Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2345 results about "Microcrystalline wax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microcrystalline waxes are a type of wax produced by de-oiling petrolatum, as part of the petroleum refining process. In contrast to the more familiar paraffin wax which contains mostly unbranched alkanes, microcrystalline wax contains a higher percentage of isoparaffinic (branched) hydrocarbons and naphthenic hydrocarbons. It is characterized by the fineness of its crystals in contrast to the larger crystal of paraffin wax. It consists of high molecular weight saturated aliphatic hydrocarbons. It is generally darker, more viscous, denser, tackier and more elastic than paraffin waxes, and has a higher molecular weight and melting point. The elastic and adhesive characteristics of microcrystalline waxes are related to the non-straight chain components which they contain. Typical microcrystalline wax crystal structure is small and thin, making them more flexible than paraffin wax. It is commonly used in cosmetic formulations.

Materials for selective deposition modeling

InactiveUS6133355AHandling dimensionalToughness handlingAdditive manufacturing apparatusPaper coatingParaffin waxMicrocrystalline wax

A novel thermopolymer material adapted for use in thermal stereolithography. More particularly, a thermopolymer material comprising a mixture of: a low shrinkage polymer resin; a low viscosity material such as paraffin wax; at least one microcrystalline wax; a toughening polymer; a plasticizer. Alternative embodiments further include components to improve the materials ability to transfer heat and to improve strength. The subject material, together with the described process greatly reduce part building distortions while retaining desirable toughness, strength and jetting properties.

Owner:3D SYST INC

Dispersible pharmaceutical compositions

ActiveUS7842791B2Good dispersionEfficacious level of antibacterialAntibacterial agentsOrganic active ingredientsDiseaseMicrocrystalline wax

A pharmaceutical composition is provided comprising a vehicle that comprises (a) an amphipathic oil that is water dispersible and ethanol insoluble, (b) microcrystalline wax, and (c) a pharmaceutically acceptable non-aqueous carrier; and having an antibacterial substance in an antibacterially effective amount stably dispersed in the vehicle. The composition is suitable for administration by intramammary infusion to a milk producing animal for treatment and / or prevention of mastitis or other diseases of the udder, as well as for otic administration for treatment and / or prevention of an ear infection.

Owner:ZOETIS SERVICE LLC

Thin-walled natural rubber latex material substantially free of sulfur and nitrosamines

InactiveUS6051320AEfficient processingEasy to useLayered productsGlovesMicrocrystalline waxGas phase

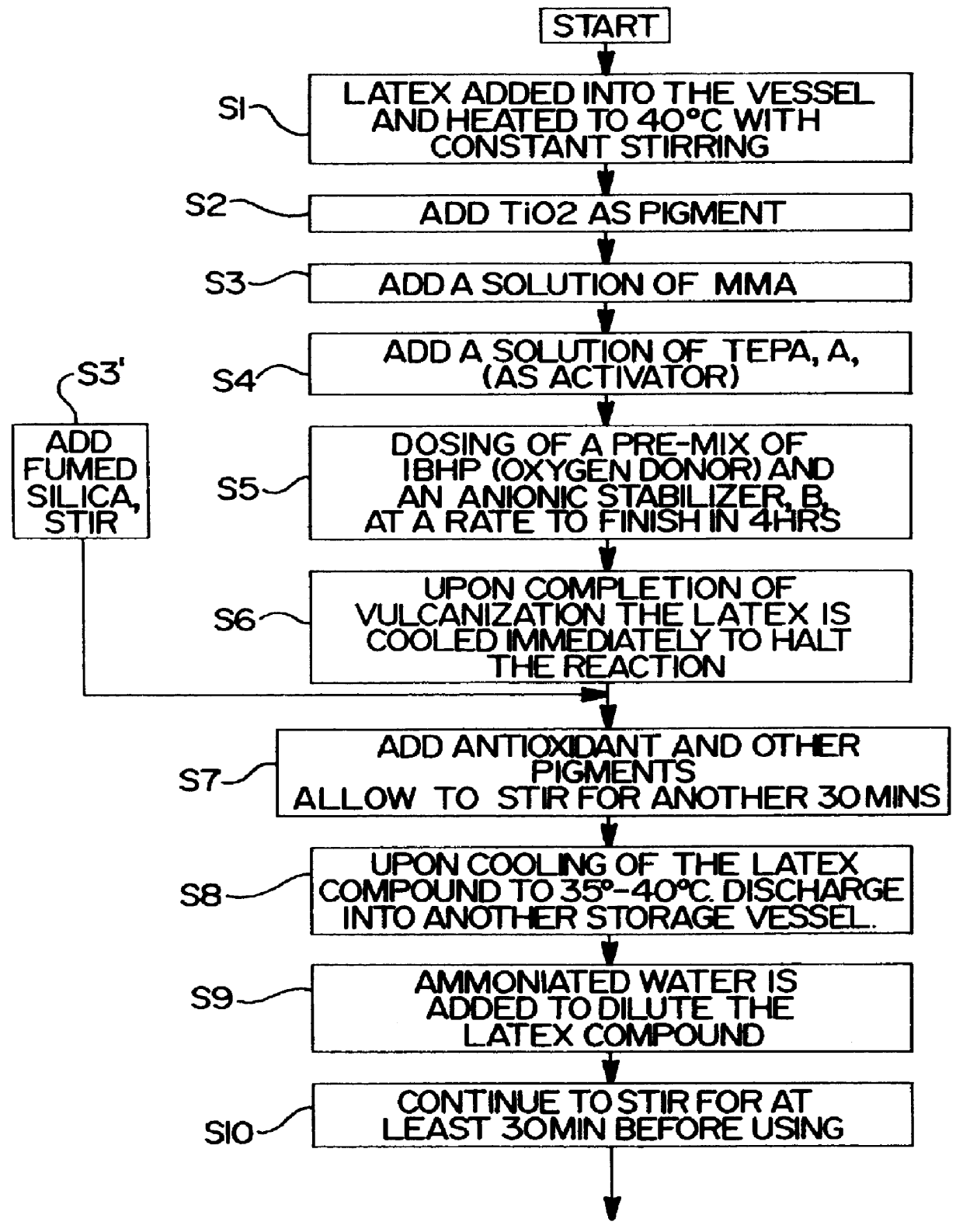

A thin walled natural rubber latex material is disclosed suitable for forming thin walled products including gloves, dental dams and shields, catheter tubing, penrose surgical drains, finger cots, coverings for body parts, and the like. The thin walled material is formed from a latex emulsion containing natural rubber, sulphur-free, oxygen-donating curing agents, and a strength enhancing agent which may be an inorganic substance such as fumed silica and / or an organic substance such as monomers and polymers of families of acrylics and esters. The emulsion also preferably includes microcrystaline wax as an oxygen barrier, and the material is also provided with a heat resistant and water resistant coating which blocks transfer of latex proteins from the material and enhances slip of the material.

