Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111 results about "Rongalite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rongalite is a chemical compound with the molecular formula Na⁺HOCH₂SO₂⁻. This salt has many additional names, including Rongalit, sodium hydroxymethylsulfinate, sodium formaldehyde sulfoxylate, and Bruggolite. It is listed in the European Cosmetics Directive as sodium oxymethylene sulfoxylate (INCI). It is water-soluble and generally sold as the dihydrate. The compound and its derivatives are widely used in the dye industry.

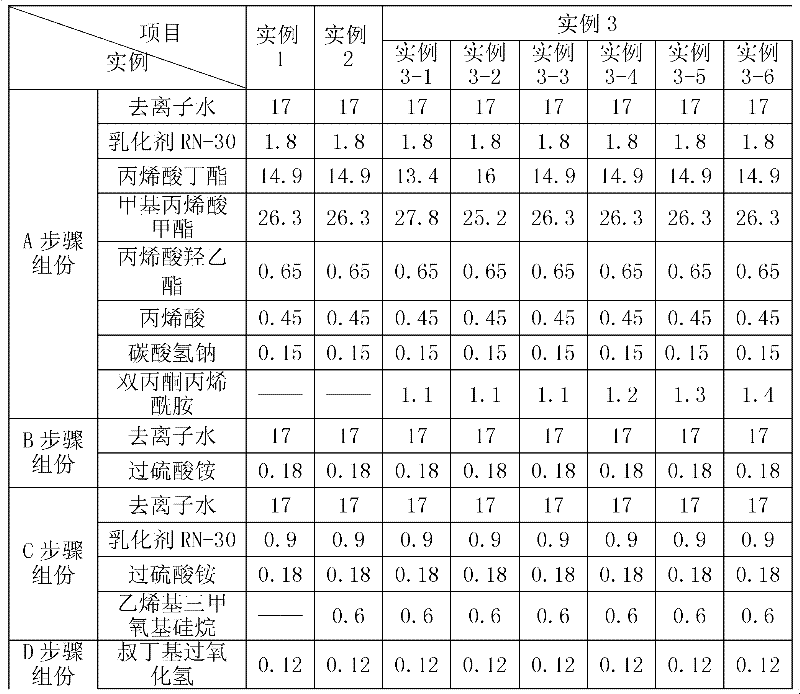

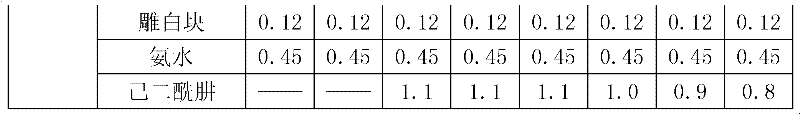

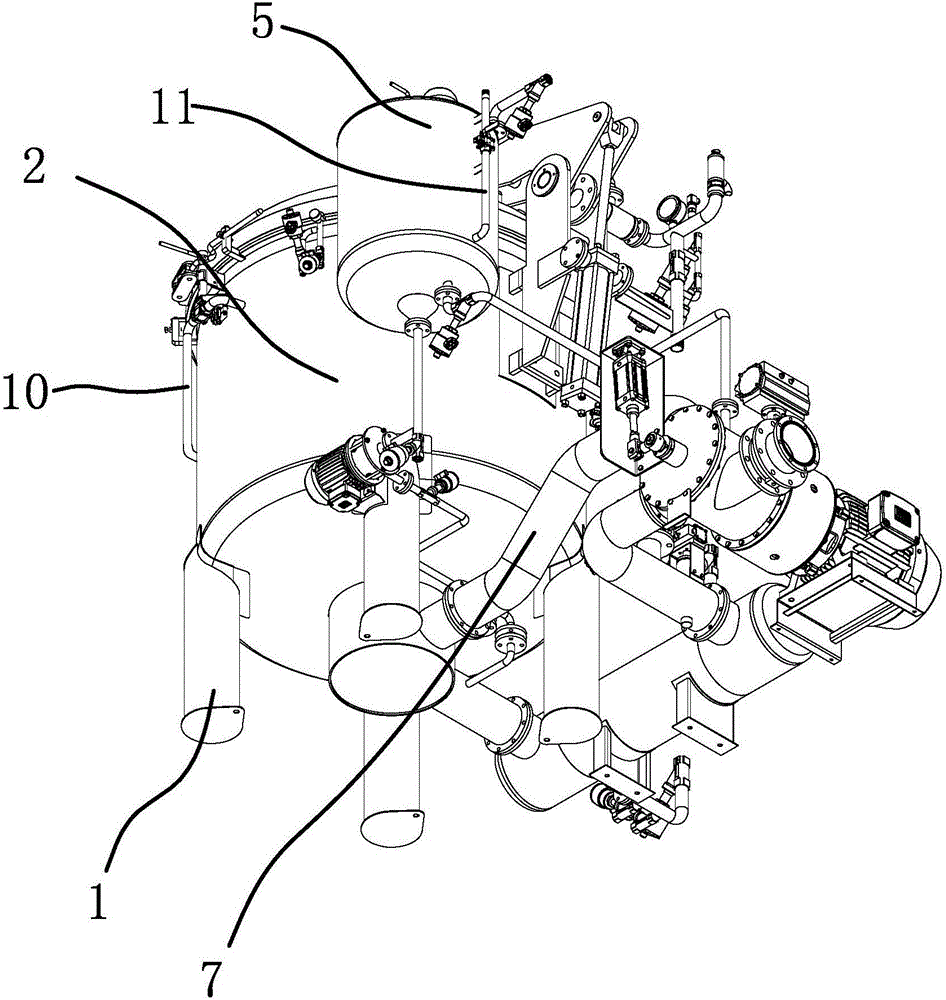

Normal temperature self-crosslinking acrylic emulsion and preparation method thereof

The invention discloses a normal temperature self-crosslinking acrylic emulsion and a preparation method thereof. The acrylic emulsion is obtained by radical-initiated polymerization of the following raw materials by weight: 50 to 52 parts of deionized water, 2 to 3 parts of emulsifier RN-30, 12 to 16 parts of butyl acrylate, 22 to 28 parts of methyl methacrylate, 0.5 to 1 part of hydroxyethyl acrylate, 0.3 to 0.6 part of acrylic acid, 0.4 to 0.8 part of vinyltrimethoxy silane, 0.1 to 0.3 part of sodium bicarbonate, 0.2 to 0.4 part of ammonium persulfate, 1 part to 2 parts of diacetone-acryloamide, 0.5 part to 1.5 parts of adipic dihydrazide, 0.1 to 0.14 part of the oxidizing agent tert-butyl hydroperoxide, 0.1 to 0.14 part of the reducing agent rongalite and 0.3 to 0.6 part of ammoniacalliquor. The normal temperature self-crosslinking acrylic emulsion provided in the invention has better water resistance and oil resistance and greatly enhances the problems of after tack at high temperature and embrittlement at low temperature under the condition that the quality of a final product is guaranteed to be no worse than the quality of products of a same kind.

Owner:山东奔腾漆业股份有限公司

Room-temperature preparation method for high-efficiency polycarboxylic acid water reducing agent

The invention relates to the technical field of building material admixtures, in particular to a room-temperature preparation method for a high-efficiency polycarboxylic acid water reducing agent. The preparation method adopts methyl allyl polyethenoxy ether and acrylic acid as reactive monomers, and adopts hydrogen peroxide as an oxide agent and sodium formaldehyde sulfoxylate as a reducing agent to build an oxidation-reduction system. The specific synthetic method comprises the following steps: adopting methyl allyl polyethenoxy ether, hydrogen peroxide and deionized water as a base solution; dropwise adding a water solution A of acrylic acid and a chain transferring agent, and a water solution B of sodium formaldehyde sulfoxylate; enabling radical polymerization reaction at room temperature. The preparation method can be carried out for synthesis at the room temperature, and is economical, environment-friendly, low in energy consumption and simple in preparation technology, and the synthesized water reducing agent is high in water-reducing rate, good in fluidity and good in slump retaining performance.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

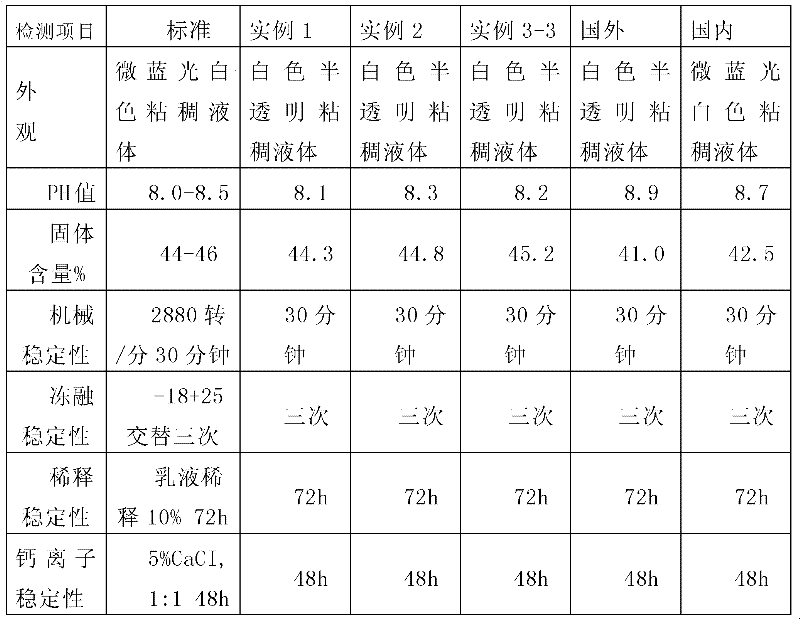

Foodstuff safety multiple item quick detector

InactiveCN101105443AGo digitalEasy to operateColor/spectral properties measurementsMicrocontrollerHuman–machine interface

The invention relates to a multi-project detector for detecting the security of food. The operational power supply separately provides the power to a light path part, a monolithic processor and an auxiliary circuit part. The monolithic processor is separately connected with the light path part, the auxiliary circuit part, an input part and an output part. And the monolithic processor and the auxiliary circuit part are used for calculating and controlling, the input part and the output part are used to input and output the information. The invention can detect the chemical substances which have harm to human body like agricultural chemicals, sulphur dioxide, nitrous acid, rongalite lump, hydrogen peroxide, methyl alcohol, dairy product protein, nitrate and heavy metal, the detecting result is accurate, the detecting speed is quick, the density can be directly showed, the man-machine contact surface is friendly, and the invention has the functions of data storage, inquiry, result printing and GPRS wireless transmission to data server. The invention can be used in real-time, and has the advantages of high detecting efficiency and high automaticity, convenient carrying, practical using, low cost and good effect.

