Multi-scale combined method for improving high hard and brittle ceramic base material soldering connection strength

A connection strength, ceramic-based technology, applied in the direction of welding equipment, workpiece edge parts, manufacturing tools, etc., can solve the problems of thermal expansion coefficient difference, low joint strength, large residual stress, etc., and achieve less surface stress of the incision, processing efficiency and accuracy High, reduce the effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific implementation mode 1: This implementation mode is a multi-scale joint method for improving the brazing connection strength of high-hard and brittle ceramic-based materials, which is completed according to the following steps:

[0037] 1. Surface treatment of connecting surface of high-hard and brittle ceramic base material:

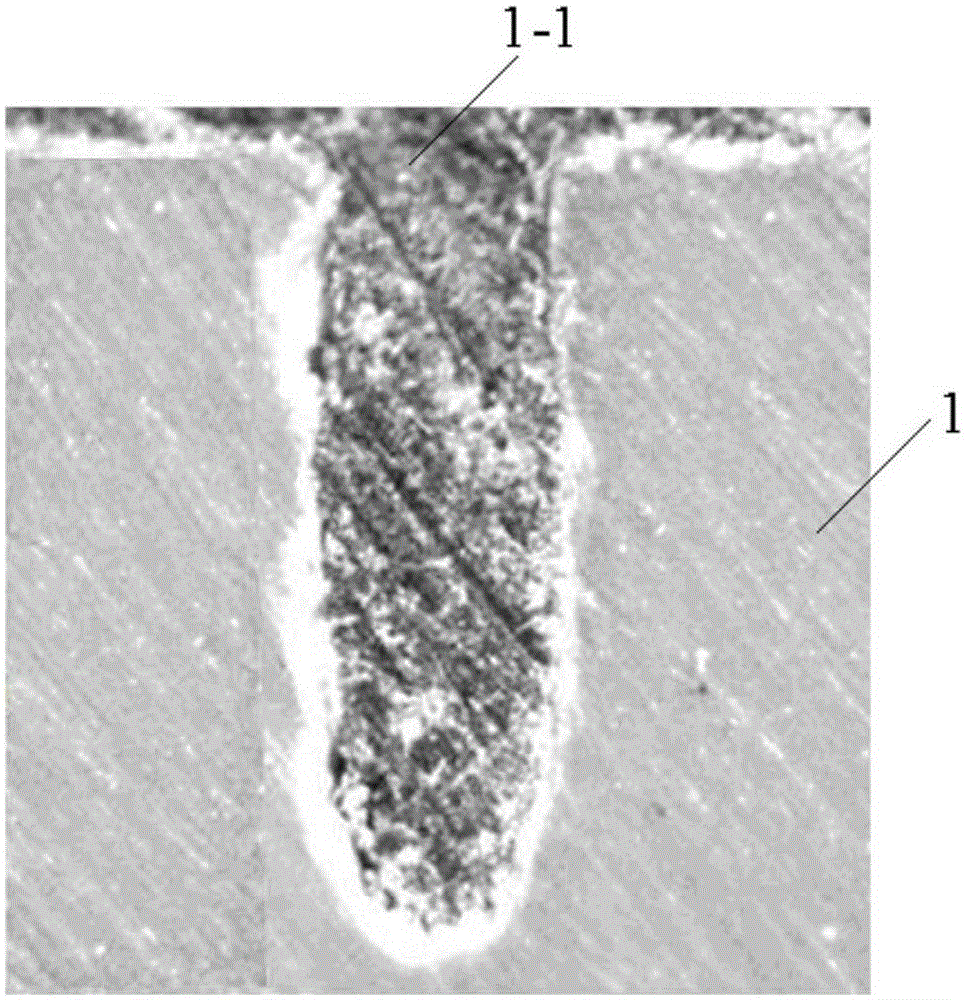

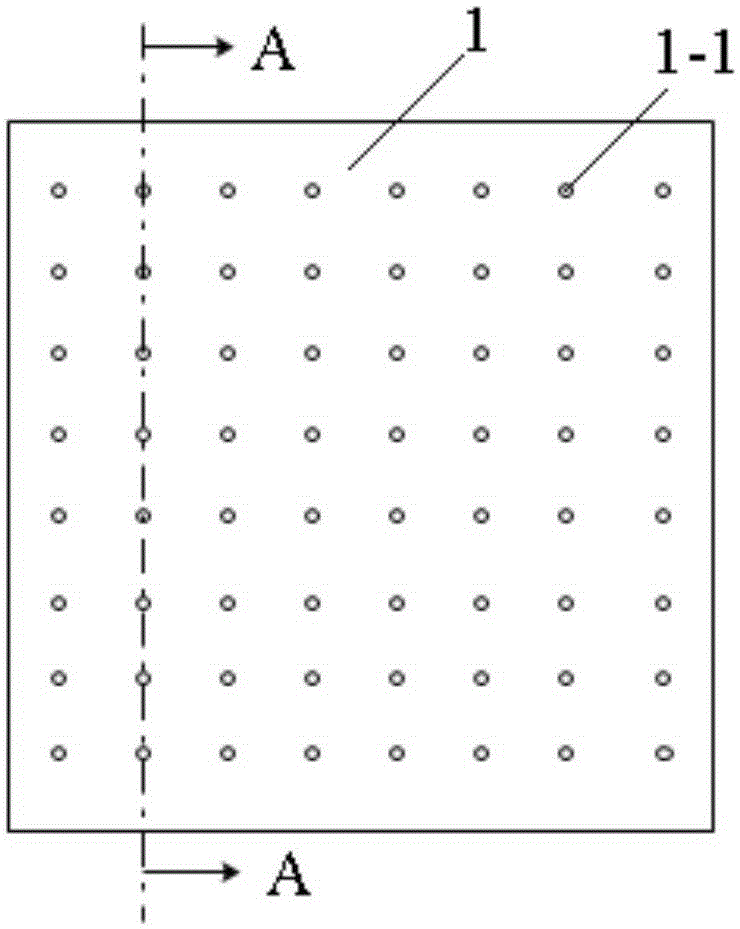

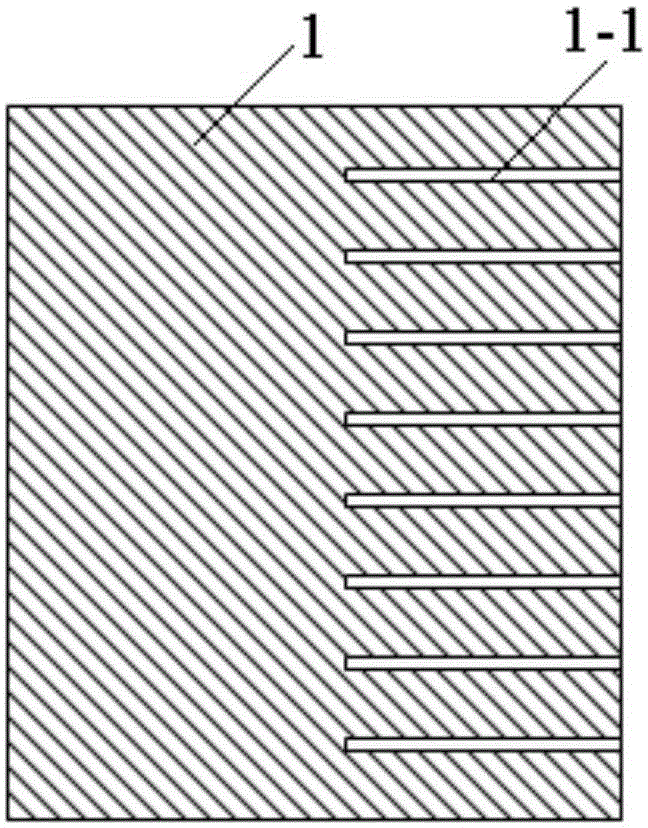

[0038] Using ultra-short pulse laser drilling technology to process blind holes in an array on the connecting surface of the high-hard and brittle ceramic base material, and obtain a high-hard and brittle ceramic base material with an array of blind holes on the connecting surface; Grinding the high-hard and brittle ceramic base material and connecting parts to obtain a bright connecting surface with an array of blind holes and bright connecting parts; use acetone to polish the bright connecting surface with an array of blind holes The brittle ceramic-based base material and the bright connecting piece are ultrasonically cleaned with acet...

specific Embodiment approach 2

[0063] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ultrashort pulse laser described in step 1 is picosecond laser or femtosecond laser. Other steps are the same as in the first embodiment.

[0064] The picoseconds described in this implementation are 10 -12 second, femtosecond is 10 -15 second.

specific Embodiment approach 3

[0065] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the cross-section of the blind hole on the connection surface of the high-hard and brittle ceramic base material described in step 1 is circular or square, and the blind hole The cross-sectional shape of the hole can be adjusted depending on the shape of the laser spot. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com