Owner:HAU HO TEON +1

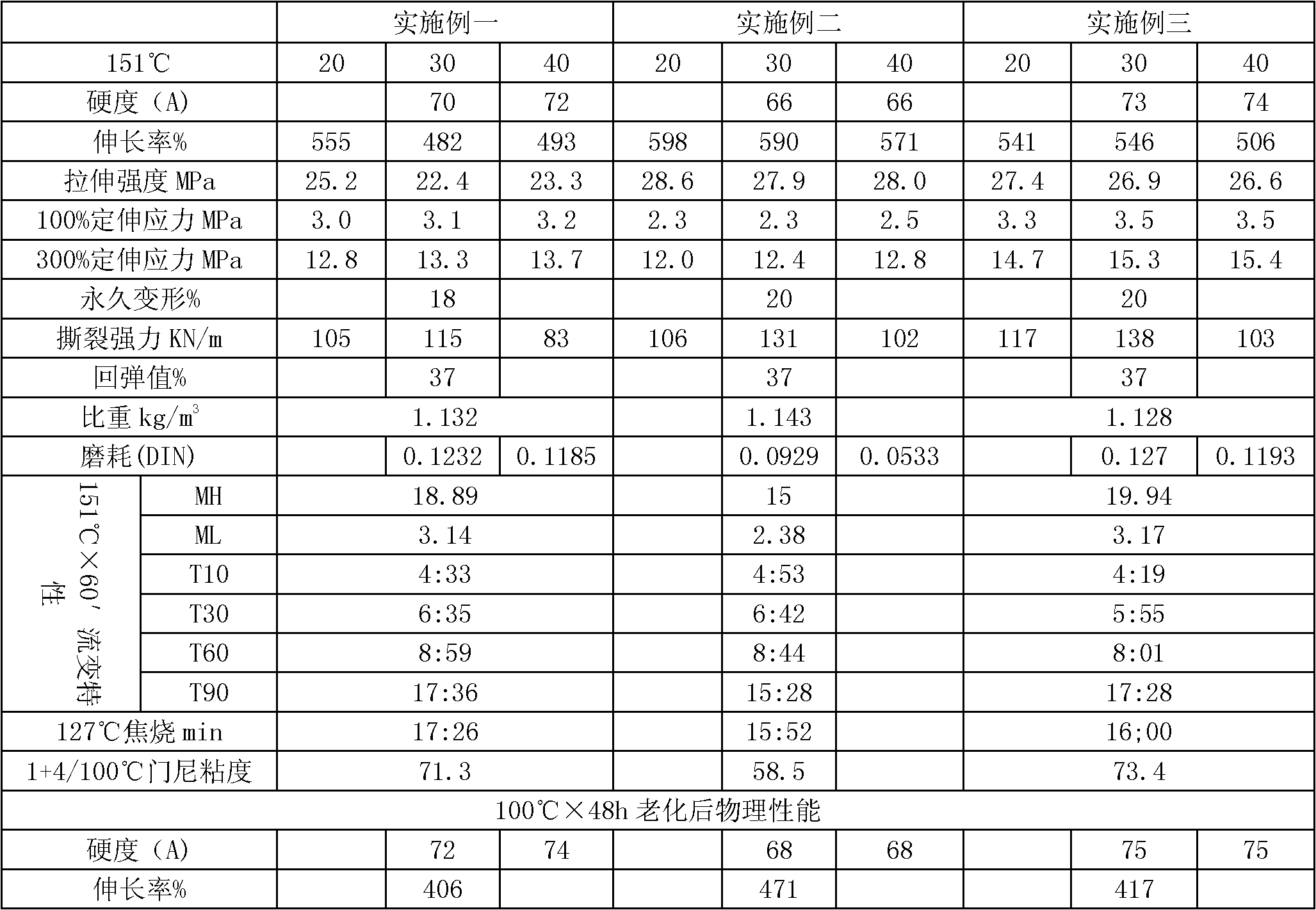

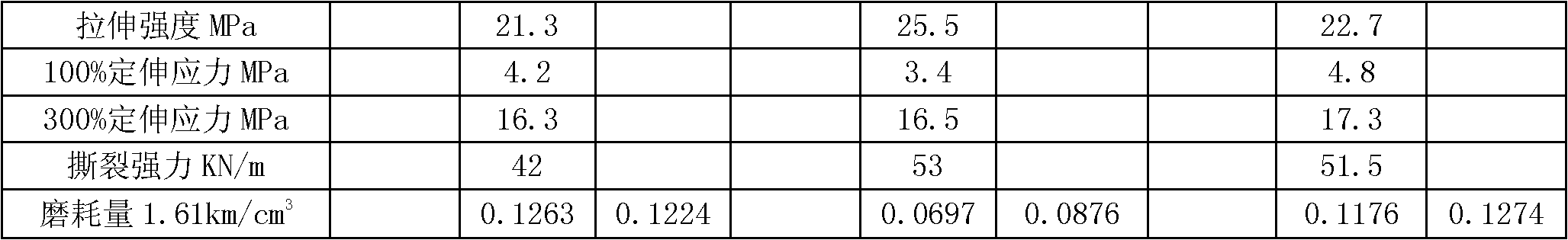

High abrasion-resistant tread rubber for middle and long distance highway transportation type radial tire and producing method thereof

ActiveCN102030926AImprove wear resistanceLower Mooney ViscositySpecial tyresMicrocrystalline waxEngineering

