Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3922results about How to "Small coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

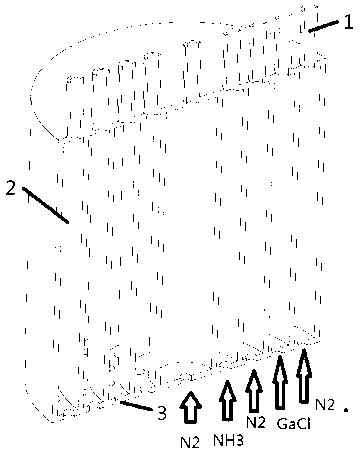

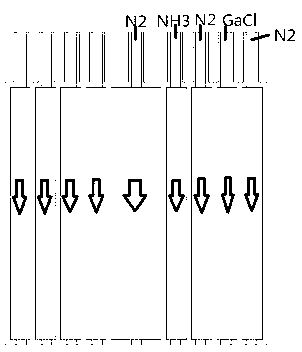

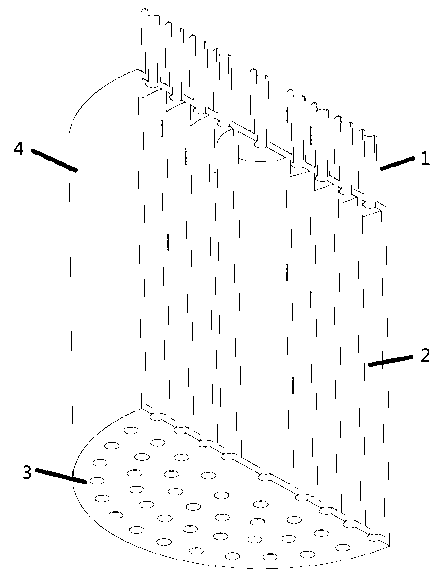

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

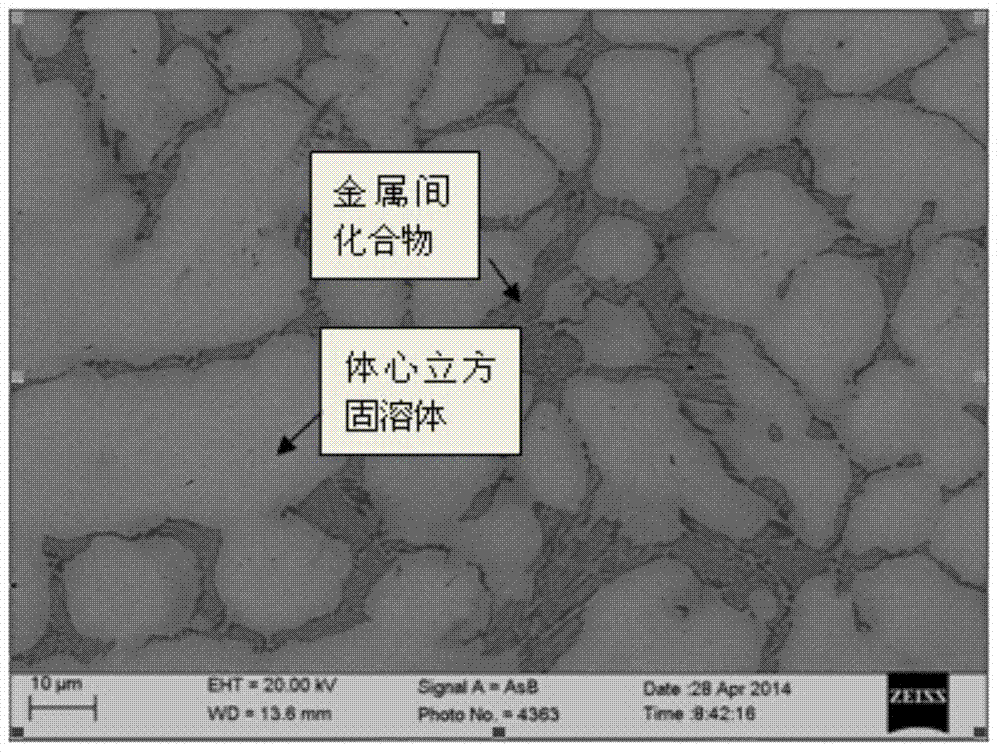

Low thermal expansion coefficient NaMxAlySiz high entropy alloy and preparation method thereof

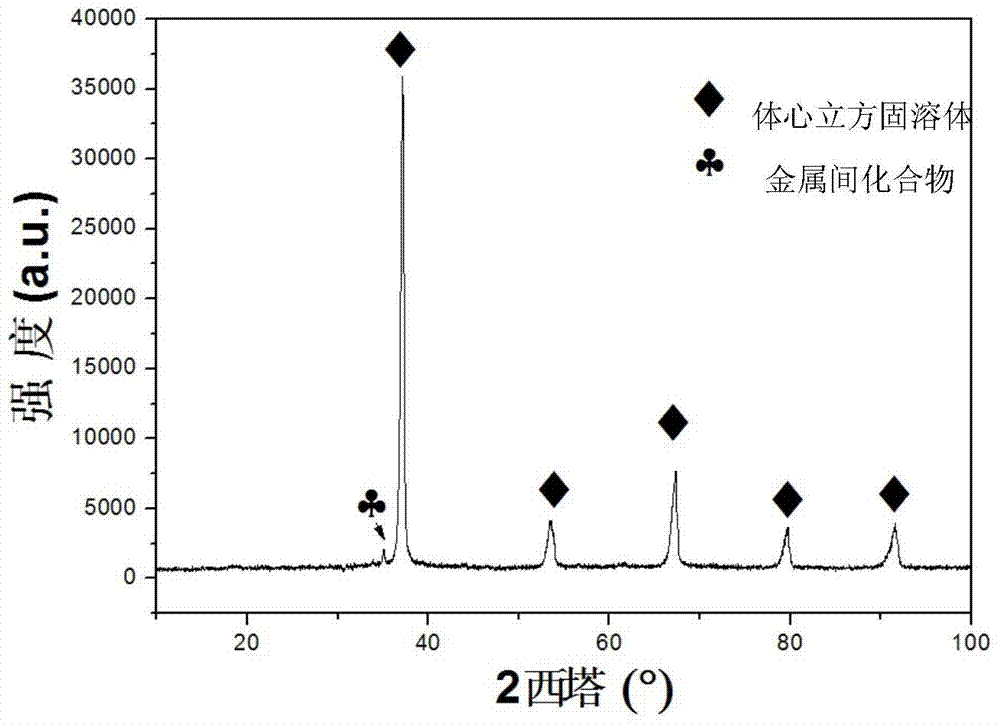

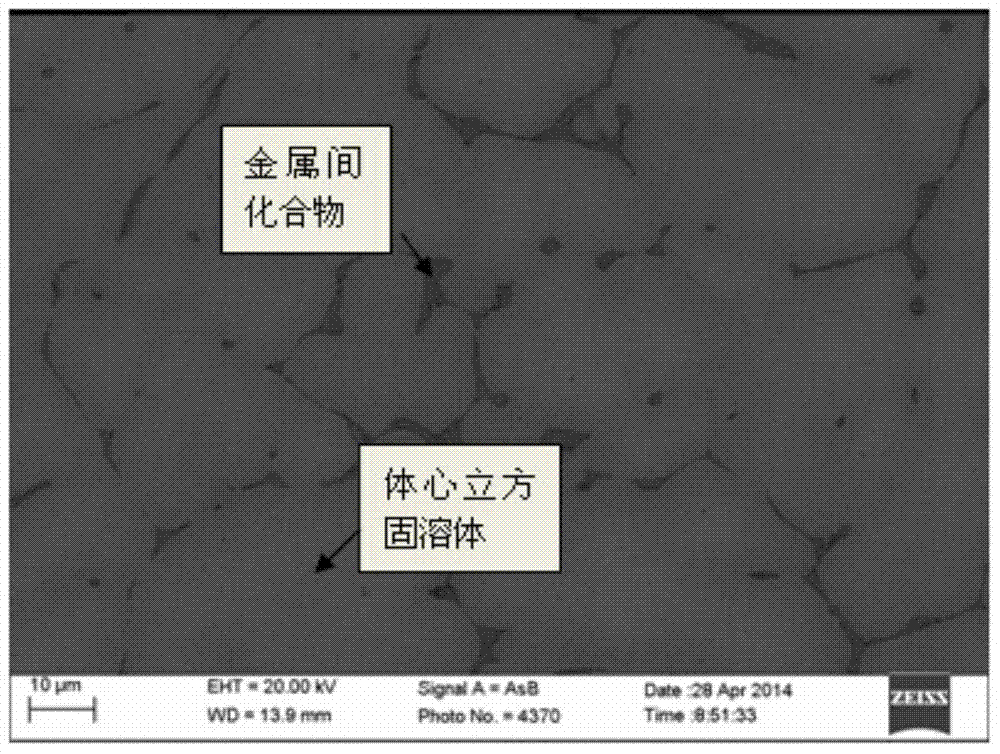

The invention relates to a low thermal expansion coefficient NaMxAlySiz high entropy alloy and a preparation method thereof, the chemical components of the alloy are as follows: 75 <= a <= 100%, 0 <= x <= 10%, 0<= y<= 10%, 0<= z<= 5%, N is arbitrary three or more than three of Ta, Nb, Hf, Zr, Ti, Mo and W, and M is any one or more than one of V, Mn, Fe, Co, Ni and Cr. The alloy phase structure is as follows: a body centered cubic solid solution and an intermetallic compound. The alloy is prepared by arc melting method in three stages. The NaMxAlySiz high entropy alloy has a low thermal expansion coefficient at the temperature in the range of room temperature to 1000 DEG C, the change rate is less than 20%, and the alloy has a broad application prospect in the high temperature industrial field.

Owner:UNIV OF SCI & TECH BEIJING

Production method of once-fired super-spar ceramic tile and ceramic tile

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

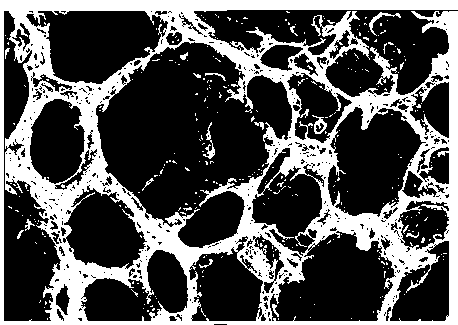

Three-dimensional graphene/phase change energy storage composite material and preparation method thereof

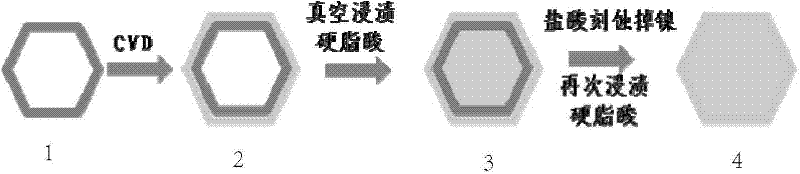

InactiveCN102585776AImprove thermal conductivityLow densityHeat-exchange elementsPorous grapheneLiquid state

The invention provides a three-dimensional graphene / phase change energy storage composite material and a preparation method thereof. The technical scheme is as follows: graphene and a phase change energy storage material are in situ compounded, wherein porous graphene with a three-dimensional structure is used as a heat conductor and a compound die, and a solid-liquid phase change organic material is used as the energy storage material and filler. The three-dimensional porous graphene is compounded with the phase change material, the phase change energy storage material is partitioned in a plurality of pore spaces and is in tight joint with the graphene wall so as to greatly increase the effective heat contact area, and the highly linked graphene three-dimensional heat conduction network channels can realize rapid system heat exchange. In addition, due to the capillary adsorption capacity of porous graphene, the liquid-state phase change energy storage material is localized, so as to effectively prevent seepage. Therefore, the three-dimensional graphene foam has good designability, and becomes a lighter and more effective heat dissipation material for electronic devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ultra-low-expansion ceramic pot and manufacturing method thereof

The invention discloses an ultra-low-expansion ceramic pot. The ultra-low-expansion ceramic pot comprises a ceramic pot blank and a glaze coated on the surface of the ultra-low-expansion ceramic pot. The ceramic pot blank comprises main materials and one or more nucleation agents. The main materials comprise: by weight, 10 to 50% of petalite, 10 to 50% of spodumene, 25 to 40% of kaolin, 2 to 15% of quartz and 2 to 5% of calcined talcum. Preferably, the main materials comprise: by weight, 40 to 50% of petalite, 10 to 20% of spodumene, 30 to 35% of kaolin, 2 to 6% of quartz and 2 to 5% of calcined talcum. The weight of the one or more nucleation agents is 0.2 to 0.8% of that of the main materials. The invention also discloses a manufacturing method of the ultra-low-expansion ceramic pot. The ultra-low-expansion ceramic pot has excellent quick-cooling and quick-heating resistance and ultra-low thermal expansion coefficients. The manufacturing method provided by the invention obviously improves product use performances and stability, has simple processes and good repeatability, is suitable for industrial production and is conducive to promotion of ceramic cooker application and development.

