Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Overcome solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

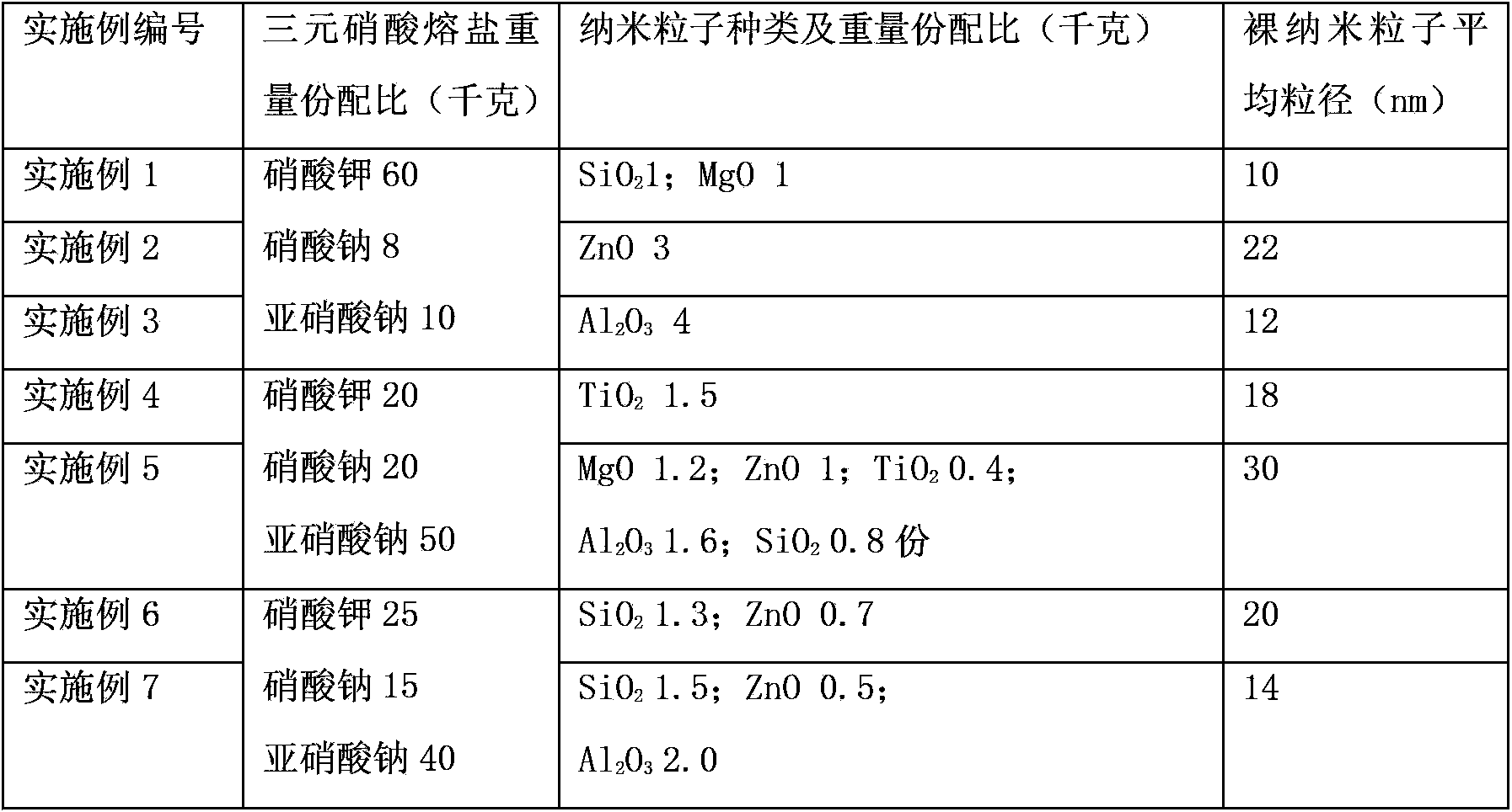

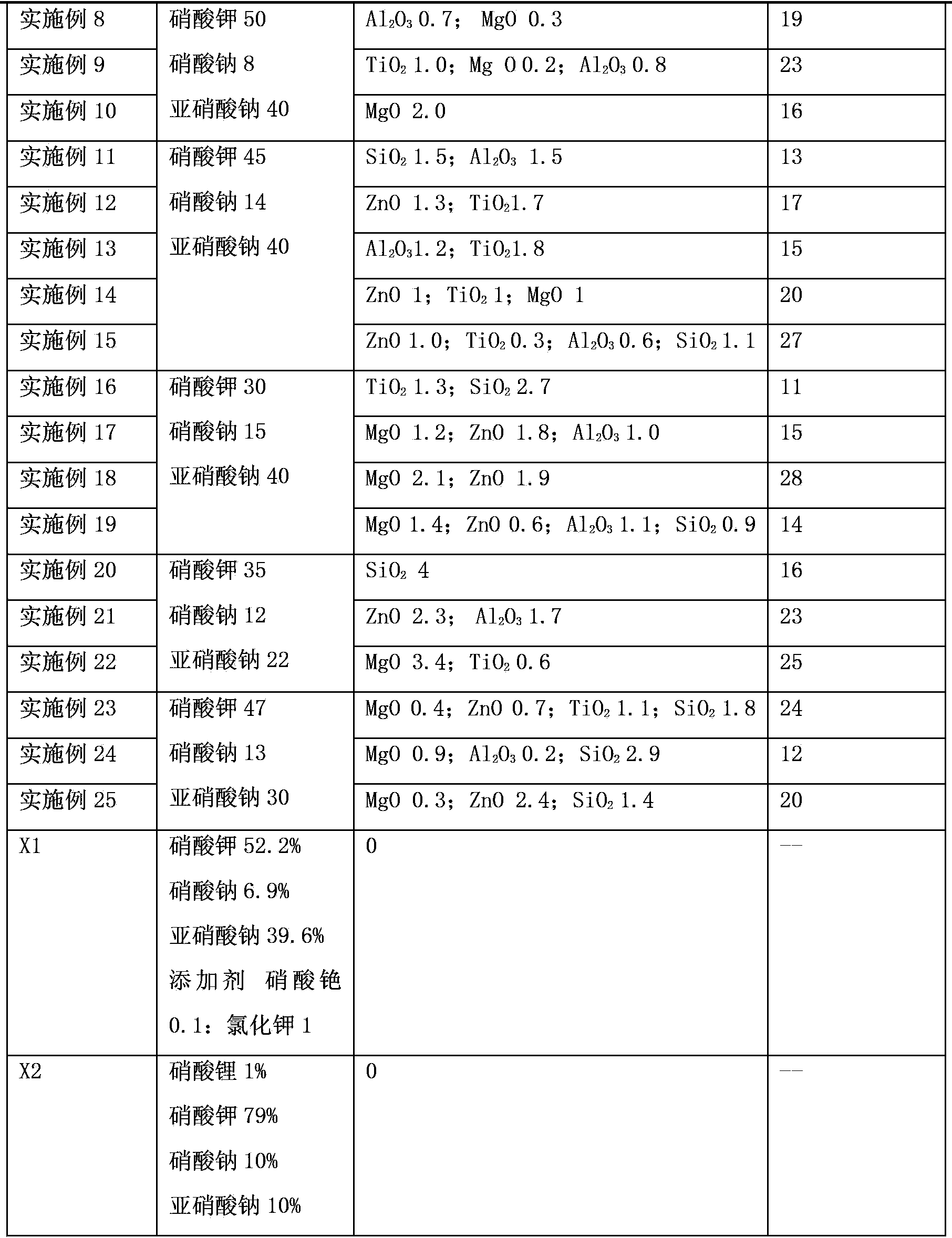

Ternary nitric acid nano-molten salt heat transfer and storage medium, preparation method and application thereof

InactiveCN103881662AOvercome solubilityOvercoming thermal conductivityHeat-exchange elementsMetal oxide nanoparticlesNanoparticles dispersion

Belonging to the technical field of heat storage and transfer, the invention provides a ternary nitric acid nano-molten salt heat transfer and storage medium, a preparation method and application thereof. The ternary nitric acid nano-molten salt heat transfer and storage medium contains a ternary nitric acid molten salt system formed by potassium nitrate, sodium nitrate and sodium nitrite. The ternary nitric acid nano-molten salt heat transfer and storage medium is characterized in that it also includes metal oxide nanoparticles and / or non-metal oxide nanoparticles. The nanoparticles are dispersed into the ternary nitric acid molten salt system to undergo compounding so as to form the ternary nitric acid nano-molten salt heat transfer and storage medium. The ternary nitric acid nano-molten salt involved in the invention has a low melting point, an upper limit use temperature up to 600DEG C, good thermal stability, and high heat conductivity, thus being very suitable for the heat storage and transfer system of industrial energy storage and solar-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

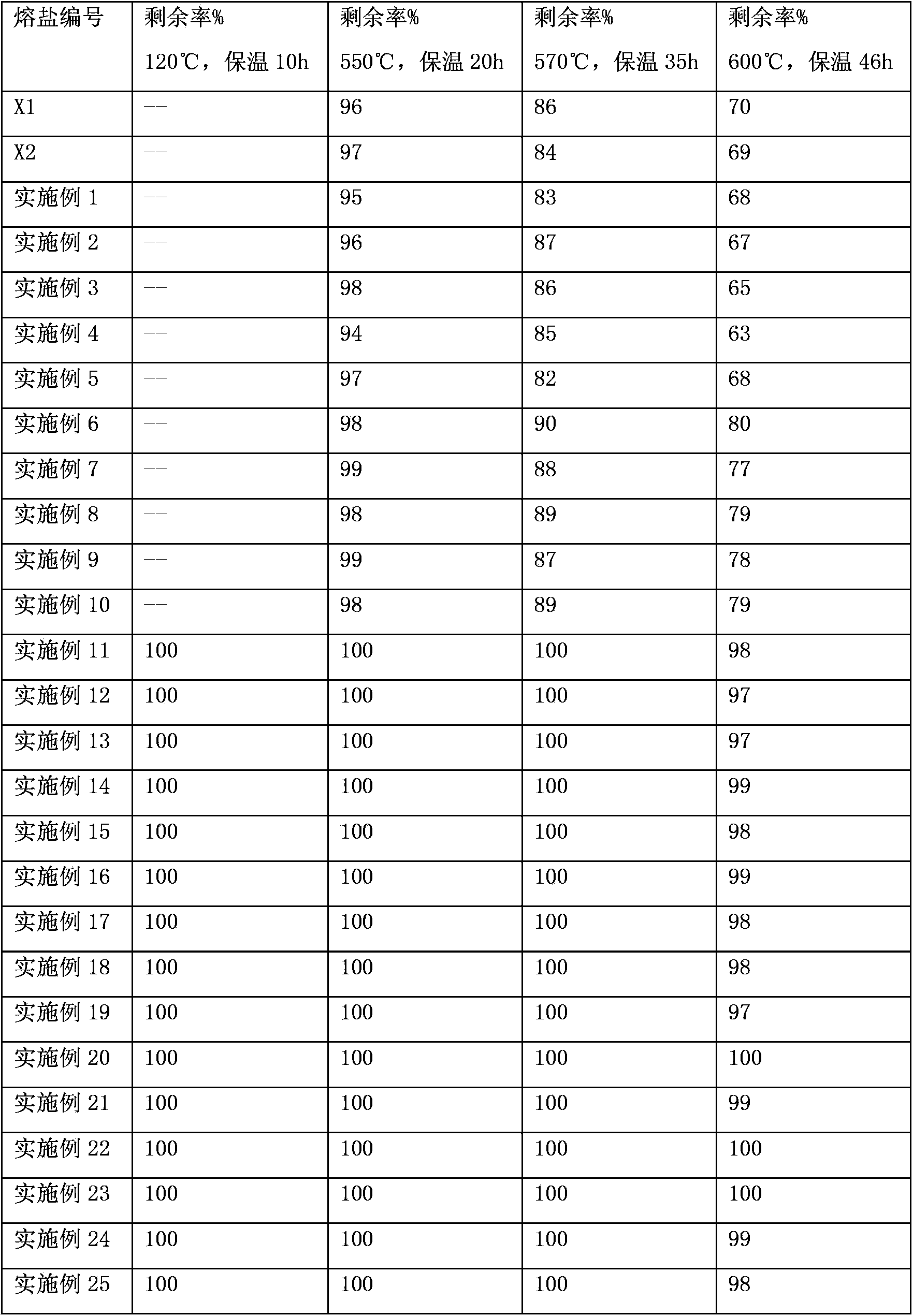

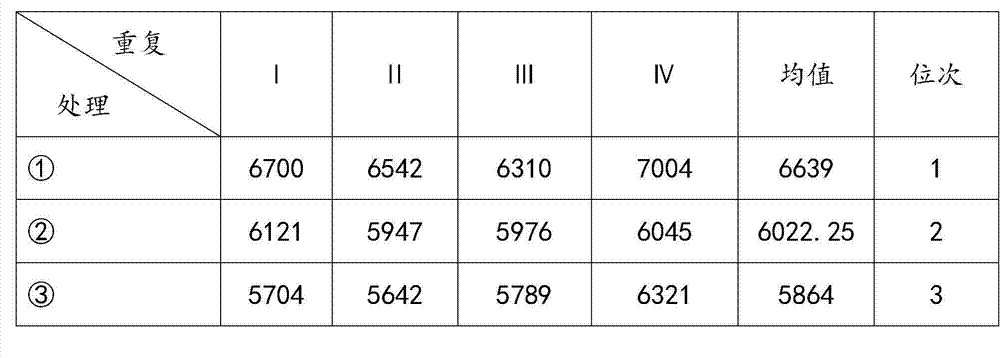

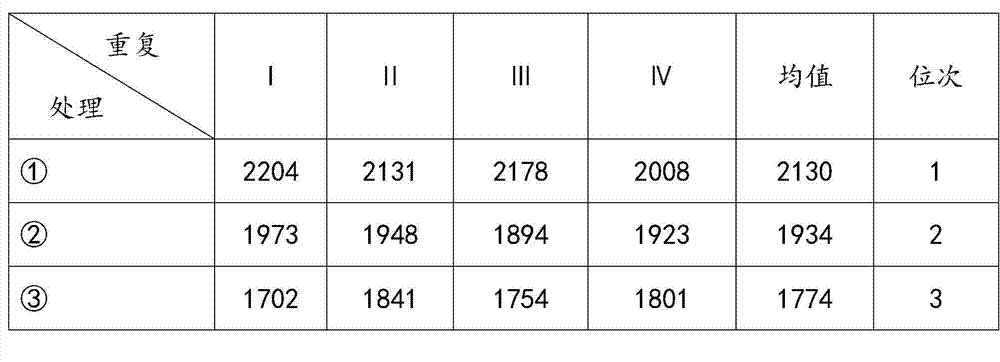

Compound water soluble fertilizer used for citrus crops, preparation method and application method

ActiveCN103073348AAvoid YieldReduce qualityFertilising methodsFertilizer mixturesTrace elementPlant nutrition

The invention discloses a compound water soluble fertilizer used for citrus crops, a preparation method and an application method. The compound water soluble fertilizer used for citrus crops is mainly used in plant nutrition field, and comprises the following components: an amino acid raw material, macroelements P and K, secondary elements Mg and Ca, trace elements Fe, Mn, Zn, B, Mo and Cu, a beneficial element Si, an auxiliary agent, a PH conditioning agent and an aqueous solution. The preparation method is characterized in that composite amino acid chelates Mn, Fe, Cu, Mg, Ca and Zn at normal temperature of 15-35 DEG C and prepares the water soluble fertilizer with six metallic elements, the reasonable fertilizing can be carried out at different growth period of the crops, the balance supplement of a plurality of nutrient elements required by citrus crops can be realized, and the output and quality of the citrus crops can be increased.

