Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

188 results about "Composite solder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-aqueous solvent cleaning of paste processing residue from substrates

A process of cleaning of objects that relate to semiconductor fabrication processes, such as, for example, conductive paste screening in the production of multilayer ceramic substrates and composite solder paste by stencil printing in electronic circuit assembly. Specifically, the process removes a metal / polymer composite paste from screening masks and associated paste making and processing equipment used in printing conductive metal pattern onto ceramic green sheet in the fabrication of semiconductor packaging substrates. The process also cleans solder paste residue from stencil printing equipment used in electronic module assembly surface mount technology for SMT discretes, solder column attachment, and BGA (Ball Grid Array) attachment on ceramic chip carrier or for screening solder paste onto printed circuit board. More particularly, paste residue is cleaned from metal, ceramic, and plastic substrates by a non-alkaline semi-aqueous cleaning method employing high boiling propylene glycol alkyl ether or mixtures of propylene glycol alkyl ether and propylene glycol solvents.

Owner:INT BUSINESS MASCH CORP

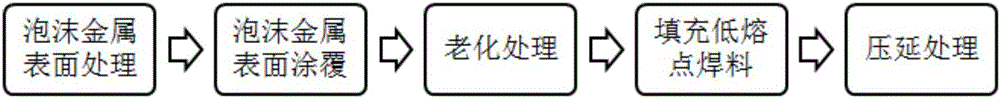

Preparation method of foam metal composite solder piece

ActiveCN106825999AOvercoming the lack of low strengthHigh strengthHot-dipping/immersion processesWelding/cutting media/materialsPorosityChemical plating

The invention discloses a preparation method of a foam metal composite solder piece. According to the method, firstly, the surface of foam metal is treated, the surface of a foam metal matrix is coated with one or more layers of active metal with an electroplating or chemical plating process, annealing treatment is performed, the foam metal with an active metal plating layer is infiltrated into molten solder and taken out after filling is performed, foam metal enhanced low-melting-point composite solder is obtained, finally, calendaring machining is performed, metal solder foil with certain thickness is obtained, and the purposes of improving the strength and the welding performance of foam metal composite solder are achieved. The foam metal is used for enhancing Sn-based or Zn-based solder, and the applied active metal plating layer can improve the strength of the foam metal matrix to a certain extent and make up the influence of foam metal porosity on the strength of the foam metal. Besides, the active metal plating layer is also beneficial to filling of low-melting-point solder to the foam metal and relieves the unfavorable situation that tin and matrix metal are difficult to infiltrate and interface bonding is not firm.

Owner:无锡继平新材料科技有限公司

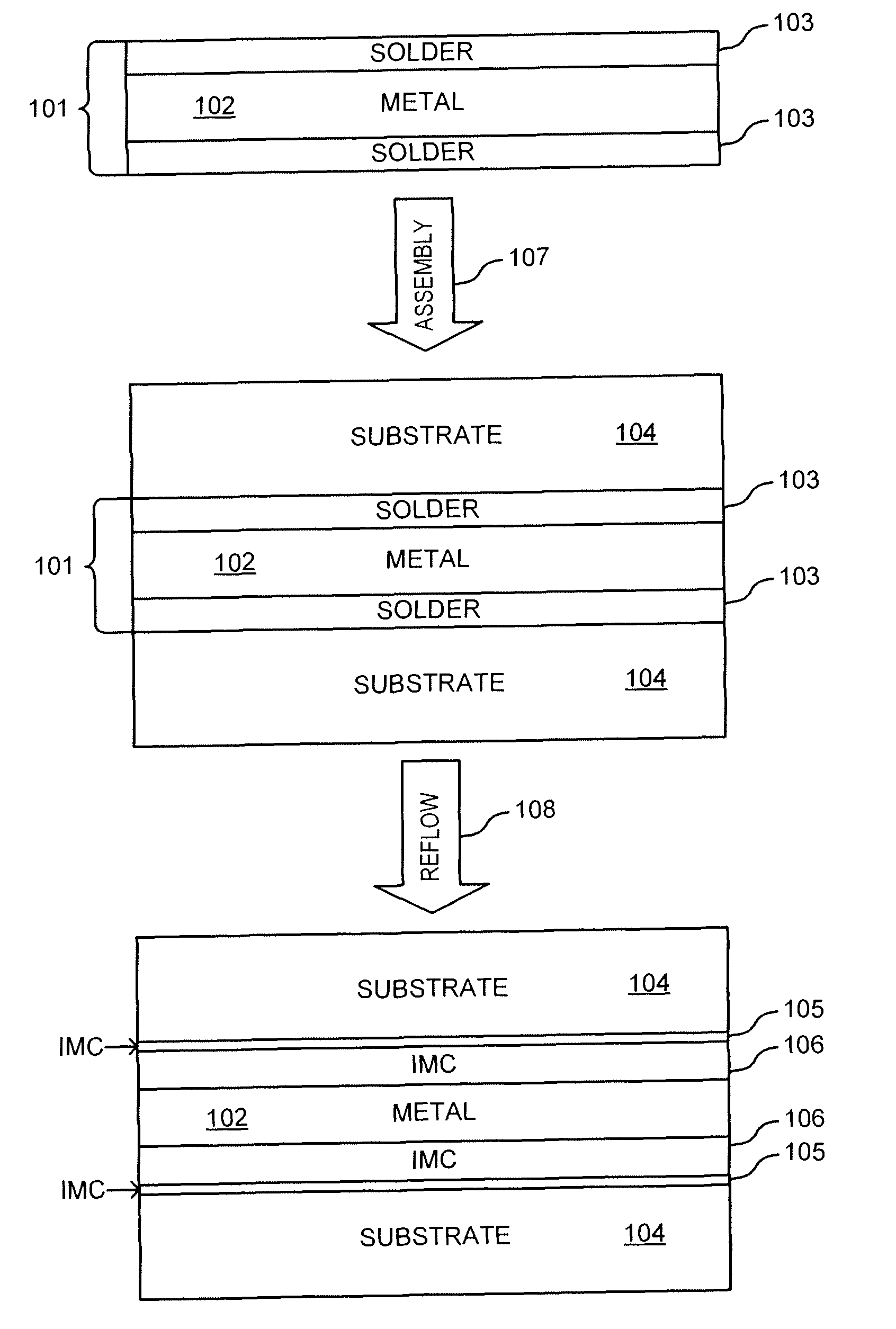

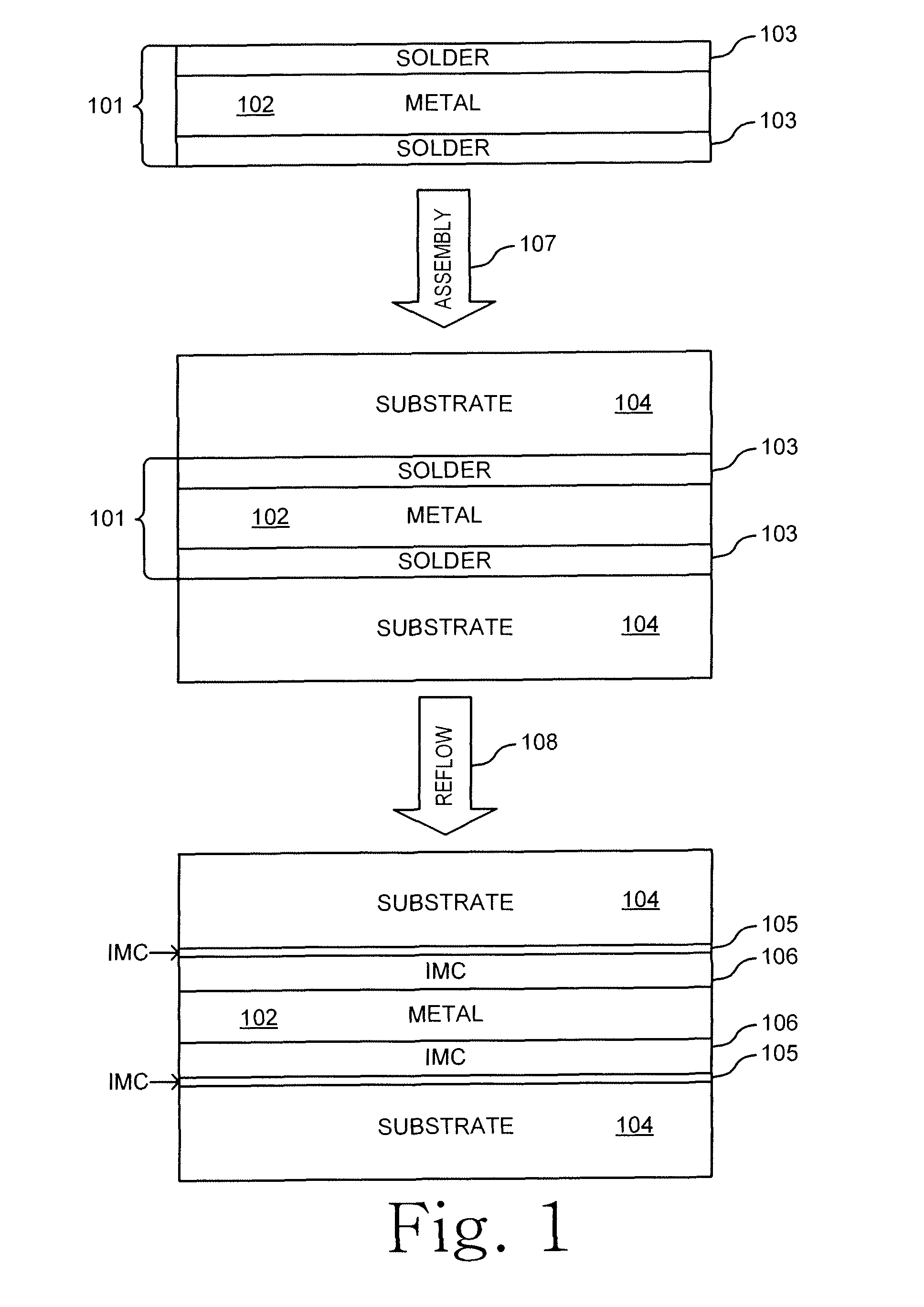

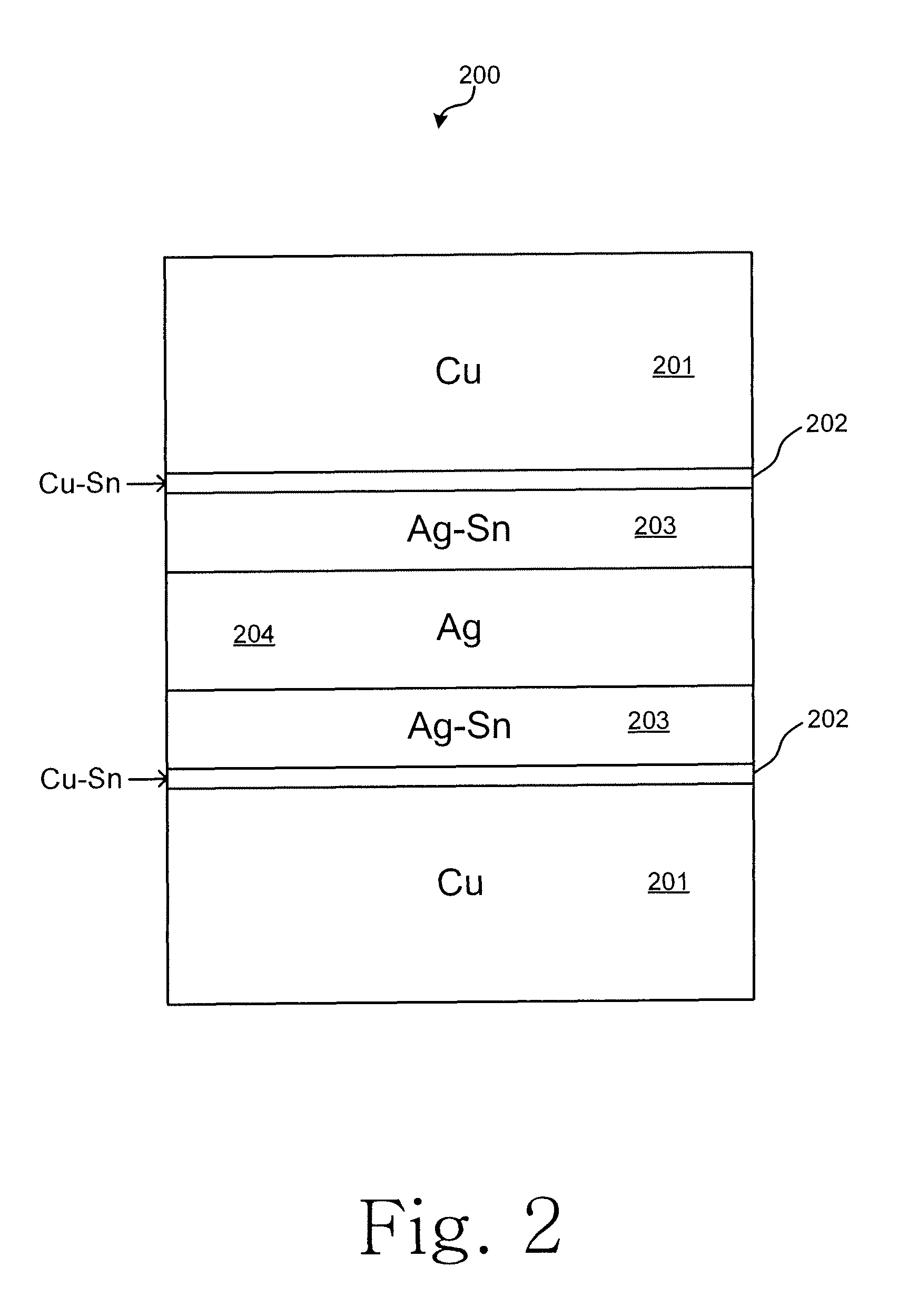

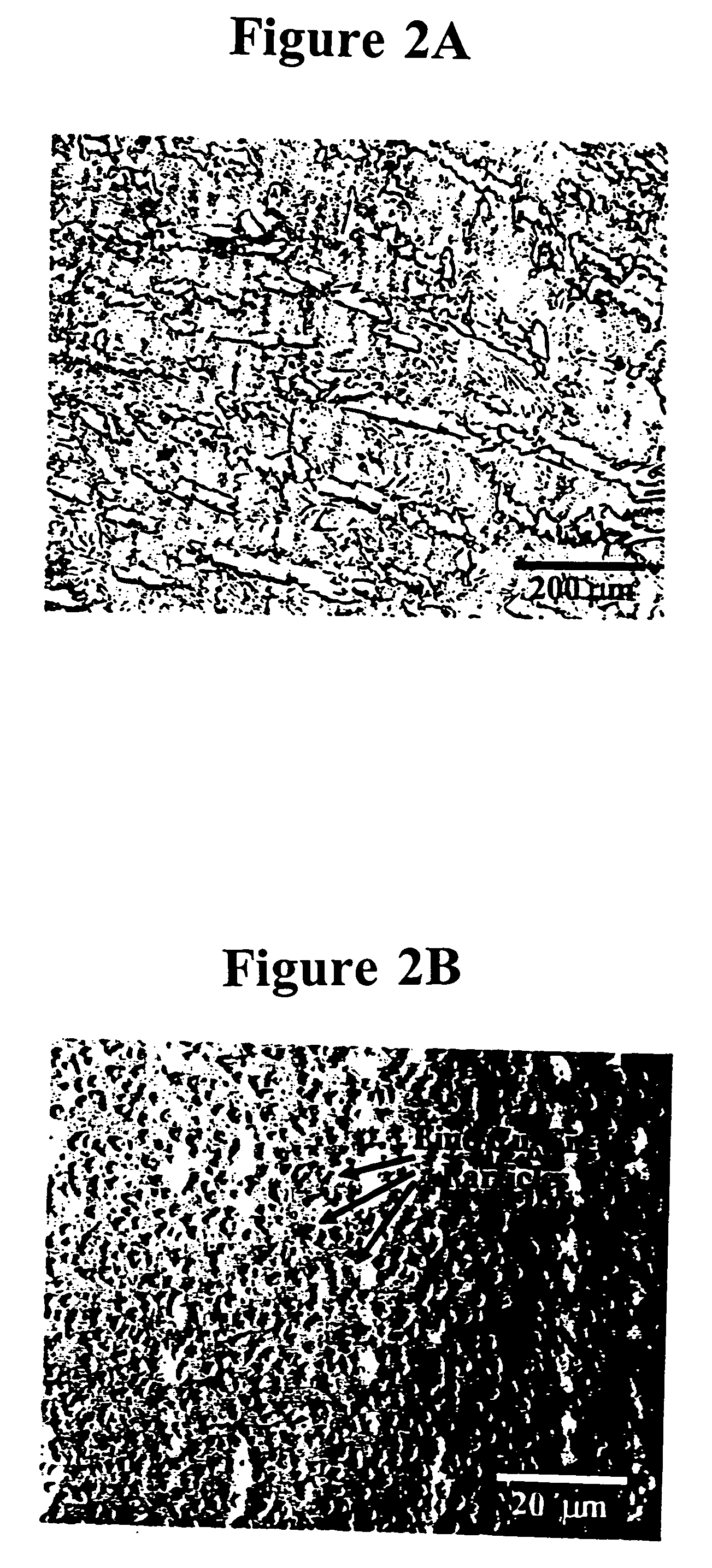

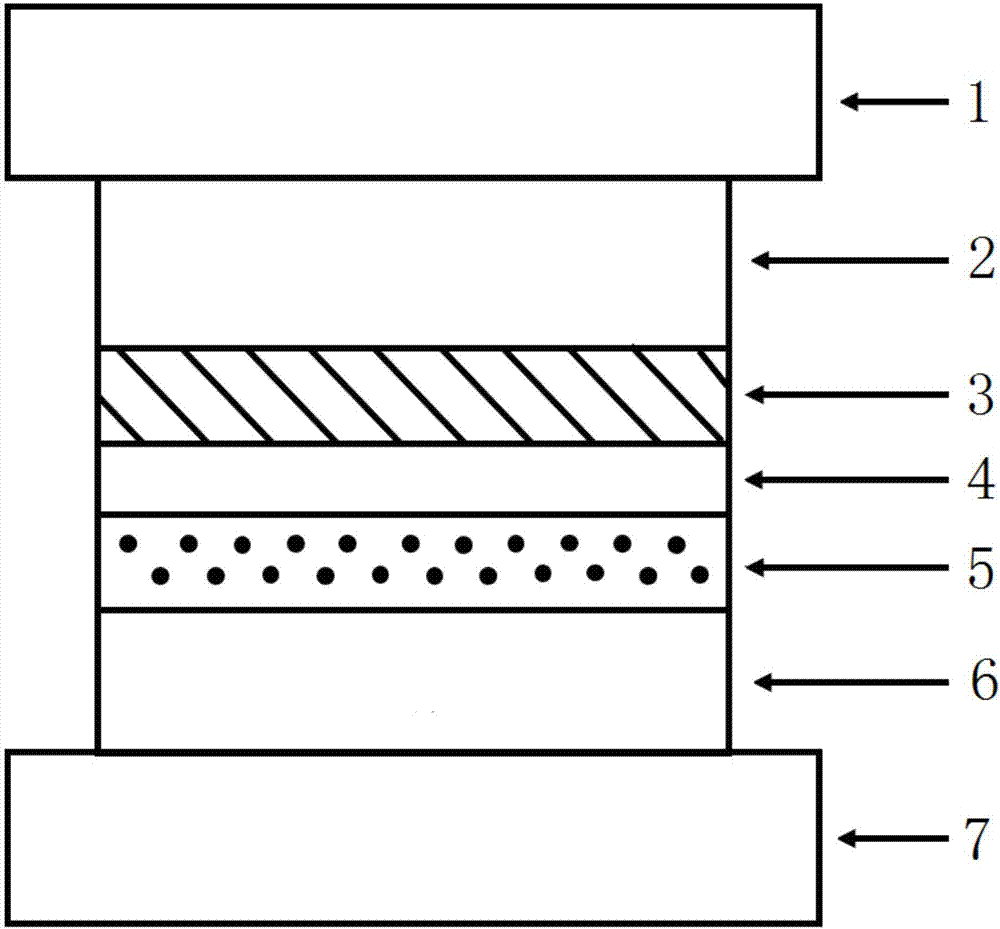

Composite solder alloy preform

ActiveUS8348139B2High remelting temperatureSolid-state devicesWelding/cutting media/materialsComposite solderMelting temperature

Various embodiments of the invention provide laminate composite preform foils for high-temperature Pb-free soldering applications. The laminate composite preform foil is composed of a high-melting, ductile metal or alloy core layer and a low-melting solder coating layer at either side of the core layer. During soldering, the core metal, liquid solder layer, and substrate metals react and consume the low-melting solder phase to form high-melting intermetallic compound phases (IMCs). The resultant solder joint is composed of a ductile core layer sandwiched by the IMCs layers at substrate sides. The joint has a much higher remelt temperature than the original melting temperature of the initial solder alloy coating, allowing subsequent mounting of packaged devices.