Owner:JINGDEZHEN CERAMIC INSTITUTE

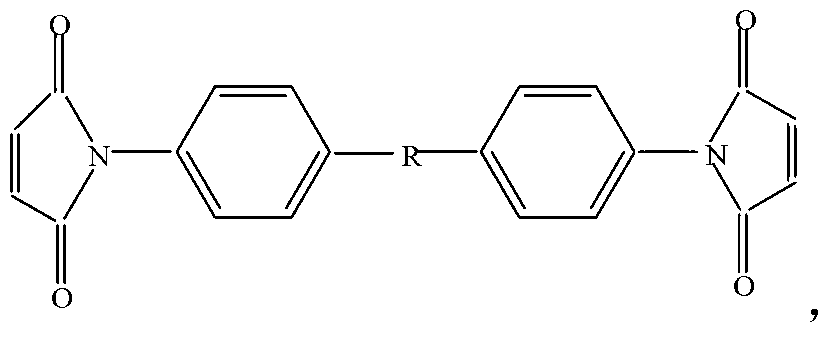

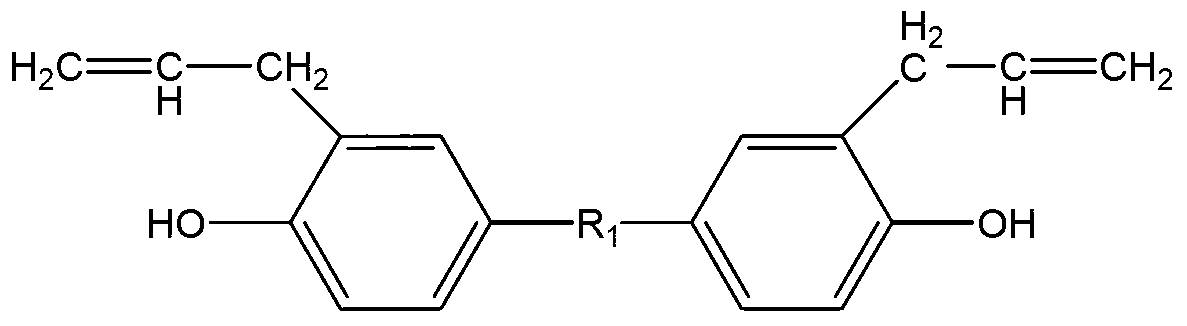

Thermosetting resin composition for integrated circuit as well as prepreg and laminated board both fabricated by using composition

ActiveCN103265791AImprove heat resistanceHigh Tg characteristicSynthetic resin layered productsHigh densityPrepolymer

The invention discloses a thermosetting resin composition for an integrated circuit. The thermosetting resin composition comprises (a) 10-60 parts of an allyl modified bismaleimide resin prepolymer, (b) 10-40 parts of an anhydride compound, (c) 10-50 parts of benzoxazine resin, (d) 5-50 parts of epoxy resin, (e) 5-50 parts of a fire retardant, (f) 0-5 parts of a curing accelerator and (g) 0-35 parts of inorganic stuffing, wherein the number-average molecular weight of the allyl modified bismaleimide resin prepolymer is 1500-8000 g / mol. The resin composition provided by the invention keeps high heat resistance and high Tg characteristic of the allyl modified bismaleimide resin prepolymer, and achieves UL94V-0 level in halogen-free flame retardant aspect on the basis of low phosphorus content, and simultaneously, has low dielectric constant of the anhydride; and therefore, the resin composition is capable of meeting the requirements of the production process of high-performance printed circuit boards such as a high-density interconnected integrated circuit package.

Owner:SHENGYI TECH SUZHOU

Method for preparing sharp type epoxide resin binding agent diamond abrasive tool

ActiveCN103056788AImprove bindingInhibit sheddingAbrasion apparatusGrinding devicesFirming agentEpoxide

The invention discloses a method for preparing a sharp type epoxide resin binding agent diamond abrasive tool. A working layer is mainly made of diamond abrasive, an epoxide resin binding agent, a curing agent, an auxiliary abrasive, a filler and an auxiliary assistant. The method comprises steps of uniformly mixing 5-20 parts by mass of self-sharpening diamond, 5-28 parts by mass of auxiliary abrasive, 10-40 parts by mass of filler and 0.5-10 parts by mass of auxiliary assistant through a machine; uniformly mixing the mixture, 17-25 parts by mass of liquid epoxide resin and 5-25 parts of curing agent; injecting the fluid mixture to a plastic die through a pouring mode; and obtaining the sharp type epoxide resin binding agent diamond abrasive tool after curing. Compared with the method for preparing the abrasive tool through hot press molding, the method has the advantages that the process is simple, the energy is saved, the emission is reduced, the pollution of solid powder on the environment is reduced, the method is environment-friendly, the production speed is quick, the sharpening degree is high, the self-sharpening performance is good, the polishing effect is good and the service life is long.

Owner:惠安宇信金刚石工具有限公司

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

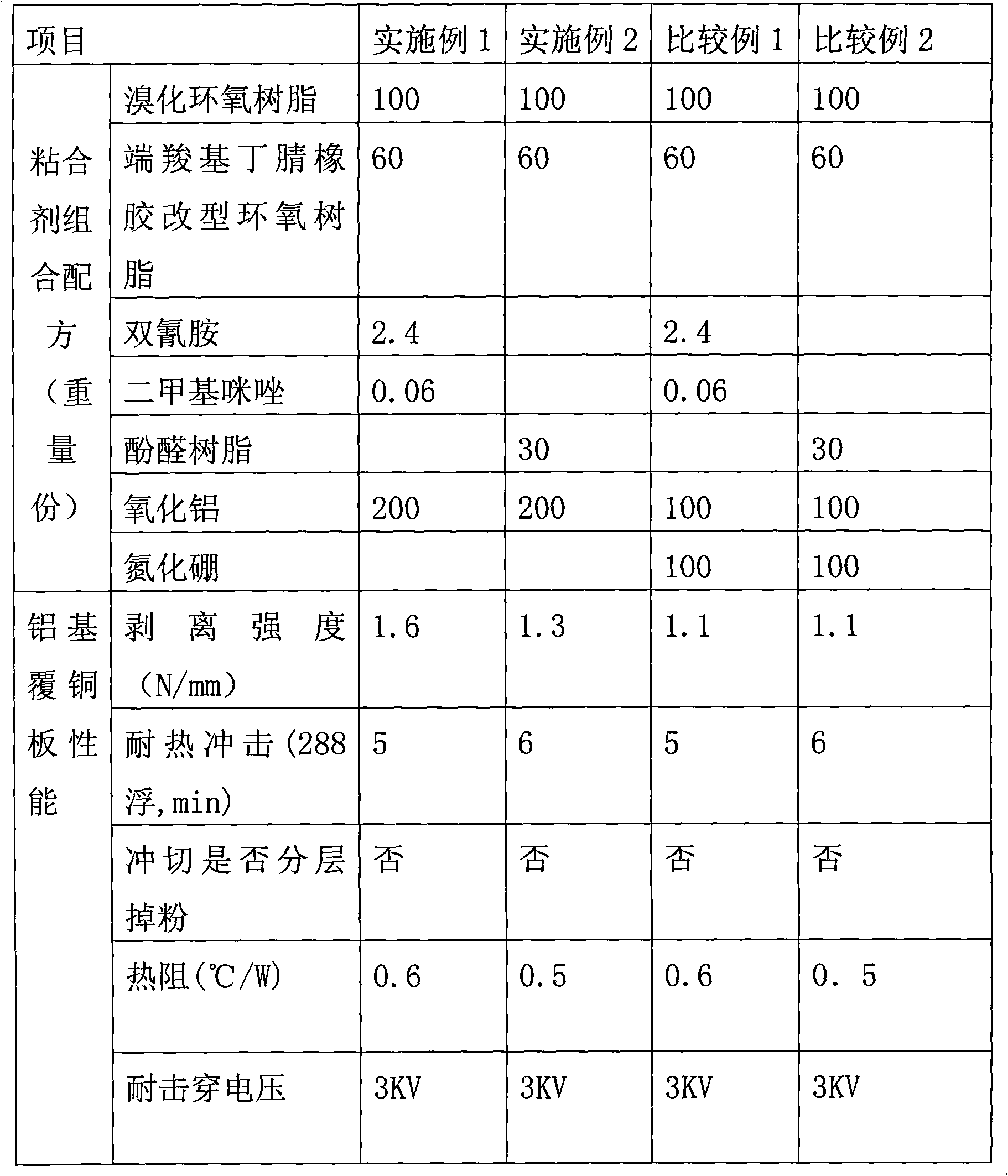

Epoxy resin composition, glue film made of same and preparation method

The invention discloses an epoxy resin composition, a continuous glue film made of the same and a preparation method. The epoxy resin composition comprises solid ingredients and organic solvents, wherein the solid ingredients comprise epoxy resin (A), thermoplastic resin or / and synthetic nitrile rubber (B), solidified agents (C), curing accelerators (D) and inorganic heat-conducting fillers (E). In addition, the invention also relates to the continuous glue film made of the epoxy resin composition and the preparation method. Because the continuous glue film is made by automated equipment, thecontinuous glue film has good consistency on thickness and performance, so that the breakdown voltage of a metal based copper-clad laminate and the stability of thermal resistance are ensured. The product made by the invention has good heat-conducting performance and electric insulation performance.

