Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3166 results about "Interface bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

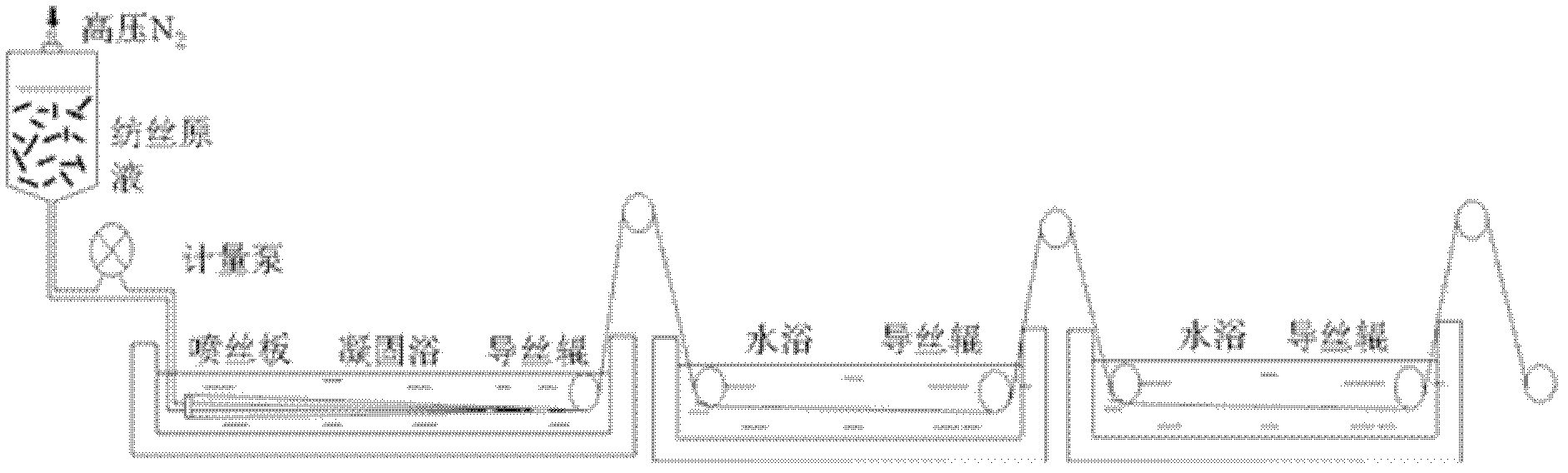

Preparation method of graphene modified nylon 6 fiber

ActiveCN103215689AImprove performanceImprove interfacial bond strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberNylon 6

The invention relates to a preparation method of a graphene modified nylon 6 fiber and belongs to the technical field of a functional fiber material. The preparation method comprises the following steps of: carrying out carboxylation and acylating chlorination treatment on graphene; then carrying out diamine treatment to obtain graphene oxide with an active amino on the surface; carrying out polymerization reaction by utilizing the aminated graphene and caprolactam through an initiator 6-aminocaproic acid to prepare a modified nylon 6 melt of the graphene; and carrying out spinning and stretching through a fusion and spinning process to obtain the graphene modified nylon 6 fiber. The technical scheme of the invention utilizes aminated graphene enhanced 6 to improve the interface bonding strength with a base resin, so as to be good for improving the whole performance of the graphene modified nylon 6 fiber. A fiber material prepared by the preparation method provided by the invention can be widely applied to the technical fields of aerospace, cars and ships, communication and transportation, mechano-electronics and the like.

Owner:SUZHOU UNIV

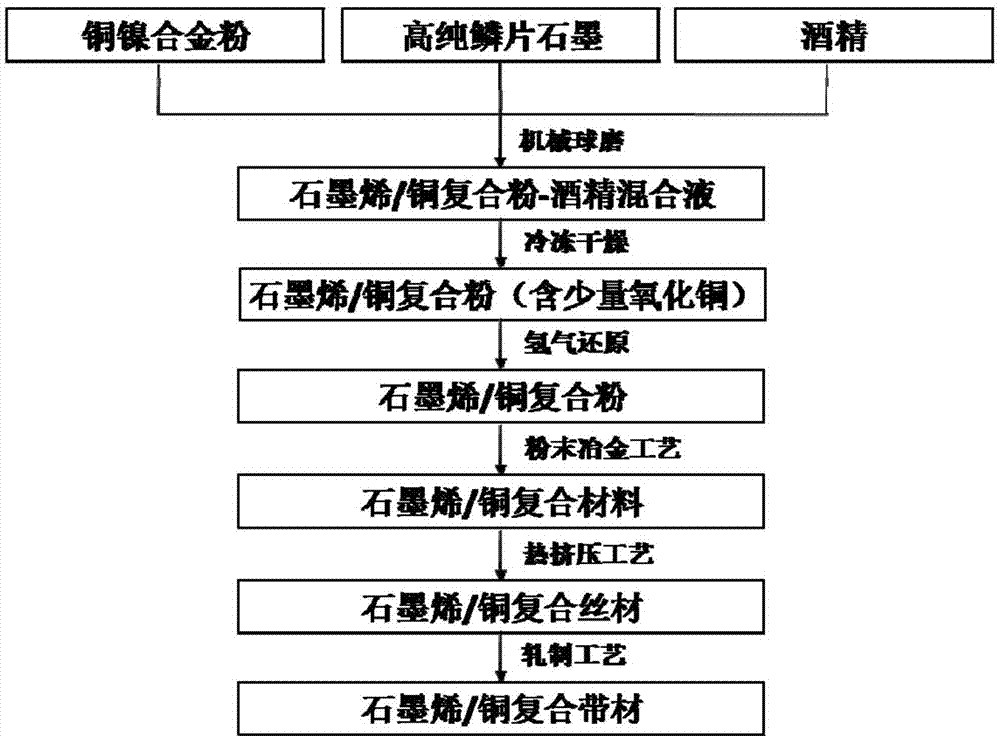

Graphene/copper composite and preparation method thereof

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

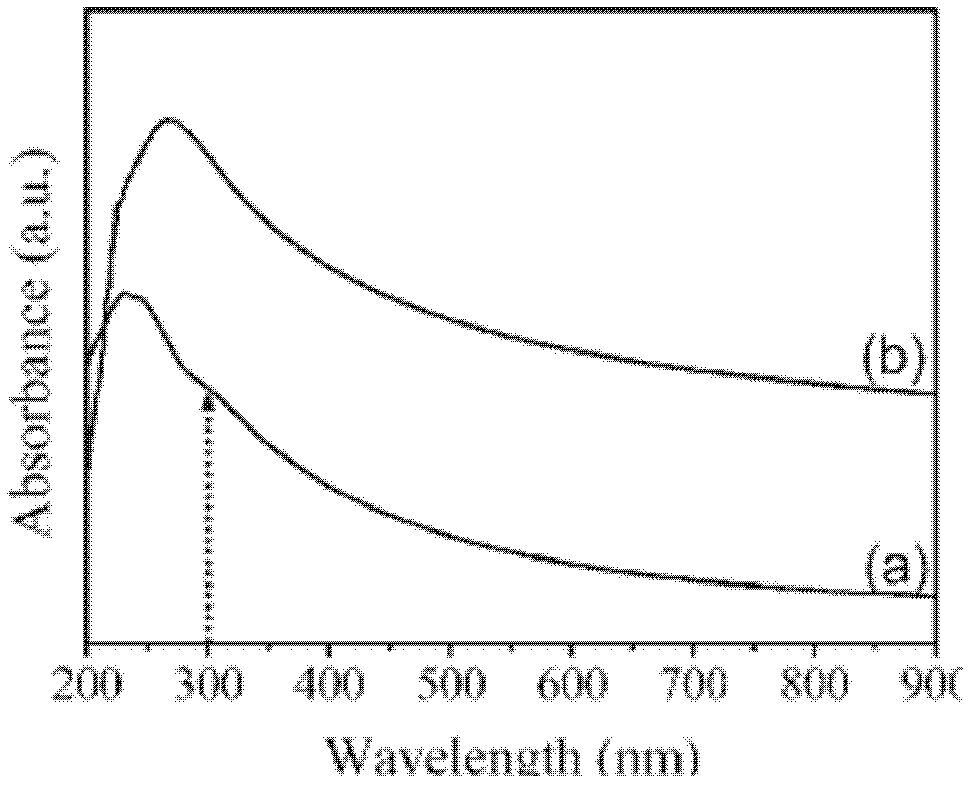

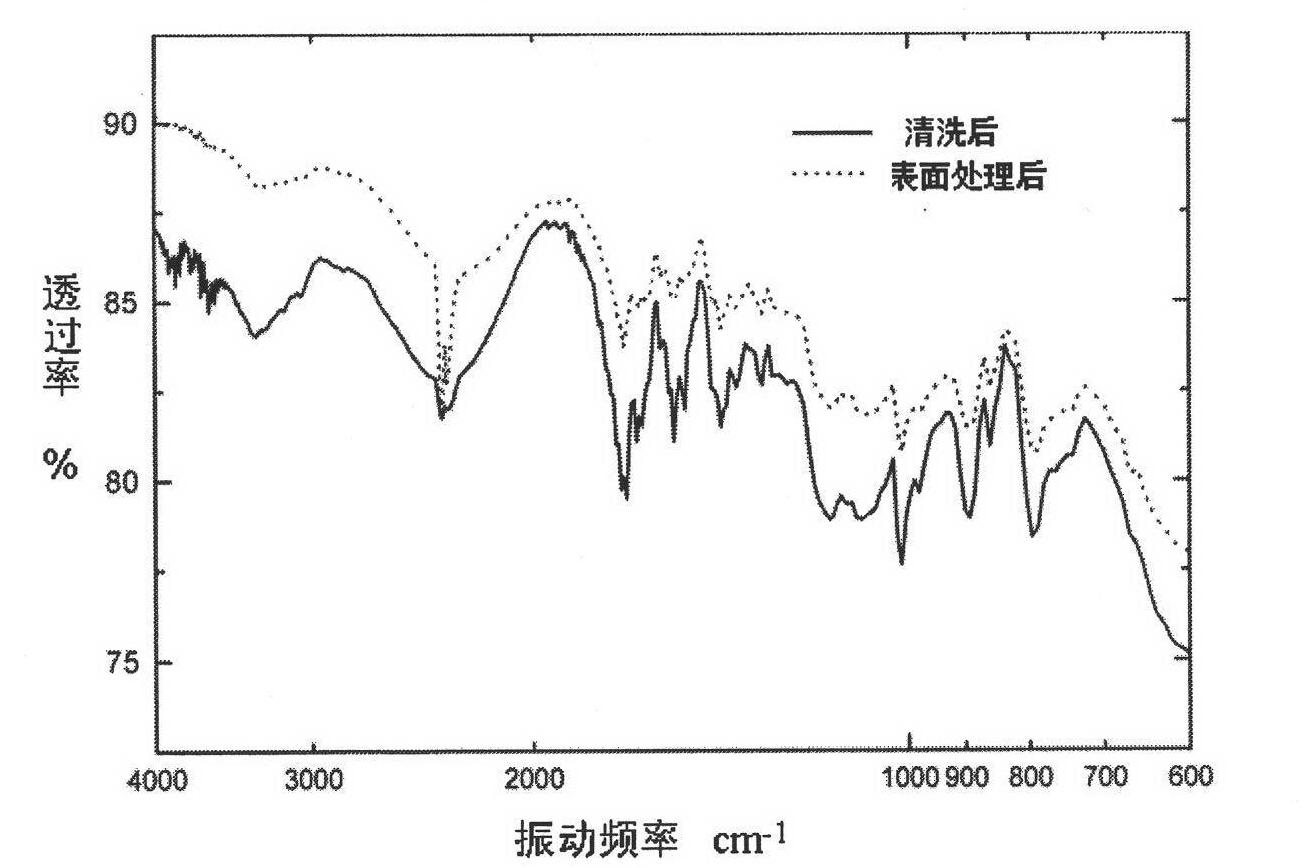

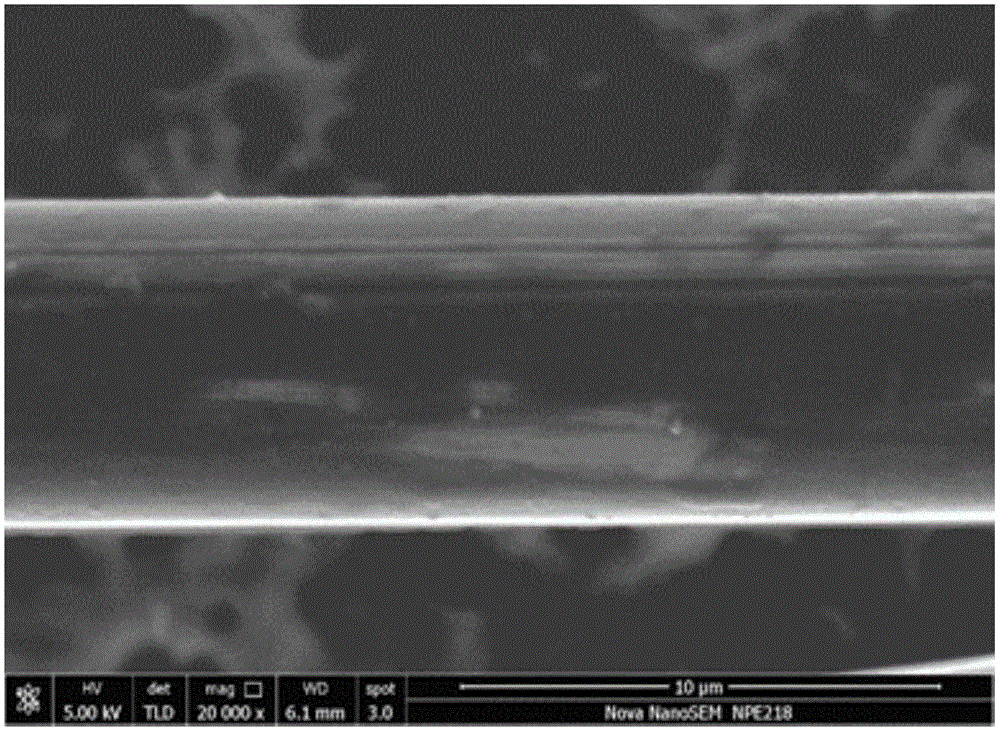

Method for preparing graphene-reinforced polyacrylonitrile carbon fibers

InactiveCN102586952AGood dispersionImprove bindingArtifical filament manufactureCarbon fibersCvd graphene

The invention relates to a method for preparing graphene-reinforced polyacrylonitrile carbon fibers. The method comprises the following steps of: (1) preparing graphene or graphene oxide; (2) preparing a graphene / polyacrylonitrile spinning solution; (3) preparing graphene / polyacrylonitrile-based composite fibers; and (4) preparing graphene / polyacrylonitrile-based carbon. By the method, the dispersibility and interface bonding strength of the graphene oxide in a polymer matrix are effectively improved, and the comprehensive performance of the carbon fibers is further improved; the mechanical properties of the prepared carbon fibers are obviously improved, and the prepared carbon fibers can be used in the fields such as material reinforcement, electric conduction, anti-static electricity and heat conduction; and moreover, the preparation process is simple, easy to control and low in cost.