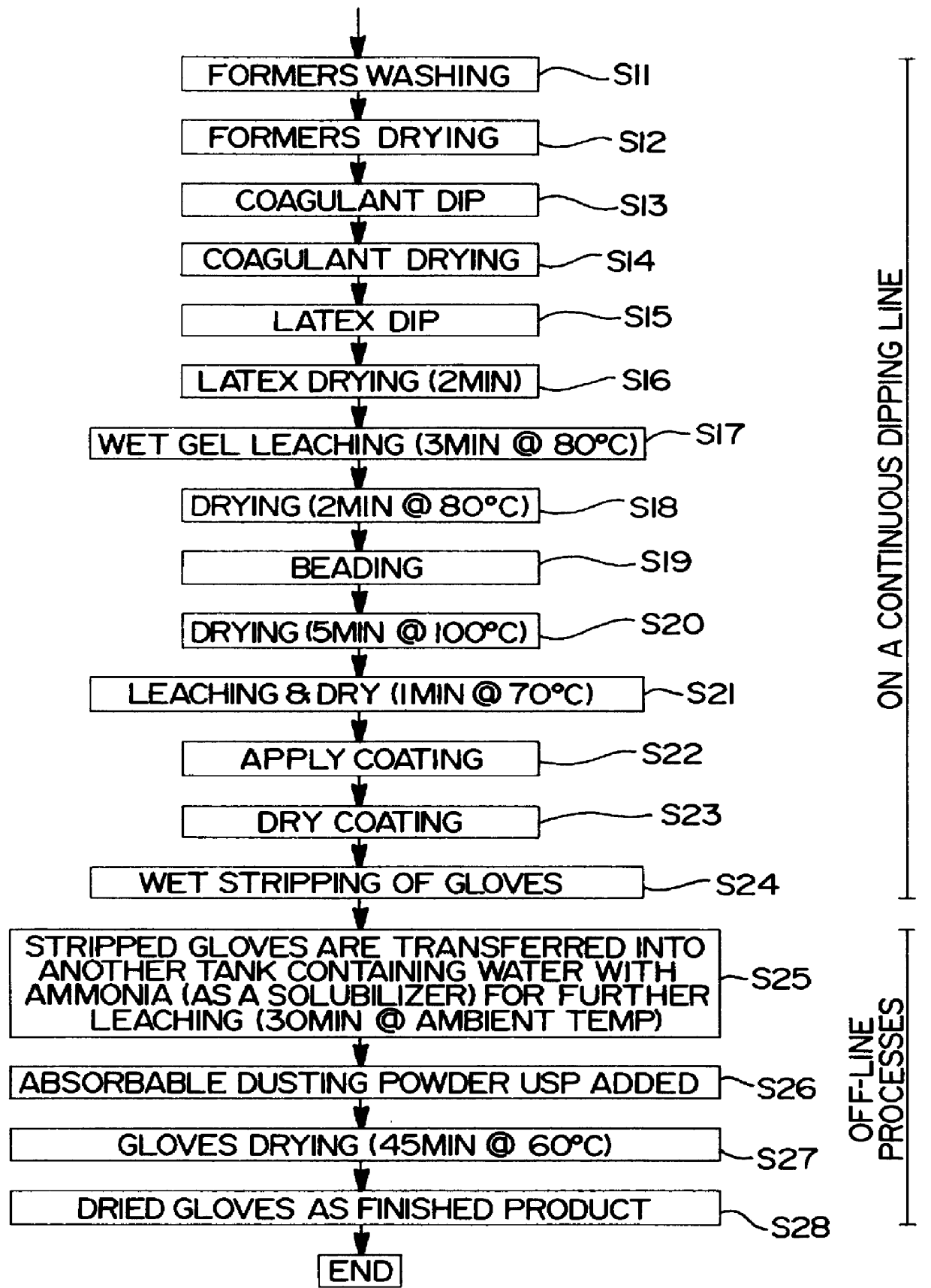

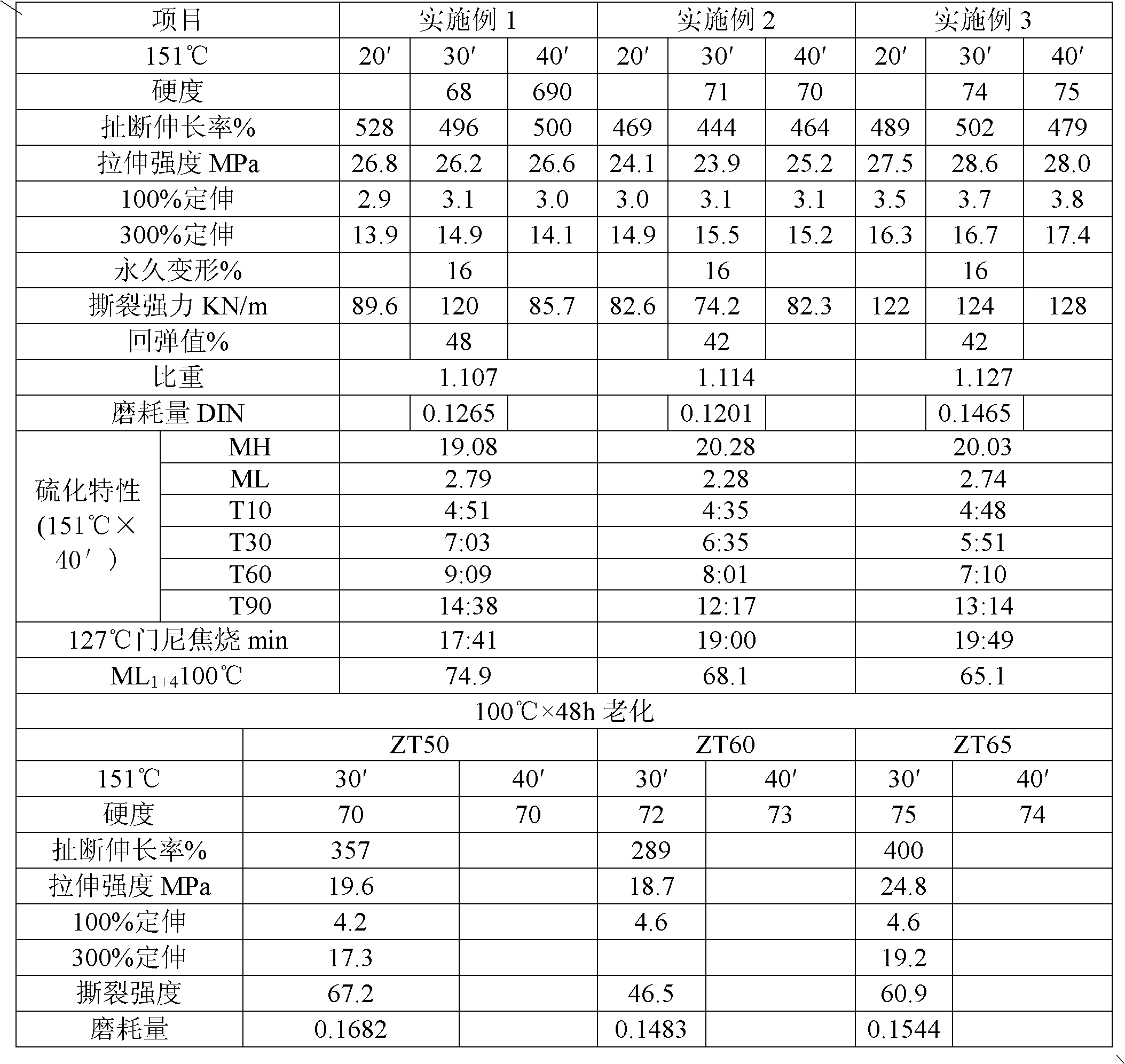

The invention relates to a high abrasion-resistant tread rubber for a middle and long distance highway transportation type radial tire and a producing method of the tread rubber, wherein the producing method comprises the following processing steps:(1) first-stage mixing: adding nature rubber SMR20,butadiene rubber, butadiene styrene rubber and peptizer into a mixing chamber for raw rubber plastication, then adding N234 carbon black, white carbon black, a silane coupling agent, zinc oxide, stearic acid, a dispersing agent and a plasticizer for mixing, finally adding N234 carbon black for mixing, and obtaining the first-stage original rubber by discharging rubber; (2) standing for first time; (3) second-stage mixing: adding first-stage original rubber, the N234 carbon black, an anti-aging agent RD, an anti-aging agent 4020 and microcrystalline wax into an internal mixer for mixing, and obtaining second-stage original rubber by discharging rubber after the mixing; (4) standing for second time; and (5) final mixing: adding the second-stage original rubber, sulphur, an accelerator NS and a scorch retarder CTP (cytidine triphosphate) into the mixing chamber for mixing, and obtaining the tread rubber by discharging rubber. In the invention, the abrasion resistance of middle and long distance highway transportation type radial tires can be greatly enhanced, the producing and working efficiency is enhanced, and energy is greatly saved.

Owner:JIANGSU GENERAL SCI TECH

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

All-steel radial ply tyre tread base and preparation method thereof

The invention discloses tread base for an all-steel radial tire and a preparation method thereof. The tread base for the all-steel radial tire comprises the following compositions in weight portion: 100 weight portions of natural gum SMR20, 0.1 to 0.5 weight portion of chemical peptizer, 30 to 45 weight portions of carbon black, 7 to 15 weight portions of white carbon black, 3 to 5 weight portions of zinc oxide, 1.5 to 3 weight portions of silane coupling agent Si-69, 1.5 to 3 weight portions of stearic acid, 1 to 2 weight portions of antiaging agent 4020, 0.5 to 2 weight portions of micro-crystalline wax, 0.5 to 2 weight portions of antiaging agent RD, 1 to 2 weight portions of fatigue protective agent G-108, 2 to 3 weight portions of oil-filled insoluble sulfur, 0.5 to 1 weight portion of accelerant NS, 0.5 to 1 weight portion of accelerant CZ and 0.1 to 0.5 weight portion of antiscorcher CTP. The tread base for the all-steel radial tire is prepared by one-stage mixing, standing for the first time, two-stage mixing, standing for the second time and final mixing.

Owner:JIANGSU GENERAL SCI TECH

Precisive ornament casting moulding material

ActiveCN101074320AHigh hardnessLow shrinkageFoundry moulding apparatusMINERAL WAXMicrocrystalline wax

A precision-casting mold material for ornament consists of hydrogenated microcrystalline wax, paraffin, petroleum resin, high-molecular polymer, mineral wax and animal and vegetable wax. It has better bending strength, surface hardness, thermal stability, fluidity, reutilization and less linear shrinkage rate. It can be used for gold and silver ornaments.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Method for preparing environment-friendly type anti-corrosive and anti-fingerprint metal surface coating

InactiveCN101392142AImprove anti-corrosion performanceGood fingerprint resistancePretreated surfacesAnti-corrosive paintsEpoxyMicrocrystalline wax

The invention relates to a composition for protecting metal surfaces, in particular to a preparation method of an environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. The composition contains an A component and a B component, the A component takes waterborne epoxy resin as a matrix resin and nano-silica, a silane coupling agent, microcrystalline wax disperse liquid, zirconium complex, deionized water, defoamer and a levelling agent are added, thus obtaining the A component; the B component contains a waterborne epoxy modified amine curing agent and a certain quantity of epoxy curing promoter. The two components are mixed and stirred evenly at a ratio of 4:1 to 3:1 to form the environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. After coating, metal can be heated by going through a baking channel at a certain temperature, the film forming time can be controlled by adjusting the heating period and finally a transparent coating layer which has quite good anticorrosive protection function over metal and fingerprint resistant function is formed.