Owner:广东全宝科技股份有限公司

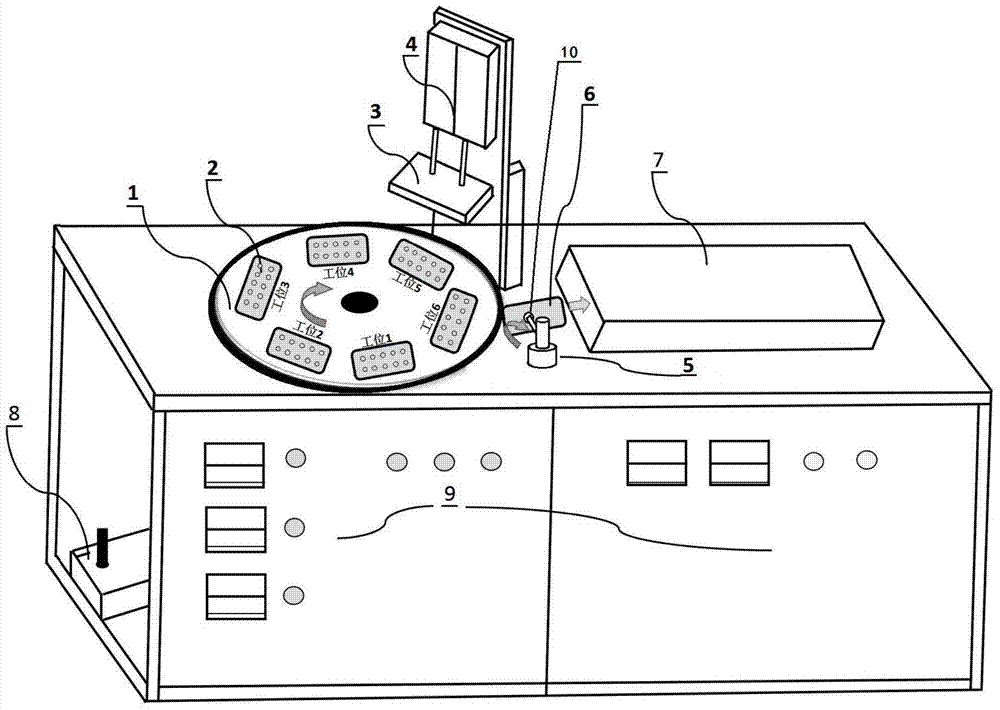

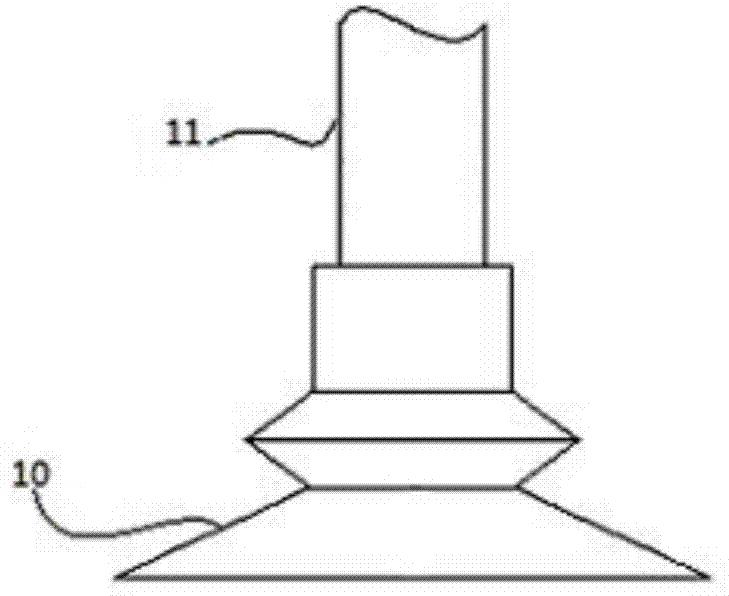

3D Curved ultrathin glass bending and forming device and manufacturing method

ActiveCN104843976ASmooth surfaceReduce stressGlass reforming apparatusGlass productionPhysicsElectrical control

The invention discloses a 3D curved ultrathin glass bending and forming device and a manufacturing method. The device comprises a rotor disc, concave dies, a convex die, a cylinder, a glass transfer mechanism, a tunnel furnace, a vacuum system and an electric control operating system, and a plurality of concave dies are arranged on the rotor disc. By adopting the device, the concave dies and the convex die are quickly heated in different stages; the ultrathin glass is sequentially placed on the concave dies of the rotor disc and is subjected to preheating; when the ultrathin glass rotates and reaches the corresponding work station on the convex die, the convex die is pressed, and a far infrared lamp tube is utilized to quickly heat to the glass softening point; in addition, the ultrathin glass on the concave dies is sucked and the convex die is pressurized by virtue of the vacuum system, so that the ultrathin glass is bended; the ultrathin glass is transferred to the tunnel furnace to be cooled by virtue of the glass transfer mechanism, so that the 3D curved ultrathin glass can be manufactured.

Owner:海程光电科技有限公司

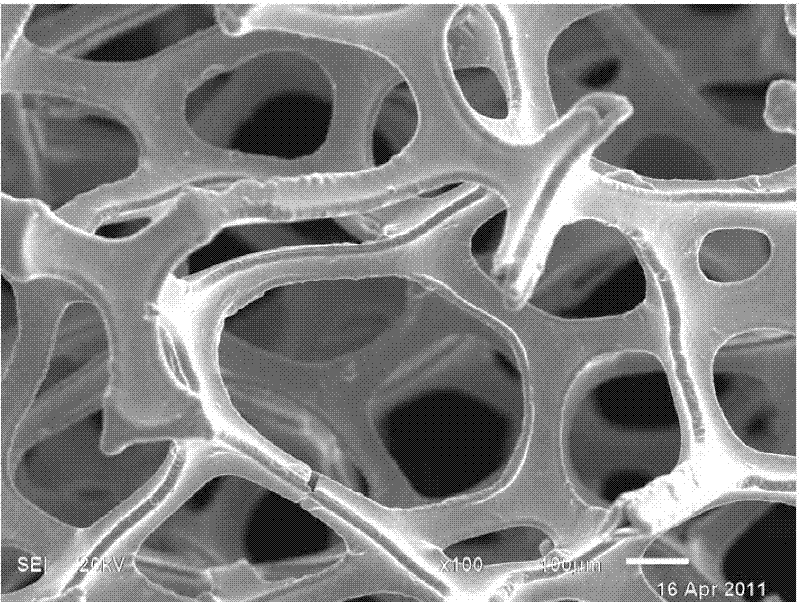

Silicon carbide foamed ceramics and preparation method thereof

The invention discloses silicon carbide foamed ceramics which comprises the following raw materials in parts by weight: 80-95 parts of silicon carbide micro powder particles, 5-20 parts of polycarbosilane powder and 40-170 parts of organic solvent. A template of the silicon carbide foamed ceramics is made of polymeric sponge. According to the invention, by using the characteristic that the polycarbosilane can be dissolved in the organic solvent, the polycarbosilane and ceramic powder are made into organic solvent slurry, polyurethane foam is dipped in the organic solvent slurry through adopting a powder sintering process principle, and thermally oxidized so that the yield of polycarbosilane ceramics is increased, the silicon carbide foamed ceramics is prepared through sintering under an inert atmosphere. A preparation method has the advantages of low sintering temperature, high efficiency and high production purity, and effectively avoids the difficulties of complex procedures, too many introduced impurities and high sintering temperature of the traditional preparation method for preparing the silicon carbide foamed ceramics.