Owner:DONGHUA UNIV

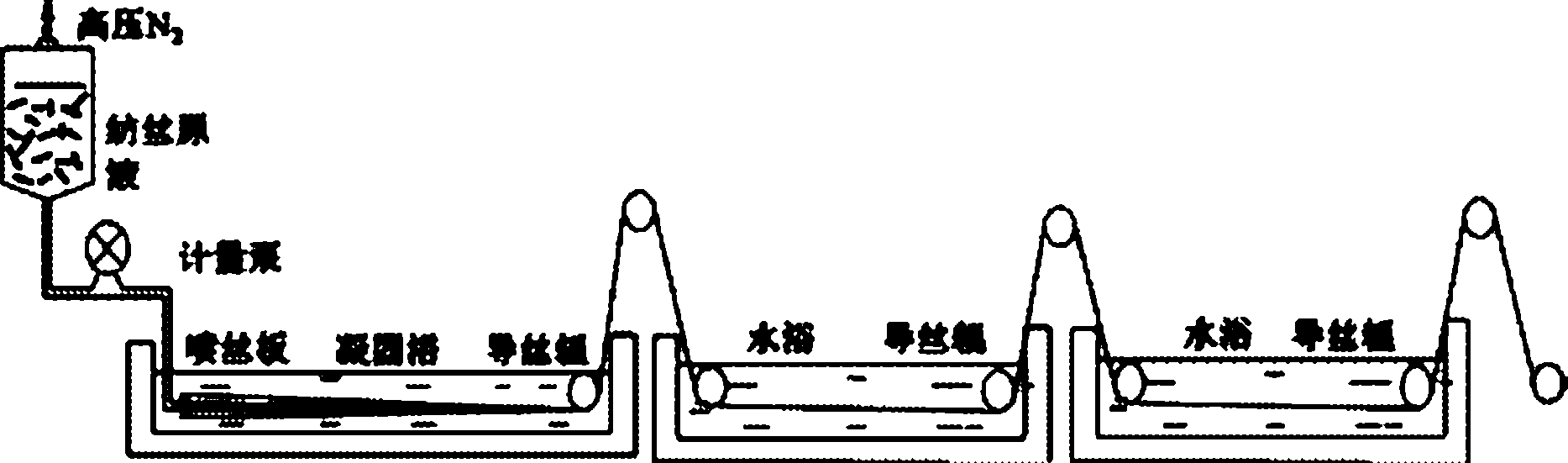

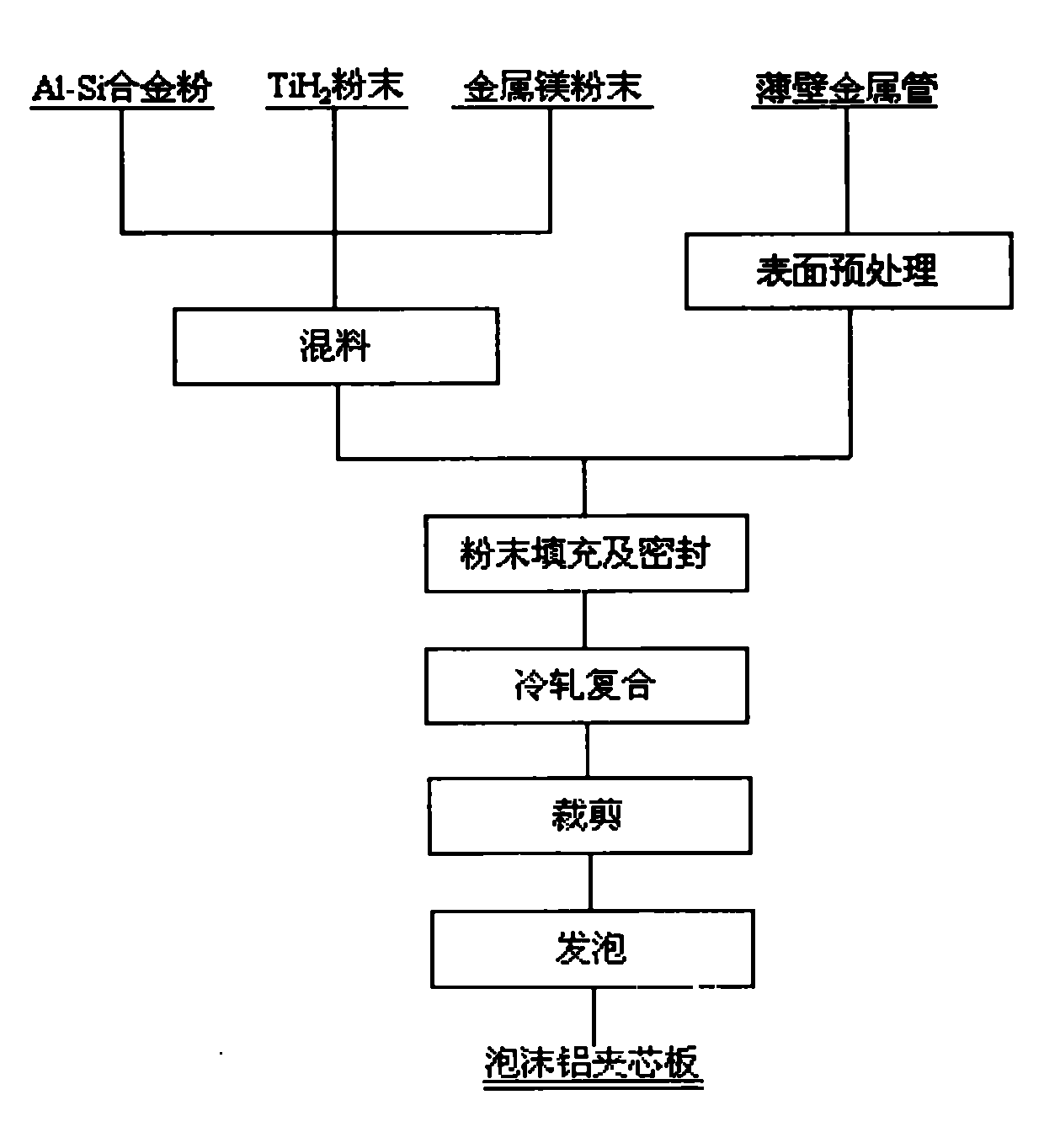

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

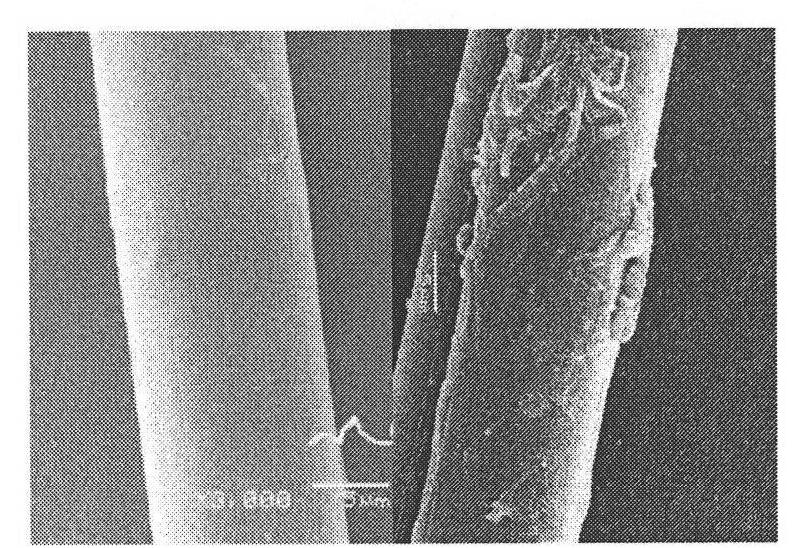

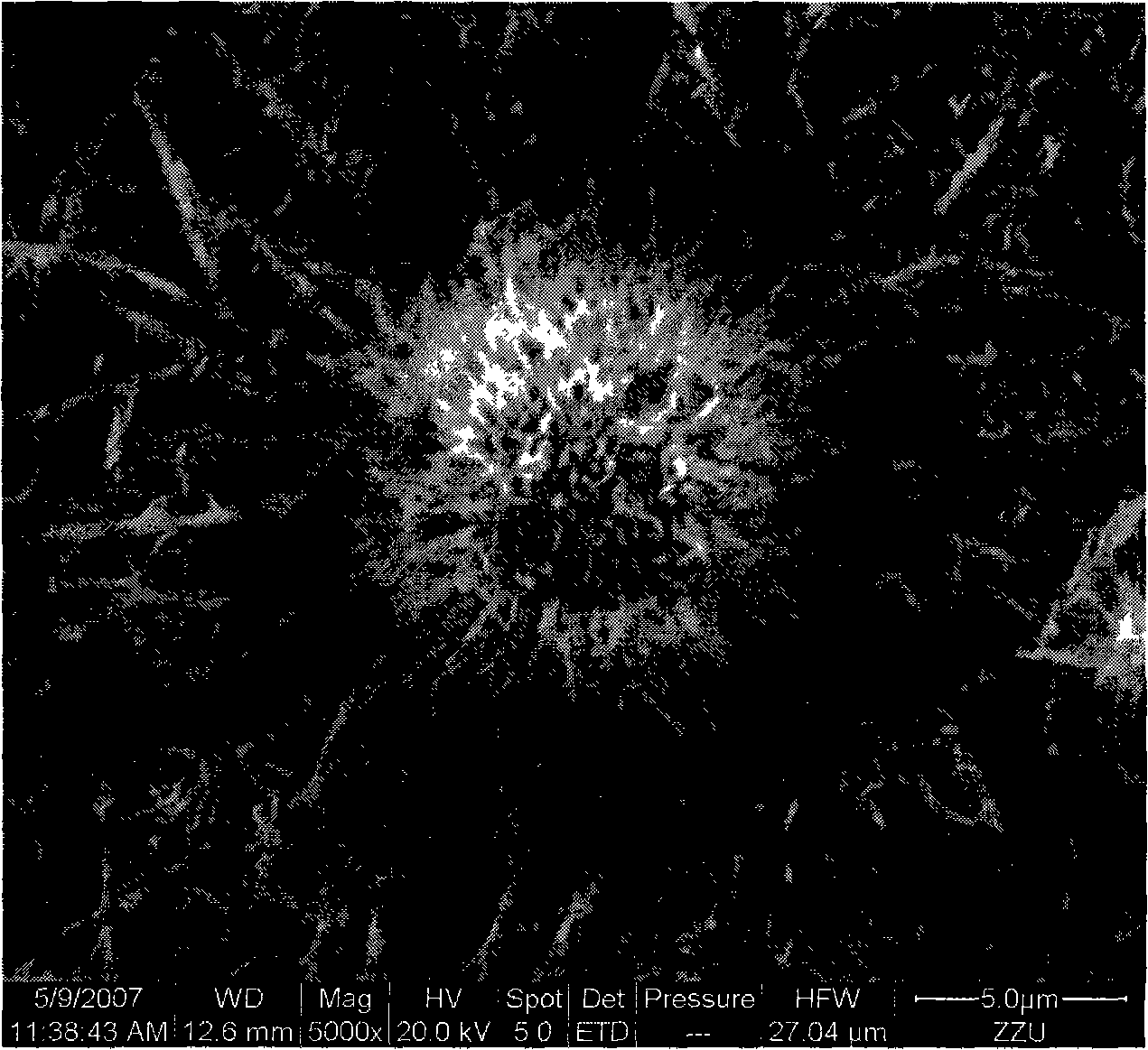

Method for modifying aramid fiber by using carbon nano tubes

InactiveCN101831800AImprove adhesionImprove mechanical propertiesPhysical treatmentFibre typesEpoxyResearch Object

The invention relates to a method for modifying aramid fiber by using carbon nano tubes, which comprises the following steps of: selecting an epoxy resin / aramid fiber composite material as a research object, selecting the carbon nano tubes as a surface modification material, forming free amino groups in a certain ratio on the aramid fiber by a chemical modification method, soaking the aramid fiber into N-methylpyrrolidone solution (NMP), and reacting the solution and the surface carboxylation carbon nano tubes with the aid of ultrasonic, wherein part of carbon nano tubes enter the interior of Kevlar fiber, and the other part of carbon nano tubes are fixed on the surface of the fiber through amido bonds formed by the carbon nano tubes and amino, thus, a aramid fiber complex inside and outside which the carbon nano tubes are doped is formed. Single fiber tensile test results and single fiber pull-out test results show that the mechanical property of the modified aramid fiber and the interface bonding strength with the epoxy resin are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

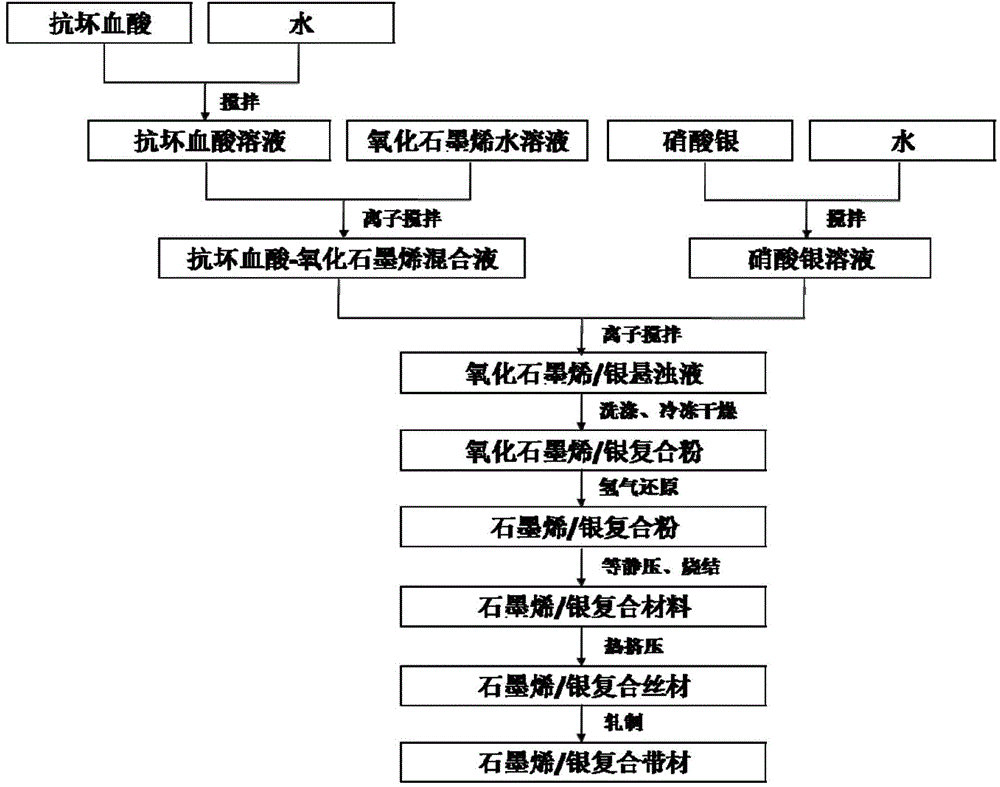

Graphene/silver composite material and preparation method thereof

ActiveCN104700961AEvenly distributedTo achieve the effect of continuous productionMetal/alloy conductorsCarbon-silicon compound conductorsReducing agentGraphite oxide

The invention provides a graphene / silver composite material and a preparation method thereof. The preparation method comprises the steps of adding a reducing agent and silver nitrate successively into a graphene oxide solution, combining silver powder obtained by reduction and graphene oxide in the solution, so as to obtain graphene oxide / silver composite powder; drying the graphene oxide / silver composite powder to obtain graphene / silver composite powder; and obtaining graphene / silver composite blocks, composite wires and composite strips through powder metallurgy, hot extrusion and rolling techniques. According to the graphene / silver composite material and the preparation method provided by the invention, the graphene is dispersed uniformly in the composite material, the interface bonding between a substrate and an enhanced body is good, and the composite materials is excellent in physical performance; meanwhile, the preparation method is simple in process, is likely to control the process and likely to realize large-scale production and application.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

