Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

220 results about "Magnesium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, titanate usually refers to inorganic compounds composed of titanium oxides. In some cases, the term is used more generally for any titanium-containing anion, ... An example of such a material is the magnesium titanate (Mg 2 TiO 4), which adopts the spinel structure.

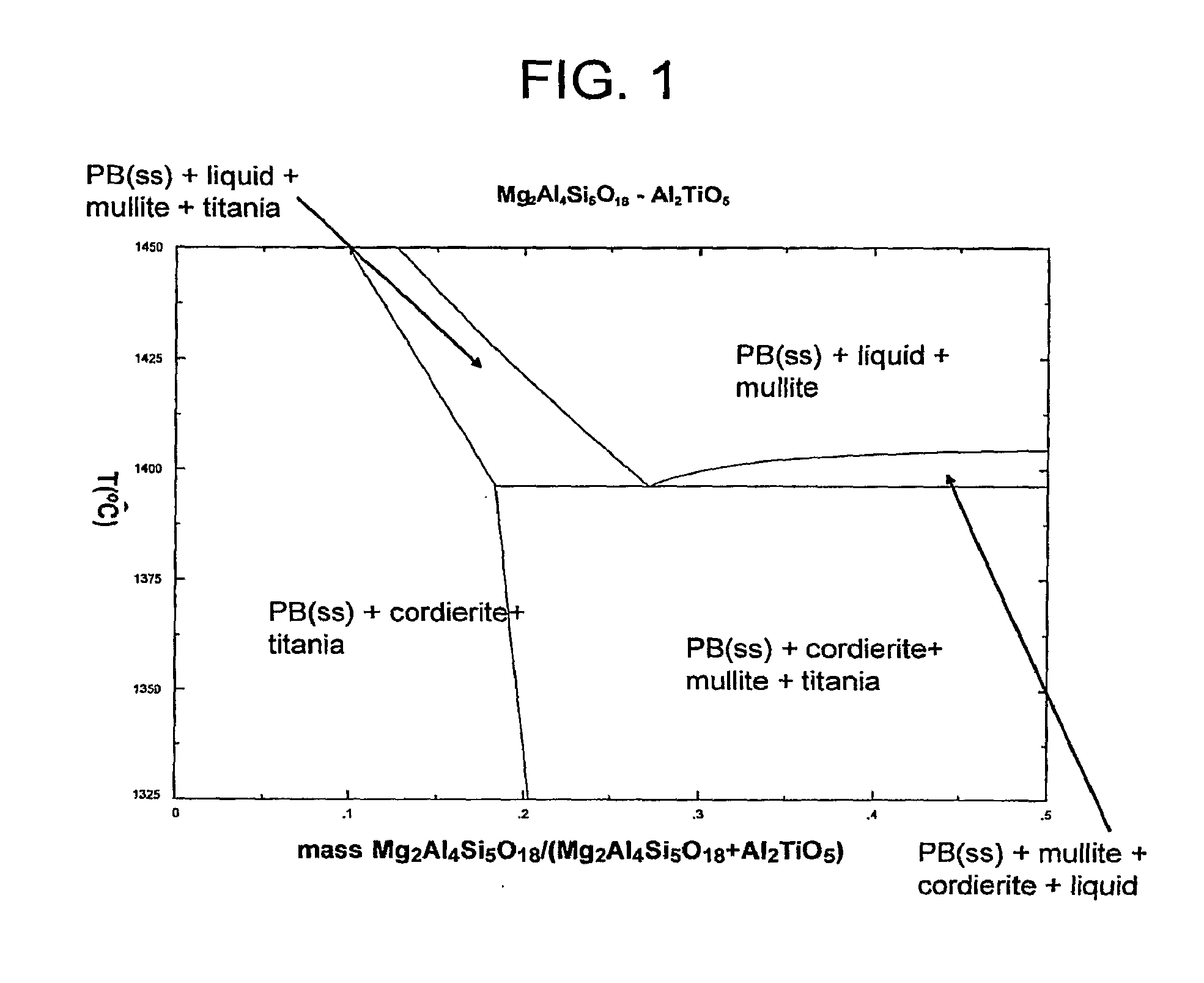