Owner:GUIZHOU NORMAL UNIVERSITY

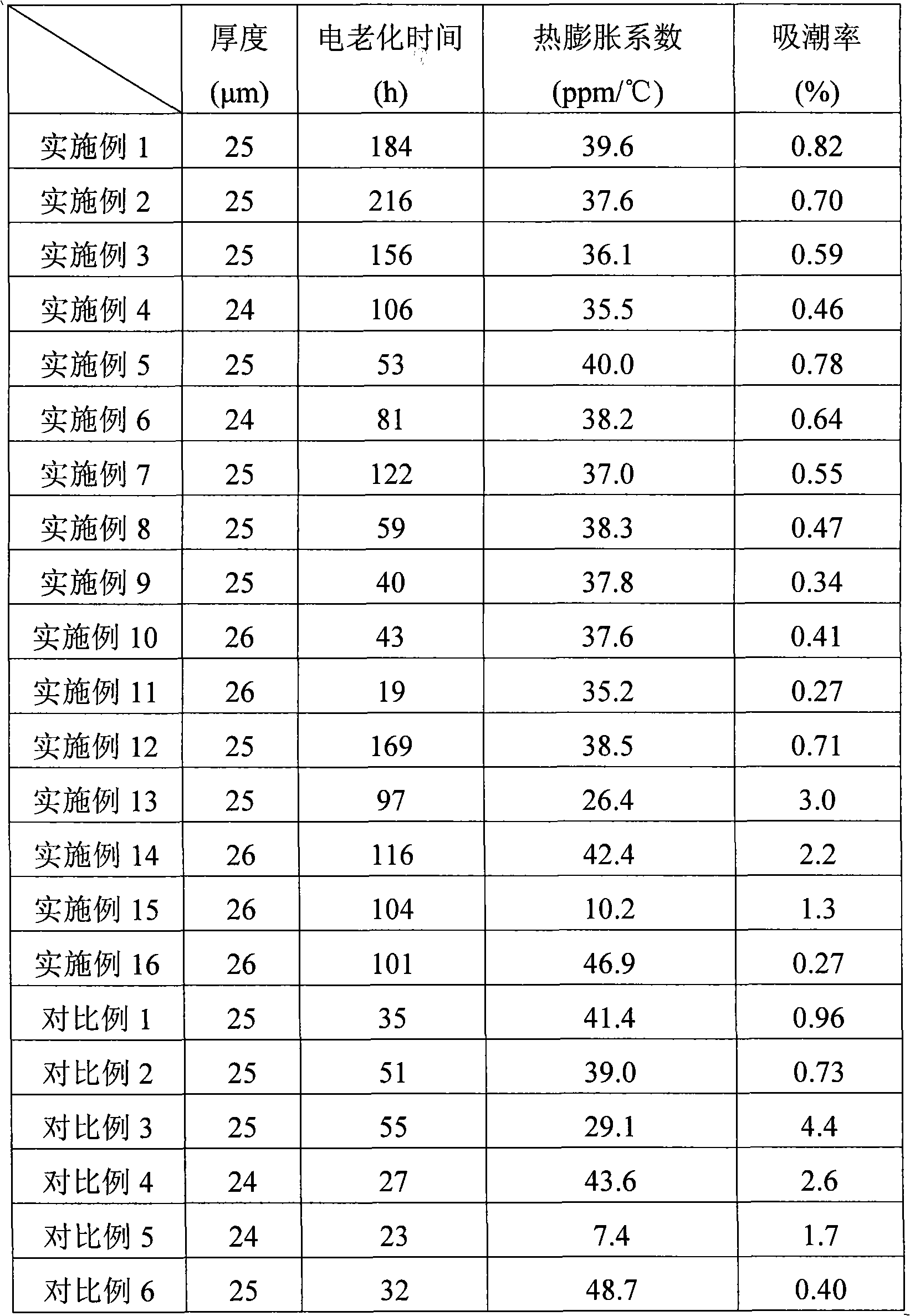

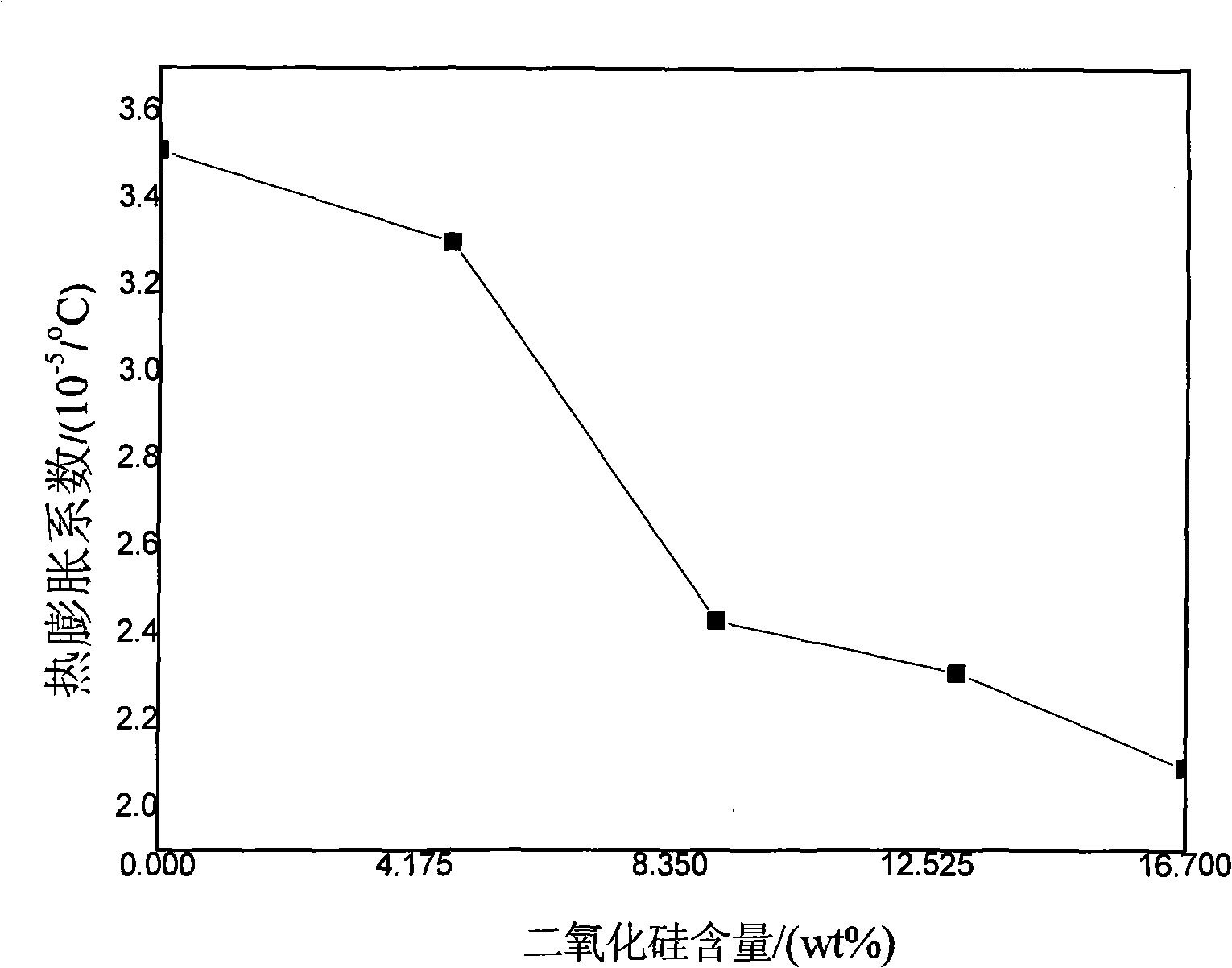

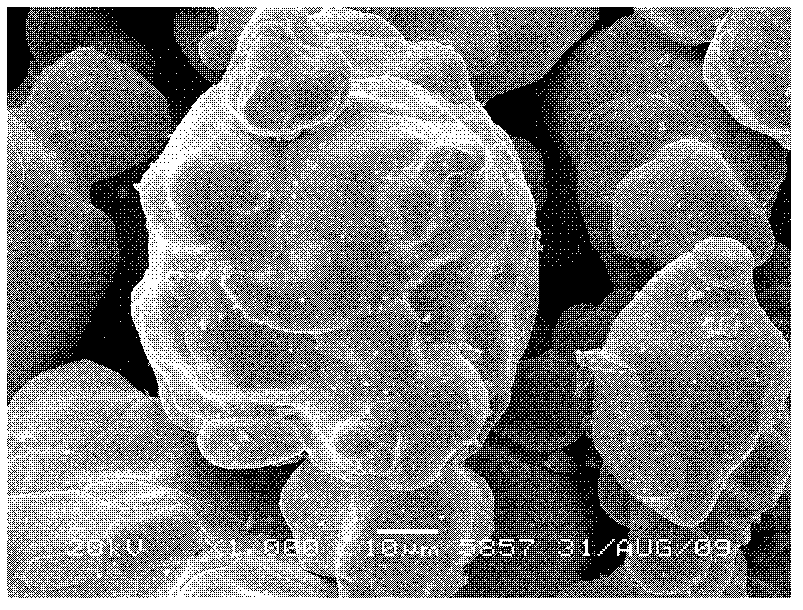

Spherical silica/polyimides composite membrane, preparation thereof and applications

ActiveCN101289542ACorona resistantImprove corona resistanceInsulating bodiesAdhesiveThermal coefficient

The invention discloses a spherical silicon dioxide / polyimide composite film and a method for making the same as well as an application. The method for making the spherical silicon dioxide / polyimide composite film comprises the following steps that: 1) spherical silicon dioxide particles are scattered into an organic solvent evenly to obtain the spherical silicon dioxide particle suspension liquid; 2) a surface treatment agent, a molecular weight modifying agent, an auxiliary adhesive, a flatting agent and aromatic series diamine are dissolved inside the spherical silicon dioxide particle suspension liquid; organic dicarboxylic anhydride is added to be stirred in order to obtain a spherical silicon dioxide / polyamide acid mixing resin solution; 3) the mixing resin solution is coated on the surface of a flat substrate and is heated up to make the solvent volatilize and complete the imide reaction to obtain the spherical silicon dioxide / polyimide composite film. The spherical silicon dioxide / polyimide composite film has good mechanical property, good corona resistance, low thermal coefficient of expansion and low moisture absorption ratio, and has important application value in an insulating system of a frequency conversion speed motor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

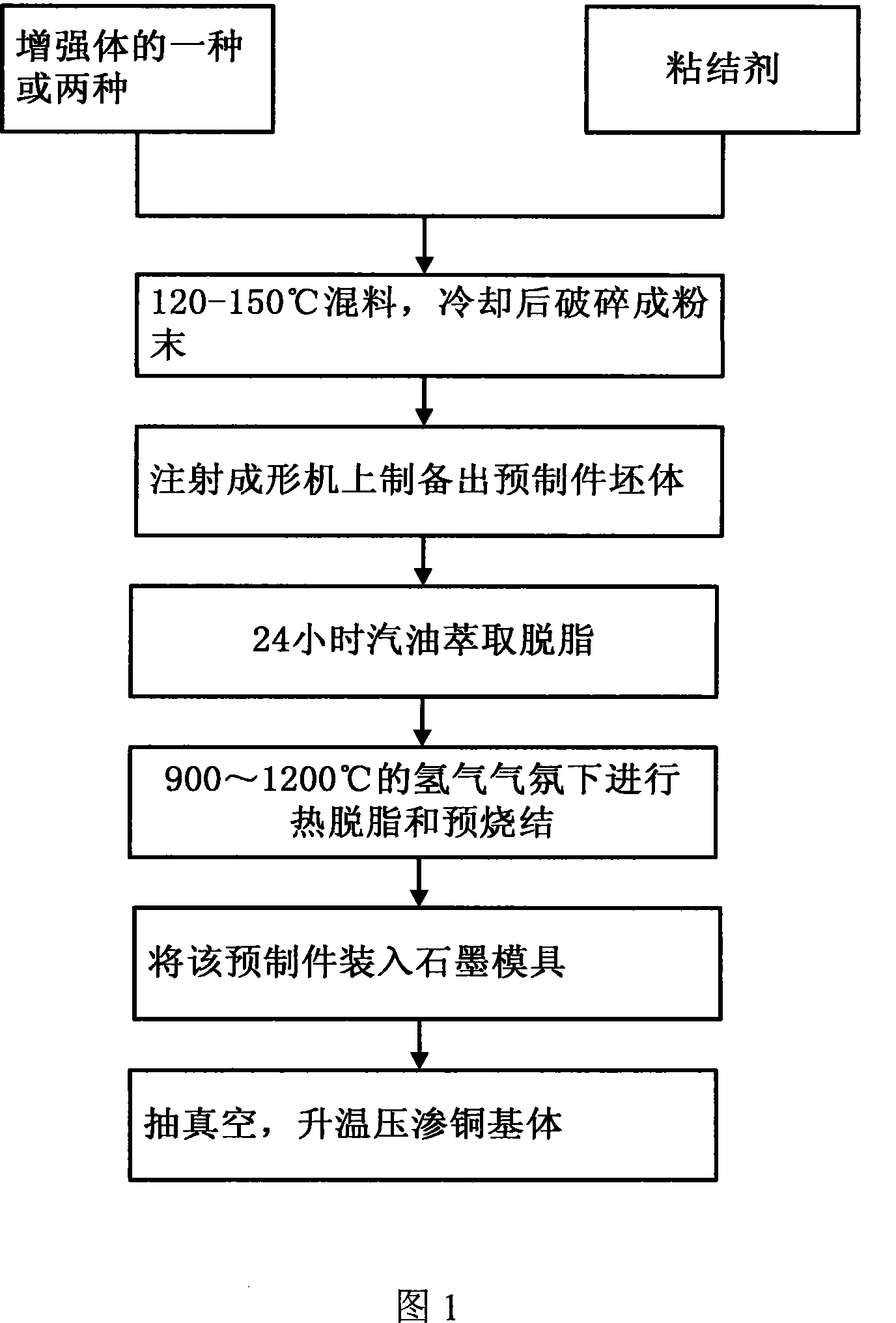

High heat conductivity copper-base composite material and preparation method thereof

The invention belongs to the technical field of preparation of electronic packaging materials, and particularly designs a copper-based composite material with high thermal conductivity and a preparation method thereof. The copper-based composite material is made of a reinforcement and a binder through a prefabricated injection molding process to make a reinforcement prefabricated part, wherein the size of the reinforcement particle is 7-60 μm, and it is composed of silicon carbide particles, diamond particles or aluminum nitride particles. One or two of them; the copper matrix is directly placed on the reinforcement preform, wherein the copper matrix is electrolytic copper or oxygen-free copper, and the volume ratio of the reinforcement to the copper matrix is 50-75%: 25-50 %, made by pressure infiltration process. The preparation method adopts the injection molding process of the prefabricated part and the pressure impregnation process to prepare the high thermal conductivity copper matrix composite material. The thermal conductivity of the copper-based composite material in the present invention is higher than that of the aluminum-based composite material with the same reinforcement system, the material itself has low density and small thermal expansion coefficient, which meets the requirement of light weight of the packaging material.

Owner:GRIMAT ENG INST CO LTD

A preparation method of gum-free flexible copper-coating plate

PendingCN101157077AImprove heat resistanceGood flexibilityPretreated surfacesCoatingsDielectricCopper foil

The invention discloses a preparation method for a non-glue type flexible copper clad laminate. The invention has the method that monomer aromatic diamine is dissolved in non-protonic polar solvent, and aromatic tetracid dianhydride with the equal molar is added into the solution, thereby generating polyamic acid solution with 10 to 30 percent of the solid content in a polyamic way; dehydrating agent and catalyst are dropwise added into the solution, and the chemical imidization is performed at 10 to 80 DEG C, thereby obtaining polyimide precursor solution; the polyimide precursor solution is coated on the copper foil surface with the 60 to 70 micron thickness, and heated to remove the solvent, and the thermal imidization is further performed at 250 to 300 DEG C, thereby obtaining the non-glue type flexible copper clad laminate. The non-glue type flexible copper clad laminate of the invention has the excellent heat resistant performance, is suitable for the non-lead welding meeting the environmental protective requirement, has small crimpability, good dimensional stability, better mechanical strength, high peel strength, and high flexibility resistance, and simultaneously has lower thermal expansion coefficient, dielectric constant, and water absorption.