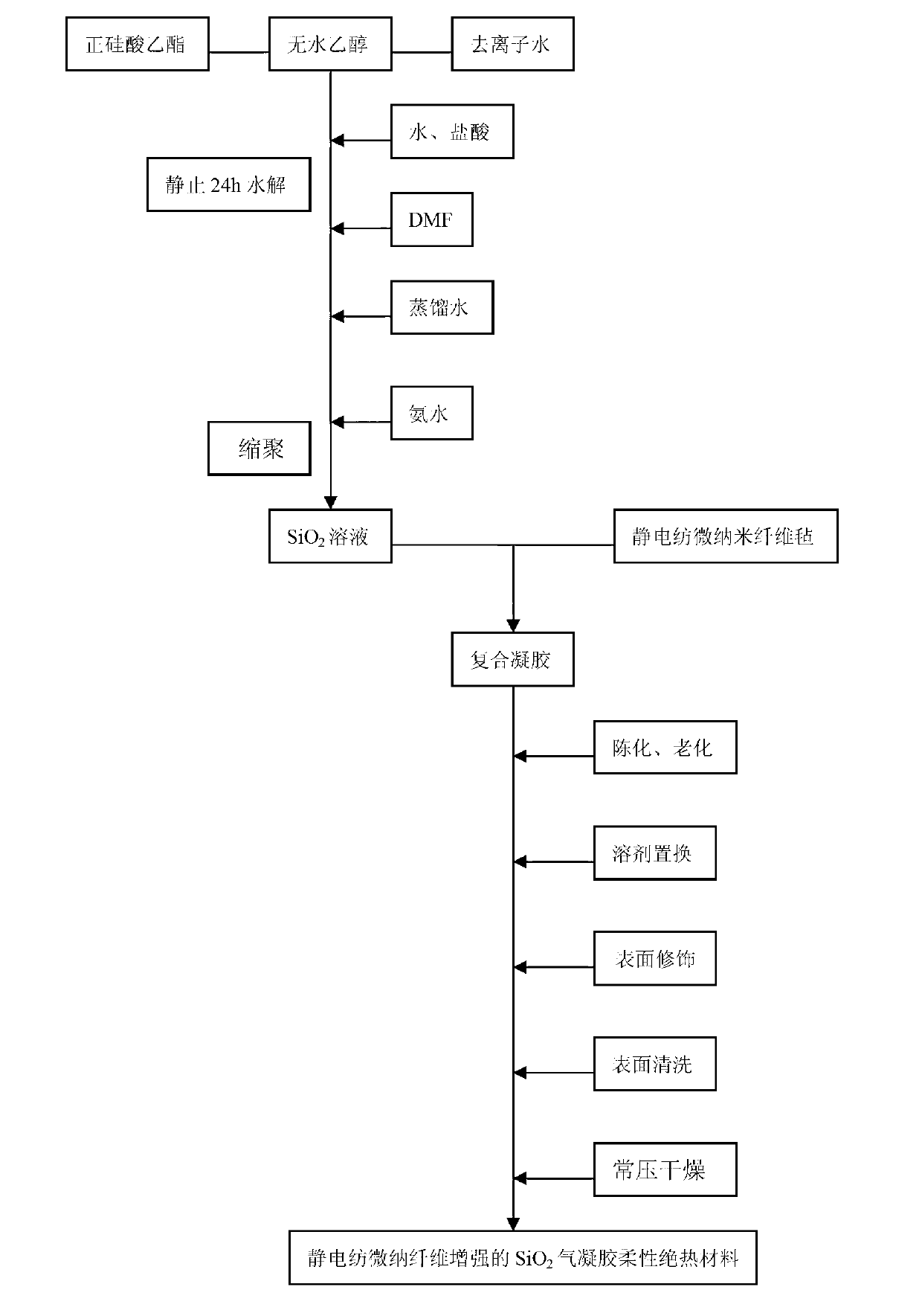

Electrospun micro-nanofiber reinforced aerogel flexible thermal insulation material and its preparation method

ActiveCN103102135AImprove thermal conductivityImprove heat transfer performanceMicro nanoPolymer science

Belonging to the field of heat preservation and thermal insulation materials, the invention puts forward an electrospun micro-nanofiber reinforced aerogel flexible thermal insulation material and its preparation method. The method takes electrospun micro-nanofiber as a reinforcement body, which is mixed with an SiO2 sol. A sol-gel process is employed to prepare an electrospun micro-nanofiber and aerogel composite thermal insulation material with a stable structure under normal temperature and pressure conditions. The method provided in the invention employs micro-nanoscale electrospun micro-nanofiber to reinforce the aerogel, so that the composite material can have better flexibility, interface bonding property and structural integrity. While the mechanical properties of the aerogel thermal insulation composite material are improved, the material also can maintain good thermal insulation performance.

Owner:吴会军

Preparation method of titanium-steel composite plate

InactiveCN101992344ASolve easy oxidationIncreased interfacial shear strengthLaminationLamination apparatusComposite plateVacuum chamber

The invention relates to a preparation method of a composite steel plate, in particular to a preparation method of a titanium-steel composite plate. The preparation method comprises the following steps of: firstly selecting titanium plates and steel plates which have equal width and length and removing rusty layers and oxide layers; then making surfaces of the titanium plates and the steel plates opposite, and completely coinciding to form a combined blank; then sealing up the periphery of the combined blank by taking four titanium plates as side seal plates, and clamping the side seal plates and the combined blank by using a clamp and then putting the side seal plates and the combined blank into a vacuum chamber together; tightly welding all contact seams of the combined blank and the side seal plates, then conveying the combined blank and the side seal plates into a heating furnace together and heating to 600-1200 DEG C, and carrying out heat preservation for 0.1-2h; and finally, conveying the heated combined blank into a rolling mill for rolling to obtain the titanium-steel composite plate with the interface bonding strength of 350MPa. The invention well solves the problem that the interface of the titanium-steel composite plate is oxidized and improves the interface bonding strength of the composite plate, and moreover, argon or brazing filler metal does not need to be added, thereby saving the cost and simplifying the flow of the production process.

Owner:沈阳科安捷材料技术有限公司

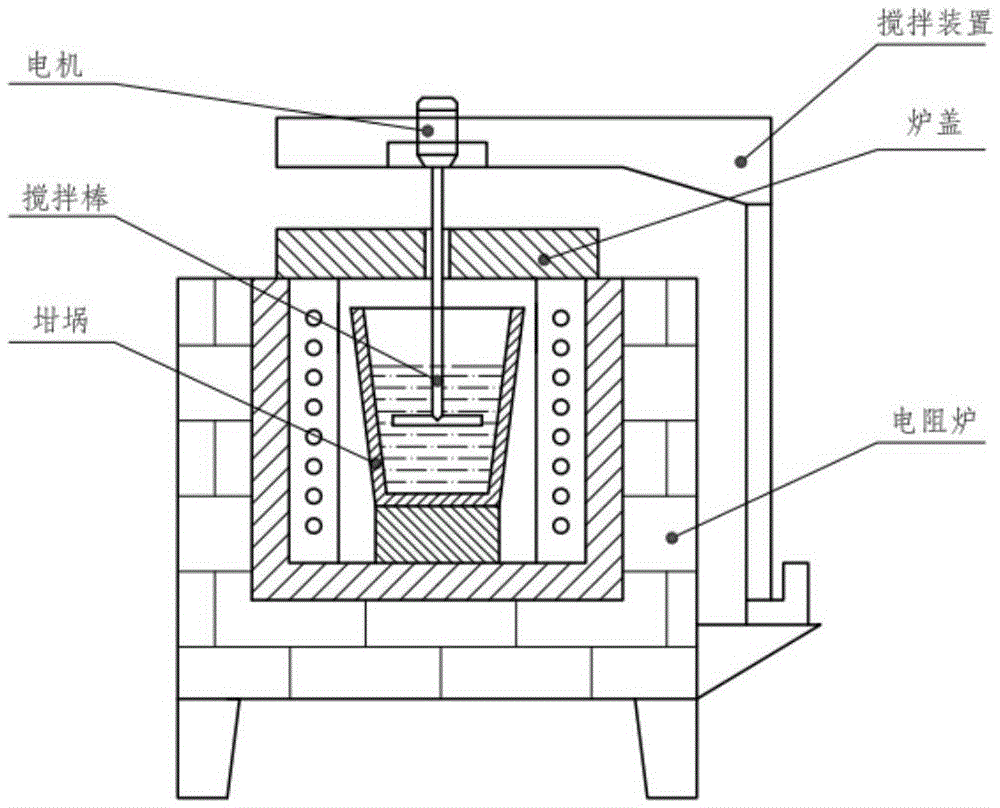

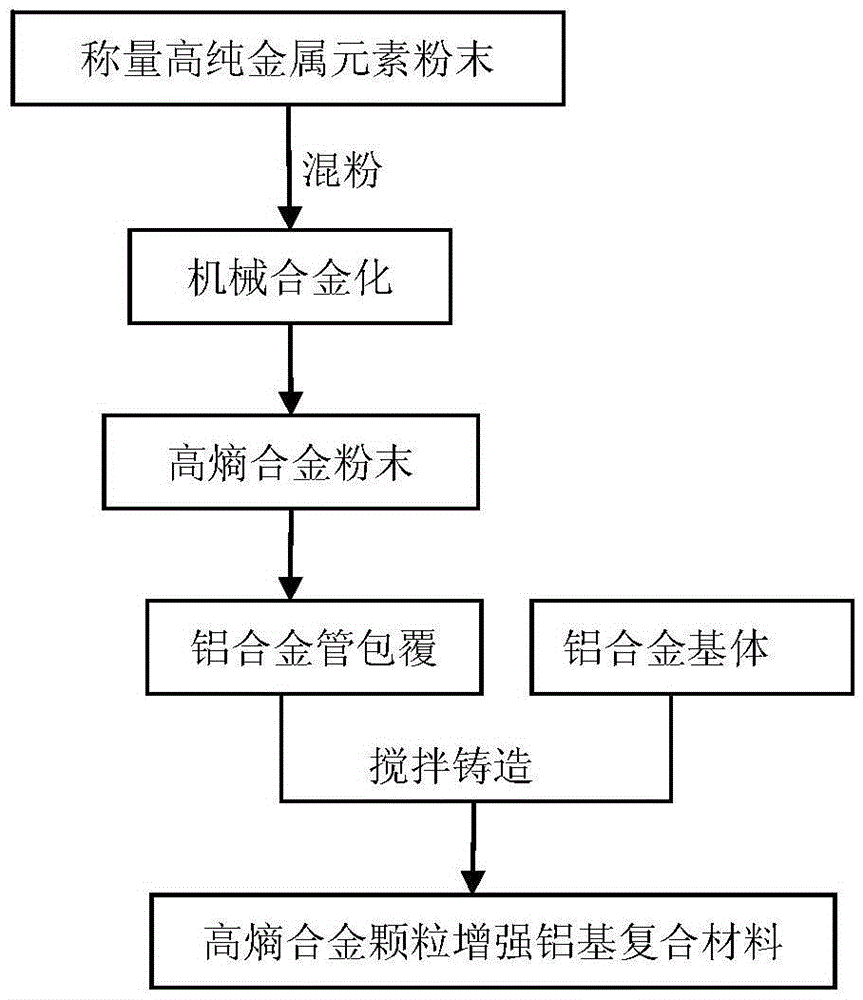

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

Grafting modification method for solution-polymerized styrene-butadiene rubber with low gel rate

The invention relates to a preparation method of polar solution-polymerized styrene-butadiene rubber with low gel rate. The method involves grafting polar monomers on solution-polymerized styrene-butadiene rubber by means of free radical solution method, so as to change the polarity and further improve the interface bonding force of styrene-butadiene rubber and carbon black or white carbon black, so that the wet-skid resistance, wear resistance and dynamic mechanical property of vulcanized rubber are improved and the rolling resistance is reduced. The polar monomers used comprise maleic anhydride, acrylic acid, acrylamide, N-vinyl pyrrolidone and the like. The grafting rate of modified styrene-butadiene rubber is 1-5% and the gel rate is 1-3%; and the rubber polarity changes obviously.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Carbon nano tube surface functionalization method

Owner:BEIJING UNIV OF CHEM TECH

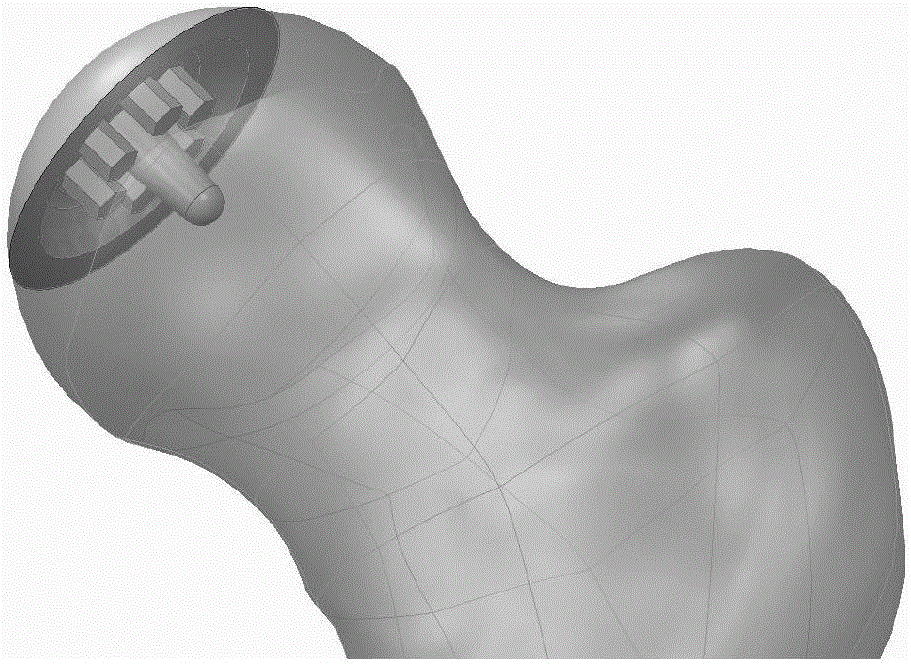

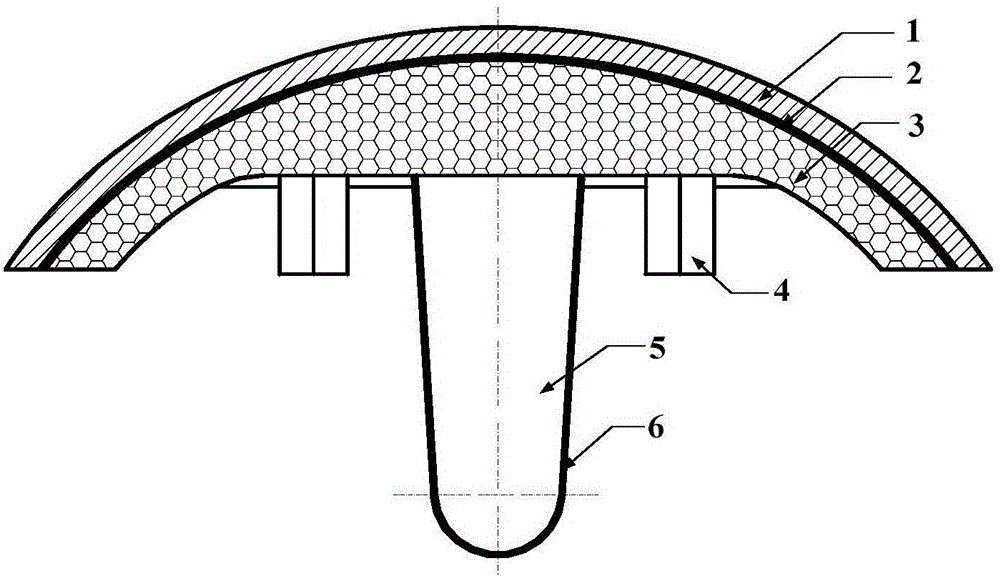

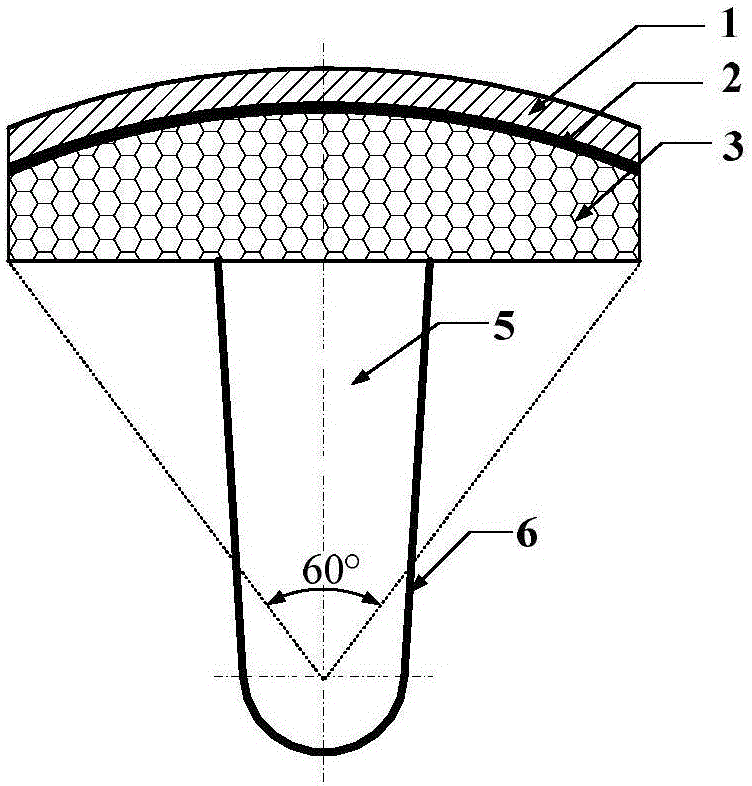

Biomimetic artificial hip joint with internal growth function

ActiveCN105105875AImprove tribological propertiesImprove fault toleranceJoint implantsHip jointsArticular surfacesBiomechanics

