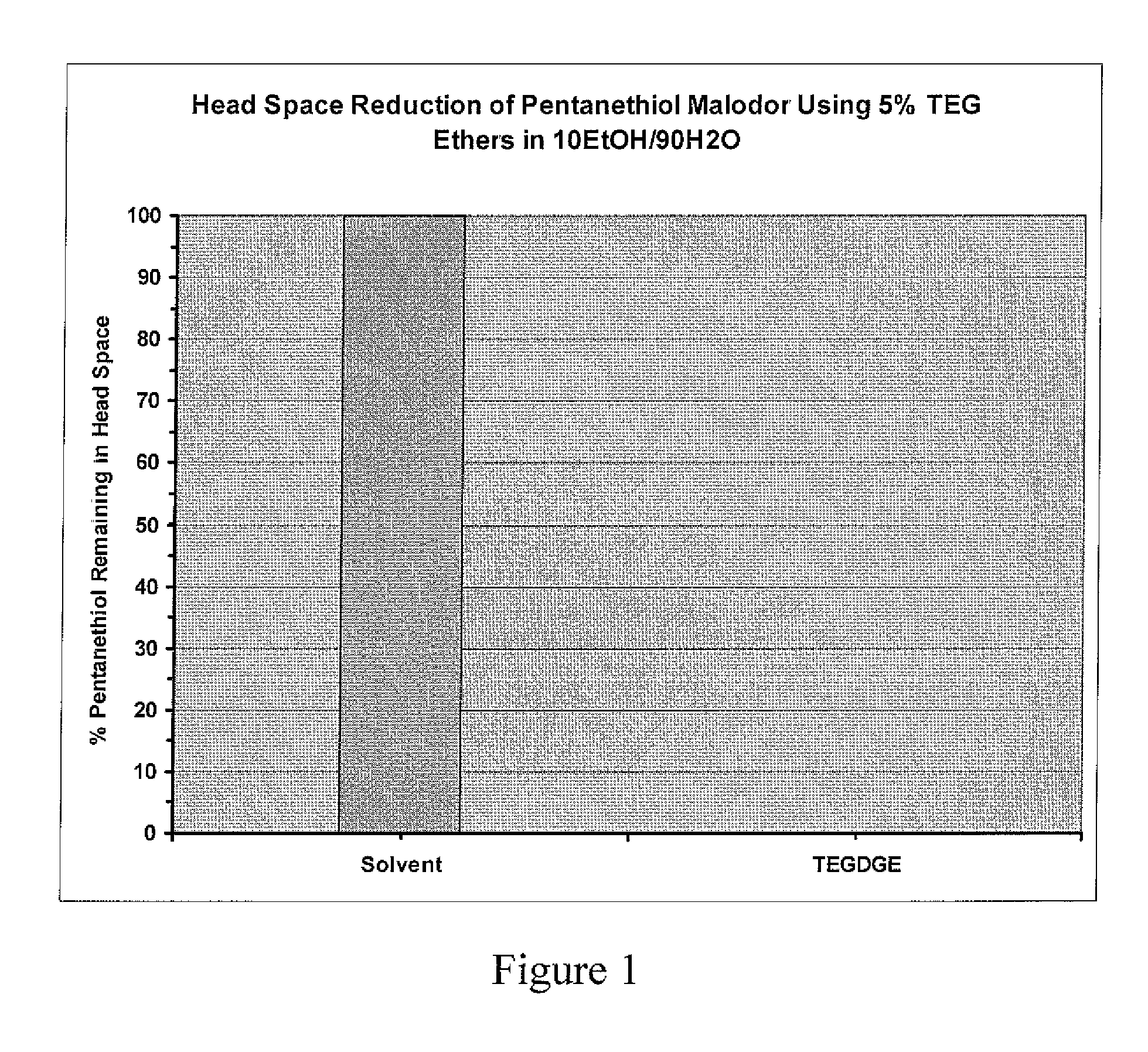

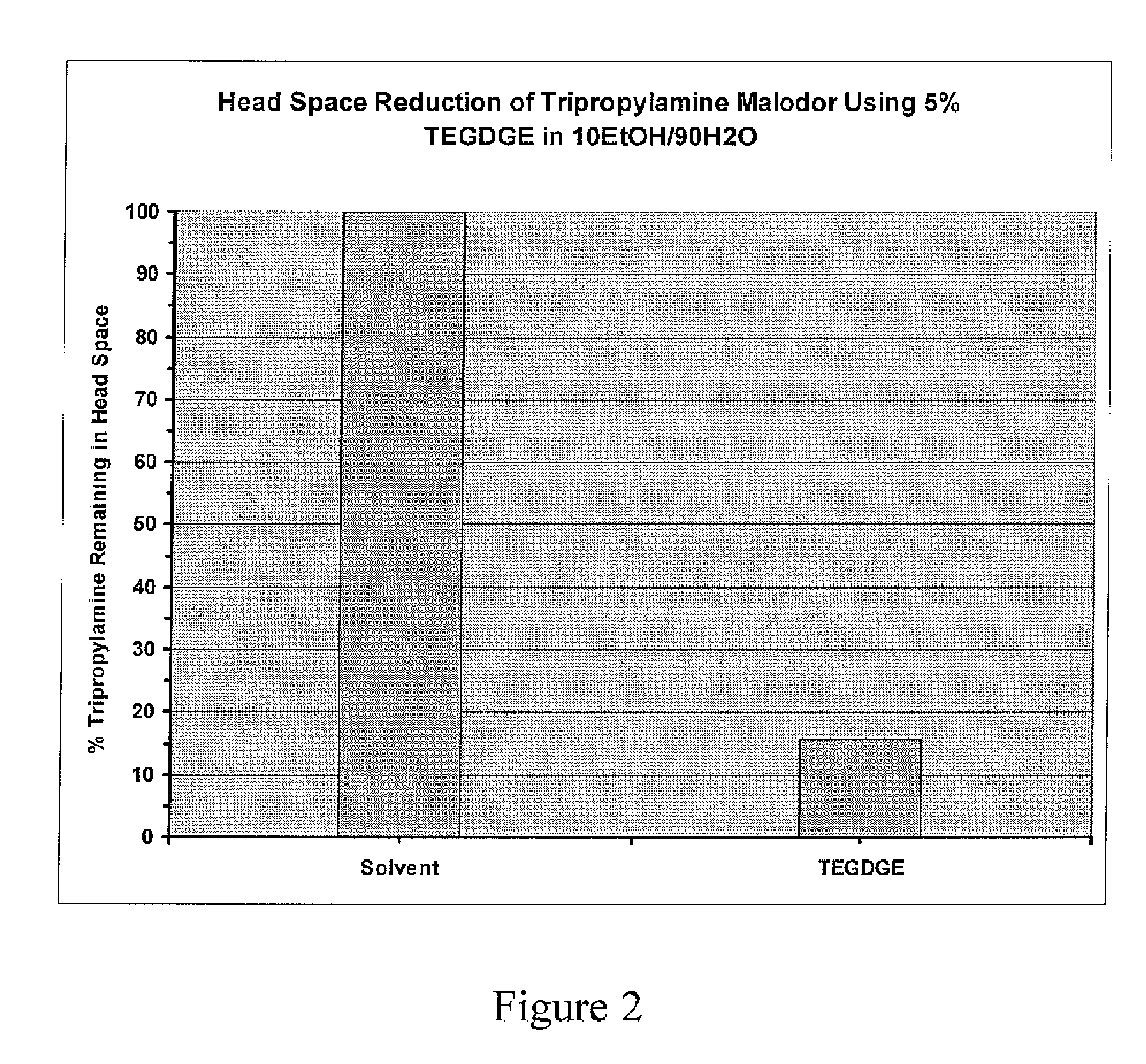

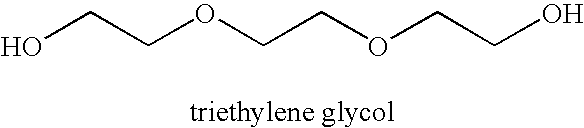

Odor elimination and air sanitizing composition

A deodorizing composition for eliminating airborne and surface malodors is disclosed. The composition comprises triethylene glycol di- and / or mono-glycidyl ether as the malodor counteractant(s). Optionally, the composition may further include triethylene glycol and / or other malodor counteractants. The deodorizing composition eliminates malodors at least by modification reactions between odor-causing molecules and triethylene glycol di- and / or mono-glycidyl ether thereby rendering the odor-causing molecules innocuous.