Owner:HUBEI GREAT BIOTECH

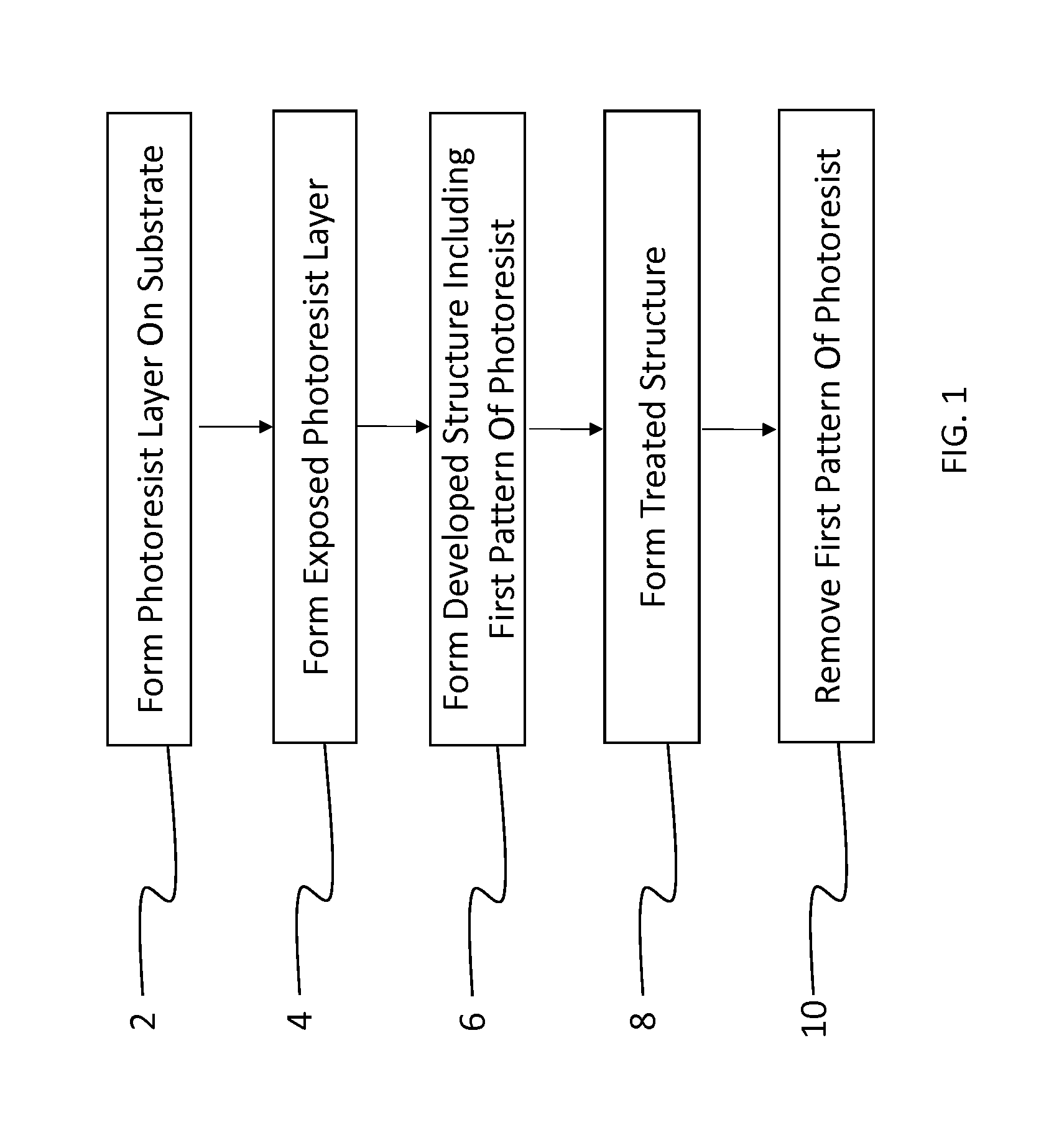

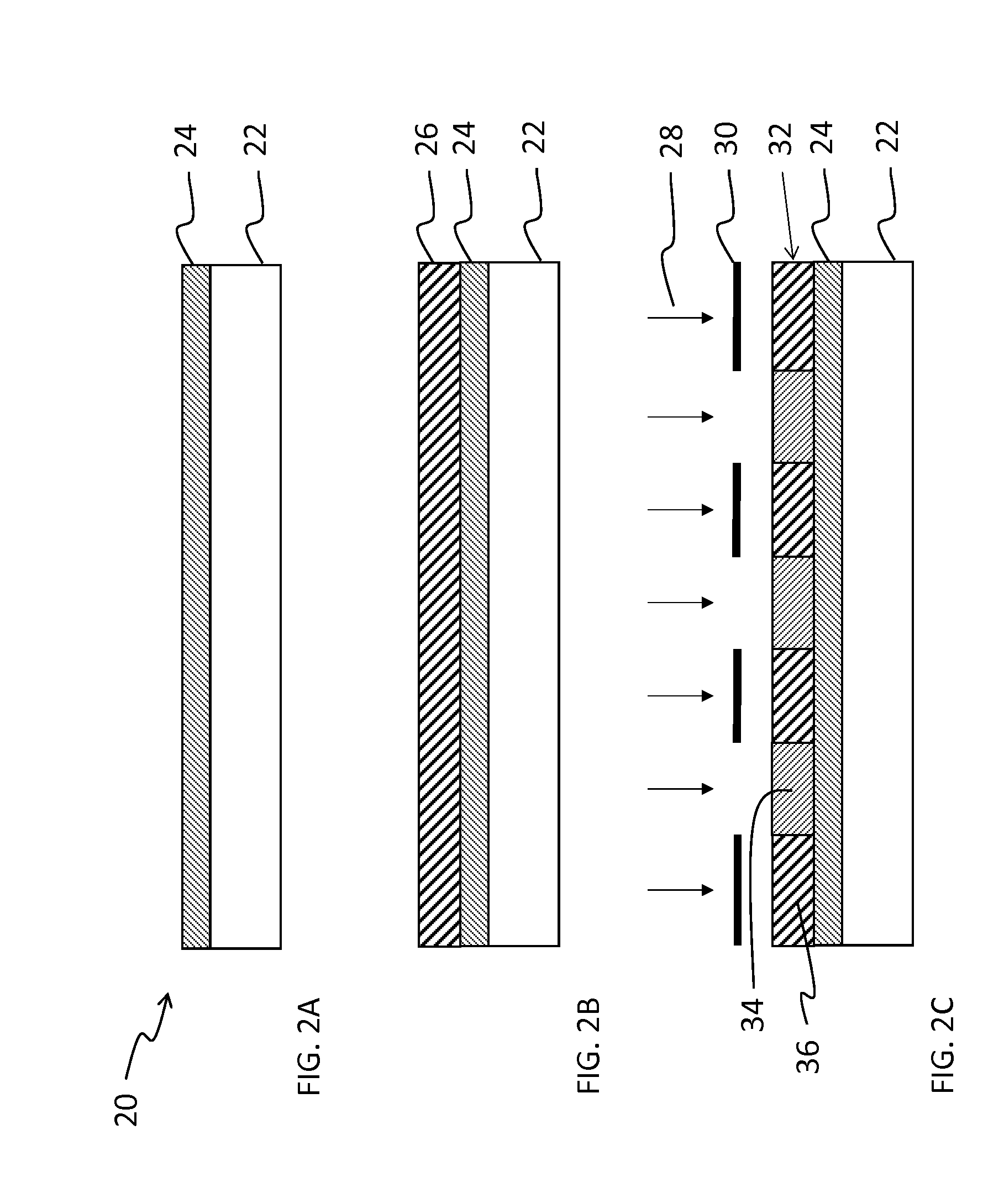

Fluorinated photopolymer with integrated anthracene sensitizer

InactiveUS20140356789A1High light sensitivityLess exposure energyPhotosensitive materialsPhotomechanical exposure apparatusAnthraceneAlcohol

A method of patterning a device comprises providing on a device substrate a layer of a fluorinated photopolymer comprising at least three distinct repeating units including a first repeating unit having a fluorine-containing group, a second repeating unit having an acid- or alcohol-forming precursor group, and a third repeating unit having an anthracene-based sensitizing dye. The photopolymer has a total fluorine content in a range of 15 to 60% by weight. The photopolymer layer is exposed to patterned light and contacted with a developing agent to remove a portion of exposed photopolymer layer in accordance with the patterned light, thereby forming a developed structure having a first pattern of photopolymer covering the substrate and a complementary second pattern of uncovered substrate corresponding to the removed portion of photopolymer. The developing agent comprises at least 50% by volume of a fluorinated solvent.

Owner:ORTHOGONAL

Multi-functional ionic liquid compositions for overcoming polymorphism and imparting improved properties for active pharmaceutical, biological, nutritional, and energetic ingredients

ActiveUS8232265B2Good curative effectOvercome solubilityAntibacterial agentsPowder deliverySolubilityDelivery problems

Disclosed are ionic liquids and methods of preparing ionic liquid compositions of active pharmaceutical, biological, nutritional, and energetic ingredients. Also disclosed are methods of using the compositions described herein to overcome polymorphism, overcome solubility and delivery problems, to control release rates, add functionality, enhance efficacy (synergy), and improve ease of use and manufacture.

Owner:UNIVERSITY OF ALABAMA

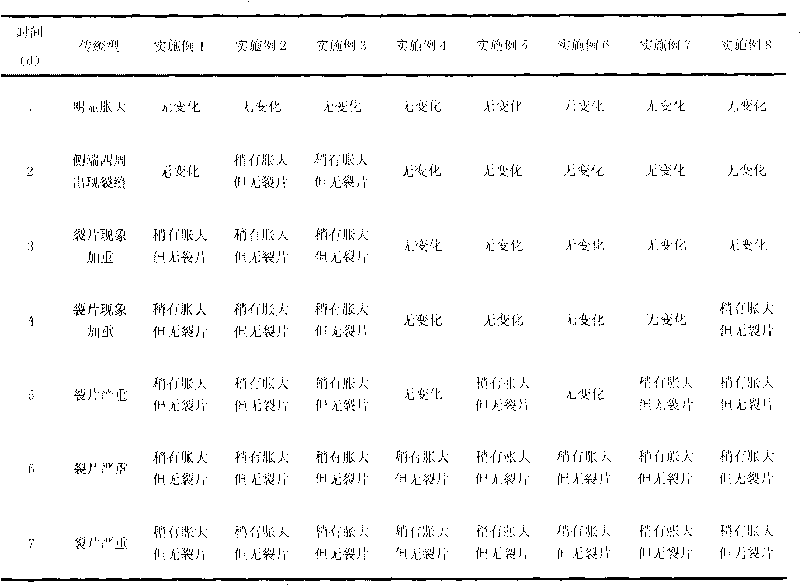

Film-coating premixing auxiliary material and preparation method thereof

ActiveCN101691429AGood dispersionGood flexibilityPharmaceutical delivery mechanismMethacrylic acid-ethyl acrylate copolymerPolyethylene glycol

The invention relates to a film-coating premixing auxiliary material which mainly comprises hydroxypropyl methylcellulose, polyvinylpyrrolidone-vinyl acetate copolymer (6:4), polyvinyl alcohol-polyethylene glycol copolymer, methacrylic acid-ethyl acrylate copolymer (1:1), polyethylene glycol, talcum powder and a colorant. The film-coating premixing auxiliary material has the advantages of favorable dampproof and anti-cracking properties, can disintegrate at a suitable time and uses water as dissolvent.