Owner:INDIUM CORPORATION

Graphene-enhanced Al-based composite solder auxiliary soldering method

InactiveCN105382440AHigh thermal conductivityLow densityWelding/cutting media/materialsSoldering mediaReduction treatmentGas phase

The invention relates to a solder auxiliary soldering method, in particular to a graphene-enhanced Al-based composite solder auxiliary soldering method. The method solves the problems that existing graphene is poor in aluminum base enhancing effect and poor in dispersibility. The method comprises the steps that an oxidized graphene suspension and an aluminum solder suspension are mixed, dried and then placed into a plasma enhanced chemical vapor deposition vacuum device for reduction treatment, then, the mixture is pressed into foils, the graphene / aluminum-based solder foils are placed between to-be-soldered faces of metal to be soldered for vacuum soldering, and the graphene-enhanced Al-based composite solder auxiliary soldering method is completed. The method is used for graphene-enhanced Al-based composite solder auxiliary soldering.

Owner:HARBIN INST OF TECH

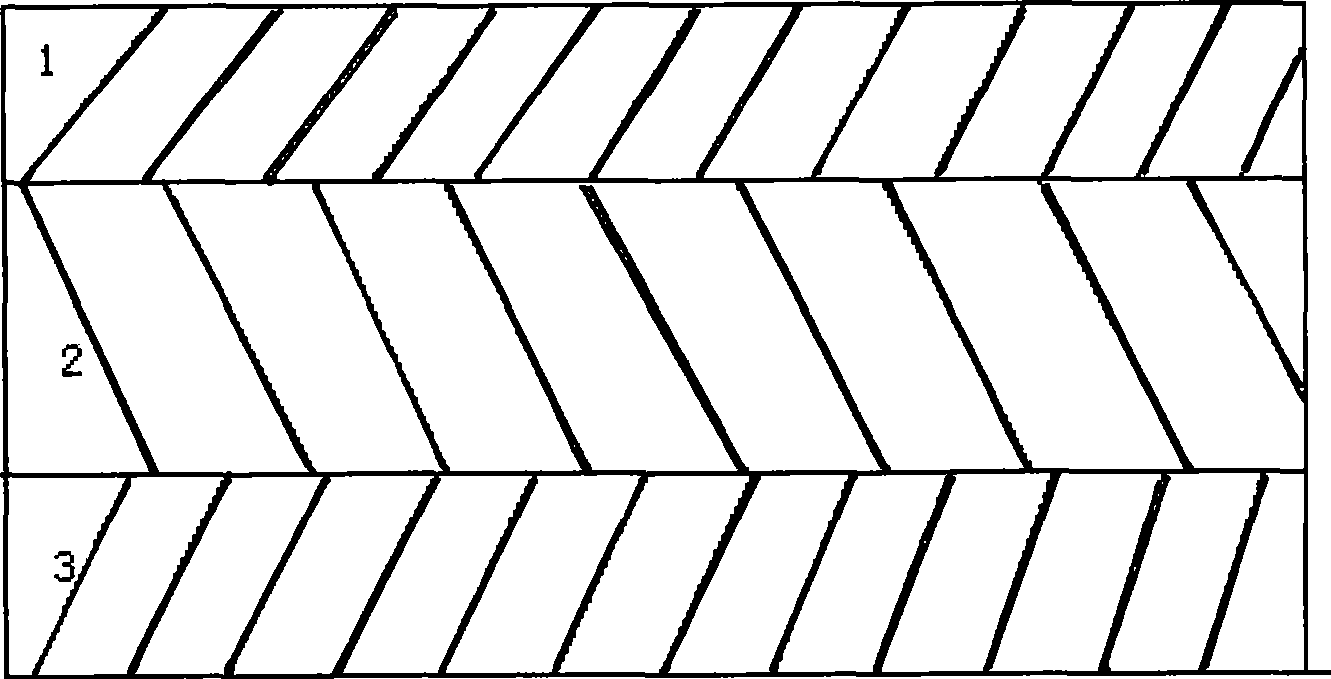

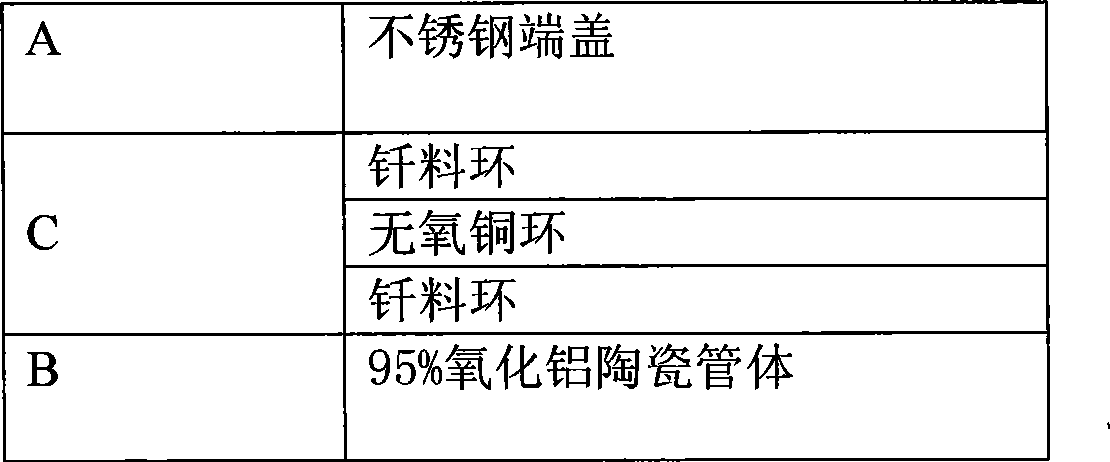

Stainless steel / alumina ceramic low stress hermetic seal solder

InactiveCN101475395AStrong stress absorption effectWelding/cutting media/materialsSoldering mediaAlloy compositeComposite solder

The invention relates to a silver alloy composite solder strip for a vacuum switch tube stainless steel and 95 percent alumina ceramic low-stress hermetic seal joint. The cross section of the composite solder strip has a three-layer overlapping structure of a solder alloy layer, a copper core layer and a solder alloy layer, wherein solder in the composite solder comprises the following compositions in percentage by mass: 55 to 72 percent of silver, 19.0 to 43.0 percent of copper and 0.50 to 4.50 percent of nickel; the melting temperature of the solder is between 780 and 835 DEG C, and the hermetic seal temperature is between 820 and 850 DEG C; the unilateral thickness of the solder alloy layer in the composite solder is between 0.08 and 0.20 millimeter; the copper core layer in the composite solder is copper with the purity of more than or equal to 99.95 percent or oxygen free copper; the interlayer composite proportion of the composite solder, namely the thickness of the solder layer to the thickness of the copper core layer to the thickness of the solder layer, is 1:X:1 (wherein, X is between 1.8 and 3.5); and firm metallurgical combination is formed between various layers. The intensity of the vacuum switch tube stainless steel and 95 percent alumina ceramic joint is more than or equal to 90 MPa, and the leakage rate of the joint is less than or equal to 1*10Pa.m / s.

Owner:SINO PLATINUM METALS CO LTD

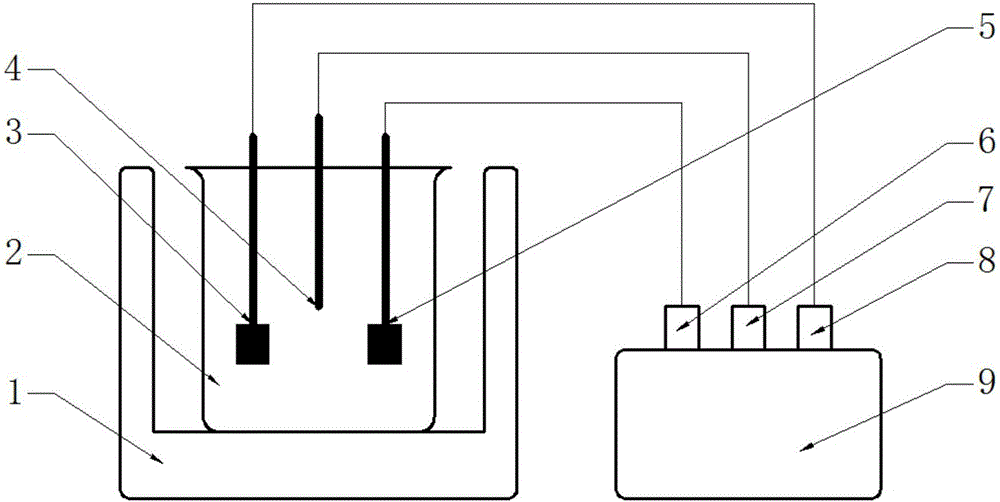

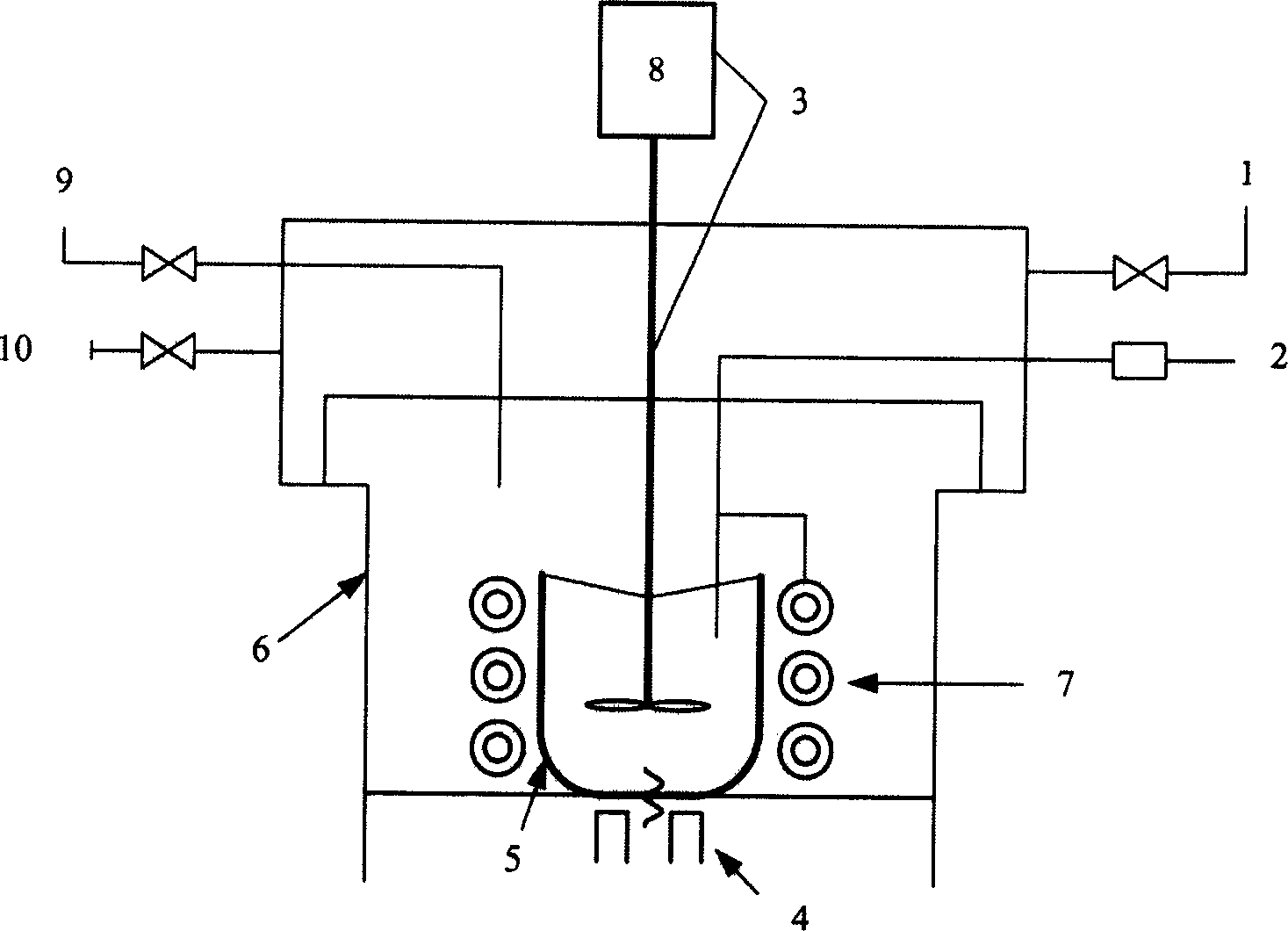

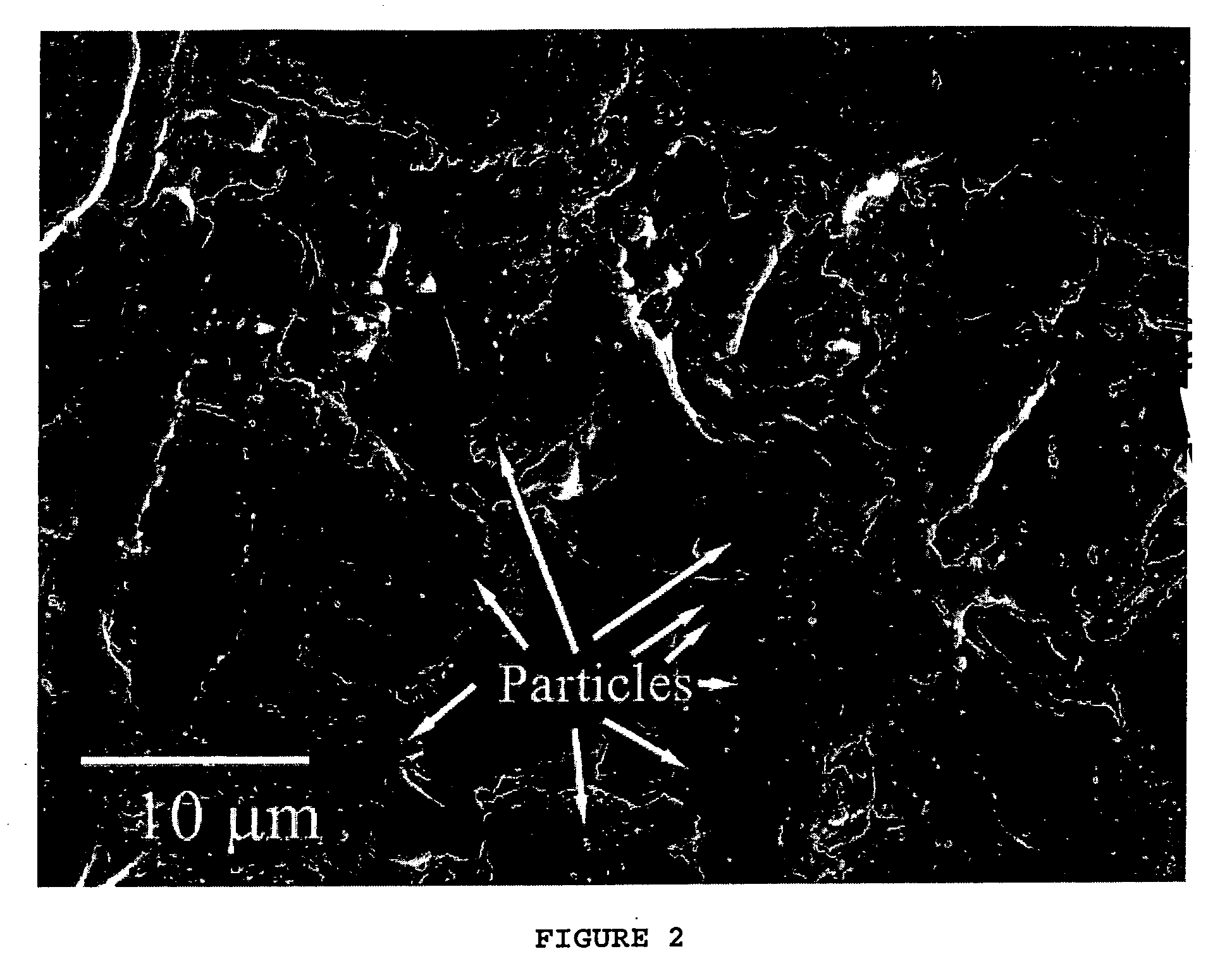

Method and apparatus for preparing composite solder for welding particle enhanced aluminium-based composite material

InactiveCN1827809AEasy to use for weldingAvoid pollutionWelding/cutting media/materialsSoldering mediaSlagShielding gas

The invention provides the preparing method and device for combined welding rod used for particle enhancement composite material aluminium. The method comprises the following steps: putting the clean alloy into crucible, starting vacuum pump to 5 X10-5, then charging protective gas into vacuum system, heating the alloy, controlling the temperature, the lowest which is higher than liquid line of alloy, and the highest of which is lower than liquid line plus 100-125Deg.C, melting alloy, canceling vacuum, carrying out slag-out treatment, adding clean reinforcement particle according to volume fraction, charging protective gas, starting agitating device and ultrasonic vibrator, after stirring and ultrasonic vibration, carrying out slag-out treatment, cooling, and getting casting ingot. The invention improves the preparing efficiency, overcomes the defect that it is not sufficient to wet the enhancement phase / base, and optimizes the alloy solidification structure.