Owner:赵澎涛

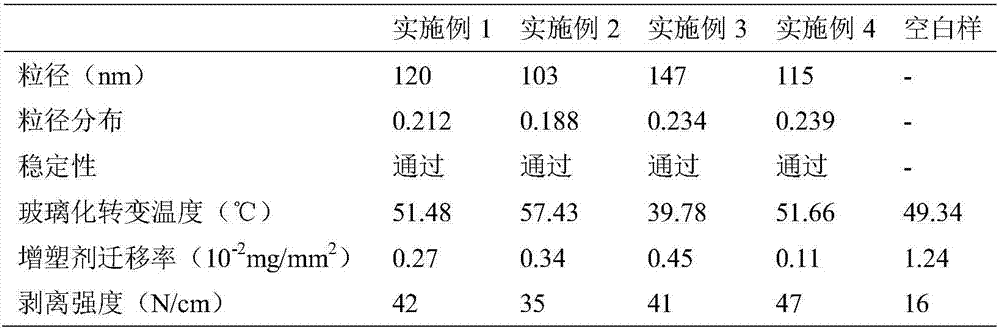

Water-based ink resin for PVC furniture membranes and preparation method of water-based ink resin

The invention provides water-based ink resin for PVC furniture membranes and a preparation method of the water-based ink resin. Raw materials of the water-based ink resin for the PVC furniture membranes comprise an anionic emulsifier, a nonionic emulsifier, a pH buffering agent, an initiator, a chain transfer agent, a methyl methacrylate monomer, a methyl acrylate monomer, a glycidyl methacrylate monomer, tert-butyl hydroperoxide, rongalite, a preservative, and deionized water; based on a design concept of ''polymer welding'', an emulsion-type resin which is well compatible to PVC and of which glass transition temperature is similar to that of the PVC is prepared and designed, wherein the main body of the emulsion-type resin is poly(methyl methacrylate-methyl acrylate), and the high peeling strength of the water-based ink resin and the PVC furniture membranes is guaranteed; and meanwhile, a characteristic that the PVC furniture membranes have a large number of plasticizers is combined, a proper amount of the glycidyl methacrylate monomer with epoxy groups is introduced to a copolymerization monomer system, and therefore the plasticizer migration resistant ability of the water-based ink resin is improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Dye discharging ink for inkjet printing

InactiveUS20080250967A1Avoid corrosionImprove suppression propertiesOther chemical processesDuplicating/marking methodsAlcoholDecomposition

A dye discharging ink for inkjet printing including at least a reducing agent and an amine compound. Embodiments of the dye discharging ink include, as the reducing agent, a sulphur reducing agent such as Rongalite, and, as the amine compound, an alcohol amine compound such as triethanolamine. Embodiments of the dye discharging ink also include a surface active surfactant and / or an antirust agent, and a pH in a range from 9.5 to 11.0. The dye discharging ink for inkjet printing can prevent corrosion of head nozzles due to acidic substances produced by decomposition of a reducing agent, so as to decrease inhibition of linear advancing property of ejected ink, and can prevent decrease in discharging capability due to hydrolysis of the reducing agent.

Owner:MIMAKI ENG

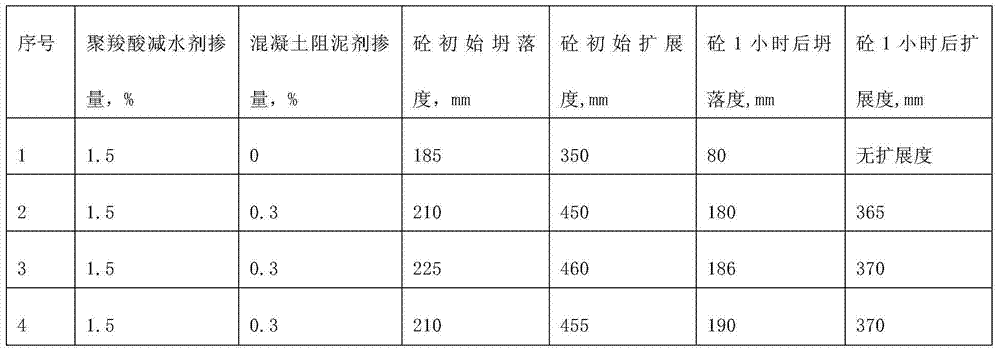

Concrete mud retarder

The invention discloses a concrete mud retarder. The concrete mud retarder comprises 50-80wt% of an aqueous polymer, 5-20wt% of gallic acid and 10-30wt% of diethylene glycol. A production technology of the aqueous polymer comprises the following steps: 1, taking 4-7 parts by weight of hydrogen peroxide and 8 parts by weight of water, and completely dissolving hydrogen peroxide in water to obtain a solution I; 2, taking 2-4 parts by weight of rongalite and 8 parts by weight of water, and completely dissolving rongalite in water to obtain a solution; 3, adding 35-40 parts by weight of water, respectively adding 7 parts by weight of acrylamide, 9 parts by weight of maleic anhydride and 21 parts by weight of allyl ether, and stirring; 4, adding 0.5-2 parts by weight of a chain transferring agent; and 5, heating to 40DEG C, simultaneously adding the solution I and the solution II in a dropwise manner, and controlling the reaction temperature to be 40-50DEG C and the dropwise addition time to be 2-4h, and cooling to 30DEG C after the above reaction in order to obtain the aqueous polymer with the solid content of 38-42%. The concrete mud retarder can reduce adsorption of a concrete water reducer on soil particles, improves the fluidity of a high-mud concrete system, and greatly improves the slump keeping property of the concrete water reducer.

Owner:SOUTHEAST UNIV

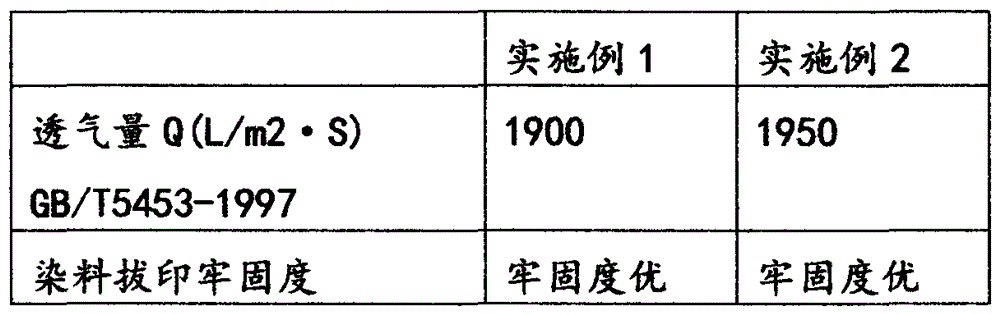

Dyeing and finishing process of viscose woven fabric

InactiveCN107177992AThe texture is clear and firmMeet needsSucessive textile treatmentsDyeing processViscoseOil water

The invention relates to a dyeing and finishing process of viscose woven fabric. The dyeing and finishing process of the viscose woven fabric comprises the steps of dyeing and pretreating a viscose woven fabric semi-finished product: cooking the water-washed viscose woven fabric semi-finished product in a dyeing pretreatment solution, and carrying out discharge print on the sized viscose woven fabric semi-finished product by adopting a mixed dye of vasekine and rongalite, wherein the mass ratio of the rongalite to the vasekine is 1 to 1; adding table salt and sodium carbonate into a rope rinsing machine, wherein the masses of the table salt and the sodium carbonate are equal; placing the dyed viscose woven fabric into a color fixing agent, softening the color-fixed dyed viscose woven fabric by putting into 1g / L of Taigu oil water solution. A discharge print dyeing pattern obtained through the method provided by the invention is high in three-dimensional effect, firm in dye, and good in air permeability.

Owner:SHAOXING SUBO TEXTILE CO LTD

Method for bleaching high-concentration kaolin pulp

InactiveCN101445249AImprove product qualityReduce consumptionSilicon compoundsHigh concentrationKaolin clay

The invention relates to a method for bleaching high-concentration kaolin pulp. The kaolin pulp concentration is 25%-30%. The method comprises the following steps: adding an alkaline agent to water, mixing and adding rongalite to prepare rongalite aqueous solution, wherein, the weight ratio of sodium hydroxide to sodium carbonate in the alkaline agent is 0.33-0.47:10, the weight ratio of the rongalite to the alkaline agents is 100:10.3-10.5, rongalite volume concentration of the rongalite aqueous solution is 10-15% and the pH value of the rongalite aqueous solution is 7.0-8.0; delivering the rongalite aqueous solution and the high-concentration kaolin pulp to a conduit by a pump for mixing, and delivering the mixture to a pulp storage tank, wherein, the added amount of the rongalite aqueous solution is 1.4-2.3% of that of the high-concentration kaolin pulp; and keeping standing and bleaching for 15-20 hours, and adjusting the pH value of the pulp to 2.5-3.0 after bleaching. The method has the advantages of reasonable technical proposal, easy control of operation, stable process, and the bleached high-concentration pulp is beneficial to subsequent filter pressing dehydration processing, which improves the production capacity, reduces the energy consumption and medicament consumption, lowers the production cost and stabilizes quality of kaolin products.