Owner:浙江瓯伦包衣技术有限公司

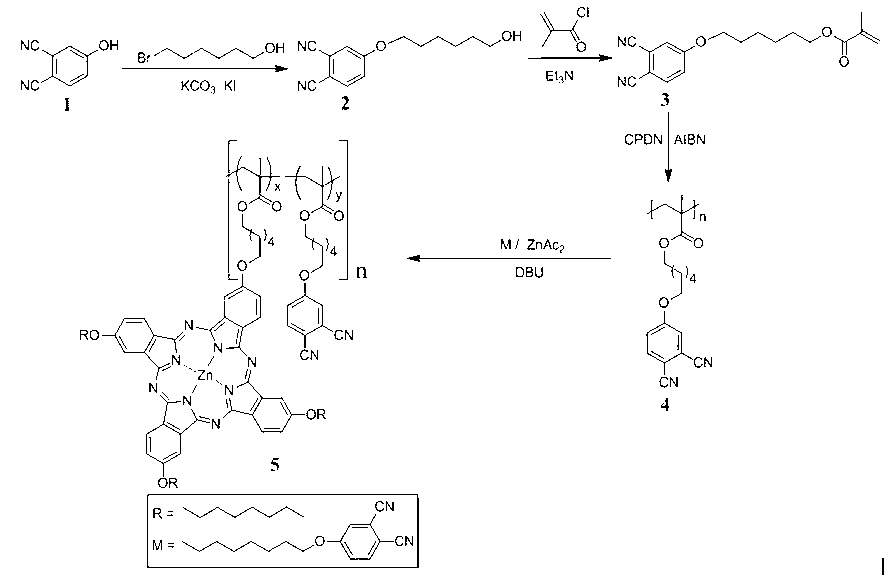

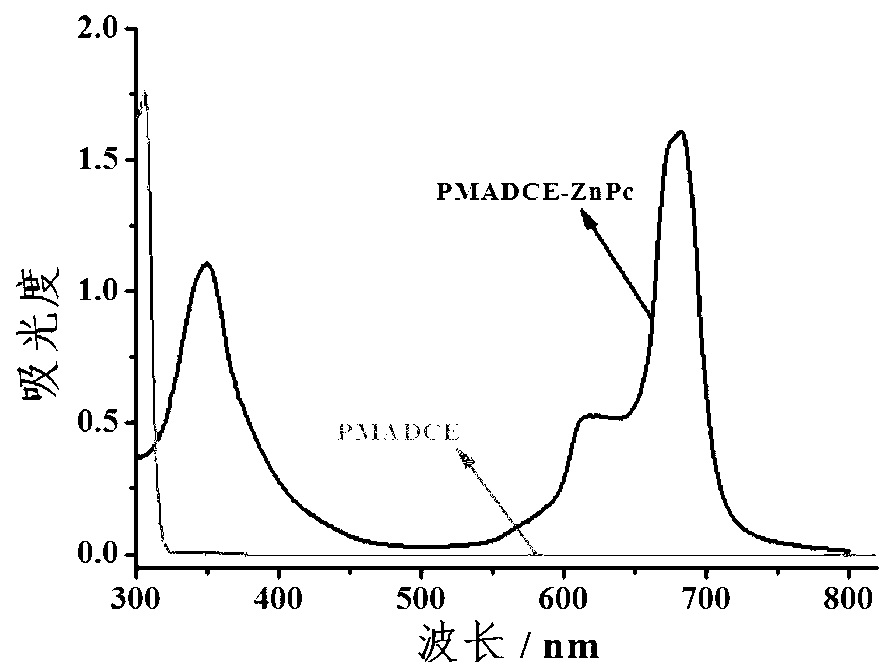

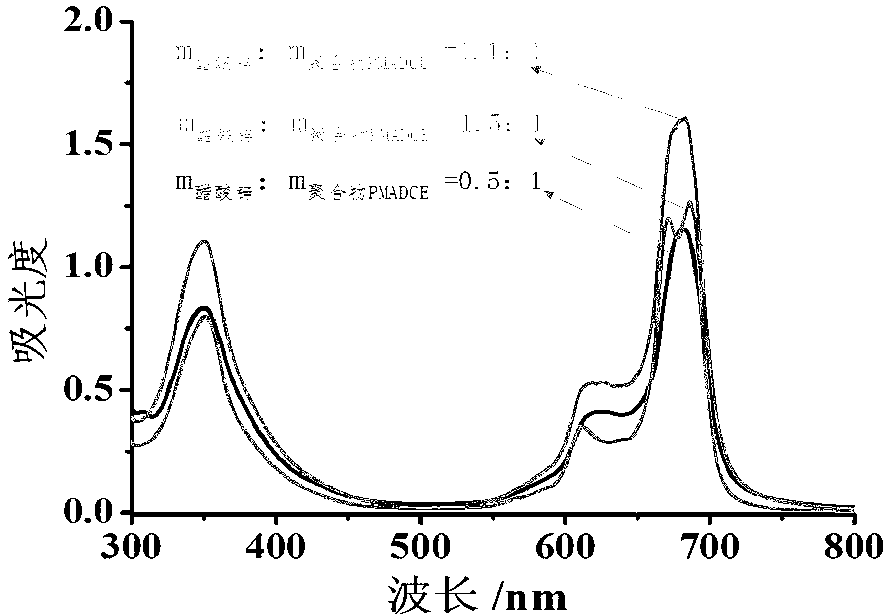

Copolymer containing zinc-phthalocyanine group on side chain and preparation method thereof

ActiveCN103193912AReduce wasteRealize rational utilizationSolid-state devicesSemiconductor/solid-state device manufacturingSolubilitySide chain

The invention discloses a copolymer containing a zinc-phthalocyanine group on a side chain and a preparation method thereof. The preparation method of the copolymer combines RAFT (reversible addition-fragmentation chain transfer) and a phthalocyanin annulation method for the first time to prepare the copolymer containing a zinc-phthalocyanine group on a side chain, and comprises the following steps of: on the presence of an initiator and a chain transfer agent, performing RAFT polymerization on a monomer methacrylic acid-6-(3,4-dicyanophenoxy)caprolactone to obtain a polymer PMADCE (polymethyl acrylic acid-6-(3,4-dicyanophenoxy)caprolactone) containing a phthalonitrile functional group on a side chain; and using the phthalonitrile functional group on the side chain of the PMADCE as a reaction point to perform phthalocyanin annulation with 4-(octyloxy)phthalonitrile in the presence of a heat-sensitive catalyst and zinc acetate so as to obtain a polymer PMADCE-ZnPc containing the zinc-phthalocyanine group on the side chain. The preparation method is few in step, simple, feasible, convenient in purification process, mild in reaction condition, controllable in process and high in conversion rate; and the PMADCE-ZnPc prepared by the method has good solubility and phthalocyanin functionality, can be used as a photoelectric material, and has good application prospects in solar cells, sensors and information storage.

Owner:蚌埠格识知识产权运营有限公司

Preparation method of stable compound halogen organic disinfectant

InactiveCN103891727AIncrease profitOvercome stabilityBiocideDisinfectantsSodium bicarbonateCompound organic

The invention discloses a preparation method of a stable compound halogen organic disinfectant. The stable compound organic disinfectant provided by the invention comprises main effective components of 1,3-dibromo-5,5-dimethylhydantoin (or 1,3-dichloro-5,5-dimethylhydantoin or 1-bromo-3-chloro-5,5-dimethylhydantoin) and trichloroisocyanuric acid (or sodium dichloroisocyanurate); necessary auxiliary additives (anhydrous sodium sulfate, sodium chloride or sodium bromide, sodium carbonate or sodium bicarbonate and sodium alkyl benzene sulfonate) are added; and dosage forms include powder, granules and tablets.

Owner:NAN JING RHINE PHARM TECH

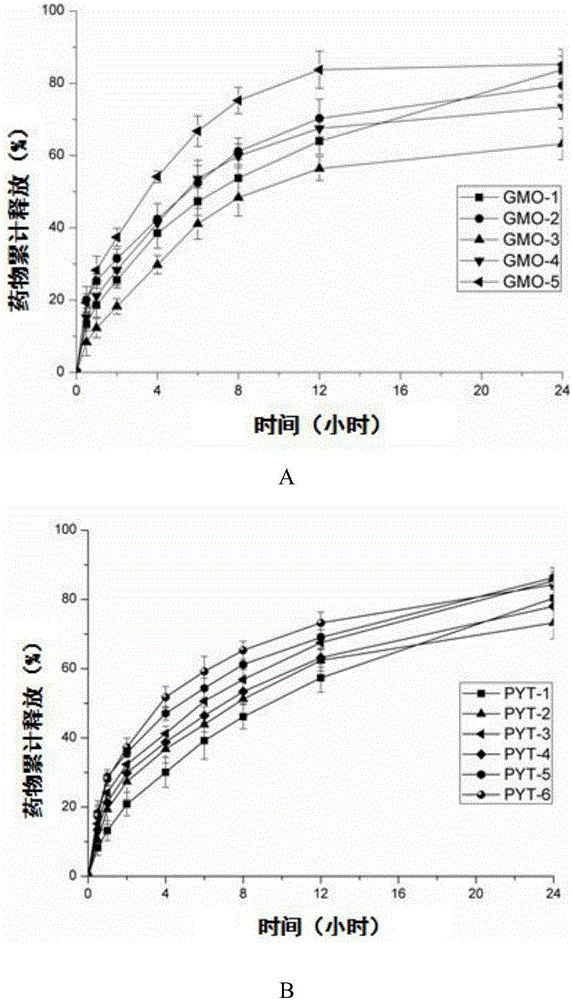

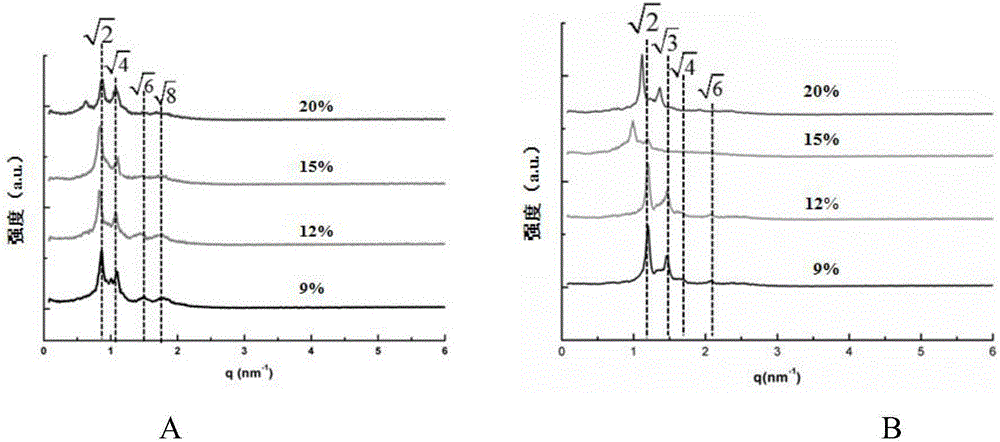

Oridonin cubic liquid crystal nanoparticle and preparation method thereof

ActiveCN106727336AHigh encapsulation efficiencyOvercome the disadvantage of low oral bioavailabilityPowder deliveryOrganic active ingredientsMass ratioSolvent

The invention relates to an oridonin cubic liquid crystal nanoparticle and a preparation method thereof. The oridonin cubic liquid crystal nanoparticle is prepared from the following raw materials in percentage by weight: 0.1 to 0.5 percent of oridonin, 7 to 64 percent of amphiphilic lipid material, 6 to 29 percent of solvent, 1 to 8 percent of stabilizer, and 25 to 65 percent of water, wherein the amphiphilic lipid material is glycerol mono-oleate or phytould likeriol; the mass ratio of a liquid crystal material to the stabilizer is 1 to (0.01 to 0.30). The oridonin cubic liquid crystal nanoparticle provided by the invention is smaller in particle size, good in uniformity, and beneficial to endocytosis and transfer of enterocyte; by utilizing a unique structure of cubic liquid crystal, a dissolution barrier and a permeation barrier of the oridonin during an oral absorption process are effectively overcome, the oral relative bioavailability of the oridonin is remarkably improved, and meanwhile, the oridonin can be slowly released.

