Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

528 results about "Alkali feldspar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The alkali feldspar group are those feldspar minerals rich in the alkali elements, potassium and sodium. The alkali feldspars include albite, anorthoclase, microcline, orthoclase and sanidine. Albite is considered as one of the alkali feldspars according to its chemical composition and it is also the alkali endmember of the plagioclase series. Potassium and sodium feldspars are not perfectly miscible in the melt at low temperatures, intermediate compositions of the alkali feldspars therefore occur only in higher temperatures environments.

Transparent lead-free fritted glaze with low expansion coefficient and preparation method thereof

The invention relates to a transparent lead-free fritted glaze with low expansion coefficient and a preparation method thereof. The fritted glaze comprises the following chemical ingredients of: 59 to 66 percent of SiO2, 10 to 15 percent of Al2O3, 5 to 10 percent of B2O3, 3 to 6 percent of CaO, 4 to 8 percent of MgO, 0 to 3 percent of K2O, 0 to 2 percent of Na2O, 0 to 1 percent of Li2O, 1 to 5 percent of ZnO and 0 to 2 percent of SrO; and the fritted glaze comprises the raw materials of: 10 to 25 percent of kaolin, 15 to 30 percent of quartz, 10 to 25 percent of potassium feldspar, 0 to 8 percent of dolomite, 2 to 6 percent of grammite, 10 to 20 percent of roasted talc, 1 to 6 percent of zinc oxide, 2 to 8 percent of boric acid, 5 to 15 percent of calcium borate, 1 to 5 percent of alumina, 0 to 2 percent of lithium carbonate and 0 to 3 percent of strontium carbonate. The expansion coefficient of the fritted glaze is 3.7-4.5*10-6 / DEG C (RT to 500 DEG C), the melted temperature is 1400 DEG C to 1500 DEG C, the glaze firing temperature is 1130 DEG C to 1230 DEG C; and the transparent lead-free fritted glaze has fine and bright glaze surface, high transparency, low expansion coefficient as well as no lead precipitation and is particularly suitable for double-fired hard porcelain body with lower expansion coefficient.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

Longquan celadon crackle glaze wine bottle and preparation method thereof

ActiveCN104150873ANovel preparation methodSatisfy the wine storage functionClaywaresPotassiumWine bottle

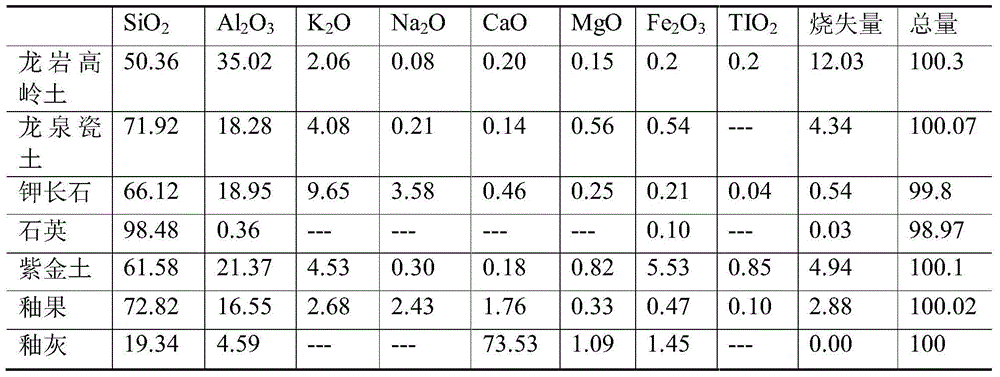

The invention relates to a longquan celadon crackle glaze wine bottle and a preparation method thereof. Raw material proportions of a blank material, an internal glaze and an external glaze of the bottle are respectively described as follows: the blank material comprises: 40-55% of Longyan kaolin, 15-25% of Longquan china clay, 8-20% of potassium feldspar, 7-15% of quartz and 5-10% of zijin clay; the internal glaze comprises: 65-70% of glaze fruit, 12-25% of glaze ash and 5-10% of zijin clay; and the external glaze comprises: 60-70% of potassium feldspar, 8-15% of quartz, 8-13% of Longyan kaolin, 8-15% of glaze ash, 5-13% of zijin clay and 0.2-0.4% of Fe2O3. On the basis of above raw materials, the longquan celadon crackle glaze wine bottle is prepared by following steps: preparing slurry, performing an injection moulding process to obtain a wet blank; performing a drying process, a trimming process and a biscuiting process to complete a blank manufacturing process; and finally applying the internal glaze and the external glaze and performing a glazing firing process to obtain a finished product of the longquan celadon crackle glaze wine bottle. The bottle is free of stripes on the internal glaze. The external glaze is decorated through crackles. The bottle is good in quality and is free of internal leakage of wine. The method is low in cost and good in effect.