Owner:梁明

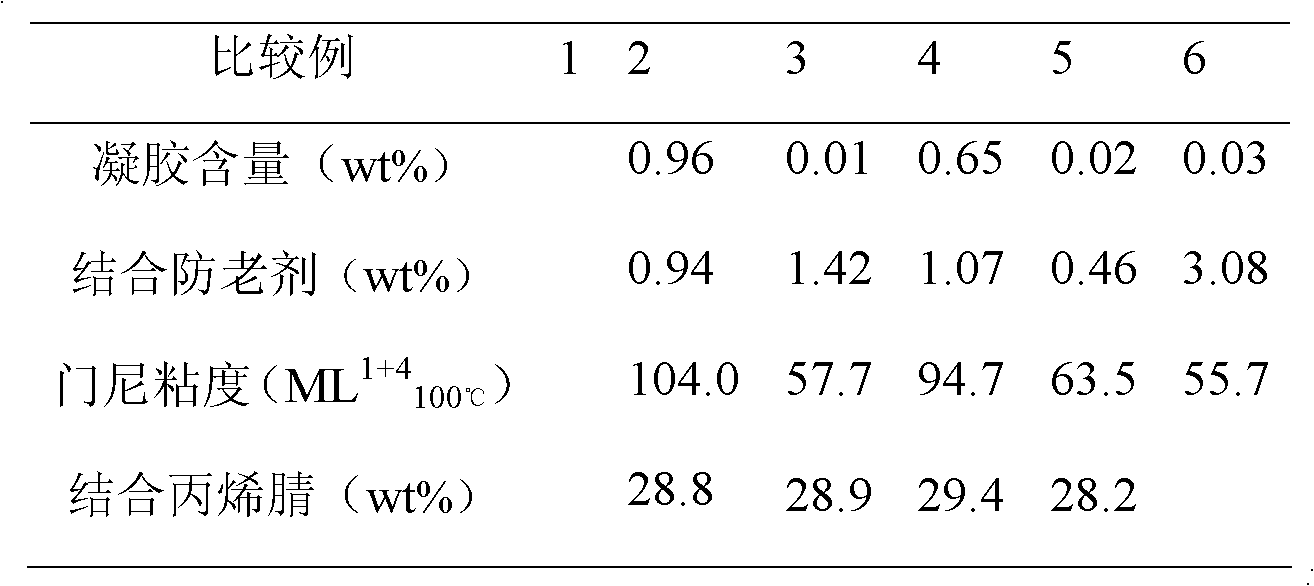

Nitrile rubber and preparation method thereof

Owner:PETROCHINA CO LTD

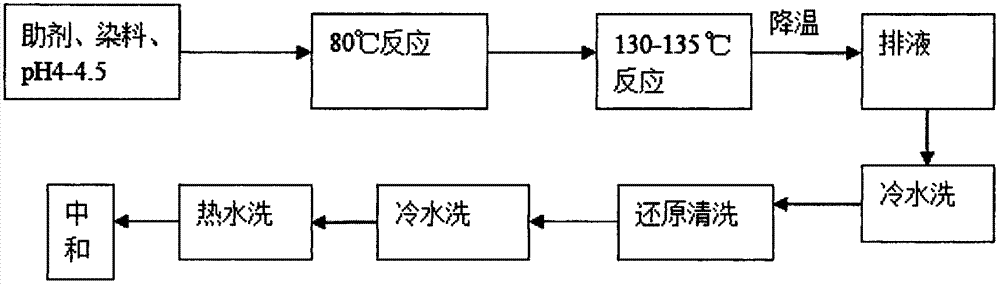

Top dyeing and post-processing method of flame retardant polyester fiber

InactiveCN101457489ADo not change colorGuaranteed fastnessDry-cleaning apparatus for textilesDyeing processDisperse dyeAcetic acid

The invention relates to wool top dyeing of flame-retardant polyester fibers and a post-treatment method thereof. The method comprises the following steps: the flame-retardant polyester fiber wool top is placed in a wool top dyeing machine and operates for 3-5 min at the temperature of 40-50 min, glacial acetic acid is added and PH Value is adjusted to 5-6, monoammonium phosphate and Yuri Huading DIF are added for operating for 5-10min, disperse dye is added for operating for 5-10 min before the temperature rises, the temperature stops rising until 85 DEG C, then the temperature is maintained for 10-15 min, the temperature rises to 100-120 DEG C for operating for 30-60 min, liquor drainage and flushing are carried out with a bath ratio of 1:20-50; the dyed flame-retardant polyester fiber wool top is put into lotion soap with 2-5% of fiber fabric by weight, the lotion soap is processed for 20-30 min at the temperature of 80-90 DEG C, or, the dyed the flame-retardant polyester fiber wool top is first placed in bath consisting of 0.5-2g / L sodium hudroxide , 0.5-2g / L rongalite and 0.5-1g / L nonionic surface active agent for being processed for 20-30 min at the temperature of 70-80 DEG C and then placed in glacial acetic acid bath with 1-4% of fiber fabric by weight for being processed for 10-15 min at the temperature of 40-45 DEG C; the bath ratio is 1:20-1:50. The wool top dyeing of the invention features good levelling of dyeing and high color fastness of dyeing wool top.

Owner:HEILAN HOME

Kaoline alkaline static bleaching technology

InactiveCN101531372AReduce the rate of hydrolysisAvoid ineffective hydrolysisPigmenting treatmentAluminium silicatesSlurryEngineering

The invention relates to kaoline alkaline static bleaching technology. The technology comprises: evenly mixing classified kaoline ore slurry and rongalite, standing the mixture for a while, adding a regulator into the mixture, controlling the ore slurry pH value to between 3 and 5, and evenly stirring the mixture to obtain the product. The technology has the advantages of simple operation, easy realization in production and obvious effect, can be widely used in kaoline processing enterprises and has great popularization value and application prospect.

Owner:茂名市银华高岭土实业有限公司

Method for preparing anti-bacteria, water-proof and anti-ageing nano propyl-phenyl emulsion

The invention is the antibacterial, waterproofing, anti-aging nanometer benzene-acrylic emulsion relating to a kind of constructing emulsion used for preparing inside and outside wall dope. The component proportions of the invention are: deionized water 42%, n-butyl acrylate (BA) 24.4%, styrene (St) 24%, non-ionic emulsifier (MS-01) 1.8%, nano-ZnO 1.8%, nano-TiO2 1.2%, anion emulsifier (DSB) 1%, N-methylolacrylamide (N-MAM) 1%, methylacrylic acid (MAA) 1%, tert-butyl hydroperoxide (TDHP) 0.6%, sodium formaldehydesulfoxylate (SFS) 0.6%, ammonium persulfate (APS) 0.4%, NaHCO3 0.2%, and AMP-95 0.2%. According to the said weight proportions, prepare the emulsion through pre-emulsifying, milling, and polymerizing at high temperature.

Owner:何一军

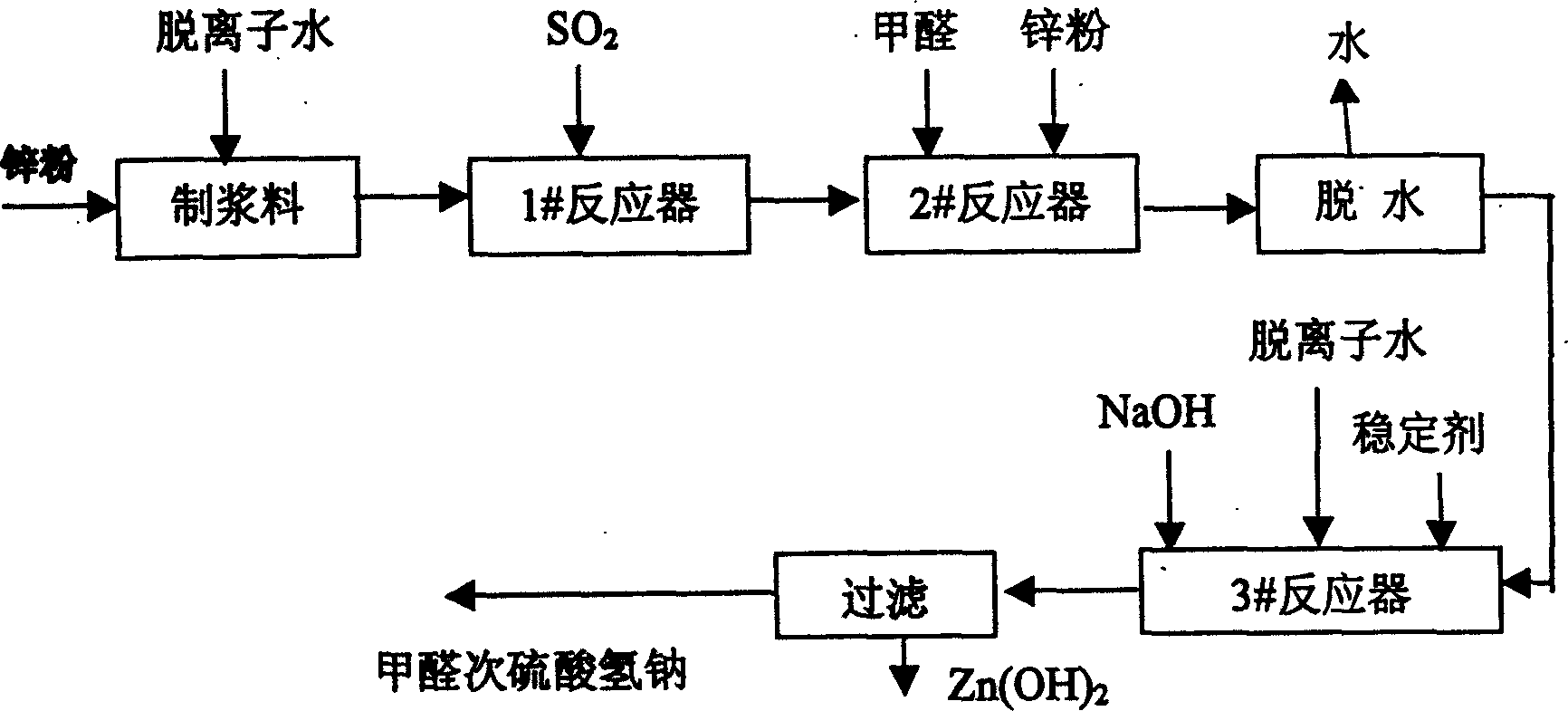

Improvement of production method of activating and modifying sodium bisulfoxylate formaldehyde

InactiveCN1557695ASignificant positive effectImprove stabilityOrganic chemistrySulfur compoundsSlurrySodium bisulfate

The improved production process of formaldehyde sodium sulfoxylate activator includes making slurry with zinc powder and deionized water in the weight ratio of 1 to 4.545; pumping the slurry into the first reactor and introducing SO2 gas at 55 deg.c until the material becomes yellow; adding formaldehyde in 1.65 times the initial zinc powder weight into the second reactor, adding the material from the first reactor, heating to 100 deg.c while stirring, adding zinc powder of 0.82 time the initial amount, lowering the temperature to 70 deg.c, said vacuum dewatering to water content of not more than 20 %; adding deionized water in the amount of 1.3 times the initial water weight to the third reactor, adding the dewatered material, heating to 70 deg.c under stirring, adding EAC stabilizer in the amount of 1 % of zinc powder weight slowly, adding NaOH after 10 min to pH 11, filtering and collecting product.