Owner:湖北省化学研究院

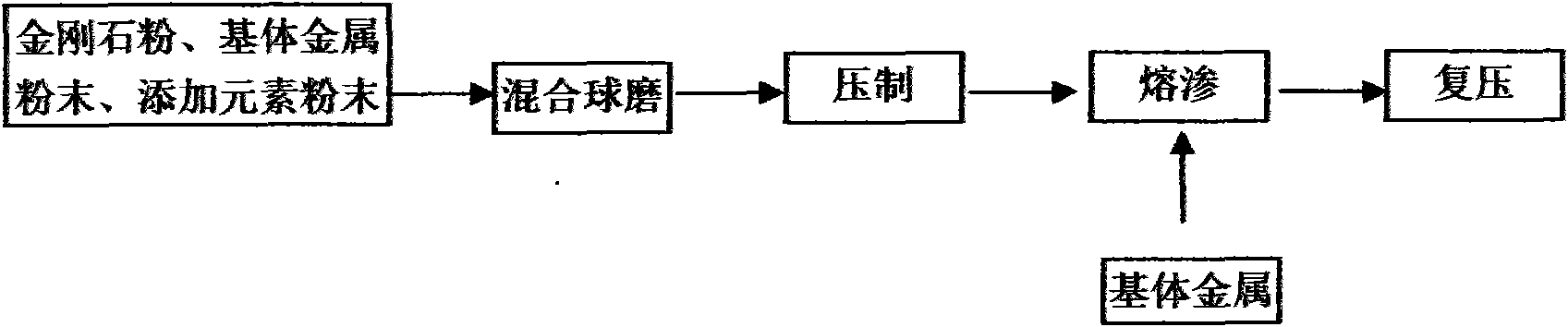

Diamond reinforced metal-base composite material for electronic packaging and preparation method thereof

ActiveCN101649400AImprove wettabilityImprove thermal conductivitySemiconductor/solid-state device manufacturingThermal expansionMetal matrix composite

The invention discloses a diamond reinforced metal-base composite material for electronic packaging and a preparation method thereof. The material comprises the following components by volume percent:30%-90% of diamond, 0.1%-5% of addition element and 10%-70% of metal substrate, wherein the addition element comprises one or more of Zr, Cr, Ti and B and the metal substrate comprises one metal of Ag, Cu and the like. The preparation method of the material comprises the following steps: mixing powder, pressing, infiltrating and pressing again. Owning to the adopted alloy element addition method,the wettability among phases is greatly improved. Therefore the material prepared by the method of the invention has better thermal conductivity, thermal expansion coefficient and mechanical properties compared with the former electronic packaging material and the adopted liquid phase infiltration method has the advantages of simple operation, low cost and capability of mass production.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

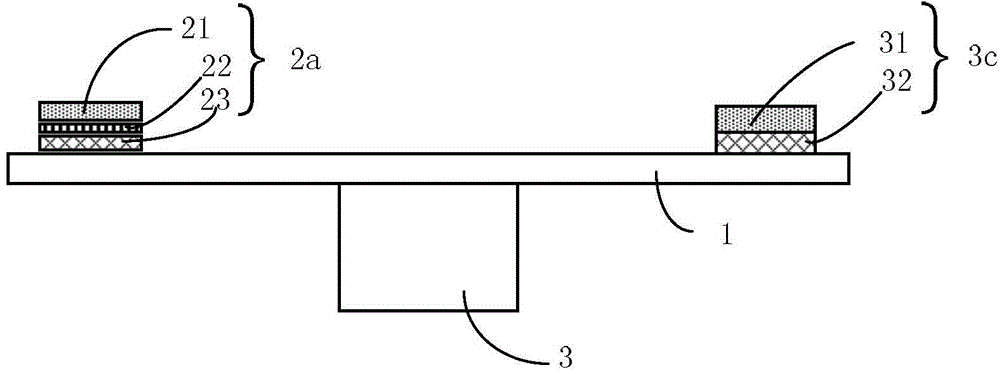

Manufacturing method of wavelength conversion device

ActiveCN104566229ALower interface thermal resistanceNot difficult to attachElectrical apparatusElectroluminescent light sourcesWavelength conversionCeramic substrate

Disclosed is a manufacturing method for a wavelength conversion device, comprising: preparing a plurality of wavelength conversion modules (2a, 2b, 2c), each wavelength conversion module (2a, 2b, 2c) comprising a ceramic substrate (23), a reflecting layer (22) and a fluorescent powder layer (21), said layers being stacked sequentially and formed into one piece; installing and fixing the plurality of wavelength conversion modules (2a, 2b, 2c) on one surface of a base substrate. By arranging different fluorescent powders respectively on the different wavelength conversion modules (2a, 2b, 2c), a plurality of wavelength conversion modules (2a, 2b, 2c) can be produced separately at the same time, thereby significantly shortening the production cycle. Each such module is produced independently and is thus not subject to the restrictions of the characteristics of other fluorescent powders. This is beneficial for the optimization of the various processes, and a wavelength conversion device having optimal performance is thereby obtained.

Owner:APPOTRONICS CORP LTD

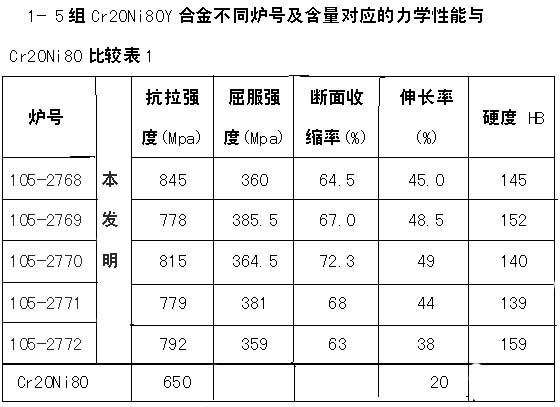

High-resistance electrothermal alloy material and preparation method thereof

The invention discloses a high-resistance electrothermal alloy material, which comprises the following components in percentage by weight: 0.02 to 0.08 percent of C, 0.75 to 1.6 percent of Si, 0.1 to 0.5 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.015 percent of S, 20 to 23 percent of Cr, 0.1 to 0.5 percent of Al, 0.2 to 0.8 percent of Y, 0.2 to 1.0 percent of Fe, and the balance of Ni and inevitable impurities. The preparation method for the high-resistance electrothermal alloy material comprises the following steps of: smelting; forging; coiling; annealing; rinsing; mold drawing, and the like. Compared with Cr20Ni80, the high-resistance electrothermal alloy material has higher antioxidation performance, and is an electrothermal alloy material with small thermal expansion coefficient, high high-temperature strength and processability, long service life and high resistivity.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Flame-retardant heat-conducting double-component epoxy resin pouring sealant and preparation method thereof

InactiveCN104152093ALow coefficient of linear thermal expansionReduce packing settlingNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal conductivityPolymer chemistry

The invention relates to a flame-retardant heat-conducting double-component epoxy resin pouring sealant and a preparation method thereof. The pouring sealant is composed of a component A and a component B in a weight ratio of 100: 80 to 100: 120. The pouring sealant prepared in the invention has the advantages of a long operation period, a low thermal expansion coefficient after curing, a high flame retardation grade, reaching grade UL94-V0, good thermal conductivity and excellent electrical properties, and is applicable to high temperature electric packaging of power semiconductors, rectifiers, transformers, etc.

Owner:YANTAI DARBOND TECH

Preparation of high modulus, low thermal expansion coefficient polyimide hybridization film

The invention relates to a preparation method of thermosetting polyimide film with high modulus and low coefficient of thermal expansion, which obtains an objective product by copolymerization, sol-gel process and condensation. Rigid diamine and dianhydride are adopted in the polyreaction. A sol-gel in situ method is adopted, the reaction process is easy to be controlled, the uniformity is good; the amount of hybridization of inorganic particles can be increased; and the obtained solution is heated step by step to generate condensation reaction. The preparation technique is simple and is easy to be controlled; and the obtained product has higher elastic modulus and low coefficient of thermal expansion; therefore, the invention has higher application value in industry.

Owner:连云港达昇新材料科技有限公司

Graphene oxide modified compound type heat conducting silicone rubber and preparation method thereof

ActiveCN103937259AFlexibility does not affectImprove thermal conductivityHeat conductingCoordination complex

The invention discloses graphene oxide modified compound type heat conducting silicone rubber and a preparation method thereof. According to the preparation method, the compound type silicon resin with high heat conduction property and low expansion factor is prepared by using 0.5-1 part of graphene oxide as heat conducting stuffing and an inorganic crosslinking agent, 10-50 parts of nanometer SiO2 as the heat conducting stuffing, 5-30 parts of compound of two MQ silicone resin containing hydroxyl and vinyl and different in viscosity as a special bonding modifying agent, 1-10 parts of organic hydrogen polysiloxane as an organic crosslinking agent, 0.1-2 parts of platinum complex as a catalyst, 0.01-0.001 part of alkynol substance as an inhibitor and 60-100 parts of polysiloxane resin as base rubber and adopting a nanometer compounding method, wherein the graphene oxide is partially modified by a silane coupling agent, and the nanometer SiO2 is prepared by a sol-gel method. The compound type silicon resin can be widely applied to encapsulation of various electronic components and plays a role in shock absorption and heat dissipation.

Owner:东莞九天量子科技有限公司

Extra coarse grain WC-Co hard alloy and preparation process thereof

ActiveCN102534344APromote grain growthIncrease the carbon content of tungsten carbideCemented carbideGrain distribution

The invention relates to an extra coarse grain WC-Co hard alloy. The hard alloy comprises 5 to 15 weight percent of Co and the balance of WC, wherein the average grain size of the WC is 6 to 10mu m. A preparation process for the hard alloy comprises the following steps of: pre-ball-milling coarse and fine tungsten carbide to prepare mixed tungsten carbide powder, preparing mixed tungsten carbide powder-cobalt-former mixed powder, pressing, and sintering, wherein the sintering step is divided into a former removing part and a high-temperature sintering part. The average grain size of a metallographic structure of the WC-Co hard alloy prepared by the process is 6mu m or more than 6mu m, the process method is simple and convenient to operate, the prepared hard alloy has a large average grainsize, a narrow grain distribution range, a low thermal expansion coefficient and high heat conductivity, high-temperature wear resistance, transverse rupture strength and rupture toughness, and is suitable for a mining tool and an excavating tool, and the thermal fatigue crack resistance of the alloy is effectively improved.