Owner:TONGJI UNIV

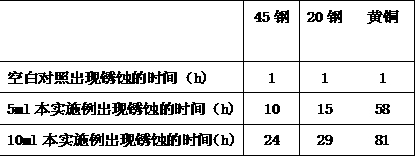

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

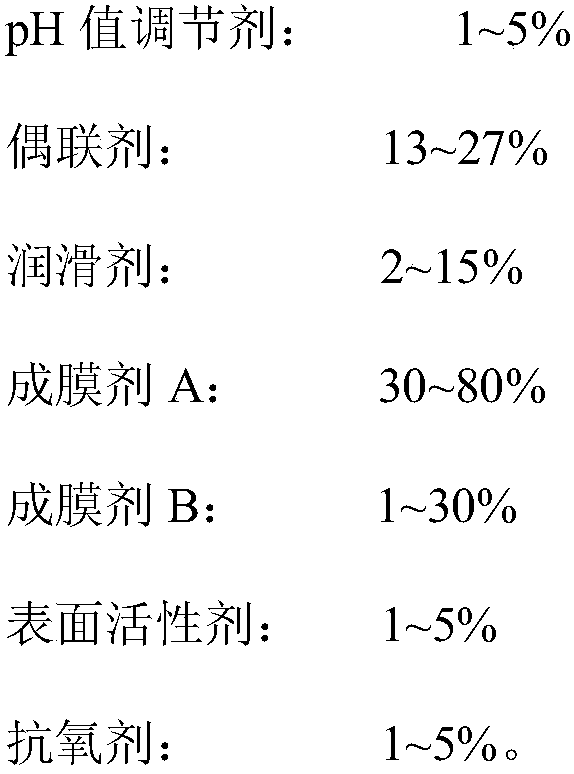

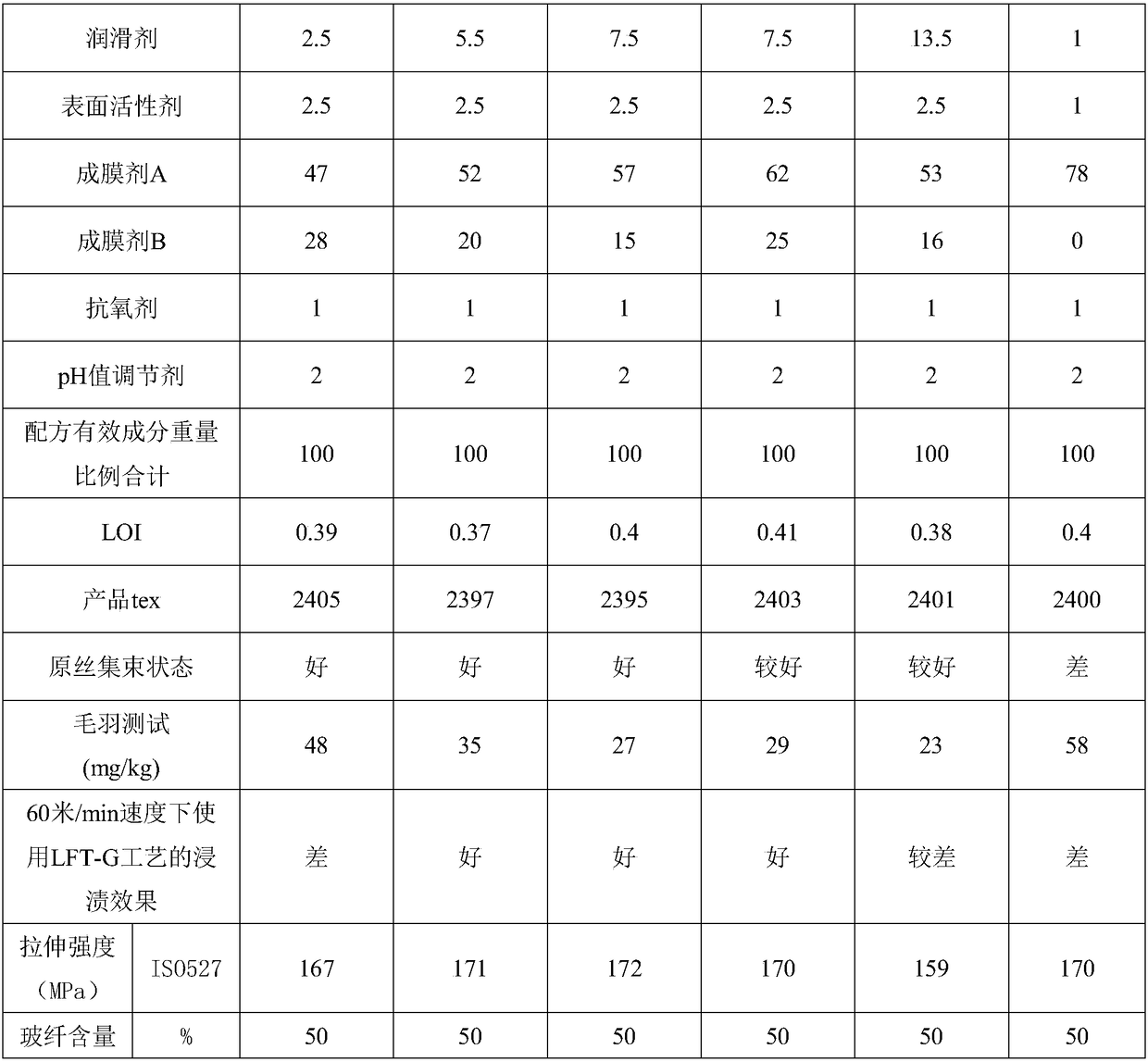

High-dipping-property alkali-free glass fiber impregnating agent for LFT reinforced polypropylene as well as application thereof

ActiveCN108996923AIncrease productivityImprove interface compatibilityAlkali freeMicrocrystalline wax

The invention relates to a high-dipping-property alkali-free glass fiber impregnating agent for LFT reinforced polypropylene as well as the application thereof. The impregnating agent comprises a pH value regulator, a silane coupling agent, a film-forming agent A, a film-forming agent B, a lubricating agent, a surfactant, an antioxidant and deionized water, wherein the film-forming agent A is a maleic anhydride grafted and modified polypropylene wax emulsion; the film-forming agent B is a maleic anhydride grafted and modified polyethylene emulsion; the lubricating agent is the combination of aPEG lubricating agent and a mineral oil lubricating agent; the surfactant is the combination of microcrystalline wax emulsion and cationic polyacrylamide emulsion; and the antixodiant hypophosphite is hypophosphite. The invention also provides the application of the impregnating agent to production of alkali-free glass fiber for the LFT reinforced polypropylene. The glass fiber produced by the impregnating agent has a high interface bonding property, can be rapidly fused with polypropylene resin at high temperature, is high in dipping speed, has good processing property, high wear resistanceand little filoplume, and has a high dipping property, so that the production efficiency can be improved and the production cost can be reduced.

Owner:JUSHI GRP CO

Special lubricating grease composition for steel wire rope

ActiveCN102250670AImprove water resistanceImprove the protective effectLubricant compositionMicrocrystalline waxLithium 12-hydroxystearate

The invention relates to a special lubricating grease composition for a steel wire rope. The composition comprises the following components in percentage by weight: 2.0-5.2% of lithium 12-hydroxystearate soap, 0.5-1.3% of lithium stearate soap, 53.5-76% of mineral base oil, 15.0-40.0% of extract oil, 1.3-6.3% of microcrystalline wax and 0.2-1.2% of diphenylamine. The lubricating grease provided by the invention has the characteristics that blended base oil containing high-viscosity extract oil is utilized to prepare specific-thickness semi-fluid lubricating grease for the steel wire rope, theadhesion and infiltration capability of the product are improved, and the problems of oil splashing, loss, atmospheric environment pollution and the like of the existing product are solved; and a microcrystalline wax additive is used for improving the water resistance and protective properties of the lubricating grease for the steel wire rope. The lubricating grease provided by the invention has dropping point larger than 165 DEG C, is free of volatile solvent, is convenient for coating, has low production cost and enhanced lubrication effects, and can effectively meet the internal and external lubrication and protection requirements of the steel wire rope during operation.

Owner:CHINA PETROLEUM & CHEM CORP

Solvent dewaxing method

ActiveCN1648216AImprove crystal structureEasy to separateMineral wax recovery/refiningParaffin waxMicrocrystalline wax

During solvent dewaxing, the mixture of wax containing material oil, dewaxing solvent and dewaxing assistant is made to pass through two stages of dewaxing material oil and deoiling cerate; the filtrate from the deoiling stage is returned to the dewaxing stage completely; and dewaxed oil and deoiled wax are obtained after recovering the solvent. The dewaxing assistant is ashless polymer mixture of high branched chain degree polymer and low branched chain degree polymer. The method improves the crystal structure of wax, raises oil-wax separating effect, raises dewaxed oil yield and filtering speed obviously, lowers the solvent ratio and lowers the oil content in cerate. The cerate may be used in producing paraffin or microcrystal wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tyre tread rubber composition used in hard mine area and production method of tyre tread rubber composition in hard mine area

ActiveCN102634089AGood dispersionImprove puncture resistanceSpecial tyresMicrocrystalline waxVulcanization

The invention relates to the technical field of rubber, in particular to a tyre tread rubber composition used in a hard mine area and a production method of the tread rubber composition in the hard mine area. The tyre tread rubber composition comprises the following materials by weight: 50-90 parts of styrene butadiene rubber, 10-50 parts of natural rubber, 45-55 parts of carbon black, 15-25 parts of white carbon black, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 2-4.5 parts of silane coupling agent, 2-5 parts of cutting resistant resin, 10-20 parts of aromatic oil, 1-3 parts of antioxidant N-(1,3-dimethylbutyl)-N'-phenyl p-phenylenediamine, 1-2 parts of antioxidant 2, 2, 4-trimethyl-1,2-dihydroquinoline polymer, 1-3.5 parts of microcrystalline wax, 1-2 parts of sulfur, 1.0-2.0 parts of vulcanization accelerant N-tertiary butyl-2-benzothiazole sulfonamide, 0.5-1.0 parts of vulcanization accelerant N,N-diphenylguanidine and 0.1-0.3 parts of scorch retarder. The tyre tread rubber composition used in a hard mine area and the production method provided by the invention can obviously improve puncture resistant property, the chipping resistant property, the safety and the service life of a tyre in the hard mine area.

Owner:TRIANGLE TIRE

Rubber protecting wax and preparation method thereof

The invention relates to rubber protecting wax which comprises the components in percentage by weight: 20-40% of fully refined paraffin wax, 25-45% of half refined paraffin wax, 20-53% of microcrystalline wax and 0.5-5% of ethylene-vinyl acetate copolymer EVA. The invention further discloses a preparation method of the rubber protecting wax. The rubber protecting wax provided by the invention is used in a rubber product and has a good protective effect, and the service life of the rubber product can be prolonged.

Owner:QINGDAO FIHONOR CHEM SCI & TECH

High-damping rubber support base and manufacturing method thereof

InactiveCN103865130AWide temperature rangeForm pollutionMetal layered productsMicrocrystalline waxEngineering

The invention relates to a high-damping rubber support base and a manufacturing method thereof. The high-damping rubber support base disclosed by the invention comprises the following components in parts by weight: 60-80 parts of rubber, 10-50 parts of plastic particles, 15-50 parts of resin, 5-25 parts of carbon black, 30-100 parts of mica powder, 5-30 parts of plasticizer, 5-30 parts of hindered phenol, 2-5 parts of microcrystalline wax, 1-3 parts of anti-aging agent, 1-3 parts of stabilizer, 2-5 parts of accelerant, and 1-4 parts of vulcanizing agent. The preparation method disclosed by the invention comprises the steps of preparing raw materials, mixing, adding sulphur, rolling a rubber piece, forming and vulcanizing. The equivalent damping ratio of the prepared high-damping rubber support base achieves 20-30%. The high-damping rubber support base prepared by the manufacturing method disclosed by the invention is high in damping; all the components are natural components; pollution to the environment cannot be caused; the preparation method of the high-damping rubber support base is simple in process.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