Owner:吉林市大宇化工有限公司

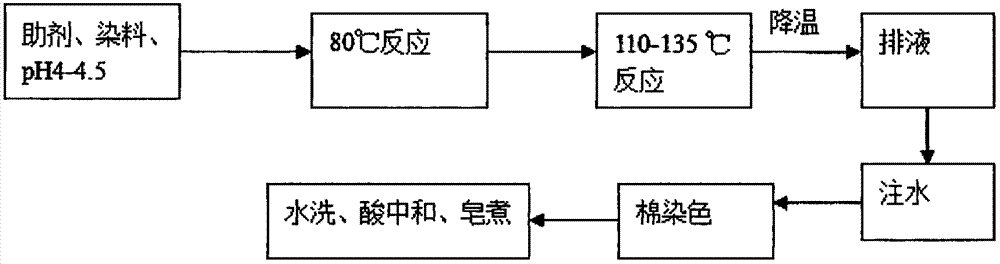

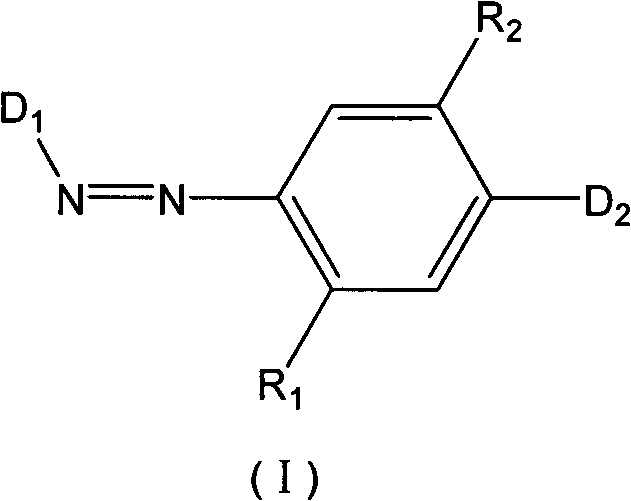

Disperse dye composition and applications thereof

ActiveCN102888129ASave energyIncrease productivityOrganic dyesDyeing processBenzoic acidDisperse dye

The invention relates to a disperse dye composition and an application method of the disperse dye composition. During dyeing polyester-cotton blended fabrics, the disperse dye composition can be adopted to remove traditional necessary technical step of reducing and cleaning after dyeing through the disperse dye, therefore, the energy is saved, the production efficiency is improved, and high color fastness can be ensured. The benzoic acid is added to the disperse dye composition to be served as a carrier, therefore, the disperse dye composition provided by the invention can be used for dyeing the polyester fiber at 110 to 120 DEG C without influencing the color fastness and degree of dyeing; meanwhile, the benzoic acid is served as a solid food additive; compared with a traditional carrier, the disperse dye composition can not harm a human body, and has high environmental-protection characteristics; and when the disperse dye composition is applied to pure terylene fabric, the residual dyeing temperature can be utilized for reducing and cleaning by adding sodium formaldehyde sulfoxylate composition without draining liquid, therefore, the resource consumption is reduced, and the production efficiency is improved.

Owner:SHANGHAI YILIAN CHEM TECH

Method for preparing anti-bacteria, water-roof and anti-ageing purified propyl emulsion

The invention is the antibacterial, waterproofing, anti-aging nano pure-acrylic emulsion relating to a kind of constructing emulsion used for preparing inside and outside wall dope. The component proportions of the invention are: deionized water 42%, n-butyl acrylate (BA) 24%, methyl methacrylate (MMA) 23.6%, non-ionic emulsifier (MS-01) 2%, nano-ZnO 1.8%, nano-TiO2 1.2%, anion emulsifier (DSB) 1%, N-methylolacrylamide (N-MAM) 1%, acrylic acid (AA) 0.8%, tert-butyl hydroperoxide (TDHP) 0.6%, sodium formaldehydesulfoxylate (SFS) 0.6%, ammonium persulfate (APS) 0.4%, polymerizable emulsifier (AMPS) 0.4%, NaHCO3 0.2%, and AMP-95 0.2%. According to the said weight proportions, prepare the emulsion through pre-emulsifying, milling, and polymerizing at high temperature.

Owner:何林道

Method for synthesizing nano composite silicon propyl emulsion

The invention is the synthesizing method of nano compound emulsion relating to a kind of constructing emulsion used for preparing inside and outside wall dope. The component proportions of the invention are: deionized water 42%, n-butyl acrylate (BA) 22%, methyl methacrylate (MMA) 22%, organosilicon monomer (ethylene triethoxy silicon hydride A-151) 4.1%, non-ionic emulsifier (OP-10) 1.5%, nano-SiO2 1.5%, nano-TiO2 1.2%, anion emulsifier (DSB) 1%, N-methylolacrylamide (N-MAM) 1%, methylacrylic acid (MAA) 1%, polymerizable emulsifier AMPS 0.5%, ammonia 0.5%, tert-butyl hydroperoxide (TDHP) 0.5úÑ, sodium formaldehydesulfoxylate (SFS) 0.5%, ammonium persulfate (APS) 0.4%, and NaHCO3 0.3%. According to the said weight proportions, prepare the emulsion through emulsifying, milling, drop adding and polymerizing at high temperature.

Owner:何一军

Polyacrylate emulsion microgel and preparation method thereof

The invention provides a polyacrylate emulsion microgel, which is composed of the following raw materials in parts by weight: 2 to 2.4 parts of anionic emulsifier, 1.6 to 1.8 parts of nonionic emulsifier, 0.1 to 0.2 part of pH buffering agent, 1.5 to 3.3 parts of initiator, 25 to 35 parts of methyl methacrylate monomer, 65 to 75 parts of butyl acrylate monomer, 0.06 to 0.08 part of tert-butyl hydroperoxide, 0.06 to 0.08 part of rongalite, and 114.6 to 116.5 parts of deionized water. The microgel has the advantages of simple technology, compact and uniform film, and good waterproof property.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Novel discharging agent for textile printing and dyeing

InactiveCN104805720AImprove discharge effectOvercome solubilityDyeing processTextile printerSolubility

The invention discloses a novel discharging agent for textile printing and dyeing. The novel discharging agent is prepared by the following components in parts by weight: 3 to 8 parts of fatty alcohol-polyoxyethylene ether, 3 to 6 parts of epichlorohydrin, 3 to 7 parts of boric acid, 5 to 10 parts of polyethylene glycol oil-based ether, 3 to 7 parts of polyvinylpyrrolidone, 2 to 3 parts of N-benyl-2-naphthylamine, 3 to 7 parts of sodium hydroxide, 11 to 12 parts of thiourea dioxide, 3 to 6 parts of rongalite, 7 to 12 parts of linear alkyl benzene sulphonic acid, 3 to 5 parts of ammonium sulfate, 17 to 22 parts of ethylene glycol, and 20 to 30 parts of deionized water. The novel discharging agent has the advantages that a modifying method is simple, the stability of a product is good, and the discharging effect of the thiourea dioxide can be improved; the defects of low solubility because of using the convention thiourea dioxide as the discharging agent for discharging and dyeing and the poorer dispersing uniformity, poorer net permeating property, insufficient playing of discharging function and the like in the discharging liquid are overcome.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

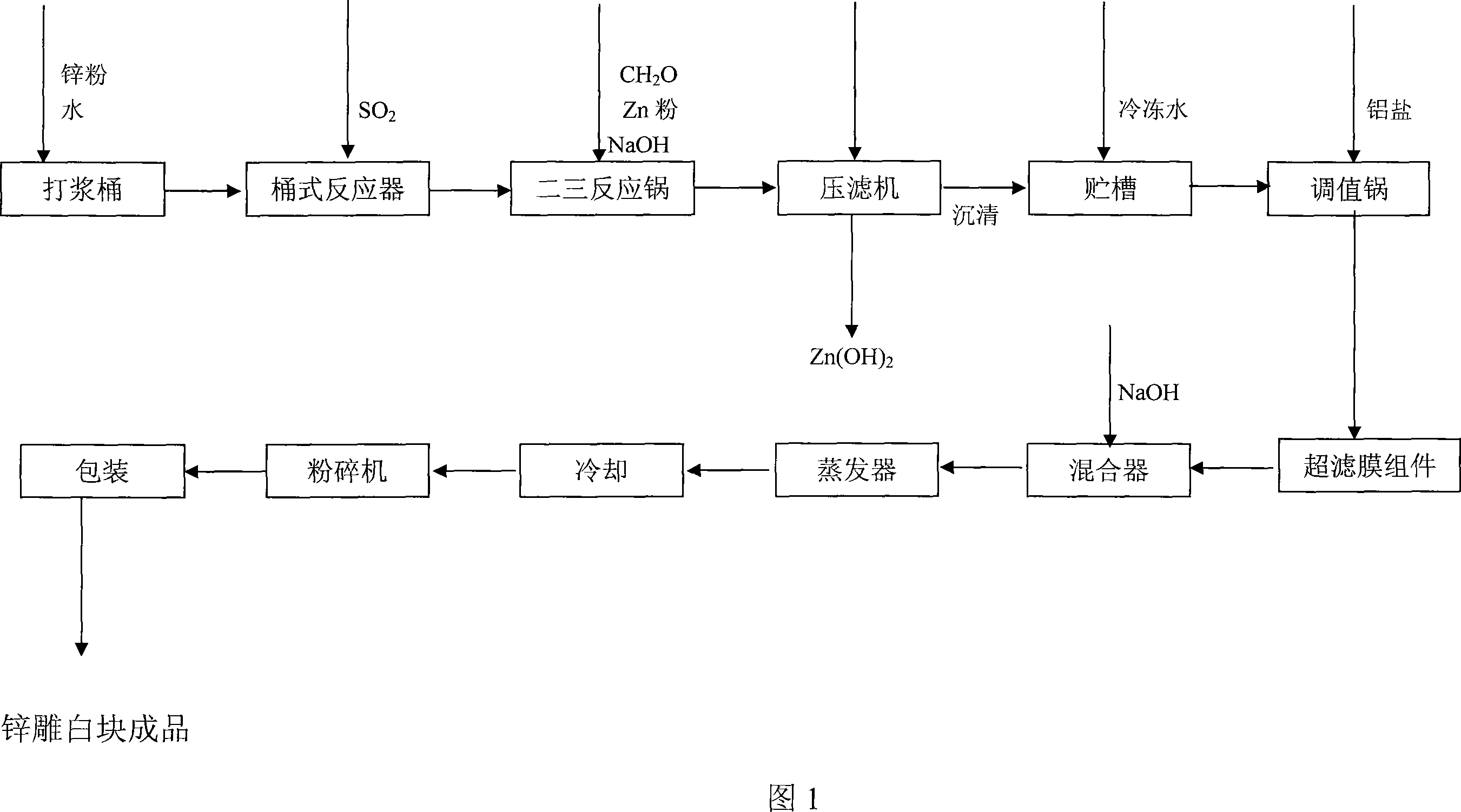

Method for producing rongalite with low zinc

InactiveCN101092422AReduce manufacturing costHigh content of finished productsSodium organic compoundsSodium/potassium compoundsPlastics industryDithionous acid

This invention relates to a method for producing low-zinc rongalite. The method comprises: mixing water and zinc powder, beating, adding SO2, reacting to obtain zinc hydrosulfite, placing in a reaction pot, adding formaldehyde and zinc powder, reacting to obtain alkaline sodium formaldehyde sulfoxylate, precipitating, removing the supernatant, adding NaOH, reacting to obtain sodium formaldehyde sulfoxylate, filtering, standing for settlement, cooling, adjusting the pH value, performing ultrafiltration, mixing, adding NaOH, sending into an evaporator, evaporating to obtain melt of low-zinc sodium formaldehyde sulfoxylate, cooling, solidifying, and pulverizing to obtain the final product. The obtained low-zinc rongalite can satisfy the requirements of pharmaceutical and plastic industries. The zinc content is less than or equal to 50 ppm. The low-zinc rongalite has such advantages as high purity, high stability, low production cost and convenient usage.