Owner:GUANGZHOU ZHONGDA NANSHA TECH INNOVATION IND PARK +1

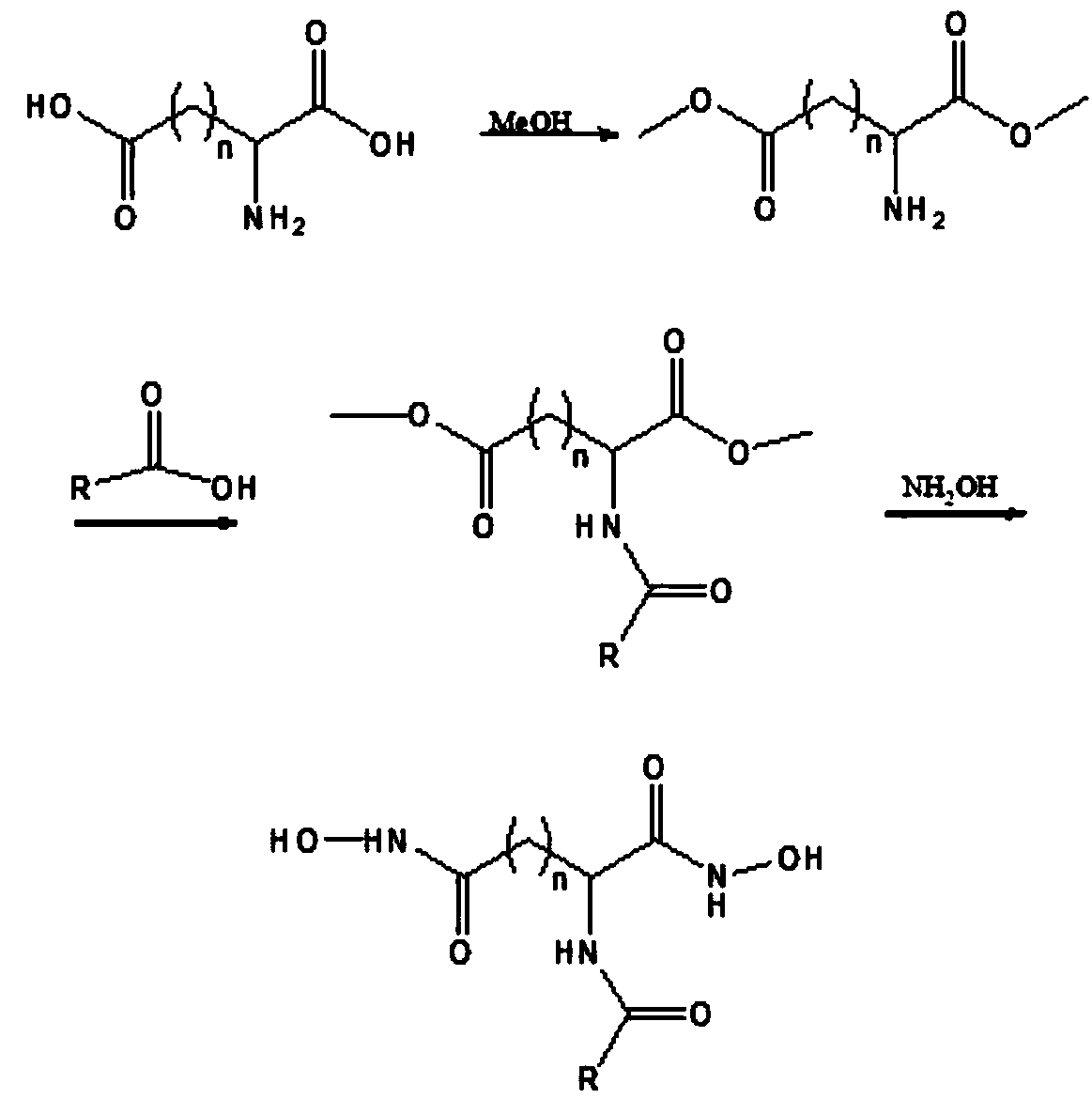

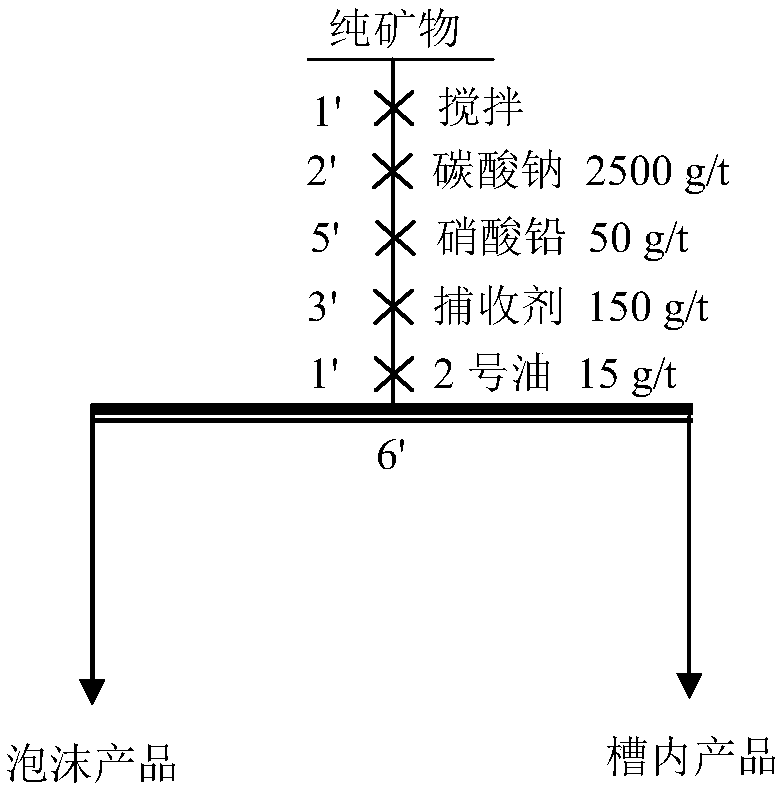

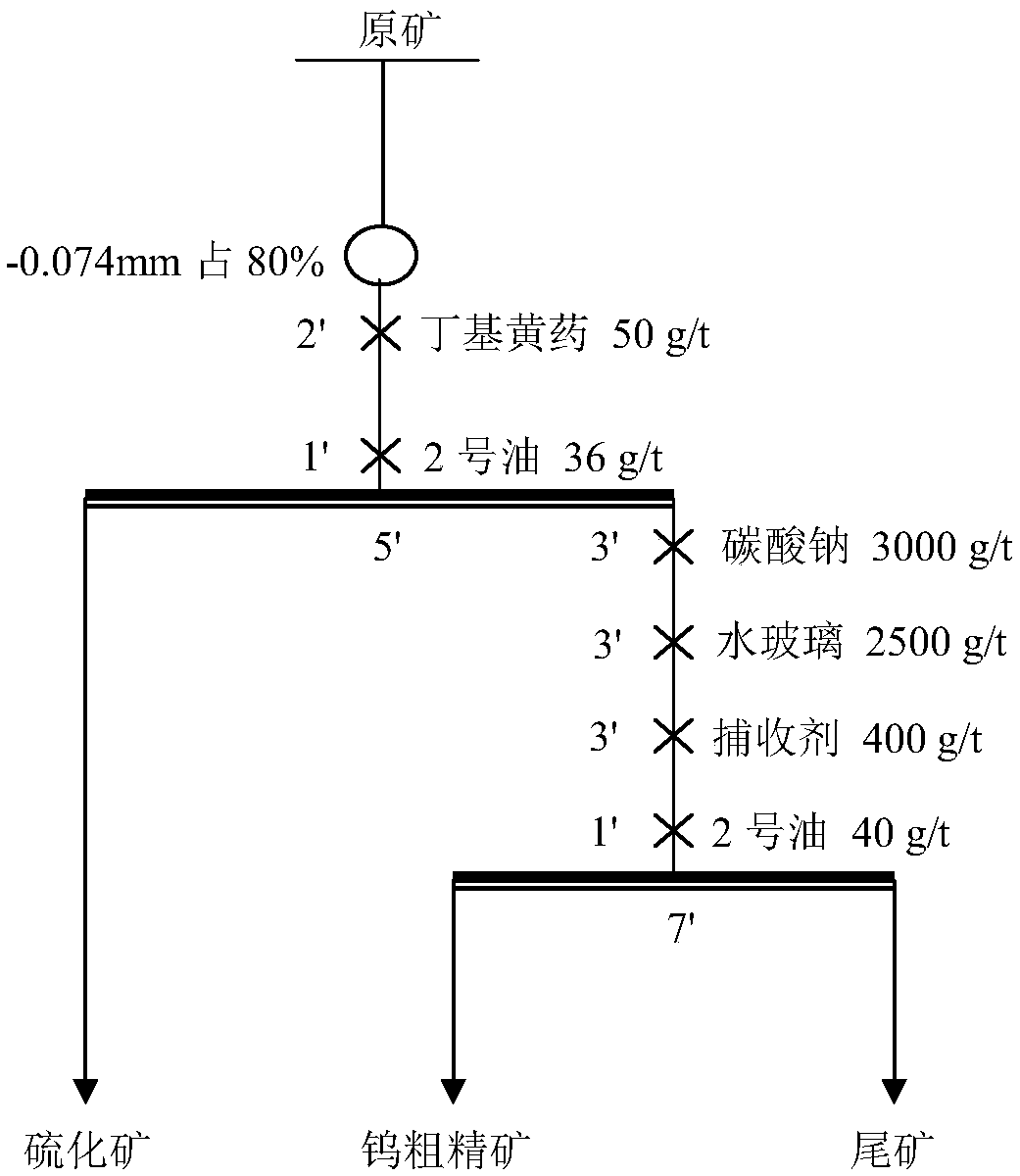

Hydrocarbon amide-bi-hydroxamic acid compound and application thereof in mineral flotation

ActiveCN108906331AStrong harvesting abilityImprove flotation recoveryFlotationHydroxamic acidRare earth

The invention provides a hydrocarbon amide-bi-hydroxamic acid compound and application thereof in mineral flotation. The structural formula of the hydrocarbon amide-bi-hydroxamic acid compound is as shown in the description, wherein R represents an aliphatic hydrocarbon group of C2 to C18, and n ranges from 1 to 10. The hydrocarbon amide-bi-hydroxamic acid compound serving as a collector can enhance the chelation and recognition to metal oxidized ores, promote the ordered arrangement of the collector on a mineral surface and effectively recover tungsten ores, rare earth ores, tin ores or ilmenite by flotation, has the advantages of strong collecting capacity, high selectivity, low consumption of tons of ores, etc., and is especially suitable for processing hard dressing fine grained ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE

Carbon-coated molybdenum sulfide/water hyacinth biomass carbon composite material and preparation method and use thereof

InactiveCN109273679ALow priceWide variety of sourcesCell electrodesSecondary cellsCarbon coatingWater baths

A carbon-coated molybdenum sulfide / water hyacinth biomass carbon composite material and a preparation method and use thereof comprise the following steps of: Including: the first step, using sodium molybdate and thioacetamide as raw materials, through a 160-200 DEGC hydrothermal method, growing a MoS2 nanosheet array on the surface of the bulbous water hyacinth biomass carbon; the second step, 80-100 DEG C water bath method is coated on the MoS2 nanosheet array with a layer of dopamine polymer; the third step is to carbonize the polymerized dopamine to form a carbon coating layer by calcination at 500 to 800 DEG C in an inert atmosphere to obtain carbon coated molybdenum sulfide. / Water hyacinth biomass carbon core shell composite. The invention has simple operation, large output and uniform coating layer . The invention has the advantages of simple operation, large output and uniform coating layer. The composite material has the advantages of low cost, high reversible charge-dischargecapacity, long cycle life and excellent rate performance when it is used as a sodium ion negative electrode material.

Owner:DONGGUAN UNIV OF TECH

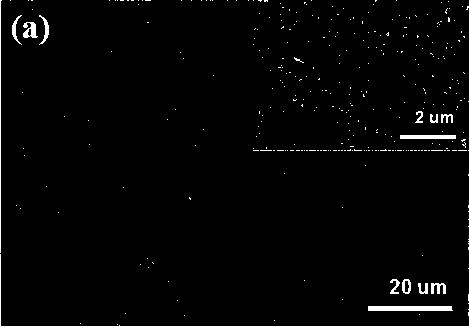

Biosynthesis method of caffeic acid phenethylester by means of transesterification

The invention discloses a biosynthesis method of caffeic acid phenethylester by means of transesterification. The caffeic acid phenethylester is prepared by reacting caffeic acid alkyl ester with phenylethyl alcohol in an ionic liquid by taking the ionic liquid as a reaction medium and lipase as a catalyst, the caffeic acid alkyl ester and the phenylethyl alcohol are added at a molar ratio of 1:(1-40), the lipase is added according to the molar ratio of the caffeic acid alkyl ester to the lipase of 1:(1-40), the ionic liquid is added according to the volume ratio of the phenylethyl alcohol to the ionic liquid of 1:(5-50), reaction temperature is 40-90 DEG C, oscillation rotation speed is 120-300 rpm (revolutions per minute), and reaction time is 10-72 hours. The transesterification method provided by the invention takes the ionic liquid as the reaction medium, is capable of increasing the solubility of a substrate with a product, improving the catalytic activity and reaction efficiency of an enzyme and shortening the reaction time, is simple in operation, mild in conditions, high in product yield, and environmentally-friendly, and has good application prospect.

Owner:JIANGSU UNIV OF SCI & TECH

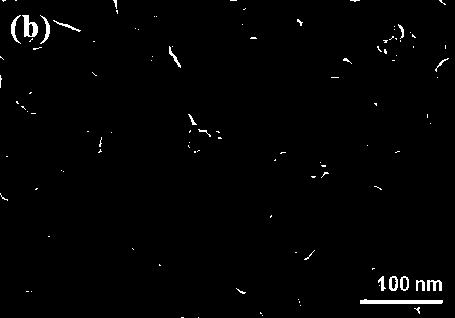

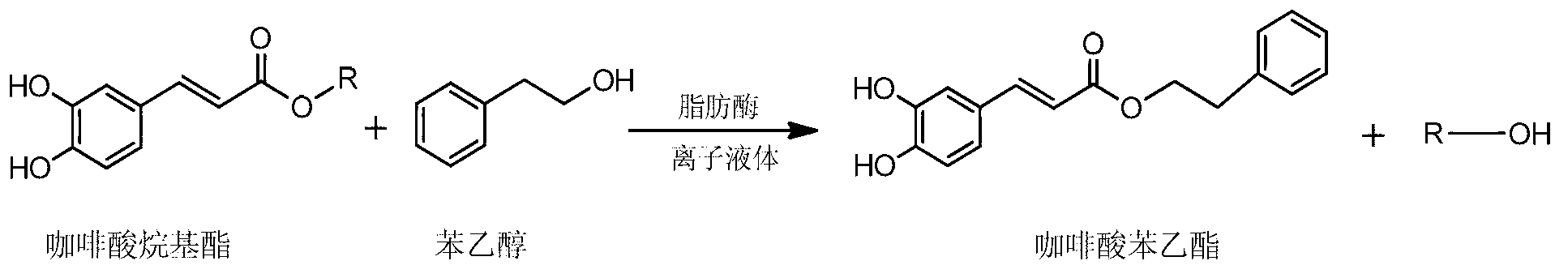

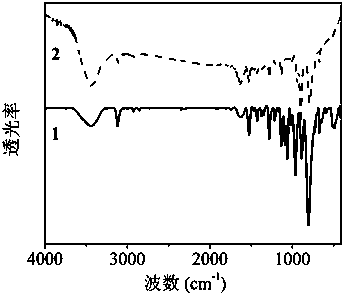

Method for detecting methane by thin film fluorescent

InactiveCN101183076ARealize detectionOvercome solubilityFluorescence/phosphorescenceSolubilityCryptophane

The present invention discloses a firedamp detecting method by using a film fluorescent light. A main body molecule cryptophane-A, which can send the fluorescent light is prepared into the film with good toughness by using a cyclone technique. The firedamp gas is directed reacted with the element and covered by the cavity of the molecule cryptophane-A. The content of the firedamp is detected according to the change of the fluorescence spectrum before and after covering. With the reaction of the main body molecule cryptophane-A film prepared by the cyclone technique and the firedamp, the problems in the prior art that the solubility of the firedamp in organic solution is low and the organic solvent is easy to be volatilized are solved. The method has selectivity to the firedamp gas and is of low cost, easy to be operated, high response speed and can be used in the detection of the firedamp gas.