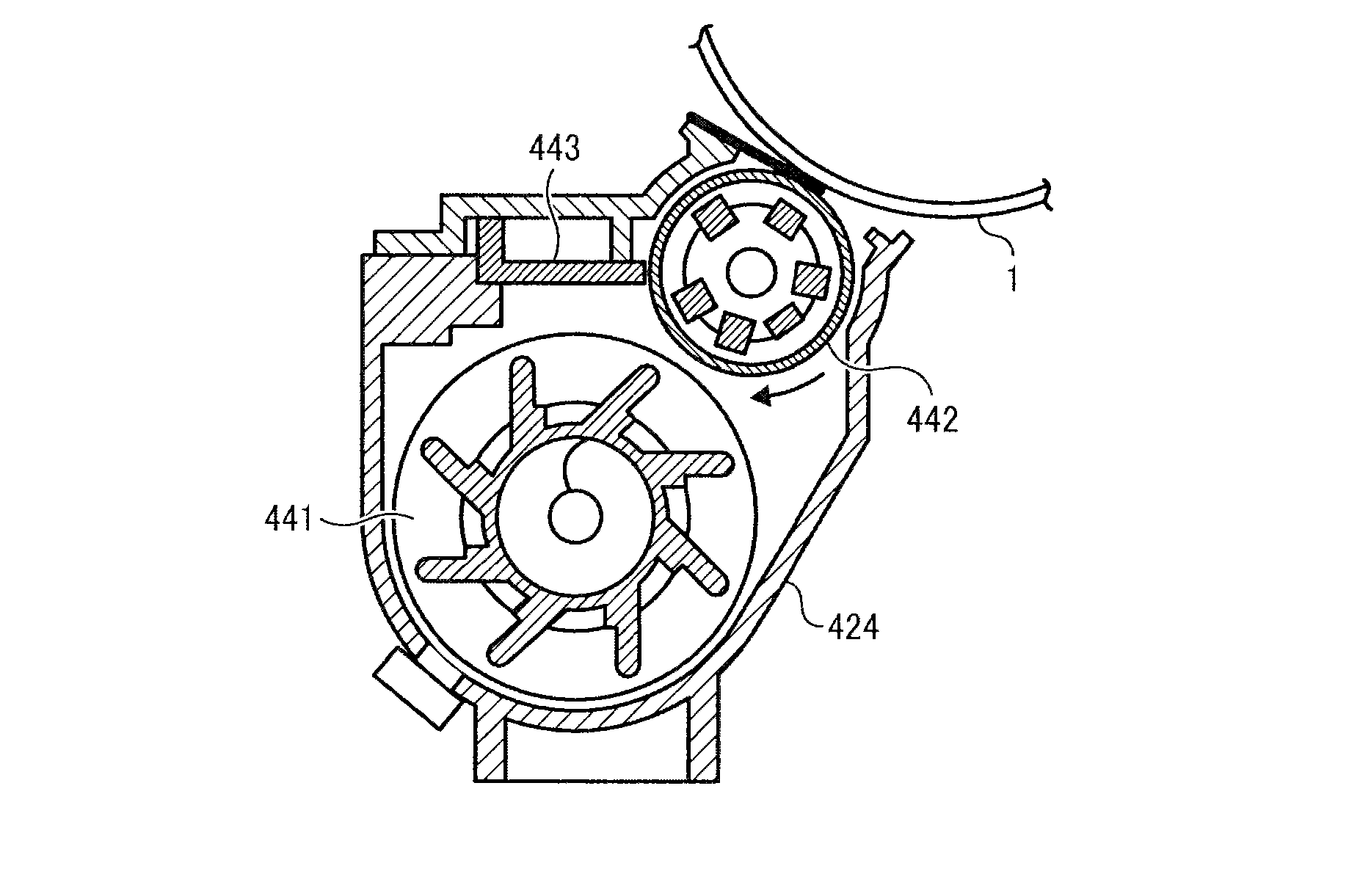

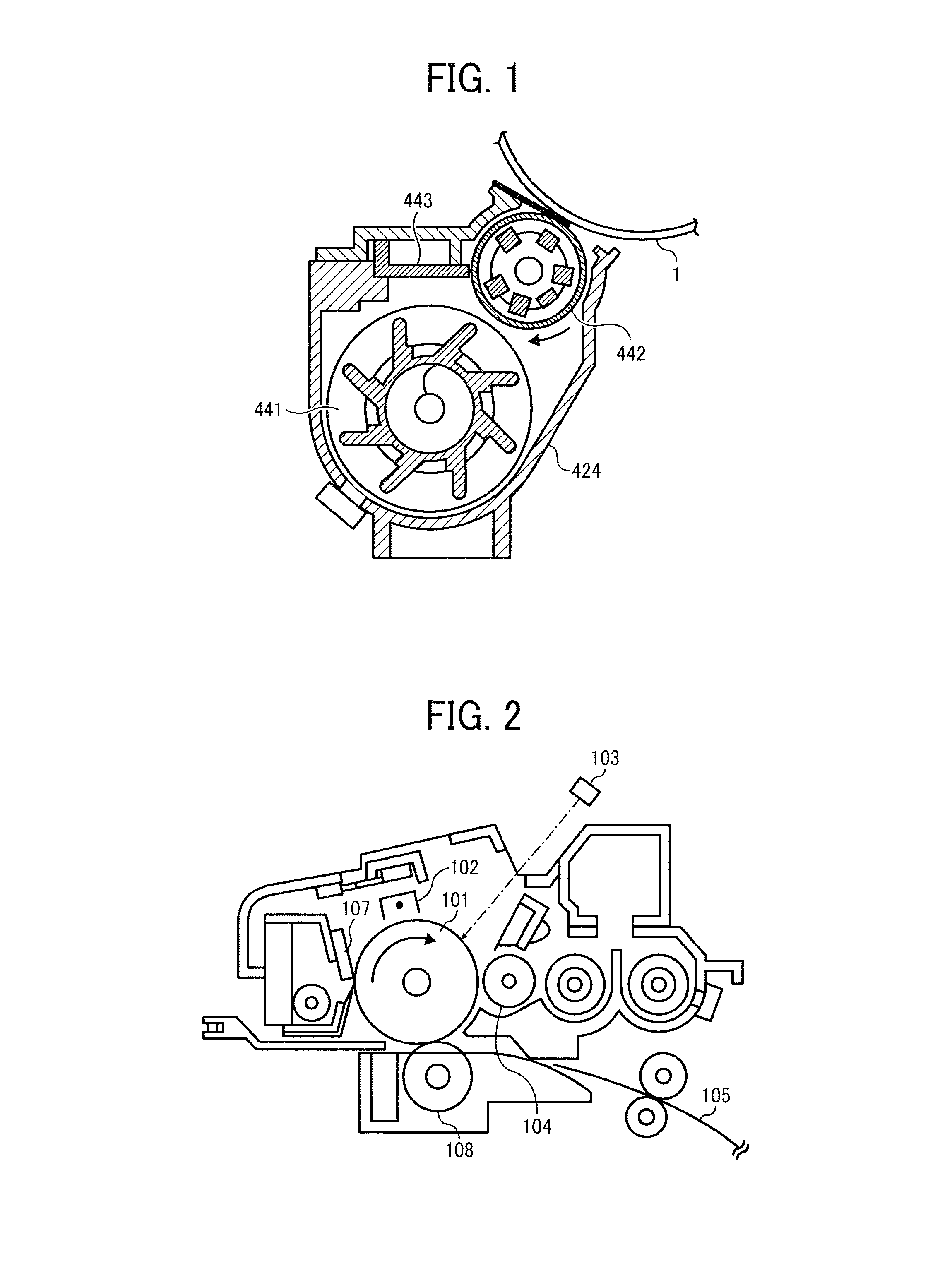

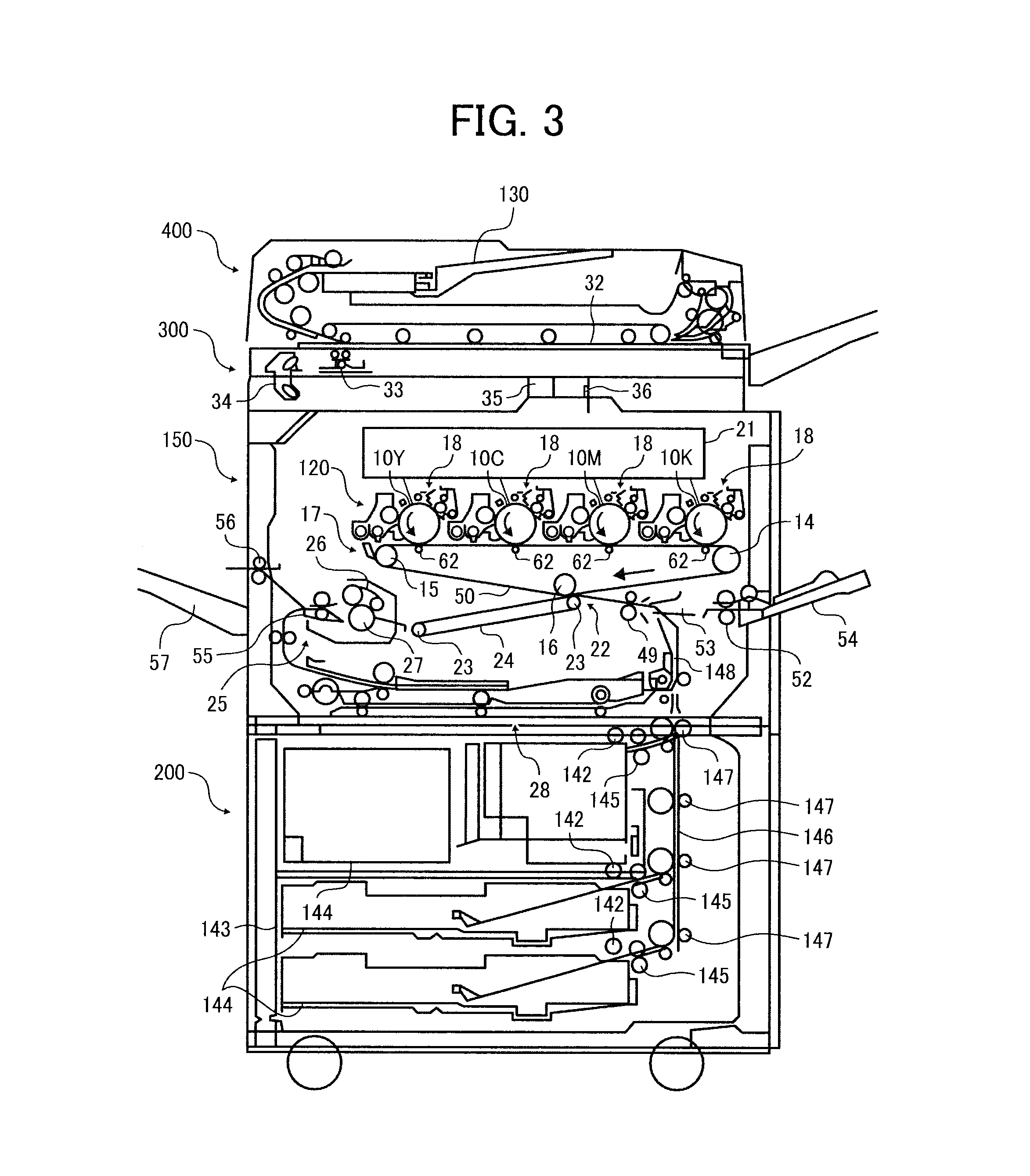

Toner and development agent, image forming apparatus, and process cartridge using the same

InactiveUS20130078563A1Readily apparentElectrographic process apparatusDevelopersCarbamateMicrocrystalline wax

A toner includes a coloring agent, a binder resin comprising a crystalline resin having a urethane skeleton and / or urea skeleton, and a releasing agent (a microcrystalline wax). A development agent, a process cartridge, and an image forming apparatus employ the toner to form images on recording media electrophotographically.

Owner:RICOH KK

Double-layer coated fertilizer and preparation method thereof

InactiveCN104609964AGood sustained releaseImprove water retentionFertilizer mixturesControl releaseMicrocrystalline wax

The invention discloses a double-layer coated fertilizer and a preparation method thereof. The double-layer coated fertilizer is composed of a core fertilizer, and an inner-layer coating material and an outer-layer coating material both covering the core fertilizer; the inner-layer coating material is microcrystalline wax; the outer-layer coating material comprises a water-retaining agent and a coating agent; the mass ratio of the core fertilizer, the inner-layer coating material and the outer-layer coating material is 100:(0.5-2):(3-20); the mass ratio of the water-retaining agent to the coating agent is 100:(5-30). The preparation method comprises the following steps: adding the core fertilizer and the inner-layer coating material to a coating machine, blasting air and heating until the inner-layer coating material is melted to cover the core fertilizer, thereby obtaining the fertilizer covered with the inner-layer coating material; 2) covering the fertilizer covered with the inner-layer coating material with the outer-layer coating material for at least once, thereby obtaining the double-layer coated fertilizer. The double-layer coated fertilizer has better controlled release and water retaining effects; the preparation method is simple; the coating agent is good in dissolving effect, and advantageous for coating; the production method is suitable for batch production.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Mine-type all-steel radial truck tire tread rubber and preparation method thereof

InactiveCN102276881AImprove crack resistanceImprove fracture resistanceMicrocrystalline waxCrack resistance

The present invention relates to a kind of preparation method of mine-type all-steel radial truck tire tread rubber, which comprises the following process steps: (1) masticating natural rubber, styrene-butadiene rubber and peptizer in a mixing chamber, and then adding charcoal black, silica, silane coupling agent, zinc oxide, stearic acid, plasticizer and anti-crack resin, continue mixing, then add carbon black for mixing, and finally inject aromatic oil for mixing, and carry out mixing after mixing Glue removal to obtain one section of masterbatch; (2) cooling one section of masterbatch to normal temperature; (3) mixing one section of masterbatch with carbon black, antioxidant A, antioxidant B and microcrystalline wax in the mixing chamber, mixing After refining, carry out debinding to obtain the second-stage masterbatch; (4) cool the second-stage masterbatch to normal temperature; (5) mix the second-stage masterbatch and sulfur, accelerator and anti-scorch agent in the mixing chamber, mix After the rubber is discharged, the finished tread rubber is obtained. The invention can improve the crack resistance, fracture resistance, fatigue resistance and impact resistance of the radial tire tread.