Owner:HARBIN INST OF TECH

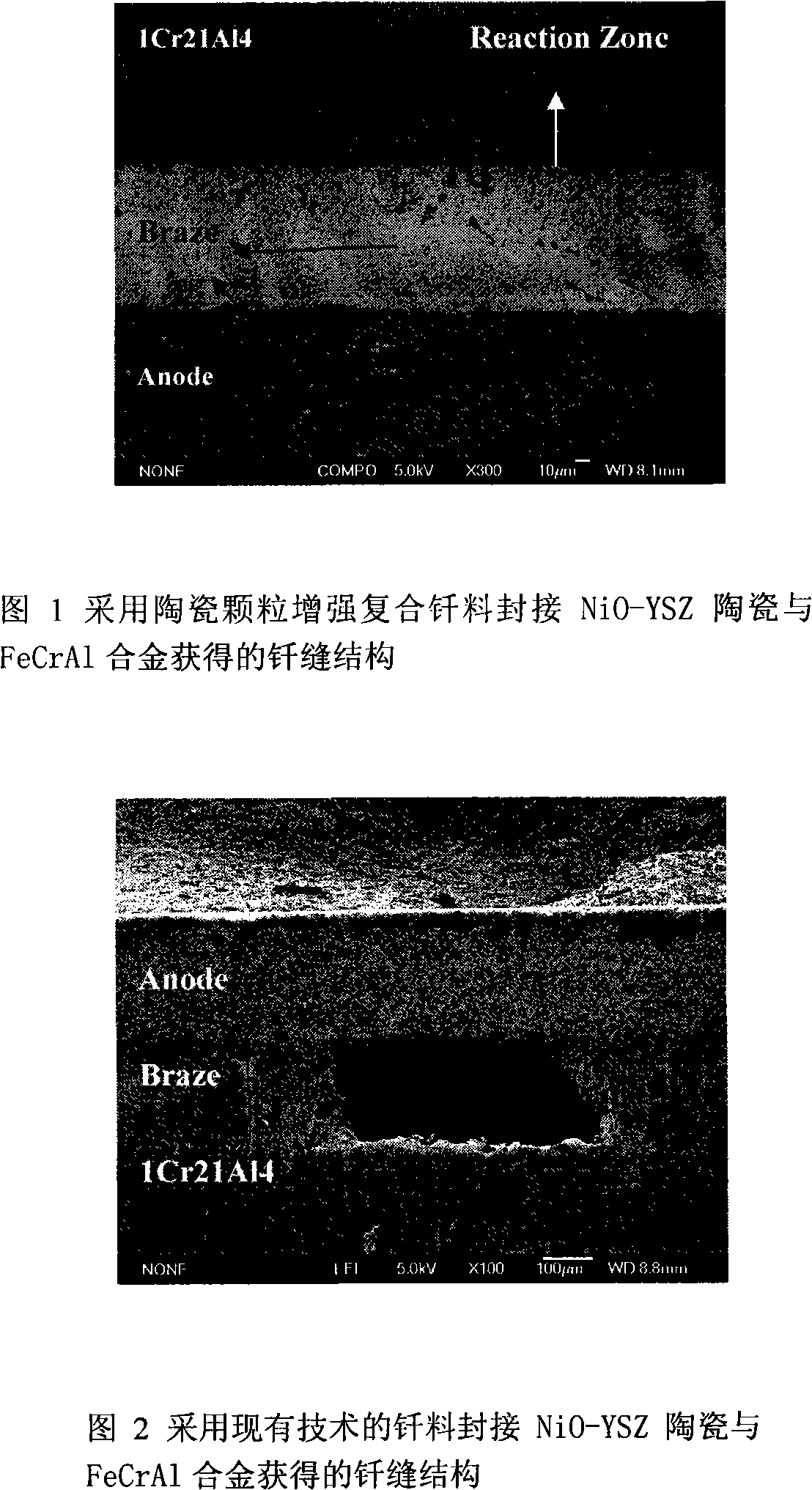

Ceramic granule reinforced composite material

InactiveCN101288928ACoefficient of thermal expansion matchingHigh Prepositioned Functional ViscosityWelding/cutting media/materialsSoldering mediaReducing atmosphereComposite solder

The present invention relates to a ceramic particle strengthening composite solder used for ceramic / ceramic or ceramic / metal solder. The ceramic particle strengthening composite solder consists of 90 to 99.8 percent of metal powder A and 0.2 to 10 percent of ceramic particle B according to the weight percentage; the metal powder A is formed by mixing Ag powder and Cu powder; relatively to the metal powder A, the mol rate of the Ag powder is 80 to 99.5 percent and the mol rate of the Cu powder is 0.5 to 20 percent. The ceramic particle strengthening composite solder provided by the present invention can reduce the generation of air holes in welding line, work at the high temperature of around 800 DEG C, and prolong the service life of the welding line at the high temperature and in the oxidizing atmosphere and the reducing atmosphere, thus obtaining the welding with high joint performance.

Owner:UNIV OF SCI & TECH OF CHINA +1

Composite metal matrix castings and solder compositions, and methods

InactiveUS20050034791A1Improve service performancePrinted circuit assemblingPrinted circuit aspectsComposite solderMaterials science

A composite composition and methods for making the composition, providing a metal matrix and dispersed inorganic oxide particles with a bound organofunctional group on a surface of the particles are described. A composite solder composition and methods for making and using the composition, providing a metal matrix and dispersed inorganic oxide particles with a bound organofunctional group on a surface of the particles are described. An apparatus comprising this composite solder composition is also described. In particular, organofunctional POSS, and POS, particles are described. The compositions provide cast metals and solders.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Preparation method of tin-based silver graphene lead-free composite solder

InactiveCN105171277AImprove distribution uniformityUniform compositionTransportation and packagingWelding/cutting media/materialsSolder matrixRoom temperature

The invention discloses a preparation method of tin-based silver graphene lead-free composite solder. The method comprises the steps that a certain amount of graphene and lauryl sodium sulfate are mixed, then a certain amount of dimethylformamide is added, ultrasonic treatment is performed for 2 h, a certain amount of silver nitrate is added into a mixed solution, ultrasonic treatment is performed continuously, and finally a self-made silver graphene nanosheets are obtained; and required solder matrix powder is weighed according to different graphene mass fractions and poured into a ball milling tank for ball milling for 5 h, the powder is placed into a stainless steel mold after being dried and placed under a hydraulic machine to be pressed and molded at the pressure of 500 Mpa, and then a cylinder obtained through cold pressing is placed into a high-vacuum tubular resistance furnace for vacuum sintering for 2 h at the temperature of 175 DEG C and placed under the hydraulic machine after being cooled to the room temperature to obtain a cylinder through impact extrusion. According to the preparation method, Ag-particle-modified graphene is selected as a strengthening material so as to improve load transmitting between the nano-silver-modified graphene and a Sn matrix, and therefore the better strengthening effect is achieved.

Owner:TIANJIN UNIV

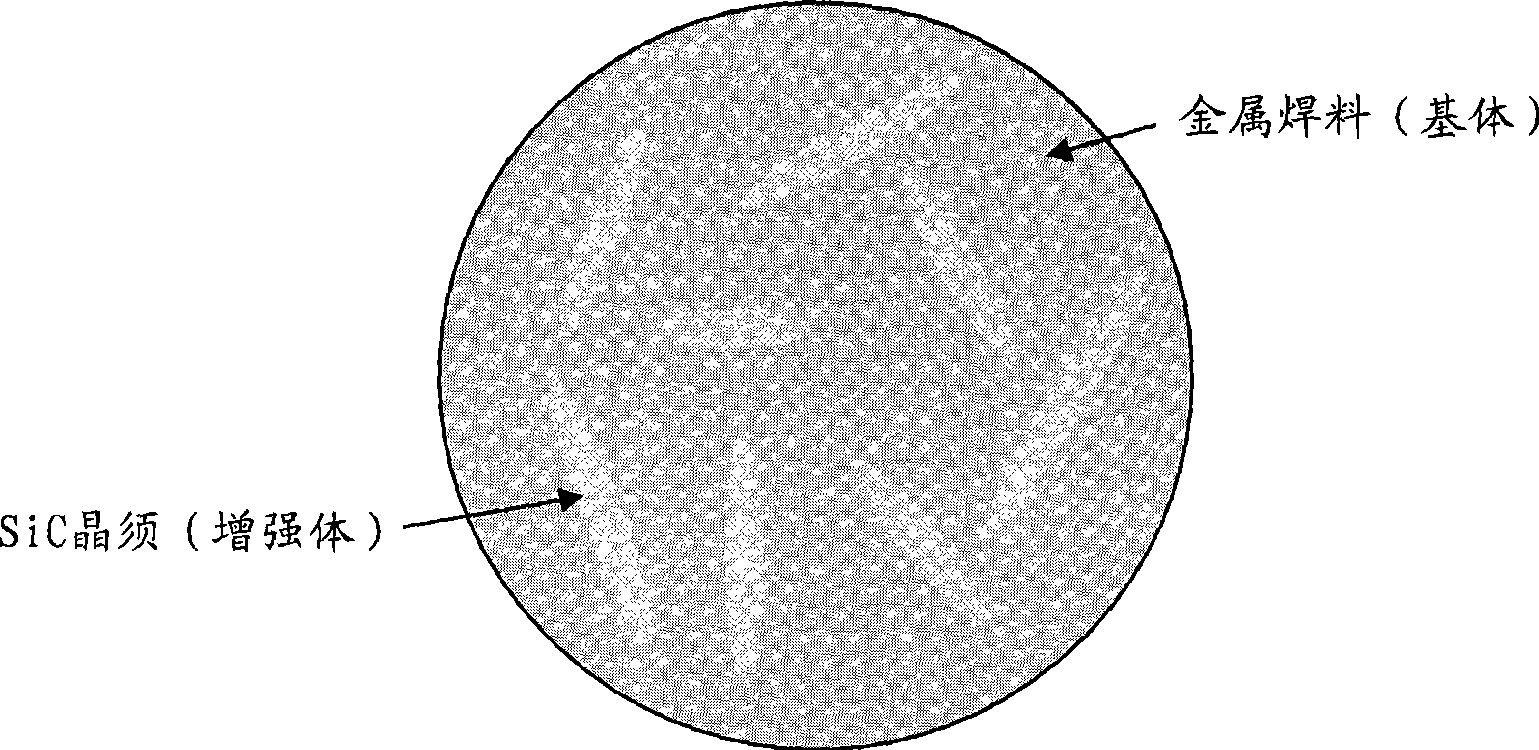

Solder with composite material and preparation method thereof

InactiveCN101480763AImprove the immunityImprove acceleration performanceWelding/cutting media/materialsSoldering mediaWhiskersComposite solder

The invention discloses a composite solder and a preparation method thereof. The composite solder comprises a metal solder as a substrate and SiC crystal whisker as a reinforcement, wherein the metal solder can be a lead metal solder or lead-free metal solder; the volume percent of the SiC crystal whisker can be 0.1-30 percent, the diameter can be 0.5-1 micron and the slenderness ratio can be 20:1 to 40:1. The composite solder has high ability of resisting creep deformation and crack extension.

Owner:SAMSUNG ELECTRONICS CO LTD +1

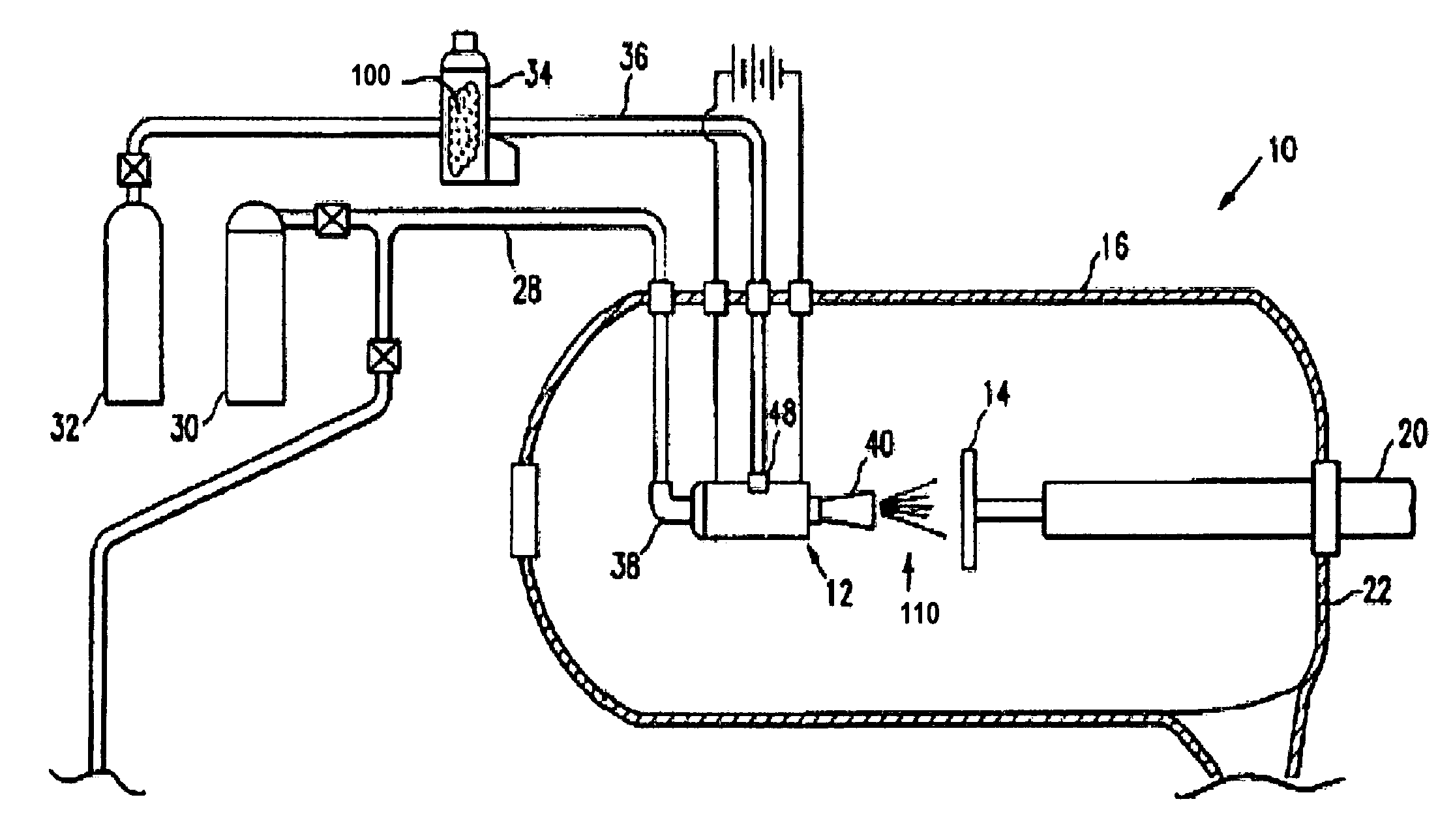

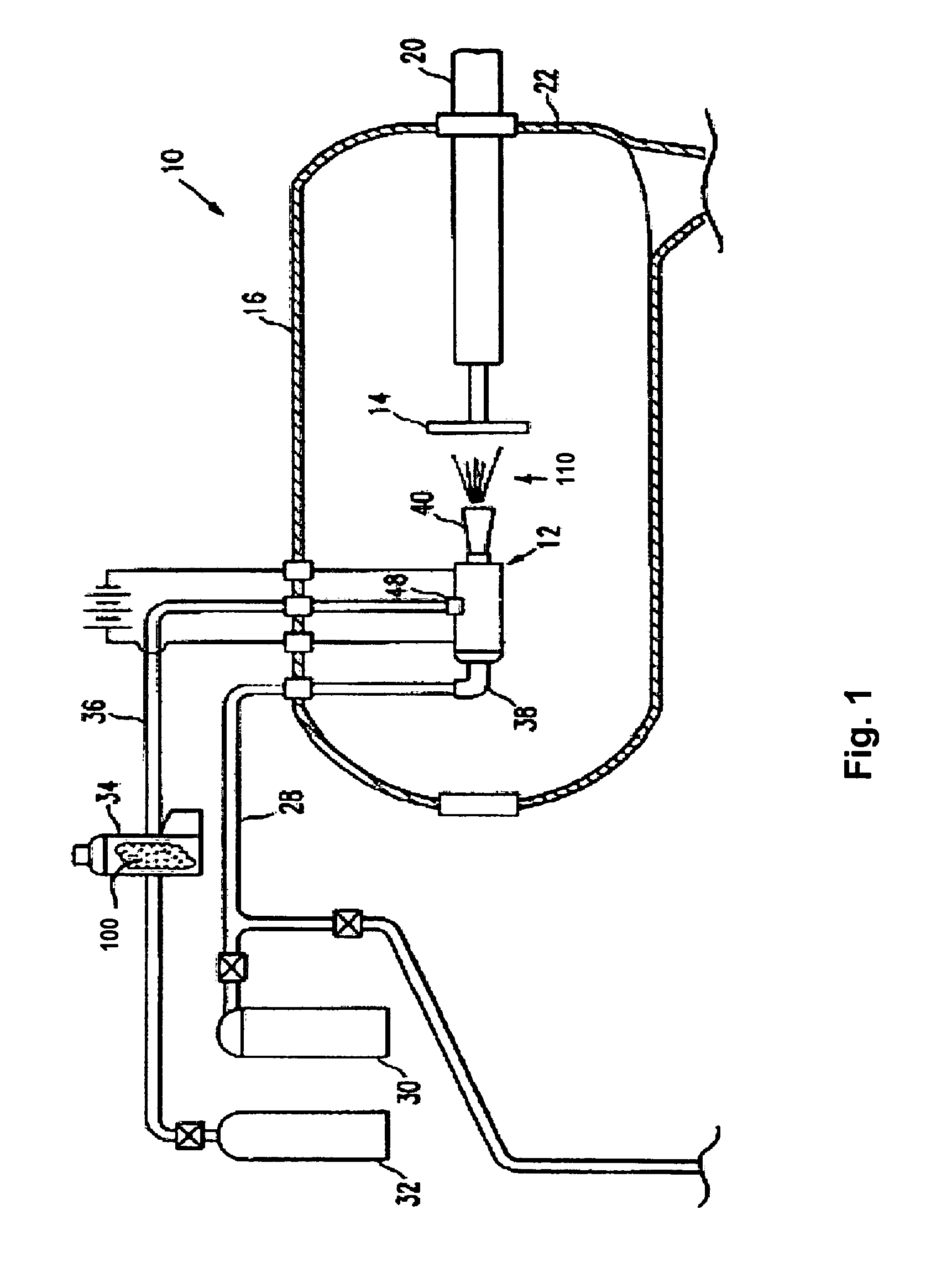

Semi-aqueous solvent cleaning of paste processing residue from substrates

InactiveUS20030066540A1Eliminate residueElectrostatic cleaningSemiconductor/solid-state device manufacturingStencil printingSolvent

The present invention relates generally to a new process of cleaning of objects that relate to semiconductor fabrication processes, such as, for example, conductive paste screening in the production of multilayer ceramic substrates and composite solder paste by stencil printing in electronic circuit assembly. Specifically, this invention is concerned with removing a metal / polymer composite paste from screening masks and associated paste making and processing equipment used in printing conductive metal pattern onto ceramic green sheet in the fabrication of semiconductor packaging substrates. This invention is also concerned with cleaning of solder paste residue from stencil printing equipment used in electronic module assembly surface mount technology for SMT discretes, solder column attachment, and BGA (Ball Grid Array) attachment on ceramic chip carrier or for screening solder paste onto printed circuit board. More particularly, this invention is concerned with cleaning of paste residue from metal, ceramic, and plastic substrates by a non-alkaline semi-aqueous cleaning method employing high boiling propylene glycol alkyl ether or mixtures of propylene glycol alkyl ether and propylene glycol solvents.

Owner:IBM CORP

Cold spray-coating method for composite solder of conduit and fin of aluminium alloy heat exchanger

InactiveCN1962941AIncrease productivityQuality improvementWelding/cutting media/materialsHeat exchange apparatusSpray coatingAlclad

The invention discloses a preparing method of automobile aluminium alloy exchanger, which comprises the following steps: 1. blending Al-Si and Zn powder and brazing flux with weight rate at 9: 3-4: 0.5-4; drying; preparing cold spraying powder; 2. cleaning the conductor and fin surface; drying to make cold spraying powder; adopting cold-spraying method to sediment powder on the surface of conductor and fin; 3. assembling the base conductor; brazing according to NOCOLOK technique to obtain the product.

