Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about How to "Overcome temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

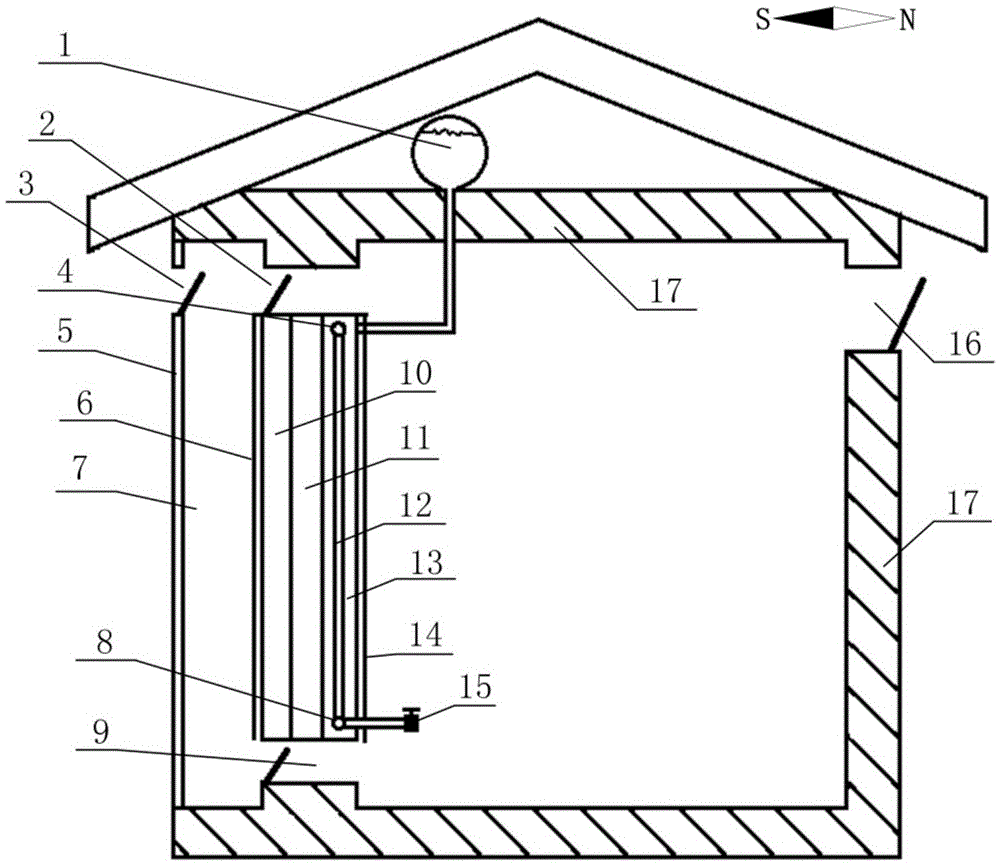

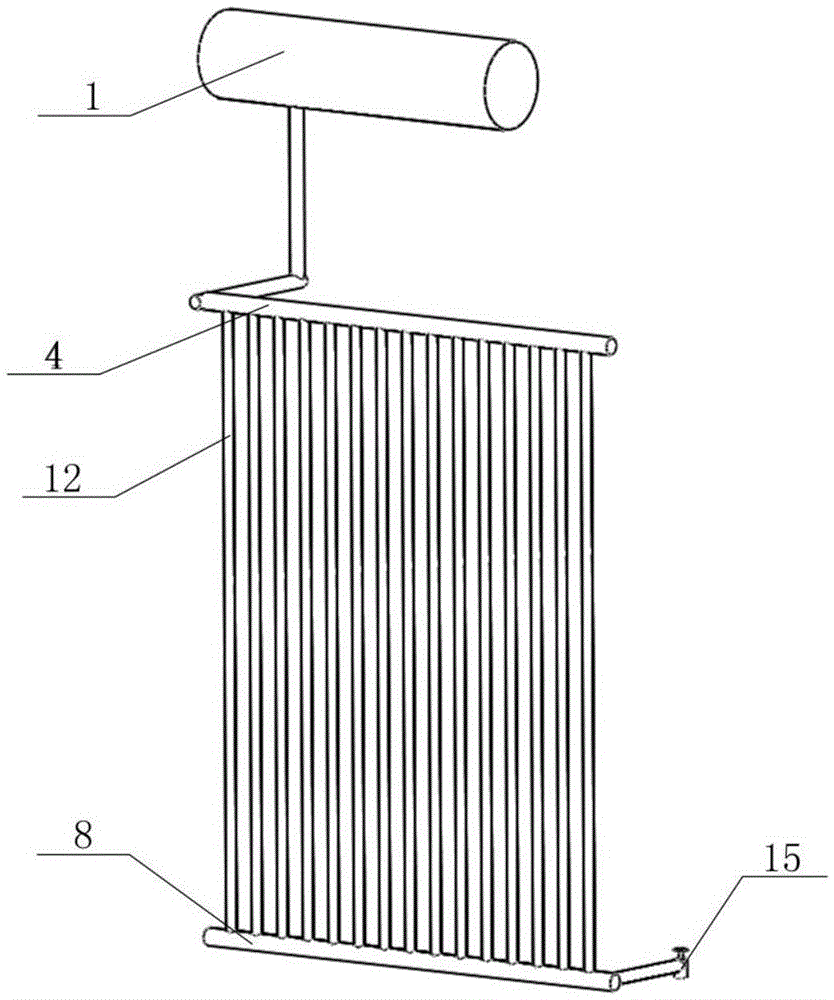

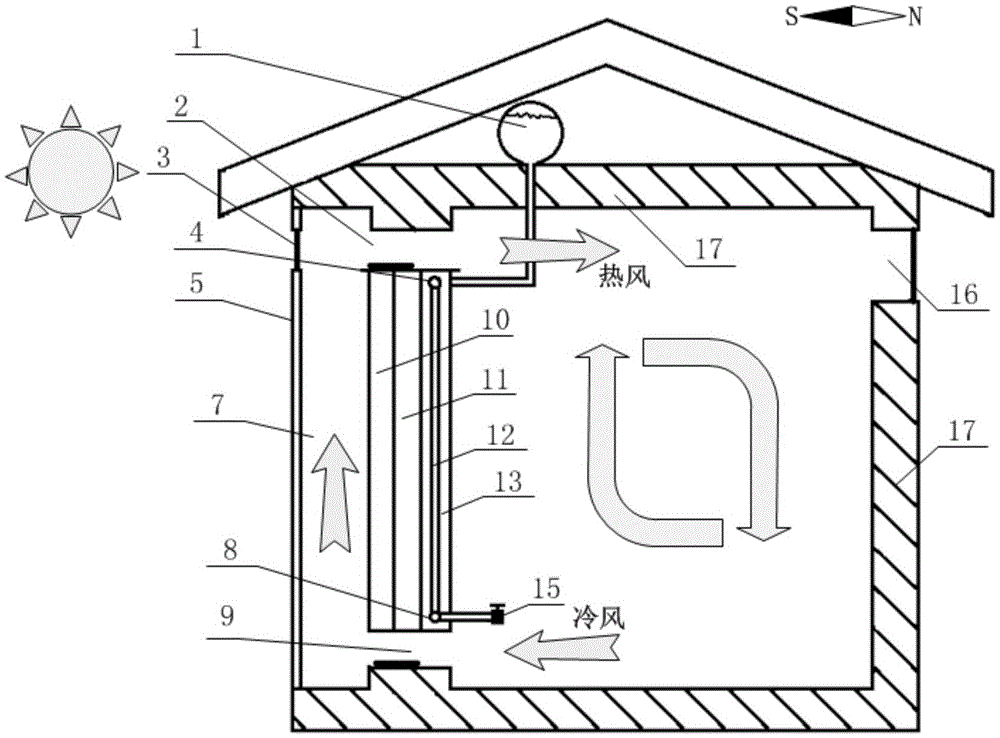

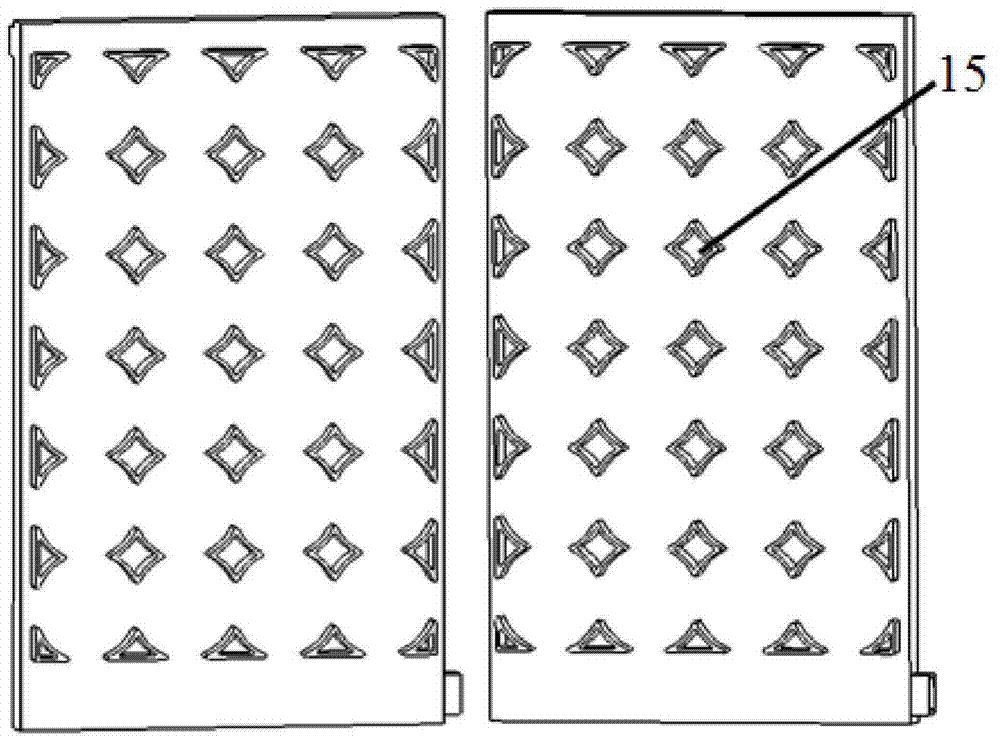

Solar phase change heat storage wall and ventilation system provided with same

ActiveCN105569213AAvoid instabilityIncrease heat storageSolar heating energyMechanical apparatusGlass coverEngineering

The invention provides a solar phase change heat storage wall and a ventilation system provided with the same. The solar phase change heat storage wall is formed by connecting a high-temperature phase change layer, a medium-temperature phase change layer and a low-temperature phase change layer sequentially, wherein the phase change temperatures of the high-temperature phase change layer, the medium-temperature phase change layer and the low-temperature phase change layer are set from high to low. A glass cover plate is arranged on the south side of the outer wall of the ventilation system; the rest part of the ventilation system is composed of an enclosure structure; an outdoor air inlet is formed in the upper part of the north side of the outer wall; and an outdoor air outlet is formed in the upper part of the south side. The solar phase change heat storage wall is positioned in the outer wall and close to the glass cover plate; the high-temperature phase change layer faces south; and an upper vent hole and a lower vent hole are formed in the upper part and lower part of the solar phase change heat storage wall respectively. A hot water system penetrates through the solar phase change heat storage wall to perform heat exchange. The solar phase change heat storage wall can overcome shortcomings of a conventional heat collection wall, has the advantages of good heat storage capability, diversified functions, simplicity for operation and no energy consumption, can achieve the effects of cooling by ventilation and domestic water heating in summer, and can be used for providing heat in winter, thereby having good application prospects.