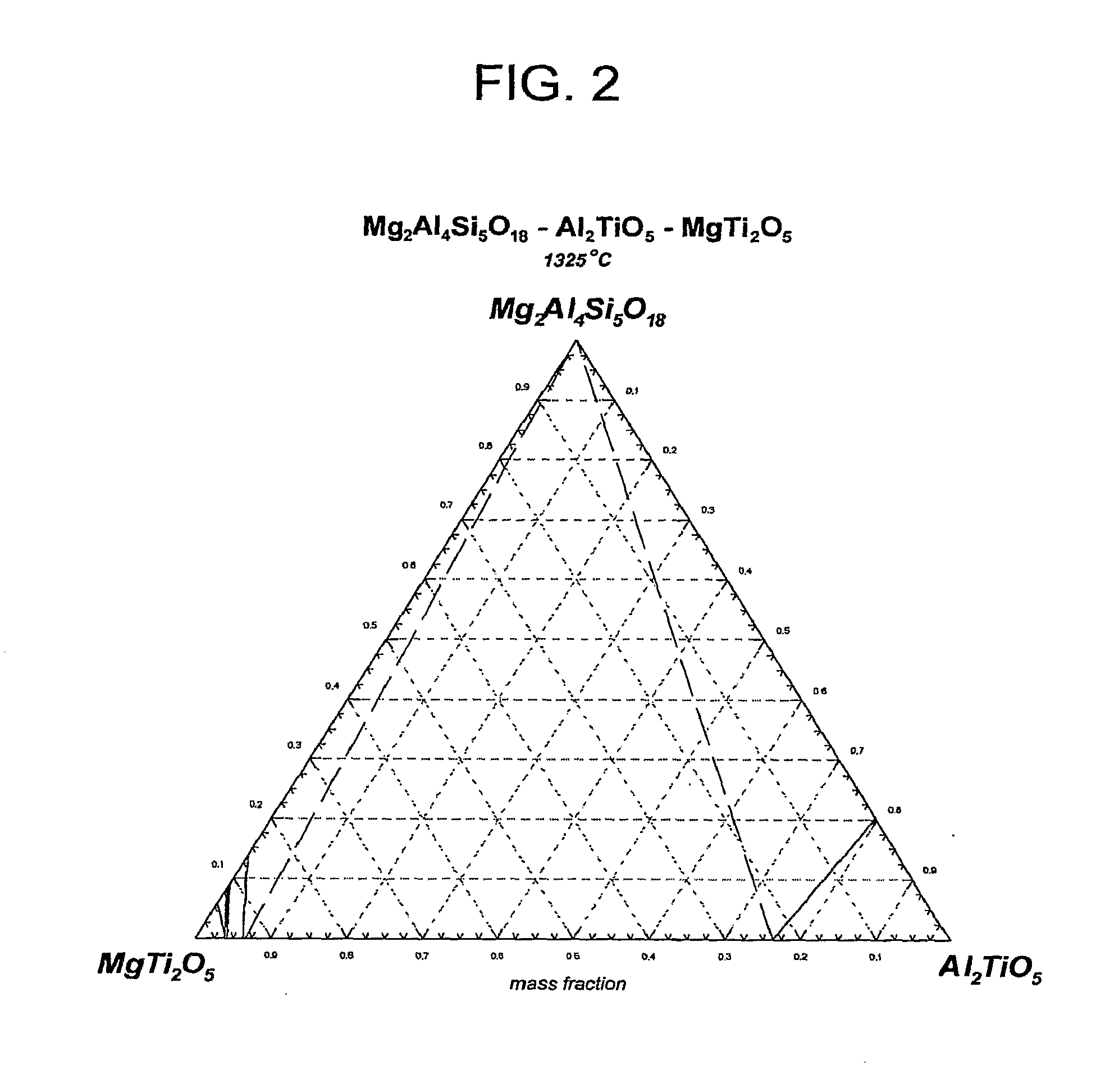

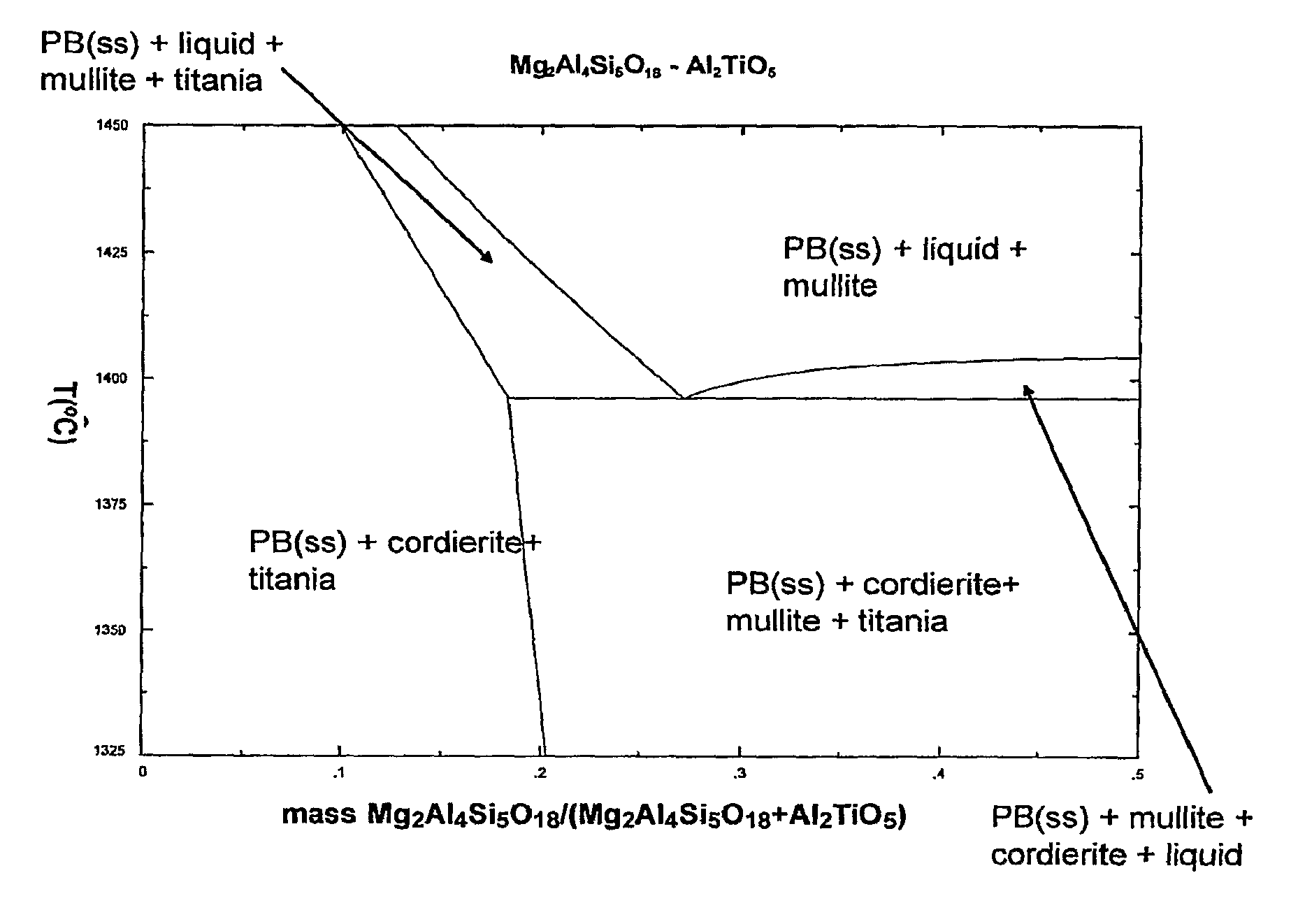

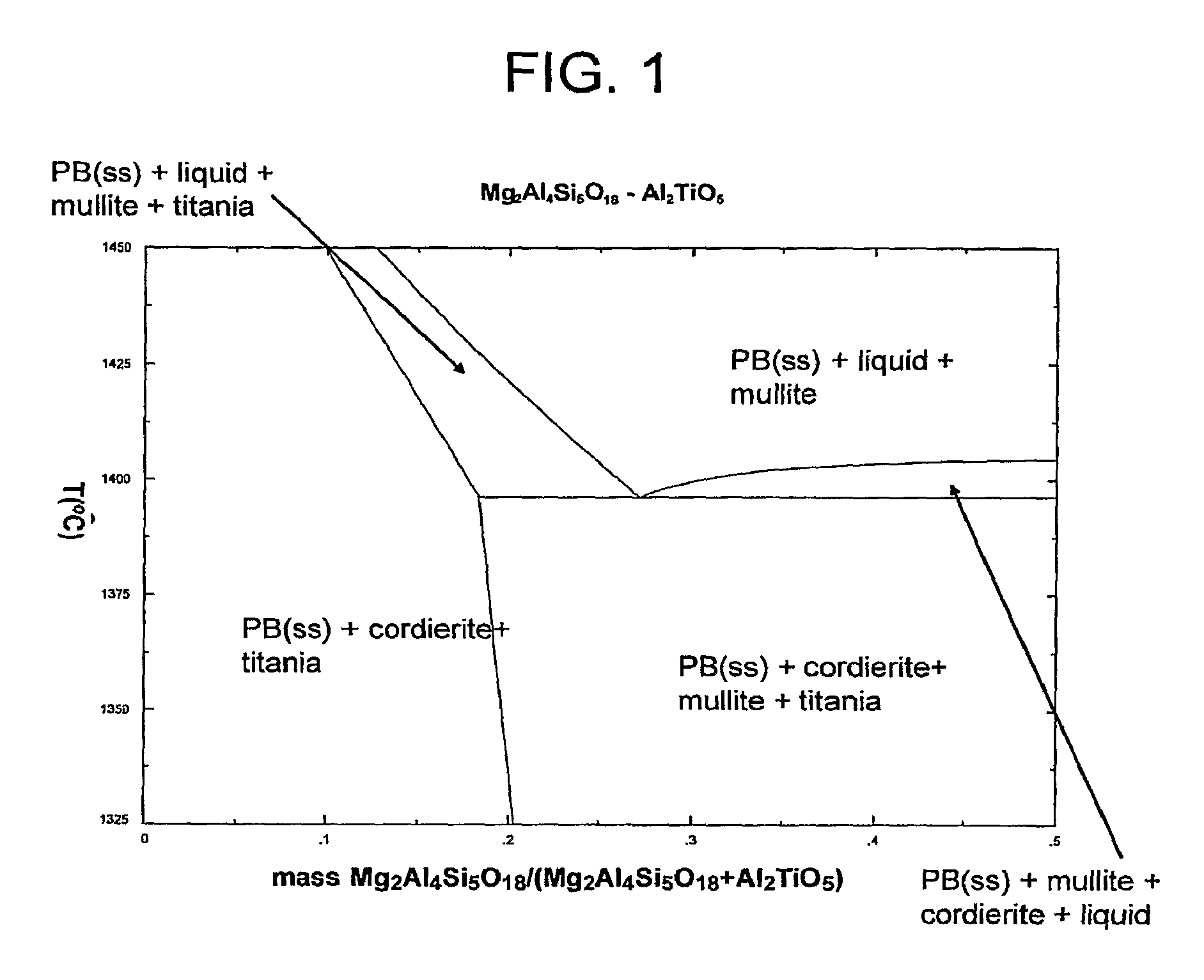

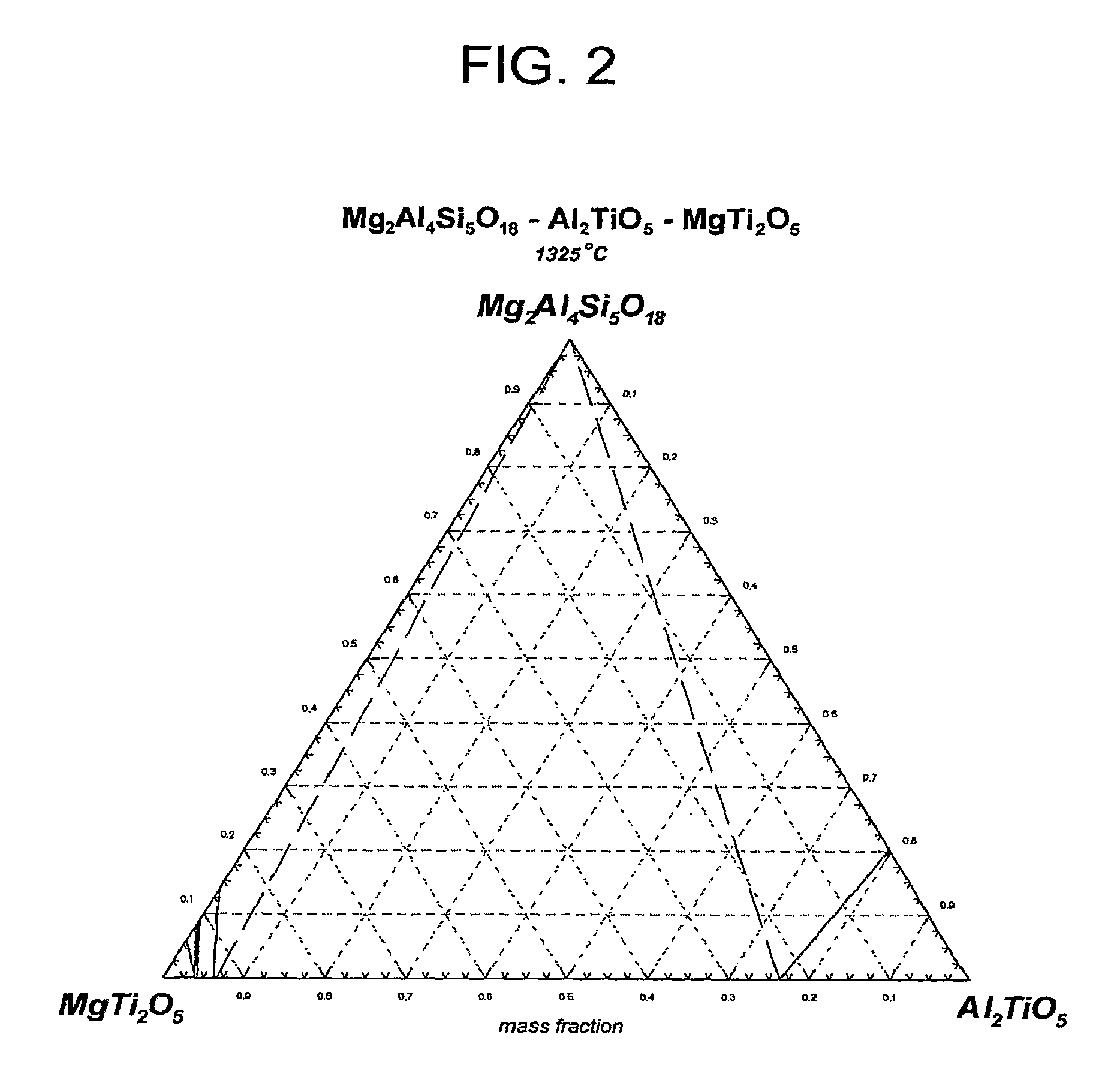

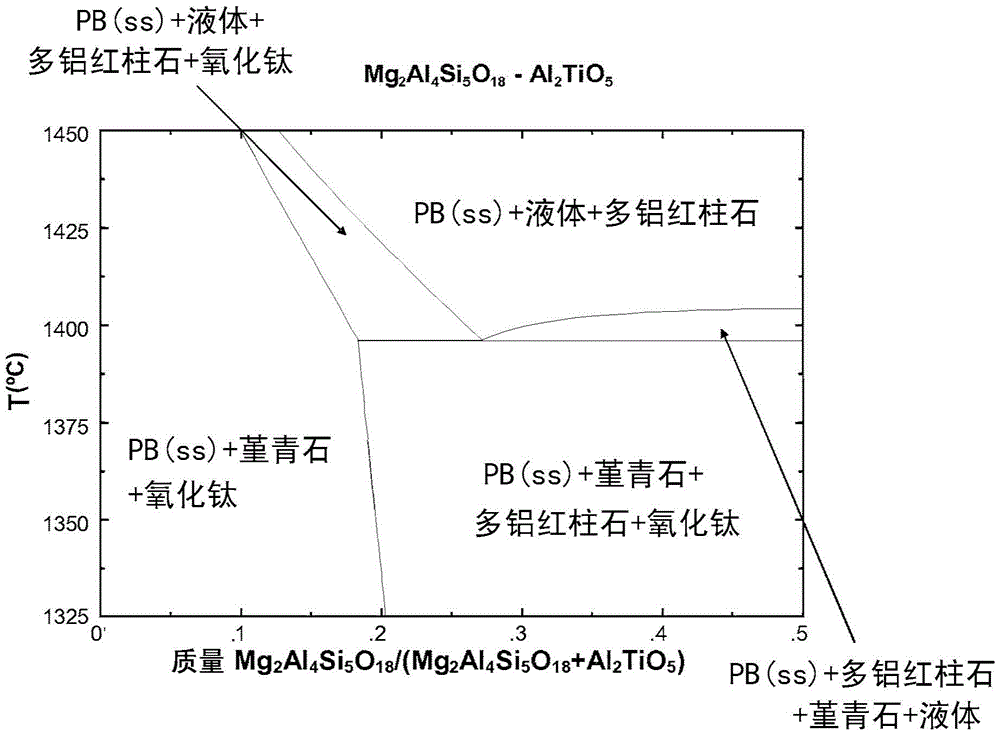

Cordierite Aluminum Magnesium Titanate Compositions And Ceramic Articles Comprising Same

Disclosed are ceramic bodies comprised of composite cordierite aluminum magnesium titanate ceramic compositions and methods for the manufacture of the same.