The invention discloses a biomimetic artificial hip joint with an internal growth function. The joint is composed of an artificial cartilage layer, an interface bonding layer and a porous bracket, wherein the artificial cartilage layer and the porous bracket have elliptic surfaces; the surface wrapping angle of the joint is 60-120 degrees; when the wrapping angle is 80-120 degrees, 3-6 convex columnar bodies, which are uniformly distributed, are designed on the inner surface of a prosthesis along the peripheral direction; a porous coating with biological activity is prepared on the outer surface of a femoral component and materials of the coating have gradient changes from inside to outside; the porous bracket is designed into a porous structure with gradient according to a finite element optimization result, and the pore diameter is 300-800 microns; the porosity is 20%-85%. According to the biomimetic artificial hip joint disclosed by the invention, bone mass and biomechanical characteristics of thigh bones can be kept to the greatest extent; the biomimetic artificial hip joint has good mechanical properties and tribological properties; the growth of bone cells is induced or promoted so as to guarantee effective interface bonding intensity between a prosthesis implantation material and a natural bone, the stability of the planted prosthesis is improved and the service life is prolonged.

Owner:XI AN JIAOTONG UNIV

Lithium ion rechargeable battery and process for producing the lithium ion rechargeable battery

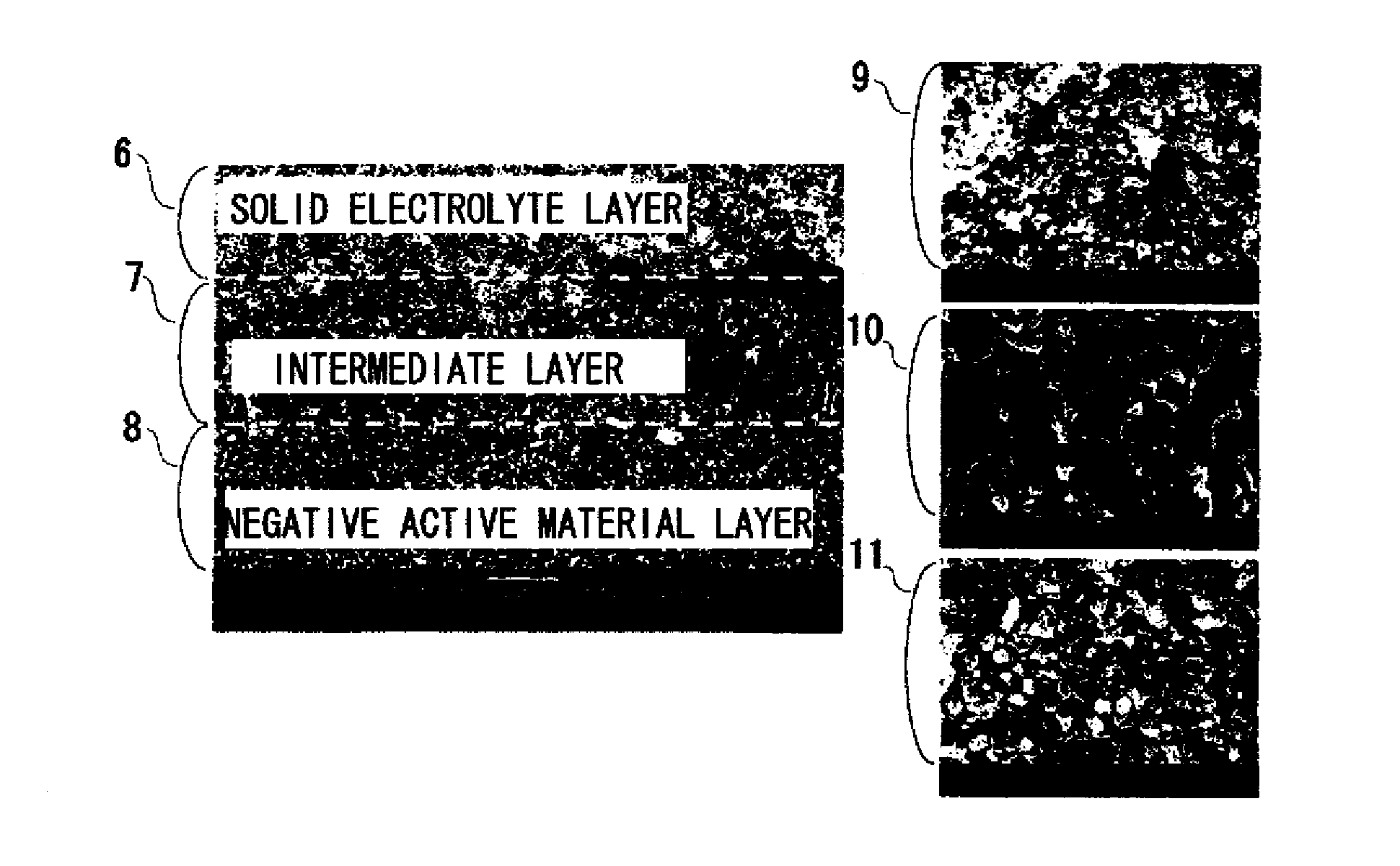

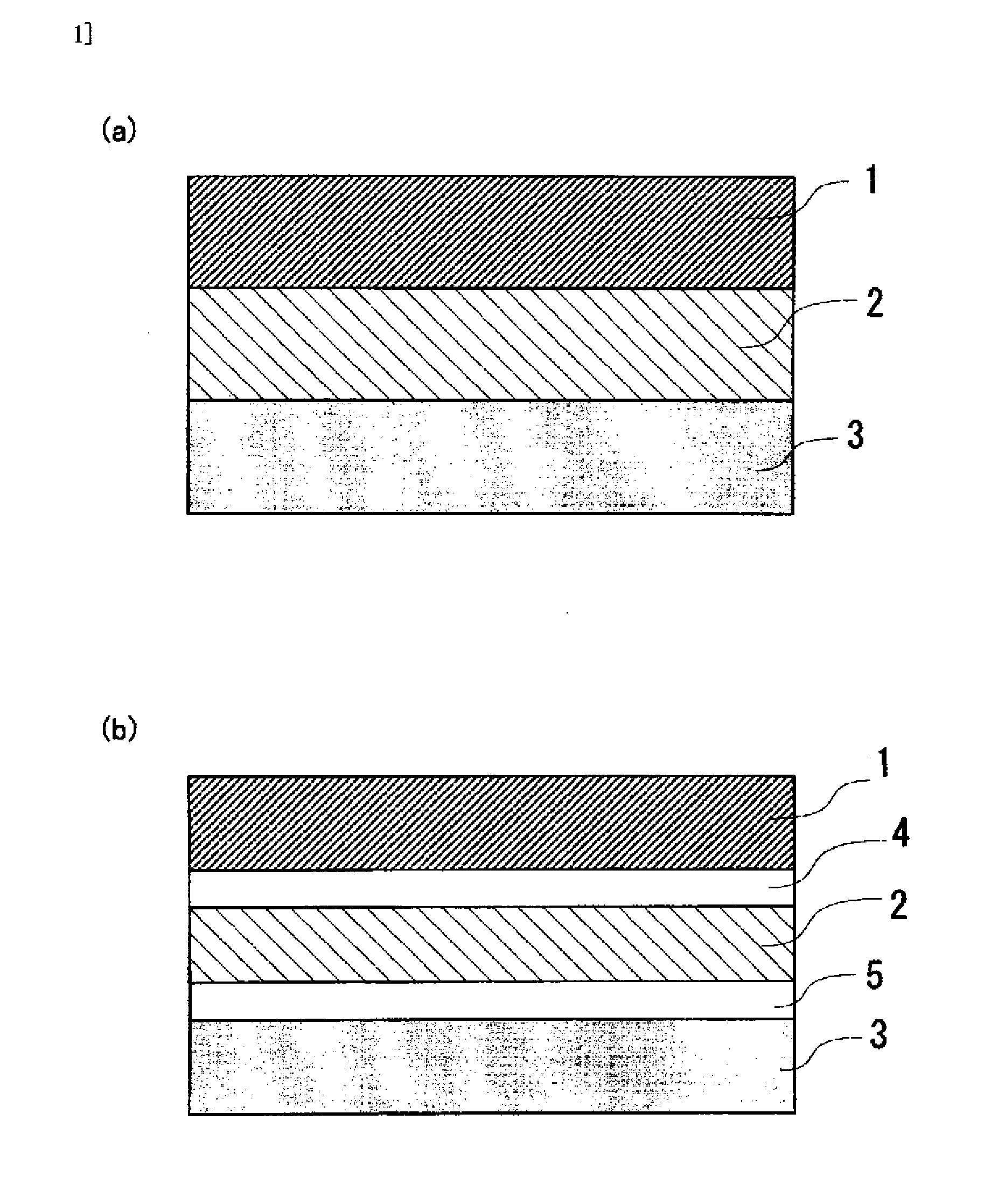

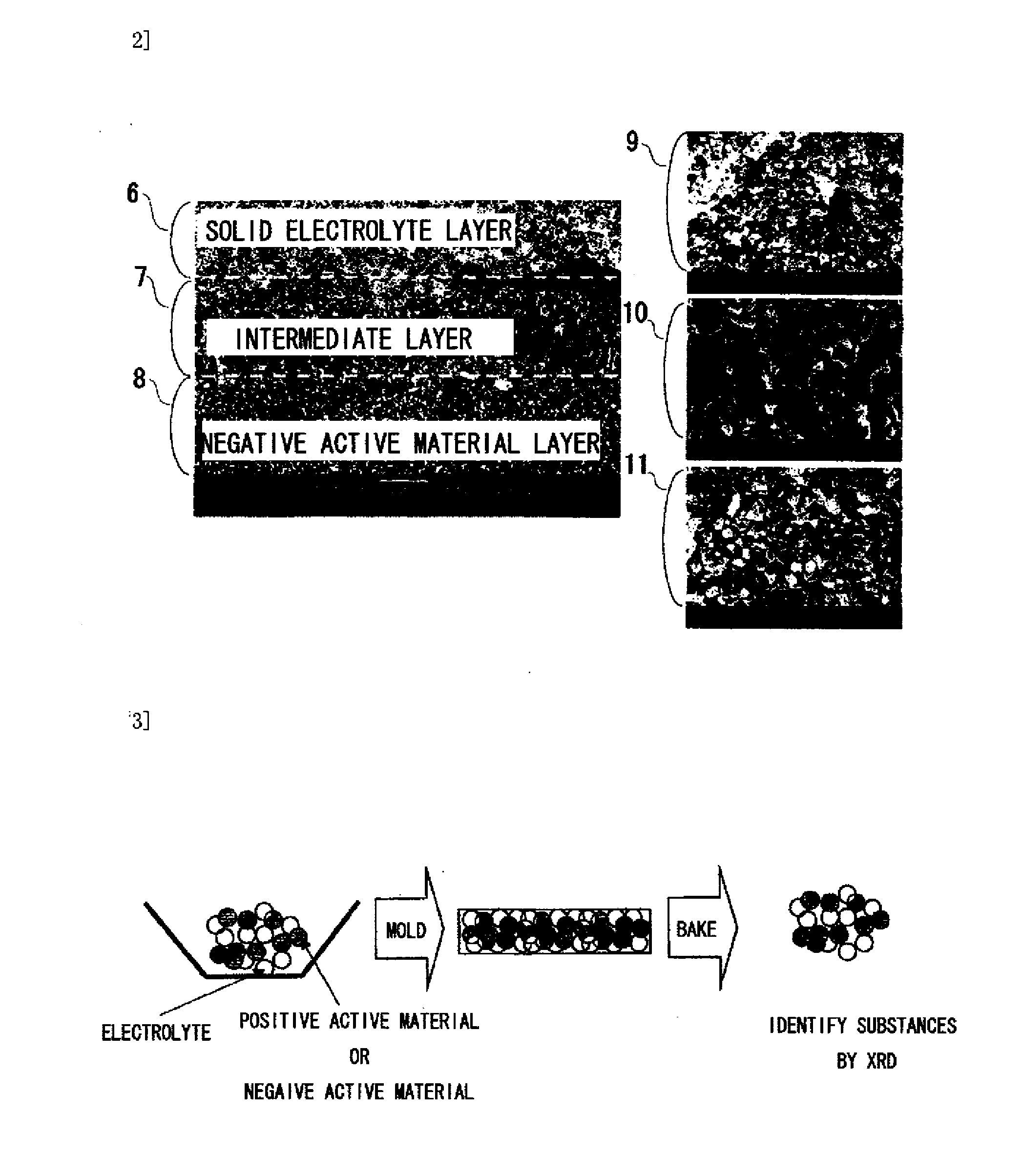

InactiveUS20100216032A1Enhanced interface bindingReduce interface resistanceFinal product manufactureElectrode carriers/collectorsCooking & bakingLithium

Conventional ion rechargeable batteries having an electrode layer on an electrolyte layer suffer from an impurity layer formed at the interface, degrading performance. Conventional batteries with no such impurity layer have a problem of weak interface bonding. In the present invention, in a baking process step after an electrode layer is laminated on an electrolyte layer, materials for an electrode layer and an electrolyte layer are selected such that an intermediate layer formed of a reaction product contributing to charging and discharging reactions is formed at the interface of the electrode layer and the electrolyte layer. In addition, a paste that an active material is mixed with a conductive material at a predetermined mixing ratio is used to form a positive electrode layer and a negative electrode layer. Reductions in electrode resistance and interface resistance and improvement of charging and discharging cycle characteristics are made possible.