Owner:HARBIN INST OF TECH

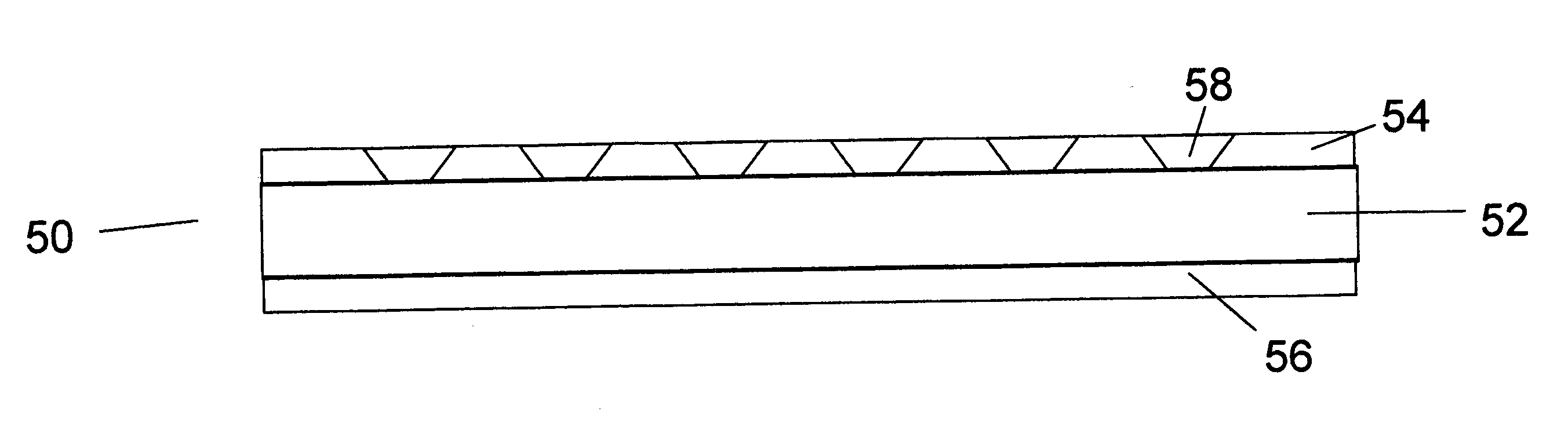

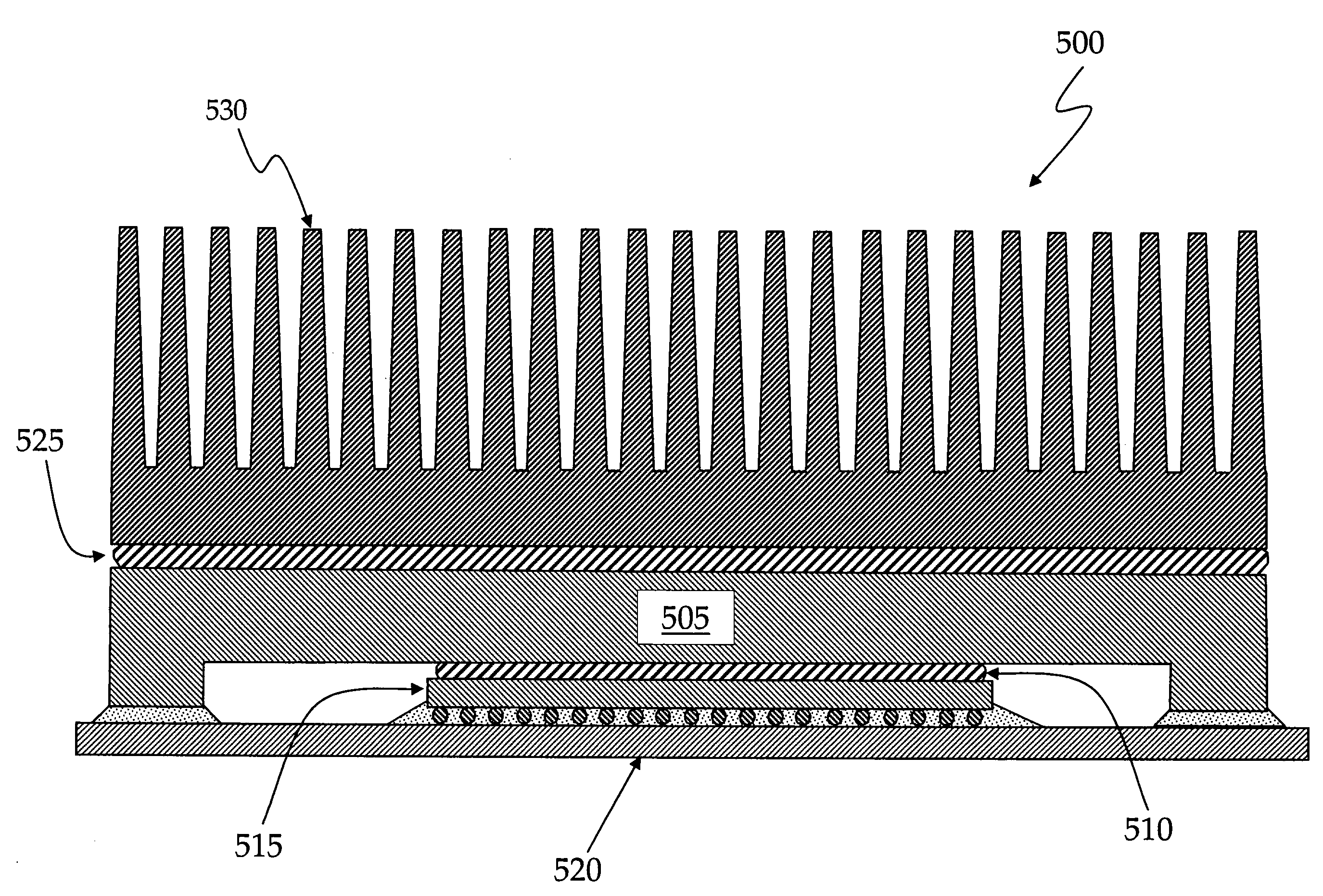

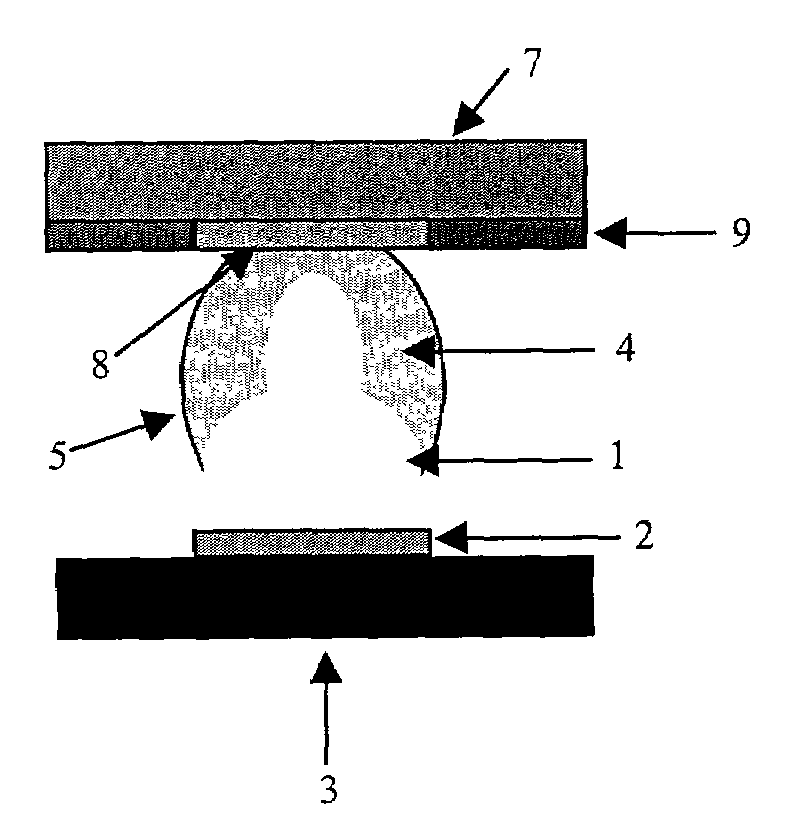

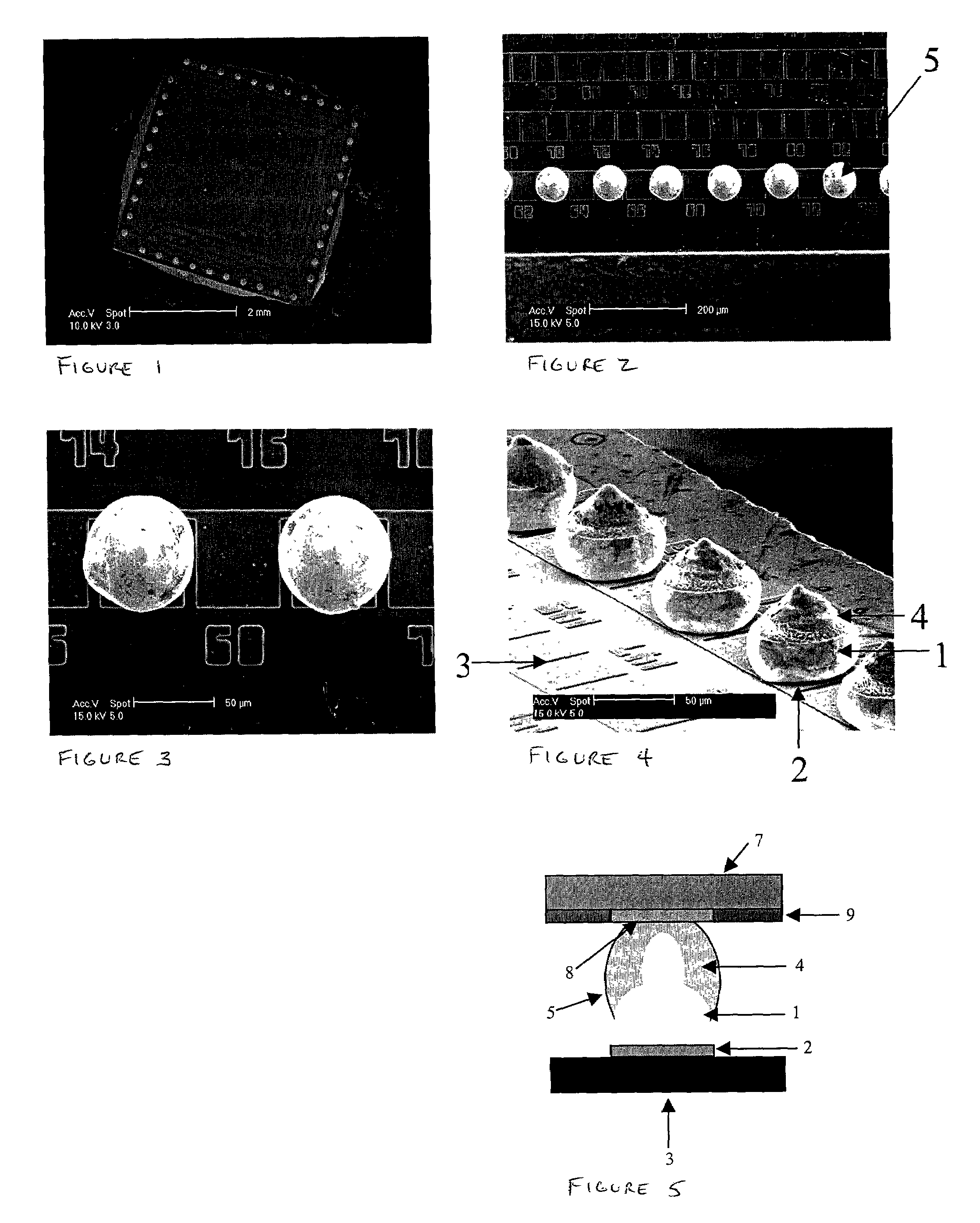

Composite solder transfer moldplate structure and method of making same

InactiveUS20060289607A1Simple and inexpensive processEasy to produceWelding/cutting auxillary devicesAuxillary welding devicesRoom temperatureThermal expansion

A method for constructing a composite solder transfer moldplate for flip chip wafer bumping of a substrate, comprising the steps of coating at least one polymer layer onto a first side of a transparent plate, the plate having a thermal expansion coefficient similar to that of the substrate; and forming a multiplicity of cavities in a polymer layer on one side of the plate, each cavity being for receiving solder. A moldplate made by the method. The structure has required behavior through temperature excursions between room temperature and various solder molten temperatures.

Owner:BUCHWALTER STEPHEN L +5

Melting-point-changeable lead-free composite soldering material, soldering paste, thire preparation and use

InactiveCN101069938AStrong anti-collapse abilityReduce short circuitPrinted circuit assemblingMixing methodsComposite solderSolder paste