Owner:CORNING INC

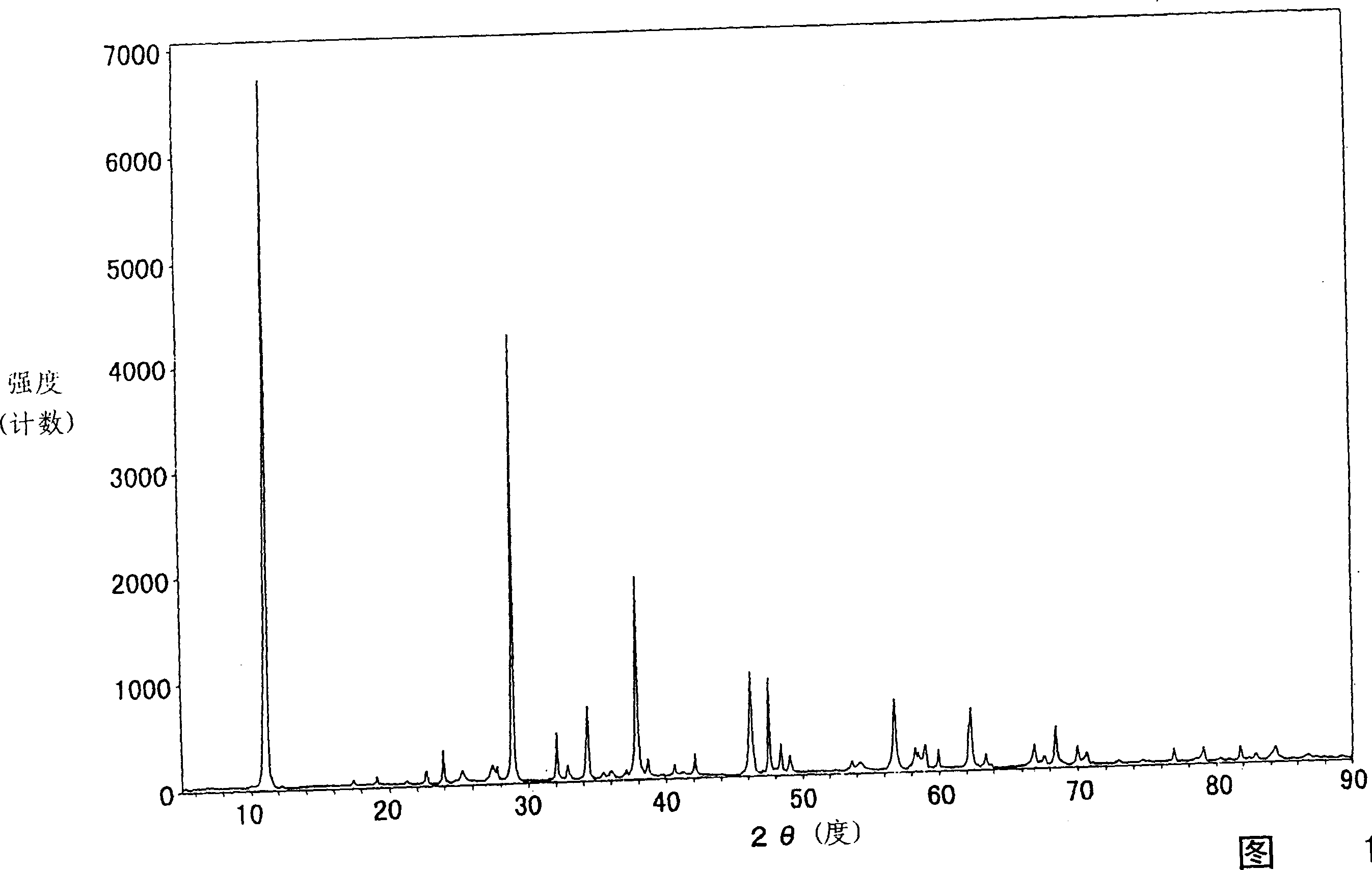

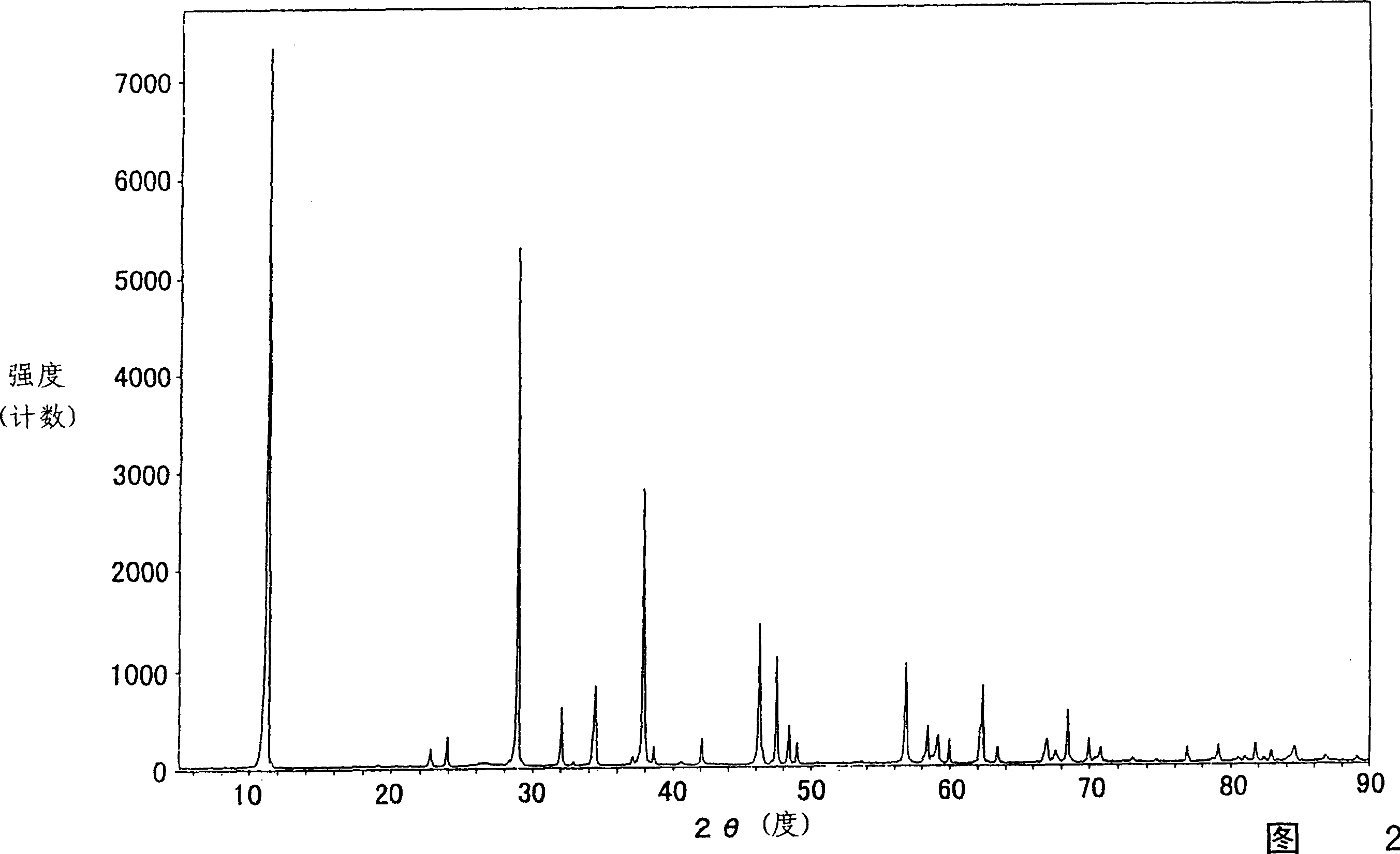

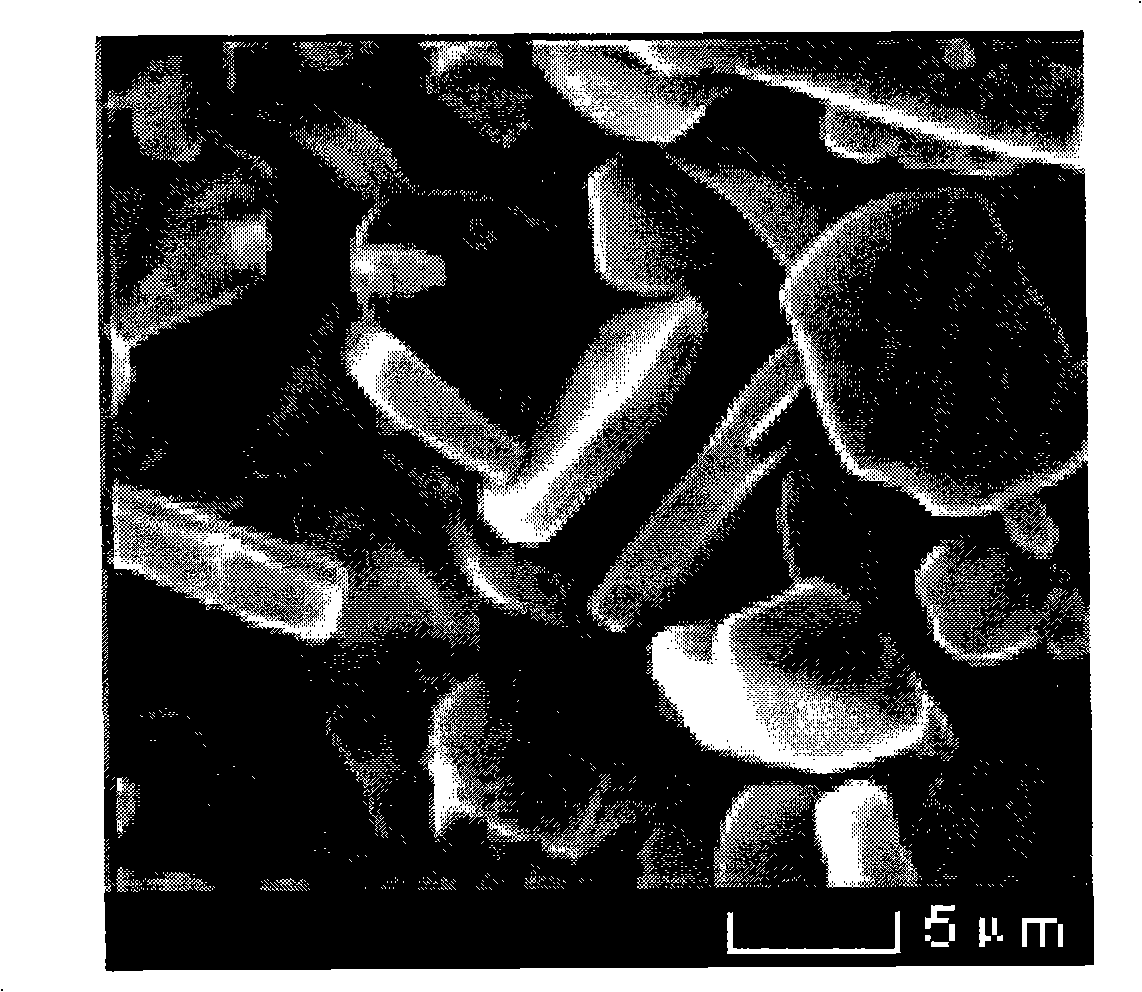

Lepidocrosite type potassium magnesium titanate and method for production thereof, and friction material

Lepidocrocite potassium magnesium titanate having a composition represented by the formula K0.2-0.7Mg0.4Ti1.6O3.7-4 and obtainable by subjecting an aqueous slurry of lepidocrocite potassium magnesium titanate having a composition represented by the formula K0.8Mg0.4Ti1.6O4 to an acid treatment and subsequent calcination. <IMAGE>

Owner:OTSUKA CHEM CO LTD

Cordierite aluminum magnesium titanate compositions and ceramic articles comprising same

Disclosed are ceramic bodies comprised of composite cordierite aluminum magnesium titanate ceramic compositions and methods for the manufacture of the same.

Owner:CORNING INC

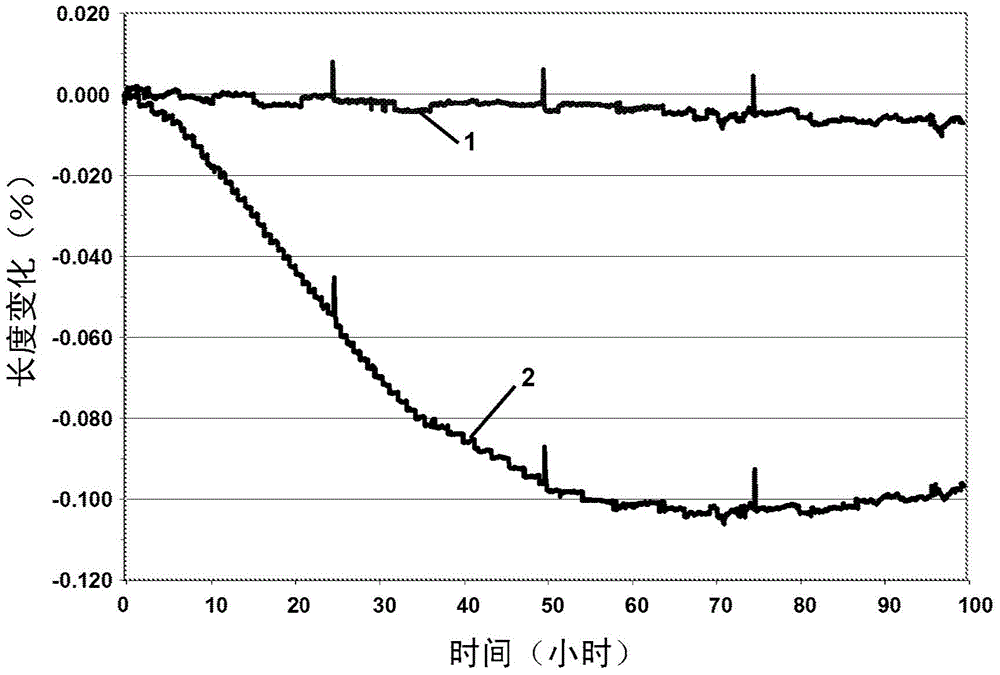

Magnesium Aluminum Titanate Crystal Structure and Method for Producing Same

InactiveUS20070224110A1Increase resistanceSmall coefficient of thermal expansionTitanium oxides/hydroxidesThermal expansionEmpirical formula