Owner:NAMICS CORPORATION

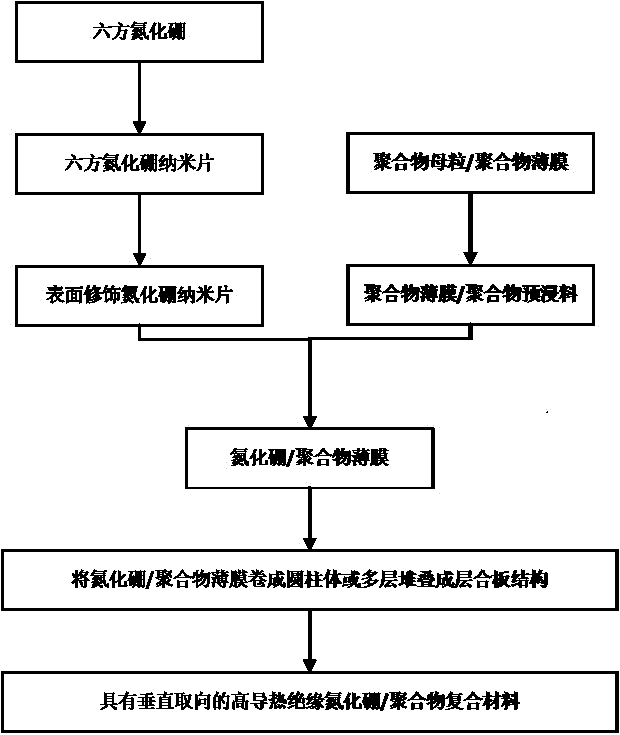

Preparation method for vertically oriented boron nitride/high polymer insulating heat conducting material

InactiveCN106832877AImprove insulation performanceImprove thermal conductivityLayered productsHeat-exchange elementsHeat conductingBoron nitride

The invention provides a preparation method for a vertically oriented boron nitride / high polymer insulating heat conducting material, and belongs to the field of radiating material preparation. The method comprises the following steps: first, modifying the surfaces of boron nitride nano-sheets by using dopamine or a silane coupling agent; then, coating the modified boron nitride nano-sheets between two layers of high polymers; next, pressing the three layers of materials into a thin film with a certain thickness by utilizing a hot pressing process; finally, laminating the thin film into a block body or winding the thin film into a cylinder. The preparation method is simple in process and suitable for batch production; the boron nitride cannot aggregate in the polymers, and a highly oriented heat conducting network is formed, and quick conducting of heat is facilitated. The surface of the boron nitride is modified; the interface bonding between the boron nitride and resin can be enhanced; the mechanical properties and the thermal properties are further improved. The boron nitride / high polymer composite material has high heat conductivity, excellent mechanical properties, and the electrical properties of high insulating and low dielectric loss, and has wide application in the field of electronics.

Owner:PEKING UNIV +1

Gradient laminated porous scaffold based on microsphere selective laser sintering and preparation method thereof

ActiveCN102935019APrecise regulationImprove mechanical propertiesBone implantSelective laser sinteringMicrosphere

The invention relates to a gradient laminated porous scaffold based on microsphere selective laser sintering and a preparation method thereof. The scaffold is prepared by taking polymer microspheres and compound microspheres of high polymers and calcium-phosphate materials as sintering raw materials and carrying out selective laser sintering on the sintering raw materials, the contents of the calcium-phosphate materials in the scaffold are ascended in a layer by layer manner from the surface layer to the bottom layer of the scaffold, and bore diameters and porosities of the scaffold are gradually ascended. The preparation method comprises the following steps of: preparing calcium-phosphate materials / high polymer composite microspheres by a solvent evaporation method; designing a three-dimensional model of the gradient-laminated porous scaffold by computer modeling software; and realizing precise manufacturing of the gradient laminated porous scaffold by virtue of a selective laser sintering device through feeding controlling and single-layer manufacturing. The mutual communication and the gradient distribution of the scaffold are beneficial for nutrient transport and tissue penetration; and the contents of calcium-phosphate materials are in continuous gradient distribution in space, the disadvantage of interface bonding strength is effectively solved, and the biological functions of the scaffold in comprehensive defect repairing of cartilages and subchondral bones are beneficially exerted.

Owner:ASIA BIOMATERIALS WUHAN CO LTD

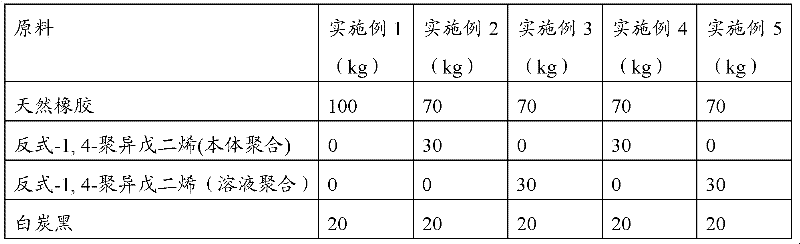

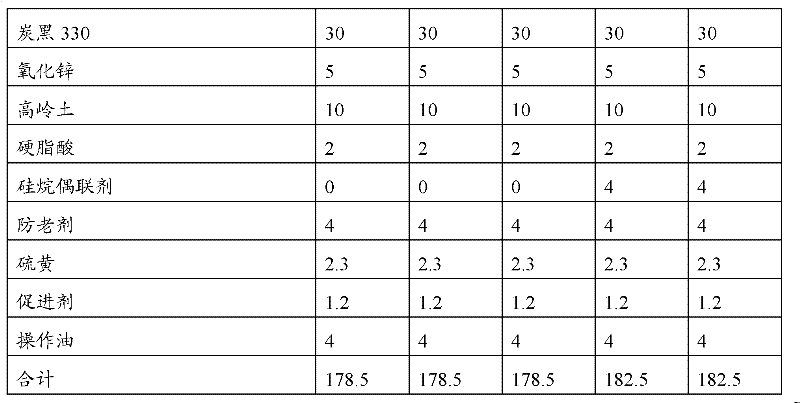

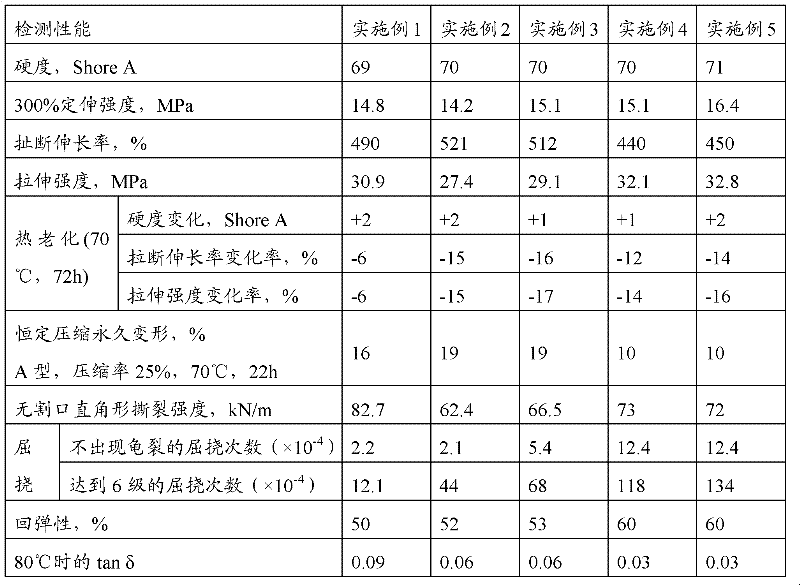

Isoprene rubber blend and its preparation method

InactiveCN102382338AImprove fatigue resistanceGood resistance to flex crackingPolymer scienceCrack resistance

The invention discloses an isoprene rubber blend and its preparation method, the isoprene rubber blend comprises the following raw materials: 60-100 parts of isoprene rubber, 5-50 parts of trans-1,4-polyisoprene, 5-100 parts of reinforcing filler, 1-25 parts of in-situ grafted modification additive, 0-40 parts of cooperated rubber and 0-25 parts of first additive. Compared with the prior art, the in-situ grafted modification additive is performed chemical reaction with the reinforcing filler, and is simultaneously performed grafting reaction with function groups like double bond of a rubber molecular chain, so that the interface bonding strength between the organic polymer and the reinforcing filler as well as the dispersion level of the reinforcing filler in rubber can be substantially enhanced, and the fatigue resistance performance of the isoprene rubber blend is increased. The test results indicate that the isoprene rubber blend of the invention has favorable flex cracking resistance and excellent general mechanical performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

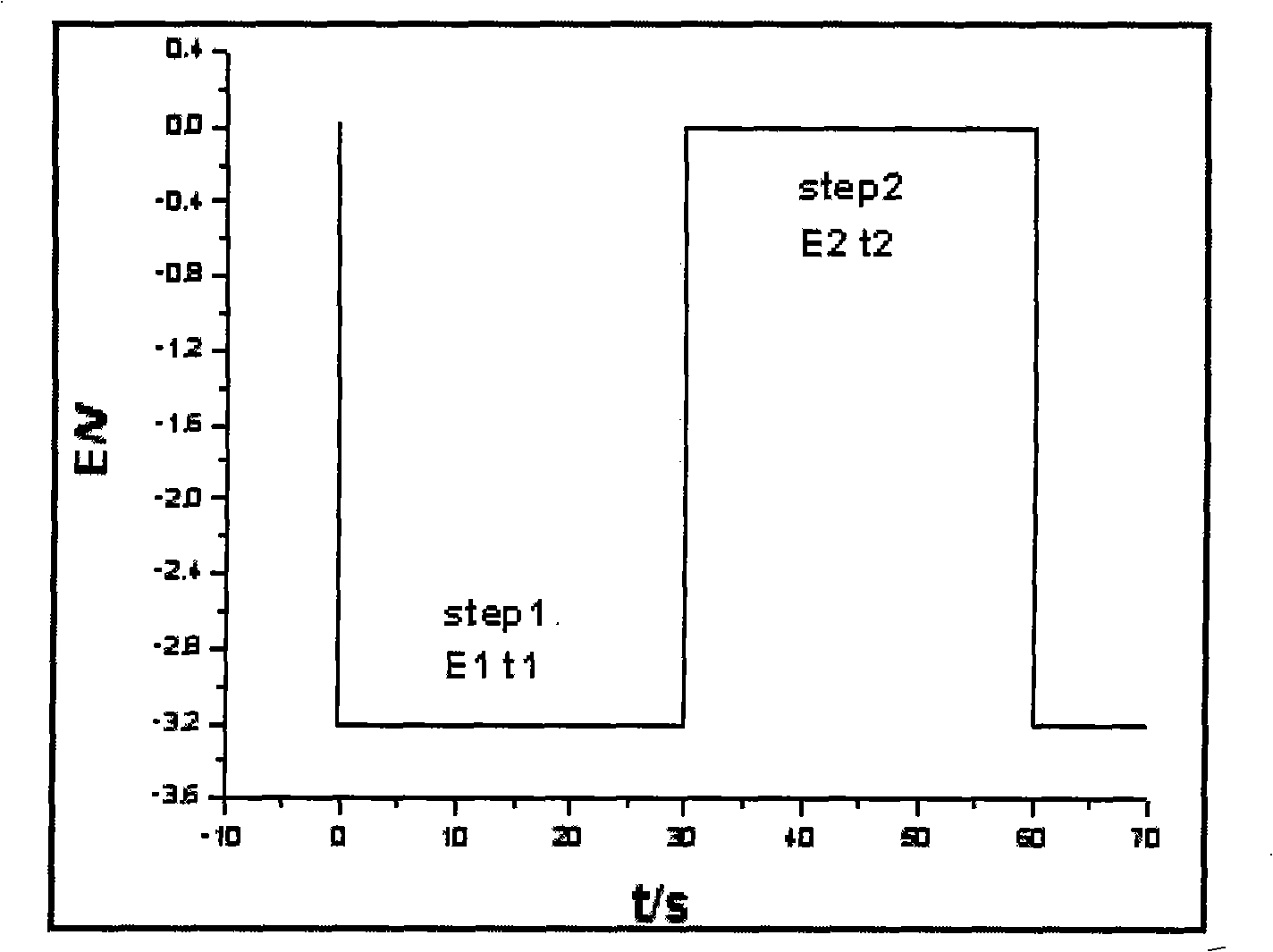

Preparation of nano-HAP coating/magnesium alloy composite biological material

InactiveCN101302638AHigh bonding strengthImprove biological activityElectrolytic inorganic material coatingProsthesisMagnesium phosphateBiocompatibility Testing

The invention provides a method for making a nano HAP coating / magnesium alloy composite biomaterial. The method is as follows: the method takes a magnesium alloy as a cathode and graphite as an anode; the magnesium alloy and the graphite are placed in electrolyte containing NH4H2PO4, NaHO3 and Ca(OH3)2.4H2O so as to carry out stepped electrodeposition at a temperature of between 60 and 95 DEG C and a voltage of between minus 5 V to minus 1 V and 0 V, thereby effectively improving the interface bonding between a coating and a matrix and reducing hydrogen evolution during electrodeposition; meanwhile, the increase of magnesium ions at an interface can realize in-situ doping of magnesium ions and hydroxyapatite so as to generate a magnesium phosphate transition layer on the surface of the magnesium alloy and to increase bonding strength; thus, a degradable nano acicular hydroxyapatite / magnesium alloy coating composite biomaterial with excellent mechanical property, biocompatibility and corrosion resistance can be obtained. Meanwhile, the method also has the advantages of low cost of raw materials and simple technological operation, etc.

Owner:ZHENGZHOU UNIV

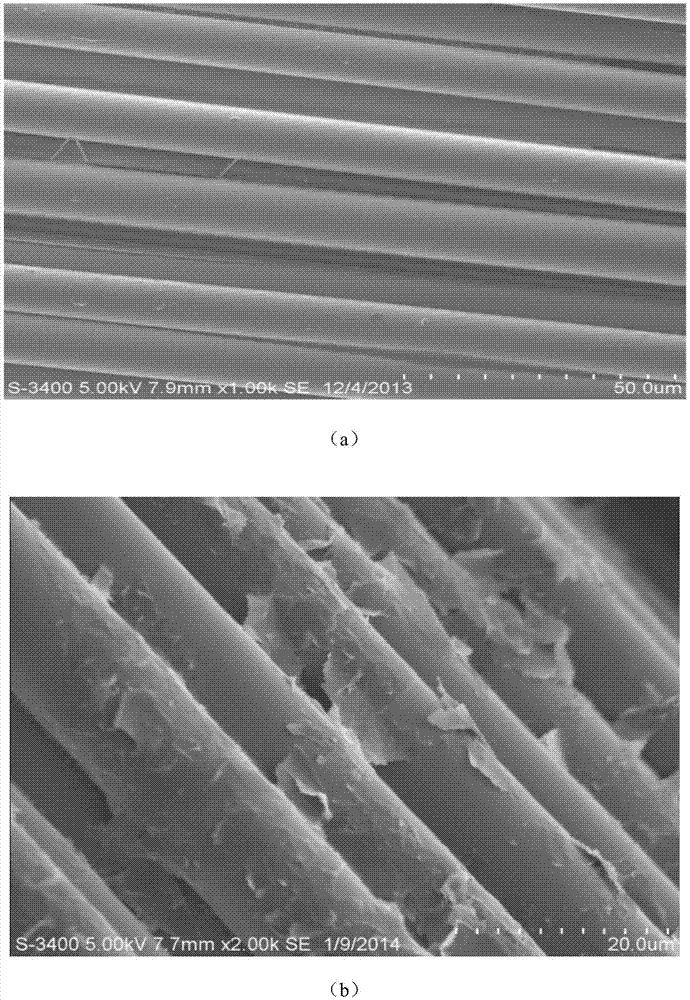

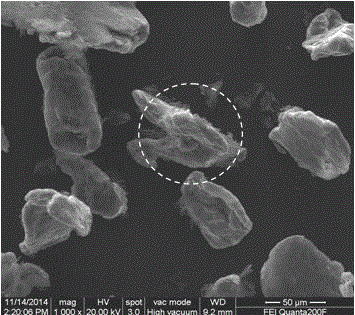

Graphene-coated glass fiber reinforced resin-based composite material and preparation method thereof

ActiveCN104262953ASolve the problem of fragmentationImprove bending strengthGlass fiberGraphene coating

The invention provides a graphene-coated glass fiber reinforced resin-based composite material. The preparation method comprises the following steps of dispersing graphene modified by a silane coupling agent in water to obtain a uniformly-dispersed aqueous dispersion, dipping glass fibers into the aqueous dispersion of the modified graphene so that compact and uniform graphene coatings are formed on surfaces of the glass fibers under the action of electrostatic adsorption, and carrying out compounding molding on the glass fibers with the graphene coatings and a resin matrix to obtain a composite material. The graphene coatings are arranged on the surfaces of the glass fibers so that the interaction area and interface bonding strength of the fibers and the matrix are improved, graphene dispersion is avoided and excellent composite material mechanical properties are obtained. The preparation method has simple processes, a low cost and good practicality.