Owner:陕西中为能源技术有限公司

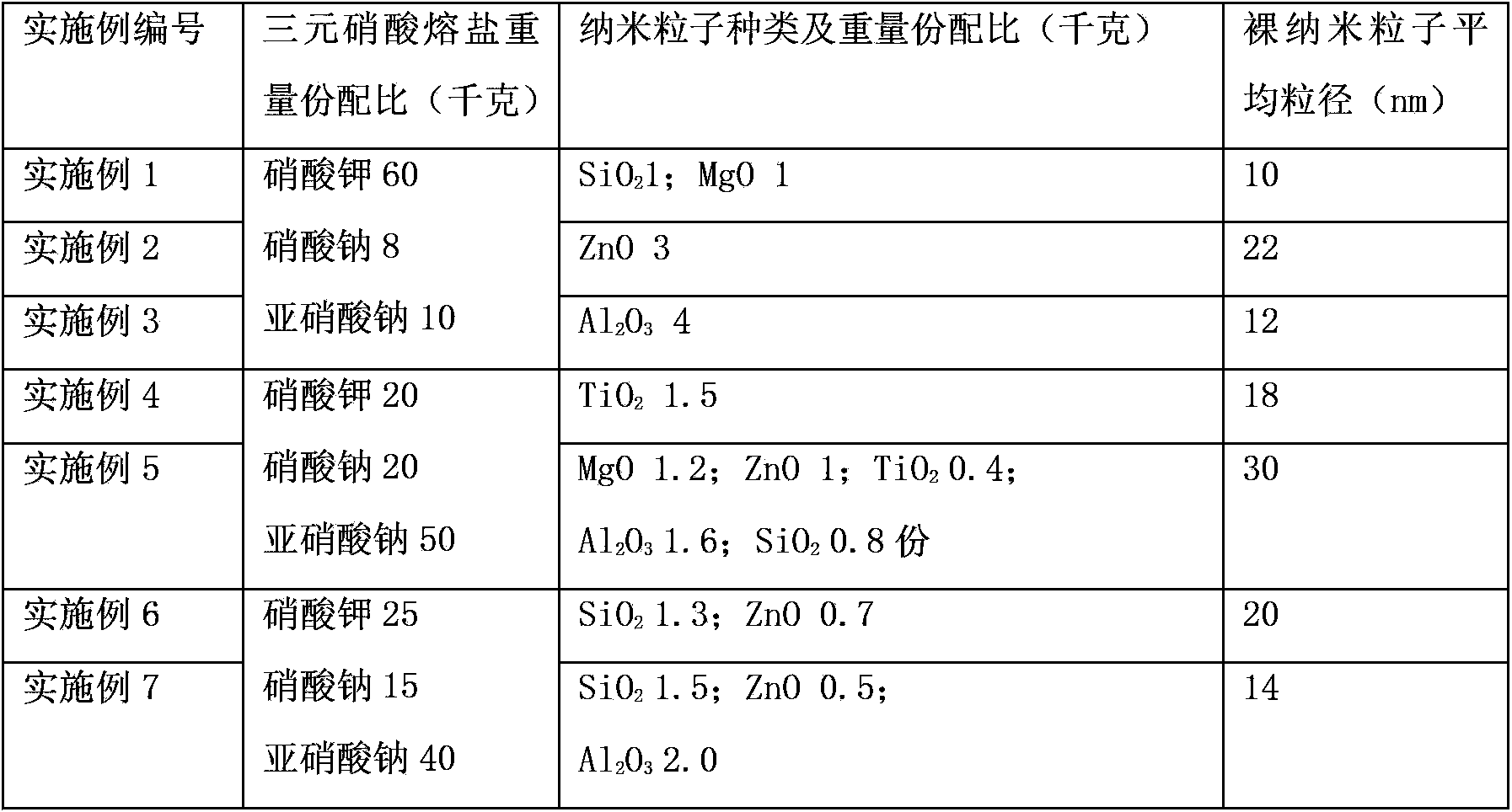

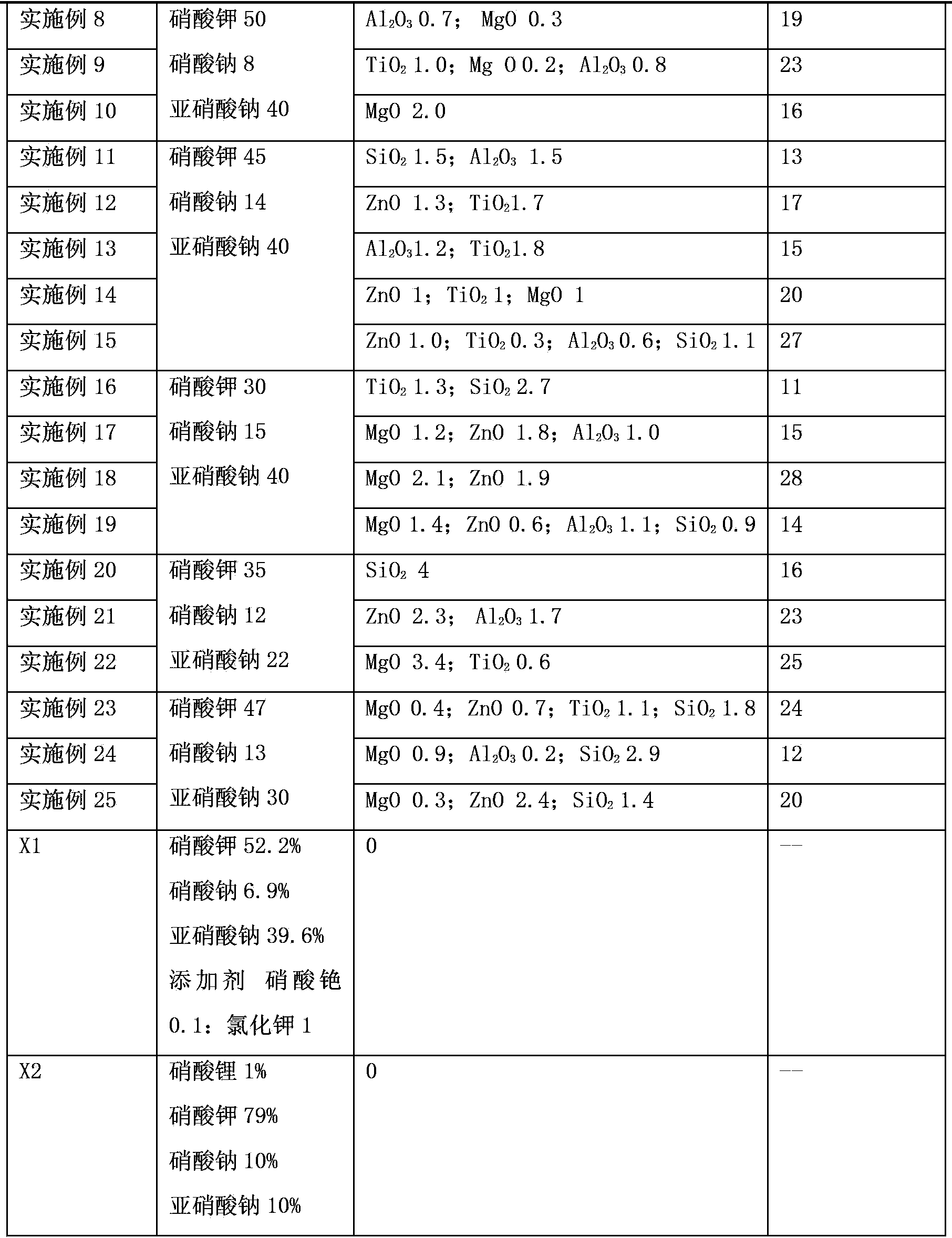

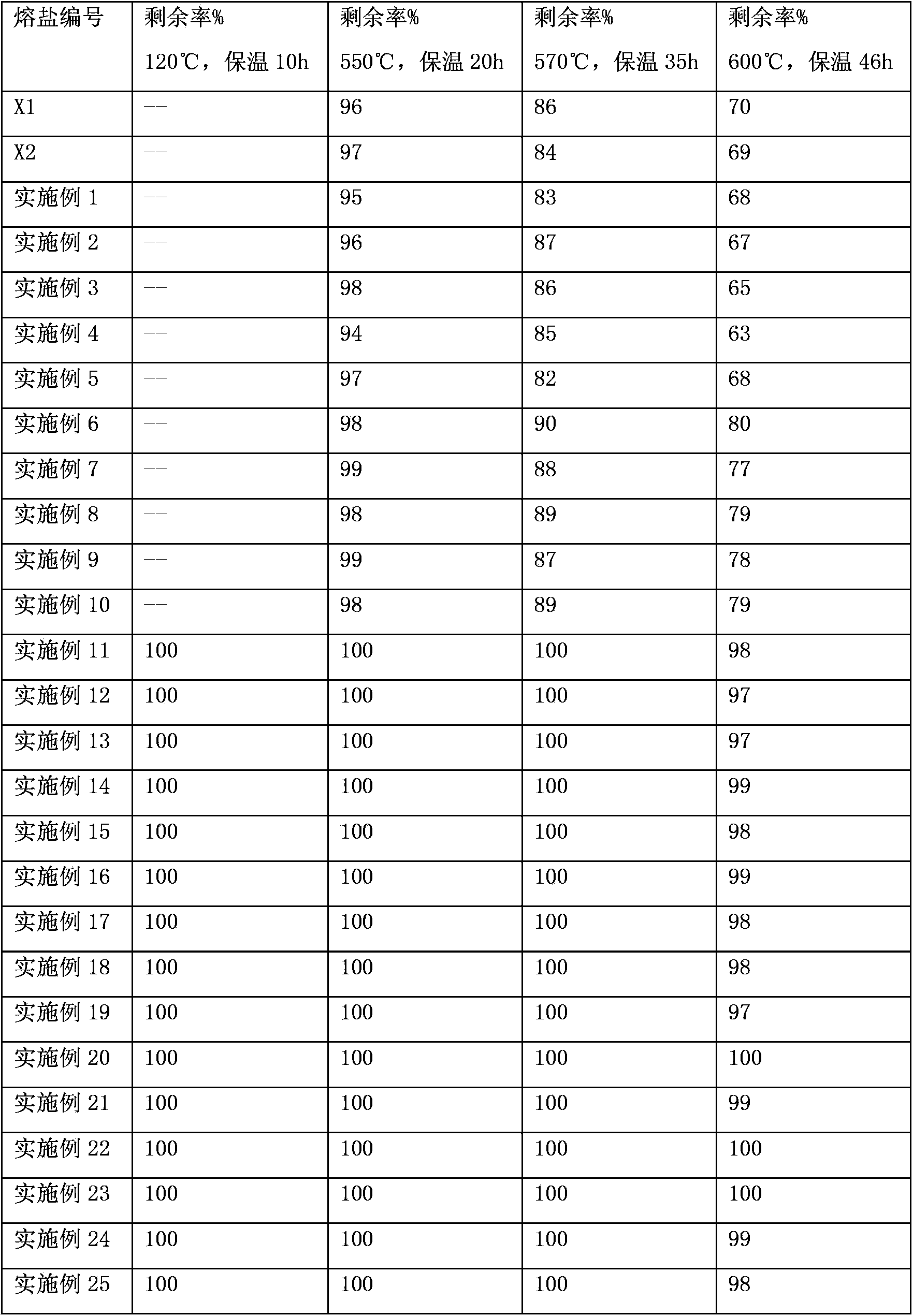

Ternary nitric acid nano-molten salt heat transfer and storage medium, preparation method and application thereof

InactiveCN103881662AOvercome solubilityOvercoming thermal conductivityHeat-exchange elementsMetal oxide nanoparticlesNanoparticles dispersion

Belonging to the technical field of heat storage and transfer, the invention provides a ternary nitric acid nano-molten salt heat transfer and storage medium, a preparation method and application thereof. The ternary nitric acid nano-molten salt heat transfer and storage medium contains a ternary nitric acid molten salt system formed by potassium nitrate, sodium nitrate and sodium nitrite. The ternary nitric acid nano-molten salt heat transfer and storage medium is characterized in that it also includes metal oxide nanoparticles and / or non-metal oxide nanoparticles. The nanoparticles are dispersed into the ternary nitric acid molten salt system to undergo compounding so as to form the ternary nitric acid nano-molten salt heat transfer and storage medium. The ternary nitric acid nano-molten salt involved in the invention has a low melting point, an upper limit use temperature up to 600DEG C, good thermal stability, and high heat conductivity, thus being very suitable for the heat storage and transfer system of industrial energy storage and solar-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

Halogen-free intumescent flame-retardant polypropylene/ethylene vinyl acetate cable material

ActiveCN101649088AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesExtensibilityUv absorber

The invention relates to a halogen-free intumescent flame-retardant polypropylene / ethylene vinyl acetate cable material which is characterized by comprising the following components by weight part: 20-40 parts of polypropylene, 60-80 parts of ethylene vinyl acetate, 45-65 parts of compound flame retardant, 5-15 parts of grafting agent, 1.0-2.0 parts of antioxidizer, 1.0-2.0 parts of ultraviolet absorbent and 1.0-3.0 of processing aid. With the advantages of favorable flexibility, high breakage extensibility, favorable tensile strength, excellent electrical insulating property and good flame retardant, the material favorably meets the requirements on the burning property, the mechanical property and the heat property of the cable material and is mainly used as the outer coating material ofcables.

Owner:应急管理部四川消防研究所

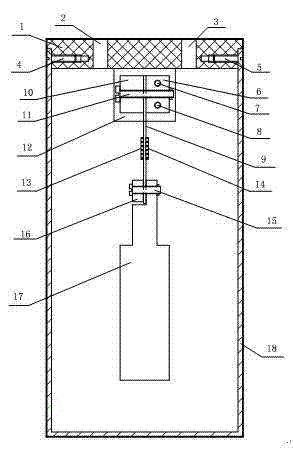

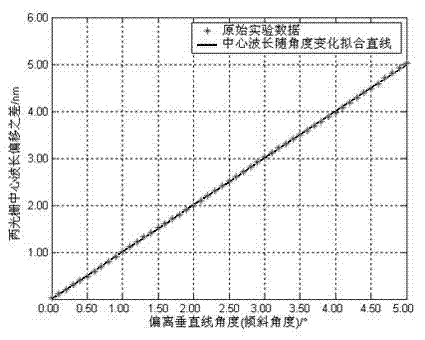

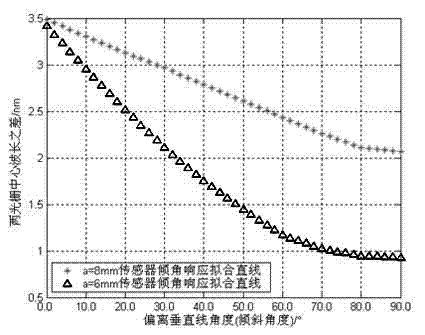

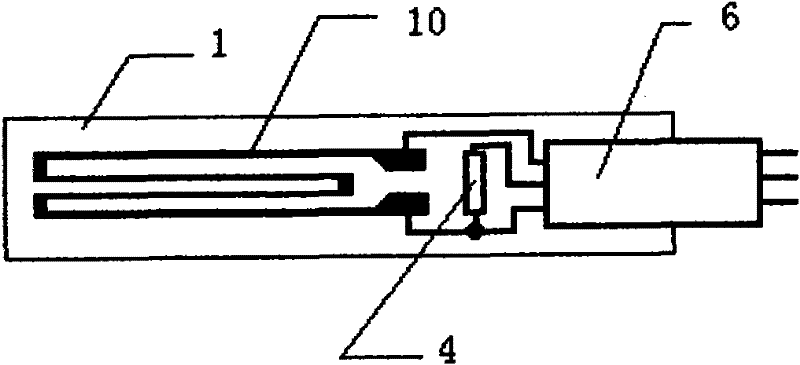

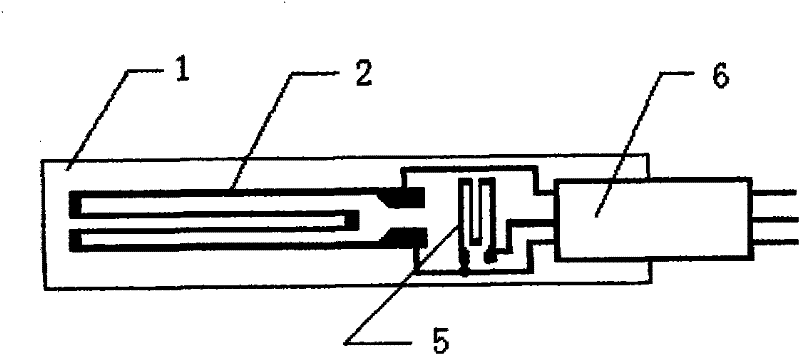

Inclination Sensor Based on Fiber Bragg Grating and Its Inclination Measurement Method

InactiveCN102288162AHigh measurement accuracyImprove machining accuracyIncline measurementGratingFiber Bragg grating

The invention relates to a tilt angle sensor based on optical fiber Bragg gratings and a method for measuring a tilt angle of the tilt angle sensor and belongs to the technical field of measurement of a structural tilt angle. The tilt angle sensor comprises a fixed base plate (12), a fixed pressing block (6), a thin-wall type uniform-section metal beam (9) and a quality block (7), wherein the upper end of the thin-wall type uniform-section metal beam (9) is arranged on the fixed base plate (12) in a mode of fitting with the fixed pressing block through a first movable pressing block (10) and a fifth screw (11); the quality block (7) is fixed at the lower end of the thin-wall type uniform-section metal beam (9) through a sixth screw (15) and a second movable pressing block (16); and a first optical fiber Bragg grating (13) and a second optical fiber Bragg grating (14) are respectively adhered to opposite positions on two sides of the thin-wall type uniform-section metal beam (9). By the method, the size and direction of the tilt angle can be detected according to a correspondence relation between the change of central wavelengths of the two optical fiber Bragg gratings and the tiltangle. The invention is high in measurement accuracy and has a temperature self-compensation function.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Low-surface energy antifouling seagoing ship paint and its prepn

InactiveCN1388196ANon-toxicMeet environmental protection requirementsAntifouling/underwater paintsPaints with biocidesEmulsionOrganic solvent

The antifouling paint is prepared with core-shell type fluorous acrylate emulsion as base material, heavy CaCO3 stuffing, pigment, densifier, dispersant, glycol filming assistant, lubricant, leveling agent, preservative, defoaming agent, deionized water and ammonia water. Its preparation process includes semi-continuous polymerization to synthesize core-shell fluorous emulsion, mixing the emulsion with filming assistant, mixing with other components and filtering. The antifouling paint has low surface energy and indexes meeting the requirement for environment protection, and is soluble in common organic solvent.