Owner:BEIJING COMPO ADVANCED TECH

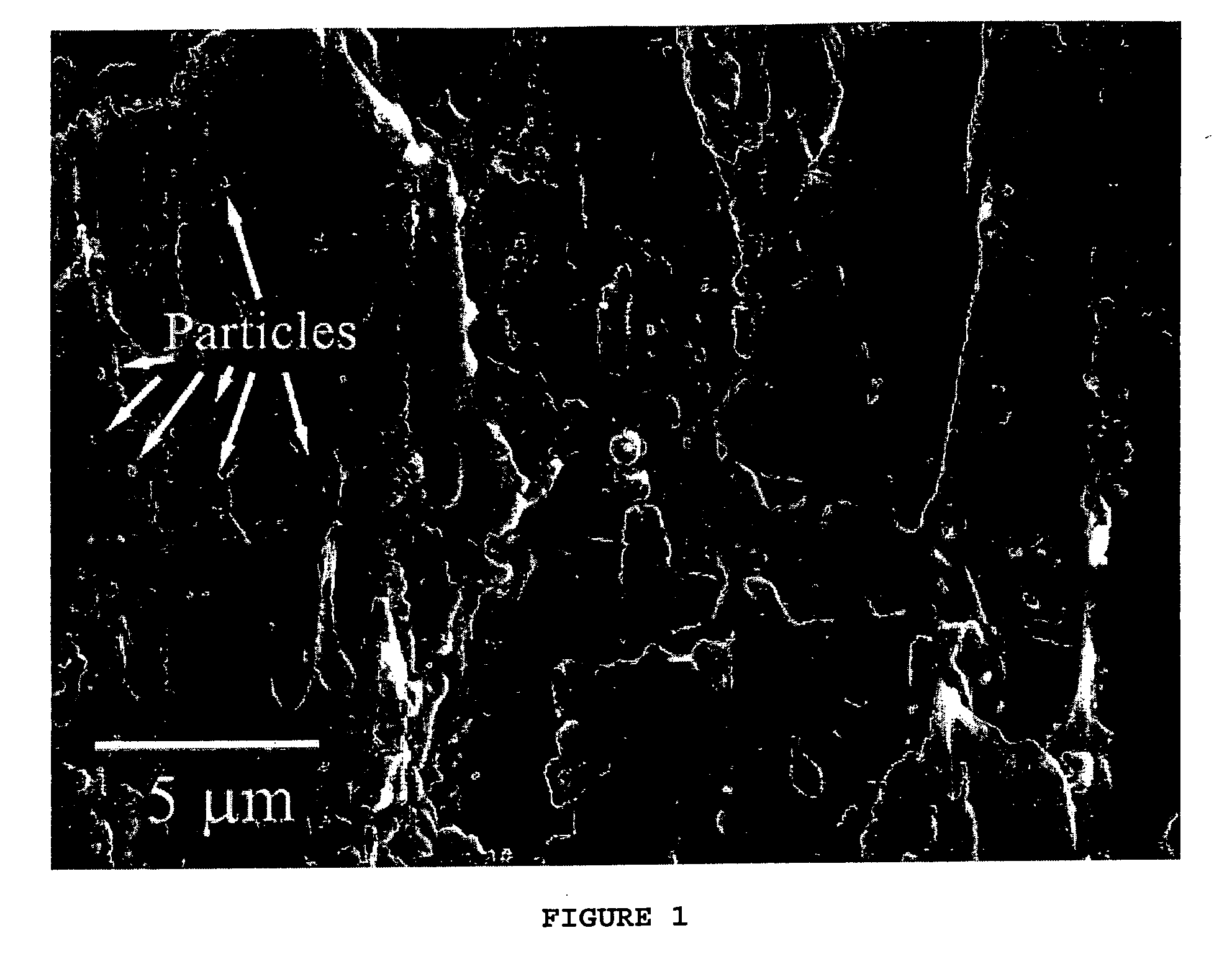

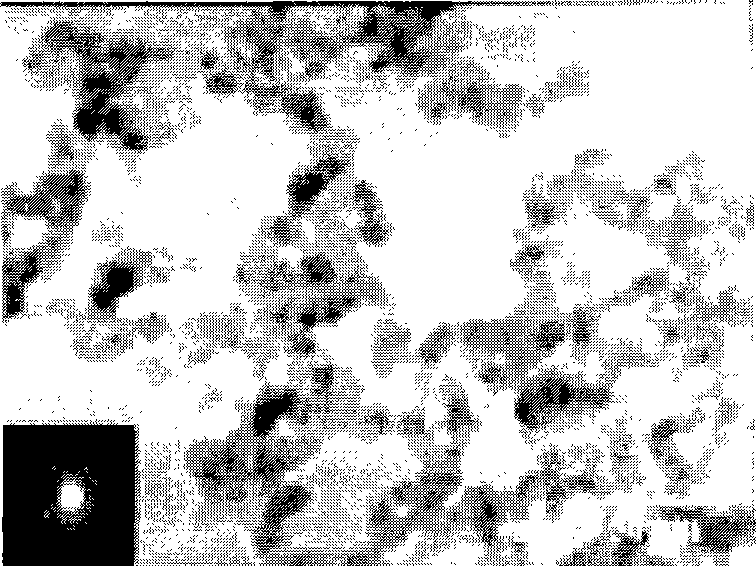

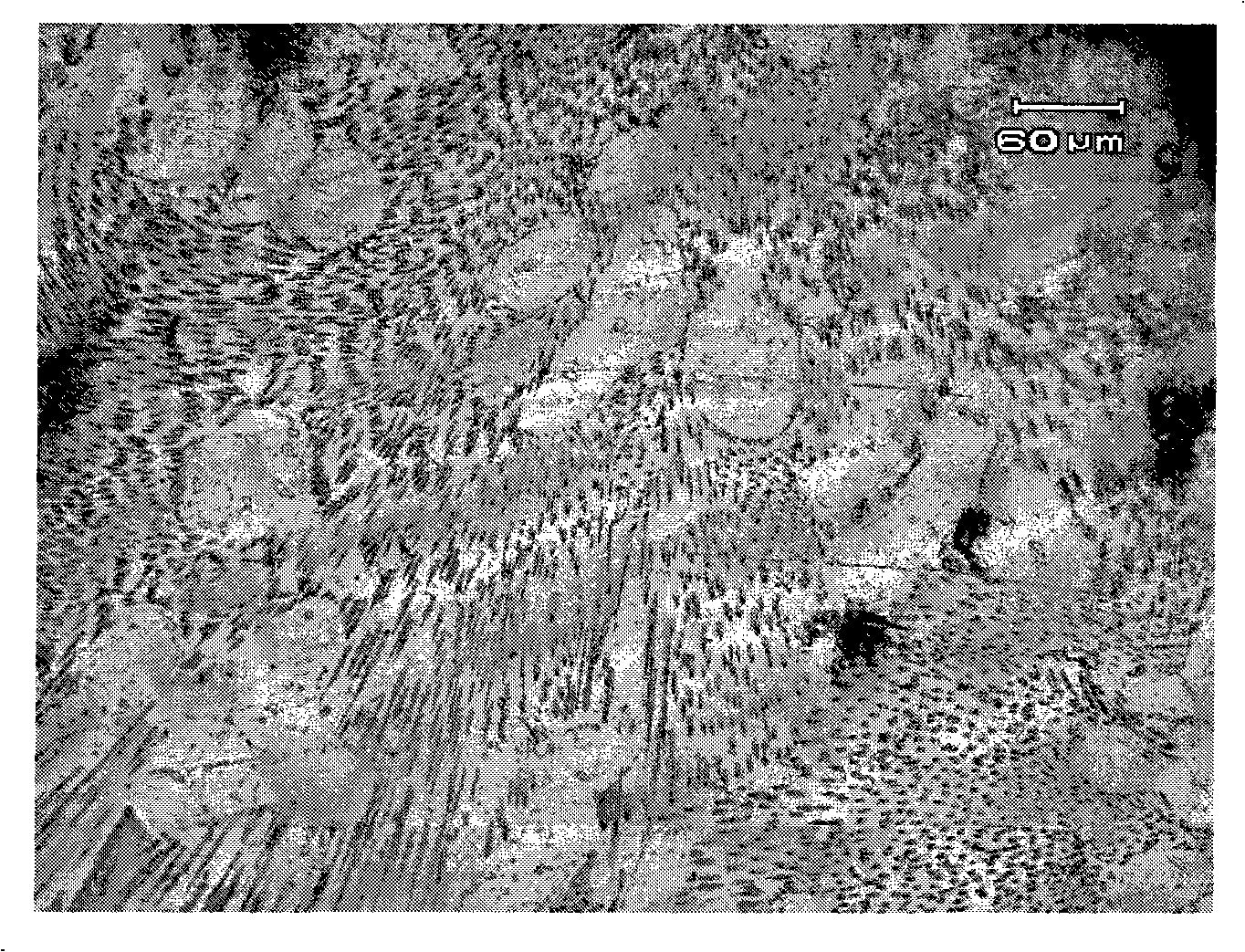

Methods for producing lead-free in-situ composite solder alloys

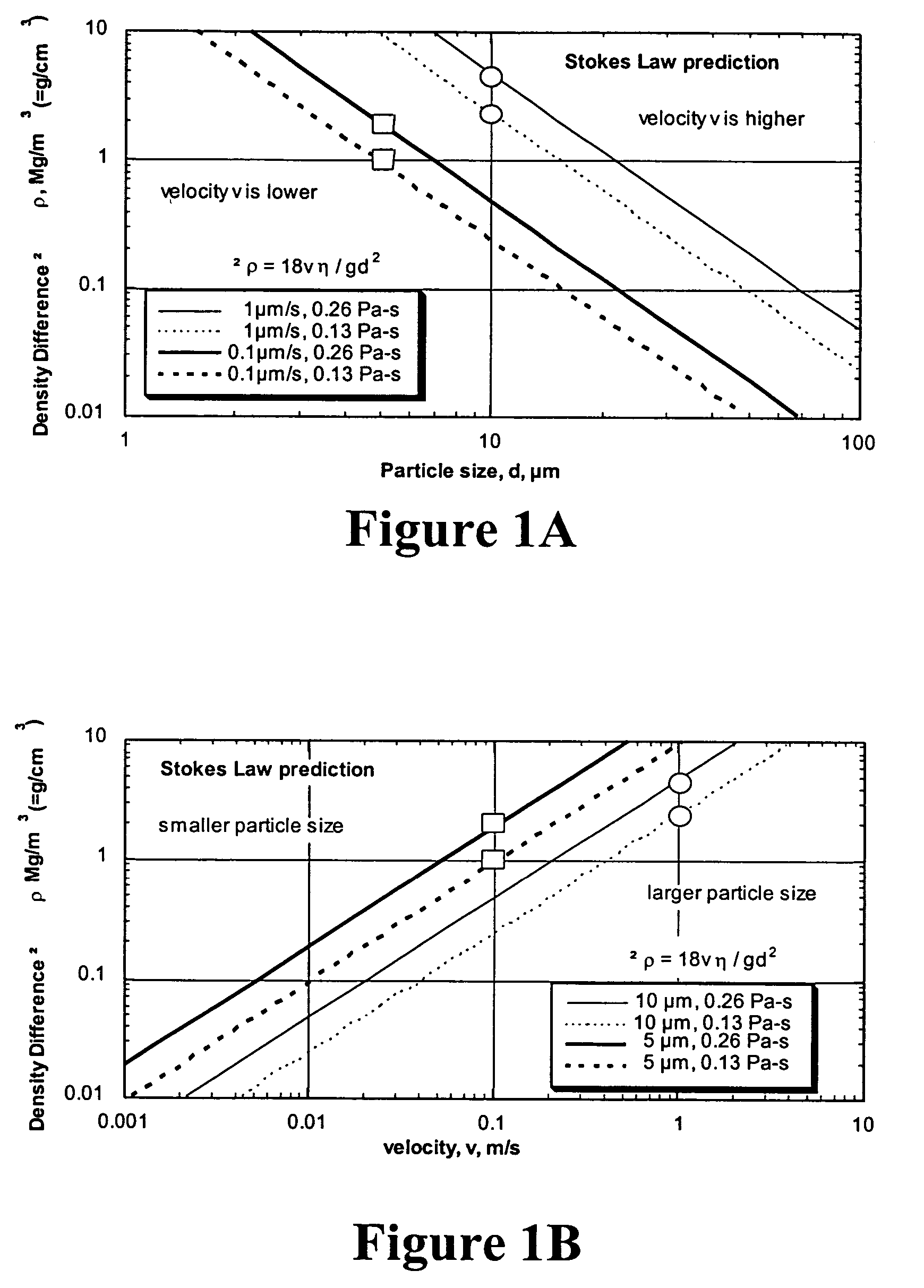

InactiveUS7771547B2High strengthLow creep ratePrinted circuit assemblingWelding/cutting media/materialsParticulatesSolder matrix

Methods are disclosed for producing in-situ composite solders having a particulate intermetallic phase homogeneously distributed throughout the solder matrix. An eutectic solder is mixed with the components of the intermetallic phase, melted and rapidly cooled to form the desired solder. In-situ composite solder alloys formed by the disclosed method provide greater solder joint strength and fatigue resistance.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

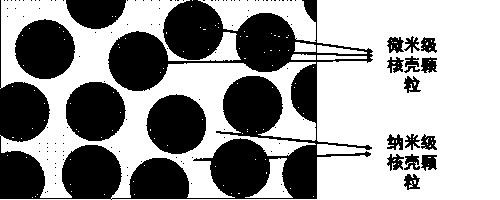

Multi-scale micro-nano particle composite soldering paste for field of electronic packaging and preparation method of multi-scale micro-nano particle composite soldering paste

ActiveCN109664049ASolve the disadvantages of poor oxidation resistance and difficulty in preservationSolve uneven distributionWelding/cutting media/materialsSoldering mediaMicro nanoActive agent

The invention provides the multi-scale micro-nano particle composite soldering paste for the field of electronic packaging and a preparation method and an application process of the multi-scale micro-nano particle composite soldering paste. The novel composite soldering paste is formed by mixing metal powder and a soldering flux, the metal powder is composed of 30 to 70 nm in particle size and 3 to 7 microns, 15 to 25 microns of Cu @ Ag particles, 40 to 60 nm of Ni @Ag particles and 1 to 2 microns of Ag particles, the scaling powder is composed of solvent isopropanol, an active agent stearicacid, a film-forming agent mixed rosin, polyethylene glycol, a modifier triethanolamine and a surfactant octylphenol polyoxyethylene ether, the existence of Cu @ Ag particles in the composite solder paste is reduced relative to the cost of the nano-silver solder paste, the electromigration resistance can be improved, the Ag particles can protect the integrity of the Cu @ Ag core-shell structure, under a high-frequency induction process condition, the magnetism of the Ni @ Ag particles ni enables the particle distribution to be more uniform, the density is improved, and the electric conductionheat conduction performance is improved. The method is low in cost, simple and controllable in process and high in efficiency, the problems that an existing device pasting material is high in cost, low in service temperature, long in process time and the like are solved.

Owner:哈尔滨景成创业投资管理有限公司

Soldering coal composition used for preparing tin solder paste

InactiveCN1757481AImprove printing effectExcellent resistance to hot and cold collapseWelding/cutting media/materialsSoldering mediaAlkylphenolSolvent

A composite solder flux used to prepare the tin solder for PCB is composed of carrier, activator and solvent. Said carrier consists of the rheological agent prepared from p-methylenebenzyl sorbitol and at least one of amide stearate, amide aciculate, amide ethylenedistearate, and hydrogenated castor oil or modified hydrogenated castor oil, the stabilizer prepared from nonylphenol polyoxyvinylether, (modified) alkylphenol polyoxyvinylether, reducer, benzimimidazole lipoamine salt and benzimimidazole, and the resin.

Owner:李昕

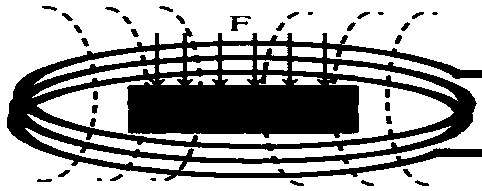

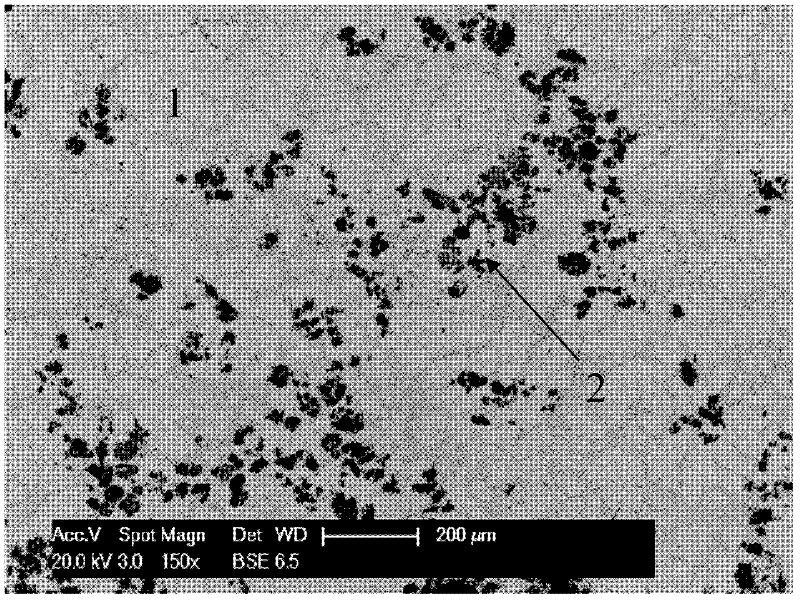

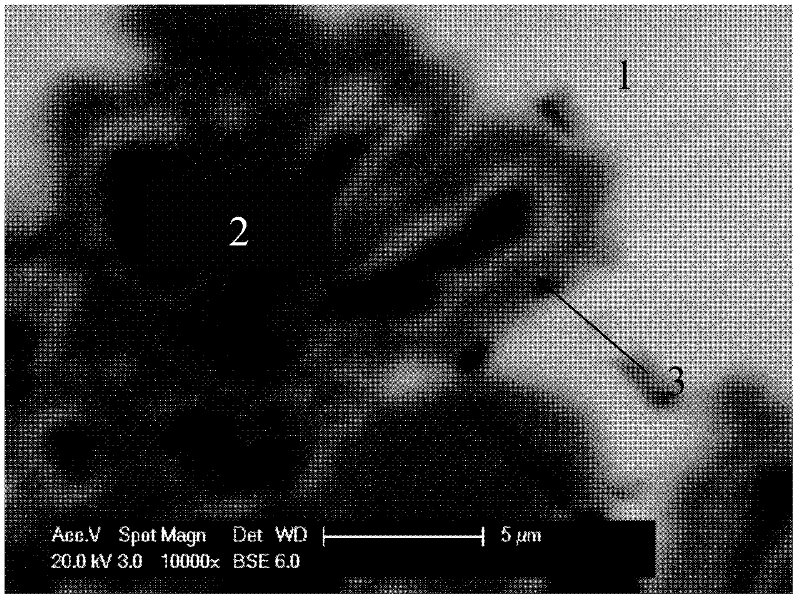

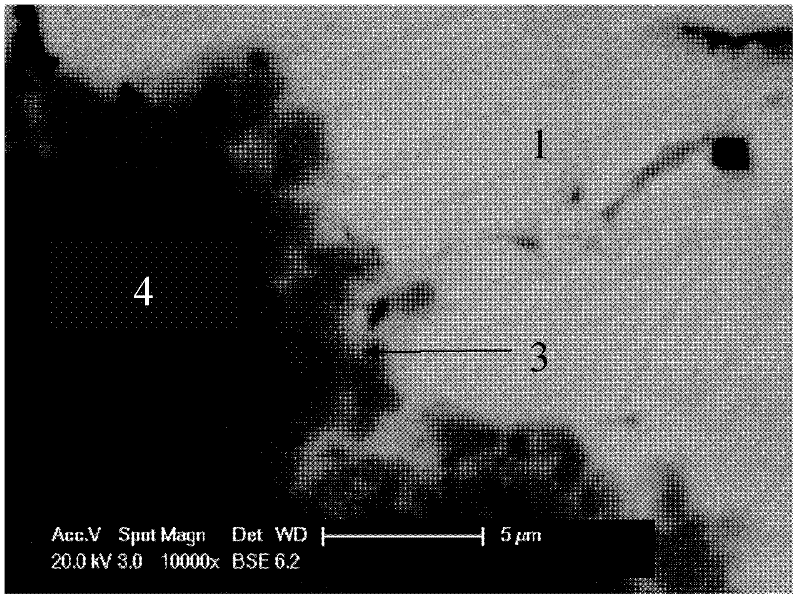

Magnetic particle tin-zinc matrix composite solder and preparation method thereof

InactiveCN102513719AImprove mechanical propertiesImprove performanceLiquid/solution decomposition chemical coatingWelding/cutting media/materialsSolder matrixComposite solder

The invention discloses a magnetic particle tin-zinc matrix composite solder and a preparation method thereof. The magnetic particle tin-zinc matrix composite solder comprises a Sn-Zn-based solder matrix and 10 percent of magnetic particles, wherein the tin-zinc-based solder matrix comprises Sn and Zn, and Zn accounts for 8 to 10 percent relative to the weight of the tin-zinc-based solder matrix in percentage by weight; and the magnetic particles are Fe particles of which the surfaces are plated with Ni layers. Because of the presence of the plated Ni layers, the Fe particles can be more easily added into the solder matrix, so that a method for adding the particles is simplified, the particles and the matrix are combined more tightly, the magnetic force can play a greater role, the same effect can be achieved by using fewer magnetic particles, raw materials are saved, and the cost is saved; and part of the plated Ni layers is blended into the matrix to improve the performance of the matrix. The magnetic particle tin-zinc matrix composite solder disclosed by the invention has a simple preparation method, special magnetic performance and good wetting property.

Owner:SOUTHEAST UNIV

Composite solder TIM for electronic package

ActiveUS20080090405A1Semiconductor/solid-state device detailsSolid-state devicesIndiumComposite solder