Owner:JIANGSU GENERAL SCI TECH

Ultra-high-pressure steel wire winding composite hose

ActiveCN104100783AImprove stress resistanceImprove pulse lifeFlexible pipesPolymer scienceMicrocrystalline wax

The invention discloses an ultra-high-pressure steel wire winding composite hose, which comprises an inner rubber pipe, a framework layer, a middle rubber layer and an outer rubber layer, wherein the framework layer is arranged outside the inner rubber pipe, the middle rubber layer and the framework layer are made into a whole, the outer rubber layer is arranged outside the middle rubber layer, inner rubber of the inner rubber pipe is prepared from the following ingredients including nitrile rubber, high styrene rubber, solution polymerized styrene-butadiene rubber, sulphur S, vulcanizing agents DTDM, vulcanization accelerators CZ, accelerators D, nanometer zinc oxides, stearic acid, scorch retarders CTP, flowing exhaust agents SC617, integral anti-aging agents 4020, anti-aging agents BLE, microcrystalline wax, carbon black, nanometer silicon dioxide, bonding agents RC, bonding agents RC-23, tackifying resin SP1068, dioctyl sebacate and polyolefin, and the middle rubber layer and the outer rubber layer are respectively made of different materials. The rubber pipe belongs to the ultra-high-pressure steel wire winding composite hose capable of bearing the pressure as high as 50 to 300 Mpa, and belongs to an ultra-high-pressure hydraulic rubber pipe meeting the requirements of engineering machinery and oil drilling.

Owner:河南亿博科技股份有限公司

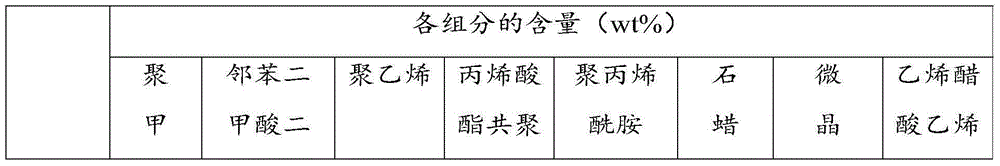

Binding agent for powder injection moulding, preparation method and application method of binding agent

The invention provides a binding agent for powder injection moulding, a preparation method of the binding agent and an application method of the binding agent. The binding agent is mainly prepared from the following components in percentage by mass: 65 to 75 percent of polyformaldehyde, 4 to 9 percent of dioctyl phthalate, 6 to 13 percent of polyethylene, 1 to 3 percent of acrylate copolymer, 3 to 8 percent of polyacrylamide, 1.5 to 4 percent of paraffin, 2 to 6 percent of microcrystalline wax and 0.5 to 2 percent of ethylene vinyl acetate copolymer. In the binding agent provided by the invention, multiple types of components are combined through scientific compatibility, so that the compatibility between metal powder or ceramic powder and the binding agent can be obviously improved, and meanwhile, the binding agent can be quickly removed in a degreasing process without causing the defects of bubbling and cracking of a green body, so as to guarantee the quality of the green body.

Owner:王有才

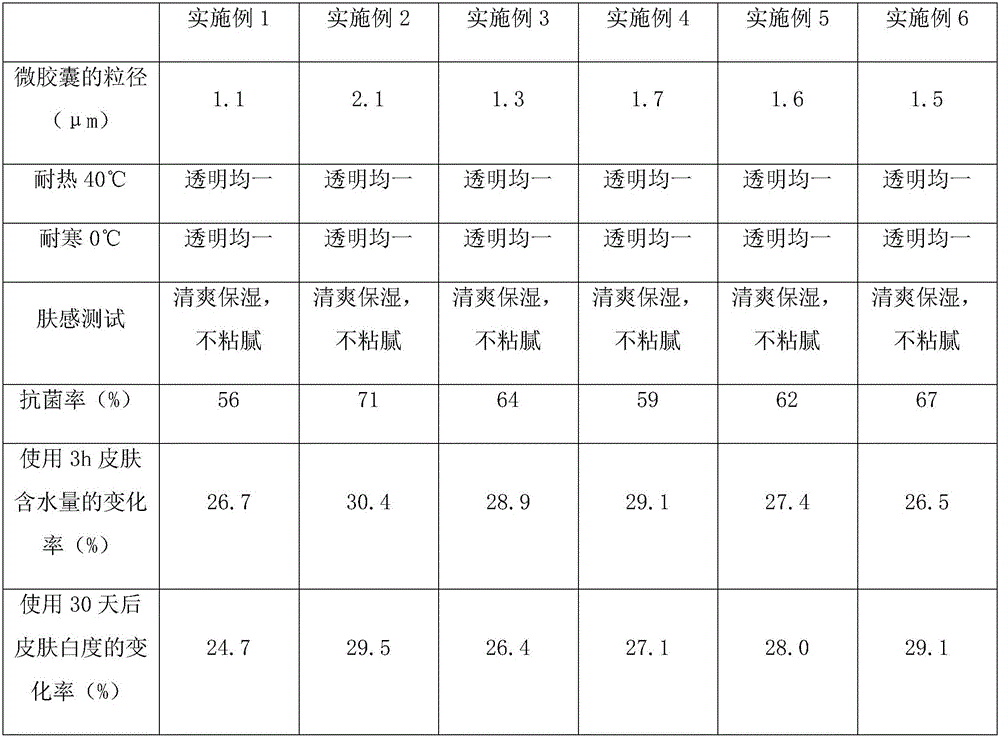

Herbaceous plant nutritive water based on emulsified microcapsule and preparation method of herbaceous plant nutritive water