Owner:HUBEI UNIV

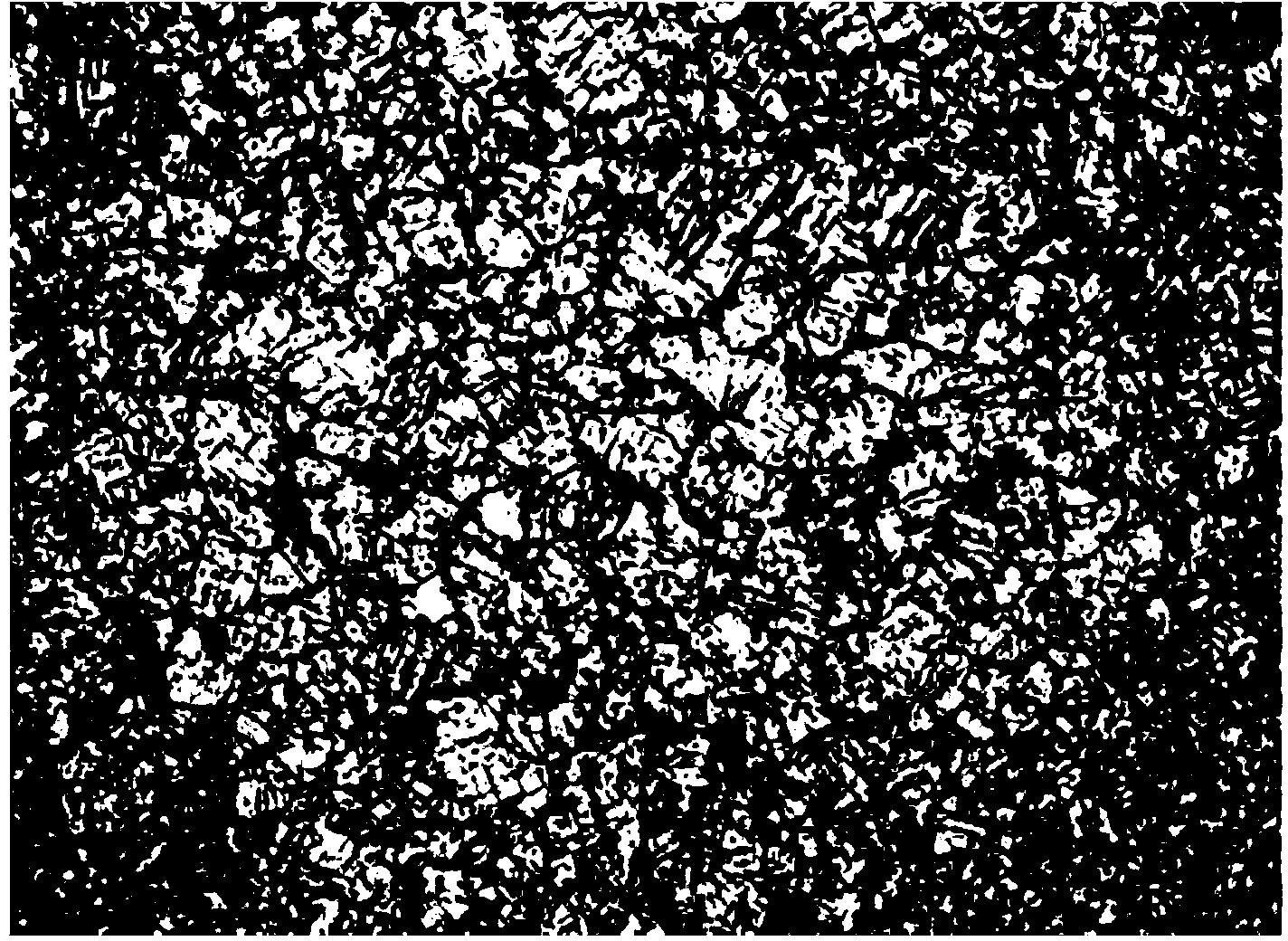

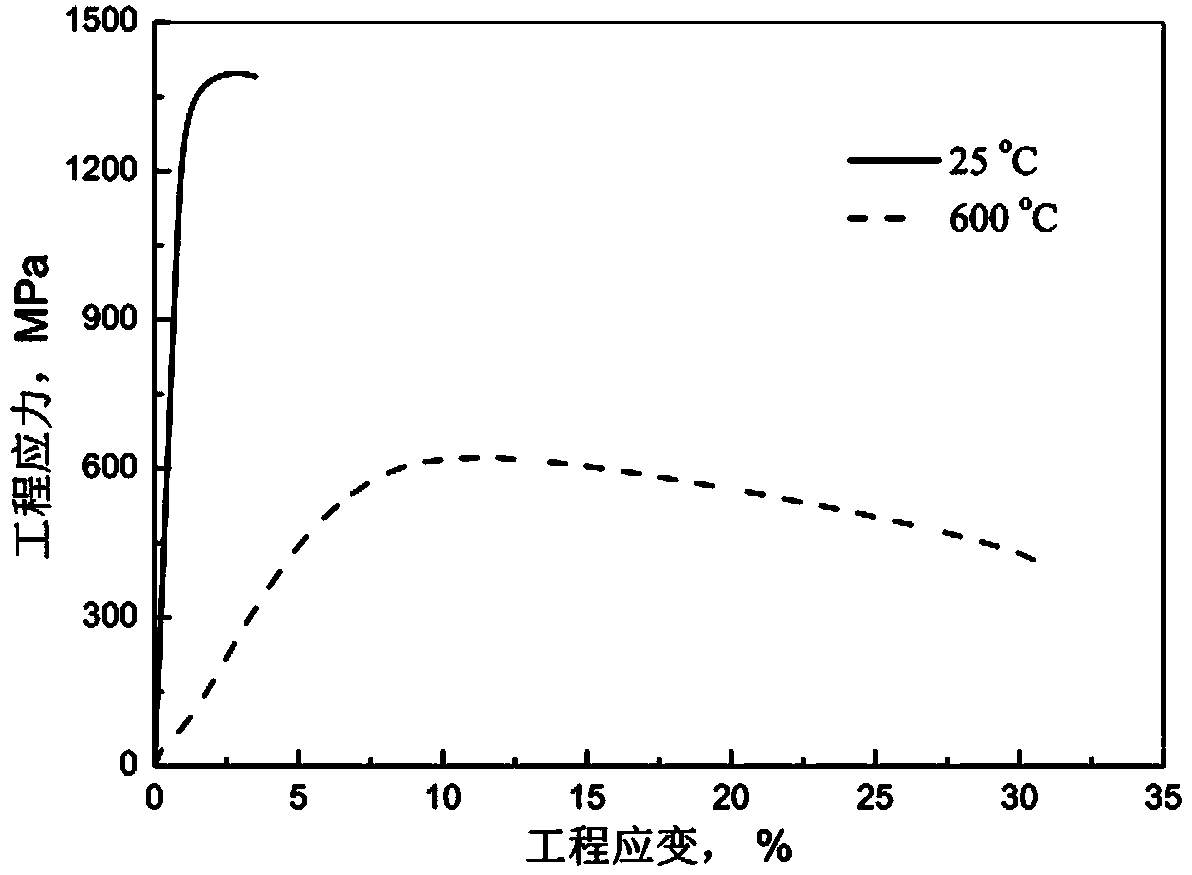

Preparation method of TiBw/Ti-6Al-4V composite bar adopting quasi-continuous reticular structure

The invention relates to a preparation method of a TiBw / Ti-6Al-4V composite bar adopting a quasi-continuous reticular structure and solves problems that existing Ti-6Al-4V composites are harsh in technological condition, high in equipment requirement, low in production efficiency, difficult to produce on a large scale and the like. The method comprises steps as follows: low-energy ball milling and mixing are performed on spherical Ti-6Al-4V powder and TiB2 powder firstly; then TiB2 / Ti-6Al-4V mixed powder is placed in a metal sheath for cold press molding, and vacuum degassing and sheath sealing welding are performed to obtain an extrusion billet; finally, short-time pre-sintering is performed on the obtained extrusion billet, and hot extrusion deformation is performed on the pre-sintered extrusion billet to obtain a required material. The method can be applied to preparation of a TiBw / Ti-6Al-4V composite adopting the quasi-continuous reticular structure.

Owner:HARBIN INST OF TECH AT WEIHAI

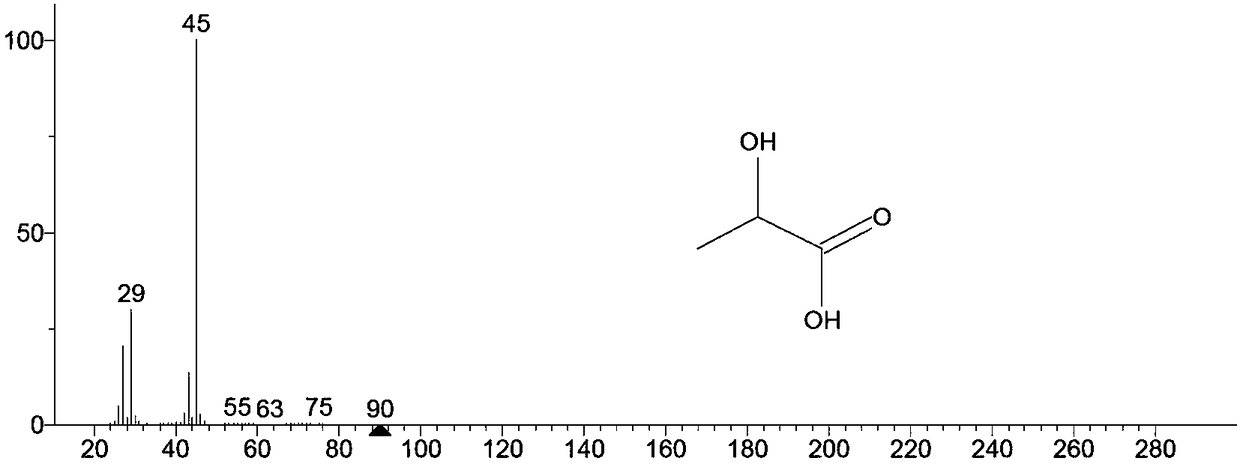

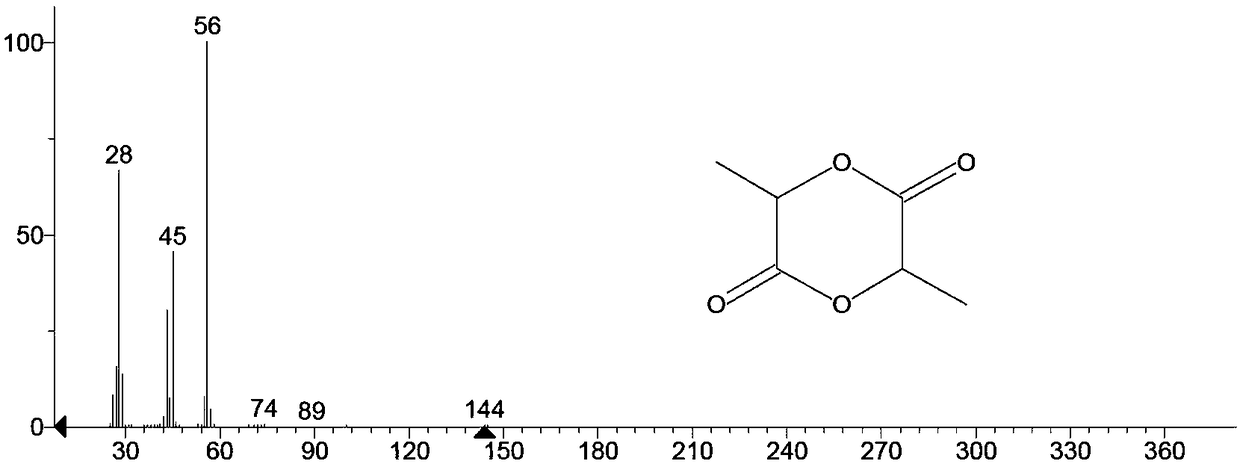

Preparation method of lactide

The invention provides a preparation method of lactide. The method comprises the following step: lactic acid is subjected to a heating reaction under reduced pressure in presence of an H-beta molecular sieve, and lactide is obtained, wherein the reaction pressure is 50-1500 Pa. With adoption of the method adopting vacuum and heating, lactic acid reaction is catalyzed by the H-beta molecular sieve,synthesis of lactide from lactic acid is finished directly, lactide with high optical purity (higher than 96%) is obtained, and the defects of long technological process and high reaction temperaturecaused by the that that oligomerization and high-temperature pyrolysis are needed in the conventional lactide are overcome. No organic solvent is used in the whole preparation process, only wastewater is produced during preparation, and little environmental pollution is caused; the reaction temperature is low, repeated catalysis is realized through hydrolysis of a lactic acid oligomer, the H-betamolecular sieve can be recycled, and the preparation process is simple and environmentally friendly and has potential large-scale application prospect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

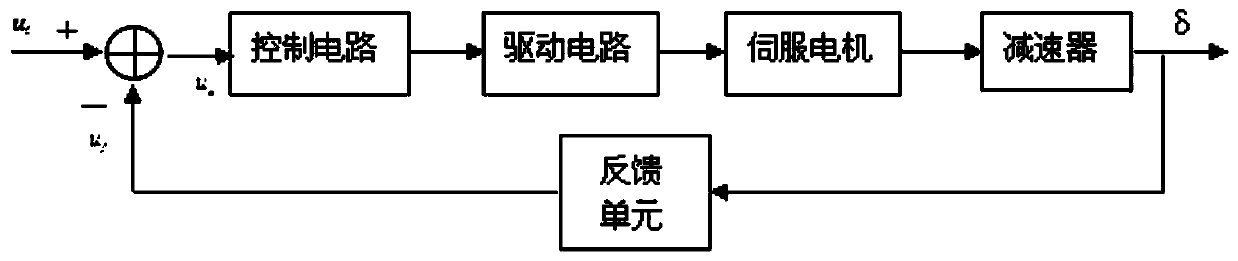

Position loop control-based electric steering engine system

InactiveCN103699134AOvercoming dispersionOvercome temperaturePosition/course control in three dimensionsLoop controlControl signal

The invention relates to an electric steering engine system, and particularly discloses a position loop control-based electric steering engine system, which is implemented in a way of combining hardware and software. A DC / DC (direct current / direct current) power supply with isolated output is adopted for a power circuit in a hardware design, and missile power is transformed to be supplied to each unit circuit; TMS320F2812 is adopted as a master control unit of a control circuit, and is used for acquiring a rudder control signal and a rudder deflection angle feedback signal, integrating and amplifying errors of the rudder control signal and the rudder deflection angle feedback signal, calculating an actually output PWM (pulse width modulation) signal by using a fuzzy PID (proportion integration differentiation) algorithm, and providing the PWM signal for a driving circuit; the driving circuit is used for performing power amplification on the signal, and driving a steering engine execution mechanism to rotate, thereby realizing closed-position loop control on the electric steering engine system.