Owner:SHANXI UNIV

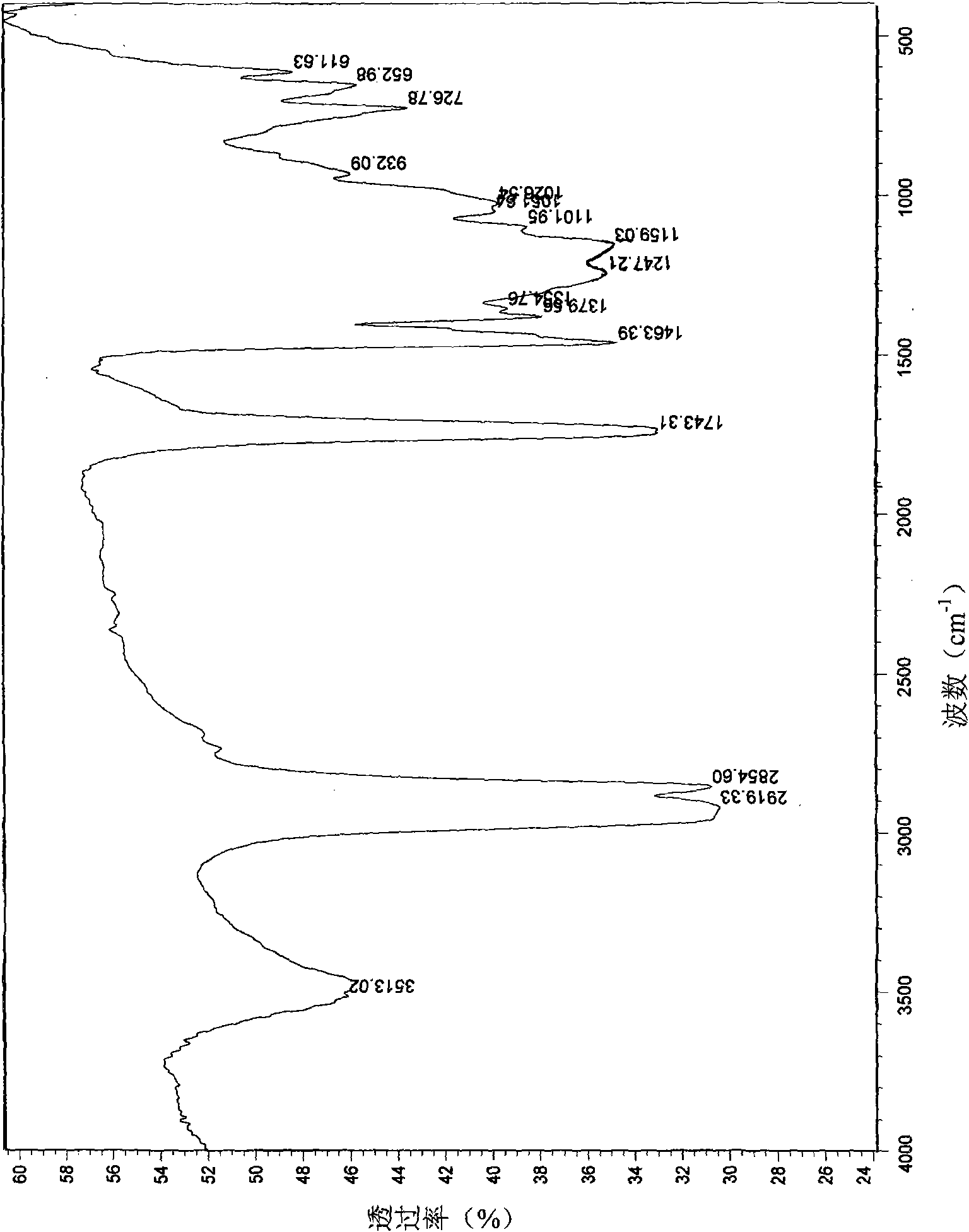

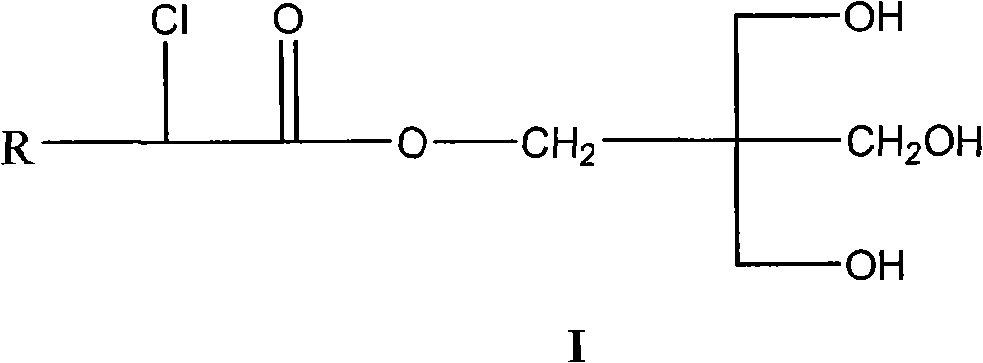

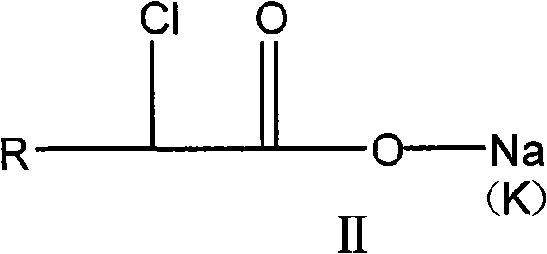

Composite floating chemical and method for preparing same

InactiveCN101549327AHigh selectivityOvercome solubilityPreparation from carboxylic acid halidesFlotationPotassiumCompound (substance)

The present invention relates to a composite floating chemicals and a method for preparing same which includes steps as follows: preparing chloro fatty acid pentaerythrite monoesters and chloro sodiumsoap / potassium salt, combining chloro fatty acid pentaerythrite monoesters with chloro sodium soap / potassium salt for obtaining the composite floating chemicals. Compared with a normal technique, which uses modification sodium soap / potassium as a collecting agent, a non-ionic chloro fatty acid pentaerythrite monoesters can increase selectivity, simultaneity, overcome disadvantage of low dissolvability and poor capture ability by using chloro fatty acid pentaerythrite monoesters as the collecting agent, both materials mix and have complementary advantage for generating cooperation effect whichmakes the modification emulsive material having better emulsive effect, and mineral concentration synthetize efficiency increasing obviously; the method has easy obtained material, low cost, simple syntheticroute, low mineral concentration cost, and can overcome sufficient in prior technology.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

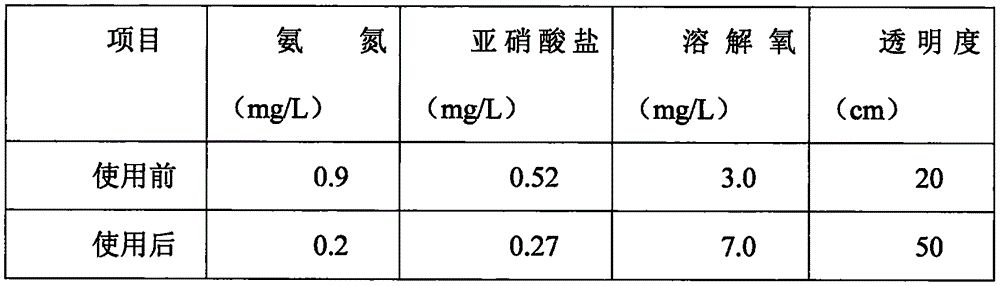

High-efficiency water quality improving agent and preparing method thereof

InactiveCN105967344AOvercome solubilityOvercome absorbencyBiological water/sewage treatmentChemistryYeast

The invention discloses a high-efficiency water quality improving agent. The high-efficiency water quality improving agent is composed of the following materials by weight percentage: 3-7% of industrial glucose, 3-7% of soluble silicon fertilizer, 1-3% of beer yeast, 3-6% of calcium hydrophosphate, 1% of functional beneficial bacterium, 1-3% of aquatic premix and the balance of microelement. The invention further provides a preparing method of the high-efficiency water quality improving agent. The preparing method comprises the steps of fully and evenly mixing all raw materials, fermenting in a normal temperature, smashing and packaging. The high-efficiency water quality improving agent can improve breeding and growth of beneficial phytoplankton like aquatic diatom, improves primary productivity of water, stabilizes a PH value of water and reduces the disease probability of bred animals like shrimp, crab, sea cucumber, jellyfish and fish. Furthermore, the high-efficiency water quality improving agent can complex and reduce heavy metal and pesticide residues in water, degrades poisonousness of hazardous substances like ammonia nitrogen, improves liveness and appetite of the bred animals, improves production and improves harvest. After being matched with the beneficial bacterium, the high-efficiency water quality improving agent is favorable for decomposition and utilization of residual feeds and faeces in water, maintenance of self cleaning ability of water and improvement of green and healthy cultivation.

Owner:ZHENGZHOU ZHITUO BIOTECH CO LTD

Novel discharging agent for textile printing and dyeing

InactiveCN104805720AImprove discharge effectOvercome solubilityDyeing processTextile printerSolubility

The invention discloses a novel discharging agent for textile printing and dyeing. The novel discharging agent is prepared by the following components in parts by weight: 3 to 8 parts of fatty alcohol-polyoxyethylene ether, 3 to 6 parts of epichlorohydrin, 3 to 7 parts of boric acid, 5 to 10 parts of polyethylene glycol oil-based ether, 3 to 7 parts of polyvinylpyrrolidone, 2 to 3 parts of N-benyl-2-naphthylamine, 3 to 7 parts of sodium hydroxide, 11 to 12 parts of thiourea dioxide, 3 to 6 parts of rongalite, 7 to 12 parts of linear alkyl benzene sulphonic acid, 3 to 5 parts of ammonium sulfate, 17 to 22 parts of ethylene glycol, and 20 to 30 parts of deionized water. The novel discharging agent has the advantages that a modifying method is simple, the stability of a product is good, and the discharging effect of the thiourea dioxide can be improved; the defects of low solubility because of using the convention thiourea dioxide as the discharging agent for discharging and dyeing and the poorer dispersing uniformity, poorer net permeating property, insufficient playing of discharging function and the like in the discharging liquid are overcome.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

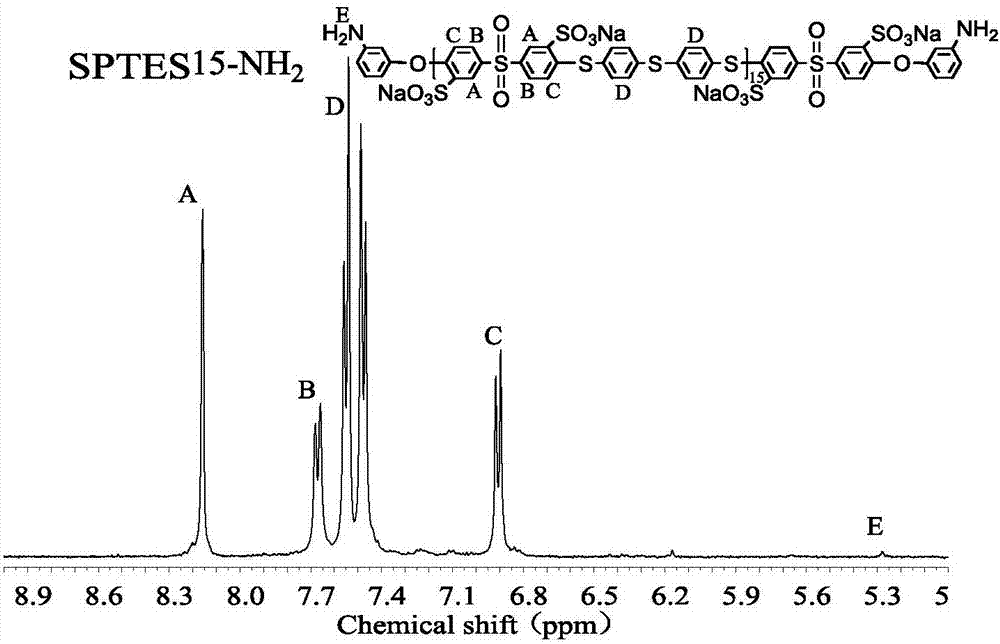

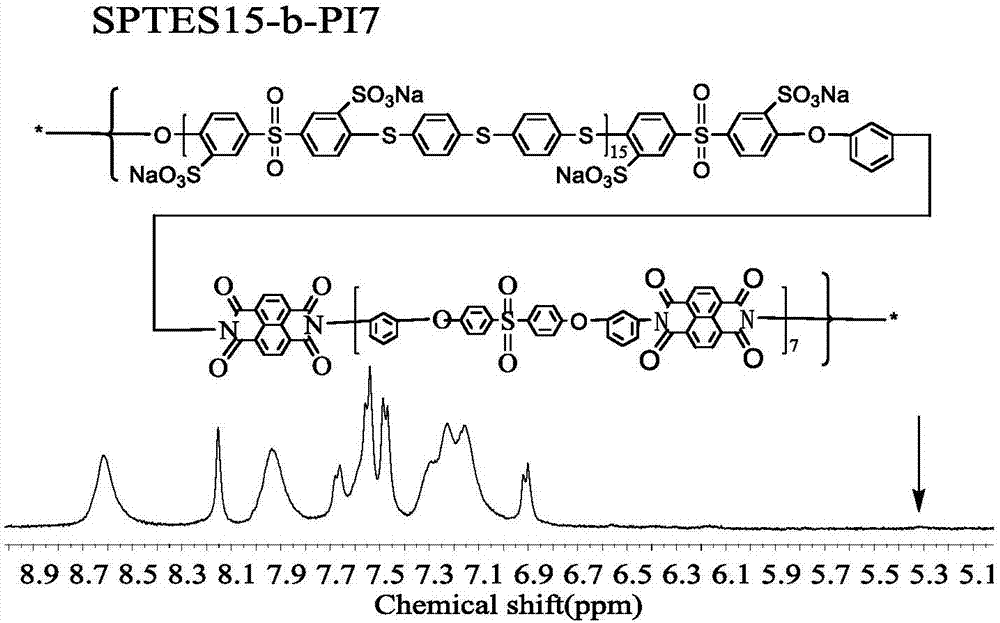

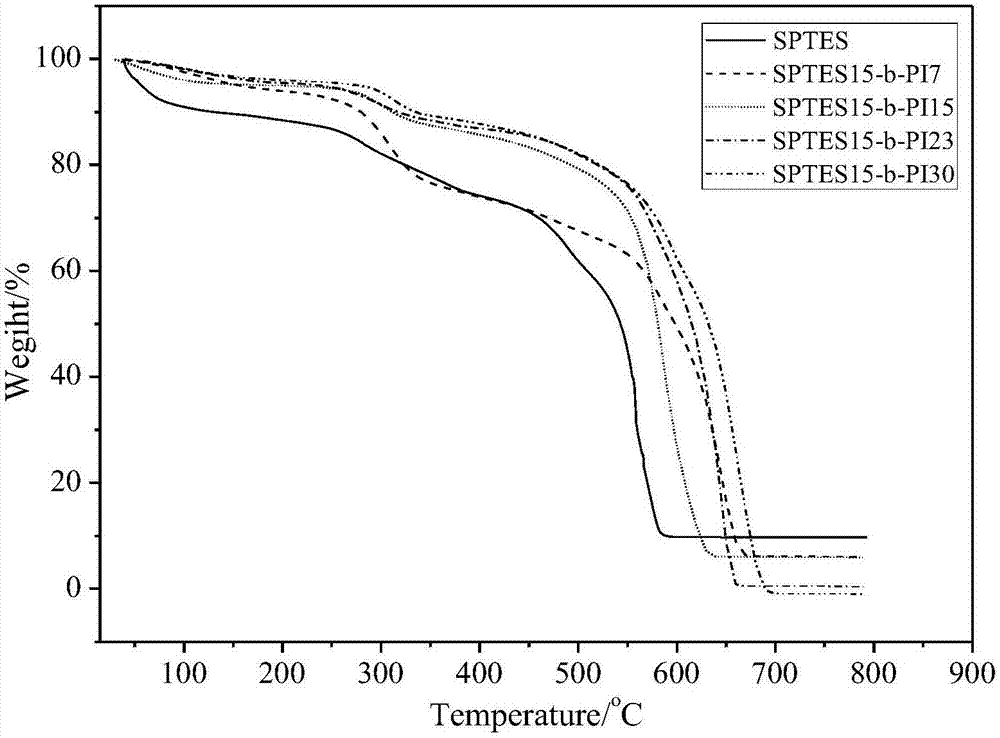

Preparation method of sulfonated poly (arylene sulfide sulfone) / polyimide block type proton exchange membrane material

The present invention discloses a preparation method of a sulfonated poly (arylene sulfide sulfone) / polyimide block type proton exchange membrane material. The method adopts a two-step method for termination, a meta-or para-amino functional group is introduced into the terminal end of a sulfonated poly (arylene sulfide sulfone) chain section by end-capping reaction of the polymer chain section, and a block copolymer is synthesized by imidization coupling reaction of the amino-terminated sulfonated poly (arylene sulfide sulfone) hydrophilic section and an anhydride terminated polyimide hydrophobic section. The method not only overcomes the problem that a sulfonated poly(arylenethioethersulfone) film is very easy to swell and dissolve in high humidity or water, also guarantees that PEM has high thermal stability and proton conductivity especially proton conductivity under high temperature and humidity.