Owner:龙泉市尚唐瓷艺发展有限公司 +1

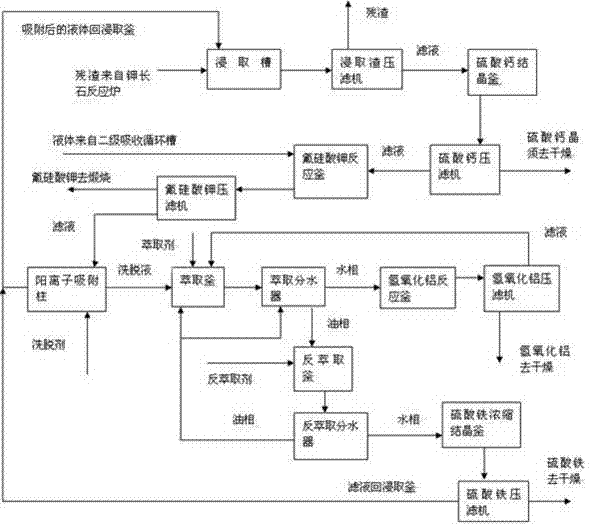

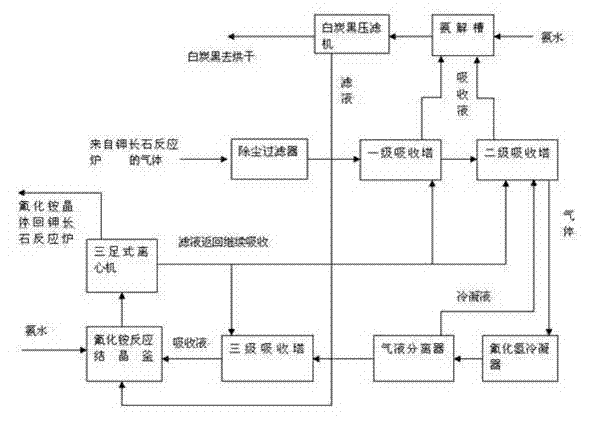

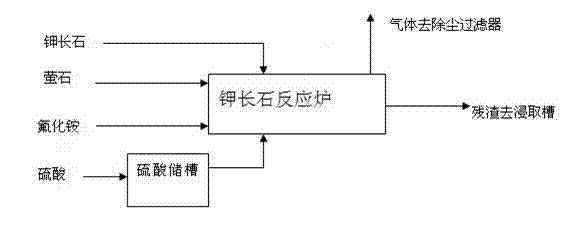

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

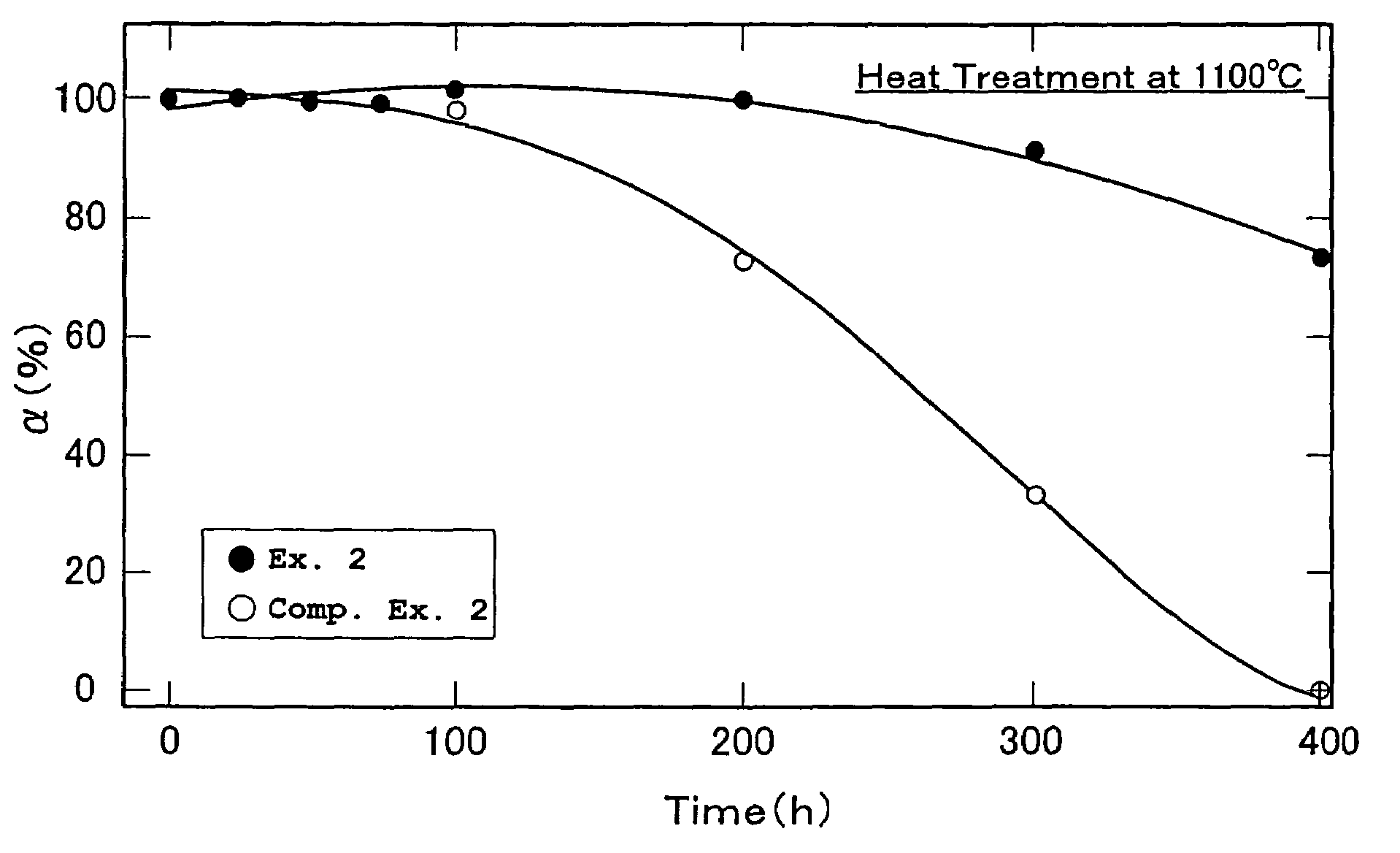

Method for producing aluminum titanate sintered object

InactiveUS20030015829A1Reduction factorImprove corrosion resistanceCeramic shaping apparatusTitanium compoundsBarium titanateThermal expansion

The present invention provides a process for preparing an aluminum-titanate-based sintered body comprising the step of firing, at 1250 to 1700° C., a formed product prepared from a raw material mixture containing 100 parts by weight of a mixture of TiO2 and Al2O3 in a weight ratio of TiO2:Al2O3=40:60 to 60:40, and 1 to 15 parts by weight of an alkali feldspar represented by the formula:(NaxK1-x)AlSi3O8 wherein 0<=x<=1. According to the process of the present invention, it is possible to obtain an aluminum-titanate-based sintered body in which inherent properties of an aluminum titanate, i.e., a low coefficient of thermal expansion and high corrosion resistance are maintained, the mechanical strength thereof is improved, and which can be stably used even under high temperature conditions.

Owner:OHCERA CO LTD

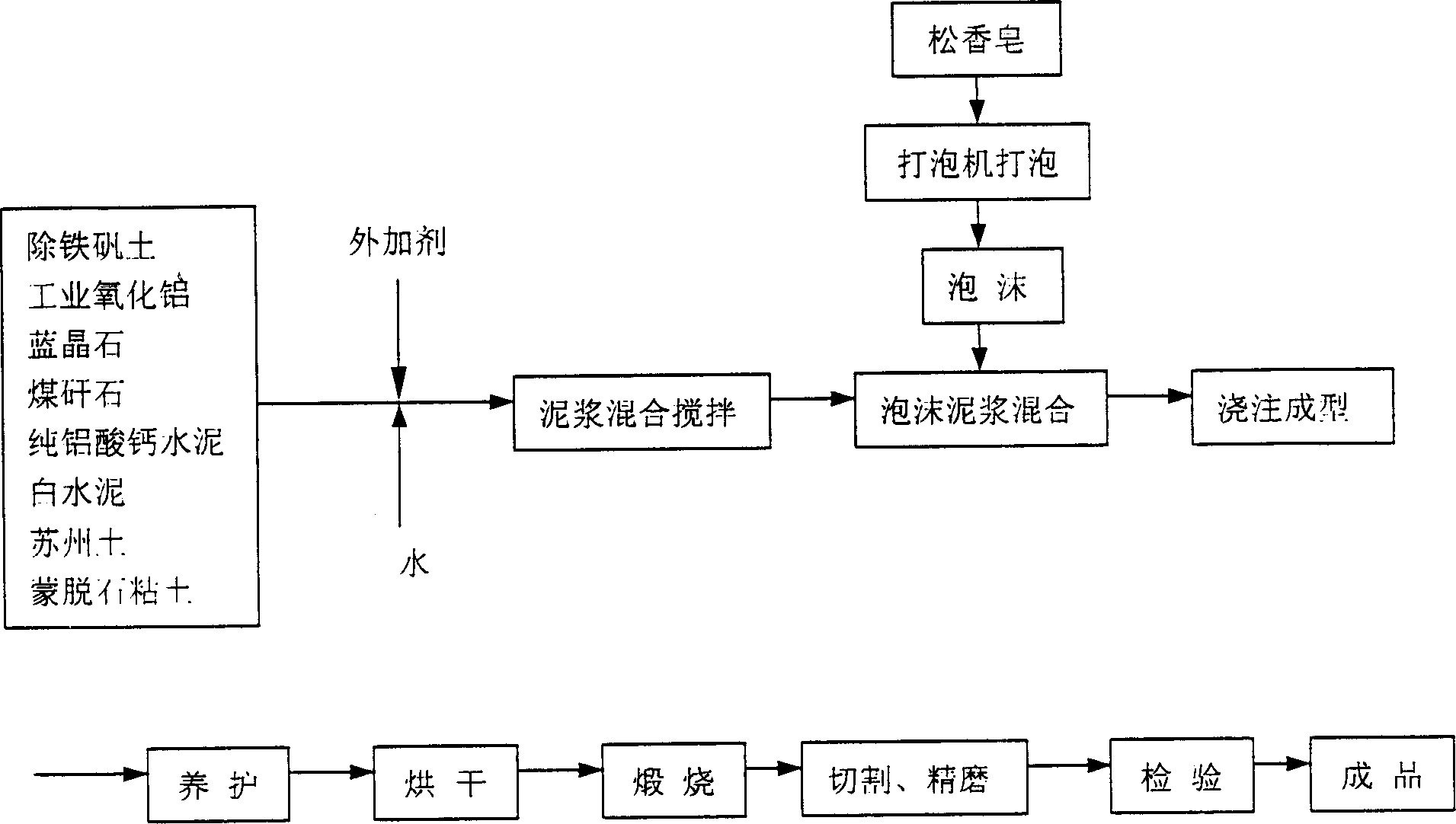

Building external wall thermal insulation foamed ceramic material and production method thereof

InactiveCN102584326AEfficient use ofLow costSolid waste disposalCeramicwareThermal insulationEnergy conservation

The invention belongs to the field of building materials, and in particular relates to a building external wall thermal insulation foamed ceramic material and a production method thereof. The building external wall thermal insulation foamed ceramic material is prepared from the following raw materials in part by weight: 60 to 80 parts of industrial solid waste, 15 to 35 parts of fluxing material and 2 to 5 parts of foaming agent, wherein the industrial solid waste is a mixture of two or three of coal gangue, metal tailing and polishing waste in any ratio; the fluxing material is one or a mixture of two of albite and bottle waste glass in any ratio; and the foaming agent is silicon carbide powder. The method comprises the following steps of: mixing the raw materials, grinding, filling in a recrystallized silicon carbide die, feeding into a kiln, firing, naturally cooling, cutting, and inspecting to obtain the foamed ceramic material which meets the building external wall thermal insulation requirement. The building external wall thermal insulation foamed ceramic material has the characteristics of A-level non-inflammability, high thermal insulation and heat preservation performance, energy conservation, environment friendliness and low cost.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Porous ceramicite and preparation method and application thereof

InactiveCN101693631AHigh activityTo promote metabolismWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processRare earthBiological activation

A porous ceramicite and a preparation method and an application thereof in the field of water purifying and filtering technologies, the porous ceramicite comprises the following components in percentage by weight: 2.5%-4.5% of titanium dioxide nanometer grade micro powder, 2%-4.5% of silicon dioxde nanometer grade micro powder, 2.5%-5.5% of zinc oxide nanometer micro powder, 12%-29% of polarity mineral tourmaline powder, 0.5%-1.5% of rare-earth activating agent, 1.5%-3% of ferric oxide red, 3%-10% of feldspar ores, 5%-8% of bergmeal ores, 15%-47% of light clay ores, and the other is water. The method ionizes water into negative ions through realizing infrared, cuts off hydrogen keys through resonance and splits the hydrogen keys into small water molecules (five-six), improves the activation, enables the small molecules into a body, can activate cells, prompts metabolism and acid-base balance, reduces the function of the oxidation-reduction potential ORP value of a water body, and the method can be used for processing water in cups and containers, such as tanks, tower pools, grooves and the like.