Owner:陕西航天导航设备有限公司

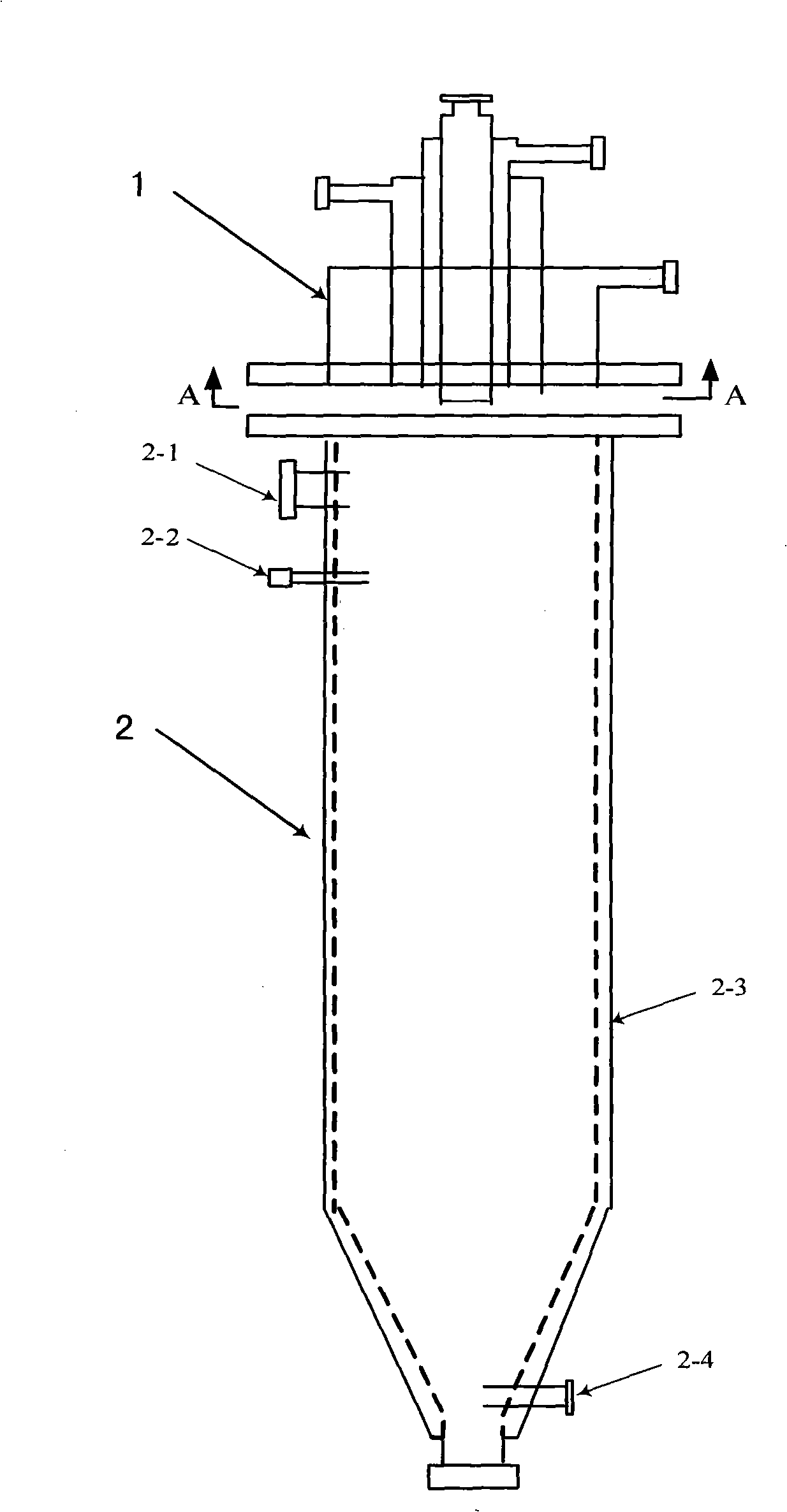

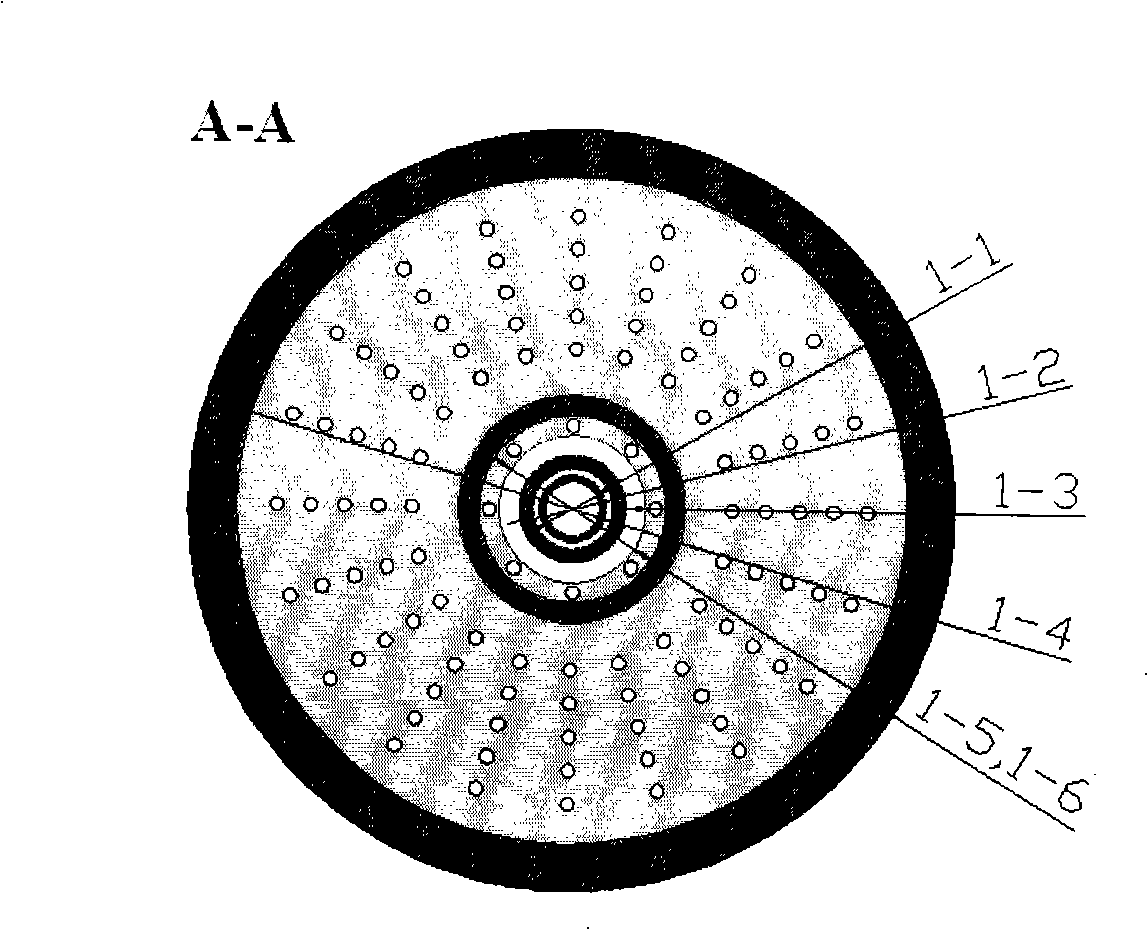

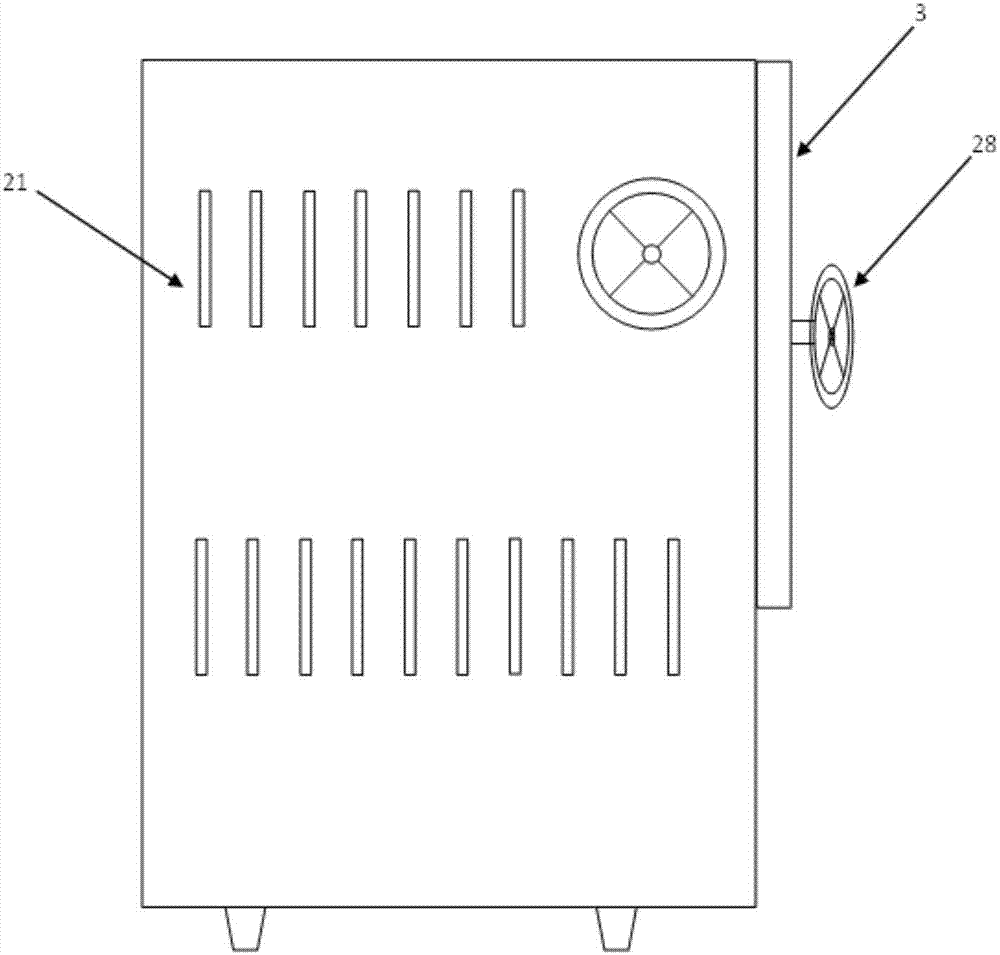

Gas-phase combustion reactor for preparing nano granule and its industrial application

ActiveCN101264433AAvoid scaringOvercome temperatureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTin dioxideGas phase

The invention discloses a gas phase combustion reactor for preparing nanometer particles and the industrial application method. By changing the nozzle structure of the reactor in the prior art, the reactor enables the reaction material and the combustion gas to be evenly mixed to form ultrahigh speed jet flame, overcomes the defects of uneven temperature field and concentration field and liability to scab of nozzle, and enables continuous production for long period. The gas phase combustion reactor can be used for industrial and continuous preparation of various oxide nanometer particles such as nanometer titanium dioxide, silicon dioxide, aluminum oxide, and antimony doped tin dioxide.

Owner:EAST CHINA UNIV OF SCI & TECH

Nutrient solution matrix-free seedling raising and cultivating system and seedling raising method

ActiveCN101965795AAvoid restrictionsAvoid disadvantagesAgriculture gas emission reductionCultivating equipmentsNutrient solutionOxygen

The invention discloses a nutrient solution matrix-free seedling raising and cultivating system and a seedling raising method. The system comprises a nutrient solution seedling raising tank, a seedling grid plate, seeding paper and covering paper, wherein the nutrient solution seedling raising tank is filled with water or nutrient solution; the seedling raising grid plate is arranged on the nutrient solution seedling raising tank, and water through holes are formed on the side faces of the grid plate holes of the seedling raising grid plate; the seeding paper is laid on the seedling raising grid plate; and after seeding, the covering paper is covered on the seeding paper bearing seeds. The method comprises: sowing seeds on the seeding paper, covering the covering paper with high water absorbing performance and breathability and covering the perlite or vermiculite on the covering paper; and after the seeds germinate, the roots of the seedlings penetrate the seeding paper to grow downward to absorb water and nutrients from the nutrient solution below. When the system is used, a matrix which is adopted by the conventional industrial seeding raising technique is not used, the overall accurate control over the temperature, water, nutrient and oxygen required by plants for growth in the whole seedling raising process is realized, the industrialization of the seedling raising processis realized, and the uniformity, strong seedling rate and robust degree of the seedlings are improved.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

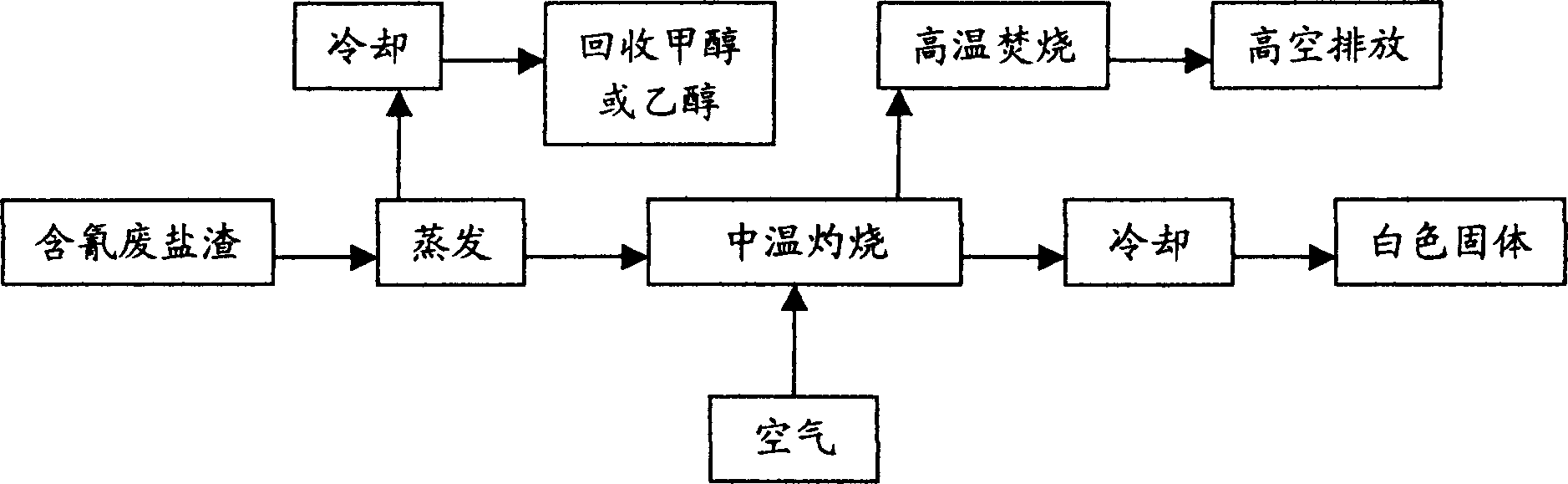

Method for treating waste salt dregs containing cyanogen

The invention relates to a processing method for cyanogens contained waste salt dredge, the process steps are: the cyanogens contained waste salt dredge is put into the drier to be heated; the heating temperature is controlled with 60-120deg.C, the carbinol and the alcohol volatilize from the dredge, the carbinol and the alcohol are reclaimed with high purity after beings cooled in the condenser; the cyanogens contained waste salt dredge without carbinol and alcohol is baked in oxygen condition, the oxide in the dredge is fully oxidized, the organic is oxidized or volatilized off, thus eliminates the cyanogens and organic in the salt dredge; the gas generated in the baking process is transmitted to the burning furnace, the temperature is not lower than 1100deg.C, thus the tail gas may accord the discharging standard.

Owner:邱滔 +1

Manganese oxide mineral sulfur-based fire reduction method

The invention discloses a manganese oxide mineral sulfur-based fire reduction method, which comprises: crushing a manganese oxide mineral and a sulfur-based reducer respectively till the mass percentage content of 1.0-millimeter particles is over 80 percent, and uniformly mixing the crushed manganese oxide mineral and the crushed sulfur-based reducer in a mass ratio of 1:(0.05-0.5); and placing in a closed environment and heating for roasting, wherein the obtained product of the roasting is a mixture of MnO and MnSO4. The method can realize the reduction of the manganese oxide mineral at a lower temperature and has the advantages of low energy consumption, high conversion efficiency, simple process and the like. The method overcomes the drawbacks of high temperature, low efficiency and high energy consumption of the conventional reduction roasting with the carbon-based reducer, and is suitable for processing manganese oxide minerals including pyrolusite, psilomelane, hausmannite, braunite, manganite, metamanganate and the like. In the invention, the process is simple, the operation is convenient, the roasting temperature is low, the energy consumption is low, the rate of the conversion from high-valence manganese to divalent manganese is high; the reduction roasting cost of the manganese oxide minerals can be reduced obviously; and the method is suitable for industrial application. Particularly, the method is suitable for preparing manganese sulfate and electrolytic manganese high-quality materials.

Owner:CENT SOUTH UNIV

Method for preparing WC-Co cemented carbide through microwave sintering

The invention provides a method for preparing WC-Co cemented carbide through microwave sintering. The method comprises the steps of WC powder and Co powder batching and mixing, compacting and sintering, wherein in the step of sintering, compacts, SiC chips, carbon black and alumina powder are put in an alumina fiber insulating bag sleeve and then the alumina fiber insulating bag sleeve is put in a microwave high temperature furnace, the products in the furnace are heated to 500-600 DEG C at a heating speed of 5-10 DEG C / min and the heat is preserved and then the products are heated to 1400-1500 DEG C at a heating speed of 30-80 DEG C / min and the heat is preserved, thus obtaining the WC-Co cemented carbide. The method has the advantages of simple process, convenience in operation, short sintering period and low energy consumption, can replace the existing WC-Co cemented carbide processes, is used for producing the WC-Co cemented carbide by adopting the intermittent or continuous microwave sintering mode and is suitable for industrial application. The prepared WC-Co cemented carbide has excellent performances.