Owner:JIANGSU DONGTAI FINE CHEM

Synthesizing method for confecting inner-outer wall coating water-proof stain-resistant latex

InactiveCN101096400AEnvironmentally friendlyWaterproofAntifouling/underwater paintsPaints with biocidesBottleEthyl acrylate

The invention discloses a method for synthesizing the water resistance antibiotic emulsion of inner or exterior wall paint, which comprises the following steps: dissolving sodium carbonate decahydrate in the water; dissolving the ammonium peroxodisulfate with the water; dispersing the nanometer powder with the water; dissolving the tert-butyl hydroperoxide with the water; dissolving sodium formaldehyde sulfoxylate in the water; adding various emulsifier in the deionized water; getting preemulsion by adding butyl acrylate, ethyl acrylate, methyl methacrylate and N-methylol acrylamide and mixing; adding the nanometer material after adding the rest water, emulsifier and sodium carbonate decahydrate solution in the bottle and mixing; heating; adding the preemulsion and initiating agent solution; dropping the rest preemulsion and initiating agent solution after reacting; keeping the temperature; reducing the temperature; adding tert-butyl hydroperoxide solution; adding formaldehyde sodium sulphoxylate solution; proceeding with the reaction; reducing the temperature; adjusting pH value with smmonia water; stopping mixing; getting the material by filtering. The invention has the water resistance, the environmental protection, the age resistance and the antibiosis.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