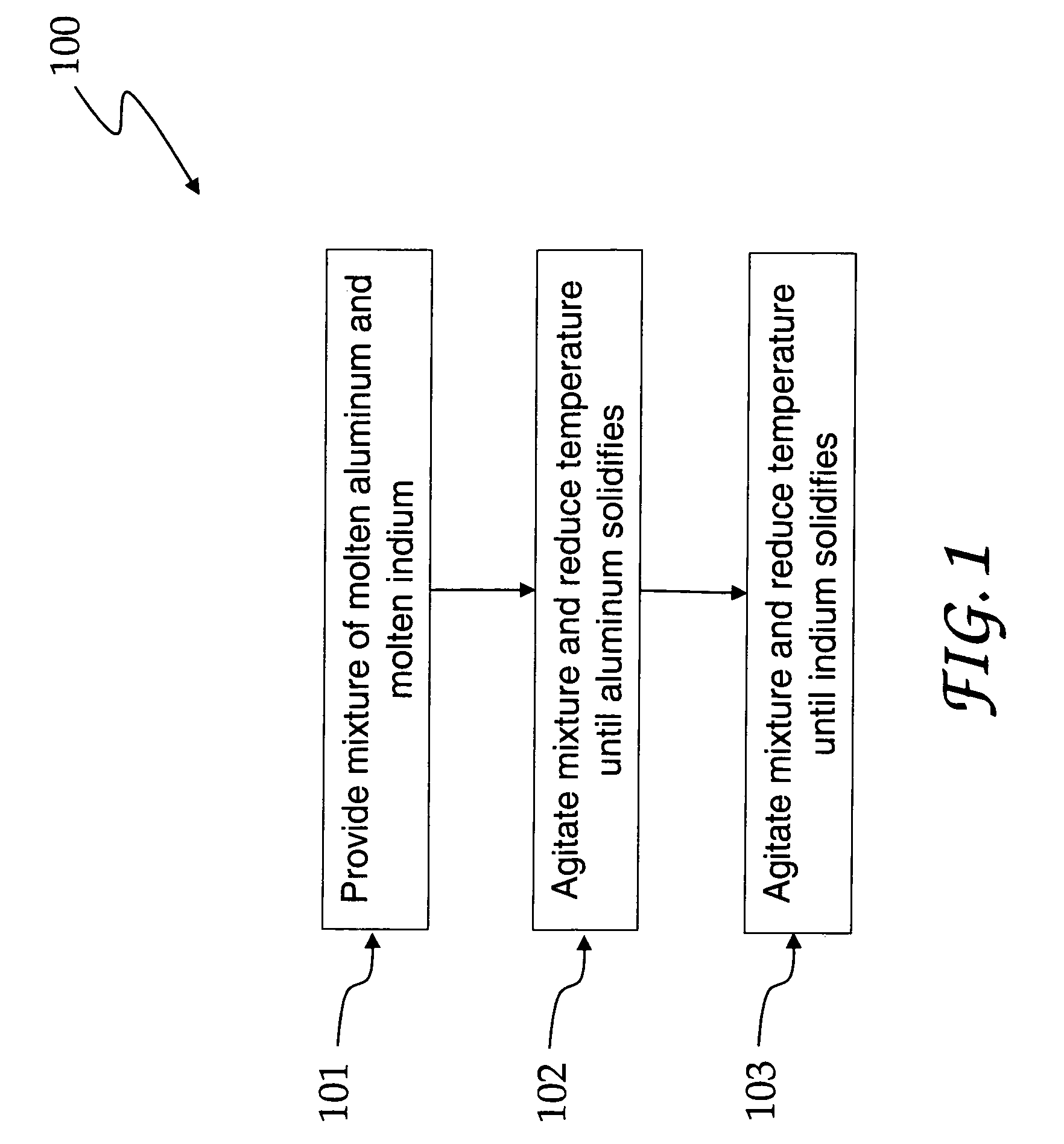

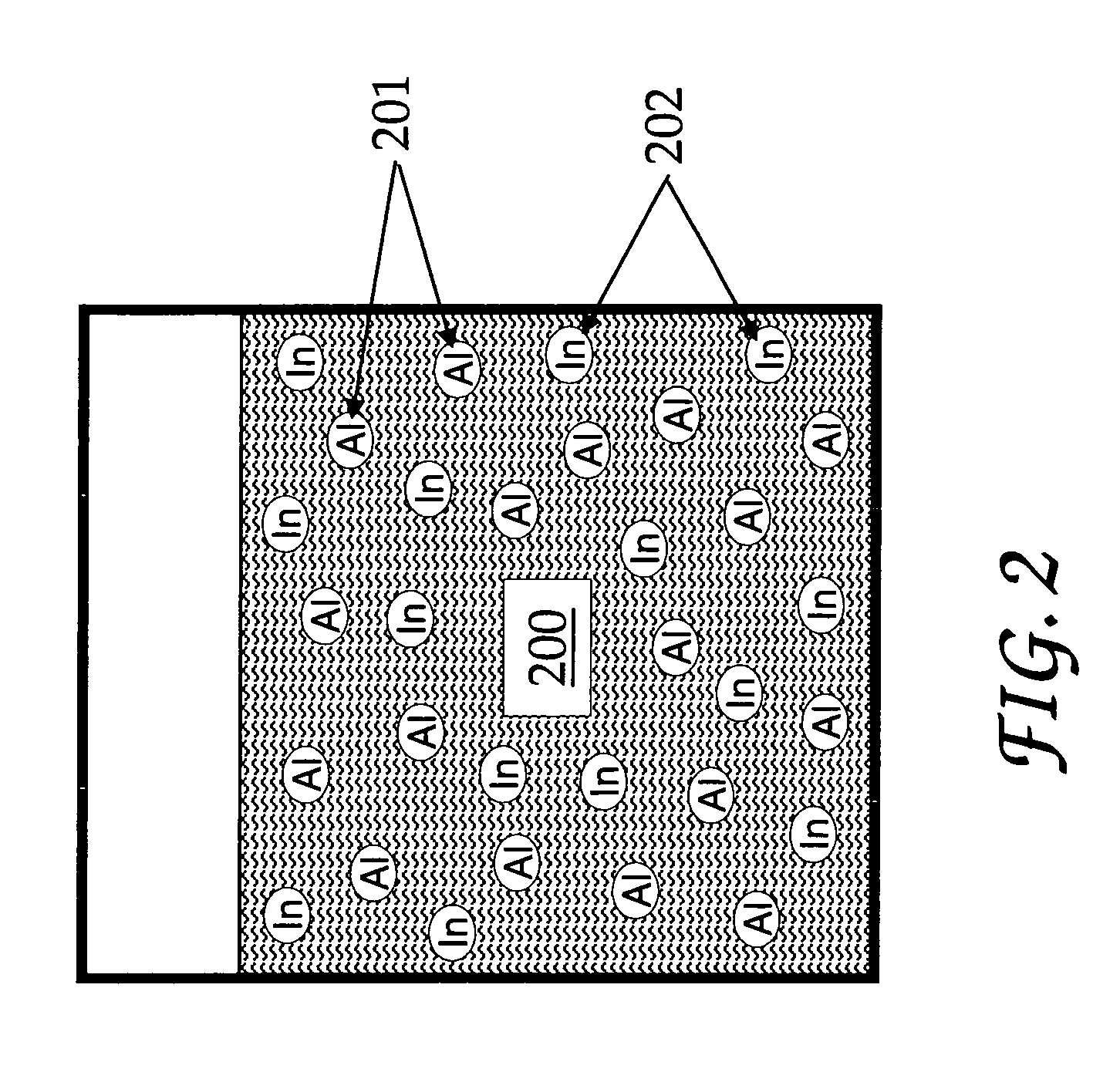

A method includes providing a mixture of molten indium and molten aluminum, and agitating the mixture while reducing its temperature until the aluminum changes from liquid phase to solid phase, forming particles distributed within the molten indium. Agitation of the mixture sufficiently to maintain the aluminum substantially suspended in the molten aluminum continues while further reducing the temperature of the mixture until the indium changes from a liquid phase to a solid phase. A metallic composition is formed, including indium and particles of aluminum suspended within the indium, the aluminum particles being substantially free from oxidation.The metallic (solder) composition can be used to form an assembly, including an integrated circuit (IC) device, at least a first thermal component disposed adjacent to the IC device, and a solder TIM interposed between and thermally coupled with each of the IC device and the first thermal component.

Owner:INTEL CORP

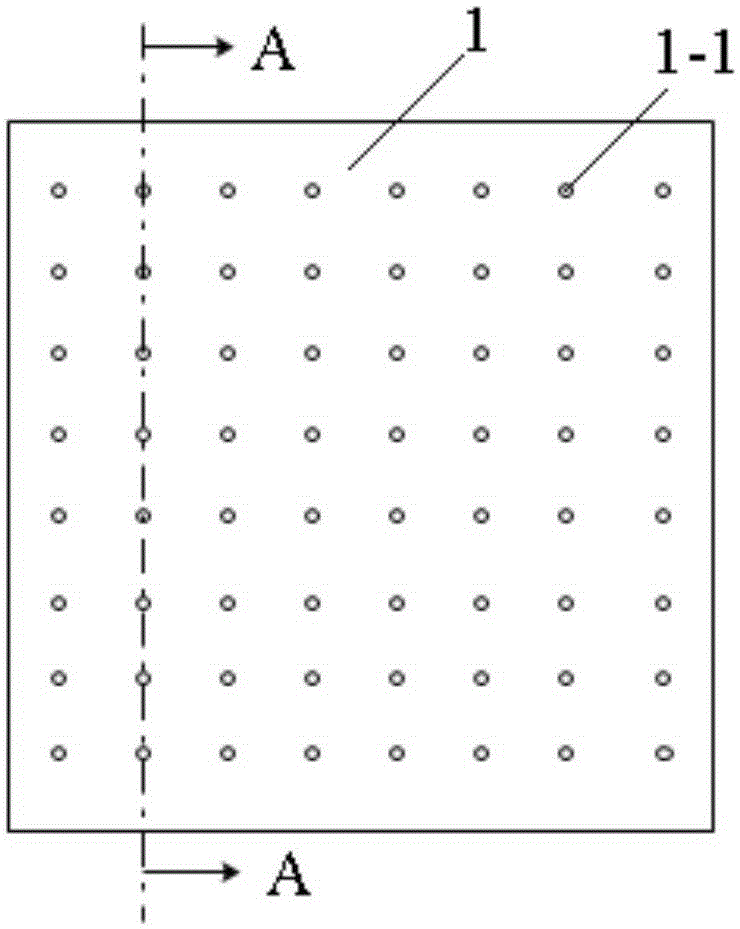

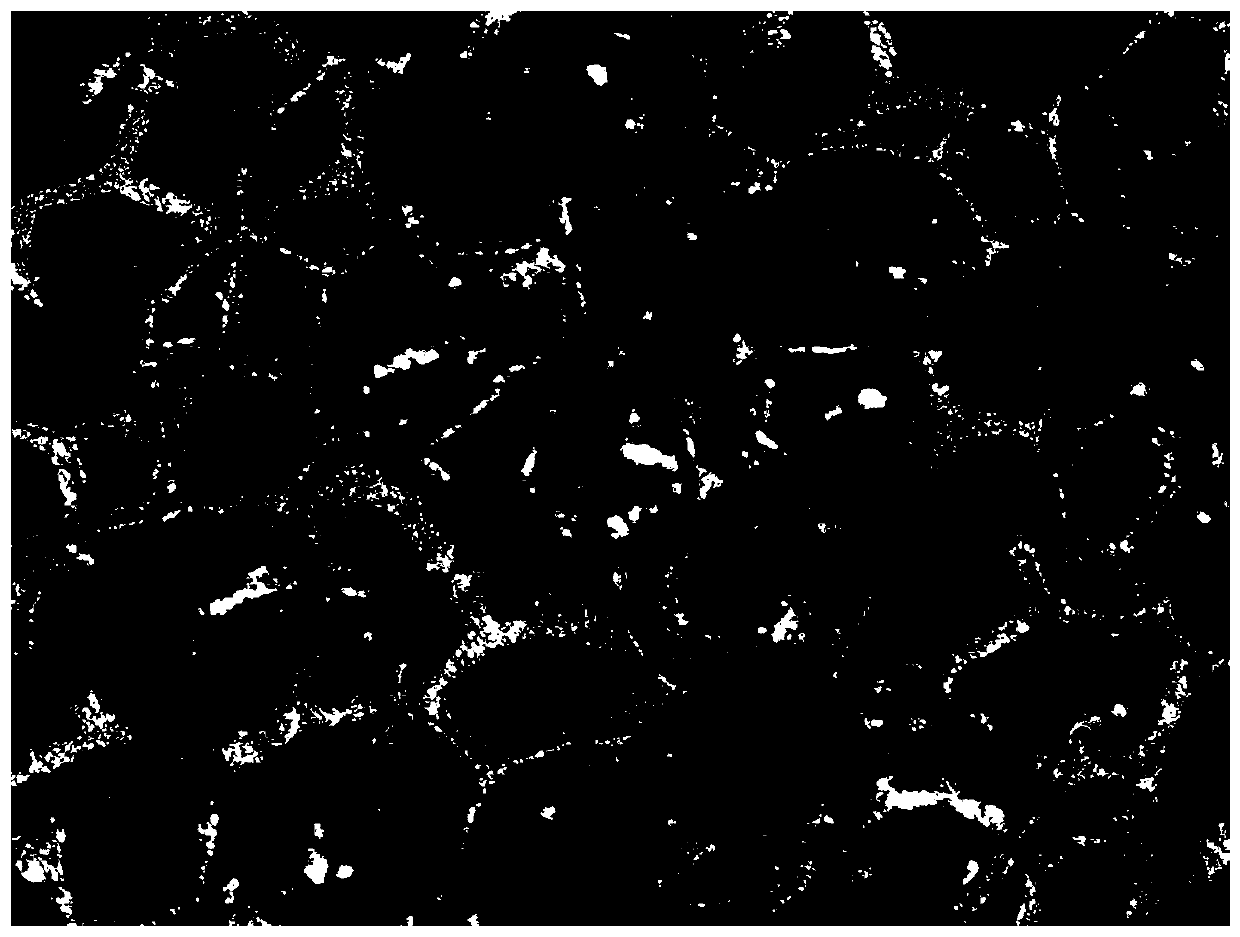

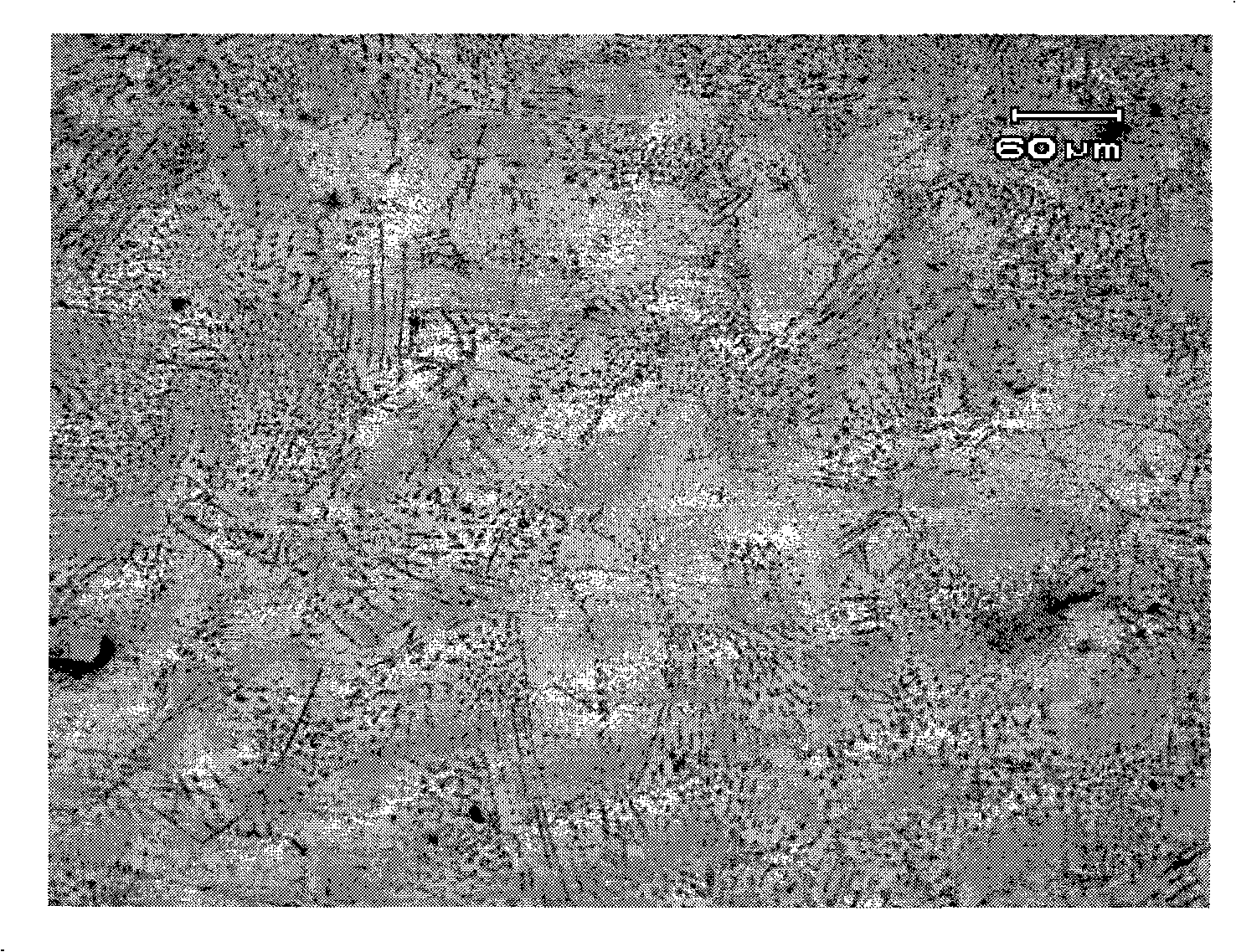

Multi-scale combined method for improving high hard and brittle ceramic base material soldering connection strength

ActiveCN105195847AReduce stress concentrationImprove processing efficiencySoldering apparatusWorkpiece edge portionsCombined methodThermal expansion

The invention relates to a method for improving the ceramic base material soldering connection strength, in particular to a multi-scale combined method for improving the high hard and brittle ceramic base material soldering connection strength. The method solves the problems that a joint connected through an existing ceramic base material soldering method is low in strength and the residual stress is large and the reliability is low due to the thermal expansion coefficient difference of ceramic base materials and metal. The method comprises the steps of 1, surface treatment of a high hard and brittle ceramic base material connection surface, 2, solder powder preparation, 3, composite solder paste preparation, 4, coating and 5, vacuum soldering connection, so that a high-strength high hard and brittle ceramic base material soldered joint is obtained. The compression-shear resistant strength of the obtained high hard and brittle ceramic base material soldered joint is 105-196 MPa, and the strength of the soldered joint is improved by 115-275% compared with a soldered joint adopting a conventional straight interface and no wild phase.

Owner:HARBIN INST OF TECH

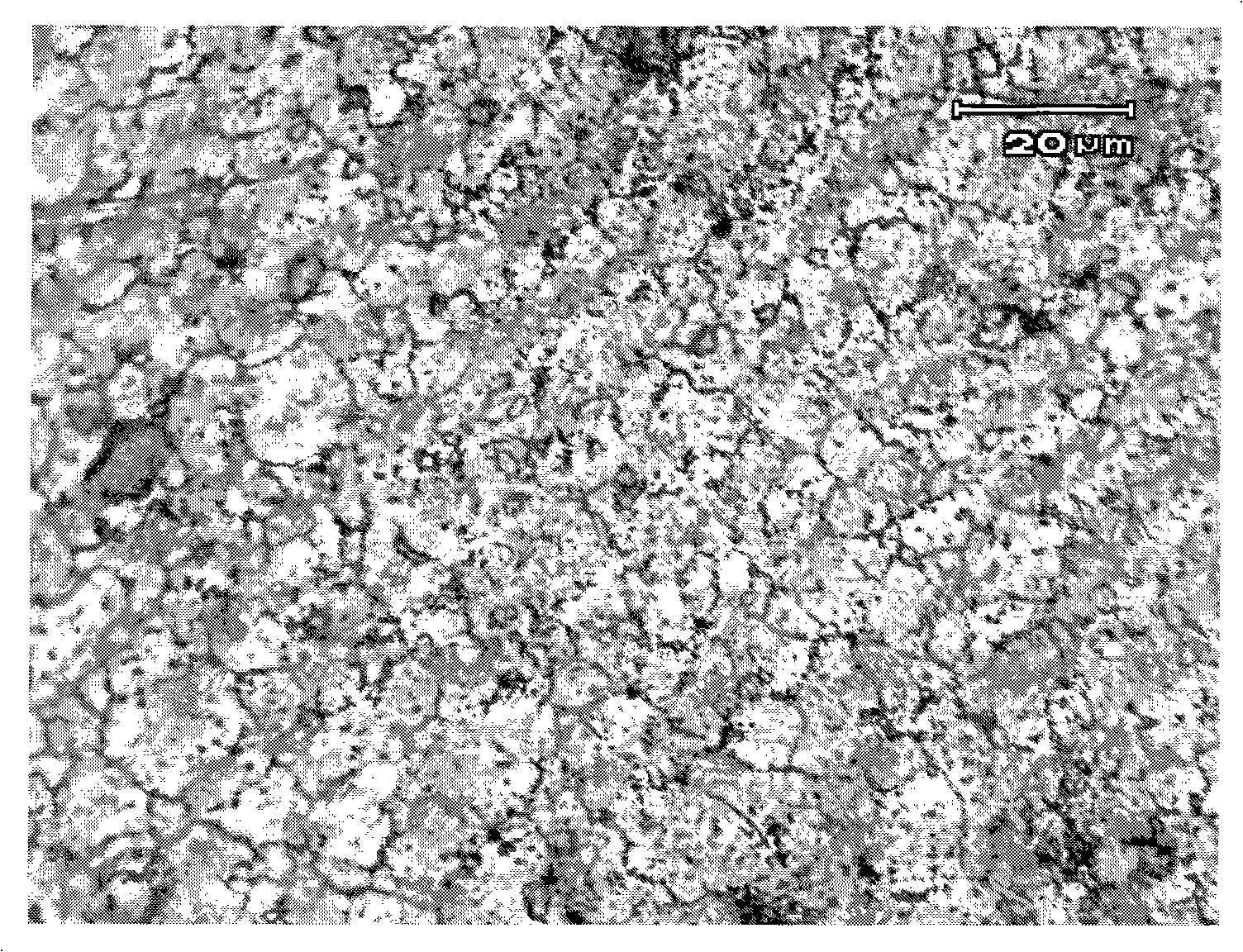

Ceramic phase reinforced copper-based composite solder and preparation method thereof

InactiveCN102211260ALow costLow melting pointWelding/cutting media/materialsSoldering mediaWhiskersComposite solder

The invention discloses a ceramic phase reinforced copper-based composite solder and a preparation method thereof, relates to a copper-based composite solder and a preparation method thereof, and aims to solve the problems that an Ag-Cu-Ti solder has high cost, and low joint strength caused by residual stress in the conventional ceramic connection method. The ceramic phase reinforced copper-based composite solder comprises Cu powder, Sn powder, Ti powder and B powder. The method comprises the following steps of: mixing the Cu powder, the Sn powder, the Ti powder and the B powder to obtain mixed powder; and adding the mixed powder and ceramic balls into a ball-milling tank of a planetary ball mill, and performing ball milling for 1 to 5 hours at a rate of 300r / min under the protection of argon gas to obtain a uniformly mixed Cu-Sn-Ti-B composite solder. Soldering cost is reduced, and thermal mismatching between metal and ceramic is adjusted by growing TiB crystal whiskers in a joint in situ, so that the usability of the soldered joint is improved. The solder is applied to the soldering connection of the ceramic.