Owner:SHANGHAI JIAO TONG UNIV

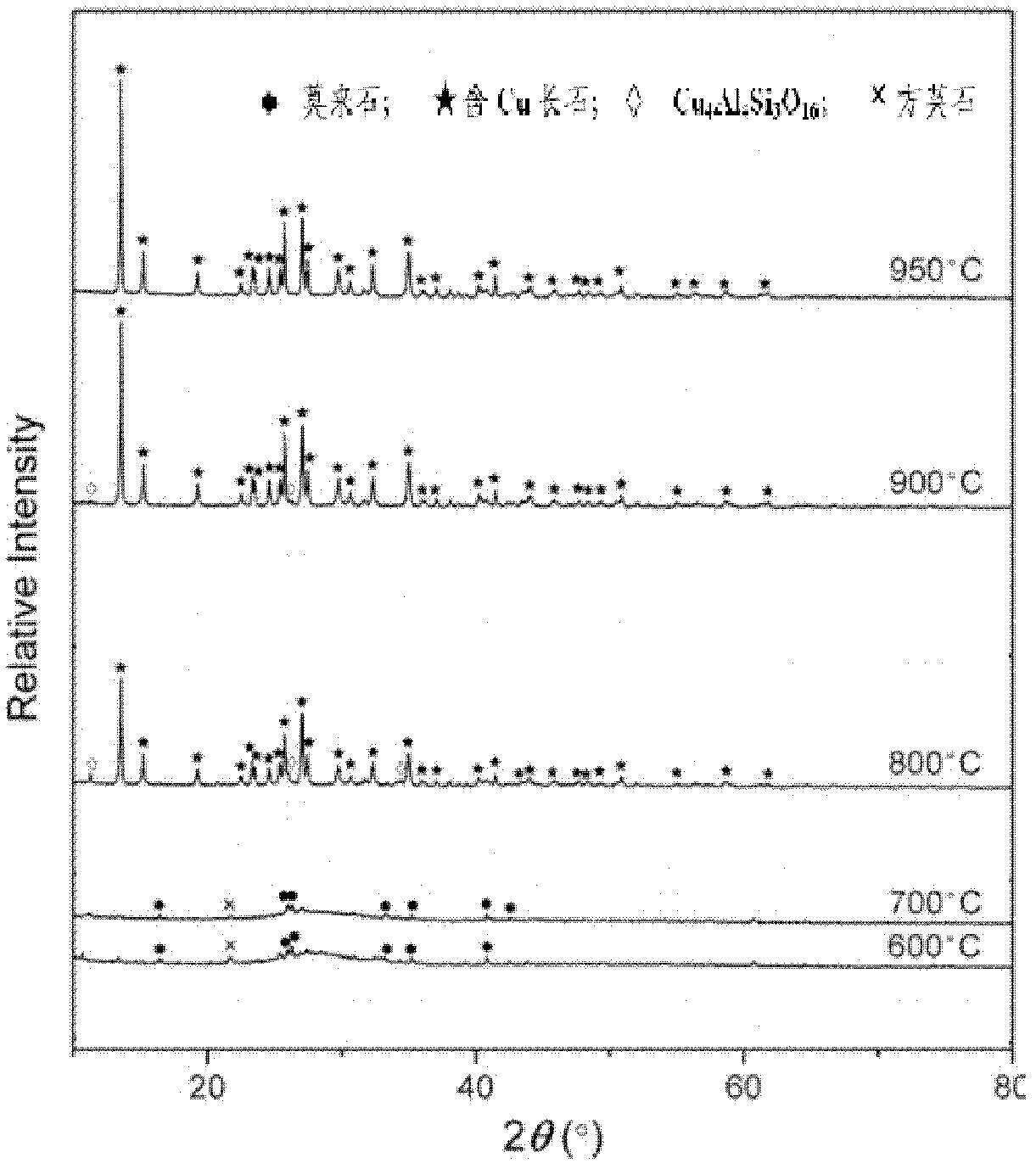

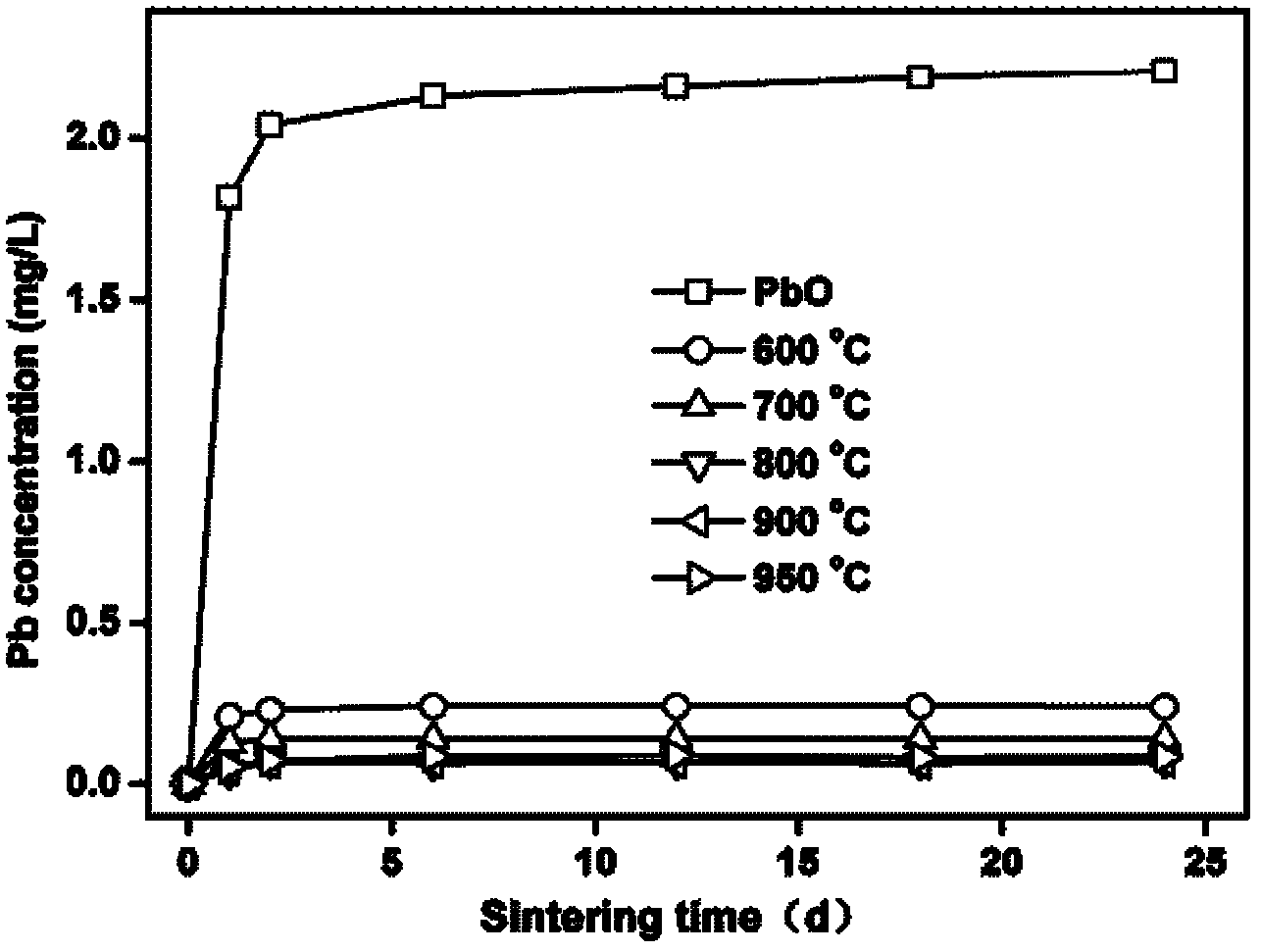

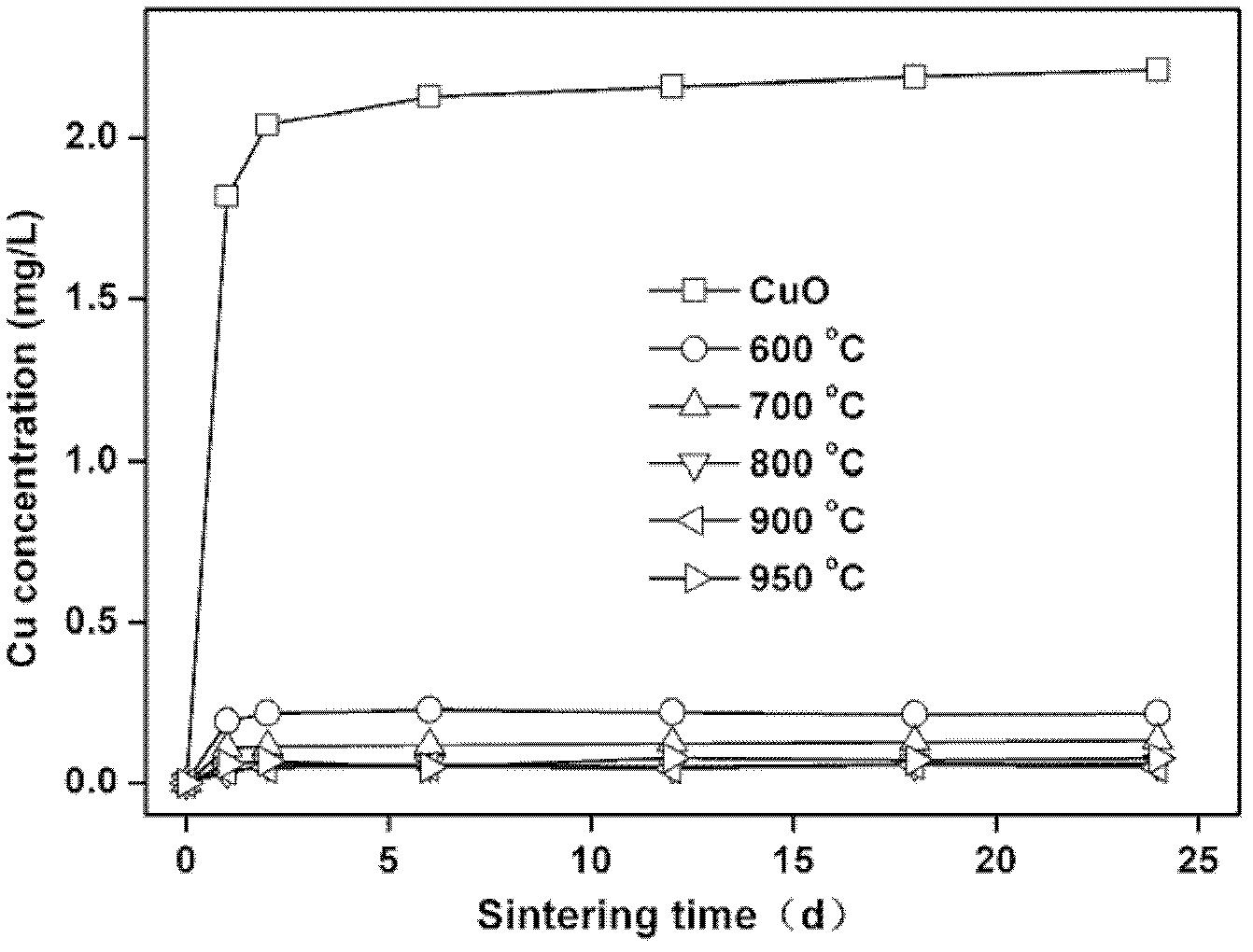

Clay-based heavy metal thermal curing agent and its method for curing heaving metal

ActiveCN102657925ANothing producedEasy to handleContaminated soil reclamationOrganic fertilisersMass ratioStone dust

The invention discloses a clay-based heavy metal thermal curing agent and its method for curing heavy metal. The clay-based heavy metal thermal curing agent comprises, by weight, 40-60% of clay, 5-15% of iron oxide, 20-30% of fly ash and 15-25% of stone flour. The method provided by the invention comprises the following steps of: uniformly mixing the clay-based heavy metal thermal curing agent and a heavy metal pollutant according to the mass ratio of 1: 5-10: 1, carrying out extrusion moulding on the mixed sample at the pressure of 300-1000Mpa, and sintering the molded sample at the temperature of more than 800 DEG C for 2-5 h to obtain a recycled material. According to the invention, heavy metal is coalesced by absorption of clay to heavy metal; fly ash and stone flour are used to fully mix heavy metal with the clay-based heavy metal thermal curing agent during the mixing process; iron oxide and alumina components in the clay-based heavy metal thermal curing agent react with heavy metal at the temperature of more than 800 DEG C for high-temperature fusion glass transition so as to form a spinel structure; and heavy metal in the form of spinel and feldspar crystal structural components is fixed in the heavy metal thermal curing agent to form the recycled material.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Light refractory bricks

InactiveCN1424280AIncrease optionalityReduce manufacturing costFurnace componentsCeramicwareMulliteAluminum silicate

A light-weight refractory brick used for liner of high-temp furnace is prepared from mullite as primary crystal phase, huronite as binding phase, disthene and coal gangue. Its main chemical components are Al2O3 (54-57 wt.%), SiO2 (40-43), CaO (1-2), Fe2O3 (0.1-1) and impurities (0.1-0.7). Its advantages are light weight, low heat conductivity and volume density, and high strength.

Owner:UNIV OF SCI & TECH BEIJING

Superfine dry granular porcelain glazed tile

The invention discloses a superfine dry granular porcelain glazed tile which belongs to the field of preparation of porcelain glazed tiles. The superfine dry granular porcelain glazed tile comprises agreen body, ground glaze and surface glaze, wherein the surface glaze comprises the following raw materials in percent by weight: 22-25wt% of potassium feldspar, 6-8wt% of calcined talc, 17-20wt% ofbarium carbonate, 2-5wt% of calcined alumina, 3-5wt% of calcined zinc oxide, 3-5wt% of quartz, 5-8wt% of kaolin, 6-8wt% of dolomite and 26-30wt% of 10,139 # dry granules. The green body of the tile islow in water absorption and high in breaking strength; the green body, the bottom glaze and the surface glaze are good in combinability, and the tile in good in flatness; the superfine dry granules form a slightly rugged surface in the surface glaze, and the grain size of each of granular crystals protruding out of the glaze is 0.12-0.18mm, so that an anti-skidding and abrasion-proof effect can be achieved on the glaze, and the defect that dirt is hided and adsorbed in the glaze can be overcome.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

Daily-used fine porcelain with high property and preparation method thereof