Owner:HUNAN BOYUN DONGFANG POWDER METALLURGY

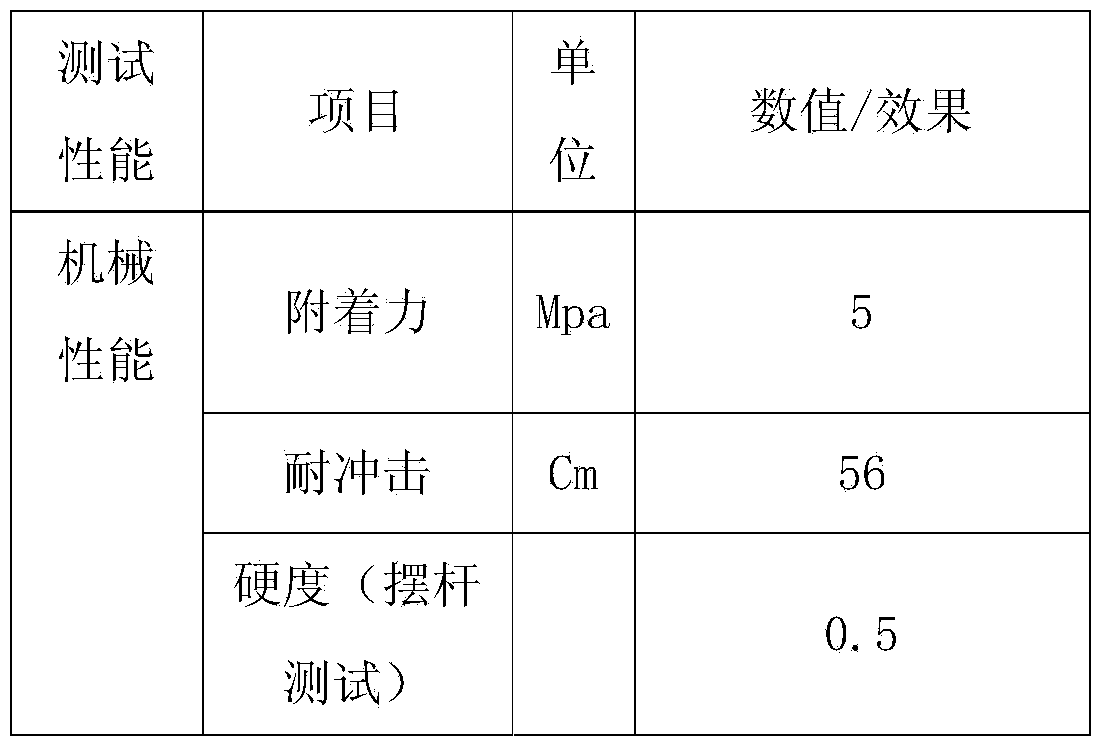

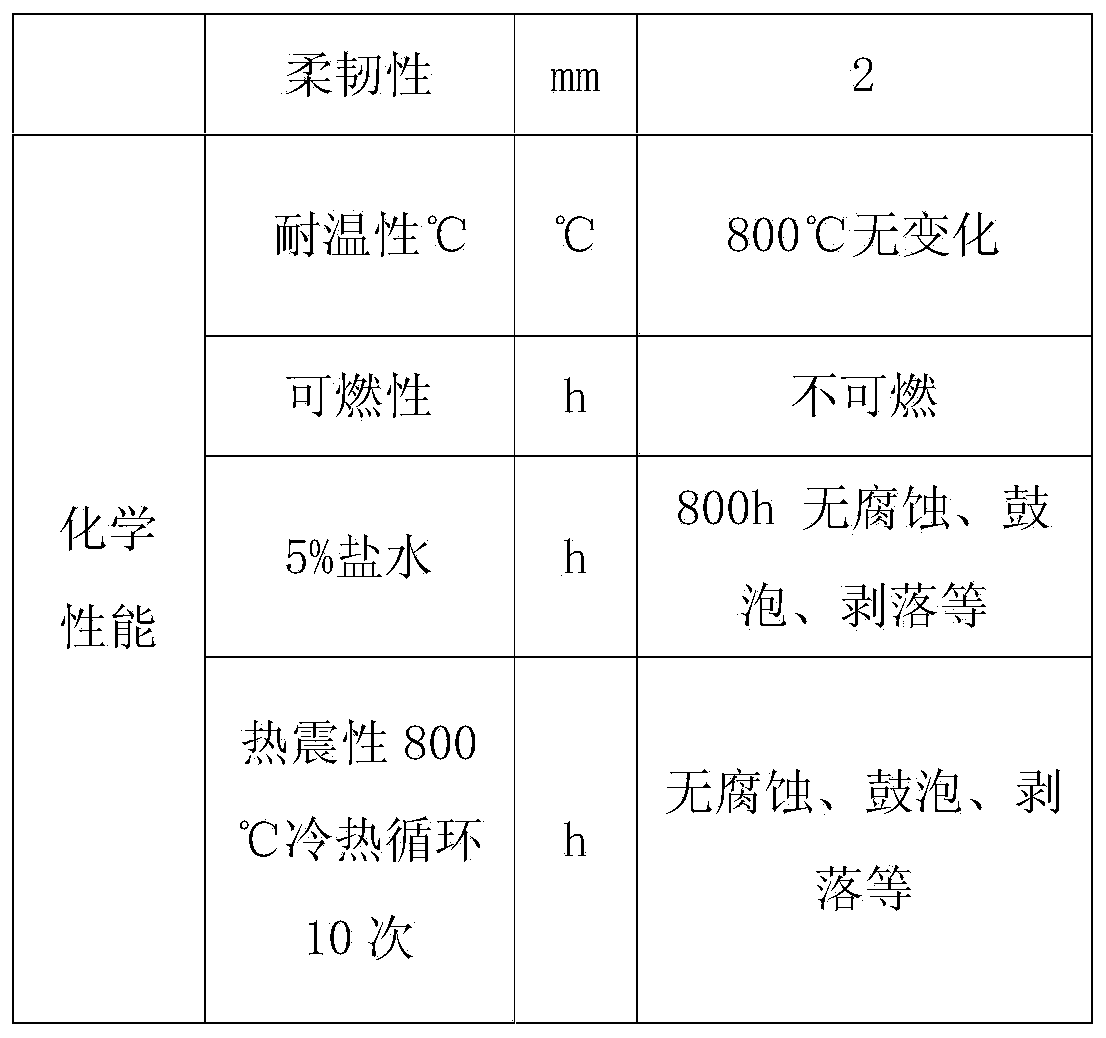

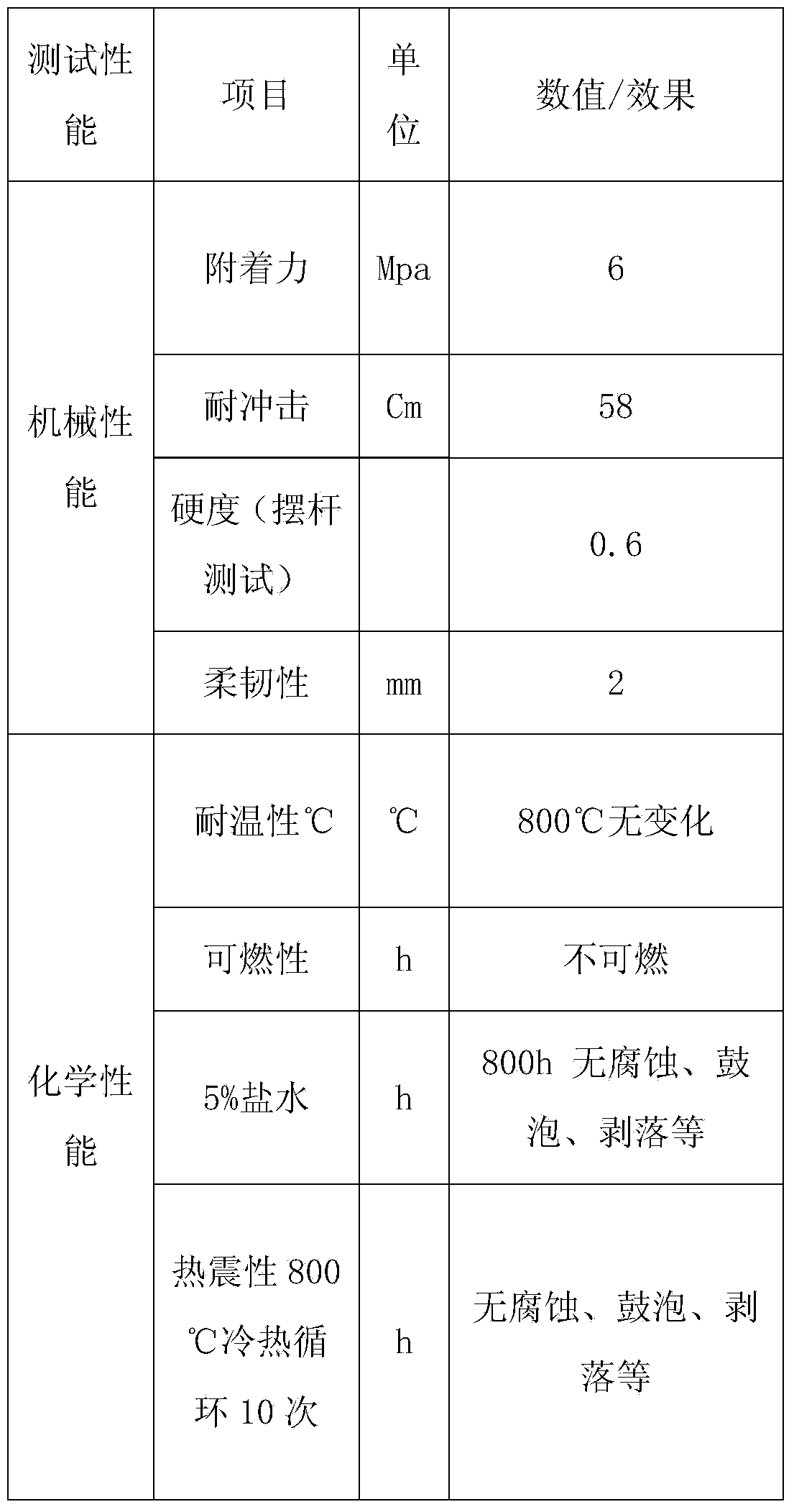

Boron-modified organic silicon resin high-temperature-resistant coating and preparation method thereof

The invention discloses a boron-modified organic silicon resin high-temperature-resistant coating which comprises the following components in percentage by mass: 45%-58% of boron-modified organic silicon resin, 35%-45% of heat-resisting pigment fillers and 2%-4% of auxiliary agents, wherein the boron-modified organic silicon resin is boric-acid-modified organic silicon resin or epoxy-modified silicon-boron resin; and the mass ratio of nanometer silicon dioxide to barrier function fillers to aluminum powder which are contained in the heat-resisting pigment fillers is 1.5:1:1. The invention also discloses a preparation method of the boron-modified organic silicon resin high-temperature-resistant coating. The preparation method disclosed by the invention can be implemented on an existing coating preparation production line without increasing equipment investment; the prepared high temperature-resistant organic silicon coating can be coated by adopting a spray coating process and constructed by adopting a roll coating process, can be subjected to high temperature of 800 DEG C for a long time and has corrosion-resistant property.

Owner:JIANGSU MARINE VICTORY COATING

Magnesium Aluminum Titanate Crystal Structure and Method for Producing Same

InactiveUS20070224110A1Increase resistanceSmall coefficient of thermal expansionTitanium oxides/hydroxidesThermal expansionEmpirical formula

To provide an aluminum magnesium titanate crystal structure which can be used stably in variable high temperatures, because of its excellent heat resistance, thermal shock resistance, high thermal decomposition resistance and high mechanical property, and a process for its production. An aluminum magnesium titanate crystal structure, which is a solid solution wherein at least some of Al atoms in the surface layer of aluminum magnesium titanate crystal represented by the empirical formula MgxAl2(1−x)Ti(1+x)O5 (wherein 0.1≦x<1) are substituted with Si atoms, and which has a thermal expansion coefficient of from −6×10−6 (1 / K) to 6×10−6 (1 / K) in a range of from 50 is to 800° C. at a temperature raising rate of 20° C. / min, and a remaining ratio of aluminum magnesium titanate of at least 50%, when held in an atmosphere of 1,100° C. for 300 hours.