Owner:CENT SOUTH UNIV

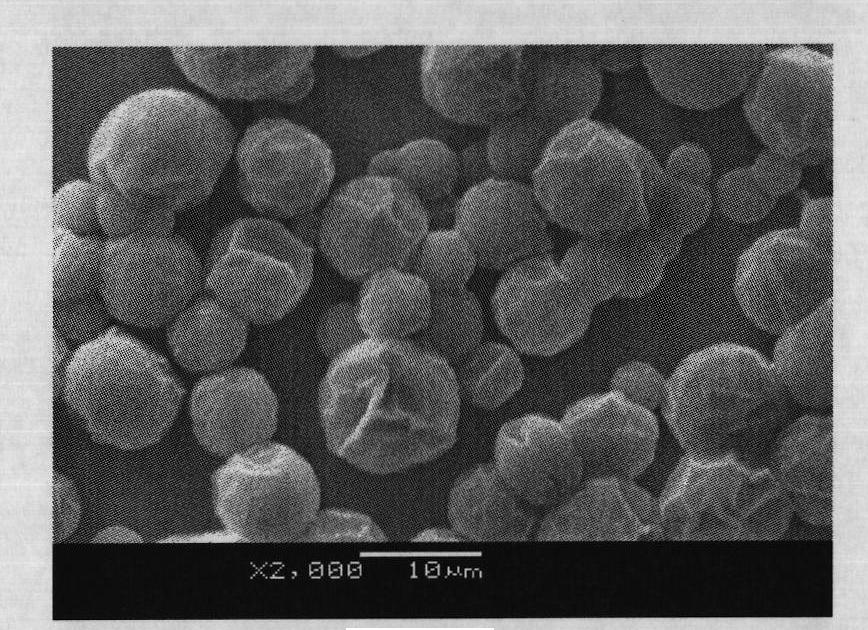

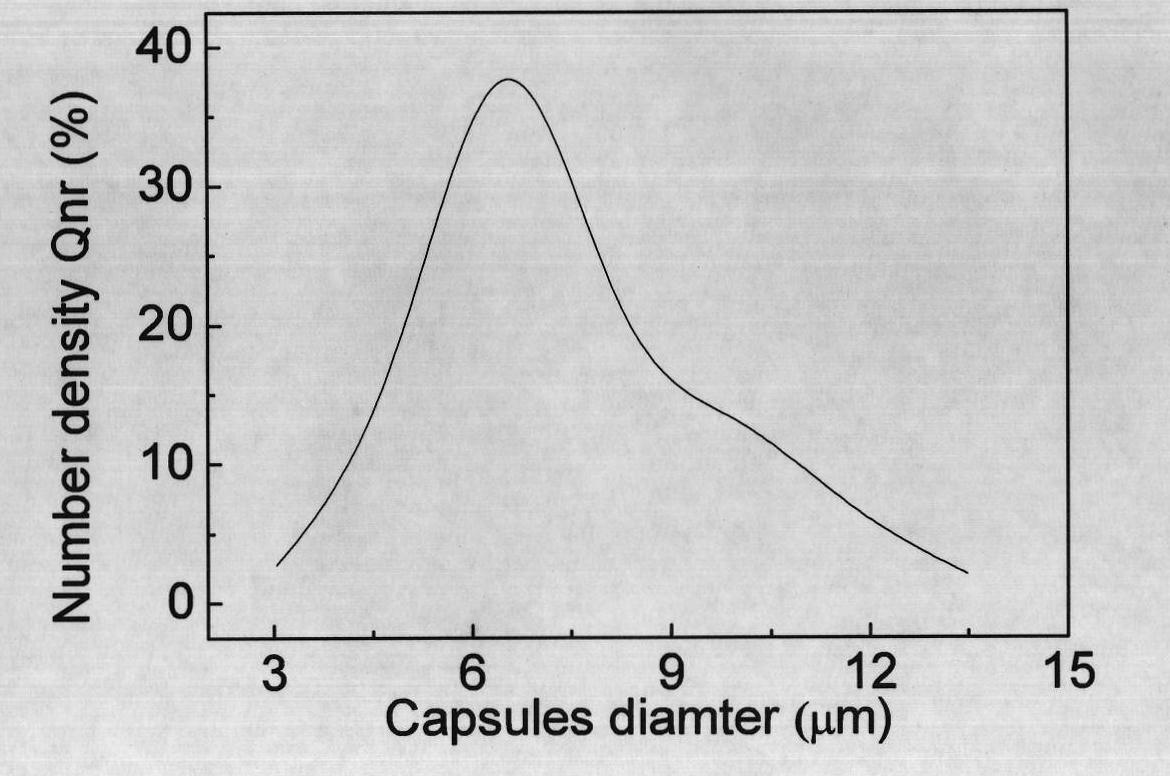

Preparation method of aromatic polyamide core-shell paraffin phase change microcapsule

InactiveCN101982231AReduce coverageReduce manufacturing costMicroballoon preparationMicrocapsule preparationFiberEthylene diamine

The invention relates to a preparation method of an aromatic polyamide core-shell paraffin phase change microcapsule, belonging to the field of preparation of the paraffin phase change microcapsule, and aiming to provide a preparation method of the paraffin phase change microcapsule of which the product has good heat resistance, chemical stability and compactness. In the method, trimesoyl chloride is adopted as an oil phase monomer, organic amine--ethylene diamine or piperazine is adopted as a water phase monomer, and the wall material of the prepared paraffin phase change microcapsule is cross-linking aromatic polyamide. The product microcapsule prepared by the technology of the invention does not contain autopolymer of a cyst wall material, the microcapsules do not adhere to each other, and a monodisperse state can be formed in a substrate easily. The coating ratio of the microcapsule is as high as 87.7%. The microcapsule prepared by the technology of the invention has no slow release, and the 5% thermo gravimetric temperature is 220 DEG C. The aromatic polyamide core-shell paraffin phase change microcapsule prepared by the technology of the invention can be applied to the fields of thermal-storage thermo-regulated fiber, solar energy and nuclear energy utilization, enhanced heat transfer, electronics, spaceflight and composite materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

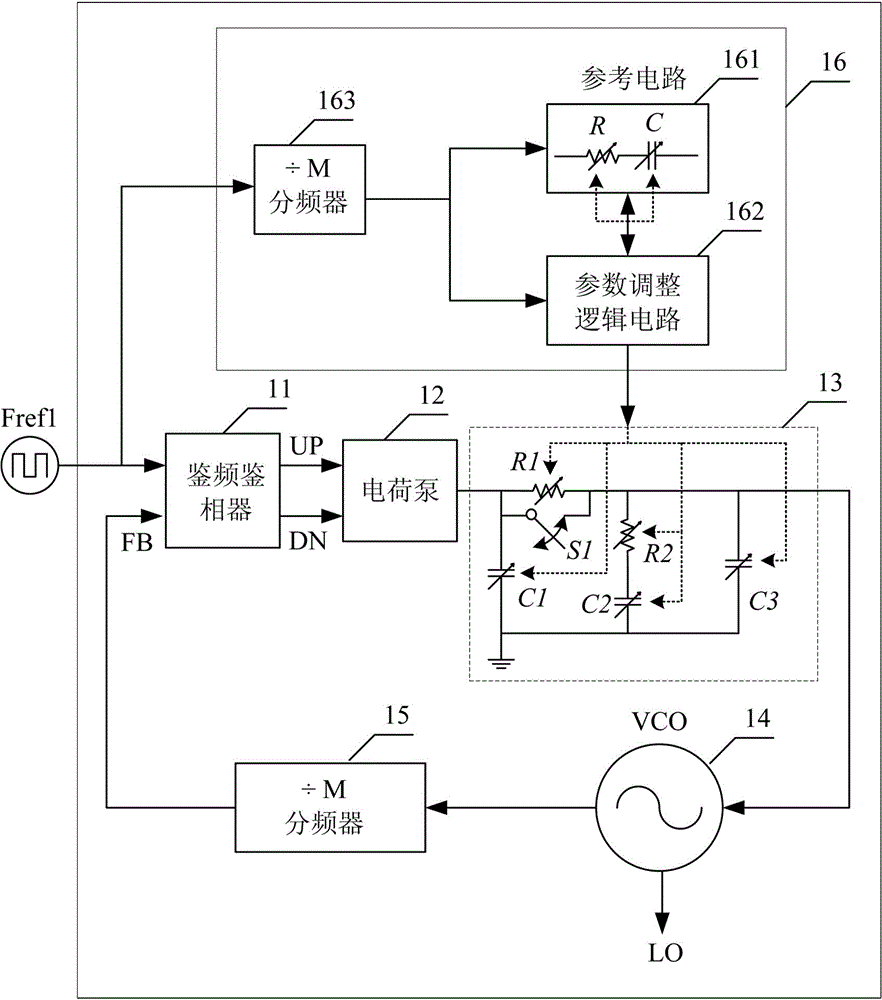

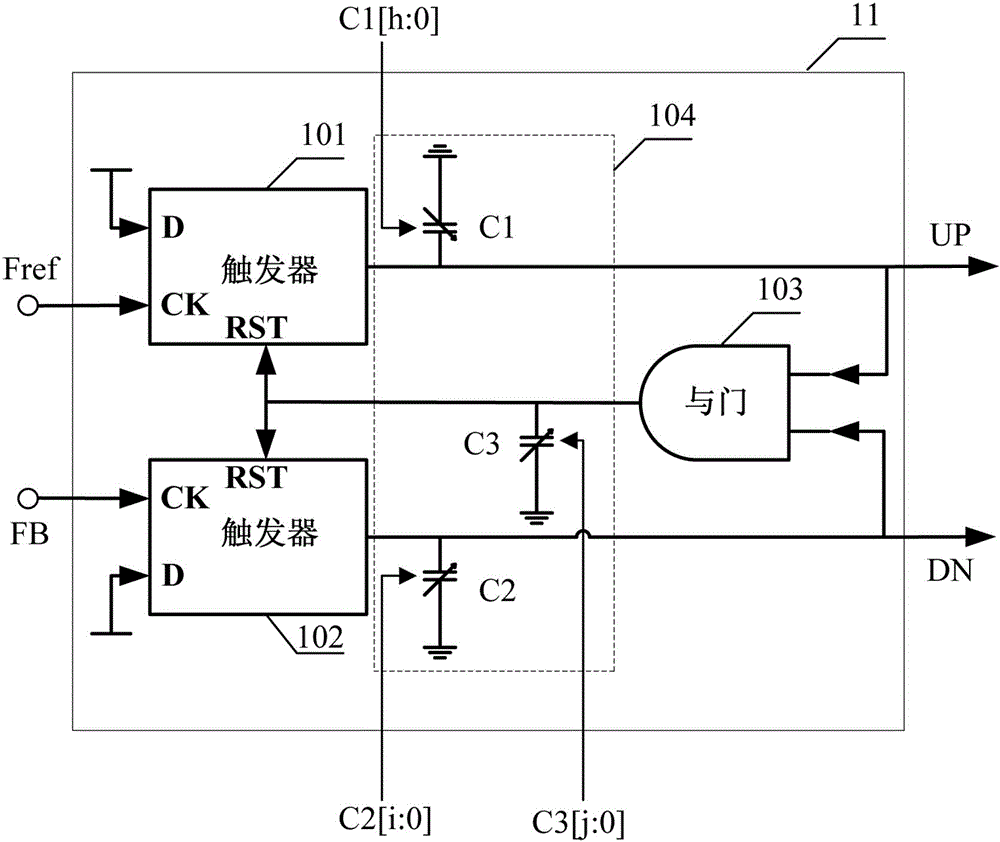

Self-calibration device and method for loop parameters of phase-locked loop

The invention discloses a self-calibration device and method for the loop parameters of a phase-locked loop. The self-calibration device comprises a phase frequency detector, a charge pump, a loop filter, a loop parameter correcting module and a main frequency divider. The phase frequency detector, the charge pump and the loop filter are sequentially connected. The loop parameter correcting module shares a common reference signal Fref input end with the phase frequency detector, and is connected to the loop filter. The main frequency divider is connected with the output end of the loop filter and passes through the main frequency detector to be fed back and input to the feedback input end of the phase frequency detector. The self-calibration device and method for the loop parameters of the phase-locked loop can overcome the defects that in the prior art, the area of a chip is large, manufacturing cost is high, and a temperature compensation effect is bad are overcome, and achieve the advantages of being small in chip area, low in manufacturing cost and good in temperature compensation effect.