The invention belongs to the technical field of daily-used ceramics, relating to daily-used fine porcelain with high property and a preparation method thereof. The chemical constituents of the daily-used fine porcelain are 52-60% of SiO2, 32-40% of Al2O3, 1-3% of K2O, 1-3% OF Na2O, 1.5-3.5% of CaO, 0.5-1.5% of MgO and 1-2% of P2O5. The adopted raw material formulation is as follows: 40-45% of kaoline, 15-25% of quartz, 10-15% of potassium feldspar, 10-20% of alumina and 8-15% of antireflective agent. The daily-used fine porcelain of the invention integrates three characteristics of high strength, high white and high transparence, and has the characteristics of good molding property, wide sintering arrange and high thermal stability and the like, thereby overcoming the defect of bad light transmittance of normal strengthened porcelain, and solving the problems of uneasy molding and narrow sintering arrange of high-grade porcelain such as steatite porcelain and bone porcelain. The porcelain is sintered at the temperature of 1270-1320 DEG C, is easy to be produced and promoted, and is hopeful to become novel high-grade daily-used fine porcelain after bone porcelain and steatite porcelain.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Production raw material of foamed glass and process for producing foamed glass

The invention relates to raw materials for producing foam glass and a method for applying the same to produce the foam glass. The compositions by weight portion of the raw materials are: 380 to 580 portions of quartz sand, 105 to 250 portions of potassium feldspar, 130 to 270 portions of albite, 115 to 200 portions of dolomite, 5 to 25 portions of calcite, 150 to 250 portions of calcined soda, 0.5 to 30 portions of glauber salt, 1.0 to 12 portions of magnesium carbonate and 1.0 to 8.5 percent of potassium carbonate. The method comprises the following steps that: firstly, various raw material compositions are mixed into uniform glass mixture; secondly, the glass mixture is melted and cooled into cullet; thirdly, ball milling, foaming and annealing of the cullet are performed, and then foam glass is obtained. The method can automatically control and adjust the chemical compositions of the glass and add various functional compositions as required to meet the demand of producing the foam glass with different performances by adoption of common mineral and chemical raw materials of the natural world.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

Low-temperature sintered ceramic glazed tile and preparation method thereof

The invention discloses a low-temperature sintered ceramic glazed tile and preparation method thereof. The ceramic glazed tile comprises a tile blank, a top glaze layer, and a print glaze layer. In tile blank component raw materials, petalite (LiAlSi4O10) is adopted as a tile blank temperature-reducing material. A product is obtained through the steps of blending, ball milling and sieving, drying, press-molding, top glaze applying, roller printing, print glaze applying, and sintering. Sintering temperatures are that: sintering is carried out for 15-20min at a temperature of 970 DEG C when the material is delivered into a kiln; sintering is carried out for 20-25min at a temperature of 970-1150 DEG C; sintering is carried out for 5-10min at a temperature of 1150-1200 DEG C; temperature is maintained for 5-10min at 1200 DEG C; and sintering is carried out for 20-25min at a temperature of 1200-150 DEG C. According to the invention, lithium feldspar in lithium ore tailings is adopted as a tile blank temperature reducing material, such that defects of high sintering temperature and long sintering time of glazed tile in prior arts are overcome. Therefore, glazed tile low-temperature fast sintering is realized, energy consumption is reduced, and resource utilization rate is improved.