InactiveCN105726456AGood skin tightening effectRich in nutrientsCosmetic preparationsToilet preparationsWater basedVegetable oil

The invention provides herbaceous plant nutritive water based on an emulsified microcapsule and a preparation method of the herbaceous plant nutritive water. The preparation method comprises the following specific steps: mixing hydrogenated vegetable oil, low erucic acid rapeseed oil , siloxane, microcrystalline wax and diglycerol, heating and uniformly stirring, and performing heat reservation and sterilization to obtain an oil phase; adding ethylene glycol, propylene glycol, glycine betaine, urea, poly-sodium glutamate, triethanolamine, caprylhydroxamic acid and hexylene glycol into deionized water, heating and uniformly stirring, performing heat preservation and sterilization to obtain a water phase; adding the oil phase into the water phase, performing heating, homogenization and low-speed stirring, adding cetyl ethyl hexanoate and stearic acid, then slowly adding PEG-40 hydrogenated castor oil and a microcapsule wall material, cooling, adding tremella, centella asiatica, polygonum cuspidatum, scutellaria baicalensis, tea leaves, glycyrrhiza glabra, female chrysanthemum, rosemary leaves, beer saccharomycete and grape fruit cell extract active components, and adding chondrus crispus extracts, bio-saccharide gum-1, diglycerol, palmitoyl tripeptide-1 and essence for mixing to obtain the herbaceous plant nutritive water based on the emulsified microcapsule.

Owner:广州市有喜化妆品有限公司

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

Formula of tread of low-rolling-resistance tire and preparation method thereof

ActiveCN103450508AHigh viscoelasticityReduce rolling resistanceTyresSpecial tyresPolymer scienceMicrocrystalline wax

The invention discloses a formula of a tread of a low-rolling-resistance tire and a preparation method thereof. The formula of the tread of the low-rolling-resistance tire comprises the following components: 10-20% of natural rubber, 10-20% of polybutadiene rubber, 20-40% of solution polymerized styrene butadiene rubber, 20-40% of high-dispersion white carbon black, 0.5-1% of a peptizer A-8, 1-2% of a chemical anti-aging agent 6PPD, 1-2% of a physical anti-aging agent microcrystalline wax, 1-3% of an active agent ZNO, 1-3% of an active agent SA, 1-3% of polyethylene glycol PEG, 1-3% of a vulcanizing agent S-325, 1-3% of an accelerant NS, 0.1-0.8% of a special accelerant CTP and 4-8% of a coupling agent SI69. The formula of the tread of the low-rolling-resistance tire has the beneficial effects that the rolling resistance of the tire is low and can reach an A level or a B level, various physical and mechanical properties of the tire are basically consistent to those of a tire having non-low rolling resistance, and the advantages of road holding of the tire on a wetland and a dry land are retained.

Owner:KENDA RUBBER CHINA

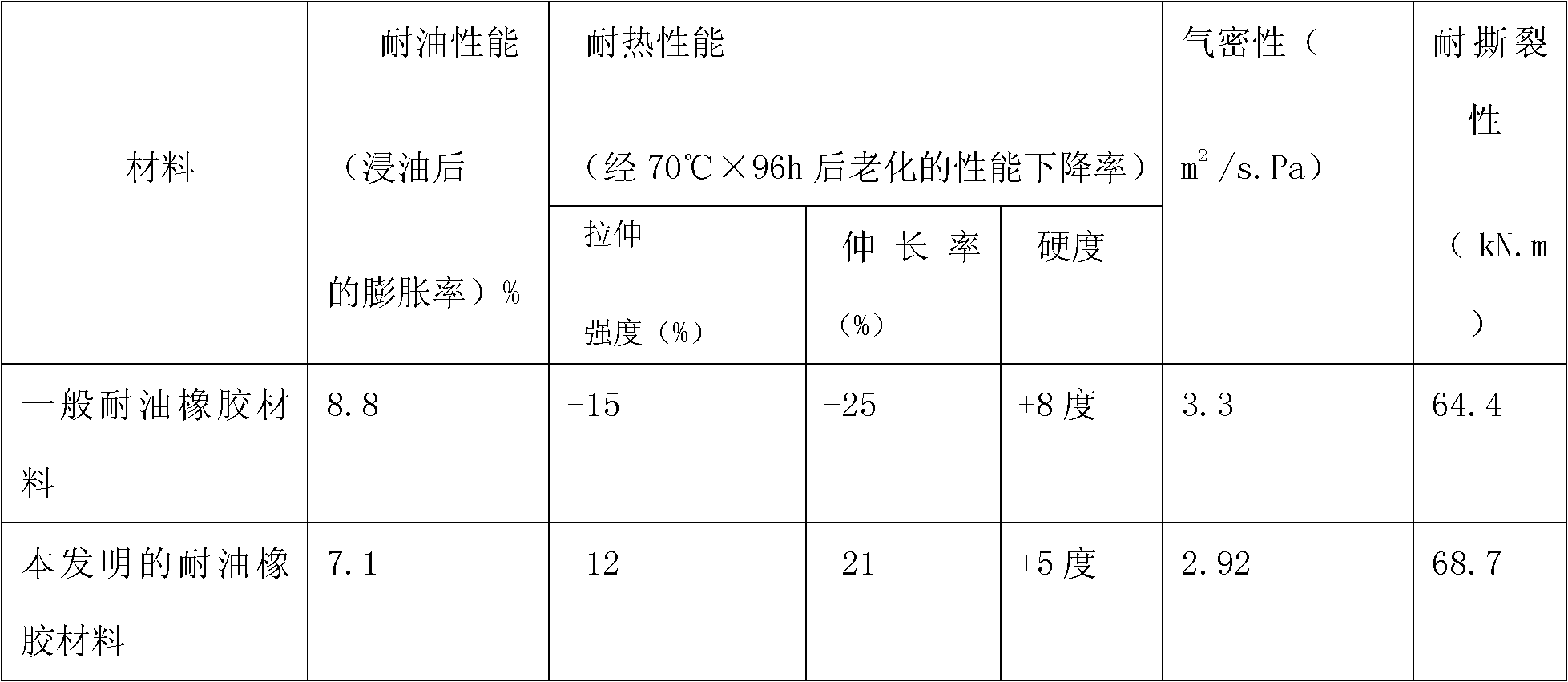

Oil resistant sealing member rubber material and preparation method thereof

The invention discloses an oil resistant sealing member rubber material prepared from equal-proportioned and mixed components of an A rubber material and a B rubber material. The A rubber material comprises components of, by weight: 85 to 95 parts of butyronitrile rubber N41, 0.3 to 0.5 parts of sulfur, 4 to 6 parts of zinc oxide, 3 to 4 parts of stearic acid, 1 to 2 parts of an anti-aging agent RD, 1 to 2 parts of an anti-aging agent 4010NA, 3 to 4 parts of micro-crystalline wax, 22 to 25 parts of fast extruding furnace carbon black N660, 62 to 65 parts of high abrasion furnace black N330, 18 to 22 parts of DOP, 25 to 35 parts of calcium sulfate, 3 to 4 parts of a promoter DM, 1 to 2 parts of a promoter TMTD, and 1 to 2 parts of a promoter TETD. The B rubber material comprises components of, by weight: 82 to 87 parts of unitary homo-polymerized chlorohydrin rubber, 12 to 18 parts of copolymerized chlorohydrin rubber, 1 to 2 parts of zinc stearate, 1 to 3 parts of an anti-aging agent RD, 0.4 to 0.6 parts of Gum Easy T-78, 1 to 2 parts of clariant wax, 45 to 55 parts of fast extruding furnace carbon black, 10 to 14 parts of diatomite, 5 to 8 parts of DOP, 4 to 6 parts of dilead tetraoxide 0.4 to 0.6 parts of sulfur, and 1 to 2 parts of a promoter Na-22. Oil resistant sealing members (oil cylinder sealing members) produced from the rubber material provided by the invention has good oil resistance, heat resistance, air-tightness, flame retardance, tearing resistance, and low cost.