Owner:WUXI ZHONGKE MICROELECTRONICS IND TECH RES INST

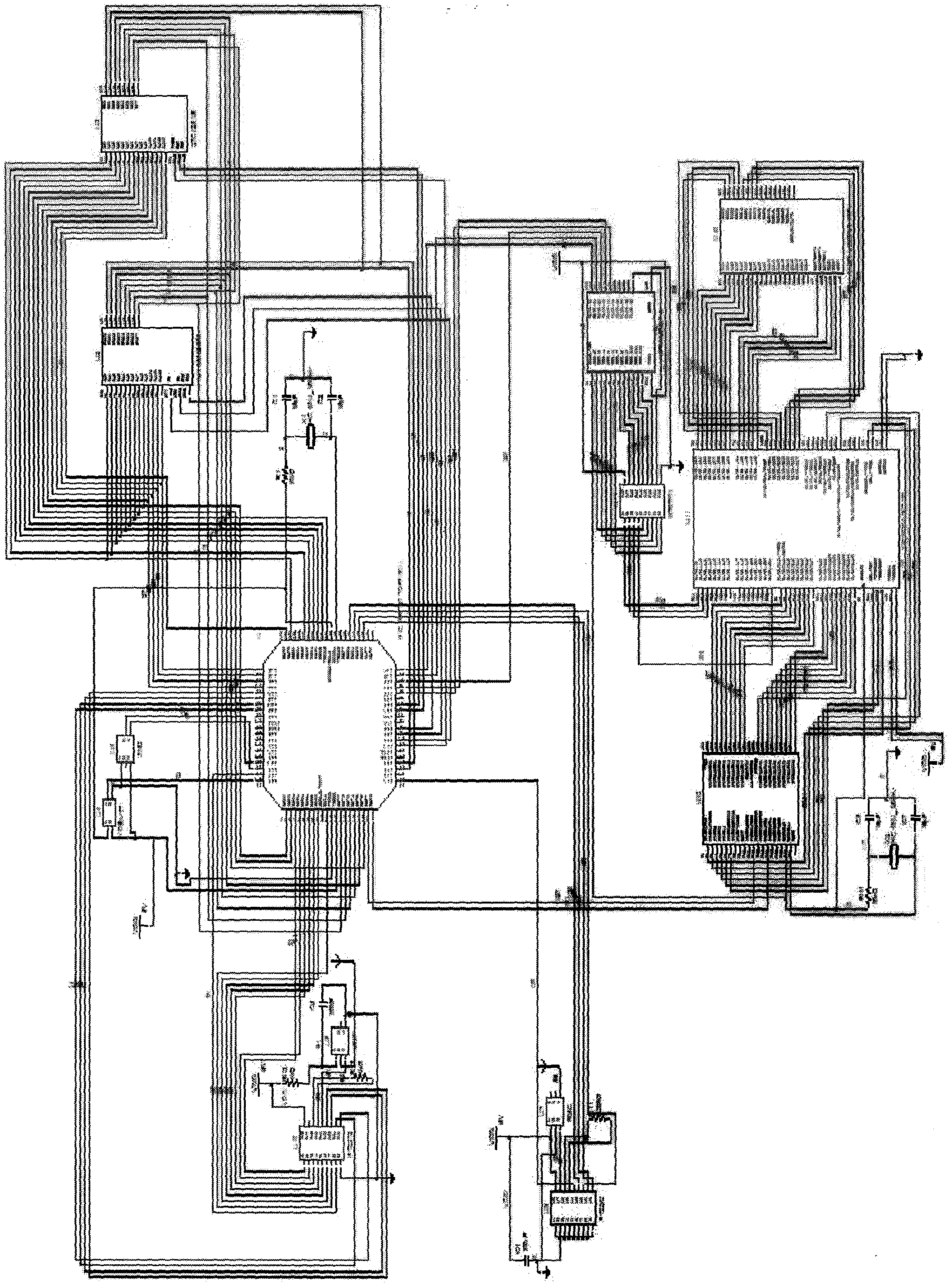

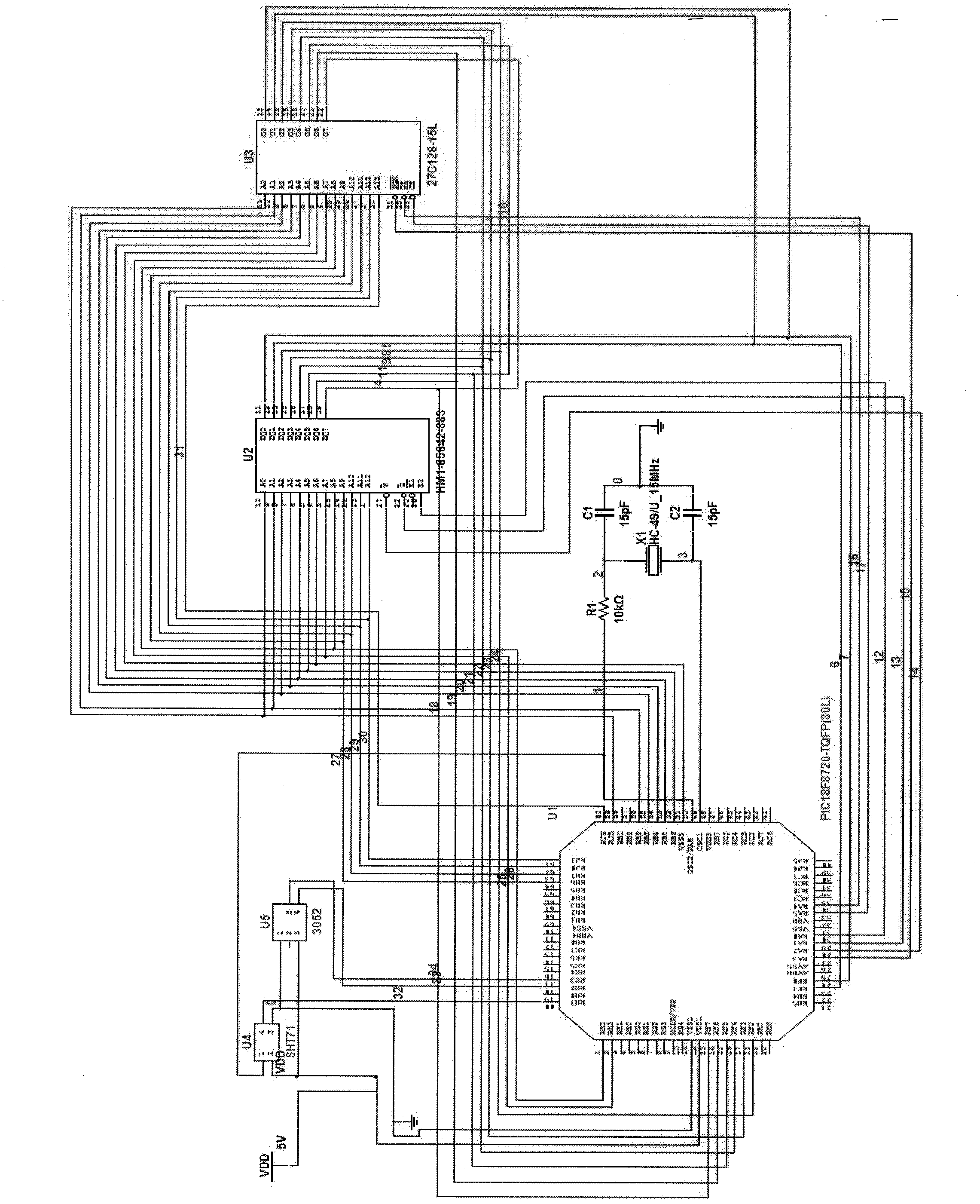

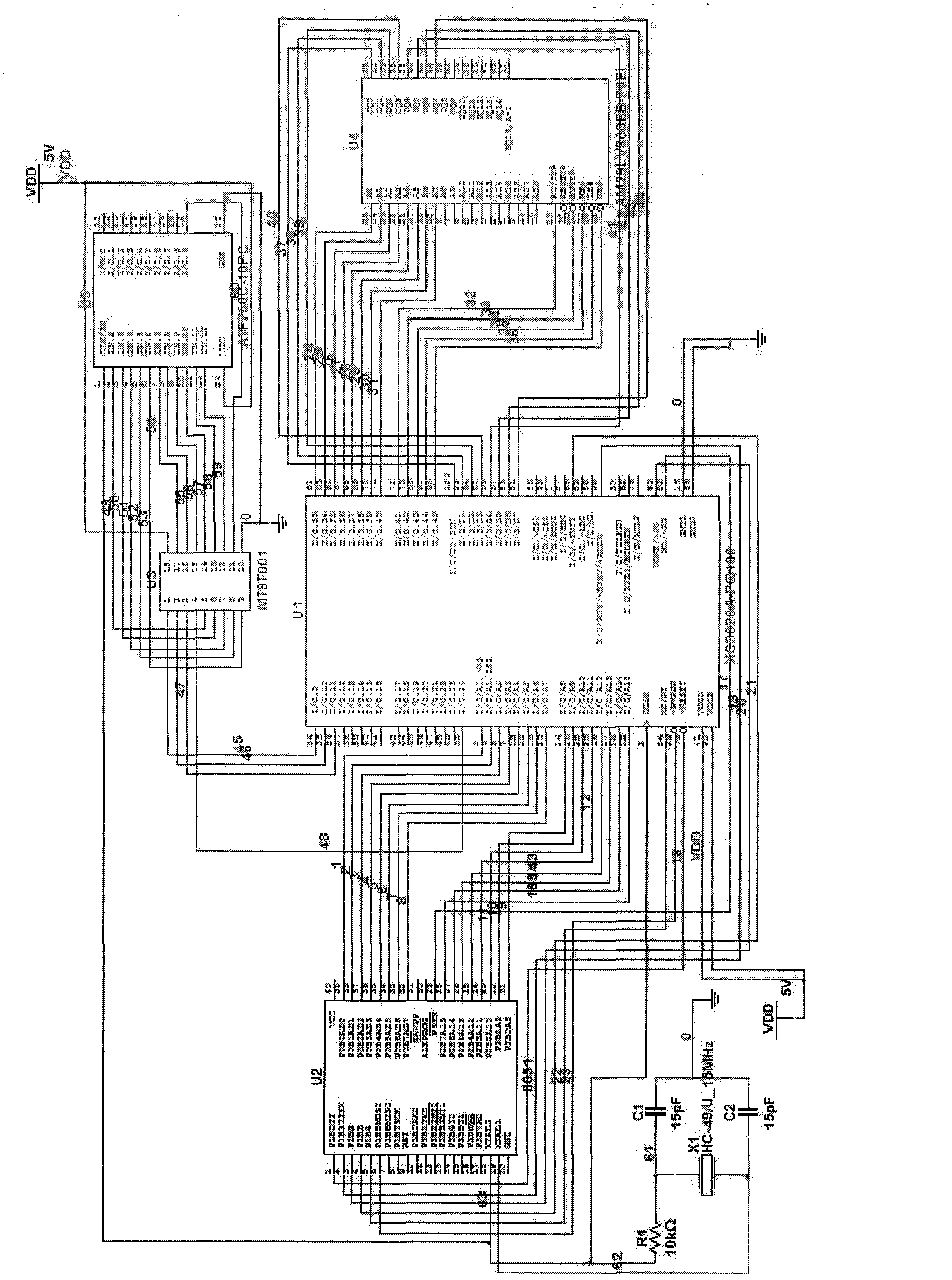

Information processing method based on environmental benefit monitoring sensing network and system and device adopting same

InactiveCN102595392ARealize data fusionImprove accuracyTransmission systemsNetwork topologiesMonitor modeInformation processing

The invention discloses an information processing method based on an environmental benefit monitoring sensing network, and a system and a device both adopting the information processing method. The information processing method is characterized by comprising the steps as follows: S1, a central node and a network switching node or a data transceiver module of a monitoring server can be in a continuous or intermittent monitoring mode according to preset programs or manual input commands or the commands that are transmitted through a network device or an active or passive wake-up circuit after the central node and the network switching node of a background processing system are installed or called or the monitoring server starts up, and then data transmitted by a monitoring unit on a wireless sensor network acquisition node is collected; and meanwhile, in S2, the central node and the network switching node or the monitoring server can transmit the commands to the wireless sensor network acquisition node when the background processing system sends the commands according to the preset programs or the manual input commands or the commands that are transmitted through the network device or the active or passive wake-up circuit. The system and the device can direct to open-ended commands and services. The technology is suitable for being applied to WSN (Wireless Sensor Network) projects such as Sensing China, Smarter Planet and the like.

Owner:吴晓平

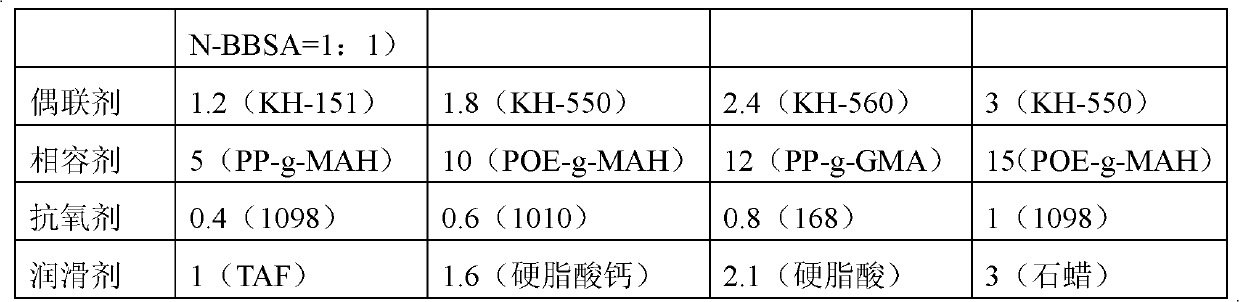

Polyamide wood-plastic composite material and preparation method thereof

The invention belongs to the technical field of a high-molecular material and discloses a polyamide wood-plastic composite material and a preparation method thereof. The material is prepared from the following components in parts by weight: 100 parts of nylon 6, 30-100 parts of wood filler, 5-15 parts of inorganic filler, 1-5 parts of processing aid, 0-15 parts of compatilizer, 0.5-3 parts of coupling agent, 0.2-1 part of antioxygen and 0-3 parts of lubricating agent. The preparation method comprises the following steps of: (1) adding 100 parts of nylon 6, 0-15 parts of compatilizer, 1-5 parts of processing aid and 0.2-1 part of antioxygen into a high-speed mixer to uniformly mix them at a high speed so as to obtain a mixed material; (2) adding 30-100 parts of wood fillers, 5-15 parts of inorganic fillers, 0.5-3 parts of coupling agent and 0-3 parts of lubricating agent into the high-speed mixer for uniform mixing at high speed so as to obtain a mixed material; and (3) adding the mixed material obtained in step (1) and the mixed material obtained in step (2) into a double-screw extruder for extrusion-pelleting so as to obtain a polyamide wood-plastic composite material. The material provided by the invention has better intensity and flowability, and can be injection-molded.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Process for preparing peroxide urea

InactiveCN1418871AGood storage stabilityOvercome temperatureOrganic chemistryInorganic ChemicalReaction temperature

The preparation method of urea peroxide uses hydrogen peroxide and urea as raw material, and is characterized by that adding urea in hydrogen peroxide whose mass percentage concentration is above 50%, at the same time adding stabilizing agent and crystal habit modification agent, after reaction, obtaining wet urea peroxide, drying to obtain white crystal granules, at the same time coating the surface of said urea peroxide white crystal granule with a layer of coating compound. Said invention is economic and practical, its simple batch yield rate can be up to above 85%, the ure peroxide content is up to above 92%.

Owner:陶华西

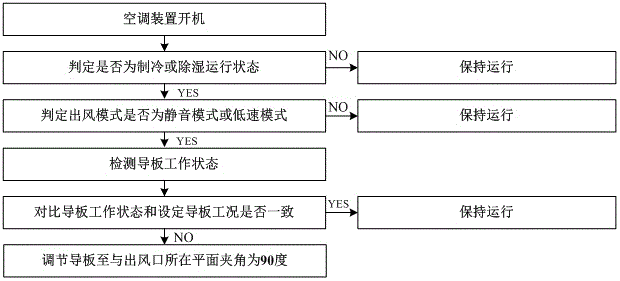

Control method of air conditioner device and air conditioner device

ActiveCN106524427AOvercome temperatureOvercome humidityMechanical apparatusSpace heating and ventilation safety systemsLow speedRefrigeration

The invention provides a control method of an air conditioner device and the air conditioner device. When the air conditioner device is in an operation state, a working mode is judged; if the air conditioner device is in a refrigeration or dehumidification working mode, an air supply mode is judged; if the air supply mode is the low-speed air supply mode or the mute air supply mode, the working state of an air outlet guide plate is detected, and a working state signal of the air outlet guide plate is fed back to a processor; the processor compares the fed-back working state signal of the air outlet guide plate with a stored set working condition of the air outlet guide plate; if the fed-back working state signal of the air outlet guide plate accords with the set working condition of the air outlet guide plate, the operation state and the air supply mode of the air conditioner device are kept; if the fed-back working state signal of the air outlet guide plate does not accord with the set working condition of the air outlet guide plate, the air conditioner device is operated according to the set air conditioner working state; and in the set air conditioner working state, the included angle between the air outlet guide plate and the plane of an air outlet is 90 degrees, and / or an air supply fan keeps the largest rotating speed. The control method has the advantages of being high in control precision and good in automation.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

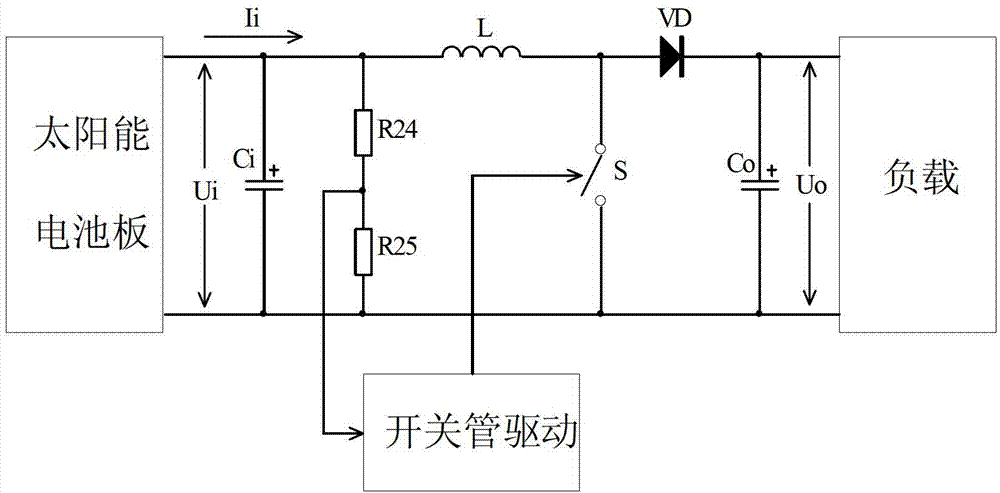

Solar electricity-taking combined energy-storage uninterruptible power supply device

ActiveCN103326419AExtended service lifeImprove short-term high power output capabilityBatteries circuit arrangementsElectric powerTerminal voltageHigh energy

The invention discloses a solar electricity-taking combined energy-storage uninterruptible power supply device which comprises a solar cell pole plate, an MPPT, a cell management module, a storage cell, a buffer circuit, a super capacitor and a DC-DC converter. The solar electricity-taking combined energy-storage uninterruptible power supply device has the advantages of overcoming the defect that due to the fact that a traditional MPPT control algorithm is complex and is easily affected by sunshine intensity and environment temperature changes, the tracking precision is low, ensuring the optimal state of working of the storage cell by sampling terminal voltages, discharging currents, environment temperatures and the cell capability of the storage cell and adopting the efficient PWM storage cell charging mode, utilizing the storage cell and the super capacitor for conducting combination so as to store the energy, enabling a system to have higher energy density and power density at the same time, prolonging the service life of the power source system, improving stability, just needing the solar cell to supply power, and being capable of working for a long time, convenient to install, flexible to use and free from limitation of power supply facilities in the use environment.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of polyacrylate/nano ZnO composite leather finishing agent

InactiveCN103113804AOvercome the disadvantage of poor polymerization stabilityHigh tensile strengthFibre treatmentCoatingsPolymer scienceEmulsion

The invention relates to a preparation method of a polyacrylate / nano ZnO composite leather finishing agent. Nano ZnO is widely applied to modifying polyacrylate but the blending method and the in-situ dispersion method are not beneficial for nano ZnO to be uniformly dispersed in a polymer matrix, so that excellent performance of nano ZnO is hard to exert. The preparation method comprises the following steps of: preparing an emulsifier aqueous liquor; sequentially adding part of oxidant aqueous liquor, part of reducer aqueous liquor and part of acrylic monomers into the emulsifier aqueous liquor to insulate and react; then adding zinc acetate aqueous liquor, residual acrylic monomers, oxidant aqueous liquor and reducer aqueous liquor to insulate and react to obtain the composite leather finishing agent. The preparation method provided by the invention overcomes the deficiency of poor polymerization stability of a polyacrylate / nano ZnO composite emulsion prepared by single in situ method, the tensile strength of the film is improved by 8.75%, and the water resistance is improved by 43.54%.

Owner:SHAANXI UNIV OF SCI & TECH

Screw-driven and multi-degree-of-freedom controllable mechanism type excavating mechanism

InactiveCN103015472ALarge working spaceIncrease flexibilityMechanical machines/dredgersMulti degree of freedomExcavator

Owner:GUANGXI UNIV

Device and method for continuously rectifying 3-chloropropyl triethoxysilane

InactiveCN102580338AShorten the timeFast distillationGroup 4/14 element organic compoundsFractional distillationRefluxTriethoxysilane

The invention provides a method for continuously rectifying 3-chloropropyl triethoxysilane, belonging to the field of chemical engineering separation. The device is characterized by comprising an ethanol rectifying separating device and a 3-chloropropyl triethoxysilane rectifying separating device which are structured the same and connected in series by a conveying pipeline and a material transforming pump, wherein each of the two rectifying separating devices which are structured the same comprises a rectifying tower, a condenser and a finished product storage tank which are connected with the top of the rectifying tower by a reflux pipeline, a condenser and a crude product storage tank which are connected with the bottom of the rectifying tower by the conveying pipeline. The crude product storage tank is connected with a next group of a rectifying separating device by the material transforming pump. In the first tower, ethanol is removed at normal pressure to reach a purity of more than 99.8%; in the second tower, 3-chloropropyl triethoxysilane is removed by rectifying at a negative pressure of -0.0098Mpa to reach a purity of more than 99.5%.