Owner:景德镇欧神诺陶瓷有限公司

Method for producing aluminum magnesium titanate sintered product

InactiveUS7166552B2Improve stabilityHigh strengthCeramic shaping apparatusClaywaresContinuous useAlkali feldspar

The present invention provides a process for preparing a sintered body comprising as a basic component aluminum magnesium titanate represented by the composition formula: MgxAl2(1−x)Ti(1+x)O5 wherein the value of x is 0.1≦x<1. The process comprises a step of sintering a formed product from a raw material mixture comprising 100 parts by weight, calculated on an oxide basis, of a mixture comprising a Mg-containing compound, an Al-containing compound and a Ti-containing compound at the same metal component ratio as the metal component ratio of Mg, Al and Ti in the above composition formula, and 1–10 parts by weight of an alkali feldspar represented by the composition formula: (NayK1−y)AlSi3O8 wherein the value of y is 0≦y≦1.According to the process of the present invention, a sintered body of aluminum magnesium titanate having stability in continuous use at high temperatures and excellent mechanical strength, while maintaining inherently low thermal expansibility of a sintered body of aluminum magnesium titanate, can be obtained.

Owner:OHCERA CO LTD

Process for refining hematite type potassium feldspar sand powder

The invention provides a process for refining hematite type potassium feldspar sand powder. The process comprises the following steps: firstly crushing potassium feldspar to be formed into particles, and then adopting dry method ore grinding or wet method ore grinding to obtain sand powder or sand mortar; screening the sand powder prepared through a dry method, and adopting a multistage high magnetic separator to conduct magnetic separation; adopting the magnetic separator to conduct magnetic separation on the sand mortar prepared through wet method sand making, and adopting an electromagnetic separator to conduct magnetic separation on the classified sand mortar, then dehydrating, drying, calcinating iron not removed completely through a boiling furnace to be removed through high magnetic separation, removing the iron still not removed through a pickling manner, and finally separating quartz particles from potassium feldspar through a flotation method so as to obtain the high purity potassium feldspar sand powder. The refining process not only can meet requirements of domestic glass, ceramic and enamel industries on high-brightness potassium feldspar sand powder, but also can conduct industrial production, is environment-friendly, has no waste acid, waste water or waste gas discharge, and is an environment-friendly refining production line.