Owner:HARBIN INST OF TECH

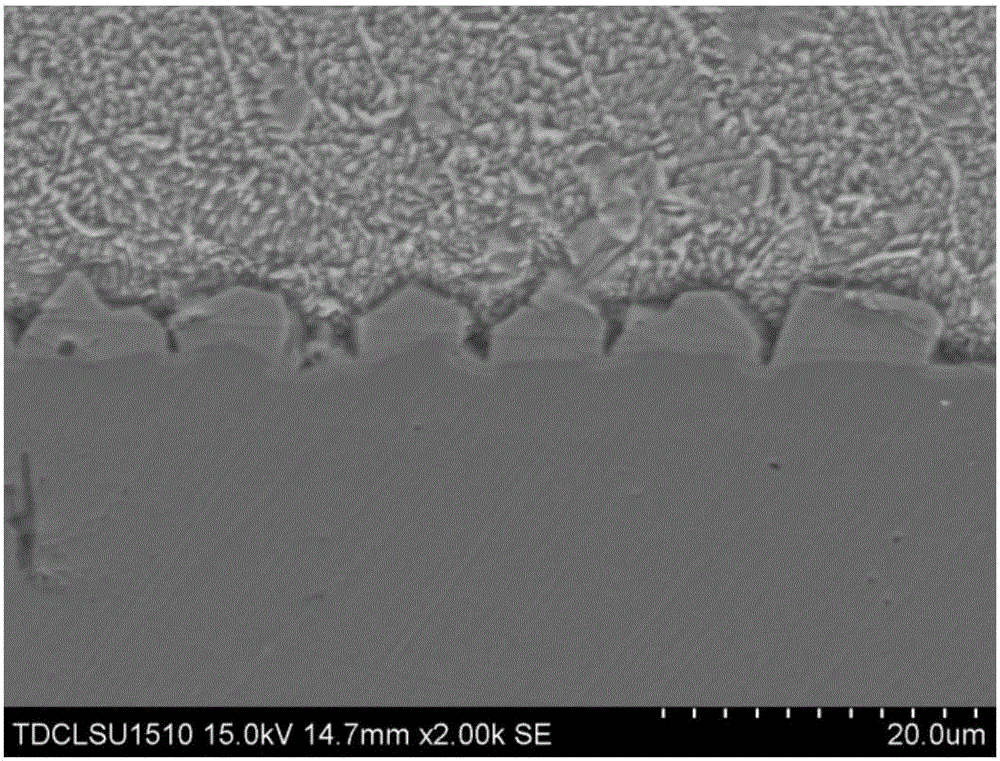

Preparation method of Sn-base composite solder sheet based on porous Ni/Cu alloy

ActiveCN109848611AControl thicknessChange sintering timeWelding/cutting media/materialsSoldering mediaComposite solderUltimate tensile strength

The invention relates to a preparation method of a Sn-base composite solder sheet based on a porous Ni / Cu alloy. The preparation method comprises the steps that first of all, a layer of Cu is preparedon the surface of porous Ni metal, and then high-temperature sintering is carried out, so that mutual diffusion between Ni and Cu is facilitated, and bonding of Ni and Cu is further tight; and then the porous Ni / Cu alloy is immersed into the molten Sn-base solder, and finally is rolled into a foil. In the porous Ni / Cu alloy subjected to high-temperature sintering treatment, the bonding strength of Ni and Cu is higher and the oxidation resistance is better through the mutual diffusion between Ni and Cu, and the relatively high strength, good plasticity, high corrosion resistance and high ductility are shown. Along with change of sintering parameters and electroplating parameters, concentration distribution gradients of Ni and Cu in the porous Ni / Cu alloy are different, reaction between theporous Ni / Cu alloy and the Sn-base solder is rapider in the brazing process, and the soldering reliability is high.

Owner:无锡继平新材料科技有限公司

Nanostructure-enhanced tin-silver-copper-base leadless compound solder and preparation thereof

InactiveCN101279405AImprove mechanical propertiesImprove reliabilityWelding/cutting media/materialsSoldering mediaManufacturing technologyTin-silver-copper

The invention relates to a tin, silver and copper based lead-free composite solder with enhanced nanometer-structure and a preparation method thereof, which belong to the technical field of the manufacturing of metal-based lead-free composite solders. The existing spreading process for SnSn-Ag-Cu series lead-free solder is characterized by poor processing performance, short creep rupture service life and high cost. The composite solder of the invention consists of 97 wt percent to 99 wt percent of commercial Sn-3.0Ag-0.5Cu solder paste and 1 wt % to 3 wt % of enhanced particles (POSS1, POSS2 or POSS3). The solder paste consists of 85 wt percent of Sn-3.0Ag-0.5Cu solder and 15 wt % of flux. The tin, silver and copper based lead-free composite solder with enhanced nanometer-structure is prepared by stirring and mixing the solder paste and enhanced particles according to the component concentration for 15 to 30 minutes. The composite solder of the invention has the advantages of good wettability and good creep rupture resistance, high shearing strength, excellent mechanical property, long creep rupture service life of the soldered joint and simple preparation process, etc.

Owner:BEIJING UNIV OF TECH

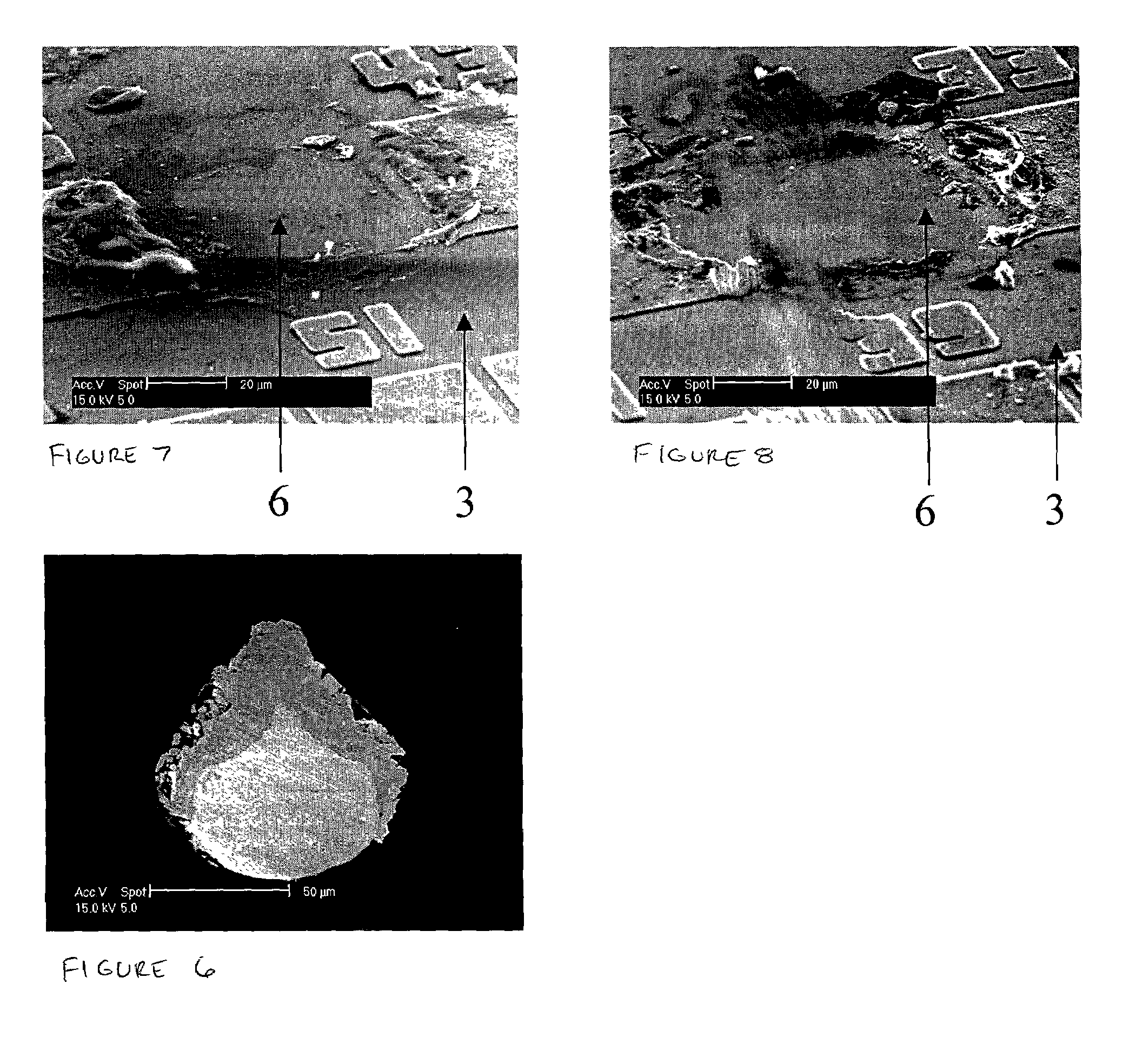

Forming an electrical contact on an electronic component

InactiveUS7015132B2Improve integrityLow resistance connectionPrinted circuit assemblingFinal product manufactureContact formationContact pad

A method of constructing an electrical contact on an electronic component comprises first forming a protruding electrically conducting stud at a contact location by wire bonding a metal wire to a contact pad of the component. The stud is then contacted with solder, without using a mask, so that a solder bump is deposited on and adheres to the metal stud to form a composite solder contact which is able to form with a contact of another component a solder joint which has good electrical and mechanical properties and which may be reliable fabricated at high density by a low cost method. An electronic component provided with such solder contacts and an electronics component package including such a component are also disclosed.

Owner:AGENCY FOR SCI TECH & RES

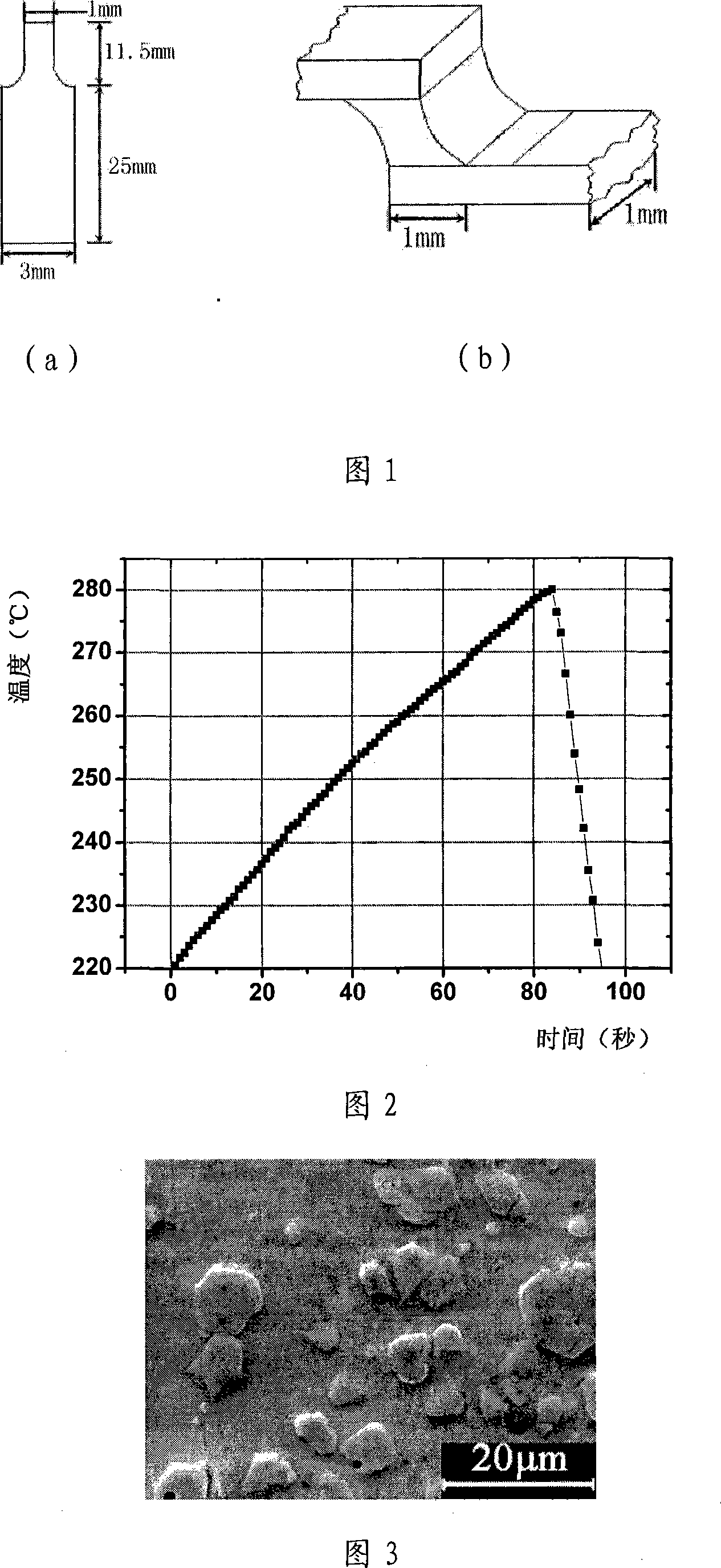

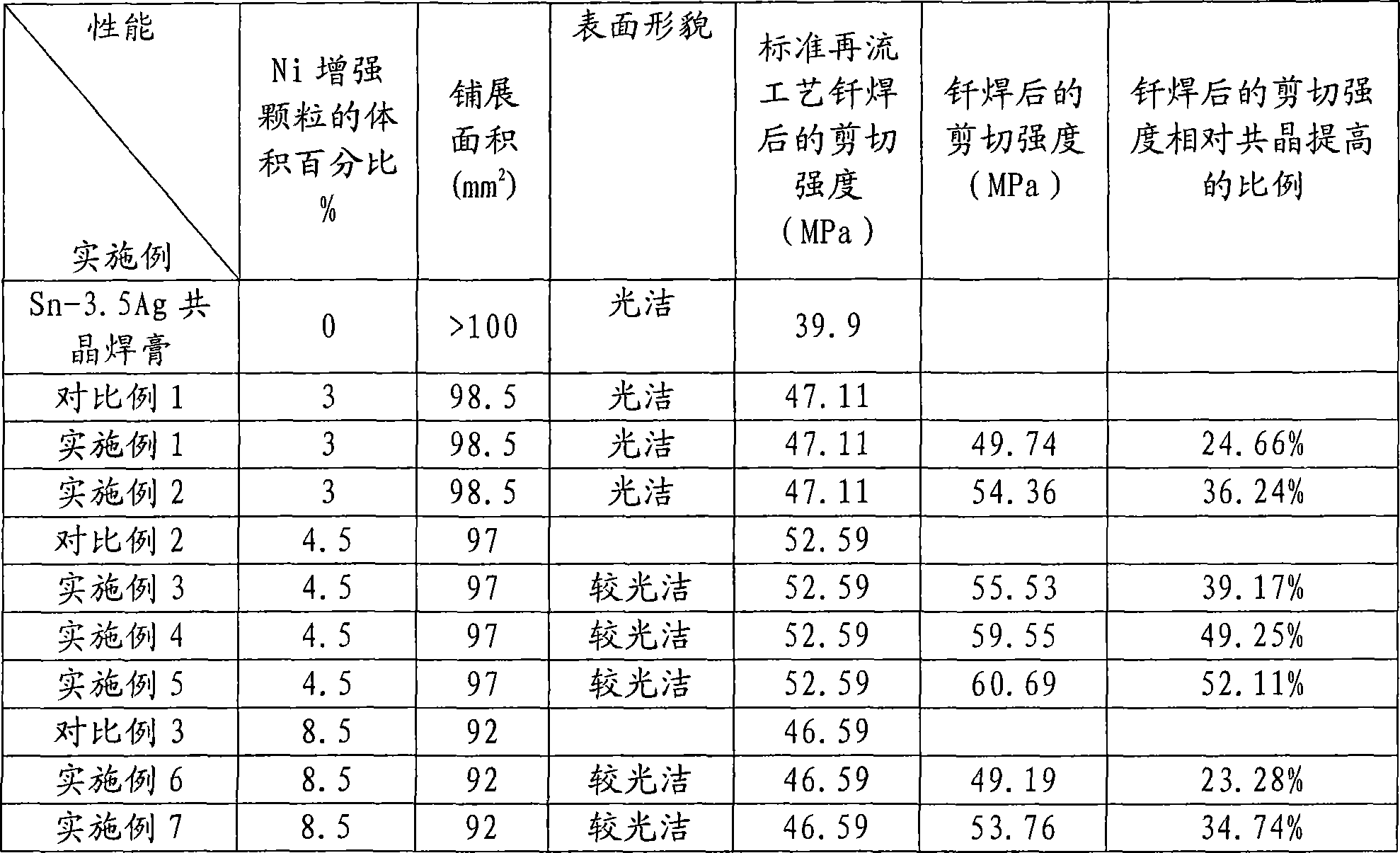

Lead-free compound solder by Ni particle strengthening tin and silver group and preparing method thereof

InactiveCN101224526AGood physical propertiesGood spreadabilityWelding/cutting media/materialsSoldering mediaFurnace temperatureComposite solder

The invention provides a Ni grain reinforced tin-silver-based lead-free composite solder and a preparation method thereof, belonging to the manufacture technical field of solders used for the surface assembly of an electronic element. The invention solves the problem that the existing composite solder has poor mechanical performance and is lack of effective brazing technique. The solder of the invention consists of the Ni reinforced grain with the volume percentage of 3-8.5% and the Sn-3.5Ag eutectic crystal soldering paste with the volume percentage of 91.5-97%; the particle size of the Ni grain is 2-3Mum . The Ni grains and the Sn-3.5Ag eutectic crystal soldering paste of the invention are mixed through a mixed machine according to the proportion for 20-30 minutes and are brazed with the furnace temperature kept at 330 DEG C; after the solder is melted, the solder is heated under the temperature-rising speed of 0.6-14 DEG C / sec; after the temperature reaches 280 DEG C, the solder is cooled to solid state with the cooling speed of 5.5 DEG C / sec. The Ni grains and a basic body of the invention carry out metallurgical bonding, thus keeping good physical performance and spreadability, and improving the shearing strength at the same time.