Owner:淄博市临淄齐泉工贸有限公司

Nano-silver inkjet conductive ink subjected to low-temperature post-treatment and stabilization, and preparation method

InactiveCN102504646AIncrease concentrationDoes not affect post-processing temperatureInksAlkyl amineSilver Nano

The invention discloses an inkjet nano-silver conductive ink and a preparation method of the ink. The inkjet nano-silver conductive ink comprises the following components by mass percent (the sum of mass percent of all components is 100%): 5-45% of silver nanoparticle, on the surface of which organic protecting agent with the particle diameter being smaller than 10nm is coated, and 55-95% of ink solvent. The preparation method comprises two steps, including preparation of the silver nanoparticle, on the surface of which organic protecting agent is coated, by taking silver acetate as raw material, and the preparation of nano-silver conductive ink. The method takes a small amount of alkyl hydrosulfide with strong effect on nano-silver and a large amount of alkylamine with weak effect on nano-silver as protecting agent to prepare the silver nanoparticle, so that the inkjet nano-silver conductive ink has the characteristics of high nano-silver concentration, low post-treatment temperatureand good dispersion stabilization, and is particularly suitable for being printed on flexible substrate.

Owner:TIANJIN UNIV

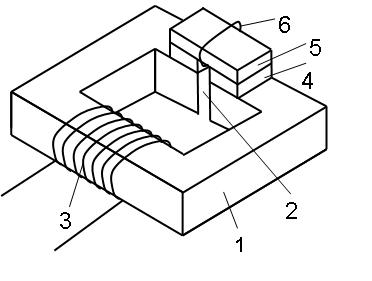

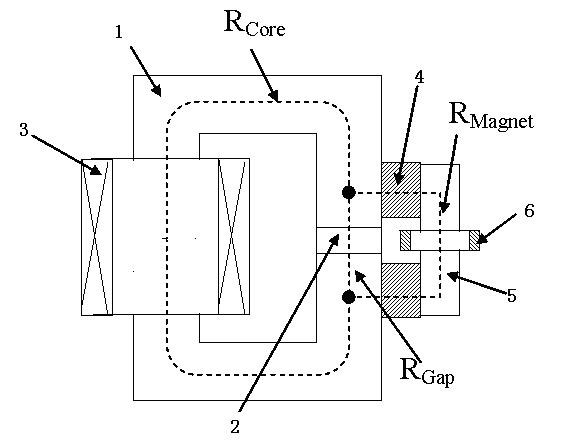

Magnetic element with permanent magnetic bias

InactiveCN101789304AReduce the cross-sectional areaShorten the lengthPermanent magnetsTransformers/inductances magnetic coresDc currentFlux loop

The invention relates to a magnetic element with permanent magnetic bias, which comprises a magnetic core which is used for forming a magnetic flux loop and provided with at least one air gap fracture. The magnetic element is characterized in that a working coil is wound on the magnetic core, at least one lateral surface of the air gap fracture of the magnetic core is provided with a pair of permanent magnets, the permanent magnets are provided with at least one soft magnetic core for communicating the two permanent magnets so as to form a permanent magnet containing magnetic branch connected in parallel with the air gap fracture, and the reluctance of the permanent magnet containing magnetic branch connected in parallel with the air gap fracture is more than 5 times as high as the reluctance of the air gap fracture of the magnetic element. The direct-current bias resistance of the magnetic core of the magnetic element can be effectively improved, the inductance under certain direct-current bias current is improved, or the section area of the magnetic core is reduced, and the volume is reduced or the length and electric resistance of the copper used for the working coil is reduced; and meanwhile, the defects that the traditional magnetic element with the permanent magnet is easy to be demagnetized by the current pulse and the eddy-current loss of the permanent magnet under the high-frequency flux causes temperature rise to result in failure of the permanent magnet at the high temperature.

Owner:FUZHOU UNIV

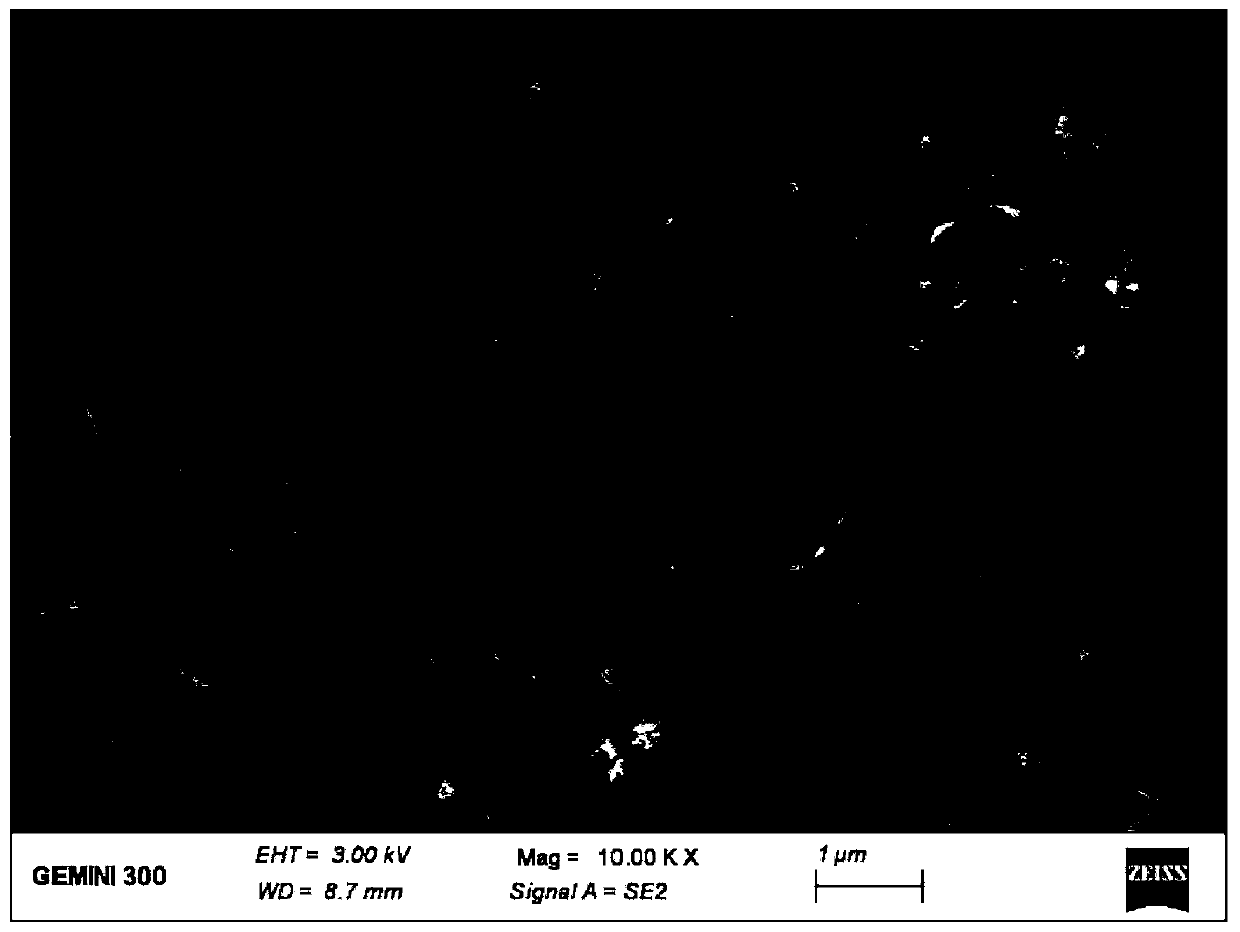

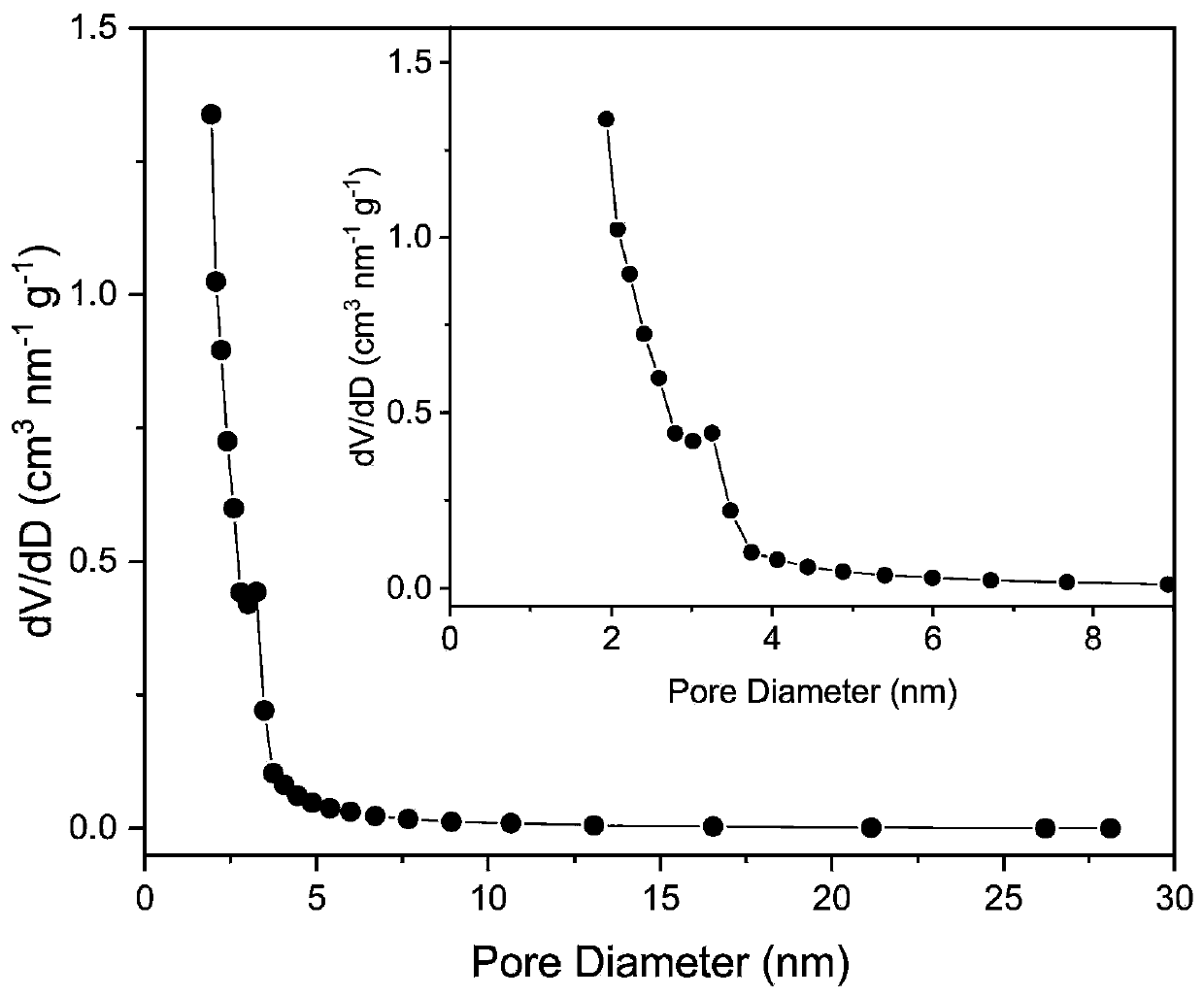

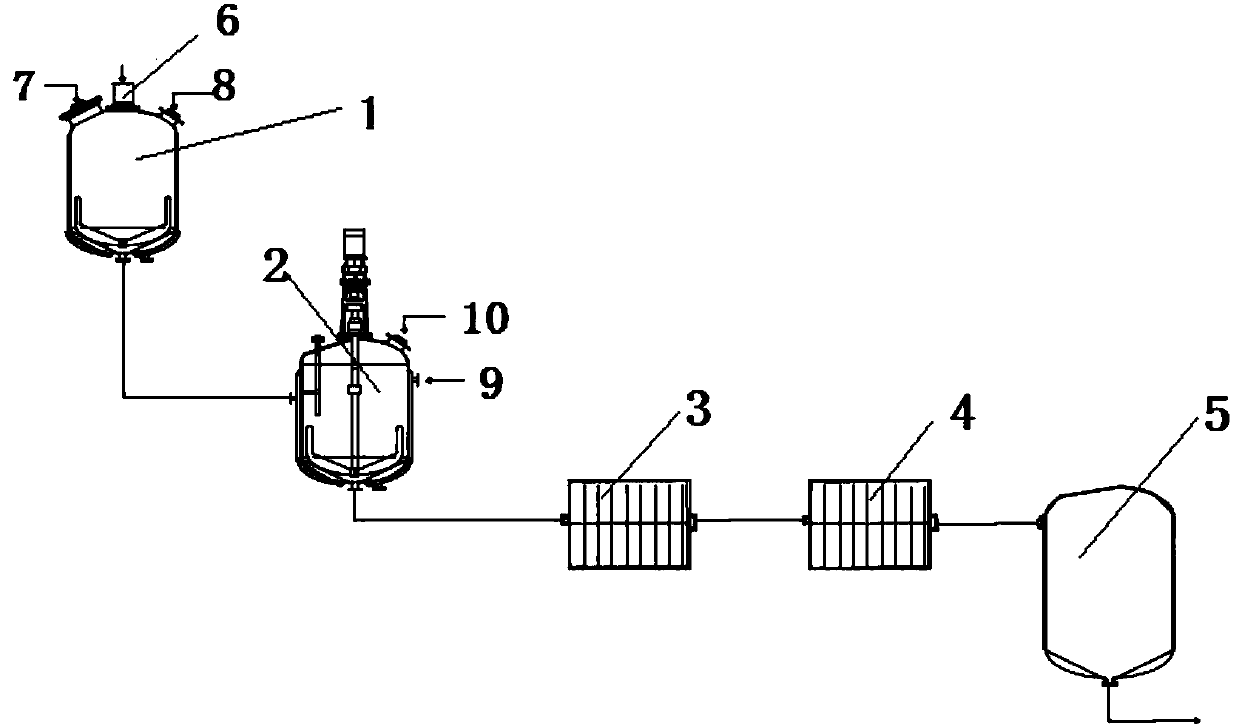

Preparation method and application method of nitrogen-doped porous carbon based on straw hydrothermal carbonization

PendingCN111017927AOvercome temperatureOvercome energy consumptionCarbon compoundsHybrid capacitor electrodesPorous carbonFiltration

The invention provides a preparation method and an application method of nitrogen-doped porous carbon based on straw hydrothermal carbonization. The preparation method comprises the following steps: 1, crushing a biomass raw material rice straw, screening, and drying in a 105 DEG C blast drying oven for 12 hours; 2, carrying out hydrothermal treatment on the crushed rice straw, naturally cooling to room temperature after the reaction is finished, carrying out suction filtration, washing with absolute ethyl alcohol and ultrapure water to remove impurities, and drying to obtain brownish black straw hydrothermal carbon; 3, mixing the straw hydrothermal carbon, an activating agent and melamine according to a certain mass ratio, and fully grinding in a mortar; and 4, putting the ground mixtureinto a tubular furnace, carrying out high-temperature activation in an inert gas atmosphere, naturally cooling to room temperature, and carrying out acid washing, water washing and drying on the obtained material to obtain the nitrogen-doped straw hydrothermal carbon-based porous carbon for the supercapacitor. The method comprises the following steps: A, a working electrode preparation method; andB, a supercapacitor preparation method.

Owner:ZHEJIANG UNIV

Method for preparing regenerated high-shrinkage polyester by waste polyester alcoholysis method

ActiveCN107793560AQuality improvementProduct quality indicators are stablePlastic recyclingPolyesterCyclohexanedimethanol

The invention discloses a method for preparing regenerated high-shrinkage polyester by a waste polyester alcoholysis method. The method comprises the following steps: (1) pretreatment of waste polyester, (2) alcoholysis of the waste polyester, (3) quality regulation and control of ester and addition of isophthalic acid or 1,4-cyclohexanedimethanol comonomer, and (4) polycondensation and preparation of sections. The intrinsic viscosity of the finally obtained regenerated high-shrinkage polyester is 0.60-0.70 dl / g, the melting point is 210-230 DEG C, the content of diethylene glycol is 3.0+ / - 0.3%, and a chroma b value is less than 6. The prepared regenerated high-shrinkage polyester can be used for preparation of high-shrinkage polyester filaments, short fibers and high-shrinkage polyesterfilms; and high-valued recycling of the waste polyester is realized.