Owner:HUANGGANG NORMAL UNIV

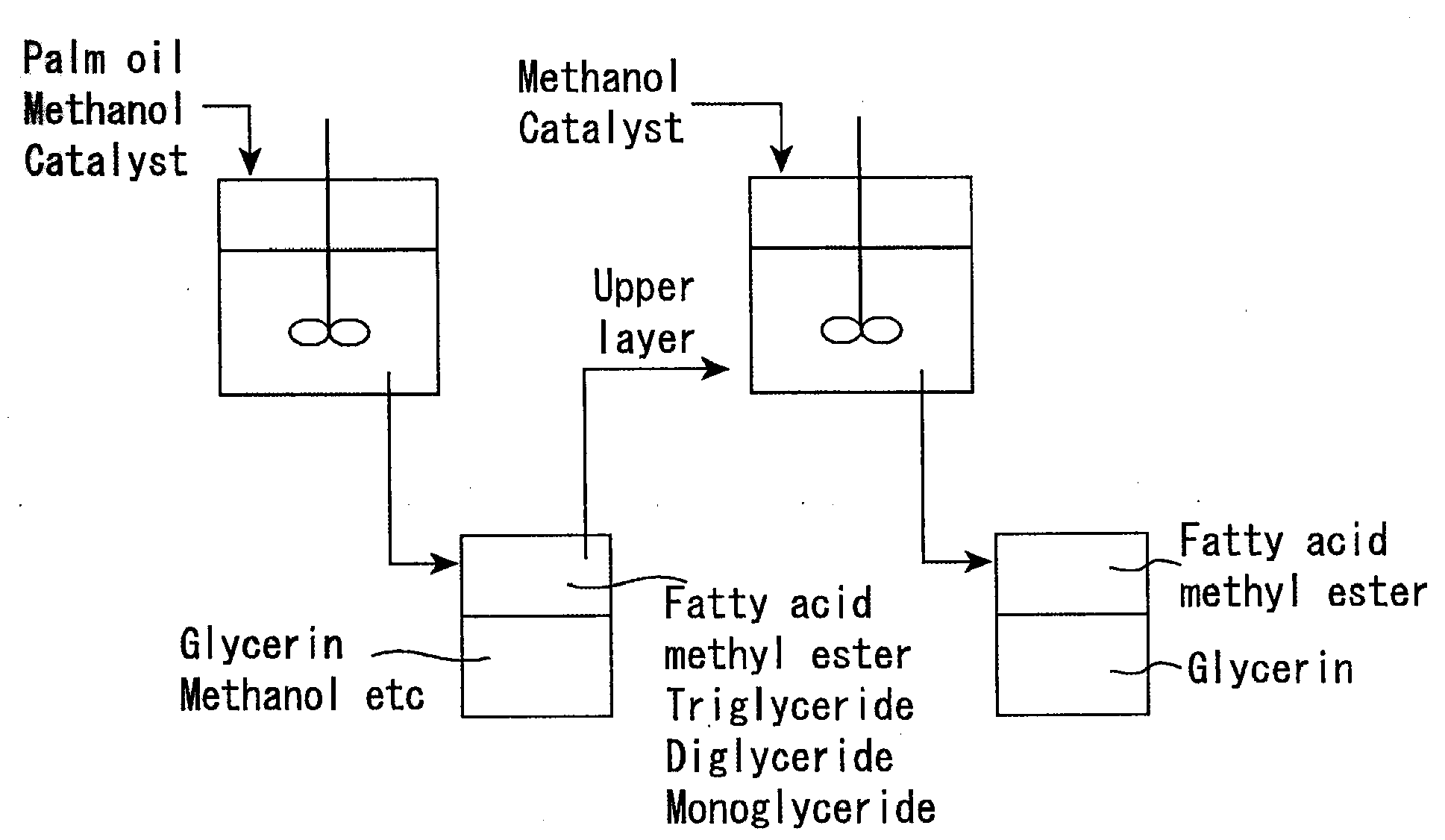

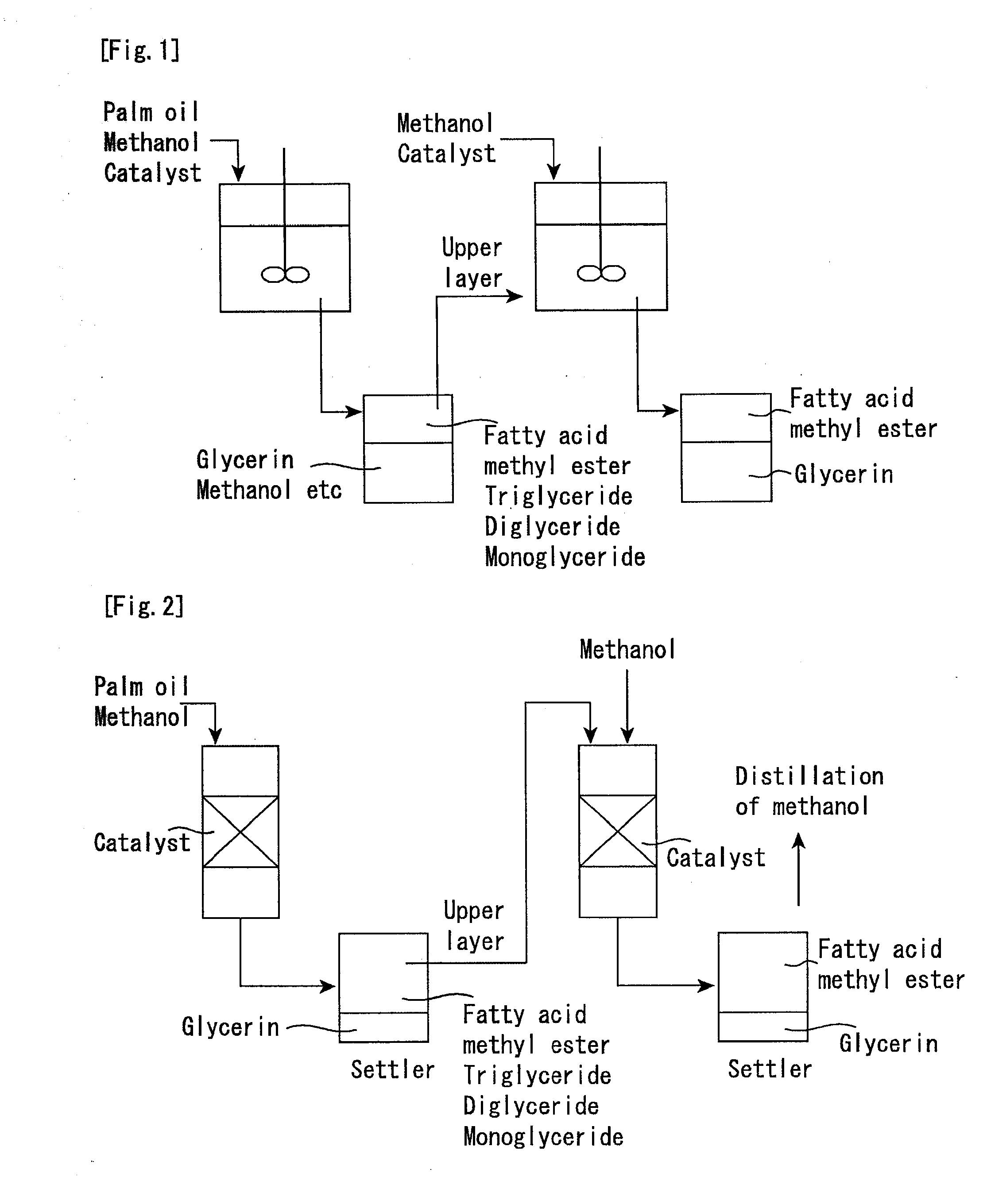

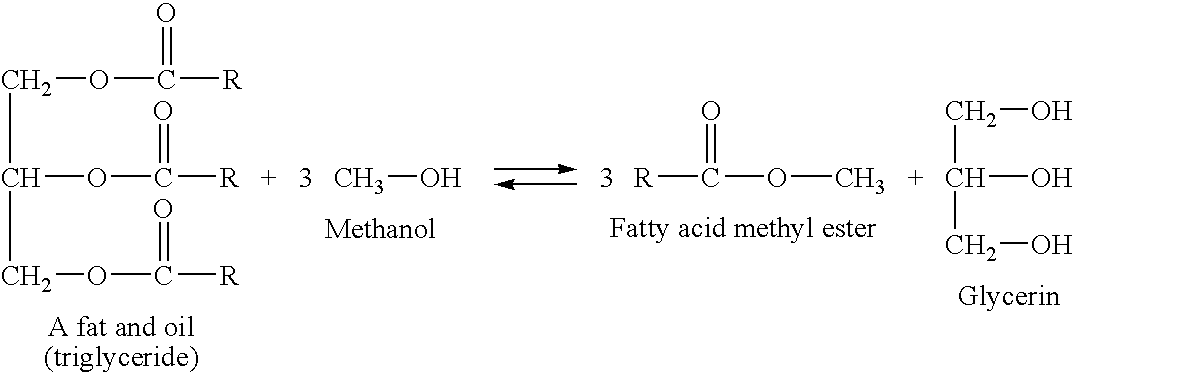

Method for producing fatty acid alkyl esters and/or glycerin

InactiveUS20090069586A1Reduce componentsAvoid leachingNitrogen compoundsFatty acid esterificationGlycerolHigh activity

To provide: a production method using a catalyst which can substantially suppress leaching of active metal components and exhibit high activity for both reactions of transesterification of glycerides and esterification of free fatty acids each contained in a fat or oil; and the catalyst. A method for producing fatty acid alkyl esters and / or glycerin comprising a step of bringing a fat or oil into contact with an alcohol in the presence of a catalyst, wherein the catalyst is at least one catalyst selected from the group consisting of the following (I) to (V):(I) a metal oxide having an ilmenite structure and / or a slyrankite structure;(II) an oxide containing a metallic element belonging to the Group 12 and a metallic element belonging to the Group 4;(III) a mixed oxide containing a metallic element belonging to the Group 12 and a tetravalent transition metallic element;(IV) a metal oxide containing zirconium and at least one metallic element selected from the group consisting of metallic elements belonging to the Groups 4, 5 and 8; and(V) a metal oxide containing anatase type titanium oxide and / or rutile type titanium oxide, and the metal oxide containing a sulfur component of 700 ppm or less.

Owner:NIPPON SHOKUBAI CO LTD +1

Green body of red soil ceramic and formula of transmutation glaze of red soil ceramic

The invention relates to a green body of red soil ceramic. The green body of the red soil ceramic is prepared from the following raw materials: red soil, quartz, talc, limestone and dolomite; the transmutation glaze of the red soil ceramic is prepared from the following raw materials: potassium feldspar, albite, calcium oxide, barium oxide, kaolin, quartz powder, sodium tripolyphosphate, titaniumoxide, rutile, zinc oxide and a coloring agent. By addition of other mineral raw materials, chemical raw materials and the like, the physical performance and the chemical performance of the green body are changed and the technical problems that the green body glaze of the red soil product is difficult to combine and the product is loose and fragile are solved; the firing temperature of the glaze is reduced from 1,310 DEG C to 1,230 DEG C, so thatthe firing temperature is reduced by 80 DEG C, the using amount of the fuel and the discharge quantity of harmful gas are reduced, environmental protection is contributed and production cost is greatly saved; and by development of the lead-free transmutation glaze, the lead-free transmutation glaze is suitable for being combined with the green body of the red soil ceramic, so that the problem of pollution to the ceramic decorative environment is solved fundamentally.

Owner:FUJIAN JIAMEI GRP +1

Crystalline glaze of iron, zinc and augite and its material compounding process

The iron and zinc augite crystalline glaze is prepared through introducing great amount of ferric oxide and zinc oxide into augite crystalline glaze and through a conventional color glaze sintering process. Chemically, the iron and zinc augite crystalline glaze consists of SiO2 50-60 wt%, AL2O3 5-8 wt%, K2O 0-1 wt%, Na2O 2.5-3.5 wt%, CaO 6-7 wt%, MgO 5 -6 wt%, Fe2O3 5-15 wt% and ZnO 3-10 wt%. The iron and zinc augite crystalline glaze is prepared with the materials including albite 20-35 weight portions, calcite 10-18 weight portions, talcum 15-25 weight portions, iron red 5-15 weight portions, zinc oxide 3-10 weight portions, kaolin 3-5 weight portions and quartz 20- 30 weight portions.

Owner:HUNAN HUALIAN CHINA IND

Refractory material for steel tapping hole of converter and preparation method for refractory material

The invention relates to a refractory material for a steel tapping hole of a converter and a preparation method for the refractory material. The technical scheme of the invention is as follows: the preparation method comprises the steps of spraying the surface of a magnesia-carbon brick body with a glaze slip coating with the thickness of 1mm to 2mm, carrying out drying, and carrying out heat preservation, thereby preparing the refractory material for the steel tapping hole of the converter. A preparation method for the magnesia-carbon brick body comprises the steps: mulling magnesia fines, flake graphite fines, expandable graphite, aluminum powder and silicon powder in a high-speed mulling machine, so as to prepare mixed fine powder; and then, mulling fused magnesia granules and artificial graphite granules, adding phenol-formaldehyde resin into the mixture, carrying out mulling, then, adding granulated graphite and the mixed fine powder into the mulled mixture, carrying out mulling, carrying out aging, carrying out shaping, and carrying out standing, thereby preparing the magnesia-carbon brick body. A preparation method for glaze slip comprises the steps of adding water into glass powder, spodumene, potassium feldspar, silicon micropowder, potassium carbonate, SiC fines, chrome green and aluminum dihydrogen phosphate, which serve as raw materials of the glaze slip, and carrying out grinding, thereby preparing the glaze slip. The refractory material for the steel tapping hole of the converter, prepared by the preparation method, has the characteristics that the thermal shock stability is good, the integrity is good, the oxidation resistance is good, the erosion resistance is good, and the life is long.