Owner:OHCERA CO LTD

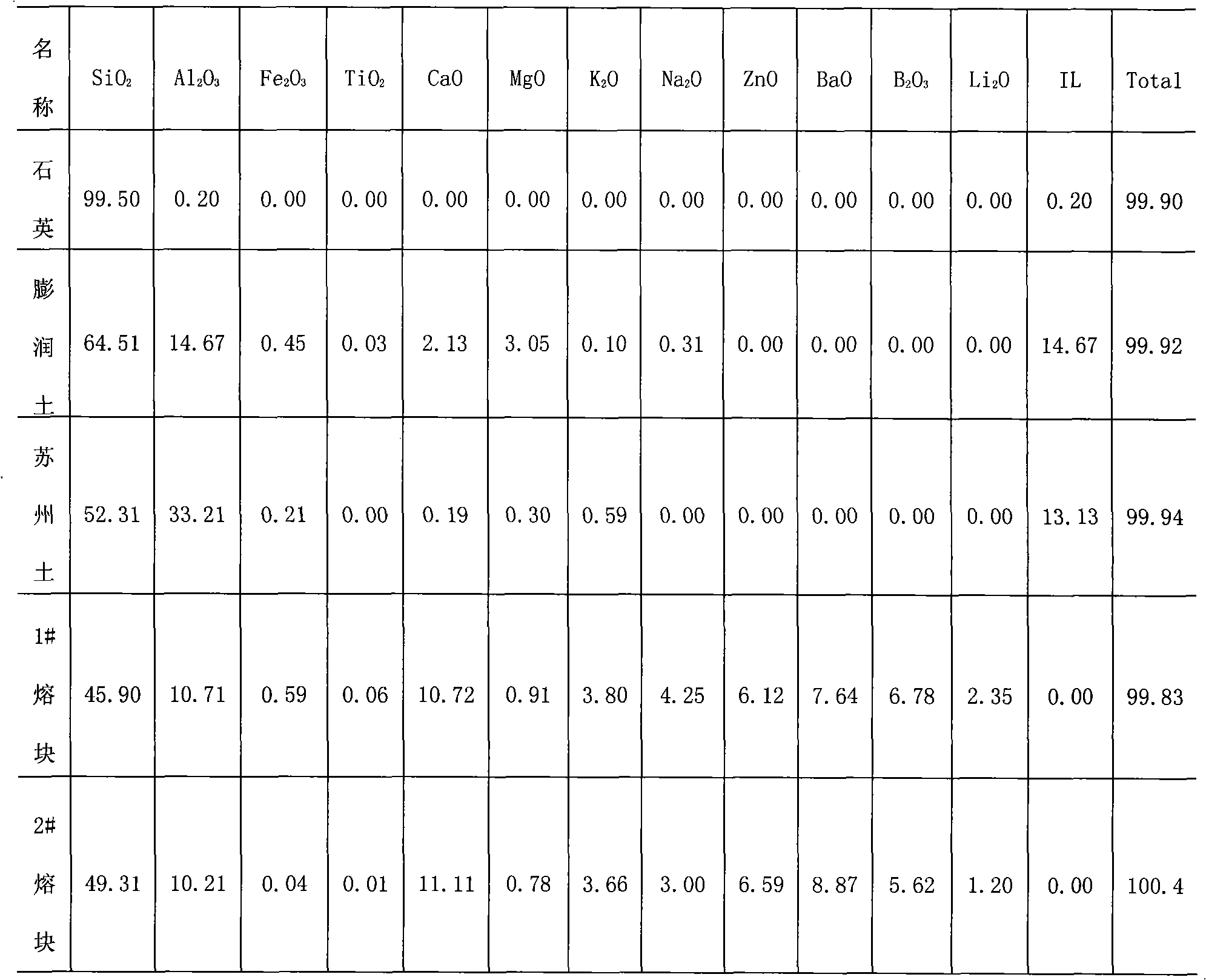

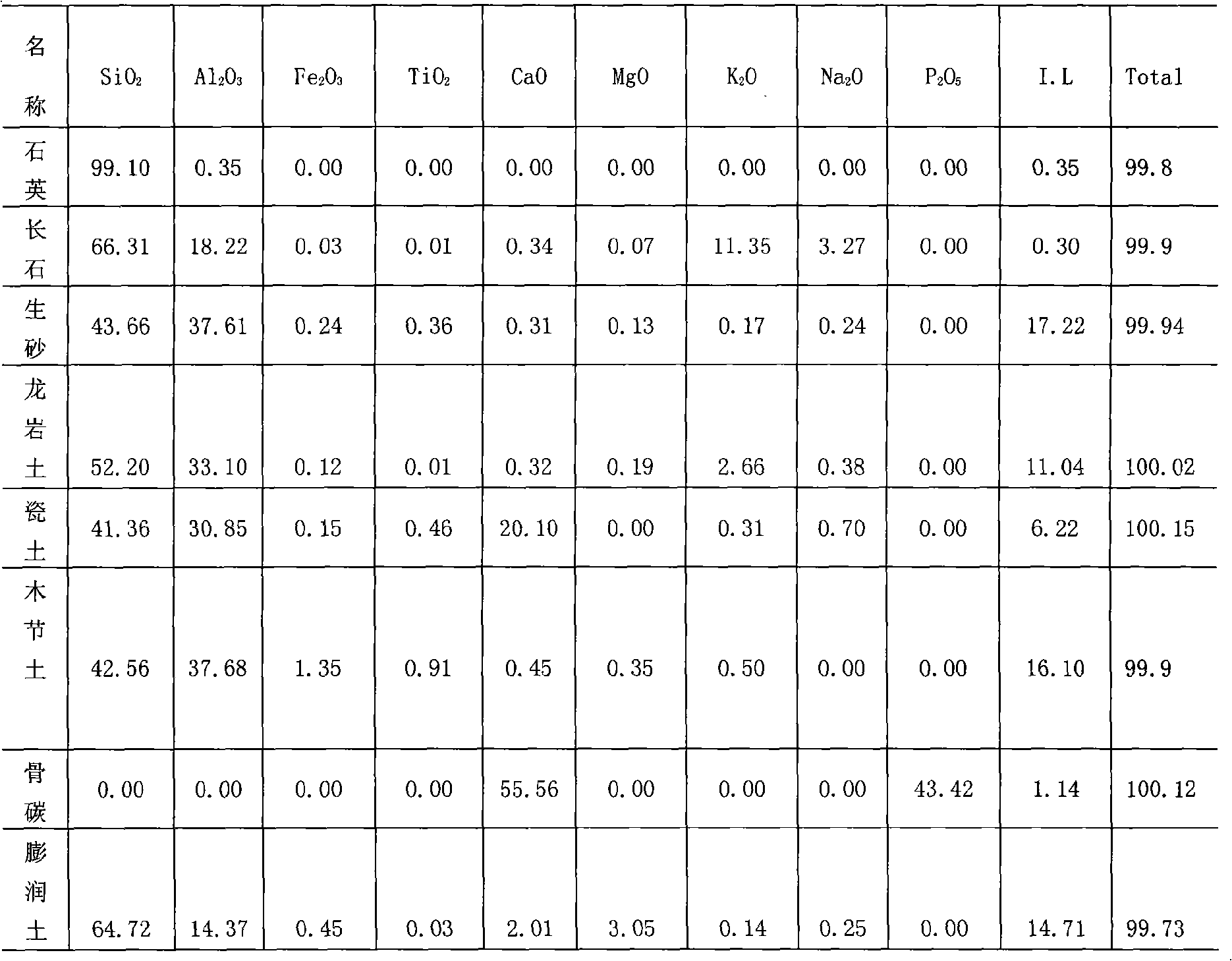

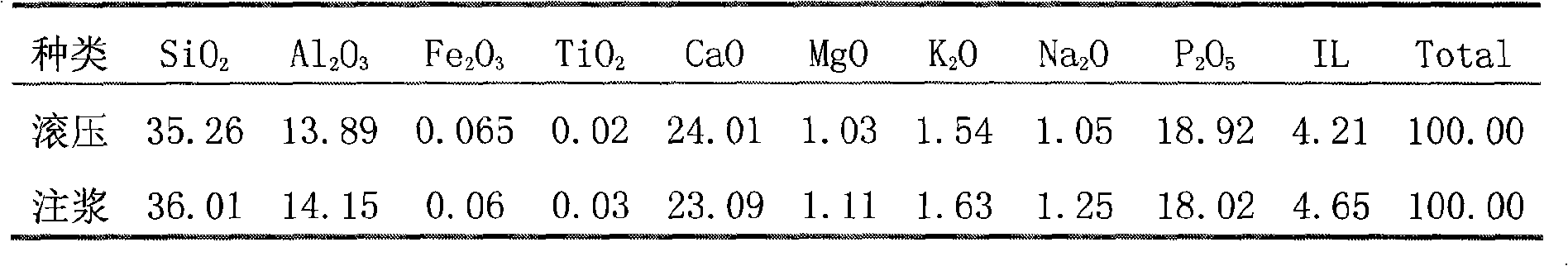

Bone porcelain with high resistance of heat shocks and production method thereof

InactiveCN101289307AReduce contentSmall coefficient of thermal expansionClaywaresHigh resistanceSodium Bentonite

The invention relates to a bone china with high resistance to heat shocks and a manufacture method thereof. The raw material components of the bone china stock and the weight percentages are: 9 to 12 of quartz, 7 to 10 of feldspar, 11 to 14 of greensand, 4 to 7 of Longyan clay, 5 to 8 of china clay, 4 to 7 of kibushi clay, 42 to 46 of bone coal and 7 to 10 of bentonite; the raw material components and the weight percentages of glaze material are: 5 to 8 of the quartz, 2 to 5 of the bentonite, 3 to 6 of Suzhou clay, 50 to 53 of model one fused block and 34 to 37 of model two fused block; the bone china has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C for once. The manufacture steps are as follows: preparing stock paste, preparing glaze paste, roller forming, grouting and forming, biscuit firing, glazing, glaze firing and decorating firing. The enamel layer of the invention has the advantages of large elasticity, good toughness and mechanical property. The raw material ingredients have no lead and zero radioactivity, which are green. The manufacture method is scientific and reasonable, and the product has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C at one time.

Owner:唐山隆达骨质瓷有限公司

Low-temperature high-strength devitrified glass ceramics wedding agent

InactiveCN101195517ASatisfy the speed of useLower sintering temperatureSuperhard materialThermal expansion

The invention discloses a low-temperature high-strength microcrystalline glass vitrified bond used for preparing grinding tools made of superhard material diamond and cubic boron nitride. The components and the weight percentage are that SiO2 takes 40-70%, B2O3 takes 5-25%, Al2O3 takes 2-5%, Na2O takes 2-15%, K2O takes 2-5%, MgO takes 2-4%, CaO takes 2-4%, Li2O takes 1-10%, ZrO2 takes 2-5% and Sb2O3 takes 2-5%. The microcrystalline glass is abtaind by sintering the powder, the temperature of sintering-crystallization is 700-900 DEG C, the thermal expansion coefficient is 4-10*10-6 / DEG C and the bending strength can reach 160-200MPa. The grinding tool prepared by the combination of the microcrystalline glass and the powders of diamond and cubic boron nitride can satisfy the using speed of 160m / s or more. The invention has the advantages of low sintering temperature of the bond, low thermal expansion coefficient and high strength.

Owner:TIANJIN UNIV

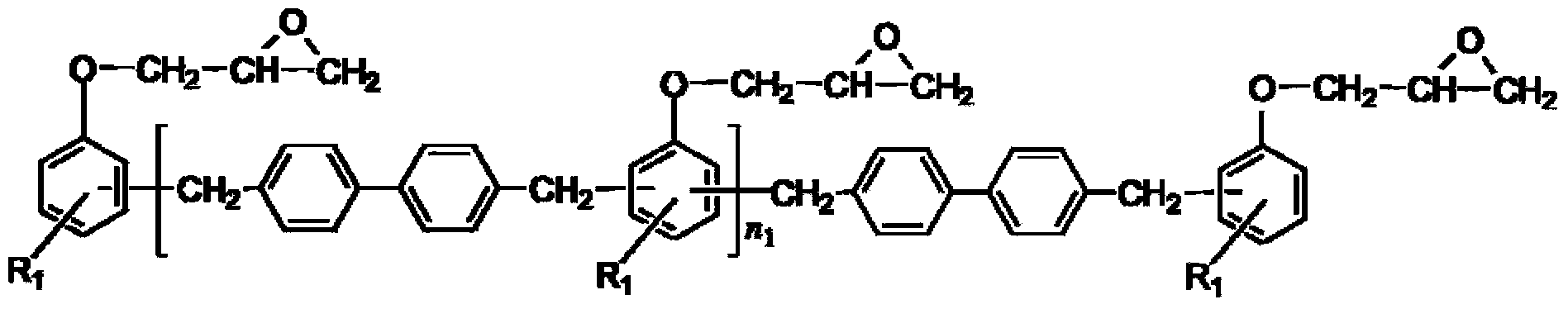

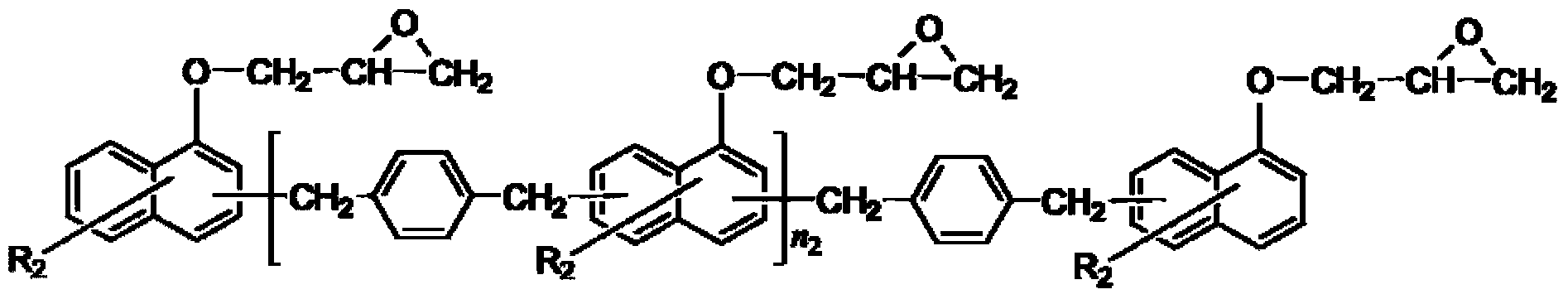

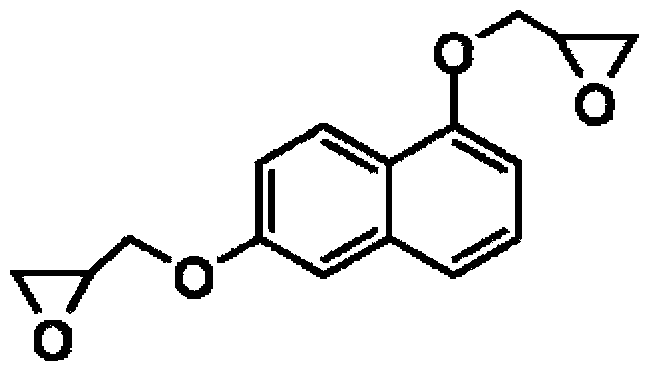

Resin composition used for forming dielectric layer of dielectric substrate for antenna and application of resin composition