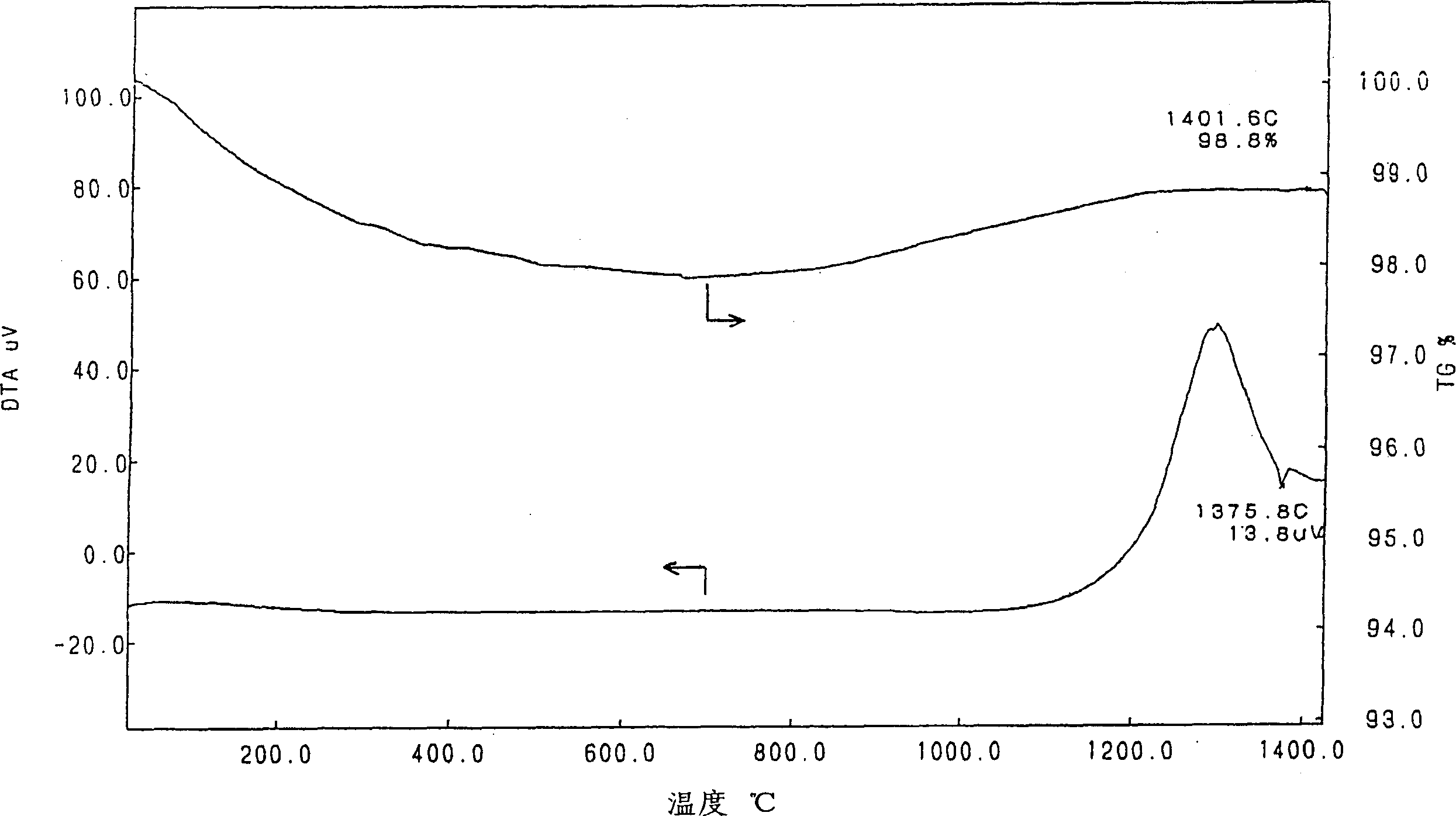

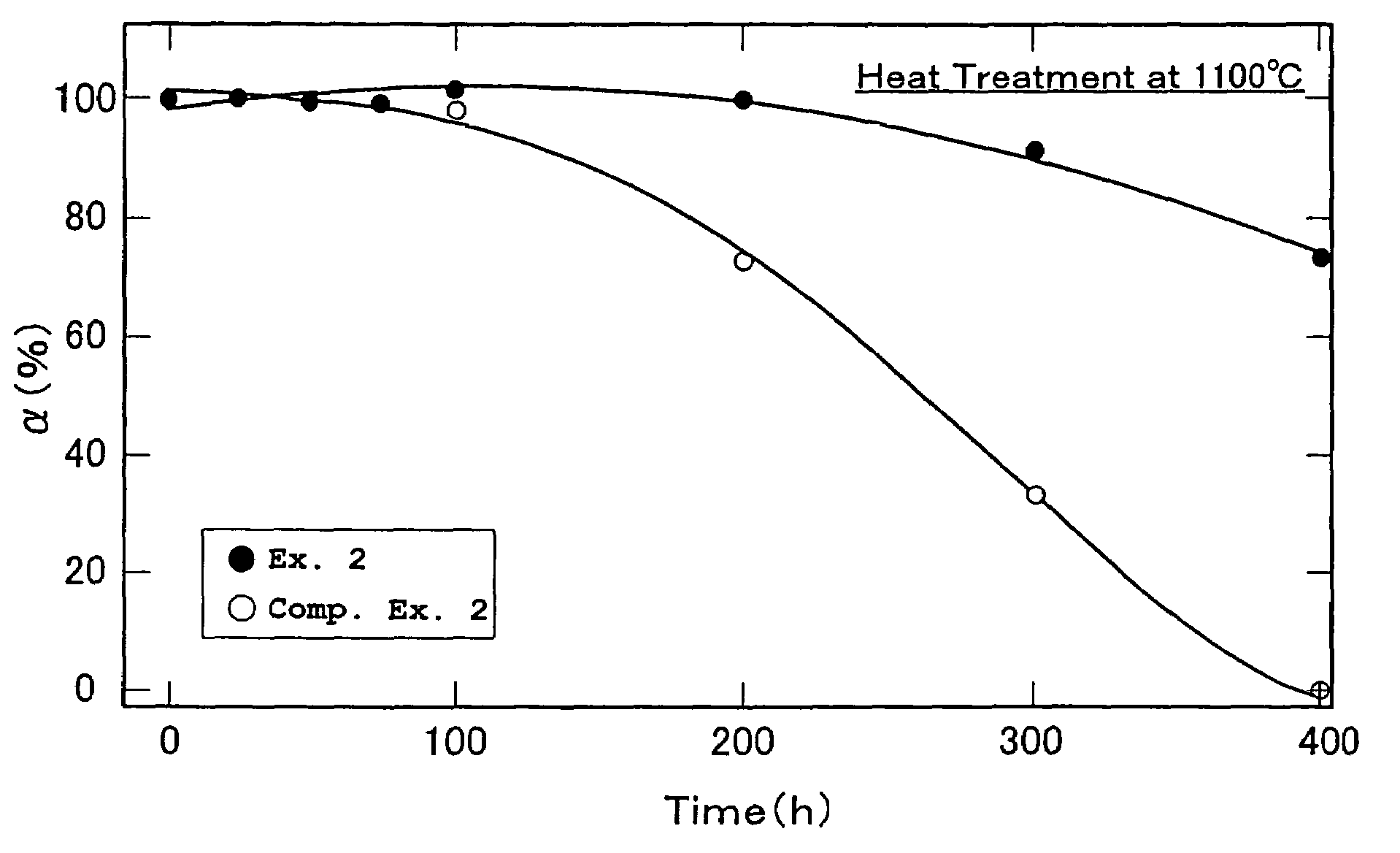

To provide an aluminum magnesium titanate crystal structure which can be used stably in variable high temperatures, because of its excellent heat resistance, thermal shock resistance, high thermal decomposition resistance and high mechanical property, and a process for its production. An aluminum magnesium titanate crystal structure, which is a solid solution wherein at least some of Al atoms in the surface layer of aluminum magnesium titanate crystal represented by the empirical formula MgxAl2(1−x)Ti(1+x)O5 (wherein 0.1≦x<1) are substituted with Si atoms, and which has a thermal expansion coefficient of from −6×10−6 (1 / K) to 6×10−6 (1 / K) in a range of from 50 is to 800° C. at a temperature raising rate of 20° C. / min, and a remaining ratio of aluminum magnesium titanate of at least 50%, when held in an atmosphere of 1,100° C. for 300 hours.

Owner:OHCERA CO LTD

Method for producing aluminum magnesium titanate sintered product

InactiveUS7166552B2Improve stabilityHigh strengthCeramic shaping apparatusClaywaresContinuous useAlkali feldspar

The present invention provides a process for preparing a sintered body comprising as a basic component aluminum magnesium titanate represented by the composition formula: MgxAl2(1−x)Ti(1+x)O5 wherein the value of x is 0.1≦x<1. The process comprises a step of sintering a formed product from a raw material mixture comprising 100 parts by weight, calculated on an oxide basis, of a mixture comprising a Mg-containing compound, an Al-containing compound and a Ti-containing compound at the same metal component ratio as the metal component ratio of Mg, Al and Ti in the above composition formula, and 1–10 parts by weight of an alkali feldspar represented by the composition formula: (NayK1−y)AlSi3O8 wherein the value of y is 0≦y≦1.According to the process of the present invention, a sintered body of aluminum magnesium titanate having stability in continuous use at high temperatures and excellent mechanical strength, while maintaining inherently low thermal expansibility of a sintered body of aluminum magnesium titanate, can be obtained.

Owner:OHCERA CO LTD

CO2-Sorptive Pellets and Uses Thereof

CO2 sorptive pellets and / or granules and their use for removing CO2 from CO2-containing gases and for producing hydrogen. CO2 sorptive pellets are suitable for use in fixed bed reactors and the like due to sufficient crush strength. CO2 sorptive granules are suitable for moving, ebullated, expanded and fluidized beds. The CO2 sorptive pellets and / or granules comprise calcium oxide and / or magnesium oxide and at least one binding agent such as calcium titanate, calcium aluminate, calcium zirconate, magnesium titanate, magnesium aluminate, and magnesium zirconate. A method for making the CO2-sorptive pellets is described. The CO2 sorptive pellets optionally comprise at Ni, Pd, Pt, and / or Rh.

Owner:AIR PROD & CHEM INC

Method for preparing high Q-value magnesium titanate base microwave medium ceramics by adopting reactive sintering method

This invention relates to a method for preparing high Q-value magnesium titanate base microwave medium ceramics by adopting a reactive sintering method. The steps are as follows: (1) mixing according to the ingredients of the magnesium titanate base microwave medium ceramics and the mass percent of the ingredients: MgTiO3- mwt%MO, wherein MO is an additive CoO, NiO, ZnO, MnO2, ZrO2 or SnO2, and mis larger than or equal to 0 and smaller than or equal to 10; (2) drying and screening ball-milled materials; (3) granulating and screening, pressing to form a green body, and sintering at the temperature of 1250-1400 DEG C; and (4) conducting physical and dielectric property detection. This invention omits pre-burning and secondary ball-milling of powder materials, saves time and energy costs, and provides the reactive sintering method of magnesium titanate base microwave medium ceramic materials, wherein the reactive sintering method is simple in preparation technology, has an extremely high quality factor and improves the resonant frequency temperature coefficient of the magnesium titanate base microwave medium ceramic materials; and with the method, the application of the materials in microwave communication is wider.

Owner:TIANJIN UNIV

Ba1-xSrxTiO3-Mg2TiO4 two-phase composite ceramic material and its preparing process