Owner:WUHAN UNIV OF SCI & TECH

Light blue jun porcelain and firing method thereof

ActiveCN106045563ADoes not affect strengthHelp to combineCeramic materials productionCeramicwareTin dioxidePotassium

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Calcium feldspar porous ceramics with controllable structure and adjustable performance and preparation method thereof

The invention provides calcium feldspar porous ceramics with controllable structure and adjustable performance; the invention also provides a preparation method of the calcium feldspar porous ceramic with controllable structure and adjustable performance. Because the preparation method has the advantages of both a mechanical foaming method and a gel injection molding method, the prepared calcium feldspar porous ceramics have excellent physical properties: the apparent porosity is 61.23%-90.19%, the volume density is 0.26-1.04 g / cm<3>, the compressive strength is 0.27-13.39 MPa, and the room-temperature vacuum thermal conductivity is 0.018-0.27 W / m.K.

Owner:BEIJING JIAOTONG UNIV

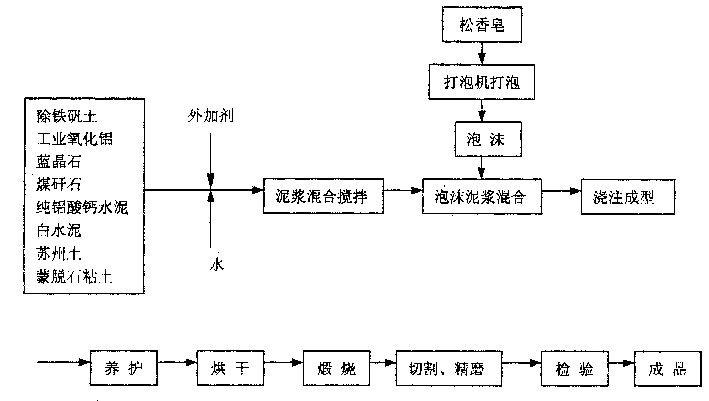

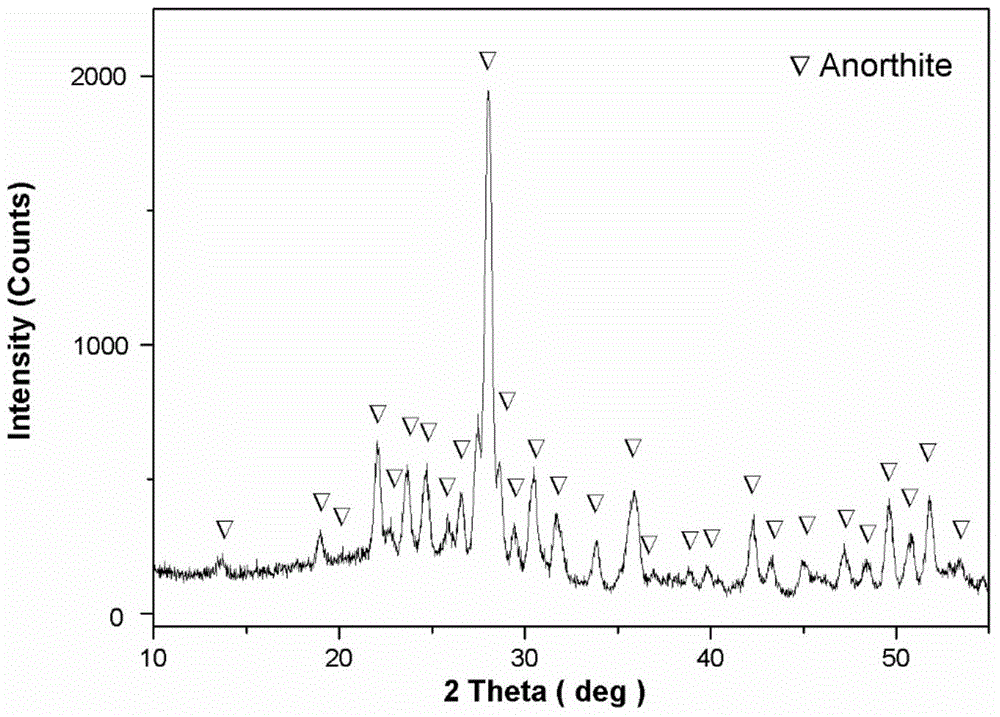

Anorthite light refractory brick and preparation method thereof

The invention relates to an anorthite light refractory brick and a preparation method thereof and belongs to the field of refractory materials. The brick comprises 35-37% of Al2O3, 40-50% of SiO2, less than 1% of Fe2O3, 10-15% of CaO and less than 1.1% of Na2O+K2O. The volume concentration is in a range from 480Kg / m3 to 510Kg / m3, the compressive strength is more than 1.0 Mpa, the thermal conductivity is 0.14W / m.K below 400 DEG C, and the reheating linear change rate is 1200 DEG C *24h<-1.0%. According to the preparation method, raw materials are normal, large in quantity, easy to obtain and low in cost in the market. The requirement of the preparation method for devices is low.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Method for producing aluminum magnesium titanate sintered product

ActiveUS20060009347A1High mechanical strengthImprove stabilityCeramic shaping apparatusClaywaresContinuous useTitanium

The present invention provides a process for preparing a sintered body comprising as a basic component aluminum magnesium titanate represented by the composition formula: MgxAl2(1−x)Ti(1+x)O5 wherein the value of x is 0.1≦x<1. The process comprises a step of sintering a formed product from a raw material mixture comprising 100 parts by weight, calculated on an oxide basis, of a mixture comprising a Mg-containing compound, an Al-containing compound and a Ti-containing compound at the same metal component ratio as the metal component ratio of Mg, Al and Ti in the above composition formula, and 1-10 parts by weight of an alkali feldspar represented by the composition formula: (NayK1-y)AlSi3O8 wherein the value of y is 0≦y≦1. According to the process of the present invention, a sintered body of aluminum magnesium titanate having stability in continuous use at high temperatures and excellent mechanical strength, while maintaining inherently low thermal expansibility of a sintered body of aluminum magnesium titanate, can be obtained.

Owner:OHCERA CO LTD

Castorite/cordierite multi-phase low-buckling ceramic and preparation method thereof

The invention relates to a petalite / cordierite multiphase low expansion ceramic and preparation method thereof. The invention is characterized in that: the invented low expansion ceramic with a main crystal phase of compound petalite and cordierite multiphase crystal structure is made from the following materials that are: petalite, kaolin and talc, and adopts common sintering method of ceramic. The heat expansion coefficient Alpha is 1.0-2.0 multiplied by 10-6 DEG C. The low expansion ceramic with good thermal stability can be made without using expensive lithium containing material such as spodumene and lithium carbonate. The invention can be broadly used in making kiln furniture, high temperature clamp, high temperature radiation baffle, homely heat-resistant tableware, and thermocouple protective tube, etc.

Owner:JINGDEZHEN CERAMIC UNIV

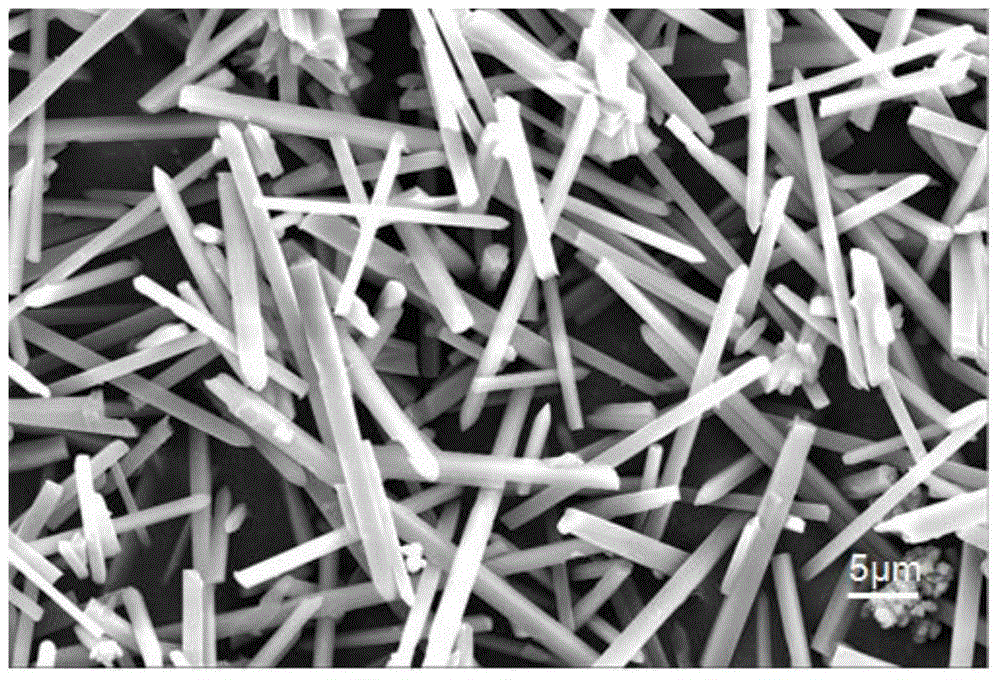

Mullite-whisker-reinforced anorthite porous ceramic and preparation method thereof