Owner:HEBEI UNIV OF TECH

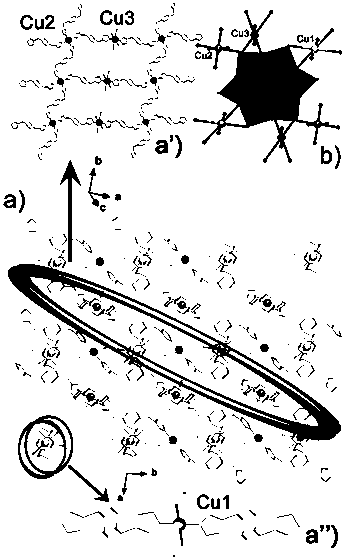

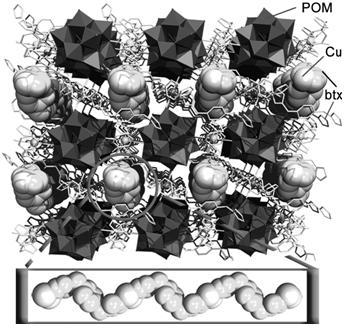

Preparation and applications of two three dimensional pseudo-rotaxane type metal organic framework materials with multiple acid groups

InactiveCN108948100AOvercome solubilityOvercome conductivityGroup 1/11 organic compounds without C-metal linkagesOrganic chemistry methodsCapacitanceMetal-organic framework

The invention relates to preparation and applications of two three dimensional pseudo-rotaxane type metal organic framework materials with multiple acid groups. The invention aims to solve the problemthat the capacitance of a super capacitor whose electrodes are made of some metal organic framework materials with multiple acid groups is not high, and provides a material used as the electrode of asuper capacitor to increase the capacitance and a preparation method thereof. The chemical formulas of two materials are [CuIICuI3(H2O)2(btx)5(PWVI10WV2O40)].2H2O(1) and [CuII2CuI2(btx)5(SiMoVI10MoVI10MoV2O40)].6H2O(2), wherein btx represents 1,4-bis(triazole-1-methyl) benzene. The preparation method comprises following steps: adding polyacid, copper salts, and organic ligands into distilled water, evenly stirring, adjusting the pH value, and carrying out reactions for three days at a temperature of 160 DEG C. The specific capacitance values of two materials are 138.4 F g<-1> (1) and 82.1 F g<-1> (2) under a current density of 2 A / g. A research model is provided for improving the super electrical performance of metal organic framework materials with multiple acid groups only by changing the polyacid kinds.

Owner:HARBIN UNIV OF SCI & TECH

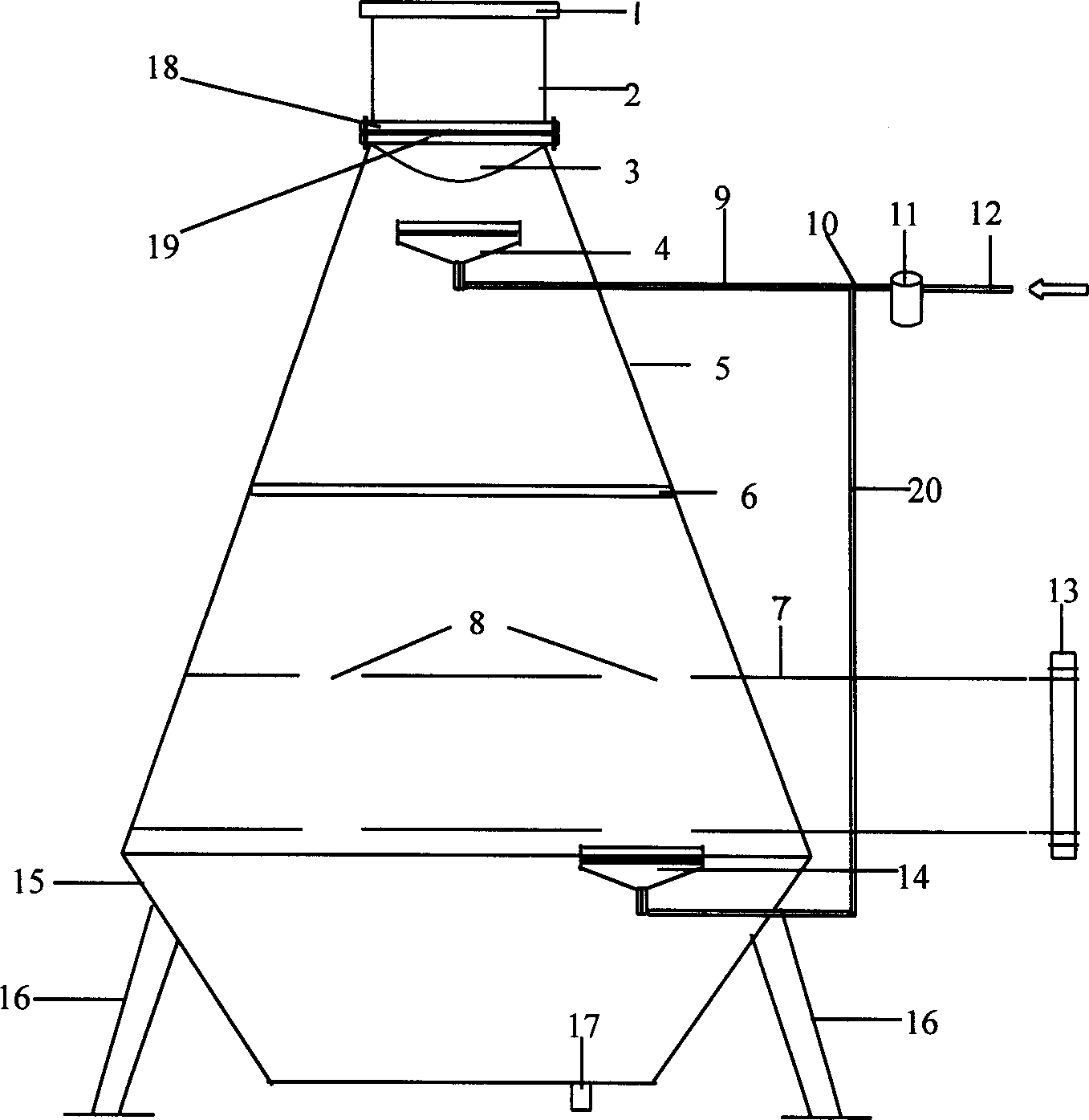

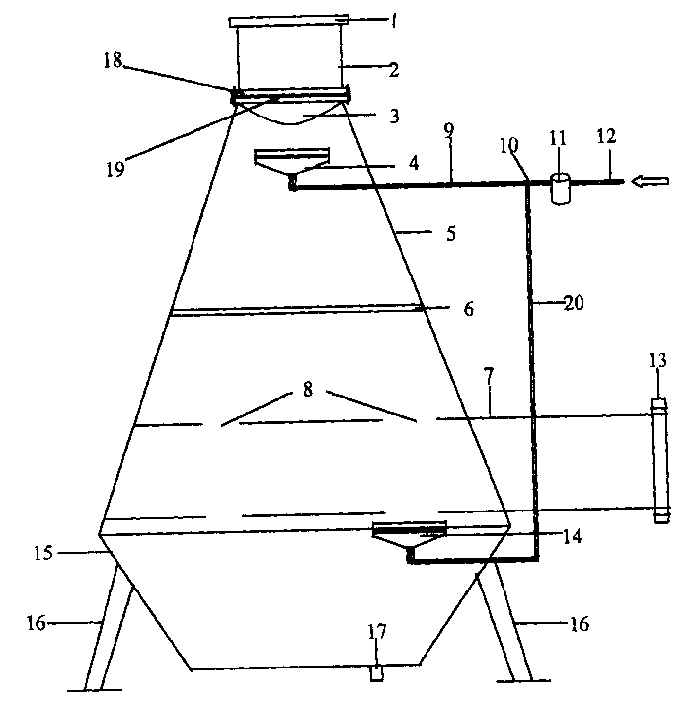

Conical aerator

InactiveCN1425282AImprove solubilityWon't escapeClimate change adaptationPisciculture and aquariaHigh densityAquatic product

The present invention relates to the water treatment technology in aquaculture, and is especially one pure oxygen aerator for high-density fish culture. The aerator includes one section of cylindrical pipe, one section of gradually expanding truncated cone and one section of gradually reducing truncated cone bottom, which are connected successively to constitute one sealed container. Inside the container, there are one aeration unit connected to oxygen pipe and water draining pipe in the bottom stretching beyond the container. Inside the sealed container, oxygen can dissolved repeatedly without escape and this results in high oxygen solubility and low power consumption.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

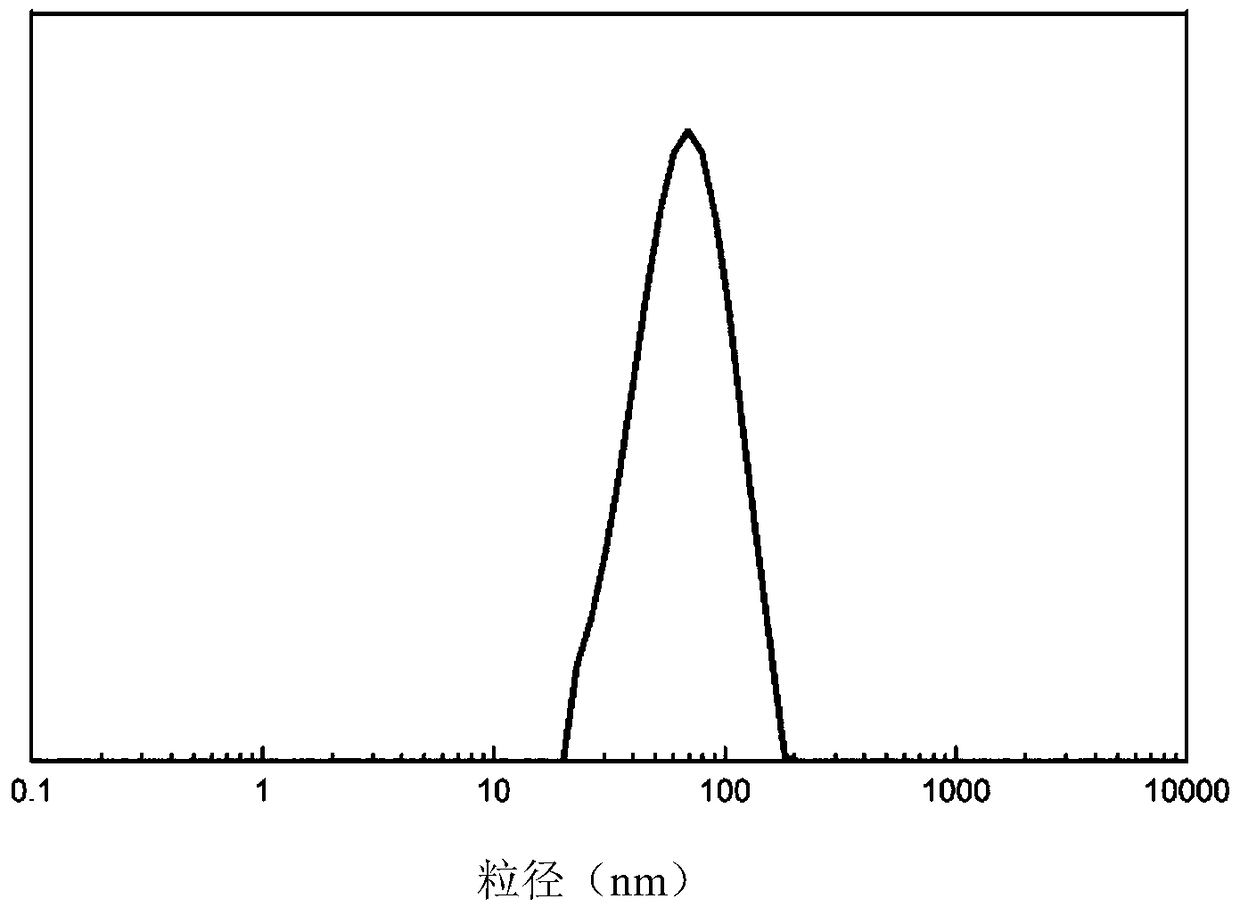

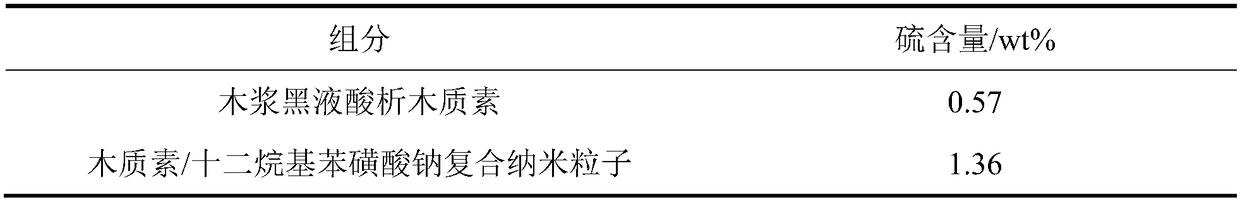

Lignin/surfactant composite nanoparticle and preparation method thereof

The invention belongs to the technical field of nanomaterials and discloses a lignin / surfactant composite nanoparticle and a preparation method thereof. The preparation method comprises the followingsteps: (1) dispersing 100 parts by mass of lignin into alkaline liquid, adjusting the pH value of the system to 9-12, adding 10-25 parts by mass of epoxy chloropropane, carrying out cross-linking reaction at 80-95 DEG C for 1-3 hours, so as to obtain high molecular weight lignin; (2) adding high molecular weight lignin, alkali and a surfactant into water, so as to obtain a mixed solution with thepH value of 9-12; and (3) adding acid into the mixed solution until the pH value of the mixed solution is 4-6, and stirring, so as to obtain a water dispersion solution of the lignin / surfactant composite nanoparticle. The lignin / surfactant composite nanoparticle prepared by virtue of the preparation method has excellent water dispersion performance, the hydrodynamic radius is 40nm-500nm, and the lignin / surfactant composite nanoparticle can be very stably dispersed into water and can be easily mixed with other components.