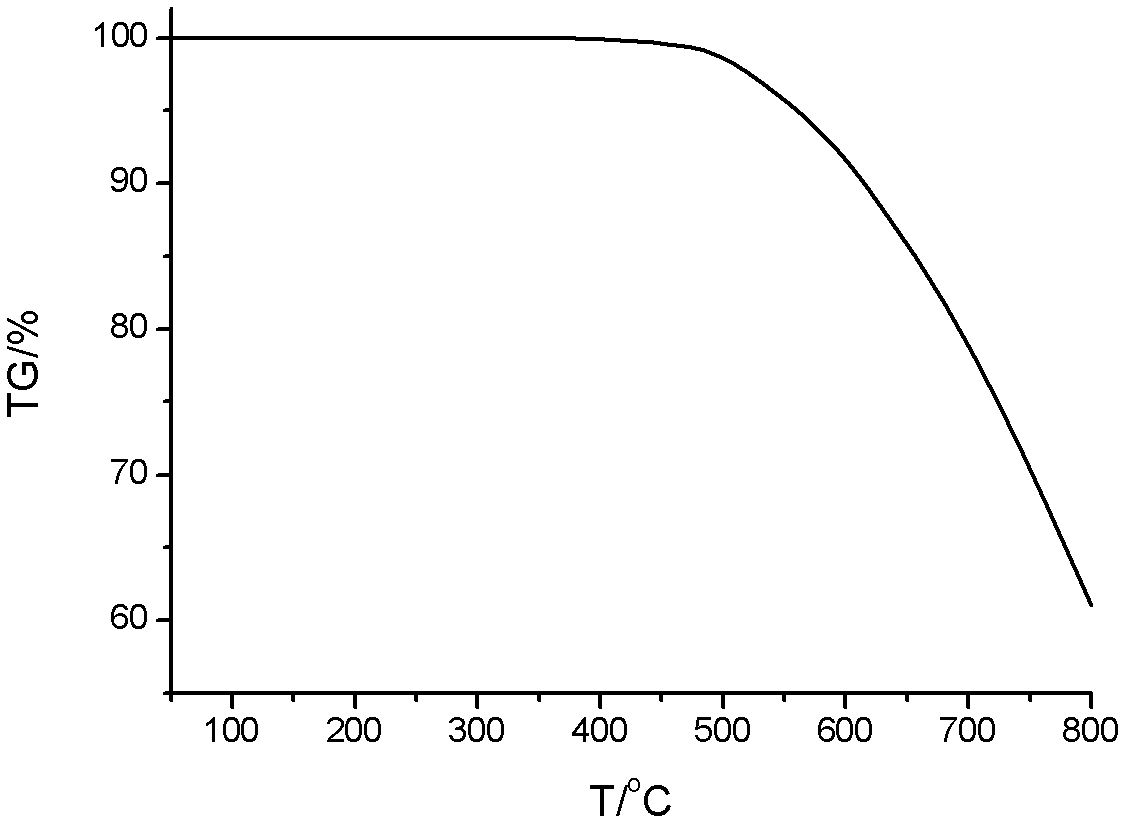

Preparation method of aromatic polybenzimidazole

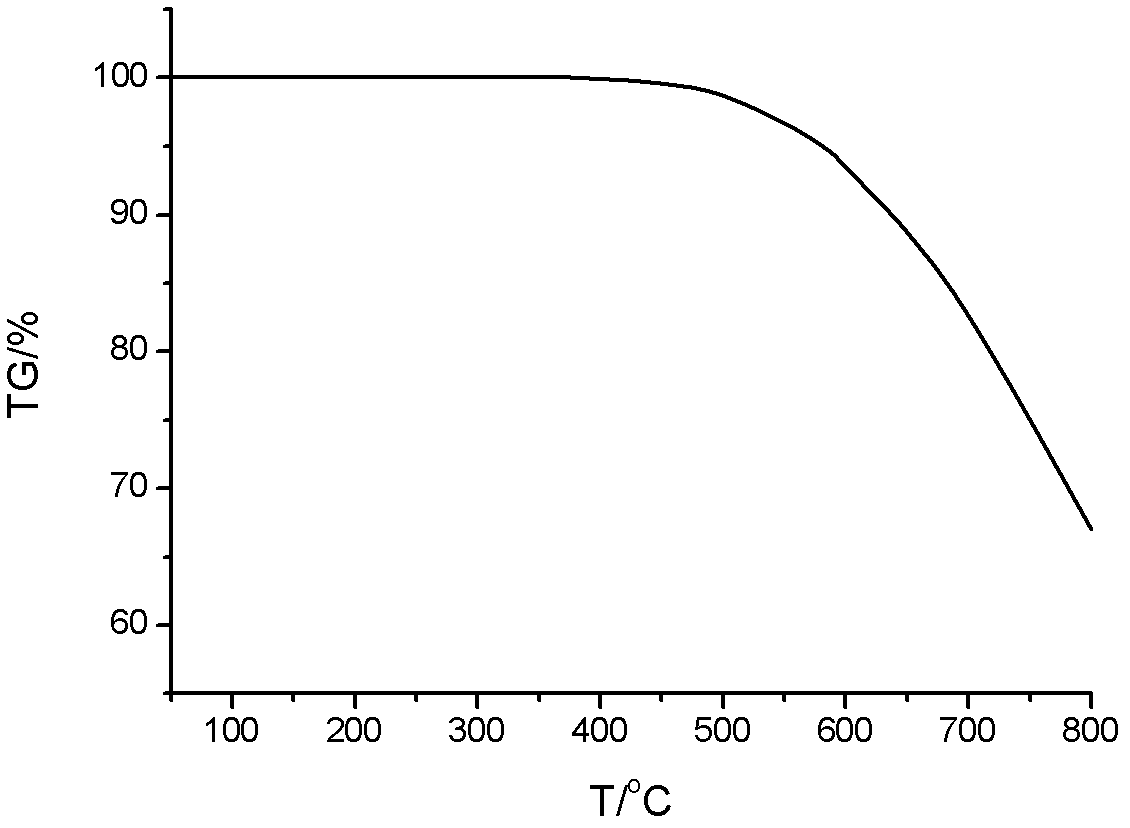

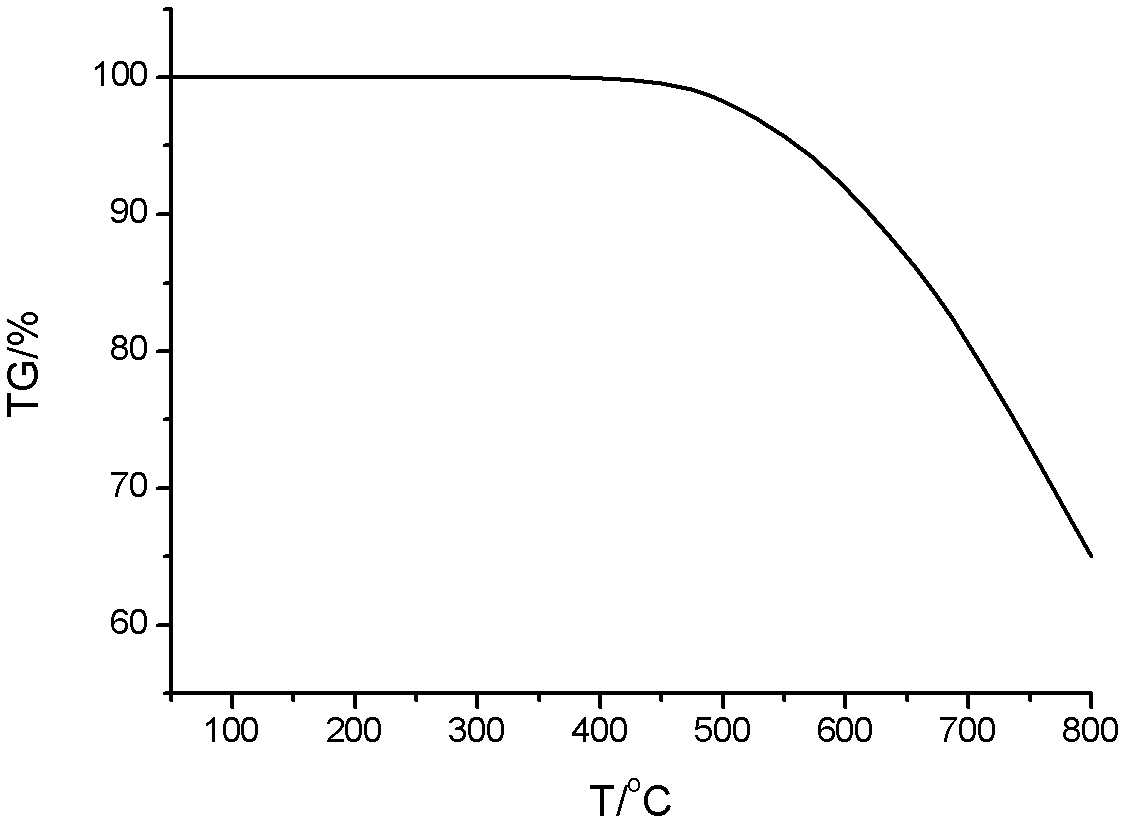

The invention discloses a preparation method of aromatic polybenzimidazole, comprising the following steps: 1, under the protection of nitrogen, adding aromatic tetramine and diacid monomer with equimolar ratio in a strongly acidic solution to conduct condensation polymerization with the reaction temperature of 100-250 DEG C and the reaction time of 0.5-30h; 2, pouring the product of the step 1 in water and precipitating to obtain a polymer, washing the polymer with water repeatedly, immersing in an alkaline solution to remove residual acid, and then immersing in boiling water containing rongalite for 0.5-6h; and 3, drying the product of the step 2 in a vacuum environment with the temperature of 50-150 DEG C to obtain the aromatic polybenzimidazole. The method has the advantages of high molecular weight, good thermal stability, excellent dissolubility and film forming property, etc.

Owner:SHANGHAI DIAIBI CHEM TECH

Yarn dyeing method

ActiveCN105821613AImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsRing dyeingDye injection

The invention provides a yarn dyeing method, and belongs to the technical field of textile related equipment. The technical problems that for an existing dyeing method, the dyeing efficiency is low, and dyeing is inconvenient are solved. The yarn dyeing method comprises the steps of 1, yarn preparation and inspection, wherein the yarn quality is inspected before yarn dyeing is conducted, and it is required that the appearance of yarns is clean and free of stain, the yarns are neutral, the stacking time must not be over 8 h, and the yarns are covered with wet cloth; 2, feeding, wherein yarns are put into a dye vat and arranged on a yarn dyeing rod; 3, dye preparation, wherein anthraquinone vat dye is prepared in a dye barrel, 5 g-6 g of caustic soda and 5-6 g of rongalite are added according to each part by mass of raw material with an anthraquinone type structure, water is injected to obtain a solution, and 0.2 g / L-0.5 g / L of bone glue retarding agent is added; 4, dye injection and dyeing, wherein the prepared dye is injected into the dye vat; 5, yarn taking-out. The yarn dyeing method has the advantages of being high in dyeing efficiency and uniform in dyeing, and the yarns subjected to dyeing is fluffy and full in hand feeling.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

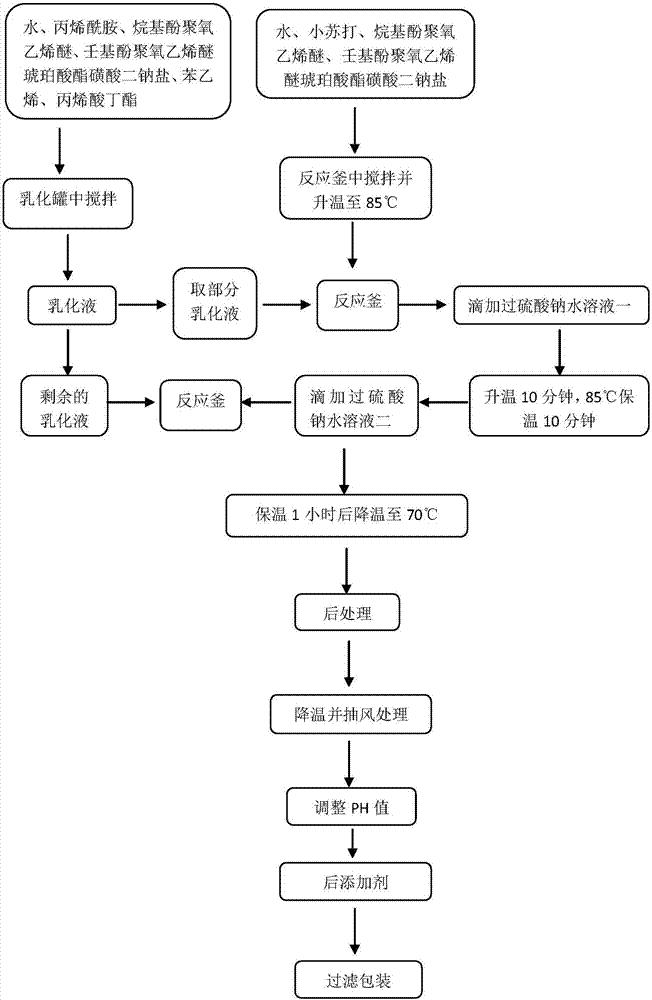

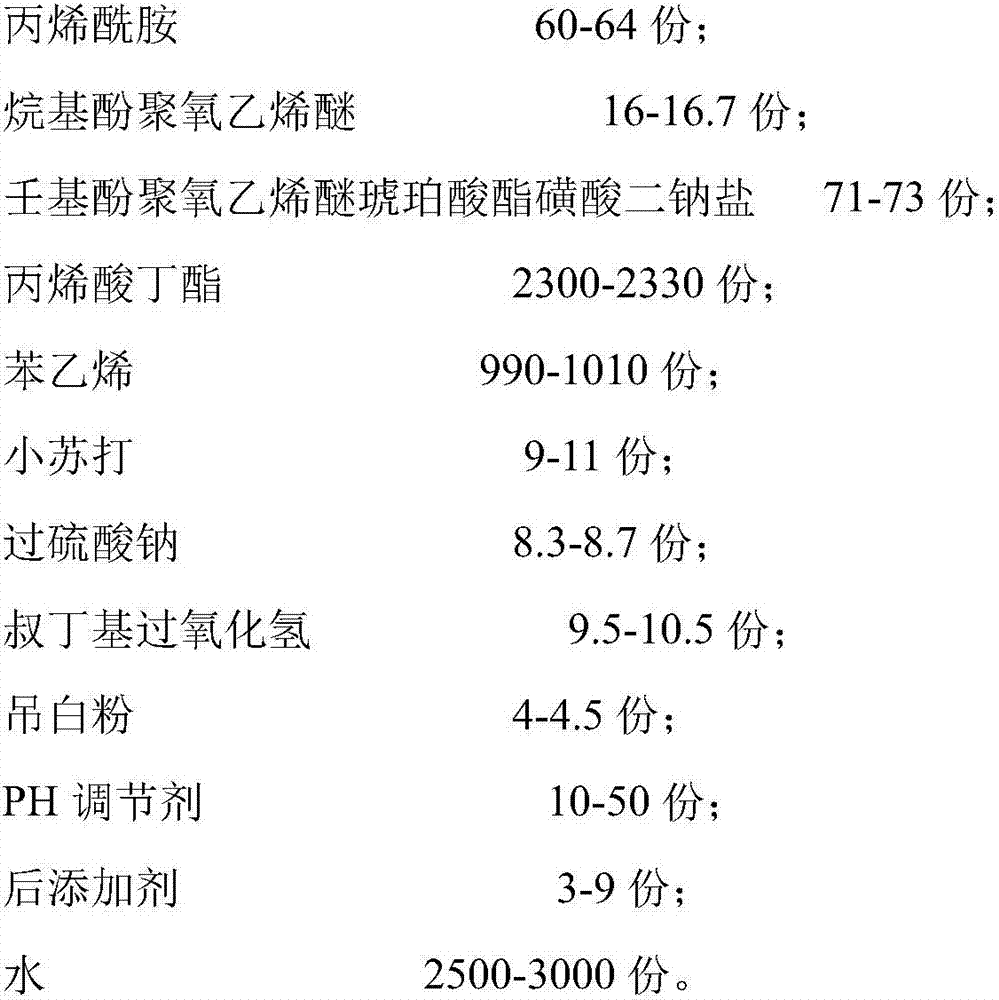

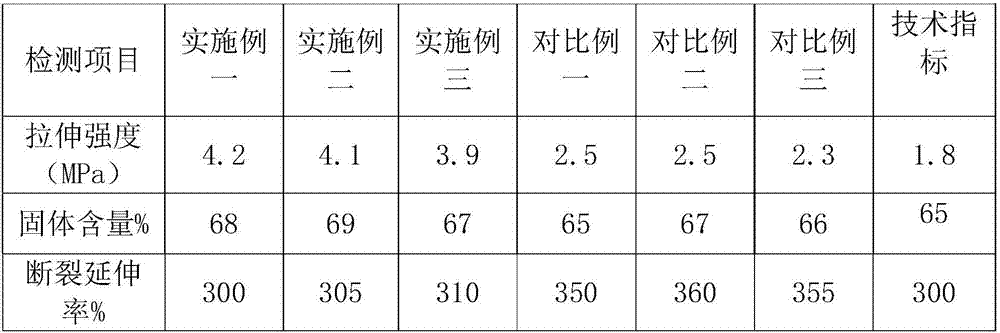

High-strength waterproof emulsion, and preparation method thereof

The invention discloses a high-strength waterproof emulsion. The high-strength waterproof emulsion comprises, by weight, 60 to 64 parts of acrylamide, 16 to 16.7 parts of alkylphenol polyoxyethylene,71 to 73 parts of disodium nonylphenol polyoxyethylene ether sulfosuccinate, 2300 to 2330 parts of butyl acrylate, 990 to 1010 parts of styrene, 9 to 11 parts of sodium bicarbonate, 8.3 to 8.7 parts of sodium persulfate, 9.5 to 10.5 parts of tert-butyl hydroperoxide, 4 to 4.5 parts of rongalite powder, 10 to 50 parts of a pH conditioning agent, 3 to 9 parts of a later additive, and 2500 to 3000 parts of water. The high-strength waterproof emulsion possesses enough high tensile strength, and is capable of satisfying requirements on the strength of waterproof materials under different using conditions.