ActiveCN103351578ASmall coefficient of thermal expansionLittle change in thicknessSynthetic resin layered productsMetal layered productsEpoxyDielectric substrate

The invention relates to a resin composition used for forming a dielectric layer of a dielectric substrate for an antenna. The resin composition comprises (A), epoxy resin containing a naphthalene nucleus or diphenyl structure, (B), any one of or a mixture of at least two of tri(4-hydroxyphenyl) methane type epoxy resin, o-cresol type novolac epoxy resin and phenol type novolac epoxy resin, (C), a resin fusion viscosity modifier, and (D), spherical ceramic powder after presintering treatment. With the adoption of the resin composition, the obtained dielectric substrate has a high dielectric constant, high peeling strength, a low thermal expansion coefficient and very good thickness consistency, and can meet a performance requirement of the high dielectric constant antenna substrate.

Owner:江苏生益特种材料有限公司

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

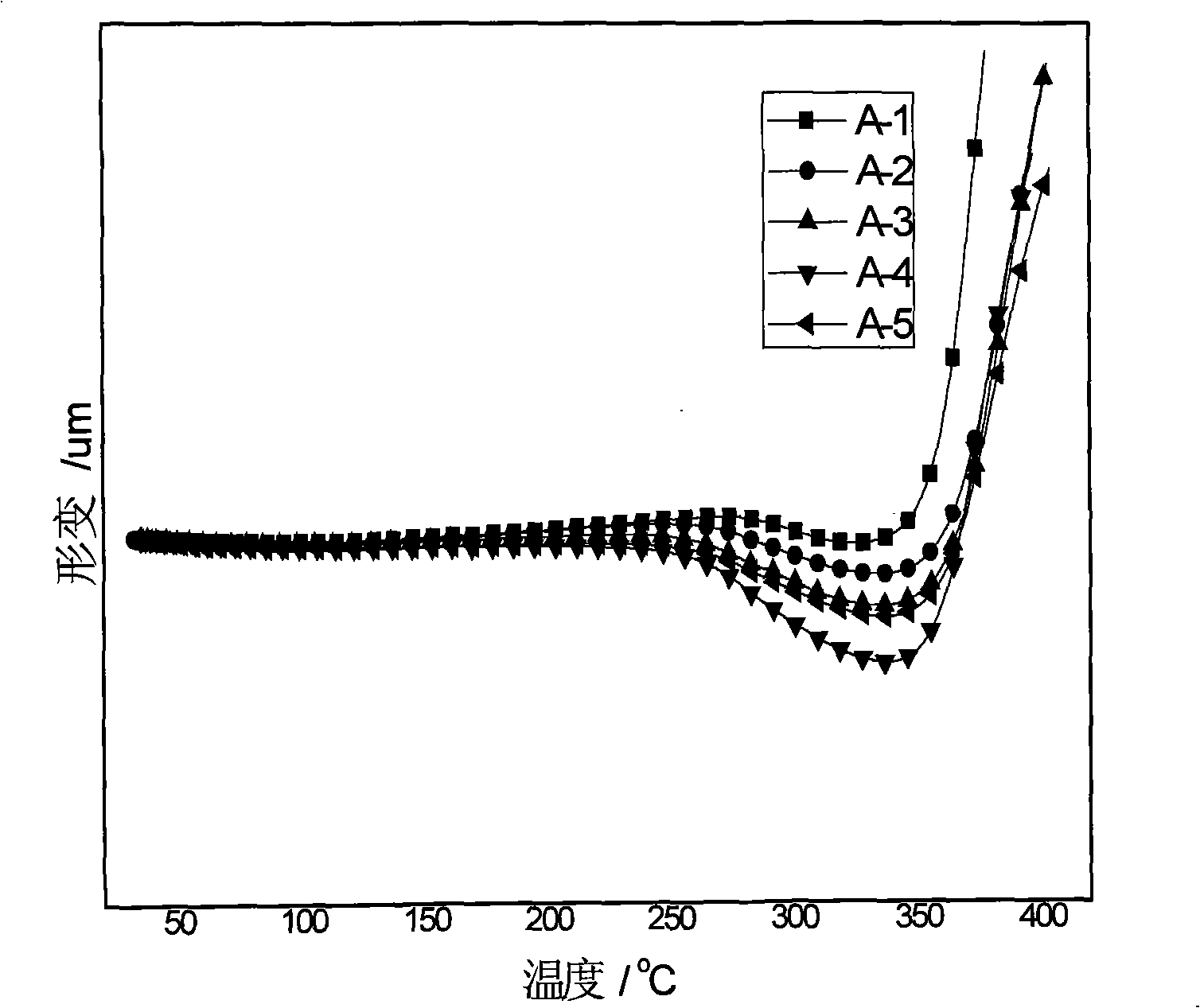

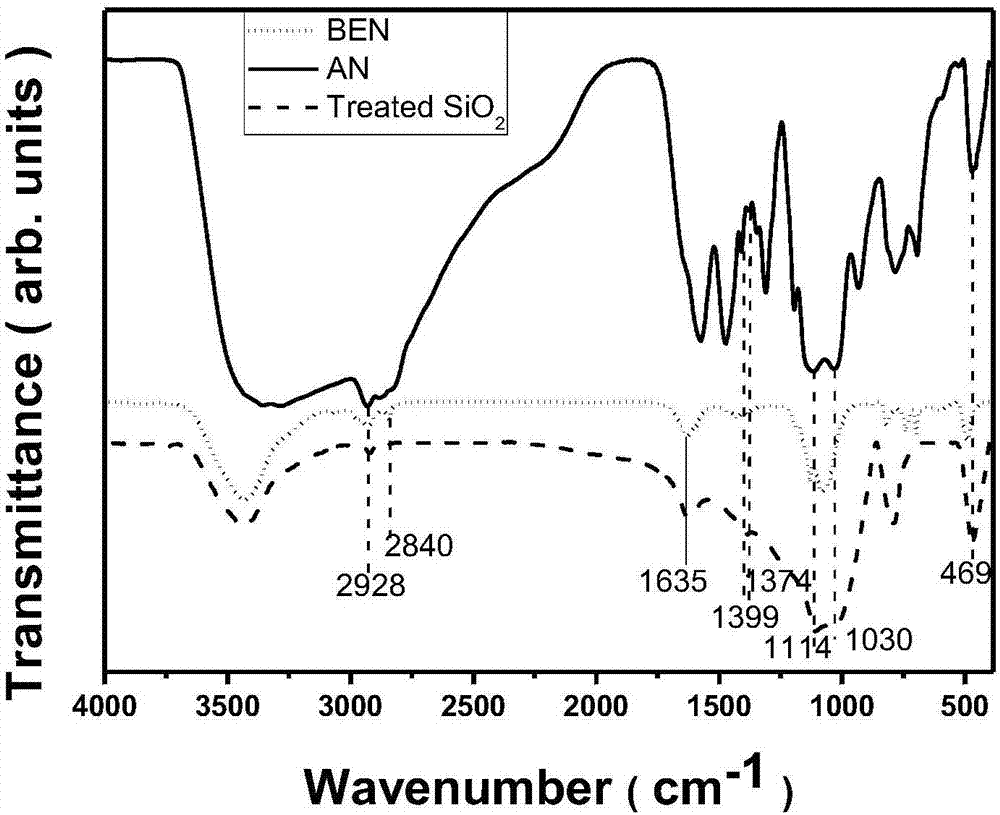

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate is disclosed. The method includes 1) adding silicon dioxide ceramic powder into a liquid mixture of hydrogen peroxide and concentrated hydrochloric acid after the silicon dioxide ceramic powder is dried, and heating the mixture to 50-70 DEG C to obtain a suspension; 2) subjecting the suspension to suction filtration and drying a product in a vacuum environment; 3) adding the silicon dioxide ceramic powder obtained in the step 2) into a solution mixture of deionized water and absolute alcohol, adjusting the pH value to be 3-5, weighing a coupling agent the weight of which is 1.0-2.5% of the weight of the silicon dioxide ceramic powder, performing ball milling, and fully mixing the mixture to obtain a material mixture; 4) filtering and drying the material mixture to obtain modified silicon dioxide ceramic powder; 5) ball-milling and mixing the modified silicon dioxide powder, chopped glass fibers and polytetrafluoroethylene, and then performing demulsification to obtain dough; and 6) subjecting the dough to molding and hot-pressed sintering. The ceramic-filled material prepared by the method has a low dielectric constant (with epsilon being equal to 2.94), ultralow dielectric loss (with tg[delta] being less than 0.0008, 10 GHz), low water absorption (less than 0.02%) and a small thermal expansion coefficient (less than 20 ppm / DEG C).

Owner:汕头超声覆铜板科技有限公司

Process for magnesium alloy surface micro-arc oxidation

InactiveCN1772968ASmall coefficient of thermal expansionStrong corrosion resistanceAnodisationAluminateMicro arc oxidation

The present invention relates to a magnesium alloy surface microarc oxidation method. Said method includes the following steps: (1), pretreatment; (2), preparing alkaline silicate electrolyte or alkaline aluminate electrolyte; and (3), placing the pretreated magnesium alloy in the alkaline silicate electrolyte or alkaline aluminate electrolyte and making microarc oxidation; applying DC current, continuously rising voltage, constant current, current density is 1-15 A / sq.dm, galvanization time is 5-90 min and electrolyte temperature is less than 40 deg.C.

Owner:HARBIN INST OF TECH

Novel high-silicon aluminum alloy electronic packaging material and preparation method thereof

InactiveCN102978485AImprove thermal stabilityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesIngotElectronic packaging

A novel high-silicon aluminum alloy electronic packaging material and a preparation method thereof. The alloy of the present invention consists of the following ingredients, in percentage by mass: 12-40% of Si, 0.3-0.6% of Fe, 0.3-0.45% of Mn, 0.3 to 0.5% of Mg, and the balance being industrial pure aluminum. Spray deposition is used to prepare ingots; and then a plurality times of small deformation thermal densification are carried out for the ingots after annealing for elimination of thermal stress, to prevent cracking of the alloy during processing, thereby enhancing the density of the material. The alloy of the present invention has the characteristics of high strength, low coefficient of expansion, high thermal conductivity and good air tightness.

Owner:CHANGSHA HUAXI METAL MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com