Owner:JUSHI GRP CO

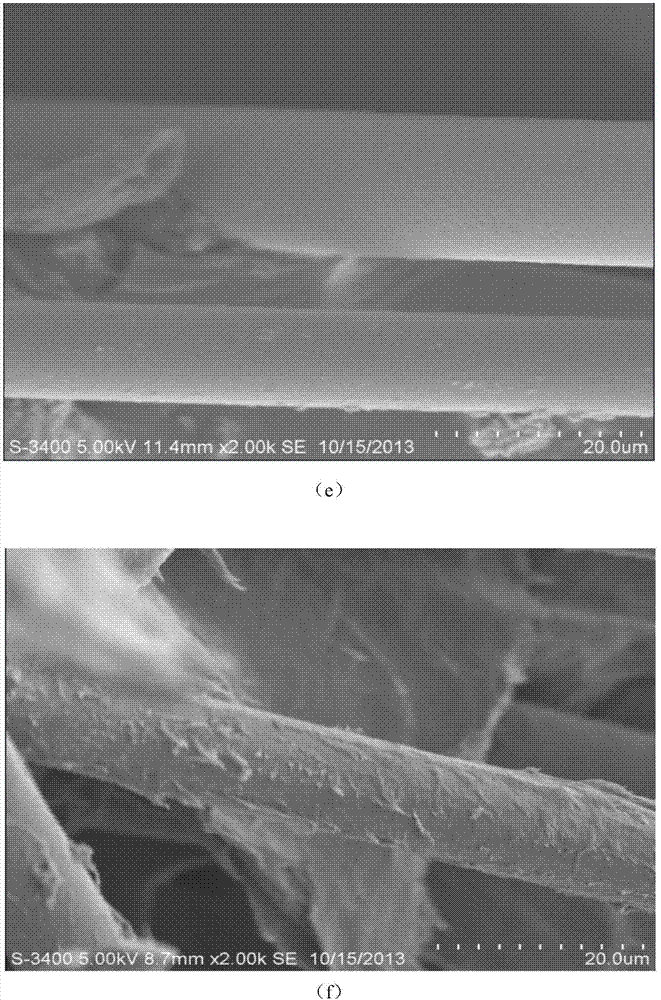

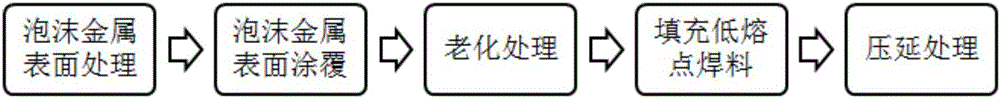

Preparation method of foam metal composite solder piece

ActiveCN106825999AOvercoming the lack of low strengthHigh strengthHot-dipping/immersion processesWelding/cutting media/materialsPorosityChemical plating

The invention discloses a preparation method of a foam metal composite solder piece. According to the method, firstly, the surface of foam metal is treated, the surface of a foam metal matrix is coated with one or more layers of active metal with an electroplating or chemical plating process, annealing treatment is performed, the foam metal with an active metal plating layer is infiltrated into molten solder and taken out after filling is performed, foam metal enhanced low-melting-point composite solder is obtained, finally, calendaring machining is performed, metal solder foil with certain thickness is obtained, and the purposes of improving the strength and the welding performance of foam metal composite solder are achieved. The foam metal is used for enhancing Sn-based or Zn-based solder, and the applied active metal plating layer can improve the strength of the foam metal matrix to a certain extent and make up the influence of foam metal porosity on the strength of the foam metal. Besides, the active metal plating layer is also beneficial to filling of low-melting-point solder to the foam metal and relieves the unfavorable situation that tin and matrix metal are difficult to infiltrate and interface bonding is not firm.

Owner:无锡继平新材料科技有限公司

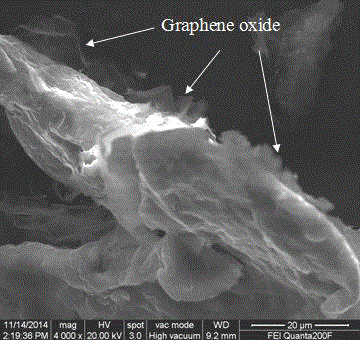

Preparation method of carbon fiber/graphene/epoxy resin prepreg and carbon fiber composite material

A method for preparing carbon fiber / graphene / epoxy resin prepreg and carbon fiber composite materials, belonging to the field of carbon fiber composite material preparation. In this invention, graphene prepared by the modified Hummers method is surface modified, and -NH is grafted on the surface or edge of the graphene. 2 , improve its dispersion in the resin matrix, and at the same time, it can effectively increase the interfacial adhesion between micron-sized carbon fiber and epoxy resin matrix, reduce the existence of void defects, and thereby improve the mechanical properties of epoxy resin-based composite materials. The carbon fiber / graphene / epoxy resin composite material provided by the invention has optimal mechanical properties when the addition amount of graphene is 0.5wt%, with a bending strength of 1525.4MPa and an interlayer shear strength of 91.14MPa. Compared with carbon fiber reinforced rings, Oxygen resin composites improved by 15.41% and 14.14% respectively. The invention has the characteristics of simple process, low solvent toxicity, and is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

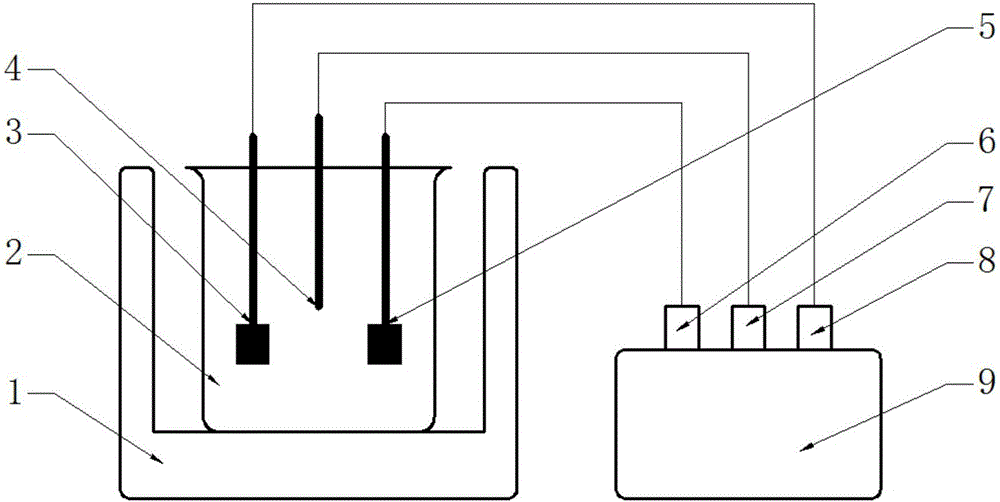

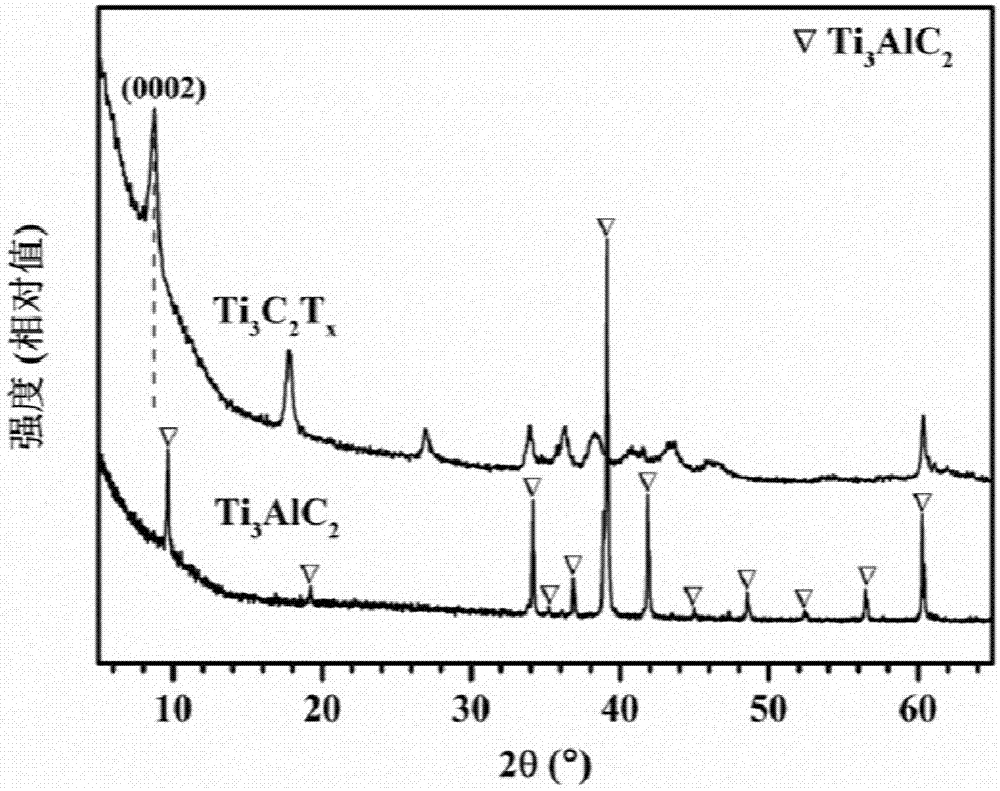

Two-dimensional slice material enhanced metal-based composite

The invention provides a two-dimensional slice material enhanced metal-based composite. According to the composite, metal is adopted as a base body, two-dimensional transition metal carbide or carbonitride, namely, MXenes is adopted as a reinforced phase, and MXenes particles are evenly dispersed in metal base body particles. Due to the fact that the MXenes material comprises a hollow carbon position and tends to metallicity, the metal base body has good wettability, and the interface bonding strength of the metal-based composite can be effectively improved. Therefore, the mechanical performance, wear resistance and other performance of the metal-based composite are enhanced. Meanwhile, the electronic coupling effect of the MXenes material and a metal base body interface is better, and the problem that in the prior art, the mechanical performance and corrosion resistance of the metal-based composite are improved through the reinforced phase, and meanwhile the heat conducting and electrical conducting performance of the metal-based composite is reduced can be avoided.