Owner:威县双赢化工有限公司

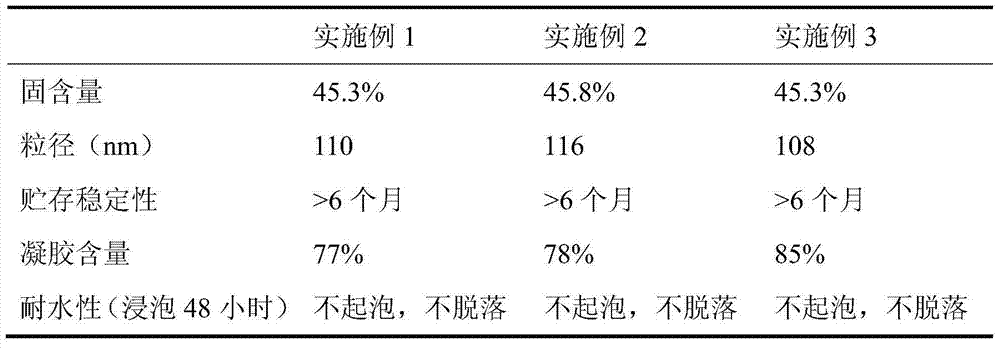

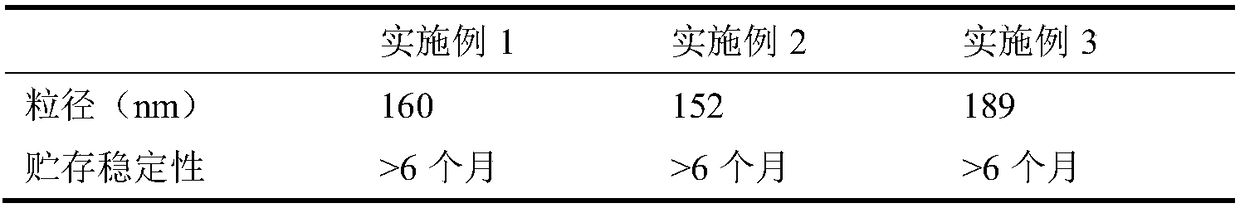

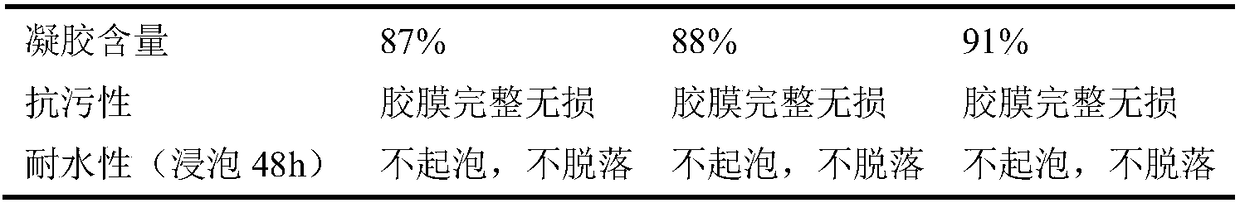

Anti-fouling and water-resistant silicone-acrylate emulsion and preparation method thereof

ActiveCN108424488AHigh gel volumeImprove stain resistanceAntifouling/underwater paintsInksSuperoxideWater resistant

The invention provides an anti-fouling and water-resistant silicone-acrylate emulsion and a preparation method thereof. The silicone-acrylate emulsion comprises the following raw materials in part byweight: 2-4 parts of a reactive anionic emulsifier, 1.8-3.1 parts of a reactive non-ionic emulsifier, 0.2-0.4 part of a pH buffering agent, 1.5-2.3 parts of an inorganic superoxide initiator, 0.6-0.8part of an oxidation initiator, 0.55-0.6 part of a reduction initiator, 7-10 parts of a methyl methacrylate monomer, 68-72 parts of an N-butyl acrylate monomer, 20-25 parts of an organosiloxane monomer, 1.2-1.5 parts of low-molecular alcohol, 0.06-0.08 part of tert-butyl hydroperoxide, 0.06-0.08 part of rongalite and 126-130 parts of deionized water. The silicone-acrylate emulsion provided by theinvention is excellent in anti-fouling and water-resistant properties, has an organosilicon monomer content of higher than 20 percent and is stable and controllable in the polymerization process, small in particle size and optimal in storage stability.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Method for detecting rongalit in food by gas chromatograph mass spectrometer

InactiveCN104807916AReduce usageEasy and fast handlingComponent separationSodium acetateEthylene diamine

The invention discloses a method for detecting rongalit in food by a gas chromatograph mass spectrometer. The method comprises the following steps that 1, 1g of food specimens are added into a top hollow bottle; 1 to 3ml pf 0.05 mol / L EDTA (ethylene diamine tetraacetic acid) solution and 1 to 3 ml of 0.05 mol / L sodium acetate solution are added, and the materials are compacted after being uniformly stirred and are fed onto a machine to be tested; 2, the gas chromatograph mass spectrometer is adopted for testing the content of sodium formaldehyde sulfoxylate in the top hollow bottle. The invention aims at providing the method for detecting the rongalit in food by the gas chromatograph mass spectrometer with the advantages that the testing is accurate, the operation is simple, and the time consumption is low.

Owner:WUZHOU INST FOR FOOD & DRUG CONTROL

Rust remover for liquid passage system of haemodialysis machine

The invention discloses a rust remover for a liquid passage system of a haemodialysis machine. The rust remover is characterized by comprising the following components in percentage by weight: 6 to 10 percent of sodium hydrogen sulfite, 4 to 6 percent of sodium hydrosulfite (rongalite) and 84 to 90 percent of distilled water. The rust remover solves the problem that rust deposited on the inner wall of the liquid passage system of the haemodialysis machine affects the integral performance of the haemodialysis machine, and is adaptive to clearing use of the inner wall of the liquid passage of the haemodialysis machine.

Owner:刘思波

Conductive adhesive

InactiveCN104371564AImprove conductivityImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium bicarbonatePolymer science

The invention discloses a conductive adhesive prepared from the following raw materials in parts by weight: 9-15 parts of waterborne polyurethane latex, 3-10 parts of butyldiglycol, 3-10 parts of a coupling agent, 3-8 parts of organobentonite of 20-50 meshes, 2-6 parts of a water-based leveling agent, 2-5 parts of asphalt, 3-8 parts of rubber powder, 2-6 parts of terpene resin, 8-14 parts of maleic anhydride, 3-8 parts of a tert-butyl hydroperoxide rongalite mixture, 4-6 parts of alkyl phenyl polyoxyethylene ether, 3-6 parts of glycidyl methacrylate, 2-7 parts of sodium bicarbonate, 3-5 parts of silicone oil, 2-6 parts of nano calcium oxide and 10-20 parts of a conductive filler. The conductive adhesive disclosed by the invention has the beneficial effects of good conductivity, uniform distribution of the conductive filler, stable performance and good cohesiveness.