InactiveCN105198478ARaw materials are easy to getGood lookingCeramicwareSolid state reaction methodSilicon dioxide

The invention provides a mullite-whisker-reinforced anorthite porous ceramic and a preparation method thereof. The preparation method comprises the following steps: preparing pure-phase high-length-diameter-ratio high-dispersibility mullite whisker by a solid reaction process, preparing a porous ceramic billet from the mullite whisker, alpha-aluminum oxide, silicon dioxide and calcium carbonate powder by a foam gelcasting process, and finally, sintering at 1450 DEG C for 5 hours to obtain the mullite-whisker-reinforced anorthite porous ceramic. The material prepared by the method has the advantages of high porosity, low thermal conductivity and high strength. The apparent porosity of the sample, in which the addition amount of the mullite whisker is 50 wt.%, is up to 90%; the room-temperature vacuum thermal conductivity is only 0.045 W / m.K; and the compression strength is up to 1.1 MPa. The research shows that the added mullite whisker inhibits the growth of the anorthite grains, and the high porosity, complicated pore structure and fine grains are main reasons for low thermal conductivity. The tight combination between the added whisker and base greatly enhances the strength of the material.

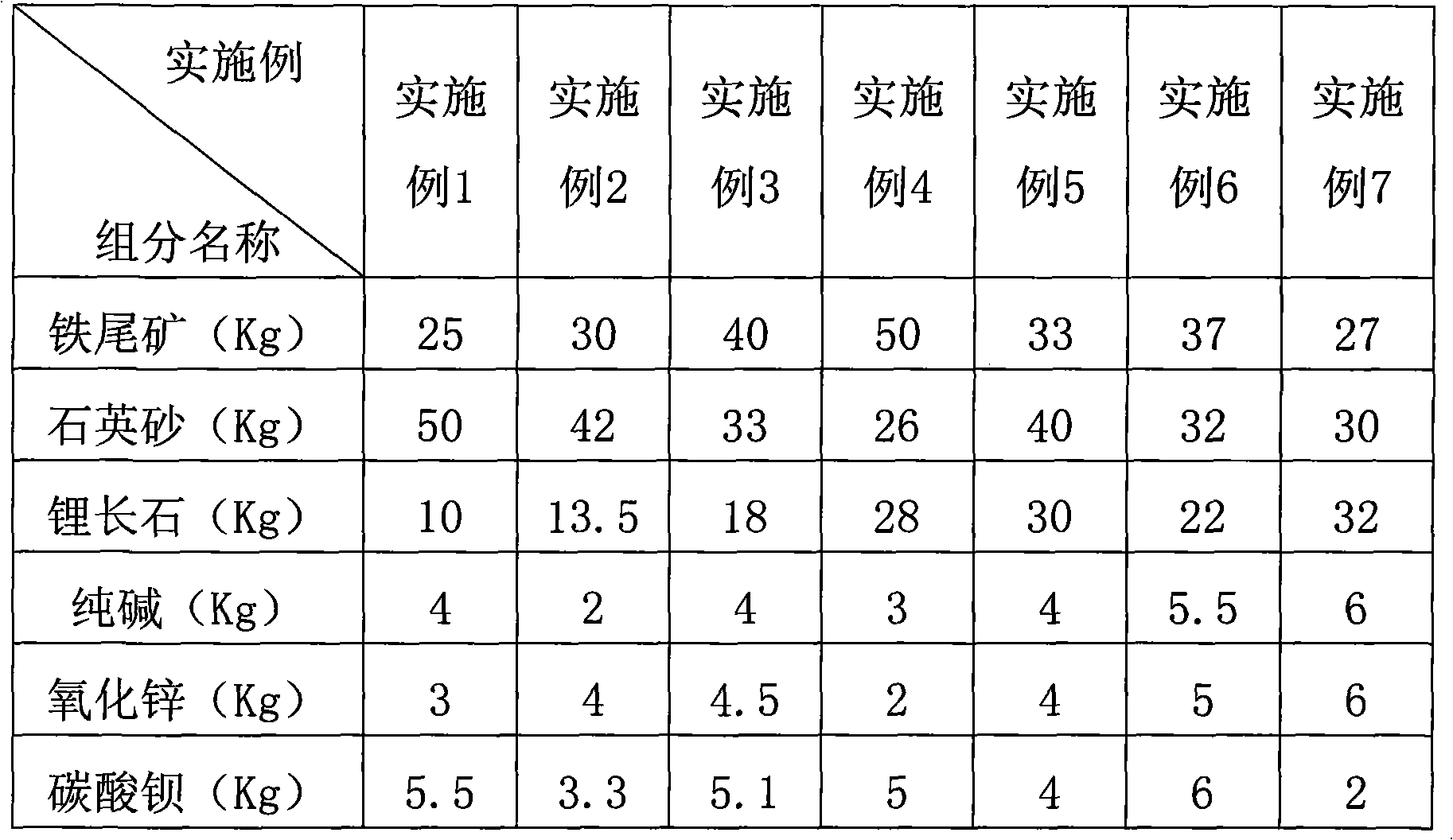

Black glass ceramic and production method thereof

The invention discloses a black glass ceramic and a production method thereof in order to solve the problems of the conventional glass ceramic, i.e. single color and high production technique cost. The black glass ceramic is produced with the following components in part by weight: 25 to 50 parts of iron tailings, 20 to 50 parts of quartz sand, 10 to 32 parts of petalite, 2 to 6 parts of sodium carbonate, 2 to 6 parts of zinc oxide, 2 to 6 parts of barium carbonate, 0 to 0.1 part of copper oxide, 0 to 2 parts of manganese dioxide, 0 to 0.2 part of cobalt oxide, 0 to 2 parts of chromic oxide and 0 to 3 parts of sodium nitrate. Since the invention utilizes the discarded iron tailings as the material of the black glass ceramic, the waste is made profitable, pollution is reduced, the environment is protected, moreover, the physicochemical performance of the product can be enhanced, and the single-color problem of the black glass ceramic is solved; the corrosion of the refractory material of a glass furnace by molten glass is reduced, and thereby the service life of the equipment is prolonged; and the application range of the black glass ceramic is wide.

Owner:浮山县晋盛新型建筑材料有限责任公司

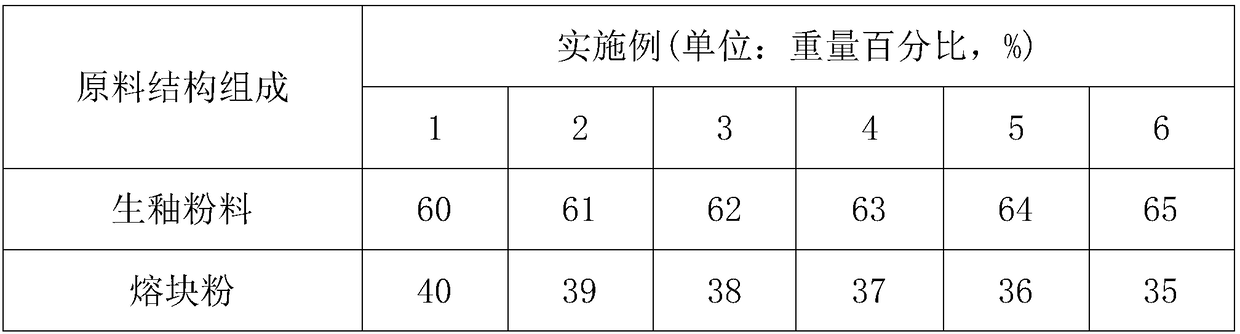

Silk texture anti-skid matt glaze, preparation method and ceramic tile using silk texture anti-skid matt glaze

The invention discloses a silk texture anti-skid matt glaze, a preparation method and a ceramic tile using the silk texture anti-skid matt glaze. In percentage by weight, a raw material of the silk texture anti-skid matt glaze consists of 60 to 65% of raw glaze powder and 35 to 40% of frit powder; in percentage by weight, a mineral composition of the raw material comprises: 15 to 20% of potassiumfeldspar, 12 to 16% of burnt talc, 8 to 12% of kaolin, 10 to 15% of barium carbonate, 2 to 5% of zinc oxide, 2 to 5% of calcined alumina and 35 to 40% of frit powder. The surface texture of the silk texture anti-skid matt glaze is smooth just like silk and a decorative effect of a pattern decorative layer is not influenced; glossiness is smaller than 10 degrees, and both a dry static friction coefficient and a wet static friction coefficient are greater than or equal to 0.55; wear resistance reaches the fourth level and over in the standard.

Owner:FOSHAN DONGPENG CERAMIC +3

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com