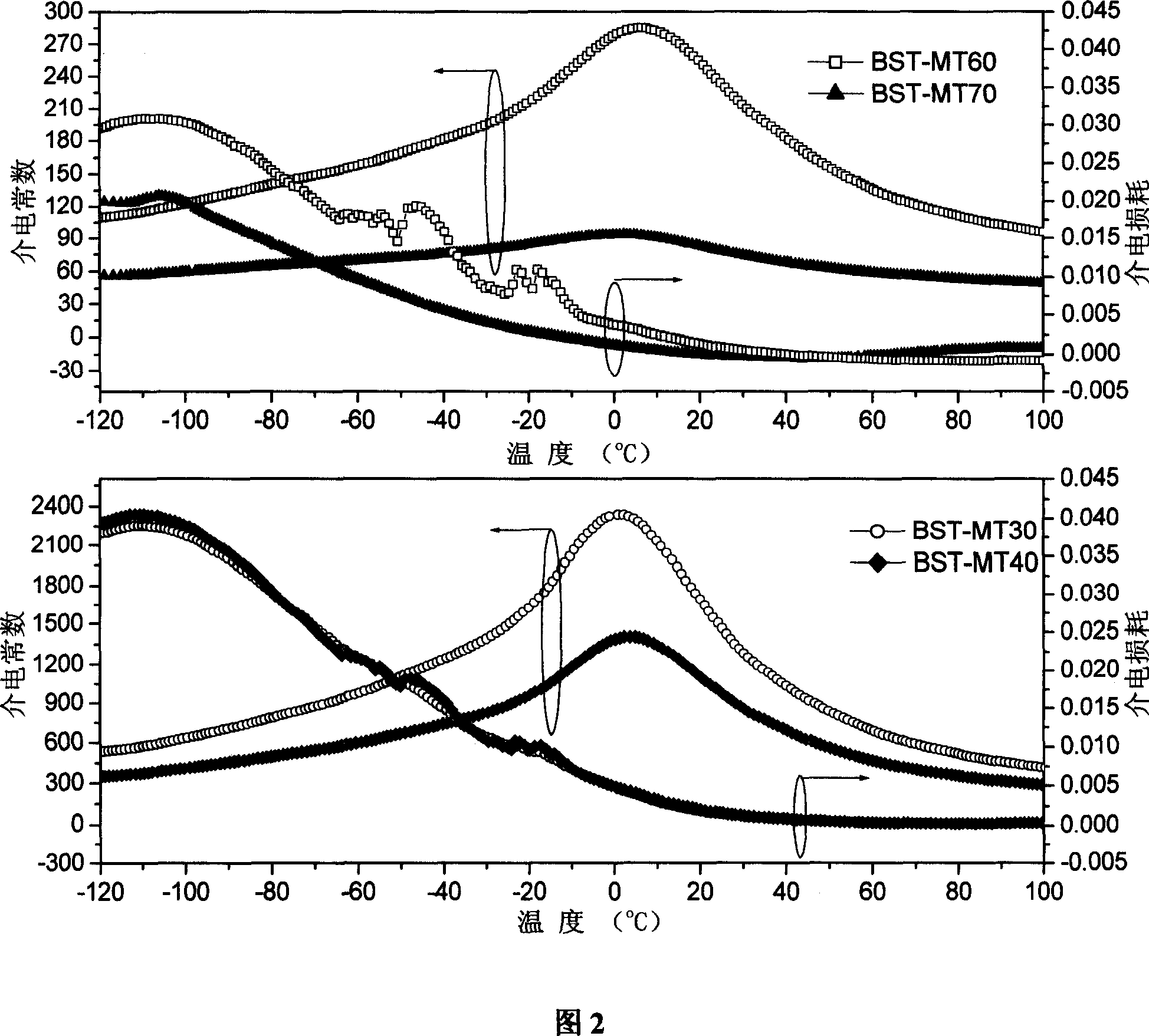

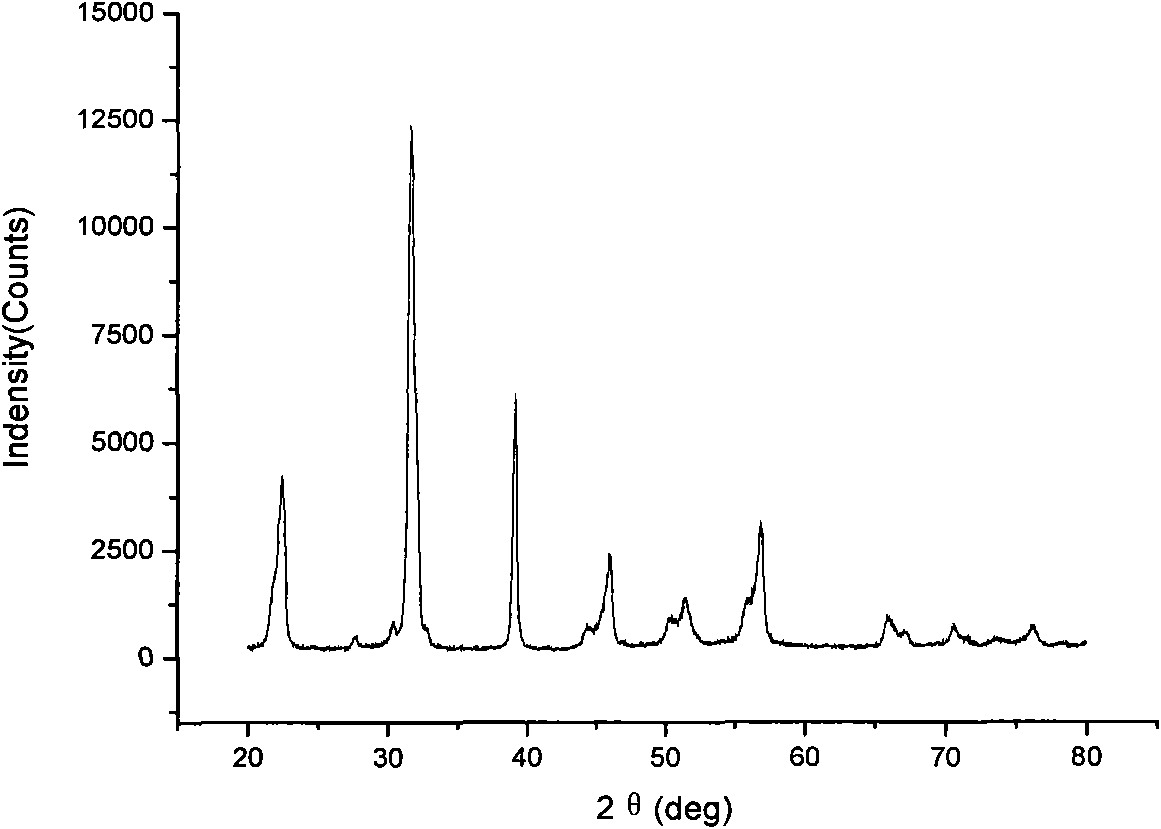

InactiveCN101007736AExcellent dielectric propertiesHas dielectric tunable propertiesStrontium titanium oxideMicrowave

The invention discloses a two-phase composite ceramic material of being used to microwave modulator, which comprises 80.0-20.0wt% Ba(1-x)SrxTiO3(x=0.3-0.6) and 20.0-80.0wt% Mg2TiO4. The invention is characterizes by the following: adopting traditional electronic ceramic preparing craft; selecting microwave dielectric material normal magnesium titanate with good dielectric property; proceeding two-phase gradient composition with strontium titanate barium ferroelectric materials different Ba / Sr ingredient; getting the product.

Owner:TONGJI UNIV

Method for producing aluminum magnesium titanate sintered product

ActiveUS20060009347A1High mechanical strengthImprove stabilityCeramic shaping apparatusClaywaresContinuous useTitanium

The present invention provides a process for preparing a sintered body comprising as a basic component aluminum magnesium titanate represented by the composition formula: MgxAl2(1−x)Ti(1+x)O5 wherein the value of x is 0.1≦x<1. The process comprises a step of sintering a formed product from a raw material mixture comprising 100 parts by weight, calculated on an oxide basis, of a mixture comprising a Mg-containing compound, an Al-containing compound and a Ti-containing compound at the same metal component ratio as the metal component ratio of Mg, Al and Ti in the above composition formula, and 1-10 parts by weight of an alkali feldspar represented by the composition formula: (NayK1-y)AlSi3O8 wherein the value of y is 0≦y≦1. According to the process of the present invention, a sintered body of aluminum magnesium titanate having stability in continuous use at high temperatures and excellent mechanical strength, while maintaining inherently low thermal expansibility of a sintered body of aluminum magnesium titanate, can be obtained.

Owner:OHCERA CO LTD

Self-reacting alumina-base composite ceramic mold core for fine casting and preparation method thereof

InactiveCN101386546ALow thermal shock resistanceImprove thermal shock resistanceFoundry mouldsFoundry coresComposite ceramicMullite

The invention provides a self-reaction alumina-based composite ceramic core for precision casting, and a preparation method thereof. The composite ceramic core consists of alundum powder, in-situ synthesized aluminum titanate, MgTi2O5 and mullite. The composite ceramic core is prepared from the following raw materials in weight percentage: 70 to 85 percent of alundum powder with different particle sizes, 0 to 2 percent of magnesium oxide powder, 8 to 20 percent of titanium dioxide powder and 6 to 10 percent of kyanite powder, and carbon powder accounting for 1 to 3 percent of the gross mass of the four raw materials is added as an easy-breakdown agent. The method prepares the composite ceramic core through the following steps of mixing, dry-pressing, shaping and firing the raw materials at high temperature. As other raw materials are added to an alumina matrix of the invention, the prepared composite ceramic core has the advantages of good high-temperature chemical stability and thermal stability, low thermal expansion coefficient and small shrinkage factor after sintering, and meets the requirements of a ceramic core for precision casting on room temperature and high temperature strength.

Owner:SOUTH CHINA UNIV OF TECH

Cordierite aluminum magnesium titanate compositions and ceramic articles comprising same

Disclosed are ceramic bodies comprised of composite cordierite aluminum magnesium titanate ceramic compositions and methods for the manufacture of same.

Owner:CORNING INC

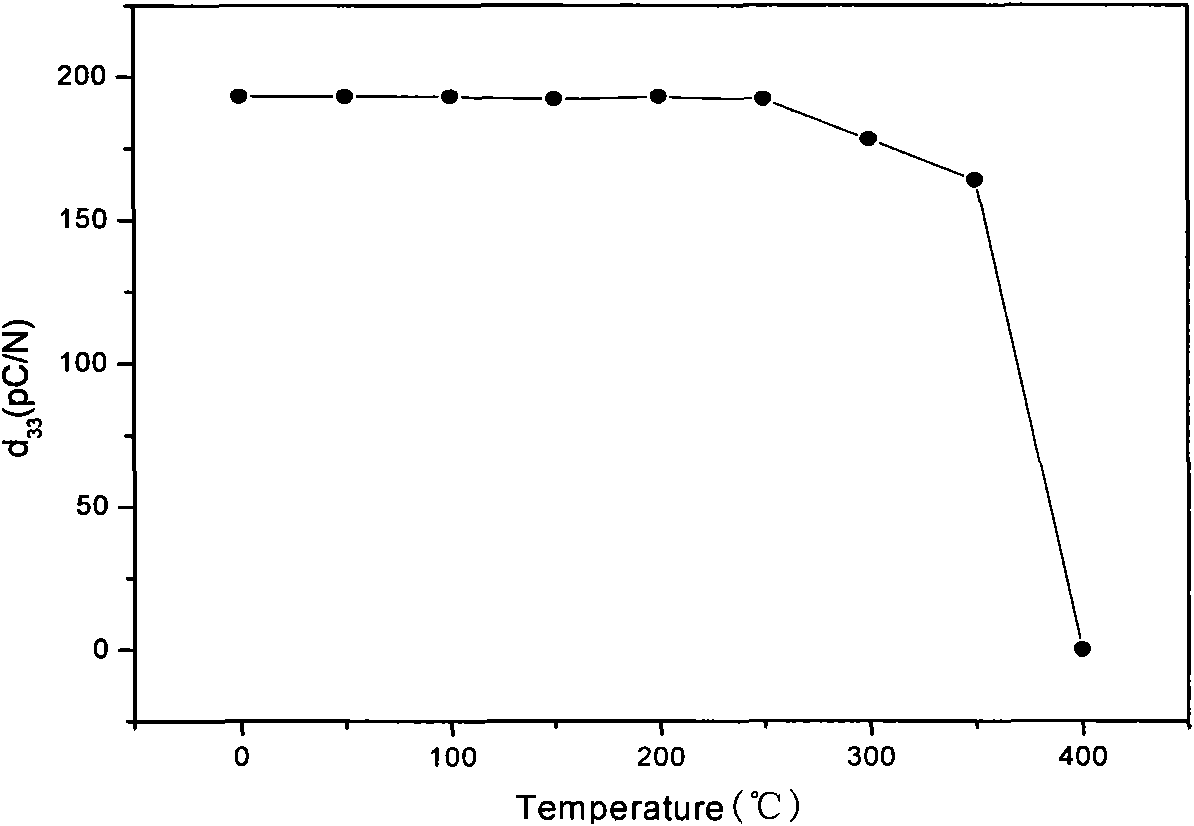

Magnesium titanate bismuth-lead titanate piezoelectric ceramics suitable for high-temperature field

The invention discloses a magnesium titanate bismuth-lead titanate piezoelectric ceramics suitable for a high-temperature field, belonging to perovskite structure piezoelectric ceramics. The invention can be represented by the general formula: (1-x)Bi(Mg1 / 2Ti1 / 2)O3-xPbTiO3+alphaMnO2(mol%), wherein x=0.32-0.42, x represents the molar percent of PbTiO3, alpha=0-2 mol%, and the alpha is the molar percent for MnO2 to account for the raw material total amount; MnO2 is a doped metallic oxide and can lower the loss factor of the piezoelectric ceramics. The piezoelectric ceramics is prepared by the traditional piezoelectric ceramics preparation technology, lead tolerance is lower than 42 mol%; d33 can be kept at 170 pC / N at the temperature of 350 DEG C; and after MnO2 is doped, Curie temperature Tc can be 520 DEG C, d33 is 120 pC / N, and the loss factor tan delta is lowered to 0.018. The invention has huge high-temperature application potential and practical application value.

Owner:TIANJIN UNIV

Honeycomb filter for clarifying exhaust gas and method for manufacture thereof

InactiveUS20070059484A1Improved thermal decomposition resistanceStable crystal structureNitrogen compoundsInternal combustion piston enginesSolid particleEmpirical formula

To provide a honeycomb filter for cleaning exhaust gas, which is excellent in heat resistance and thermal shock resistance and has high thermal decomposition resistance and high mechanical strength and which is thus capable of being used with stability at high and fluctuating temperatures, and a process for its production. A honeycomb filter for removing fine solid particles containing carbon as the main component in an exhaust gas, characterized in that the material for the honeycomb filter is an aluminum magnesium titanate sintered product obtained by firing at from 1000 to 1700° C. a formed product from a mixture comprising a Mg-containing compound, an Al-containing compound and a Ti-containing compound in the same metal component ratio as the metal component ratio of Mg, Al and Ti in aluminum magnesium titanate represented by the empirical formula MgxAl2(1−x)Ti(1+x)O5 (wherein 0<x<1), or a mixture comprising 100 parts by mass, as calculated as oxides, of the above-mentioned mixture and from 1 to 10 parts by mass of an alkali feldspar represented by the empirical formula (NayK1−y)AlSi3O8 (wherein 0≦y≦1).

Owner:OHCERA CO LTD

Insulation material, film, circuit board and method of producing them

ActiveUS7700185B2Increase volumeHigh dielectric constantPlastic/resin/waxes insulatorsFixed capacitor dielectricStrontium titanium oxideBarium titanate

There is provided an insulation material having a dielectric constant of 10 or more, comprising a filler having a dielectric constant of 50 or more and having two peaks in different particle size ranges in a particle size distribution and an insulating resin combined with each other; an insulation material having a dielectric constant of 10 or more comprising, as essential components, 1) at least one filler selected from the group consisting of barium titanate, strontium titanate, potassium titanate, magnesium titanate, lead titanate, titanium dioxide, barium zirconate, calcium zirconate and lead zirconate, 2) an insulating resin and 3) a dispersant containing a carboxylic group; or an insulation material comprising a filler having a dielectric constant of 50 or more, a dispersant for dispersing the filler and an insulating resin as essential components, wherein an extract of a cured product of the insulation material obtained by extraction with water at 120° C. for 20 hours using a pressure vessel has a pH of 6 or higher.