Owner:SHANGHAI UNIV +1

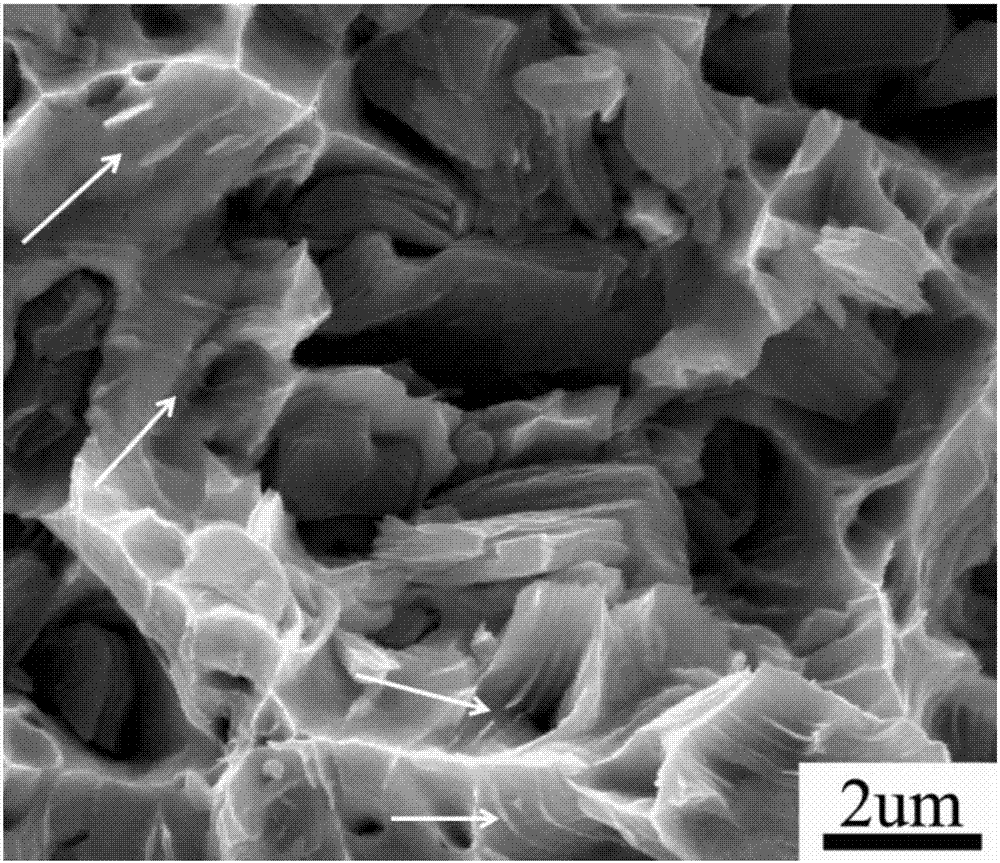

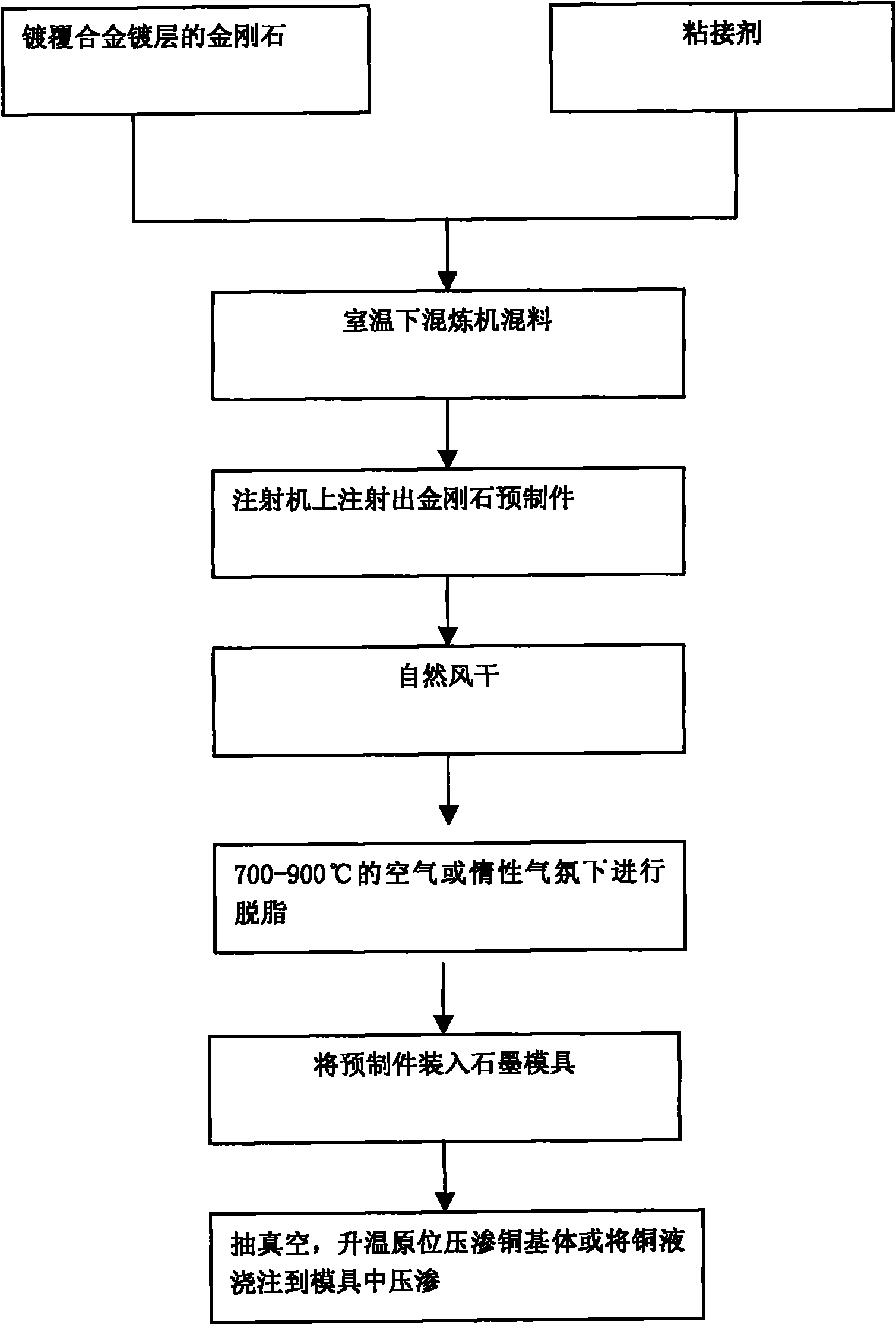

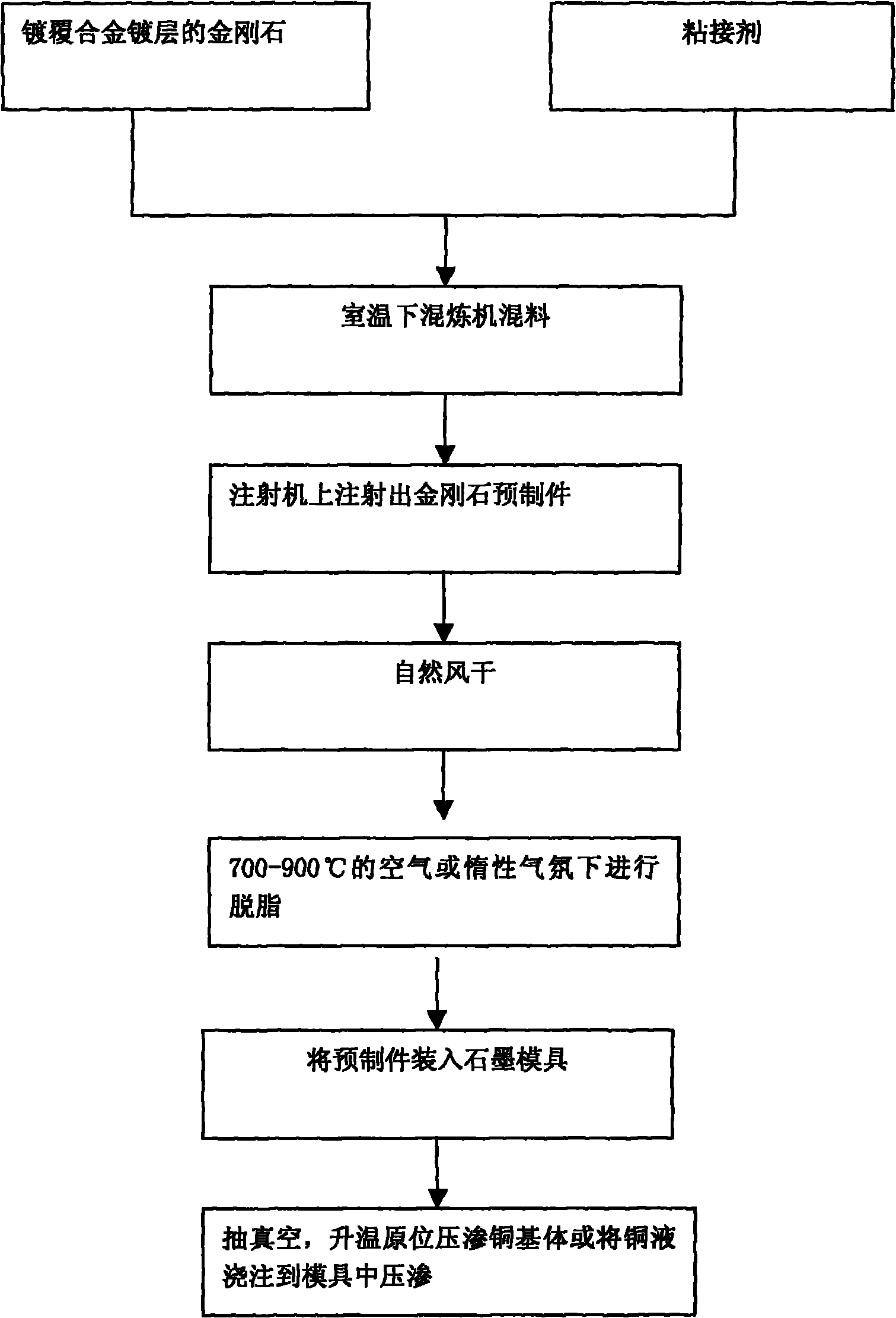

High heat-conducting copper-based composite material and preparation method thereof

InactiveCN101831584ALow densitySmall coefficient of thermal expansionVacuum evaporation coatingSputtering coatingInterfacial thermal resistanceThermal expansion

The invention relates to a high heat-conducting copper-based composite material and a preparation method thereof, belonging to the technical field of electronic packaging materials. The copper-based composite material consists of 50-80 percent by volume of electroplated diamond particles and 20-50 percent by volume of copper. The electroplated diamond particles and a caking agent are mixed according to the volume ratio of 1:1-4:1 and are produced into a diamond prefabricated part by using an injection forming process of the prefabricated part; and a copper matrix is directly placed on the diamond prefabricated part or is melt and poured on the diamond prefabricated part to be produced into the high heat-conducting copper-based composite material by using a pressure infiltration process. The copper-based composite material has higher heat conductivity ratio than that of an aluminum-based composite material; by plating the surface of diamond, the interface bonding of the matrix copper and the diamond can be improved and the interface heat resistance can be reduced; in addition, the material has low density and small thermal expansion coefficient and meets the requirement for light quality of packaging materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

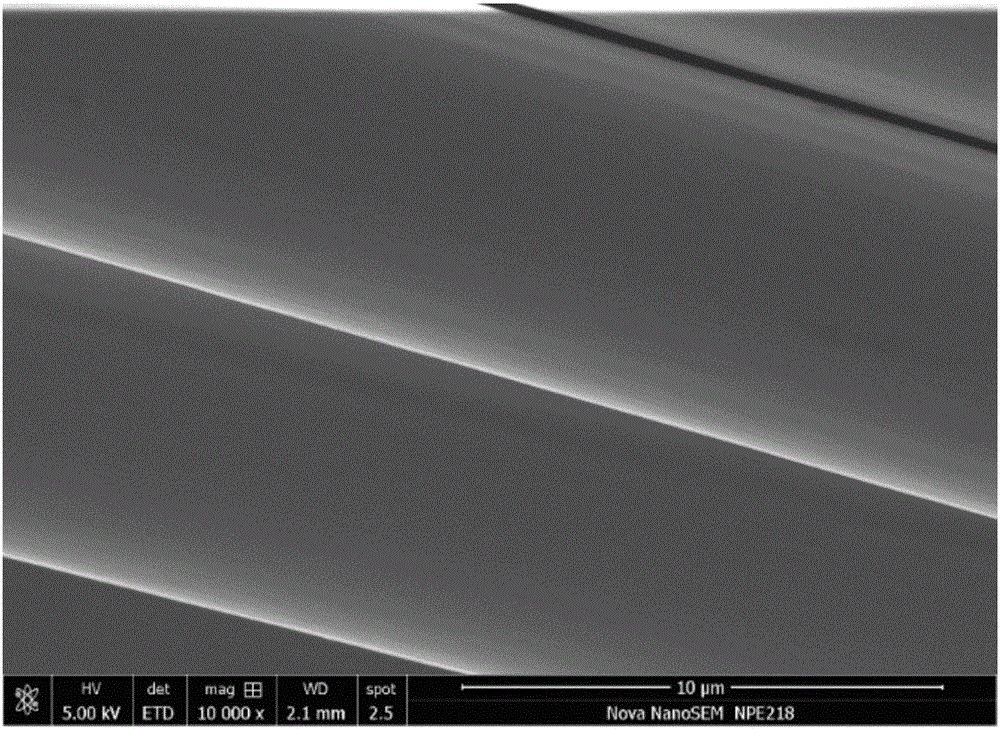

Method for performing amino functionalizing on carbon fiber surface

InactiveCN105113260AWill not damage the structureRetain high-strength and high-model featuresCarbon fibresFiberState of art

The invention relates to a method for performing amino functionalizing on a carbon fiber surface. The method comprises the steps that the fiber surface is coated with a copolymer coating containing a large amount of active amino by utilizing a Michael addition and Schiff base reaction of dopamine and poly-amino molecules through a one-step solution dipping method. Compared with the prior art, the method is simple in technology and mild in condition, does not damage a fiber body structure and can effectively increase active groups of the carbon fiber surface, and therefore the interface bonding property between fiber and resin is improved.