Owner:芜湖禾田汽车工业有限公司

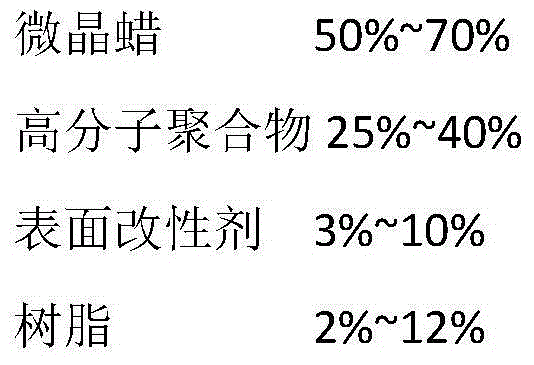

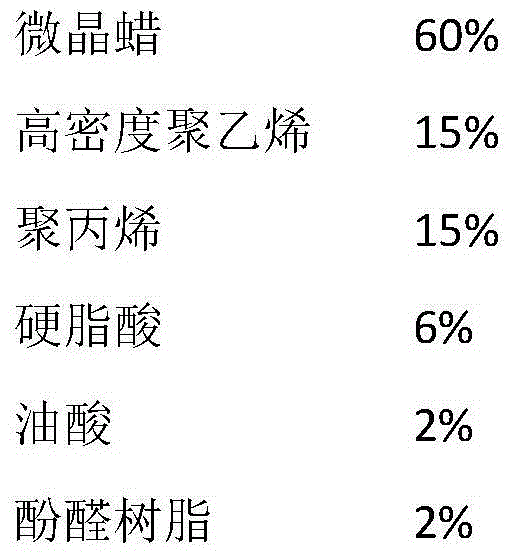

Adhesive agent for injection molding of aluminum nitride ceramic and application method of adhesive agent

The invention belongs to the technical field of ceramic material preparation and discloses an adhesive agent for injection molding of aluminum nitride ceramic and an application method of the adhesive agent. The adhesive agent comprises the following ingredients: 50-70% of microcrystalline wax, 25-40% of high polymer, 3-10% of surface modifier and 2-12% of resin. The application method of the adhesive agent comprises the following steps of mixing aluminum nitride powder and the adhesive agent, putting in a mixing mill for heating and mixing to prepare a feed, carrying out the injection molding to prepare a green body, preparing a degreased blank after degreasing, carrying out high-temperature sintering at last to form a finish product. In a sintering process, heat preservation is carried out at a specific temperature point to achieve carbon thermal reduction to further reduce an oxygen content, and then the temperature is raised to the maximum temperature for sintering and compacting. The adhesive agent has excellent liquidity and shape preserving property, and a specific carbon residue rate after thermal degreasing, and the aluminum nitride ceramic prepared by the adhesive agent has upper heat conductivity.

Owner:UNIV OF SCI & TECH BEIJING

Thermoplastic polymer propellant compositions

Owner:CESARONI ANTHONY JOSEPH

Automobile cleaning water wax and preparation method thereof

InactiveCN103614083ASave flushingOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsParaffin waxAlcohol

The invention discloses automobile cleaning water wax and a preparation method thereof, and relates to cleaning wax and a preparation method thereof. The wax comprises the following components in percentage by weight: 1% of beewax, 2% of liquid paraffin, 5% of microcrystalline wax, 2% of a compound abradant, 13% of a compound emulsifying agent, 2% of cosurfactant lower alcohol, 2% of methylsilicone oil, 10% of solvent oil and the balance of deionized water. As water is used as a solvent of the wax, no water is needed when the wax is used, an automobile can be rapidly cleaned, and the surface brightness is improved. The wax can be sprayed on the surface of the automobile, soft wax and hard wax are perfectly matched, fine scratch can be eliminated, the paint can be protected, and dirt can be eliminated and the surface is bright and smooth when the wax is wiped off with a piece of dry cloth, so that the wax is simple to operate and convenient to use.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Toner, developer, developer container, method of manufacturing toner, and image forming method

InactiveUS20110129773A1DevelopersElectrographic processes using charge patternPolyesterMicrocrystalline wax

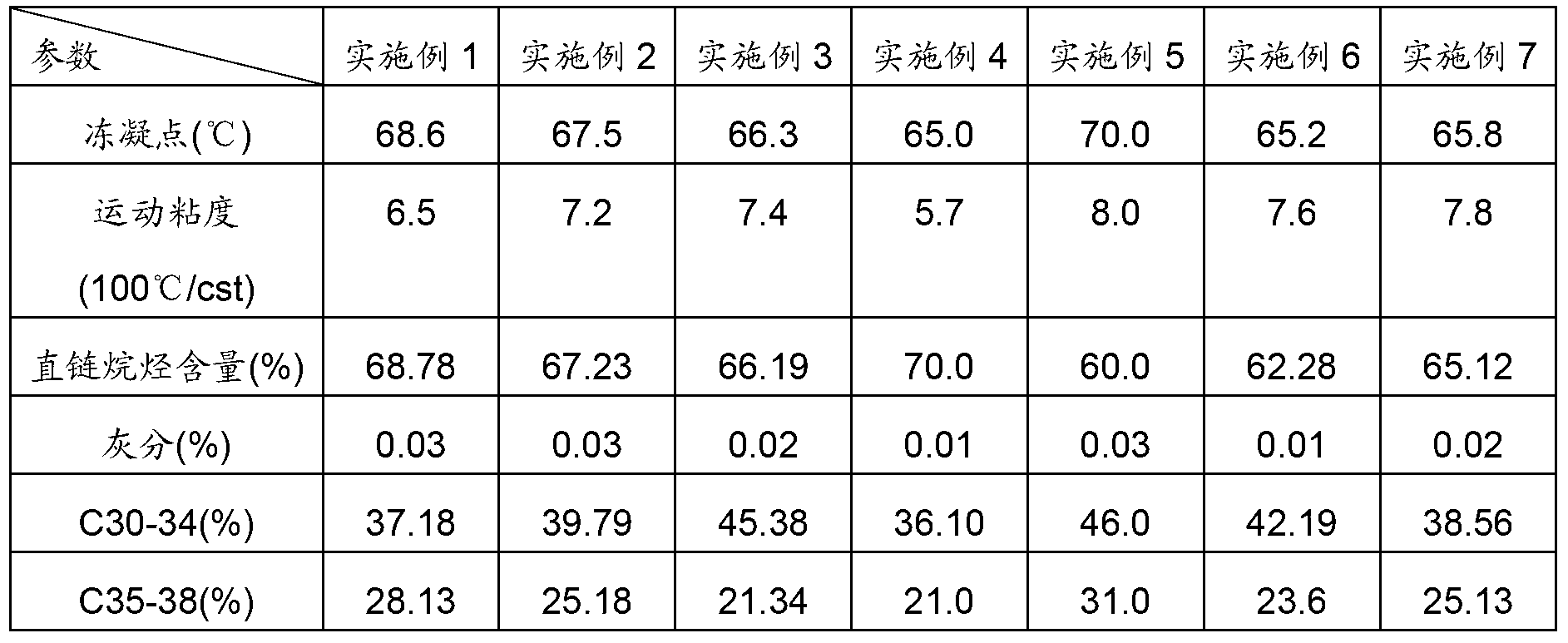

A toner including a binder resin comprising a modified polyester having an ester bond and a chemical bond other than the ester bond, and a crystalline polyester; and a release agent comprising a microcrystalline wax comprising a hydrocarbon having 20 to 80 carbon atoms which comprises 55 to 70% by weight of a linear hydrocarbon. The microcrystalline wax has an acid value of from 0.1 to 20 mgKOH / g and a melting point of from 65 to 90° C. The melting point is a temperature at which a local maximum endothermic peak is observed in a differential thermal curve measured by differential scanning calorimetry (DSC). The release agent is dispersed in the toner with a dispersion diameter of from 0.06 to 1.50 μm.

Owner:RICOH KK

Matt lipstick and preparation method thereof

InactiveCN107496216AMaintain and enhance structureMaintain and Enhance FunctionCosmetic preparationsMake-upMicrocrystalline waxIrritation

The invention provides a matte lipstick, which comprises the following components in mass percentage: ozokerite 1-10%, carnauba (COPERNICIA CERIFERA) wax 1-5%, pentaerythritol tetrastearate 5-15%, bis- Diglycerol Polyacyl Adipate‑2 1‑5%, Microcrystalline Wax 1‑5%, Hydrogenated Polycyclopentadiene 1‑5%, Beeswax 1‑5%, Diisostearyl Malate 5‑ 15%, Phenyl Trimethicone 1‑5%, Dimethicone / Vinyl Dimethicone Crosspolymer 1‑5%, Capryl Methicone Alkanes 1-10%, Polyglyceryl-3 Diisostearate 0.1-3%, Star Fruit Palm Fruit Oil 1-5%, Toner 10-20%, Mica 1-10%, Polypropylene 1-5% , silica 1‑10%, polyglyceryl‑2 triisostearate balance. In the present invention, the dosage and physical and chemical properties of each raw material are carefully selected to produce a coordination effect, and a lipstick different from the prior art is obtained, which has little irritation, good compatibility and anti-allergy.

Owner:FOSHAN JIAOFU BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com