Owner:RESONAC CORPORATION

Microwave medium ceramic and preparation method thereof

ActiveCN102659399AExcellent dielectric propertiesNo pollution in the processCeramicsMicrowaveAdhesive

The invention relates to a microwave medium ceramic and a preparation method thereof. The structural formula of the microwave medium ceramic is a(MgxMyTizO3)-b[(La0.5Li0.5)TiO3], wherein M refers to Co, Zn, Zr or Sb; x=0.9-1, y=0.01-0.1, z=0.9-0.1, and x+y+z=2; and a=0.9-0.99, b=0.1-0.01, and a+b=1. The preparation method comprises the following steps: weighing raw materials in a chemical ratio of MgxMyTizO3 to (La0.5Li0.5)TiO3, and ball-milling and drying to obtain powder with uniform particles; and pre-sintering the powder, mixing in a ratio of a:b of (0.9-0.99):(0.1-0.01), performing secondary ball milling, drying the mixed powder, adding an adhesive, granulating and grinding, sieving and pressing into a green body, and sintering the green body at high temperature to obtain the microwave medium ceramic. The magnesium titanate system microwave medium ceramic material has the dielectric constant of 15-25, the quality factor (Qf) of more than 200,000GHz and the near-zero temperature coefficient of resonance frequency tau f of -2ppm / DEG C, and the dielectric property of magnesium titanate ceramics is greatly improved.

Owner:NANJING UNIV OF TECH

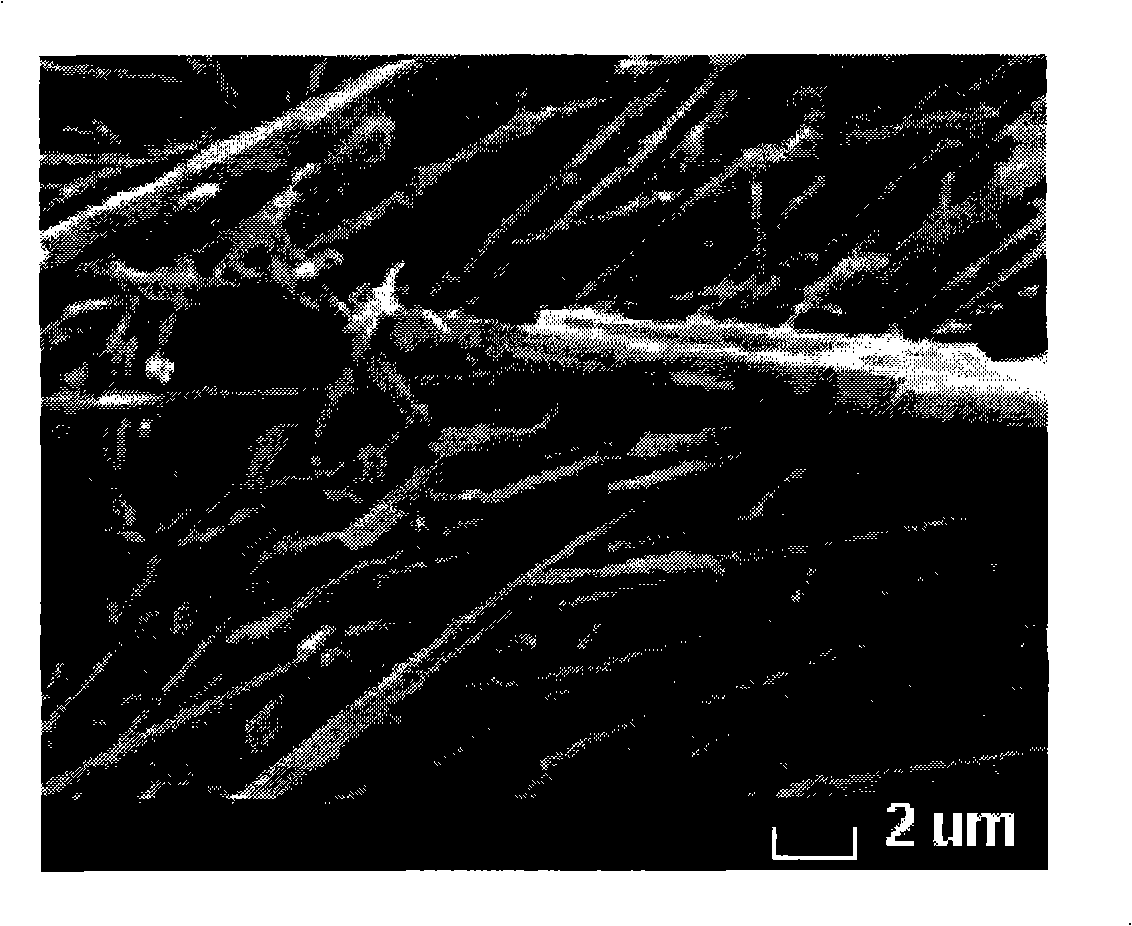

Preparation method of flaky potassium hexatitanate

InactiveCN102390864ANo pollution in the processEasy to controlTitanium compoundsLamellar crystalsPotassium

The invention discloses a preparation method of flaky potassium hexatitanate, belonging to the field of preparation of reinforced materials, frictional materials and heat-resisting materials. The preparation method comprises the following steps of: with potassium magnesium titanate lamellar crystals as a precursor, carrying out acid washing, alkaline washing, hydrothermal treatment, and calciningto generate the potassium magnesium titanate laminar crystals with the average diameter size of 2-3.5 mum and thickness of 100-200nm. The potassium hexatitanate produced by utilizing the preparation method disclosed by the invention has the advantages of small size, good dispersibility, high crystallinity, uniform shapes and benefit to industrial production.

Owner:CENT SOUTH UNIV

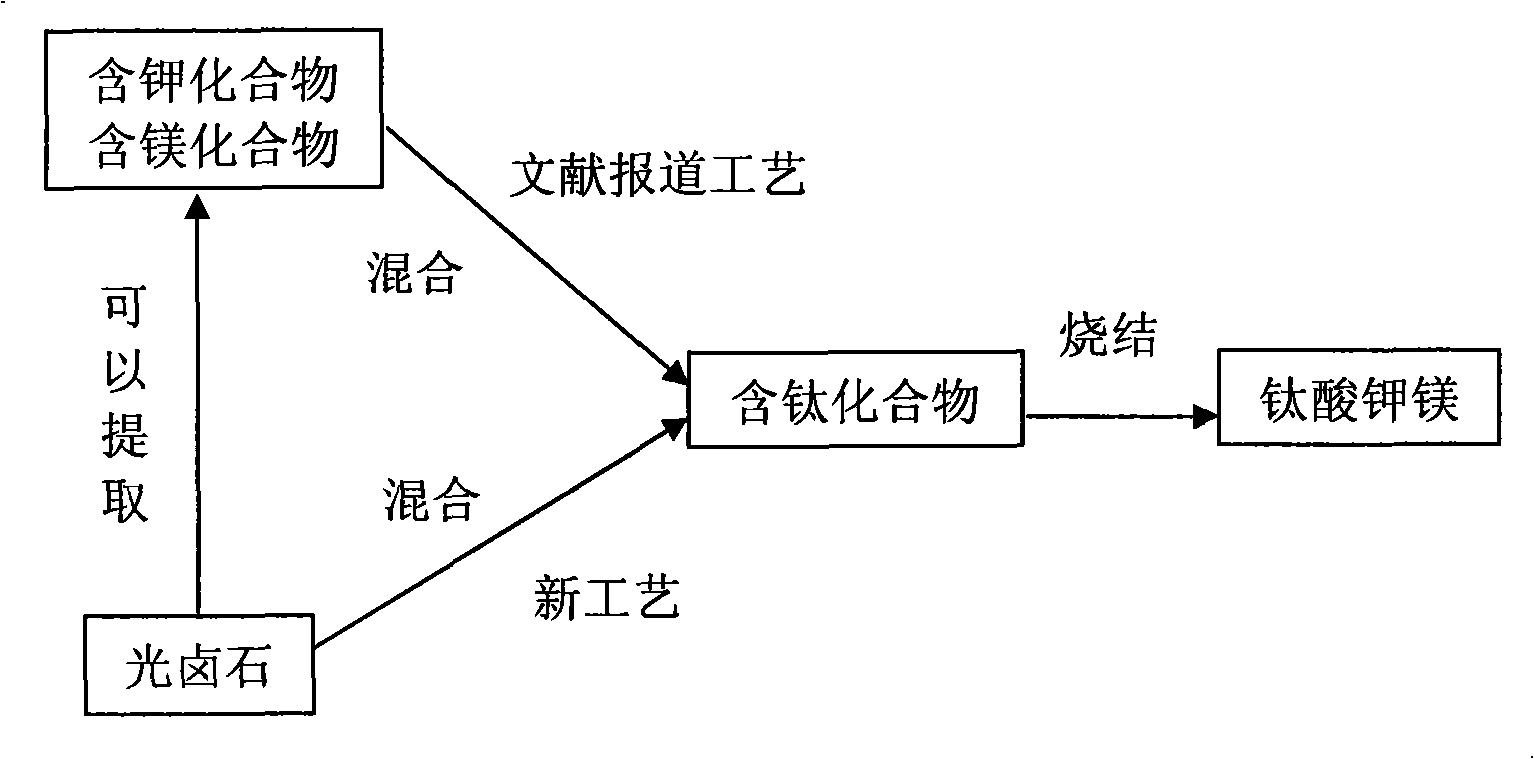

Method for preparing kalium-magnesium titanate by carnallite

The invention discloses a method for preparing potassium magnesium titanate, which includes using carnallite, titanium-containing and potassium-containing compounds as the material, mixing evenly; sintering at 800-1100 DEG C for 30 min-12 h, pulverizing, water washing, filtering, and heat-treating to obtain potassium magnesium titanate. The natural carnallite is used as the material to reduce the material cost of potassium magnesium titanate. Whiskers or lamellas of different purpose can be obtained by adjusting the material proportion. The preparation method simplifies the technological process and improves the production efficiency and is more suitable for large-scale production.

Owner:NANJING UNIV OF TECH

Hollow structure potassium magnesium titanate whisker material and method for preparing the same

InactiveCN104947176AWide variety of sourcesReduce manufacturing costPolycrystalline material growthFrom solid stateFiltrationPhysical chemistry

The invention relates to a hollow structure potassium magnesium titanate whisker material and a method for preparing the same. The technical scheme is that the method comprises evenly mixing a titanium-containing raw material, a magnesium-containing raw material and a binding agent, performing forming, performing heat treatment and then grinding the mixture to obtain a material A with the particle size of 0.088-1 mm and a material B with the particle size smaller than 0.088 mm; evenly mixing a potassium-containing raw material, a titanium-containing raw material and a binding agent, performing forming, performing heat treatment and then grinding the mixture to obtain a material C with the particle size smaller than 0.088 mm; evenly mixing the material A, the material B, the material C and a potassium-containing raw material, performing heat treatment and then grinding the mixture to obtain a ground material; finally adding the material C, the potassium-containing raw material and water to the ground material, mixing the mixture, pressing the mixture into green bodies, drying the green bodies, performing heat treatment, and then performing washing, filtration and drying to obtain the hollow structure potassium magnesium titanate whisker material. The external diameters of whiskers of the prepared hollow structure potassium magnesium titanate whisker material are 0.1-5 microns, the internal diameters of the whiskers are 0.05-1 micron, and the lengths of the whiskers are 3-30 microns. The hollow structure potassium magnesium titanate whisker material is high in crystallinity and uniform in size.