Owner:SHANGHAI JIAO TONG UNIV

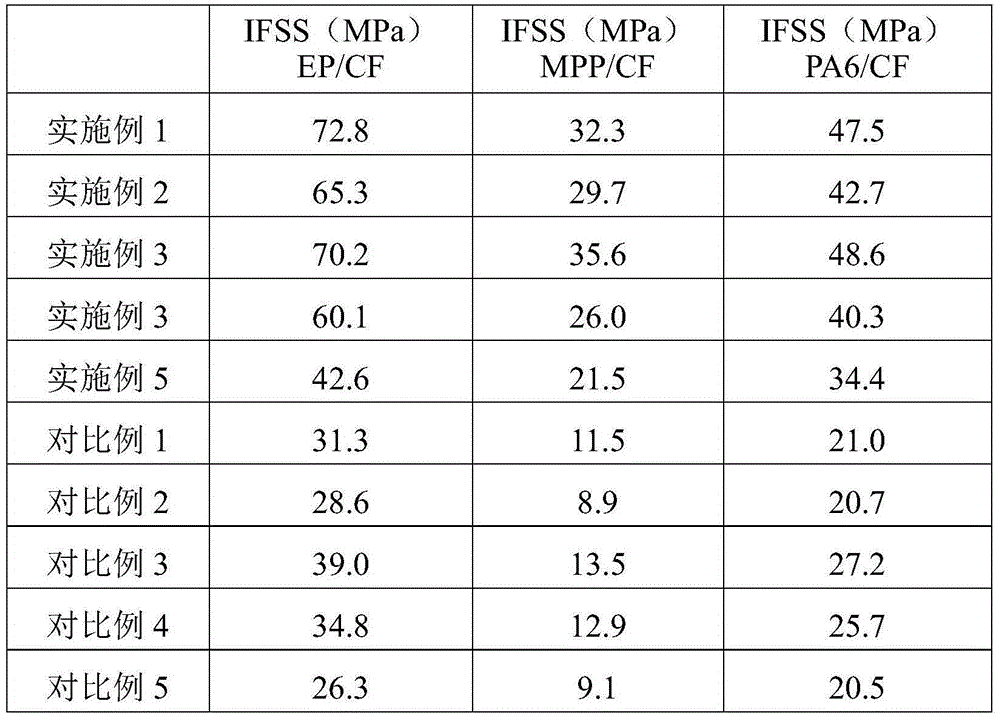

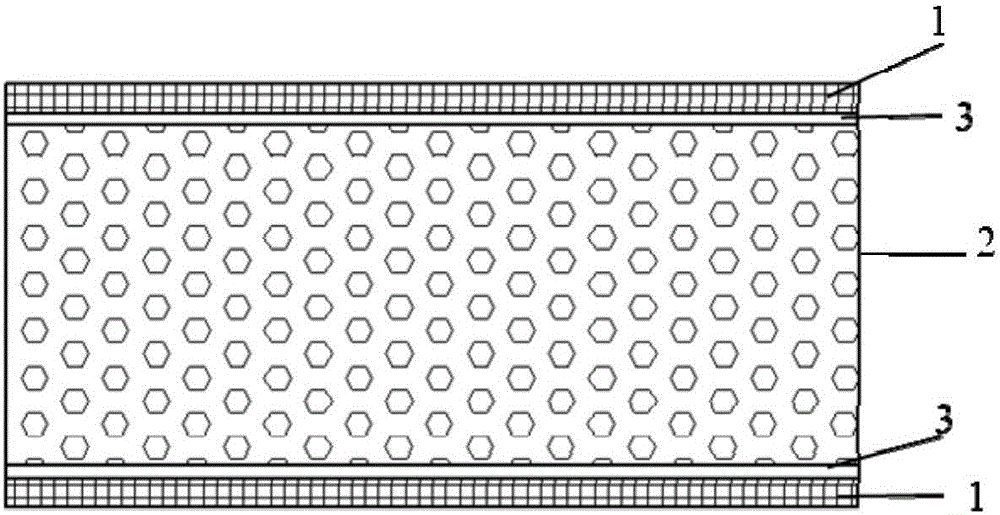

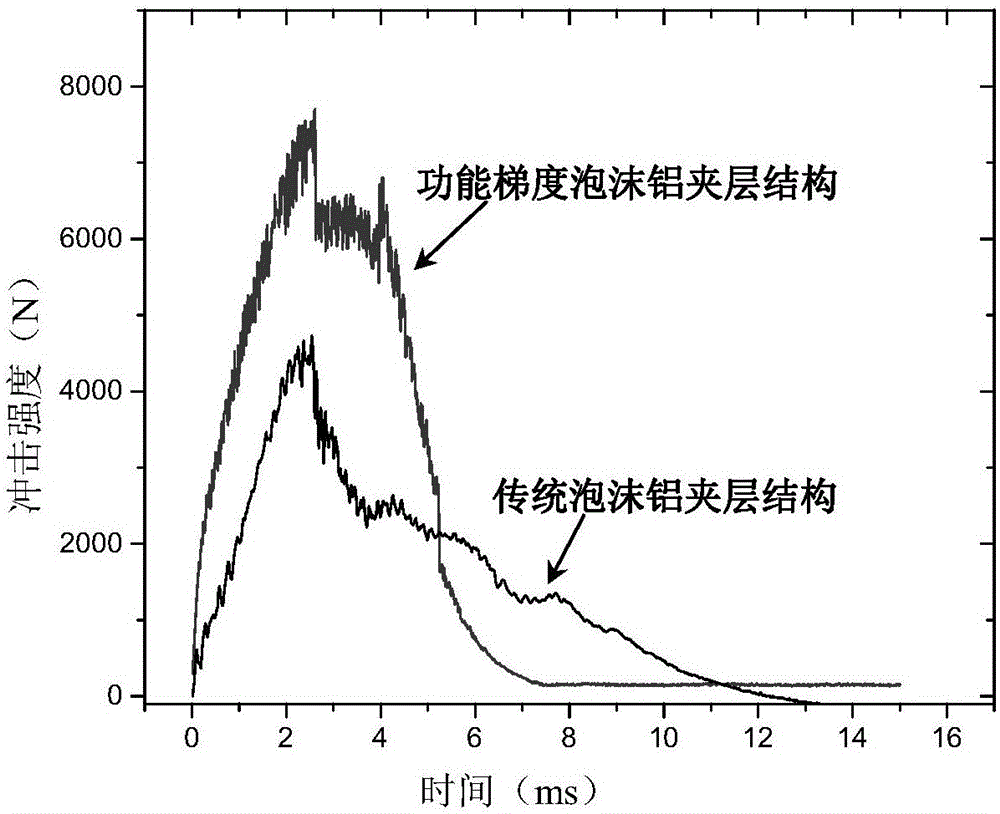

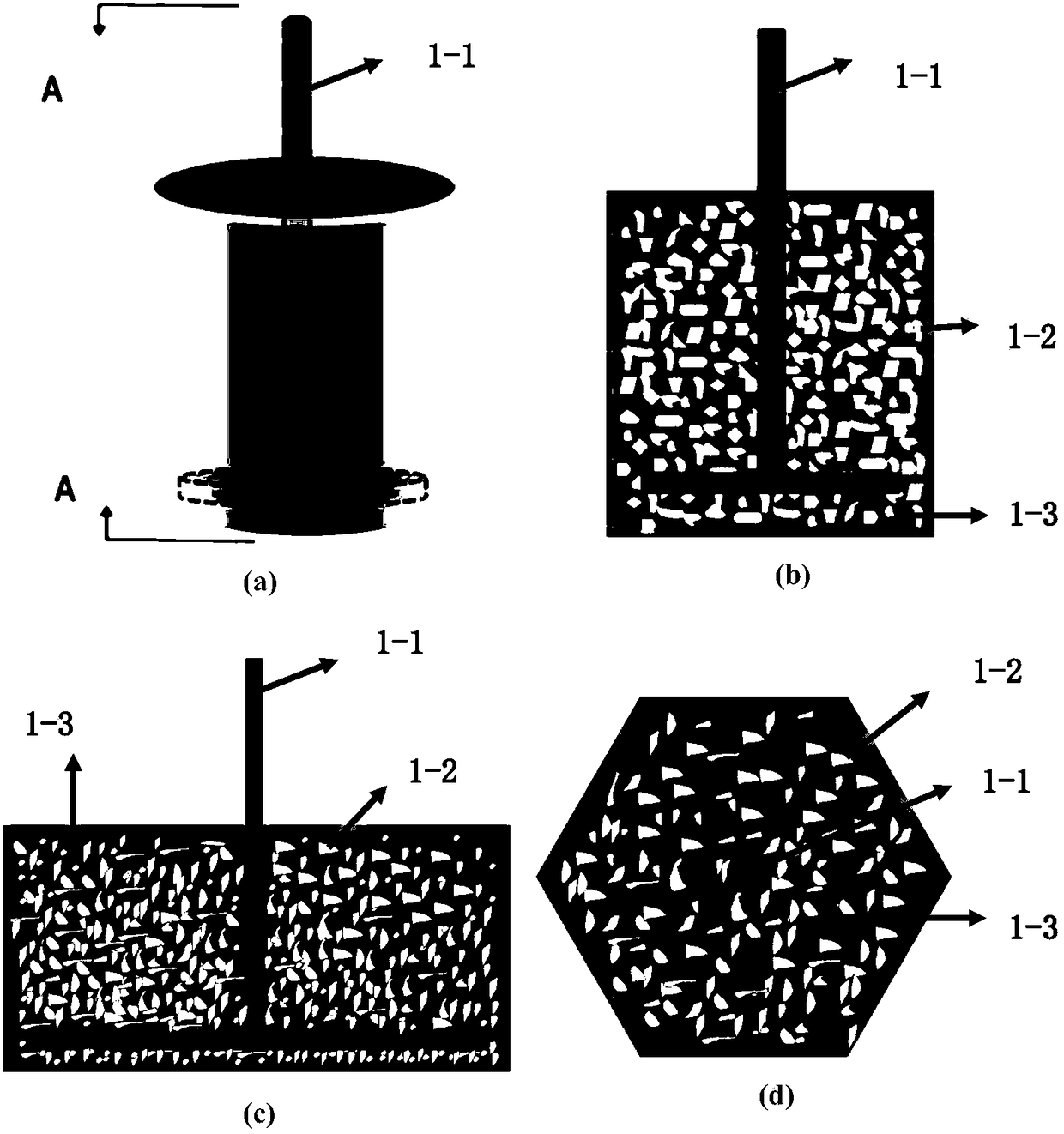

Foamed aluminum sandwich structure composite material and preparing method thereof

ActiveCN106273902AImprove the interface bonding strengthSmall difference in coefficient of thermal expansionSynthetic resin layered productsVehicle componentsFiberEpoxy

The invention provides a foamed aluminum sandwich structure composite material and a preparing method thereof. The foamed aluminum sandwich structure composite material comprises a foamed aluminum core material, a toughening interface layer and skin, wherein the toughening interface layer is located between the foamed aluminum core material and the skin, the toughening interface layer is made of an epoxy resin composite material, and the epoxy resin composite material is composed of an epoxy resin matrix, a toughening agent, a diluent, hollow microspheres, chopped fiber, a curing agent and an accelerant; pores in the surface of the foamed aluminum core material is filled with the epoxy resin composite material to form the toughening interface layer. According to the technical scheme, the toughening interface layer is formed between the composite material skin and the foamed aluminum core material by means of multi-component low-density epoxy filling adhesive, and interface bonding strength can be effectively improved; by means of the skin designed based on functional gradient, the interface bonding property of the foamed aluminum sandwich structure in a humid and hot environment is improved, and the impact resistance of the foamed aluminum sandwich structure is improved.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

High performance chlorinated polyethylene-epoxy resin anticorrosive coating system

InactiveCN101691464AGive full play to corrosion resistanceGive full play to the bonding effectAnti-corrosive paintsPolyamide coatingsChemical industryEpoxy

The invention discloses a high performance chlorinated polyethylene-epoxy resin anticorrosive coating system, which consists of a surface coating, an intermediate coating and a prime coating which are matched, wherein the surface coating is a high performance chlorinated polyethylene anticorrosive finish paint; the intermediate coating is a high performance chlorinated polyethylene / epoxy resin semi-interpenetrating network anticorrosive middle coating; and the prime coating is an epoxy resin micaceous iron oxide anti-corrosive primer. The preparation for the coating system comprises the preparation of surface coating and the intermediate coating; the coating construction is orderly multi-layer coating construction on the surface of a metal substrate; and finally the functionally graded anticorrosive coating is formed so as to effectively improve interface bonding force and adhesive force of various layers and fully exert the corrosion resistance of the high performance chlorinated polyethylene and the substrate bonding function of the epoxy resin; and the functionally graded anticorrosive coating has good corrosion resistance, such as the resistance to acid, alkali, saline water, gasoline and the like, and also has good physical and mechanical properties, such as shock resistance and flexibility, so the functionally graded anticorrosive coating has important application value in anticorrosive fields such as steel structures, bridges, metallurgy, chemical industry and the like, in particular heavy duty anticorrosive field of petrochemical industry.

Owner:郭再春

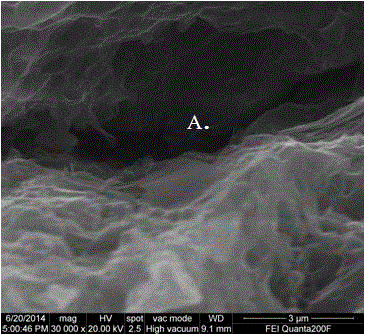

Preparation method of in-situ reduced graphene reinforced magnesium-matrix composite

The invention discloses a preparation method of an in-situ reduced graphene reinforced magnesium-matrix composite. The method comprises the following steps: dissolving graphite oxide in an appropriate amount of ethanol solution, and performing ultrasonic treatment for 0.5-2h to obtain a graphene oxide ethanol solution with concentration of less than or equal to 2mg / ml; adding appropriate AZ91 magnesium alloy powder with the particle size of less than or equal to 325 meshes into the mixed solution, and performing ultrasonic treatment and mechanical stirring for 2h to obtain mixed slurry; performing vacuum drying of the mixed slurry, transferring into a mould, and pressing into a composite green under the pressure of 100-600MPa at room temperature; sintering the composite green for 2-4h at 500-600 DEG C in argon protection; and finally performing hot extrusion of the sintered composite at 350-400 DEG C. The preparation method disclosed by the invention is simple in preparation process and safe and reliable; the reduced graphene has good dispersity in magnesium alloy; and the reduction byproduct MgO is good for improving the interface bonding strength so that the reinforcing effect is better and the performance of the composite is excellent. Compared with the method of directly adding graphene into the magnesium matrix, the cost is lower and the dispersity is better; and the preparation method is suitable for industrial preparation of a high-performance graphene reinforced magnesium alloy composite.

Owner:NANCHANG UNIV

Wood-plastic composite material and preparation method thereof

The invention belongs to the field of high-molecular material modified technology, and discloses a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material is prepared by the following components of, by weight, 40-75 parts of a plastic substrate, 20-50 parts of wood powder and 5-10 parts of auxiliary agents. The preparation method of the wood-plastic composite material comprises the following steps of (1) mixing 20-50 parts of the wood powder, 40-75 parts of the plastic substrate and 5-10 parts of the auxiliary agents which are treated by silanization adequately, for 10-60 min; (2) extruding and granulating the uniform mixture obtained from the step (1) by using a double screw extruder, forming by introducing the obtained materials into an injection machine or flat-panel vulcanizing machine, or forming by introducing the uniform mixture obtained from the step (1) into the flat-panel vulcanizing machine. An inorganic layer is formed on the surface of the wood powder, thereby facilitating improving the interface bonding property between the inorganic layer and the plastic matrix, increasing heat resistant temperature of the wood powder and allowing the wood powder not to be decomposed in a processing process.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

High-abrasion-resistant metal ceramic composite roller sleeve and preparation method thereof

ActiveCN108342657AHigh hardnessExtended service lifeFurnace typesGrain treatmentsInverted-T shapeInverted t

The invention discloses a high-abrasion-resistant metal ceramic composite roller sleeve and a preparation method thereof and belongs to the technical field of abrasion resistant materials. The high-abrasion-resistant metal ceramic composite roller sleeve comprises a preset inner sleeve and an outer sleeve. The preset inner sleeve is made of common low and medium carbon steel or low alloy steel. Casting materials of the outer sleeve are high-abrasion-resistant alloy and a metal ceramic composite material reinforced block. An inverted-T-shaped stainless steel part is put into the bottom of sintering powder, the tip part, exceeding the metal ceramic composite material reinforced block, of the T shape is inserted into a sand mold according to a specified position, and then high-abrasion-resistant alloy liquid is poured into the part between the metal ceramic composite material reinforced block and the preset inner sleeve. Through subsequent heat treatment, the overall composite performanceis promoted, interface bonding of the obtained composite roller sleeve is good, and holes, segregation, cracks and other macroscopic defects are avoided. According to the preparation method, the preparation process is simple, operation is easy, and industrialized mass production is convenient.

Owner:一重集团(天津)新材料有限公司

Novel biodegradable master batch and preparation method thereof

The present invention provides a biodegradable master batch and a preparation method thereof. The biodegradable master batch is prepared by in situ polymerization according to the following formula, wherein the formula comprises the following components, by weight, 10-80 parts of a biodegradable monomer or a prepolymer, 0.01-5 parts of a catalyst, 0.05-5 parts of a reaction activator, 0.1-5 parts of a heat stabilizer, 0-80 parts of a flame retardant, 0-80 parts of a filler, 0-80 parts of an antistatic agent, 0-80 parts of a pigment, 0-80 parts of a foaming agent and 0-5 parts of a surface coupling agent. According to the present invention, the biodegradable master batch with a good dispersion effect and good interface bonding ability, and the preparation method thereof are provided.

Owner:肖同剑

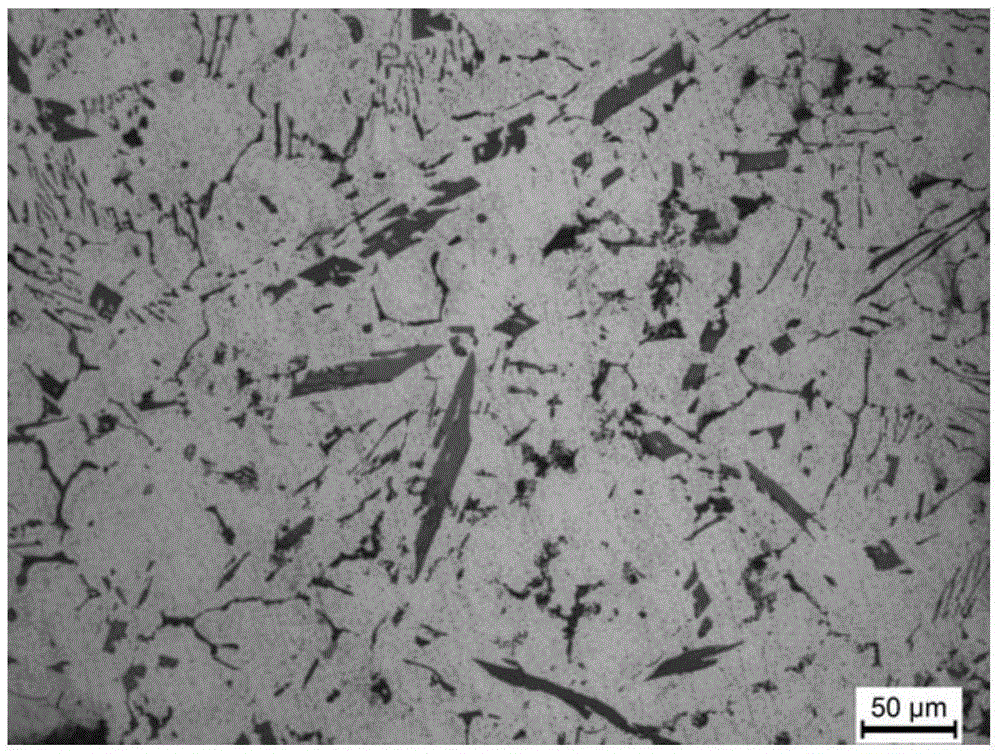

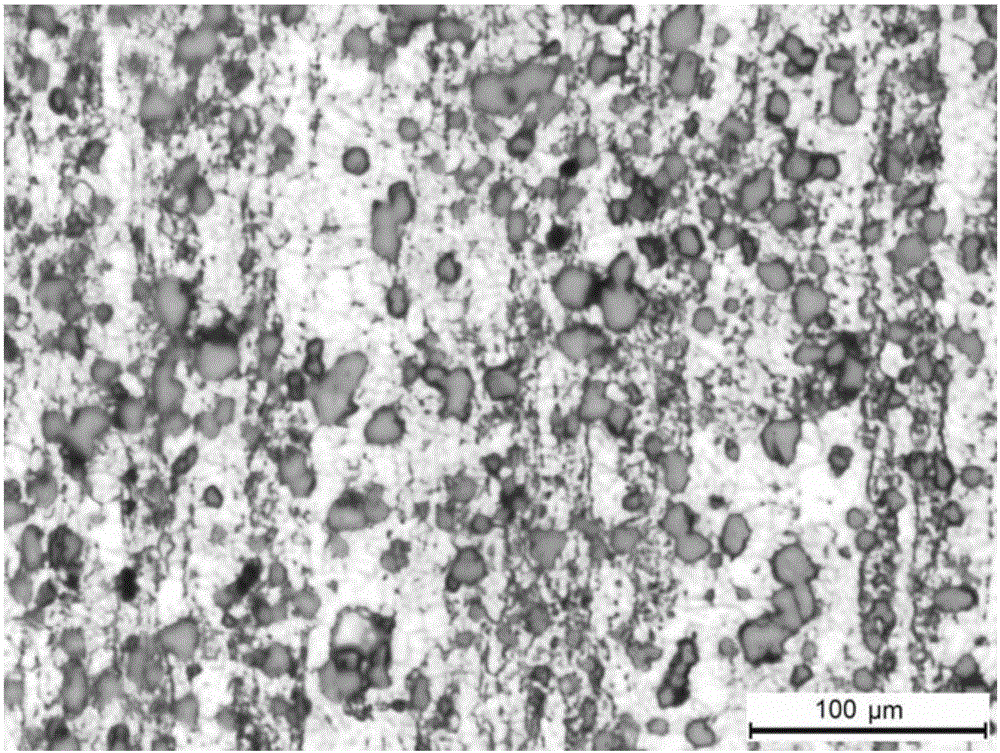

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com