Owner:BEIJING UNIV OF TECH

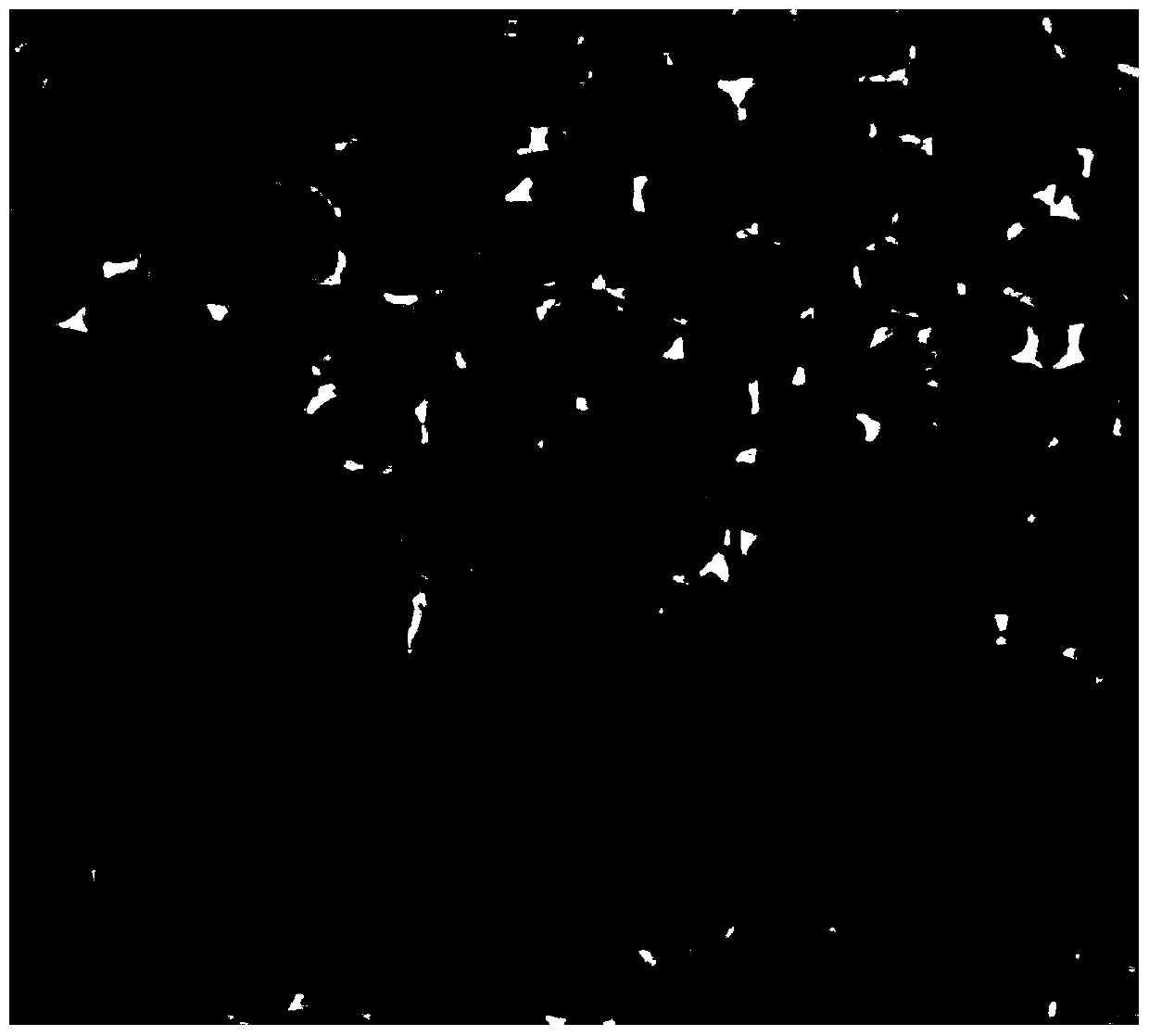

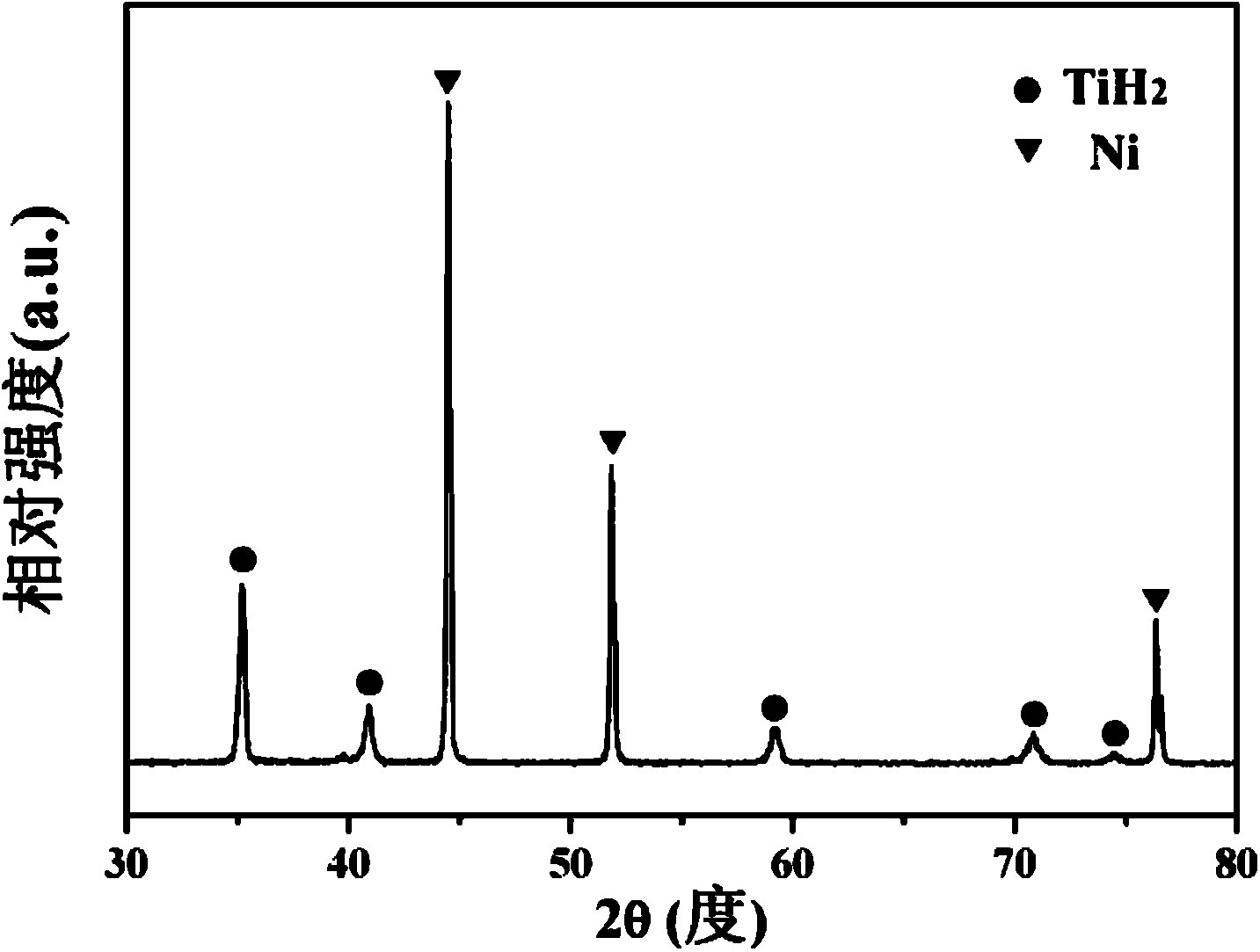

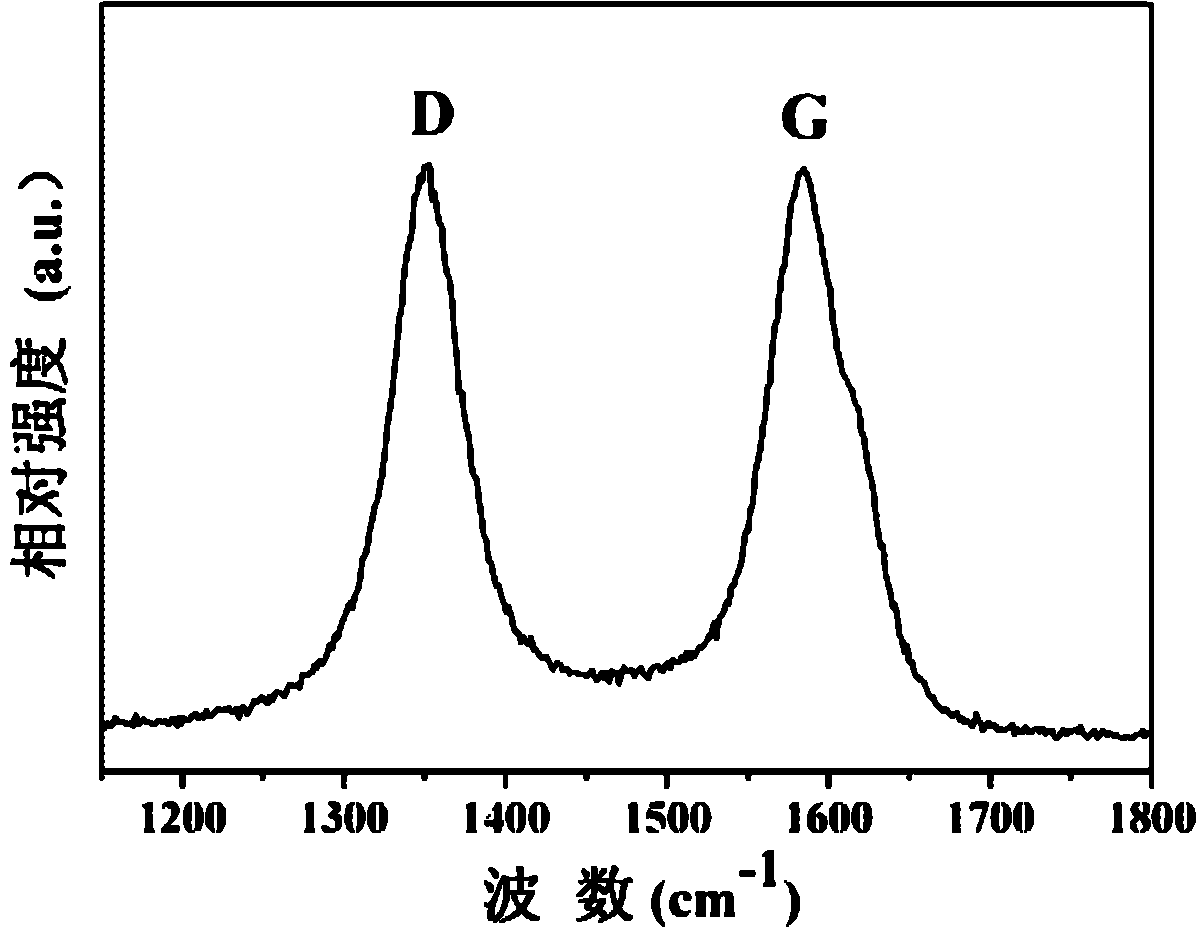

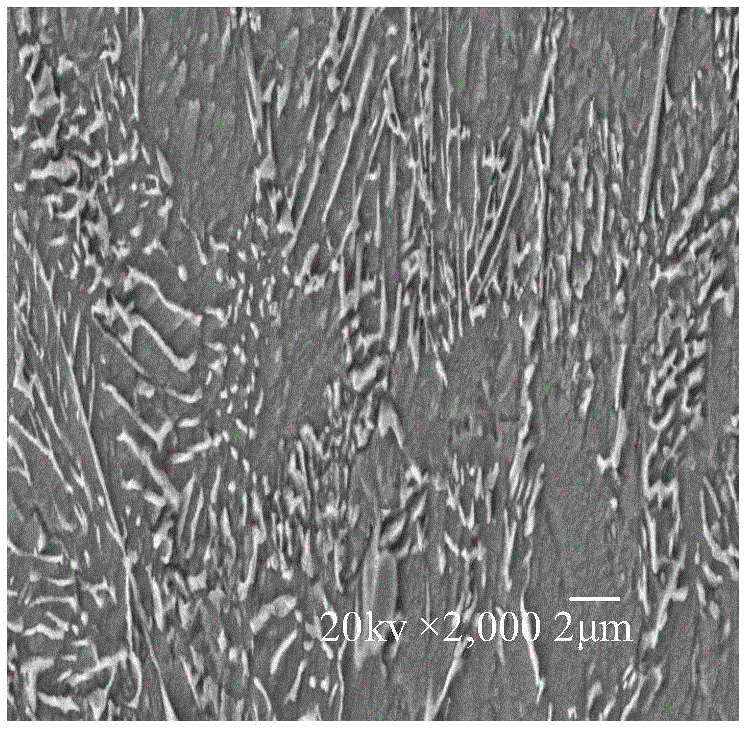

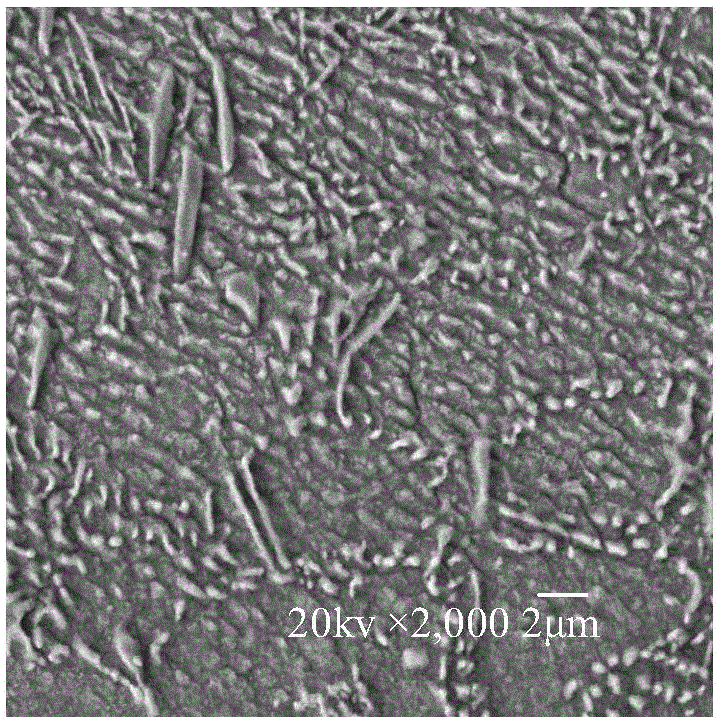

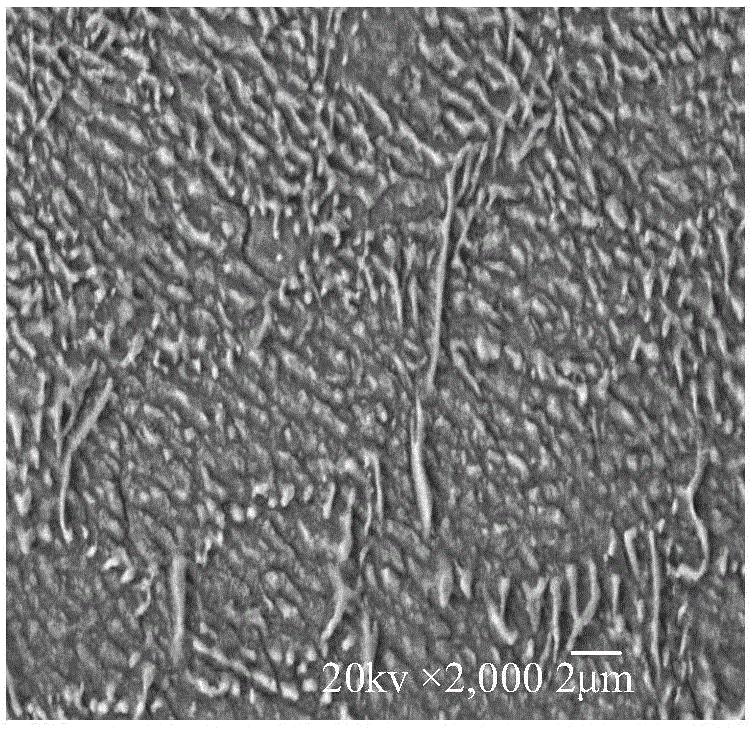

Method for preparing in-situ growed carbon nano tube reinforcing TiNi high-temperature solders

ActiveCN102534300AIncrease elasticityHigh tensile strengthWelding/cutting media/materialsSoldering mediaCarbon nanotubeComposite solder

The invention relates to a method for preparing in-situ growed carbon nano tube reinforcing TiNi high-temperature solders, belonging to the field of solder preparation. According to the method, the homogeneous dispersion and structural integrity of carbon nano tubes in composite solders are realized, the mutual reaction of titanium and carbon is avoided, and therefore the problems of large thermal stress and poor high temperature mechanical properties of joints existing in the traditional TiNi solders during soldering connection with ceramics, composite materials and metal are solved. The method comprises the following steps of: 1, mixing TiH2 powder with Ni powder, adding nickel nitrate hexahydrate and ethanol, mechanically stirring, and heating the ethanol to volatilize; and 2 and then laying the mixture in a quartz boat, cooling to a room temperature after vapor phase deposition, and obtaining the carbon nano tube reinforcing TiNi high-temperature solders. The carbon nano tubes / the carbon nano tubes in the TiNi composite solders are homogeneously dispersed on a composite solder matrix, the length can reach 1-5 Mum, the tube diameter is 10-15nm, and the content of the carbon nano tubes in the composite solders is about 1.5-5 percent. The method is suitable for the field of spacelight.

Owner:HARBIN INST OF TECH

Material and method of manufacture of a solder joint with high thermal conductivity and high electrical conductivity

ActiveUS7758916B2Increased thermal and electrical conductivityEasy to controlMolten spray coatingPrinted circuit aspectsElectricityPowder mixture

Owner:SULZER METCO (US) INC

Silicon carbide granule enhancement type tin-silver-zinc compound solder and manufacture method thereof

InactiveCN101323062AEasy to prepareImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaZinc compoundsComposite solder

Owner:太仓市南仓金属材料有限公司

Method for brazing stainless steel and cemented carbide through gradient material method

ActiveCN106862694AImprove mechanical propertiesMitigate the effects of differences in linear expansion coefficientsWelding/cutting media/materialsWelding/soldering/cutting articlesGraphiteComposite solder

The invention provides a method for brazing stainless steel and cemented carbide through a gradient material method and relates to the method for brazing the stainless steel and cemented carbide. The method aims at solving the problems that by means of an existing cemented carbide and stainless steel brazing connecting technology, a lot of welding defects are formed and residual stress of welding joints is large in the welding process of the welding joints. The method comprises the steps of firstly, preparing composite solder powder; secondly, performing stirring; thirdly, preparing composite solder foil; fourthly, cleaning and stacking the stainless steel, the cemented carbide, interlayer metal and the composite solder powder into a graphite clamp and obtaining a part to be welded; and fifthly, performing brazing. According to the method, by the adoption of the gradient material method, auxiliary brazing is conducted on the cemented carbide and the stainless steel, through the gradient material method, the influence brought by the difference of the linear expansion coefficients is relieved greatly, the residual stress is reduced, and the welding defects are eliminated. The method is suitable for brazing of the stainless steel and the cemented carbide.

Owner:哈尔滨工大华策科技有限公司

Tin-silver-copper composite solder paste enhanced by titanium dioxide nanoparticles and preparation method thereof

InactiveCN105057911AGrowth inhibitionAvoid abnormal growthWelding/cutting media/materialsSoldering mediaTin-silver-copperComposite solder

The invention belongs to the technical field of welding materials and discloses tin-silver-copper composite solder paste enhanced by titanium dioxide nanoparticles and a preparation method thereof. The composite solder paste is obtained by blending tin-silver-copper lead-free solder paste and the titanium dioxide nanoparticles. The preparation method includes the following steps that the titanium dioxide nanoparticles are added into the tin-silver-copper lead-free solder paste with the mass ratio being 96.5:3:0.5, the titanium dioxide nanoparticles are evenly distributed in the tin-silver-copper lead-free solder paste through mechanical stirring, and accordingly the tin-silver-copper composite solder paste enhanced by the titanium dioxide nanoparticles is obtained. According to the tin-silver-copper composite solder paste, by adding the titanium dioxide nanoparticles, growth of an Ag3Sn phase in the solder paste is restrained, microhardness and mechanical property of the composite solder paste are improved, and growth of intermetallic compounds of a solder joint interface can be effectively restrained, crystal grains of the intermetallic compounds of the solder joint interface are refined, soldering reliability is improved, and the application prospect is good.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com