Owner:WUHAN UNIV OF SCI & TECH

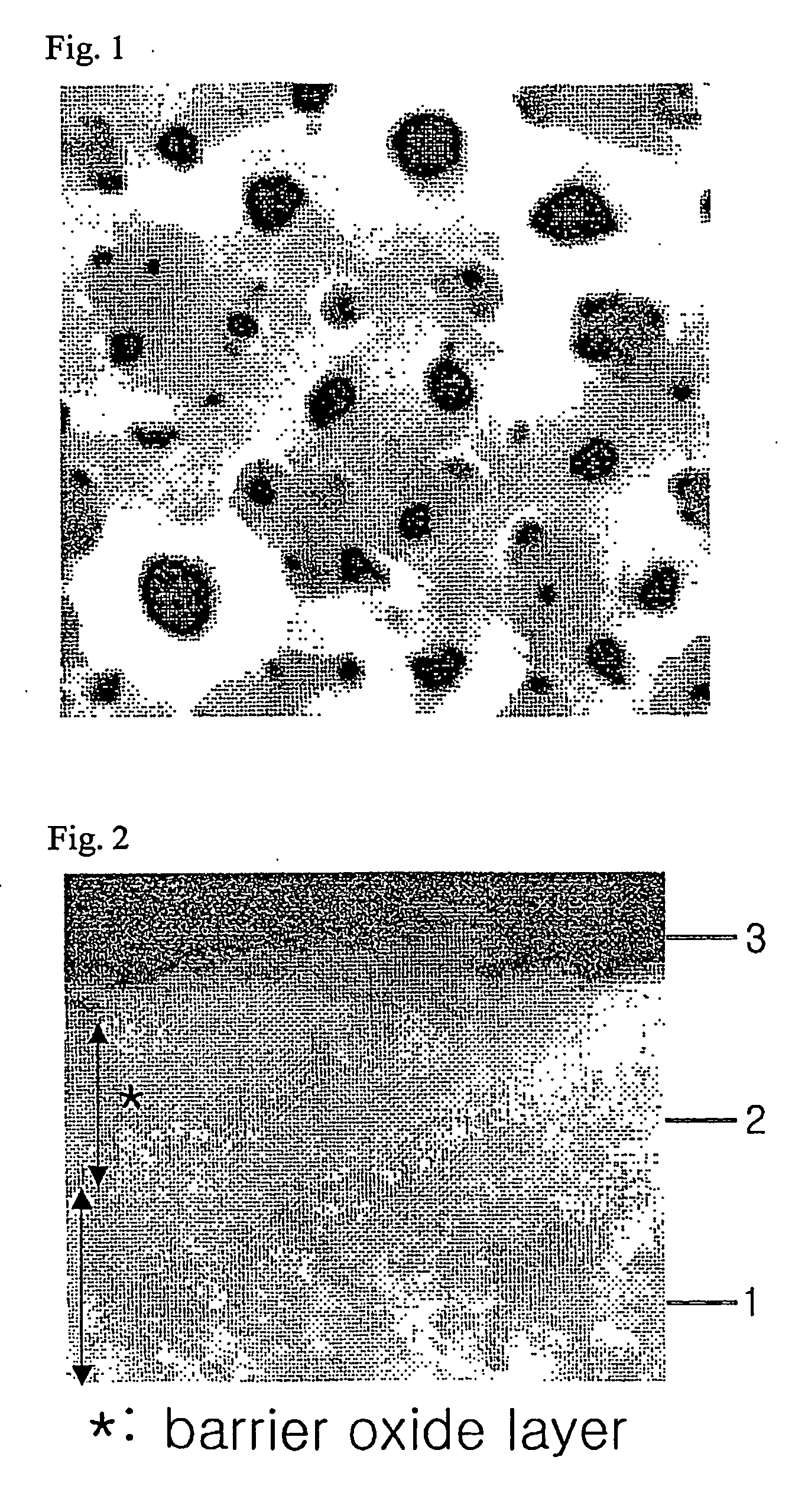

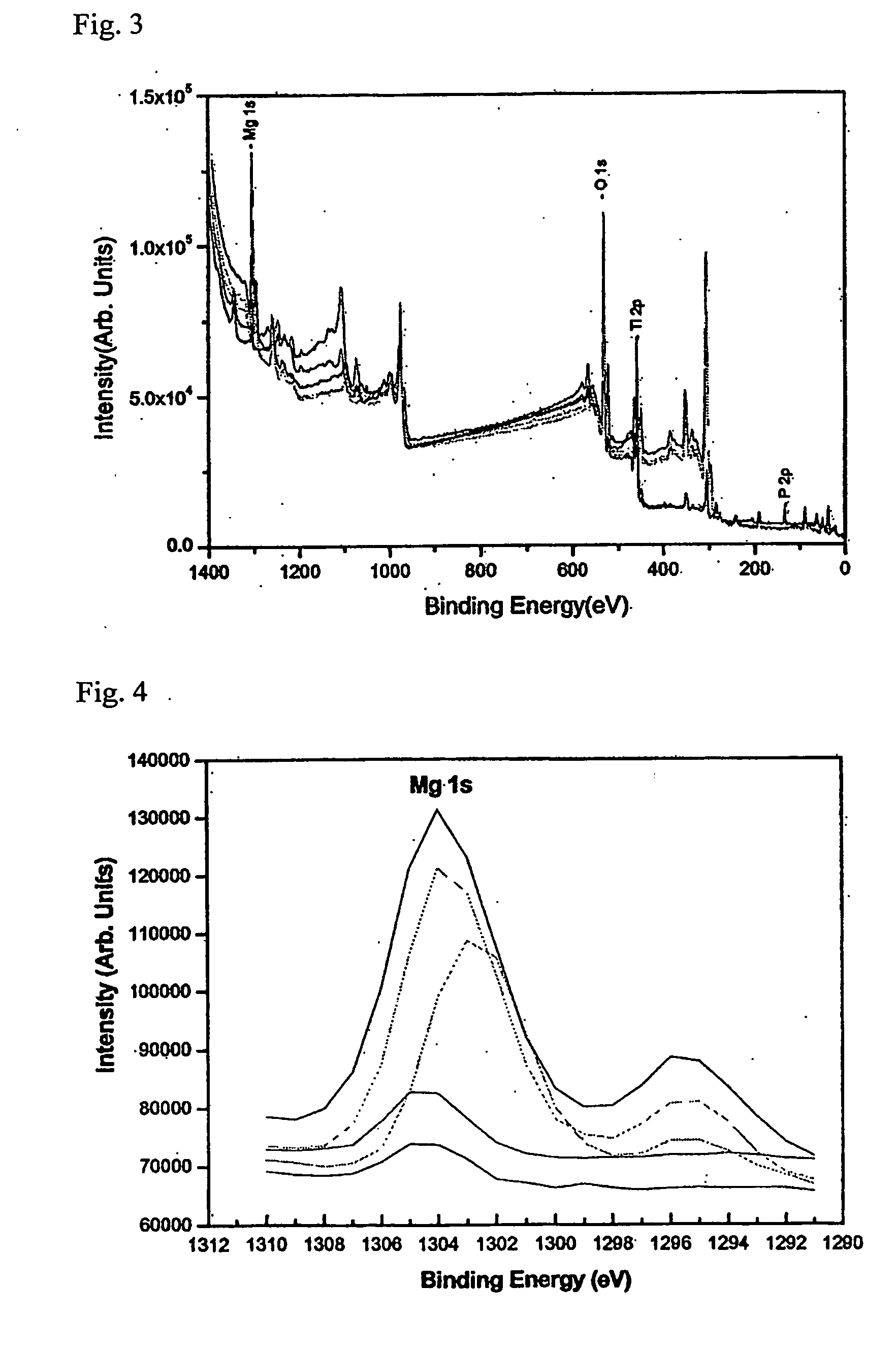

Osseoinductive magnesium-titanate implant and method of manufacturing the same

InactiveUS7452566B2Rapid and strong osseointegrationFast osseointegrationDental implantsImpression capsOsseointegrationTitanium

A magnesium titanate oxide film implant, and a method for preparing the same. The magnesium titanate oxide film implant is prepared by forming a titanium oxide film (a magnesium titanate oxide film) in which magnesium is incorporated into the surface of titanium or a titanium alloy. A magnesium titanate oxide film implant is prepared by irradiating UV light on an implant body made of titanium or a titanium alloy in distilled water, dipping the UV light-irradiated implant body in an electrolyte solution containing magnesium, and coating a magnesium titanate oxide film on the dipped implant body by anodic oxidation. Therefore, the present invention can provide an implant having increased bioactivity of a titanium oxide film formed by anodic oxidation, and provides an optimum magnesium titanate oxide (TixMgyOz) thickness for successful osseointegration of the magnesium titanate (TixMgyOz) implant.

Owner:SUL YOUNG TAEK

Insulation material, film, circuit board and method of producing them

ActiveUS20070060672A1Increase volumeEasy to operatePlastic/resin/waxes insulatorsFixed capacitor dielectricStrontium titanateBarium titanate

There is provided an insulation material having a dielectric constant of 10 or more, comprising a filler having a dielectric constant of 50 or more and having two peaks in different particle size ranges in a particle size distribution and an insulating resin combined with each other; an insulation material having a dielectric constant of 10 or more comprising, as essential components, 1) at least one filler selected from the group consisting of barium titanate, strontium titanate, potassium titanate, magnesium titanate, lead titanate, titanium dioxide, barium zirconate, calcium zirconate and lead zirconate, 2) an insulating resin and 3) a dispersant containing a carboxylic group; or an insulation material comprising a filler having a dielectric constant of 50 or more, a dispersant for dispersing the filler and an insulating resin as essential components, wherein an extract of a cured product of the insulation material obtained by extraction with water at 120° C. for 20 hours using a pressure vessel has a pH of 6 or higher.

Owner:RESONAC CORP

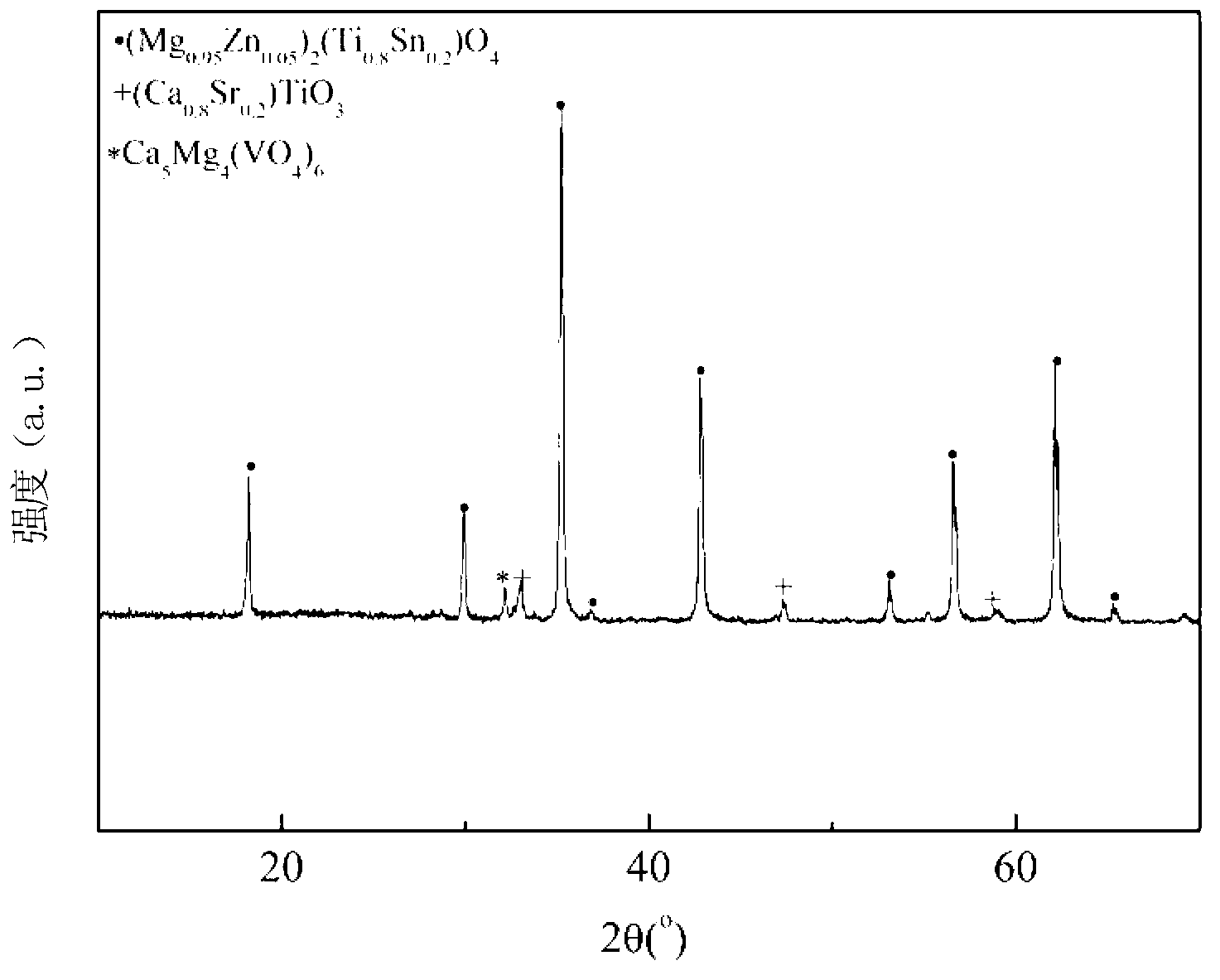

Magnesium titanate based composite ceramic sintered at low temperature and preparation method thereof

The invention relates to magnesium titanate based composite ceramic sintered at low temperature and a preparation method thereof. The magnesium titanate based composite ceramic is composed of the material adopting the following general formula: 0.9 (Mg0.95Zn0.05)2(Ti0.8Sn0.2)O4-0.1(Ca0.8Sr0.2)TiO3-3.0wt%LiF-0.8wt%Fe2O3-xwt%V2O5, wherein x is between 0.5 and 3.0. The sintering temperature of the magnesium titanate based composite ceramic can be decreased to 900 to 975 DEGC, so that the defect of the large temperature coefficient of the resonant frequency of the ceramic material is overcome; and thus the temperature stability of the material is ensured. According to a preparation method, the adopted raw materials are abundant and low in cost, thereby being favorable for industrial production. The magnesium titanate based composite ceramic can be widely used for manufacturing microwave devices such as low-temperature co-fired ceramic systems, GPS (Global Positioning System) antennae, wave filters for wireless local area networks, multilayer dielectric resonators and the like.