Owner:SOUTH CHINA UNIV OF TECH

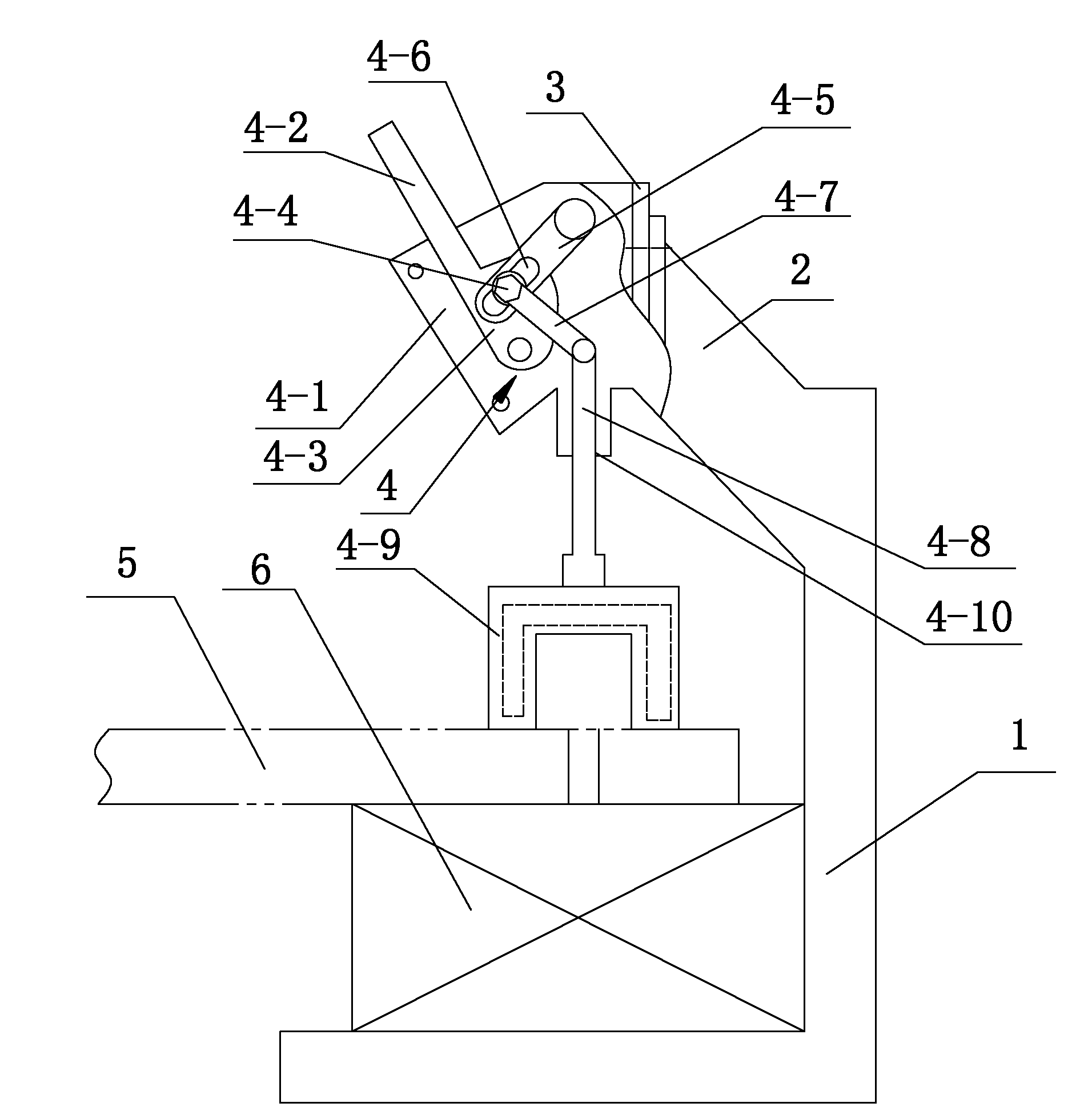

Method for manufacturing pole coil

InactiveCN102069252AAvoid processing qualityOvercome solubilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCopper

The invention relates to a method for manufacturing a pole coil, which is characterized by comprising the following steps of: (1) firstly, installing a clamping / positioning device on a brazing machine; (2) then, installing a soldering lug between craters of two copper bars, and operating a handle so as to enable a pressure head to be pressed against and then welded on the copper bars; (3) adjusting the position of the pressure head so as to keep the pressing force to be in a tendency of an equilibrium state; and (4) finally, electrifying a high-frequency induction power of the high-frequency brazing machine so as to enable an inductance coil to induce and heat the craters and the soldering lug of the copper bars, and keeping the pressing force for three to five seconds, then after the soldering lug is solidified, starting up the clamping / positioning device so as to complete the manufacturing of the pole coil. The method provided by the invention has the advantages that the defects of turn-to-turn faults and the like caused by uneven dissolved silver soldering lugs and poor soldering existing in the process of welding the copper bars are overcome, and the efficiency and quality of welding are improved; after the crater is processed by a pressing mechanism, the quality of the crater is good; meanwhile, the method also has the advantages of improving the utilization rate of materials, expanding the range of design size, reducing the unit cost, achieving the purpose of accurately machining workpieces, and effectively solving the problem of machining quality of a large four-head welding pole coil.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

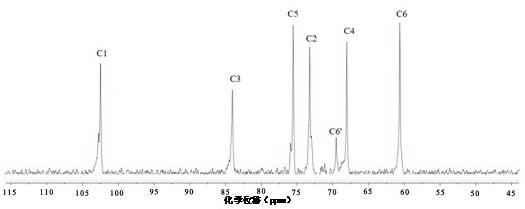

Water-soluble beta-glucan, preparation method thereof and application of water-soluble beta-glucan in preparation of immunopotentiation and anti-tumor medicines and health care products

ActiveCN111690075AGood water solubilityStrong reaction rate constantOrganic active ingredientsImmunological disordersImmunocompetenceFreeze-drying

The invention discloses water-soluble beta-glucan, a preparation method thereof and application of the water-soluble beta-glucan in preparation of immunopotentiation and anti-tumor drugs and health care products. The preparation method comprises the following steps: firstly, preparing an alkaline urea aqueous solution, carrying out cryopreservation, then adding insoluble beta-glucan, stirring to dissolve the beta-glucan, freezing, then heating to a proper temperature, dropwise adding a hydrogen peroxide aqueous solution while stirring, adjusting the pH value to be neutral, carrying out dialysis, and carrying out reduced pressure concentration and freeze drying on dialysis internal liquid, so as to obtain the water-soluble beta-glucan. According to the method, the technical problem that insoluble beta-glucan is difficult to degrade is solved through homogeneous degradation in an alkaline urea aqueous solution. The water-soluble beta-glucan obtained by using the method can significantlyenhance the immunocompetence of macrophages RAW 264.7 and effectively antagonize tumor cells. The beta-glucan prepared by the invention has the advantages of easily available raw materials, simple preparation process, strong biological activity, easiness in industrial production and the like, and has a prospect of being developed into immunopotentiation and anti-tumor drugs.

Owner:OCEAN UNIV OF CHINA

Oral nifedipine slow-release preparation and preparation method thereof

InactiveCN101416965AImprove solubilityImprove wettabilityOrganic active ingredientsPharmaceutical delivery mechanismSolubilityNifedipine

The invention provides an oral nifedipine sustained-release preparation which comprises the following ingredients by weight: 4 percent to 30 percent of nifedipine, 50 percent to 85 percent of excipients which have sustained-release function and are acceptable in pharmacy, and other medical excipients, the amount of which ranges from a proper amount to 100 percent and are acceptable in the pharmacy. Nifedipine sustained-release capsules of the invention can not only improve the solubility of the nifedipine in water, but also continuously release the nifedipine. The invention also provides a preparation method of the oral nifedipine sustained-release preparation, which comprises the step of evenly blending the nifedipine, the excipients which have sustained-release function and are acceptable in the pharmacy and other excipients acceptable in the pharmacy.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

Platinum refining process

InactiveCN109234528AOvercome calcinationOvercome solubilityProcess efficiency improvementSodium chlorateSodium metabisulfite

The invention relates to a platinum refining process, which comprises the following steps that deionized water is added into crude ammonium chloroplatinate; pulpifying is performed to obtain pulpifiedliquid; after the pulpified liquid is heated, sodium metabisulfite is added into the pulpified liquid in a stirring state; continuous stirring is performed; heat insulation reaction is performed until the ammonium chloroplatinate is completely dissolved; first reaction liquid obtained through reaction is cooled and filtered; filtering liquid obtained through filtering is heated; then, hydrochloric acid and sodium chlorate are sequentially added under the stirring state; continuous stirring is performed; heat insulation reaction is performed until the ammonium chloroplatinate is completely separated out; second reaction liquid obtained through reaction is cooled; ammonium chloride is added; stirring is performed until the ammonium chloride is dissolved; then, filtering is performed; filterslag obtained through filtering is washed by a hydrochloric acid-ammonium chloride solution; then, the first to third steps are repeated for 2 to 3 times; pure ammonium chloroplatinate is obtained; calcination is performed; spongy platinum can be obtained. The sodium pyrosulfite is used for reduction; the ammonium chloroplatinate is dissolved; a series of problems of ammonium chloroplatinate calcination, royal water dissolution and denitration processes in the prior art can be solved.

Owner:JINGCHU UNIV OF TECH

Alkali slag concrete composite activator and preparation method of concrete mixture

The invention relates to an alkali slag concrete composite activator and a preparation method of a concrete mixture. The composite activator in alkali slag concrete is made by mixing solid sodium hydroxide with a composition of one or two of solid alkali metal carbonate and alkali metal bicarbonate; the preparation method of the mixture includes the following steps: first, preparing activated powdery material, the composite activator and mixing water material; second, mixing materials of solid components; third, after adding all the solid components, adding mixing water and stirring; by using the composite activator and the preparation method thereof according to the technical scheme, it is possible to overcome the technical defect that sodium hydroxide in alkali slag concrete is currently dissolved sodium hydroxide so that the production process has a complex flow; the solid activator need not be dissolved and cooled first, the production process is simplified, production cost is reduced, the applicable range is wide, and there is no need for additive retarders.

Owner:张彭成

Method for producing alkaline water-soluble fertilizers by utilizing vegetable wastes

InactiveCN111285733AEfficient use ofAvoid secondary pollutionCalcareous fertilisersBio-organic fraction processingAlkaline waterAgricultural engineering

The invention relates to a method for producing alkaline water-soluble fertilizers by utilizing vegetable wastes. The method comprises the following steps: (1) adding the vegetable wastes into a fermentation tank, carrying out anaerobic fermentation, and filtering to obtain a fermentation base solution; (2) adding a seed solution, calcium carbonate and a defoaming agent into the fermentation basesolution, fermenting, filtering, and sterilizing at high temperature; (3) adding an acidifying agent into the fermentation filtrate, adding potassium phosphate in batches, and monitoring the pH valueof the solution; (4) adding a mixed material consisting of medium trace elements, organic matters and the like, stirring and dissolving; (5) adding acid and alkali to adjust the pH value to a proper pH value; and (6) adding a microbial inoculum, dissolving and uniformly mixing, and customizing alkaline water-soluble fertilizers with different pH values. The method can improve the utilization rateof the vegetable wastes, and the prepared product can realize cyclic planting of crops and improve and fertilize soil.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

Virginiamycin soluble powder and preparation method thereof

ActiveCN104208657AIncrease internal stressOvercome granularityAntibacterial agentsPowder deliveryVirginiamycinPolyethylene glycol

The invention relates to virginiamycin soluble powder and a preparation method thereof, belonging to the technical field of medicines. The soluble powder is prepared from the following components in parts by weight: 0.01-20 parts of virginiamycin, 30-70 parts of polyethylene glycol-4000 and / or polyethylene glycol-6000, 1-10 parts of povidone K30, 0.5-2 parts of lauryl sodium sulfate and 1-10 parts of Fumei powder. The soluble powder provided by the invention is good in water solubility and uniform to dissolve, medicines are not separated out, and a water line is not blocked. Compared with the conventional manner of delivery by feed, the soluble powder is more convenient to use and provides a novel virginiamycin medication manner for the market. In addition, the medicine provided by the invention is good in stability and strong in operability of production processes, thereby facilitating market promotion.

Owner:HENAN SOAR VETERINARY PHARMA

Soluble graphdiyne derivative and preparation method and application thereof

ActiveCN111574465AOvercoming dispersionOvercome solubilityOrganic chemistryChlorobenzeneOrganic solvent

The invention belongs to the technical field of functional materials, and particularly relates to a soluble graphdiyne derivative, and a preparation method and application thereof. Compared with graphdiyne, the dissolvability of the graphdiyne derivative disclosed by the invention in an organic solvent is greatly improved. For example, the graphdiyne derivative provided by the invention has good solubility in polar organic solvents such as dichloromethane, chlorobenzene, N-methylpyrrolidone (NMP) and tetrahydrofuran, and the concentration of the graphdiyne derivative is up to 5mg.ml<-1> in chlorobenzene; and therefore, the problem that graphdiyne is difficult to disperse or dissolve in a solution is solved, and the graphdiyne derivative has great application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

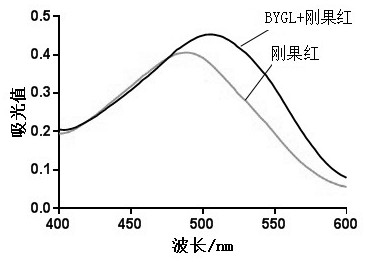

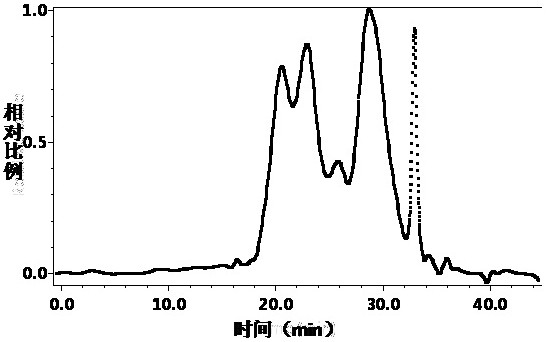

Metal ion-enhanced enzymatic method for synthesizing isoquercitrin

A method for synthesizing isoquercitrin by a metal ion-reinforced enzyme method comprises the step of adding metal ions into an enzymatic isoquercitrin synthesis system in order to increase the efficiency of synthesization. The method is easy to operate, reaction conditions are mild, the product yield is high, the method is environment-friendly, and overcomes the defect of conventional glycosidase-catalysed synthesis, i.e. low efficiency, and high-purity isoquercitrin can be easily produced industrially.