Owner:ZHEJIANG SCI-TECH UNIV

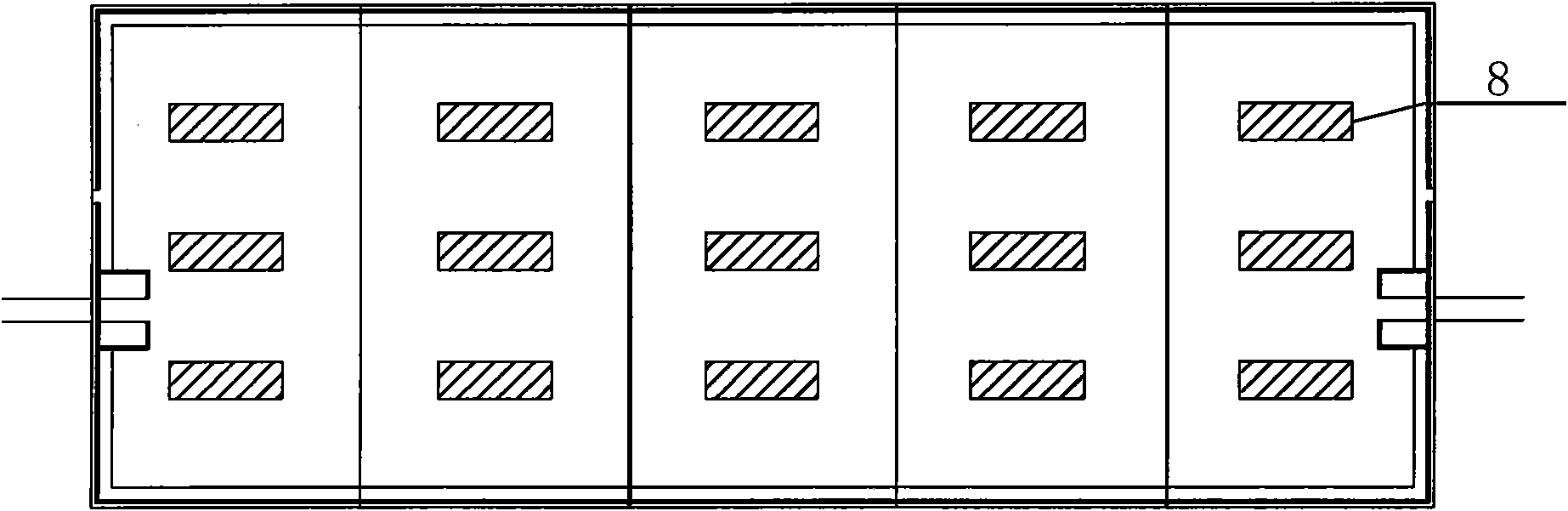

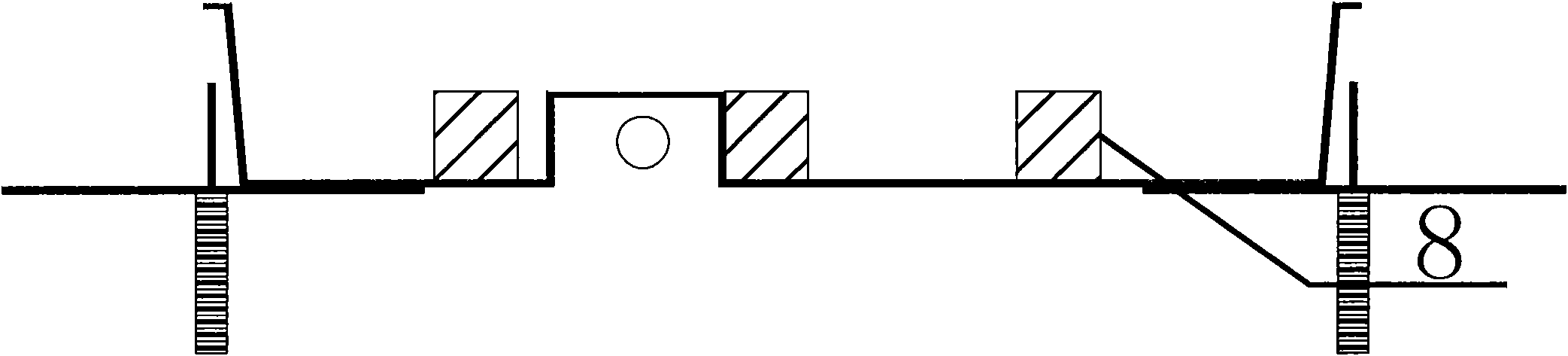

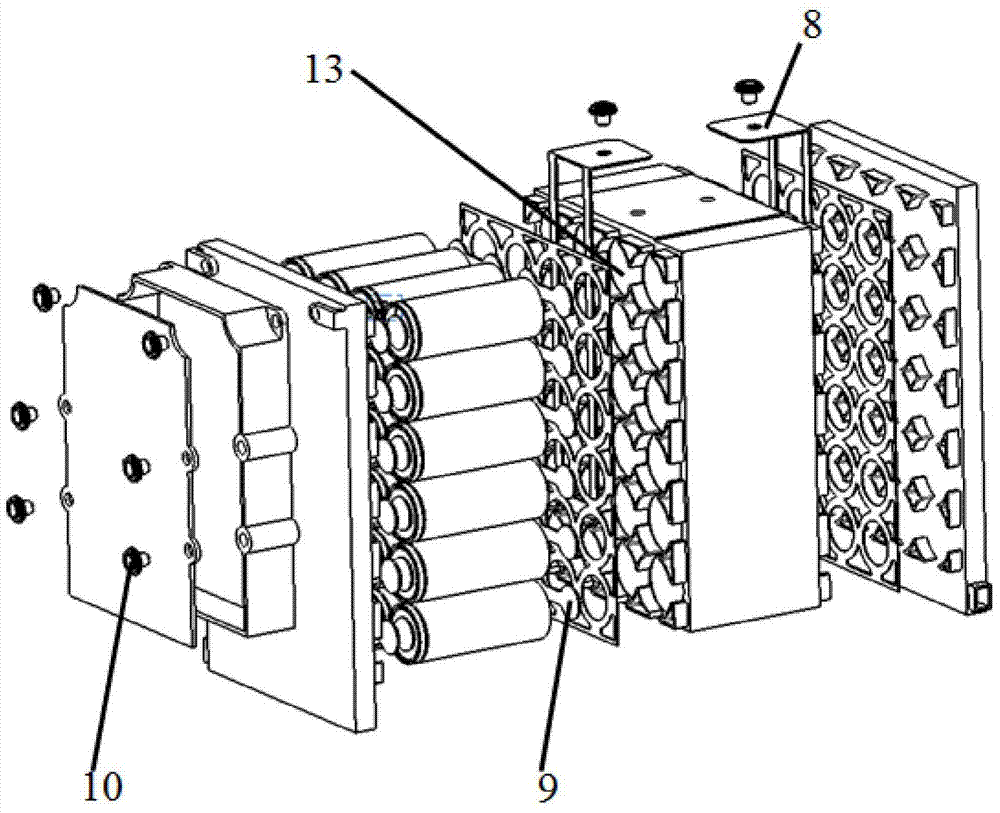

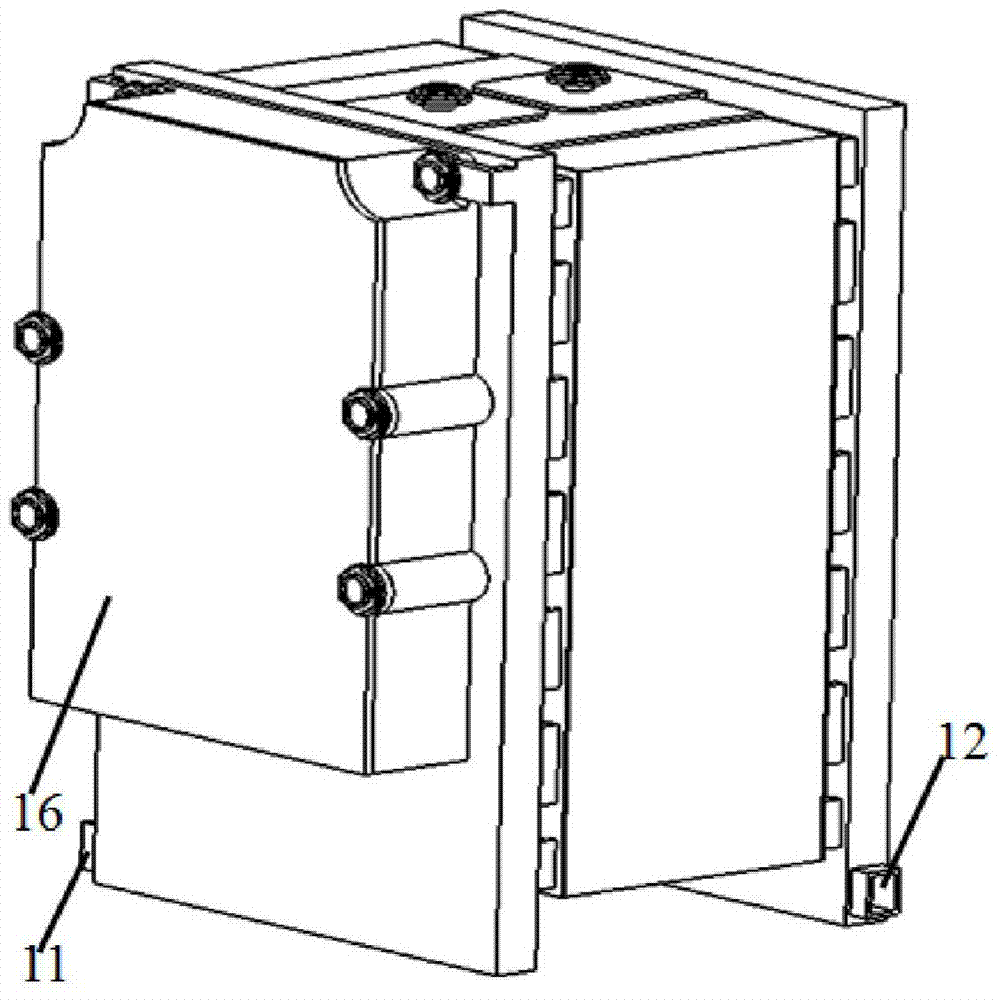

Lithium ion powder battery liquid cooling structure

InactiveCN103811831AIncrease mass flowIncrease the heat exchange areaSecondary cellsLithiumInterference fit

The invention relates to a lithium ion powder battery liquid cooling structure. The structure comprises a main body framework, a water intake end cover, a water exhaust end cover, a gasket, battery single bodies, a monitoring device, converged plates, converged sheets, bolts and other components, wherein the water intake end cover and the water exhaust end cover are connected together with the main body framework through interference fit so as to form 24 cylindrical empty cavities and 35 cooling liquid flow channels; the gasket is configured between the end covers and the main body framework; the battery single bodies are installed in the cylindrical empty cavities, and are connected in parallel by the converged sheets, and the positive and negative poles are leaded out by the converged plates; the monitoring device comprises two parts including a monitoring device main body and a monitoring device end cover, and is installed on the water intake end cover, and are fixed by fastening bolts. The lithium ion powder battery liquid cooling structure provided by the invention is novel, is convenient to manufacture and maintain, is significant in cooling effect, can control the working temperature of the battery within a reasonable temperature range, and can prevent safety hazard of thermal runaway and the like.

Owner:JILIN UNIV

A self-compensating concrete-integrated strain gauge

InactiveCN102269567AReduce volumeEliminate the effect of detection sensitivityElectrical/magnetic solid deformation measurementFiberElectrical resistance and conductance

The invention discloses a self-compensating concrete integrated strain gauge, which is mainly characterized in that a compensation resistor is provided on the strain gauge, the compensation resistor and the working piece form a half-bridge or full-bridge working mode, and the compensation resistor adopts a high-precision resistor with no stress output Or small grid strain gauges, which can automatically compensate the influence of temperature on the bridge and wires, overcome the difficulty that it is impossible to equip each measuring point with a compensation block and ensure that its temperature and change are consistent; it can also eliminate the influence of wire length on detection sensitivity At the same time, the reinforced fiber insulation base and flexible waterproof sealing material are used to carry out the overall waterproof sealing treatment, which not only ensures the technical requirements of the insulation resistance of the strain gauge, but also has the effect of convenient, fast, accurate and safe on-site installation. .

Owner:陈彦平

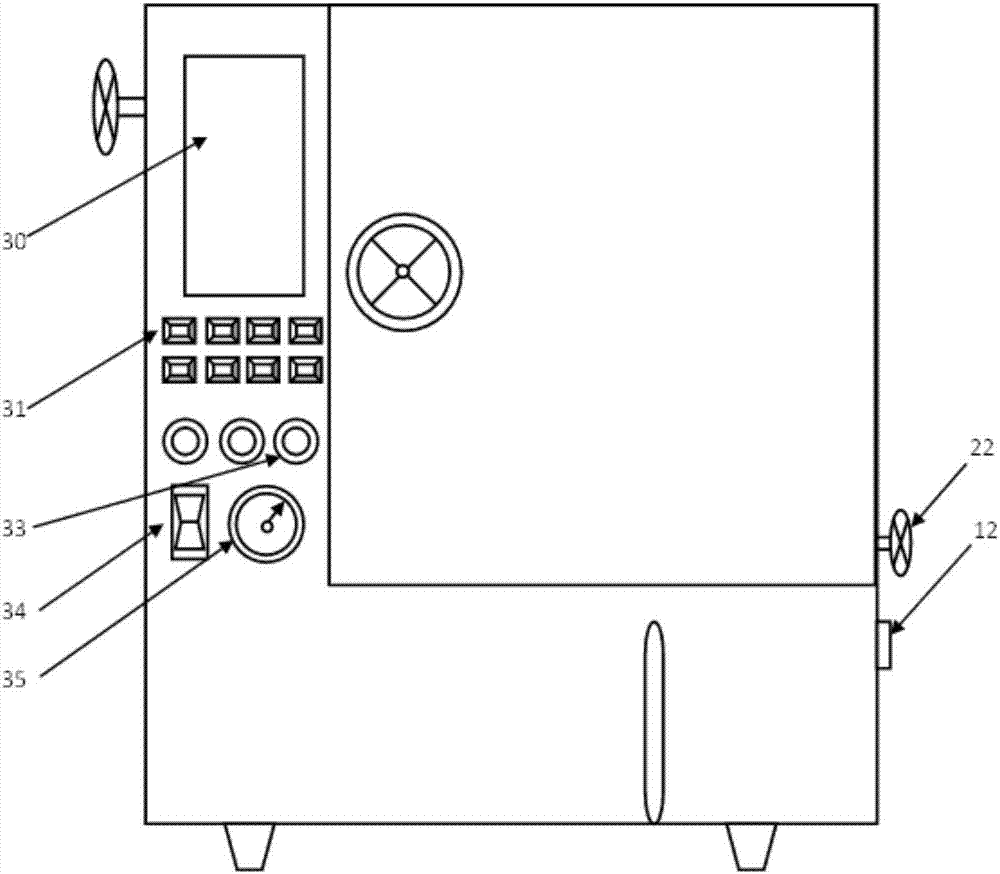

Multifunctional comprehensive ageing experiment box

PendingCN107300938AShorten aging timeTo achieve the effect of one machine with multiple functionsWeather/light/corrosion resistanceSimultaneous control of multiple variablesControl systemUltraviolet lights

The invention relates to the field of ageing equipment and discloses a multifunctional comprehensive ageing experiment box. The multifunctional comprehensive ageing experiment box comprises a box body, an ageing chamber arranged in the box body and a sealing box door arranged at an opening of the ageing chamber; and an ultraviolet light system, a heating system, a humidifying system, an exhausting and pressure-reducing system, a pressurizing system and a control system are arranged in the box body. The multifunctional comprehensive ageing experiment box provided by the invention has multiple ageing functions and can obtain an ageing sample of a sample accurately and quickly, so as to effectively shorten the ageing time.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com