Owner:SHAANXI NORMAL UNIV

Ultra-low-loss lithium magnesium titanate microwave dielectric ceramic material and preparation method thereof

ActiveCN104692795AExcellent microwave dielectric propertiesEasy to prepareRadar systemsDielectric resonator

The invention discloses an ultra-low-loss lithium magnesium titanate microwave dielectric ceramic material and a preparation method thereof. A chemical component of the ceramic material is Li2Mg3TiO6; the dielectric loss is 0.000037-0.000048; Q*f is 123,000-152,000GHz; the dielectric constant is 14.5-15.5; the temperature coefficient of the resonance frequency is -42ppm / DEG C to -36ppm / DEG C; and the ultra-low-loss lithium magnesium titanate microwave dielectric ceramic material is prepared by a high-temperature solid reaction method. The microwave dielectric ceramic material is simple in preparation method, abundant in used raw material, low in cost, and beneficial to industrialized production; and the prepared microwave dielectric ceramic is stable in performance, can be used as a manufacturing material for an electronic circuit substrate, a dielectric resonator, a filter, a high-frequency satellite microwave device substrate and a microstrip line, and has important application prospect and economic value in the fields of electronic circuits, microwave mobile communication, satellite communication and radar systems.

Owner:SHAANXI NORMAL UNIV

Medium-temperature sintered magnesium titanate-based microwave dielectric ceramics with high quality factor

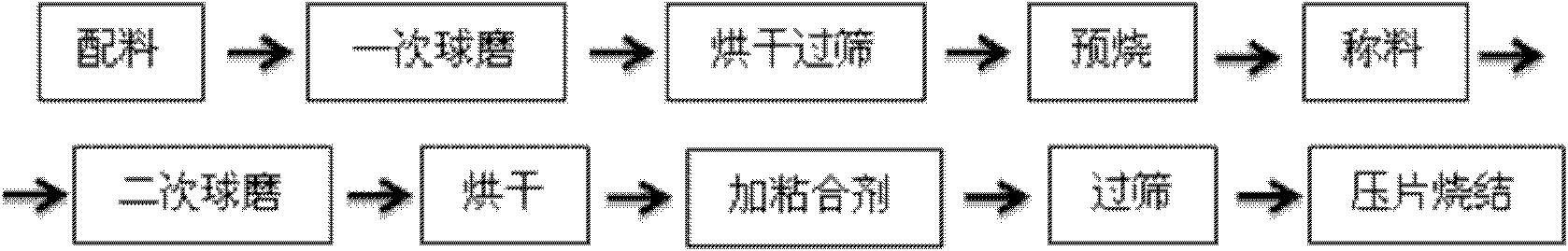

InactiveCN102219500ASave the granulation linkPromote commercial applicationPolyvinyl alcoholDielectric ceramics

The invention discloses a medium-temperature sintered magnesium titanate-based (MgTiO3-based) microwave dielectric ceramics with a high quality factor. Preparation steps for the magnesium titanate microwave dielectric ceramics comprise: (1) weighing MgO and TiO2 according to a stoichiometric ratio of the MgTiO3, and carrying out ball milling; (2) carrying out drying and sieving; (3) calcining the resulting mixture at a temperature below 900 DEG C; (4) adding polyvinyl alcohol, followed by carrying out secondary ball milling; (5) sequentially carrying out drying, sieving, pressing for shaping, followed by carrying out sintering at a temperature of 1120-1200 DEG C; (6) detecting physical property and dielectric property. With adding the polyvinyl alcohol and carrying out the secondary ball milling, the medium-temperature sintered (1140 DEG C) MgTiO3-based microwave dielectric ceramics with high quality factor is obtained, a disadvantage of the high sintering temperature (1450 DEG C) in the prior art is overcome, such that the MgTiO3-based microwave dielectric ceramics has advantages of wide application, low cost and environmental-protection production process so as to provide a ideal material for microwave millimeter wave communication devices.

Owner:TIANJIN UNIV

Novel treatment fluid for chromium-free passivation of aluminum alloy

InactiveCN102181853AImprove corrosion resistanceImprove adhesionMetallic material coating processesChromium freeZirconate

The invention relates to treatment fluid for surface passivation of an aluminum alloy, and particularly discloses novel treatment fluid for chromium-free passivation of the aluminum alloy. The novel treatment fluid consists of the following substances in percentage by mass: 20 to 30 percent of a mixture of potassium titanate, sodium titanate and magnesium titanate salts, 5 to 15 percent of a mixture of potassium zirconate, sodium zirconate and magnesium zirconate salts, 5 to 15 percent of modified organic silicon resin, and 40 to 50 percent of urethane resin. The novel treatment fluid for the chromium-free passivation of the aluminum alloy is specifically used for surface treatment of aluminum and alloys thereof, and magnesium and alloys thereof, and not only can improve the corrosion resistance per se of a material, but also can enhance the adhesive force of the material and a coating layer thereof. The treatment fluid has the advantages of simple using process, low cost, no pollution and the like.

Owner:广州立铭环保科技有限公司

Zinc-magnesium titanate system ceramic dielectric material and prepared ceramic capacitor

InactiveCN1635593AImprove frequency characteristicsExcellent dielectric propertiesFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorZinc

This invention discloses a high frequency thermal stable ceramic material and its ceramic capacitor. The material comprises the main component and assistant components, wherein the main components are 40í½55úÑ of Mg(1-x)ZnxTiO3(0.0001íœXíœ0.05) and 20í½25úÑ of Mg(2-y)ZnySiO4(0.0001íœXíœ0.05); the assistant components are 10í½15úÑ of ZnO and 3.0í½7.0úÑ of Al2O3 and 2.0í½6.0úÑ of SrO. The assistant components also comprise the following: 1.0í½2.5úÑ of B2O3íó0.5í½2.0úÑ of Nd2O5íó0.1í½0.5úÑ of MnO2íó0.1í½0.4úÑ of Co3O4 and one or more materials from K2OíóFe2O3íóCeO2 and SnO.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Osseoinductive magnesium-titanate implant and method of manufacturing the same

InactiveUS20060161263A1Fast osseointegrationReinforce mechanical osseointegrationDental implantsImpression capsOsseointegrationUltraviolet

The present invention relates to a magnesium titanate oxide film implant for insertion into a living body, utilized in medical fields such as dentistry, orthopedic surgery, maxillofacial surgery and plastic surgery, and a method for preparing the same. The magnesium titanate oxide film implant in accordance with the present invention is prepared by forming a titanium oxide film (a magnesium titanate oxide film) in which magnesium is incorporated into the surface of titanium or a titanium alloy. A process for preparing a magnesium titanate oxide film implant in accordance with the present invention comprises irradiating UV light on an implant body made of titanium or a titanium alloy in distilled water for more than 2 hours; dipping the UV light-irradiated implant body in an electrolyte solution containing magnesium; and coating a magnesium titanate oxide film on the dipped implant body by anodic oxidation at a voltage of 60 to 500 V. Therefore, the present invention can provide an implant having increased bioactivity of a titanium oxide film formed by anodic oxidation, and provides an optimum magnesium titanate oxide (TixMgyOz) thickness for successful osseointegration of the magnesium titanate (Tix,MgyOz) implant.

Owner:SUL YOUNG TAEK

Cordierite aluminum magnesium titanate compositions and ceramic articles comprising same

Disclosed are ceramic bodies comprised of composite cordierite aluminum magnesium titanate ceramic compositions and methods for the manufacture of same.

Owner:CORNING INC

Cordierite aluminum magnesium titanate compositions and ceramic articles comprising same

Disclosed are ceramic bodies comprised of composite cordierite aluminum magnesium titanate ceramic compositions and methods for the manufacture of same.

Owner:CORNING INC

Brake pad having noise reducing function and preparation method of same

InactiveCN107502290AImprove wear resistanceReduce noiseOther chemical processesFriction liningFiberLamellar crystals

The invention relates to the technical field of brake pads, and provides a brake pad having noise reducing function, which includes, by weight, 5-10 parts of butyl-butadiene styrene rubber, 5-10 parts of modified phenolic resin, 5-10 parts of butadiene styrene rubber, 10-15 parts of nitrile butadiene rubber, 5-6 parts of potassium magnesium titanate lamellar crystal, 3-6 parts of polypropylene, 15-20 parts of flake graphite, 6-10 parts of boron nitride, 1-2 parts of a binding agent, 1-2 parts of feldspar powder, 0.5-3 parts of zinc oxide, 5-10 parts of rubber powder, 1-2 parts of fluorite powder, 0.5-1 part of silicon carbide, 3-4 parts of glass fibers, 2-3 parts of carbon fibers, and 4-6 parts of steel fibers. The invention also provides a preparation method of the brake pad having noise reducing function, which includes the steps of mixing and uniformly stirring the raw materials, performing hot pressing, and performing thermal-treatment to the pressed brake pad. The brake pad is wear-resistant and high-temperature-resistant, is not liable to deform, and has noise reducing function.

Owner:杭州西湖摩擦材料有限公司

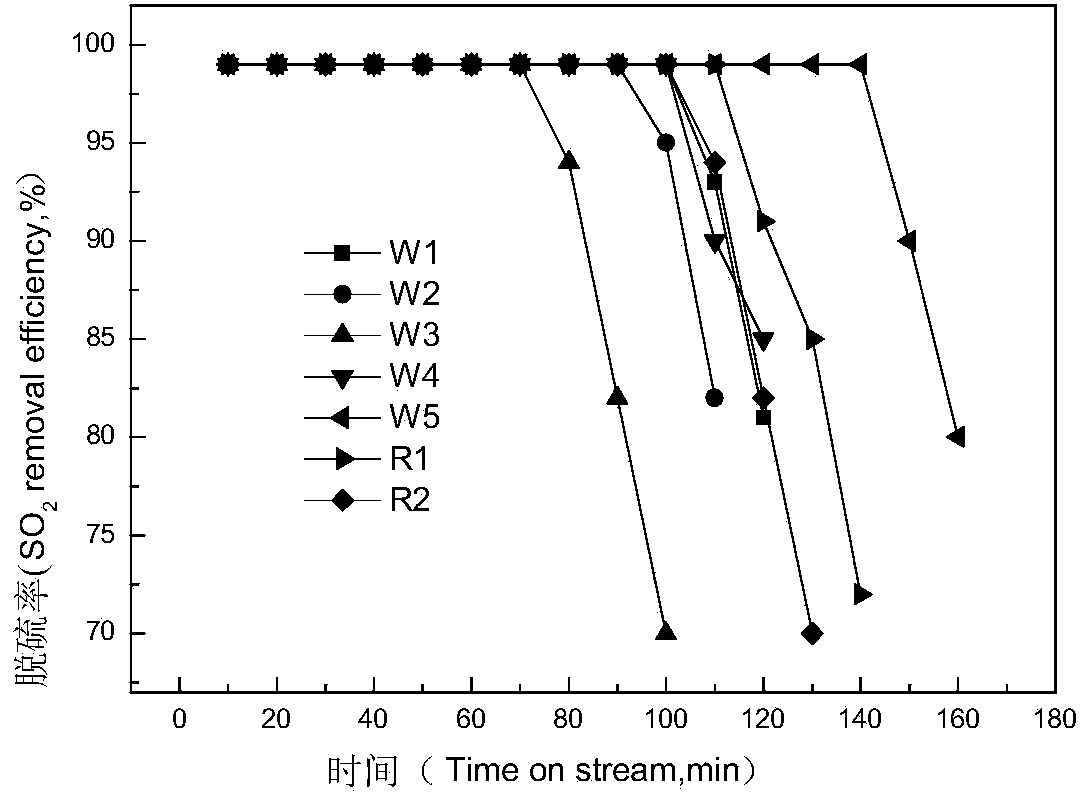

Catalytic cracking flue gas sulfur transfer agent adopting mixed crystal phases as well as preparation method and application thereof

InactiveCN103861436AHigh desulfurization activityImprove desulfurization effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAccelerantMixed crystal

The invention provides a catalytic cracking flue gas sulfur transfer agent adopting mixed crystal phases as well as a preparation method and application thereof. The sulfur transfer agent is prepared by using three mixed crystal phases including magnesium oxide, magnesium titanate and magnesium aluminate spinel as desulfurization carriers and desulfurization active centers, and loading metal oxides as redox accelerants by adopting a reverse coprecipitation method, wherein based on the total weight of the sulfur transfer agent, the mass percents of magnesium oxide, magnesium titanate, spinel and the metal oxides are respectively 1-50%, 1-90%, 1-90% and 5-50%. The sulfur transfer agent has the beneficial effects that a composite structure is formed by utilizing titanium-magnesium structure materials and a magnesium aluminate spinel material, thus greatly enhancing the desulfurization effect of the sulfur transfer agent and prolonging the service life of the sulfur transfer agent as well as expanding the composition range of the sulfur transfer agent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com