Owner:田琳琳

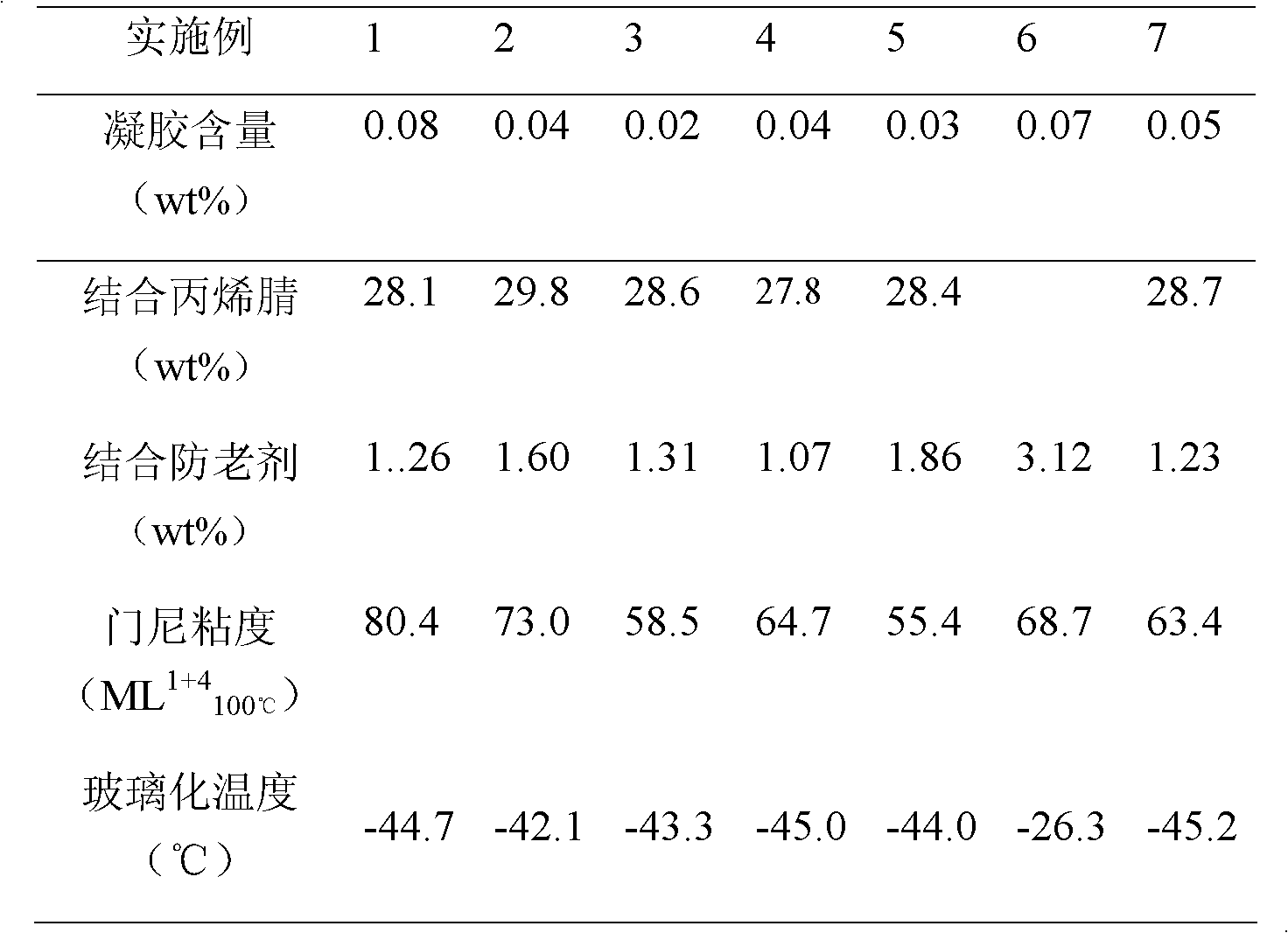

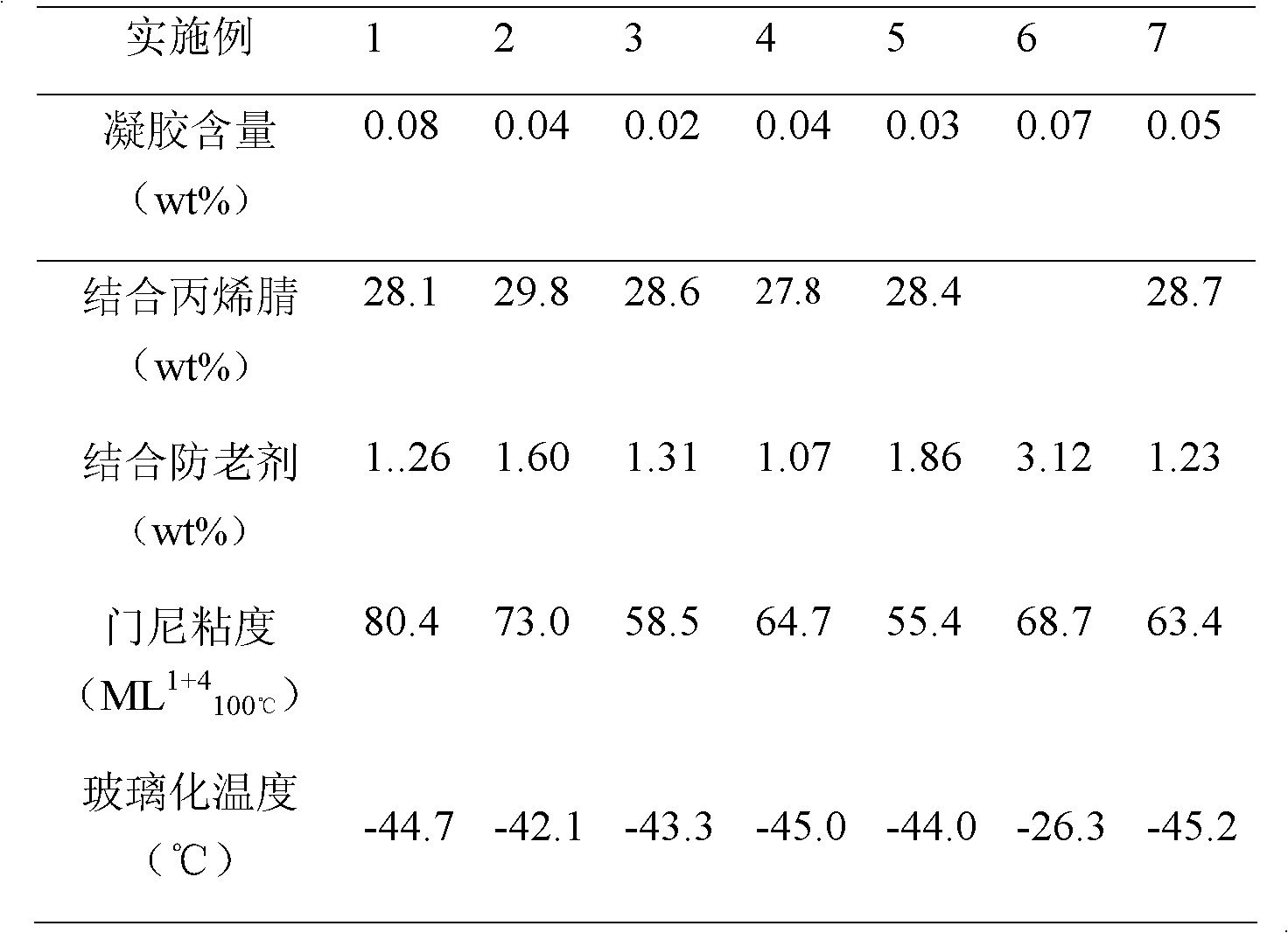

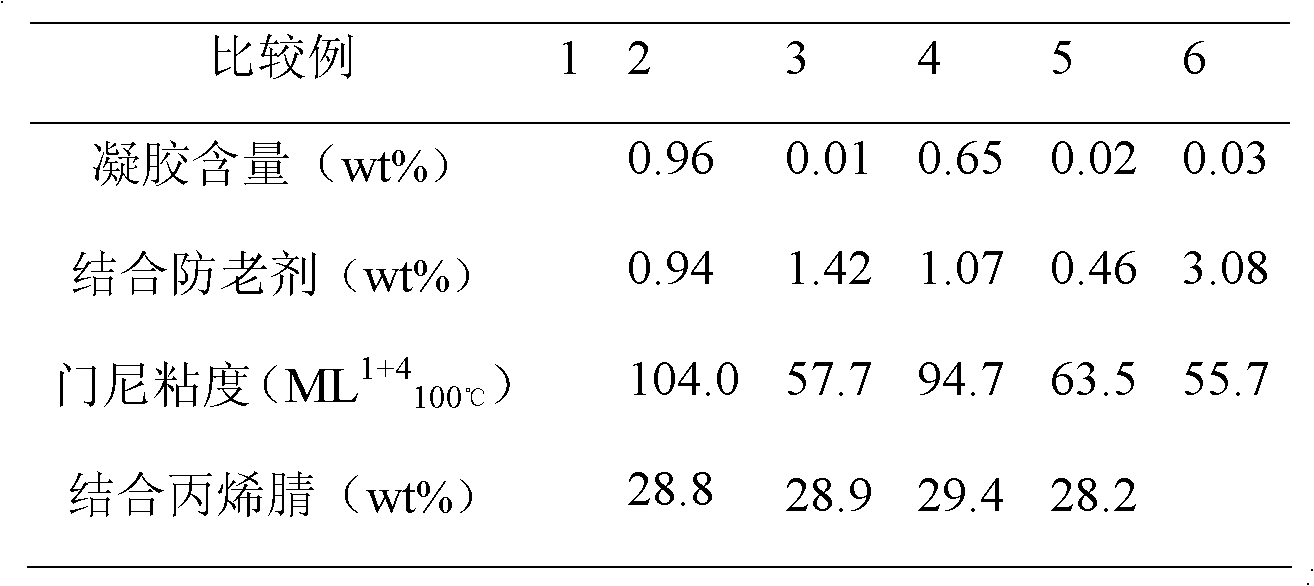

Nitrile rubber and preparation method thereof

The invention relates to a nitrile rubber and a preparation method thereof. The nitrile rubber is prepared from the following polymerization monomers by mass percent: 50-78% of C4-C5 aliphatic conjugate diene monomer, 20-48% of vinyl nitrile monomer and 1.0-5.0% of unsaturated amine or phenolic antioxidant monomer. By adopting a low-temperature polymerization way, an organic peroxide rongalite is used for oxidizing and reducing an initiating system, by increasing the addition of an emulsion system and a molecular weight regulator, the polymerization reaction is carried out smoothly, and molecular parameters of a polymer can be effectively regulated. The preparation method is simple in process and high in polymerization rate, and improves the stability of mucilage in the polymerization process. The content of N-(p-anilino phenyl) unsaturated amide or imide in the polymer is higher, and effective copolymerization of an antiager monomer of the N-(p-anilino phenyl) unsaturated amide or imide and C4-C5 aliphatic conjugate dienes and cyanoethylene is realized.

Owner:PETROCHINA CO LTD

Method for preparing low zinc low iron clarification rongalite

InactiveCN101353354AEasy to controlMeet control requirementsSodium organic compoundsSodium/potassium compoundsChromiumIon

The invention relates to a method for preparing low-zinc low-iron clear rongalite, which comprises the steps that: rongalite solution is used as a raw material and quinoline organic precipitator is used for precipitating zinc and ferrous ions in the solution before concentration; then, sampling and filtering are carried out, ammonia-ammonium chloride with the pH of 10 is used for buffering the solution with Eriochrome black T as a visualization reagent, and the content of the residual zinc ions in filtrate is measured by colorimetry; after the measured value meets the control requirement of 1 to 3mg / L, stirring is stopped, after precipitation and aging are carried out for 2 to 3 hours, precipitates are filtered away and then the filtrate is colorless and transparent; then, cooling for crystallization, crushing and packaging are carried out for obtaining the products of the clear rongalite with zinc and ferrous contents lower than 10PPm after the filtrate is concentrated to the content of over 98 percent at a vacuum level ranging from minus 0.085 to minus 0.095mPa and temperature lower than 75 DEG C. The invention has the advantages that the products prepared by the method have good stability and zinc and ferrous contents of lower than 10PPm, thus meeting special requirements on rongalite products by industries such as medicine and rubber, etc.

Owner:湖南中成化工有限公司

Method for producing salicylic acid by refining salicylic acid solution

InactiveCN101143817AReduce consumptionSimple production processOrganic compound preparationCarboxylic compound preparationActivated carbonSodium Phenolate

The invention relates to a method which utilizes sodium salicylate solution to refine, process and produce salicylic acid. Phenol reacts with liquid alkali, so that sodium phenolate is generated, the dried sodium phenolate reacts with carbon dioxide to generate sodium salicylate, which is then resolved in water, and therefore the sodium salicylate solution is produced. The first step is to regulate the pH value, that is, the sodium salicylate solution with twenty to forty percent of mass concentration is heated until 50 DEG C to 75 DEG C, and the pH value is regulated to four to six; the second step is to preserve heat, that is, the sodium salicylate solution is added with activated carbon and thermally insulated for two to four hours under the condition of temperature between 50 DEG C and 75 DEG C; the third step is filtration, the sodium salicylate solution is filtered, the filtrate is added with rongalite when filtrate is clean, and after five to twenty minutes, the filtrate is filtered into an acid eduction pot; in the fourth step, the salicylic acid is separated out from the acid eduction pot by utilizing vitriol to regulate the pH valve to one to two point five, and a pure product with more than ninety nine point three percent of content is produced after temperature reduction, filtration, washing and drying of the salicylic acid. The production technique of the invention has the advantages of simple process, convenient operation, little pollution, low material consumption and high purity of products, and meanwhile, the invention is convenient for industrialized production.

Owner:SHANDONG XINHUA LONGXIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com