Owner:SC JOHNSON & SON INC

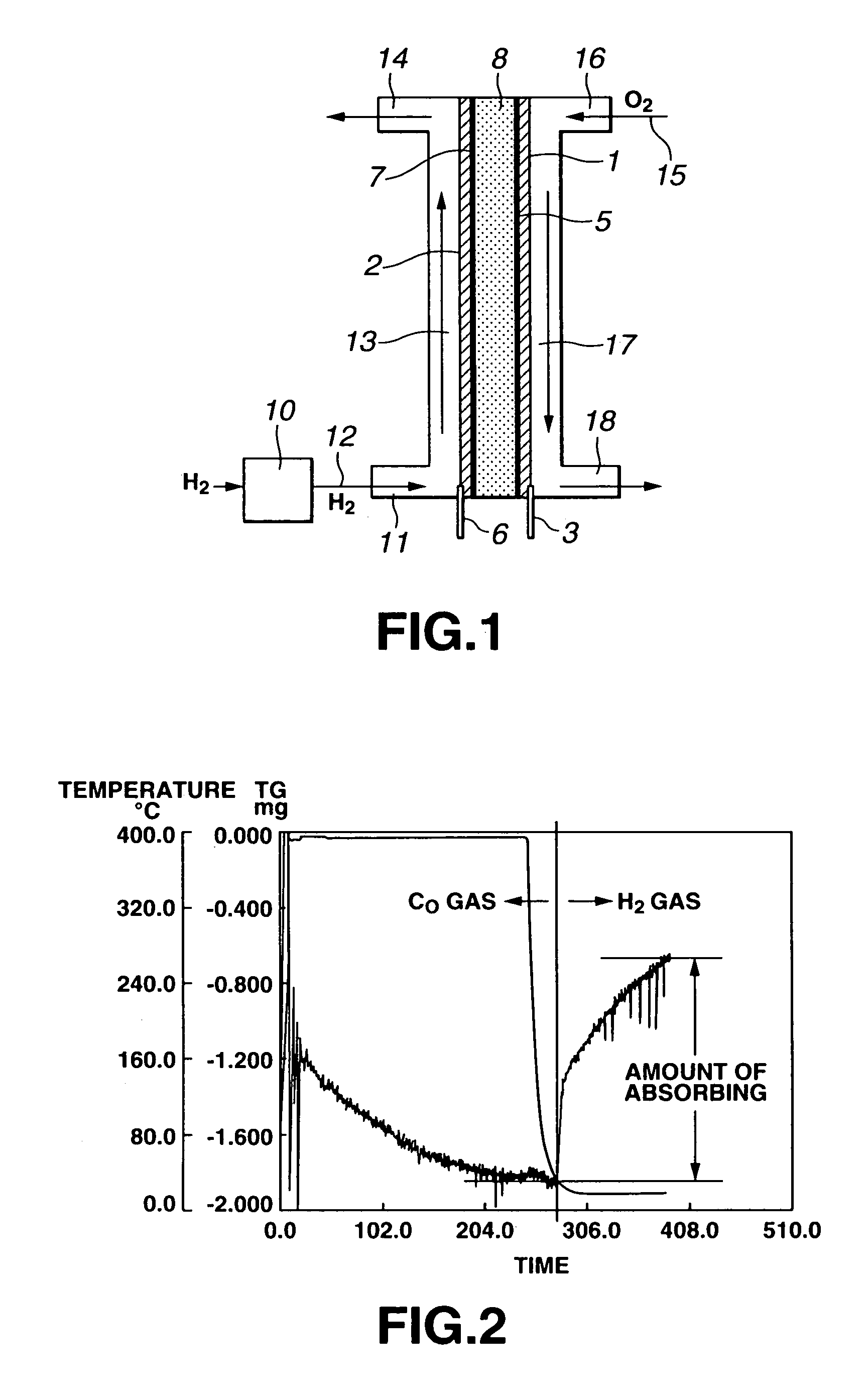

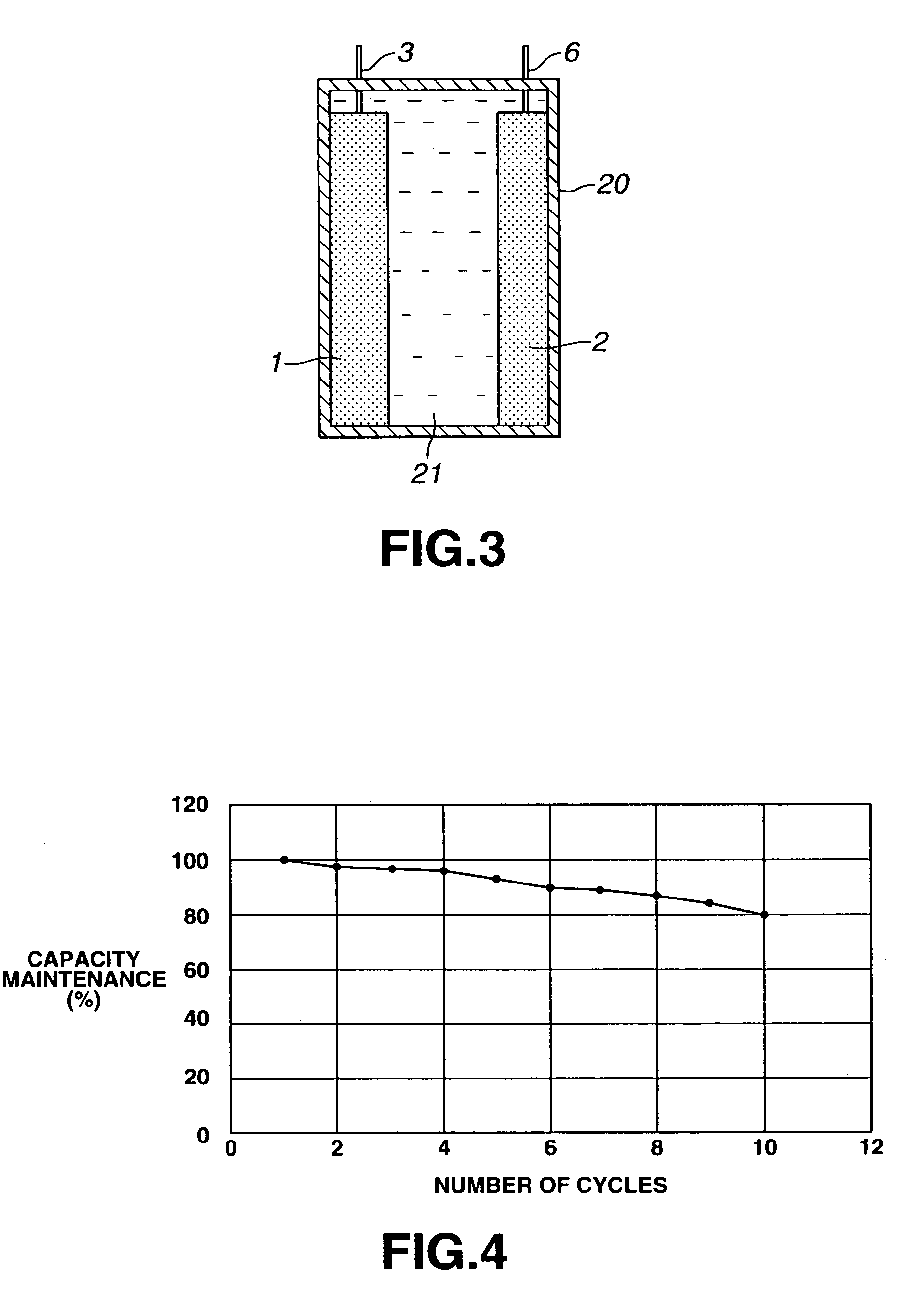

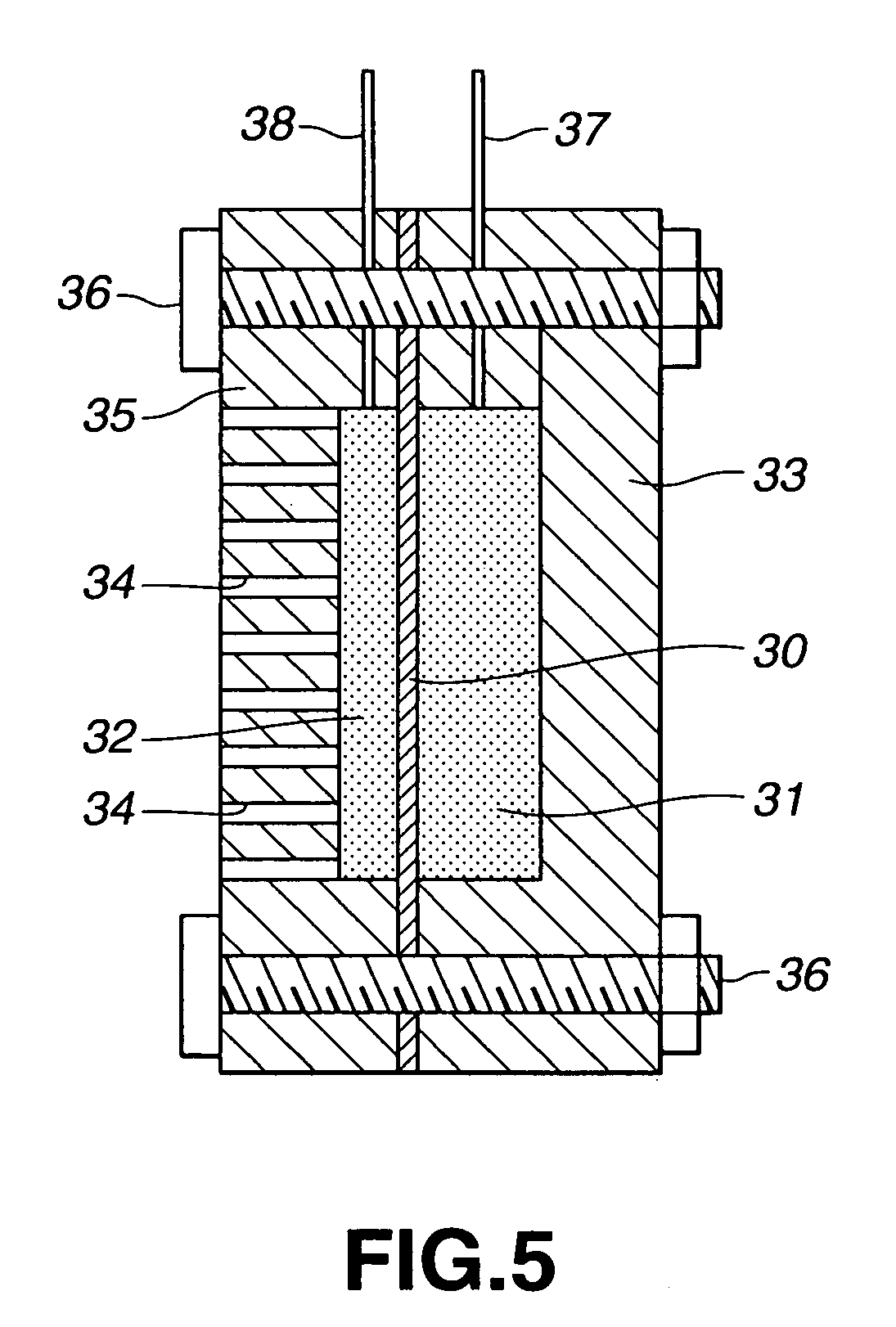

Hydrogen-storing carbonaceous material and method for producing the same, hydrogen-stored carbonaceous material and method for producing the same and battery and fuel cell using hydrogen-stored carbonaceous material

InactiveUS7008725B2Minimal impactImprove abilitiesMaterial nanotechnologyHydrogenFuel cellsProduct gas

A hydrogen-storing carbonaceous material is provided. The present invention provides a hydrogen-storing carbonaceous material obtained by heating a carbonaceous material at more than about 50° C. under the atmosphere of reducing gas, a hydrogen-stored carbonaceous material obtained by hydrogen storage in the carbonaceous material heated at more than about 50° C. under the atmosphere of reducing gas, and a battery or a fuel cell using the hydrogen-stored carbonaceous material.

Owner:SONY CORP

Methods of removing defects in surfaces

Methods of abrading surfaces by rotationally reciprocating abrasive surfaces in contact with the surfaces, abrasive articles for use in rotationally reciprocating tools, and methods of removing defects in a surface, where the methods include sanding using a rotationally reciprocating abrasive surface followed by one or more polishing operations are disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Low profile ink jet cartridge assembly

A low-profile ink jet cartridge assembly for an ink jet printer. The low profile ink jet cartridge assembly includes a substantially rectangular ink jet cartridge body having a printhead side, opposing side surfaces attached to the printhead side and a length, a height, and a width, wherein the length is greater than the height and the width. A printhead containing a semiconductor substrate is attached to the printhead side of the ink cartridge. A flexible circuit having a width, a length, a first edge along the length thereof, a second edge along the length thereof, first printer contact pads along at least a portion of the length thereof adjacent the first edge, and second printer contact pads along at least a portion of the length thereof adjacent the second edge is attached to the ink cartridge on the opposing side surfaces of the cartridge body.

Owner:FUNAI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com