Owner:JIANGSU UNIV OF SCI & TECH

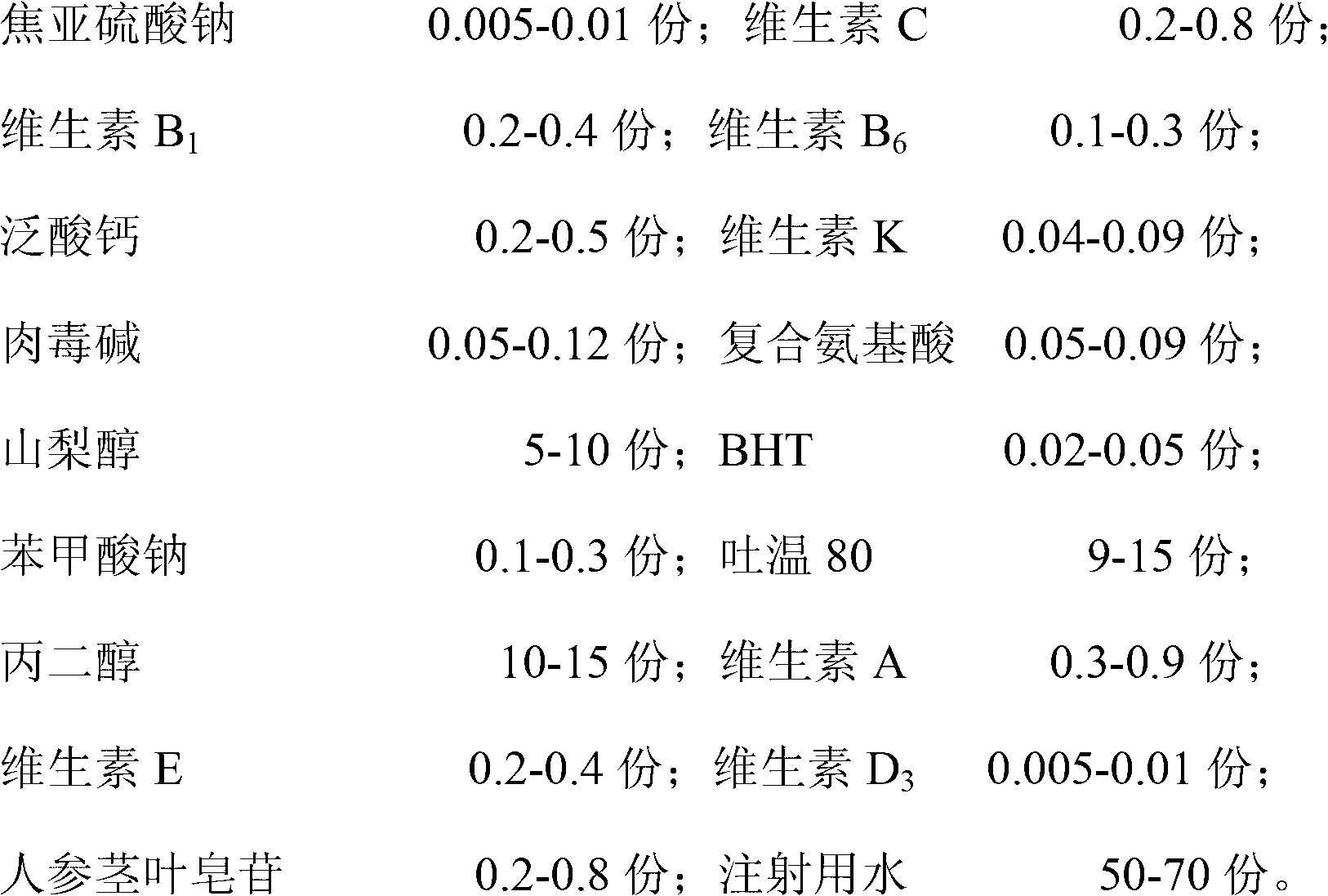

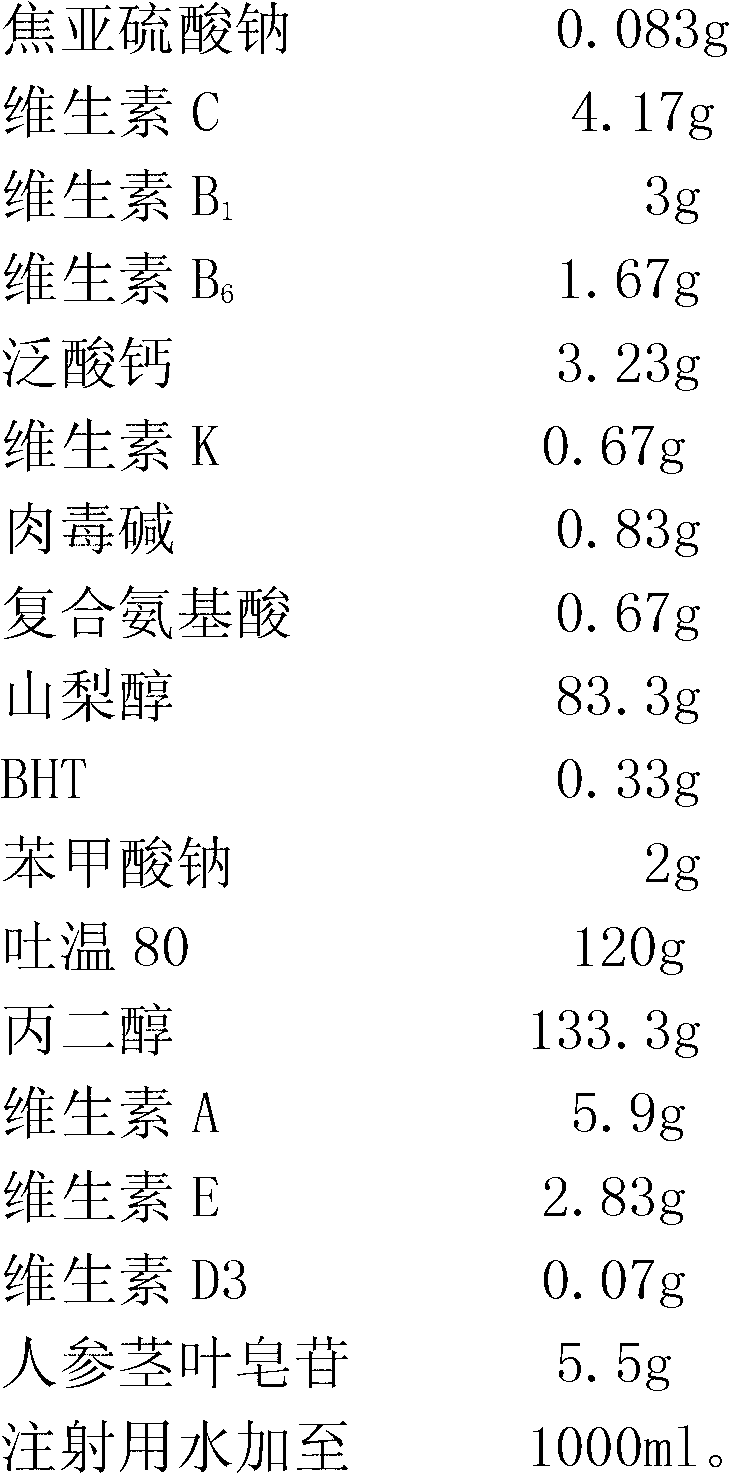

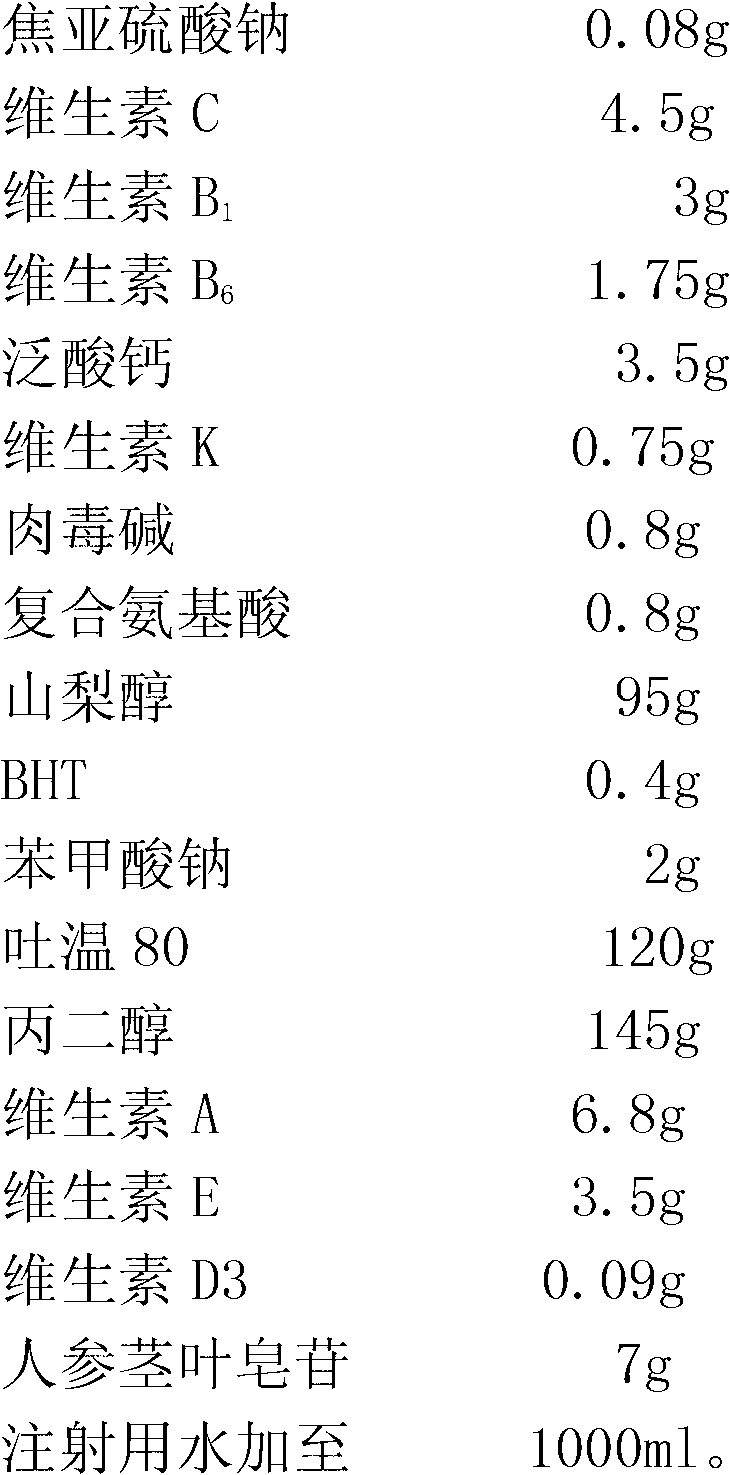

Novel liquid vitamin for breeding hen or laying hen and preparation method of novel liquid vitamin

InactiveCN102846686AEnhance immune functionIncrease egg productionAntibacterial agentsHydroxy compound active ingredientsVitamin b6Vitamin C

The invention provides a novel liquid vitamin for a breeding hen or a laying hen and a preparation method of the novel liquid vitamin. The liquid vitamin is prepared from the following components in parts by weight: 0.005-0.01 part of sodium pyrosulfite, 0.2-0.8 part of vitamin C, 0.2-0.4 part of vitamin B1, 0.1-0.3 part of vitamin B6, 0.2-0.5 part of calcium pantothenate, 0.04-009 part of vitamin K, 0.05-0.12 part of carnitine, 0.05-009 part of compound amino acid, 5-10 parts of sorbitol, 0.02-0.05 part of BHT (Butylated Hydroxytoluene), 0.1-0.3 part of sodium benzoate, 9-15 parts of Tween80, 10-15 parts of propylene glycol, 0.3-0.9 part of vitamin A, 0.2-0.4 part of vitamin E, 0.005-0.01 part of vitamin D, 0.2-0.8 part of ginseng stem and leaf saponins and 50-70 parts of injection water.

Owner:河北幕尼斯农牧科技有限公司

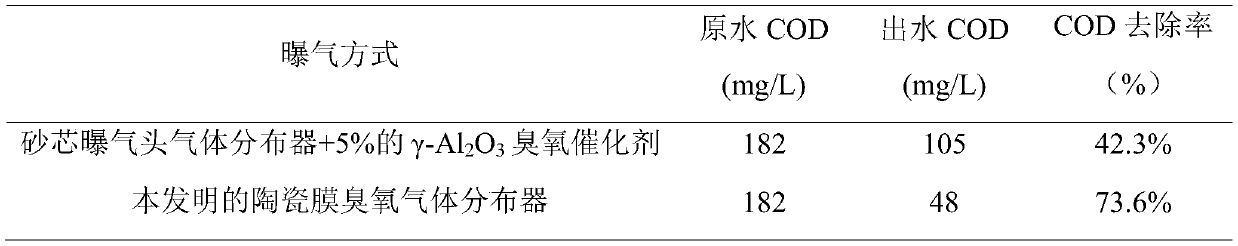

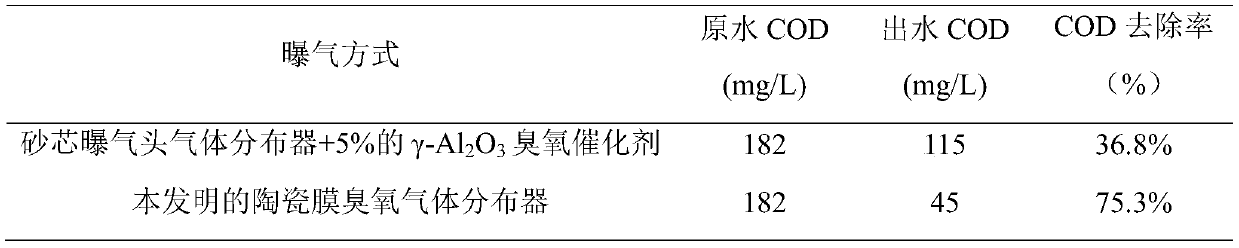

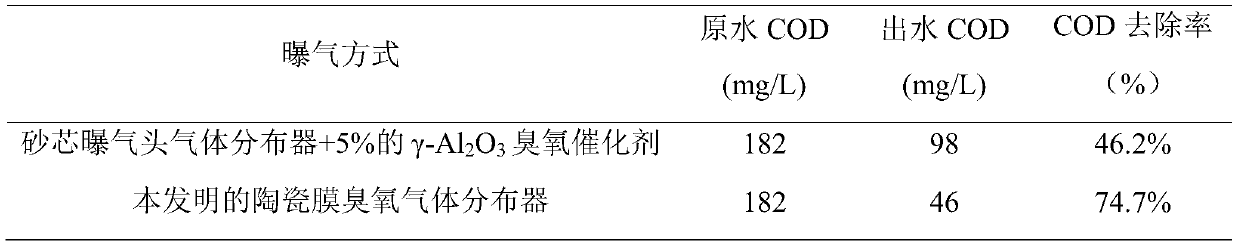

Integrated catalytic membrane ozone gas distributor as well as preparation method and application thereof

InactiveCN111252884AImprove mass transfer efficiencyIncrease contact areaWater contaminantsWater/sewage treatment by oxidationPtru catalystPetrochemical

The invention belongs to the field of wastewater treatment, and discloses an integrated catalytic membrane ozone gas distributor as well as a preparation method and application thereof. The integratedcatalytic membrane ozone gas distributor takes a ceramic membrane with micron-sized pore channels as a main body, and an ozone active catalytic material layer is loaded on the outer surface of the ceramic membrane. The main component of the catalytic material layer comprises gamma-Al2O3. The integrated catalytic membrane ozone gas distributor disclosed by the invention can be effectively used foradvanced treatment of degradation-resistant fine chemical wastewater in industries such as medicines, pharmacy, dyes, petrochemical engineering and intermediates. The ceramic membrane is used in theozone distributor for ozone aeration and a catalyst carrier at the same time, ozone aeration and ozone catalysis are achieved through micron-scale pore channels in the surface of the ceramic membrane,the ozone utilization efficiency is improved through cooperation of the ozone distributor and the catalyst carrier, and therefore the wastewater treatment efficiency is improved.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com